Steering Page 9–1

Page 9–1

Section 9

Steering

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Cautions And Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 Service Operations................................................................................................................................3

2.1 Power Steering gear...............................................................................................................................................3

Remove ...................................................................................................................................................................5

Reinstall ..................................................................................................................................................................5

2.3 Power Steering Fluid Cooler and Hose/Pipe Routing.........................................................................................6

Arrangement...........................................................................................................................................................6

3 Torque Wrench Specifications............................................................................................................. 9

Techline

Techline

Techline

Techline

Techline

Techline

Steering Page 9–2

Page 9–2

1 General Information

The power assisted steering system for MY2004 VY All Wheel Drive Wagon carries over from MY2004 VY & V2 Series

vehicles with the following exceptions.

• The steering gear pinion shaft is longer due to the unique new cross member design of the All Wheel Drive

Wagon, catering for the higher ground clearance and front drive train. The lower steering coupling to the

steering gear remains unchanged.

• The steering gear retains the VY steering gear specification, but utilises the roll imprinted Monaro control valve.

This control valve improves steering assist boost for parking speeds to offset the increase in front end weight.

• The location of the steering gear assembly mounting points are lower due to the unique new cross member

design of the All Wheel Drive Wagon, catering for the higher ground clearance and front drive train.

• New power steering oil pipes, hoses and cooler locations catering for the unique new cross member design of

the All Wheel Drive Wagon.

For information not contained within this Section, refer to Section 9, Steering in the MY2004 VY and V2 Series Service

Information.

NOTE

A driver’s inflatable restraint (airbag) is fitted as

standard equipment on all MY2004 VY & V2

Series vehicles. For detailed information

regarding the driver's airbag, including system

enable and disable procedures, refer to

Section 12M, Occupant Protection System in the

MY2004 VY & V2 Series Service Information.

Steering Page 9–3

Page 9–3

2 Service Operations

ATTENTION

All steering gear fasteners are important attaching parts as they affect the performance of vital components

and/or could result in major repair expense. Where specified in this Section, fasteners MUST be replaced with

parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality or

substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this Section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at kerb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Power Steering gear

LT Section No. – 06-275

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

#$ Steering gear pinion shaft to intermediate steering shaft coupling attaching nut.

The following fasteners MUST be replaced when performing this operation:

!

!!

! Steering gear to cross member attaching nut.

Steering Page 9–4

Page 9–4

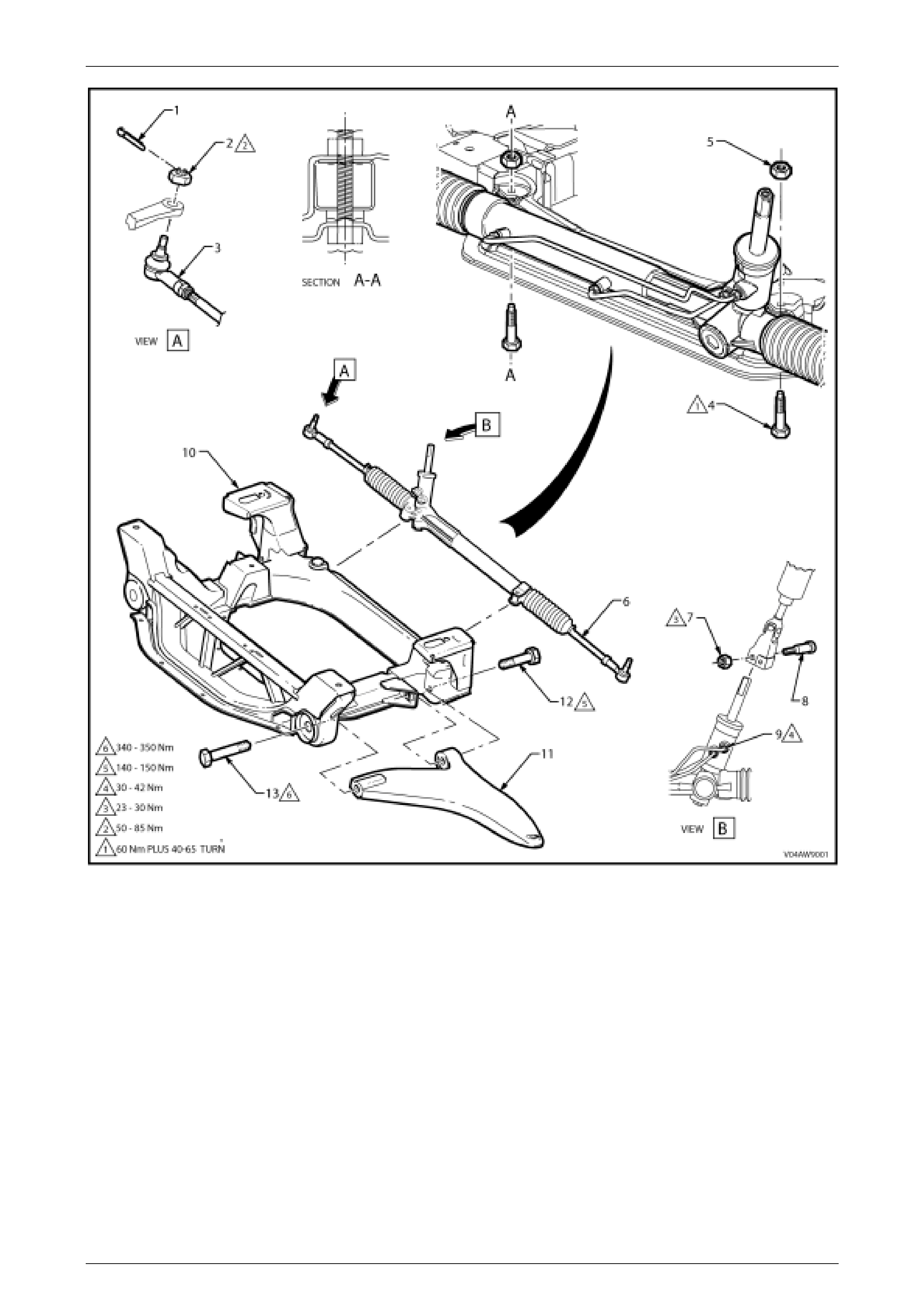

Figure 9-1Legend

1 Pin – Split, Tie Rod Socket Retaining Nut

2 Nut – Retaining, Tie Rod Socket to Steering Knuckle

3 Tie Rod Socket Assembly

4 Bolt – Attaching, Steering Gear to Cross Member

5 Nut – Attaching, Steering Gear to Cross Member

6 Steering Gear Assembly

7 Nut – Retaining, St eeri ng Coupling Cam Bolt

8 Cam Bolt – Attaching, Steering c oupling

9 Pipe – Fluid, Steering Gear

10 Cross Member Assembly

11 Control Arm – Lower

12 Bolt – Attaching, Lower Control Arm, Rear

13 Bolt – Att aching, Lower Control Arm, Front

Steering Page 9–5

Page 9–5

Remove

For removal procedure information not contained within this Section, refer to Section 9, Steering in the MY2004 VY and

V2 Series Service Information.

Reinstall

For reinstallation procedure information not contained within this Section, refer to Section 9, Steering in the MY2004 VY

and V2 Series Service Information.

For wheel alignment information refer to Section 3, Front Suspension in the MY2004 VY and V2 Series Service

Information.

! Steering gear to cross member

retaining nut torque specification.....................................

Stage 1.................................................................60 Nm

Stage 2............................................ 40º – 60º turn angle

% Steering coupling cam bolt

attaching nut torque specification.................23 – 30 Nm

Steering gear tie-rod lock

nut torque specification ................................ 40 – 60 Nm

Tie-rod socket attaching

nut torque specification ................................ 50 – 85 Nm

Steering gear fluid pipe flare nut

torque specification ...................................... 30 – 42 Nm

Steering Page 9–6

Page 9–6

2.3 Power Steering Fluid Cooler and

Hose/Pipe Routing

LT Section No. – 06-400

Arrangement

Refer to Figure 9-2 for the general layout of the power steering fluid cooler, pipes, hoses and fittings.

Steering Page 9–7

Page 9–7

Figure 9-2

Legend

Steering Page 9–8

Page 9–8

1 Steering Gear Assembly

2 O-ring – Power Steering Fluid Hose

3 Flare Nut – Power Steering Fluid Hose

4 Pipe and Hose Assembly – Steering Gear to Fluid Cooler

5 Pipe and Hose Assembly – Power Steering Pump to

Steering Gear

6 Clamp – Power Steering Fluid Reservoir Hose t o Pum p

7 Hose – Power Steering Fluid Reservoir to Pump

8 O-ring – Power Steering Pump Outlet Pipe

9 Flare Nut – Power Steering Pump Outlet Pipe

10 Hose – Power Steering Flui d Return to Reservoir, corpora

ting a restrict or at the reservoir end.

11 Bolt – Attaching, Return Pipe to Cross Member

12 Clamp – Power Steering Flui d Return Hose t o Return Pipe

13 Pipe – Power Steering Fluid Return

14 Bolt – Attaching, Return Pipe to Cross Member

15 Reservoir – Power Steering Fluid

16 Clamp – Power Steering Flui d Reservoir Out l et Hose to

Pump

17 Bolt – Attaching, Fluid Pipe Mounting Bracket t o Engine Oil

Pan

Steering Page 9–9

Page 9–9

3 Torque Wrench Specifications

ATTENTION

All exhaust system fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this Section, fasteners MUST be

replaced with parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior

quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this Section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at kerb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

Nm

! Steering gear to cross member attaching nut................................................

Stage 1.................................................................................................60

Stage 2......................................................................40º – 60º turn angle

% Steering gear pinion shaft to intermediate steering shaft coupling

attaching nut..........................................................................................23 – 30

Steering gear tie-rod lock nut.................................................................40 – 60

Steering gear fluid pipe flare nut............................................................30 – 42

Flare Nut – Power Steering Fluid Hose..................................................30 – 42

Flare Nut – Power Steering Pump Outlet Pipe.......................................30 – 42

Clamp – Power Steering Fluid Reservoir Hose to Pump.....................2.0 – 3.0

Clamp – Power Steering Fluid Return Hose to Return Pipe ................2.0 – 3.0

Bolt – Attaching, Return Pipe to Cross Member ..................................5.5 – 7.5

Bolt – Attaching, Return Pipe to Cross Member ..................................5.5 – 7.5

Bolt – Attaching, Fluid Pipe Mounting Bracket to Engine Oil Pan..........20 – 30