Sheetmetal and Subfram e Page 1B–1

Page 1B–1

Section 1B

Sheetmetal and Subfram e

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 Service Operations – Crew Cab ........................................................................................................... 3

2.1 Body Structure Replacement Parts ......................................................................................................................3

Underbody ..............................................................................................................................................................4

Upperbody Sheetmetal..........................................................................................................................................6

Body Assembly ......................................................................................................................................................8

Rear Tray Body Assembly...................................................................................................................................10

2.2 Rear Tray Body Assembly...................................................................................................................................12

Remove .................................................................................................................................................................13

Reinstall ................................................................................................................................................................14

2.3 Inner Side Panel Extension Cover......................................................................................................................16

Remove .................................................................................................................................................................16

Reinstall ................................................................................................................................................................16

2.4 Front End Panel Cover.........................................................................................................................................17

Remove .................................................................................................................................................................17

Reinstall ................................................................................................................................................................17

2.5 Subframe Assembly.............................................................................................................................................18

Remove .................................................................................................................................................................18

Disassemble.....................................................................................................................................................19

Reassemble......................................................................................................................................................19

Reinstall ................................................................................................................................................................20

3 Torque Wrench Specifications........................................................................................................... 23

Sheetmetal and Subfram e Page 1B–2

Page 1B–2

1 General Information

With the following exceptions, MY 2004 VY Regular Cab and Crew Cab Sheetmetal and Rear Subframe information

carries over from MY 2004 VY Series vehicles and MY 2003 VY Regular Cab vehicles.

Crew Cab:

• Body structure replacement parts

• Rear tray body assembly

• Inner side panel ex tension cover

• Front End panel cover

• Subframe Assembly

For information not contained within this Section, refer to Section 1B Sheetmetal in the MY 2004 VY and V2 Series

Service Information and Section 1B Sheetmetal and Rear Subframe in the MY 2003 VY Regular Cab Service

Information.

Endgate service information carries over from the MY 2004 VY Utility. For all endgate service information, refer to

Section 1A4 Hood, Rear Compartment Lid, Liftgate and Endgate in the MY 2004 VY and V2 Series Service Information.

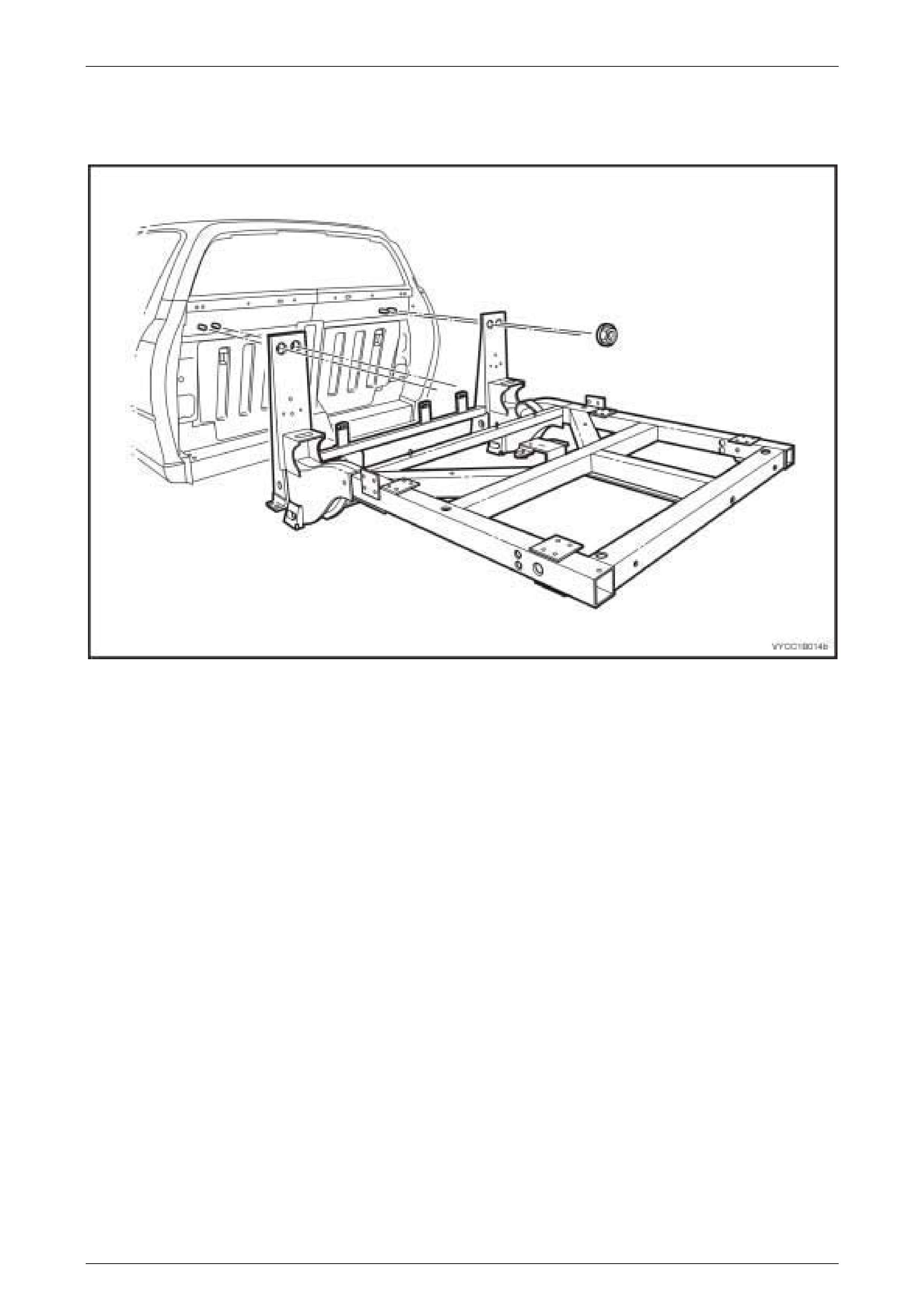

The MY 2004 VY Crew Cab rear tray body assembly is attached to the subframe assembly using six mounting points

and has an additional four supports attached to the subframe and body assembly. Figure 1B – 5 illustrates the locations

of these mounting points and the shows a detailed view of the supports.

Sheetmetal and Subfram e Page 1B–3

Page 1B–3

2 Service Operations – Crew Cab

2.1 Body Structure Replacement Parts

The following illustrations and tables describe the Crew Cab body structure assemblies and panels that are available for

se rvice replacement.

The purpose of this information is to provide the repairer with a better understanding of available replacement sections.

For further information regarding the body structure, refer to the VY Regular Cab and Crew Cab Service Information

Supplement, Body Structure Repair.

Sheetmetal and Subfram e Page 1B–4

Page 1B–4

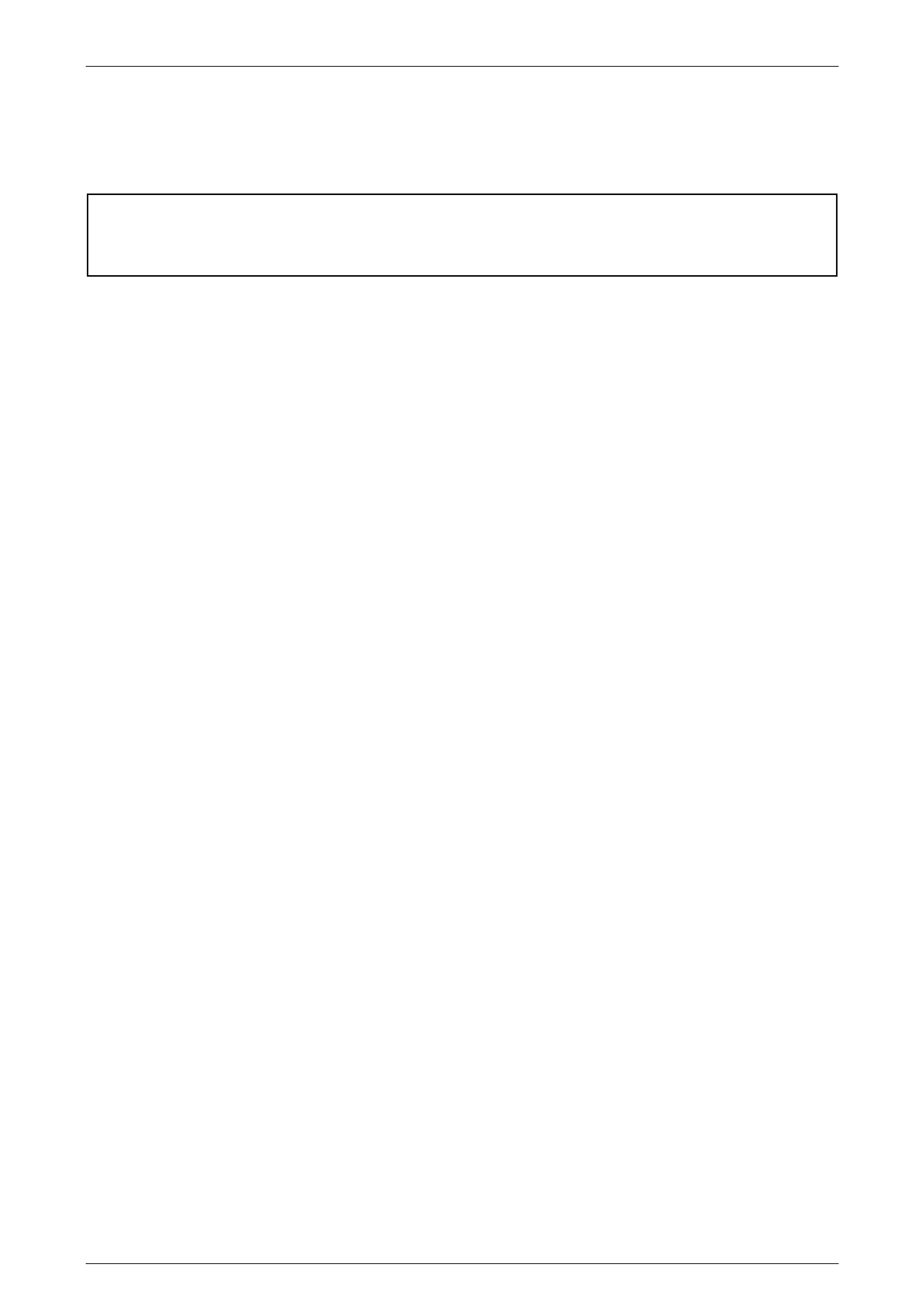

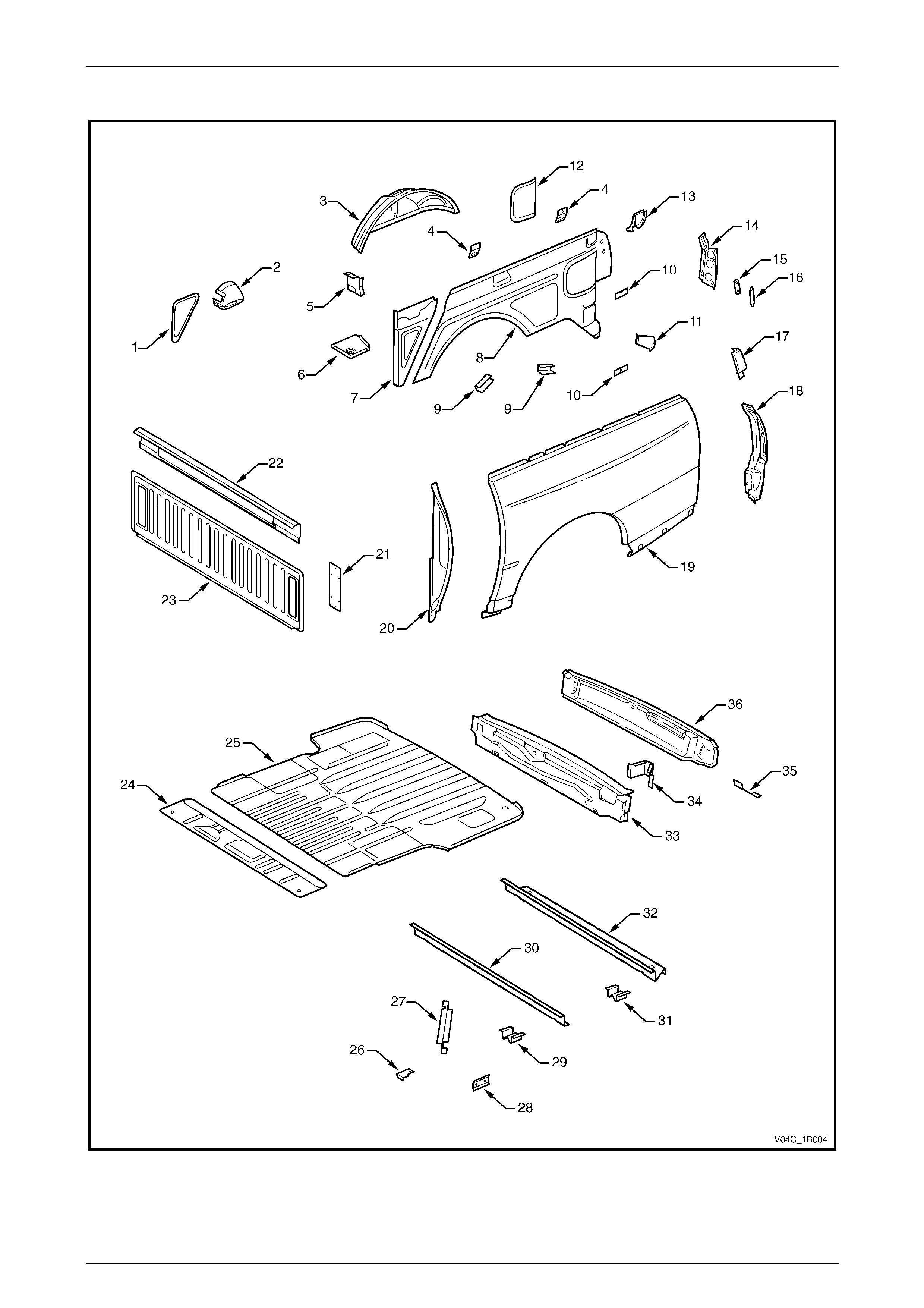

Underbody

Figure 1B – 1

Sheetmetal and Subfram e Page 1B–5

Page 1B–5

Legend

1 Inner Rocker P anel Assembl y

2 Seat Inner Bracket Assembly

3 Seat Outer Bracket Ass embly, RH/ LH

4 Front Floor Panel Assembly

5 Transmission Support Bracket, LH/ RH

6 Front Floor Panel Extension

7 Front Side Rail Brace, RH/ LH

8 ABS Modulator Bracket Assembly

9 Front Wheelhouse Panel Assembly

10 Horn Bracket Assembly

11 Battery Tray Assembly

12 Front End Panel Assembly

13 Headlamp Panel, LH/ RH

14 Radiator Lower Support Ass em bly

15 Headlamp & Front Fascia Mount Bracket, LH/ RH

16 Fender Front Lower Bracket, LH/ RH

17 Front Side Rail Assembly, LH/ RH

18 Radiator Side Mounting B rack et, LH/ RH

19 Front Wheelhouse Bracket Assembly, LH/ RH

20 Front Bumper Impact Bar Bracket, LH/ RH

21 Front Wheelhouse Panel Bracket, LH/ RH

22 Rear Lower Body Panel Assem bly, LH/ RH

23 Rear Lower Body Panel

24 Front Floor Panel Extension Assembly

25 Floor Panel Plate Assembly, 2 each LH/ RH

26 Rear Seatbelt Anchor Plat e Assembly, 3 places

27 Propeller Shaft Hanger Assembly

Sheetmetal and Subfram e Page 1B–6

Page 1B–6

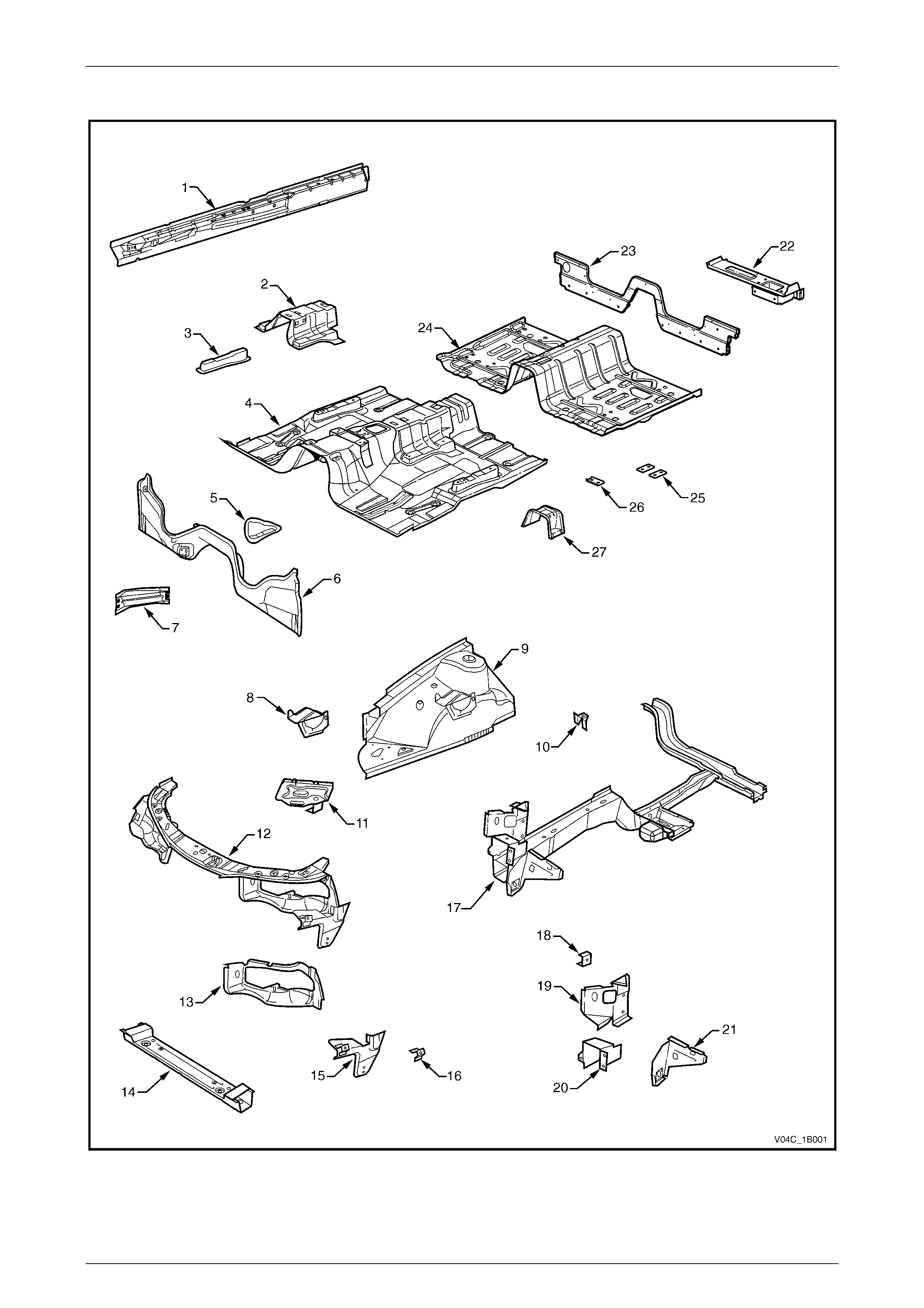

Upperbody Sheetmetal

Figure 1B – 2

Sheetmetal and Subfram e Page 1B–7

Page 1B–7

Legend

1 Roof Front Header Panel

2 Roof Panel

3 Roof Bow Panel

4 Roof Rear Header Inner Panel

5 Roof Rear Header Outer Panel

6 Rear Body Upper Outer Panel Assembly

7 Rear Body Upper Inner Panel Assembly

8 Rear Body Lower Panel Assem bly

9 Quarter Panel Inner Assembl y

10 Quarter Panel Inner Extensi on

11 Hinge Pillar Inner Panel Assembly

12 Hinge Pillar Trim Panel Bracket

13 Quarter Panel

14 Door Opening Frame Assembly

15 Door Striker Anchor Plate

16 Underbody Jack i ng Locator

17 Fender Rear Bracket

18 Fender Lower Rear Bracket

19 Fender Upper Rear Bracket

20 Front Wheelhouse Panel Upper Side Rail

21 Front Fender

Sheetmetal and Subfram e Page 1B–8

Page 1B–8

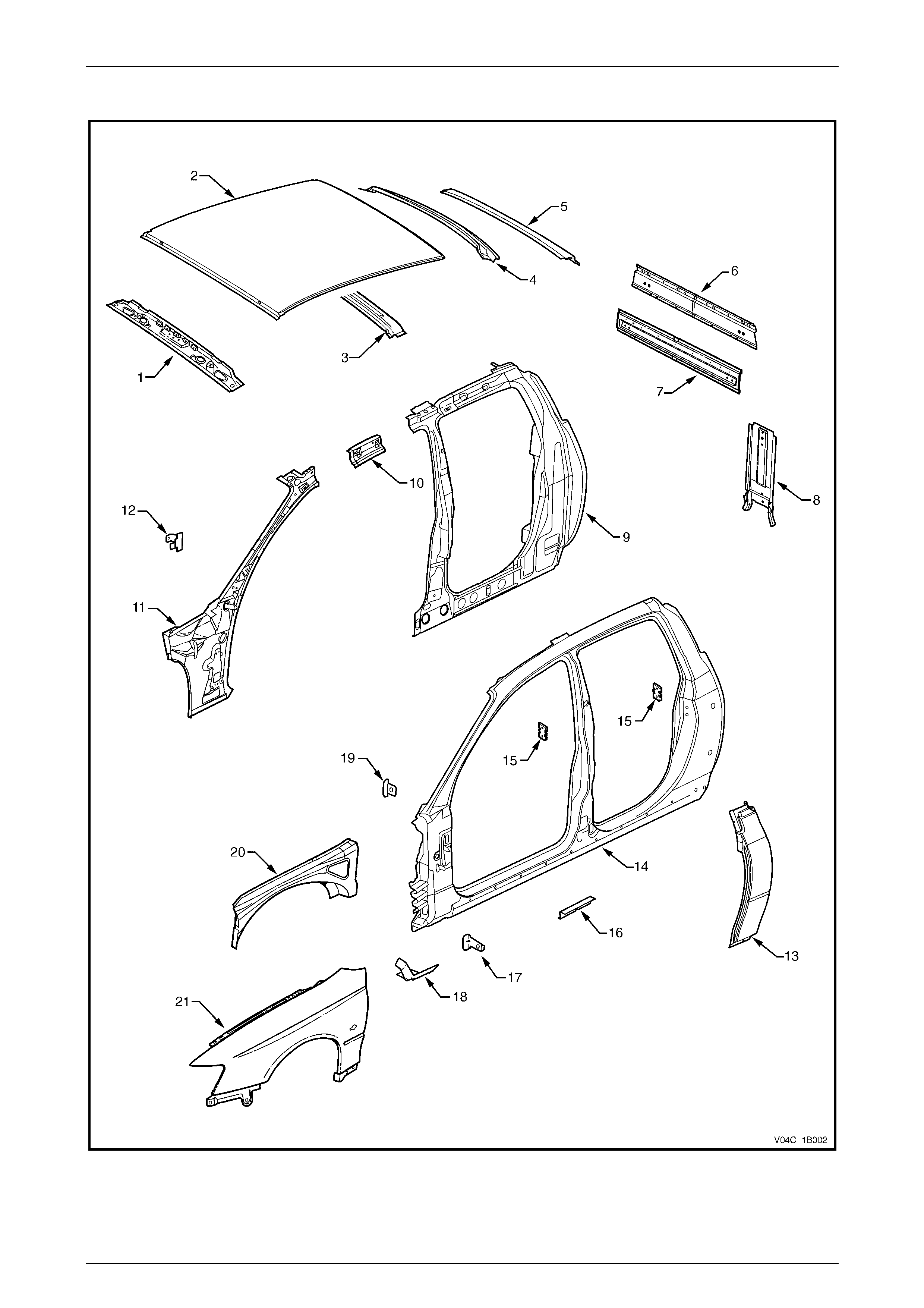

Body Assembly

Figure 1B – 3

Sheetmetal and Subfram e Page 1B–9

Page 1B–9

Legend

1 Body Assembly

2 Dash Panel Assembly

3 Front Bumper Impact Bar Assembly

4 Hood Assembly

5 Hood Hinge Assembly

6 Front Door Outer Panel

7 Front Door Assembly

8 Front Door Hinge (door side)

9 Front Door Hinge (body side)

10 Rear Door Outer Panel

11 Rear Door Assembl y

12 Rear Door Hinge (door side)

13 Rear Door Hinge (body side)

14 Fuel Tank Lower Strap, LH

15 Fuel Tank Lower Strap, RH

16 Fuel Tank Upper Strap LH/ RH

17 Floor Support Frame

18 Subframe Assembly

19 Rear Tray Body Assembly

20 Endgate Hinge Assembly

21 Endgate Assembly

22 Endgate Outer Panel

Sheetmetal and Subfram e Page 1B–10

Page 1B–10

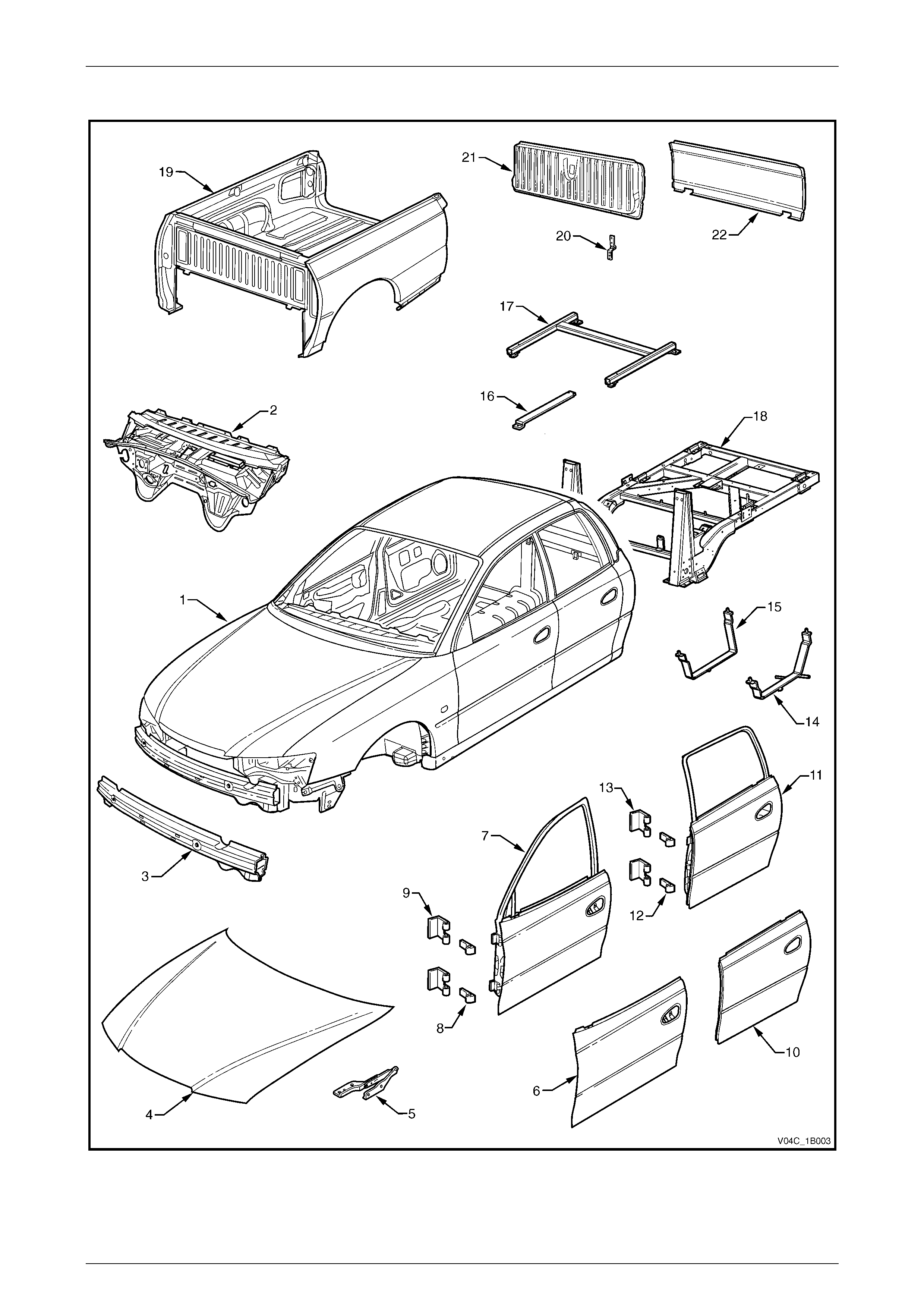

Rear Tray Body Assembly

Figure 1B – 4

Sheetmetal and Subfram e Page 1B–11

Page 1B–11

Legend

1 Inner Side Panel Extension Cover, RH

2 Fuel Filler Pipe Housing, RH

3 Rear Wheelhouse Inner Panel

4 Cargo Tie Down Bracket

5 Front Cover Attachment B eam

6 Load Floor Panel Front Extension

7 Inner Side Panel Extension Assem bly

8 Inner Side Panel

9 Wheelhouse Filler Panel Bracket

10 Cargo Tie Down Bracket Anchor Plate Assembly

11 Quarter Panel Rear Brace

12 Rear Inner Side Panel Cover

13 Quarter Lower Rear Panel

14 Quarter Inner Lower Rear Extension

15 Endgate Striker Anchor Plate

16 Endgate Striker Anchor Plate Retainer

17 Quarter Panel Upper Extension

18 Quarter Panel Extension

19 Rear Quarter Panel

20 Quarter Panel Front Gusset

21 Front End Panel Cover

22 Front End Panel Sill Assembly

23 Front End Panel

24 Load Floor Front Extension

25 Load Floor Panel

26 Front End Panel Locator

27 Load Floor Panel Support

28 Load Floor Panel Side Support

29 Load Floor Panel Locator

30 Load Floor Panel Front Support

31 Load Floor Panel Locator Guide

32 Load Floor Panel Rear Support

33 Rear End Panel

34 Endgate Hinge Reinforcement

35 Rear Fascia Centre Bracket

36 Rear End Lower Panel

Sheetmetal and Subfram e Page 1B–12

Page 1B–12

2.2 Rear Tray Body Assembly

Figure 1B – 5

Sheetmetal and Subfram e Page 1B–13

Page 1B–13

Remove

1 Disconnect the wiring harness at the rear of the cab, refer to Section 12A Battery & Cables.

2 Remove the fuel filler neck, refer to Section 8A1, 2.2 Fuel Filler Neck and Splash Guard.

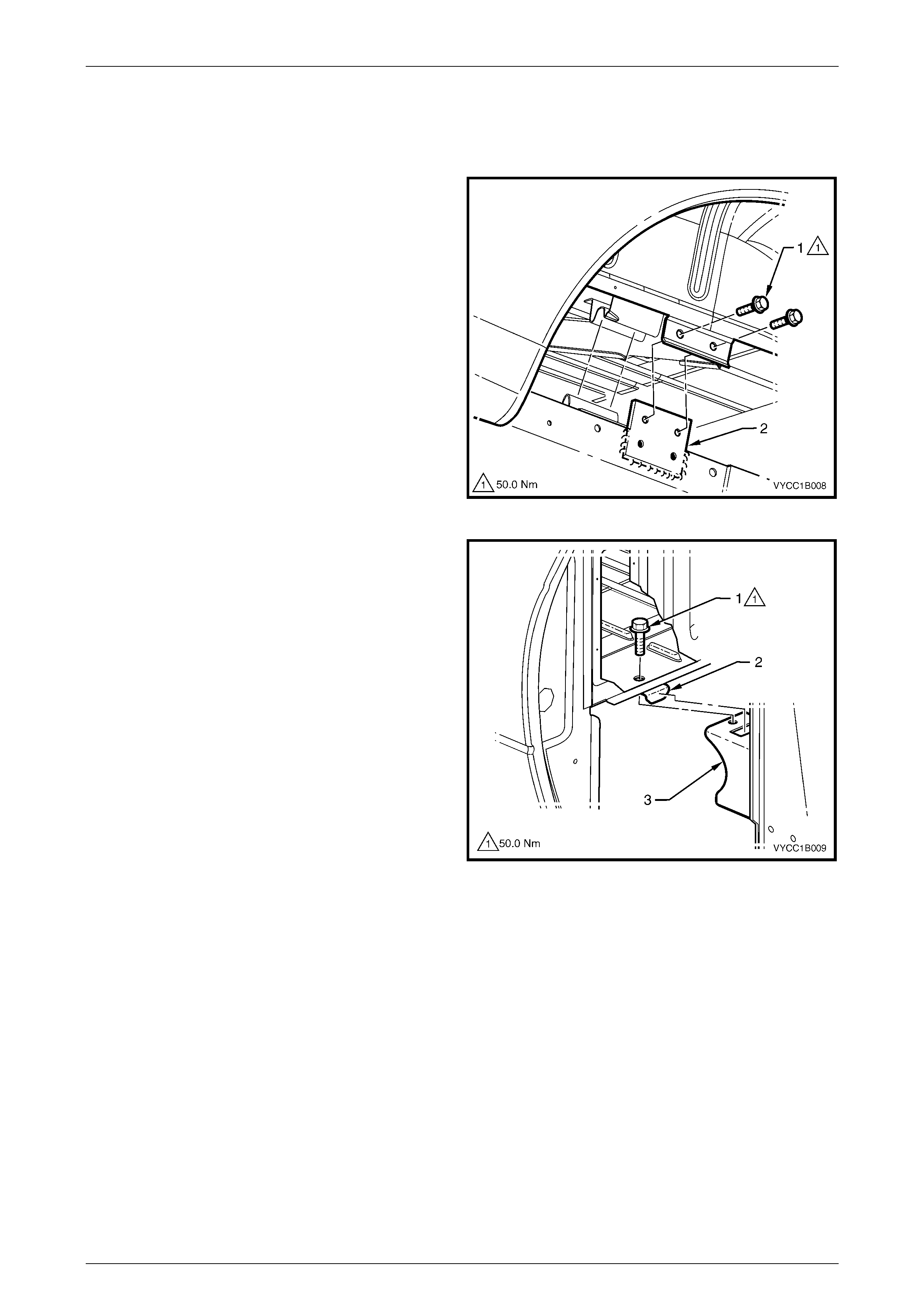

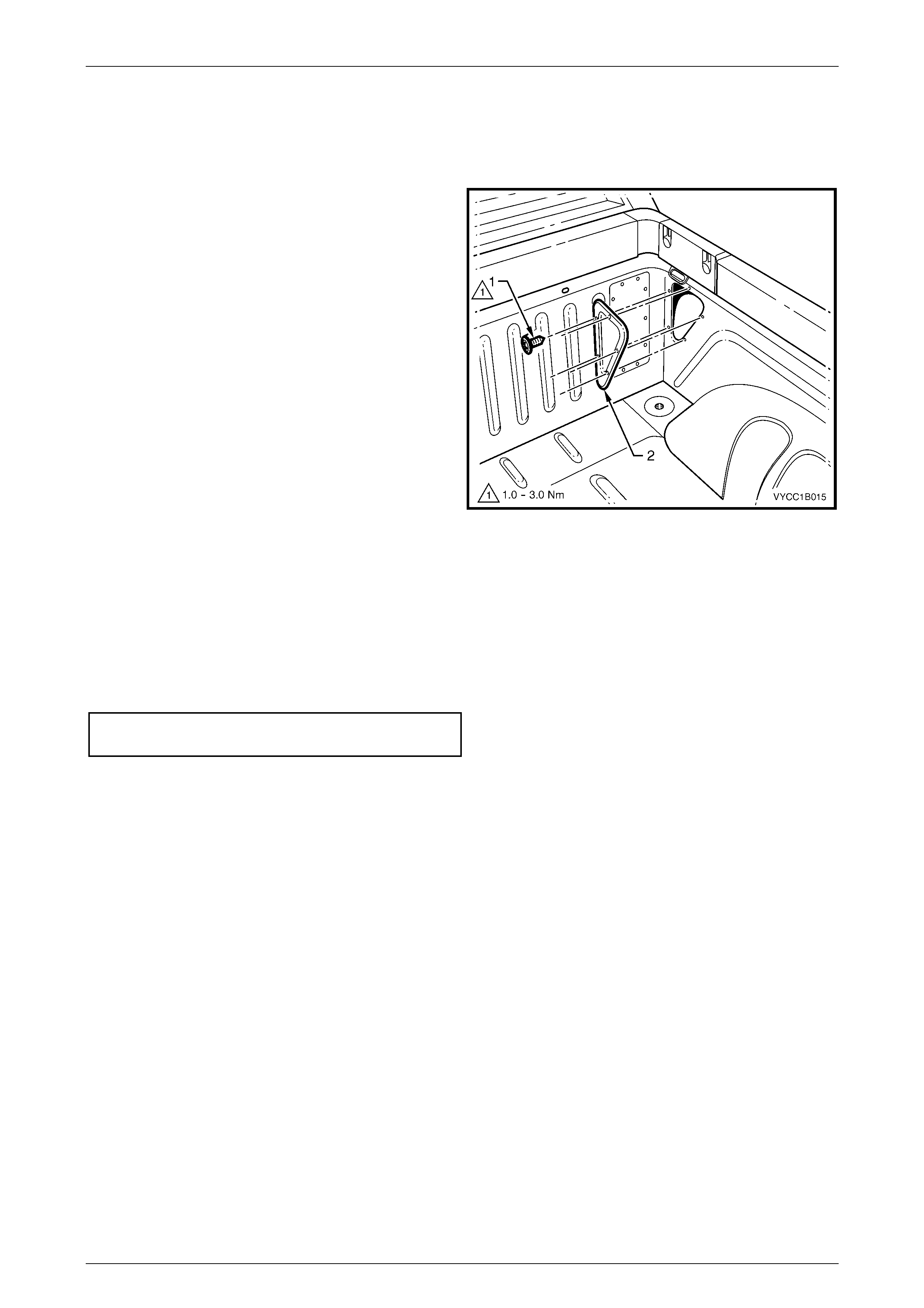

3 Remove the mounting bolt (1), 2 places each side of

the vehicle, attaching the rear tray body assembly to

the subframe centre moun t (2) .

Figure 1B – 6

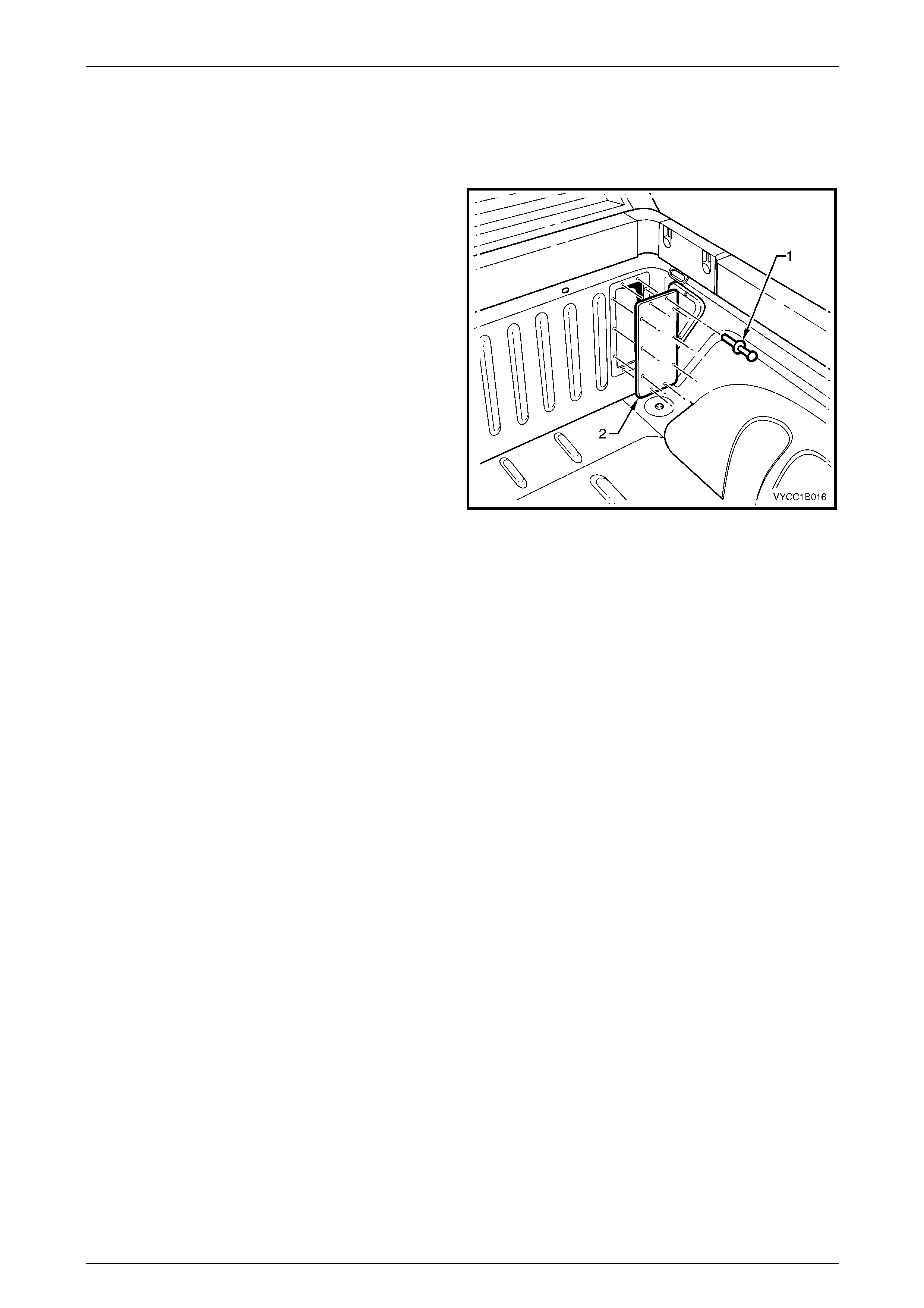

4 Remove the bolt (1), one place each side attaching

each front corner of the body assembly (2) to the

subframe (3).

Figure 1B – 7

Sheetmetal and Subfram e Page 1B–14

Page 1B–14

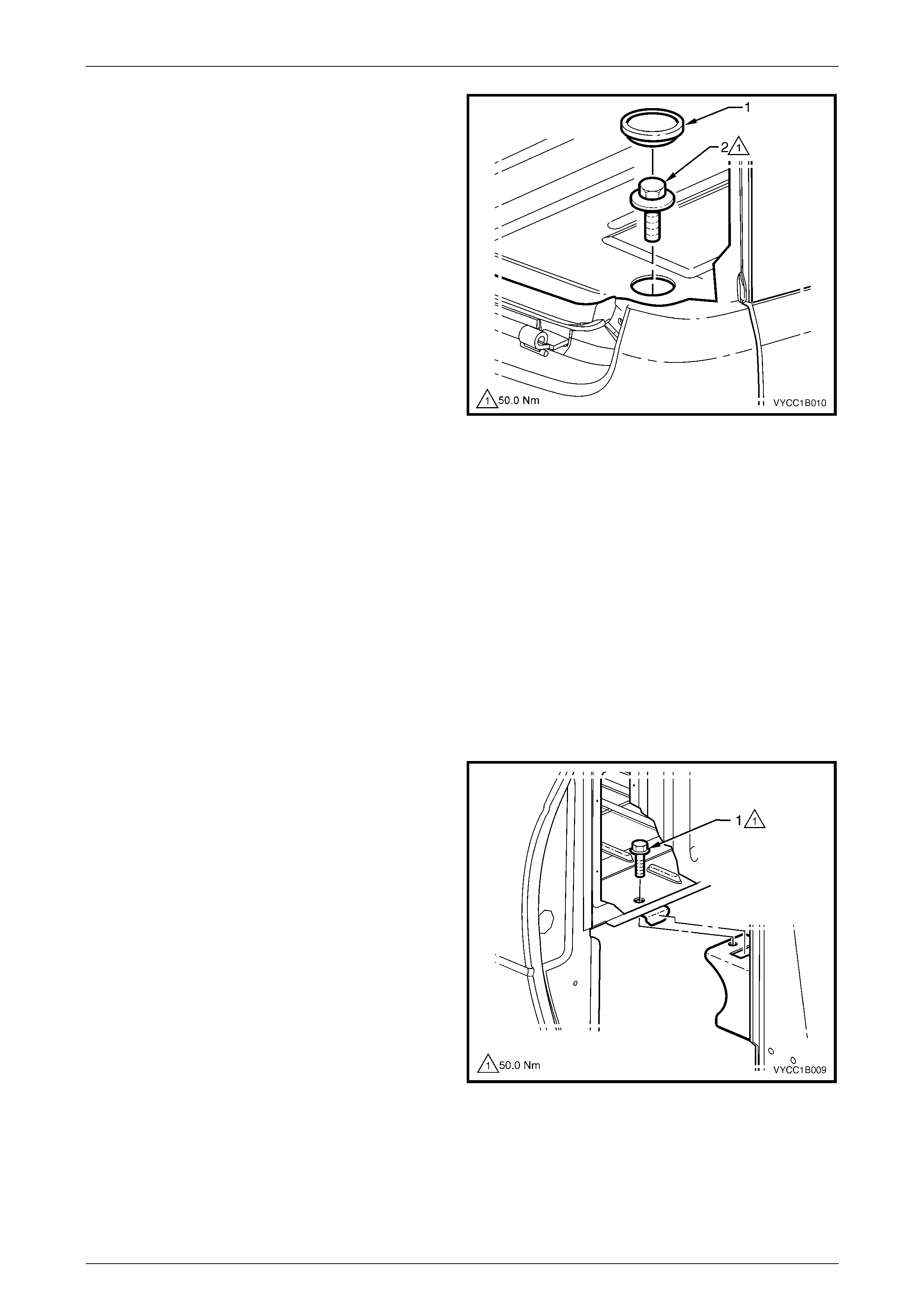

5 Remove the grommet (1), one place each side to allow

access to the mounting bolt (2).

6 Remove the bolt, one place each side attaching each

rear corner of the body assembly to the subframe.

7 With the aid of several assistants or using a suitable

lifting hoist, carefully raise the body assembly clear of

the vehicle and remove.

Figure 1B – 8

Reinstall

NOTE

The floor support frame has strips of foam glued

to it. If the foam is damaged, replace it with

commercially available high-density foam and fix

with contact adhesive.

1 With the aid of several assistants or using a suitable lifting hoist, carefully position the rear tray body assembly over

the subframe.

NOTE

Ensure the front location tab is positioned in the

slot of the front subframe mount correctly.

2 Slide the tray as far forward as possible, then reinstall

the bolt (1), one place in each front corner, but do not

tighten.

Figure 1B – 9

Sheetmetal and Subfram e Page 1B–15

Page 1B–15

3 Reinstall the bolt (1), one place in each rear corner,

but do not tighten. Do not install the grommet (2) at

this stage.

Figure 1B – 10

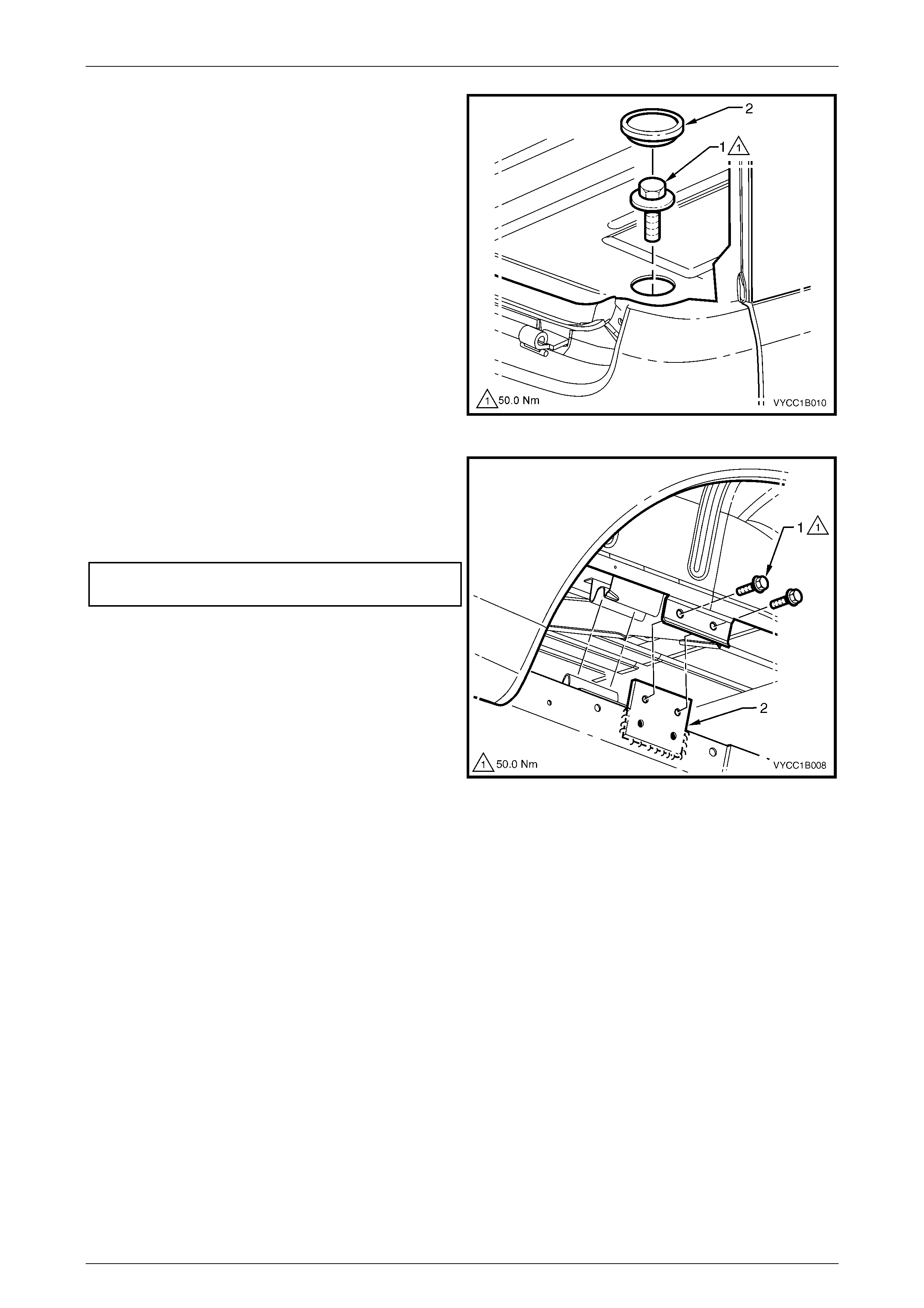

4 Reinstall the two bolts (1) in the centre mount (2),

each side of the vehicle, but do not tighten.

5 Ensure the rear body is positioned correctly on all

mounting points and tighten all fixtures to the specified

torque.

Rear tray body assembly mounting bolt

torque specific atio n ...........................................50.0 Nm

6 Reinstall the grommet (2), one place each side in the

rear body floor, refer to Figure 1B – 10.

7 Refit the fuel filler neck, refer to Section 8A1, 2.2 Fuel

Filler Neck and Splash Guard.

8 Reconnect the wiring harness at the rear of the body,

refer to Section 12A Battery & Cables.

9 Ensure all lights are working correctly.

Figure 1B – 11

Sheetmetal and Subfram e Page 1B–16

Page 1B–16

2.3 Inner Side Panel Extension Cover

Remove

1 Remove the screw (1) five places, attaching the inner

side panel extension cover (2).

NOTE

Protect the paintwork with a rag when performing

the following operation.

2 Using a flat-blade screwdriver or suitable lever,

carefully prise the corner of the cover from the inner

side panel to break the sealer.

3 Remove t he cover .

Figure 1B – 12

Reinstall

1 Clean off any old sealer and ensure the cover and inner side panel are clean and dry.

2 Apply a continuous bead of sealer such as non-hardening butyl sealer around the perimeter of the cover.

3 Install the cover ensuring it is correctly orientated.

4 Start all screws and then, tighten to the specified torque.

Inner side panel ex tension cover attachi ng

screw torque specification.......................... 1.0 – 3.0 Nm

5 Remove any residual sealer as required.

Sheetmetal and Subfram e Page 1B–17

Page 1B–17

2.4 Front End Panel Cover

Remove

1 Remove the 10 pop rivets (1) attaching the front end

panel cover (2) to the front end panel by drilling the

heads of the rivets.

NOTE

Use a rag to avoid damage to the front end

panel or paintwork when removing the front end

panel cover.

2 Using a flat-blade screwdriver, carefully prise the

corner of the cover from the front end panel to break

the sealer.

3 Remove t he cover .

Figure 1B – 13

Reinstall

1 If required, clean off any old sealer and ensure the front end panel cover and front end panel are clean and dry.

2 Apply a continuous bead of sealer such as non-hardening butyl sealer around the perimeter of the cover.

3 Install the cover ensuring it is correctly orientated and attach with new pop rivets

4 Remove any residual sealer as required.

Sheetmetal and Subfram e Page 1B–18

Page 1B–18

2.5 Subframe Assembly

Any collision that has damaged the subframe assembly to the extent that it needs to be replaced may, have caused

some deformation to the cab structure and a complete thorough inspection and a dimensions check of the cab bodywork

is recommended.

Where a replacement of the subframe assembly is required, ancillary components will need to be removed from the

subframe. In this case it may be more convenient for the technician to remove these components while the subframe

assembly is still assembled to the vehicle.

The vehicle may become unbalanced on

stands or a hoist once the subframe

assembly, rear axle or rear suspension is

removed. Ensure the cab and subframe are

supported sufficiently to avoid injury or

damage before proceeding.

Remove

1 If required, remo ve the rear tray body assembly, refer to 2.2 Rear Tray Body Assembly.

2 Disconnect and plug the fuel lines at the connectors located just behind the cab and, if required, remove the fuel

tank, refer to Section 8A1 Fuel Tank.

3 Disconnect the handbrake cable and brake lines, refer to Section 5A Service & Park Braking System.

4 If fitted, disconnect the rear ABS sensor leads, refer to Section 5B ABS.

5 Remove the rear and intermediate exhaust assemblies, refer to Section 8B Exhaust System.

NOTE

Once the propeller shaft has been removed from

the transmission, it may be necessary to fit a

blanking plug into the rear of the transmission to

prevent any loss of transmission fluid.

6 Remove the propeller shaft, refer to Section 4C Propeller Shaft and Universal Joint.

NOTE

Removal of the rear suspension and axle

assemblies is not a mandatory requirement for

the removal of the subframe assembly. The rear

suspension and axle assembly may if required,

be removed from the subframe assembly as a

complete unit. If removed, support the subframe

with a suitable jack or lifting crane.

7 If required, remove the rear axle assembly, refer to Section 4B Rear Axle.

8 If required, remove the rear suspension assembly, refer to Section 4A Rear Suspension.

9 Remove the outer trim panel and noise reduction foam from between the subframe mounts and the cab, refer to

Section 1A9, 2.10 Rear Outer Trim Panel and NVH Foam.

Sheetmetal and Subfram e Page 1B–19

Page 1B–19

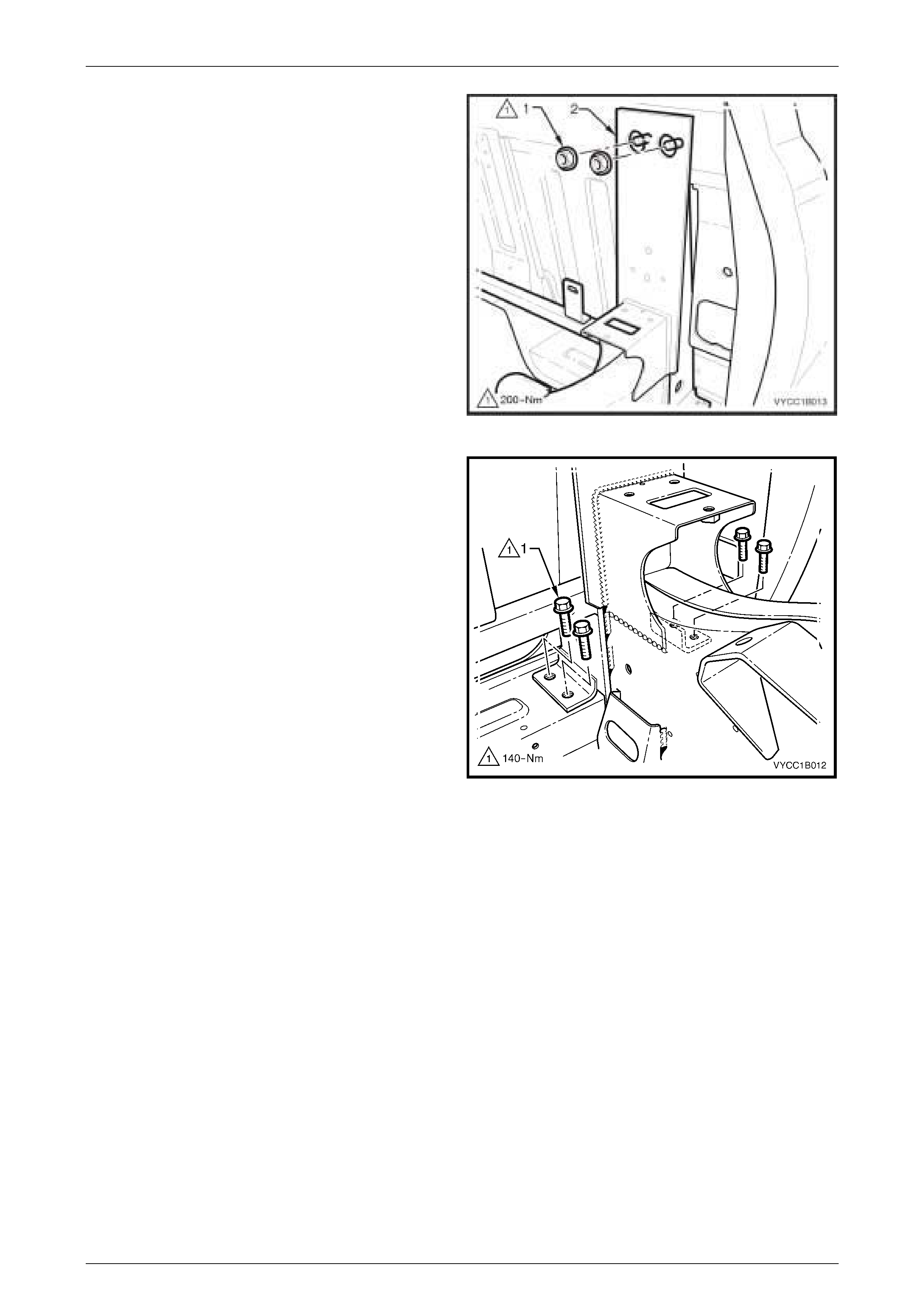

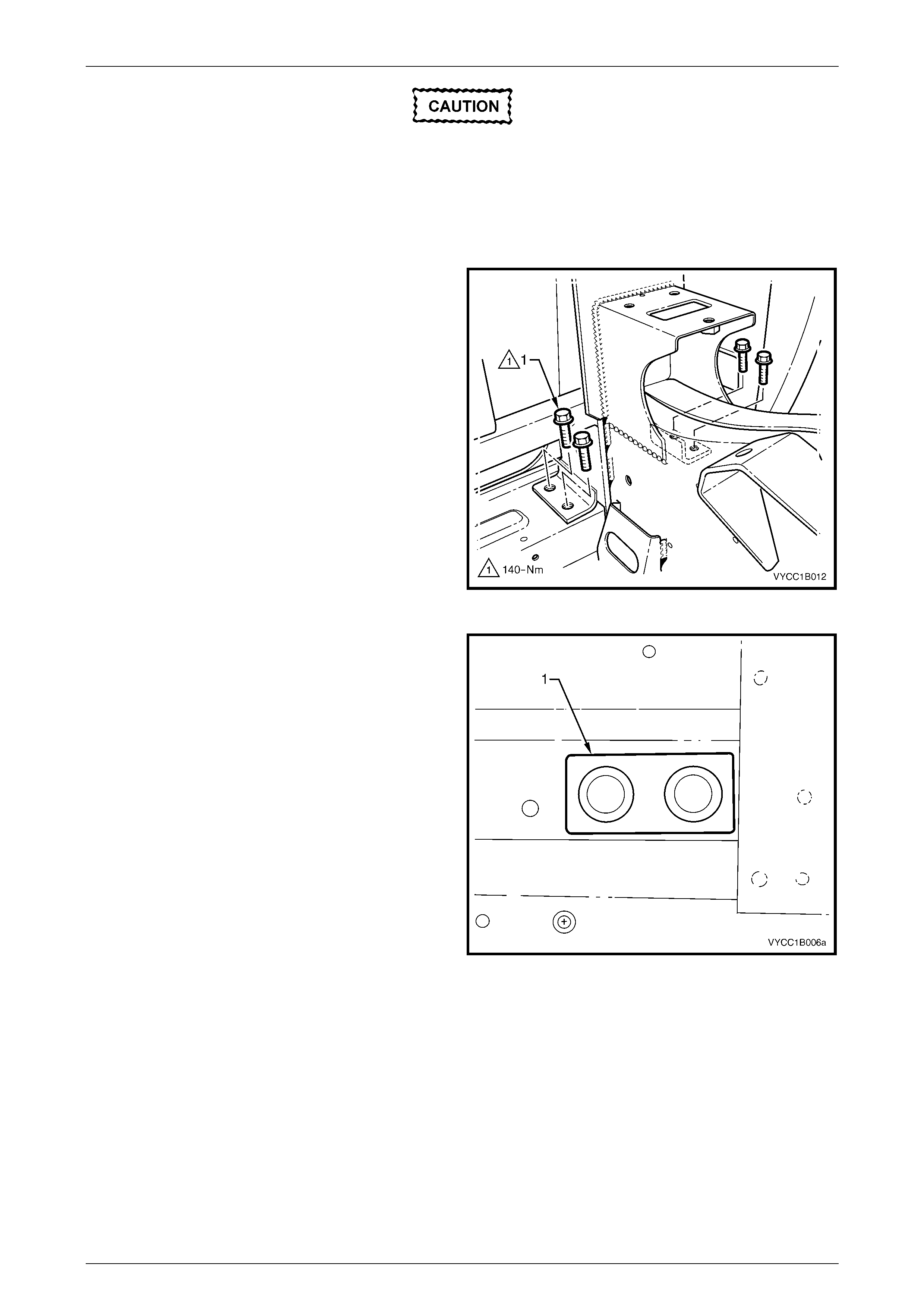

10 Remove the two flange nuts (1), either side, attaching

the subframe assembly (2) to the cab.

Figure 1B – 14

11 Remove the lower bolt (1), four plac es each side of the

vehicle.

12 With the aid of an assistant, remove the subframe

assembly from the cab by either, lifting or rolling it

clear of the cab.

Figure 1B – 15

Disassemble

If not already removed, as required remove the following:

1 Remove the fuel tank, carbon canister, fuel filler neck, lower fuel tank straps, heat shield and the remaining fuel

and vapour lines attached to the subframe, refer to Section 8A1 Fuel Tank.

2 Remove the brake proportioning valve and the remaining rear brake lines, refer to Section 5A Service & Park

Braking System.

3 Remove the rear axle assembly, refer to Section 4B Final Drive and Drive Shafts.

4 Remove the rear suspension, shock absorbers and bump stops, refer to Section 4A Rear Suspension.

5 Remove the spare wheel winch, refer to Section 10 Wheels & Tyres.

Reassemble

1 Reassemble the subframe components in the reverse order of the disassemble process. Follow the assembly

procedures in the Sections referred to for the relevant components.

Sheetmetal and Subfram e Page 1B–20

Page 1B–20

Reinstall

1 With the aid of an assistant and using a suitable jack or lifting device, align the subframe assembly squarely to the

cab and position the subframe on to the mating surfaces of the cab lower cross member, refer to Figure 1B – 16.

Figure 1B – 16

2 Slide the subframe forward until the upper face contacts the back of the cab.

Sheetmetal and Subfram e Page 1B–21

Page 1B–21

Ensure new subframe stud plates, mounting

bolts and nuts are used when reinstalling the

rear subframe. When installing the new

attaching nuts and bolts do not use any

sealers or thread locking compounds on the

bolts, nuts or between the joints on the

subframe mounts.

3 Insert the new lower bolt (1), four places each side of

the vehicle, but do not tighten.

Figure 1B – 17

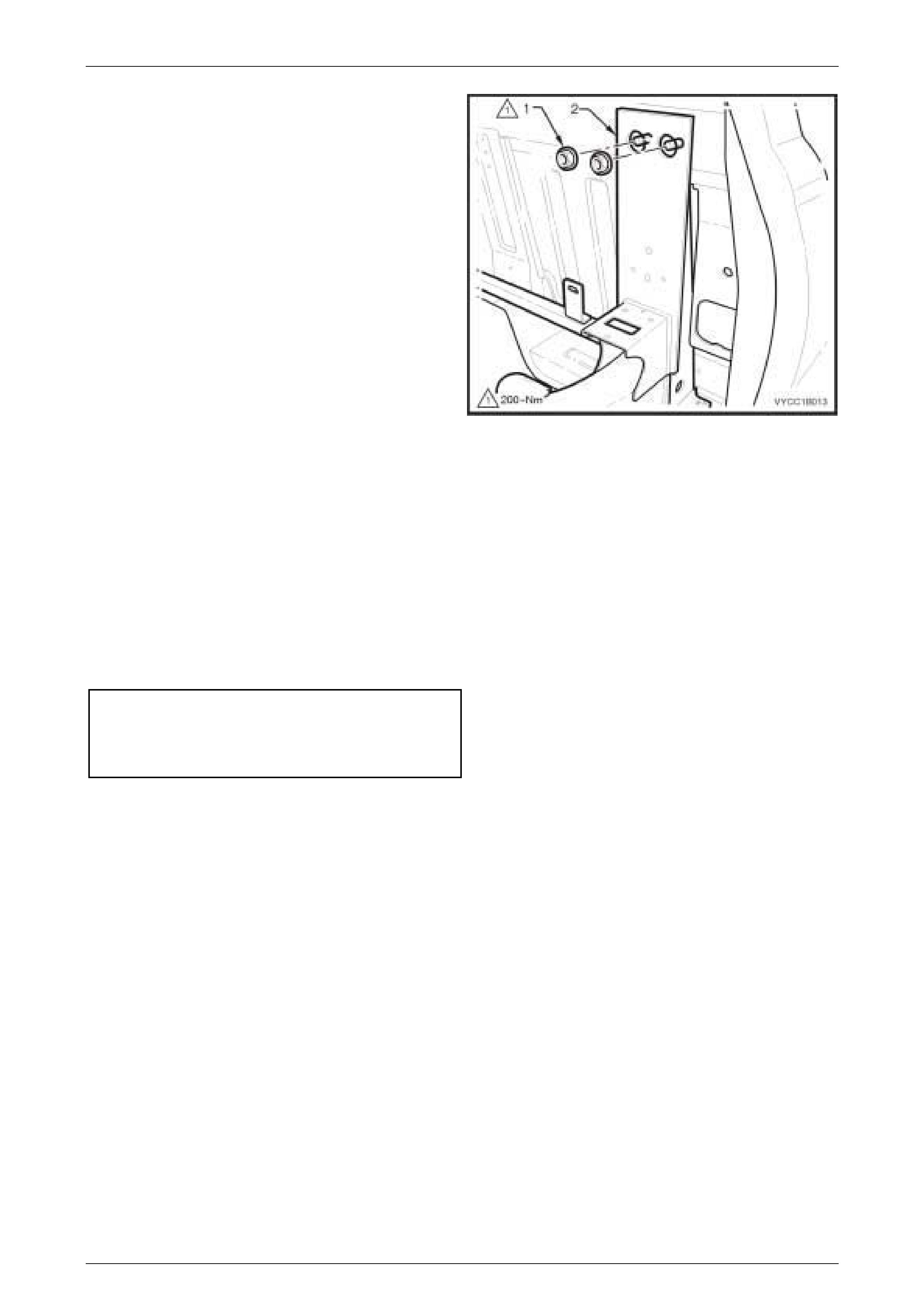

4 If removed, from inside the vehicle reinstall the stud

plate (1) through the rear body upper panel, one place

each side of the vehicle.

Figure 1B – 18

Sheetmetal and Subfram e Page 1B–22

Page 1B–22

5 Install the two new top flange nuts (1), either side,

attaching the subframe assembly (2) to the cab, but do

not tighten.

Figure 1B – 19

NOTE

Support the subframe assembly so that the

weight of the subframe does not hang on the

mounting points causing an adverse effect on the

tightening of the bolt s.

6 Initially tighten all mounting fixtures to obtain the correct location of the subframe assembly, ensuring there are no

gaps at the mounting points to the cab.

7 Tighten the four lower mounting bolts in a diagonal pattern to the specified torque, repeat for the other side of the

vehicle.

8 Tighten the two top mounting nuts to the specified torque, repeat for the other side of the vehicle.

Subframe assembly lower attaching bolt

torque specific atio n .........................................140.0 Nm

Subframe assembly top stud plate nut

torque specific atio n .........................................200.0 Nm

9 To ensure correct alignment of the subframe to the cab, it is recommended that a check of the body dimensions be

performed, refer to Section 1A2 Body Dimensions.

10 Reinstall the remaining components in the reverse order to removal, referring to the appropriate Sections.

NOTE

To ensure that the vehicle’s steering and

handling is at its optimum performance, it is

recommended that a wheel alignment be

performed after the subframe assembly has been

removed and refitted, refer to Section 3 Front

Suspension.

Sheetmetal and Subfram e Page 1B–23

Page 1B–23

3 Torque Wrench Specifications

Rear Tray Body Assembly Mounting Bolt .............................................50.0 Nm

Inner Side Panel Extension Cover Attaching Screw......................1.0 – 3.0 Nm

Subframe Assembly Lower Attaching Bolt..........................................140.0 Nm

Subframe Assembly Top Stud Plate Attaching Nut.............................200.0 Nm