Engine Mechanical – GEN III V8 Engine Page 6A3–1

Page 6A3–1

Section 6A3

Engine Mechanical –

GEN III V8 Engine

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices w ith regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 General Description...............................................................................................................................................3

Oil Pan.....................................................................................................................................................................3

Positive Crankcase Ventilation.............................................................................................................................4

Water Pump ............................................................................................................................................................5

Exhaust System......................................................................................................................................................5

2 Service Operation.................................................................................................................................. 6

2.1 Engine Oil Level Check..........................................................................................................................................6

2.2 PCV Oil Separator ..................................................................................................................................................7

Remove ...................................................................................................................................................................7

Clean and Inspect ..................................................................................................................................................7

Reinstall..................................................................................................................................................................8

3 Specifications......................................................................................................................................... 9

4 Torque Wrench Specification............................................................................................................. 10

Techline

Techline

Techline

Techline

Techline

Techline

Engine Mechanical – GEN III V8 Engine Page 6A3–2

Page 6A3–2

1 General Information

With the following exceptions, MY 2004 VY and V2 Series GEN III V8 Engine Mechanical Service Information carries

over from MY 2003 VY Series vehicles. For information not contained within this Section, refer to Section 6A3, Engine

Mechanical – Gen III V8 Engine in the MY 2003 VY and V2 Series Service Information.

• New oil pan.

• New Positive Crankcase Ventilation (PCV) system.

• Revised oil checking procedure.

• New wate r pump.

• New exhaust system.

• Specification Changes:

• New engine oil specification.

• New spark plug specification.

• New piston clearances specification.

Engine Mechanical – GEN III V8 Engine Page 6A3–3

Page 6A3–3

1.1 General Description

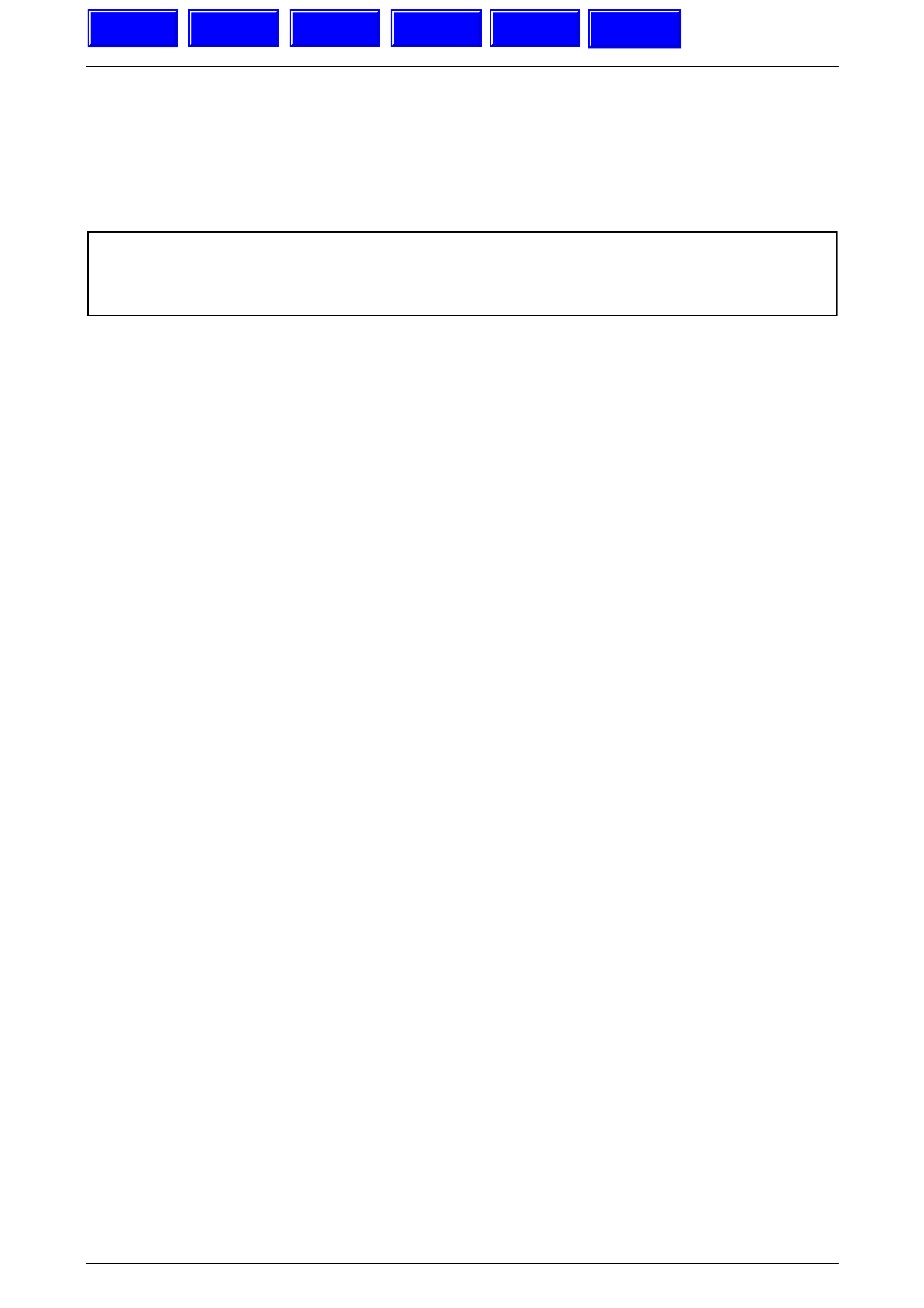

Oil Pan

NOTE

The changes in the engine oil pan design do not

affect the oil pan service procedure. Where the

service procedure includes the removal of the oil

pan, refer to Section 6A3, Engine Mechanical –

Gen III V8 Engine in the MY 2003 VY and V2

Series Service Information.

To prevent oil starvation and oil aeration during

acceleration, braking and cornering manoeuvres, the new

engine oil pan (1) and oil pan baffle plate (2) features the

following:

• Dams and return oil ridges are integrated with the oil

pan baffle plate to improve the flow of return oil back

into the oil pump pick-up screen (3) area. This

minimises oil migration during acceleration, braking

and cornering manoeuvres.

• Increased engine oil capacity.

In addition, a crankshaft oil deflector (4) mounted to the

main bearing caps further improves the flow of return oil by:

• Controlling windage.

• Removing return oil from the crankshaft.

• Facilitating the return oil drain back into the oil pan.

• Reducing engine oil aeration.

The oil pan is made from cast aluminium and is an integral

part of the powertrain structure. The oil pan provides a 360°

mounting for the automatic or manual transmission.

The oil pan gasket (5) is a controlled compression

aluminium carrier gasket using silicone material as a

sealing agent.

Two O-ring seals (6) are fitted to the oil transfer cover (7)

studs to prevent oil leak along the studs.

The oil filter mounting boss (8) is incorporated in the oil pan

design.

Figure 7B2 – 1

Engine Mechanical – GEN III V8 Engine Page 6A3–4

Page 6A3–4

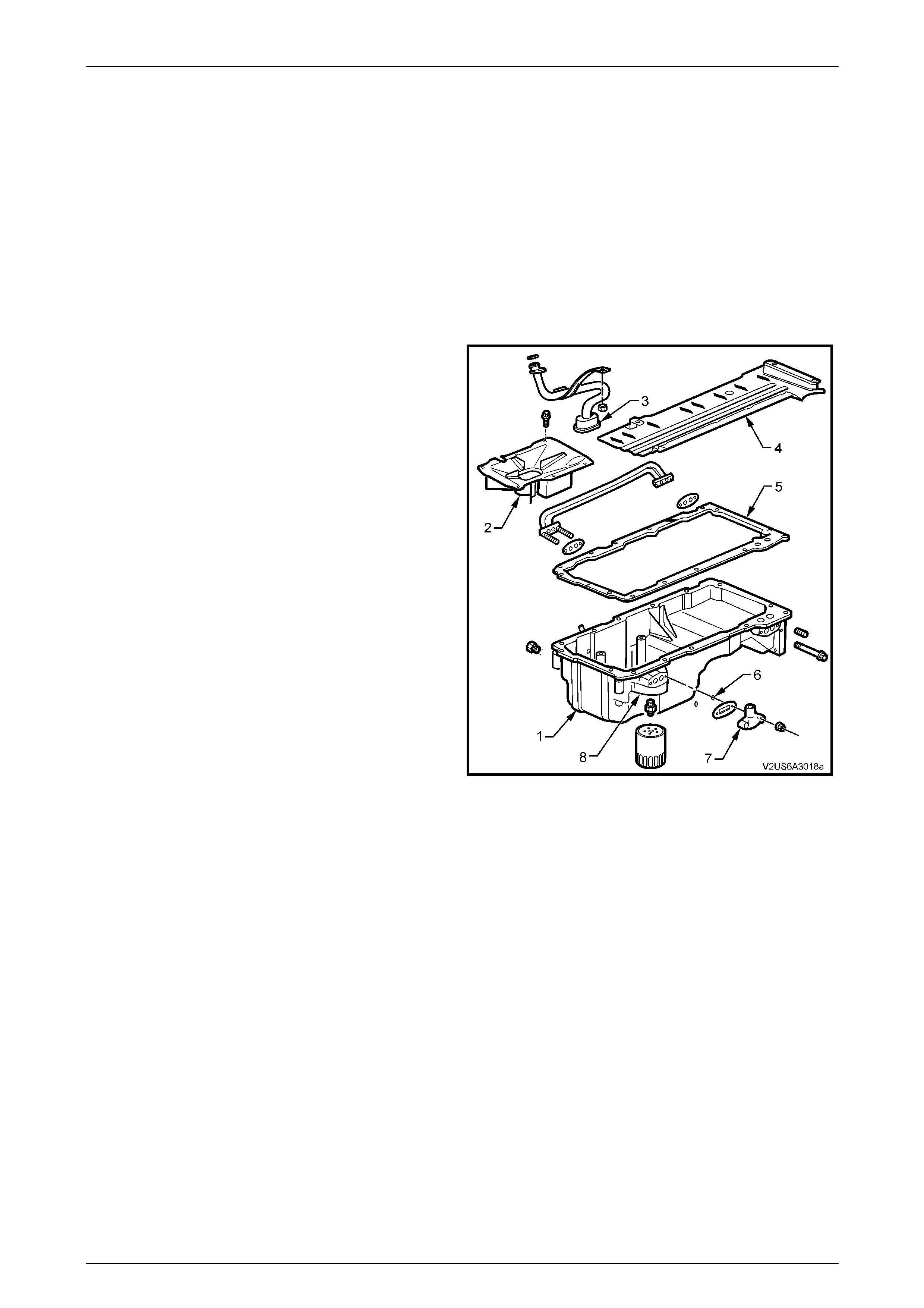

Positive Crankcase Ventilation

The engine ventilation system was developed to remove the

engine combustion blow-by vapours and minimise the

following:

• Crankcase pressure build-up

• Oil deterioration

• Oil consumption

• Evaporative/exhaust emissions

During normal idle and part throttle operation, filtered fresh

air is routed from upstream of the throttle body (1) blade

to the front of the right rocker cover via the fresh air inlet

hose (2).

Blow-by gas (oil vapour) in the crankcase valley passes

through the oil separator (3) and then flows through the

fixed internal flow-restricting orifice (4).

Via the foul air hose (5), the blow-by gas is directed from

the valley cover right-hand corner to the inlet manifold

downstream of the throttle body.

Under heavy load operation and high engine speeds, an

acceptable reverse flow condition may occur in the fresh air

inlet hose.

Figure 7B2 – 2

During sustained maximum lateral acceleration (A), the

outboard rocker cover may be overloaded with oil (1). If the

blow-by gas is drawn from the rocker cover as in previous

design, oil may be ingested into the intake manifold.

The Central Valley Ventilation System is designed to

eliminate oil ingestion during severe vehicle cornering

manoeuvres.

Instead of the blow-by gas being drawn from the rocker

cover, a high efficiency oil separator (2) in conjunction with

an internal flow-restricting orifice (3) is fitted under the

valley cover to draw the blow-by gas from the

crankcase (B).

NOTE

Where a service procedure includes the removal

of a Positive Crankcase (PCV) System

component that is not covered in this Section,

refer to Section 6E3, Emission Control – Gen III

V8 Engine. Figure 7B2 – 3

Engine Mechanical – GEN III V8 Engine Page 6A3–5

Page 6A3–5

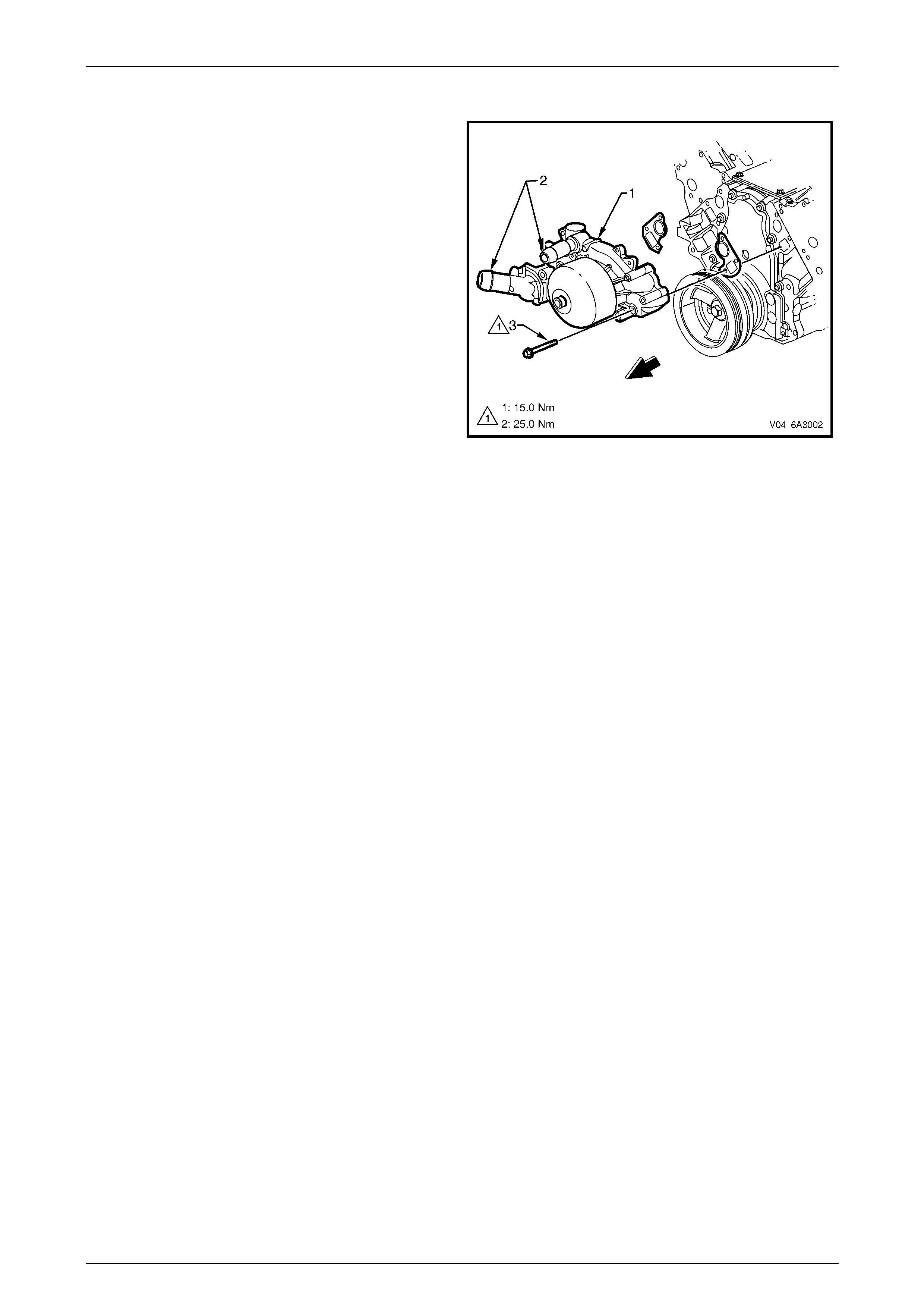

Water Pump

The length of the water pump (1) inlet and outlet tubes (2)

has been extended for easier coolant hose installation and

to improve the coolant rubber hose fit to the water pump.

NOTE

The changes in the water pump design do

not affect the water pump service procedure. For

water pump service procedure, refer to Section

6B3, Engine Cooling – Gen III V8 in the MY

2003 VY and V2 Series Service Information.

Figure 7B2 – 4

Exhaust System

Where a service procedure includes the removal of an exhaust system component, refer to Section 8B, Exhaust

System.

Engine Mechanical – GEN III V8 Engine Page 6A3–6

Page 6A3–6

2 Service Operation

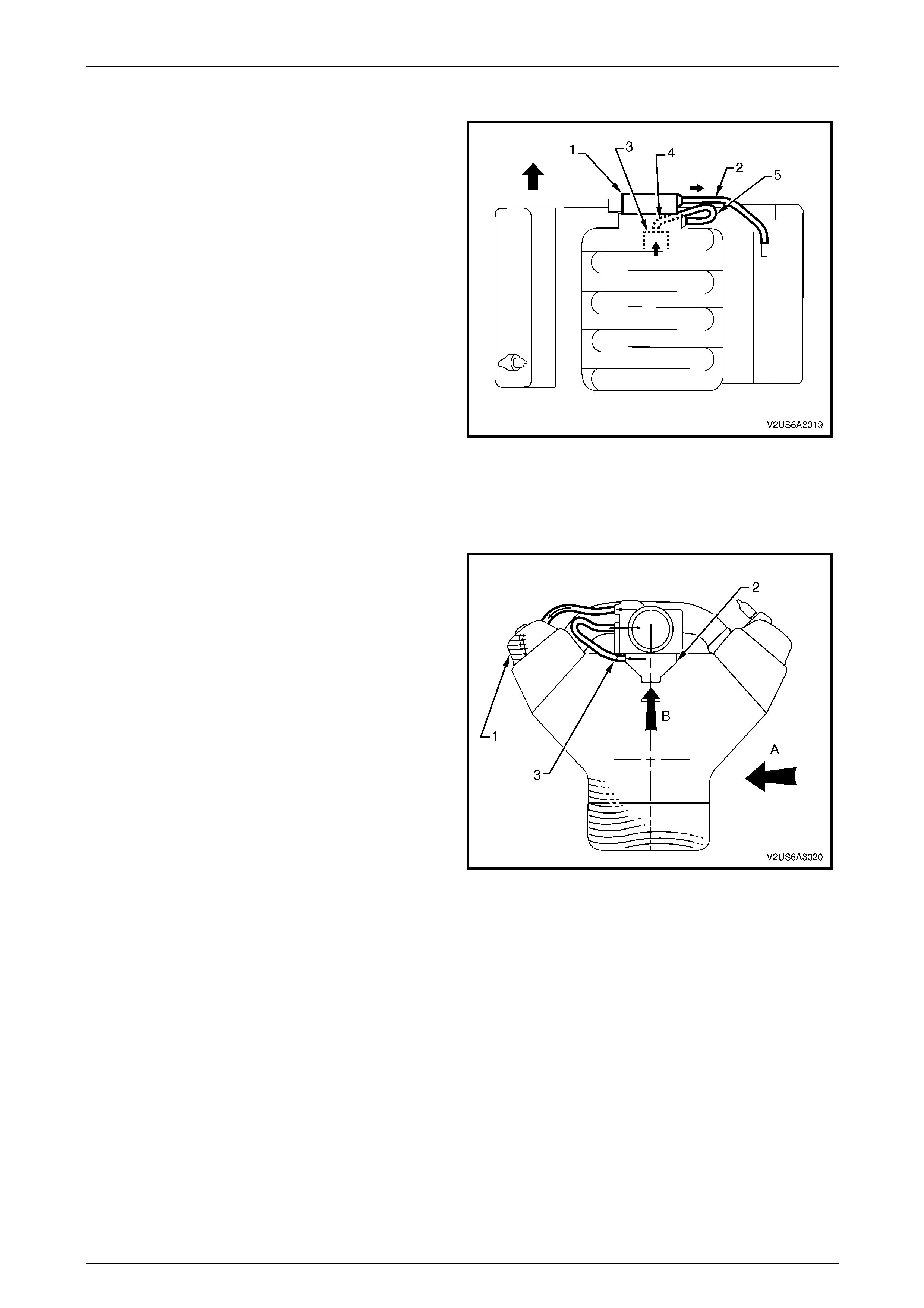

2.1 Engine Oil Level Check

1 The engine must be at normal operating temperature (drive the vehicle for 15 minutes).

2 Park the vehicle on a level surface.

• Do not check the oil level for at least 10

minutes after the engine is switched-off.

This allows time for the oil to drain back

into the oil pan.

• A sloping surface will affect the accuracy

of the measurement.

3 Remove the dipstick and wipe clean.

4 Reinstall the dipstick. Ensure that it is fully seated. Leave for several seconds and remove slowly to avoid

smearing the oil (level); then hold the dipstick horizontally to prevent the oil (level) moving along the dipstick.

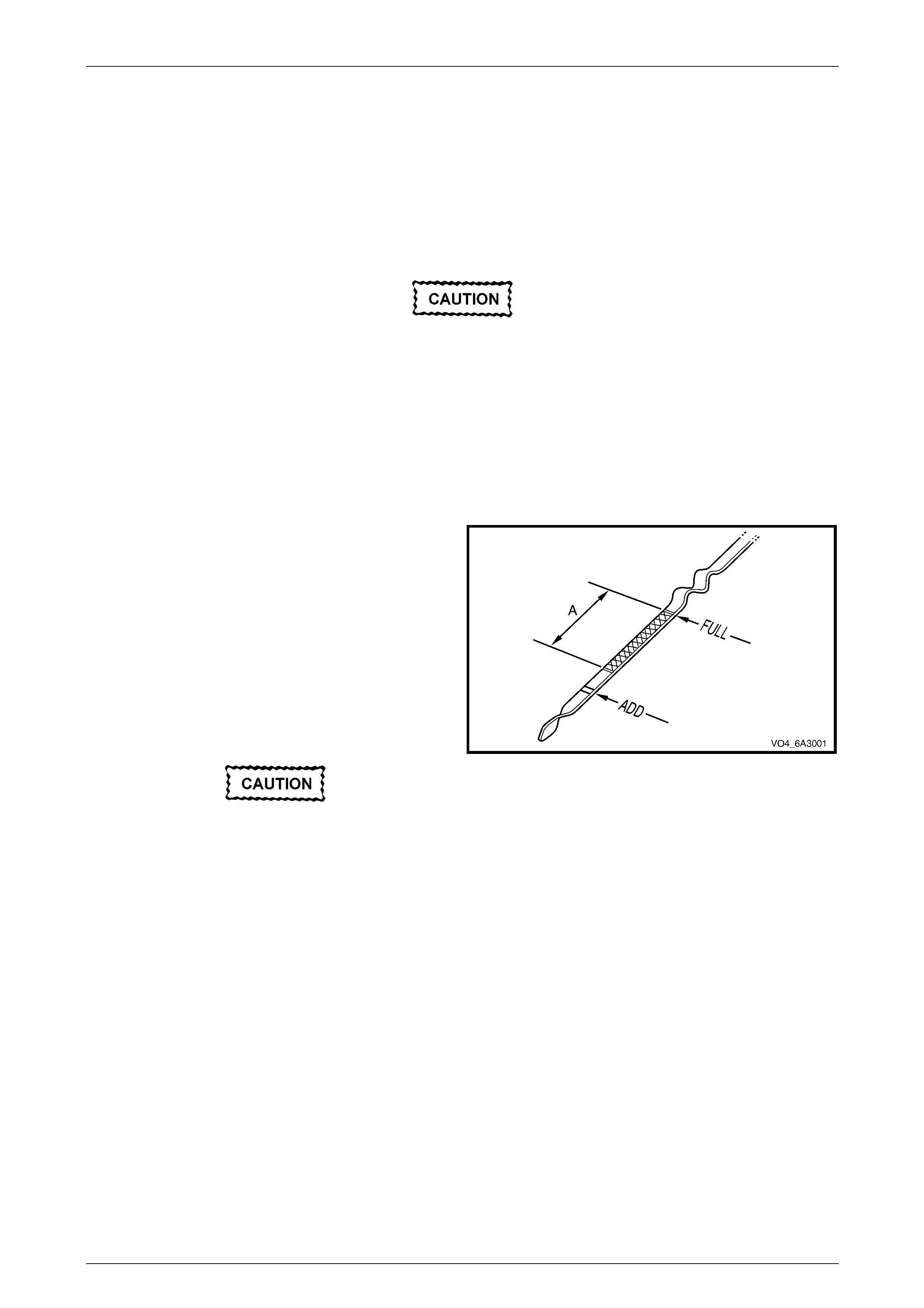

5 Observe the oil level where it passes over the centre

line of the dipstick.

NOTE

As an easy guide for how much oil to add, the

crosshatch area (A) represents 1-litre of oil and

the ADD mark represents 1.6 litres of oil is

required.

6 If the level is lower than, or close to the ADD mark,

top-up the engine with enough oil to reach the FULL

mark.

Do not fill over the FULL mark.

7 Allow several minutes for the added oil to drain down

into the oil pan then recheck the oil level.

Figure 7B2 – 5

Engine Mechanical – GEN III V8 Engine Page 6A3–7

Page 6A3–7

2.2 PCV Oil Separator

Remove

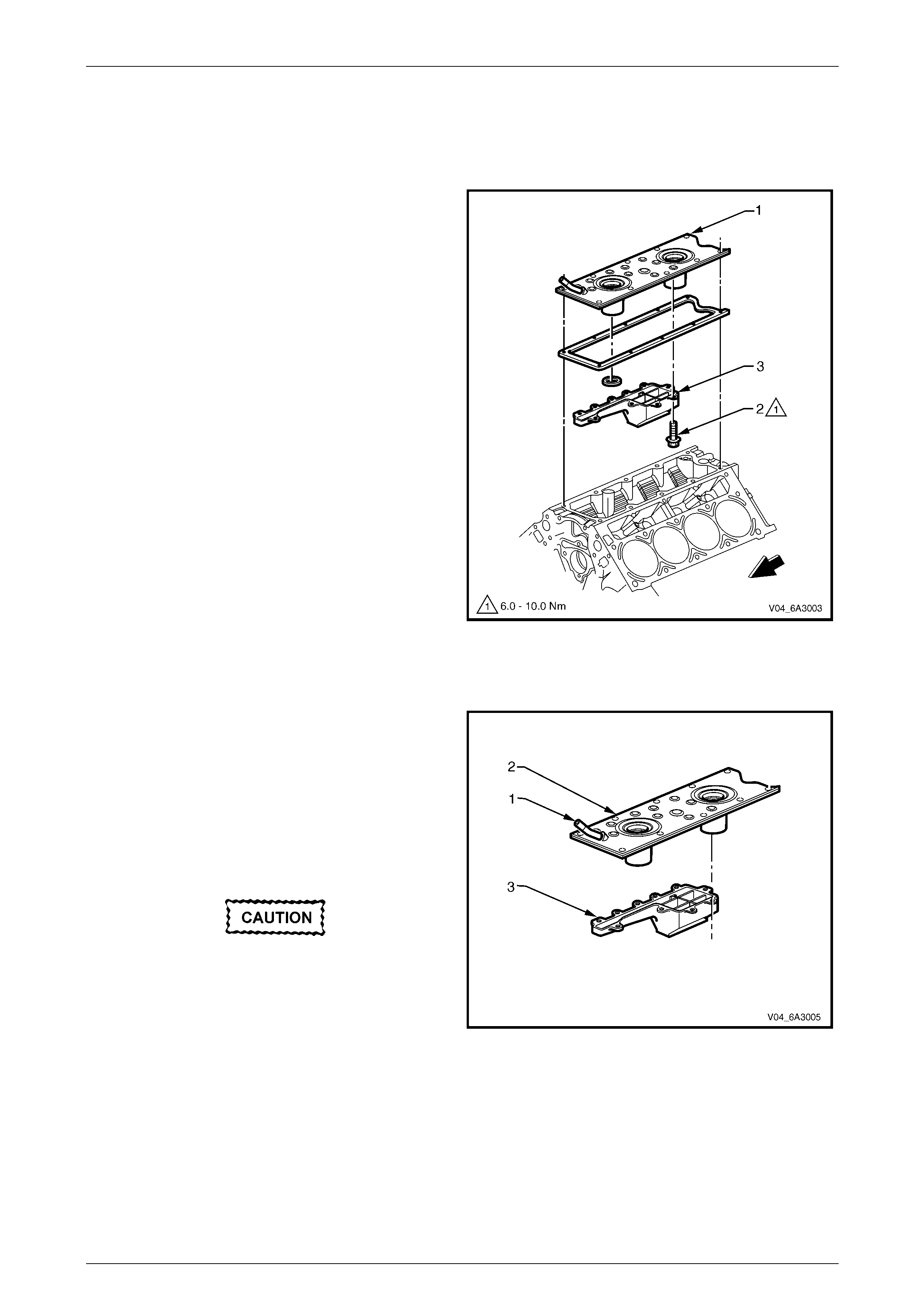

1 Remove the engine valley cover (1). Refer to Section

6A3, Engine Mechanical – Gen III V8 Engine in the

MY 2003 VY and V2 Series Service Information.

2 Remove the bolt (2) attaching the PCV oil separator

(3) to the engine valley cover.

3 Remove the PCV oil separator from the engine valley

cover.

Figure 7B2 – 6

Clean and Inspect

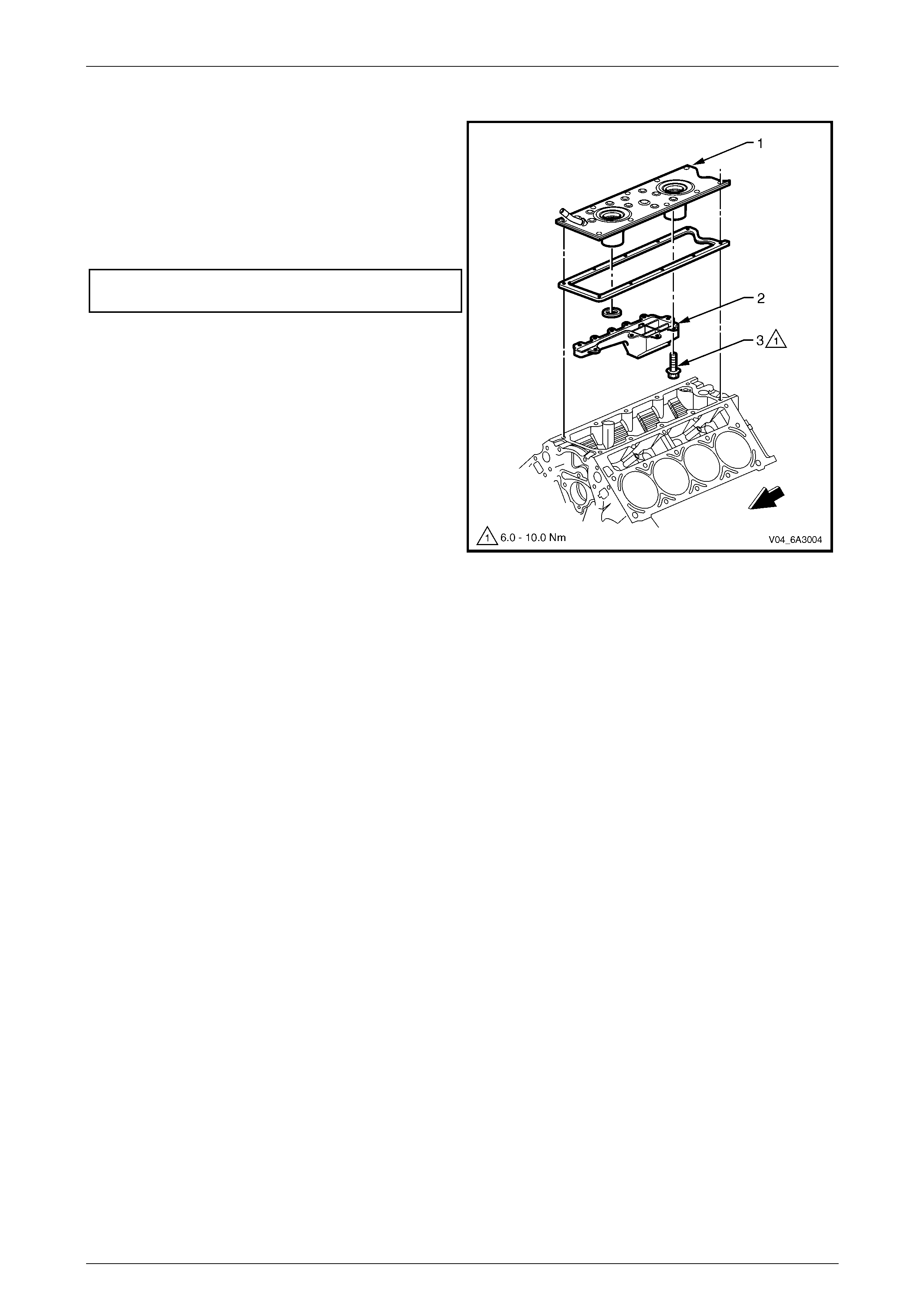

1 Thoroughly wash all components in a suitable

cleaning solvent.

2 Ensure that the fixed internal flow-restricting orifice (1)

is not blocked.

3 Ensure that the engine valley cover (2) to PCV oil

separator (3) mating surfaces are free of burrs and

traces of old sealant.

4 Inspect the PCV oil separator for cracks or defects.

Wear safety glasses w hen using compressed

air to avoid eye injury.

5 Blow-dry all components using compressed air.

Figure 7B2 – 7

Engine Mechanical – GEN III V8 Engine Page 6A3–8

Page 6A3–8

Reinstall

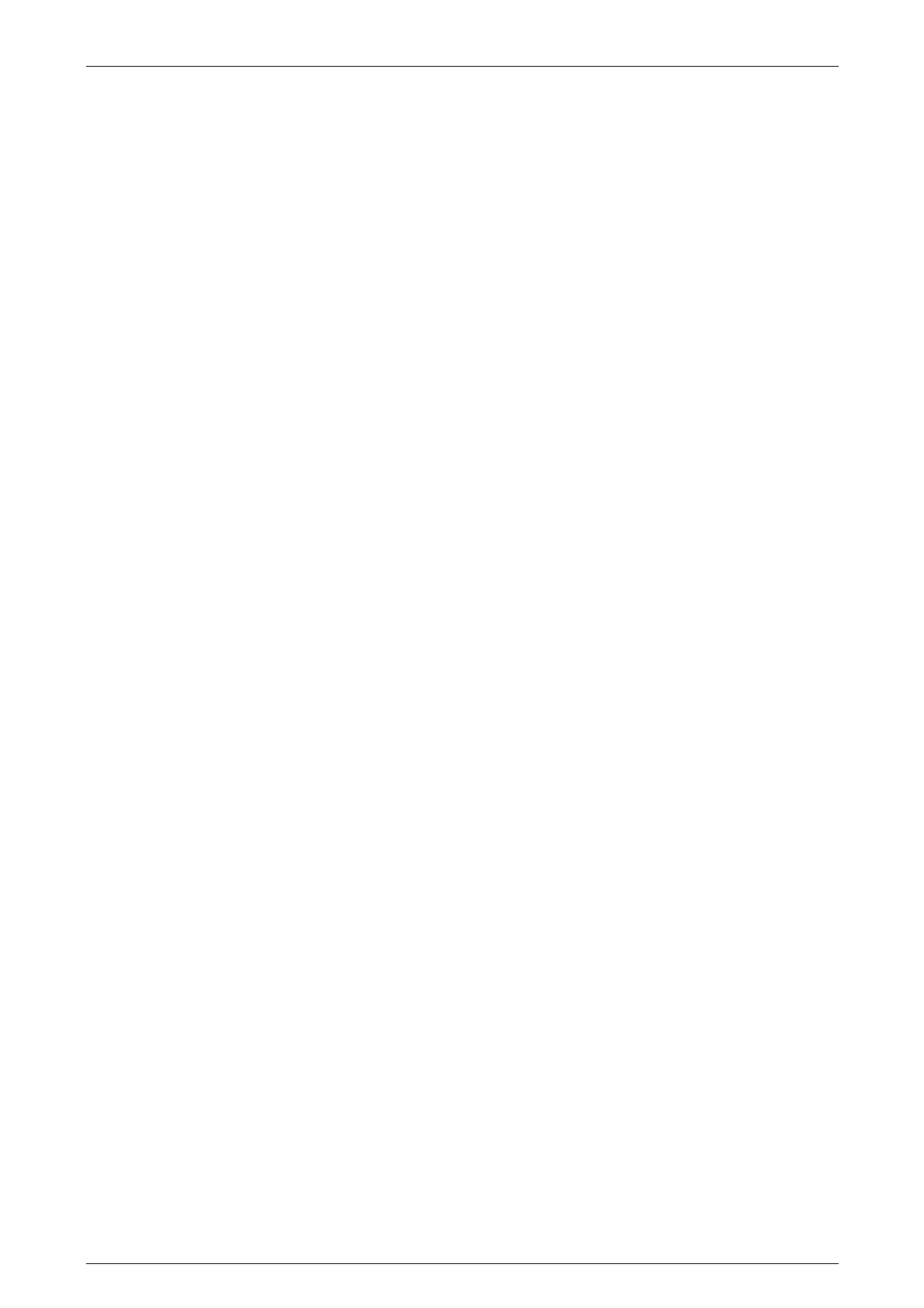

1 Apply sealant to the engine valley cover (1) to PCV oil

separator (2) mating surfaces.

2 Reinstall the PCV oil separator to the engine valley

cover.

3 Reinstall the bolt (3) attaching the PCV oil separator

to the engine valley cover and tighten to the correct

torque specification.

PCV oil separator attaching bolt

torque specification..................................6.0 – 10.0 Nm

4 Reinstall the engine valley cover. Refer to Section

6A3, Engine Mechanical – Gen III V8 Engine in the

MY 2003 VY and V2 Series Service Information.

Figure 7B2 – 8

Engine Mechanical – GEN III V8 Engine Page 6A3–9

Page 6A3–9

3 Specifications

Spark Plug

Type..............................................................................................................AC Delco 41-985

Gap.......................................................................................................1.02 +0.08 / -0.07 mm

Lubrication System

Oil Capacity (without Oil Filter Change)......................................................................5.7 litres

Oil Capacity (with Oil Filter Change)...........................................................................6.2 litres

Dry Engine Oil Capacity..............................................................................................6.5 litres

Oil Pressure (Minimum-Hot) ................................................................... 45 kPa @ 1,000 rpm

.............................................................................................................. 125 kPa @ 2,000 rpm

.............................................................................................................. 165 kPa @ 4,000 rpm

Oil Type.........................................................................................................10W - 30 SJ GF2

Piston

Piston Outside Diameter (at Size Point & incl. coating)...........................98.995 - 99.027 mm

Piston Skirt Dimensional Variation.........................................................0.032 mm (Maximum)

Piston to Bore Clearance (Service Limit)

Interference.............................................................................................................. 0.027 mm

Clearance ................................................................................................................ 0.023 mm

Piston Pin

Pin Clearance to Piston Bore (Service Limit)............................ 0.008 - 0.016 mm (Maximum)

Pin Diameter................................................................................................23.997 - 24.0 mm

Pin Fit in Connecting Rod......................................................0.020 - 0.043 mm (Interference)

Engine Mechanical – GEN III V8 Engine Page 6A3–10

Page 6A3–10

4 Torque Wrench Specification

PCV oil separator attaching bolt..................................................6.0 – 10.0 Nm