Automatic Transmission – 5L40–E – Unit Repair 7E5 – 1

7E5 – 1

Section 7E5

Hydra-Matic 5L40–E Automatic Transmission –

Unit Repair

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

WARNINGS, CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1 Transmission Disassemble...................................................................................................................4

1.1 General Service Information................................................................................................................................. 4

Teflon Sealing Rings .............................................................................................................................................4

Thrust Washer Surfaces........................................................................................................................................ 4

1.2 Transmission Preparation..................................................................................................................................... 5

Torque Converter Assembly Removal................................................................................................................. 5

Holding Fixture Installation................................................................................................................................... 5

Draining Transmission Fluid................................................................................................................................. 6

1.3 Extension Housing ................................................................................................................................................ 7

Remove................................................................................................................................................................... 7

1.4 Pan and Filter Assembly ....................................................................................................................................... 8

Removal.................................................................................................................................................................. 8

1.5 Wiring Harness....................................................................................................................................................... 9

Remove................................................................................................................................................................... 9

1.6 Control Valve Body and Accumulator Assembly.............................................................................................. 10

Remove................................................................................................................................................................. 10

1.7 Output Shaft Speed Sensor ................................................................................................................................ 12

Remove................................................................................................................................................................. 12

1.8 Input Speed Sensor............................................................................................................................................. 13

Remove................................................................................................................................................................. 13

1.9 Torque Converter Housing.................................................................................................................................. 14

Removal................................................................................................................................................................ 14

1.10 Direct and Reverse Clutch - Forward and Coast Clutch................................................................................... 15

Remove................................................................................................................................................................. 15

1.11 Input Sun Gear Shaft........................................................................................................................................... 16

Remove................................................................................................................................................................. 16

1.12 Direct Clutch Hub................................................................................................................................................. 17

Remove................................................................................................................................................................. 17

1.13 Intermediate Clutch Sprag Assembly ................................................................................................................ 18

Remove................................................................................................................................................................. 18

1.14 Overdrive Clutch Housing................................................................................................................................... 19

Remove................................................................................................................................................................. 19

1.15 Low Clutch Sprag ................................................................................................................................................ 20

Removal................................................................................................................................................................ 20

1.16 Centre Support..................................................................................................................................................... 21

Remove................................................................................................................................................................. 21

1.17 Input and Reaction Carrier.................................................................................................................................. 22

Remove................................................................................................................................................................. 22

1.18 Output Shaft......................................................................................................................................................... 23

Remove................................................................................................................................................................. 23

1.19 Park System Components .................................................................................................................................. 24

Remove................................................................................................................................................................. 24

1.20 Transmission Case Assembly............................................................................................................................ 26

Inspect .................................................................................................................................................................. 26

Techline

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 2

7E5 – 2

1.21 Transmission Case Components....................................................................................................................... 27

Disassemble......................................................................................................................................................... 27

Reassemble.......................................................................................................................................................... 27

1.22 Park System Components .................................................................................................................................. 28

Reinstall................................................................................................................................................................ 28

1.23 Output Shaft and Rear Internal Ring Gear......................................................................................................... 30

Disassemble......................................................................................................................................................... 30

Reassemble.......................................................................................................................................................... 30

1.24 Input and Reaction Carrier.................................................................................................................................. 32

Disassemble......................................................................................................................................................... 32

Reassemble.......................................................................................................................................................... 32

1.25 Centre Support..................................................................................................................................................... 35

Disassemble......................................................................................................................................................... 35

Reassemble.......................................................................................................................................................... 38

Alternative Reassembly Method....................................................................................................................... 42

1.26 Low Clutch Sprag ................................................................................................................................................ 43

Reassemble.......................................................................................................................................................... 43

1.27 Overdrive and Intermediate Clutch .................................................................................................................... 44

Disassemble......................................................................................................................................................... 44

Reassemble.......................................................................................................................................................... 46

1.28 Intermediate Clutch Sprag .................................................................................................................................. 53

Inspect .................................................................................................................................................................. 53

Reassemble.......................................................................................................................................................... 54

1.29 Direct Clutch Hub................................................................................................................................................. 55

Reassemble.......................................................................................................................................................... 55

1.30 Input Sun Gear Shaft........................................................................................................................................... 56

Disassemble......................................................................................................................................................... 56

Reassemble.......................................................................................................................................................... 57

1.31 Forward and Coast Clutch .................................................................................................................................. 59

Disassemble......................................................................................................................................................... 59

Reassemble.......................................................................................................................................................... 60

1.32 Direct and Reverse Clutch .................................................................................................................................. 65

Disassemble......................................................................................................................................................... 65

Reassemble.......................................................................................................................................................... 67

1.33 Direct and Reverse Clutch - Forward and Coast Clutch................................................................................... 70

Reinstall................................................................................................................................................................ 70

Alternative Reassembly Method....................................................................................................................... 70

1.34 Fluid Pump ........................................................................................................................................................... 72

Remove................................................................................................................................................................. 72

Disassemble......................................................................................................................................................... 74

1.35 Torque Converter Seal ........................................................................................................................................ 76

Remove................................................................................................................................................................. 76

1.36 Fluid Pump ........................................................................................................................................................... 77

Reassemble.......................................................................................................................................................... 77

1.37 Torque Converter Housing.................................................................................................................................. 83

Reinstall................................................................................................................................................................ 83

1.38 Torque Converter Seal ........................................................................................................................................ 85

Reinstall................................................................................................................................................................ 85

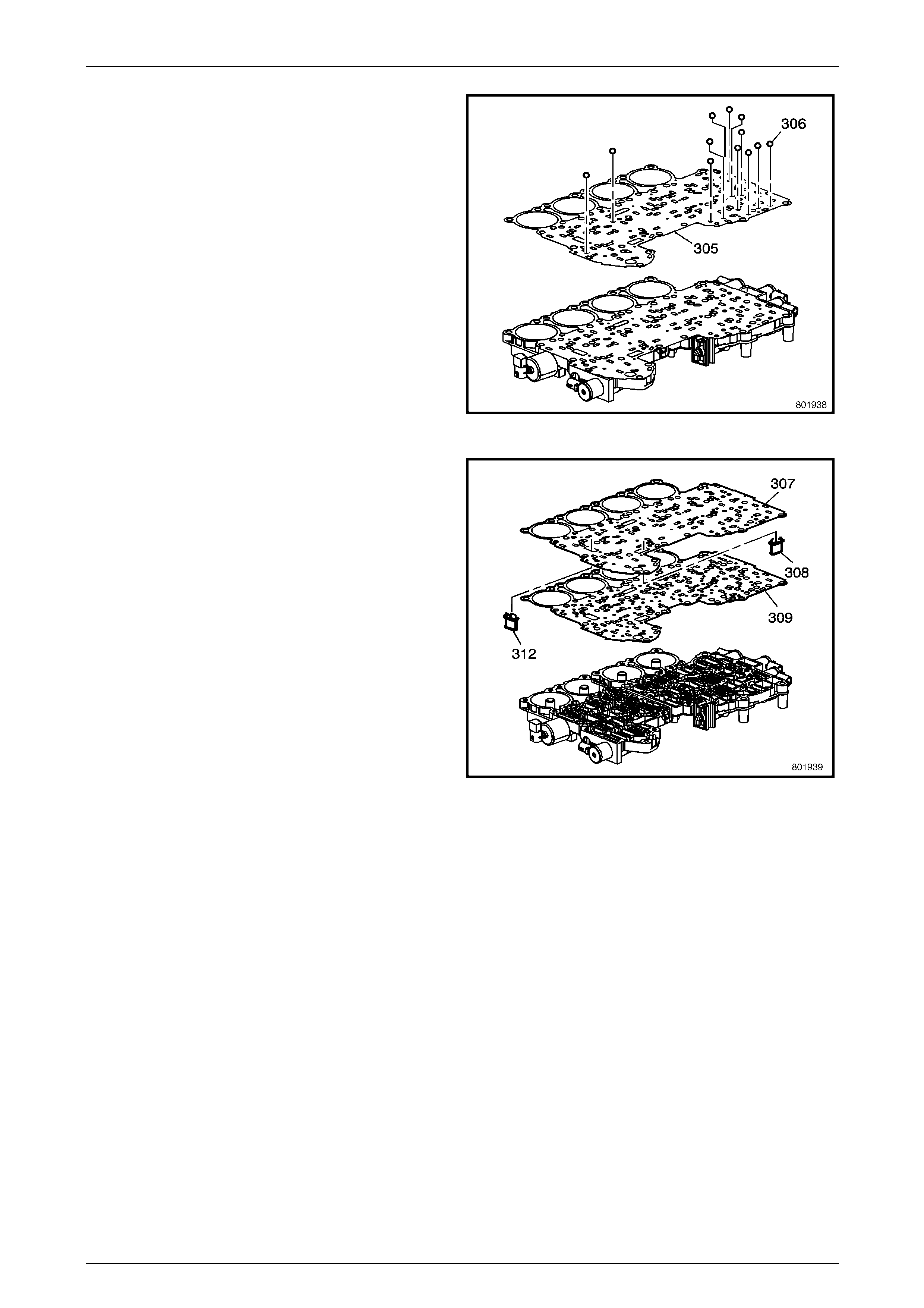

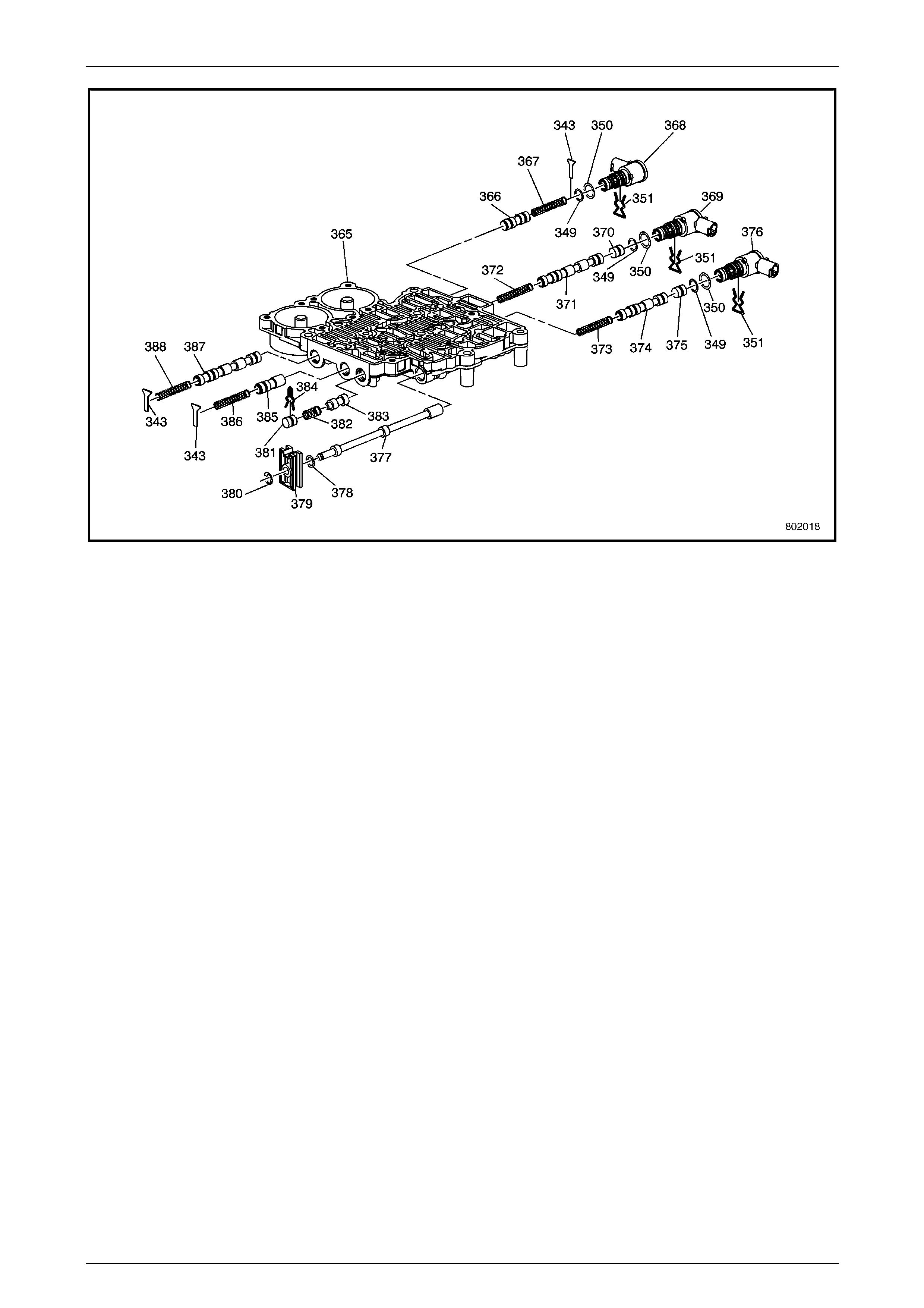

1.39 Control Valve Body and Accumulator Assembly.............................................................................................. 86

Disassemble......................................................................................................................................................... 86

Rear Control Valve Body Inspection.................................................................................................................. 92

Rear Control Valve Body Disassemble.............................................................................................................. 92

Rear Control Valve Body Assemble................................................................................................................... 95

Front Control Valve Body Inspection................................................................................................................. 97

Front Control Valve Body Disassemble............................................................................................................. 98

Front Control Valve Body Assemble.................................................................................................................. 99

Control Valve Body and Accumulator Assembly............................................................................................ 101

Assemble ....................................................................................................................................................... 101

1.40 Input Speed Sensor Installation ....................................................................................................................... 106

1.41 Output Shaft Speed Sensor Installation .......................................................................................................... 107

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 3

7E5 – 3

1.42 Control Valve Body and Accumulator Assembly............................................................................................ 108

Reinstall.............................................................................................................................................................. 108

1.43 Wiring Harness................................................................................................................................................... 110

Reinstall.............................................................................................................................................................. 110

1.44 Pan and Filter Assembly................................................................................................................................... 111

Reinstall.............................................................................................................................................................. 111

1.45 Extension Housing ............................................................................................................................................ 112

Reinstall.............................................................................................................................................................. 112

1.46 Propeller Shaft Flange....................................................................................................................................... 115

Reassemble........................................................................................................................................................ 115

1.47 Holding Fixture Removal................................................................................................................................... 116

1.48 Torque Converter Assembly............................................................................................................................. 117

Reinstall.............................................................................................................................................................. 117

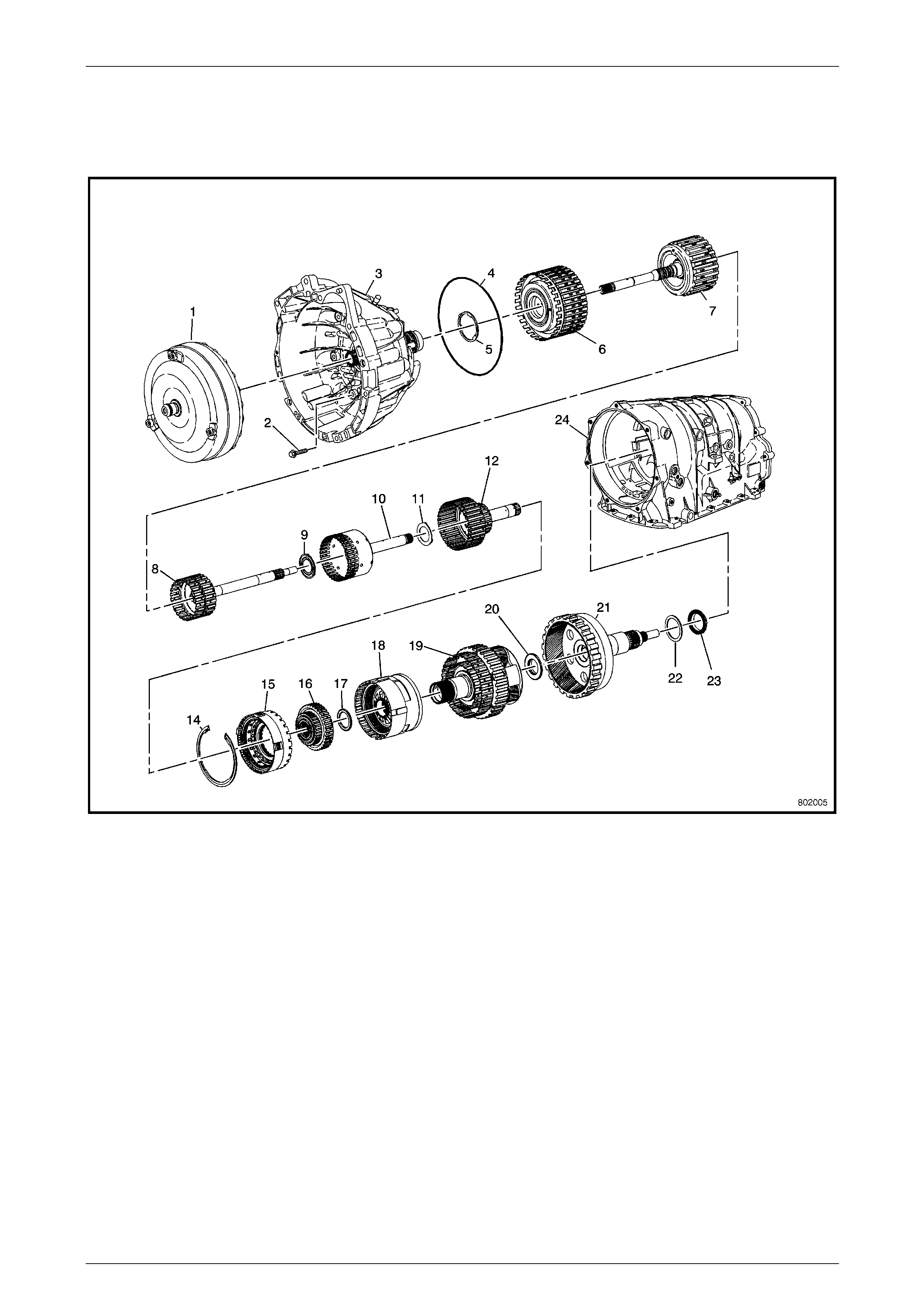

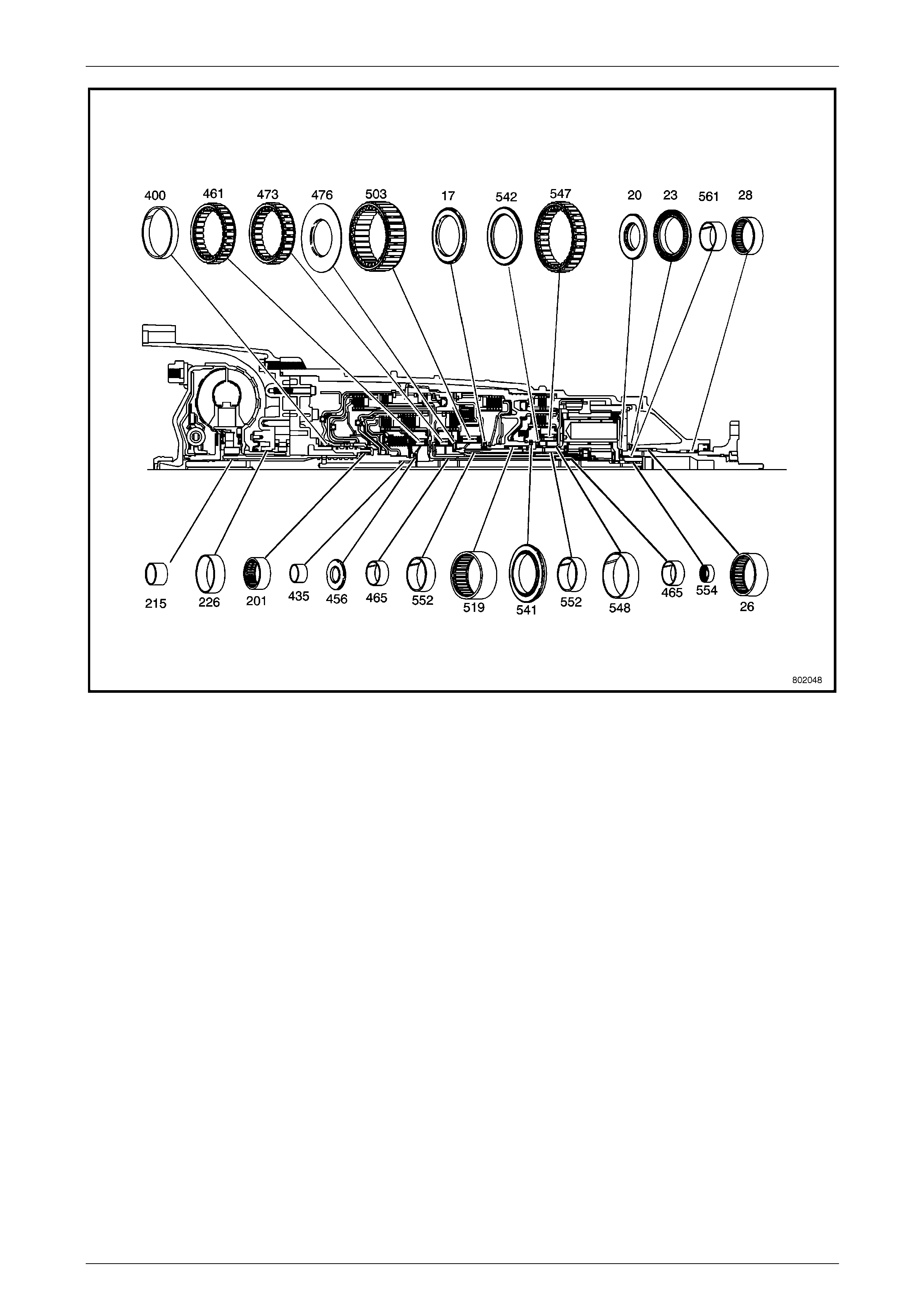

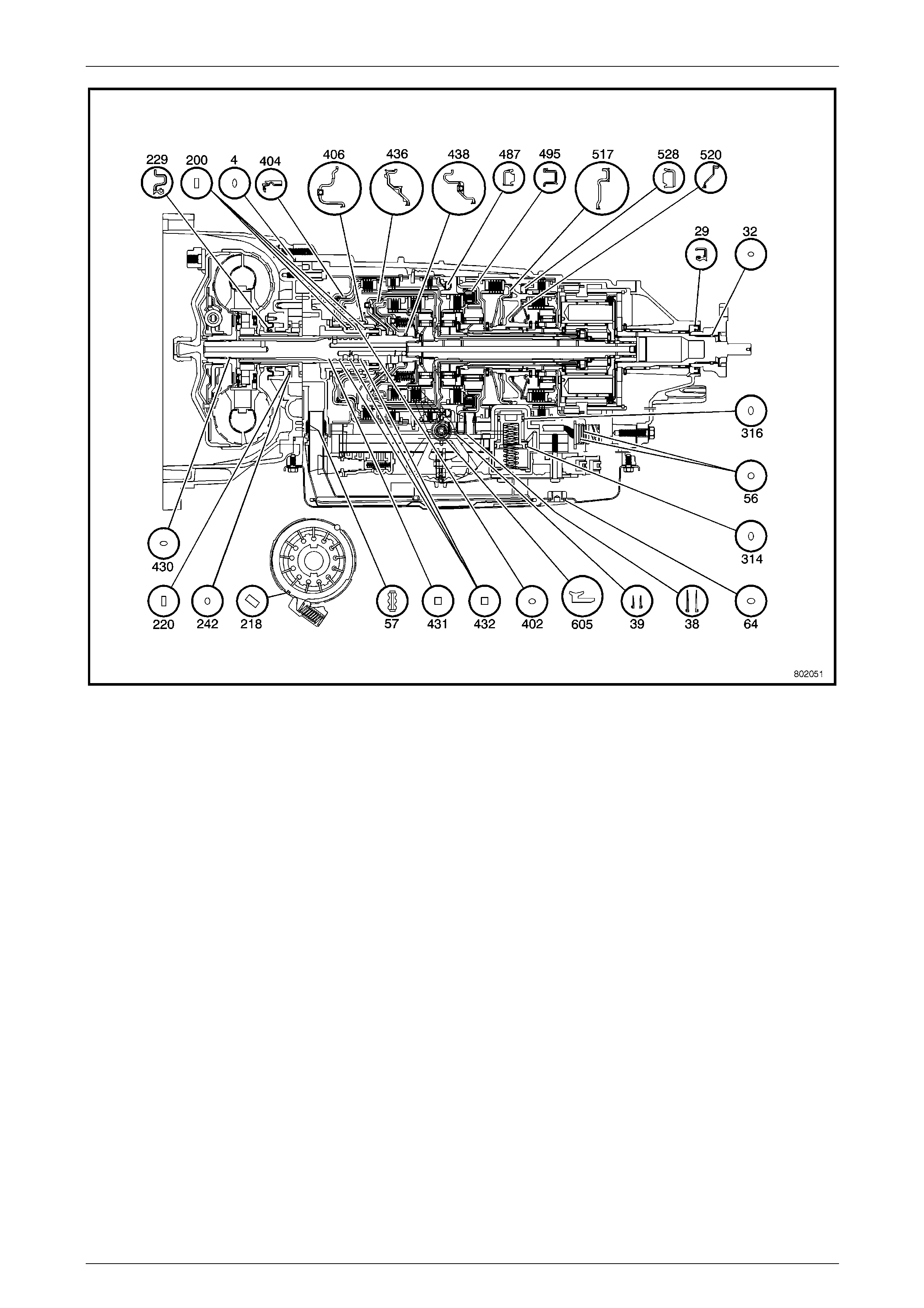

2 Transmission Reference Diagrams..................................................................................................118

3 Specifications.....................................................................................................................................138

4 Torque Wrench Specifications..........................................................................................................143

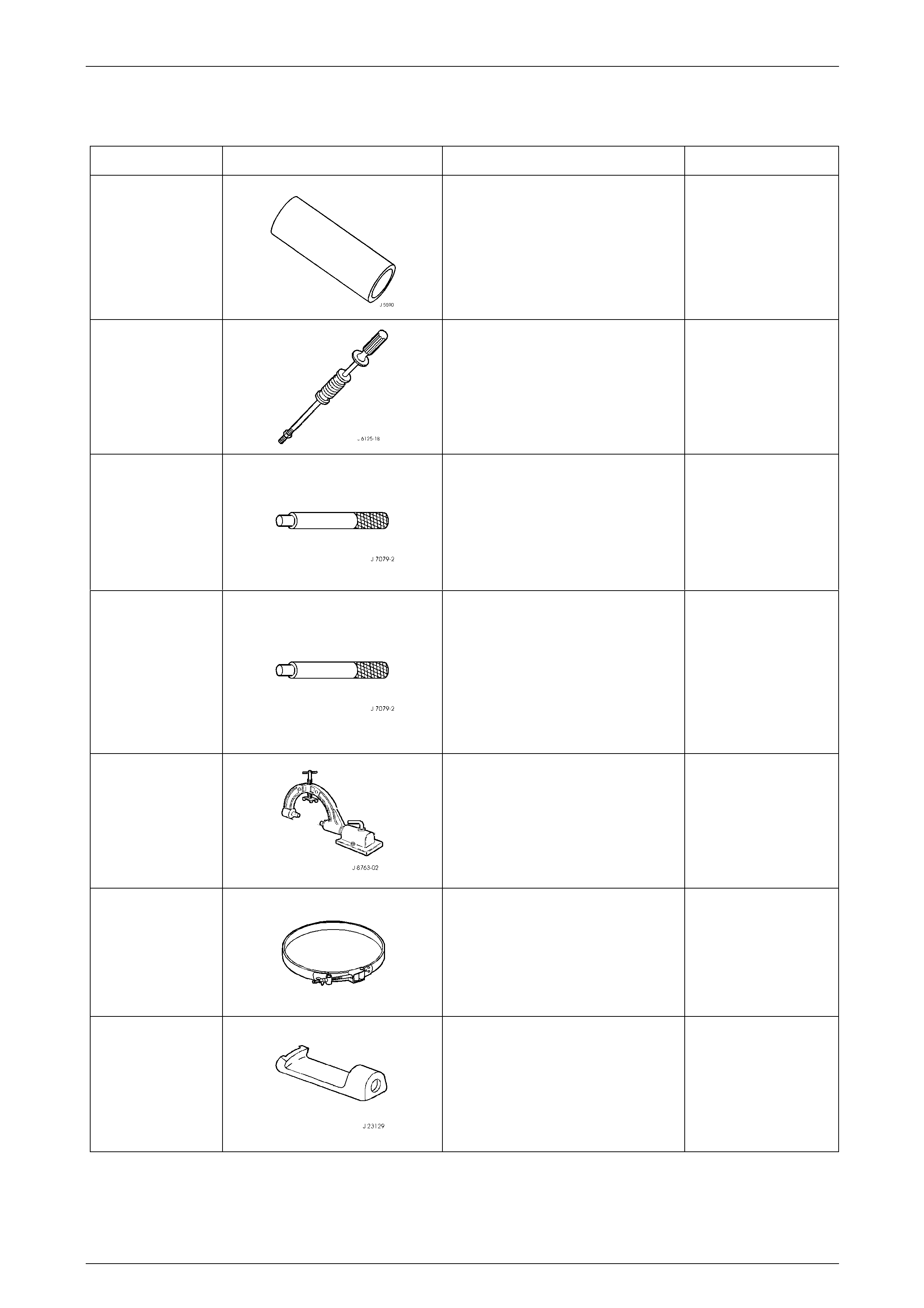

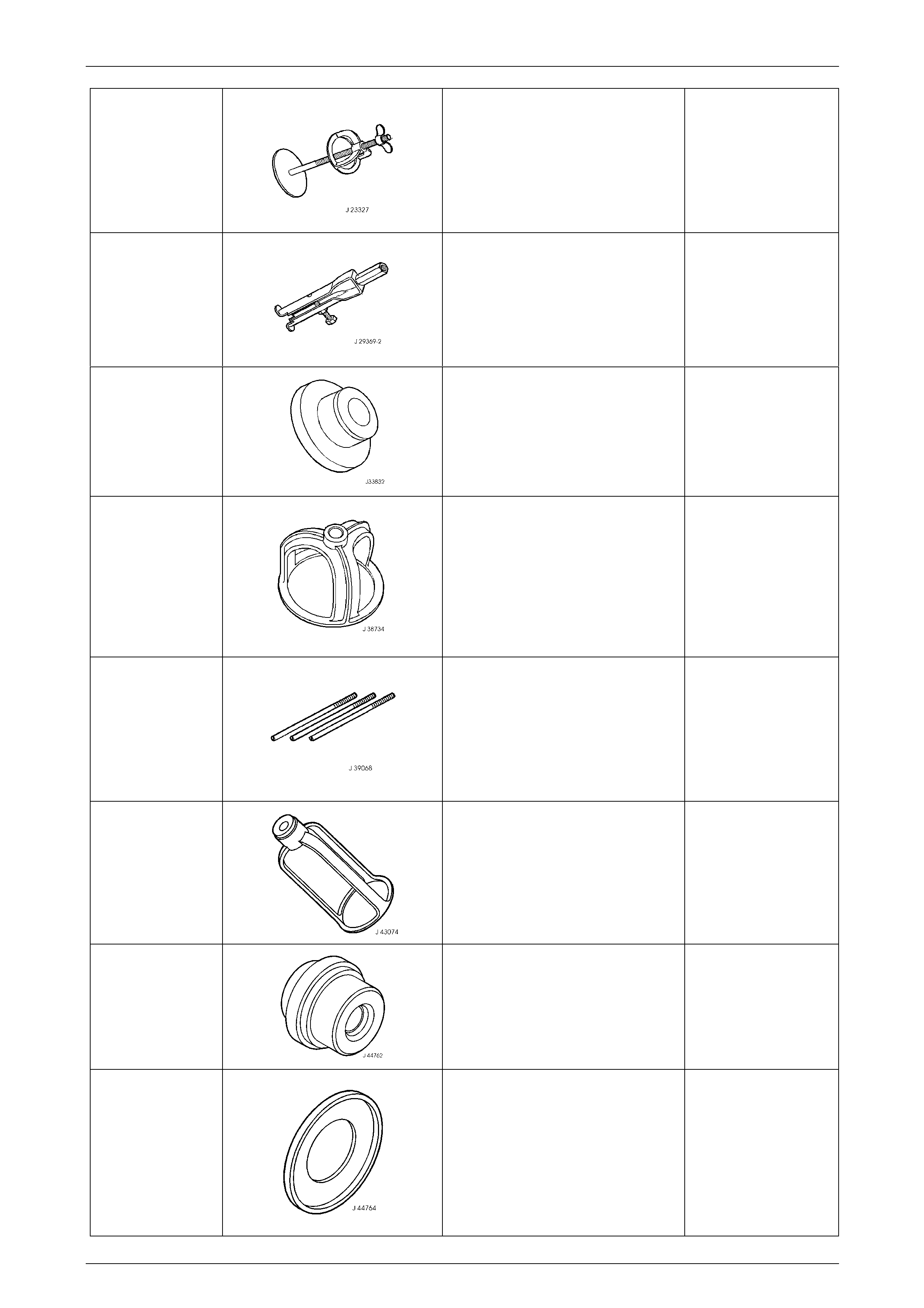

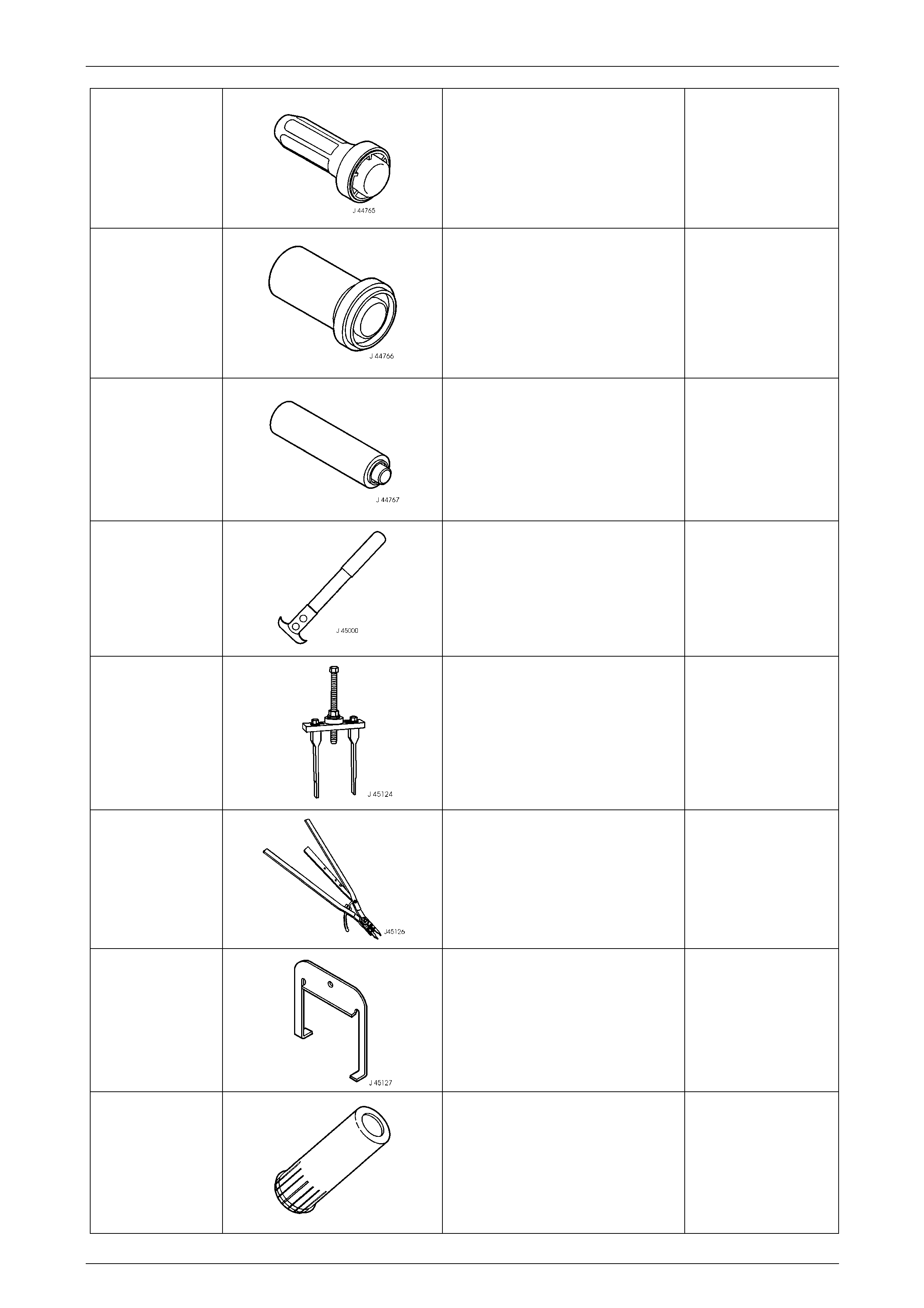

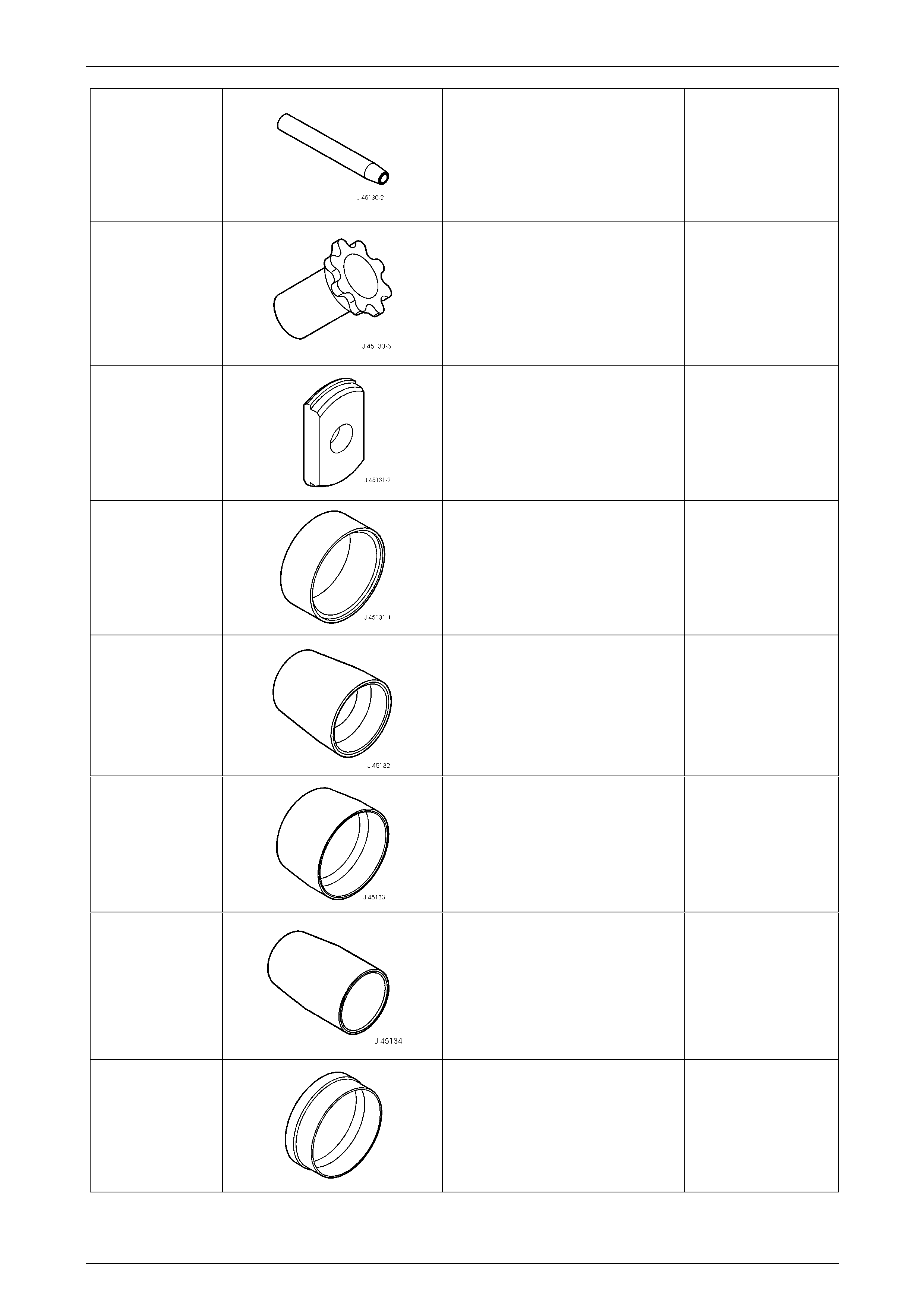

5 Special Tools ......................................................................................................................................144

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 4

7E5 – 4

1 Transmission Disassemble

1.1 General Service Information

The use of air powered tools to disassemble or reassemble this transmission is not recommended. Apart from the fact

that thread stripping is most likely when incorrect torque values are applied to fasteners, component parts can be

distorted to the point where malfunctions will occur.

Teflon Sealing Rings

If any sealing rings are found to be damaged, cut or do not rotate freely in their groove, check that the ring groov e has no

trapped debris, is not burred or damaged in such a way that early failure of a replaceme nt ring will occur.

Thrust Washer Surfaces

On inspection, thrust washer bearing surfaces may appear to be polished at points of contact. This is a normal condition

and should not be considered as damage, requiring replacement.

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 5

7E5 – 5

1.2 Transmission Preparation

Machined surfaces on alloy castings have

extremely sharp edges that can easily cause

injury and blood loss, through severe cuts.

Take extreme care when working under these

conditions.

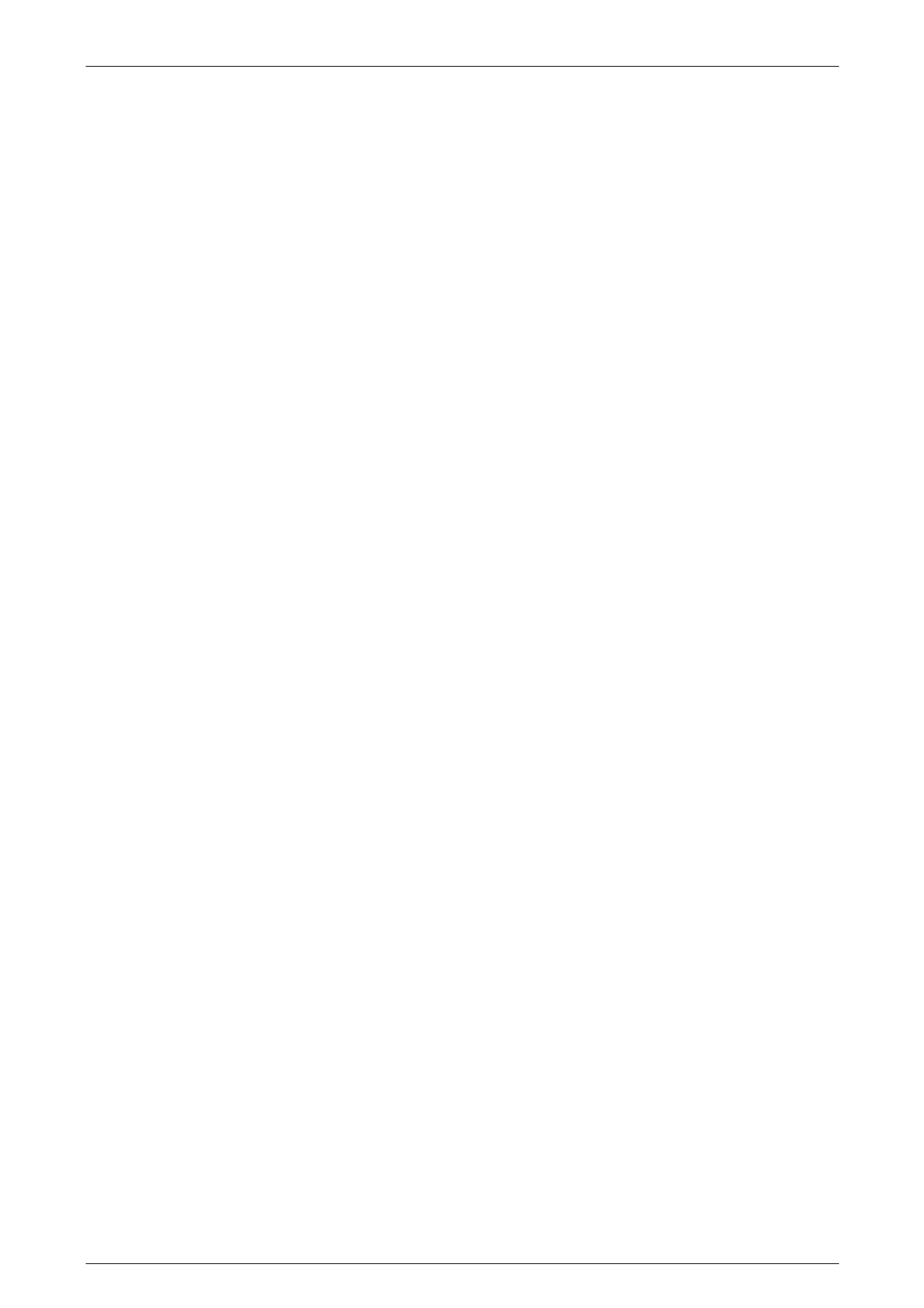

Torque Converter Assembly Removal

Take care when removing the torque

converter as it is a heavy assembly

(approximately 12 kilograms) and personal

injury may result if lifted incorrectly.

1 Remove the torque converter assembl y (1) by sliding

clear of input turbine shaft. Drain stored converter fluid

into a suitable container.

Figure 7E5 – 1

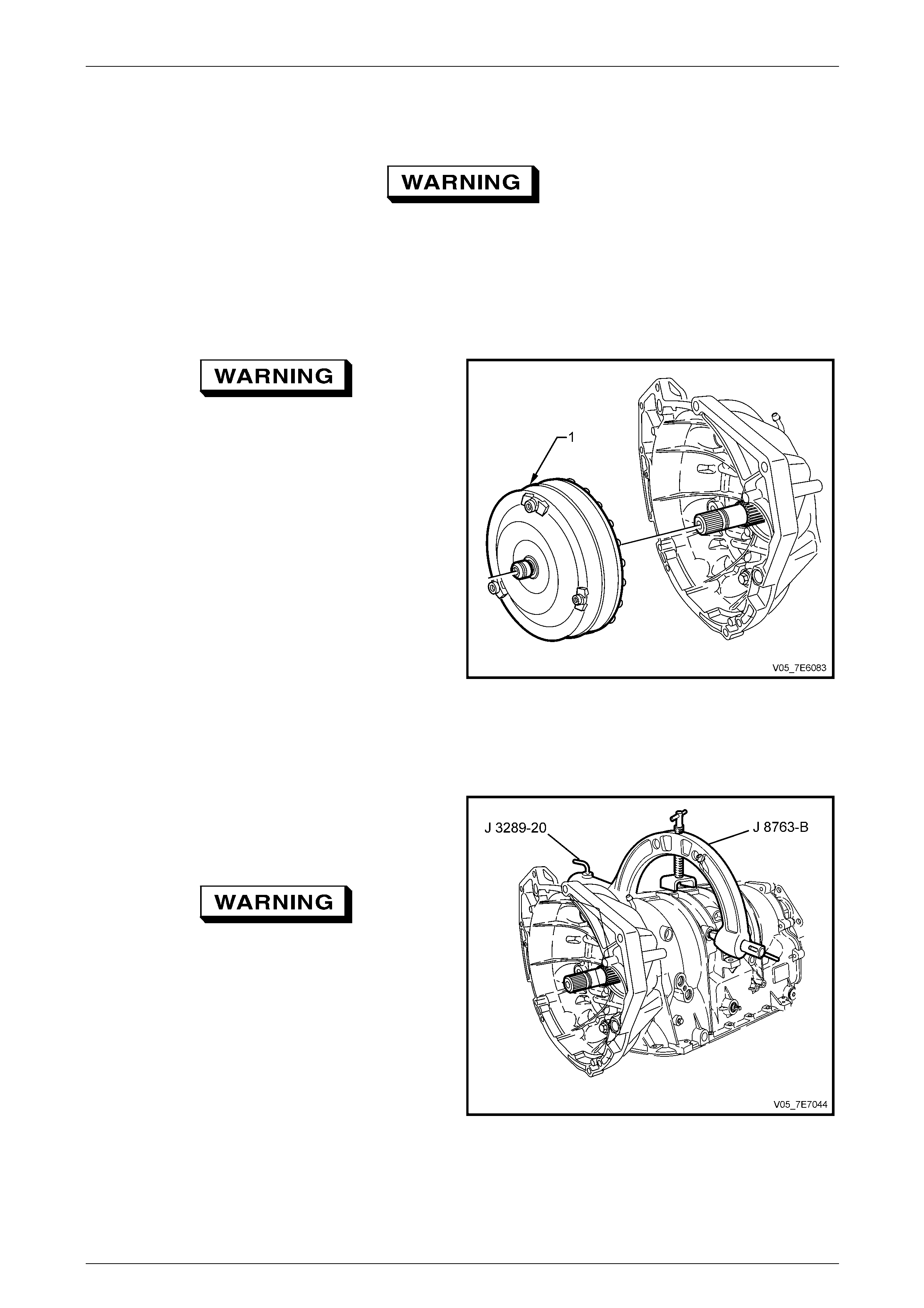

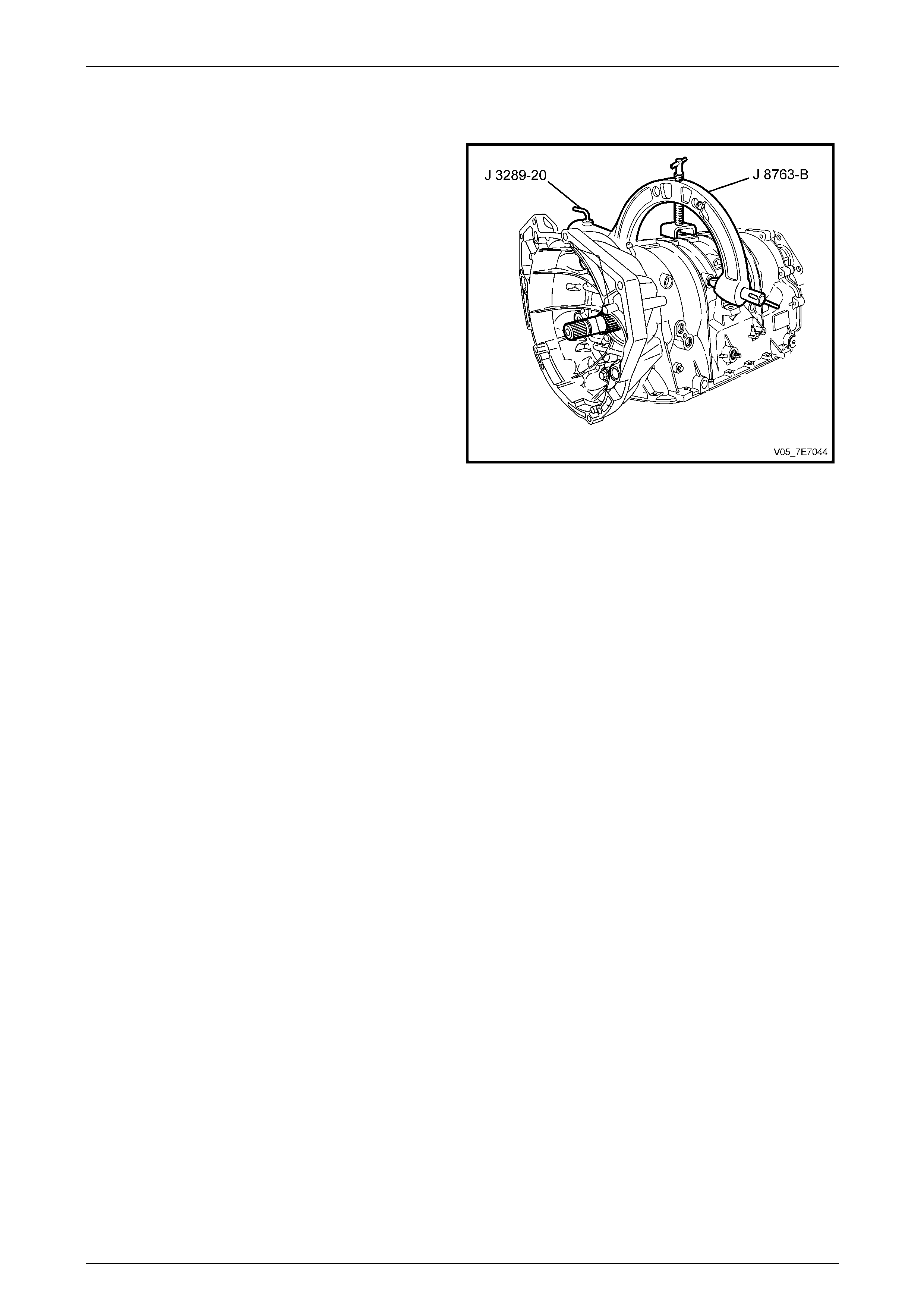

Holding Fixture Installation

1 Plug all transmission ope nings and thoroughly clean

the exterior of the transmission.

2 Install the transmission holding fixture (2) J 8763-02

(or E1363) as shown onto the transmission assembly.

Take care when installing the transmission to

the tool base. Use suitable lifting equipment

as the transmission assembly without the

torque converter is still a heavy assembly

(approximately 70 kilograms) and personal

injury may result if lifted incorrectly.

Also, be mindful that the weight of the

transmission, could tip the workbench over.

3 Install the transmission assembl y and holding fixture

into the tool base and use the pin (1) to lock the

holding fixture i n place. Figure 7E5 – 2

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 6

7E5 – 6

4 Using a fine bladed screwdriver, lever out and remove

the input turbine shaft seal (430).

NOTE

If the O-ring seal is not removed at this time,

then removal of the torque co nverter housing will

not be possible.

Figure 7E5 – 3

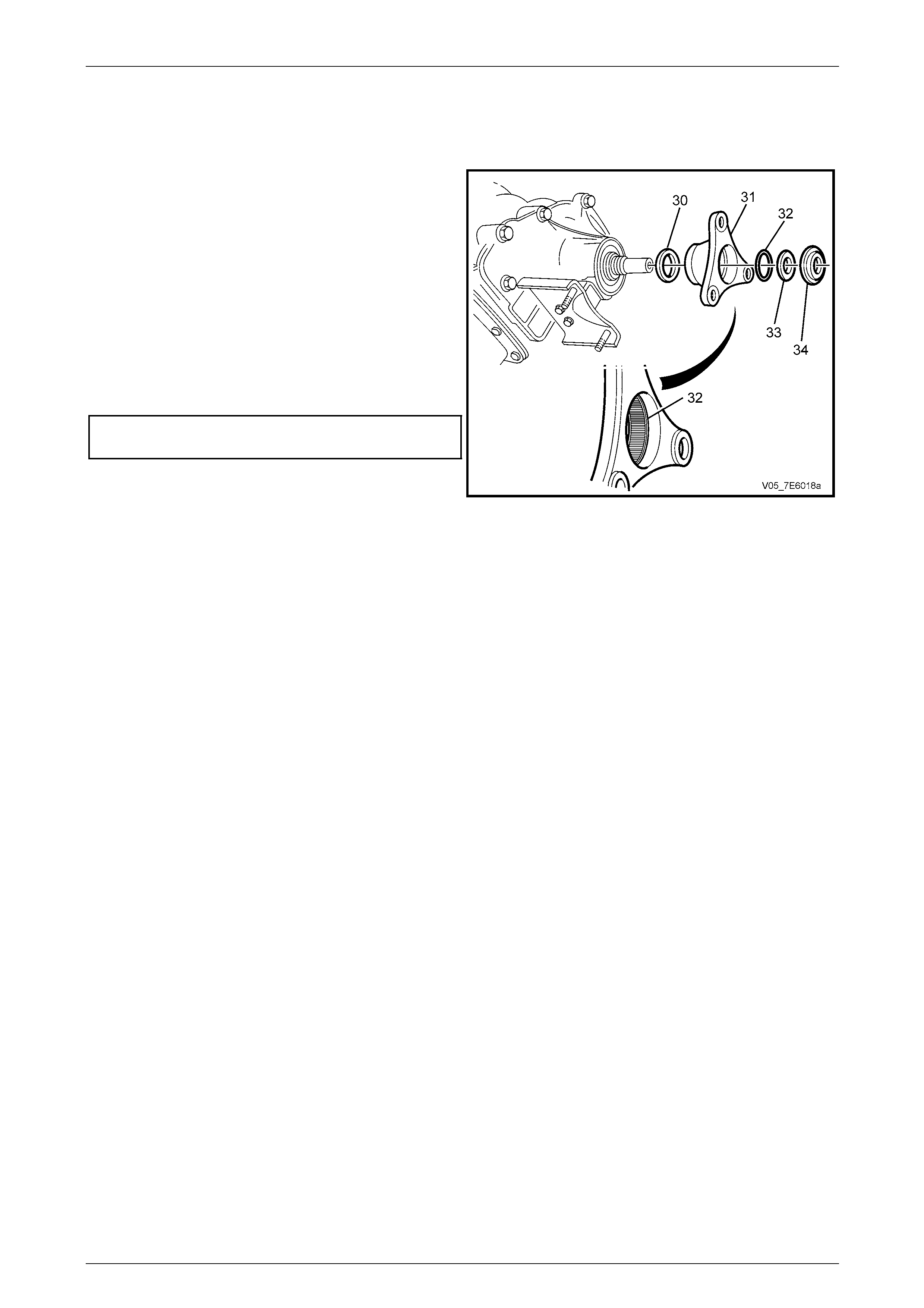

Draining Transmission Fluid

1 Using a T-45 Torx bit and suitable equipment, remove

the fluid pan drain plug (63) a nd seal (64), and allow

the transmission fluid to drain in to a suitable sized

container (approximatel y 6 litr es).

Figure 7E5 – 4

2 Put transmission in Park.

3 Remove the propeller shaft flange n ut (34), u s ing a 30

mm deep socket and suitable equ ipment.

4 Remove the dished washer (33) from the transmission

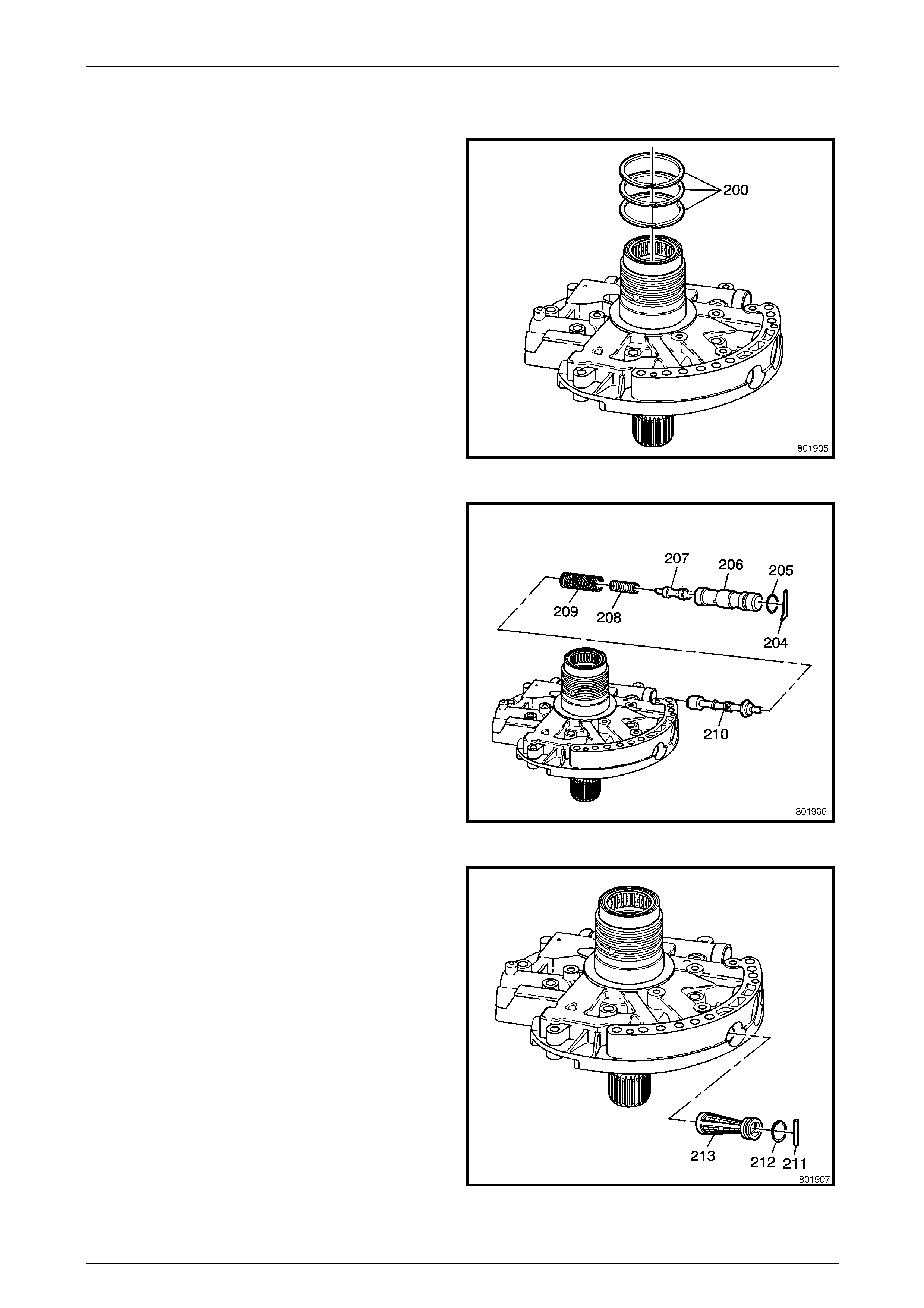

output shaft.

5 Remove the propeller shaft flange (3 1) and O-ring seal

(32) from the transmission output shaft. Using a small

screwdriver blade, remove the O-ring seal (3 2) and

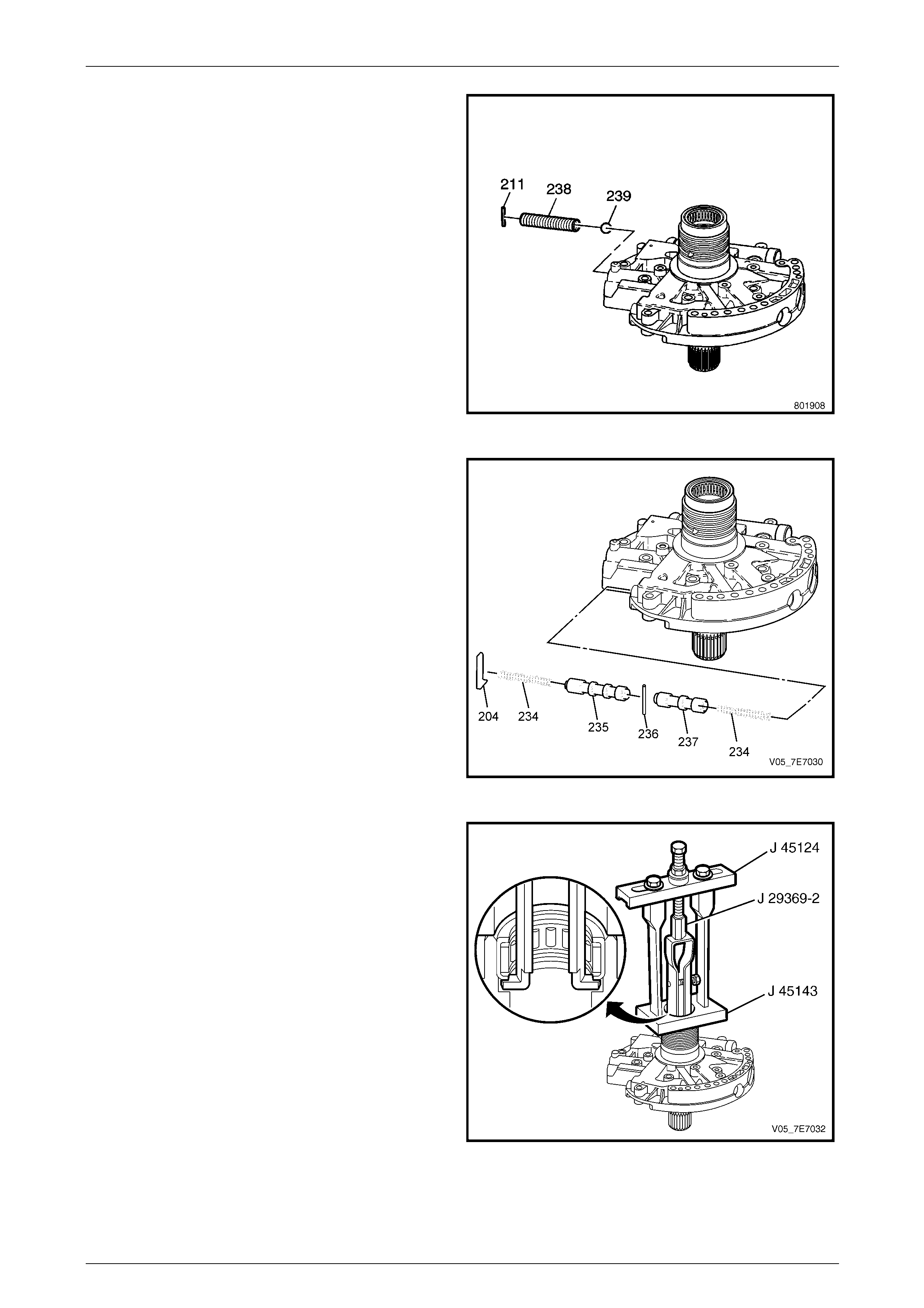

discard.

6 Remove holding fixture tool base pin and slowly rotate

the transmission and holding fixture to a vertic al

position, with the torque converter housin g facing up.

Re–insert tool base pin with transmission in this

position and allow any excess fluid to drain into the

suitable container.

Figure 7E5 – 5

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 7

7E5 – 7

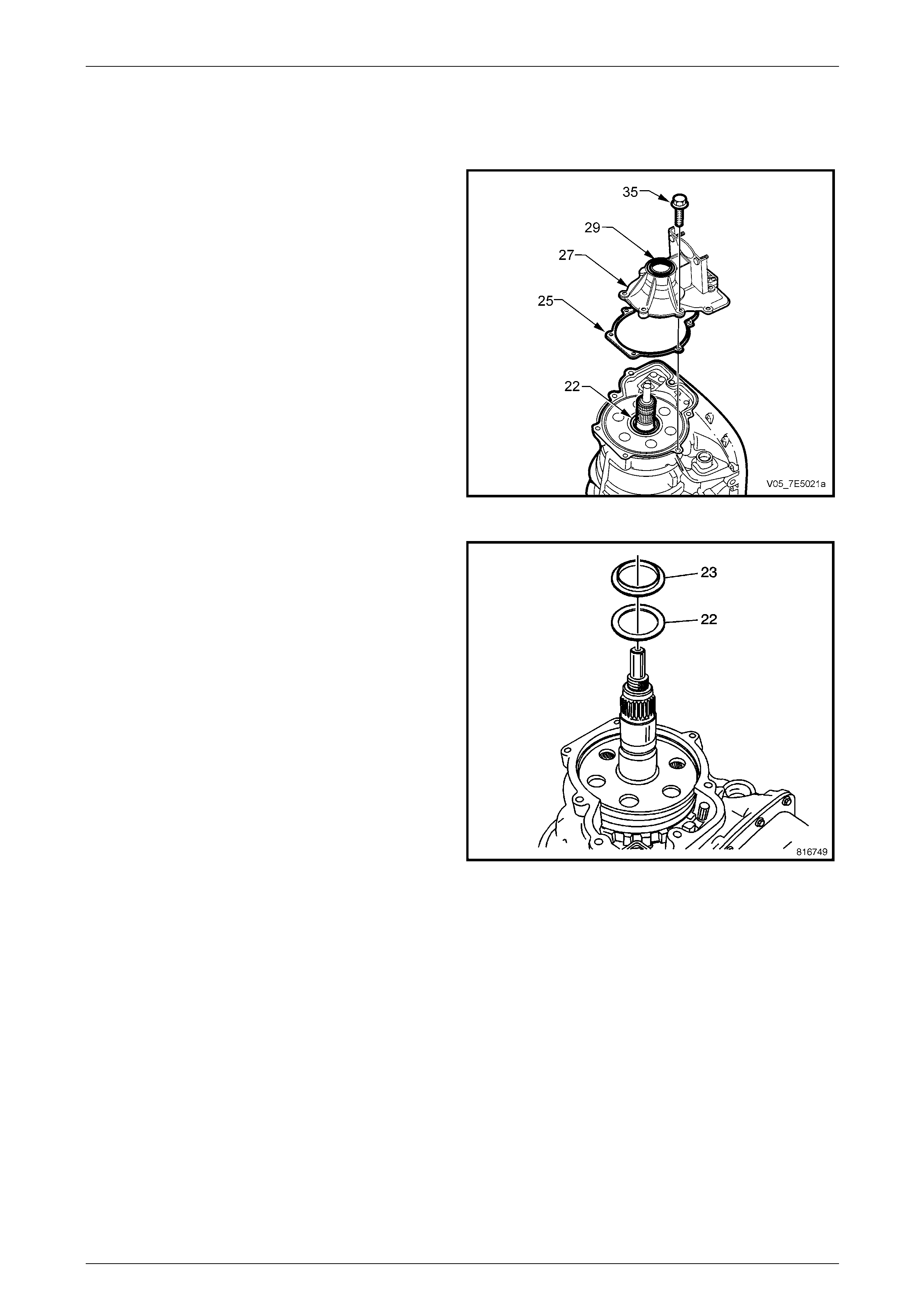

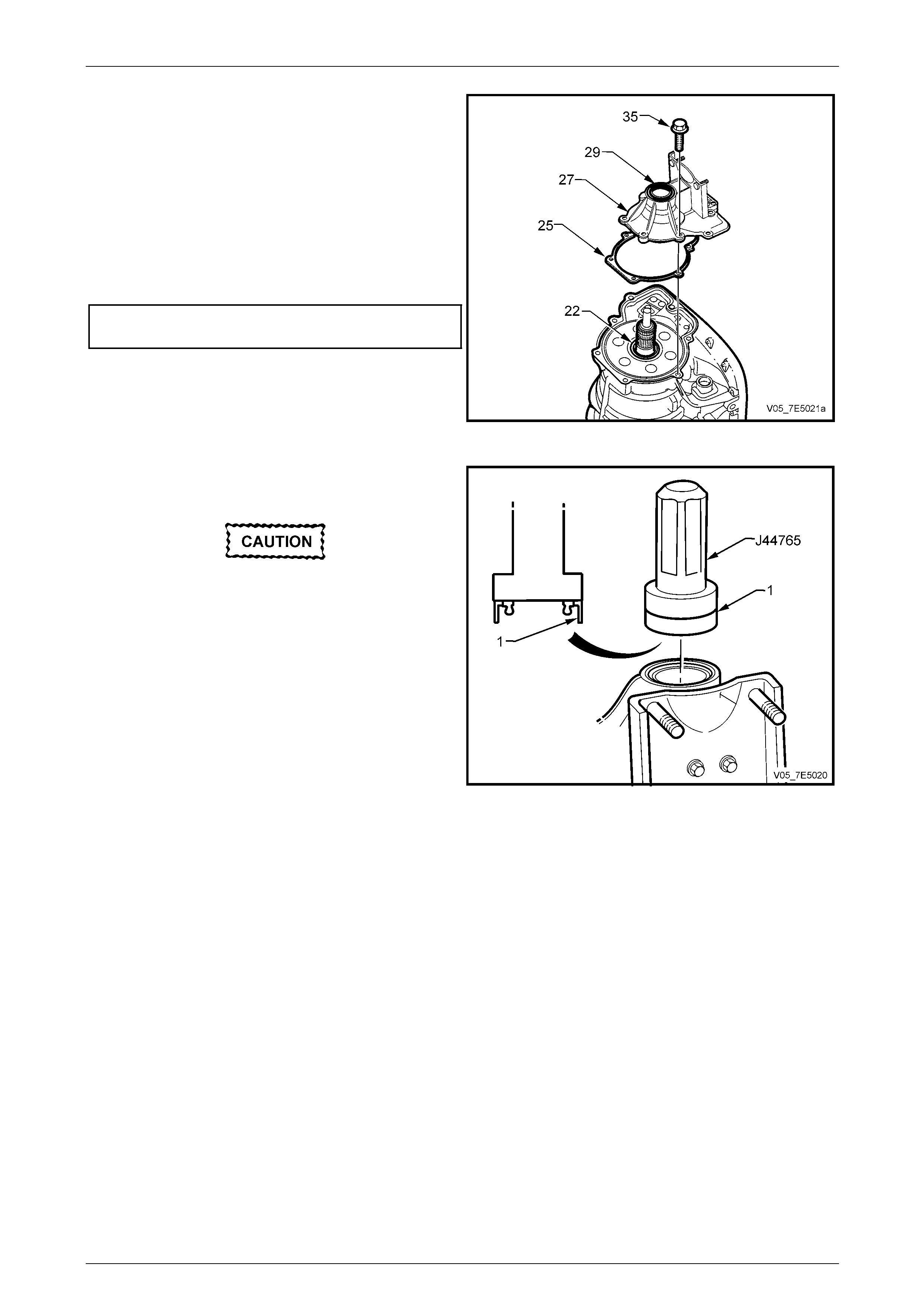

1.3 Extension Housing

Remove

1 Rotate the transmission through 180° to a vertical

position with the extension housing facing up.

2 Using seal remover E308 (or commercial equivalent)

and suitable socket equipment, remove the propeller

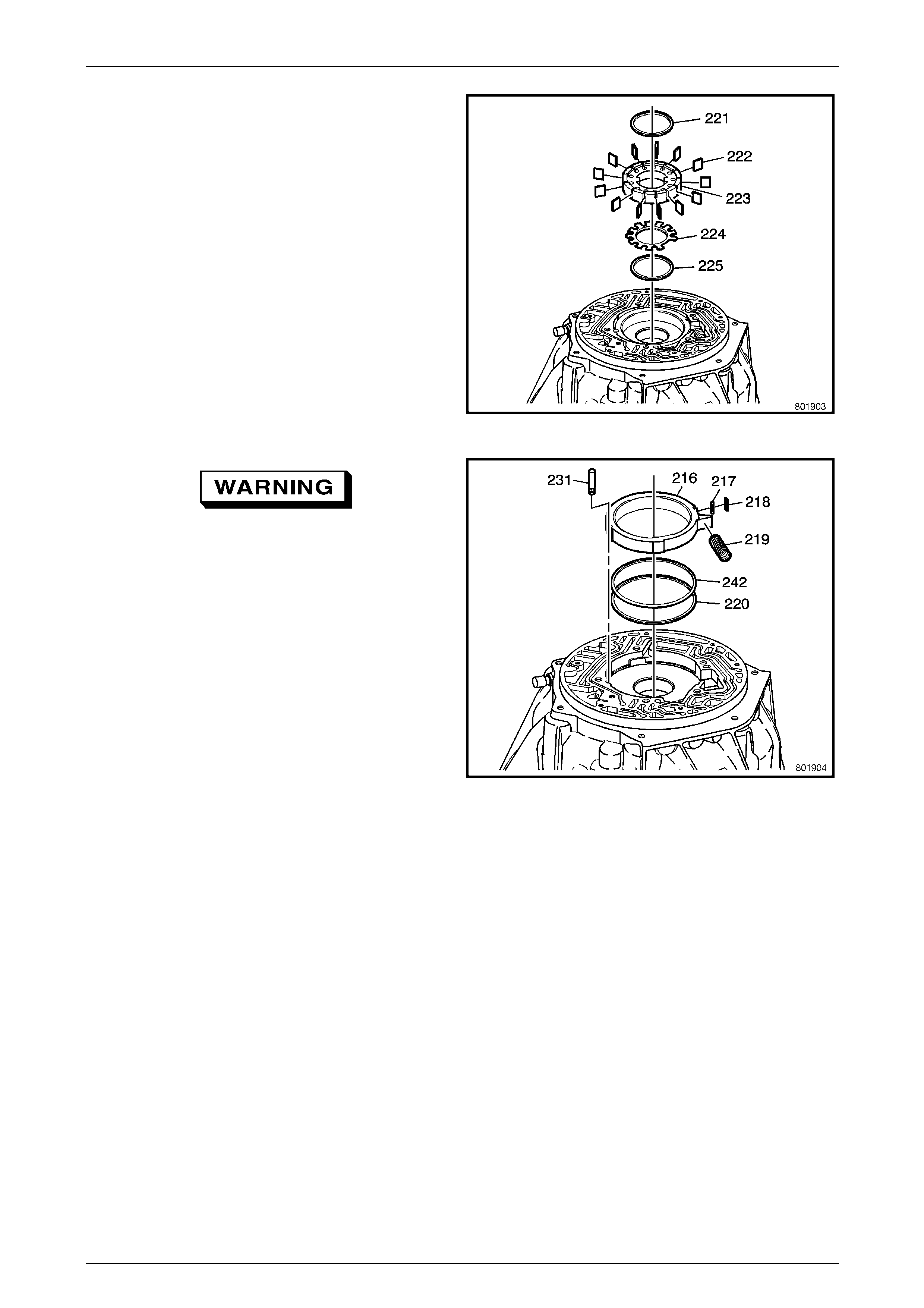

shaft flange oil seal (29).

3 Using suitable snap ring pliers remove the output shaft

assembly retainer (30) (refer Figure 7E5-5).

4 Remove the extension housin g bolts (35).

5 Remove the extension housin g (27).

6 Remove the extension housing gasket (25).

Figure 7E5 – 6

7 If not retained in the extension housing on removal,

remove the input and reaction carrier thrust bearing

(23) and selective washer (22), from the output shaft

assembly.

NOTE

If the thrust bearing and washer are not removed

at this time, they will probably fall off when the

transmission is rotated for other procedures.

Figure 7E5 – 7

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 8

7E5 – 8

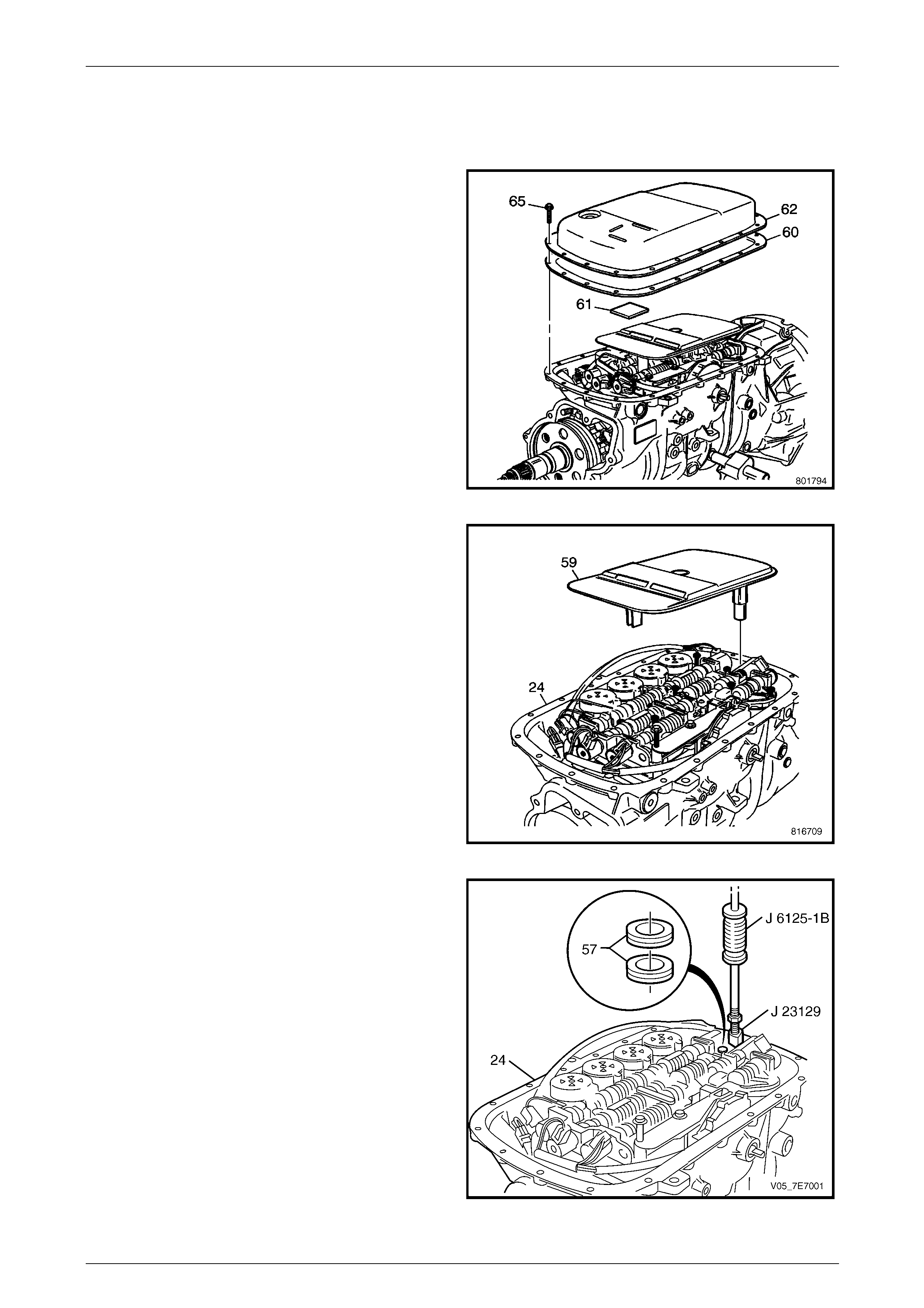

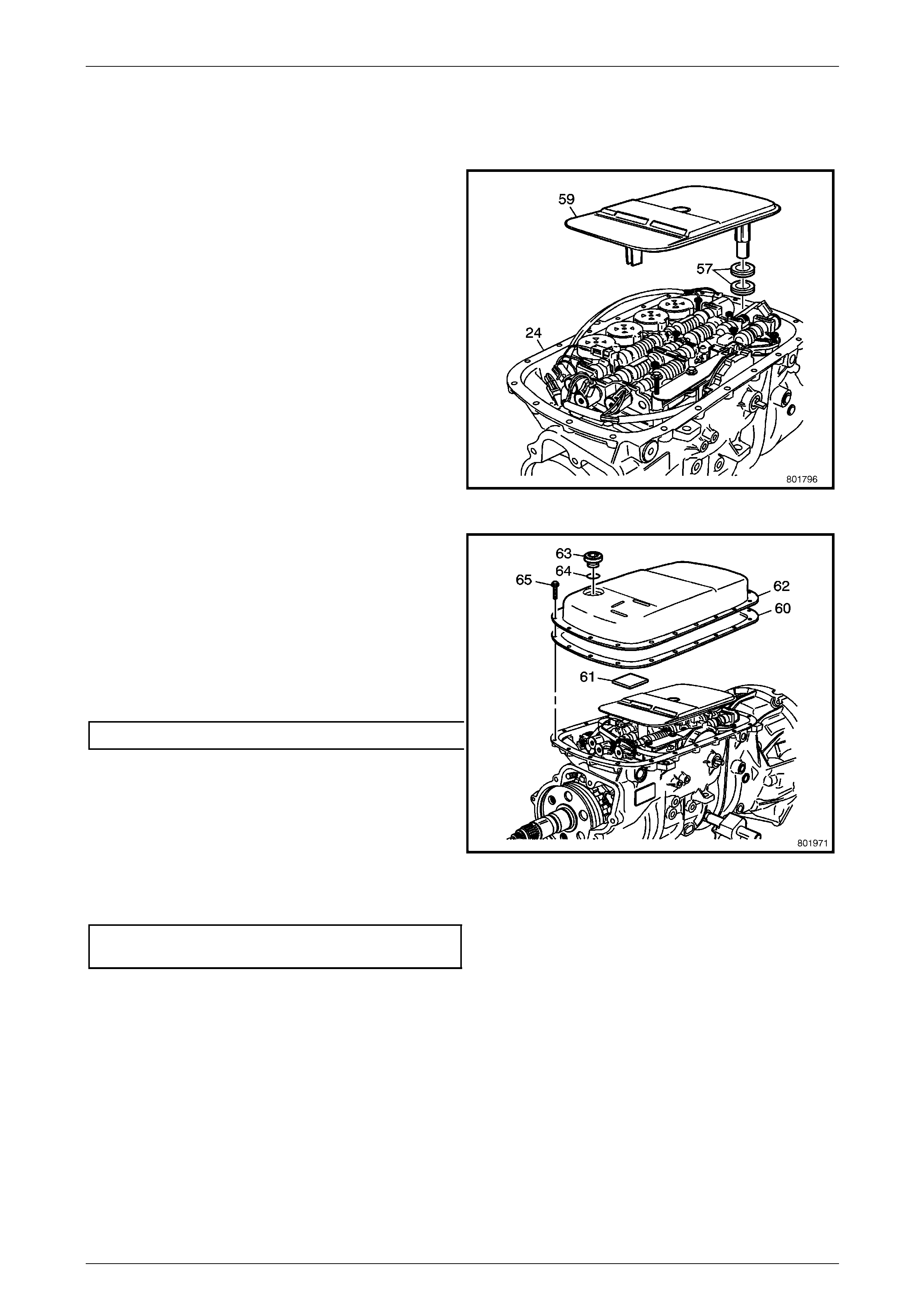

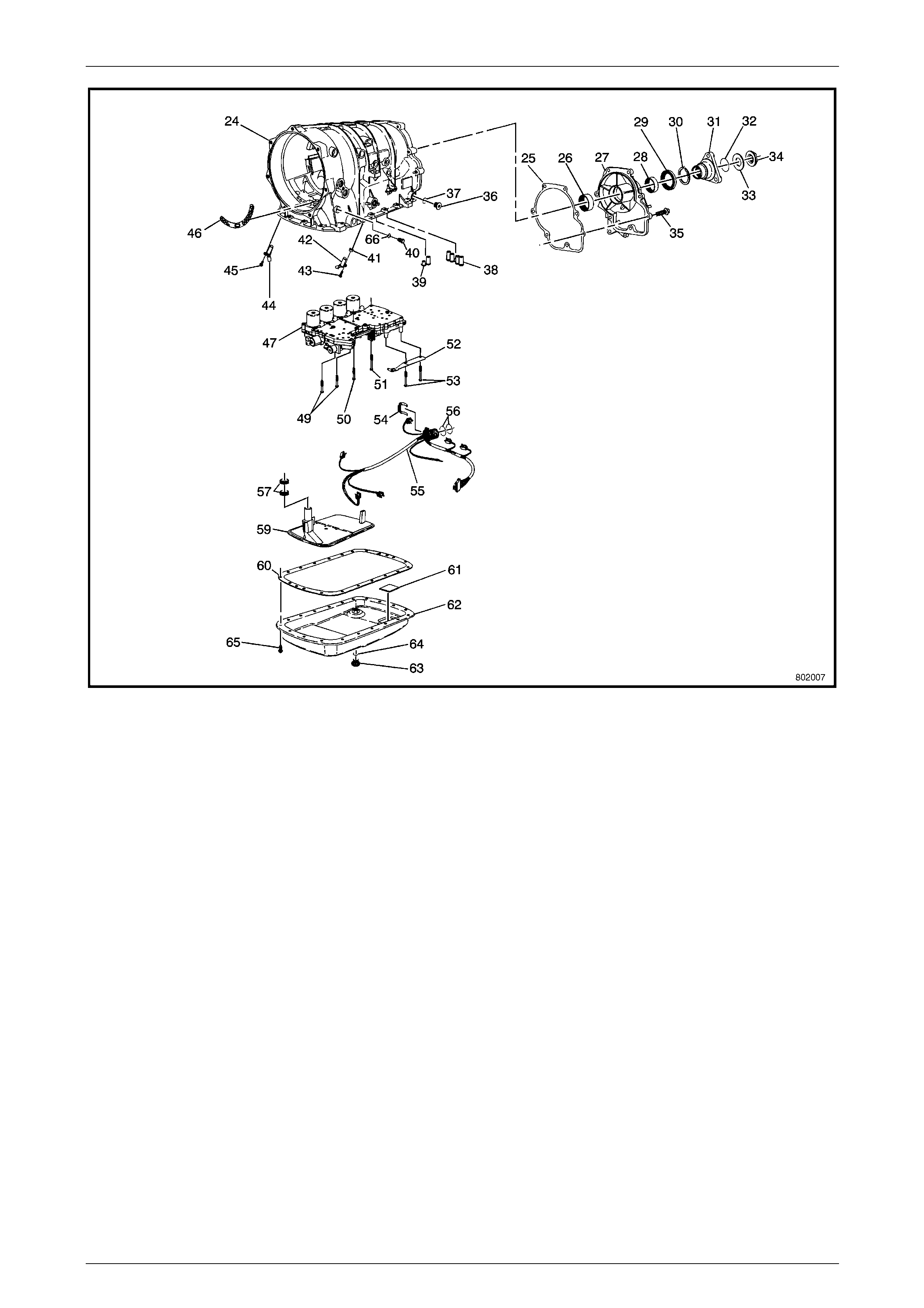

1.4 Pan and Filter Assembly

Removal

1 Remove holding fixture tool base pin and slowly rotate

the transmission and holding fixture so that the fluid

pan (62) is facing up.

Re–insert tool base pin with transmission in this

position.

2 Remove the 10 mm hexagon headed fluid pan bolts

(65), the fluid pan (62) and the gasket (60).

Figure 7E5 – 8

3 Remove the fluid filter (59) from the case (24).

NOTE

Fluid seals (57) will probably remain in the

transmission case (24) after fluid filter (59) has

been removed.

Figure 7E5 – 9

4 Assemble universal seal remover tool J 23129 and

slide hammer tool J 6125-1B together to remove the

fluid filter seals (57) from the case (24).

Figure 7E5 – 10

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 9

7E5 – 9

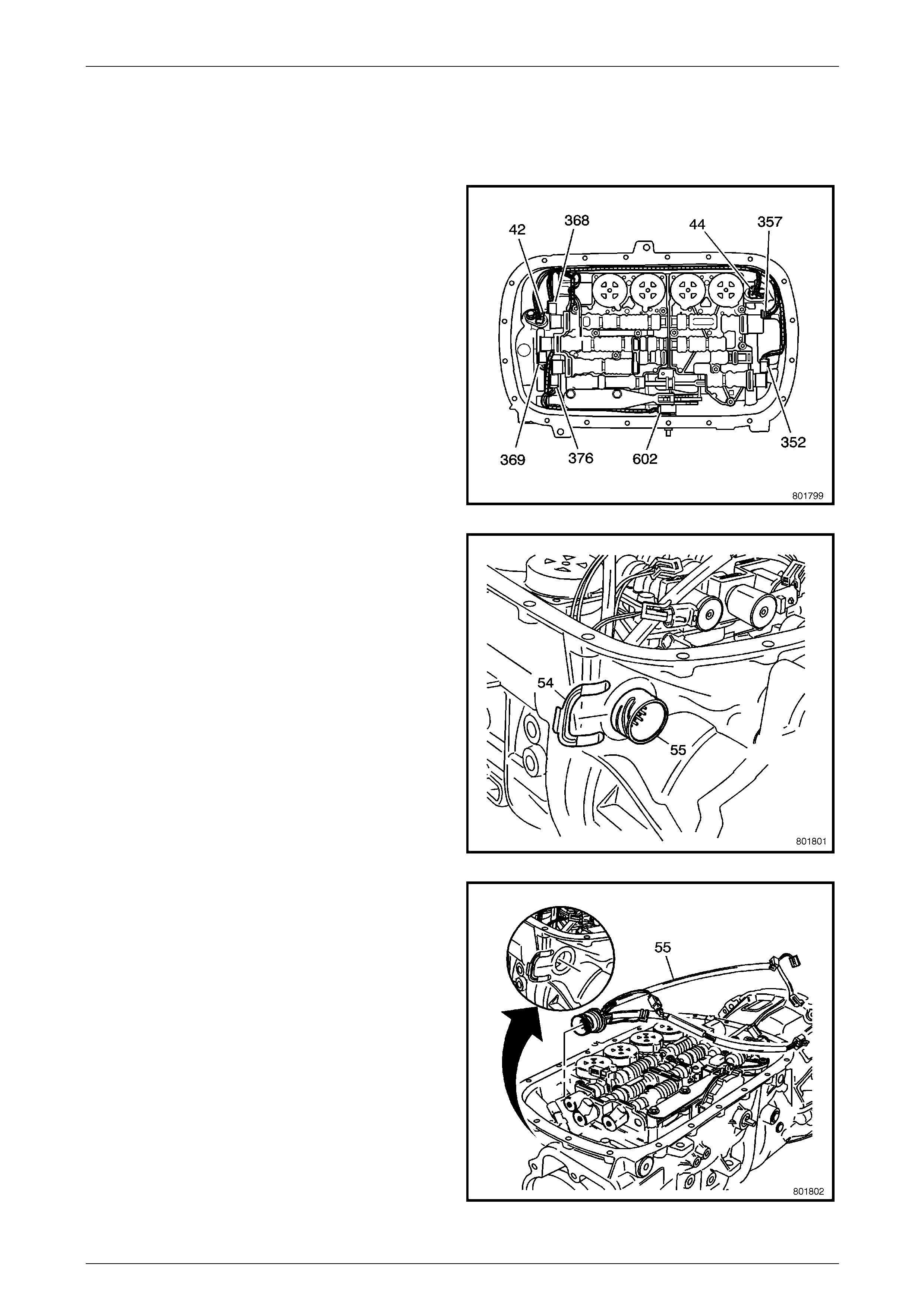

1.5 Wiring Harness

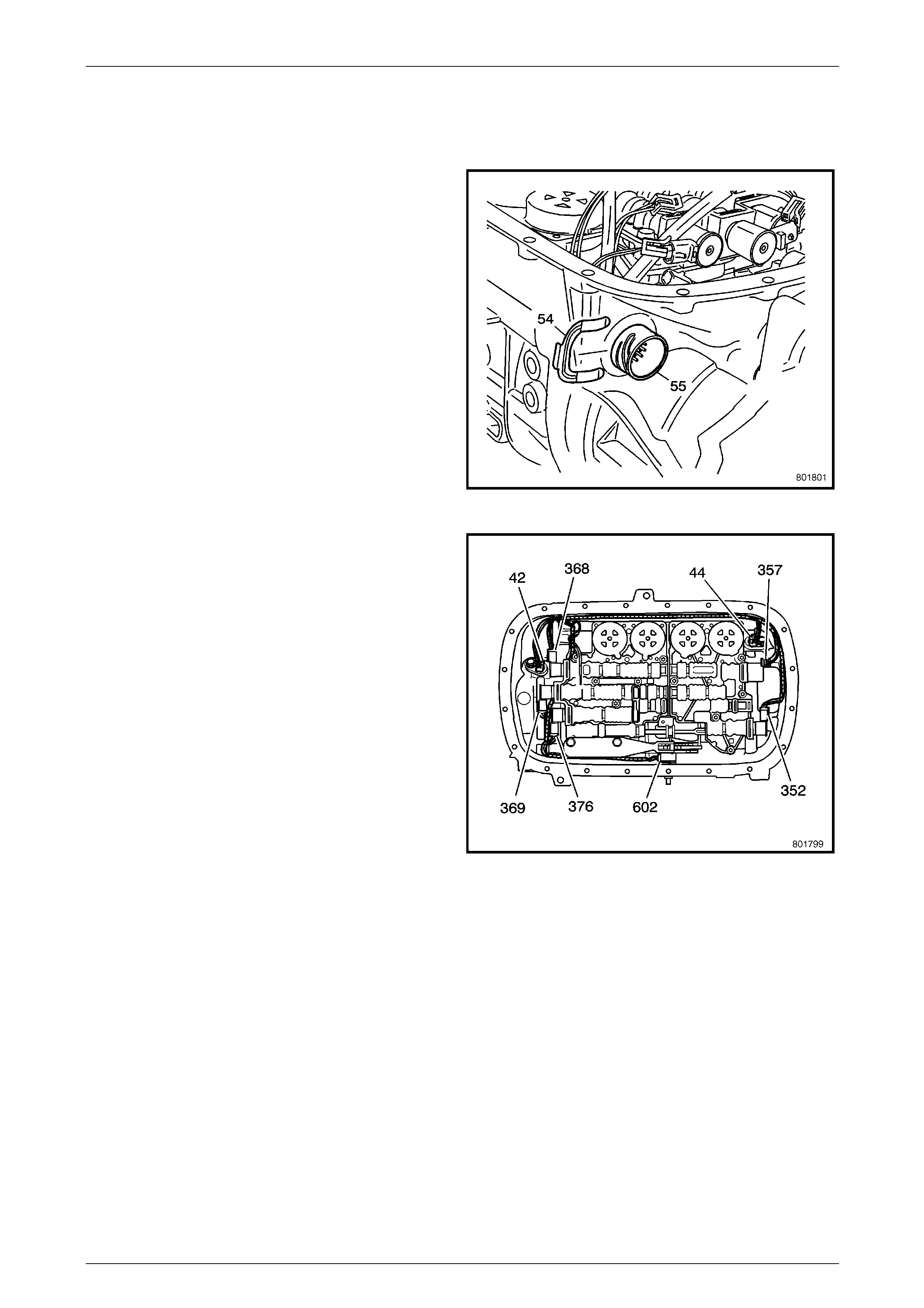

Remove

1 Using a small scre wdriver to lift the transmission

connector locking tangs, remove the wiring harness

connectors from the following components:

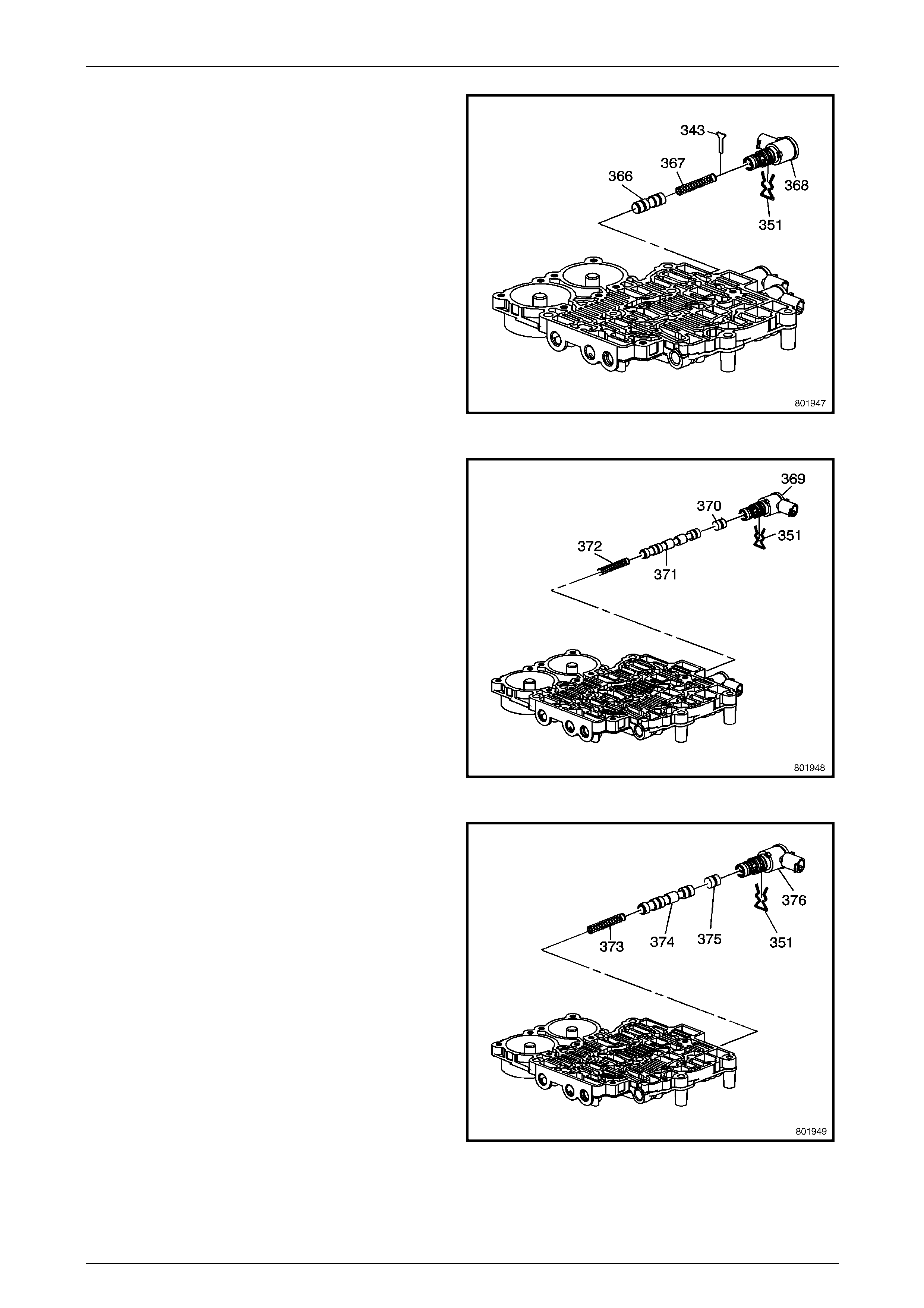

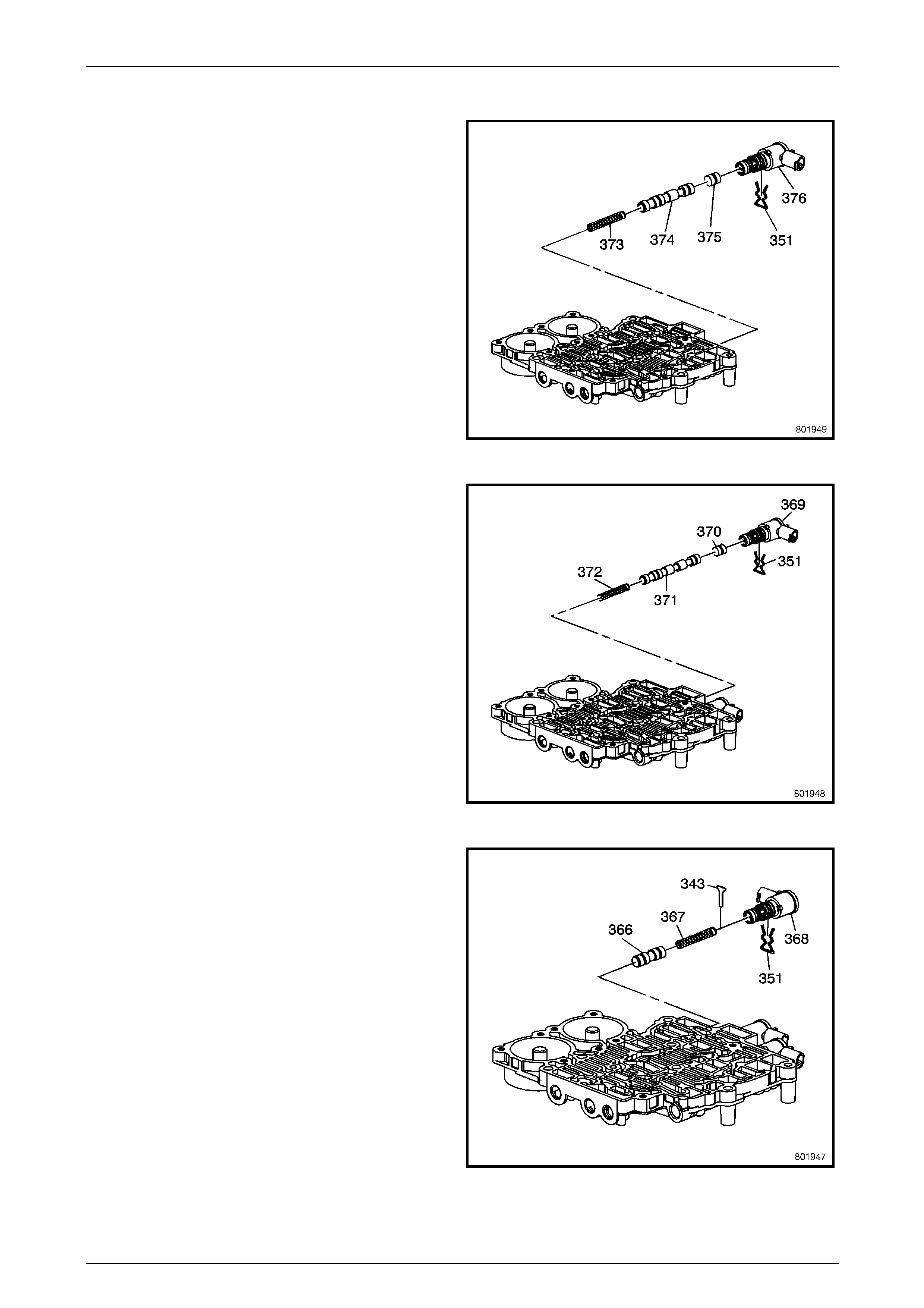

• Pressure Control Solenoid (3 57)

• TCC PWM Solenoid (352)

• 1–2 Shift Solenoid (368)

• 2–3 Shift Solenoid (369)

• 4–5 Shift Solenoid (376)

• Manual Shift Shaft Switch (602)

• Input Speed Sensor (44)

• Output Speed Sensor (42)

Figure 7E5 – 11

2 Using a flat bladed screwdriver, remove the connector

retainer (54) from the transmission case (24).

Figure 7E5 – 12

3 Remove the wiring harness (55) from the transmission

case (24).

Figure 7E5 – 13

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 10

7E5 – 10

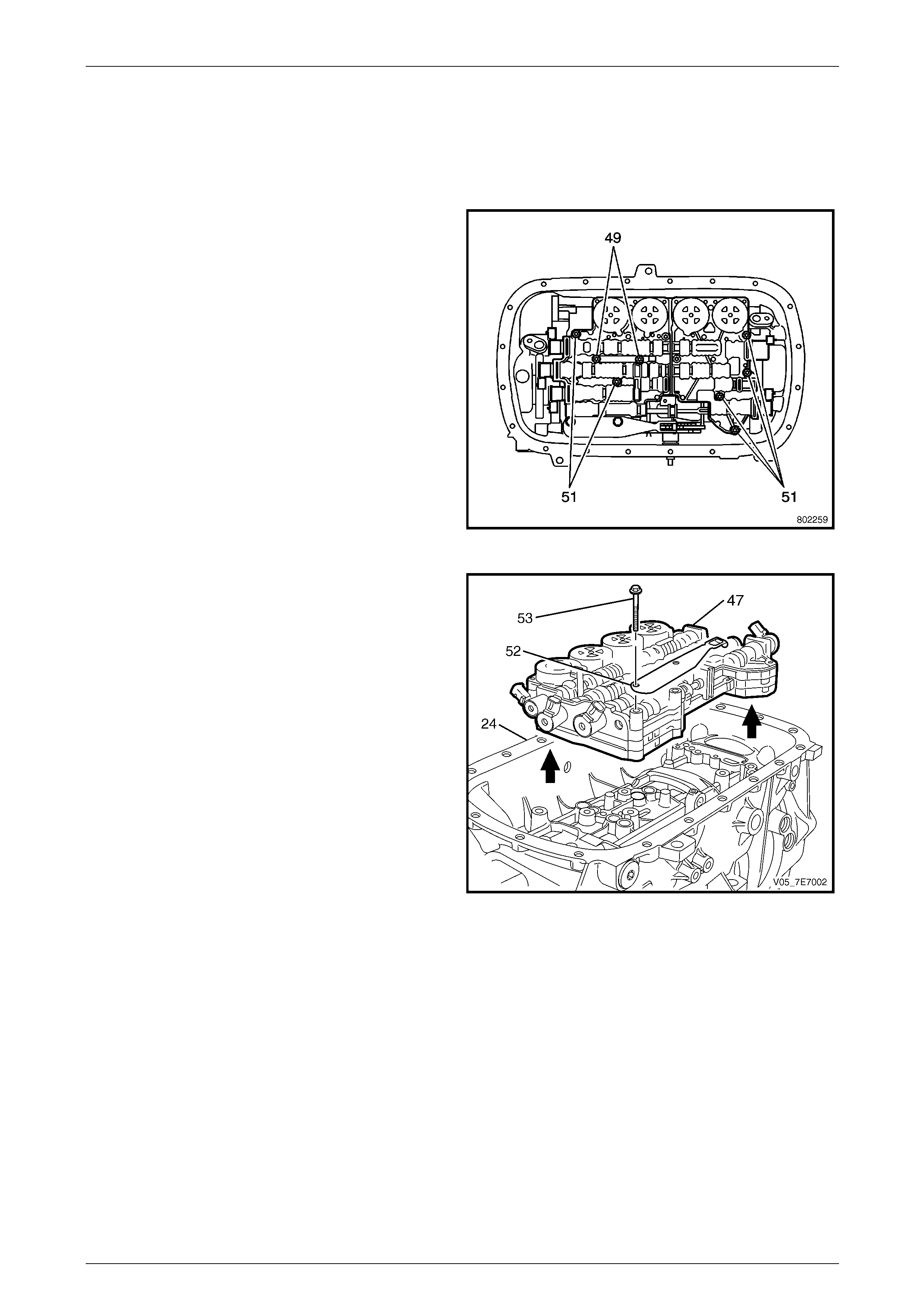

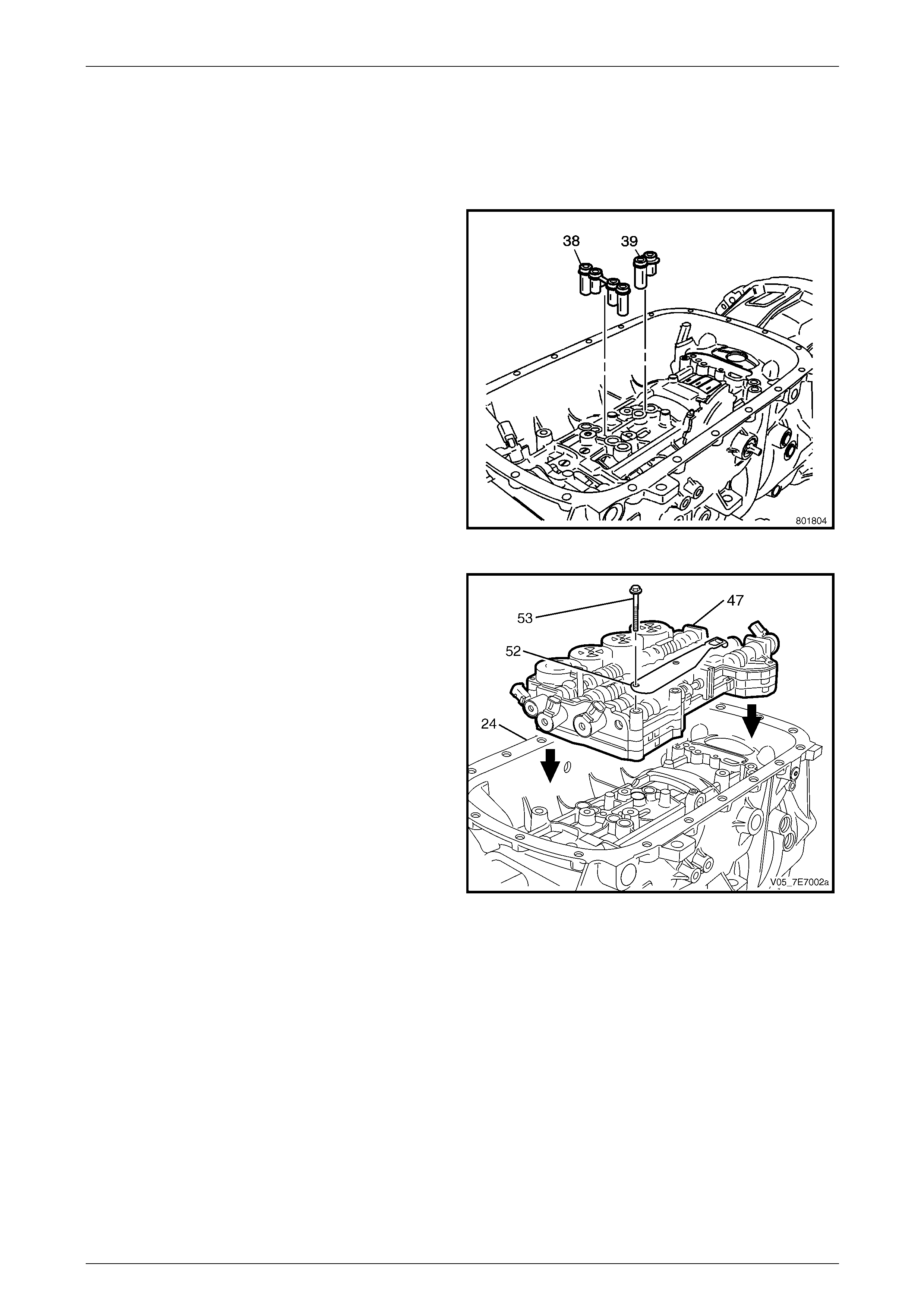

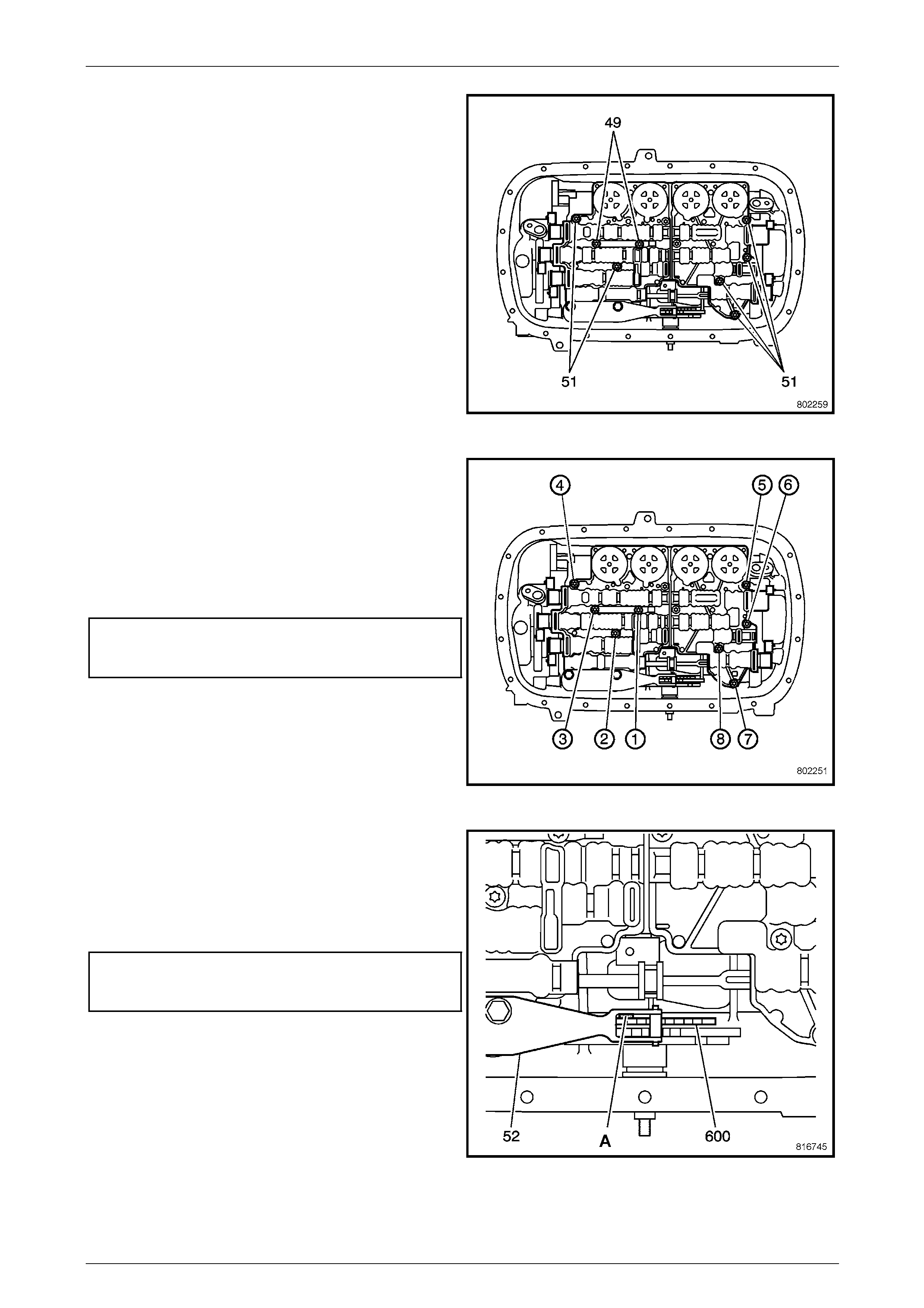

1.6 Control Valve Body and Accumulator

Assembly

Remove

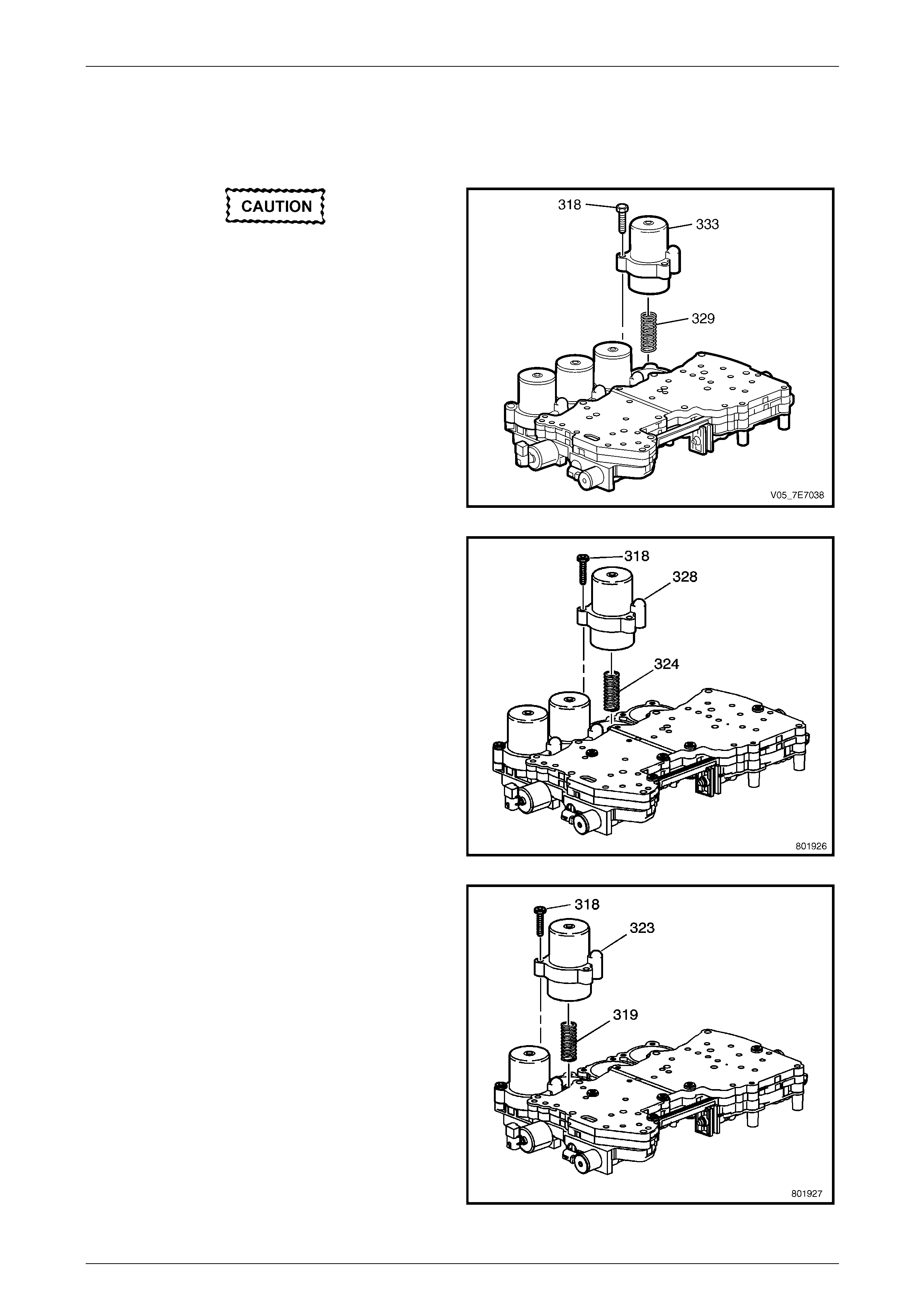

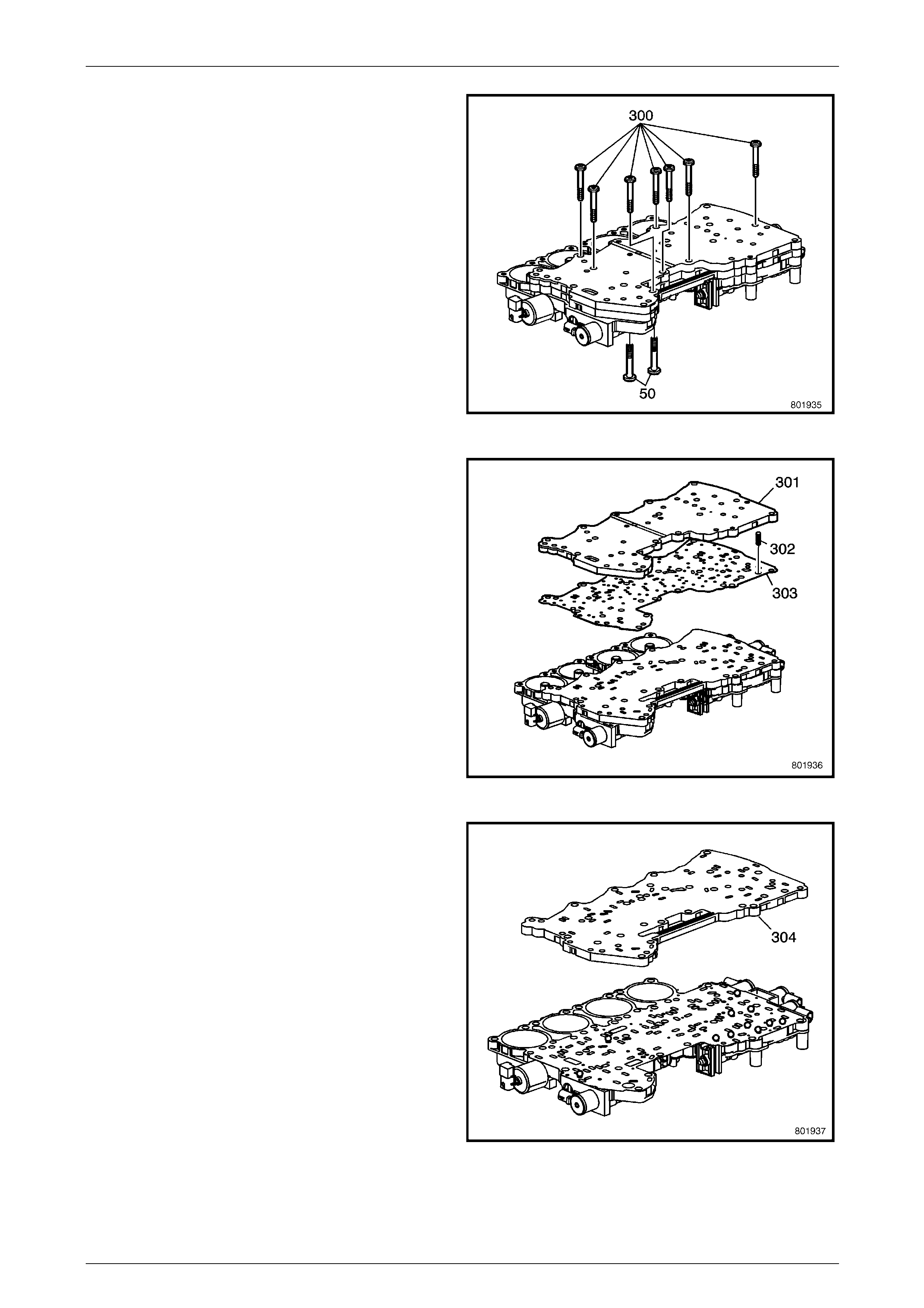

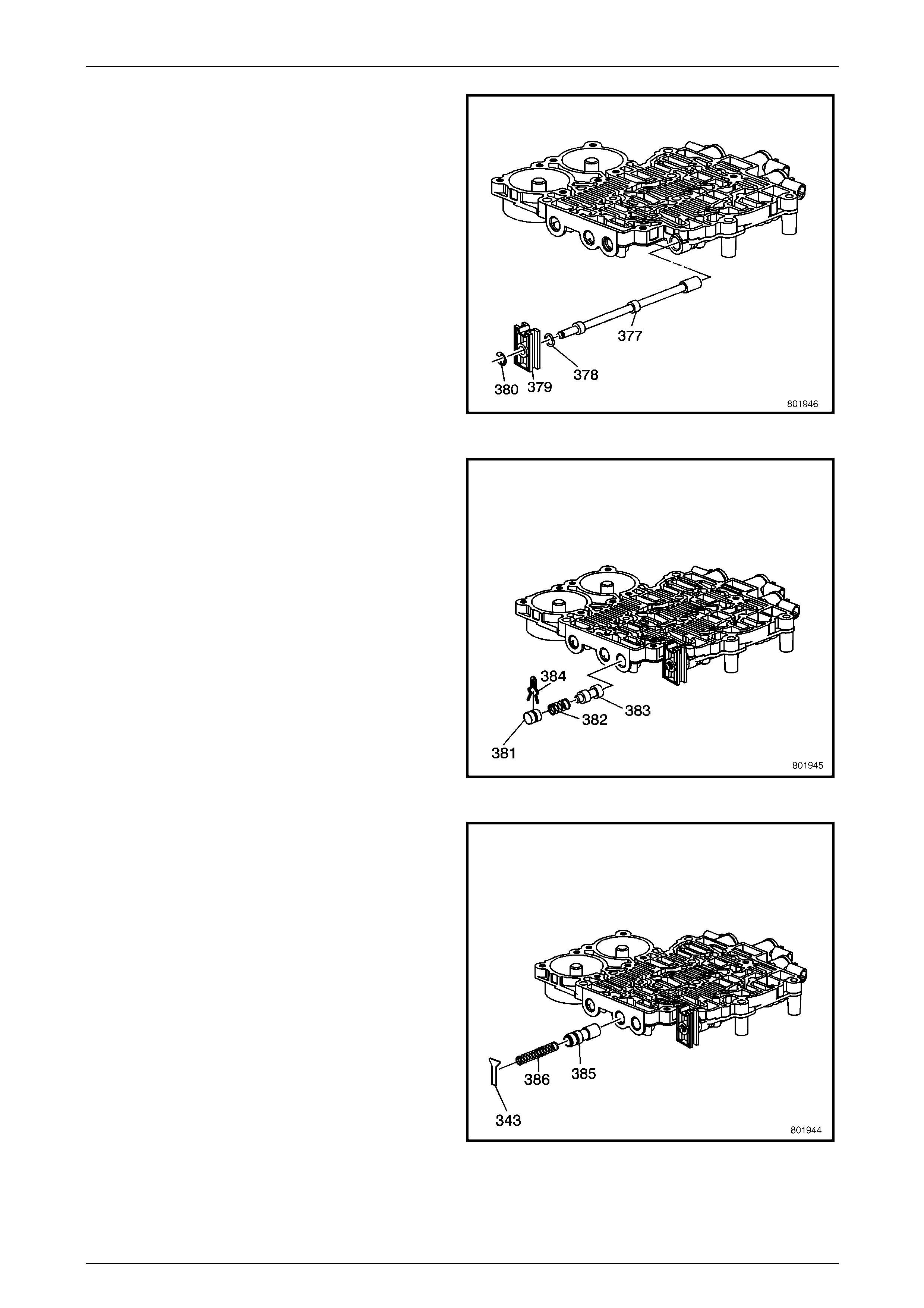

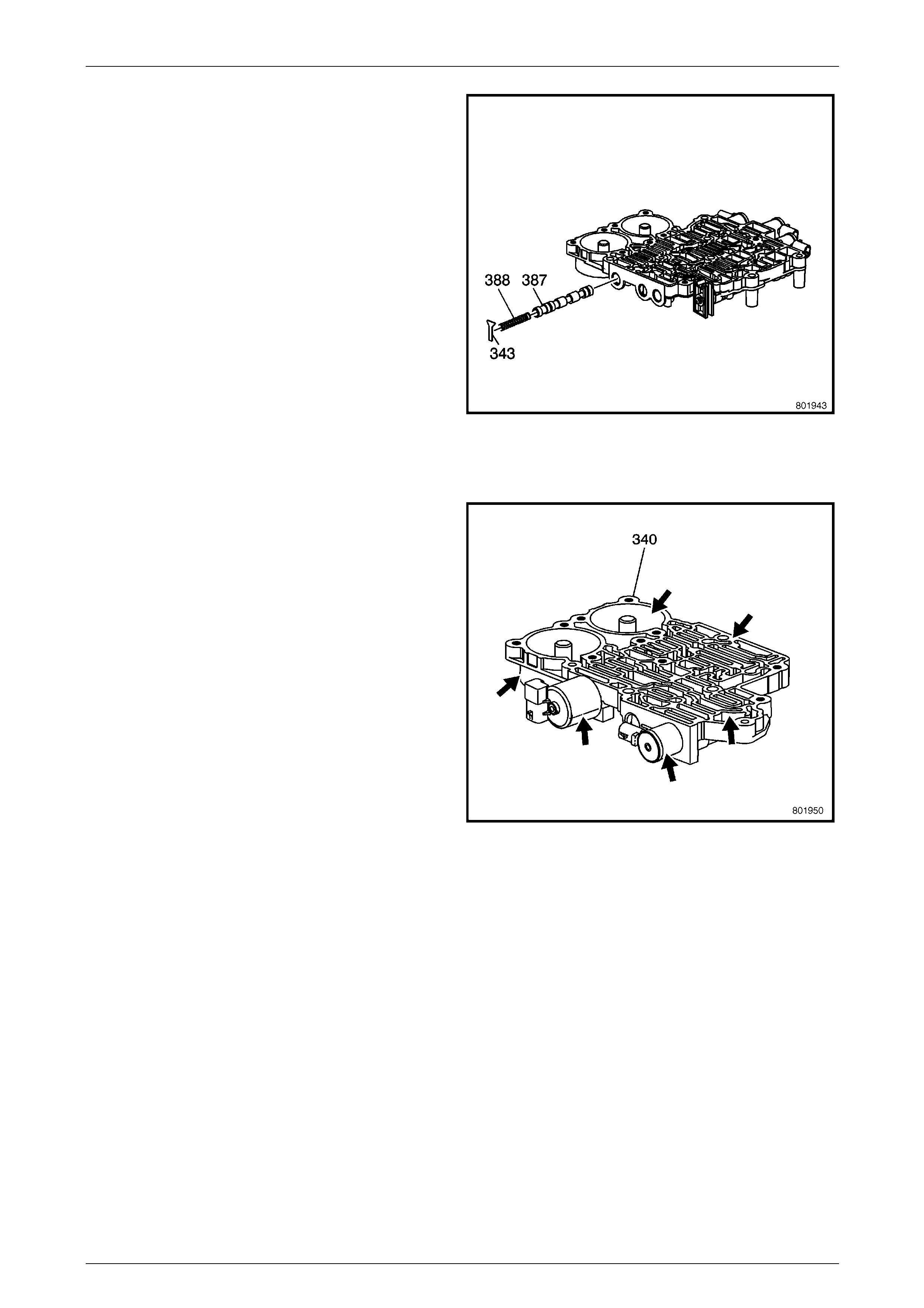

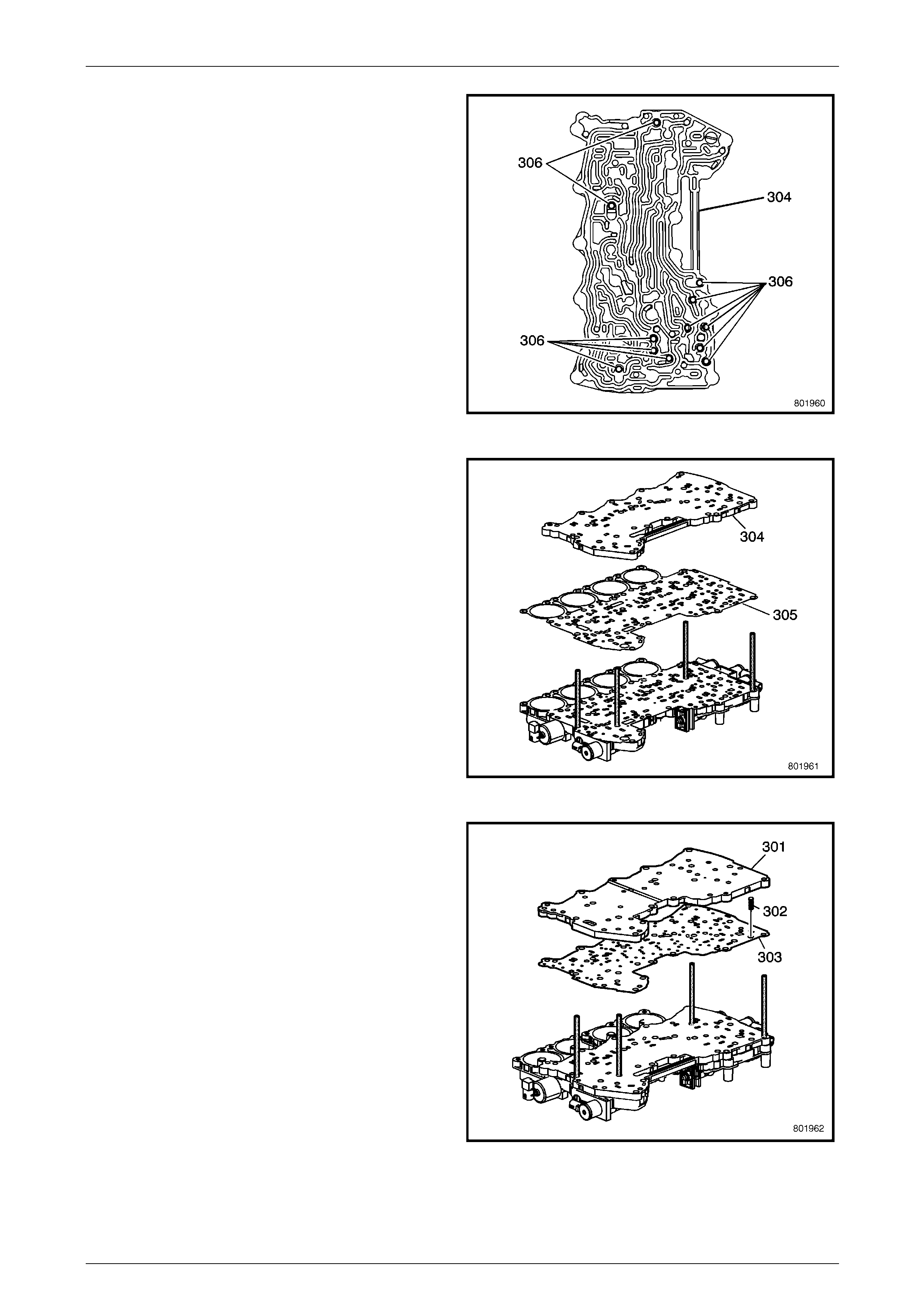

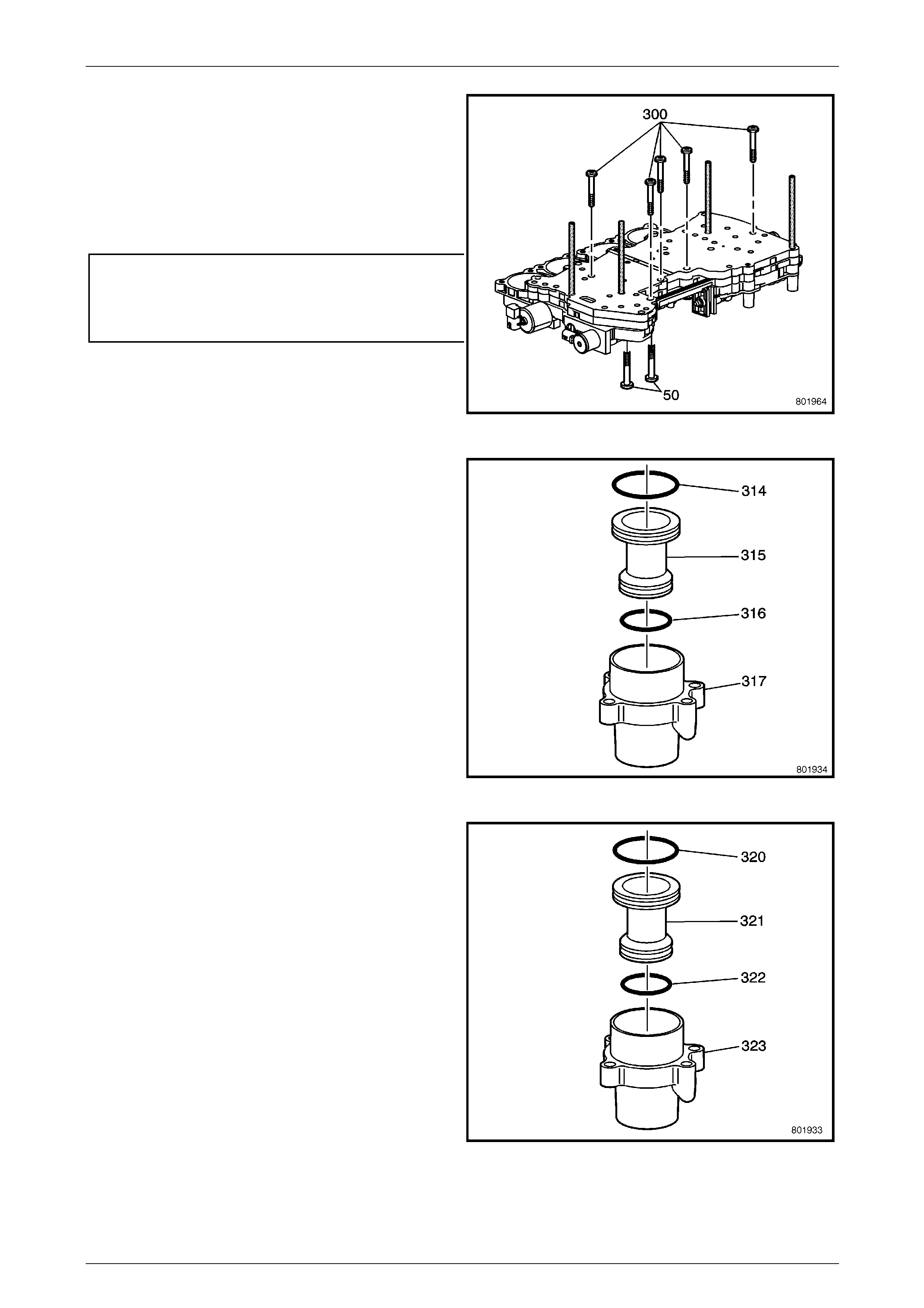

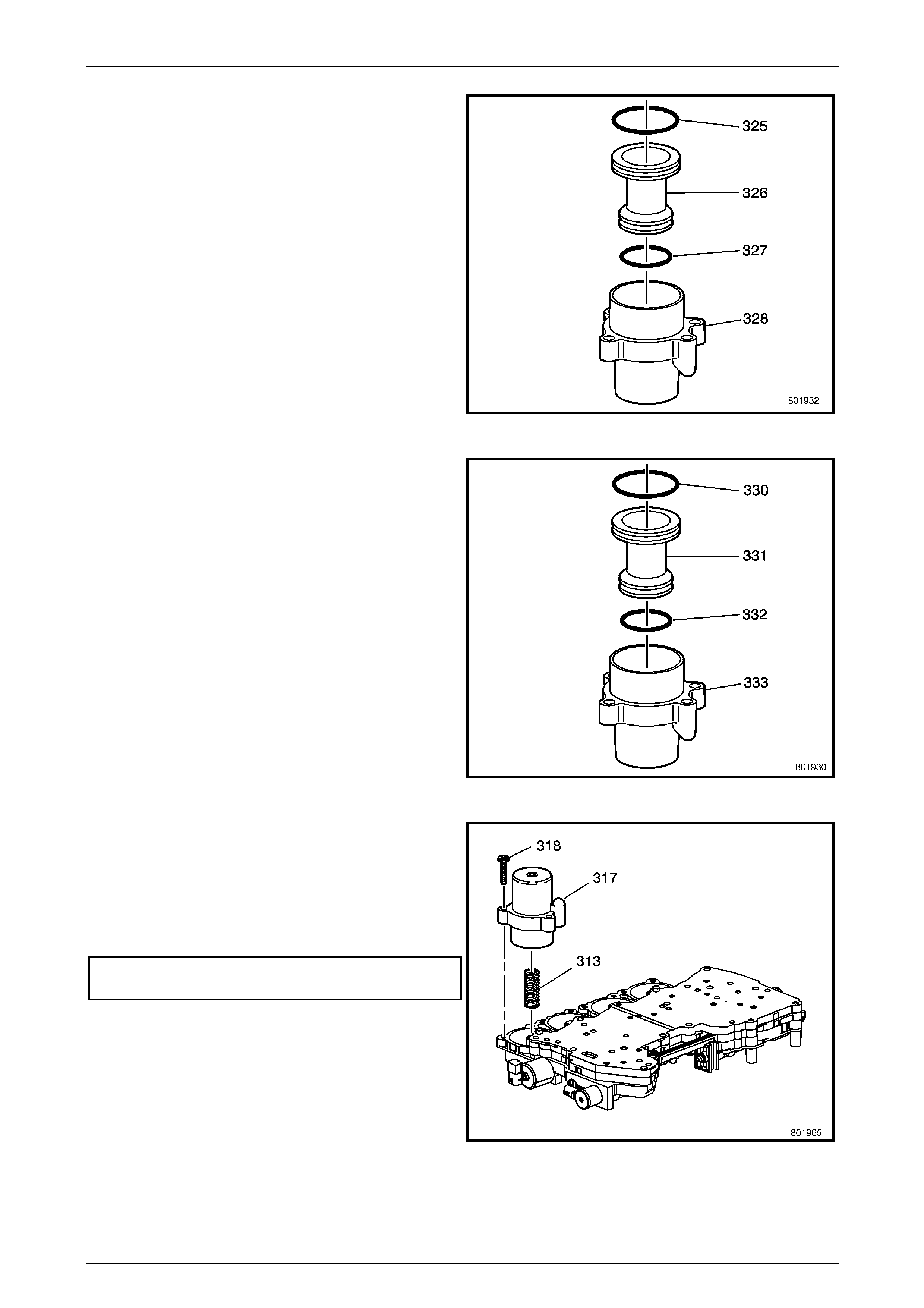

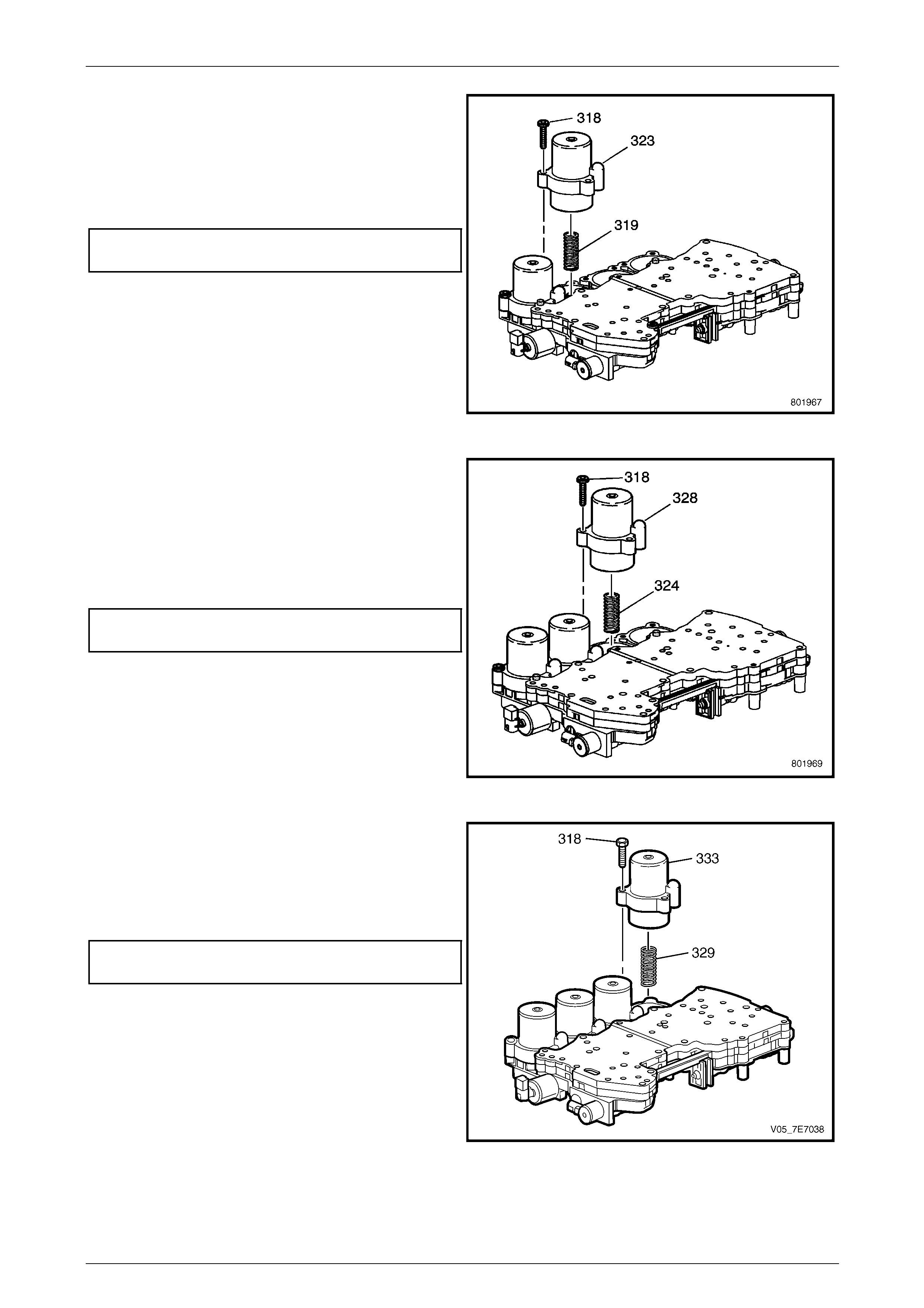

1 Remove the E8 Torx headed control valve body bolts

(49, 51).

NOTE

Only remove the bolts (49, 51) nominated in

Figure 7E5-13. Do not remov e the t wo remaining

TX-30 Torx screws at this stage.

Figure 7E5 – 14

2 Remove the 10 mm hexagon headed control valve

body bolts (53).

3 Remove the manual shaft detent lever sprin g

assembly (52).

4 Remove the control valve body and accumulator

assembly (47) from the transmission case (24).

Figure 7E5 – 15

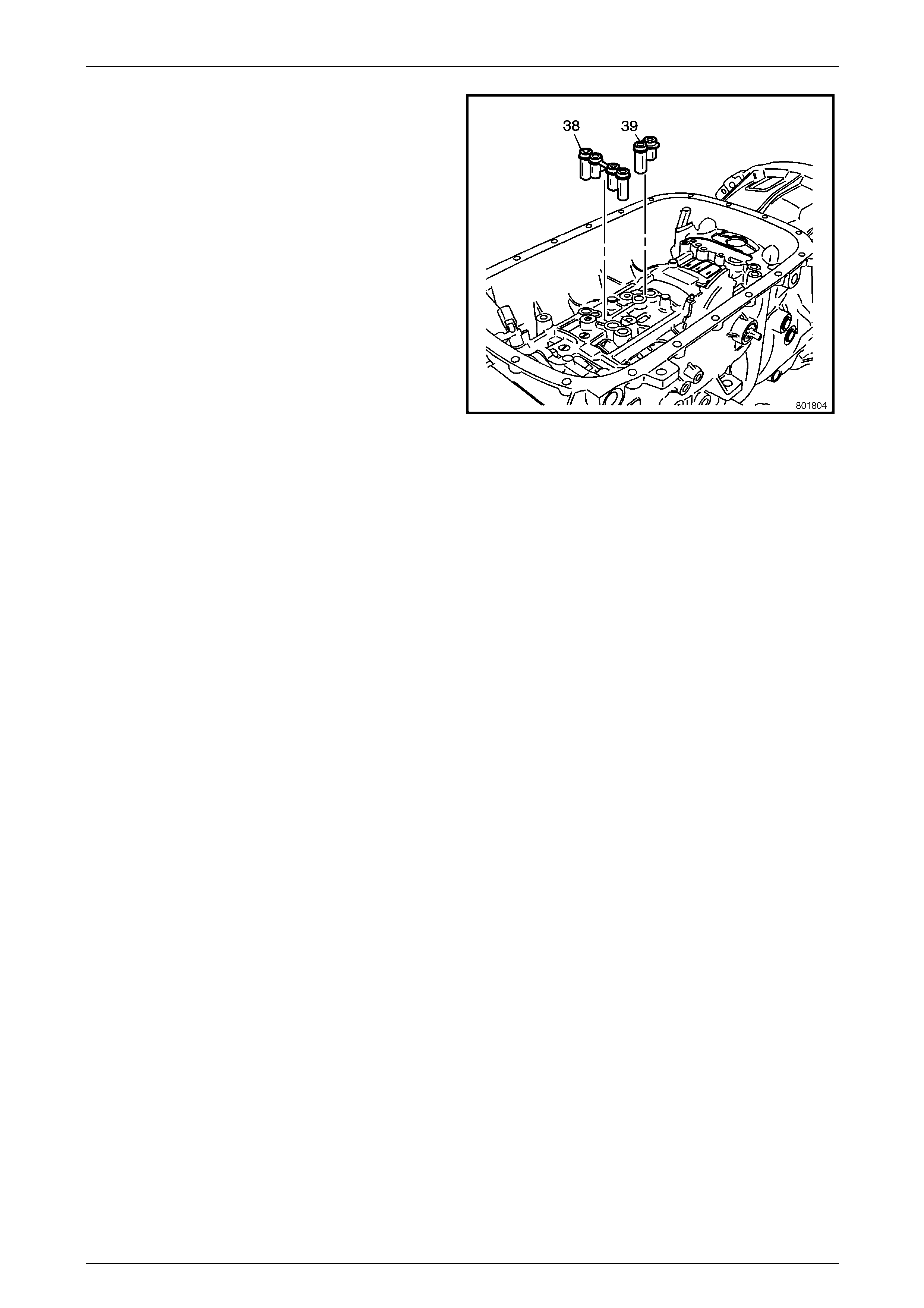

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 11

7E5 – 11

5 Remove the centre support fluid pass ag e sle eve (38)

and the overdrive clutch fluid passage sleeve (39)

from the transmission case (24).

Figure 7E5 – 16

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 12

7E5 – 12

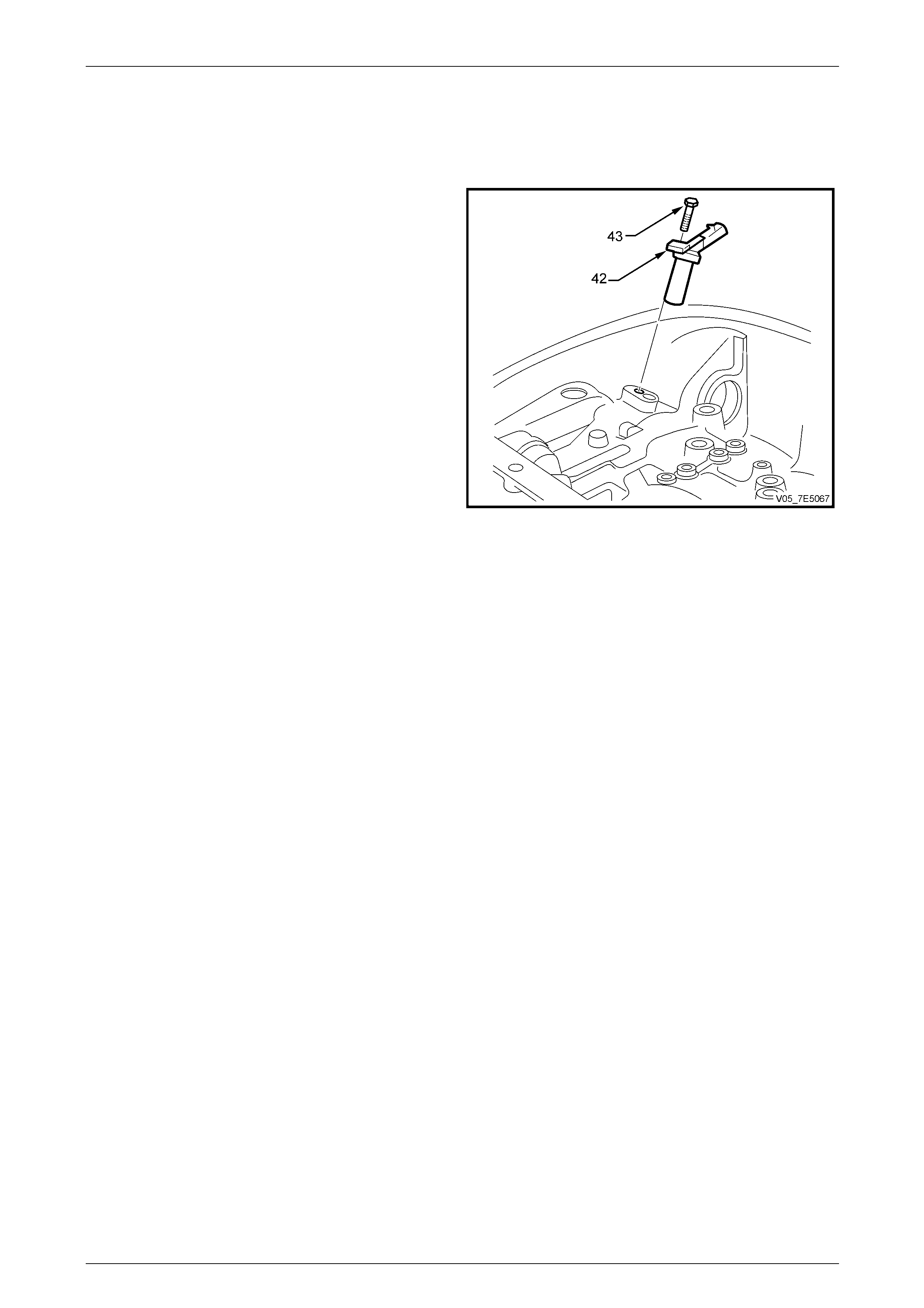

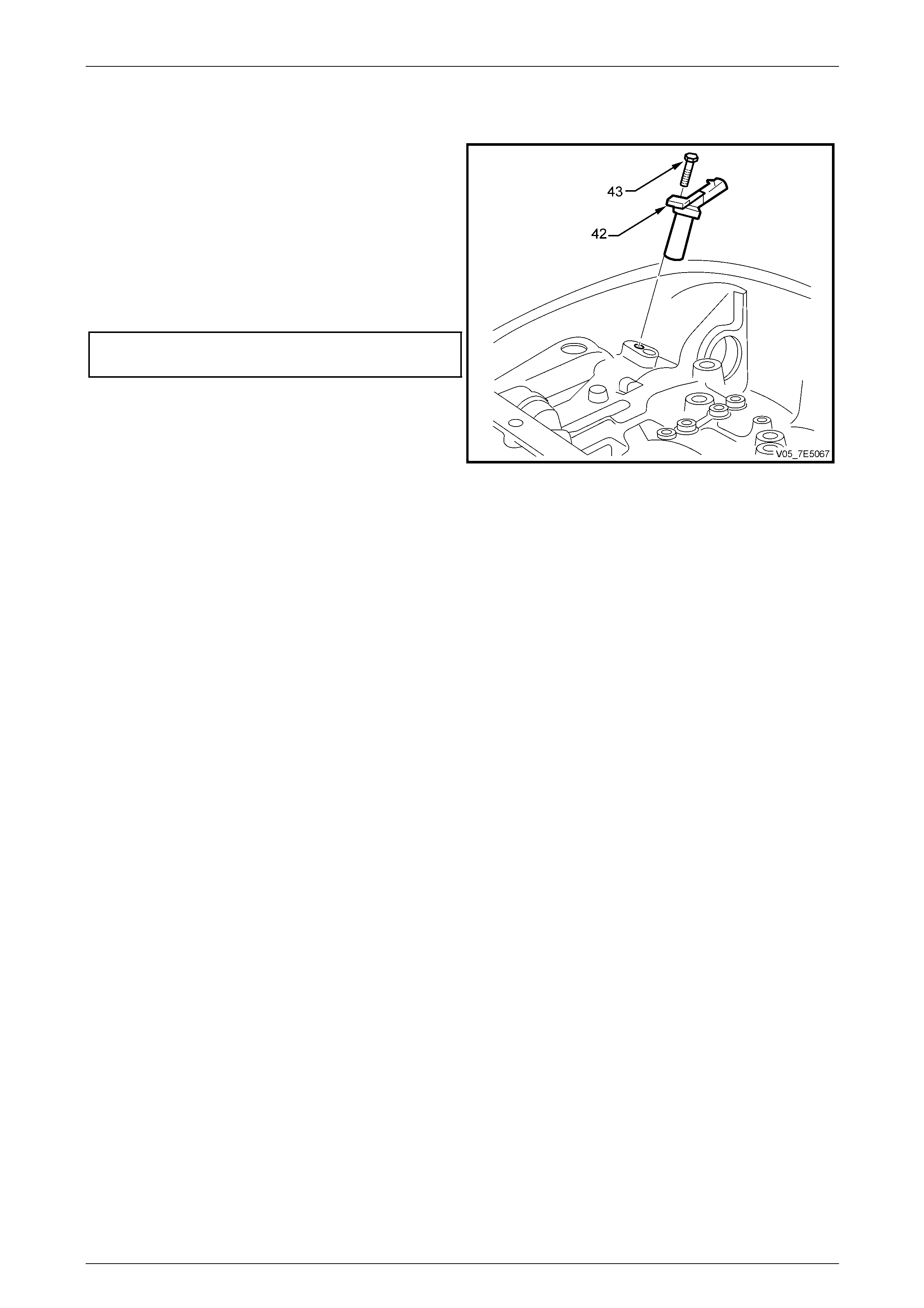

1.7 Output Shaft Speed Sensor

Remove

1 Remove the 10 mm headed output speed sensor

screw (43).

2 Remove the output speed sensor (42).

Figure 7E5 – 17

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 13

7E5 – 13

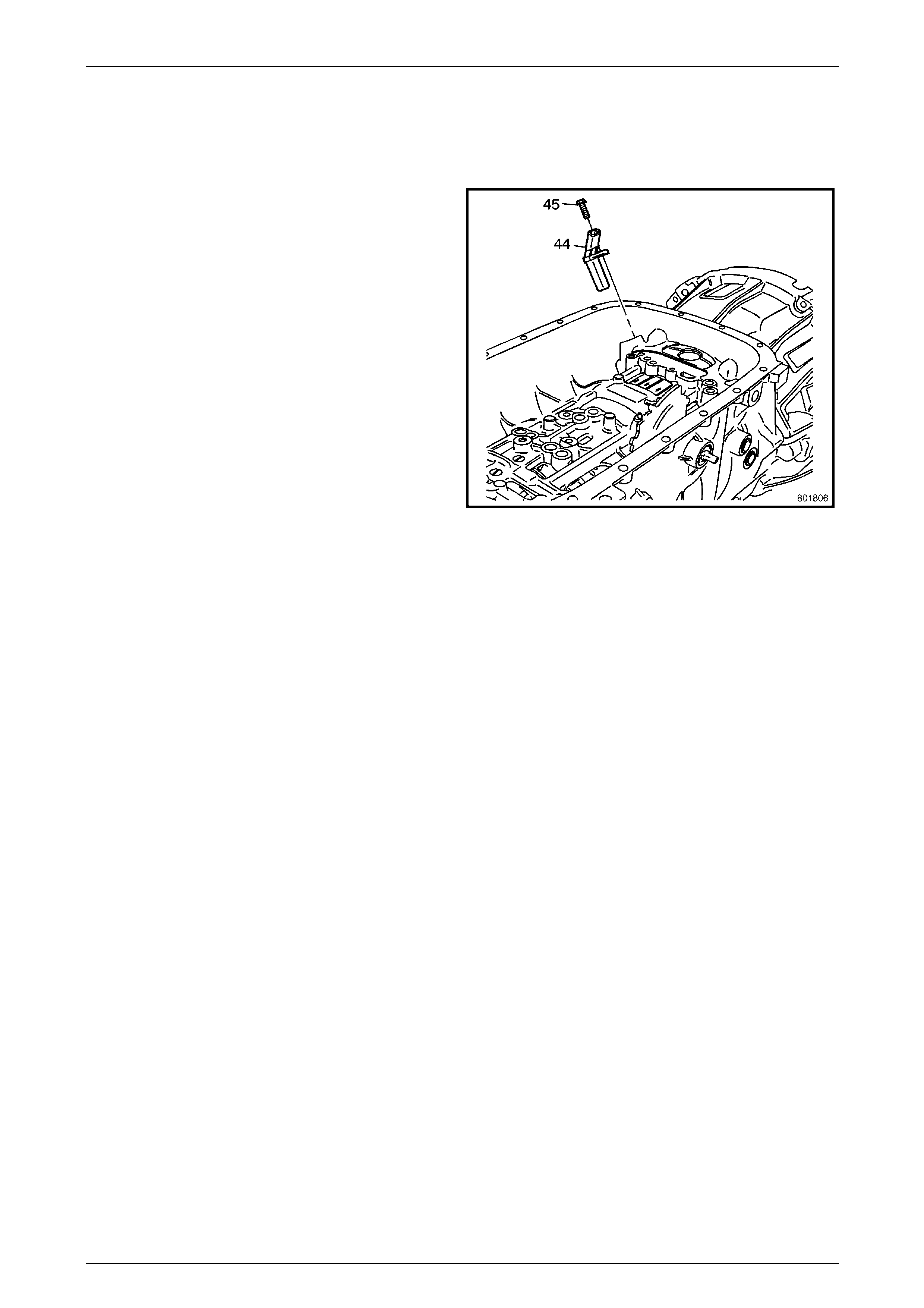

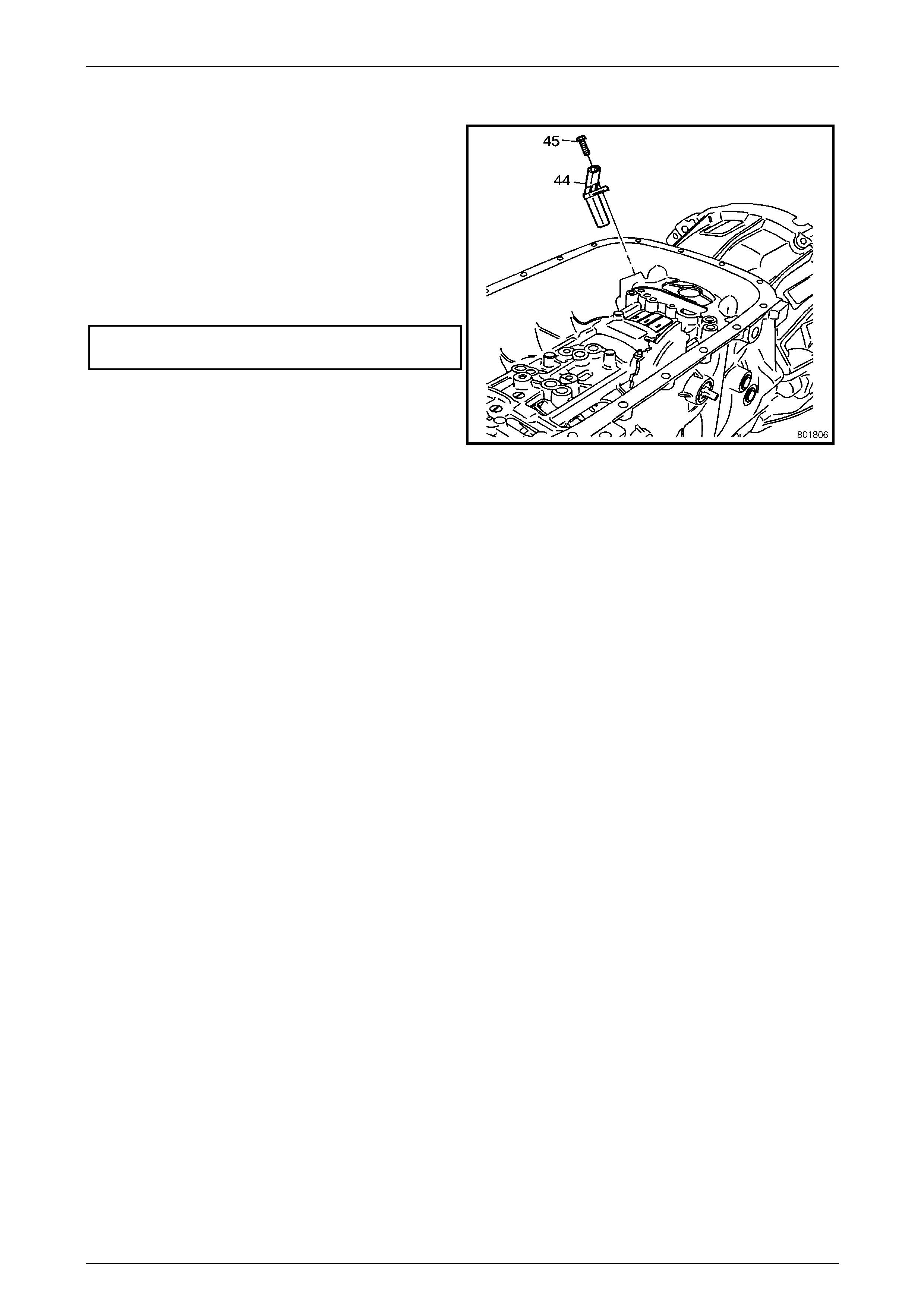

1.8 Input Speed Sensor

Remove

1 Remove the 10 mm hexagon headed input speed

sensor bolt (45).

2 Remove the input speed sensor (44) from the case

(24).

Figure 7E5 – 18

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 14

7E5 – 14

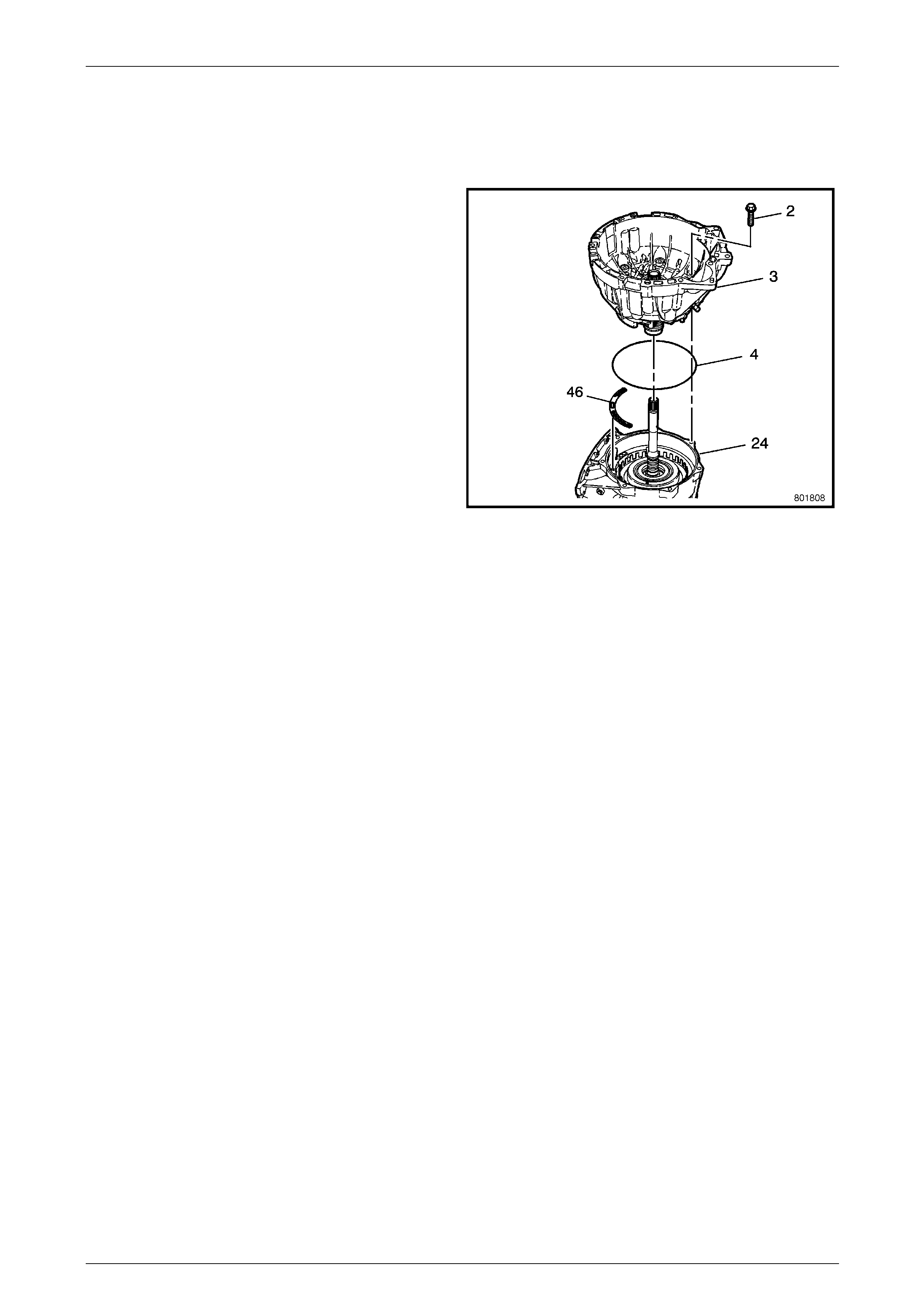

1.9 Torque Converter Housing

Removal

1 Rotate the transmission assembly 90° so the torque

converter housing is facing up . Remove the torque

converter housing to transmission case bolts (2) from

the torque converter housing (3).

2 Remove the torque converter housing assembly (3)

from the transmission case (24).

NOTE

The transmission fluid pump is attached to the

torque converter housing, making the assembly

heavier than expected.

3 Remove the torque converter housing fluid seal

assembly (4).

4 Remove the fluid pump cover gasket (46).

Figure 7E5 – 19

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 15

7E5 – 15

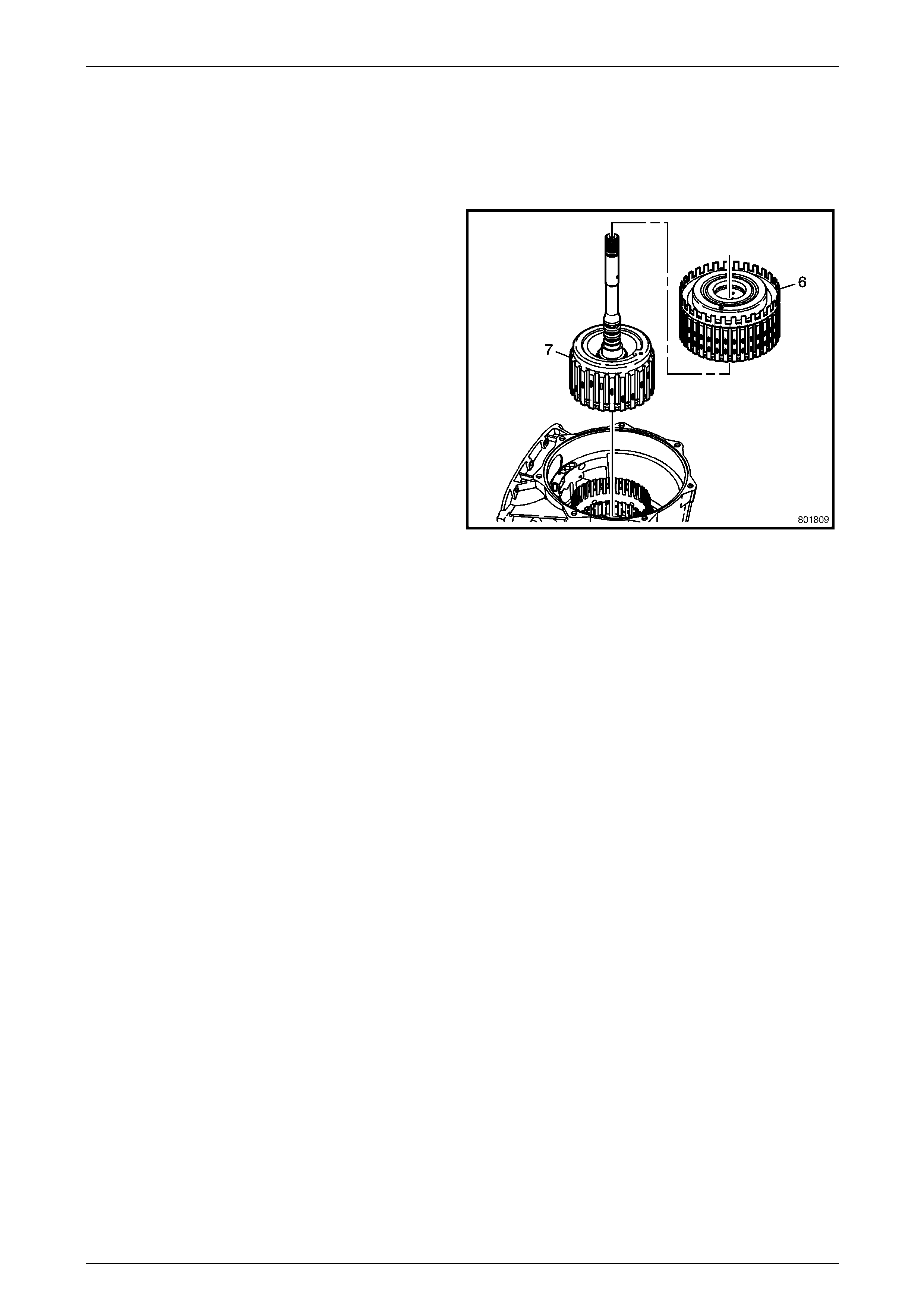

1.10 Direct and Reverse Clutch - Forward and

Coast Clutch

Remove

1 Remove the forward and coast clutch assembly (7)

and the direct and reverse clutch assembly (6) from

the case (24).

NOTE

Do not damage the input shaft fluid seals when

removing or installing the direct and reverse

coast clutch assembly.

2 Lift the direct and reverse clutch assembly (6) off of

the forward and coast clutch assembly (7).

Figure 7E5 – 20

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 16

7E5 – 16

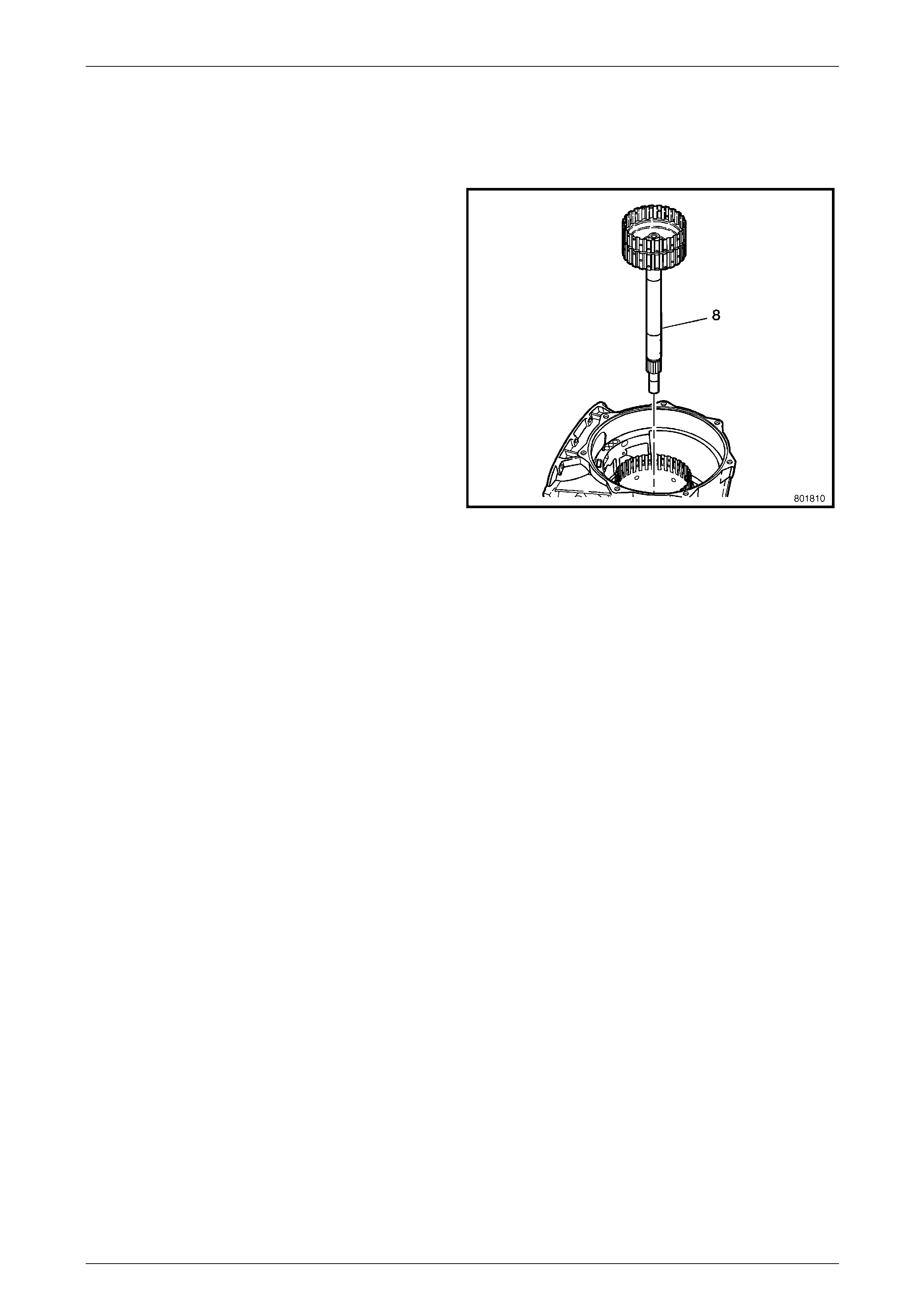

1.11 Input Sun Gear Shaft

Remove

1 Remove the input sun gear shaft (8) from the case

(24).

Figure 7E5 – 21

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 17

7E5 – 17

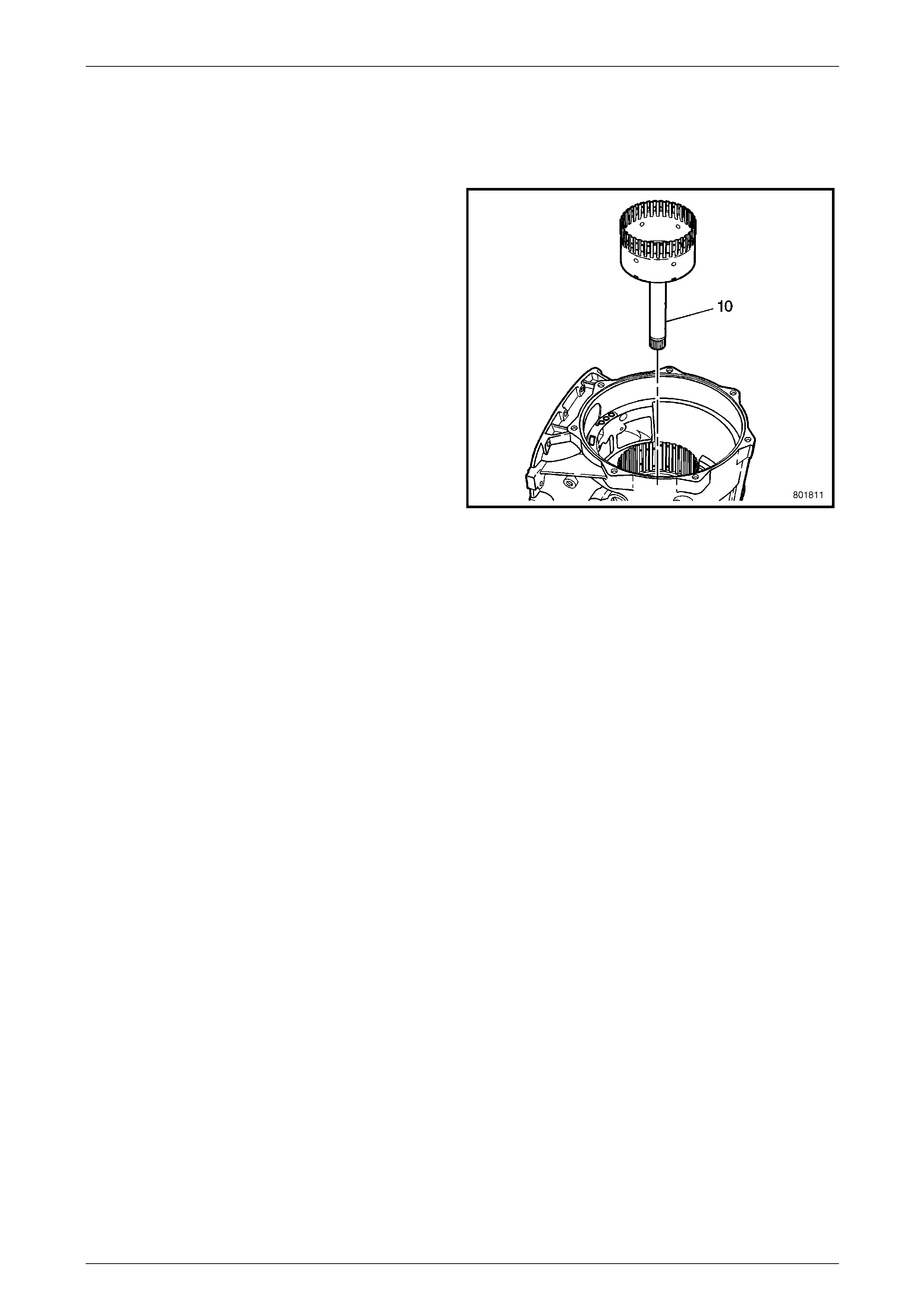

1.12 Direct Clutch Hub

Remove

1 Remove the direct clutch hub assembly (10) from the

case (24).

Figure 7E5 – 22

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 18

7E5 – 18

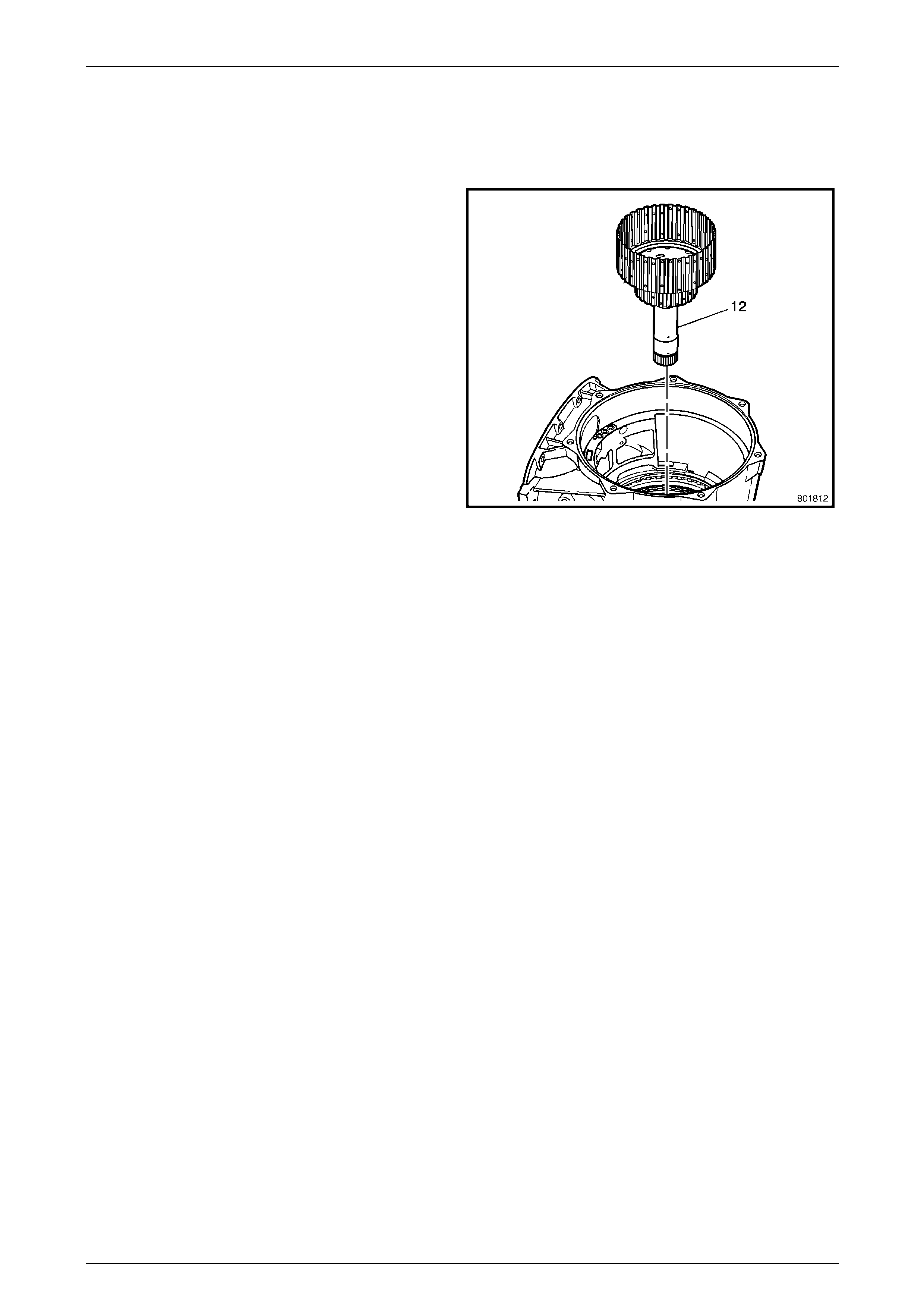

1.13 Intermediate Clutch Sprag Assembly

Remove

1 Remove the intermediate clutch sprag assembly (12)

from the case (24).

Figure 7E5 – 23

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 19

7E5 – 19

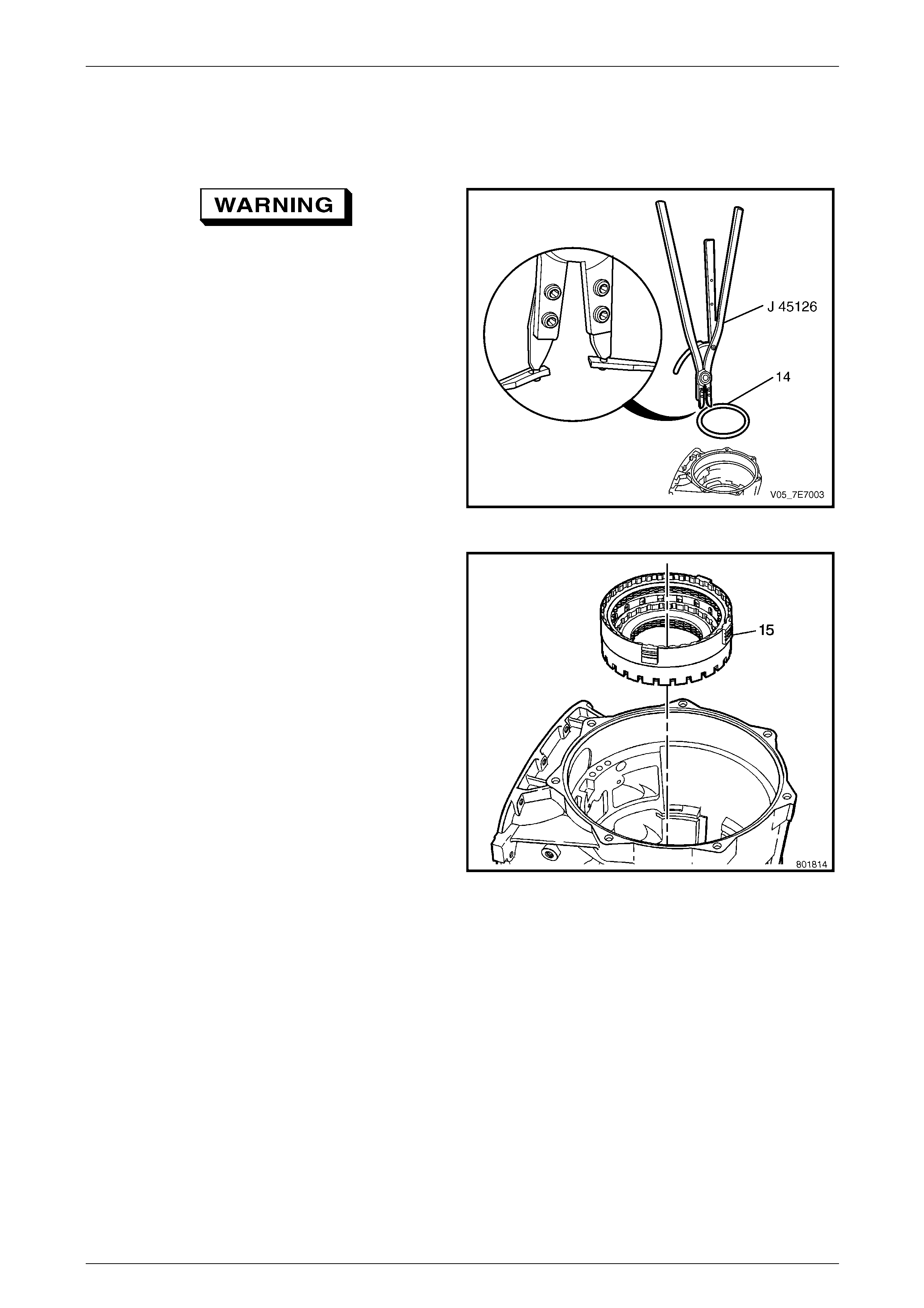

1.14 Overdrive Clutch Housing

Remove

Use care when removing or installing the

snap ring. Be sure the J 45126 snap ring

pliers are installed properly onto the retainer

ring or bodily injury may occur.

1 Using suitable snap ring pliers such as J 45126 or

equivalent, remove overdrive clutch housing to

transmission case retainer ring (14).

Figure 7E5 – 24

2 Lift out the overdrive clutch housing (15) from the

transmission case (24).

Figure 7E5 – 25

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 20

7E5 – 20

1.15 Low Clutch Sprag

Removal

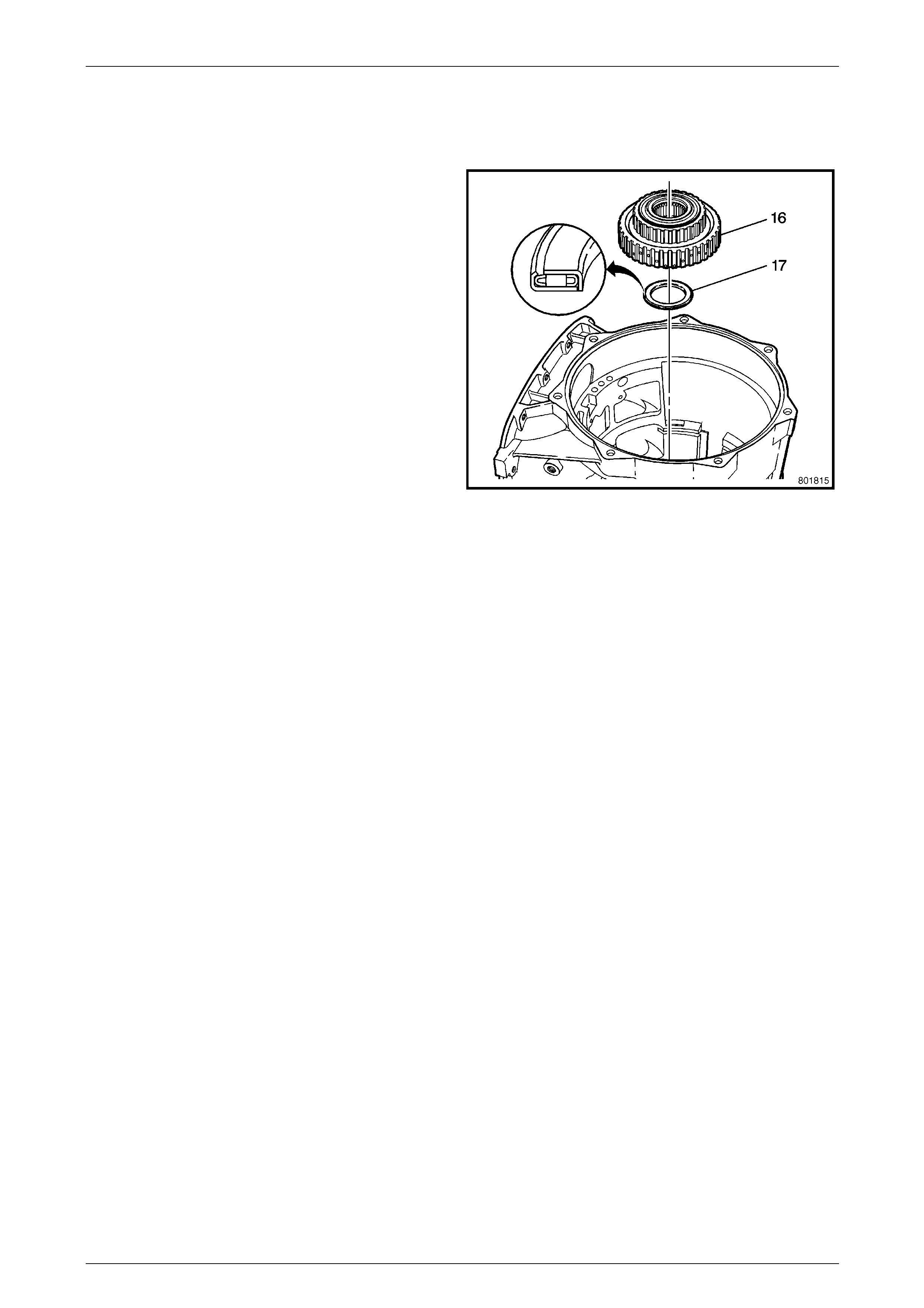

1 Remove the low clutch sprag assembly (16) from the

transmission case (24).

2 Remove the low clutch roller thrust bearing (17).

Figure 7E5 – 26

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 21

7E5 – 21

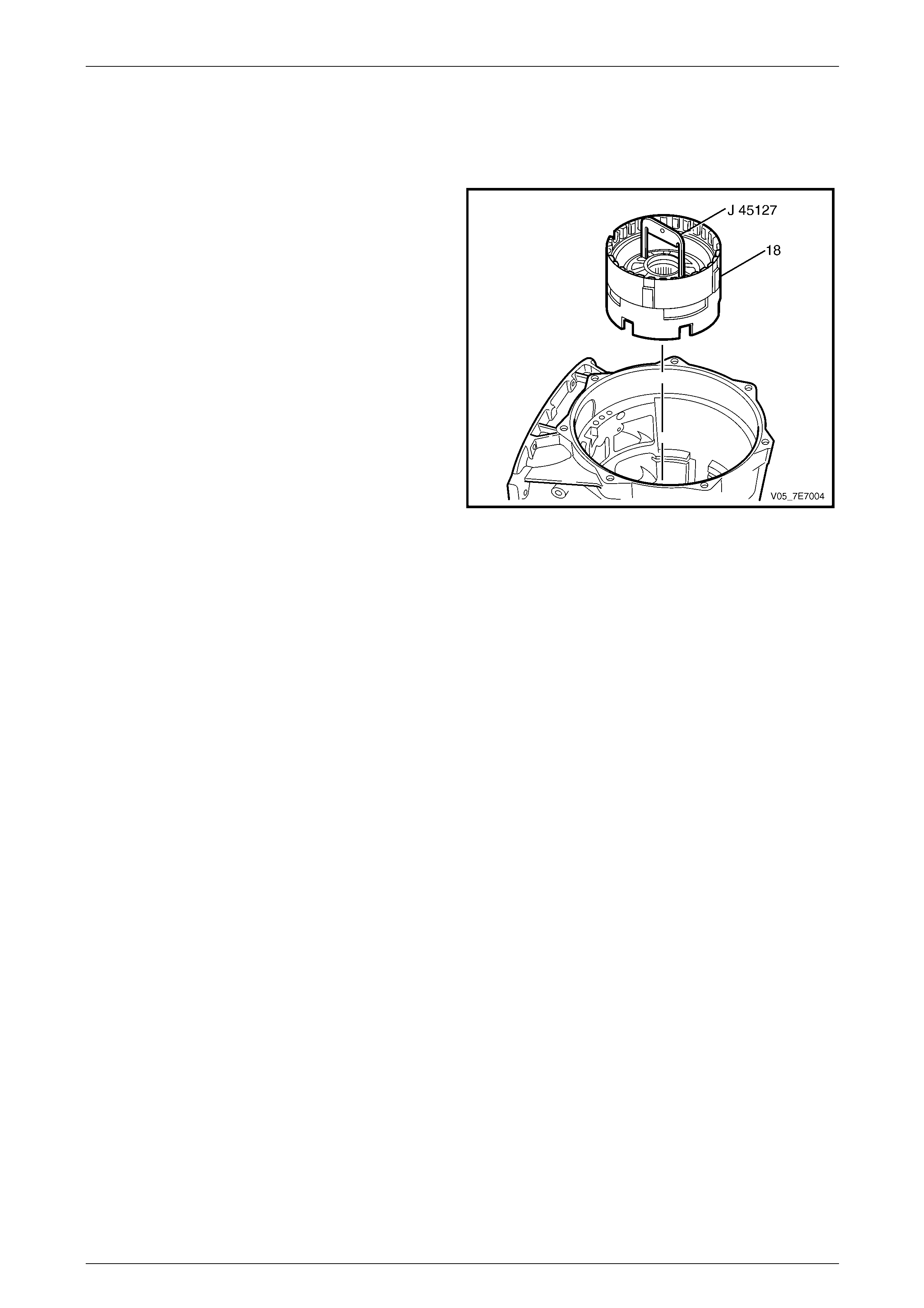

1.16 Centre Support

Remove

1 Using centre support removal tool J 45127, engage

and lift out centre support (18) from the transmission

case (24).

Figure 7E5 – 27

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 22

7E5 – 22

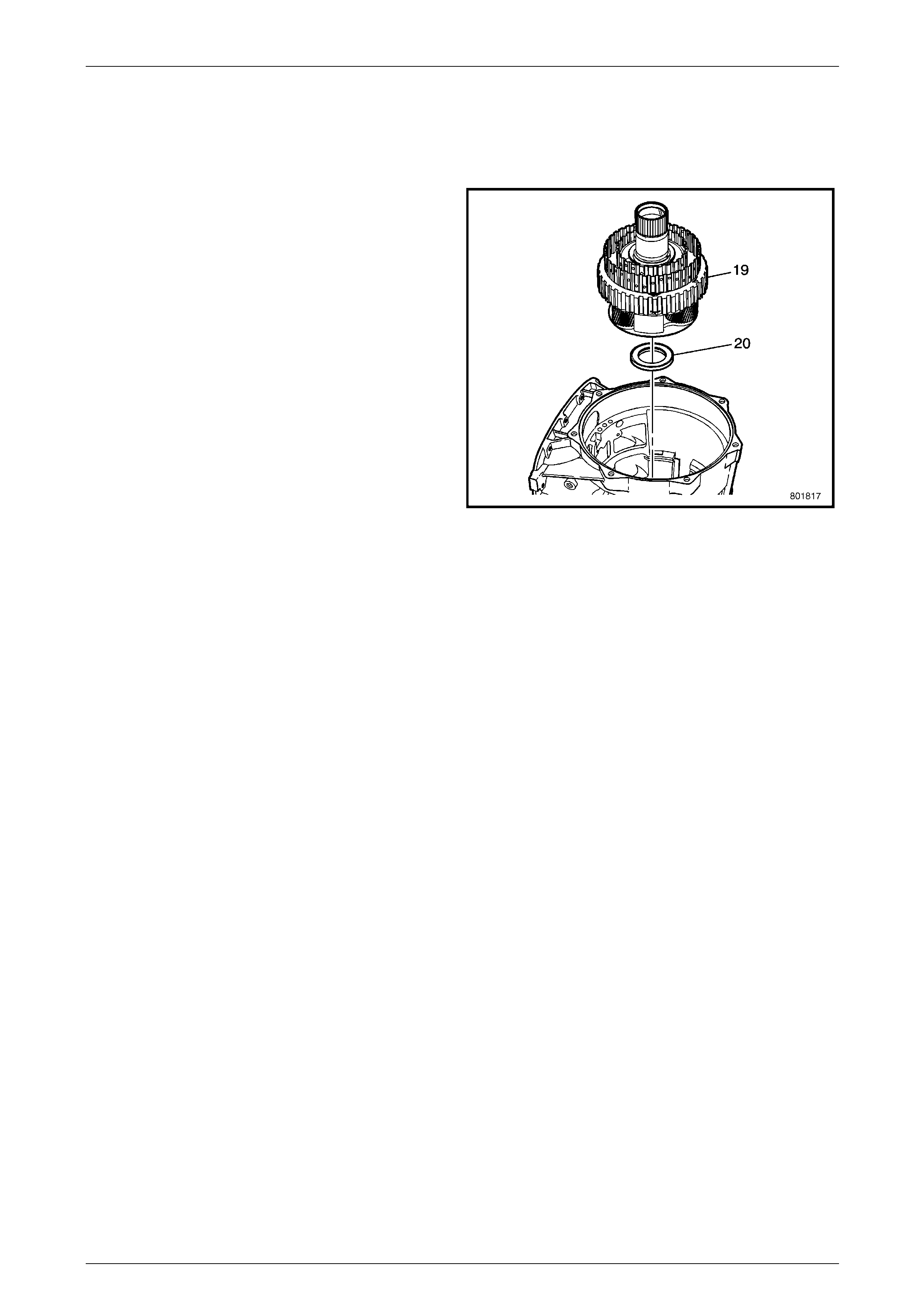

1.17 Input and Reaction Carrier

Remove

1 Remove the input and reaction carrier (19) from the

transmission case (24).

2 Remove the input and reaction carrier thrust bearing

(20) from the case (24).

Figure 7E5 – 28

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 23

7E5 – 23

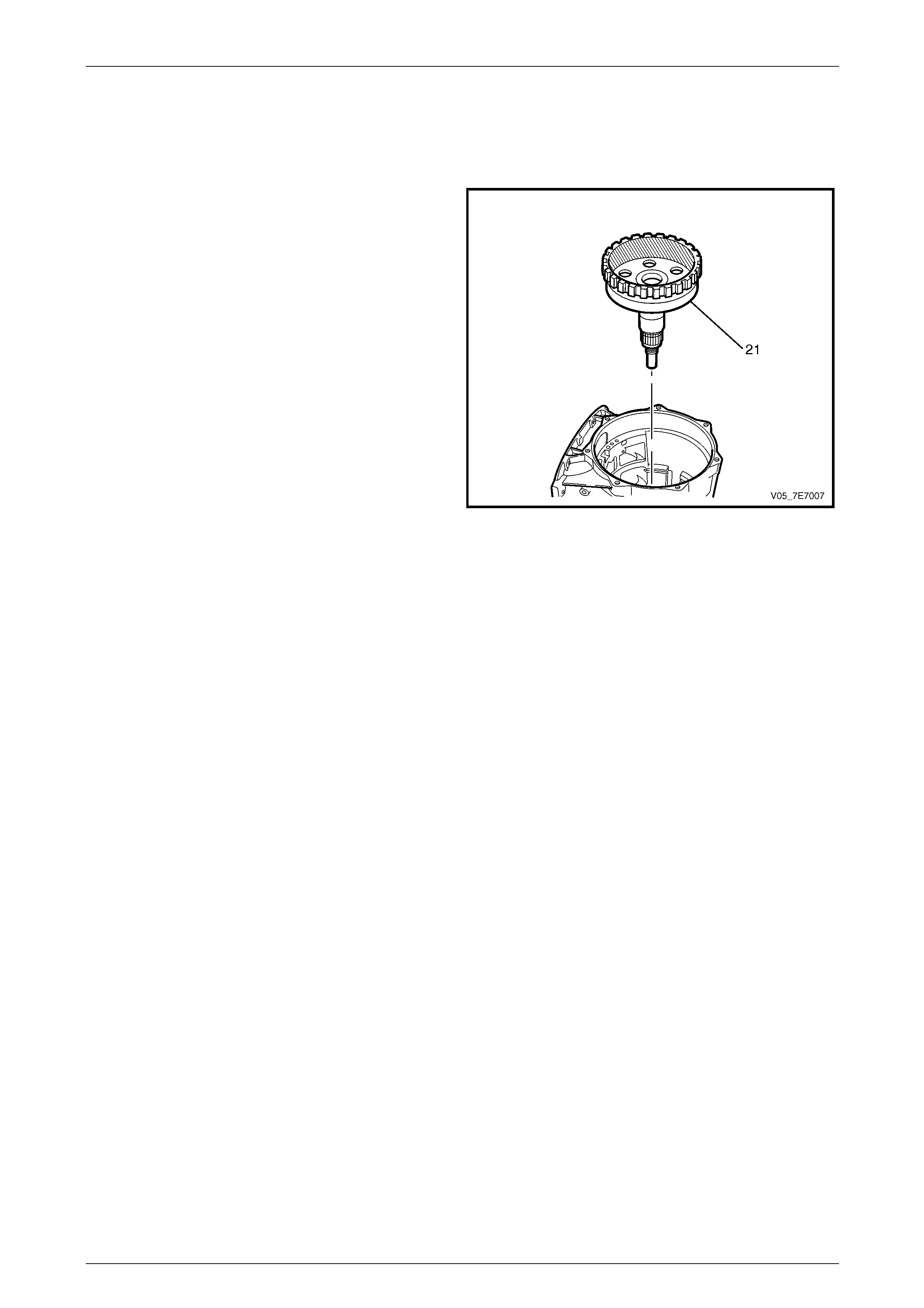

1.18 Output Shaft

Remove

1 Remove the output shaft assembly (21) from the

transmission case (24).

NOTE

The input and r eaction carrier thrust bearin g (23)

and selective washer (22), have already been

removed, refer to 1.3 Extension Housing, in this

Section.

Figure 7E5 – 29

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 24

7E5 – 24

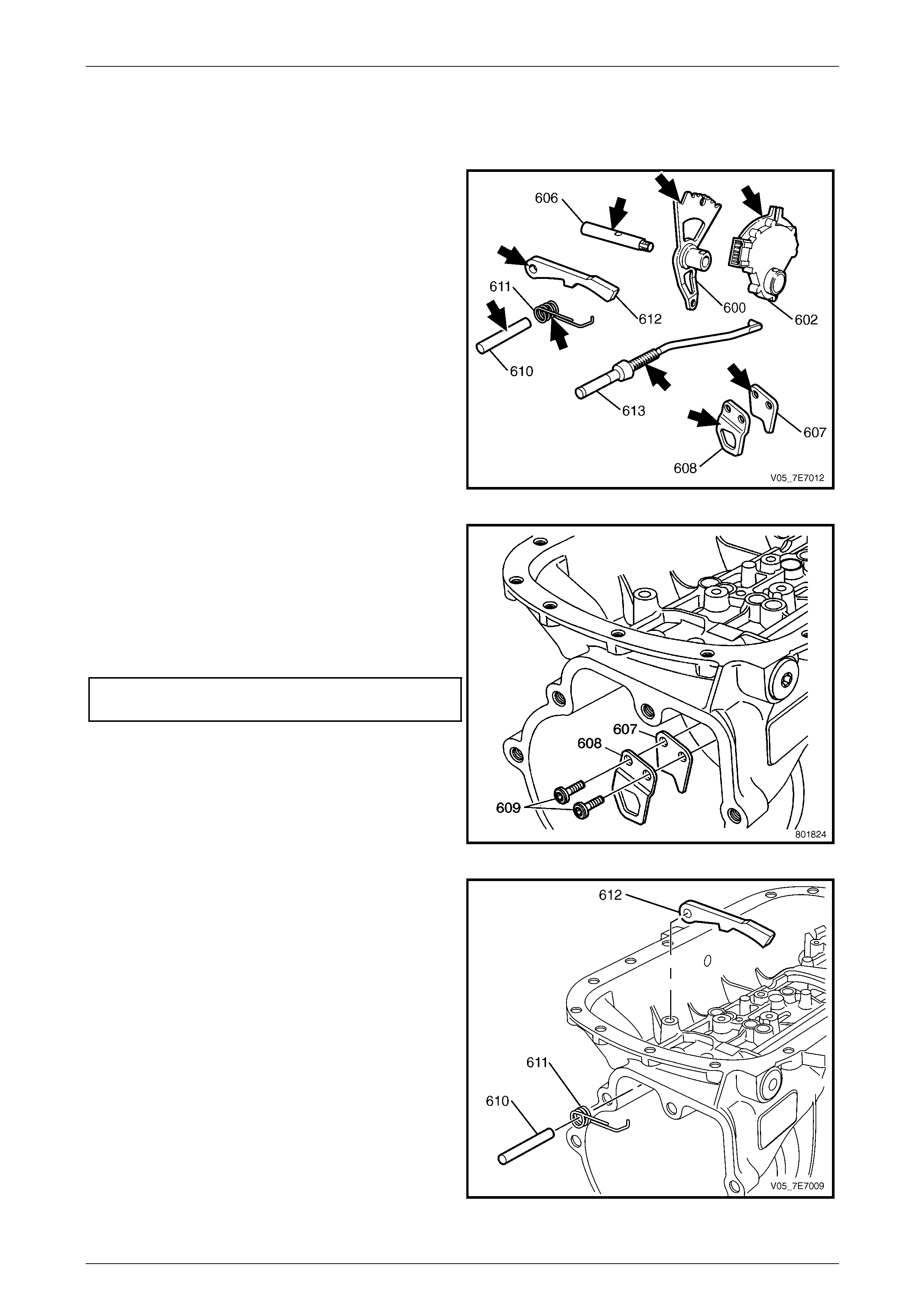

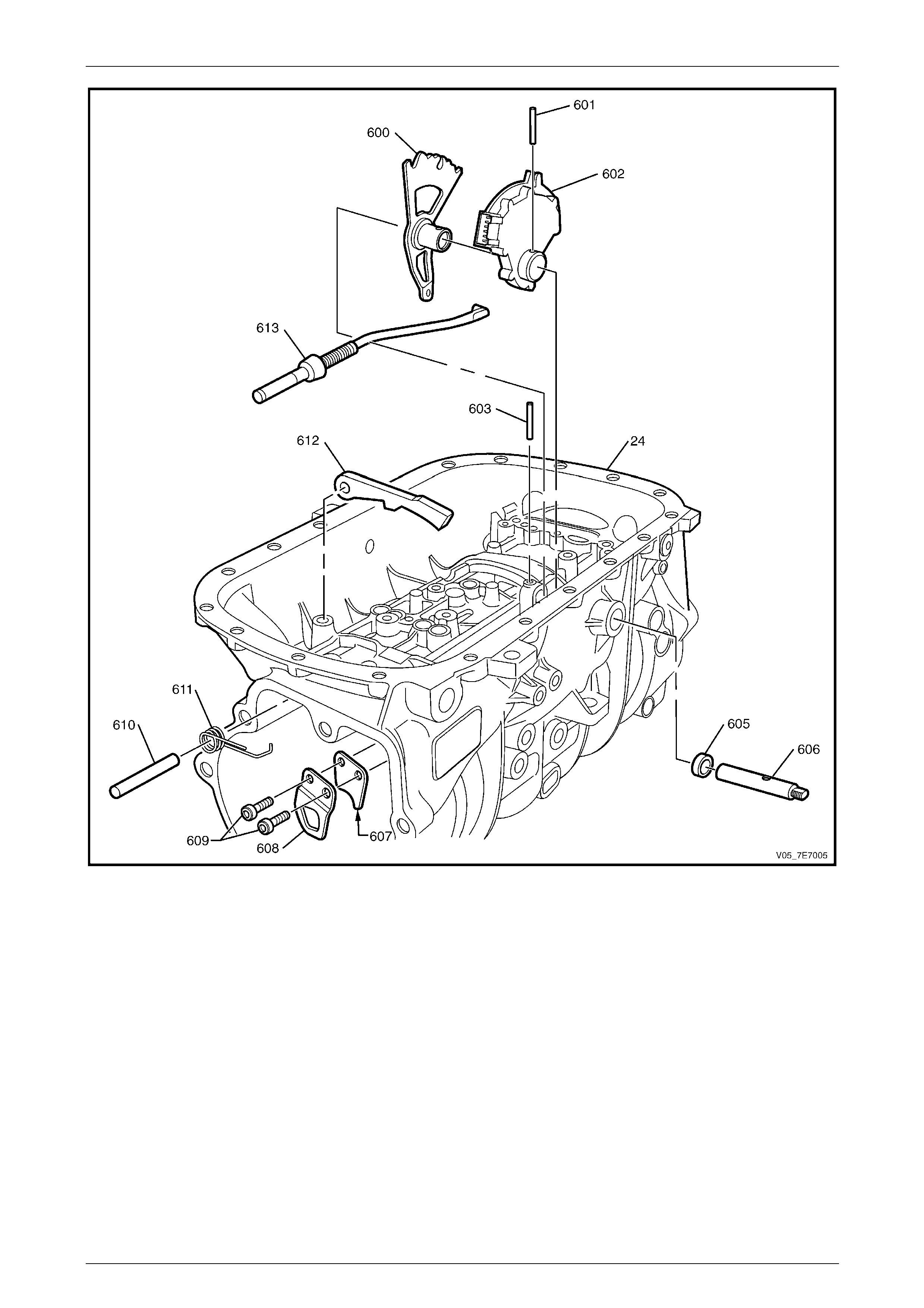

1.19 Park System Components

Remove

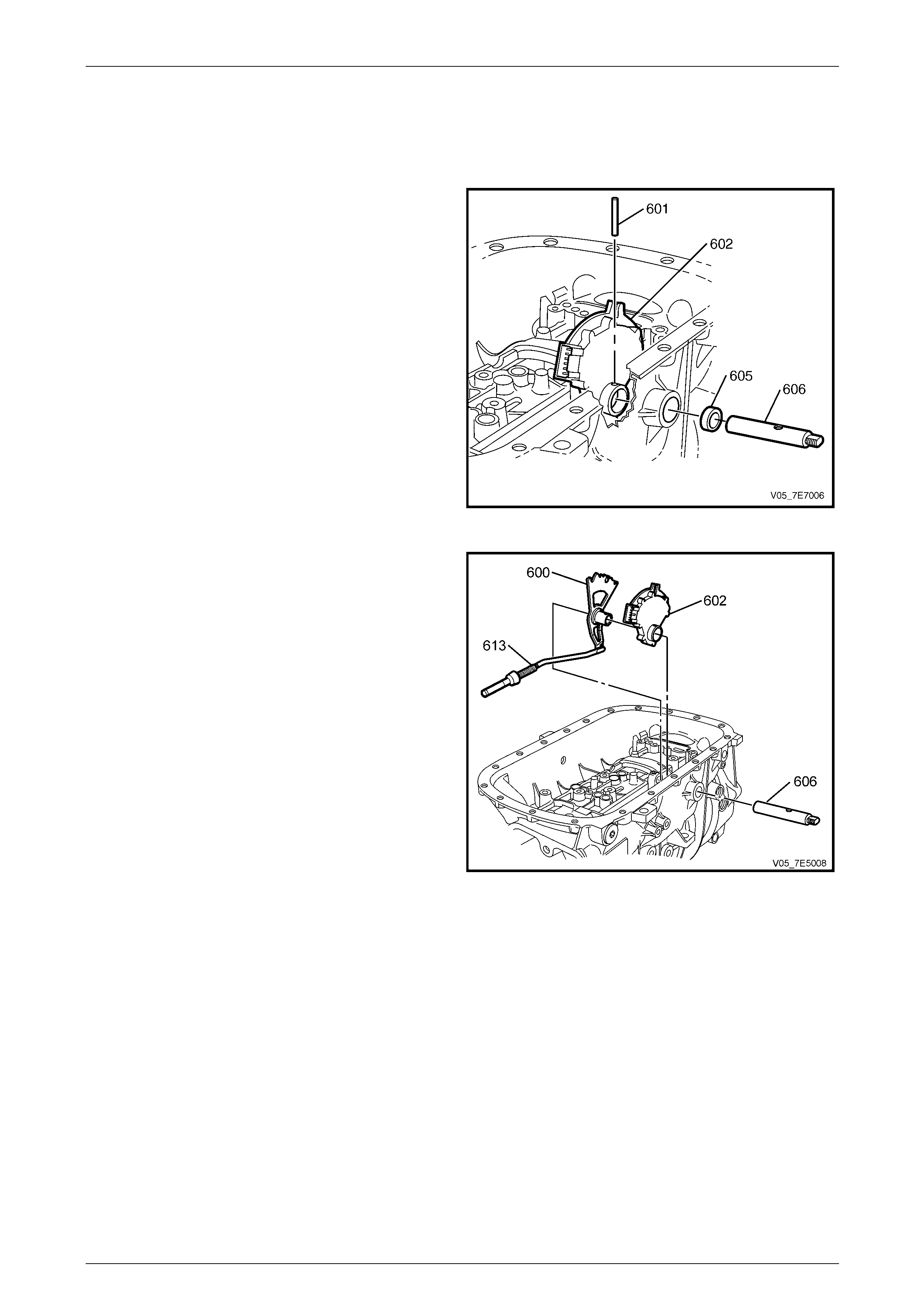

1 Rotate the transmission 90 degrees, so the underside

of the transmission case is facing up ward.

2 Using a suitable sized pin punch and hammer,

carefully knock out the manual shaft detent le ver pin

(601) from the manual shaft (606).

Figure 7E5 – 30

3 Remove the manual shift shaft (606) from the

transmission case (24).

4 Remove the manual shaft detent lever (600), the

manual shaft shift switch assembly (602) and park

pawl actuator assembly (613) from the transmission

case (24).

5 Disconnect the park pawl actuator (613) from the

manual shaft detent lever (600).

Figure 7E5 – 31

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 25

7E5 – 25

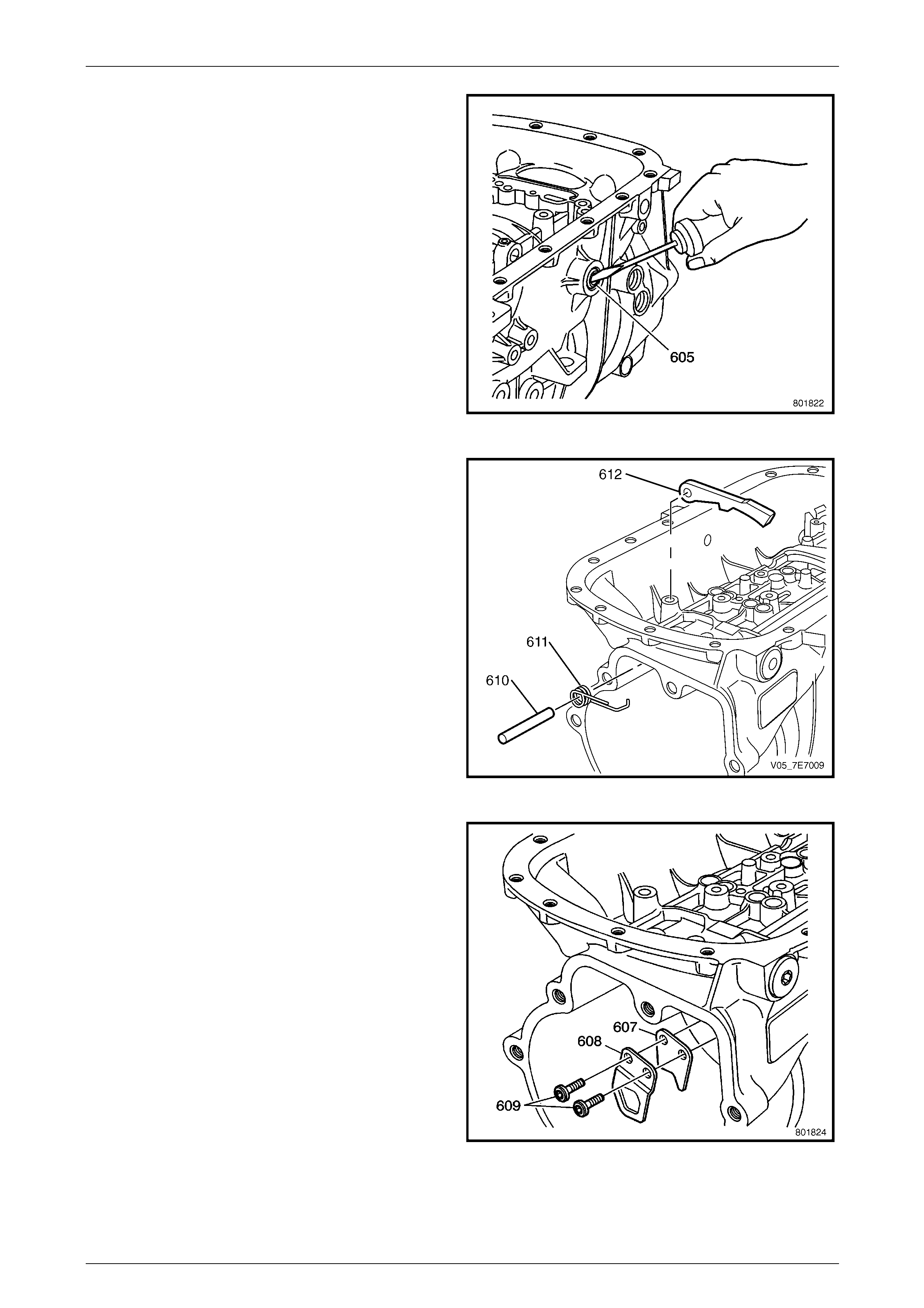

6 Using a small scre wdriver, prise the manu al shaft shift

seal (605) from the transmission case (24).

Figure 7E5 – 32

7 Release the park pawl spring t ension, then remove the

spring (611) from the park pawl shaft (610).

8 Remove the park pawl shaft (610) and the park pawl

(612) from the transmission case (24).

Figure 7E5 – 33

9 Remove the park pawl actuator bracket, internal T45

Torx headed bolts (609) from the transmissi on case

(24).

10 Remove the park pawl actuator brackets (607, 608)

from the transmission case (24).

Figure 7E5 – 34

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 26

7E5 – 26

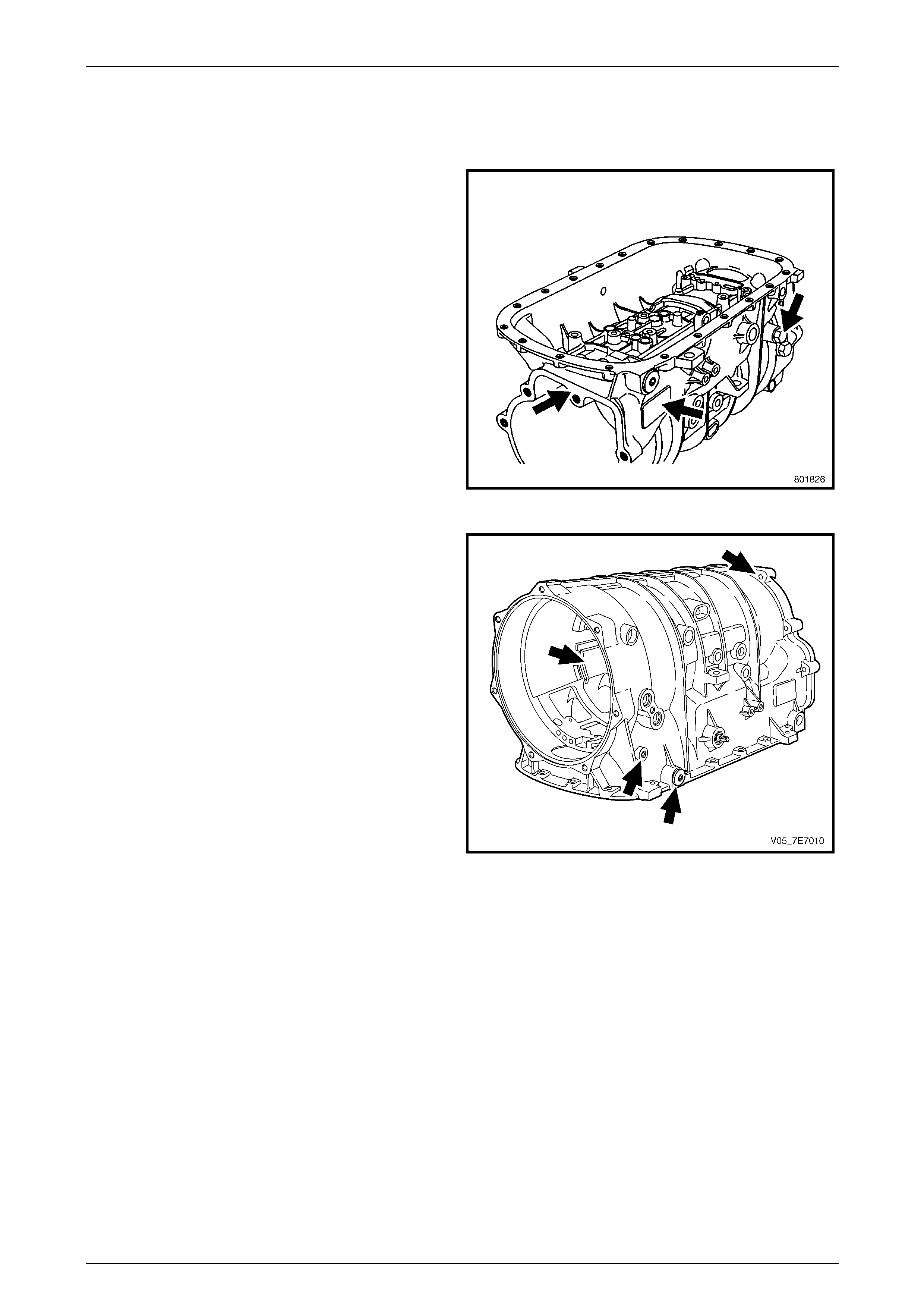

1.20 Transmission Case Assembly

Inspect

1 Inspect the components that are still on the

transmission case for the following conditions:

• Loose, cross-threaded, or damage d threads on

the transmission oil cooler fittings.

• A loose, missing, or damaged transmission

name plate.

Figure 7E5 – 35

2 Inspect the transmission case for the following

conditions:

• Gasket sealing surfaces that are damaged or

have porosity.

• Bolt and screw holes that are stripped or

damaged – repair with thread insert.

• Damaged or porous case and fluid passages.

• Damaged snap ring grooves or housing splines.

• A loose, cross threaded, or damaged pressure

test plug and fluid level hole plug.

Figure 7E5 – 36

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 27

7E5 – 27

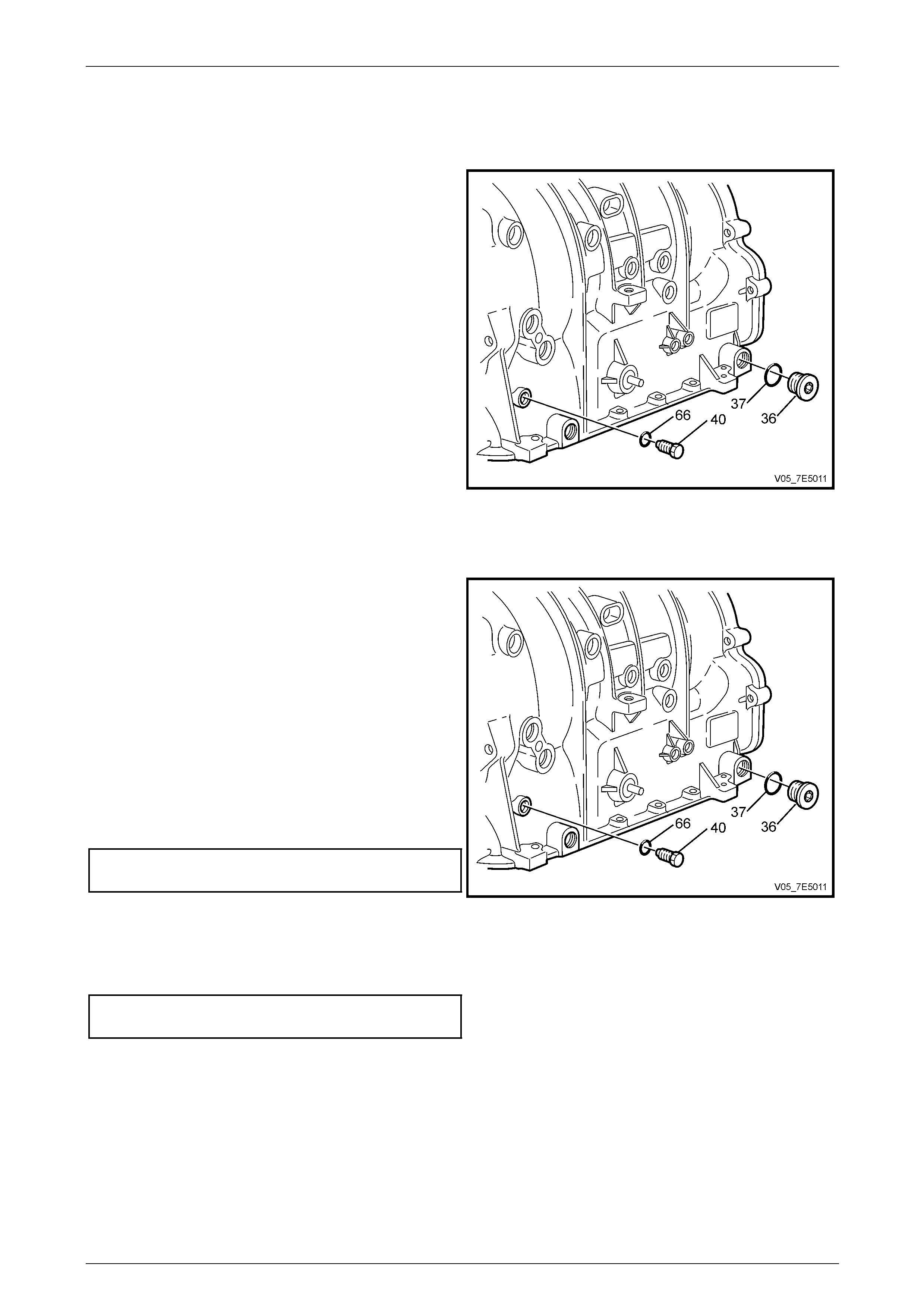

1.21 Transmission Case Components

Disassemble

1 Using a 5 mm Allen key socket and suitable

equipment, remove the pressure test plug (40) and O-

ring seal (66).

2 Use a T45 Torx bit and suit able equipment to remove

the level hole plug (36) and O-ring (3 7) from the

transmission case (24).

Figure 7E5 – 37

Reassemble

NOTE

Refer to 4.30 Fasteners in Section 00 Warnings,

Cautions and Notes of this Service Information.

NOTE

If the pressure test plug (40), O-ring (66), level

hole plug (36) and O-rin g (37) are not damaged,

they may be reused.

1 Inspect the pressure test hole plug (40) and O-ring

(66) for damage.

2 Install the pressure test plug (40) and O-ring (66), then

tighten the plug to the correct torque specification.

Transmission pressure test plug

to case torque specification..................................11 N.m

3 Inspect the level hole plug (36) and O-ring (37) for

damage. Figure 7E5 – 38

4 Reinstall the transmission flu id level hole plug O-ring (37) and the transmission level hole plug (36), then tighten the

plug to the correct torque specification.

Transmission level hole plug

to case torque specification..................................11 N.m

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 28

7E5 – 28

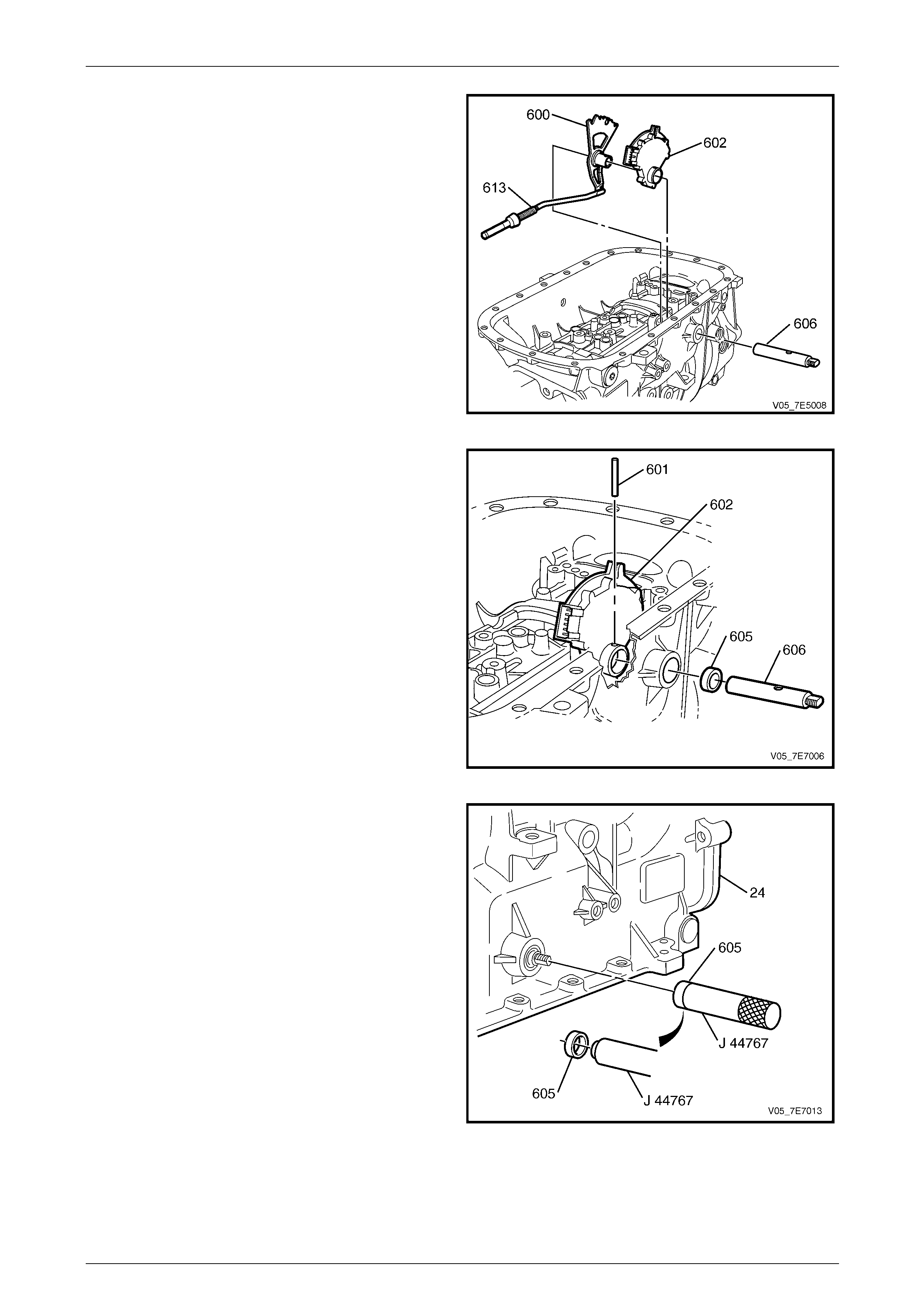

1.22 Park System Components

Reinstall

1 Inspect the park system components for the following:

• Worn park pawl actuator brackets (607, 608).

• A damaged or bent park pa wl actuator assembl y

(613).

• A damaged manual shaft detent lever (600).

• A damaged manual shaft shift switch assembly

(602).

• A worn or stripped manual shaft (606).

• A worn or damaged park pawl shaft (610), park

pawl spring (611), and park pawl (612).

Figure 7E5 – 39

2 Install the park pawl actuator brackets (607, 608) onto

the case (24).

NOTE

Refer to 4.30 Fasteners in Section 00 Warnings,

Cautions and Notes of this Service Information.

3 Reinstall the bracket bolts (609) and tighten to the

correct torque specification.

Park pawl actuator bracket to transmission

case bolt torque specification...............................22 N.m

Figure 7E5 – 40

4 Install the park pawl (612), the park pawl shaft (610)

and the park pawl spring (611) into the case (24).

Figure 7E5 – 41

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 29

7E5 – 29

5 Assemble the park pawl actuator (613) to the detent

lever (600).

6 Assemble the shift switch assembly (602) to the detent

lever (600).

7 Reinstall the shift switch assembly (602), detent lever

(600) and park pawl actuator (613) into the

transmission case (24).

8 Reinstall the manual sh aft (606) into the case (24).

Figure 7E5 – 42

9 Align the groove for a NEW manual shaft pin (601)

with the pin hole in the detent lever/shift switch

assembly.

10 Install the NEW manual shaft pin (601) into the manual

shift shaft (606), using a suitable sized pin punch and

hammer.

Figure 7E5 – 43

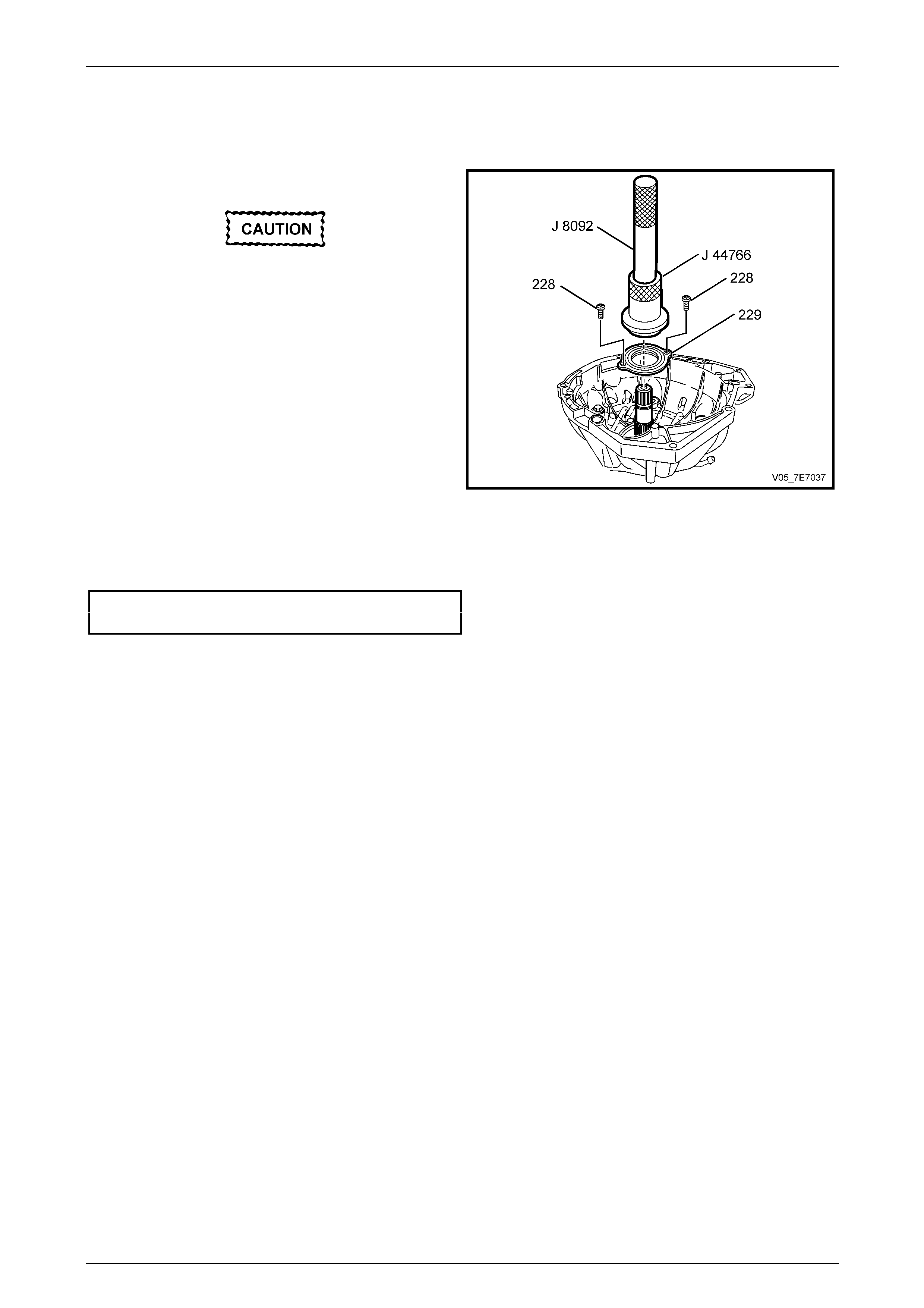

11 Install a NEW manual shaft seal (605) onto J 44767.

12 Use J 44767 to install the NEW manual shaft seal

(605) into the case (24).

Figure 7E5 – 44

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 30

7E5 – 30

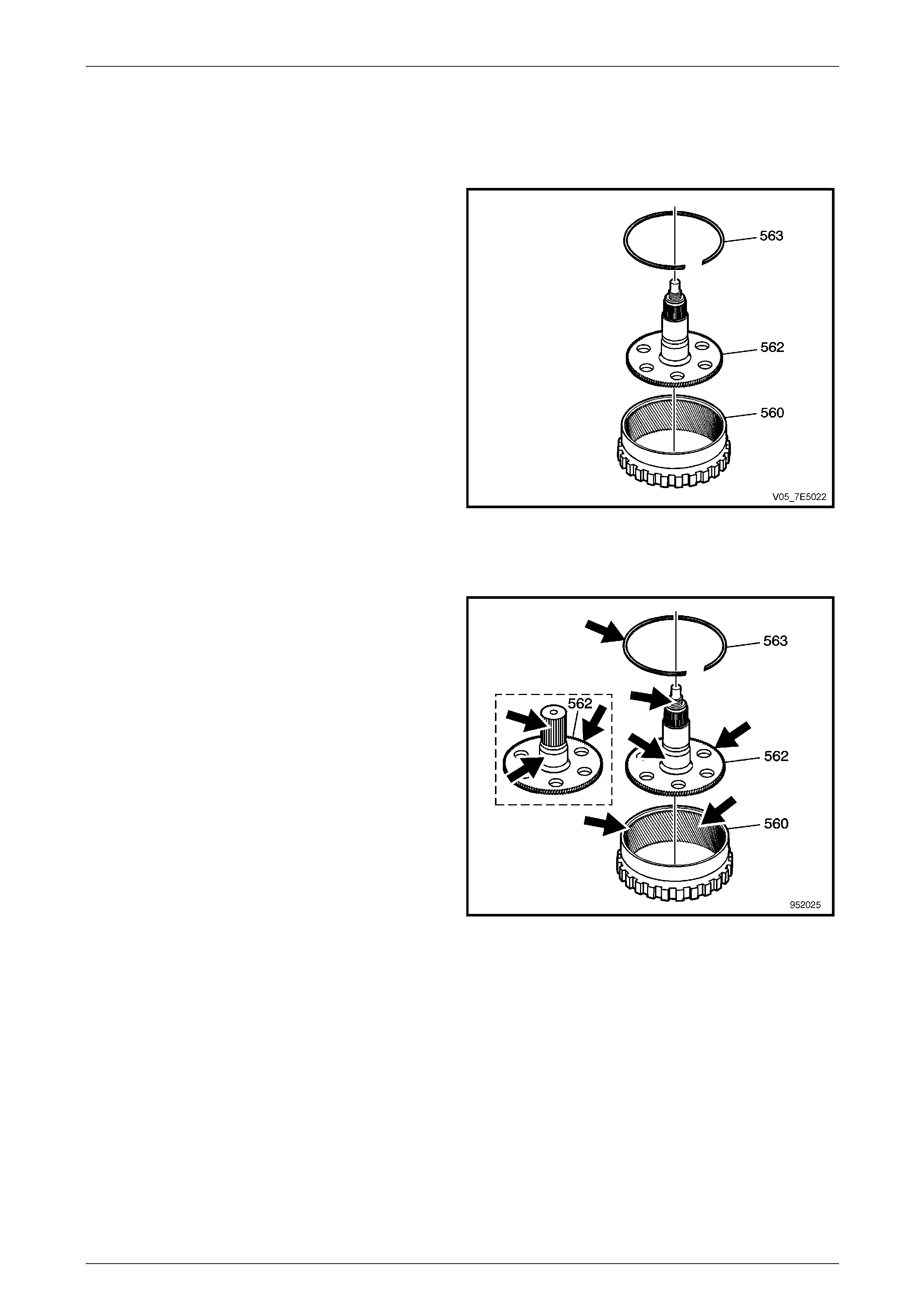

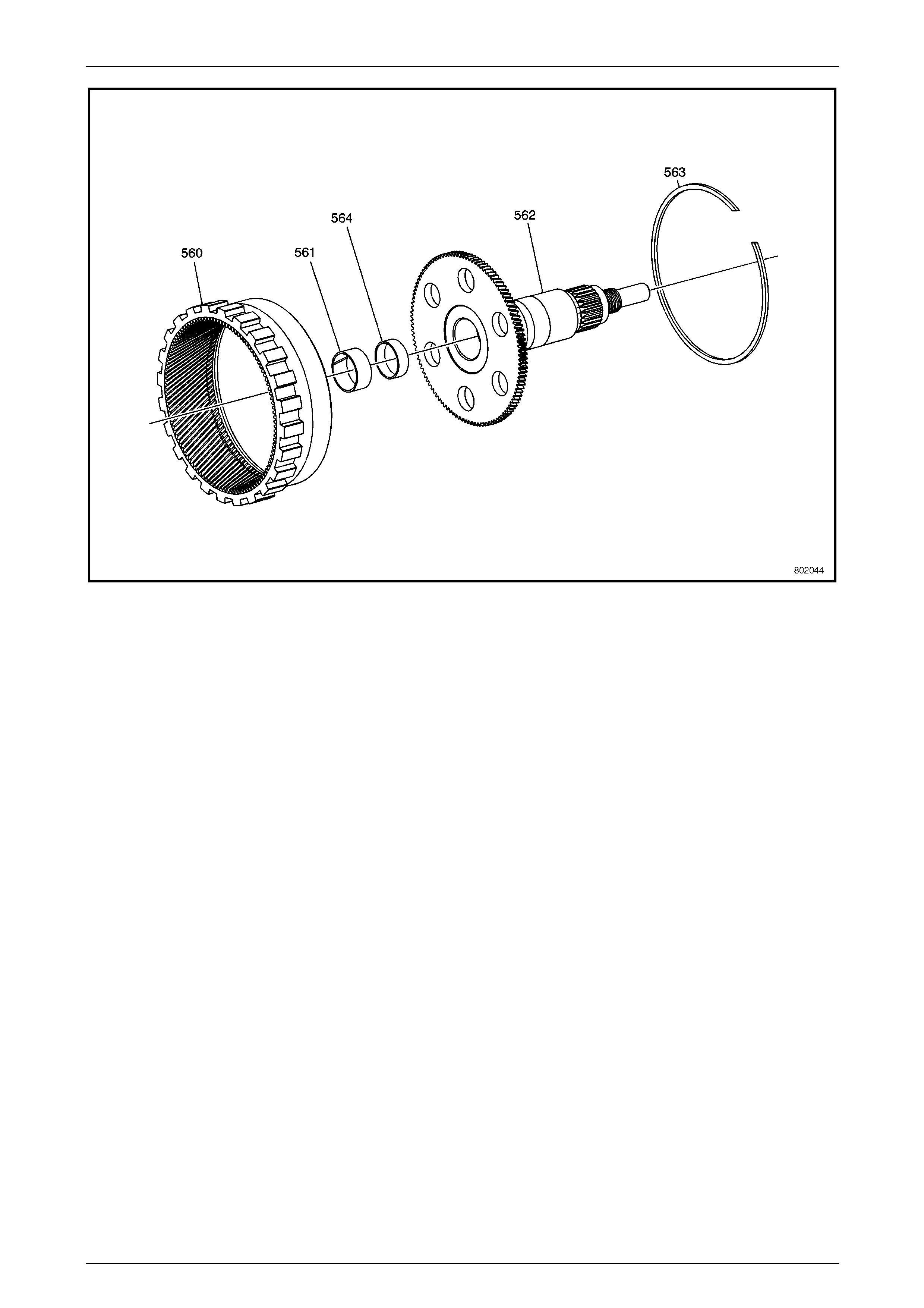

1.23 Output Shaft and Rear Internal Ring Gear

Disassemble

1 Remove the snap ring (563).

2 Remove the output shaft (562) from the rear internal

gear (560).

Figure 7E5 – 45

Reassemble

1 Inspect the output shaft (562) and the rear internal

gear (560) for the following:

• Damaged or worn bushings

• Damaged splines

• Damaged or worn snap ring (563)

• Damaged or worn gear teeth

• Damaged or worn snap ring groove

• Damaged or cross-threaded threads

• Damaged or worn bearings

Figure 7E5 – 46

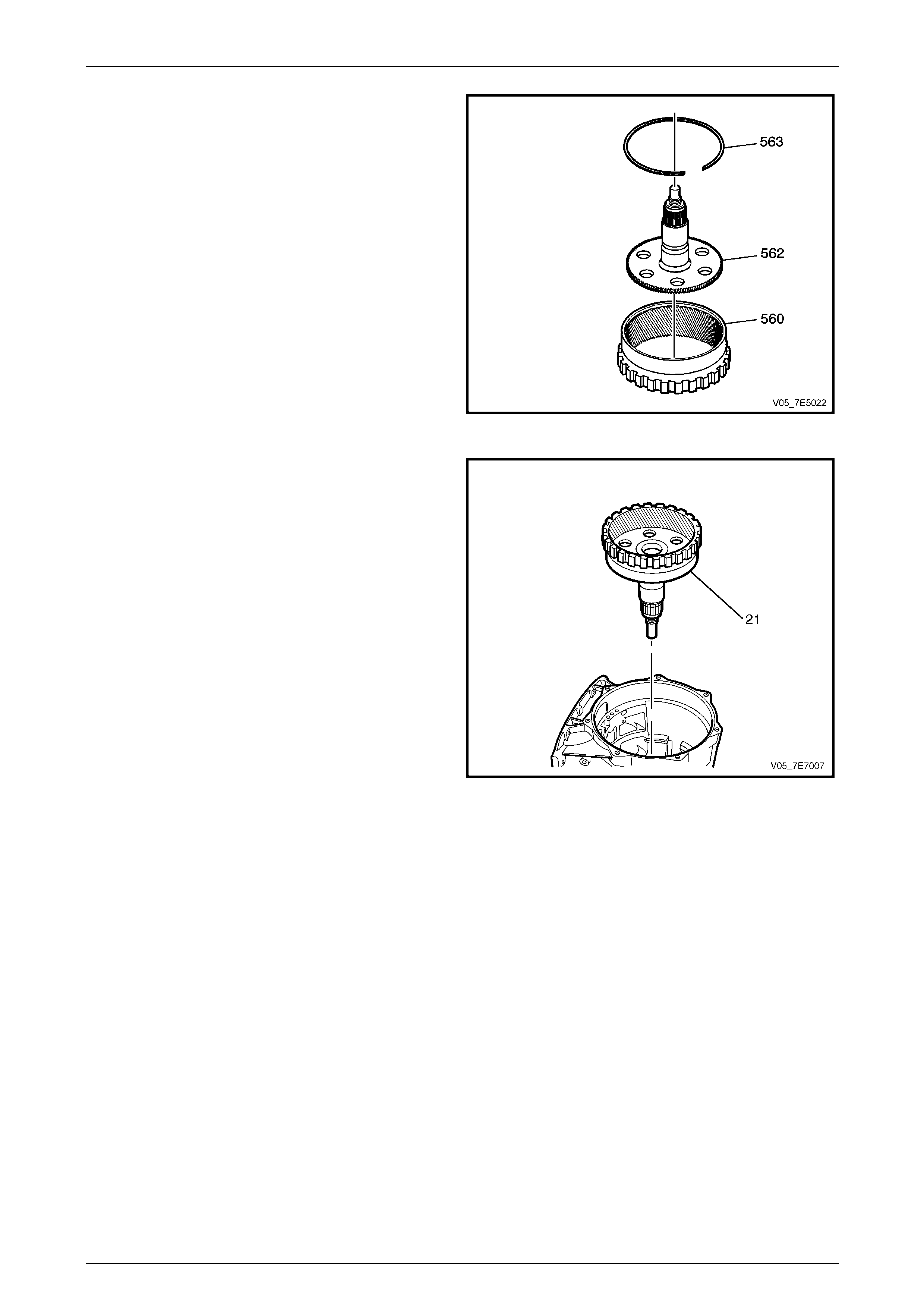

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 31

7E5 – 31

2 Install the output shaft (562) onto the rear internal gear

(560).

3 Install the snap ring (563) onto the rear internal rin g

gear (560). Be sure it is seated in the groove.

Figure 7E5 – 47

4 Rotate the transmission 90° so the main ope nin g of

the transmission case is facing upward.

5 Install the output shaft assembly (21) into the case

(24).

Figure 7E5 – 48

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 32

7E5 – 32

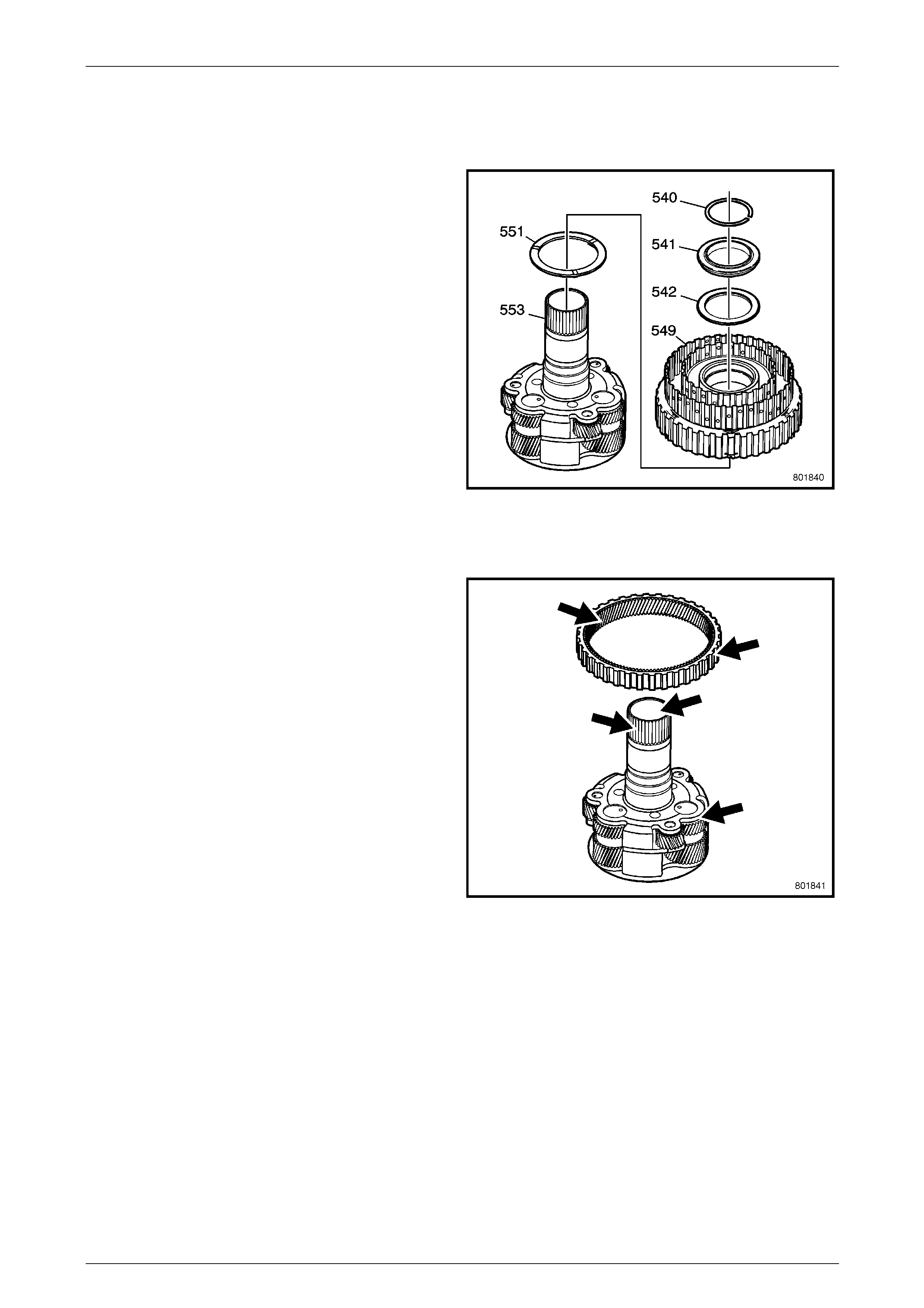

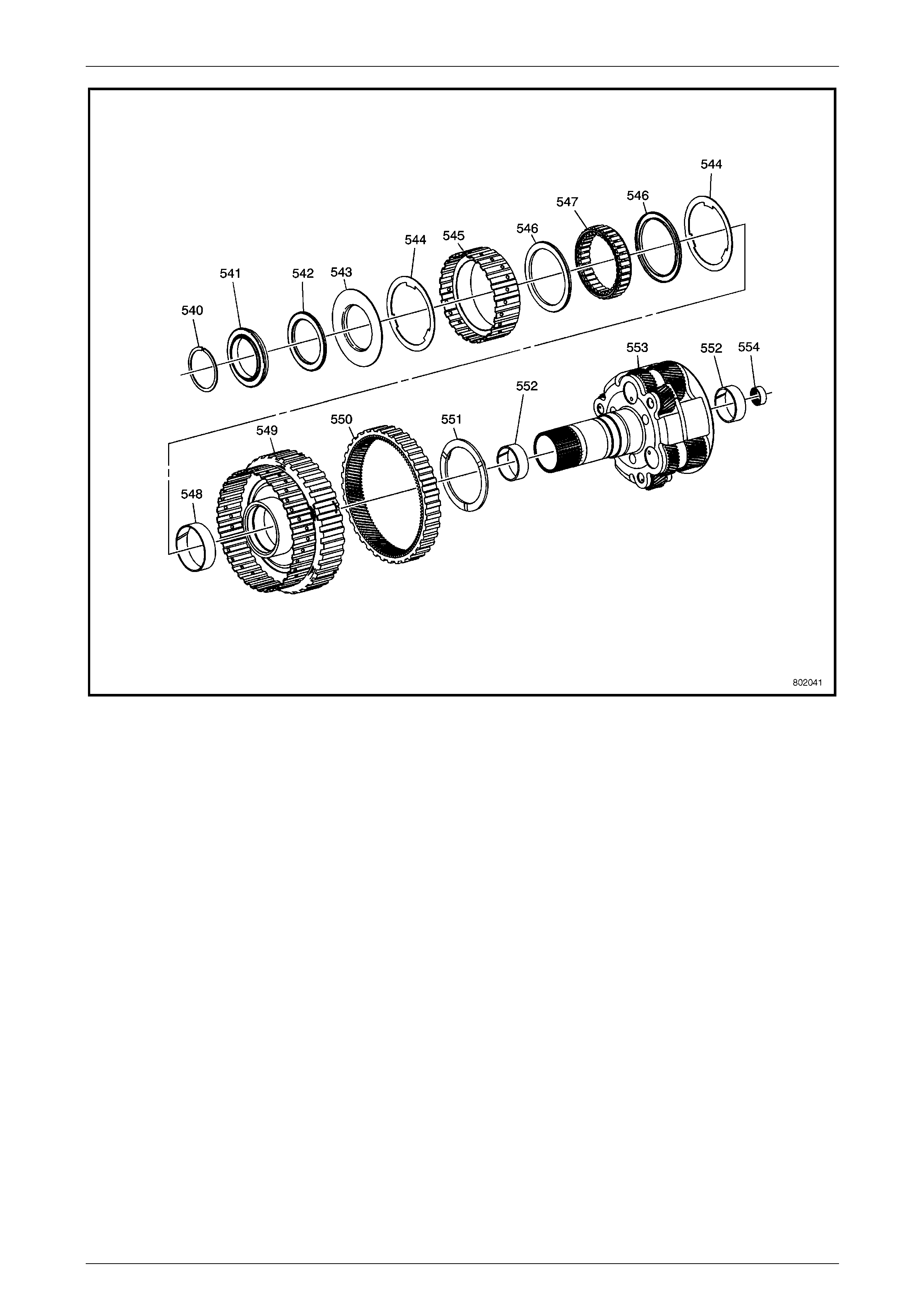

1.24 Input and Reaction Carrier

Disassemble

1 Remove the snap ring (540) and discard.

2 Remove the input and reaction bear ing (541).

3 Remove the 2nd clutch roller inner race bearing (542).

4 Remove the 2nd clutch sprag (549).

5 Remove the reaction internal gear flange washer

(551).

Figure 7E5 – 49

Reassemble

1 Inspect the reaction internal gear and the 2nd clutch

sprag for the following:

• Damaged or worn gear teeth

• Damaged or worn splines

2 Inspect the input and reaction carrier for the follo wing:

• Damaged or worn teeth

• Damaged or worn splines

• Worn or nicked bushings

• Worn or damaged bearings

Figure 7E5 – 50

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 33

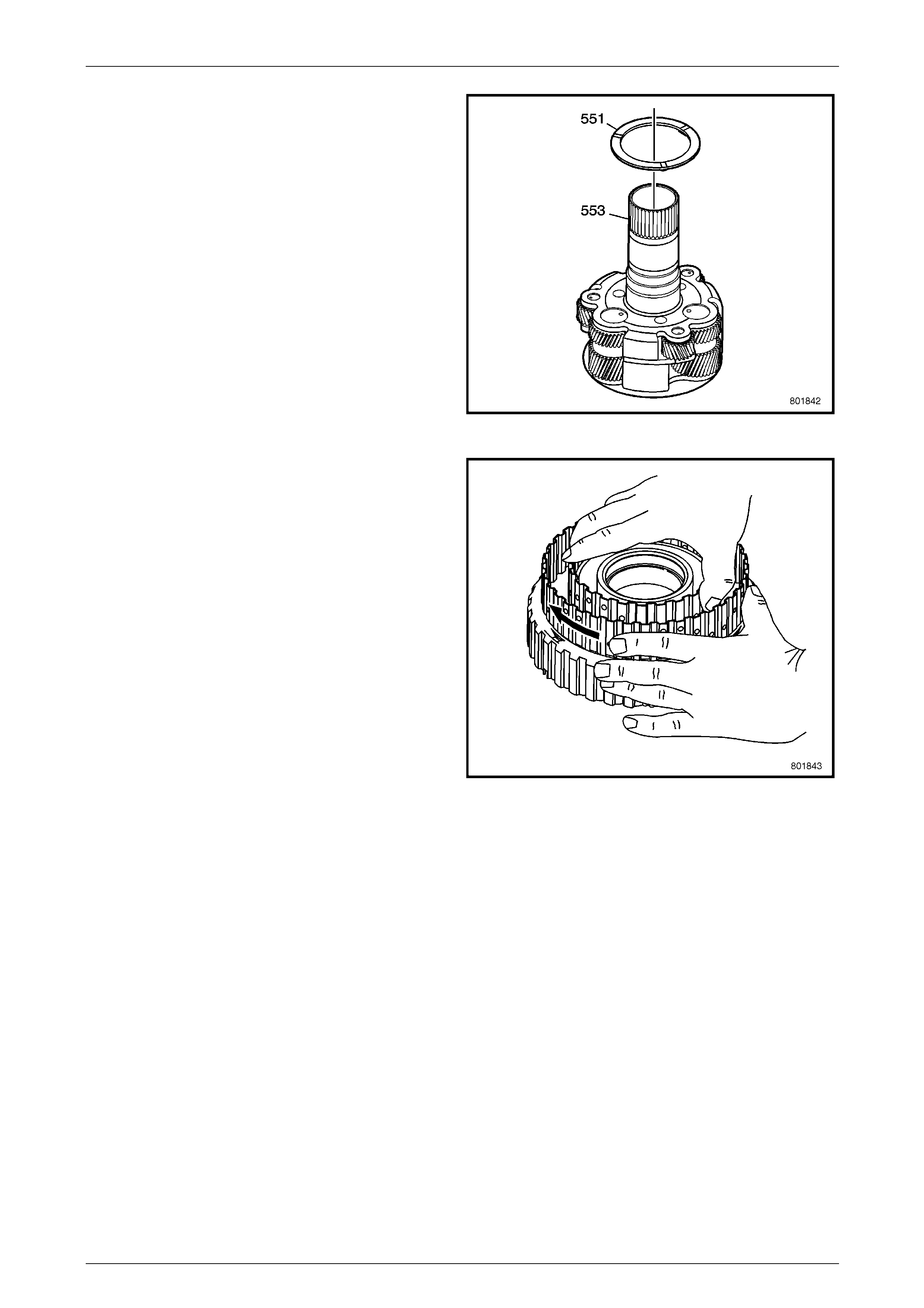

7E5 – 33

3 Lightly coat the reaction internal gear flan ge washer

(551) with petroleum jelly and install onto the front of

the input and reaction carrier assembly.

Figure 7E5 – 51

4 While holding the inner member, check that the outer

member of the 2nd clutch sprag free wheels (arrow)

and locks up in the opposite direction.

Figure 7E5 – 52

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 34

7E5 – 34

5 Install the 2nd clutch sprag (549) onto the input and

reaction carrier (553).

6 Install the 2nd clutch roller inner race bearing

assembly (542) onto the input and reaction carrier

(553).

7 Install the input and reaction bearing assembly (541)

onto the input and reaction carrier (553).

8 Install the NEW input and reaction carrier outer ring

(540) onto the input and reaction carrier (553 ).

Figure 7E5 – 53

9 Install the input and reaction c arrier thrust be aring (20)

into the front of the output shaft and rear internal ri ng

gear assembly (21).

10 Install the input and reaction c arrier (19) into the case

(24), engaging the mating gear teeth.

Figure 7E5 – 54

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 35

7E5 – 35

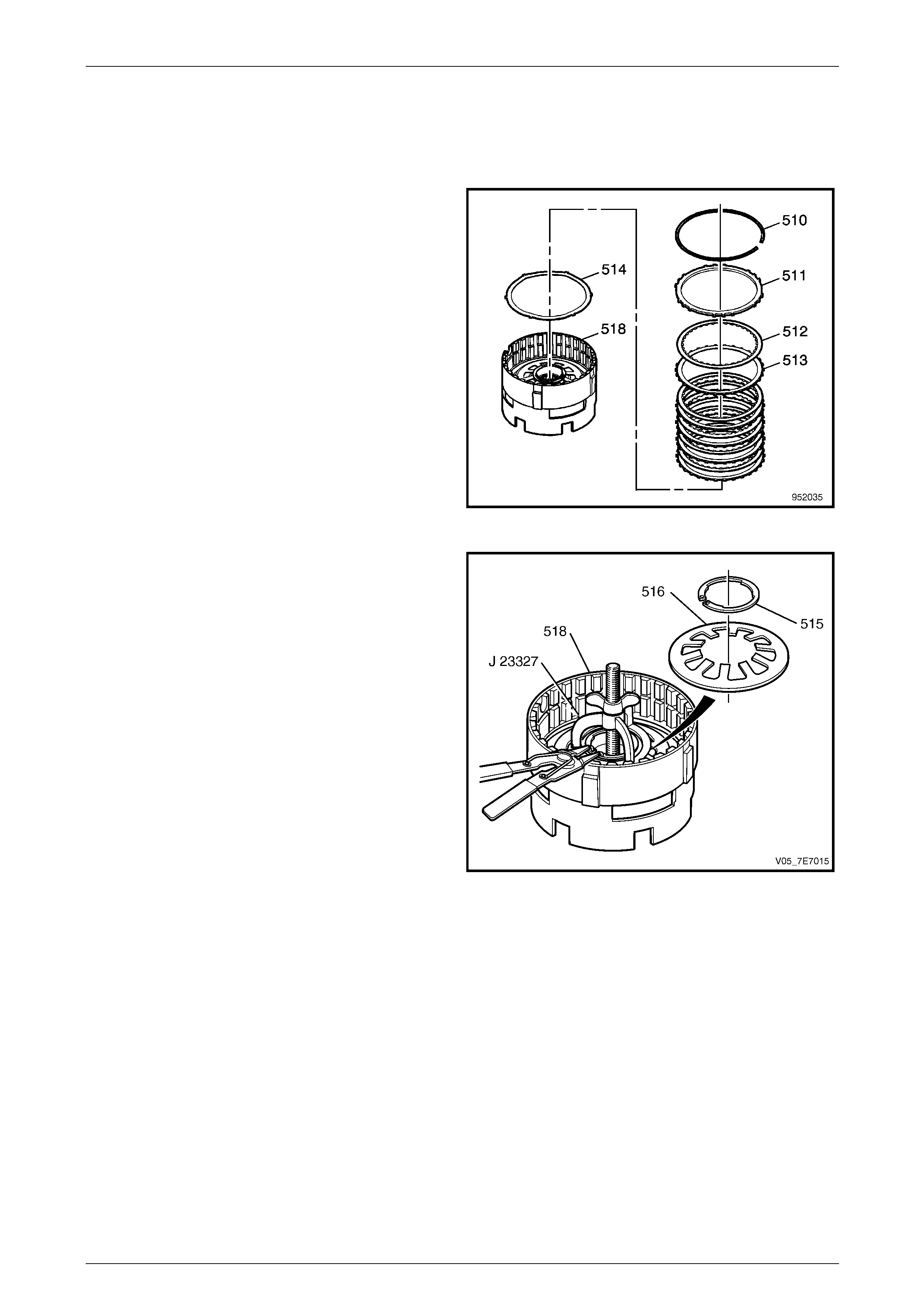

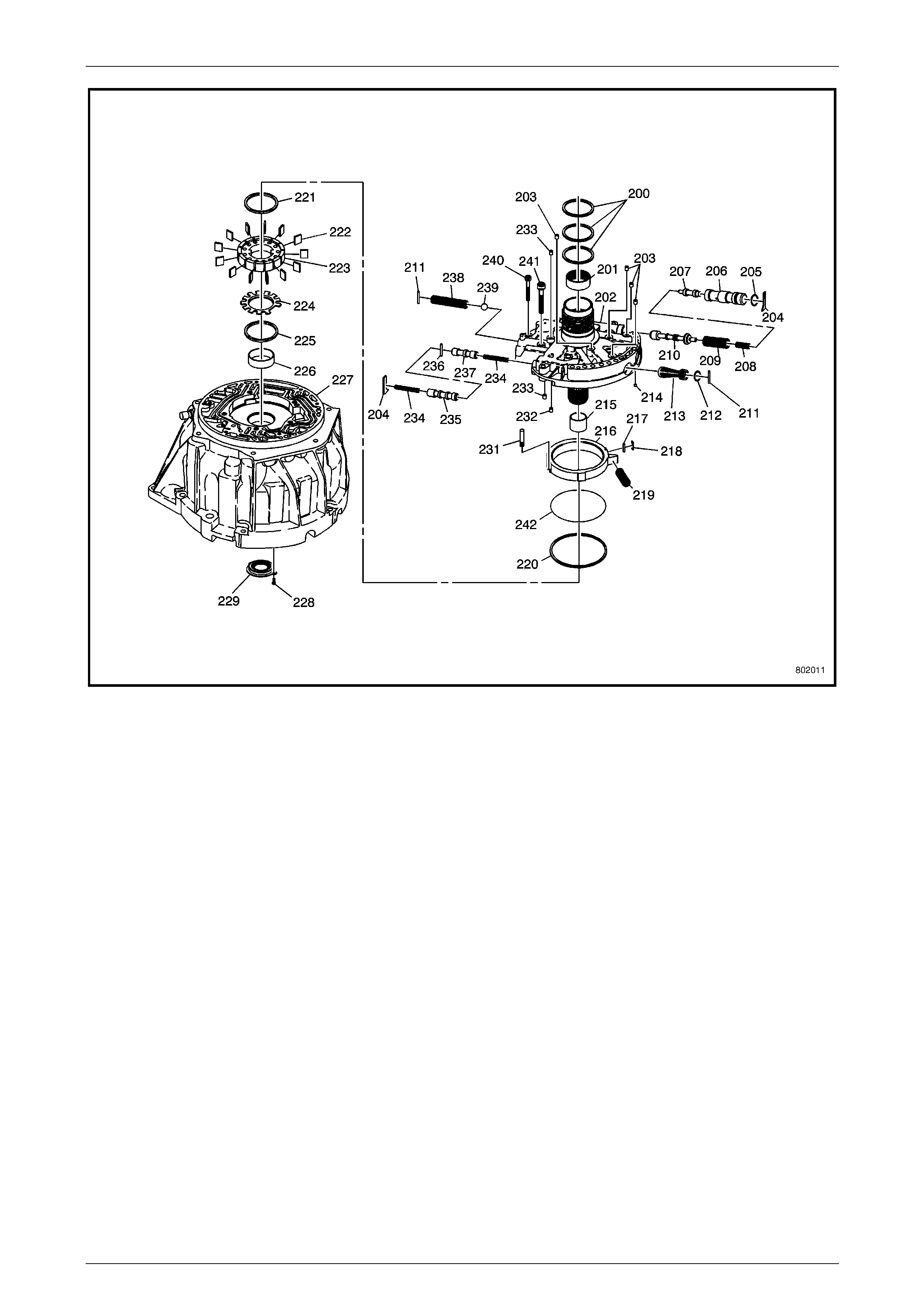

1.25 Centre Support

Disassemble

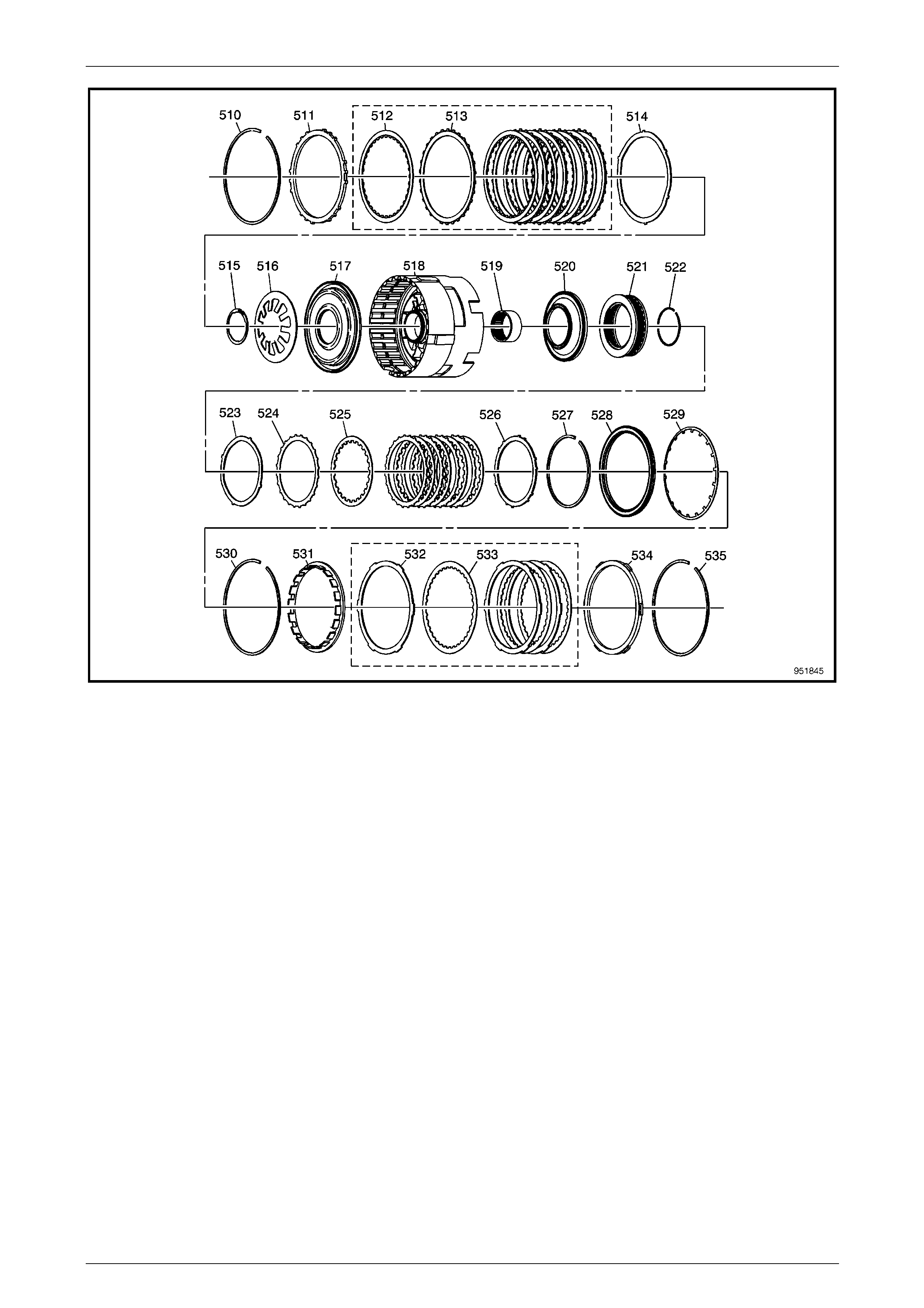

1 Using a flat bladed screwdriver, remove the snap ring

(510) from the centre support.

2 Remove the low and reverse backing plate (511).

3 Remove the clutch plates (512, 513), five inner spl ined

plates and five outer splined pl ates (all models).

NOTE

Each clutch plate has a composition lining on

one side while the other is plai n steel.

4 Remove the low and reverse, waved apply plate (514).

Figure 7E5 – 55

5 Using Tool J 23327, compres s the low and reverse

clutch spring (516).

6 Using suitable snap ring pliers, remove the low

reverse clutch spring retainer ring (515) from the

centre support retaining groove.

7 Loosen and remove T ool J 23327 from the centre

support (518).

8 Remove the low and reverse clutch spri ng retainer ring

(515) and clutch spring (516) from the centre supp ort

(518).

Figure 7E5 – 56

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 36

7E5 – 36

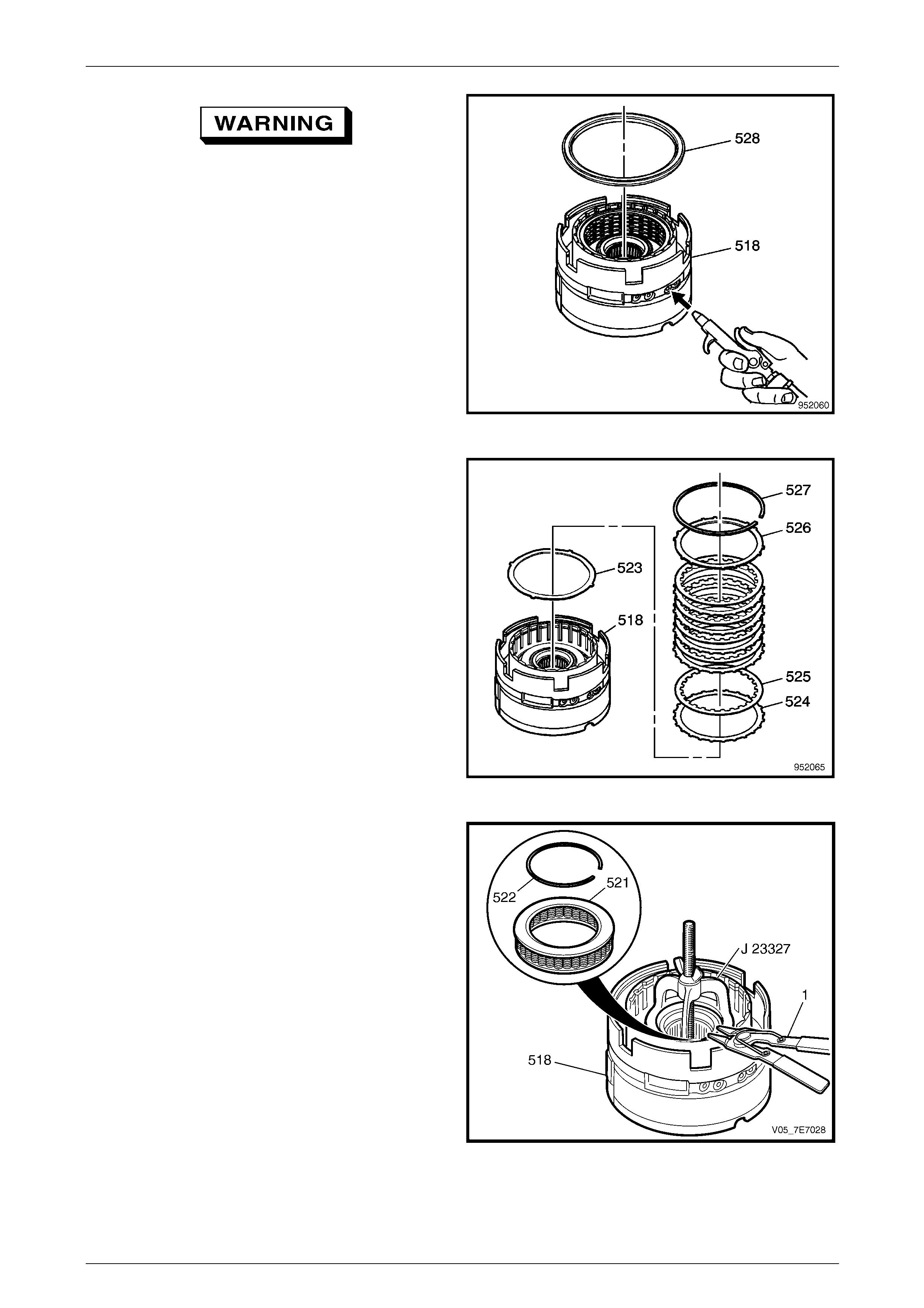

Wear eye protection to prevent potential

injury.

9 Remove the low and reverse piston (517) from the

centre support (518).

NOTE

It may be necessary to apply air pressure to the

centre support port as shown, to assist in piston

removal.

Figure 7E5 – 57

10 Turn the centre support assembly over and using a

fine bladed screwdriver, remove the 2nd coast clutch

plate retainer ring (535) from the centre support (518).

11 Remove the 2nd coast clutch backing plate (534) from

the centre support (518).

12 Remove the clutch plates (532, 533), three (two for

5HEG) inner splined plates and three (two for 5HEG)

outer splined plates.

NOTE

Each clutch plate has a composition lining on

one side while the other is plai n steel.

13 Remove the 2nd coast clutch spacer (531) from the

centre support (518).

Figure 7E5 – 58

14 Using a flat bladed screwdrive r , remove the 2nd coast

clutch spring retainer (530).

15 Remove the 2nd coast clutch spring (529) from the

centre support (518).

Figure 7E5 – 59

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 37

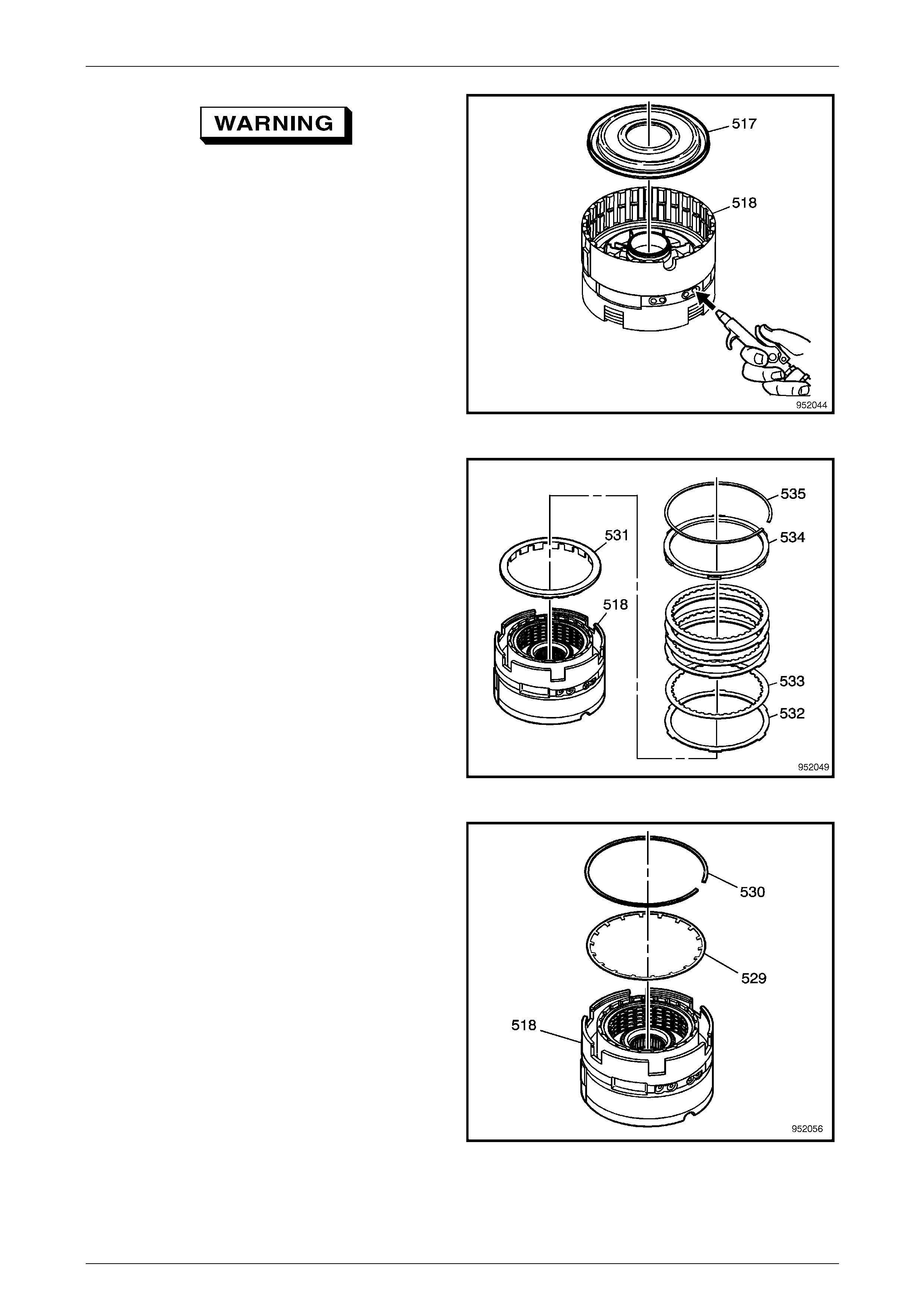

7E5 – 37

Wear eye protection to prevent potential

injury.

16 Remove the 2nd coast clutch piston (528) fro m the

centre support (518).

NOTE

It may be necessary to apply air pressure to the

centre support port as shown, to assist in the

removal of the piston.

Figure 7E5 – 60

17 Using a flat bladed screwdriver, remove the retainer

ring (527) from the centre support (518).

18 Remove the 2nd clutch backing plate (526) from the

centre support (518).

19 Remove the clutch plates (524, 525), five inner spl ined

plates and five outer splined pl ates (all models) from

the centre support (518).

20 Remove the 2nd clutch apply plate (523) from the

centre support (518).

Figure 7E5 – 61

21 Using Tool J 23327, compres s the 2nd clutch piston

spring (521).

22 Using suitable snap ring pliers, remove the retainer

ring (522) from the centre support (518) retai nin g

groove.

23 Loosen and remove T ool J 23327 from the centre

support (518).

24 Remove the 2nd clutch piston spring (521) fro m the

centre support (518).

Figure 7E5 – 62

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 38

7E5 – 38

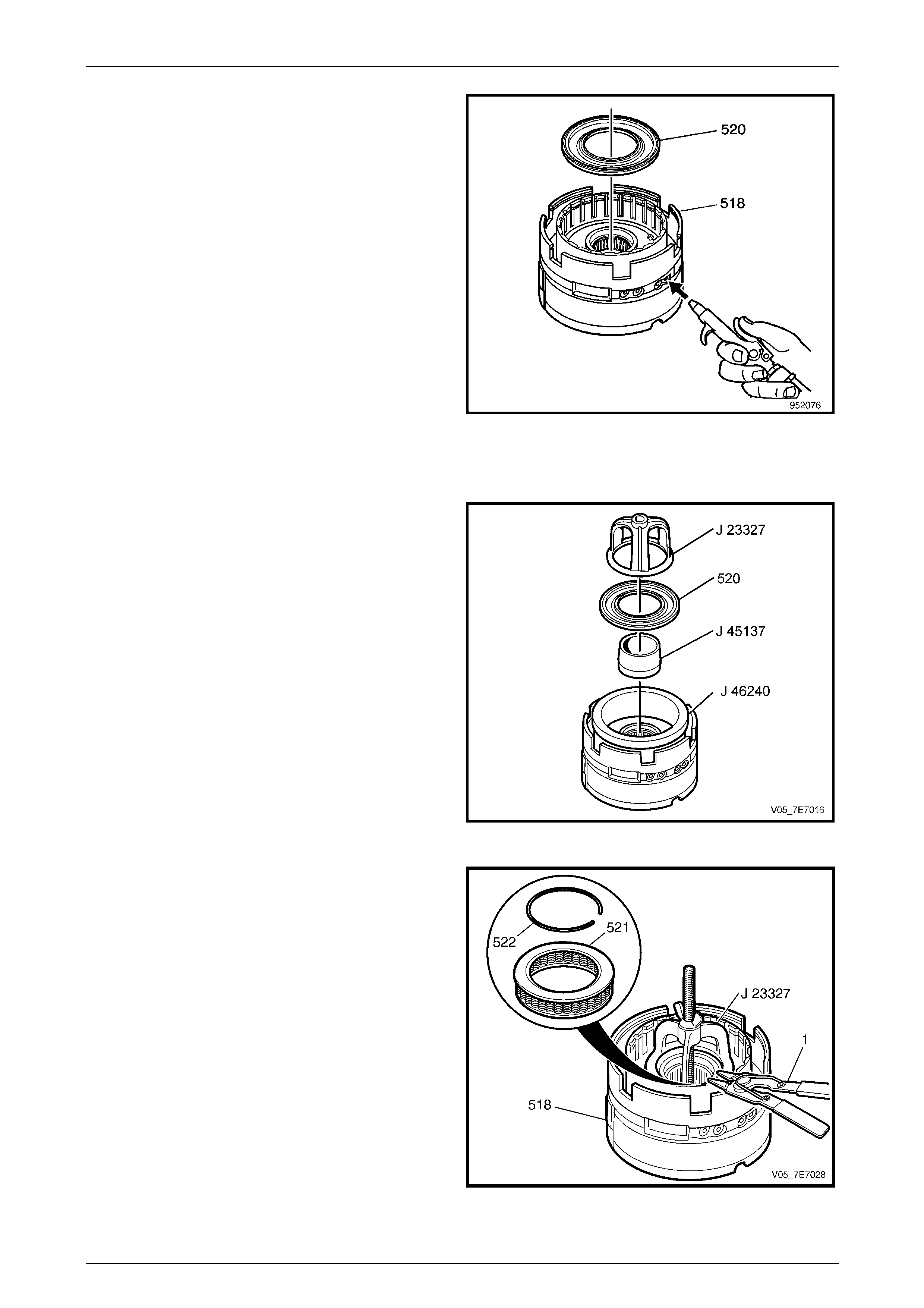

25 Remove the 2nd clutch piston (520) from the centre

support (518).

NOTE

It may be necessary to apply air pressure to the

centre support port as shown, to assist in the

piston removal.

Figure 7E5 – 63

Reassemble

1 Inspect the centre support components for the

following:

• Plugged fluid passages

• Worn or damaged splines

• Worn or damaged pistons

• Worn or damaged clutch plates

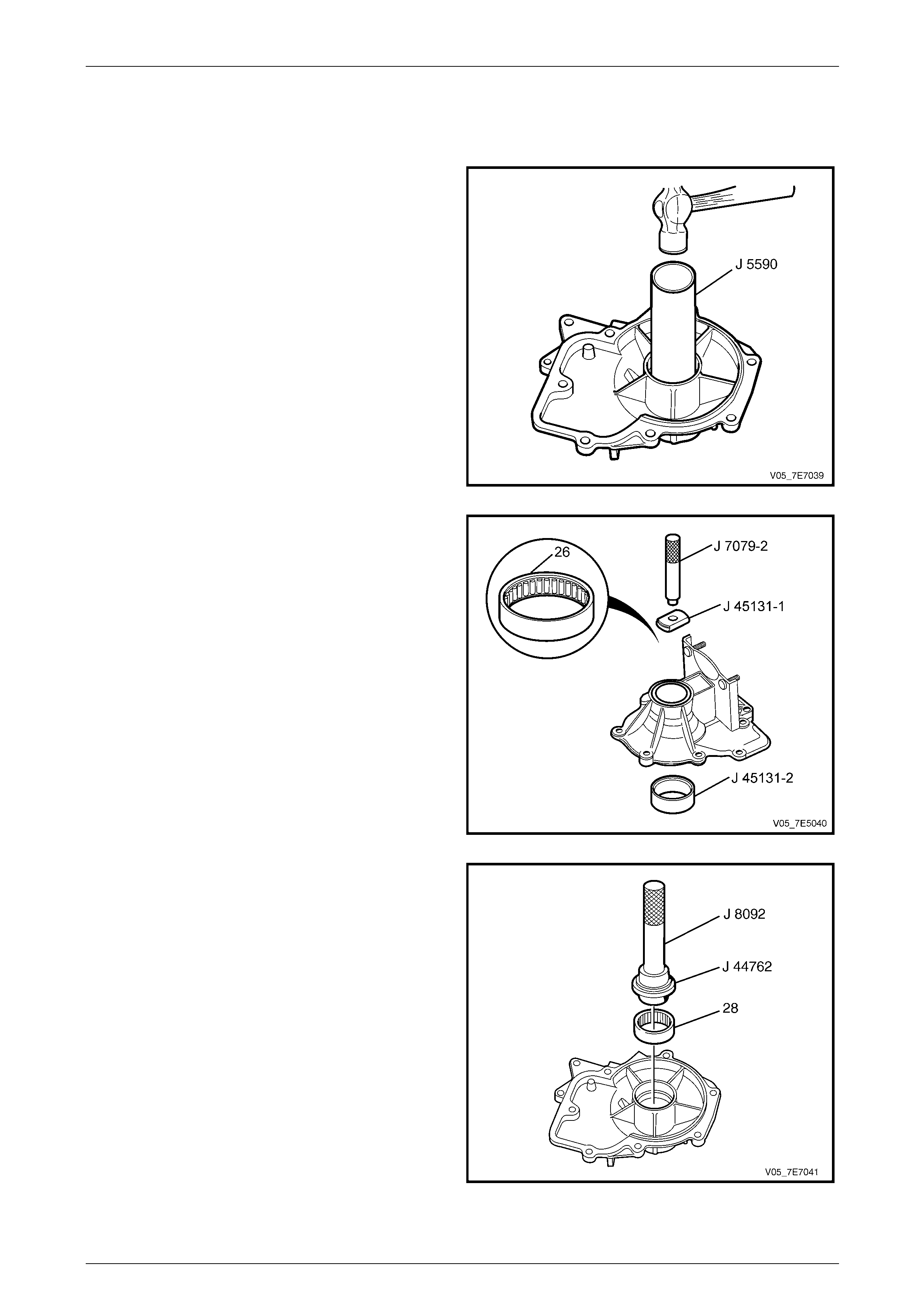

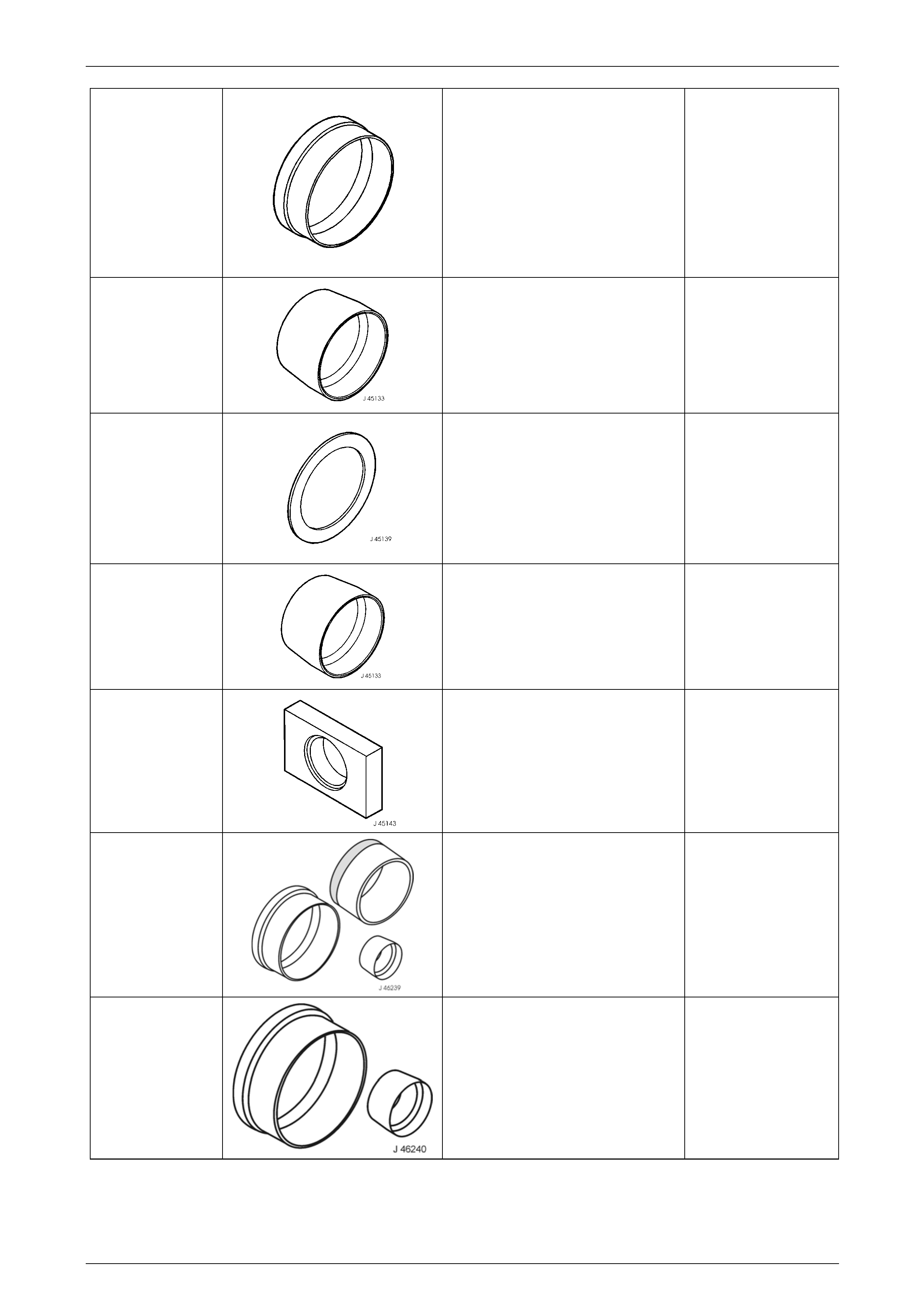

2 Install 2nd clutch inner seal protector (Tool J 45137)

and piston protector (Tool J 46240), into the centre

support.

3 Lubricate the 2nd clutch piston and protectors with

clean transmission lubric ant. Install the 2nd clutch

piston (520) into the centre support, using J 233 27 to

assist in the installation process.

Remove Tools J 46240 an d J 45137 once 2nd clutch

piston is installed. Figure 7E5 – 64

4 Install the 2nd clutch piston spring (521) into the

centre support (518), and place the 2nd clutch spring

retainer snap ring (522) on top of the piston spring.

5 Using Tool J 23327, compres s the 2nd clutch piston

spring (521).

6 Using suitable snap ring pliers, install a NEW 2nd

clutch spring retainer ring (522) into the centre support

(518) retaining groove.

7 Loosen and remove T ool J 23327 from the centre

support (518).

Figure 7E5 – 65

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 39

7E5 – 39

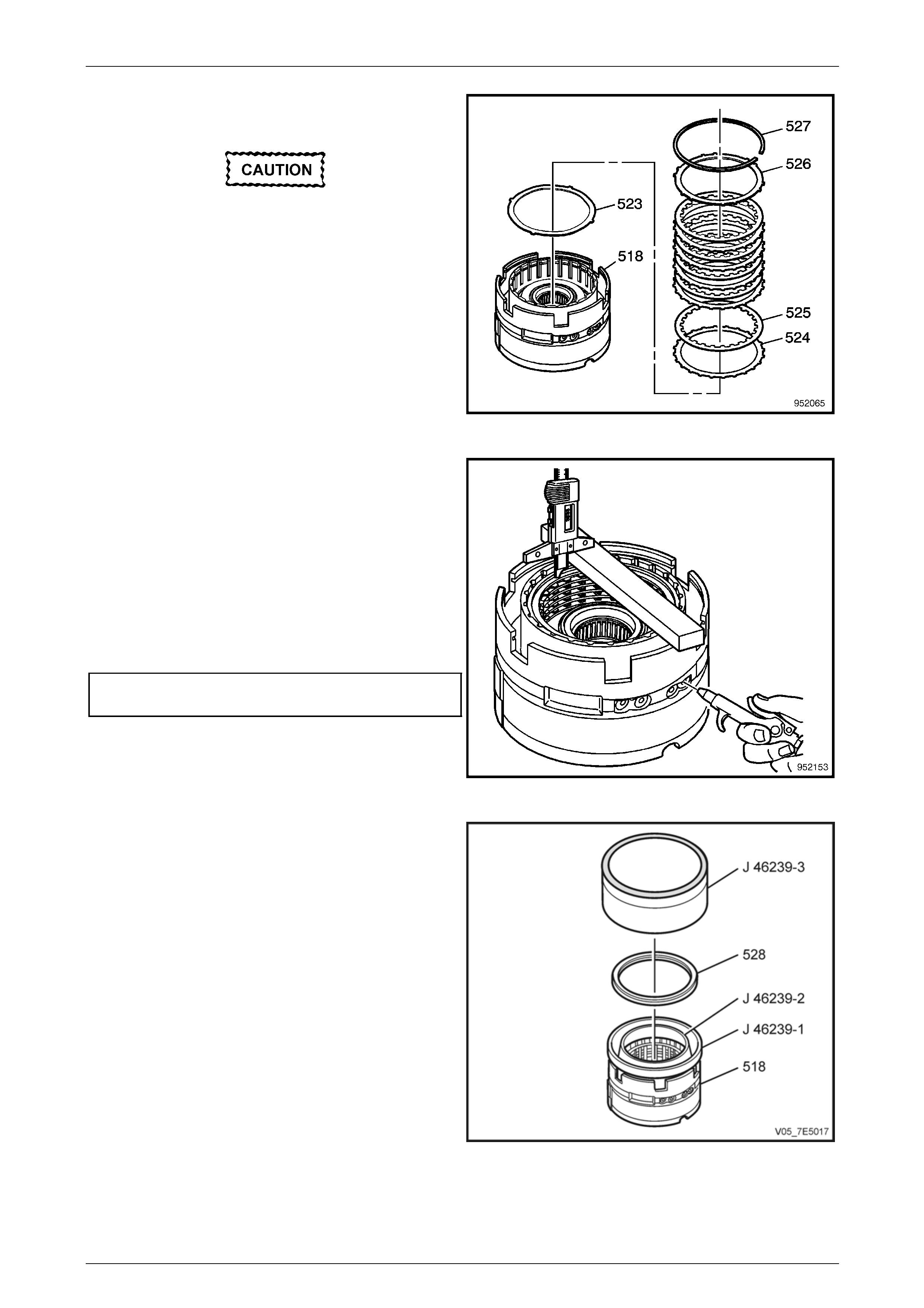

8 Install the 2nd clutch apply plate (523) into the centre

support (518).

Ensure that the composition side of each

plate faces upwards.

9 Install the 2nd clutch plates. Start by installing the 2n d

clutch plate (524) with external splines.

Alternate with the 2nd clutch plate (525) with internal

splines.

10 Install the 2nd clutch backing plate (526) into the

centre support (518).

11 Install the 2nd clutch backing plate retainer ring (527)

into the centre support (518).

Figure 7E5 – 66

12 Measure the distance between the 2nd clutch backing

plate and the bottom of the gauge bar. Measure three

times in different locations on the backing pla t e.

Record this as H1.

13 Apply air pressure – 450 kPa, to the specified port.

Measure the distance between the 2nd clutch backing

plate and the bottom of the gauge bar. Measure three

times in different locations on the backing pla t e.

Record this as H2.

14 Subtracting H2 from H1 will give the clutch pack travel

dimension.

2nd Clutch Pack

Travel Specification................................ 1.47 – 1.92 mm

Figure 7E5 – 67

15 Install inner piston seal protector (Tool J 46239-2) and

outer piston seal protector (J 46239-1) into the centre

support (518).

16 Coat inner and outer piston seal surfac es with

petroleum jelly (e.g. Vaseli ne™ or equivalent), then

install the 2nd coast piston (528), using installer (Tool

J 48239-3), into the centre support (518).

Figure 7E5 – 68

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 40

7E5 – 40

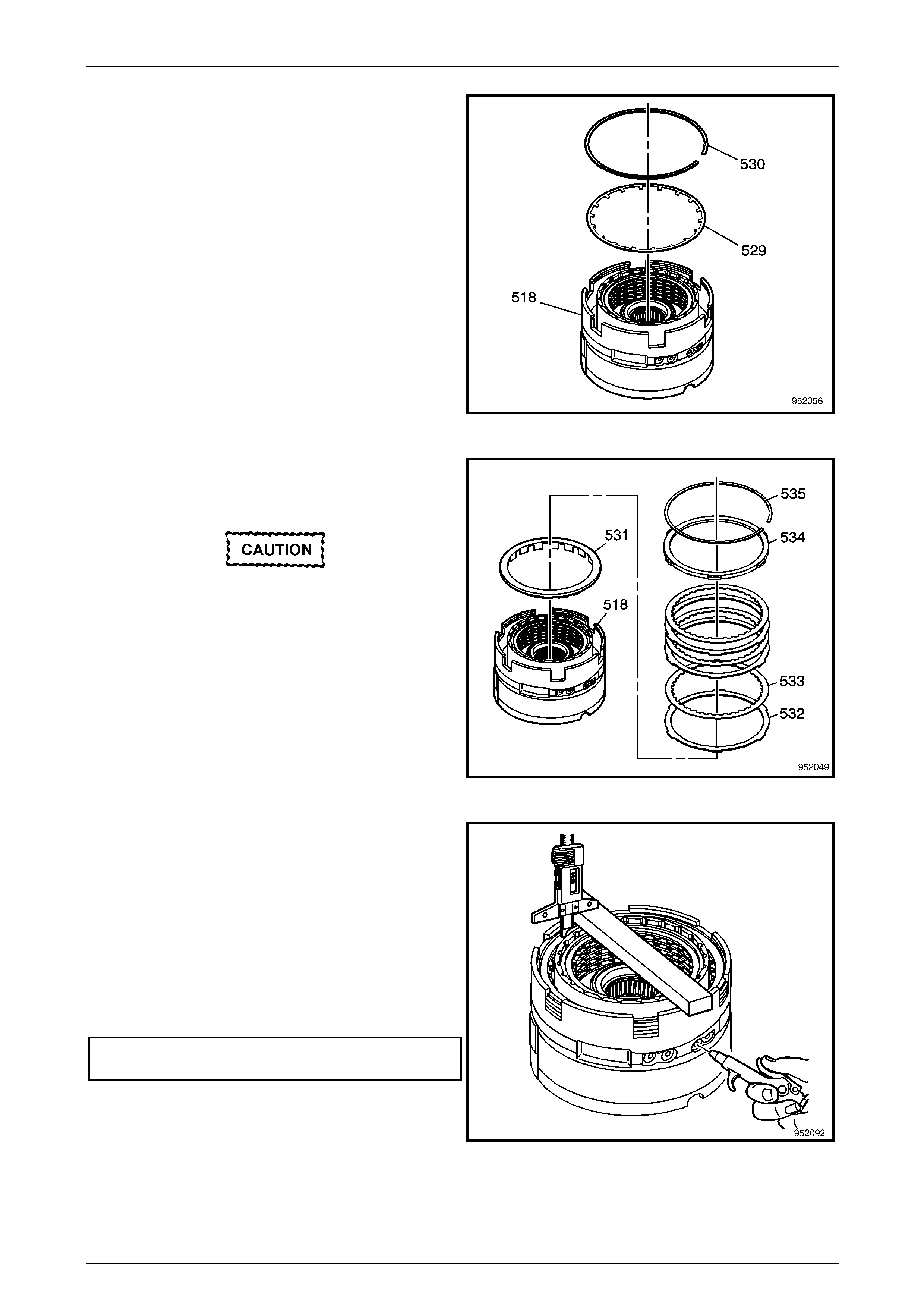

17 Install the 2nd coast clutch spring (529) into the centre

support (518), with the inner tangs facing downward.

18 Install one end of the coast clutch spring retai ner (530)

into the centre support groove.

19 Using a screwdriver blade as needed, fully install the

retainer by working around its len gth, until the retainer

is fully engaged.

Figure 7E5 – 69

20 Install the 2nd coast clutch spacer (531) into the

centre support (518), checking that the support cut-

outs straddle the coast clutch spring legs.

Ensure that the composition side of each

plate faces upwards.

21 Install the 2nd coast clutch plates, starting with the 2nd

coast clutch plate (532) with external splines. Alternate

with the 2nd coast clutch plate (533) with internal

splines.

22 Install the 2nd coast clutch backing p late (5 34).

23 Install the 2nd coast clutch backing plate retainer ring

(535).

Figure 7E5 – 70

24 Measure the distance between the 2nd coast clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H1.

25 Apply air pressure – 450 kPa, to the specified port.

Measure the distance between the 2nd coast clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H2.

26 Subtracting H2 from H1 will give the clutch pack travel

dimension.

2nd Coast Clutch Pack

Travel Specification................................ 0.94 – 1.39 mm

Figure 7E5 – 71

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 41

7E5 – 41

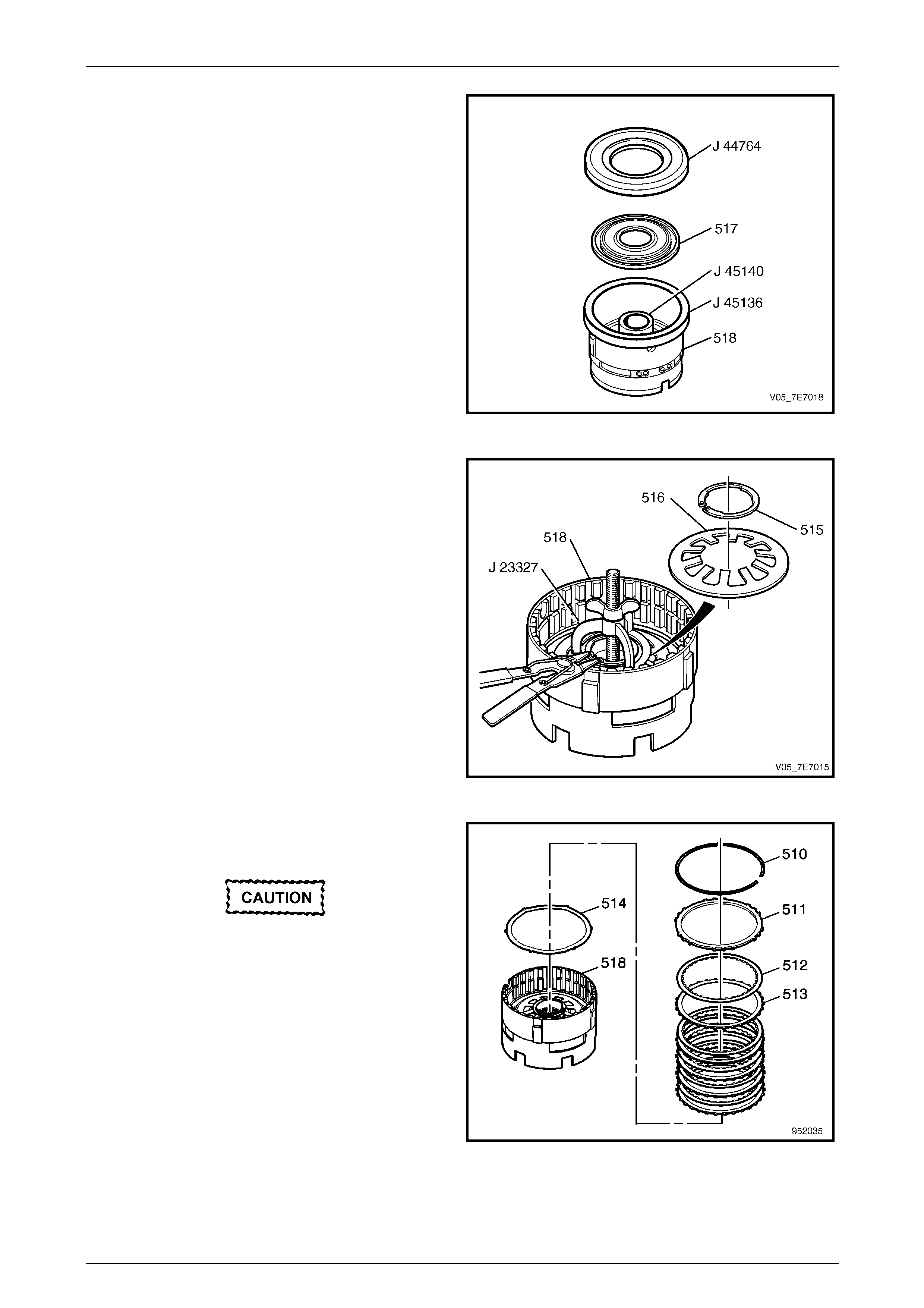

27 Using Tool J 45140 inner seal protector, and Tool J

45136 outer seal protector, install the lo w and reverse

clutch piston (517) into the centre support (518), using

J 44764 to assist.

Figure 7E5 – 72

28 Assemble low and reverse clutch spring (51 6) and a

NEW retainer ring (515) onto the low and reverse

clutch piston.

29 Using Tool J 23327, spring compressor, compress the

low and reverse clutch piston spring (516).

30 Using suitable circlip pliers, install the low and reverse

clutch spring retainer circlip (515) into the centre

support (518) retaining groove.

Loosen and remove T ool J 23327 once circlip (515) is

installed.

Figure 7E5 – 73

31 Install the low and reverse apply pl ate (514) into the

centre support (518).

Ensure that the composition side of each

plate faces upwards.

32 Install the low and reverse clutch plates. Start with the

low and reverse clutch plate (513) with external

splines. Alternate with the low and reverse clutch plate

(512) with internal splines.

NOTE

The external splined plates (513) with the

missing spline, aligns with the large centre

support lug.

33 Install the low and reverse clutch backing p late (511)

and the retainer ring (510) into the centre support

(518). Figure 7E5 – 74

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 42

7E5 – 42

34 Measure the distance between the low and reverse

clutch backing plate and the bottom of the ga uge bar.

Measure three times in different locations on the

backing plate. Record this as H1.

35 Apply air pressure – 450 kPa, to the specified port.

Measure the distance between the low and reverse

clutch backing plate and the bottom of the ga uge bar.

Measure three times in different locations on the

backing plate. Record this as H2.

36 Subtracting H2 from H1 will give the clutch pack travel

dimension.

Low and Reverse Clutch Pack

Travel Specification................................ 1.72 – 2.17 mm

Figure 7E5 – 75

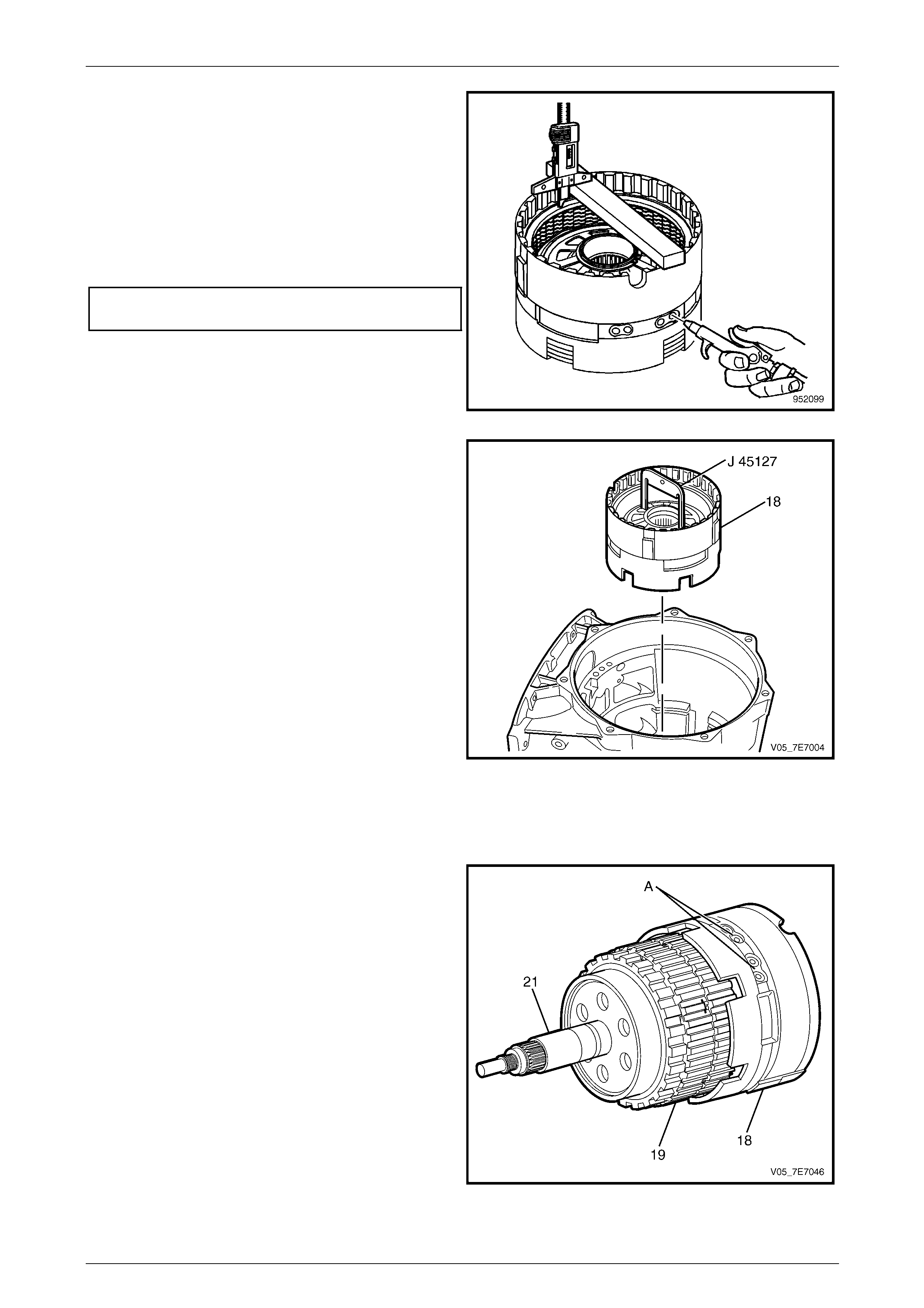

37 Using Tool J 45127, install the centre support

assembly (18) into the transmission case (24),

ensuring that the 2nd clutch and 2n d coast clutch

plates fully engage over the mating splines on the

second clutch sprag assembly (545 and 54 9).

Figure 7E5 – 76

Alternative Reassembly Method

Rather than install the individual transmission components described to this point, the following procedure may be more

convenient.

1 Assemble the centre support assembly (18) to the

planetary carrier and 2nd clutch sprag assemblies (19)

and the rear internal gear output shaft (21).

2 With the transmission case in a horizontal position,

install the pre-assembled compon ents into the case.

NOTE

If all clutch plates are correctly engaged, the flui d

passage access holes in the centre support (A),

will be aligned with those in the transmission

case.

Figure 7E5 – 77

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 43

7E5 – 43

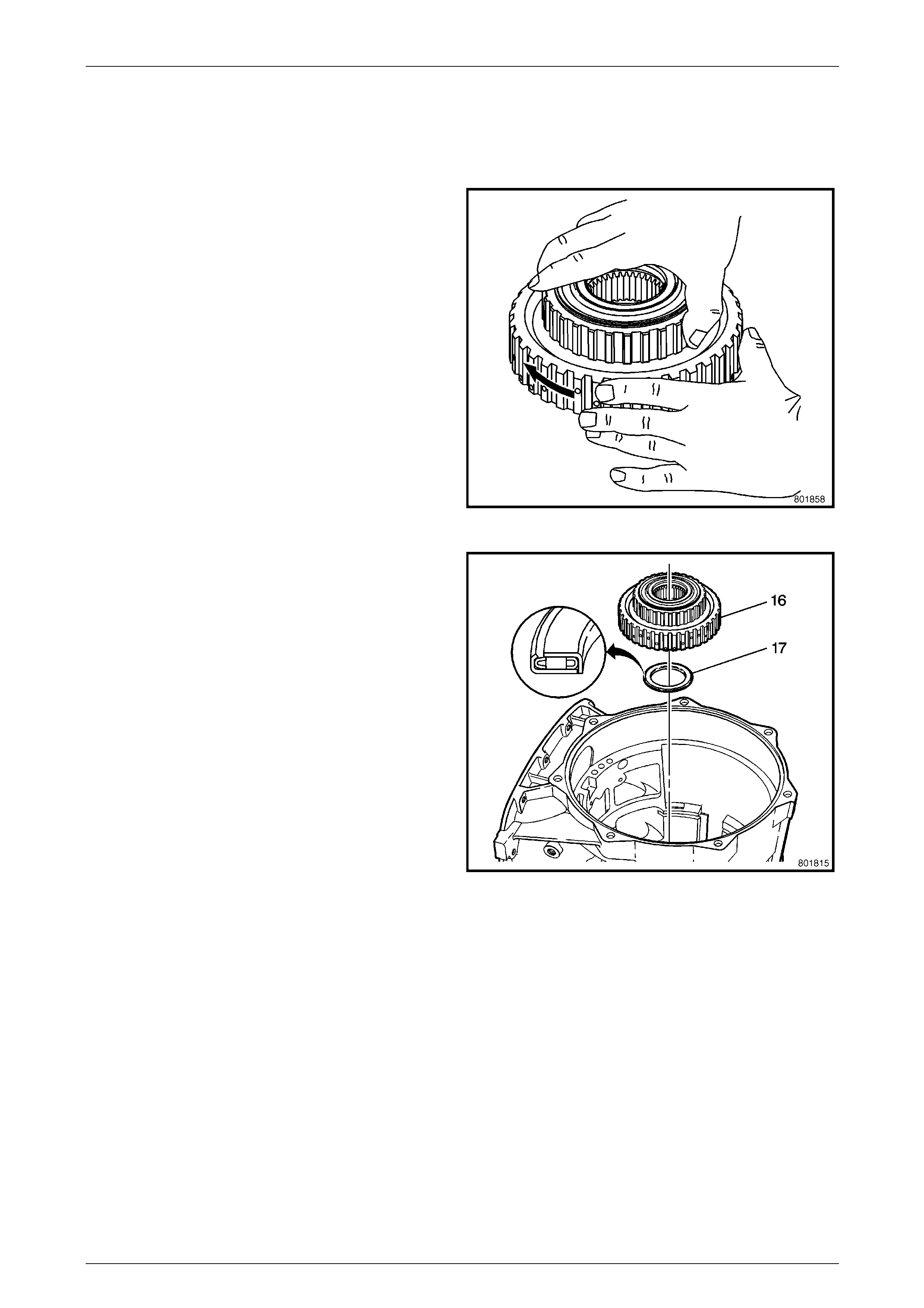

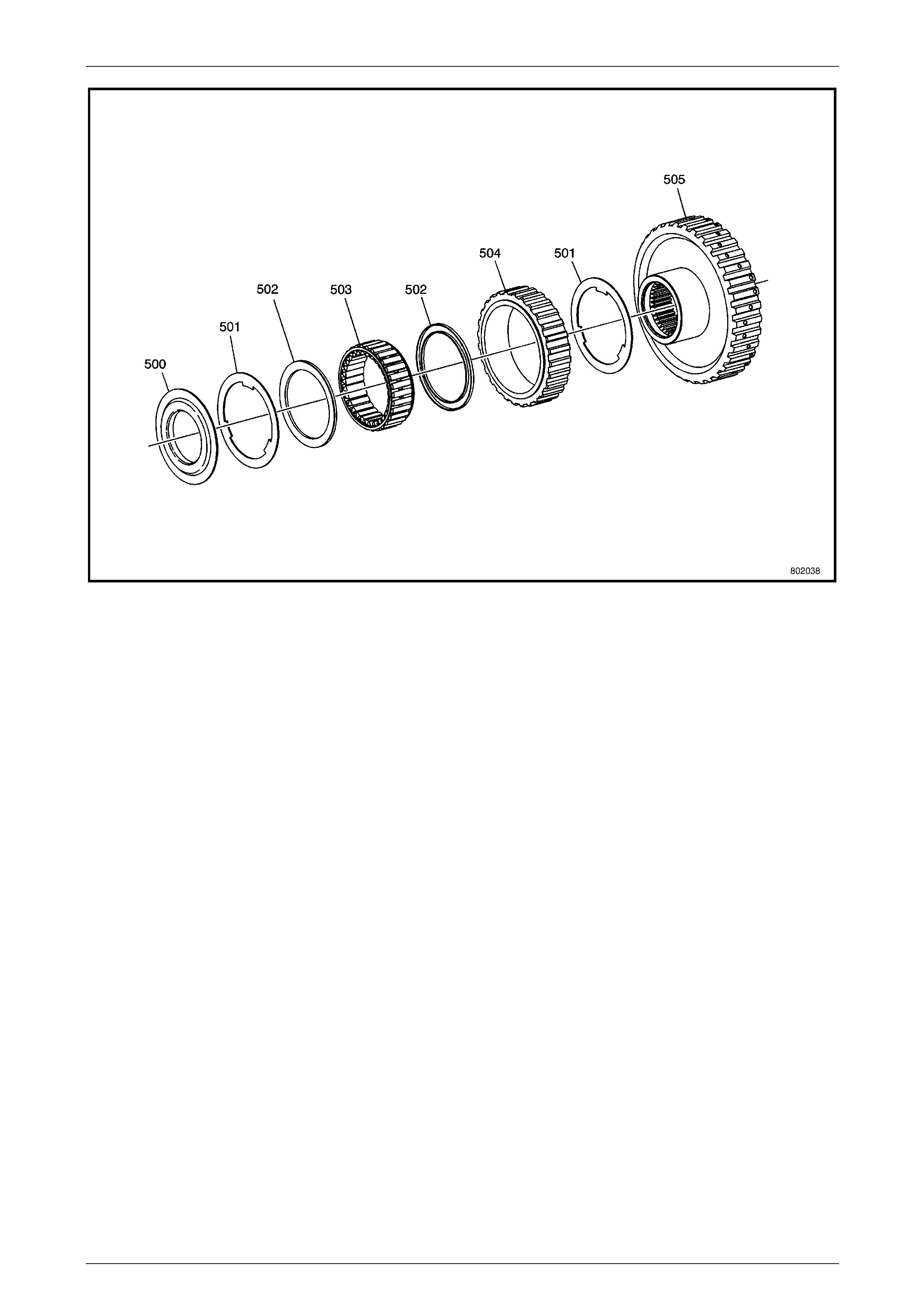

1.26 Low Clutch Sprag

Reassemble

1 Inspect the low clutch sprag for the follo wing:

• Worn or damaged splines

• Scoring on the inside diameter of the races

• Wear or cracks

2 Check that the low clutch sprag rotation freewheels

and locks up in the correct direction.

Figure 7E5 – 78

3 Install the low clutch roller thrust bearing (17 ).

4 Install the low clutch sprag (16) into the transmission

case (24), ensure that the splines on the inner race

(505) engage fully with the low and reverse clutch

plates (512).

Figure 7E5 – 79

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 44

7E5 – 44

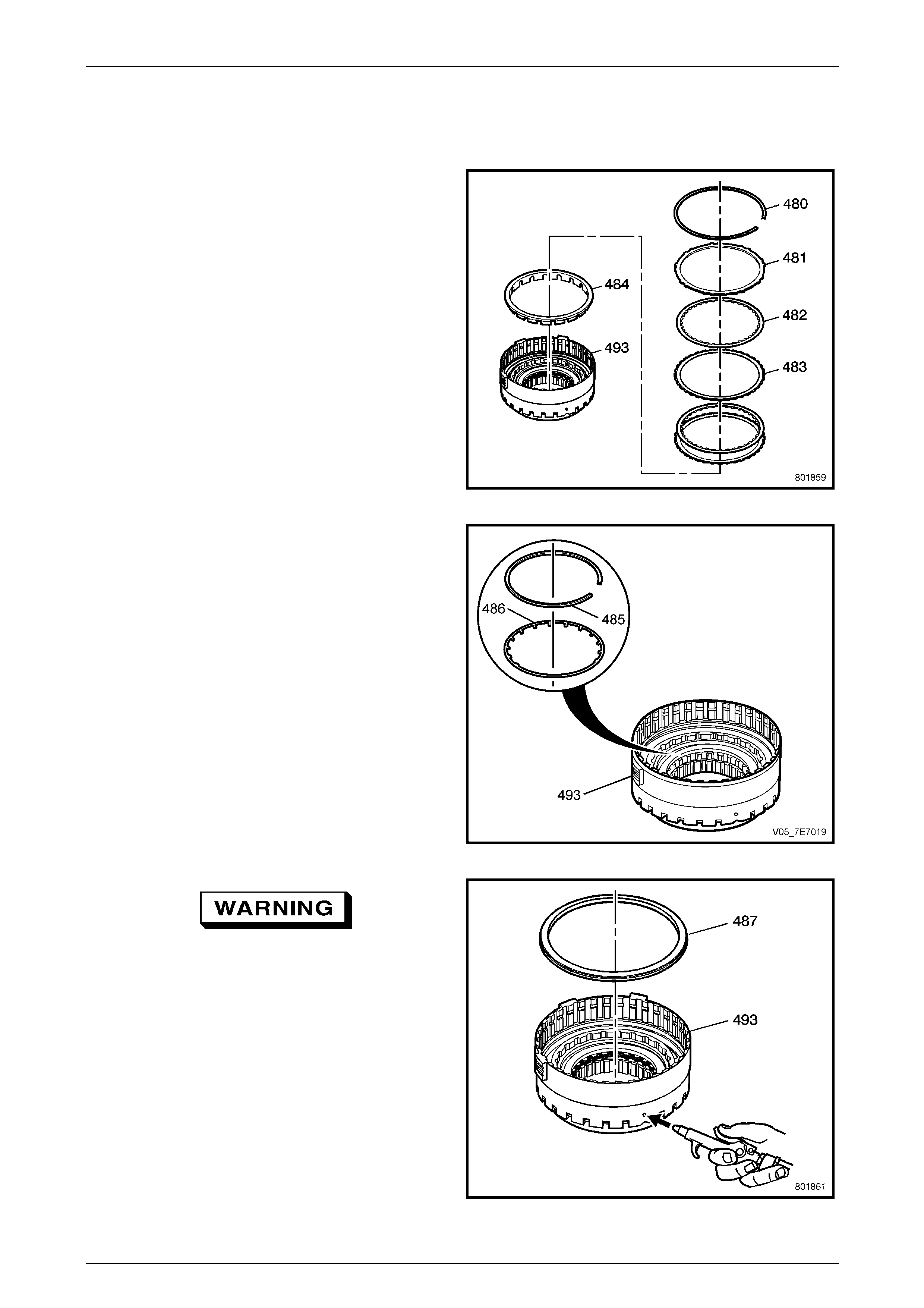

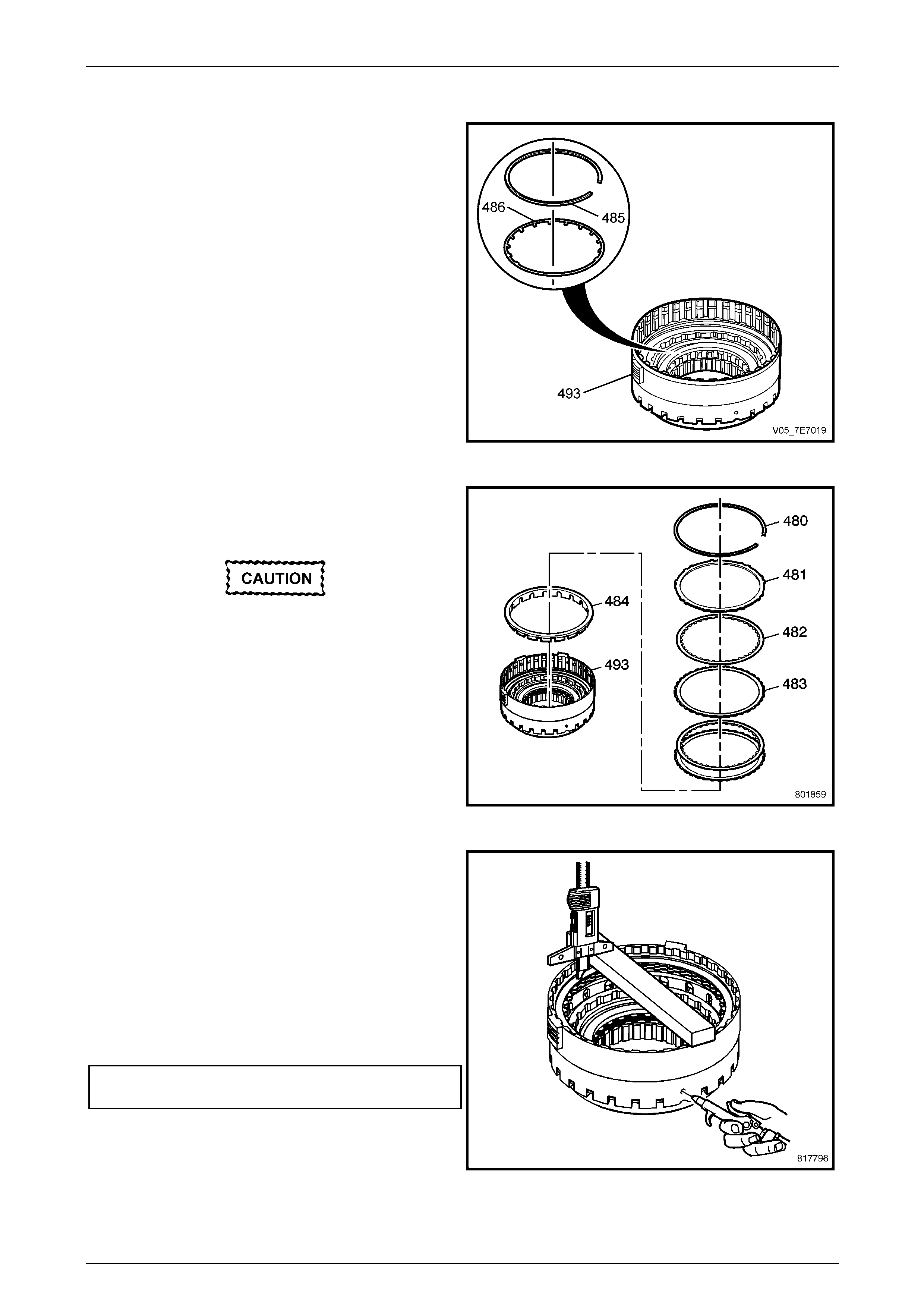

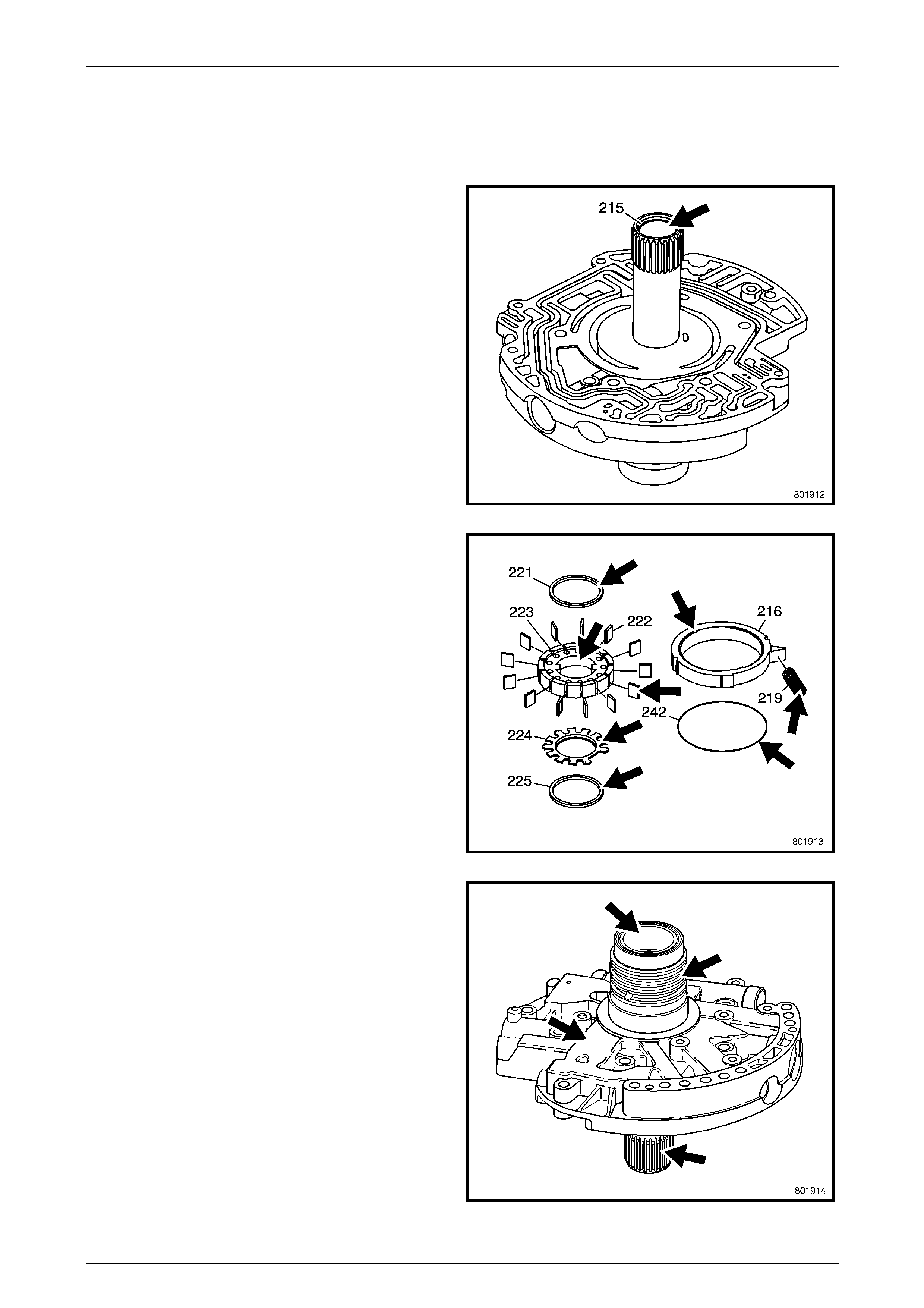

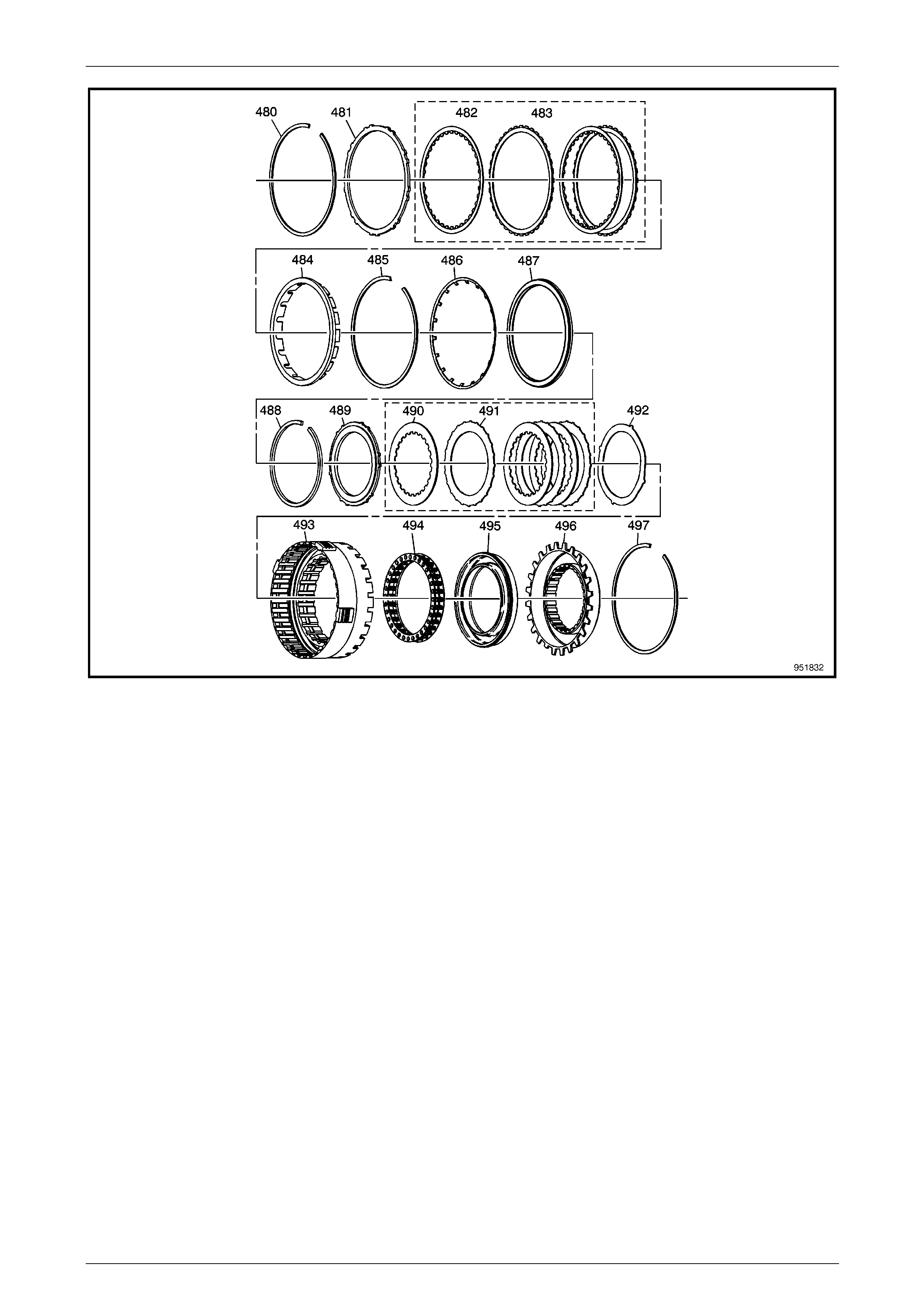

1.27 Overdrive and Intermediate Clutch

Disassemble

1 Using a flat bladed screwdriver, remove the overdrive

clutch retainer (480) from the overdrive clutch housing

(493).

2 Remove the overdrive clutch backin g plate (481) from

the overdrive clutch housing (493).

3 Remove the overdrive clutch plates (48 2, 483 ), three

inner splined plates and three outer splined plates (all

models).

4 Remove the overdrive clutch spacer (484) from the

overdrive clutch housin g (493).

Figure 7E5 – 80

5 Using a bladed screwdriver, r ele ase one end of the

clutch piston spring retainer ring (485), then gradually

release the ring remainder until free from the retaining

groove in the overdrive clutch housing (493).

6 Remove the retainer ring (485 ) and the overdrive

clutch spring (486) from the overdrive clutch h ousing

(493).

Figure 7E5 – 81

Wear eye protection to prevent potential

injury.

7 Remove the overdrive clutch piston (48 7) from the

overdrive clutch housin g (493).

NOTE

It may be necessary to apply air pressure to the

overdrive clutch housi ng port as sho wn, to assist

in piston removal.

Figure 7E5 – 82

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 45

7E5 – 45

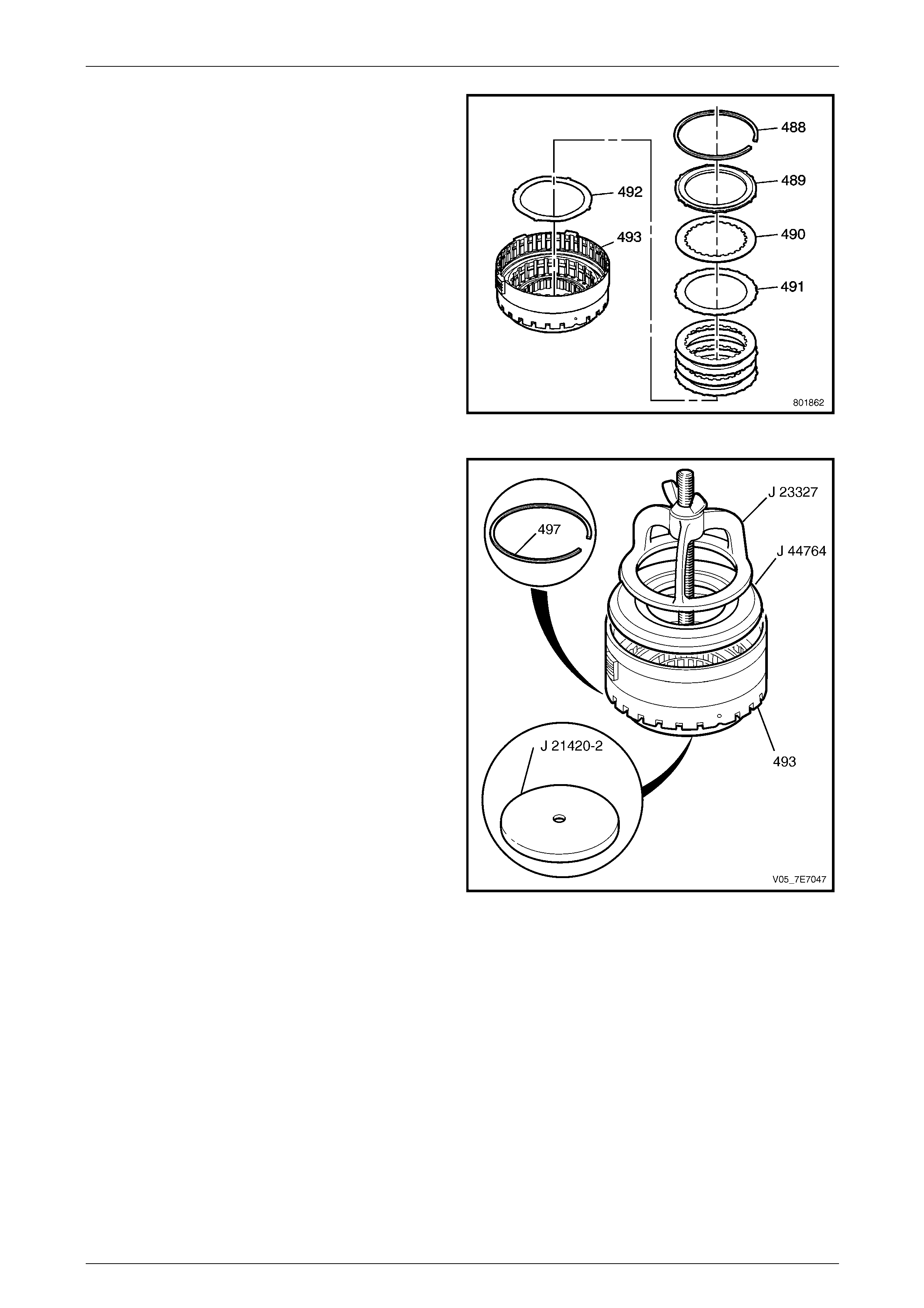

8 Using a fine bladed screwdriver, remove the

intermediate clutch backing pl ate retainer ring (488)

from the overdrive clutch housing (493).

9 Remove the intermediate clutch backing plate (489)

from the overdrive clutch housing (493).

10 Remove the intermediate clutc h plates (4 90, 491), four

(three for 5HEG) inner splined plates and four (three

for 5HEG) outer splined plates from the overd r ive

clutch housing (493).

11 Remove the intermediate clutch apply plate (492) from

the overdrive clutch housing (493).

Figure 7E5 – 83

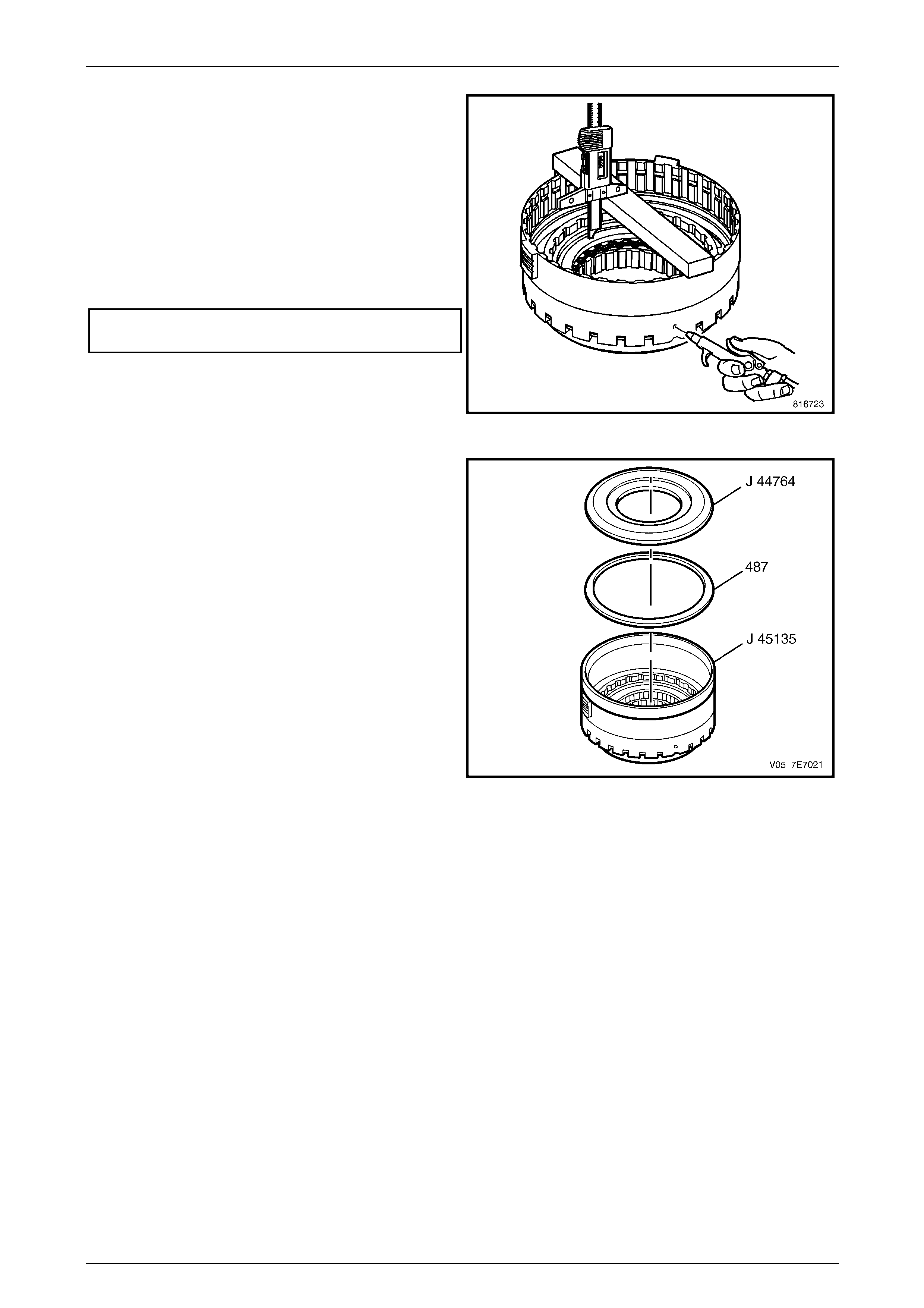

12 Assemble plate, Tool J 2142 0-02 against the

intermediate clutch cover (496) and Tools J 447 64 and

J 23327 to the overdrive housing (49 3) and tighten

wing nut to draw in the intermediate clutch housing

(496).

13 Using a flat bladed screwdriver, remove the

intermediate clutch housing retain er ring (497) from

the overdrive clutch housing (493).

Figure 7E5 – 84

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 46

7E5 – 46

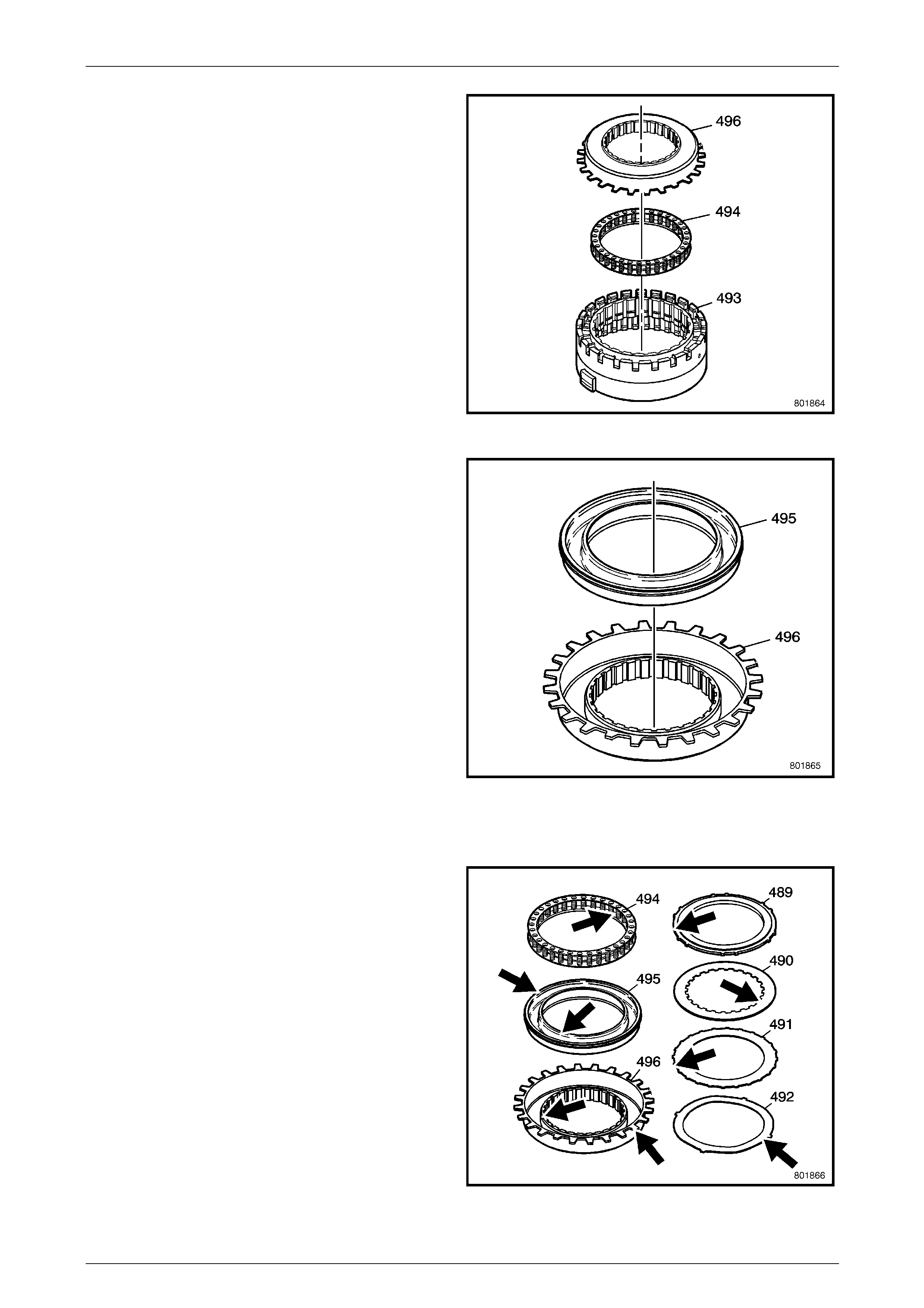

14 Loosen and remove Tools J 44764 and J 23327 from

the overdrive clutch housing (493).

15 Remove the intermediate clutch housing (496), and

the intermediate clutch spring (494) from the overdrive

clutch housing (493).

Figure 7E5 – 85

16 Remove the intermediate clutc h piston (495) from the

overdrive clutch housin g (496).

Figure 7E5 – 86

Reassemble

1 Inspect the housing for the following:

• Plugged feed passages

• Worn or damaged splines

• Damaged or worn springs

• Damaged or worn pistons

• Worn or damaged clutch plates

Figure 7E5 – 87

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 47

7E5 – 47

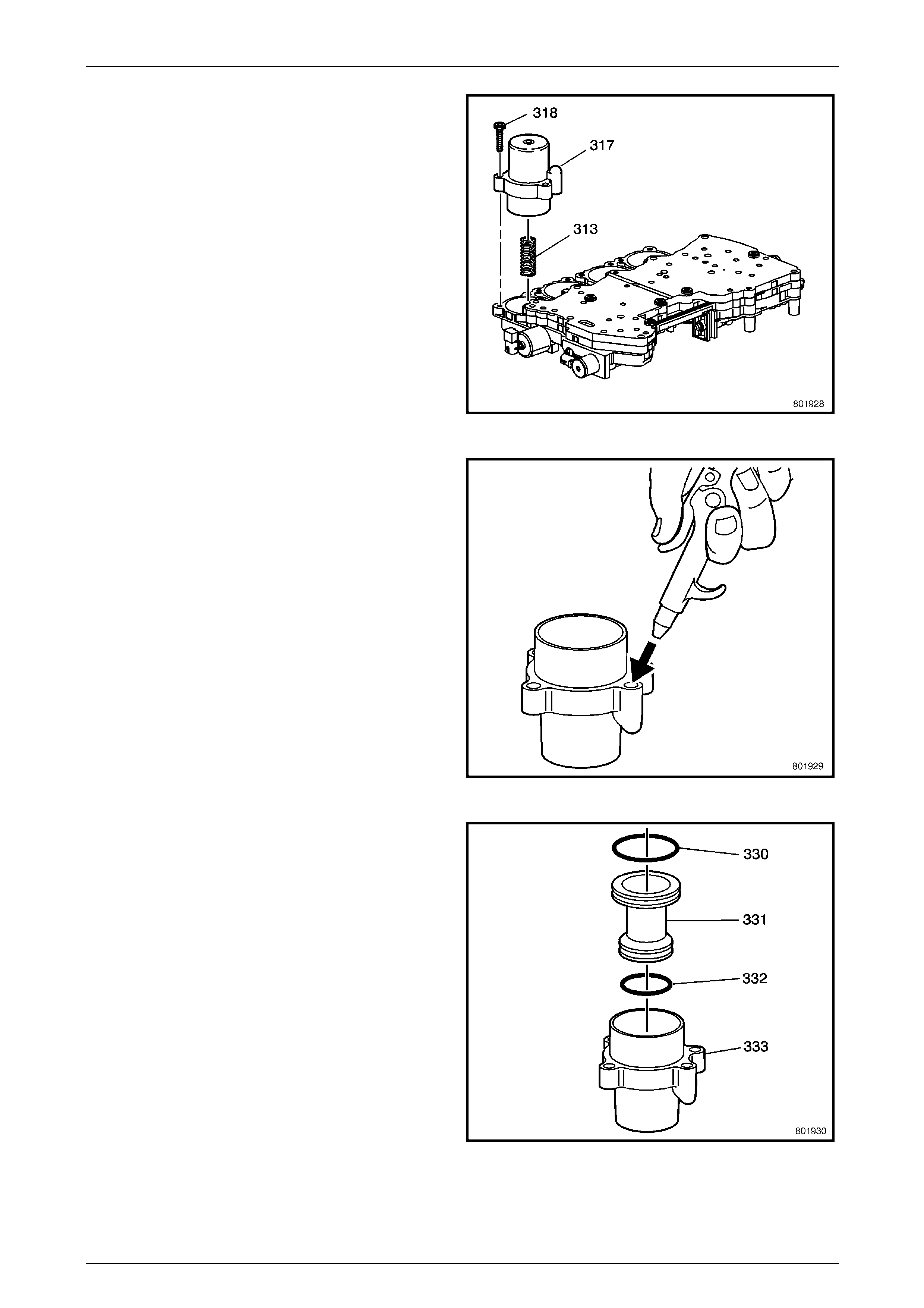

2 After lubricating the inner and outer sealing lips of the

intermediate piston (495) with clean transmission fluid,

install piston (495) into the intermedi ate clutch housing

(496).

Figure 7E5 – 88

3 Install the intermediate clutch spring (494) into the

overdrive clutch housin g (493).

4 Install the intermediate housing (496) into the

overdrive clutch housin g (493).

Figure 7E5 – 89

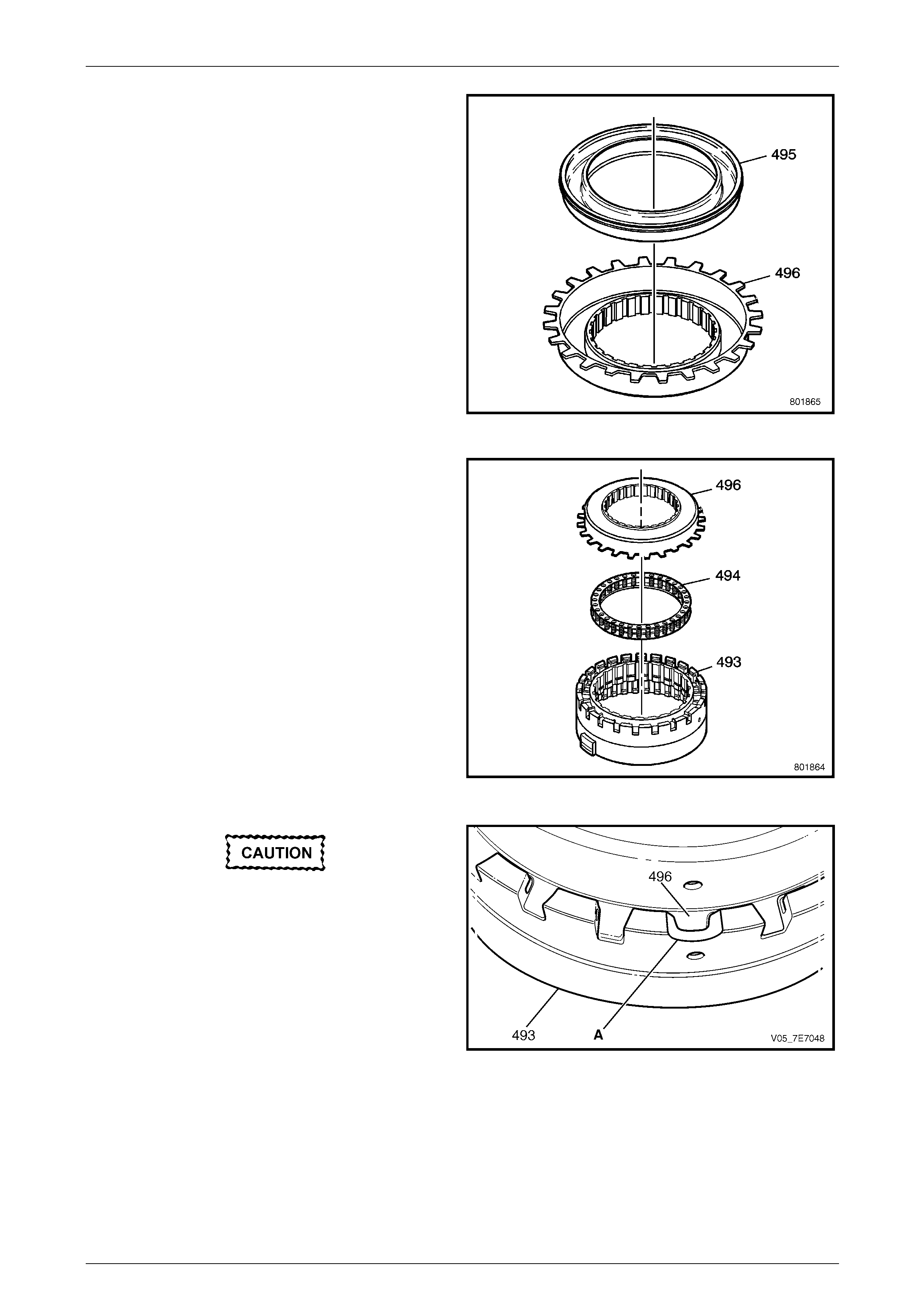

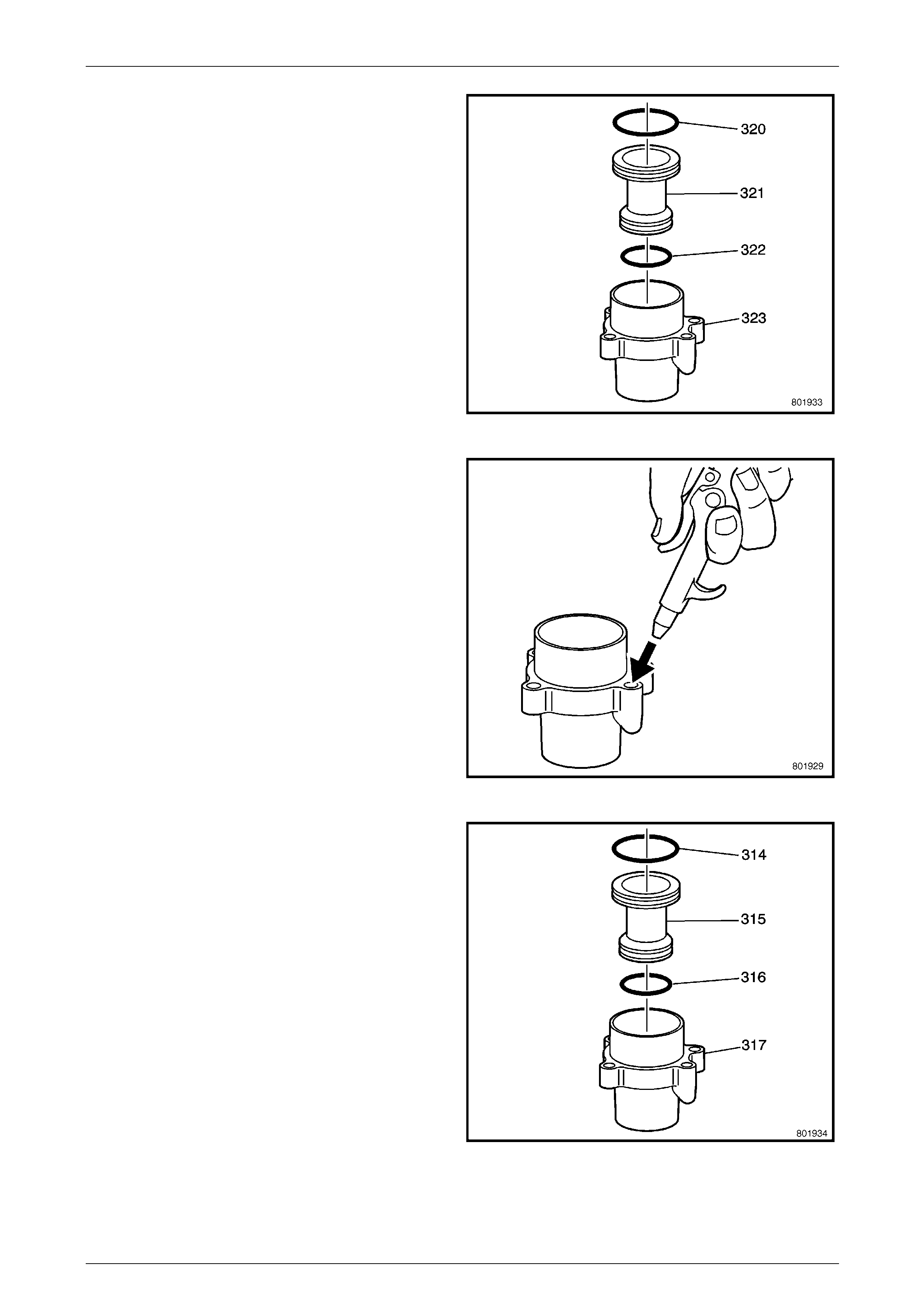

Align the short tang on the intermediate

housing (496) with the semi-circular cut-out

(A) in the overdrive clutch housing (493).

Figure 7E5 – 90

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 48

7E5 – 48

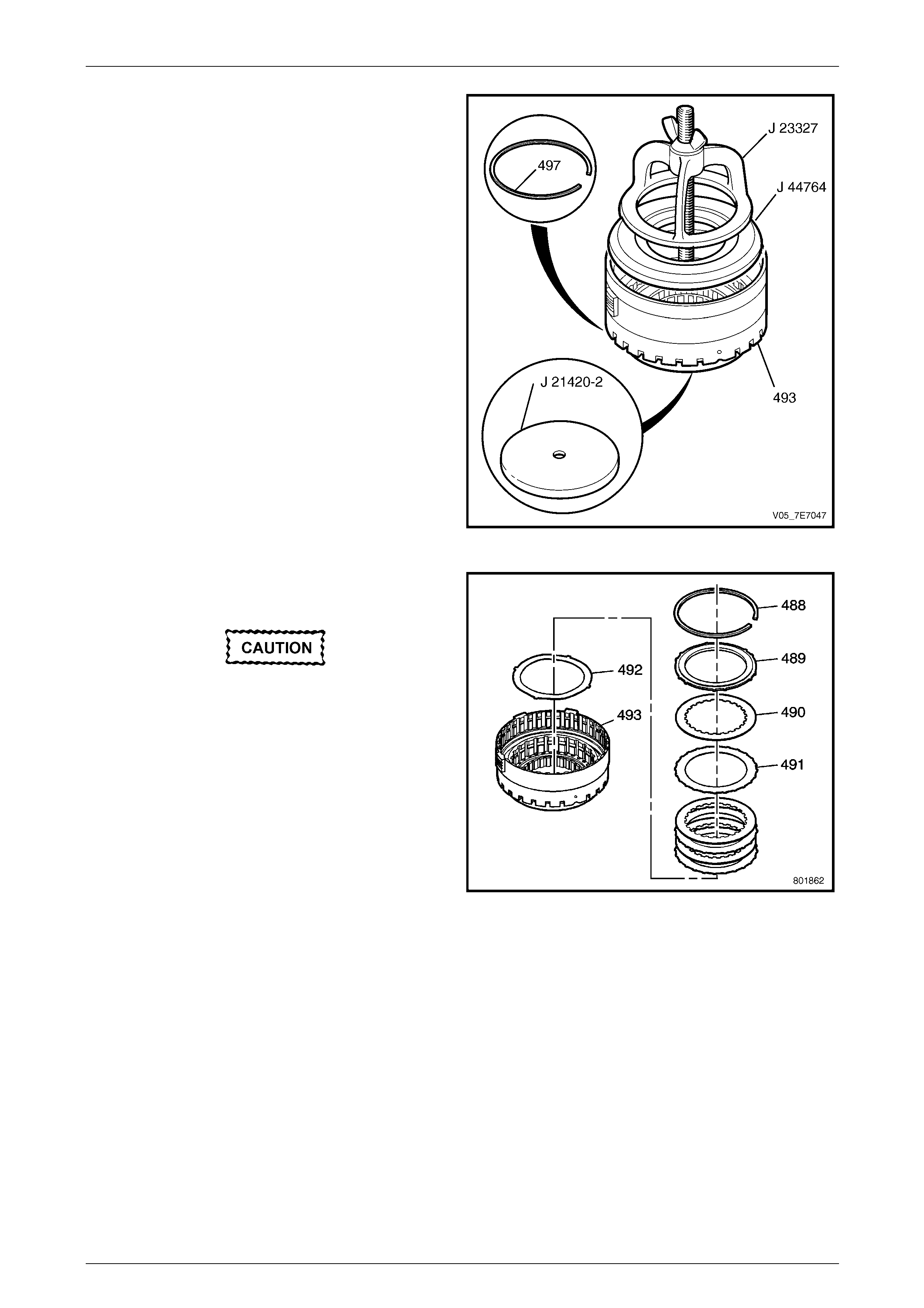

5 Assemble plate, Tool J 2142 0-02 against the

intermediate clutch cover and Tools J 4476 4 and

J 23327 to the overdrive housing (49 3) and tighten the

wing nut to draw in the intermediate clutch housing

(496).

6 Install the intermediate clutch housing retainer ring

(497) to the retaining groove in the overdrive housing

(493).

7 Loosen and remove all tools.

Figure 7E5 – 91

8 Install the intermediate clutch, waved apply plate

(492).

Ensure that the composition side of each

plate faces upwards.

9 Install the intermediate clutch plates. Starting with the

intermediate clutch plates (491) with external splines.

Alternating with the intermediate clutch pl ates (490)

internal splines.

10 Install the backing plate (489) wit h the recessed edge

facing outward.

11 Install the intermediate backing plate retainer ring

(488) into the overdrive housing (493) retaining

groove. Figure 7E5 – 92

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 49

7E5 – 49

12 Measure the distance between the intermediate clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H1.

13 Apply air pressure – 450 kPa, to the specified port.

Measure the distance between the intermediate clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H2.

14 Subtracting H2 from H1 will give the clutch pack travel

dimension.

Intermediate Clutch Pack

Travel Specification................................ 1.13 – 1.58 mm

Figure 7E5 – 93

15 Assemble Tools J 45135 and J 44764 to the overdrive

clutch housing. Coat the piston and to ols using the

correct transmission lubricant and install th e overdrive

piston (487).

Remove tools once piston in correctly install ed.

Figure 7E5 – 94

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 50

7E5 – 50

16 Install the overdrive piston spr ing (4 86) into the

overdrive clutch housing, with the inner tangs facing

downward.

17 Install one end of the coast clutch spring retai ner into

the centre support groove then, using a screwdriver

blade as needed, fully install the retainer by working

around its length, until the retainer is fully engaged.

Figure 7E5 – 95

18 Install the overdrive clutch spacer (484), ensuring that

the spacer cut-outs straddle the overdrive clutch piston

spring blades.

Ensure that the composition side of each

plate faces upwards.

19 Install the overdrive clutch plat es. Starting with the

overdrive clutch plates (483) with e xternal splines.

Alternate with the overdrive clutch plates (48 2) with

internal splines.

20 Install the overdrive backing plate (481).

21 Install the overdrive clutch retainer ring (480).

Figure 7E5 – 96

22 Measure the distance between the overdrive clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H1.

23 Apply air pressure – 450 kPa, to the specified port.

Measure the distance between the overdrive clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H2.

24 Subtracting H2 from H1 will give the clutch pack travel

dimension.

Overdrive Clutch Pack

Travel Specification................................ 1.60 – 2.05 mm

Figure 7E5 – 97

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 51

7E5 – 51

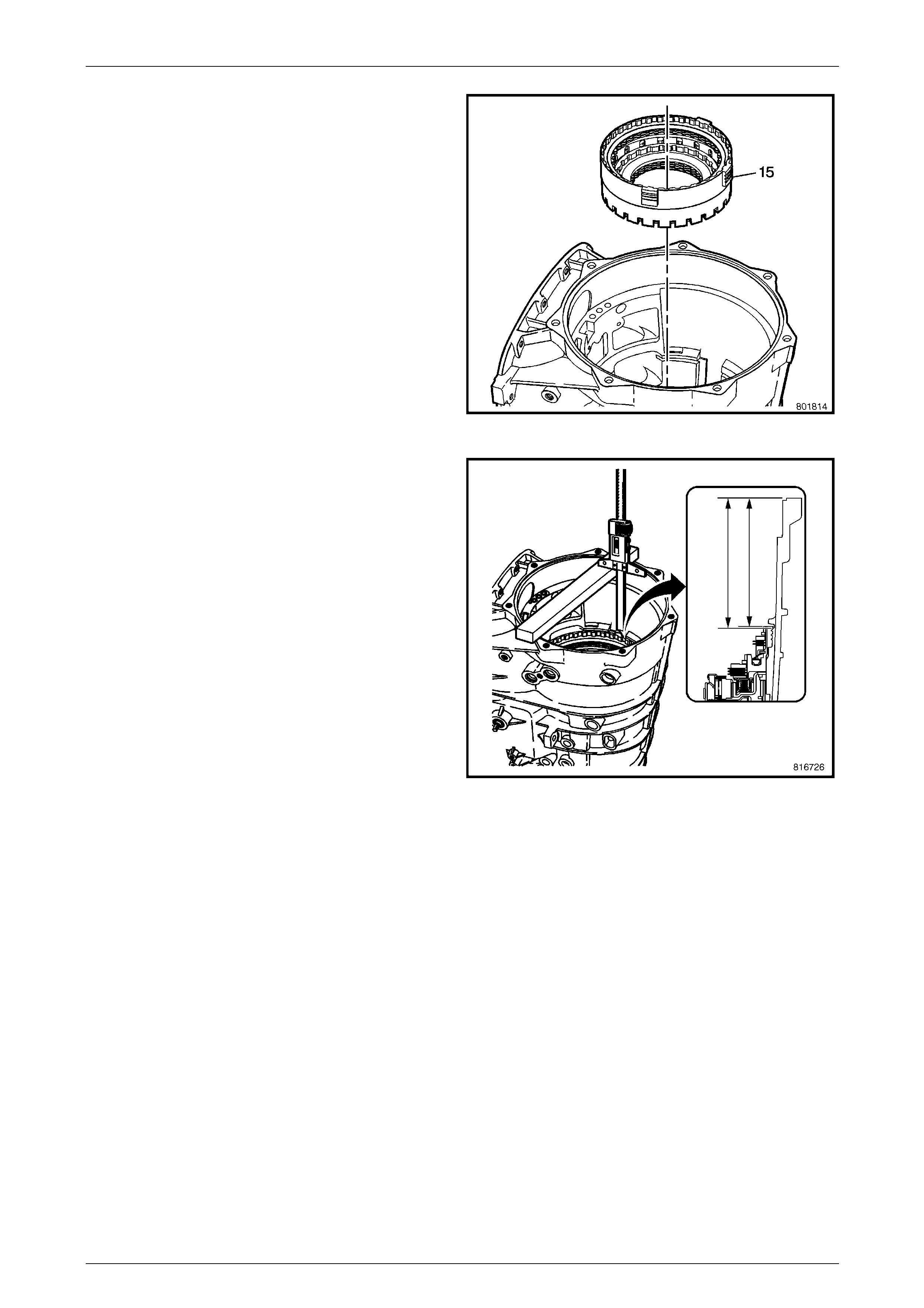

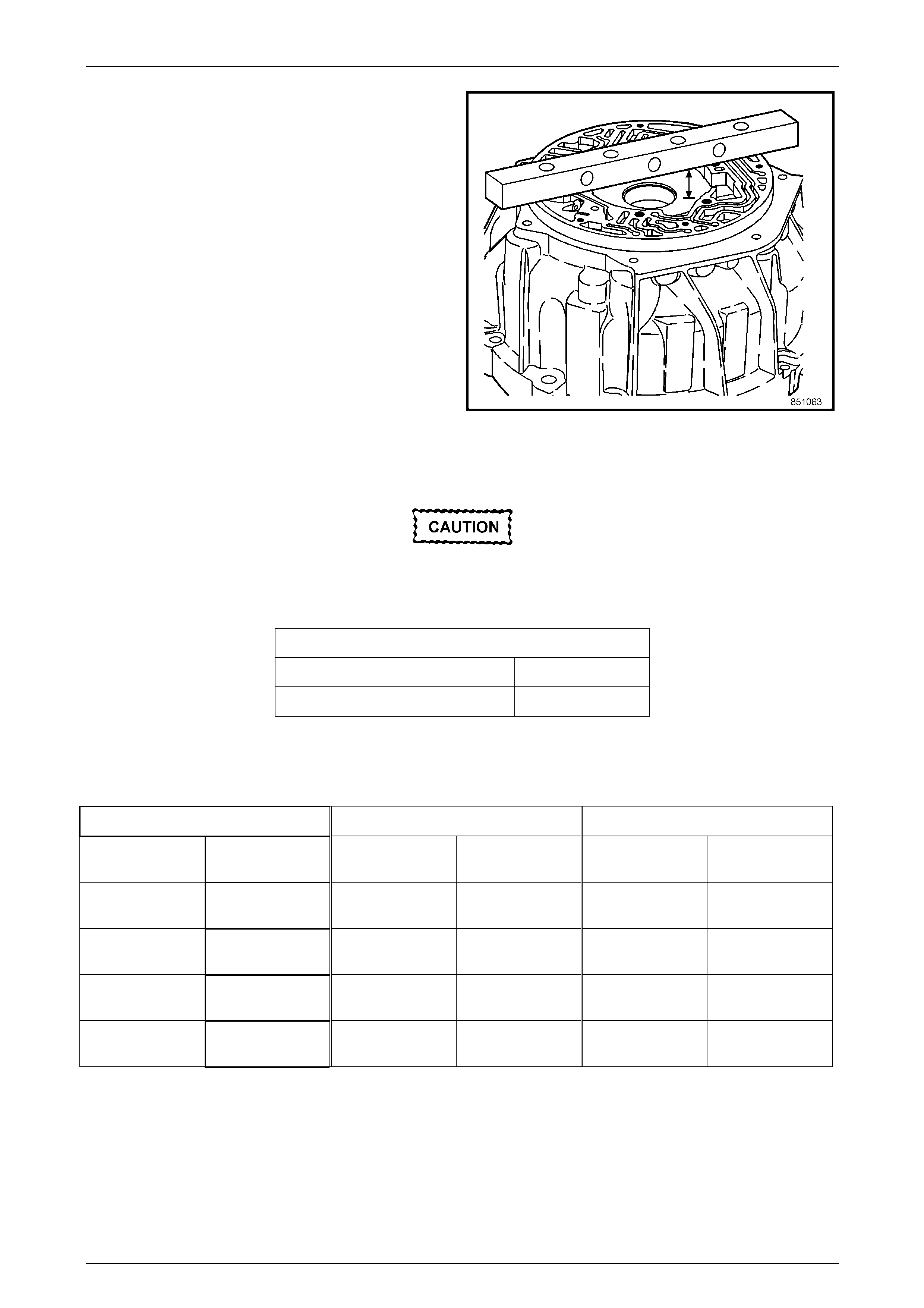

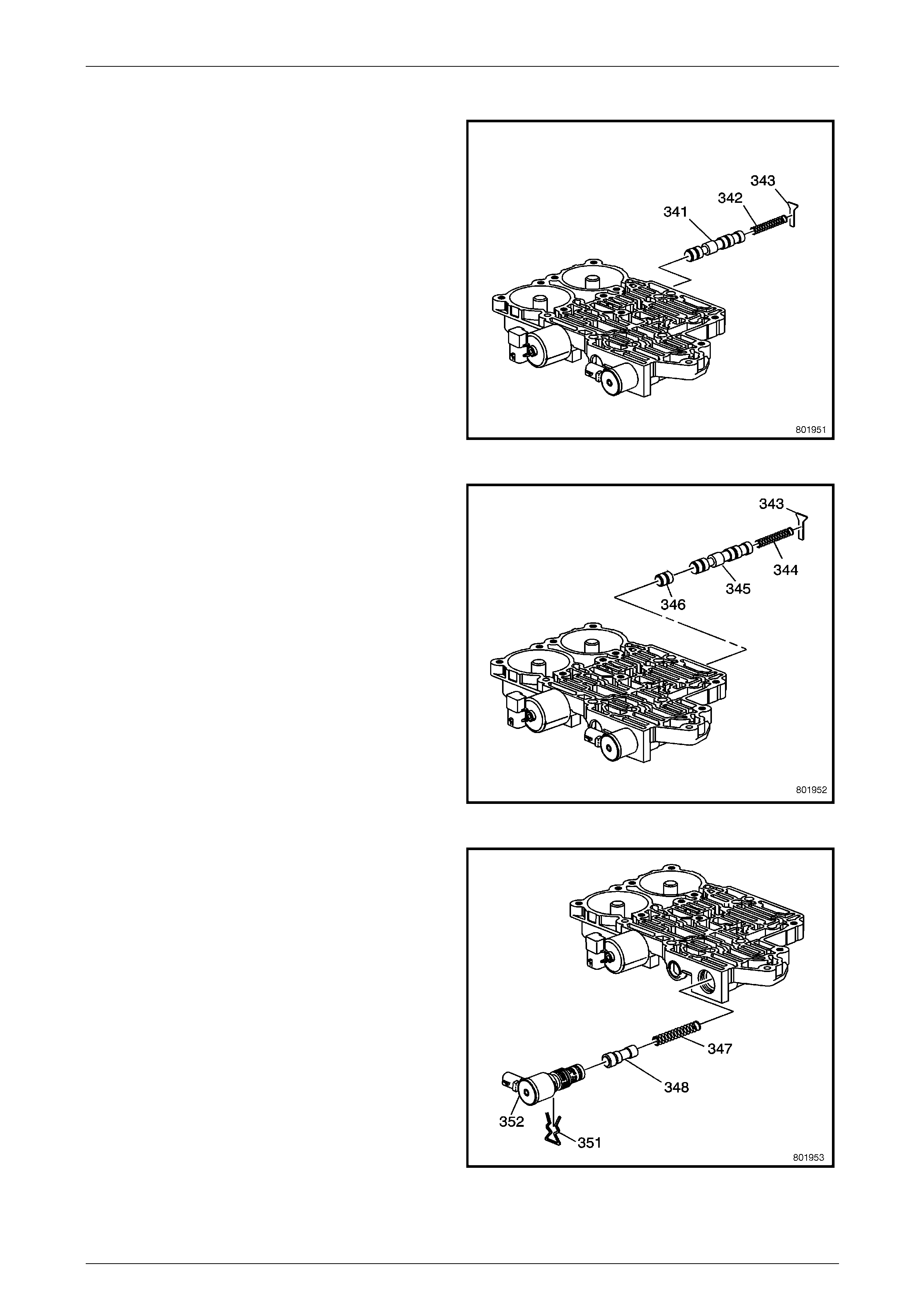

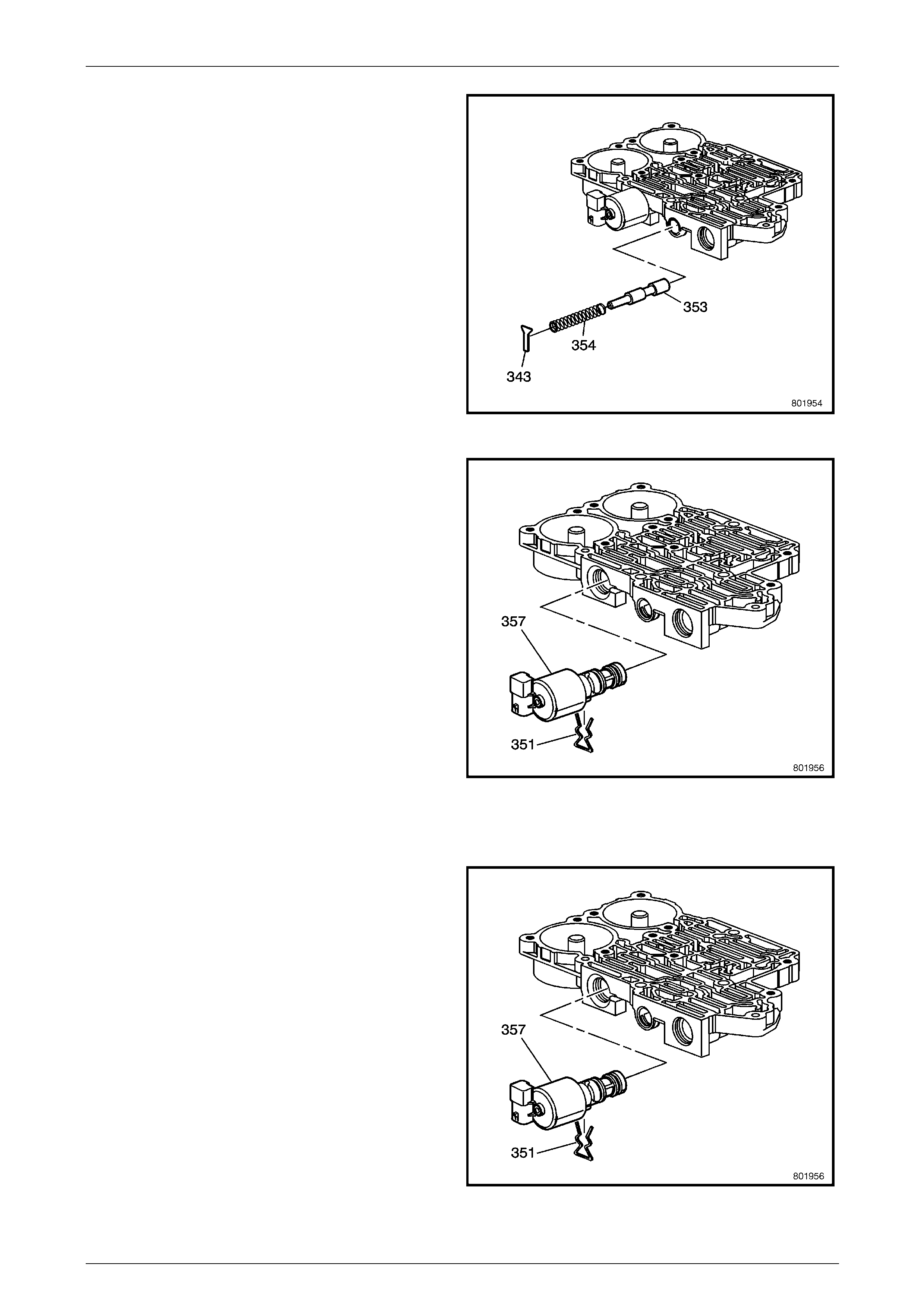

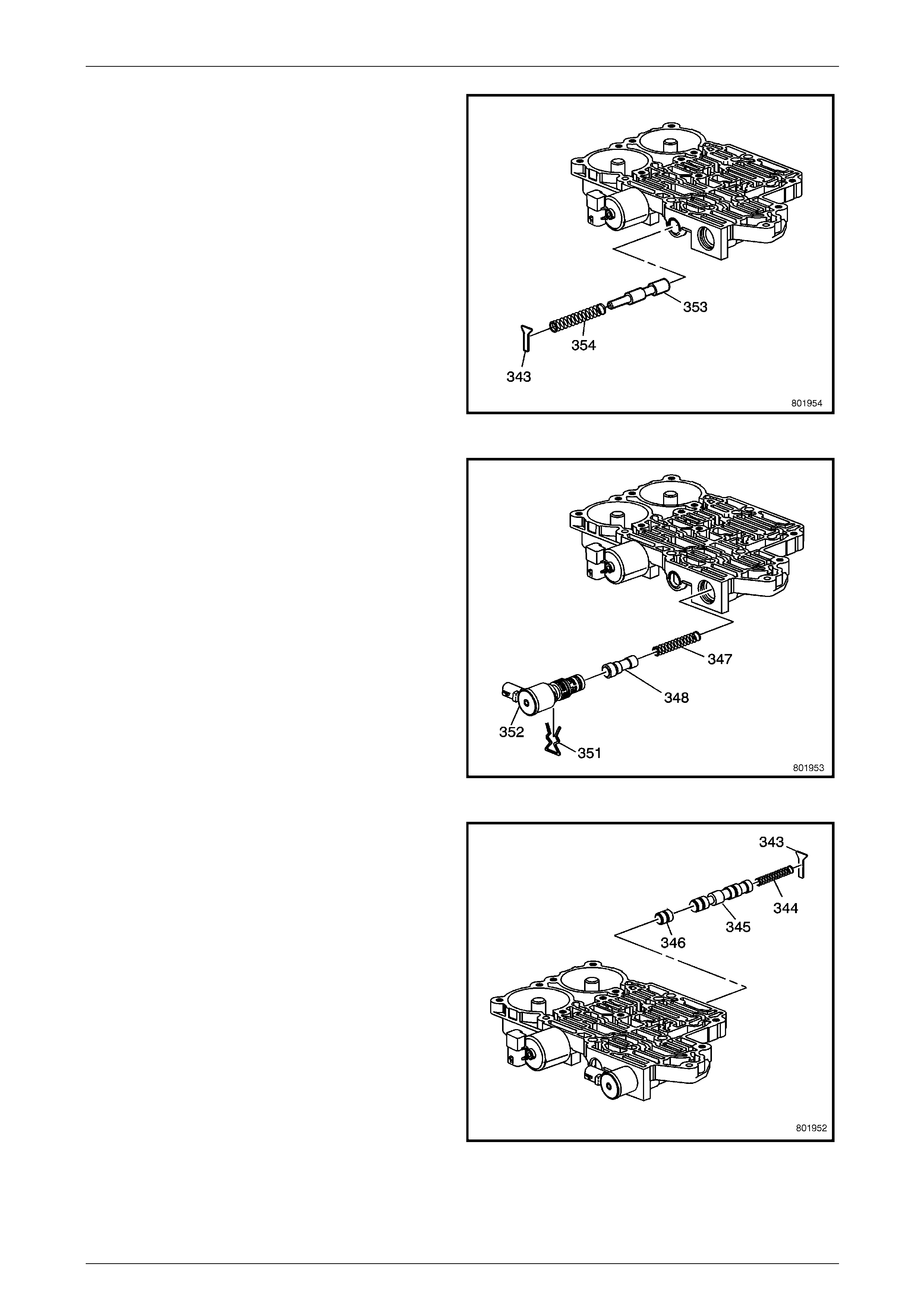

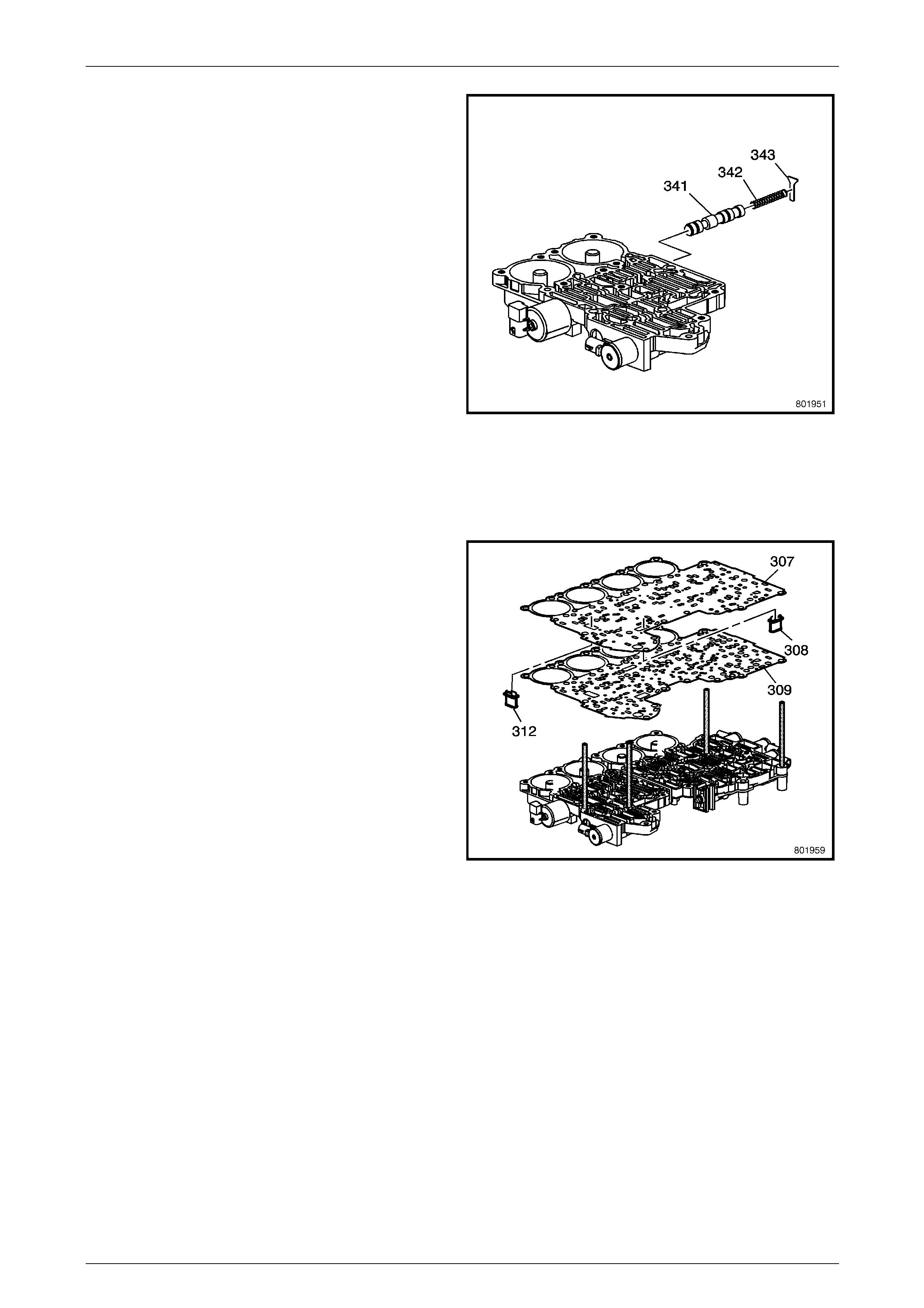

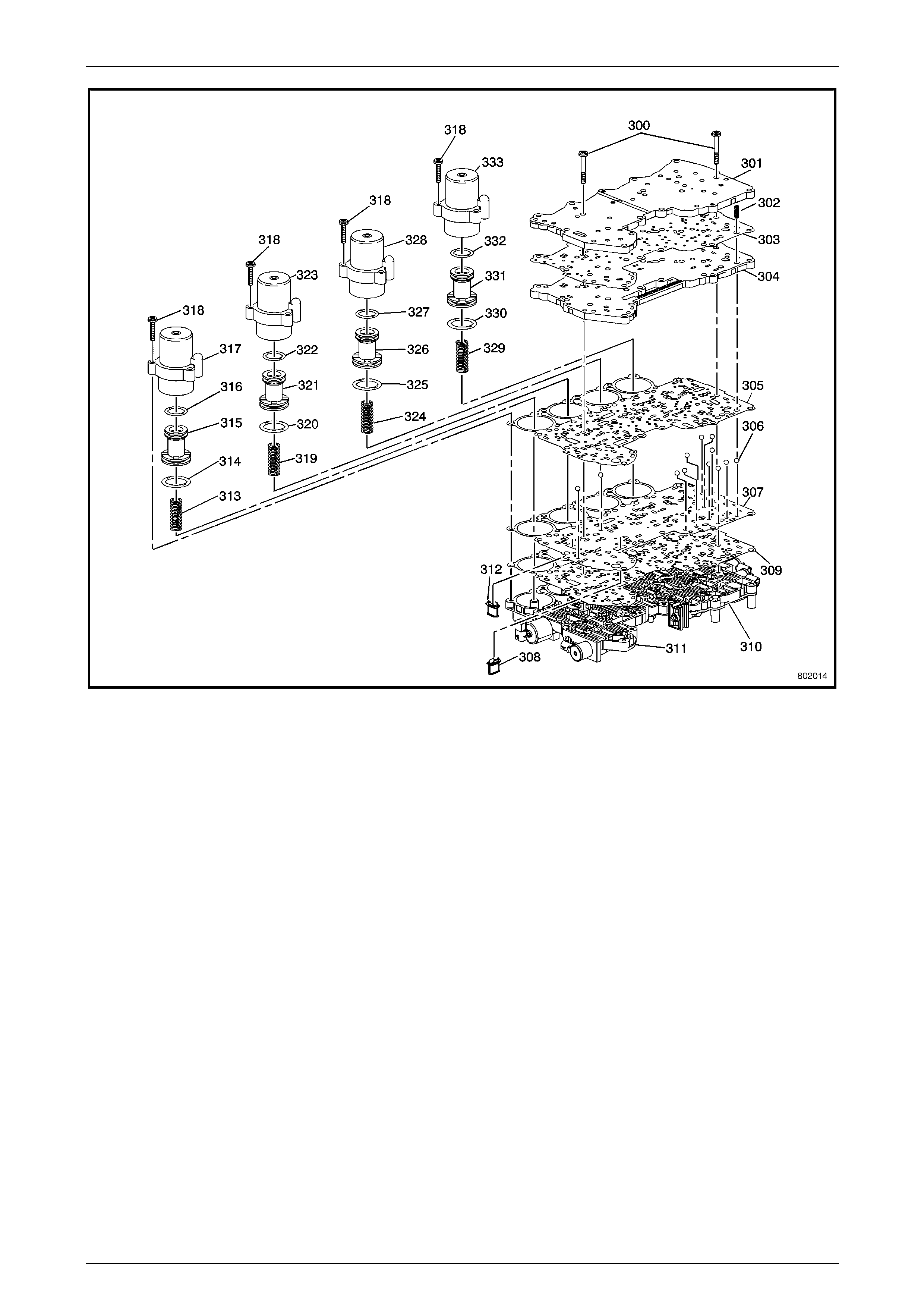

25 With the transmission case rotated to a vertical

position as shown, install the overdrive clutch housing

(15) into the transmission case (24).

Check that the mating splines on the intermediate

clutch plates (490) engage fully over the low and

reverse sprag assembly outer race (505).

Figure 7E5 – 98

26 Measure the distance from the bottom of the gaug e

bar to the top of the overdrive and intermedia t e clutch.

Record this as M1.

27 Measure the distance from the bottom of the gaug e

bar to the bottom of the intermediate and overdrive

retainer ring groove in the case. Record this as M2.

28 Subtract M2 from M1. This will be Dimension 'M' .

Figure 7E5 – 99

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 52

7E5 – 52

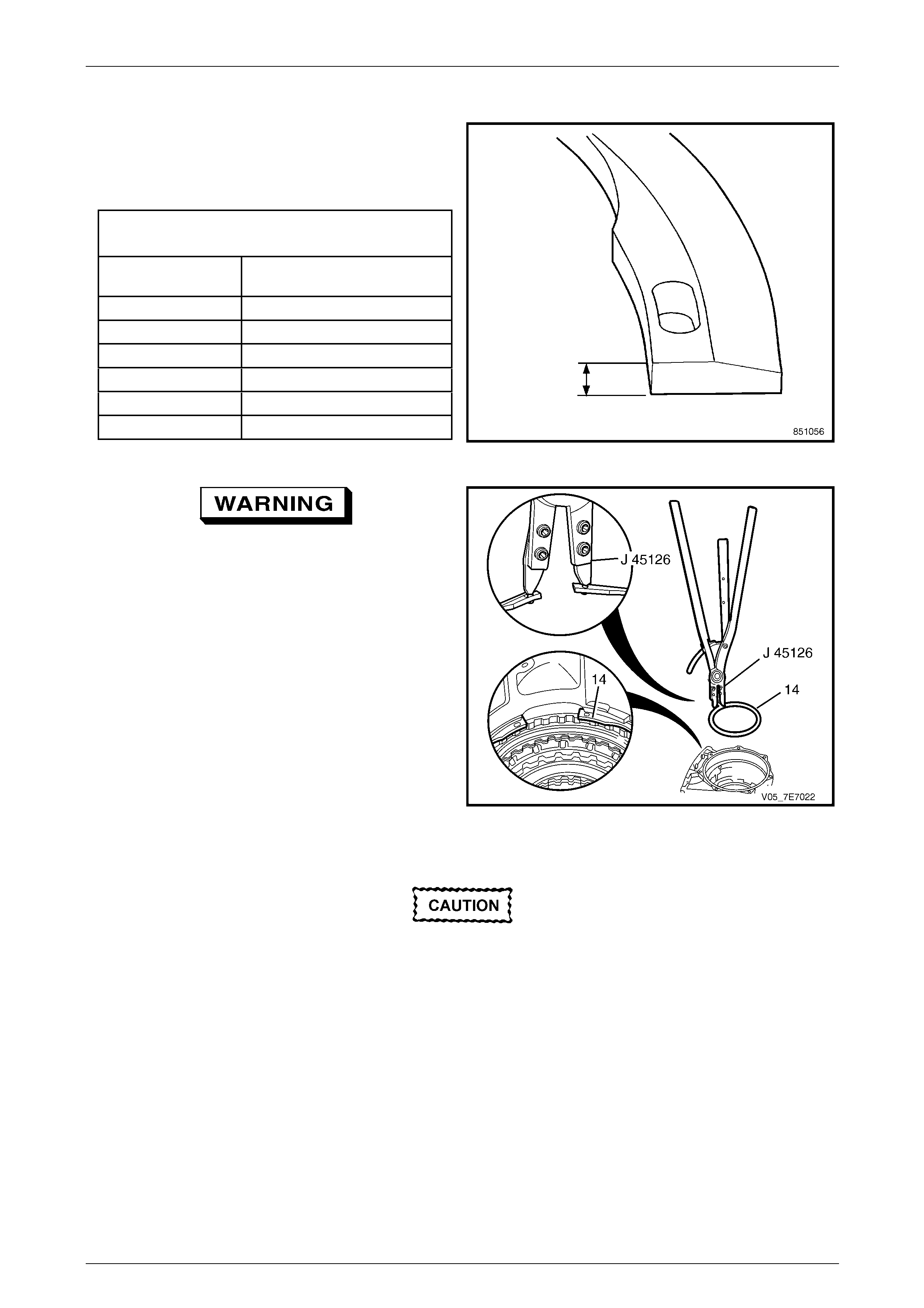

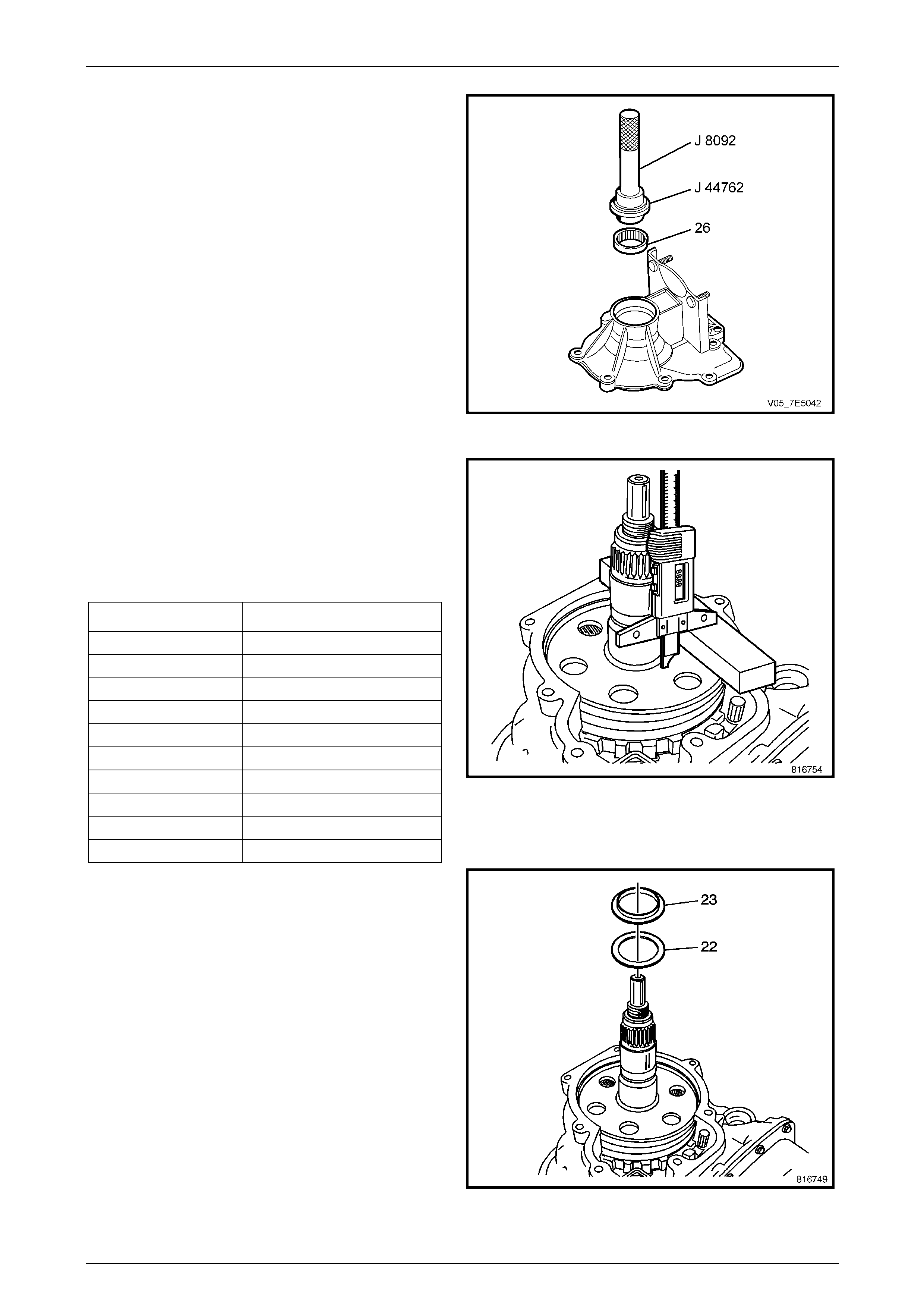

29 Measure the intermediate and overdrive clutch

housing retaini ng ring (14).

Refer to the following Intermediate and Overdrive

Clutch Housing Retaining Rin g Specifications for the

correct size retainer ring to use.

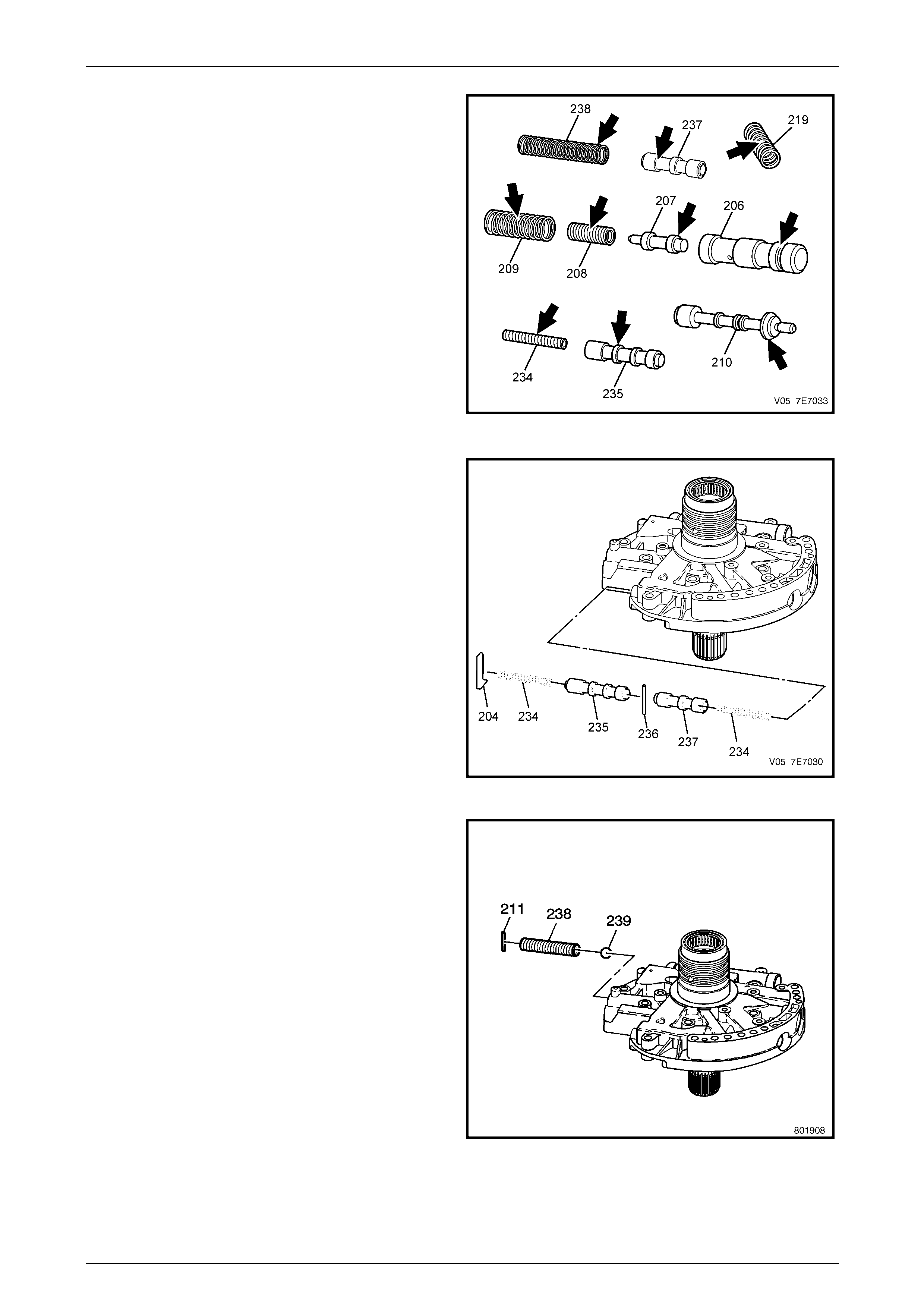

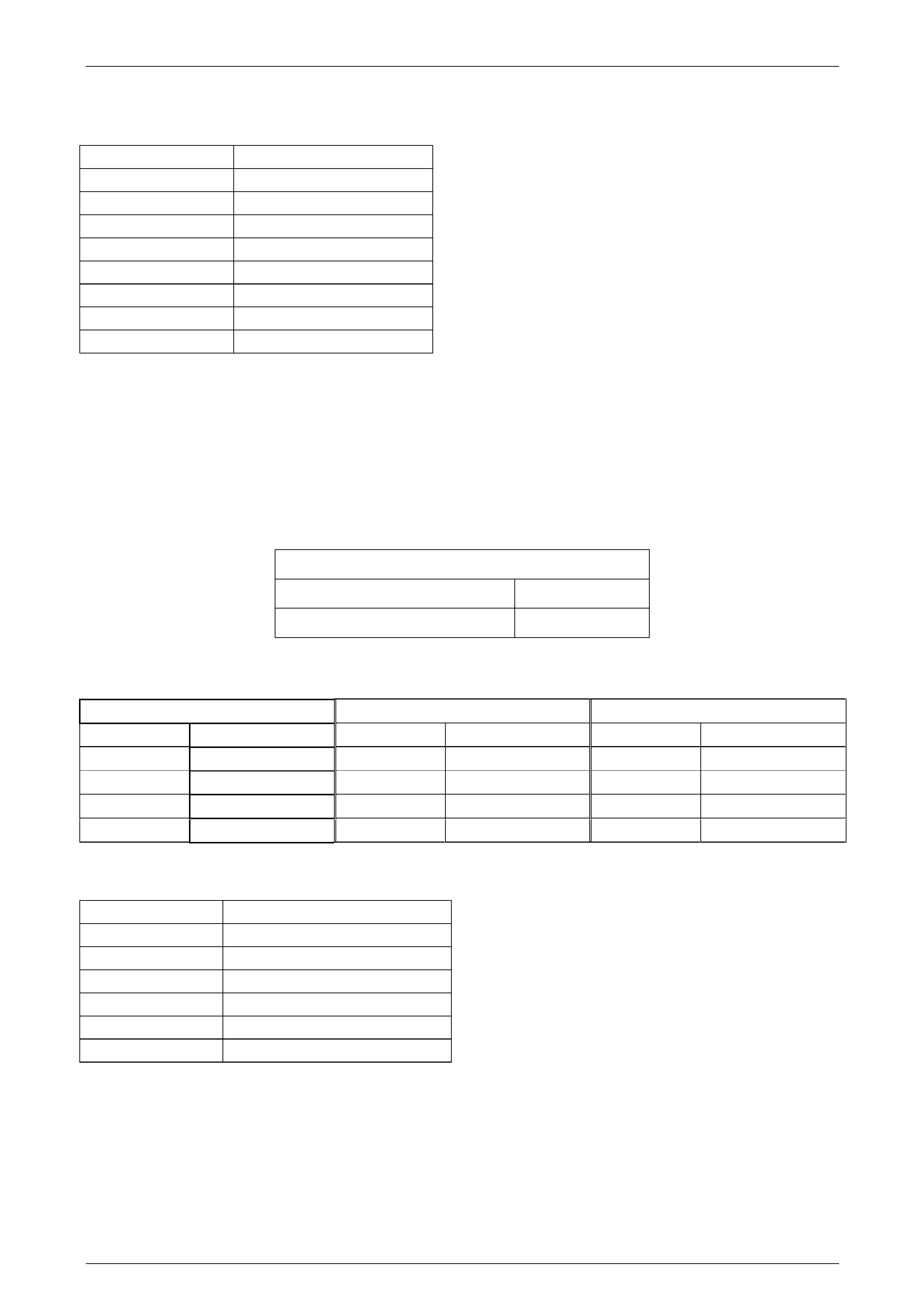

Intermediate and Overdrive Clutch Housing

Retainer Ring Specification

Dimension 'M' Retainer Ring Thickn ess

(mm)

0.75 mm–0.85 mm 3.90–4.00

0.85 mm–0.95 mm 3.80–3.90

0.95 mm–1.05 mm 3.70–3.80

1.05 mm–1.15 mm 3.60-3.70

1.15 mm–1.25 mm 3.50–3.60

1.25 mm–1.35 mm 3.40–3.50

Figure 7E5 – 100

Use care when removing or installing the

circlip (14). Be sure the circlip pliers are

installed properly onto the circlip 'eyes' or

bodily injury may occur.

NOTE

If any of the following components are replaced,

then an end play measurement must be taken

(refer to 1.45 Extension Housing, in this

Section.):

15 Overdrive Clutch Housing

16 Low Clutch Sprag Assembly

17 Low Clutch Roller Thrust Bearing

18 Centre Support

19 Input and Reaction Carrier Assembly

Figure 7E5 – 101

It is critical that the ends of the circlip are

aligned with the opening in the transmission

case. Otherwise the control valve body

cannot be installed.

30 Using suitable circlip pliers such as Tool J 45126 or equivalent, install the intermediate and overdrive clutch

housing retaining circlip (14) into the transmission case (24). Ensure that the ends of the circlip are positio ned as

shown.

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 53

7E5 – 53

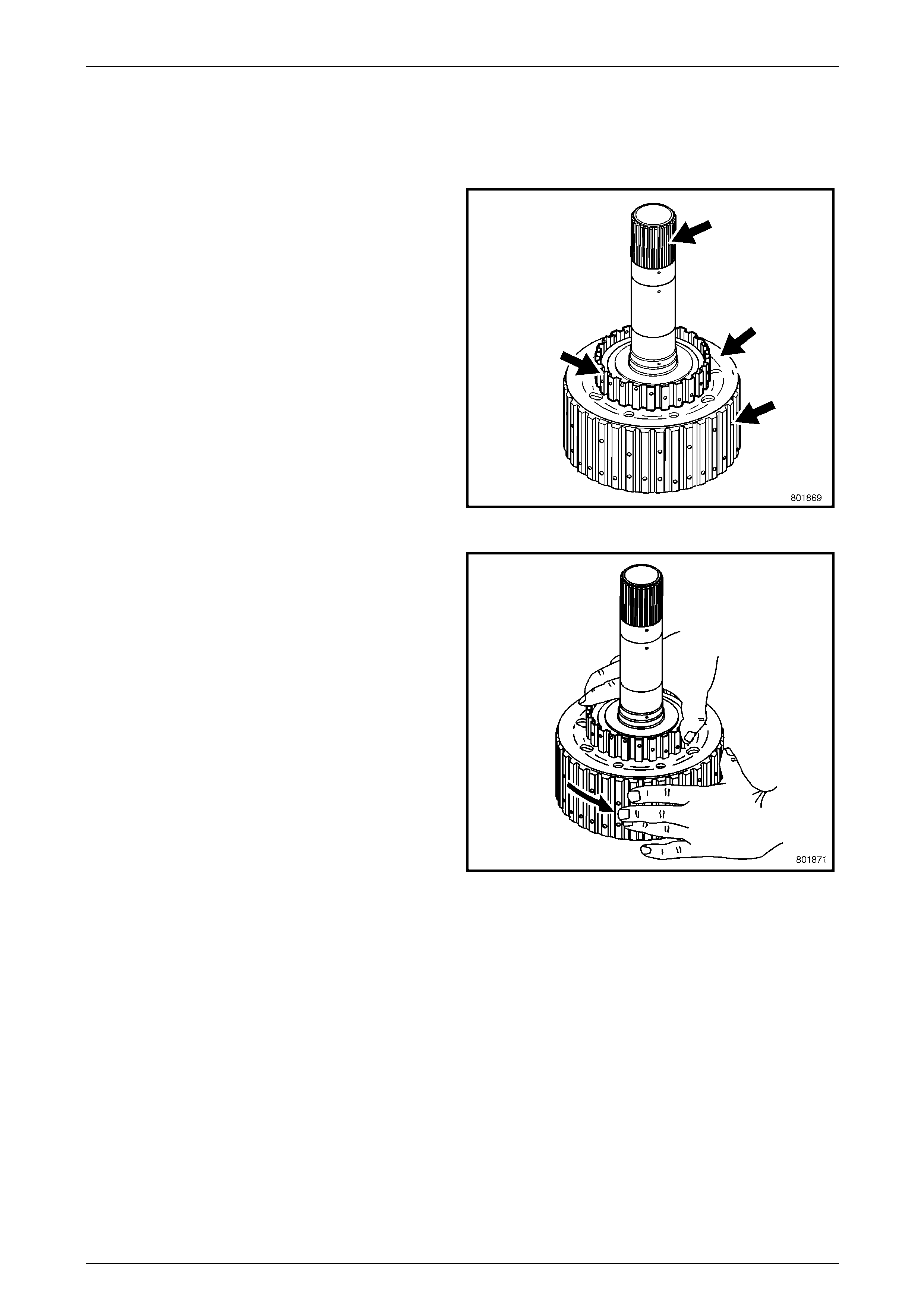

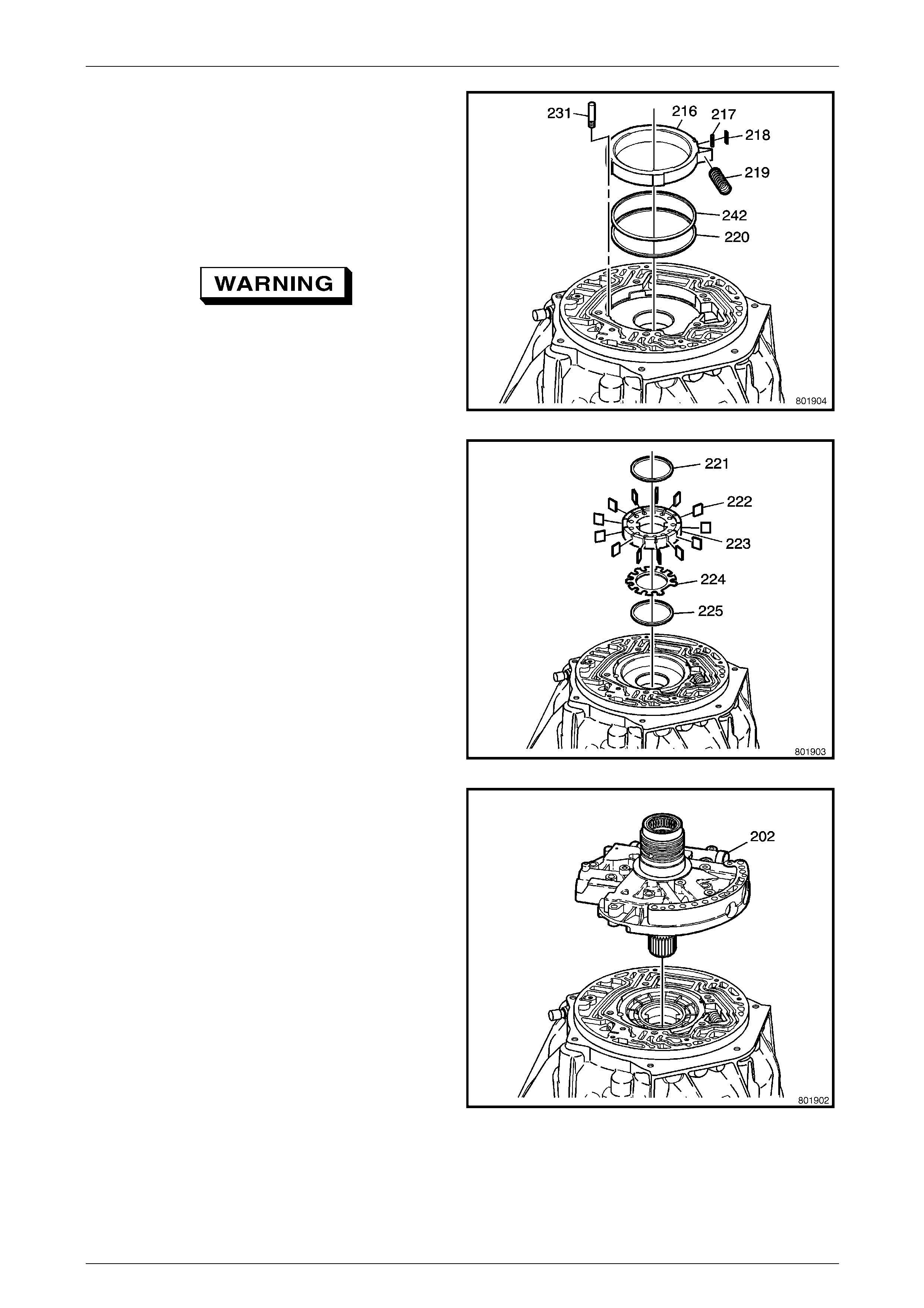

1.28 Intermediate Clutch Sprag

Inspect

1 Inspect the intermediate sprag clutch for the following

conditions:

• Scoring.

• Wear or cracks.

Figure 7E5 – 102

2 Check that the intermediate sprag clutch rotation

freewheels and locks up in the correct direction.

Figure 7E5 – 103

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 54

7E5 – 54

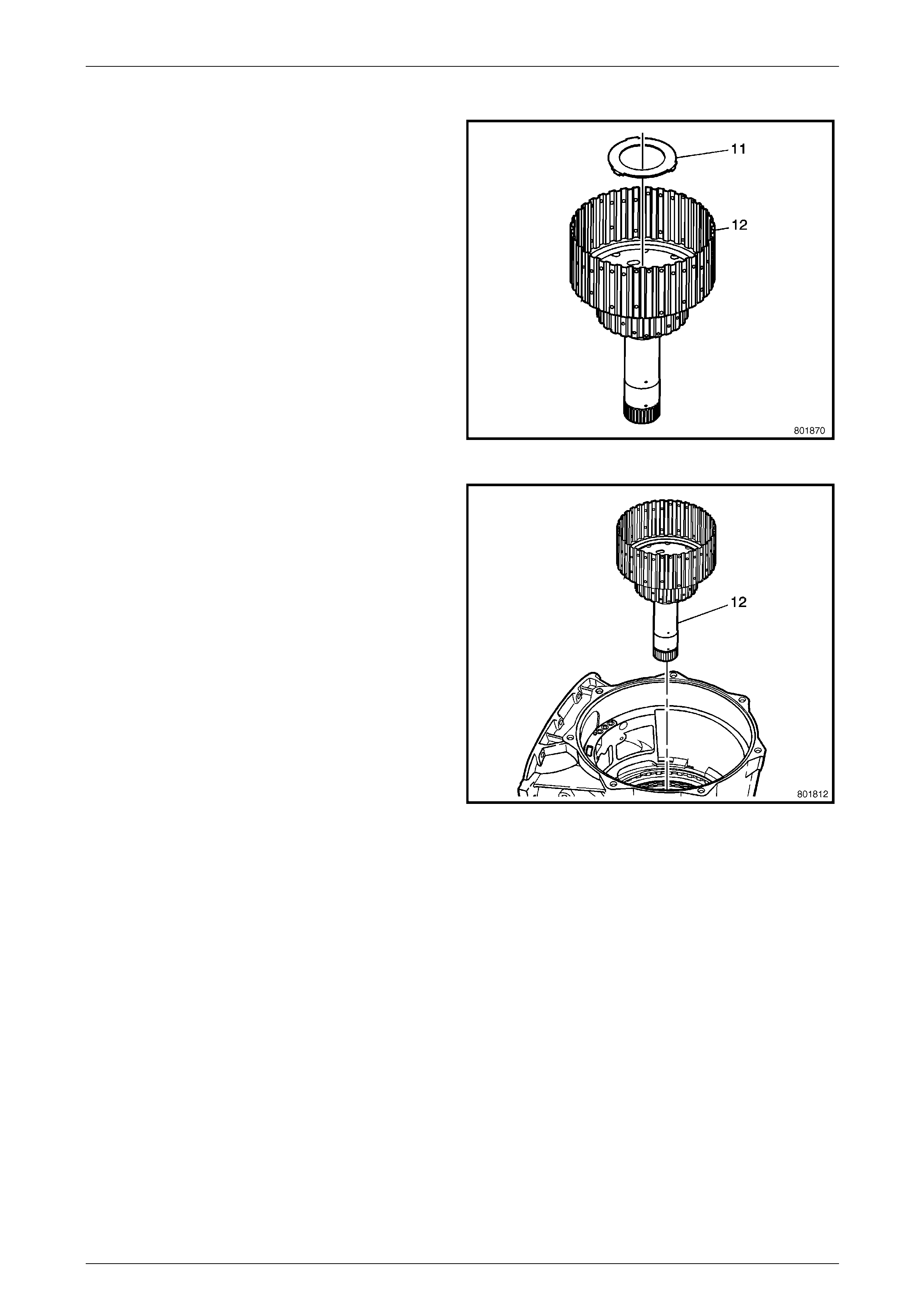

Reassemble

1 Apply some petroleum jelly to the input and reaction

carrier inner shaft thrust washer (11) and install into

the intermediate sprag clutch assembly (12).

Figure 7E5 – 104

2 Install the intermediate sprag clutch assem bly (12) into

the transmission case (24), ensuring that the mating

splines on the intermediate sprag clutch (1 2) engage

fully over both the overdrive clutch plates (482) and

the intermediate clutch plates (490).

Figure 7E5 – 105

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 55

7E5 – 55

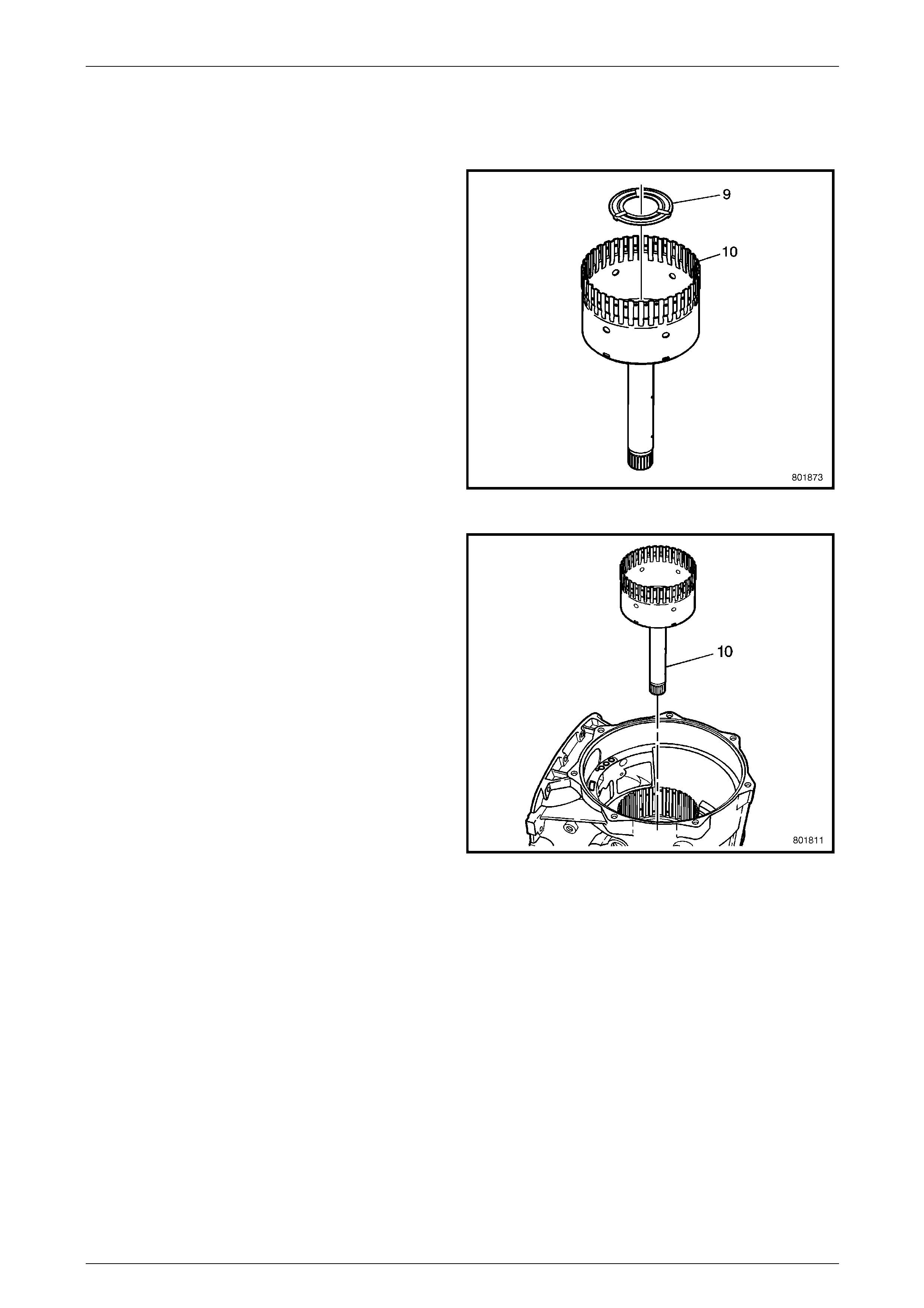

1.29 Direct Clutch Hub

Reassemble

1 Inspect the drum for the following:

• Worn or damaged splines

• Worn or damaged bushings

• Wear, cracks and scoring on the shaft

2 Install the direct clutch drum hub thrust washer (9) into

the drum (10).

Figure 7E5 – 106

3 Install the direct clutch drum (10) into the transmission

case (24).

Figure 7E5 – 107

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 56

7E5 – 56

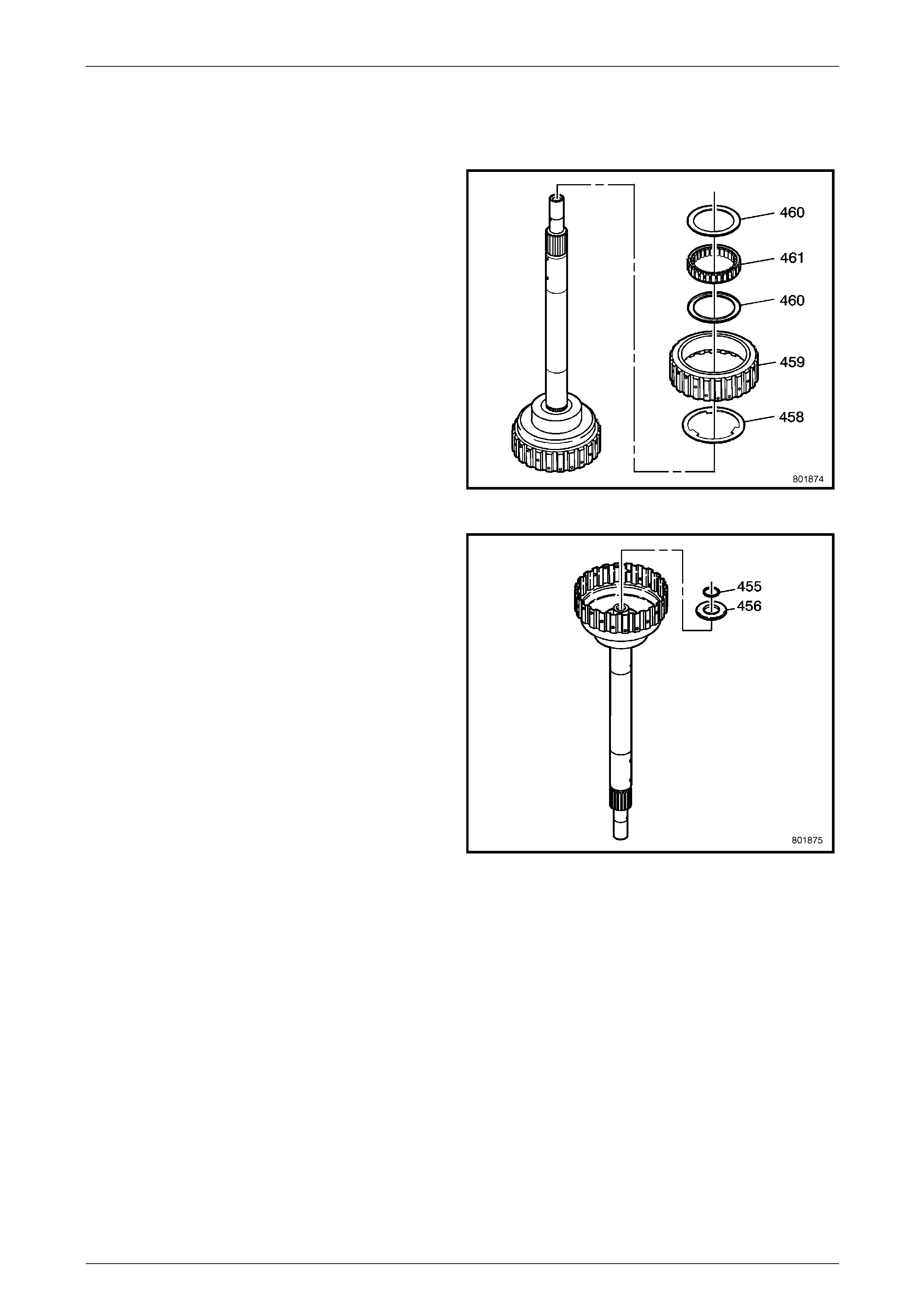

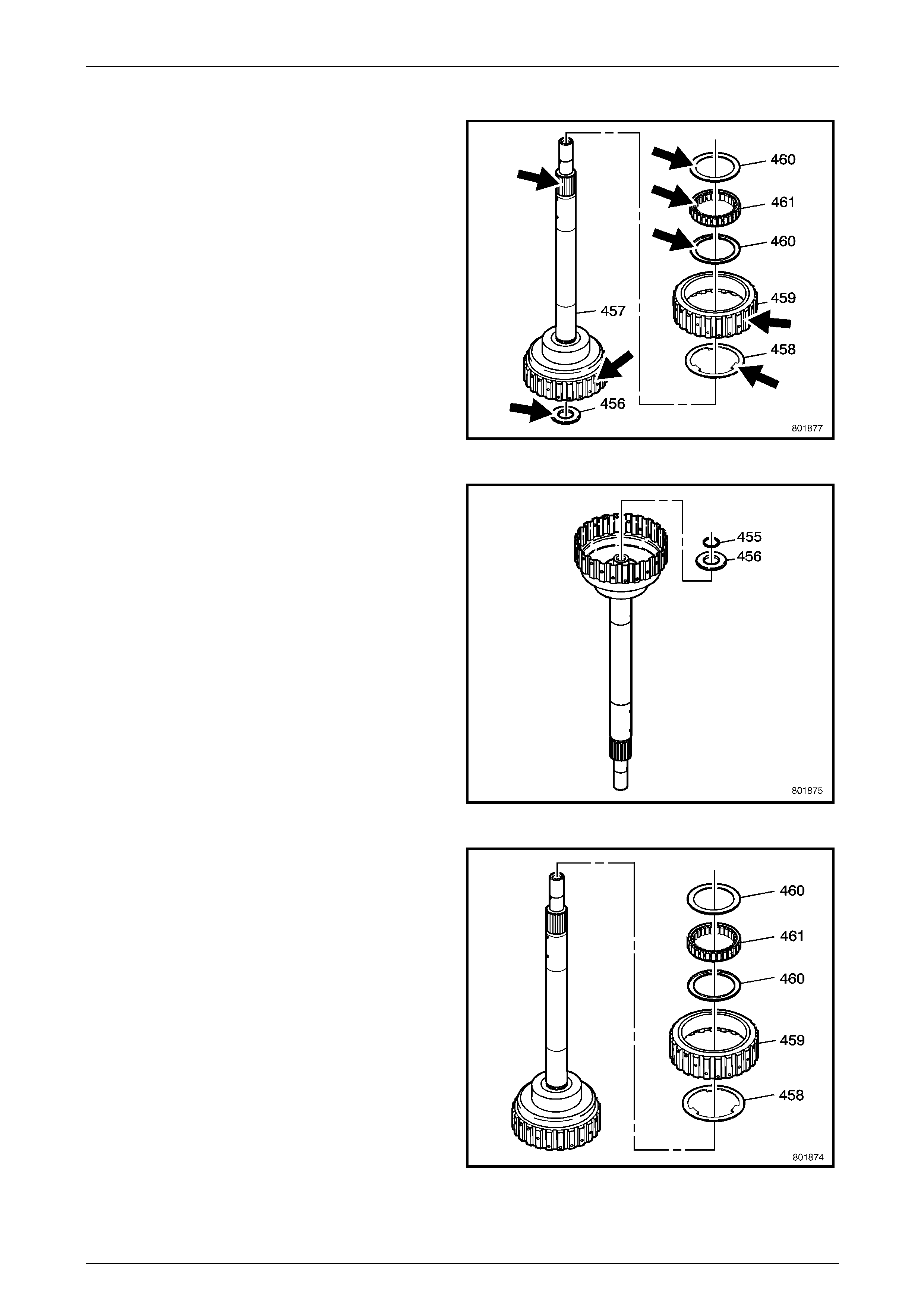

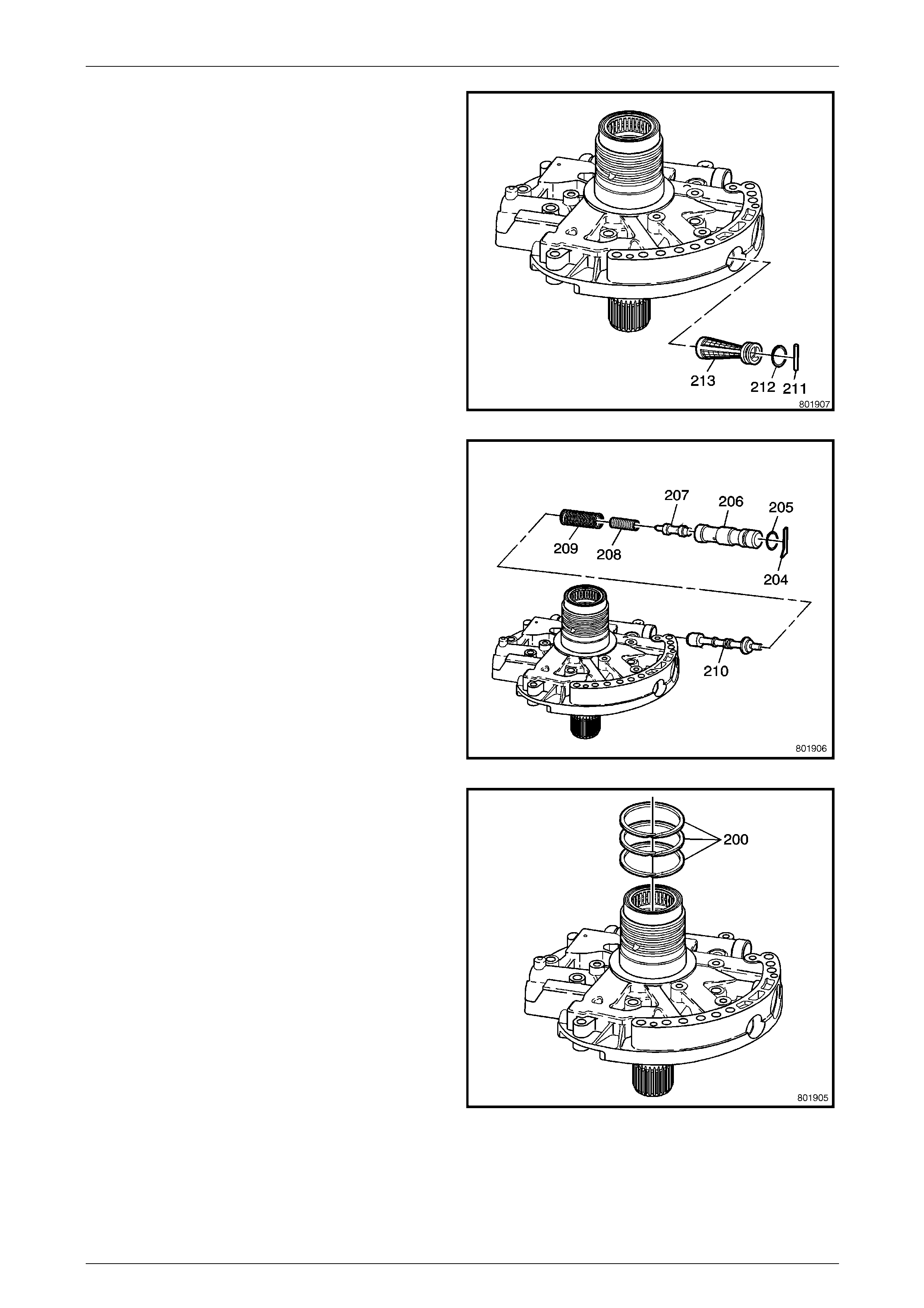

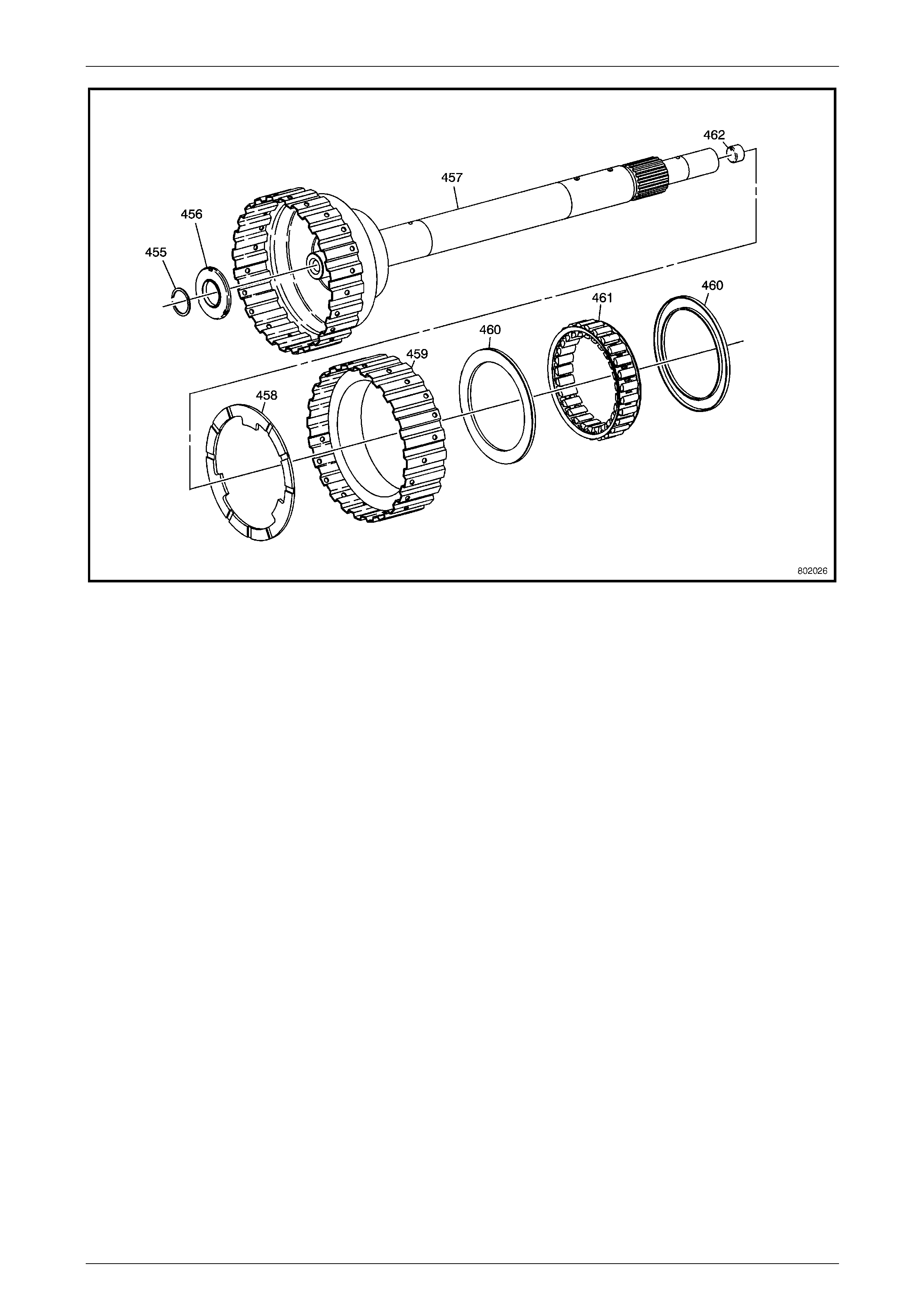

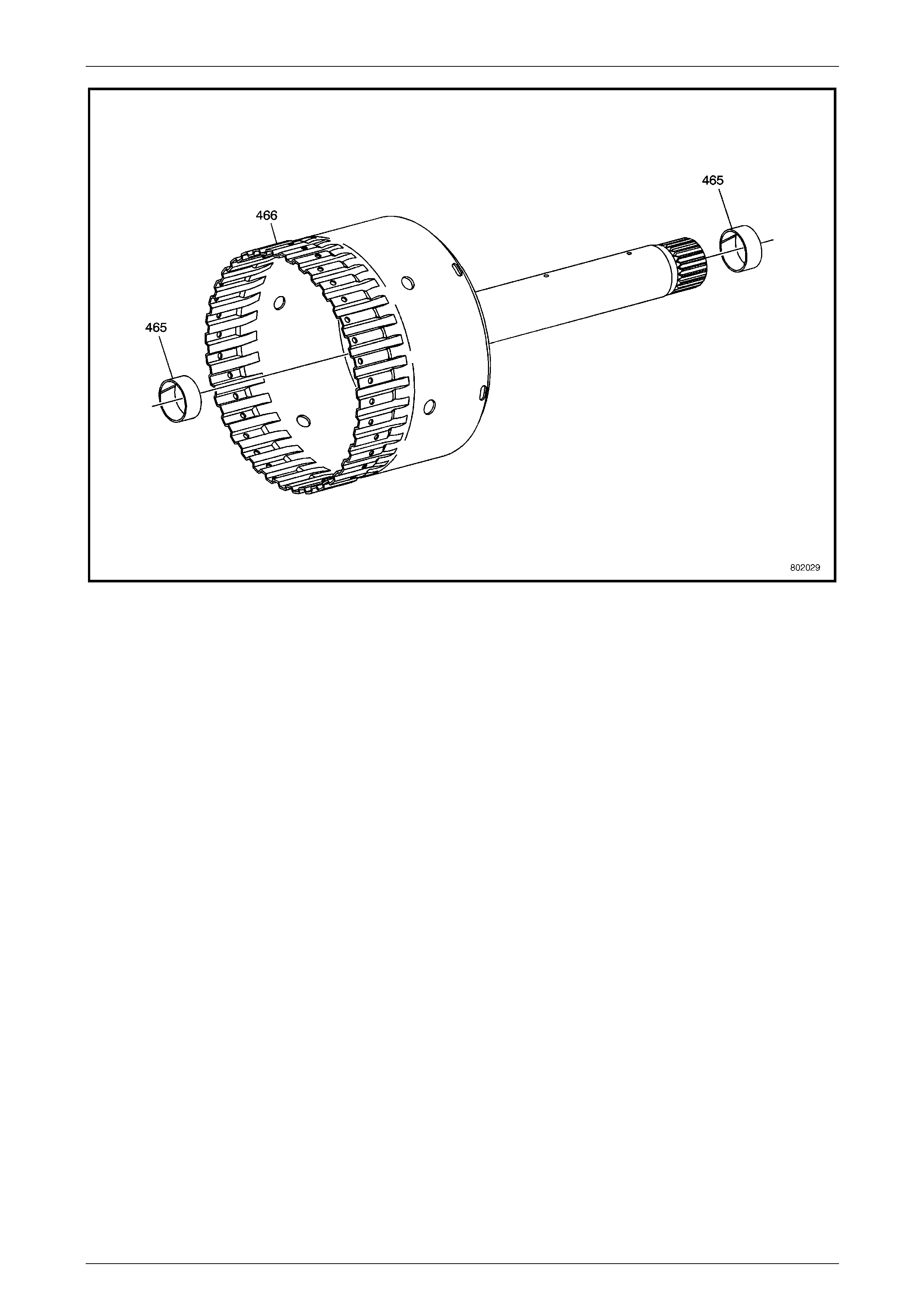

1.30 Input Sun Gear Shaft

Disassemble

1 Remove the forward clutch sprag outer race (459).

2 Remove the forward clutch outer race washer (458).

3 Remove the forward clutch sprag assembly retaining

rings (460).

4 Remove the forward clutch sprag (461).

Figure 7E5 – 108

5 Remove the forward clutch roller inner thrust race

thrust snap ring (455), using suitable snap ring pliers.

6 Remove the inner thrust bearing (456).

Figure 7E5 – 109

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 57

7E5 – 57

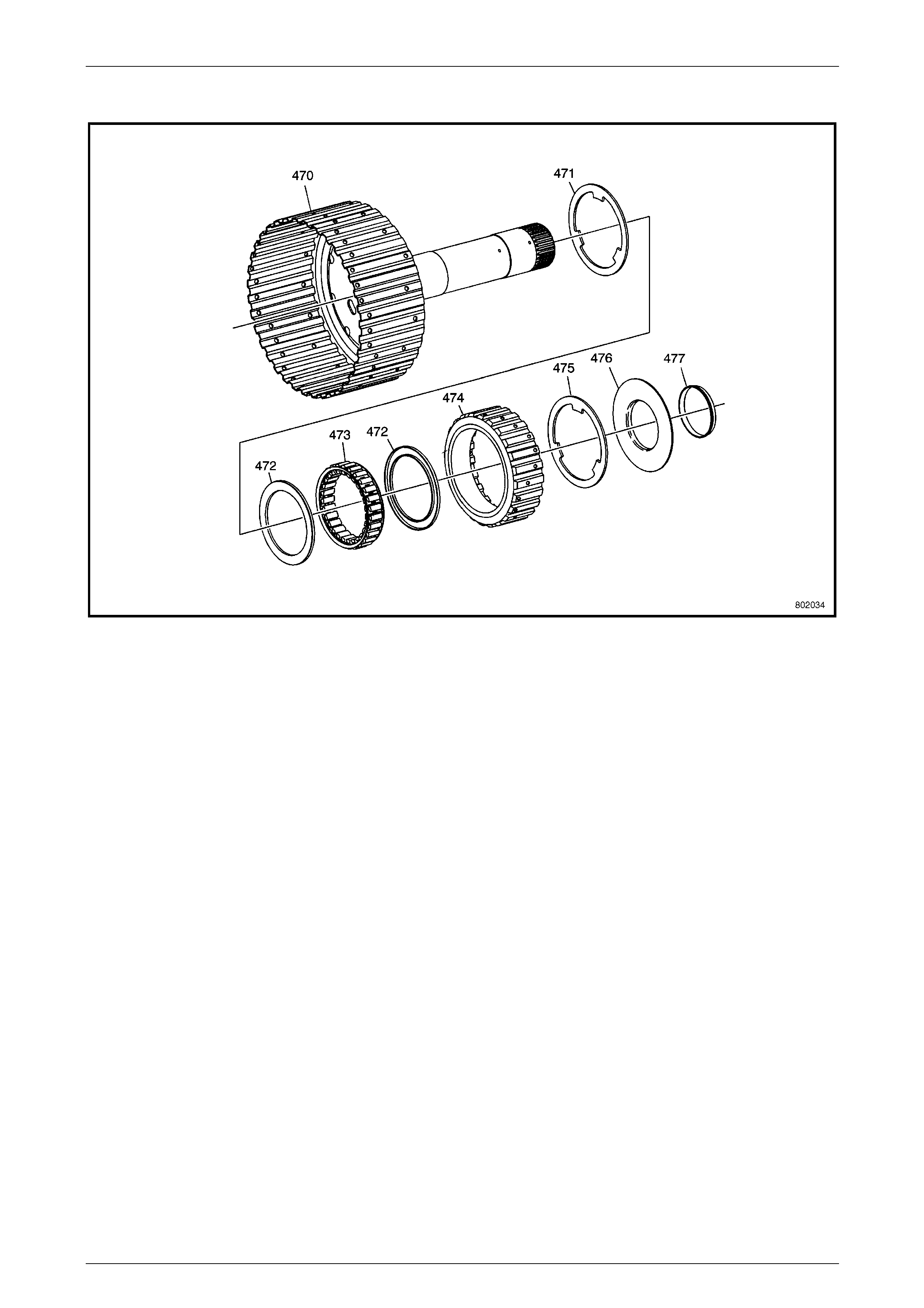

Reassemble

1 Inspect the outer race and input shaft for the following:

• Worn or damaged splines

• Scoring inside the diameter of the race

• Wear or cracks

2 Inspect the sprag elements for flat spots.

3 Inspect the cage for distortion or broken ribbon tabs.

4 Inspect the inner bearing for cracks.

Figure 7E5 – 110

5 Install the forward clutch roller inner thrust beari ng

(456).

6 Install a NEW inner race snap ring (455).

Figure 7E5 – 111

7 Install the outer race washer (458) onto the outer race

(459).

8 Install the retaining rings (460) and the forward clutch

sprag (461) onto the outer race (459).

9 Install the sprag assembly (460, 461, 459) onto the

sun gear shaft (457).

Figure 7E5 – 112

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 58

7E5 – 58

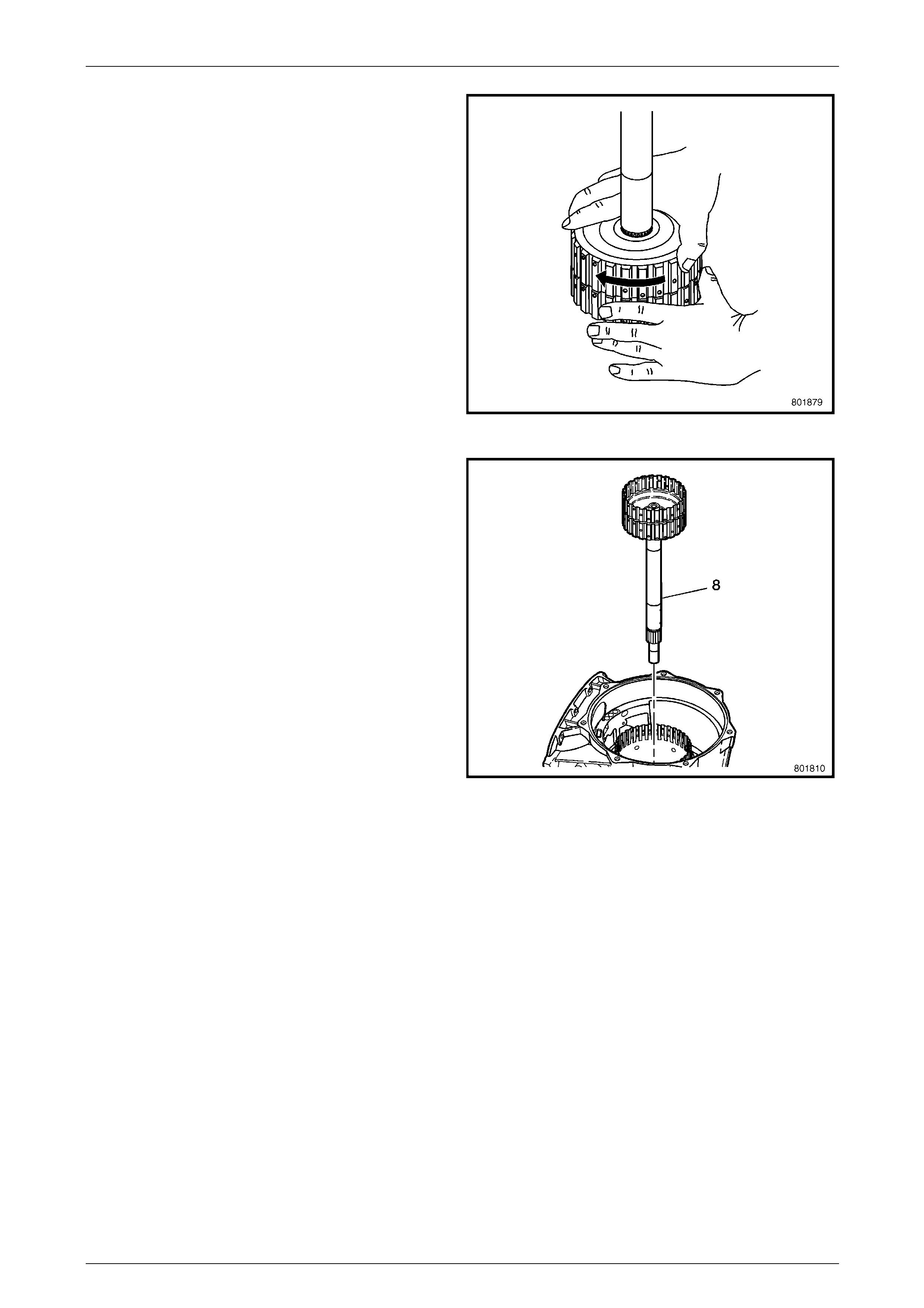

10 While holding the forward clutch sprag race with the

left hand, check that the sun gear shaft (457) rotates in

the direction shown and locks in the reverse direction.

Figure 7E5 – 113

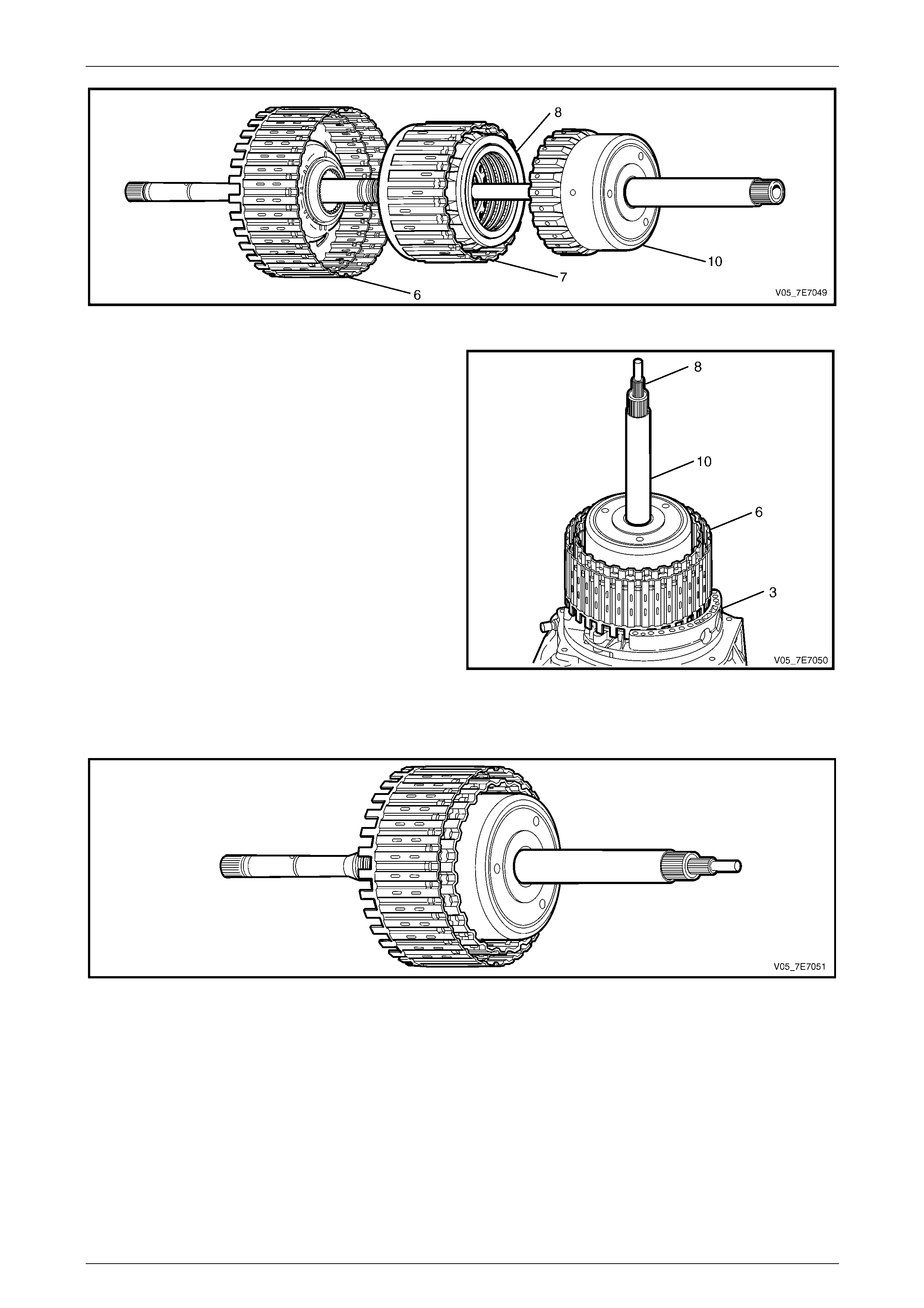

11 Install the input sun gear shaft (8) into the

transmission (24).

Figure 7E5 – 114

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 59

7E5 – 59

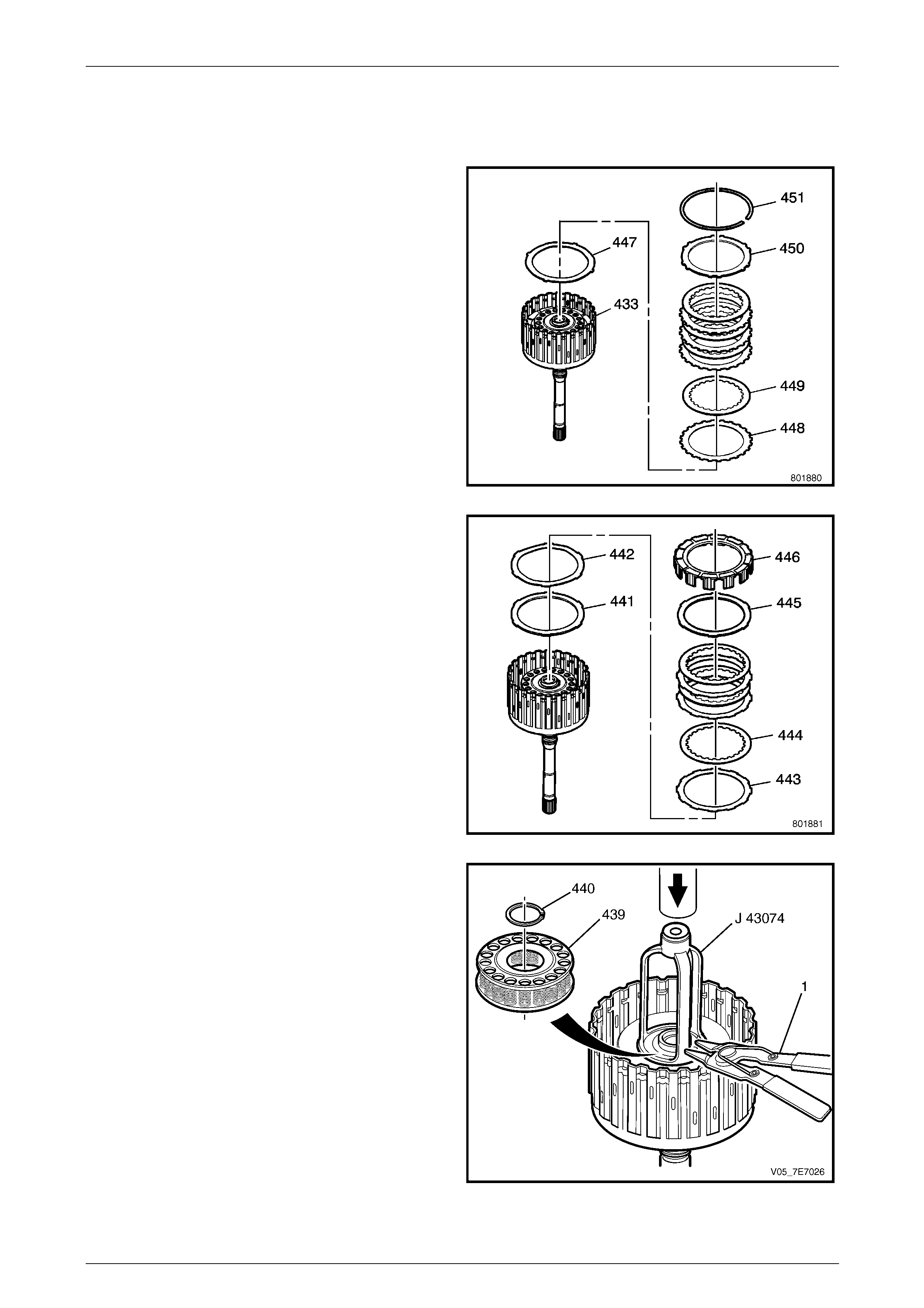

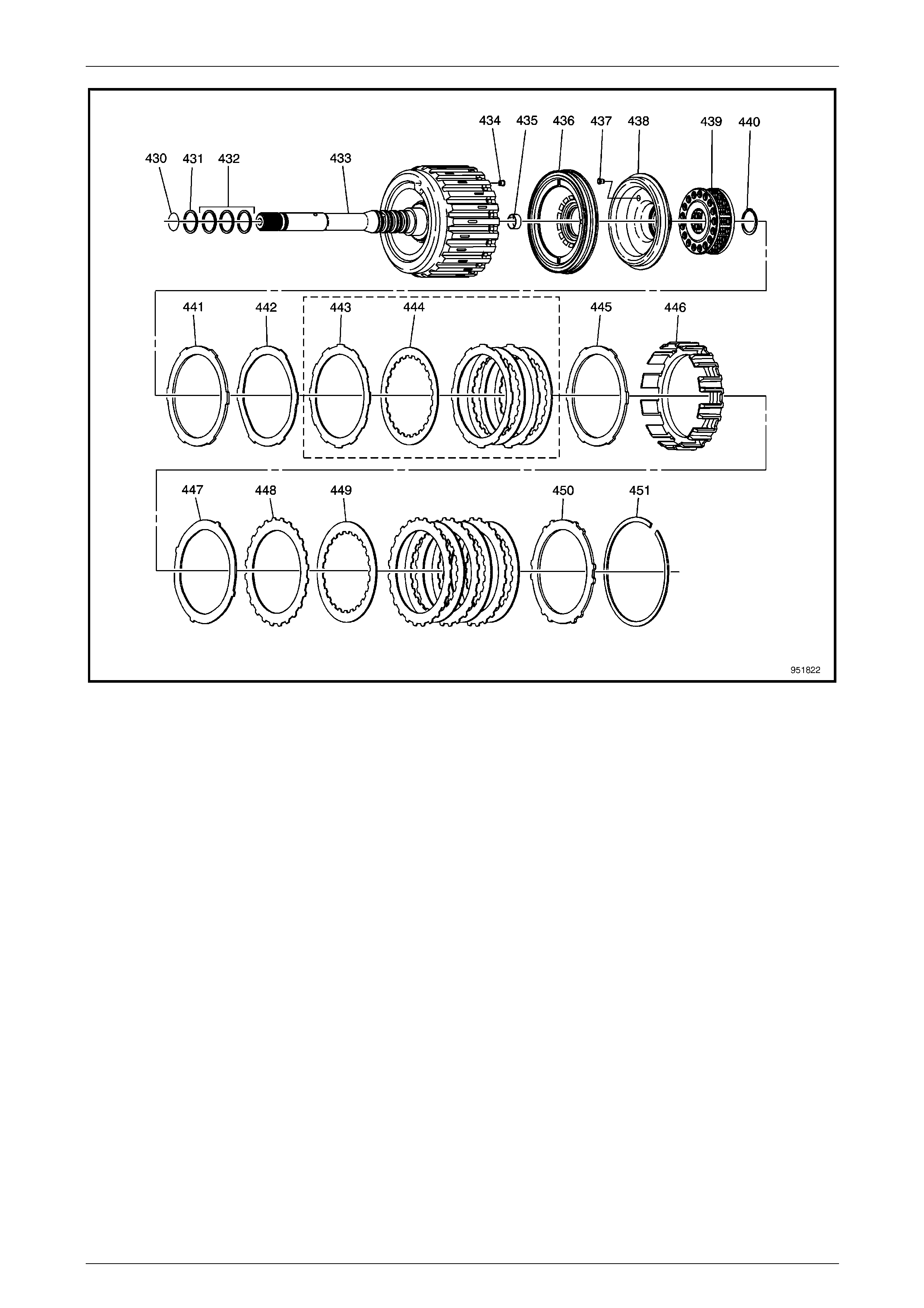

1.31 Forward and Coast Clutch

Disassemble

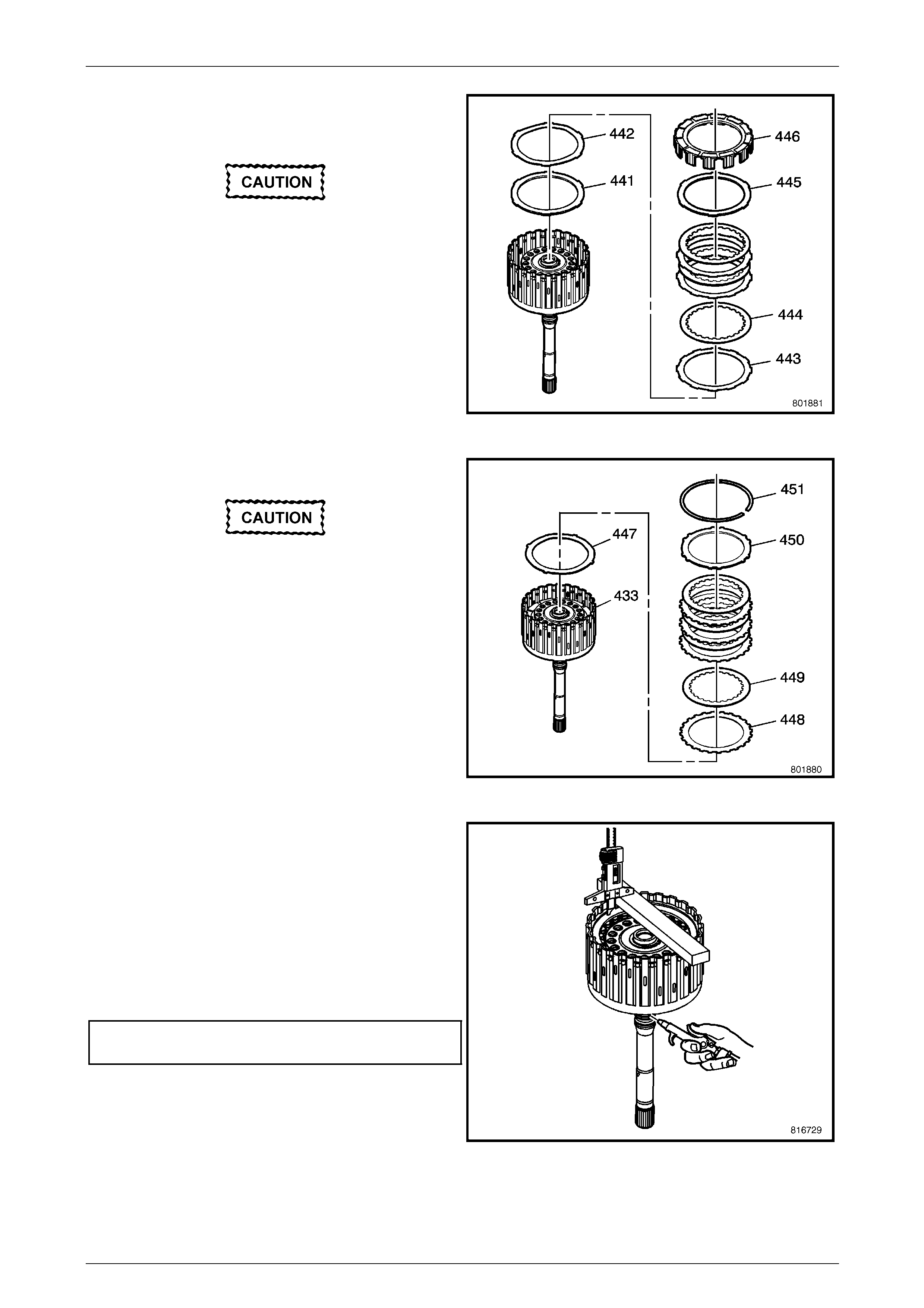

1 Using a flat bladed screwdriver, remove the forward

clutch backing plate retainer ring (45 1).

2 Remove the forward clutch backing plate (450).

3 Remove the forward clutch plates (448, 449) .

4 Remove the forward apply p late (447).

Figure 7E5 – 115

5 Remove the coast clutch housing (4 46).

6 Remove the coast backing plat e (445).

7 Remove the coast clutch plates (443, 444).

8 Remove the coast apply plate (442).

9 Remove the coast clutch spacer plate (441).

Figure 7E5 – 116

10 Position the forward clutch housing assembly (433) on

suitable flat press plates and place in a press.

Using Tool J 43074, clutch spring compressor, press

down on the forward and coast clutch spring (439) just

enough to allow access to the retaining circlip (440).

NOTE

As an alternative to J 43074, using J 23327-1

and adaptor plate J 25018-A is also effective .

11 Using suitable circlip pliers, re move the retaining

circlip (440) from the forward clutch housing retainer

ring groove.

12 Release the press and remove Tool J 43074 (or

J 23327-1 / J 25018-A).

13 Remove the forward clutch housing assembly (433)

from the press and remove the clutch spring (439).

Figure 7E5 – 117

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 60

7E5 – 60

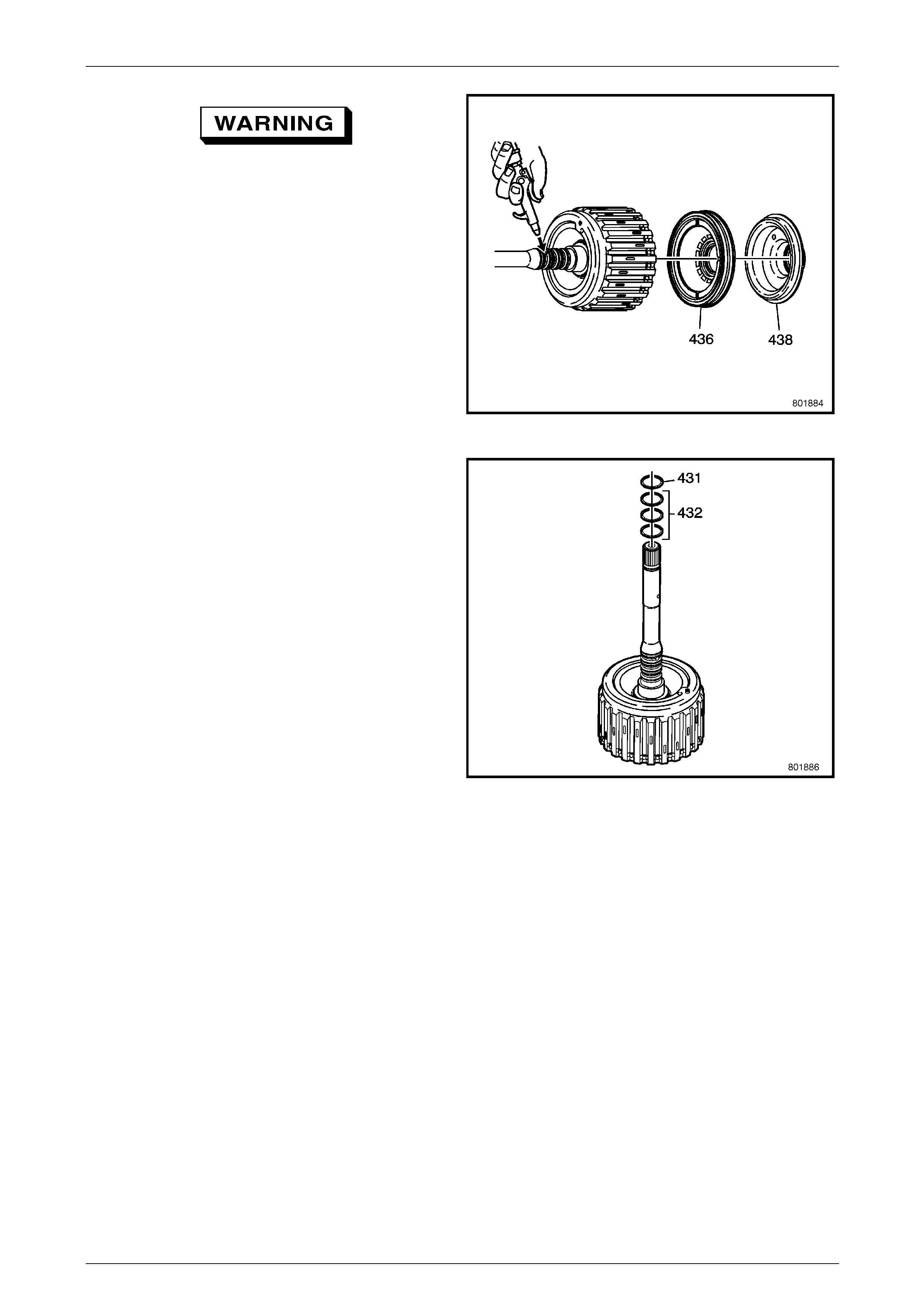

Wear eye protection to prevent potential

injury.

14 Remove the coast clutch piston (438).

15 Remove the forward clutch piston (436).

NOTE

It may be necessary to apply air pressure to the

forward clutch housing assembly port as shown,

to assist in the removal of the pistons.

Figure 7E5 – 118

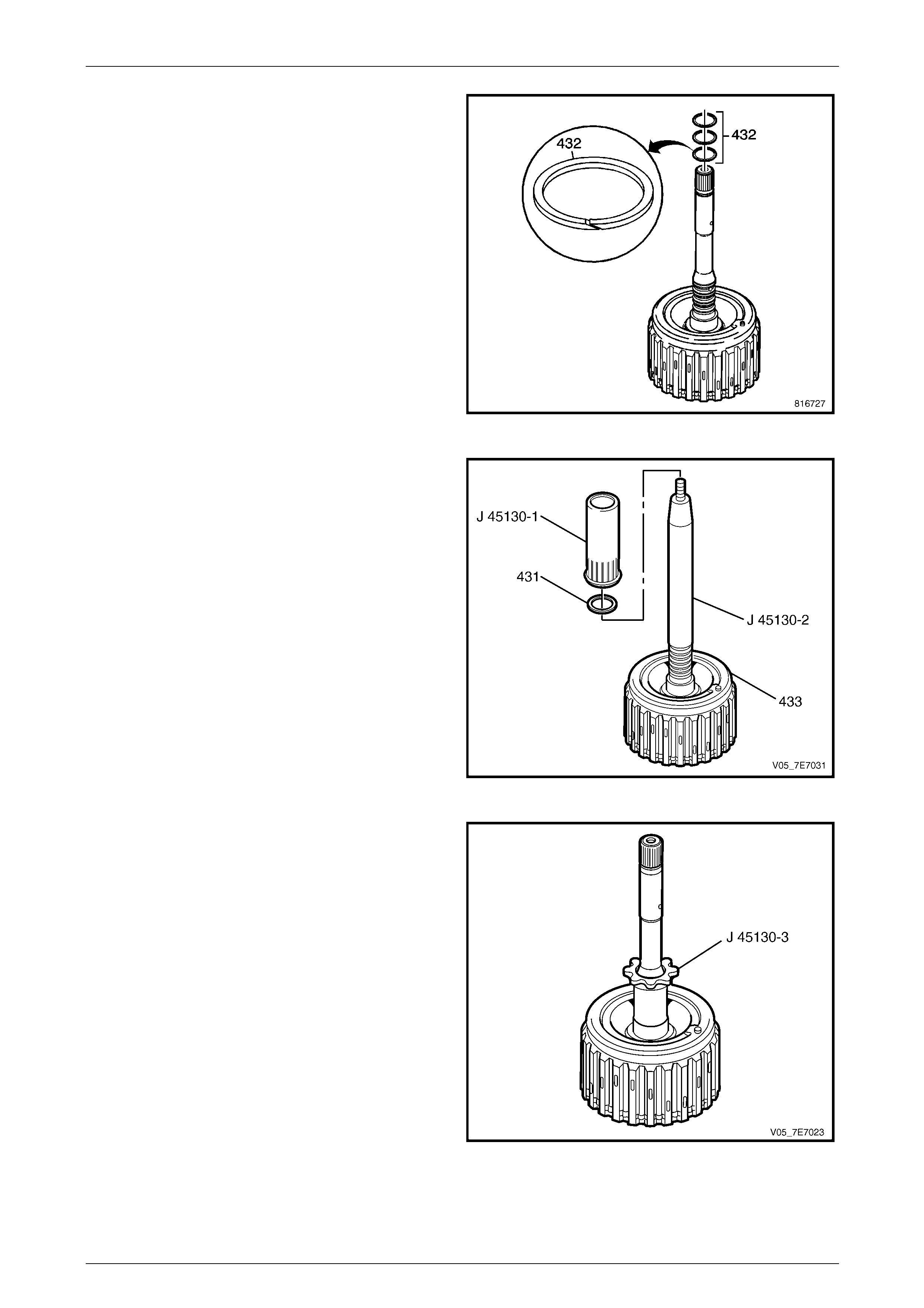

16 Remove the solid input shaft fluid seal (431) by

carefully cutting the seal ring.

17 Remove the three scarf cut input shaft fluid seals

(432).

Figure 7E5 – 119

Reassemble

1 Inspect the forward clutch housing (433) for the following:

• Plugged feed passages.

• Damaged ball check valve (434).

• Worn or damaged splines.

• Seal ring groove nicks or burrs.

• Cracked or blocked fluid passages in the input shaft.

• Worn or damaged clutch plates.

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 61

7E5 – 61

2 Inspect the NEW input shaft fluid seals (431, 432) for

damage.

3 After lubricating with clean transmission flui d, carefully

install the NEW input shaft fluid seals (432), installing

the one closest to the forward clutch housi ng (433)

first, then work outwards.

Figure 7E5 – 120

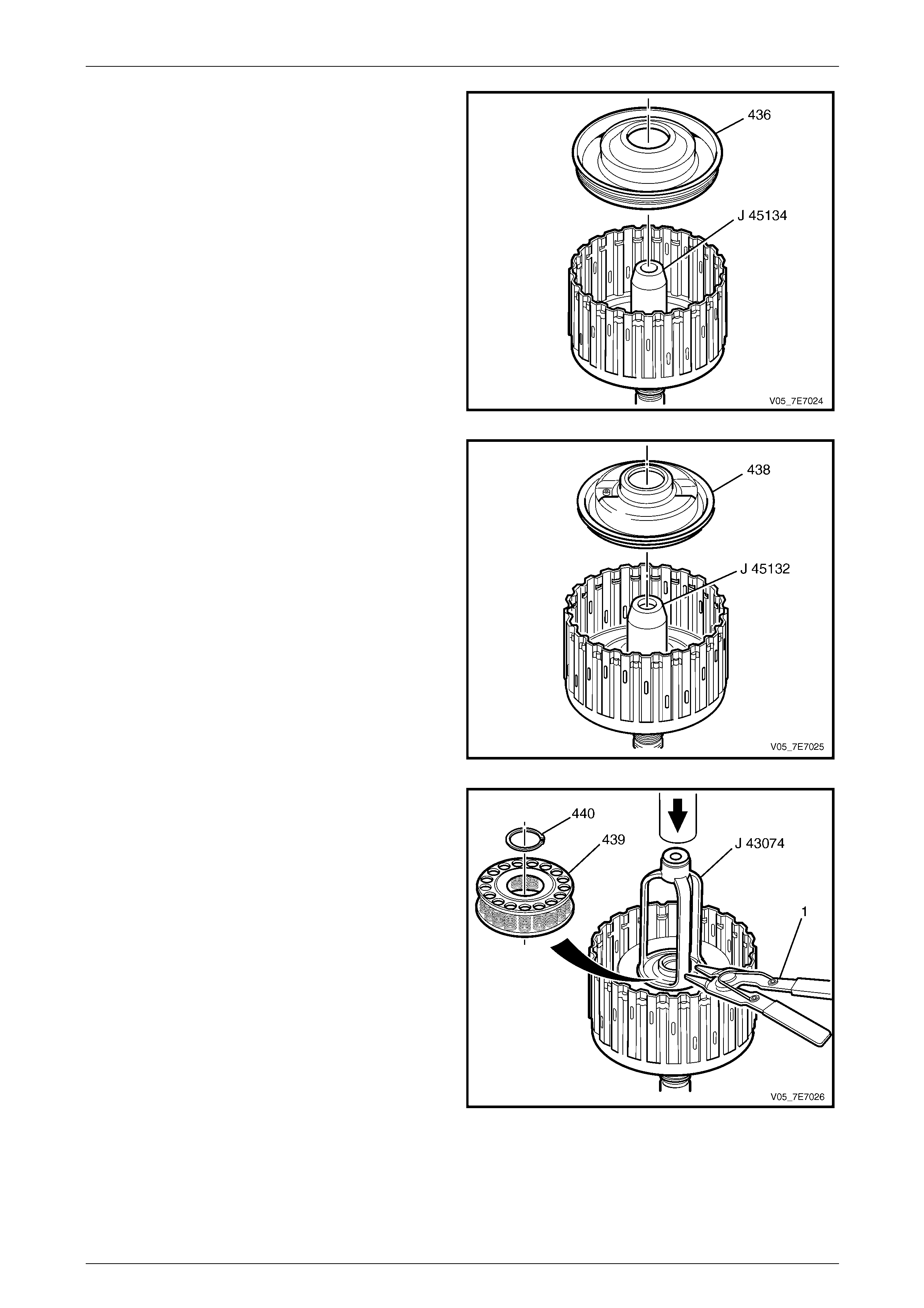

4 Slide Tool J 45130-2 over the input shaft. Adjust the

position of Tool J 45130-2 b y twisting the adjusting

screw at the top of the tool so that the bottom end is at

the seal groove furthest from the housin g. Coat J

45130-2 with clean transmission fluid.

5 Guide a NEW seal (431) onto T ool J 45130-2 and

slide the seal into the groove with T ool J 45130-1.

6 Remove Tool J 45130-2.

Figure 7E5 – 121

7 After lubricating the inner surface of Tool J 45130-3

with clean transmission lubricant, size the seals (431,

432) by carefully install the sizing Too J 45130-3 over

them.

8 Leave Tool J 45130-3 in place for at least five minutes.

If possible, leave Tool J 45130-3 in place until you

install the assembly into the transmission case.

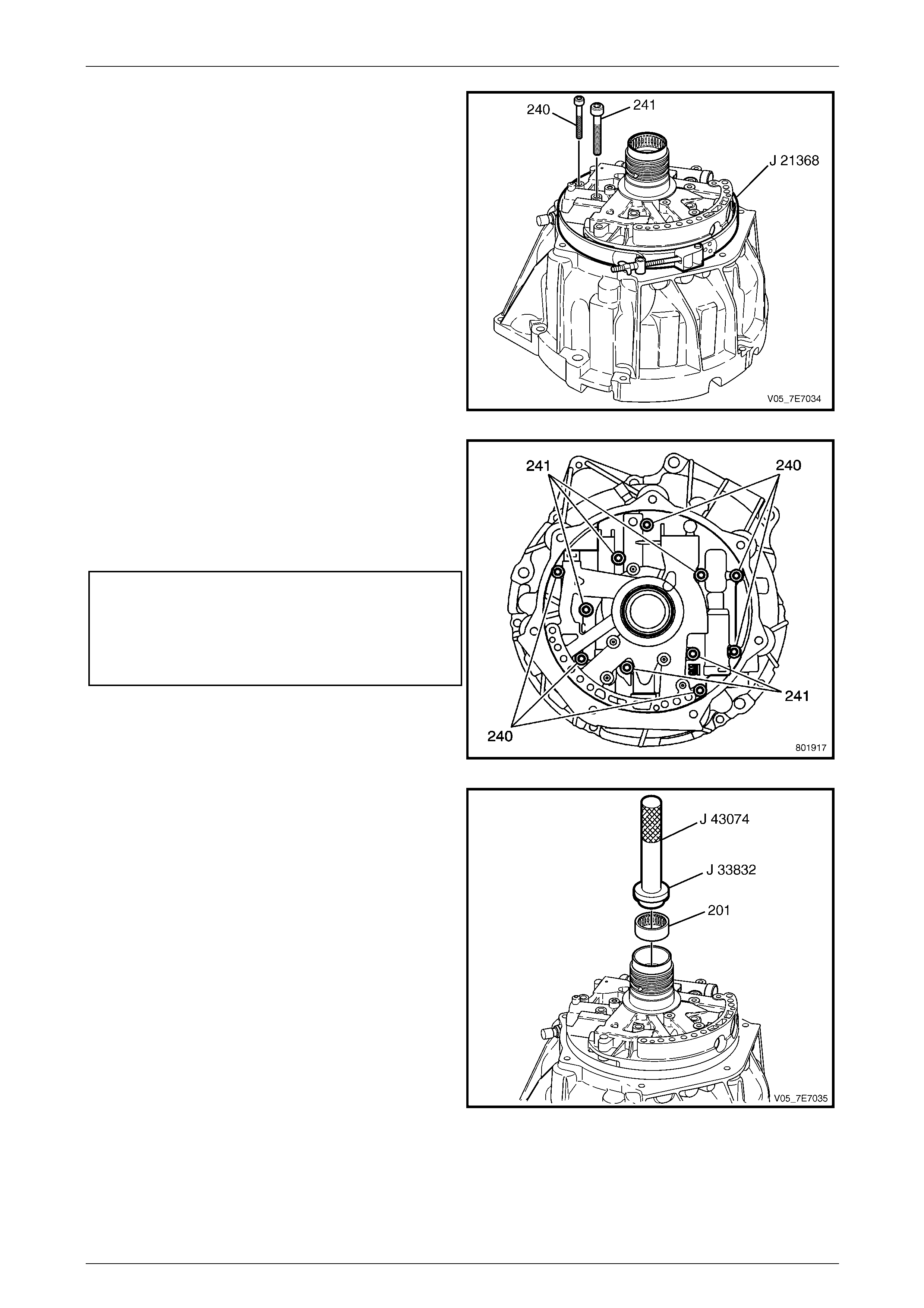

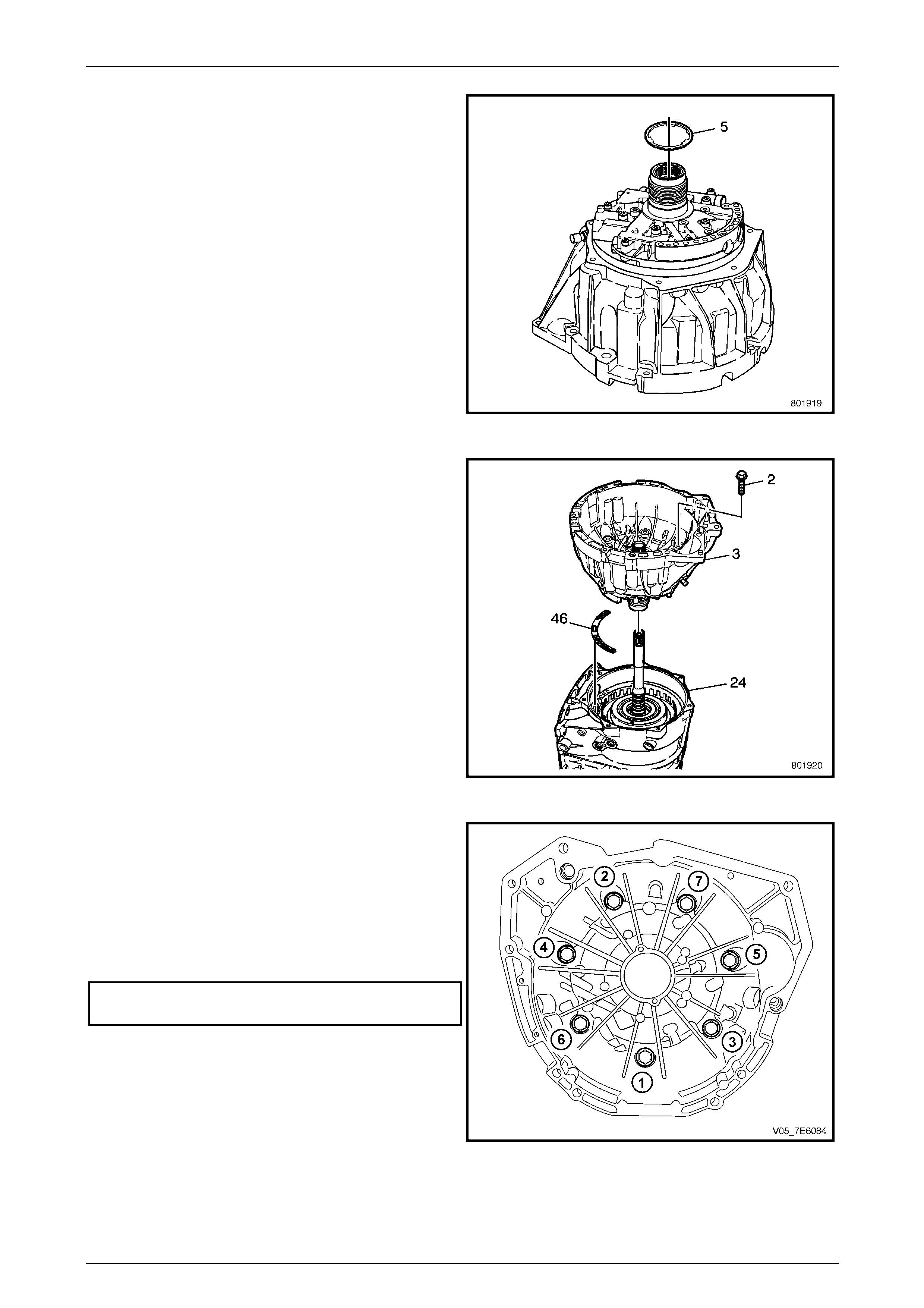

Figure 7E5 – 122

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 62

7E5 – 62

9 Inspect the forward piston and the coast clutch piston

for the following:

• Cracks or damage to seal grooves.

• Wear on the piston.

• Worn or damaged clutch plates.

10 Use Tool J 45134 to install the forward clutch piston

(436). Coat Tool J 45134 and the for ward clutch piston

seals with clean transmission fluid. Assembly the

forward clutch piston over the tool and push down into

the forward clutch housing.

Remove Tool J 45134.

Figure 7E5 – 123

11 Use Tool J 45132 to install the coast clutch piston

(438). Coat Tool J 45132 and the coast clutch piston

seals with clean transmission fluid. Assembly the

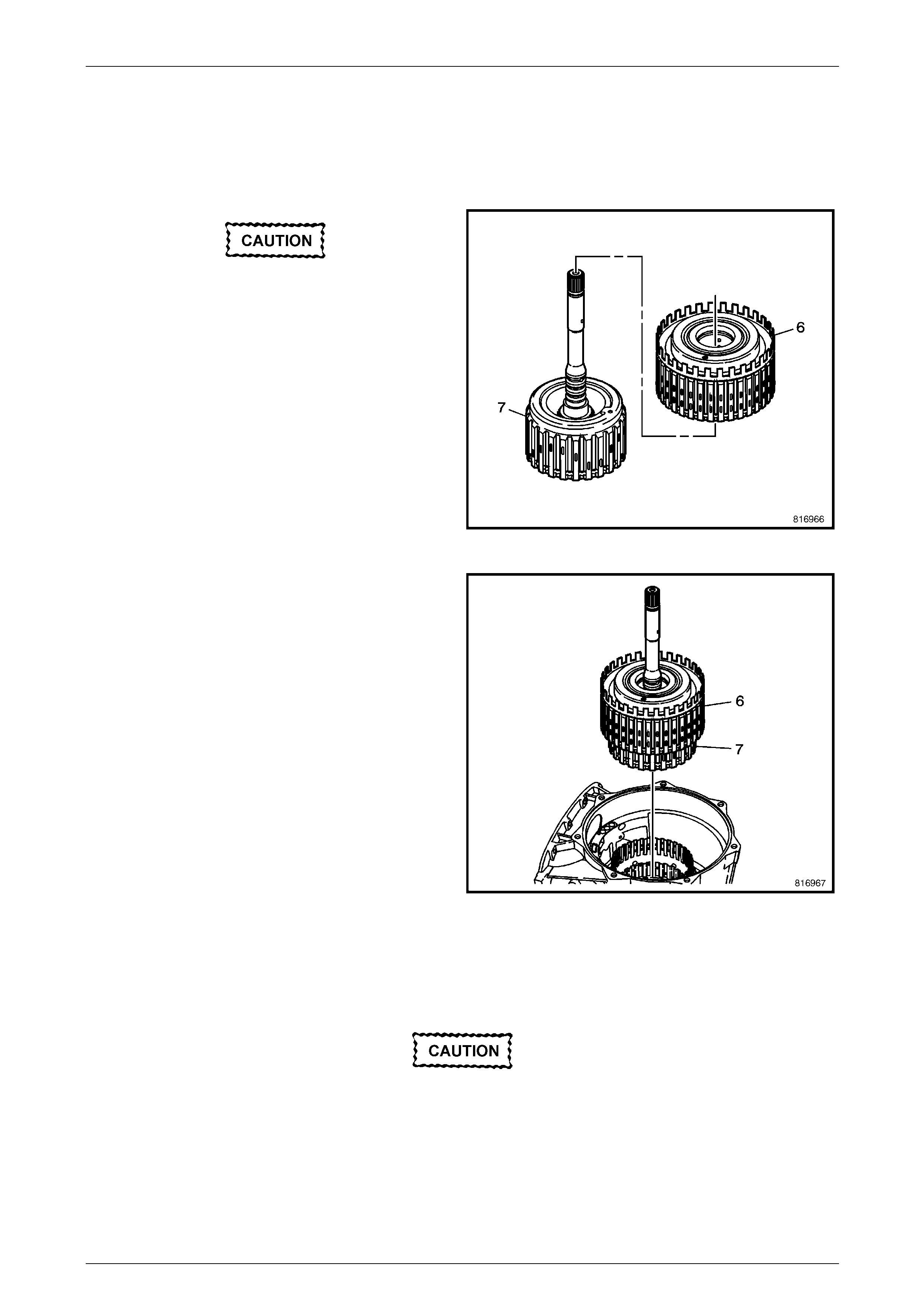

coast clutch piston over the tool and push do wn into

the forward clutch housing.

Remove Tool J 45132.

Figure 7E5 – 124

12 Inspect the forward and coast clutch piston spring for

the following:

• Damaged cage.

• Distorted or missing springs.

13 Install the piston spring (439).

14 Position the forward clutch housing assembly (433) on

suitable flat press plates and place in a press.

Using Tool J 43074 (J , clutch spring com pre ssor,

press down on the forward and coast clutch spring

(439) just enough to allo w access to the retaining

circlip groove. NOTE

As an alternative to J 43074, using J 23327-1

and adaptor plate J 25018-A is also effective .

15 Using suitable circlip pliers, install the retaining circlip

(440) to the forward clutch housing retainer ring

groove.

16 Release the press and remove Tool J 43074 (or

J 23327-1 / J 25018-A).

17 Remove the forward clutch housing from the press.

Figure 7E5 – 125

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 63

7E5 – 63

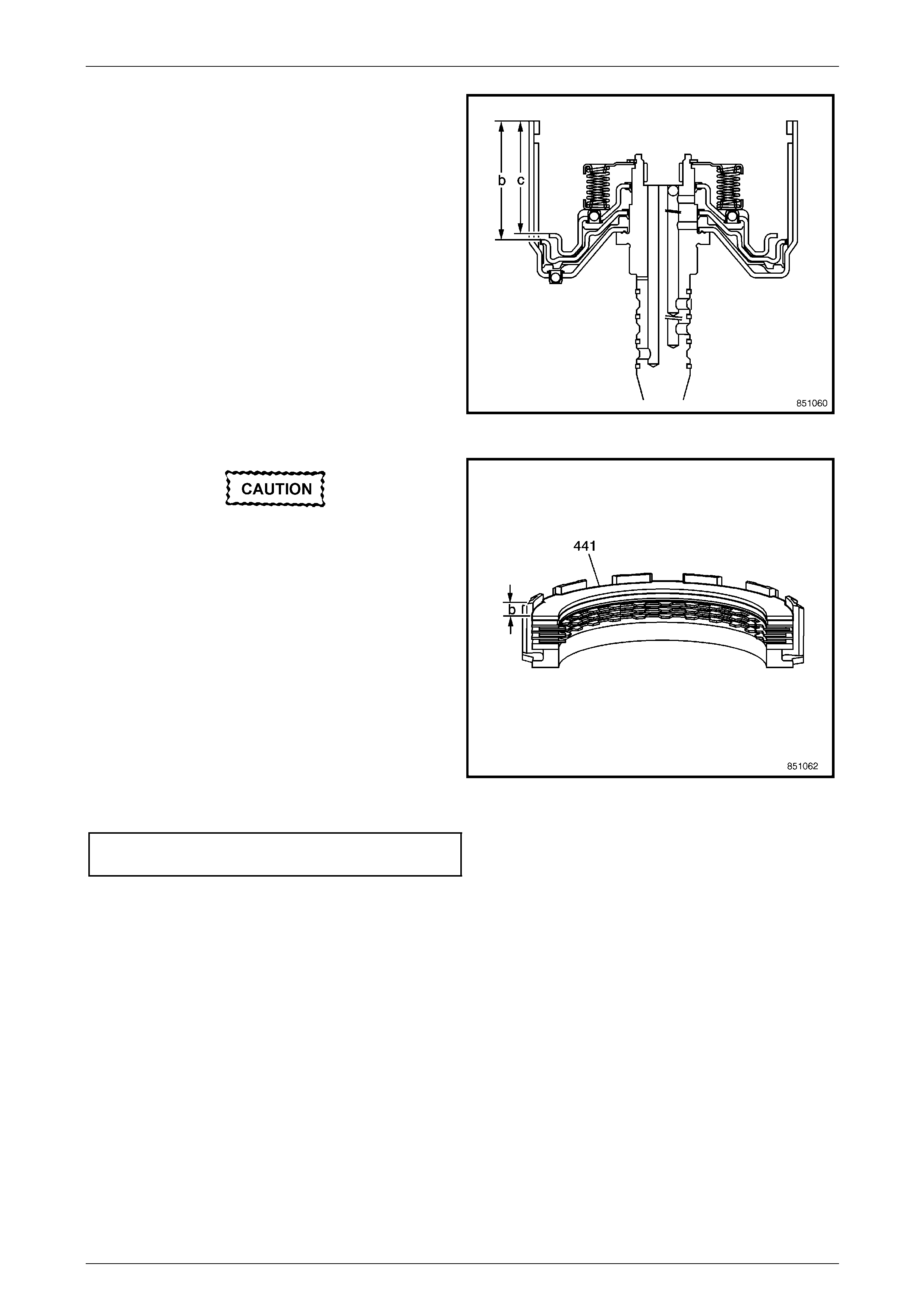

18 Measure the distance from the top of the forward

clutch housing to the coast clutch piston (438), record

this as dimension C.

19 Measure the distance from the top of the forward

clutch housing to the forward clutch pisto n (4 36),

record this as dimension B.

20 Subtract dimension C from dimension B. This is now

dimension A.

21 Install the coast clutch backing plate (445) into the

coast clutch housing (446).

Figure 7E5 – 126

Ensure that the composition side of each

plate faces upwards.

22 Install the coast clutch plates into the coast clutch

housing (446). Starting with the coast clutch plate

(443) with outer splines. Alternating with the coast

clutch plate (444) with inner splines.

23 Install the coast clutch apply plate into the coast clutch

housing (446).

24 Install the coast clutch spacer plate (441) into the

coast clutch housing (446).

25 Measure the distance from the top of the coast clutch

housing (446) to the top of the coast clutch spacer

plate (441), record this as dimension B.

26 Subtract dimension B from dimension A, this is clutch

pack travel.

Coast Clutch Pack

Travel Specification................................ 1.17 – 1.67 mm

Figure 7E5 – 127

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 64

7E5 – 64

27 Install the coast clutch spacer plate (441).

28 Install the coast clutch waved appl y plate (442).

Ensure that the composition side of each

plate faces upwards.

29 Install the coast clutch plates, starting with the coast

clutch plate (443) with the outer splines, alternating

with the coast clutch plate (444) with inner splines.

30 Install the coast clutch backing plate (445).

31 Install the coast clutch housing (446).

Figure 7E5 – 128

32 Install the forward clutch apply plate (447).

Ensure that the composition side of each

plate faces upwards.

33 Install the forward clutch plates. Starting with the

forward clutch plate (448) with outer splines.

Alternating with the forward clutch plate (449) with

inner splines.

34 Install the forward clutch backing plate (450).

35 Install the forward clutch backing plate retainer ring

(451).

Figure 7E5 – 129

36 Measure the distance between the forward clutch

backing plate and the bottom of the gauge bar.

Measure three times in different locations on the

backing plate. Record this as H1.

37 Apply air pressure to the specified port. Measure the

distance between the forward clutch backing plate and

the bottom of the gauge bar. Measure three times in

different locations on the backing plate. Record this as

H2.

38 Subtract H2 from H1 this is the clutch pack travel.

Forward Clutch Pack

Travel Specification................................ 1.20 – 1.65 mm

39 At this time you do not install the forward and coast

clutch assembly (7) into the transmission case. Set

aside until told to do so.

Figure 7E5 – 130

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 65

7E5 – 65

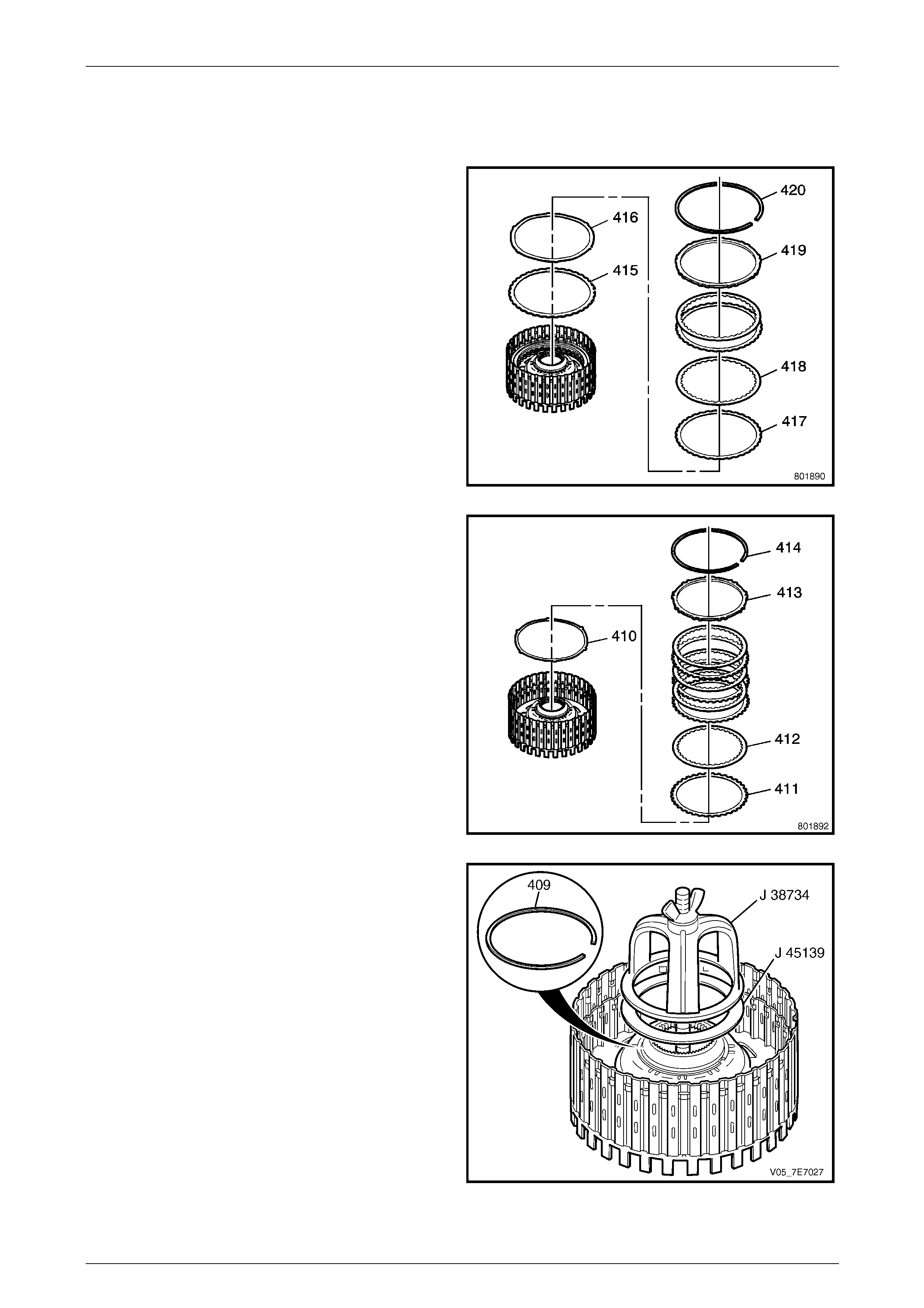

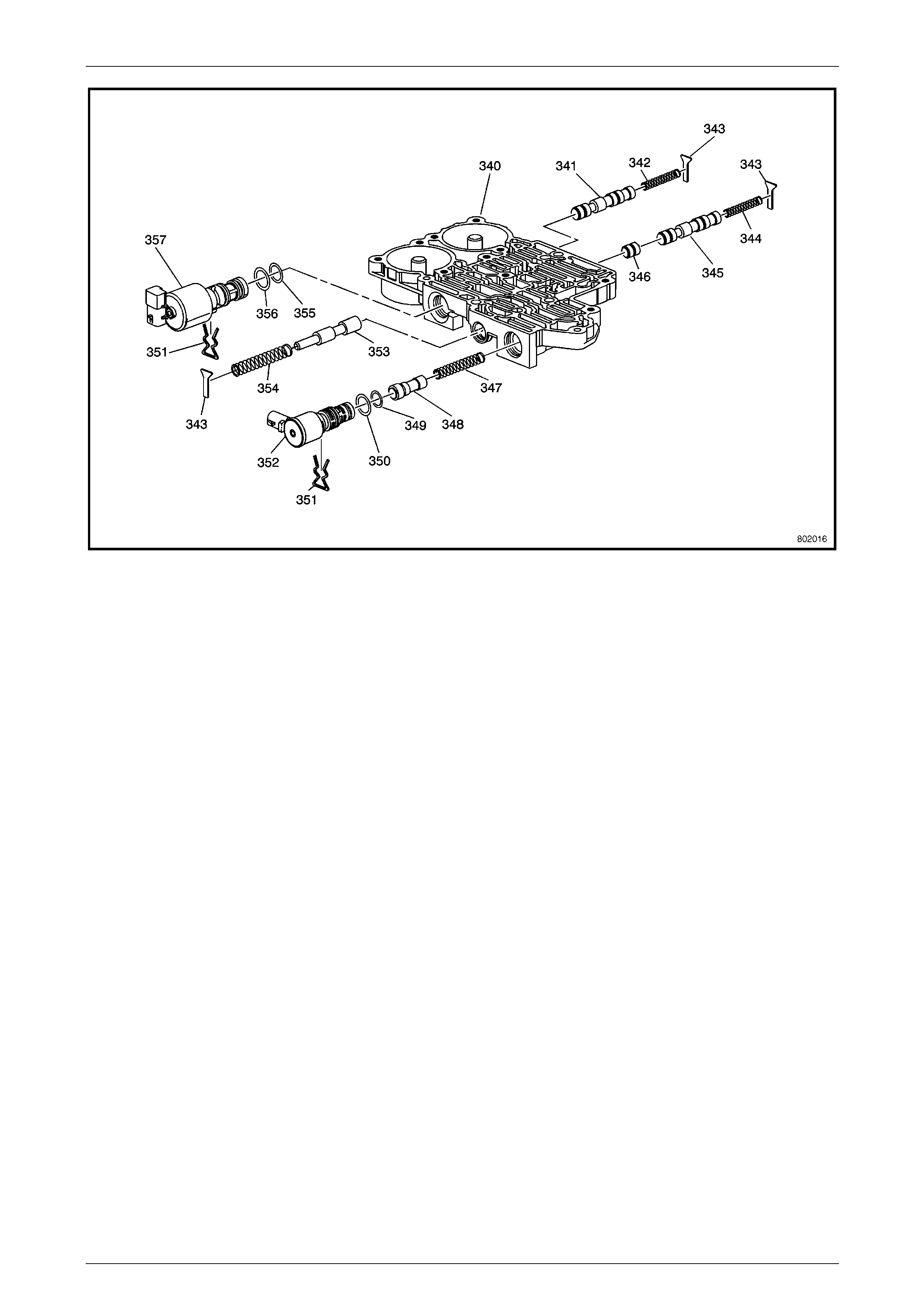

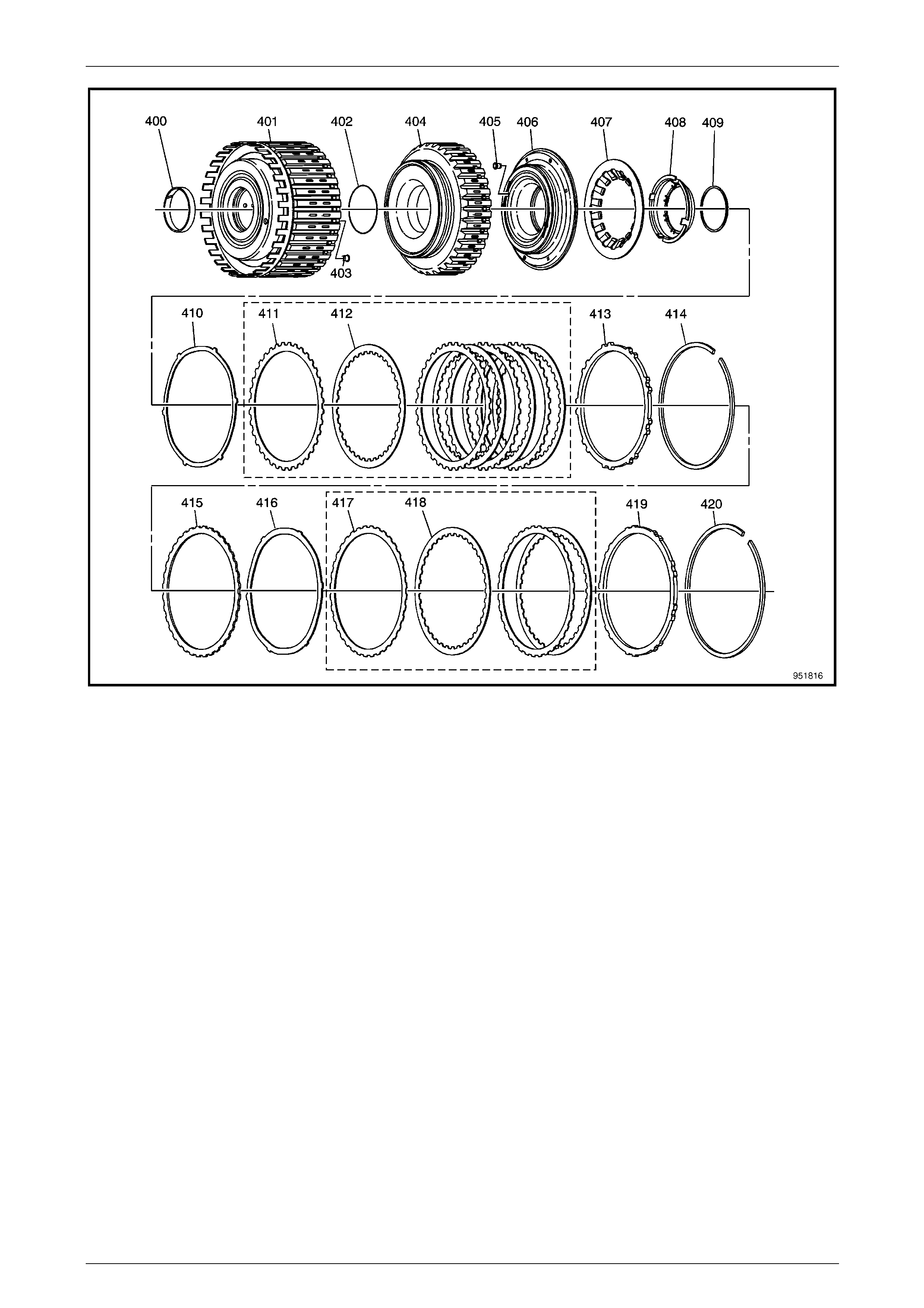

1.32 Direct and Reverse Clutch

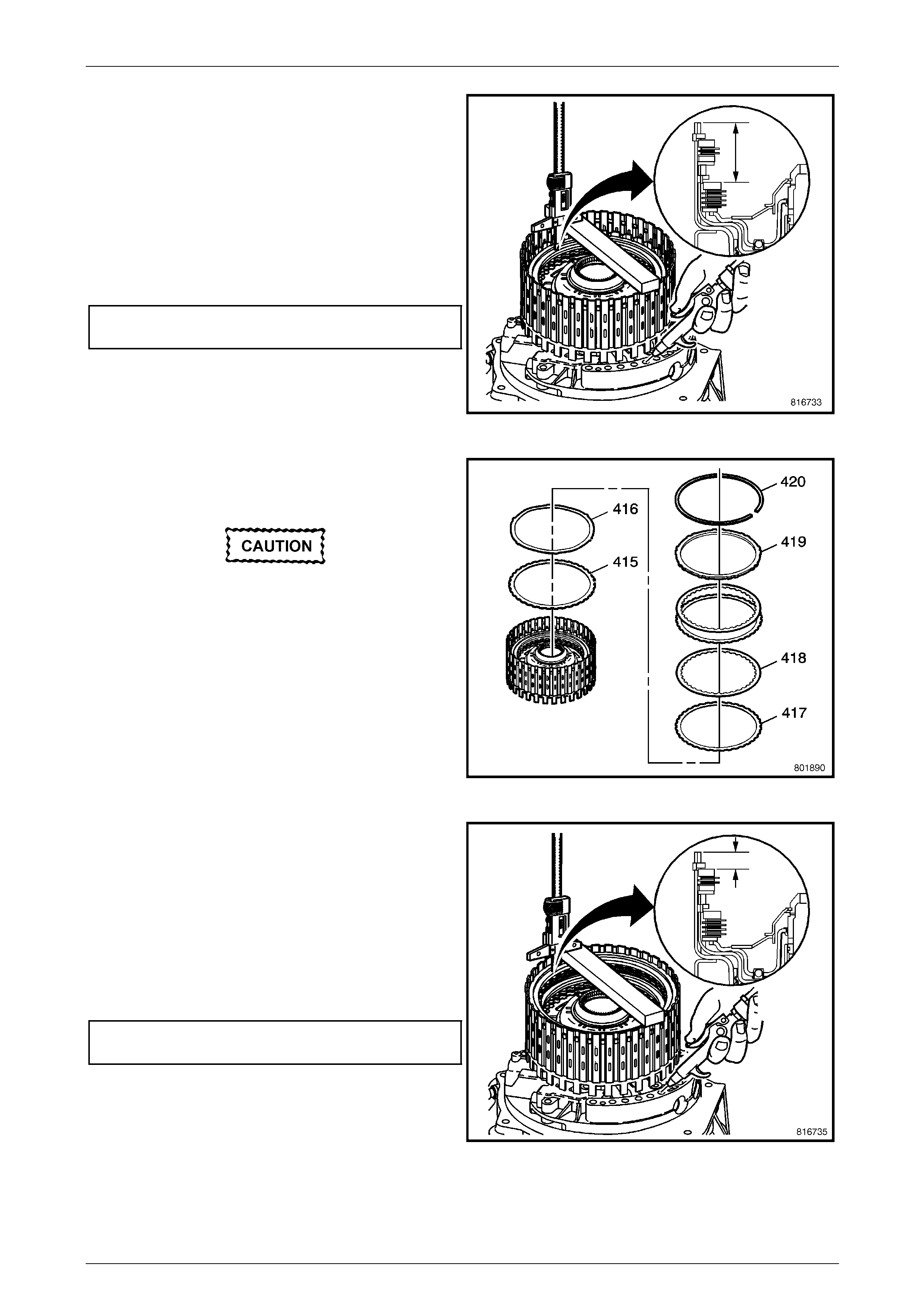

Disassemble

1 Using a fine bladed screwdriver, remove the reverse

clutch backing plate retainer ring (42 0).

2 Remove the backing plate (419).

3 Remove the clutch plates (418, 417).

4 Remove the apply plate (416).

5 Remove the reverse clutch spacer (415).

Figure 7E5 – 131

6 Remove the direct clutch backing plate reta iner ring

(414).

7 Remove the backing plate (413).

8 Remove the clutch plates (412, 411).

9 Remove the apply plate (410).

Figure 7E5 – 132

10 Using Tools J 38734 and J 45139, compress the direct

and reverse piston spring (407).

11 Using suitable snap ring pliers, remove the direct and

reverse clutch spring retainer ring (409).

12 Loosen and remove J 387 34 and J 45139.

Figure 7E5 – 133

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 66

7E5 – 66

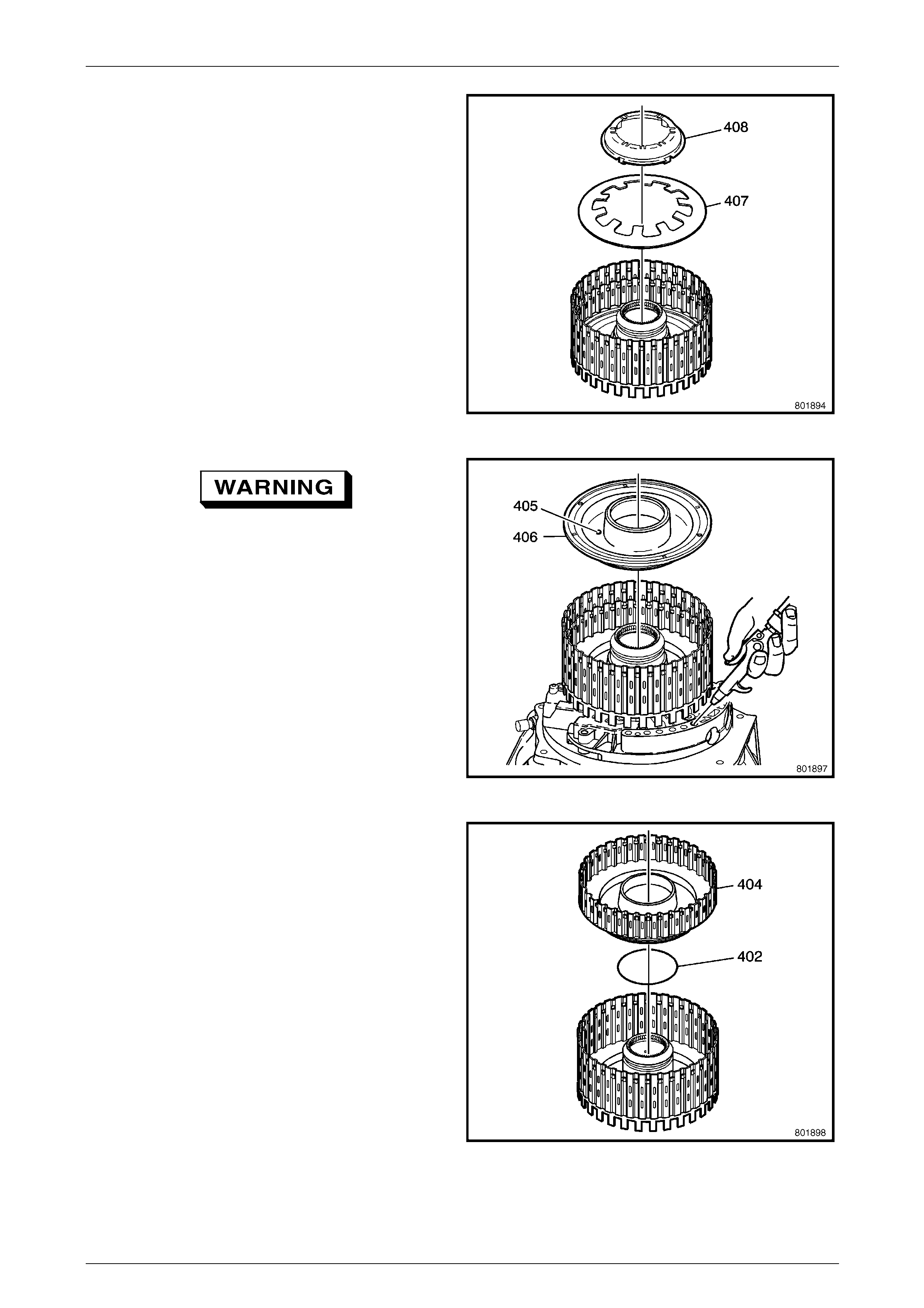

13 Remove the spring retainer (408).

14 Remove the spring (407).

Figure 7E5 – 134

Wear eye protection to prevent potential

injury.

15 To remove the direct clutch piston (406), assembl e the

reverse clutch housing to the fluid pump assembly.

Then apply air pressure to the fluid pump assembly

port as shown, to remove the piston.

Figure 7E5 – 135

16 Remove the reverse clutch piston (404).

17 Remove the reverse clutch piston inner O-ring sea l

(402).

Figure 7E5 – 136

Automatic Transmission – 5L40–E – Unit Repair 7E5 – 67

7E5 – 67

Reassemble

1 Inspect the reverse clutch housing (401) for the

following:

• Plugged feed passages

• Worn or damaged splines

• Seal ring groove nicks or burrs

• Cracked or blocked fluid passages

• Worn or damaged bushing

2 Inspect the reverse clutch piston and the direct clutch

piston for the following:

• Cracks or damage to seal grooves

• Wear on the piston

• Inner seal damage

• Damaged ball check valve (405)

• Worn or damaged clutch plates

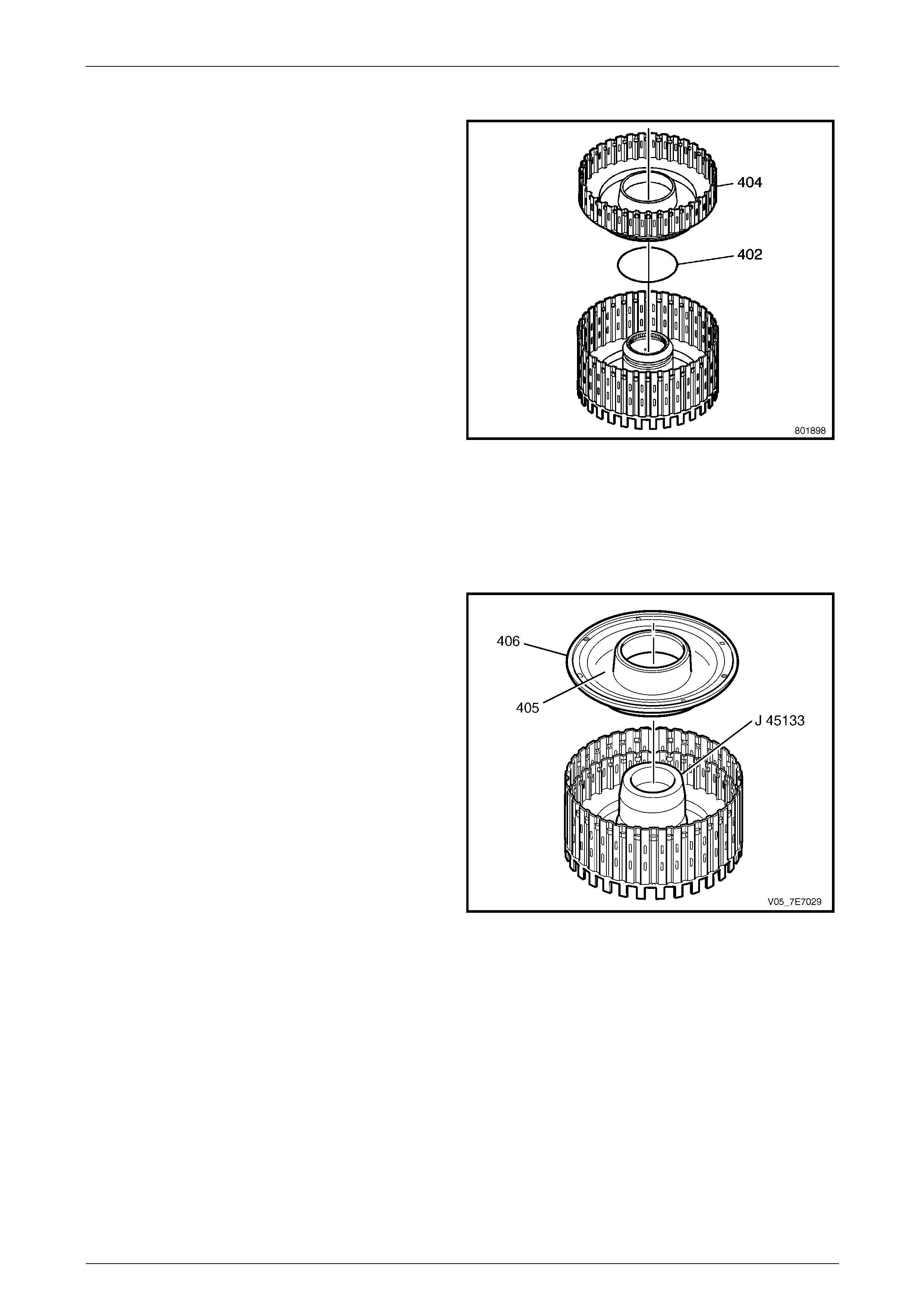

3 Install a NEW reverse clutch piston inner O-ring seal

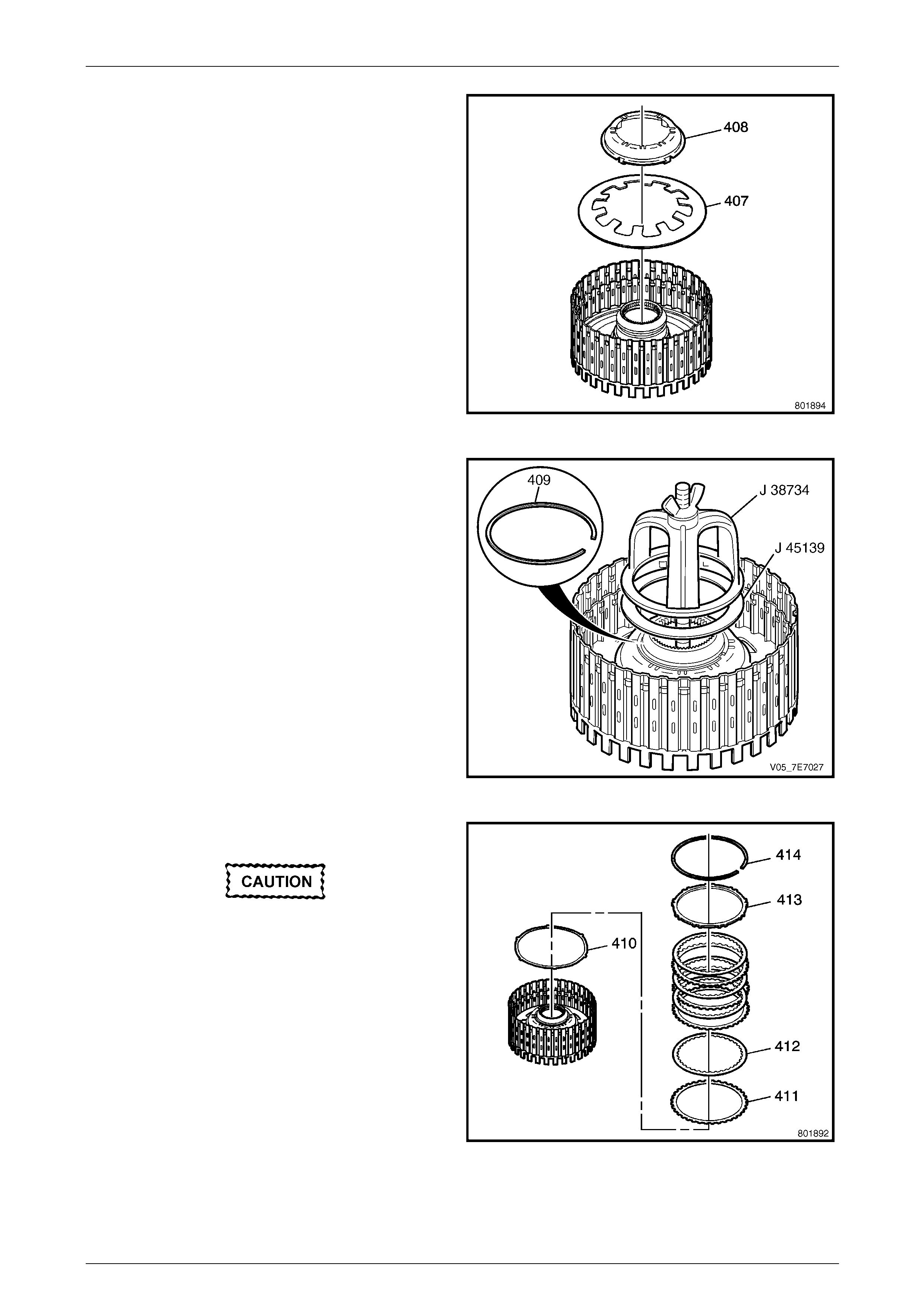

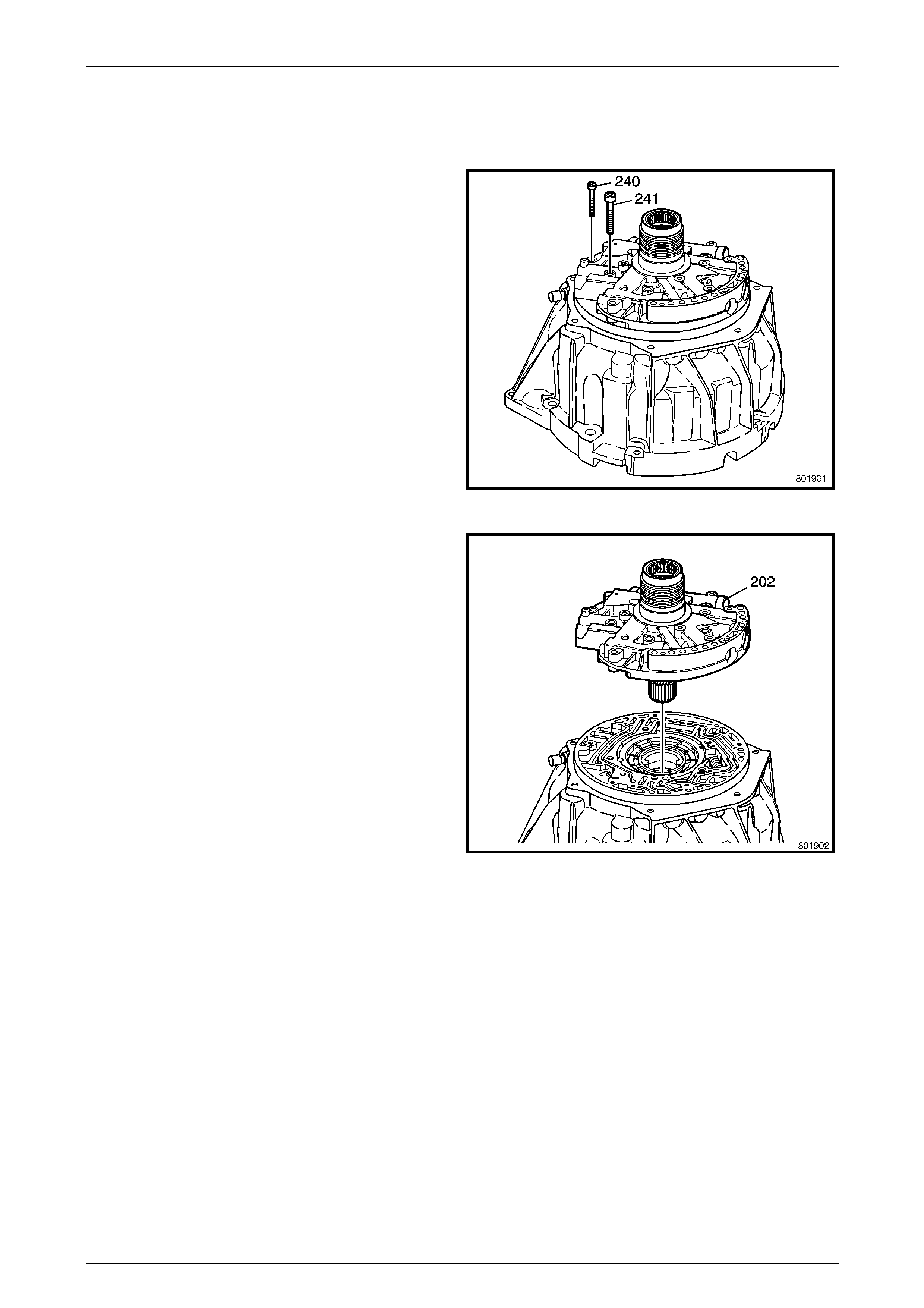

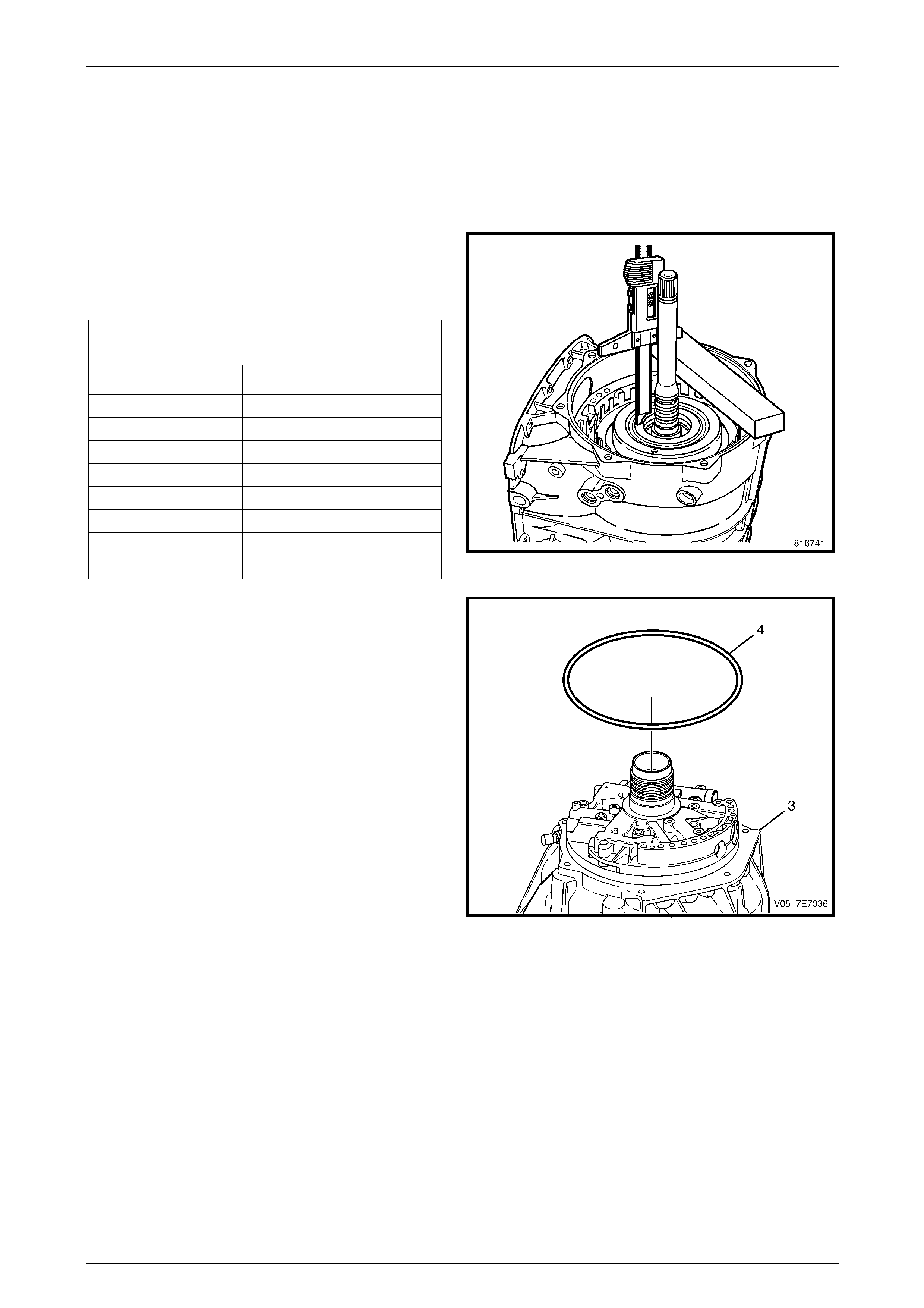

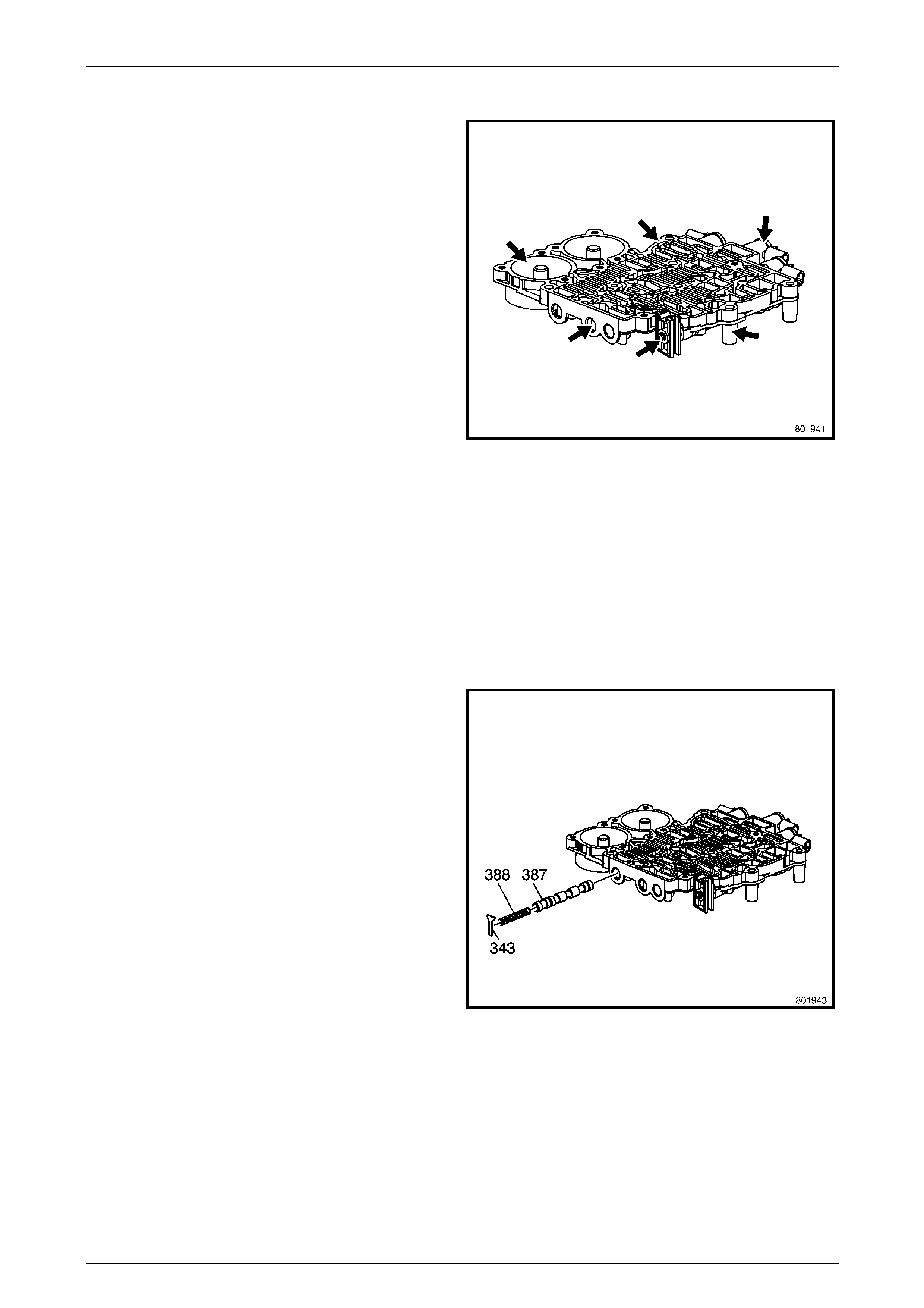

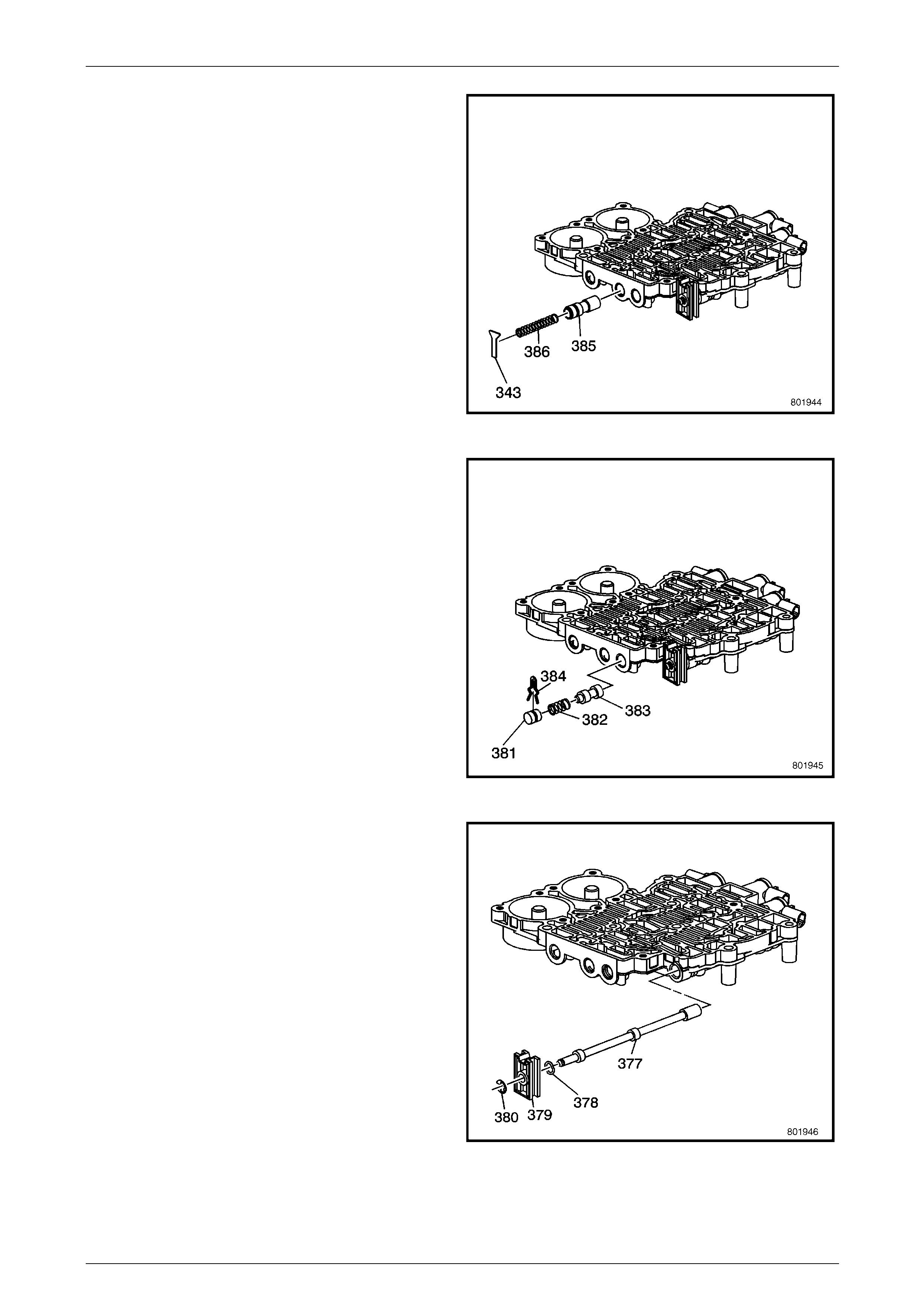

(402).