Hydra-Matic 4L60-E A utomatic Transm is sion, On–Vehicle Servicing Page 7C4–1

Page 7C4–1

Section 7C4

Hydra-Matic 4L60-E Automatic Transm ission,

On–Vehicle Servicing

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 4L60E Automatic Transmission Mass Damper................................................................................... 3

2.1 Mass Damper..........................................................................................................................................................3

Remove ...................................................................................................................................................................4

Reinstall ..................................................................................................................................................................5

3 Torque Wrench Specifications............................................................................................................. 6

Hydra-Matic 4L60-E A utomatic Transm is sion, On–Vehicle Servicing Page 7C4–2

Page 7C4–2

1 General Information

The Hydra-Matic 4L60-E four speed automatic transmission on-vehicle servicing information for MY 2004 VY Regular

Cab and MY 2004 VY Crew Cab Models carries over from previous MY 2004 VY & V2 Series Models and MY 2003 VY

Regular Cab Service Information.

For information relating to Hydra-Matic 4L60-E four speed automatic transmission on-vehicle servicing information for

MY 2004 VY Regular Cab and MY 2004 VY Crew Cab Models not covered in this Section, refer to Section 7C, Hydra-

Matic 4L60-E Automatic Transmission in the MY 2004 VY & V2 Series Service Information.

Hydra-Matic 4L60-E A utomatic Transm is sion, On–Vehicle Servicing Page 7C4–3

Page 7C4–3

2 4L60E Automatic Transmission

Mass Damper

ATTENTION

All rear axle fasteners are important attaching parts as they affect the performance of vital components

and/or could result in major repair expense. Where specified in this Section, fasteners MUST be replaced with

parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality or

substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this Section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at kerb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Mass Damper

ATTENTION

The following fasteners have either micro encapsulation or incorporate a mechanical thread lock and should

only be used once. If in doubt, replacement is recommended when performing this operation:

#$ Transmission mass damper retainer plate attaching bolts and nuts.

#$ Transmission mass damper retaining nuts

The 4L60E automatic transmission is fitted with a transmission mass damper. The mass damper is attached to the rear

extension housing assembly by a retainer plate and fasteners to reduce the amount of driveline noise transmitted to

cabin of the vehicle.

Hydra-Matic 4L60-E A utomatic Transm is sion, On–Vehicle Servicing Page 7C4–4

Page 7C4–4

Remove

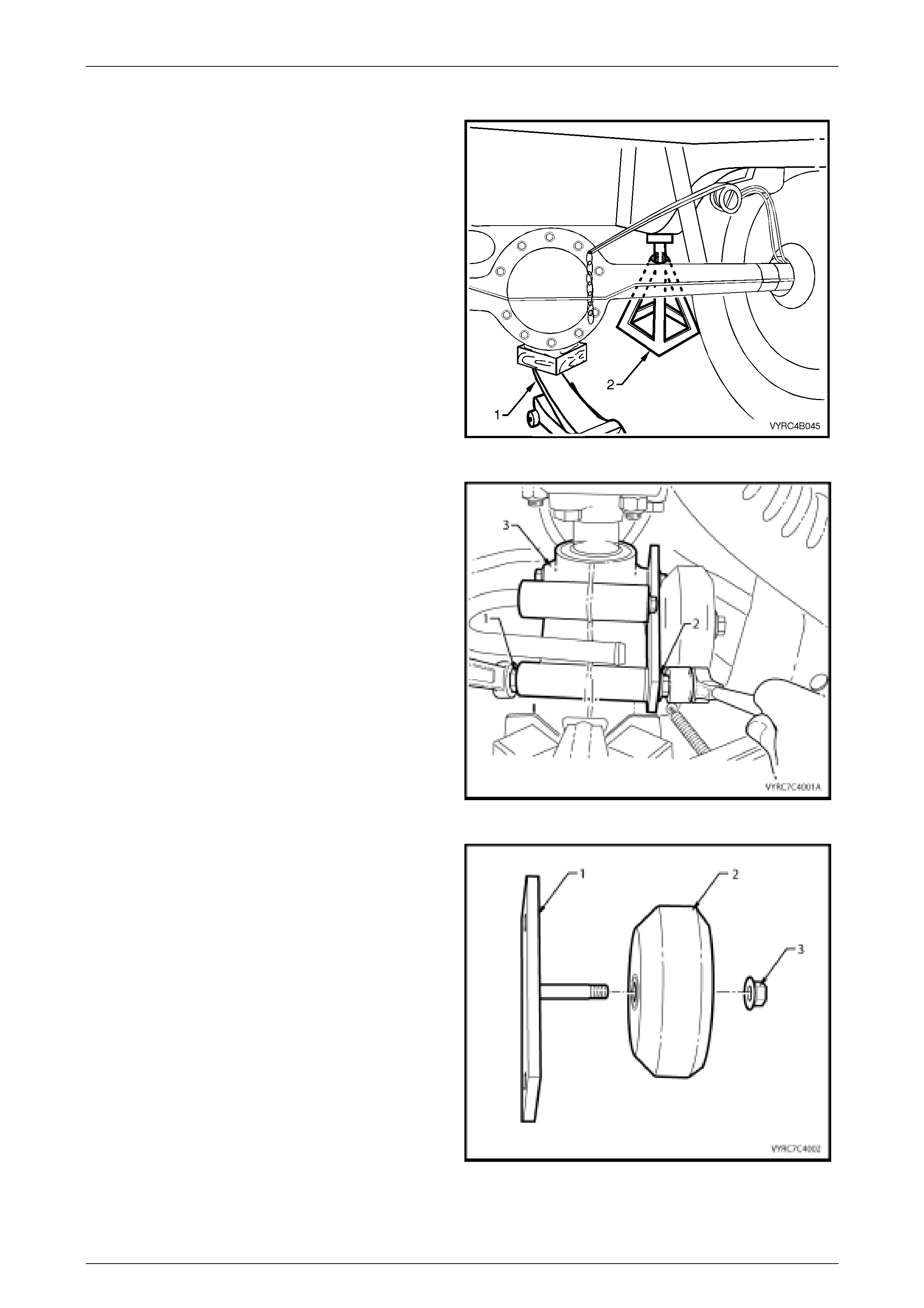

1 Using a floor jack under the centre of the rear axle

assembly (1), jack up rear of vehicle, then place

safety stands under the rear chassis (2) on both the

left-hand and right-hand sides to support the weight of

the vehicle as shown in Figure 7C4-1.

Figure 7C4-1

2 Using suitable spanners remove the mass damper

retainer plate attaching bolts (1) and nuts (2) from the

transmission rear extension housing (3). Refer to

Figure 7C4-2.

3 Remove the mass damper and retainer plate

assembly.

Figure 7C4-2

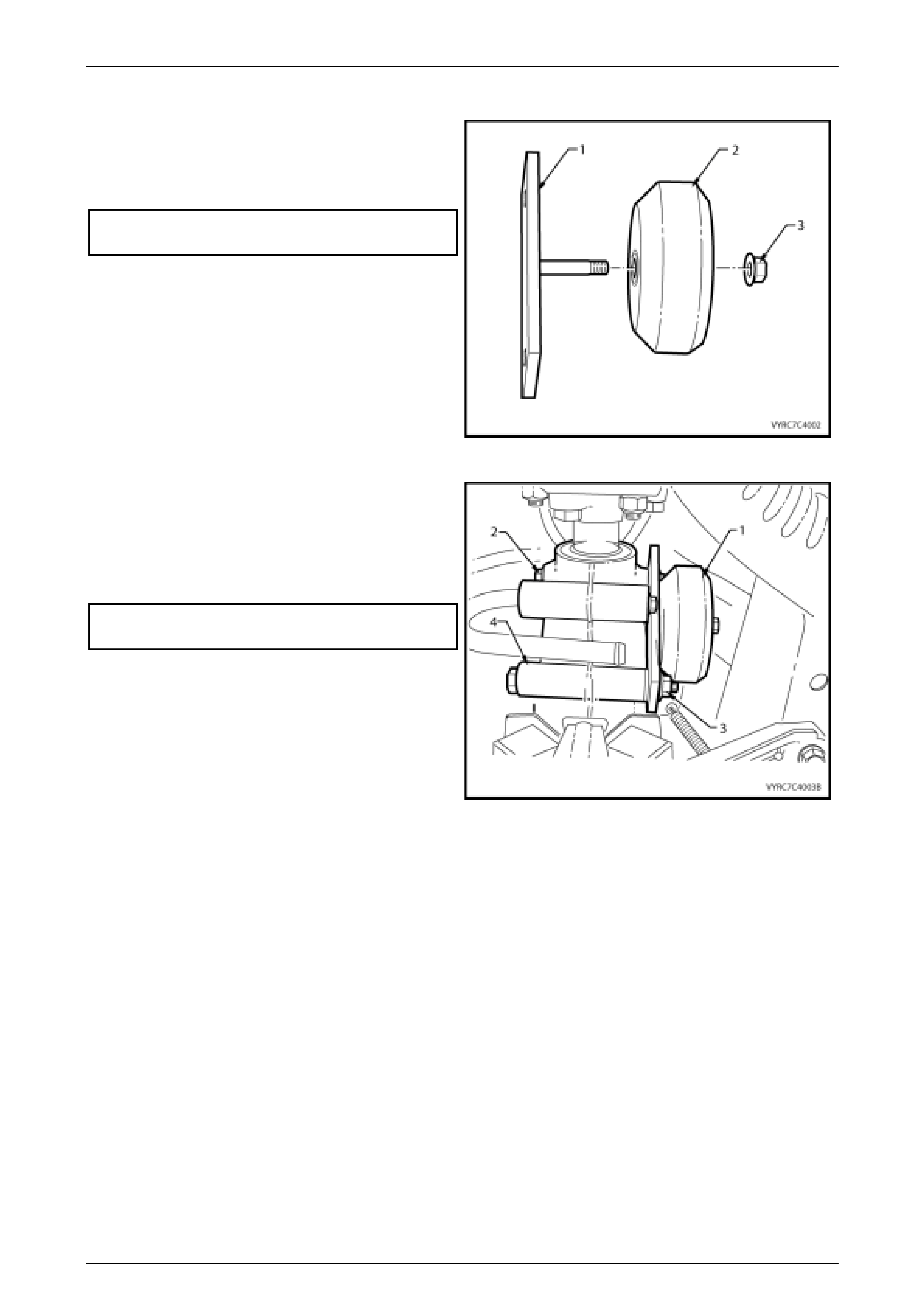

4 Using a suitable spanner remove the mass damper

retaining nut (3) from the retainer plate (1) and

remove the mass damper (2). Refer to Figure 7C4-3.

Figure 7C4-3

Hydra-Matic 4L60-E A utomatic Transm is sion, On–Vehicle Servicing Page 7C4–5

Page 7C4–5

Reinstall

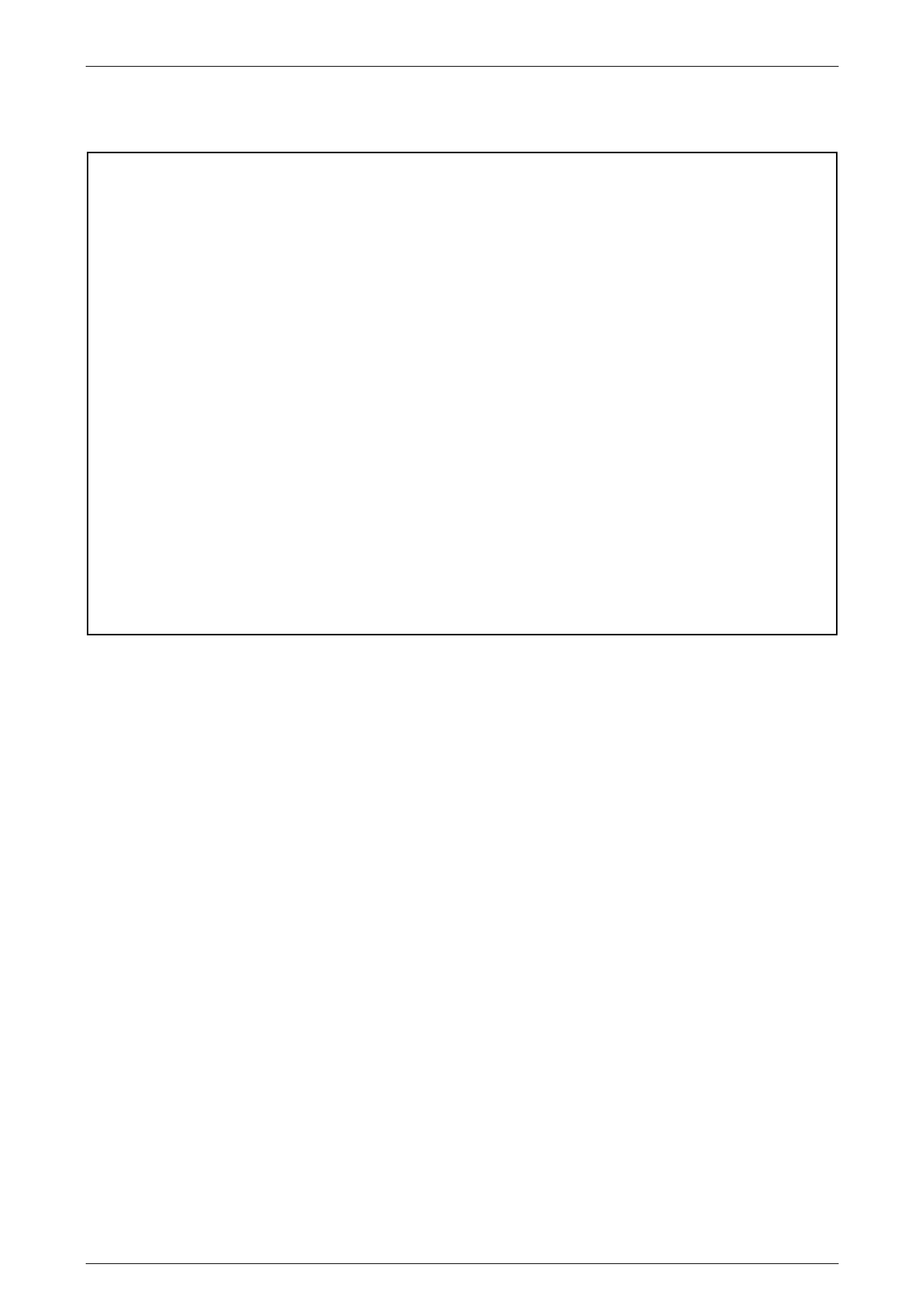

1 Install the mass damper (2) and retaining nut (3) to

the retainer plate (1). Refer to Figure 7C4-4.

2 Tighten the mass damper retaining bolt to the correct

torque.

% Mass damper retaining nut

torque specific atio n ........................................ 34 ± 5 Nm

Figure 7C4-4

3 Install the mass damper retainer plate assembly (1)

and attaching bolts (2) and nuts (3) to the

transmission rear extension housing (4). Refer to

Figure 7C4-5.

4 Tighten the mass damper retainer plate attaching

bolts and nuts to the correct torque.

% Mass damper retainer plate attaching

bolts and nuts torque specification................. 34 ± 5 Nm

Figure 7C4-5

Hydra-Matic 4L60-E A utomatic Transm is sion, On–Vehicle Servicing Page 7C4–6

Page 7C4–6

3 Torque Wrench Specifications

ATTENTION

All Rear Suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this section, fasteners MUST be

replaced with parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior

quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all steering

components.

Through out this section, fastener torque wrench specifications may be accompanied with the following

Identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

Nm

% Mass Damper Retainer Plate Attaching Bolts and Nuts.......................34 ± 5

% Mass Damper Retaining Nut................................................................34 ± 5