Instruments Page 12C–1

Page 12C–1

Section 12C

Instruments

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 General Description...............................................................................................................................................2

Instrument Cluster Programming.........................................................................................................................2

Fuel Sender Circuit Variations..............................................................................................................................2

Fuel Calibration......................................................................................................................................................2

TECH 2 Testing..................................................................................................................................................3

Fuel (Petrol) Sender Resistance .........................................................................................................................3

Speedometer Pulses ..........................................................................................................................................4

Seat Belt Warning Switch......................................................................................................................................5

Seat Belt Alarm Description................................................................................................................................5

2 Diagnostics............................................................................................................................................. 7

DTC 1 – Petrol Level Sender Signal Voltage Too Low........................................................................................7

Circuit Description...............................................................................................................................................7

Petrol Level Sender Signal Voltage Too Low Diagnostic Chart..........................................................................8

DTC 2 – Petrol Level Sender Signal Voltage Intermittent .................................................................................10

Circuit Description.............................................................................................................................................10

Petrol Level Sender Signal Voltage Intermittent Diagnostic Chart....................................................................11

DTC 3 – Petrol Level Sender Signal Voltage Too High .....................................................................................13

Circuit Description.............................................................................................................................................13

Petrol Level Sender Signal Voltage Too High Diagnostic Chart.......................................................................14

3 Specifications....................................................................................................................................... 16

Fuel Calibration Part Number..............................................................................................................................16

Speedometer Pulses............................................................................................................................................16

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Instruments Page 12C–2

Page 12C–2

1 General Information

This Section provides information on the instrument clusters fitted to the MY 2004 VY and V2 Series vehicles. For all

other instrument cluster related information not covered in this Section, refer to Section 12C Instruments in the MY 2003

VY and V2 Series Service Information.

1.1 General Description

Instrument Cluster Programming

When an instrume nt clu ster is repla ced in a vehicle, the fuel gauge calibr ation, configura tion and speedomet er functions

must be programmed into the new instrument cluster using TECH 2. Some differences in configuration values exist

between the MY 2003 and MY 2004, VY and V2 Series vehicles. These differences are highlighted in this Section.

For more instrument cluster programming information, refer to Section 12C, 3.15 Program in the MY 2003 VY and V2

Series Service Information.

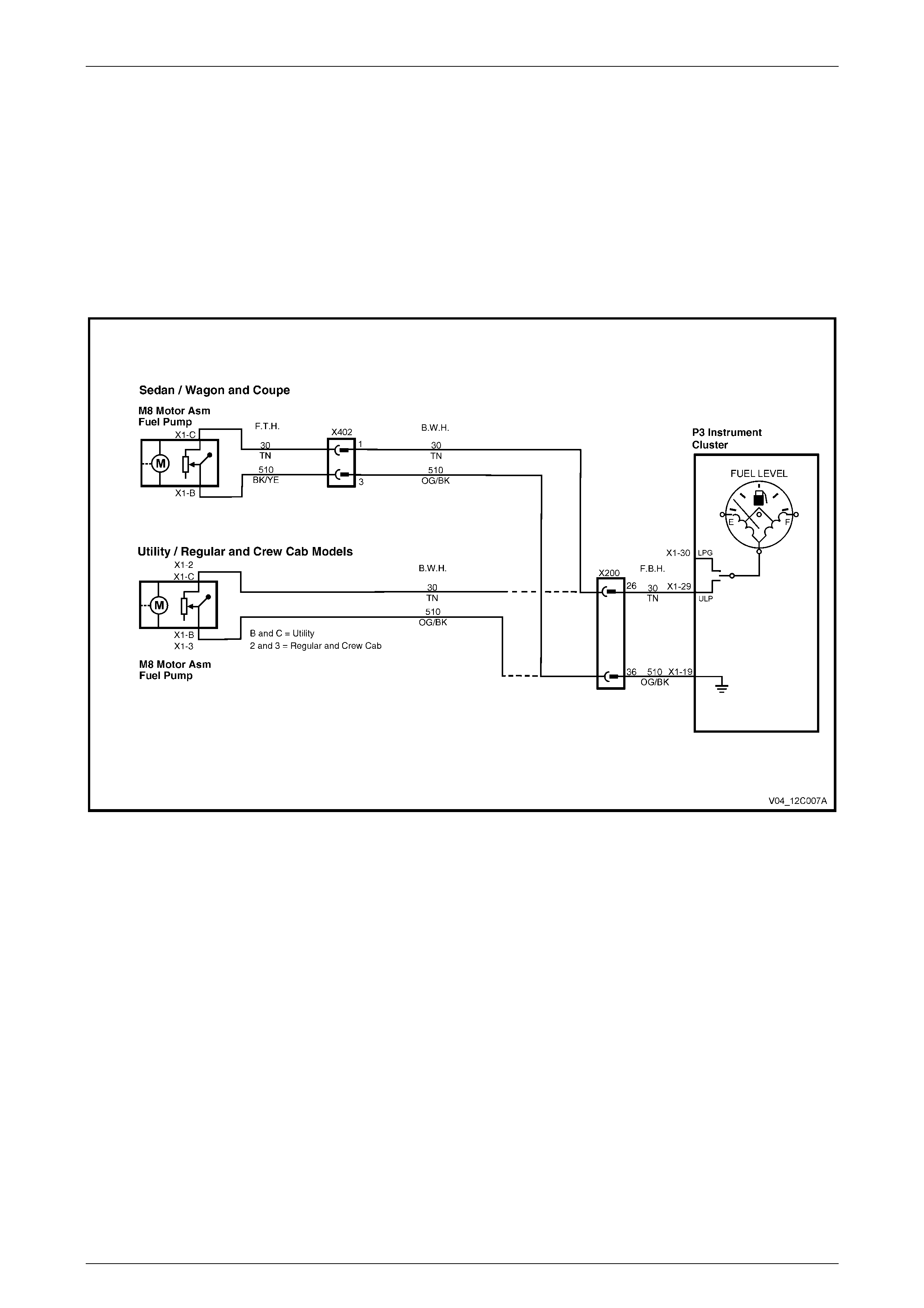

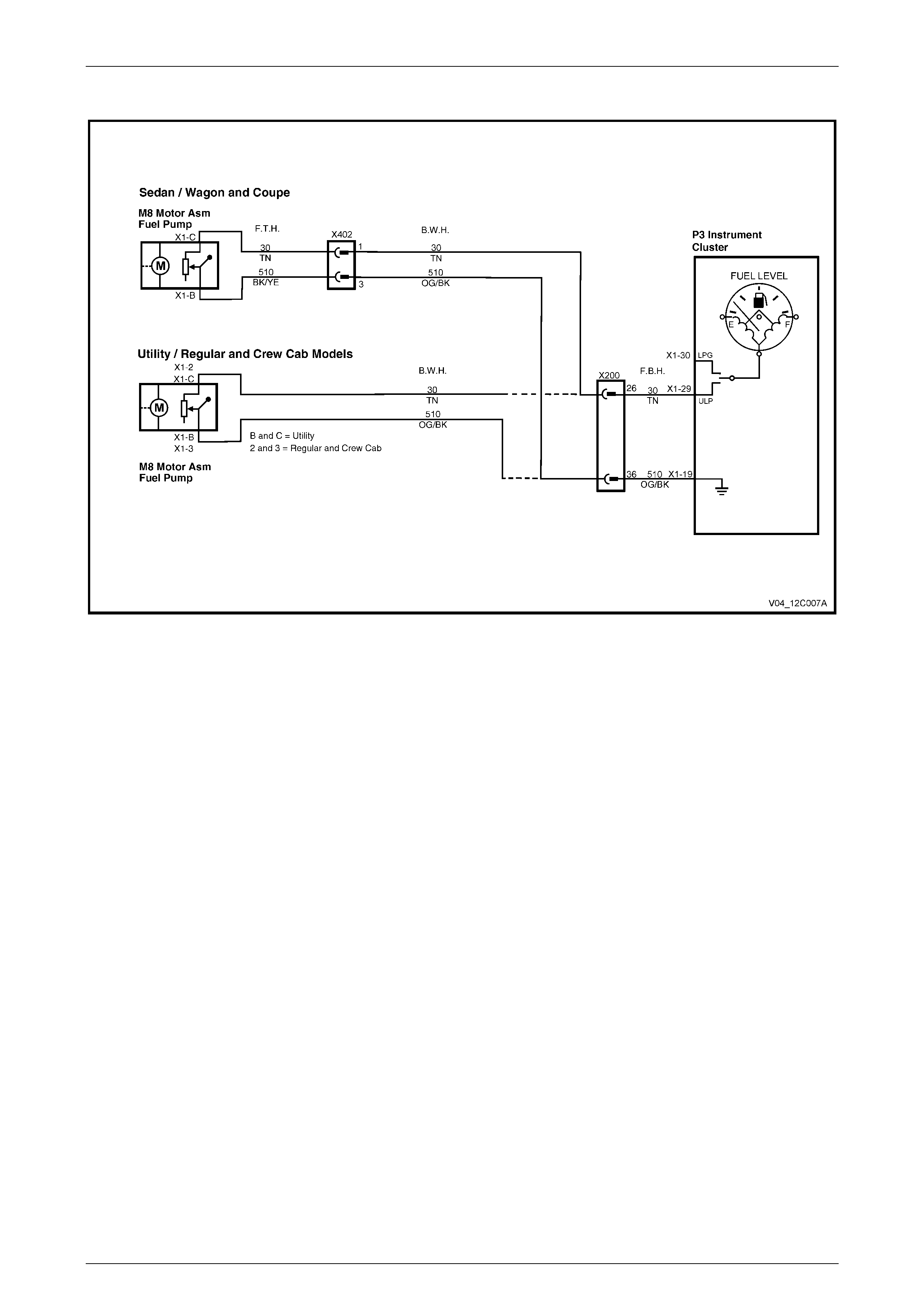

Fuel Sender Circuit Variations

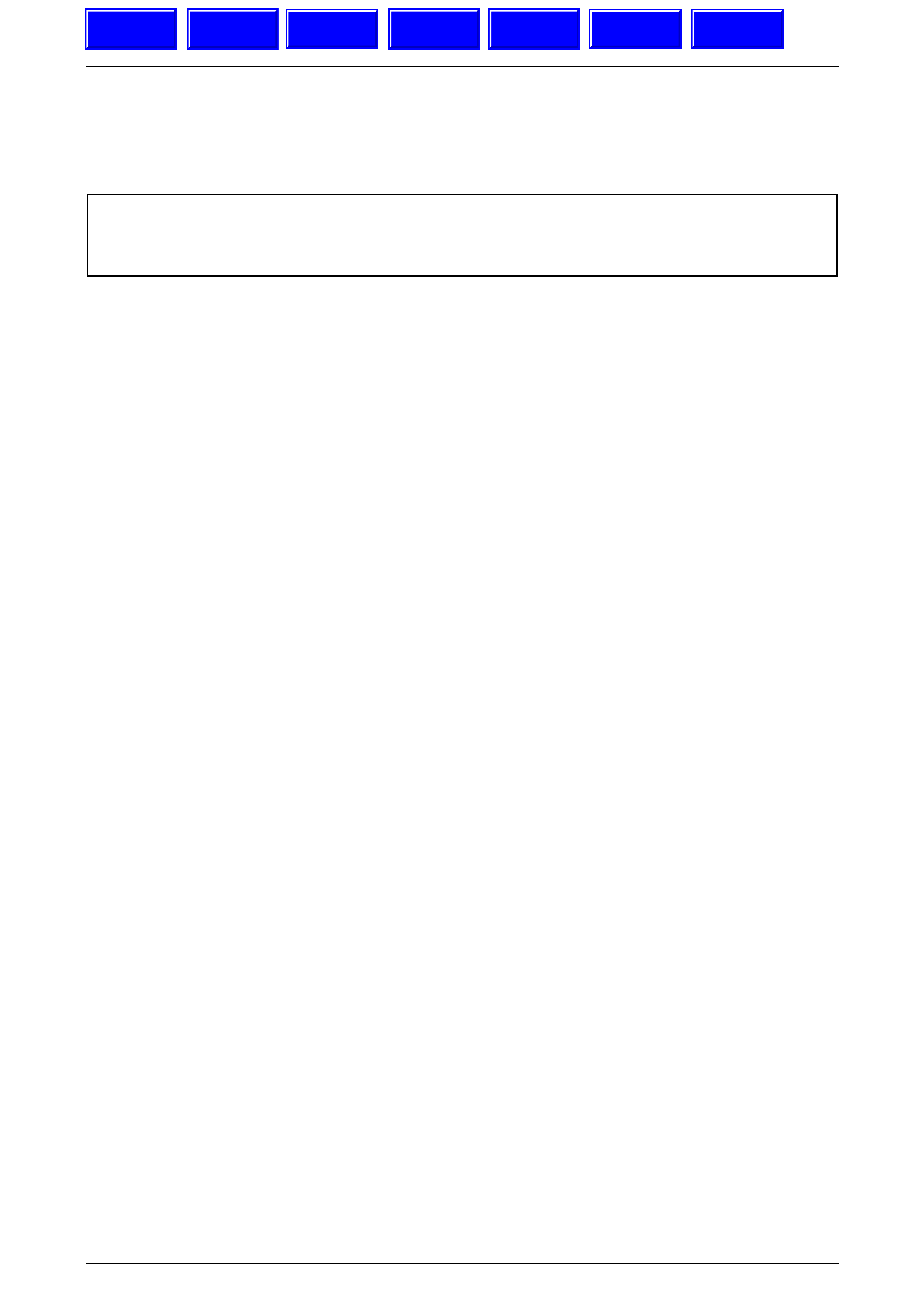

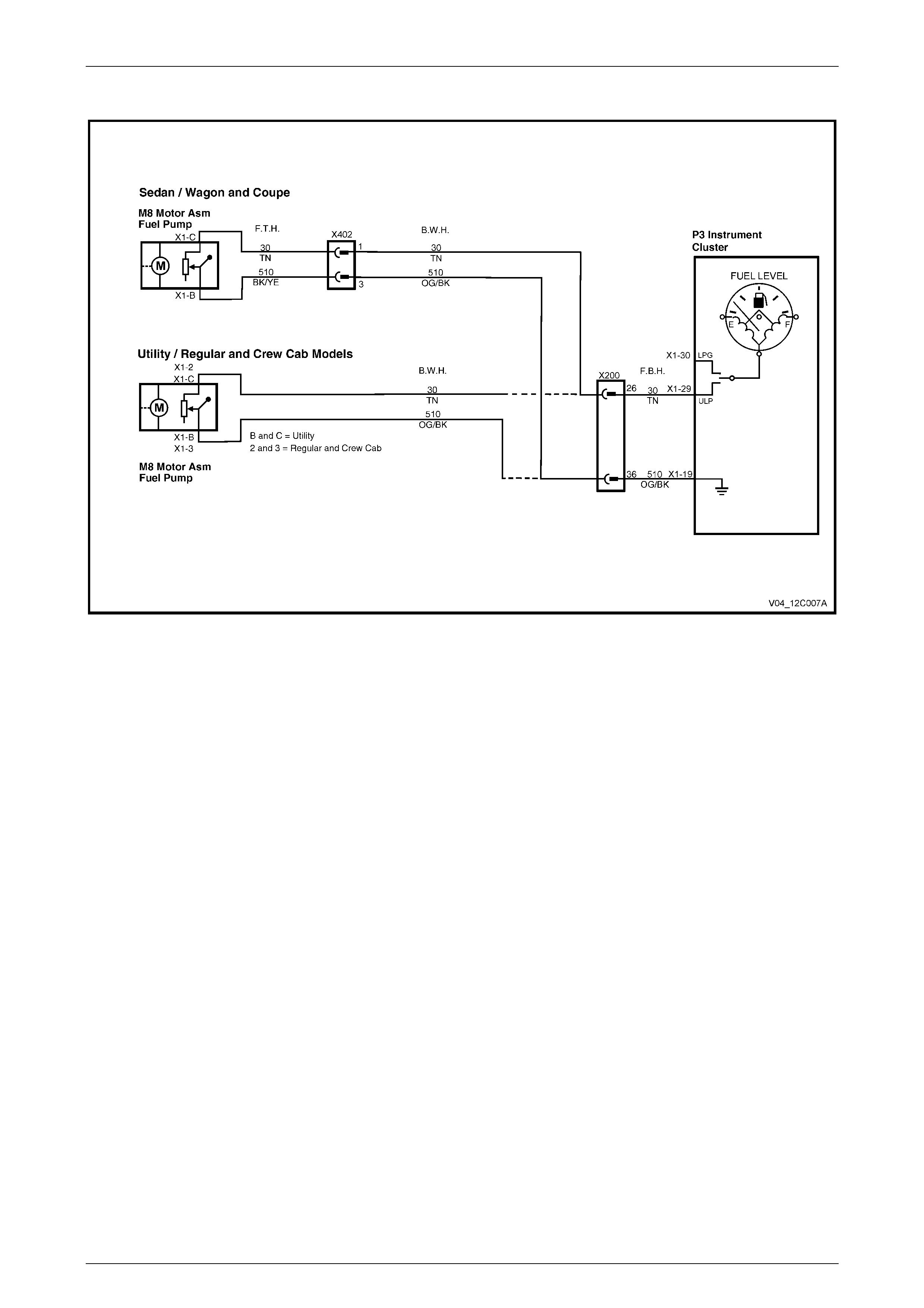

There are two fuel sender circuits used in the MY 2004 VY and V2 Series vehicles. Refer to Figure 12C – 1. Both of

these circuits pass through a larger in-line terminal connector (X200) whereas in the MY 2003 VY and V2 Series

vehicles, this connector is X201.

Figure 12C – 1

Fuel Calibration

Calibration software compatible with the vehicle configuration must be applied to the instrument cluster. Fuel calibration

software is entered using TECH 2. A Code Index number, with a version number following, represents each fuel

calibration software program and is selected with TECH 2.

The MY 2004 VY and V2 Series vehicles are fitted with a different series of fuel sender assemblies than the MY 2003

Series vehicles. The resistance values of the sender assemblies have been reversed for the MY 2004 vehicles, making

them incompatible with the MY 2003 vehicles. For the MY 2004 vehicles, the same range values of 40 ± 5 ohms to

250 ± 5 ohms exist, but the lowest resistance value now indicates a full tank. A complete description of how to measure

Instruments Page 12C–3

Page 12C–3

the fuel level sender resistance values at the connector terminals is described in Section 8A1, 2.1 Modular Fuel Pump

and Sender Assembly in this Service Information.

For information relating to the removal of the fuel sender from the fuel tank, refer to one of the following references as

required, in the MY 2003 VY and V2 Series Service Information:

Section 8A1, 2.6 Modular Fuel Pump and Sender Assembly – Sedan, Wagon and Coupe

Section 8A1, 2.7 Modular Fuel Pump and Sender Assembly – Utility

Section 8A1, 2.8 Fuel Level Sender Assembly – V6 Supercharged and Vehicles Exported to Brazil

For correct fuel gauge operation, ensure that the correct instrument cluster, fuel tank and fuel level sender assembly

combination are fitted for the vehicle configuration. For confirmation of this, refer to the latest parts information.

NOTE

These fuel calibration software codes apply to all

MY 2004 VY and V2 Series models. For

calibration codes applicable to MY 2003 vehicles,

refer to Section 12C, 3.15 Program in the

MY 2003 VY and V2 Series Service Information.

Fuel Calibration Part Numbers and Code Index Numbers for MY 2004 VY and V2 Series vehicles are as follows:

Vehicle Model Market Body Style Engine Fuel Calibration

Code Part Number Code Index /

Version

VY Domestic Sedan V6 (not S/C) and V8 92160974 6 / 2

VY Domestic Wagon (inc AWD) V6 (not S/C) and V8 92160975 7 / 2

VY Export (not Brazil) Sedan V6 (not S/C) and V8 92160974 6 / 2

VY Export Wagon V6 (not S/C) 92160975 7 / 2

VY Export (Brazil) Sedan V6 92160977 9 / 1

VY Domestic / export Sedan V6 (S/C) 92160977 9 / 1

VY Domestic / export Utility V6 (not S/C) and V8 92160976 8 / 1

V2 Domestic Coupe V8 92160974 6 / 2

V2 Export Coupe V6 (not S/C) and V8 92160974 6 / 2

TECH 2 Testing

When TECH 2 is connected to the vehicle and is switched on, it determines what version of software is installed in the

instrument cluster. From this information, it recognises what type of seat belt switch hardware and fuel sender unit should

be fitted to the vehicle. The correct simulated values for testing of the instruments are then applied when required.

NOTE

Refer to the latest Parts Information to verify that

the correct instrument cluster, fuel tank and fuel

sender assembly are installed for the vehicle.

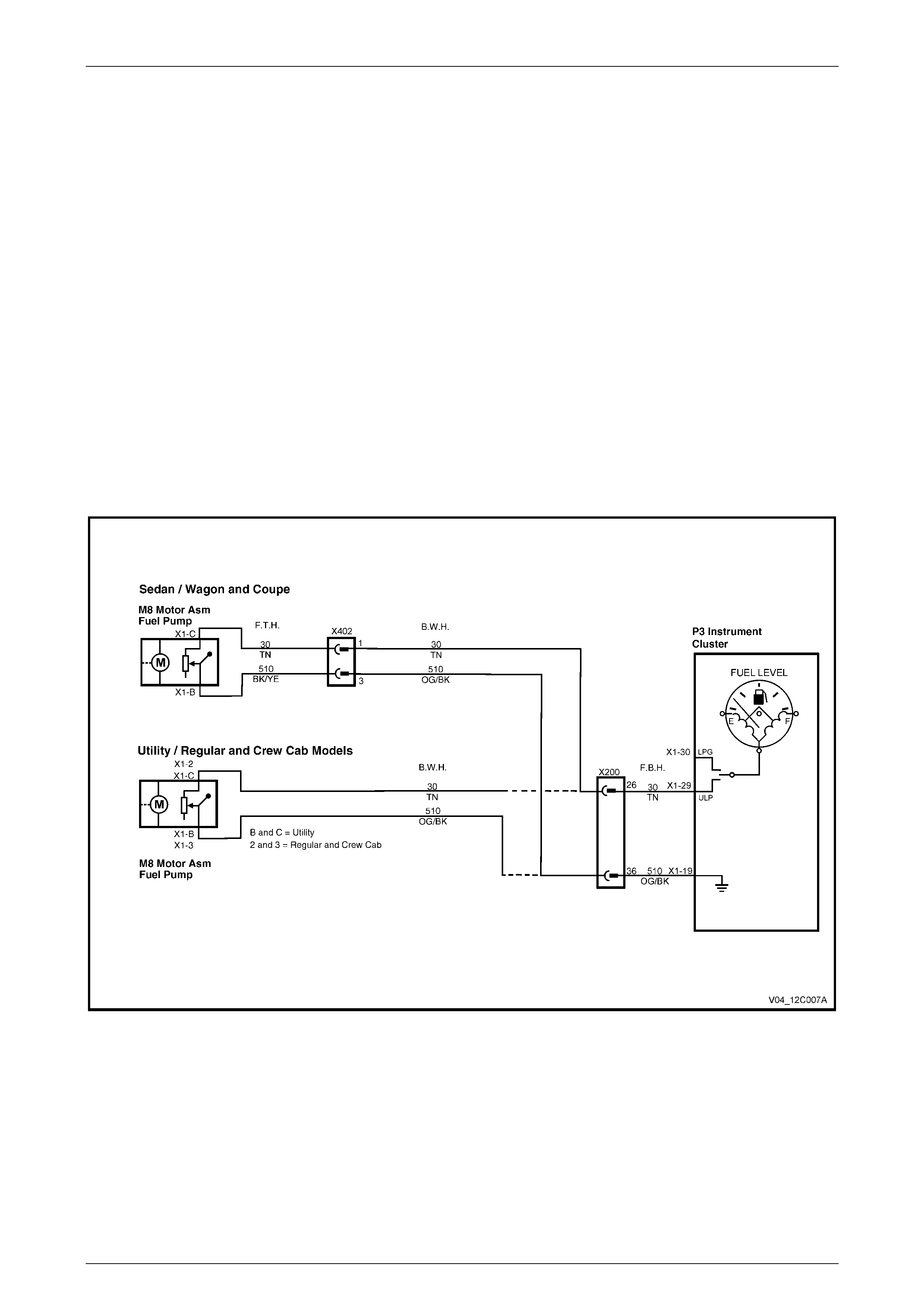

Fuel (Petrol) Sender Resistance

With the instrument cluster in Diagnostic Mode, the current

fuel sender resistance can be displayed. To access the

instrument cluster Diagnostic Mode, refer to Section 12C,

3.3 Ins trum ent Cluster Diagnostics in the MY 2003 VY and

V2 Series Service Information.

Figure 12C – 2

The fuel sender resistance should be between 40 ± 5 ohms and 250 ± 5 ohms. However, unlike MY 2003 Series VY and

V2 Series vehicles, this resistance should decrease as the tank is filled and increase as the tank is emptied.

Also refer to Section 12C, 3.15 Program in the MY 2003 VY and V2 Series Service Information.

Instruments Page 12C–4

Page 12C–4

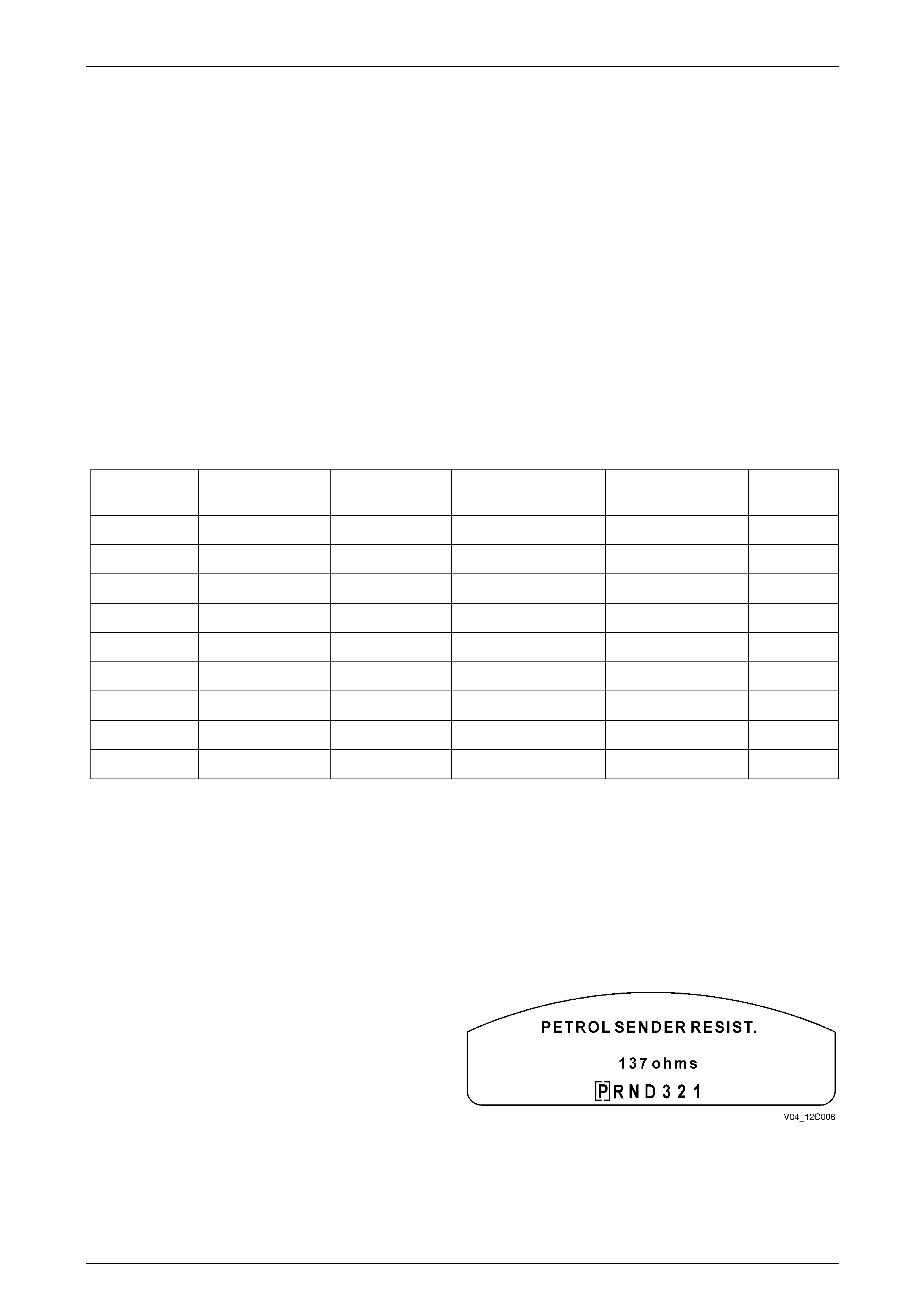

Speedometer Pulse s

The speedometer Pulses Per Kilometre (PPK) values are shown in the following table for all MY 2004 VY and V2 Series

vehicles.

Bod y

Type Engine

Type Transmission

Type Tyre

Size PPK

Value

Sedan / Wagon V6 Auto / Man 205/65R15 6272

Sedan / Wagon V6 Auto / Man 225/60R15 6238

Sedan / Wagon V6 Auto / Man 215/60R16 6077

Sedan / Wagon V6 Auto / Man 225/55R16 6173

Sedan / Wagon V6 Auto / Man 225/50R16 6391

Sedan / Wagon V6 Auto / Man 235/45R17 6301

Sedan / Wagon V6 Auto / Man 225/50R17 6100

Utility V6 Auto 205/65R15 6272

Utility V6 Auto 225/55R16 6173

Utility V6 Auto 235/45R17 6300

Utility V6 Man 205/65R15 6450

Utility V6 Man 225/55R16 6307

Utility V6 Man 235/45R17 6480

Sedan / Wagon / Utility V8 Auto / Man 205/65R15 6272

Sedan / Wagon / Utility V8 Auto / Man 225/60R15 6238

Sedan / Wagon / Utility V8 Auto / Man 225/55R16 6173

Sedan / Wagon / Utility V8 Auto / Man 235/45R17 6301

Sedan / Wagon / Utility V8 Auto / Man 225/50R17 6100

Sedan / Wagon / Utility / Coupe V8 Auto / Man 235/40R18 6230

HSV V8 Auto 225/50ZR16 6355

HSV V8 Auto 235/45ZR17 6210

HSV V8 Auto 235/40ZR18 6210

HSV V8 T56 235/45ZR17 6300

HSV V8 T56 235/40ZR18 6300

HSV V8 Getrag 225/50ZR16 6355

HSV V8 Getrag 235/45ZR17 6210

HSV V8 Getrag 235/40ZR18 6210

NOTE

For PPK values relating to MY 2004 VY

Regular and Crew Cab Series vehicles, refer to

the speedometer pulse table provided in

Section 12C Instruments, in the MY 2004 VY

Regular and Crew Cab Series Service

Information.

Instruments Page 12C–5

Page 12C–5

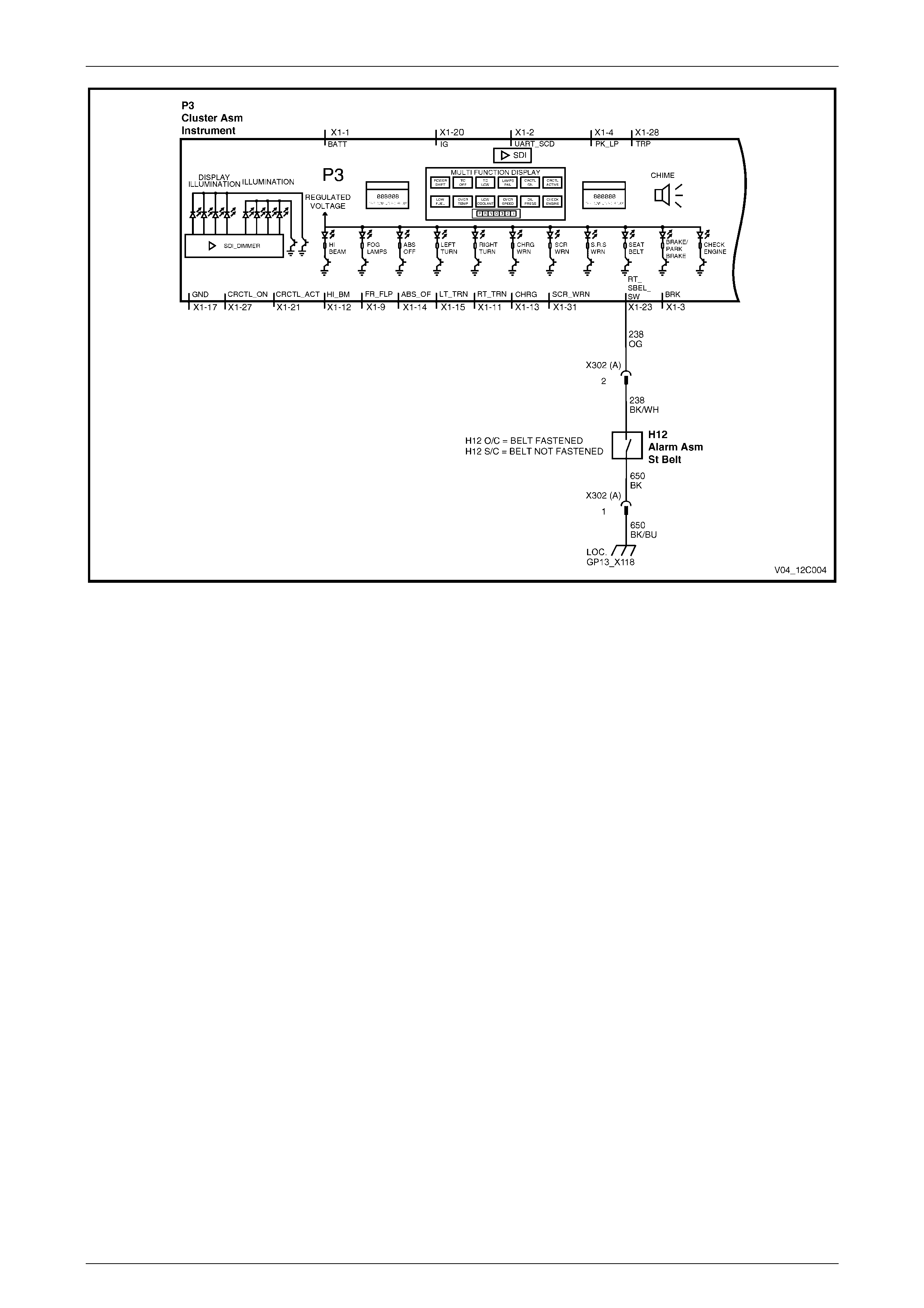

Seat Belt Warning Switch

All MY 2004 VY or V2 Series vehicles (with the exception of the utilities) are now fitted with a seat belt warning alarm

indication for the driver’s seat belt only. This feature applies to both domestic and export vehicles.

Seat Belt Alarm Description

The seat belt warning light is designed to primarily remind the driver to fasten his or her seat belt and to remind the other

passengers to do the same.

Sedan, Wagon and Coupe

Where the driver has buckled the seat belt

correctly before switching the ignition on, the

red Seat Belt warning indicator will remain

extinguished. However, if the driver’s seat belt

is not fastened at ignition on, the warning

indicator flashes for up to 60 seconds, or

extinguishes if the seat belt is fastened during

this time.

Figure 12C – 3

A ‘Fasten Driver’s Seat Belt’ warning message

also appears on the display of the instrument

cluster. If the driver’s seat belt still has not been

fastened after this 60 second period, the

indicator flashes for a further 90 seconds

before extinguishing if the seat belt has still not

been fastened.

Figure 12C – 4

The instrument cluster produces two sequences of chimes while the driver’s seat belt remains unbuckled after the

ignition has been turned on, or while the vehicle is moving. For more detailed information related to the chime function,

refer to Section 12C, 1.1 General Description in the MY 2003 VY and V2 Series Service Information.

Utility

When the ignition is first switched on, the seat belt warning indicator will be displayed for approximately 8 seconds before

extinguishing. The seat belt warning light is provided as an initial reminder to the driver to fasten the seat belt.

Electrical Wiring (Sedan, Wagon and Coupe)

The electrical wiring connec ting the switch located in the driver’s seat belt buckle to the P3 instrument cluster assembly

is shown in Figure 12C – 5. The seat buckle switch is integrated into the seat wiring harness via a three-way seat

connector.

For further inform ation relating to the seat belt buckle switch, refer to Section 12M Occupant Protection System.

Instruments Page 12C–6

Page 12C–6

Figure 12C – 5

Instruments Page 12C–7

Page 12C–7

2 Diagnostics

Due to the changes in vehicle wiring connectors and fuel sender units for MY 2004 VY and V2 Series vehicles (as

described earlier in this Section), as well as the introduction of the VY Series Regular and Crew Cab models, the

following Instrument Cluster Diagnostic charts have been revised to reflect these changes and are included in this

Section for use on those vehicles so affected.

A complete description of how to measure the fuel level sender resistance values at the connector terminals is described

in Section 8A1, 2.1 Modular Fuel Pump and Sender Assembly in this Service Information.

DTC 1 – Petrol Level Sender Signal Voltage Too Low

Figure 12C – 6

Circuit Description

The instrument cluster supplies a 12 volt reference voltage and a ground circuit to the fuel gauge sender unit. The fuel

sender provides a resistance value to the instrument cluster based on its position relative to the fuel level. The fuel

sender resistance will vary between 40 ± 5 ohms (full tank) and 250 ± 5 ohms (no fuel in the tank).

DTC 1 will set if the fuel sender resistance is less than 12.9 ohms for a period of 30 seconds. The DTC is reset when the

fuel sender resistance returns to its normal operating range for a period of 60 seconds. The DTC is logged as a History

DTC.

When a DTC 1 is set the fuel gauge will display the fuel tank level as empty irrespective of actual fuel level.

Diagnostic Aids

The TECH 2 diagnostic tool reads fuel sender position as a voltage between 0 and 5 volts. The fuel sender signal

resistance should be betw een 40 ± 5 ohms and 250 ± 5 ohms when the fuel sender is functioning correctly. The fuel

sender voltage should increase at a steady rate as the fuel level increases.

The multimeter allows continuity of the wiring harness to be checked. Harness voltage can also be confirmed at

connector locations.

Check for any damage to the harness which could cause an intermittent open or short to ground or backed-out terminals

at the instrument cluster connectors, broken connector locks, improperly formed or damaged terminals.

Instruments Page 12C–8

Page 12C–8

Petrol Level Sender Signal Voltage Too Low Diagnostic Chart

Step Action Value(s) Yes No

1 Was the Diagnostic Circ uit Check performed? Go to Step 2. Go to Diagnostic

Circuit Check chart

in Section 12C of

the MY 2003 VY

and V2 Series

Service Information.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body

/ Instrument / Data Display / Instrument.

Scroll to the Fuel Level Sender Resistance signal.

Is the value as specified?

Less than

12.9 ohms Go to Step 3. Go to DTC 2 –

Petrol Level Sender

Signal Voltage

Intermittent

diagnost ic cha rt in

this Section.

3 From the Body Menu, select Miscellaneous Tests /

Gauge Control Tests / Fuel Gauge, and conduct the

test as directed by soft keys at the bottom of the

TECH 2 screen.

Does the fuel gauge operate correctly?

Go to Step 4. Replace the

instrument cluster.

Refer to

2.3 Instrument

Cluste r Assembly

in Section 12C of

the MY 2003 VY

and V2 Series

Service

Information.

4 Disconnect the battery. Refer to Section 00, 5 Battery

Disconnection Procedures.

Disconnect the body harness connector from the main

wiring harness connector X200.

Using an ohmmeter, check for continuity between

X200-26 circuit 30 and X200-36 circuit 510 on the main

wiring harness.

Using an ohmmeter, check for continuity between

X200-26 circuit 30 and a known good ground.

Is there continuity?

Go to Step 5. For Sedan / Wagon

and Coupe Models,

go to Step 6.

For Utility / Regular

Cab and Crew Cab

Models, go to

Step 8.

5 Remove the instrument cluster. Refer to 2.3 Instrument

Cluster Assembly in Section 12C of the MY 2003 VY

and V2 Series Service Information.

Using an ohmmeter, check for continuity between

X200-26 circuit 30 and X200-36 circuit 510 on the main

wiring harness.

Using an ohmmeter, check for continuity between

X200-26 circuit 30 and a known good ground.

Is there continuity?

Short circuit in main

wiring harness

between connector

X200 and

instrument cluster

connector P3.

Repair harness.

Replace the

instrument cluster.

Refer to

2.3 Instrument

Cluste r Assembly

in Section 12C of

the MY 2003 VY

and V2 Series

Service

Information.

6 Disconnect the fuel tank harness from the body

harness connector X402 located under the rear of the

vehicle.

Using an ohmmeter, check for continuity between

X402-1 circuit 30 and X402-3 circuit 510 on the body

harness connec tor.

Using an ohmmeter, check for continuity between

X402-1 circuit 30 and a known good ground.

Is there continuity?

Short circuit in body

harness betw een

X402 and X200.

Repair harness.

Go to Step 7.

Instruments Page 12C–9

Page 12C–9

Step Action Value(s) Yes No

7 Using an ohmmeter, check resistance across X402-1

circuit 30 and X402-3 circuit 510 on the fuel tank

harness.

Is the value as specified?

Between

40 ± 5 ohms

and

250 ± 5 ohms

Go to DTC 2 –

Petrol Level Sender

Signal Voltage

Intermittent

diagnost ic cha rt in

this Section.

Go to Step 8.

8 For Sedan / Wagon / Coup e and Utility:

Drain and remove the fuel tank. Refer to Sectio n 8A1,

2.1 Fuel Tank – Sedan and Wagon, 2.2 Fuel Tank –

Coupe or 2.3 Fuel Tank – Utility in the MY 2003 VY

and V2 Series Service Information as appropriate.

Using an ohmmeter, check for continuity between fuel

pump M8 connector X1-C circuit 30 and X1-B on the

fuel tank harness.

Using an ohmmeter, check for continuity between X1-C

circuit 30 and a known good ground.

For Regular and Crew Cab models:

Disconnect rear body harness connector X1 from the

modular fuel sen der assem bly M8.

Using an ohmmeter, check for continuity between X1-2

circuit 30 and M8 X1-3 on the rear body harness.

Using an ohmmeter, check for continuity between X1-2

circuit 30 and a known good ground.

Is there continuity?

Short circuit in

wiring harness

between the fuel

sender unit and

connector X402

(Sedan / Wagon

and Coupe) or

X200 (Utility /

Regular Cab and

Crew Cab). Repair

harness.

Replace faulty fuel

sender unit.

For Sedan / Wagon

/ Coupe or Utility,

refer to

Section 8A1, in the

MY 2003 VY and

V2 Series Service

Information.

For Regular Cab

and Crew Cab,

refer to

Section 8A1 of the

MY 2004 VY Series

Regular and Crew

Cab Service

Information.

9 1. From the Body Menu, select Diagnostic Trouble

Codes / Clear DTC Information on the TECH 2.

Has the DTC cleared?

End of diagnostic

checking. Refer to

corresponding

diagnost ic cha rt in

this Section or

Section 12C of the

MY 2003 VY and

V2 Series Service

Information.

WHEN ALL DIAG NOSIS AND REPAIRS ARE COMPLETED, CLEAR ALL DTC

AND VERIFY CORRECT OPERATION

Instruments Page 12C–10

Page 12C–10

DTC 2 – Petrol Level Sender Signal Voltage Intermittent

Figure 12C – 7

Circuit Description

The instrument cluster supplies a 12 volt reference voltage and a ground circuit to the fuel gauge sender unit. The fuel

sender provides a resistance value to the instrument cluster based on its position relative to the fuel level. The fuel

sender resistance will vary between 40 ± 5 ohms (full tank) and 250 ± 5 ohms (no fuel in the tank).

DTC 2 will set if there is an intermittent fault in the connection between the fuel sender and the instrument cluster. The

DTC is set when the fuel sender resistance is greater than 290 ohms for 30 seconds or if the fuel sender resistance is

less than 37.5 ohms for 30 seconds. The DTC is reset when the fuel sender is detected as being open circuit or short

circuit or the sender resistance is within its normal operating range for a period of 60 seconds. The DTC is logged as a

Histo r y DTC.

Diagnostic Aids

By manipulating the harnesses at the various connectors and points along the harness it is possible to isolate the cause

of the circuit interruption. By working through the chart in the specified order it is possible to work out which harness

contains the fault. This harness can then be removed and repaired.

The TECH 2 diagnostic tool reads fuel sender position as a voltage between 0 and 5 volts. The fuel sender signal

resistance should be betw een 40 ± 5 ohms and 250 ± 5 ohms when the fuel sender is functioning correctly. The fuel

sender voltage should increase at a steady rate as the fuel level increases.

The multimeter allows continuity of the wiring harness to be checked. Harness voltage can also be confirmed at

connector locations.

Check for any damage to the harness which could cause an intermittent open or short to ground or backed out terminals

at the instrument cluster connectors, broken connector locks, improperly formed or damaged terminals.

Instruments Page 12C–11

Page 12C–11

Petrol Level Sender Signal Voltage Intermittent Diagnostic Chart

Step Action Value(s) Yes No

1 Was the Diagnostic Circ uit Check performed? Go to Step 2. Go to Diagnostic

Circuit Check chart

in Section 12C of

the MY 2003 VY

and V2 Series

Service

Information.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body

/ Instrument / Miscellaneous Tests / Gauge Control

Tests / Fuel Gauge, and conduct the test as directed by

soft keys at the bottom of the TECH 2 screen.

Does the fuel gauge operate correctly?

Go to Step 3. Replace the

instrument cluster.

Refer to

2.3 Instrument

Cluste r Assembly

in Section 12C of

the MY 2003 VY

and V2 Series

Service

Information.

3 From the Body Menu, select Diagnostic Trouble Codes

/ Clear DTC Information.

Turn the ignition off then on.

From the Body Menu, select Data Display / Instrument.

Scroll to the Fuel Level Sender Resistance signal.

Have an assistant manipulate the main wiring harness

between connector X200 and the instrument cluster

connector P3 to induce an intermittent fault.

Did the fuel level sender resistance vary during the

manipulations, or

Did DTC 2 set again?

Repair faulty main

wiring harness. Go to Step 4.

4 Have assistant mani pulate the body wiring harness

between connectors X200 and X402 (Sedan / Wagon

and Coupe) or X200 and X–1 for Utility / Regular and

Crew Cab models to induce an intermittent fault.

Did the fuel level sender resistance vary during the

manipulations, or

Did DTC 2 set again?

Repair faulty body

wiring harness. Go to Step 5.

5 For Sedan / Wagon / Coup e and Utility:

Drain and remove the fuel tank. Refer to Sectio n 8A1,

2.1 Fuel Tank – Sedan and Wagon, 2.2 Fuel Tank –

Coupe or 2.3 Fuel Tank – Utility in the MY 2003 VY

and V2 Series Service Information as appropriate.

For Regular Cab and Crew Cab:

Disconnect rear body harness connector X1 from the

modular fuel sen der as sembly .

For all models, have assistant manipulate the fuel tank

wiring harness between connector X402 (Sedan /

Wagon and Coupe) or X200 (Utility / Regular and Crew

Cab models) and the fuel sender connector X–1 to

induce an intermittent fault.

Did the fuel level sender resistance vary during the

manipulations, or

Did DTC 2 set again?

Repair faulty fuel

tank wiring

harness.

Replace faulty fuel

sender unit.

For Sedan / Wagon

/ Coupe or Utility,

refer to

Section 8A1, in the

MY 2003 VY and

V2 Series Service

Information.

For Regular Cab

and Crew Cab,

refer to

Section 8A1 of the

MY 2004 VY Series

Regular and Crew

Cab Service

Information.

Instruments Page 12C–12

Page 12C–12

Step Action Value(s) Yes No

6 From the Body Menu, select Diagnostic Trouble Codes

/ Clear DTC Information on the TECH 2.

Has the DTC cleared?

End of diagnostic

checking. Refer to

corresponding

diagnost ic cha rt in

this Section or

Section 12C of the

MY 2003 VY and

V2 Series Service

Information.

WHEN ALL DIAG NOSIS AND REPAIRS ARE COMPLETED, CLEAR ALL DTC

AND VERIFY CORRECT OPERATION

Instruments Page 12C–13

Page 12C–13

DTC 3 – Petrol Level Sender Signal Voltage Too High

Figure 12C – 8

Circuit Description

The instru ment cluster supp lies a 12 volt ref erence voltage and a ground circuit to the fuel gauge send er un it. The fuel

sender provides a resistance value to the instrument cluster based on its position relative to the fuel level. The fuel

sender resistance will vary between 40 ± 5 ohms (full tank) and 250 ± 5 ohms (no fuel in the tank).

DTC 3 will set if the fuel sender circuit provides a resistance above 290 ohms for a duration longer than 30 seconds. The

DTC is reset when the fuel sender resistance returns to its normal operating range for a period of 60 seconds. The DTC

is logged as a History DTC.

When a DTC 3 is set the fuel gauge will display the fuel tank level as empty irrespective of actual fuel level.

Diagnostic Aids

The TECH 2 diagnostic tool reads fuel sender position as a voltage between 0 and 5 volts. The fuel sender signal

resistance should be betw een 40 ± 5 ohms and 250 ± 5 ohms when the fuel sender is functioning correctly. The fuel

sender voltage should increase at a steady rate as the fuel level increases.

The multimeter allows continuity of the wiring harness to be checked. Harness voltage can also be confirmed at

connector locations.

Check for any damage to the harness, which could cause an intermittent open or short to ground or backed-out terminals

at the instrument cluster connectors, broken connector locks, improperly formed or damaged terminals.

Instruments Page 12C–14

Page 12C–14

Petrol Level Sender Signal Voltage Too High Diagnostic Chart

Step Action Value(s) Yes No

1 Was the Diagnostic Circ uit Check performed? Go to Step 2. Go to Diagnostic

Circuit Check chart

in Section 12C of

the MY 2003 VY

and V2 Series

Service

Information.

2 Connect TECH 2 to the DLC.

Select Diagnostics / Model Year / Vehicle Model / Body

/ Instrument / Data Display / Instrument.

Scroll to the Fuel Level Sender Resistance signal.

Is the value as specified?

Greater than

290 ohms Go to Step 3. Go to DTC 2 –

Petrol Level Sender

Signal Voltage

Intermittent

diagnost ic cha rt in

this Section.

3 From the Body Menu, select Miscellaneous Tests /

Gauge Control Tests / Fuel Gauge, and conduct the

test as directed by soft keys at the bottom of the

TECH 2 screen.

Does the fuel gauge operate correctly?

Go to Step 4. Replace the

instrument cluster.

Refer to

2.3 Instrument

Cluste r Assembly

in Section 12C of

the MY 2003 VY

and V2 Series

Service

Information.

4 Disconnect the battery. Refer to Section 00, 5 Battery

Disconnection Procedures.

Remove the instrument cluster. Refer to 2.3 Instrument

Cluster Assembly in Section 12C of the MY 2003 VY

and V2 Series Service Information

Disconnect the main wiring harness connector X200

from the body wiring harness.

Using an ohmmeter, check for continuity of circuit 30

between the instrument cluster P3, connector X1-29,

and main wiring harness connector X200-26.

Is there continuity?

Go to Step 5. Repair open circuit

in main wiring

harness, cir cui t 30.

5 Using an ohmmeter, check for continuity of circuit 510

between the instrument cluster P3, connector X1-19

and main wiring harness connector X200-36.

Is there continuity?

For Sedan / Wagon

and Coupe Models,

go to Step 6.

For Utility / Regular

Cab and Crew Cab

Models, go to

Step 8.

Repair open circuit

in main wiring

harness,

circuit 510.

6 Disconnect the body wiring harness connector X402

from the fuel tank harness.

Using an ohmmeter, check for continuity of circuit 30

between the main wiring harne ss connector X200-26

and the body wiring harness connector X402-1.

Is there continuity?

Go to Step 7. Repair open circuit

in body wiring

harness, cir cui t 30.

7 Using an ohmmeter, check for continuity of circuit 510

between the main wiring harne ss connector X200-36

and the body wiring harness connector X402-3.

Is there continuity?

Go to Step 8. Repair open circuit

in body wiring

harness,

circuit 510.

Instruments Page 12C–15

Page 12C–15

Step Action Value(s) Yes No

8 For Sedan / Wagon / Coup e and Utility:

Drain and remove the fuel tank. Refer to Sectio n 8A1,

2.1 Fuel Tank – Sedan and Wagon, 2.2 Fuel Tank –

Coupe or 2.3 Fuel Tank – Utility in the MY 2003 VY

and V2 Series Service Information as appropriate.

For all models:

Disconnect the wiring harness connector from the fuel

sender unit M8.

Using an ohmmeter, check for continuity of circuit 30

between the fuel tank wiring harness connector X1 and

the body wiring harness connector X402 (Sedan /

Wagon and Coupe) or main wiring harness connector

X200 (Utility / Regular and Crew Cab models).

Is there continuity?

Go to Step 9. Repair open circuit

in fuel tank wiring

harness, cir cui t 30.

9 Using an ohmmeter, check for continuity of circuit 510

between the fuel tank wiring harness connector X1 and

the body wiring harness connector X402 (Sedan /

Wagon and Coupe) or main wiring harness connector

X200 (Utility / Regular and Crew Cab models).

Is there continuity?

Go to Step 10. Repair open circuit

in fuel tank wiring

harness,

circuit 510.

10 Using an ohmmeter, check for continuity across the

fuel sender.

Is there continuity?

Replace the

instrument cluster.

Refer to

2.3 Instrument

Cluste r Assembly

in this Section.

Replace faulty fuel

sender unit.

For Sedan / Wagon

/ Coupe or Utility,

refer to

Section 8A1, in the

MY 2003 VY and

V2 Series Service

Information.

For Regular Cab

and Crew Cab,

refer to

Section 8A1 of the

MY 2004 VY Series

Regular and Crew

Cab Service

Information.

11 From the Body Menu, select Diagnostic Trouble Codes

/ Clear DTC Information on the TECH 2.

Has the DTC cleared?

End of diagnostic

checking. Refer to

corresponding

diagnost ic cha rt in

Section 12C of the

MY 2003 VY and

V2 Series Service

Information.

WHEN ALL DIAG NOSIS AND REPAIRS ARE COMPLETED, CLEAR ALL DTC

AND VERIFY CORRECT OPERATION

Instruments Page 12C–16

Page 12C–16

3 Specifications

Fuel Calibration Part Number

For fuel calibration, code index and version number specifications, refer to Fuel Calibration in this Section.

Speedometer Pulses

For Pulses Per Kilometre (PPK) specifications, refer to Speedom eter Pulses in this Section.