LPG System Page 8A2–1

Page 8A2–1

Section 8A2

LPG System

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information............................................................................................................................... 2

1.1 Principals Of Operation.........................................................................................................................................2

Mixer........................................................................................................................................................................2

2 Service Operations................................................................................................................................3

2.1 Euro 2 Mixer............................................................................................................................................................3

2.2 LPG Set-up Procedure...........................................................................................................................................4

Preliminary Check..................................................................................................................................................5

Mixture Set-up ........................................................................................................................................................6

Tamper Proof Plug..............................................................................................................................................6

Mixture Adjustment.............................................................................................................................................7

2.3 Front Service Line..................................................................................................................................................8

3 Special Tools..........................................................................................................................................9

Techline

LPG System Page 8A2–2

Page 8A2–2

1 General Information

With the following exceptions, MY 2004 VY and V2 Series LPG system information carries over from MY 2003 VY Series

vehicles.

• Euro 2 Mixer

• LPG set-up procedure

• Front service line

To comply with Australian Design Rule ADR79, MY 2004 VY and V2 Series vehicles are fitted with the Impco Euro 2

tamper proof LPG mixer. The fuel mixture settings are set at the factory and should not require adjustment during normal

service. The mixer is a sealed unit, therefore, if a repair is required, the mixer will need to be replaced as a complete unit.

For information not contained in this Section, refer to Section 8A2 LPG System in the MY 2003 VY and V2 Series

Service Informatio n.

1.1 Principals Of Operation

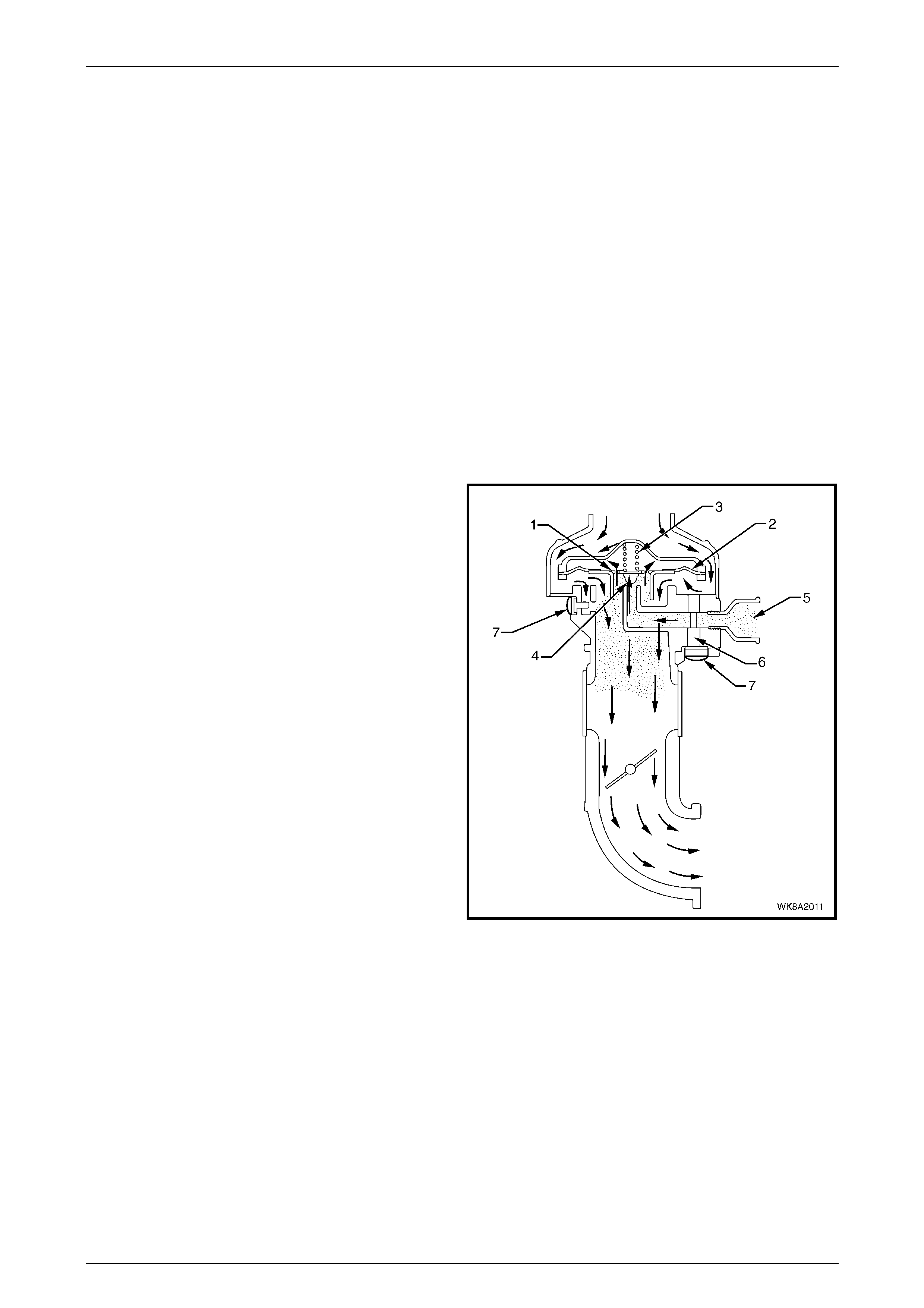

Mixer

The mixer is installed between the engine intake manifold

and the intake air filter.

When the engine is cranked or running, manifold vacuum is

transmitted through vacuum ports in the air valve (1) to the

upper side of the mixer diaphragm (2). As a result,

atmospheric pressure pushing upwards on the underneath

side of the diaphragm, lifts it against the downward force of

the metering valve spring (3).

The pressure applied to the upper side of the diaphragm

varies with engine speed and throttle position. The pressure

difference betw een atm osp heric pressure act ing on the

underneath side of the diaphragm and the pressure acting

on the upper side of the diaphragm determines the metering

valve (4) position.

The position and the shape of the metering valve

determines, the amount of LPG vapour (5) delivered to the

engine.

Maximum fuel delivery is determined by the power valve (6),

which limits the maximum fuel flow. The power valve is pre-

calibrated in the factory and is not adjustable in service. Idle

air by-pass adjustment is provided by the adjustment screw

and once set, the mixture adjusters are sealed off with a

tamper proof blanking plug (7).

Figure 8A2 – 1

For a further description of the KL7 LPG system operation and components not covered in this section, refer to

Section 8A2, 2 Principals Of Operation in the MY 2003 VY and V2 Series Service Inform ation.

LPG System Page 8A2–3

Page 8A2–3

2 Service Operations

2.1 Euro 2 Mixer

LT Section No. – AA-650Q

Removal and reinstallation of the Impco Euro 2 tamper proof mixer fitted to the MY 2004 VY and V2 Series vehicles

carries over from the MY 2003 VY Series. However, Euro 2 tamper proof mixer components are not serviced and any

fault with the mixer where it requires an overhaul or repair will require the mixer to be replac ed as a complete unit.

The Impco Euro 2 mixture settings are set and sealed at the time of installation and should not require any further

adjustment of the mixtures during regular service. Where adjustment or repl acement of the Euro 2 mixer is required, the

idle mixture may need to be adjusted prior to installing a new tamper proof plug.

To adjust the mixture of the Impco Euro 2 mixer, a mixture adjusting tool is required, refer to 3 Special Tools.

For further mixture adjustment service information, refer to 2.2, LPG Set-up Procedure.

LPG System Page 8A2–4

Page 8A2–4

2.2 LPG Set-up Procedure.

If a new Euro 2 mixer has been installed or the LPG idle mixture is out of specification, the mixer will require adjustment.

Following completion of adjustment, the idle mixture adjuster is to be plugged with a steel blanking plug. New Euro 2

mixers are supplied with the power valve mixture set at the factory. However the tamper proof plug is not fitted but must

be done on mixer installation.

With exception to the following, the LPG set-up procedure for the MY 2004 VY and V2 Series vehicles carries over from

the MY 2003 VY Series Sedan.

• Idle Mixture Adjustment

• Tamper Proof Plugs

The LPG Set-up procedure allows the idle mixture to be adjusted under the following controlled conditions:

• Short and Long-Term Fuel Trim Cells set to zero.

• Fixed Spark advance.

• Fixed idle air control valve steps.

• Fuel control valve duty cycle fixed at 40%.

NOTE

Prior to adjusting the mixture or removing the

tamper proof plug, perform a Preliminary Check

to establish if the mixtures are set within the

specifications.

LPG System Page 8A2–5

Page 8A2–5

Preliminary Check

NOTE

The following procedure must be performed when

any LPG system component (mixer, converter,

FCV or PCM) has been replaced, overhauled,

reprogrammed, or when the engine assembly has

been replaced or overhauled.

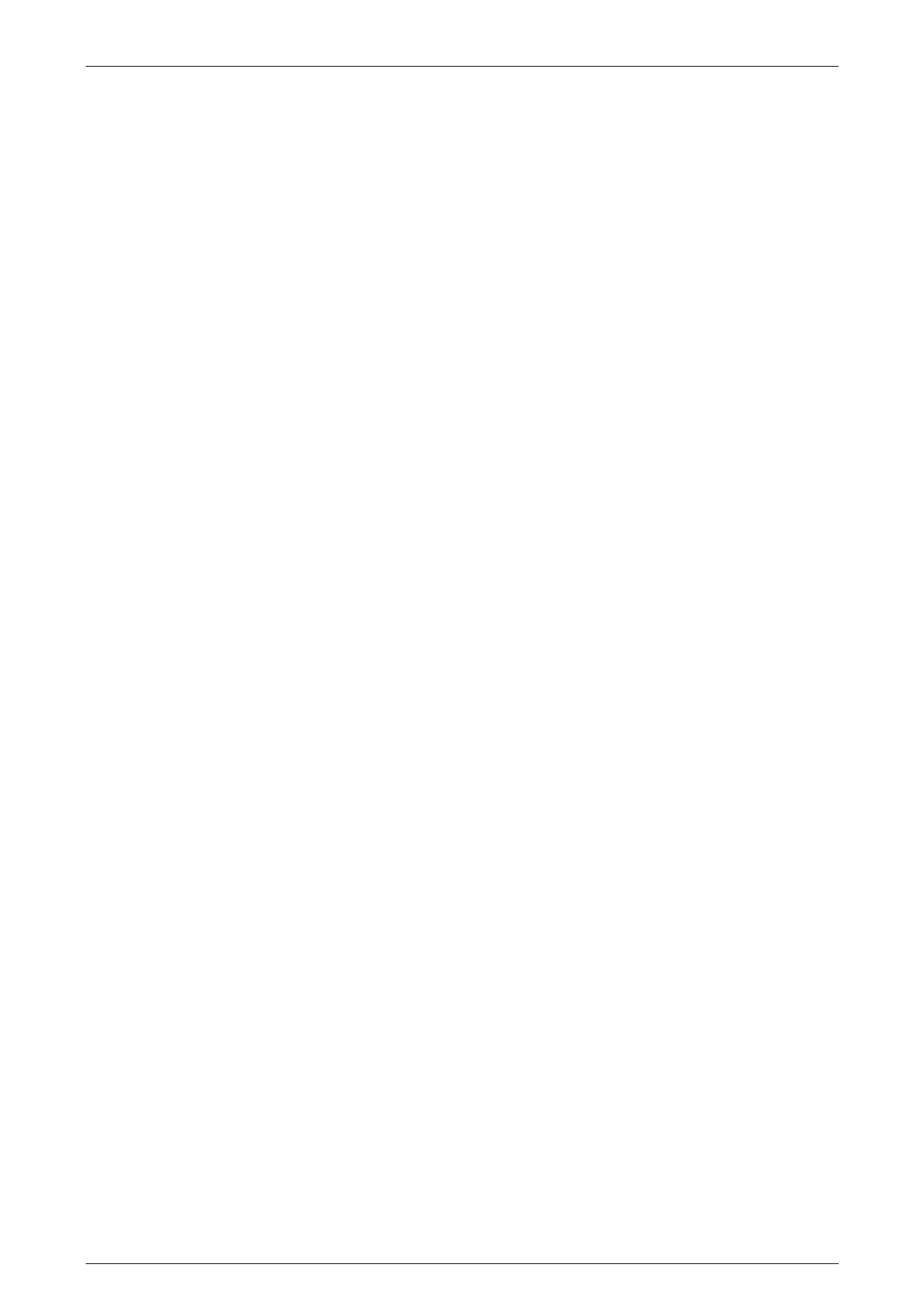

1 Connect TECH 2 (4) to the DLC (1) with the adapter

(2) and cable (3).

NOTE

For further information on Tech 2 connection

and operation procedures refer to

Section 0C TECH 2.

2 With the vehicle in LPG mode, start the engine.

3 With no load on the engine, air conditioning off

(if fitted), all electrical consumers turned off and park

position selected, allow the engine and oxygen

sensors to reach operating temperature.

Figure 8A2 – 2

4 On TECH 2 select:

• F0: Diagnostics / (3) 2004 / VY/ F0: Engine / V6 /

F5: Function Tests / F5: LPG Set-up.

5 During the set-up procedure, Tech 2 ensures the

following engi ne opera ting conditions are met and

maintained:

• Engine Coolant Temperature greater than 91°C,

• Operating in closed loop mode,

• Right hand oxygen sensor is ready,

• The engine cooling fan is off, (engine coolant

temperature less than 104°C).

6 Once all the preconditions have been met, Tech 2 will

display the right-hand oxygen sensor voltage and

status.

Engine

LPG Setup

Right O2 Sensor

Righ t O2 Status 500 mV

Rich

VXLPG001

Confirm

Figure 8A2 – 3

7 If the right-hand oxygen sensor voltage is not as close to 500 mV as possible with the status of the right-hand

oxygen sensor not cons tantly toggling between rich and lean, the idle mixture will require adjustment, refer to

Mixture Adjustment in this Section.

LPG System Page 8A2–6

Page 8A2–6

Mixture Set-up

If the preliminary check shows that the idle mixture requires adjustment and the tamper proof plug has been installed, the

plug will require removing to gain access to the idle mixture adjuster.

The power valve adjustment is preset at the factory and must not be adjusted, therefore, the tamper proof plug does not

need to be removed.

New Euro 2 mixers are supplied with the power valve preset and the tamper proof plugs for the mixture and power valve

not installed. When fitting a new mixer, tamper proof plugs must be installed once the set-up procedure has been

completed.

Tamper Proof Plug

1 Remove the mixer, refer to Section 8A2, 3.21 Mixer in the MY 2003 VY and V2 Series Service Information.

NOTE

The tamper proof plugs fitted to the Euro 2 mixer

are surface hardened and will require this

hardening to be removed by carefully grinding the

top of the plug slightly prior to centre punching or

drilling.

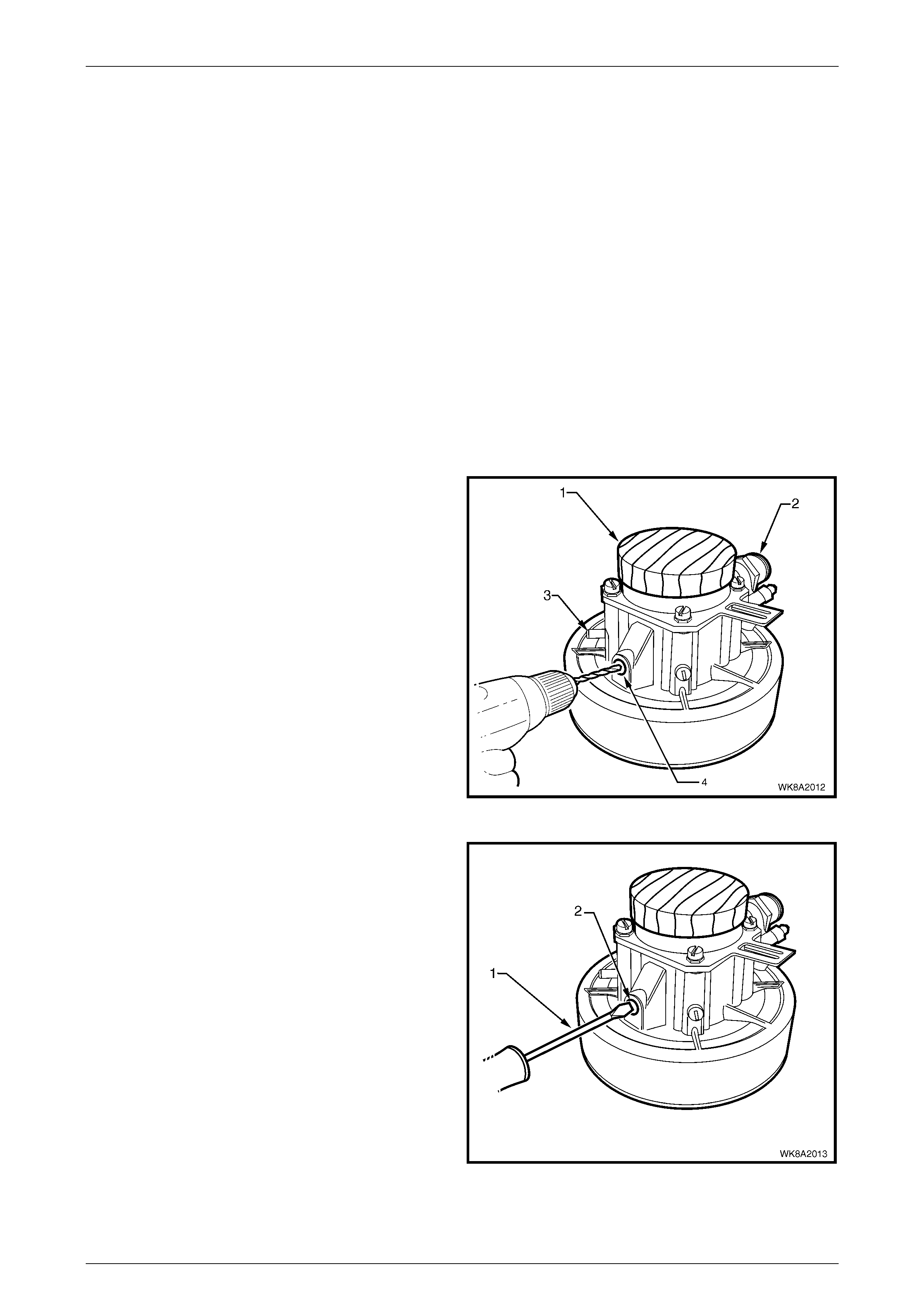

2 Seal of both ends of the mixer (1) the LPG vapour inlet

port (2) and the vacuum line port (3) with masking tape

to prevent metal swarf from the grinding and drilling

process from entering the internals of the mixer.

3 Grind the top of the mixture adjuster tamper proof plug

(4) slightly to remove the surface hardening and centre

punch the plug.

4 Drill the centre of the tamper proof plug with a suitable

size drill bit for the screwdriver to be used in step 5.

Figure 8A2 – 4

5 Using a suitable size screwdriver (1), prise out the

tamper proof plug (2).

6 Remove the masking tape from the mixer prior to

reinstalling the mixer to the vehicle.

7 Reinstall the mixer to the vehicle, refer to Section 8A2,

3.21 Mixer in the MY 2003 VY and V2 Series Service

Information.

Figure 8A2 – 5

LPG System Page 8A2–7

Page 8A2–7

Mixt ure Adjustment

At the completion of the LPG set-up procedure the idle mixture adjuster will require resealing with a tamper proof plug.

There are two plugs fitted to the Impco Euro 2 mixer, one for the power valve adjuster and one for the idle mixture

adjuster. If a new mixer has been fitted the power valve adjuster will also require the fitting of a tamper proof plug.

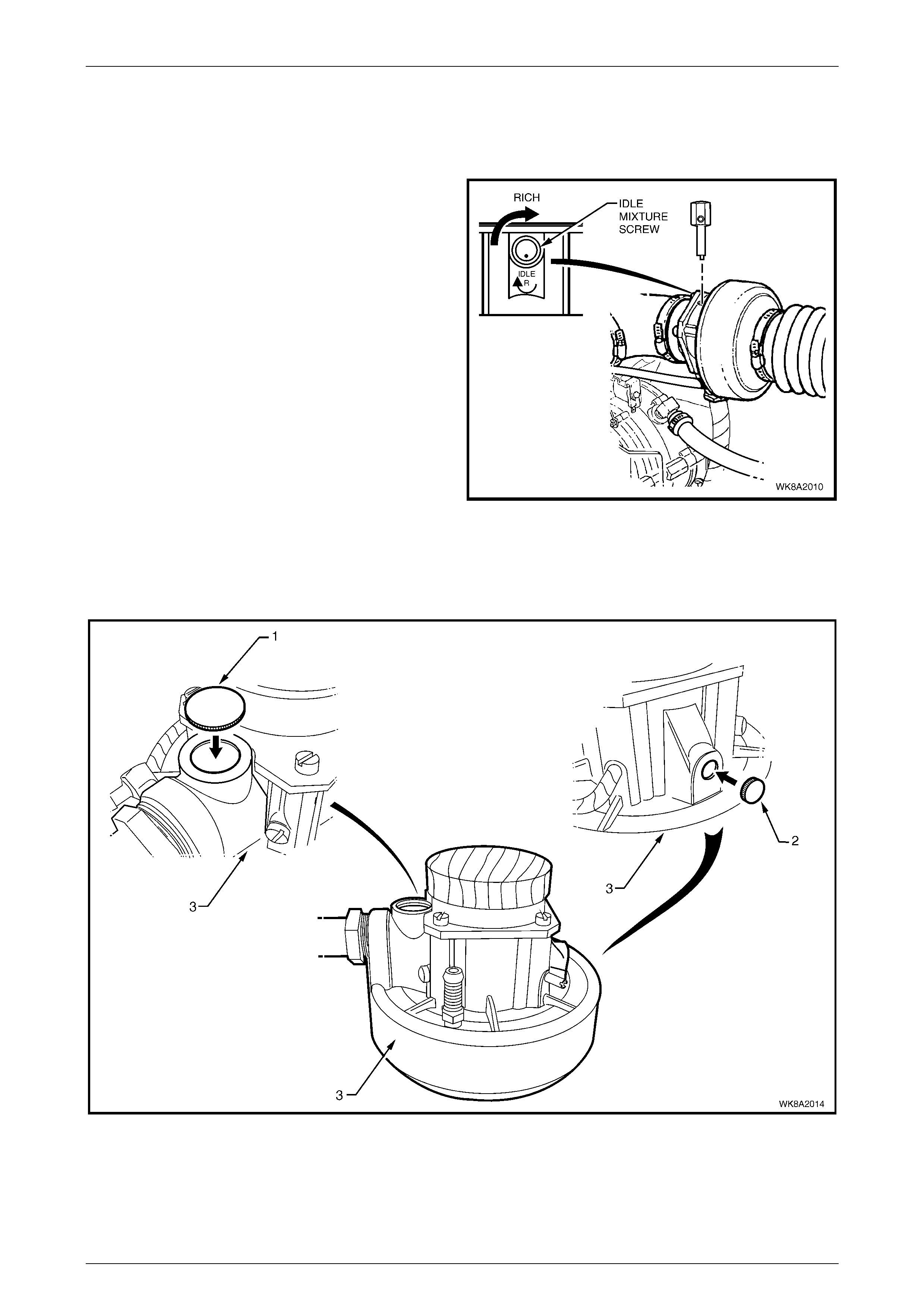

1 Adjust the mixer as required, using the idle mixture

adjusting tool and adjust the idle mixture screw until

Tech 2 shows the right-hand oxygen sensor voltage is

as close to 500 mV as possible and the status of the

right oxygen sensor is constantly toggling between rich

and lean.

• An oxygen sensor voltage greater than 500 mV

indicates a rich mixture. Turn the idle mixture

screw anti-clockwise to lean-off the mixture.

• An oxygen sensor voltage of less than 500 mV

indicates a lean mixture. Turn the idle mixture

screw clockwise to richen the mixture.

NOTE

If the engine coolant temperature exceeds

104°C, the engine cooling fan will operate and

Tech 2 will suspend the set-up procedure. When

the engine cools, the cooling fan will cease

operation and Tech 2 will continue with the set-

up procedure.

Figure 8A2 – 6

2 Install the tamper proof plugs by positioning the power valve plug (1) if required, and mixture adjuster plug (2)

squarely to the mixer housing (3) and using a hammer, gently tap the tamper proof plug into the mixer until it is

level with the mixer housing, refer to Figure 8A2 – 7.

Figure 8A2 – 7

LPG System Page 8A2–8

Page 8A2–8

2.3 Front Service Line

The removal and reinstallation procedure of the front service line carries over from the MY 2003 VY Series vehicles .

However, due to the fitment of close coupled catalytic converters in the exhaust system required for Australian Design

Rule ADR79, it is recommended to remove the right-hand front exhaust assembly, refer to Section 8B Exhaust System.

For front service line service information, refer to Section 8A2, 3.14 Front Service Line in the MY 2003 VY and V2 Series

Service Informatio n.

LPG System Page 8A2–9

Page 8A2–9

3 Special Tools

With the following exception, LPG special tool requirements for the MY 2004 VY and V2 Series KL7 LPG system carry

over from the MY 2003 VY Series. For further information relating to special tools, refer to Section 8A2, 10 Special Tools

in the MY 2003 VY and V2 Series Service Information.

• Mixer Idle Adjusting Tool

Tool Number Illustration Description Tool Classification

T7 – 17392

Idle Mixture Adjuster

Used to adjust idle mixtures.

Mandatory