Rear Final Drive and Live Axle Page 4B2 – 1

Section 4B2

Rear Final Drive and Live Axle

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................2

1.1 General Description............................................................................................................................................... 2

Cone Type Limited Slip Differential – M78 Series............................................................................................... 3

1.2 Alloytec Engined Rear Axle Assembly Identification......................................................................................... 4

Rear Axle Label...................................................................................................................................................... 5

2 Minor Service Operations......................................................................................................................6

2.1 Service Warnings, Cautions and Notes............................................................................................................... 6

2.2 Rear Axle Assembly Minor Maintenance............................................................................................................. 7

2.3 Checking Rear Axle Lubricant Level.................................................................................................................... 8

2.4 Changing/Flushing Rear Axle Lubricant.............................................................................................................. 9

2.5 Rear Final Drive Rear Cover................................................................................................................................ 10

Remove................................................................................................................................................................. 10

Clean and Inspect................................................................................................................................................ 10

Reinstall................................................................................................................................................................ 11

3 Specifications.......................................................................................................................................12

4 Torque Wrench Specifications............................................................................................................13

5 Special Tools ........................................................................................................................................14

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 2

1 General Information

1.1 General Description

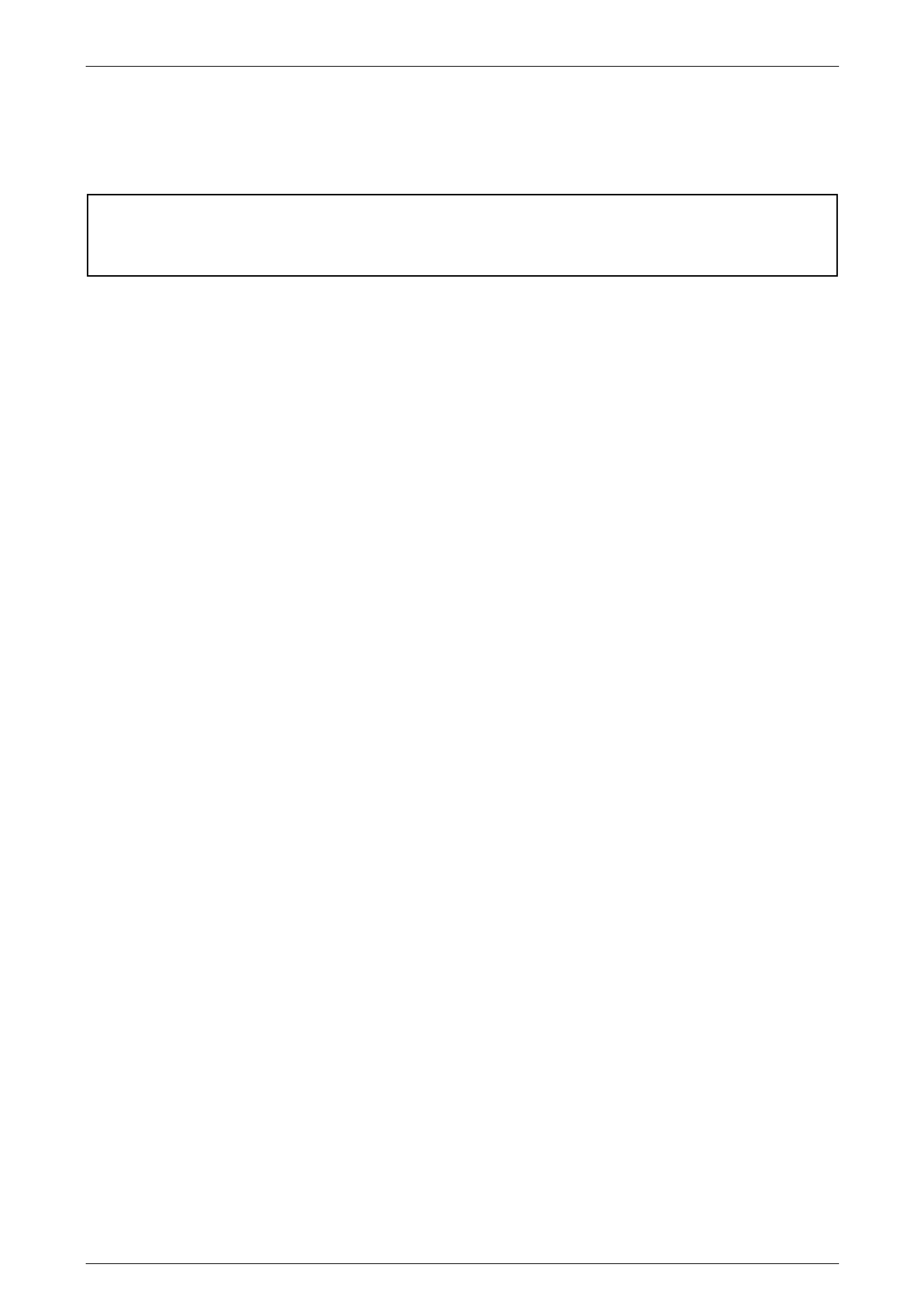

The rear final drive and live ax le assembly fitted to those MY 2006 VZ Update Series vehicles with the HFV6 engine and

the live rear axle with leaf springs, is a Salisbury (Unitised carrier) type rigid live axle, mounted to a leaf spring rear

suspension system with tubular shock absorbers, as standard equipment. Crew Cab models d o not have a rear stabiliser

bar fitted.

On V6 models, the mass dampers have been relocated from the springs to the rear of the final dr ive housing. This has

meat that an aluminium cover is now fitted, instead of the pressed stee l cover, used previously. Apart from this change,

all subsequent service operations not d etaile d here, remain as detailed in the MY 2005 VZ series fitted with a live axle. In

these instances refer to Section 4B2 Rear Final Drive an d Live Axle, in the MY2005 VZ Service Information.

Figure 4B2 – 1

Legend

1 Rear Axle Assembly

2 Rear Leaf Spring Assembly

3 Rear Shock Absorber

4 Chassis Frame

5 Rear ABS Sensor

The range of final drive variants in the MY2006 VZ Update models with Alloytec engines can best described in tabular

form:

Production Option # Ring Gear Diameter Final Drive Ratio Application

GU4 197 mm 3.08:1 V6 – Auto and Manual Trans, RWD

Production option G80, Limited Slip Differential (LSD), (also referred to as Spin Resistant Differential – ‘SRD’) is

available as an option on al l V6 models.

No changes have been made to the rear final drive on GEN IV models, with the live axle.

The rear axle assembly is mounted to the ch assis via leaf springs, ‘U’ bolts, spring shackles and spring eye bus hings.

The differential case, hypoid ri ng gear and pinion are mounted with opposing taper ed roller bearings in the rear ax le

housing. Differential side bearing preload adjustment is controlled by shims located between the tapered roller bearing

cups and the sides of the rear axle housing. A collapsible spacer and companion flange retaining nut provide pinion

bearing preload.

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 3

Torque is transferred from the propeller shaft to the rear axle assembl y via the pinion flange, which is spline d to the

hypoid pinion gear. The torque is then transferred from the hypoid pi nion gear through the hypoid ring gear, differential

case, differential pinion cross shafts, differential pinion gears, side gears and then via splines on the axle shafts to the

road wheels.

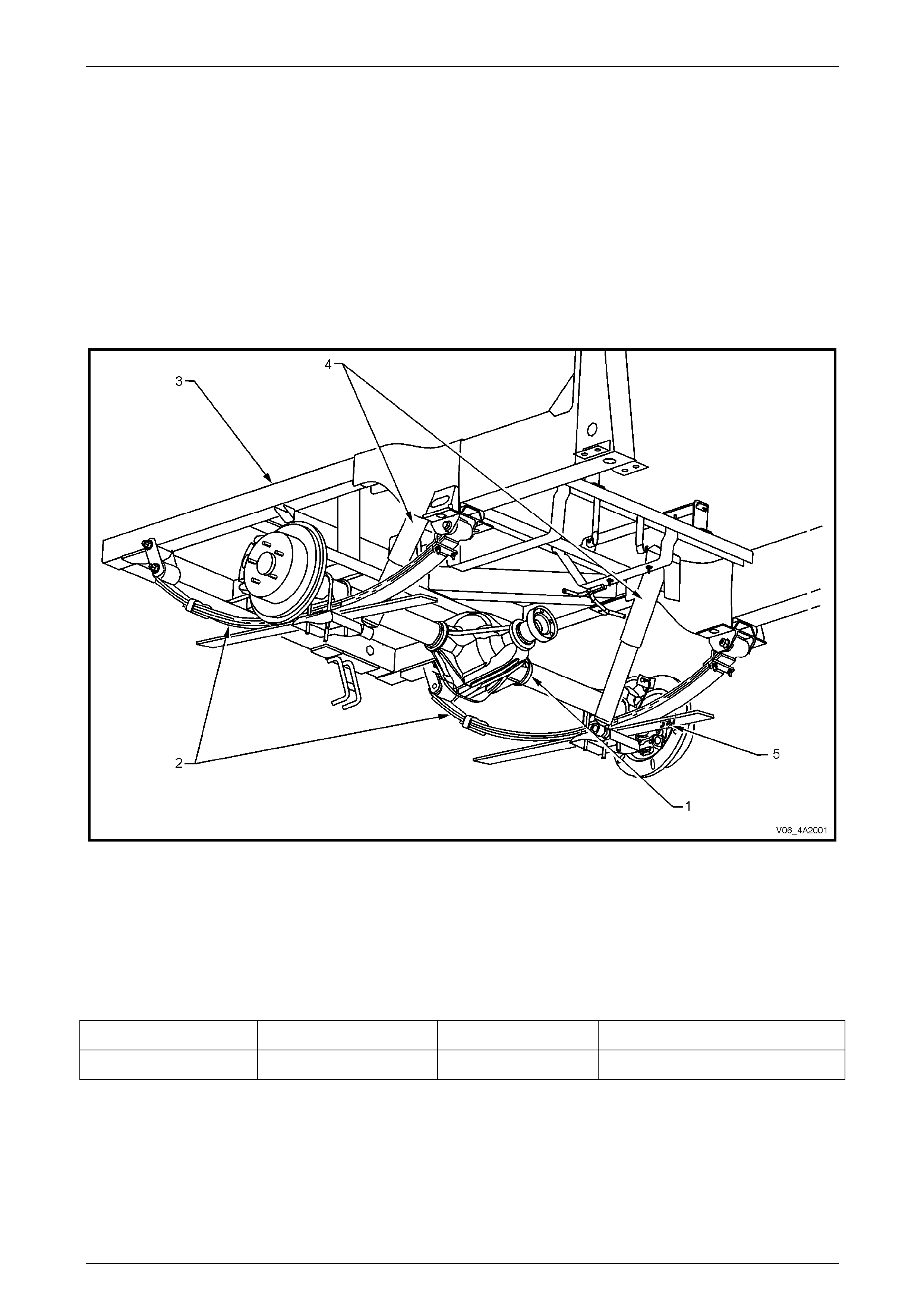

Cone Type Limited Slip Differential – M78 Series

The M78 Series Limited Slip Differential (LSD), used with V6 models, performs the same functions as the conventional

type differential but in addition, transfers driving force to the wheel with traction, should the opposite wheel begin to spin.

The differential case houses two cone type clutches behind the side gears that are splined to the inner ends of the axle

shafts and their tapered faces contact corresponding faces in the differential case.

On this LSD, the cones form an integral part of the side gears. The four pinion type LSD has three preload springs

enclosed in the centre of the pinion cross shaft. The LSD directs the major driving force to the wheel with the greater

amount of traction, but will not interfere with steering characteristics or differential action. The inhere nt separating forces

between the side gears and pinions automatically increase the partial locking action, due to the spring load on the cones,

which progressively increases the resistance in the differe ntial as applied torque is increased.

Legend

1 Gear – Differential Side

2 Spring – Outer, Differential Preload

3 Spring – Intermediate, Differential Preload

4 Spring – Inner, Differential Preload

5 Washer – Thrust, Differential Pinion Gear

6 Gear – Differential Pinion

7 Cone – Clutch

8 Plate – Thrust, Spring

9 Shaft – Differential Pinion Cross

Figure 4A2 – 2

When the rear wheels are under extremely unbalanced conditio ns, such as a wheel on a dry road and the other in mud

or ice, with the standard differential, wheel spin easily occurs if over-acceleration is attempted. However, with a LSD,

when the tendency for wheel spin occurs, the friction generated inside the case, therefore transfers greater driving force

to the non-spinning wheel. In the event of continued spinning, a whirring sound from the over-running cones is produced

but this condition/sound does not indicate failure of the unit.

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 4

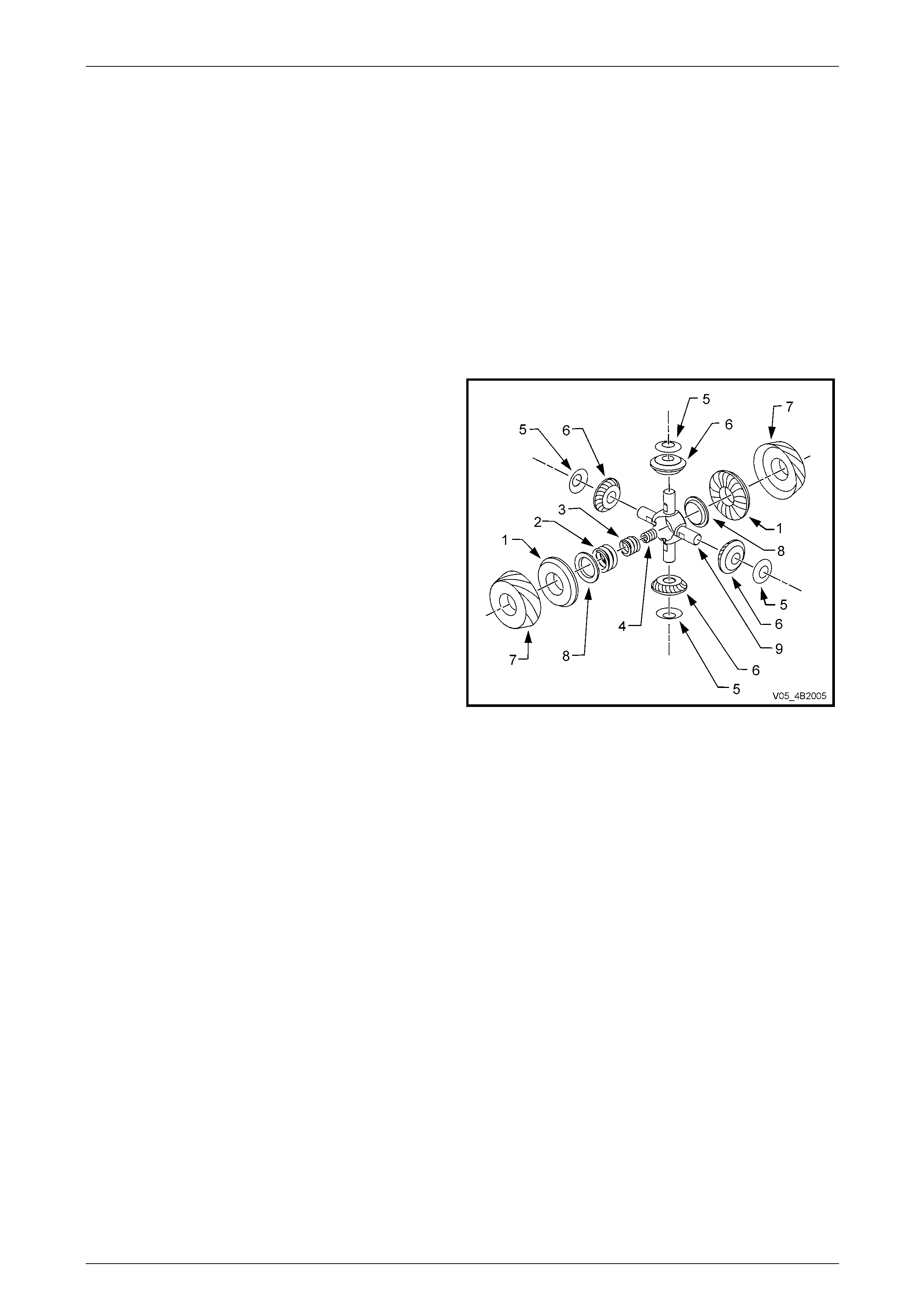

1.2 Alloytec Engined Rear Axle Assembly

Identification

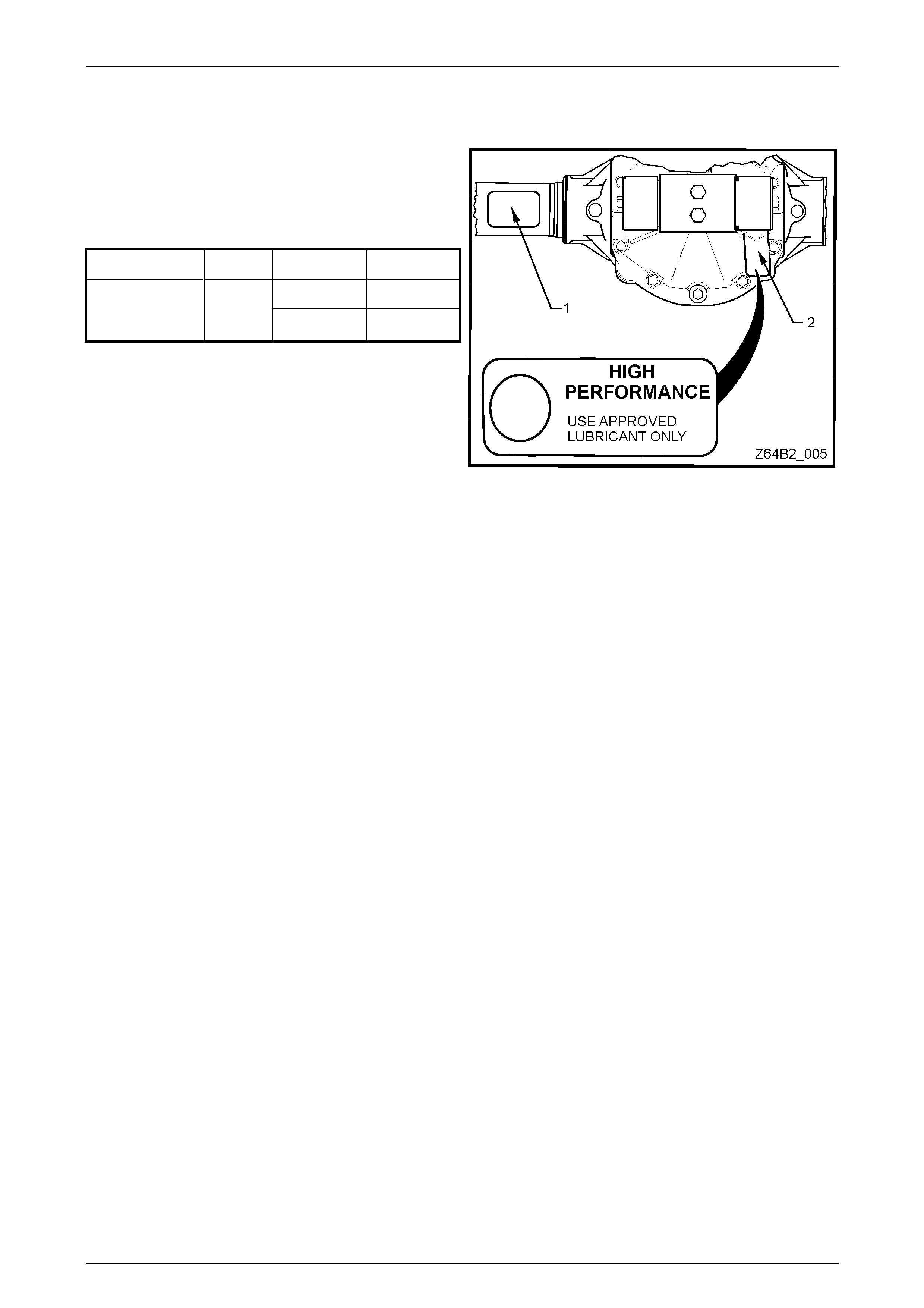

The type of differential fitted to the rear axle assembly can be identified by referring to either the identification label (4)

attached to the LHS of the axle housing or from the lubrication tag (9) under the filler plug (8) on the rear cover.

Figure 4B-3

Legend

1 Rear Axle Shaft

2 Pinion Flange

3 Rear ABS Sensor Mount

4 Identification Label

5 Drain Plug

6 Rear Cover

7 Breather

8 Filler Plug

9 Lubrication Tag

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 5

Rear Axle Label

The locations of the identification label (1) and lubrication tag (2) are shown next.

The identification label (1) car r ies the rear axle assembly

part number, the rear axle ratio, the serial number and the

I.D. code of the assembly.

The code number and bar co de is used for production

identification of the rear axle assembly.

Usage Ratio Type I.D. Code

ABS (Std) TYV

V6 with Manual

or Automatic

Transmission 3.08:1 LSD & ABS TYU

Figure 4A2 – 4

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 6

2 Minor Service Operations

2.1 Service Warnings, Cautions and Notes

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. W here specified in this section, fasteners MUST be replaced w ith parts of the

same part number or an app roved equivalent. Do not use fasteners of an inferior quality or substitute desig n.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening .

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanic al thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

ABS Components

• Whenever any component that forms part of the ABS (if fitted) is disturbed during Service

Operations, it is vital that the complete ABS system be checked, refer to Section 5B ABS.

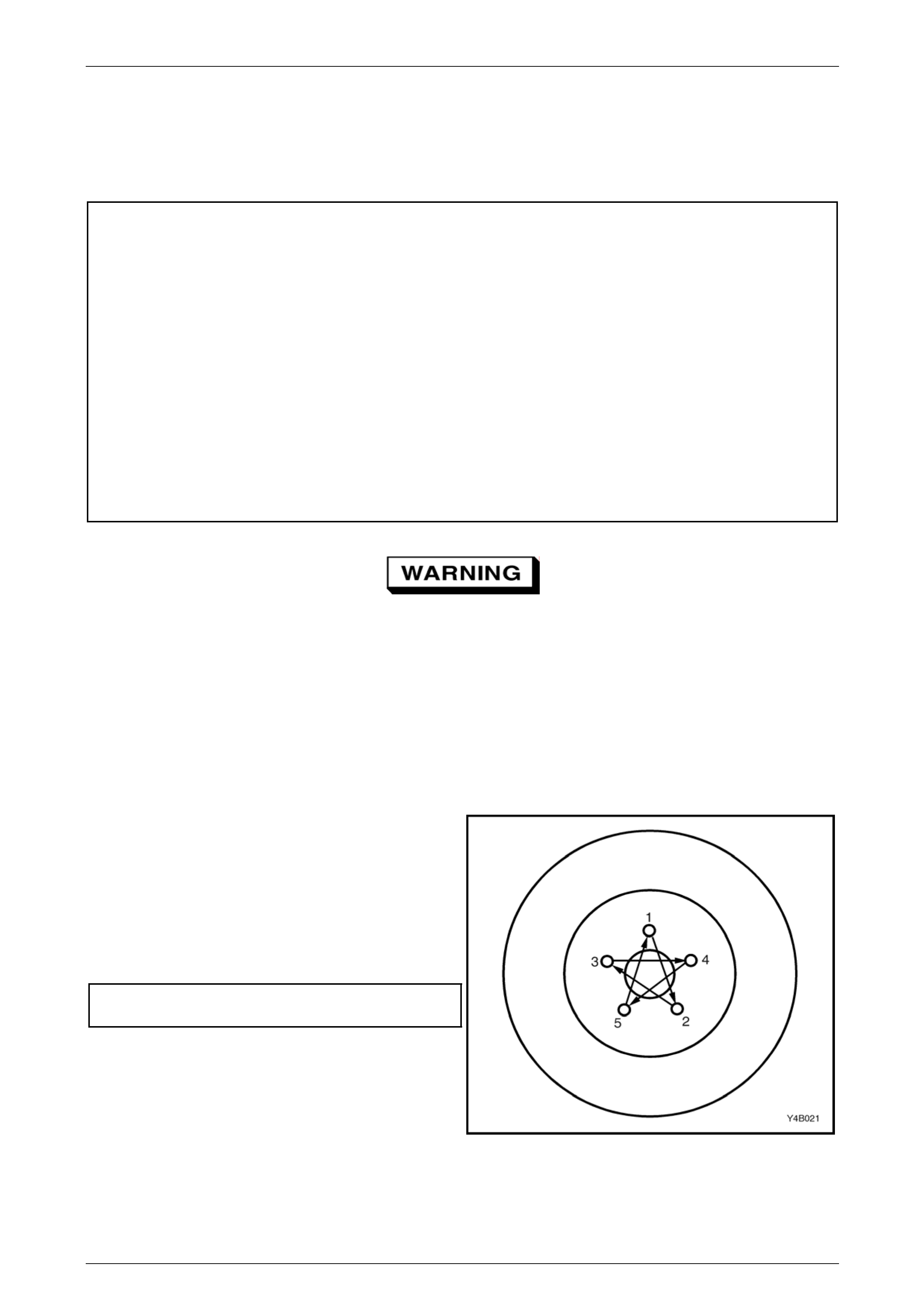

Road Wheels

• Whenever a road w heel and/or brake di sc is removed from the vehicle, the relatio nship of the road

wheel and the disc to the hub MUST be marked with a felt tipped pen or similar, to allow those

parts to be reinstalled in their original positions. This is critical to minimise the brake disc and

road wheel runout dimension.

• When reinstalling road wheels, do not use

an impact gun to tighten wheel nuts

unless the impact gun is fitted with a

torque limiter socket (Tool No. AU 534 or

a commercial equivalent). Failure to

correctly tighten w heel nuts to the correct

torque specification and in the correct

order (as shown), may result in a

distorted brake disc, leading to the

development of brake shudder.

Road wheel attaching nut

torque specification.................................... 110 – 140 Nm

Figure 4B2 – 5

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 7

2.2 Rear Axle Assembly Minor Maintenance

For procedures on any of the following minor servicing items, refer to Section 4B2 Rear Final Drive and Live Axl e in the

MY2005 VZ Service Information:

• Rear Axle Shaft Check For Run-Out and End Float

• Rear Axle Shaft Wheel Studs

• Combined Rear Axle B acklash Check

• Limited Slip Differential Torque Check

• Rear Axle Shaft Assembly

• Rear Axle Shaft, ABS Pulse Ring, Oil Seal, Bearing and Retainer Collar

• Pinion Oil Seal

• Pinion Flange

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 8

2.3 Checking Rear Axle Lubricant Level

LT Section No: 05-400

CAUTION

When servicing any rear axle assembly fitted

with a Limited Slip Differential (LSD), gloves

and safety glasses are recommended when

handling the lubrication additive to prevent

any possible irritation of the skin or eyes.

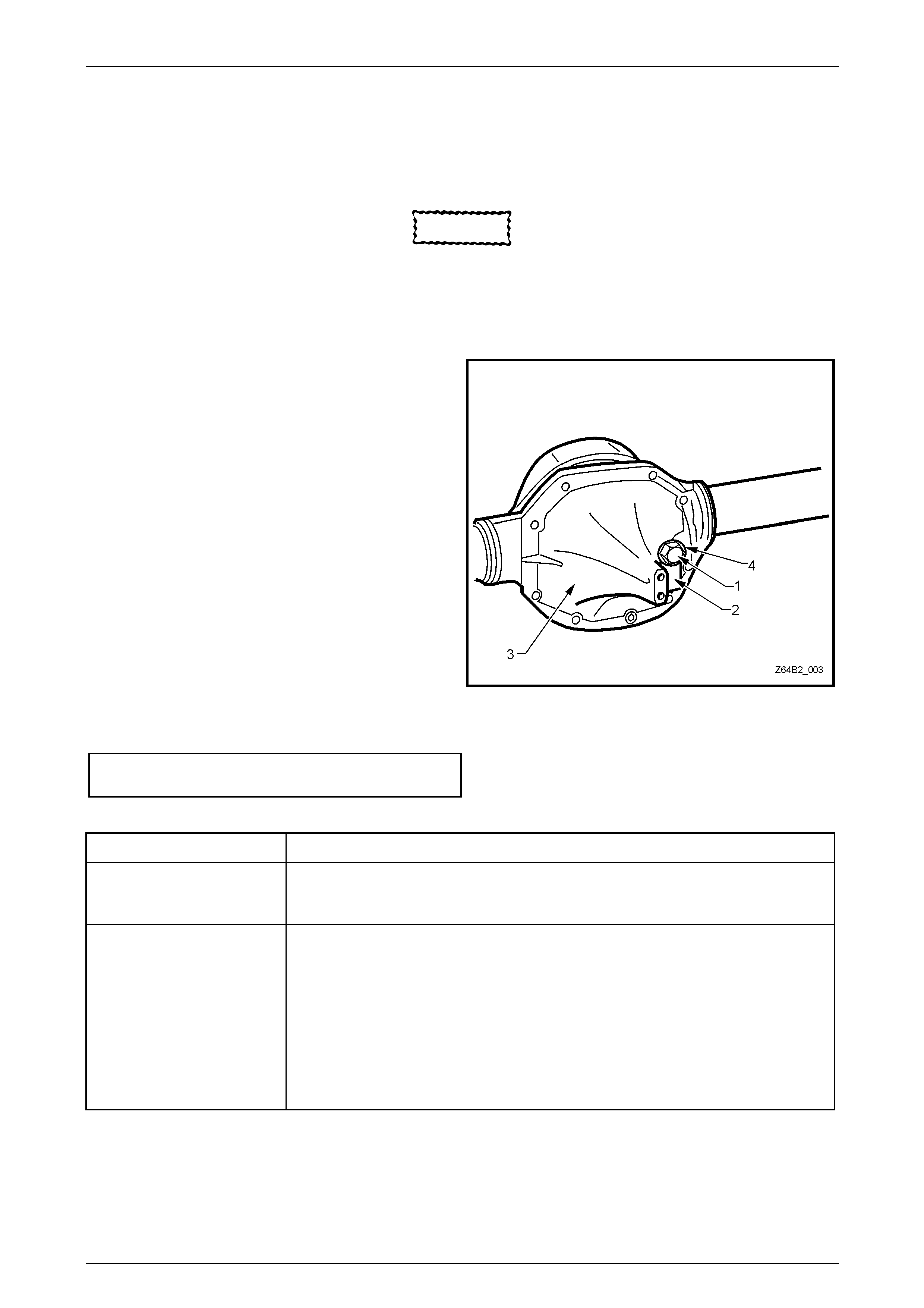

1 Check that the vehicle is level and resting on all four

wheels.

2 Clean area around filler plug (1).

3 Remove filler plug (1) from rear cover (3) (do not lose

the lubrication tag (2) from the plug, if fitted).

4 The lubricant level is to be maintaine d at the bottom

edge of the filler plug hole.

NOTE

• The rear axle lubricant level MUST be

checked when the rear axle is cold, or

overfilling and oil leaks ma y occur.

• Use only the recommended lubricant.

5 Inspect filler plug (1) and sealing washer (4) for

damage, if OK, reinstall to the rear cover (3) (includi ng

the lubrication tag (2). If damaged, replac e plug and

the sealing washer.

6 Tighten filler plug (1) to the correct torque

specification.

Rear axle filler plug

torque specification...............................................28 Nm

Figure 4A2 – 6

Engine & Axle Type Recommended Lubricant

V6

M78 Series

Non LSD

Synthetic Hypoid Gear Oil, such as; MOBIL Mobilube SHC ID, CASTROL SAF-XA or

equivalent lubricant to Holden's Specification HN2040.

V6

M78 Series LSD

(Cone Type)

Synthetic Hypoid Gear Oil, such as; MOBIL Mobilube SHC ID, CASTROL SAF-XA or

equivalent lubricant to Holden's Specification HN2040.

In addition to the synthetic, hypoid gear oil, additive kit (part number 92 145121) must

also be used.

The additive kit consists of:

• LSD Sturaco Additive – 100 ml special conta iner

• Material Safety Data Sheet

• Lubrication ID Tag

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 9

2.4 Changing/Flushing Rear Axle Lubricant

LT Section No: 05-400

CAUTION

When servicing any rear axle assembly fitted

with a Limited Slip Differential (LSD), gloves

and safety glasses are recommended when

handling the lubrication additive to prevent

any possible irritation of the skin or eyes.

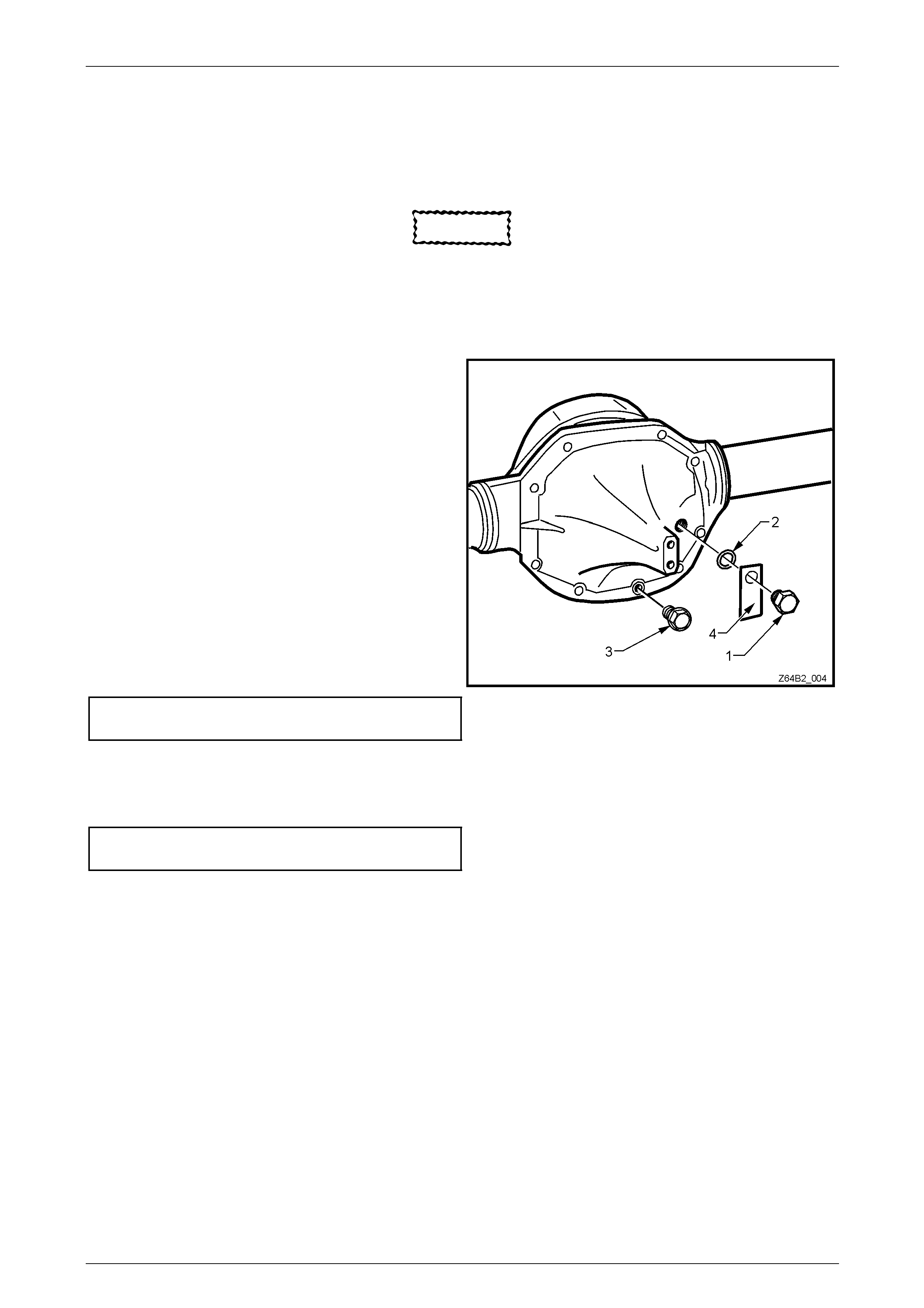

1 Place a clean container under the rear axle with a

2 litre minimum capacity.

NOTE

Draining warm oil takes less time and is more

complete than for cold oil.

2 Remove the filler plug (1), lubrication tag (4), sealing

washer (2) and the drain plug (3).

3 Allow the (preferably warm) lubricant to drain into the

container.

4 If flushing is required, use an undiluted quantity of the

recommended lubricant for the operation.

5 When the draining (and flushing if required) operation

is complete, apply thread-sealing tape to drain plug (3)

thread. Install and tighten drain plug (3) to the correct

torque specification.

Rear axle drain plug

torque specification...............................................28 Nm Figure 4B2 – 7

6 Fill the rear axle assembly with a total of 1.7 litres of the recommended lub r ic ant (or 1.6 litres of lubricant plus 100

ml of LSD additive, as appropriate), install the filler plug (1) wit h the sealing washer (2) and lubricati on tag (4).

7 Tighten the filler plug to the correct torque specification.

Rear axle filler plug

torque specification...............................................28 Nm

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 10

2.5 Rear Final Drive Rear Cover

Remove

1 Raise the rear of the vehicle and support in a safe manner.

2 Because of the weight involved, it is recommend ed that the mass dampers are removed. Refer to

Section 4A2 Rear Leaf Spring Suspension for details.

3 Remove the filler and drai n plugs and drain the oil (prefera bly warm) from the final drive assembly, refer to

2.4 Changing/Flushing Rear Axle Lubricant.

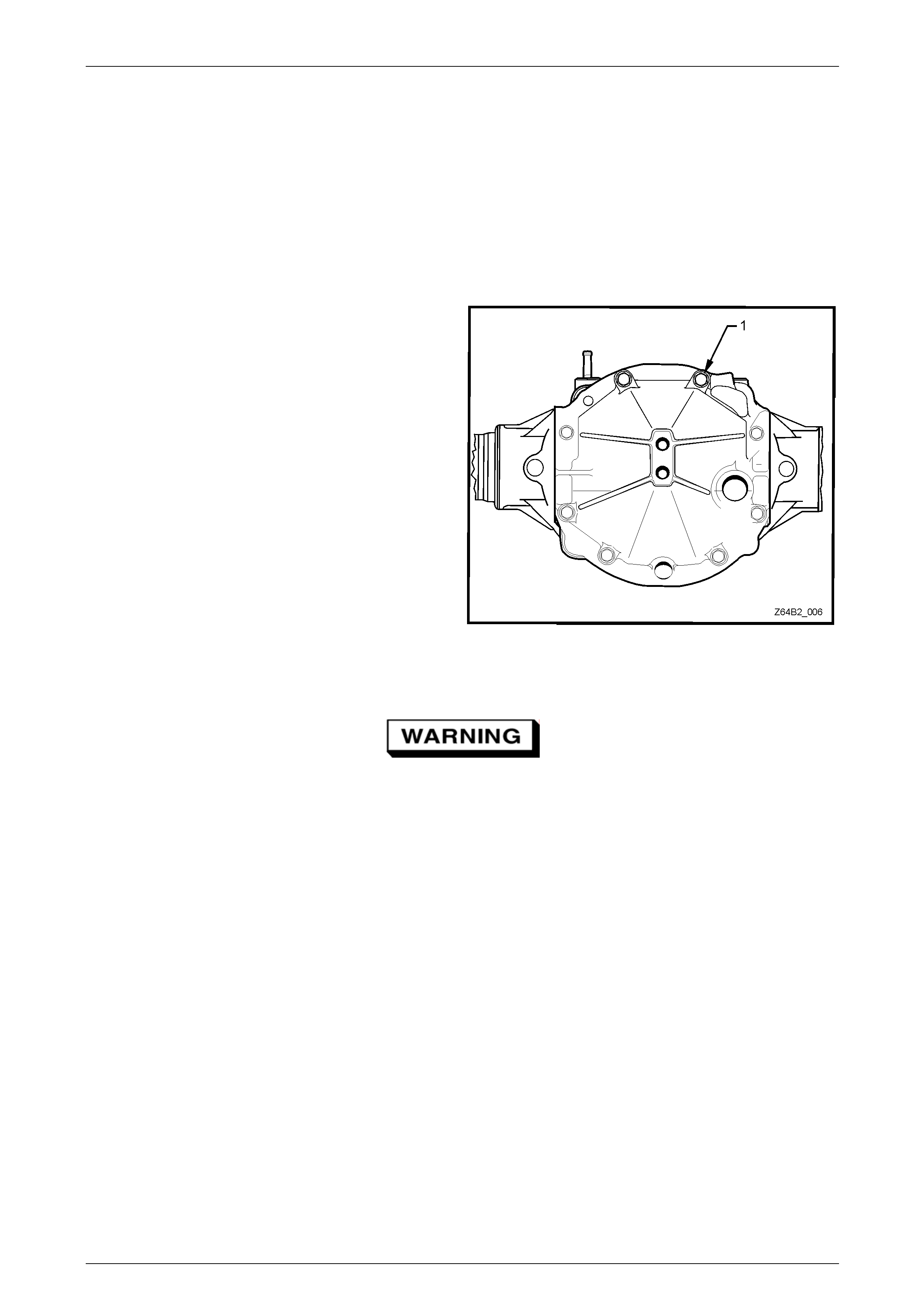

4 Using suitable socket equipment, remove the rear

cover to final drive housing bolts (1), in eight places.

5 Tap the side of the cover with a soft faced hammer to

break the sealant seal, then remove the cover.

Figure 4B2 – 1

Clean and Inspect

Wear eye protection to prevent potential

injury when using compressed air.

1 Using a plastic scraper, clean sealant residue from the final drive housing and the cover.

2 Using a wire brush, clean all traces of thread sealant from the bolt threads.

3 Wash the cover with suitable cleaning solvent and dry usin g compressed air.

4 Inspect the bolt threads for a sound thread condition, replacing any that are damag ed.

5 Inspect the final drive housing bolt threads for damage repairing, as required.

6 Check the rear cover for any warpage and/or damage to the drain plug threads. Re place the cover if any of this

defects are found.

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 11

Reinstall

1 Apply a 1 mm bead of sealan t such as Loctite 525 (or equivalent) to the rear cover, ensuring that the sealant bead

flows on the inside of each bolt hole.

2 Reinstall the cover and secure by installing the eight bo lts that have had sealant such as Loctite 525 (or equivalent)

applied to cleaned threads.

3 Tighten the cover bolts to the correct torque specification.

Rear axle rear cover attaching

bolts torque specification ......................................28 Nm

4 Reinstall the drain plug and tighten to the correct torque spe cification.

Rear axle drain plug

torque specification...............................................28 Nm

5 Refill the final drive with the correct lubricant, refer to 2.4 Changing/Flushing Rear Axle Lubricant.

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 12

3 Specifications

NOTE

Only those specifications that are of a general

nature or relate to the service operations

described here, are shown. For all remaining

specifications, refer to Section 4B2 Rear Final

Drive and Live Axle in the MY2006 VZ Service

Information.

General

Rear Axle Assembly ....................................................V6 – Dana/Spicer – SAA – M78 Series

Axle Type............................................................................................................Semi Float ing

Housing Type .............................................................................Unitised Carrier Construction

Standard and LSD Axles

Gear Type......................................................................................................................Hypoid

Gear Ratio (See I.D. label on axle tube housing) ...............V6 Automatic/V6 Manual – 3.08:1

3.08:1

No. of Teeth – Ring Gear......................................................................................................40

No. of Teeth Drive Pinion Gear.............................................................................................13

Ring Gear Diameter..........................................................................................................7.75”

No. Teeth – Differential Pinion Gear.....................................................................................10

Differential Side Gear........................................................................................16

Lubricants

Total Rear Axle Lubricant Capacity ...........................................................................1.7 Litres

NOTE

For rear axles with LSD the lubricant fill

comprises of 1.6 Litres of rear axle lubricant and

100 ml of Sturaco LSD additive.

Rear Axle Lubricant Type ................................................................Synthetic Hypoid Gear Oil

Holden Specification HN2040 or Mobilube SHC ID

LSD Additive........................................................................................................Sturaco 7098

Pre-lubricant as Specified in Text...................NLGI No. 2 lithium soap based EP grease with

molybdenum disulphide, such as Shell Retinax HDX2

grease or BP Energrease LMS-EP 23 (or eq uivalent).

Sealants and Thread Locking Compound

Rear Cover to Carrier Housing ..................................... Loctite 587 ('Ultra Blue') or equivalent

Rear Axle Fasteners, Pinion Nut and Breather...............Loctite 262 or commercial equivalent

to GM Specification 9985283.

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 13

4 Torque Wrench Specifications

ATTENTION

Fasteners must be repl aced after loosening .

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

NOTE

Only those torque specifications that relate to the

service operations described here, are shown.

For the remaining torque specifications, refer to

Section 4B2 Rear Final Drive and Liv e Axle in the

MY2006 VZ Service Information.

Rear Axle Drain Plug...........................................................................................28 Nm

Rear Axle Filler Plug ...........................................................................................28 Nm

Rear Cover to Carrier Housing Bolts...................................................................28 Nm

Page 4B2 – 14

Rear Final Drive and Live Axle Page 4B2 – 14

5 Special Tools

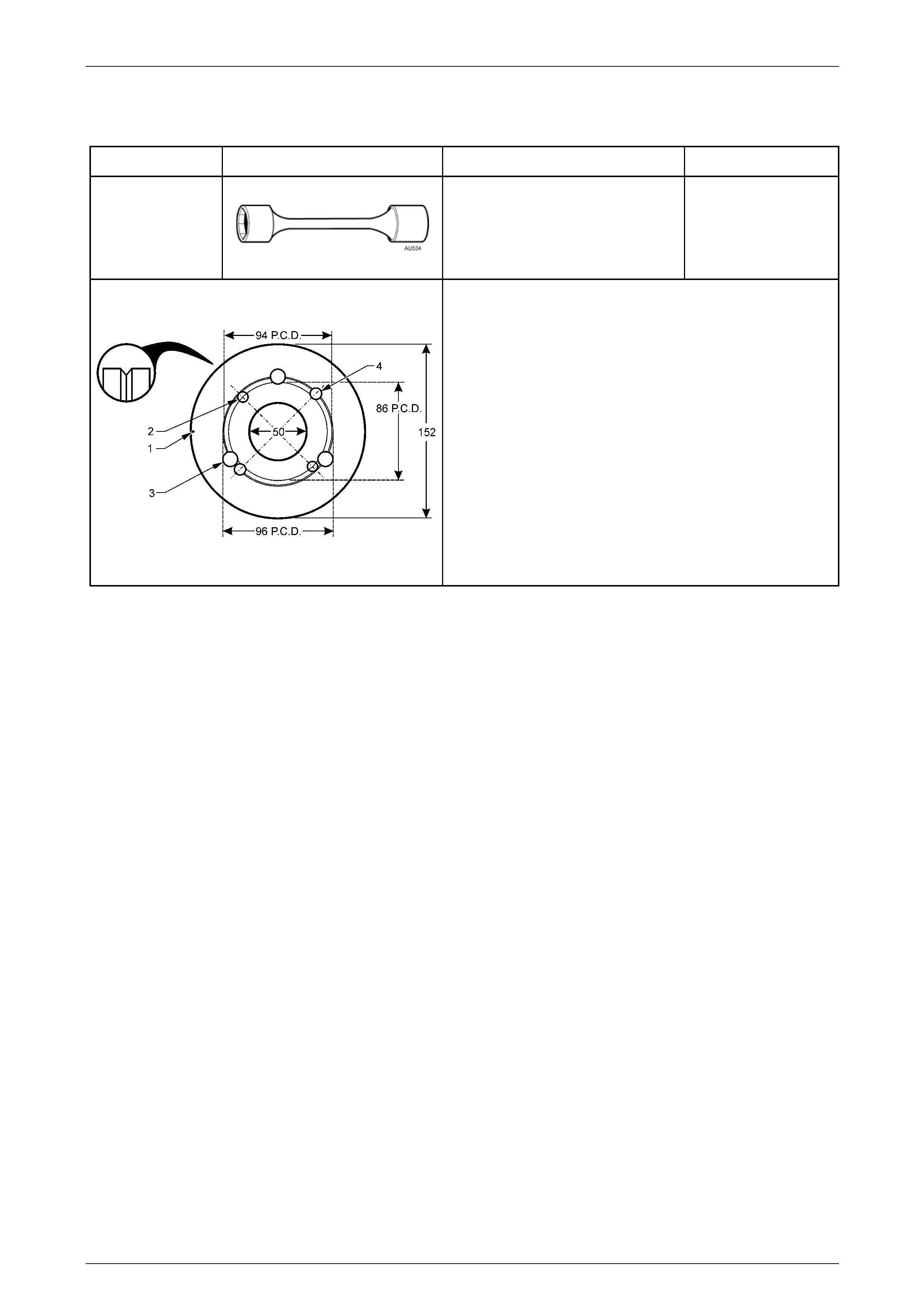

Tool Number Illustration Description Tool Classification

AU534

Torque Limiting Socket

Used in conjunction with an impact

gun to tighten wheel nuts.

Previously released.

Mandatory

Pinion Flange Pulley

Fabricate this pulley to incl ude all VZ applications.

1 152 mm diameter pulley made from a 13 mm thick piece

of wood with a 1 mm deep groove (inset) turned around

the circumference.

2 Drill a small hole at '1' and attach a one metre length of

string at this point, looped at one end, knotted at the

other.

3 Drill two, 8.5 mm holes (2) opposite to each other on a

pitch circle diameter of 86 mm (AWD Wagon).

4 Drill three, 13 mm holes (3) on a pitch circle diameter of

96 mm, 120 mm apart (All VZ models with IRS).

5 Drill two, 10 mm holes (4) opposite to each other on a

pitch circle diameter of 94 mm (All VZ Live Axle models).

Page 4B2 – 14