VZ L.P.G. Conversion Kit Page 8A2–1

Page 8A2–1

Section 8A2

VZ L.P.G. Conversion Kit

Section 1 Passenger Compartment........................................................................................................8A2-2

Section 2 Manifold Modification............................................................................................................8A2-17

Section 3 Engine Compartment............................................................................................................8A2-21

Owner’s Handbook.................................................................................................................................8A2-41

Techline

Techline

Techline

Techline

Techline

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS:

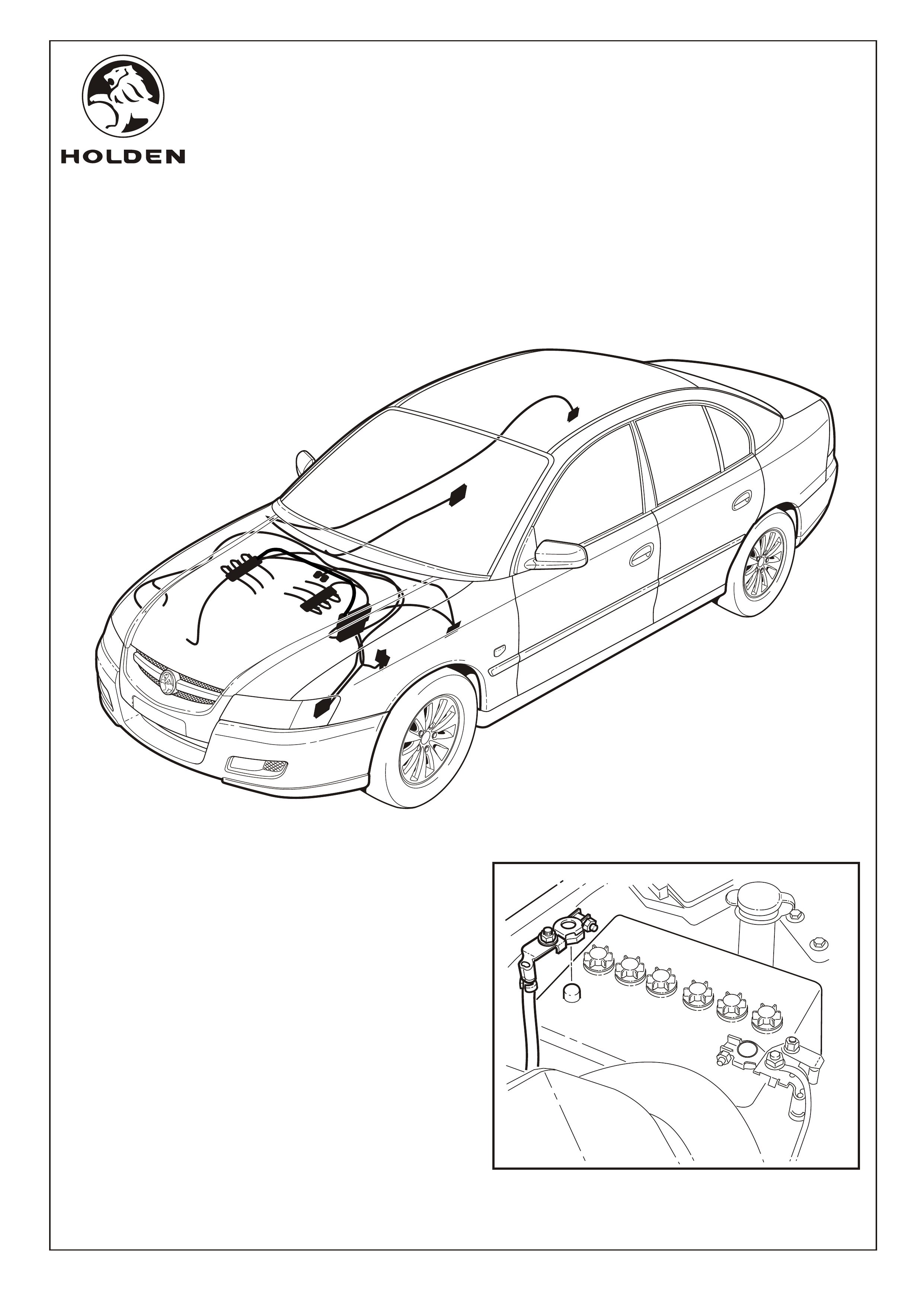

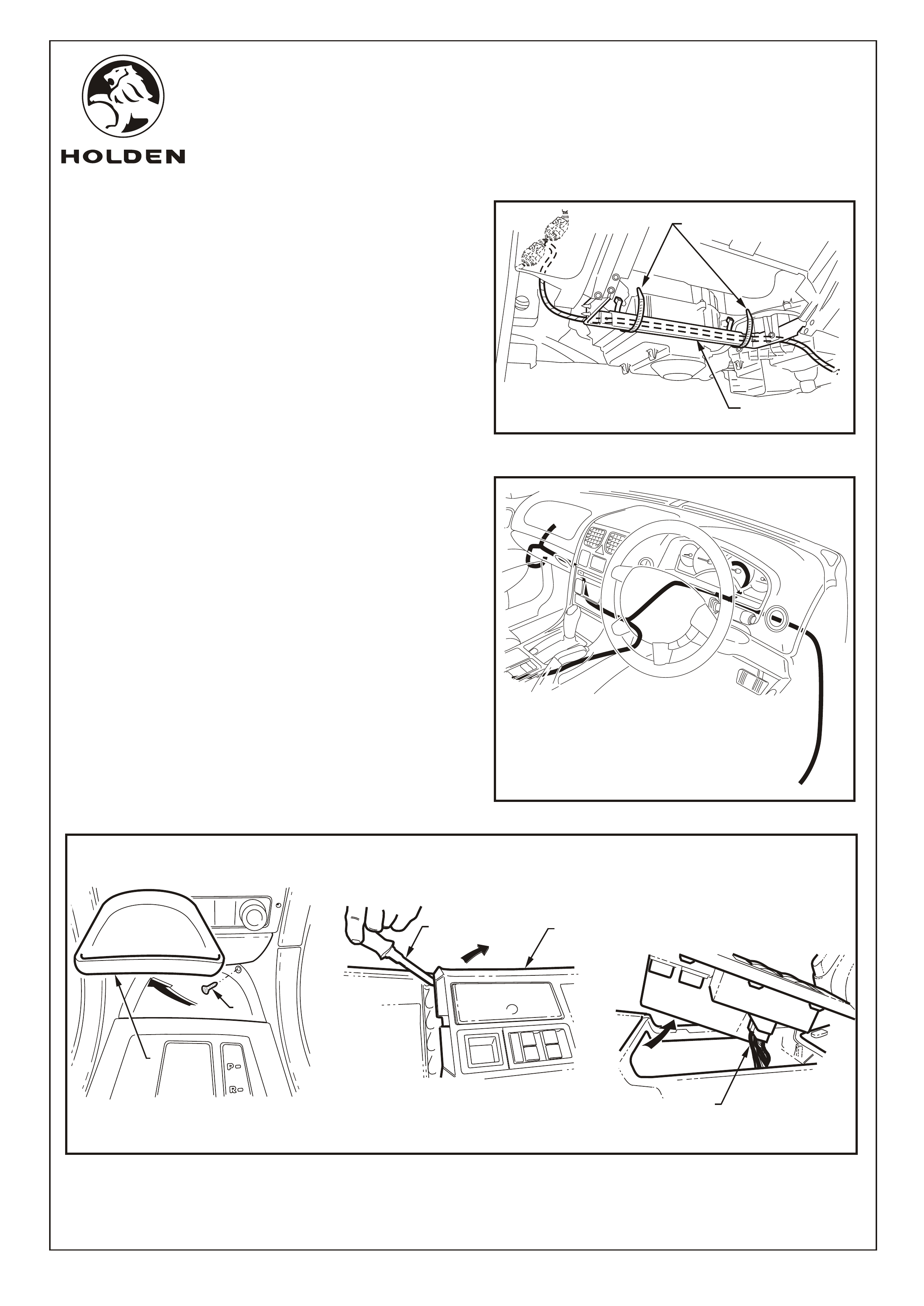

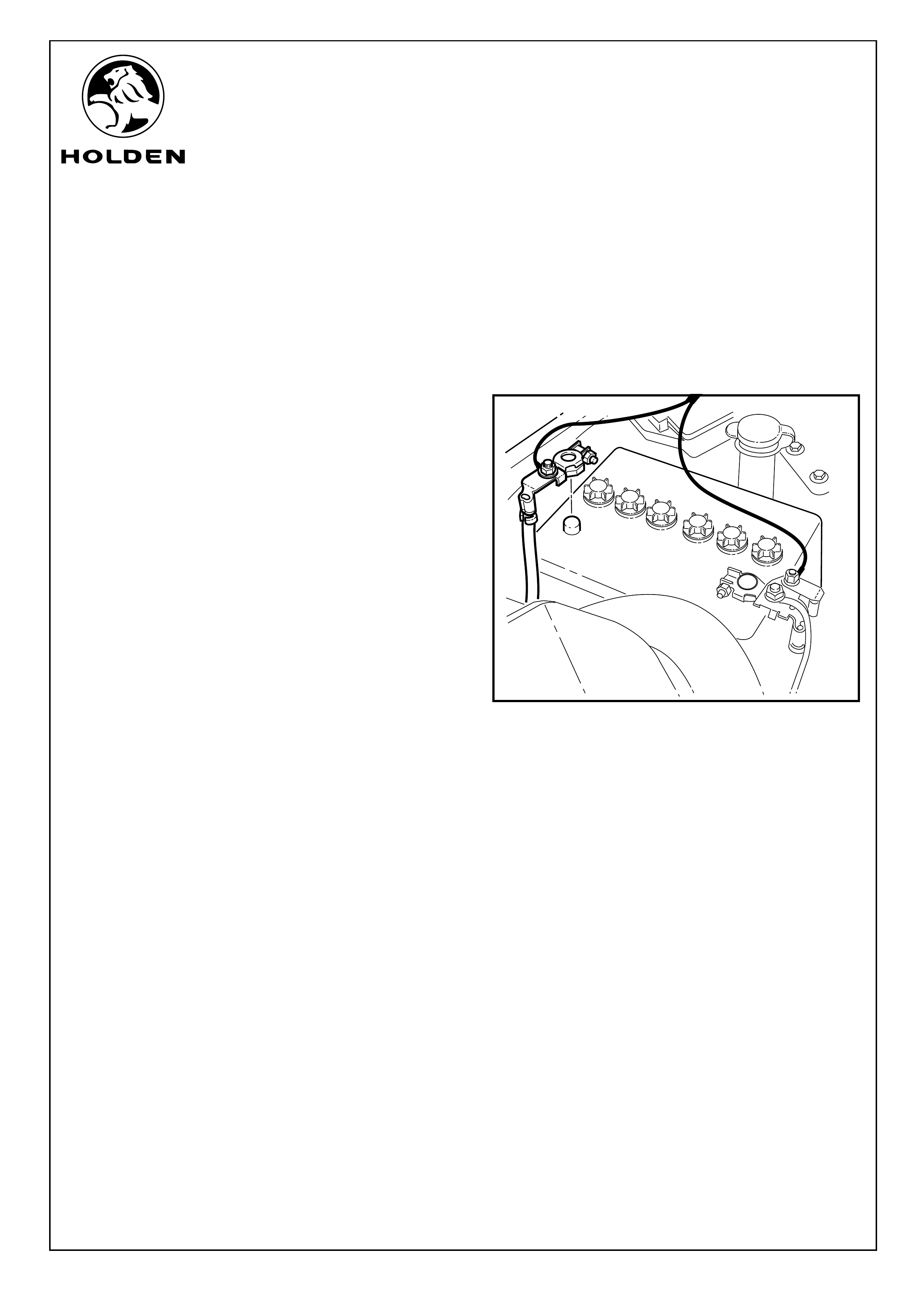

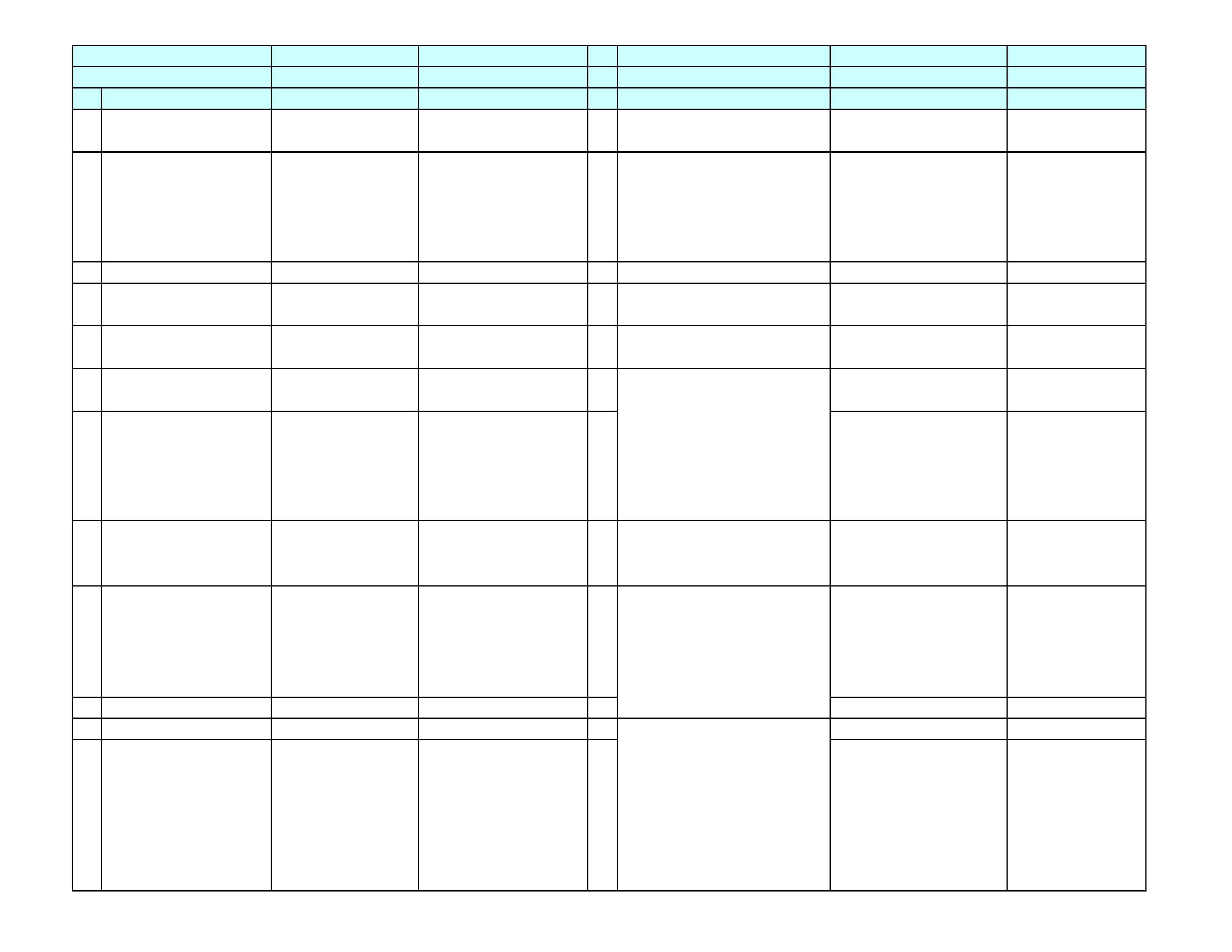

1. Disconnect the vehicle battery. Refer to Figure 1.

IMPORTANT: Disconnecting the vehicle battery may

impact or damage electrical systems in the vehicle -

Body Control Module, Entertainment System, Electric

Sunroof, etc unless correct instructions are followed.

Please contact your Holden Retailer for further

information.

NOTE: To reinstate the audio system, the security code will

be required.

SECTION 1

PASSENGER COMPARTMENT

Page 1 of 15

FIGURE 1

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

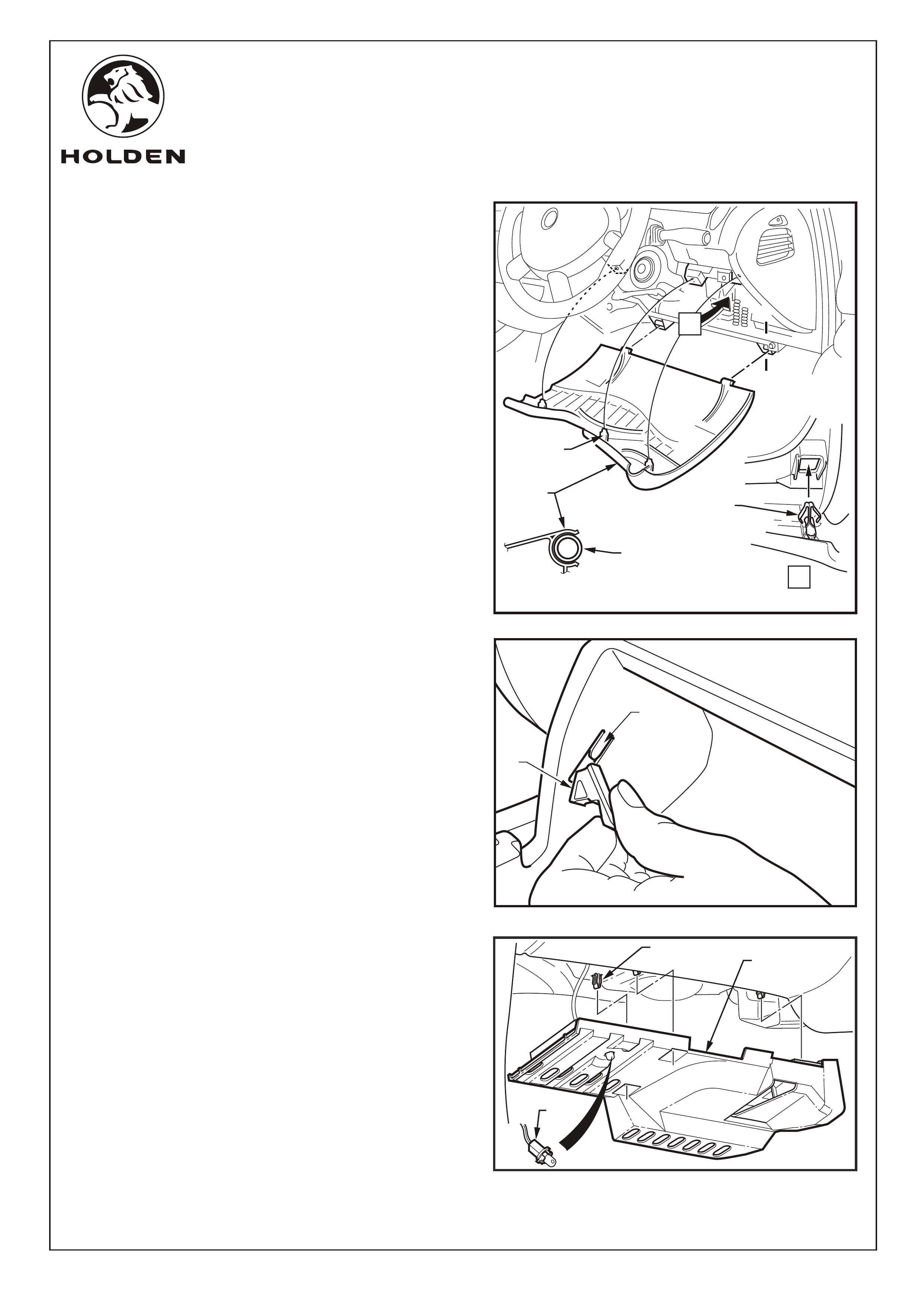

Refer to Figure 4 for the following:

5. Remove the left-hand side instrument panel lower trim

plate assembly as follows:

a. Grasp the instrument panel lower trim plate

assembly (1) and carefully pull downward to

disengage the retaining clips (2) (3 places).

b. Lower the plate assembly slightly and if fitted

remove the foot well lamp (3) by rotating the socket

and removing from the plate assembly.

c. Remove the plate assembly.

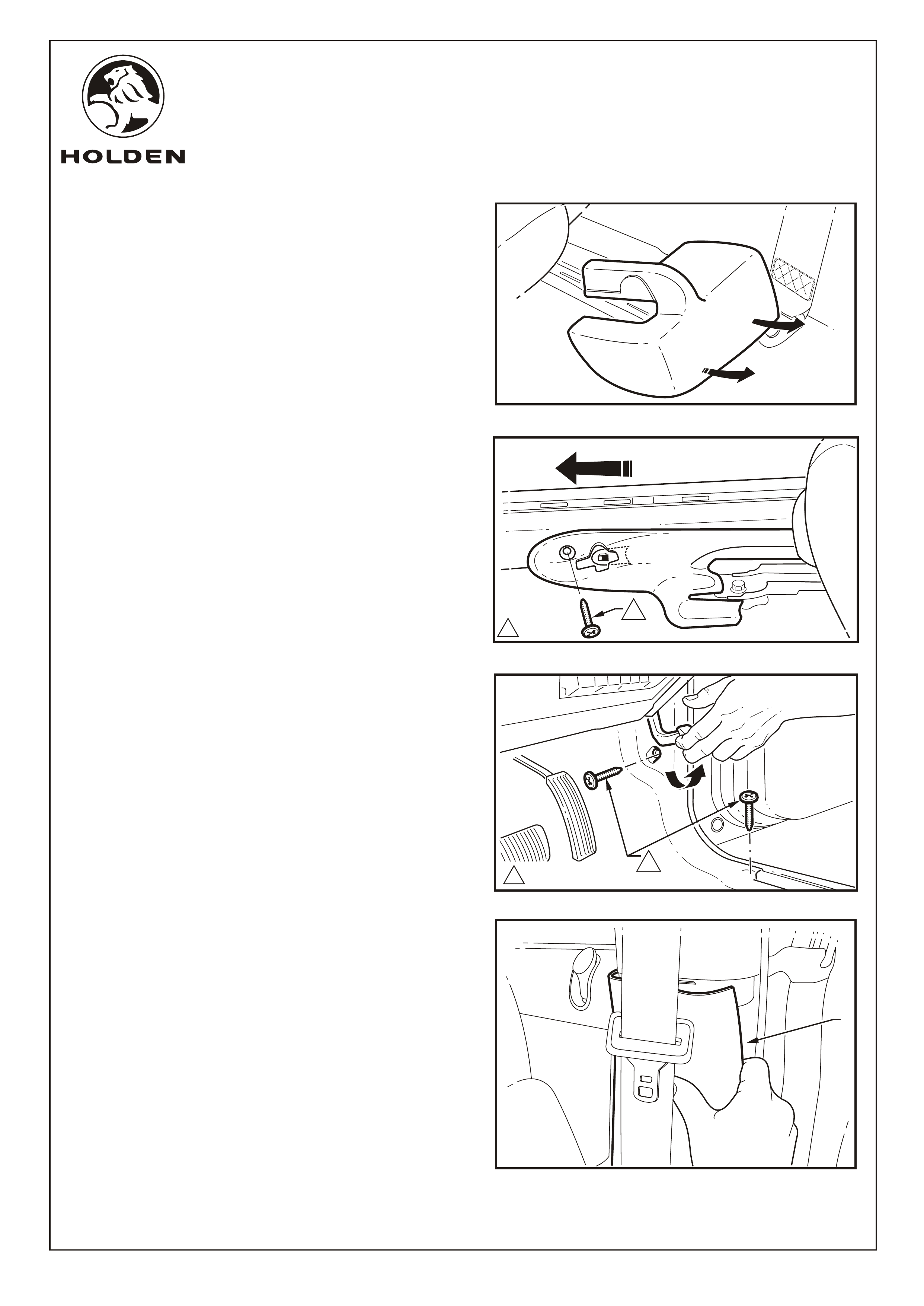

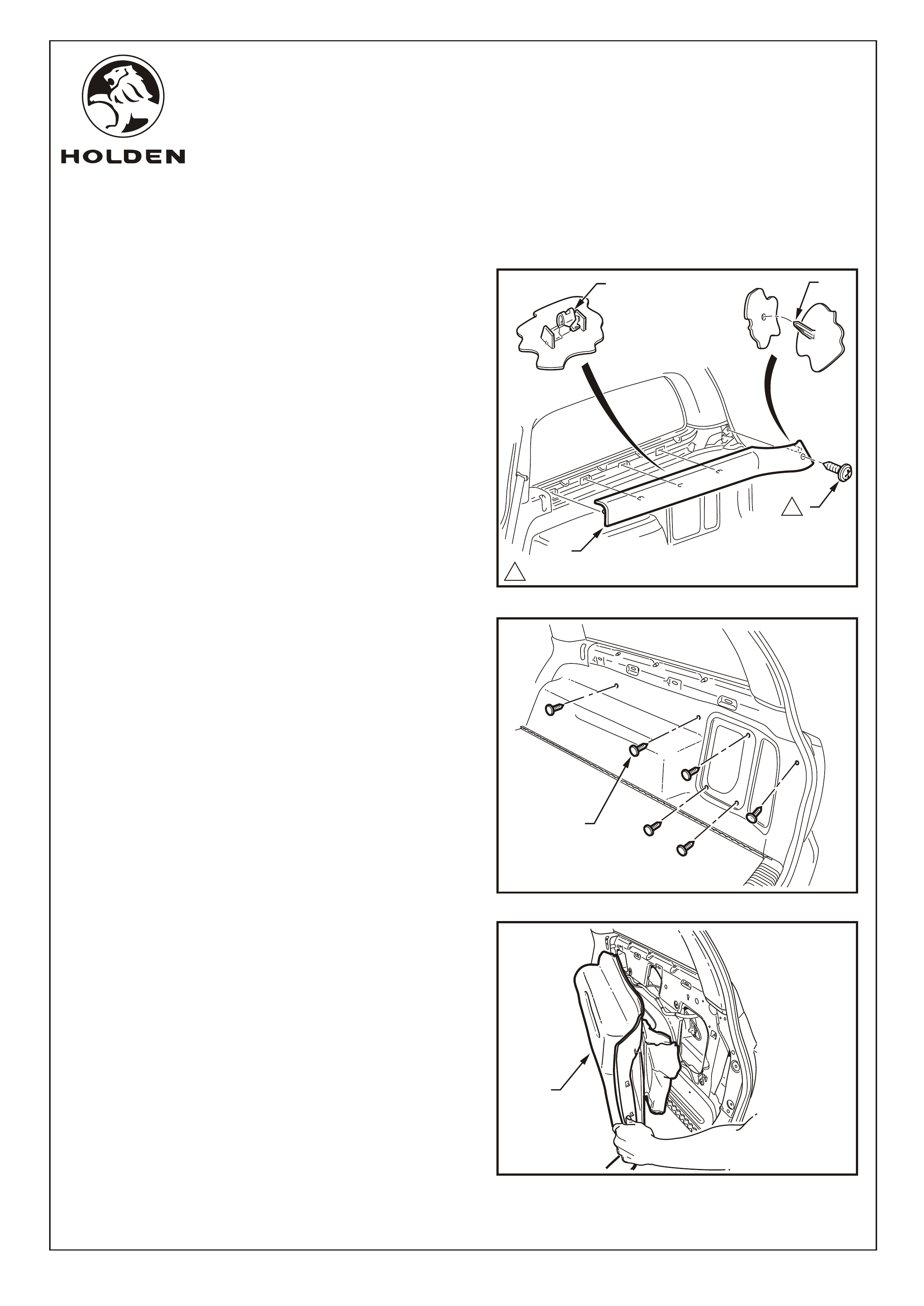

Refer to Figure 2 for the following:

2. Remove the lower instrument trim panel (1) assembly

as follows:

a. Adjust the steering wheel to upper-most position.

b. Grasp the top edge of the lower instrument trim

panel assembly and pull outwards to disengage the

three retaining clips (2).

c. Swing the panel assembly open.

d. Holding each side of the panel assembly pull

rearwards to disengage it from the instrument panel

lower trim panel retainer (3) (2 places).

Refer to Figure 3 for the following:

3. Open the glovebox and remove the two travel limiting

lugs (1). This is done by carefully raising the rubber tabs

on the limiting lugs and pulling them rearwards. Once

pulled rearwards, gently pull the rubber tabs towards the

center of the glovebox. To release the glovebox, pull

glovebox towards the rear of the vehicle.

NOTE: Care must be taken not to break the tongues (2)

off during travel limiting lug removal.

4. Refit travel limiting lugs and place glovebox to one side.

FIGURE 2

LOWER

TRIM

PANEL

A-A

A

A

A

A

RETAINING

CLIP

RETAINING

CLIP

(3 PLACES)

LOWER TRIM

PANEL

RETAINER

(2 PLACES)

FIGURE 3

1

2

FIGURE 12

3

1

2

FIGURE 4

Page 2 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

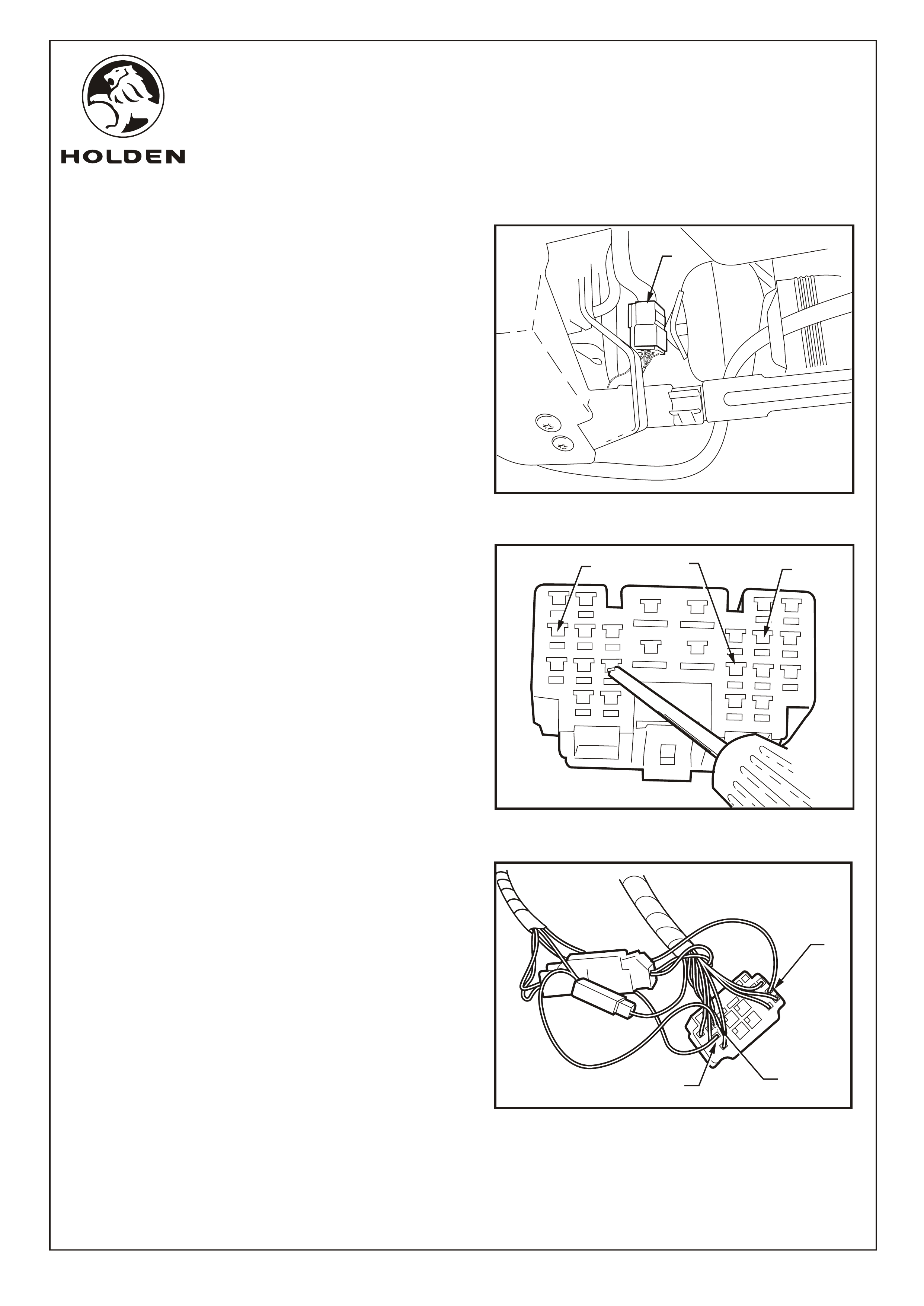

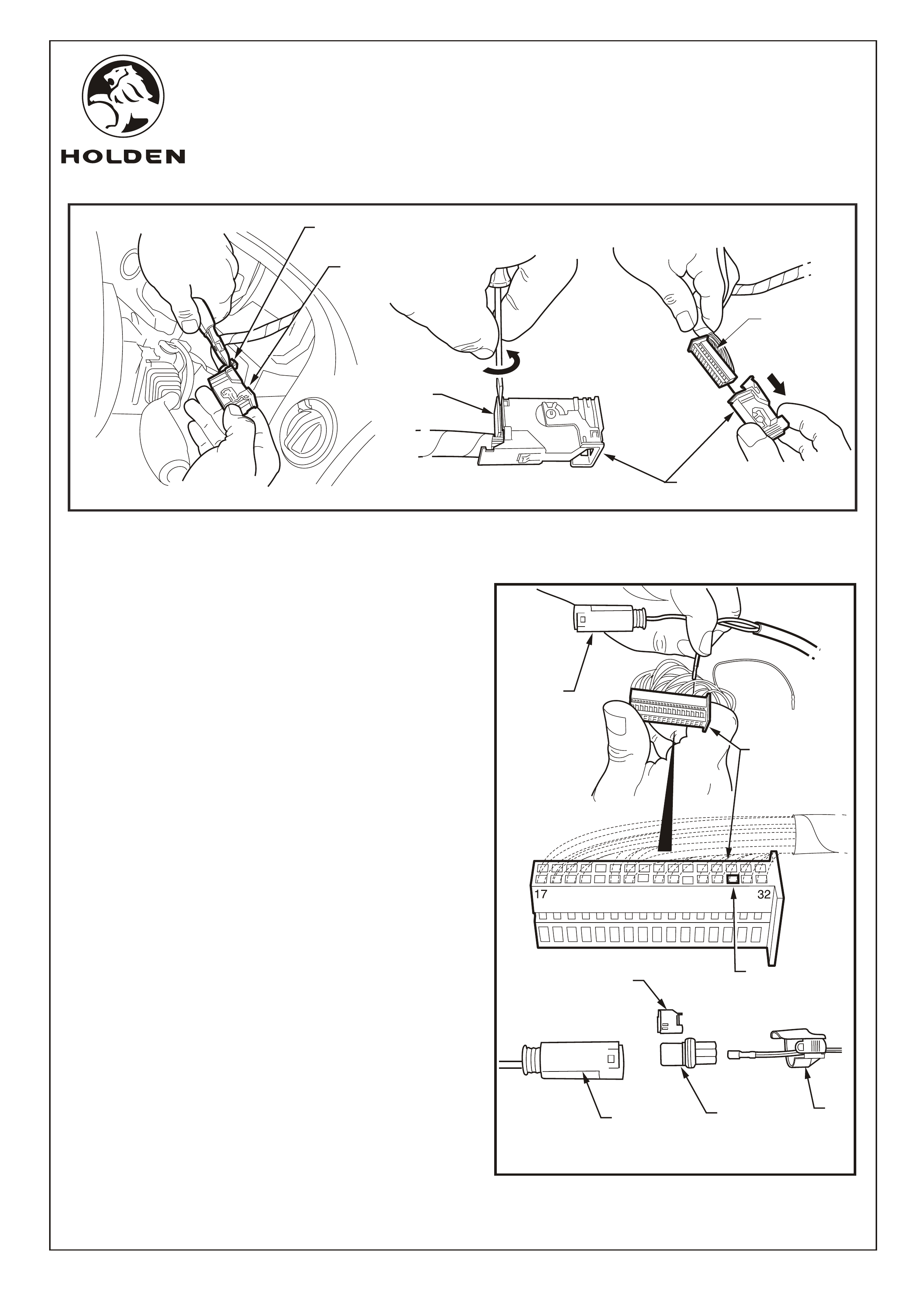

6. Press the release lever of the X206 connector (1) to

separate the connectors. Refer to Figure 5.

IMPORTANT: As the two wires in pin 11 and 17 are the

same colour it is critical that each wire is back out and

the new connections completed before backing out the

second wire.

Refer to Figure 6 for the following:

7. To connect the L.P.G. harness into the female X206

harness connector:

a. Identify Pins 8, 11 and 17 on the inner face of the

connector.

b. The brown and blue wire in pin 8 is connected to

the brown wire in the single connector block of

the LPG harness. Fit the brown fly wire

originating from the LPG harness single

connector into the pin 8 position of the X206

connector.

c. The purple wire in pin 11 is connected to the pink

coloured wire in the LPG harness twin connector

block and the pink and blue fly wire is inserted

into the pin 11 position.

d. The purple wire in pin 17 is connected to the

yellow coloured wire in the LPG harness twin

connector block and the yellow and blue fly wire

is inserted into the pin 17 position.

NOTE: When the terminals are in the connector

block properly they will lock into position and not

come back out. A small pull on the wires is a good

check for positive locks. Ensure all terminals are

completely covered by the connector block.

8. To back out the pin terminals:

a. Use a small jewellers screwdriver to push

between the terminal and the plastic terminal

lock to release the first of the terminals next to the

body harness connector lock. Refer to Figure 5.

NOTE: When the terminal lock is released the

terminal will slide out without significant force.

b. Gently remove the terminal and connect as

indicated in step 7. Refer to Figure 7.

9. Reconnect the body harness connector and refit the

connector to it's fixing point.

FIGURE 5

1

Page 3 of 15

17

11

FIGURE 6

FIGURE 7

PIN 17

PIN 8

PIN 11

8

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FIGURE 8

A

11.0 - 3.0 Nm

A

11

2

VIEW

FITTING INSTRUCTIONS: Continued...

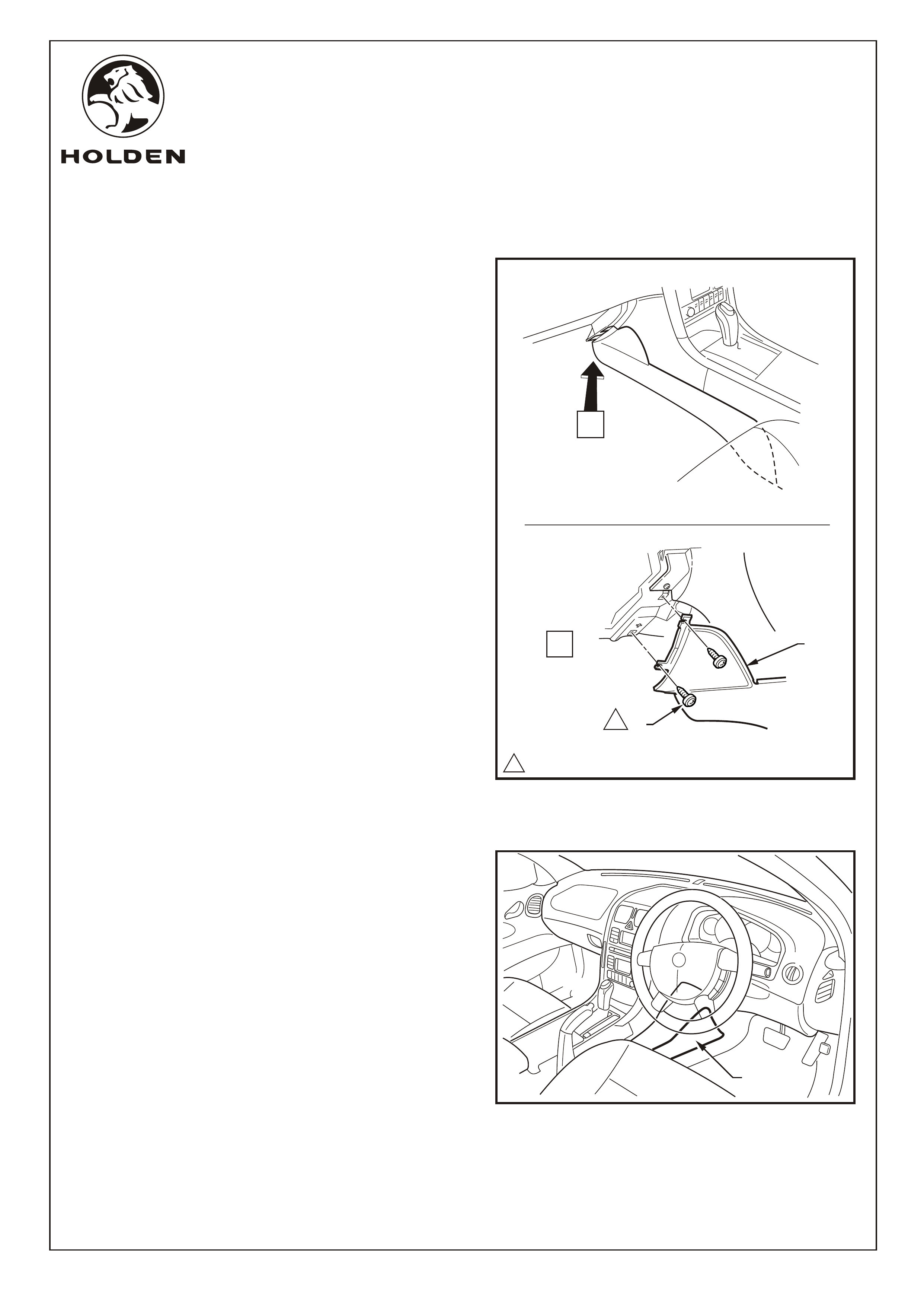

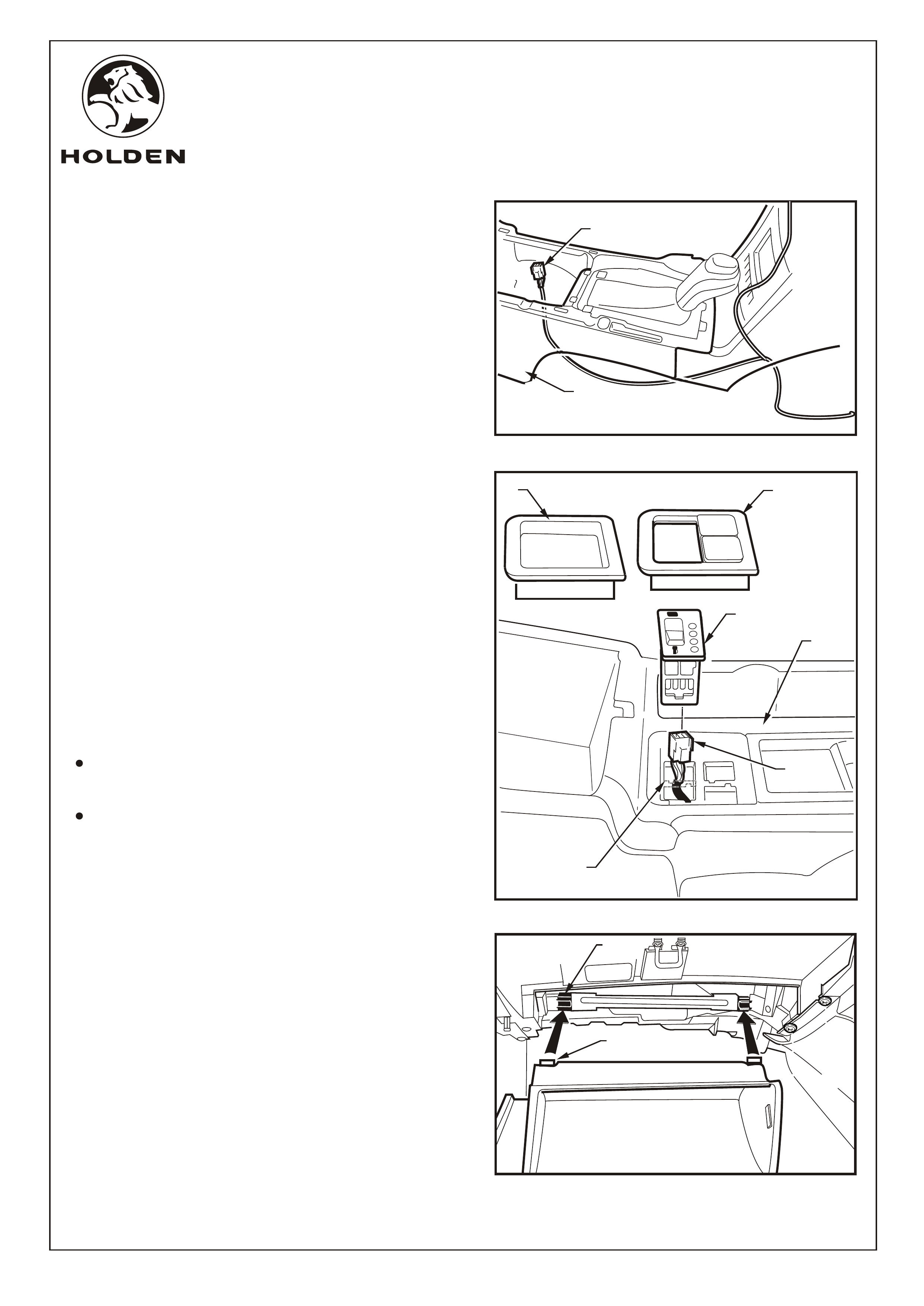

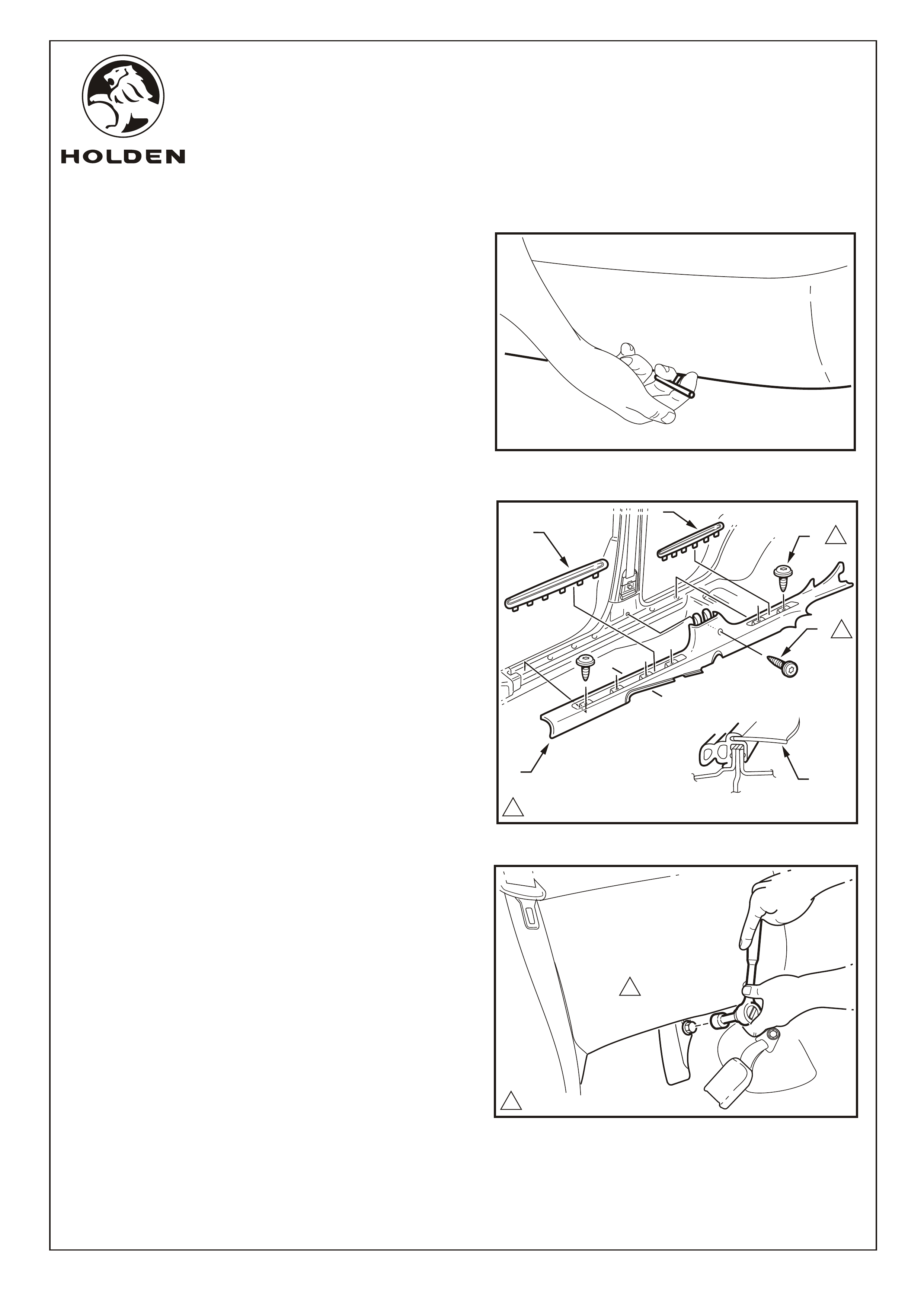

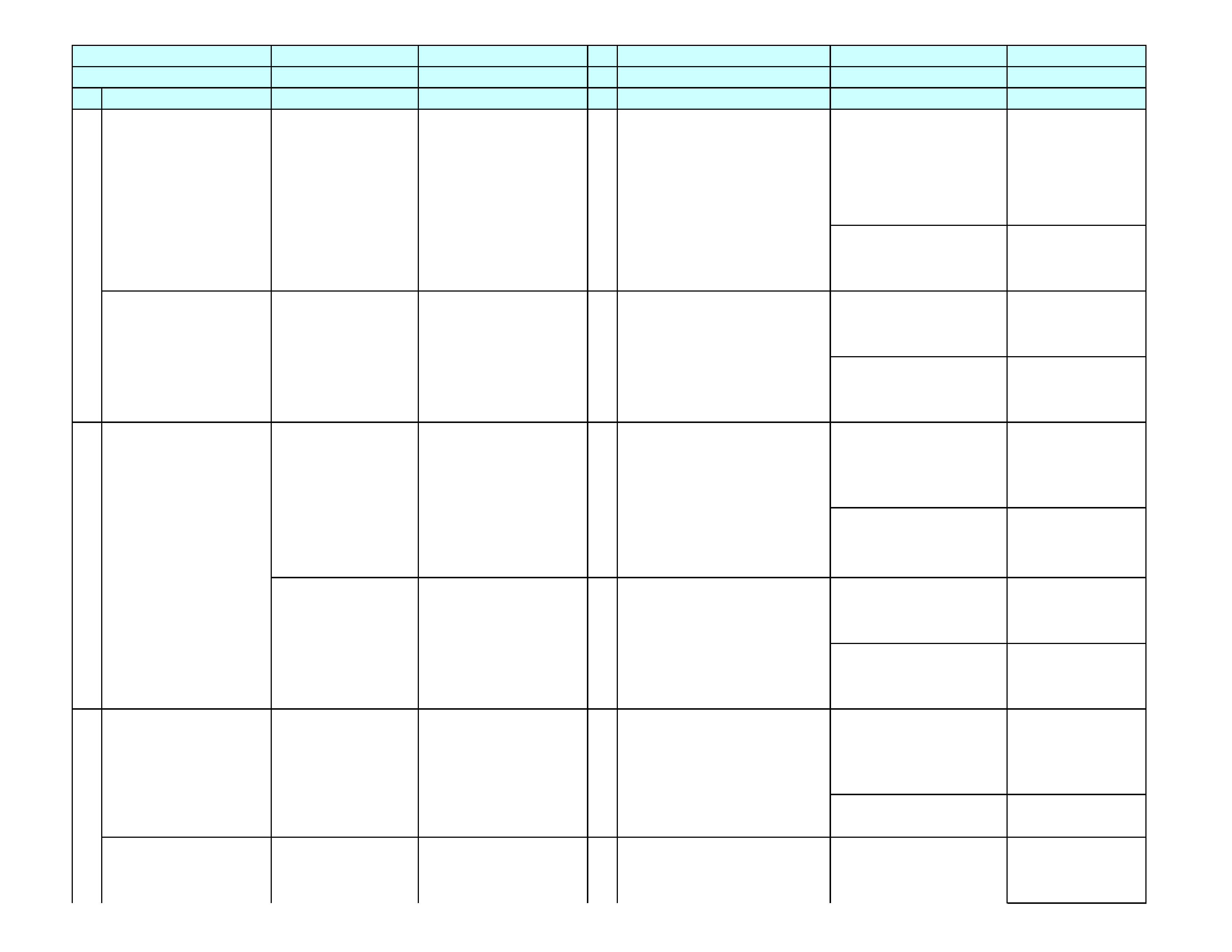

10. Remove the passenger side front floor console

extension side trim by removing the two screws (1) (2

places) attaching the console extension side trim (2) to

the instrument panel and allow to swing down. Refer to

Figure 8.

11. Remove the screws (2 places) retaining the drivers

side lower centre floor console extension trim (1) and

allow to rest on the floor. Refer to Figure 9.

12. Feed the harness across the back support rail of the

glovebox and through the cavity forward of the floor

mounted centre console.

FIGURE 9

1

Page 4 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

1

2

FITTING INSTRUCTIONS: Continued...

13. Run the L.P.G. harness across the back of the glovebox

support rail (1) and fix in place with two cable ties (2).

Refer to Figure 10.

14. Pass the harness through the cavity forward of the floor

mounted centre console. Refer to Figure 11.

15. Remove the front compartment cover (1) to allow

access to the console cover assembly retaining screw

(2) and remove the screw. Raise the armrest; starting at

the rear of the console cover assembly (3), use a trim

removal tool (4) to lever up and release the console

cover. Disconnect the window operating switch

harness and remove the cover assembly. Refer to

Figure 12.

NOTE: If sat nav is fitted remove remote control

cradle.

FIGURE 12

4

3

FIGURE 11

FIGURE 10

1

2

5

Page 5 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: Continued...

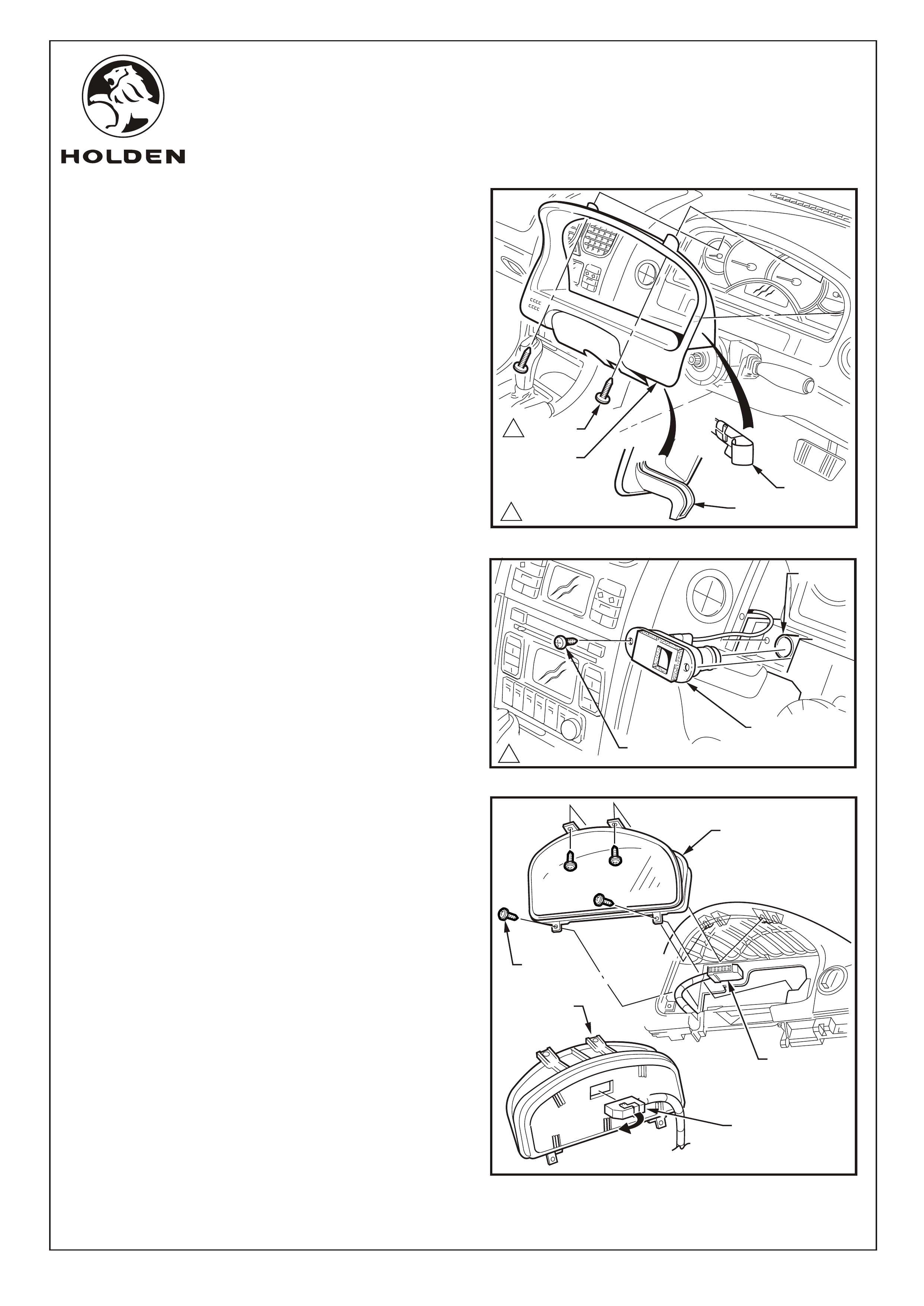

Refer to Figure 13 for the following:

16. Feed the L.P.G. switch/Gauge harness connector (1)

into the rear switch cavity of the console. Shown with

console cover removed for clarity.

17. Remove the console switch blanking plate or rubber

liner (1) from the rear right corner of the centre console

cover (2). Cut the front to back switch cross bar (3) off in

the rear switch position. Fit the replacement cover (4)

into the console. Fit the L.P.G. control switch (5) into the

rear switch position. Connect the switch to the L.P.G

harness connector (6). Fit the switch blank if required

Refer to Figure 14.

18. Continue running the harness across the drivers side

dashboard to the side of the vehicle.

NOTE:

Ensure wire is routed clear of the steering column

mechanisms.

Ensure wire is retained correctly and can not loop

down into foot well.

19. Refit the floor mounted centre consol extension trims.

20. Refit the glovebox, align the pivots (1) (2 places) on

the back of the glovebox with the receiving lugs (2) (2

places) in the glovebox cavity; push home and close

the glovebox. Refer to Figure 15.

FIGURE 13

1

2

FIGURE 14

FIGURE 15

1

2

Page 6 of 15

1

2

6

3

5

4

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

3

SCREWS

(4 PLACES)

INSTRUMENT

CLUSTER

FITTING INSTRUCTIONS: Continued...

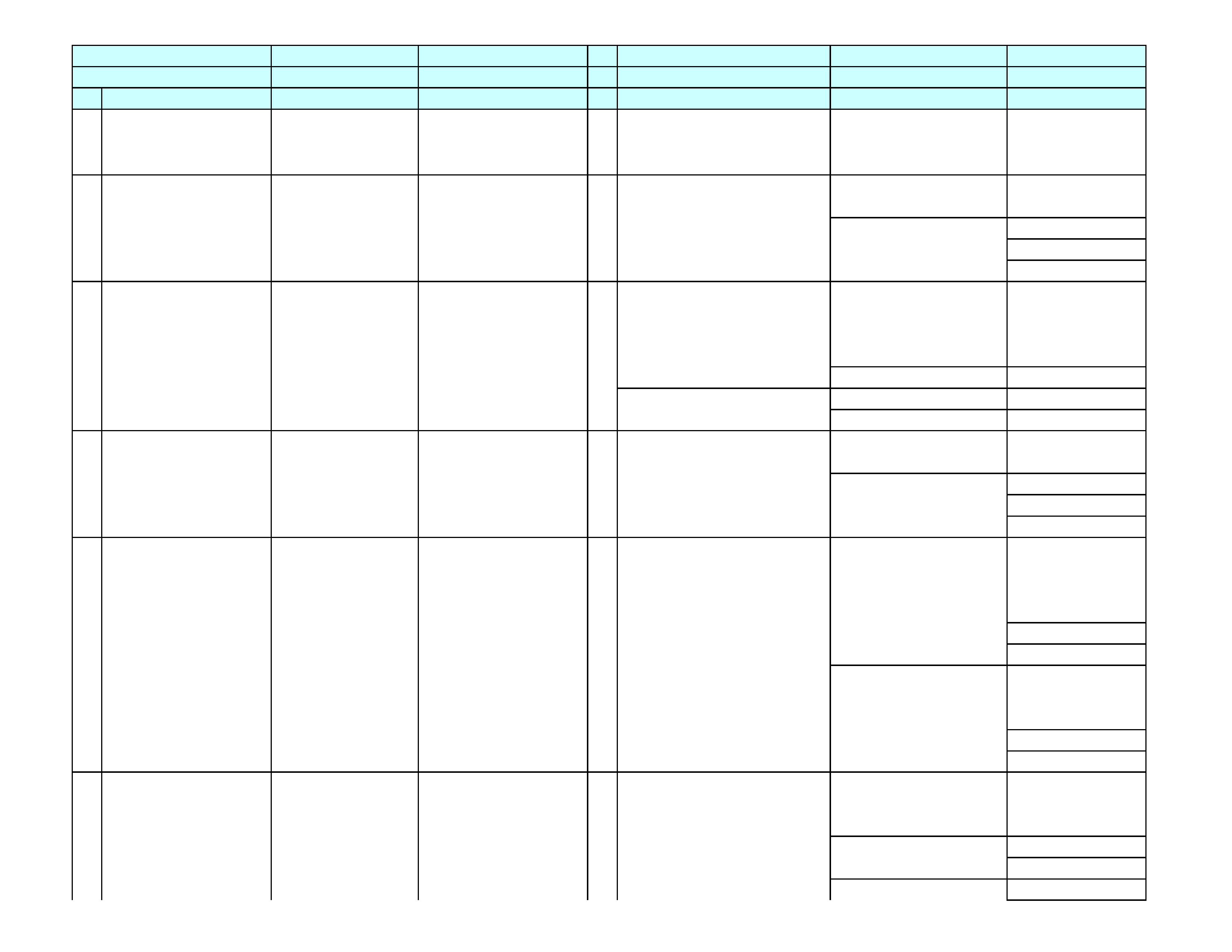

Refer to Figure 16 for the following:

21. Remove the instrument cluster trim panel assembly

as follows:

NOTE: The steering wheel is not shown for clarity, the

cluster trim can be removed with the steering wheel

installed.

a. Release the steering column adjustment lever and

move the steering column to its lowest position.

b. Remove the two screws attaching the instrument

cluster trim assembly to the instrument panel.

c. Depress the top of the trim assembly slightly and tilt

the top of the trim assembly out of the instrument

panel pad, disengaging the retaining clips (3

places) each side.

d. Unhook each lug from the instrument panel pad.

e. Remove the trim assembly.

in-car air

temperature sensor

Refer to Figure 18 for the following:

23. Remove the instrument cluster as follows:

a. Remove the four screws attaching the instrument

cluster to the instrument panel.

b. Roll the top of the instrument cluster from its

cavity.

c. Using a fine flat blade screwdriver, open the

wiring connector locking tab on the back of the

cluster.

d. Remove the cluster assembly.

NOTE: When reinstalling the instrument cluster,

tighten the screws in the sequence indicated.

Refer to Figure 18.

22. Remove the screw attaching the

to the instrument panel. Extract

the sensor assembly from the cavity and disconnect

the air tube. Refer to Figure 17.

11.0 - 3.0 Nm

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

IN-CAR

TEMPERATURE

SENSOR

FIGURE 17

SCREW

FIGURE 16

11.0 - 3.0 Nm

1SCREWS

CLIPS

(3 PLACES

EACH SIDE)

LUG

INSTRUMENT

CLUSTER

TRIM ASSEMBLY

2

4

1

INSTRUMENT

CLUSTER

WIRING

CONNECTOR

WIRING

CONNECTOR

FIGURE 18

AIR TUBE

Page 7 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FIGURE 19

FITTING INSTRUCTIONS: Continued...

Refer to Figure 19 for the following:

24. Cut the cable tie securing the instrument cluster

connector housing to the wiring harness

25. Place a small flat blade screwdriver between the front

edge of the connector housing and the inner connector

(1). Twist as shown to release the housing and withdraw

from the inner connector.

26. Route the section of the harness with exposed wires

and female connector through from the end of the

dashboard to the instrument cluster connection.

27. Identify pin 30 (2),use a small jewellers screw driver and

back out pin 30. The pin numbering sequence is on the

inner connector (stamped on the side of the connector

body). Insert the L.P.G. terminal into pin 30.

Refer to Figure 20 for the following:

28 Slide the outer connector shield (3) over the wire that

was back out. Slide the terminal into the connector

inner (4) and slide the terminal lock (5) into position.

Connect to the female connector (6) on the LPG

harness.

NOTE: Make certain the terminal aligns with the

terminal in the other connector.

Ensure the wires are securely fitted then reassemble

the inner connector to the housing connector and

secure with a cable tie.

29. Reconnect the instrument cluster connector and

reinstall the instrument cluster.

INSTRUMENT CLUSTER

WIRING CONNECTOR

CUT CABLE TIE

CONNECTOR

HOUSING

INNER

CONNECTOR

INNER

CONNECTOR

TWIST TO

RELEASE

2

FIGURE 20

Page 8 of 15

1

3

4

5

6

6

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FIGURE 23

FIGURE 21

FIGURE 22

FITTING INSTRUCTIONS: - continued...

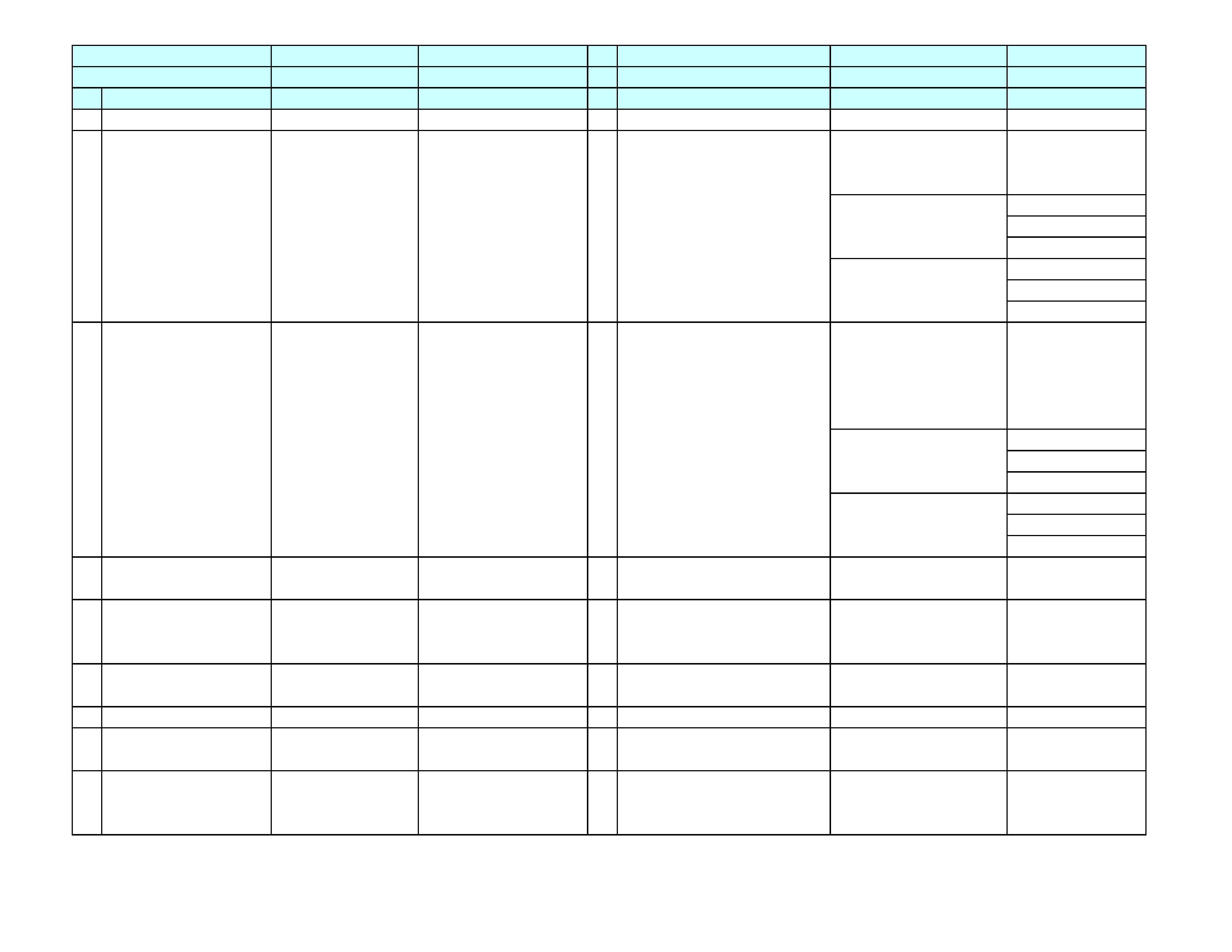

30. Unclip the rear section of the front seat rail cover (both

sides) by pushing down on the join between the front

and rear covers and pull the rear cover back and up to

remove. Refer to Figure 21.

31. Remove screw from behind fuel release lever (drivers

side only). Slide the front section of the front seat rail

cover out towards the front of the vehicle. Repeat on

passenger side front seat rail cover. Refer to Figure 22.

Refer to Figure 23 for the following:

32. Remove the screws (2 places) holding the front side

kick panel in position and pull back on the front side kick

plate to release the two clips. Remove the side kick

panel. Repeat on other side of the vehicle.

NOTE: The bonnet release handle will need to be pulled

back to expose the screw head of one of the screws on

the drivers side.

33. Pull off the drivers lower “B” pillar trim panel (1).

Refer to Figure 24.

1

FIGURE 24

Page 9 of 15

11.0 - 3.0 Nm

1

11.0 - 3.0 Nm

1

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FIGURE 26

1.0 - 3.0 Nm

1

1

1

1

A-A

A

A

2

4

3

2

1

FITTING INSTRUCTIONS: - continued...

34. Remove the rear seat base by pulling on the toggles

under the seat and removing. Refer to

Figure 25.

Refer to Figure 26 for the following:

35. Carefully lever the front and rear side sill trim plates (1)

from the side sill trim (2), starting at the front of each

plate and moving rearwards, revealing the attaching

screws.

CAUTION: Take care not to break the sill trim plates.

36. Remove the Torx head screws (3) (4 places in front door

opening, 2 places rear door opening) from the side sill

trim.

37. Remove the screw (4) from the side sill trim to the centre

pillar.

38. Remove the side sill trim.

(Ste ) SEDAN ONLY

39. Use a socket to remove the bolt securing the rear

drivers side seat back. Push up on the seat back to

release and remove from the vehicle. Refer to

Figure 27.

ps 39 - 44

FIGURE 25

FIGURE 27

Page 10 of 15

1.0 - 3.0 Nm

1

1

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

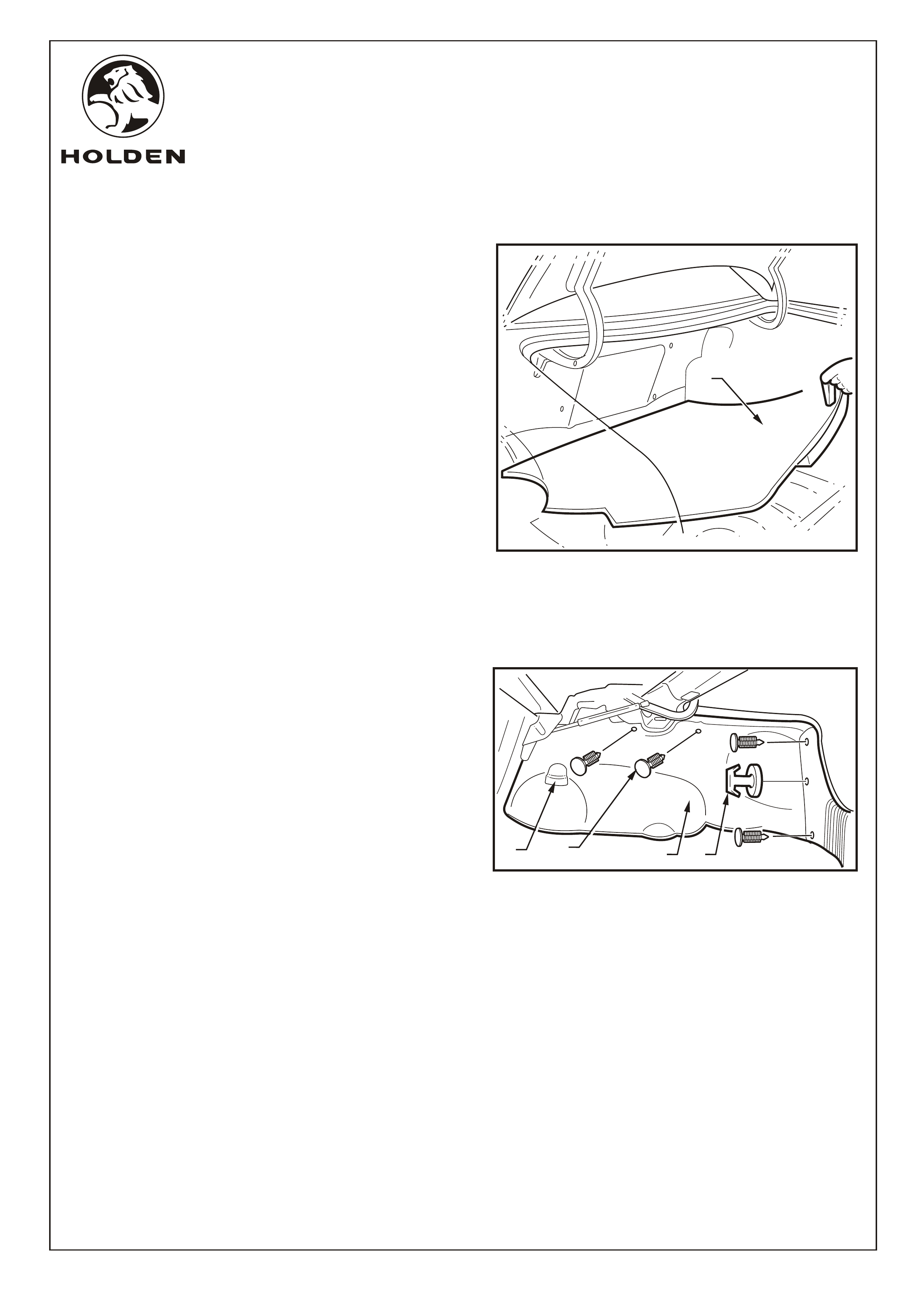

40. Remove the rear compartment floor carpet assembly

(1) from the vehicle. Refer to Figure 28.

Refer to Figure 29 for the following:

41. Carefully prise off the drivers side rear shock absorber

cover (1).

42. Using a trim removing tool, carefully remove the retainer

(2) away from the drivers side quarter inner rear side

carpet (3).

43. Unhook the carpet flap from the rear compartment lid

hinge bracket.

44. Carefully remove the drivers side rear quarter inner

carpet.

45. Disconnect the rear boot net (if fitted) and unscrew and

remove the drivers side boot net fixing (4).

FIGURE 28

1

COPYRIGHT

FIGURE 29

123 4

Page 11 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

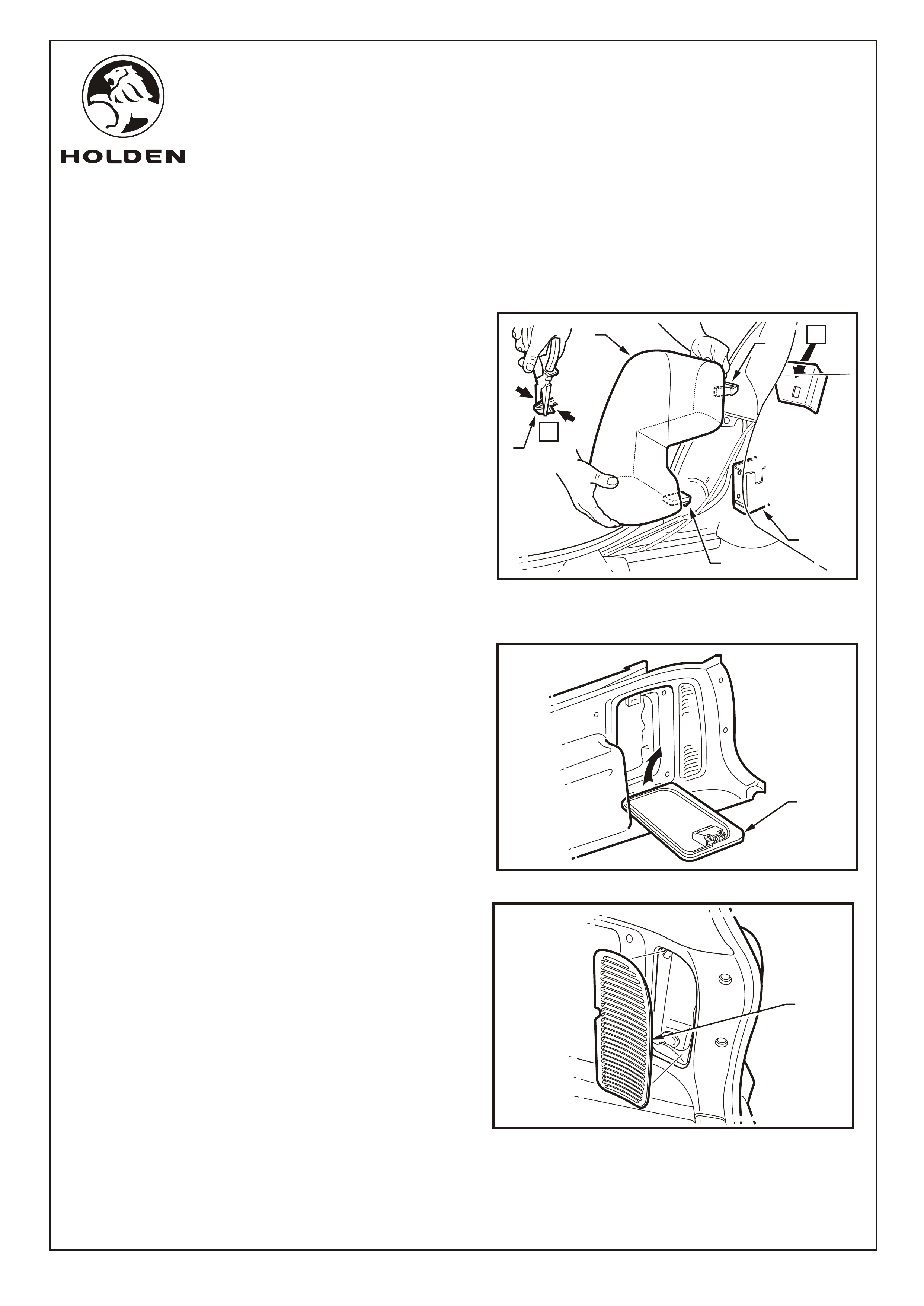

48. Open the door (1) on drivers side of wagon boot trim

Refer to Figure 31.

49. Lever the centre of the rear edge of the vent (1) away

from trim panel on the drivers side. Refer to Figure 32.

(Ste WAGON ONLY

Refer to Figure 30 for the following:

46. Using pliers, squeeze the tangs of the rear drivers side

seat upper bolster retaining clip (1) together and pull the

rear bolster assembly (2) towards the front of the

vehicle.

47. To disengage, lift the lower retainer retaining tang (3) up

and pull the bolster forward, out of the seat-back

retaining bracket (4) towards the front of the vehicle.

ps 45 - 52)

FIGURE 31

1

FIGURE 30

A

A

2

1

1

4

3

FIGURE 32

1

Page 12 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

Refer to Figure 33 for the following:

50. Remove the screw (1) retaining the upper trim on the

drivers side (2).

51. Pull the rear edge of the upper trim away from the body

side panel and working forwards, disengage the

garnish clips (3) (4 places). Ensure that the garnish clips

are retained on the upper trim.

NOTE: When removing the upper trim ensure that care

is taken not to damage the locating pin (4).

52. Use a trim removal tool to remove the retainers (1) (7

places) on the quarter inner trim panel assembly. Refer

to Figure 34.

53. Remove the driver side boot quarter trim panel

assembly (1) by raising the edge of the rear

compartment floor carpet and lifting it forward over the

rear seat back striker. Refer to Figure 35.

1.0 - 3.0 Nm

1

34

1

1

2

FIGURE 33

FIGURE 34

1

COPYRIGHT

FIGURE 35

1

Page 13 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

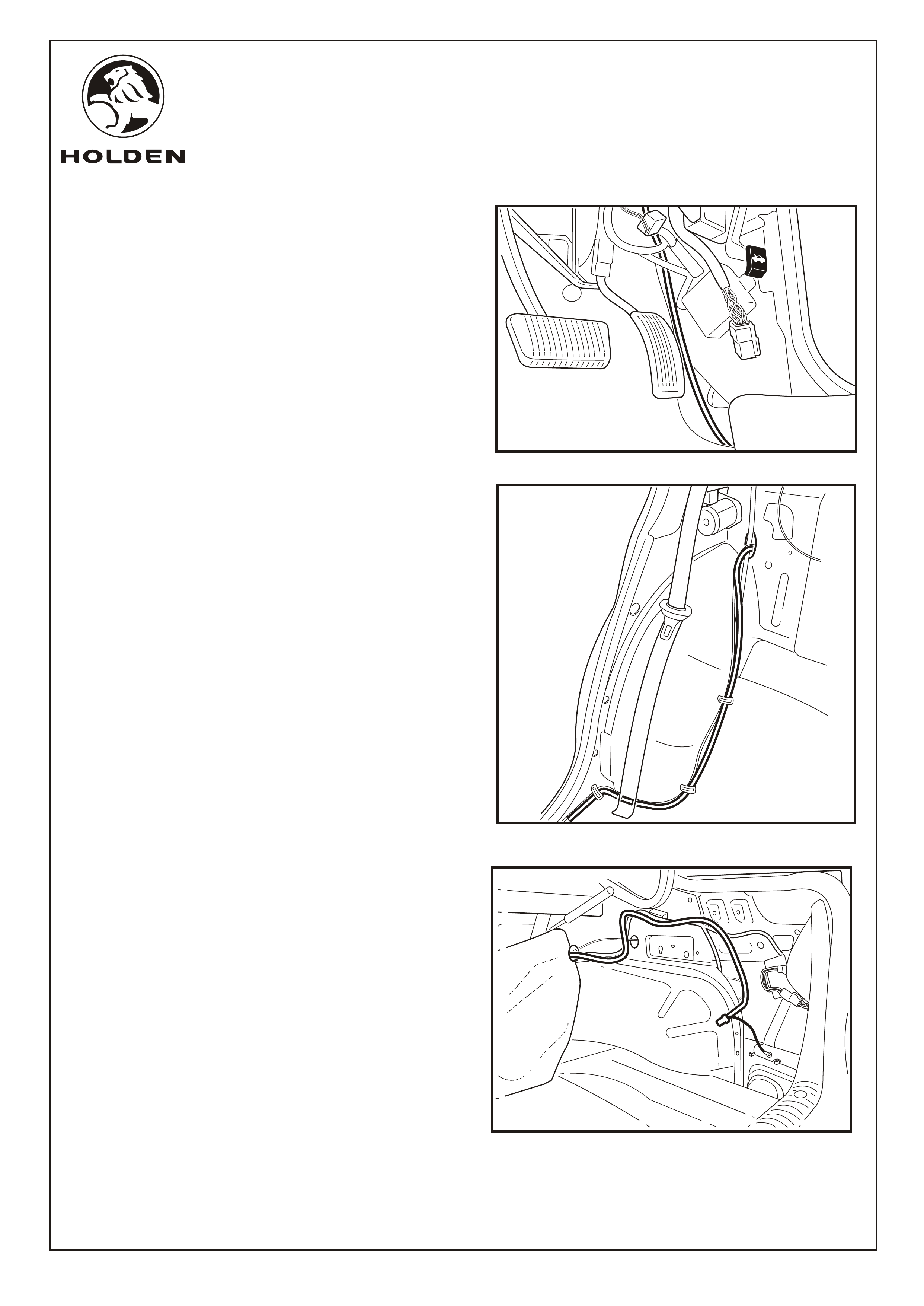

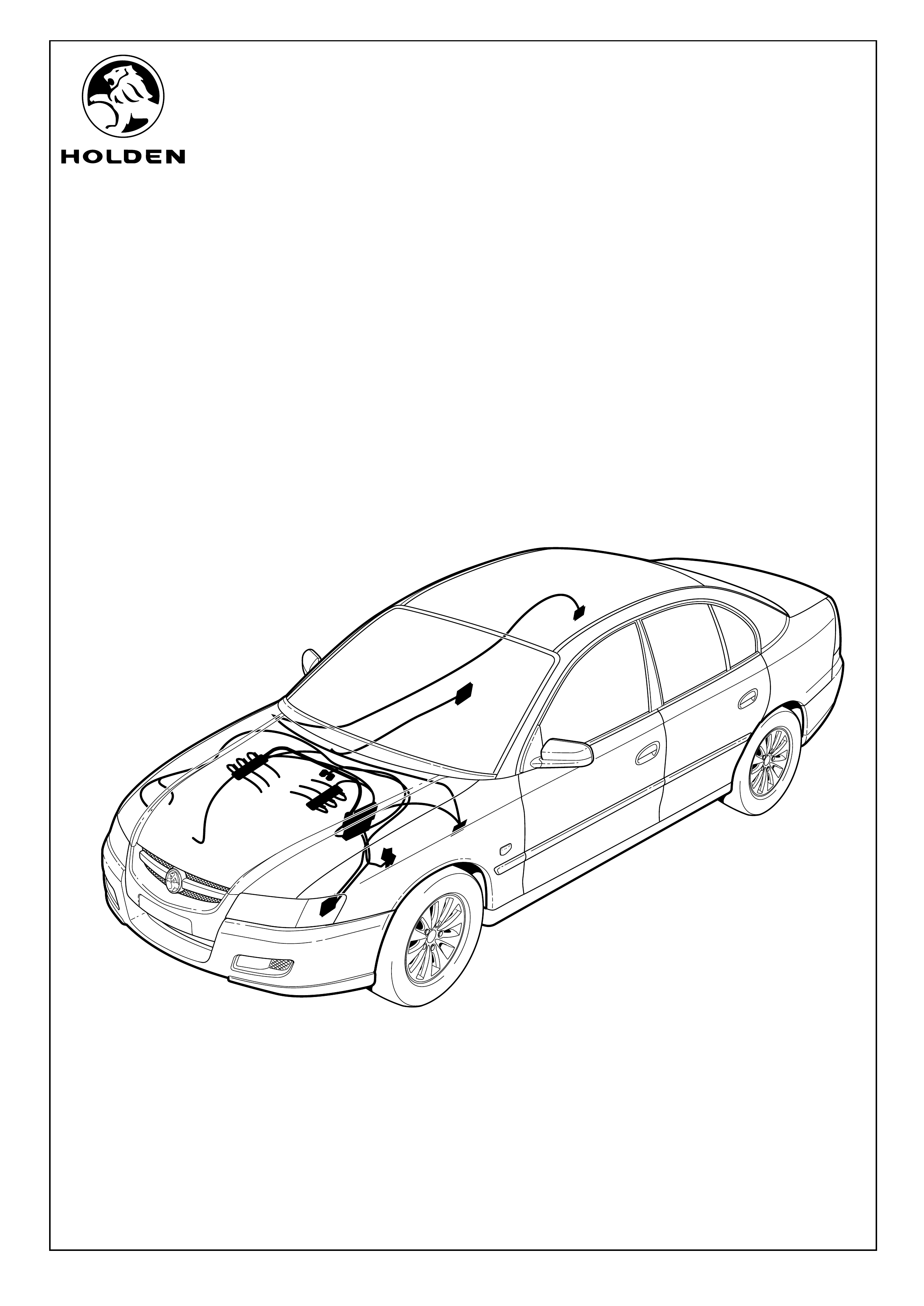

54. Run the power outlet harness from the fuse panel,

down the side of the vehicle behind the bonnet release

cable. Refer to Figure 36.

55. Run the power outlet harness along the drivers side

inner sill. Apply cable ties at vehicle body mounted

cable tie positions.

s 56 -57

56. Run along

.

(Step ) SEDAN ONLY

the wheel arch, through the hole in the rear

seat back panel Refer to Figure 37.

57. Run the power outlet harness along the vehicle body

harness. Cable tie power outlet harness at the same

positions as body harness fixing points. Refer to

Figure 38.

FIGURE 36

FIGURE 37

FIGURE 38

Page 14 of 15

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS FOR

VZ L.P.G. CONVERSION KIT

FITTING INSTRUCTIONS: - continued...

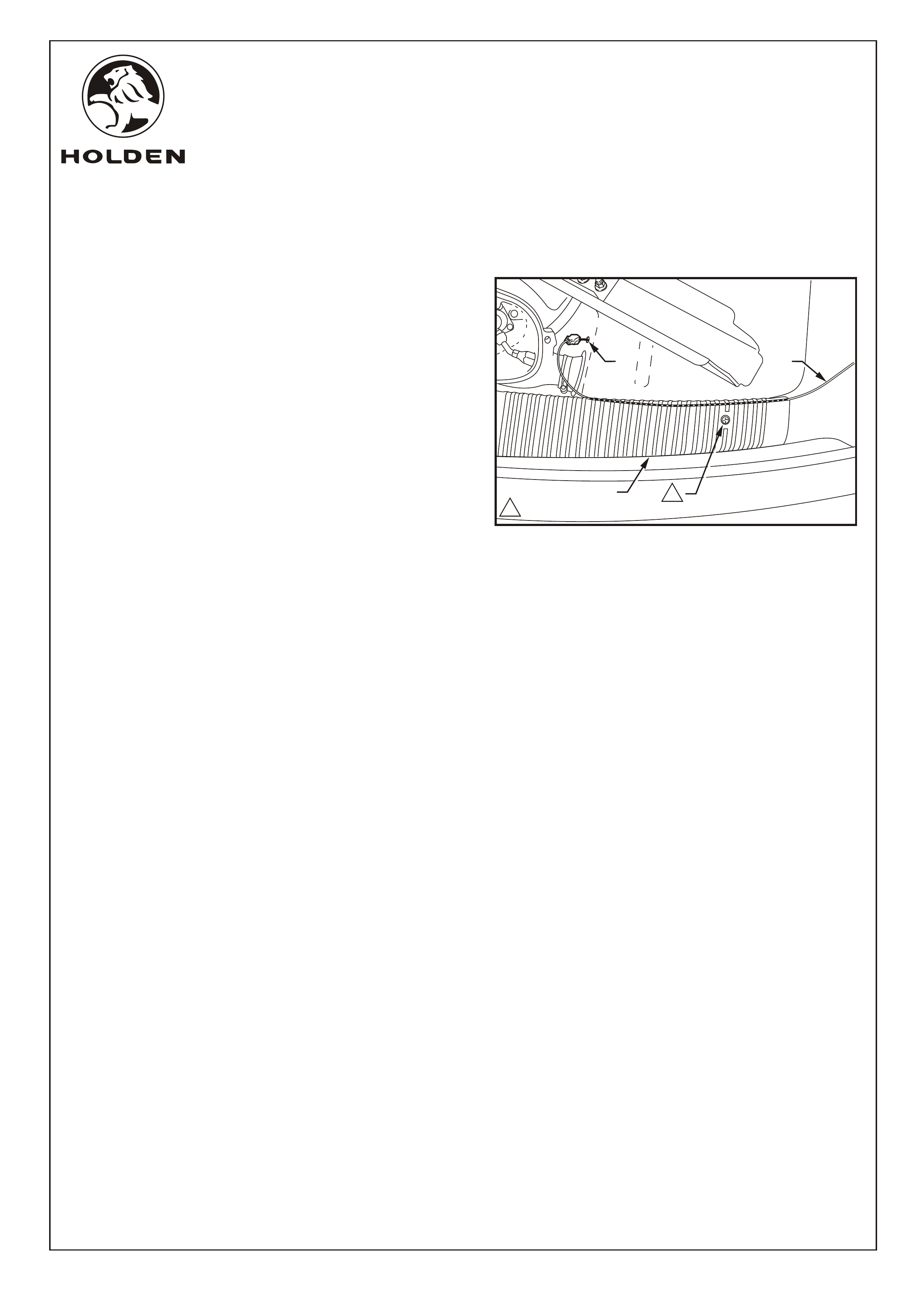

(Step ) WAGON ONLY

Refer to Figure 39 for the following:

58. Run the LPG harness (1) out from the rear drivers side,

side panel across the rear tailgate sill trim (2)and into

the spare wheel well.

59. Drill a 25mm hole (3) by the side of the 70mm cylinder

outlet hole. Deburr the hole and paint any unpainted

metal with a high zinc corrosion prevention primmer.

60. Pass the cylinder electrical connector into the spare

wheel well and fit the grommet.

61. Connect the LPG harness and the Cylinder harness

together.

s 58- 61

Page 15 of 15

FIGURE 39

2

31

1.0 - 3.0 Nm

1

1

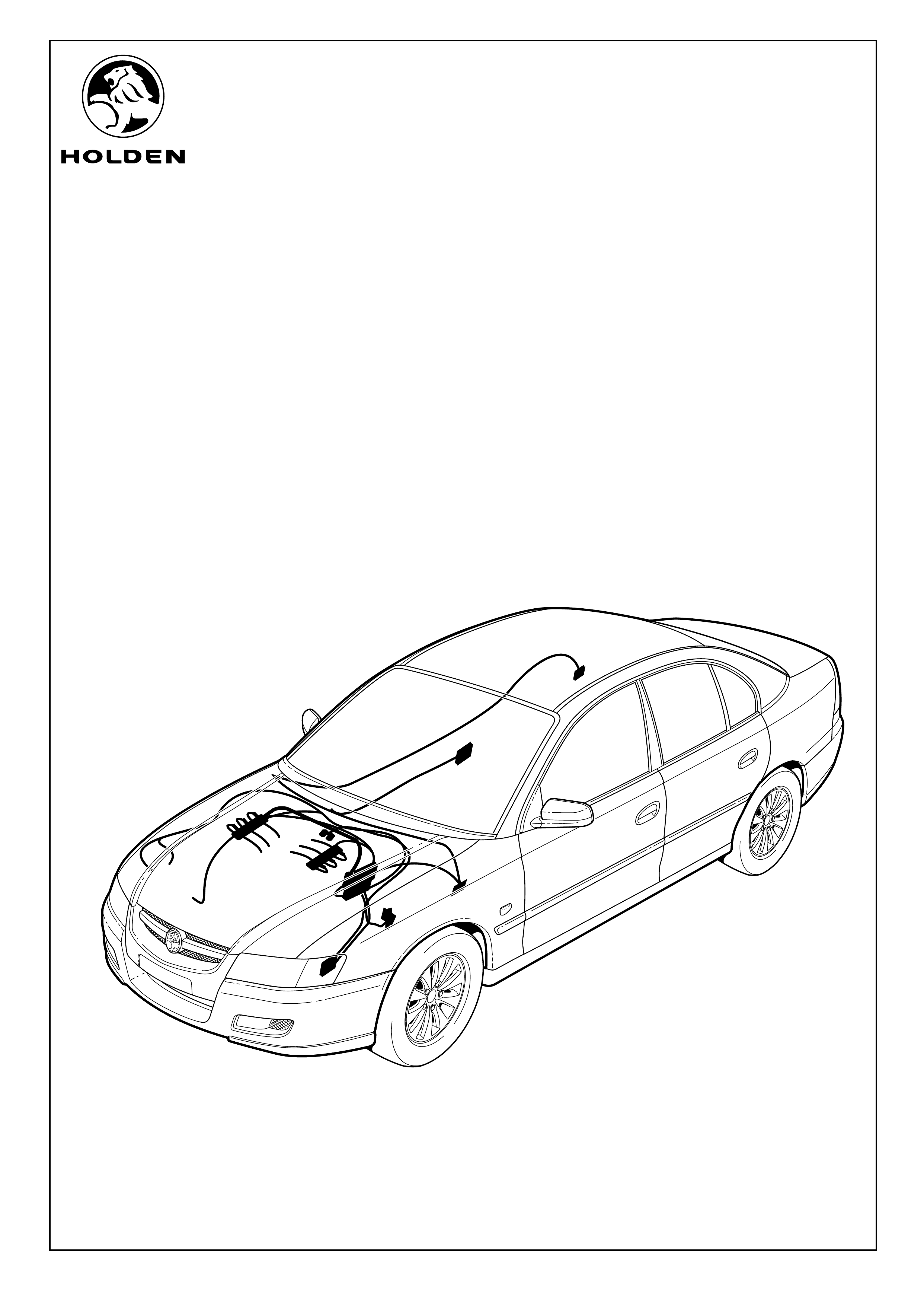

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Page 1 of 4

SECTION 2

MANIFOLD MODIFICATION

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FIGURE 1

FITTING INSTRUCTIONS:

NOTE: Place the lower inlet manifold on a clean soft surface

to protect the machined faces from scratches.

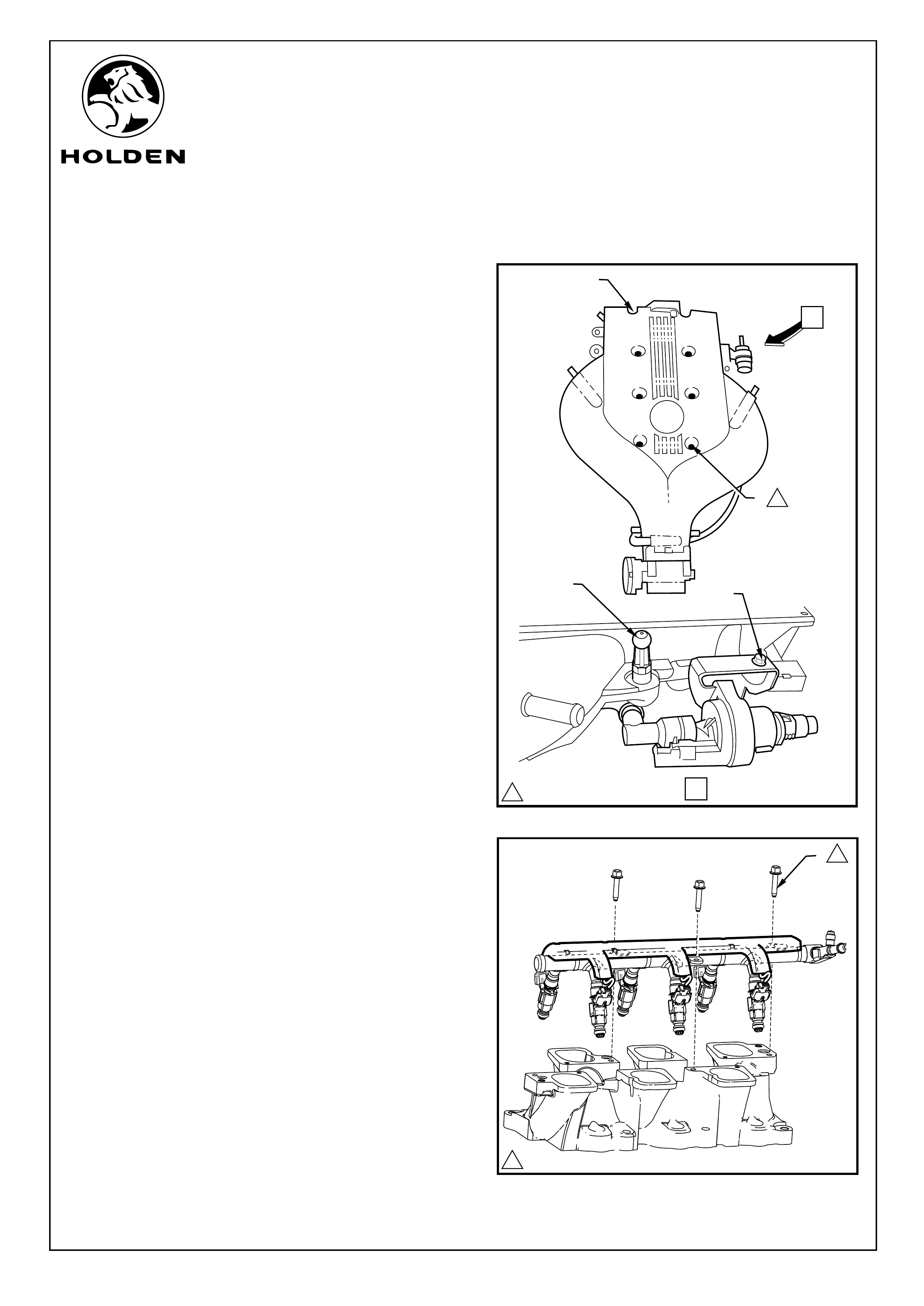

Refer to Figure 1 for the following:

1. Remove the two remaining bolts (1) holding the upper

and lower intake manifolds together and separate.

2. Remove the bolt (2) securing the Emission Canister

Purge Valve Solenoid to the upper intake manifold.

3. Remove the two engine cover retaining lugs (3) from

either side of the upper intake manifold.

4. Remove the three bolts (1) (3 places) retaining the petrol

injector assembly to the lower intake manifold and

remove the petrol injector assembly. Refer to Figure 2.

Page 2 of 4

A

VIEW A

1

1

32

1

FIGURE 2

125 N.m

1

1

115 N.m

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

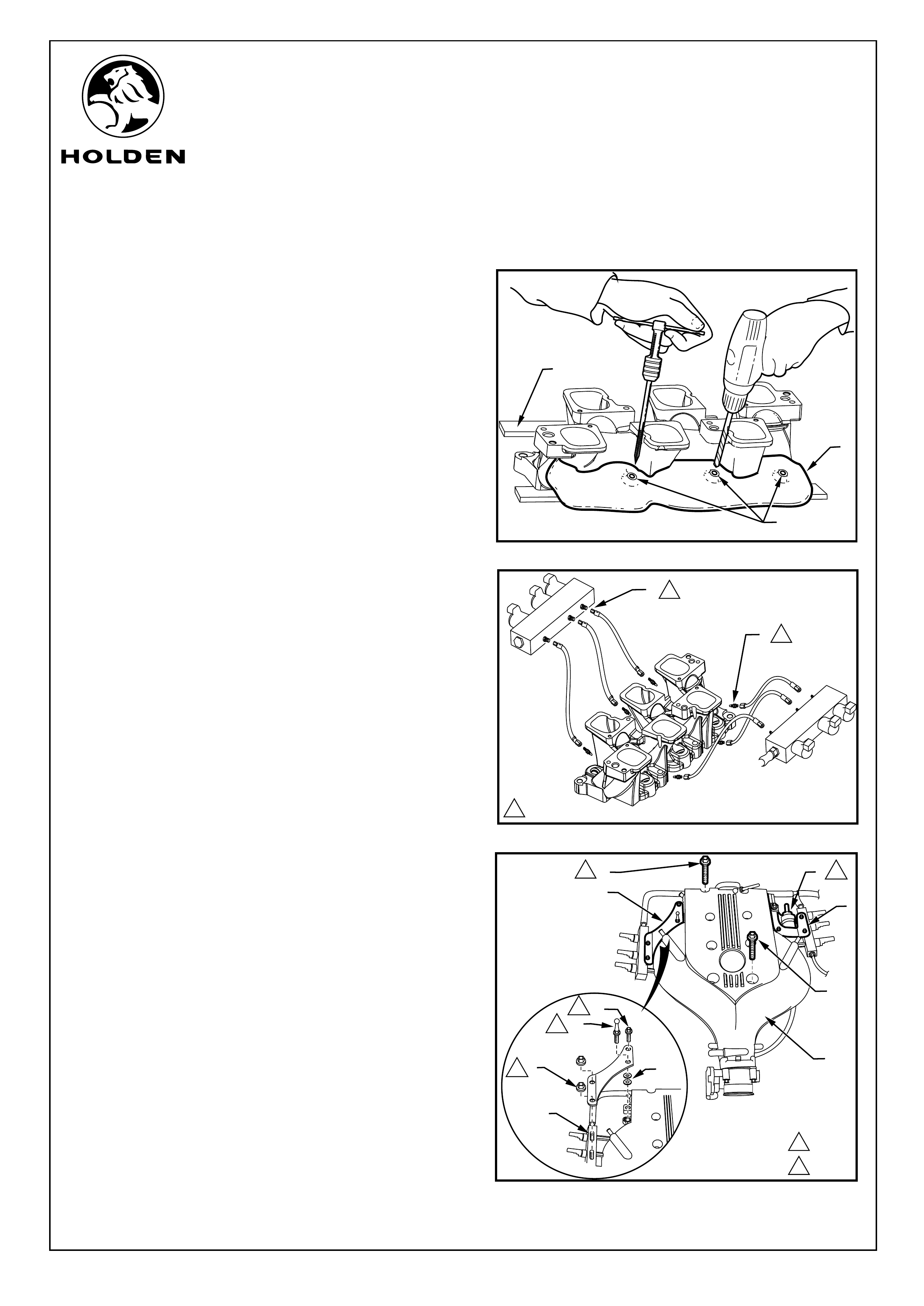

Refer to Figure 3 for the following:

5. Place the lower intake manifold into the drilling jig base

(1).

6. Position the drill guide on the manifold, drill and tap the

first three gas injector holes (2). Rotate the manifold and

repeat on the other side.

Refer to Figure 4 for the following:

7. Place some Loctite 577 on the threads of the manifold

gas injection ports (1) and screw into the taped gas

injector hole (1). Tighten. Repeat for all six locations.

8. Connect the gas injector hoses to the six intake manifold

injector ports (2).

9. Connect the injector hose unions to the gas manifolds

and tighten to the specified toque.

10. Refit the petrol injection assembly and tighten the bolts

to the specified toque.

Refer to Figure 5 for the following:

11. Refit the upper intake manifold gaskets.

12. Refit the upper intake manifold to the lower intake

manifold and refit the two bolts (1) that hold the two

manifolds together. Tighten to the specified toque.

13. Fit the two gas injector manifold brackets (2) to the

upper intake manifold (3) with the bolts (4) provided on

the two back holes of the brackets and the two engine

cover retaining lugs (5) with two packer washers (6)

under the mounting brackets in the front position.

Tighten to the specified toque.

NOTE: The Emission Canister Purge Valve Solenoid (7)

is reattached to the LHS rear mounting bolt.

14. Put the gas manifold studs (8) through the holes in the

mounting brackets secure with nuts (9) supplied.

Tighten to the specified toque.

Page 3 of 4

1

2

1

2

2

1

3

FIGURE 3

FIGURE 4

FIGURE 5

1

5

3

2

1

1

1

115 N.m

4

2

125 N.m

25 N.m

6

7

8

2

2

2

9

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

09MA05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

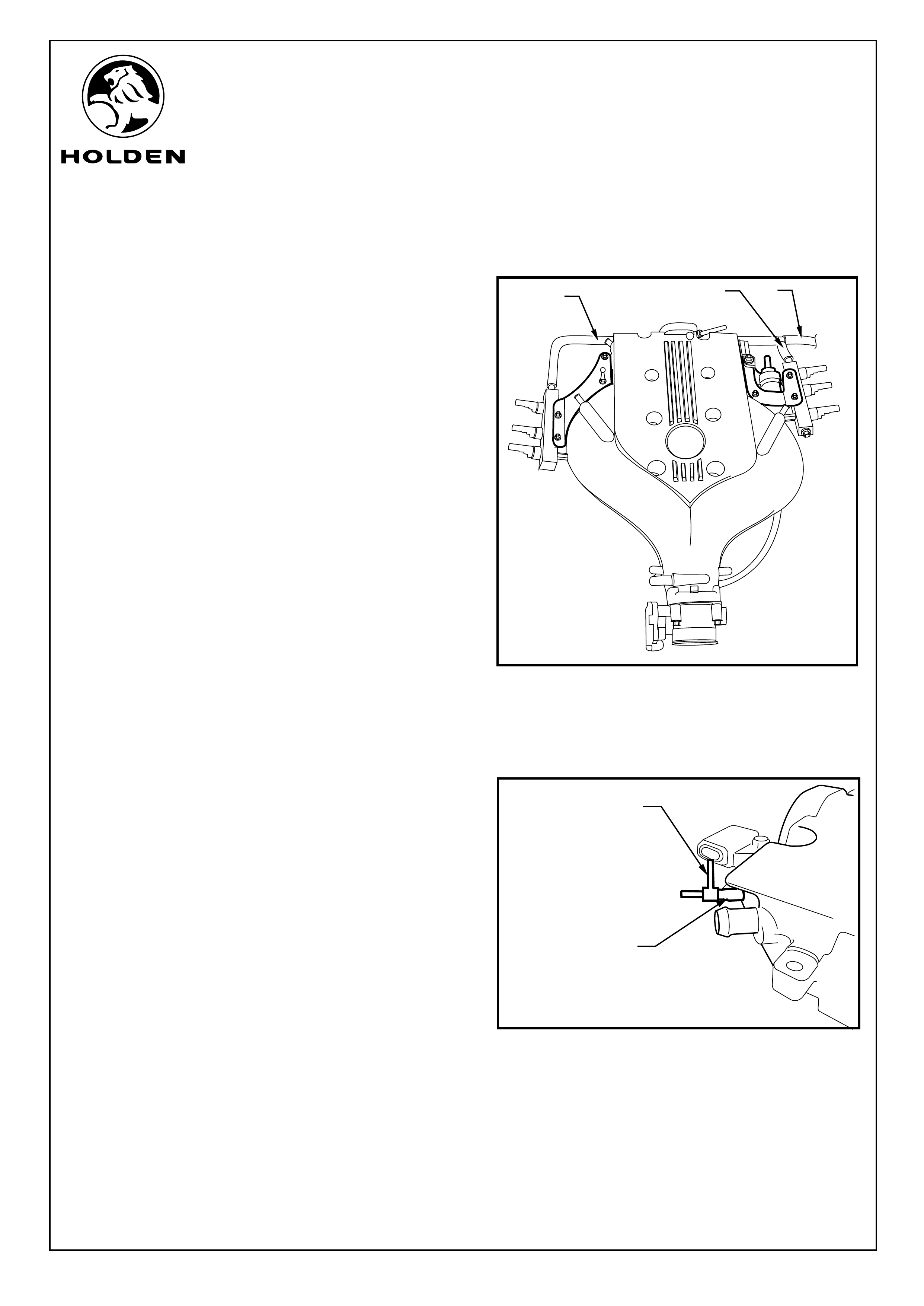

Refer to Figure 6 for the following:

15. Fit the two gas injector manifolds supply hoses. The

short hose (1) to the left injector manifold and the L

shape hose to the right (2) injector manifold.

16. Connect the two supply hoses to the third hose (3) that

will connect to the supply filter with the tee provided. Use

the clips supplied to clamp all connections.

NOTE: The injector manifolds supply hose is routed

over the top of the petrol manifold.

17. Fit the hose Tee (1) to the upper intake manifold

ventilation vacuum hose outlet (2). Refer to Figure 7.

18. Refit assembly back on vehicle.

1

2

FIGURE 6

213

FIGURE 7

Page 4 of 4

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Page 1 of 15

SECTION 3

ENGINE COMPARTMENT

1

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

1

2

FIGURE 2

FITTING INSTRUCTIONS:

1. Turn the ignition to the "OFF" position.

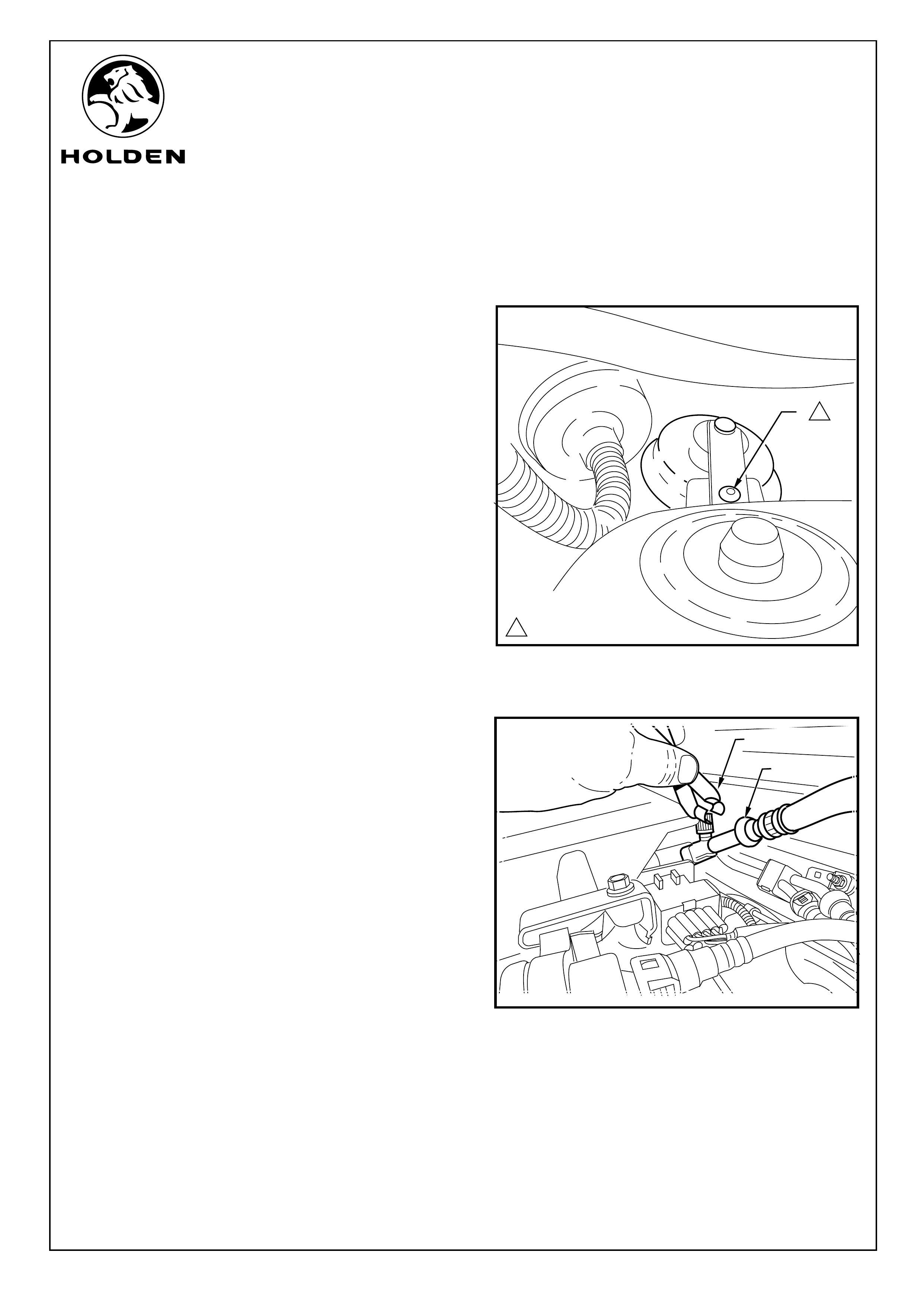

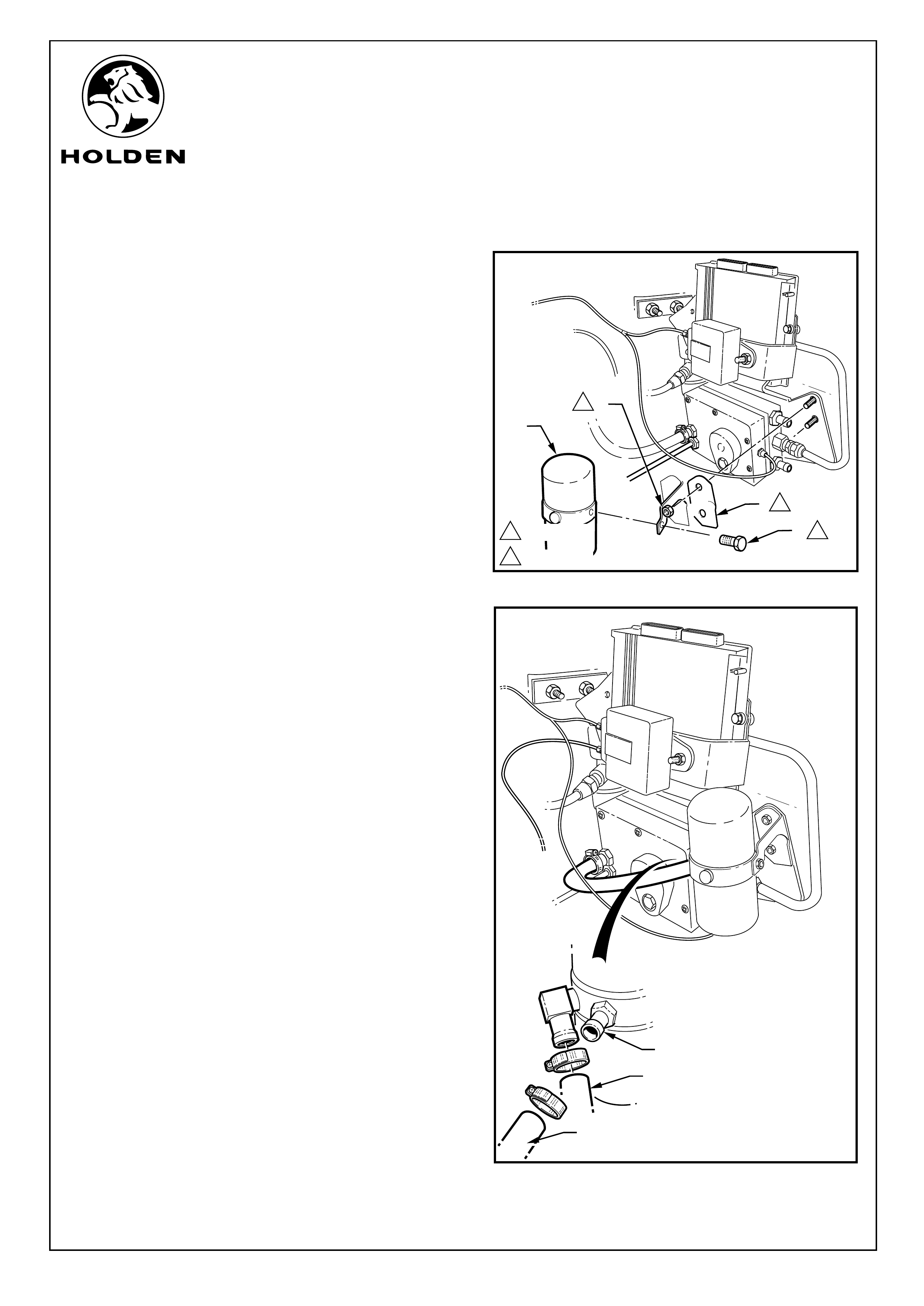

Refer to Figure 1 for the following:

3. For ease of access to the grommet on the fire wall.

Disconnect the vehicle security siren. Use a Torx 30 bit

(1) to remove the siren.

4. Remove the grommet from the firewall.

NOTE: If the vehicle is a wagon, disconnect the rear

window wash tube at the join in the engine bay and pull

through into vehicle cabin.

Refer to Figure 2 for the following:

5. Wrap a workshop cloth around the lower intake manifold

supply line pressure release the thumbscrew. Gradually

open the thumbscrew to release the fuel pressure. Close

the thumbscrew once the pressure has been released.

CAUTION: The workshop cloth will be highly

flammable and must be disposed of where the cloth

or the vapours cannot come into contact with a

naked flame.

6. Place the release tool (1) around the fuel pipe (2) and

push into the quick release fitting. Pull the join apart and

catch any remaining fuel with a workshop cloth.

NOTE: Cover the ends of the pipes to prevent dirt from

entering the lines.

2. Remove the left and right engine covers.

Page 2 of 15

FIGURE 1

115 N.m

1

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

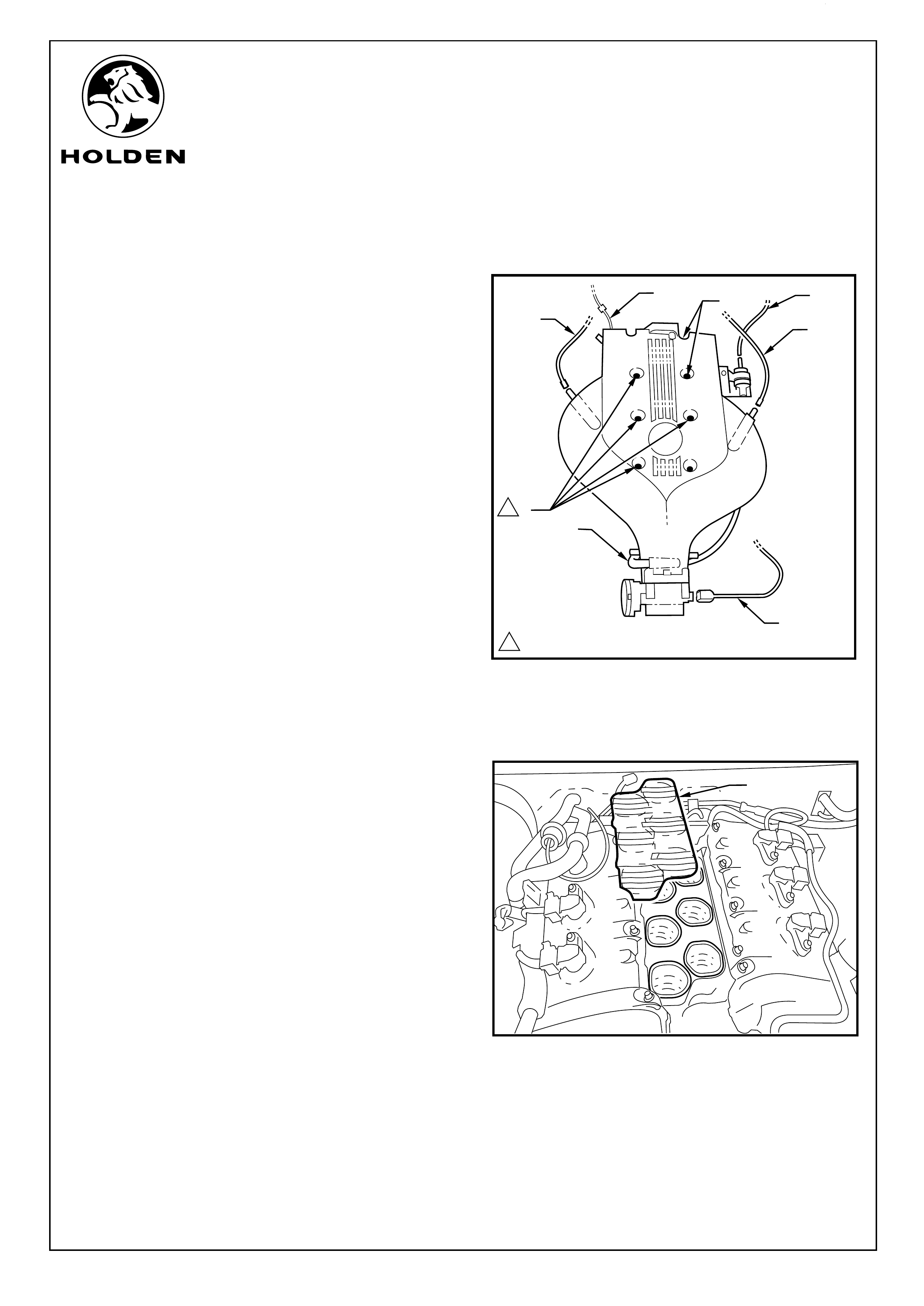

Refer to Figure 3 for the following:

7. Disconnect the engine breather (1) hose from both sides

of the intake manifold and from the rear of the RHS

rocker cover. Remove the hose.

8. Disconnect the vehicle ventilation system vacuum hose

(2).

9. Disconnect the throttle body wiring connector (3).

10. Disconnect Emission Canister Purge Valve Solenoids

vacuum hose (4) from the upper intake manifold behind

the throttle body.

11. Disconnect the Emission Canister Purge Valve

Solenoid electrical connector and vacuum hose (5).

12. Use a socket to remove the six bolts (6) of the eight

manifold bolts that hold both the upper and lower inlet

manifolds to the engine block, (back LHS, front RHS and

the four centre bolts) fixing the upper and lower

manifolds to the engine. Remove the intake manifolds

from the vehicle.

NOTE: The back RHS and the front LHS bolts are not

removed, these two bolts keep the upper and lower

manifolds together.

13. Cover the engine inlet ports (1) with the workshop

blanking plate or clean workshop cloth. Refer to

Figure 4.

Page 3 of 15

FIGURE 3

FIGURE 4

1

1

1

2

3

4

5

6

6

1

112 - 18 N.m

FIGURE 7

1

1

2

FIGURE 6

FIGURE 5

6

9

10

1

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

Page 4 of 15

FITTING INSTRUCTIONS: - continued...

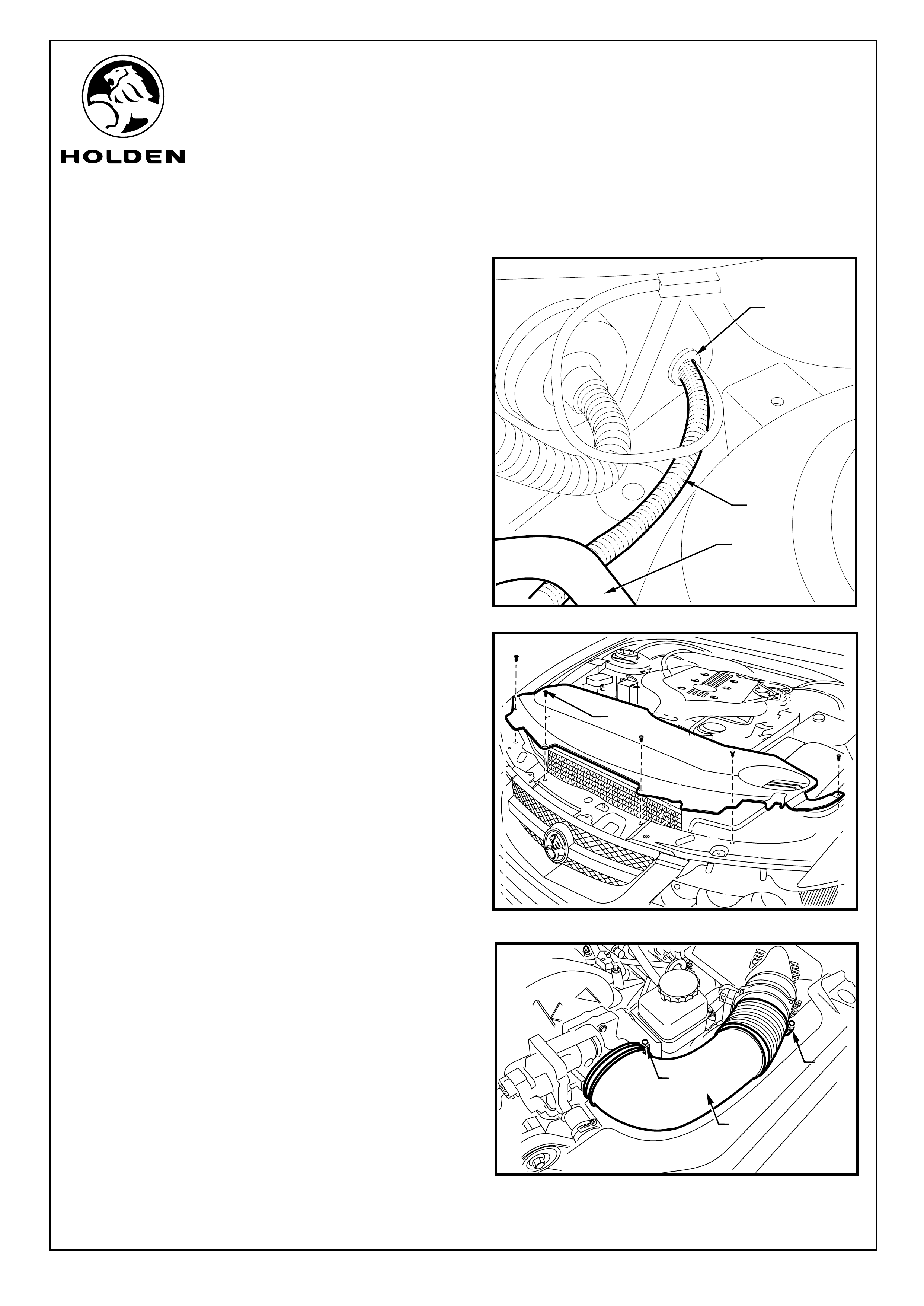

Refer to Figure 5 for the following:

14. Identify the part of the injection system harness (1) that

runs through the vehicle and feed it under the AC

supply pipe (2) through the grommet hole (3) into the

vehicle cabin until the grommet is in place and push the

grommet into position.

NOTE: On wagons cut off the end of the grommet

nipple.

15. On wagons pass the window washer back through into

the engine compartment and reconnect it.

16. From under the bonnet, remove the scrivets (1) (5

places) securing the upper radiator shroud and remove

the shroud. Refer to Figure 6.

Refer to figue 7 for the following:

17. Disconnect the airflow sensor from the intake air duct.

18. Loosen the clamps (1) (2 places) retaining the air ducts

between the throttle body and the air cleaner. Remove

the air ducts from the vehicle.

19. Unscrew and remove the top of the air cleaner box.

Remove the air cleaner element.

20. Use a 30 Torx bit to remove the three bolts (2 in the air

cleaner box and 1 outside) attaching the air cleaner

base to the vehicle. Remove the air cleaner base.

3

1

2

1

4

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

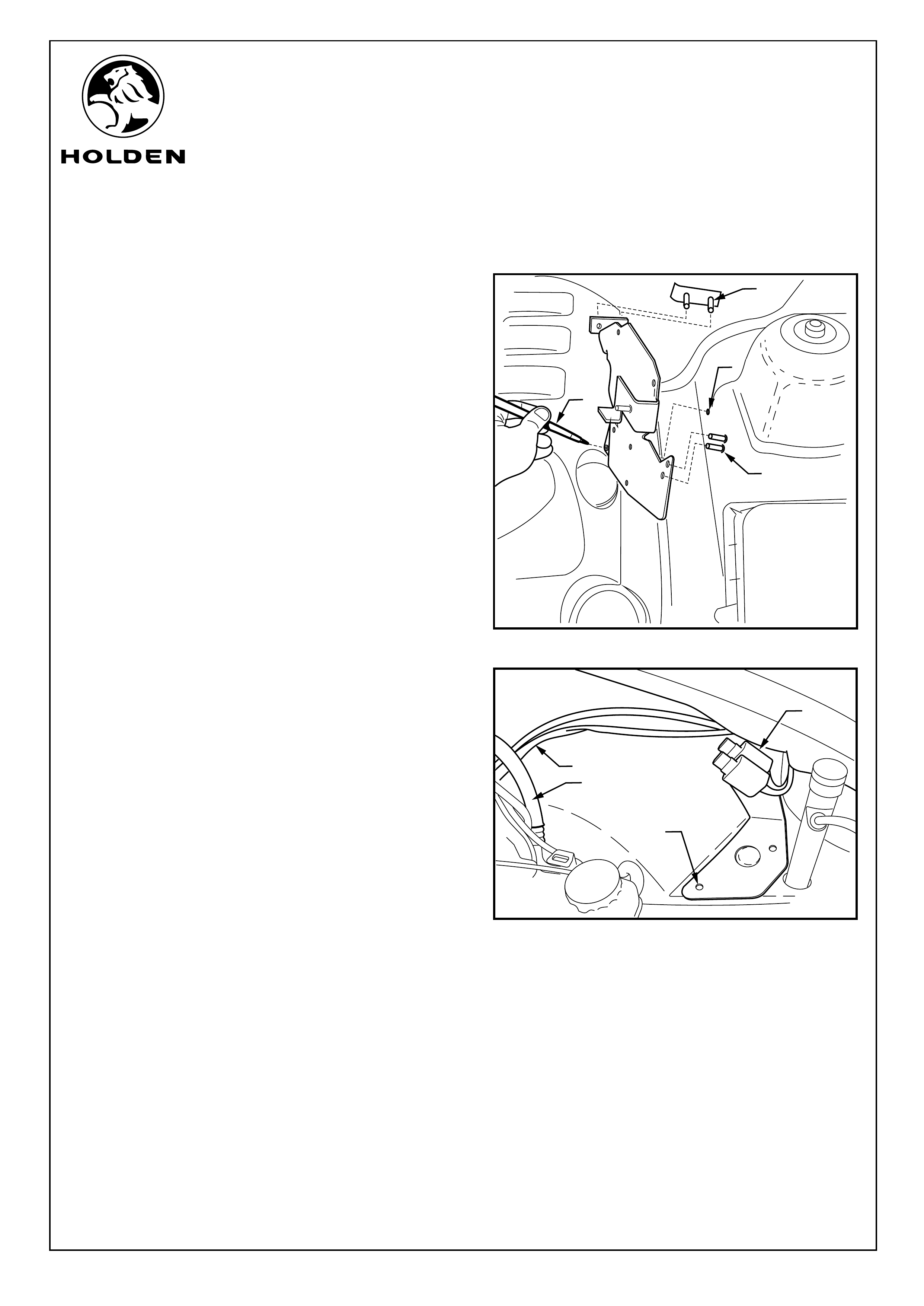

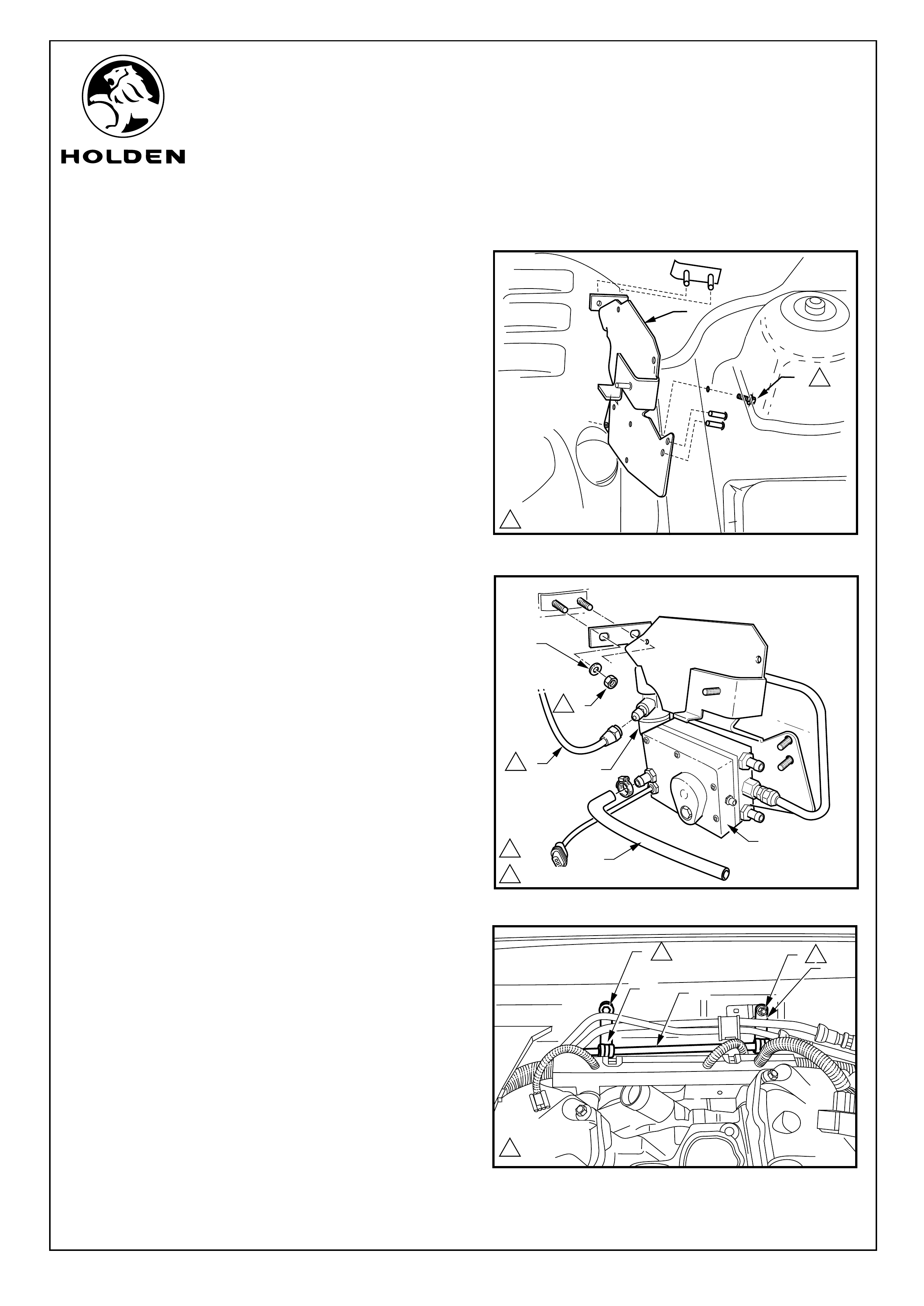

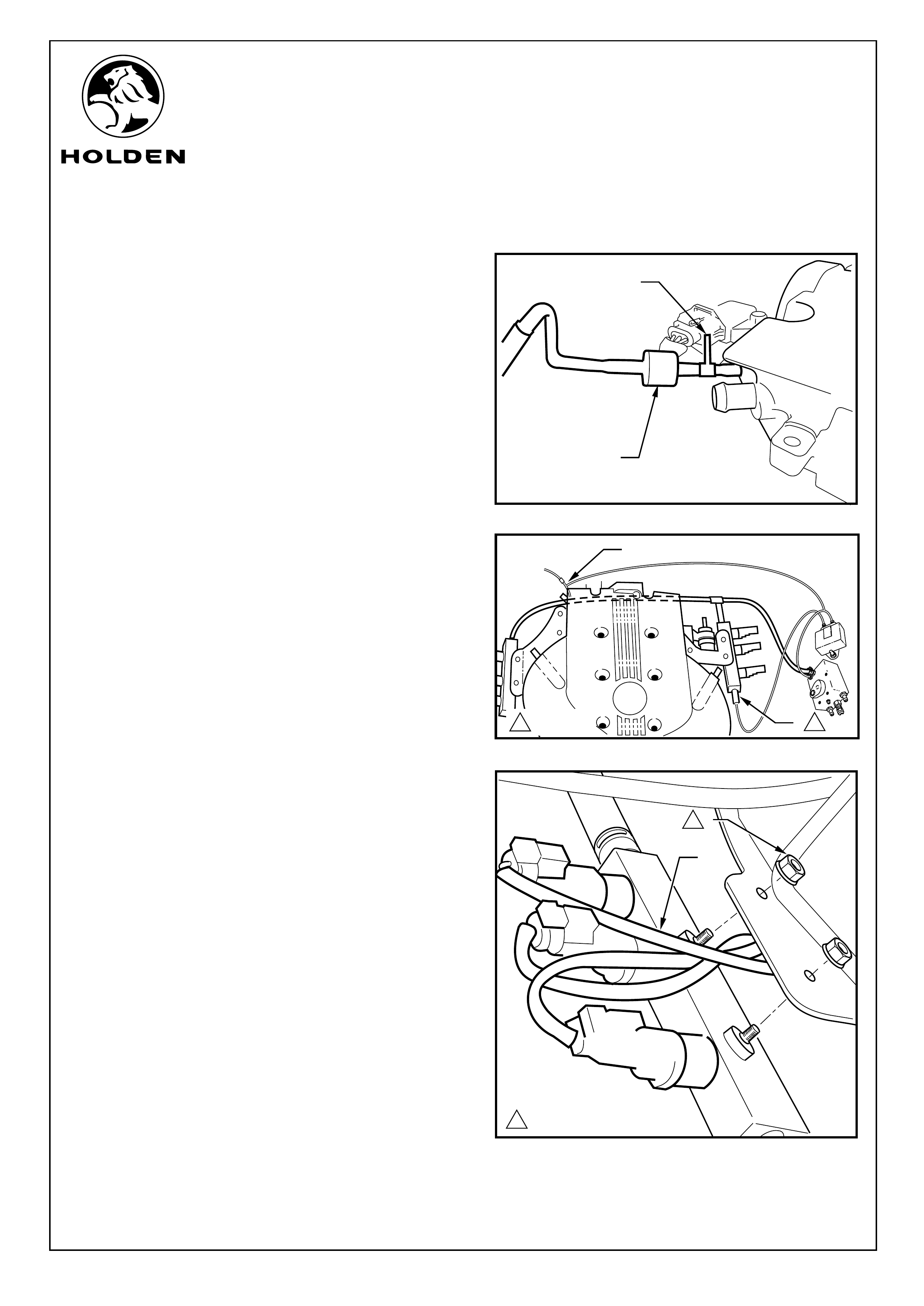

Refer to Figure 8 for the following:

NOTE: The ECU Mounting Bracket is mounted using the

two studs on the passenger side firewall (1) and the two

studs on the wheel arch (2).

21. Place the ECU mounting bracket onto the studs and

use a marker pen (3) to mark the position of the fifth

hole position (4). Remove the ECU mounting bracket

and use a 90-degree drill with a 7mm drill bit to drill out

the hole.

22. Paint the edges of the hole with a high Zinc content

corrosion resistant paint and allow to dry.

Refer to Figure 9 for the following:

23. Pass the ECU emulator harnesses (1) under the AC

supply line (2) and run along the LHS inner wheel arch

fit the emulator boxes to the bracket.

NOTE: The emulator boxes with the four pin (3)

connections will be fitted nearest the inner wheel arch.

24. Use the nut and bolt provided to fit the emulators to the

emulator-mounting bracket. Place the bracket into

position aligning the holes with the air cleaner base

fixing holes (4).

1

2

4

3

1

2

3

FIGURE 9

FIGURE 8

Page 5 of 15

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

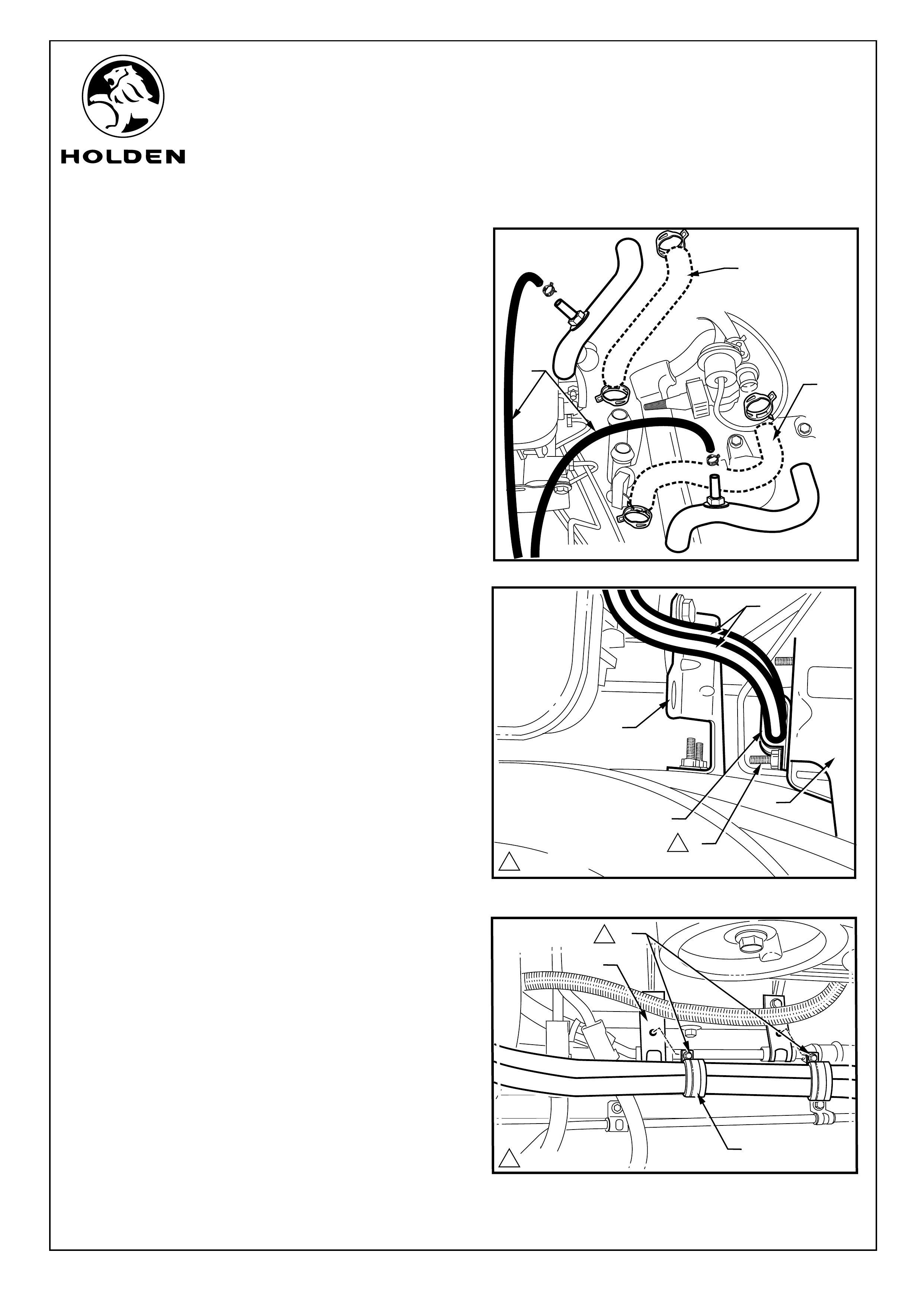

Refer to figure 10 for the following:

Refer to figure 11 for the following:

Refer to figure 12 for the following:

25. Remove the front heater hose (1) from between the

engine supply line and the heater control valve and

discard.

26. Remove the back heater hose (2) and discard.

27. Fit the replacement hoses and clips supplied.

28. Fit the two converter supply lines (3) to the two heater

hoses.

29. Run the two converter hoses down between the ABS

mounting bracket (1) and the Master brake cylinder

support bracket (2). Fit the hose clip (3) around the two

converter supply hoses (4) and fit to the stud (5) on the

rear face of the ABS bracket, use the nut provided to

secure the clip. Tighten to specified torque.

30. Run the two converter hoses down and across the front

cross member. On the LHS of the vehicle, fit the hose

clip around the two converter supply hoses and use the

nut provided to secure them to the stud in the wheel

arch under the air cleaner box.

31. Drill out the two power steering support brackets holes

(1) attached to the front cross member to 7mm.

32. Use two clips (2) and their fastenings to fix the converter

supply lines to the power steering support brackets on

the front cross member.

FIGURE 10

FIGURE 12

TRANS/LOCK

TRANS/LOCK

1

2

3

Page 6 of 15

FIGURE 11

1

2

3

1

2

4

5

1

13.0 - 4.0 N.m

13.0 - 4.0 N.m

13

1

110 - 12 N.m

1

2

1

2

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

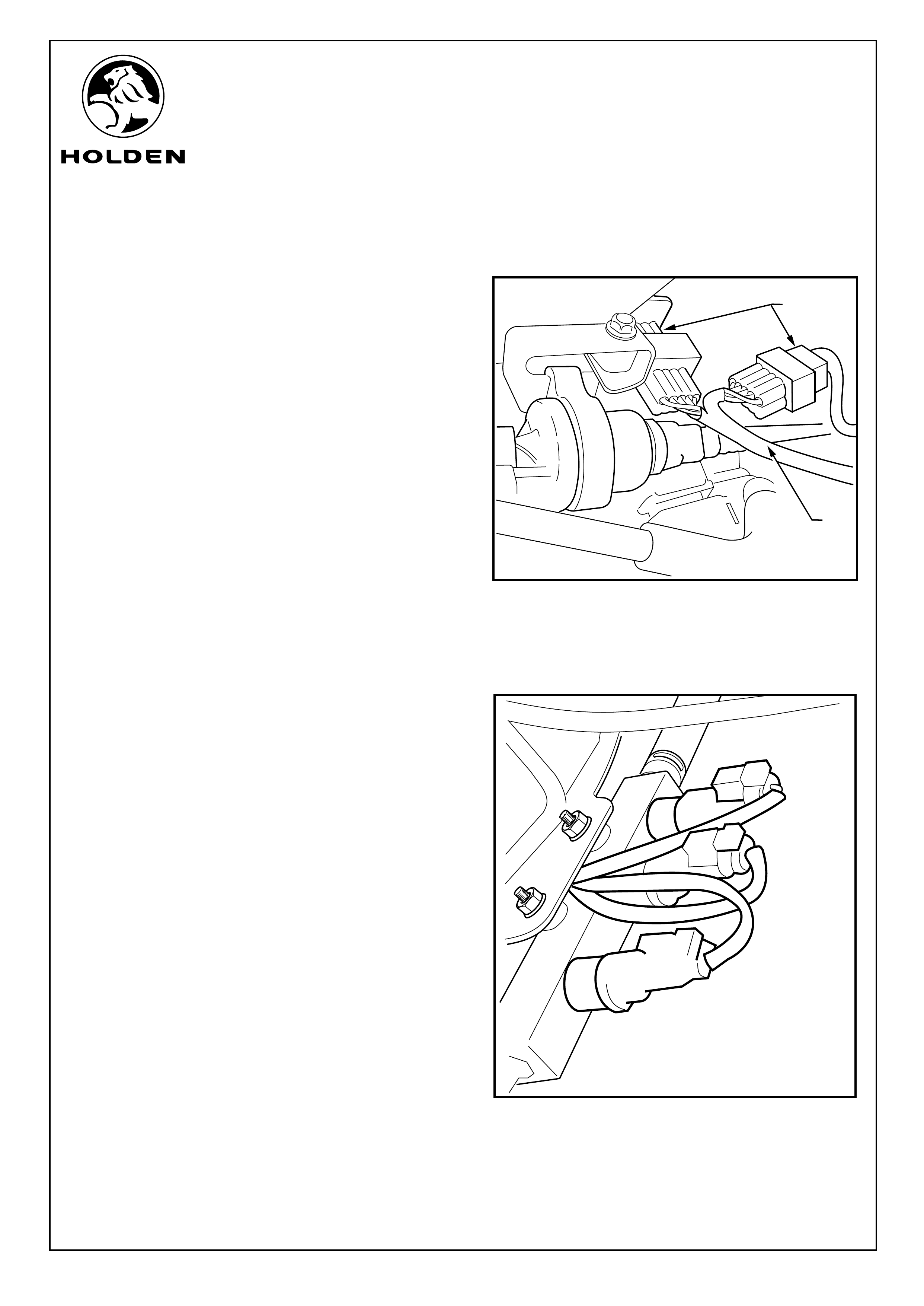

33. Refit the ECU mounting bracket (1). Fit the bolt (2)

through from the wheel arch and tighten to specified

toque. Refer to Figure13.

Refer to figure 14 for the following:

34. Fit two nuts (1) and washers (2) supplied to the two studs

on the firewall and tighten to the specified torque.

NOTE: Do not fit the two nuts and washers to the studs

on the wheel arch at this time.

35. Connect the high-pressure supply pipe (3) to the gas

lock valve (4) mounted to the rear of the ECU Mounting

bracket and tighten to specified torque.

36. Fit the piece of gas supply hose 300mm long (5) to the

converter (6) outlet and secure with a hose clamp.

37. Remove the nut (1) and bolt (2) on the two pipe support

brackets on the firewall. Fit two clips (3) to the gas high-

pressure supply pipe (4) and secure to the firewall with

the nut and bolt from the pipe support brackets. Tighten

to specified torque. Refer to Figure 15.

1

2

34

3

1

2

FIGURE 13

FIGURE 15

FIGURE 14

Page 7 of 15

2

1

34

5

6

1

2

10 - 12 N.m

14 - 5 N.m

12 - 18 N.m

1

14 - 5 N.m

11.0 - 3.0 N.m

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

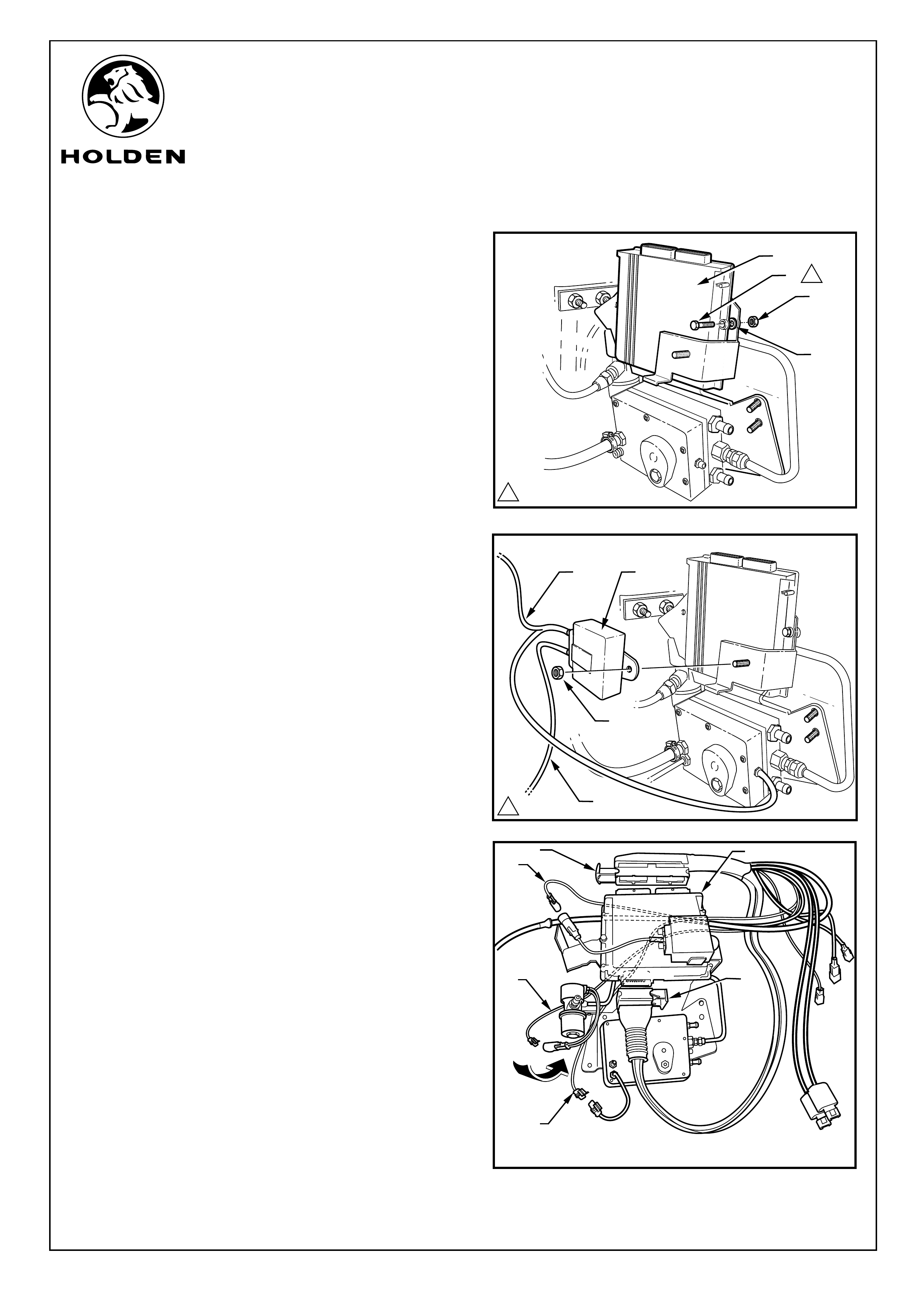

FITTING INSTRUCTIONS: - continued...

38. Fit the ECU module (1) into the ECU mounting bracket.

Fix the ECU in position with the nuts, (2) bolts (3) and

washers (4) supplied. Refer to Figure 16.

NOTE: Fit a washer between the ECU module and the

ECU mounting bracket.

Refer to Figure 17 for the following:

39. Fit the MAP sensor box (1) to the stud on the ECU

mounting bracket using the nut (2) supplied. Tighten to

specified toque.

40. Connect the forked end of the vacuum pipe (3) to the

top connection on the MAP sensor and the sensor on

the converter.

41. Connect gas pressure supply sensor hose (4) to the

lower connection of the MAP sensor.

Refer to Figure 18 for the following:

42. Open the locks on the two main harness ECU (1)

connectors and connect them to the ECU (2), close the

connector locks.

43. Pass the four wire harness connector (3), the twin

harness connector (4) and the three wire harness

connector (5) around the back of the ECU bracket.

44. Connect the four wire harness connector into the MAP

sensor harness.

45. Connect the two-way wiring harness connector into the

gas lock valve connector.

46. Connect the three-way wiring harness connector into

the converter.

FIGURE 16

FIGURE 17

FIGURE 18

1

2

3

4

1

3

4

Page 8 of 15

1

1

2

3

4

5

2

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

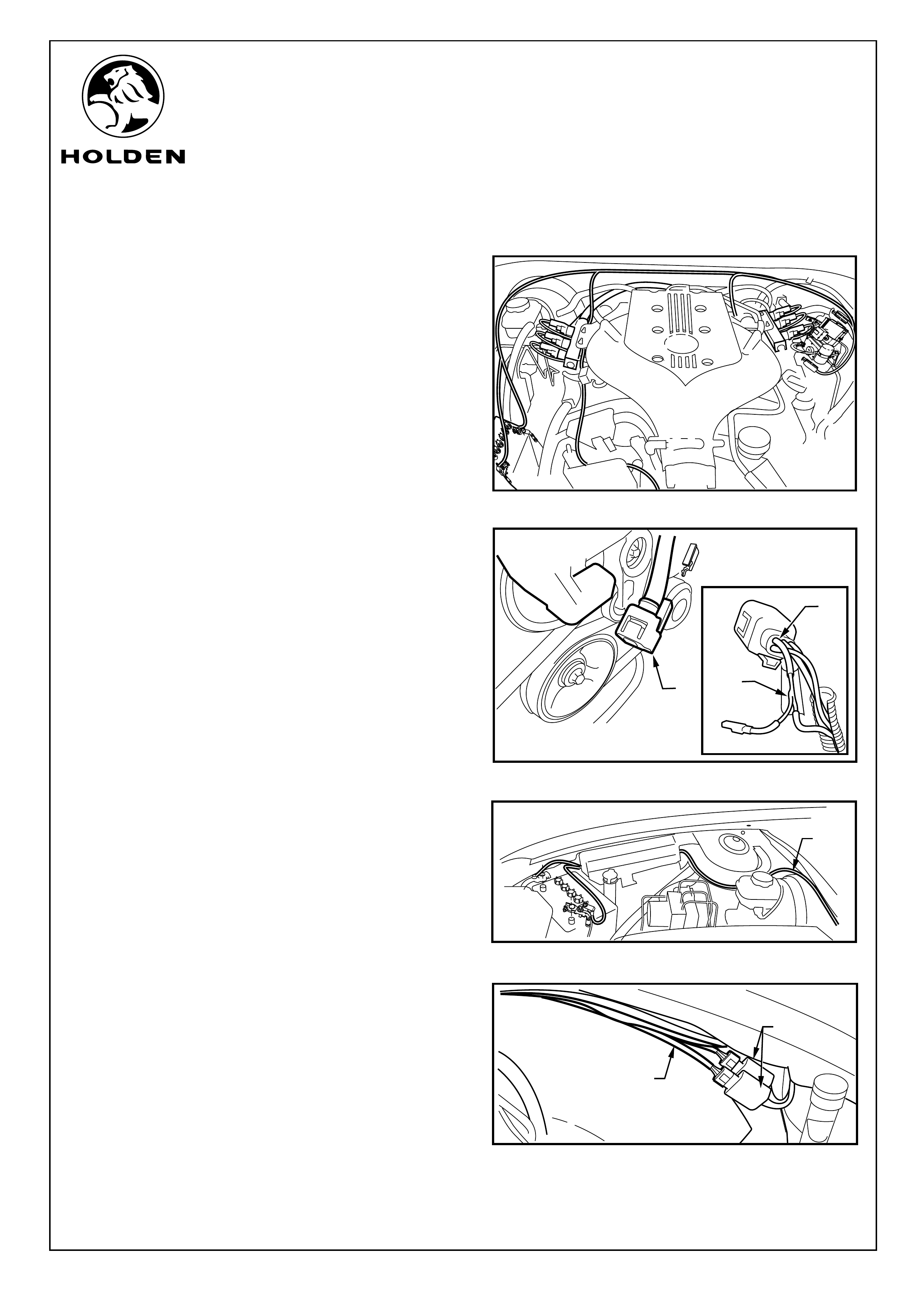

FITTING INSTRUCTIONS: - continued...

Refer to Figure 19 for the following:

47. The two fuel injector harnesses and the battery

harness are pass around the back of the ECU to the

vehicle body harness on the firewall of the vehicle. Run

the short injector harness across to the LHS of the

engine and the long injector harness across to the RHS

of the engine.

48. Continue to run the throttle sensing wire to the front of

the engine to the throttle sensing connector.

Refer to Figure 20 for the following:

49. Release the outer connector sheath of the throttle

sensor connector and remove the locking clip. Back out

pin 1, (2) the wire is green in colour. Solder splice the

signal pickup wire (3) to the backed out wire and seal join

with shrink wrap.

50 Refit the backed out terminal. Connect the throttle

sensor harness to the throttle positioning sensor.

51. Join the gas harness throttle sensing wire to the new

connection.

52. Run the battery harness (1) across to the other side of

the vehicle, along the underside of the wiring conduit to

the battery. Refer to Figure 21.

NOTE: Do not connect to the battery at this time.

53. Connect the emulator patch harness (1) into the two

emulators (2) and run along the LHS of the vehicle,

across the vehicle harness to the connectors for the

petrol injection manifold on the LHS of the engine.

Cable tie as required. Refer to Figure 22.

FIGURE 19

1

2

FIGURE 20

FIGURE 21

FIGURE 22

1

1

Page 9 of 15

2

3

1

1

2

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

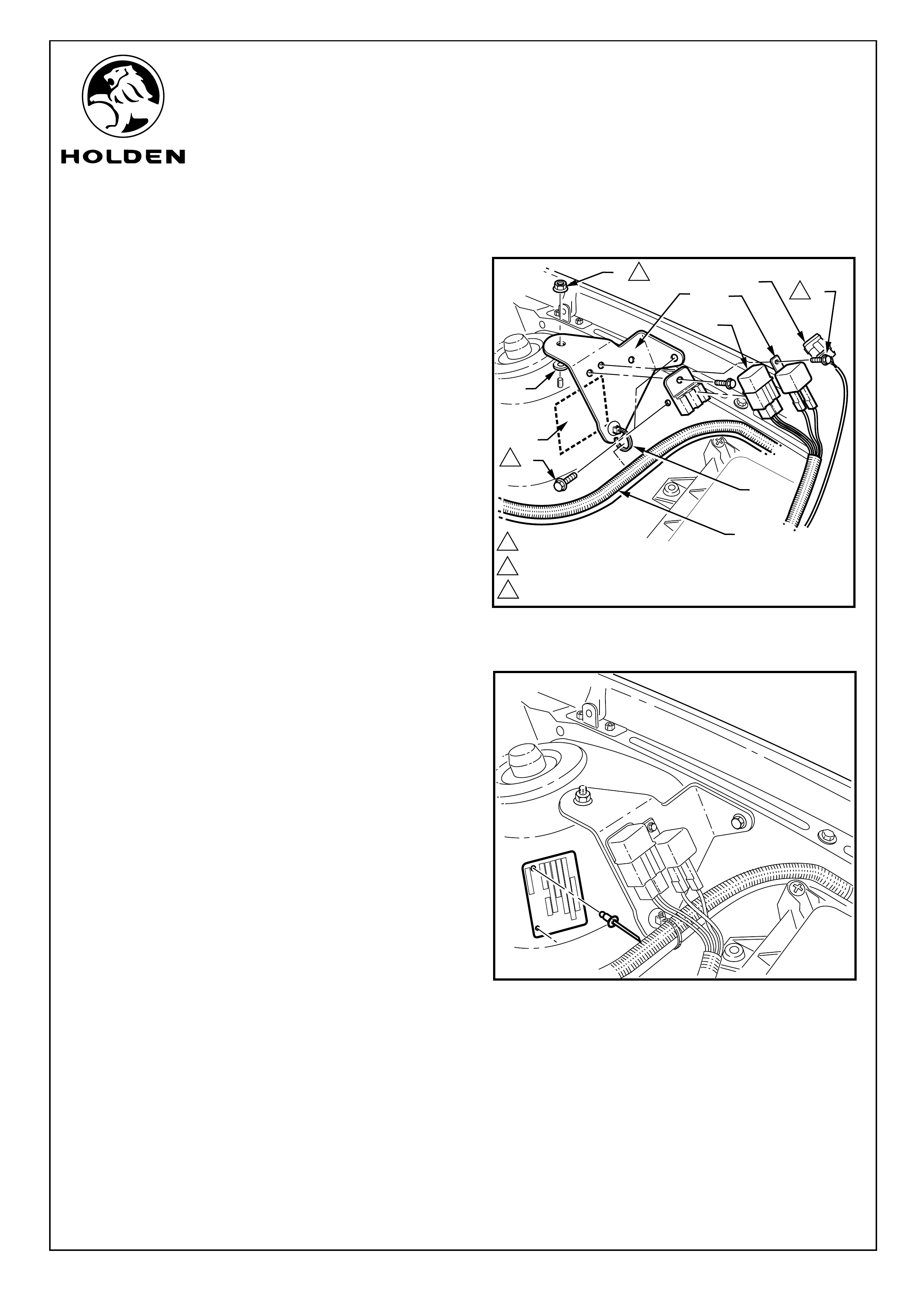

Refer to Figure 23 for the following:

54. Fit the gas filter support bracket (1) onto the two studs

used to mount the ECU bracket and use the nut (2)

provided to secure the bracket.

55. Using the nut (3) supplied fit the filter (4) to the filter

support bracket and tighten.

56. Connect the gas supply hose from the converter to the

filter (1) and secure with a hose clamp supplied. Refer to

Figure 24.

57. Remove the blanking plate or clean workshop cloth from

the engine inlet ports, refit the intake gasket.

58. Take the modified intake assembly with the gas injection

system fitted and refit to the vehicle.

59. Refit the remaining six engine intake bolts and tighten to

specified toque.

60. Connect the gas Filter to the injector manifold supply

hose (2) to the filter connector (3) and secure with the

clamps supplied. Refer to Figure 24.

61. Reconnect the petrol fuel line to the petrol injector

manifold.

FIGURE 23

FIGURE 24

Page 10 of 15

1

3

2

1

2

3

4

110 - 12 N.m

2.5 N.m

1

1

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

62. Fit the ventilation vacuum hose (1) to the Tee (2) on the

upper intake manifold. Refer to Figure 25.

Refer to Figure 26 for the following;

63. Connect the top vacuum hose from the mapping

sensor to the Tee (1) on the back of the upper intake

manifold.

64. Connect the lower hose on the mapping sensor to the

front LHS gas manifold (2) and tighten to specified

torque.

65. Remove two nuts (1) holding the gas injector manifolds

to their mounting brackets and pass the injector

harness (2) between the bracket and the manifold.

Refit the manifolds to their brackets and tighten. Refer

to Figure 27.

FIGURE 27

1

2

Page 11 of 15

FIGURE 25

FIGURE 26

2

1

1

2

11.0 - 3.0 N.m

14 - 5 N.m

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

Refer to Figure 28 for the following:

66. Connect the emulator patch harness (1) between the

engine petrol injectors and the vehicle injector

connector (2).

67. Fit all harnesses into the clips running across the

vehicle firewall.

Refer to Figure 29 for the following:

68. Pull back the black outer sheath of each of the gas

injector leads and read the injector number written on

the wire. Connect the lead to the corresponding

injector.

69. Connect the gas supply hose on the inlet manifold

assembly to the gas filter and secure with the clamp

supplied.

FIGURE 28

FIGURE 29

1

2

Page 12 of 15

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

70. Remove the ID plate (1) from the LHS wheel arch.

71. Use the nuts and bolts (2) provided to mount the fuse (3)

and relay (4) to the relay-mounting bracket (5).

72. Place a washer (6) on the front stud on the wheel arch,

fit the rely mounting bracket over the stud, place a

second washer and the nut supplied (7). Fit the bolt (8)

supplied through the bracket into the captive nut on the

inner wing. Tighten to specified toque.

73. Clip a mounting tie (9) to the bottom of the relay-

mounting bracket and clip the emulator harnesses (10)

in.

74. Clip the system diagnostic connector into the hole

along side the relay.

75. Drill and rivet the identity plate to the wheel arch.

FIGURE 30

FIGURE 31

XXXXXXX

XXX

XXXXXXX

XXX

XXXXXX

XX

XX

XX

Page 13 of 15

11.0 - 3.0 N.m

210 - 12 N.m

34 - 5 N.m

1

2

3

3

52

6

9

10

1

4

7

8

11

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

FITTING INSTRUCTIONS: - continued...

76. Connect the throttle positioning sensor wire.

77. Refit the air cleaner box, filter and ducting.

78. Fill the vehicle with gas and use a soapy liquid to check

for gas leaks on all joins up to the gas lock valve.

79. Connect the harness to the battery. Refer to Figure 32.

80. Start vehicle on petrol only mode. When satisfied that

the vehicle is running correctly on petrol switch to gas.

Run the vehicle until the temperature gauge is shows at

least ¼ of the normal operating temperature and the

gas indicator light on the gas fuel level indicator is

green, these conditions must be met before the gas

check can be carried out. Check all joins forward of the

gas lock valve for gas leaks using a soapy liquid.

IMPORTANT: The vehicle must not be left

unattended whilst the vehicle is warning up.

Monitor the vehicle for signs of leaks.

81. Check coolant levels

82. Refit all parts removed in reverse order.

83. Select petrol only mode and purge gas system of gas.

84. Place owners manual in the vehicle glovebox.

FIGURE 32

Page 14 of 15

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

PARTS LIST

PART NUMBER DESCRIPTION QUANTITY

11090684 SCREW: M8 x 1.25 x 25 8

11095803 NUT - CONELOCK - REINF TO LPG 2

92054459 CLAMP - SPARE WHEEL MOUNTING

92055707 CLAMP - HOSE TO BODY 4

92055708 CONVOLUTED TUBE - LPG HEATER HOSE 6

92055714 HEAT SHIELD-LPG SUPPLY PI 1

92055723 LABEL-LPG 1

92055723 LABEL-LPG

92055724 LABEL-LPG INSTRUCTION

92055726 BRKT-LPG CYL ATTACH-RH ST 1

92055727 BRKT-LPG CYL ATTACH-LH ST 1

92055728 REINF-LPG CYL ATTACH RHS 1

92055729 REINF-LPG CYL ATTACH-LHS 1

92055730 TANK ASSEMBLY-LPG WAGON VT/VX 1

92055731 REMOTE FILLER ASM-LPG CYL 1

92055732 HOSE ASM-LPG TANK FILLER 1

92055733 HOSE ASM-LPG CYL FILLER 1

92055736 VENT TUBE-LPG CYL TO JOIN 1

92055737 VENT TUBE-LPG FILLER TO J 1

92055738 FLOOR FLANGE-VENT TUBE AT 1

92055739 VENT TUBE-JOIN TO FLOOR F 1

92055741 SPRING-REAR 2

92055742 BRACKET ASM-SPARE WHL MTG 1

92055743 REINFORCEMENT ASM-SPARE WHEEL 1

92056796 SUPPORT-HEAT SHEILD-FRONT 1

92056797 SUPPORT-HEAT SHEILD-REAR 1

92056801 JOINER - VENT TUBE 1

92057565 FITTING-5/16 SAE STRAIGHT 2

92057566 P CLAMP - LPG SUPPLY 2

92058200 GROMMET - VENT HOSE 1

92058201 POCKET FLANGE - FUEL 1

92058202 WASHER - FILLER VALVE 1

92058203 NUT - FILLER VALVE 1

92075623 REINFORCEMENT-LPG TANK MTG-RHF 1

92075624 REINFORCEMENT-LPG TANK MTG-RHR 1

92075625 REINFORCEMENT-LPG TANK MTG-LHF 1

92075626 REINFORCEMENT-LPG TANK MTG-LHR 1

92076266 ISOLATOR-DUAL COMPRESS-LP TANK 4

92076267 REINFORCEMENT-S/WHL MTG-FRT 1

92076268 REINFORCEMENT-S/WHL MTG-FRT 1

92076269 SPACER PLATE-S/WHL MTG-LHS 1

92076272 CRUSH TUBE-S/WHL BRKT MTG-LHS 1

92076273 CRUSH TUBE-S/WHL MTG BRKT-FRT 1

92076274 CRUSH TUBE-LPG TANK MTG-RHF BO 1

92076275 CRUSH TUBE-LPG TANK MTG-RHR 63 1

92076276 CRUSH TUBE-LPG TANK MTG-LHF 71 1

92076277 CRUSH TUBE-LPG TANK MTG-LHRý74 1

92076279 REMOTE FILLER ASM-LPG TANK 1

92076280 PIPE ASM-CONN LPG TANK REM FLR 1

92077227 CAP-FUEL FILLER 1

92091859 REGO LABEL ASM-LPG 2

92138020 SCREW 4

92138212 TIE-CABLE. 14

92138551 SCREW-POCKET FLANGE (M6x2 2

92141576 CLAMP - Main pipe to underbody 9

92145288 PIPE-REAR ASSEMBLY 1

92145289 PIPE-MID ASSEMBLY 1

70G-990201 NUTSERT - M6x1 1

92055716NK COVER-SPARE WHEEL - ANTHRACITE

92055760NK CARPET & INSULATOR ASM-CARGO

H213000201 STRAP-REMOTE BOOT RELEASE 1

Page 15 of 15

WAGON PARTS KIT

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

PART NUMBER DESCRIPTION QUANTITY

SP1543 / 92138003 CLAMP-VALVE BOX VENT TUBE 4

SP1618 CLAMP - HOSE 25mm-38mm 3

SP2754 / 92138040 CLAMP-FILLER HOSE VENT TU 2

SP3945 / 92138241 BOLT-M10x1.5x26 HEX HEAD 2

SP4163 / 92138381 RIVET 25

06M-052001 INJECTOR RAIL ASM. 1

BRC INJECTOR MOD MAX 6

GAS PIPE, 5x10 0.61

SLEEVE, REFLECTOTHERM, 32MM 330

CLAMP, CLICK, 10-11 DIA 2

RAIL, INJECTOR VZ, 2

NUT FOR 4X10 RUBBER PIPE 2

JOINT FOR 4X10 RUBBER PIPE 2

BUMPER-BRKT PUM 4

HOSE, P1 sensor. 1

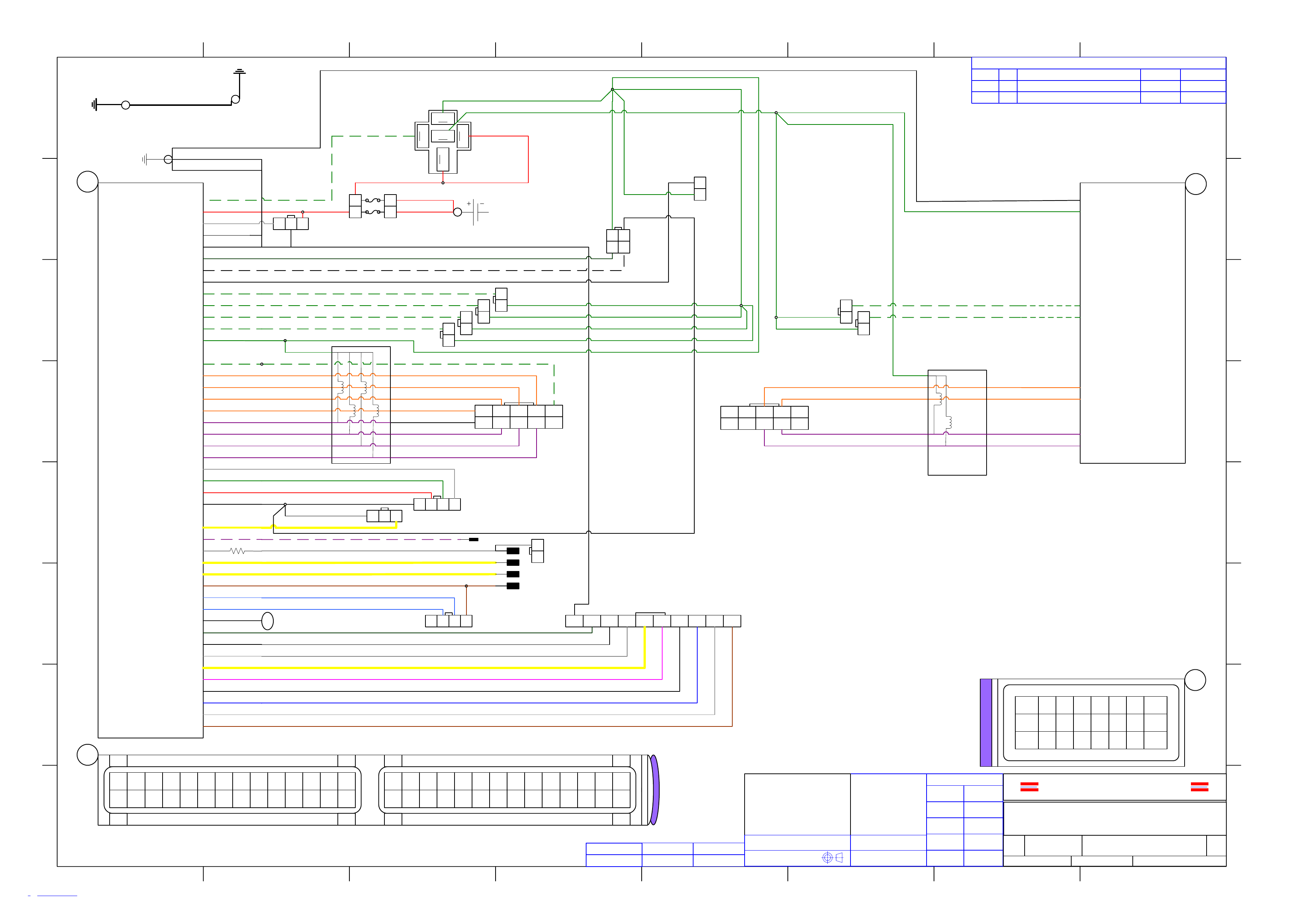

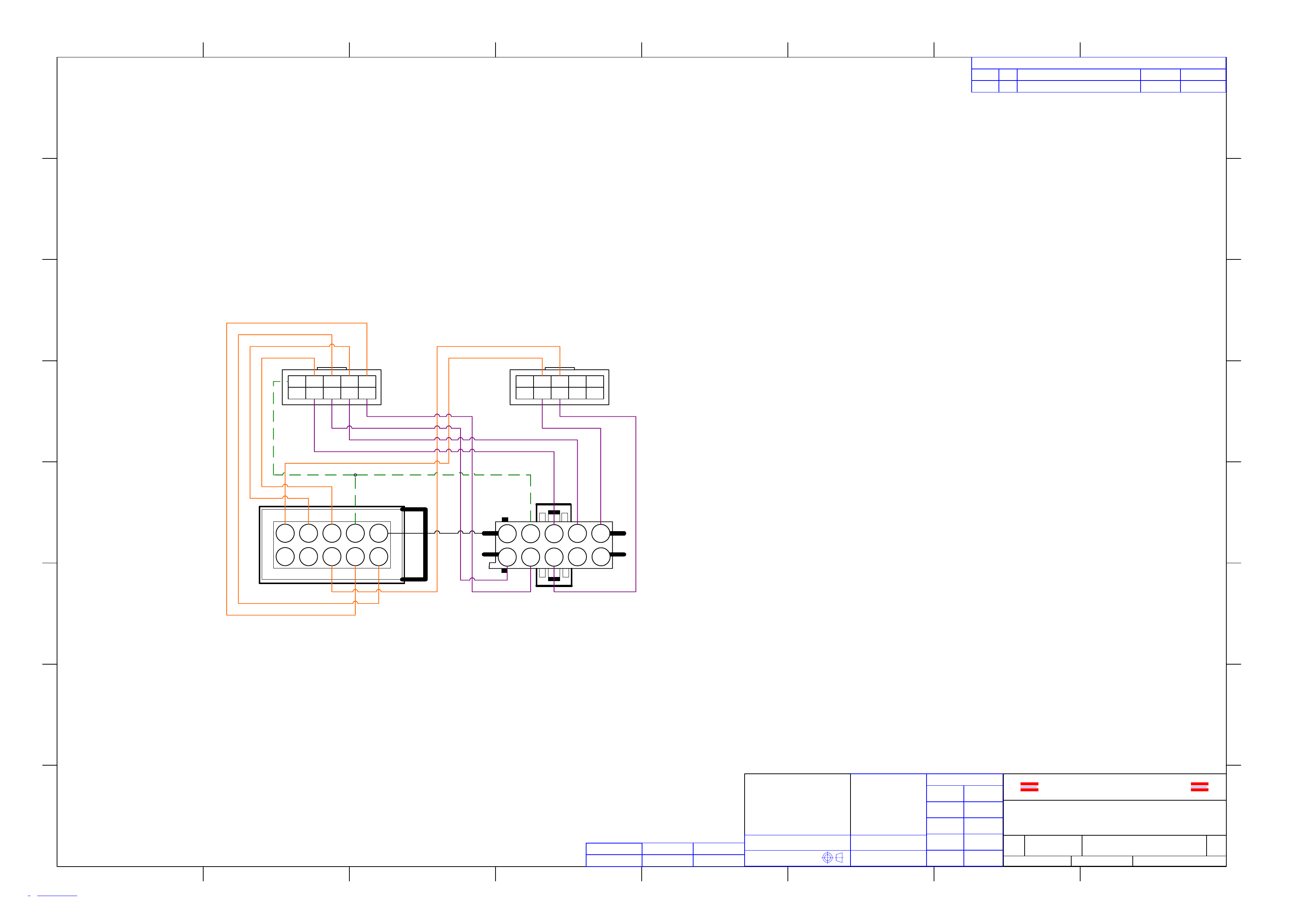

12H-052001 WIRING HARNESS VZ LPG 1

ASSY, WIRING HARNESS VZ

06M-052002 CONVERTER LPG ASM 1

BRC LPG GENIUS REDUCER 1

Flare union 1

BRC, LPG Solenoid Valve mod. 1

Flare union 1

ELBOW / CONVERTOR 1

BRC DOUBLE FJ1 FILTER 1

NIPPLE, 1/4 NPT X 5/16 FLARE 2

PIPE, SERVICE, L/OFF TO REG 1

VACUUM HOSE, 5MM 112

BKT, CONVERTOR MOUNTING 1

BKT, FILTER FJ1 DOUBLE 1

TEE 1

M6 x 12 SET SCREW, HEX HD 5

6mm Spring Washer Zn 5

M6 FLANGED NUT - Zn plated 1

HOSE, Vapour LPG 90 deg 1

CLAMP, CLICK, 17-18 DIA 2

SLEEVE, Heat Shield 15

06M-052003 INJECTOR HOSE ASM 1

BRC, Nut 4 x 10 Rubber pipe 12

BRC, Joint 4 x 10 rubber pipe 12

BRC, Clamp Click 10-11 12

BRC, Gas hose pipe 5 x 10 1.26m

06M-052004 HOSE ASM - MAP Sensor 1

4mm Vacuum hose 108

BRC, Nut 4 x 10 Rubber pipe 2

BRC, Joint 4 x 10 rubber pipe 2

4mm Tee - plastic 2

06M-052005 HOSE ASM - INJECTOR FEED 1

BRC, Gas pipe 12 x 19 "E67" 0.87

Tee 1

BRC, Clamp Click 17-189 6

Corrugated tube, 16mm 15

06M-052006 STANDOFF, SERVICE LINE, FRONT 1

74A-052001 CLAMP, INSULATED, 6MM 4

12G-052001 SWITCH BEZEL (with laser cut hole) (92111638) 1

06K-052001 HEATER HOSE 3/8 2.2 metres 2

06K-052002 HOSE HEATER OUTLET (Mod 92155841) 1

WAGON PARTS KIT Continued...

PARTS LIST

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

PART NUMBER DESCRIPTION QUANTITY

06K-052003 1

74A-052002 CLAMP - MOO (Coolant hose to regulator) 2

06K-052004 FRONT SERVICE LINE (Modified 92145290) 1

06M-052007 BKT, INJECTOR RAIL RH BANK 1

06M-052008 BKT, INJECTOR RAIL LH BANK 1

06M-052009 BKT, EMMULATORS, VZ 1

12H-052002 BKT, FUSE, RELAY VZ 1

12H-052003 BKT, WIRING INJECTOR 1

06M-052010 M6 NOZZLE FOR MANIFOLD 6

92111636 SWITCH BLANK, VY LPG 1

73A-052001 M6 x 25 HT 8.8 Hex head Set Screw -Zn plated 2

71A-052001 6MM FLAT WASHER ZINC 2

70B-052001 M8 NUT - Zn plated 4

71A-052002 8MM SPRING WASHER, ZINC 4

92138351 M6 x 16 HT 8.8 Hex head Set screw - Zn plated 4

08A-052001 TANK ASSEMBLY-LPG SEDAN V (Mod 92055725) 1

12F-052002 BRC 6 Cyl ECU 1

12F-052003 BRC SWITCH WITH BUZZER 1

12F-052004 BRC P1-MAP 1

74A-052003 CLAMP, CLICK, 17-18 DIA 8

HOSE HEATER VALVE (Mod 92157583)

PARTS LIST

PART NUMBER DESCRIPTION QUANTITY

11090684 SCREW: M8 x 1.25 x 25 8

11095803 NUT-CONELOCK-REINF TO LPG 2

92055707 CLAMP - HOSE to BODY 4

92055708 Convoluted tube - LPG heater hose 6

92055714 HEAT SHIELD-LPG SUPPLY PI 1

92055723 LABEL-LPG 1

92055726 BRKT-LPG CYL ATTACH-RH ST 1

92055727 BRKT-LPG CYL ATTACH-LH ST 1

92055728 REINF-LPG CYL ATTACH RHS 1

92055729 REINF-LPG CYL ATTACH-LHS 1

92055731 REMOTE FILLER ASM-LPG CYL 1

92055733 HOSE ASM-LPG CYL FILLER 1

92055736 VENT TUBE-LPG CYL TO JOIN 1

92055737 VENT TUBE-LPG FILLER TO J 1

92055738 FLOOR FLANGE-VENT TUBE AT 1

92055739 VENT TUBE-JOIN TO FLOOR F 1

92055741 SPRING-REAR 2

92056801 JOINER - VENT TUBE 1

92057565 FITTING-5/16 SAE STRAIGHT 2

92057566 P CLAMP - LPG SUPPLY 2

92058200 GROMMET - VENT HOSE 1

92058201 POCKET FLANGE - FUEL 1

92058202 WASHER - FILLER VALVE 1

92058203 NUT - FILLER VALVE 1

92077227 CAP-FUEL FILLER 1

0G-990201 NUTSERT-M6x1 1

92091859 REGO LABEL ASM-LPG 2

SP1618 CLAMP - HOSE 25mm-38mm 3

H213000201 STRAP-REMOTE BOOT RELEASE 1

92138020 SCREW 4

SP2754 / 92138040 CLAMP-FILLER HOSE VENT TU 2

92138212 TIE-CABLE. 1

SEDAN PARTS KIT

PARTS LIST

WAGON PARTS KIT Continued...

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

PART NUMBER DESCRIPTION QUANTITY

11090684 SCREW: M8 x 1.25 x 25 8

11095803 NUT-CONELOCK-REINF TO LPG 2

92055707 CLAMP - HOSE to BODY 4

92055708 Convoluted tube - LPG heater hose 6

92055714 HEAT SHIELD-LPG SUPPLY PI 1

92055723 LABEL-LPG 1

92055726 BRKT-LPG CYL ATTACH-RH ST 1

92055727 BRKT-LPG CYL ATTACH-LH ST 1

92055728 REINF-LPG CYL ATTACH RHS 1

92055729 REINF-LPG CYL ATTACH-LHS 1

92055731 REMOTE FILLER ASM-LPG CYL 1

92055733 HOSE ASM-LPG CYL FILLER 1

92055736 VENT TUBE-LPG CYL TO JOIN 1

92055737 VENT TUBE-LPG FILLER TO J 1

92055738 FLOOR FLANGE-VENT TUBE AT 1

92055739 VENT TUBE-JOIN TO FLOOR F 1

92055741 SPRING-REAR 2

92056801 JOINER - VENT TUBE 1

92057565 FITTING-5/16 SAE STRAIGHT 2

92057566 P CLAMP - LPG SUPPLY 2

92058200 GROMMET - VENT HOSE 1

92058201 POCKET FLANGE - FUEL 1

92058202 WASHER - FILLER VALVE 1

92058203 NUT - FILLER VALVE 1

92077227 CAP-FUEL FILLER 1

0G-990201 NUTSERT-M6x1 1

92091859 REGO LABEL ASM-LPG 2

SP1618 CLAMP - HOSE 25mm-38mm 3

H213000201 STRAP-REMOTE BOOT RELEASE 1

92138020 SCREW 4

SP2754 / 92138040 CLAMP-FILLER HOSE VENT TU 2

92138212 TIE-CABLE. 14

SP4163 / 92138381 RIVET 25

92138551 SCREW-POCKET FLANGE (M6x2 2

92145288 PIPE-REAR ASSEMBLY 1

92145289 PIPE-MID ASSEMBLY 1

SP3945 / 92138241 BOLT-M10x1.5x26 HEX HEAD 2

SP1543 / 92138003 CLAMP-VALVE BOX VENT TUBE 4

92141576 CLAMP - Main pipe to underbody 9

M6 x 12 SET SCREW, HEX HD

M6 FLANGED NUT - Zn plated 11

8MM FLAT WASHER, ZINC

06M-052001 INJECTOR RAIL ASM. 1

BRC INJECTOR MOD MAX 6

GAS PIPE, 5x10 0.61

SLEEVE, REFLECTOTHERM, 32MM 330

CLAMP, CLICK, 10-11 DIA 2

RAIL, INJECTOR VZ, 2

NUT FOR 4X10 RUBBER PIPE 2

JOINT FOR 4X10 RUBBER PIPE 2

BUMPER-BRKT PUM 4

HOSE, P1 sensor. 1

12H-052001 WIRING HARNESS VZ LPG 1

ASSY, WIRING HARNESS VZ

SEDAN PARTS KIT Continued...

PARTS LIST

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

PART NUMBER DESCRIPTION QUANTITY

06M-052002 CONVERTER LPG ASM 1

BRC LPG GENIUS REDUCER 1

Flare union 1

BRC, LPG Solenoid Valve mod. 1

Flare union 1

ELBOW / CONVERTOR 1

BRC DOUBLE FJ1 FILTER 1

NIPPLE, 1/4 NPT X 5/16 FLARE 2

PIPE, SERVICE, L/OFF TO REG 1

VACUUM HOSE, 5MM 112

BKT, CONVERTOR MOUNTING 1

BKT, FILTER FJ1 DOUBLE 1

TEE 1

M6 x 12 SET SCREW, HEX HD 5

6mm Spring Washer Zn 5

M6 FLANGED NUT - Zn plated 1

HOSE, Vapour LPG 90 deg 1

CLAMP, CLICK, 17-18 DIA 2

SLEEVE, Heat Shield 15

06M-052003 INJECTOR HOSE ASM 1

BRC, Nut 4 x 10 Rubber pipe 12

BRC, Joint 4 x 10 rubber pipe 12

BRC, Clamp Click 10-11 12

BRC, Gas hose pipe 5 x 10 1.26m

06M-052004 HOSE ASM - MAP Sensor 1

4mm Vacuum hose 108

BRC, Nut 4 x 10 Rubber pipe 2

BRC, Joint 4 x 10 rubber pipe 2

4mm Tee - plastic 2

06M-052005 HOSE ASM - INJECTOR FEED 1

BRC, Gas pipe 12 x 19 "E67" 0.87

Tee 1

BRC, Clamp Click 17-189 6

Corrugated tube, 16mm 15

06M-052006 STANDOFF, SERVICE LINE, FRONT 1

74A-052001 CLAMP, INSULATED, 6MM 4

12

06K-052004 FRONT SERVICE LINE (Modified 92145290) 1

06M-052007 BKT, INJECTOR RAIL RH BANK 1

06M-052008 BKT, INJECTOR RAIL LH BANK 1

06M-052009 BKT, EMMULATORS, VZ 1

12H-052002 BKT, FUSE, RELAY VZ 1

12H-052003 BKT, WIRING INJECTOR 1

06M-052010 M6 NOZZLE FOR MANIFOLD 6

92111636 SWITCH BLANK, VY LPG 1

73A-052001 M6 x 25 HT 8.8 Hex head Set Screw -Zn plated 2

71A-052001 6MM FLAT WASHER ZINC 2

70B-052001 M8 NUT - Zn plated 4

71A-052002 8MM SPRING WASHER, ZINC 4

G-052001 SWITCH BEZEL (with laser cut hole) (92111638) 1

06K-052001 HEATER HOSE 3/8 2.2 metres 2

06K-052002 HOSE HEATER OUTLET (Mod 92155841) 1

06K-052003 HOSE HEATER VALVE (Mod 92157583) 1

74A-052002 CLAMP - MOO (Coolant hose to regulator) 2

PARTS LIST

SEDAN PARTS KIT Continued...

FITTING INSTRUCTIONS FOR

VZ COMMODORE

LPG GAS INJECTION KIT

FD1349

21MR05

COPYRIGHT

Reproduction in whole or part

prohibited without written approval

HOLDEN LTD

Division of HOLDEN Ltd ACN 006 893 232

PART NUMBER DESCRIPTION QUANTITY

92138351 M6 x 16 HT 8.8 Hex head Set screw - Zn plated 4

08A-052001 TANK ASSEMBLY-LPG SEDAN V (Mod 92055725) 1

12F-052002 BRC 6 Cyl ECU 1

12F-052003 BRC SWITCH WITH BUZZER 1

12F-052004 BRC P1-MAP 1

74A-052003 CLAMP, CLICK, 17-18 DIA 8

PARTS LIST

SEDAN PARTS KIT Continued...

CCOPYRIGHT HOLDEN 2004

Reproduction in whole or part prohibited

without written approval of Holden LTD

Dual Fuel

Owner's Handbook

05SP05

FD1379

Table of Content

Emergency Procedures 1

Preface 2

Vehicle Operation 3

Fuel Indication 4

Refuelling 5

Vehicle Storage 5

Vehicle Trip Computer 5

Using Vehicle Boot (sedan only) 5

Towing Capacities 5

Radio Operation 5

Service and Maintenance 6

Service Coupons 7

Warranty Information 12

Content 1

Page 1 of 14

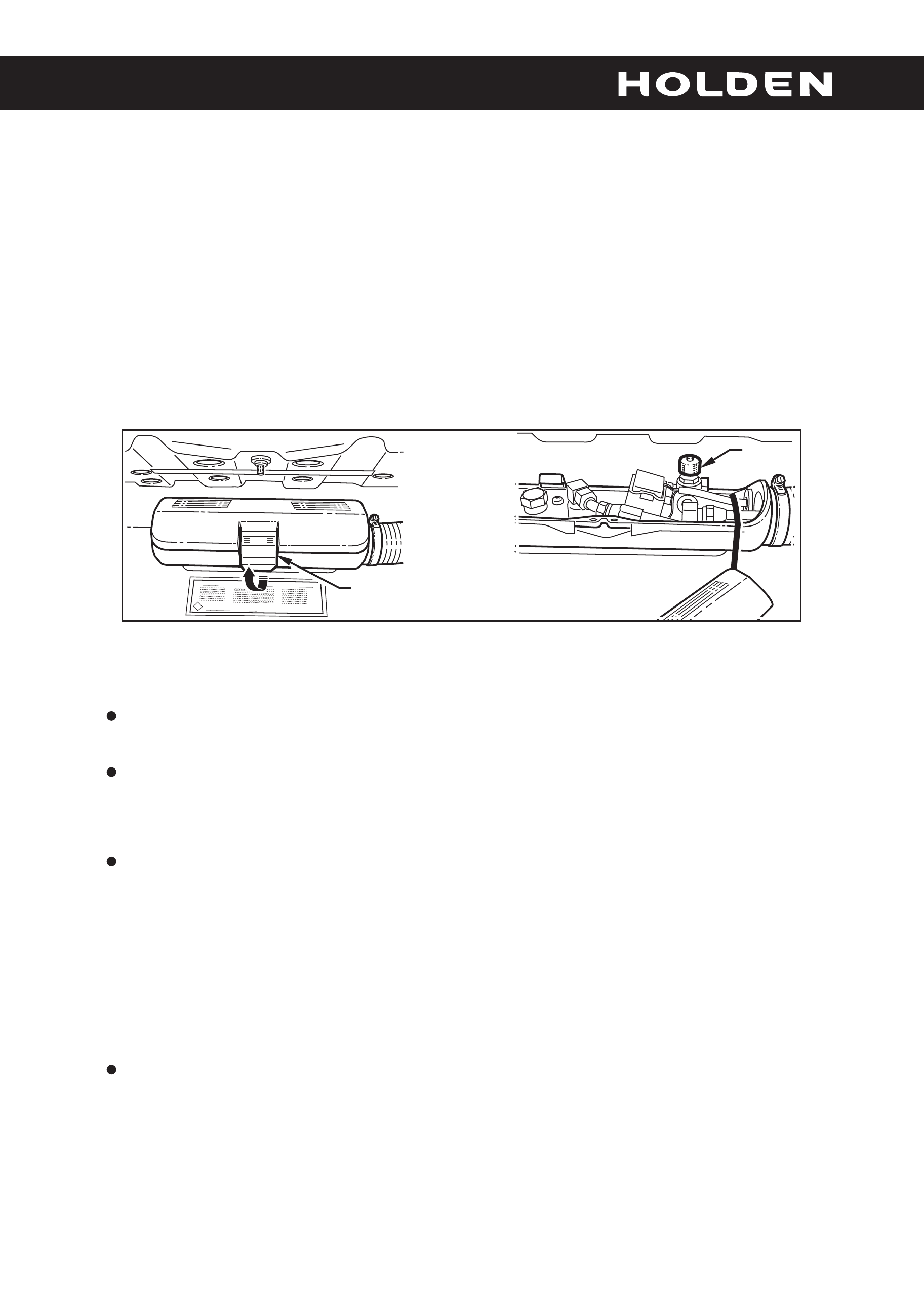

Emergency Procedures

LPG has an odour that enables any leaks in the vehicle LPG system to be

detected, should this odour be detected in or around the vehicle or in the event of

an accident, fire, or other abnormal circumstance:

1. Turn the vehicle ignition OFF.

2. Turn the manual service valve on LPG cylinder to OFF (turning in a

clockwise direction) See diagram below.

3. Contact nearest authorised IMPCO LPG repairer or Holden dealer for

advice.

WARNINGS:

LPG is heavier than air and if not dispersed tends to collect in low-lying

areas.

Accident or Fire

Call the emergency fire services to the scene and keep people away from

the vehicle.

Whilst Filling

Ensure that there is no gas leakage. If a leak is detected whilst filling the

vehicle stop filling the vehicle, notify the filling station operator of a potential

problem with the pump. If the odour still persists when disconnected, Carry

out the Emergency Procedures steps I and 2. Select petrol operation with

the fuel selector switch and take the vehicle to nearest authorised LPG

repairer for advice. NOTE: If frost is present do not touch the area until the

frost has dissipated.

Suspected Gas Leak

Carry out the Emergency Procedures steps I through 3. Once the steps have

been followed and the odour is no longer present, select petrol operation

with the fuel selector switch and take vehicle to nearest authorised LPG

repairer for advice.

APA

APAAPA

PULL TO OPENPULL TO OPEN

WNINAR G SAFETY INSTRUCTIONS CL

NER

TSIGY

ID ETN

M NU AC UR D I AU TR L AA F T E N SA I

1

2

Preface

Congratulations on purchasing a Holden 'Dual Fuel' vehicle. Not only will you

appreciate the savings in fuel costs, but as importantly you will reap the benefit of

a fully integrated LPG engine management system. Your Holden Dual Fuel

system will maximise your Holden vehicles performance in both fuel modes

whilst minimise exhaust emissions, retaining vehicle reliability and performance.

It is Important to understand that the engine in your 'Dual Fuel' Holden vehicle will

always start on petrol and if LPG is selected on the dual fuel control switch the

vehicle will automatically transfer over to LPG when the engine has warmed up

sufficiently.

The Holden Dual Fuel System has been designed to comply with the relevant

Australian Standard AS/NZS 1425:2003.

It is recommended to advise your insurance company that your new vehicle

operates on both petrol and LPG as failure to do so may invalidate your

insurance policy. Your vehicle is required to display the LPG decal on both the

front and rear numberplates.

The information contained in this manual is designed to cover the Holden Dual

Fuel System. Information provided was accurate at the time this manual was

approved for printing. Holden Ltd., reserves the right subject to all applicable

laws and regulations to change specifications at any time without incurring any

liability what so ever.

Page 2 of 14

VEHICLE OPERATION

New Engine Run-In Procedure

It is recommended that the engine of your vehicle be run in on petrol for 1000km

before running the vehicle on LPG.

Starting the Engine

There are no special requirements for starting your Dual Fuel engine with either

fuel selected, always follow starting directions as indicated in the vehicle

Owner's Handbook.

Changing Fuels and Starting

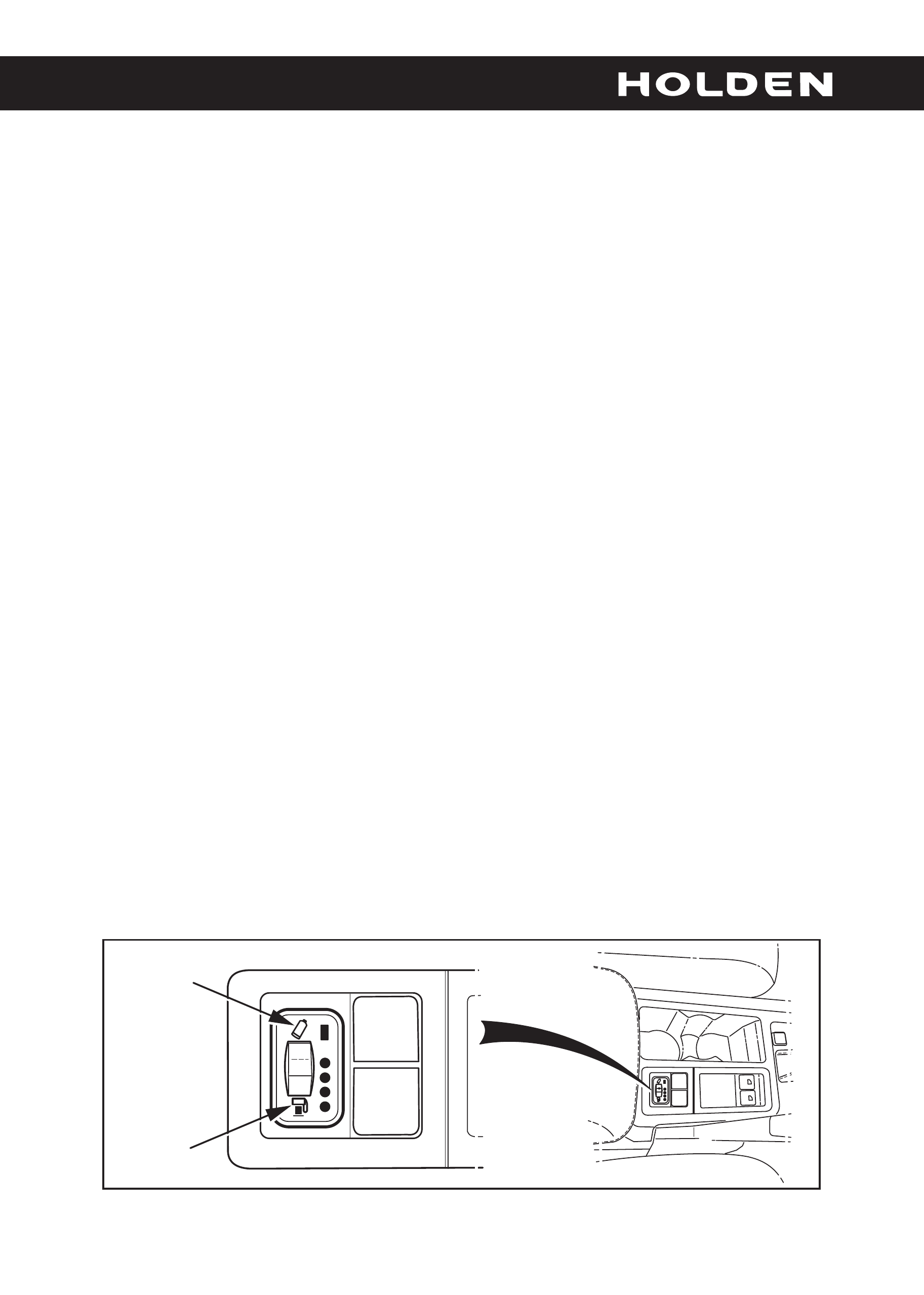

The fuel selector switch is located on the centre floor mounted console. Fuel

selection may be done at any time by simply changing the switch to the desired

fuel.

Fuel Selector Switch

The switch has two positions and a fuel operation indicator lamp, which will

change colour to indicate which fuel mode the vehicle is currently running on.

The lamp colours are as follows:

Red Petrol operation

Amber Transition state, currently transferring to selected fuel

Green LPG operation

PETROL OPERATION:

When the switch is in the 'Petrol' position, the engine will operate on

unleaded petrol. The engine will start on petrol, and if switched from LPG, will

automatically make the transition to petrol operation.

LPG OPERATION:

When the switch is in the 'LPG' position, the engine will operate on LPG

fuel. The engine will start and run on petrol until required conditions are reached,

at which time the system will automatically transfer to LPG operation.

Page 3 of 14

LPG

PETROL

BRC

FUEL INDICATION

Petrol Fuel Level Indication

The fuel gauge on the instrument panel will show petrol tank contents.

LPG Fuel Level Indication

The 4 lights in the change over switch indicate fuel level:

4 lights illuminated full

3 lights illuminated ¾ full

2 lights illuminated ½ full

1 light illuminated ¼ full

1 light flashing LPG reserve

1 light flashing and beeper sounding Out of LPG and the system has changed

back to petrol operation. To stop the

system beeping, change fuel selection

switch to petrol.

A few quick beeps indicates system has changed back to

petrol, under high load conditions, and

will return back to LPG automatically

when ready.

Petrol Usage

Holden recommends: the petrol tank of your vehicle should always have at

least a ¼ of a tank of petrol.

When the engine is started with LPG selected, the engine will start and run on

petrol until required conditions are reached, at which time the system will

automatically begin the change to LPG operation.

IMPORTANT:

If the vehicle runs out of petrol it will not start, eliminating the ability to

changeover to LPG operation.

Operating the vehicle with 'NO' petrol in the fuel tank may cause

damage to the petrol fuel pump.

Page 4 of 14

REFUELLING

Sedan vehicles are fitted with a 94 litre cylinder with a working capacity of 75 litre

and the Wagon is fitted with a 75 litre doughnut tank with a working capacity of 60

litres.

LPG or petrol may be added, regardless of the fuel selected.

NOTE: Observe the filling instructions and warnings displayed at the filling

station.

Petrol Refuelling

Refuel the vehicle in the normal manner. Refer to the vehicle operator's manual.

LPG Refuelling

Switch off the engine.

Remove the LPG filler cap.

Connect LPG filler nozzle and fully squeeze and hold trigger.

Release the trigger when it shuts off. The AFL (Automatic Fill Limiter) shuts

off the LPG flow when your vehicle's LPG cylinder is 80% full: this is to allow

for liquid expansion.

Disconnect the LPG filler nozzle.

Screw the LPG filler cap back on.

VEHICLE STORAGE

If the vehicle is to be stored for a prolonged period, turn off the Service Valve,

located on the LPG cylinder.

VEHICLE TRIP COMPUTER

The Distance to empty and Average speed/fuel modes are not available on dual

fuel vehicles. Refer to Standard Petrol Owner's Handbook for additional

information.

USING VEHICLE BOOT (SEDAN ONLY)

Please take care when placing heavy or sharp items in the vehicle boot as these

may cause damage to the LPG tank or vent pipes. Please see your

dealer if you notice damage to these items.

TOWING CAPACITIES

The maximum towing capacity of both sedan and wagon is 1600kg.

RADIO OPERATION

Vehicles fitted with Dual Fuel may show reduced radio reception at times.

Page 5 of 14

SERVICE AND MAINTENANCE

Scheduled Maintenance

All service and repair work must be performed by a properly trained specialist. If

the repair work involves opening the high-pressure LPG lines or associated

components to the atmosphere, this should also be carried out by an authorised

LPG technician and the work must be carried out to Australian Standard

AS/NZS1425:2003.

The following coupons cover additional service requirements for Holden dual

fuel vehicles.

State / Territory Regulations

Different states/territories may have additional service requirements. The

additional work should be carried out and noted on the service coupons.

LPG Cylinder

The LPG cylinder must be removed and pressure tested by an authorised LPG

cylinder test centre once every 10 years from the original test date stamped on a

plate attached to the cylinder.

Convertor

Check the 6 screws on the converter body are at the correct torque in accordance

with the service schedule coupons.

a. Use a dynamometric spanner to check the torque of the 6 screws and

tighten to 9 Nm if required.

LPG

Page 6 of 14

LPG Service Coupons

3,000km or 3 months service

High-pressure leak check including the following:

Converter screw torque settings (9 Nm follow on torque)

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

All mounting points for tightness

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

15,000km or 12 months service

High-pressure leak check including the following:

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

Page 7 of 14

LPG Service Coupons

30,000km or 24 months service

High-pressure leak check including the following:

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

45,000km or 36 months service

High-pressure leak check including the following:

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

Converter screw torque settings (9 Nm follow on torque)

Page 8 of 14

LPG Service Coupons

60,000km or 48 months service

High-pressure leak check including the following:

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

75,000km or 60 months service

High-pressure leak check including the following:

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

Page 9 of 14

LPG Service Coupons

90,000km or 72 months service

High-pressure leak check including the following:

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

105,000km or 84 months service

High-pressure leak check including the following:

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

Page 10 of 14

LPG Service Coupons

120,000km or 96 months service

High-pressure leak check including the following:

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Inspect LPG front liquid filter

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

135,000km or 108 months service

High-pressure leak check including the following:

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

Page 11 of 14

LPG Service Coupons

150,000km or 120 months service

High-pressure leak check including the following:

Converter and lock-off

All service line connections

Filler valve

LPG cylinder connections

Fuel selector operation

Replace LPG vapour filters

Date: ___ / ___ / ___ Kms ________________

Servicing Dealer:

_______________________

Warranty

New Vehicle Warranty Period. The LPG system is 3 years / 100,000 kms,

whichever comes first.

Page 12 of 14

Refer to your Holden Dealer for further information.

Holden Ltd

ABN 84 006 983 232

241 Salmon Street Port Melbourne

Victoria 3207 Australia

Subsidiary of General Motors Corp

All correspondence to:

PO Box 1714 Melbourne

Victoria 3001 Australia

Telephone (03) 9647 1111

Facsimile (03) 9647 2550

Please note that all information, illustrations and specifications in this Handbook are based

on the latest production information available at the time of printing.

Holden reserves the right to make any changes at any time without notice and without incurring any obligation.

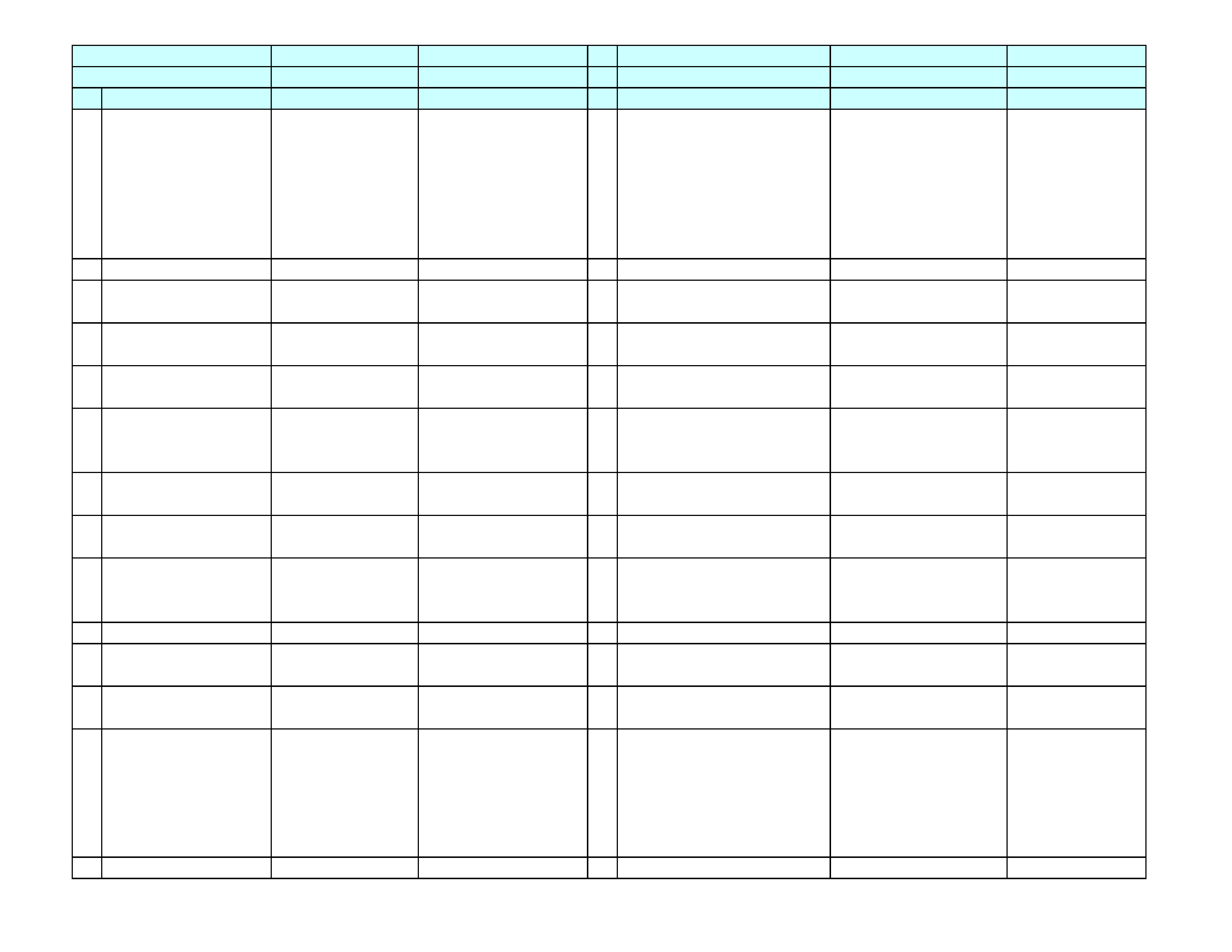

Fault Tree

Holden VZ Commodore Sequent 6 Cylinder

#S

y

m

p

toms Com

p

onents Faults .# Tests Results Action

1 Engine will not start Injector Harness Open circuit on

injector power line

1 Disconnect injector harness

from LPG harness and OEM

harness. Measure for

continuitiy between pin 1 on

the Petrol ECU connector

and pin 1 on Injector

connector

No continuity Replace injector

harness.

Continuit

y

N

o fault

LPG ECU Injector switches failed 2 Replace with known good

uni

t

Engine starts Replace unit

Engine does not start Replace main

harness

2 Engine runs in Petrol

onl

y

5A Fuse Blown 1 Check fuse continuity No continutity Replace fuse

Switch has no

illumination and no

b

ee

p

Continuity No fault

LPG ECU Switch drivers failed 2 Replace with known good

uni

t

Normal system

o

p

eration

Replace unit

No change in symptoms Replace main

harness

3 Engine runs in LPG

only

Switch has no

illumination and no

b

ee

p

Disconnected 1 Check connection on back of

switch

Not connected properly Connect and retest

Connected

p

ro

p

erl

y

Re

p

lace unit

LPG ECU Faulty switch circuitry 2 Install known good LPG

ECU

Symptom resolved Replace LPG ECU

Symptom persists Replace LPG

Main Harness

4 Engine stalls or

switches back to

Petrol. LPG is

selected. Fuel

indicator illuminates

RED.

Tank Contents empty 1 Inspect gauge at tank Showing empty Fill with LPG and

test again

N

ot showin

g

em

p

t

y

N

o fault

050801 Fault Tree.xls Page 1

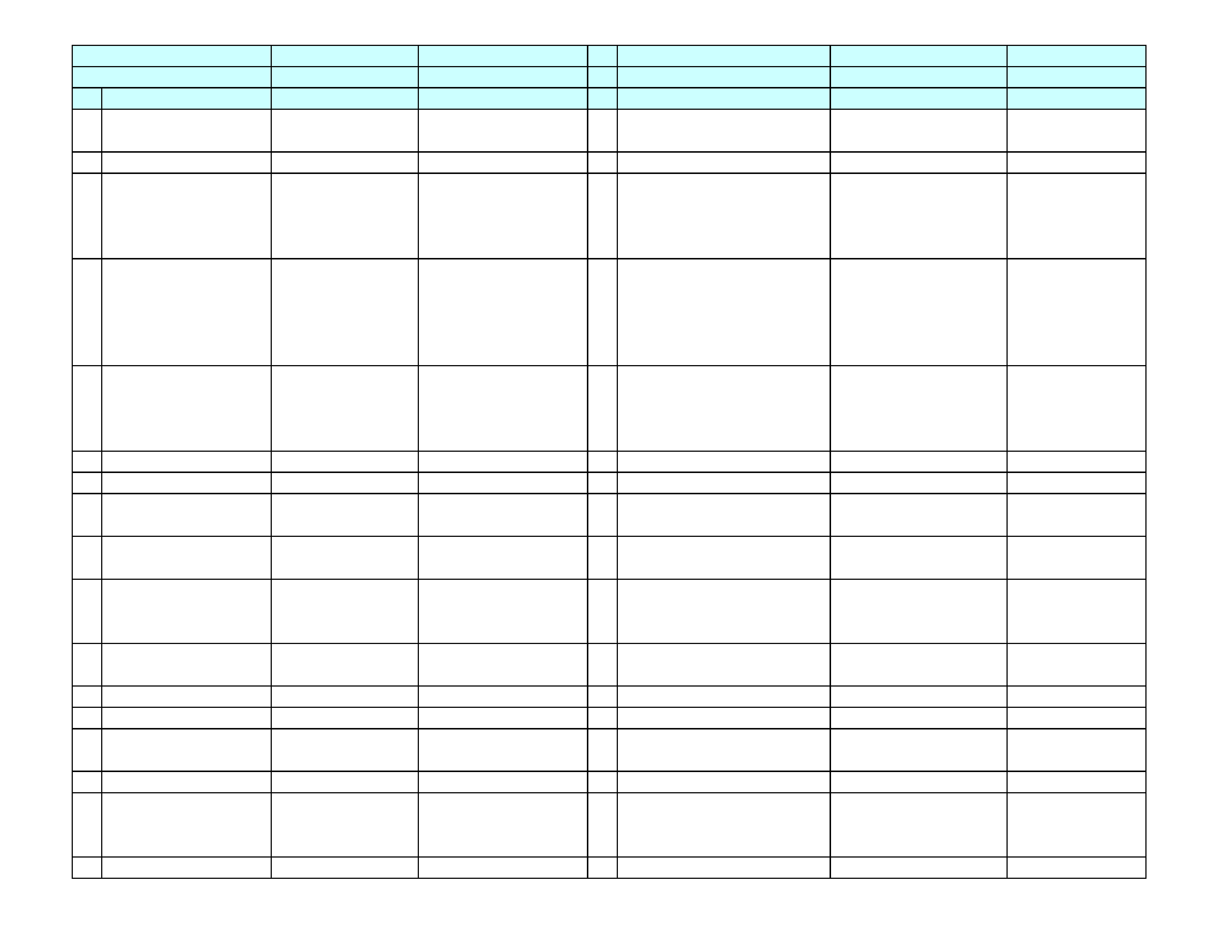

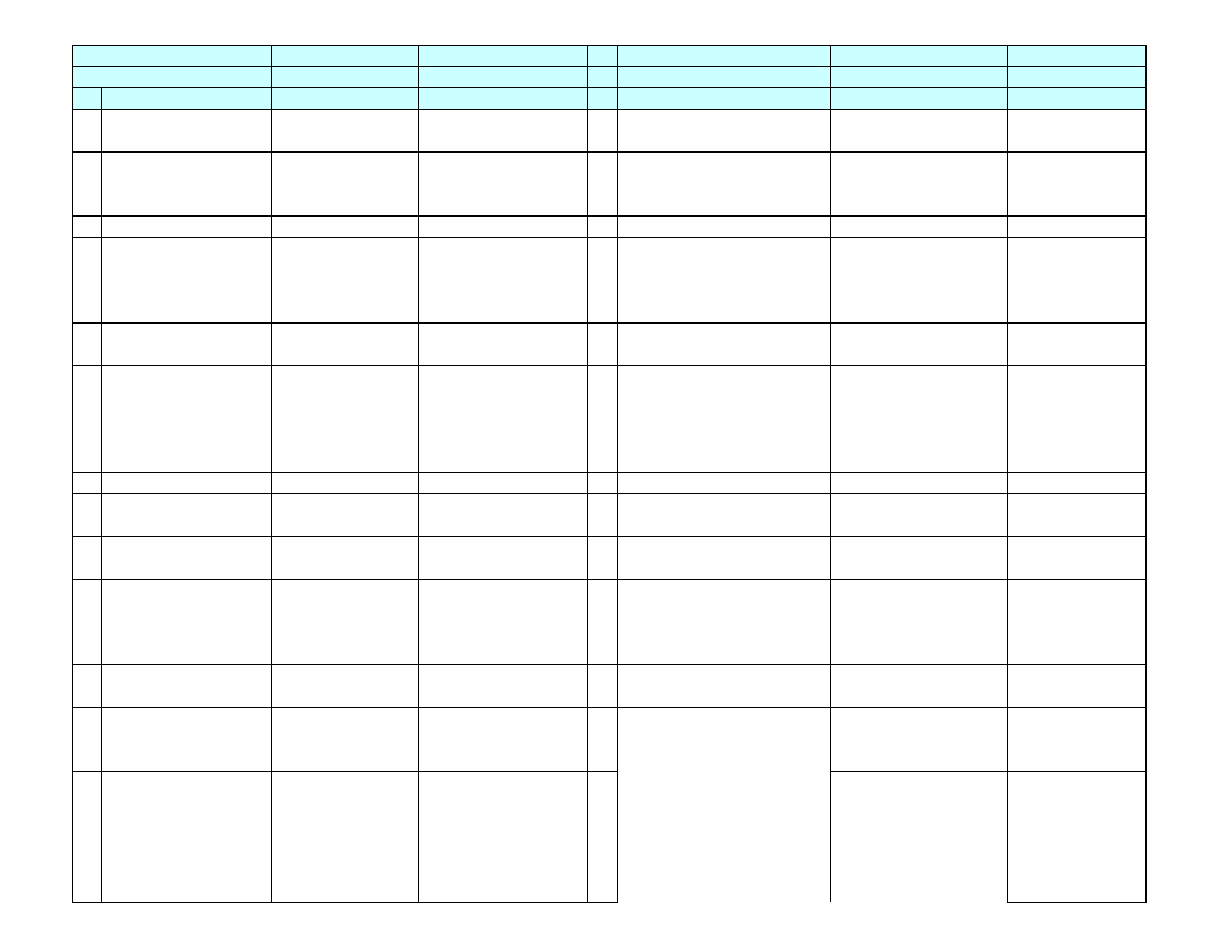

Fault Tree

Holden VZ Commodore Sequent 6 Cylinder

#S

y

m

p

toms Com

p

onents Faults .# Tests Results Action

Tank Manual Valve Closed 2 Turn valve counter-

clockwise to o

p

en

Does not open or fuel