Engine Mechanic al – V6 Engine Page 6A1–1

Page 6A1–1

Section 6A1

Engine Mechanical – V6 Engine

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices w ith regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

2 General Description............................................................................................................................... 3

2.1 Connecting Rods ...................................................................................................................................................3

3. Service Operation.................................................................................................................................. 4

3.1 Engine Oil Level Check..........................................................................................................................................4

4 Specifications......................................................................................................................................... 5

5 Torque Wrench Specifications............................................................................................................. 6

Techline

Techline

Techline

Engine Mechanic al – V6 Engine Page 6A1–2

Page 6A1–2

1 General Information

With the following exceptions, MY 2004 VY and V2 Series V6 Engine Mechanical Service Information carries over from

MY 2003 VY and V2 Series vehicles. For information not contained within this Section, refer to Section 6A1, Engine

Mechanical – V6 Engine in the MY 2003 VY and V2 Series Service Information.

• Revised engine oil level checking procedure.

• New powder forged ‘cracked’ type connecting rods where introduced as a running change during August 2003.

Engine Mechanic al – V6 Engine Page 6A1–3

Page 6A1–3

2 General Description

2.1 Connecting Rods

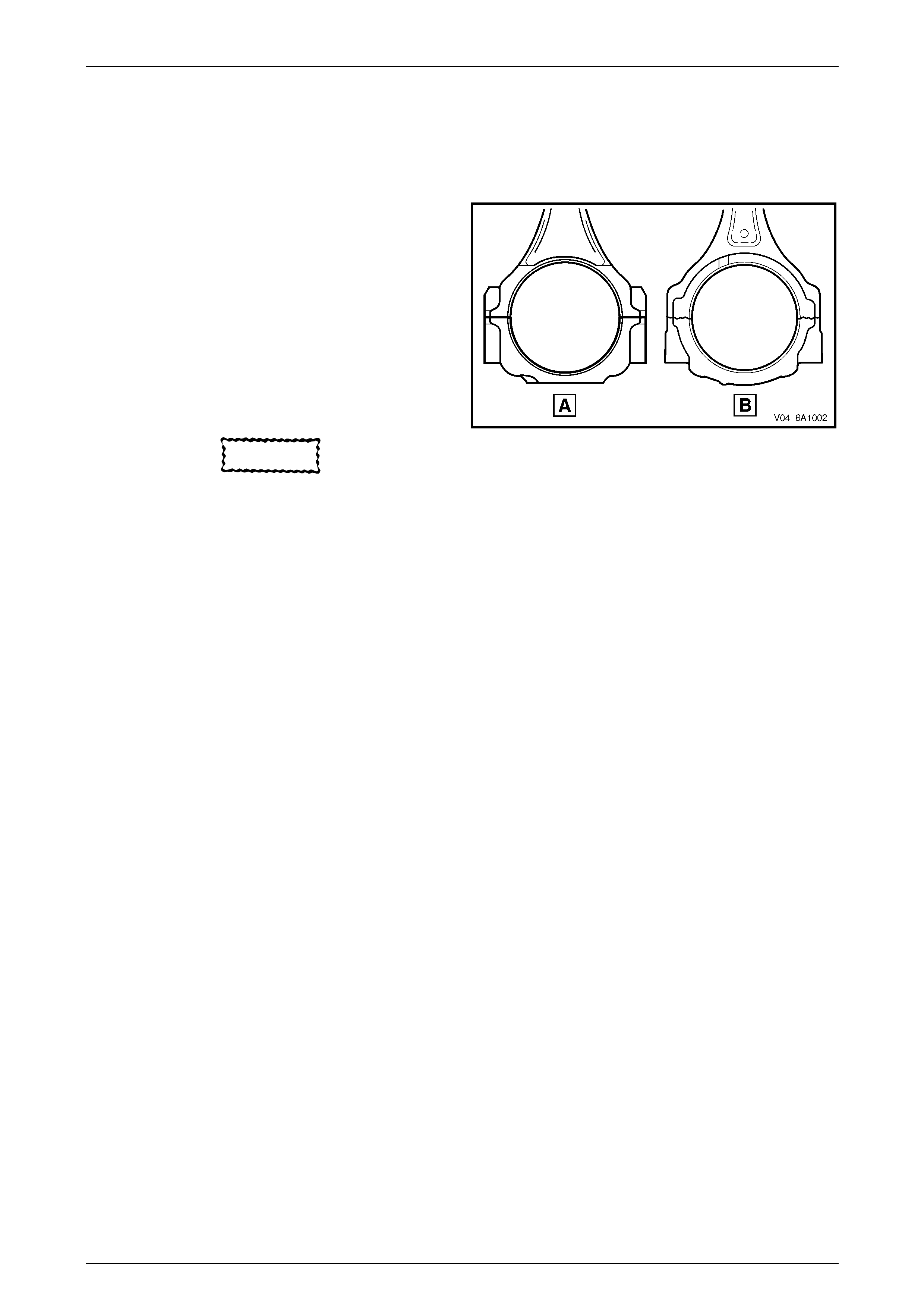

Powder forged and cracked type connecting rods where

introduced into production as a running change during

August 2003. Illustration 6A1-1 shows the difference in the

early cast and machined type (A) and later powder forged

and cracked type (B) connecting rods.

NOTE

Other than the revised manufacturing process

and a revised connecting rod cap bolt torque

specification, all other specifications and

servicing procedures relating to the connecting

rods remain unchanged.

CAUTION

The early type connecting rods can be

replaced by the late type connecting rods.

However, to avoid confusion with having

different bolt torque values, when replacing

early type connecting rods with the late

type, it is recommended that the connecting

rods be replaced as an engine set.

Figure 6A1-1

Engine Mechanic al – V6 Engine Page 6A1–4

Page 6A1–4

3. Service Operation

3.1 Engine Oil Level Check

1 The engine must be at normal operating temperature (drive the vehicle for 15 minutes).

2 Park the vehicle on a level surface.

• Do not check the oil level for at least 10

minutes after the engine is switched-off.

This allows time for the oil to drain back

into the oil pan.

• A sloping surface will affect the accuracy

of the measurement.

3 Remove the dipstick and wipe clean.

4 Reinstall the dipstick. Ensure that it is fully seated. Leave for several seconds and remove slowly to avoid

smearing the oil (level): then hold the dipstick horizontally to prevent the oil (level) moving along the dipstick.

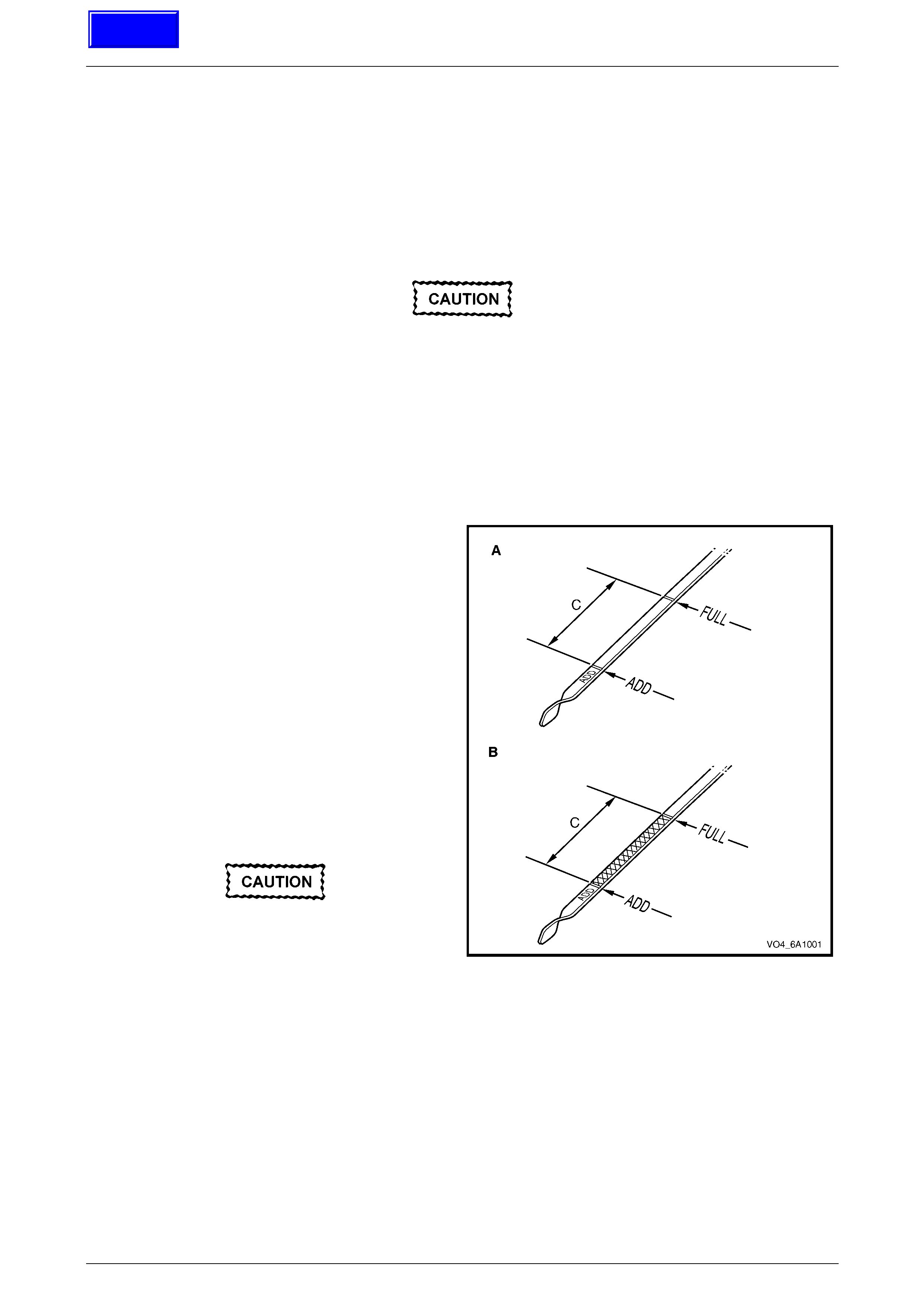

5 Observe the oil level where it passes over the centre

line of the dipstick.

NOTE

The following are easy guides for how much oil

to add:

• For Type I engine oil level dipstick (A), the

ADD to FULL mark area (C) represents 1.5

litres of oil.

• For Type II engine oil level dipstick (B), the

cross-hatch area (C) represents 1.5 litres of

oil.

6 If the level is lower than, or close to the ADD mark,

top-up the engine with enough oil to reach the FULL

mark.

Do not fill over the FULL mark.

7 Allow several minutes for the added oil to drain down

into the oil pan then recheck the oil level.

Figure 6A1 – 2

Techline

Engine Mechanic al – V6 Engine Page 6A1–5

Page 6A1–5

4 Specifications

Connecting Rods

Early Type.................................................................................Malleable Cast Iron 'I' Section

Late Type........................................................................................ Powder Forged ‘I’ Section

Length (centre to centre) ........................................................................ 145.90 – 145.80 mm

Alignment.............................................................Bend 0.020/25.4 mm, Twist 0.038/25.4 mm

Engine Mechanic al – V6 Engine Page 6A1–6

Page 6A1–6

5 Torque Wrench Specifications

Early Type Connecting Rod Cap Bolts .................................27 ±3 Nm plus 50 ±3° turn angle

Late Type Connecting Rod Cap Bolts..................................20 ±3 Nm plus 75 ±3 ° turn angle