Occupant Protection System Page 12M–1

Page 12M–1

Section 12M

Occupant Protection System

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

WARNINGS, CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1 General Information............................................................................................................................... 2

1.1 Regular Cab – General Description......................................................................................................................2

1.2 Crew Cab – General Description...........................................................................................................................3

2 Service Operations – Crew Cab ........................................................................................................... 4

2.1 Rear Seatbelt Assembly ........................................................................................................................................4

Remove ...................................................................................................................................................................6

Reinstall ..................................................................................................................................................................7

2.2 Rear Seatbelt Buckle Assembly............................................................................................................................8

Remove ...................................................................................................................................................................8

Left-hand Side ....................................................................................................................................................8

Right-hand Side..................................................................................................................................................8

Reinstall ..................................................................................................................................................................9

2.3 Child Seat Anchors..............................................................................................................................................10

3 Diagnosis – Front Seatbelt Switch – Crew Cab................................................................................11

3.1 General Description.............................................................................................................................................11

3.2 Circuit Diagram.....................................................................................................................................................12

Connector Chart...................................................................................................................................................12

3.3 Diagnostic Procedures ........................................................................................................................................13

Circuit Description...............................................................................................................................................13

Test Description...................................................................................................................................................13

Notes on the Diagnostic Chart............................................................................................................................13

Diagnostic Chart...................................................................................................................................................13

4 Torque Wrench Specifications........................................................................................................... 15

Techline

Techline

Occupant Protection System Page 12M–2

Page 12M–2

1 General Information

With the following exceptions, MY 2004 VY Regular Cab and Crew Cab occupant protection system information carries

over from MY 2004 VY Series vehicles and MY 2003 VY Regular Cab vehicles.

• Crew Cab rear seat belts

• Crew Cab child restraint anchors

• Crew Cab driver's seatbelt buckle warning indicator switch

For information not contained within this Section, refer to Section 12M Occupant Protection System in the MY 2004 VY

and V2 Series Service Information and Section 12M Occupant Protection System in the MY 2003 VY Regular Cab

Service Information.

1.1 Regular Cab – General Description

The Occupant Protection System for MY 2004 VY Regular Cab carries over from MY 2003 VY Regular Cab vehicles.

Occupant Protection System Page 12M–3

Page 12M–3

1.2 Crew Cab – General Description

The MY 2004 VY Crew Cab uses unique rear seatbelt assemblies and mounting brackets, and stalk type rear seatbelt

buckles. There are child restraint anchors permanently attached to the vehicle chassis.

A seatbelt buckle warning indicator switch is fitted to the driver's seat in all Crew Cab vehicles. The wiring diagram and

diagnosis procedures for the driver's seatbelt buckle warning indicator switch are specific to MY 2004 VY Crew Cab

vehicles.

For occupant protection system information not contained within this Section, refer to Section 12M Occupant Protection

System in the MY 2004 VY and V2 Series Service Information.

Occupant Protection System Page 12M–4

Page 12M–4

2 Service Operations – Crew Cab

2.1 Rear Seatbelt Assembly

LT Section No. – 14-425

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

!

!!

! Seatbelt Guide Attaching Bolt

!

!!

! Seatbelt Lower Anchor Bolt

!

!!

! Seatbelt Retractor Bracket Bolt

!

!!

! Seatbelt Buckle Assembly Attaching Bolt

Occupant Protection System Page 12M–5

Page 12M–5

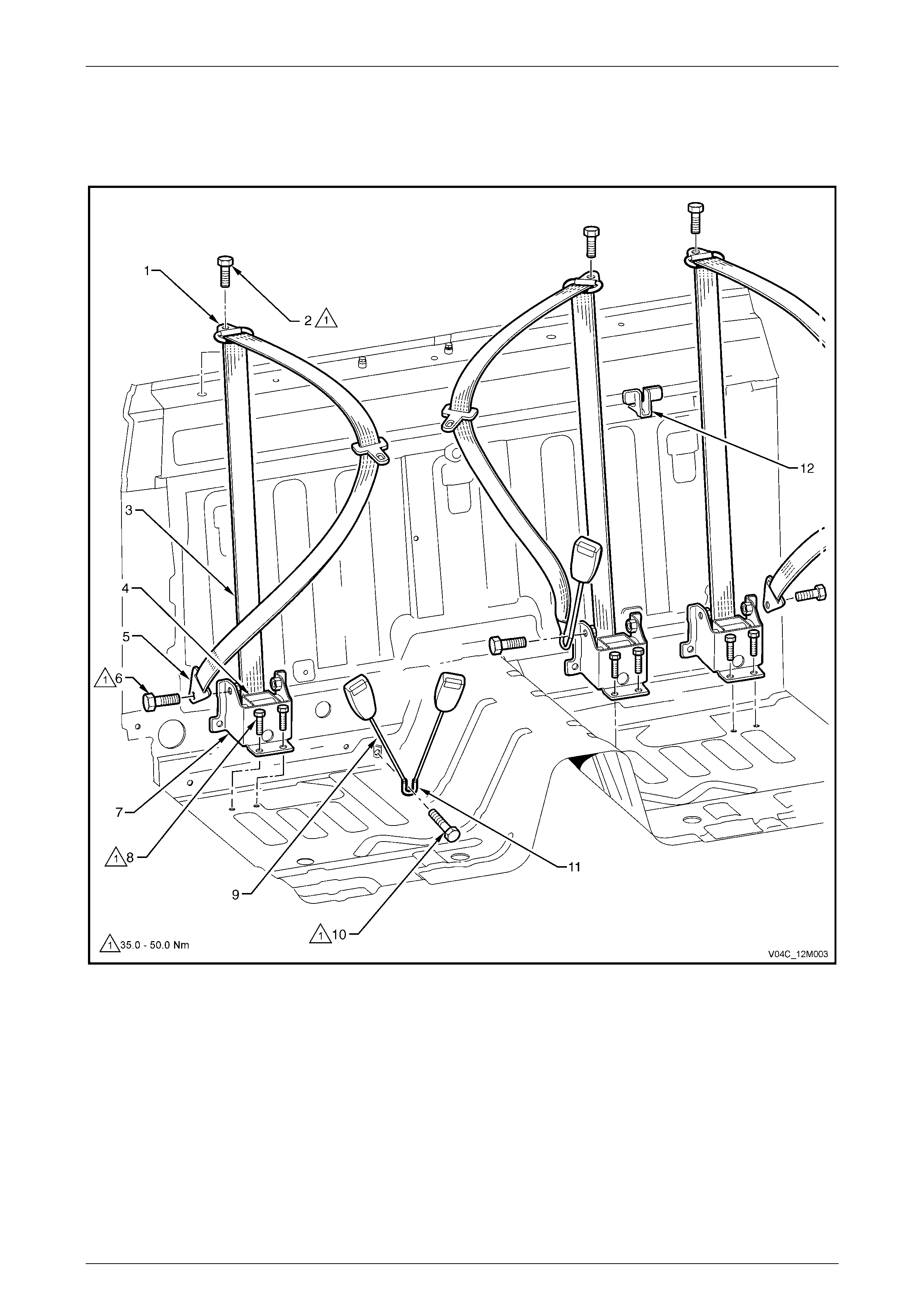

NOTE:

The following chart is included to assist with

component identification.

Figure 12M – 1

Legend

1 Seatbelt Guide

2 Seatbelt Guide Attaching Bolt

3 Seatbelt

4 Seatbelt Retractor

5 Seatbelt Lower Anchor

6 Seatbelt Lower Anchor B olt

7 Seatbelt Retractor Bracket

8 Seatbelt Ret ract o r Brack et B olt

9 Seatbelt Buckle Assembly

10 Seatbelt Buckl e Ass em bly Attaching Bol t

11 Seatbelt Buckle Bracket

12 Child Seat Anchor

Occupant Protection System Page 12M–6

Page 12M–6

Remove

NOTE

The seatbelt assemblies are similar in each of the

rear seating positions. The left-hand belt buckle

assembly is attached to the rear centre seatbelt

assembly.

1 Remove the rear seat cushion, refer to Section 1A7

Seat Assemblies.

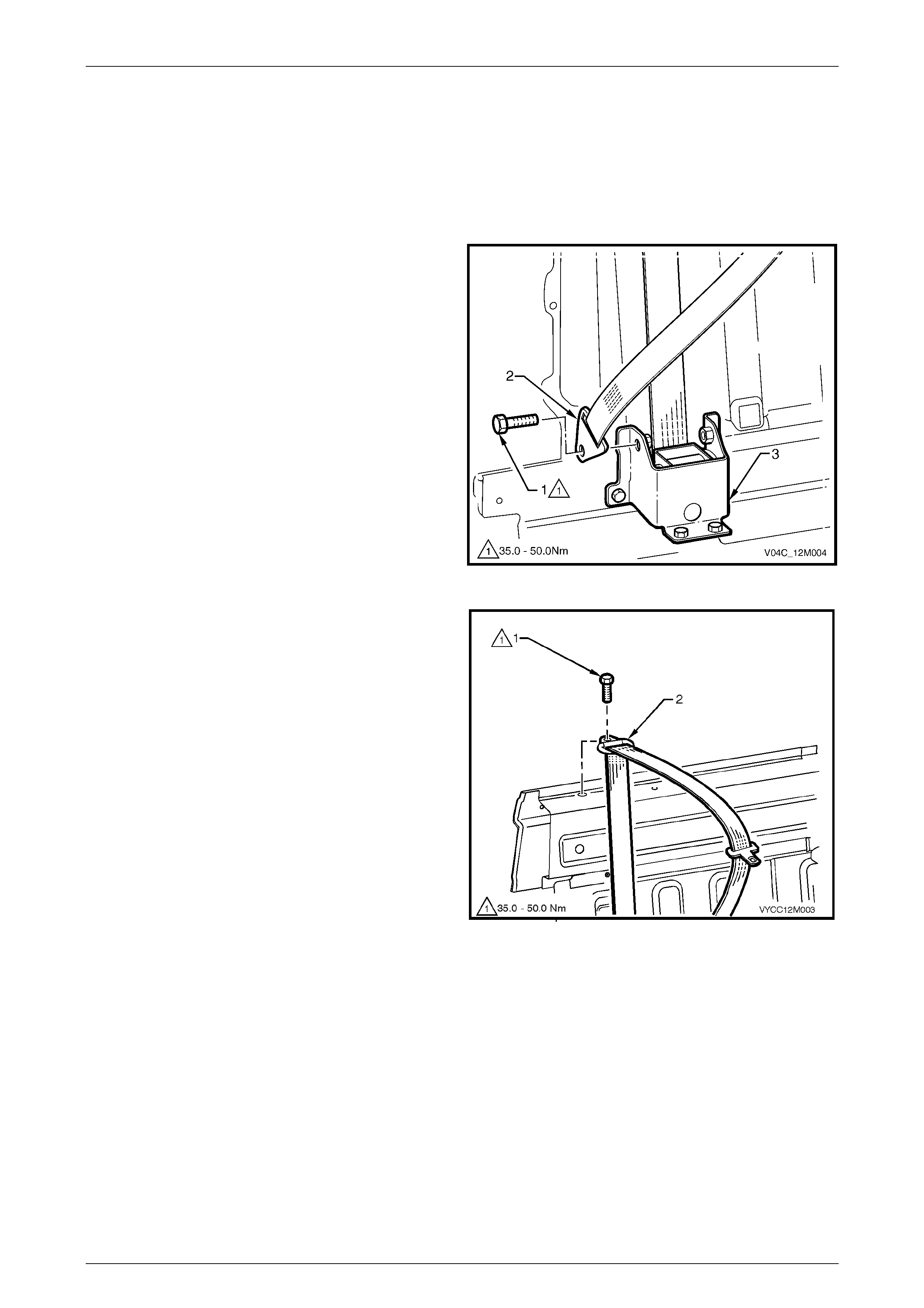

2 Remove the bolt (1) attaching the seatbelt anchor (2)

to the retractor bracket (3).

Figure 12M – 2

3 Remove the rear seat back, refer to Section 1A7 Seat

Assemblies.

4 Remove the upper cross-beam cover, refer to 1A8

Headlining and Interior Trim.

5 Remove the bolt (1) attaching the seatbelt gui de (2) to

the upper cross-beam.

Figure 12M – 3

Occupant Protection System Page 12M–7

Page 12M–7

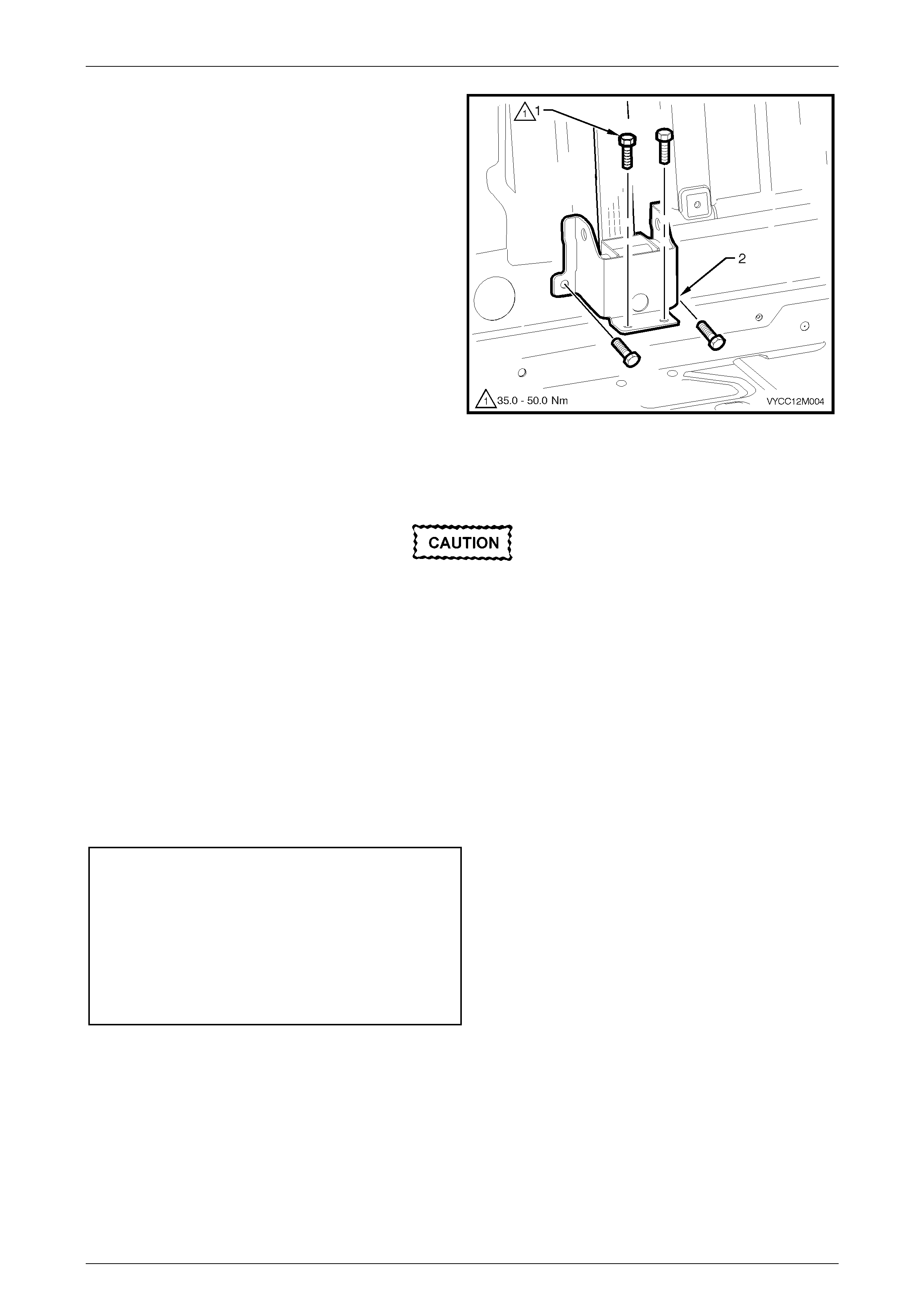

5 Remove the four bolts (1) attaching the retractor

bracket assembly (2) to the vehicle.

6 Remove the seatbelt assembly.

NOTE:

The retractor is permanently riveted to the

bracket.

Figure 12M – 4

Reinstall

If reinstalling the same retractor assembly,

inspect the anchor plates, guides and

retractor assembly for damage, and the

webbing for abrasions, fraying, cuts, etc.

Replace the seatbelt assembly with a new part

if any damage, etc. is found.

Reinstallation of the seatbelt assembly is the reverse of the removal procedure noting the following:

1 Ensure the webbing is not twisted.

2 Ensure that the threads of the retractor attaching bolts are adequately sealed with a caulking compound or a non-

hardening sealer.

3 Hand tighten all seatbelt bolts a minimum of five turns before using tools.

4 Tighten the bolts to the specified torque.

Seatbelt retractor bracket

mounting bolt torque specification................35 – 50 Nm

Seatbelt guide mounting

bolt torque specification................................35 – 50 Nm

Seatbelt anchor mounting

bolt torque specification................................35 – 50 Nm

Seatbelt bu ckle mounting

bolt torque specification................................35 – 50 Nm

5 Perform a functional check of the seatbelt to ensure correct operation.

Occupant Protection System Page 12M–8

Page 12M–8

2.2 Rear Seatbelt Buckle Assembly

LT Section No. – 14-425

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

!

!!

! Seatbelt buckle assembly mounting bolt

Remove

Left-hand Side

NOTE:

The left-hand rear seatbelt buckle is part of the

rear centre seatbelt assembly.

For the service procedure, refer to 3.1 Rear Seatbelt Assembly.

Right-hand Side

Remove the rear seat cushion, refer to Section 1A7 Seat Assemblies.

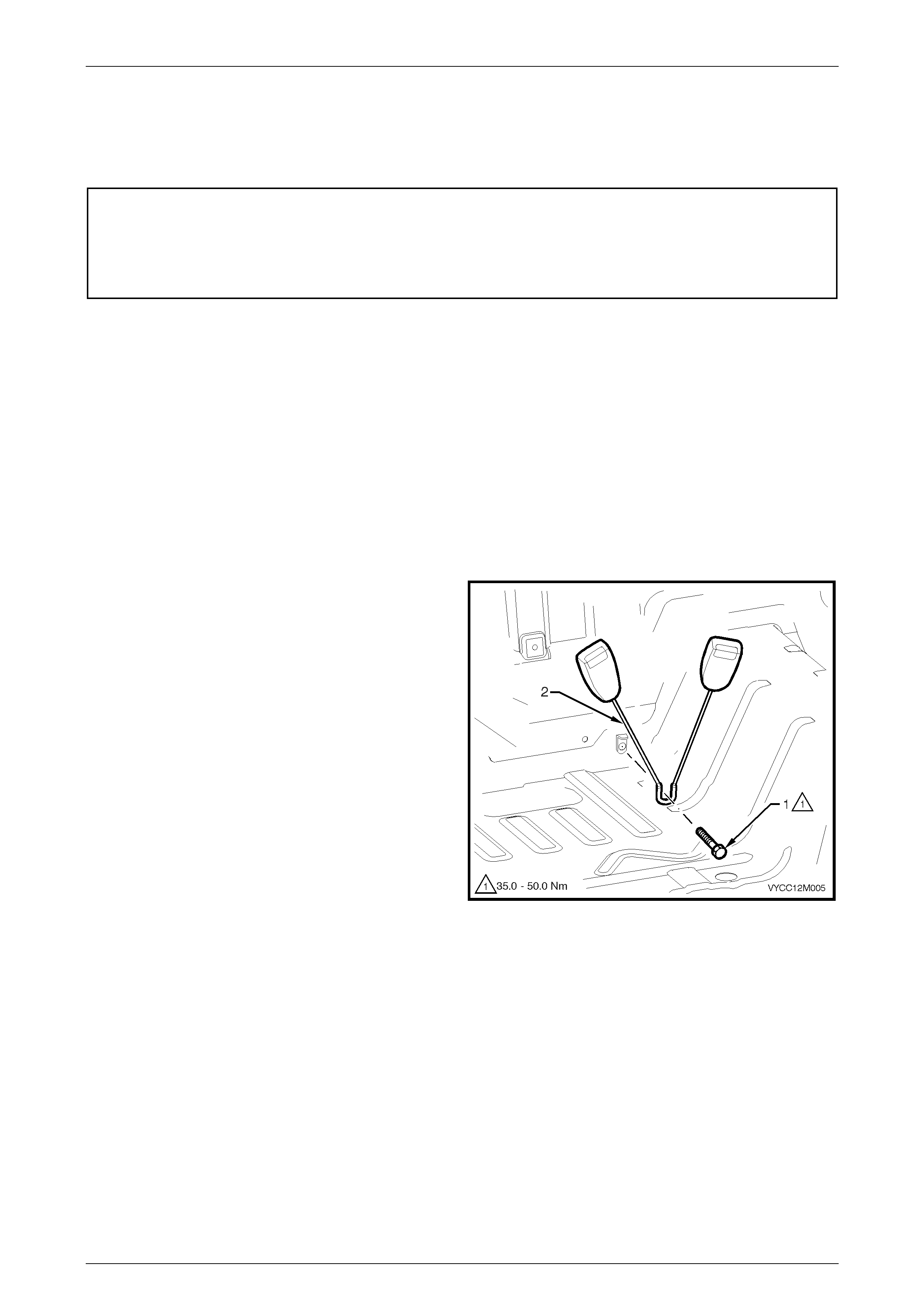

1 Remove the bolt (1) attaching the rear seatbelt buckle

anchor assembly (2) to the vehicle.

2 Remove the buckle assembly.

Figure 12M – 5

Occupant Protection System Page 12M–9

Page 12M–9

Reinstall

If reinstalling the same buckle assembly,

inspect the buckle for any damage. Replace

the buckle assembly with a new part if any

damage is found.

Installation of the seatbelt buckle assembly is the reverse of removal noting the following:

1 Hand tighten the seatbelt bolt a minimum of five turns before using tools.

2 Tighten the bolt to the specified torque.

Seatbelt buckle assembly mounting

bolt torque specification................................35 – 50 Nm

3 Perform a functional check of the seatbelt to ensure correct operation.

Occupant Protection System Page 12M–10

Page 12M–10

2.3 Child Seat Anchors

Three child seat anchors are permanently attached to the

vehicle. They are not serviced separately from the upper

rear body inner panel. For upper rear body inner panel

service operations, refer to Section 10B Body Rear in the

MY 2004 Regular Cab and Crew Cab Service Information

Supplement, Body Structure Repair.

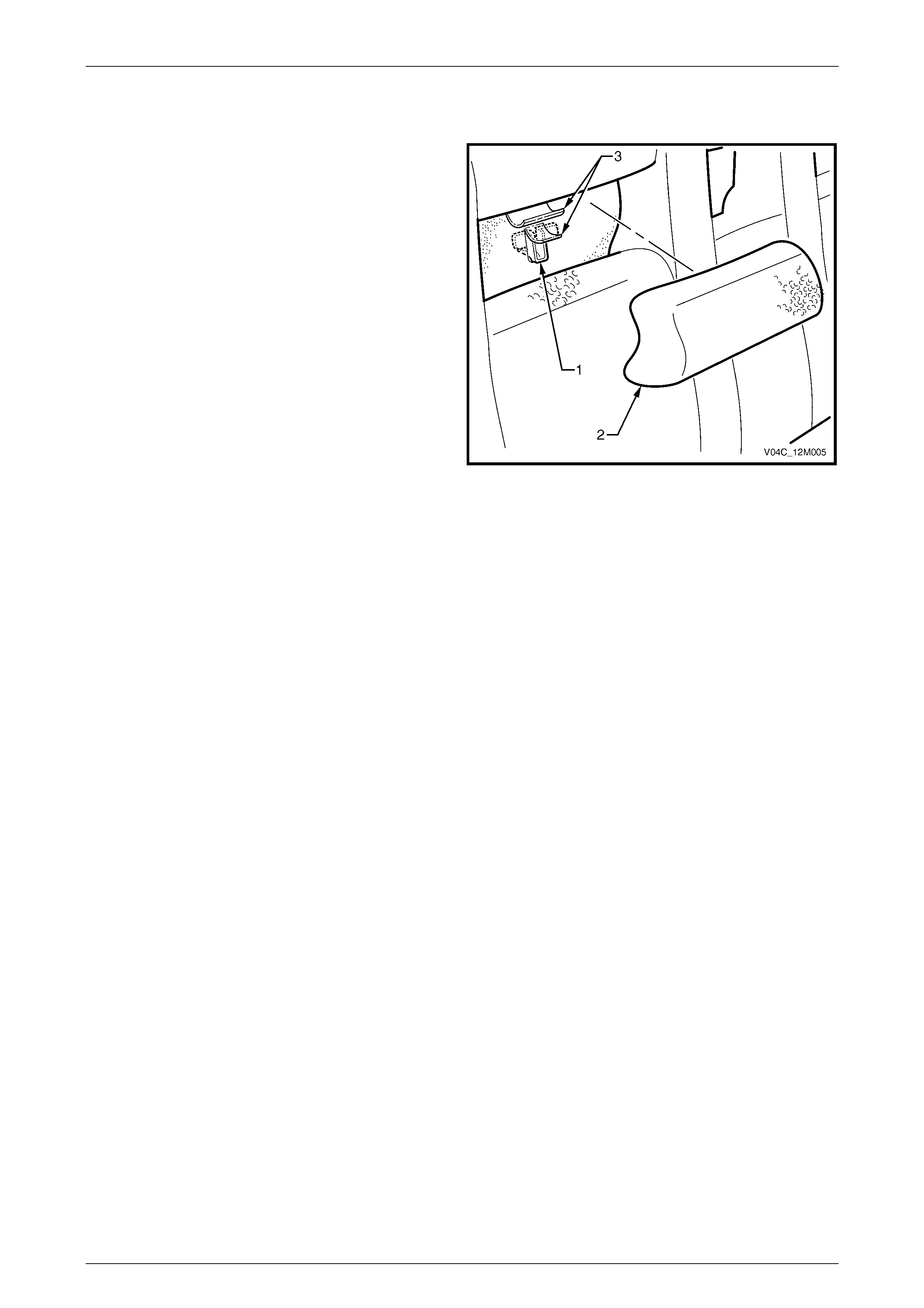

Access to each child seat anchor (1) is gained by removing

the appropriate rear seat-back insert (2), refer to Section

1A7 Seat Assemblies, and lifting the material flaps (3)

covering the anchor.

When the child seat anchors are not in use, the rear seat-

back inserts should be fitted into place.

Figure 12M – 6

Occupant Protection System Page 12M–11

Page 12M–11

3 Diagnosis – Front Seatbelt

Switch – Crew Cab

3.1 General Description

When carrying out wiring checks as directed by the following diagnostic charts, use the adaptors contained in connector

test adaptor kit KM-609 and test lead set KM-609-20. This will prevent any possibility of spreading or damaging wire

harness terminals, which could cause a system intermittent failure.

Ensure that at the completion of any diagnostic procedure, all diagnostic tools are removed and all components are

correctly reconnected.

Occupant Protection System Page 12M–12

Page 12M–12

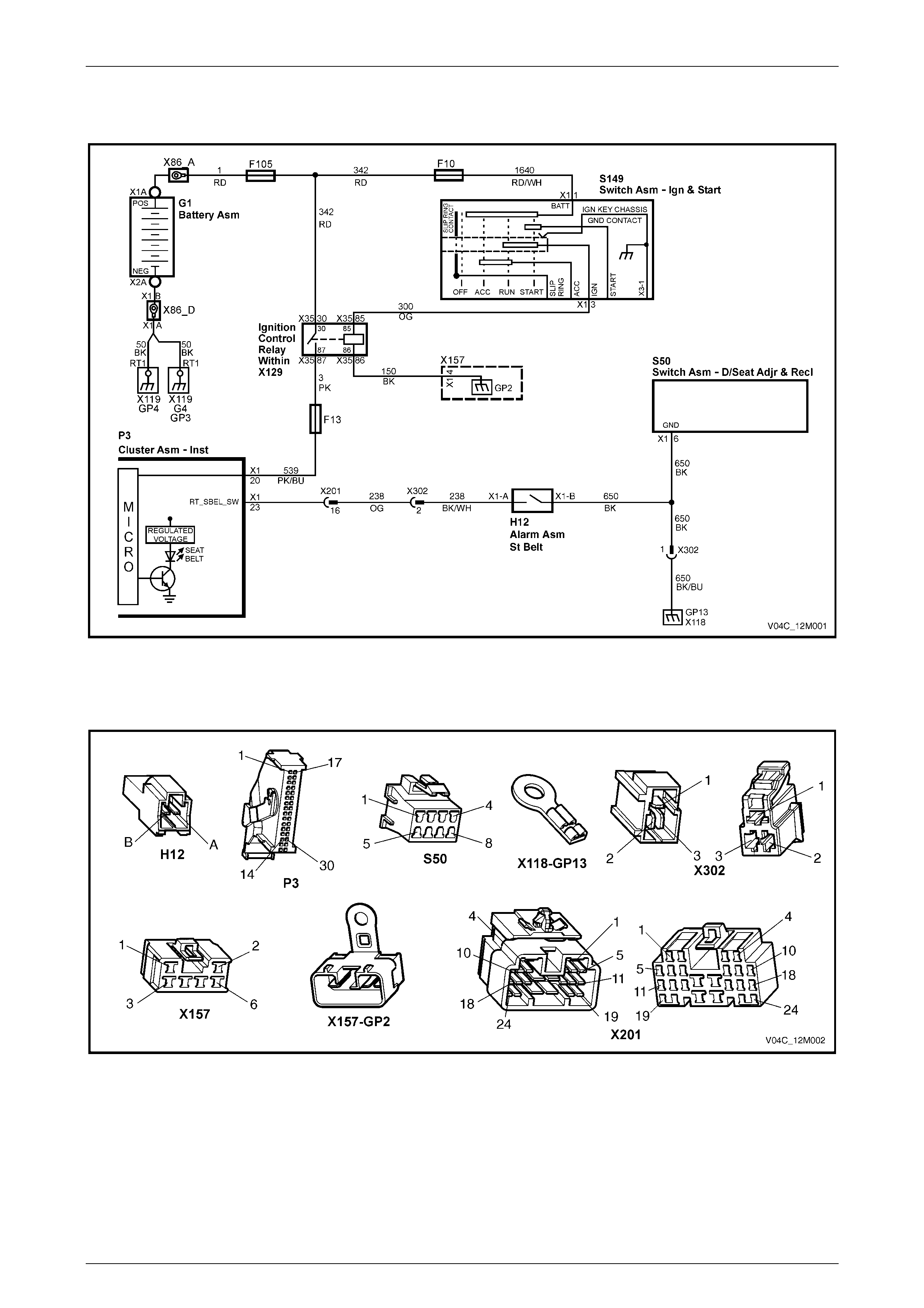

3.2 Circuit Diagram

Figure 12M – 7

Connector Chart

Figure 12M – 8

Occupant Protection System Page 12M–13

Page 12M–13

3.3 Diagnostic Procedures

Circuit Description

The purpose of the driver's seatbelt buckle warning indicator switch, H12, is to activate a seatbelt warning indicator

located in the instrument cluster assembly. The indicator is illuminated when the ignition is turned to the ON position and

the seatbelt is disengaged from the buckle.

When the seatbelt is buckled, the warning indicator switch is in an open circuit condition and when unbuckled the switch

is in a closed circuit condition.

TECH 2 can be used to check the driver's seatbelt buckle warning indicator switch operation, TECH 2 will only display

‘BUCKLED’ or ‘UN-BUCKLED’.

The seatbelt warning indicator will illuminate for four seconds when the ignition switch is turned to the ON position,

irrespective of the status of the driver's seatbelt buckle warning indicator switch.

Test Description

The following numbers refer to step numbers in the following diagnostic chart.

1 Checks if the seatbelt indicator illuminates when the ignition is turned on. This can indicate either a faulty

instrument cluster assembly or a faulty power circuit.

2 Checks if there is an intermittent fault in the circuit.

3 Checks if there is a faulty power circuit.

4 Checks the operation of the driver's seatbelt buckle warning indicator switch.

5 Checks continuity of circuit 650.

6 Checks continuity of circuit 238.

7 Checks the operation of the driver's seatbelt buckle warning indicator switch.

8 Checks for short circuit to ground in circuit 238.

Notes on the Diagnostic Chart

1 For all wiring harness fault diagnosis, refer to Section 12P Wiring Diagrams.

2 For wiring harness repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If at any time the fault is deemed to be intermittent, refer to Section 12P Wiring Diagrams.

5 For information on using and connecting Tech 2 to the vehicle, refer to Section 0C Tech 2.

Diagnostic Chart

Step Action Yes No

1 1 Install the TECH 2 to the DLC. Select BODY, INSTRUMENTS,

DATA DISPLAY and then INSTRUMENTS from the menu and

scroll down to DRIVERS SEATBELT. Refer to Note 5.

2 Unbuckle the driver's seat belt .

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator illuminate, and does the TECH 2

displa y ‘UN-BUCKLED’?

Go to Step 2. Go to Step 3.

Occupant Protection System Page 12M–14

Page 12M–14

Step Action Yes No

2 1 Turn the ignition switch off.

2 Buckle the driver's seatbelt.

3 Turn the ignition on with the engine off.

Does the seatbelt warning indicator extinguish after four seconds and

does the TECH 2 display ‘BUCKLED’?

Operation appears

to be normal. Check

for an intermittent

fault, refer to Note 4.

Go to Step 7.

3 1 Check that the following warning indicators illuminate when the

ignition is switched on with the engine off:

• ABS

• Brake

• SRS

• Generator

Do the above warning indicators illuminate when the ignition switch is

turned on with the engine off?

Go to step 4. Check continuity of

fuse F13,

fuse F105,

circuit 539, circui t 3

and circuit 342.

For additional

information, refer to

Section 12C

Instruments.

4 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 at connector H12 to probe

the operation of the driver's seatbelt buckle warning indicator

switch. Refer to Note 1.

• Seatbelt unbuckled - continuity

• Seatbelt buckled - no continuity (open circuit)

Does the driver's seatbelt buckle warning indicator switch operate as

required?

Go to Step 5.

Replace the driver's

seatbelt bu ckl e and

pretensioner

assembly, refer to

Section 12M

Occupant Pr otection

System in the

MY 2003 VY and V2

Series Service

Information.

5 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 650 between connector H12 – X1 pin B and ground point

GP13 – X118. Refer to Note 1.

Is there continuity?

Go to Step 6. There is an open

circuit in circ uit 650.

Repair or replace

circuit 650 and/or

connector, refer to

Note 2.

6 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for continuity of

circuit 238 between connector H12 – X1 pin A and

P3 – X1 pin 23. Refer to Note 1.

Is there continuity?

Replace the

instrument cluster

assembly, refer to

Section 12C

Instruments.

There is an open

circuit in circ uit 238.

Repair or replace

circuit 238 and/or

connector, refer to

Note 2.

7 1 Turn the ignition switch off and disconnect connector H12.

2 Turn the ignition on with the engine off.

Does the seatbelt warning indicator extinguish after four seconds and

does the TECH 2 display ‘BUCKLED’?

Go to step 8 Go to Step 4.

8 1 Turn the ignition off and disconnect connector H12.

2 Use a multimeter and Tool KM-609 to probe for a short circuit to

ground in circuit 238 between connector H12 – X1 pin A and

P3 – X1 pin 23. Refer to Note 1.

Is there a short circuit to ground?

Repair or replace

circuit 238, refer to

Note 4.

Replace the

instrument cluster

assembly, refer to

Section 12C

Instruments.

When all diagnosis and repairs are completed, check the system for correct operation.

Occupant Protection System Page 12M–15

Page 12M–15

4 Torque Wrench Specifications

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

!

!!

! Seatbelt Guide Attaching Bolt

!

!!

! Seatbelt Lower Anchor Bolt

!

!!

! Seatbelt Retractor Bracket Bolt

!

!!

! Seatbelt Buckle Assembly Attaching Bolt

Front Seatbelt

Seatbelt Anchor Attaching Bolt........................................................ 35 – 50 Nm

Upper Seatbelt Guide Attaching Bolt...............................................35 – 50 Nm

Seatbelt Retractor Attaching Bolt.....................................................35 – 50 Nm

Rear Seatbelt

Seatbelt Guide Attaching Bolt..........................................................35 – 50 Nm

Seatbelt Lower Anchor Bolt.............................................................35 – 50 Nm

Seatbelt Retractor Bracket Bolt........................................................35 – 50 Nm

Seatbelt Buckle Assembly Attaching Bolt ........................................35 – 50 Nm