7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–1

15–DEC–2005 Page 7D5–1

Section 7D5

Automatic Transmission – 4L65E –

Unit Repair

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 00 Warnings,

Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................5

1.1 Service Information ............................................................................................................................................... 5

1.2 General Description............................................................................................................................................... 6

1.3 Rebuilding Tips...................................................................................................................................................... 7

Teflon Sealing Rings.......................................................................................................................................... 7

Thrust Washer Surfaces..................................................................................................................................... 7

2 Transmission Disassembly...................................................................................................................8

2.1 Transmission Preparation..................................................................................................................................... 8

2.2 2 – 4 Servo Assembly............................................................................................................................................ 9

Remove................................................................................................................................................................... 9

Disassemble......................................................................................................................................................... 10

Servo Pin Length ................................................................................................................................................. 11

2.3 Speed Sensor and Extension Housing.............................................................................................................. 12

Remove................................................................................................................................................................. 12

2.4 Oil Pan and Filter Assembly................................................................................................................................ 14

Remove................................................................................................................................................................. 14

2.5 Control Valve Body And Wiring Harness........................................................................................................... 15

Remove................................................................................................................................................................. 15

2.6 Torque Converter Housing.................................................................................................................................. 16

Remove................................................................................................................................................................. 16

2.7 Transmission End Play Check............................................................................................................................ 17

2.8 Oil Pump Assembly ............................................................................................................................................. 18

Remove................................................................................................................................................................. 18

2.9 Reverse Input Clutch, Input Clutch, 2-4 Band and Input Gear Set .................................................................. 19

Remove................................................................................................................................................................. 19

2.10 Reaction Gear Set................................................................................................................................................ 21

Remove................................................................................................................................................................. 21

2.11 Low and Reverse Clutch Assembly ................................................................................................................... 25

Remove................................................................................................................................................................. 25

2.12 Manual Shaft, Inner Linkage and Seal................................................................................................................ 27

Remove................................................................................................................................................................. 27

3 Component Disassembly, Inspection, Reassembly.........................................................................29

3.1 Transmission Case.............................................................................................................................................. 29

Inspect .................................................................................................................................................................. 29

3.2 Third Accumulator Retainer and Ball Assembly............................................................................................... 32

Inspect .................................................................................................................................................................. 32

Replace................................................................................................................................................................. 32

3.3 Transmission Case Bush.................................................................................................................................... 34

Replace................................................................................................................................................................. 34

3.4 2-4 Servo Assembly............................................................................................................................................. 35

Inspect .................................................................................................................................................................. 35

Techline

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–2

15–DEC–2005 Page 7D5–2

3.5 Low and Reverse Clutch Assembly ................................................................................................................... 36

Inspect .................................................................................................................................................................. 36

Spacer Plate Selection ........................................................................................................................................ 37

3.6 Low and Reverse Clutch ..................................................................................................................................... 38

Support Assembly............................................................................................................................................... 38

3.7 Reaction Internal Gear and Carrier Assembly................................................................................................... 39

Inspect .................................................................................................................................................................. 39

3.8 Reaction Sun Gear and Shell.............................................................................................................................. 41

Inspect .................................................................................................................................................................. 41

Sun Gear Bush – Replace ................................................................................................................................... 42

3.9 Input Internal Gear and Output Shaft................................................................................................................. 43

Inspect .................................................................................................................................................................. 43

Reaction Carrier Shaft Bushes – Replace ......................................................................................................... 44

3.10 Transmission Output Speed Sensor Ring......................................................................................................... 46

Replace................................................................................................................................................................. 46

3.11 Input Carrier and Sun Gear................................................................................................................................. 47

Inspect .................................................................................................................................................................. 47

Input Sun Gear Bushes – Replace...................................................................................................................... 48

3.12 Input Clutch Housing Assembly......................................................................................................................... 49

Exploded View...................................................................................................................................................... 49

Disassemble......................................................................................................................................................... 50

3 – 4 Clutch...................................................................................................................................................... 50

Forward Clutch Assembly ................................................................................................................................ 51

Overrun Clutch Assembly................................................................................................................................. 52

3 – 4 Clutch Assembly...................................................................................................................................... 53

Inspect .................................................................................................................................................................. 53

Forward Clutch Sprag Assembly........................................................................................................................ 57

Disassemble..................................................................................................................................................... 57

Inspect.............................................................................................................................................................. 58

Reassemble ..................................................................................................................................................... 59

Reassemble.......................................................................................................................................................... 60

3-4 Clutch Assembly ........................................................................................................................................ 60

Overrun Clutch Assembly................................................................................................................................. 63

Forward Clutch Assembly ................................................................................................................................ 65

3-4 Clutch......................................................................................................................................................... 66

Input Clutch Housing Air Checks....................................................................................................................... 67

Reinstall Turbine Shaft Sealing Rings............................................................................................................... 68

3.13 Reverse Input Clutch Assembly......................................................................................................................... 69

Disassemble......................................................................................................................................................... 69

Inspect .................................................................................................................................................................. 70

Reverse Input Clutch Housing Bushes – Replace............................................................................................ 71

Reassemble.......................................................................................................................................................... 73

Reverse Input Clutch Air Check ......................................................................................................................... 75

3.14 2-4 Band................................................................................................................................................................ 76

Inspect .................................................................................................................................................................. 76

3.15 Oil Pump Assembly............................................................................................................................................. 77

Disassemble......................................................................................................................................................... 77

Oil Pump Assembly.......................................................................................................................................... 77

Oil Pump Body ................................................................................................................................................. 78

Input Speed Sensor.......................................................................................................................................... 79

Oil Pump Cover................................................................................................................................................ 80

Inspect .................................................................................................................................................................. 81

Oil Pump Bushes – Replace................................................................................................................................ 82

Pump Body Bush.............................................................................................................................................. 82

Pump Cover Bushes ........................................................................................................................................ 83

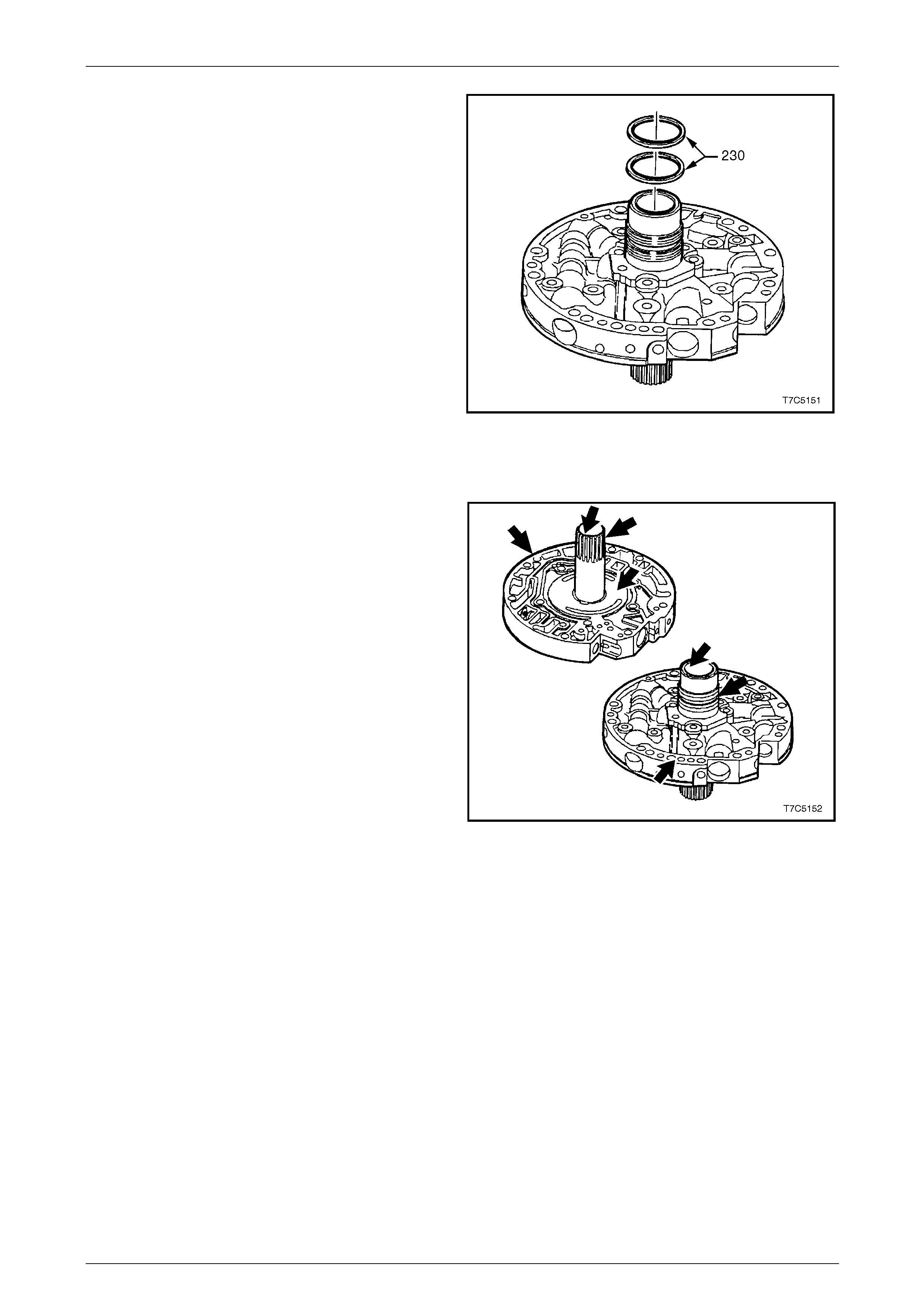

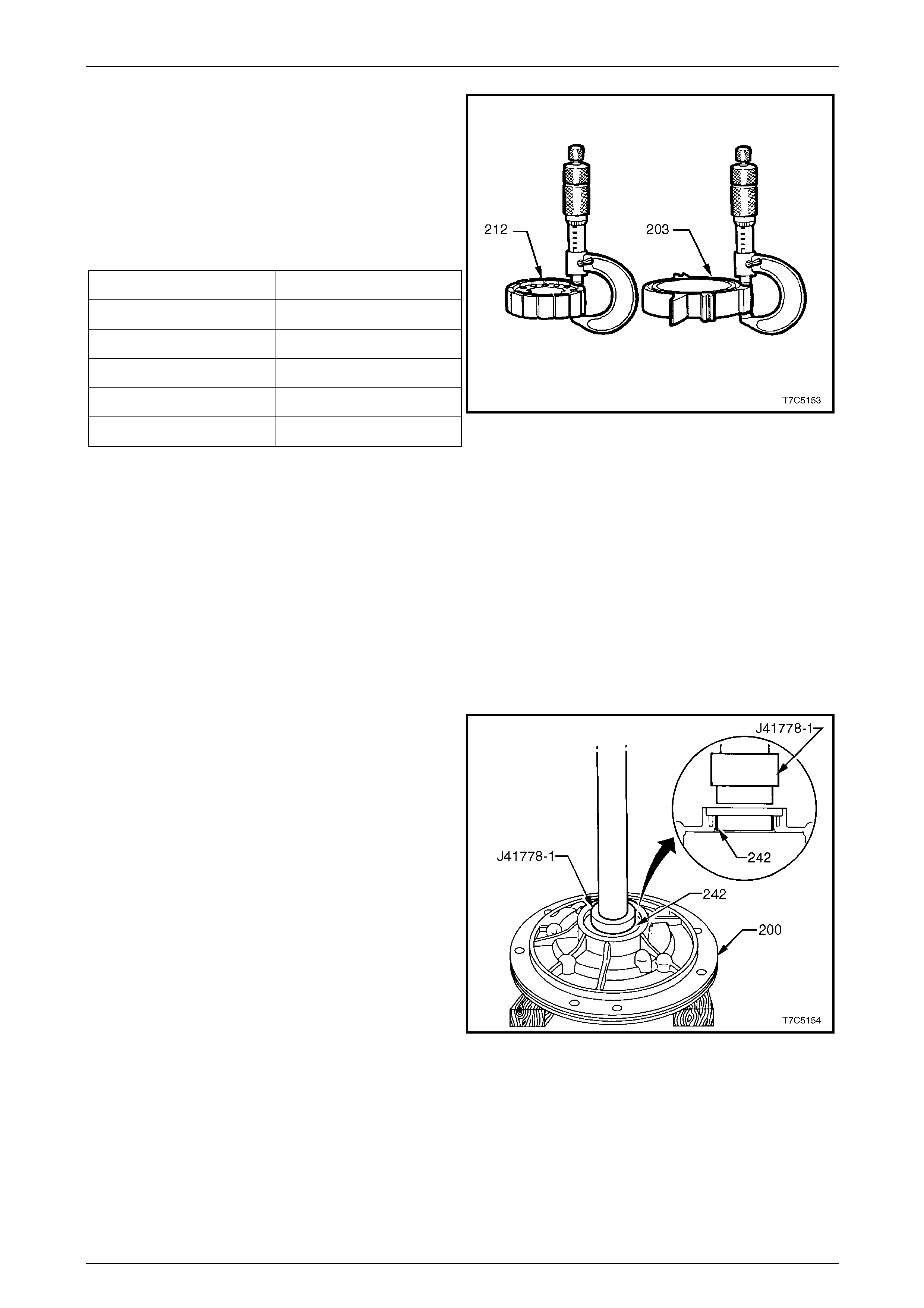

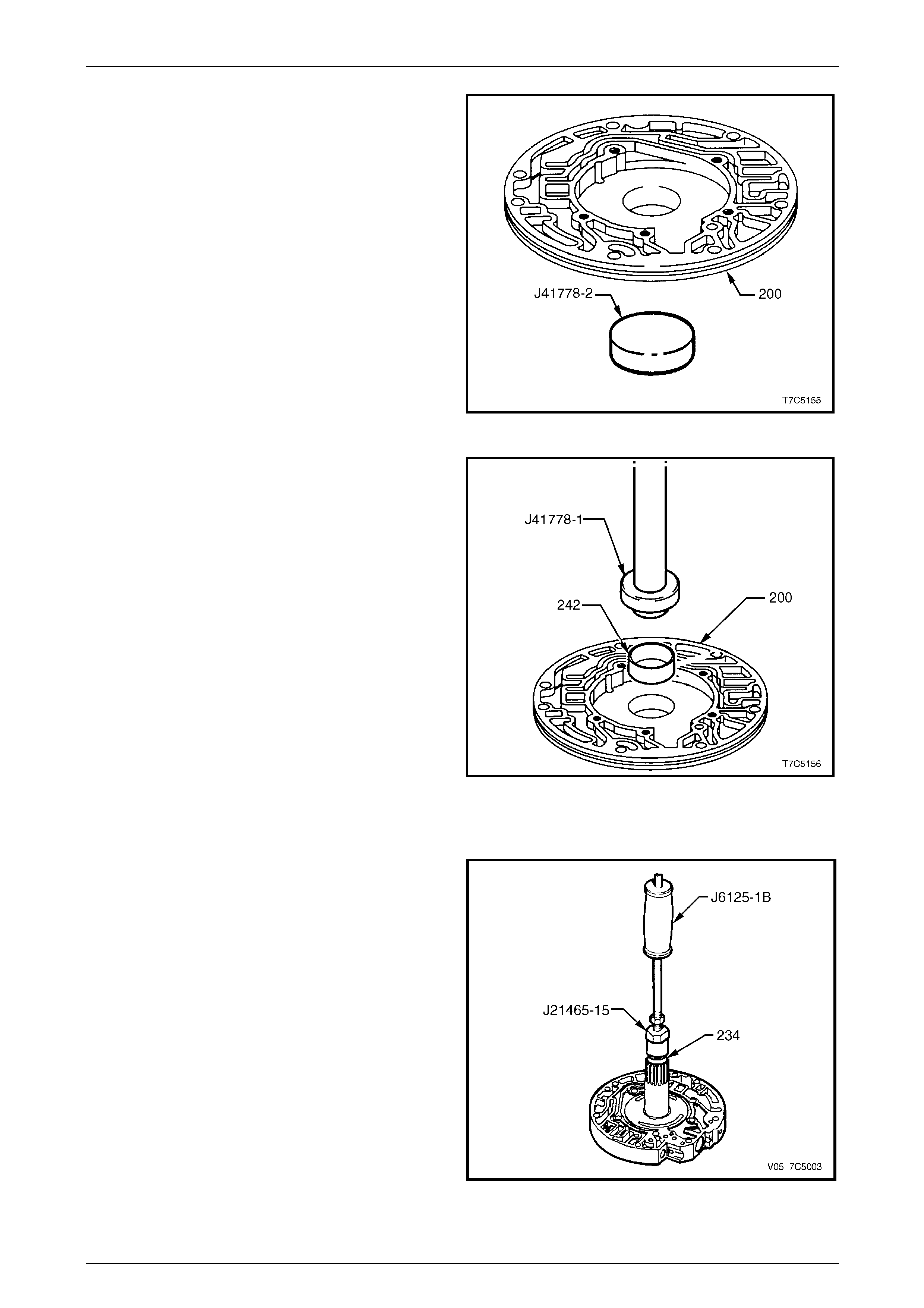

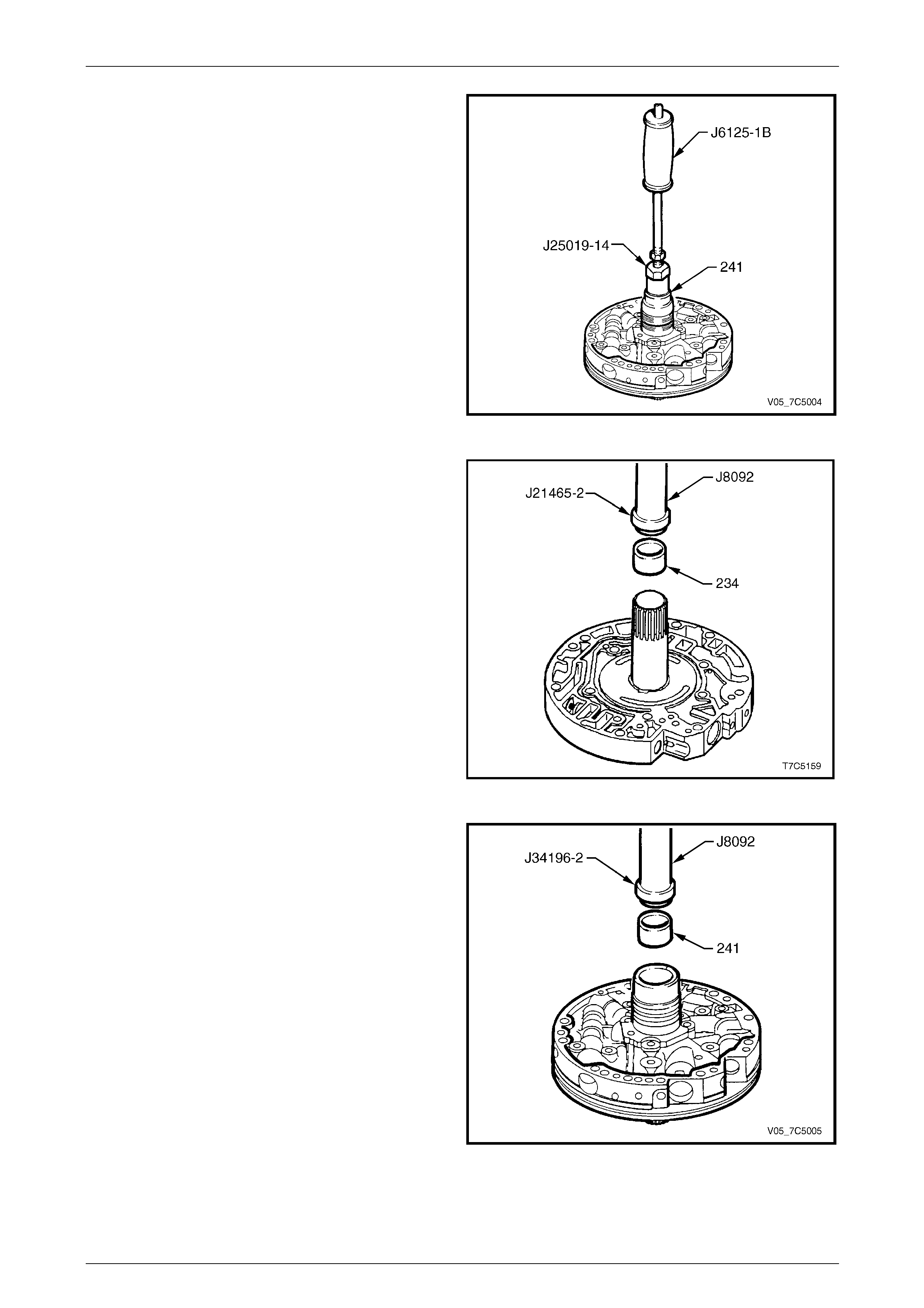

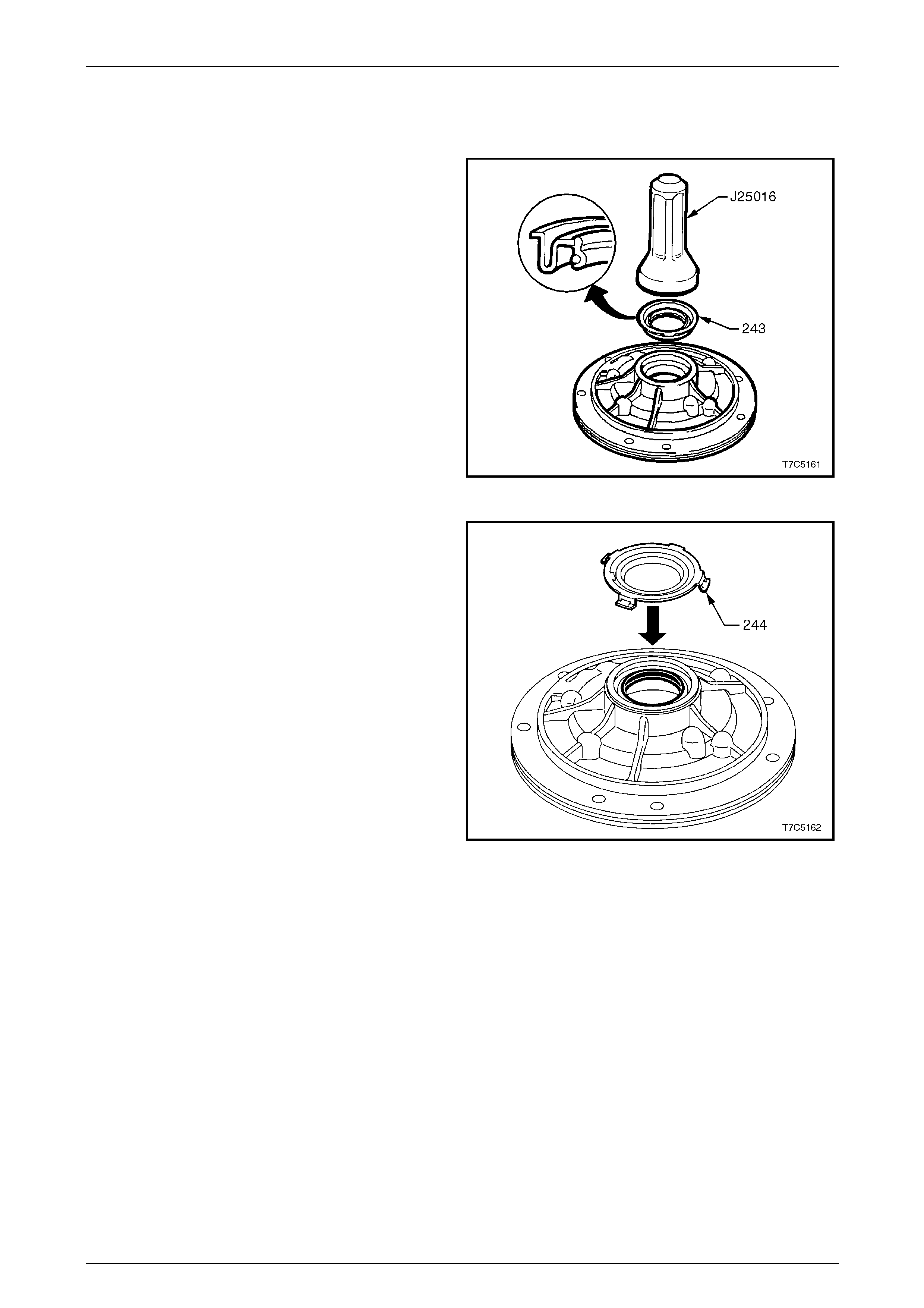

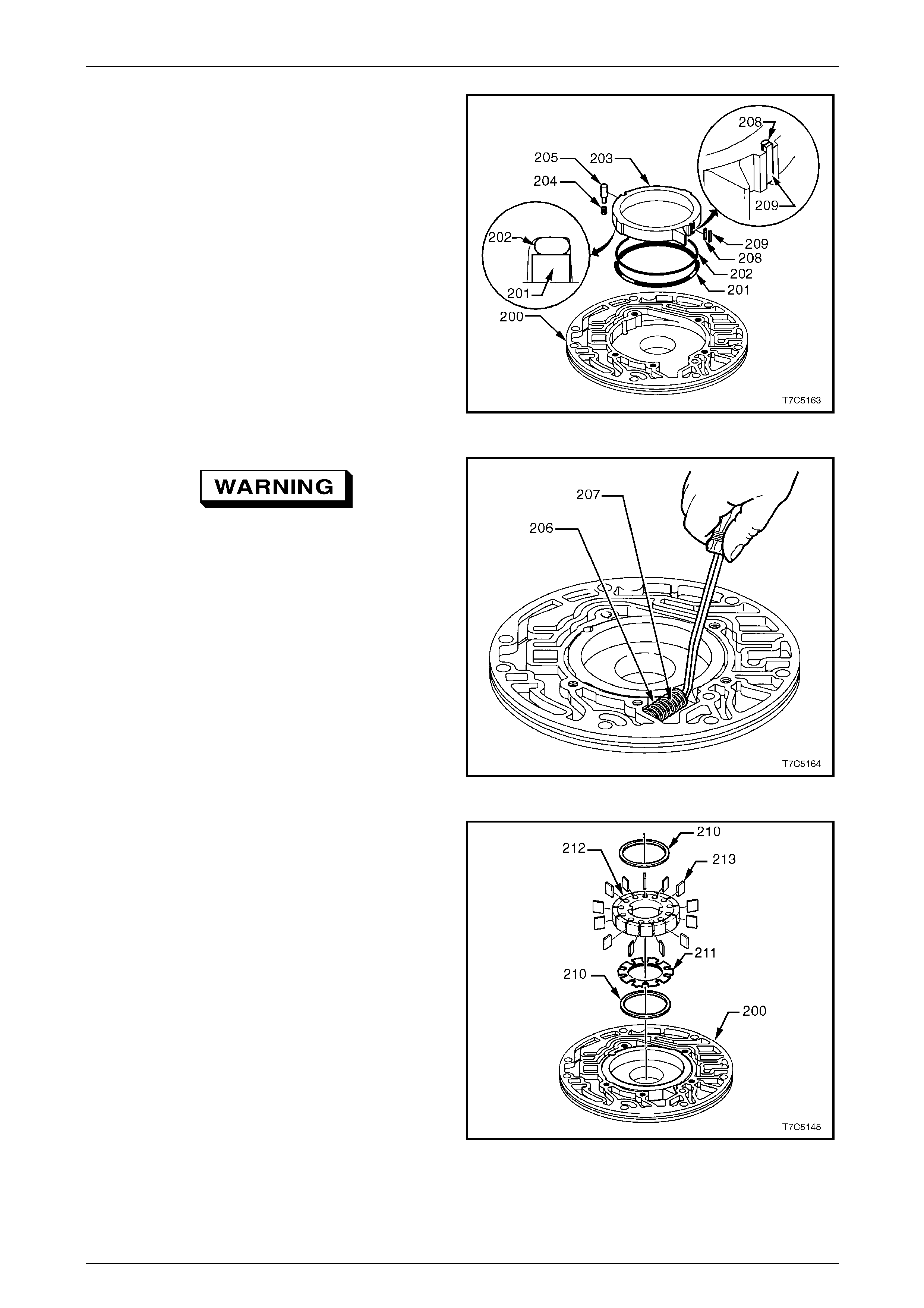

Reassemble.......................................................................................................................................................... 85

Oil Pump Body ................................................................................................................................................. 85

Oil Pump Cover................................................................................................................................................ 87

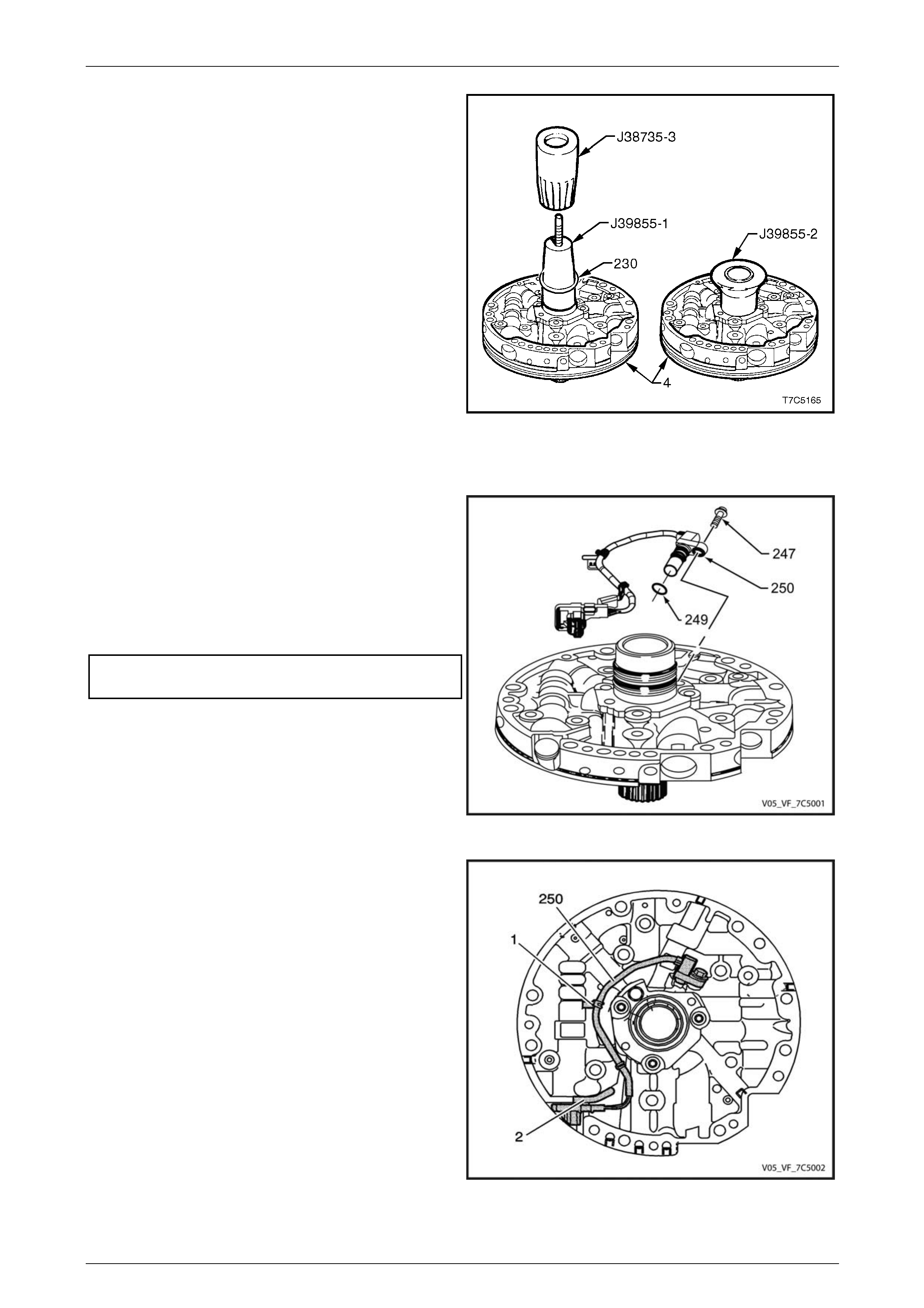

Input Speed Sensor.......................................................................................................................................... 88

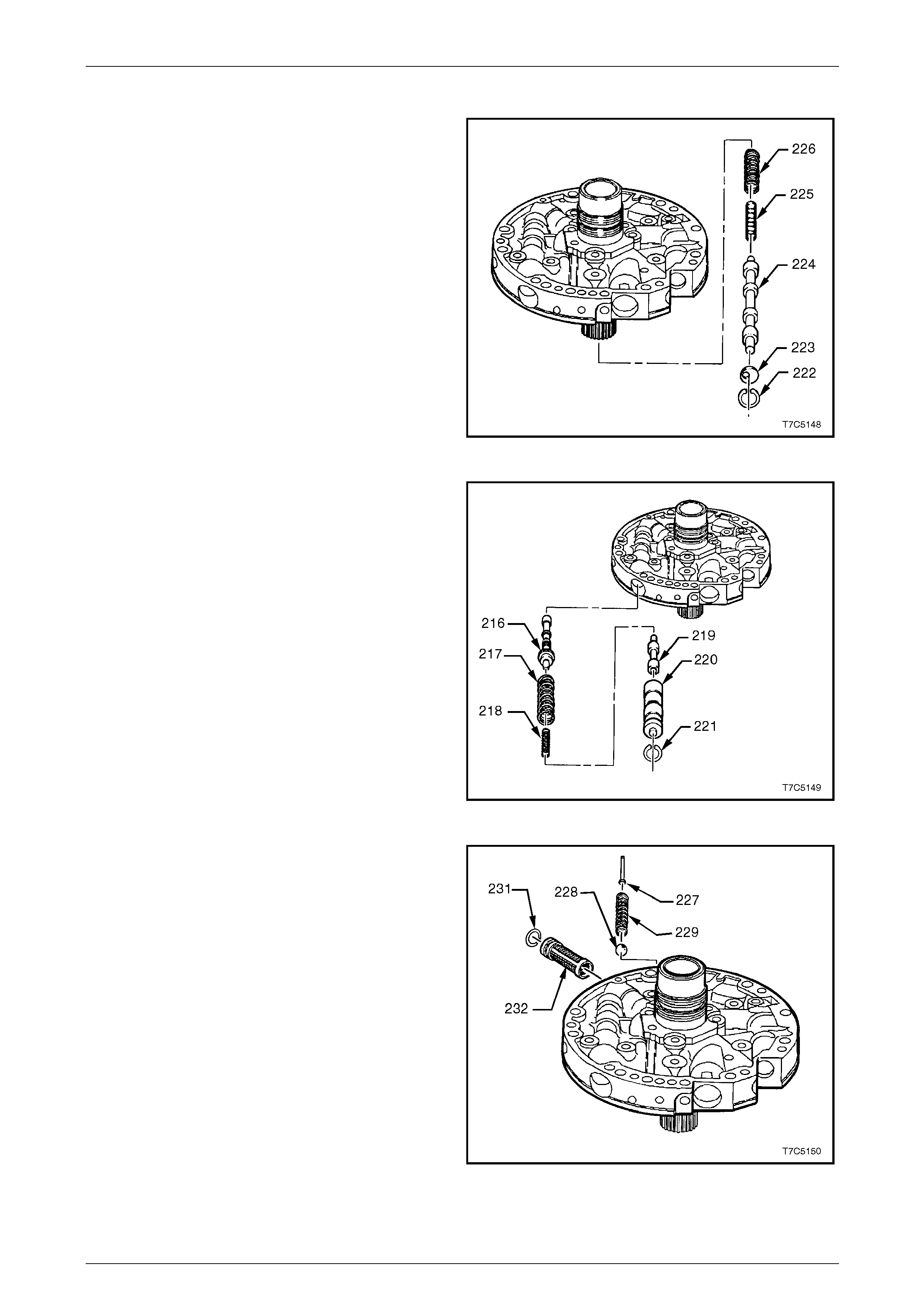

Oil Pump Assembly.......................................................................................................................................... 89

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–3

15–DEC–2005 Page 7D5–3

Oil Pump Air Checks ........................................................................................................................................... 89

Introduction ...................................................................................................................................................... 89

Air Checks Table.............................................................................................................................................. 89

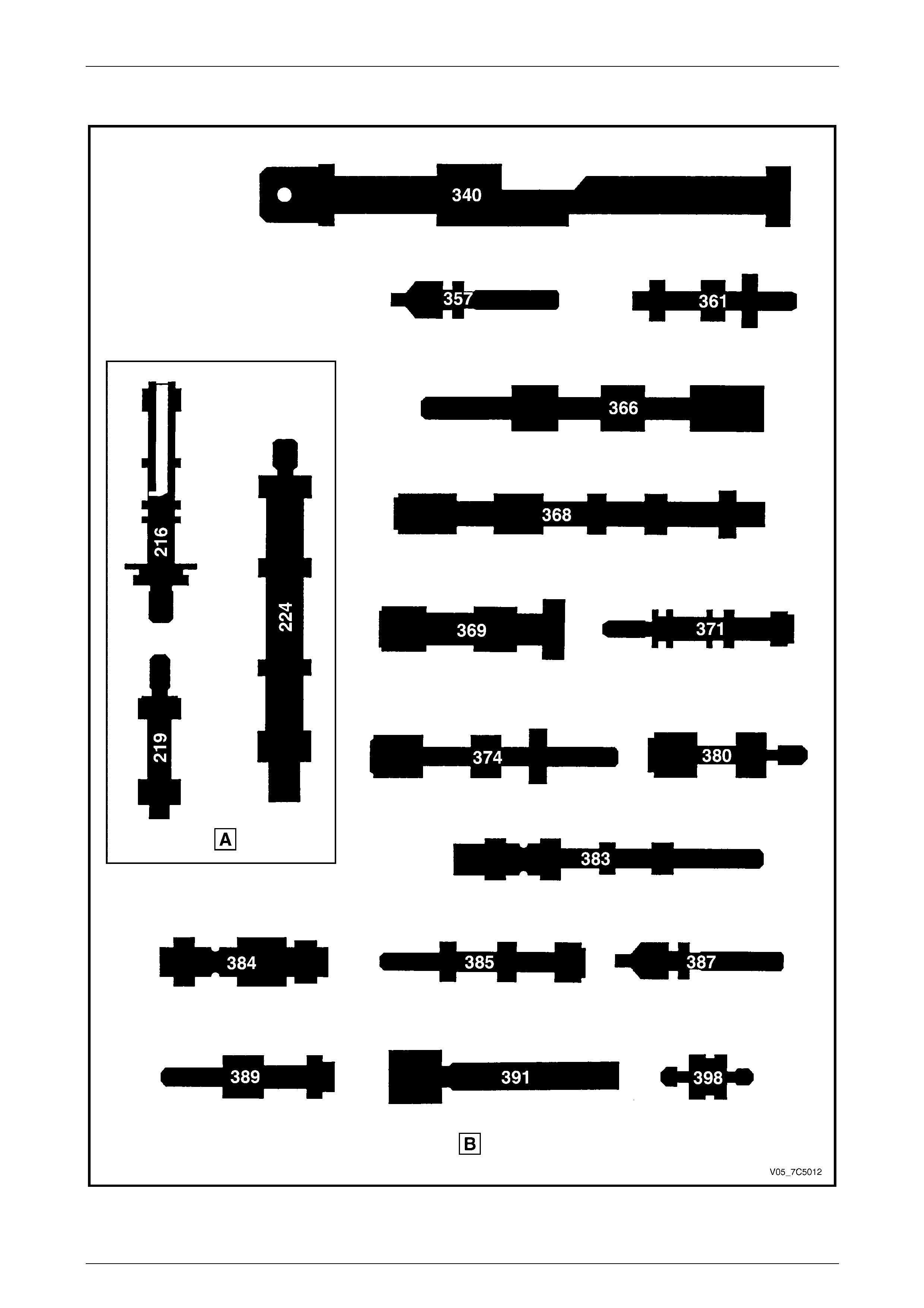

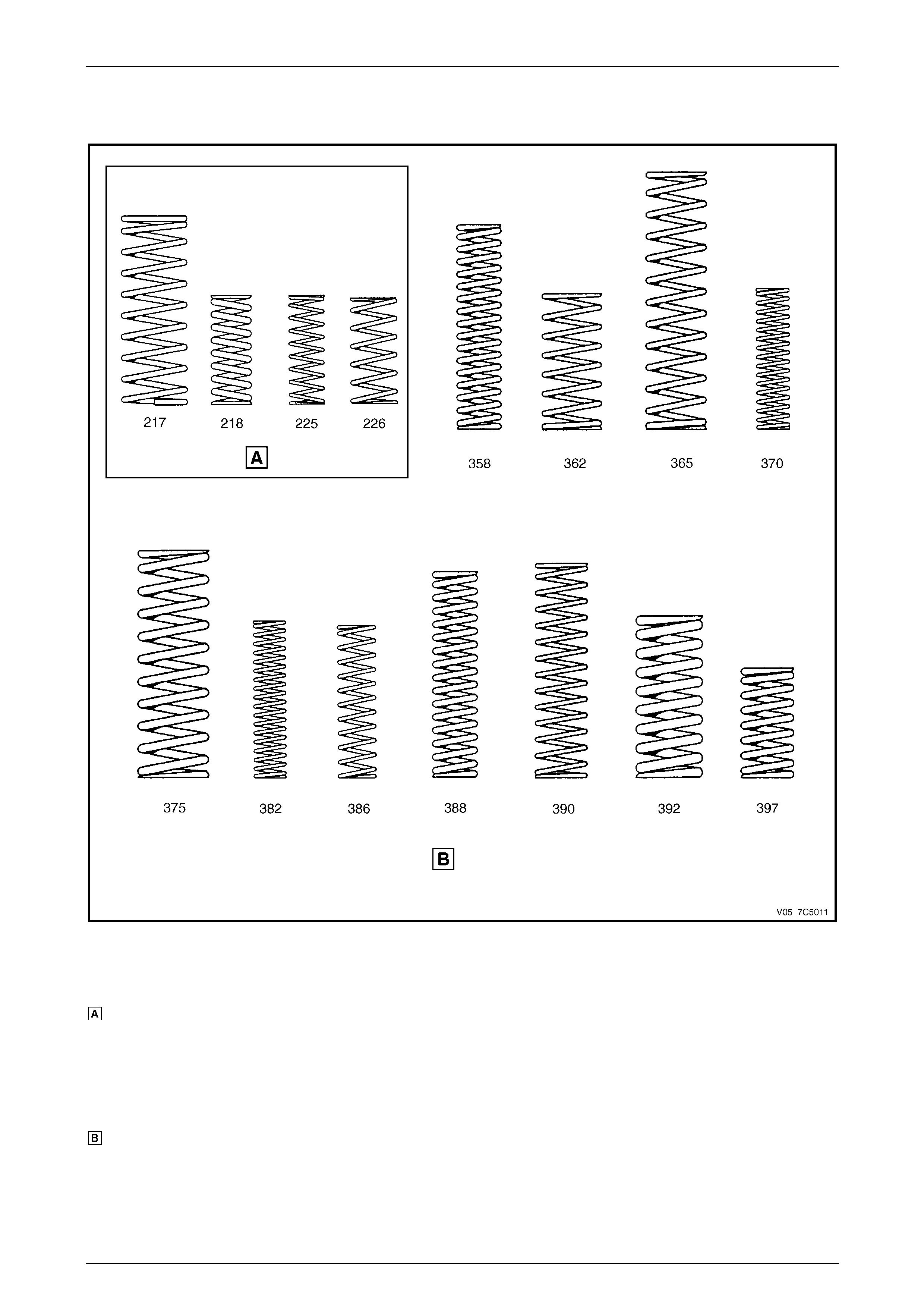

3.16 Control Valve Body.............................................................................................................................................. 91

Exploded Views.................................................................................................................................................... 91

View A.............................................................................................................................................................. 91

View B.............................................................................................................................................................. 92

Disassemble......................................................................................................................................................... 93

Clean and Inspect................................................................................................................................................ 94

Control Valve Body........................................................................................................................................... 94

Spacer Plate Evaluation................................................................................................................................... 94

Reassemble.......................................................................................................................................................... 95

4 Transmission Reassembly..................................................................................................................97

4.1 Manual Shaft, Inner Linkage and Seal................................................................................................................ 97

Reinstall................................................................................................................................................................ 97

4.2 Low and Reverse Clutch Piston ......................................................................................................................... 98

Reinstall................................................................................................................................................................ 98

4.3 Reaction Planetary Gear Set............................................................................................................................. 100

Reinstall.............................................................................................................................................................. 100

4.4 Low and Reverse Clutch Plates and Support Assembly................................................................................ 101

Reinstall.............................................................................................................................................................. 101

4.5 Reaction Gear, Input Gear and Output Shaft................................................................................................... 104

Reinstall.............................................................................................................................................................. 104

4.6 Reverse Input Clutch, Input Clutch and Input Gear Set ................................................................................. 107

Reinstall.............................................................................................................................................................. 107

4.7 2-4 Band Assembly............................................................................................................................................ 109

Reinstall.............................................................................................................................................................. 109

4.8 Oil Pump............................................................................................................................................................. 110

Reinstall.............................................................................................................................................................. 110

4.9 Torque Converter Housing................................................................................................................................ 113

Reinstall.............................................................................................................................................................. 113

4.10 Control Valve Body and Wiring Harness ......................................................................................................... 114

Reinstall.............................................................................................................................................................. 114

4.11 Oil Filter and Oil Pan.......................................................................................................................................... 115

Reinstall.............................................................................................................................................................. 115

4.12 Extension Housing and Speed Sensor ............................................................................................................ 116

Inspect ................................................................................................................................................................ 116

Extension Housing Bush – Replace................................................................................................................. 116

Reinstall.............................................................................................................................................................. 117

4.13 2-4 Servo Assembly........................................................................................................................................... 119

Servo Pin Length – Check................................................................................................................................. 119

Reassemble........................................................................................................................................................ 120

Reinstall.............................................................................................................................................................. 121

4.14 Neutral Start & Back-Up Lamp Sw itch Assembly ........................................................................................... 122

Reinstall.............................................................................................................................................................. 122

4.15 Torque Converter............................................................................................................................................... 123

Inspect ................................................................................................................................................................ 123

End Play Check.................................................................................................................................................. 123

Reinstall.............................................................................................................................................................. 124

4.16 Transmission Fixture Removal......................................................................................................................... 125

5 Transmission Diagrams.....................................................................................................................126

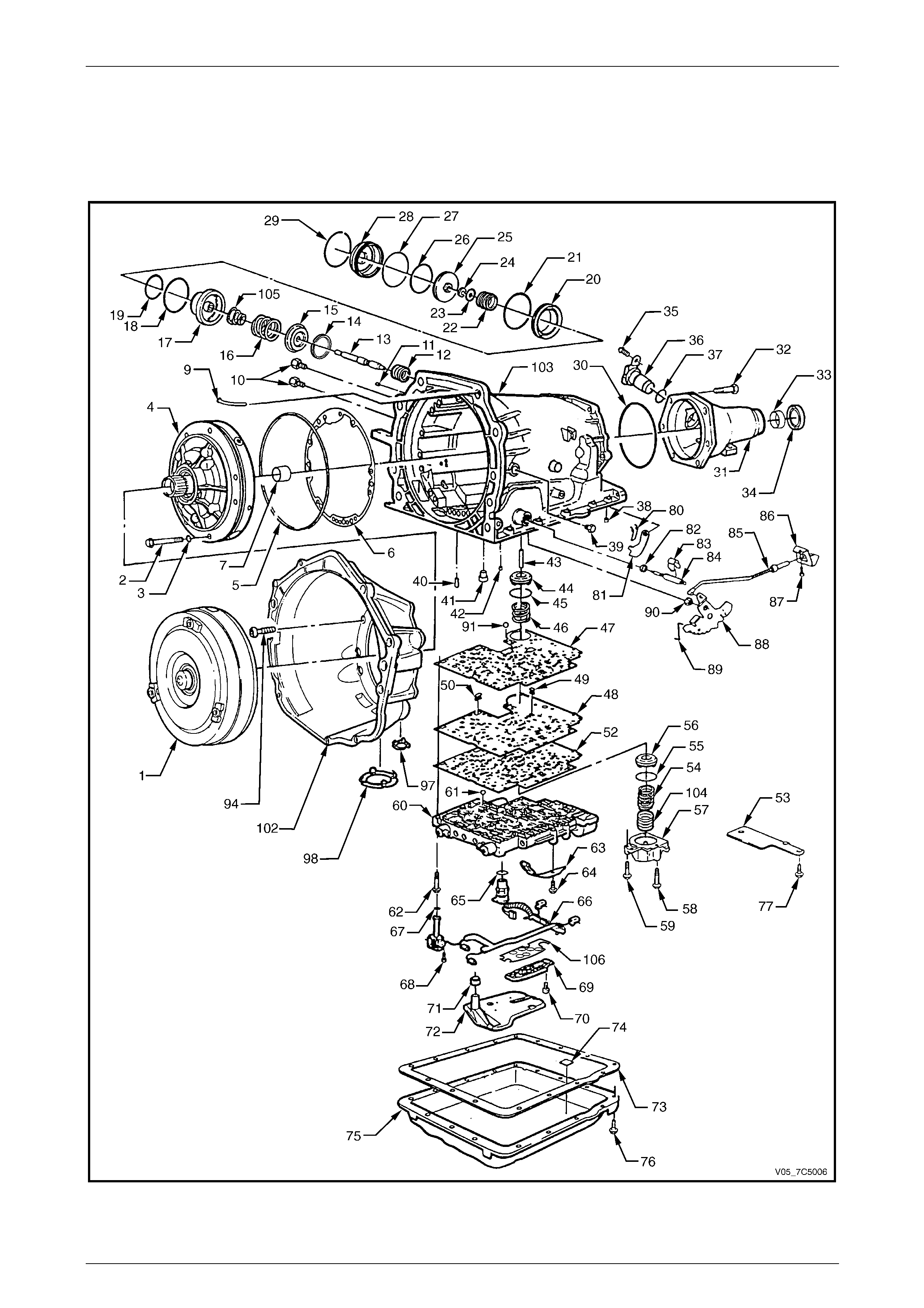

5.1 Transmission Case and External Parts............................................................................................................ 126

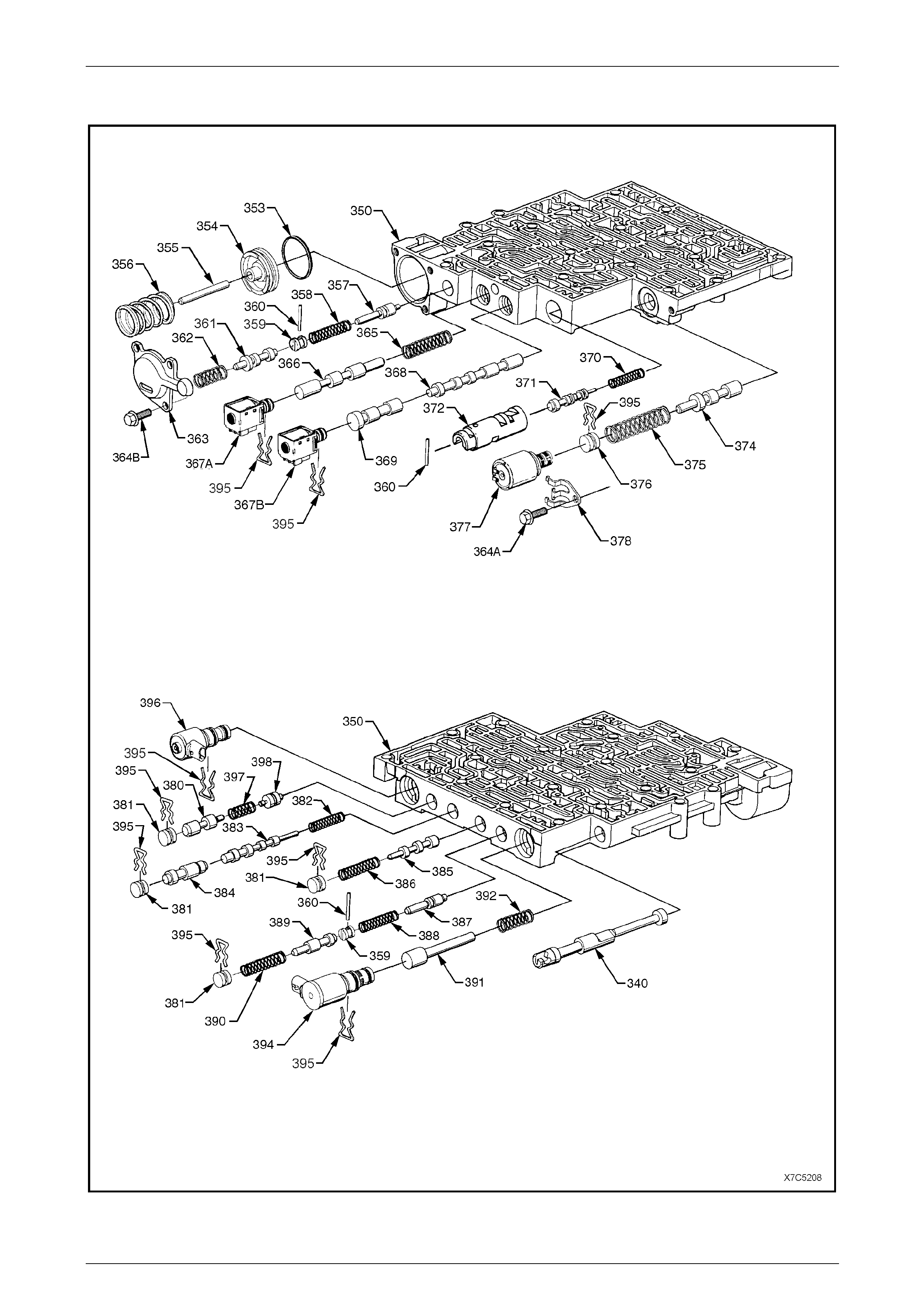

5.2 Control Valve Body Assembly.......................................................................................................................... 128

5.3 Control Valve Identification............................................................................................................................... 130

5.4 Control Valve Spring Identification.................................................................................................................. 132

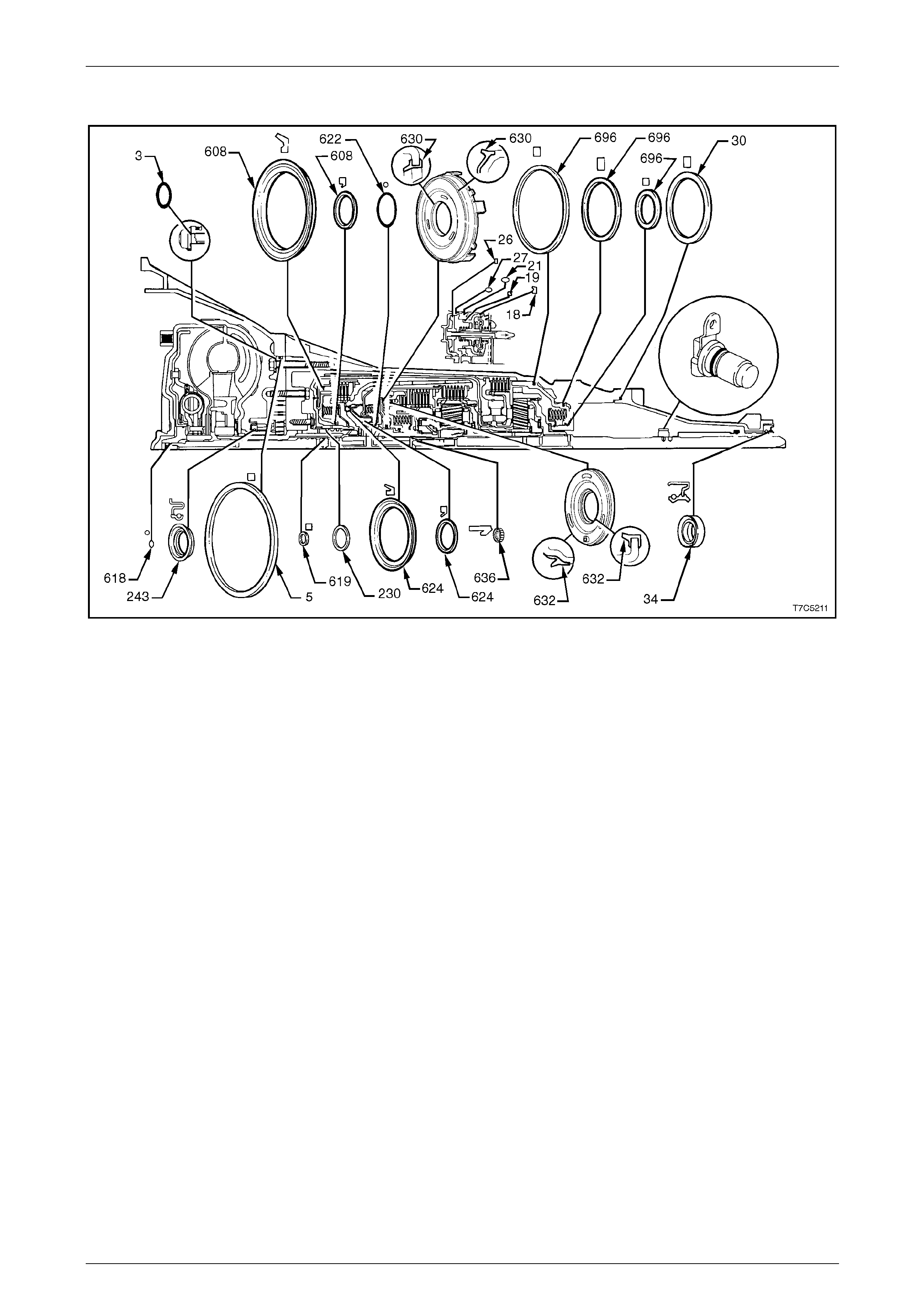

5.5 Seal Location and Orientation.......................................................................................................................... 133

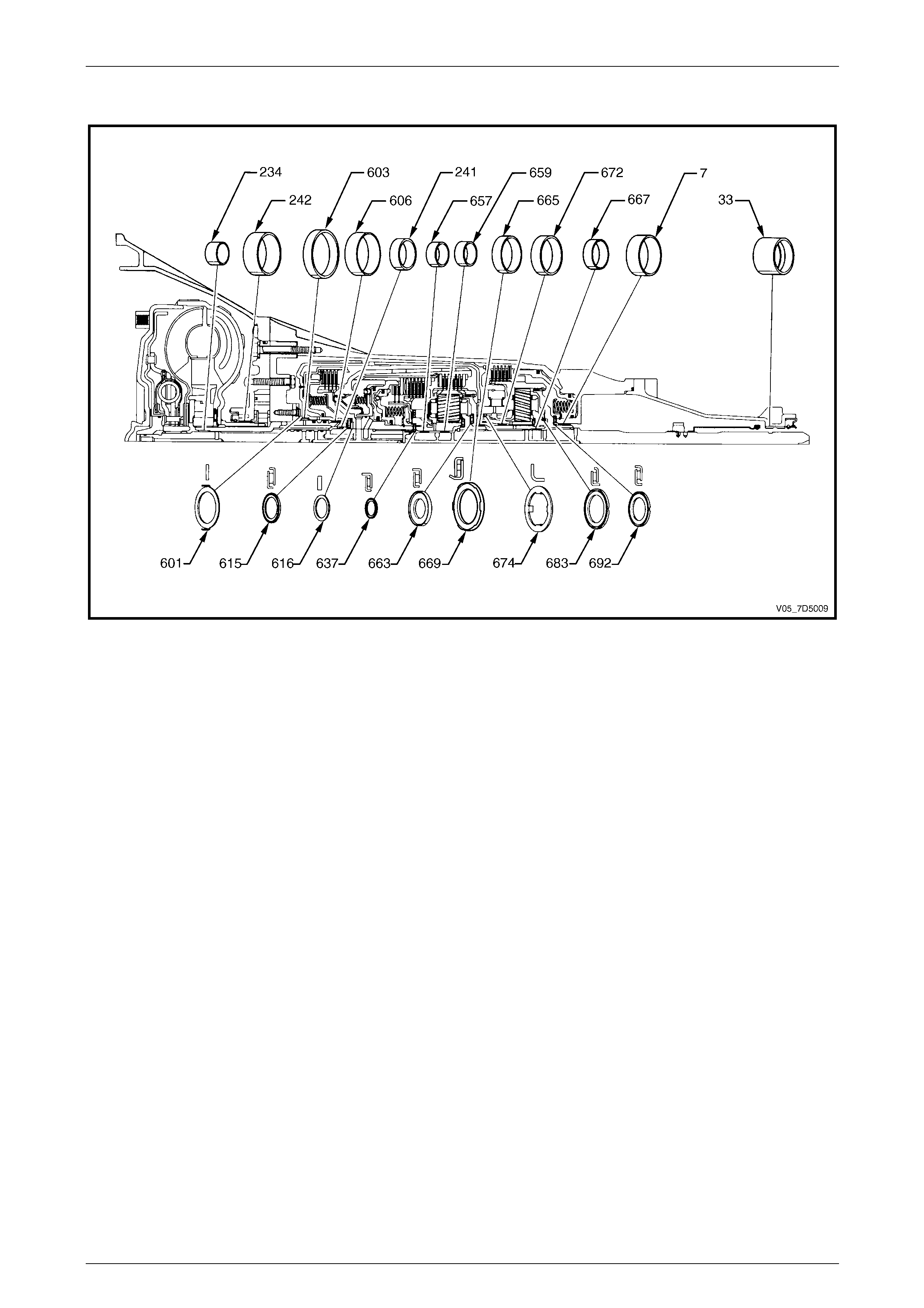

5.6 Bush/Bearing Location and Orientation .......................................................................................................... 134

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–4

15–DEC–2005 Page 7D5–4

6 Specifications.....................................................................................................................................135

7 Torque Wrench Specifications..........................................................................................................136

8 Special Tools ......................................................................................................................................137

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–5

15–DEC–2005 Page 7D5–5

1 General Information

This Section describes the disassembly and reassembly procedures of the four spee d 4L65E hydra-matic automatic

transmission as well as the associated components, with the transmission removed from the vehicle.

1.1 Service Information

Throughout the service operations within this

Section, when handling retaining clips, using

compressed air o r cleaning flu ids, w ear safety

equipment to avoid personal injury.

Refer to Section 7D1 Automatic Transmission – 4L65E – General Informat ion for the following:

• information relating to mechanical and electrical operations,

• abbreviations, transmission specificati ons, special tools and torque wrench specifications,

• servicing, cleaning and inspe c tion procedure recommendations.

It is essential to read and understand the General Information, Warnings, Cautions and Service Notes contained in that

same Section, before any service operation is performed on the four speed 4L65E hydra-matic automatic transmission or

any associated components.

Failure to comply with the procedur es and service notes can affect the reliable and efficient operation of this automatic

transmission.

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–6

15–DEC–2005 Page 7D5–6

1.2 General Description

The four speed 4L65E hydra- matic automatic transmission, although similar to the 4L60E automatic tra nsmissio n, has

been up-graded to cater for high torque and load demands.

The four speed 4L65E hydra- matic automatic transmission features the following:

• The input carrier is up-grade d to a five pinion gear construction.

• The reaction carrier is up-graded to a five pi nion gear construction.

• The sun reaction shell thrust washer is up-graded to a thru st needle bearing construction.

• An oil deflector is added for the five pinion re action carrier.

• The output shaft sleeve and output shaft seal are uni que to cater for the five pinion carrier.

• The input housing and sh aft assembly is unique to cater for high torque and load demands.

• The O-ring seal for the input shaft is unique.

• The quantity of composition pl ates and st eel plates for the 3-4 clutch plate assembly, has been increased to seven

and six respectively.

• A new selective backing plate for the 3-4 clutch assembly, has been introduced to cater for the increased qua ntity

of plates within the 3-4 clutch plate assembly.

• The control valve body gaskets and spacer plate are unique and h ave identification marking VB, CA and IPU

respectively.

• For MY06 vehicles an Input Speed Sensor (ISS) has bee n fitted

The additional pini on gear spreads torque lo ads around to reduce the load supporte d by each gear, in both compression

and bending. The 3-4 clutch has now seven friction plates, this cha ng e results in higher shift energy capacity. A heavy

duty needle bearing is now used for the interface between the reaction shaft and the reacti on sun gear and shell to

withstand increased loads.

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–7

15–DEC–2005 Page 7D5–7

1.3 Rebuilding Tips

The use of air powered tools to disassemble or reassemble this transmission is not recommended. Apa rt from the fact

that thread stripping is more likely when inc orrect torque values are applied to fasteners, component parts can be

distorted to the point where malfunctions will occur.

Teflon Sealing Rings

If any sealing rings are damaged, cut or do not rotate freely in their groove, check if the ring groove has no trapped

debris, is not burred or damaged in such a wa y that it would cause earl y failure of a replacement ring.

Thrust Washer Surfa ces

On inspection, thrust washer and thrust bear ing surfaces may appear to be polished at points of contact. This is a normal

condition and should not be considered as damage requirin g replacement.

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–8

15–DEC–2005 Page 7D5–8

2 Transmission Disassembly

2.1 Transmission Preparation

LT Section No. — 04–200

Take care when lifting or handling the

transmission as it is a heavy assembly and

personal injury may result if lifted incorrectly.

Use appropriate lifting gear.

1 Thoroughly clean exterior of transmission.

2 If the removal of the control valve body harness is

anticipated, its connector should be pushed into the

transmission case before fitting the holding fixture.

Use the connector release, Tool No. 700-4208, to

compress the connector four retaining tangs, push ing

down squarely on the connect or.

NOTE

Alternatively a 1 5/16" socket (¾" drive) may be

used.

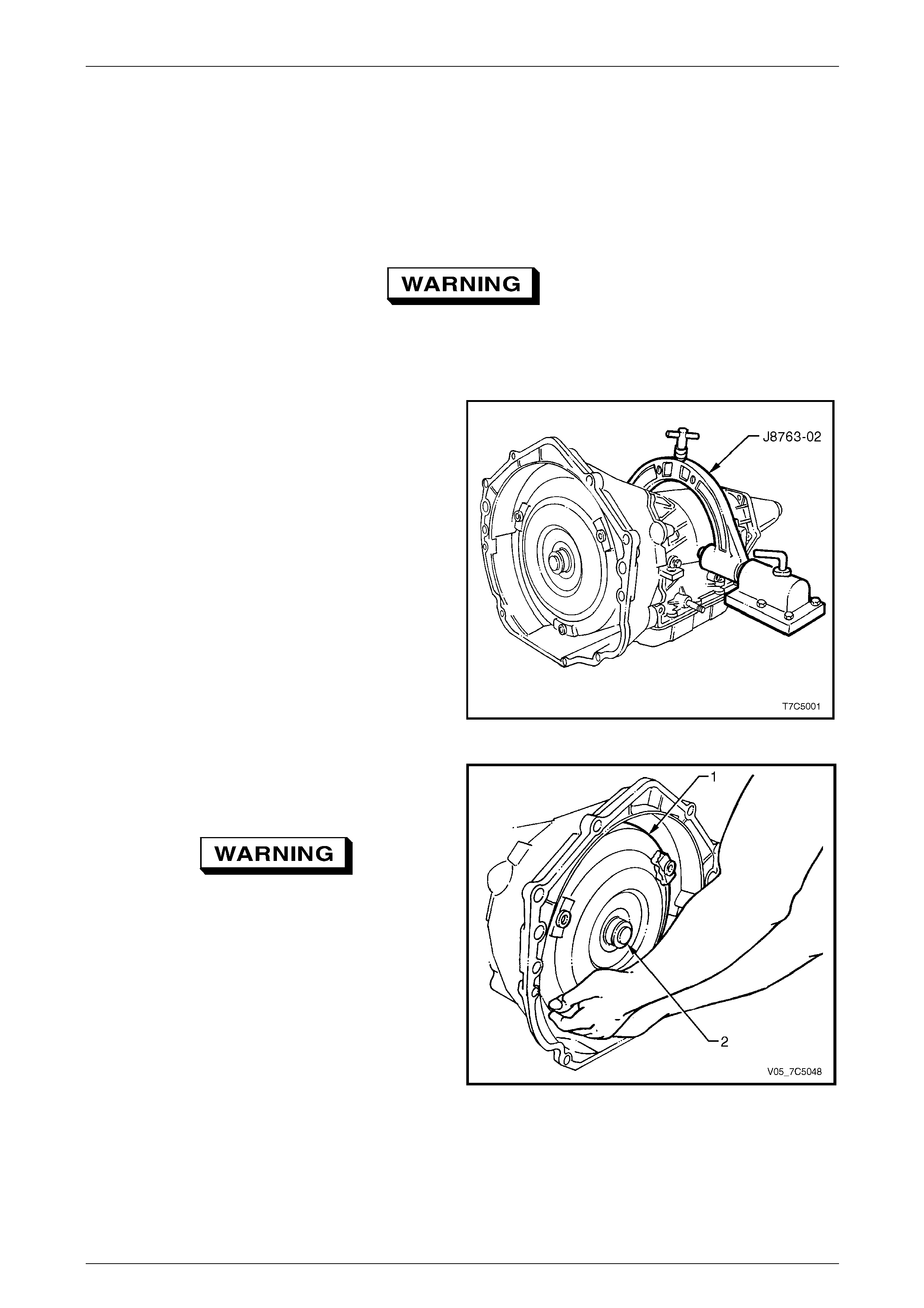

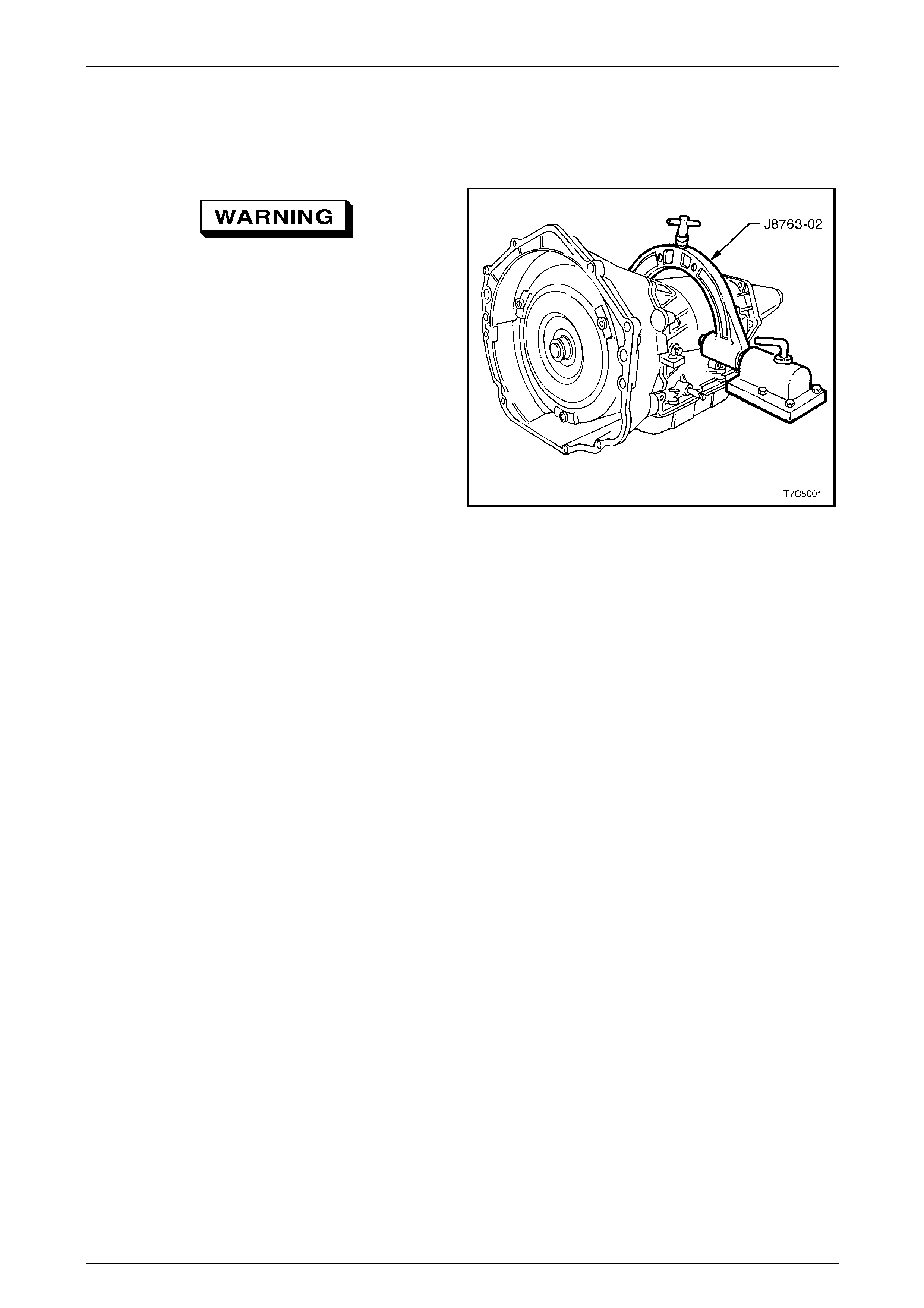

3 Install the transmission holding fixture, Tool No.

J8763-02, as shown and mount the fixture into the

base, Tool No. J3289-20, the 2-4 servo facing away

from the workbench.

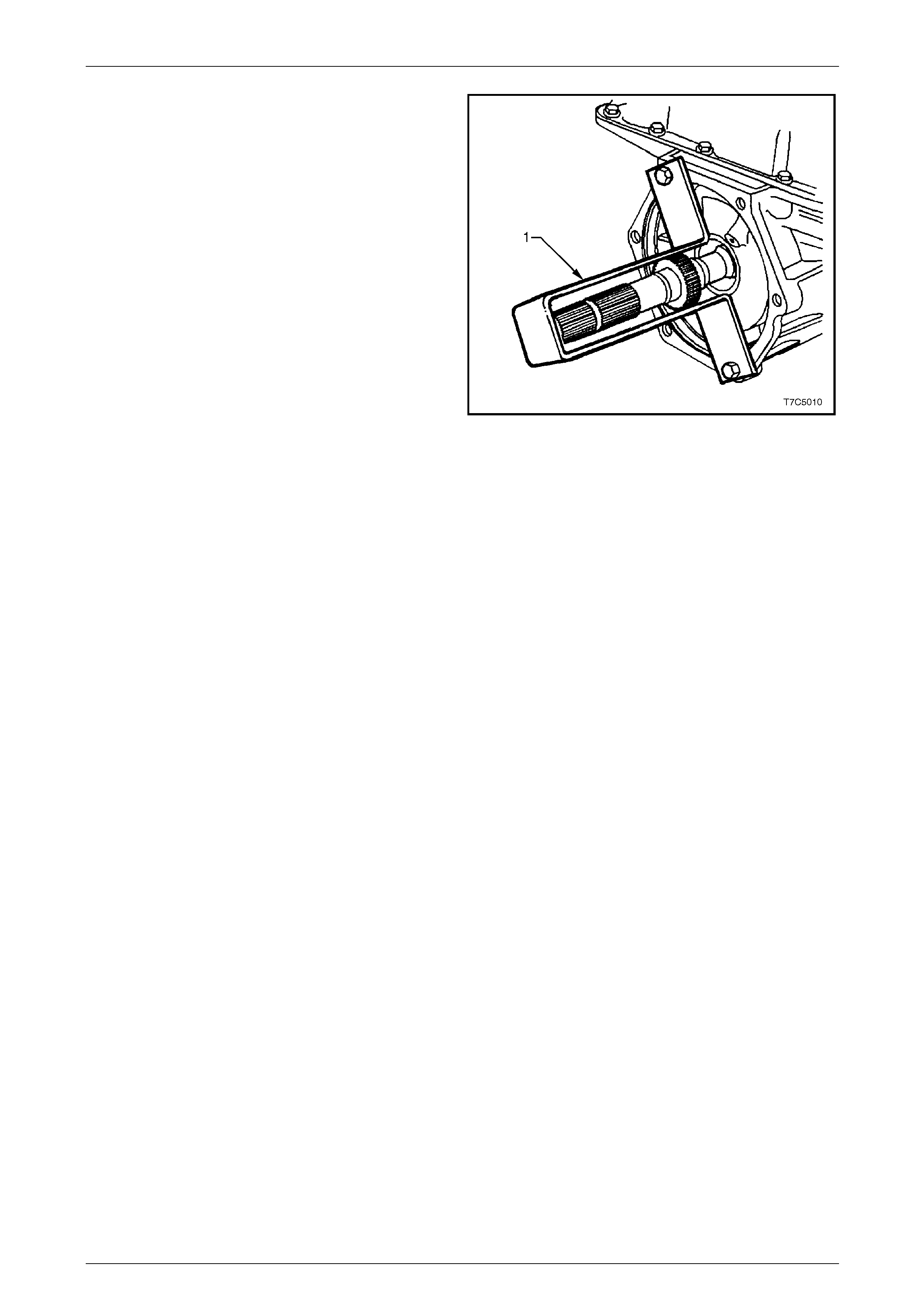

Figure 7D5 – 1

4 Remove the torque converter (1) by sliding it clear of

the input shaft (2). Drain stored converter fluid into a

suitable container.

Take care when removing the torque

converter as it is a heavy assembly and

personal injury may result if lifted incorrectly.

NOTE

Ensure the container has the capacity to hold at

least 8 litres.

5 Rotate the transmission so the converter housing

faces upward and drain the fluid from the extension

housing.

Figure 7D5 – 2

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–9

15–DEC–2005 Page 7D5–9

2.2 2 – 4 Servo Assembly

LT Section No. — 04–200

Remove

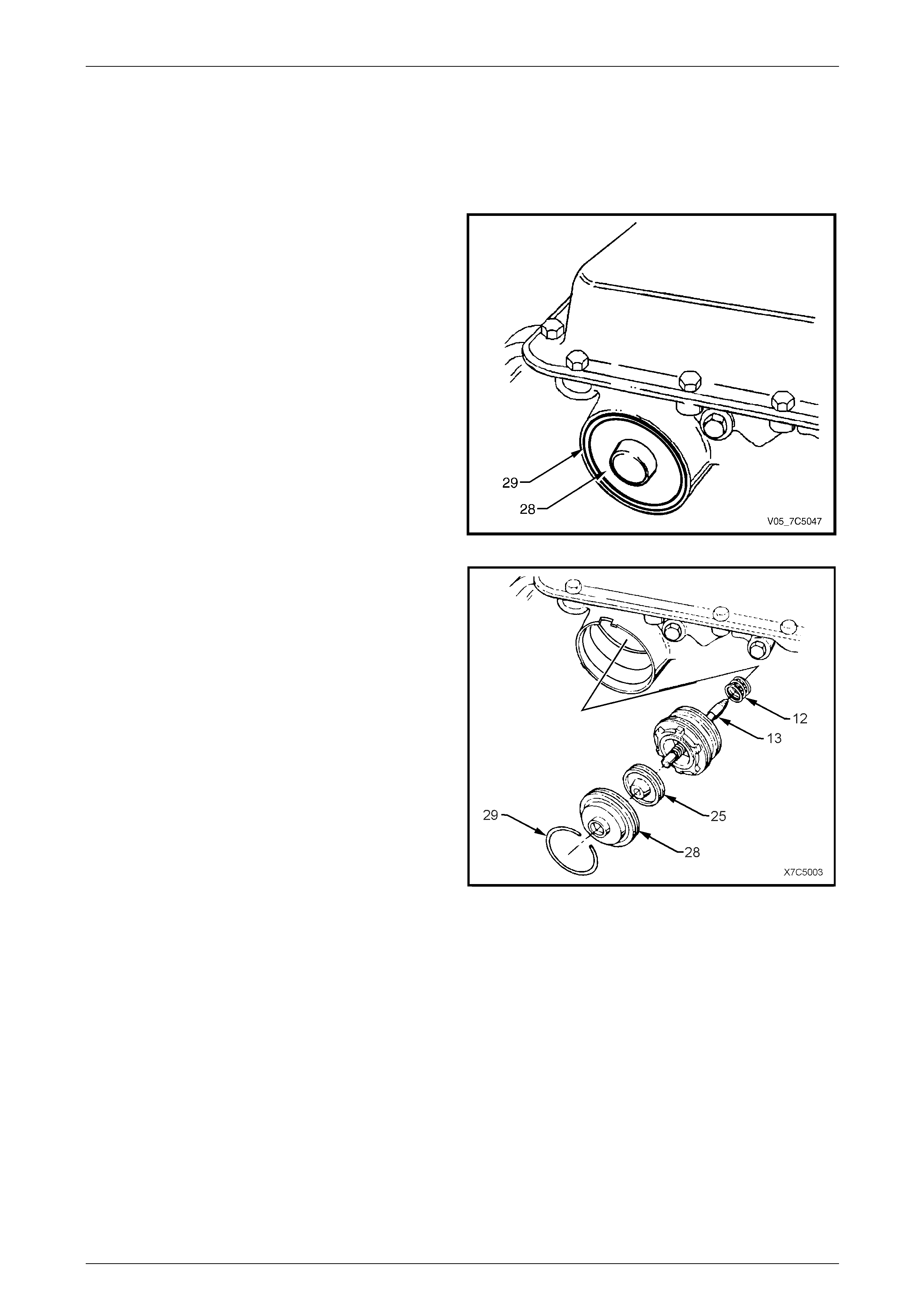

1 Depress the 2-4 servo cover (28) with a hammer

handle and hold.

2 Remove the cover retainer ring (29).

Figure 7D5 – 3

3 To remove the cover (28), either cut the O-ring seal

(not shown) and remove with thin nosed pliers first, or

stretch the O-ring by pulling it throug h one of the two

openings, while removing the cover.

NOTE

The fourth apply piston (25) may come out with

the cover (28). If so, and the piston accidentally

falls to the floor, ensure the teflon ring grooves

have not been damaged to the point where ring

binding and/or damage could occur.

4 Remove the fourth apply piston (25) from the second

apply piston assembly.

5 Remove the second apply piston and servo pin

assembly (13).

6 Remove the servo return spring (12).

Figure 7D5 – 4

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–10

15–DEC–2005 Page 7D5–10

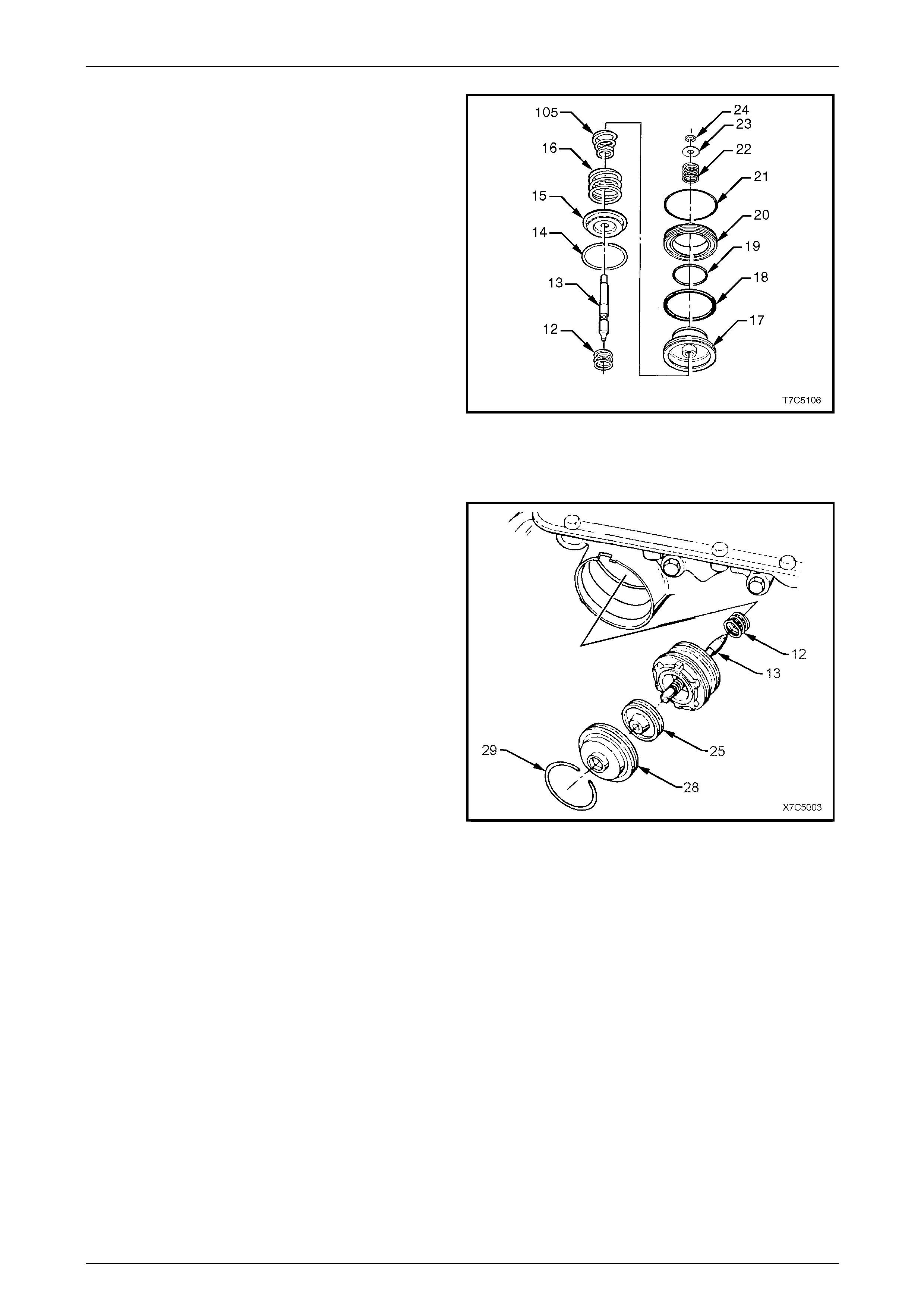

Disassemble

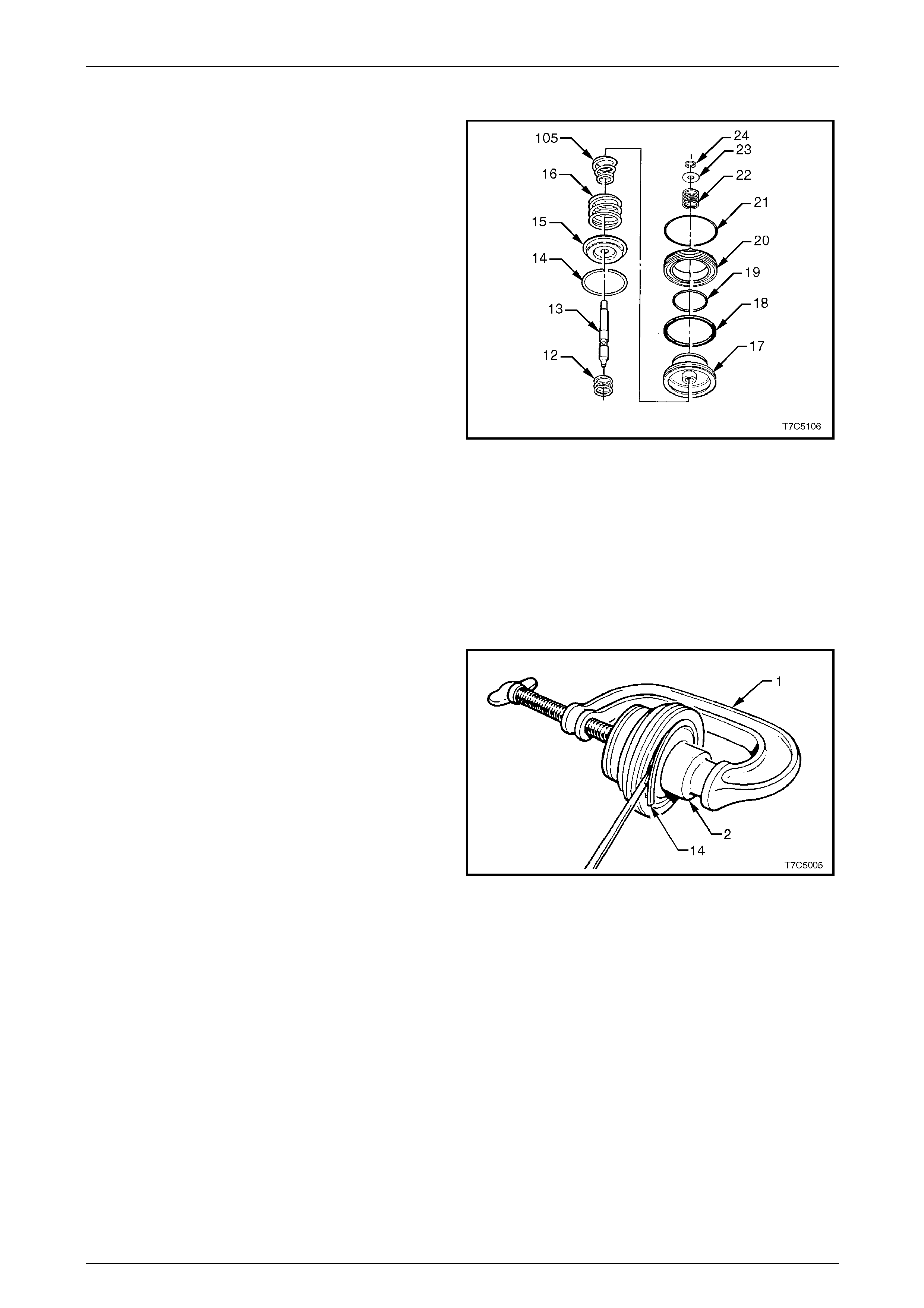

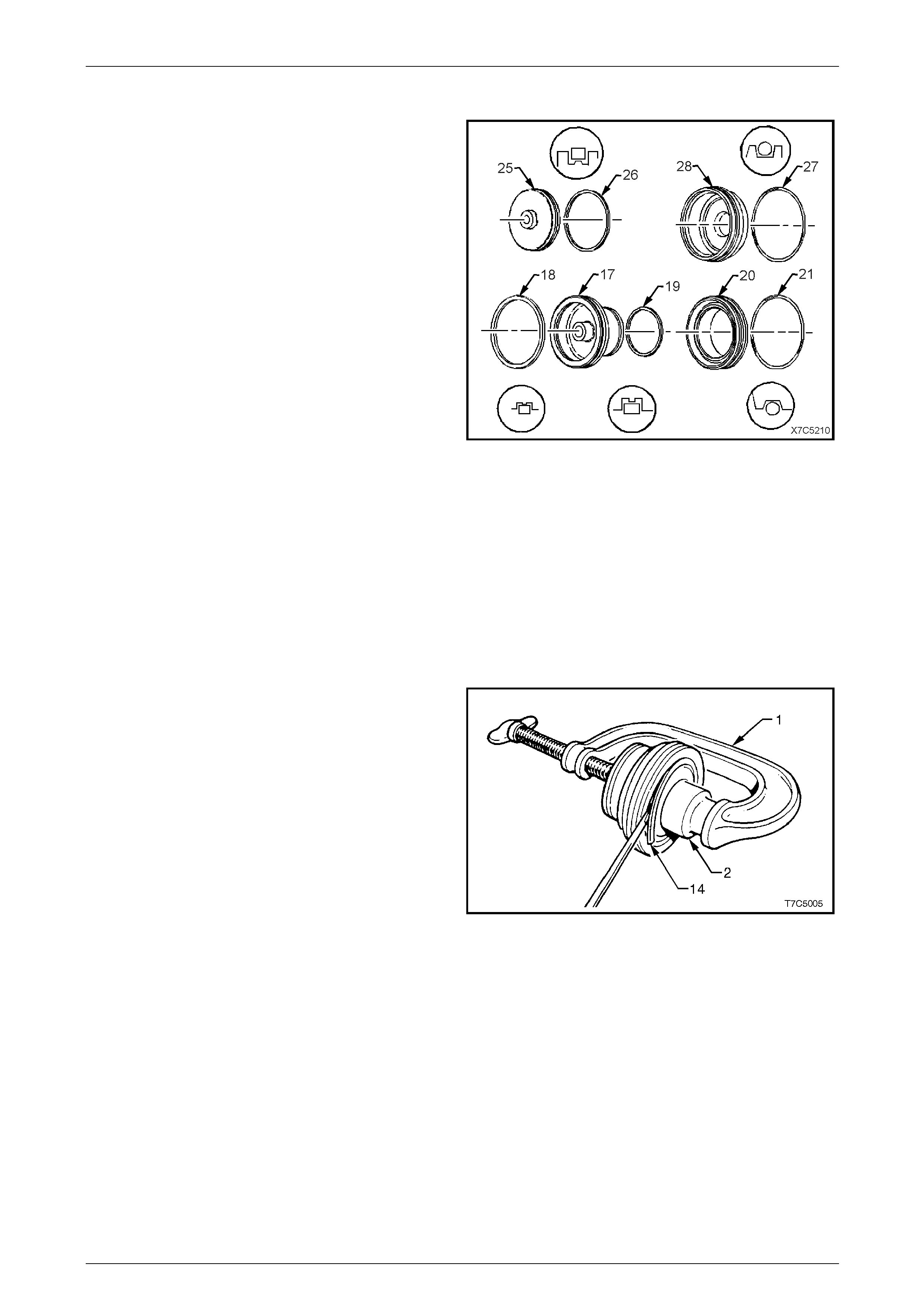

Components identification:

12 spring, servo return

13 pin, 2nd apply piston

14 ring, retainer (2nd apply piston)

15 retainer, servo cushion spring

16 spring, servo cushion (outer)

105 spring, servo cushion (inner) (V6 eng ine only).

17 piston, 2nd apply

18 ring, oil seal (2nd apply piston - outer)

19 ring, oil seal (2nd apply piston - inner)

20 housing, servo piston (inner)

21 seal, O-ring

22 spring, servo apply p in

23 washer, servo apply pin

24 C-clip retainer, servo apply pin.

1 Remove the servo pin retainer clip (24) from the

second apply piston pi n (13).

2 Remove the washer (23) and apply pin spring (22).

3 Remove second apply piston pin.

Figure 7D5 – 5

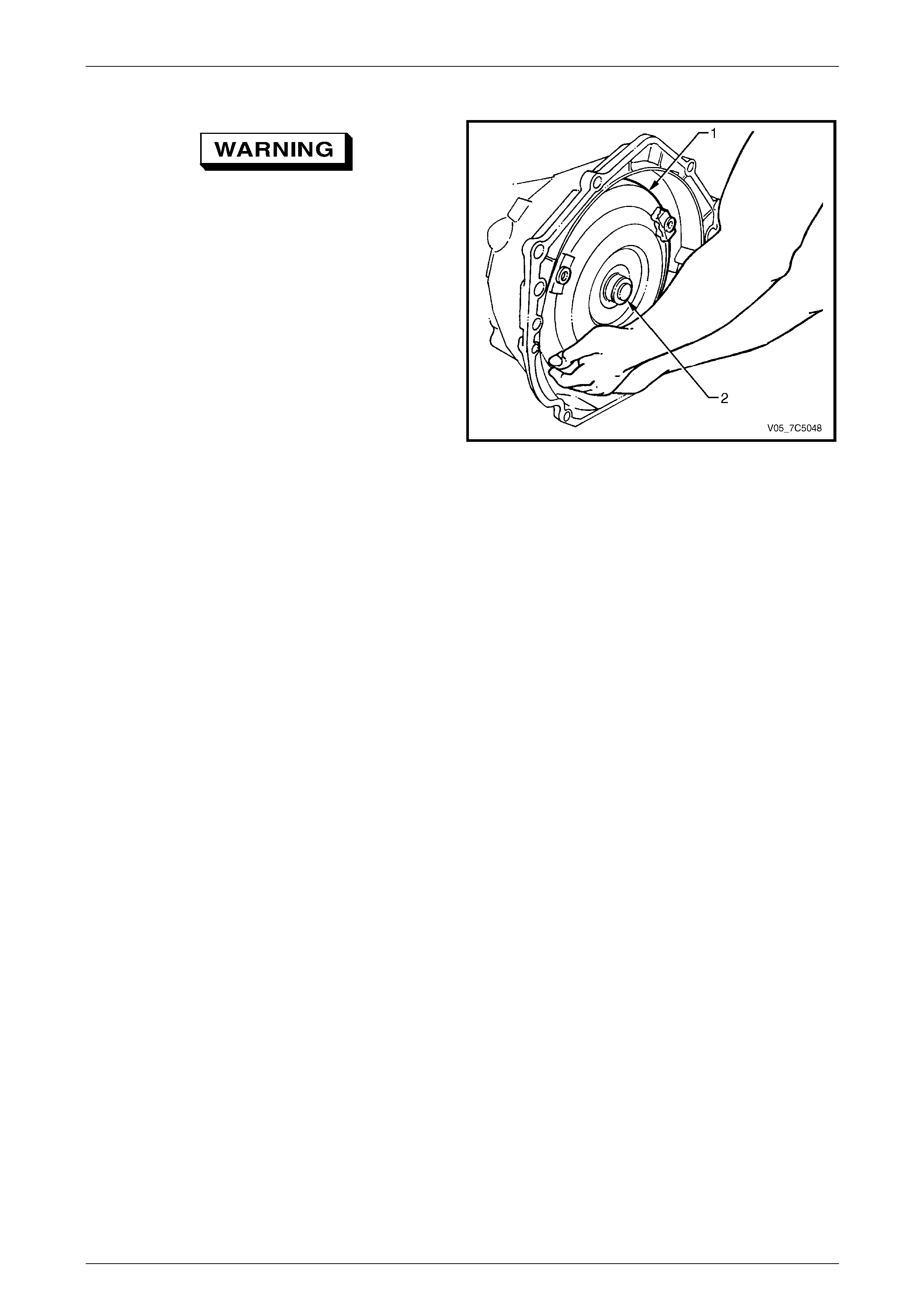

4 Fit a suitable G-clamp (1) and socket (2), to the

second apply piston assembly, as shown.

5 Use this arrangement to compress the piston

assembly.

6 Remove the second apply piston retainer ring (14).

7 Remove the G-clamp and socket.

NOTE

The tapered cushion spring (105) is not fitted to

transmission with GEN III V8 engine.

8 Remove the cushion spring (16), tapered cushion

spring (105) and retainer (15), refer to Figure 7D5 – 5.

NOTE

The reassembly of the 2 – 4 Servo is carried out

on transmission reassembly, refer to

4.13 2-4 Servo Assembly.

Figure 7D5 – 6

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–11

15–DEC–2005 Page 7D5–11

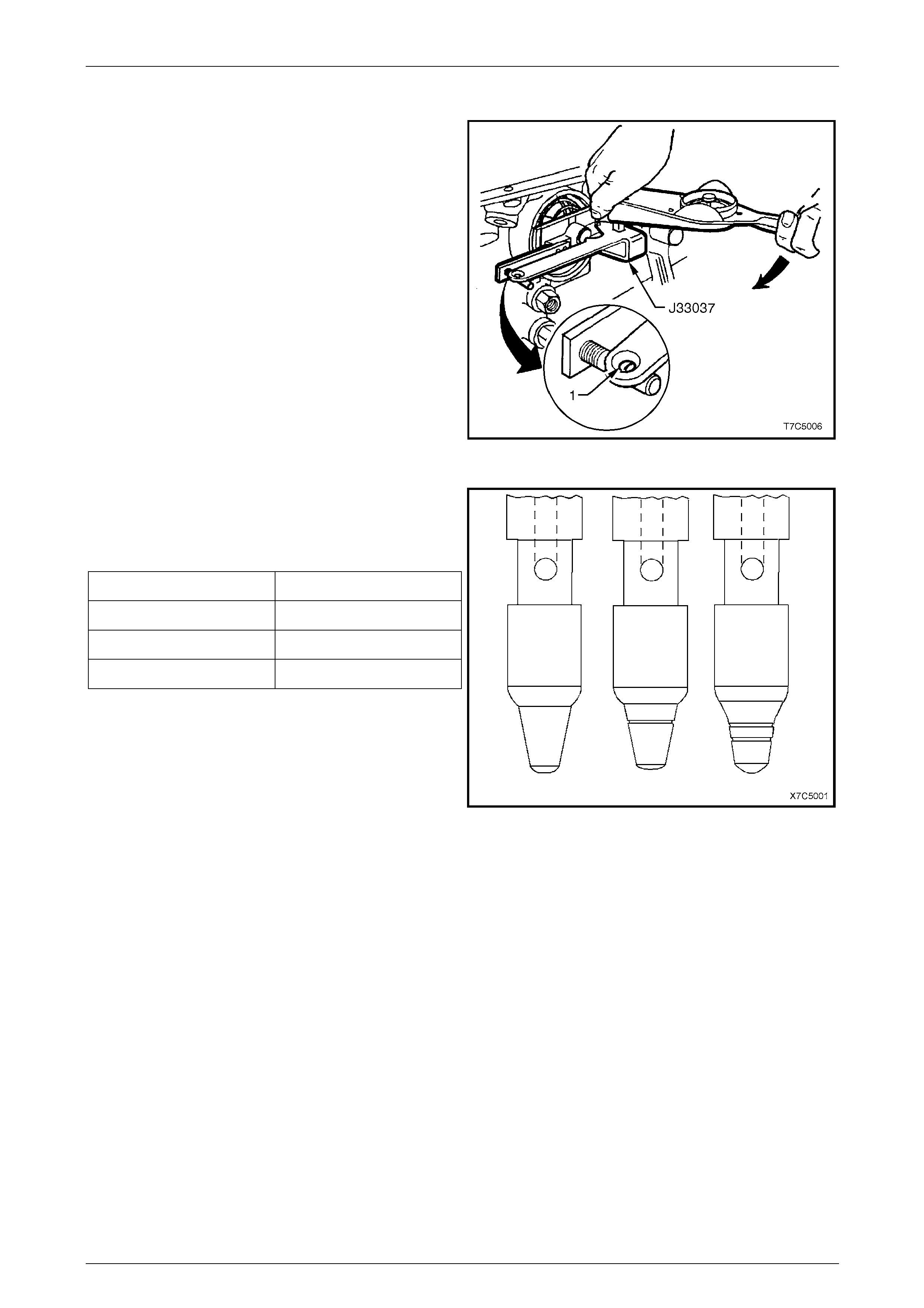

Servo Pin Length

NOTE

At this stage, it is advisable to measure the

length of the installed servo pin. If the pin is too

short or too long, look closely at the 2-4 band

and reverse input drum for wear and/or damage,

once the transmission has been disassembled.

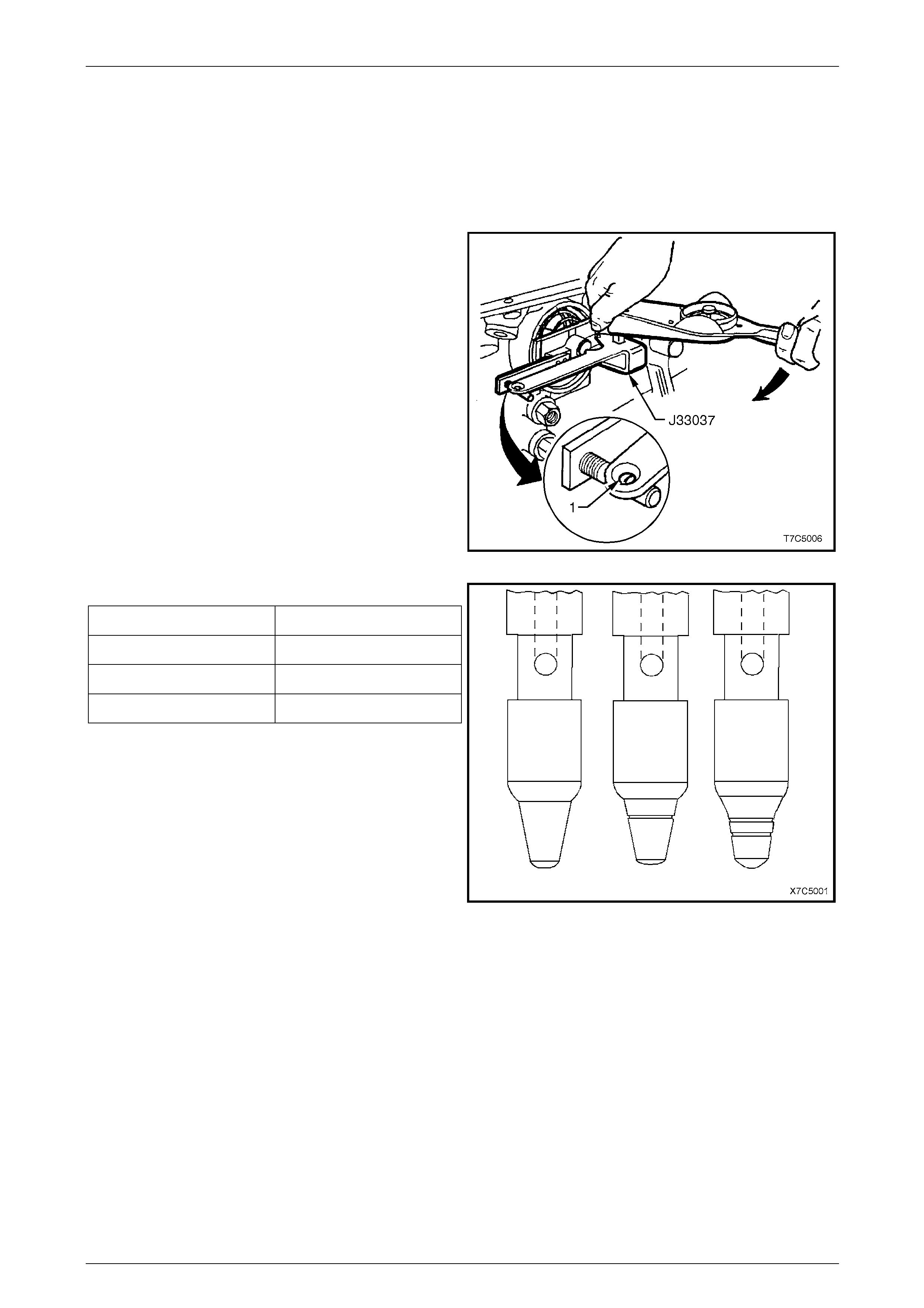

1 Install the pin, tapered end first.

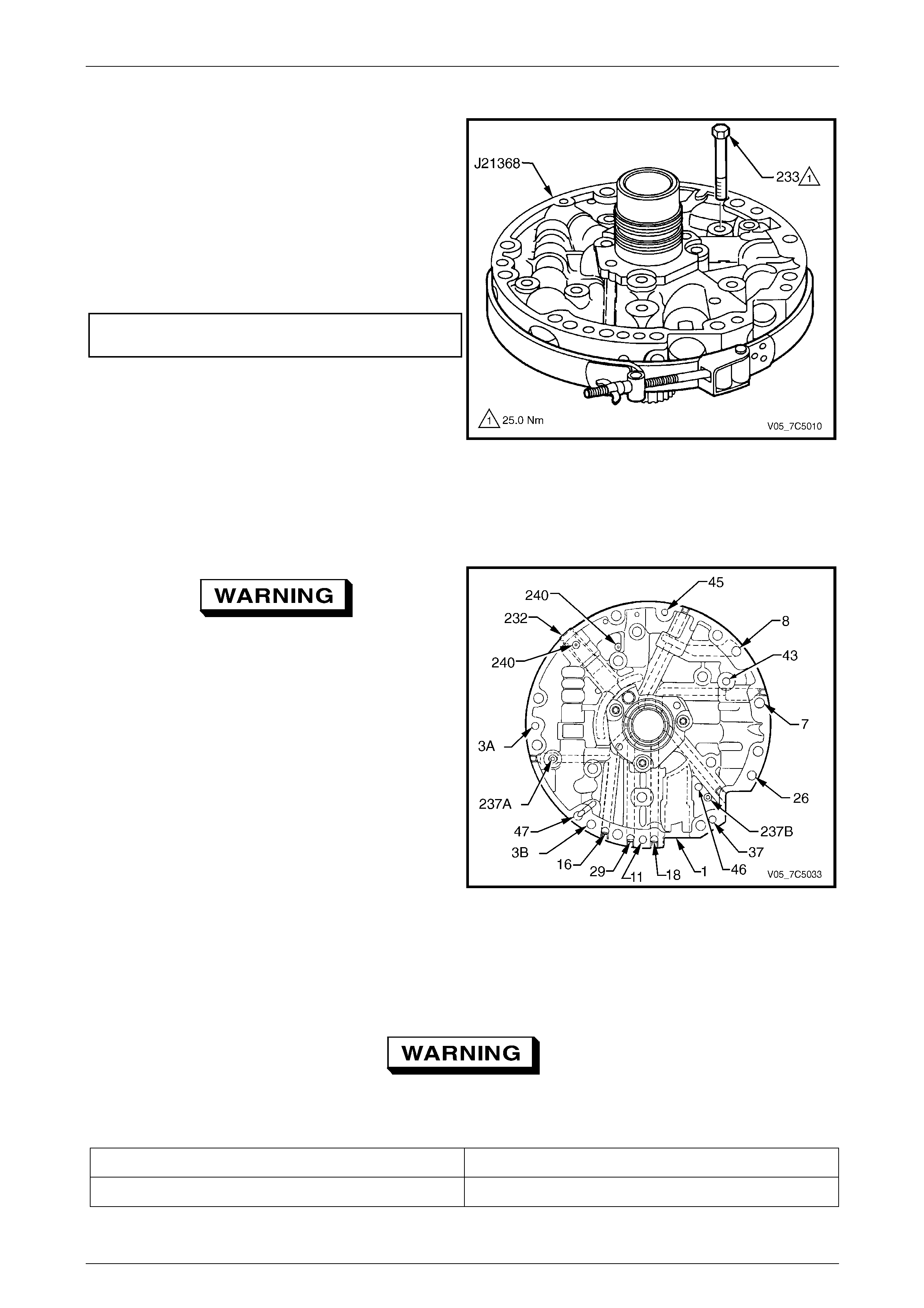

2 Install Tool No. J33037 as shown, and refit the servo

cover retaining ring to secure the tool.

3 Apply 11 Nm torque to the tool arm.

• If a white line appears in the gauge e yelet (1),

the pin length is correct.

• If the white line does not appear in the gauge

eyelet, the pin may require replac ement.

4 Remove Tool No. J33037 and the second apply piston

pin from the transmission case. Figure 7D5 – 7

5 Measure the pin length and re cord.

6 If the pin length is incorrect and requires replacement,

use the following selection table to determine the

correct pin length.

Pin Length (mm) Identification

65.82 – 66.12 1 Groove

67.23 – 67.53 2 Grooves

68.64 – 68.94 No Groove

Figure 7D5 – 8

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–12

15–DEC–2005 Page 7D5–12

2.3 Speed Sensor and Extension Housing

LT Section No. — 04–200

Remove

For service procedures of the adaptor housing and speed sensor fitted to AWD vehicles, refer to Section 7F Transfer

Case and Adaptor Housing.

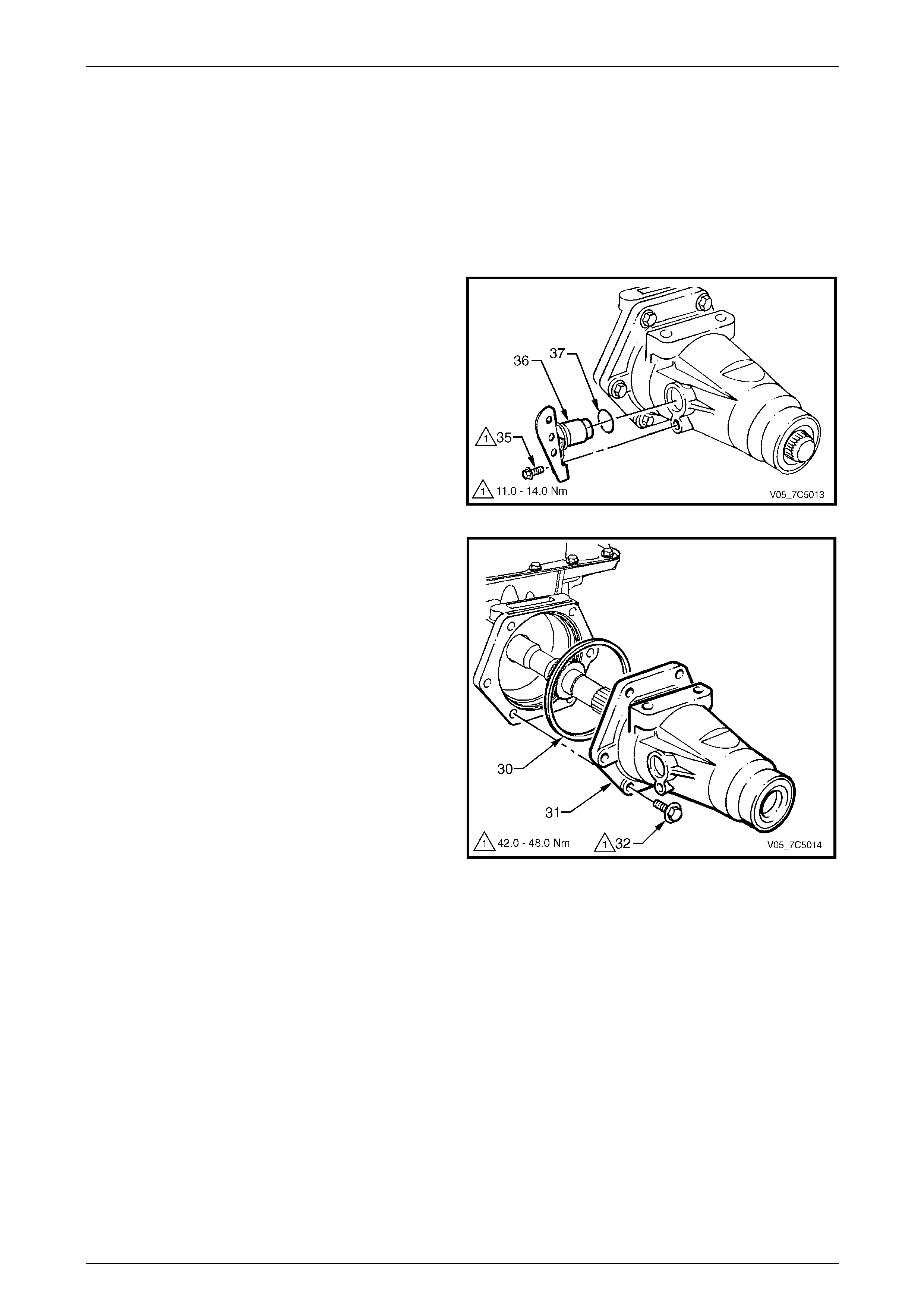

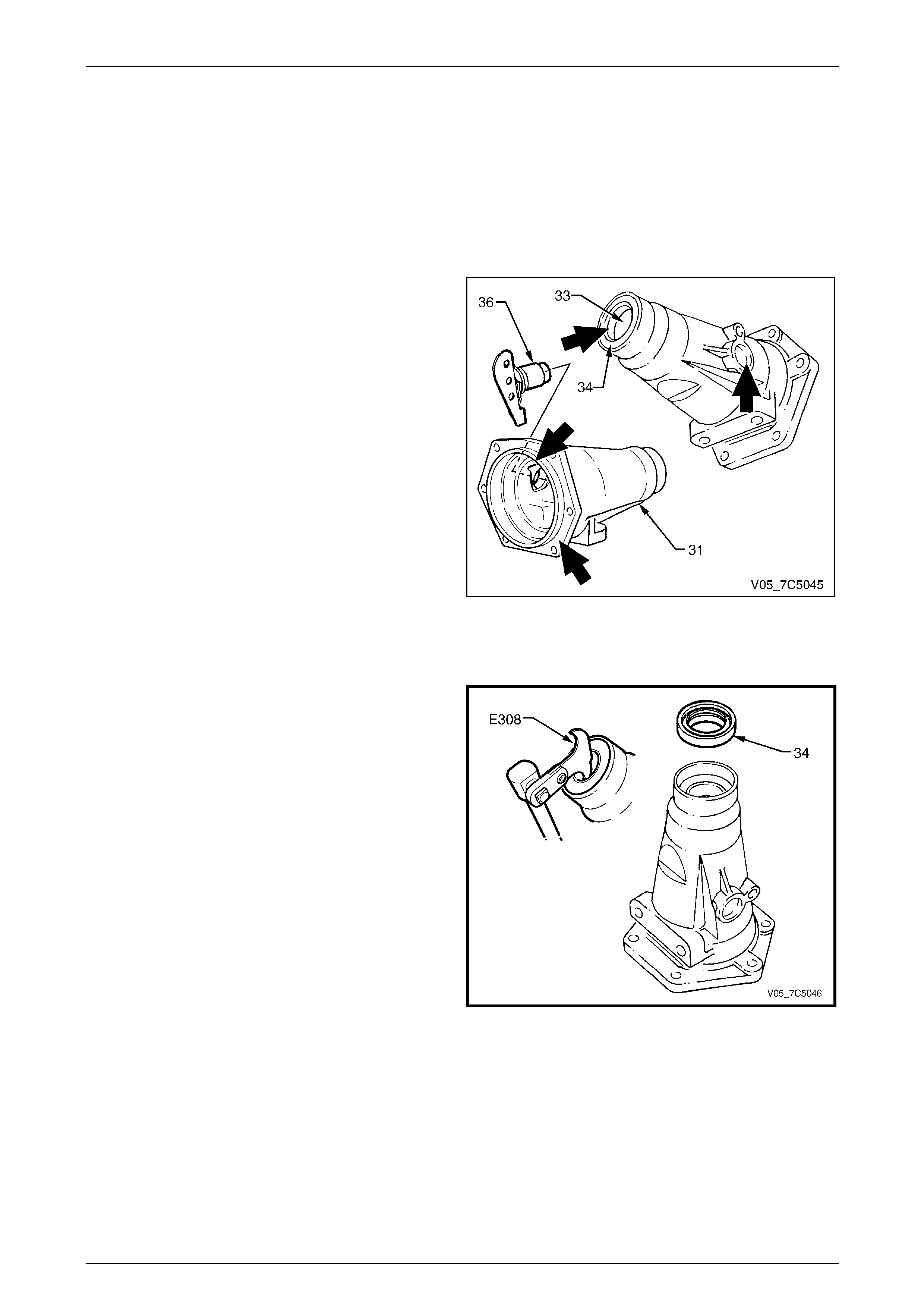

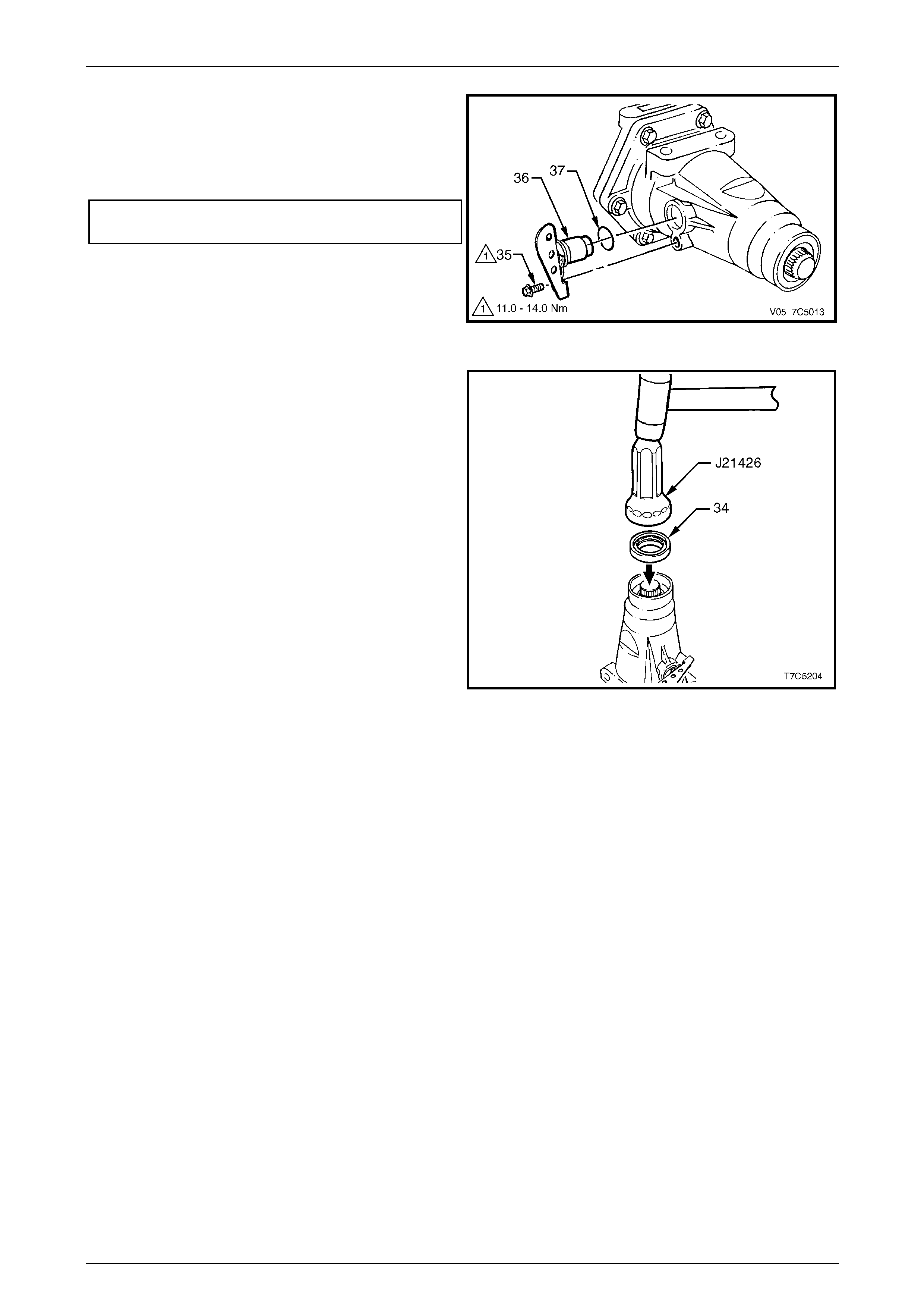

1 Remove the speed sensor retaining screw (35) from

the extension housing, then remove the sensor (36)

and O-ring (37).

Figure 7D5 – 9

2 If required, remove the extension housing seal, using

a suitable seal removing tool, such as Tool No. E308

or similar.

3 Remove the extension housin g bolt (32), six places.

4 Remove the extension housin g (31) and O-ring

seal (30).

Figure 7D5 – 10

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–13

15–DEC–2005 Page 7D5–13

5 To support and stop the output shaft falling from the

transmission at a later point in the disassembly

process, fabricate a support bracket (1) from a strip of

suitable sheet metal (as shown). Install the bracket

using two extension housin g bolts.

Figure 7D5 – 11

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–16

15–DEC–2005 Page 7D5–16

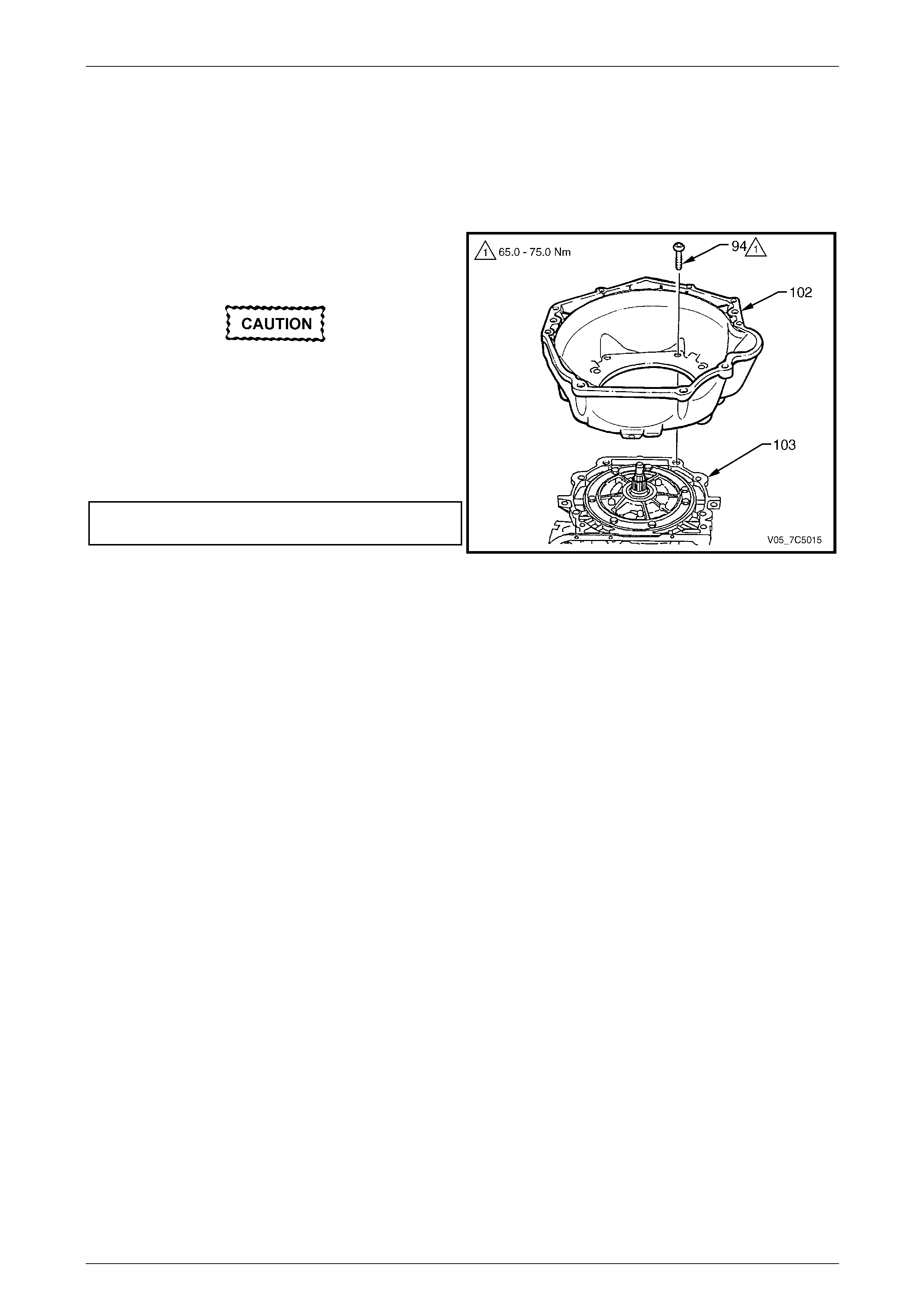

2.6 Torque Converter Housing

LT Section No. — 04–200

Remove

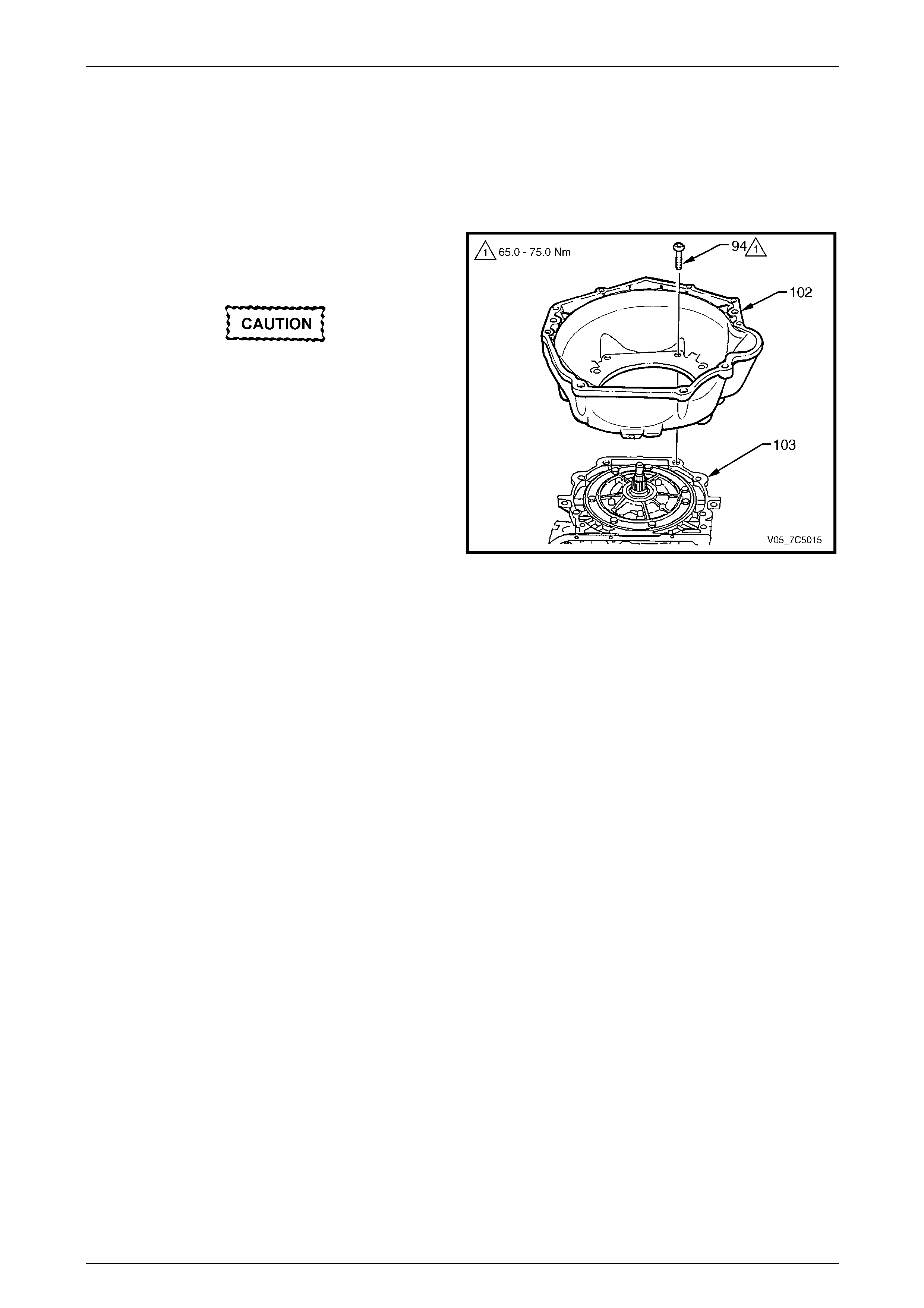

1 Rotate the transmission assembly until the torqu e

converter housing is facing up ward as sh own, then

lock the assembly in that position.

Do not use a standard , # 50 Torx® bit, as the

bolt design is such that only the Torx Plus®

bit is capable of ap pl ying sufficien t loo sening

torque without bolt damage.

2 Using Torx Plus® bit, Tool No. J41510 or commercial

equivalent, progressivel y loosen and remove the

bolts (94) attaching the torque converter housing.

3 Remove the torque converter housing (102) from the

transmission case (103).

NOTE

The torque converter housing shown is ‘typical’

and is not intended to be specific to any

particular engine applic ation.

Figure 7D5 – 12

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–17

15–DEC–2005 Page 7D5–17

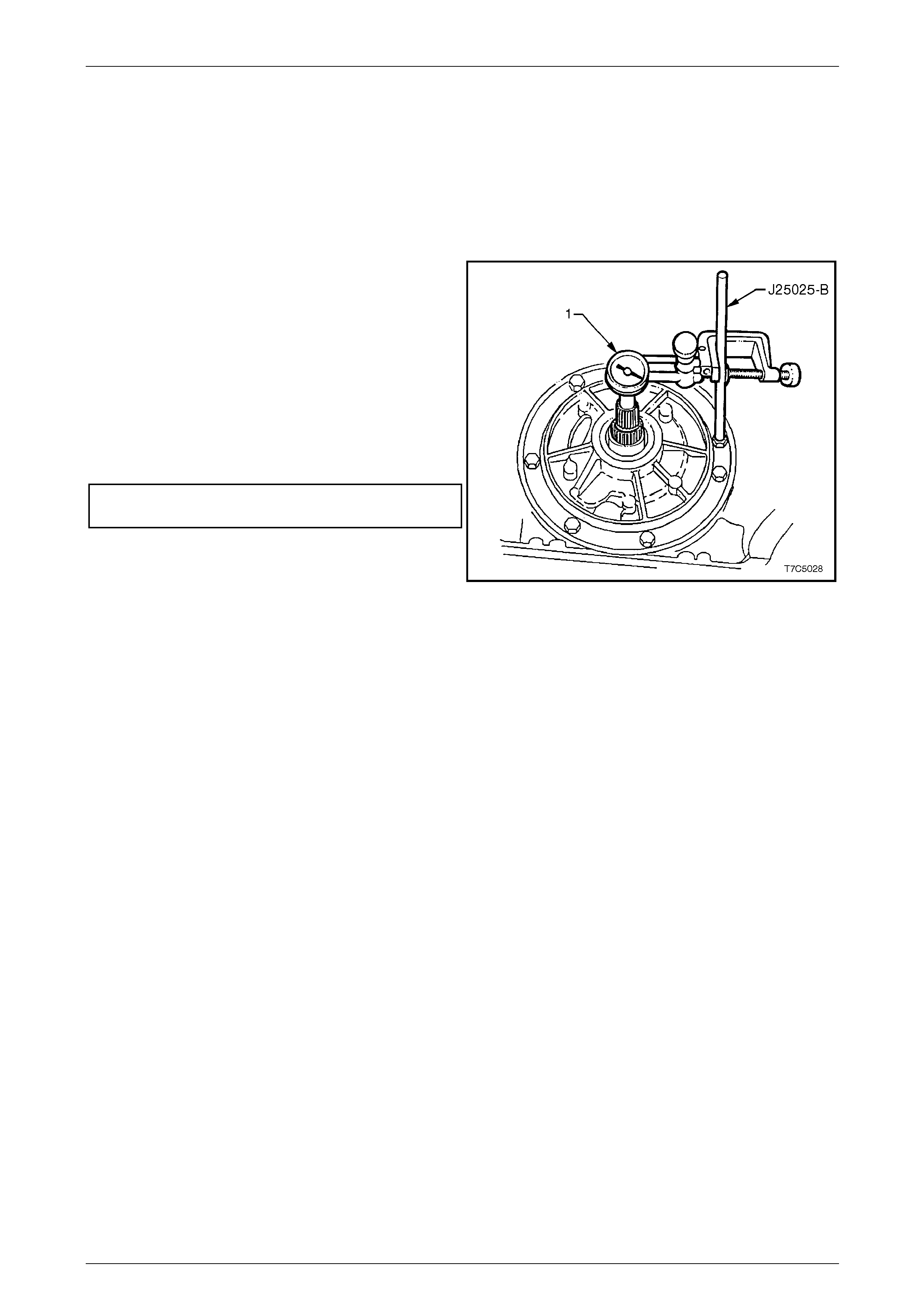

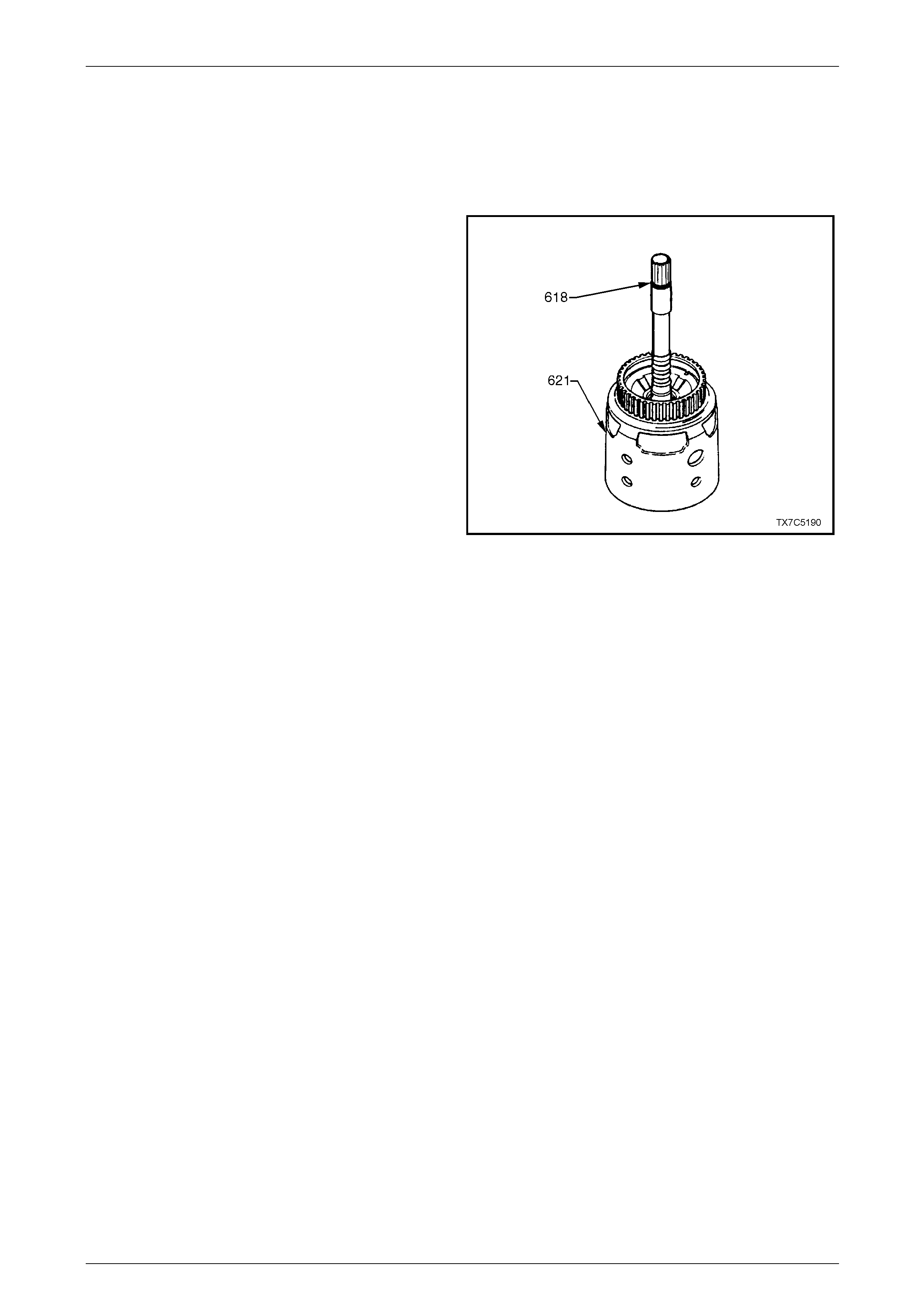

2.7 Transmission End Play Check

LT Section No. — 04–200

To assist in the diagnostic process, check the transmission end play prior to removing interna l components.

If the measured end play is outside specifications, it is corrected when reinstalli ng the selective thrust washer (616) onto

the input housing and shaft assembly (621), refer to 4.6 Reverse Input Clutch, Input Clutch and Input Gear Set.

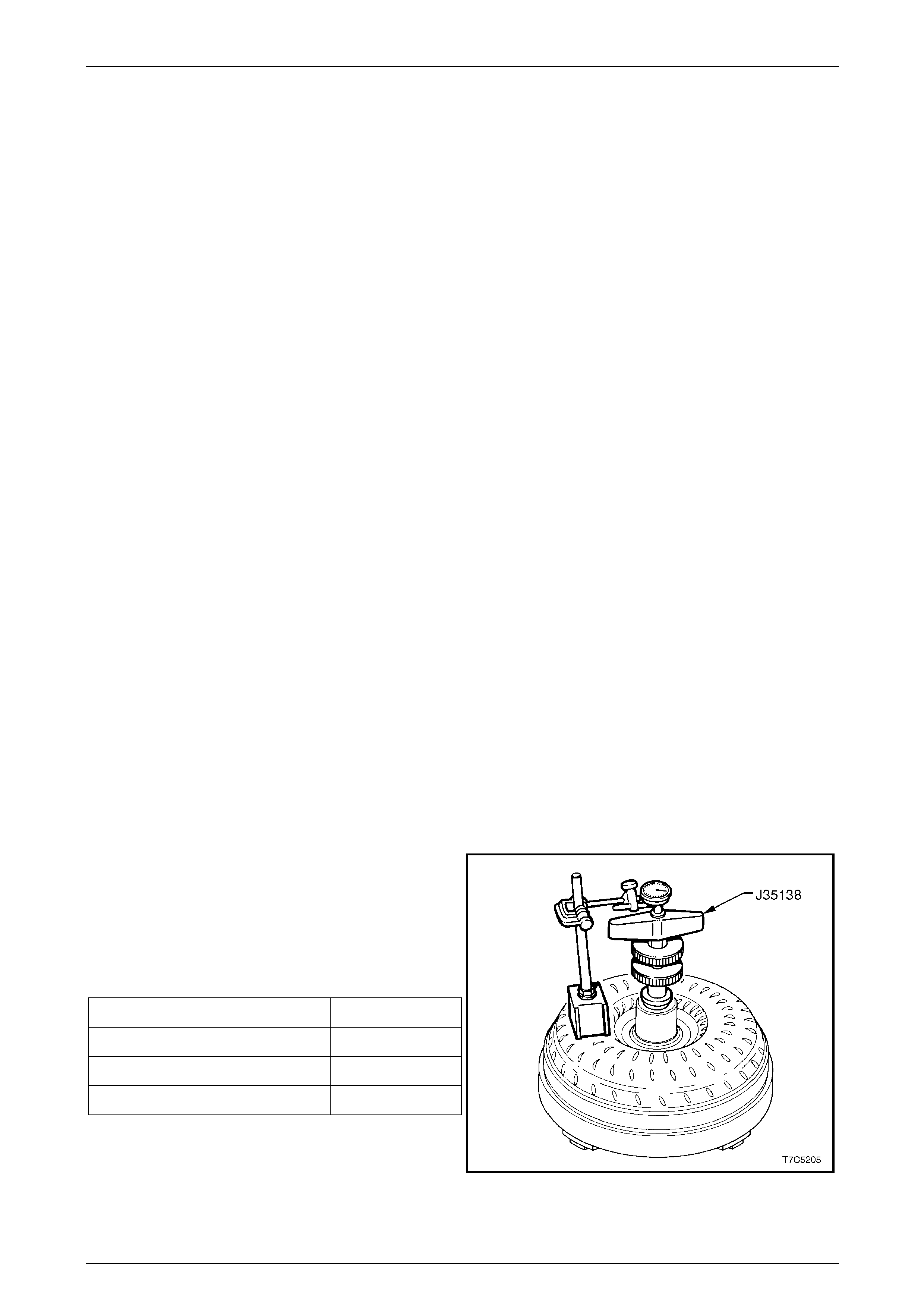

Carry out the end play check as follows:

1 Leave the transmission with the input shaft in a vertical

position.

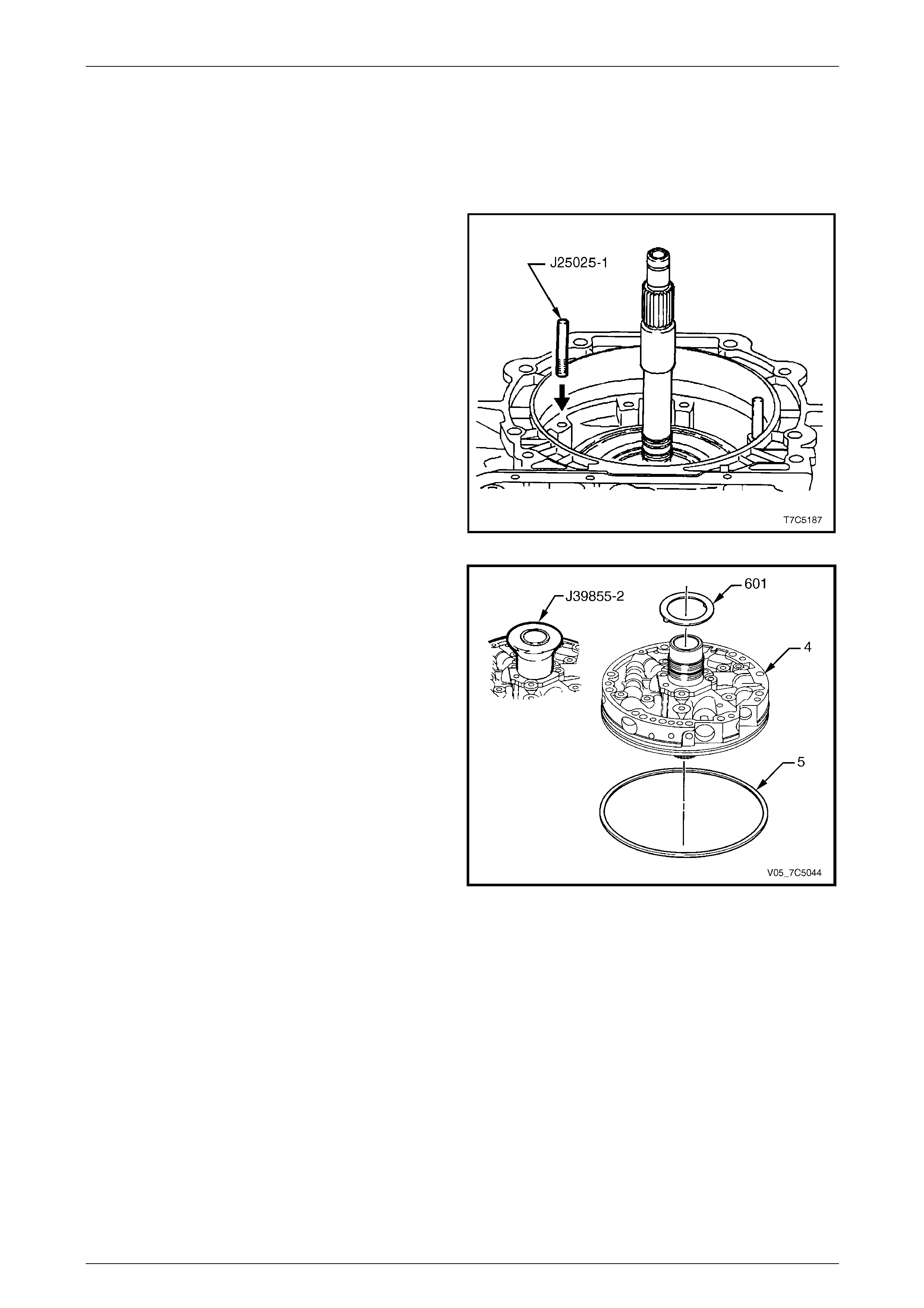

2 Remove one oil pump attaching bolt, install Tool No.

J25025-B and secure with the locknut.

3 Install a dial indicator (1) using a commercially

available clamp on Tool No. J25025-B. Set to zero the

dial indicator contacting the end of input shaft.

4 Pull up the input shaft by hand to measure the end

play.

Transmission end play

specification........................................... 0.13 – 0.92 mm

5 Remove the dial indicator and T ool No. J25025-B.

Figure 7D5 – 13

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–18

15–DEC–2005 Page 7D5–18

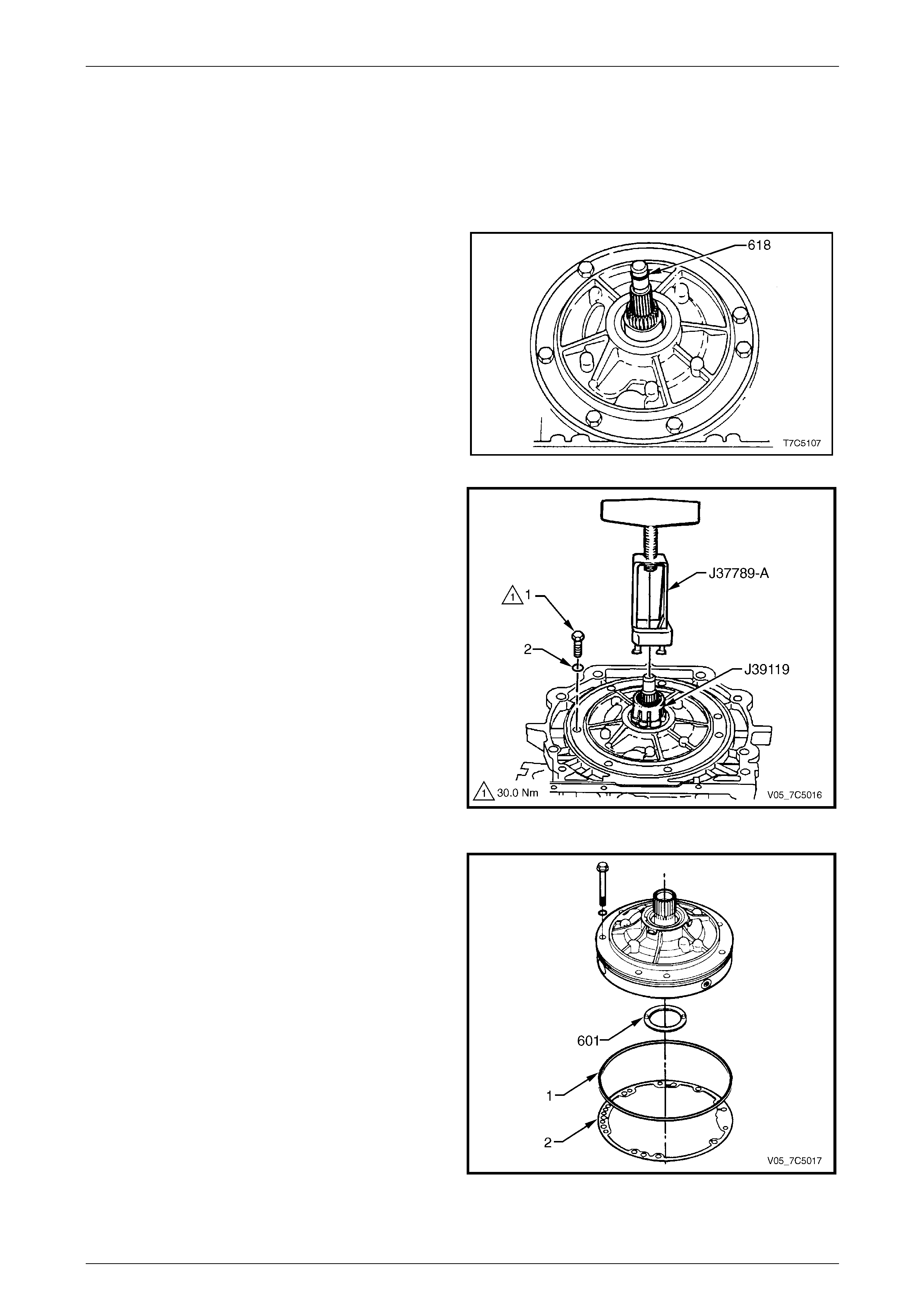

2.8 Oil Pump Assembly

LT Section No. — 04–200

Remove

1 Remove the input shaft O-ring (618) from the turbine

shaft.

2 Prise the front helix seal retainer from the oil pump

housing.

3 Using a suitable seal removing tool, such as Tool

No. E308 or similar, extract the seal and discard.

Figure 7D5 – 14

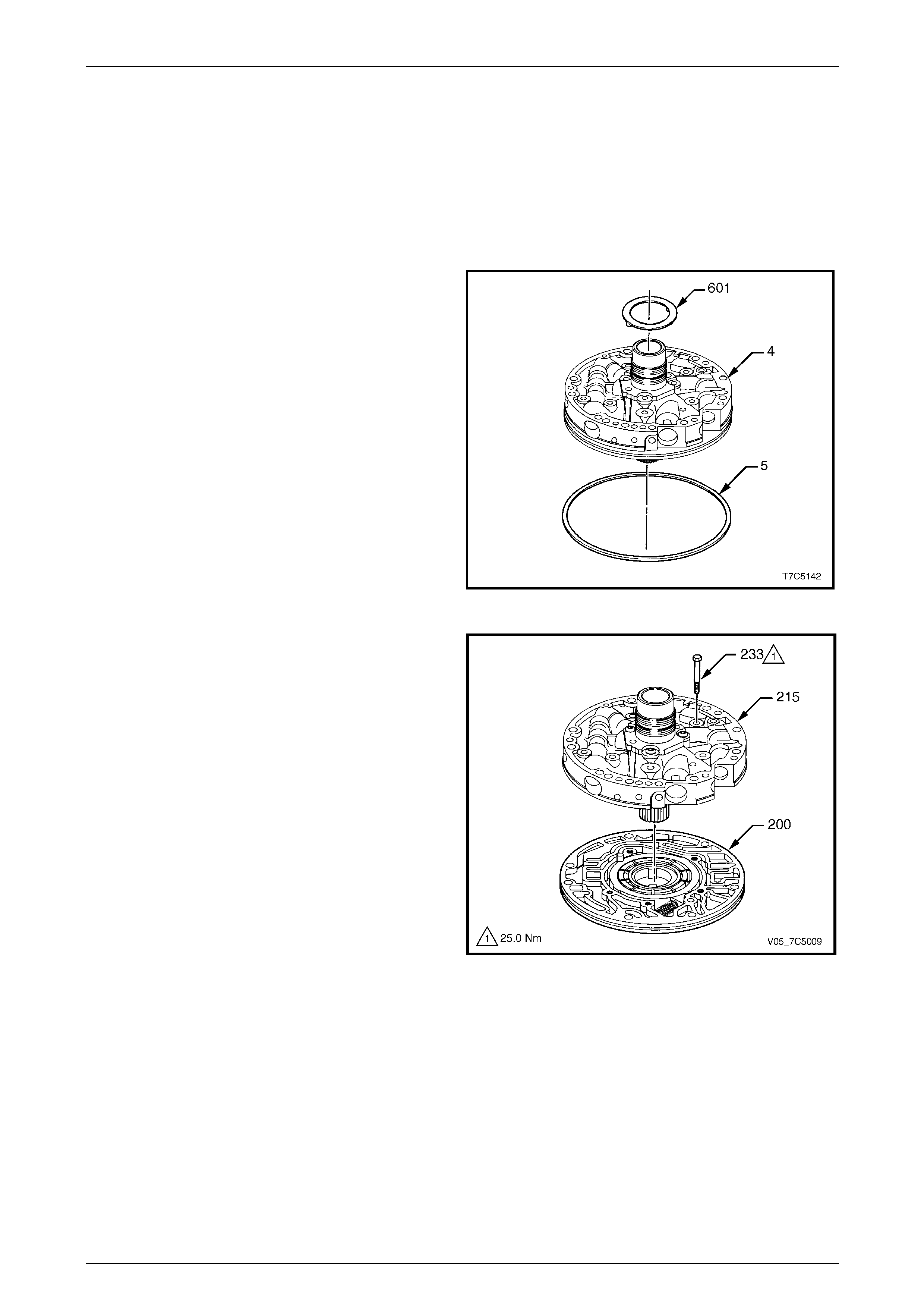

4 Remove the remaining oil pump bolt (1) and seal (2),

seven places in total.

5 Slide Tool No. J39119 over the stator shaft until it

locks under the splines. Install Tool No. J37789-A over

Tool No. J39119 and tighten the clamp bolt. Unseat

the oil pump assembly by turning the forcing screw

against the input shaft. Remove the oil pump

assembly from the transmission case.

6 Remove the special tools from the oil pump.

Figure 7D5 – 15

7 Remove the oil pump to case seal (1) and g asket (2).

8 Remove the reverse input clutch to oil pump thrust

washer (601).

NOTE

The thrust washer is selectable to obtain

correct transmission end play, measured in

2.7 Transmission End Play Check.

Figure 7D5 – 16

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–19

15–DEC–2005 Page 7D5–19

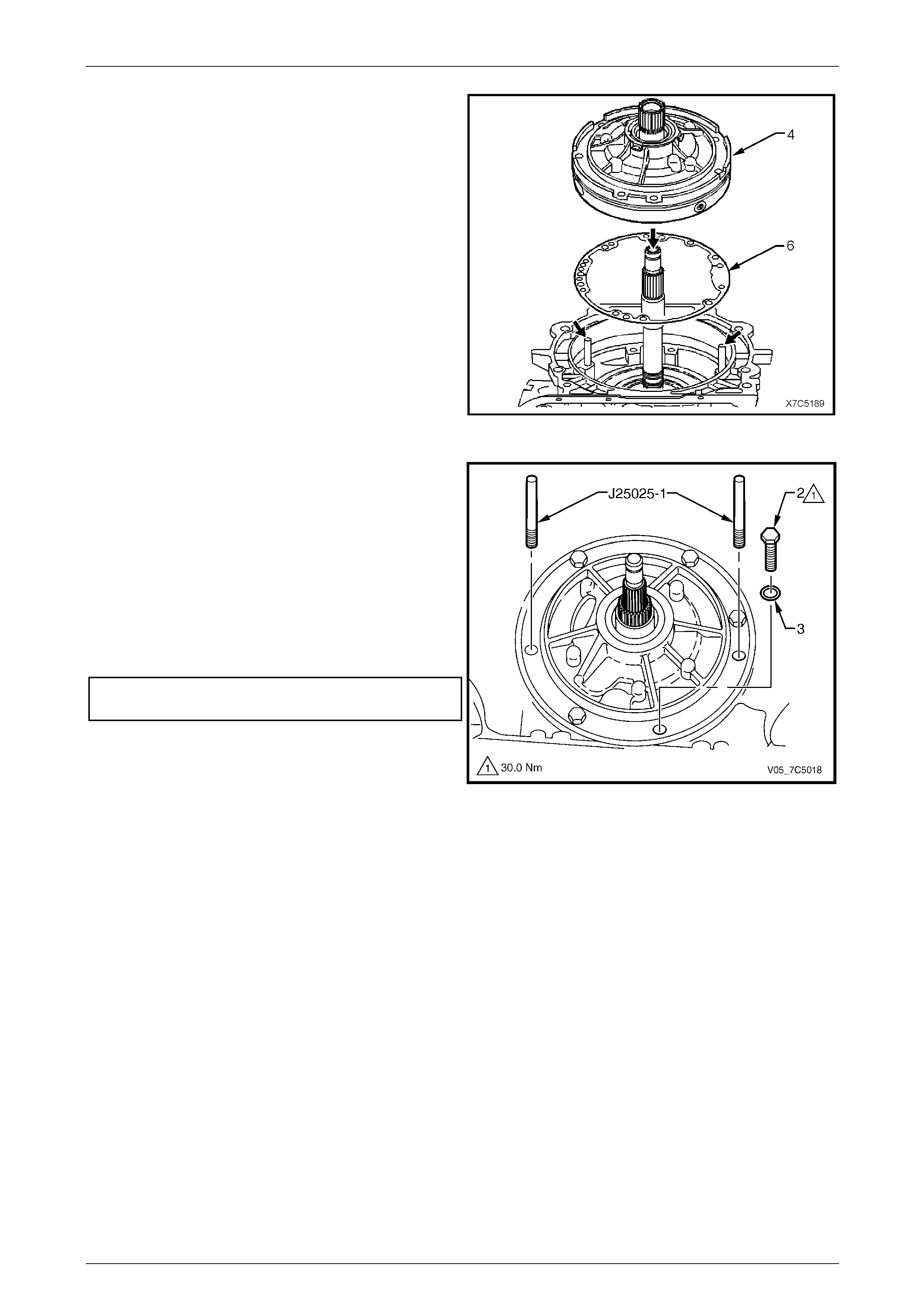

2.9 Reverse Input Clutch, Input Clutch, 2-4

Band and Input Gear Set

LT Section No. — 04–200

Remove

Take care when removing the input clutch

assembly as it is a heavy assembly and

personal injury may result if lifted incorrectly.

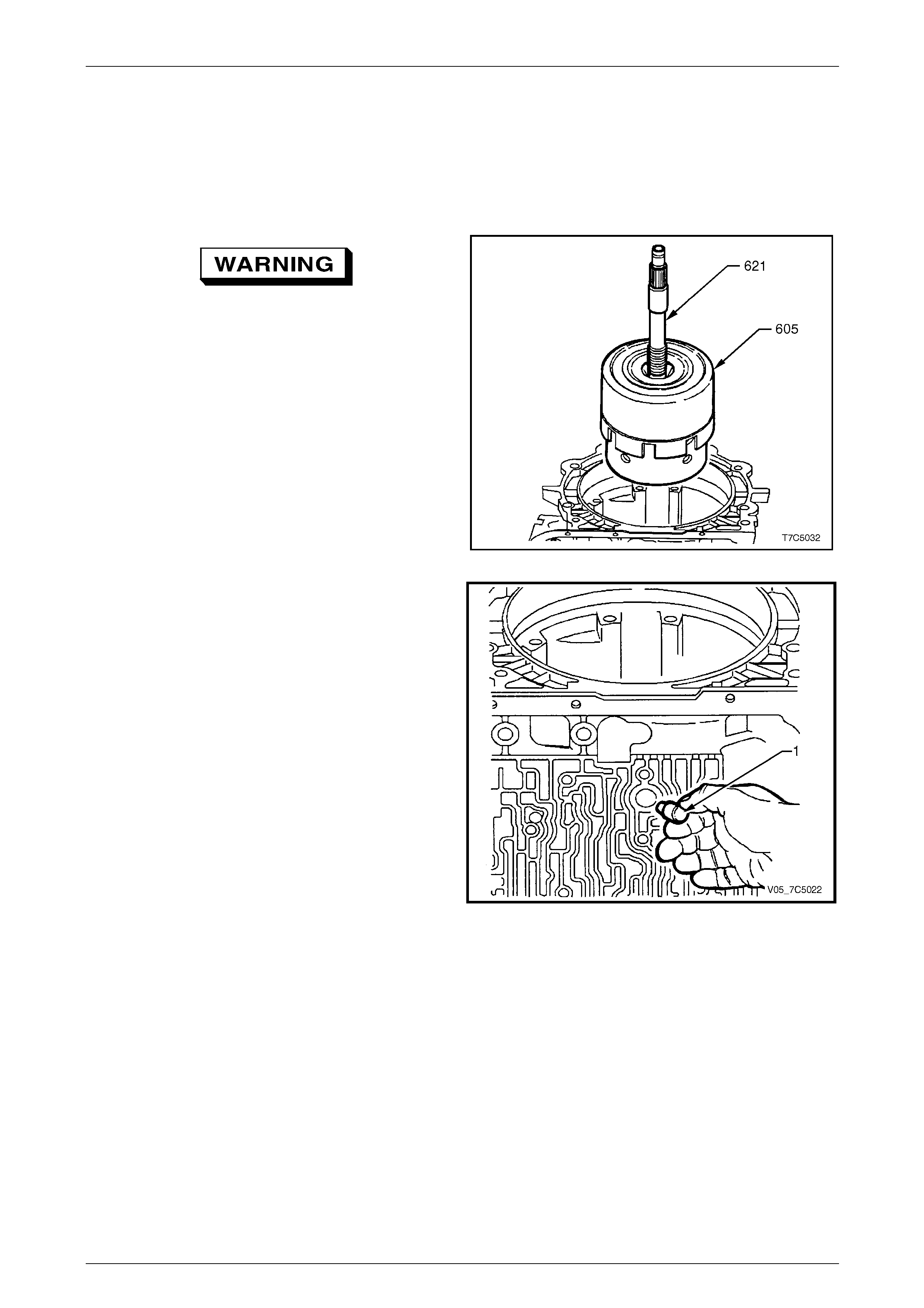

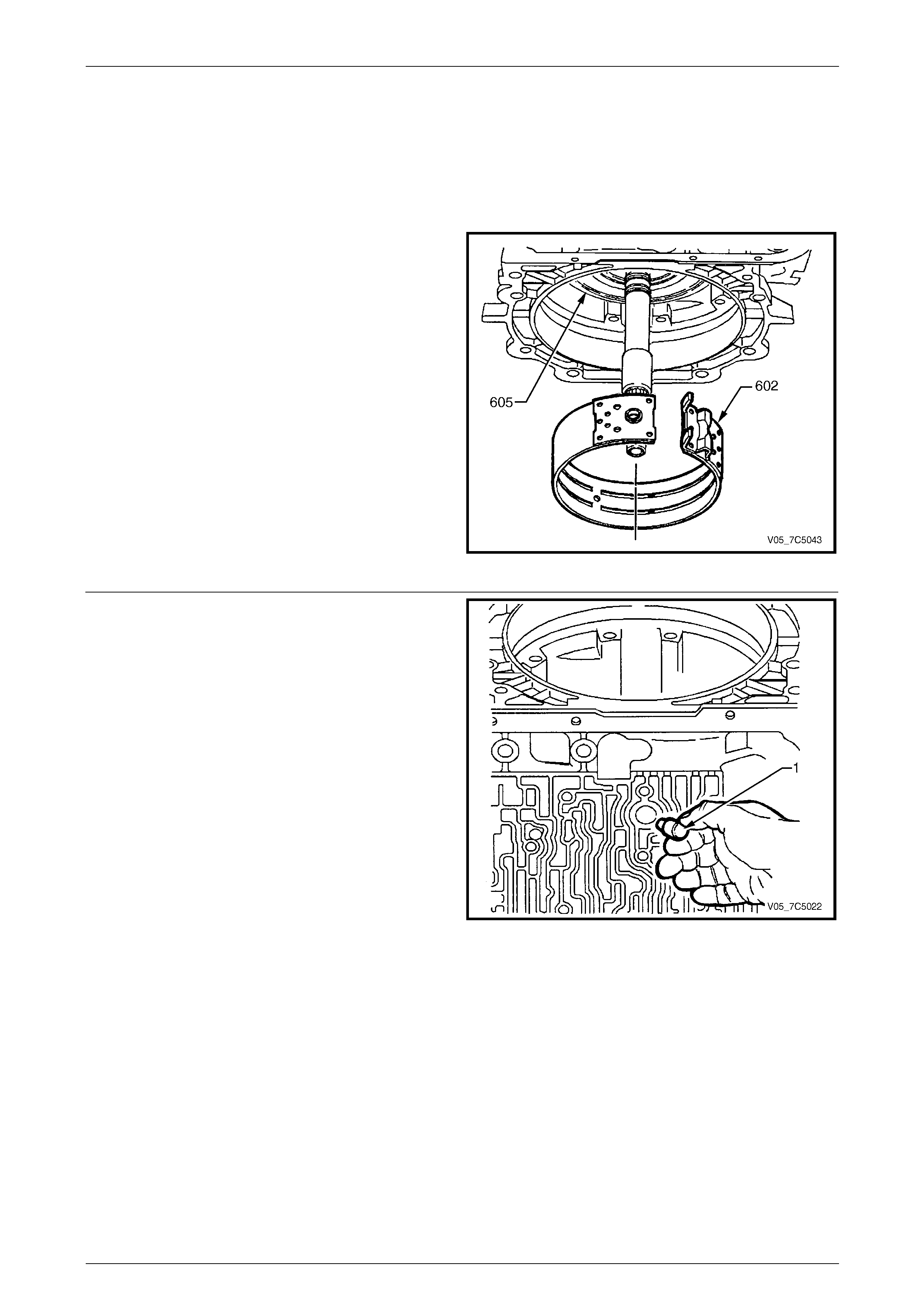

1 Remove reverse input clutch (605) and i nput clutch

assembly by grasping input shaft (621) and

withdrawing the assembl y from the transmis sion case.

Figure 7D5 – 17

2 Remove the 2-4 band anc hor pin (1) from the

transmission case.

Figure 7D5 – 18

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–20

15–DEC–2005 Page 7D5–20

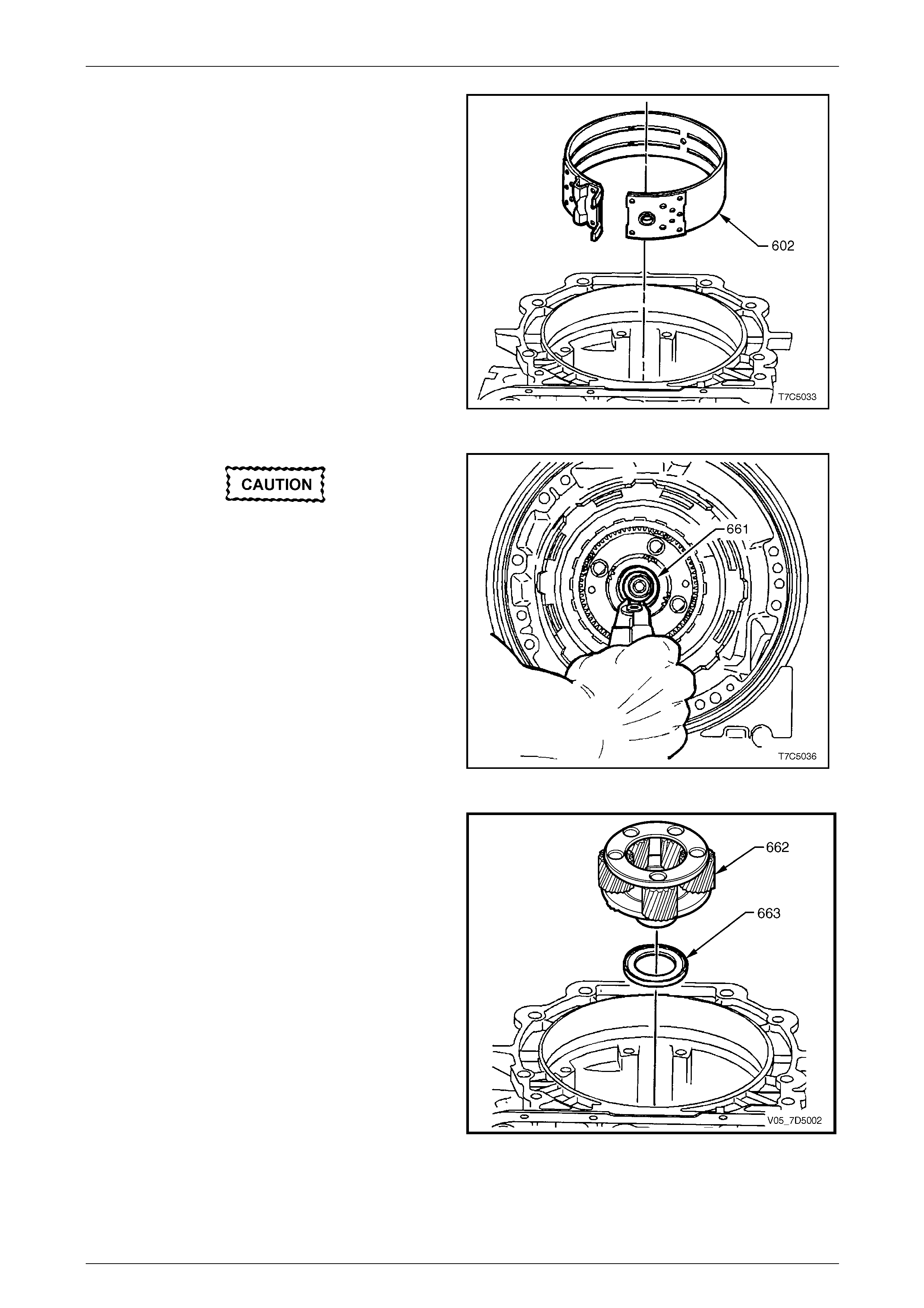

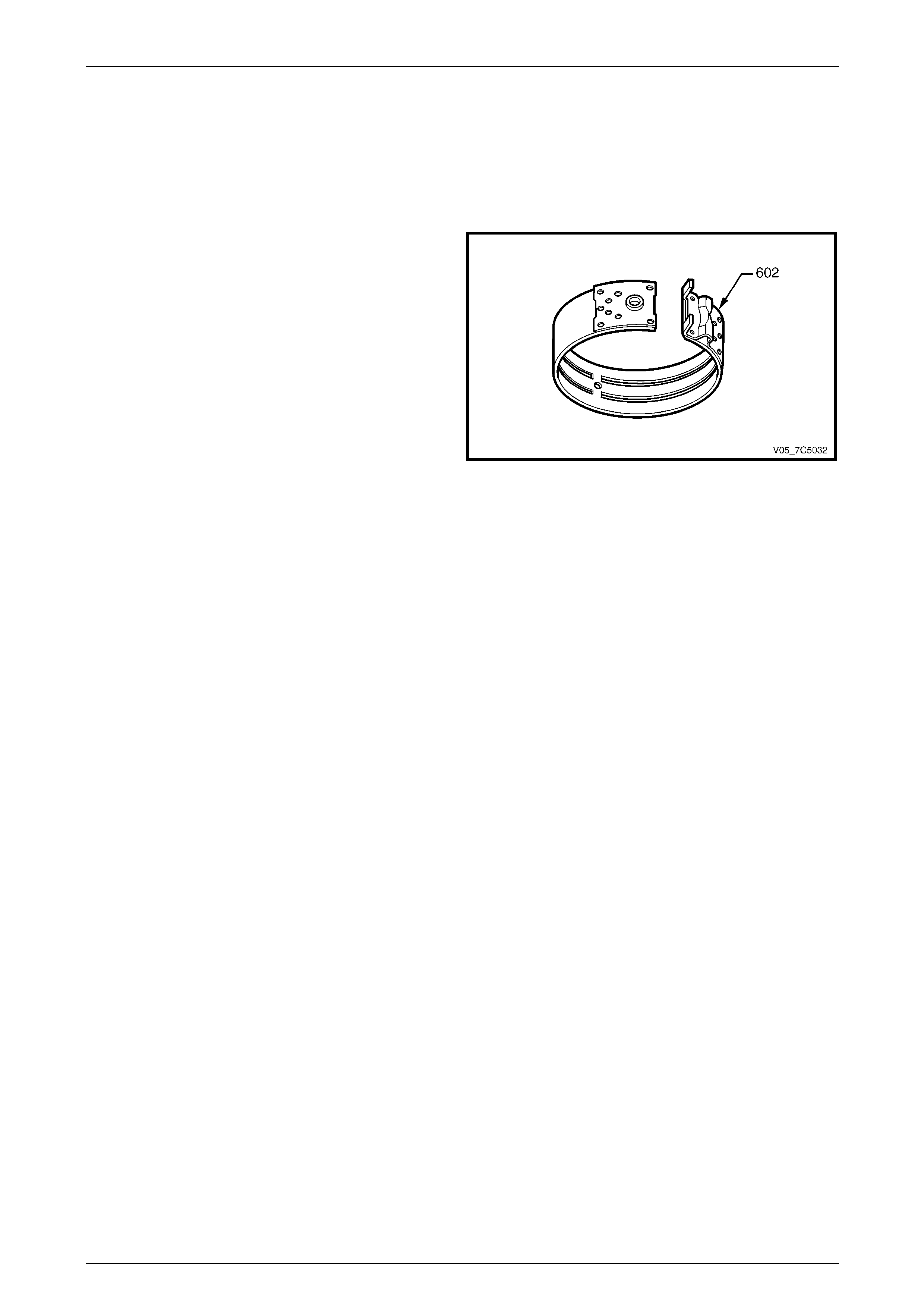

3 Remove the 2-4 band assembly (602).

Figure 7D5 – 19

When removing the snap ring note the

following:

• Do not over expand snap ring.

• Using the snap ring pliers, Tool No.

J34627, will make the removal easier and

reduce the risk of over expanding the

snap ring.

• Unless a fabricated b racket was fitted, the

output shaft will tend to fall out of the

transmission. Refer to 2.3 Speed Sensor

and Extension Housing.

4 Remove the input carrier to output shaft retaining

ring (661) using Tool No. J34627 or suitable snap ring

pliers.

Figure 7D5 – 20

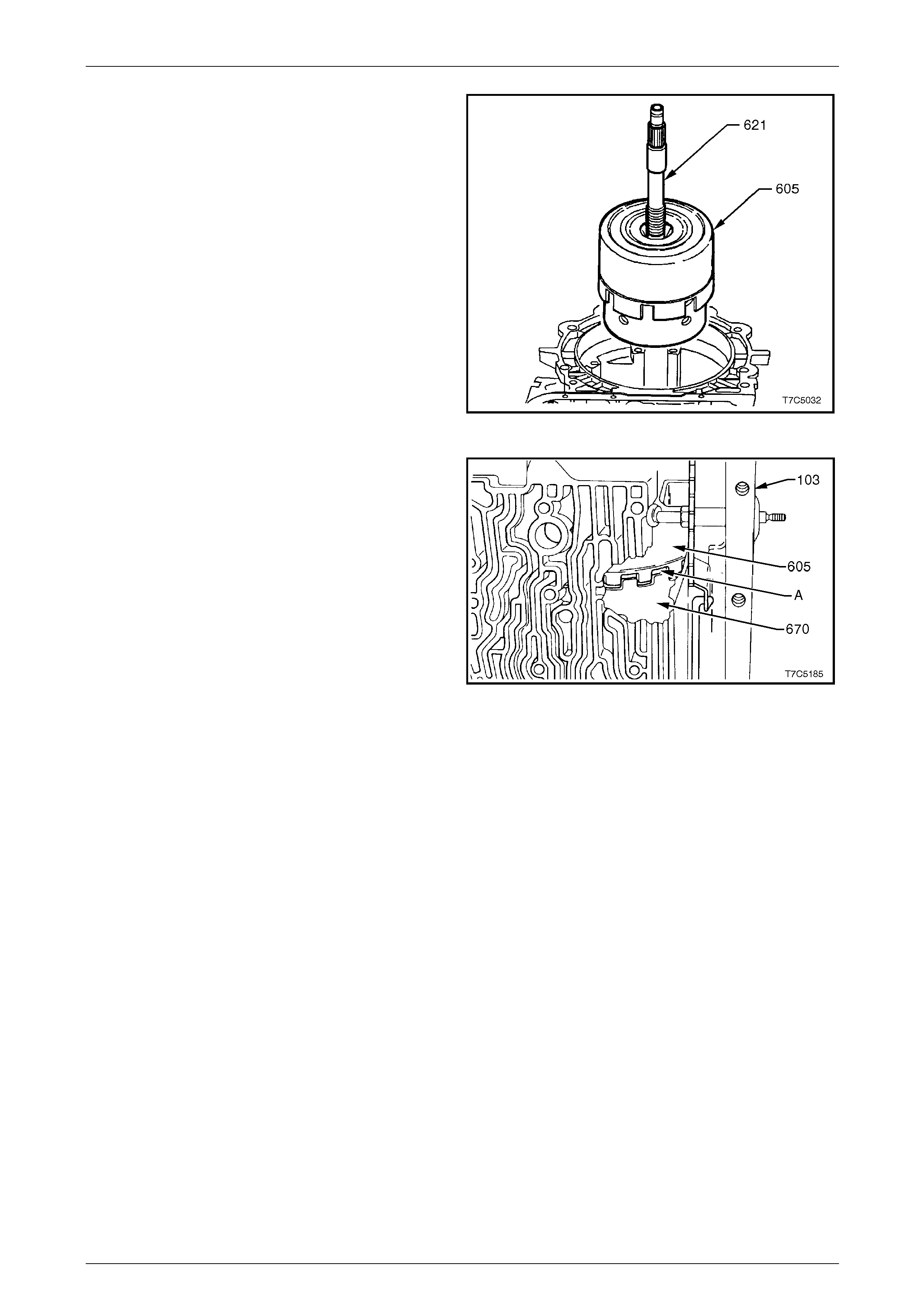

5 Remove the input carrier assembly (662).

6 Remove the thrust bearing (663).

Figure 7D5 – 21

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–21

15–DEC–2005 Page 7D5–21

2.10 Reaction Gear Set

LT Section No. — 04–200

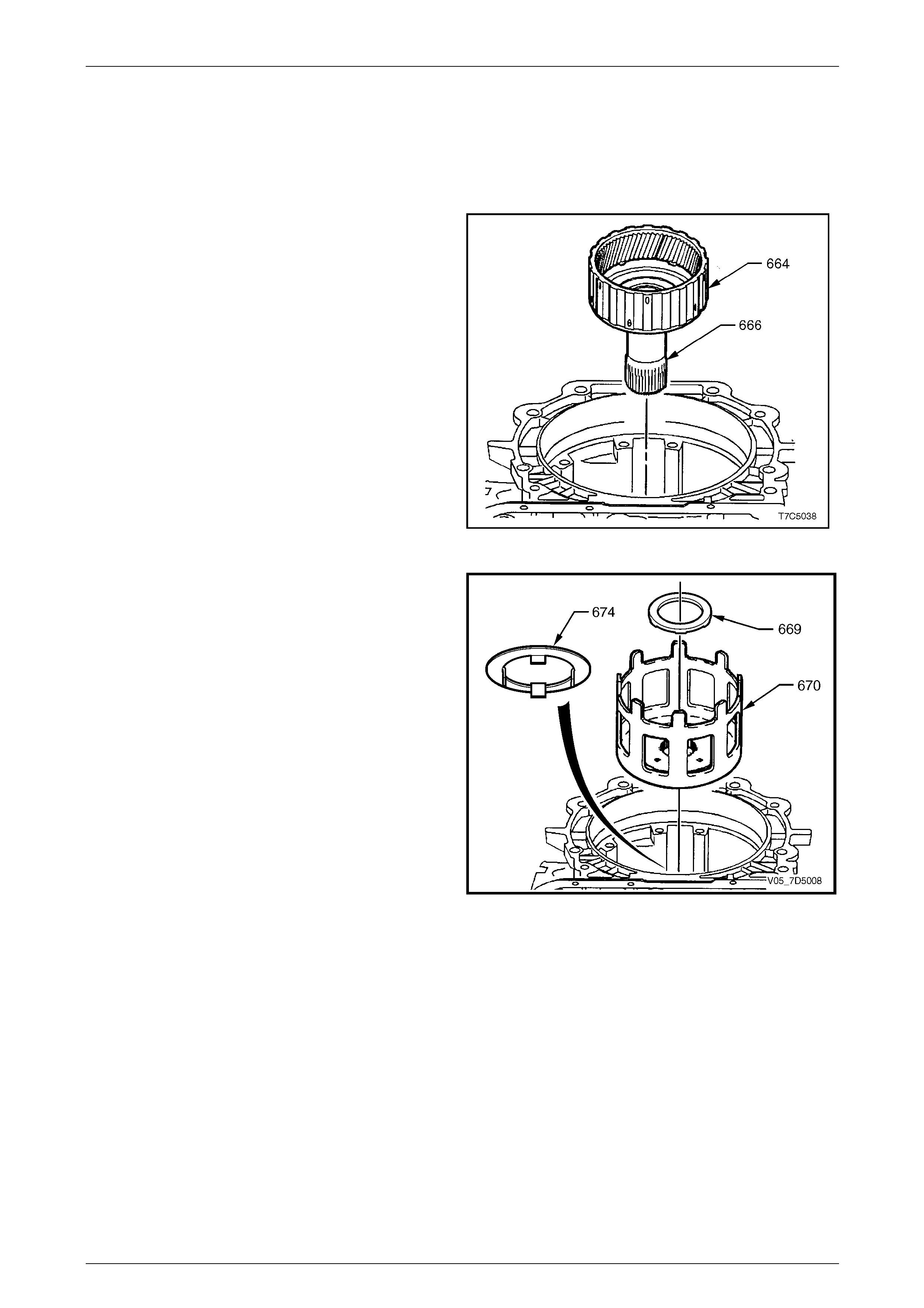

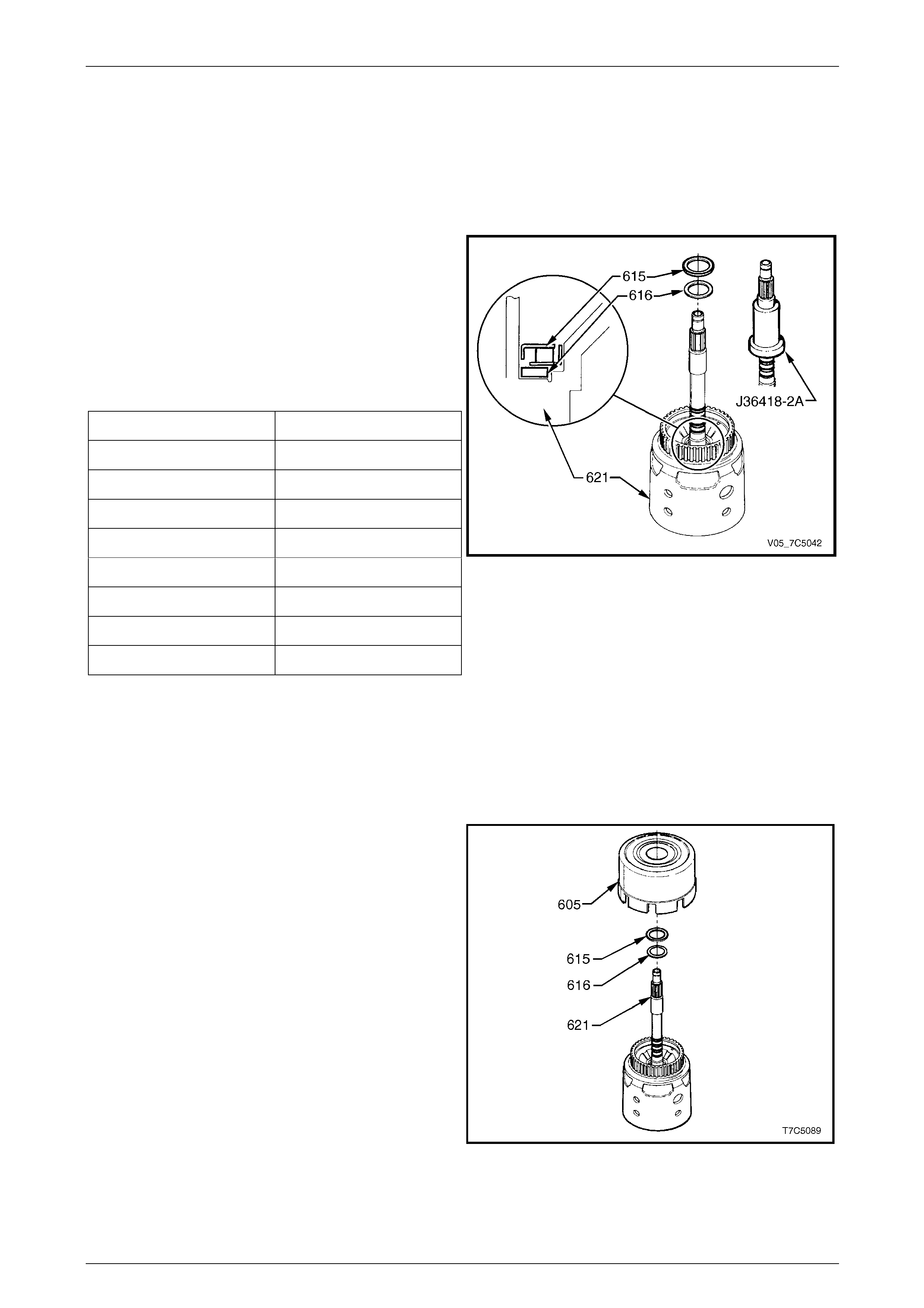

Remove

1 Remove the input internal gear (664) a nd the reaction

carrier shaft (666).

Figure 7D5 – 22

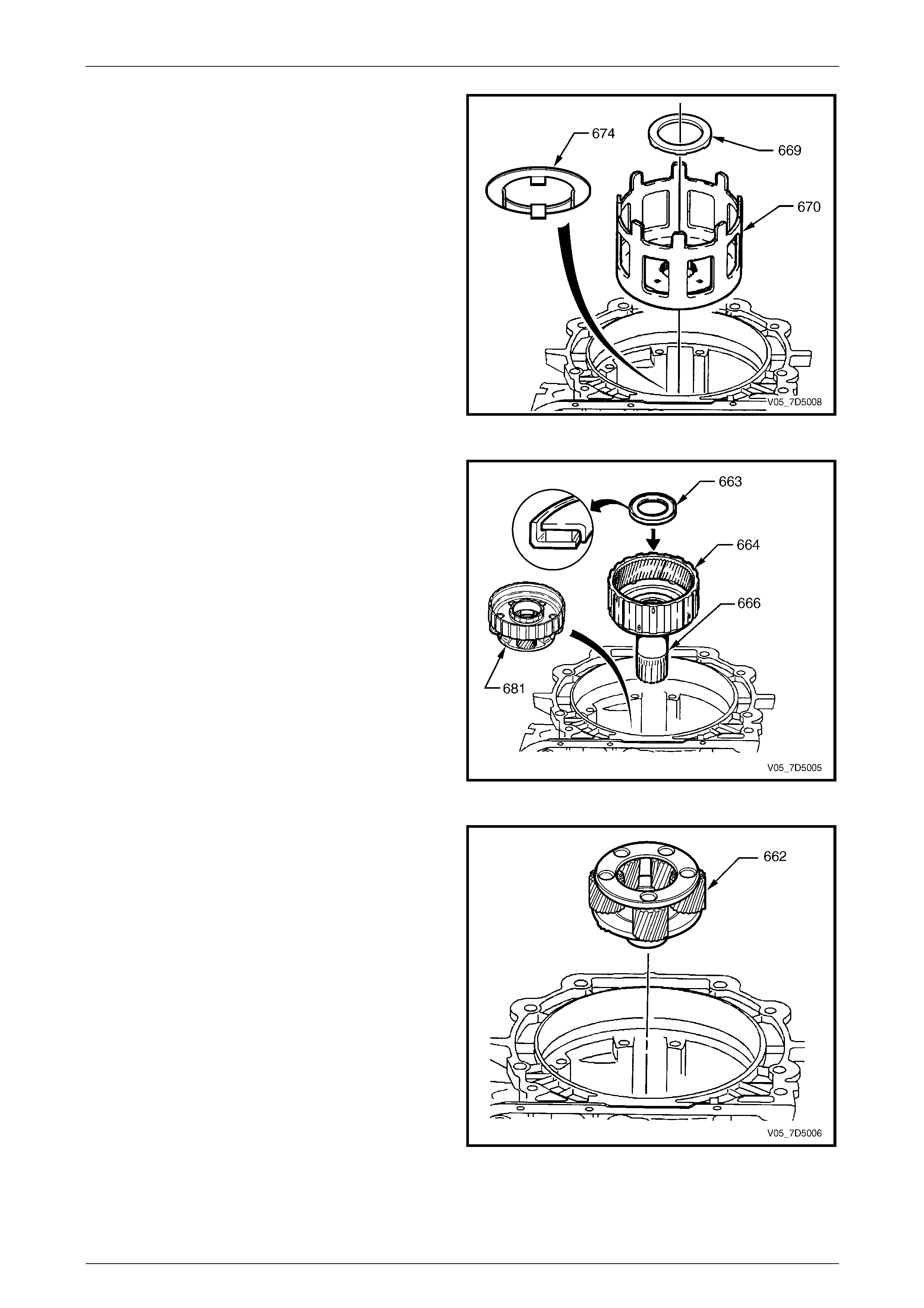

2 Remove the reaction shaft/shell thrust bearing (669)

and the reaction sun shell (670).

Figure 7D5 – 23

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–22

15–DEC–2005 Page 7D5–22

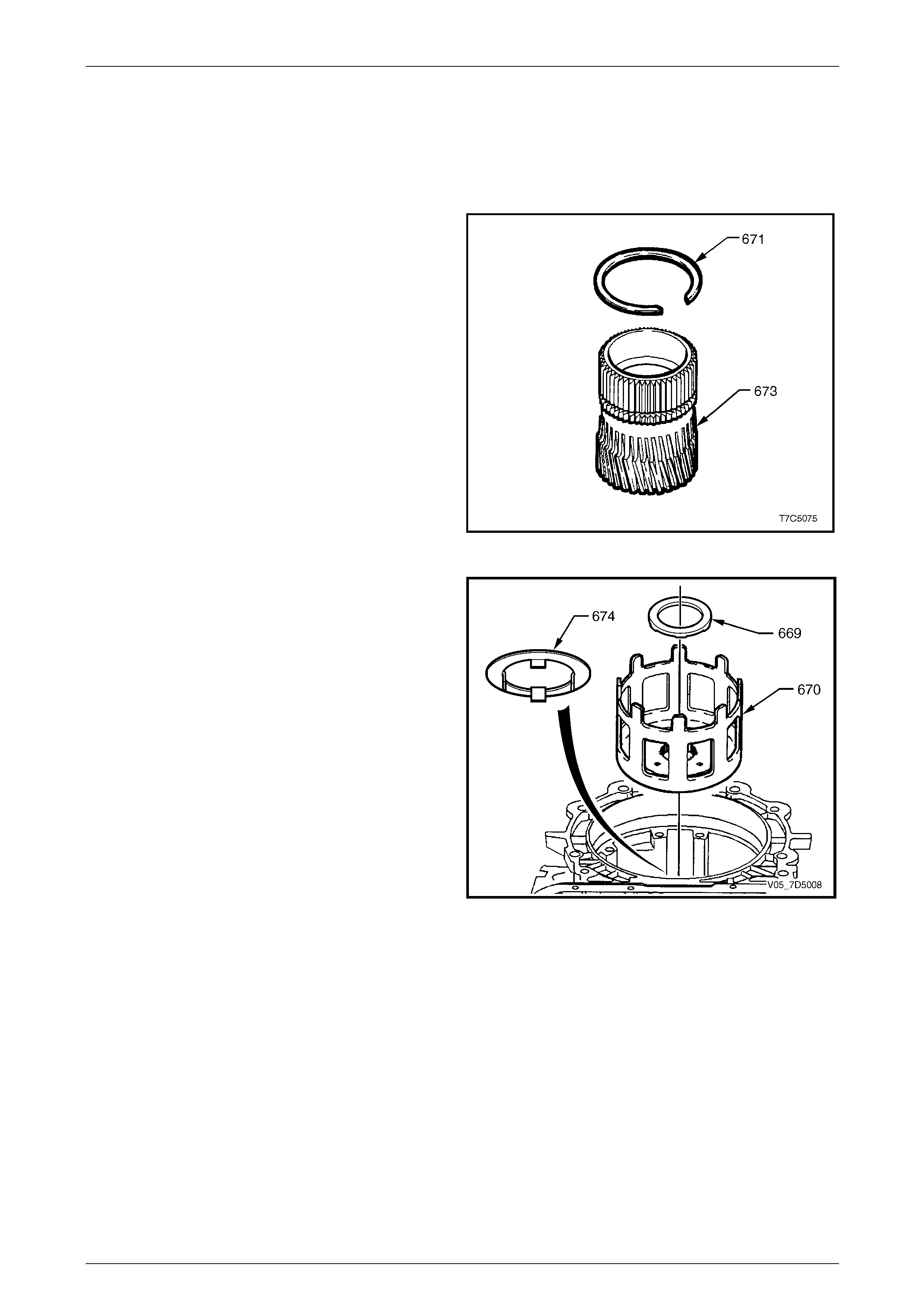

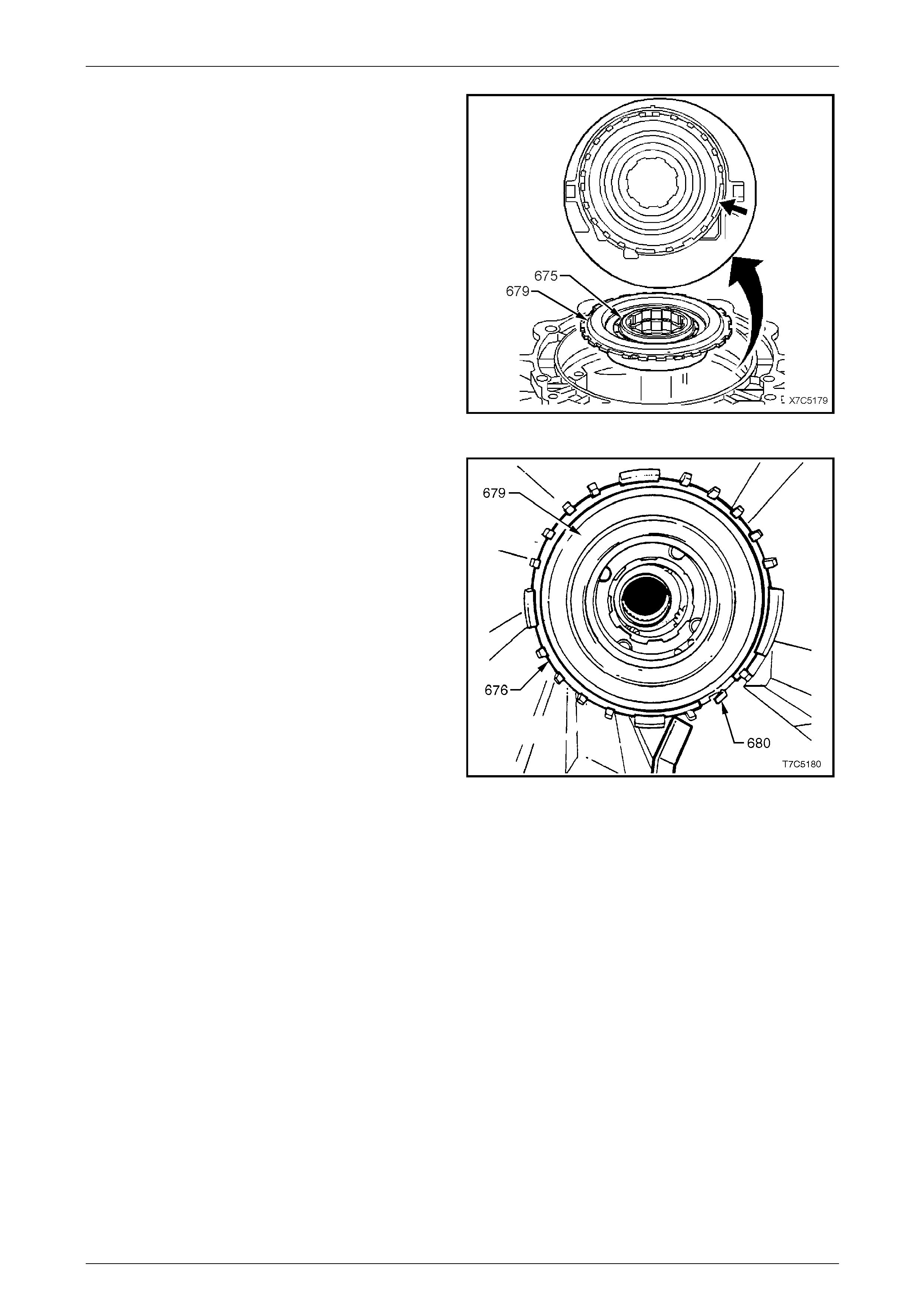

3 Remove the reaction sun gear (673).

4 Remove the race/reaction shell thrust washer (674).

5 Remove the low and reverse roller cl utch race (675),

by holding the inner surface a nd turning the race in the

clockwise (free) direction.

Figure 7D5 – 24

6 Remove the low and reverse support to case retaining

ring (676).

7 Remove the fabricated bracket, refer to

2.3 Speed Sensor and Ext ension Housing, and

withdraw the output shaft .

NOTE

Depending on the distance the transmission has

travelled, there may be some resistance to

removal of the mainshaft from the input carri er. If

so, tap the inboard end of the output shaft with a

plastic faced hammer to dislodge.

Figure 7D5 – 25

8 Reinsert the mainshaft and push up to dislo dge the

low and reverse clutch support assembly (679).

9 Remove the low and reverse clutch support from the

transmission case.

Figure 7D5 – 26

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–23

15–DEC–2005 Page 7D5–23

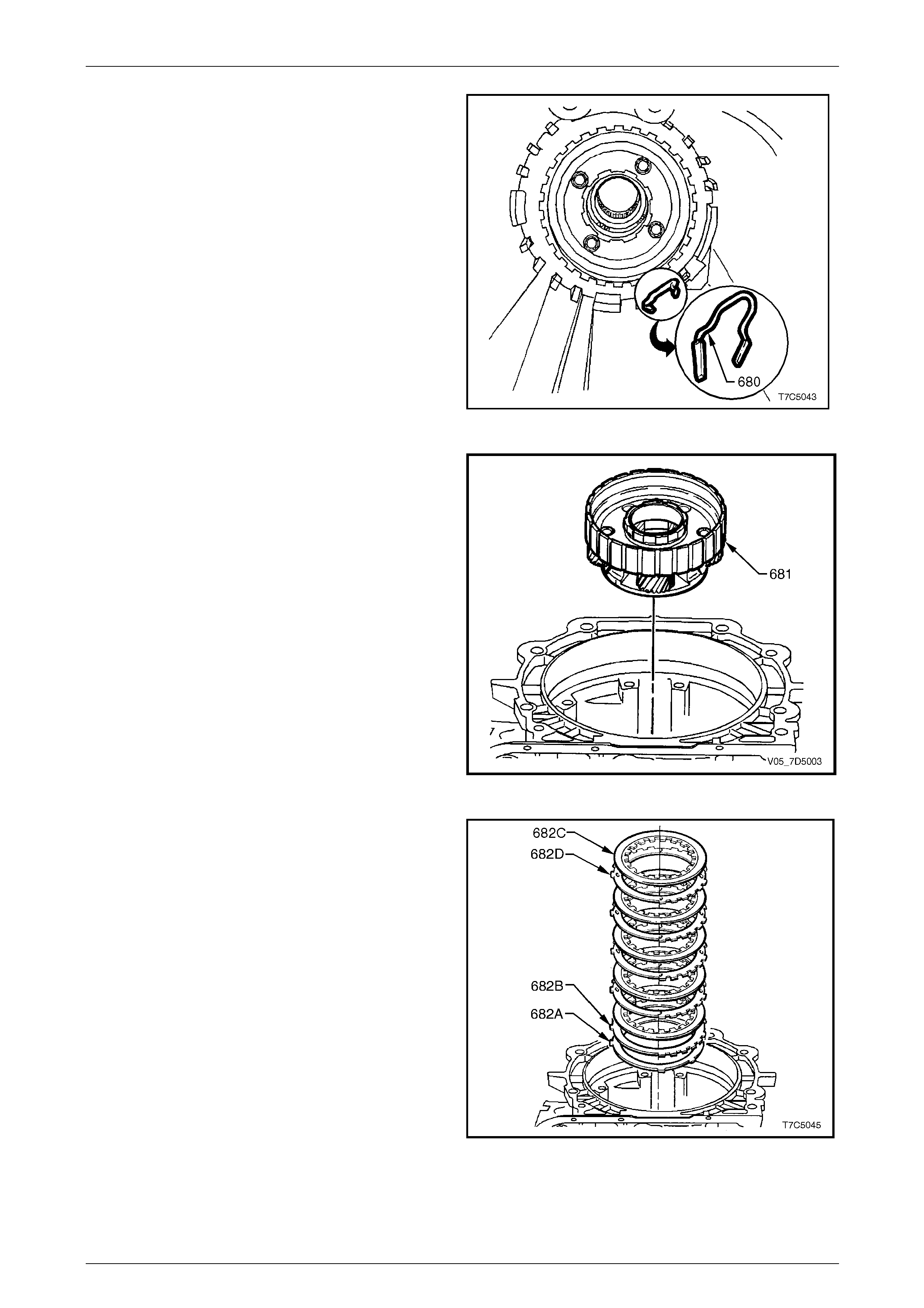

10 Remove the low and reverse clutch support retainer

spring (680).

Figure 7D5 – 27

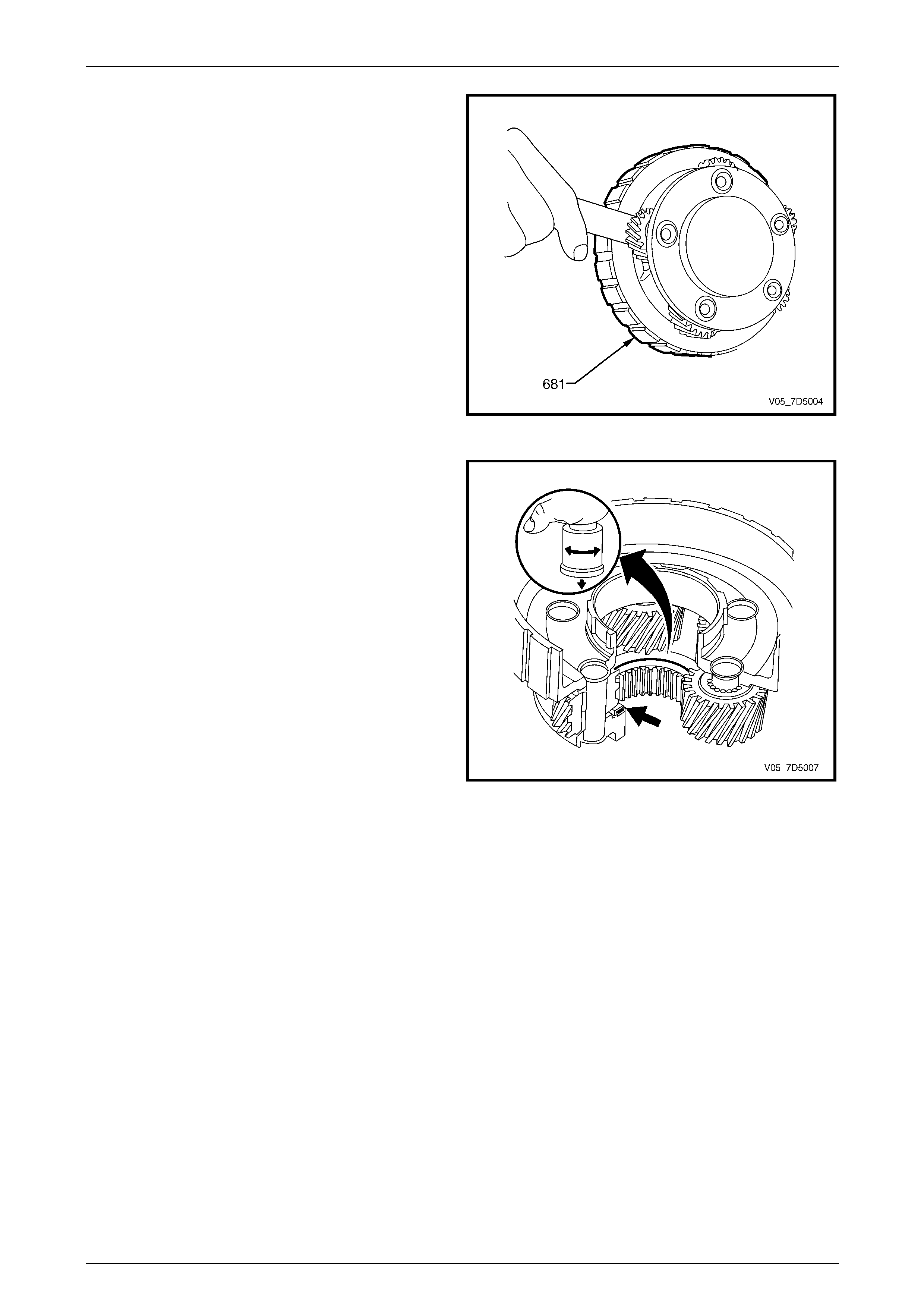

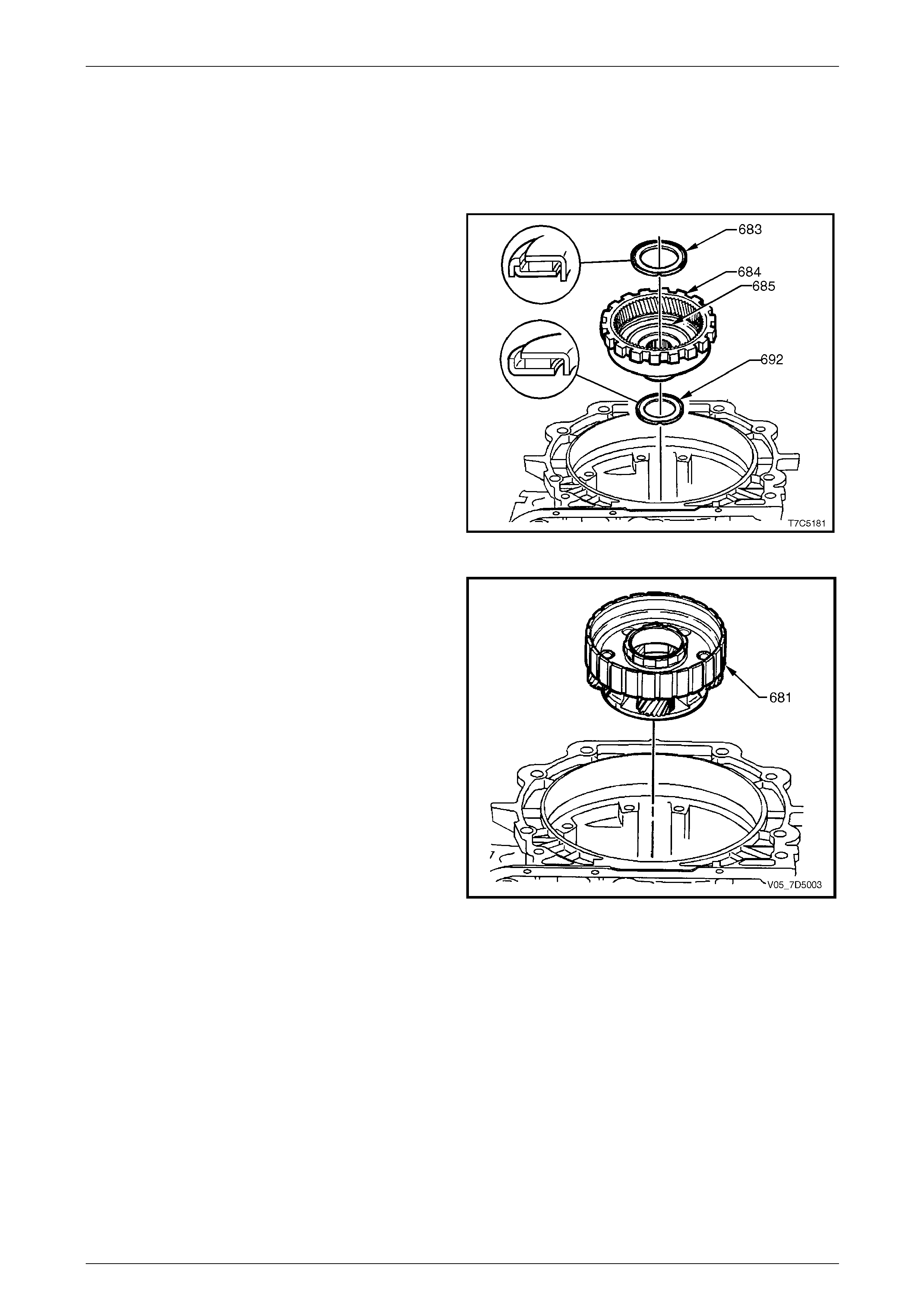

11 Remove the reaction carrier a ssembly (681).

Figure 7D5 – 28

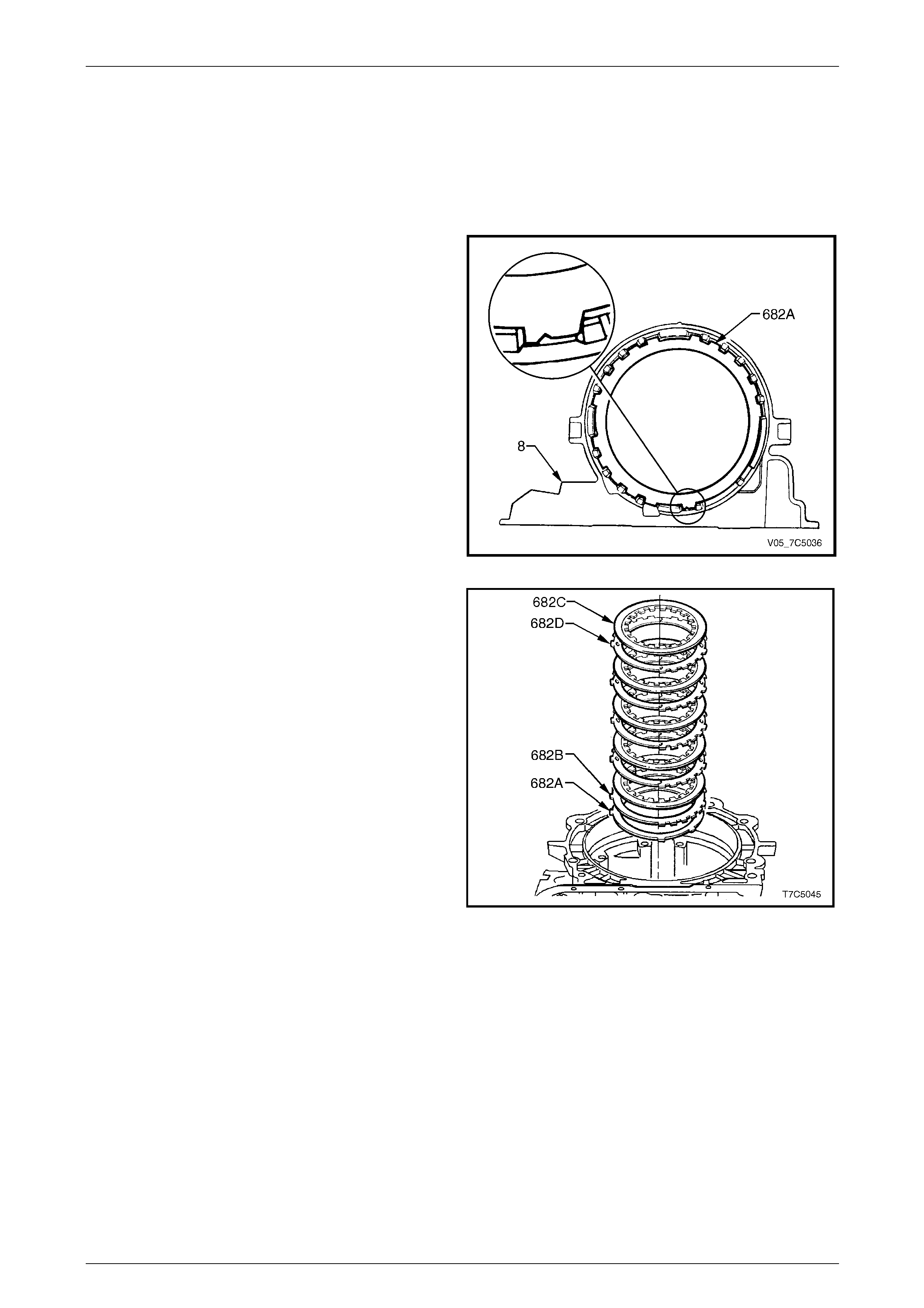

12 Remove low and reverse clutch plate assembly:

• 682C Composition plates

• 682D Steel plates

• 682B Selective spacer plate

• 682A Wave plate.

Figure 7D5 – 29

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–24

15–DEC–2005 Page 7D5–24

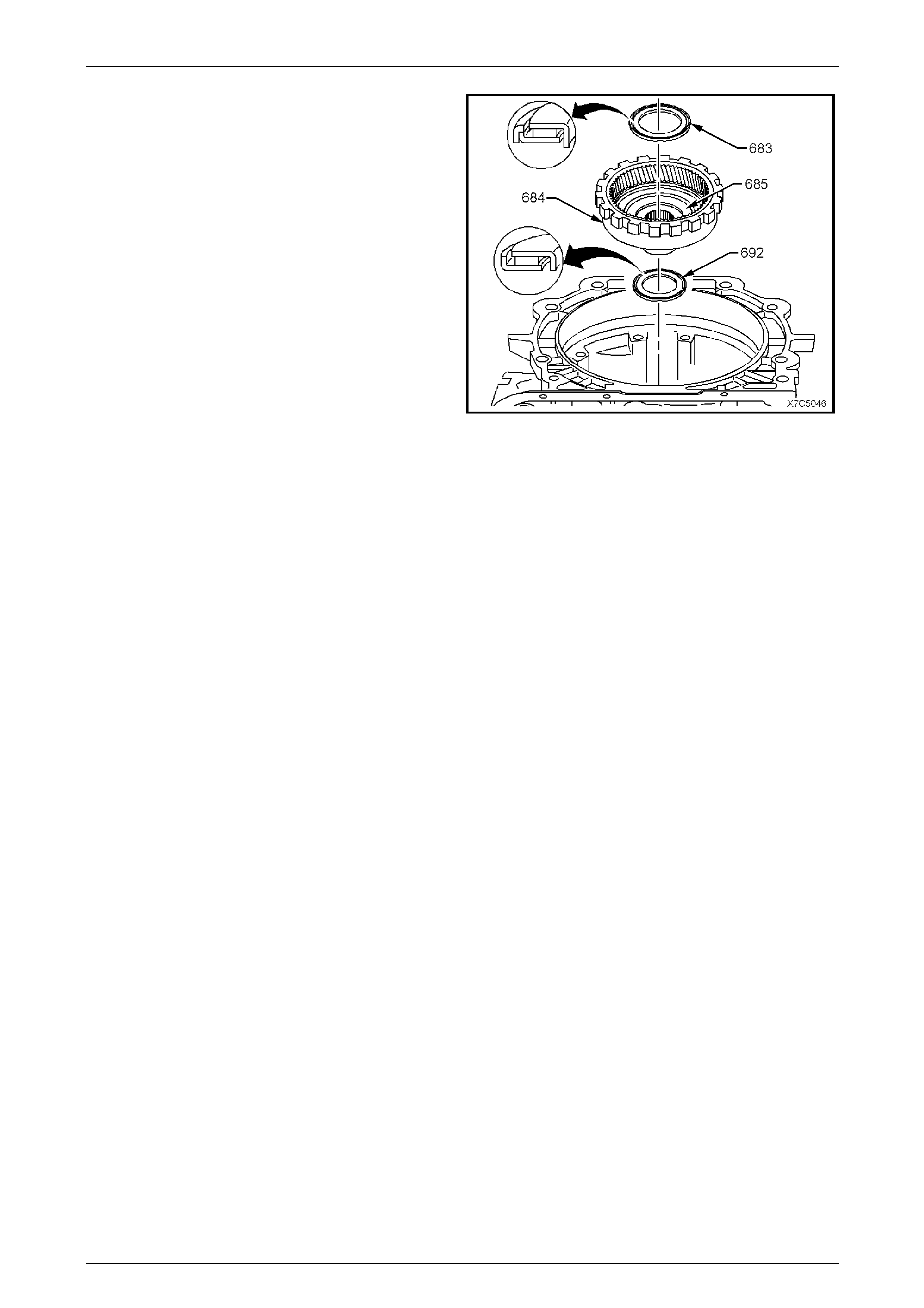

NOTE

Take note of the two thrust bearings orientation

for correct reassembly.

13 Remove the reaction carrier to supp ort thrust

bearing (683), the reaction interna l gear (6 84) and the

support assembly (685).

14 Remove the reaction gear support to case bearing

assembly (692).

Figure 7D5 – 30

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–25

15–DEC–2005 Page 7D5–25

2.11 Low and Reverse Clutch Assembly

LT Section No. — 04–200

Remove

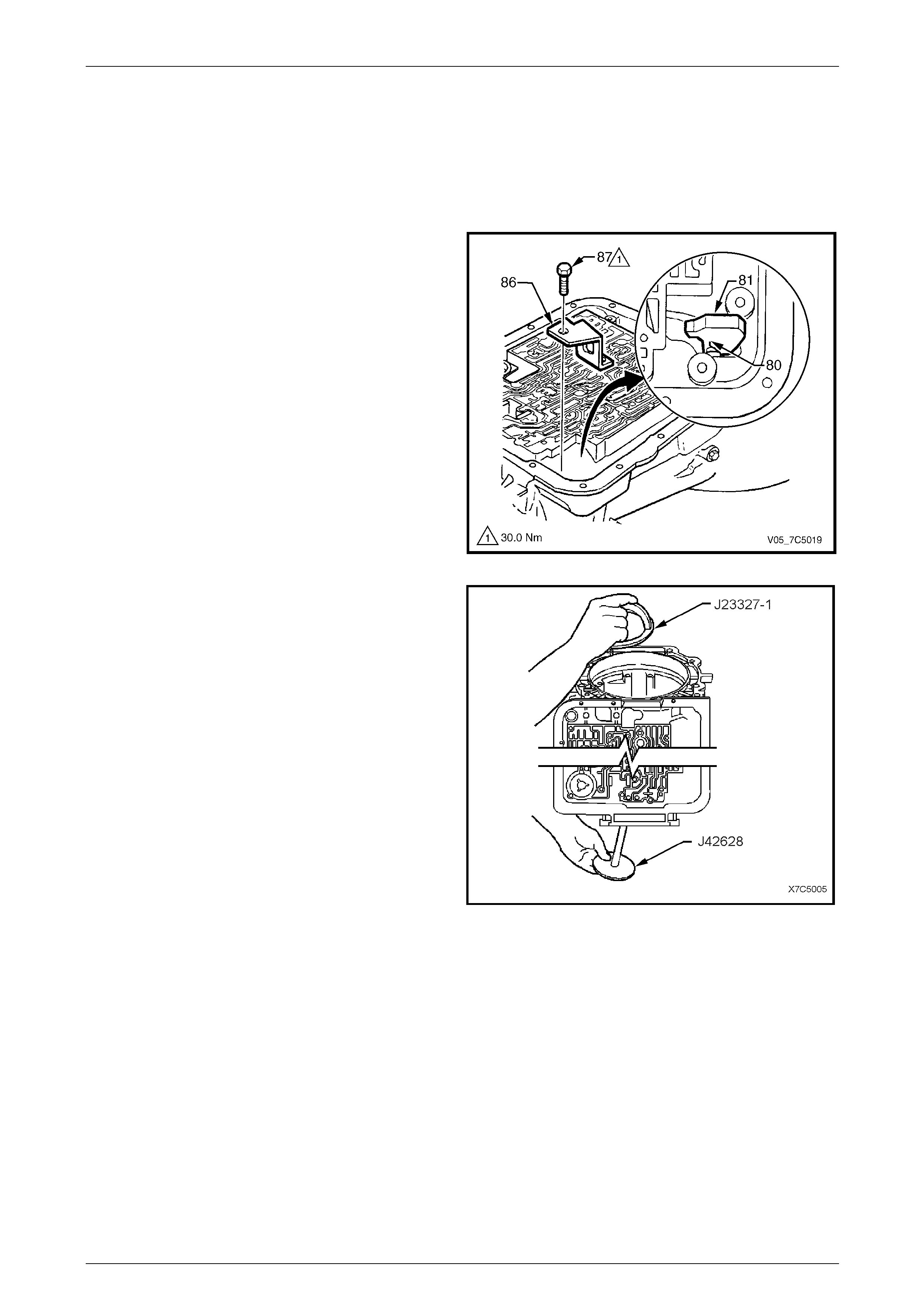

1 Remove the bolt (87), two places, securing the parki ng

pawl bracket (86). This will allow the spring (80) to

retract the parking pawl (81), providing clearance to

remove the low and reverse clutch.

NOTE

If the parking pawl needs to be removed

completely because of interference, follow the

next three steps. Otherwise, continue the

disassembly from step 5.

2 Remove the pawl shaft plug (not shown) with a

suitable screw extractor.

3 Use a magnet to remove the pa wl pivot shaft (not

shown).

4 Remove the parking pa wl bracket, pawl and spring.

Figure 7D5 – 31

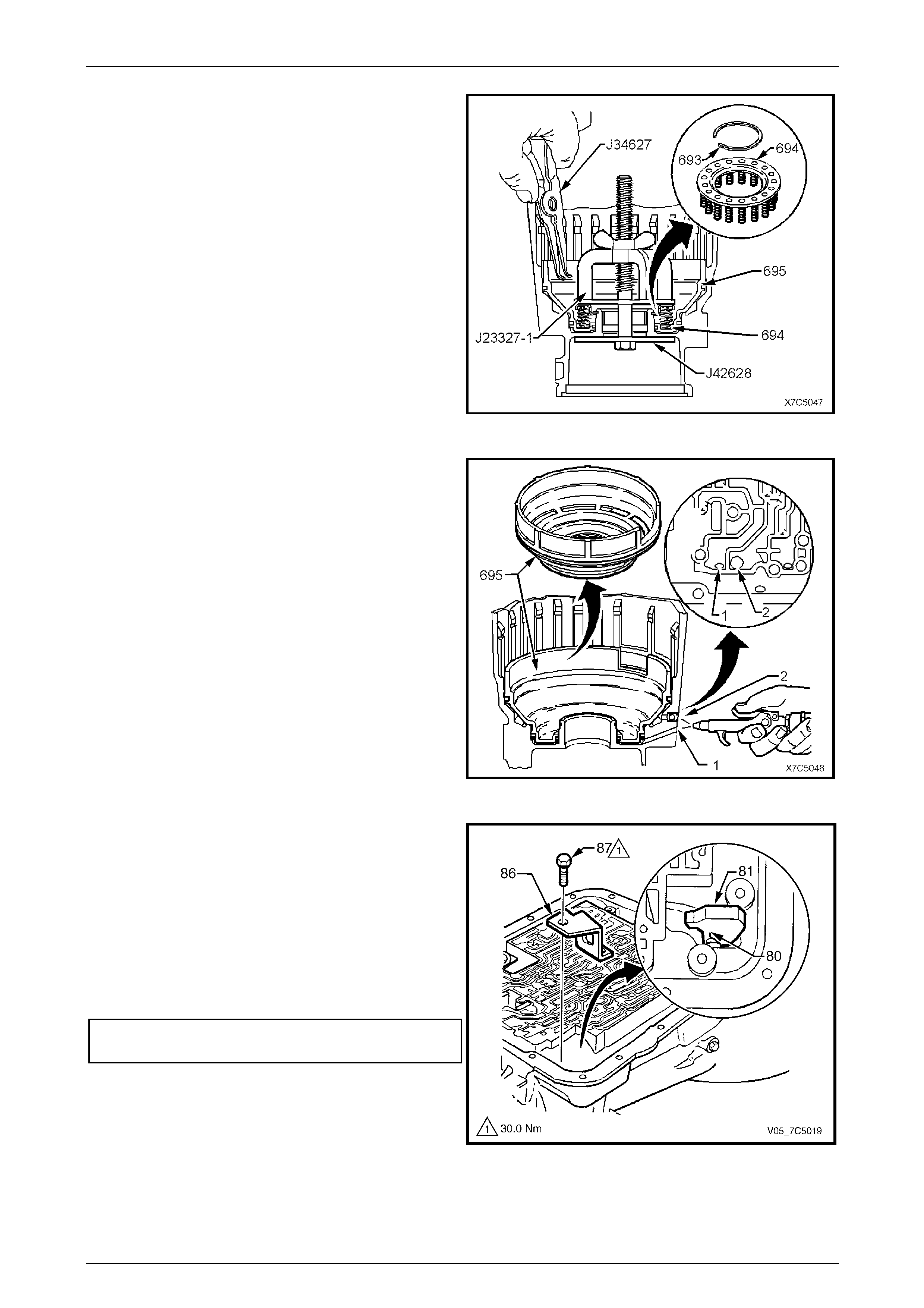

5 Install the forcing bolt of Tool No. J23327- 1 through

plate, Tool No. J42628, then install into the rear of the

transmission case.

6 Install the press cage of Tool No. J23327-1 into the

transmission case, over the forcing bolt and secure

with the provided wing nut.

Figure 7D5 – 32

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–26

15–DEC–2005 Page 7D5–26

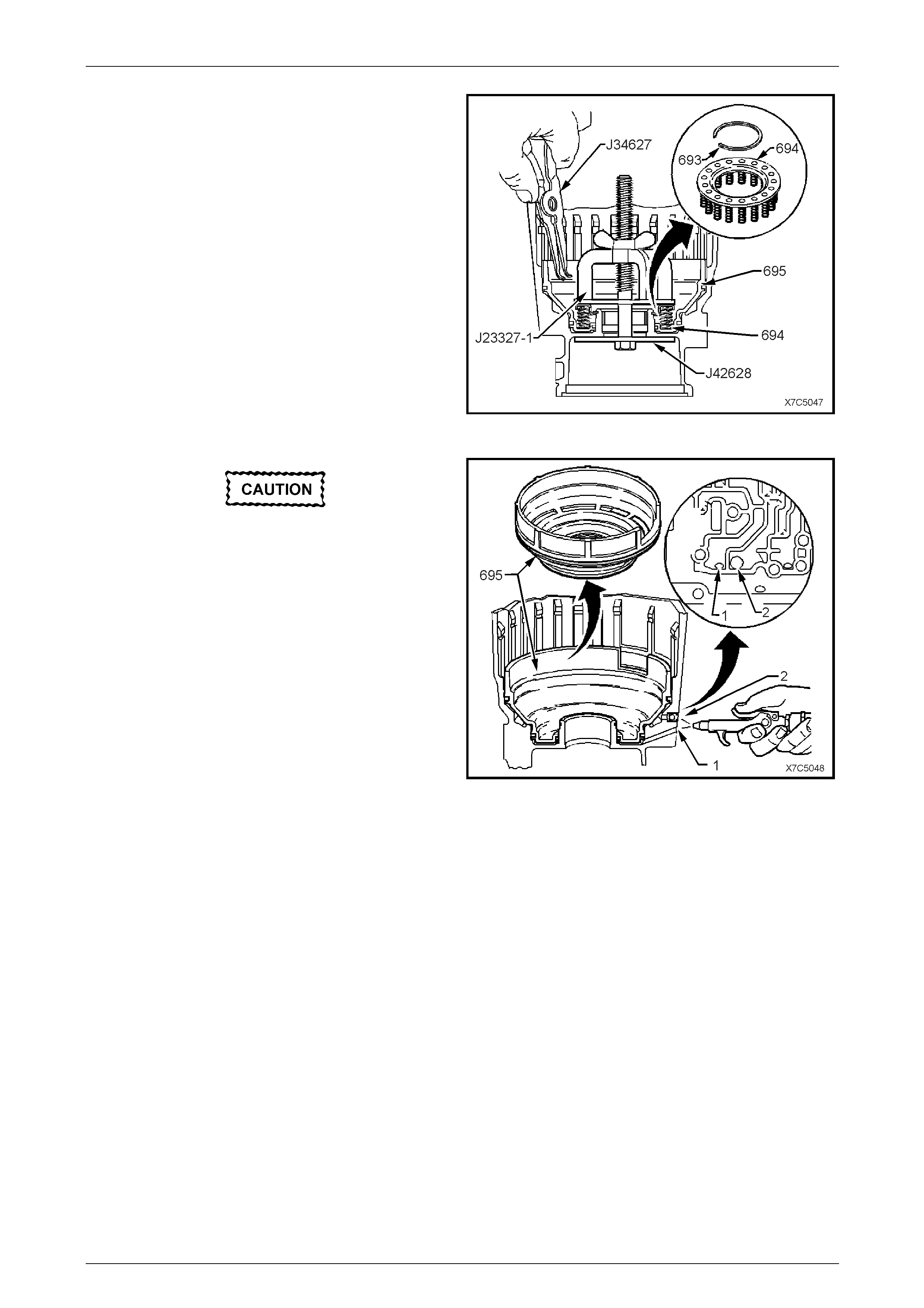

7 Tighten the wing nut of Tool No. J23327-1 to

compress the low and reverse clutch spring s (694)

and clear access to the retaining sna p rin g (6 93).

8 Remove the low and reverse clutch retaining snap

ring (693) using snap ring pliers, Tool No. J34627, or

equivalent.

9 Remove Tool No. J23327-1 and the low and reverse

clutch spring assembly (694).

Figure 7D5 – 33

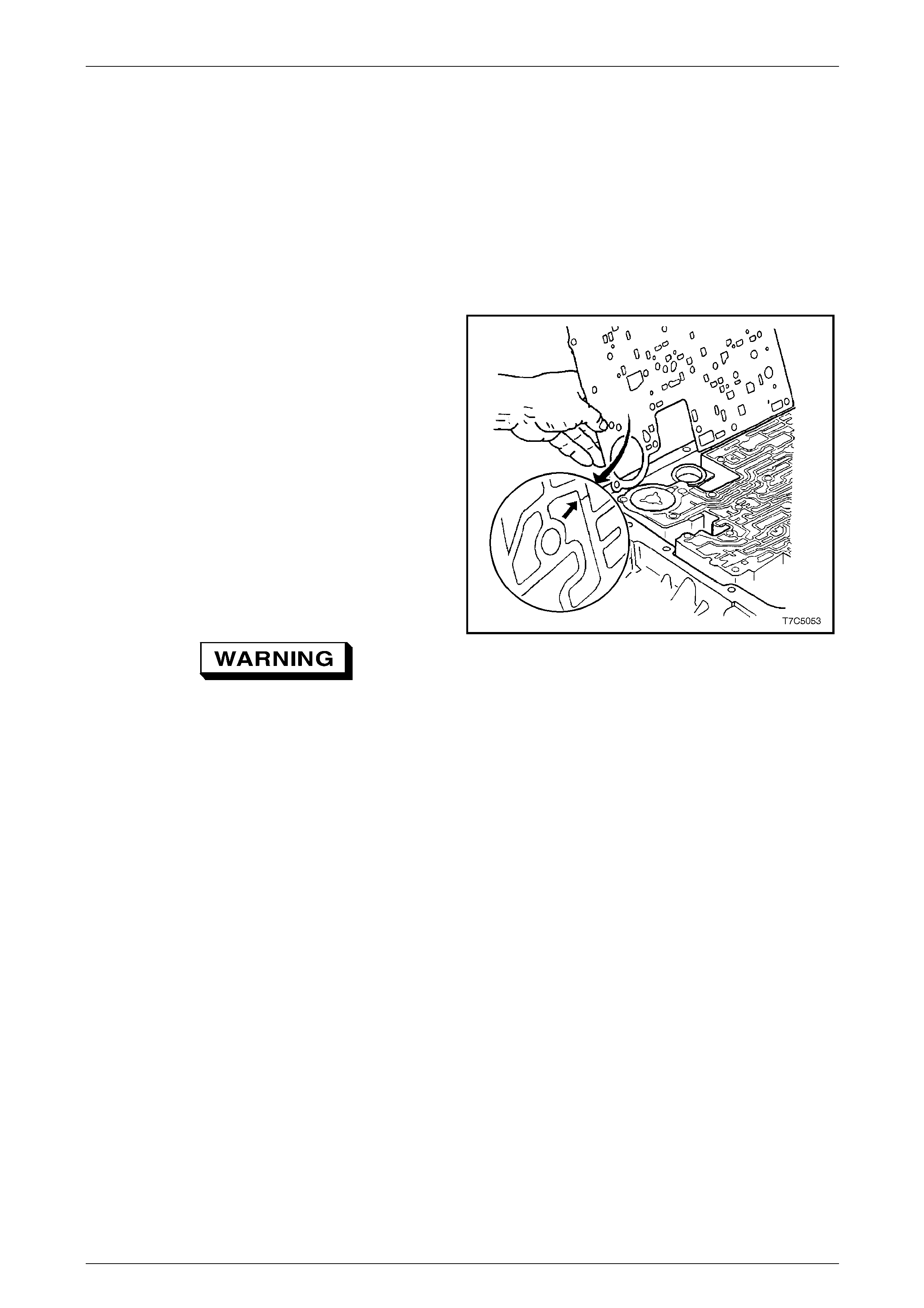

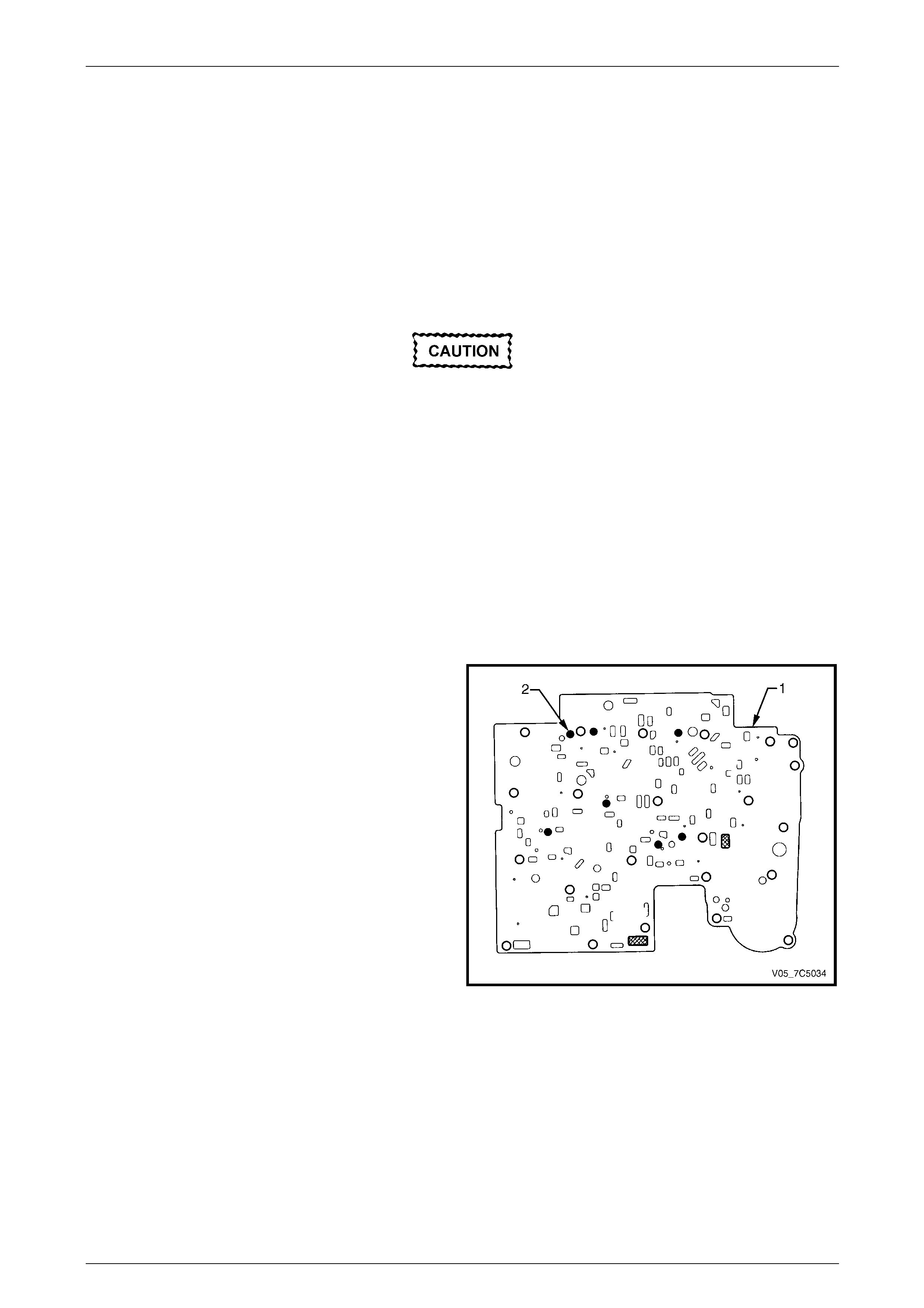

To reduce the possibility of injury, do not use

air pressure in excess of 70 kPa for this

operation.

10 Apply lo w pressure air to either the low feed

passage (1) or the reverse feed passage (2), as

shown, to assist in the removal of the low and reverse

clutch piston (695) and remove the piston.

Figure 7D5 – 34

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–27

15–DEC–2005 Page 7D5–27

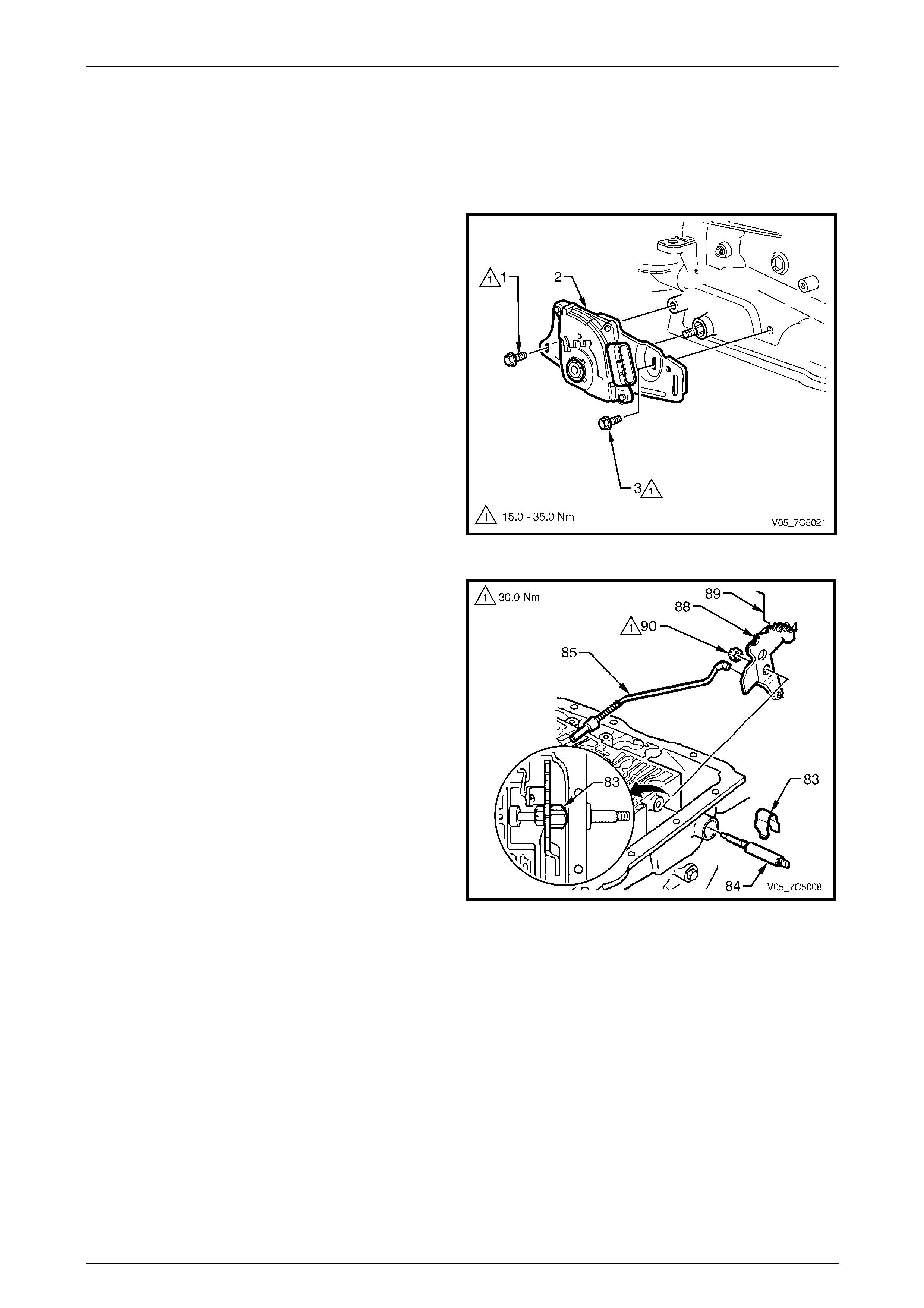

2.12 Manual Shaft, Inner Linkage and Seal

LT Section No. — 04–190

Remove

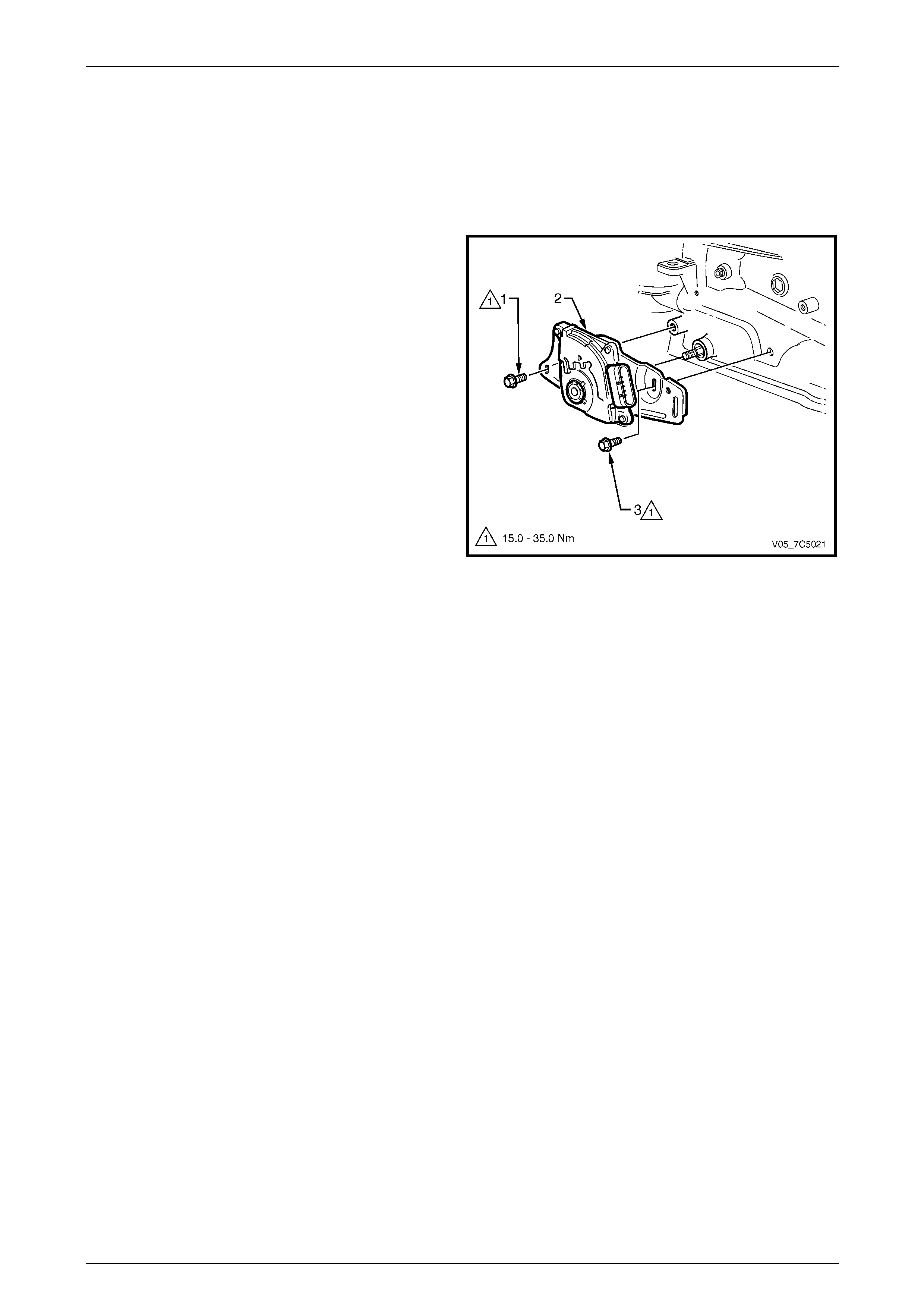

1 Remove the two screws (1 and 3) securing the neutral

start and back-up lamp s witch (2), then remove the

switch from the transmission case.

Figure 7D5 – 35

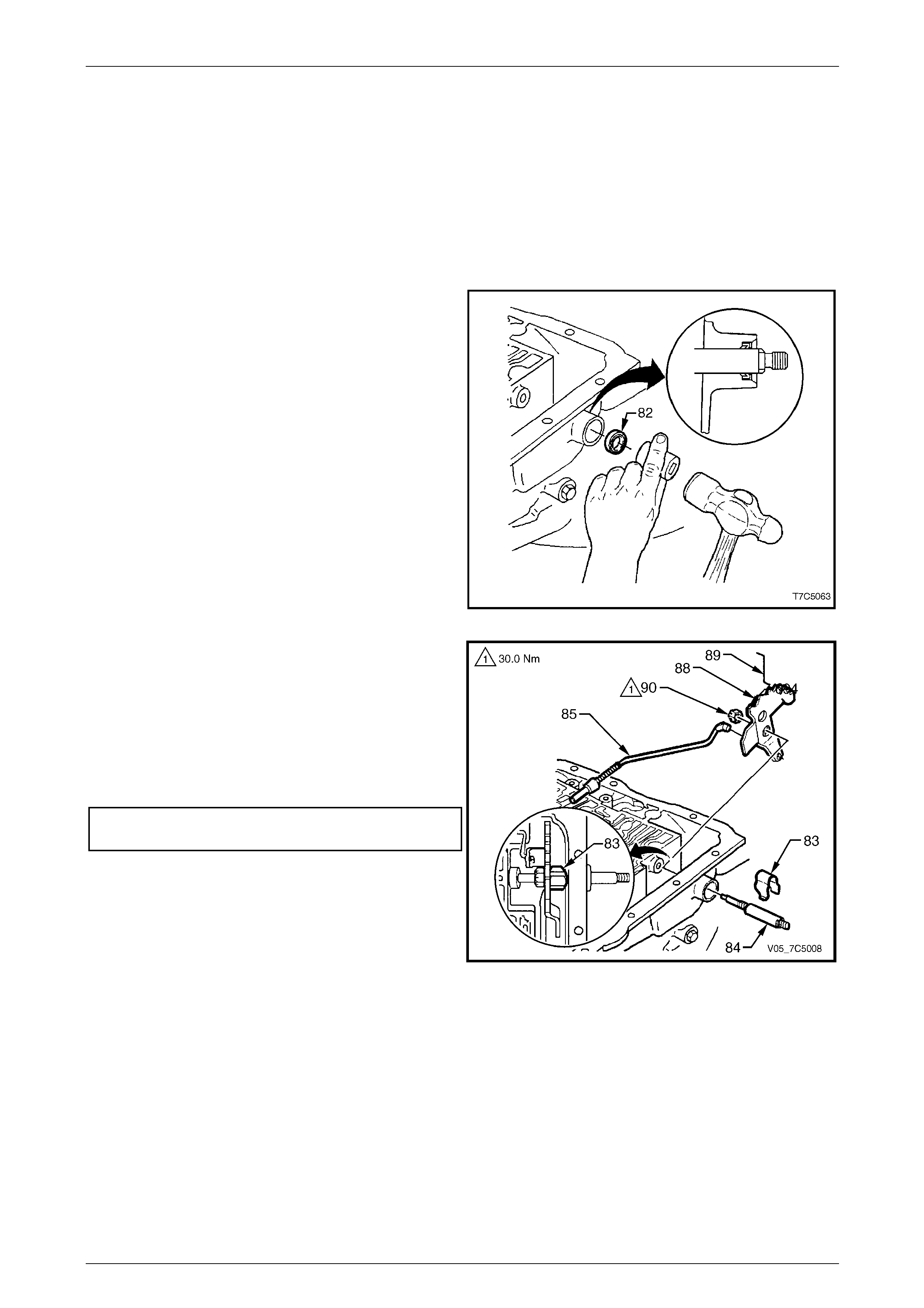

2 Remove the nut (90) securing the inner detent

lever (88) to the manual shaft (84).

3 Remove the inner detent lever and parking pawl

actuator rod (85).

4 Remove the retaining clip (83) from the manual

shaft (84).

5 Withdraw the manual shaft from the transmission

case.

Figure 7D5 – 36

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–28

15–DEC–2005 Page 7D5–28

NOTE

An alternative method to remove the seal is to

use special Tool No. AU583 as described in

7D4 Automatic Transmission – 4L65E –

On-vehicle Servicing.

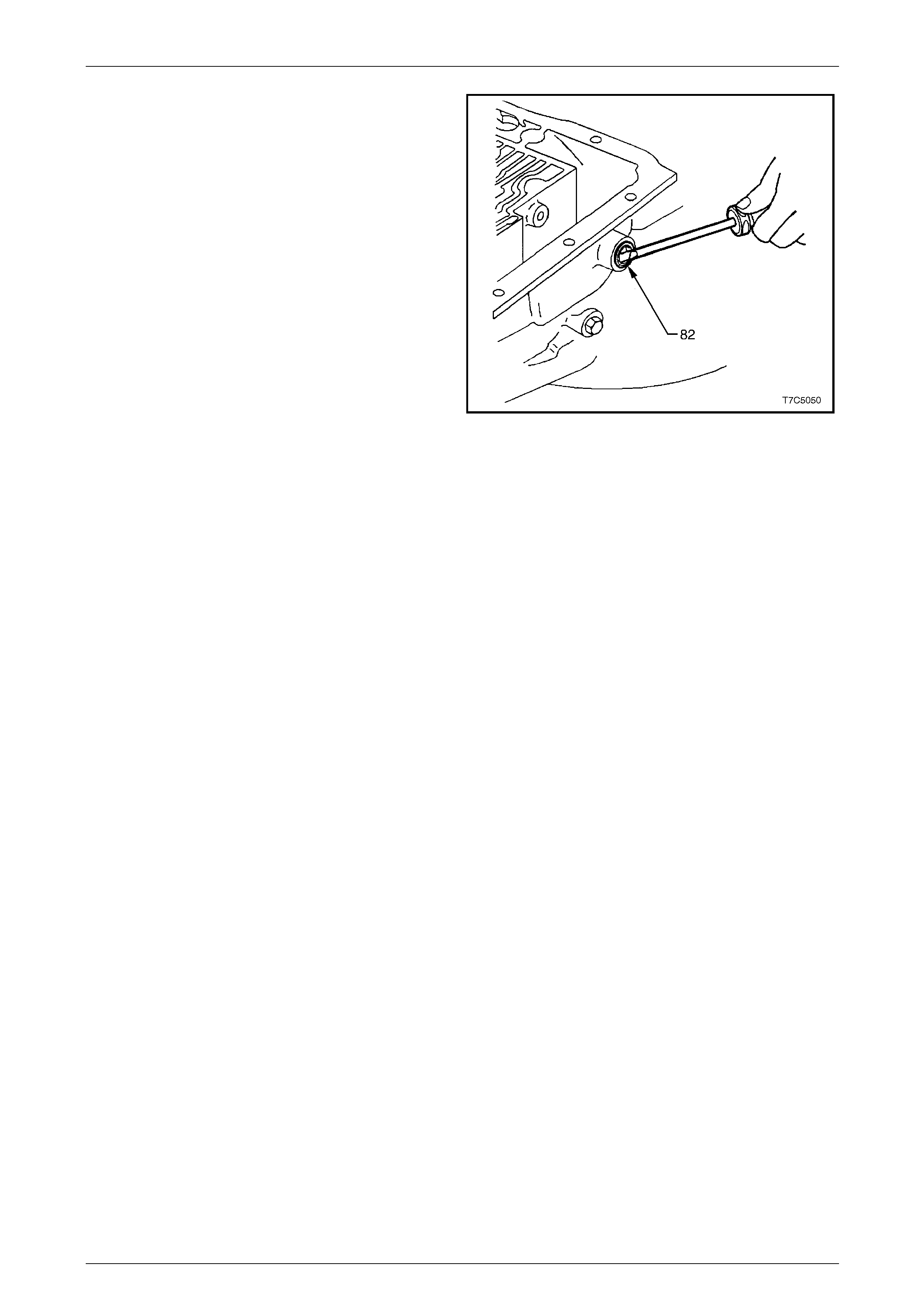

6 Pry out the manual shaft seal (82) from the

transmission case with a suitable screwdriv er.

Figure 7D5 – 37

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–29

15–DEC–2005 Page 7D5–29

3 Component Disassembly,

Inspection, Reassembly

3.1 Transmission Case

LT Section No. — 04–200

Inspect

1 Wash the transmission case thoroughly with solvent,

dry with air and blow out all oil passages.

NOTE

Do not use cloth to dry the transmission case.

2 Inspect the case for cracks or porosity.

3 Check the case to valve body face for damage,

distortion and inter-connected oil passages.

NOTE

Face flatness can be checked by inspecting the

case and spacer plate gasket for complete

witness marks. If the marks are incomplete, an

uneven case surface, or cross chann el leaks are

indicated.

When using compressed air, wear safety

equipment to avoid personal injury.

4 Using compressed air, check all oi l passages. For

identification of the transmission case fluid passages,

refer to Section 7D3 Automatic Transmission – 4L65E

– Hydraulic and Mechanical Diagnosis.

Figure 7D5 – 38

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–30

15–DEC–2005 Page 7D5–30

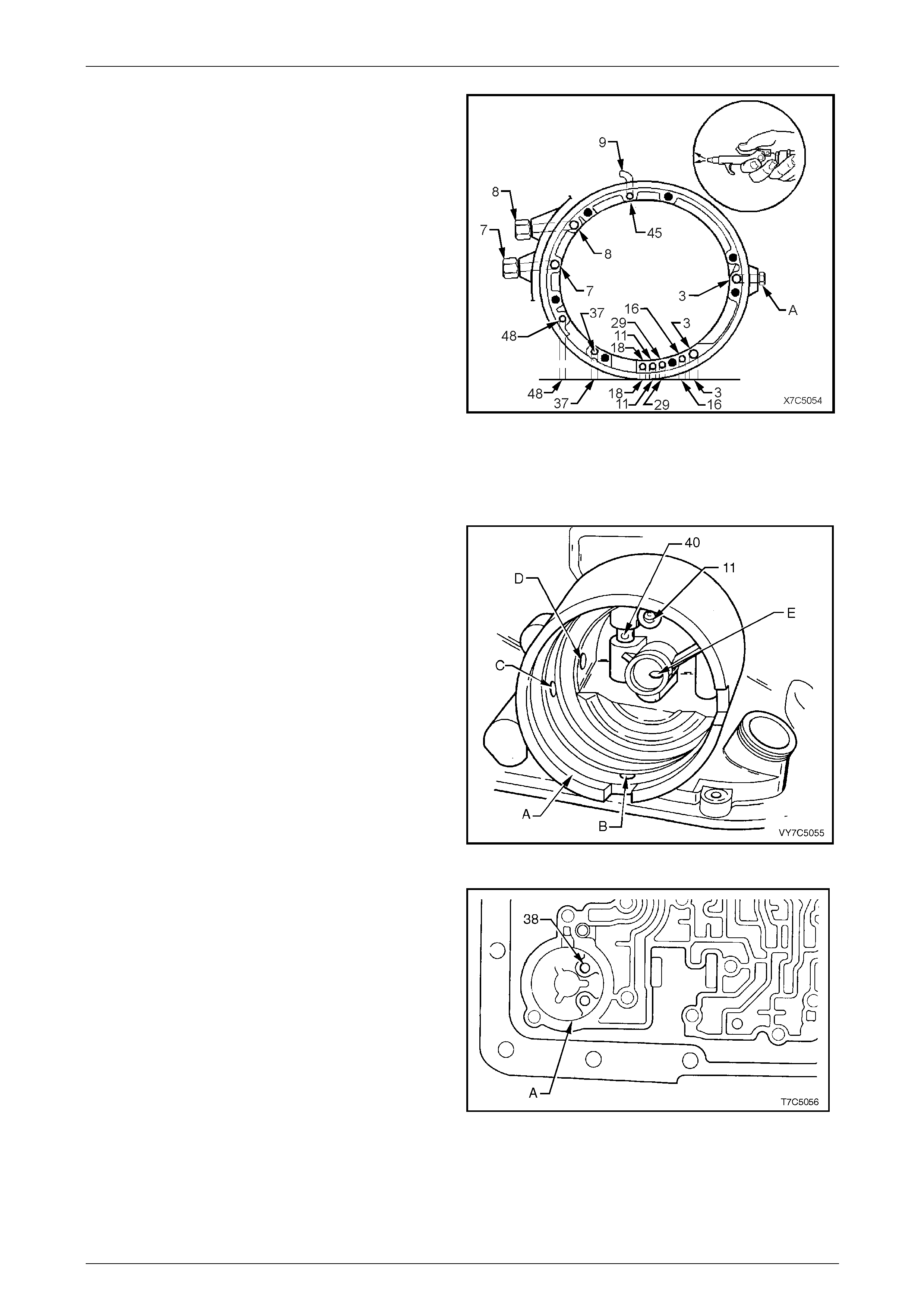

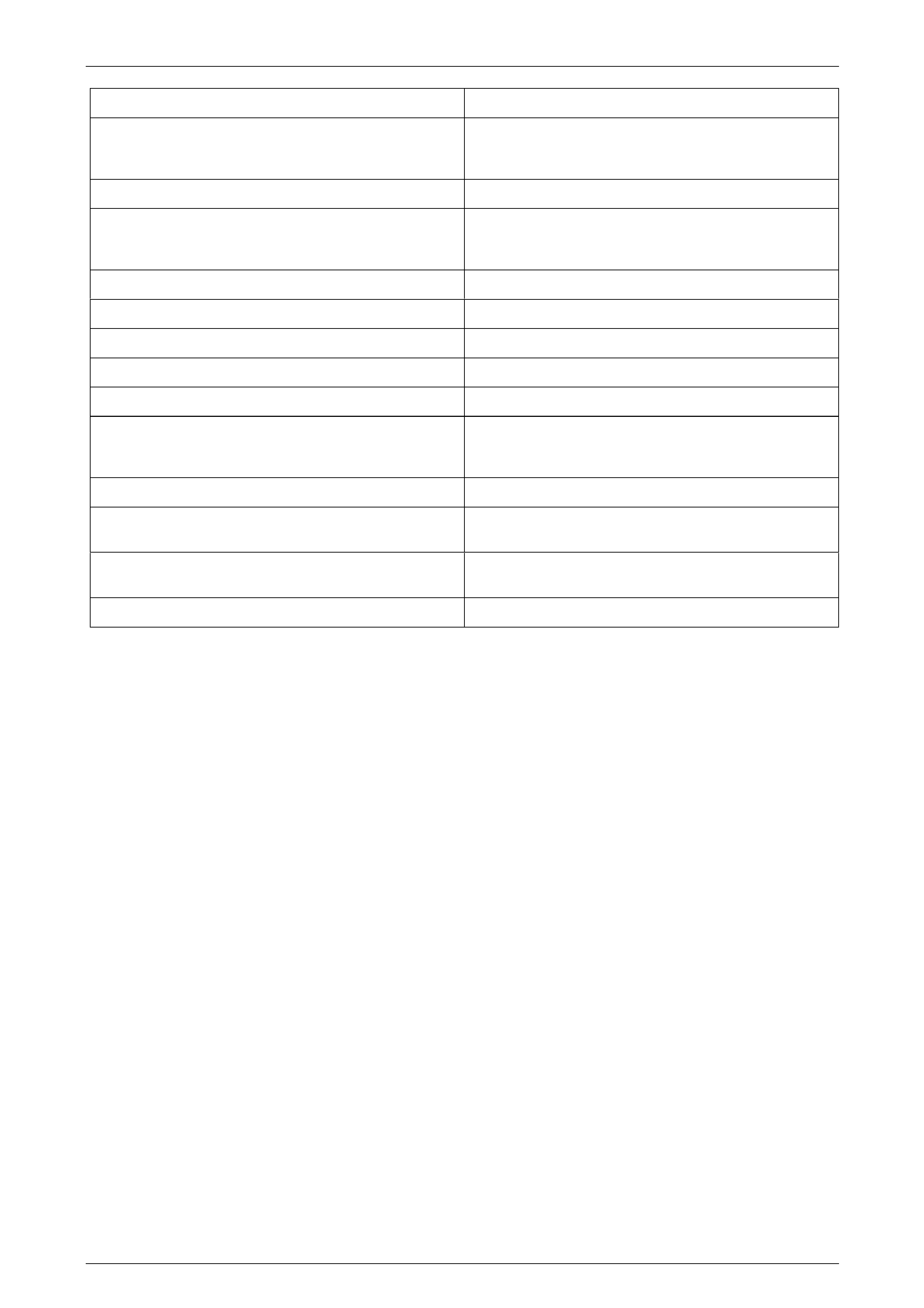

5 Check the vent tube located at the top of the

transmission case (9) for damage and/or blockage.

6 Check the oil pump fluid passages b y blowing low

pressure compressed air into the passages.

Fluid passages identification:

3 line pressure

7 quick connect fitting to external cooler

8 quick connect fitting from external cooler

11 torque signal

16 reverse input clutch

18 forward clutch feed

29 3-4 clutch

37 overrun clutch

45 vent

48 torque converter clutch regul ated apply

A line pressure plug.

Figure 7D5 – 39

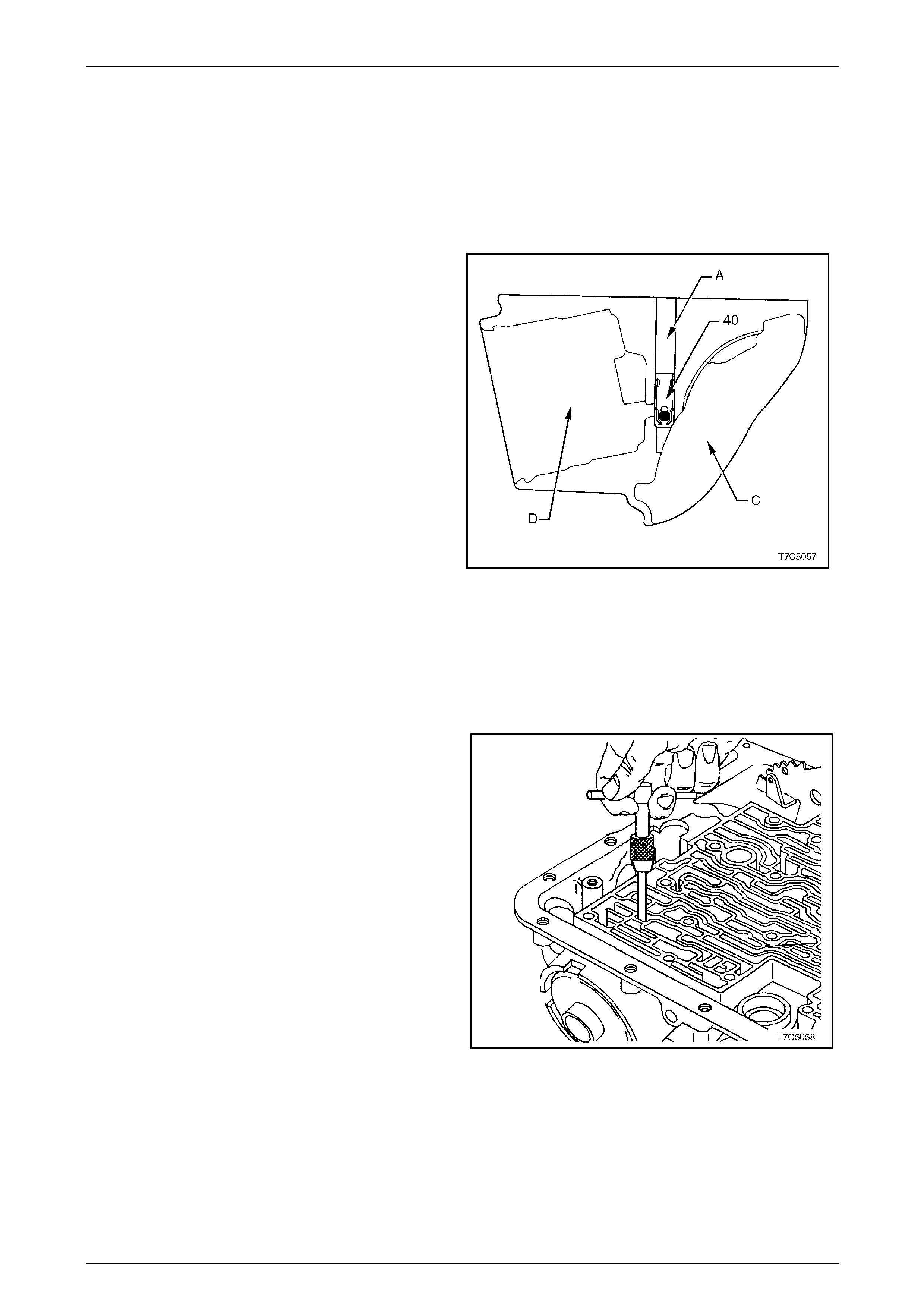

7 Inspect the 2-4 servo bore (A) for damage or poros ity.

Ensure all slots and passages are clear, check for

sharp edges. Check the orifice cup plug in the servo

bore (11) for debris or damage.

Bore passages identification:

A 2-4 servo bore

B servo exhaust hole

C 2-4 band apply passage (2nd gear)

D 3rd accumulator pressure tap passage

E 2-4 band apply passage (4th gear)

11 orifice cup plug

40 3rd accumulator retainer and ball assembly.

Figure 7D5 – 40

8 Inspect the 3-4 accumulator bore (A) and orifice cup

plug (38) for damage or porosity. Ensure all slots and

passages are clear, check for sharp edg es. Check for

pin damage.

9 Inspect the vehicle speed sender unit bore for damage

or porosity.

10 Inspect all bolt holes and oil cooler pipe connections

for thread damage. Repair with thread inserts or

equivalent, as necessary.

Figure 7D5 – 41

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–31

15–DEC–2005 Page 7D5–31

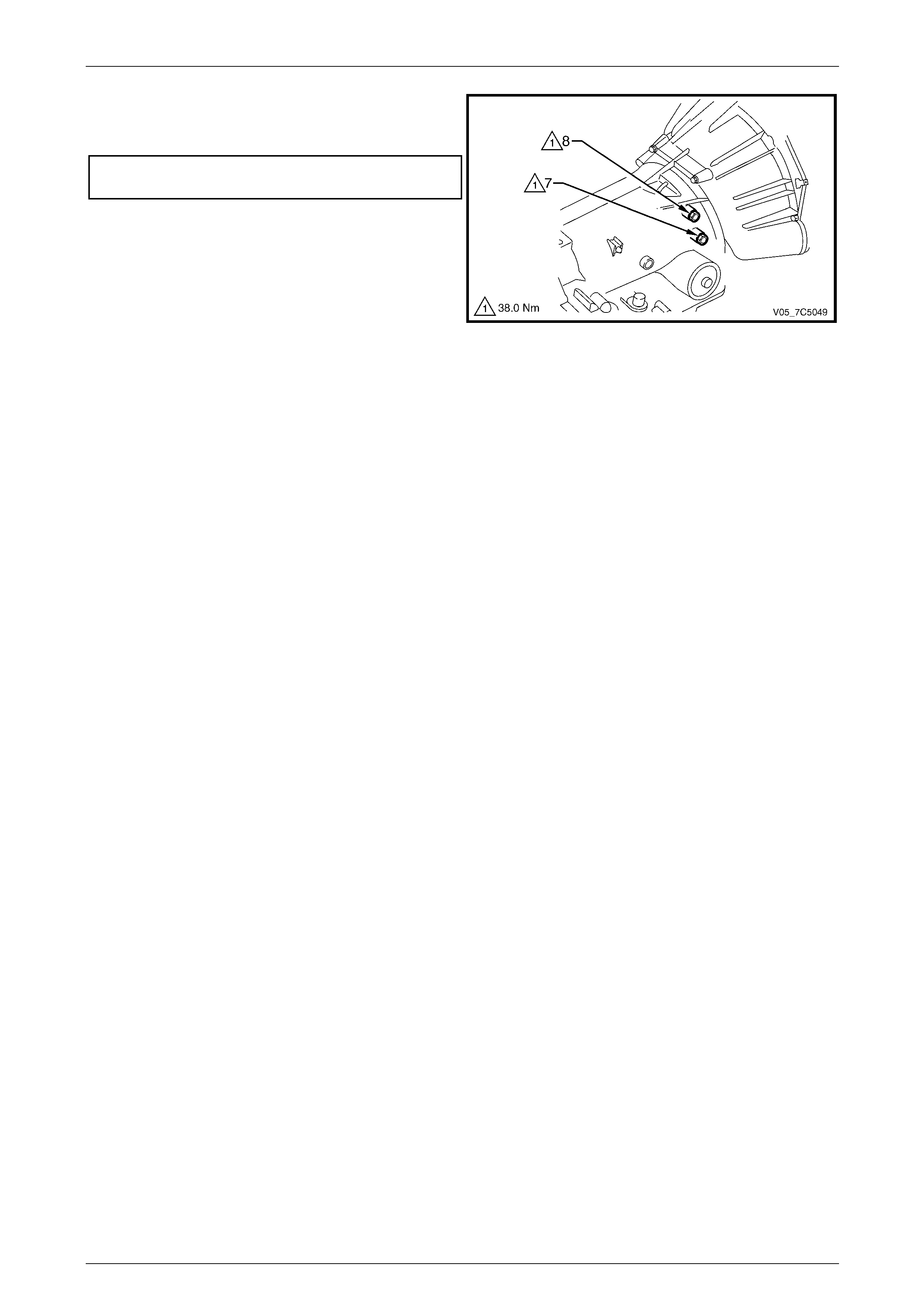

11 If removed, refit and tighten the oil cooler pipe quick

connect fittings (7 and 8) to the correct torque

specification.

Oil cooler pipe quick connect fitting

torque specification............................................38.0 Nm

Figure 7D5 – 42

12 Inspect the case interior for:

a damaged ring grooves or casting flash,

b clutch plate lugs worn or damage d,

c worn or damaged bushes.

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–32

15–DEC–2005 Page 7D5–32

3.2 Third Accumulator Retainer and Ball

Assembly

LT Section No. — 04–200

Inspect

1 Inspect the third accumulator ball and retainer (40) for:

a ball missing, damaged or sticking

b retainer loose or not seated correctly

c feed slots restricted.

2 Check the third accumulator ball ass embl y for leakage

as follows:

a Reinstall the assembled 2-4 s ervo components,

including cover and retaining ring, into the 2-4

servo bore (D).

b Pour a suitable solvent into the third accumul ator

bore (A).

c Watch for leakage into the case interior (C).

NOTE

Because fluid will flow from the orific e in the case

servo plug (11), careful observation of the fluid

leakage source will be required, refer to Figure

7D5 – 40.

d Remove the 2-4 servo components.

Figure 7D5 – 43

Replace

If leakage is coming from the third accumulator bal l

assembly, replace as follows:

1 Remove the old assembly with a suitab le screw

extractor (6.3 mm or #4).

Figure 7D5 – 44

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–33

15–DEC–2005 Page 7D5–33

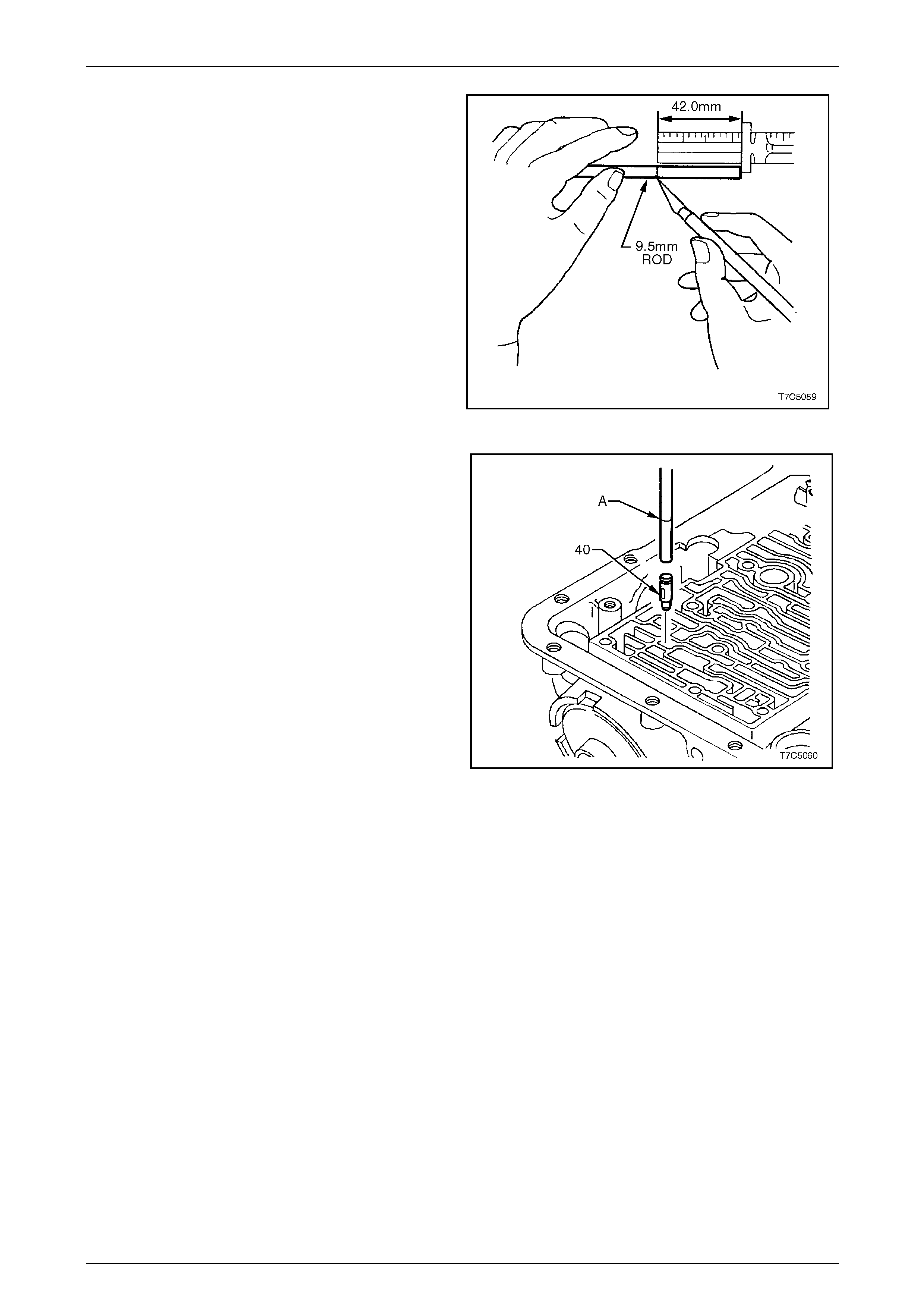

2 Select a suitable length of 9.5 mm rod and scribe a

mark, 42 mm from its squared end, to indicate the

correct depth of installation.

Figure 7D5 – 45

3 Using the 9.5 mm rod, install a new 3rd accumulator

retainer and ball check assem bly (40).

4 Align the oil feed slots with the servo bore (40), refer to

Figure 7D5 – 40.

5 Install the 3rd accumulator ball and retainer assembly

until the scribe mark (A) on the rod, is level with the

case face.

Figure 7D5 – 46

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–34

15–DEC–2005 Page 7D5–34

3.3 Transmission Case Bush

LT Section No. — 04–200

Replace

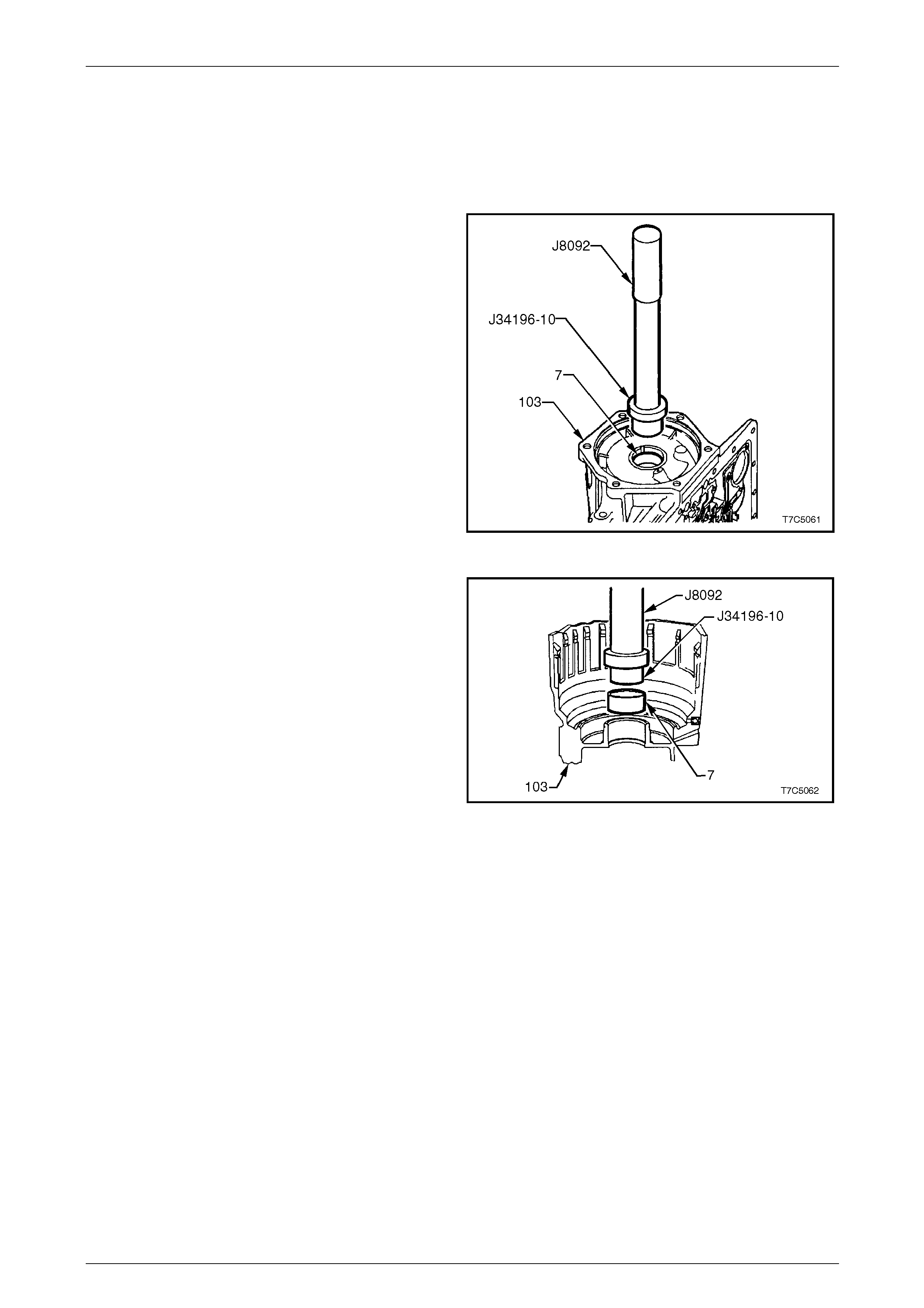

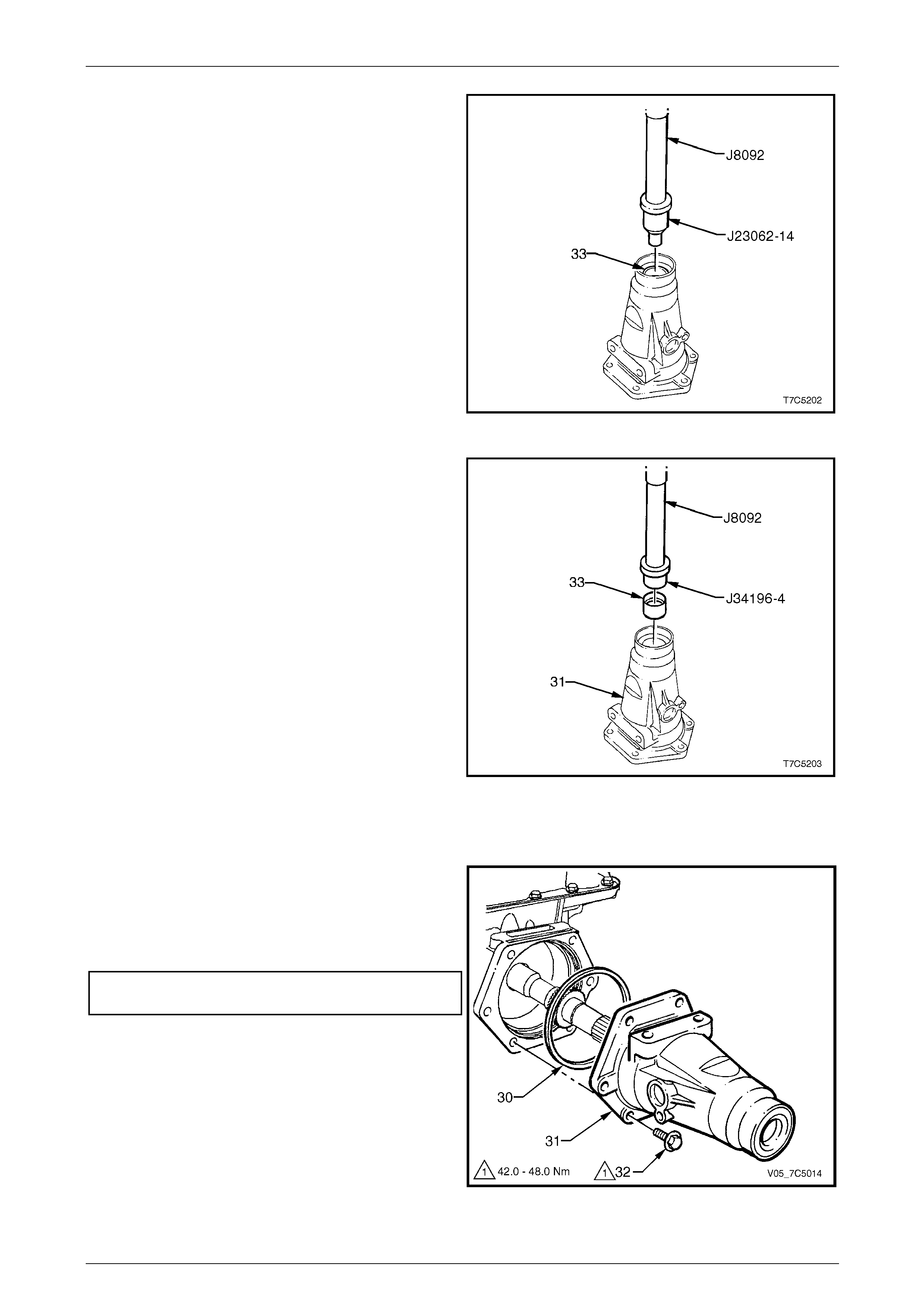

1 Using the bush remover, T ool No. J34196-10 (part of

set, Tool No. J34196-B) and driver handle, Tool No.

J8092, press the rear bush from the transmission

case (103).

Figure 7D5 – 47

2 Install a new bush (7) into the transmission case (103)

using the same tools as for removal.

Figure 7D5 – 48

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–35

15–DEC–2005 Page 7D5–35

3.4 2-4 Servo Assembly

LT Section No. — 04–200

Inspect

1 Inspect components for wear or damage, check springs for broken coils and/or distortion. For parts identif ication,

refer to 2.2 2 – 4 Servo Assembly.

2 Inspect bore in transmission case for any sharpn ess that may damage servo seals.

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–36

15–DEC–2005 Page 7D5–36

3.5 Low and Reverse Clutch Assembly

LT Section No. — 04–200

Inspect

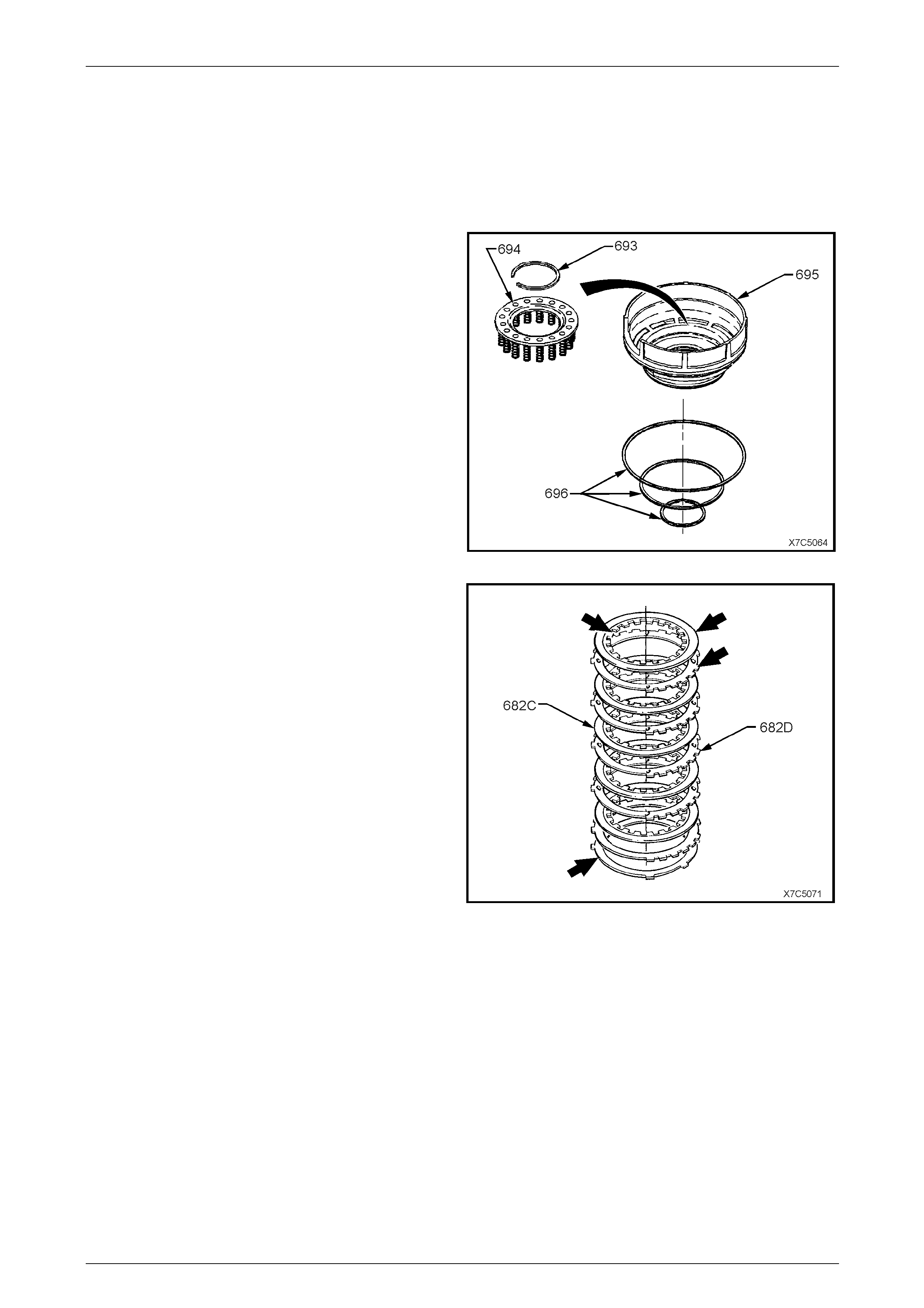

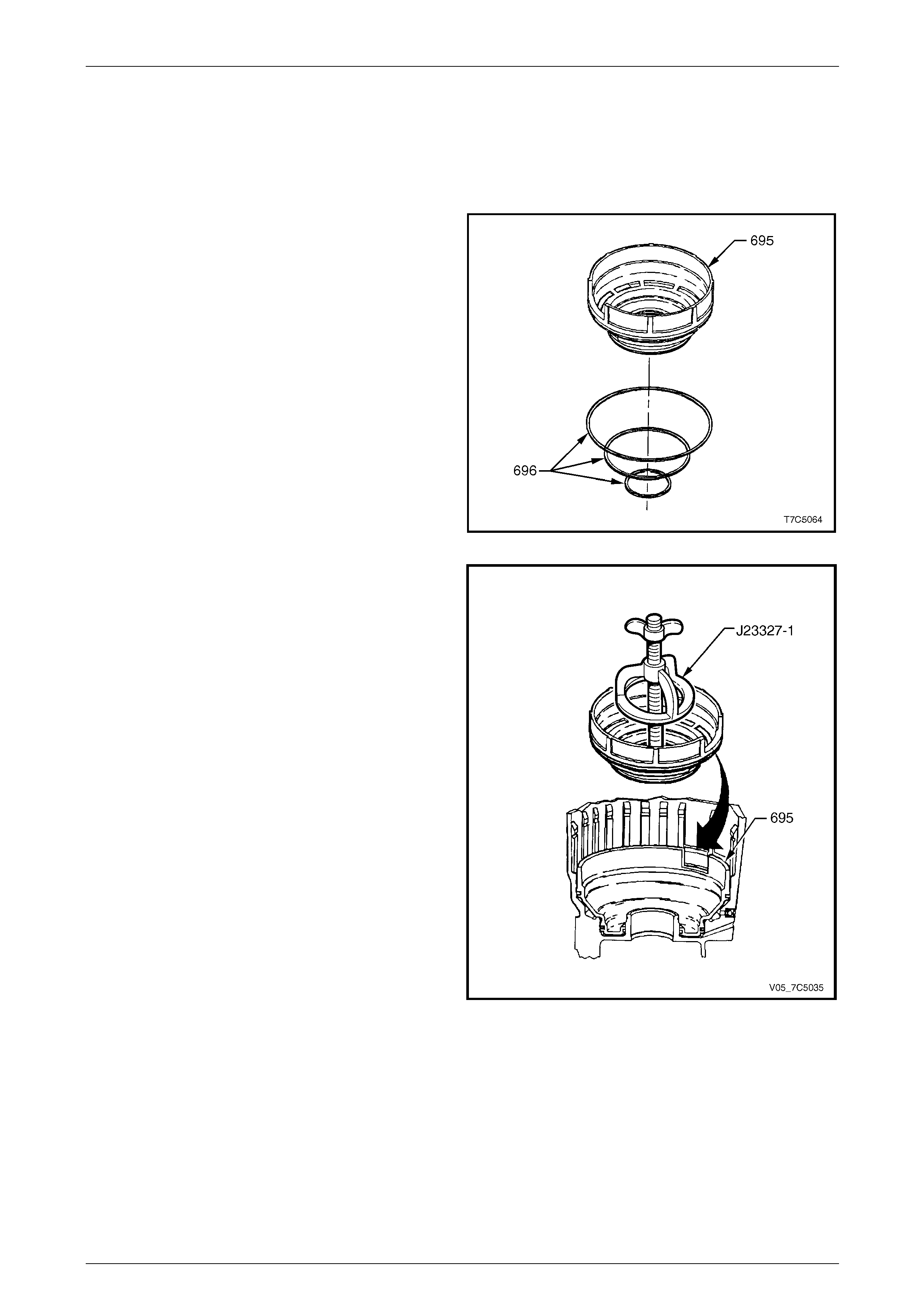

1 Inspect the piston (695) for porosit y or damage.

2 Inspect the spring assembly (694) for damage.

3 Inspect the retaining ring (693) for distortion.

4 Remove the piston seals (696) and discard. Lubricate

new seals with transmission fluid and i nstall on piston.

Figure 7D5 – 49

5 Inspect the low and reverse clutch plates as follows:

a Check the composition plates (682C) for wear,

heat damage or delami nation.

b Check the steel plates (682D) for heat dam age

or surface finish damage.

Figure 7D5 – 50

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–37

15–DEC–2005 Page 7D5–37

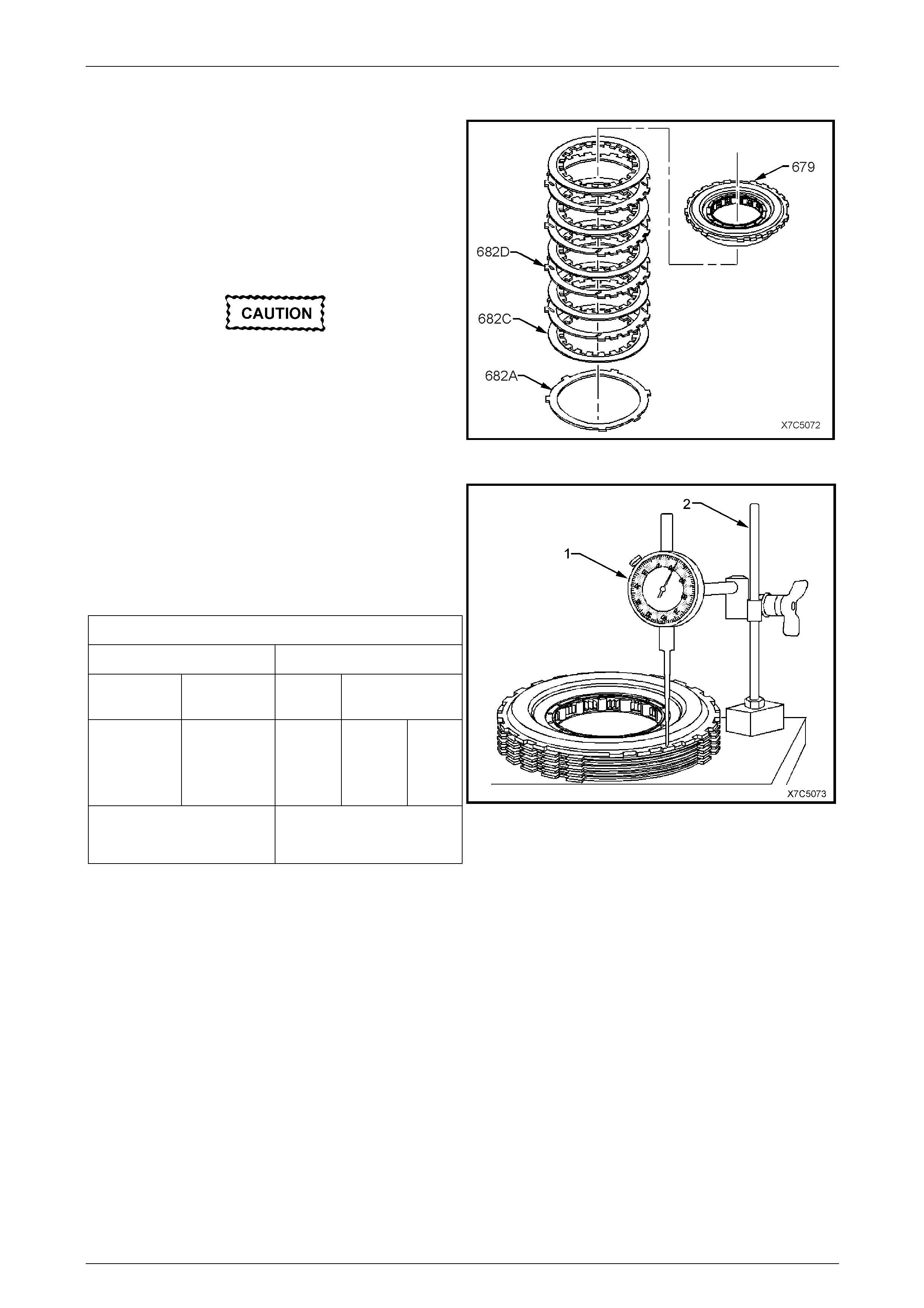

Spacer Plate Selection

1 Stack the low and reverse clutch plates on a flat

surface in the following order:

a one waved plate (682A),

b five fibre plates (682C) and four steel

plates (682D), starting with a fibre (composition)

plate and alternating with a steel plate, etc.

c low and reverse clutch support (679).

Excessive pressure will start to flatten the

wave plate, resulting in an incorrect

measurement.

2 Apply a light (approx. 2 kg), evenl y distributed load to

the low and reverse support assembly.

Figure 7D5 – 51

3 Using a commerciall y available dial indicator (1) and

magnetic stand (2), measure height of plates pack

from work surface to top of low and reverse clutch

support, noting the dimension, with the light load

applied.

4 Use the following selection chart to select the correct

spacer plate, relative to the measured height.

Low and Reverse Clutch Sp acer Plate Selection

If pack height is Use this selective plate

From (mm) To (mm) Identity Plate thickness

(mm)

27.54

28.06

27.03

28.06

28.59

27.54

None

0

1

1.68

1.17

2.20

1.83

1.31

2.34

Overall clutch pack height

(including spacer plate)

29.22 – 29.90 mm

NOTE

When referring to the above Selection Chart:

• The selective plate shown as 'None' refers to

a fifth, steel reaction plate, which is to be

used as the spacer plate.

• Should a measurement fall in an overlap,

either the thinner or thicker selective plate

can be fitted.

• Regardless of the combinations used, the

critical specification that must be achi eved, is

the overall clutch pack height (including the

spacer plate), which is to be between

29.22 mm and 29.90 mm.

5 Install the correct spacer plate bet ween the wave plate

and first composition clutch plate with identification

side facing upwards.

Figure 7D5 – 52

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–38

15–DEC–2005 Page 7D5–38

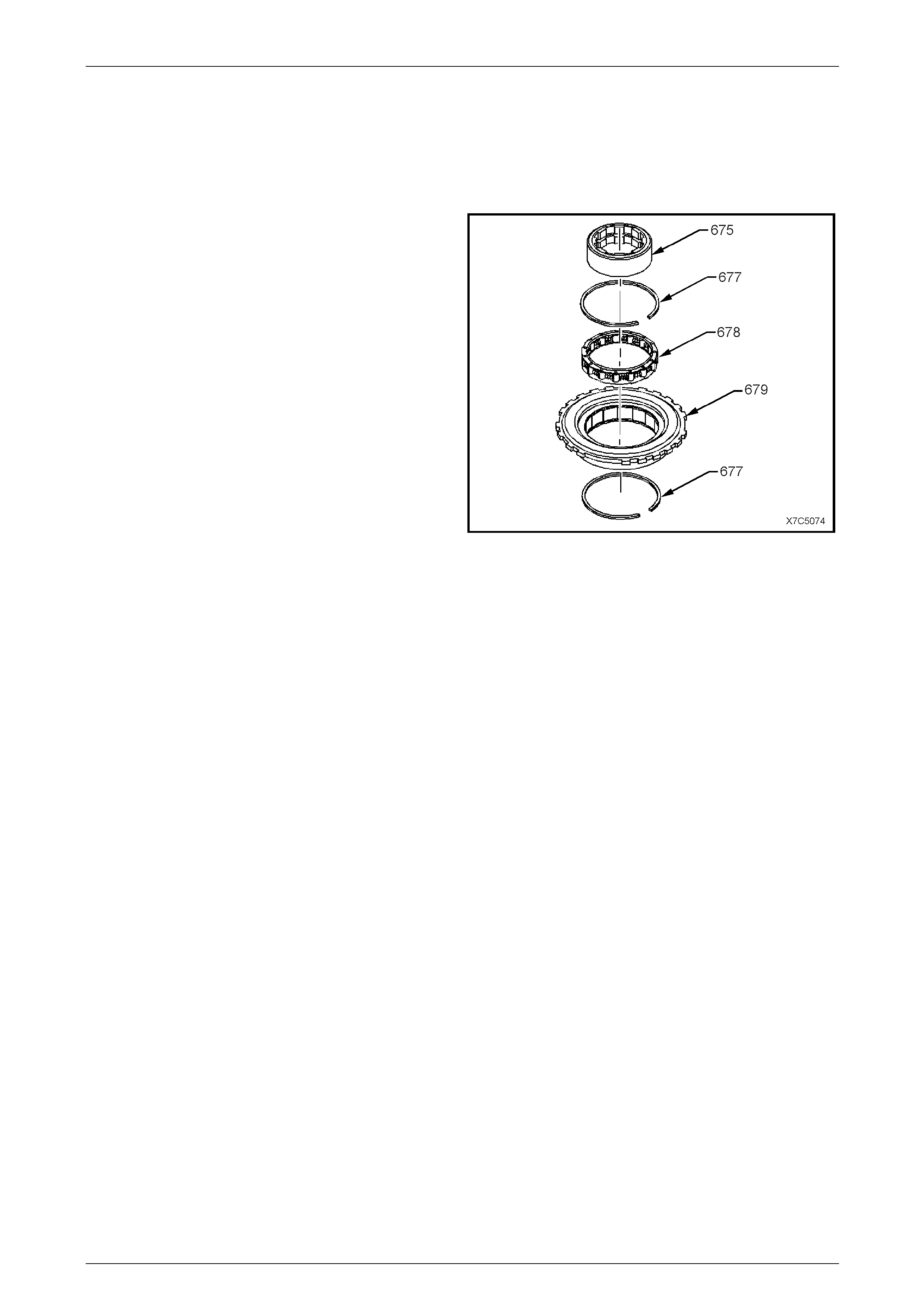

3.6 Low and Reverse Clutch

LT Section No. — 04–200

Support Assembly

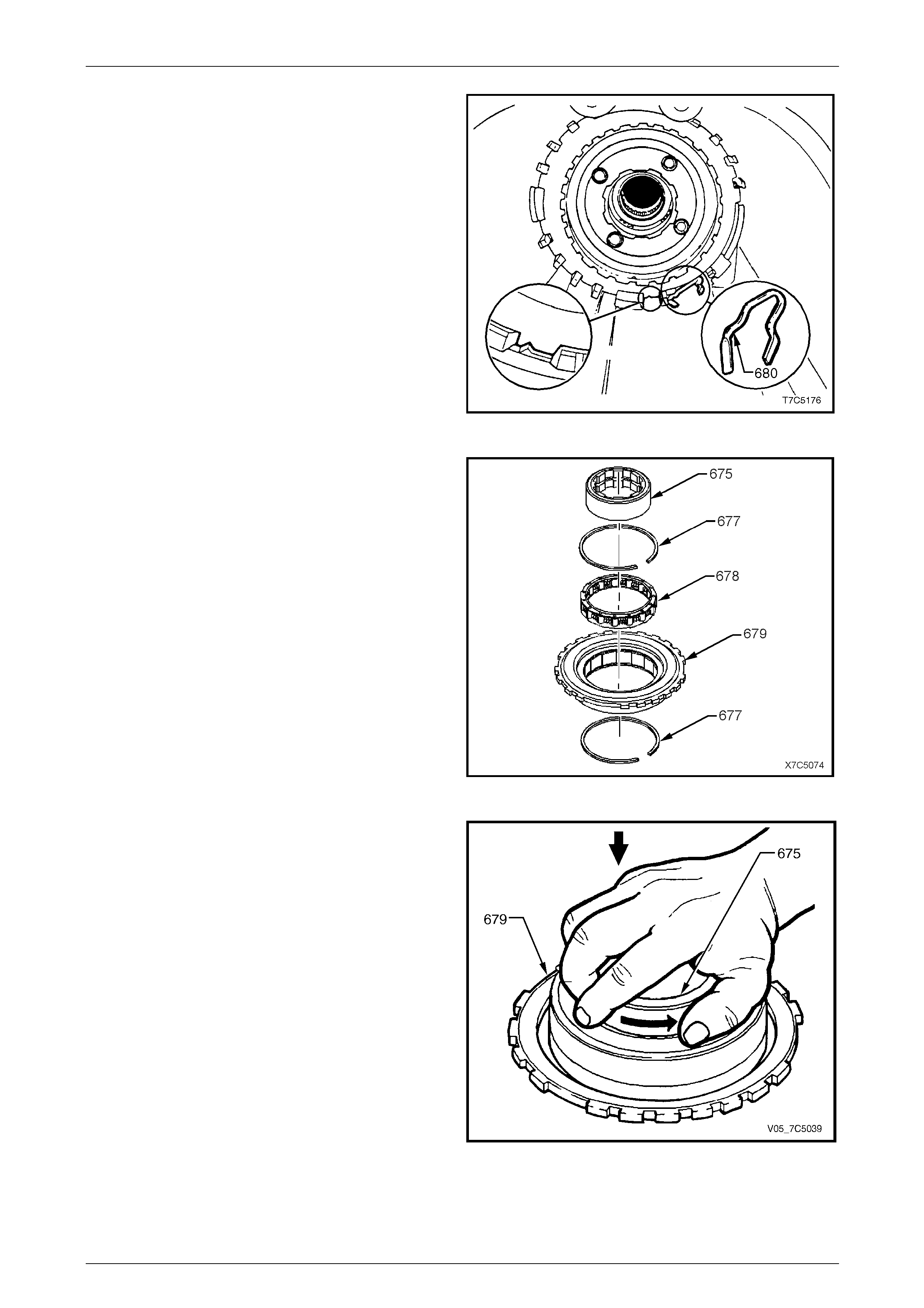

1 Disassemble the low and rev erse sup port assembly as

follows:

a remove inner race (675),

b remove one retaining ring (677) and

c remove roller clutch assembly (678).

2 Inspect the inner race for damage.

3 Inspect roller clutch assembly for damaged rollers or

broken springs.

4 Inspect the support assembly for loose cams, cracks

or damage.

NOTE

The low and reverse support assembly is

reassembled during transmission reassembly,

refer to 4.4 Low and Reverse Clutch P lates and

Support Assembly. Figure 7D5 – 53

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–39

15–DEC–2005 Page 7D5–39

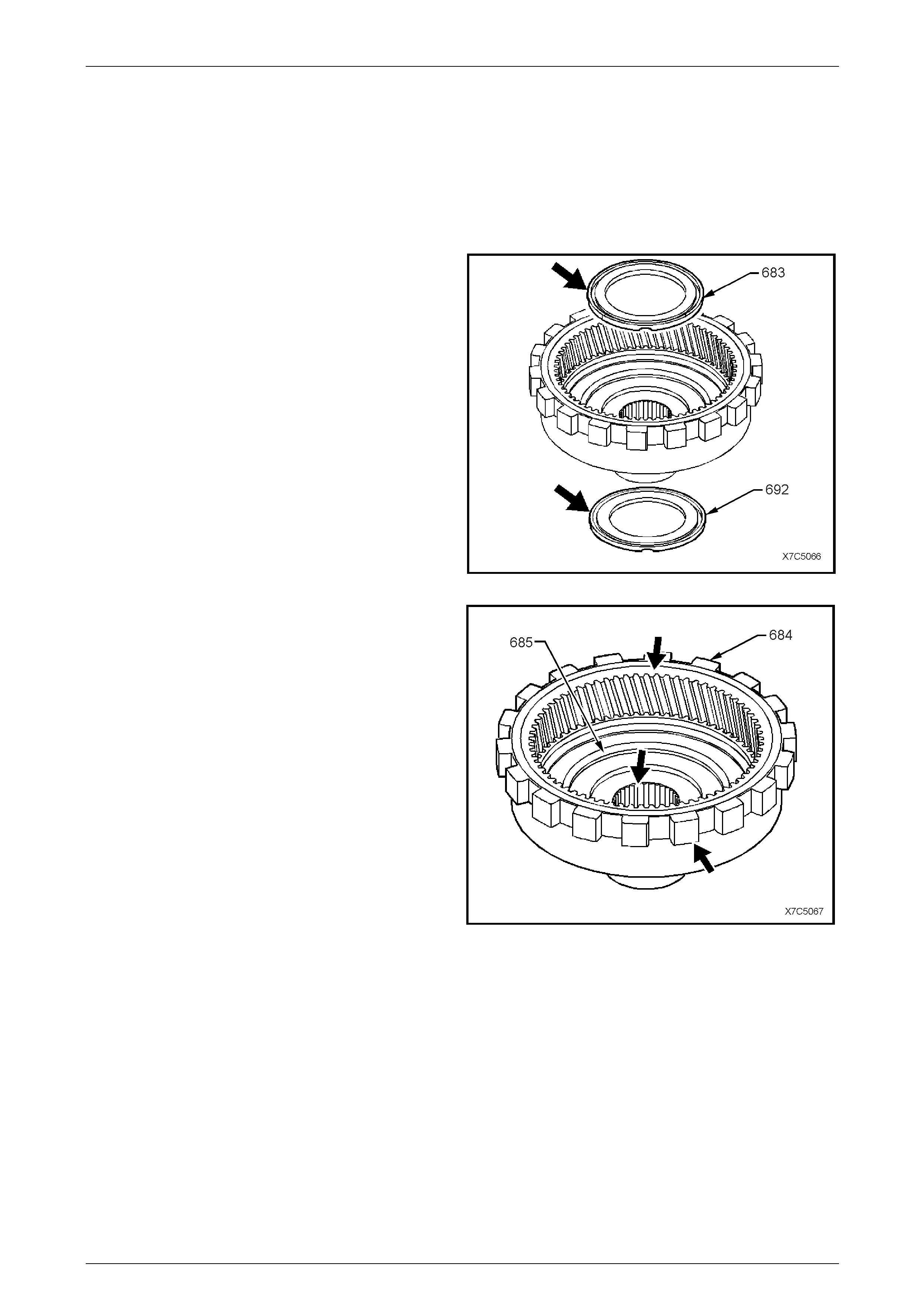

3.7 Reaction Internal Gear and Carrier

Assembly

LT Section No. — 04–200

Inspect

1 Inspect both the reaction to support thrust bearing

assembly (683) and the reaction gear to support case

bearing assembl y (692) for da mage.

Figure 7D5 – 54

2 Inspect the reaction internal gear (684) and

support (685) for correct assembly, stripped splines,

cracks, teeth or lug damage.

Figure 7D5 – 55

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–40

15–DEC–2005 Page 7D5–40

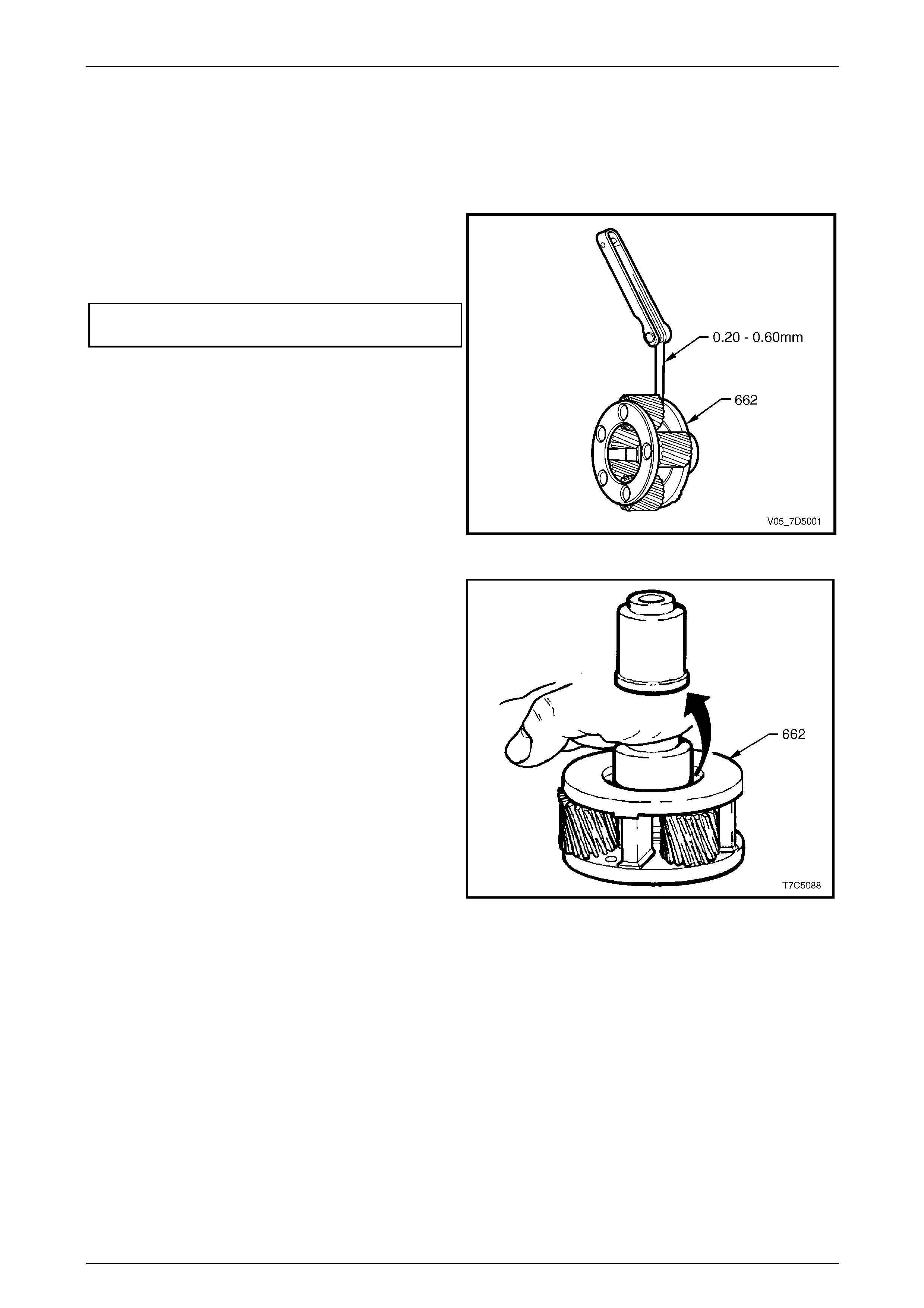

3 Inspect the reaction carrier assembly (681) for pin ion

gear wear, proper pinion staking an d free turning of

pinions.

4 Check for excessive pinion washer wear by measuring

pinion end play. End play should be 0.20 to 0.60 mm.

The reaction carrier assembly is serviced a s a

complete assembly and should be replaced if worn or

defective.

Figure 7D5 – 56

5 Check the carrier assembly captive thrust be aring

(lower arrow) as follows:

a Place a suitable bush (or socket) on bearing race

(do not contact pinion gears) and turn the bush

with the palm of your hand.

b Any imperfections will be felt through the bush.

Figure 7D5 – 57

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–41

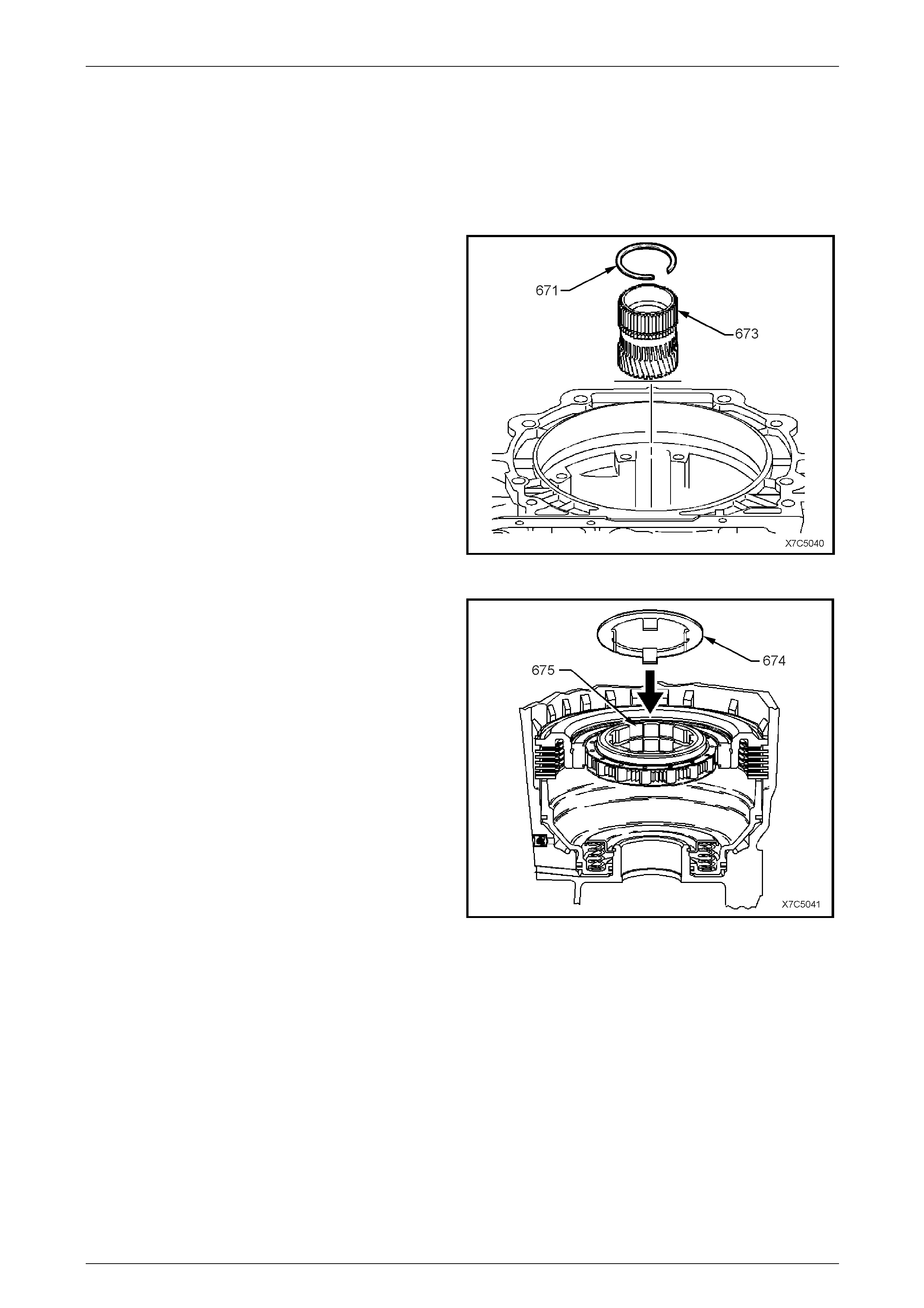

15–DEC–2005 Page 7D5–41

3.8 Reaction Sun Gear and Shell

LT Section No. — 04–200

Inspect

1 Inspect the reaction sun gear (673) for damage to the

bush, spline or teeth, loose or weak retaining ring. Do

not remove the snap ring (671) except for

replacement.

Figure 7D5 – 58

2 Inspect the reaction sun shell (670) for damage or

wear to tangs.

3 Inspect the thrust bearing (669) and thrust

washer (674) for wear or damage.

Figure 7D5 – 59

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–42

15–DEC–2005 Page 7D5–42

Sun Gear Bush – Replace

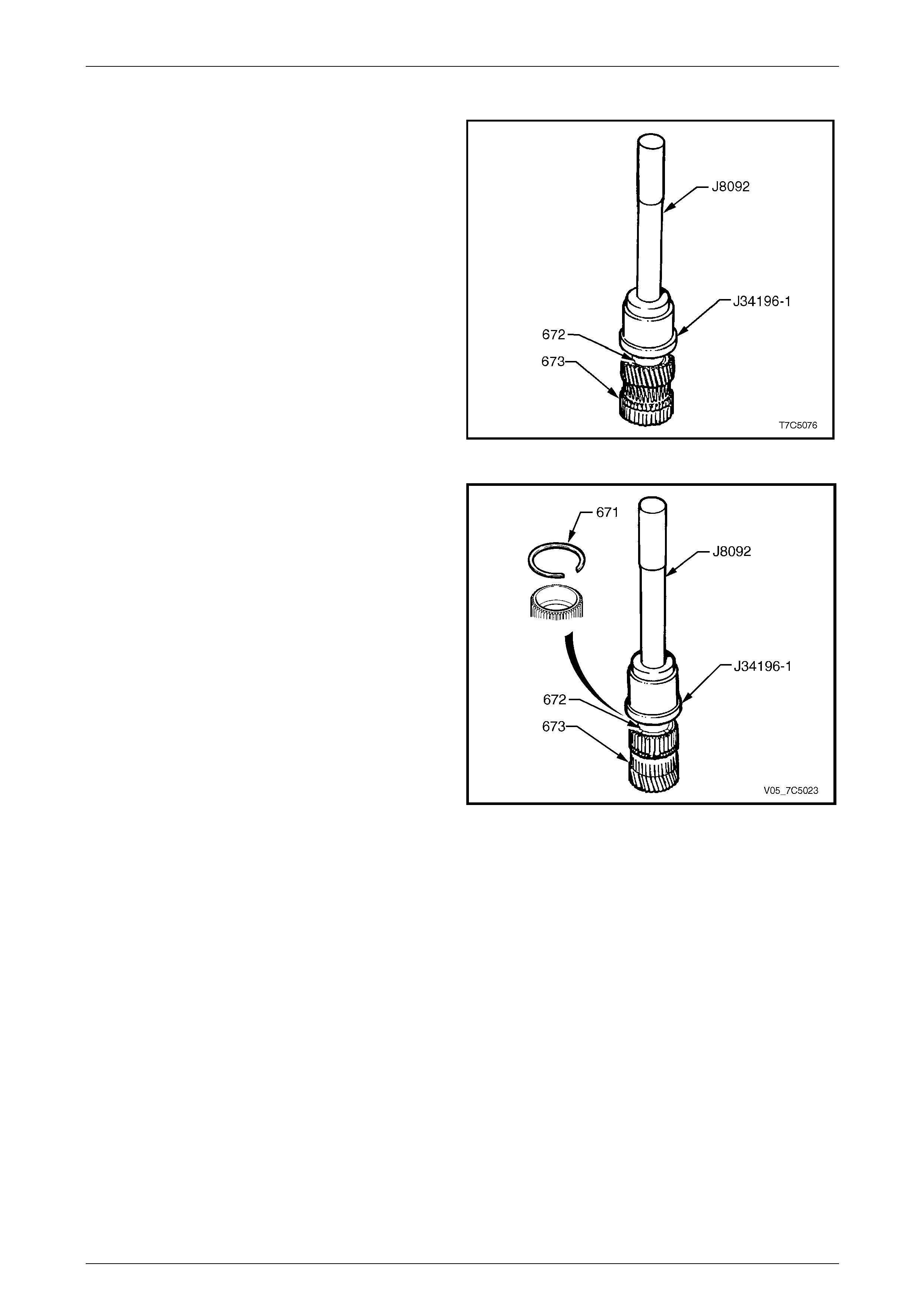

1 If the sun gear bush (672) requires replacement, use

the bush remover, Tool No. J34196-1 ( part of kit, T ool

No.J34196-B) and driver handle, Tool No. J8092, to

press the bush from the gear (673).

Figure 7D5 – 60

2 Install a replacement bush (672) using the same tools

used for removal but press the bush in from the other

side of the sun gear (673), as shown.

3 If required, install a new retaining ring (671) to the sun

gear.

Figure 7D5 – 61

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–43

15–DEC–2005 Page 7D5–43

3.9 Input Internal Gear and Output Shaft

LT Section No. — 04–200

Inspect

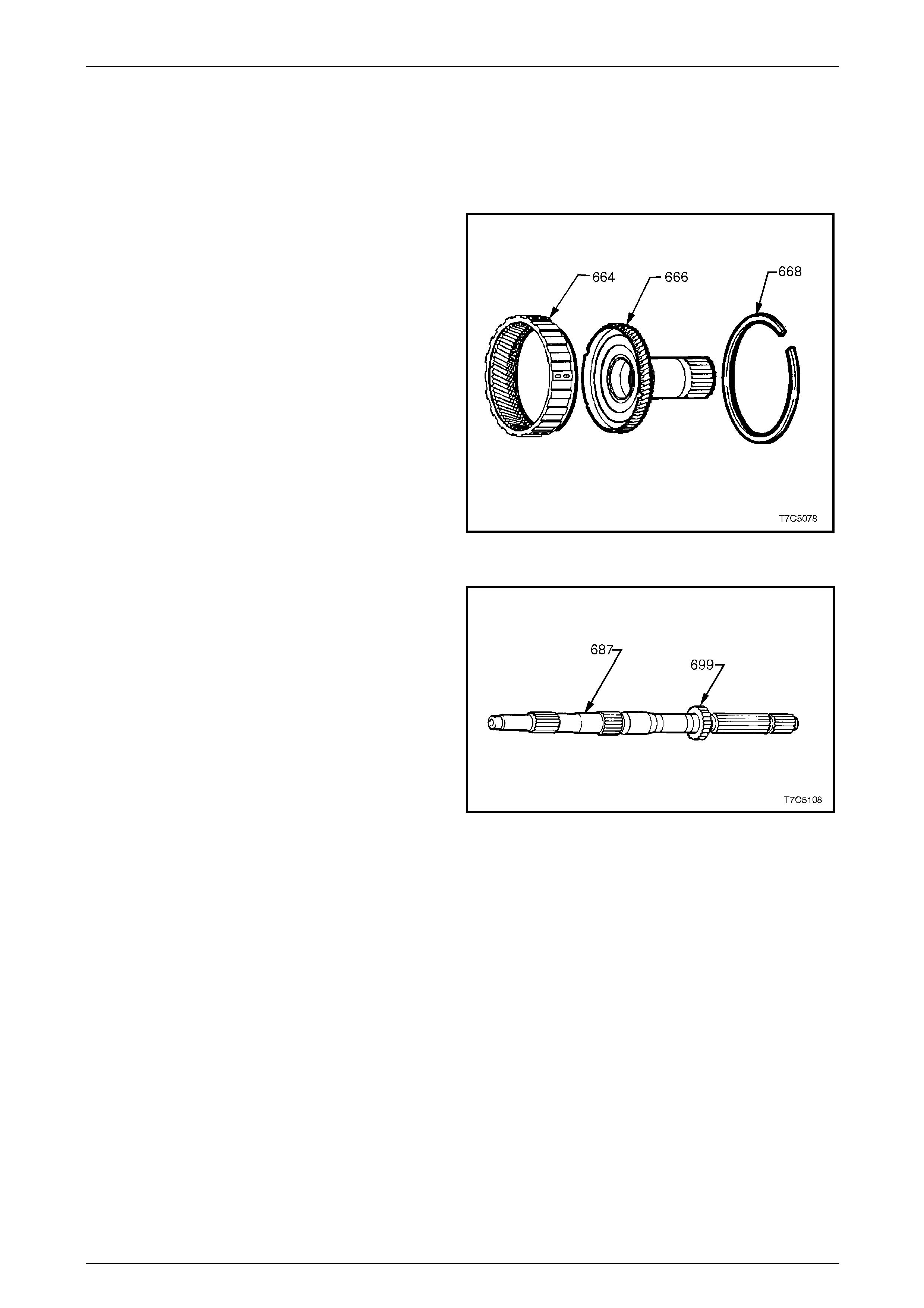

1 Remove the retaining ring (668) from the input internal

gear (664).

2 Remove the reaction carrier shaft (666) from the input

internal gear and inspect the shaft for the following:

• damaged or worn bushes,

• cracks,

• damaged spline or gear teeth and

• undercutting around shaft from interferenc e wit h

sun gear.

3 Inspect the input internal gear (664) for cracked or

damaged splines or gear teeth.

4 Inspect the carrier to reaction shaft thrust bearing (not

shown) for wear or damage.

5 If all parts are serviceable, reassemble the reactio n

carrier shaft (666) into the input internal gear (664)

and install the retaining ring (668). Figure 7D5 – 62

6 Inspect the transmission output shaft (687) for the

following:

• blocked or restricted lube p assages,

• damage to splines or ring groove,

• burrs or damage to bearing journals,

• burrs or damage to extension housing seal

surface (polish with crocus cloth if necessary),

• tooth damage to transmission output shaft

sensor rotor (699).

Figure 7D5 – 63

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–44

15–DEC–2005 Page 7D5–44

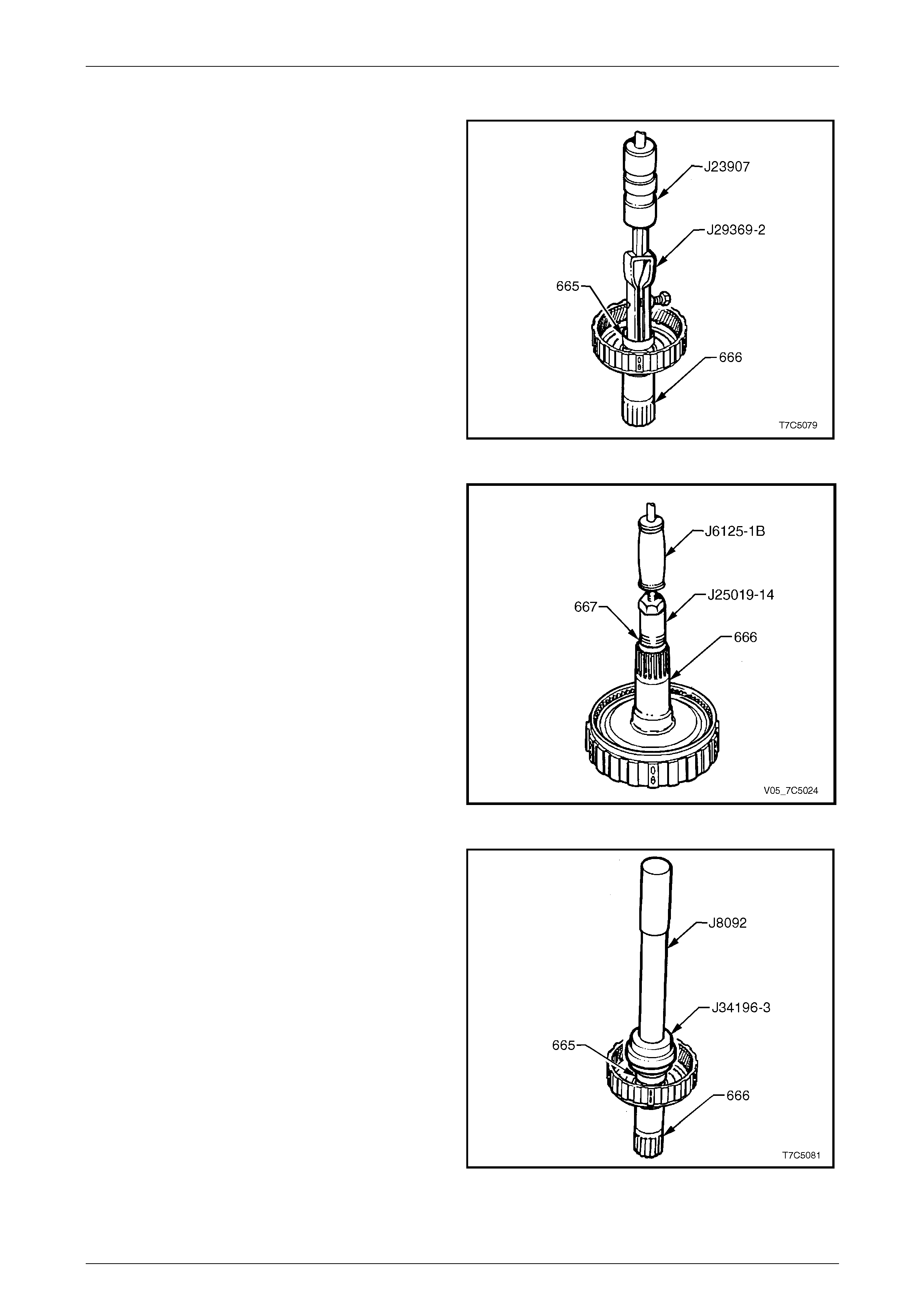

Reaction Carrier Shaft Bushes – Replace

1 Using the universal bush remover, T ool No. J29369-2

and slide hammer, Tool No. J239 07, or equivalent,

remove the front bush (665) from the reaction carrier

gear shaft (666).

Figure 7D5 – 64

2 Remove the rear bush (667) from the reaction carrier

gear shaft (666) using the bush puller, Tool No.

J25019-14 and slide hammer, Tool No. J6125-1B, or

equivalent.

Figure 7D5 – 65

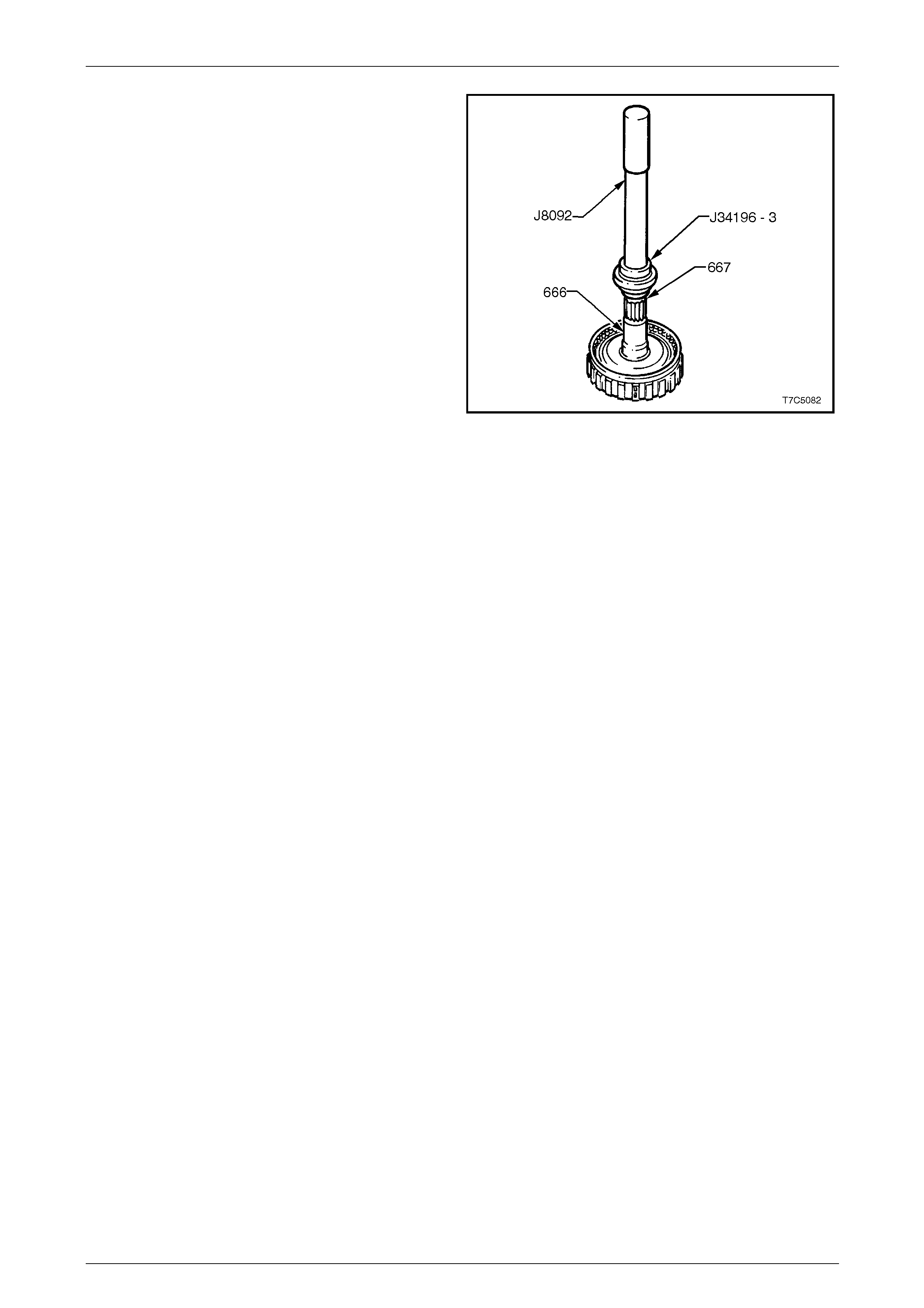

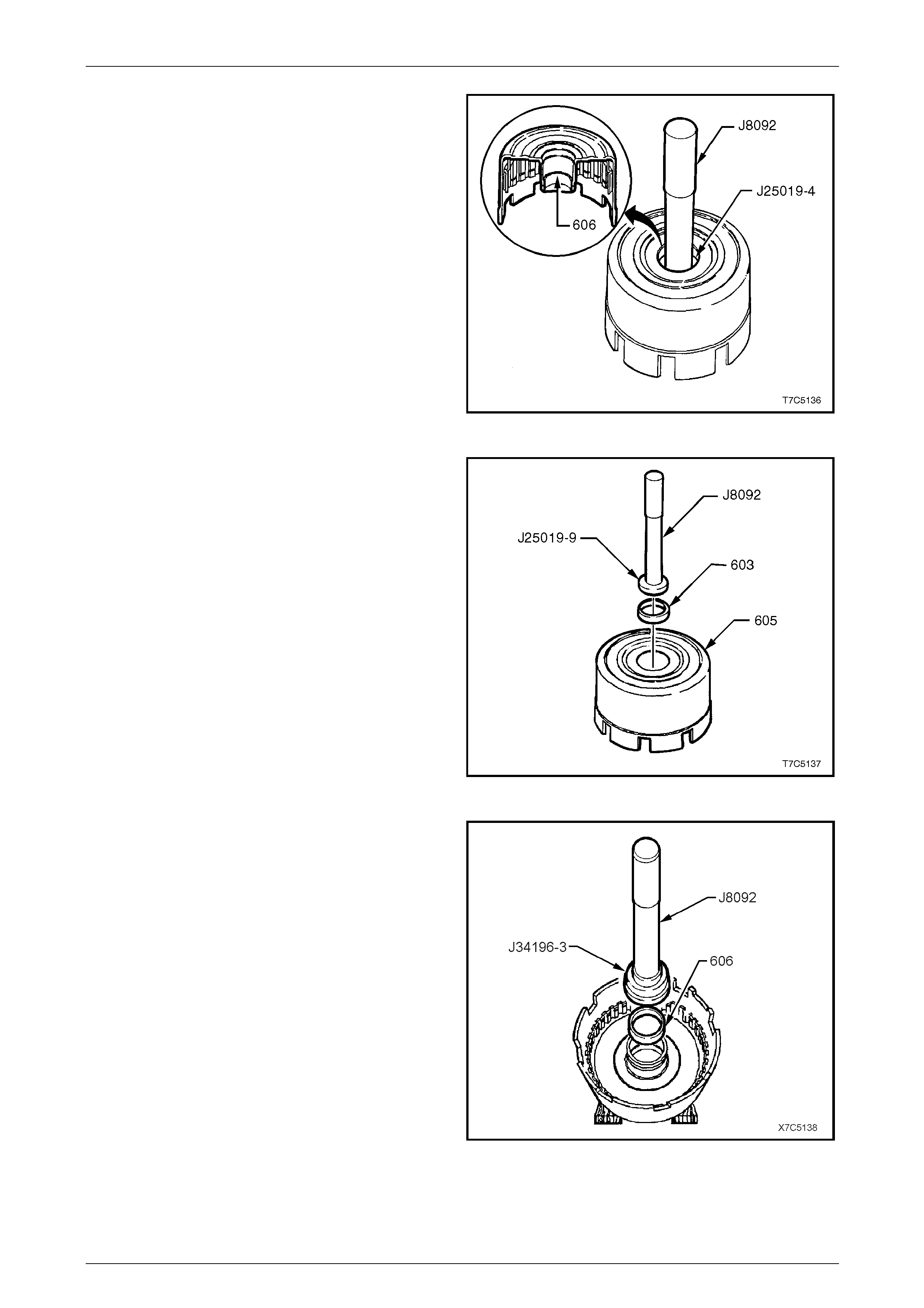

3 Install the front bush (665), using bush installer, Tool

No. J34196-3 (part of kit Tool No. 34196-B) and driver

handle, Tool No. J8092.

Figure 7D5 – 66

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–45

15–DEC–2005 Page 7D5–45

4 Install the rear bush (667), using bus h installer, Tool

No. J34196-3 (part of kit Tool No. 34196-B) and driver

handle, Tool No. J8092.

Figure 7D5 – 67

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–46

15–DEC–2005 Page 7D5–46

3.10 Transmission Output Speed Sensor Ring

LT Section No. — 04–200

Replace

NOTE

Normally this operation is not necessary and

should only be carried out, if inspection of the

speed sensor ring (699) reveals tooth damage

has occurred. Once removed, the ring must be

replaced and not re-used.

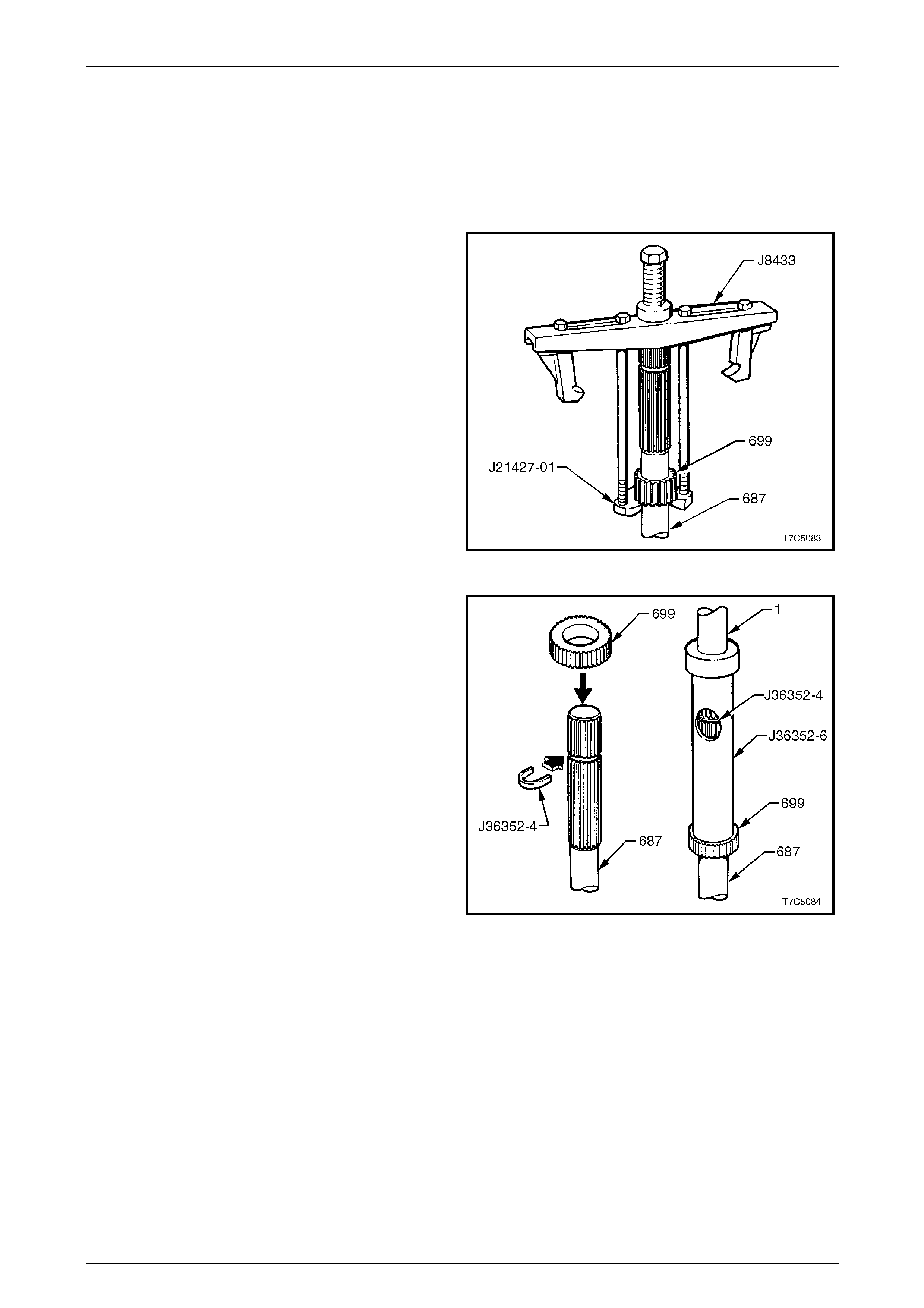

1 Using Tool Nos J8433 and J21427-01, remove the

speed sensor ring (699) from the output shaft (687).

Figure 7D5 – 68

2 Place a new speed sensor ring (699) over the

transmission output shaft (687).

3 Insert the C-washer, Tool No. J36352-4, into the

groove on the transmission output shaft (687).

4 Place Tool No. J36352-6 over the output shaft and

press the sensor ring onto the output shaft until the

tube contacts the C-washer, in the window.

Figure 7D5 – 69

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–47

15–DEC–2005 Page 7D5–47

3.11 Input Carrier and Sun Gear

LT Section No. — 04–200

Inspect

1 Inspect the carrier assembly (662) for pini on gear

wear, proper pinion staking and free turning of pinions.

2 Check for excessive wear of pinion washer by

measuring the pinion end play.

Pinion gear end play

specification........................................... 0.20 – 0.60 mm

NOTE

The input carrier assembly is serviced as a

complete assembly and must be replaced if

components are worn or defective.

Figure 7D5 – 70

3 Check the carrier assembly captive thrust be aring as

follows:

a Place a suitable bush (or socket) on the bearing

race (do not contact the pinion gears) and turn

the bush with the palm of your hand.

b Any imperfections will be felt through the bush.

Figure 7D5 – 71

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–48

15–DEC–2005 Page 7D5–48

Input Sun Gear Bushes – Replace

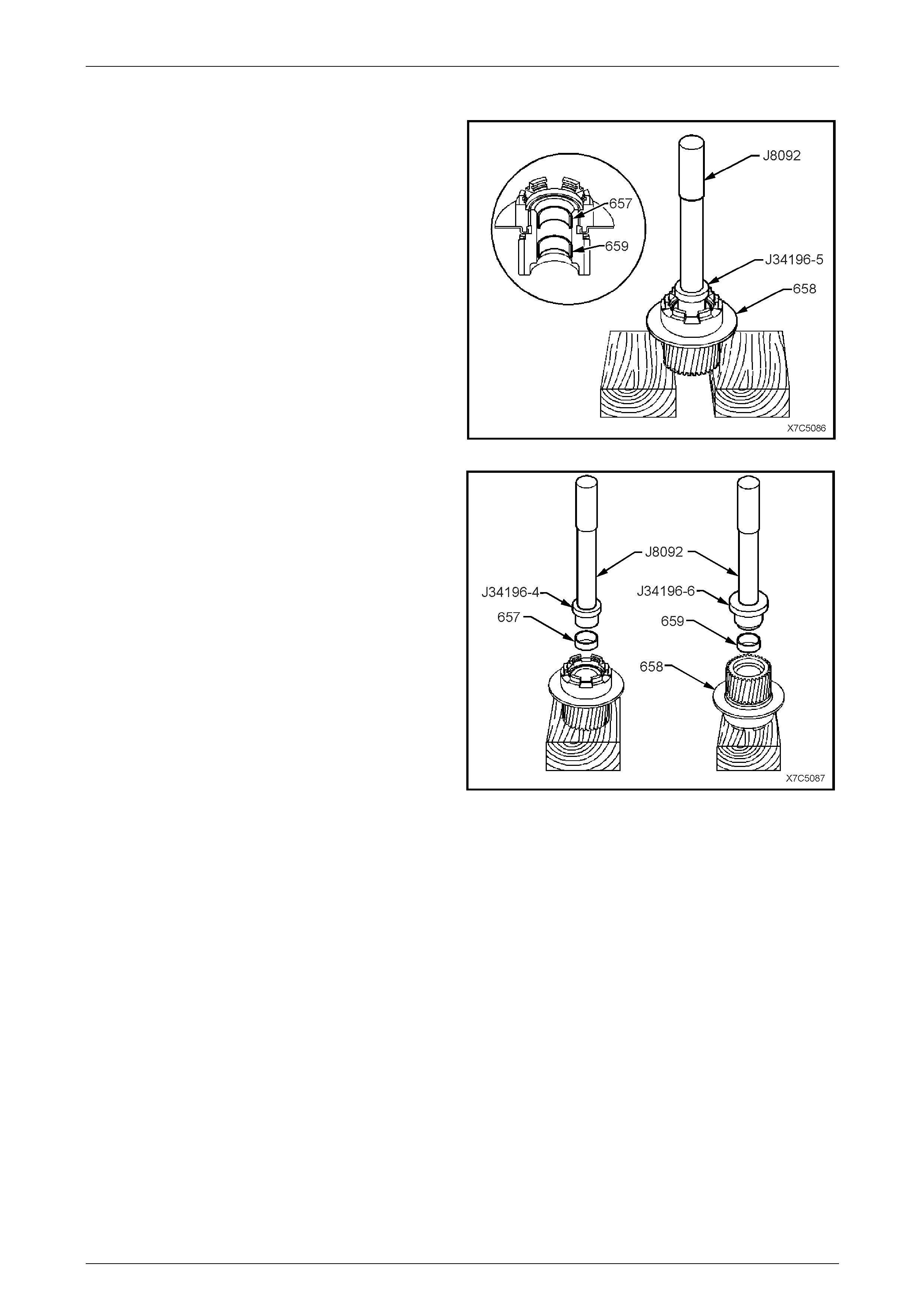

1 Using the bush remover, T ool No. J34196-5, (part of

kit, Tool No. J34196-B) and driver handle, Tool No.

J8092, press both sun gear bushes (657 and 659)

from the gear (658).

Figure 7D5 – 72

2 Press the front sun gear bush (657) into the

gear (658), using Tool No. J34196-4 (part of kit, Tool

No. J34196-B) and driver han dle, Tool No. J8092.

3 Press the rear sun gear bush (659) into the g ear,

using Tool J34196- 6 (part of kit, T ool No. J34196-B)

and driver handle, Tool No. J809 2.

Figure 7D5 – 73

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–49

15–DEC–2005 Page 7D5–49

3.12 Input Clutch Housing Assembly

LT Section No. — 04–200

Exploded View

Figure 7D5 – 74

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–50

15–DEC–2005 Page 7D5–50

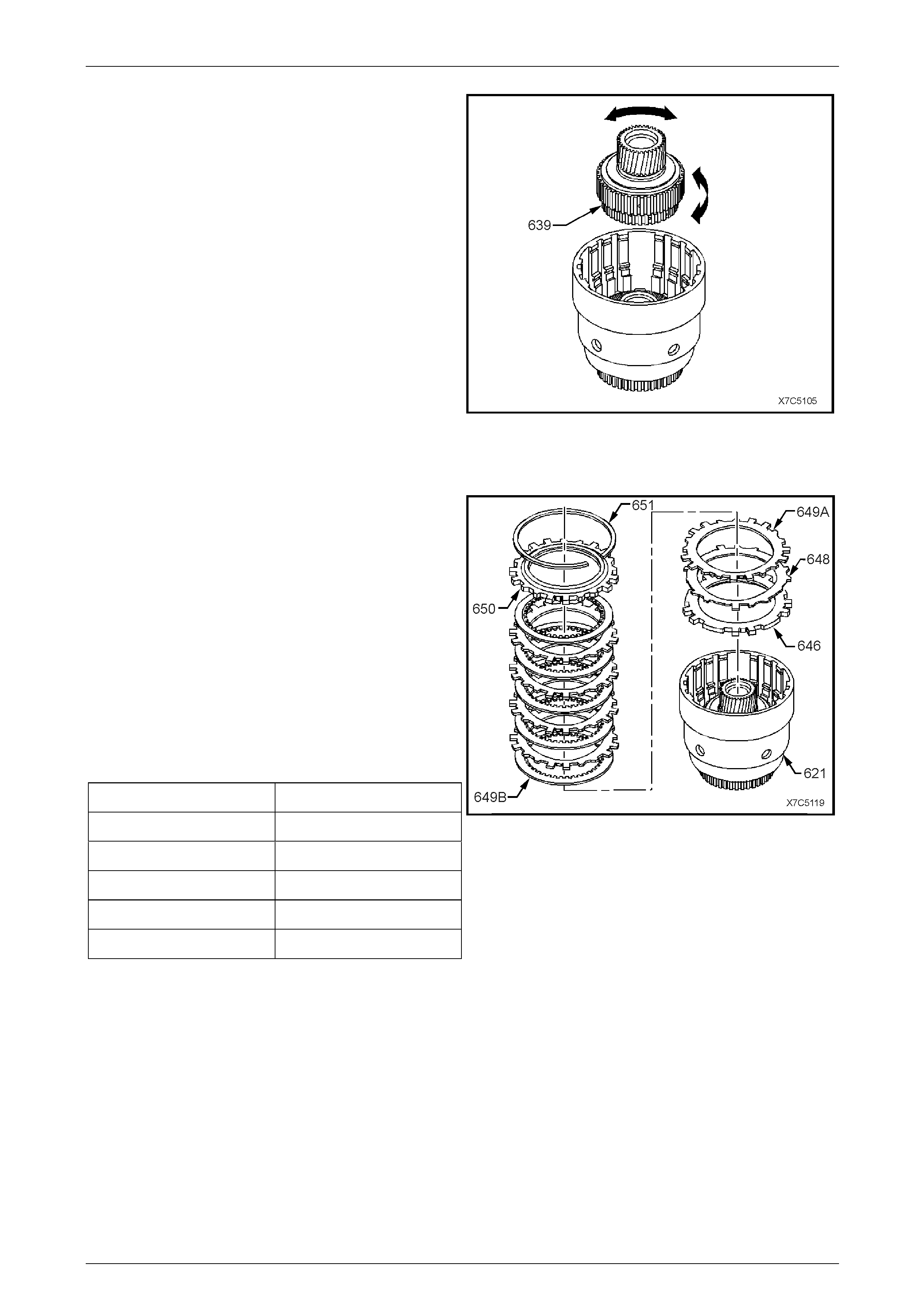

Legend

600 Spring Assembly, 3-4 Clutch Boost - 5 places

615 Bearing Assembly, Stator Shaft – Selective Washer

616 Washer, Thrust Selective

617 Retainer & Ball Assy., Check Valve

618 Seal, O-Ring, Turbine Shaft

619 Ring, Oil Seal (Solid)

620 Retainer & Checkball Assembly

621 Input Housing and Shaft Assembly.

622 Seal, O-Ring Input to Forward Clutch Housing

623 Piston, 3rd and 4th Clutch

625 Ring, 3rd & 4th Clutch (Apply)

626 Spring Assembly, 3rd and 4th Clutch

627 Retainer & Ball Assembly, Forward Clutch Housing

628 Housing, Forward Clutch

630 Piston, Forward Clutch

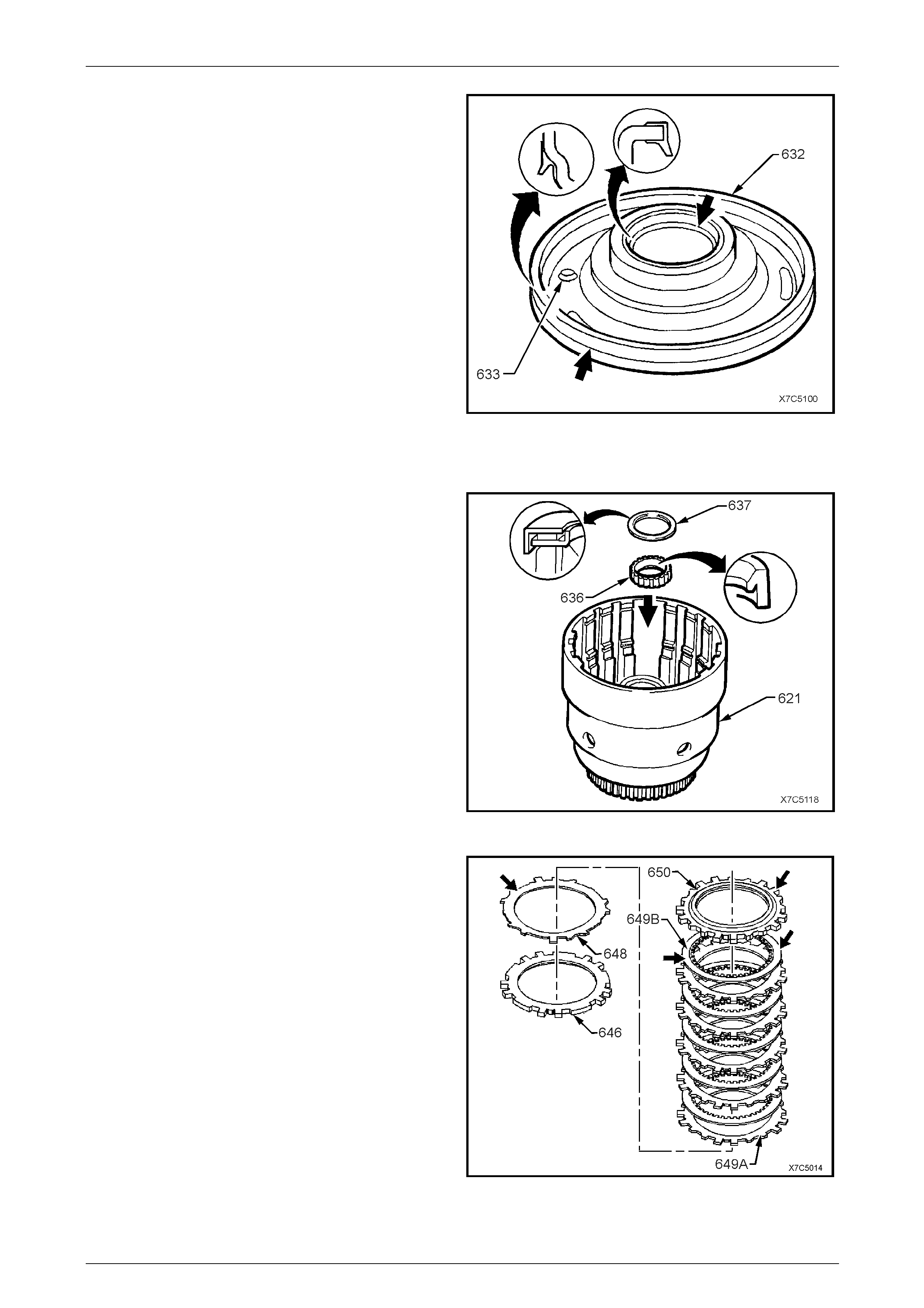

632 Piston, Overrun Clutch

633 Ball, Overrun Clutch

634 Spring Assembly, Overrun Clutch

635 Snap Ring, Overrun Clutch Spring Retainer

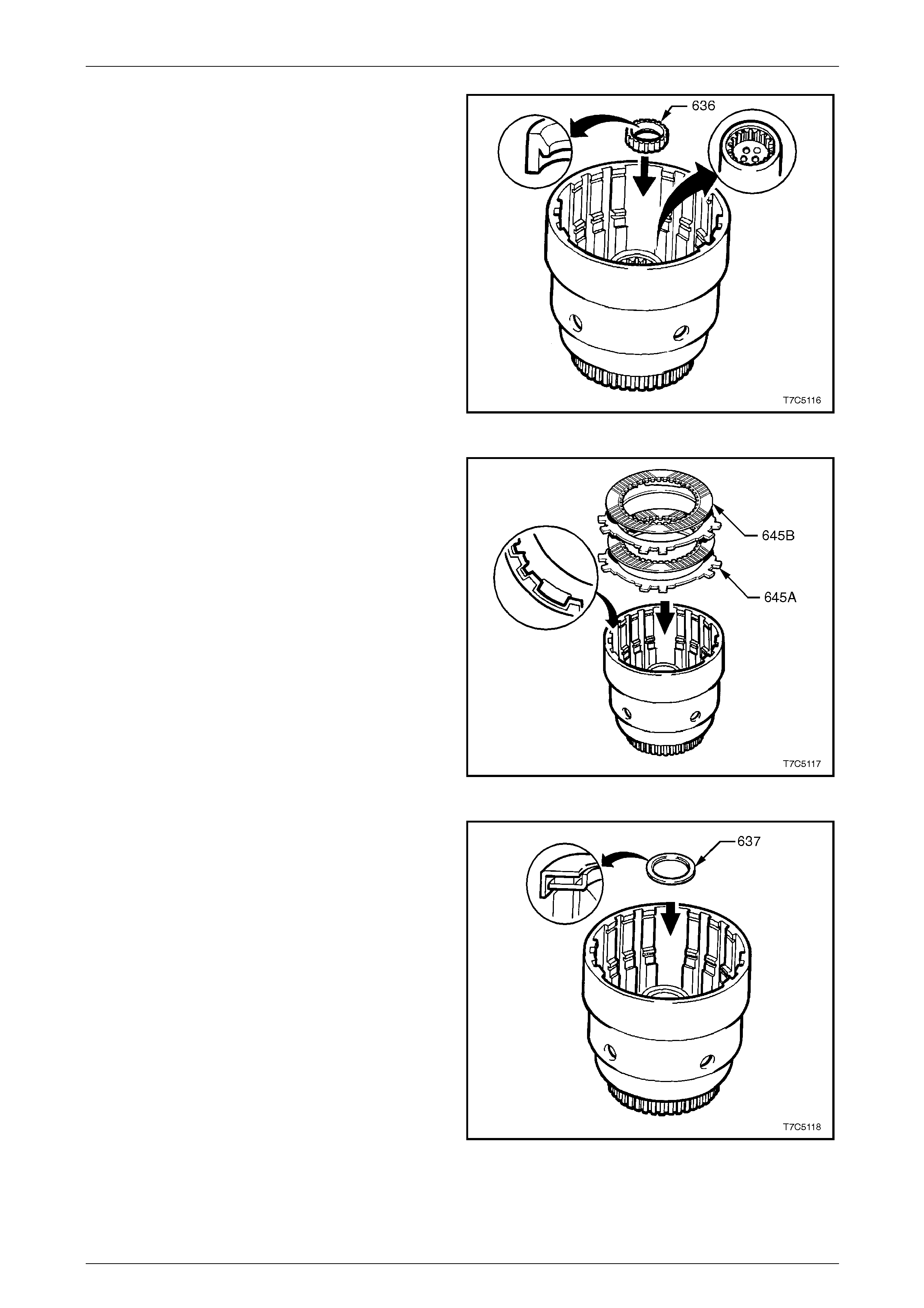

636 Seal, Input Housing to Output Shaft

637 Bearing Assembly , Input Sun Gear

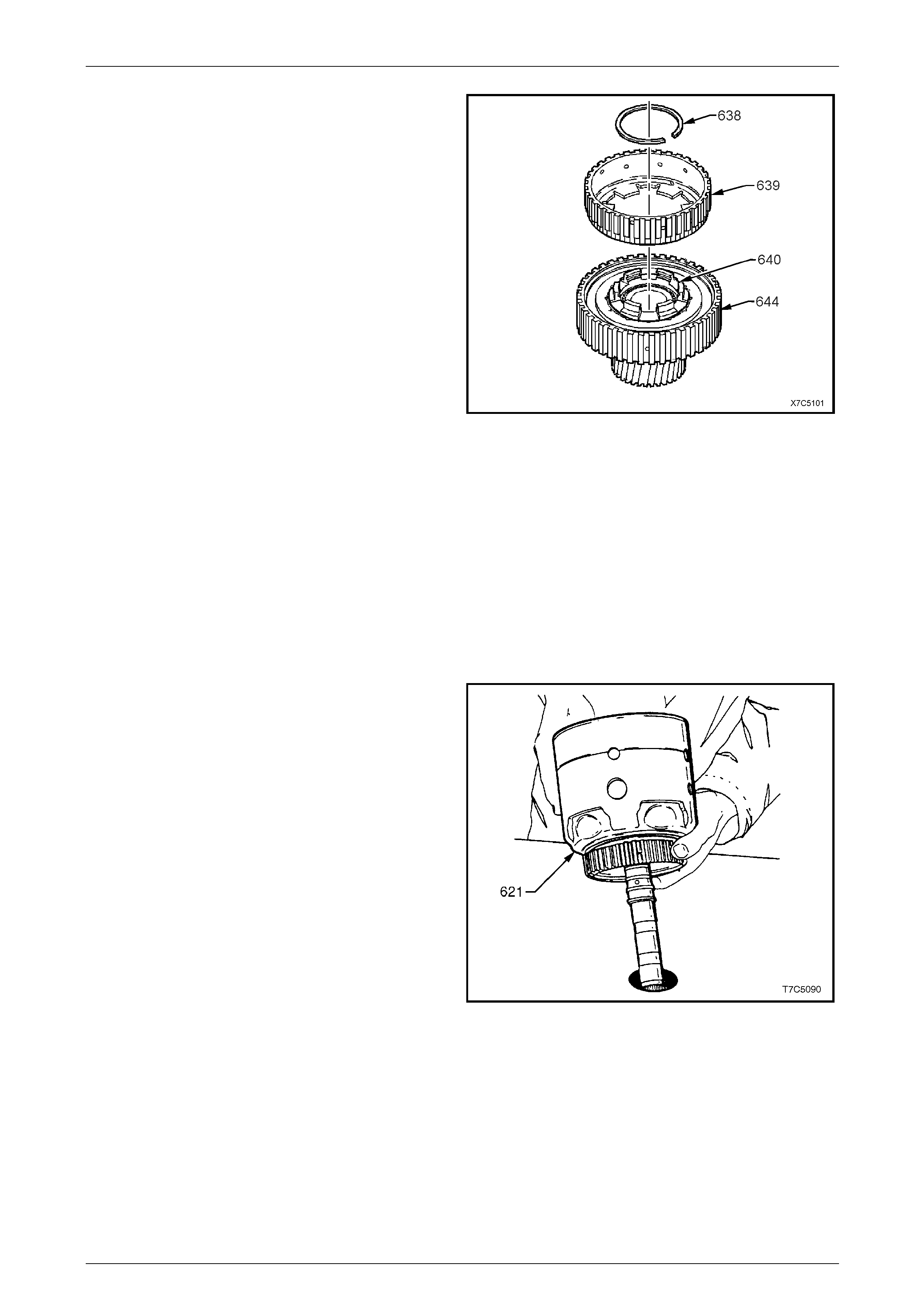

638 Snap Ring, Overrun Clutch Hub Retaining

639 Hub, Overrun Clutch

640 Forward Sprag Clutch Inner Race & Input Clutch Assembly

642 Forward Sprag Assembly

643 Retainer Ring, Sprag Assembly

644 Race, Forward Clutch (Outer)

645a Plate Assy., Overrun Clutch (Steel)

645b Plate Assy., Overrun Clutch (Composition)

646 Plate, Forward Clutch (Apply)

648 Plate, Forward Clutch (Waved)

649a Plate, Forward Clutch (Steel)

649b Plate Assy., Forward Clutch (Composition)

650 Plate, Forward Clutch Backing (Selective)

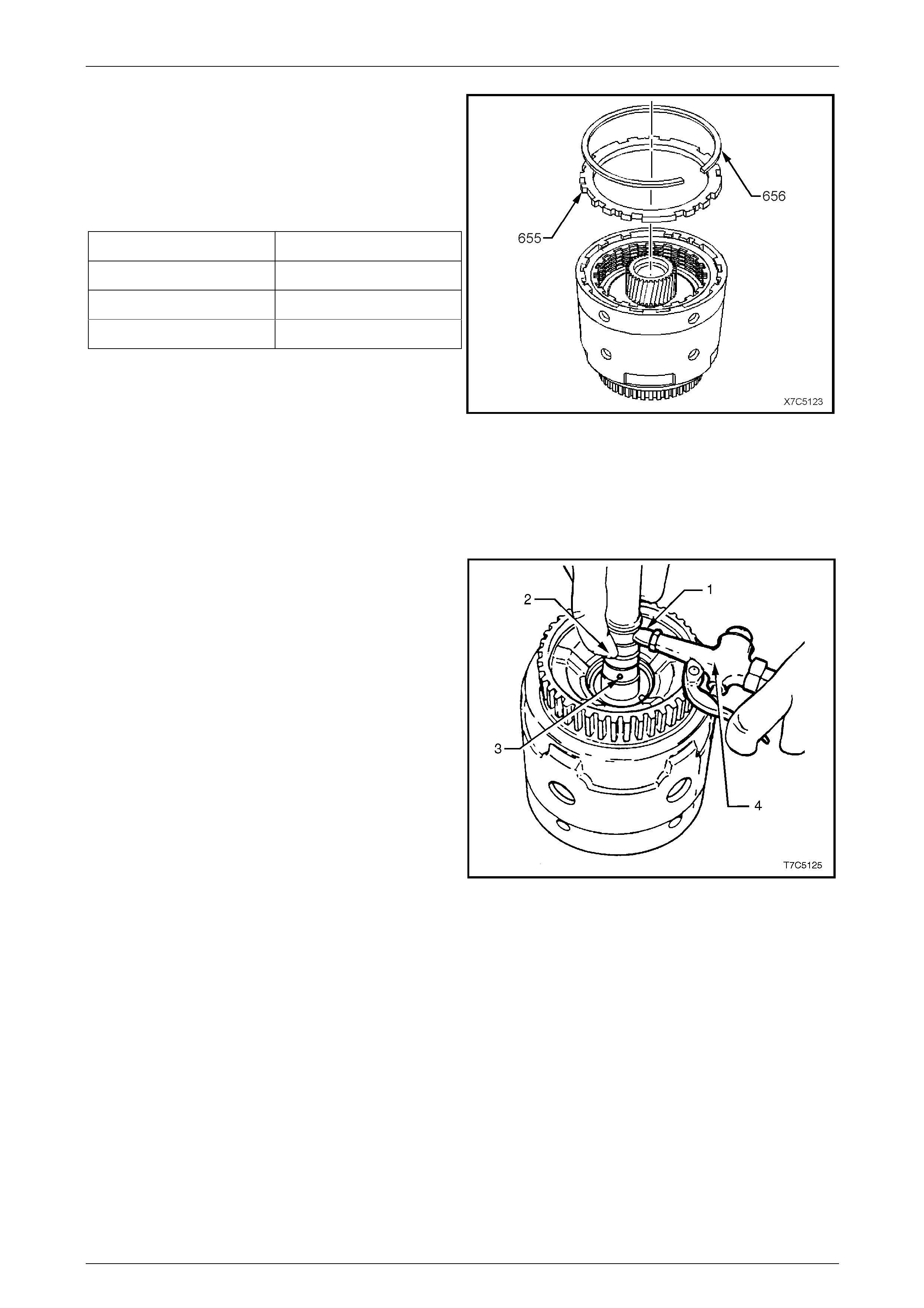

651 Ring, Forward Clutch Backing Plate Retainer

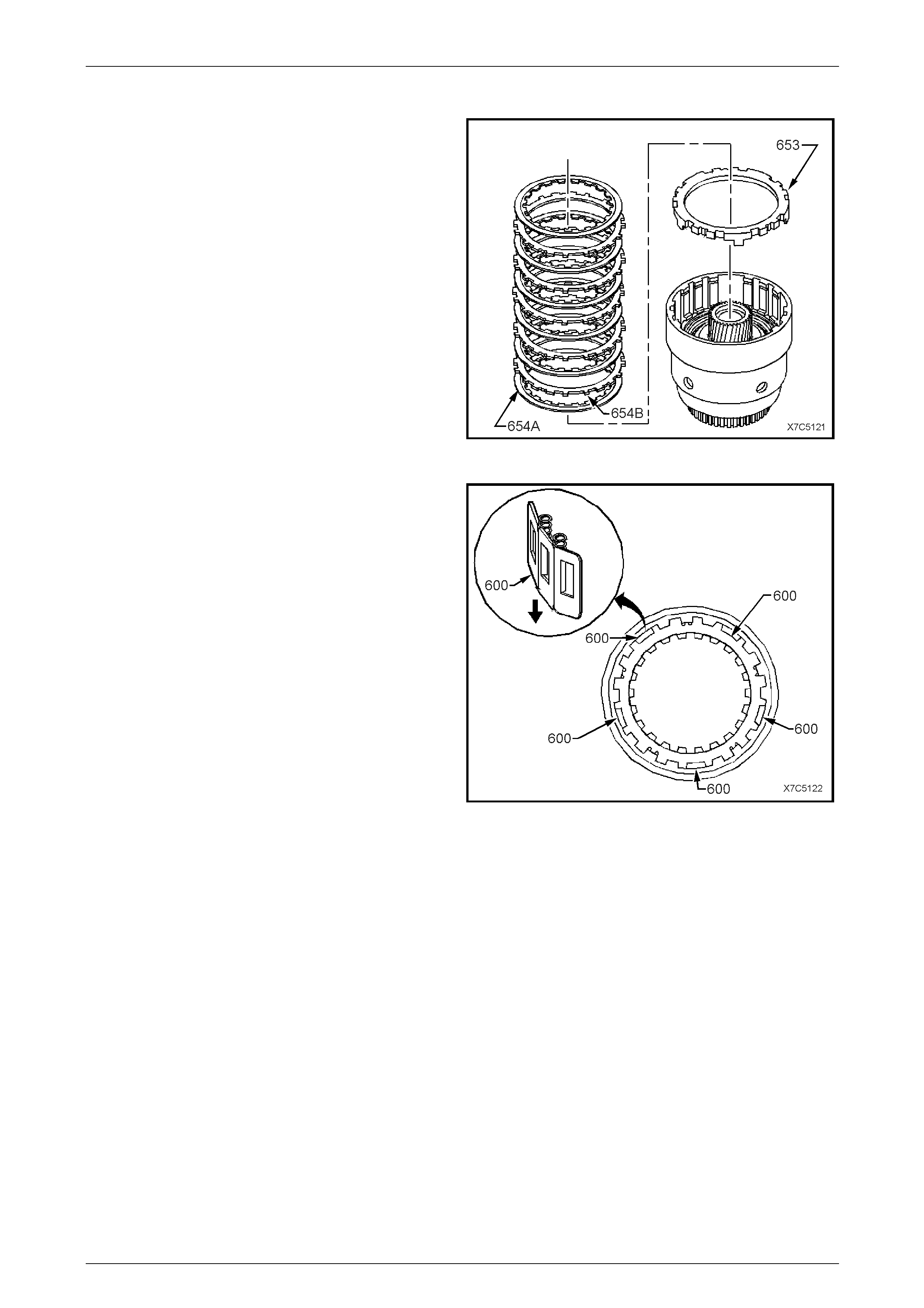

653 Plate, 3rd & 4th Clutch Apply (Stepped)

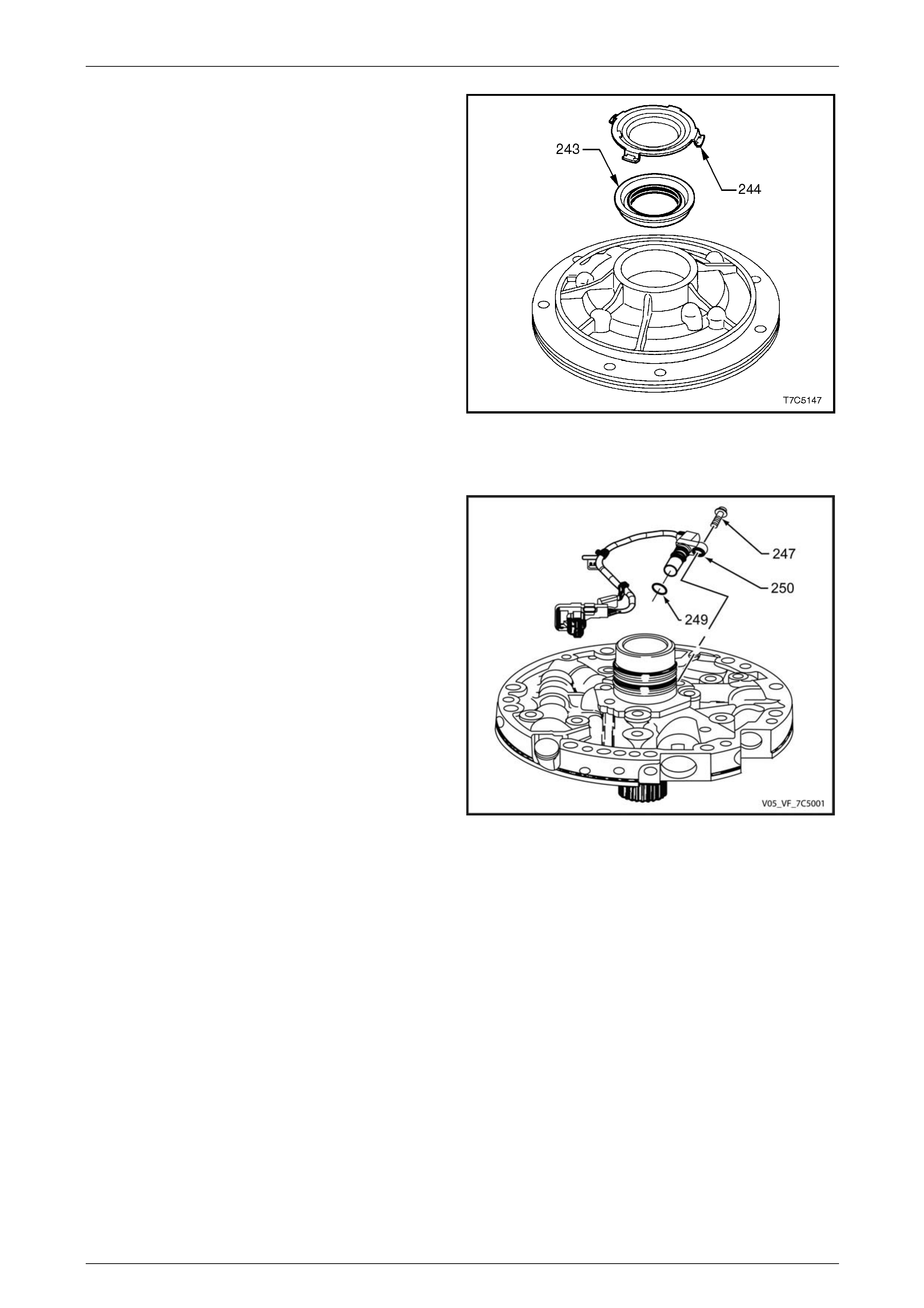

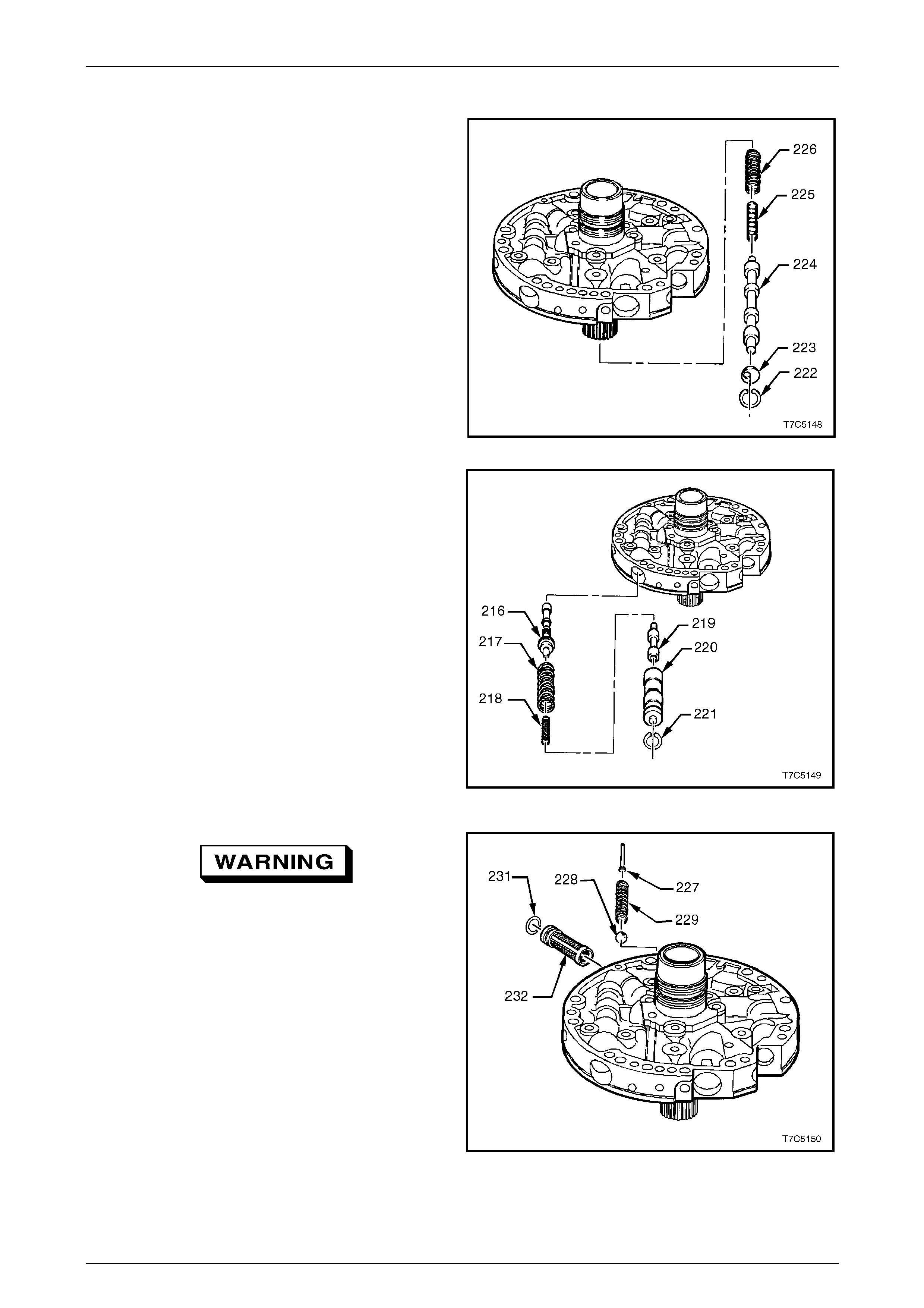

654a Plate Assy., 3rd & 4th Clutch (Composition)

654b Plate Assy., 3rd & 4th Clutch (Steel)

655 Plate, 3rd & 4th Clutch Backing (Selective)

656 Ring, 3rd & 4th Clutch Backing Plate Retainer

657 Bush, Input Sun Gear, Front

659 Bush, Input Sun Gear, Rear

688 Plug, Cup

698 Plug, Orifice Cup

Disassemble

Disassemble the component s of the input clutch housing assembly as follows:

1 3 – 4 Clutch,

2 Forward Clutch Assembly,

3 Overrun Clutch Assembly and

4 3 – 4 Clutch Assembly.

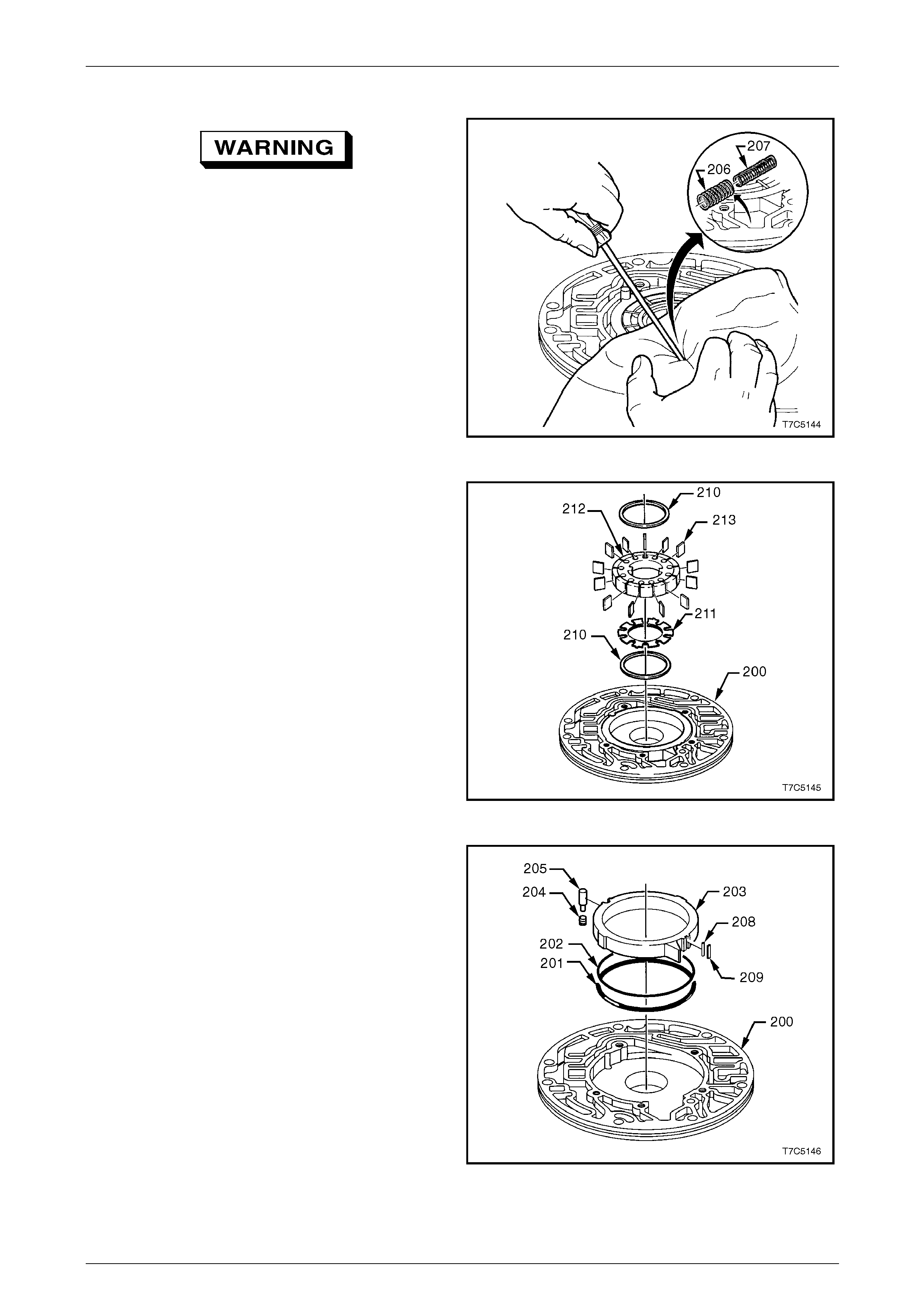

3 – 4 Clutch

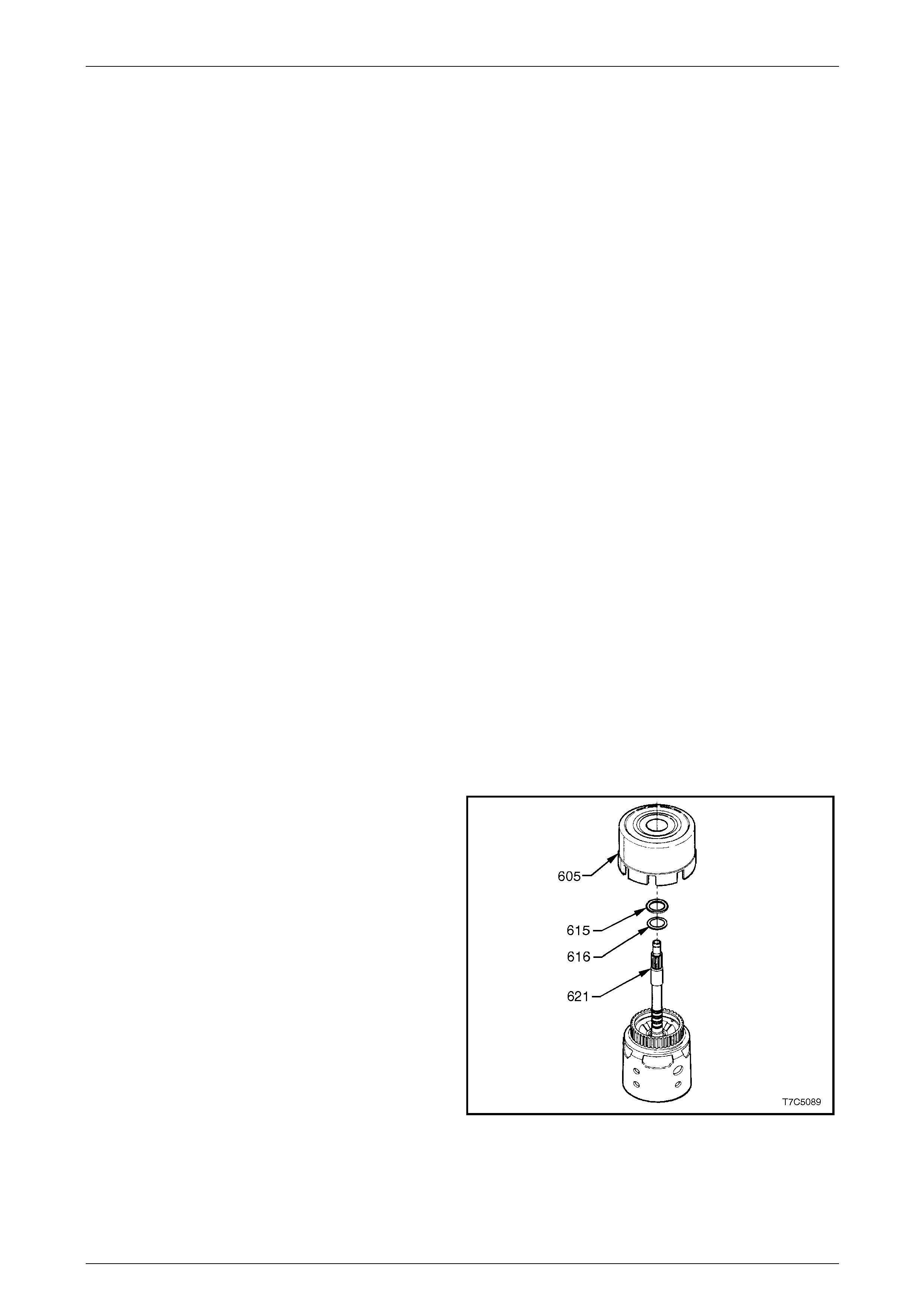

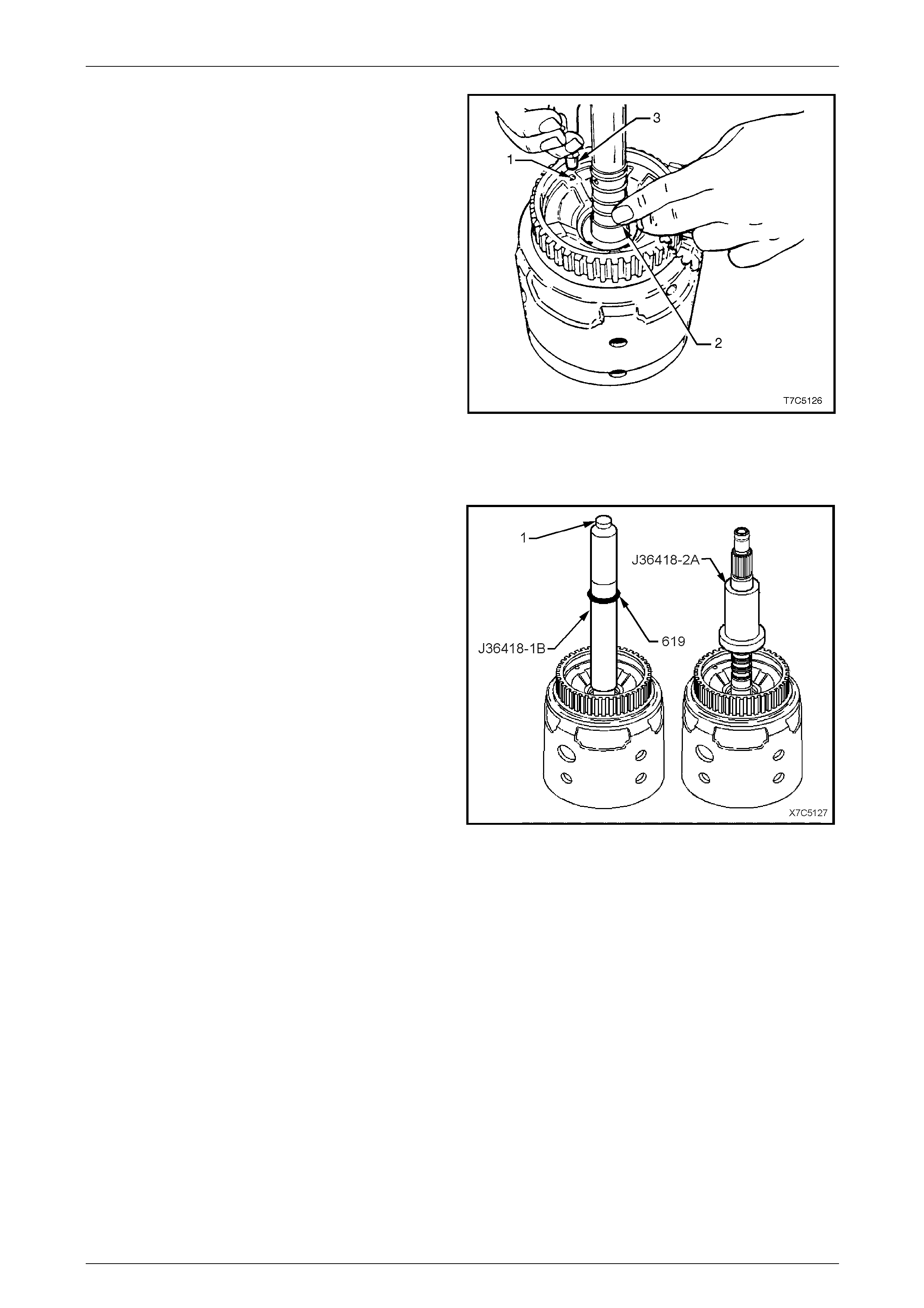

1 Remove the reverse input clutch housing and drum

assembly (605) from the input housi ng and shaft

assembly (621).

2 Remove the thrust bearing (615) and sel ecti v e thrust

washer (616).

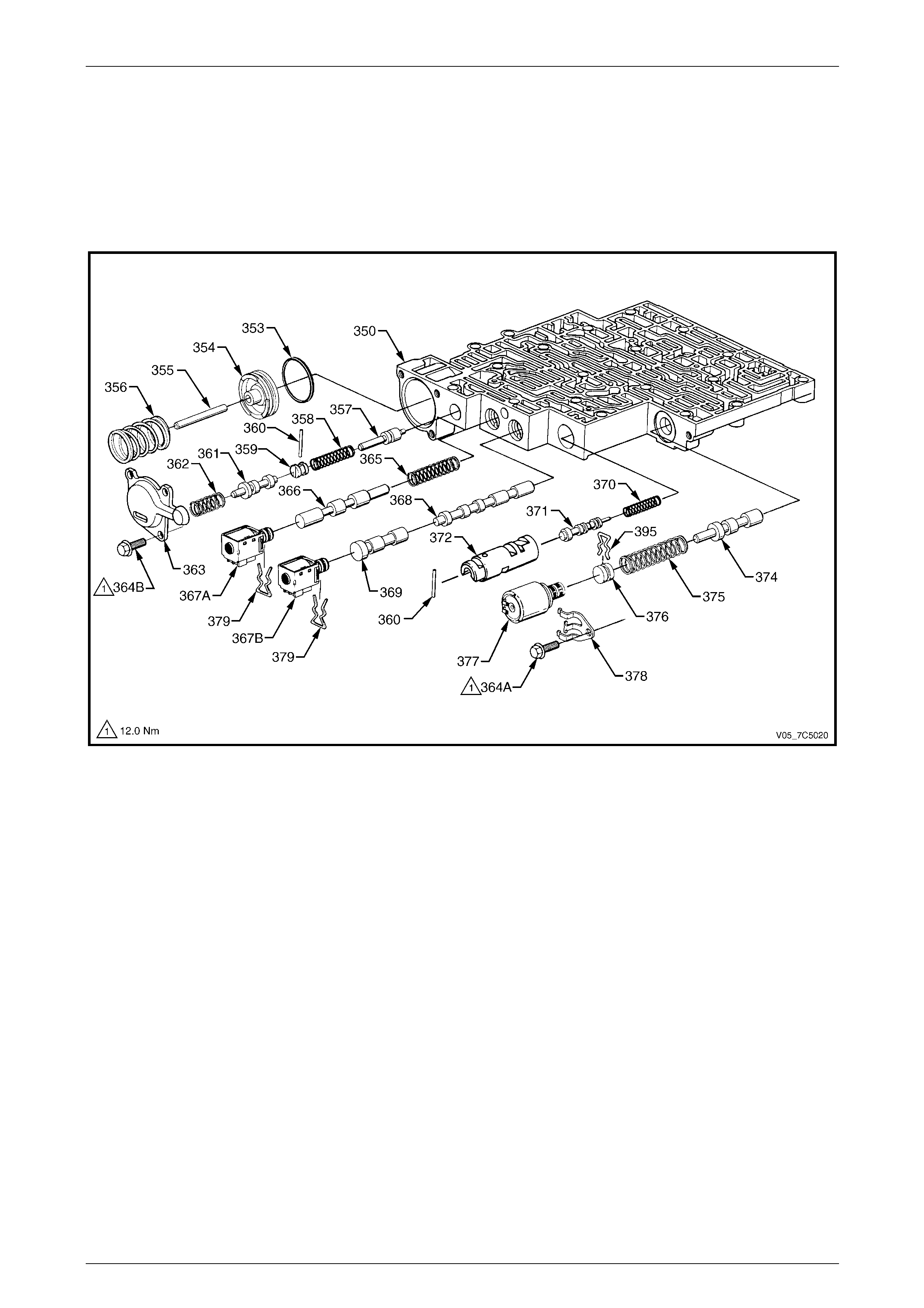

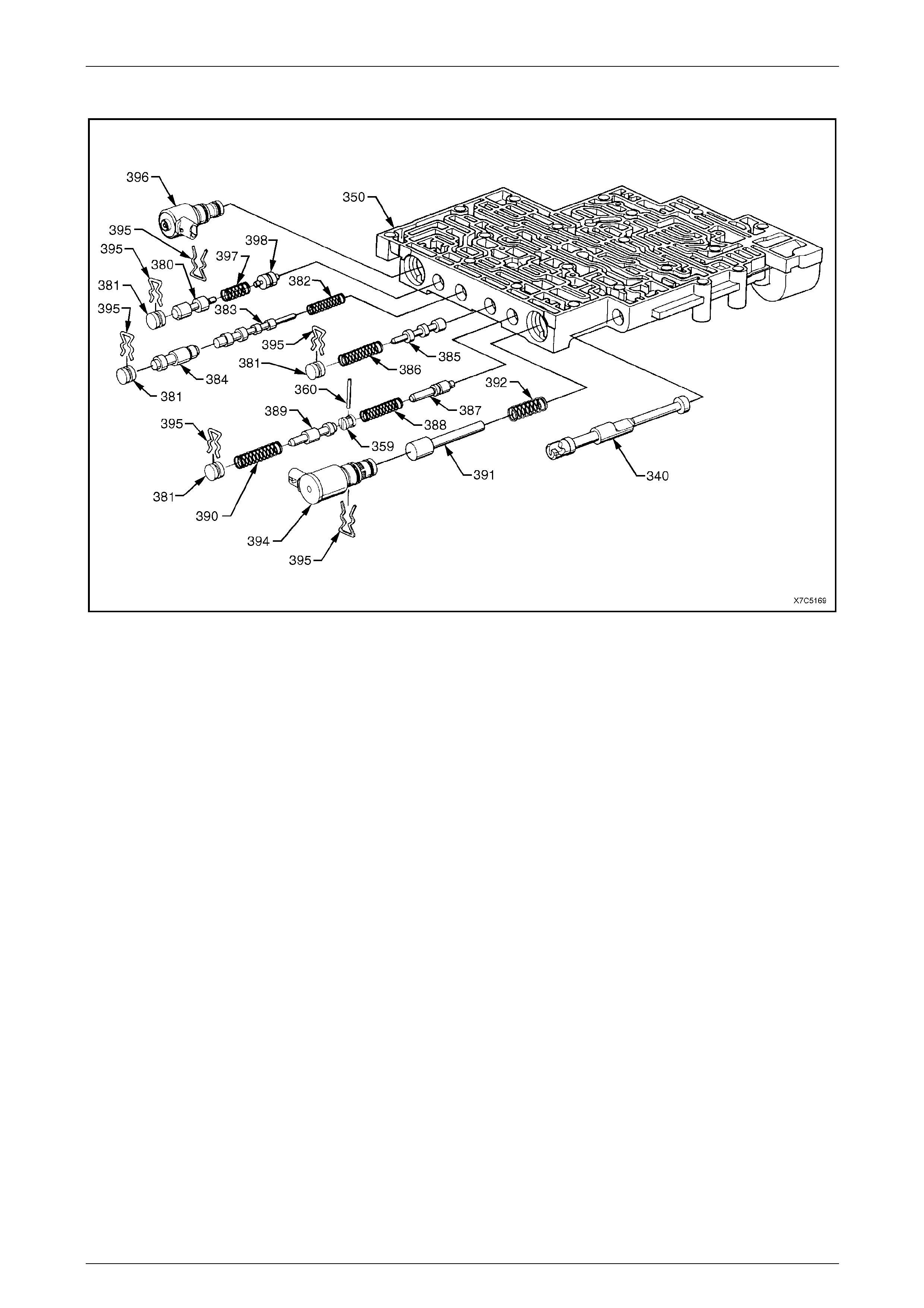

Figure 7D5 – 75

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–51

15–DEC–2005 Page 7D5–51

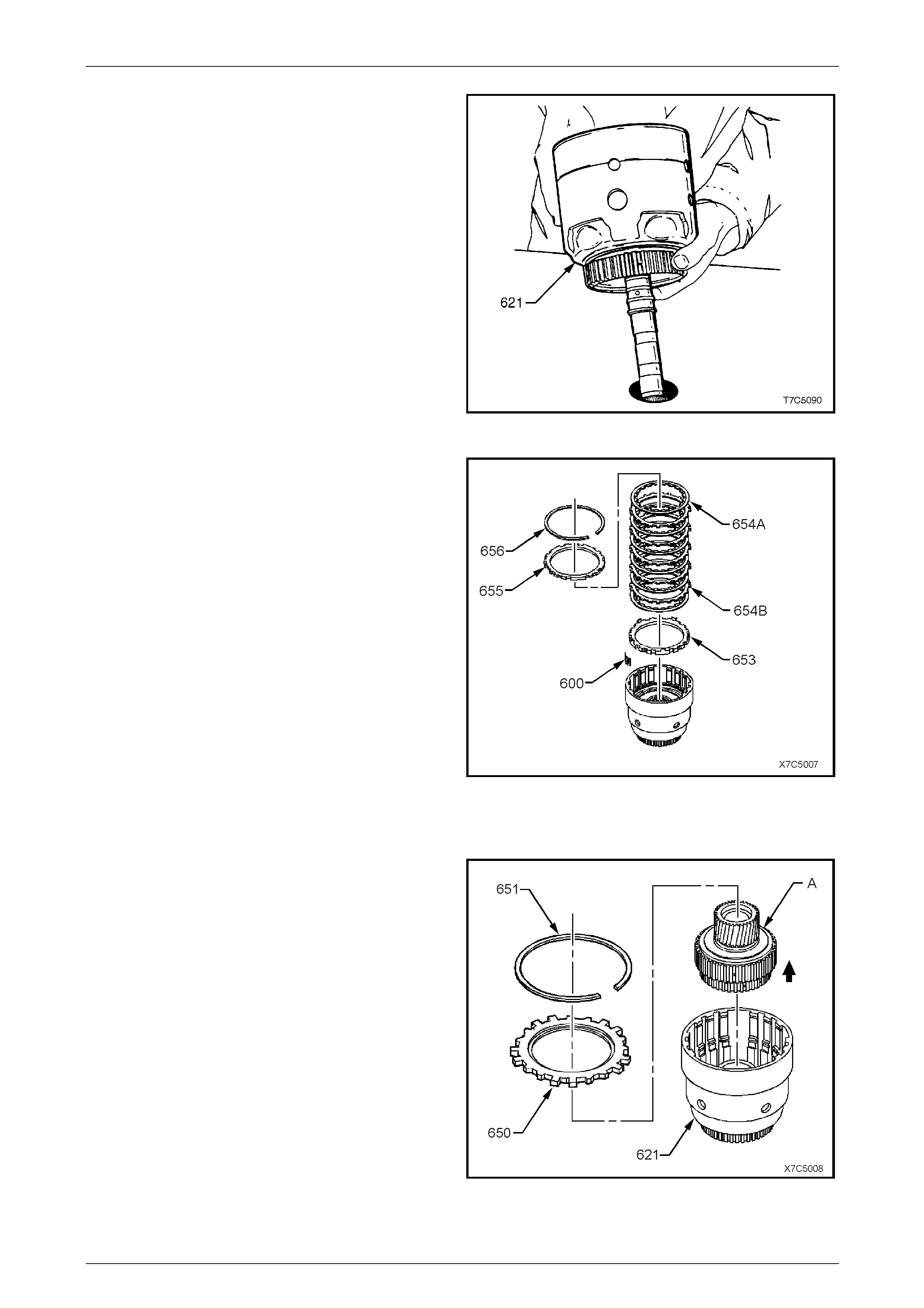

3 Place the input clutch housing and drum

assembly (621) on a work bench with the input shaft

protruding through a hol e in the workbench.

Figure 7D5 – 76

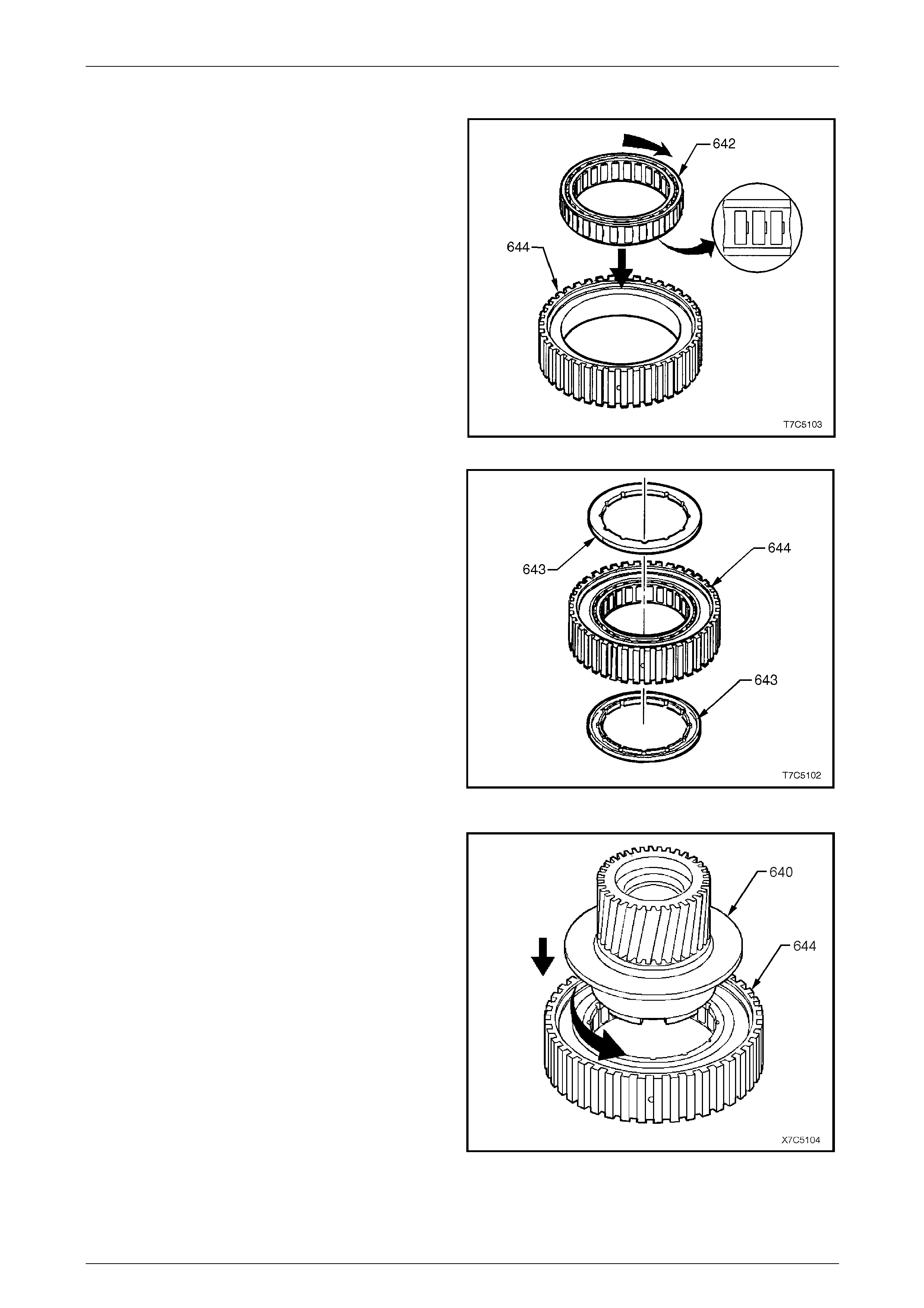

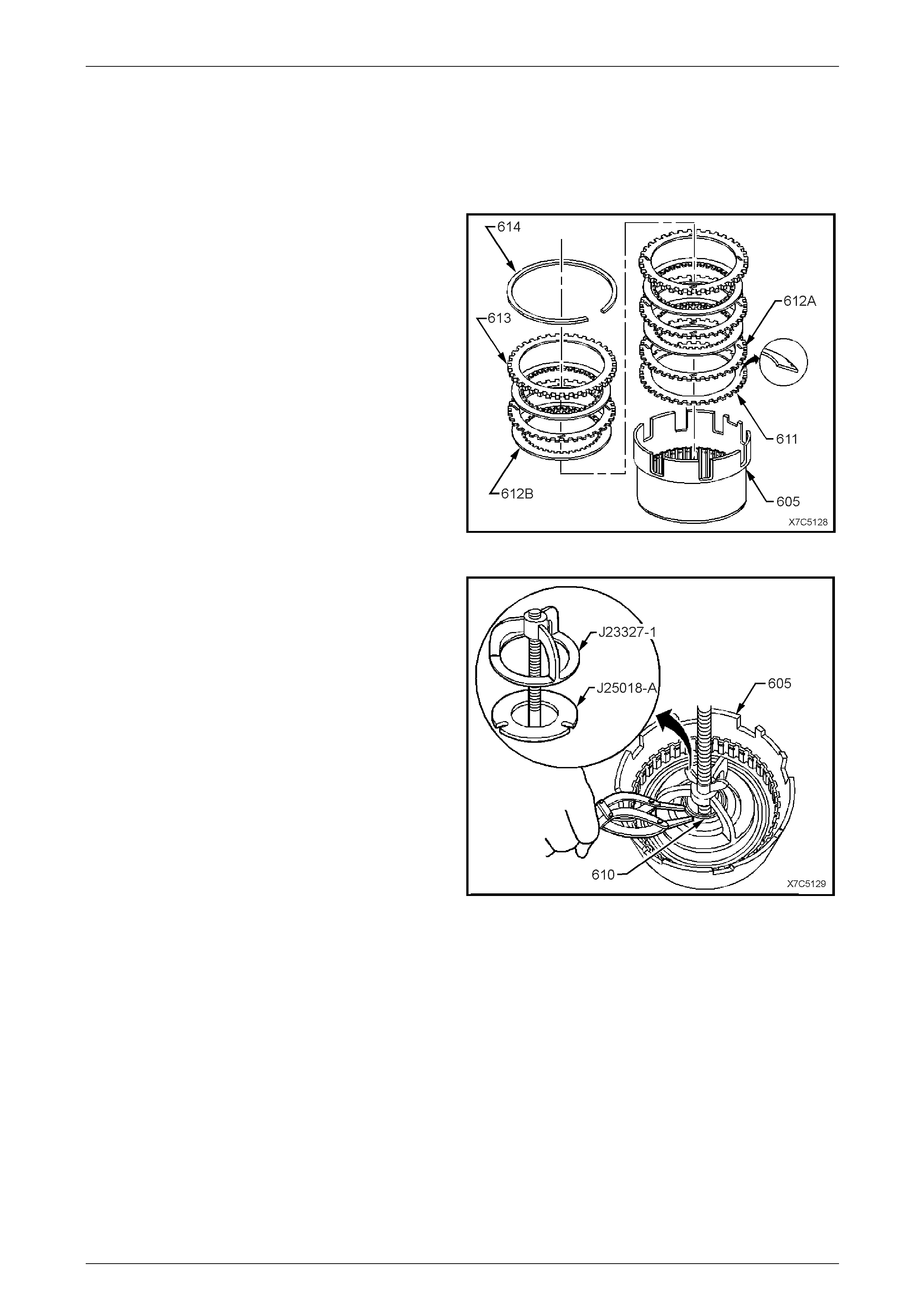

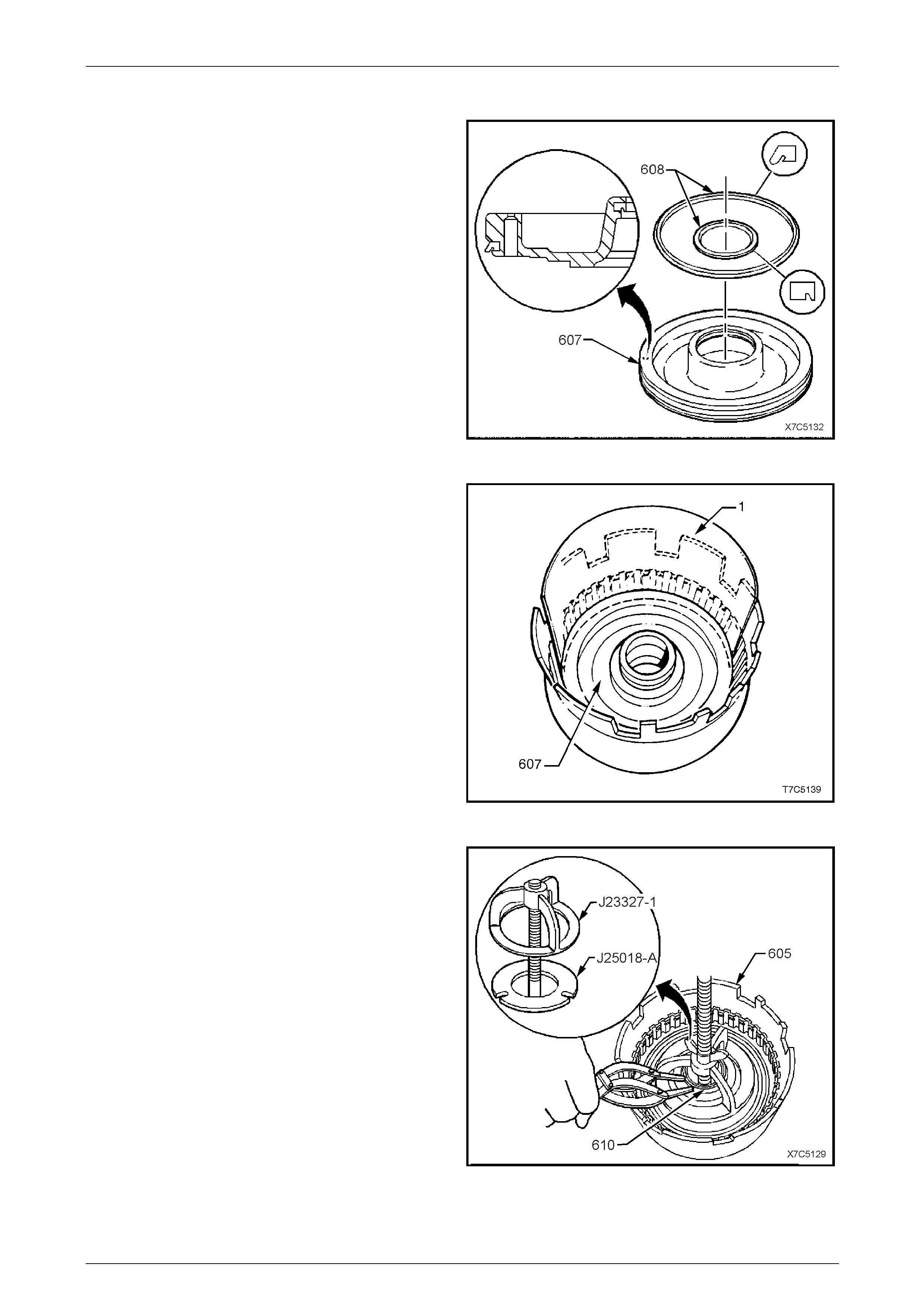

4 Remove the 3-4 clutch plate retaining ring (656) and

backing plate (655).

5 Remove the 3-4 clutch plates (654B and 654B).

6 Remove the 3-4 clutch boost spring assembly (600),

five places.

7 Remove the 3-4 clutch apply stepped plate (653).

Figure 7D5 – 77

Forward Clutch Assembly

1 Remove the forward clutch backing plate reta ining

ring (651) and backing pl ate (650).

2 Lift the forward clutch sprag and input sun gear

assembly (A) from the input shaft and housing

assembly (621).

Figure 7D5 – 78

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–52

15–DEC–2005 Page 7D5–52

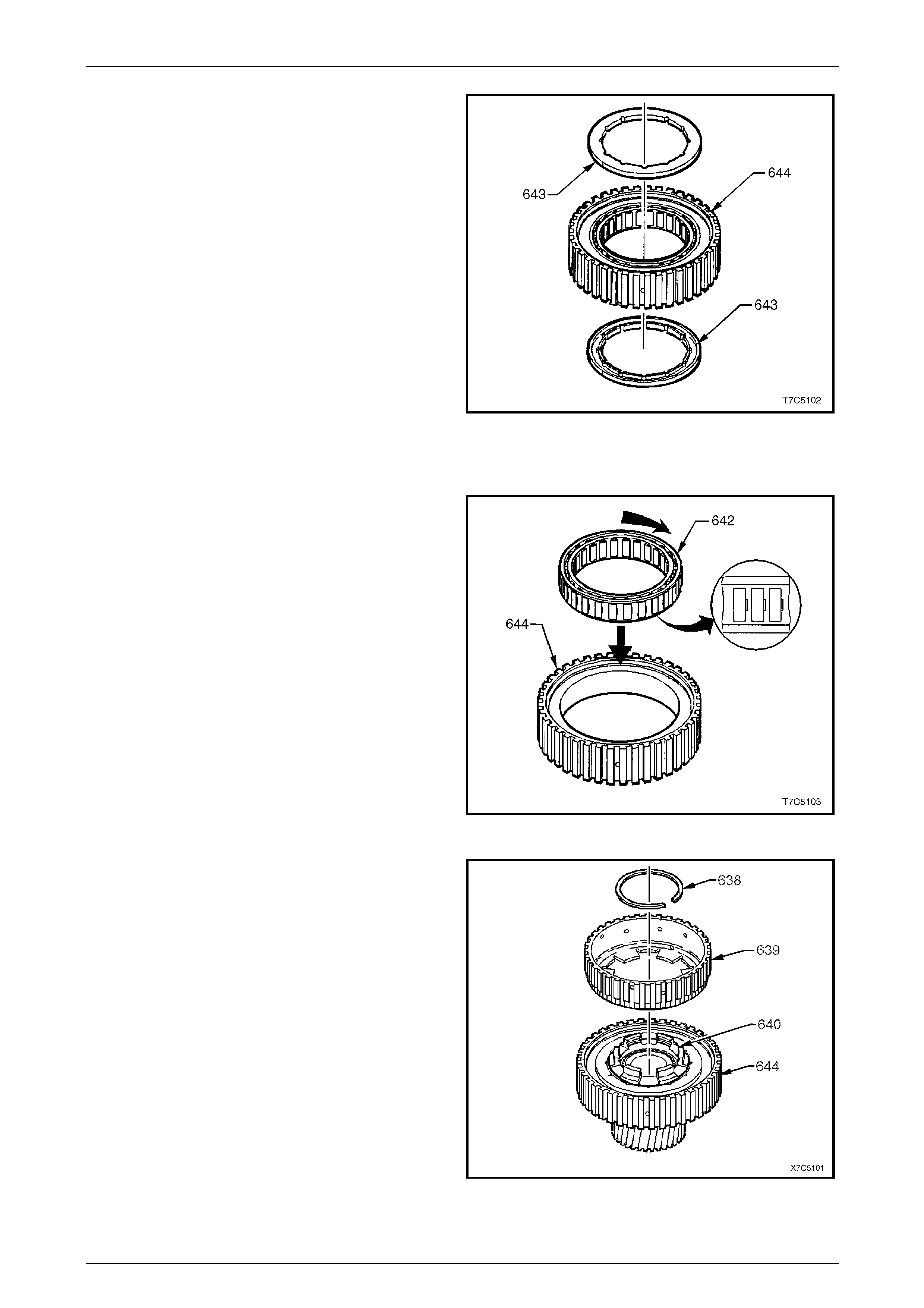

3 Remove the forward clutch plates (649A and 649B).

4 Remove the forward clutch wave plate (64 8).

5 Remove the forward clutch apply plate (646).

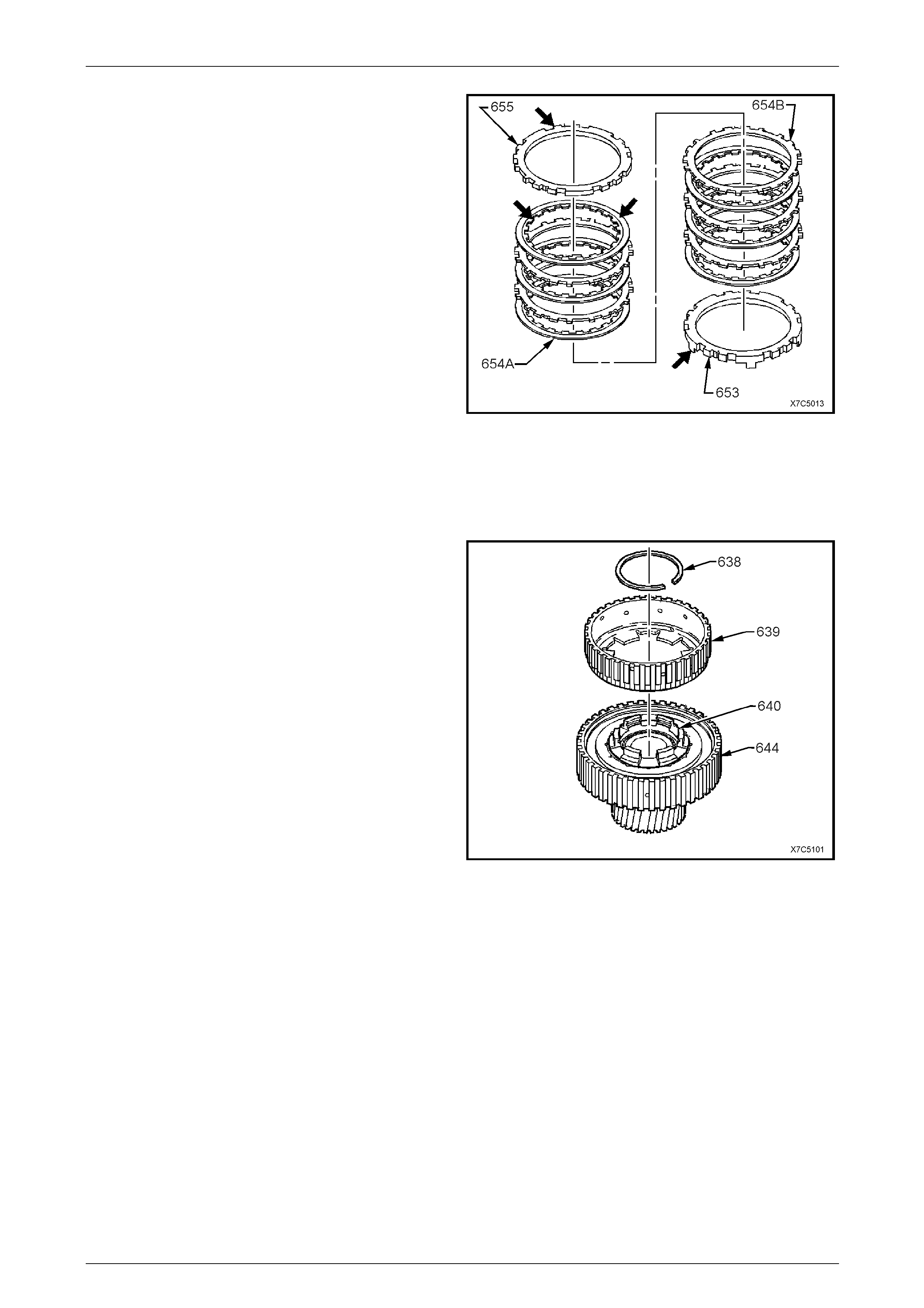

6 Remove the input sun gear bearing assembly (637).

7 Remove the input housing to output sh aft lip

seal (636).

8 Remove the overrun clutch plates (645A and 645B).

Figure 7D5 – 79

Overrun Clutch Assembl y

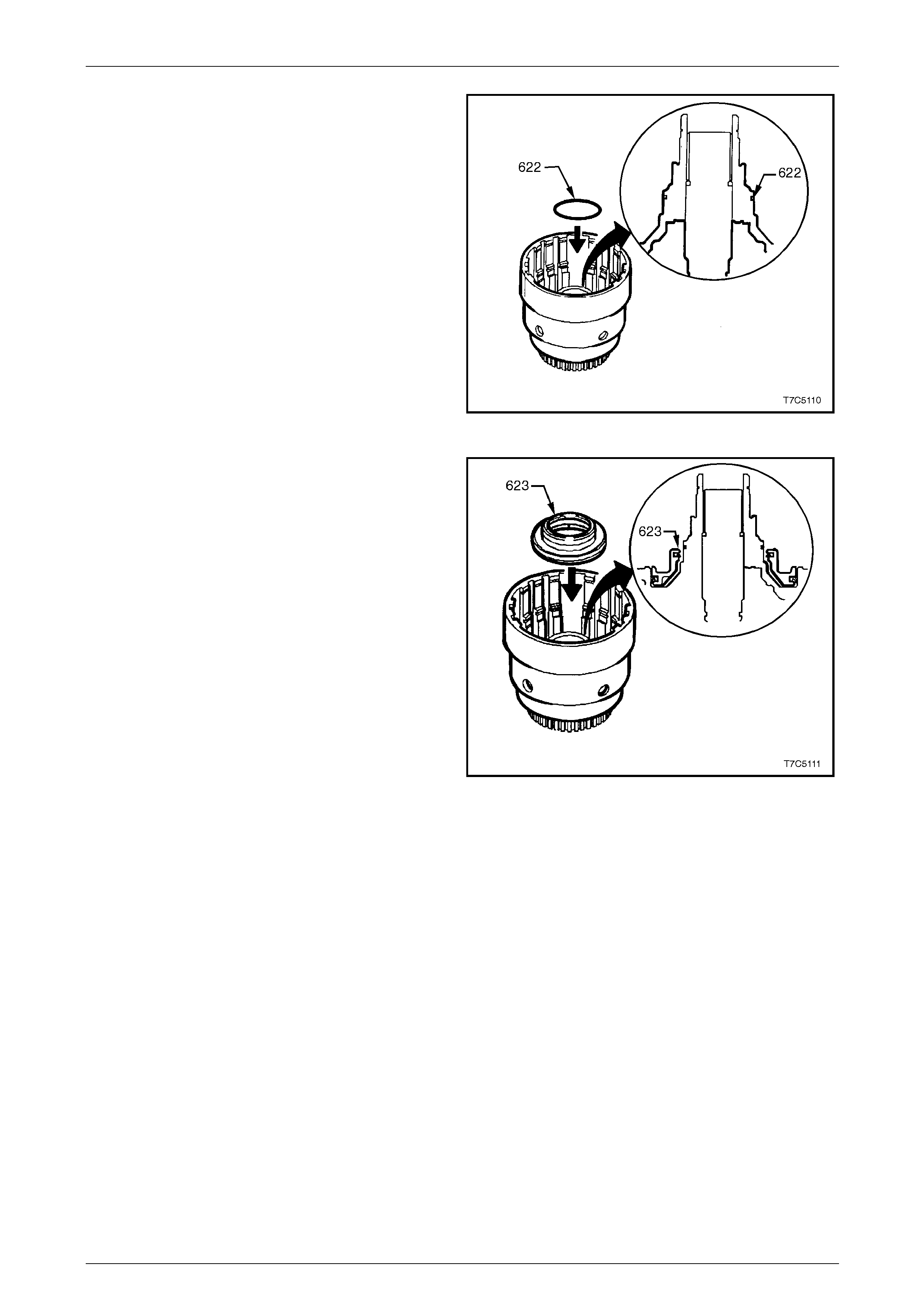

1 Place the input housing and shaft assembly (621) in a

suitable press.

2 Install part of Tool Nos J23327-1 and J25018-A

underneath, as shown.

Do not over-compress the springs or over-

expand the retaining ring.

3 Compress the overrun clutch spring assembly (not

visible) in press and remove the overrun clutch

retaining ring (635), using suitable snap ring pliers (1).

4 Return the input housing and shaft assembly to the

workbench.

Figure 7D5 – 80

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–53

15–DEC–2005 Page 7D5–53

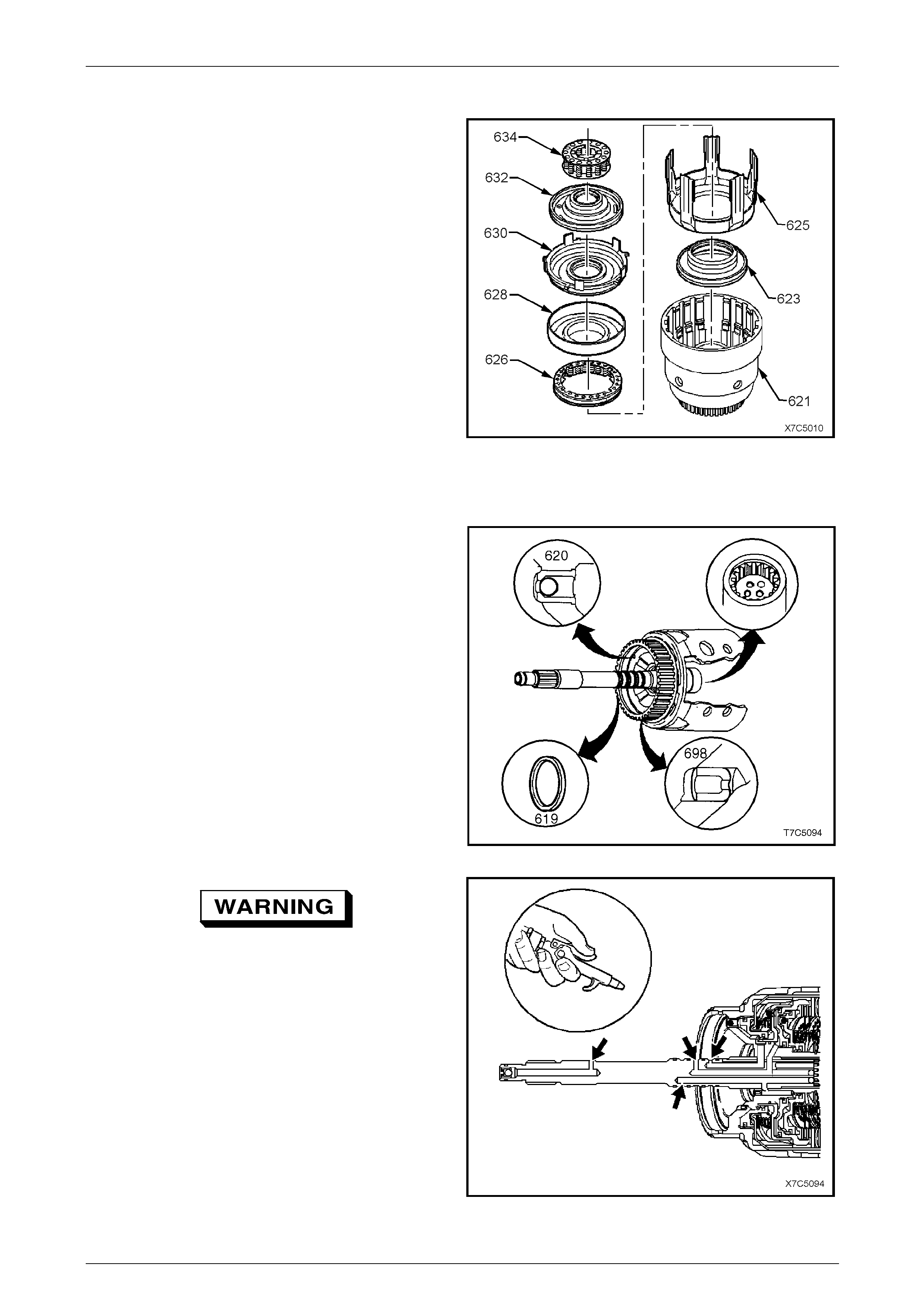

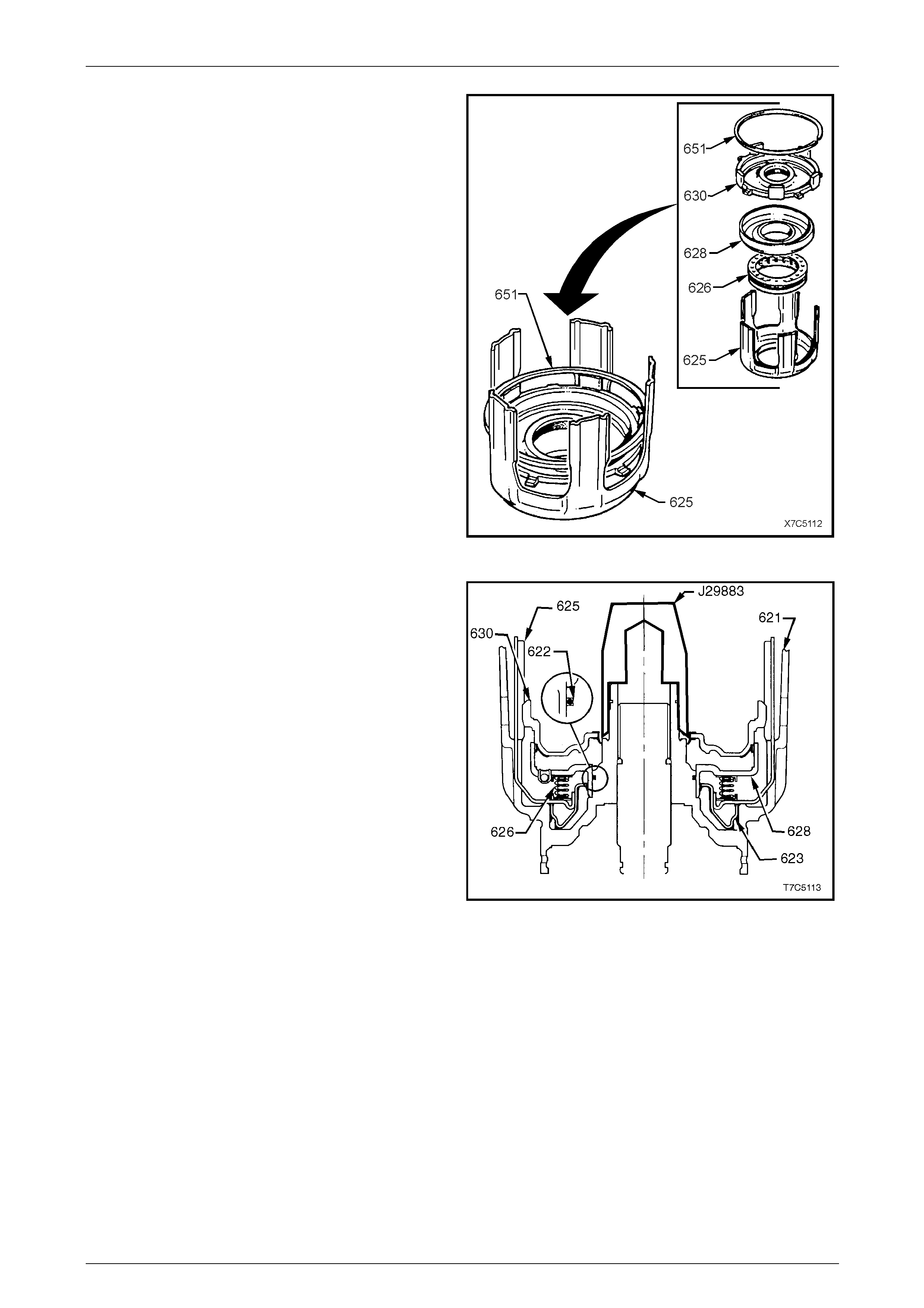

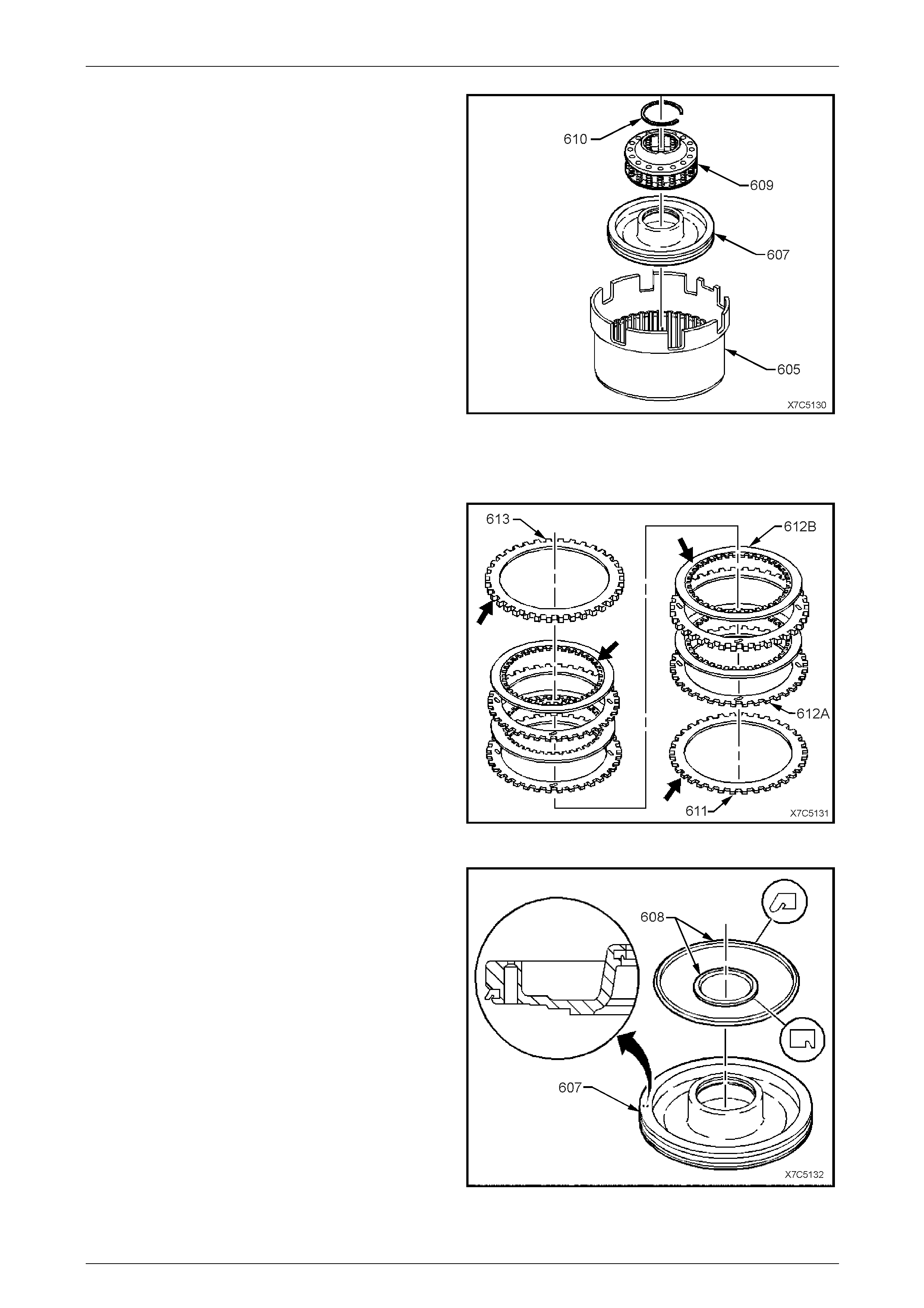

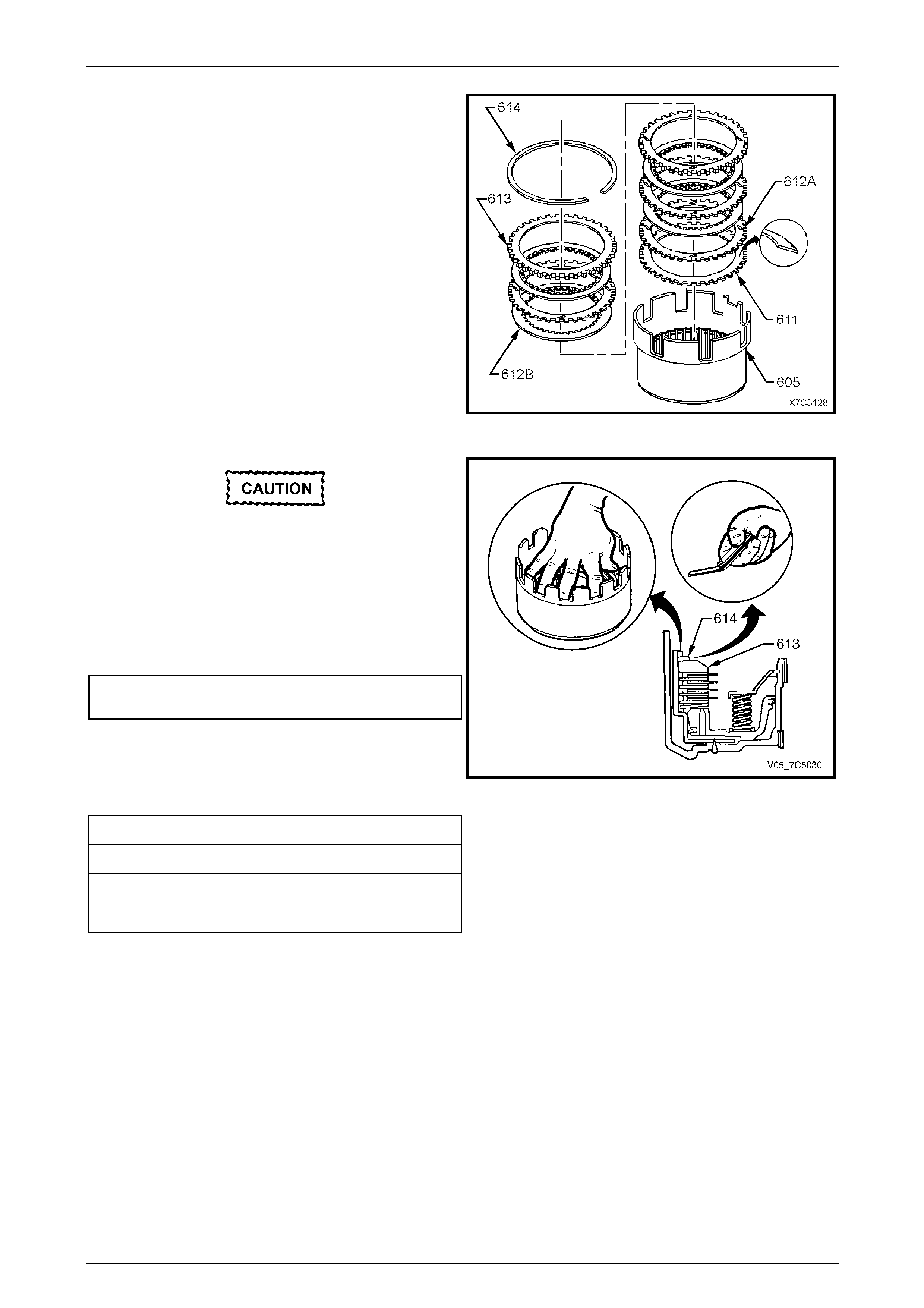

3 – 4 Clutch Assembly

1 Remove the overrun clutch spring assembly (634).

2 Remove the forward clutch piston assembl y (630),

together with the overrun clutch piston (6 32).

3 Separate the two pistons and remove all seals.

NOTE

Separate assembly by impacting the input

housing assembly on a wooden block.

4 Remove the forward clutch housing (628).

5 Remove the 3-4 clutch spring assembly (626).

6 Remove the 3-4 clutch appl y ring (625) and

piston (623) with seals.

7 Discard all removed seals.

Figure 7D5 – 81

Inspect

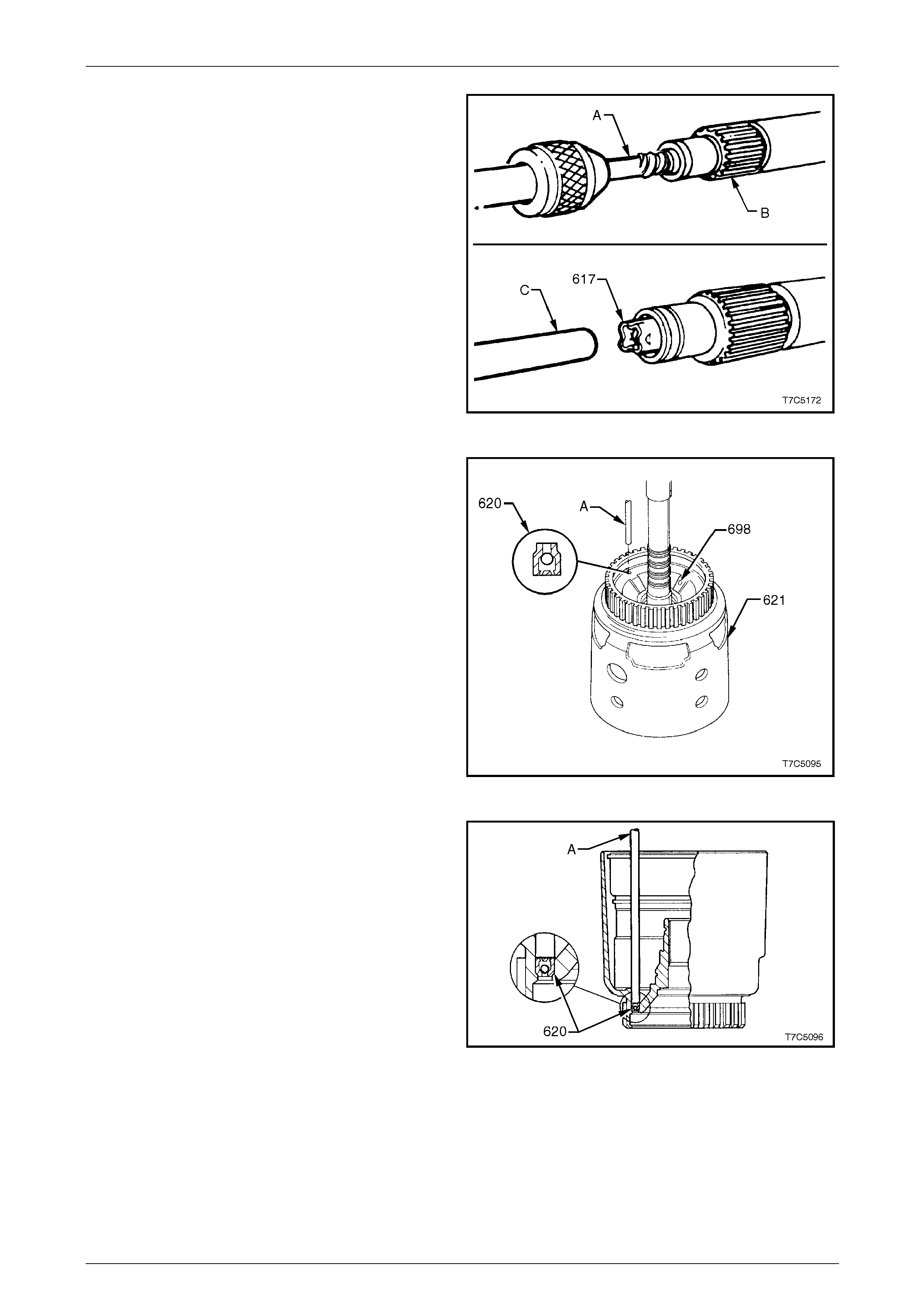

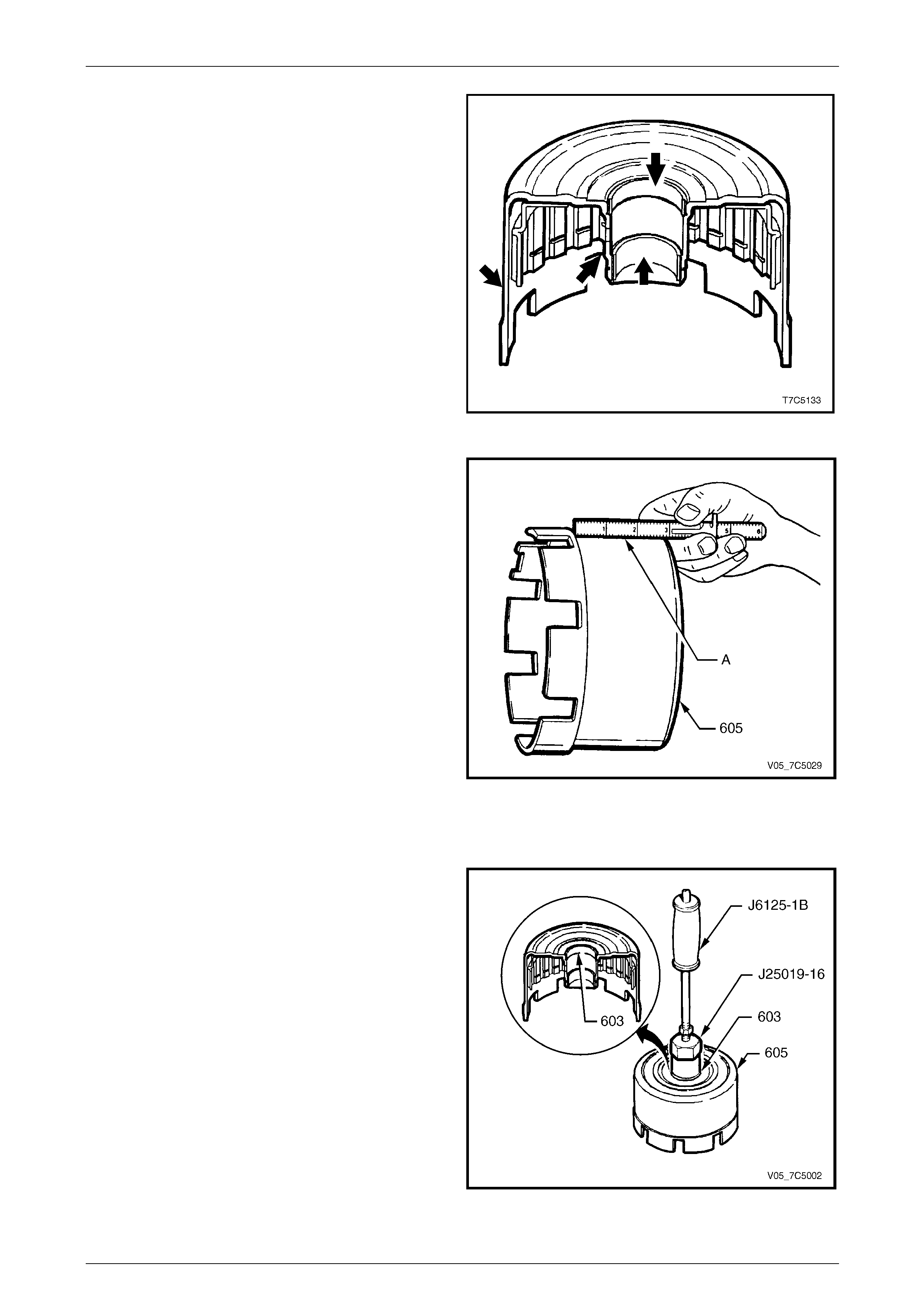

1 Inspect the input housing and shaft assembly for

porosity, wear or damage.

2 Check if the orifice cup plug (698) is not missing.

3 Check for cracks at all lube holes.

4 Check if the turbine shaft four sealing rings (619)

rotate freely in their grooves and if they are not

damaged and free from burrs.

5 Inspect the check ball and retainer (620). Check if the

ball moves freely and if the retainer is not lo ose in the

housing. Leak test the check ball, with solvent.

Figure 7D5 – 82

When using compressed air wear safety

equipment to avoid personal injury.

6 Blow through all input shaft passages with

compressed air. The three turbine shaft seal ing balls

must not be loose or leaking.

Figure 7D5 – 83

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–54

15–DEC–2005 Page 7D5–54

7 If required, replace the turbine shaft retainer and

check the ball assembly (617) as follows:

a Straighten the retainer tangs and remove the

ball.

b Use a suitable screw extractor (A) to remove the

retainer from the turbine shaft (B).

c Install a new check ball and retain er

assembly (617), using a 9.5 mm rod (C), until the

retainer is 3.0 mm below the end of the input

shaft.

d Ensure the check ball moves freely.

NOTE

The end of the turbine shaft (B) may vary,

depending on t he engine application.

Figure 7D5 – 84

8 If necessary, replace the input shaft housing check

ball assembly, as follows:

a Tap out the retainer and bal l assembly (620),

using a 5.7 mm (1/4 inch) rod (A).

Figure 7D5 – 85

b Install new check ball assembly (620) with a

5.7 mm rod (A) until the shoulder is seated in the

housing from the input shaft side, as shown.

Figure 7D5 – 86

9 Inspect the 3-4 clutch piston (623) for porosity or damage, refer to Figure 7D5 – 74.

10 Inspect the 3-4 clutch apply ring (625) for be nt tangs.

11 Inspect the 3-4 clutch spring assembly (626) for distortion or damage.

12 Inspect each of the 3-4 clutch five spring ass embli es (600) for damage or distortion.

13 Inspect the 3-4 clutch plates for damaged tangs, delamin ation and/or excessive wear.

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–55

15–DEC–2005 Page 7D5–55

NOTE

The green/black appearance of the 3-4 clutch

plates is normal. T herefore, do not assume these

plates are burned because of colour.

14 Inspect the forward clutch housing (628) for:

• correct check ball (627) operation,

• damage, distortion or cracks and

• burrs in seal areas.

Figure 7D5 – 87

15 Inspect the forward clutch piston (630) for:

• porosity or damage,

• ring groove damage a nd

• apply leg damage.

NOTE

As the inner and outer piston seals are bonded

to the forward clutch piston, if any seal damage

is found, the piston assembly must be replaced.

Figure 7D5 – 88

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–56

15–DEC–2005 Page 7D5–56

16 Inspect the overrun clutch piston (632) for:

• porosity or damage,

• ring groove damage,

• seal damage and

• check ball (633) operation (overrun).

NOTE

As the inner and outer piston seals are now

bonded to the overrun clutch piston, if any seal

damage is found, then the piston assemb ly must

be replaced.

17 Inspect the overrun spring assembl y (634) for damage

or distortion, refer to Figure 7D5 – 74.

18 Inspect the overrun clutch plates (645 a/b), forward

clutch plates (649a/b) and 3-4 clutch plates (654a/b).

Check the composition plates for damaged tangs,

delamination or excessive wear. Check the steel

plates for damaged tangs, wear or heat damage.

Figure 7D5 – 89

19 Inspect the input sun gear bearin g assembly (637) and

the input housing to output shaft seal (636) for wear,

damage or distortion.

Figure 7D5 – 90

20 Inspect the forward clutch waved plate (648), apply

plate (646), steel plates (649A), compositio n

plates (649B) and selective backing p late (650) for:

• flatness,

• delamination of the compositio n plates (649B),

• heat damage and/or excessive wear and

• burrs, nicks and other surface finish damage.

Figure 7D5 – 91

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–57

15–DEC–2005 Page 7D5–57

21 Inspect the 3-4 clutch apply plate (653), com position

plates (654A), steel plates (654B) and selective

backing plate (655), for:

• flatness,

• delamination of the compositio n plates (654A),

• heat damage and/or excessive wear and

• burrs, nicks and other surface finish damage.

Figure 7D5 – 92

Forward Clutch Sprag Assembly

Disassemble

1 Remove the overrun clutch hub retaining snap

ring (638) and clutch hub (639).

2 Remove the forward clutch outer race (644).

3 Remove the forward sprag clutch inner race and sun

gear assembly (640) from the forward clutch sprag

assembly (644).

Figure 7D5 – 93

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–58

15–DEC–2005 Page 7D5–58

4 Remove the sprag assembly retainer rings (643).

5 Remove the forward sprag assembl y from the forward

clutch outer race (644).

Figure 7D5 – 94

Inspect

1 Inspect the forward clutch sprag assembly (642) for:

• wear or damage,

• weak or broken springs and

• damaged or missing retaining caps.

2 Inspect the forward clutch outer race (644) for:

• spline damage,

• surface finish damage and

• plugged lubricat ion holes.

Figure 7D5 – 95

3 Inspect the overrun clutch hub (639) for:

• spline damage,

• plugged lubricat ion holes,

• damaged tangs and

• cracks.

4 Inspect the forward sprag clutch inner race and input

sun gear assembly (640) for:

• spline damage,

• ring groove damage,

• surface finish damage and

• loose retainer.

Figure 7D5 – 96

7D5 Automatic Transmission – 4L65E – Unit Repair Page 7D5–59

15–DEC–2005 Page 7D5–59

Reassemble

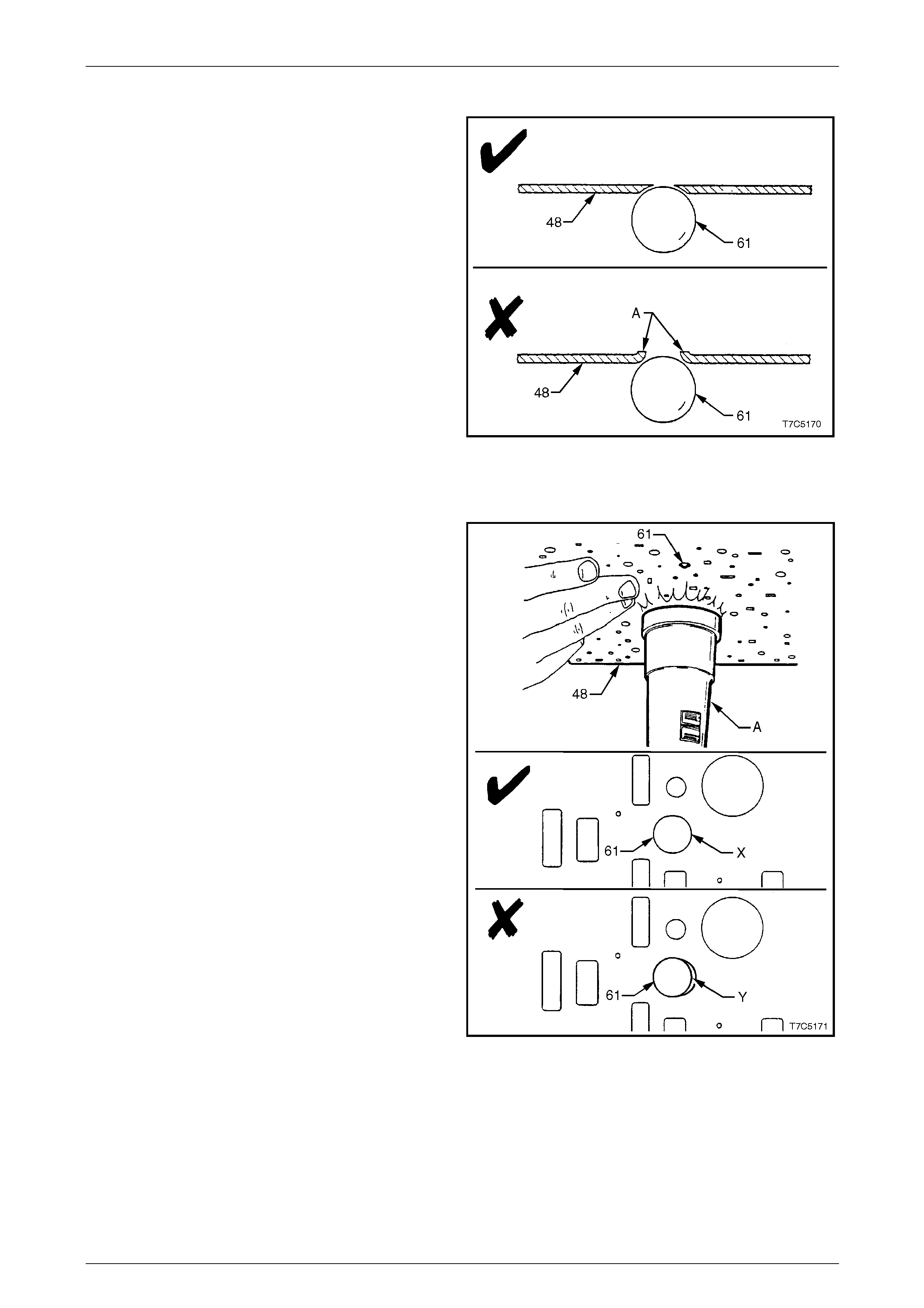

1 Reinstall the forward sprag assembly (642) into the

forward clutch outer race (644), notches in sprag cage

pointing in the direction shown.

Figure 7D5 – 97

2 Reinstall a sprag retainin g ring (643) to each side of

the forward clutch outer race (644) with the retaining

ring recesses facing outward.

Figure 7D5 – 98

3 Reinstall the forward sprag clutch inner race and input

sun gear assembly (640) into the sprag retai nin g ring

and the outer race (644), as follows:

a Hold the outer race in right hand, supporting the

forward sprag assembly with yo ur fingers at the

recessed side of the outer race.

b Insert the retaining ring and the forward sprag

clutch inner race and input sun gear assemb ly

from the opposite side of the outer race by

pushing in and turning anti-clockwise (curved

arrow).

4 Turn the assembly over and reinsta ll the remaining

sprag assembly outer retaining ring, with the recess

facing inward toward the forward sprag assembly.

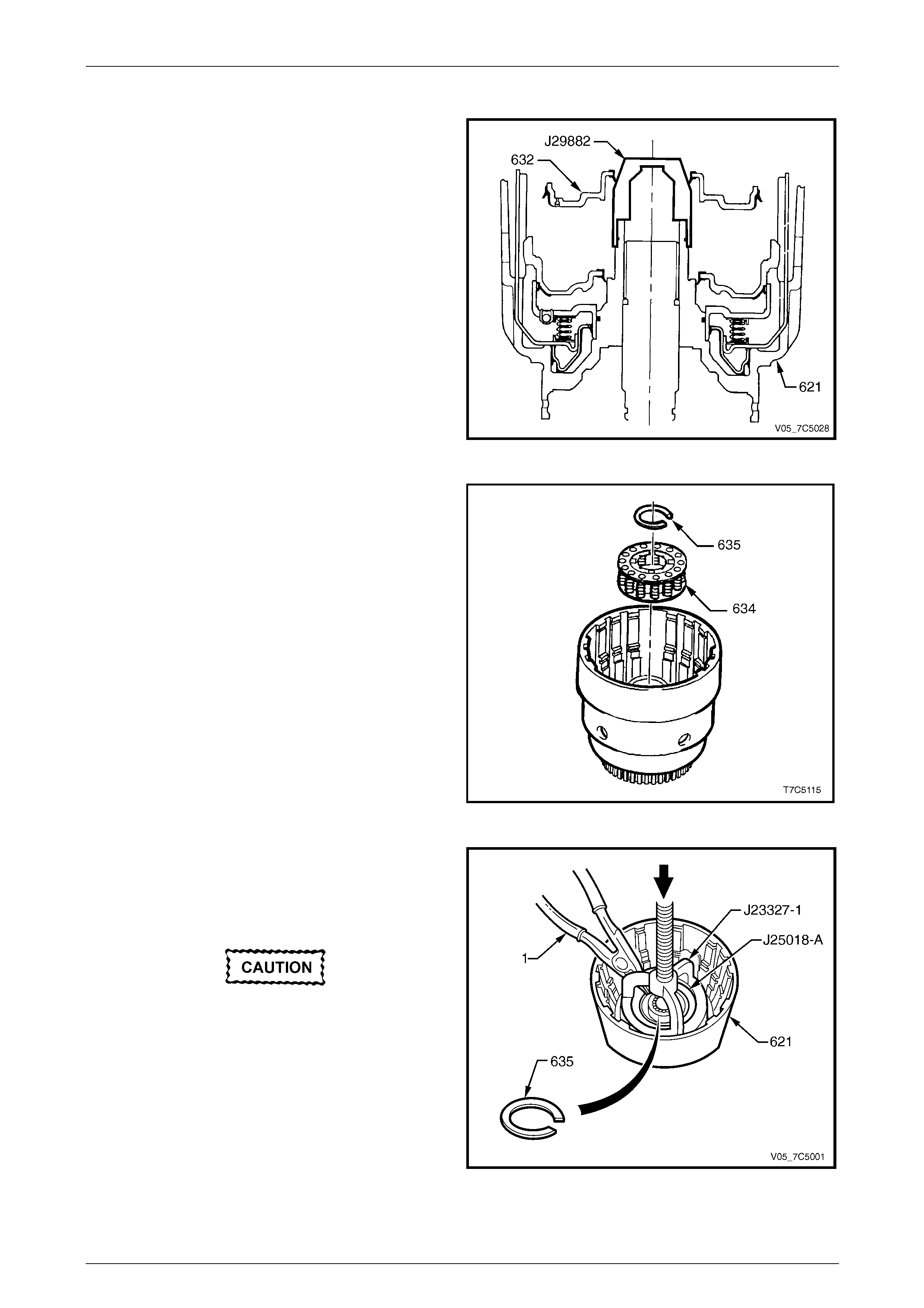

Figure 7D5 – 99