Engine Cooling – Gen III V8 Engine Page 6B3–1

Page 6B3–1

Section 6B3

Engine Cooling – Gen III V8 Engine

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 General Description...............................................................................................................................................2

Water Pump ............................................................................................................................................................2

Thermostat..............................................................................................................................................................3

Engine Cooling – Gen III V8 Engine Page 6B3–2

Page 6B3–2

1 General Information

With the following exceptions, MY 2004 VY and V2 Series GEN III V8 Engine Cooling System Service Information

carries over from MY 2003 VY Series vehicles. For information not contained within this Section, refer to Section 6B3,

Engine Cooling – Gen III V8 Engine in the MY 2003 VY and V2 Series Service Information.

• New water pump

• New thermostat

1.1 General Description

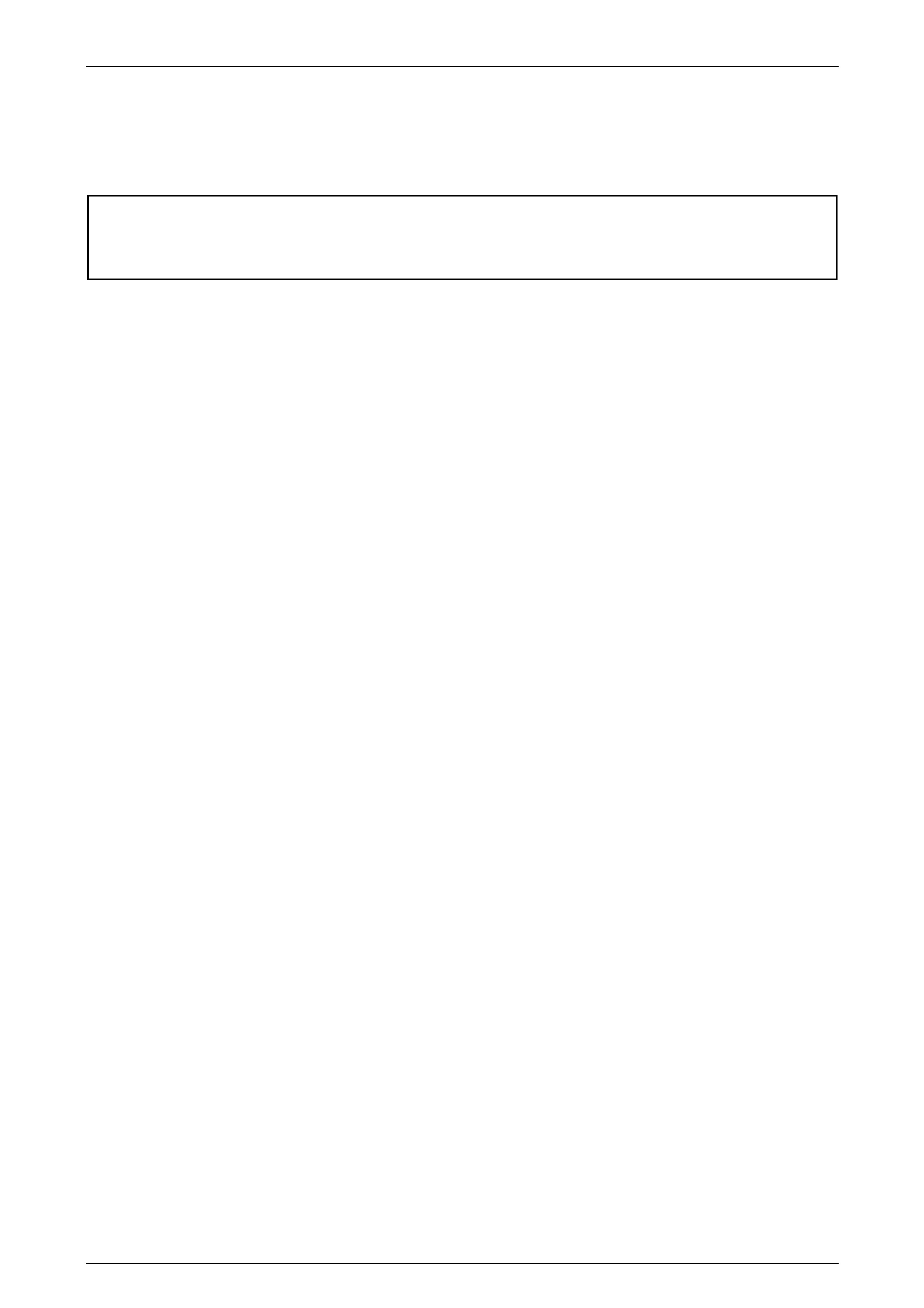

Water Pump

The length of the water pump (1) inlet and outlet tubes (2)

has been extended for easier coolant hose installation and

to improve the coolant rubber hose fit to the water pump.

NOTE

The changes in the water pump design do

not affect the water pump service procedure.

For water pump service procedure, refer to

Section 6B3, Engine Cooling – Gen III V8 in the

MY 2003 VY and V2 Series Service Information.

Figure 6B3 – 1

Engine Cooling – Gen III V8 Engine Page 6B3–3

Page 6B3–3

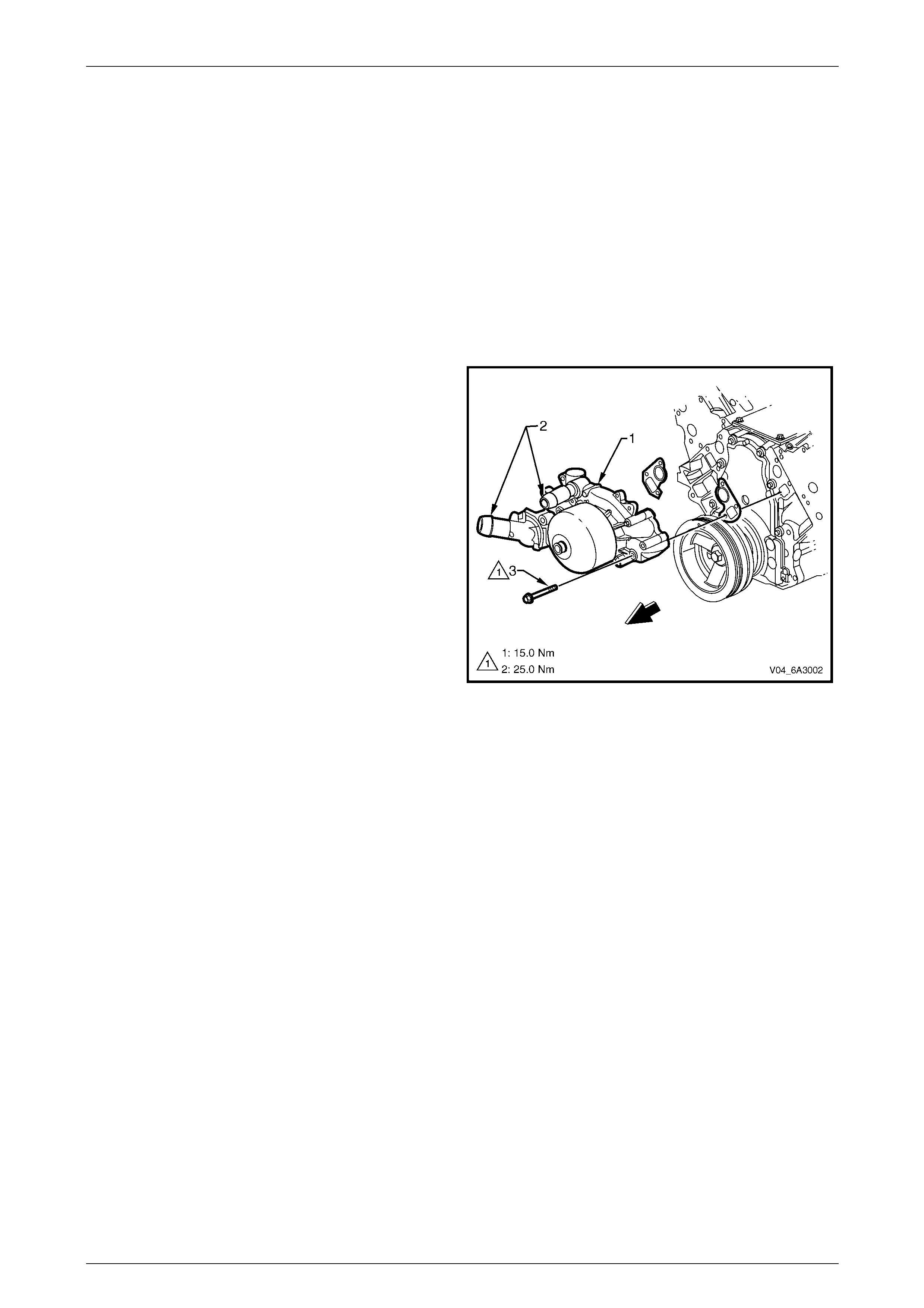

Thermostat

A wax pellet type thermostat is used to provide fast engine

warm up and to regulate the coolant temperature by

controlling the coolant flow.

The wax pellet (1) located in the thermostat brass body (2)

expands when heated and contracts when cooled.

When the engine coolant is cold, the flow control valve (3)

prevents coolant flow (A) from the radiator to the engine.

With the wax pellet contracted, the bypass valve (4) is held

open and allows coolant (B) circulating within the engine to

flow over the thermostat assembly.

The coolant flow over the thermostat assembly heats-up the

wax pellet at the same rate as the temperature increase in

the engine.

Figure 6B3 – 2

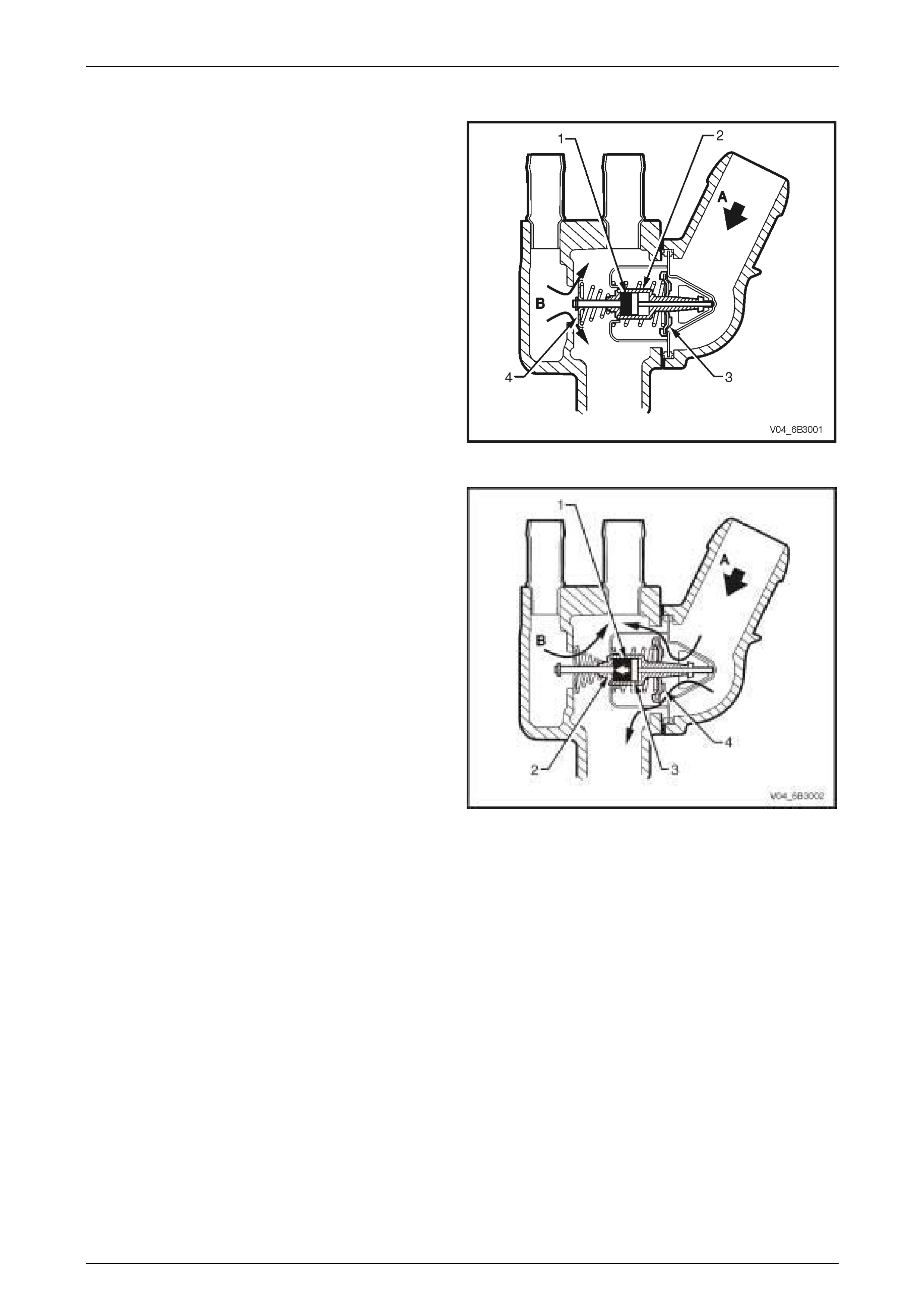

When the coolant warms up, the wax pellet (1) expands

pushing the thermostat brass body base (2) against the

piston and pin (3) causing the brass body to move within

the thermostat assembly.

As the thermostat brass body moves back, the flow control

valve (4) attached to the thermostat brass body moves with

it and allows the coolant from the radiator (A) to flow into

the engine. At the same time, the bypass valve begins to

close.

When the bypass valve is closed, a reduced flow of coolant

will continue to bypass via large crescent shaped bleed

holes located on the bypass valve. This prevents hydraulic

lock of the heater system and allows some engine bypass

coolant (B) to flow over the thermostat assembly.

The rate that the control valve opens is balanced between

the force exerted by the expanding wax, and the combining

force exerted by the bypass valve spring and the flow

control spring.

This controlled coolant flow during cold start and initial

warming of the engine provides a controlled warming cycle

necessary to control exhaust emissions during the critical

warm-up period.

NOTE

The changes in the thermostat design do not

affect the thermostat principle of operation and

service procedure. For water pump service

procedure, refer to Section 6B3, Engine Cooling

– Gen III V8 in the MY 2003 VY and V2 Series

Service Information.

Figure 6B3 – 3