Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–1

Page 1A4–1

Section 1A4

Hood, Rear Compartment Lid, Liftgate and

Endgate

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................7

2 Service Operations — Hood, Except Coupe........................................................................................8

2.1 Hood Primary Latch Striker Assembly................................................................................................................. 8

Remove................................................................................................................................................................... 8

Reinstall.................................................................................................................................................................. 8

Adjust...................................................................................................................................................................... 9

2.2 Hood Primary Latch Spring................................................................................................................................. 10

Remove................................................................................................................................................................. 10

Reinstall................................................................................................................................................................ 10

2.3 Hood Primary Latch Release Cable Assembly.................................................................................................. 11

Remove................................................................................................................................................................. 11

Reinstall................................................................................................................................................................ 12

2.4 Hood Secondary Latch Assembly...................................................................................................................... 13

Remove................................................................................................................................................................. 13

Reinstall................................................................................................................................................................ 13

2.5 Hood Insulator...................................................................................................................................................... 14

Remove................................................................................................................................................................. 14

Reinstall................................................................................................................................................................ 14

2.6 Hood Strut Assembly .......................................................................................................................................... 15

Remove................................................................................................................................................................. 15

Reinstall................................................................................................................................................................ 15

2.7 Hood Front Moulding Assembly......................................................................................................................... 16

Remove................................................................................................................................................................. 16

Disassemble......................................................................................................................................................... 16

Reassemble.......................................................................................................................................................... 17

Reinstall................................................................................................................................................................ 17

2.8 Hood and Hinge Assemblies............................................................................................................................... 18

Remove................................................................................................................................................................. 18

Reinstall................................................................................................................................................................ 19

Adjust.................................................................................................................................................................... 20

Fender Alignment............................................................................................................................................. 20

Hood Alignment................................................................................................................................................ 20

Techline

Techline

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–2

Page 1A4–2

3 Service Operations — Hood, Coupe ..................................................................................................22

3.1 Hood Primary Latch Striker Assembly............................................................................................................... 22

Remove................................................................................................................................................................. 22

Reinstall................................................................................................................................................................ 22

Adjust.................................................................................................................................................................... 23

3.2 Hood Primary Latch Spring................................................................................................................................. 24

Remove................................................................................................................................................................. 24

Reinstall................................................................................................................................................................ 24

3.3 Hood Primary Latch Release Cable Assembly.................................................................................................. 25

Remove................................................................................................................................................................. 25

Reinstall................................................................................................................................................................ 26

3.4 Hood Secondary Latch Assembly...................................................................................................................... 27

Remove................................................................................................................................................................. 27

Reinstall................................................................................................................................................................ 27

3.5 Hood Air Scoop Inlet Duct................................................................................................................................... 28

Remove................................................................................................................................................................. 28

Reinstall................................................................................................................................................................ 28

3.6 Hood Insulator...................................................................................................................................................... 29

Remove................................................................................................................................................................. 29

Reinstall................................................................................................................................................................ 29

3.7 Hood Air Scoop Assembly.................................................................................................................................. 30

Remove................................................................................................................................................................. 30

Reinstall................................................................................................................................................................ 31

3.8 Hood Strut Assembly .......................................................................................................................................... 32

Remove................................................................................................................................................................. 32

Reinstall................................................................................................................................................................ 32

3.9 Hood and Hinge Assemblies............................................................................................................................... 33

Remove................................................................................................................................................................. 33

Reinstall................................................................................................................................................................ 34

Adjust.................................................................................................................................................................... 34

Fender Alignment............................................................................................................................................. 35

Hood Alignment................................................................................................................................................ 35

4 Service Operations — Rear Compartment Lid, Sedan.....................................................................37

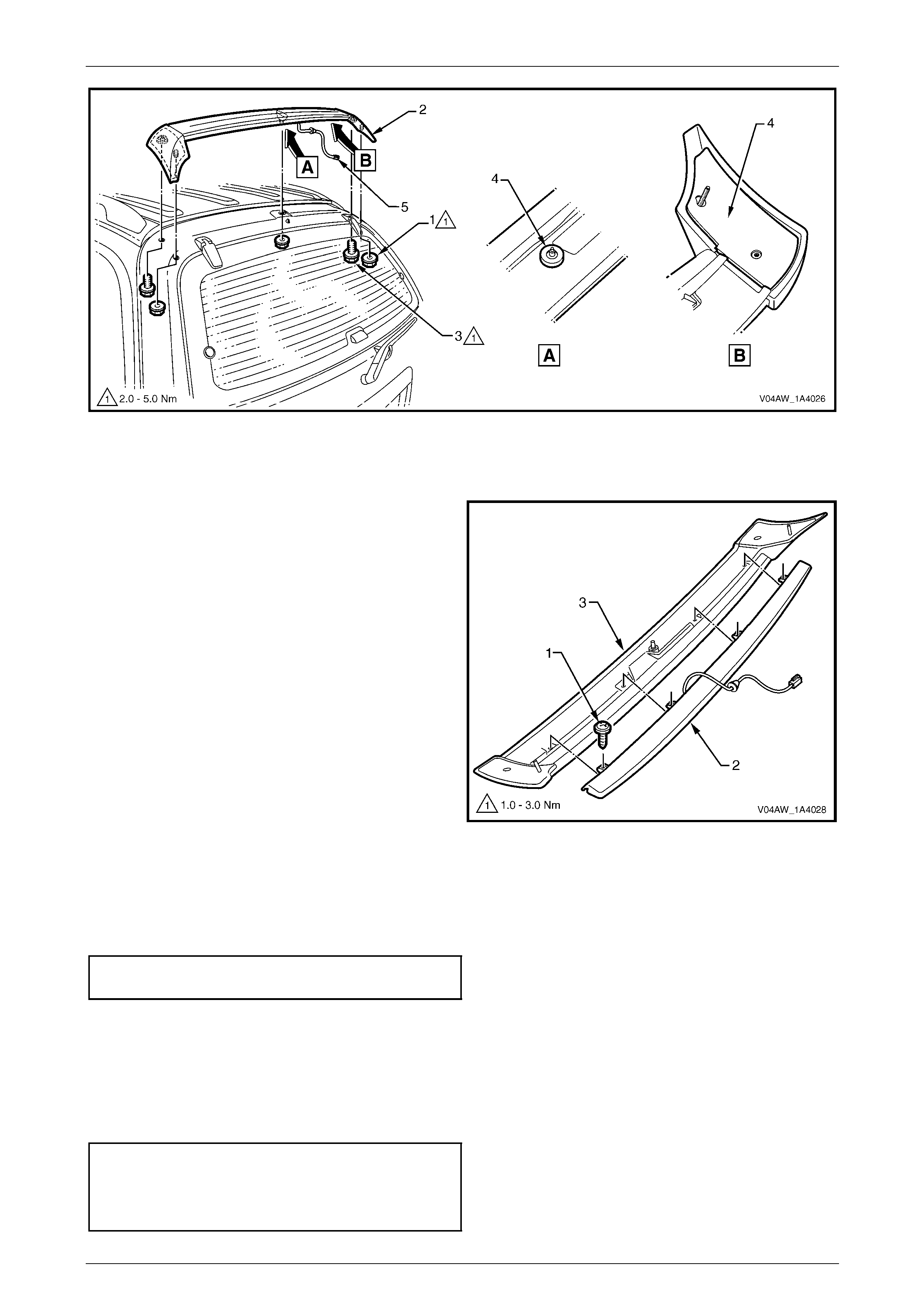

4.1 Rear Compartment Lid Carpet............................................................................................................................ 37

Remove................................................................................................................................................................. 37

Reinstall................................................................................................................................................................ 37

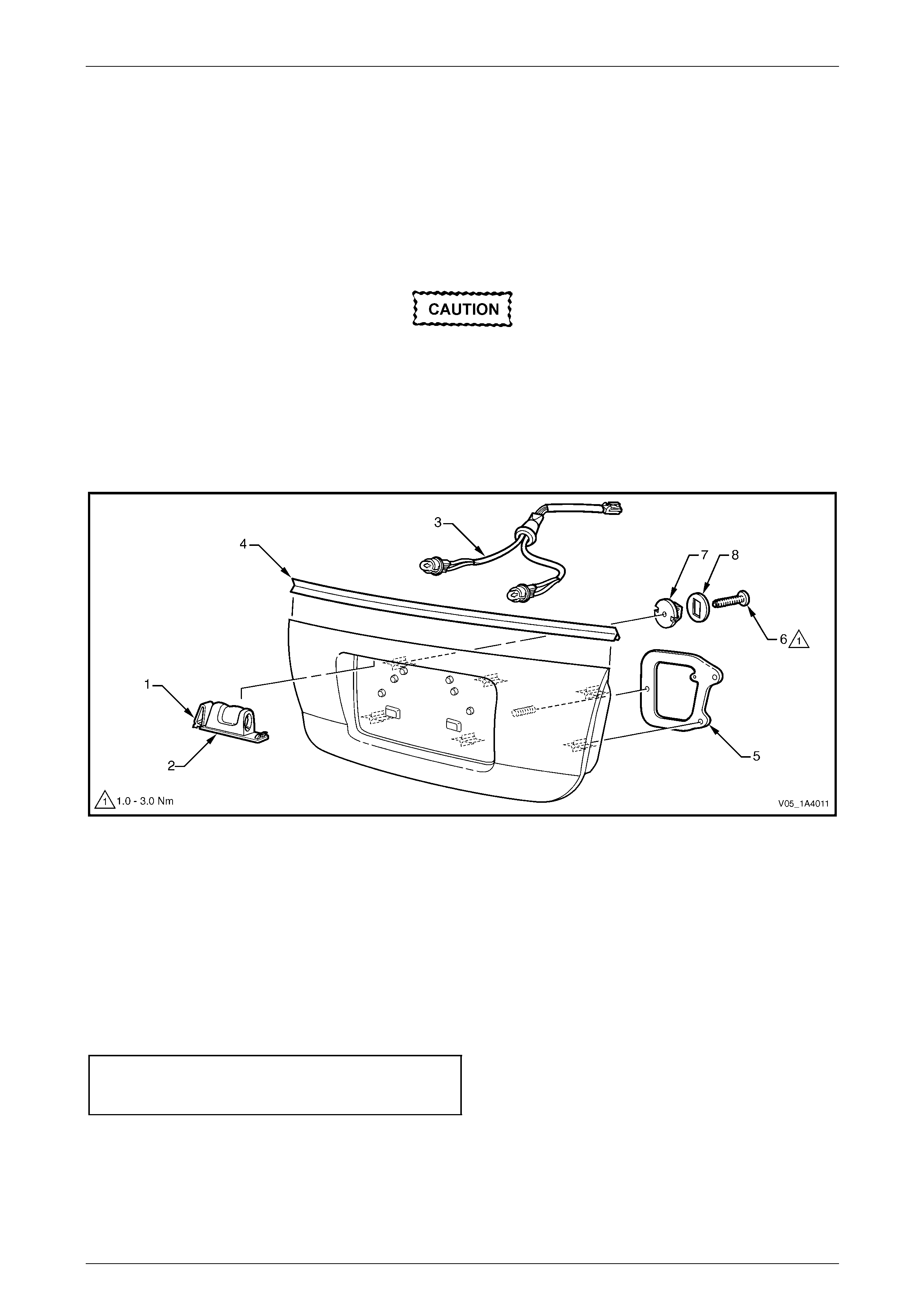

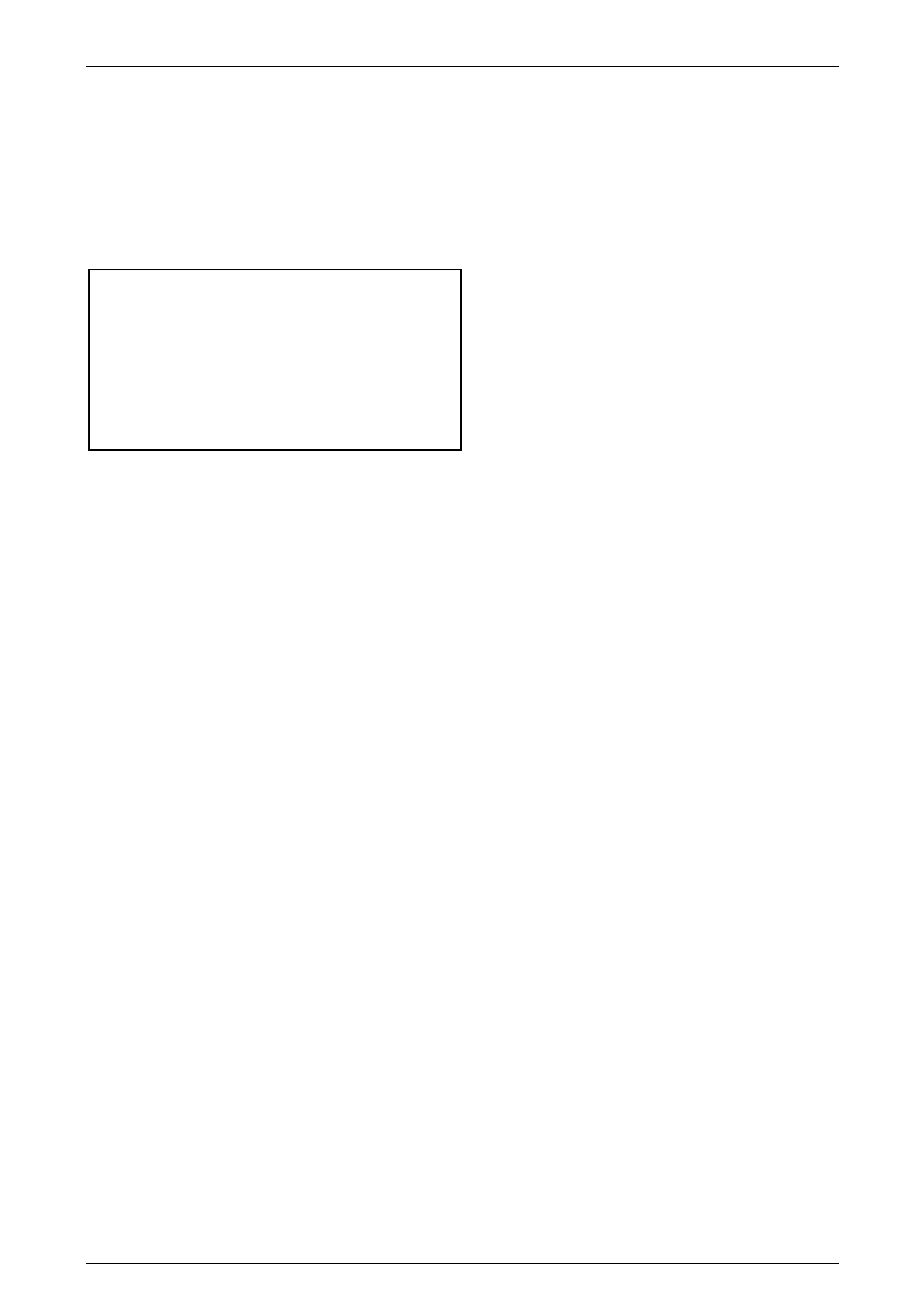

4.2 Rear Compartment Lid Appliqué Assembly...................................................................................................... 38

Remove................................................................................................................................................................. 38

Disassemble......................................................................................................................................................... 39

Reassemble.......................................................................................................................................................... 39

Reinstall................................................................................................................................................................ 39

4.3 Rear Spoiler Assembly........................................................................................................................................ 40

Introduction.......................................................................................................................................................... 40

Remove................................................................................................................................................................. 40

Disassemble......................................................................................................................................................... 41

High-mount Stop Lamp Assembly.................................................................................................................... 41

Spoiler Insert — SV6 and SV8......................................................................................................................... 41

Reassemble.......................................................................................................................................................... 41

High-mount Stop Lamp Assembly.................................................................................................................... 41

Spoiler Insert — SV6 and SV8......................................................................................................................... 41

Reinstall................................................................................................................................................................ 42

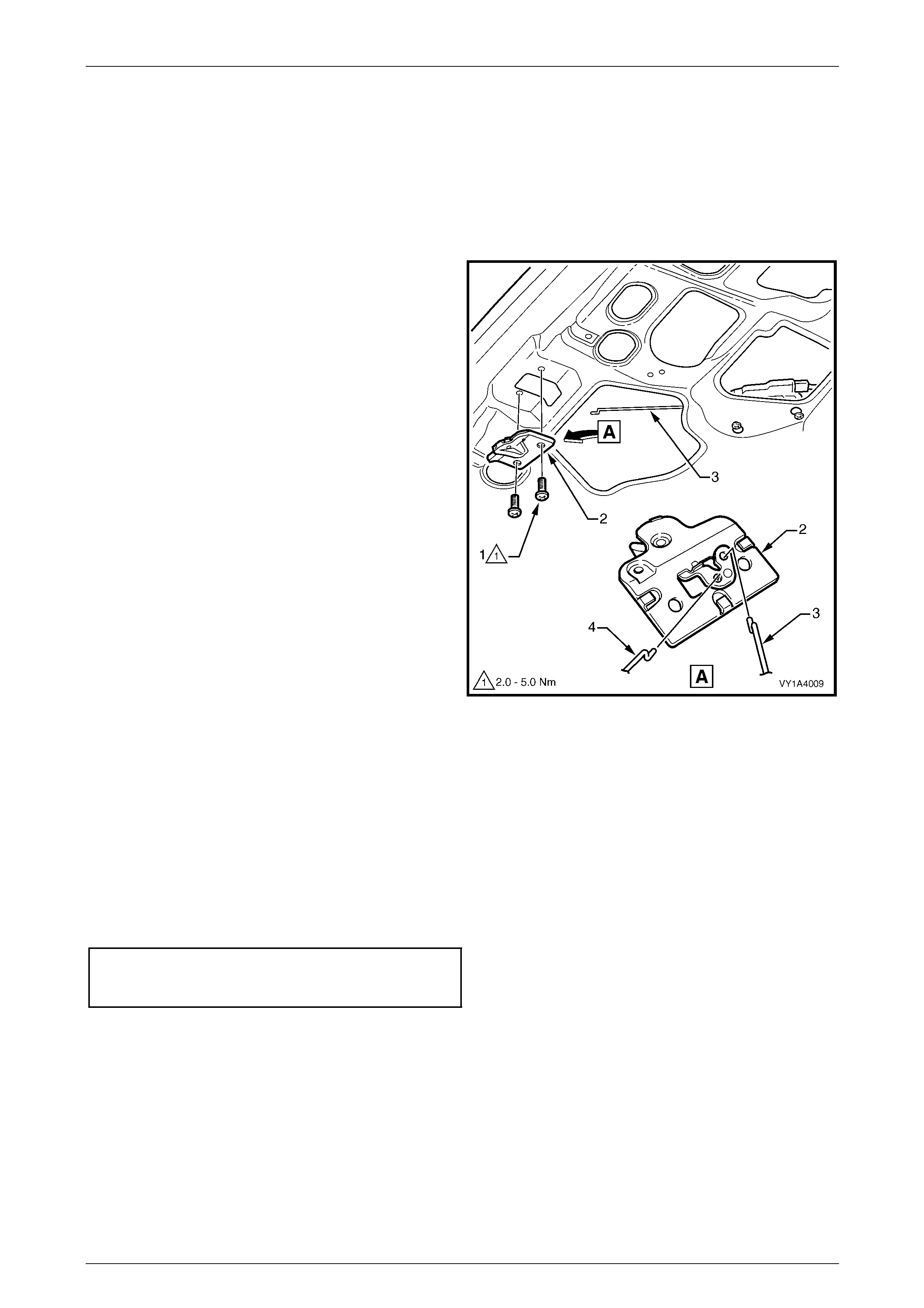

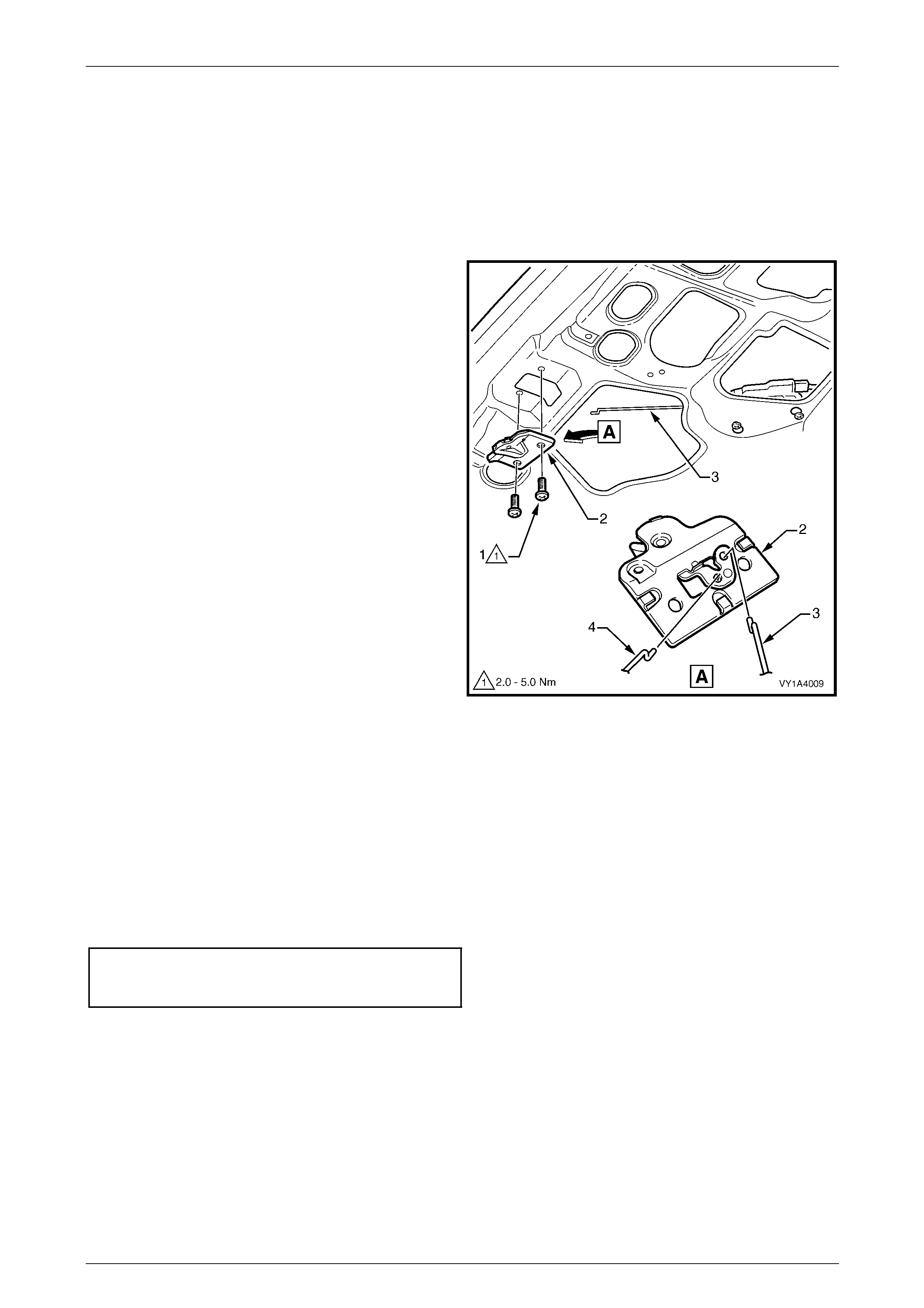

4.4 Rear Compartment Lid Latch Assembly............................................................................................ ................ 44

Remove................................................................................................................................................................. 44

Reinstall................................................................................................................................................................ 44

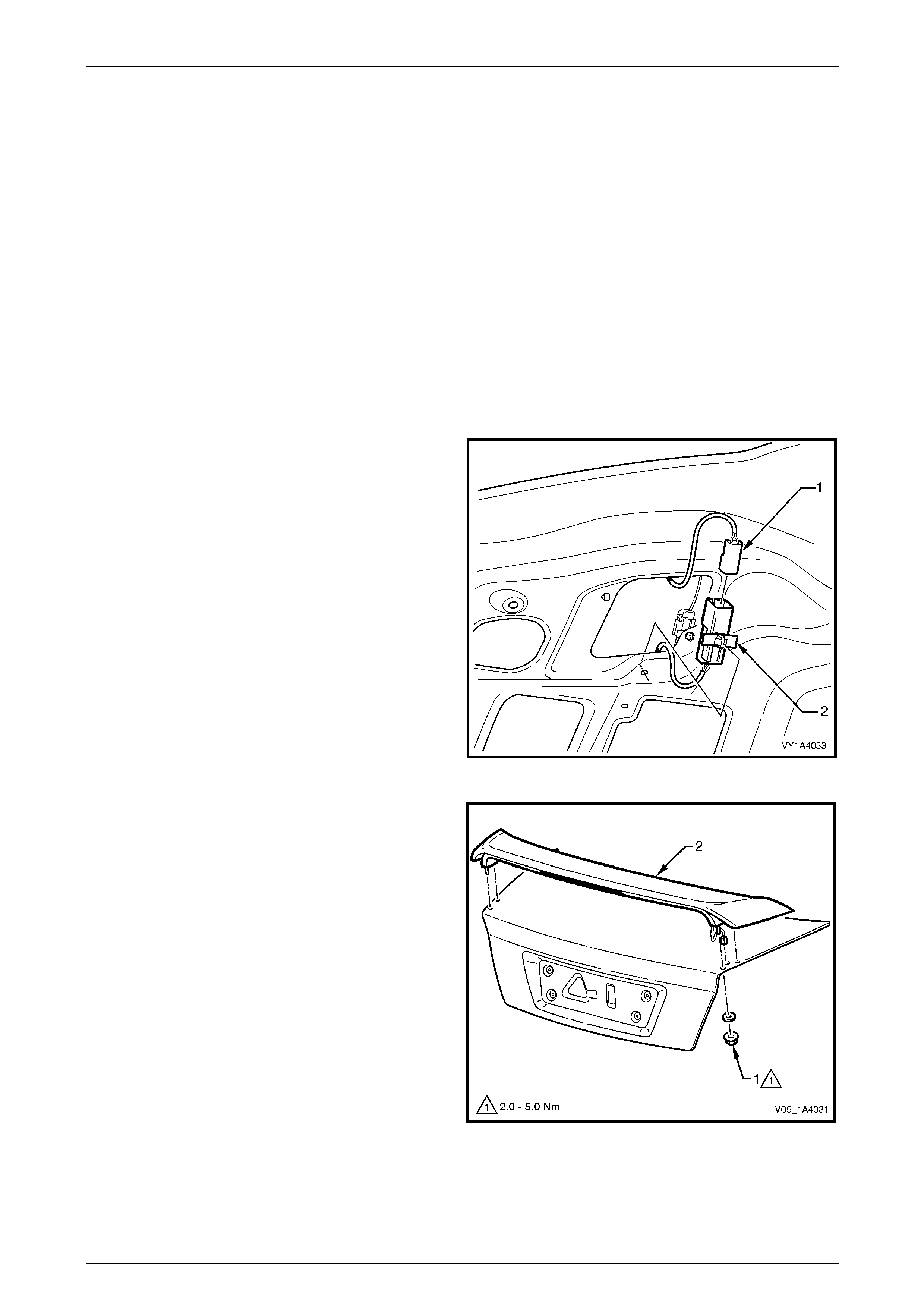

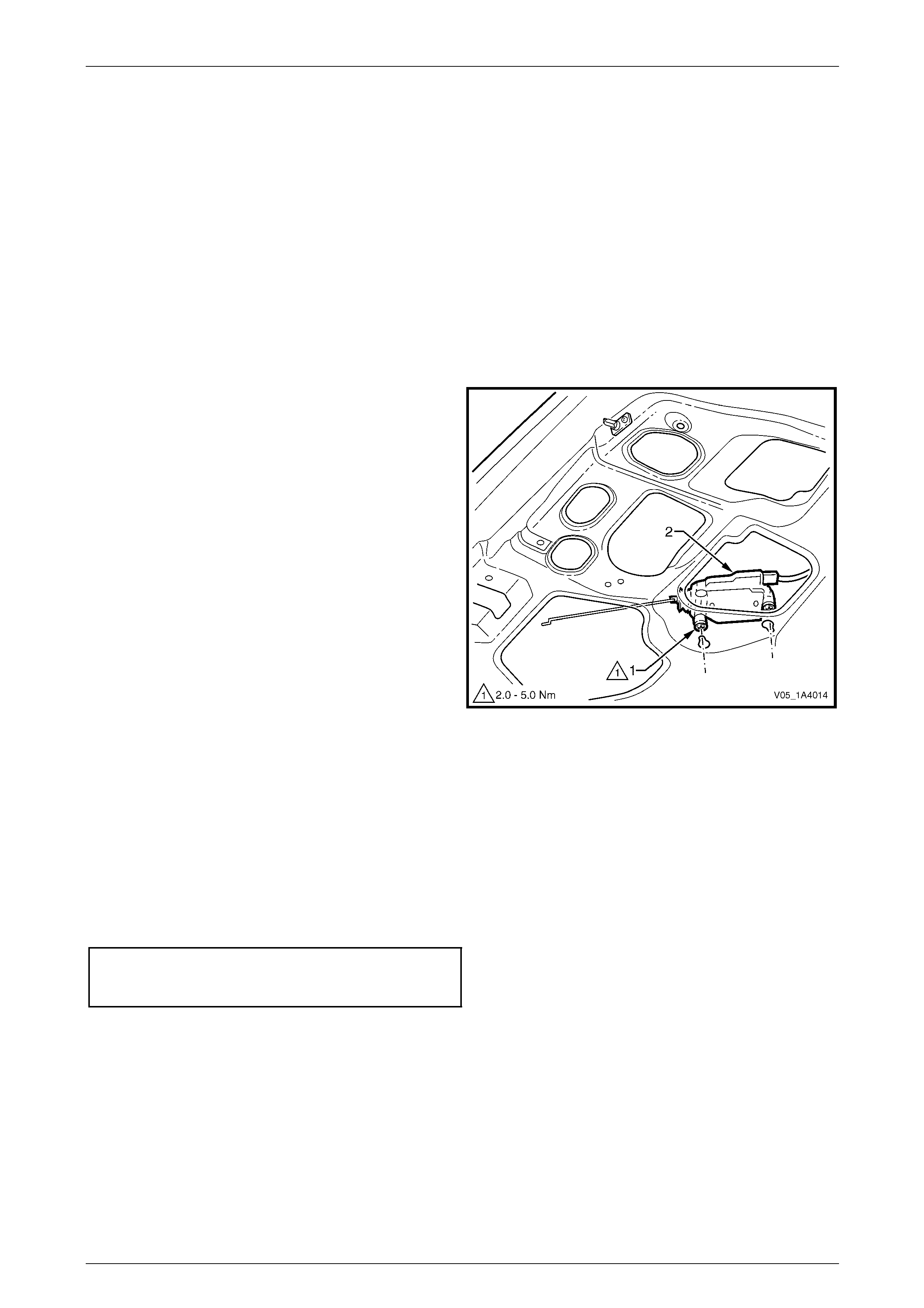

4.5 Rear Compartment Lid Actuator Assembly ....................................................................................................... 45

Remove................................................................................................................................................................. 45

Reinstall................................................................................................................................................................ 45

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–3

Page 1A4–3

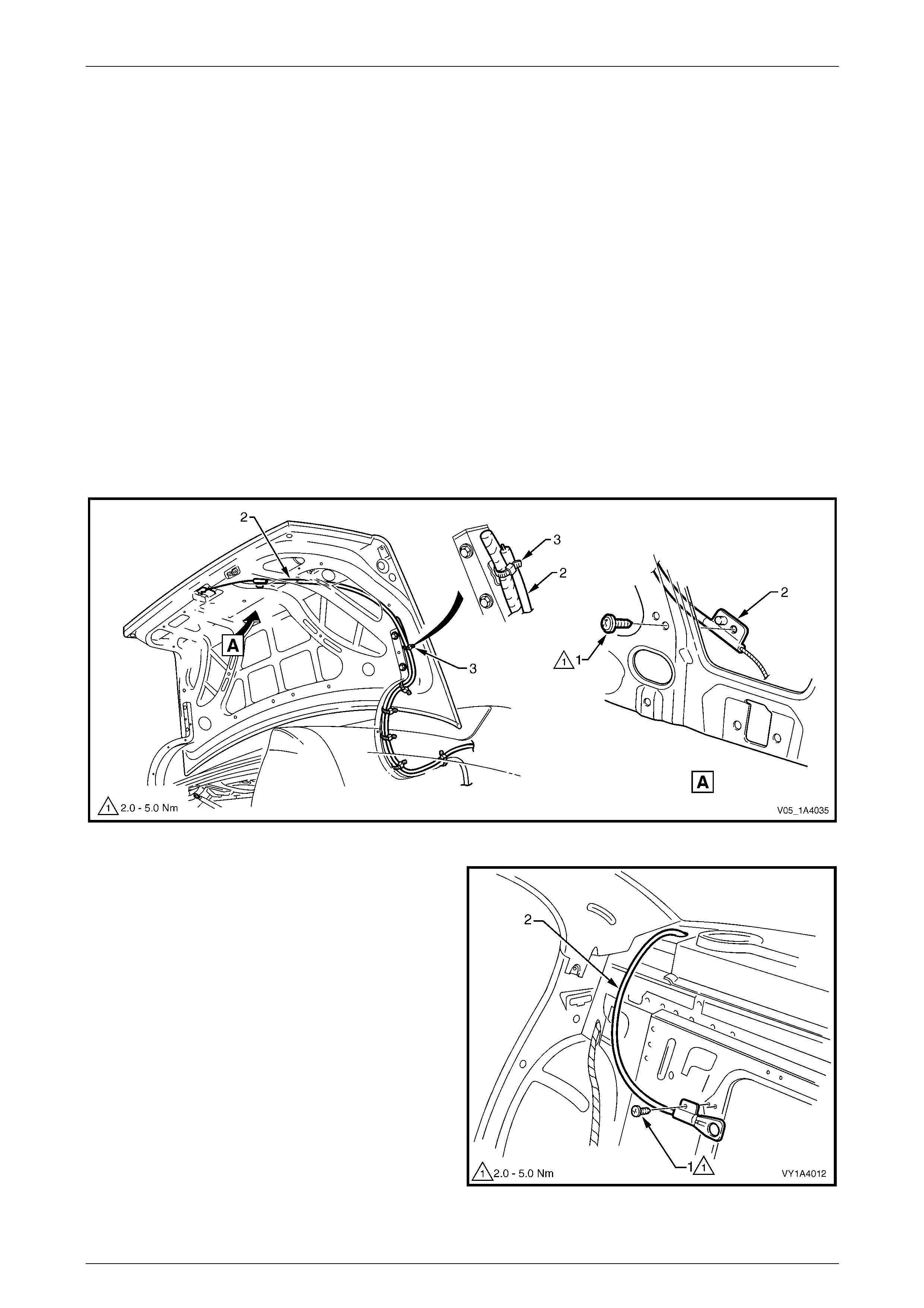

4.6 Rear Compartment Lid Release Cable Assembly............................................................................................. 46

Remove................................................................................................................................................................. 46

Reinstall................................................................................................................................................................ 47

4.7 Rear Compartment Lid Strut Assembly............................................................................................................. 48

Remove................................................................................................................................................................. 48

Reinstall................................................................................................................................................................ 48

4.8 Rear Compartment Lid Assembly ...................................................................................................................... 49

Remove................................................................................................................................................................. 49

Reinstall................................................................................................................................................................ 50

Adjust.................................................................................................................................................................... 51

4.9 Rear Compartment Lid Hinge Assembly ........................................................................................................... 52

Remove................................................................................................................................................................. 52

Reinstall................................................................................................................................................................ 52

4.10 Rear Compartment Lid Striker Assembly.......................................................................................................... 53

Remove................................................................................................................................................................. 53

Reinstall................................................................................................................................................................ 53

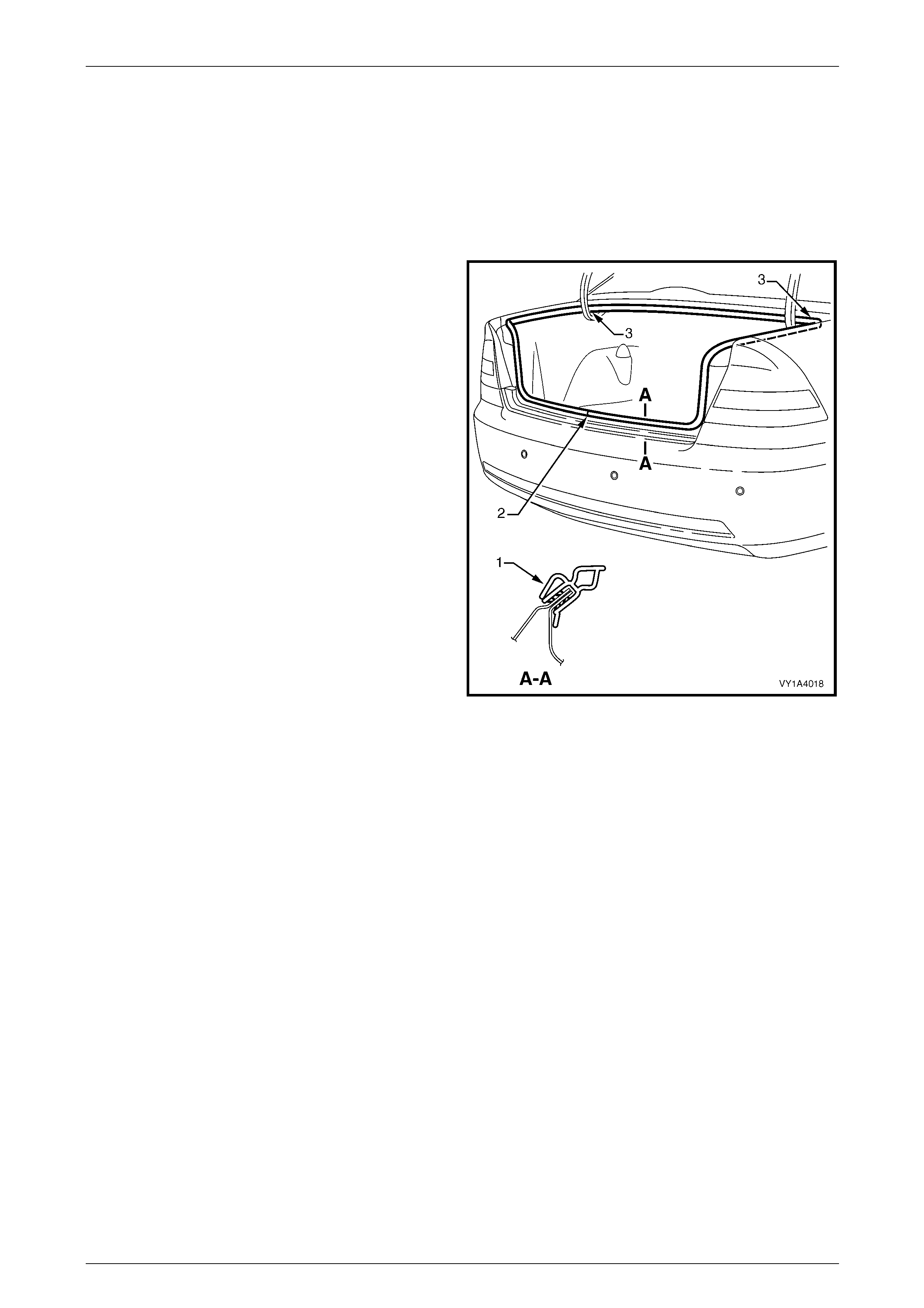

4.11 Rear Compartment Lid Weatherstrip ................................................................................................................. 54

Remove................................................................................................................................................................. 54

Reinstall................................................................................................................................................................ 54

5 Service Operations — Rear Compartment Lid, Coupe.....................................................................55

5.1 Rear Compartment Lid Carpet............................................................................................................................ 55

Remove................................................................................................................................................................. 55

Reinstall................................................................................................................................................................ 55

5.2 Rear Compartment Lid Appliqué Assembly...................................................................................................... 56

Remove................................................................................................................................................................. 56

Disassemble......................................................................................................................................................... 58

Reassemble.......................................................................................................................................................... 58

Reinstall................................................................................................................................................................ 59

5.3 Rear Compartment Lid Latch Assembly............................................................................................ ................ 60

Remove................................................................................................................................................................. 60

Reinstall................................................................................................................................................................ 60

5.4 Rear Compartment Lid Actuator Assembly ....................................................................................................... 61

Remove................................................................................................................................................................. 61

Reinstall................................................................................................................................................................ 61

5.5 Rear Compartment Lid Release Cable Assembly............................................................................................. 62

Remove................................................................................................................................................................. 62

Reinstall................................................................................................................................................................ 63

5.6 Rear Compartment Lid Strut Assembly............................................................................................................. 64

Remove................................................................................................................................................................. 64

Reinstall................................................................................................................................................................ 64

5.7 Rear Compartment Lid Assembly ...................................................................................................................... 65

Remove................................................................................................................................................................. 65

Reinstall................................................................................................................................................................ 66

Adjust.................................................................................................................................................................... 67

5.8 Rear Compartment Lid Hinge Assembly ........................................................................................................... 68

Remove................................................................................................................................................................. 68

Reinstall................................................................................................................................................................ 68

5.9 Rear Compartment Lid Striker Assembly.......................................................................................................... 69

Remove................................................................................................................................................................. 69

Reinstall................................................................................................................................................................ 69

5.10 Rear Compartment Lid Weatherstrip ................................................................................................................. 70

Remove................................................................................................................................................................. 70

Reinstall................................................................................................................................................................ 70

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–4

Page 1A4–4

6 Service Operations — Liftgate, Wagon..............................................................................................71

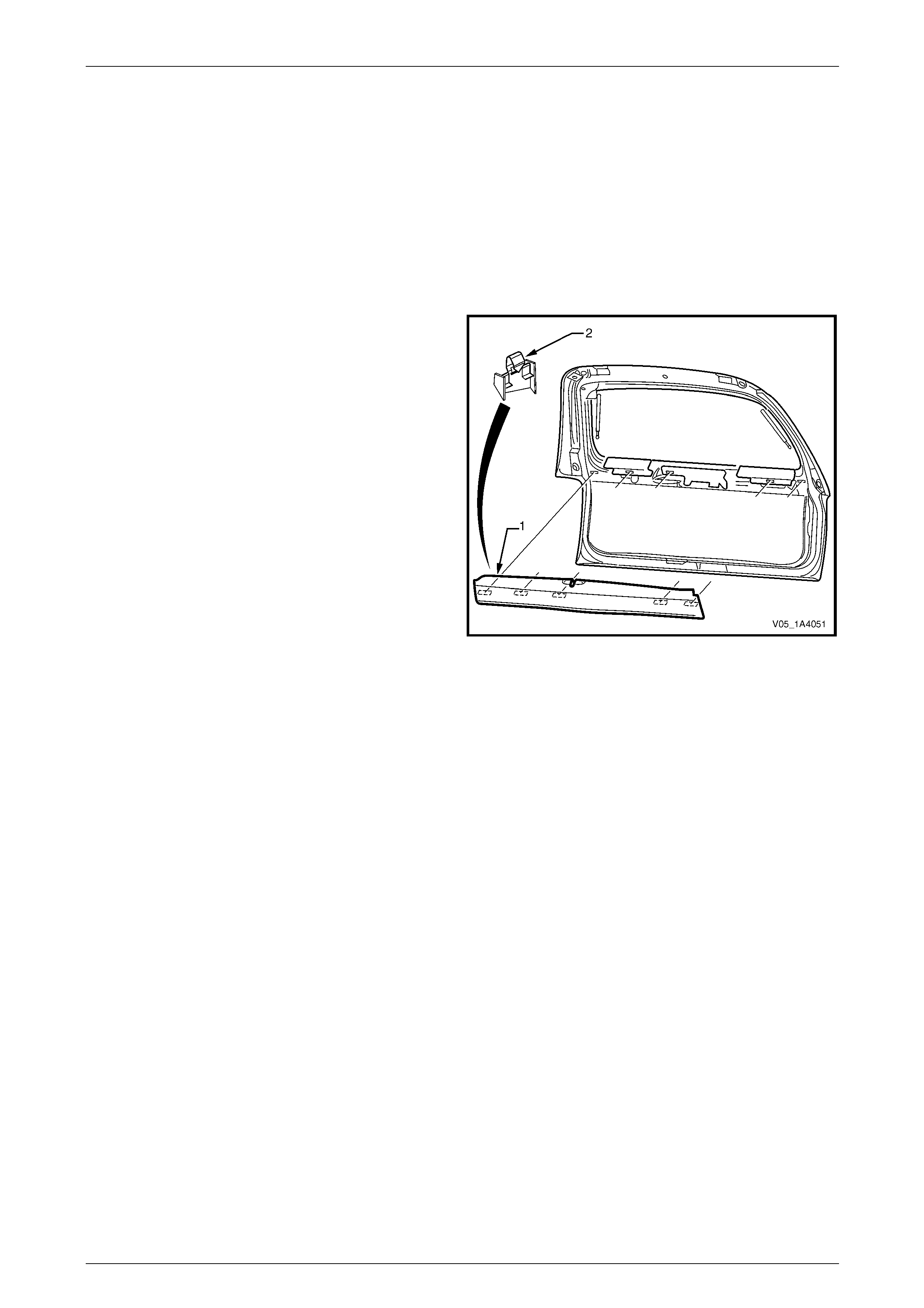

6.1 Liftgate Window Lower Garnish......................................................................................................................... 71

Remove................................................................................................................................................................. 71

Reinstall................................................................................................................................................................ 71

6.2 Liftgate Lower Trim Panel................................................................................................................................... 72

Remove................................................................................................................................................................. 72

Reinstall................................................................................................................................................................ 72

6.3 Liftgate Inside Handle.......................................................................................................................................... 73

Remove................................................................................................................................................................. 73

Reinstall................................................................................................................................................................ 73

6.4 Liftgate Window Upper Garnish ......................................................................................................................... 74

Remove................................................................................................................................................................. 74

Reinstall................................................................................................................................................................ 74

6.5 Liftgate Appliqué Assembly................................................................................................................................ 75

Remove................................................................................................................................................................. 75

Disassemble......................................................................................................................................................... 76

Reassembly.......................................................................................................................................................... 76

Reinstall................................................................................................................................................................ 76

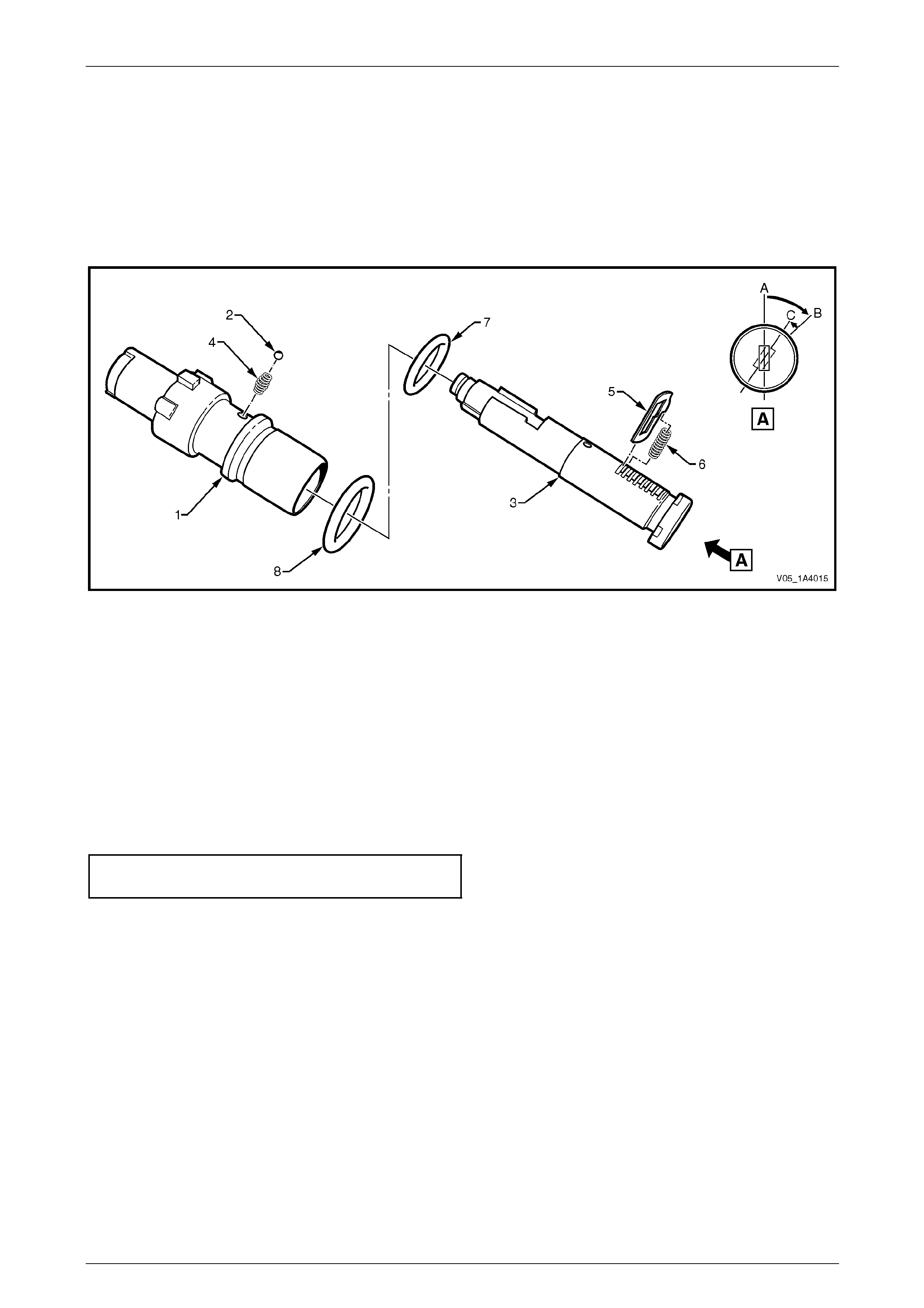

6.6 Liftgate Handle Push-button Assembly............................................................................................................. 77

Remove................................................................................................................................................................. 77

Disassemble......................................................................................................................................................... 77

Reassemble.......................................................................................................................................................... 78

Reinstall................................................................................................................................................................ 78

6.7 Liftgate Latch Assembly ..................................................................................................................................... 79

Remove................................................................................................................................................................. 79

Reinstall................................................................................................................................................................ 79

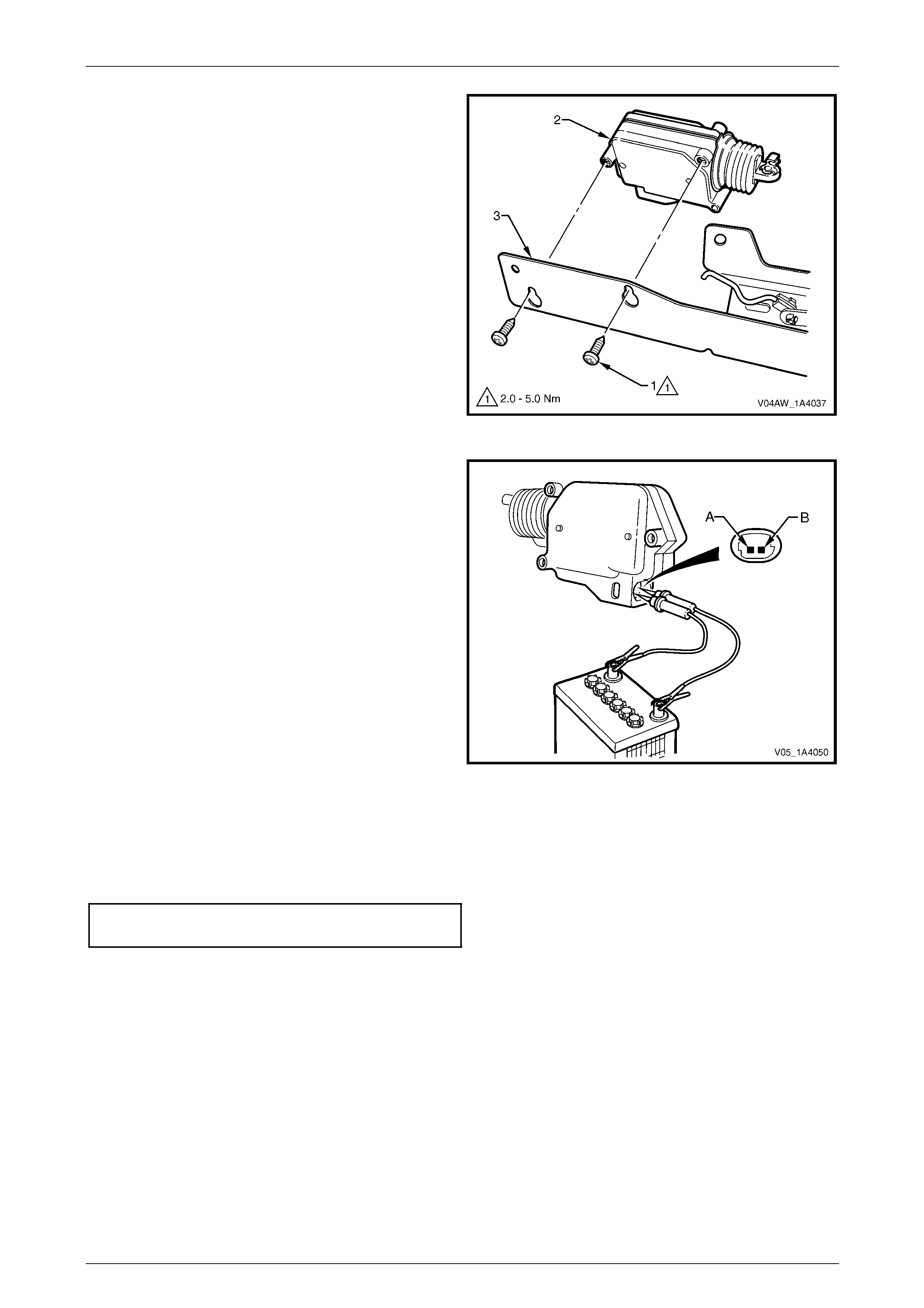

6.8 Liftgate Actuator Assembly ................................................................................................................................ 80

Remove................................................................................................................................................................. 80

Reinstall................................................................................................................................................................ 80

6.9 Liftgate Air Deflector Assembly.......................................................................................................................... 81

Remove................................................................................................................................................................. 81

Reinstall................................................................................................................................................................ 82

6.10 Rear Window Wiper Assembly ........................................................................................................................... 83

Replace................................................................................................................................................................. 83

6.11 Rear Window Washer Nozzle and Hose Assemblies........................................................................................ 84

Replace................................................................................................................................................................. 84

6.12 High-mount Stop Lamp Assembly ..................................................................................................................... 85

Replace................................................................................................................................................................. 85

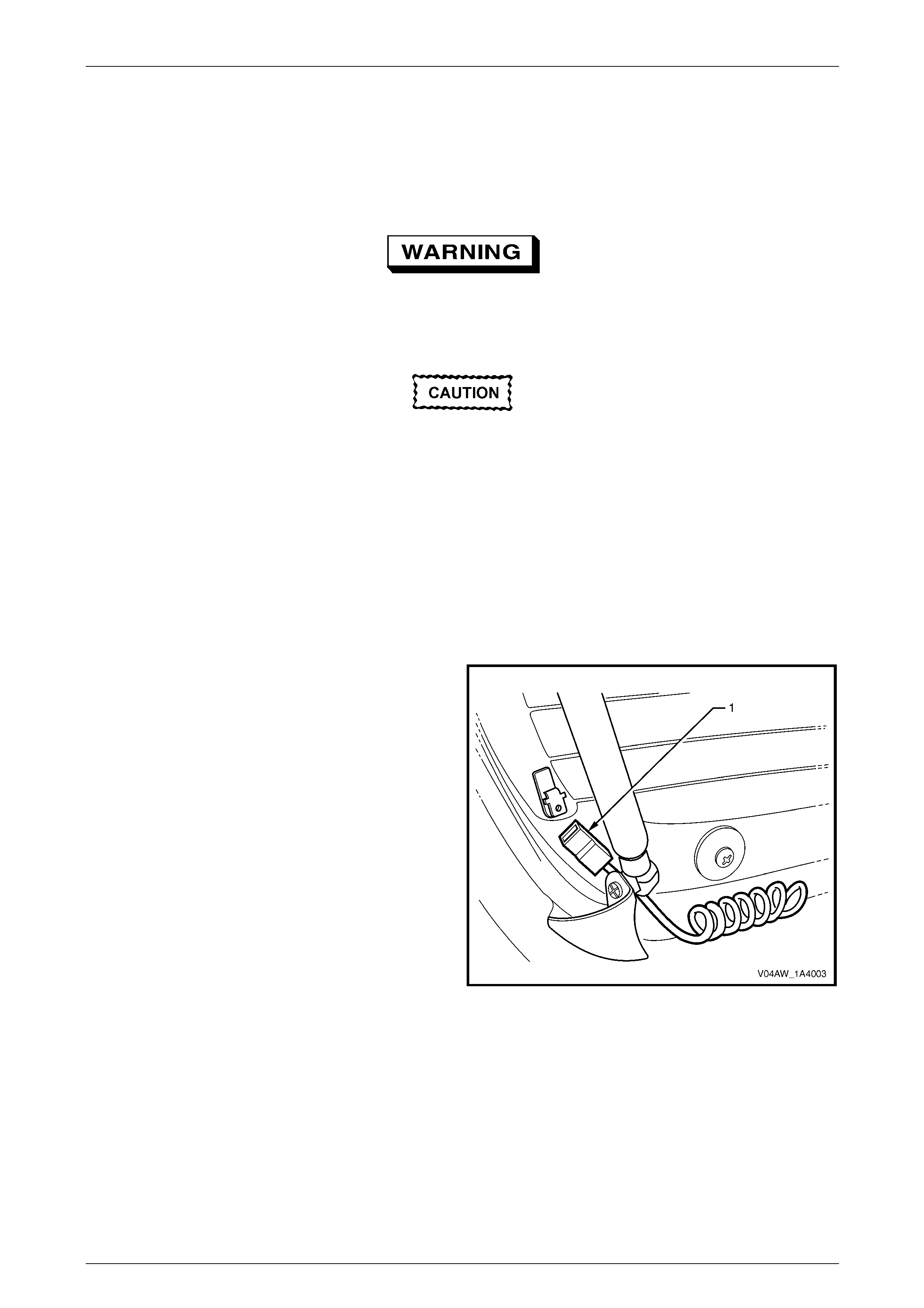

6.13 Liftgate Strut Assembly....................................................................................................................................... 86

Remove................................................................................................................................................................. 86

Reinstall................................................................................................................................................................ 86

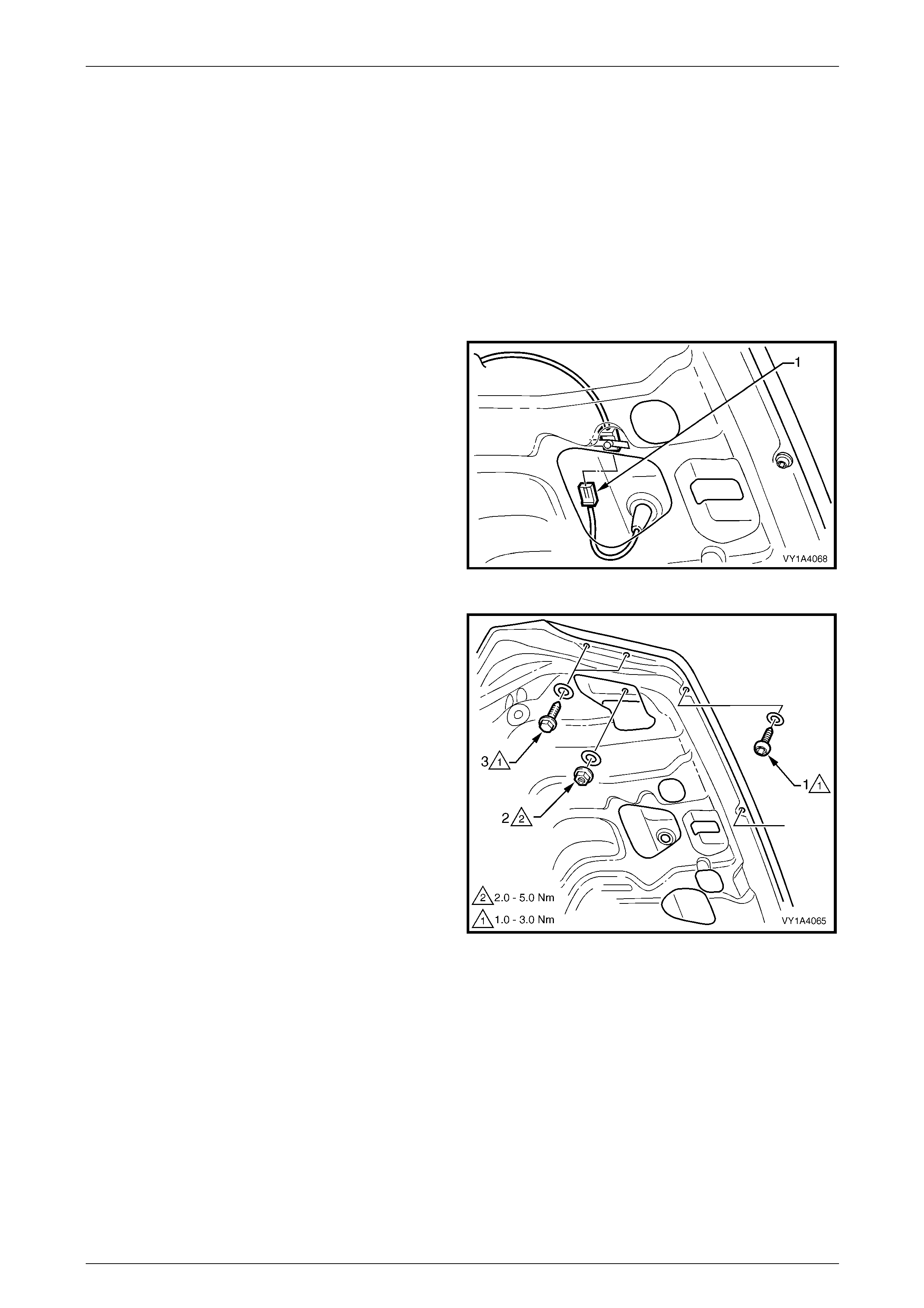

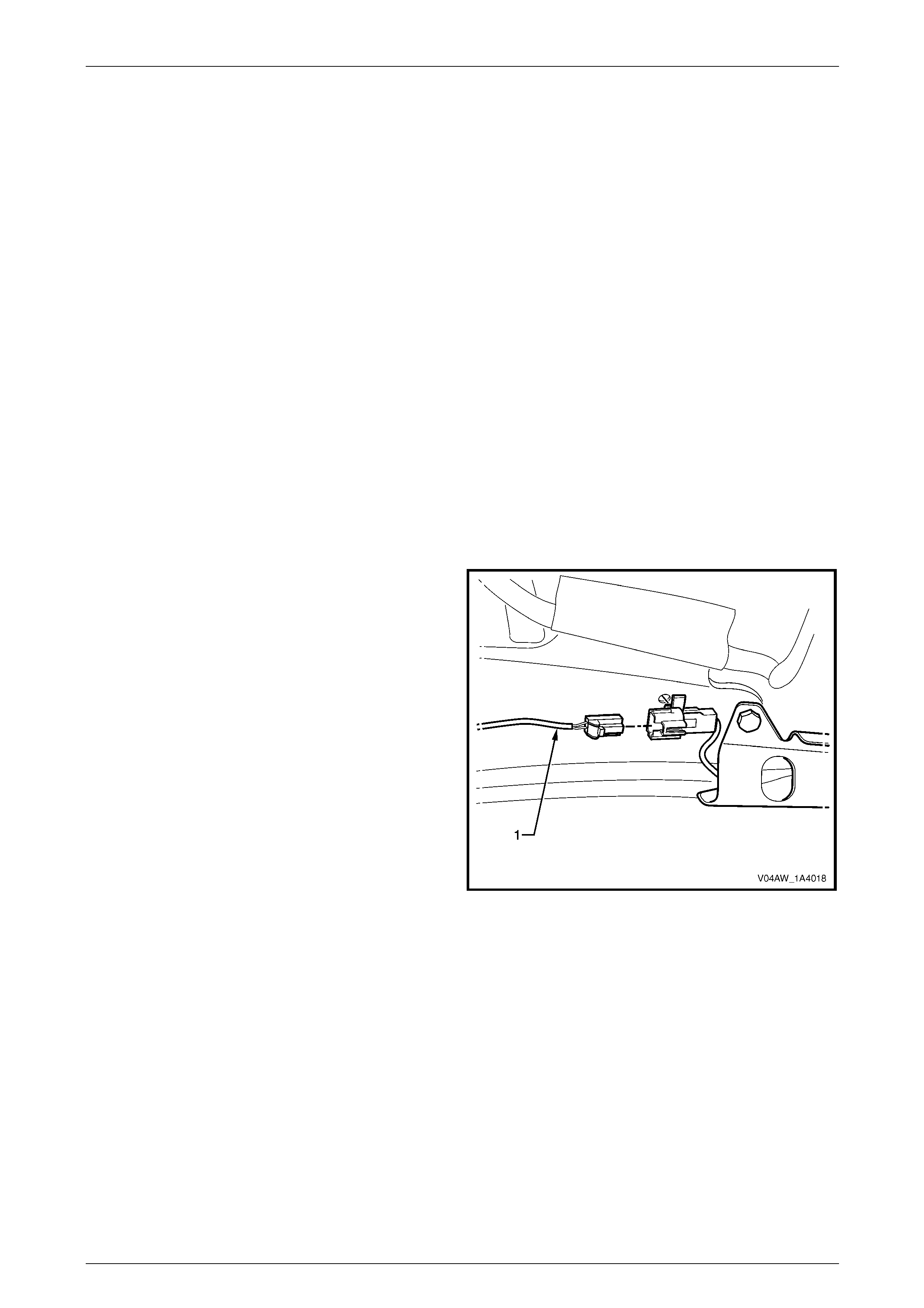

6.14 Rear Compartment Courtesy Lamp Switch Assembly..................................................................................... 87

Remove................................................................................................................................................................. 87

Reinstall................................................................................................................................................................ 87

6.15 Liftgate Bumper ................................................................................................................................................... 88

Remove................................................................................................................................................................. 88

Reinstall................................................................................................................................................................ 88

6.16 Liftgate Assembly................................................................................................................................................ 89

Remove................................................................................................................................................................. 89

Disassemble......................................................................................................................................................... 90

Reassemble.......................................................................................................................................................... 91

Reinstall................................................................................................................................................................ 91

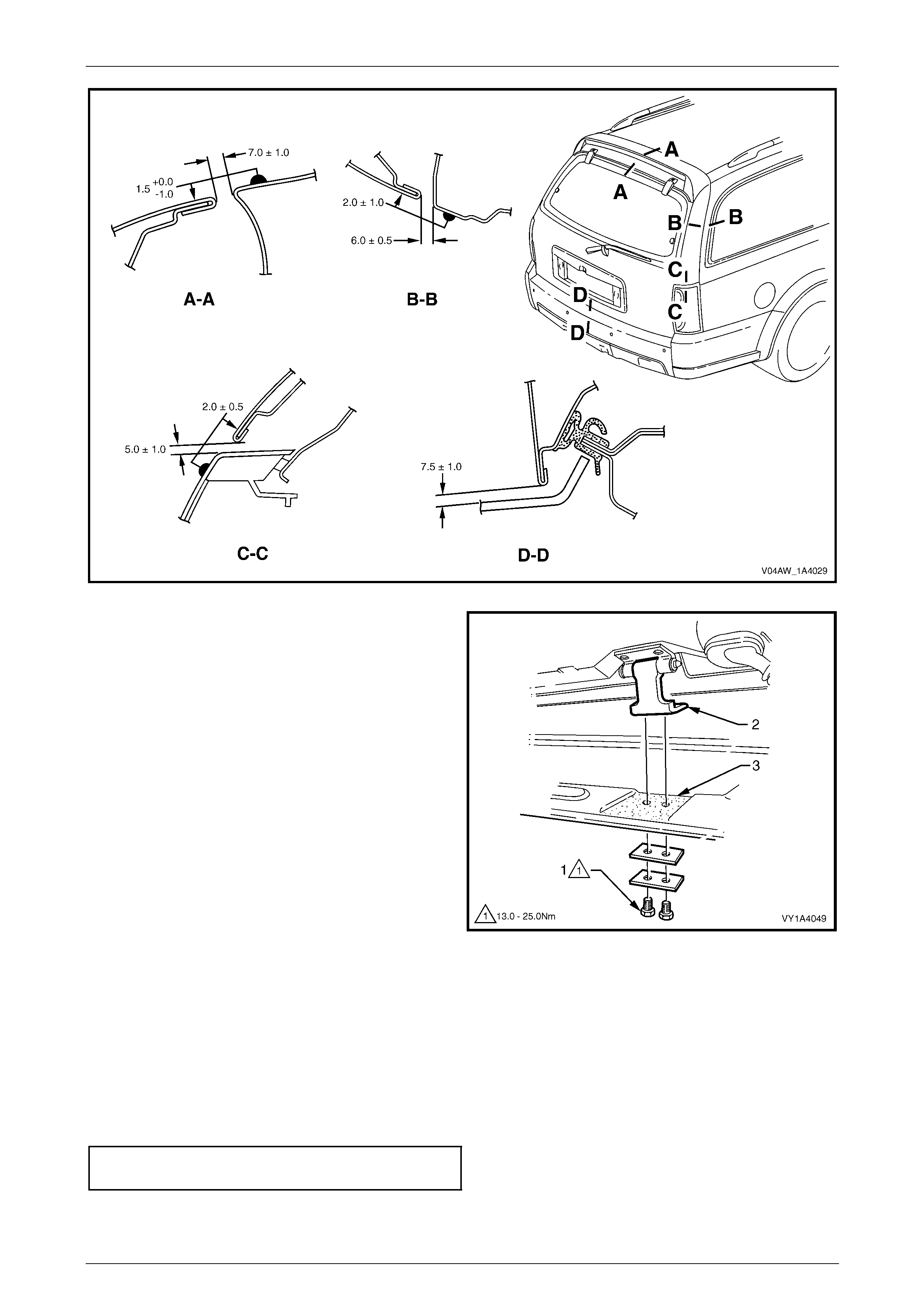

Adjust.................................................................................................................................................................... 91

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–5

Page 1A4–5

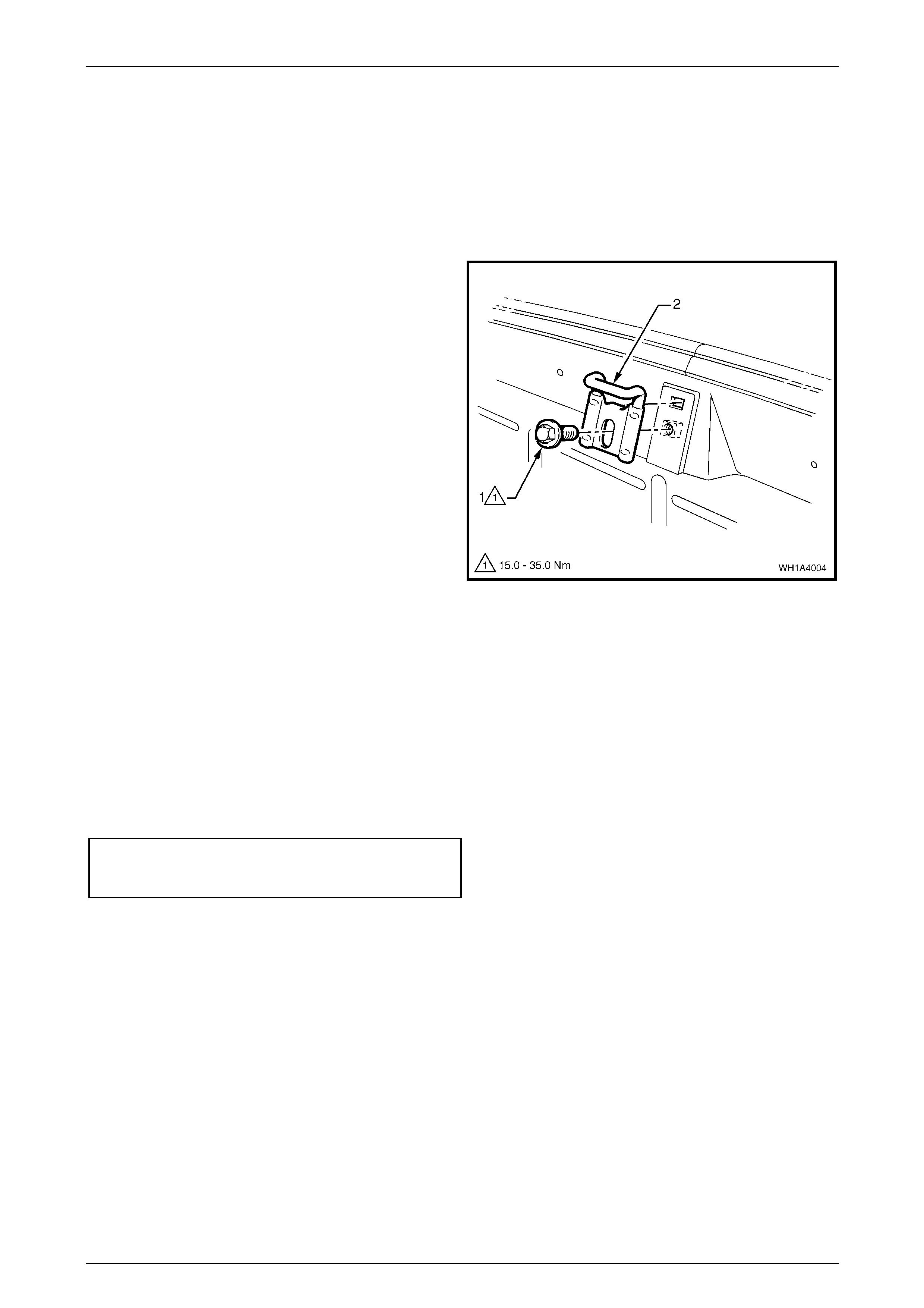

6.17 Liftgate Striker Assembly .................................................................................................................................... 93

Remove................................................................................................................................................................. 93

Reinstall................................................................................................................................................................ 93

Adjust.................................................................................................................................................................... 93

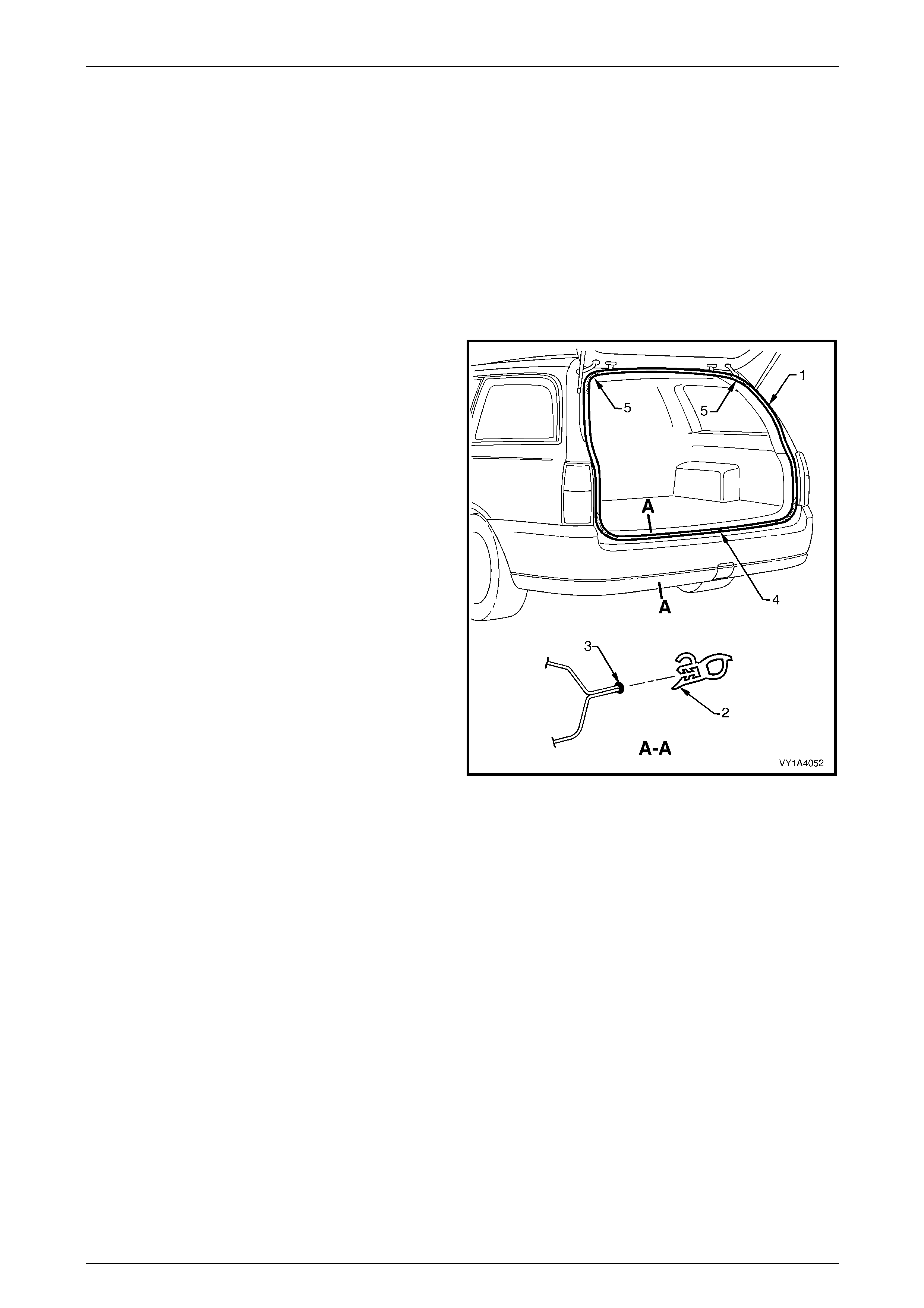

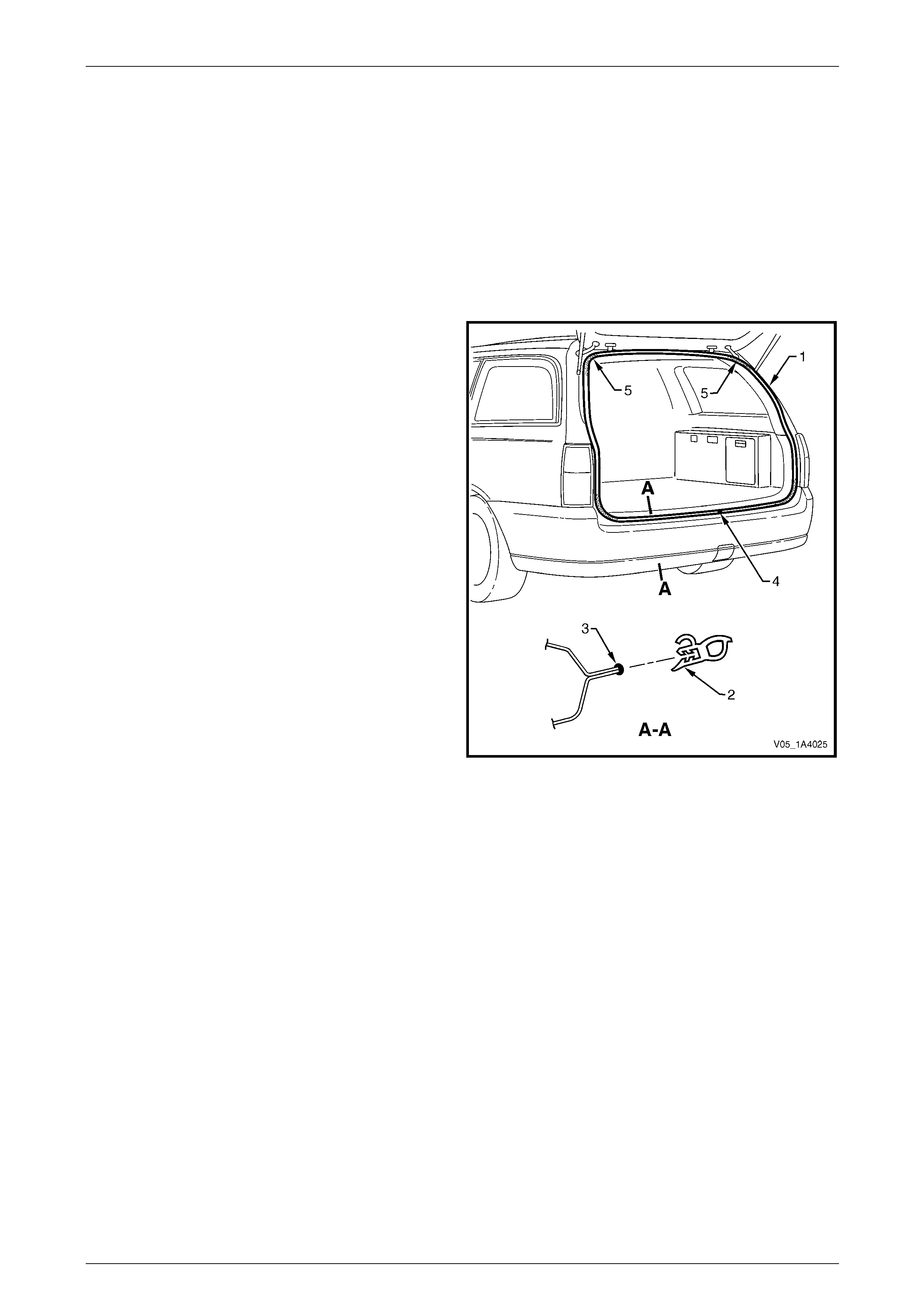

6.18 Liftgate Weatherstrip Assembly......................................................................................................................... 94

Remove................................................................................................................................................................. 94

Reinstall................................................................................................................................................................ 94

7 Service Operations — Liftgate, AWD Wagon....................................................................................95

7.1 Liftgate Window Lower Garnish......................................................................................................................... 95

Remove................................................................................................................................................................. 95

Reinstall................................................................................................................................................................ 95

7.2 Liftgate Lower Trim Panel................................................................................................................................... 96

Remove................................................................................................................................................................. 96

Reinstall................................................................................................................................................................ 96

7.3 Liftgate Window Upper Garnish ......................................................................................................................... 97

Remove................................................................................................................................................................. 97

Reinstall................................................................................................................................................................ 97

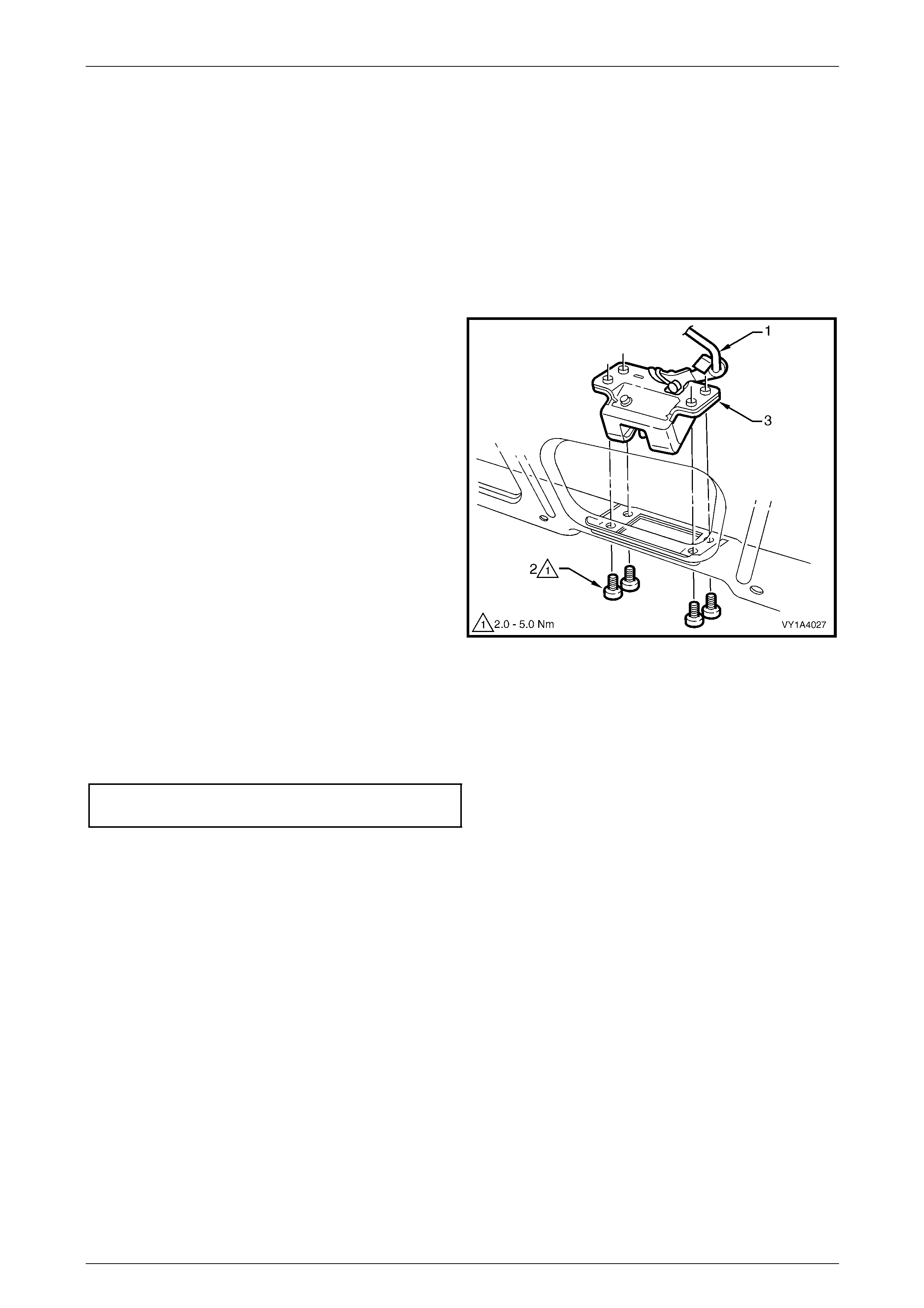

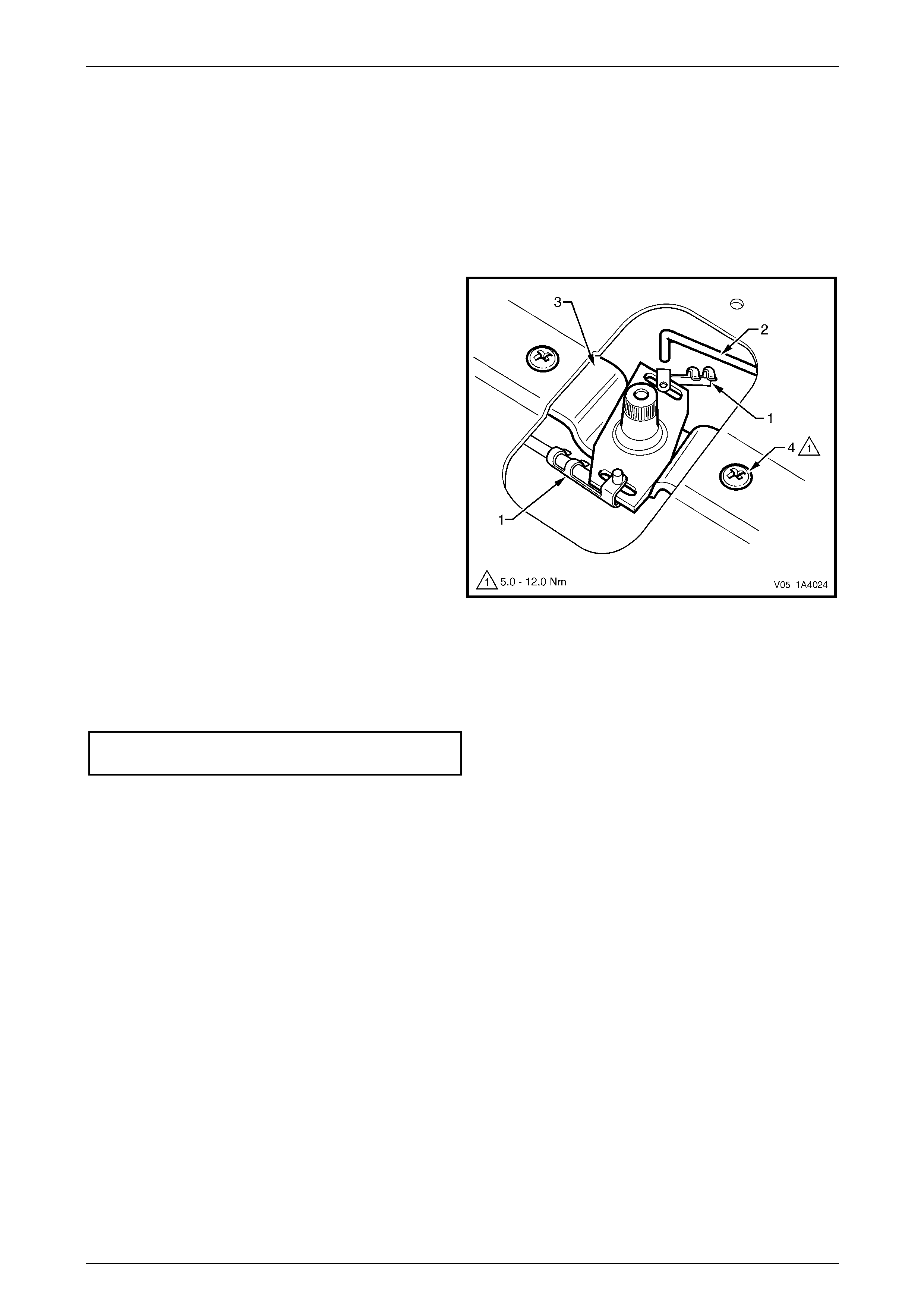

7.4 Liftgate Window Release Assembly................................................................................................................... 98

Remove................................................................................................................................................................. 98

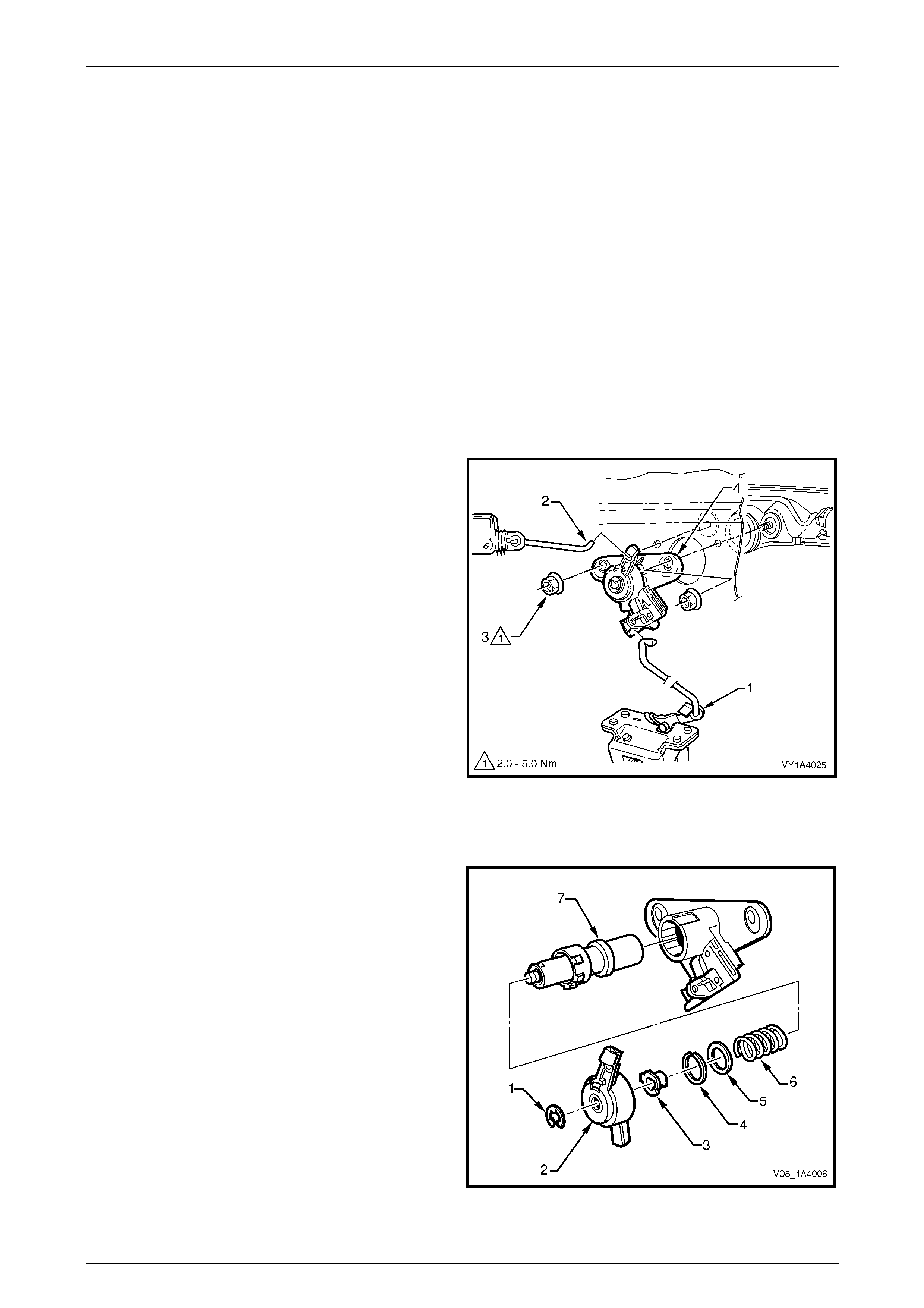

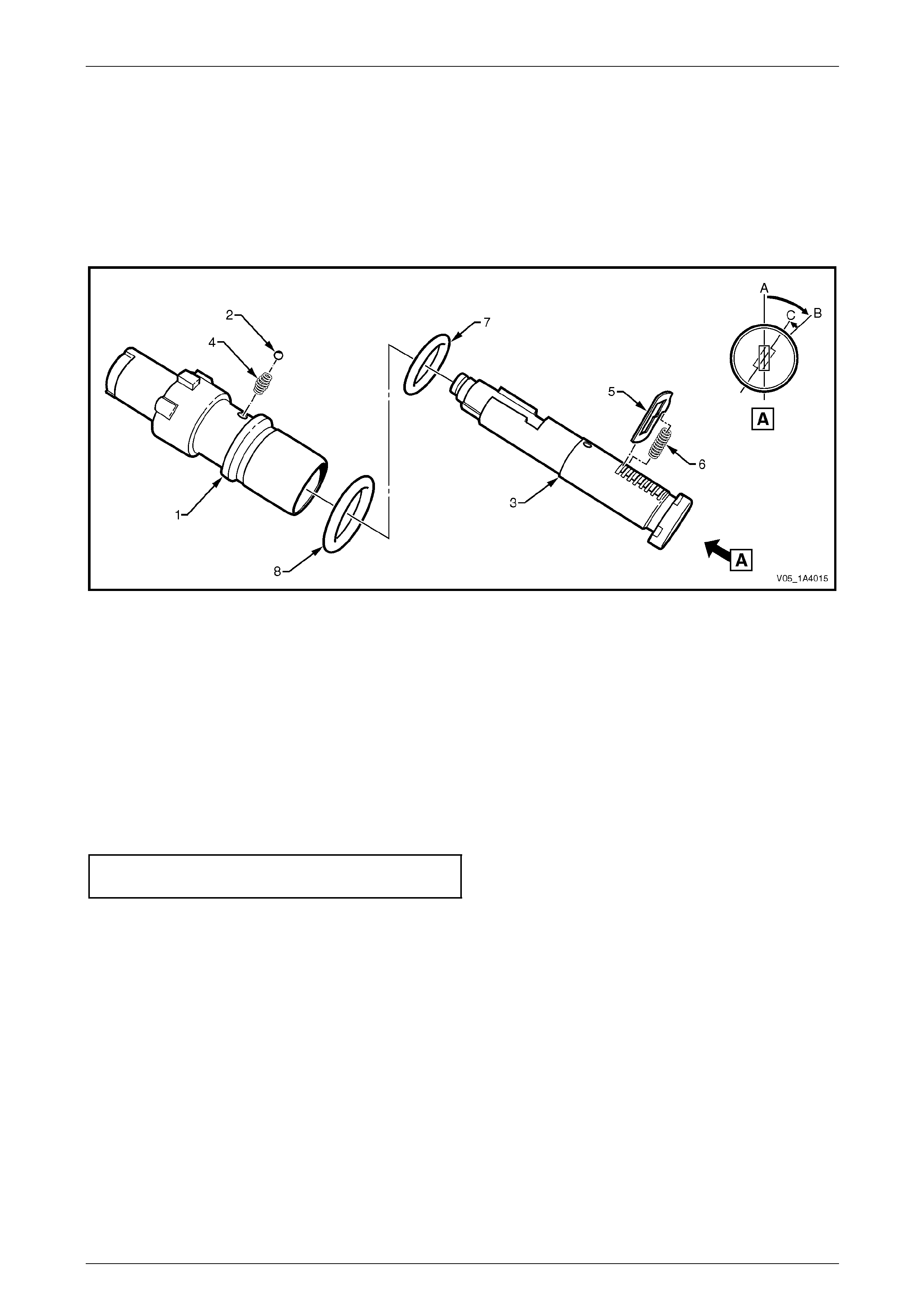

Disassemble......................................................................................................................................................... 99

Liftgate Window Release Actuator ................................................................................................................... 99

Liftgate Window Latch Assembly.................................................................................................................... 101

Liftgate Window Microswitch.......................................................................................................................... 102

Reinstall.............................................................................................................................................................. 102

7.5 Liftgate Switch ................................................................................................................................................... 103

7.6 Liftgate Appliqué Assembly.............................................................................................................................. 104

Remove............................................................................................................................................................... 104

Disassemble....................................................................................................................................................... 105

Reassemble........................................................................................................................................................ 105

Reinstall.............................................................................................................................................................. 105

7.7 Liftgate Handle Push-button Assembly........................................................................................................... 106

Remove............................................................................................................................................................... 106

Disassemble....................................................................................................................................................... 106

Reassemble........................................................................................................................................................ 107

Reinstall.............................................................................................................................................................. 107

7.8 Liftgate Air Deflector Assembly........................................................................................................................ 108

Remove............................................................................................................................................................... 108

Disassemble....................................................................................................................................................... 109

Reassemble........................................................................................................................................................ 109

Reinstall.............................................................................................................................................................. 109

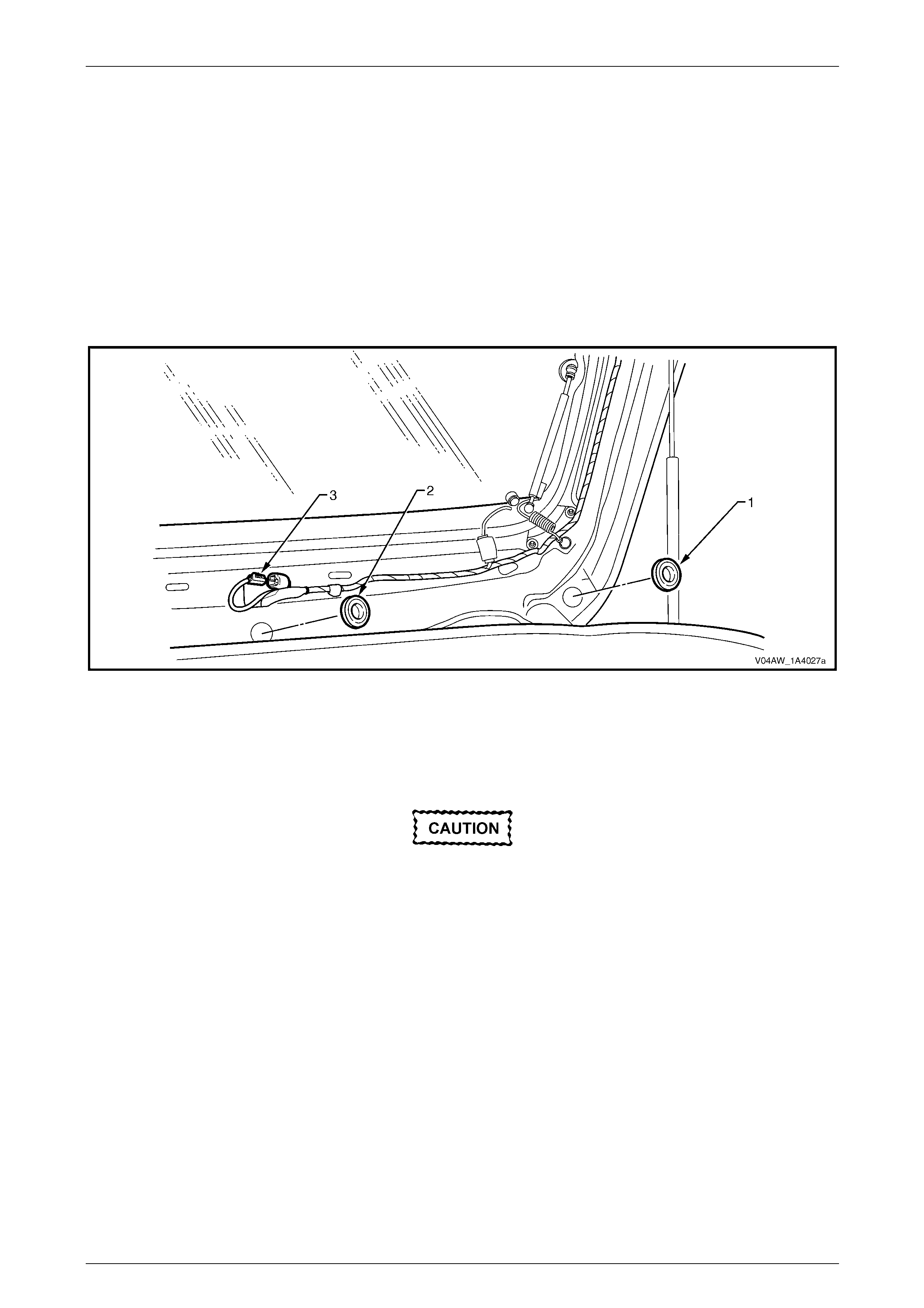

7.9 Liftgate Window Assembly ............................................................................................................................... 110

Remove............................................................................................................................................................... 110

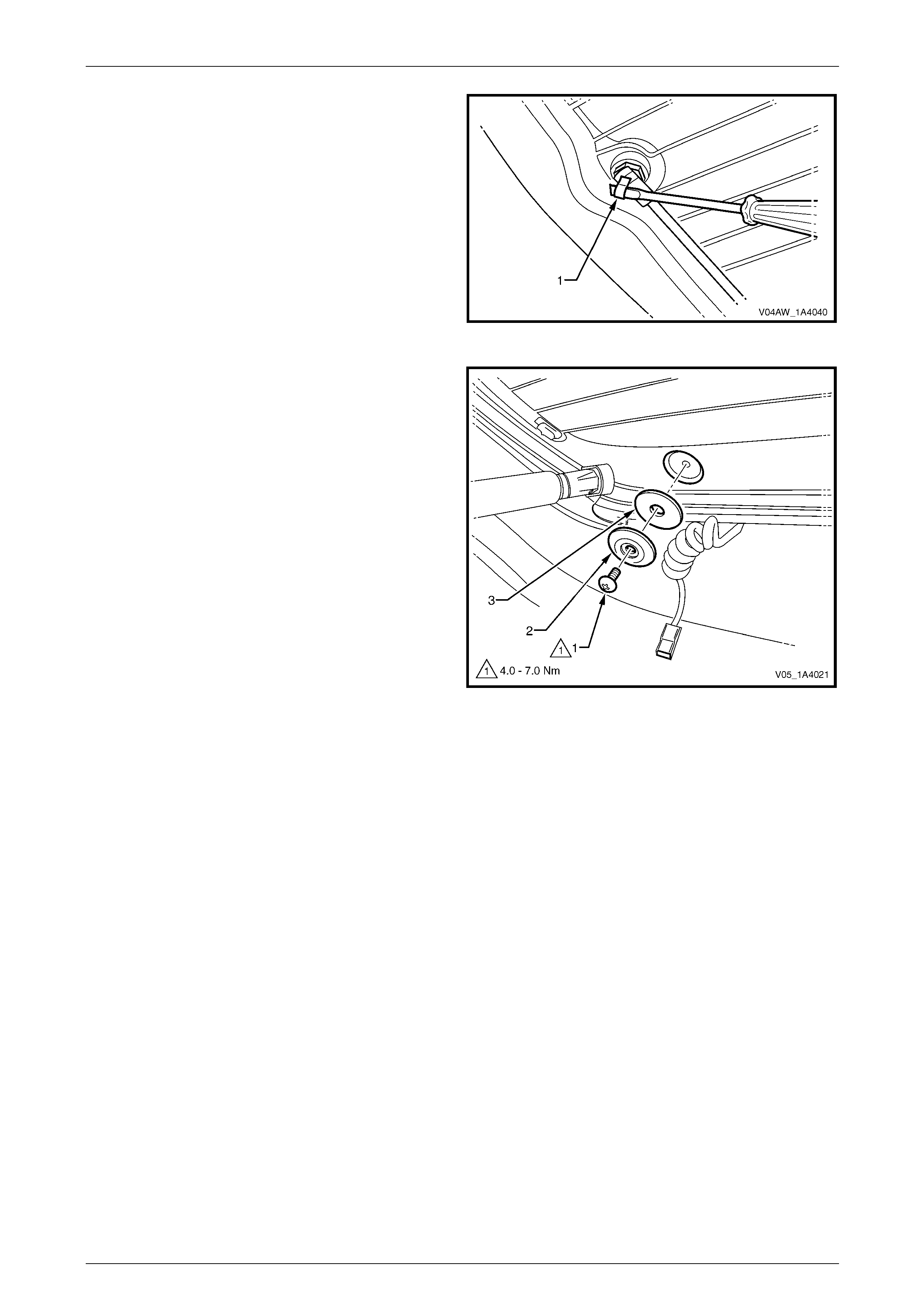

Disassemble....................................................................................................................................................... 112

Liftgate Window Striker and Handle............................................................................................................... 112

Liftgate Window Strut Ball Stud...................................................................................................................... 113

Reinstall.............................................................................................................................................................. 113

7.10 Liftgate Window Hinge ...................................................................................................................................... 114

Remove............................................................................................................................................................... 114

Reinstall.............................................................................................................................................................. 114

7.11 Liftgate Window Strut........................................................................................................................................ 115

Remove............................................................................................................................................................... 115

Reinstall.............................................................................................................................................................. 115

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–6

Page 1A4–6

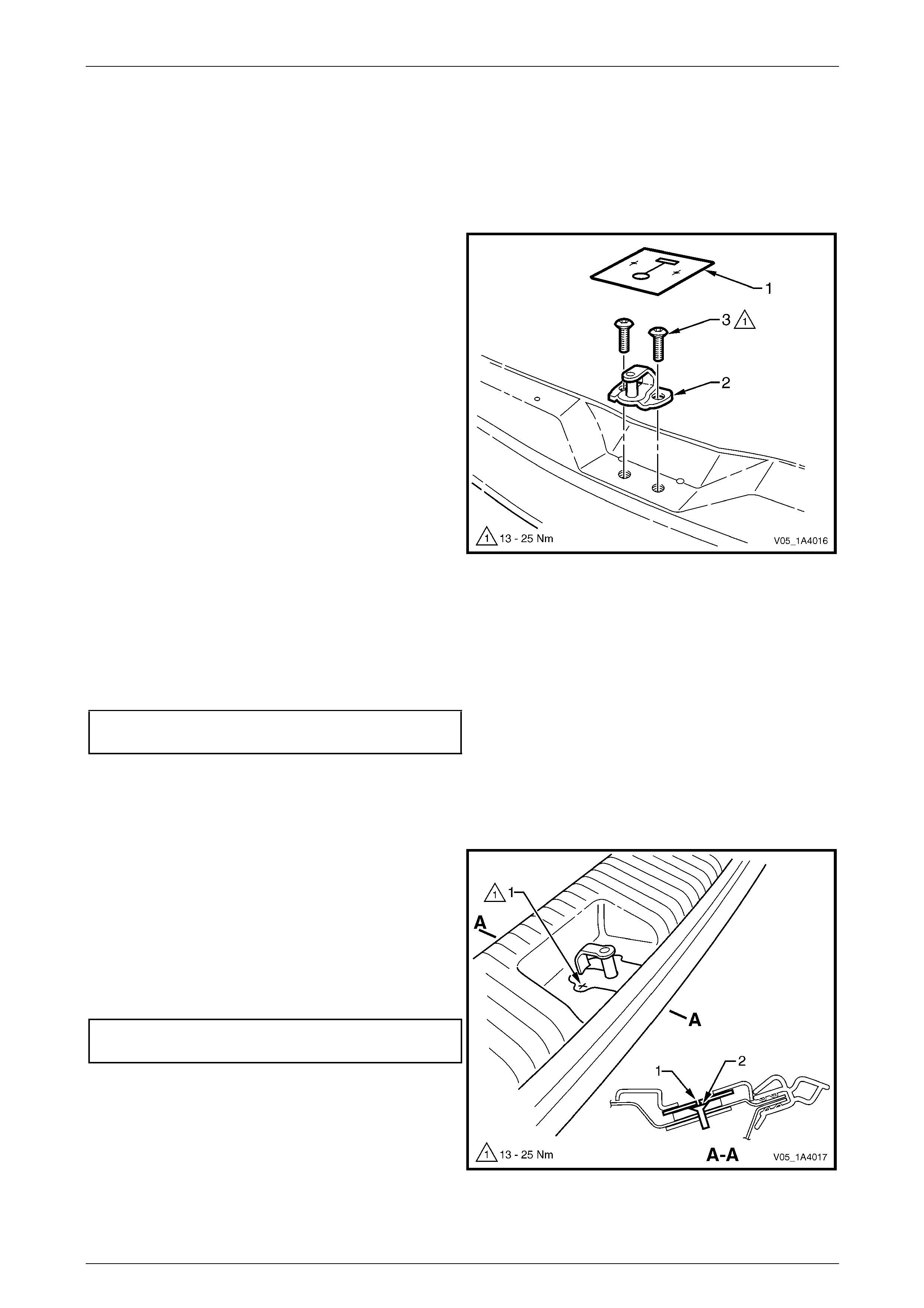

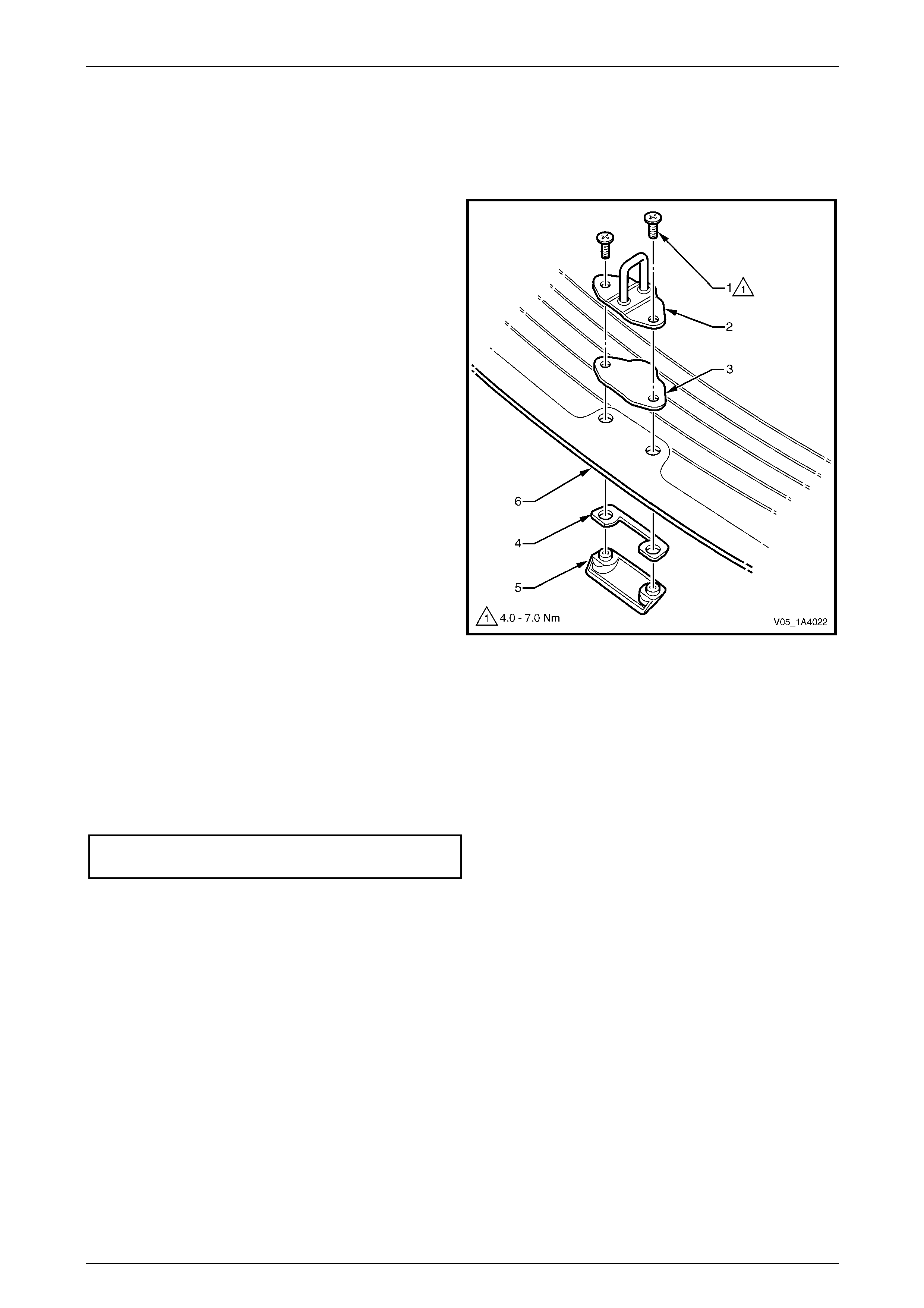

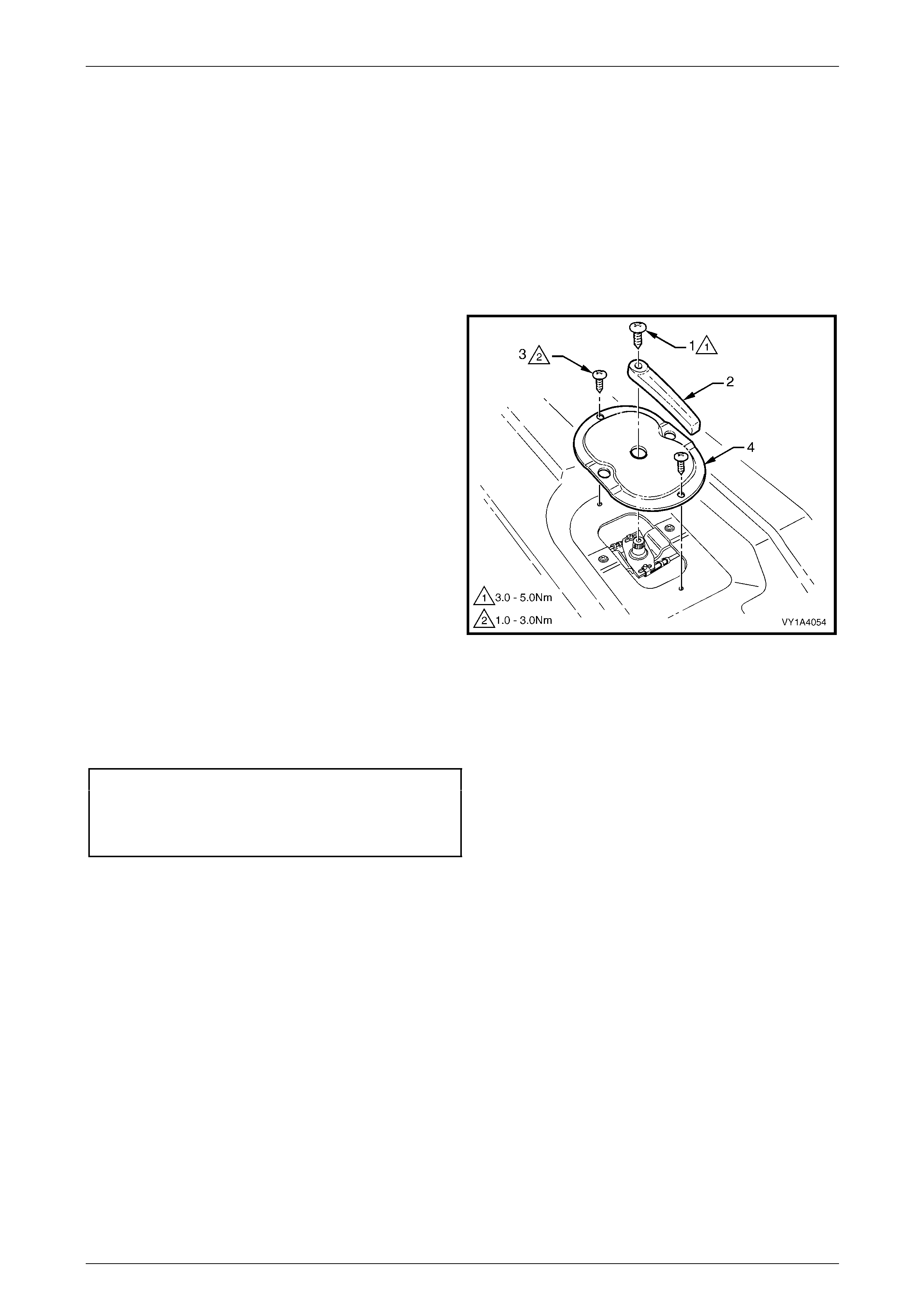

7.12 Liftgate Window Upper Strut Bracket .............................................................................................................. 116

Remove............................................................................................................................................................... 116

Reinstall.............................................................................................................................................................. 116

7.13 Liftgate Window Weatherstrip .......................................................................................................................... 117

Remove............................................................................................................................................................... 117

Reinstall.............................................................................................................................................................. 117

7.14 Liftgate Assembly.............................................................................................................................................. 118

Remove............................................................................................................................................................... 118

Disassemble....................................................................................................................................................... 119

Reassemble........................................................................................................................................................ 120

Reinstall.............................................................................................................................................................. 120

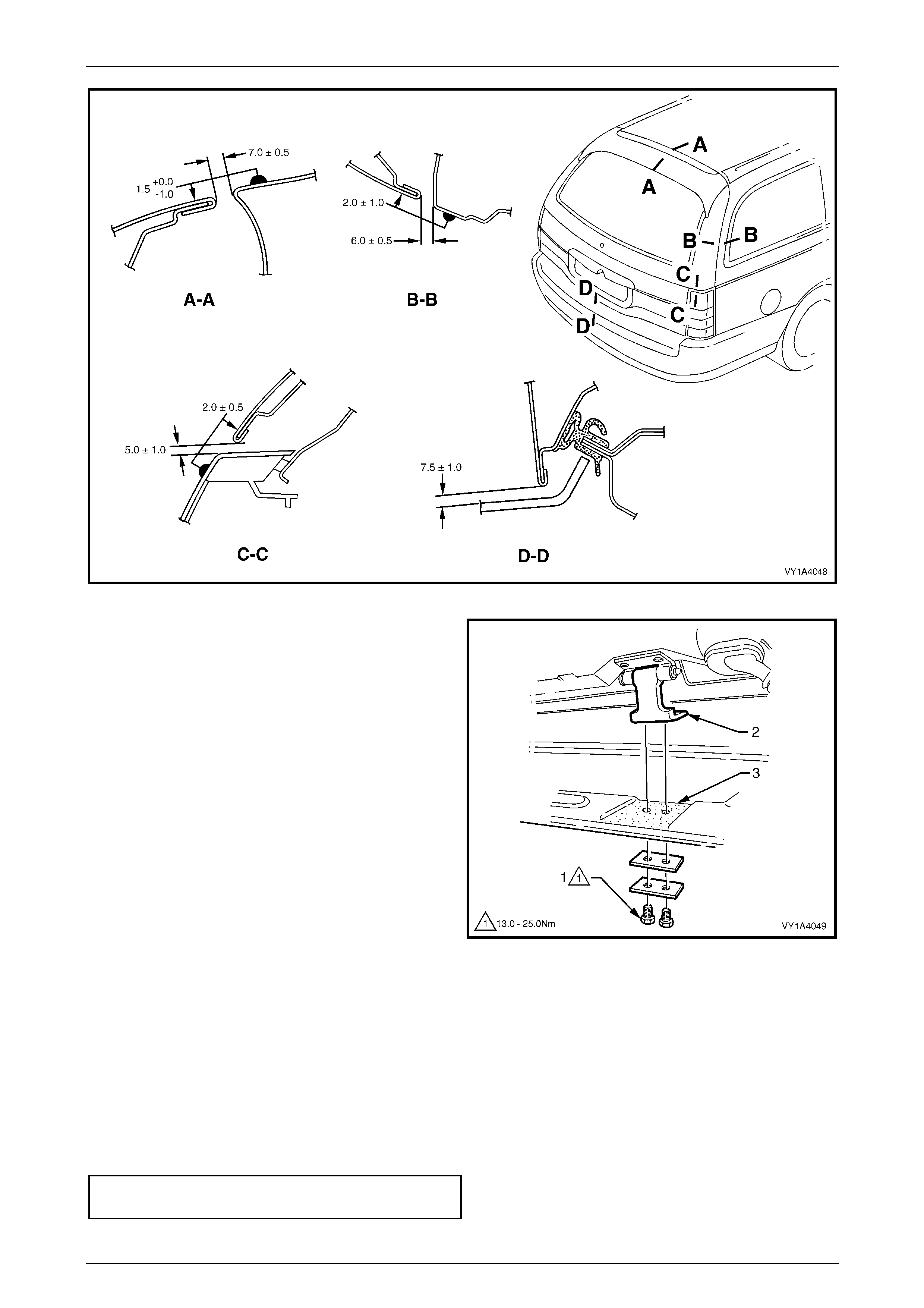

Adjust.................................................................................................................................................................. 121

7.15 Liftgate Weatherstrip Assembly....................................................................................................................... 123

Remove............................................................................................................................................................... 123

Reinstall.............................................................................................................................................................. 123

8 Service Operations — Endgate, Utility.............................................................................................124

8.1 Endgate Inner Panel Access Hole Cover......................................................................................................... 124

Remove............................................................................................................................................................... 124

Reinstall.............................................................................................................................................................. 124

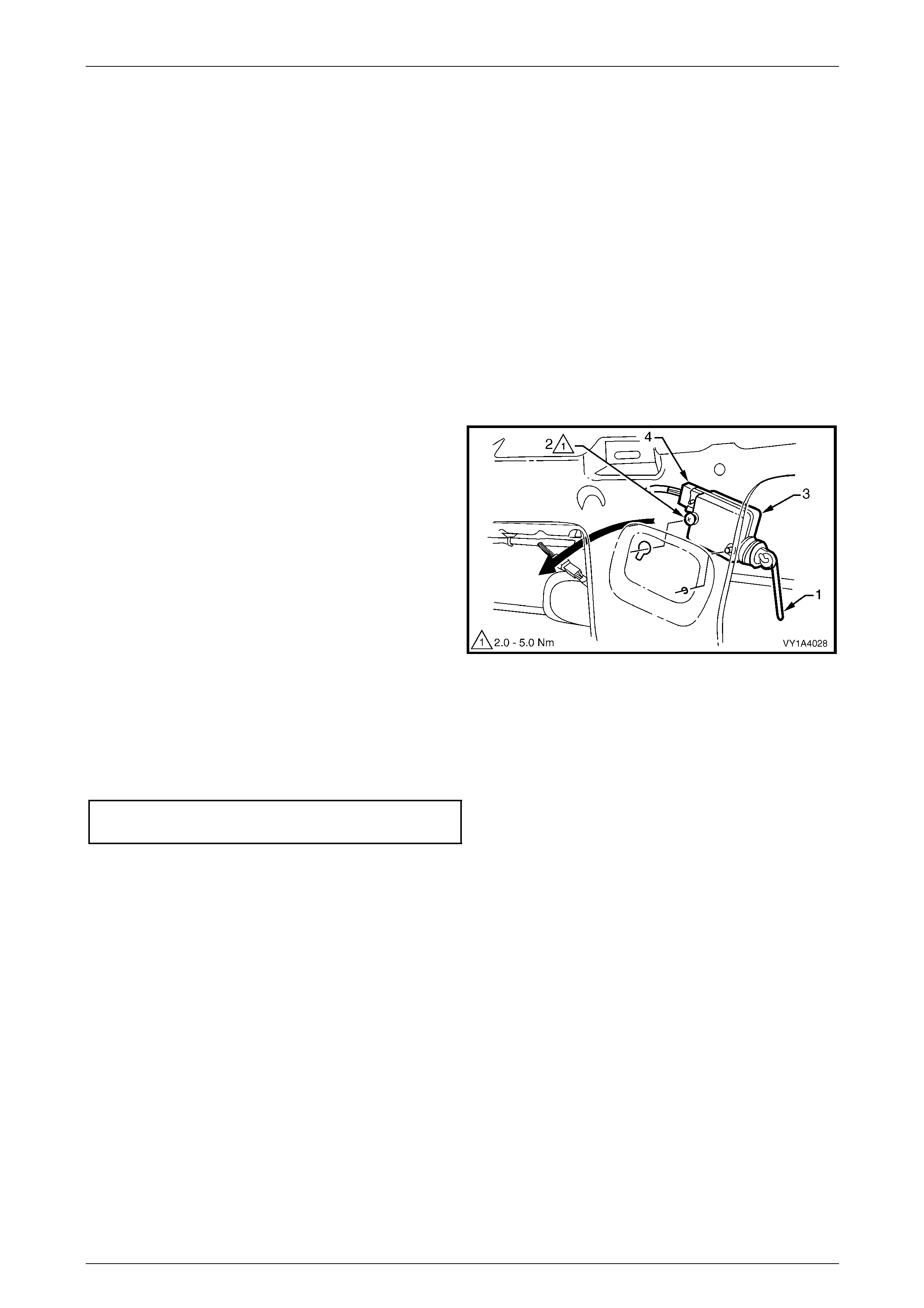

8.2 Endgate Lock Anchor Plate Assembly ............................................................................................................ 125

Remove............................................................................................................................................................... 125

Reinstall.............................................................................................................................................................. 125

8.3 Endgate Latch Assembly and Endgate Latch Bracket Assembly ................................................................. 126

Remove............................................................................................................................................................... 126

Reinstall.............................................................................................................................................................. 126

8.4 Endgate Striker and Endgate Cable Assembly ............................................................................................... 127

Remove............................................................................................................................................................... 127

Reinstall.............................................................................................................................................................. 127

8.5 Endgate Upper Moulding Assembly................................................................................................................. 128

Remove............................................................................................................................................................... 128

Reinstall.............................................................................................................................................................. 128

8.6 Endgate Assembly............................................................................................................................................. 129

Remove............................................................................................................................................................... 129

Reinstall.............................................................................................................................................................. 129

Adjust.................................................................................................................................................................. 130

8.7 Endgate Hinge Assembly.................................................................................................................................. 131

Remove............................................................................................................................................................... 131

Reinstall.............................................................................................................................................................. 131

8.8 Endgate Weatherstrip Assembly...................................................................................................................... 132

Remove............................................................................................................................................................... 132

Reinstall.............................................................................................................................................................. 132

9 Service Operations — Endgate, Crew Cab and AWD Crew Cab...................................................133

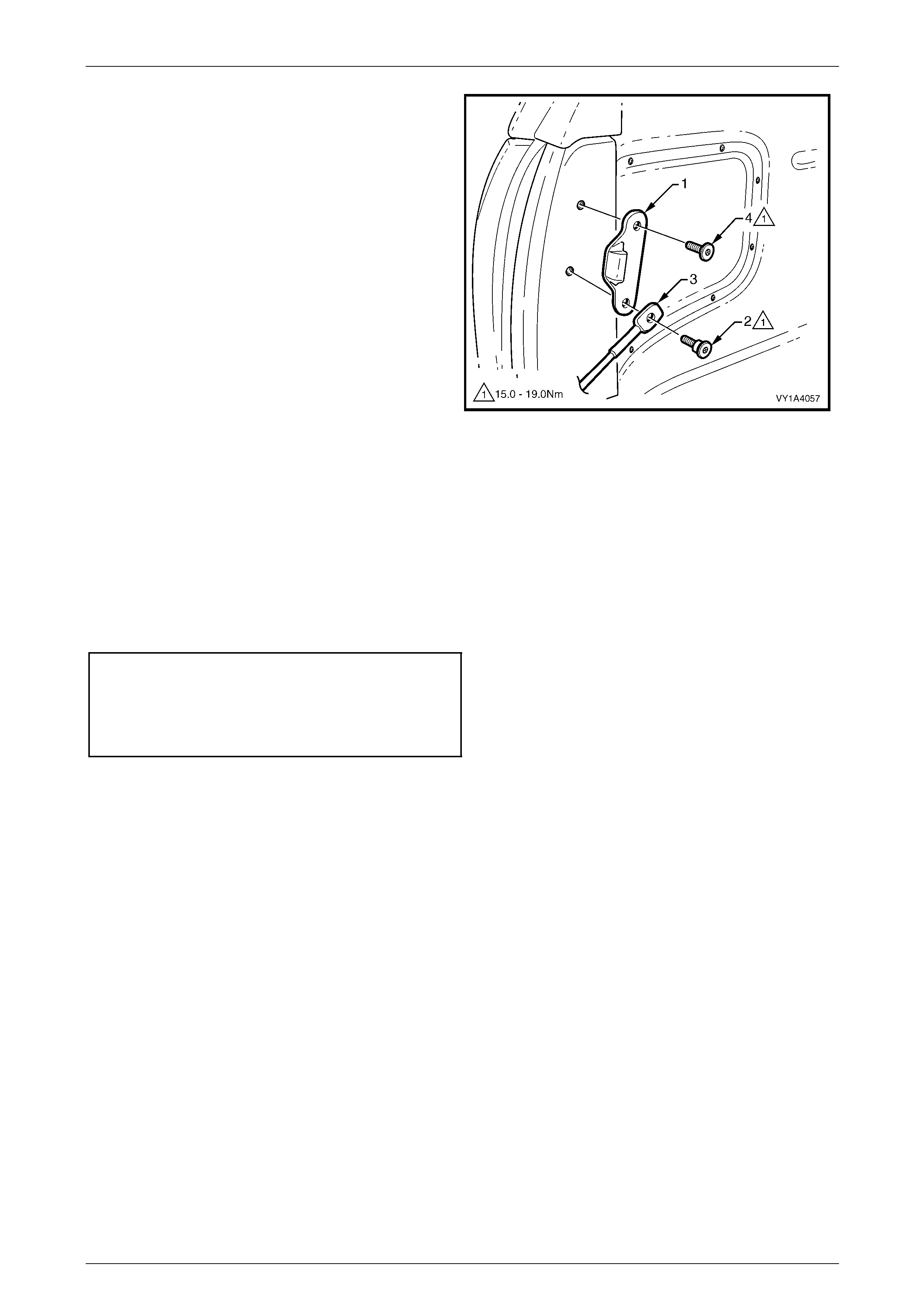

9.1 Endgate Latch Bracket and Cable Assembly, and Endgate Striker .............................................................. 133

Remove............................................................................................................................................................... 133

Reinstall.............................................................................................................................................................. 134

10 Torque Wrench Specifications..........................................................................................................135

10.1 Hood – Except Coupe........................................................................................................................................ 135

10.2 Hood – Coupe..................................................................................................................................................... 136

10.3 Rear Compartment Lid – Sedan........................................................................................................................ 137

10.4 Rear Compartment Lid – Coupe....................................................................................................................... 138

10.5 Liftgate – Wagon................................................................................................................................................ 139

10.6 Liftgate – AWD Wagon ...................................................................................................................................... 140

10.7 Endgate – Utility................................................................................................................................................. 141

10.8 Endgate – Crew Cab and AWD Crew Cab........................................................................................................ 142

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–7

Page 1A4–7

1 General Information

This Section describes the service proc edures for the hood assembly, rear compartment lid ass embly, liftgate assembly

and endgate assembly.

A new-style hood is fitted that is common to all models except Coupe. A hood front moulding is fitted to Level 2 and 3

Sedan and Wagon vehicles that integrates with the radiator grille when the hood is closed. A new hood panel assembly

is fitted to Coupe vehicles that has two hood scoop assemblies. The hood insulator has new holes to allow for the fitting

of air inlet ducts that allow air to pass through while restricting water and foreign objects.

The hood release mecha nism is common to all models and uses a cabl e and lever arrangement. The release lever is

located below the driver’s side of the instrument panel.

The rear compartment lid latch assembly is operated by an actuator which is controlled by a release switch located in the

instrument panel compartment, or by a button on the igniti on key. A rear compartment lid release cable is fitted to provide

entry to the rear compartment in case of a power failure. A handle that operates the release is accessible from behind

the rear seat centre for Sedan or under the right-hand rear seat head restraint for Coupe vehicles.

The liftgate latch on the Wagon is operated via a push-button on the handle assembly. Locking is provid ed through the

vehicle’s central locking system or manually with the ignition key. For AWD Wagon vehicles, the hinged liftgate windo w

assembly can be released an d opened while the liftgate assembly remains closed.

The endgate is common to both Utility and Crew Cab vehicles, but the endgate on the Utility can open to a near-v ertical

position. Due to the full-width rear bumper assembly, it is limited to a horizontal position on the Crew Cab.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–8

Page 1A4–8

2 Service Operations — Hood,

Except Coupe

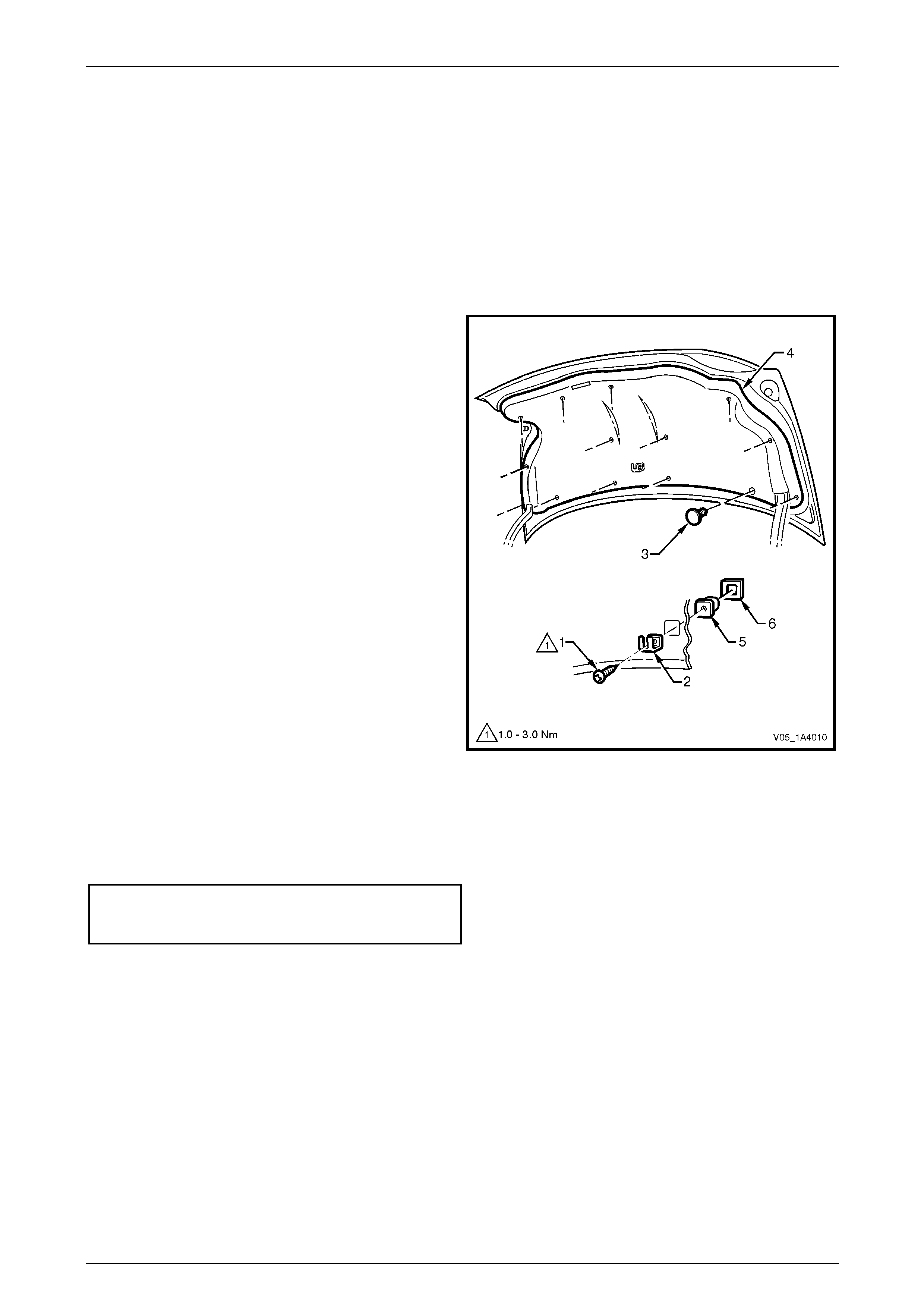

2.1 Hood Primary Latch Striker Assembly

LT Section No. — 12–050

Remove

1 Raise the hood.

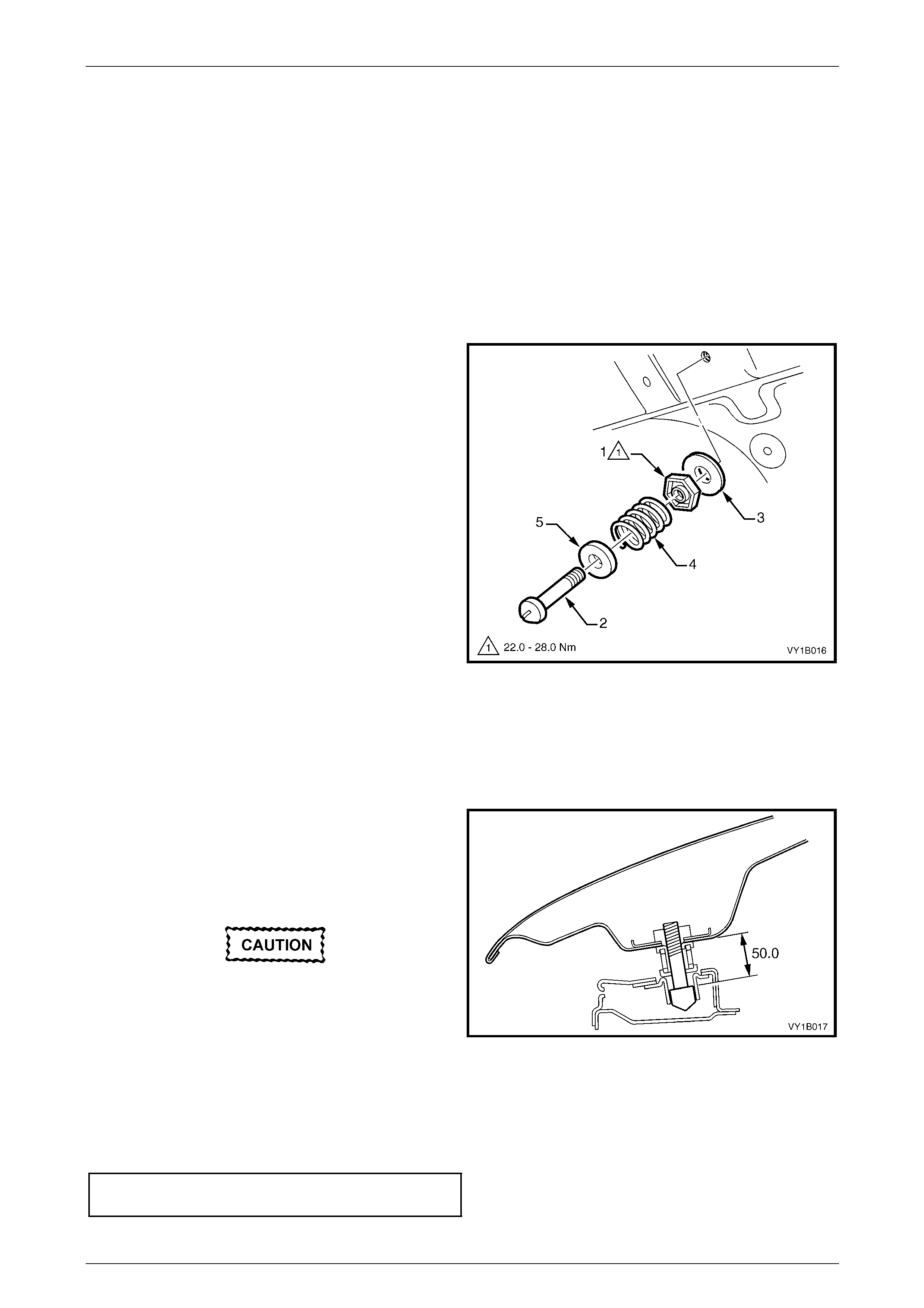

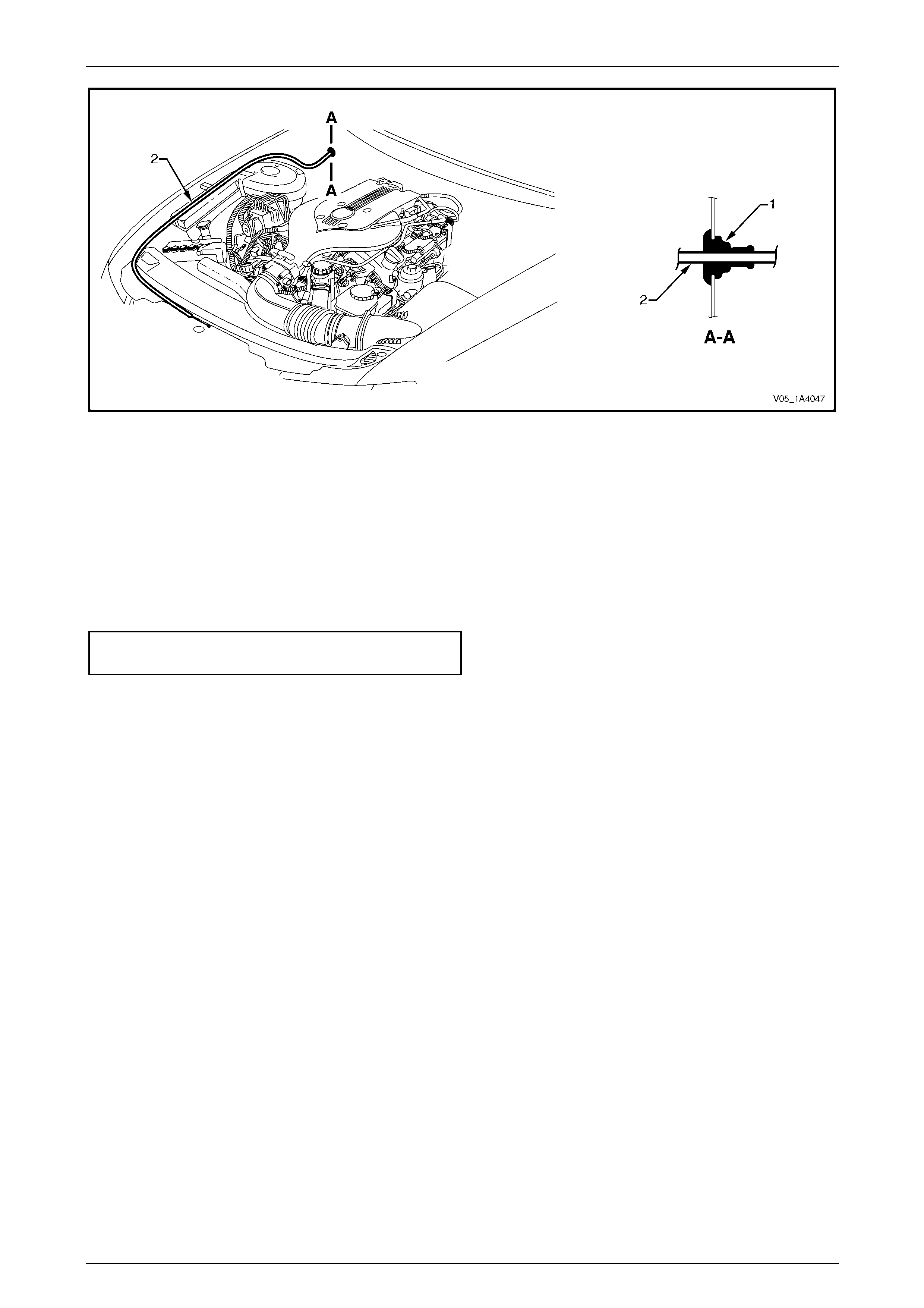

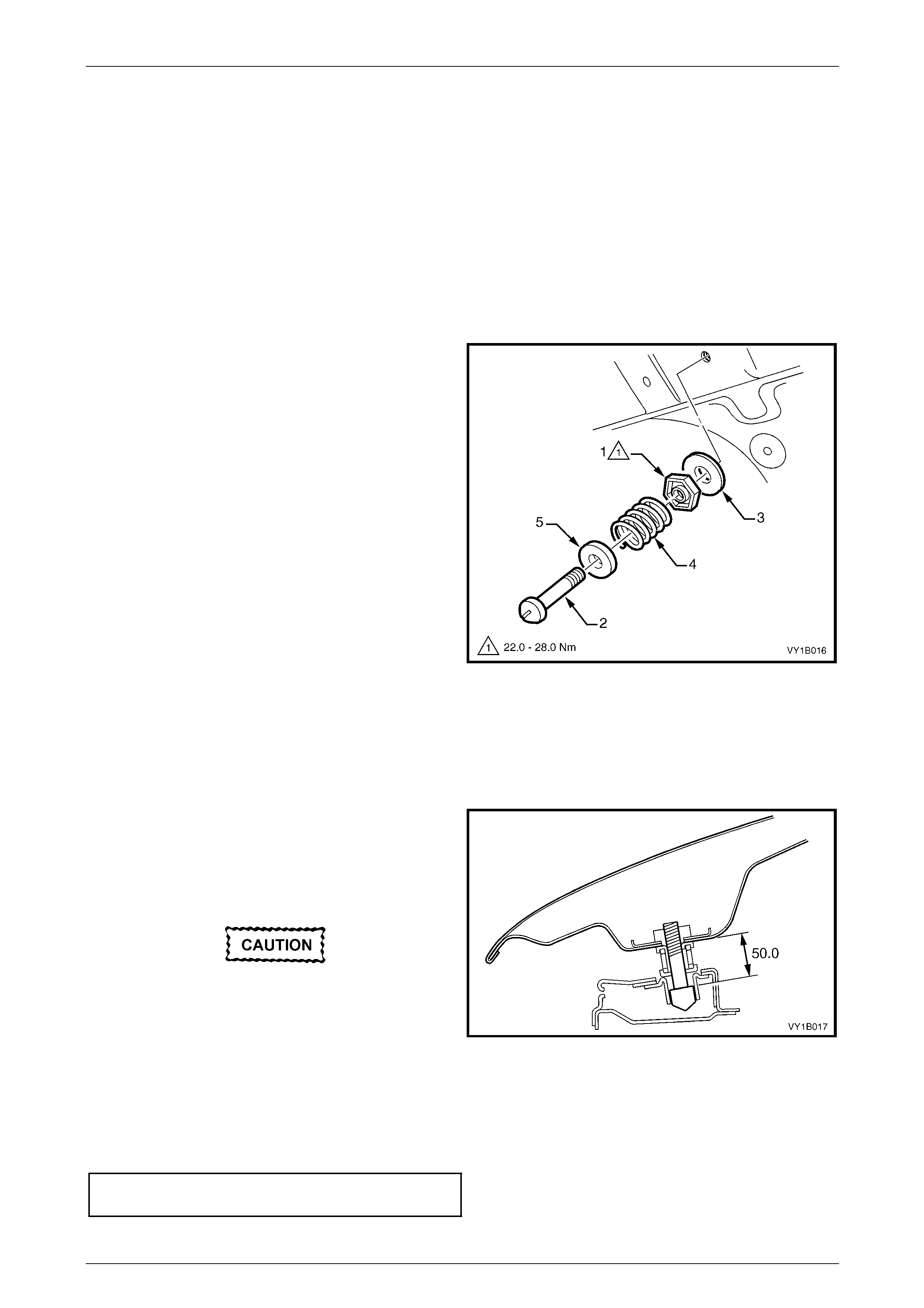

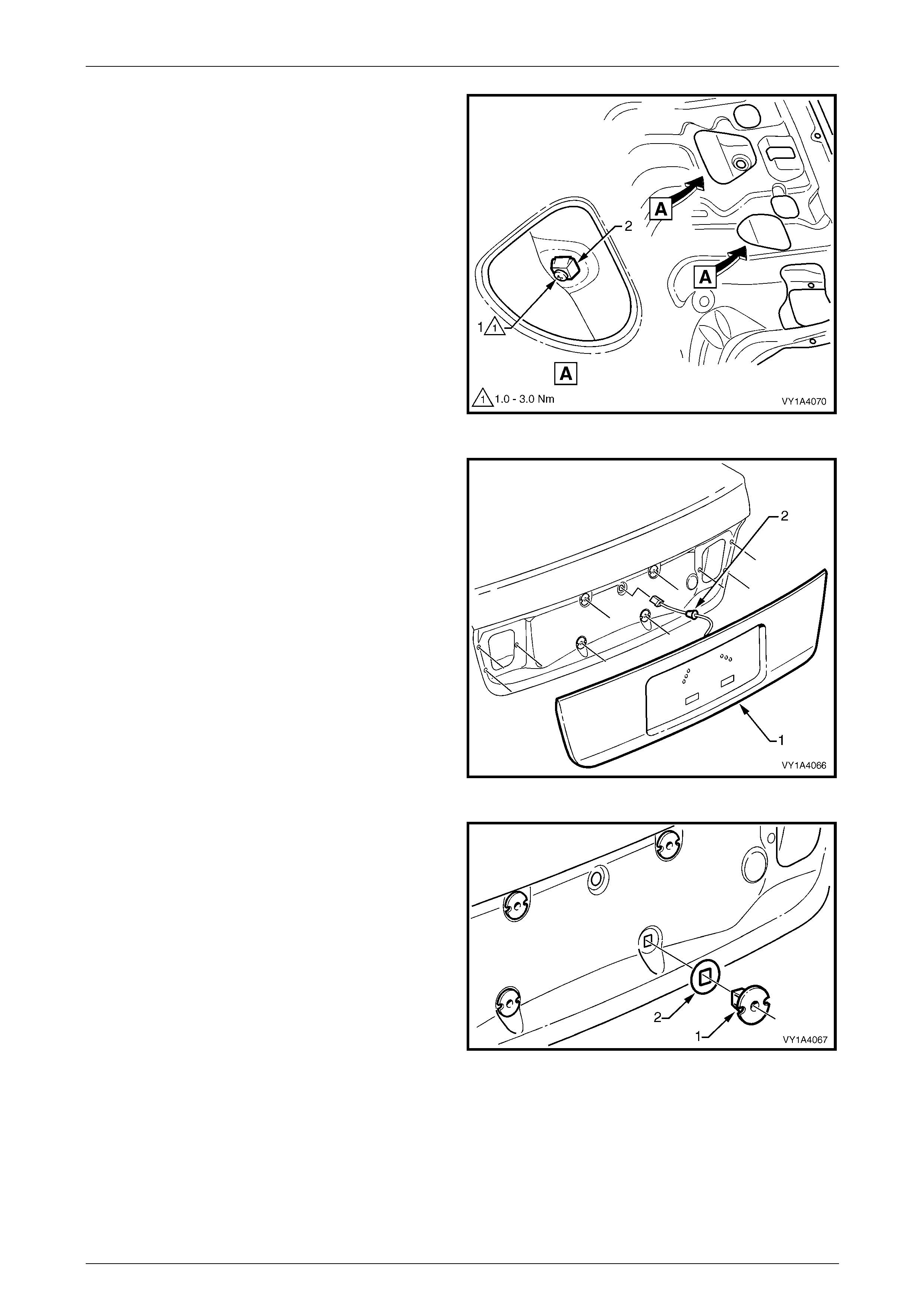

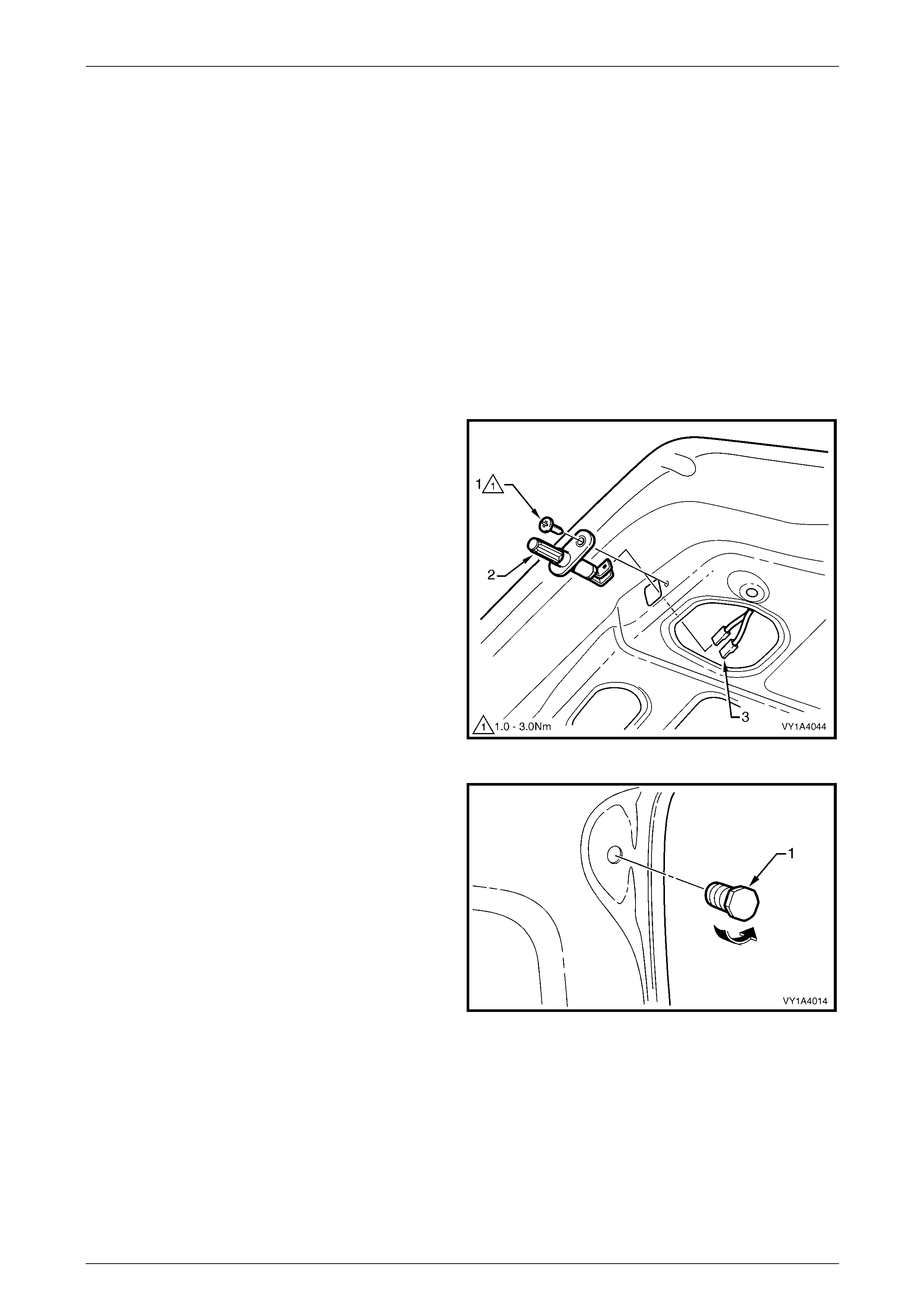

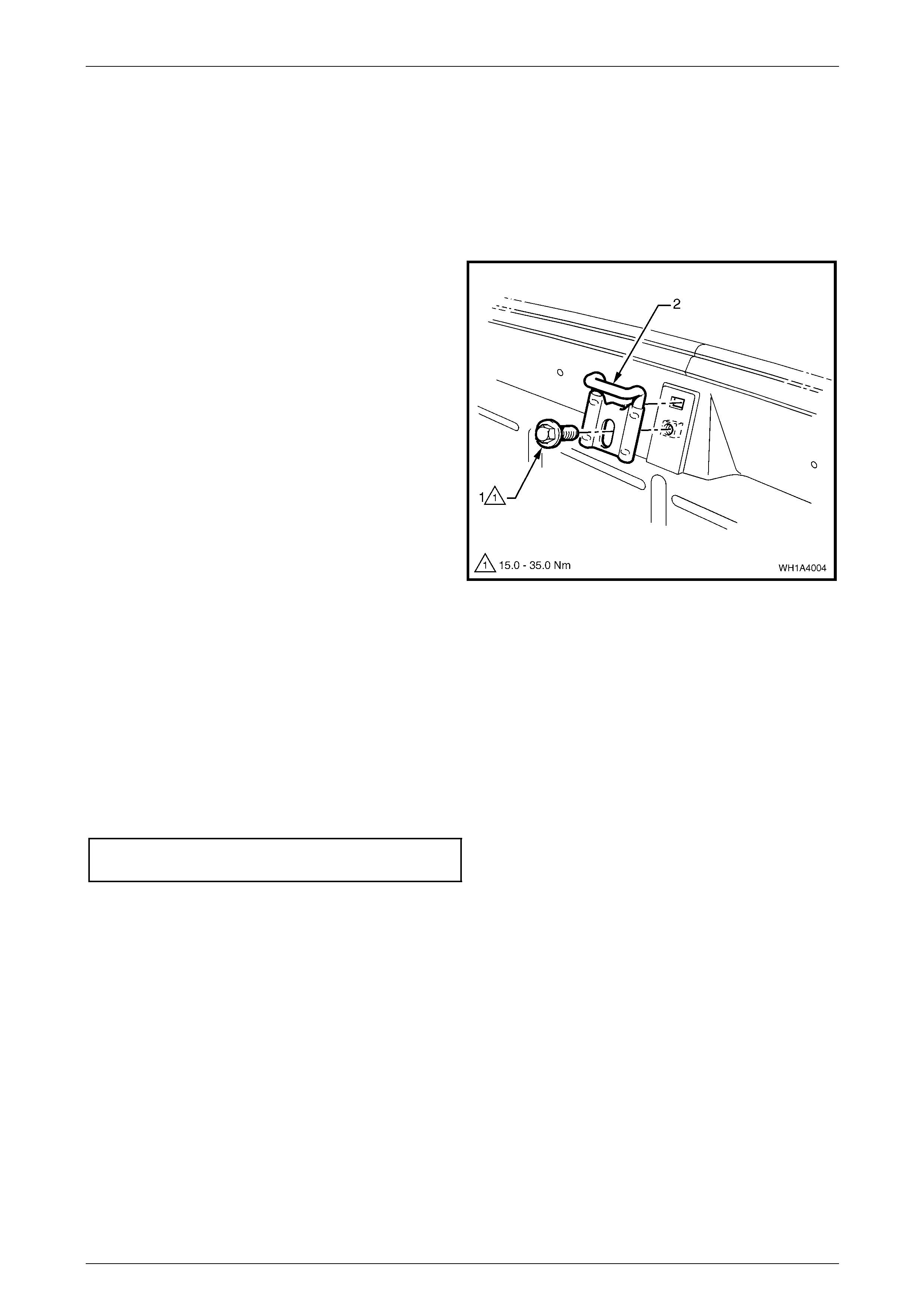

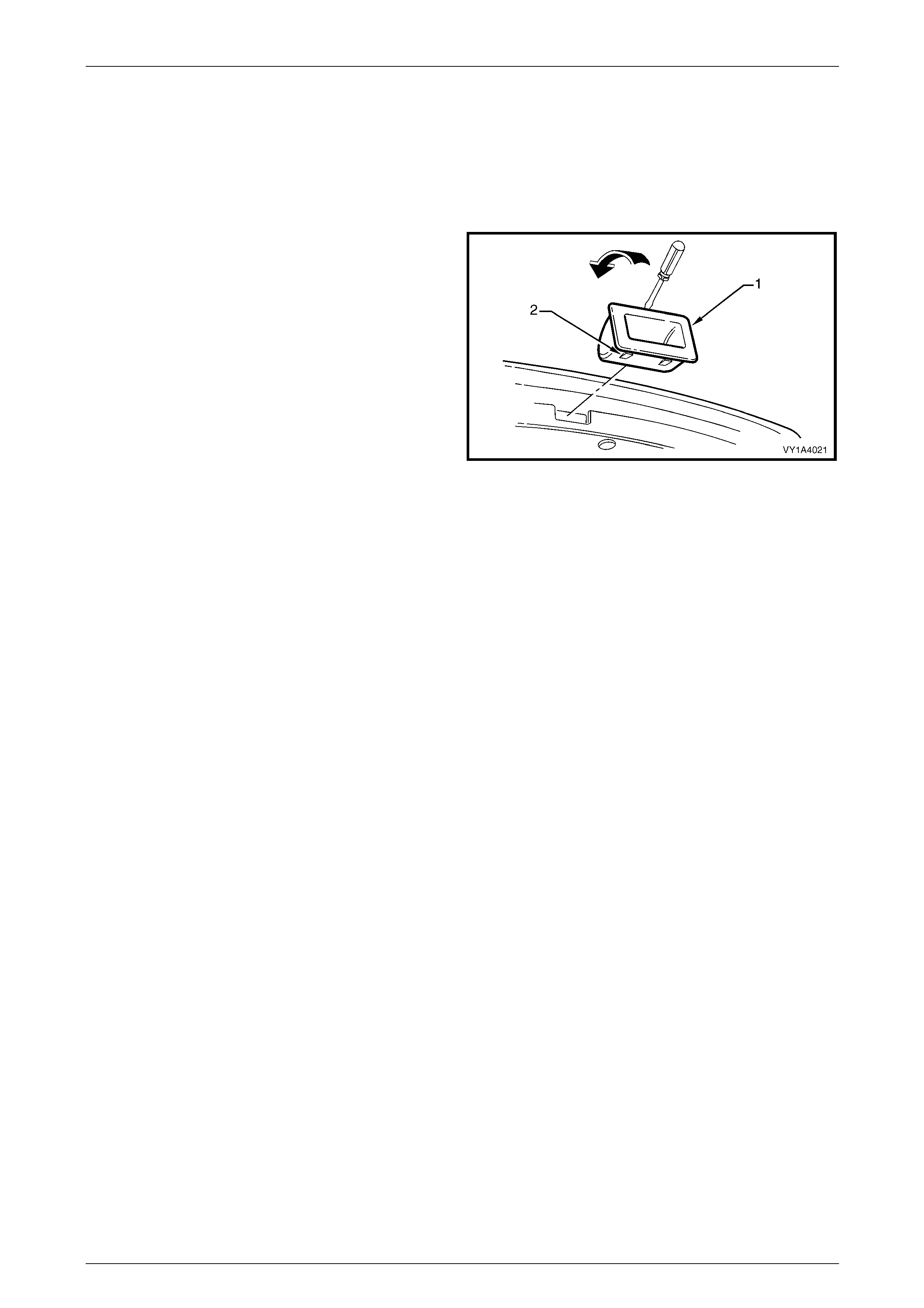

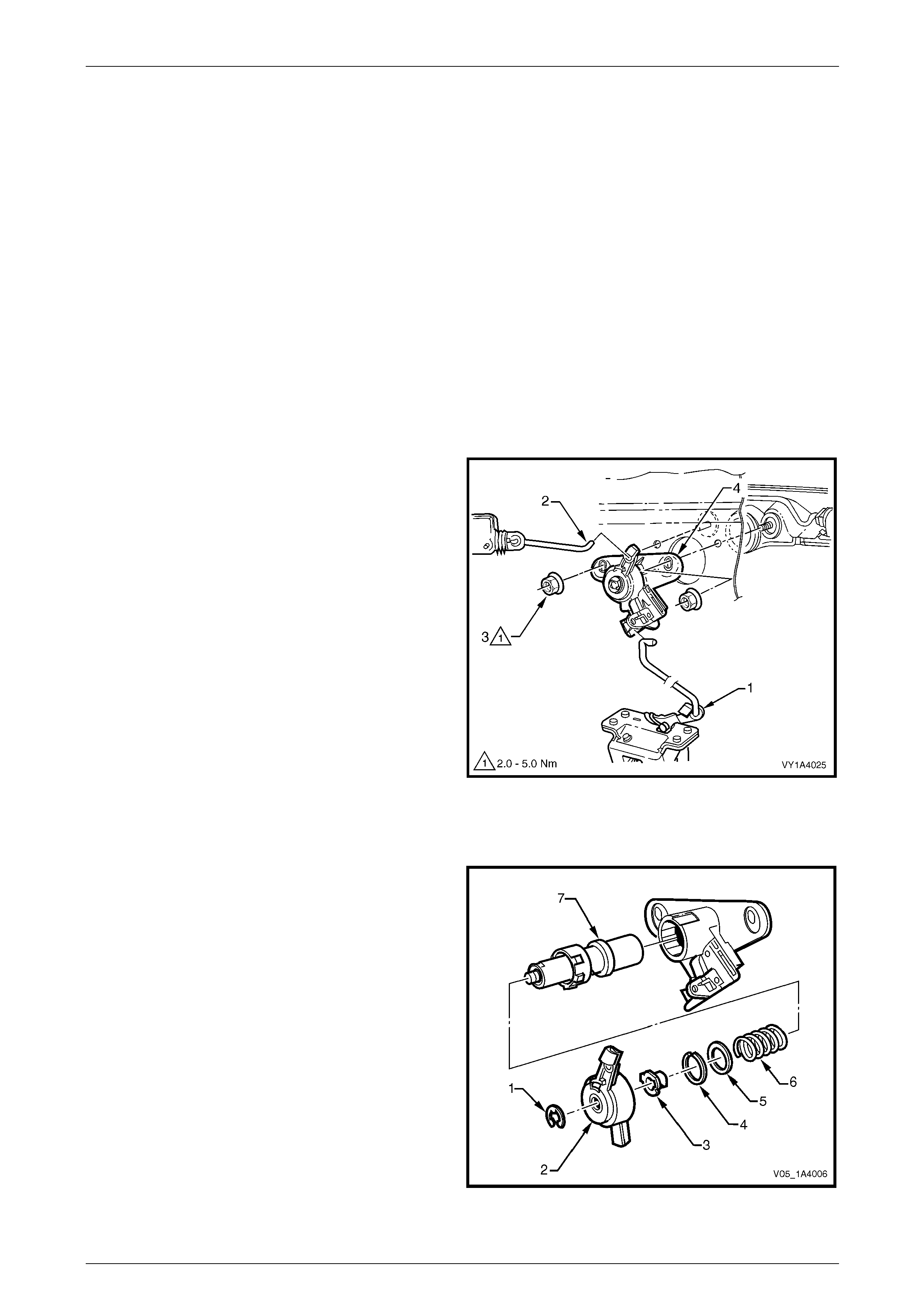

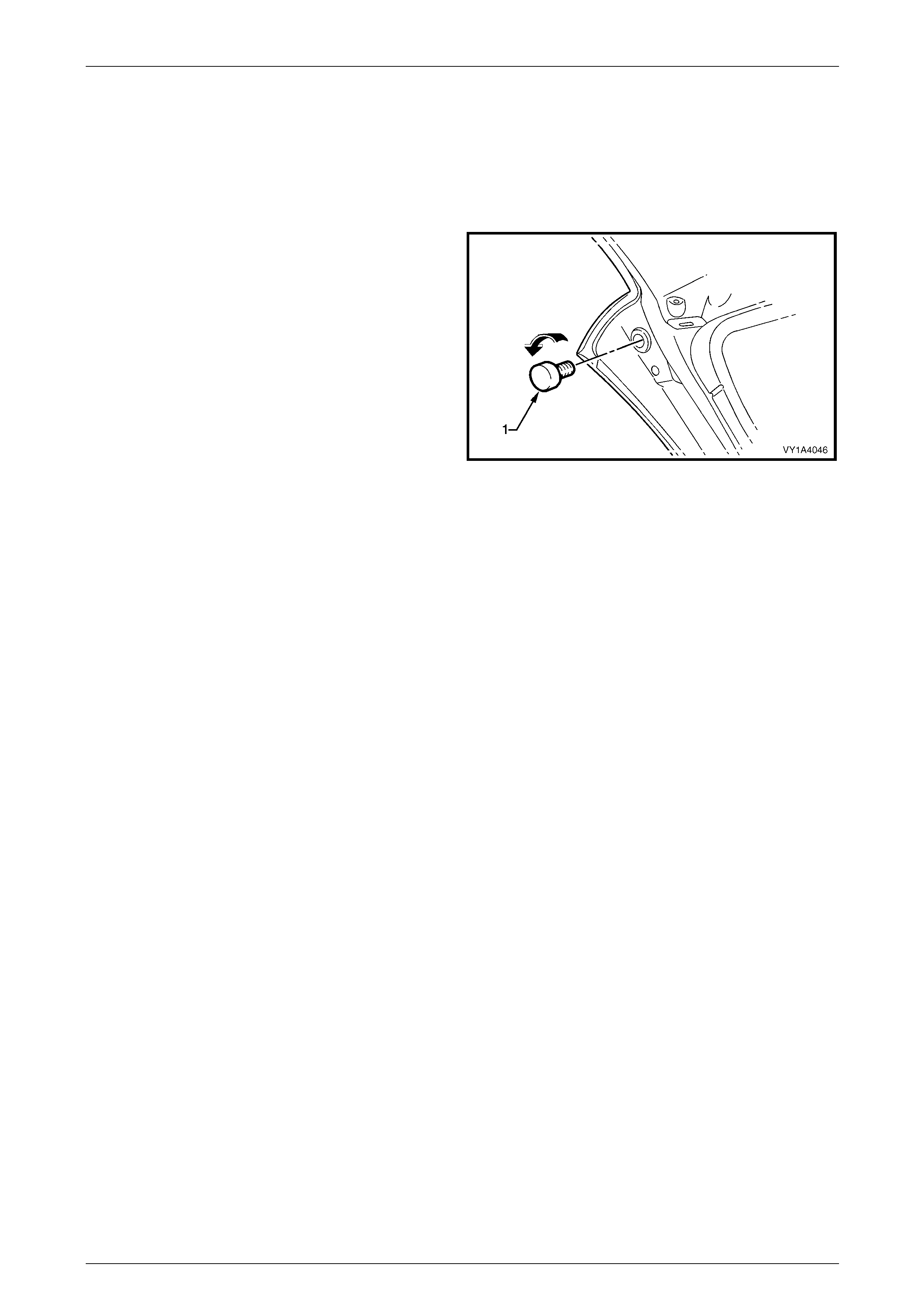

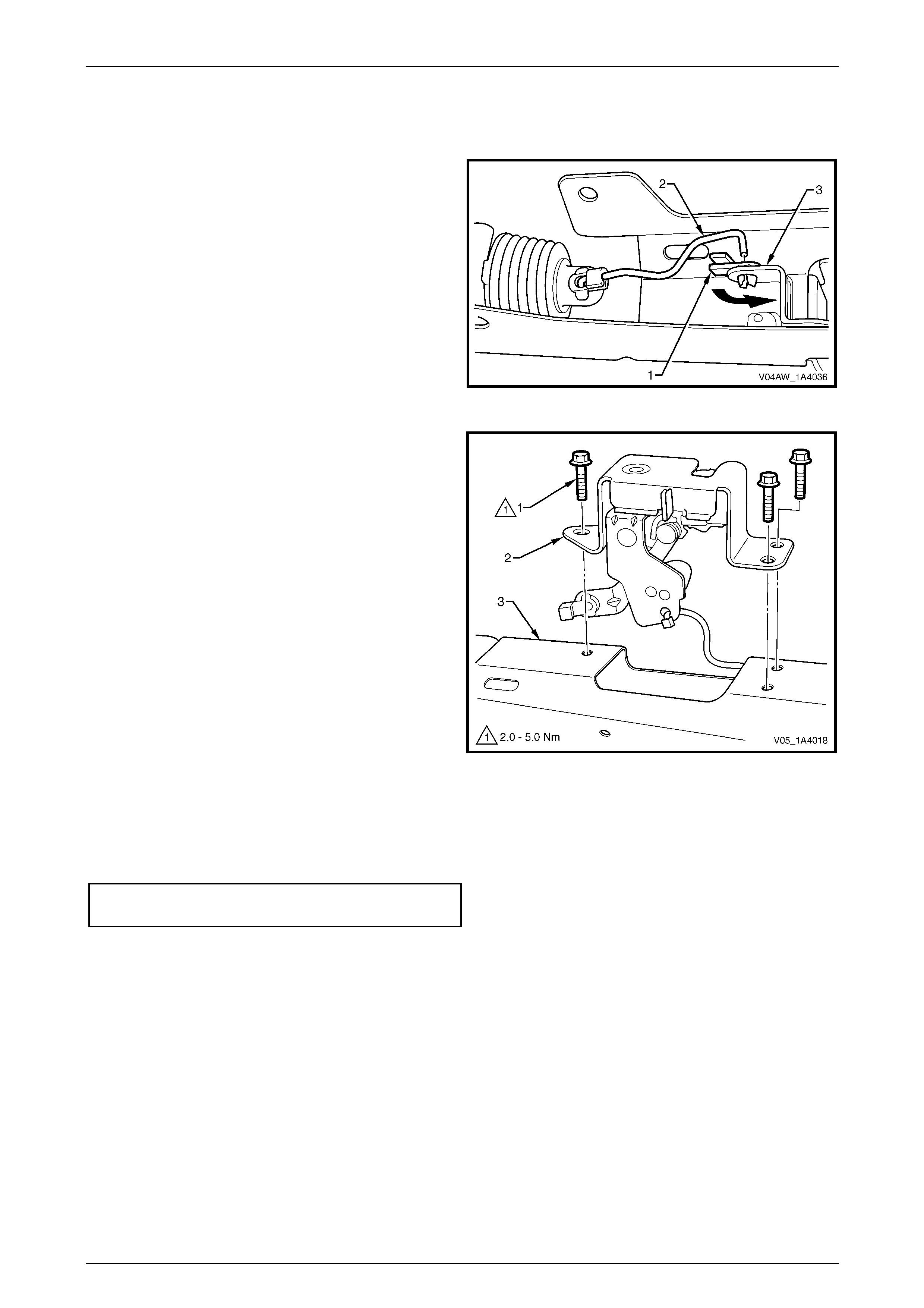

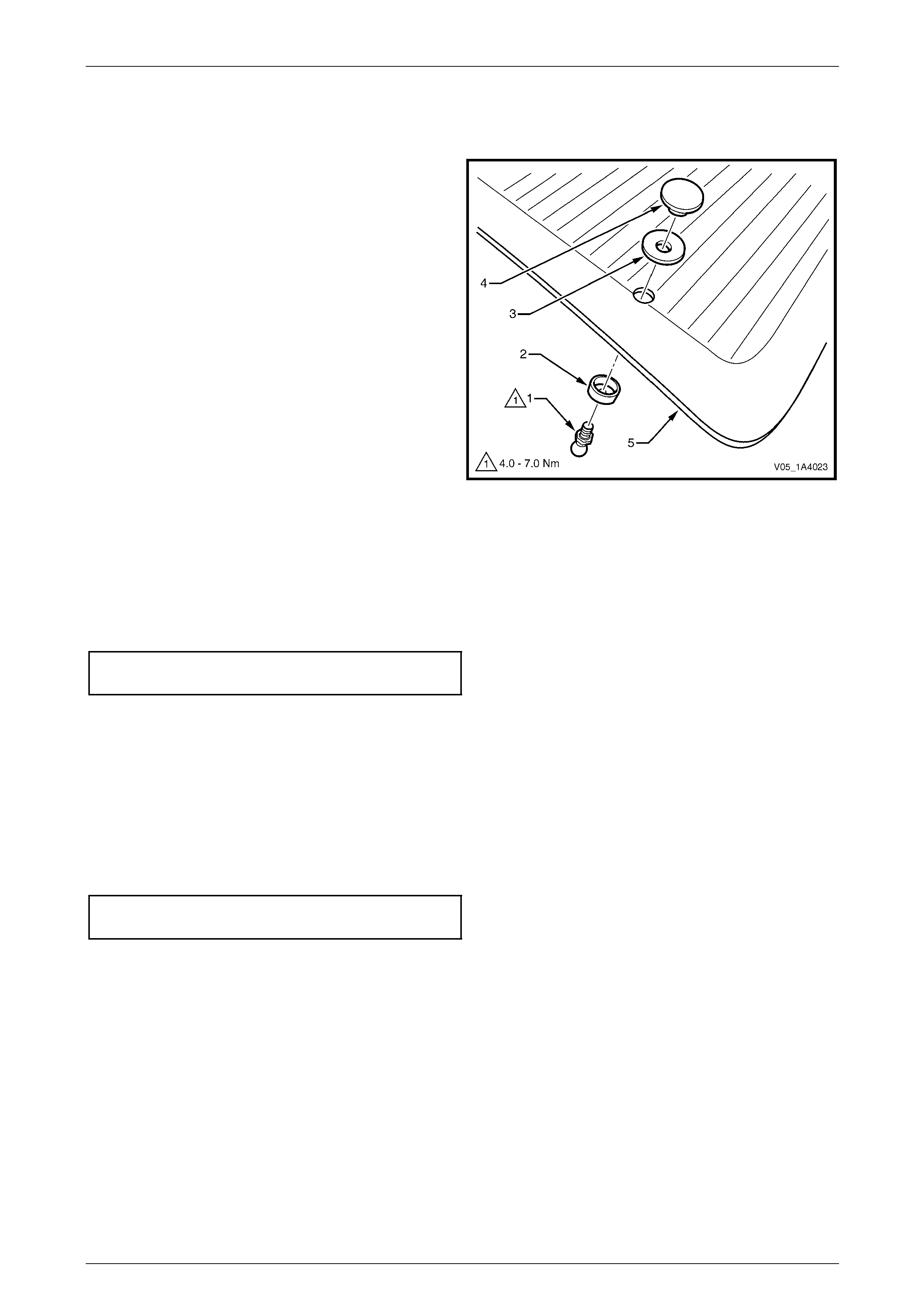

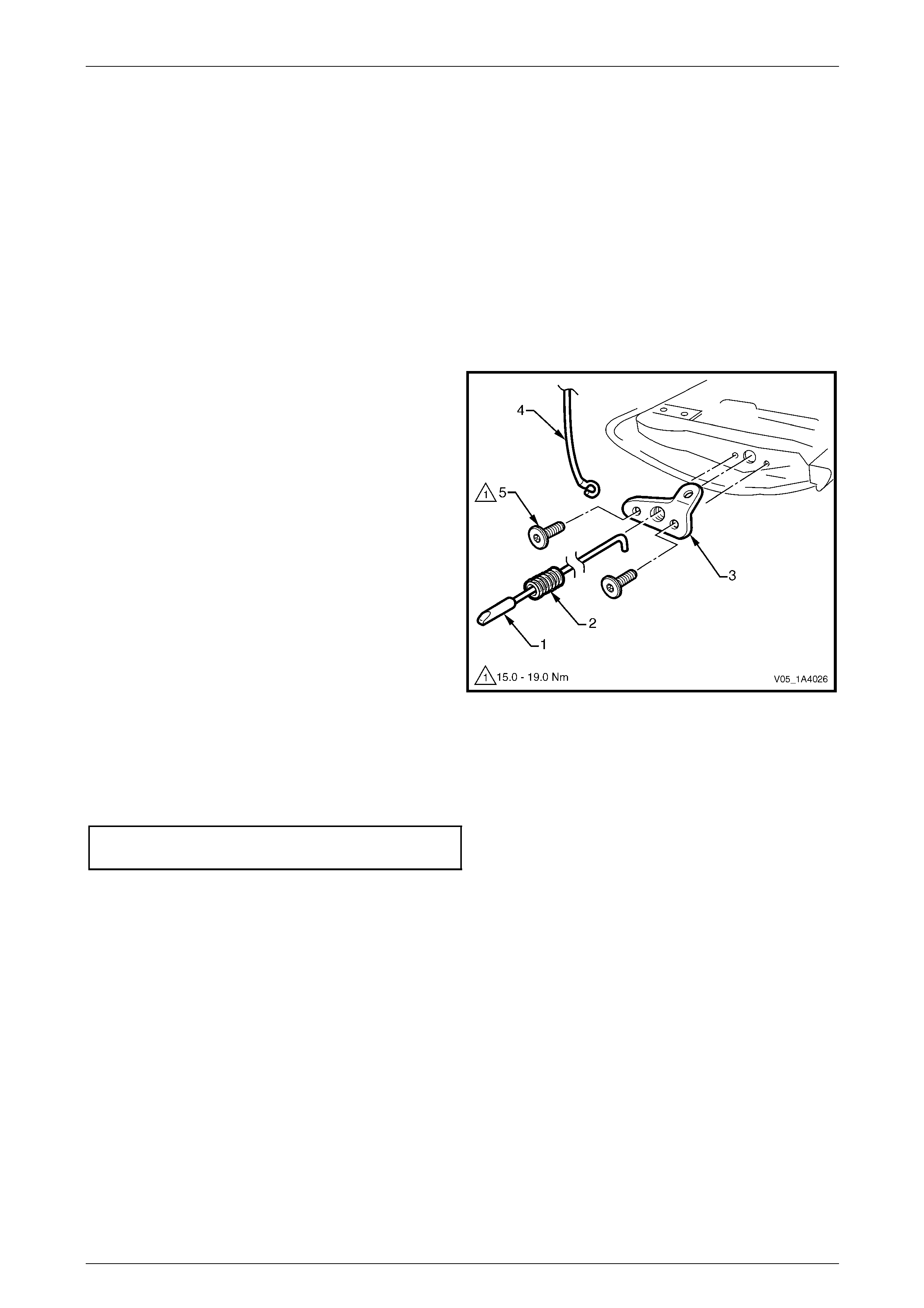

2 Loosen the hood primary latch striker nut (1).

3 Using a flat-bladed screwdrive r , unscrew the hood

primary latch striker bolt (2) and remove the assembly.

4 If required, remove the washer (3), nut, hood pop-up

spring (4) and hood pop-up s prin g retain er (5).

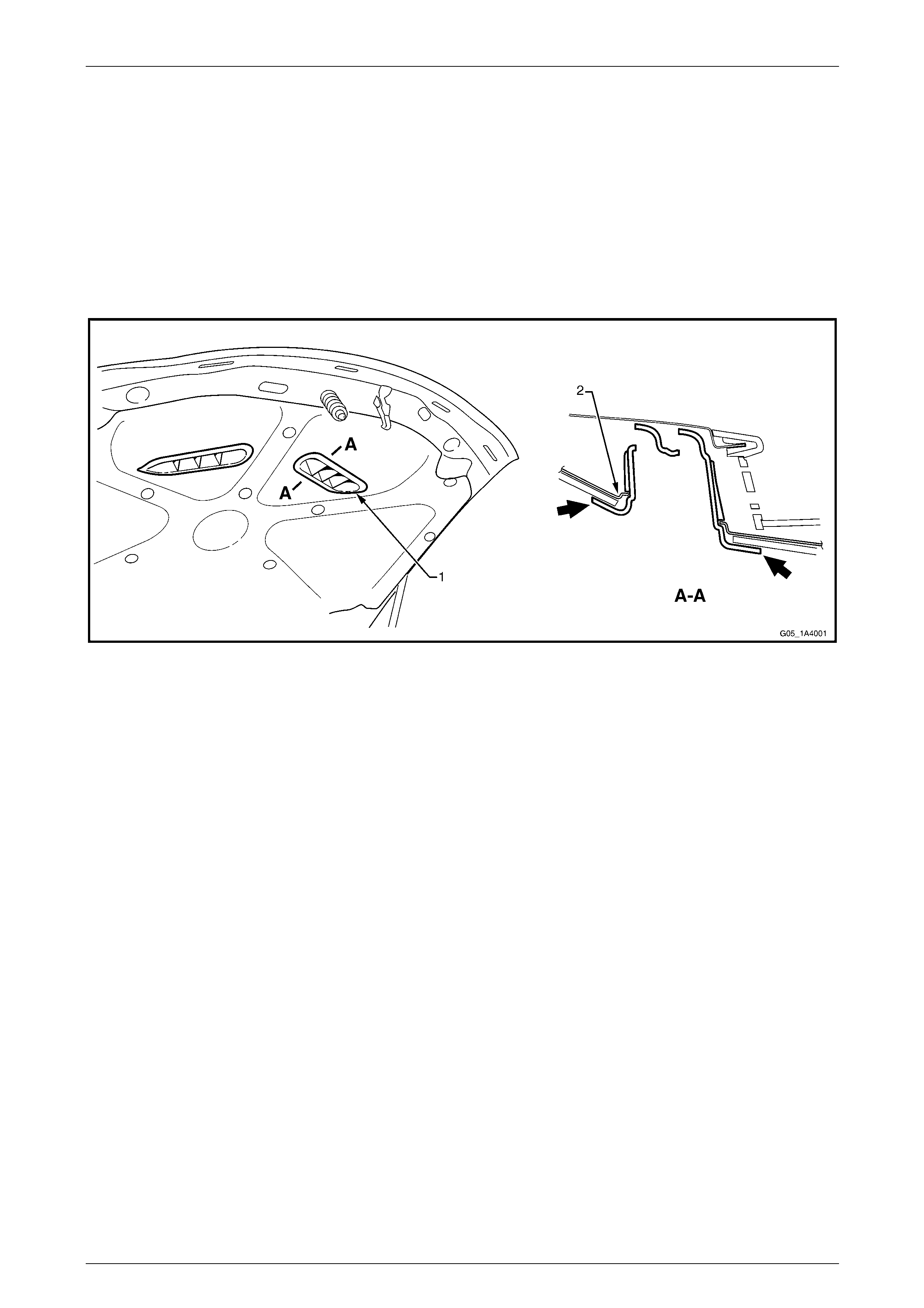

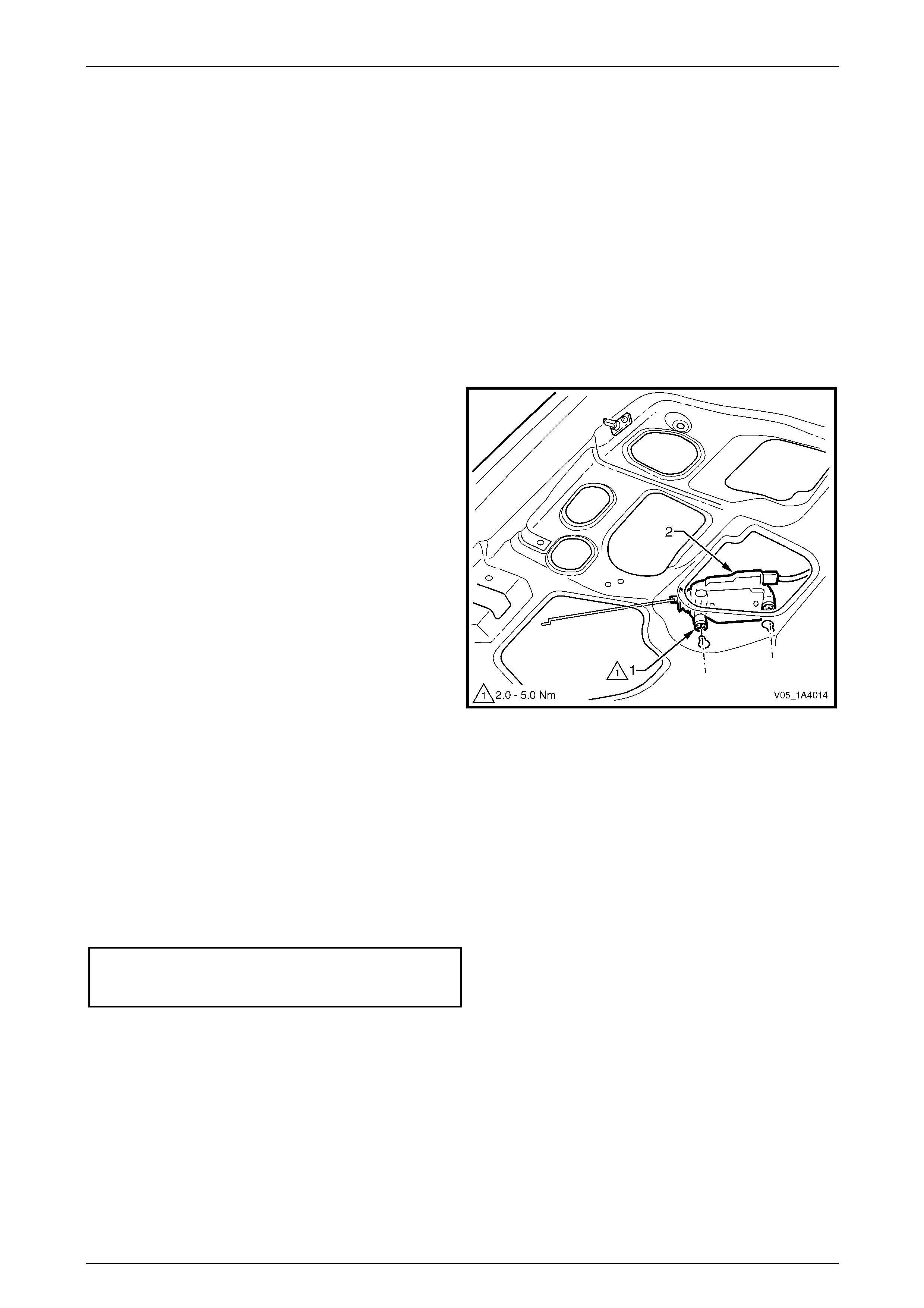

Figure 1A4 – 1

Reinstall

Reinstallation of the hood primary latch striker assembly is the reverse of the removal procedure, noting the following:

1 Reassemble the hood primary latch striker assembly components as required.

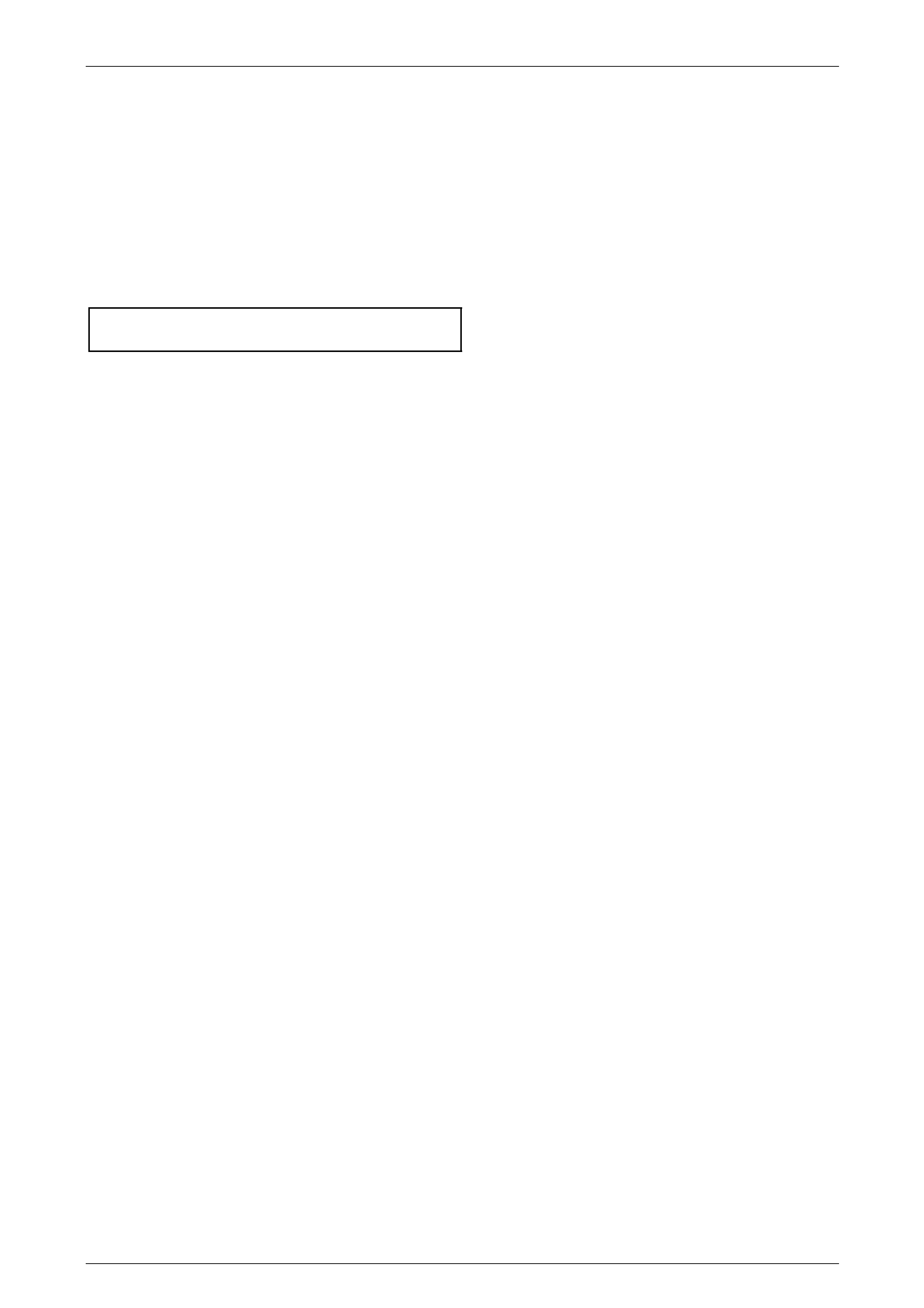

2 Install the hood primary latch striker assemb ly to the

hood and tighten the hood primary latch striker bolt to

achieve a nominal length of 50 mm.

3 Apply a lubricant (NLGI No. 1 lithium grease or

equivalent) to the end of the striker bolt.

Do not push the hood closed as damage to

the panel surface may occur. If it does not

close on the first attempt, try again from a

slightly greater height.

Figure 1A4 – 2

4 Close the hood by dropping it from a height of about 300 mm.

5 If required, adjust the usable length of the striker bolt, refer to Adjust in this Section.

6 Tighten the hood primary latch striker nut to the correct torque specification.

Hood primary latch striker nut

torque specification.................................22.0 – 28.0 Nm

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–9

Page 1A4–9

Adjust

1 Check the difference in height between the front of the hood and the fenders, refer to F igure 1A4 – 1 7.

2 To adjust the usable length of the hood primary latch striker bolt:

a Open the hood.

b Loosen and hold the hood primar y latch striker nut while rotating the hood primary latch striker bolt with a flat-

bladed screwdriver.

c If required, set the hood adjust bumper to align the hood height, refer to 2.8 Hood and Hinge Assemblies.

3 Tighten the striker nut to the correct torque specification, ref er to Reinstall i n this Section.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–10

Page 1A4–10

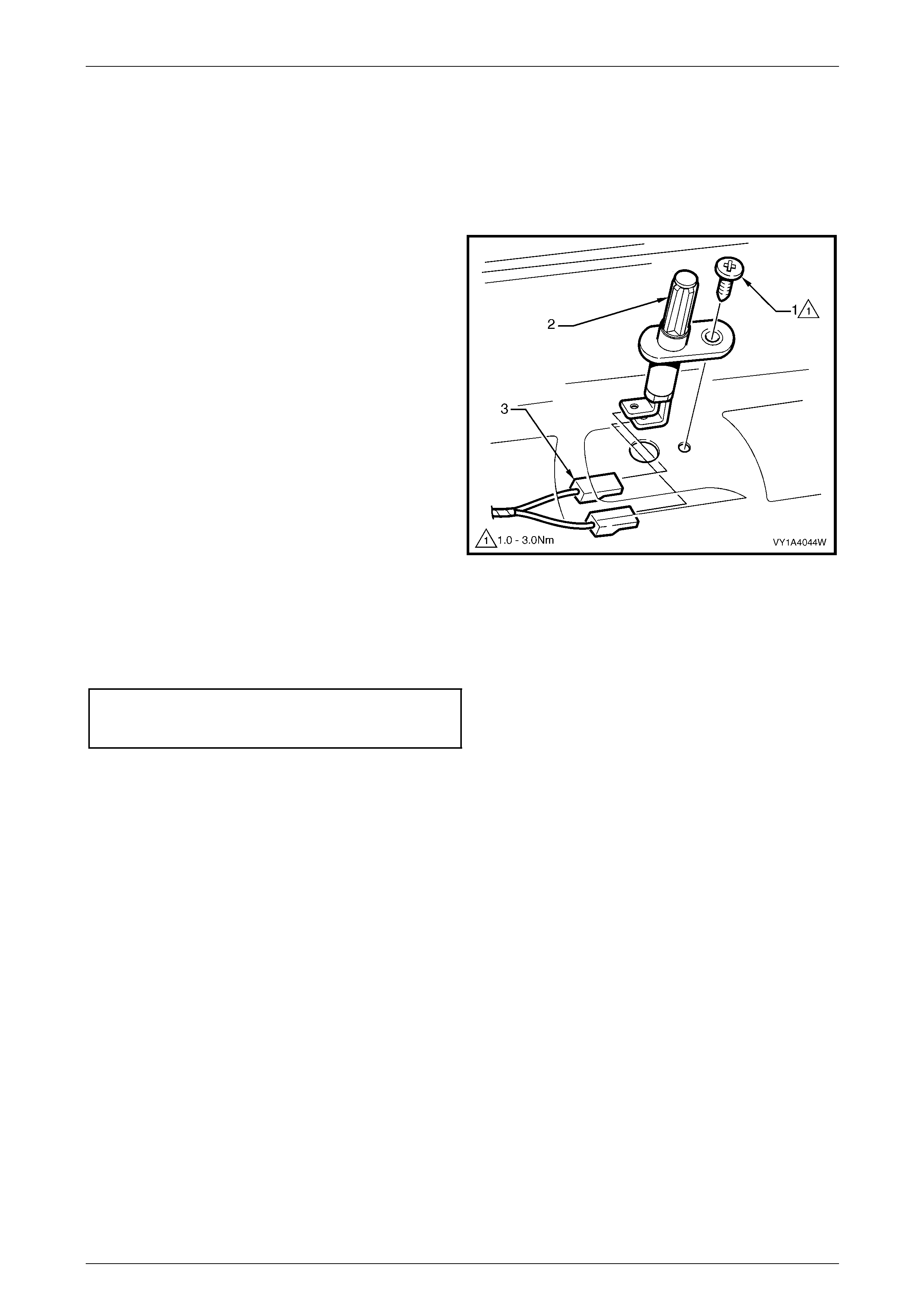

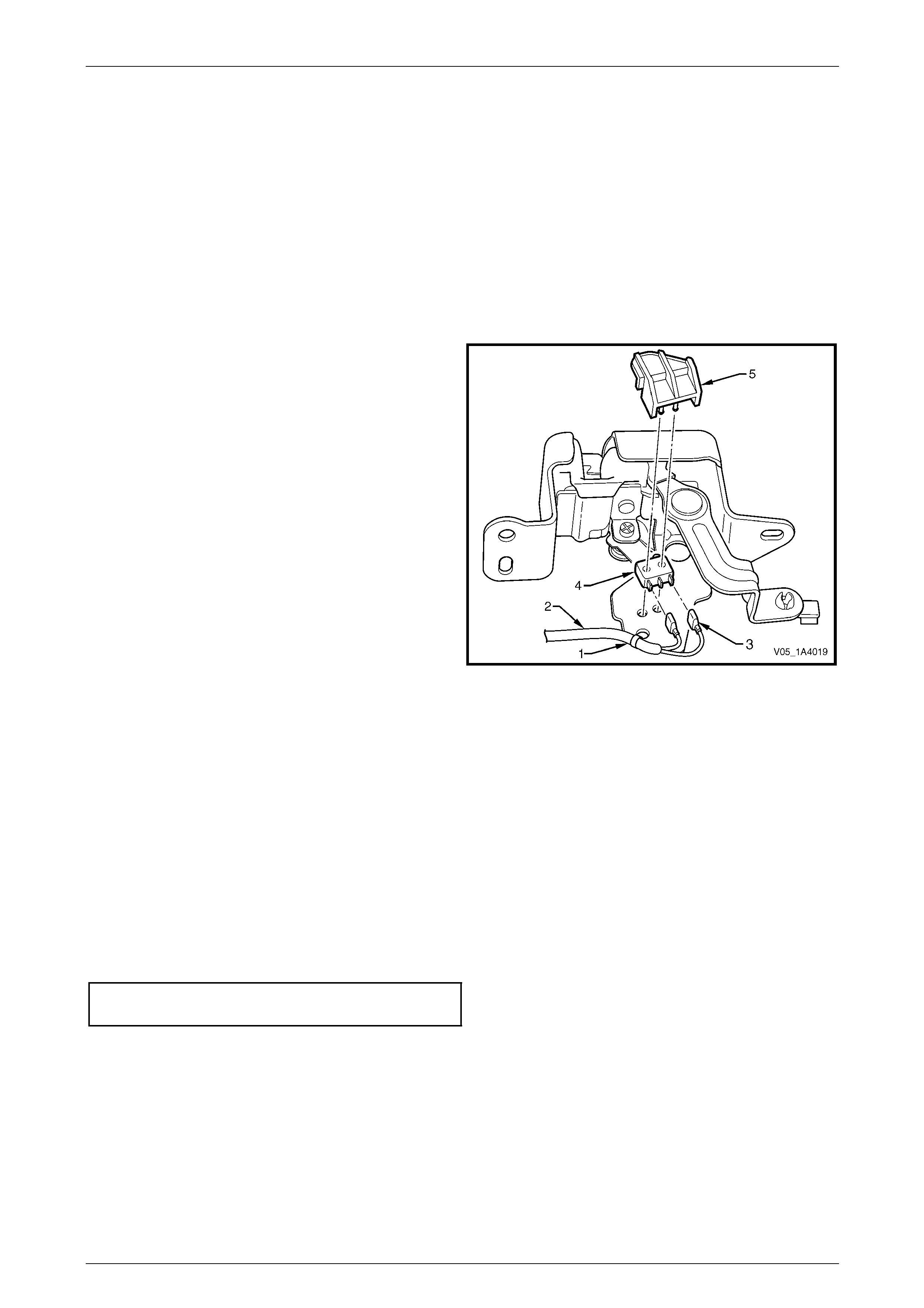

2.2 Hood Primary Latch Spring

LT Section No. — 12–050

Remove

1 Raise the hood.

2 Remove the radiator upper shroud, refer to Section 6B1 Engine Cooling – V6 or

Section 6B3 Engine Cooling – GEN III V8.

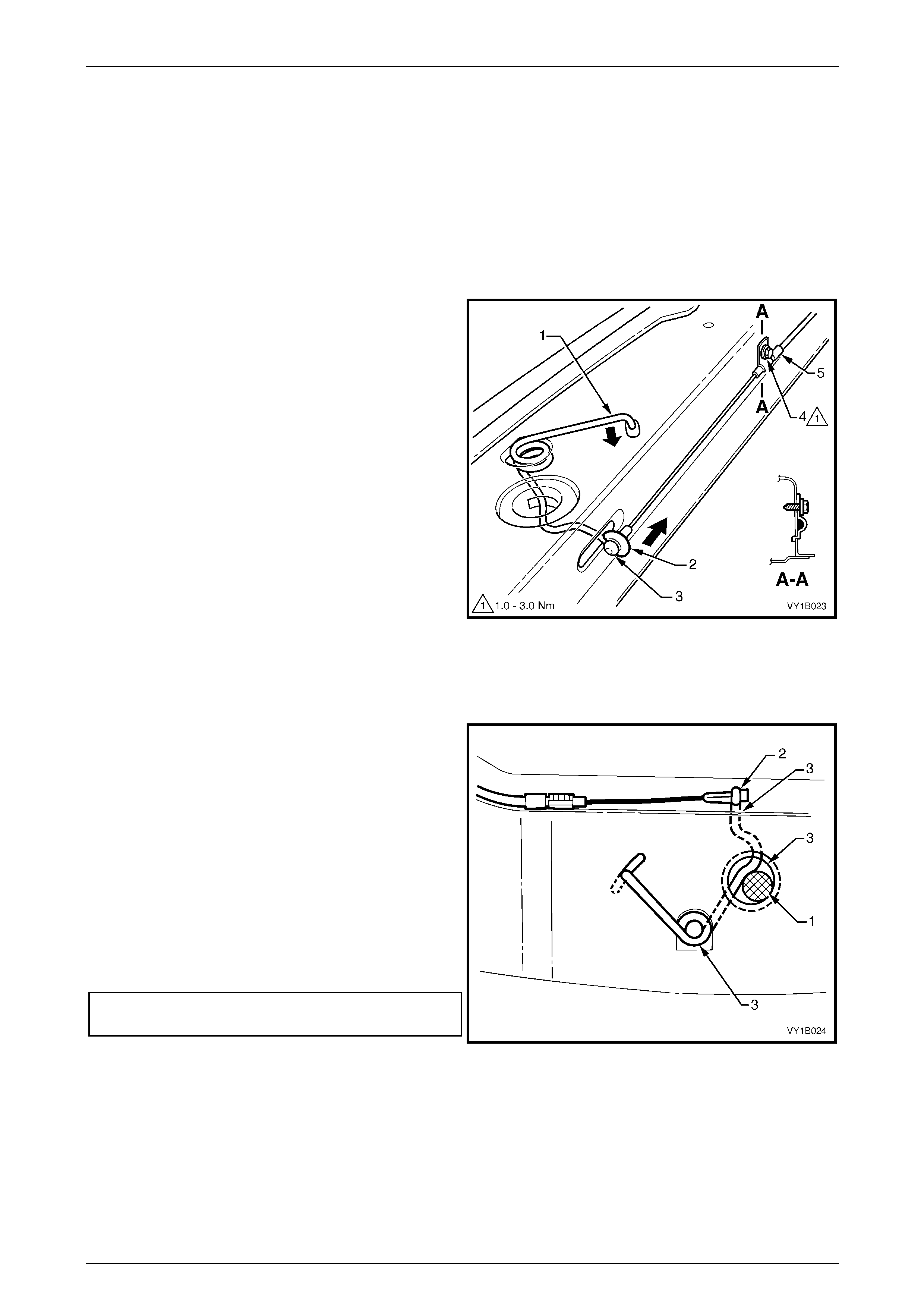

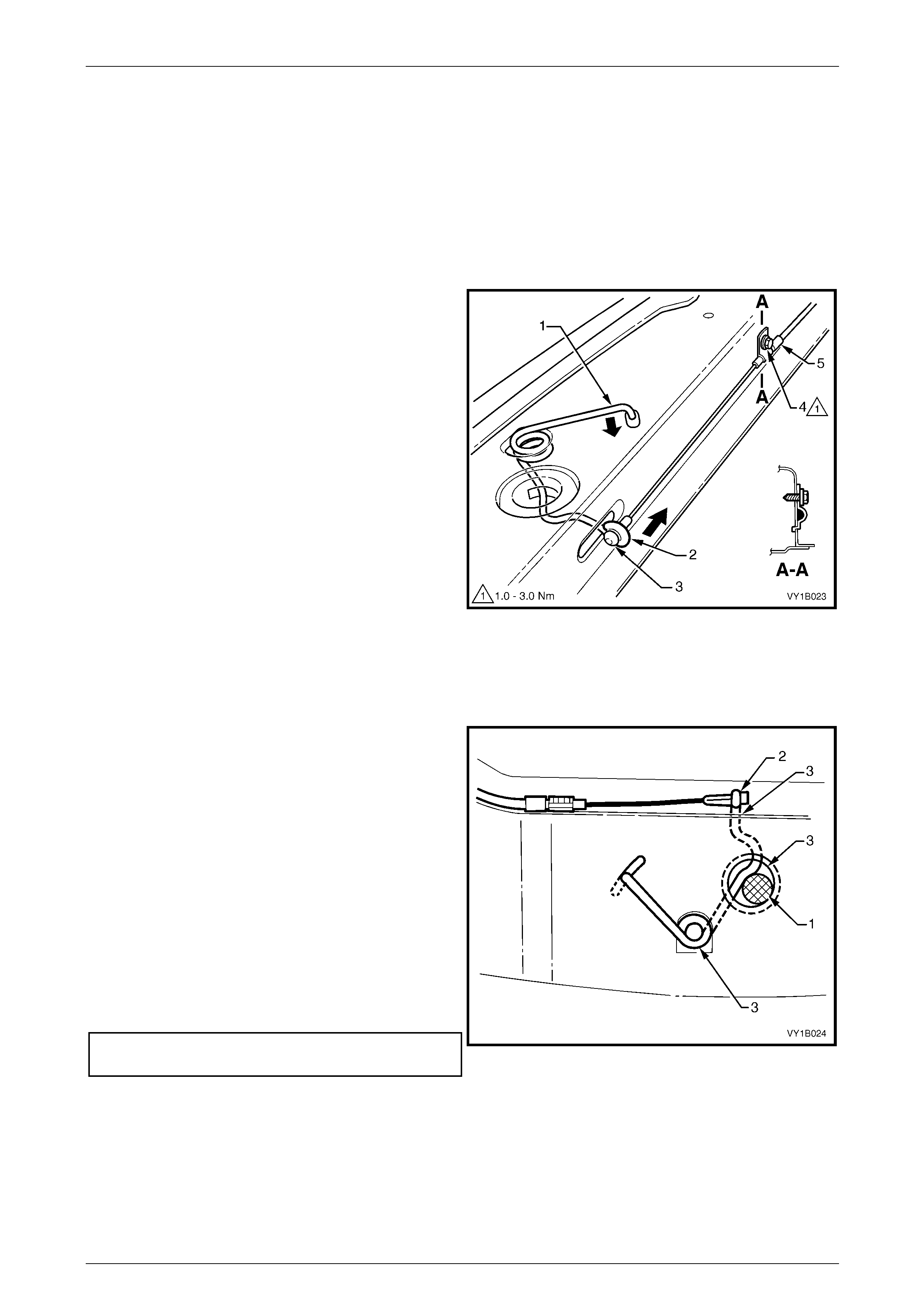

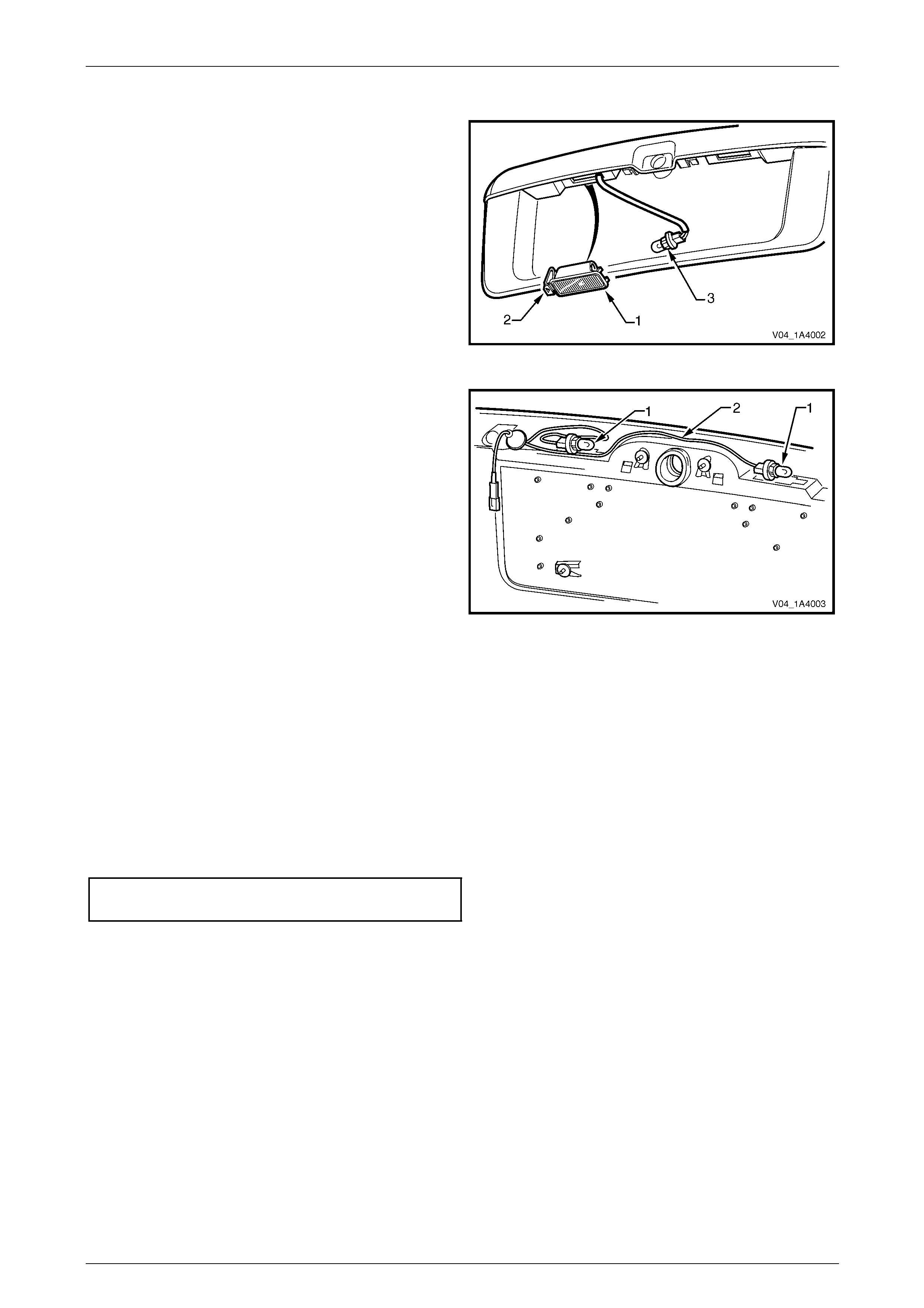

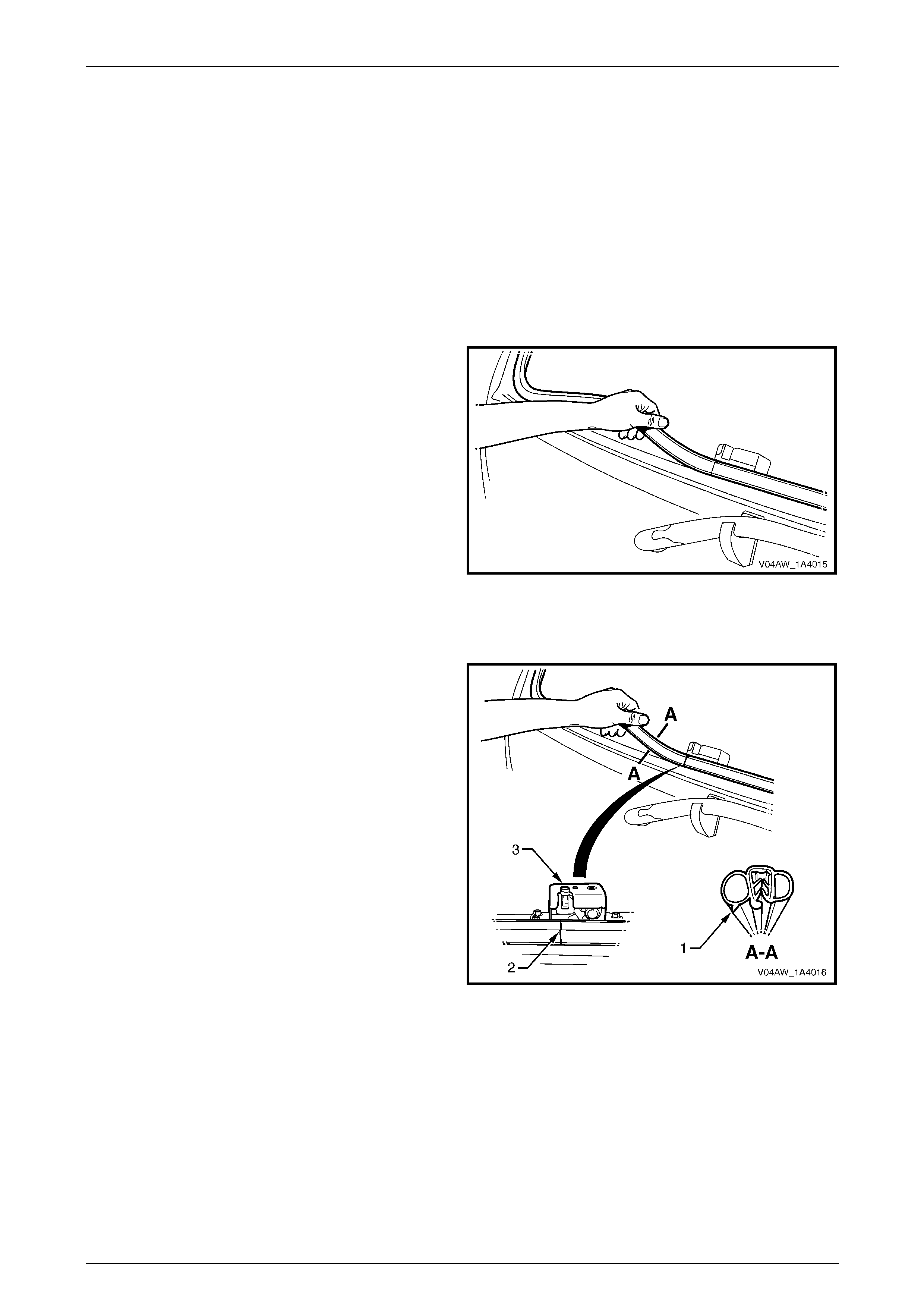

3 Using a pair of pliers, grasp th e hood primary latch

spring at point (1) and carefully dis en gage it from the

front panel in the direction shown.

4 Slide the cable end of the hood primary latch

spring (2) to the open position in the direction shown

to clear the latch hole.

5 Unhook the hood primary latch release cable

assembly (3) from the latch spring.

6 Grasp the end of the latch spring at point (1), rotate to

vertical and manipulate the section of the spri ng in the

front panel out through the spring co il hole.

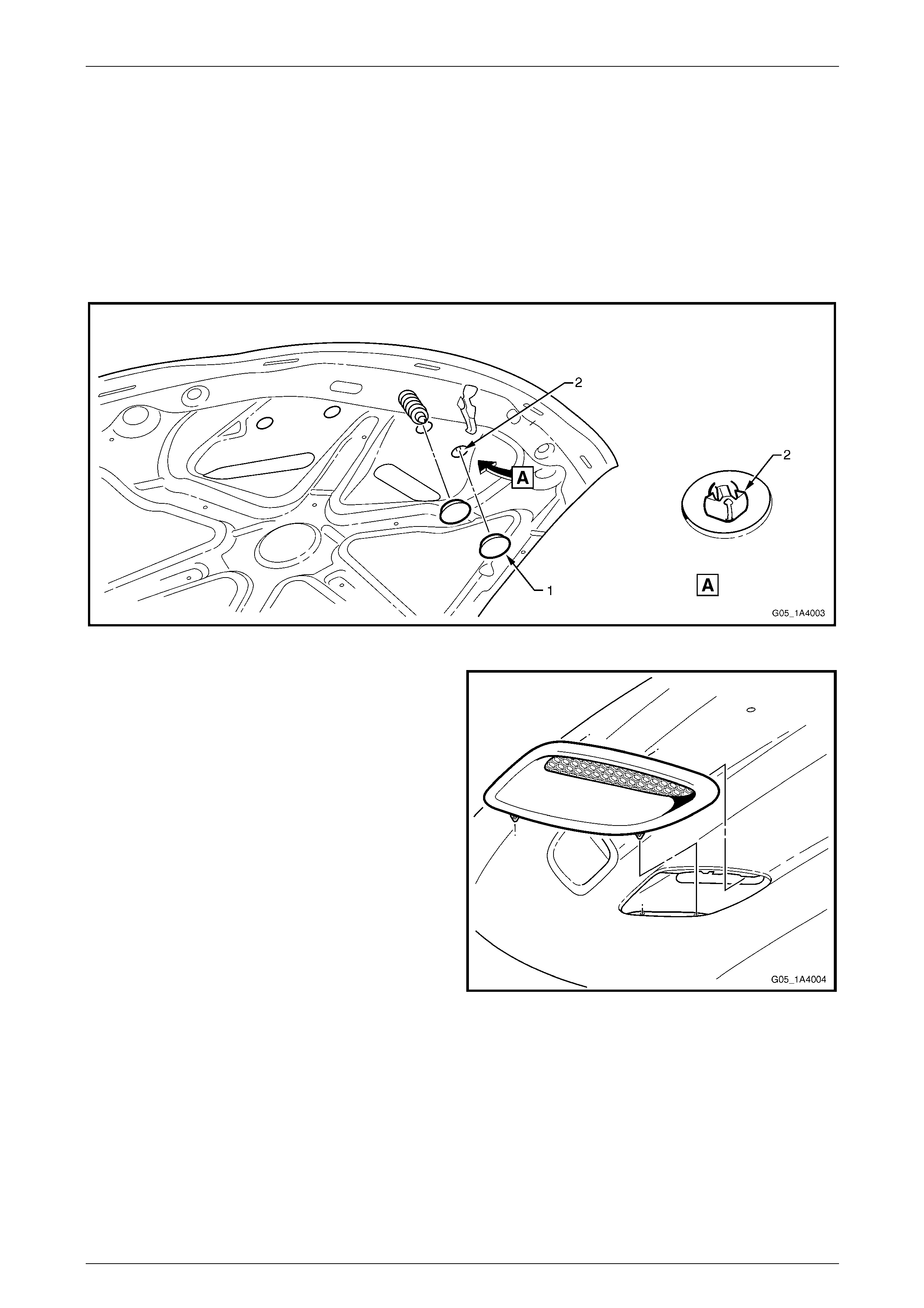

Figure 1A4 – 3

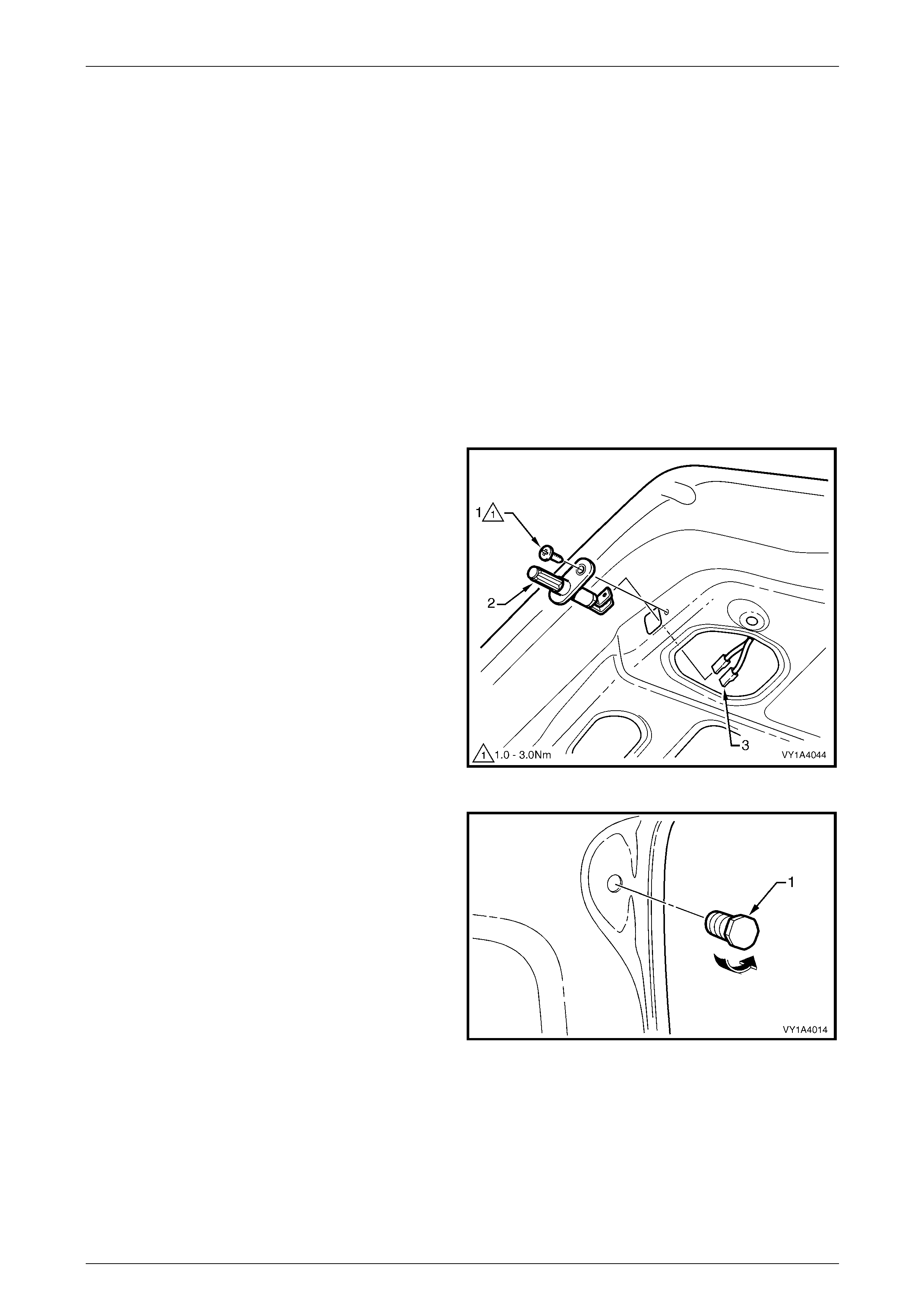

Reinstall

Reinstallation of the hood primary latch spring is the reverse of the removal procedure, noting the follo wing:

1 Check the hood primary latch release cable

adjustment by inserting a 16 mm pin (1) between the

spring and the latch hole and check there is no

clearance between the inner cable ferrule and the

spring (2).

2 If required, loosen the hood primary latch release

cable retainer screw (4), refer to Figure 1A4 – 3, and

adjust the latch release cable.

NOTE

Ensure the outer cable ferrule (5), refer to

Figure 1A4 – 3, is positioned before the retainer.

3 Tighten the retainer screw to the correct torque

specification.

Hood primary latch release cable

retainer screw torque specification..............1.0 – 3.0 Nm

Figure 1A4 – 4

4 Remove the 16 mm pin and check the hood primary latch spring for correct operation.

5 Apply NLGI No. 1 lithium grease or equivalent to the following locations, refer to the three points (3) indicated in

Figure 1A4 – 4:

• spring slot,

• latch hole to a depth of the spring slot, and

• spring coils.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–11

Page 1A4–11

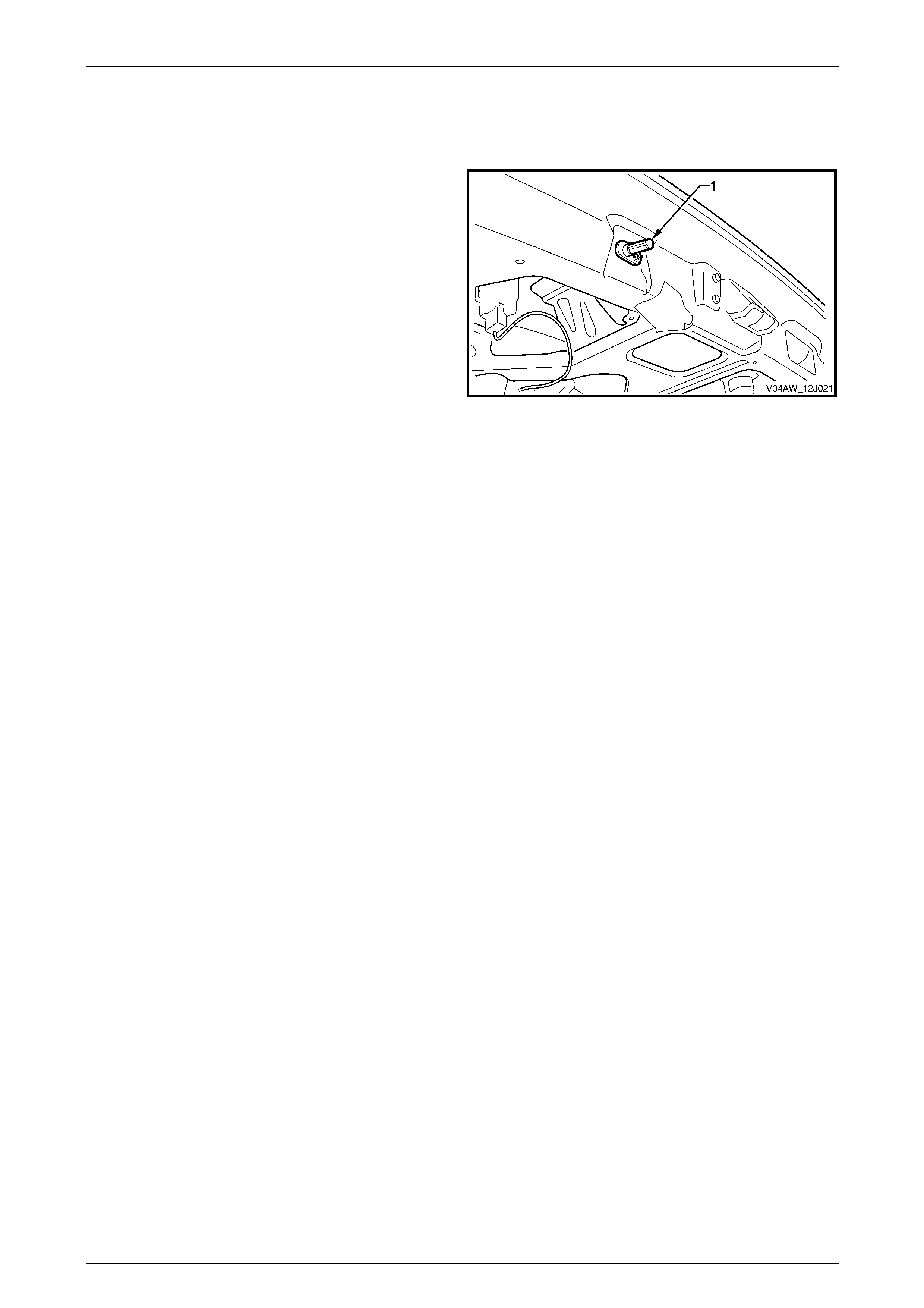

2.3 Hood Primary Latch Release Cable

Assembly

LT Section No. — 12–050

Remove

1 If required:

a Remove the radiator upper shroud, refer to Section 6B1 Engine Cooling – V6 or

Section 6B3 Engine Cooling – GEN III V8.

b Remove the right-hand instrument panel o uter cover, refer to Section 1A3 Instrument Panel and Console.

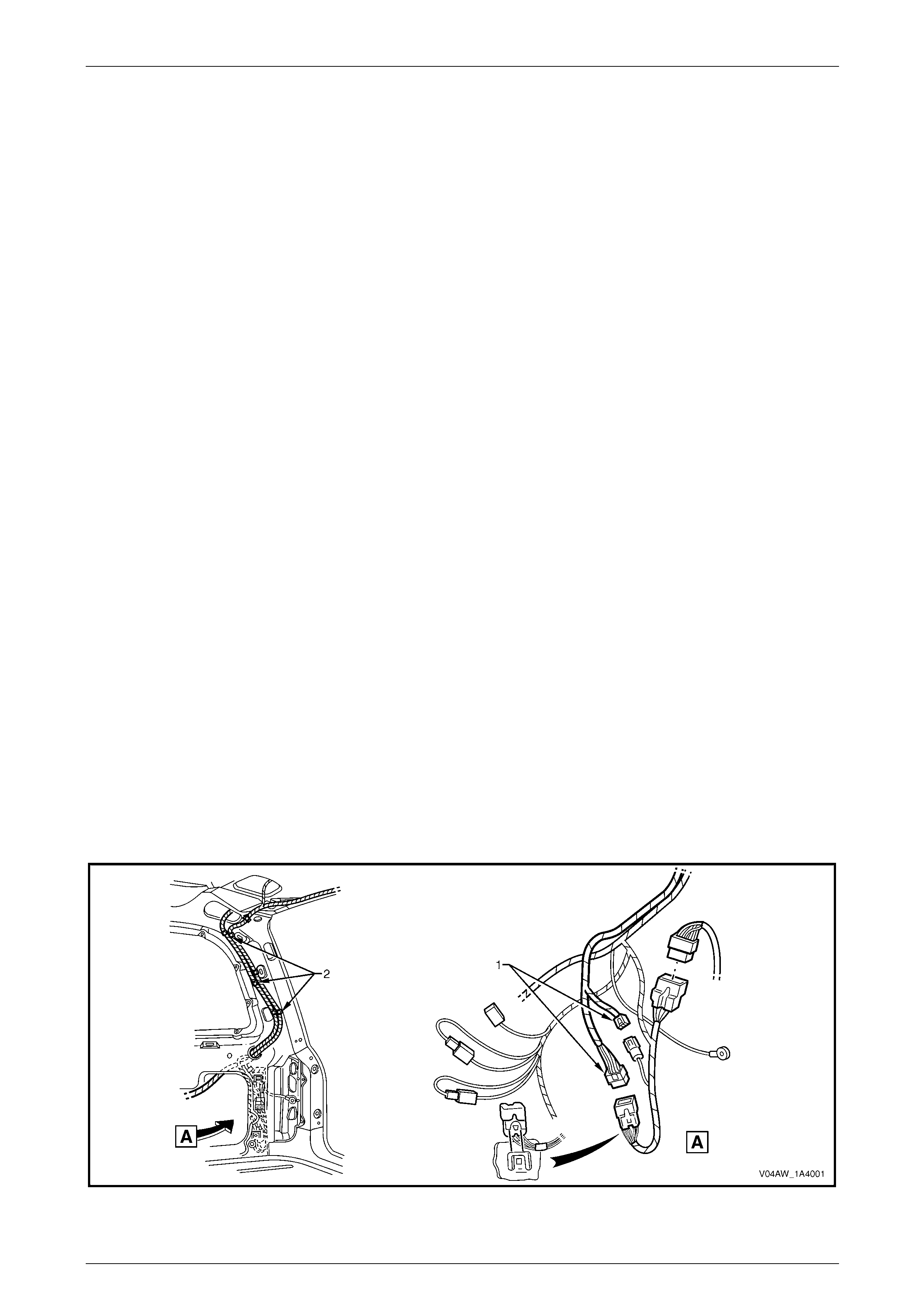

c Detach the wiring harness former from the right-ha nd strut tower,

refer to Section 12O Fuses, Relays and Wiring Harnesses.

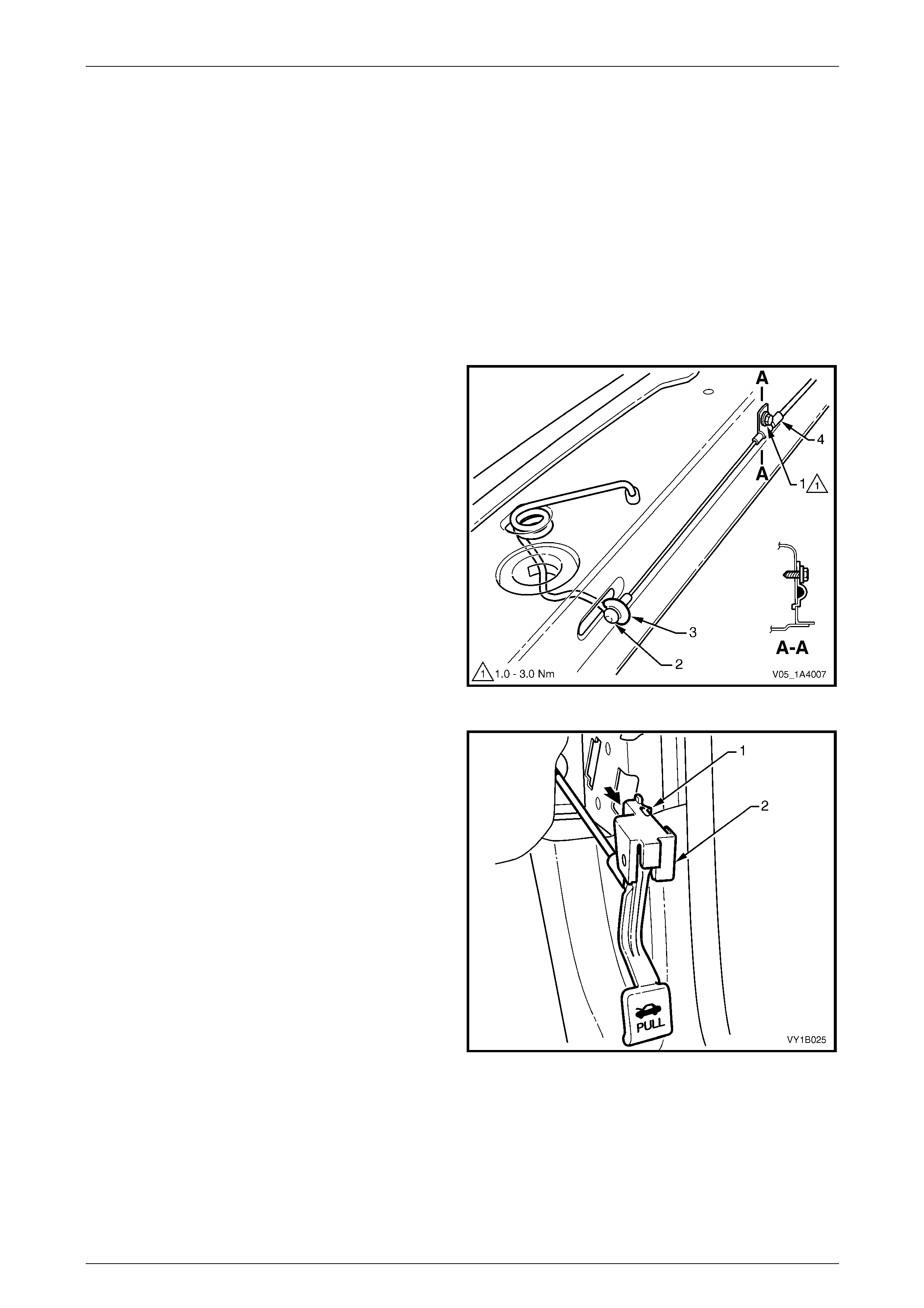

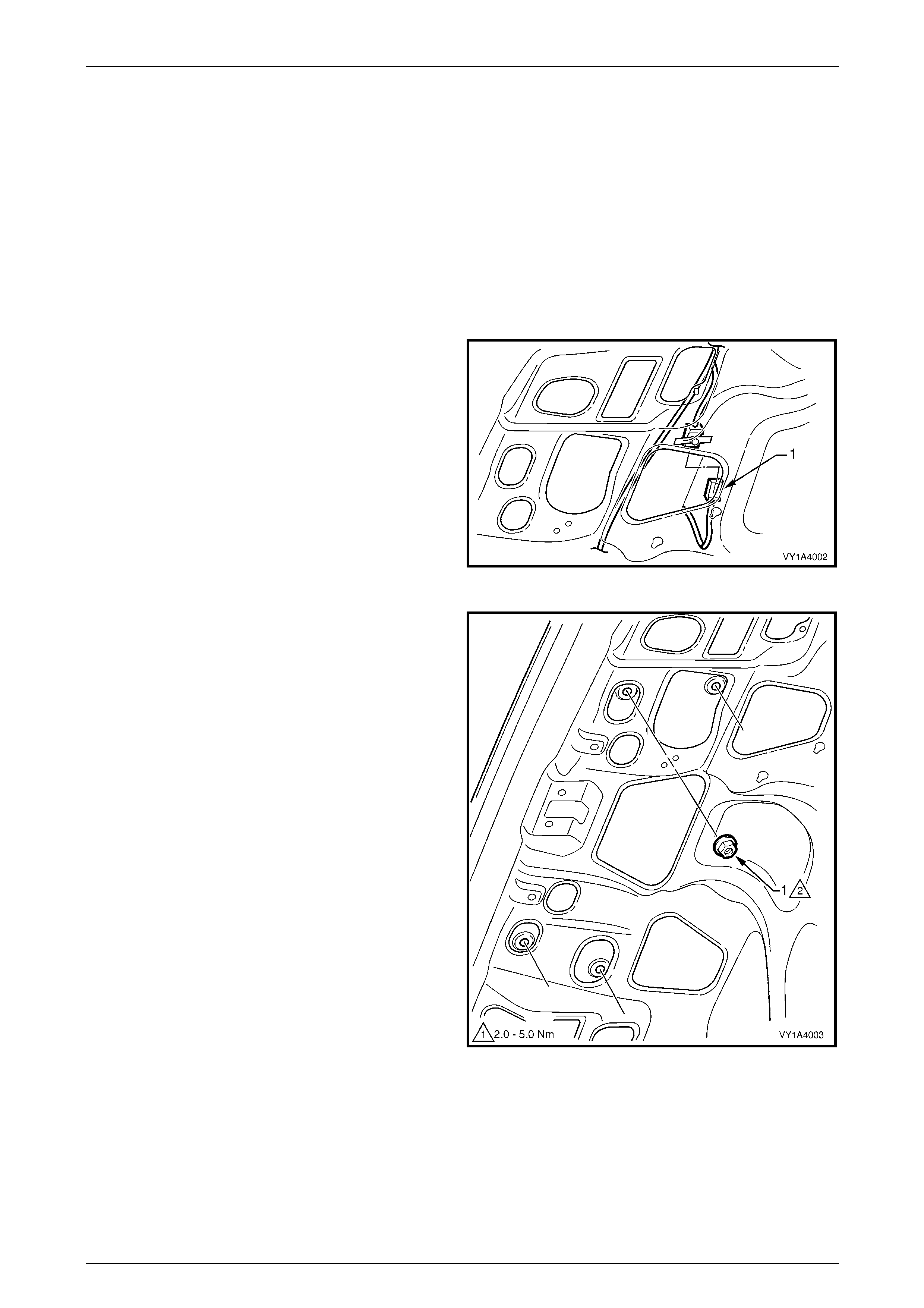

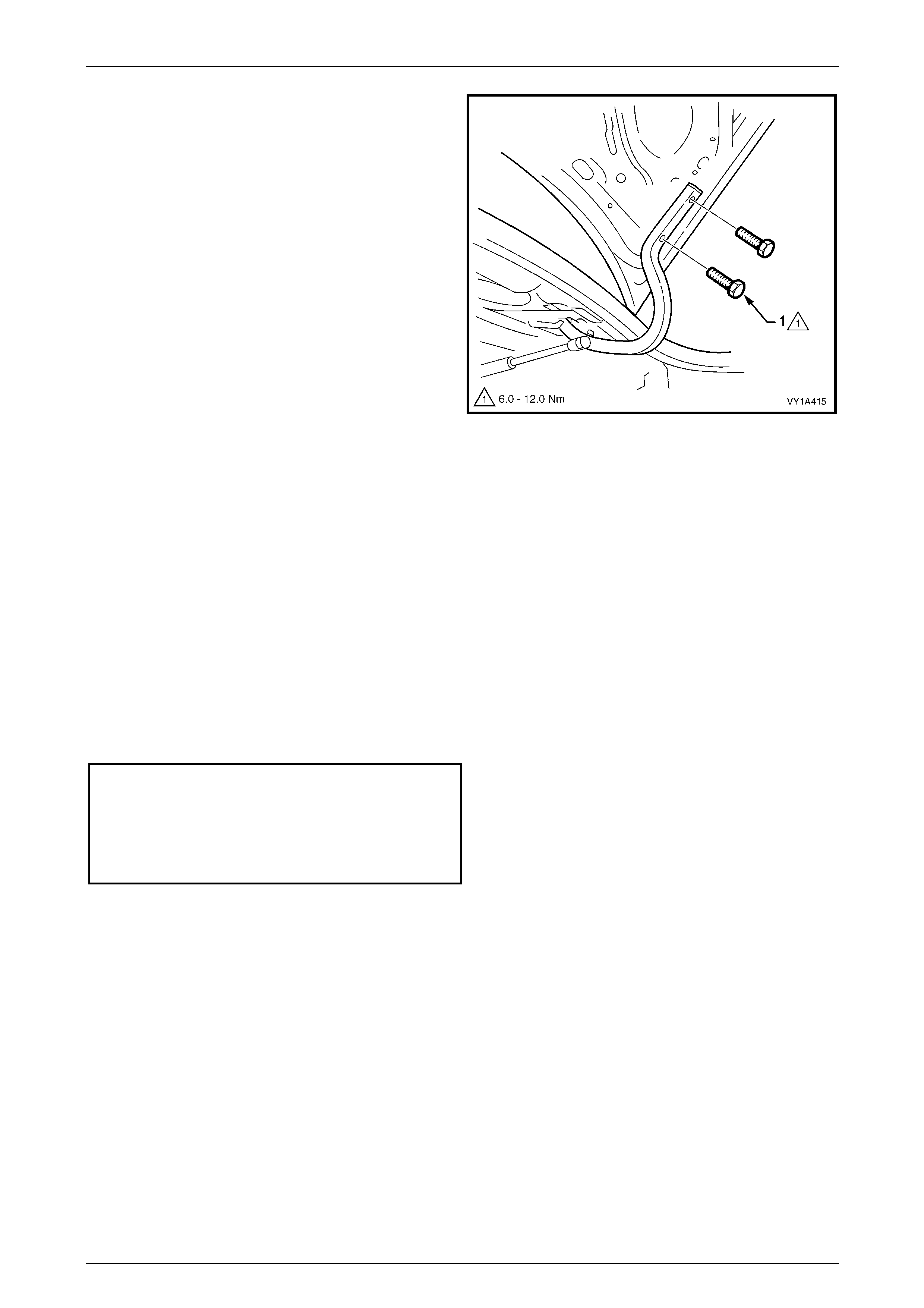

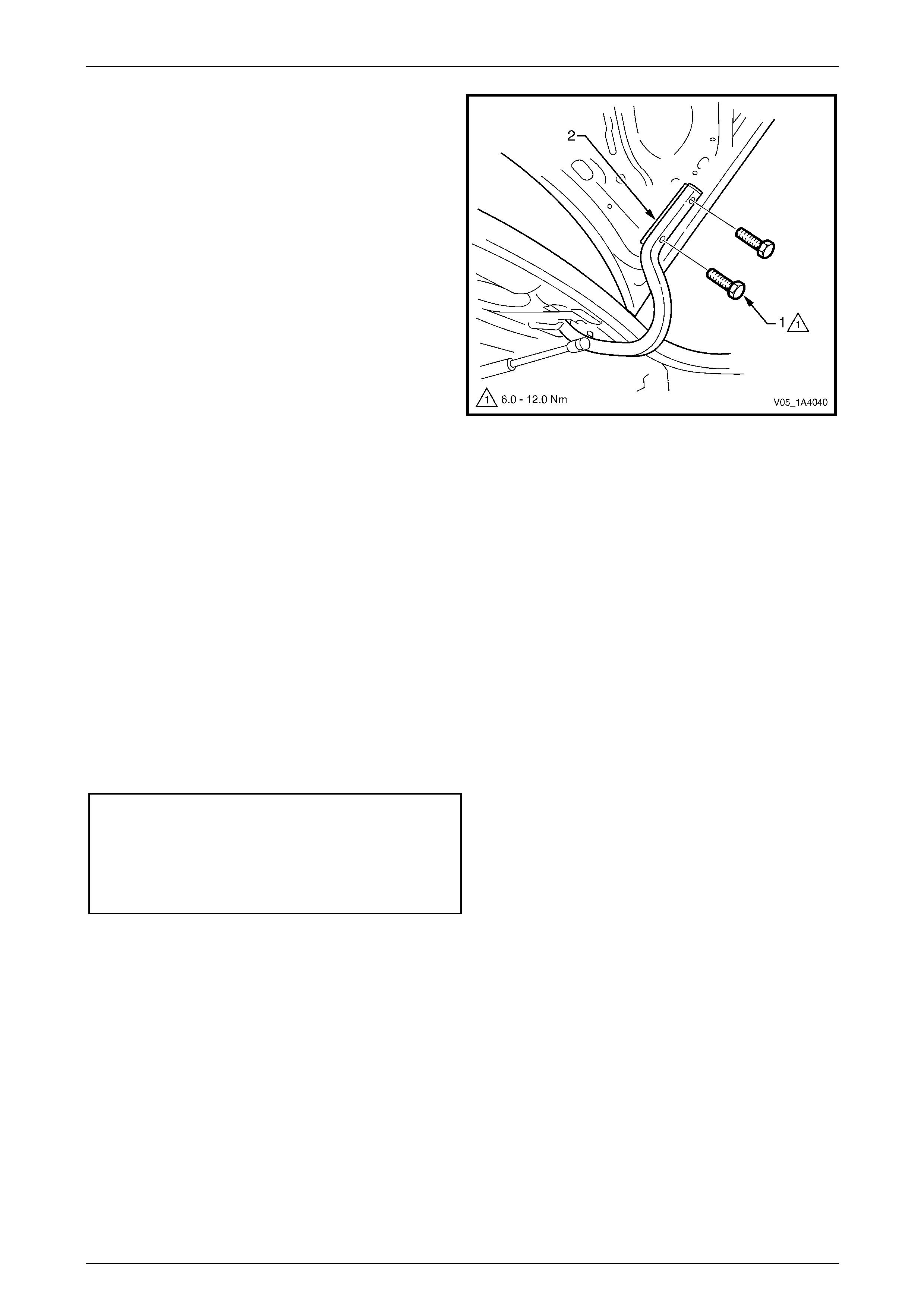

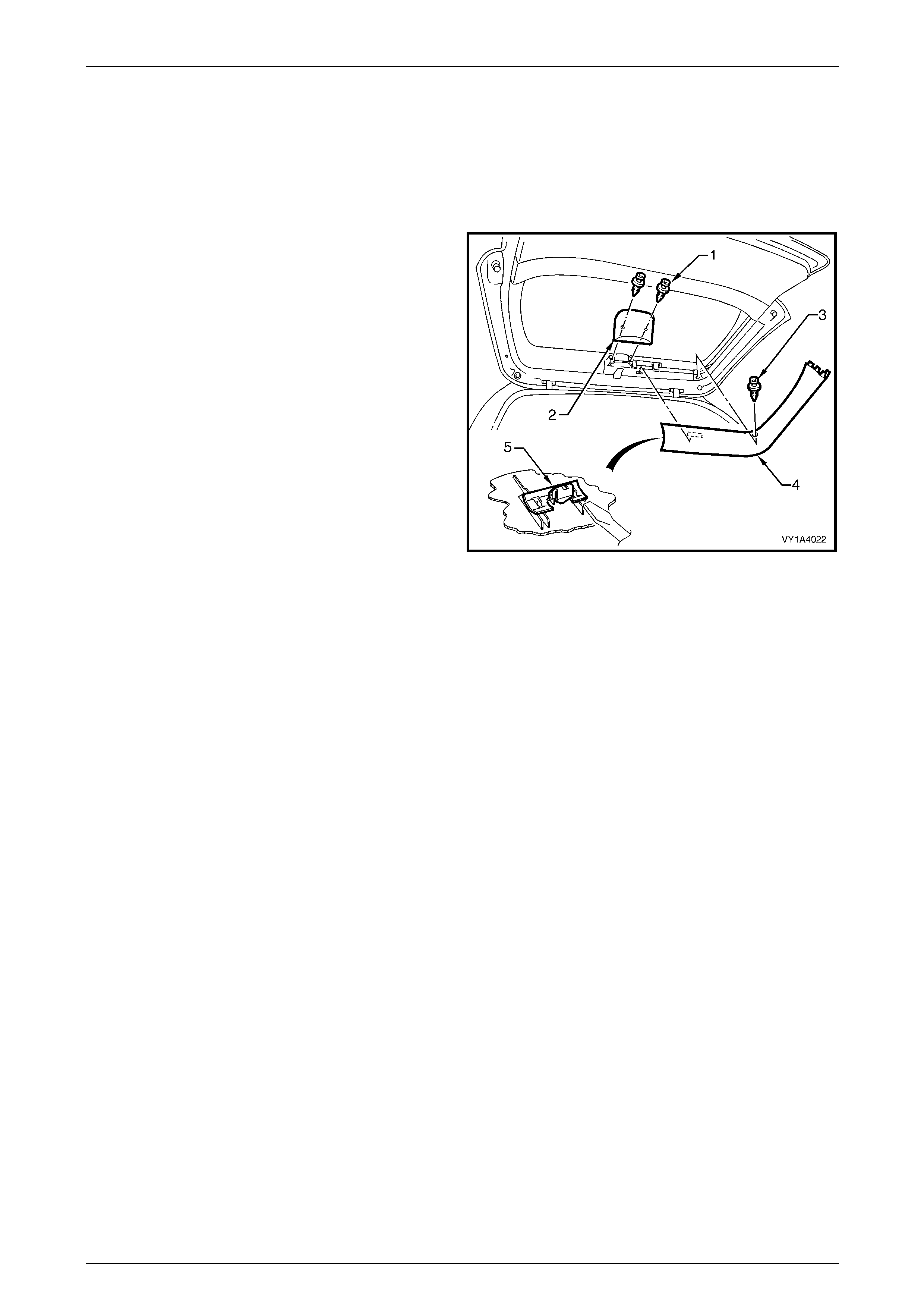

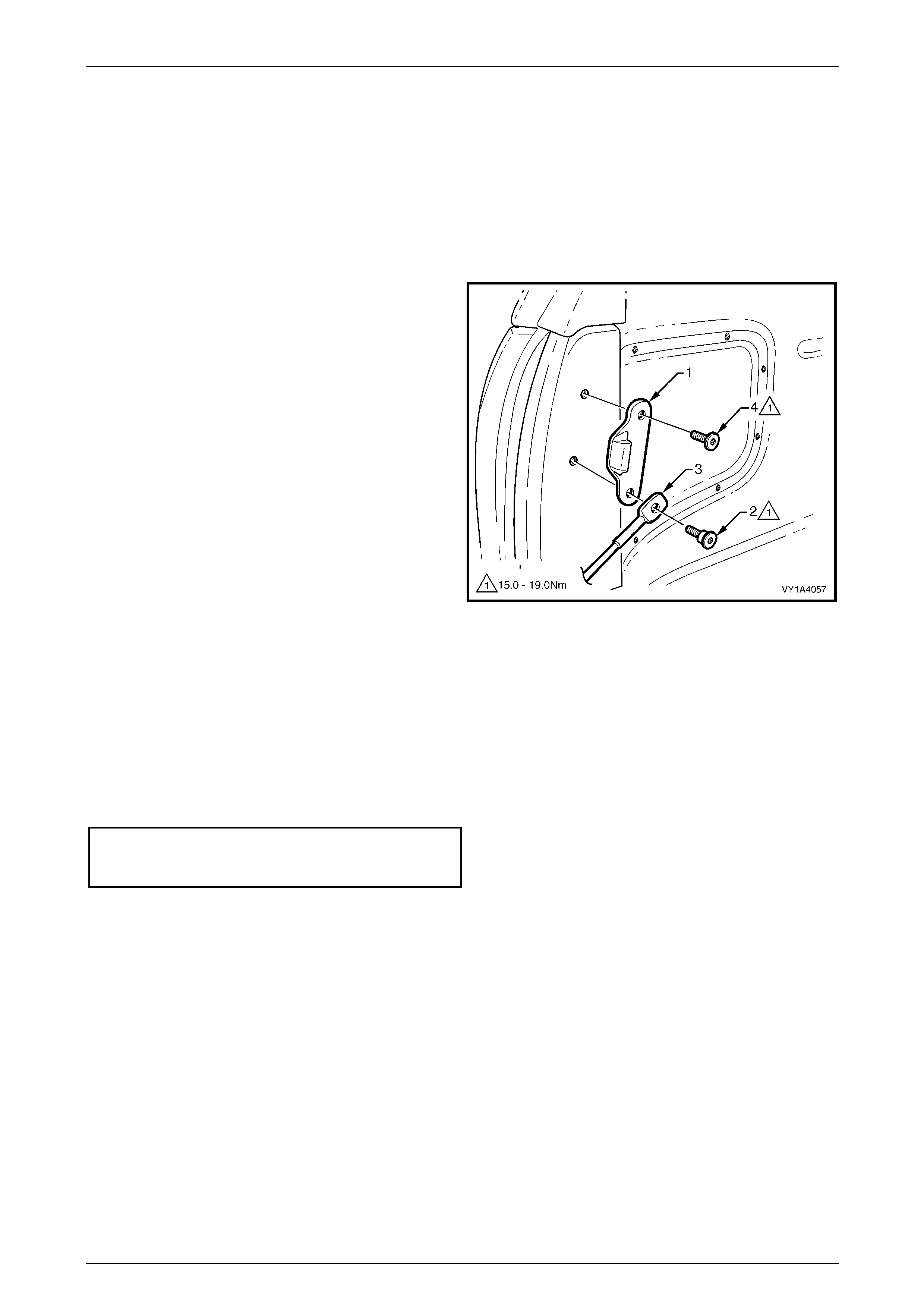

2 Remove the hood primary latch release cable retainer

screw (1) from the outer cable ferrule (4).

3 Unhook the hood primary latch release cable

assembly (2) from the hood primary latch spr ing (3).

Figure 1A4 – 5

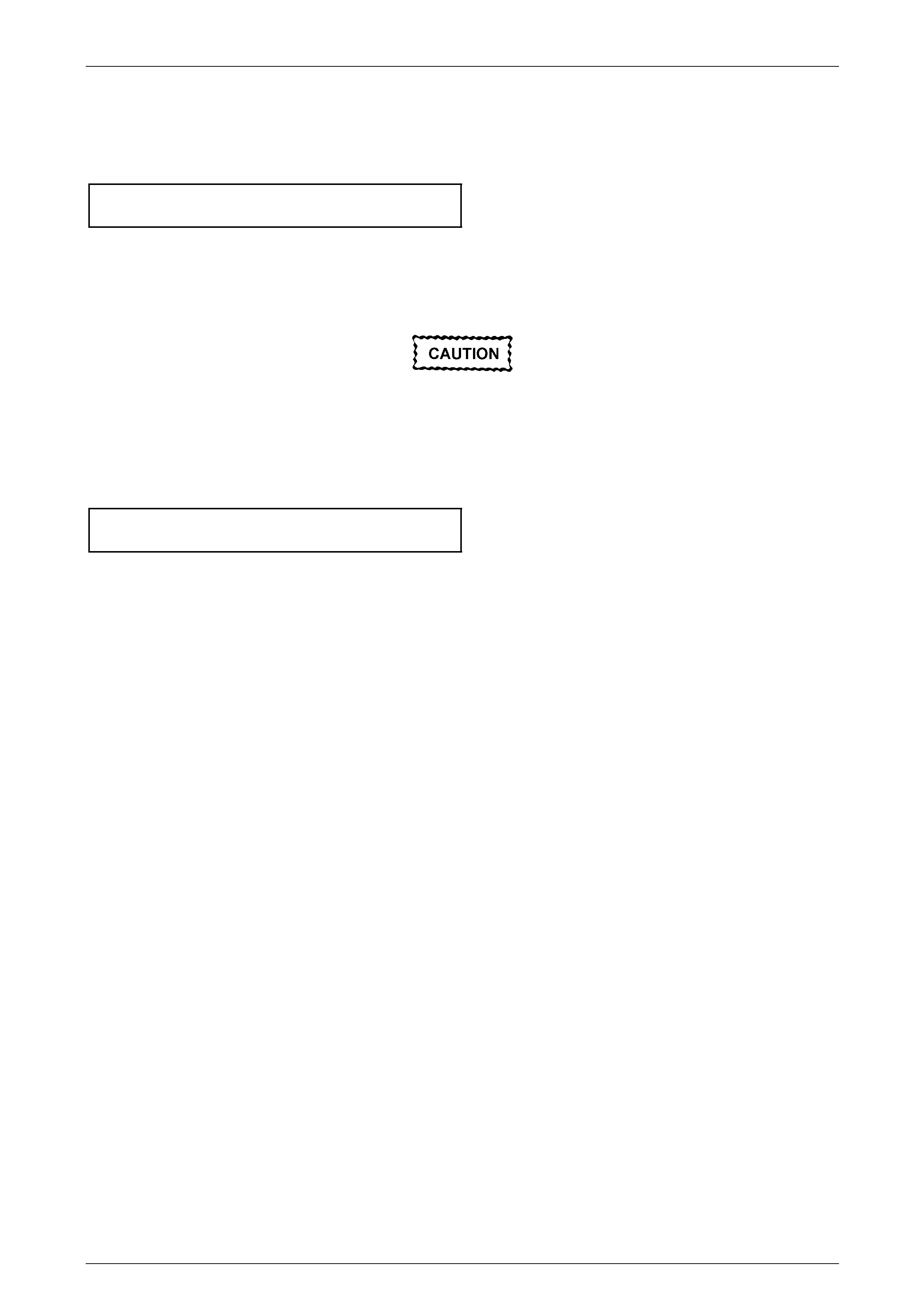

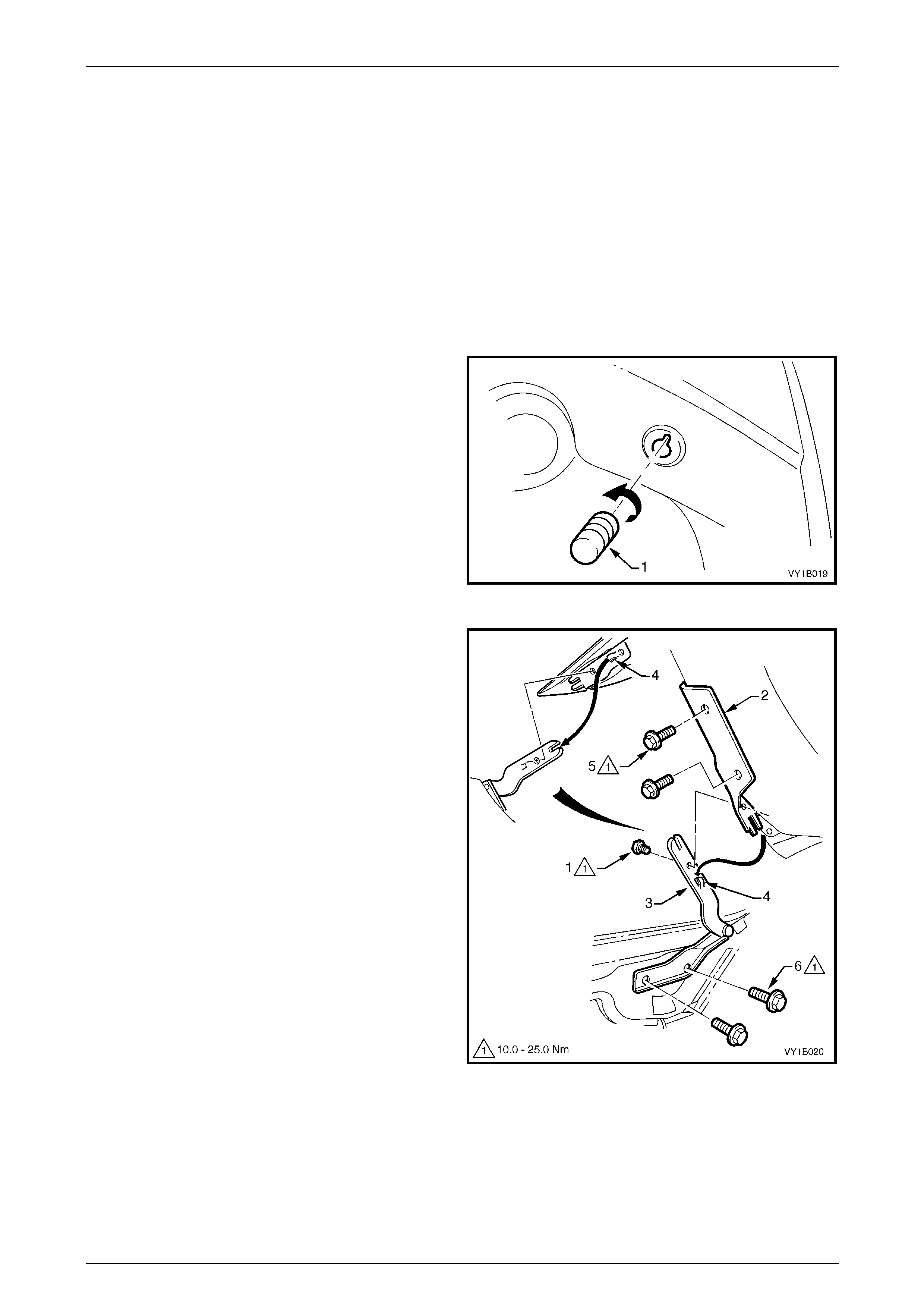

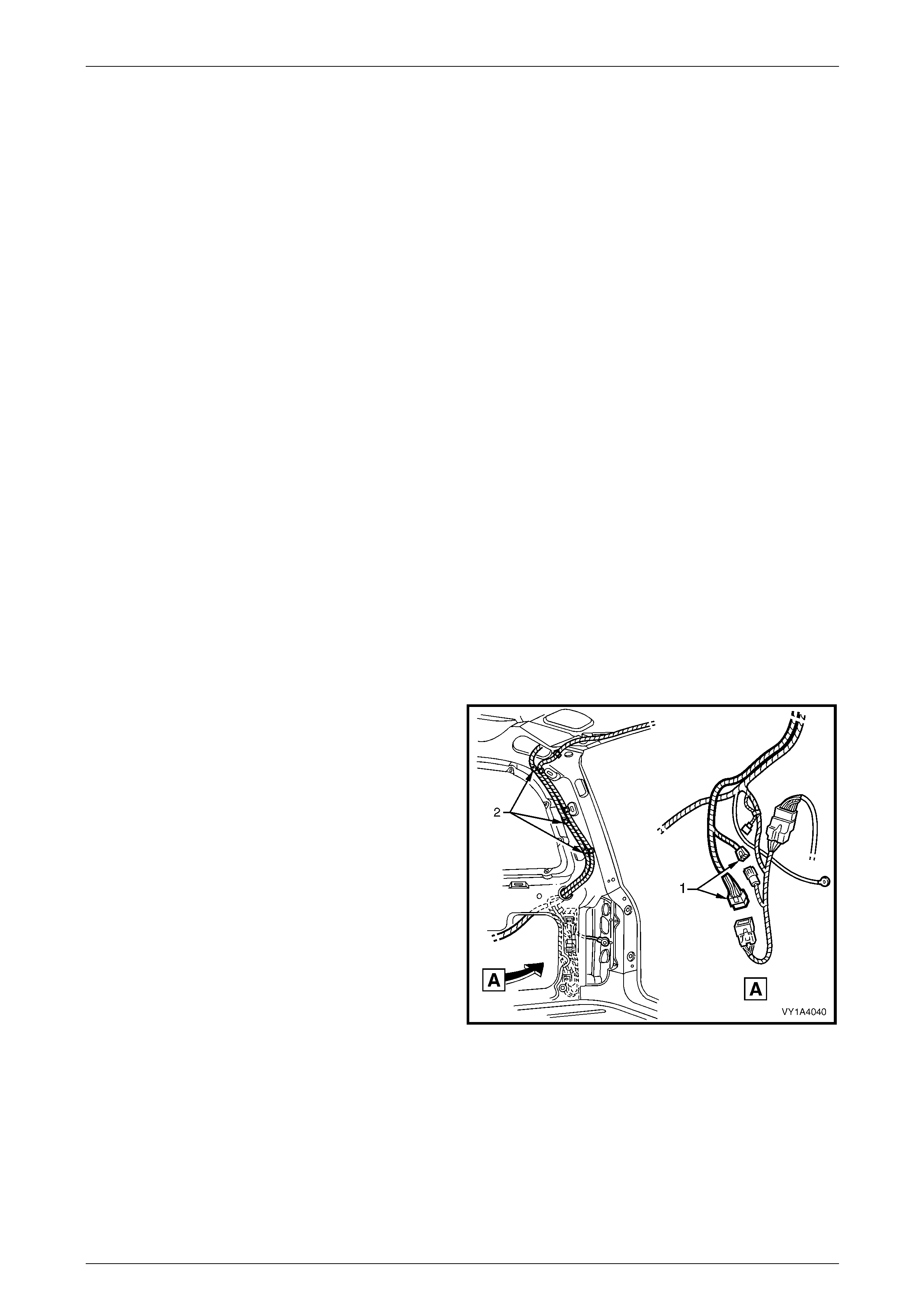

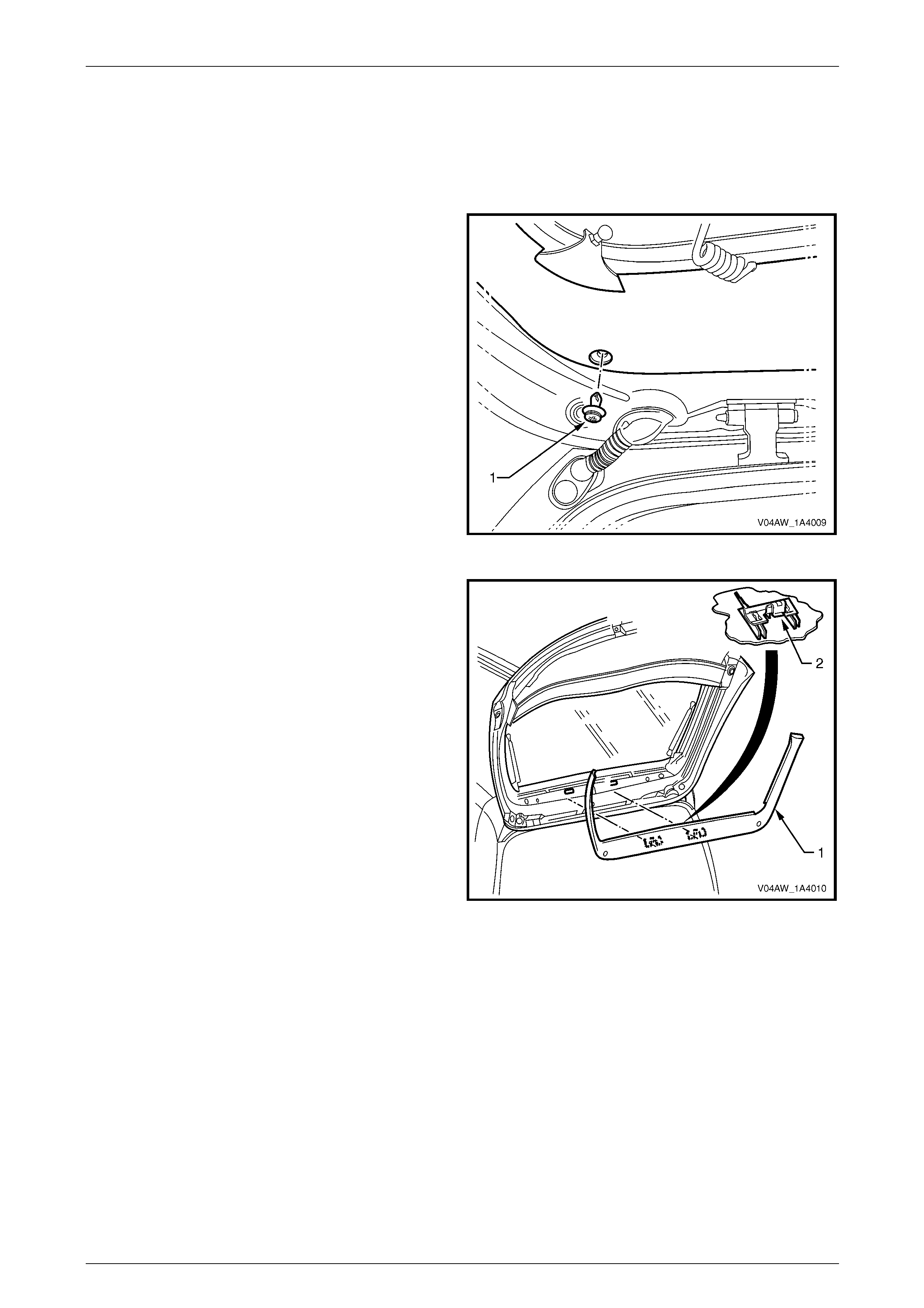

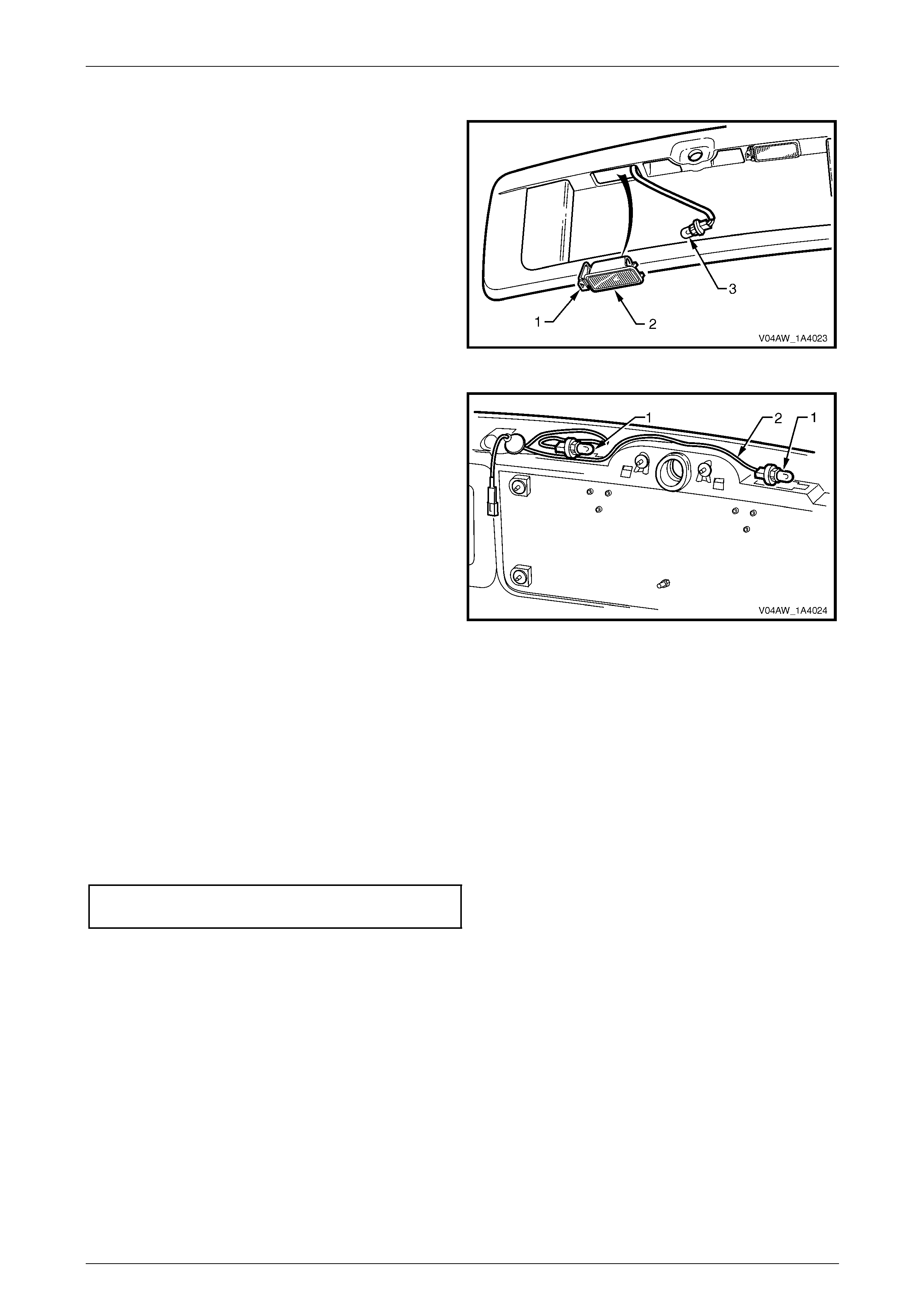

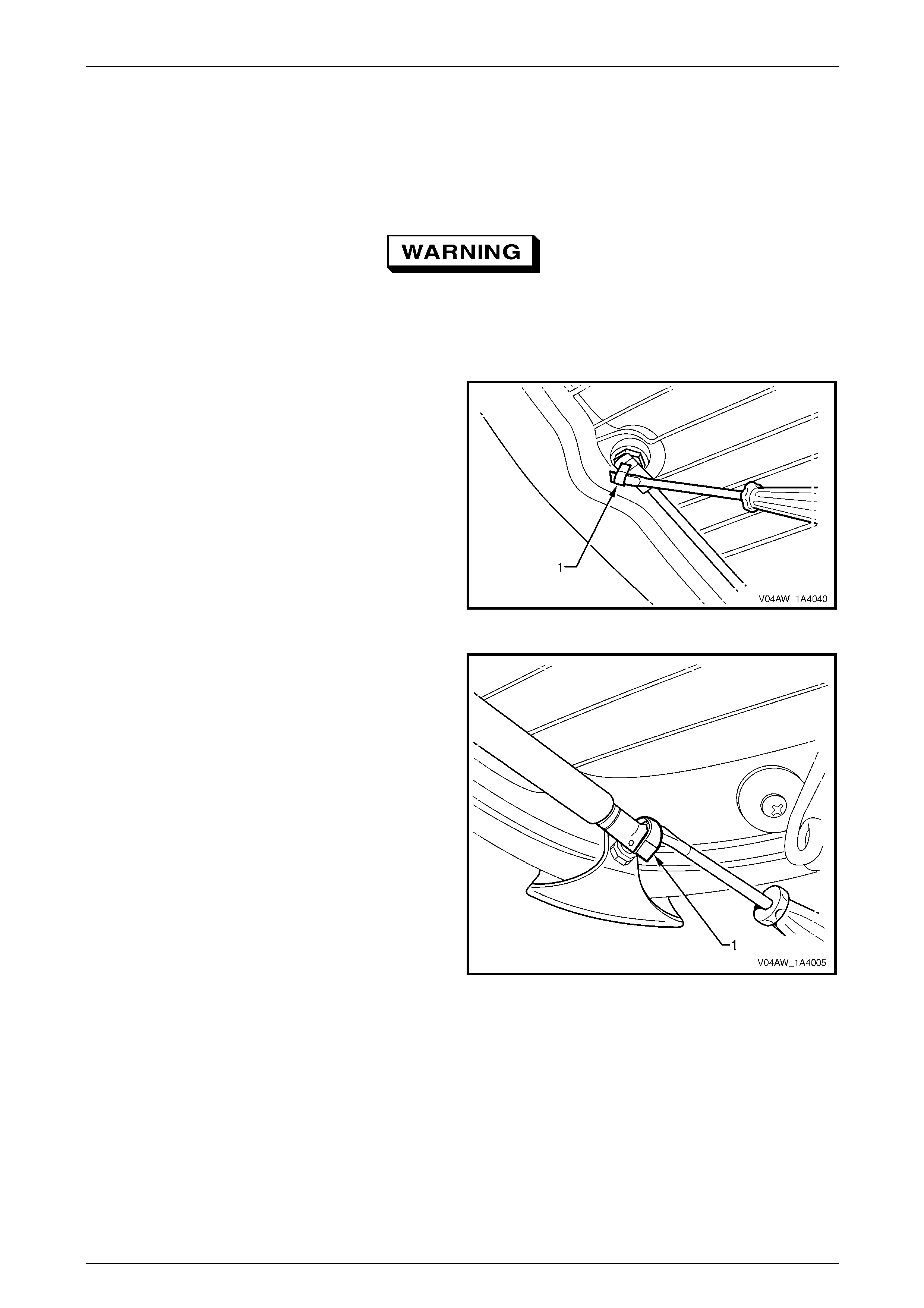

4 From inside the vehicle, using a fine flat-bl aded

screwdriver, lever the retaining tab (1) from the top

and bottom of the hood release lever ass emb ly (2) and

slide the hood release lever assembly rearward.

Figure 1A4 – 6

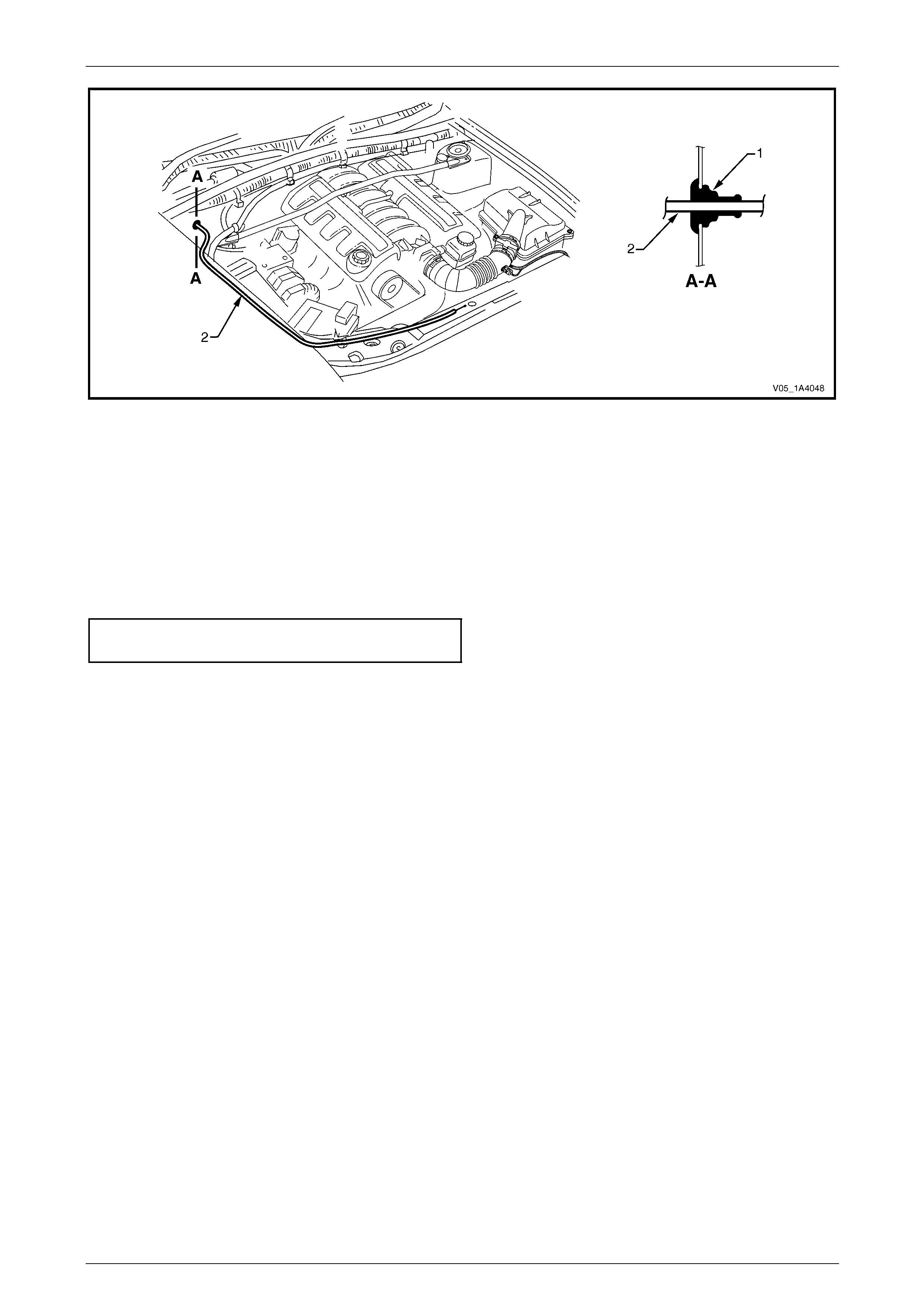

5 From within the engine compartment, push the gromm et (1) through the dash panel, refer to Figure 1A4 – 7.

6 Withdraw the cable assembly (2) from behind the fuse and relay box, across the dash panel and into the passenger

compartment.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–12

Page 1A4–12

Figure 1A4 – 7

Reinstall

Reinstallation of the hood primary latch release cable ass embly is the reverse of the removal procedure, noting the

following:

1 Ensure the outer cable ferrule (4), refer to Figure 1A4 – 5 is positioned before the retainer.

2 Ensure the cable assembly is correctl y routed and there are no sharp bends in the cable.

3 Tighten the hood primary latch release cable retai ner screw to the correct torque specification.

Hood primary latch release cable

retainer screw torque specification..............1.0 – 3.0 Nm

4 Check the cable adjustment, refer to 2.2 Hood Primary Latch Spring.

5 Attach a spring scale to the lower edge of the hood release lever assembly. The effort required to release the hood

should not exceed 40 Nm.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–13

Page 1A4–13

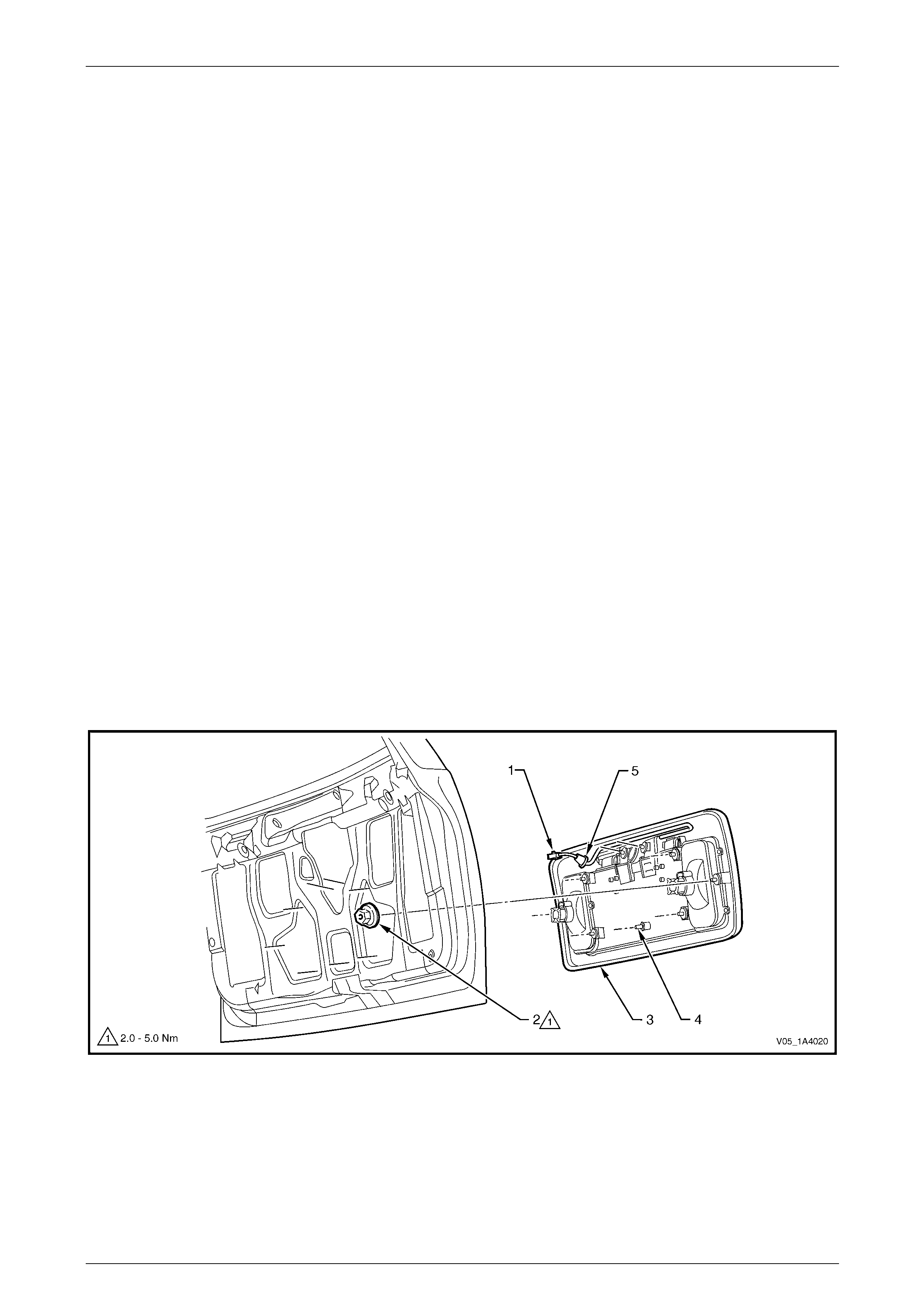

2.4 Hood Secondary Latch Assembly

LT Section No. — 12–050

Remove

NOTE

Replace the secondar y latch rivet when removing

the hood secondary latch assembly.

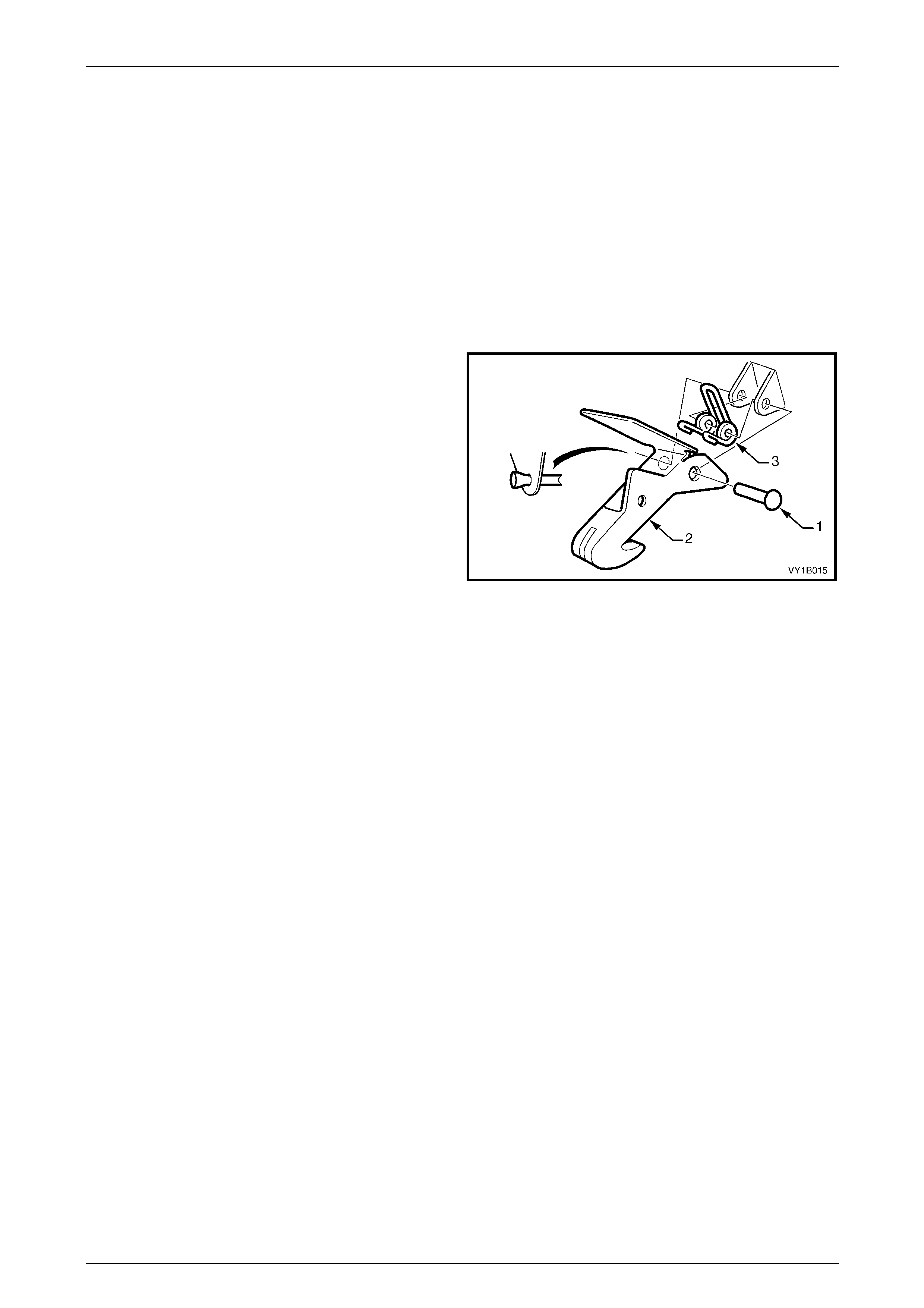

1 Raise the hood.

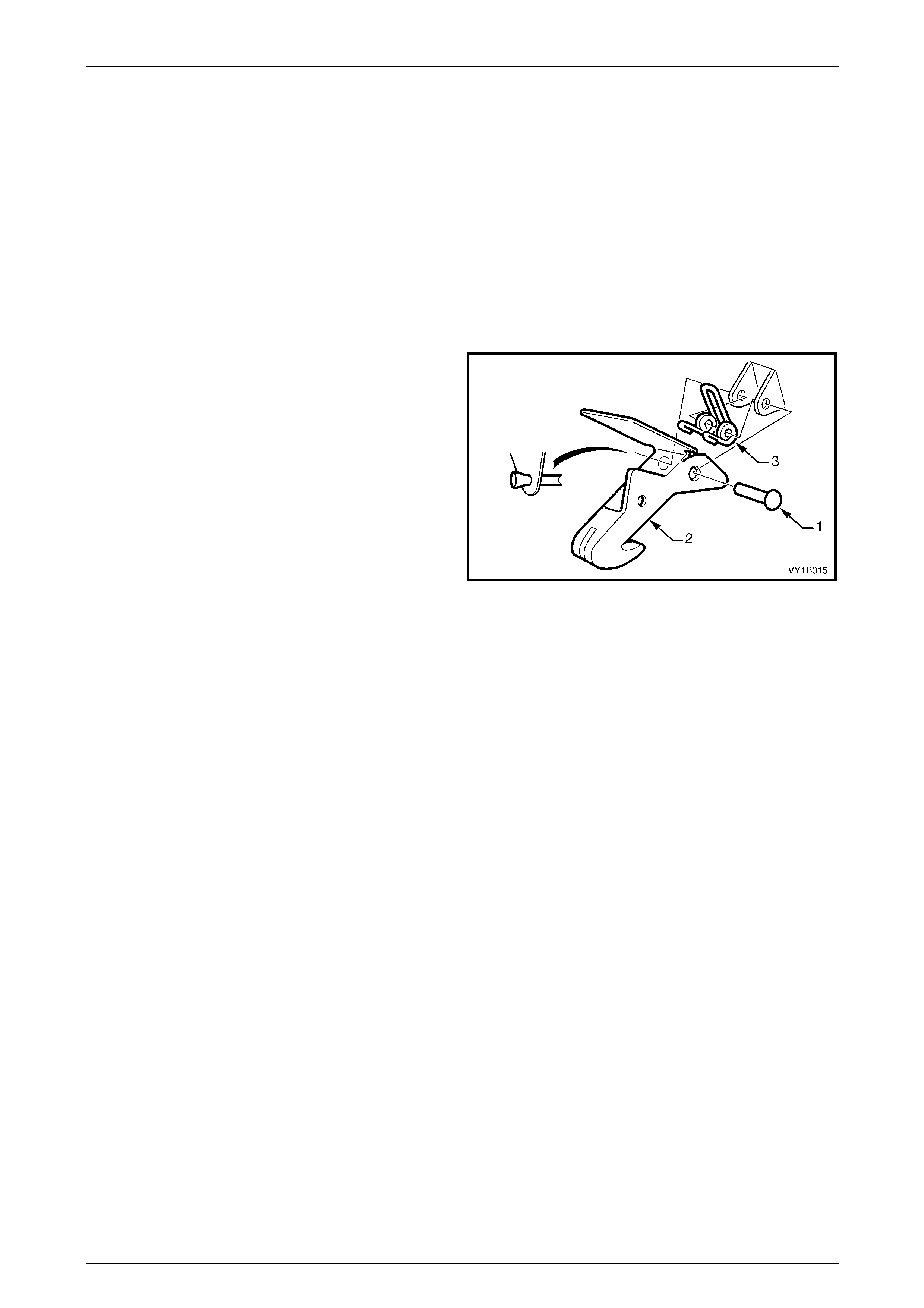

2 Carefully cut the end of the secondar y latch ri vet (1)

securing the hood secondary latch (2) and hood

secondary latch spring (3) to the hood.

NOTE

Take care not to damage the paintwork.

3 Using a pin punch, extract the rivet to remove the latch

and latch spring.

Figure 1A4 – 8

Reinstall

1 Lubricate the new secondar y latch rivet with NLGI No. 1 lithium grease or equivalent.

2 While holding t he hood secondary latch and hood secondary latch spring in position on the hood, insert the new

secondary latch rivet. Ensure the latch spring is correctly oriented, refer to Figure 1A4 – 8.

3 Crimp the end of the rivet to secure it in place.

4 Test the operation of the hood secondary latch assembly.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–14

Page 1A4–14

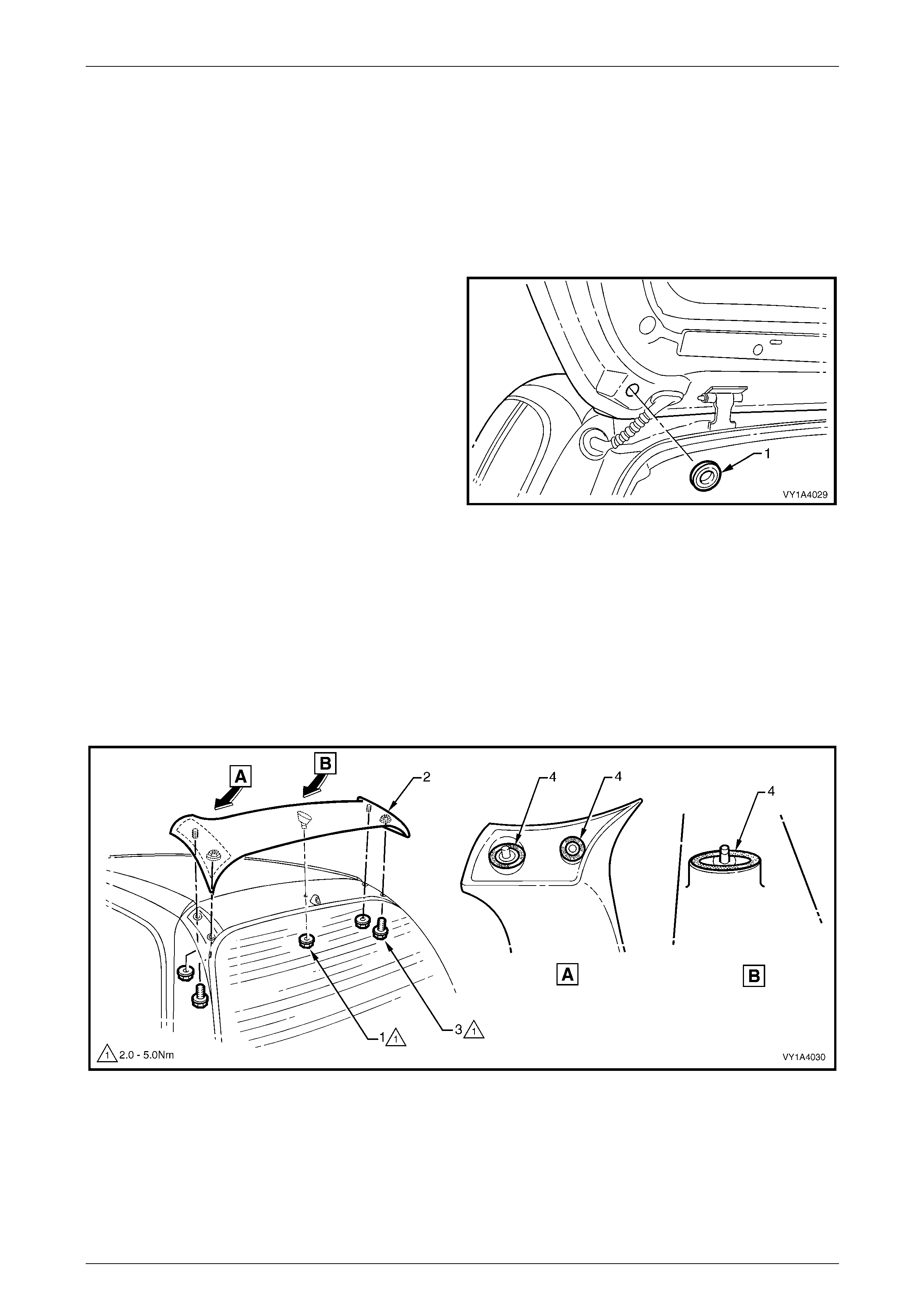

2.5 Hood Insulator

LT Section No. — 12–050

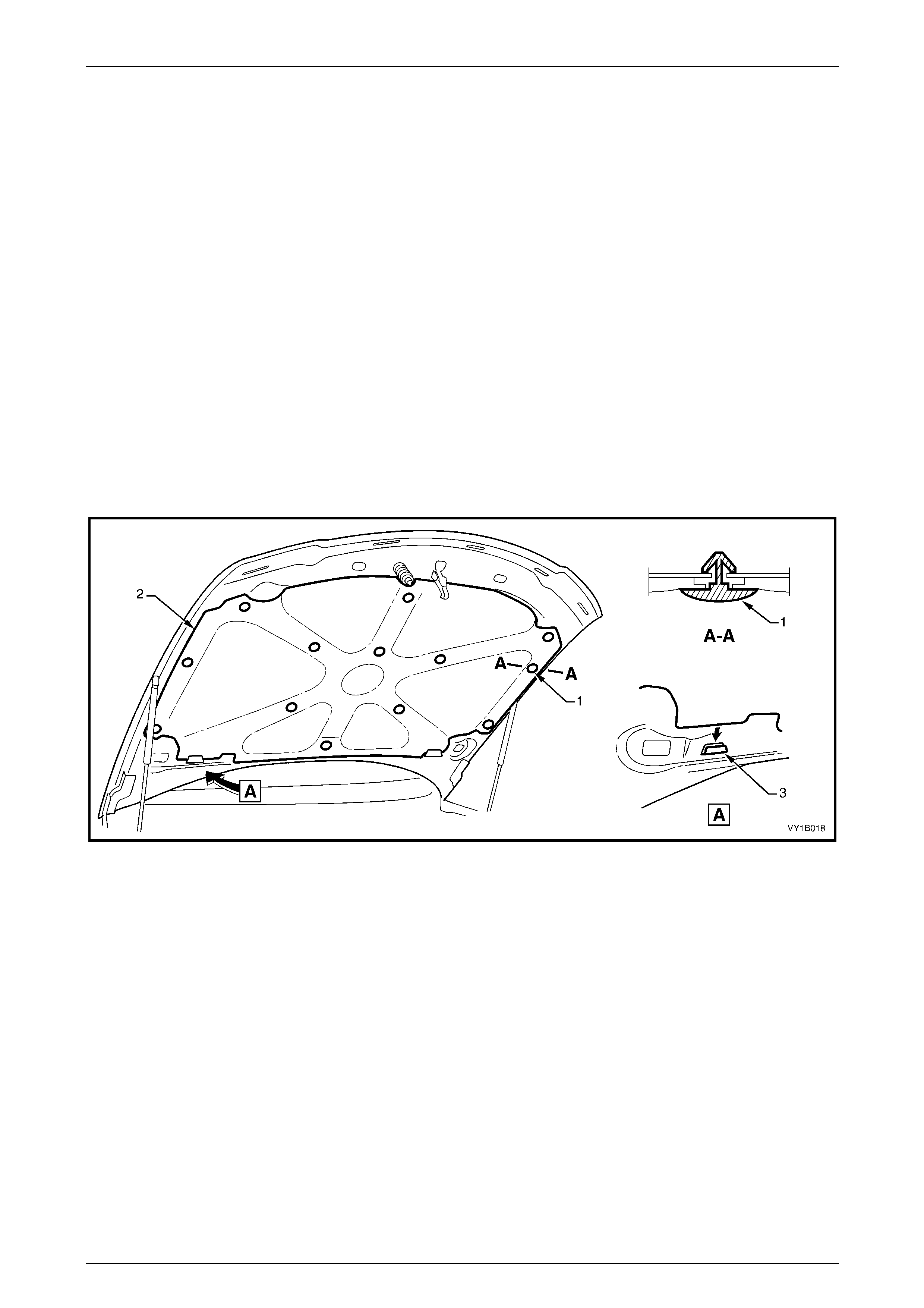

Remove

NOTE

The hood insulator retainers may require

replacement when performing this operation.

1 Raise the hood.

2 Beginning at the rear of the hood and working toward the front, remove the hood insulator retainer (1), 13 places,

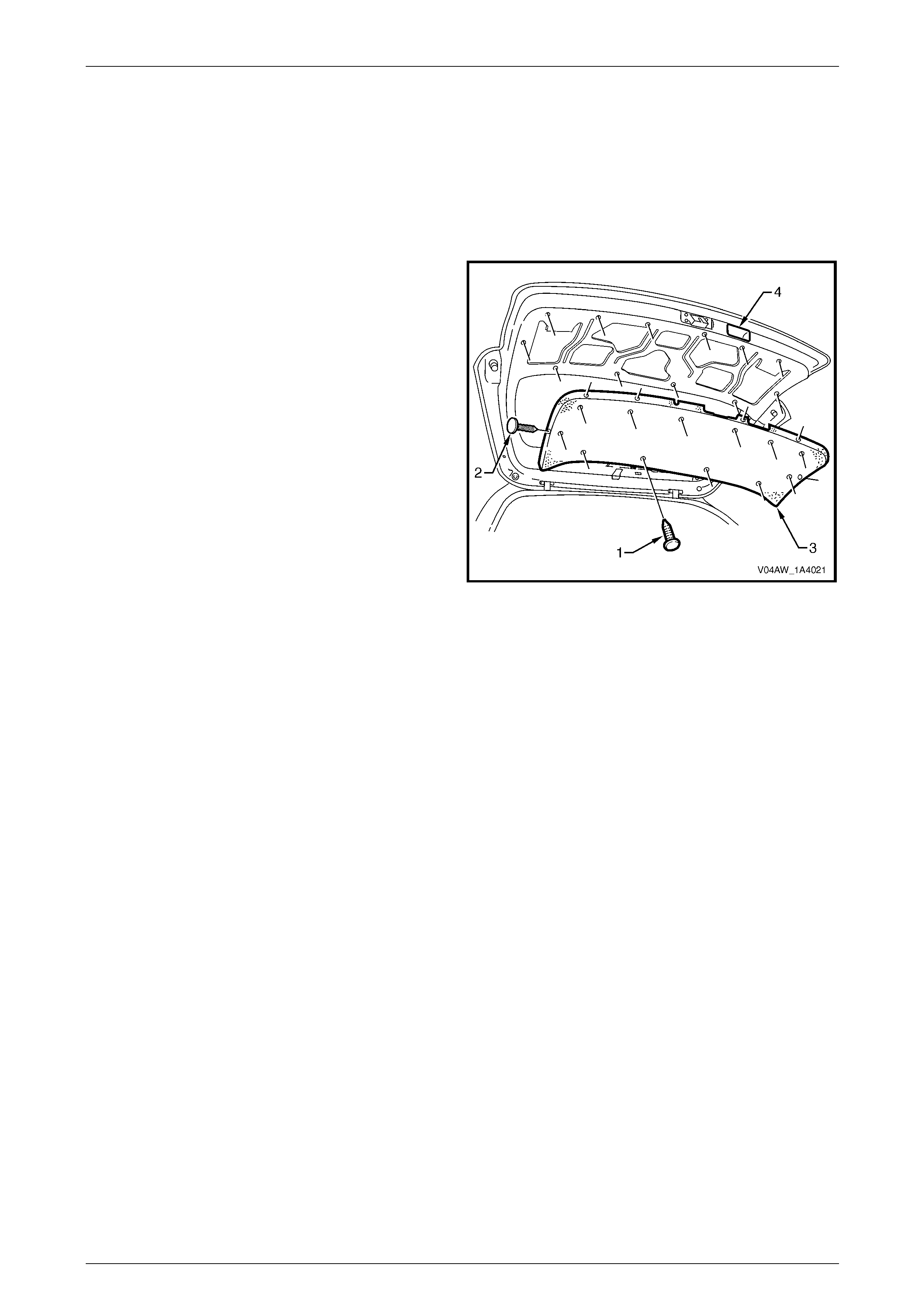

attaching the hood insulator (2) to the hood, refer to Figure 1A4 – 9.

NOTE

Take care not to crush or damage the hood

insulator.

3 Slide the insulator from the tabs (3) in the hood inn er pa nel and remove the insulator.

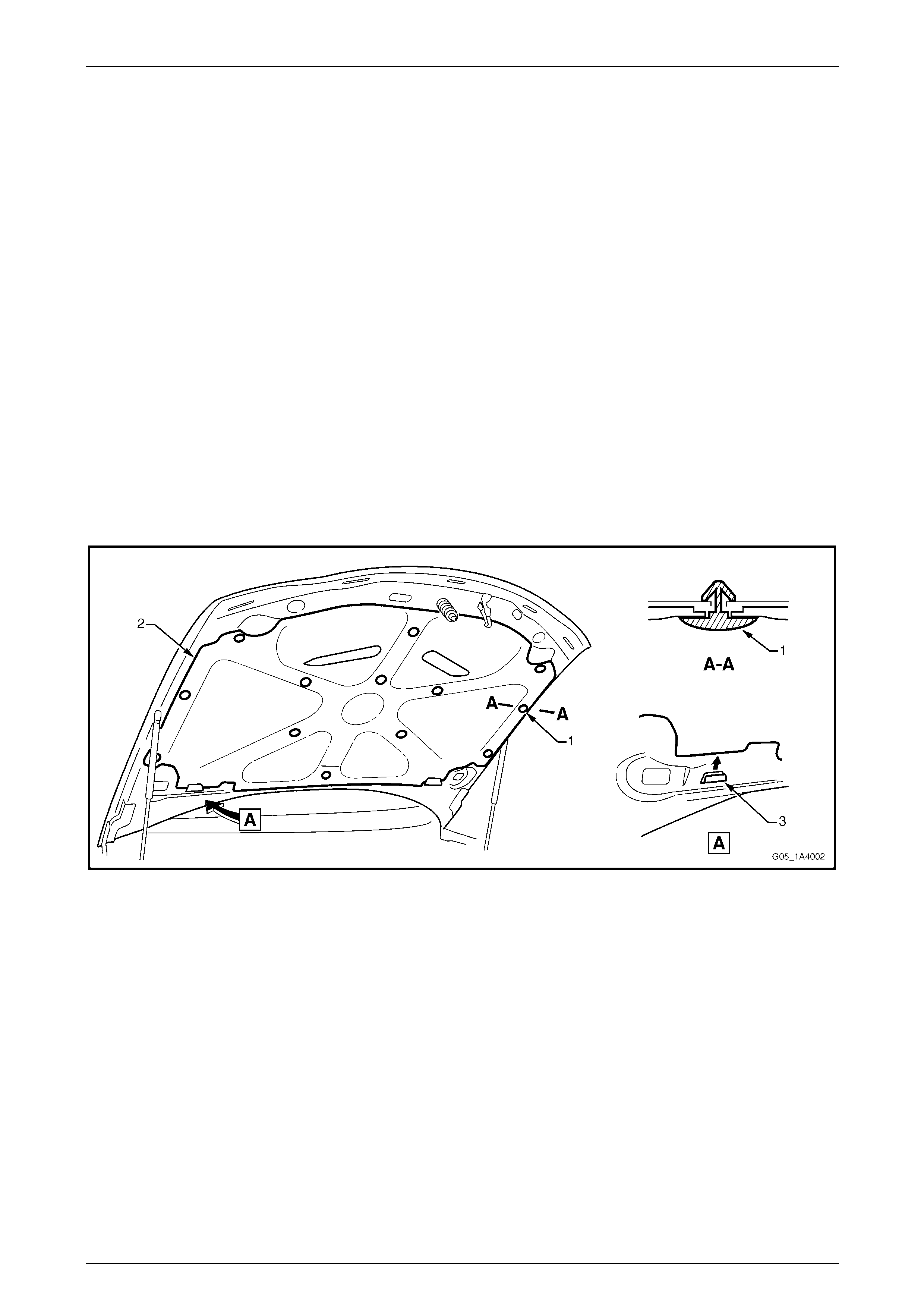

Figure 1A4 – 9

Reinstall

Reinstallation of the hood insulator is the reverse of the removal procedure.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–15

Page 1A4–15

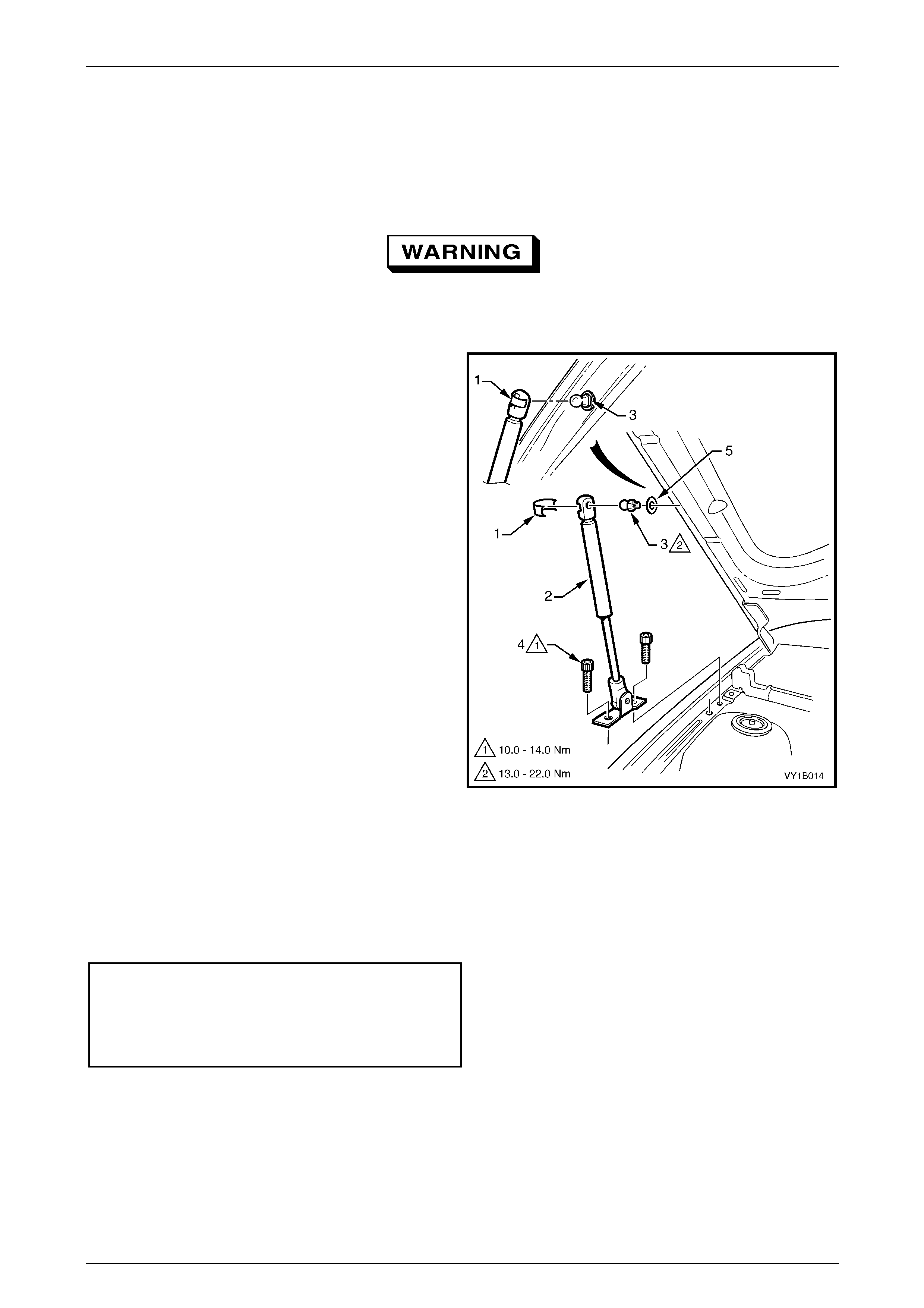

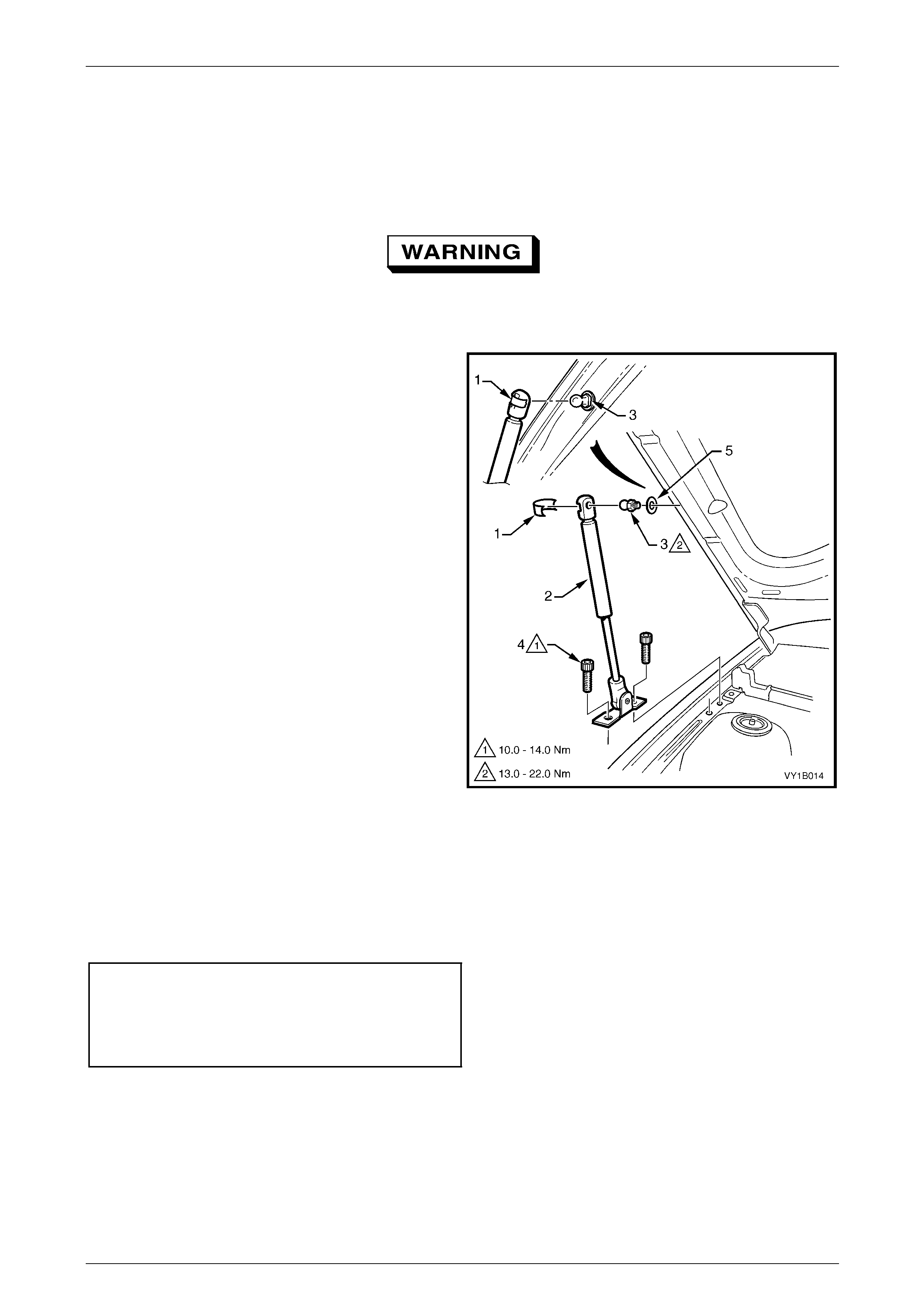

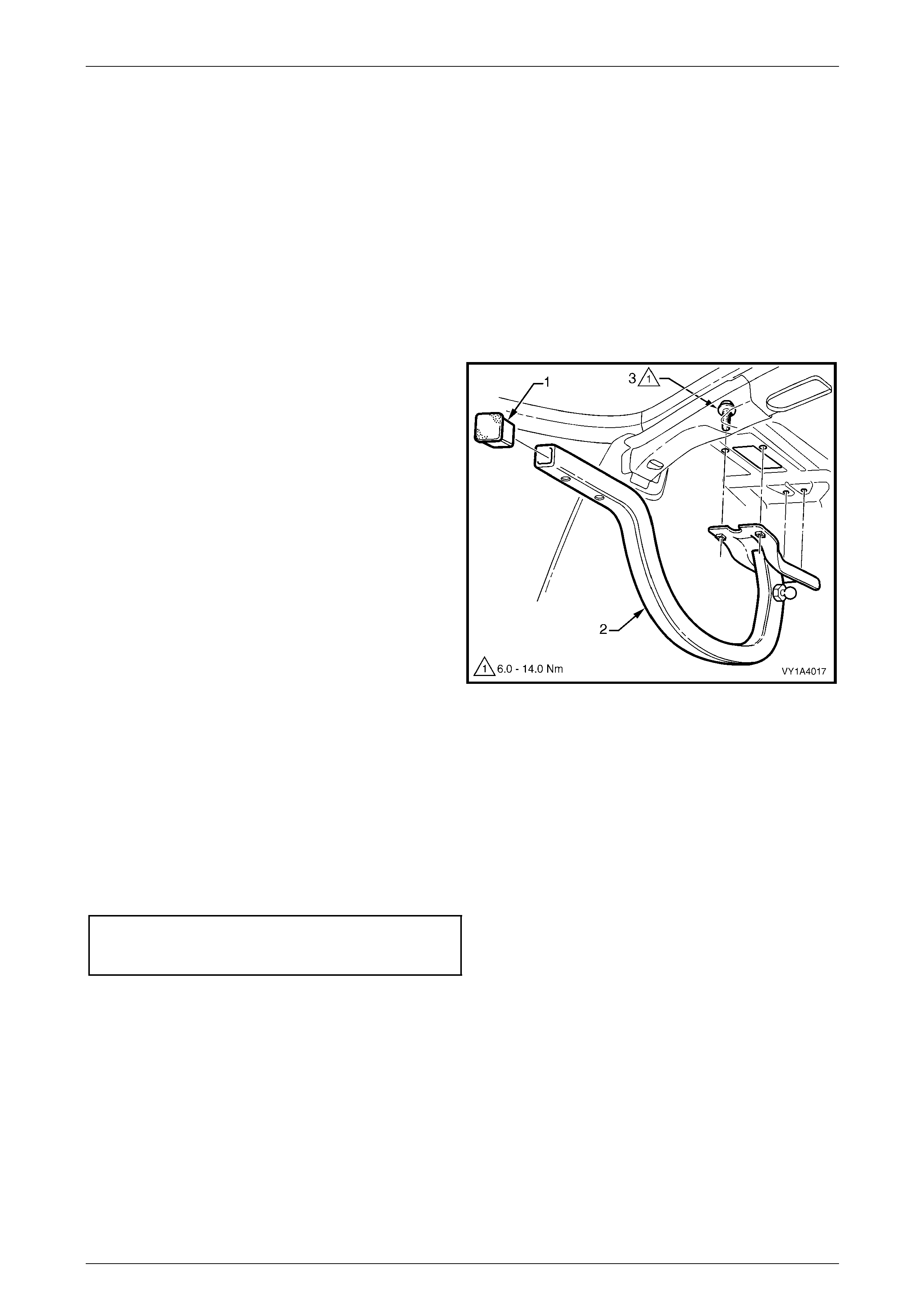

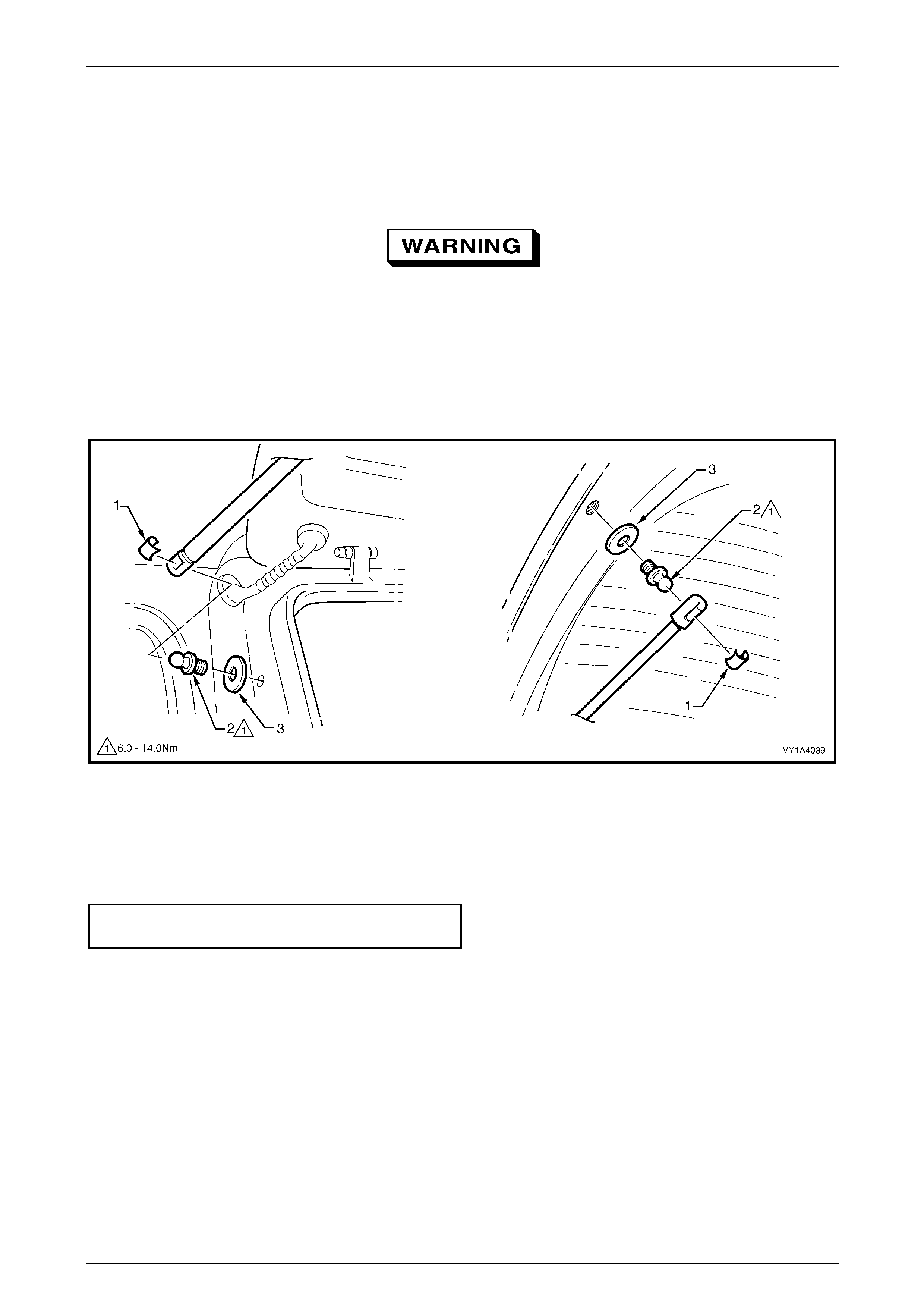

2.6 Hood Strut Assembly

LT Section No. — 12–050

Remove

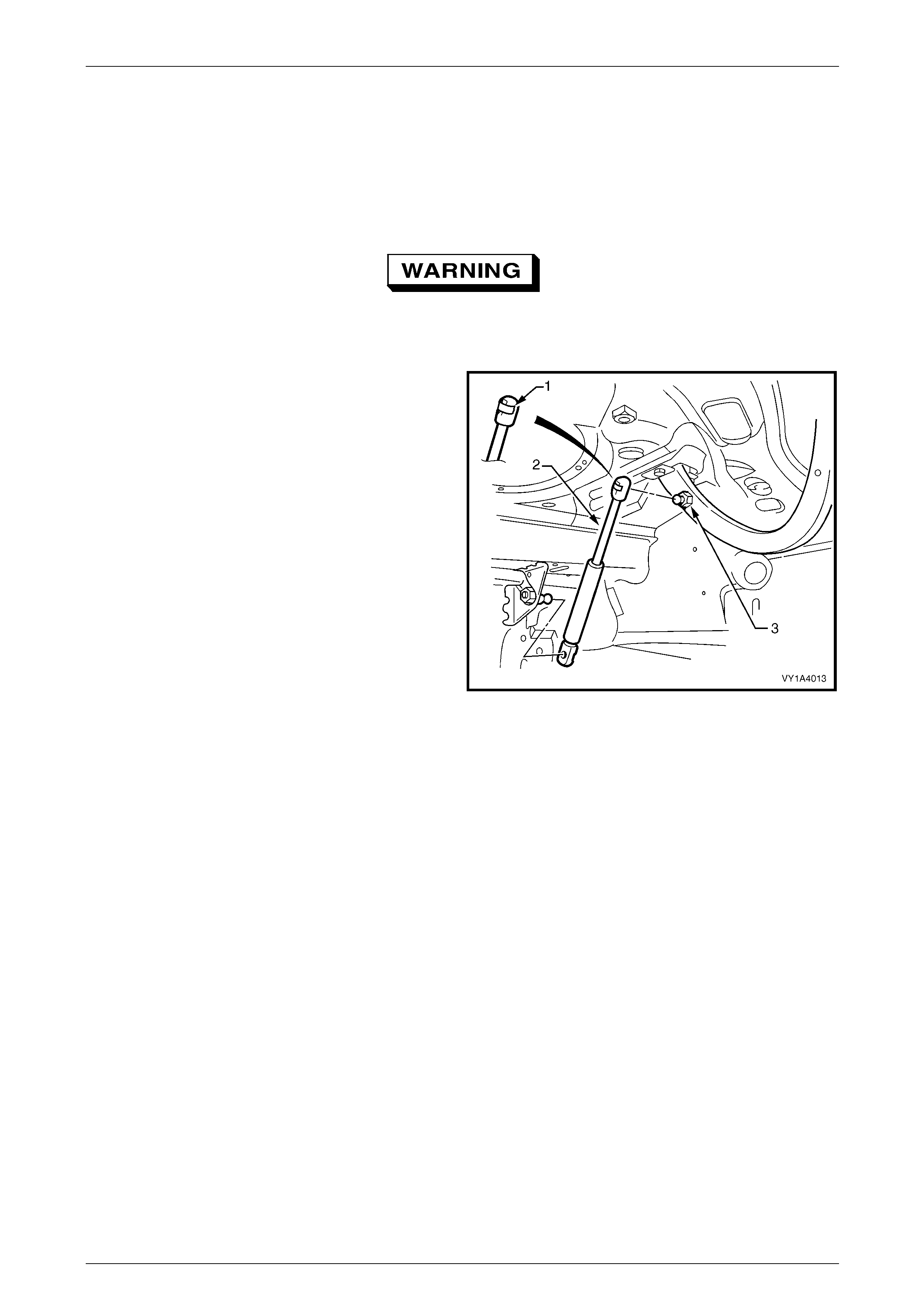

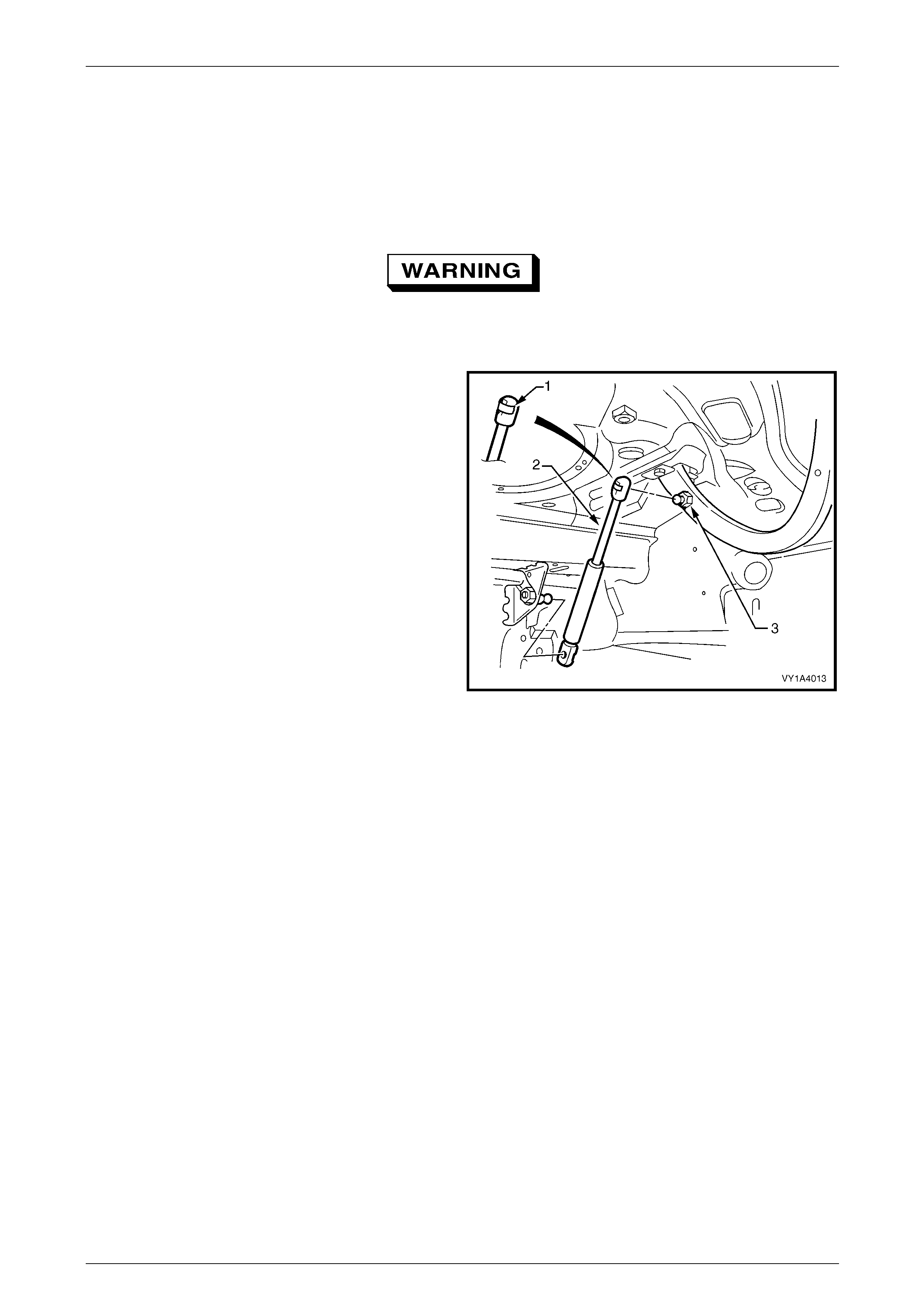

The hood struts contain pressurised gas. Do

not subject them to extreme heat, p ressure or

physical damage.

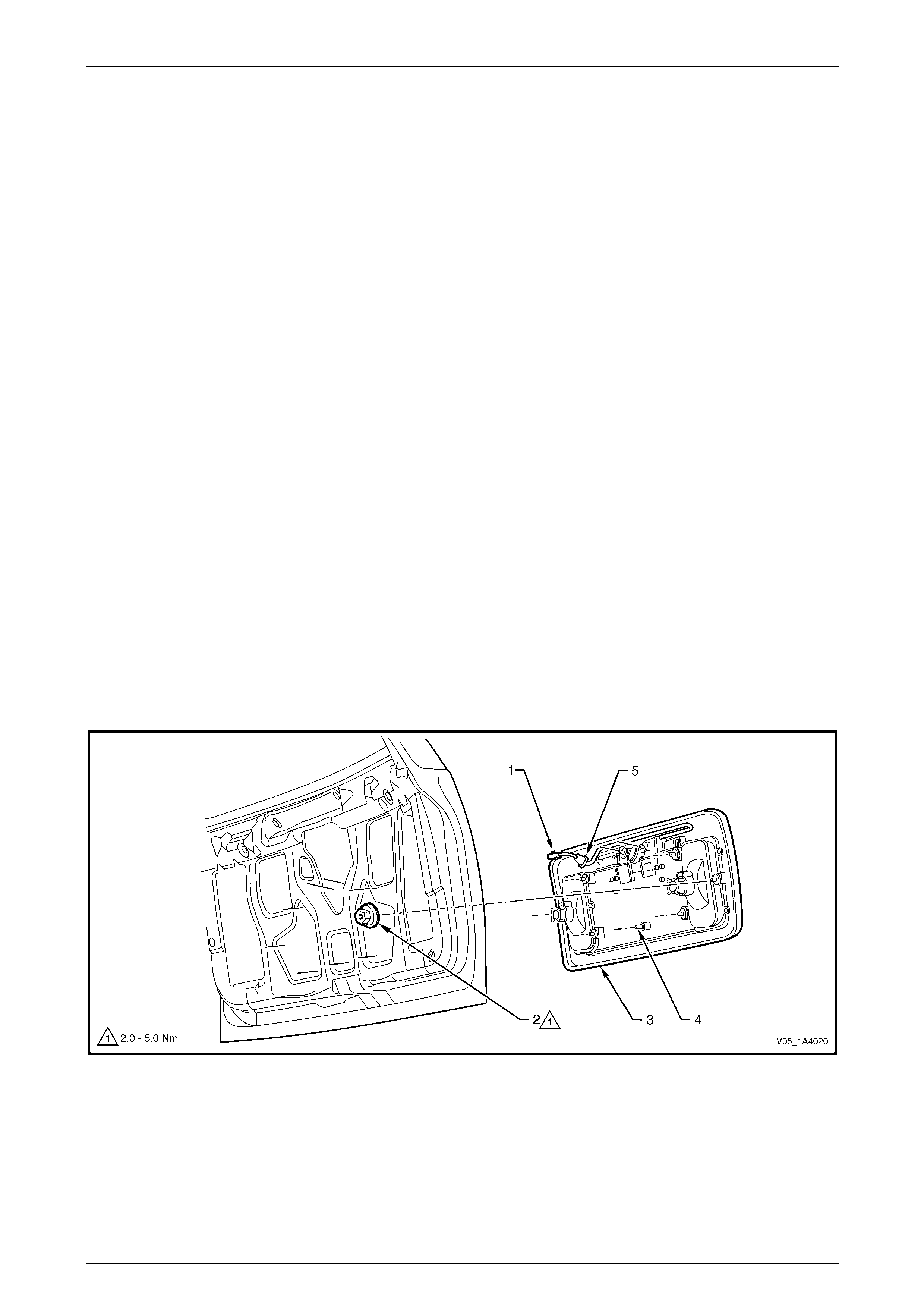

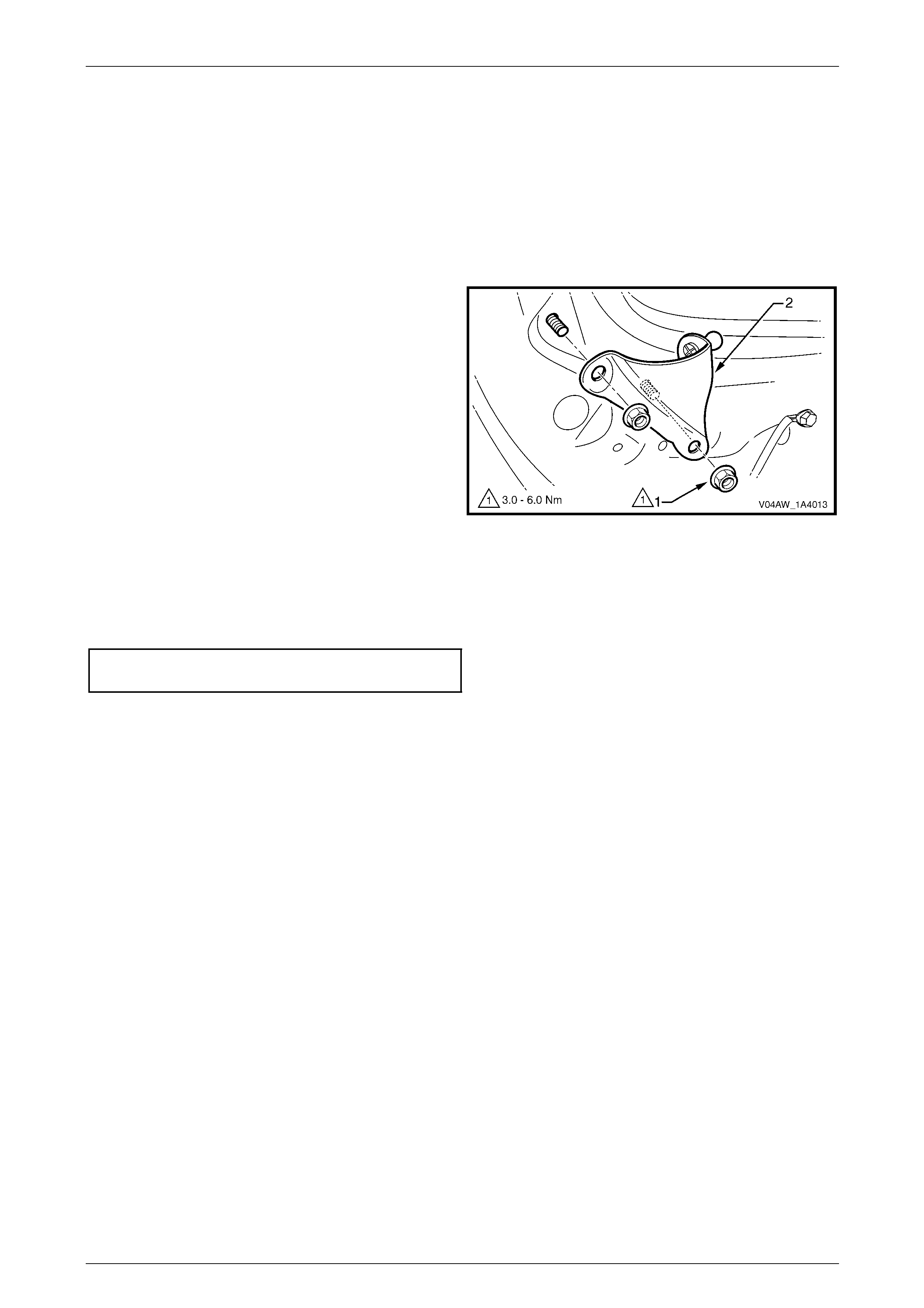

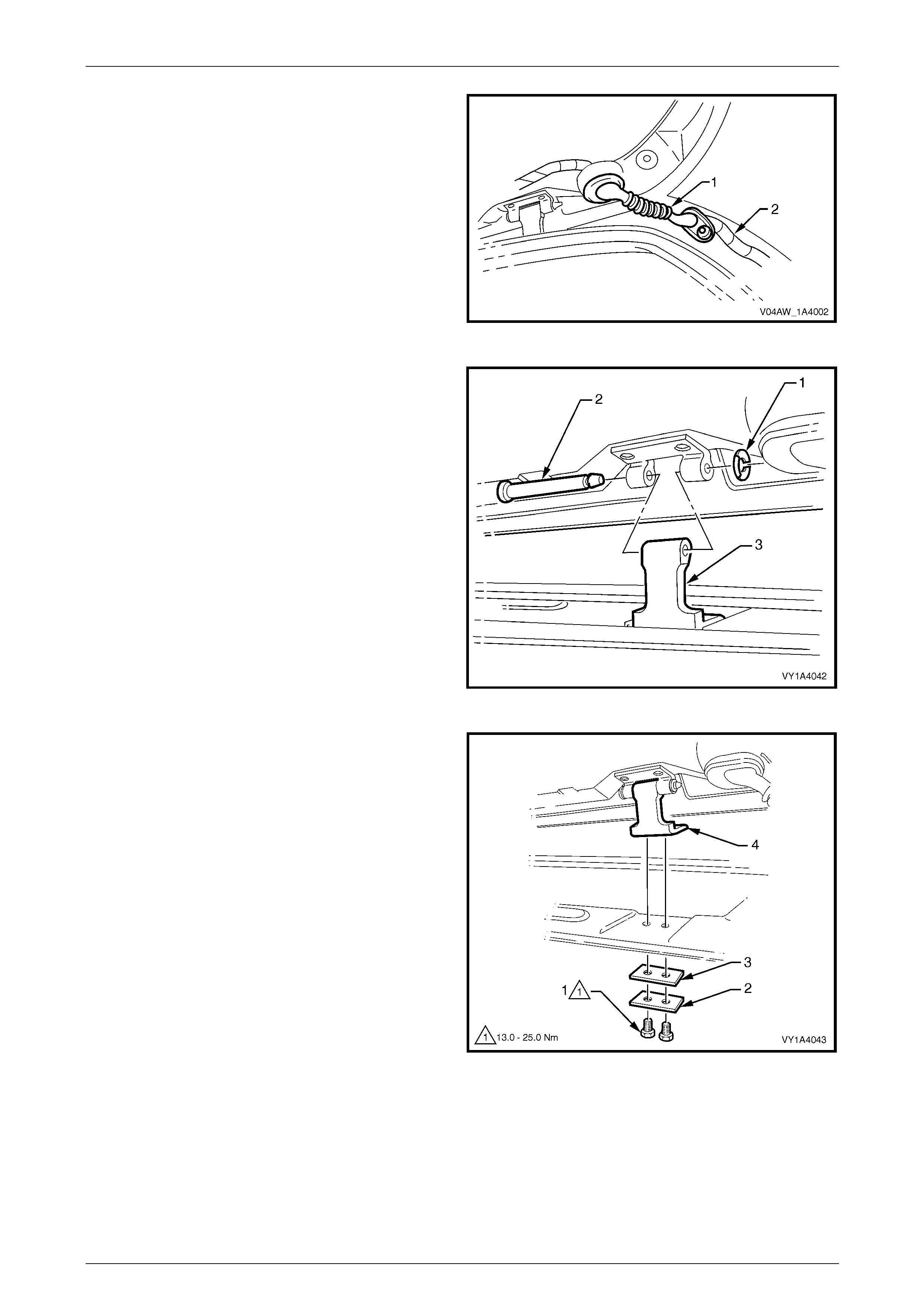

1 With the aid of an assistant to support the hood, use a

fine flat-bladed screwdriver to remove the retainer (1)

securing the hood strut assembly (2) to the hood strut

ball stud (3).

NOTE

The retainer can spring off the hood strut

assembly and be easily lost.

2 Remove the two Torx-head screws (4), attaching the

strut assembly to the fender.

3 Disconnect the strut assembly from the hood and

remove.

4 If required, unscrew the hood strut ball stud and

washer (5) from the hood.

Figure 1A4 – 10

Reinstall

Reinstallation of the hood strut assembly is the reverse of the removal procedure, noting the following:

1 Apply a small amount of NLGI No. 1 lithium grease or equivalent to the inside of the strut ball cup.

2 Tighten the fasteners to the correct torque specification.

Hood strut ball stud

torque specification.................................13.0 – 22.0 Nm

Hood strut assembly

to fender attaching screw

torque specification.................................10.0 – 14.0 Nm

3 Check for correct operation of the hood strut assembly.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–16

Page 1A4–16

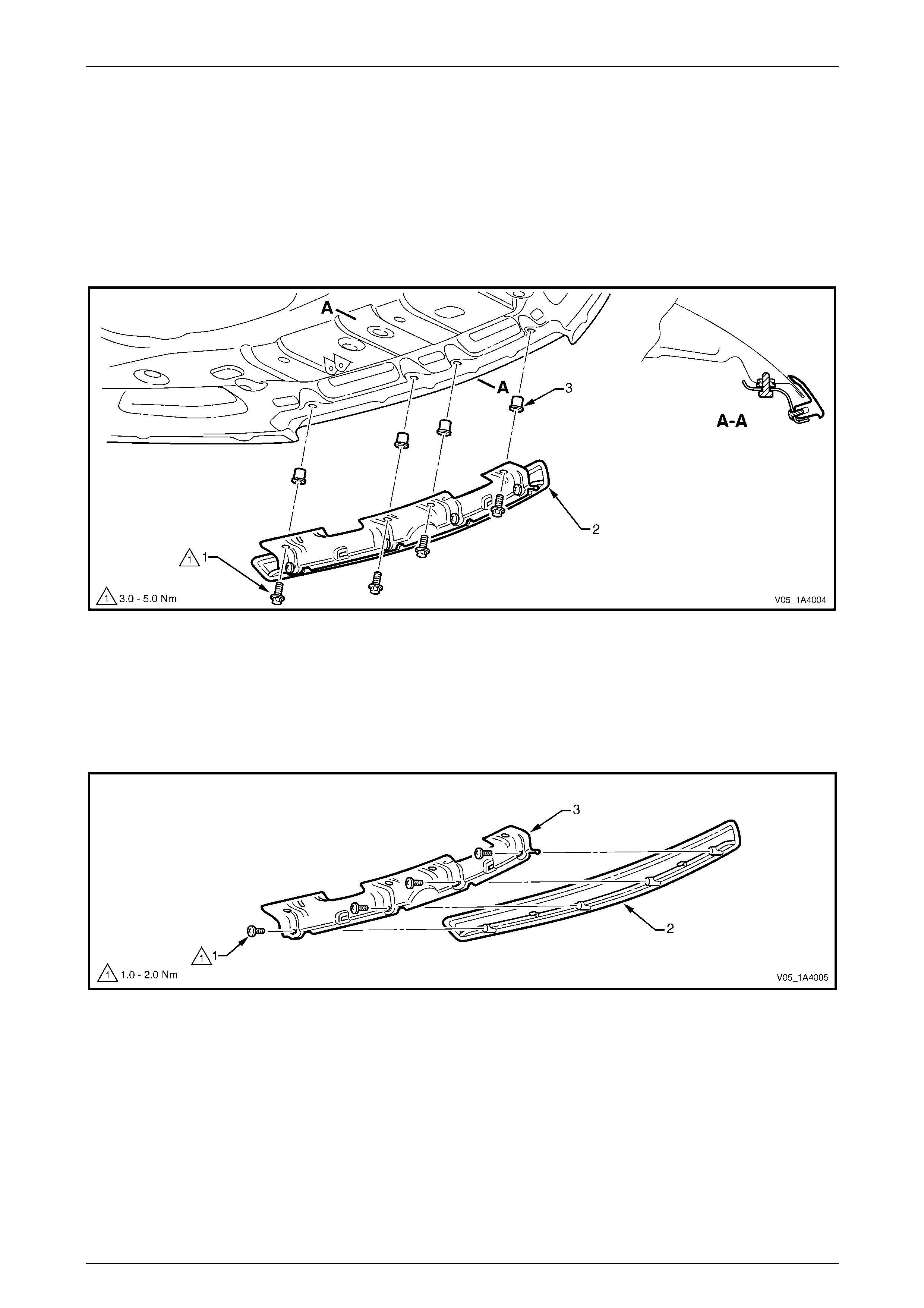

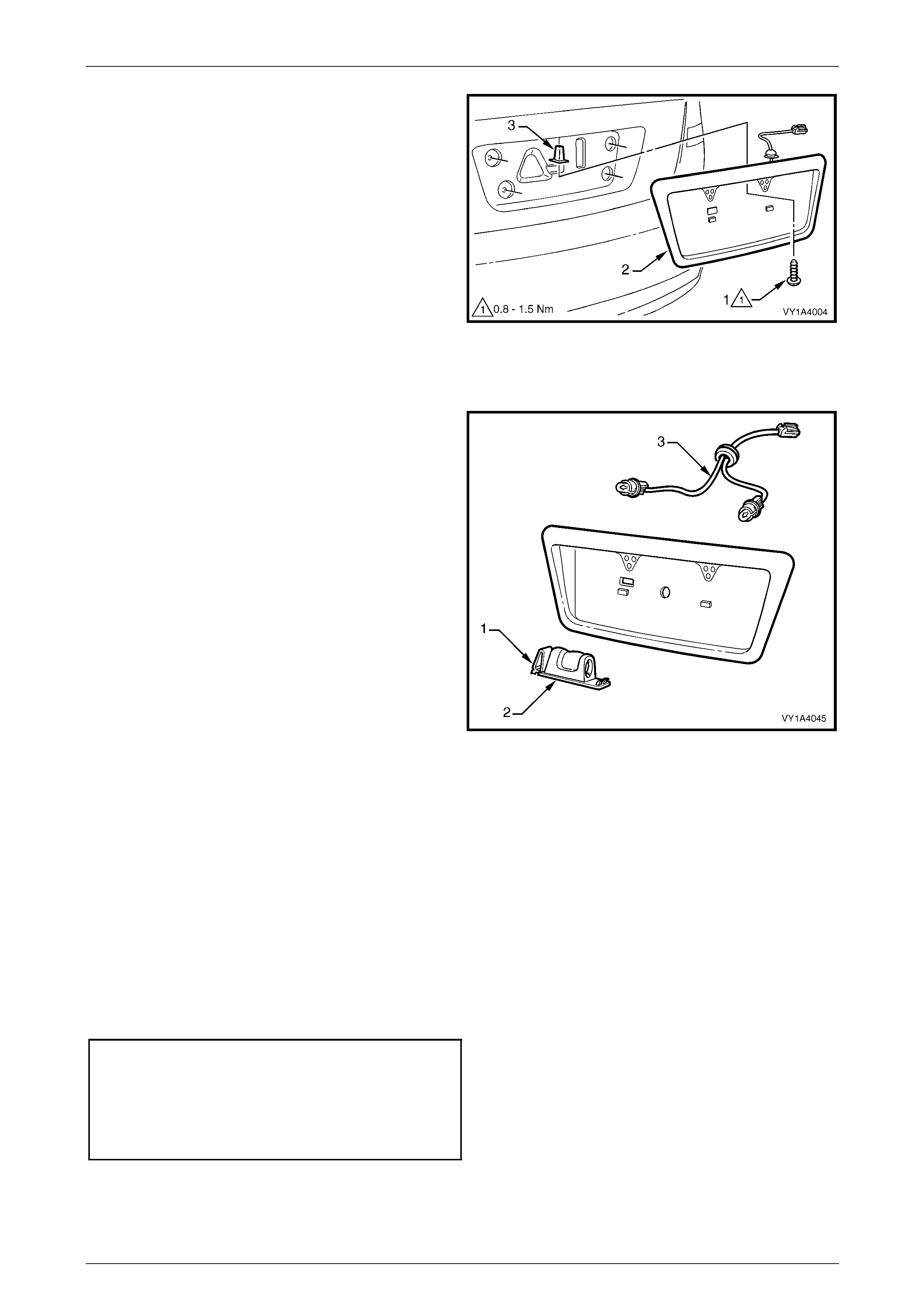

2.7 Hood Front Moulding Assembly

LT Section No. — XX–XXX

Remove

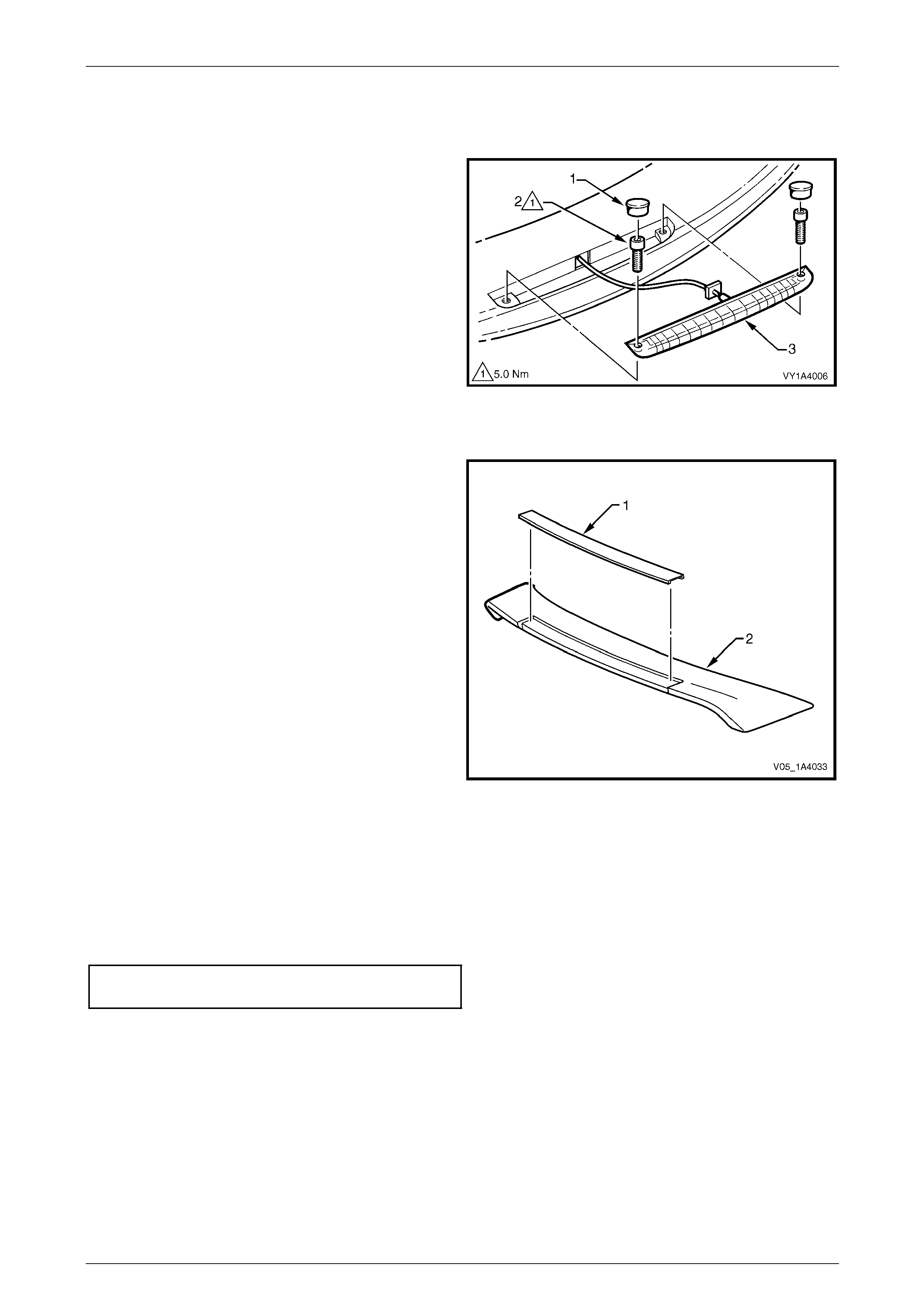

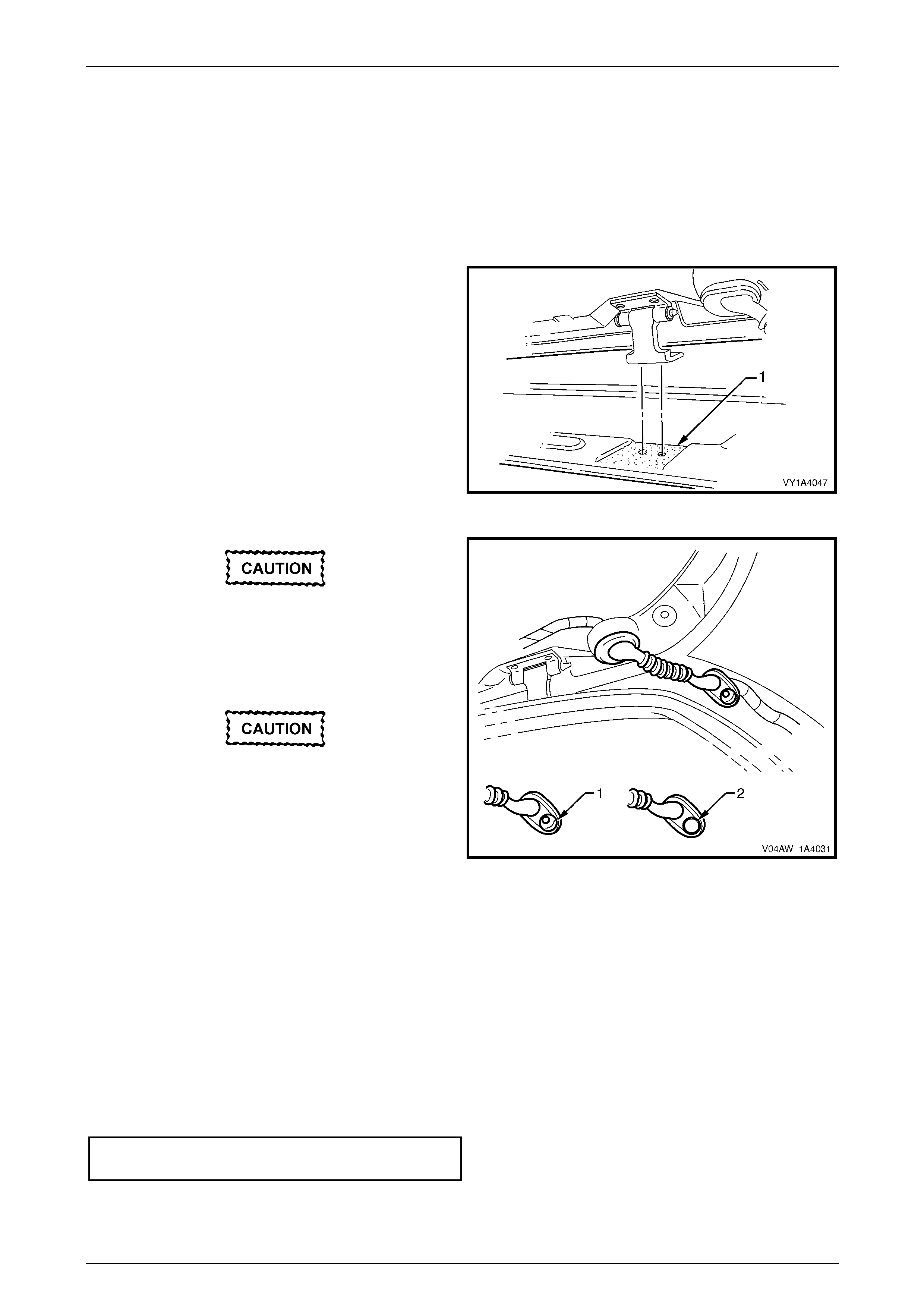

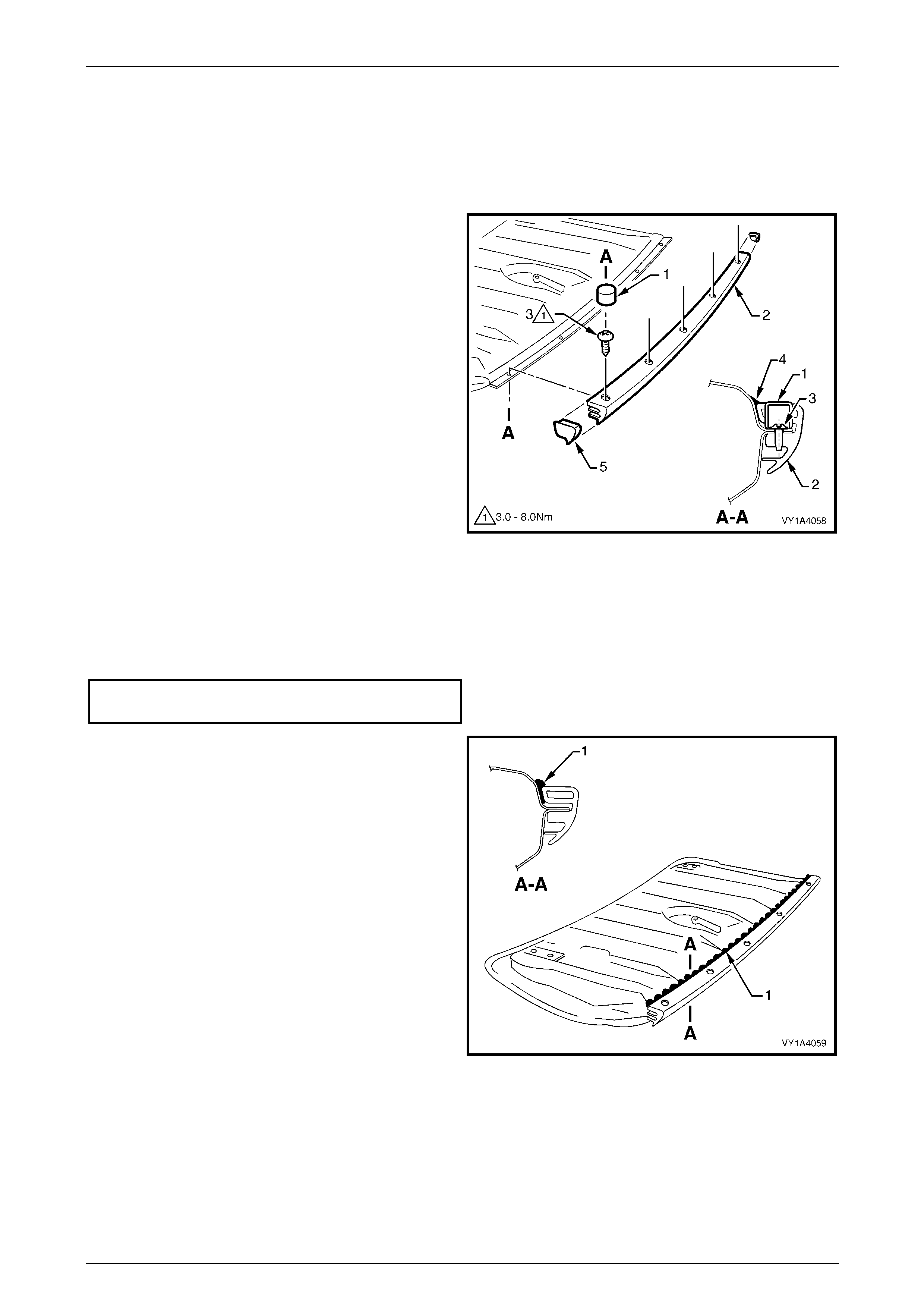

1 Raise the hood.

2 Remove the four screws (1) attaching the front moulding assembl y (2) to the hood inner panel and rem ove the

moulding assembly.

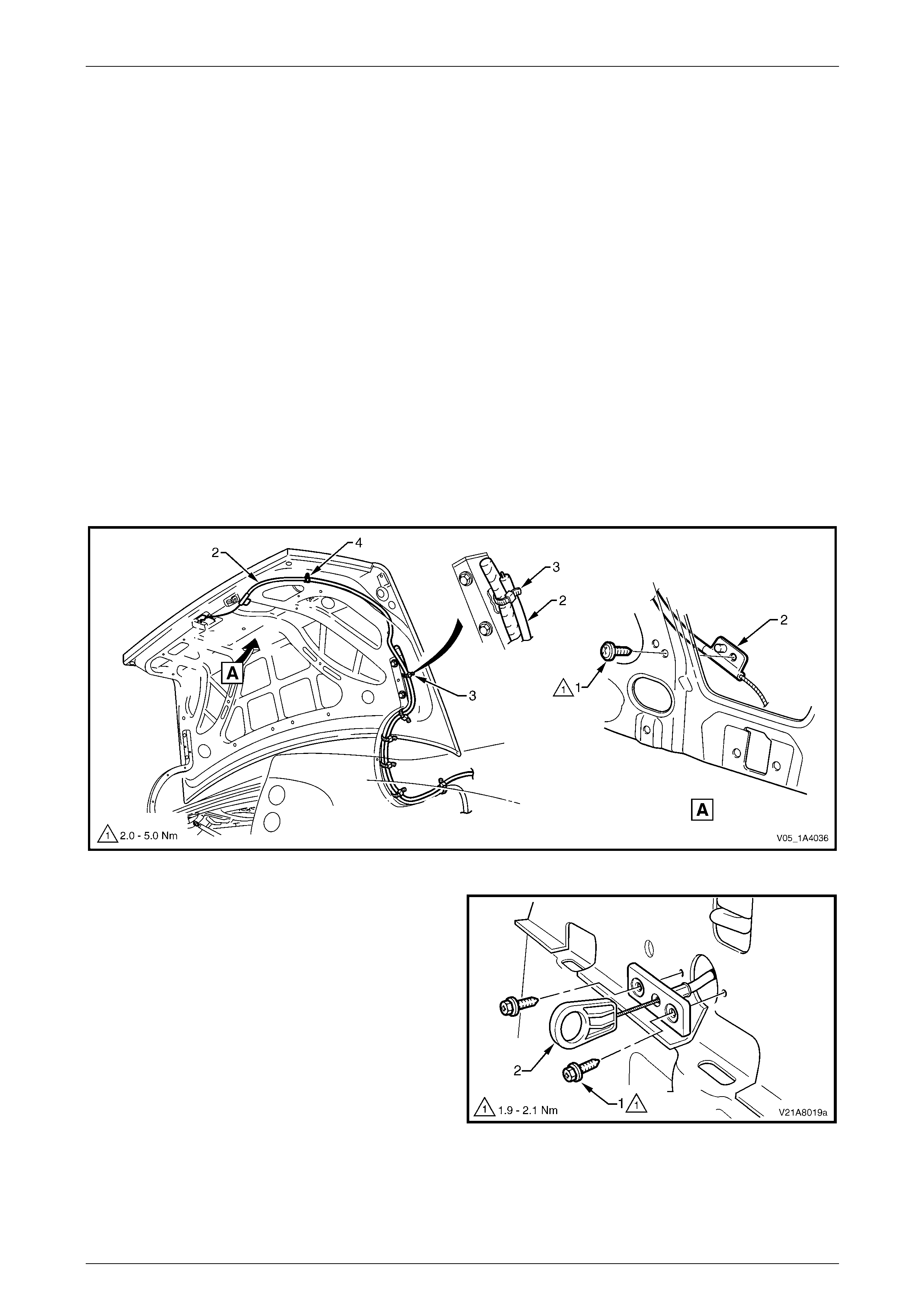

Figure 1A4 – 11

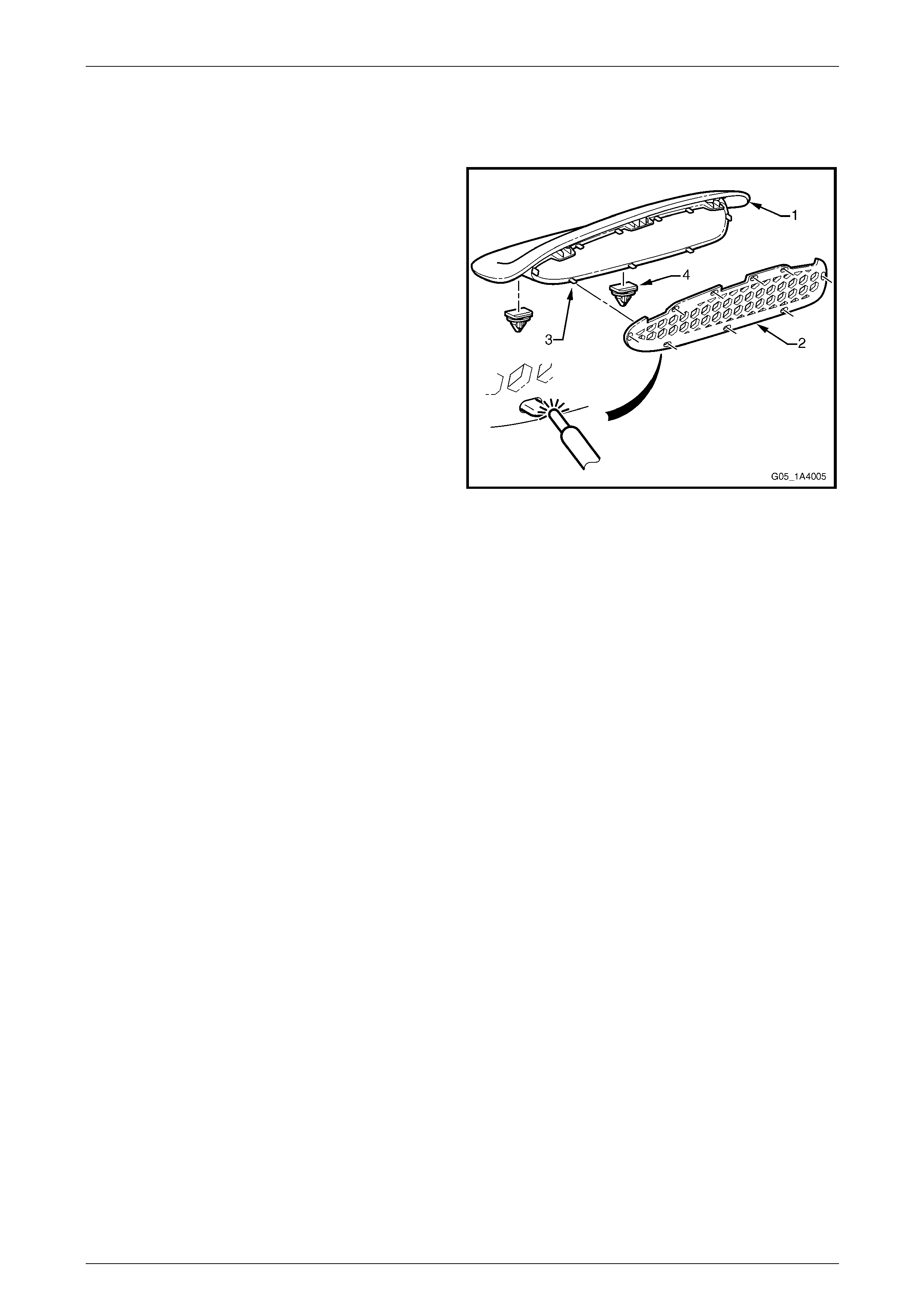

Disassemble

1 Remove the four screws (1) attaching the hood front moulding (2) to the hood moulding mounting bracket (3),

refer to Figure 1A4 – 12.

2 Unclip the moulding from the mounting bracket and remove.

Figure 1A4 – 12

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–17

Page 1A4–17

Reassemble

Reassembly of the hood front moulding assembly is the reverse of the disassembly procedur e. Tighten the screws to the

correct torque specification.

Hood front moulding attaching

screw torque specification...........................1.0 – 2.0 Nm

Reinstall

Reinstallation of the hood front moulding assembly is the reverse of the remova l procedure, noting the follo wing:

Use only M5 nutserts for this application;

some generic nutserts may not be suitable.

1 If a new hood has been fitted, install four M5 nutserts (3), refer to Figure 1A4 – 11, into the holes in the hood inner

panel using a commercially-available nutsert gun.

2 Tighten the screws to the correct torque specification.

Hood front moulding assembly

screw torque specification...........................3.0 – 5.0 Nm

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–18

Page 1A4–18

2.8 Hood and Hinge Assemblies

LT Section No. — 12–425

Remove

1 If required, remove the following components:

a Hood primary latch striker assembly, refer to 2.1 Hood Primary Latch Striker Assembly.

b Hood secondary latch assemb ly, refer to 2.4 Hood Secondary Latch Assembly.

c Hood insulator, refer to 2.5 Hood Insulator.

d Where fitted, the hood front moulding assembl y, refer to 2.7 Hood Front Moulding Assembly.

2 Raise and support the hood.

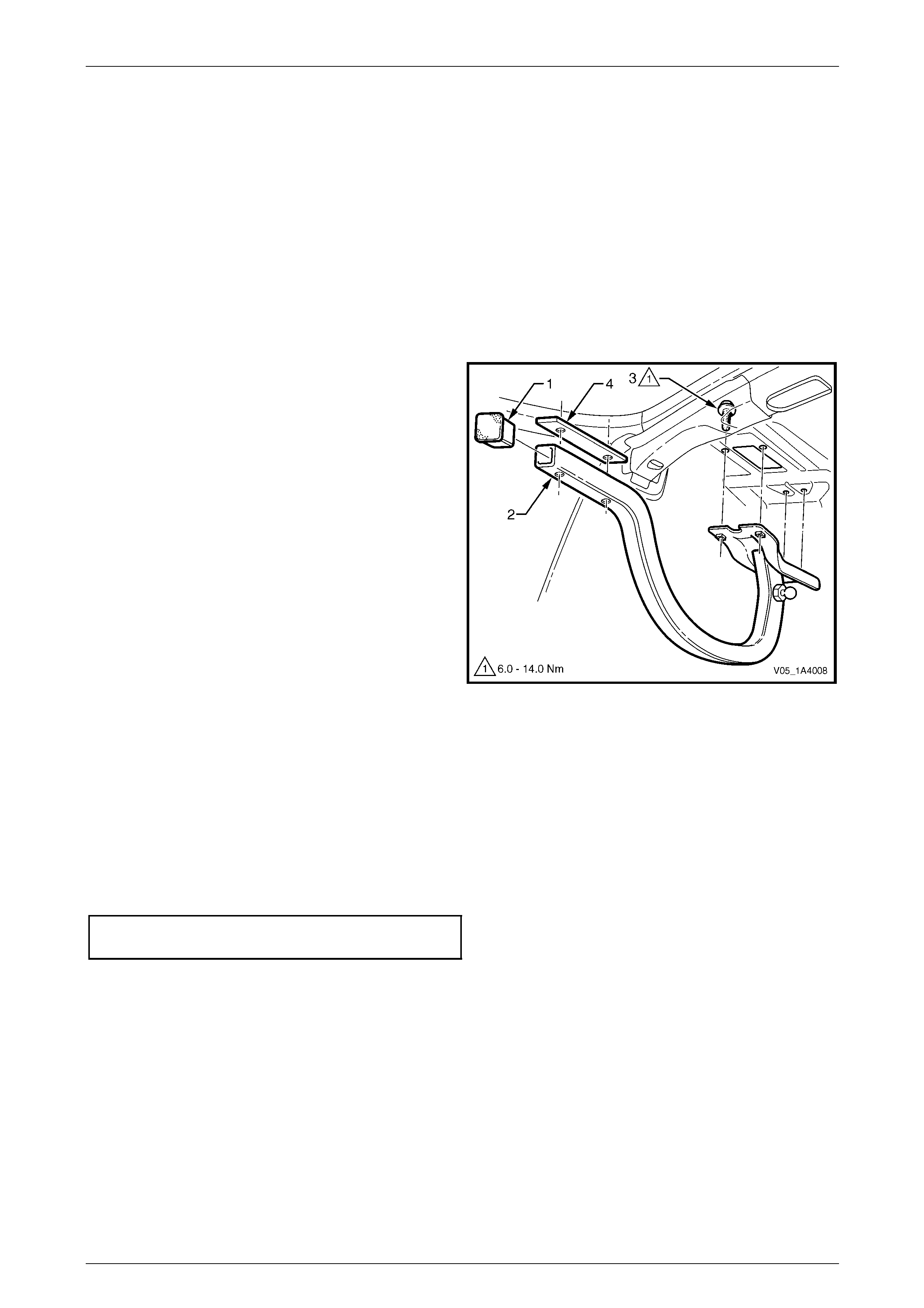

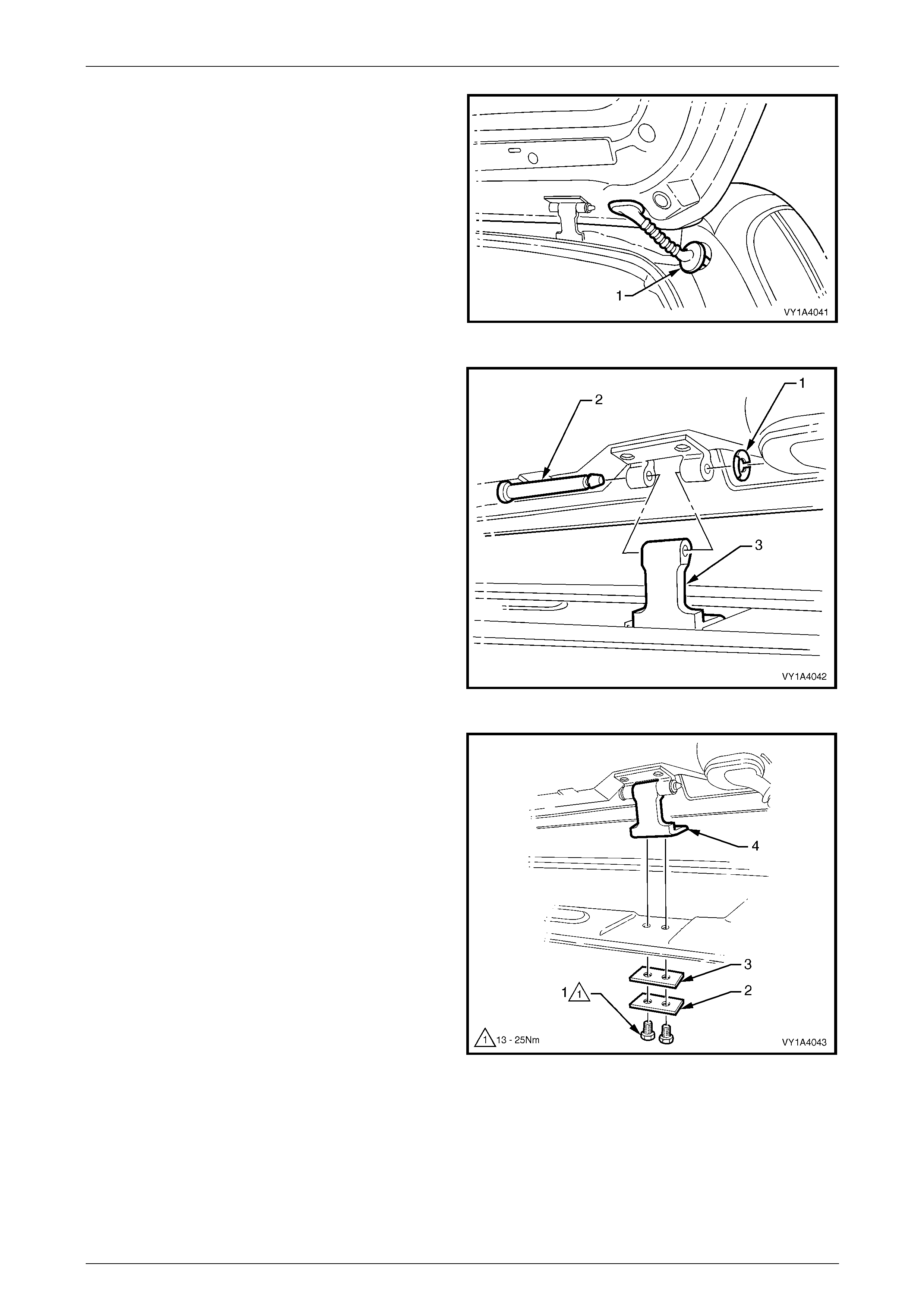

3 If required, unscrew and remove the hood adjust

bumper (1), three places, from the centre and on each

side of the hood.

4 Disconnect the hood strut assemblies from the hood,

refer to 2.6 Hood Strut Assembly.

NOTE

The lower end of the hood strut assembly does

not need to be removed.

Figure 1A4 – 13

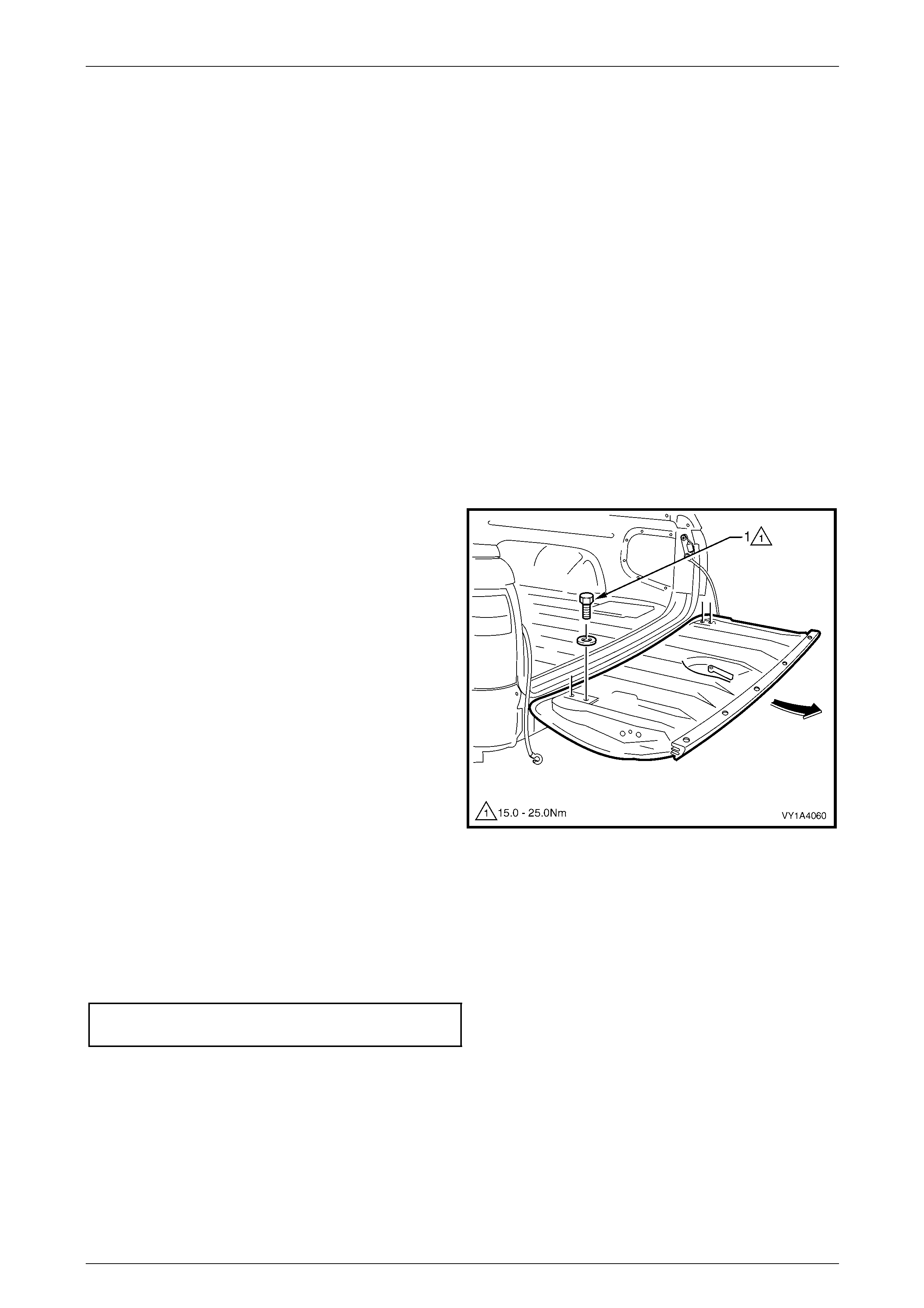

5 To remove the hood:

NOTE

Alignment of the hood is not required if the

following method is used to remove the hood.

a If the hood will be reinstalled:

(1) Remove the screw (1) attaching the upper

hinge section (2) and lower hinge

section (3) from each hood and hing e

assembly.

(2) With the aid of an assistant, slide the hood

out of the locating tabs (4) and remove the

hood.

NOTE

Alignment of the hood may be required if the

following method is used to remove the hood.

b If a new hood will be installed:

(1) Remove the two screws (5) attaching the

upper hinge section to the hood from each

hood and hinge assembly.

(2) With the aid of an assistant, remove the

hood.

Figure 1A4 – 14

6 If required, remove the lower hinge section, refer to Figure 1 A4 – 14:

a Remove the screw (1) attaching the upper hinge section (2) and lower hinge section (3).

b Remove the plenum cover assembly, refer to Section 12N Wipers, Washers and Horn.

c Remove the two screws (6) attaching the lower hinge section to the body and remove the lo wer section.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–19

Page 1A4–19

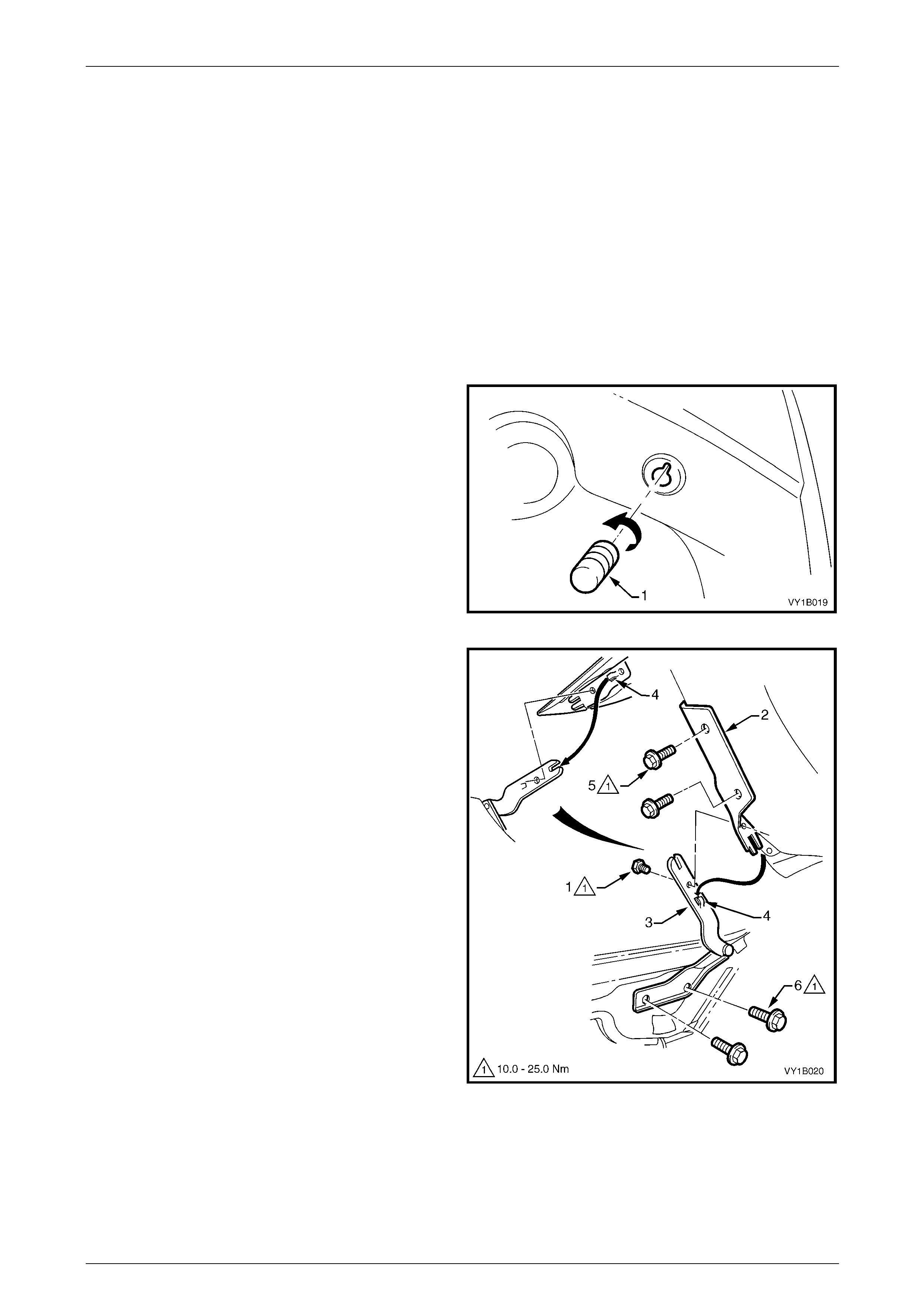

Reinstall

Reinstallation of the hood and hinge assemblies is the rev erse of the removal procedure, noting the following:

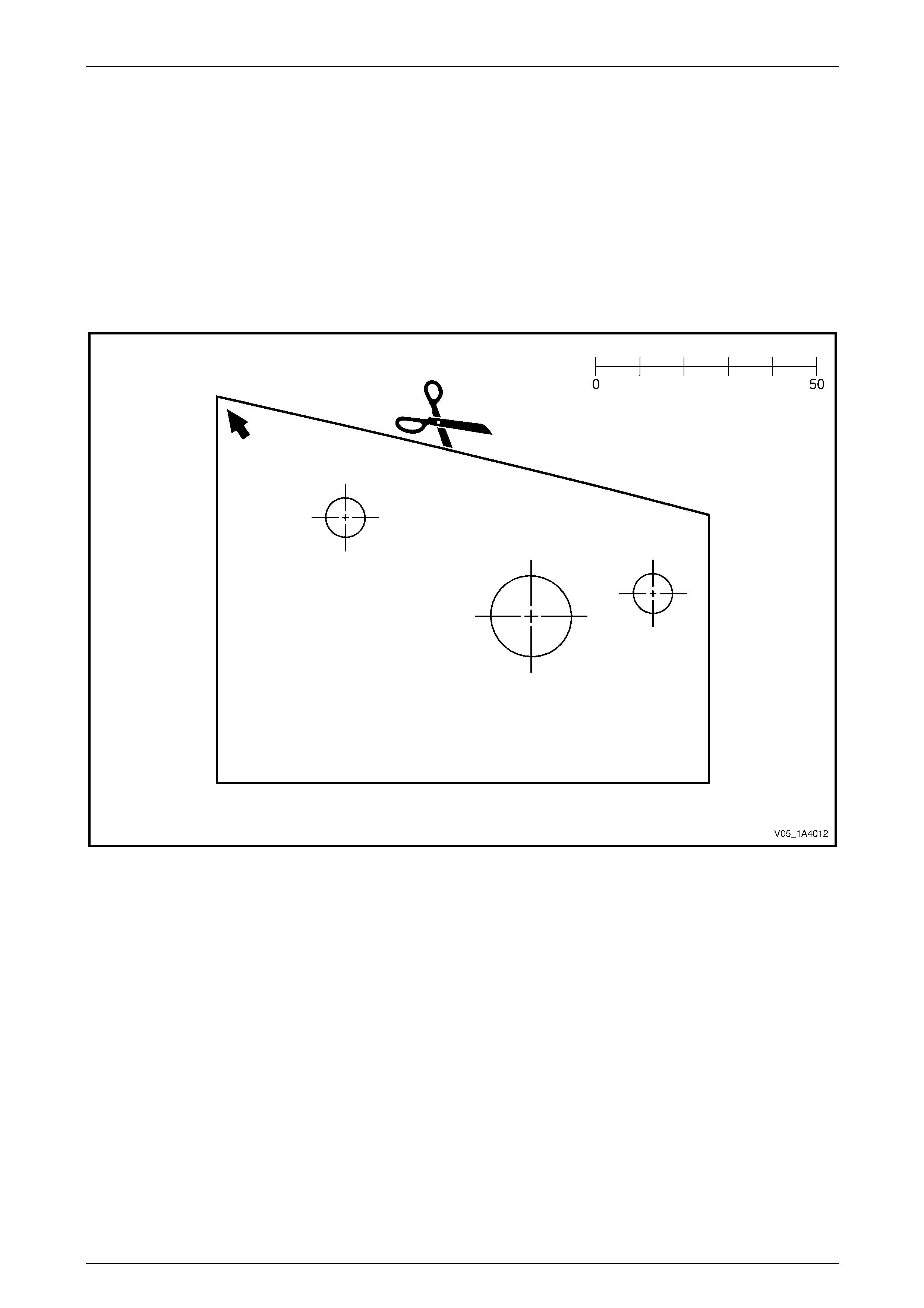

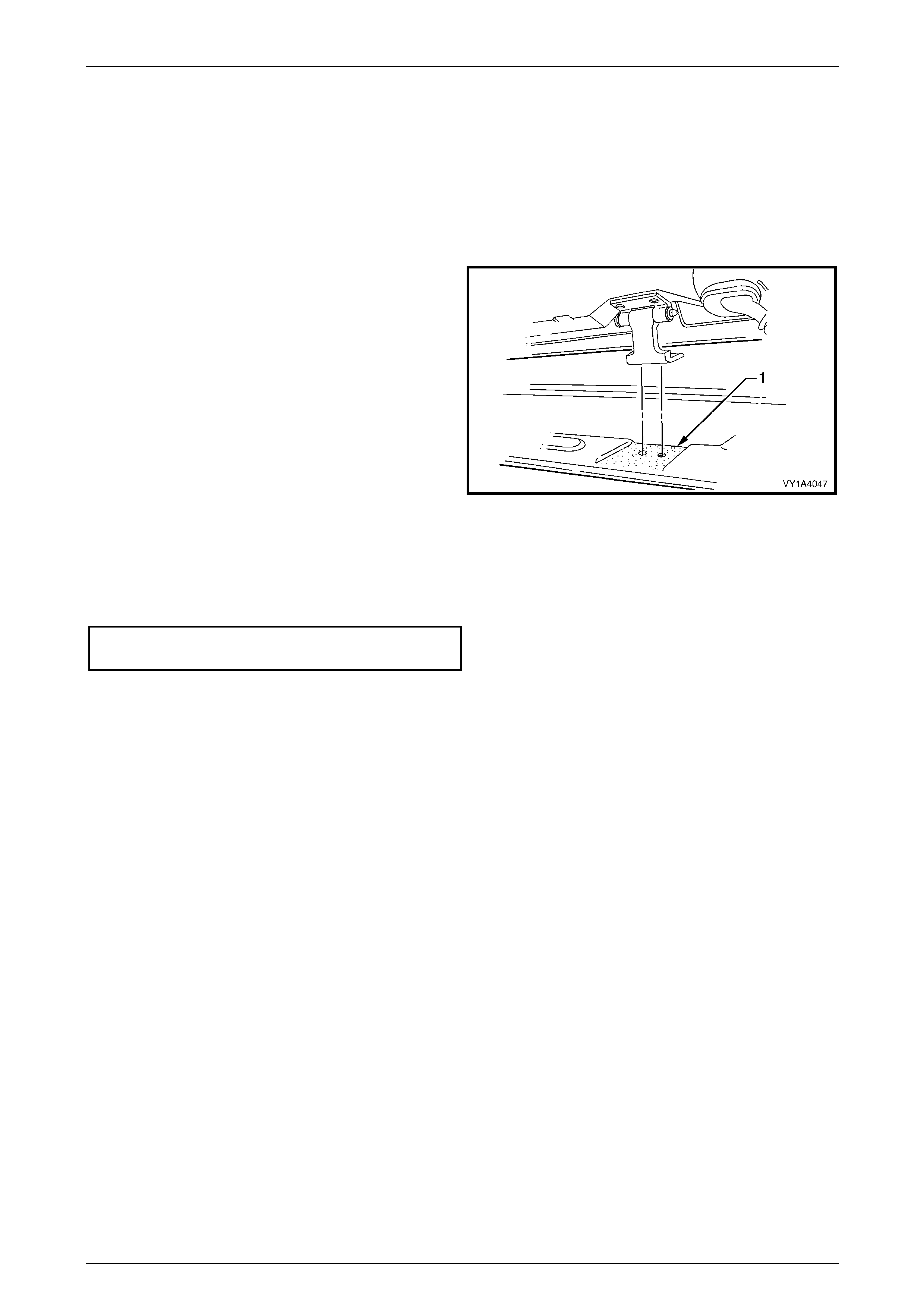

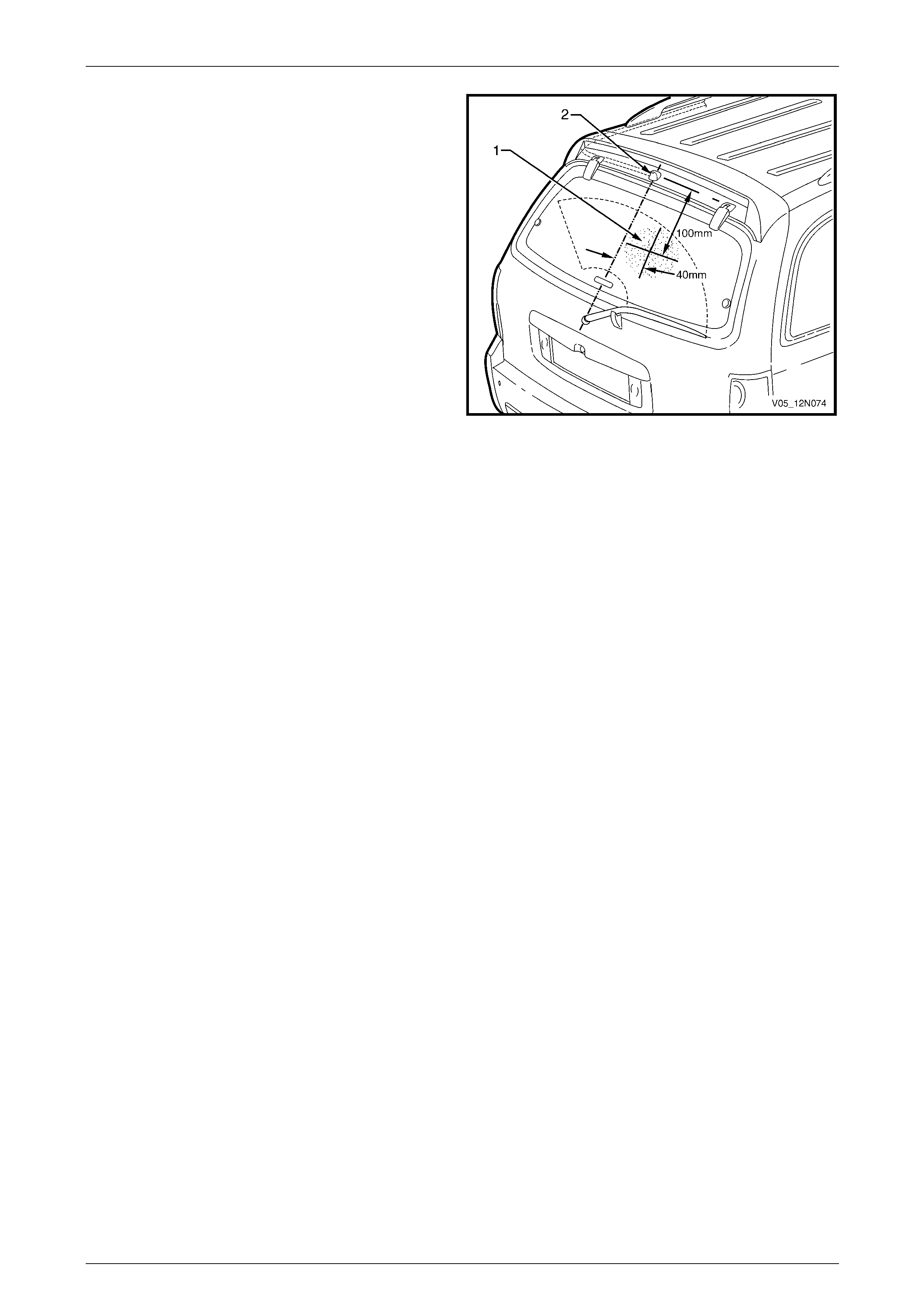

1 If fitting a replacement hood on either a Leve l 2 or 3 vehicle, before refinishing the hood panel drill a hole to

accommodate the hood front mouldin g, refer to F igure 1A4 – 15:

a Measure along the hood centre-line and mark the centre point of the hole (1).

b Drill a 3 mm pilot hole through the outer panel only.

c Enlarge and slot the hole to a width of 5 mm wide by 7 mm long.

d Remove any burrs as required.

Figure 1A4 – 15

2 If the lower hinge sections were removed from the body:

a Reinstall the lower hinge sections and, if possible, align them with any existing marks. Otherwise, install the

lower hinge sections with the screws centrally in their holes.

b Temporarily tighten the screws.

3 If the upper hinge sections were removed from the hood:

a With the aid of an assistant, reinstall the upper hinge sections to the hood and, if possible, alig n them with

any existing marks. Otherwise, install the upper hinge sections with the screws centrally in their holes.

b Temporarily tighten the screws.

4 If the screw attaching the upper hinge section and lower hinge section were removed:

a With the aid of an assistant, slide the hood and upper hing e sections onto the lower hinge sections, ensuring

the upper hinge sections and lower hinge sections are correctly seated together.

b Tighten the screws to the correct torque specification.

Upper hinge section attaching

screw torque specification.......................10.0 – 25.0 Nm

Lower hinge section attaching

screw torque specification.......................10.0 – 25.0 Nm

Hood hinge scre w

torque specification.................................10.0 – 25.0 Nm

5 Install the hood adjust bumpers to their original position or half-way along the thread, refer to Figure 1A4 – 13.

6 Install or reconnect the hood strut assemblies, refer to 2.6 Hood Strut Assembly.

7 If required, adjust the hood, refer to Adjust in this Section.

8 If removed, reinstall the plenum cover assembly, refer to Section 12N Wipers, Washers and Horn.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–20

Page 1A4–20

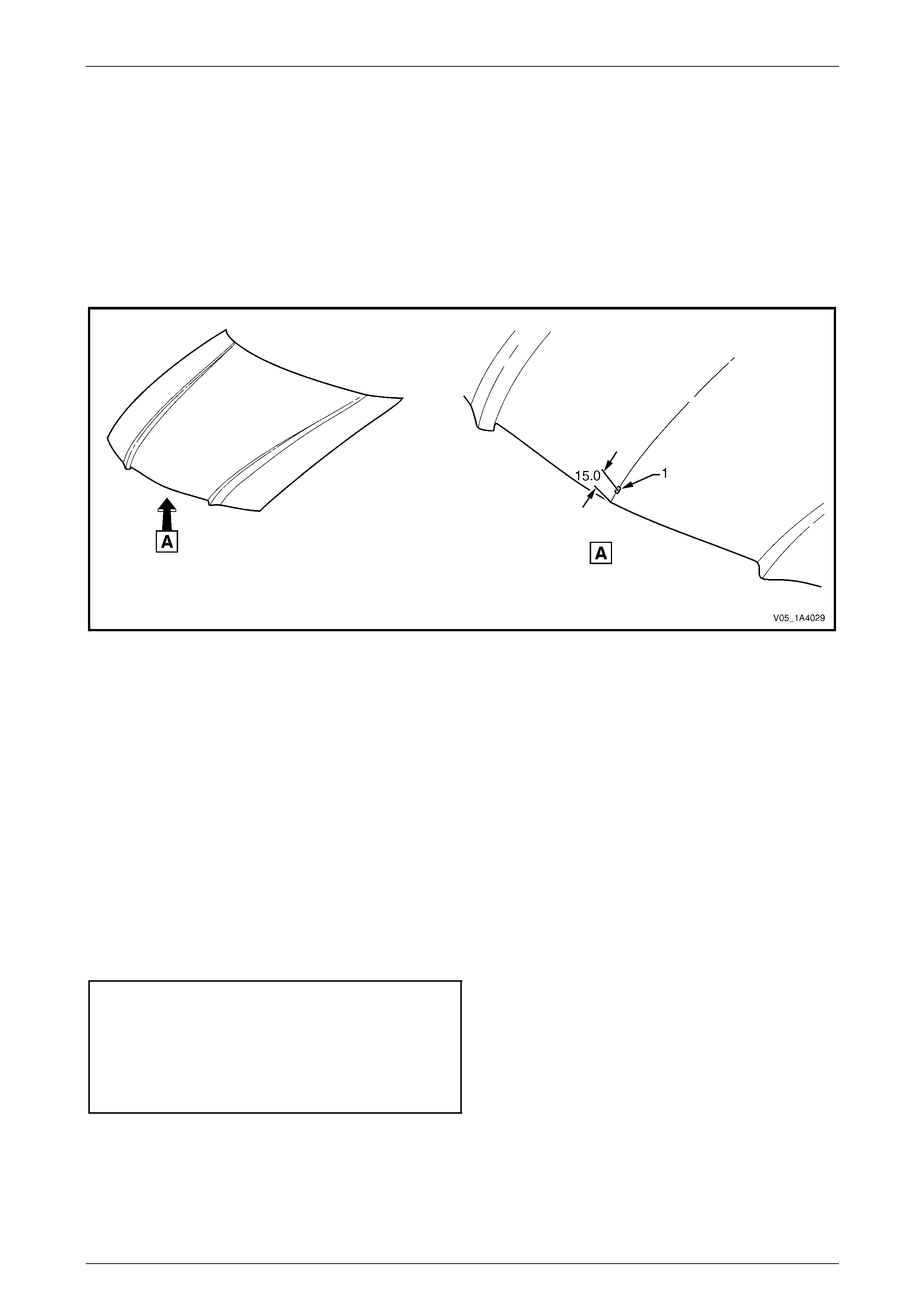

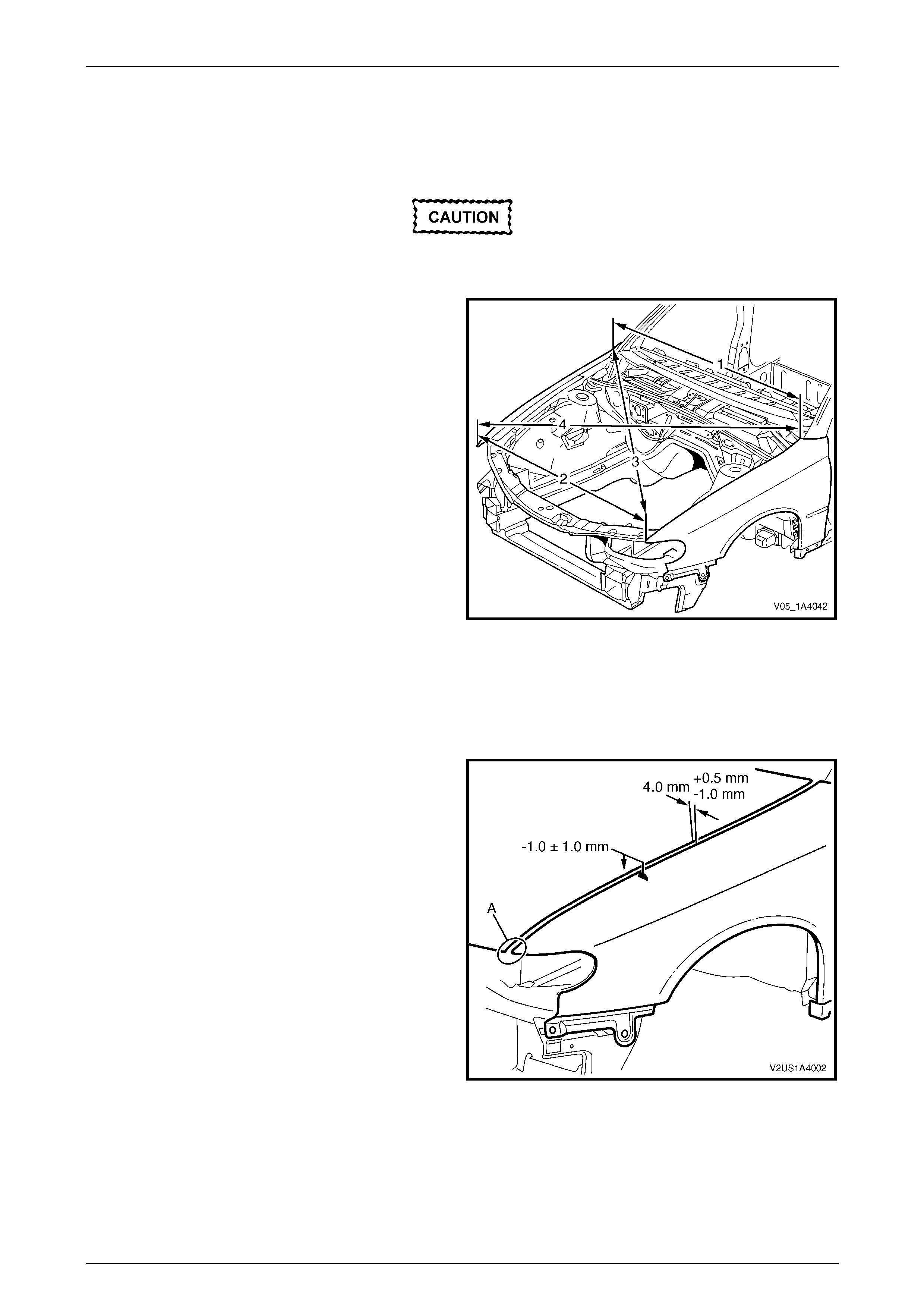

Adjust

Correct alignment of the hood is critical to its operation and to the aesthetics of the vehicle. If the fenders are not

correctly positioned, the hood can not be aligned correctly.

Depending upon the repa irs performed, it may be advantageous to p erform a measurement check between the fenders

before adjusting the hood.

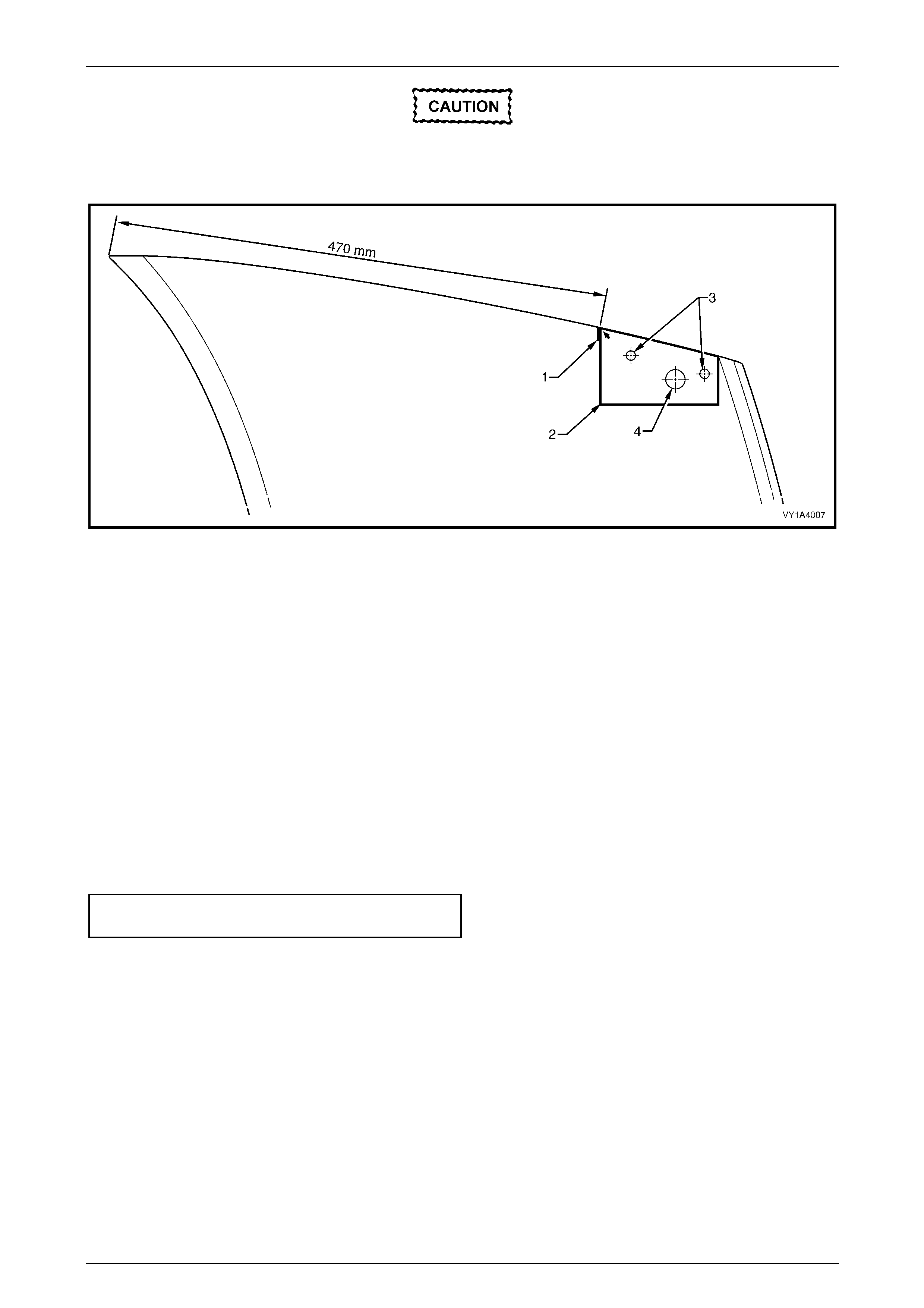

Fender Alignment

1 Check the distance between the front doors and fen ders are correct. If not correct, rectify before proceeding, refer

to Section 1B Sheetmetal.

Paint damage may occur. Use care and, if

required, touch up any paint damage.

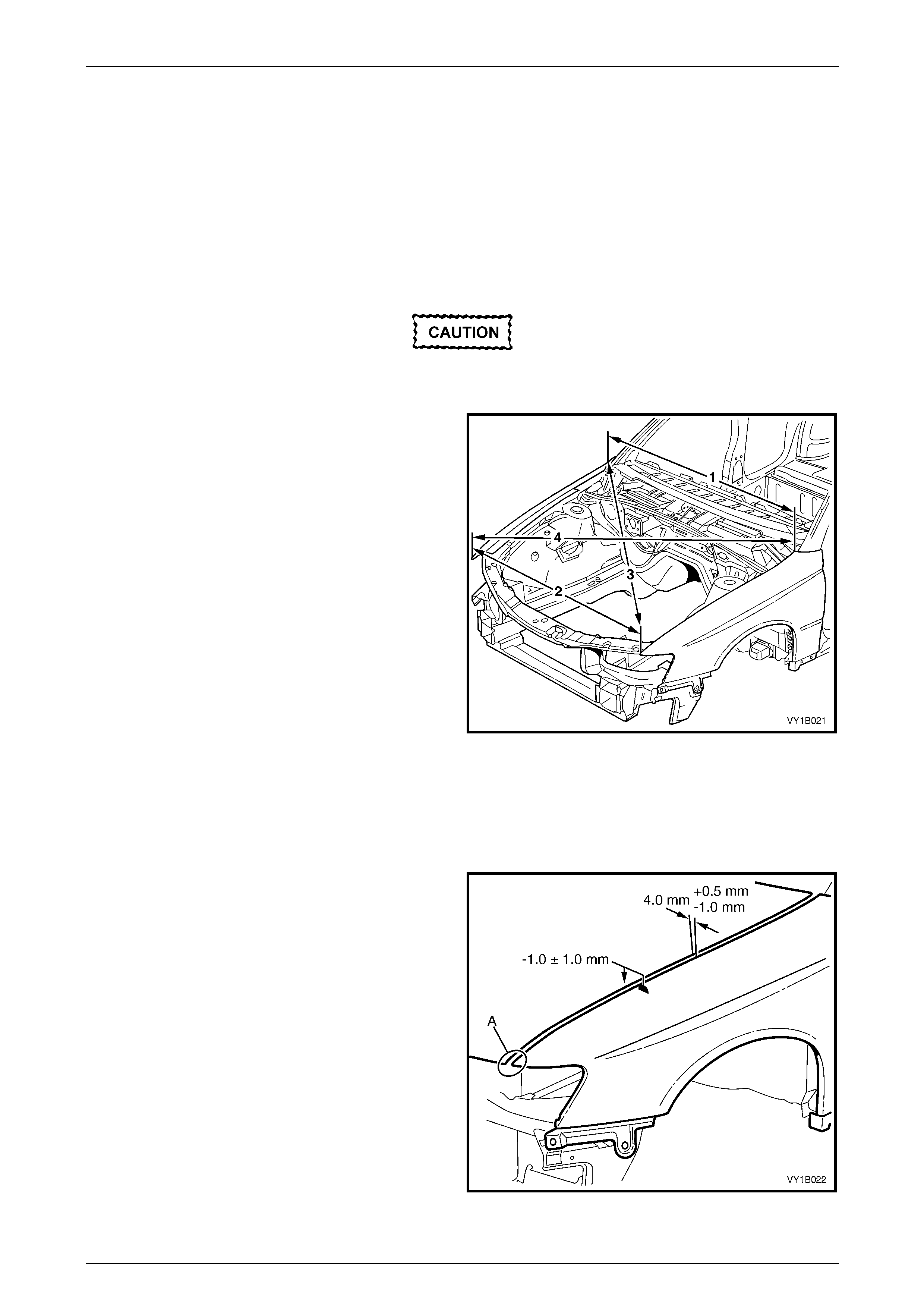

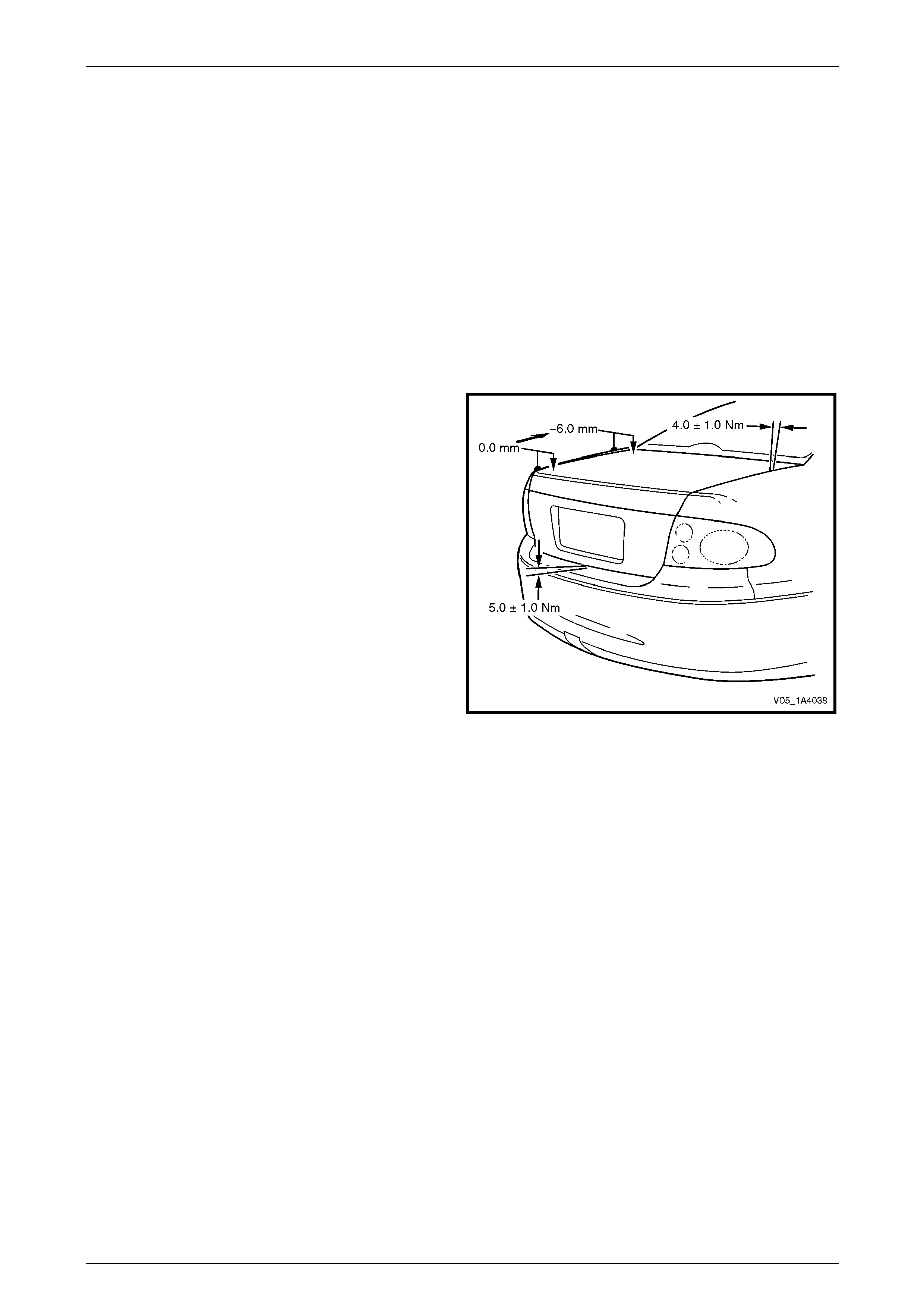

2 Measure the distance between the rear of each

fender (1). This distance should be the width of the

rear of the hood plus 8.0 mm. If not, adjust the

fenders, refer to Section 1B Sheetmetal.

3 Measure the distance between the front of each

fender (2). This should be the width of the front of the

hood plus 8.0 mm. If not, adjust the fenders, refer to

Section 1B Sheetmetal.

4 Measure the distance between a suitable point at the

rear of the left-hand fender and front of the right-hand

fender (3). Note the length.

5 Measure the distance between the opposite fender

points (4). This measurement must be within 1.5 mm

of result (3).

6 If the measurements are correct, align the hood as

follows. If not, adjust the fenders, refer to

Section 1B Sheetmetal.

Figure 1A4 – 16

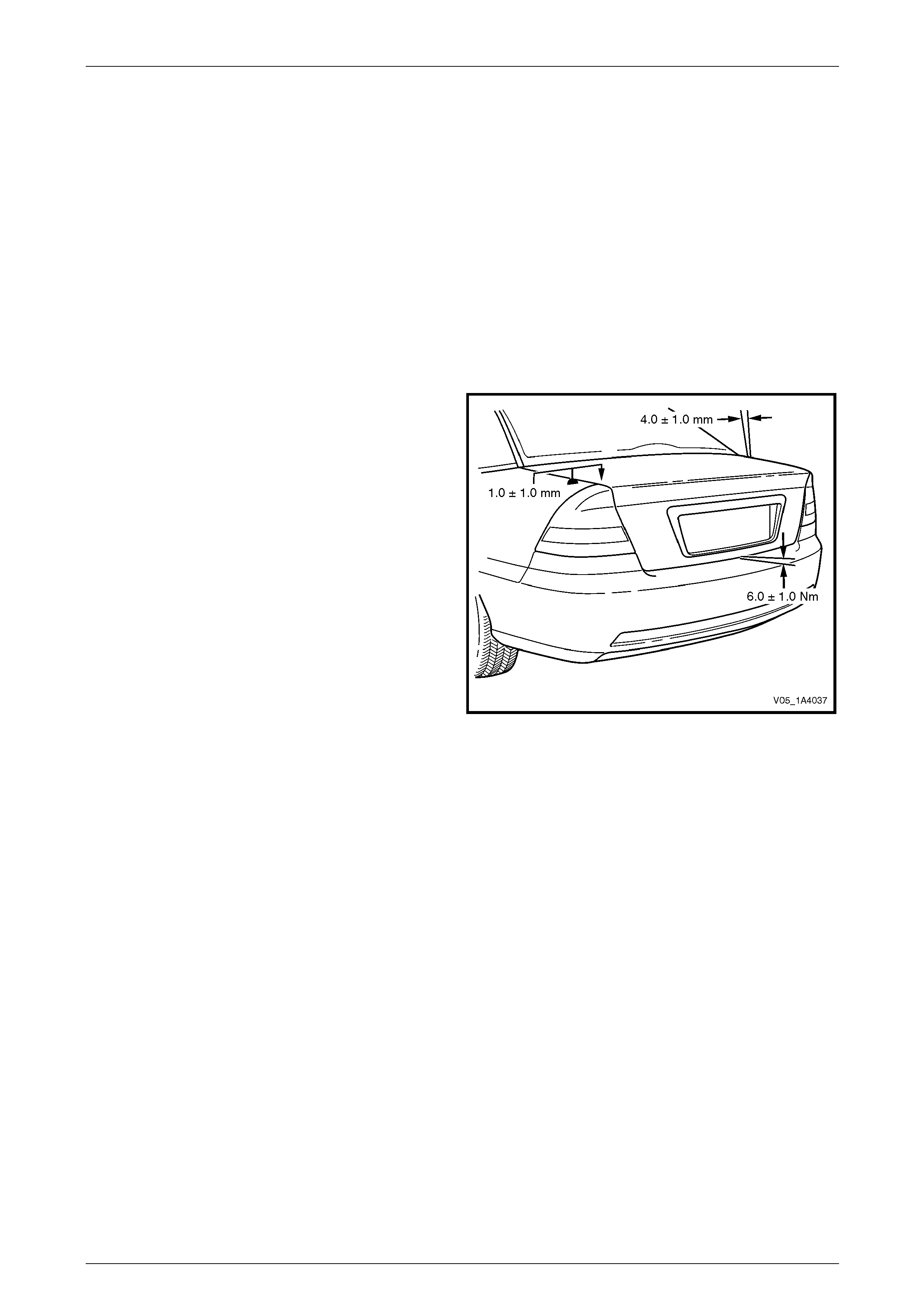

Hood Alignment

1 If fitted, remove the hood primary latch striker assembly, refer to 2.1 Hood Primary Latch Striker Assembl y.

2 Carefully close the hood, ensuring each side does not contact the fenders.

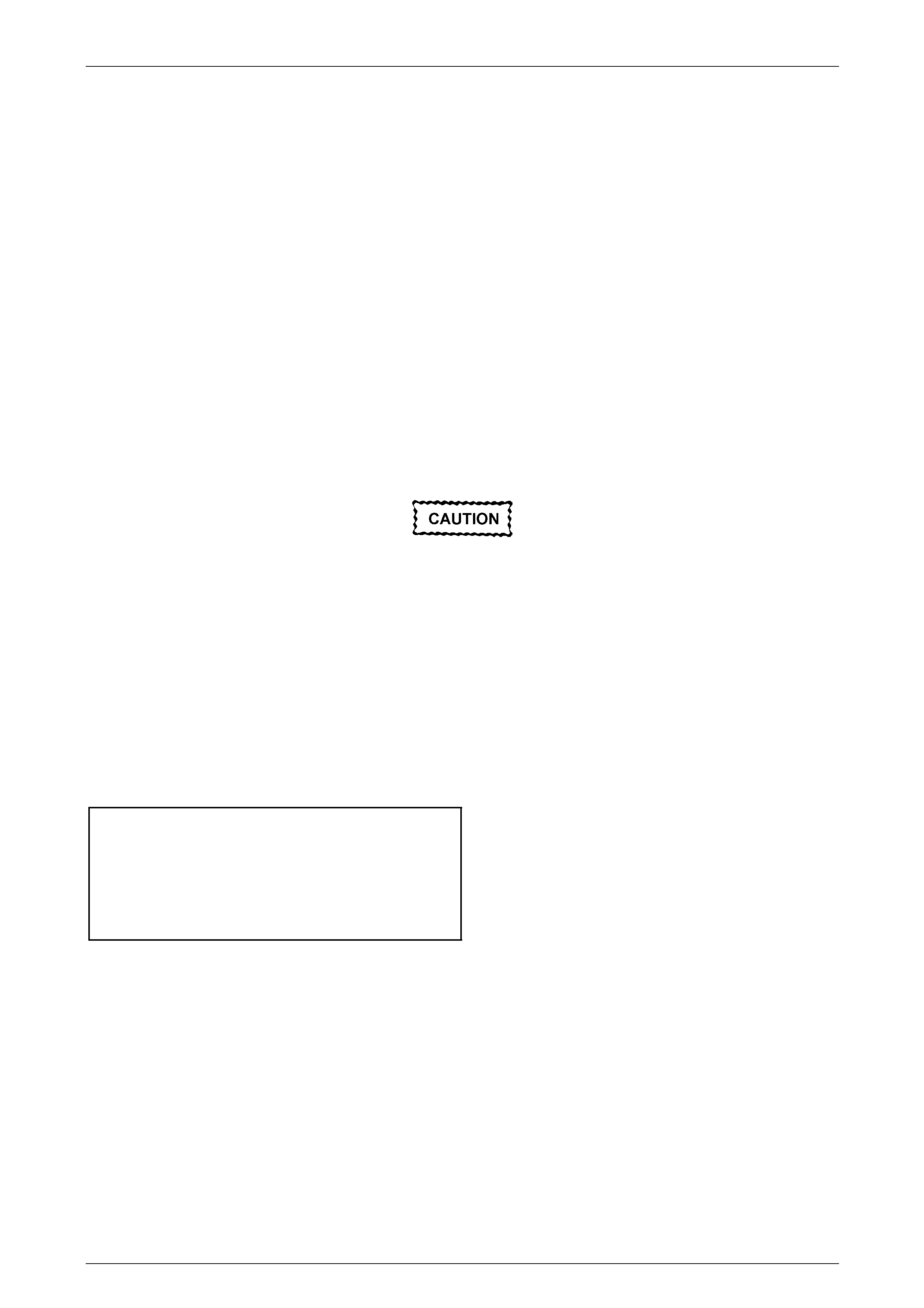

3 Check the alignment of the hood for:

• Length:

Compare to the front edge of the fenders; they

should be equal at point A.

• Width of gap:

Compare the gap bet ween the hoo d and the side

of each fender; the gap must be 4.0 mm

(+0.5 mm / –1.0 mm).

• Consistency of gap:

Compare the gap bet ween the hoo d and each

fender at the front, middle and rear; the gap

should be even.

• Height:

Compare the height of the hood with the fenders

at each corner; the hood height must be –1 mm

(±1.0 mm).

Figure 1A4 – 17

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–21

Page 1A4–21

4 Open the hood and, if required:

• Loosen the screws attaching the hood to both upper hinge sections for fore and aft adjustment, refer to

Figure 1A4 – 14.

• Loosen the scre ws attaching both lower hinge sections to the body for rear height adjustment. If required, this

also provides fore and aft adjustment, refer to Figure 1A4 – 14.

• Turn the hood adjust bumper clockwise to lower the front of the hood or anticlockwise to raise the front of the

hood, refer to Figure 1A4 – 13.

NOTE

Do not make all adjustments at once. Perform

one adjustment, then carefully close the hood;

check its position and make further adjustments

until the correct alignment is a c hieved.

5 Install the hood primary latch striker assemb ly, refer to 2.1 Hood Primary Latch Striker Assembly.

6 Lower the hood while watching the alignment of the hood primary latch striker assembly and the latch hole.

7 Check the hood primary latch striker bolt do es not foul the latch hole and the hood alignment does not alter. If

required, adjust the hood primary latch striker bolt position.

Do not push the hood closed as damage to

the panel surface may occur. If it does not

close on the first attempt, try again from a

slightly greater height.

8 Close the hood by dropping it from a height of approximately 300 mm.

9 Check the height difference between the front of the hood and both fenders:

a If required, adjust the usable length of the hood primary latch striker bolt by loosening the hood primary latch

striker nut and rotating the hood primary latch striker bolt with a flat-bladed screwdriver, refer to

Figure 1A4 – 1.

b If required, adjust the hood adjust bumpers, refer to Figure 1A4 – 13.

10 Tighten the screws and nuts to the correct torque specification.

Upper hinge section attaching

screw torque specification.......................10.0 – 25.0 Nm

Lower hinge section attaching

screw torque specification.......................10.0 – 25.0 Nm

Hood primary latch striker nut

torque specification.................................22.0 – 28.0 Nm

11 Recheck the alignment of the hood.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–22

Page 1A4–22

3 Service Operations — Hood,

Coupe

3.1 Hood Primary Latch Striker Assembly

LT Section No. — 12–050

Remove

1 Raise the hood.

2 Loosen the hood primary latch striker nut (1).

3 Using a flat-bladed screwdrive r , unscrew the hood

primary latch striker bolt (2) and remove the assembly.

4 If required, remove the washer (3), nut, hood pop-up

spring (4) and hood pop-up s prin g retain er (5).

Figure 1A4 – 18

Reinstall

Reinstallation of the hood primary latch striker assembly is the reverse of the removal procedure, noting the following:

1 Reassemble the hood primary latch striker assembly components as required.

2 Install the hood primary latch striker assemb ly to the

hood and tighten the hood primary latch striker bolt to

achieve a nominal length of 50 mm.

3 Apply a lubricant (NLGI No. 1 lithium grease or

equivalent) to the end of the striker bolt.

Do not push the hood closed as damage to

the panel surface may occur. If it does not

close on the first attempt, try again from a

slightly greater height.

Figure 1A4 – 19

4 Close the hood by dropping it from a height of about 300 mm.

5 If required, adjust the usable length of the striker bolt, refer to Adjust in this Section.

6 Tighten the hood primary latch striker nut to the correct torque specification.

Hood primary latch striker nut

torque specification.................................22.0 – 28.0 Nm

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–23

Page 1A4–23

Adjust

1 Check the difference in height between the front of the hood and the fenders, refer to F igure 1A4 – 3 5.

2 To adjust the usable length of the hood primary latch striker bolt:

a Open the hood.

b Loosen and hold the hood primar y latch striker nut while rotating the hood primary latch striker bolt with a flat-

bladed screwdriver.

c If required, set the hood adjust bumper to align the hood height, refer to 3.9 Hood and Hinge Assemblies.

3 Tighten the striker nut to the correct torque specification, ref er to Reinstall i n this Section.

Hood primary latch striker nut

torque specification.................................22.0 – 28.0 Nm

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–24

Page 1A4–24

3.2 Hood Primary Latch Spring

LT Section No. — 12–050

Remove

1 Raise the hood.

2 Remove the radiator upper shroud, refer to Section 6B3 Engine Cooling – GEN III V8.

3 Using a pair of pliers, grasp th e hood primary latch

spring at point (1) and carefully dis en gage it from the

front panel in the direction shown.

4 Slide the cable end of the hood primary latch

spring (2) to the open position in the direction shown

to clear the latch hole.

5 Unhook the hood primary latch release cable

assembly (3) from the latch spring.

6 Grasp the end of the latch spring at point (1), rotate to

vertical and manipulate the section of the spri ng in the

front panel out through the spring co il hole.

Figure 1A4 – 20

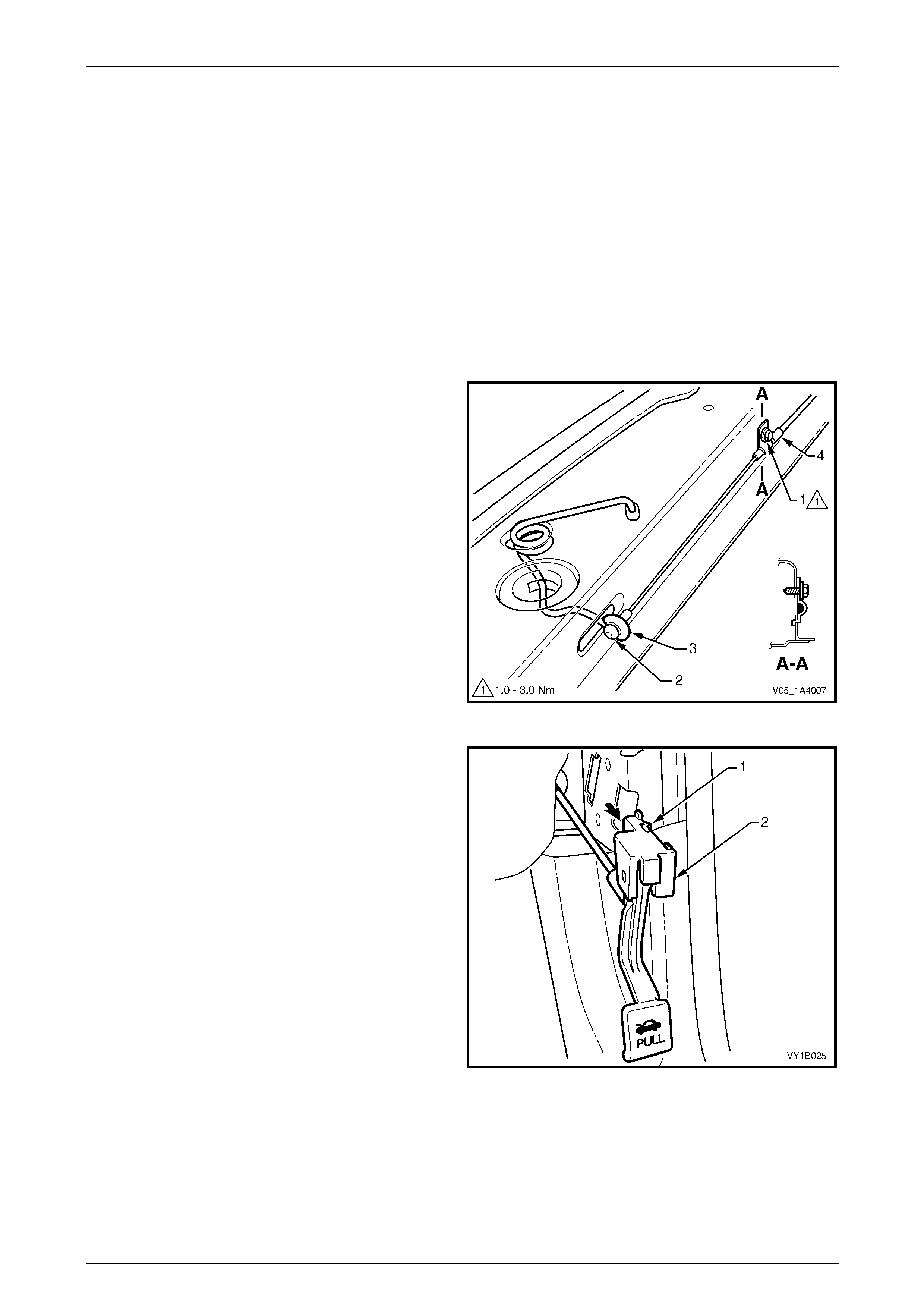

Reinstall

Reinstallation of the hood primary latch spring is the reverse of the removal procedure, noting the follo wing:

1 Check the hood primary latch release cable

adjustment by inserting a 16 mm pin (1) between the

spring and the latch hole and check there is no

clearance between the inner cable ferrule and the

spring (2).

2 If required, loosen the hood primary latch release

cable retainer screw (4), refer to Figure 1A4 – 20, and

adjust the latch release cable.

NOTE

Ensure the outer cable ferrule (5), refer to

Figure 1A4 – 20, is positioned before the

retainer.

3 Tighten the retainer screw to the correct torque

specification.

Hood primary latch release cable

retainer screw torque specification..............1.0 – 3.0 Nm Figure 1A4 – 21

4 Remove the 16 mm pin and check the hood primary latch spring for correct operation.

5 Apply NLGI No. 1 lithium grease or equivalent to the following locations, refer to the three points (3) indicated in

Figure 1A4 – 21:

• spring slot,

• latch hole to a depth of the spring slot, and

• spring coils.

Hood, Rear Compartment Lid, Liftgate and Endgate Page 1A4–25

Page 1A4–25

3.3 Hood Primary Latch Release Cable

Assembly

LT Section No. — 12–050

Remove

1 If required:

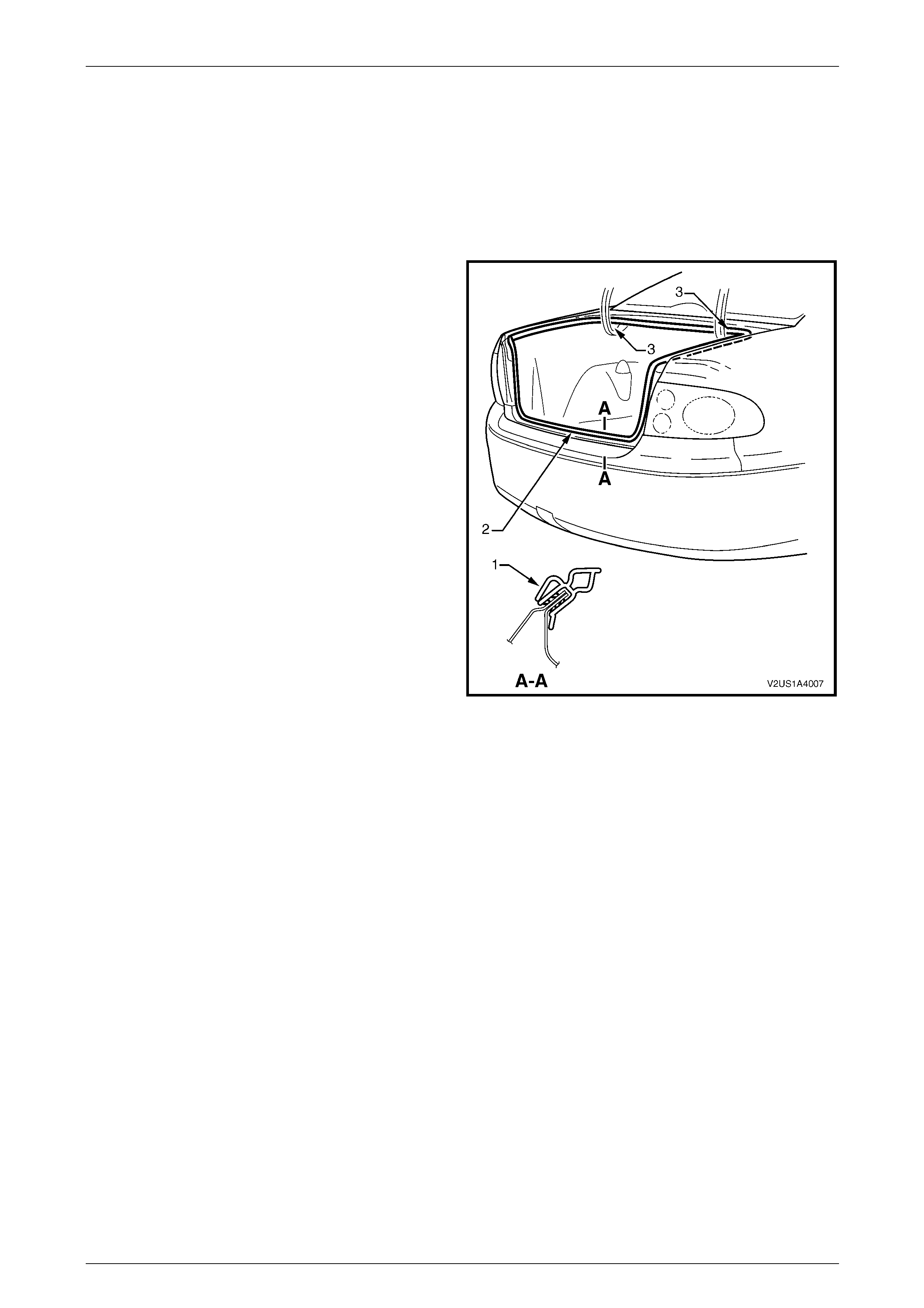

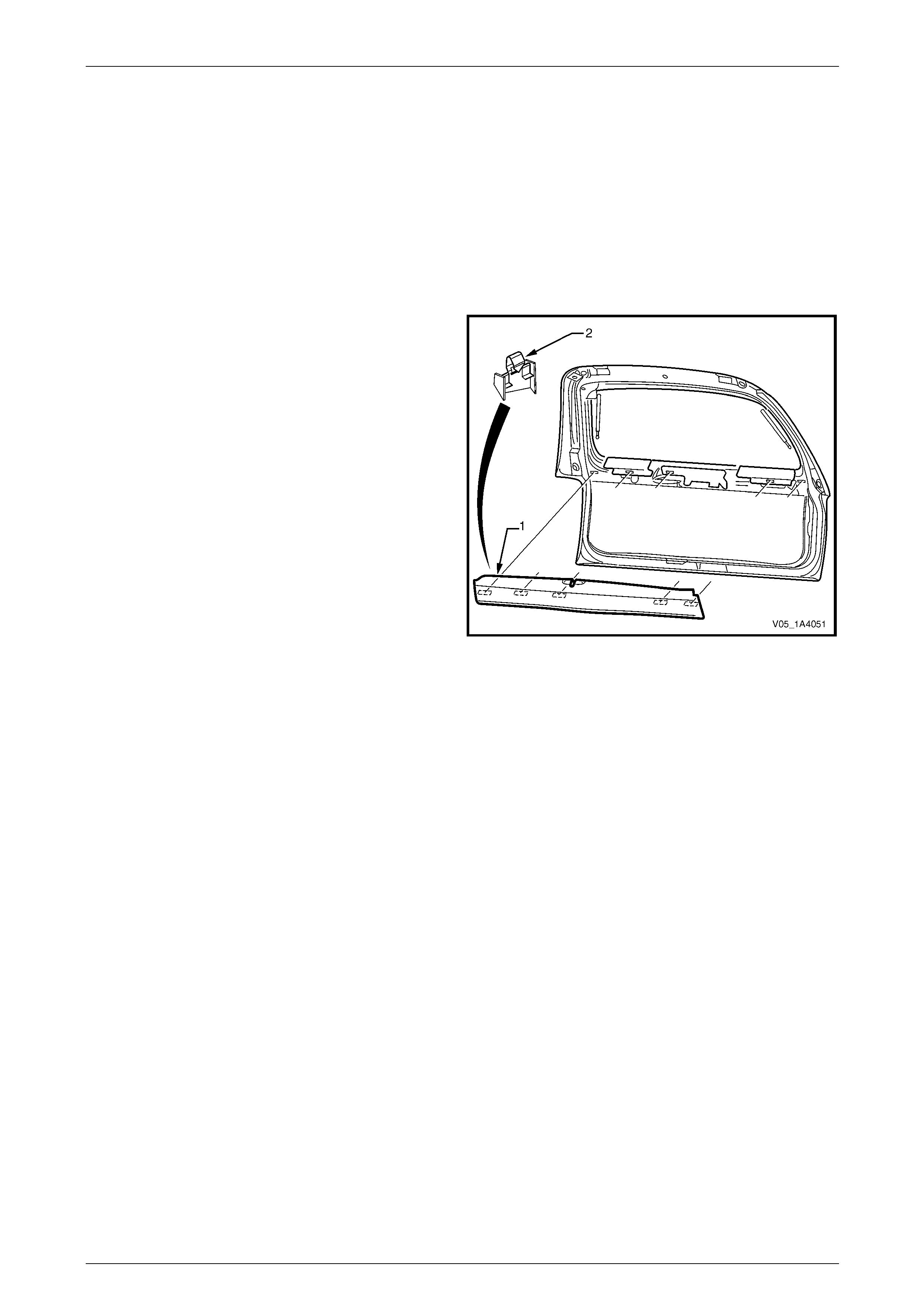

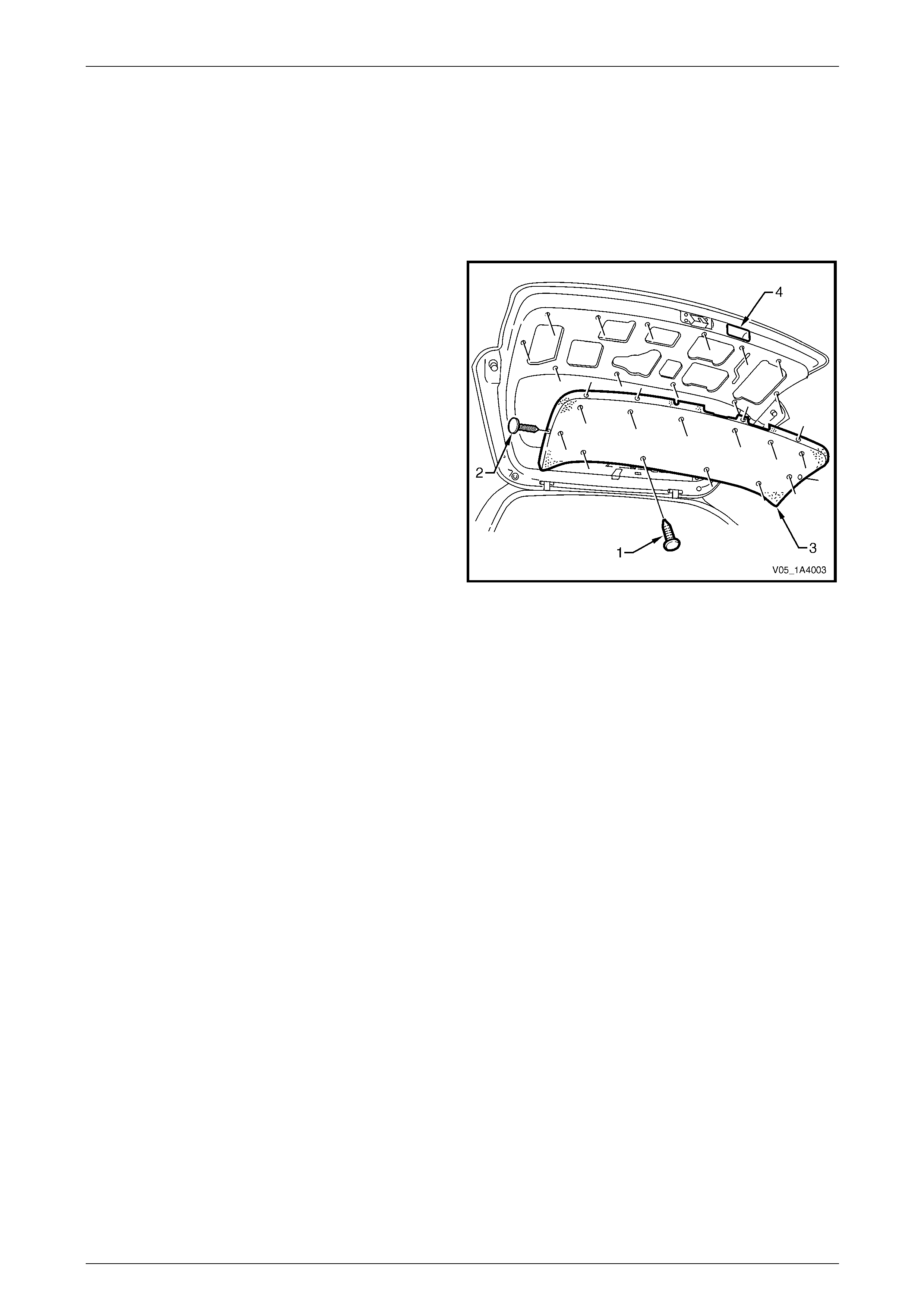

a Remove the radiator upper shroud, refer to Section 6B3 Engine Cooling – GEN III V8.