4/5L40-E

HYDRA-MATIC

2

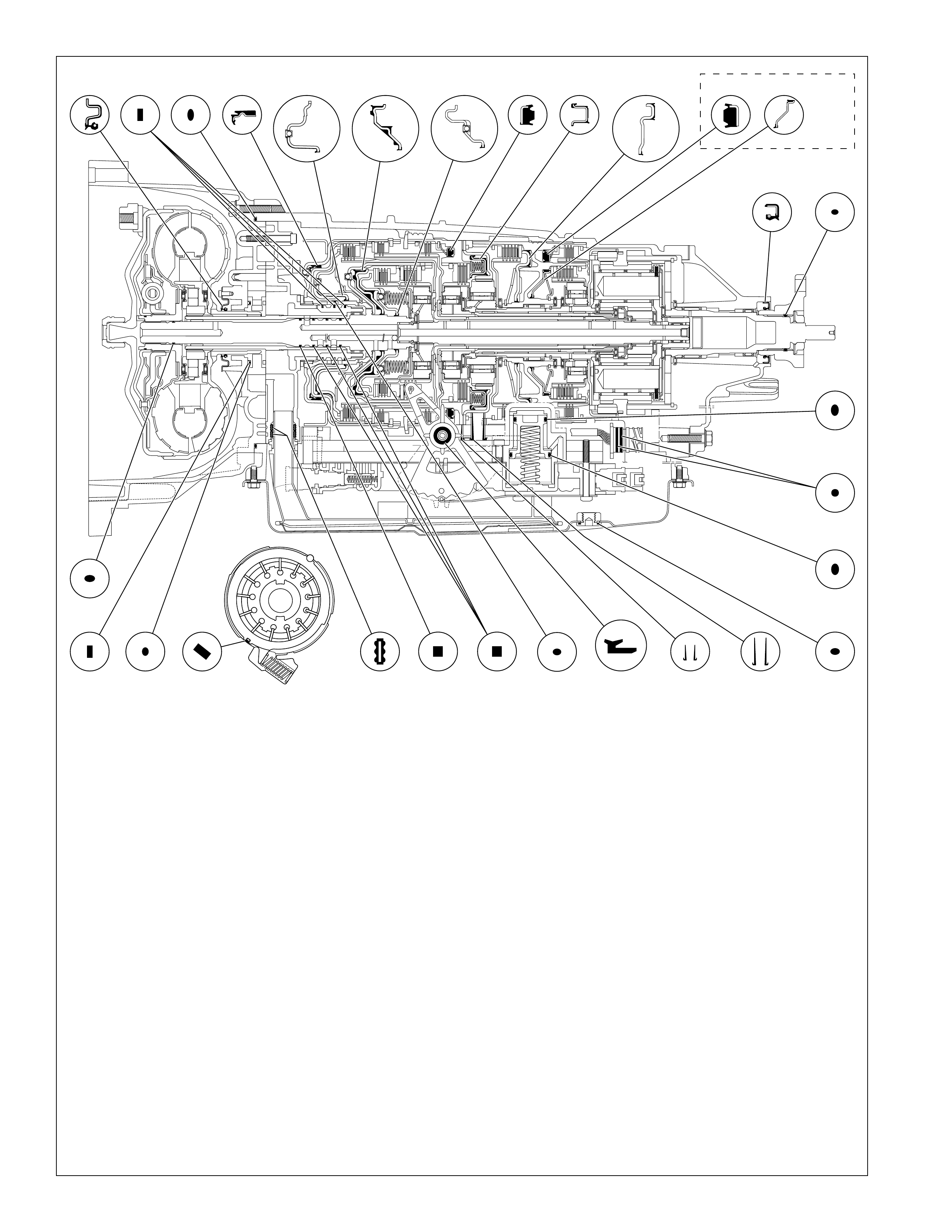

CONTENTS

INTRODUCTION..................................................................................... 3

HOW TO USE THIS BOOK ...................................................................... 4

UNDERSTANDING THE GRAPHICS ....................................................... 6

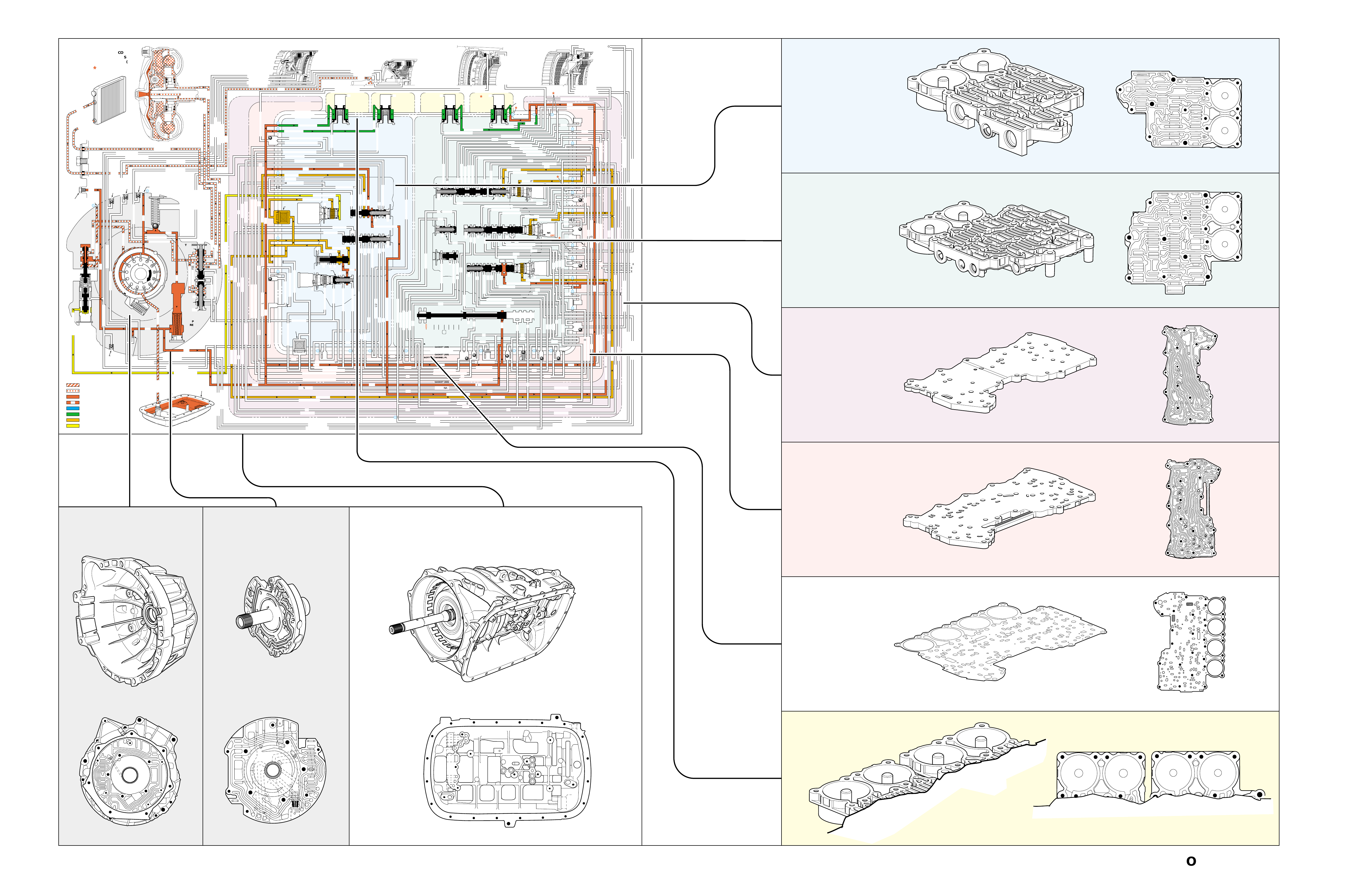

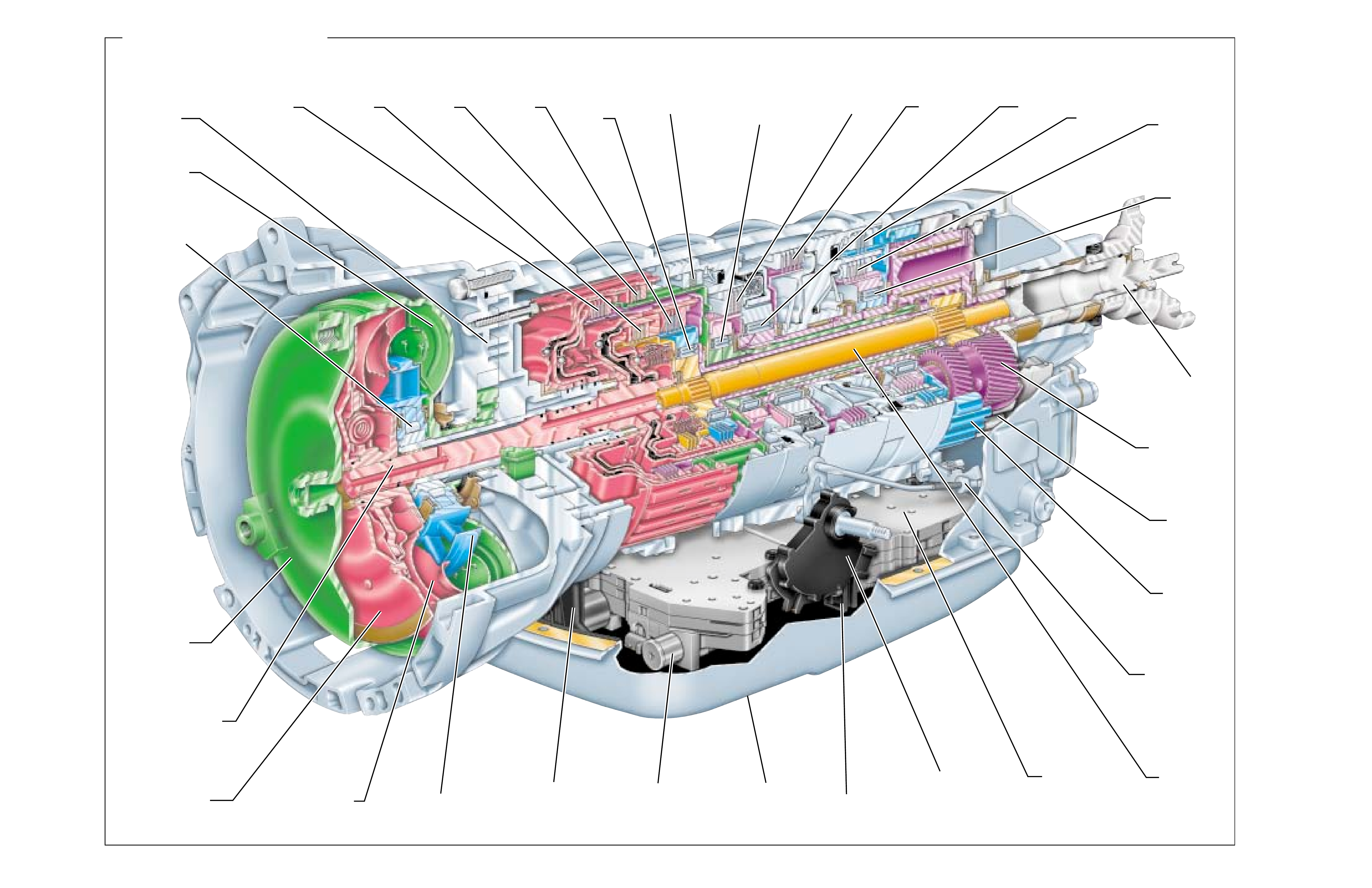

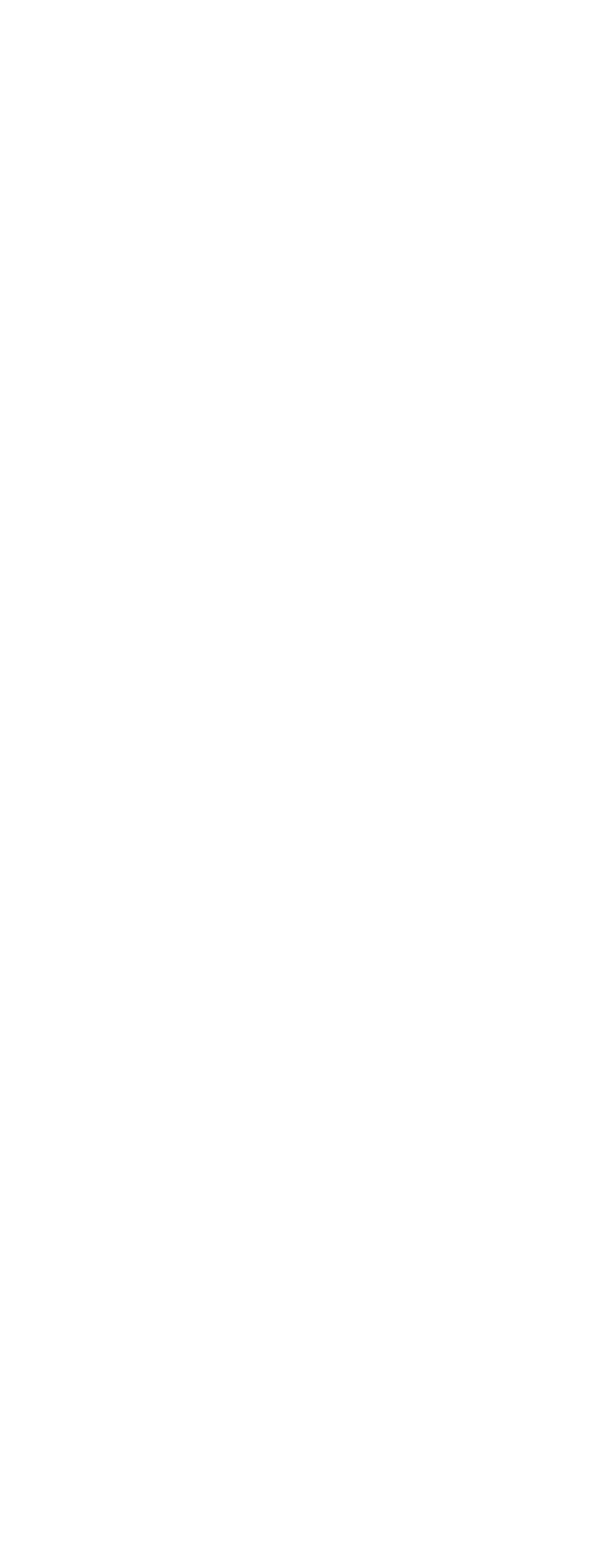

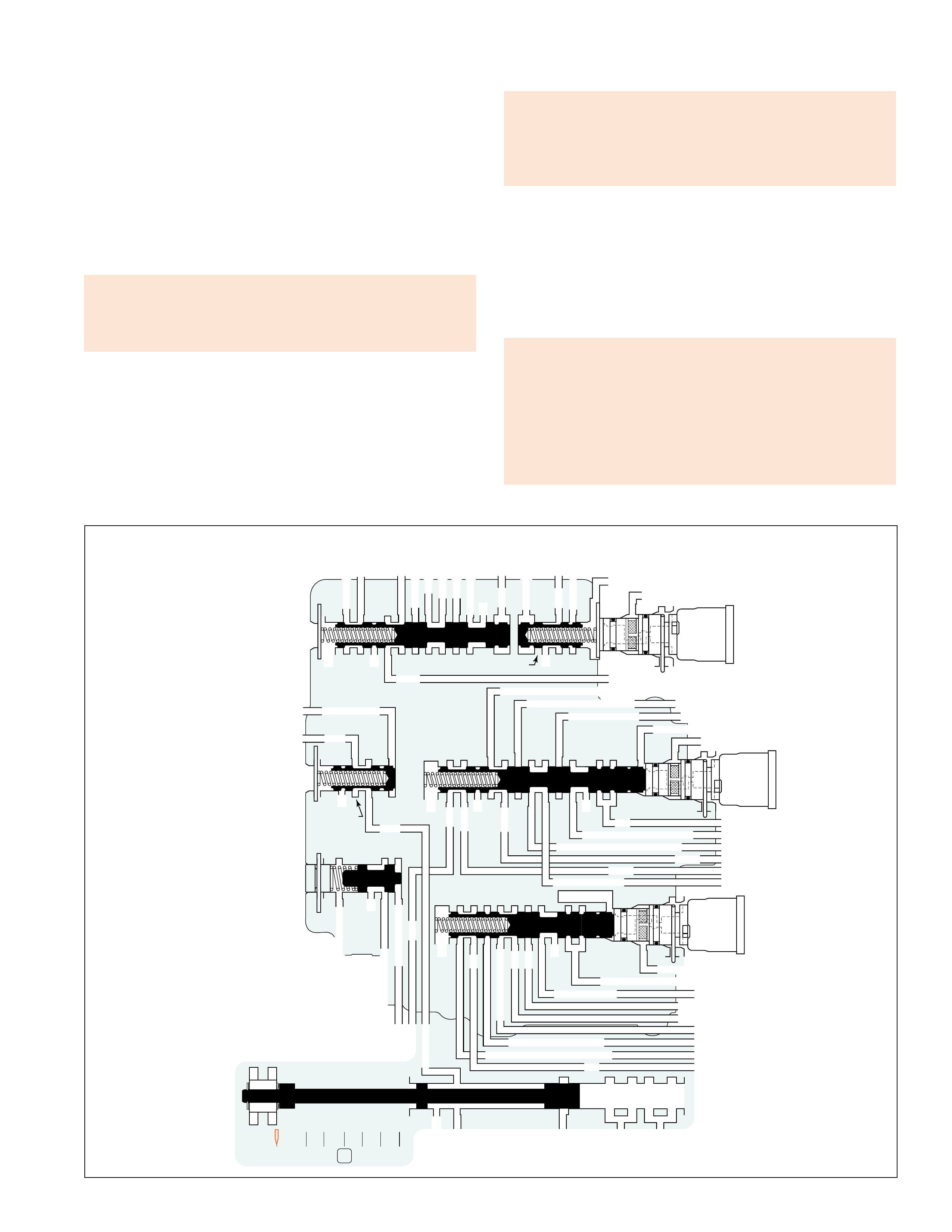

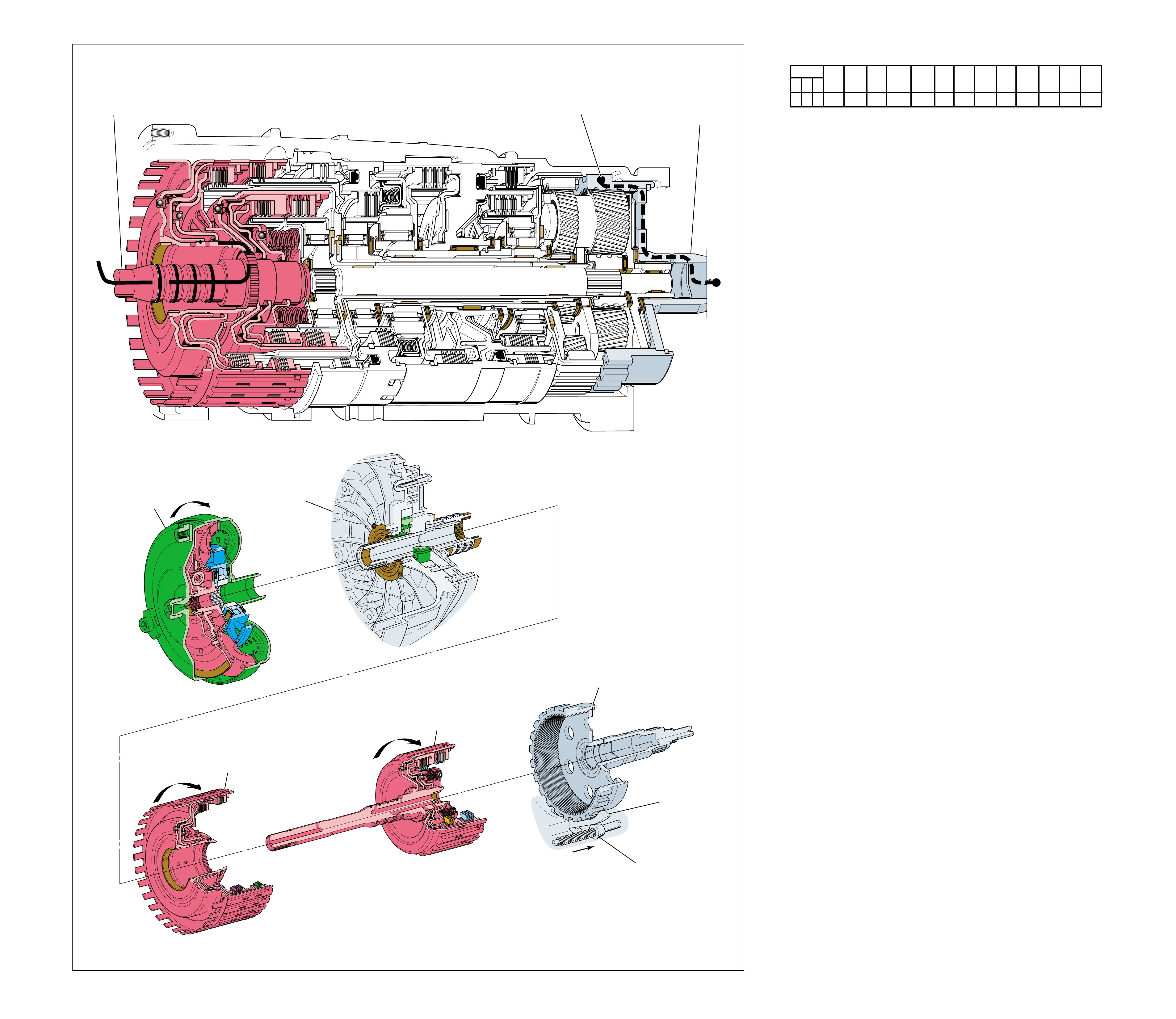

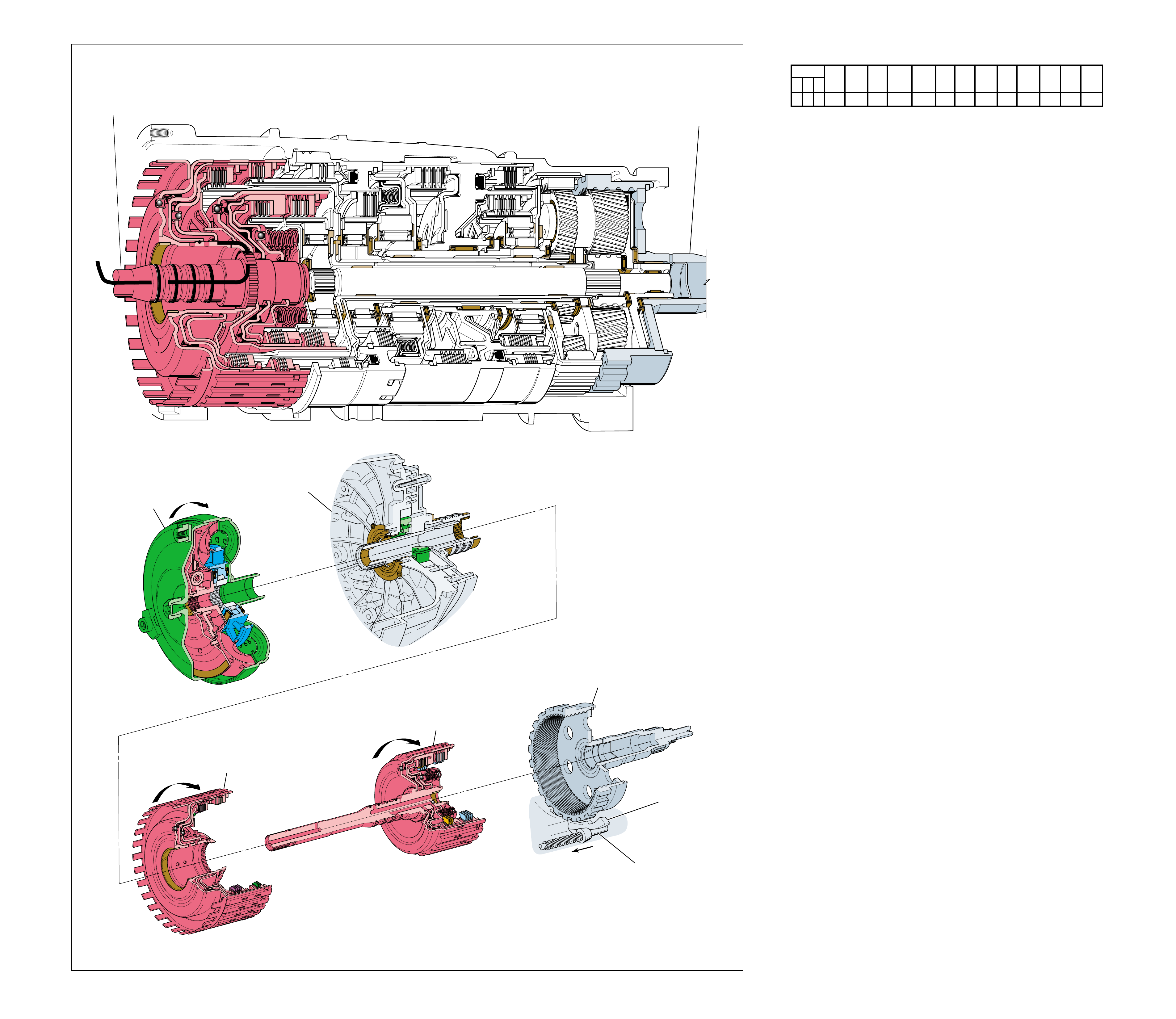

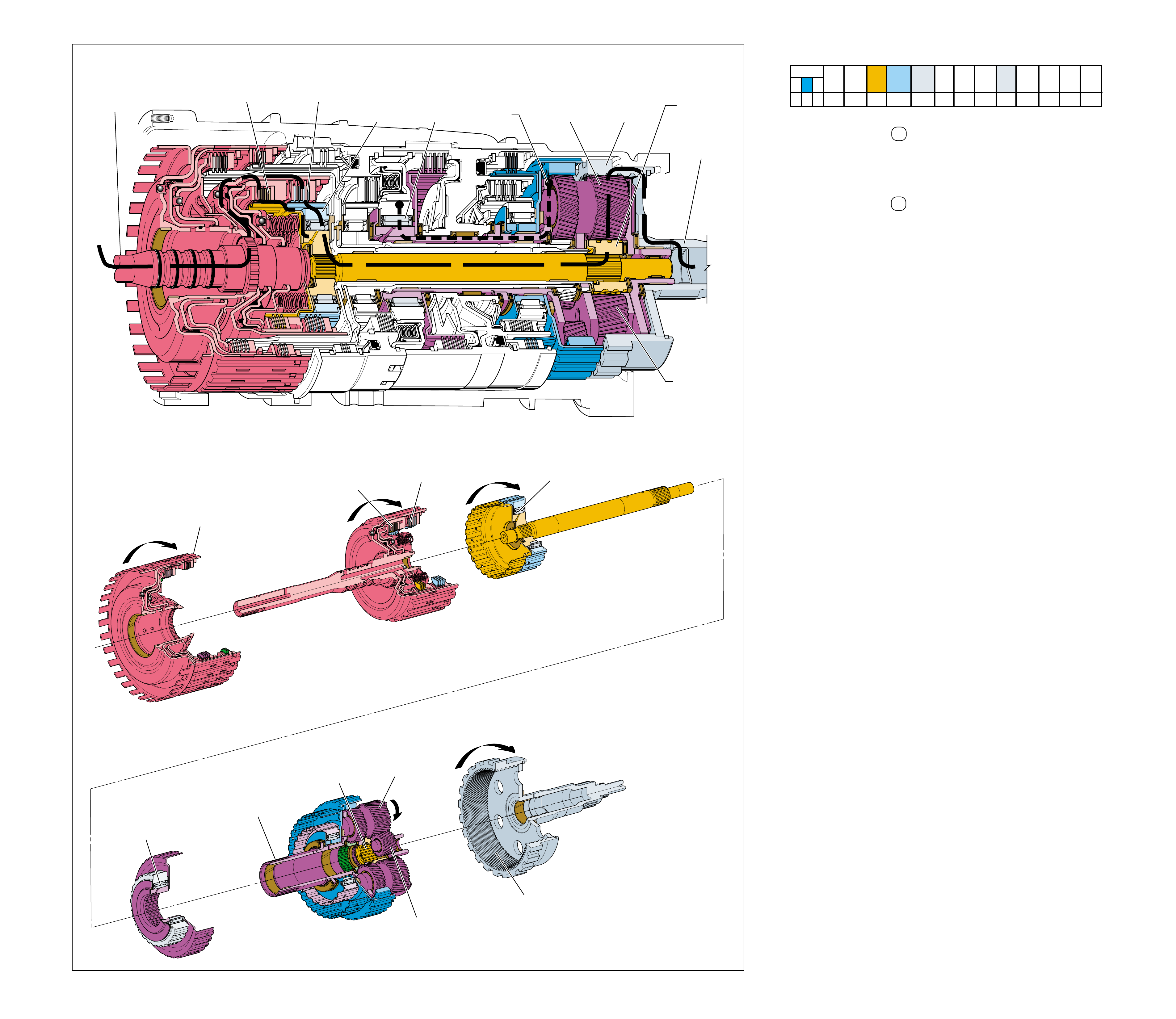

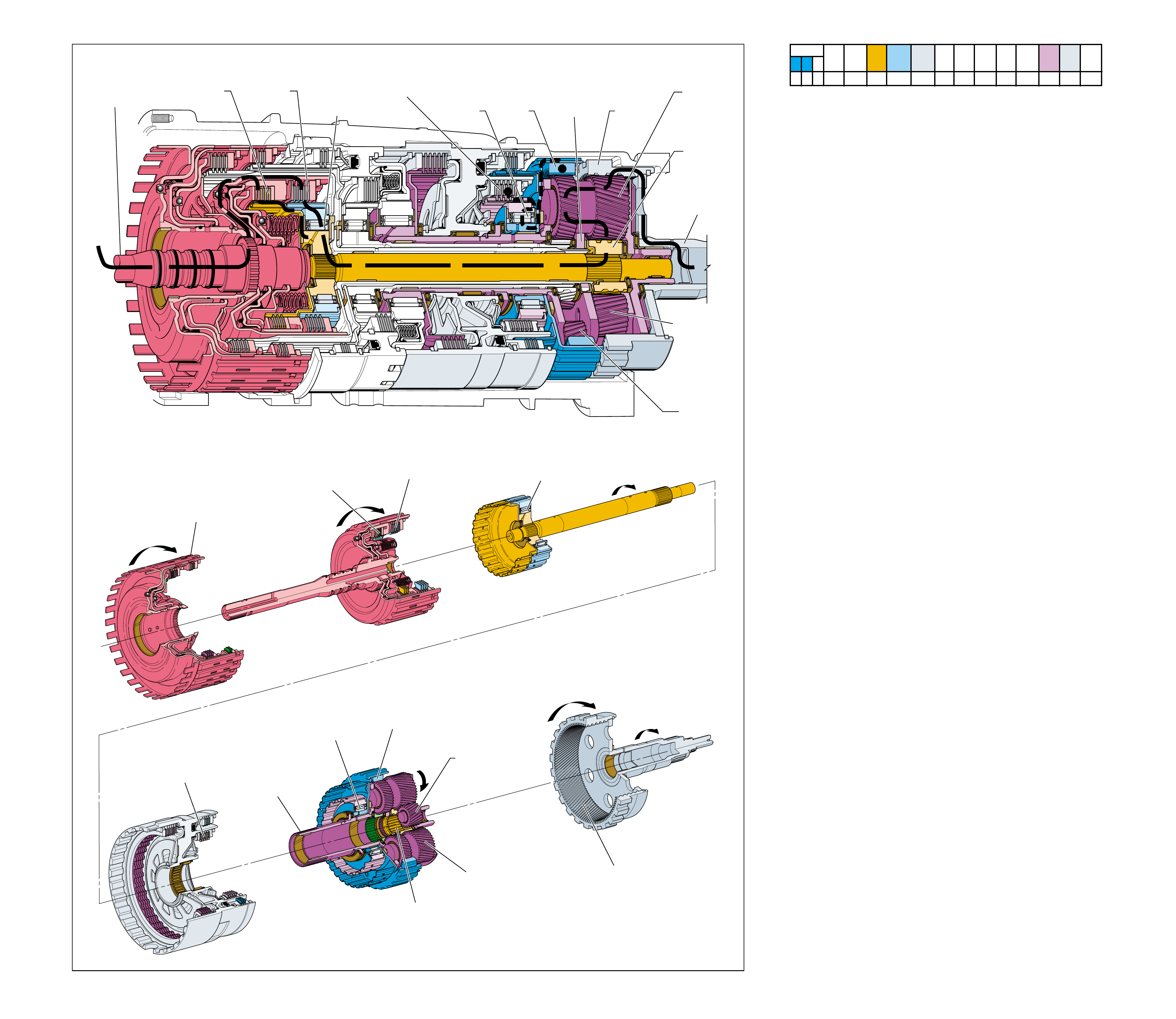

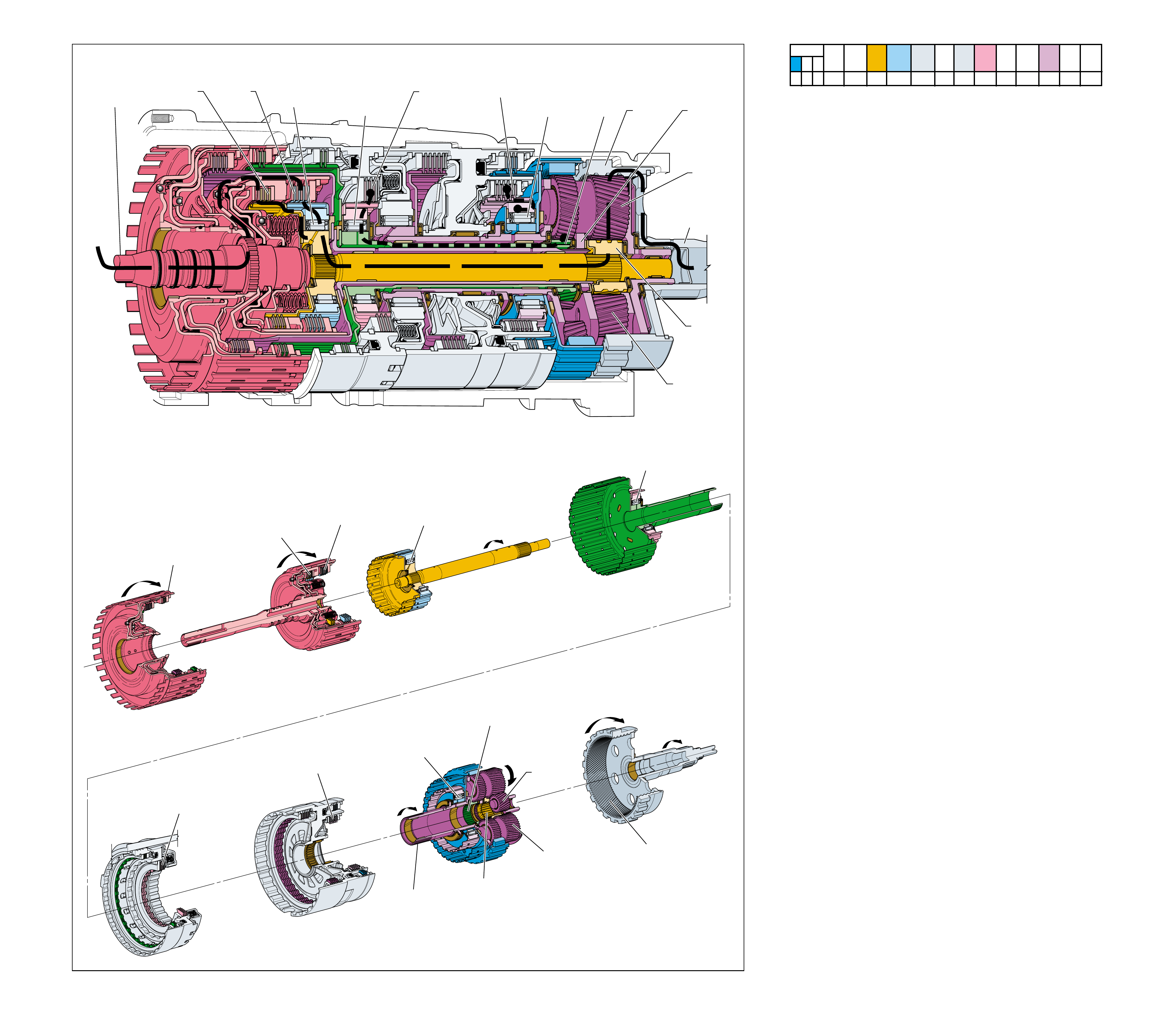

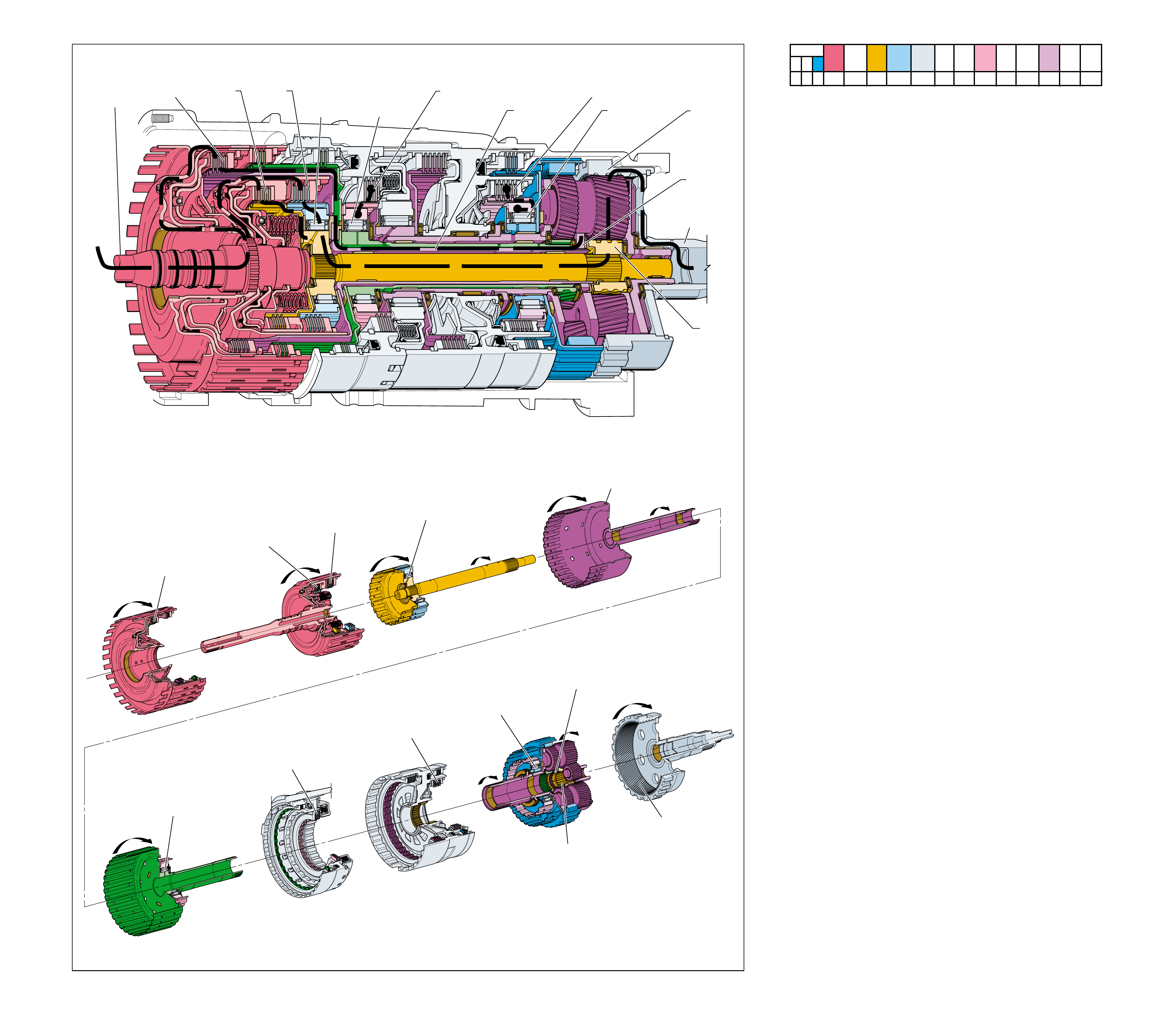

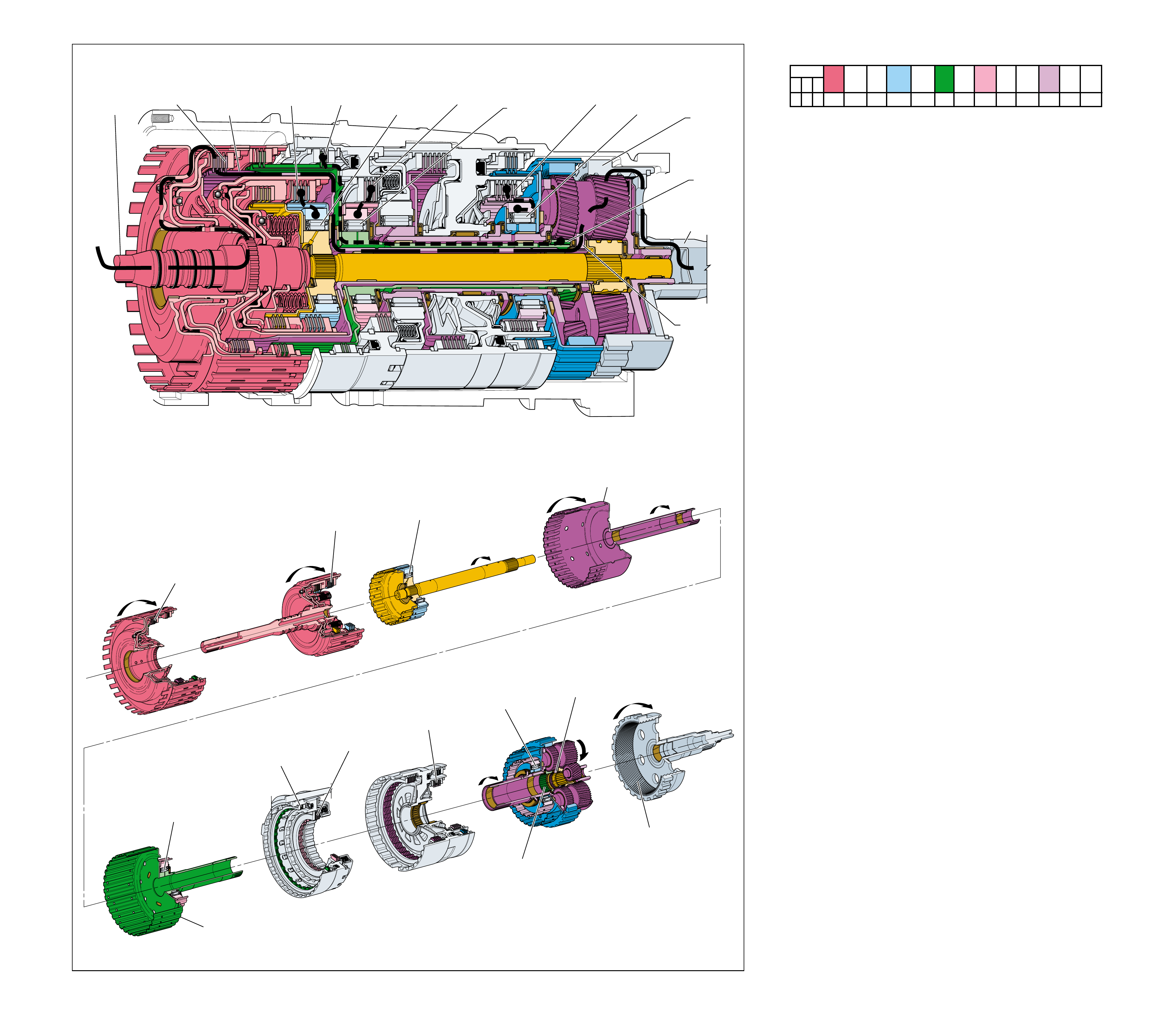

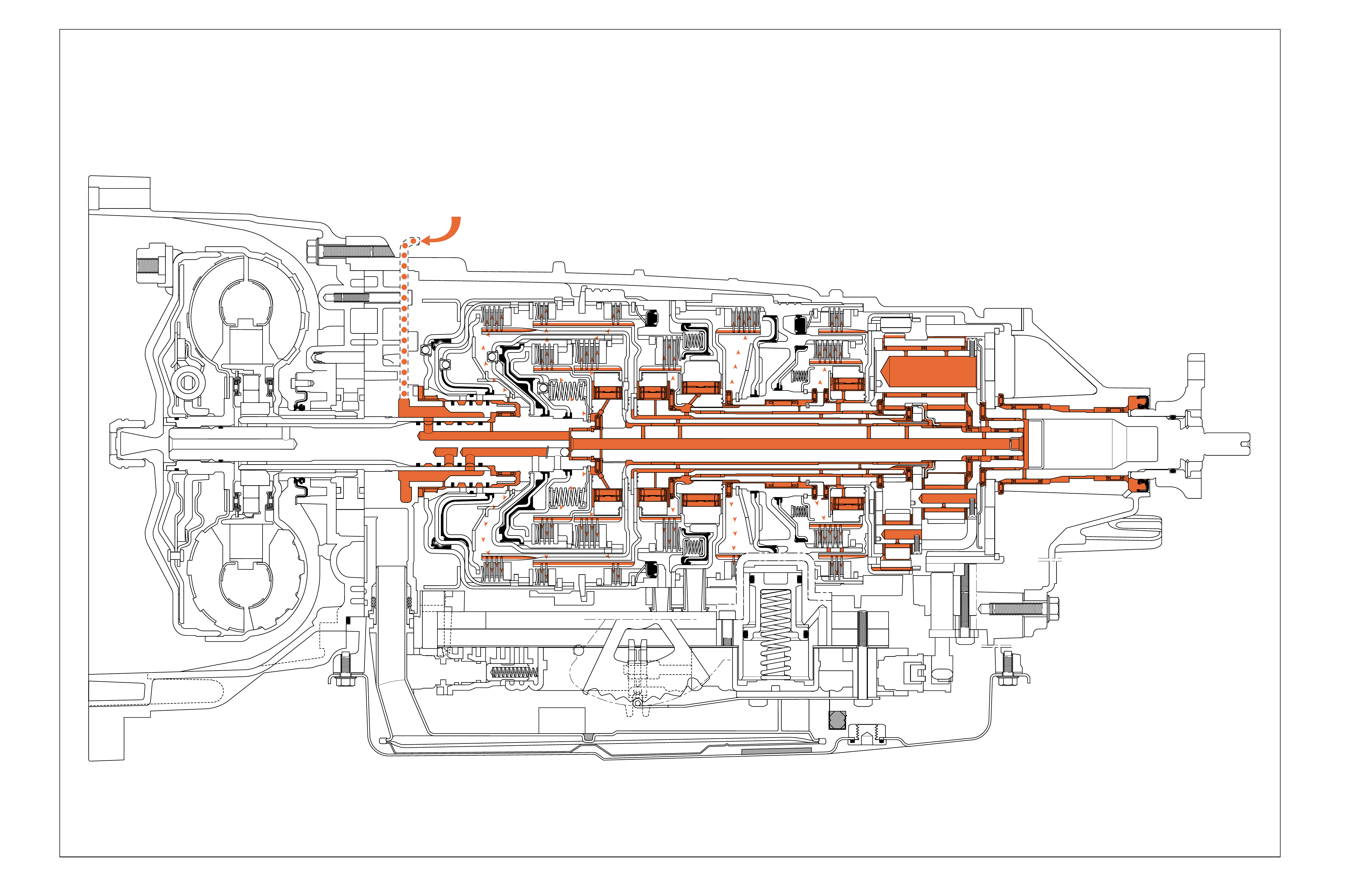

TRANSMISSION CUTAWAY VIEW (FOLDOUT) ....................................... 8

GENERAL DESCRIPTION ....................................................................... 9

PRINCIPLES OF OPERATION ............................................................... 9A

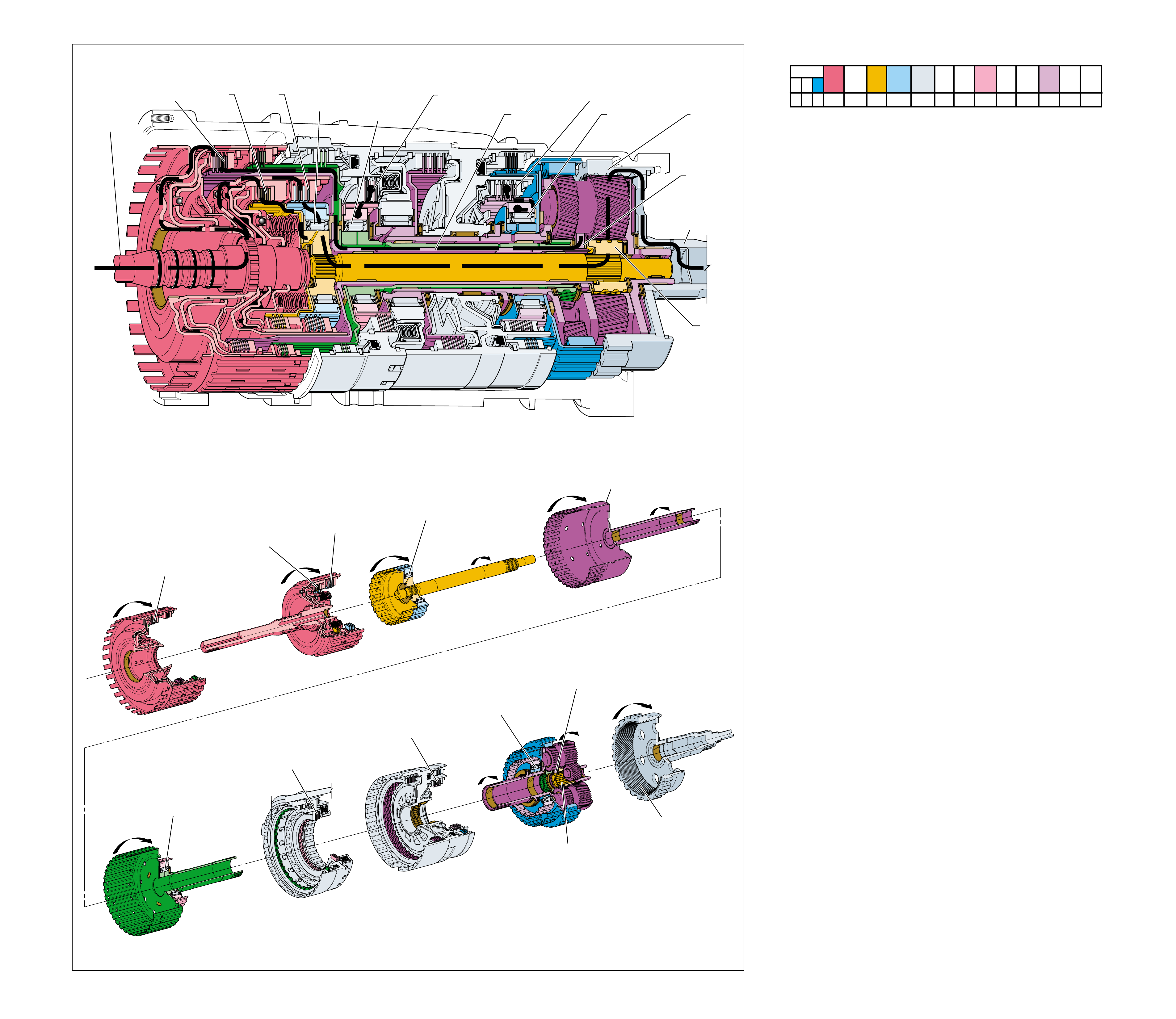

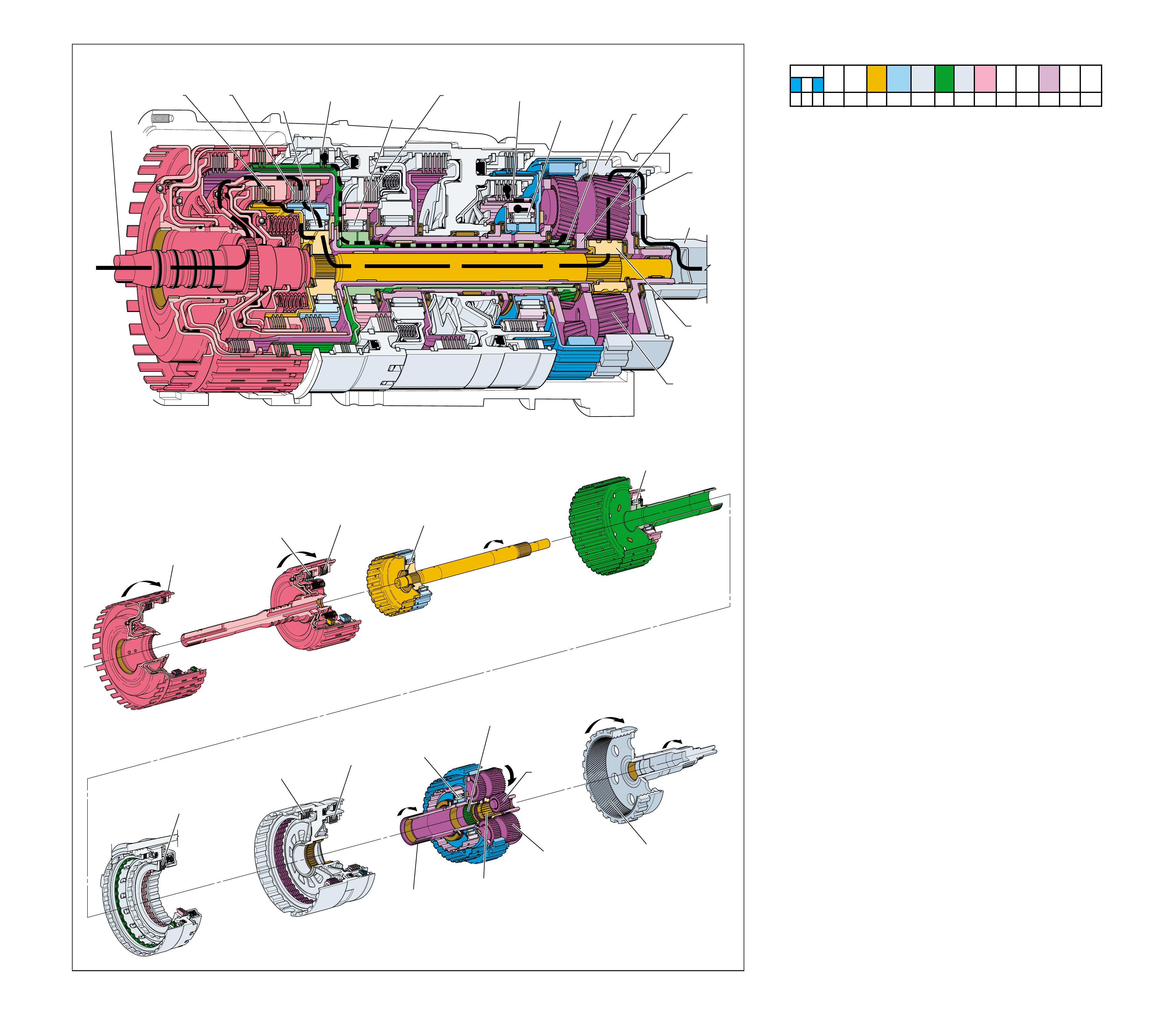

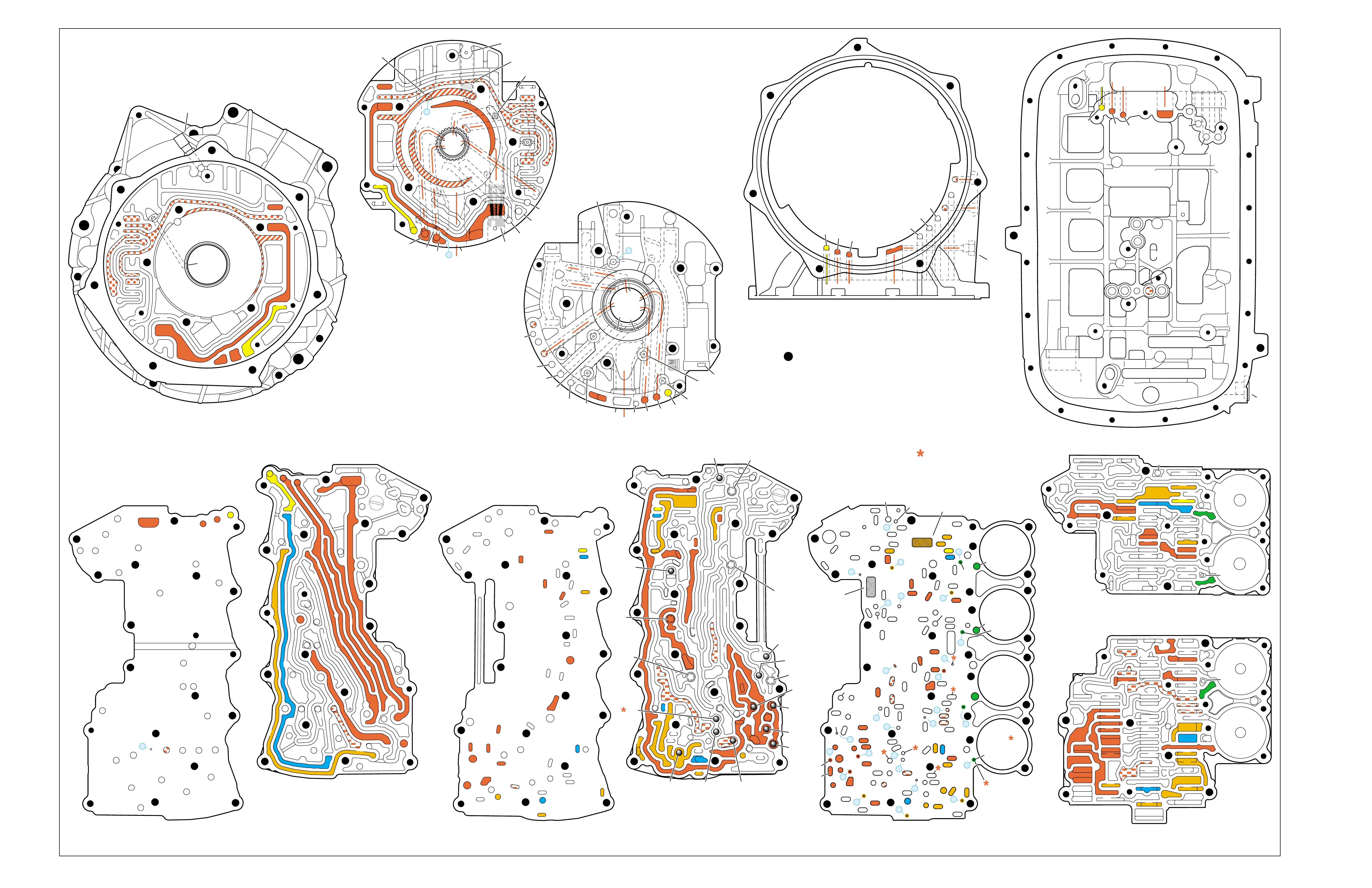

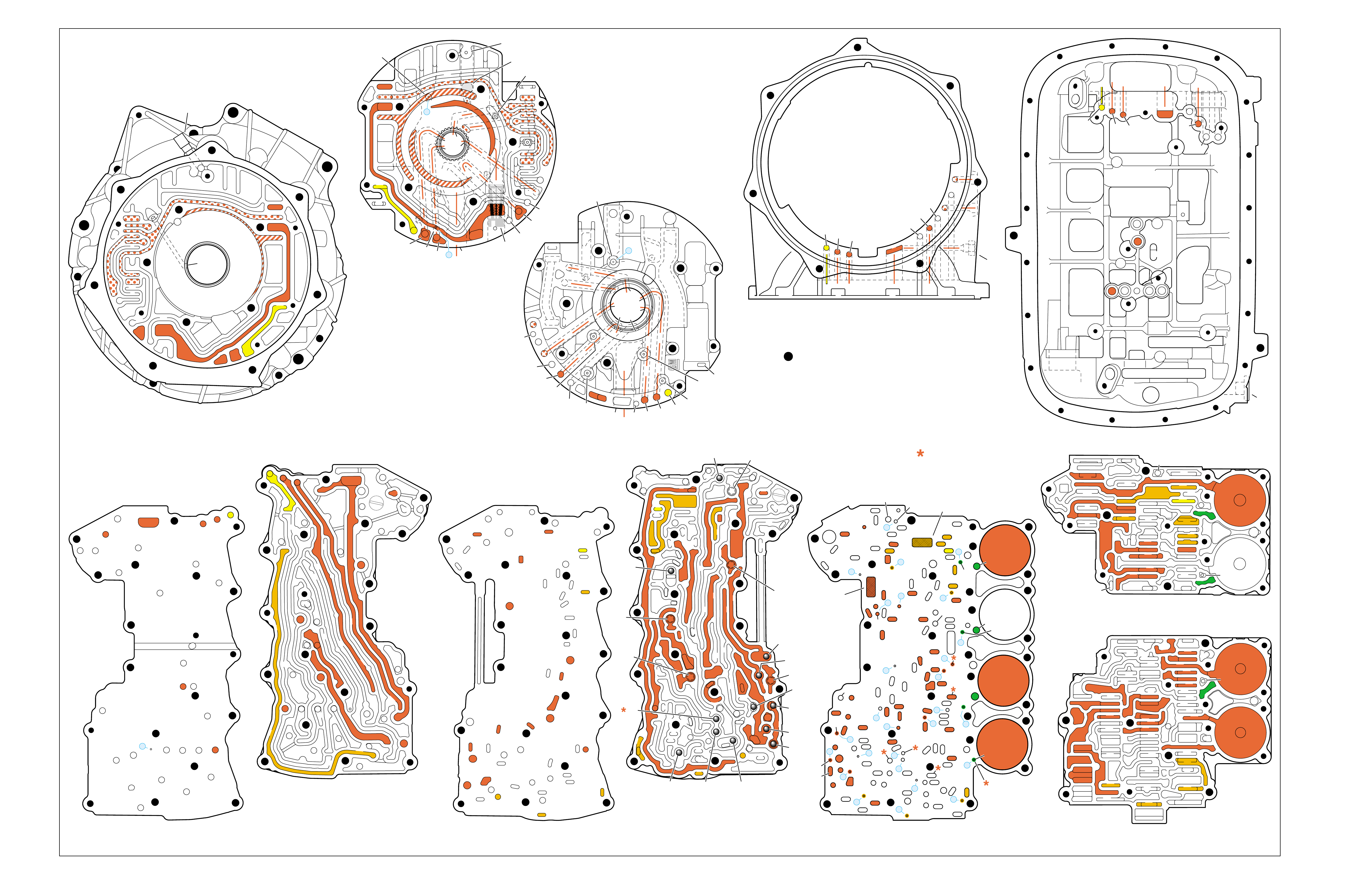

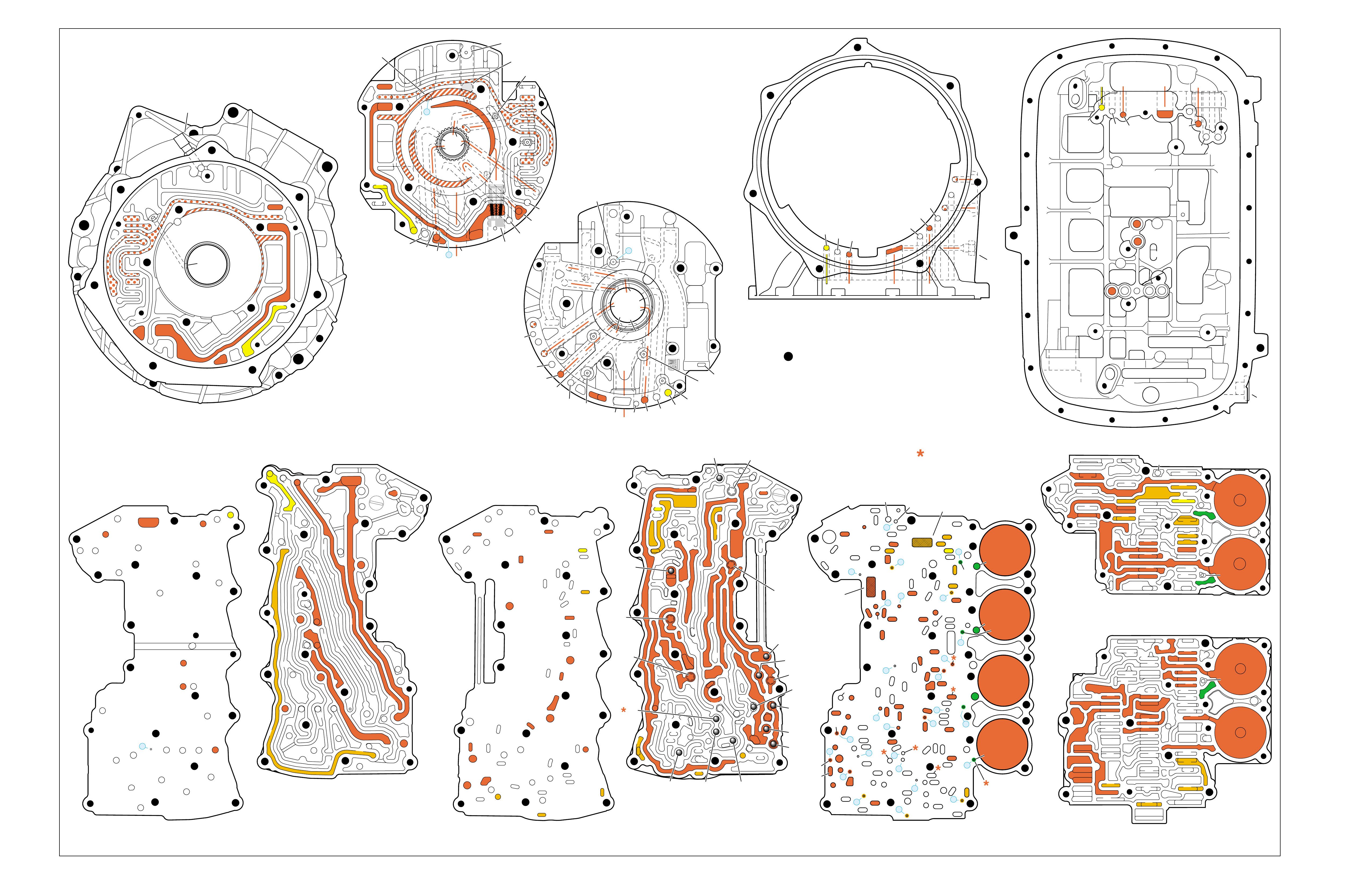

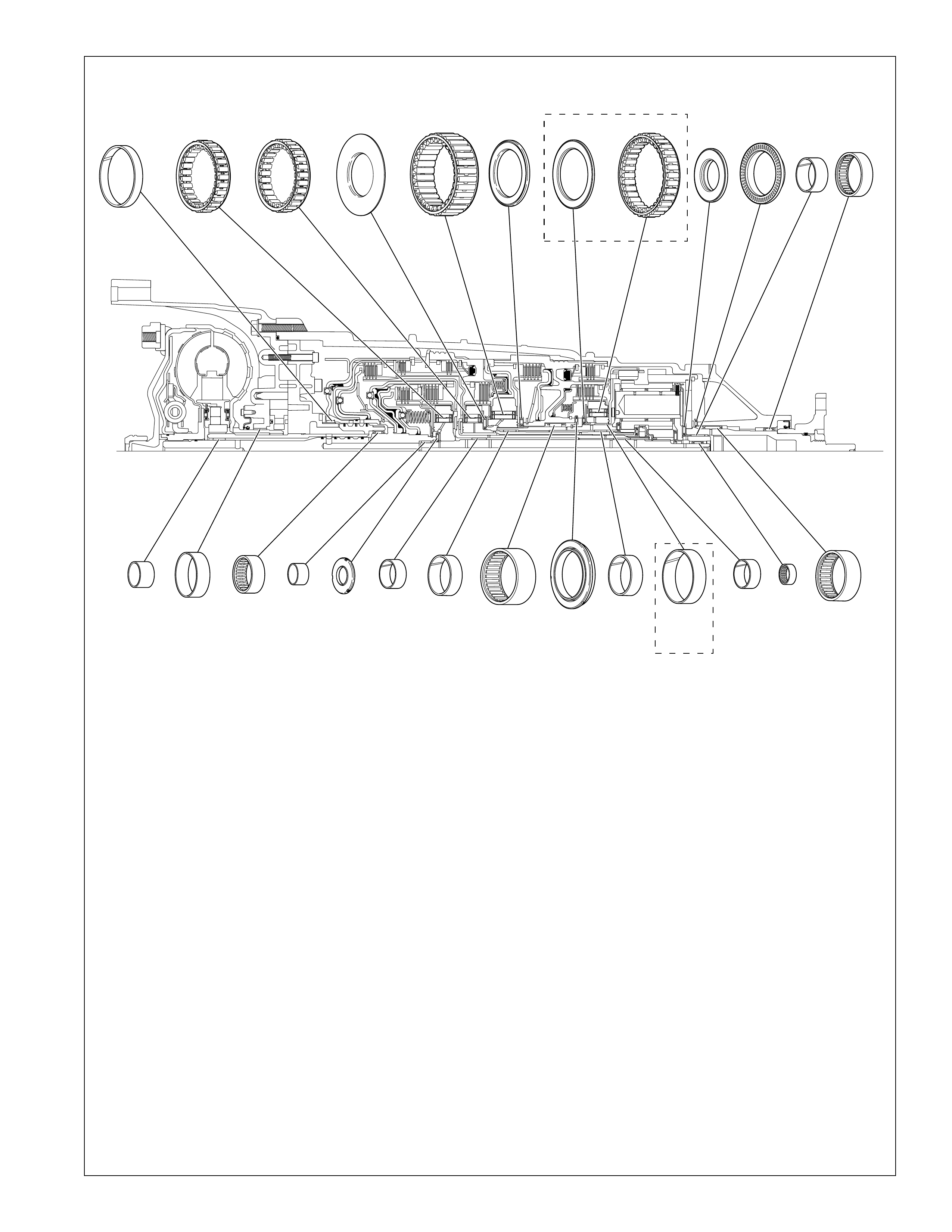

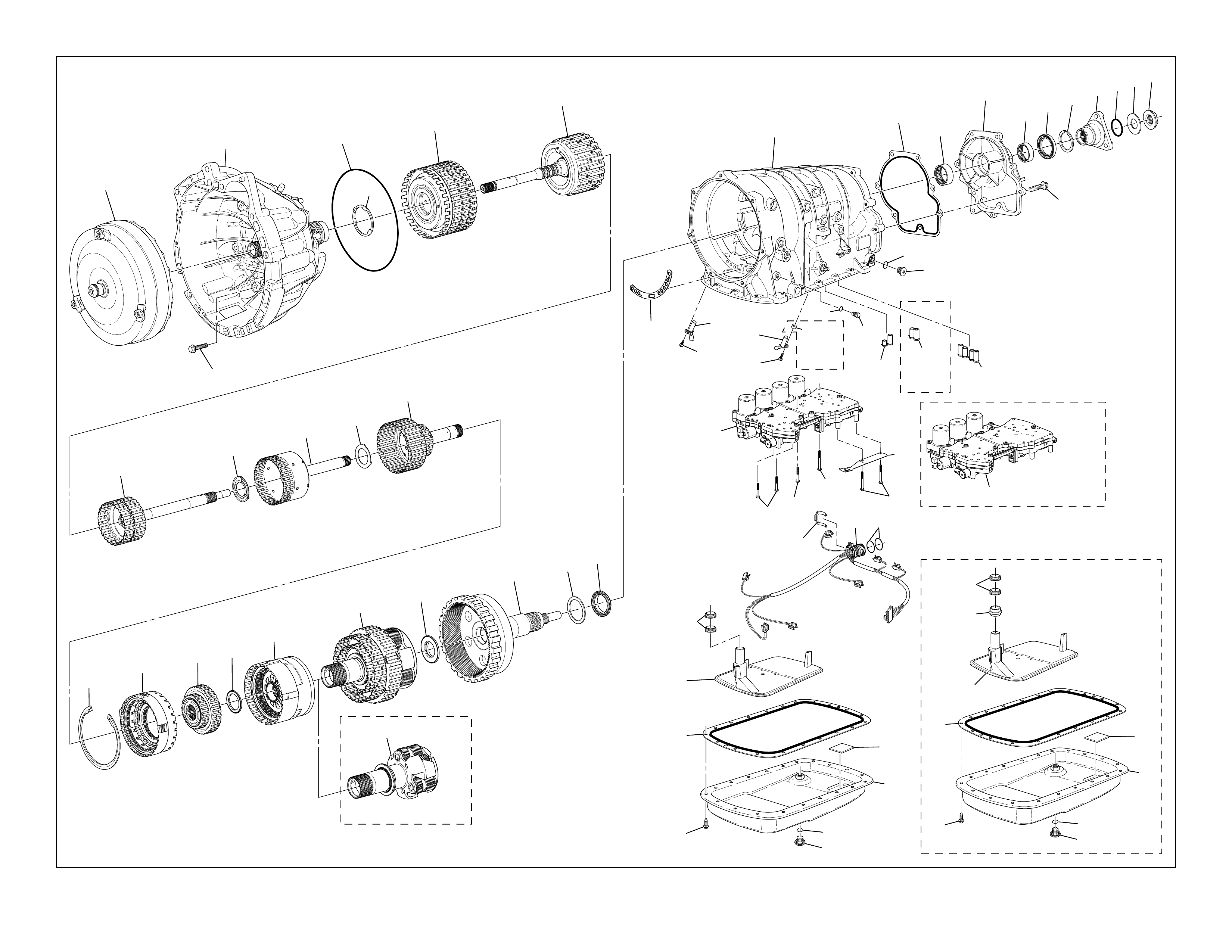

MAJOR MECHANICAL COMPONENTS (FOLDOUT) ...................... 10

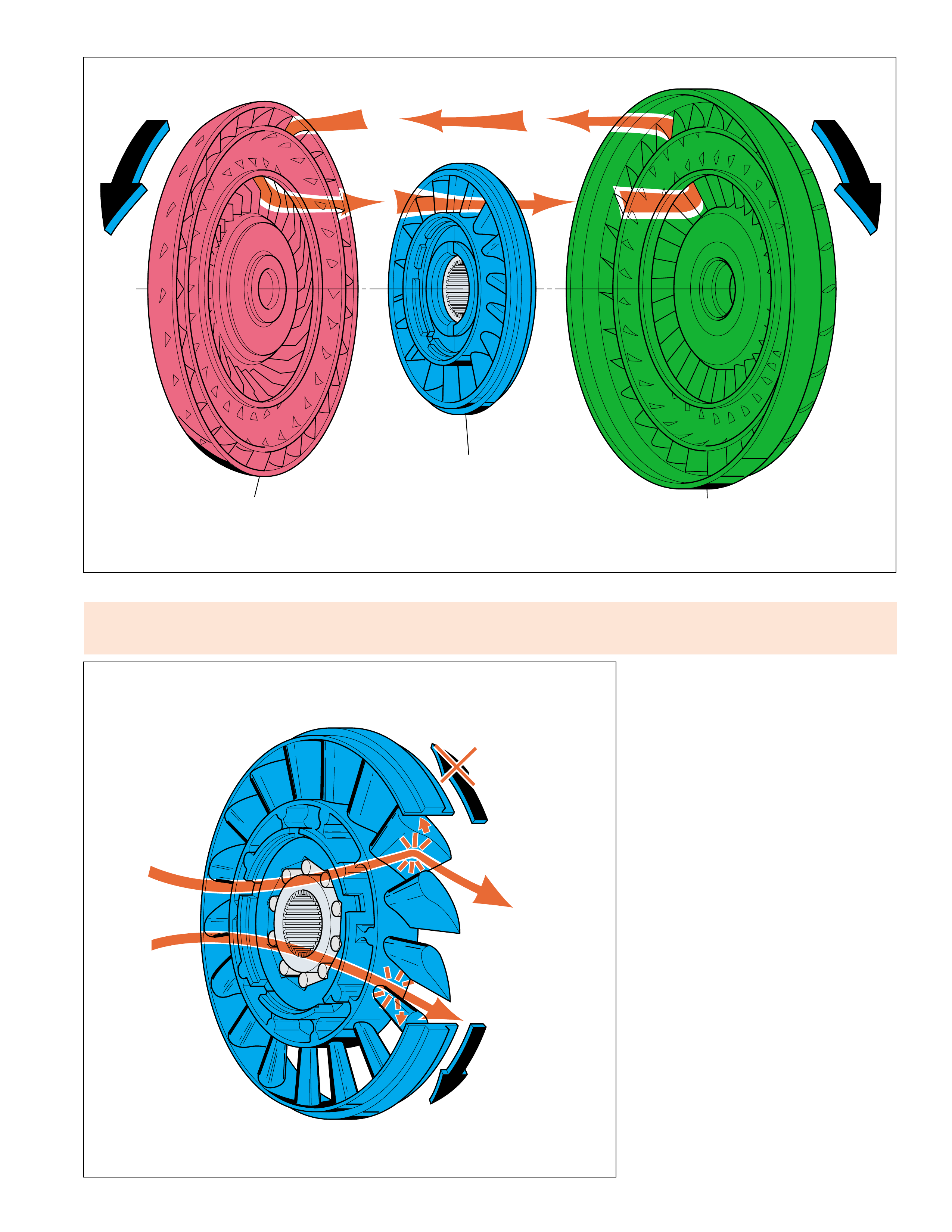

RANGE REFERENCE CHART ......................................................... 11

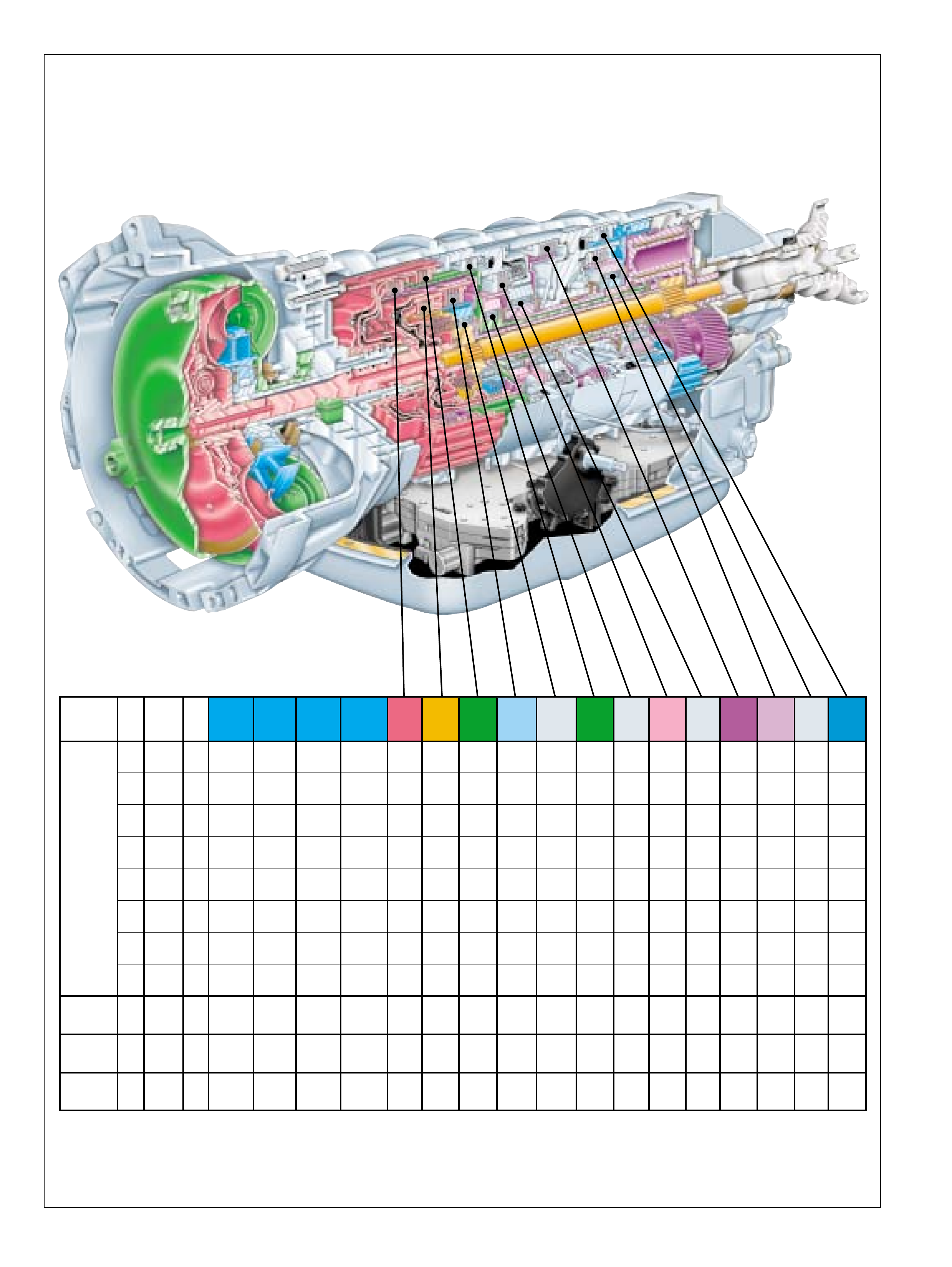

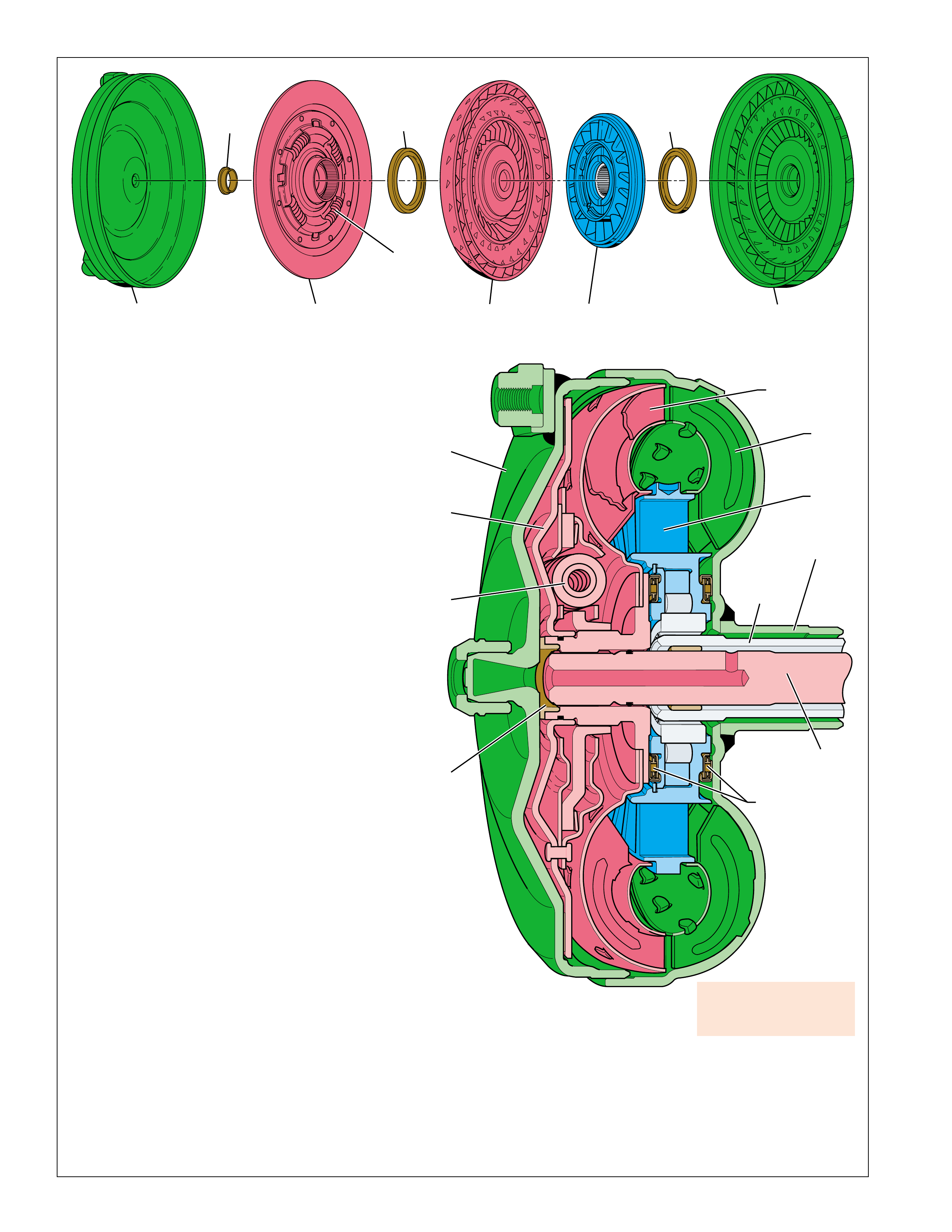

TORQUE CONVERTER .................................................................. 12

APPLY COMPONENTS ................................................................. 15

PLANETARY GEAR SETS ............................................................. 29

HYDRAULIC CONTROL COMPONENTS........................................ 32

ELECTRICAL COMPONENTS ........................................................ 45

POWER FLOW ...................................................................................... 53

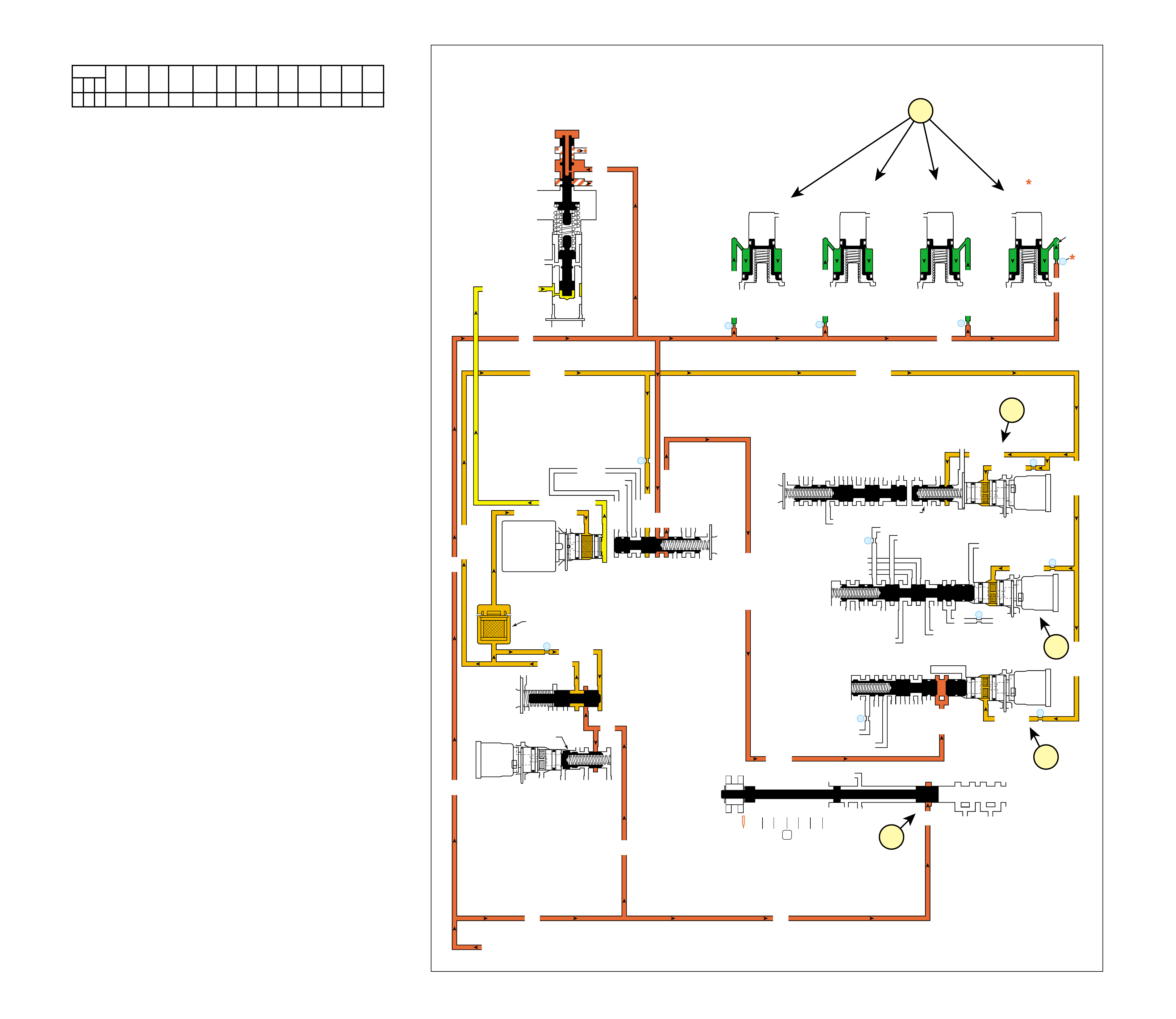

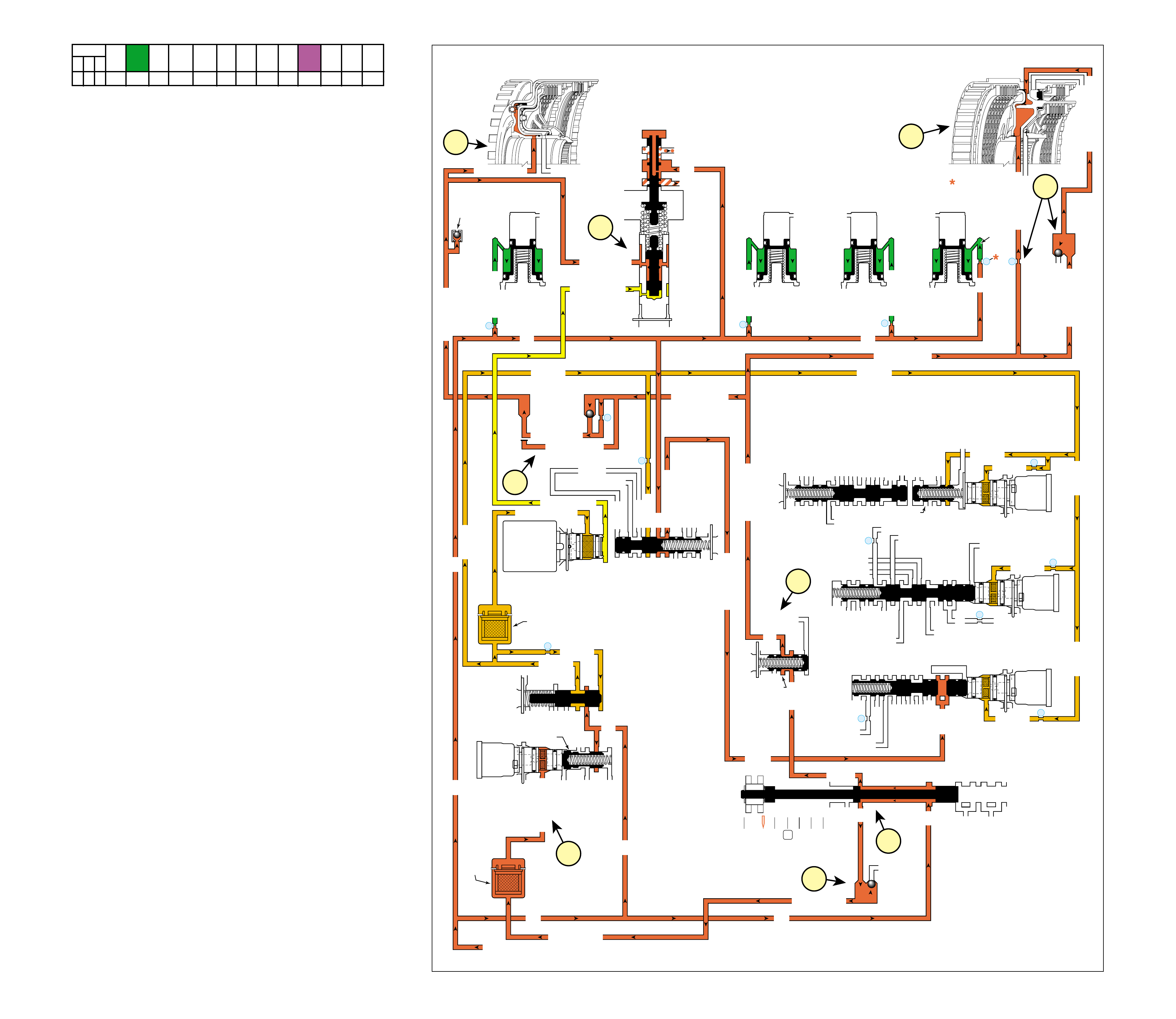

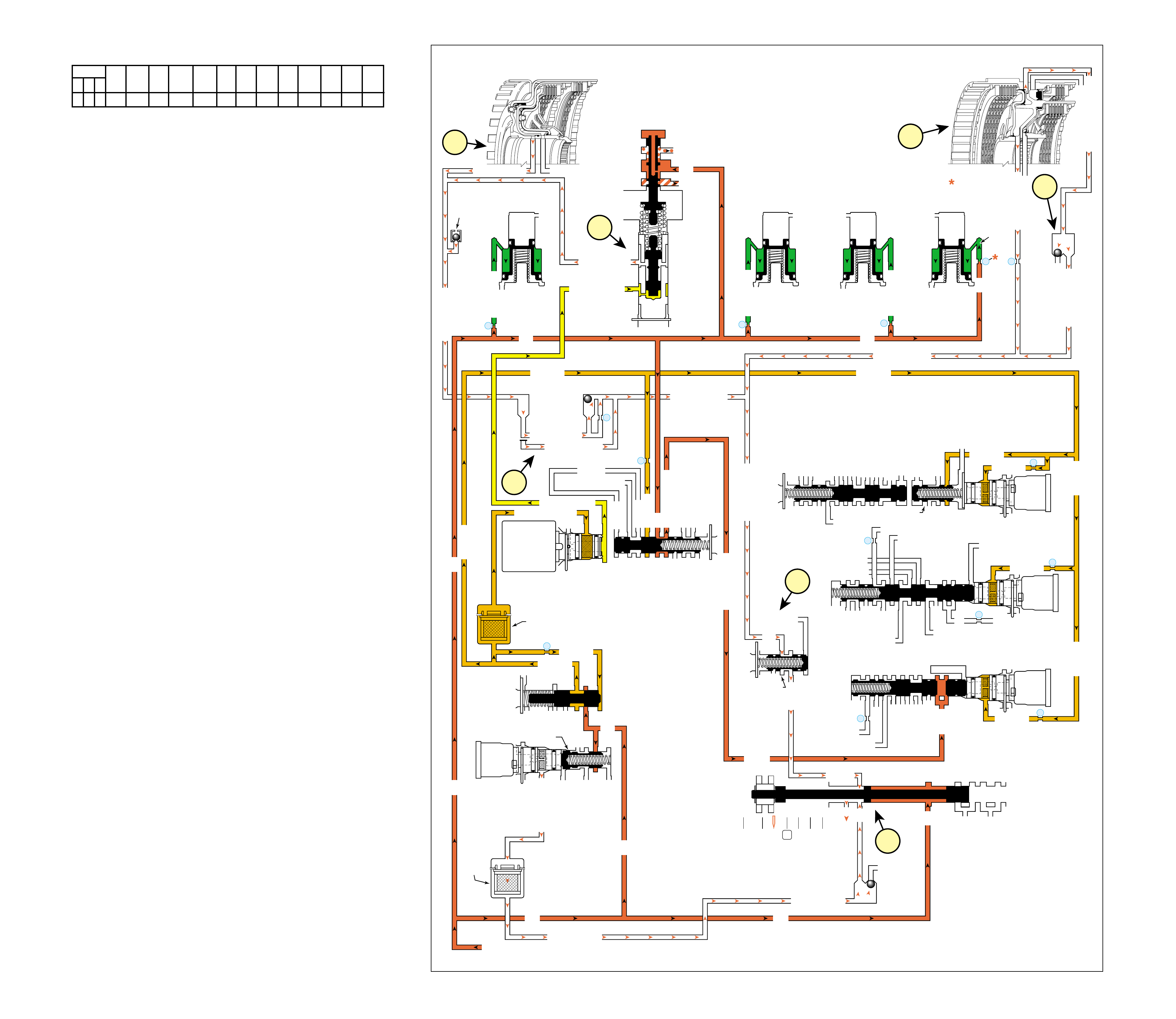

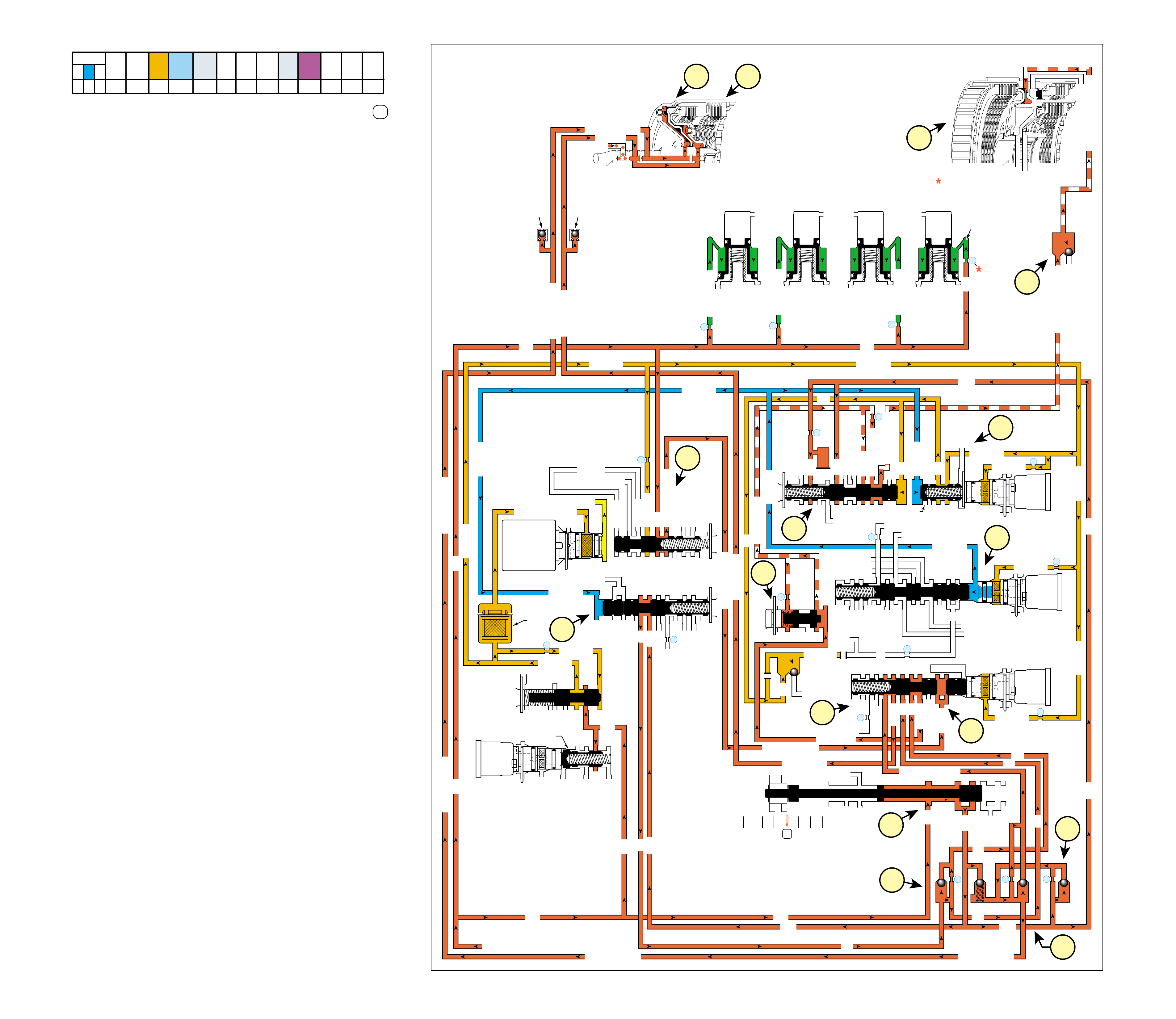

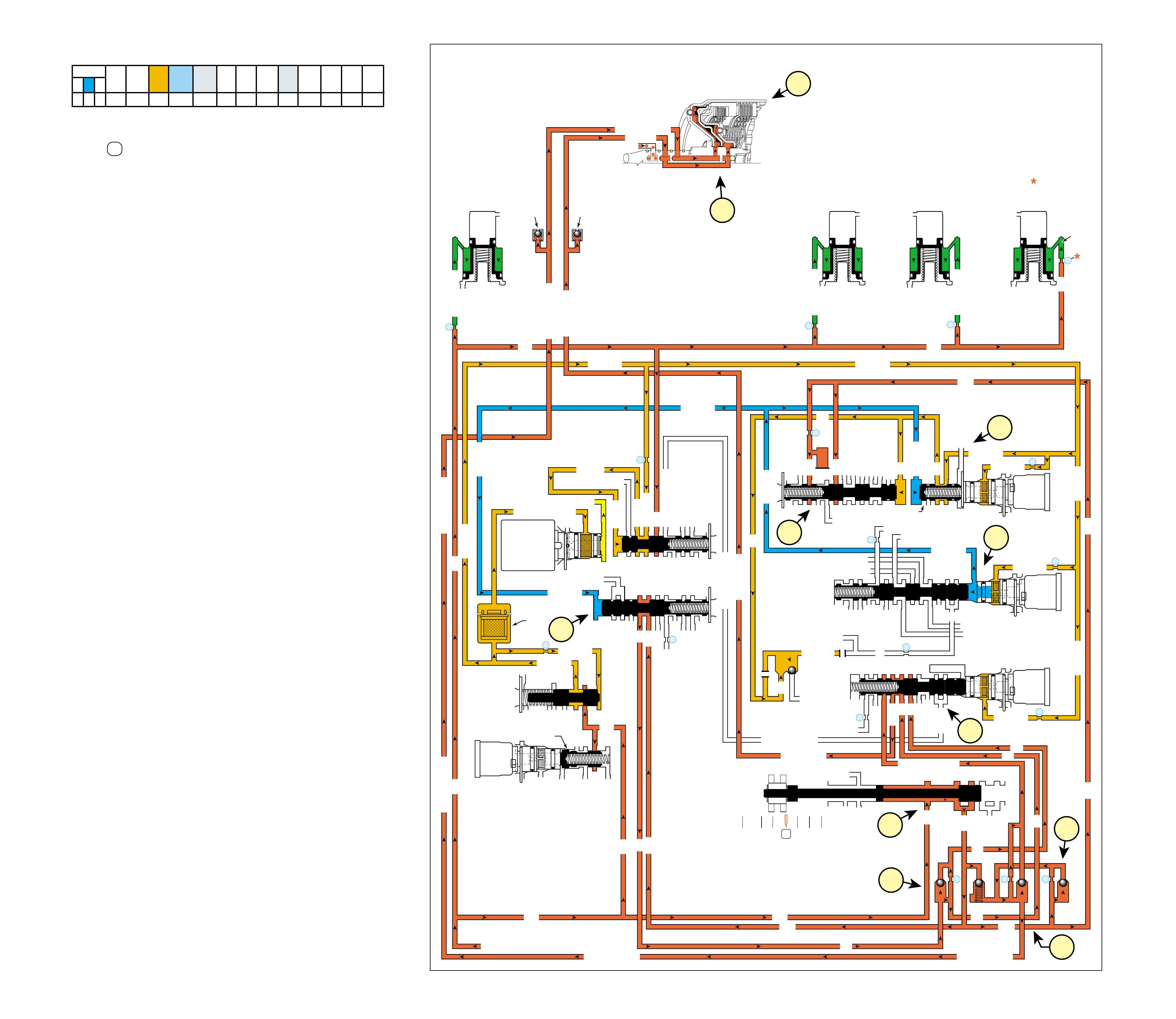

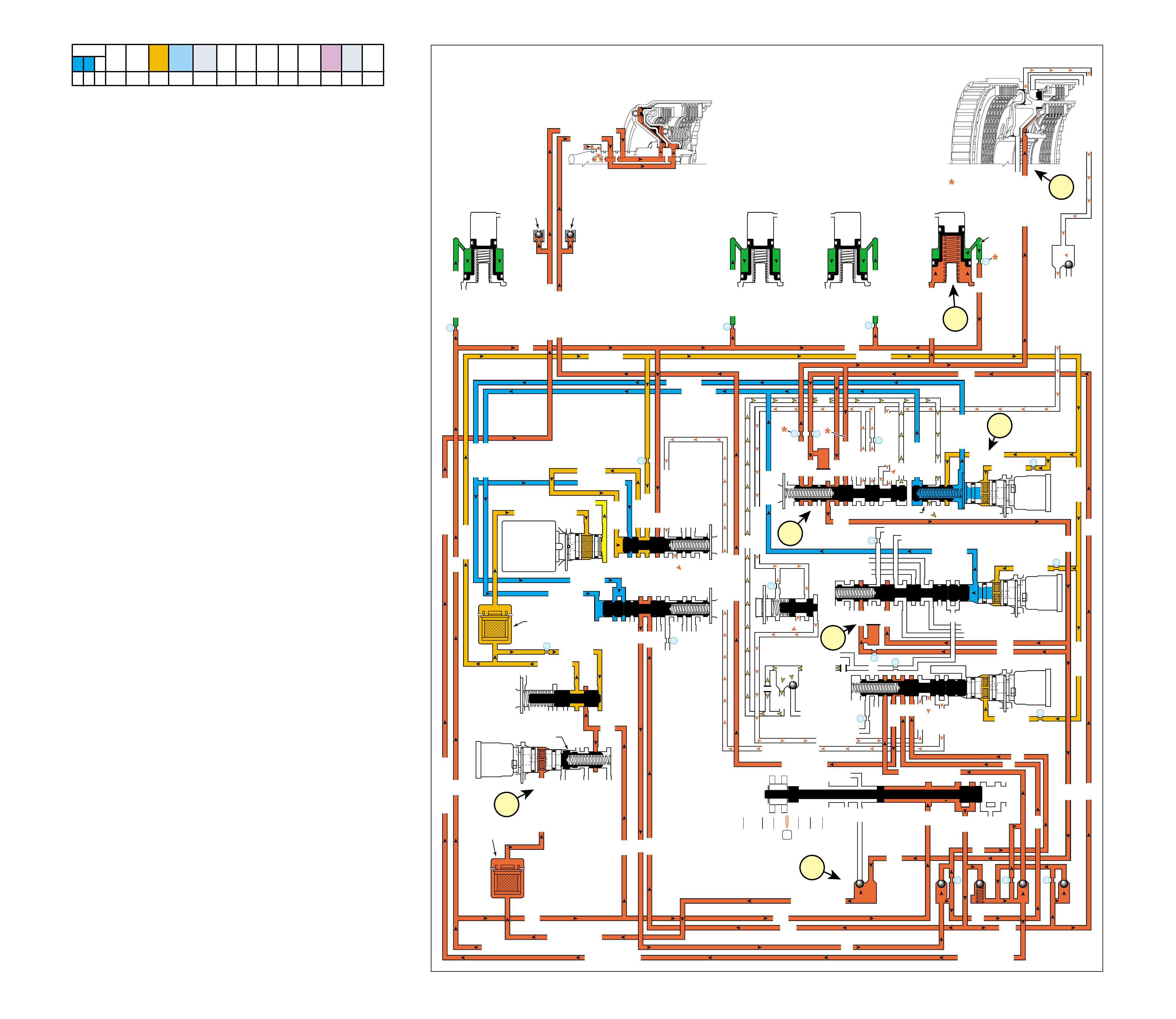

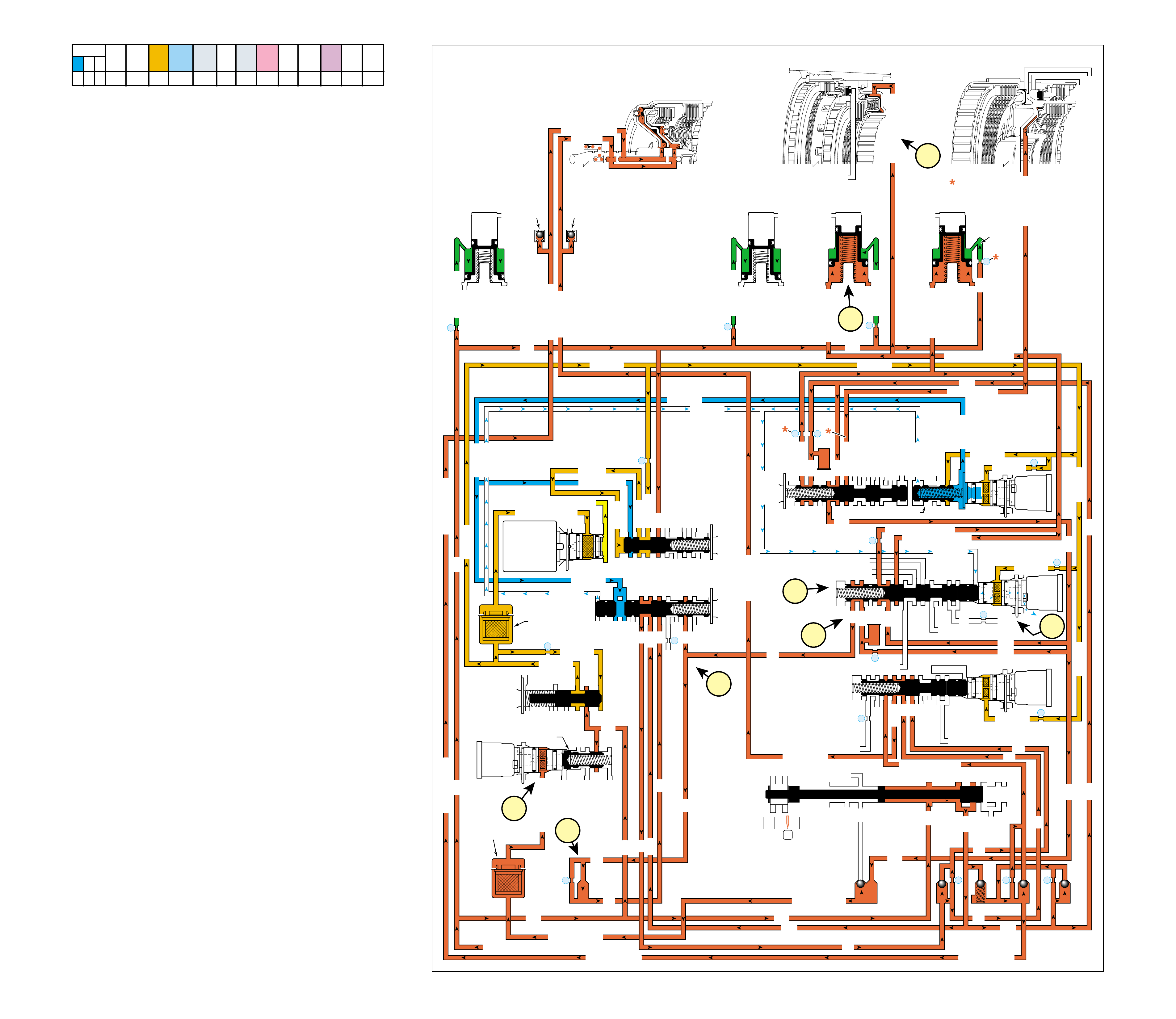

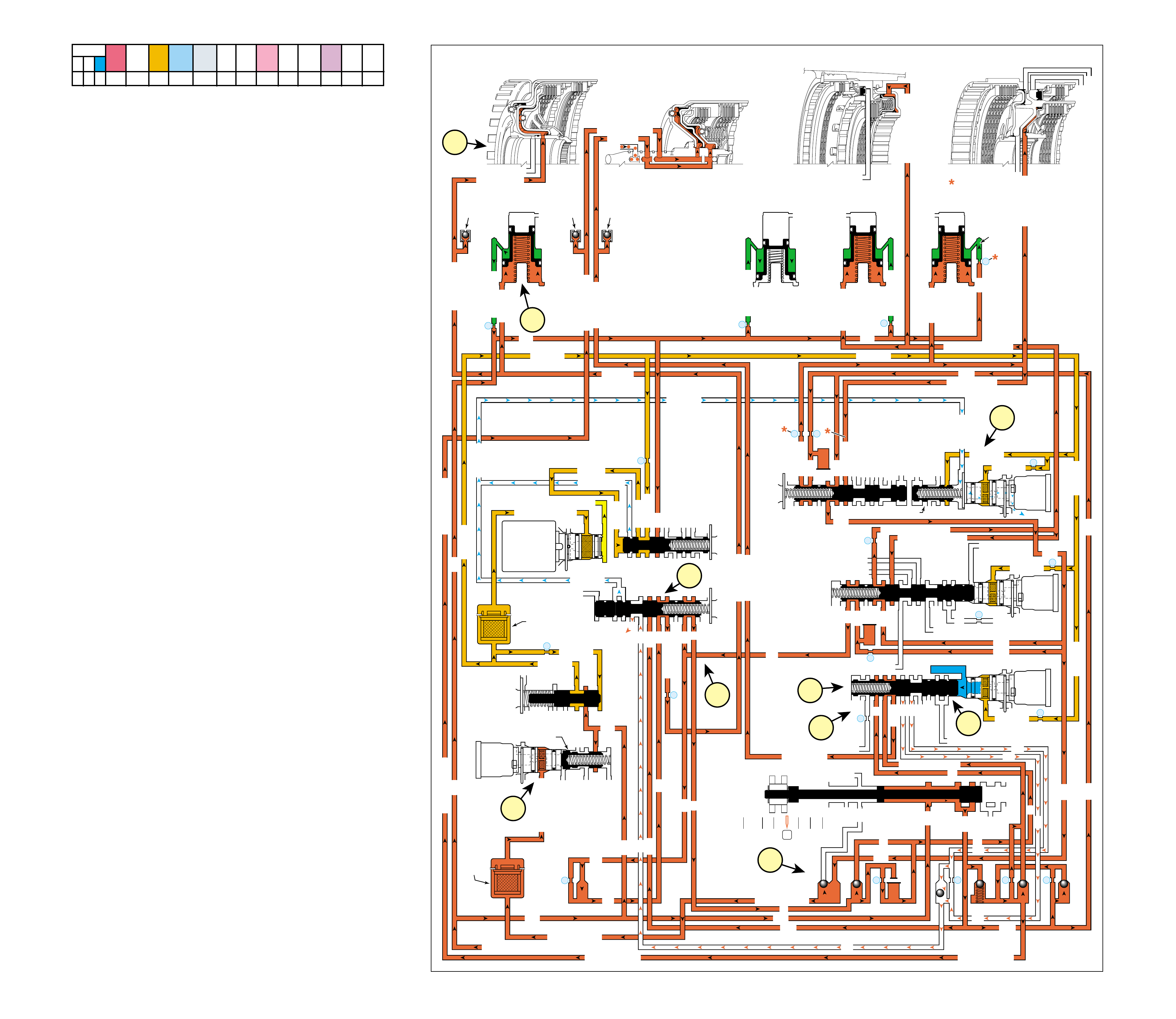

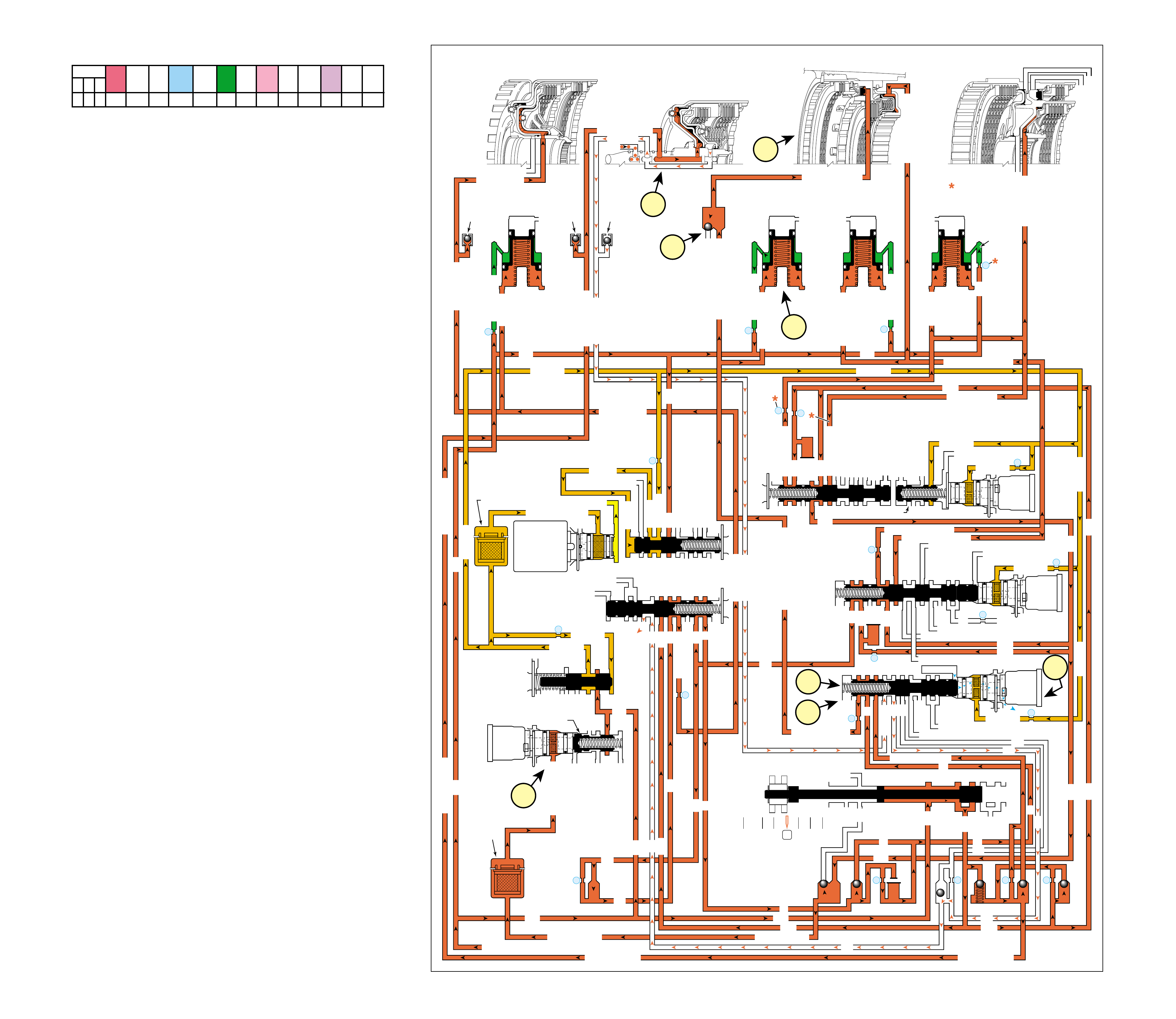

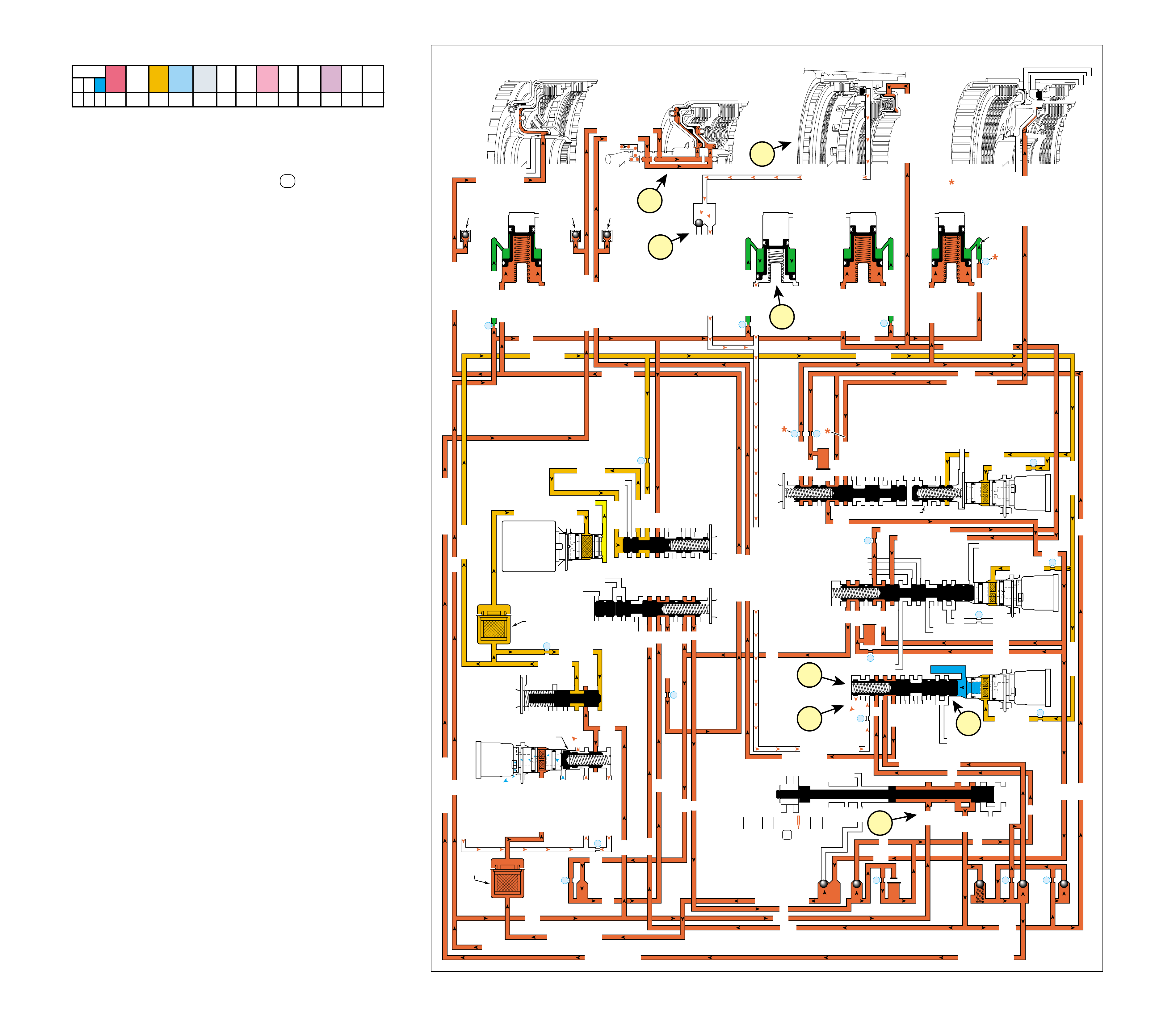

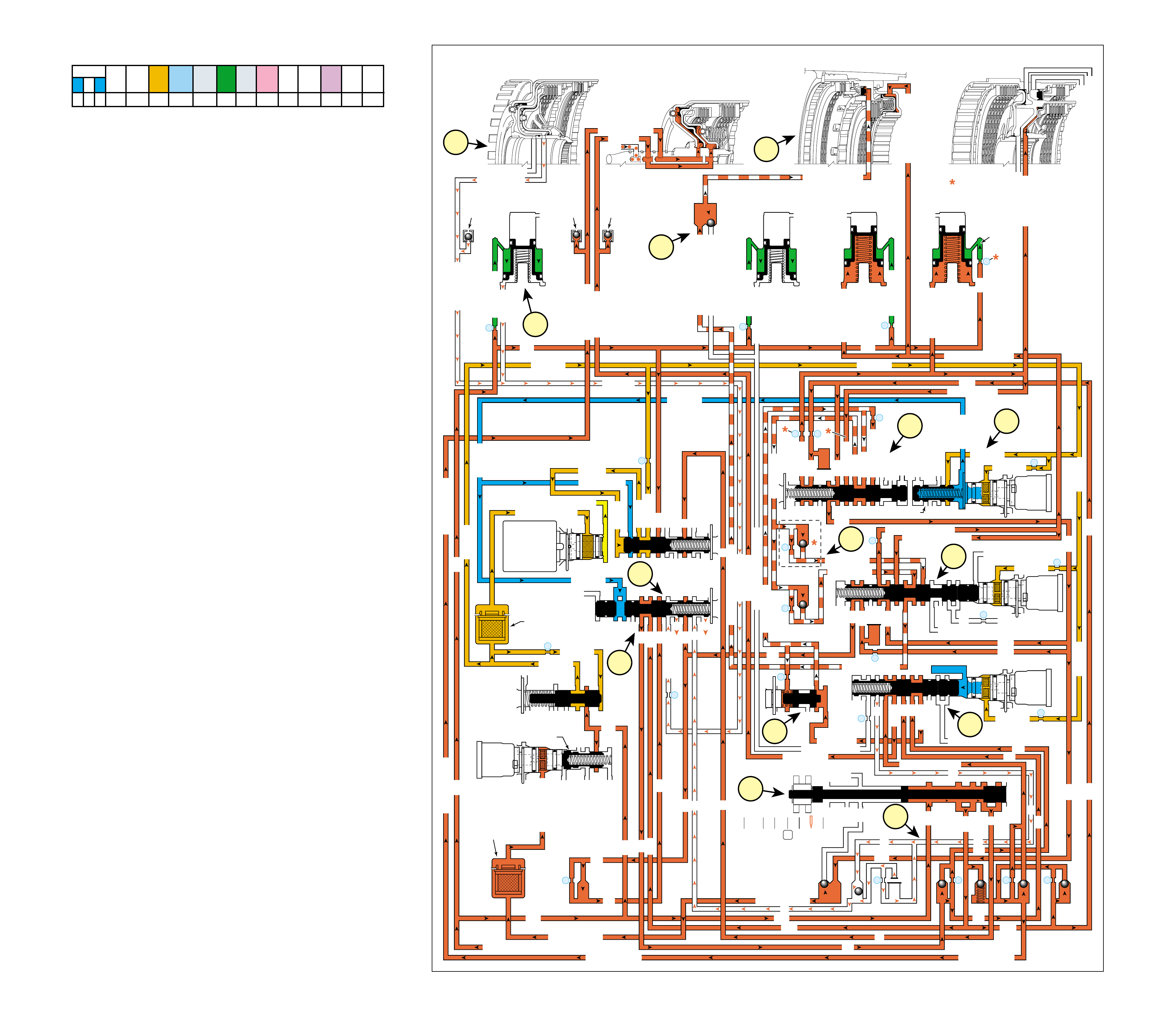

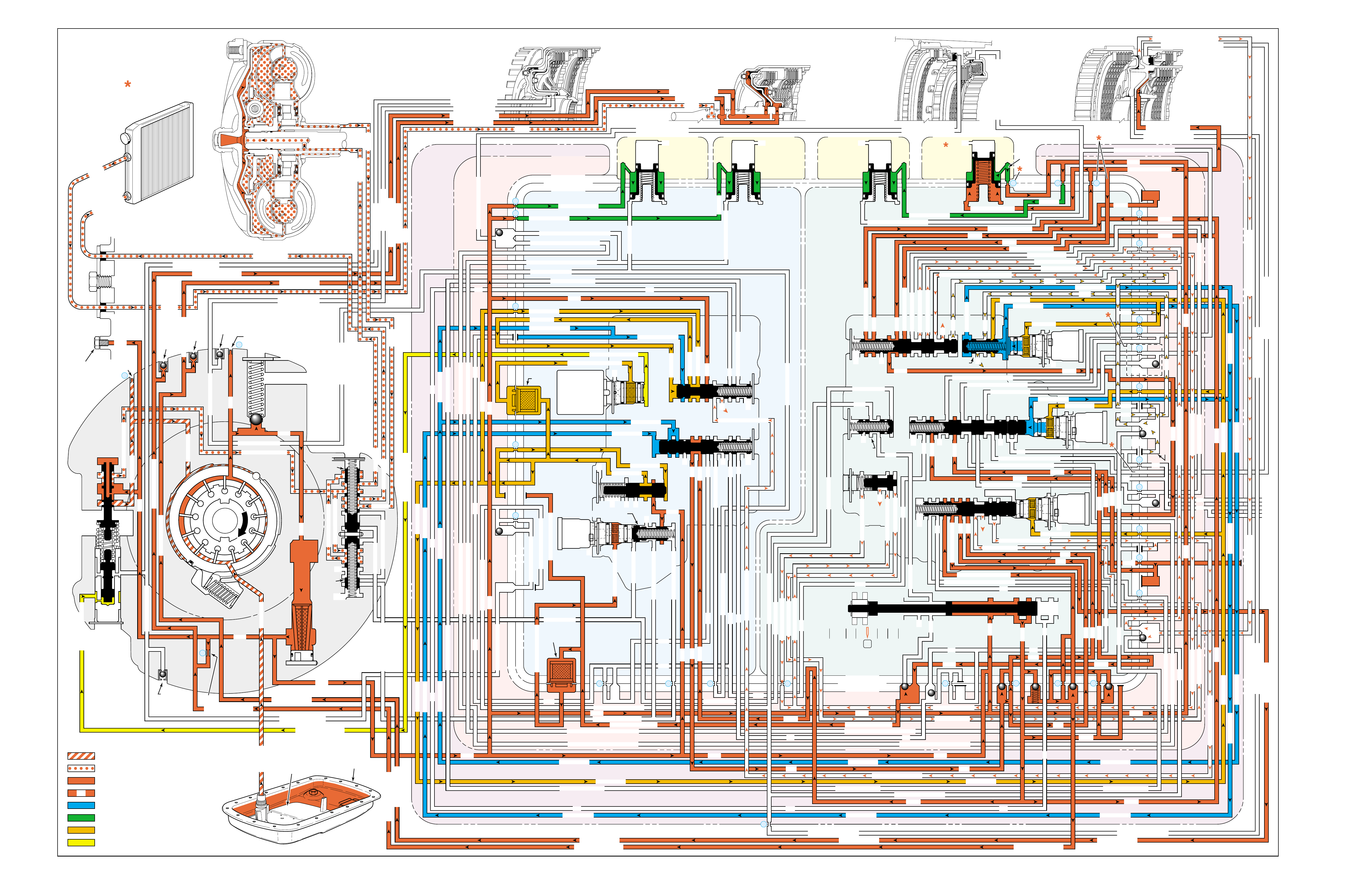

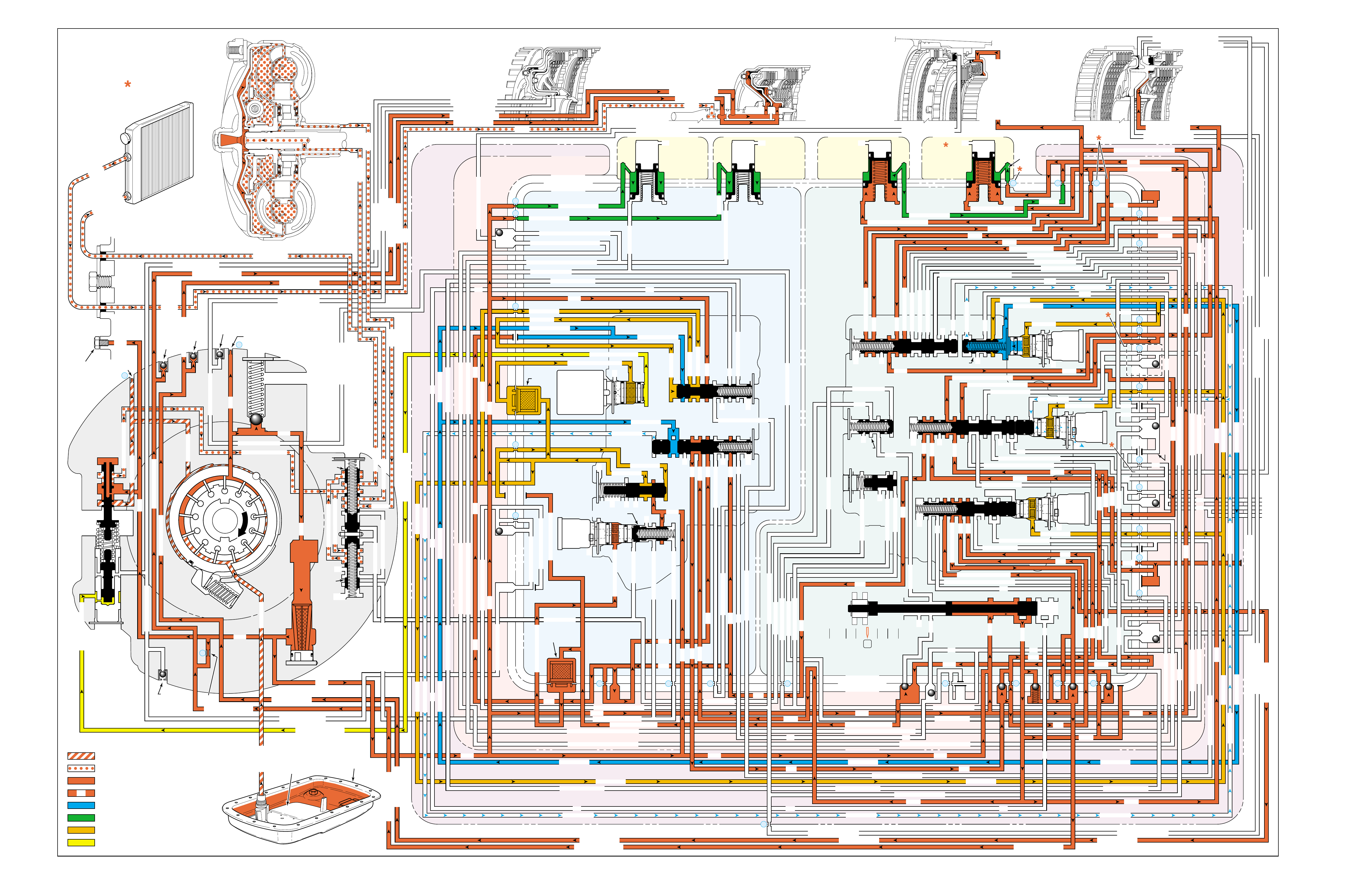

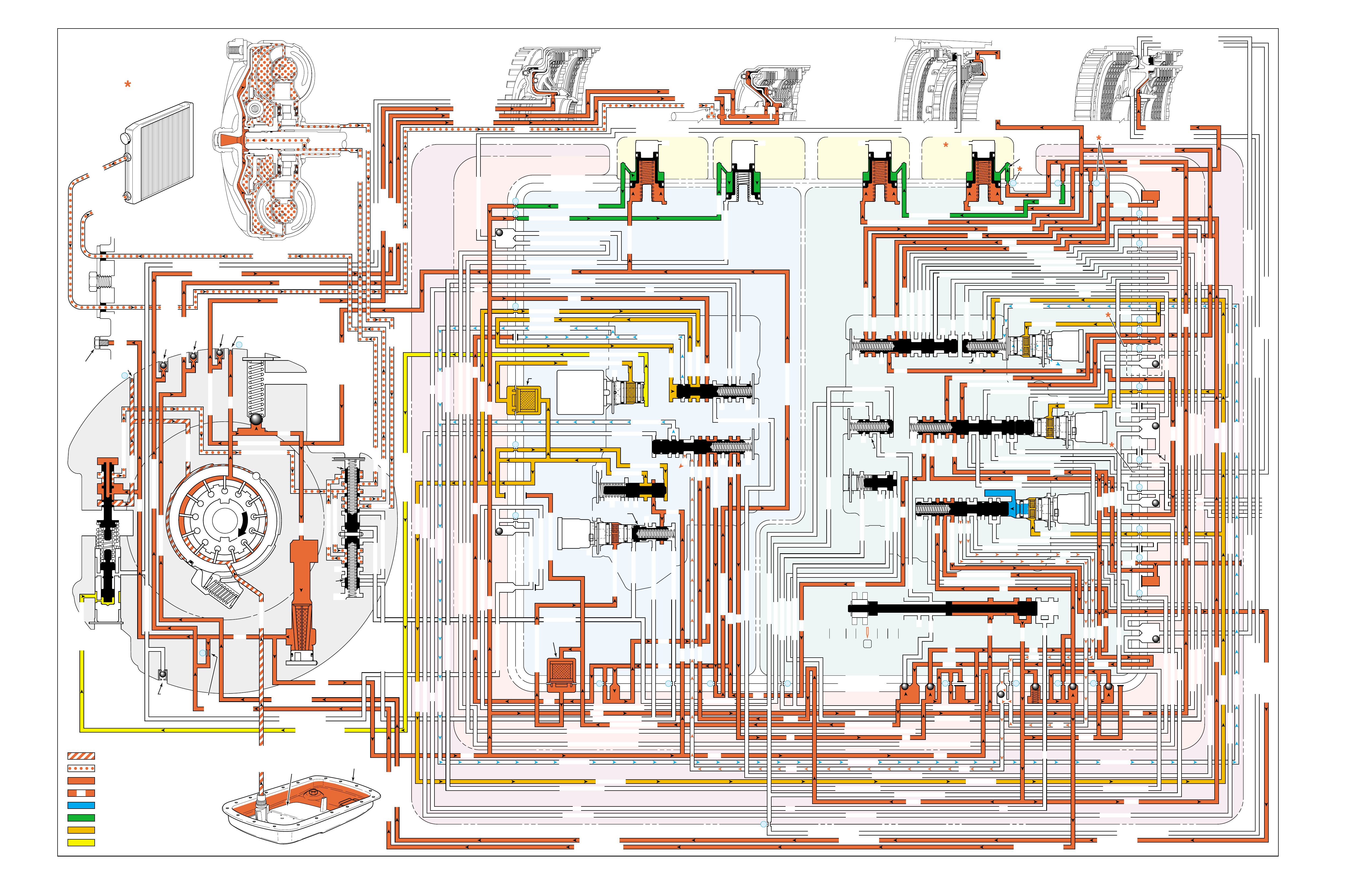

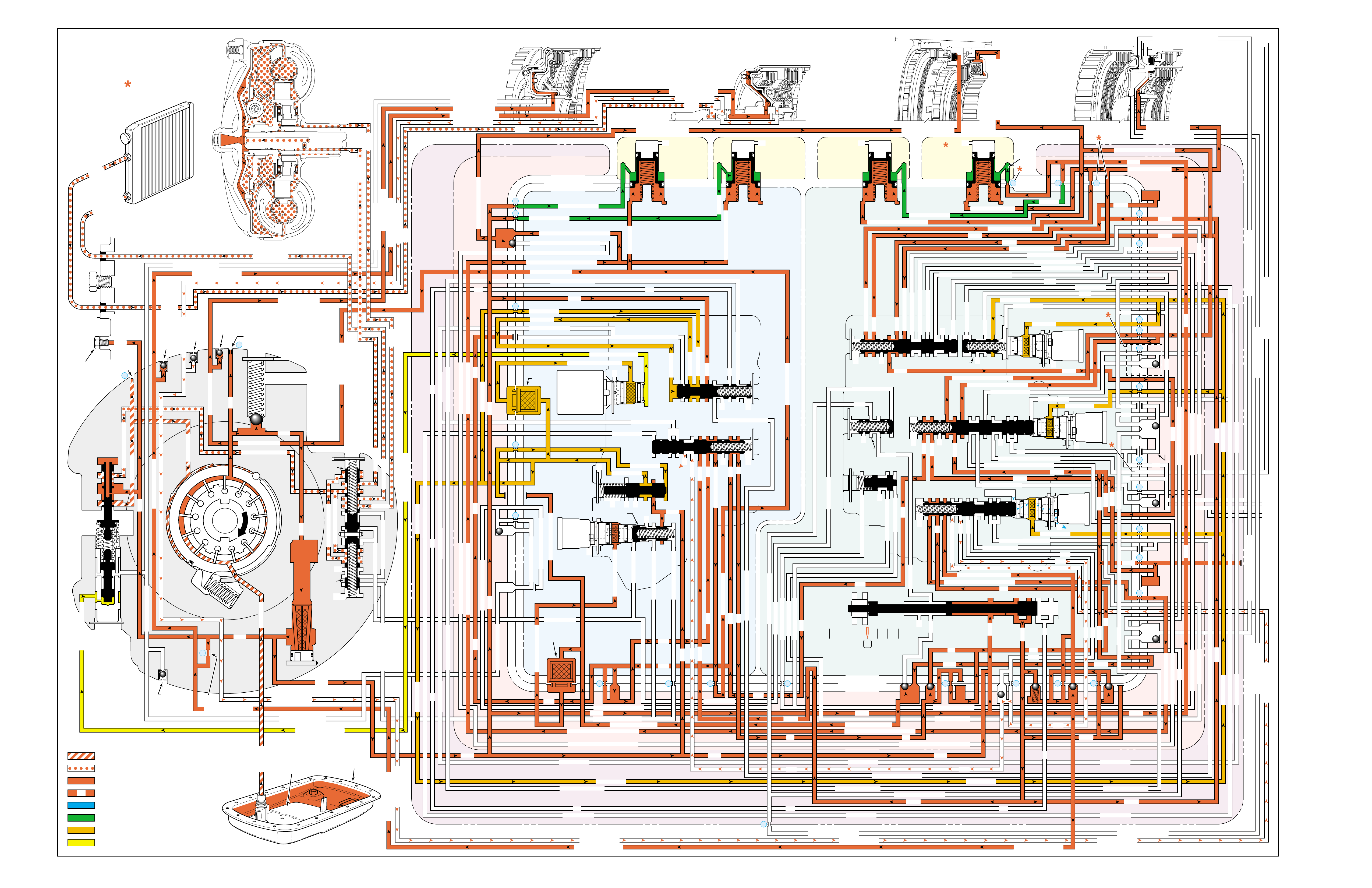

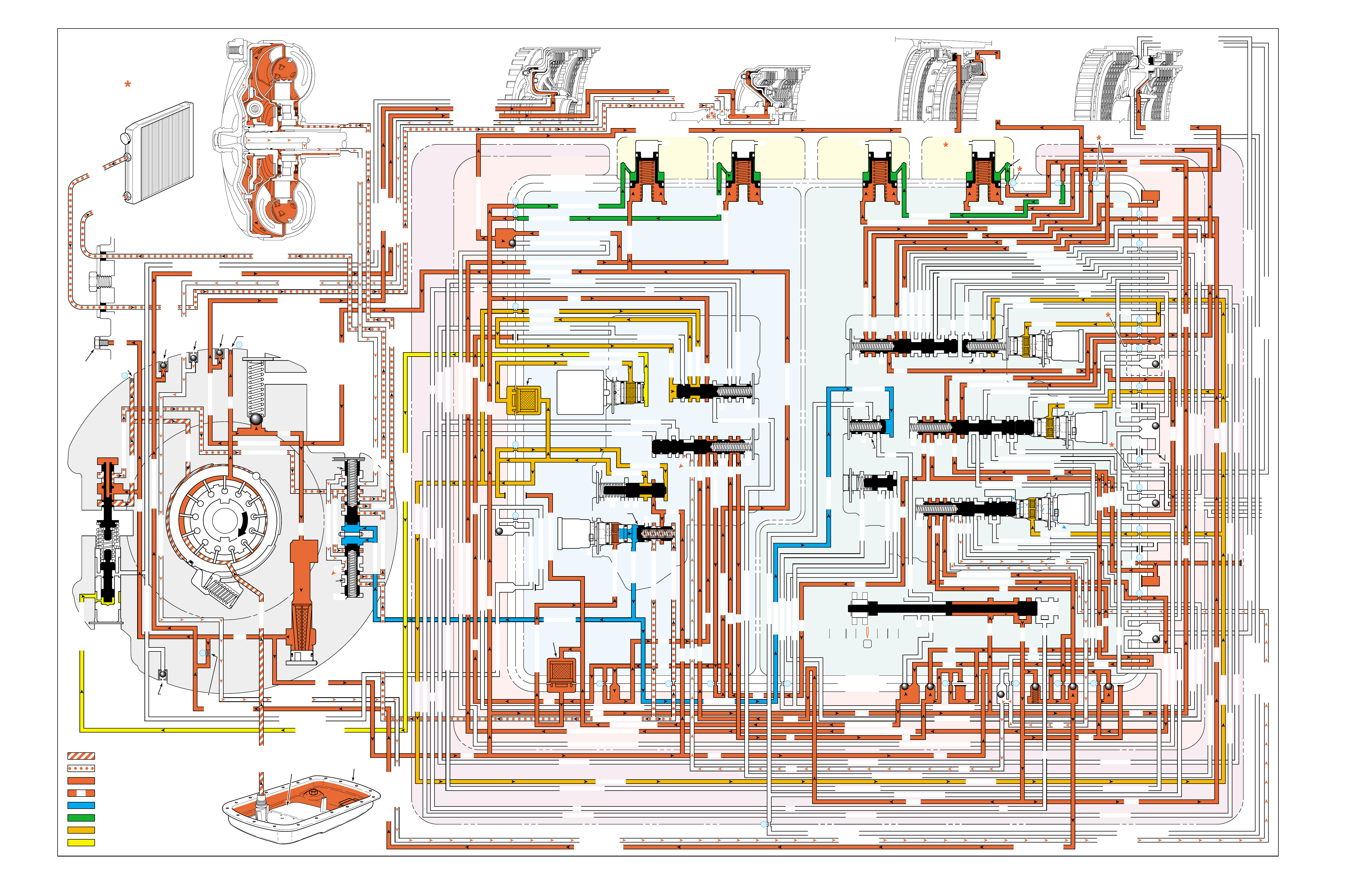

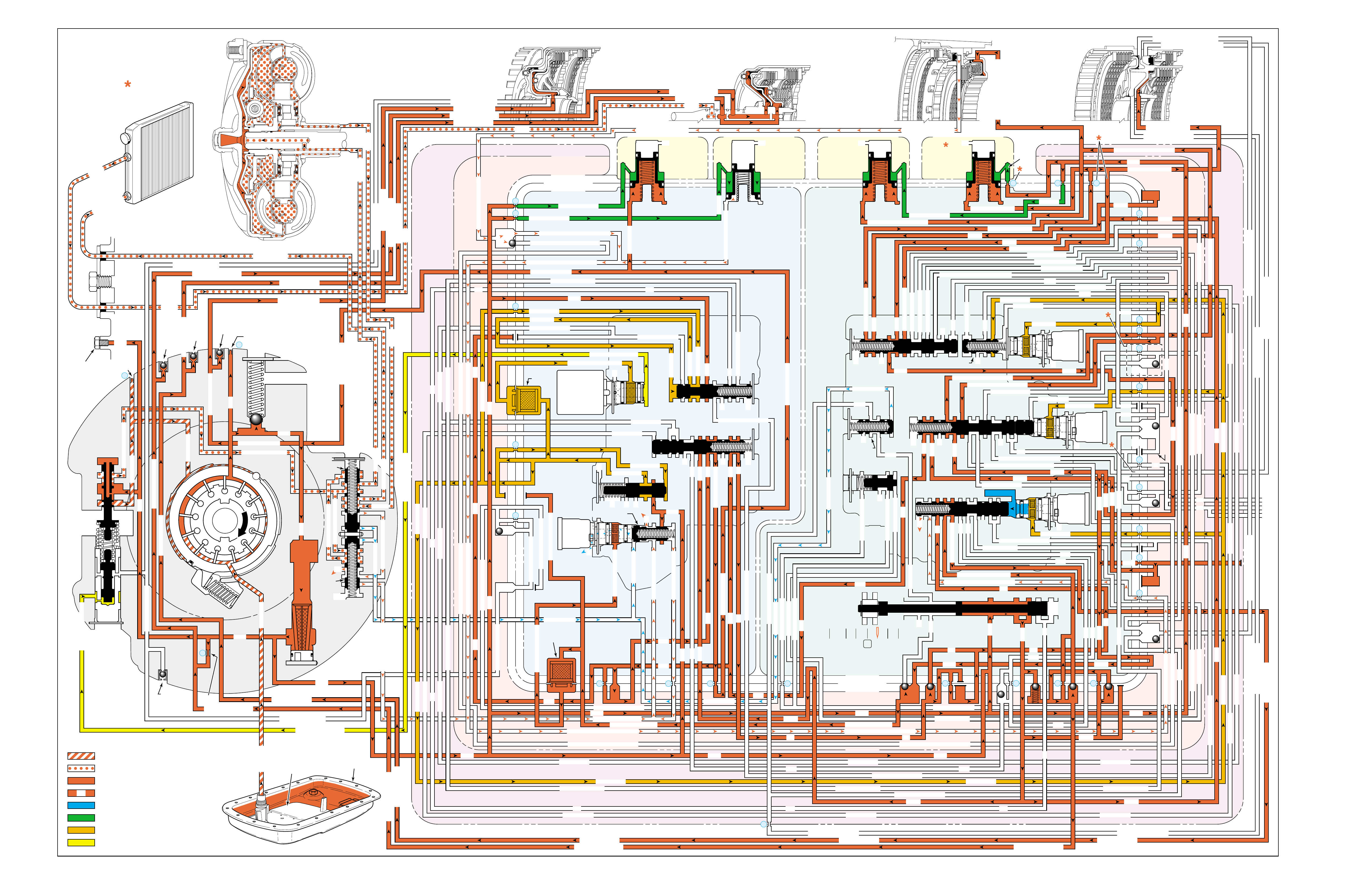

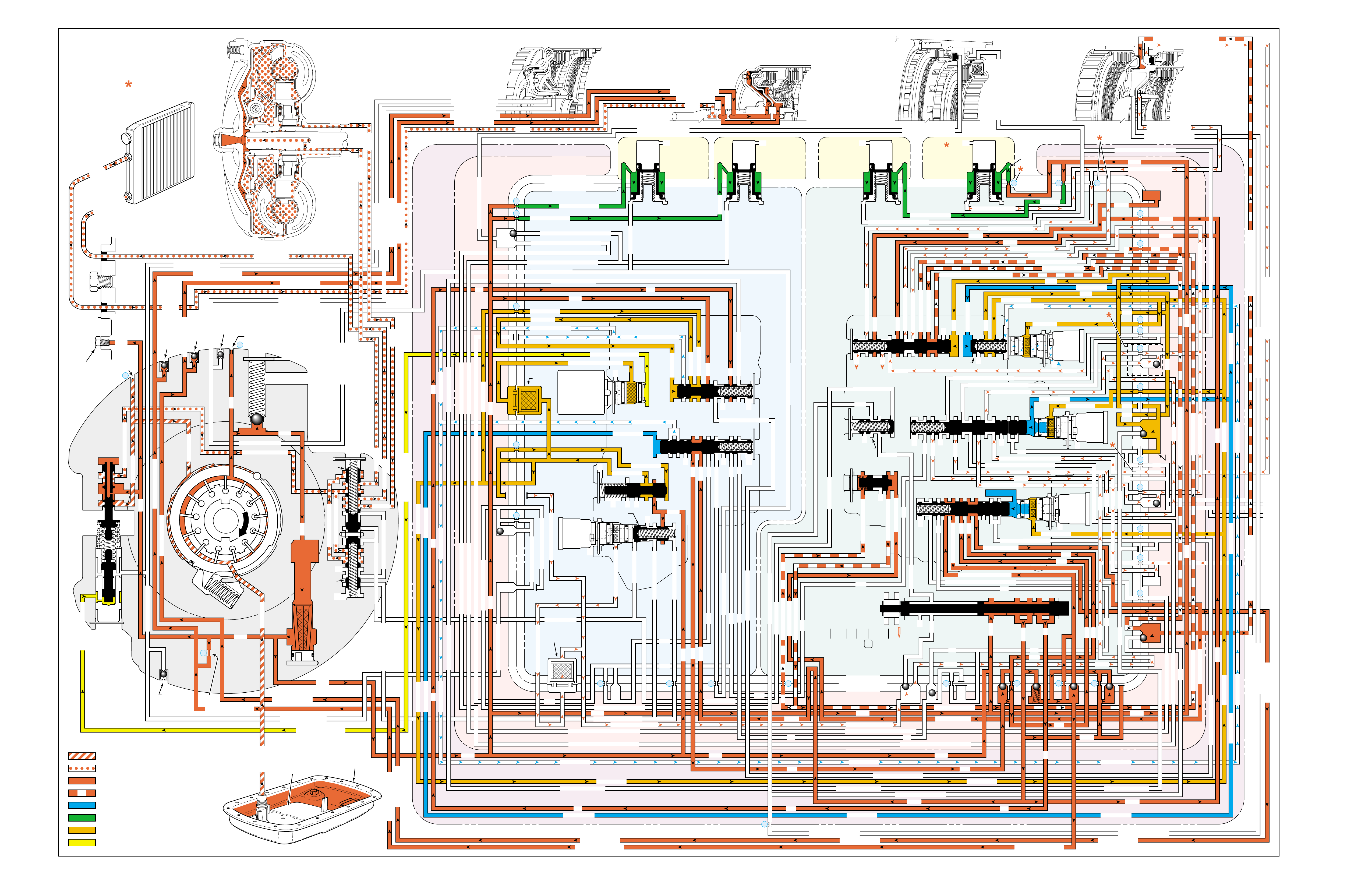

COMPLETE HYDRAULIC CIRCUITS ..................................................... 85

LUBRICATION POINTS....................................................................... 112

BUSHING AND BEARING LOCATIONS............................................... 113

SEAL LOCATIONS.............................................................................. 114

ILLUSTRATED PARTS LIST ................................................................ 115

BASIC SPECIFICATIONS .................................................................... 136

PRODUCT DESIGNATION SYSTEM ................................................... 138

GLOSSARY ........................................................................................ 140

ABBREVIATIONS ............................................................................... 142

INDEX................................................................................................ 143

PREFACE

All information contained in this book is based on the latest data available

at the time of publication approv al. T he right is reserved to mak e product or

publication changes, at any time, without notice.

No part of any GM Powertrain publication may be reproduced, stored

in any retrieval system or transmitted in any form or by any means,

including but not limited to electronic, mechanical, photocopying,

recording or otherwise, without the prior written permission of

Powertrain Group of General Motors Corporation. This includes all

text, illustrations, tables and charts.

© COPYRIGHT 2001 POWERTRAIN GROUP

General Motors Corporation

ALL RIGHTS RESERVED

The Hydra-matic 4/5L40-E Technician’s Guide is intended for automotive

technicians that are familiar with the operation of an automatic transaxle or

transmission. Technicians or other persons not having automatic transaxle

or transmission know-how may find this publication somewhat technically

complex if additional instruction is not provided. Since the intent of this

book is to explain the fundamental mechanical, hydraulic and electrical

operating principles, technical terms used herein are specific to the

transmission industry. However, words commonly associated with the

specific transaxle or transmission function have been defined in a Glossary

rather than within the text of this book.

The Hydra-matic 4/5L40-E Technician’s Guide is also intended to assist

technicians during the service, diagnosis and repair of this transmission.

However, this book is not intended to be a substitute for other General

Motors service publications that are normally used on the job. Since there

is a wide range of repair procedures and technical specifications specific to

certain vehicles and transmission models, the proper service publication

must be referred to when servicing the Hydra-matic 4/5L40-E transmission.

1

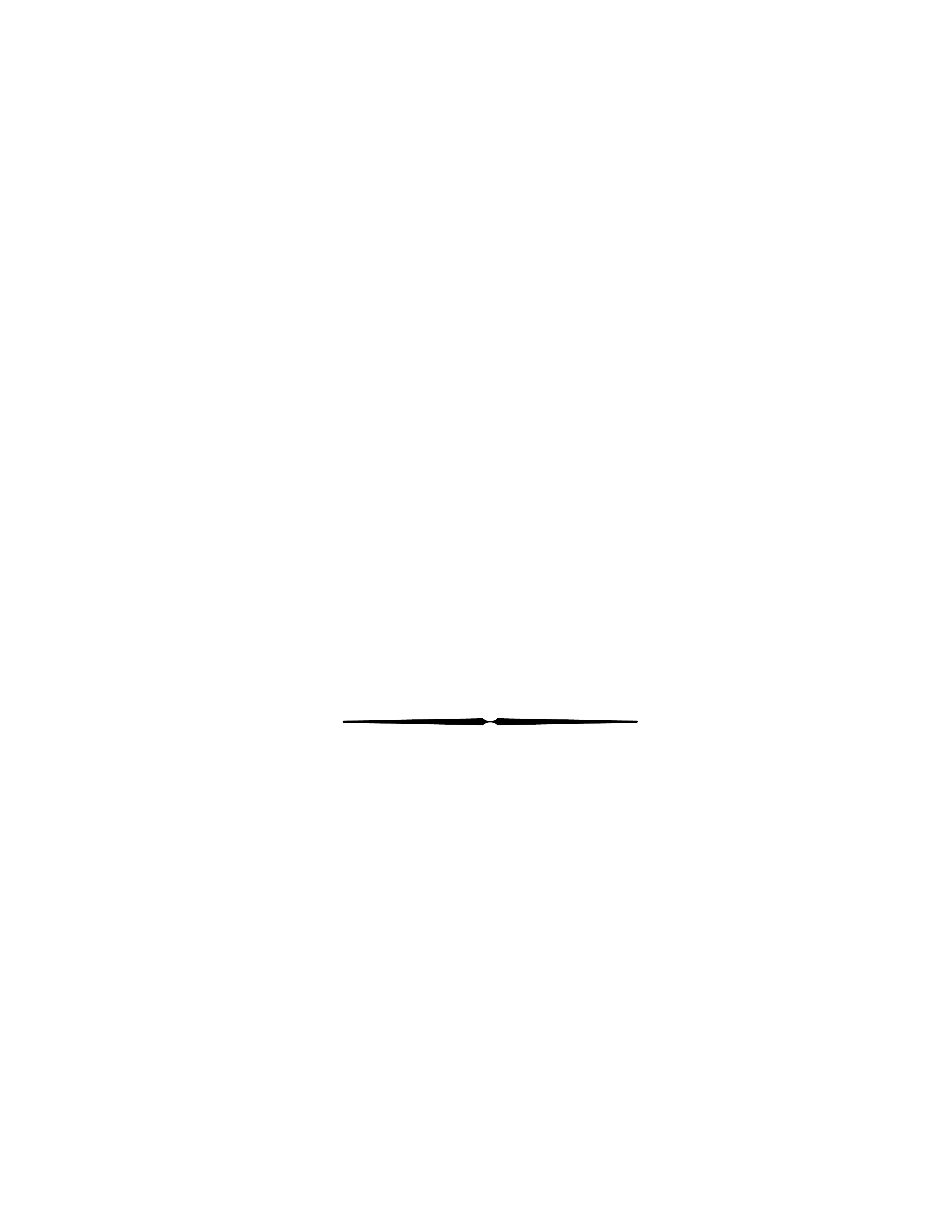

The Hydra-matic 4/5L40-E Technician’s Guide is

another Po wertrain publication from the Technician’s

Guide series of books. The purpose of this

publication, as is the case with other Technician’s

Guides, is to provide complete information on the

theoretical operating characteristics of this

transmission. Operational theories of the mechanical,

hydraulic and electrical components are presented in

a sequential and functional order to better explain

their operation as part of the system.

In the first section of this book entitled “Principles

of Operation”, detailed explanations of the major

components and their functions are presented. In

every situation possible, text describes component

operation during the apply and release cyc le as well

as situations where it has no effect at all. The

descriptive text is then supported by numerous

graphic illustrations to further emphasize the

operational theories presented.

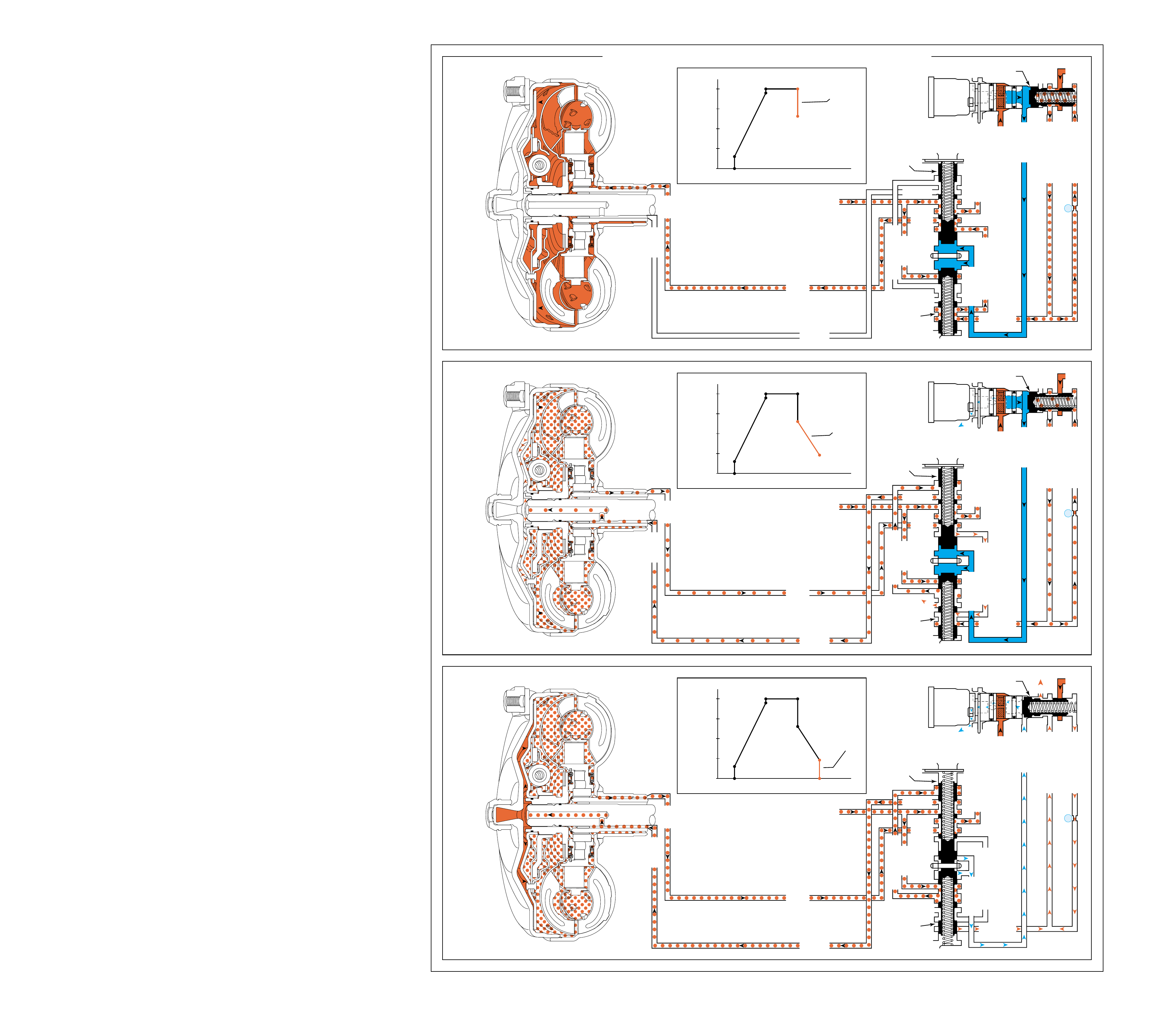

The second major section entitled “Power Flow”,

blends the information presented in the “Principles of

Operation” section into the complete transmission

assembly. The transfer of torque from the engine

through the transmission is graphically displayed on a

full page while a narrative description is provided on

a facing half page. The opposite side of the half page

contains the narrati ve description of the hydraulic fluid

as it applies components or shifts valv es in the system.

Facing this partial page is a hydraulic schematic that

shows the position of valves, ball check valves, etc.,

as they function in a specific gear rang e.

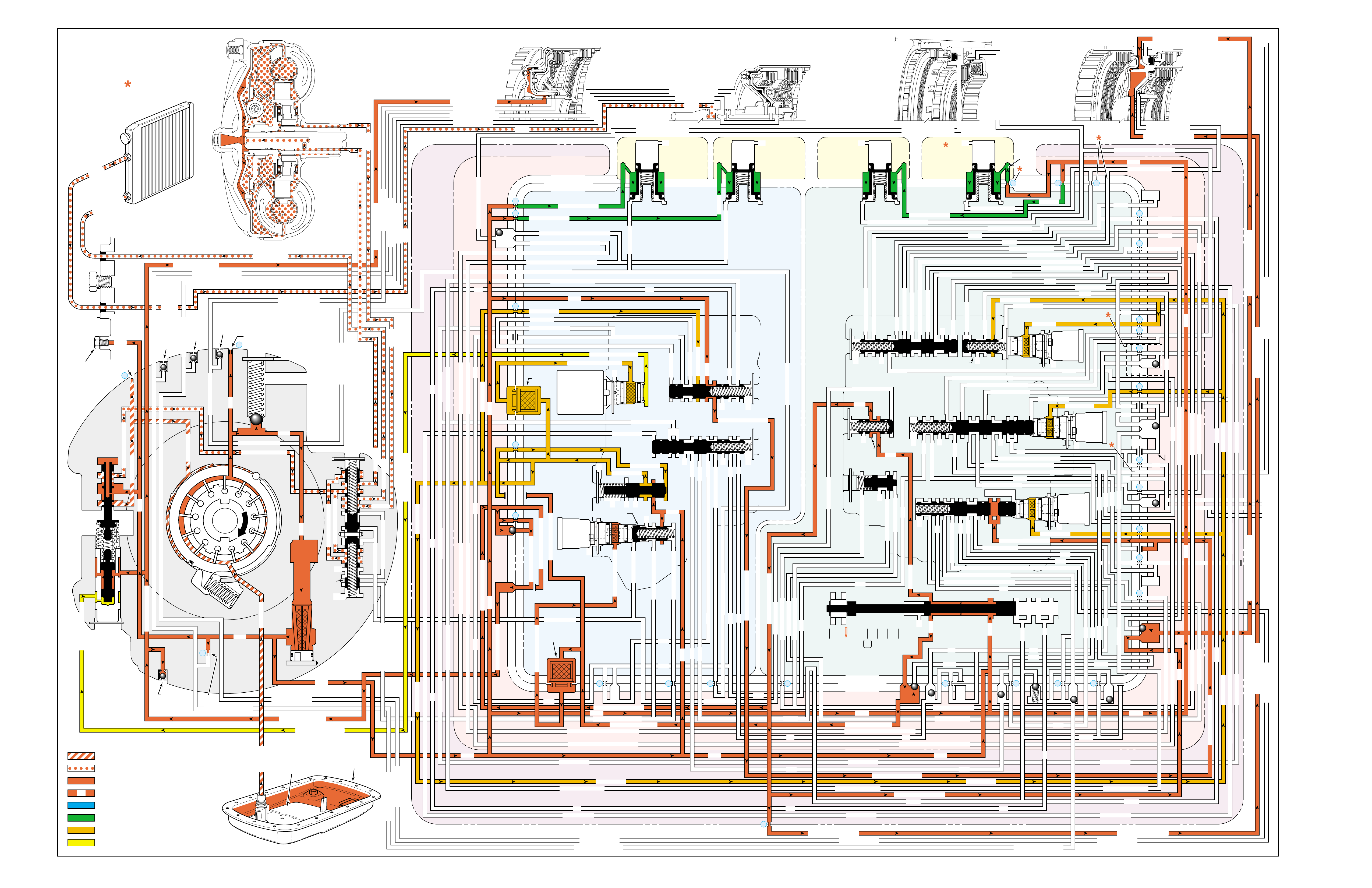

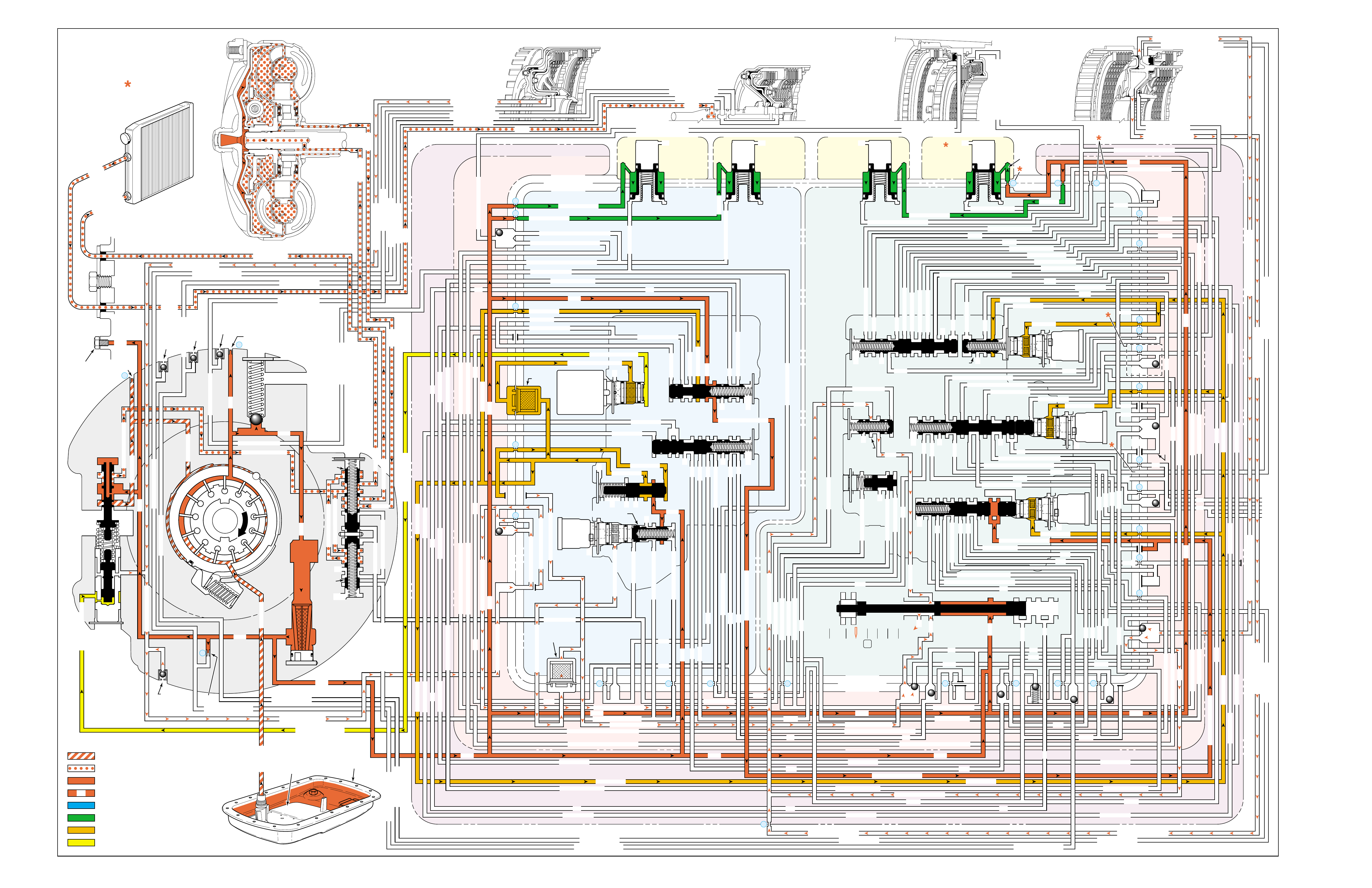

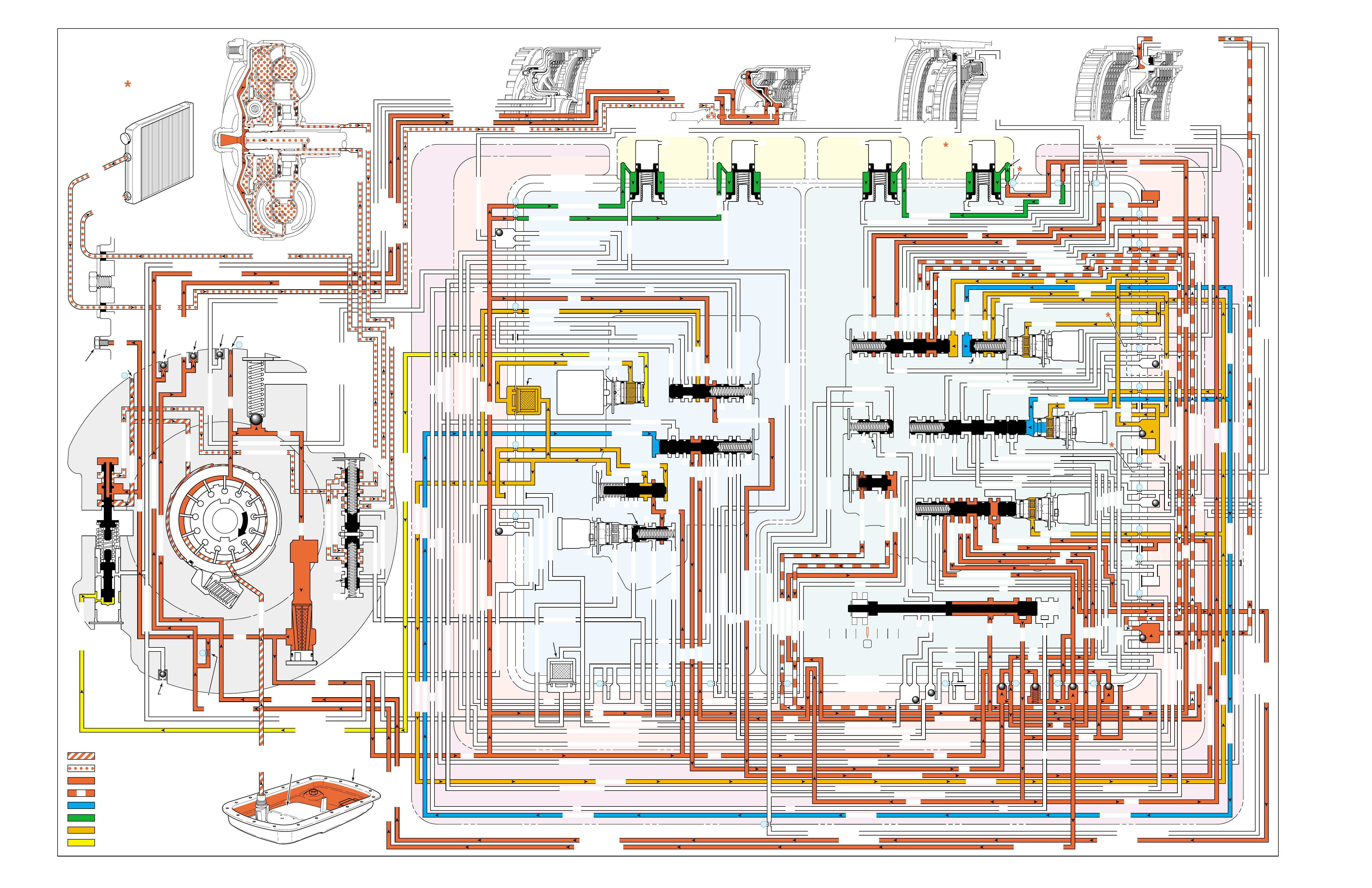

The third major section of this book displays the

“Complete Hydraulic Circuit” for specific gear

ranges. Fold-out pages containing fluid flow

schematics and two dimensional illustra tions of major

components graphically display hydraulic circuits.

This information is extremely useful when tracing

fluid circuits for learning or diagnosis purposes.

The “Appendix” section of this book provides

additional transmission information regarding

lubrication circuits, seal locations, illustrated parts

lists and more. Although this information is available

in current model year Service Manuals, its inclusion

provides for a quick reference guide that is useful to

the technician.

Production of the Hydra-matic 4/5L40-E T ec hnician’s

Guide was made possible through the combined

ef forts of many staf f areas within the General Motors

Powertrain Division. As a result, the Hydra-matic

4/5L40-E Technician’s Guide was written to provide

the user with the most current, concise and usable

information available regarding this product.

3

INTRODUCTION

specific fluid circuits that enable the mechanical

components to operate. The mechanical power

flow is graphically displayed on a full size page

and is followed b y a half page of descripti ve te xt.

The opposite side of the half page contains the

narrative description of the hydraulic fluid as it

applies components or moves valves in the system.

Facing this partial page is a hydr aulic schematic

which shows the position of valves, ball check

valves, etc., as they function in a specific gear

range. Also, located at the bottom of each half

page is a reference to the Complete Hydraulic

Circuit section that follows.

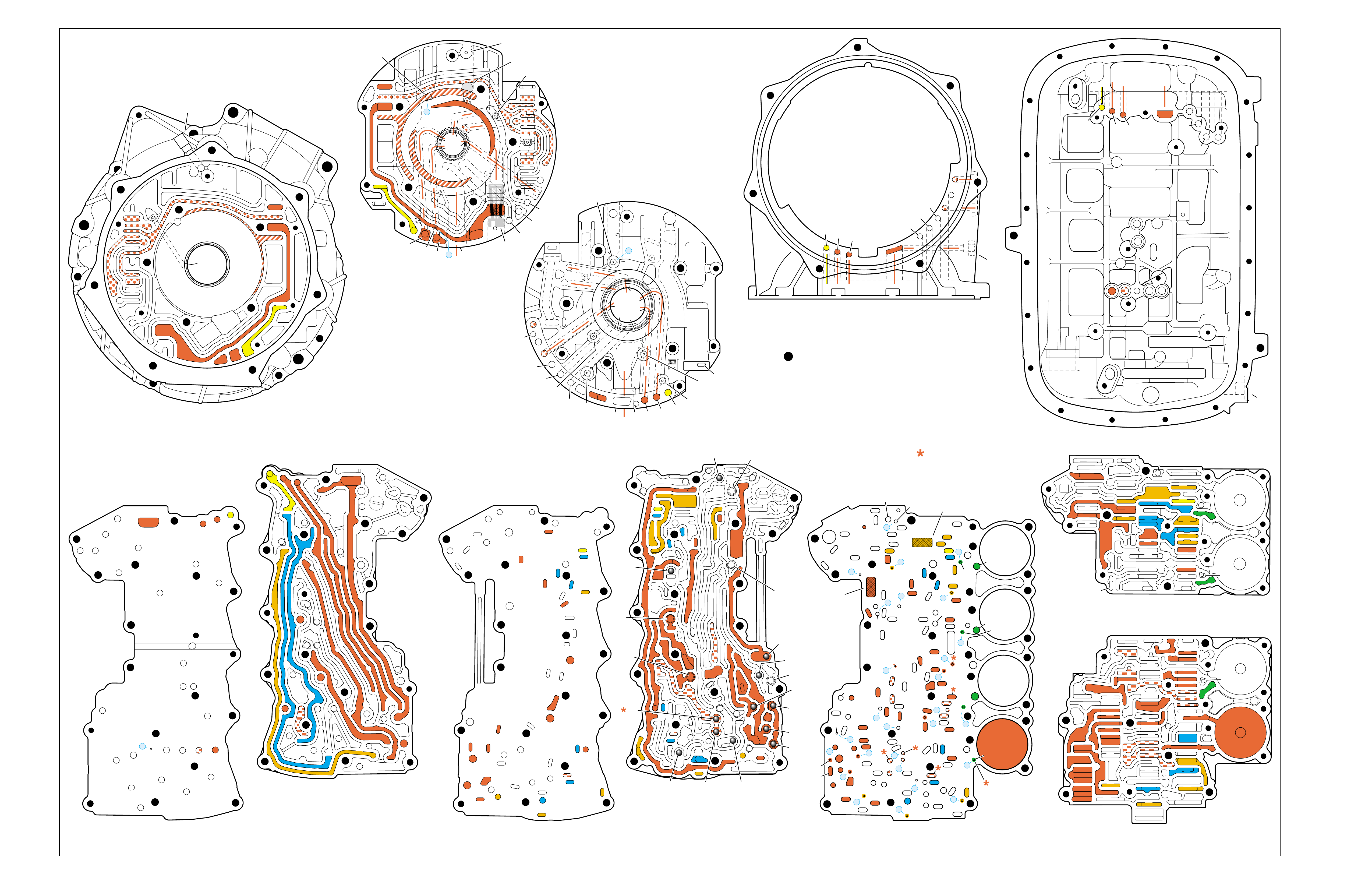

•The Complete Hydraulic Circuits section

(beginning on page 85) details the entire hydraulic

system. T his is accomplished by using a fold-out

circuit schematic with a facing page two

dimensional fold-out drawing of each component.

The circuit schematics and component drawings

display only the fluid passages for that specific

operating range.

•Finally , the Appendix section contains a schematic

of the lubrication flow through the transmission,

disassembled view parts lists and transmission

specifications. This information has been included

to provide the user with convenient reference

information published in the appropriate vehicle

Service Manuals. Since component parts lists

and specifications may change over time, this

information should be verified with Service

Manual information.

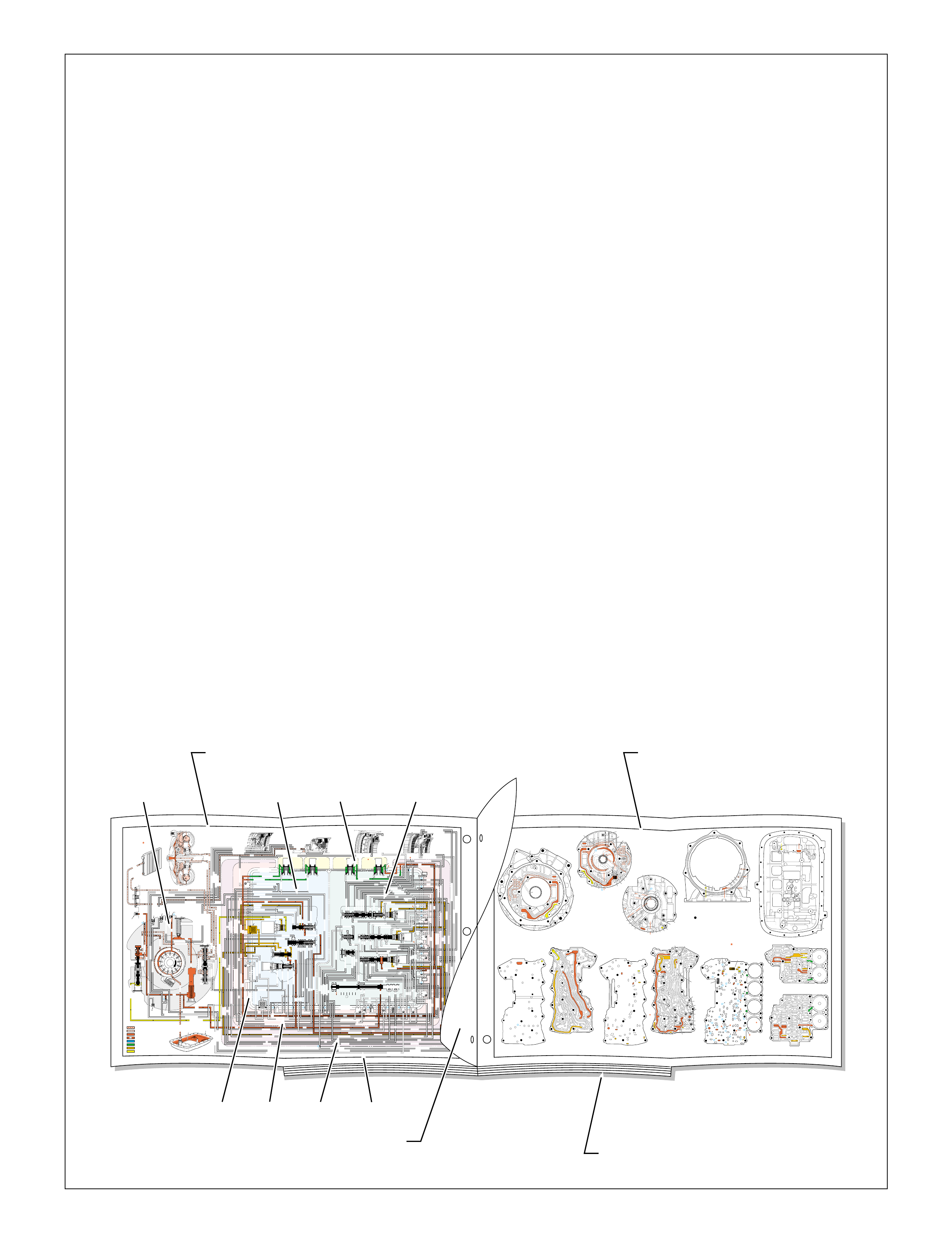

First time users of this book may find the pa ge layout

a little unusual or perhaps confusing. Ho we ver, with

a minimal amount of exposure to this format its

usefulness becomes more obvious. If you are

unfamiliar with this publication, the following

guidelines are helpful in understanding the functional

intent for the various page layouts:

•Read the following section, “Understanding the

Graphics” to know how the graphic illustrations

are used, particularly as they relate to the

mechanical power flow and hydraulic controls

(see Understanding the Graphics page 6).

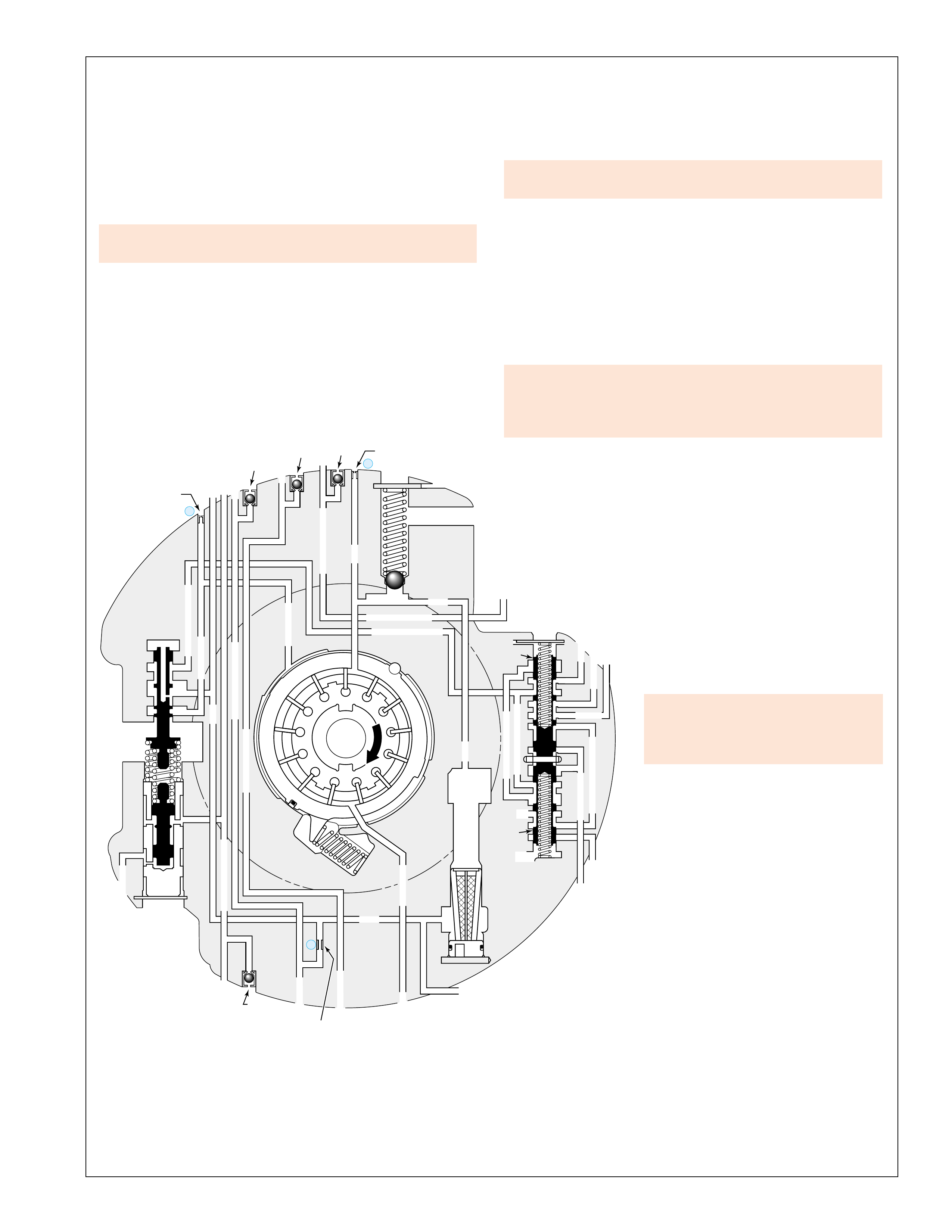

•Unfold the cutaway illustration of the Hydra-

matic 4/5L40-E (page 8) and refer to it as you

progress through each major section. This

cutaway pro vides a quick reference of component

location inside the transmission assembly and

their relationship to other components.

•The Principles of Operation section (beginning on

page 9A) presents information regarding the major

apply components and hydraulic control

components used in this transmission. This section

describes “how” specific components work and

interfaces with the sections that follow.

•The Power Flow section (beginning on page 53)

presents the mechanical and hydraulic functions

corresponding to specific gear ranges. This

section b uilds on the information presented in the

Principles of Operation section by showing

4

HOW TO USE THIS BOOK

DIRECT

CLUTCH

ASSEMBLY

(405–414)

COAST

CLUTCH

ASSEMBLY

(437–446)

TRANSMISSION

FLUID

PAN

(62)

CONVERTER

PUMP

ASSEMBLY

STATOR

ROLLER

CLUTCH

ASSEMBLY

CONVERTER

STATOR

ASSEMBLY

TORQUE

CONVERTER

ASSEMBLY

(1)

TORQUE

CONVERTER

HOUSING/PUMP

ASSEMBLY

(3)

FORWARD

CLUTCH

ASSEMBLY

(435–451)

INPUT

SUN GEAR

SHAFT

(457)

FORWARD

SPRAG

CLUTCH

ASSEMBLY

(461)

OVERDRIVE

CLUTCH

ASSEMBLY

(480–487)

INTERMEDIATE

CLUTCH

ASSEMBLY

(488–497)

INTERMEDIATE

SPRAG

CLUTCH

ASSEMBLY

(473)

TCC PWM

SOLENOID

VALVE

(352)

TRANSMISSION

FLUID

FILTER

(59)

LOW /REVERSE

CLUTCH

ASSEMBLY

(510–517)

REVERSE

CLUTCH

ASSEMBLY

(404–420)

LOW SPRAG

CLUTCH

ASSEMBLY

(503)

SECOND

COAST

CLUTCH

ASSEMBLY

(528–535)

SECOND

CLUTCH

ASSEMBLY

(520–527)

OUTPUT

SHAFT

(562)

FORWARD/COAST

CLUTCH HOUSING

SHAFT

(433)

MANUAL

VALVE

(377)

CONTROL

VALVE BODY/

ACCUMULATOR

ASSEMBLY

(47)

PRESSURE

PLATE

ASSEMBLY

PLANETARY

CARRIER

ASSEMBLY

(553)

SECOND

SPRAG

CLUTCH

ASSEMBLY

(547)

REAR

INTERNAL

GEAR

(560)

FRONT

INTERNAL

GEAR

(550)

TRANSMISSION

MANUAL SHIFT

SHAFT SWITCH

ASSEMBLY

(602)

PARK PAWL

ACTUATOR

ASSEMBLY

(613)

CONVERTER

TURBINE

ASSEMBLY

5

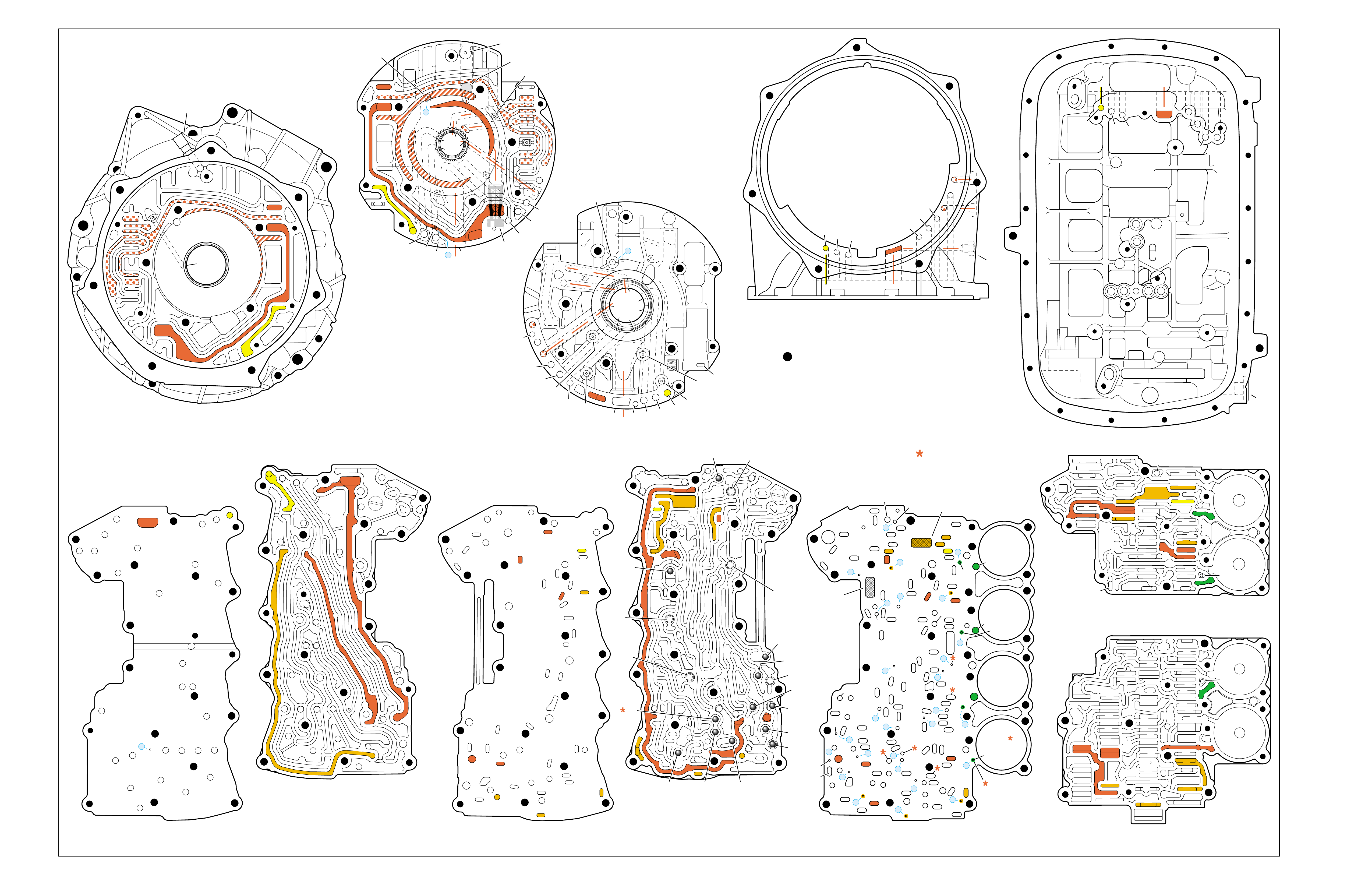

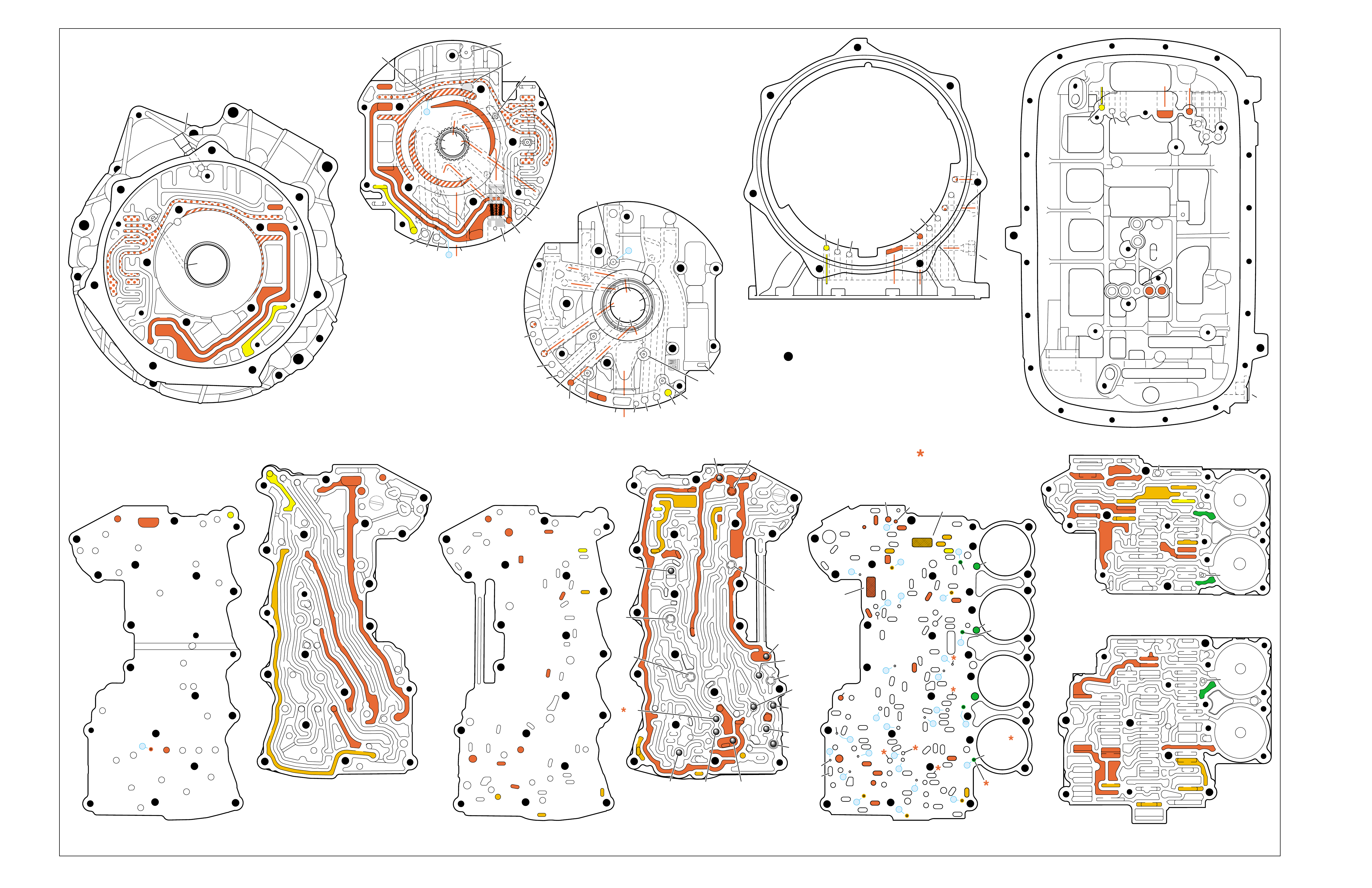

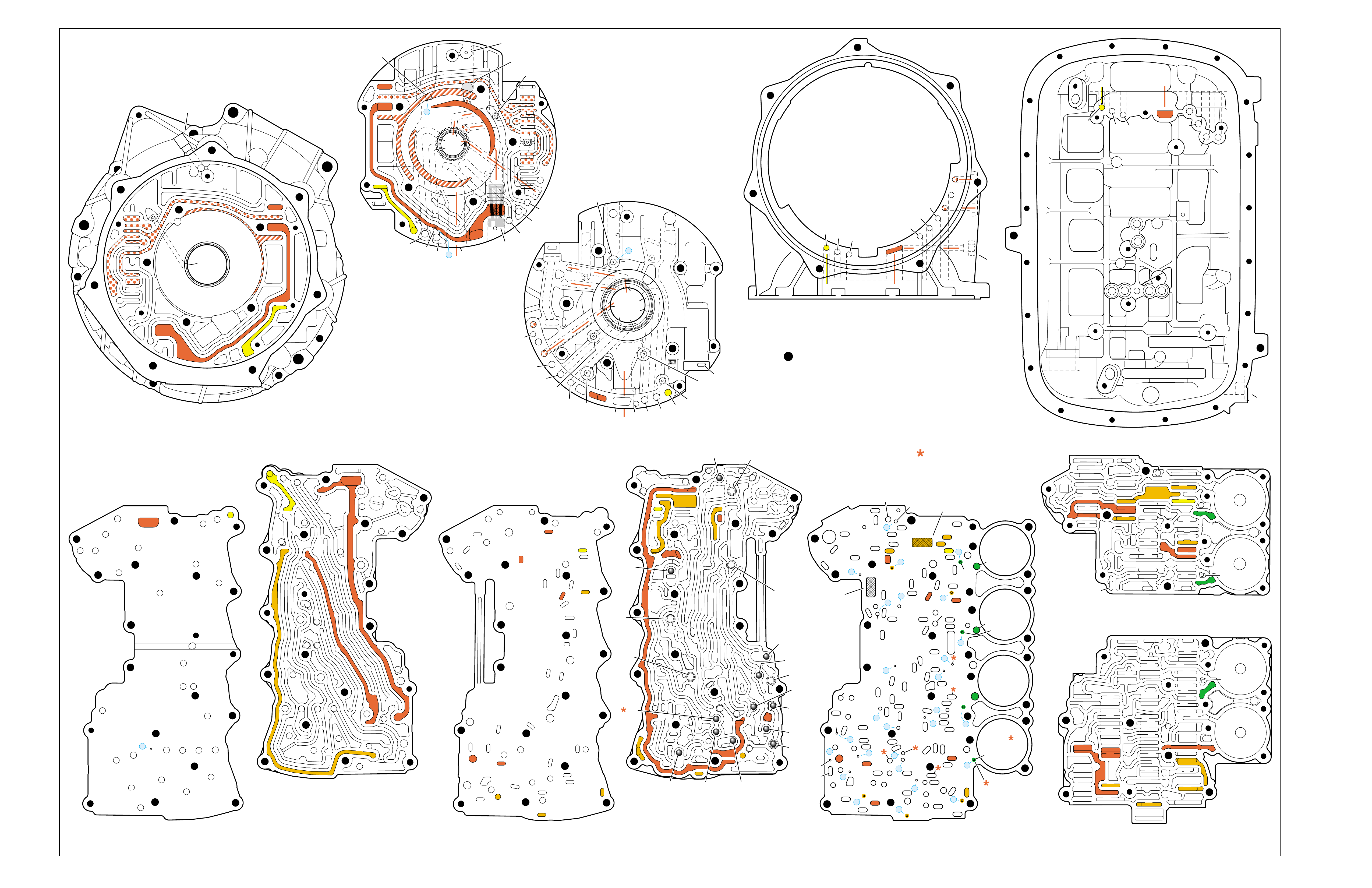

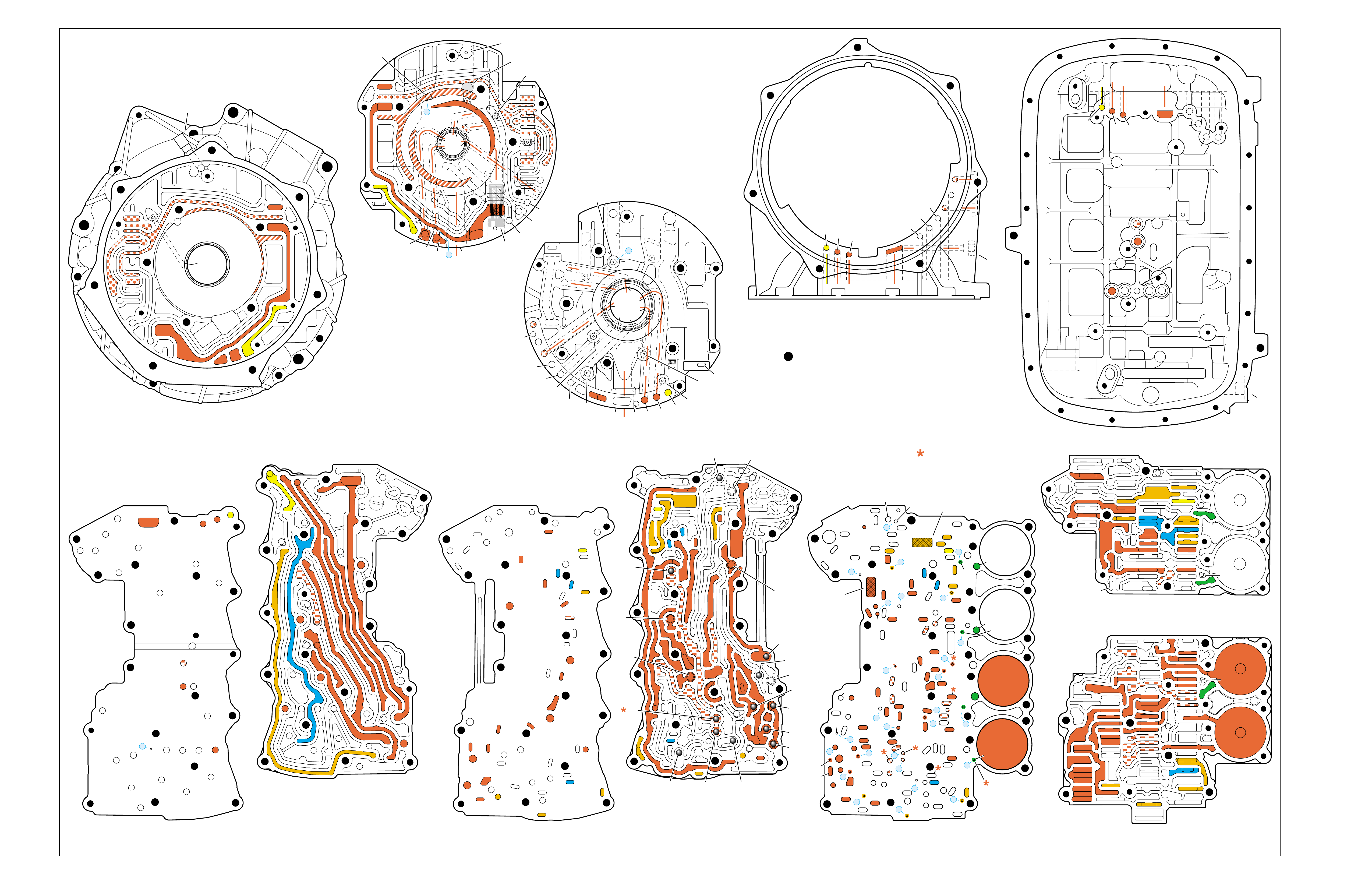

Figure 1

➤ ➤

➤➤

➤

➤

➤

TORQUE CONVERTER HOUSING (227)

(Fluid Pump Cover Side)

➤

➤

➤

➤

➤➤➤

➤

➤

➤ ➤

➤

➤

TOP CHANNEL PLATE (301)

(Case Side)

FRONT

➤

TOP CHANNEL PLATE (301)

(Bottom Channel Plate Side)

FRONT

➤

BOTTOM CHANNEL PLATE (304)

(Top Channel Plate Side)

FRONT

➤

REAR CONTROL VALVE BODY (310)

(Bottom Channel Plate Side)

FRONT

➤

CASE (24)

(Top Channel Plate Side)

FRONT

➤

CASE (24)

(Fluid Pump Cover Side)

SPACER PLATE (307)

(Bottom Channel Plate Side)

FRONT

➤

FRONT CONTROL VALVE BODY (311)

(Bottom Channel Plate Side)

FRONT

➤

BOTTOM CHANNEL PLATE (304)

(Control Valve Body Side)

FRONT

➤

NOTE:

– INDICATES BOLT HOLES

– NON FUNCTIONAL HOLES HAVE BEEN

REMOVED FROM COMPONENT DRAWINGS

TO SIMPLIFY TRACING FLUID FLOW.

– DUAL PURPOSE PASSAGES HAVE

CHANNEL PLATE SIDE NUMBERS LISTED FIRST

– EXHAUST FLUID NOT SHOWN

– PASSAGES MARKED WITH ARE USED FOR

THE 5L40-E ONLY

FLUID PUMP COVER (202)

(Case Side)

FLUID PUMP COVER (202)

(Torque Converter Housing Side)

➤

➤

➤

➤

➤

➤

➤ ➤

➤

➤

➤➤

➤

➤

➤

7

➤

25

➤

27

➤

3

➤

20

➤

16

➤

2

➤

10

➤

9

➤

24

➤

15

➤

11

➤

22

➤

29

➤

28

➤

23

➤

18

➤

17

➤

14

➤

8

➤

4

➤

5

➤

26

➤

13

➤

19

➤

21

➤

6

➤

12

(40)

➤

21

(203)

➤

16

(203)

➤➤

(232)

➤➤

(229)

➤➤

(231)

➤➤

(213)

➤

(233)

➤

TRANSMISSION

VENT

ASSEMBLY

➤➤

32

(203)

➤

37

(203)

➤➤

2/21

(214)

➤➤

(36)

➤

FILTER

(312)

➤

FILTER

(308)

➤

#12

#2

#3

#5

#6

#7

(Spring)

#8

#10 #9

#4

#1

#11

X-2

X-4

X-5

X-1

X-3

33

32

38

38

38

30

30

24

37

37

37

40

40

12

16

15

15

23 52

24

24

23

28

47

41

42

43

27

28

28

27

27

25

25

26

22

22

15

13

18 19

19

19

19

19

19

19

21

17

17

22

23

23

48

48

48

48

48

48

48

48

48

15

13

36

36

36

36

39

35

35

34

10

10 11

10

10

10

20

20

48

44

44

45

43 42

52

52

52

48

48

77

2

2

2

2

2

2

2

12a

16a

15d/16 15c/16

15b

23c

24a 24b

24c

25b

25c 25d

25e

26b

26a

32a

30a

33a

35a

39a

36a

36b

36c

36d

38a 39b

39c/41

40c/41

36e

36f

35b

35c 35d

37c

37d

37b

37a

40b

40a

38d 38b

38c

38e

40d

34a

33e

33c

33d

33b

30b

30c 30d

25a

23b

23a

20a

28c

27c/46

27b

28b

28a

27a

47b

47a

20b

20d

20c

13a

15a

19e

19h

19g

19i

19j

19f

13b15e

17a

17b

17c/18

15f/18

19b/21

19c/21

19d/21

19a

22a

22b

22c

22d

22f

21a

21b/31

21c/31

22g/23

14a/23

22e

48

48

48

48

48

48

48

48

52

52

52

52

52

52

52

52

48

48

2g

7a

7b 2a/54a

2b

42b

43a

42a

43b

44c

44d 44b

44a

44e

43c/45

44f/45

48a 48b

2c/54c

54d

2d/54e

2e 2m/54g

2f

10i

10h

10f

10e

10d

10a 10c

11b

11a/10b

10g

2h

54f

54b

12

2

23

24

48

48

48

48

48

48

48

48

52

52

52

52

52

52

52

23

36

36

36

20

27

28

46

47

47

19

16

15

13

10

10

10

11

54

2

54

37

37

37

39

38

40

42

43

40

27

7

48

48

48

52

52

52

52

52

52

52

24

25

25

25

2525

26

26

15 19 19

19

19

31

21

20 20

15 17

17

14

13

14

54

22

22

28

28

22

22

32

42 43

44

44

48

48

48

48

48

48

44

44

38

39

38

33

33

30

35

40

35

35

36

35

34

30

30

30

33

2

2

10

10 10

10

27

2

216

24

15

18

7

32

52

52

52

52 52

52

52

52

52

52

52

52

52 52

52

52

52

52

30 34

35

41

12 21 37

8

9

2

16

24

7

32

12 21

37

12

21

21

24

848

7

9

9

52

52

2

16

5

16

37

32

32

52

1

52

52

52

48

37

1

2

51

51

52

12

12

24

24

52

2

2

4

4

4

4

5

66

8

8

7

7

7

5

9

48

48

48

48

48

48

48

48

53

53

48

52

2

3

3

3

2

1

16

21

21

16

32

37

32

51

50

50

51 52

52

52

52

52

52

48

48

48

48

52

48

48

12

12

24

24

2

2

3

2

4

4

4

5

6

53

53

8

8

7

7

7

48

16

16

21 32

37

➤➤

1

➤➤

31

➤➤

30

(233)

➤➤

32

38

30

24 12

16

13

15

15

13

18

19

19

19

21

21

22

16 48

48

48

48

48

48

48

48

36

35

35

34

2

2

7

2

10

10

10

10

41

42

43

43

42

48 48

20

28

27

37

27

28

28

27

20

48

52

52

32

32

32

38

24

12 16

16

18

28

28

28

27

27

48 48

43 42

42

43

48

30

48

48

48 48

48

48

48

48

48

48

48

48

35

36

37

34

2

7

2

10

13

13

15

19

41

41

19

19

15

22

21

21

20

20

21

21

13

10

10

10

2

48

48 48

52

52

52

52

52

52

12

32

37 21

24

2

16

18

48

48

48

48

48

30

48

48

48

48

48

48

15

35

41

34

7

52

52

52

52

52

52

OVERDR CL FD 2

ACCUMULATOR

INTERMED CL

ACCUMULATOR

EX

SECOND CL

ACCUM

ACCUMULATOR

LINE

LINE

LINE

EXEXEX

DIRECT CL

4

2

5

DIRECT

CLUTCH

ACCUMULATOR

OVERDRIVE

CLUTCH

ACCUMULATOR

INTERMEDIATE

CLUTCH

ACCUMULATOR

SECOND

CLUTCH

ACCUMULATOR

3

LINE

LINE

LINE (from Pump)

LINE

FILTERED FEED LIMIT

THROTTLE SIGNAL

EX

2345 OR REVERSE

TCC SIGNAL

REGULATED APPLY

REGULATED APPLY

EX

EX

FEED LIMIT VALVE

LINE

EX

EX

EX

EX

FEED LIMIT

FEED LIMIT

EX EX

SECOND COAST CLUTCH

23 REGULATED

OVERDRIVE CL FD 1

INTERMEDIATE CLUTCH

2345

INTERMEDIATE CLUTCH

2345

345

FEED LIMIT

EX

EX

EX

EX

2-3 SIGNAL

23 REGULATED

123 BRAKING

123

EX

EX

EX

123

COAST CLUTCH

COAST CLUTCH FEED

OVERDRIVE CL FD 2

45

FEED LIMIT

LINE

FEED LIMIT

32

MEMORY

MEMORY

MEMORY

MEMORY PILOT

32 SAFETY MODE

EX

EX

FDL

D432

2345

D432

SECOND CL

23 REGULATED

123 REGULATED

SECOND CL

123 REGULATED

LOW AND REV CL

EX

EX

EX

FEED LIMIT

FEED LIMIT

FDL

1-2 SIGNAL

2-3 SIGNAL

EX

EX

RPND432

MANUAL VALVE

LINE

D432

REV

REVERSE

EX

32

LINELINE

LINE SAFETY MODE

4-5 SIGNAL

24

28

PRESSURE

CONTROL

SOLENOID

VALVE

1-2 SHIFT

SOLENOID

VALVE

N/C

(A)

OFF

2-3 SHIFT

SOLENOID

VALVE

N/C

(B)

OFF

4-5 SHIFT

SOLENOID

VALVE

N/C

(C)

OFF

TCC PWM

SOLENOID

VALVE

N/C

1-2 SHIFT VALVE

7

11

10

9

FILTER

(312)

TCC REGULATOR VALVE

1-2 SHIFT CONTROL VALVE

29

8

FEED LIMIT

FEED LIMIT FEED LIMIT

FEED LIMITFEED LIMIT

2-3 SHIFT VALVE CNTRL

CNTRL

LINE SM

LINE SM

LINE SAFETY MODE

SAFETY MODE

DECREASE

CONVERTER FEED

THROTTLE SIGNAL

LINE

EX

REVERSE CLUTCH

PRESS REG VALVEBOOST VALVE

4-5 SHIFT VLV

2c

2b

2a

1

3

PRESSURES

INTAKE & DECREASE (SUCTION)

CONVERTER & LUBE

MAINLINE

REGULATED LINE

SOLENOID SIGNAL

ACCUMULATOR

FEED LIMIT

THROTTLE SIGNAL

NOTE:

PASSAGES AND

COMPONENTS

MARKED WITH

ARE USED FOR

THE 5L40-E ONLY

GASKET (309)

GASKET (305)

GASKET (303)

BOTTOM CHANNEL PLATE (304)

TOP CHANNEL PLATE (301)

CASE (24)

REAR CONTROL VALVE BODY (310)

SPACER PLATE (307)

GASKET (309)

GASKET (305)

GASKET (303)

BOTTOM CHANNEL PLATE (304)

TOP CHANNEL PLATE (301)

CASE (24)

FRONT CONTROL VALVE BODY (311)

SPACER PLATE (307)

FLUID

PUMP

COVER

(202)

CONVERTER

HOUSING

(224)

ACCUMULATOR HOUSING (317) ACCUMULATOR HOUSING (323) ACCUMULATOR HOUSING (328) ACCUMULATOR HOUSING (333)

LUBE

LUBE

LUBE

LUBE

TO COOLER

LUBE

TO COOLER

APPLY

APPLY

APPLY

RELEASE

DECREASE

DECREASE

LINE

OVERDRIVE CLUTCH FEED 1

OVERDRIVE CL FD 1OVERDRIVE CLUTCH FEED 1

OVERDRIVE CLUTCH FEED 1 OVERDRIVE CLUTCH FEED 1

OVERDRIVE CLUTCH

2345 2345

2345

2345

2345

2345

2345 OR REVERSE

RLO

LOW AND REV CL OR RLO

LOW AND REV CL OR RLO

SECOND COAST CLUTCH

SECOND CLUTCH

SECOND COAST CLUTCH

SUCTION SUCTION

LINE

LINE

LINE LINE

LINE

LINE

LINE LINE LINE

TCC SIGNAL

CONVERTER FEED

CONVERTER FEED

RELEASE

TO COOLER

REGULATED APPLYREGULATED APPLY

LINE

EX

CONVERTER FEED

REVERSE CLUTCH

REVERSE CLUTCH

THROTTLE SIGNAL

LINE

EX

FILTERED FEED LIMIT

THROTTLE SIGNAL

THROTTLE SIGNAL

THROTTLE SIGNAL

EX

2345 OR REVERSE

2345 OR REVERSE

2345 OR REVERSE

TCC SIGNAL

TCC SIGNAL

TCC SIGNAL

REGULATED APPLY

REGULATED APPLY

REGULATED APPLY

EX

EX

FEED LIMIT VALVE

LINE

EX

EX

EX

EX

FEED LIMIT

FEED LIMIT FEED LIMIT

FEED LIMIT

FEED LIMIT

FEED LIMIT

FEED LIMIT

FEED LIMIT FEED LIMIT

FEED LIMIT

2-3 SHIFT VALVE CNTRL

EX

EX

EX

EX

EX

EX

EX EX

SECOND COAST CLUTCH

23 REGULATED

23 REGULATED

OVERDRIVE CLUTCH FEED 1

INTERMEDIATE CLUTCH

2345

2345

2345

2345

INTERMEDIATE CLUTCH

2345

345

FEED LIMIT

EX

EX

EX

EX

2-3 SIGNAL

LOW PRESSURE

123 REGULATED

123 REGULATED

EX

CNTRL

LINE SAFETY MODE

123 BRAKING

123

EX

EX

EX

123

123

123

123

123

123

123

123123

COAST CLUTCH

COAST CLUTCH FEED

OVERDRIVE CLUTCH FEED 2

45

FEED LIMIT

SAFETY MODE

LINE

FEED LIMIT

32

MEMORY

MEMORY

MEMORY

MEMORY PILOT

MEMORY PILOT

32 SAFETY MODE

LINE SAFETY MODE

EX

EX

LINE SAFETY MODE

CNTRL 3-4 SHIFT

2-3 SIGNAL

123123 D432D432

DIRECT CLUTCH

DIRECT CLUTCH

4545

1-2 SIGNAL

EX

EX

EX

1-2 SHIFT VALVE

FDL

FDL

FDL

FDL

FDL

FDL

D432

2345 2345

D432

SECOND CLUTCH

23 REGULATED

23 REGULATED23 REGULATED

123 REGULATED

LOW AND REVERSE CLUTCH

LOW AND REVERSE CL

SECOND CLUTCH

123 REGULATED

EX

EX

EX

FD LIMIT

FEED LIMIT

FDL

1-2 SIGNAL

2-3 SIGNAL

EX

EX

TCC SIGNAL

TCC SIGNAL

TCC SIGNAL

RLO

EX

REV

RPND432

MANUAL VALVE

LINE

D432

D432 D432

D432

D432

D432

D432 D432

D432

D432D432

D432

REV

REVERSE

EX

3232

LINE

EX

EX

LINE

CASE (24)

OVERDRIVE CLUTCH FEED 2

OVERDRIVE CL FD 2

OVERDRIVE CLUTCH FEED 2

ACCUMULATOR

DIRECT CLUTCH

ACCUM

INTERMEDIATE CLUTCH

INTERMEDIATE CLUTCH

INTERMEDIATE CLUTCH

ACCUMULATOR

EX

SECOND CLUTCH

SECOND CLUTCH

ACCUM

ACCUM

LINELINE

FORWARD CLUTCH

FORWARD CLUTCH FORWARD CLUTCH

ACCUMULATOR

LINE

LINELINE

LINE

OVERDRIVE CLUTCH

INTERMEDIATE CL

COAST CLUTCH

REVERSE LOCKOUT

COAST CLUTCH

REVERSE CLUTCH

REVERSE CLUTCH

REVERSE CLUTCH

4-5 SIGNAL

EXEXEX

LINE SAFETY MODE

LINE SAFETY MODE

REVERSE LOCKOUT

REVERSE LOCKOUT REVERSE LOCKOUT

COAST CLUTCH

REVERSE LOCKOUT REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE CLUTCH

REVERSE CLUTCH

LOW AND REV CL OR RLO

FORWARD CLUTCH

FORWARD CLUTCH

FORWARD CLUTCH

COAST CLUTCH

FORWARD CLUTCH

FORWARD CLUTCH

FORWARD CLUTCH

2345

2345 OR REVERSE

123 REGULATED

123 REGULATED

123 REGULATED 123 REGULATED

123 REGULATED

123 REGULATED

123 REGULATED

123 BRAKING

123 BRAKING

123 BRAKING

123 BRAKING

1-2 SIGNAL1-2 SIGNAL

1-2 SIGNAL1-2 SIGNAL1-2 SIGNAL

1-2 SIGNAL 1-2 SIGNAL 1-2 SIGNAL

2-3 SIGNAL2-3 SIGNAL2-3 SIGNAL

2-3 SIGNAL 2-3 SIGNAL

2-3 SIGNAL2-3 SIGNAL2-3 SIGNAL

2-3 SIGNAL

SECOND CLUTCH

SECOND CLUTCH

COAST CLUTCHCOAST CLUTCHCOAST CLUTCH

COAST CLUTCH

COAST CLUTCH

COAST CLUTCH

COAST CLUTCH

COAST CLUTCH

23 REGULATED

345

345

345

345 345 345

345

345

345

345

345

345

345

345

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CL

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CLUTCH

45

45

45

4545

45

OVERDRIVE CLUTCH

OVERDRIVE CL FD 1

OVERDRIVE CLUTCH FEED 2OVERDRIVE CLUTCH FEED 2

OVERDRIVE CL FD 2

OVERDRIVE CLUTCH FEED 2 OVERDRIVE CL FD 2

3232

32 32 32

323232

32 SAFETY MODE

32 SAFETY MODE 32 SAFETY MODE 32 SAFETY MODE

32 SAFETY MODE32 SAFETY MODE

32 SM 32 SM

FDL

PRESSURE

CONTROL

SOLENOID

VALVE

1-2 SHIFT

SOLENOID

VALVE

N/C

(A)

OFF

2-3 SHIFT

SOLENOID

VALVE

N/C

(B)

OFF

4-5 SHIFT

SOLENOID

VALVE

N/C

(C)

OFF

TCC PWM

SOLENOID

VALVE

N/C

PRESS REG VALVEBOOST VALVE

CONVERTER FDL

AIR

BLEED

(233)

AIR

BLEED

(233)

AIR

BLEED

(203)

AIR

BLEED

(203)

AIR

BLEED

(203)

AIR

BLEED

(203)

7

4

2

1

5

6

11

10

9

12

18

FILTER

(308)

FILTER

(312)

TCC REGULATOR VALVE

TCC

CONTROL

VALVE

TCC

ENABLE

VALVE

REVERSE

LOCKOUT

VALVE

1-2 SHIFT CONTROL VALVE

FLUID

PAN

(62)

FLUID FILTER

ASSEMBLY

(59)

FLUID

PRESSURE

TEST PLUG

(40)

TORQUE

CONVERTER

ASSEMBLY

(1)

DIRECT

CLUTCH

ACCUMULATOR

OVERDRIVE

CLUTCH

ACCUMULATOR

INTERMEDIATE

CLUTCH

ACCUMULATOR

SECOND

CLUTCH

ACCUMULATOR

COOLER

PRESSURE

RELIEF

BALL

VALVE

21 2

10d

2a

2b

42b

43a

37d

39b

40b

37c

40d

11b

10a

24a

10c

11a 10b

54b

54d

2c

54a

54c

27c 46

7a

24b

20a

13a

37b

38a

7b

47a

47b

27b

28c

12a

23a

36e

36f

23b

23c

15a

24c

26b

36a

38c

38d

36b

25a

15

2m 54g

54f

#8

18

15f

15e

17c

17b

17a

27a

44a

44e

44d

44b

25c

30a

33a

25e

19e

35c

19h

19f

10f

10h

10g

22a

35b

#7

13b

32a

26a

10i

22f

22e

43b

22b

34a

48b

39a

22c

X-1

22

22e

21a

42a

19a

20b

19b

#2

23 22g

14a

2f

2h

19g

19i

19

j

DIRECT

AND REVERSE

CLUTCH

ASSEMBLY

(400–420)

FORWARD

AND COAST

CLUTCH

ASSEMBLY

(430–451)

OVERDRIVE

AND

INTERMEDIATE

CLUTCH

ASSEMBLY

(480–497)

CENTER

SUPPORT

ASSEMBLY

(510–535)

3

2d54e

2e

30c

30d

35d

26

37a

13

#1

15c

15b

16

15d 16

15

X-2

16a

X-4 X-5

38

14

X-3

19

#6

19d

19

21

19c 21

15

#5

21b 31

21c 31

17

21

#4

20d

20c

16

25b

19

25d

20

36 46

28a

44c

28b

30b

21

#11

33e

33d

23

24

35a

#9

33c

33b

22

36d

36c

25

#12

41 40c

39c

43 13

28

40a

#10

45

45

45

44f

44

48

43c

#3

38b

38e

27

48a

29

8

10e

2310

32 SM/FDL

30

31

FLUID PUMP

SCREEN

ASSEMBLY

(213)

(214)

4-5 SHIFT VLV

1

POWER FROM

TORQUE

CONVERTER

(1)

REAR

INTERNAL

GEAR

(560)

HELD

NO POWER

TRANSMITTED

TO

DIFFERENTIAL

ASSEMBLY

TORQUE

CONVERTER

ASSEMBLY

(1)

REVERSE CLUTCH

HOUSING ASSEMBLY

(401)

FORWARD AND COAST

CLUTCH HOUSING

ASSEMBLY

(433)

REAR

INTERNAL

GEAR

(560)

HELD

TORQUE

CONVERTER

HOUSING/PUMP

ASSEMBLY

(3)

PARK

PAWL

(612)

ENGAGED

PARK

PAWL

ACTUATOR

ASSEMBLY

(613)

➤

➤

➤

PARK

(Engine Running)

FOLDOUT ➤ 87

Figure 83

Figure 82

86

PARK

(Engine Running)

(Engine Running)

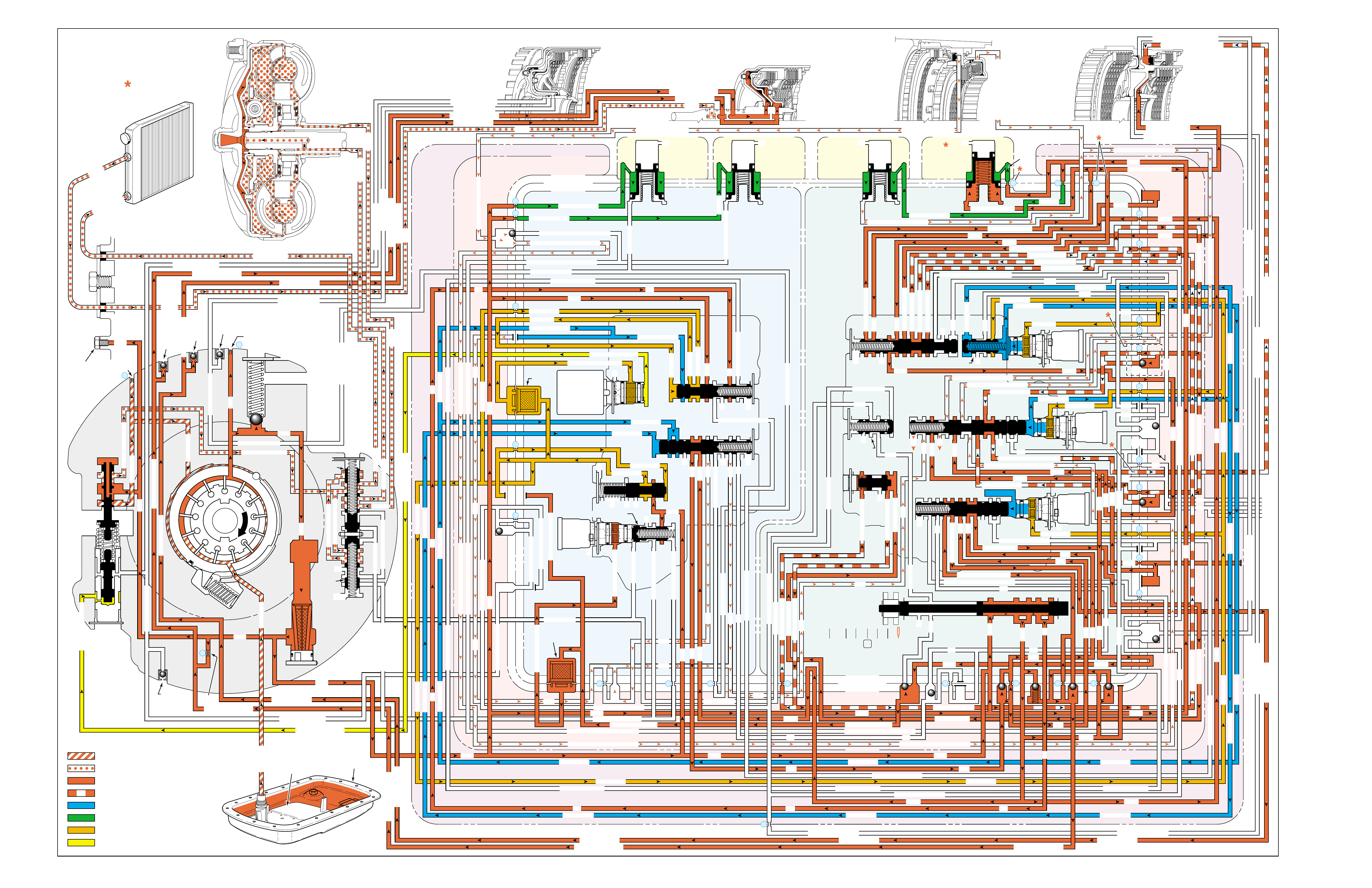

With the selector lever in the Park (P)

position, line pressure from the oil

pump is directed to the following:

Pressure Regulator Valve(218): Reg-

ulates pump output (line pressure)

according to the transmission

requirements. When pump

output exceeds the demand

of line pressure, fluid from

the pressure regulator

PARK

COMPONENTS ( )

(36) TRANSMISSION FLUID LEVEL HOLE PLUG

(40) TRANSMISSION FLUID PRESSURE TEST PLUG

(203 CHECK VALVE RETAINER AND BALL ASSEMBLY

(213) TRANSMISSION FLUID PUMP SCREEN ASSEMBLY

(214) BRASS ORIFICE INSERT

(230) TRANSMISSION VENT ASSEMBLY

(232) ORIFICE SLEEVE

(233) ORIFICE CUP PLUG

(306) CONTROL VALVE BODY BALL CHECK VALVE

(#1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12

(308) TCC PWM SOLENOID VALVE FILTER ASSEMBLY

(312) PRESSURE CONTROL SOLENOID VALVE

FILTER ASSEMBLY

86B

HOW TO USE THIS BOOK

PARK

Figure 52

56

(Engine Running)

COMPLETE HYDRAULIC CIRCUIT

PAGE 86

With the selector lever in the Park (P)

position, line pressure from the oil

pump is directed to the following:

Pressure Regulator Valve(218): Reg-

ulates pump output (line pressure)

according to the transmission

requirements. When pump

output exceeds the demand

of line pressure, fluid from

the pressure regulator

PARK

HYDRA-MATIC 5L40-E

8

Figure 6

Figure 53

57

PARK

(Engine Running)

(Engine Running)

56B

FLUID FLOW SCHEMATIC —

(FOLDOUT) FLUID FLOW THROUGH

COMPONENTS (FOLDOUT)

COMPLETE ILLUSTRATED

PARTS LIST

HALF PAGE TEXT AND LEGEND

➤

➤

➤

➤

RANGE REFERENCE CHARTLARGE CUTAWAY VIEW

OF TRANSMISSION

(FOLDOUT)

HALF PAGE TEXT FOR EASY

REFERENCE TO BOTH PAGES

PAGE NUMBER —

FOR REFERENCE TO

FLUID FLOW SCHEMATIC

➤

➤

➤

➤

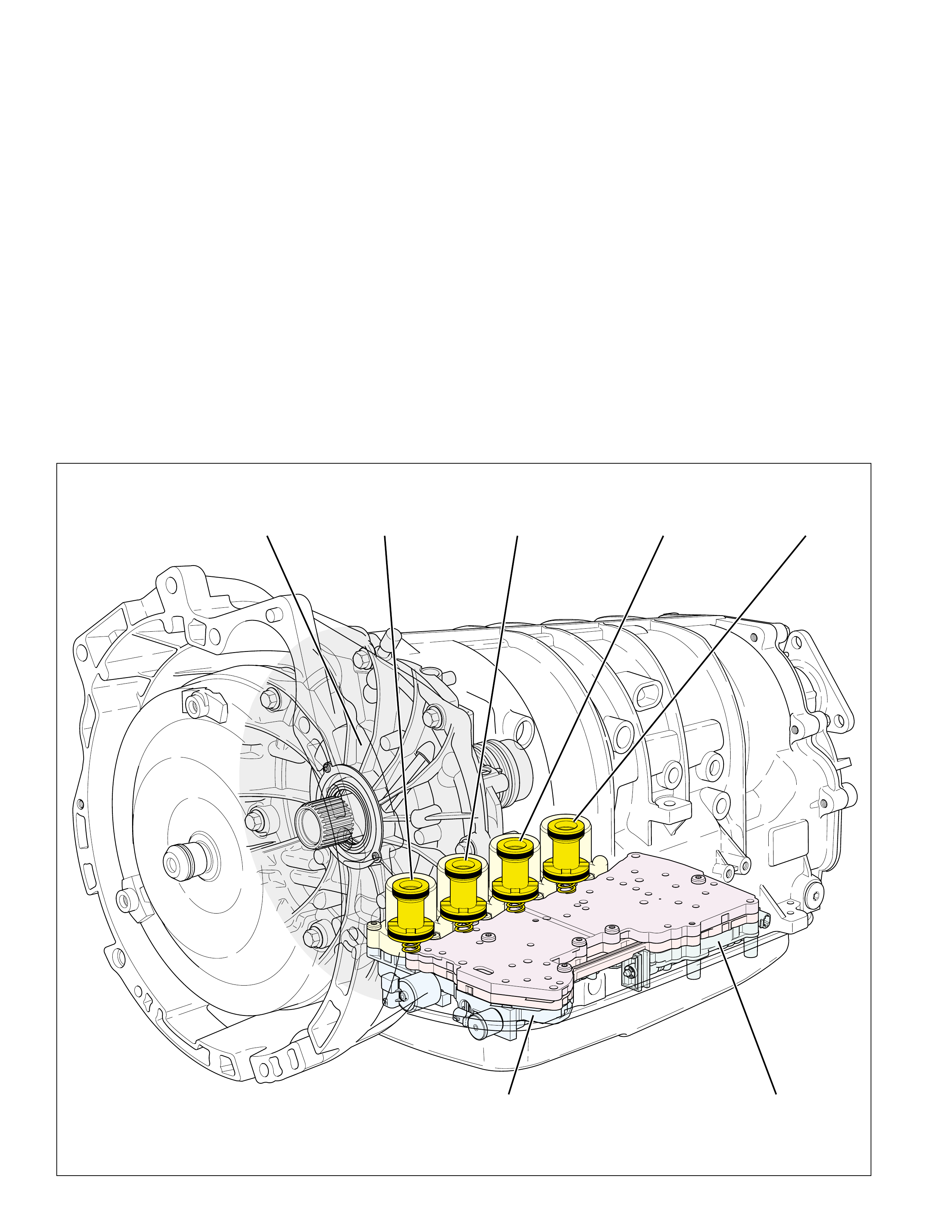

CASE

ASSEMBLY

(24)

CONTROL

VALVE BODY AND

ACCUMULATOR

ASSEMBLY

(47)

TORQUE

CONVERTER

ASSEMBLY

(1)

TORQUE

CONVERTER

HOUSING

(227)

FLUID PUMP

COVER

ASSEMBLY

(202)

GASKET

(46)

GASKET

(60)

FLUID

FILTER

(59)

FLUID

PAN

(62)

UNDERSTANDING THE GRAPHICS

6

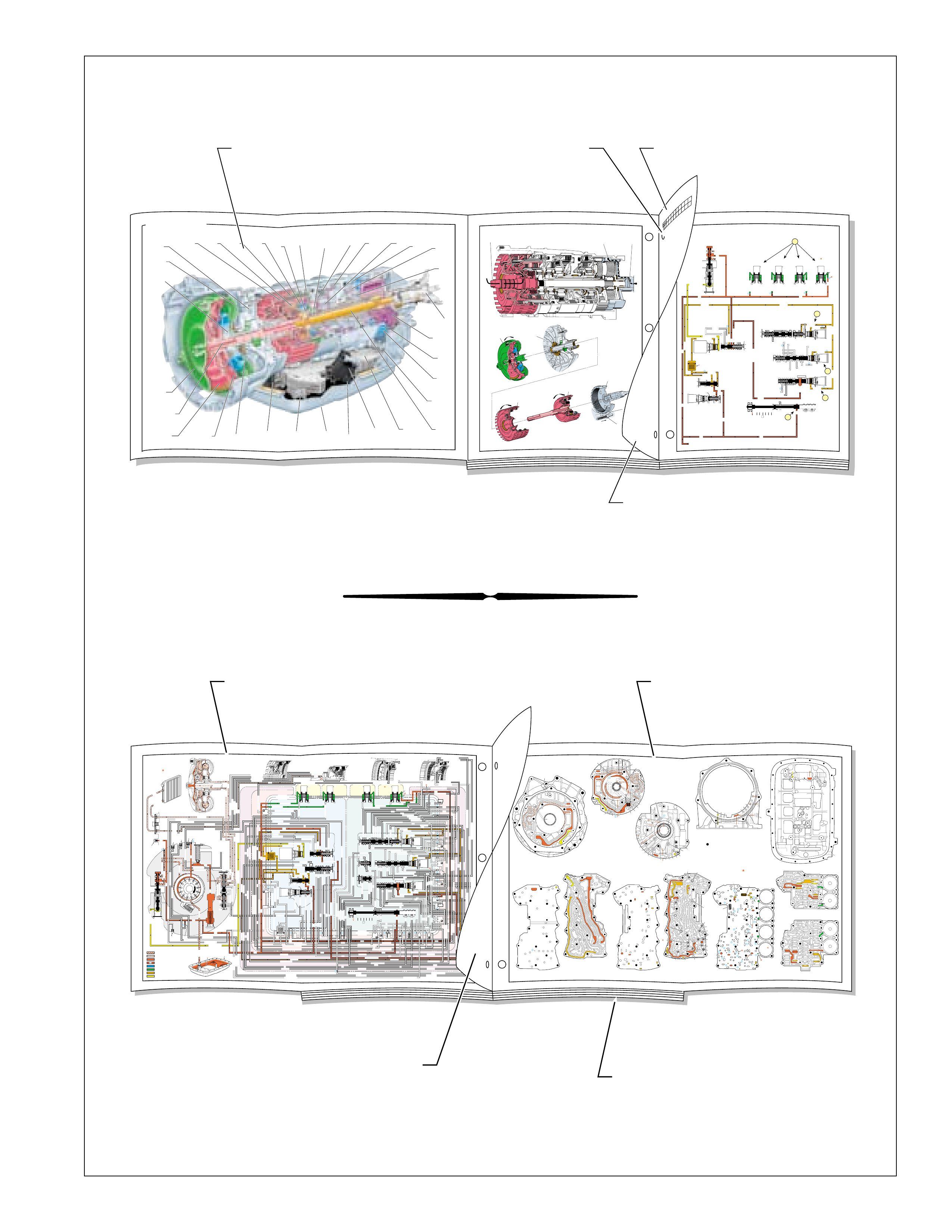

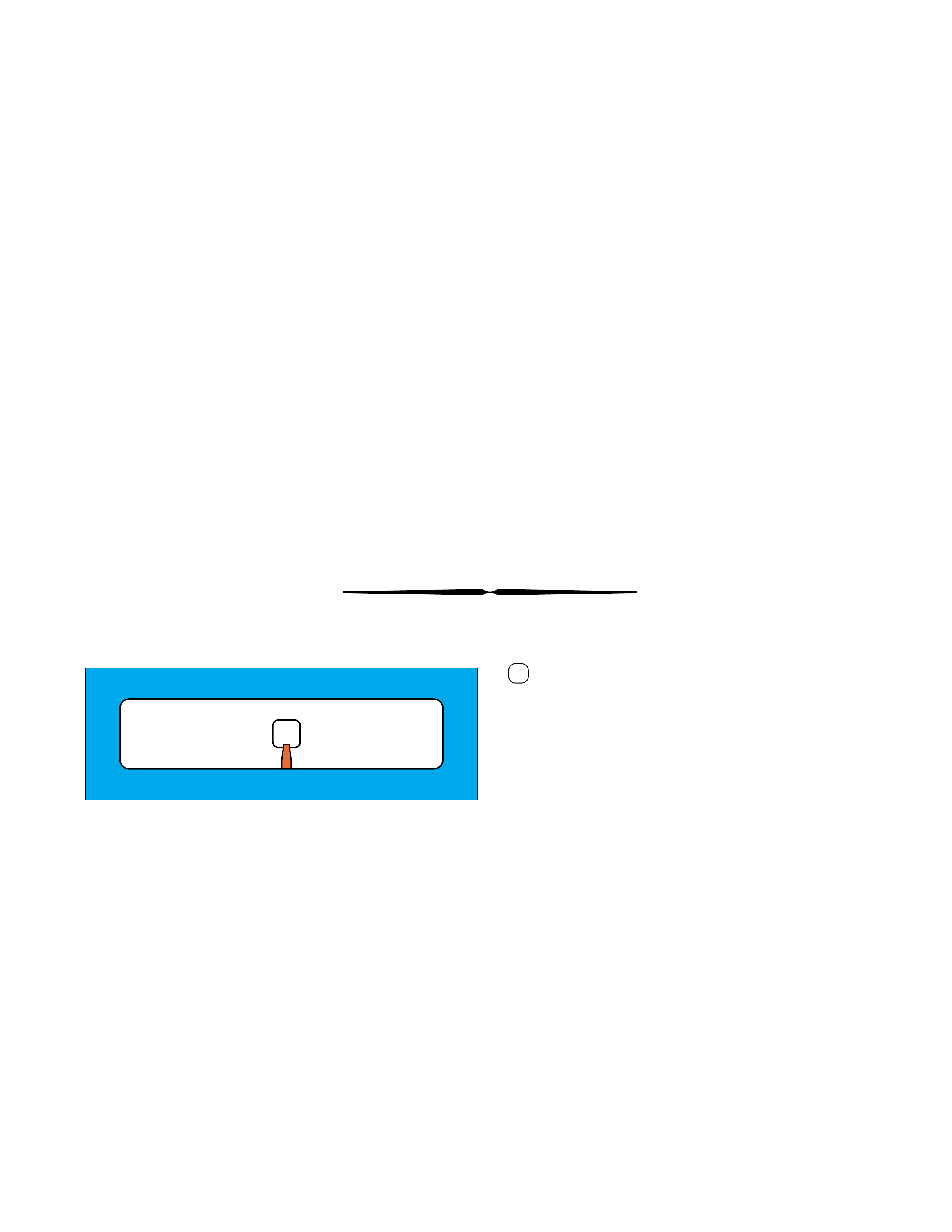

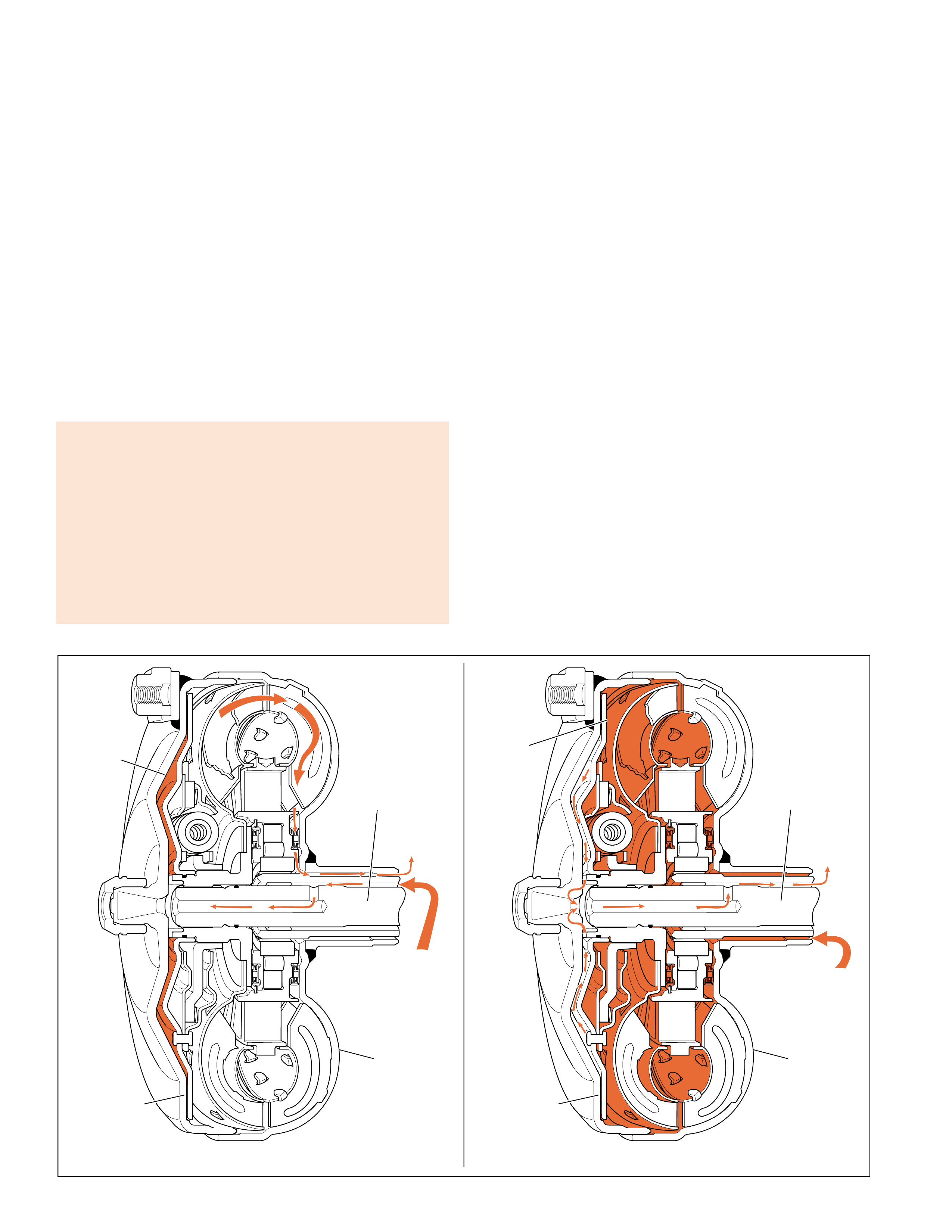

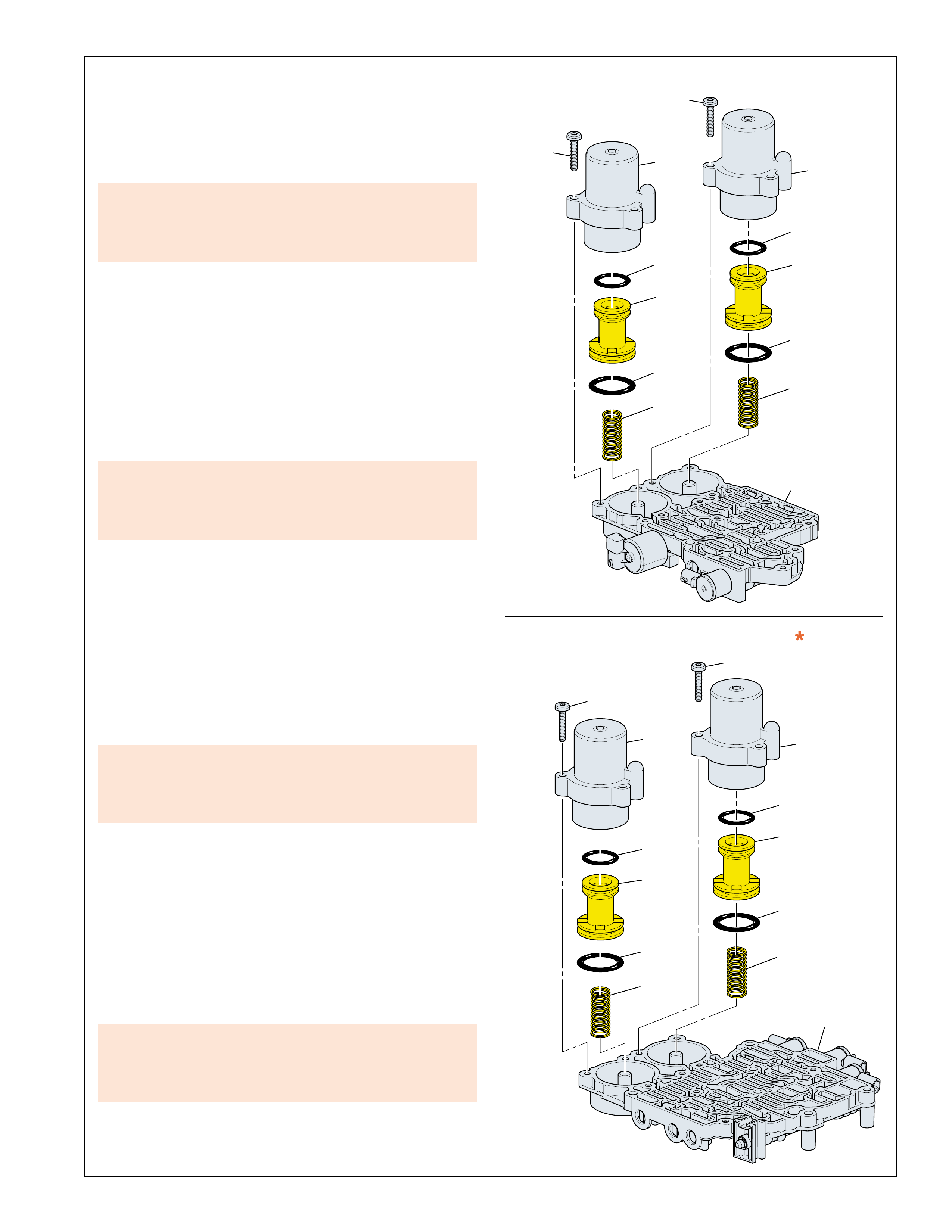

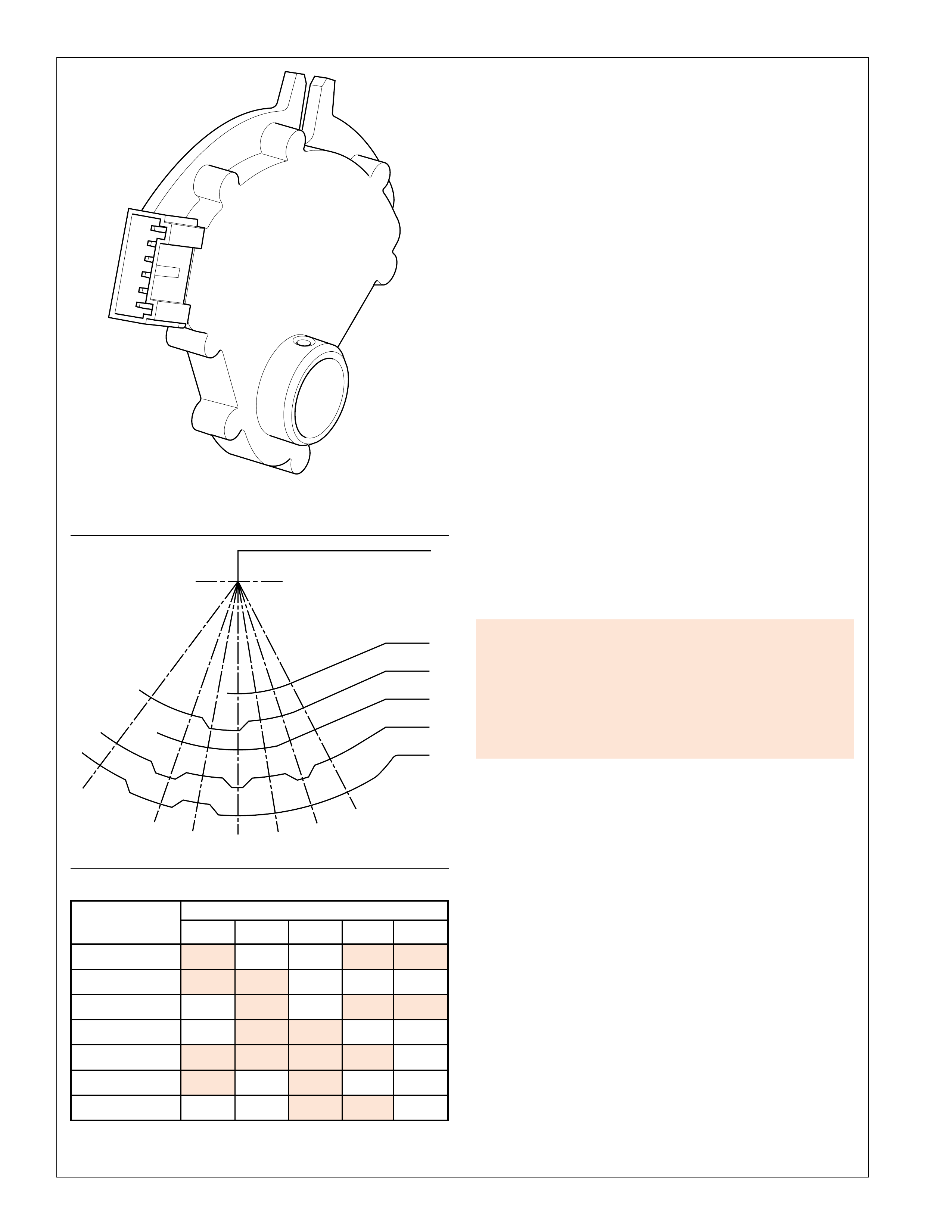

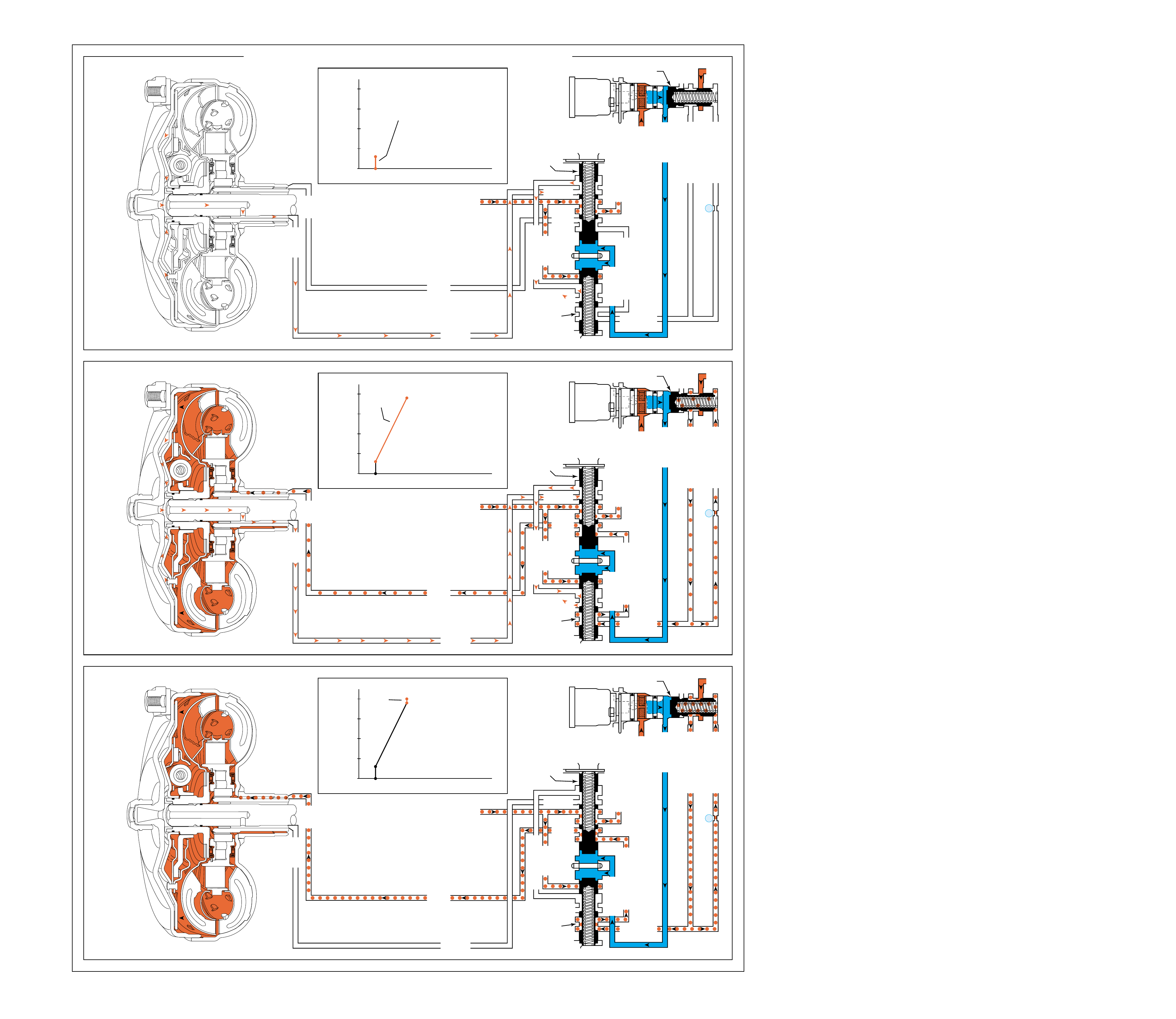

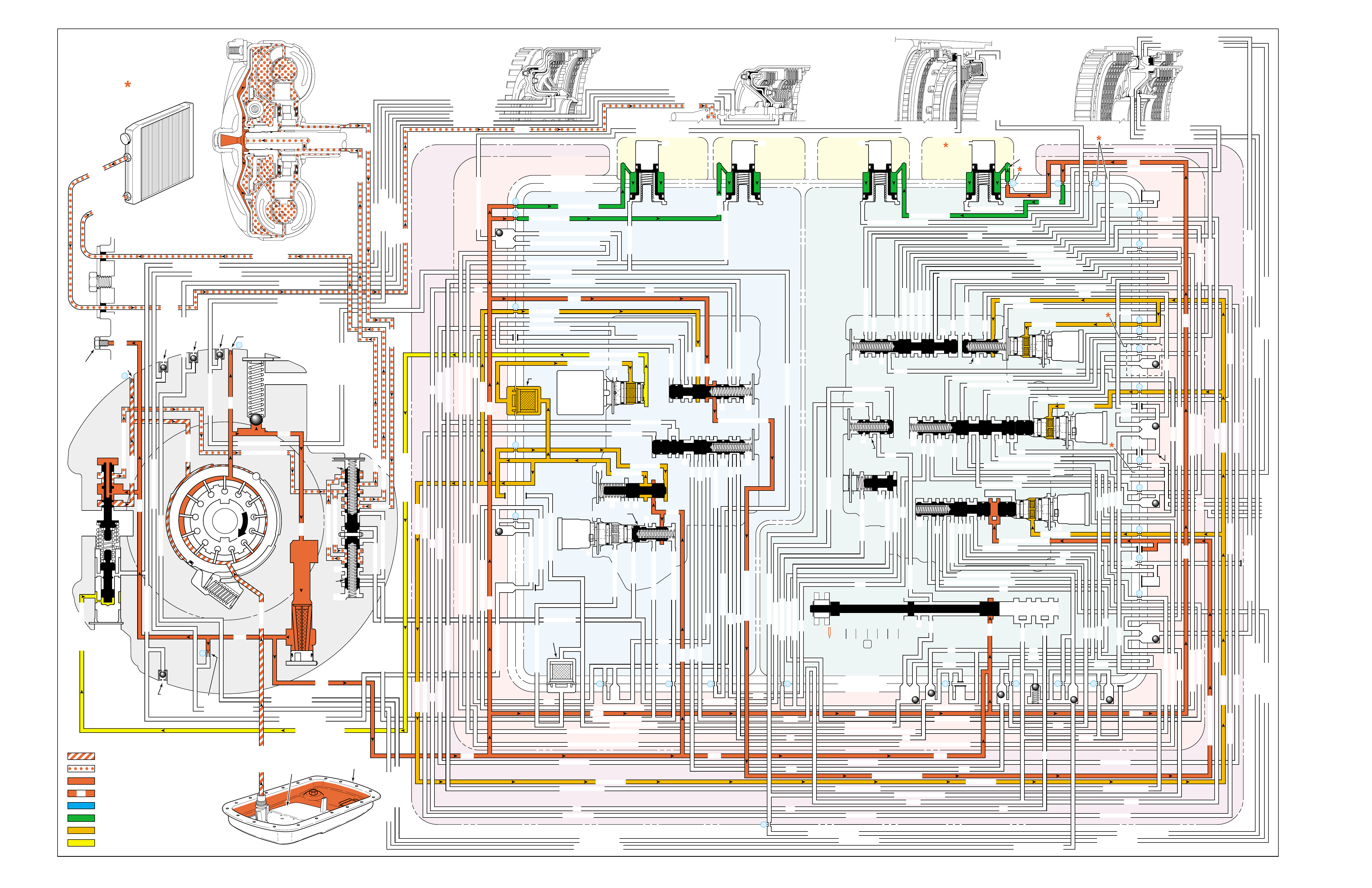

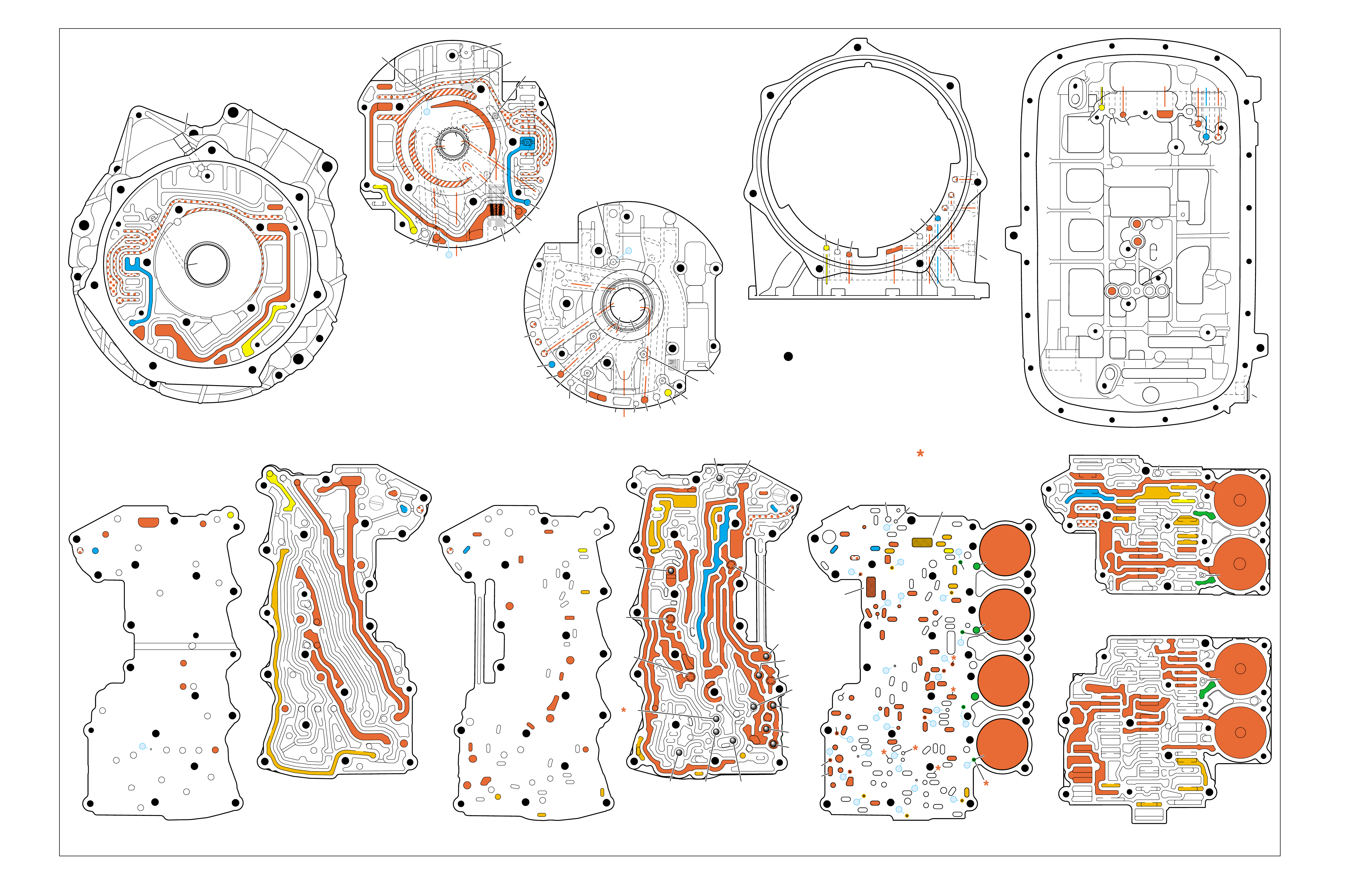

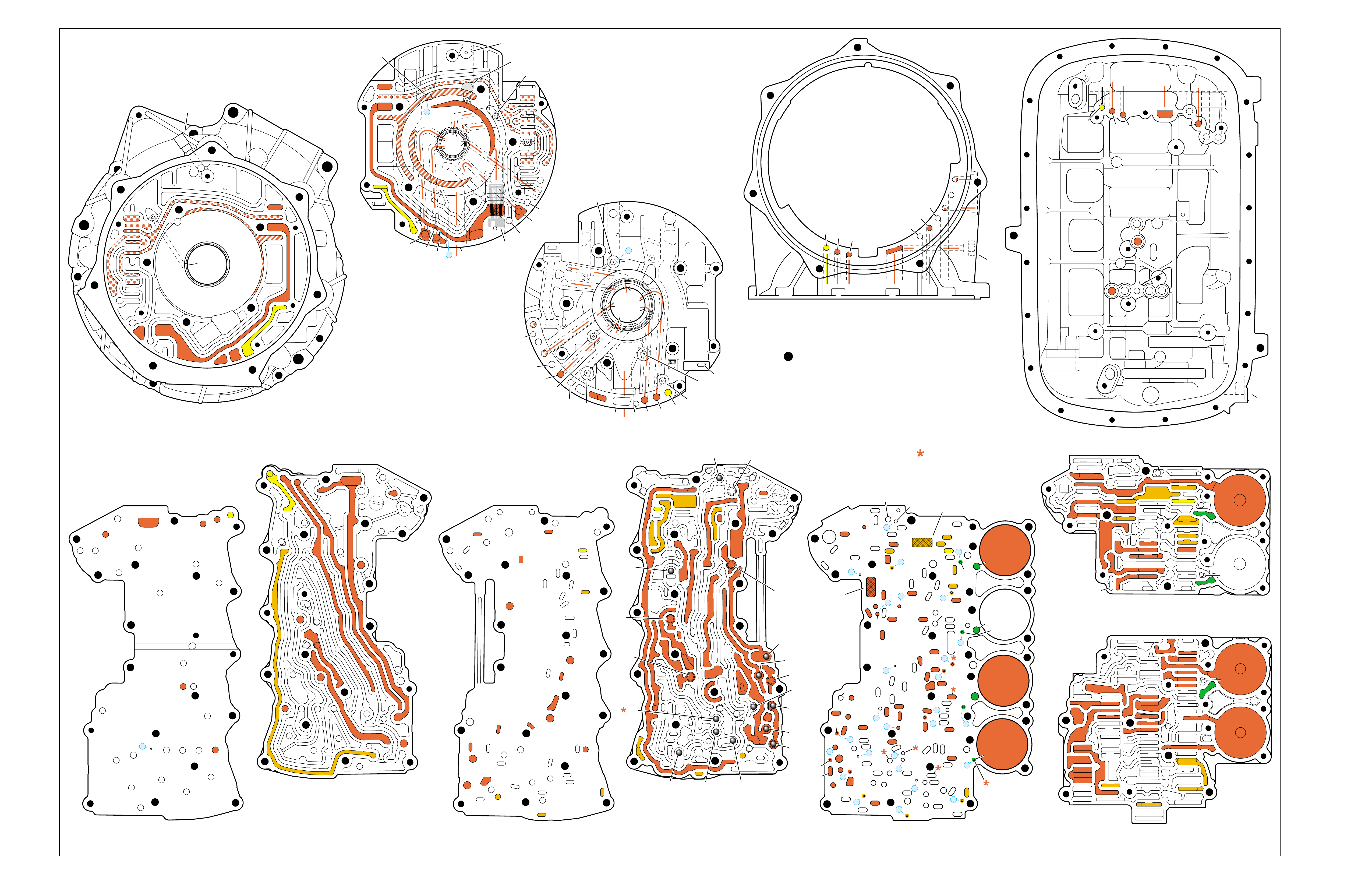

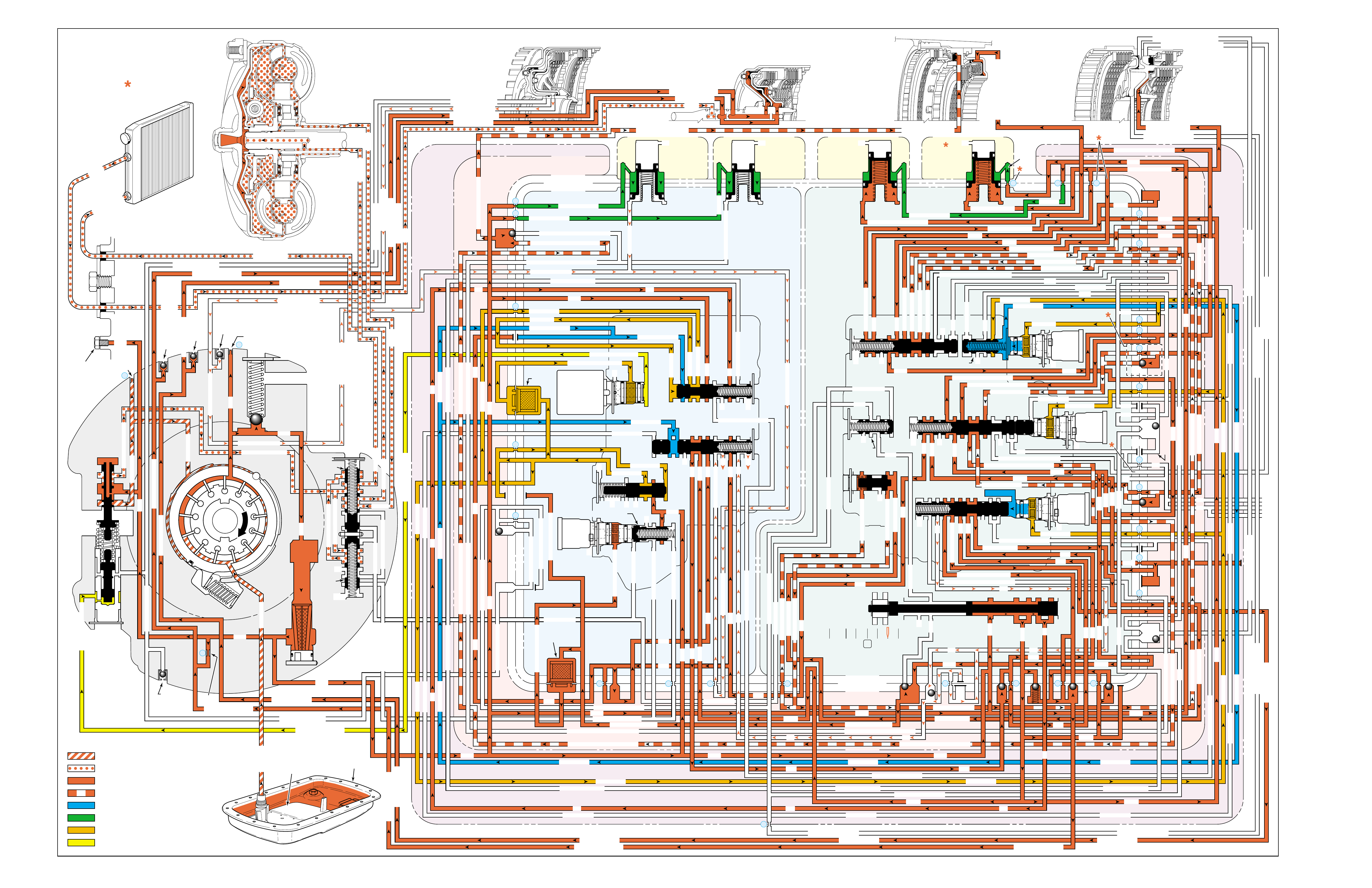

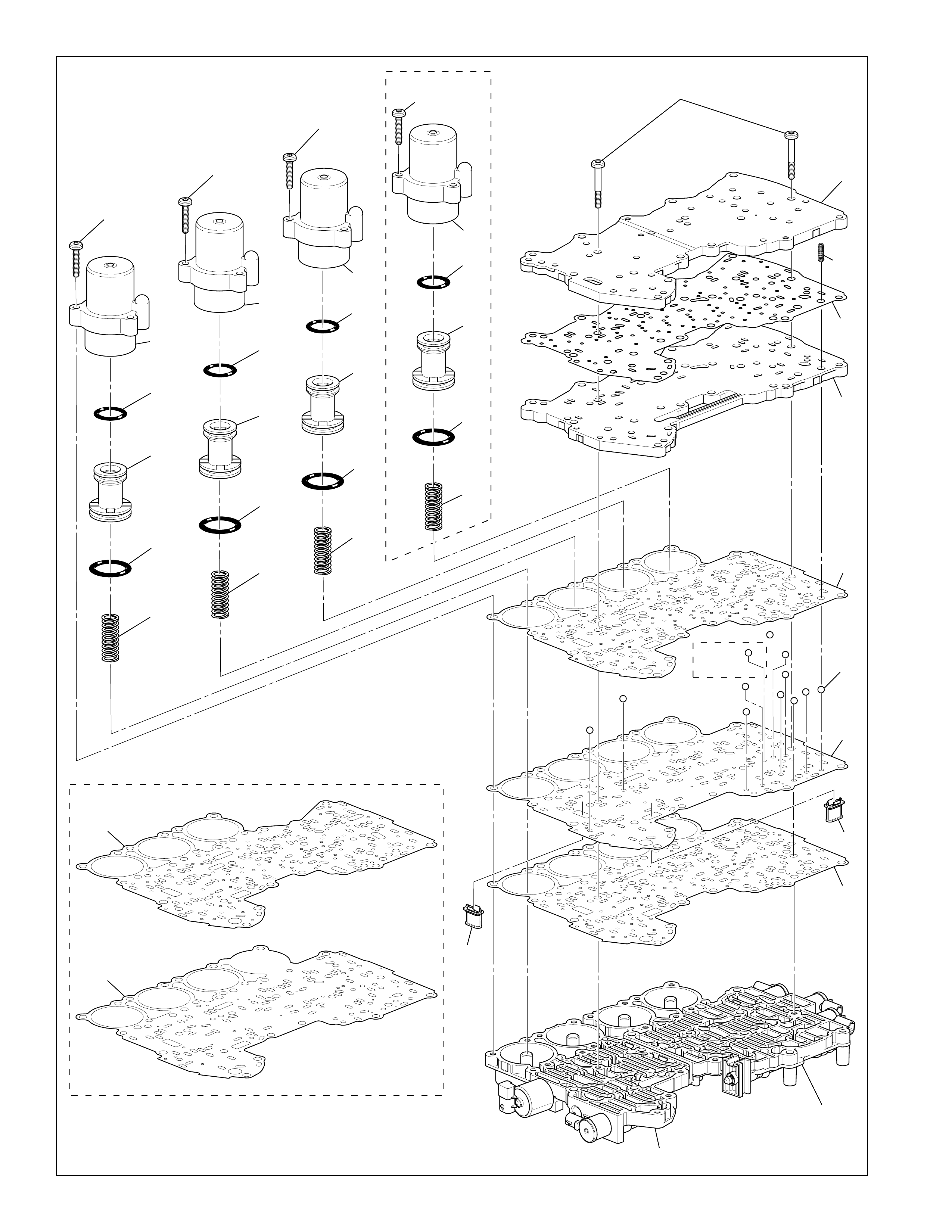

The flow of transmission fluid starts in the bottom

pan and is drawn through the f ilter , case assembly and

into the oil pump assembly. This is a basic concept of

fluid flow that can be understood by reviewing the

illustrations provided in Figure 2. Ho we v er, fluid may

pass between the control valve body, spacer plate,

case and other components many times before reaching

a valve or applying a clutch. For this reason, the

graphics are designed to show the e xact location where

fluid passes through a component and into other

passages for specific g ear range operation.

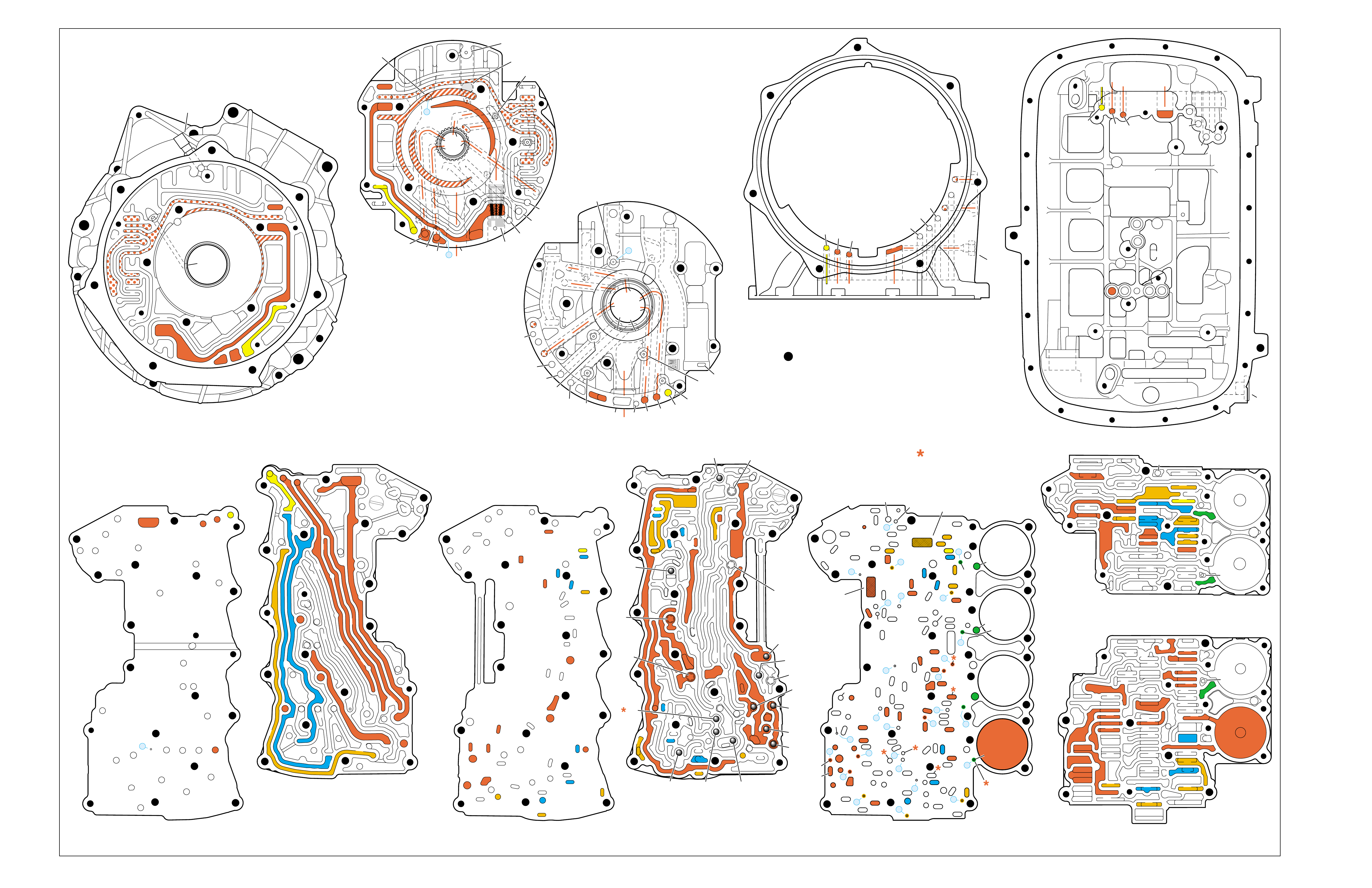

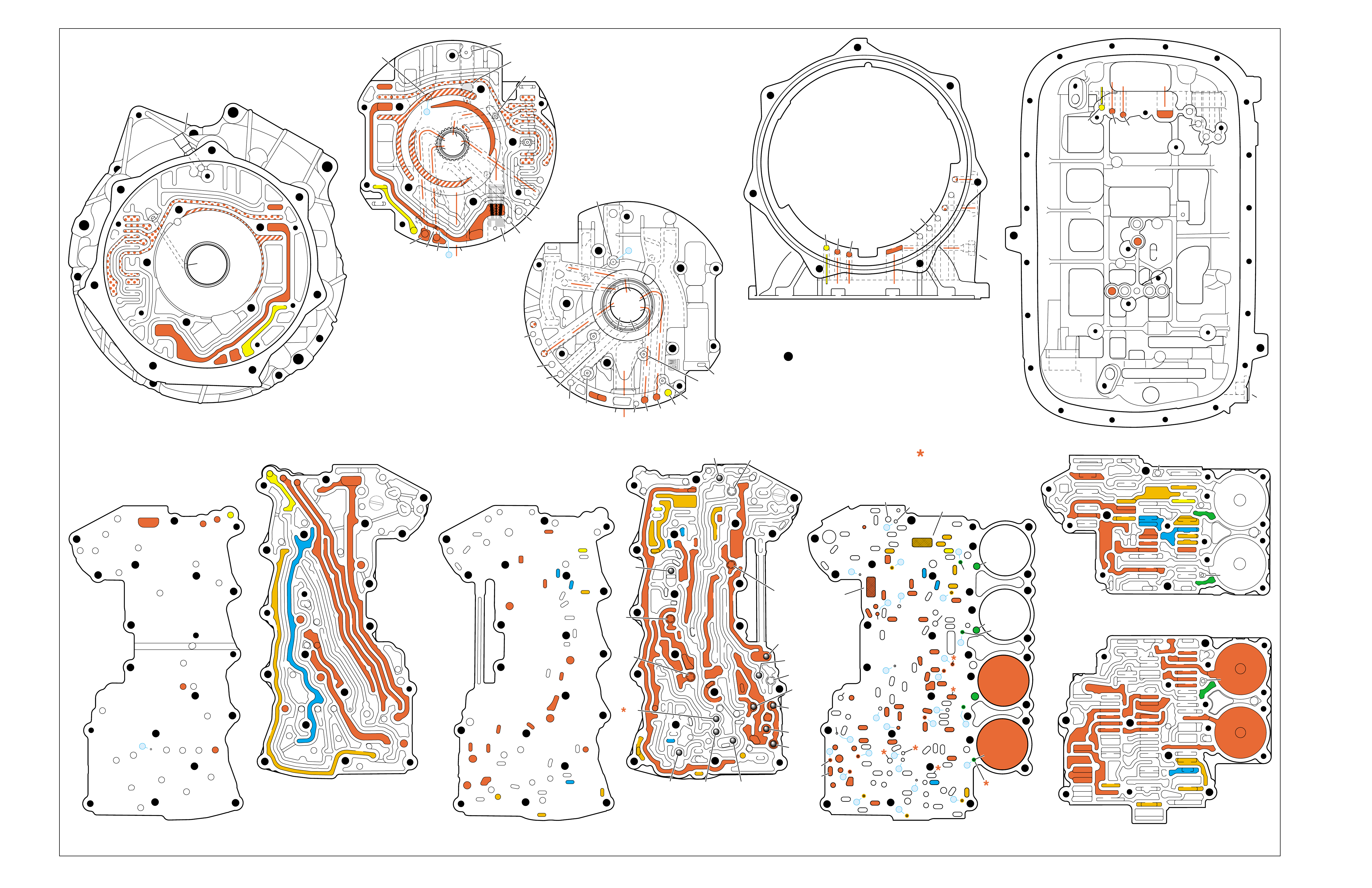

To provide a better understanding of fluid flow in

the Hydra-matic 4/5L40-E transmission, the

components in v olved with hydraulic contr ol and fluid

flow are illustrated in three major formats. Figure 3

provides an example of these formats which are:

•A three dimensional line drawing of the component

for easier part identification.

•A two dimensional line drawing of the component

to indicate fluid passages and orifices.

•A graphic schematic representation that displays

valves, ball check valves, orifices and so forth,

required for the proper function of the transmission

in a specific gear range. In the schematic drawings,

fluid circuits are represented by straight lines and

orifices are represented by indentations in a circuit.

All circuits are labeled and color coded to provide

reference points between the schematic drawing

and the two dimensional line drawing of the

components.

•Figure 4 (page 7B) provides an illustration of a

typical valve, bushing and valve train components.

A brief description of valve operation is also

provided to support the illustration.

•Figure 5 (page 7B) provides a color coded chart

that references different fluid pressures used to

operate the hydraulic control systems. A brief

description of how fluid pressures affect valve

operation is also provided.

Figure 2

PRESSURES

INTAKE & DECREASE (SUCTION)

CONVERTER & LUBE

MAINLINE

REGULATED LINE

SOLENOID SIGNAL

ACCUMULATOR

FEED LIMIT

THROTTLE SIGNAL

NOTE:

PASSAGES AND

COMPONENTS

MARKED WITH

ARE USED FOR

THE 5L40-E ONLY

;

;

;

;;

;;

;;

;

;

;

;;;

;;;

;;;

;

;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;;;

;

;

;

GASKET (309)

GASKET (305)

GASKET (303)

BOTTOM CHANNEL PLATE (304)

TOP CHANNEL PLATE (301)

CASE (24)

REAR CONTROL VALVE BODY (310)

SPACER PLATE (307)

GASKET (309)

GASKET (305)

GASKET (303)

BOTTOM CHANNEL PLATE (304)

TOP CHANNEL PLATE (301)

CASE (24)

FRONT CONTROL VALVE BODY (311)

SPACER PLATE (307)

FLUID

PUMP

COVER

(202)

CONVERTER

HOUSING

(224)

ACCUMULATOR HOUSING (317) ACCUMULATOR HOUSING (323) ACCUMULATOR HOUSING (328) ACCUMULATOR HOUSING (333)

LUBE

LUBE

LUBE

LUBE

TO COOLER

LUBE

TO COOLER

APPLY

APPLY

APPLY

RELEASE

DECREASE

DECREASE

LINE

OVERDRIVE CLUTCH FEED 1

OVERDRIVE CL FD 1OVERDRIVE CLUTCH FEED 1

OVERDRIVE CLUTCH FEED 1 OVERDRIVE CLUTCH FEED 1

OVERDRIVE CLUTCH

2345 2345

2345

2345

2345

2345

2345 OR REVERSE

RLO

LOW AND REV CL OR RLO

LOW AND REV CL OR RLO

SECOND COAST CLUTCH

SECOND CLUTCH

SECOND COAST CLUTCH

SUCTION SUCTION

LINE

LINE

LINE LINE

LINE

LINE

LINE LINE LINE

TCC SIGNAL

CONVERTER FEED

CONVERTER FEED

RELEASE

TO COOLER

REGULATED APPLYREGULATED APPLY

LINE

EX

CONVERTER FEED

REVERSE CLUTCH

REVERSE CLUTCH

THROTTLE SIGNAL

LINE

EX

FILTERED FEED LIMIT

THROTTLE SIGNAL

THROTTLE SIGNAL

THROTTLE SIGNAL

EX

2345 OR REVERSE

2345 OR REVERSE

2345 OR REVERSE

TCC SIGNAL

TCC SIGNAL

TCC SIGNAL

REGULATED APPLY

REGULATED APPLY

REGULATED APPLY

EX

EX

FEED LIMIT VALVE

LINE

EX

EX

EX

EX

FEED LIMIT

FEED LIMIT FEED LIMIT

FEED LIMIT

FEED LIMIT

FEED LIMIT

FEED LIMIT

FEED LIMIT FEED LIMIT

FEED LIMIT

2-3 SHIFT VALVE CNTRL

EX

EX

EX

EX

EX

EX

EX EX

SECOND COAST CLUTCH

23 REGULATED

23 REGULATED

OVERDRIVE CLUTCH FEED 1

INTERMEDIATE CLUTCH

2345

2345

2345

2345

INTERMEDIATE CLUTCH

2345

345

FEED LIMIT

EX

EX

EX

EX

2-3 SIGNAL

LOW PRESSURE

123 REGULATED

123 REGULATED

EX

CNTRL

LINE SAFETY MODE

123 BRAKING

123

EX

EX

EX

123

123

123

123

123

123

123

123123

COAST CLUTCH

COAST CLUTCH FEED

OVERDRIVE CLUTCH FEED 2

45

FEED LIMIT

SAFETY MODE

LINE

FEED LIMIT

32

MEMORY

MEMORY

MEMORY

MEMORY PILOT

MEMORY PILOT

32 SAFETY MODE

LINE SAFETY MODE

EX

EX

LINE SAFETY MODE

CNTRL 3-4 SHIFT

2-3 SIGNAL

123123 D432D432

DIRECT CLUTCH

DIRECT CLUTCH

4545

1-2 SIGNAL

EX

EX

EX

1-2 SHIFT VALVE

FDL

FDL

FDL

FDL

FDL

FDL

D432

2345 2345

D432

SECOND CLUTCH

23 REGULATED

23 REGULATED23 REGULATED

123 REGULATED

LOW AND REVERSE CLUTCH

LOW AND REVERSE CL

SECOND CLUTCH

123 REGULATED

EX

EX

EX

FD LIMIT

FEED LIMIT

FDL

1-2 SIGNAL

2-3 SIGNAL

EX

EX

TCC SIGNAL

TCC SIGNAL

TCC SIGNAL

RLO

EX

REV

RPND432

MANUAL VALVE

LINE

D432

D432 D432

D432

D432

D432

D432 D432

D432

D432D432

D432

REV

REVERSE

EX

3232

LINE

EX

EX

LINE

CASE (24)

OVERDRIVE CLUTCH FEED 2

OVERDRIVE CL FD 2

OVERDRIVE CLUTCH FEED 2

ACCUMULATOR

DIRECT CLUTCH

ACCUM

INTERMEDIATE CLUTCH

INTERMEDIATE CLUTCH

INTERMEDIATE CLUTCH

ACCUMULATOR

EX

SECOND CLUTCH

SECOND CLUTCH

ACCUM

ACCUM

LINELINE

FORWARD CLUTCH

FORWARD CLUTCH FORWARD CLUTCH

ACCUMULATOR

LINE

LINELINE

LINE

OVERDRIVE CLUTCH

INTERMEDIATE CL

COAST CLUTCH

REVERSE LOCKOUT

COAST CLUTCH

REVERSE CLUTCH

REVERSE CLUTCH

REVERSE CLUTCH

4-5 SIGNAL

EXEXEX

LINE SAFETY MODE

LINE SAFETY MODE

REVERSE LOCKOUT

REVERSE LOCKOUT REVERSE LOCKOUT

COAST CLUTCH

REVERSE LOCKOUT REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE LOCKOUT

REVERSE CLUTCH

REVERSE CLUTCH

LOW AND REV CL OR RLO

FORWARD CLUTCH

FORWARD CLUTCH

FORWARD CLUTCH

COAST CLUTCH

FORWARD CLUTCH

FORWARD CLUTCH

FORWARD CLUTCH

2345

2345 OR REVERSE

123 REGULATED

123 REGULATED

123 REGULATED 123 REGULATED

123 REGULATED

123 REGULATED

123 REGULATED

123 BRAKING

123 BRAKING

123 BRAKING

123 BRAKING

1-2 SIGNAL1-2 SIGNAL

1-2 SIGNAL1-2 SIGNAL1-2 SIGNAL

1-2 SIGNAL 1-2 SIGNAL 1-2 SIGNAL

2-3 SIGNAL2-3 SIGNAL2-3 SIGNAL

2-3 SIGNAL 2-3 SIGNAL

2-3 SIGNAL2-3 SIGNAL2-3 SIGNAL

2-3 SIGNAL

SECOND CLUTCH

SECOND CLUTCH

COAST CLUTCHCOAST CLUTCHCOAST CLUTCH

COAST CLUTCH

COAST CLUTCH

COAST CLUTCH

COAST CLUTCH

COAST CLUTCH

23 REGULATED

345

345

345

345 345 345

345

345

345

345

345

345

345

345

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CL

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CLUTCH

DIRECT CLUTCH

45

45

45

4545

45

OVERDRIVE CLUTCH

OVERDRIVE CL FD 1

OVERDRIVE CLUTCH FEED 2OVERDRIVE CLUTCH FEED 2

OVERDRIVE CL FD 2

OVERDRIVE CLUTCH FEED 2 OVERDRIVE CL FD 2

3232

32 32 32

323232

32 SAFETY MODE

32 SAFETY MODE 32 SAFETY MODE 32 SAFETY MODE

32 SAFETY MODE32 SAFETY MODE

32 SM 32 SM

FDL

PRESSURE

CONTROL

SOLENOID

VALVE

1-2 SHIFT

SOLENOID

VALVE

N/C

(A)

OFF

2-3 SHIFT

SOLENOID

VALVE

N/C

(B)

OFF

4-5 SHIFT

SOLENOID

VALVE

N/C

(C)

OFF

TCC PWM

SOLENOID

VALVE

N/C

PRESS REG VAL VEBOOST VAL VE

CONVERTER FDL

AIR

BLEED

(233)

AIR

BLEED

(233)

AIR

BLEED

(203)

AIR

BLEED

(203)

AIR

BLEED

(203)

AIR

BLEED

(203)

7

4

2

1

5

6

11

10

9

12

18

FILTER

(308)

FILTER

(312)

TCC REGULATOR VALVE

TCC

CONTROL

VALVE

TCC

ENABLE

VALVE

REVERSE

LOCKOUT

VALVE

1-2 SHIFT CONTROL VALVE

FLUID

PAN

(62)

FLUID FILTER

ASSEMBLY

(59)

FLUID

PRESSURE

TEST PLUG

(40)

TORQUE

CONVERTER

ASSEMBLY

(1)

DIRECT

CLUTCH

ACCUMULATOR

OVERDRIVE

CLUTCH

ACCUMULATOR

INTERMEDIATE

CLUTCH

ACCUMULATOR

SECOND

CLUTCH

ACCUMULATOR

COOLER

PRESSURE

RELIEF

BALL

VALVE

21 2

10d

2a

2b

42b

43a

37d

39b

40b

37c

40d

11b

10a

24a

10c

11a 10b

54b

54d

2c

54a

54c

27c 46

7a

24b

20a

13a

37b

38a

7b

47a

47b

27b

28c

12a

23a

36e

36f

23b

23c

15a

24c

26b

36a

38c

38d

36b

25a

15

2m 54g

54f

#8

18

15f

15e

17c

17b

17a

27a

44a

44e

44d

44b

25c

30a

33a

25e

19e

35c

19h

19f

10f

10h

10g

22a

35b

#7

13b

32a

26a

10i

22f

22e

43b

22b

34a

48b

39a

22c

X-1

22

22e

21a

42a

19a

20b

19b

#2

23 22g

14a

2f

2h

19g

19i

19

j

DIRECT

AND REVERSE

CLUTCH

ASSEMBLY

(400—420)

FORWARD

AND COAST

CLUTCH

ASSEMBLY

(430—451)

OVERDRIVE

AND

INTERMEDIATE

CLUTCH

ASSEMBLY

(480—497)

CENTER

SUPPORT

ASSEMBLY

(510—535)

3

2d54e

2e

30c

30d

35d

26

37a

13

#1

15c

15b

16

15d 16

15

X-2

16a

X-4 X-5

38

14

X-3

19

#6

19d

19

21

19c 21

15

#5

21b 31

21c 31

17

21

#4

20d

20c

16

25b

19

25d

20

36 46

28a

44c

28b

30b

21

#11

33e

33d

23

24

35a

#9

33c

33b

22

36d

36c

25

#12

41 40c

39c

43 13

28

40a

#10

45

45

45

44f

44

48

43c

#3

38b

38e

27

48a

29

8

10e

2310

32 SM/FDL

30

31

FLUID PUMP

SCREEN

ASSEMBLY

(213)

(214)

4-5 SHIFT VLV

UNDERSTANDING THE GRAPHICS

Figure 3

FOLDOUT ➤ 7AFOLDOUT ➤ 7

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

FRONT CONTROL

VALVE BODY

ASSEMBLY

(311)

BOTTOM CHANNEL PLATE SIDE

TWO DIMENSIONALTHREE DIMENSIONAL

TOP

CHANNEL PLATE

(301)

BOTTOM CHANNEL PLATE SIDE

BOTTOM CHANNEL PLATE SIDE

SPACER

PLATE

(307)

TWO DIMENSIONALTHREE DIMENSIONAL

TWO DIMENSIONALTHREE DIMENSIONAL

TWO DIMENSIONALTHREE DIMENSIONAL

TWO DIMENSIONALTHREE DIMENSIONAL

TWO DIMENSIONALTHREE DIMENSIONAL

BOTTOM CHANNEL PLATE SIDE

CONTROL VALVE BODY SIDE

ACCUMULATORS

BOTTOM

CHANNEL

PLATE

(304)

REAR CONTROL

VALVE BODY

(310)

CONTROL VALVE BODY SIDE

FLUID PUMP

COVER

ASSEMBLY

(202)

TORQUE CONVERTER

HOUSING

(227)

CASE

ASSEMBLY

(24)

FLUID PUMP COVER SIDE CONVERTER HOUSING SIDE TOP CHANNEL PLATE SIDE

THREE DIMENSIONALTHREE DIMENSIONAL THREE DIMENSIONAL

TWO DIMENSIONAL TWO DIMENSIONAL TWO DIMENSIONAL

GRAPHIC

SCHEMATIC

REPRESENTATION

7B

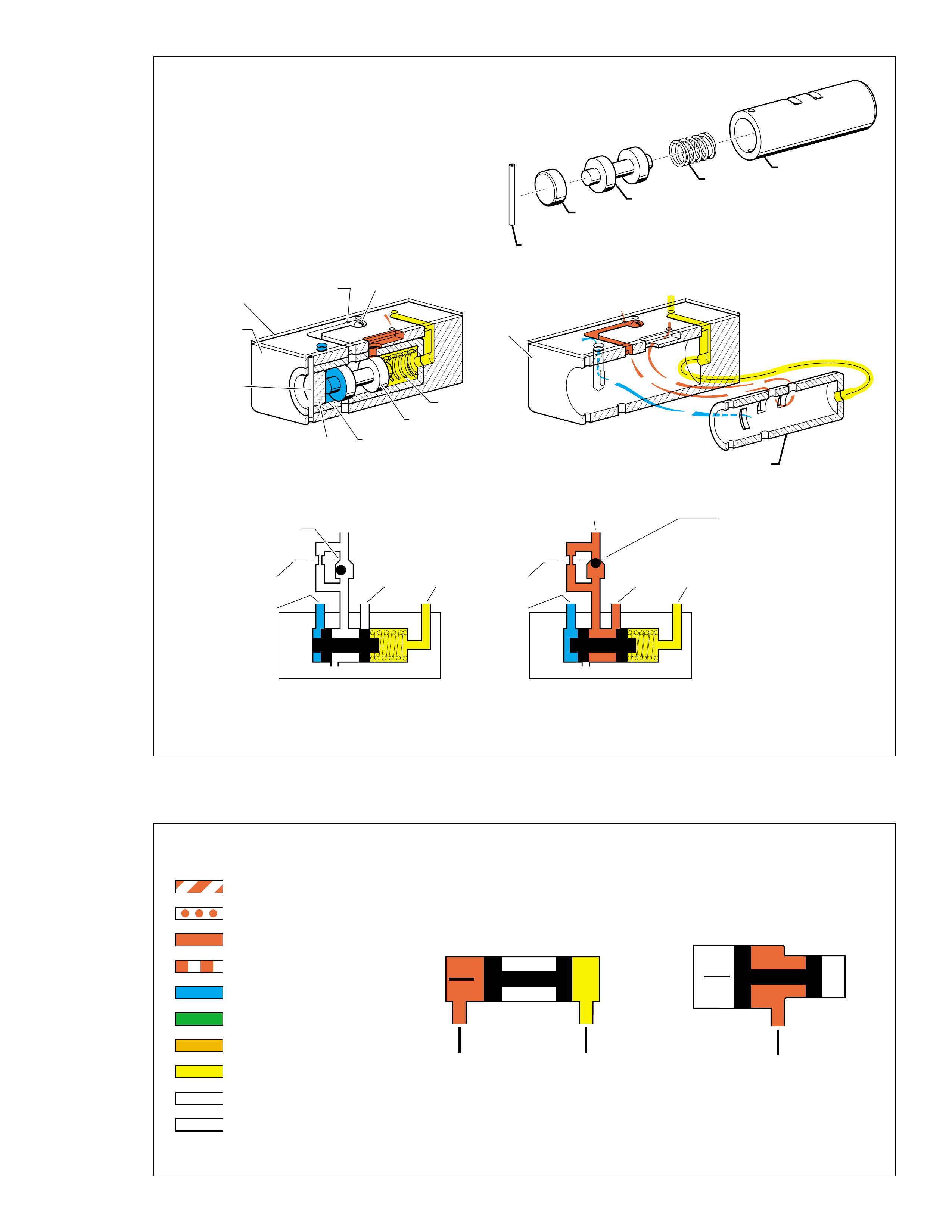

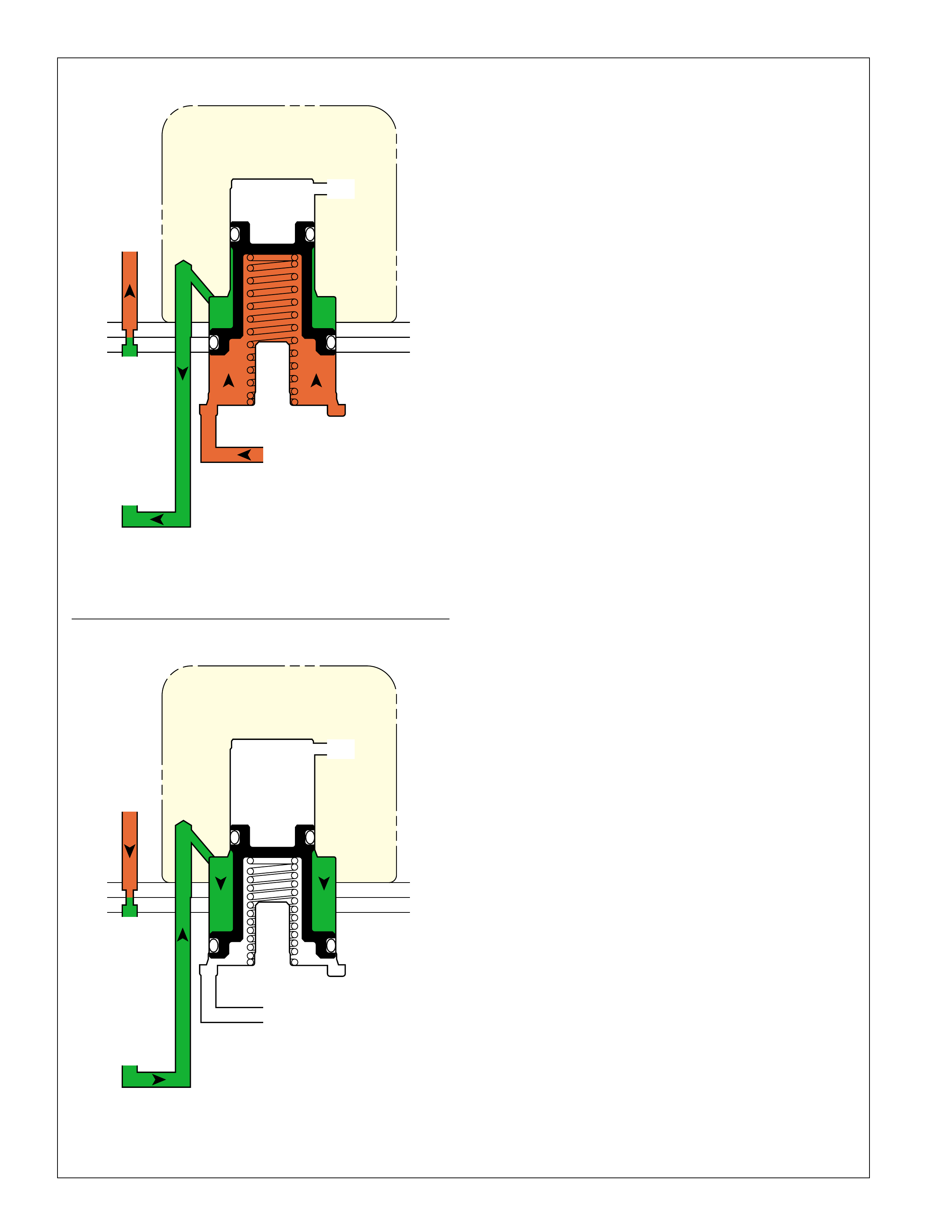

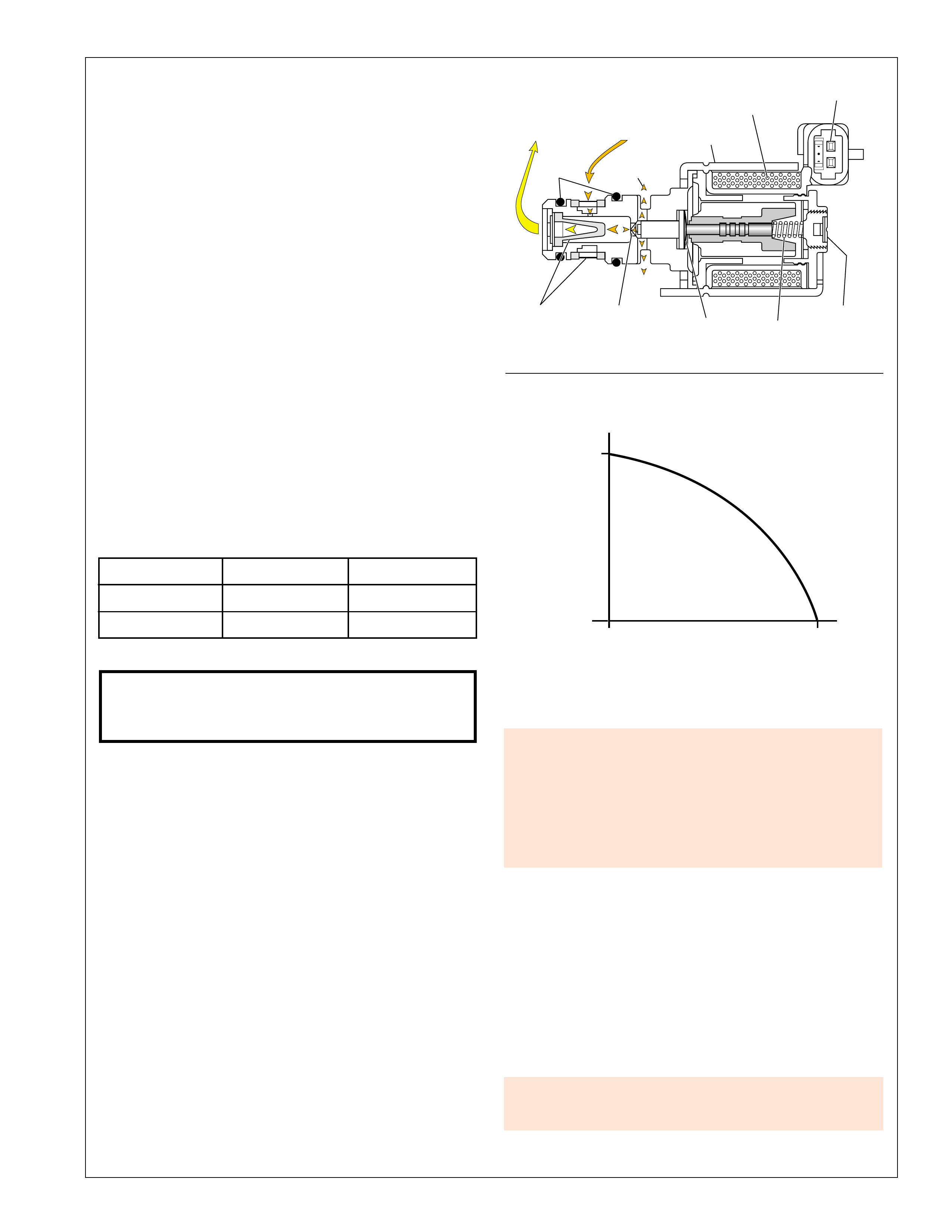

UNDERSTANDING THE GRAPHICS

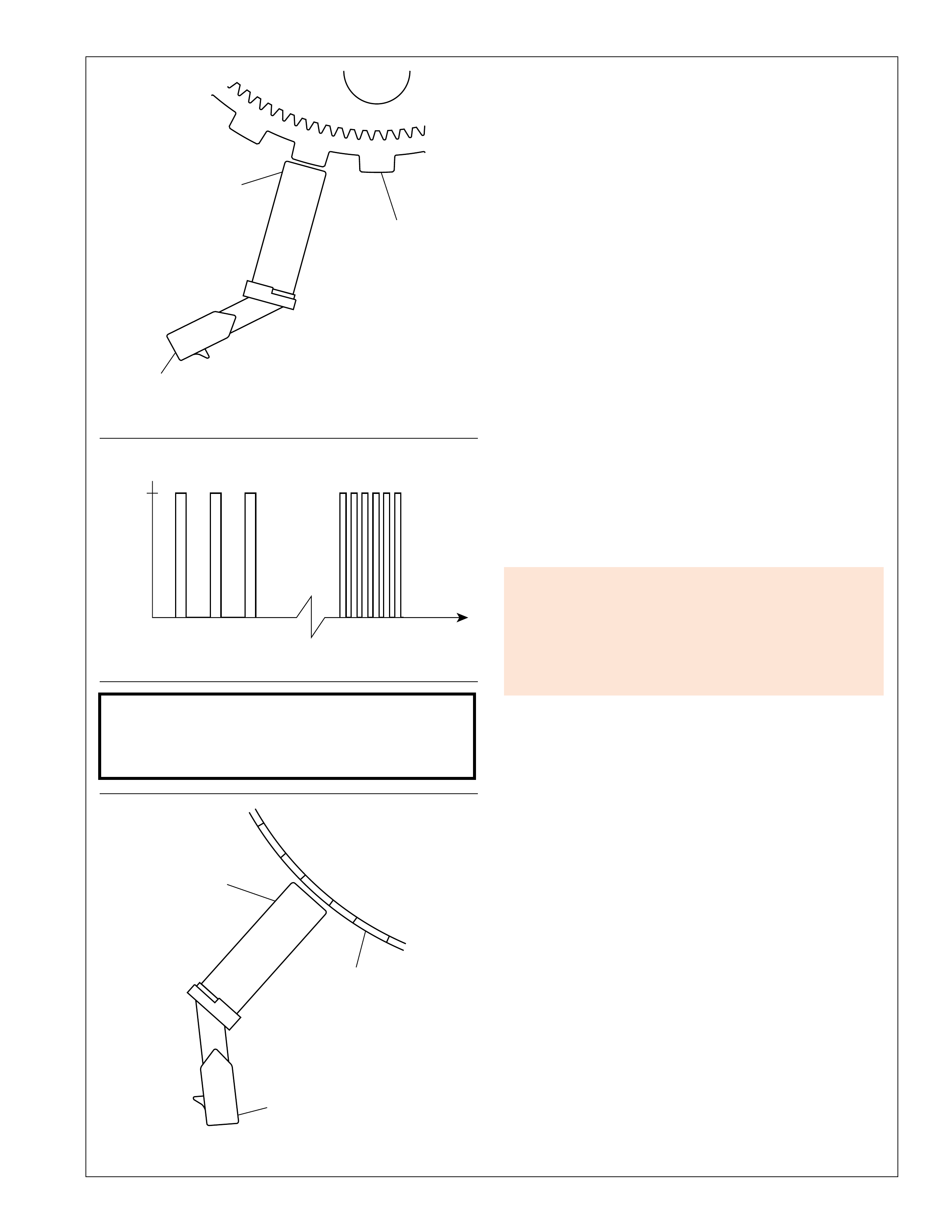

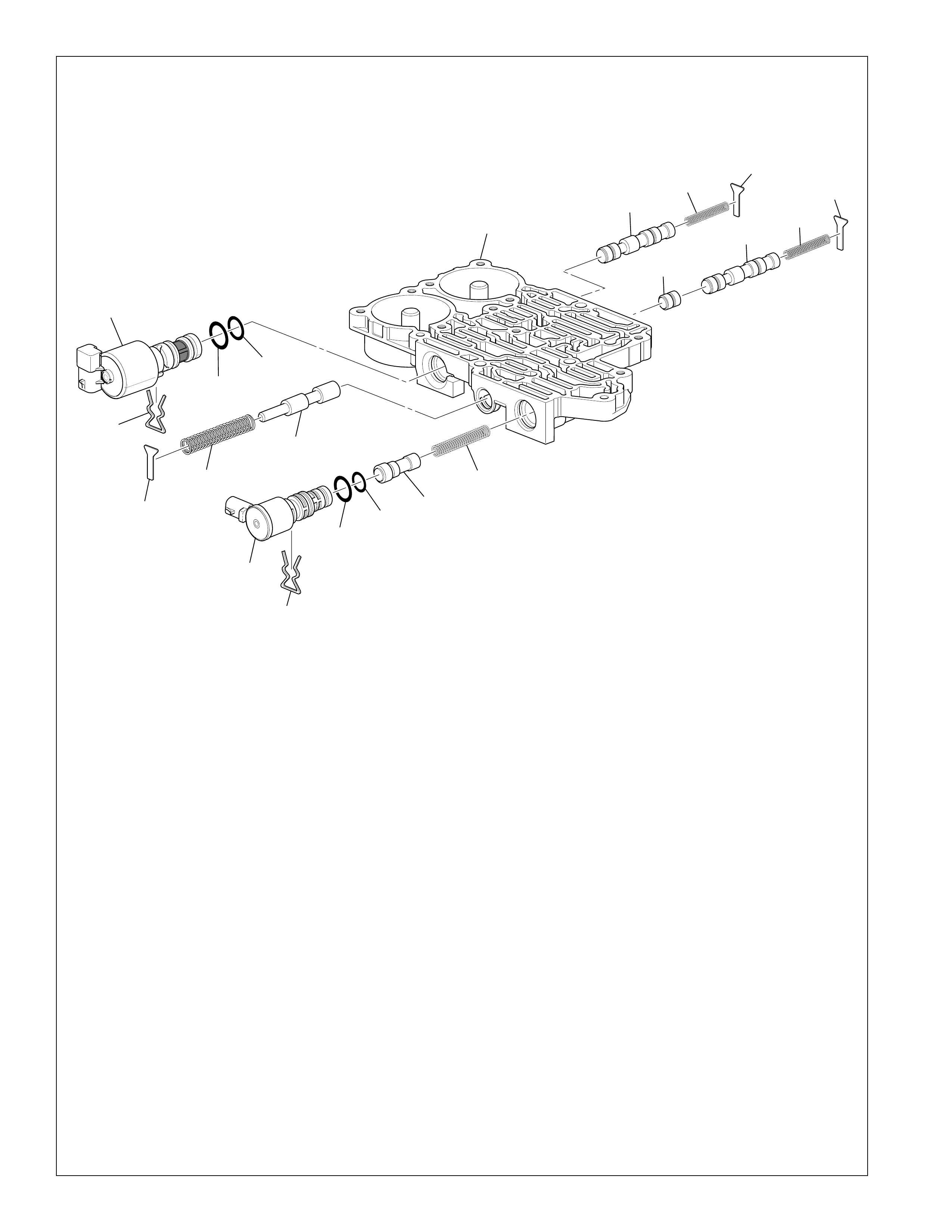

TYPICAL BUSHING AND VALVE

Figure 4

Figure 5

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

SPRING

RETAINING

PIN

BORE

PLUG

VALVE

BUSHING

EXHAUST FROM THE

APPLY COMPONENT

UNSEATS THE

BALL CHECK VALVE,

THEREFORE CREATING

A QUICK RELEASE.

TO APPLY

COMPONENT APPLY FLUID SEATS

THE BALL CHECK VALVE

FORCING FLUID THROUGH

AN ORIFICE IN THE SPACER

PLATE, WHICH CREATES

A SLOWER APPLY.

WITH SIGNAL FLUID PRESSURE

GREATER THAN SPRING AND

SPRING ASSIST FLUID PRESSURE

THE VALVE MOVES OVER.

WITH SIGNAL FLUID PRESSURE

EQUAL TO OR LESS THAN

SPRING AND SPRING ASSIST

FLUID PRESSURE THE VALVE

REMAINS IN CLOSED POSITION.

BUSHING

➤

VALVE

BODY

SPACER

PLATE

RESTRICTING

ORIFICE

BALL

CHECK

VALVE

RETAINING

PIN

BORE

PLUG

SPRING

VALVE

BUSHING

VALVE

BODY

➤

➤

➤

➤

➤

➤

➤

➤➤

➤

➤

➤➤

➤

➤

➤

SPACER

PLATE

SIGNAL

FLUID

APPLY

FLUID

SPRING

ASSIST

FLUID

EX

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

SPACER

PLATE

SIGNAL

FLUID

APPLY

FLUID

SPRING

ASSIST

FLUID

EX

➤

➤

➤

➤

➤

➤

➤

NOTE: NOT ALL VALVES ARE

USED WITH A BUSHING

FLUID PRESSURES

INTAKE & INCREASE (SUCTION)

CONVERTER & LUBE

MAINLINE

REGULATED LINE

SOLENOID SIGNAL

ACCUMULATOR

FEED LIMIT

THROTTLE SIGNAL

EXHAUST

DIRECTION OF FLOW

➤➤➤

➤

➤

AB

➤

➤

➤

➤

AB

➤

WITH EQUAL SURFACE AREAS

ON EACH END OF THE VALVE,

BUT FLUID PRESSURE "A"

BEING GREATER THAN FLUID

PRESSURE "B", THE VALVE

WILL MOVE TO THE RIGHT.

WITH THE SAME FLUID PRESSURE

ACTING ON BOTH SURFACE "A"

AND SURFACE "B" THE VALVE

WILL MOVE TO THE LEFT. THIS

IS DUE TO THE LARGER SURFACE

AREA OF "A" THAN "B".

Figure 6

HYDRA-MATIC 5L40-E

DIRECT

CLUTCH

ASSEMBLY

(405–414)

COAST

CLUTCH

ASSEMBLY

(437–446)

TRANSMISSION

FLUID

PAN

(62)

CONVERTER

PUMP

ASSEMBLY

STATOR

ROLLER

CLUTCH

ASSEMBLY

CONVERTER

STATOR

ASSEMBLY

TORQUE

CONVERTER

ASSEMBLY

(1)

TORQUE

CONVERTER

HOUSING/PUMP

ASSEMBLY

(3)

FORWARD

CLUTCH

ASSEMBLY

(435–451)

INPUT

SUN GEAR

SHAFT

(457)

FORWARD

SPRAG

CLUTCH

ASSEMBLY

(461)

OVERDRIVE

CLUTCH

ASSEMBLY

(480–487)

INTERMEDIATE

CLUTCH

ASSEMBLY

(488–497)

INTERMEDIATE

SPRAG

CLUTCH

ASSEMBLY

(473)

TCC PWM

SOLENOID

VALVE

(352)

TRANSMISSION

FLUID

FILTER

(59)

LOW /REVERSE

CLUTCH

ASSEMBLY

(510–517)

REVERSE

CLUTCH

ASSEMBLY

(404–420)

LOW SPRAG

CLUTCH

ASSEMBLY

(503)

SECOND

COAST

CLUTCH

ASSEMBLY

(528–535)

SECOND

CLUTCH

ASSEMBLY

(520–527)

OUTPUT

SHAFT

(562)

FORWARD/COAST

CLUTCH HOUSING

SHAFT

(433)

MANUAL

VALVE

(377)

CONTROL

VALVE BODY/

ACCUMULATOR

ASSEMBLY

(47)

PRESSURE

PLATE

ASSEMBLY

PLANETARY

CARRIER

ASSEMBLY

(553)

SECOND

SPRAG

CLUTCH

ASSEMBLY

(547)

REAR

INTERNAL

GEAR

(560)

FRONT

INTERNAL

GEAR

(550)

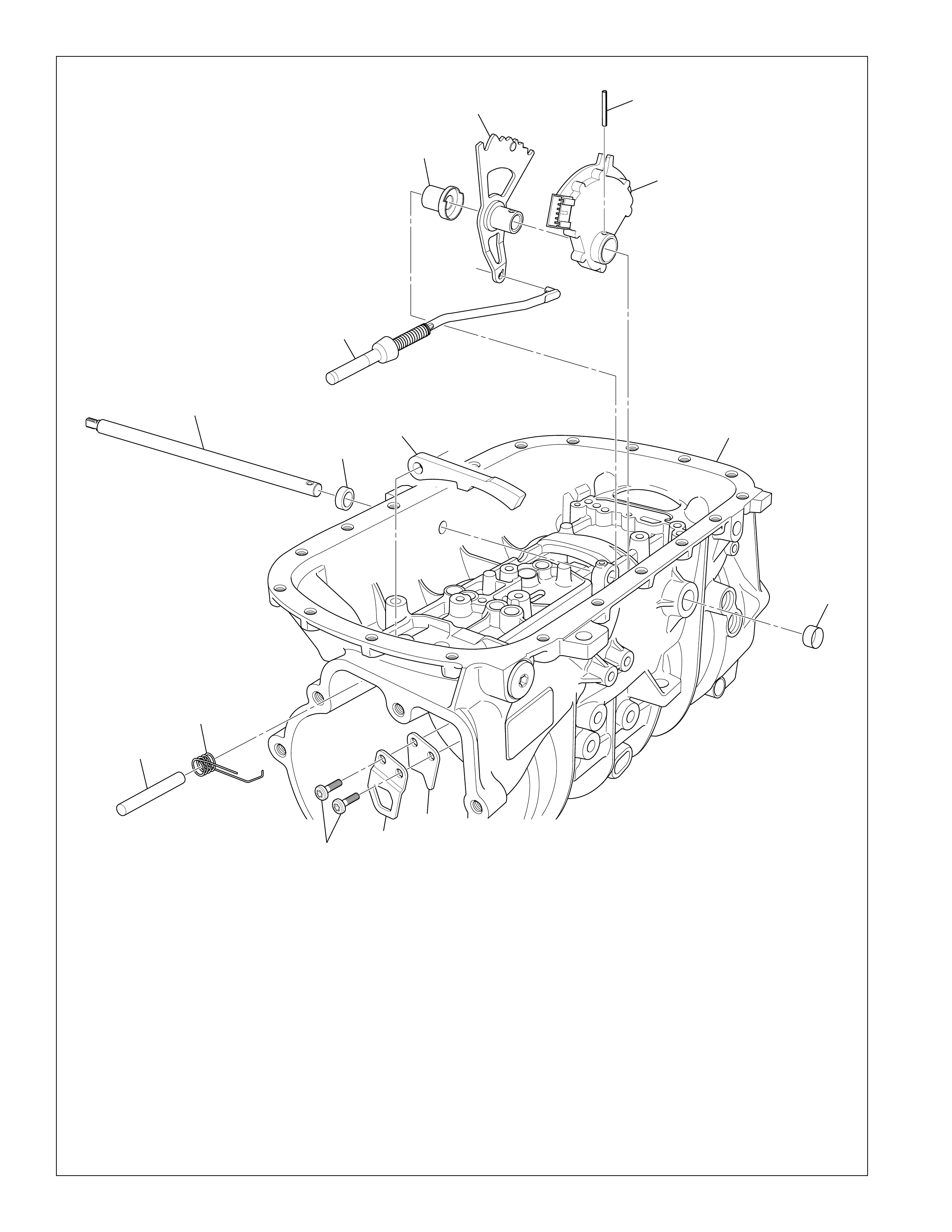

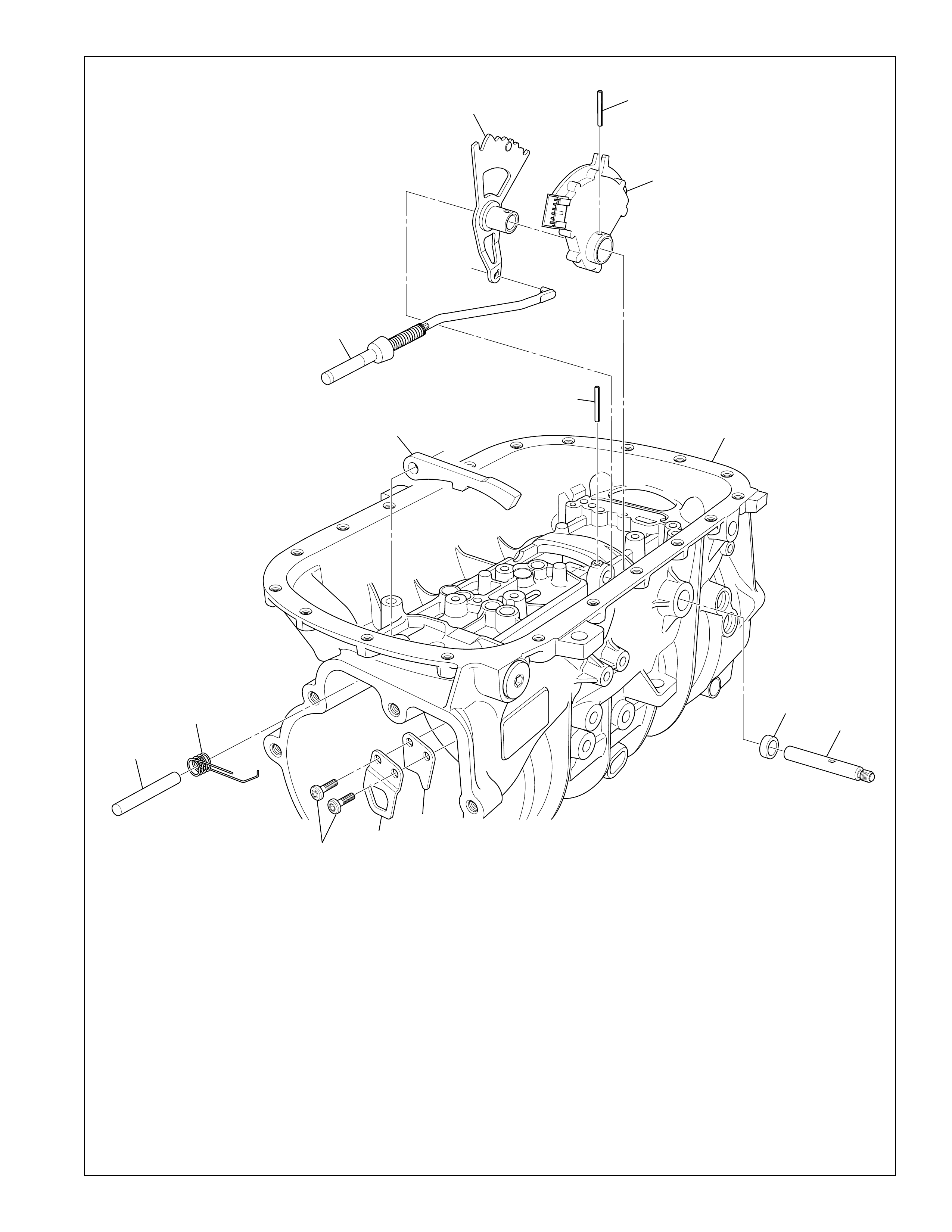

TRANSMISSION

MANUAL SHIFT

SHAFT SWITCH

ASSEMBLY

(602)

PARK PAWL

ACTUATOR

ASSEMBLY

(613)

CONVERTER

TURBINE

ASSEMBLY

8

8A

Figure 7

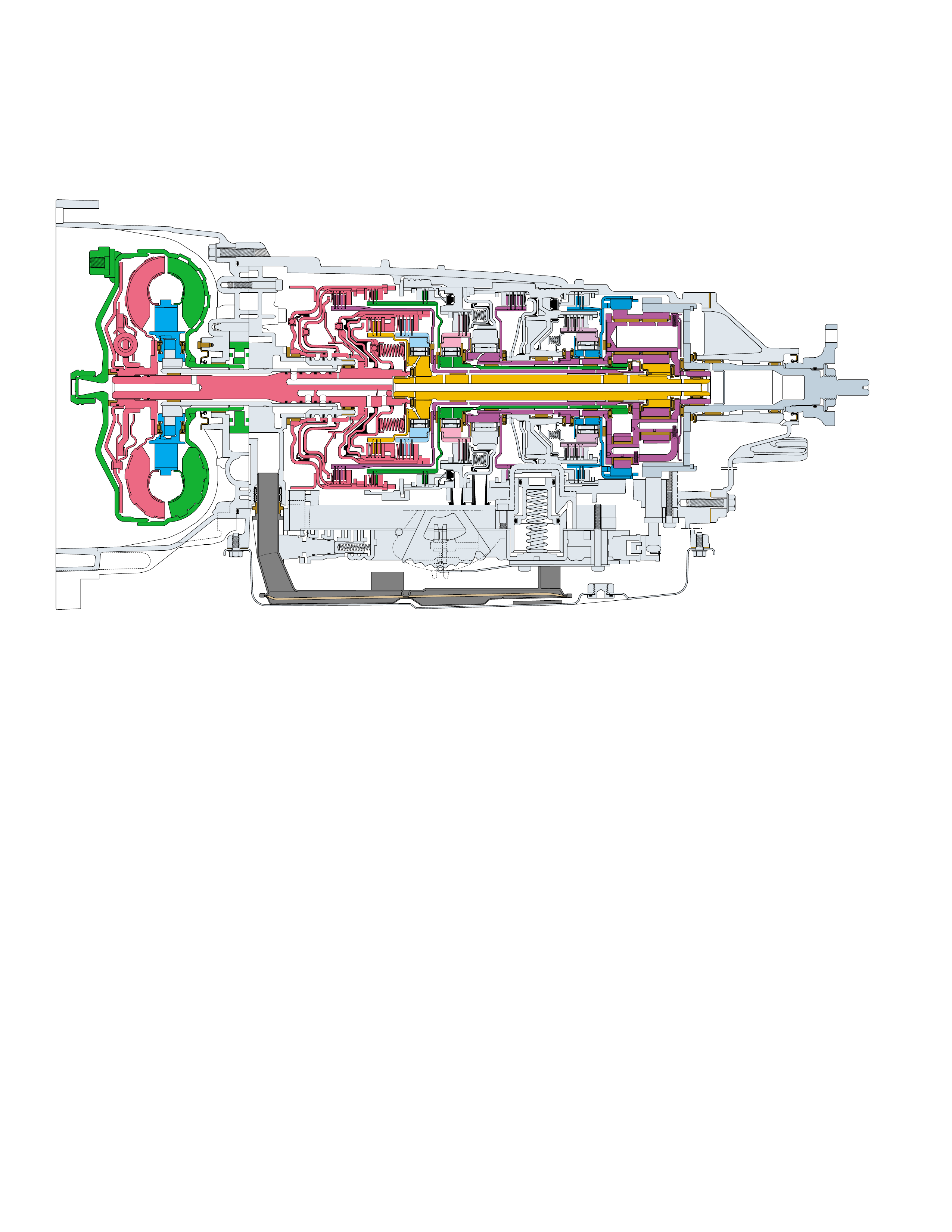

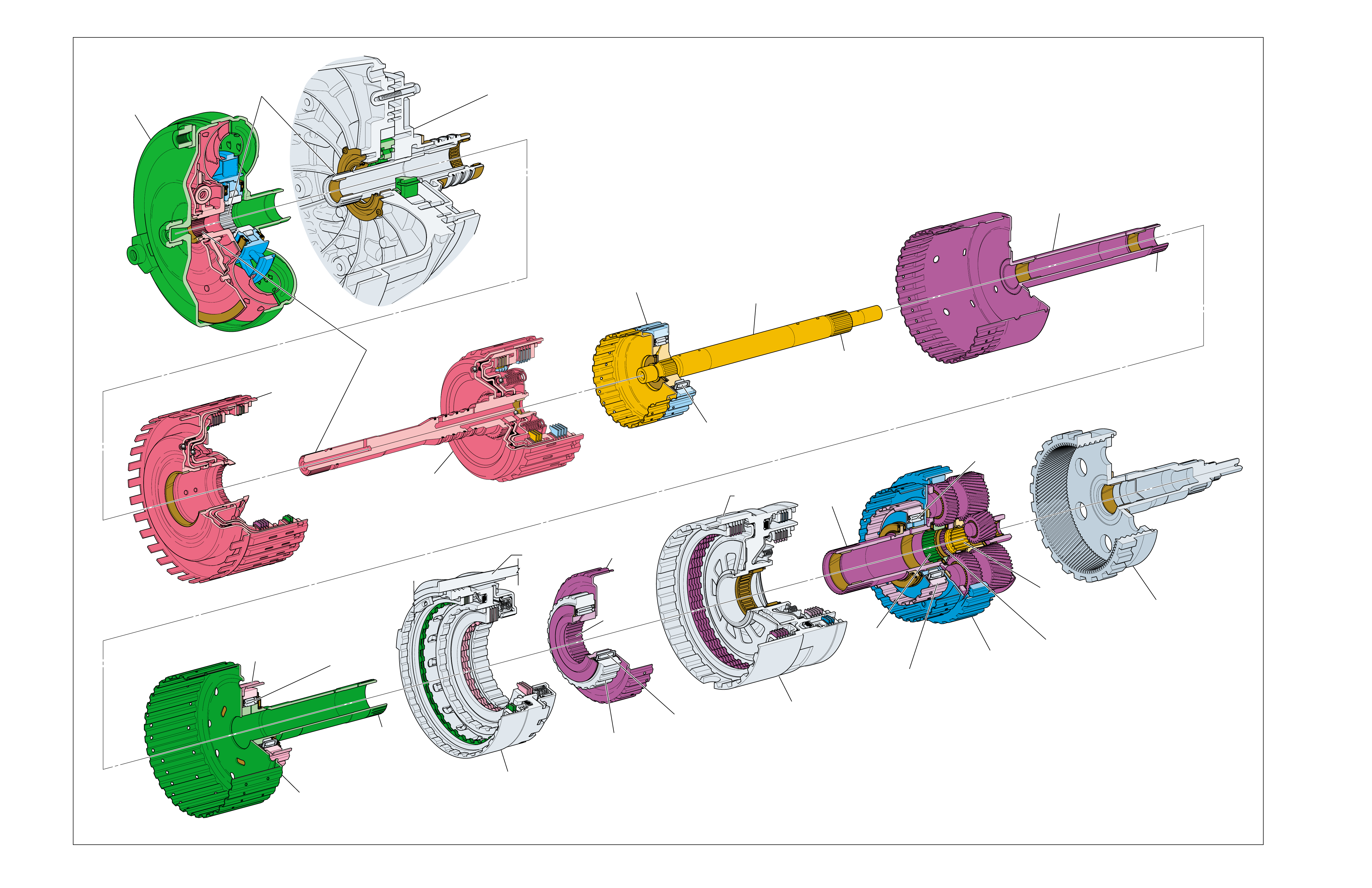

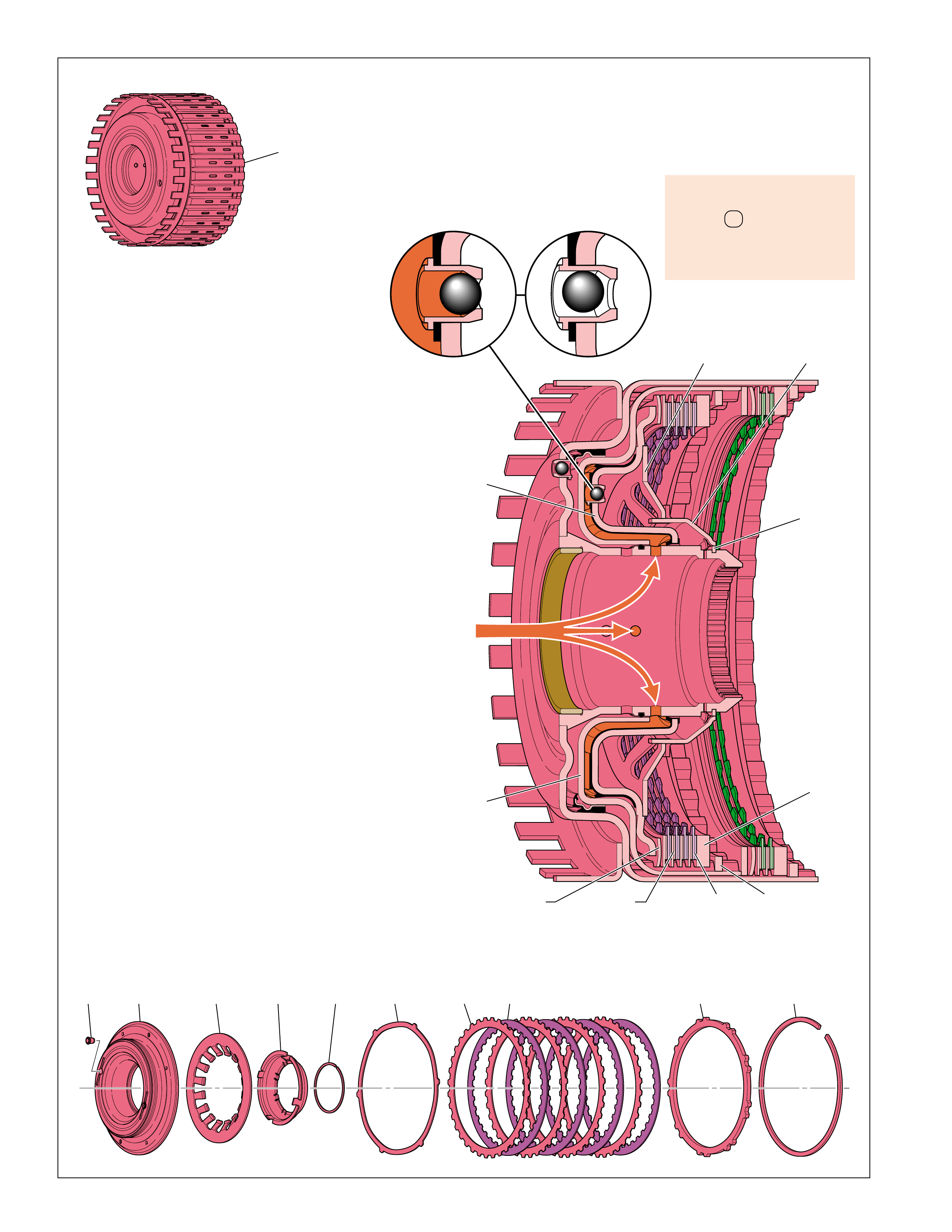

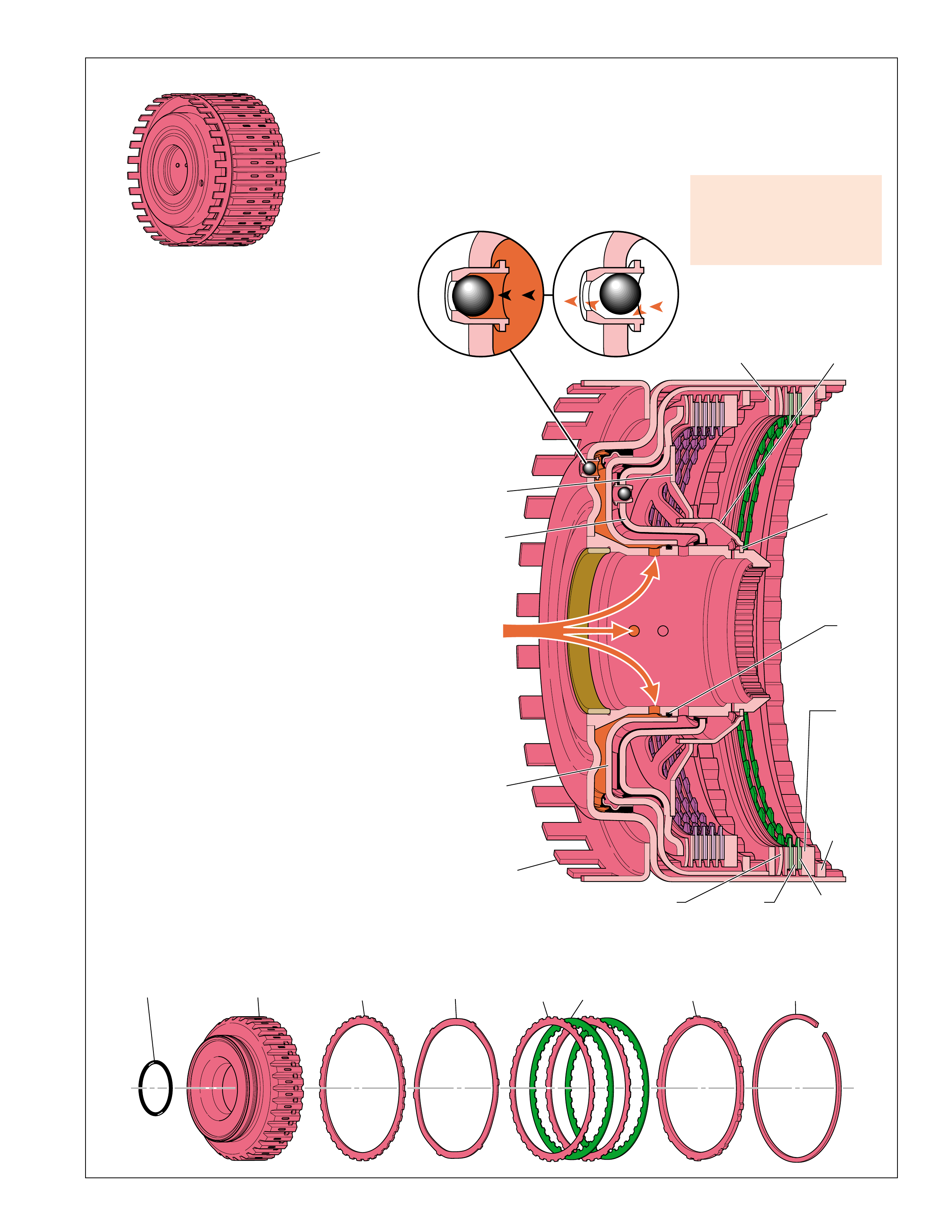

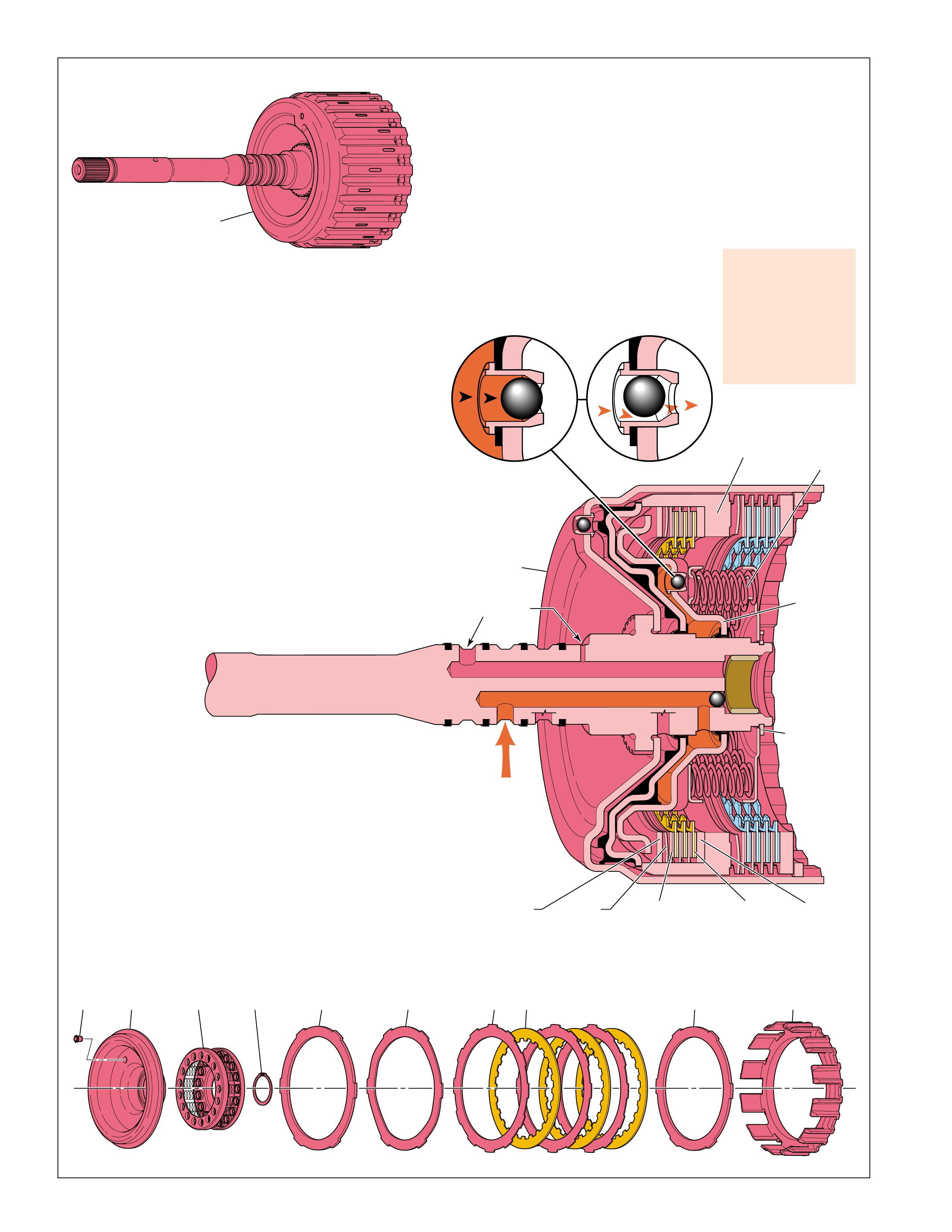

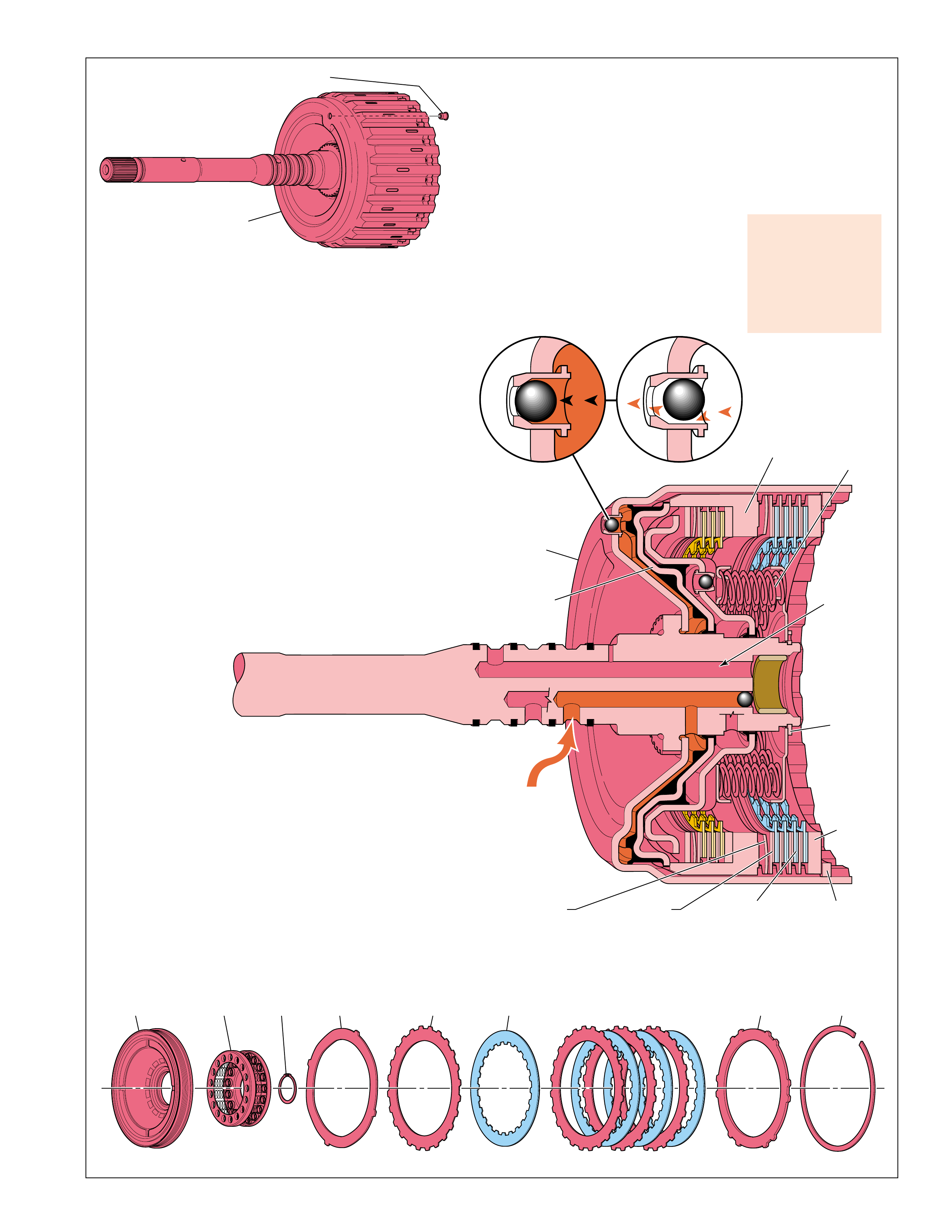

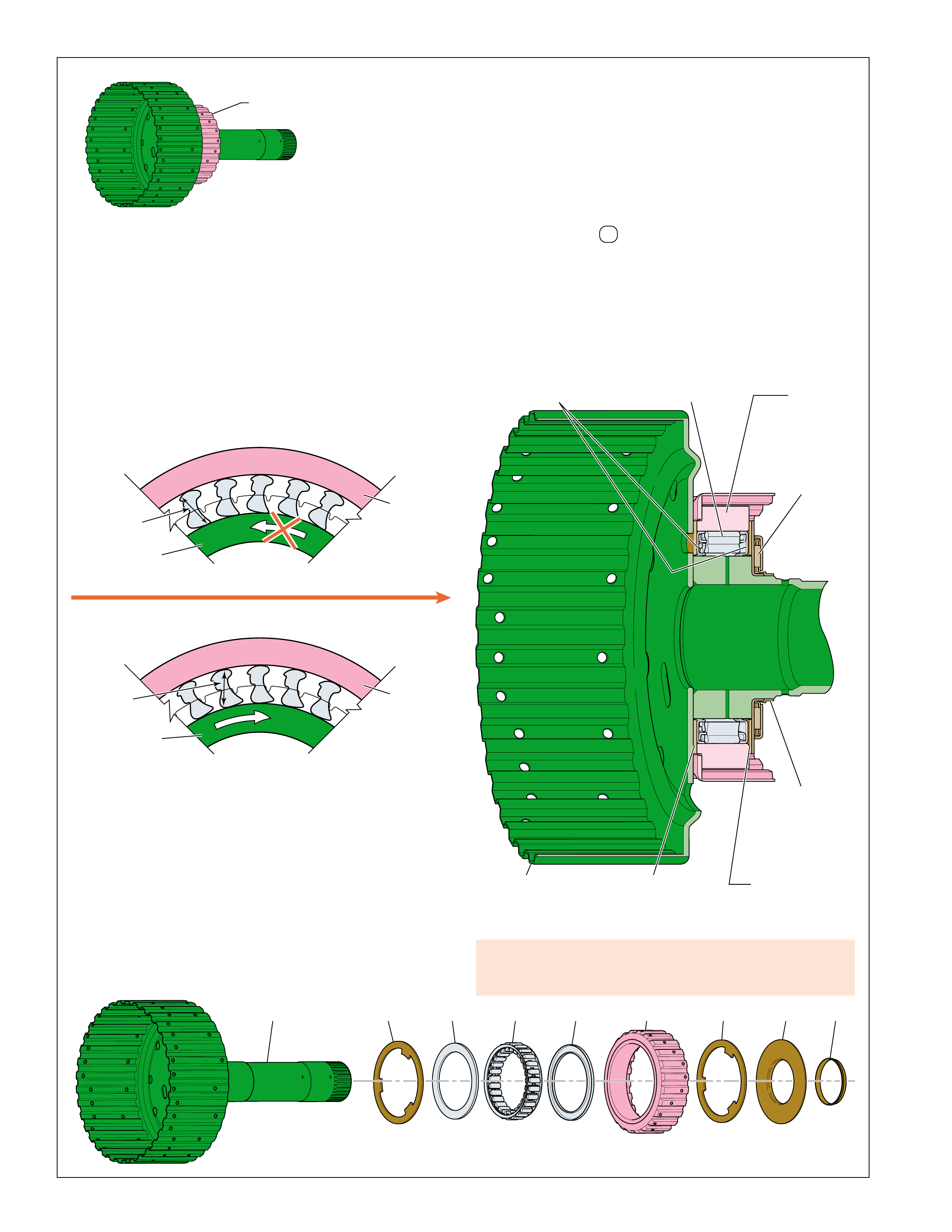

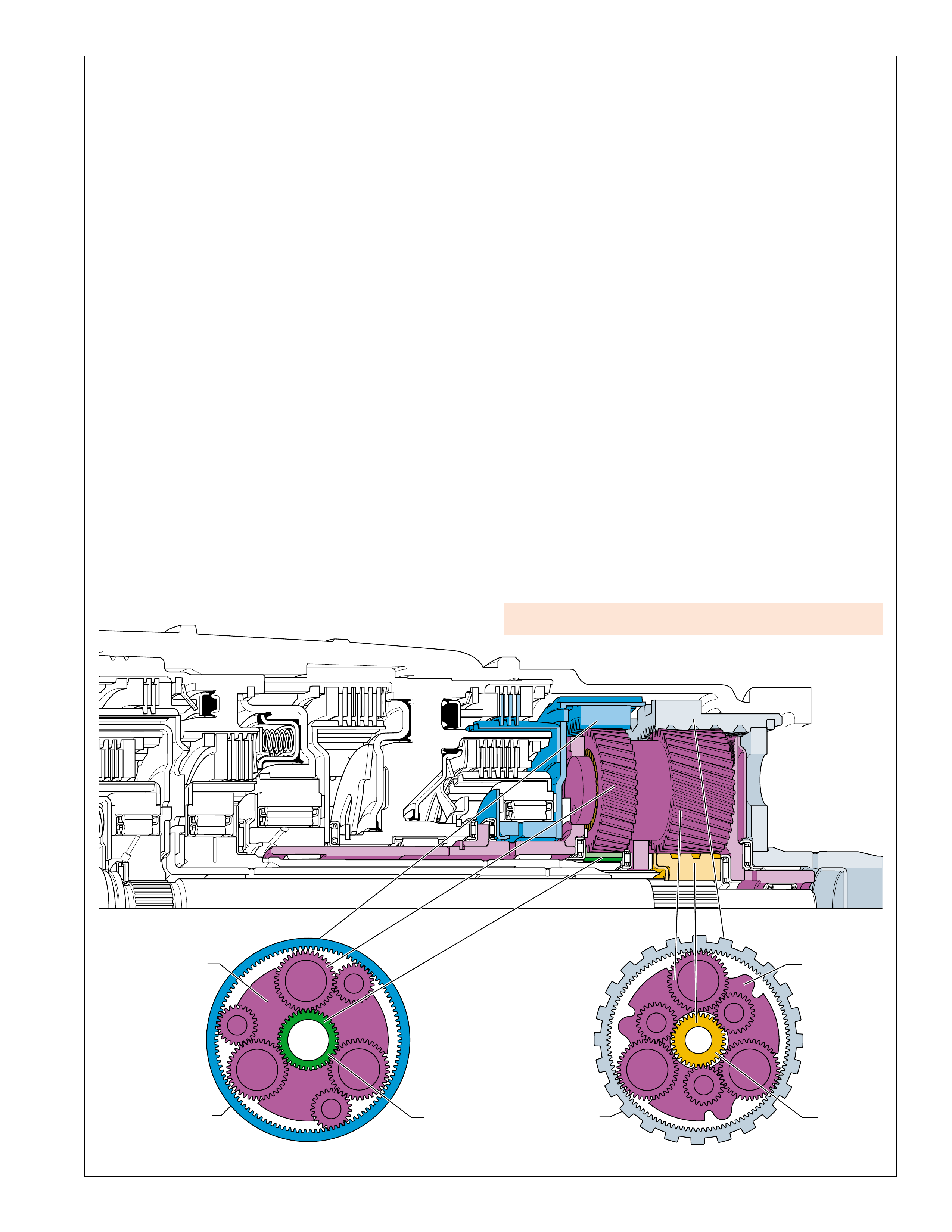

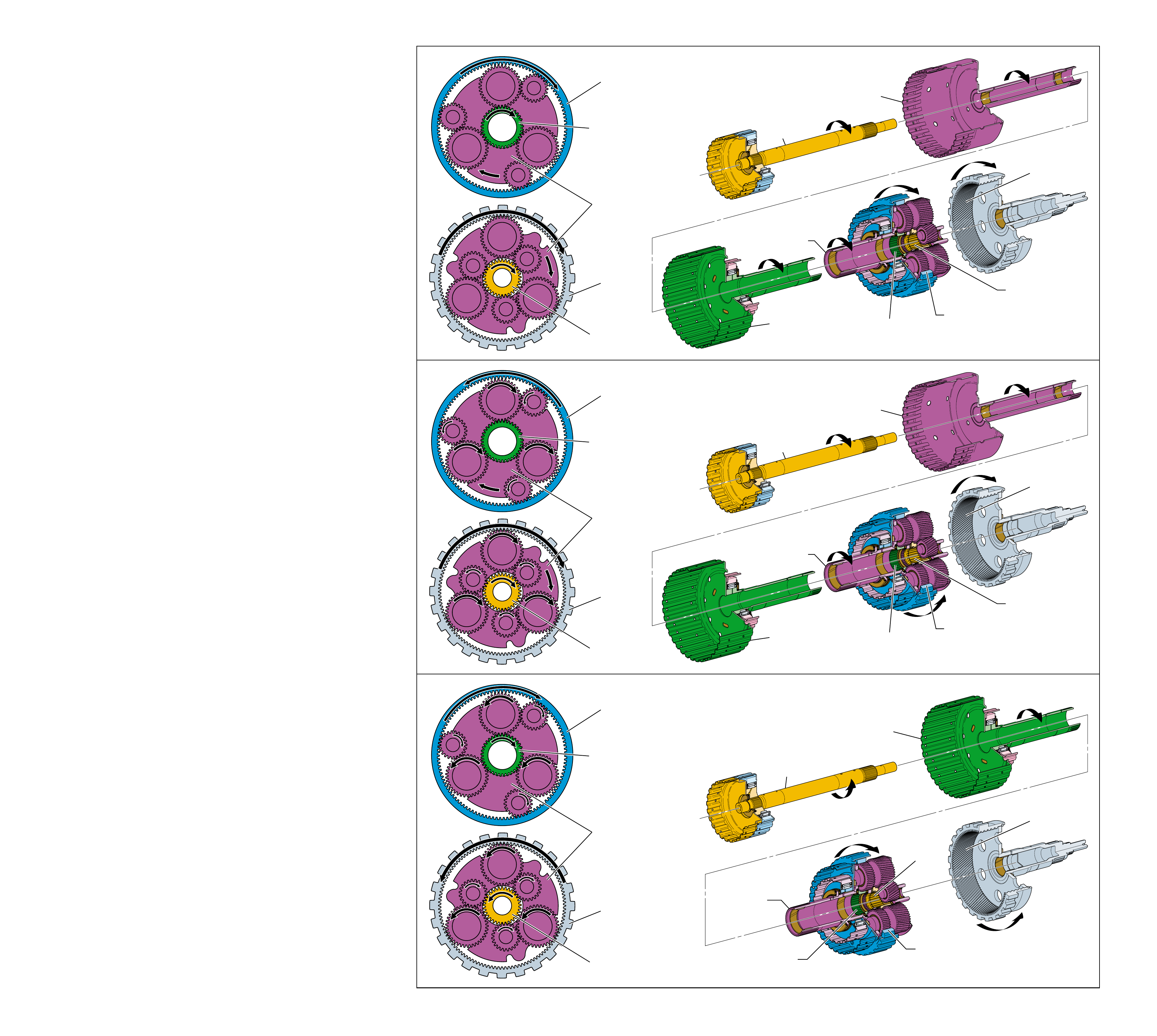

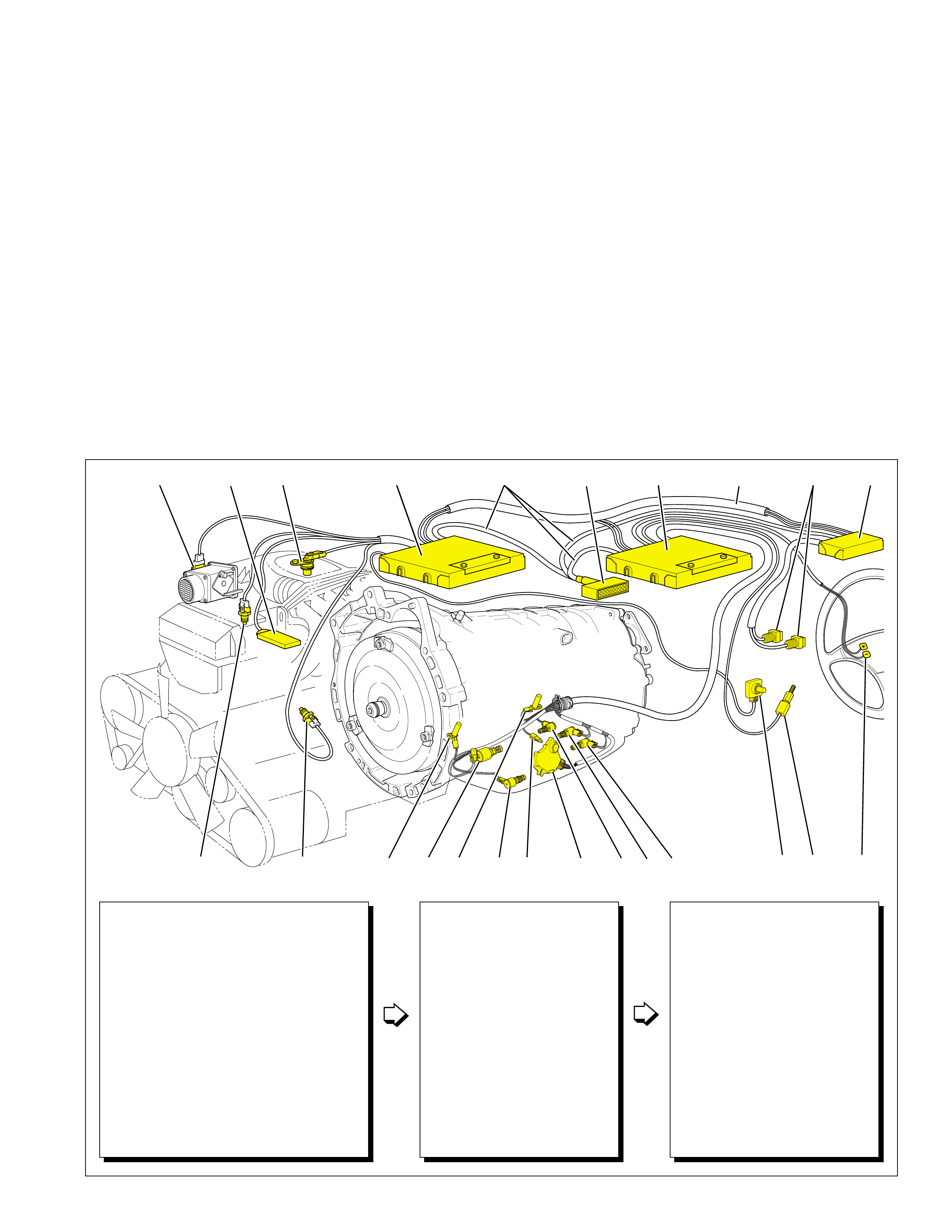

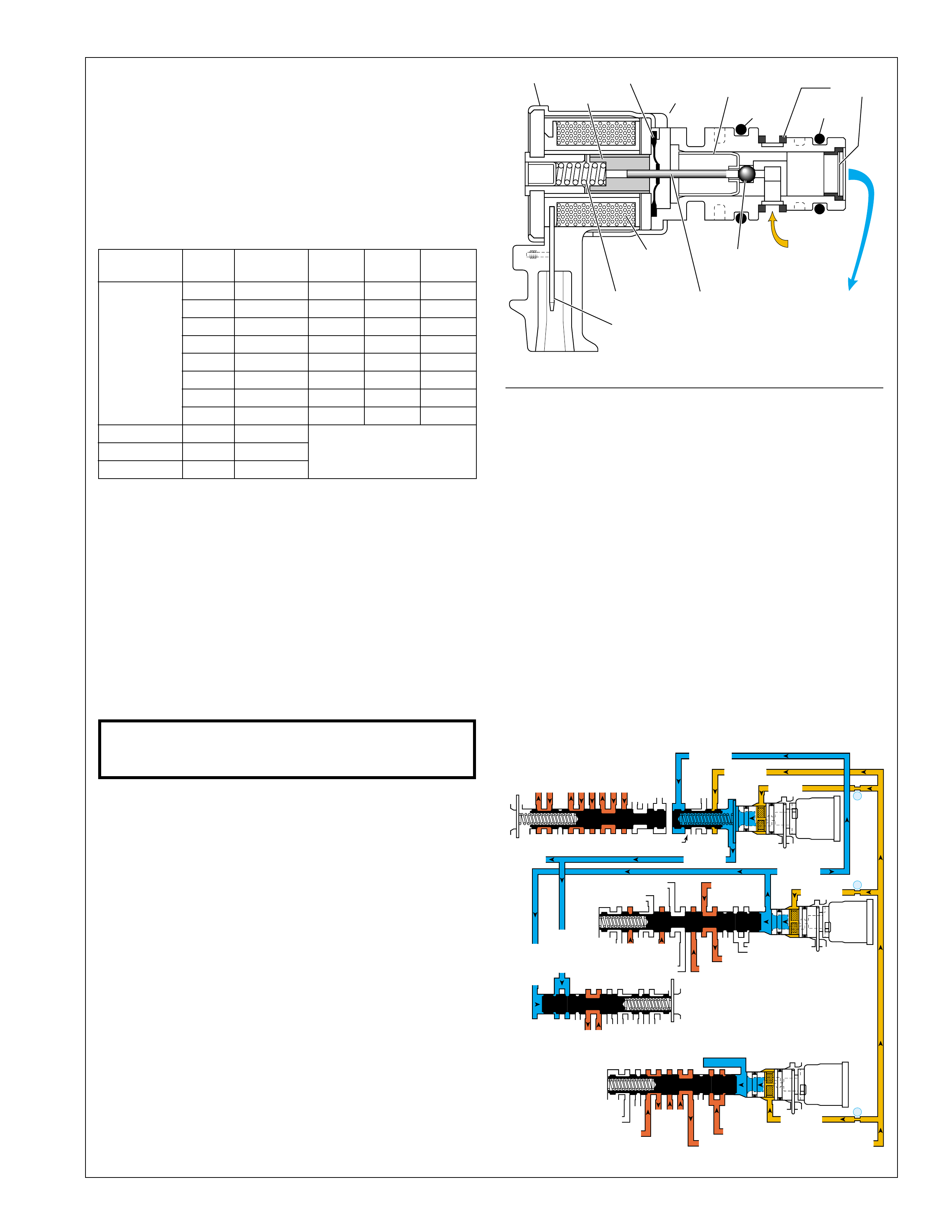

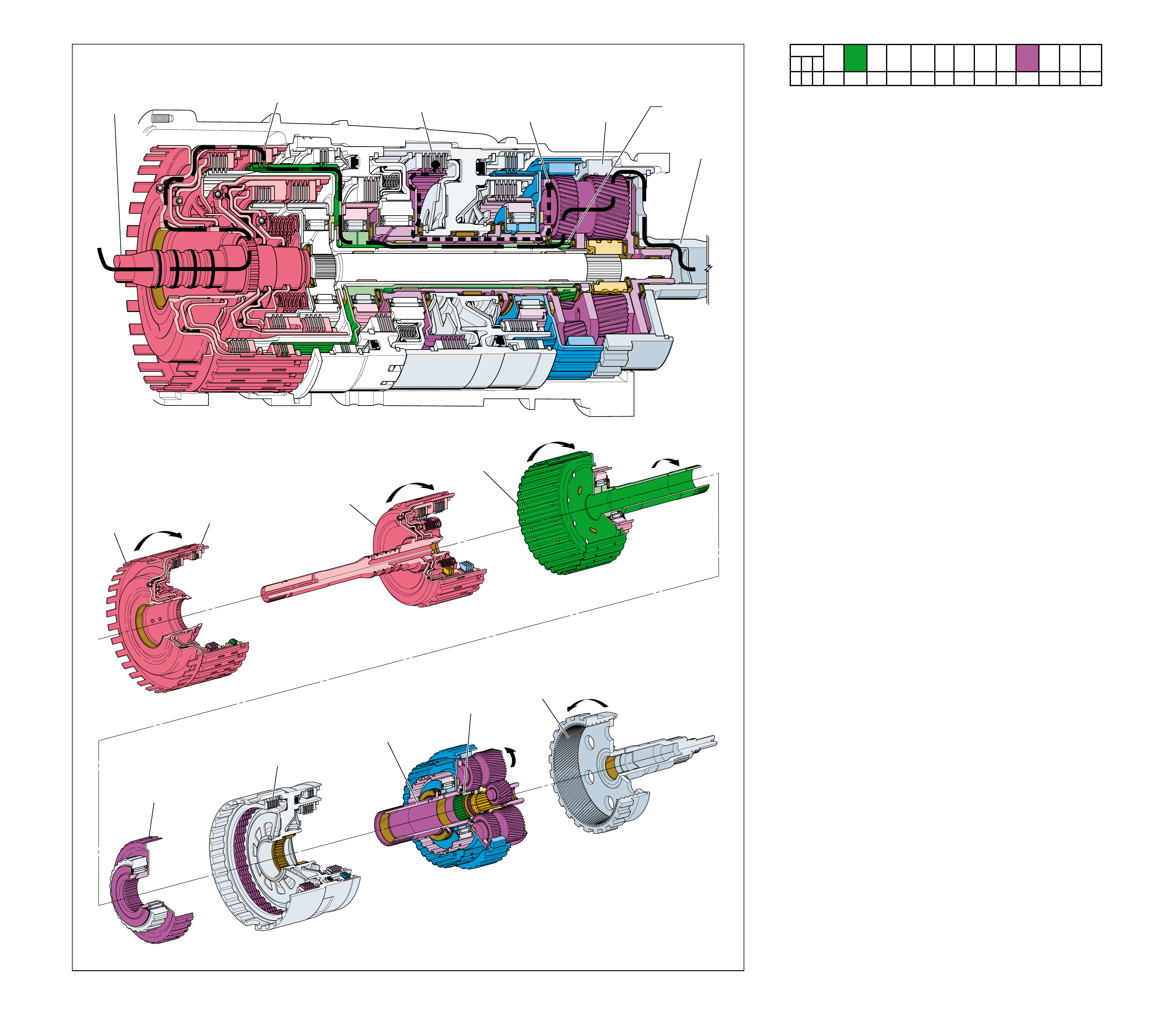

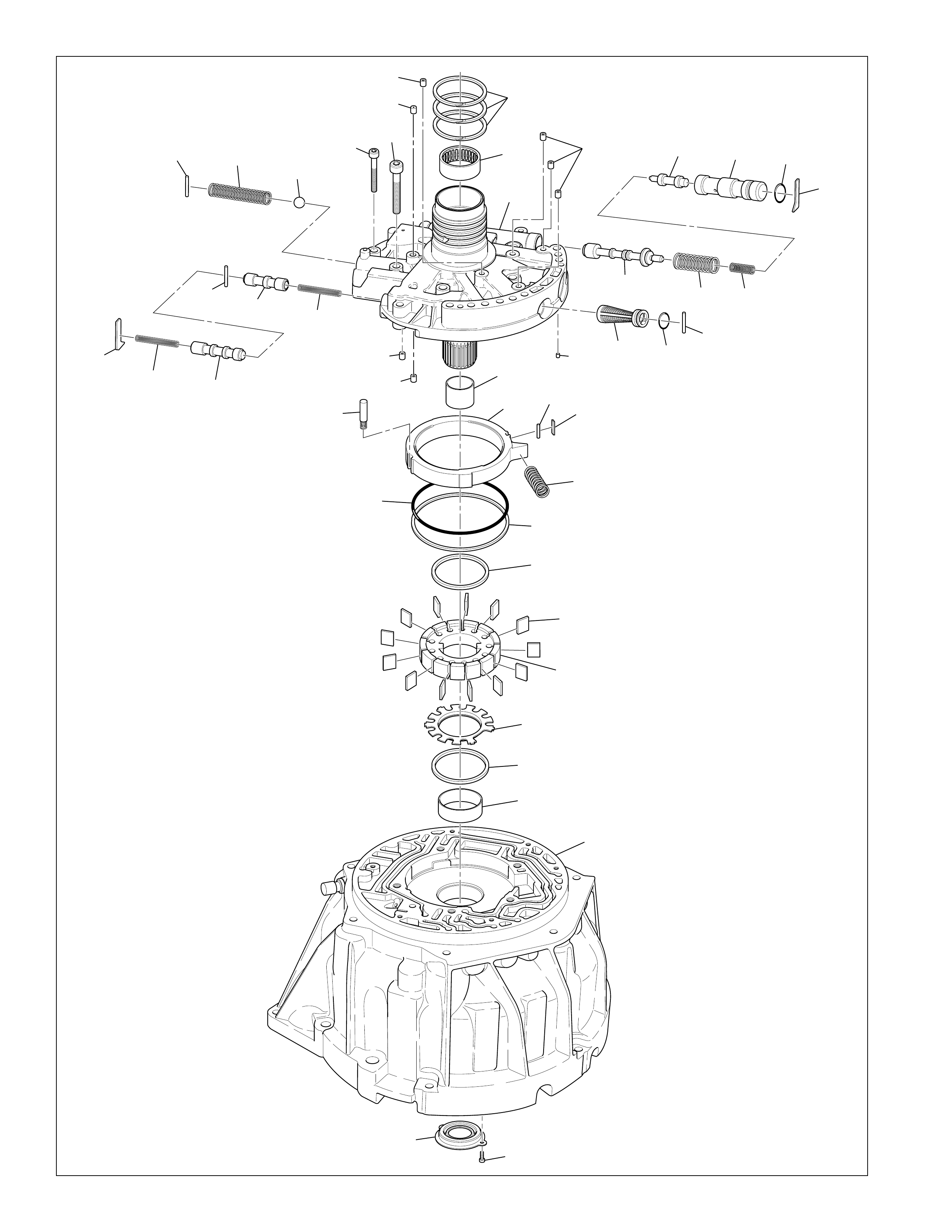

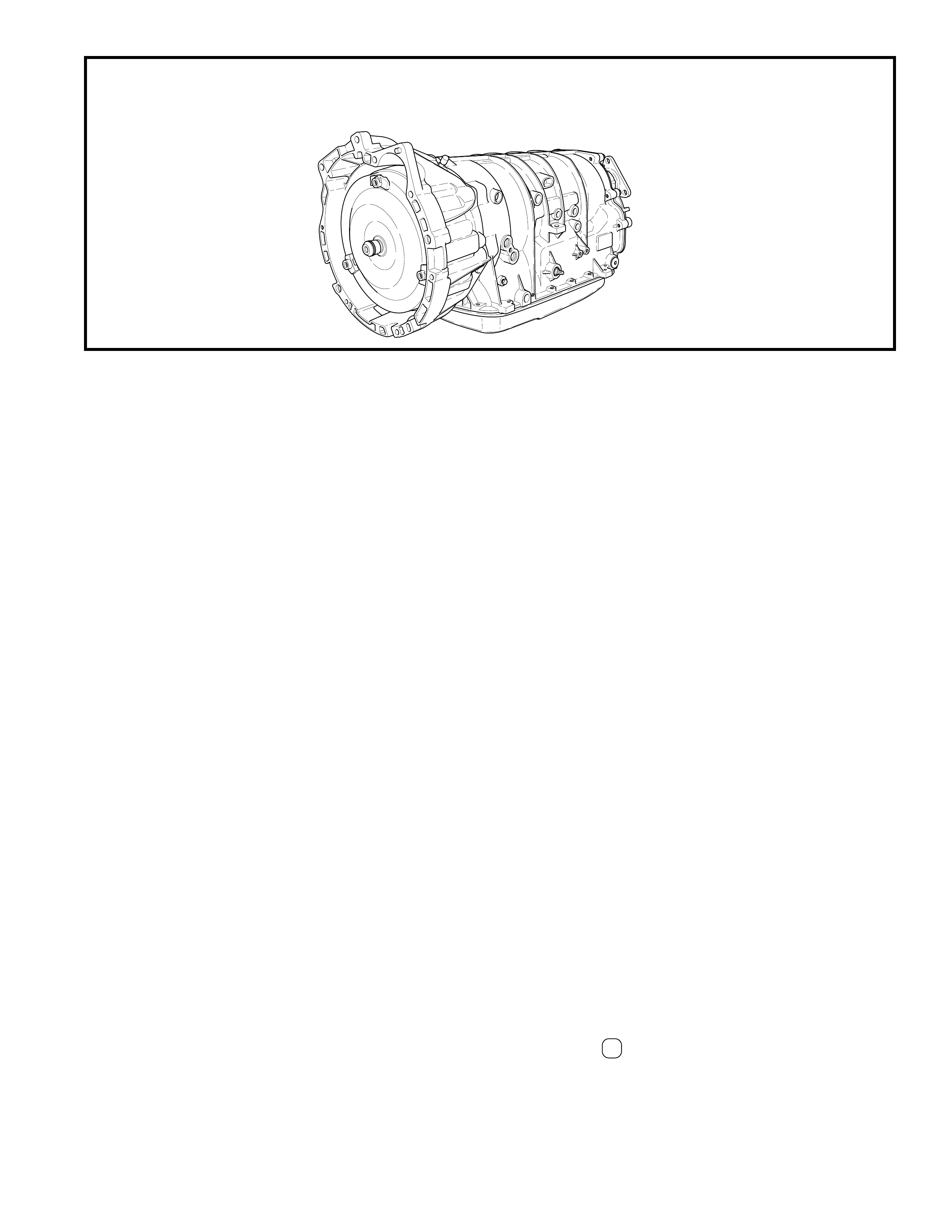

A cross sectional line drawing is typically the standard

method for illustrating either an individual mechanical

component or a complete transmission assembly.

However, unless a person is familiar with all the

individual components of the transmission,

distinguishing components may be diff icult in this type

of drawing. For this reason, a three dimensional

perspectiv e illustration (sho wn on page 8) is the primary

drawing used thr oughout this book.

The purpose for this type of illustration is to provide a

more detailed graphic representation of each component

and to show their relationship to other components

within the transmission assembly. It is also useful for

HYDRA-MATIC 4/5L40-E

CROSS SECTIONAL DRAWING

understanding the cross sectional line drawing by

comparing the same components from the three

dimensional perspective illustration. In this regard it

becomes an excellent teaching instrument.

Additionally, all the illustrations contained in this book

use a color scheme that is consistent throughout this

book. In other words, regardless of the type of

illustration or drawing , all components hav e an assigned

color and that color is used whenever that component

is illustrated. This consistenc y not only helps to provide

for easy component identification but it also enhances

the graphic and color continuity between sections.

The 4/5L40-E was designed to be a four or five speed

transmission. The same case and components are used

for both applications with the exclusion of the second

clutch and the second sprag clutch, and the use of a

smaller ravigneaux planetary carrier assembly in the

four speed version. This book will describe the five

speed model, however, the parts list will show the

differences in components between the four and five

speed. The function and operation of all components

and systems is the same for both the four and five speed

models, except that the four speed model uses third as

second gear , four th as third gear and fifth as fourth gear.

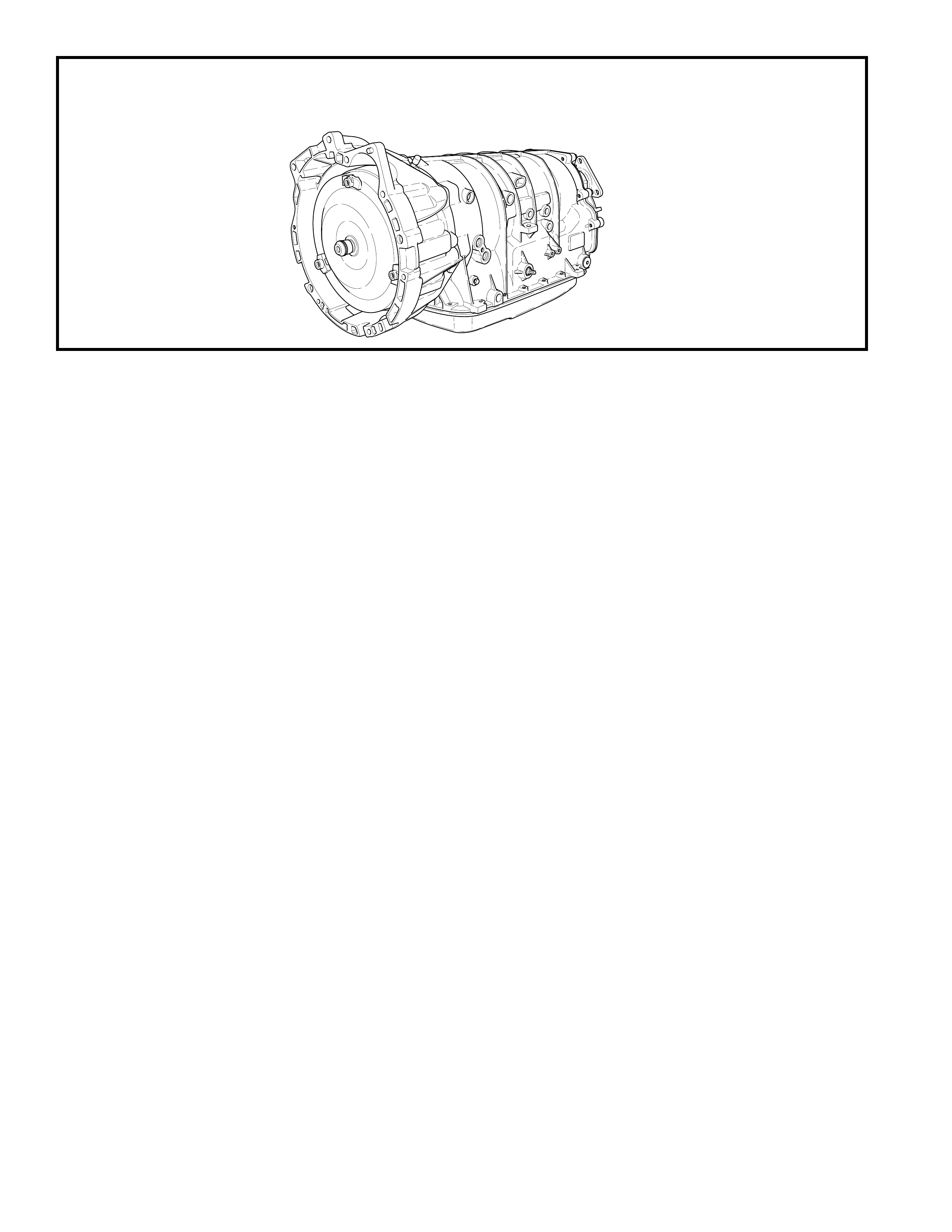

The Hydra-matic 5L40-E is a fully automatic, five speed,

rear wheel drive, electronically controlled transmission.

It consists primarily of a four-element torque conver ter,

one planetary gear set, friction and mechanical clutches

and a hydraulic pressurization and control system.

The four-element torque converter contains a pump, a

turbine, a pressure plate splined to the turbine, and a

stator assembly. The torque converter acts as a fluid

coupling to smoothly transmit power from the engine

to the transmission. It also hydraulically provides

additional torque multiplication when required. The

pressure plate, when applied, provides a mechanical

“direct dri v e” coupling of the engine to the transmission.

The planetary gear set provides the five forward gear

ratios and rev erse. Changing gear ratios is fully automatic

and is accomplished through the use of a Transmission

Control Module (TCM). The TCM recei ves and monitors

v arious electronic sensor inputs and uses this information

to shift the transmission at the optimum time.

The TCM commands shift solenoids, within the

transmission, on and off to control shift timing. The

TCM controls shift feel through the pressure control

solenoid. The TCM also contr ols the apply and release

of the torque converter clutch which allows the engine

to deliver the maximum fuel efficiency without

sacrificing vehicle performance.

The hydraulic system primarily consists of a vane type

pump, two control valve bodies, two channel plates,

converter housing and case. The pump maintains the

working pressures needed to stroke the clutch pistons

that apply or release the friction components. These

friction components (when applied or released) support

the automatic shifting qualities of the transmission.

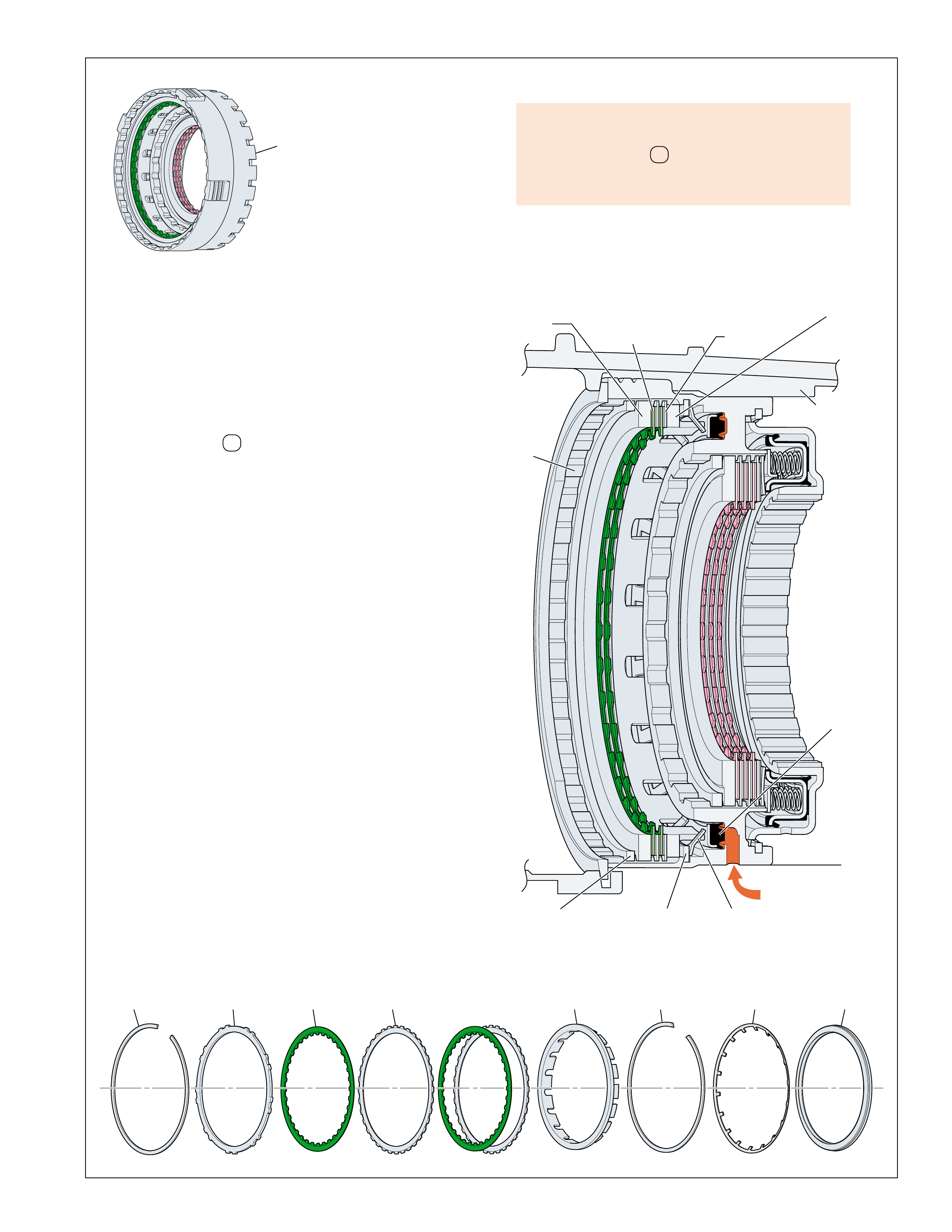

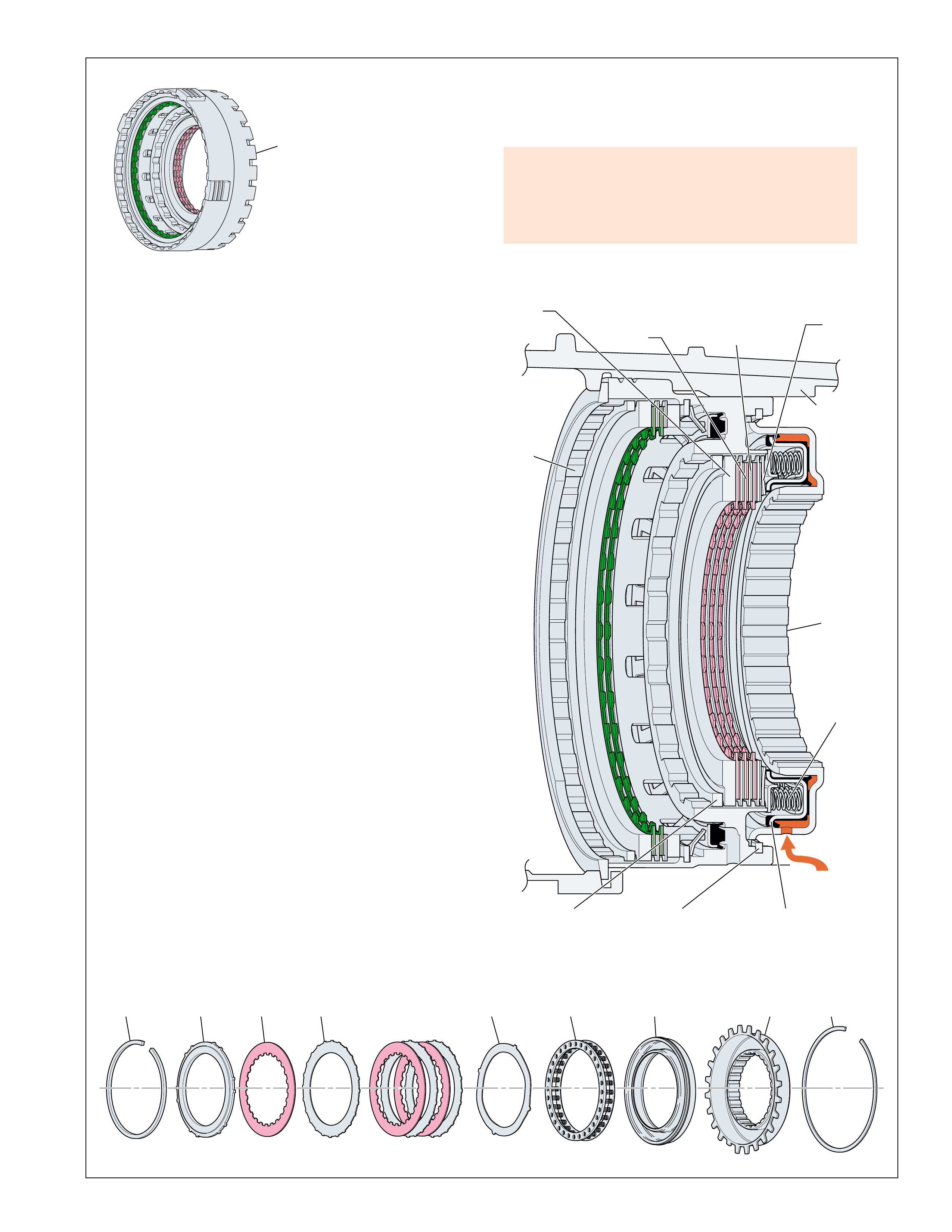

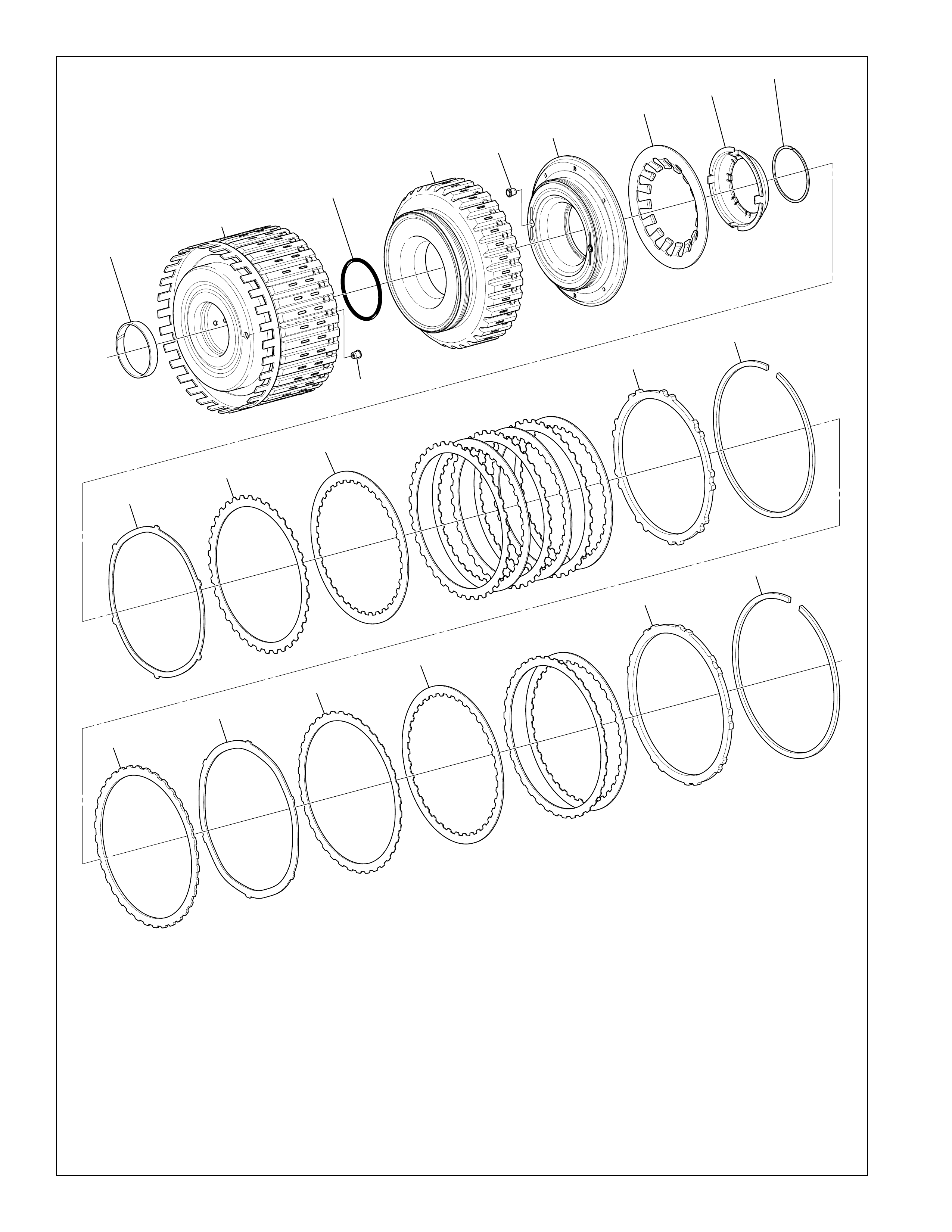

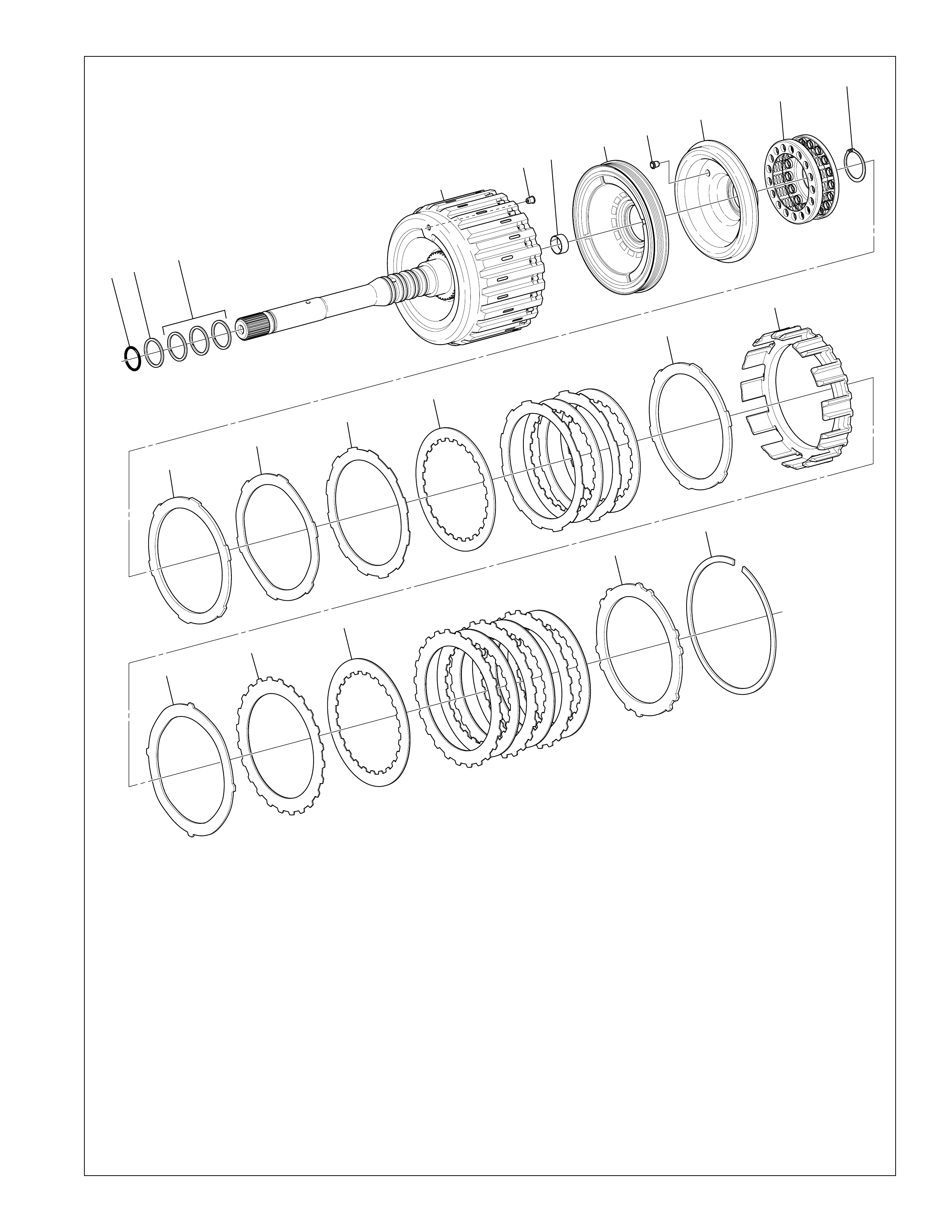

The friction components used in this transmission consist

of nine multiple disc clutches. The multiple disc clutches

combine with four mechanical sprag clutches, to deliv er

six different gear ratios through the gear set. The gear

set then transfers torque through the output shaft.

D –Overdrive range should be used for all normal

driving conditions for maximum efficiency and fuel

economy. Overdrive range allows the transmission to

operate in each of the five forward gear ratios. Down-

shifts to a lower gear, or higher gear ratio are available

for safe passing by depressing the accelerator or by

manually selecting a low er gear with the shift selector.

4–Manual Fourth can be used for conditions where it

may be desirable to use only four gear ratios. These

conditions include towing a trailer and driving on hilly

terrain as described above. This range is also helpful

for engine braking when descending slight grades. Up-

shifts and downshifts are the same as in Overdrive

range for first, second, third and fourth gears except

that the transmission will not shift into f ifth gear . Manual

Fourth can be selected at any vehicle speed but will

downshift into fourth gear only if vehicle speed is low

enough not to o verrev the engine (calibr atable in TCM).

3–Manual Third ad ds more performance for congested

traffic and hilly terrain. It has the same starting ratio

(fir st gear) as Manual Fourth but pre v ents the transmis-

sion from shifting above Third gear. Thus, Manual

Third can be used to retain third gear for acceleration

and engine braking as desired. Manual Third can be

selected at any vehicle speed but will downshift into

third gear only if vehicle speed is low enough not to

over rev the engine (calibratable in TCM).

Figure 8

EXPLANATION OF GEAR RANGES

FOLDOUT ➤ 9

GENERAL DESCRIPTION

P R N D 4 3 2

The transmission can be operated in any one of the

seven different positions shown on the shift quadrant

(Figure 8).

P–Park position enables the engine to be started while

preventing the vehicle from rolling either forward or

backward. For safety reasons, the vehicle’s parking

brake should be used in addition to the transmission

“Park” position. Since the output shaft is mechanically

locked to the case through the parking pawl and rear

internal gear, P ark position should not be selected until

the vehicle has come to a complete stop.

R–Reverse enables the vehicle to be operated in a

rearward direction.

N–Neutral position enables the engine to start and

operate without driving the vehicle. If necessary, this

position should be selected to restart the engine while

the vehicle is moving.

PRINCIPLES OF OPERATION

An automatic transmission is the mechanical

component of a vehicle that transfers power

(torque) from the engine to the wheels. It

accomplishes this task by providing a number of

forward gear ratios that automatically change as

the speed of the vehicle increases. The reason

for changing forward gear ratios is to provide

the performance and economy expected from

vehicles man ufactured today. On the performance

end, a gear ratio that develops a lot of torque

(through torque multiplication) is required in

order to initially start a vehicle moving. Once

the vehicle is in motion, less torque is required

in order to maintain the v ehicle at a certain speed.

When the vehicle has reached a desired speed,

economy becomes the important factor and the

transmission will shift into o verdriv e. At this point

output speed is greater than input speed, and,

input torque is greater than output torque.

Another important function of the automatic

transmission is to allow the engine to be started

2–

Manual Second adds more performance for

congested traffic and hill y terrain. It has the same

starting ratio (first gear) as Manual Third but pre-

vents the transmission from shifting above second

gear. Thus, Manual Second can be used to retain

second gear for acceleration and engine braking

as desired. Manual Second can be selected a t any

vehicle speed but will downshift into second gear

only if vehicle speed is low enough not to overrev

the engine (calibratable in TCM).

Some vehicles are equipped with a Driver Shift

Control (DSC) version of the selector system

(Figure 9). This configuration allows the driver

DRIVER SHIFT CONTROL GEAR RANGES

+

-

P

R

N

DM/S

Figure 9

and run without transferring torque to the wheels.

This situation occurs whenever Park (P) or

Neutral (N) range has been selected. Also,

operating the vehicle in a rearward direction is

possible whenever Reverse (R) range has been

selected (accomplished by the gear sets).

The variety of gear ranges in an automatic

transmission are made possible through the

interaction of numerous mechanically,

hydraulically and electronically controlled

components inside the transmission. At the

appropriate time and sequence, these components

are either applied or released and operate the

gear set at a gear ratio consistent with the driver’s

needs. The following pages describe the

theoretical operation of the mechanical, hydraulic

and electrical components found in the Hydra-

matic 4/5L40-E transmission. When an

understanding of these operating principles has

been attained, diagnosis of these transmission

systems is made easier.

9A

When the vehicle speed slows down to a speed

low enough not to o verre v the engine (calibratable

in TCM), the transmission will automatically shift

into first gear. This is particularly beneficial for

maintaining maximum engine braking when de-

scending steep grades.

to manually shift between Park (P), Reverse (R),

Neutral (N) and Drive (D).

D–In the Drive position, the transmission will

automatically upshift from first to fifth, and

downshift from fifth to first, according to the

Economy shift pattern programmed in the TCM.

M/S –In the M/S position, the transmission will

either automatically upshift from f irst to f ifth, and

downshift from fifth to first, according to the

Performance shift pattern programmed in the TCM

or , the driver ma y activate the manual function by

tapping the selector lever towards “+” or “-” to

cause an upshift or downshift. The transmission

will shift up or down depending on the request

that is made by tapping the selector. The TCM

will upshift automatically when maximum engine

speed is achieved and will protect from any

downshift which may overrev the engine.

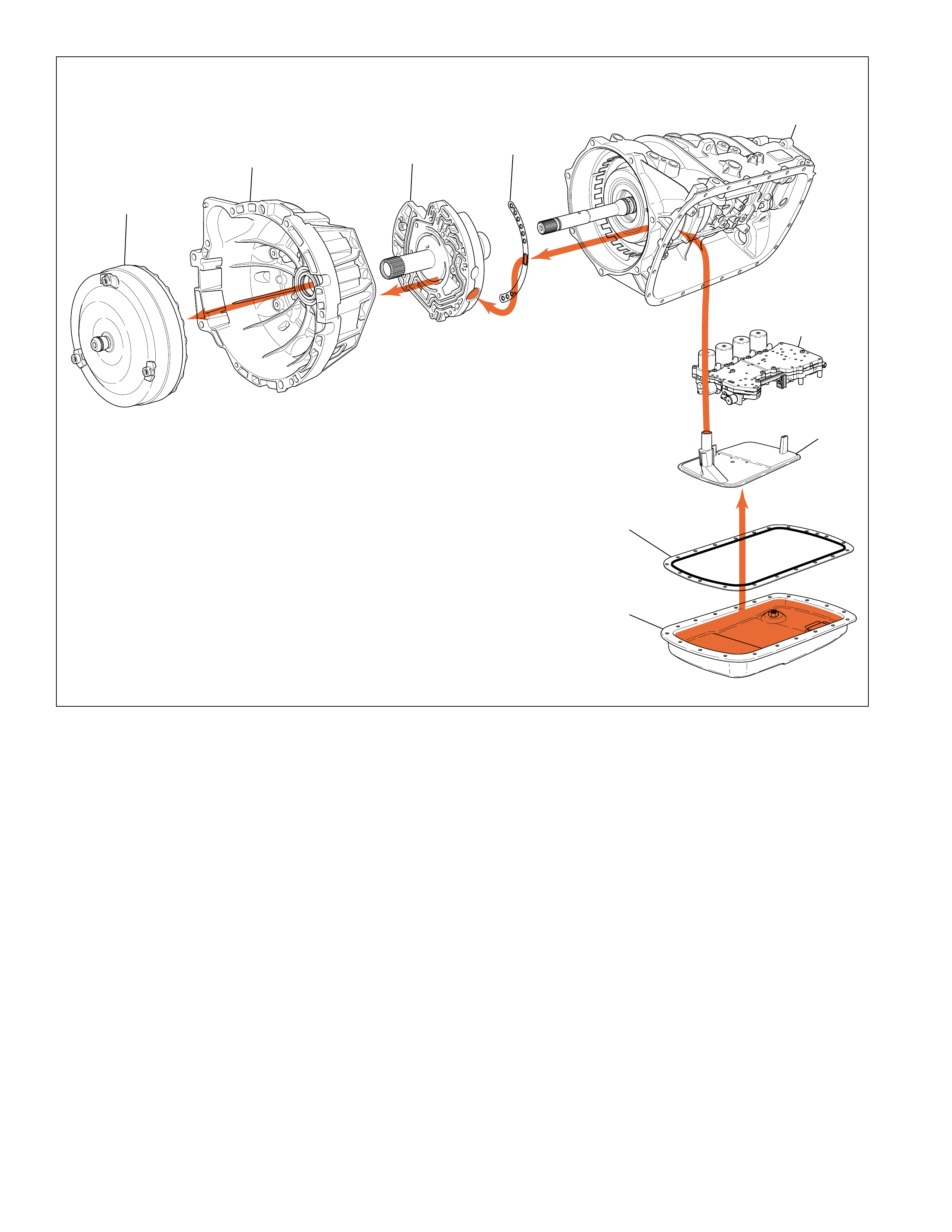

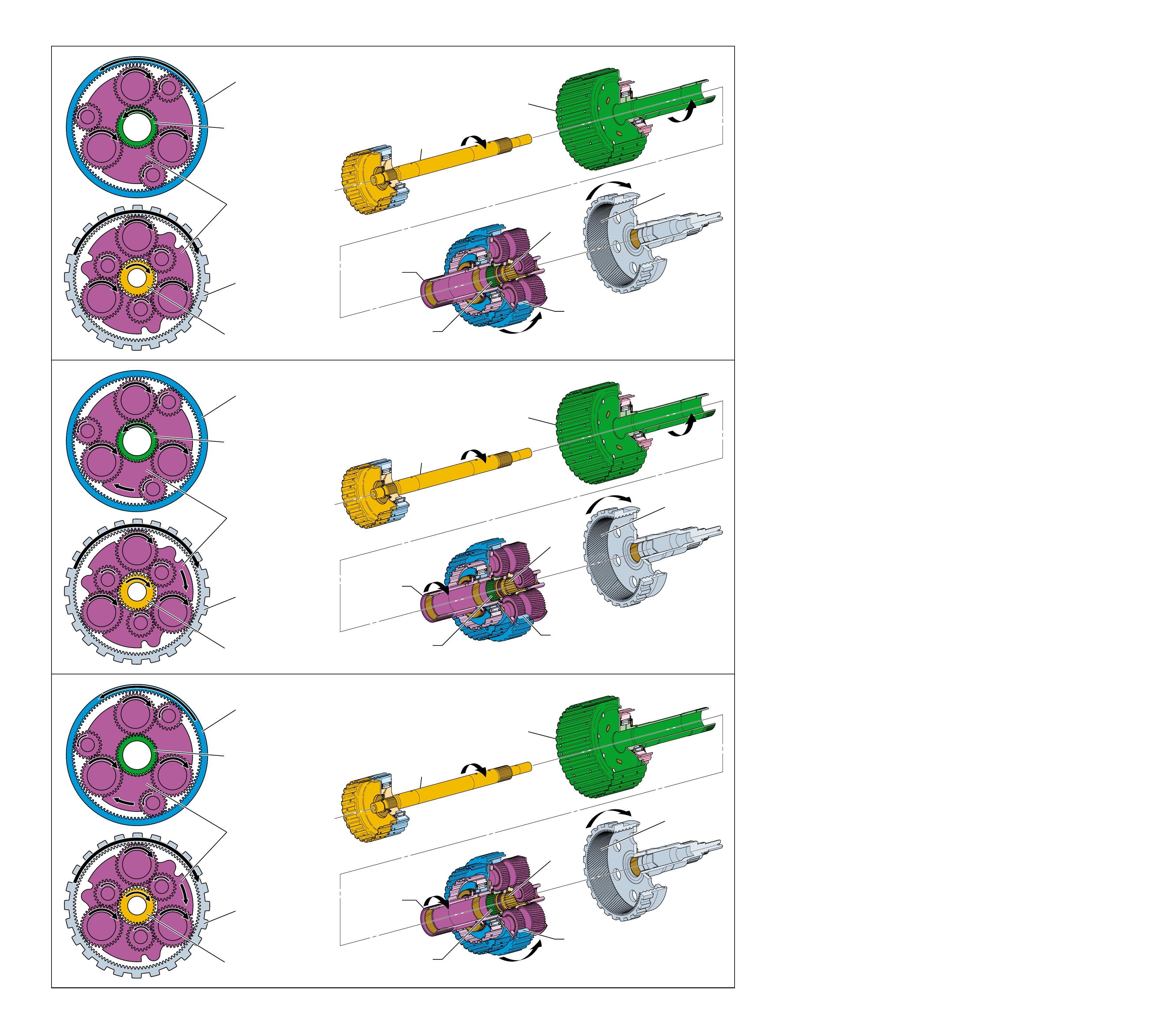

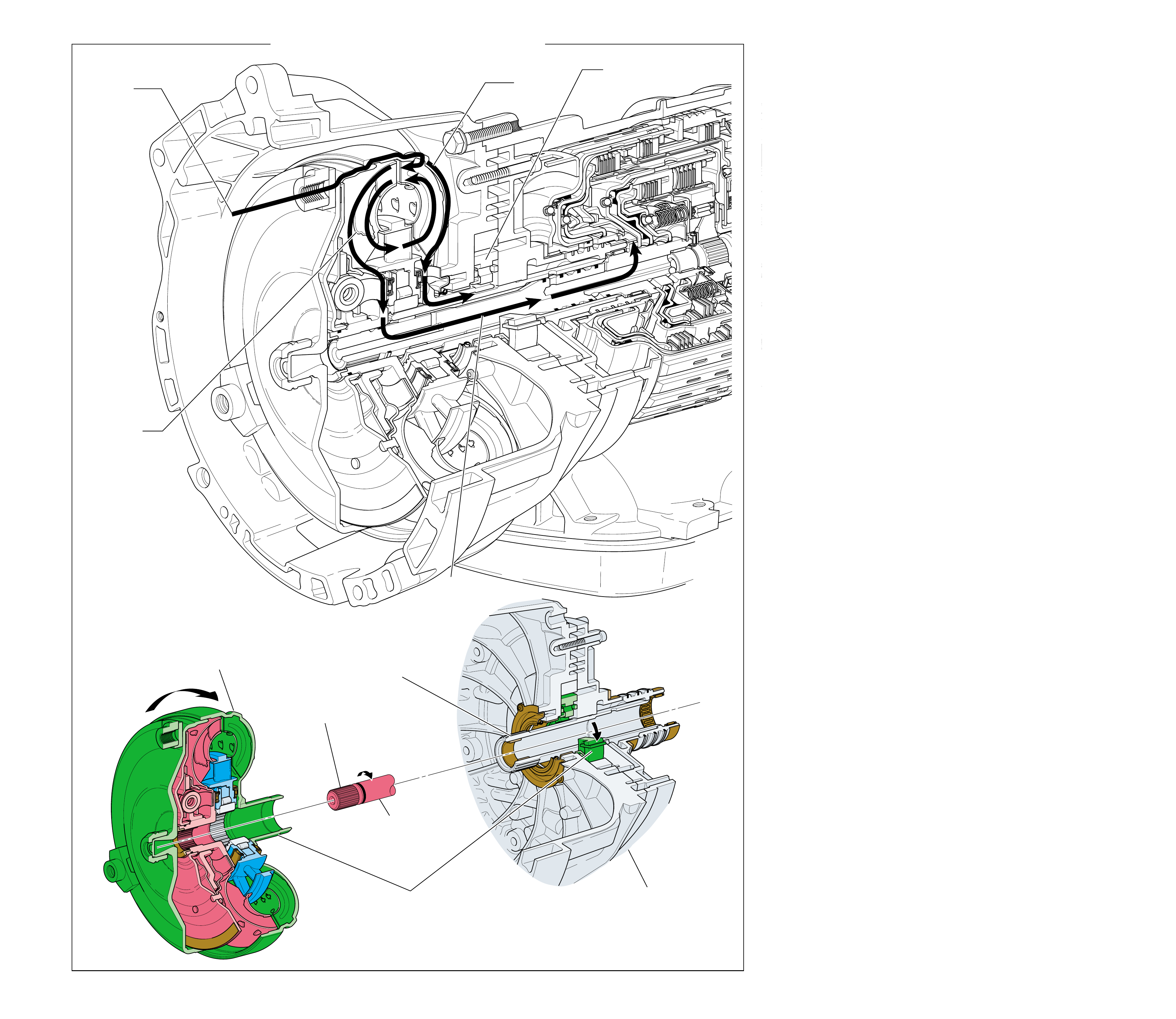

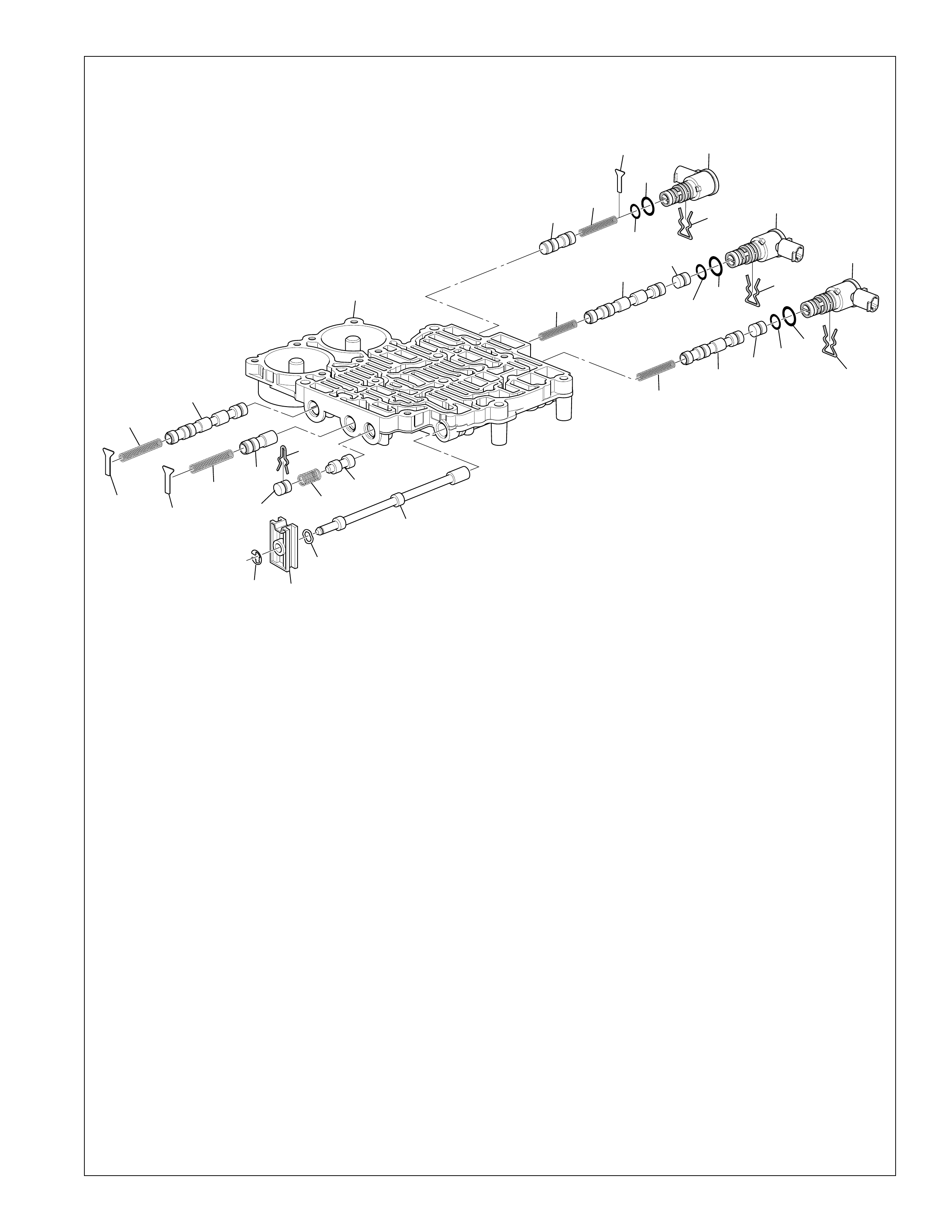

MAJOR MECHANICAL COMPONENTS

SPLINED

TOGETHER

SPLINED T O THE

FRONT INPUT

SUN GEAR

IN THE

PLANETARY

CARRIER

ASSEMBLY

SPLINED T O

PLANETARY

CARRIER

ASSEMBLY

SPLINED T O

PLANETARY

CARRIER

ASSEMBLY

SPLINED T O THE

REAR INPUT

SUN GEAR

IN THE

PLANETARY

CARRIER

ASSEMBLY

REAR

INPUT

SUN

GEAR

SPLINED T O

DIRECT

CLUTCH

INPUT

AND HUB

ASSEMBLY

(466)

SPLINED T O

TRANSMISSION

CASE (24)

FRONT

INPUT

SUN

GEAR

SPLINED

TOGETHER

TORQUE

CONVERTER

ASSEMBLY

(1)

TORQUE CONVERTER

HOUSING/PUMP

ASSEMBLY

(3)

DIRECT AND

REVERSE

CLUTCH

ASSEMBLY

(400-420)

INPUT SHAFT/

FORWARD

AND COAST

CLUTCH

ASSEMBLY

(430-451)

INPUT SUN GEAR

SHAFT

ASSEMBLY

(457)

FORWARD

CLUTCH SPRAG

OUTER RACE

(459)

FORWARD

CLUTCH SPRAG

ASSEMBLY

(461)

DIRECT CLUTCH

INPUT AND

HUB

ASSEMBLY

(466)

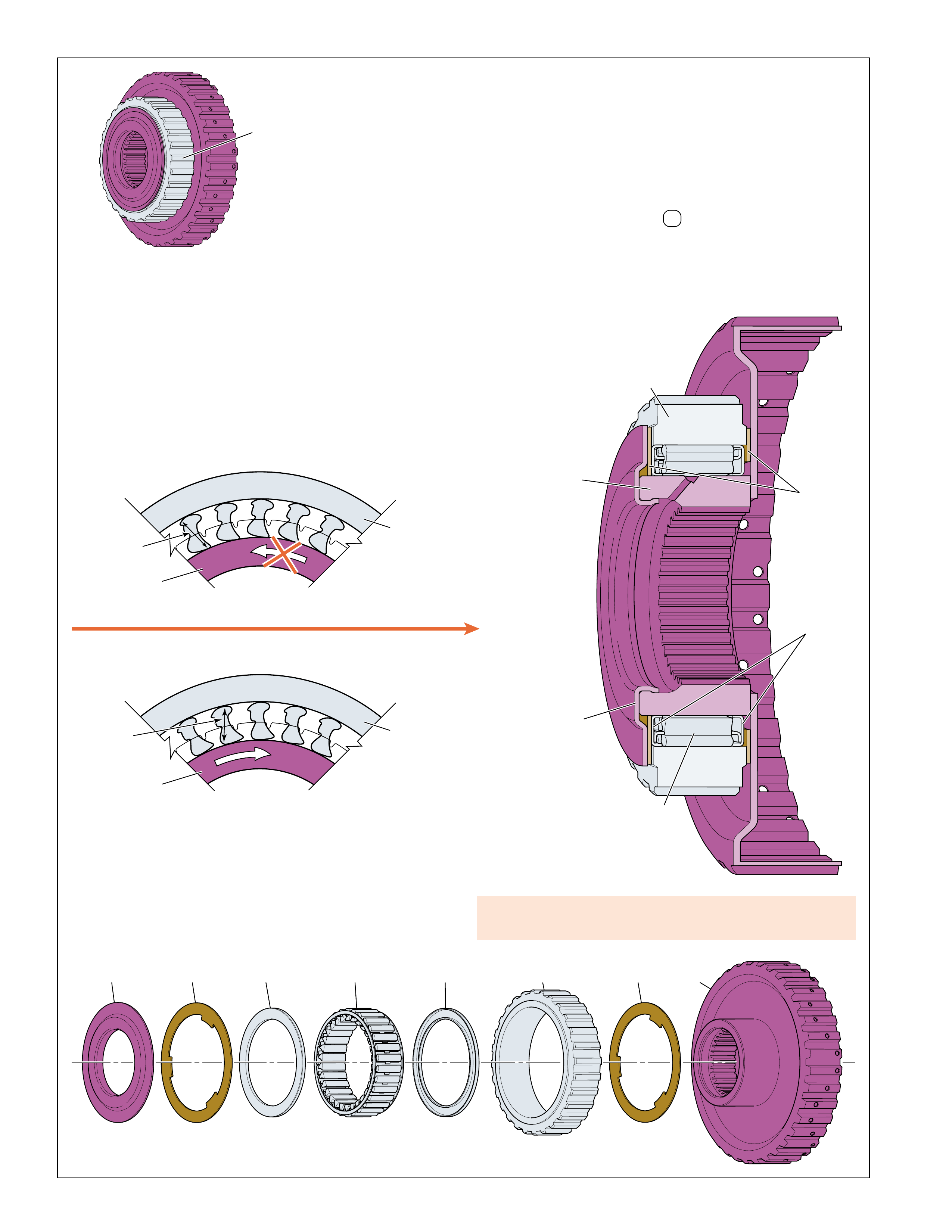

OVERDRIVE AND

REVERSE CLUTCH

HUB ASSEMBLY

(470)

INTERMEDIATE

CLUTCH SPRAG

OUTER RACE

(474)

INTERMEDIATE

CLUTCH SPRAG

ASSEMBLY

(473)

TRANSMISSION

CASE

(24)

OVERDRIVE AND

INTERMEDIATE

CLUTCH

ASSEMBLY

(480-497)

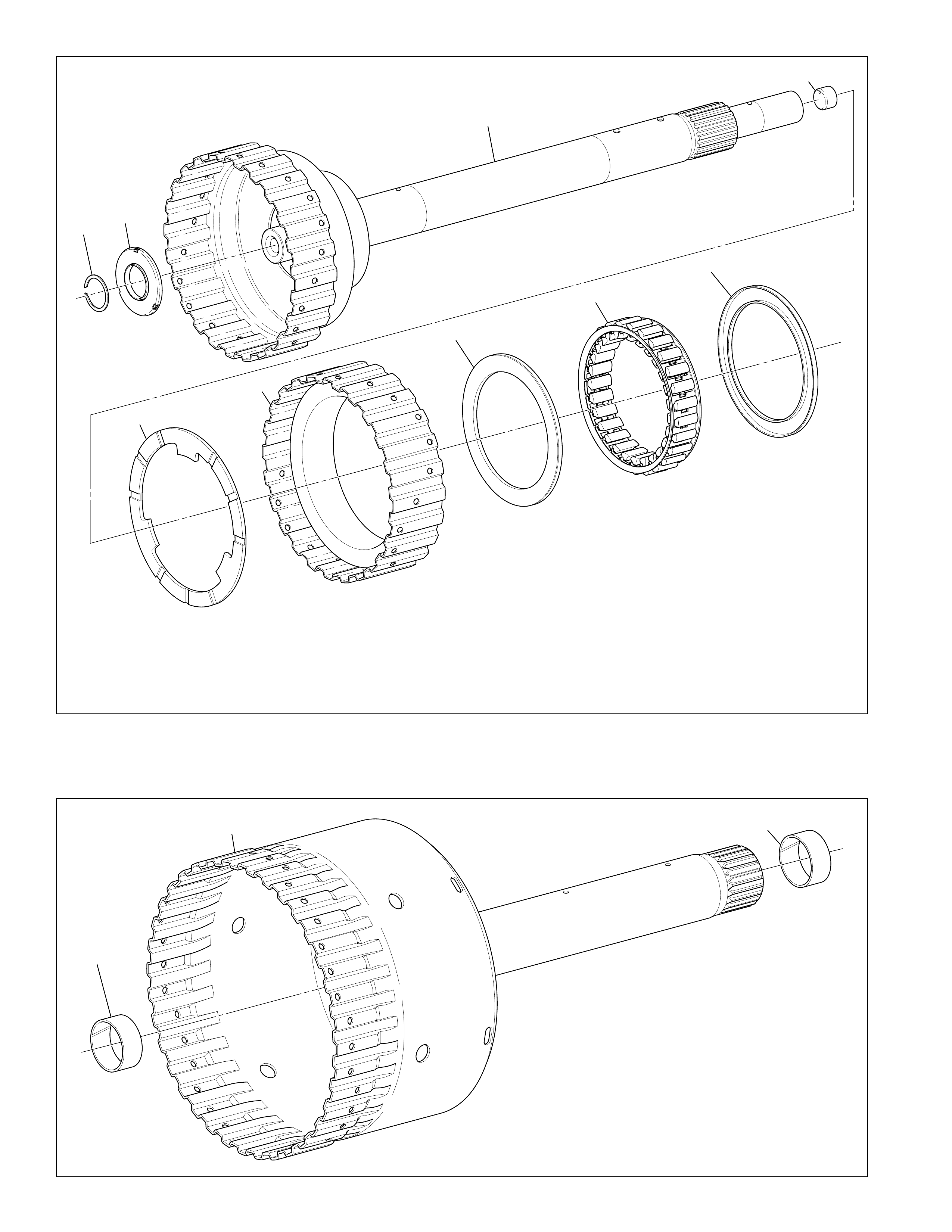

LOW

CLUTCH SPRAG

OUTER RACE

(504)

LOW

CLUTCH SPRAG

ASSEMBLY

(503)

LOW

CLUTCH SPRAG

INNER RACE

(505)

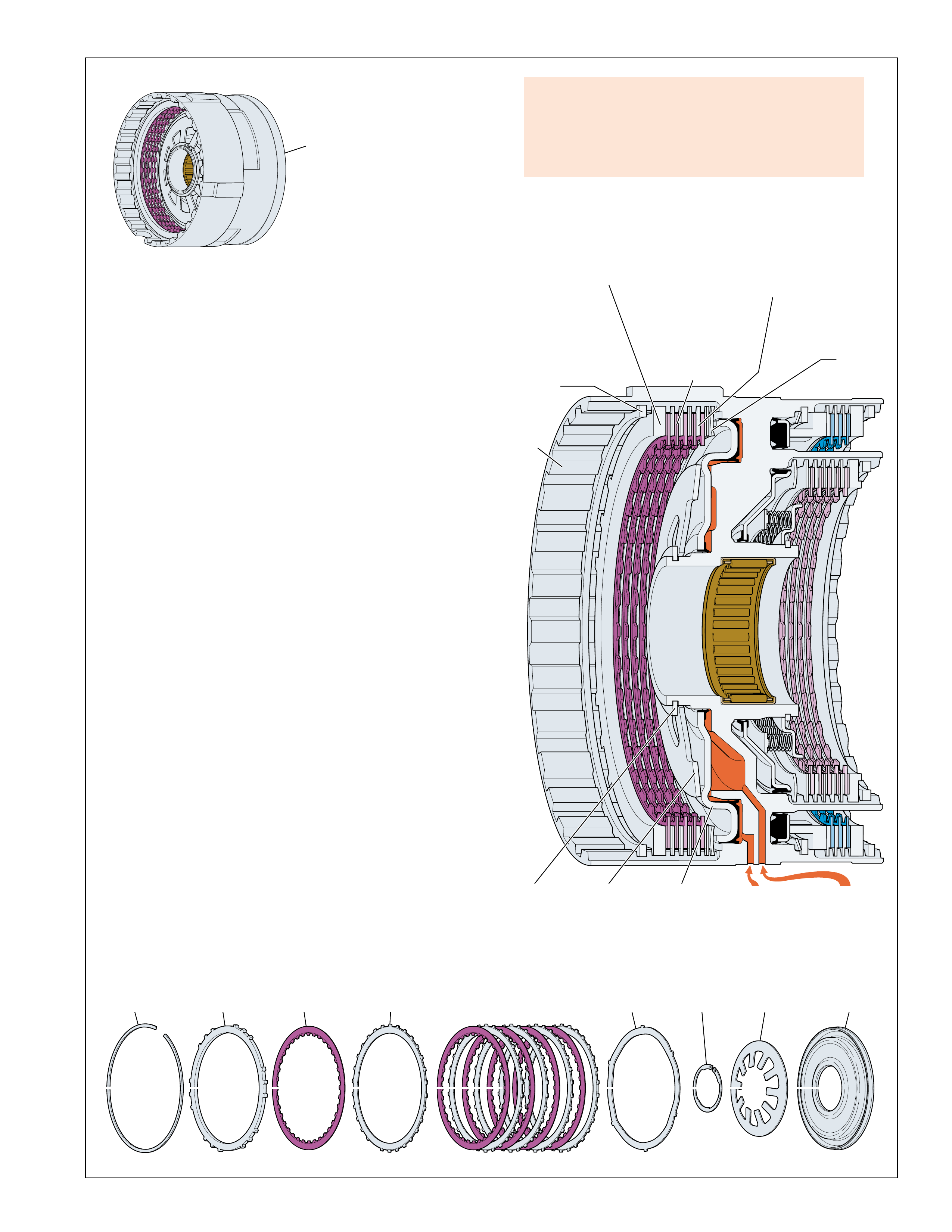

CENTER

SUPPORT

ASSEMBLY

(510-535)

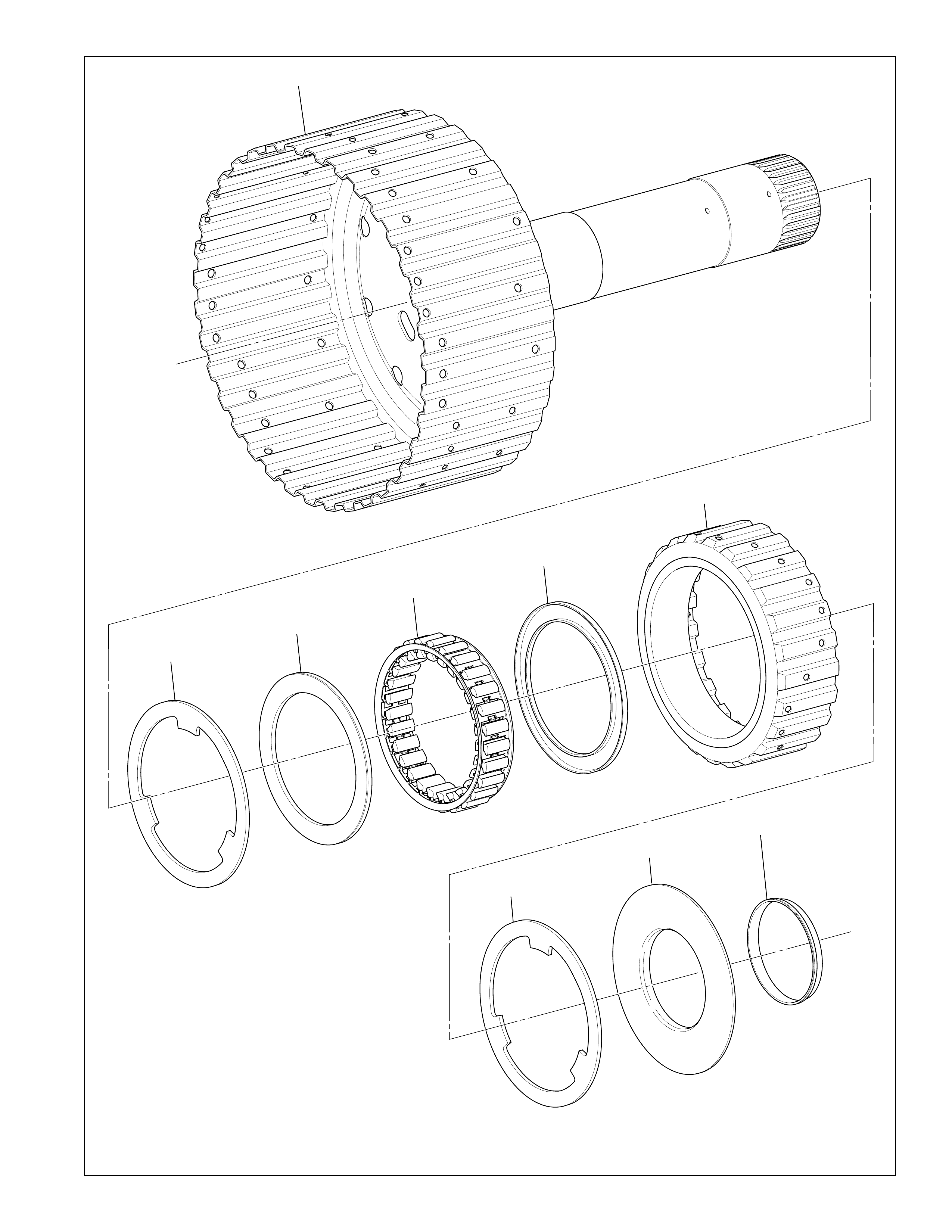

SECOND

CLUTCH SPRAG

INNER RACE

(549)

SECOND

CLUTCH SPRAG

OUTER RACE

(545)

SECOND

CLUTCH SPRAG

ASSEMBLY

(547)

PLANETARY

CARRIER

ASSEMBLY

(540-554)

REAR

INTERNAL GEAR

OUTPUT SHAFT

ASSEMBLY

(560-563)

10 Figure 10

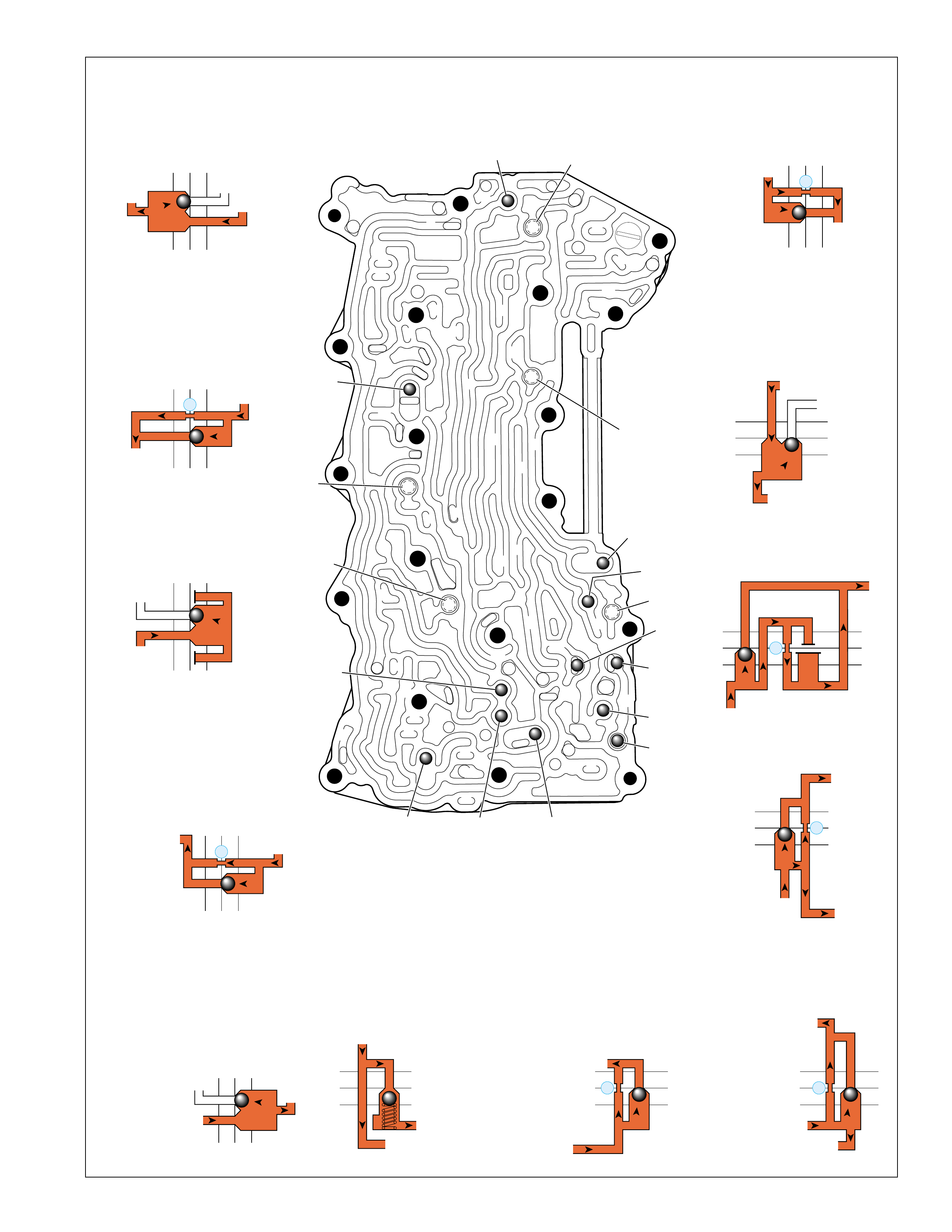

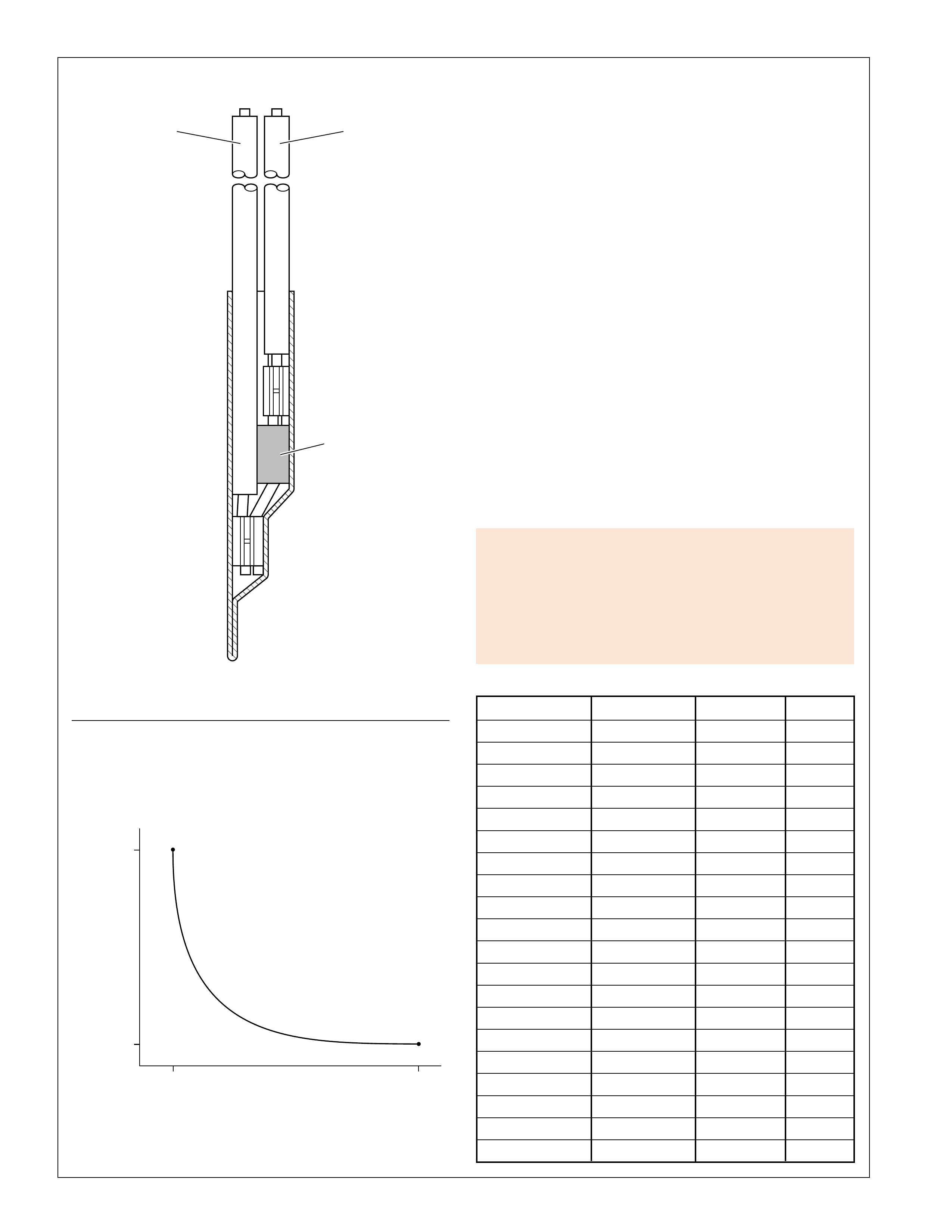

RANGE REFERENCE CHART

Figure 11

HYDRA-MATIC 4L40-E - GEAR RATIOS

FIRST 2.82 FOURTH 0.70

SECOND 1.54 REVERSE 2.38

THIRD 1.00

LD = LOCKED IN DRIVE @ THE SOLENOID'S STATE FOLLOWS A SHIFT PATTERN WHICH DEPENDS UPON VEHICLE

ON = SOLENOID ENERGIZED SPEED AND THROTTLE POSITION. IT DOES NOT DEPEND UPON THE SELECTED GEAR.

OFF = SOLENOID DE-ENERGIZED *ENGINE BRAKING IS ELECTRONICALLY CONTROLLED BY THE TCM, AND IS AVAILABLE AS

CALIBRATED FOR EACH MODEL AND APPLICATION.

ENGINE 1-2 SHIFT 2-3 SHIFT 4-5 SHIFT TCC DIRECT COAST REVERSE FORWARD FORWARD OVER- INTERM. INTER- LOW LOW AND SECOND SECOND SECOND

RANGE GEAR BRAKING RATIO SOLENOID SOLENOID SOLENOID SOLENOID CLUTCH CLUTCH CLUTCH CLUTCH CLUTCH DRIVE CLUTCH MEDIATE CLUTCH REVERSE CLUTCH CLUTCH COAST

VALVE VALVE VALVE VALVE SPRAG CLUTCH SPRAG CLUTCH SPRAG CLUTCH SPRAG CLUTCH

1

*

NO 3.42 OFF ON OFF OFF APPLIED APPLIED LD LD

1 YES 3.42 OFF ON ON OFF APPLIED APPLIED LD LD APPLIED

2

*

NO 2.21 ON ON OFF ON/OFF

@

APPLIED APPLIED LD APPLIED LD

D432

2 YES 2.21 ON ON ON ON/OFF

@

APPLIED APPLIED LD APPLIED LD APPLIED

3

*

NO 1.60 ON OFF OFF ON/OFF

@

APPLIED APPLIED LD LD APPLIED APPLIED

3 YES 1.60 ON OFF ON ON/OFF

@

APPLIED APPLIED LD APPLIED LD APPLIED APPLIED

4 YES 1.00 OFF OFF ON ON/OFF

@

APPLIED APPLIED APPLIED LD APPLIED APPLIED

5 YES 0.75 OFF OFF OFF ON/OFF

@

APPLIED APPLIED APPLIED APPLIED APPLIED

NEUTRAL

———ON/OFF ON/OFF ON/OFF

REVERSE

R YES 3.03 ON/OFF ON/OFF ON/OFF OFF APPLIED APPLIED

PARK

———ON/OFF ON/OFF ON/OFF

@@@

@@@

@@@

HYDRA-MATIC 5L40-E - GEAR RATIOS

FIRST 3.42 FOURTH 1.00

SECOND 2.21 FIFTH 0.75

THIRD 1.60 REVERSE 3.03

11

10A

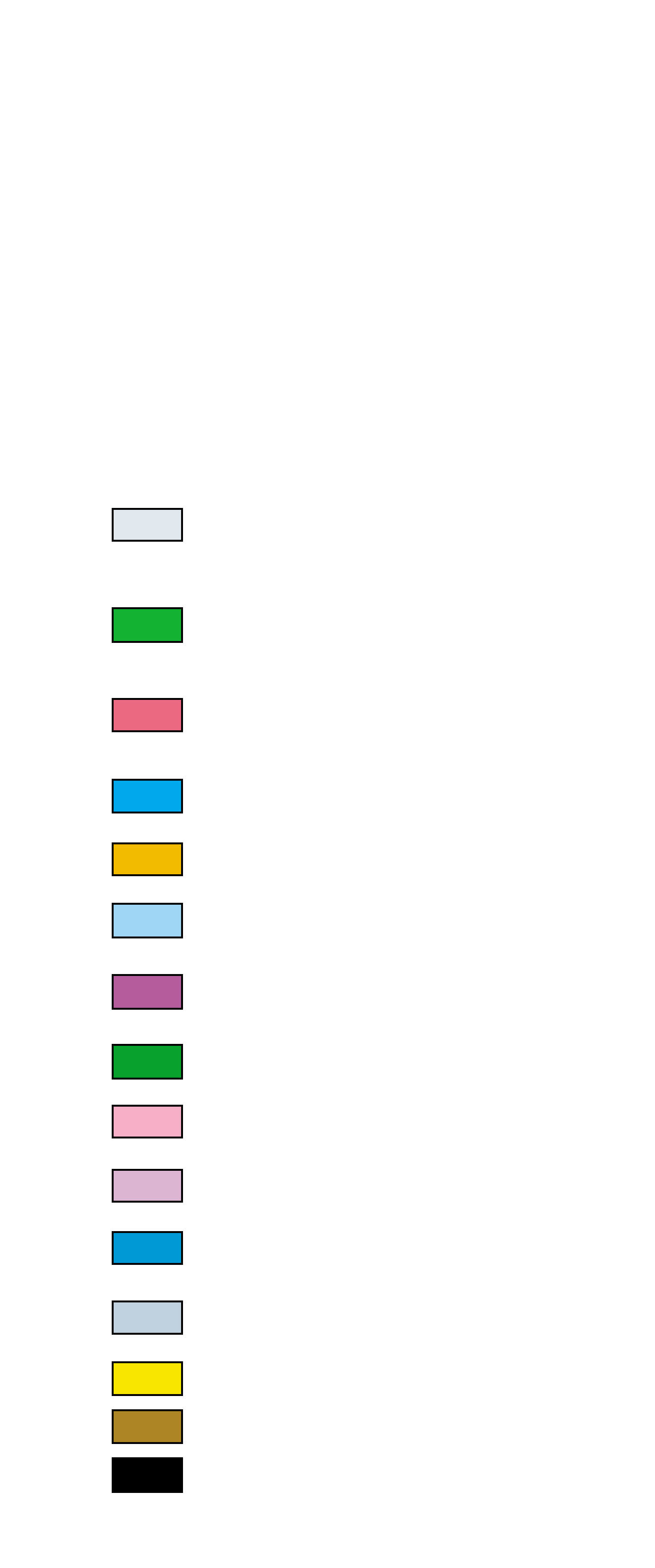

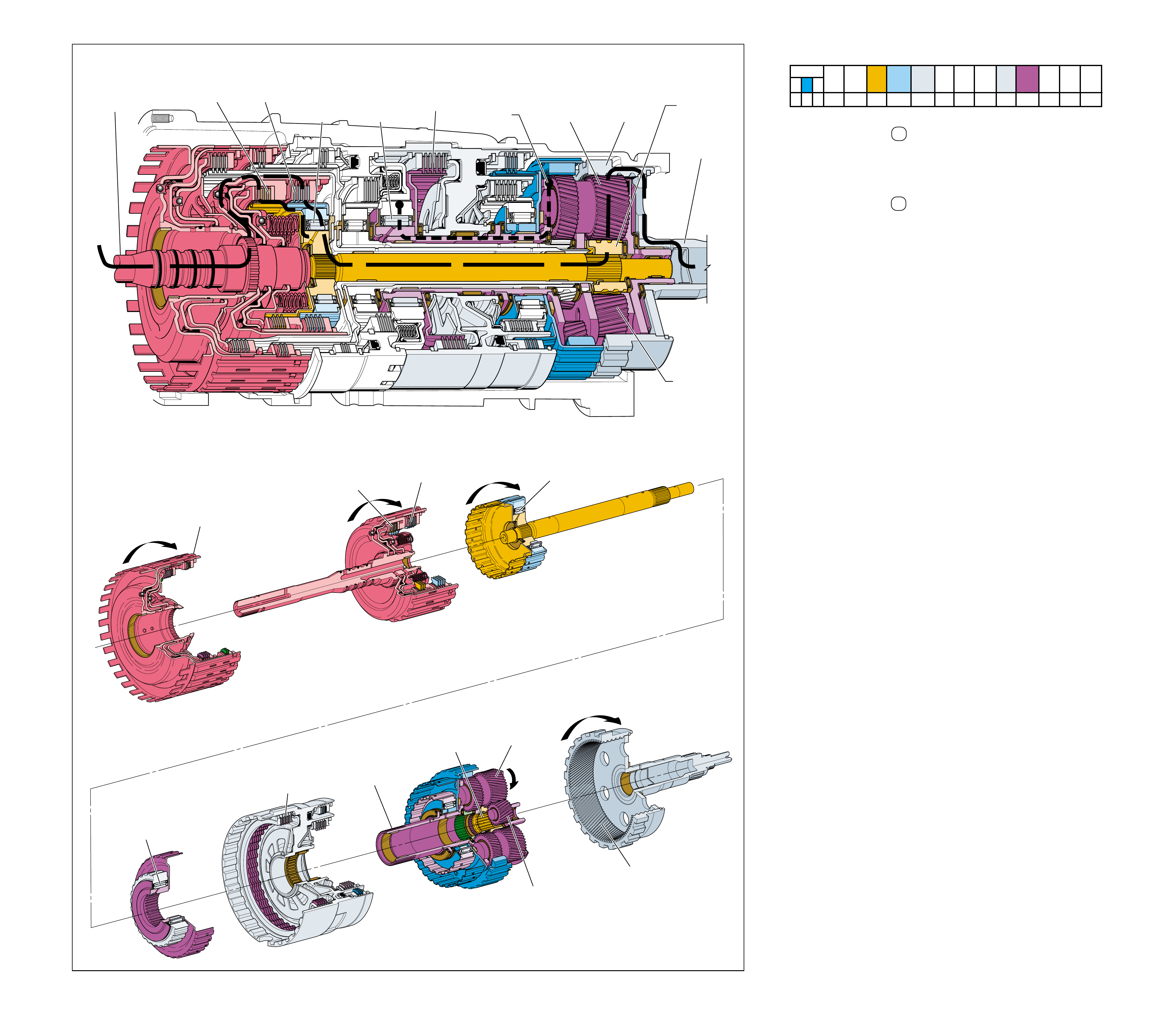

COLOR LEGEND

MAJOR MECHANICAL COMPONENTS

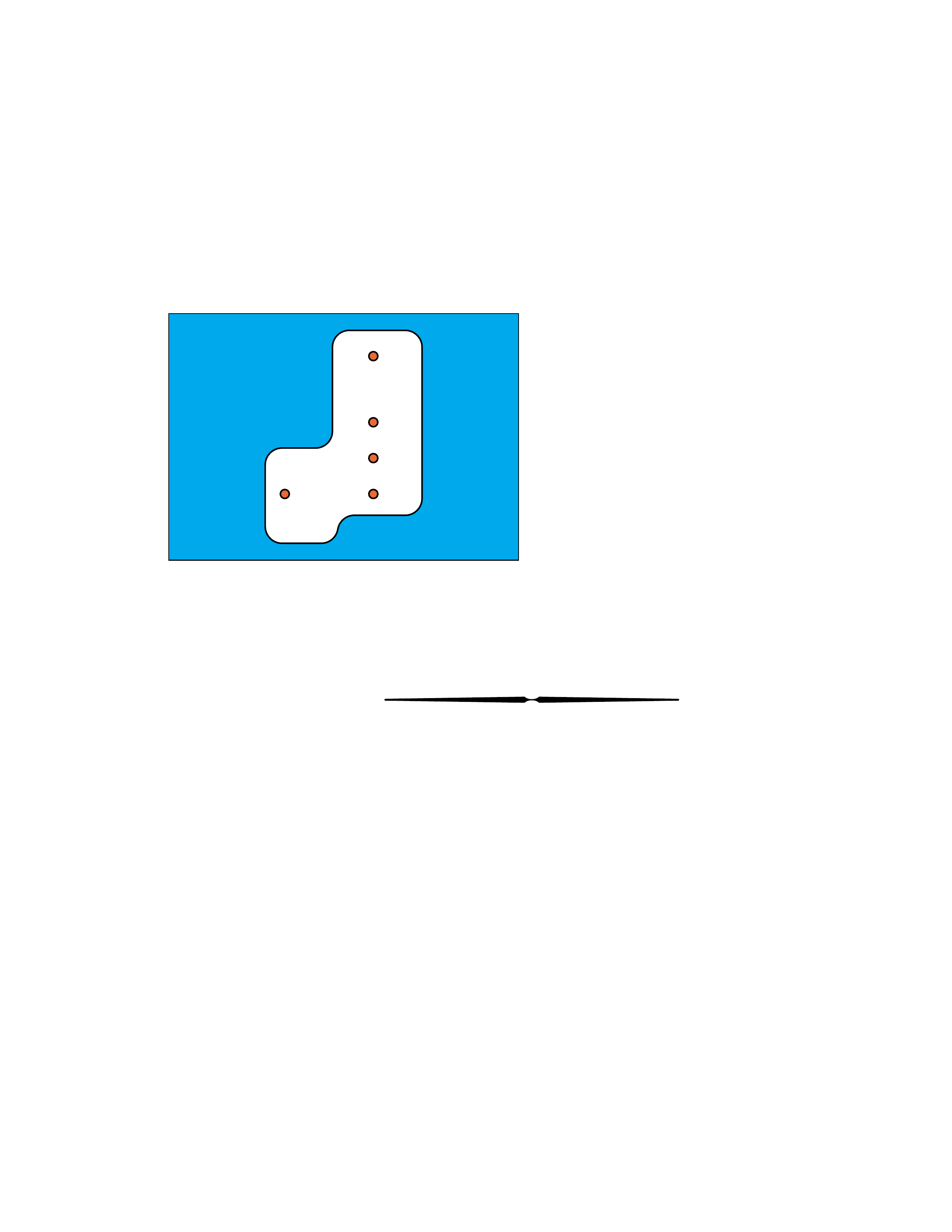

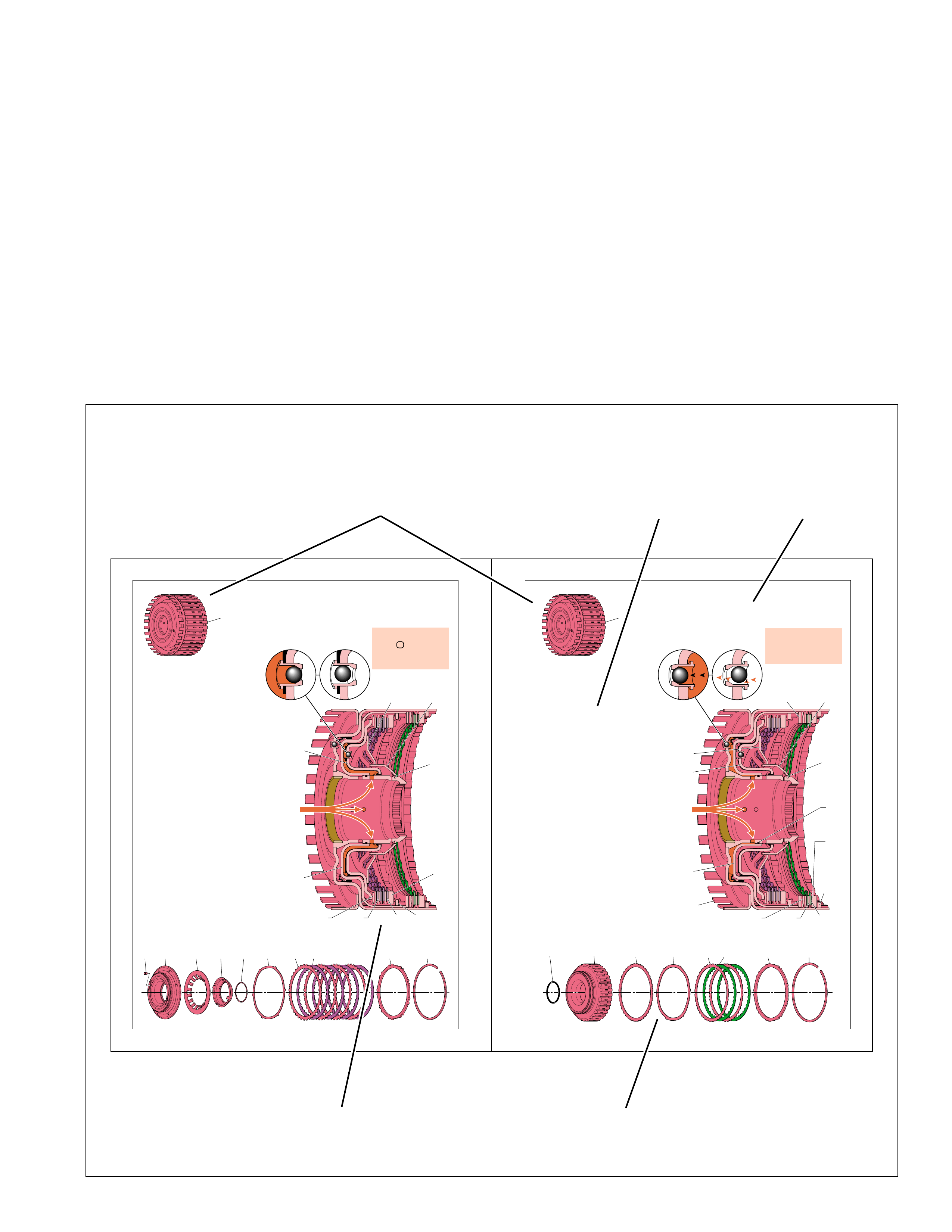

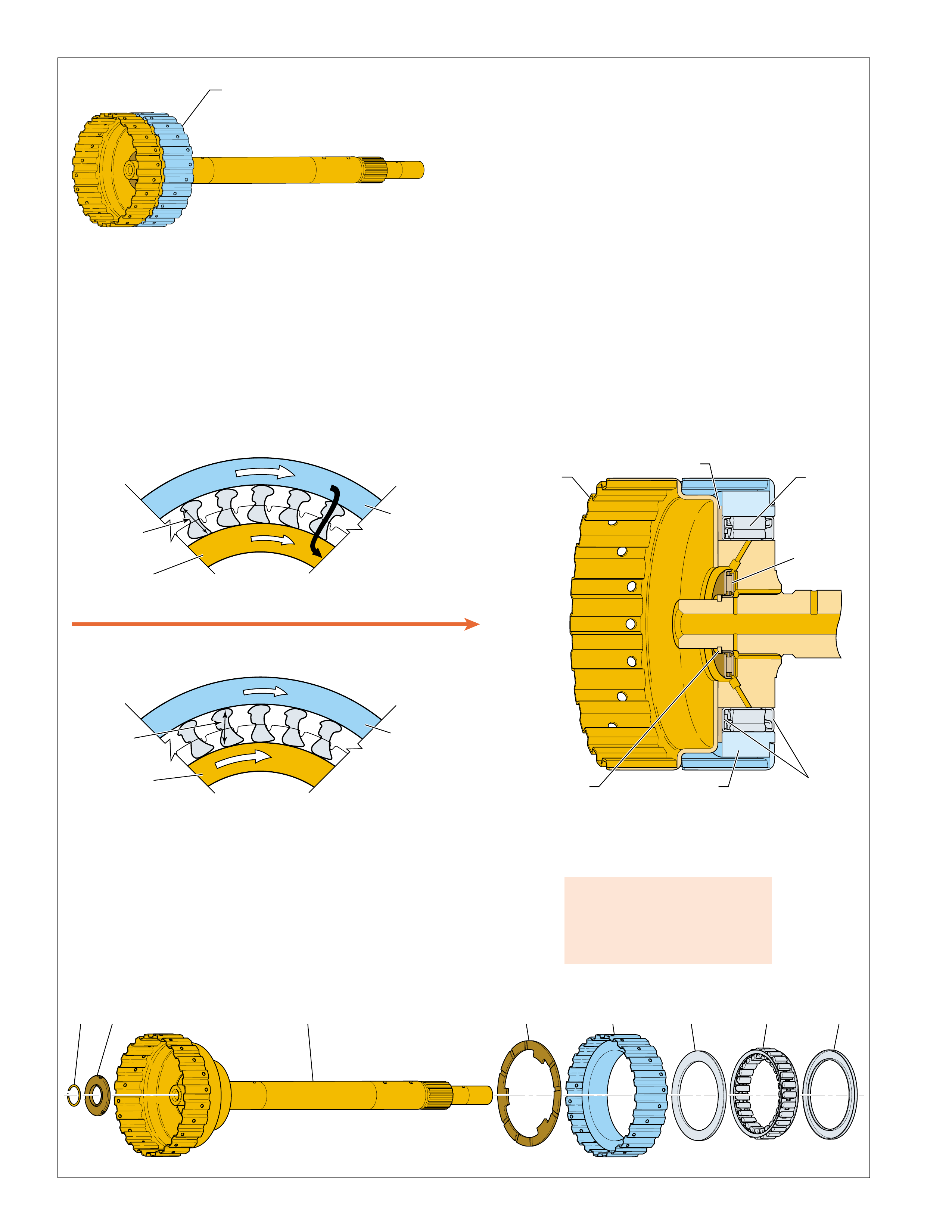

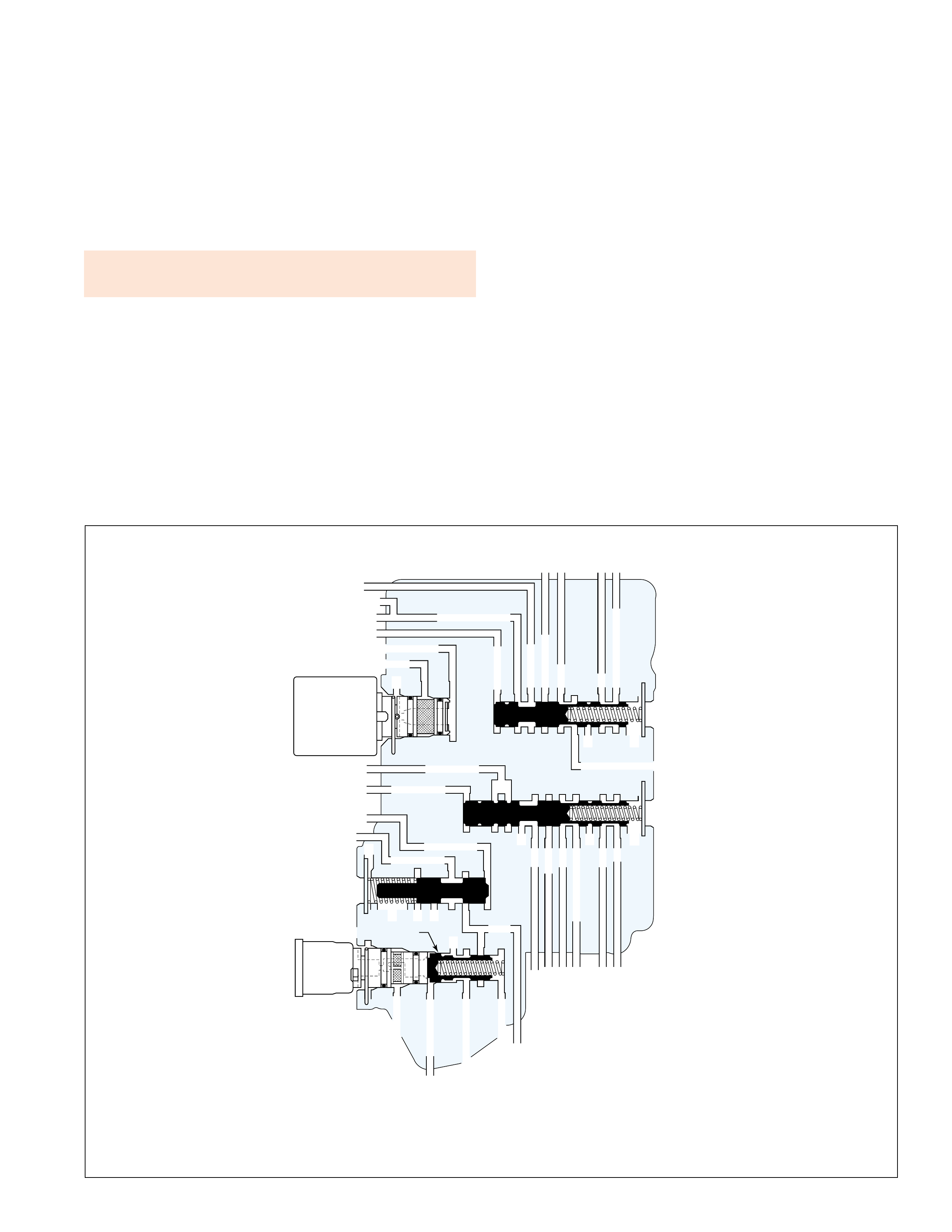

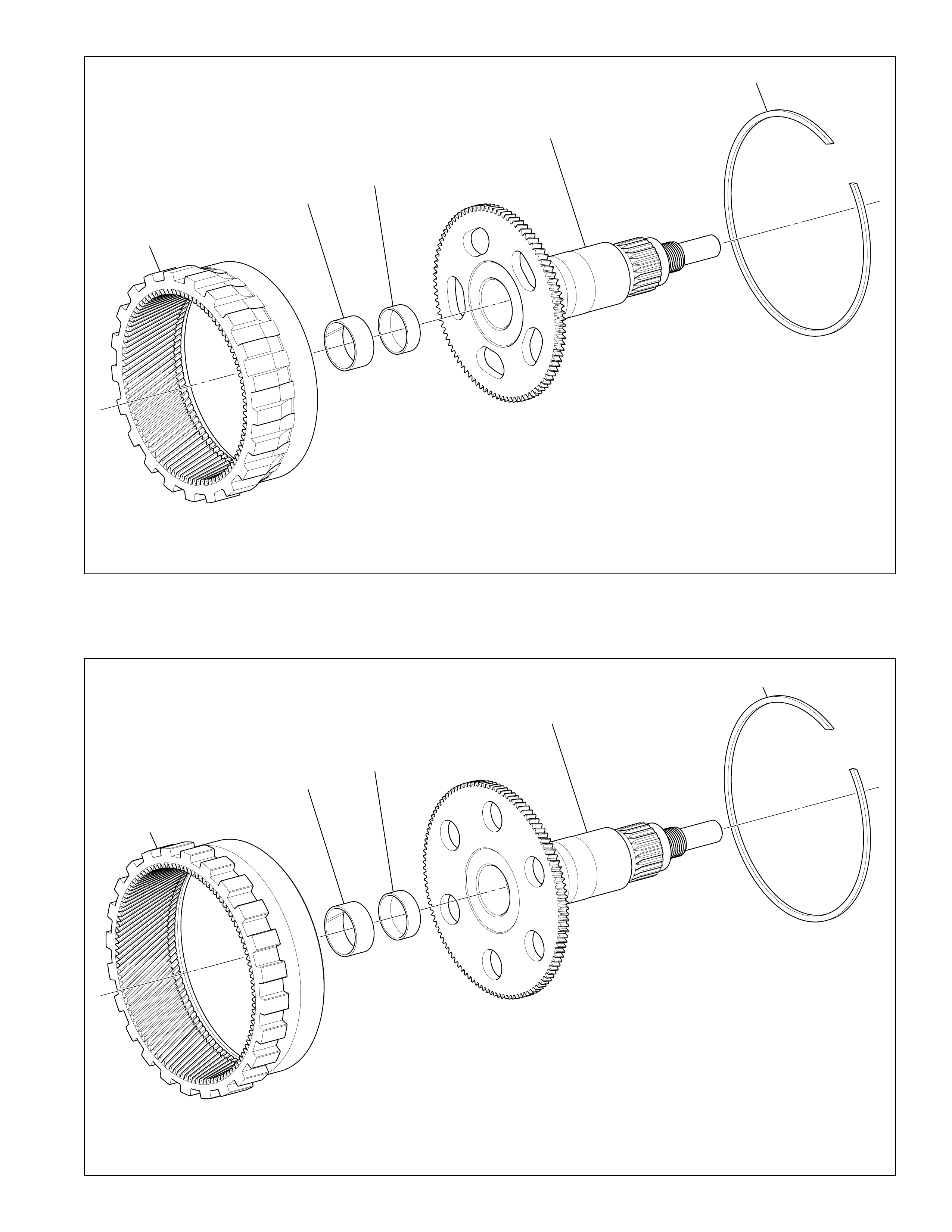

The foldout graphic on page 10 contains a disassembled drawing

of the major components used in the Hydra-matic 4/5L40-E

transmission. This drawing, along with the cross sectional

illustrations on page 8 and 8A, show the major mechanical

components and their relationship to each other as a complete

assembly. Therefore, color has been used throughout this book

to help identify parts that are splined together, rotating at engine

speed, held stationary, and so forth. Color differentiation is

particularly helpful when using the Power Flow section for

understanding the transmission operation.

The color legend below provides the “general” guidelines that

were followed in assigning specific colors to the major

components. However, due to the complexity of this

transmission, some colors (such as grey) were used for artistic

purposes rather than based on the specific function or location

of that component.

Components held stationary in the case or splined to

the case. Examples: the Fluid Pump Cover

Assembly (202), the Overdrive Clutch Housing

(493), and the Center Support (518). Also includes

the Clutch Sprag assemblies.

Components that rotate at engine speed. Examples:

the Torque Converter Assembly (1), the Fluid Pump

Rotor (223), and the Fluid Pump Vanes (222).

Components that rotate at turbine speed. Examples:

the Converter Turbine, the Forward Clutch and Input

Housing Assembly (433), and the Reverse Clutch

and Input Housing Assembly (401).

Components such as the Stator in the Torque

Converter Clutch Assembly (1).

Components such as the Input Sun Gear Shaft

Assembly (457).

Components such as the Forward Clutch Sprag Outer

Race (459).

Components such as the Direct Clutch Input and

Hub Assembly (466), and the Input and Reaction

Carrier Assembly (553).

Components such as the Overdrive and Reverse

Clutch Hub Assembly (470).

Components such as the Intermediate Clutch Sprag

Outer Race (474).

Components such as the Second Clutch Sprag Outer

Race (545).

Components such as the Second Clutch Sprag Inner

Race (549).

Components that rotate at transmission output speed.

Examples: the Output Shaft Assembly (562) and the

Input and Reaction Carrier Assembly (553).

Accumulators, Servos and Bands.

All bearings and bushings.

All seals

10B

COLOR LEGEND

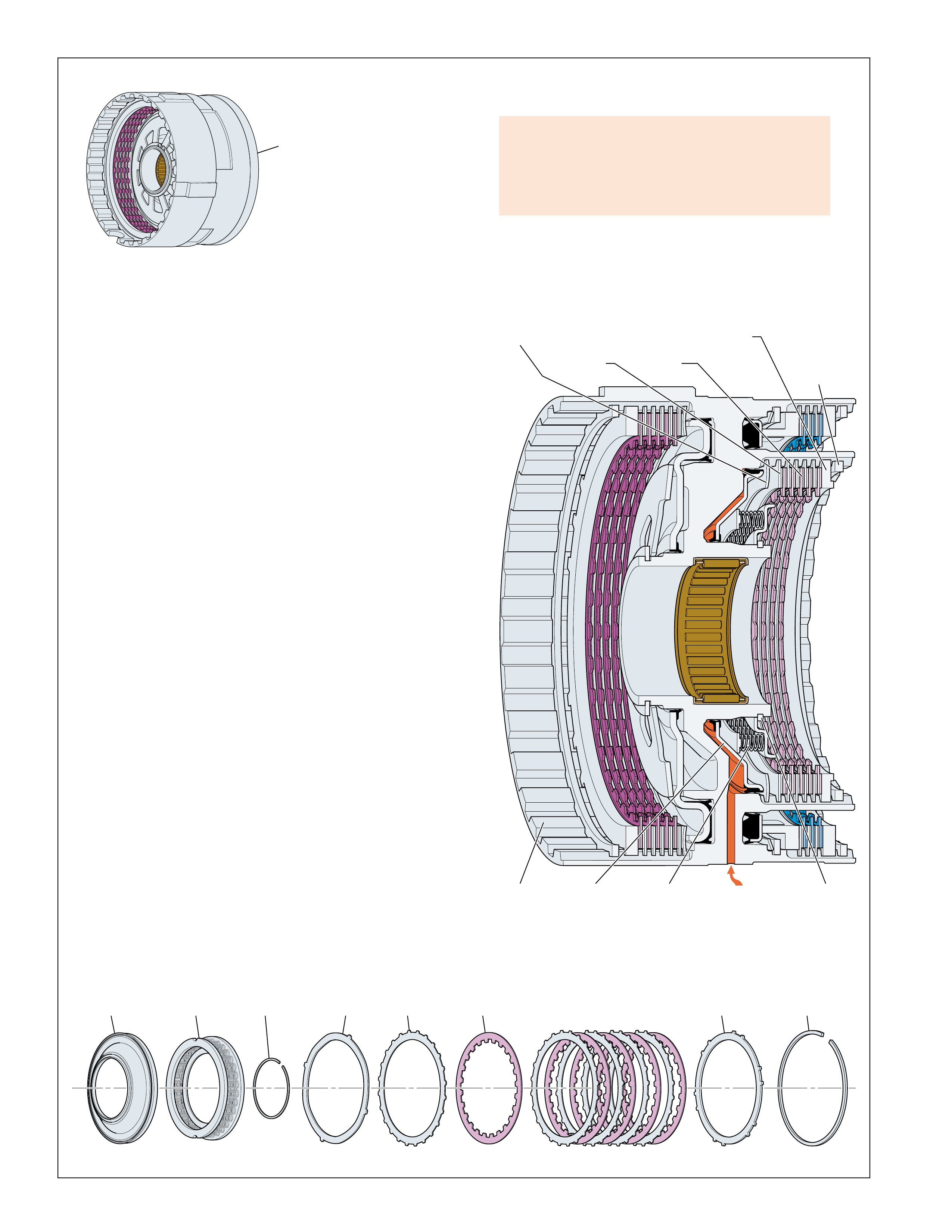

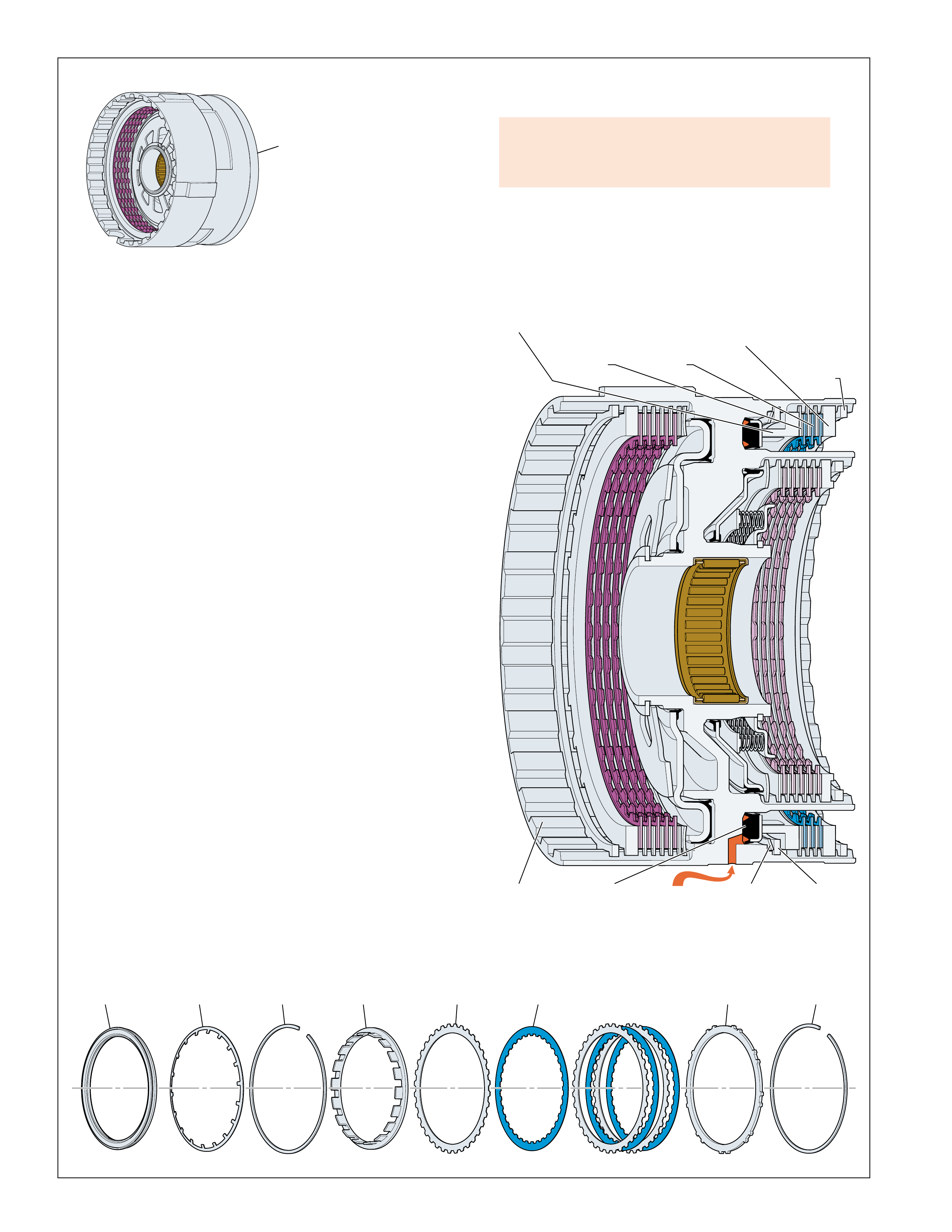

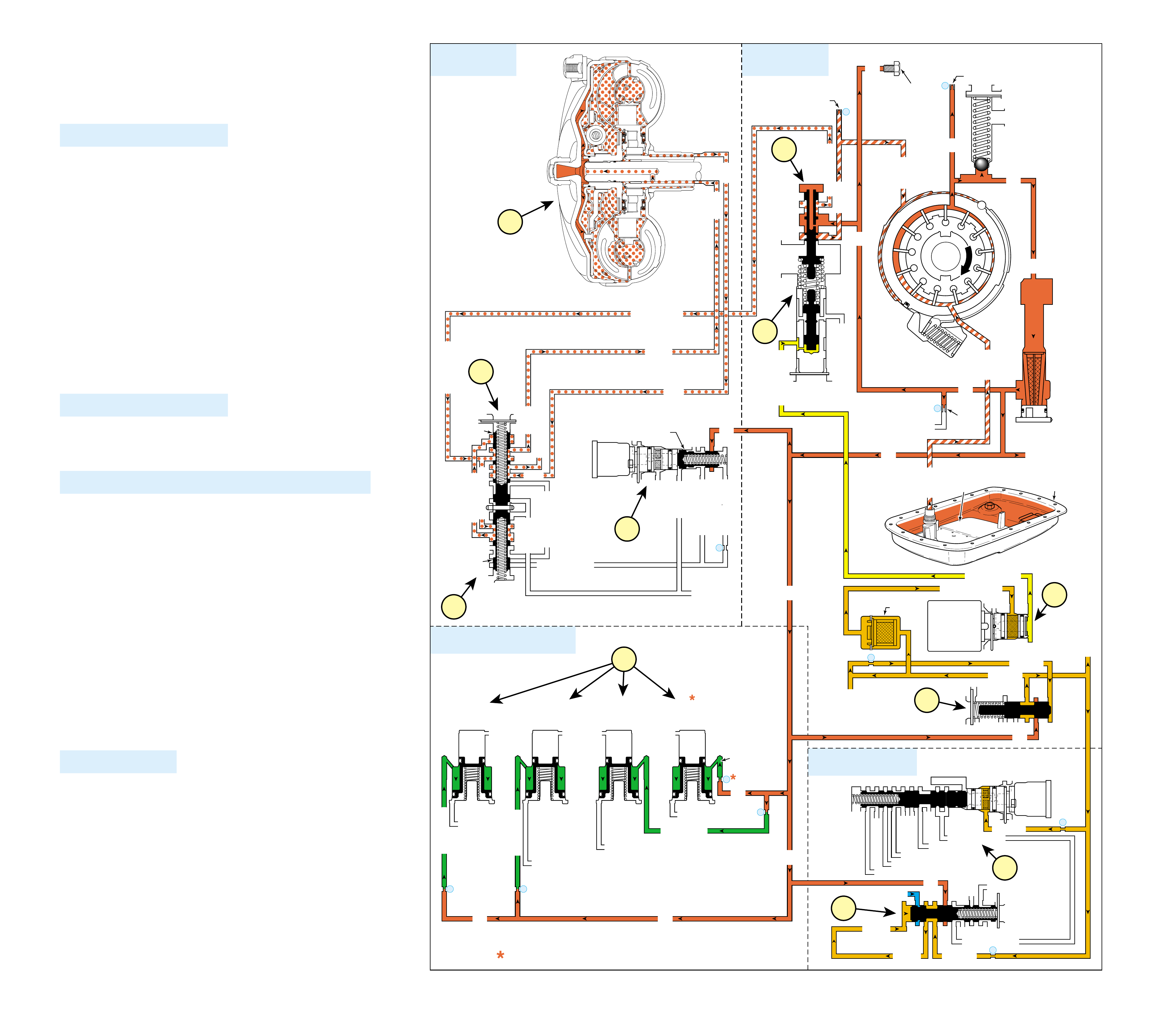

APPLY COMPONENTS

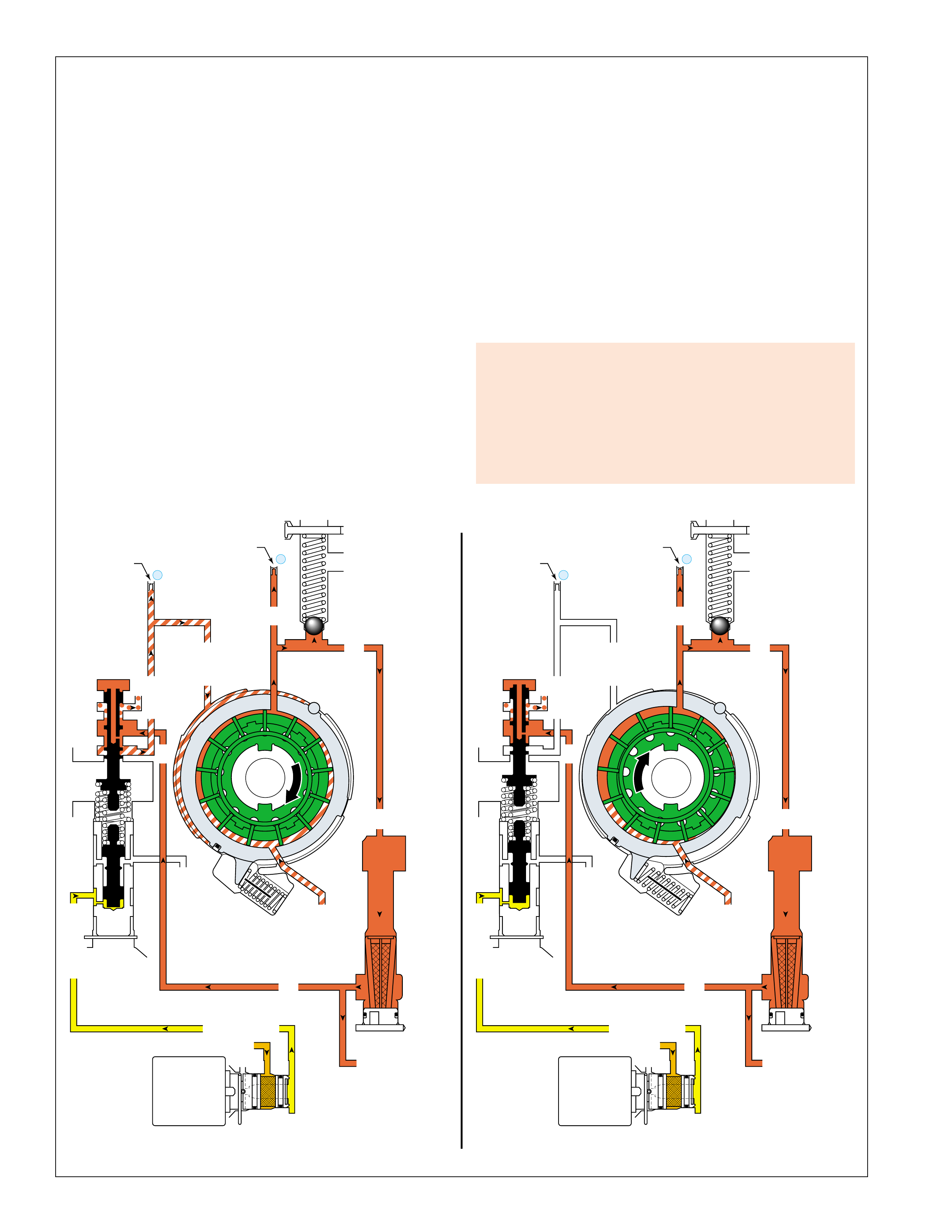

The Range Reference Chart on page 11, provides another

valuable source of information for explaining the overall function

of the Hydra-matic 4/5L40-E transmission. This chart highlights

the major apply components that function in a selected gear

range, and the specific gear operation within that gear range.

Included as part of this chart is the same color reference to each

major component that was previously discussed. If a component

is active in a specific gear range, a word describing its activity

will be listed in the column below that component. The row

where the activity occurs corresponds to the appropriate

transmission range and gear operation. An abbreviated version

of this chart can also be found at the top of the half page of text

located in the Power Flow section. This provides for a quick

reference when reviewing the mechanical power flow information

contained in that section.

RANGE REFERENCE CHART

Figure 11

HYDRA-MATIC 4L40-E - GEAR RATIOS

FIRST 2.82 FOURTH 0.70

SECOND 1.54 REVERSE 2.38

THIRD 1.00

LD = LOCKED IN DRIVE @ THE SOLENOID'S STATE FOLLOWS A SHIFT PATTERN WHICH DEPENDS UPON VEHICLE

ON = SOLENOID ENERGIZED SPEED AND THROTTLE POSITION. IT DOES NOT DEPEND UPON THE SELECTED GEAR.

OFF = SOLENOID DE-ENERGIZED *ENGINE BRAKING IS ELECTRONICALLY CONTROLLED BY THE TCM, AND IS AVAILABLE AS

CALIBRATED FOR EACH MODEL AND APPLICATION.

ENGINE 1-2 SHIFT 2-3 SHIFT 4-5 SHIFT TCC DIRECT COAST REVERSE FORWARD FORWARD OVER- INTERM. INTER- LOW LOW AND SECOND SECOND SECOND

RANGE GEAR BRAKING RATIO SOLENOID SOLENOID SOLENOID SOLENOID CLUTCH CLUTCH CLUTCH CLUTCH CLUTCH DRIVE CLUTCH MEDIATE CLUTCH REVERSE CLUTCH CLUTCH COAST

VALVE VALVE VALVE VALVE SPRAG CLUTCH SPRAG CLUTCH SPRAG CLUTCH SPRAG CLUTCH

1

*

NO 3.42 OFF ON OFF OFF APPLIED APPLIED LD LD

1 YES 3.42 OFF ON ON OFF APPLIED APPLIED LD LD APPLIED

2

*

NO 2.21 ON ON OFF ON/OFF

@

APPLIED APPLIED LD APPLIED LD

D432

2 YES 2.21 ON ON ON ON/OFF

@

APPLIED APPLIED LD APPLIED LD APPLIED

3

*

NO 1.60 ON OFF OFF ON/OFF

@

APPLIED APPLIED LD LD APPLIED APPLIED

3 YES 1.60 ON OFF ON ON/OFF

@

APPLIED APPLIED LD APPLIED LD APPLIED APPLIED

4 YES 1.00 OFF OFF ON ON/OFF

@

APPLIED APPLIED APPLIED LD APPLIED APPLIED

5 YES 0.75 OFF OFF OFF ON/OFF

@

APPLIED APPLIED APPLIED APPLIED APPLIED

NEUTRAL

———ON/OFF ON/OFF ON/OFF

REVERSE

R YES 3.03 ON/OFF ON/OFF ON/OFF OFF APPLIED APPLIED

PARK

———ON/OFF ON/OFF ON/OFF

@@@

@@@

@@@

HYDRA-MATIC 5L40-E - GEAR RATIOS

FIRST 3.42 FOURTH 1.00

SECOND 2.21 FIFTH 0.75

THIRD 1.60 REVERSE 3.03

11

10A

COLOR LEGEND

MAJOR MECHANICAL COMPONENTS

The foldout graphic on page 10 contains a disassembled drawing

of the major components used in the Hydra-matic 4/5L40-E

transmission. This drawing, along with the cross sectional

illustrations on page 8 and 8A, show the major mechanical

components and their relationship to each other as a complete

assembly. Therefore, color has been used throughout this book

to help identify parts that are splined together, rotating at engine

speed, held stationary, and so forth. Color differentiation is

particularly helpful when using the Power Flow section for

understanding the transmission operation.