Lubrication and Service Page 0B–1

Page 0B–1

Section 0B

Lubrication and Service

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................2

1.1 Service Displays .................................................................................................................................................... 2

Service Reminder Display..................................................................................................................................... 2

Prior to Service Due........................................................................................................................................... 2

Service Due........................................................................................................................................................ 2

Service Overdue................................................................................................................................................. 2

Service Well Overdue......................................................................................................................................... 2

Service Reminder Reset Procedure ..................................................................................................................... 2

Service Reset Display........................................................................................................................................ 2

2 Lubrication Specifications ....................................................................................................................3

2.1 Capacities Chart..................................................................................................................................................... 3

2.2 Recommended Lubricants.................................................................................................................................... 4

3 Servicing .................................................................................................................................................6

3.1 Maintenance Schedule – Alloytec V6 – Domestic............................................................................................... 6

Determining the proper service interval .............................................................................................................. 6

Intermediate service intervals – 7,500 km or 6 months...................................................................................... 6

Regular service intervals – 15,000 km or 12 months.......................................................................................... 6

Maintenance Schedule .......................................................................................................................................... 6

3.2 Maintenance Schedule – GEN III V8 – Domestic ................................................................................................. 7

Determining the proper service interval .............................................................................................................. 7

Intermediate service intervals – 5,000 km or 3 months...................................................................................... 7

Regular service intervals – 10,000 km or 6 months............................................................................................ 7

Maintenance Schedule .......................................................................................................................................... 7

Techline

Techline

Techline

Techline

Lubrication and Service Page 0B–2

Page 0B–2

1 General Information

This Section provides details of the lubricants and the servicing schedules for all models. The capacities of main fluid

levels as well as the International or General Motors specification are included in the tables. The Servicing part of this

Section contains tables to be utilised by the techn icia n to perform the services at the intervals stipulated.

1.1 Service Displays

Service Reminder Display

A service reminder is displayed when the ignition is

switched on or off until the trip computer is reset. The

service reminder is displayed for a total of 10 seconds.

Figure 0B – 1

Prior to Service Due

Service Due is determined from the odometer reading. The MFD shows a reminder 1000 km before a service is due. The

service interval becoming due is displ ayed on the MFD, and the spanner in the icon flashes. This service reminder is

displayed for up to 10 second s whenever the ignition is switched on or off until the service remin der is reset.

Service Due

When a service is due, the whole icon flashes. This service reminder is displayed for up to 10 seconds whenever the

ignition is switched on or off until the service remind er is reset.

Service Overdue

When a service is overdue by less than 5 000 km, the MFD shows a flashing icon for up to 10 seconds whenever the

ignition is switched on or off until the service remind er is reset.

Service Well Overdue

When a service is overdue by more than 5 00 0 km, the MF D shows a flashing icon for up to 10 seconds whenever the

ignition is switched on or off until the service reminder is reset. This event is permanently logged in the instrument cluste r

memory (EEPROM).

Service Reminder Reset Procedure

To reset the displayed service reminder, press and hold the SET button for 3 seconds. A confirmation beep sounds upon

reset.

NOTE

When a Service Due rem inder is res et, the ECM /

PCM poll responses are cleared and the

odometer readings for the last changes are

recorded. These ca n be accessed by Tech 2. The

next Service Due reminder will appear 1000 km

before the next scheduled service period.

Service Reset Display

When the service reminder is reset, the MFD shows the

Service Reset No Items screen.

After 2 seconds the MFD advances to the System Check.

For further information relating to these service display s and

other service rela ted MFD displays, re fer to

Section 12C Instruments. Figure 0B – 2

Lubrication and Service Page 0B–3

Page 0B–3

2 Lubrication Specifications

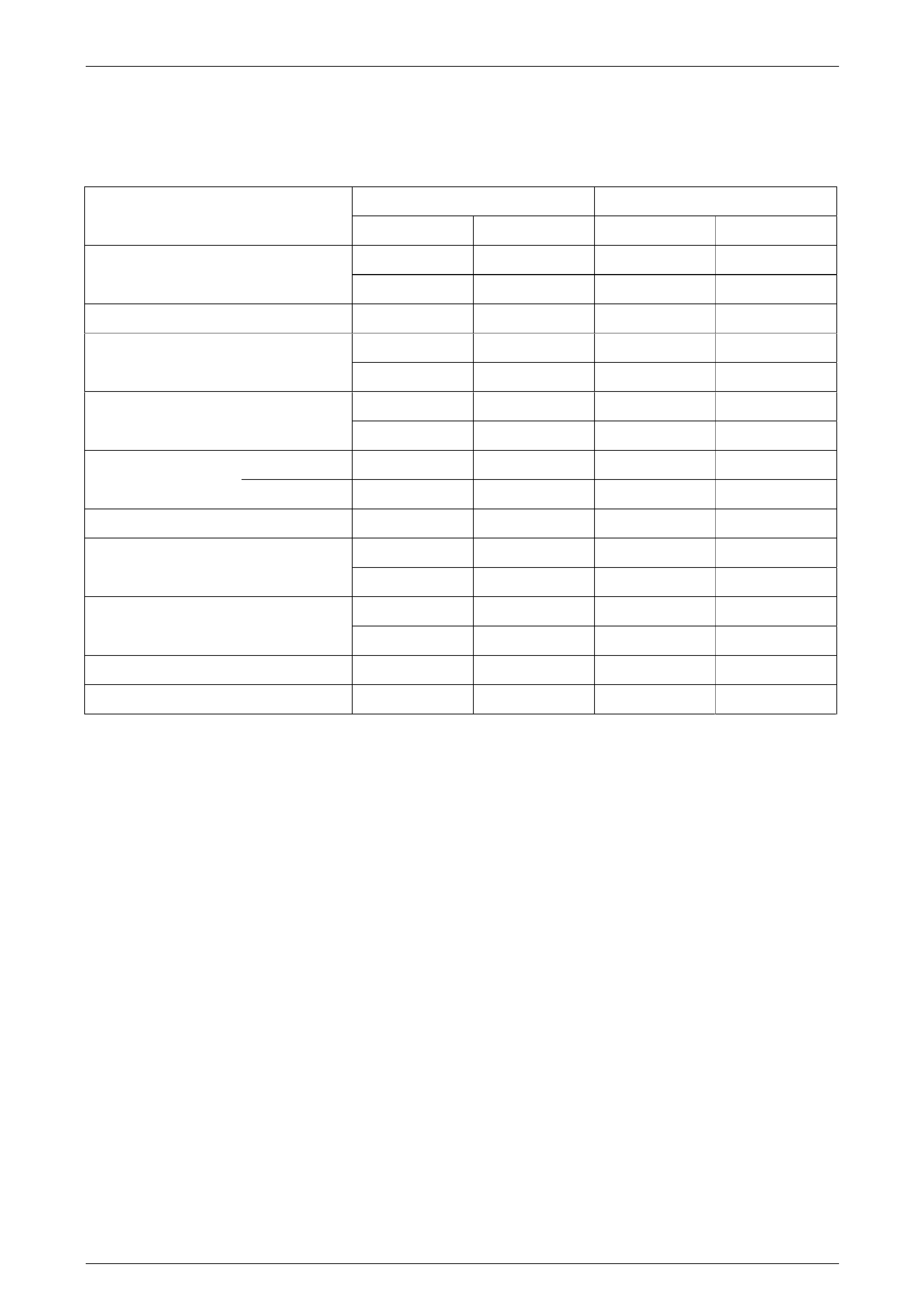

2.1 Capacities Chart

3.6 Litre Alloytec V6 5.7 Litre GEN III V8

Capacities (Litres – Approximate) 2WD AWD 2WD AWD

– Including filter 6.5 7.3 6.2 8.0

Engine Oil – Without filter 6.5 7.3 5.8 7.6

Manual Transmission 2.0 – 4.4 –

Automatic Transmission – Dry total 8.8 8.8 10.6 10.6

(4-speed) – Service refill 4.8 4.8 5.0 5.0

– Dry total 8.5 8.5 – – Automatic Transmission

(5-speed) – Service refill 4.6 4.6 – –

– Manual Trans. 10.3 10.3 11.4 11.4

Cooling System – Auto Trans. 9.9 9.9 11.0 11.0

Brake Hydraulic System 0.62 0.62 0.62 0.62

– Independent 1.7 1.7 1.7 1.7

Rear Final Drive – Live 1.6 1.6 1.6 1.6

– Dry total – 0.24 – 0.24

Transfer Case (AWD) – Service refill – 0.15 – 0.15

Front Final Drive (AWD) – 0.8 – 0.8

Power Steering 0.7 0.7 0.65 0.65

Lubrication and Service Page 0B–4

Page 0B–4

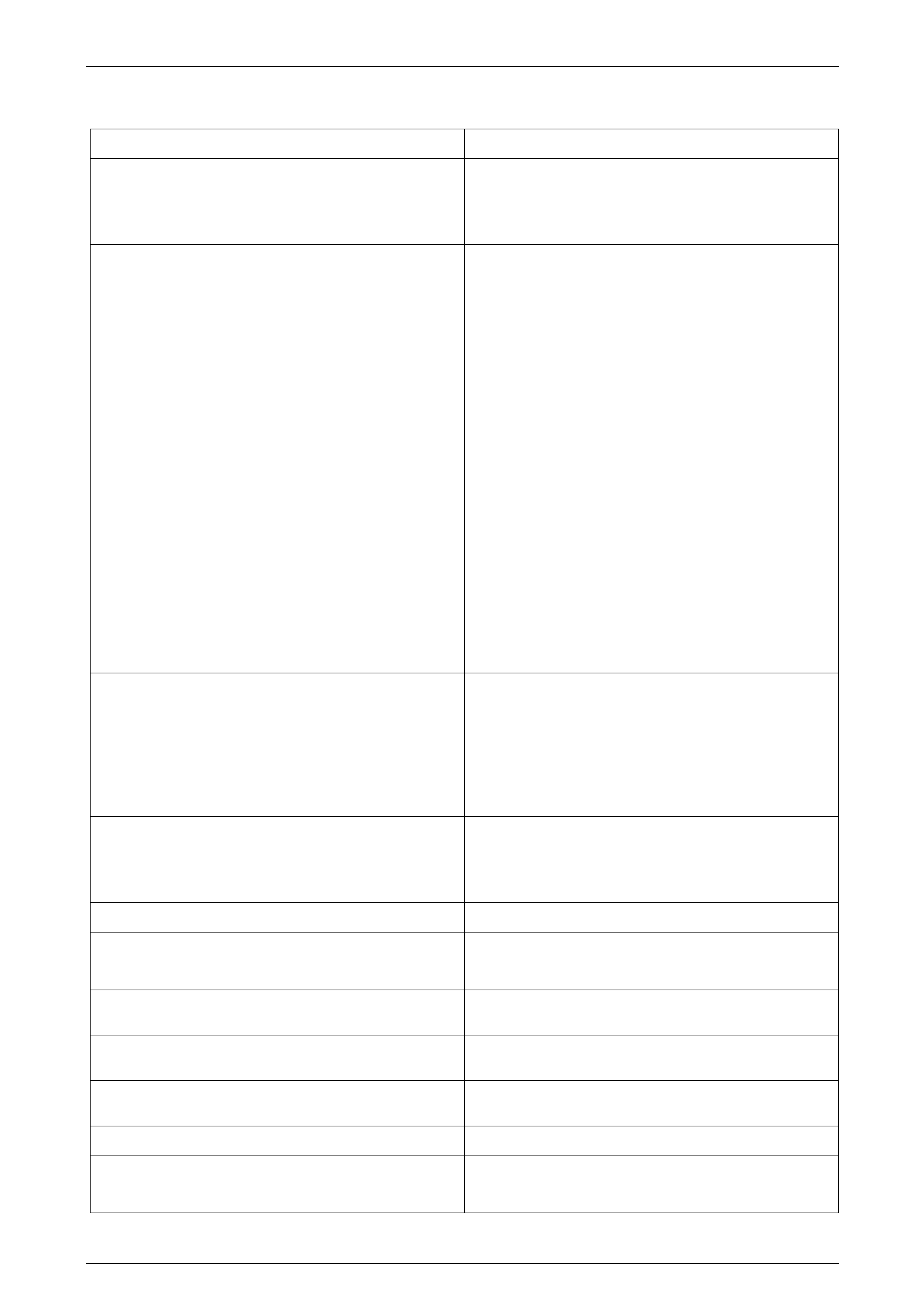

2.2 Recommended Lubricants

Application Lubricant

Door lock striker

Door lock assembly fork

Instrument compartment lid lock tongue

Drilube

Hood pilot pin assembly

Hood lock assembly

Hood hinge pins

Door check assembly

Door hinge and hold opens

Rear compartment lid hing e

Rear compartment lid lock latch

Liftgate and endgate hinges

Liftgate and endgate lock latch

Liftgate, endgate and rear compartment lock mechanism

Door window regulators

Door window guides and runners

Door lock mechanism

Front seat adjuster

Front seat track and rail assemblies

NLGI No. 1 Lithium Grease (with 9% Zinc Oxide)

Front door lock cylinder

Ignition and steering lock cylin der

Rear compartment lid lock cylinder

Instrument panel compartment lock cylinder

Liftgate lock cylinder

Powdered Graphite (applied throu gh key aperture – do not

oil)

Starter motor drive mechanism

Windshield wiper pivot points

Propeller shaft centre constant velocit y joint

NLGI No. 2 Lithium Grease (with 10% Molybde num

Disulphide)

Starter motor bearings Engine Oil at overhaul

Park brake shoe assemblies

Brake adjusting screw and nut NLGI No. 2 Clay Thickened Grease for High Temperature

Park brake shoe actuator pivots NLGI No. 2 Clay Thickened Grease with 5% minimum

Molybdenum Disulphide

Brake and clutch hydraulic system Heavy duty brake fluid, conforming to Holden Specification

Number HN 1796 (Super DOT 4).

Clutch and brake ped al pivots and bushes NLGI No. 2 Lithium Grease with 10% Molybdenum

Disulphide

Accelerator pedal pivots NLGI No. 1 Lithium Grease (with 9% Zinc Oxide)

Front Final Drive: (AWD) Mobilube SHC 1D

(Synthetic Hypoid Gear Oil SAE 80W–140 API GL5)

Lubrication and Service Page 0B–5

Page 0B–5

Application Lubricant

Transfer Case: (AWD) Esso MTF–LT–1

Rear Final Drive: Non LSD (excl. G80) LSD (G80)

• Alloytec V6 equipped vehicles fitted with 4-speed

automatic transmission

* When towing heavy loads for an extended time it

is recommended that Synthetic H ypoi d Gear oil be

used. If you are towing between than 1600 kg and

2100 kg over 80 km/h with an Alloytec V6 engine,

it is highly recommended to use s ynthetic oil .

Mineral Hypoid Gear Oil*

SAE 90 LSD (1.6 litre)

(AMPOL Gear Lube LSD 90,

Castrol LSX90, Shell Helix

LSD, Valvoline LS90)

Synthetic Hypoid Gear Oil

SAE 80W–140 API GL5

(1.5 litre)

(Mobilube SHC 1D, Castrol

SAF–XA)

Plus

Sturaco 7098 Oil Additive

(0.1 litre)

• Alloytec V6 equipped vehicles fitted with 6-speed

manual or 5-speed automatic transmissions, and

all GEN III V8 equipped vehicles

Synthetic Hypoid Gear Oil

SAE 80W–140 API GL5

(1.6 litre)

(Mobilube SHC 1D, Castrol

SAF–XA)

Synthetic Hypoid Gear Oil

SAE 80W–140 API GL5

(1.5 litre)

(Mobilube SHC 1D, Castrol

SAF–XA)

Plus

Sturaco 7098 Oil Additive

(0.1 litre)

Engine oil: (All domestic engin es e xcluding Alloytec V6 with

LPG) 10W / 30 SL GF–3 engine oil.

Universal joints NLGI No. 2 Multipurpose Grease (Lithium Soap)

Bearing face of clutch throw-out bearing, input shaft splin es

and spigot Molybdenum Disulphide Grease

Aisin 6-speed manual transmission input shaft splines NLGI No. 2 lithium soap based EP grease with

molybdenum disulphide, such as Shell Retinax HDX2

grease or BP Energrease LMS-EP 23 (or eq uivalent).

Manual transmission – Aisin 6-speed (Alloytec V6) GL-3, with a viscosity rating of 75W-90

Manual transmission – Tremec 6-speed (GEN III V8)

Automatic transmission

Power steering

Dexron® III Automatic Transmission Fluid

Automatic transmission control pivot points NLGI No. 2 Lithium Grease (with 3% Molybdenum

Disulphide)

ABS wheel speed sensor NLGI No. 2 Clay Thickened High Temperature EP Grease

(Molykote FB180 or equivalent)

Coolant specification 50% clean fresh water and 50% Extended Life Anti-freeze

Coolant conforming to Specification Number GM 6277M,

Part Number 92145527 (5 litre)

Check link housing (rear doors only) NLGI No. 2 Polyurea Grease (Mineral Oil Bas e) – 1.2 g

applied to housing

Check link arm (rear doors only) NLGI No. 2 Lithium Complex Grease – 1.2 g Applied to arm

Lubrication and Service Page 0B–6

Page 0B–6

3 Servicing

3.1 Maintenance Schedule – Alloytec V6 –

Domestic

Determining the proper service interval

The operating conditions of t he vehicle determine the service interval. Use the odometer reading or the time interval,

whichever occurs first, to determine when the service is due.

Under certain operating conditions, not only does the vehicle require more regu lar servicing, it also requires additional

servicing to ensure maximum safety, performance and longevit y.

The additional service re quirements typically include more frequent rep lacement of lubricating oils and the more frequent

inspection of steering, suspension and brake system components.

Also, brake fluid deteriorates with time and should normally be replaced every two years. However, heavy duty towing

places a higher deman d on the brake system. Therefore, brake fluid should be replaced each year if towing 1,600 kg (or

higher).

Intermediate service intervals – 7,500 km or 6 months

Service the vehicle at 7,500 km or 6 months intervals if the vehicl e is operated under any or all of the following

conditions:

• Operating on rough, dust y or loose surfaced roads.

• Towing a caravan, large trailer or boat.

• Repeated short trips of less than 5 km in cold weather, or where the engine does not reach normal oper ating

temperature.

• Extensive idling and / or low-speed driving for long distances such as p olice cars, taxis or door-to-door calls.

• Extended high-speed driving under heavy load in high temperatures.

Regular service intervals – 15,000 km or 12 months

Service the vehicle at 15,000 km or 12 months intervals if the vehicle is only occasionally operated under any of the

conditions listed under Intermediate Service Intervals.

Maintenance Schedule

As maintenance requirements can change, it is recommended that the Owners Handbook supplied with the veh icle and

Service Techlines be referred to, for all maintenance items requiring periodic attention.

Lubrication and Service Page 0B–7

Page 0B–7

3.2 Maintenance Schedule – GEN III V8 –

Domestic

Determining the proper service interval

The operating conditions of t he vehicle determine the service interval. Use the odometer reading or the time interval,

whichever occurs first, to determine when the service is due.

Under certain operating conditions, not only does the vehicle require more regu lar servicing, it also requires additional

servicing to ensure maximum safety, performance and longevit y.

The additional service re quirements typically include more frequent rep lacement of lubricating oils and the more frequent

inspection of steering, suspension and brake system components.

Also, brake fluid deteriorates with time and should normally be replaced every two years. However, heavy duty towing

places a higher deman d on the brake system. Therefore, brake fluid should be replaced each year if towing 1,600 kg (or

higher).

Intermediate service intervals – 5,000 km or 3 months

Service the vehicle at 5,000 km or 3 months intervals if the vehicl e is operated under any or all of the following

conditions:

• Operating on rough, dust y or loose surfaced roads.

• Towing a caravan, large trailer or boat.

• Repeated short trips of less than 5 km in cold weather, or where the engine does not reach normal oper ating

temperature.

• Extensive idling and / or low-speed driving for long distances such as p olice cars, taxis or door-to-door calls.

• Extended high-speed driving under heavy load in high temperatures.

Regular service intervals – 10,000 km or 6 months

Service the vehicle at 10,000 km or 6 months intervals if th e vehicle is only occasionally operated under any of the

conditions listed under Intermediate Service Intervals.

Maintenance Schedule

As maintenance requirements can change, it is recommended that the Owners Handbook supplied with the veh icle and

Service Techlines be referred to, for all maintenance items requiring periodic attention.