Stationary Windows Page 1A6–1

Page 1A6–1

Section 1A6

Stationary Windows

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions And Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................2

2 Leak Correction, Bonded Windows......................................................................................................3

2.1 Minor Water Leak Correction................................................................................................................................ 3

3 Service Operations – Front ...................................................................................................................4

3.1 Windshield Assembly............................................................................................................................................ 4

Description............................................................................................................................................................. 4

Preparation............................................................................................................................................................. 5

Remove................................................................................................................................................................... 5

Reinstall – Short Method....................................................................................................................................... 7

Description ......................................................................................................................................................... 7

Preparation......................................................................................................................................................... 7

Reinstall ............................................................................................................................................................. 8

Reinstall – Long Method ..................................................................................................................................... 11

Description ....................................................................................................................................................... 11

Preparation....................................................................................................................................................... 12

Reinstall ........................................................................................................................................................... 13

4 Service Operations – Side...................................................................................................................17

4.1 Quarter Window Assembly................................................................................................................................. 17

Preparation........................................................................................................................................................... 17

Remove................................................................................................................................................................. 17

Reinstall................................................................................................................................................................ 19

5 Service Operations – Rear...................................................................................................................20

5.1 Rear Window Assembly...................................................................................................................................... 20

Description........................................................................................................................................................... 20

Preparation........................................................................................................................................................... 20

Remove................................................................................................................................................................. 21

Reinstall – Short Method..................................................................................................................................... 23

Description ....................................................................................................................................................... 23

Preparation....................................................................................................................................................... 23

Reinstall ........................................................................................................................................................... 24

Reinstall – Long Method ..................................................................................................................................... 26

Description ....................................................................................................................................................... 26

Preparation....................................................................................................................................................... 27

Reinstall ........................................................................................................................................................... 28

5.2 Rear Window Lower Finisher .............................................................................................................................. 31

Remove................................................................................................................................................................. 31

Reinstall................................................................................................................................................................ 31

6 Special Tools ........................................................................................................................................32

7 Torque Wrench Specifications............................................................................................................33

Techline

Stationary Windows Page 1A6–2

Page 1A6–2

1 General Information

The windshield plays an important role in

occupant protection by supporting the

passenger airbag during deployment.

Therefore, it is imperative the procedures in

this Section are correctly followed, as

incorrect installation may lead to injury or

death.

This Section describes the procedures to remove and reinstall the windshield assembly, rear window assembly, rear

window lower finisher and quarter window. Also described is a procedure to repair minor leaks to urethane bonded

windows.

The w i nd s h ie l d as se mb l y i s ma n u fa c t ur e d fr om l a mi n a ted g lass and h a s a ti n te d up per ba n d . Toughened safety glass is

used for all other windows.

The windshield assembly, rear wi n d ow ass e m b ly and li f t g a te windo w assembly a r e bonded to the vehicle body window

opening with ure th ane adhesive.

The quarter window assembl y is attached to the vehicle using plastic nuts. A self adhesive foam weatherstrip is affixed to

the glass to seal the windo w opening. The nuts should be replaced after removal to maintain an effective weather seal.

The rear window is surrounde d by a one-piece rubber weatherstrip. The join is on the v ertical centre lin e at the base of

the window assembly.

A moulded plastic finisher is fitted between the rear window weatherstrip and the rear compartment lid weatherstrip.

For replacement of urethane bon de d windows, urethane service ki ts have been dev eloped and must be used to maintain

original installation requirem ents. Two different installation methods can be used when replacing the windshield

assembly or rear window assembly:

• Short Method: involves partial removal of the urethane. It is to be used when the original urethane remaining o n the

window opening flanges after the window removal can be used as a base for the new window. This method would

be used where replacement of cracked windshields or removal of intact windo ws is required. The amount of

urethane left in the window openi ng can be controlled duri ng window removal. It is recommend to leave the

maximum amount of original urethane intact on the body opening flange.

• Long Method: involves complete removal of the urethane. It is to be used when the original urethane remaining on

the window opening flanges af ter the window removal cannot serve as a base for t he replacement window. This

method would be used in cas es nee ding metal work and / or paint refinishing in the window opening or in cases

where the window has been pr eviously replaced using the s hort method. In such instances, the build up of

urethane could position the window too high in the body opening. In these cases, the original urethane must be

completely removed and replac ed with new urethane follo wing the long me thod window installation.

The windshield and rear window are structural members of the vehicle. Once the urethane adhesive cures, they aid

vehicle rigidity.

For service procedures related to the rear door fixed window, refer to Section 1A5 Front and Rear Assemblies.

Stationary Windows Page 1A6–3

Page 1A6–3

2 Leak Correction, Bonded

Windows

LT Section No. — 11–020

Safety glasses an d work glo ves must be w orn

at all times when operating with glass.

NOTE

Only use urethane adhesive Betaseal 15685 or

equivalent for water leak correction on bonded

windows.

2.1 Minor Water Leak Correction

1 Secure protective covering with masking tape adjacent

to the suspect leak area

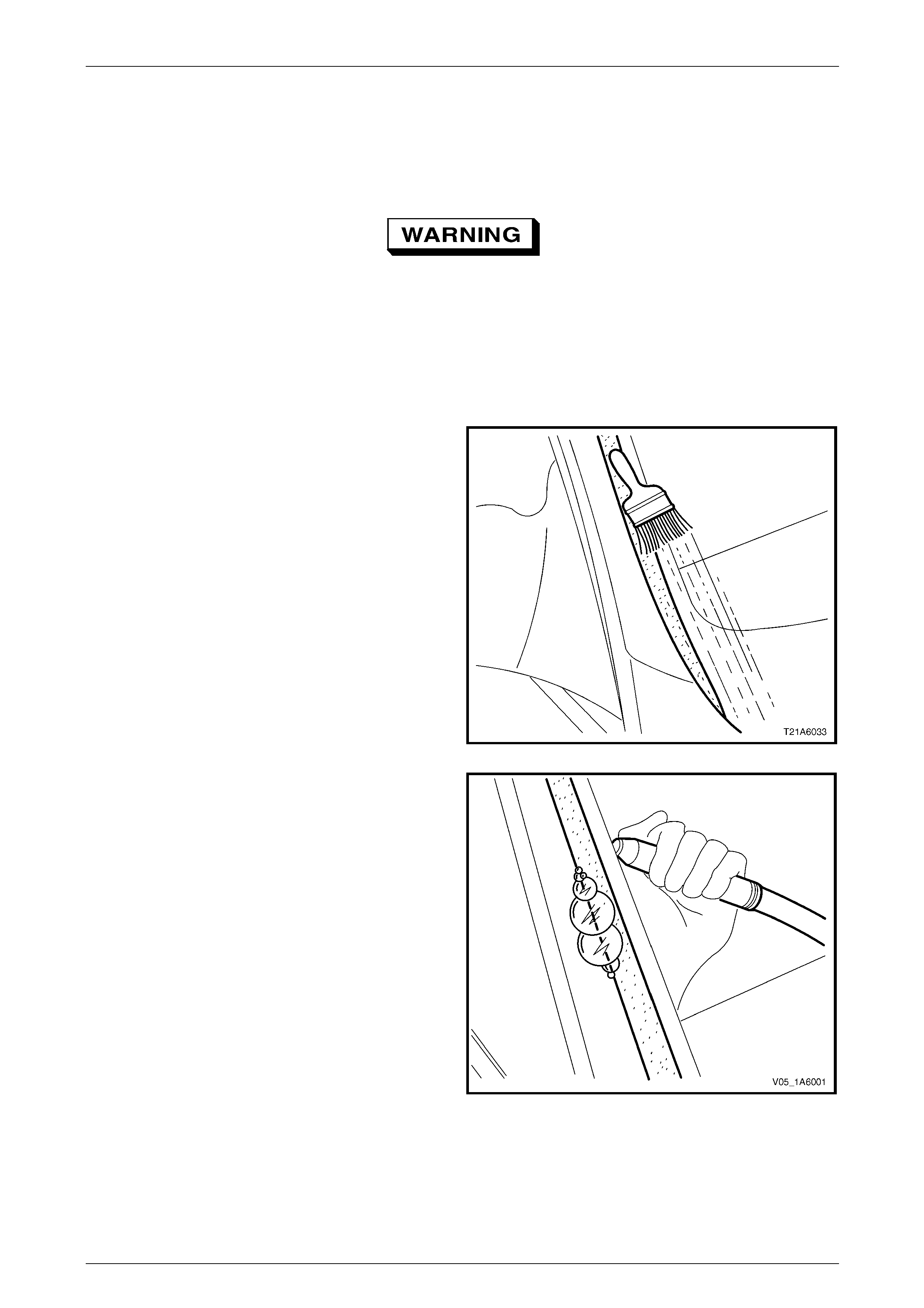

2 To determine the precise loc ation of the leak, use the

air and soap bubble leak test. T he soap and water

solution can be applied with either a spray applicator

or brush.

Figure 1A6 – 1

3 Place an air-hose nozzle on the inside of the

windshield or rear window assembly. Have an

assistant outside the vehicle apply a soapy water

solution opposit e the air source. As a low air pressure

(60 kPa) is applied, soap bubbles will form on the

outside of the window, indicating the location of the

leak.

4 If the suspect leak area is not obvious, commence the

testing across the top and down the sides until the

leak location has been determined.

5 Using a spatula, work fresh urethane such a s Betaseal

15685 or equivalent, in and around the leak area.

NOTE

It is only necessary to remove dust and foreign

matter, as water activates the curing process of

urethane.

6 Leak test the repair, using the air and soap bubble

leak test or apply a moderate spray of water.

7 Remove the masking tape and protective covers, then

clean the windo w assembly a nd adjacent paint and

trim surfaces.

Figure 1A6 – 2

Stationary Windows Page 1A6–4

Page 1A6–4

3 Service Operations – Front

3.1 Windshield Assembly

LT Section No. — 11–020

Safety glasses an d work glo ves must be w orn

at all times when operating with glass.

The windshield plays an important role in

occupant protection by supporting the

passenger airbag during deployment. It is

imperative the procedures in this Section for

replacing bonded windows are followed.

Incorrect installation may lead to injury or

death.

Care should be taken to ensure the

windshield does not strike the windshield

opening or any other object. Chipped edges

can lead to subsequent breakage of the

windshield.

NOTE

• Only use urethane adh esive such as Betaseal

15685 or equivalent.

• Skinning (partial curing) of the urethane

commences after exposure to the

atmosphere. At 23 degrees Celsius and 50

percent relative humidity, skinning

commences after 30 minutes. Complete

curing of the urethane at this temperature an d

humidity takes 72 hours.

• Urethane service kits are available from most

windshield agents. Manufacturer’s instruction s

should always be foll owed.

• Window assemblies should be installed in the

window opening within five minutes of the

application of urethane.

Description

The windshield assembly rem oval procedure is the same for both the short and long installation methods, with one

exception. If the short method installation is to be used, care must be taken during the windshield removal to ensure that

an even surface of the original remaining urethane exists in the body opening. This is required to serve as a base for the

new urethane bea d and the replacement windshield.

Stationary Windows Page 1A6–5

Page 1A6–5

Preparation

Prevent damage to the paint finish and

minimise clean up by using protective covers

and masking tape over the regions adjacent

to the windshield.

As required, remove the following compo nents:

1 Windshield wiper arm assembly and plenum cover assembly, refer to Section 12N Wipers, Washers and Horn.

2 Instrument panel end cap covers, and the windshield defroster grille assembly,

refer to Section 1A3 Instrument Panel and Consol e.

3 Windshield side garnish, refer to Section 1A8 Headlining and Interior Trim.

4 Internal rear-view mirror, refer to Section 12H Rear-view Mirrors.

Remove

NOTE

• All vehicles have a keyless entry control

module installed between the left and right-

hand windshield defroster grille assembly on

the instrument panel. It is not necessary to

remove the module, however take care to

avoid damage to it during windshield removal.

• To remove the windshield or rear window

special tool J36020 is required. Alternately

manufacture an equivalent tool. Refer to

6 Special Tools.

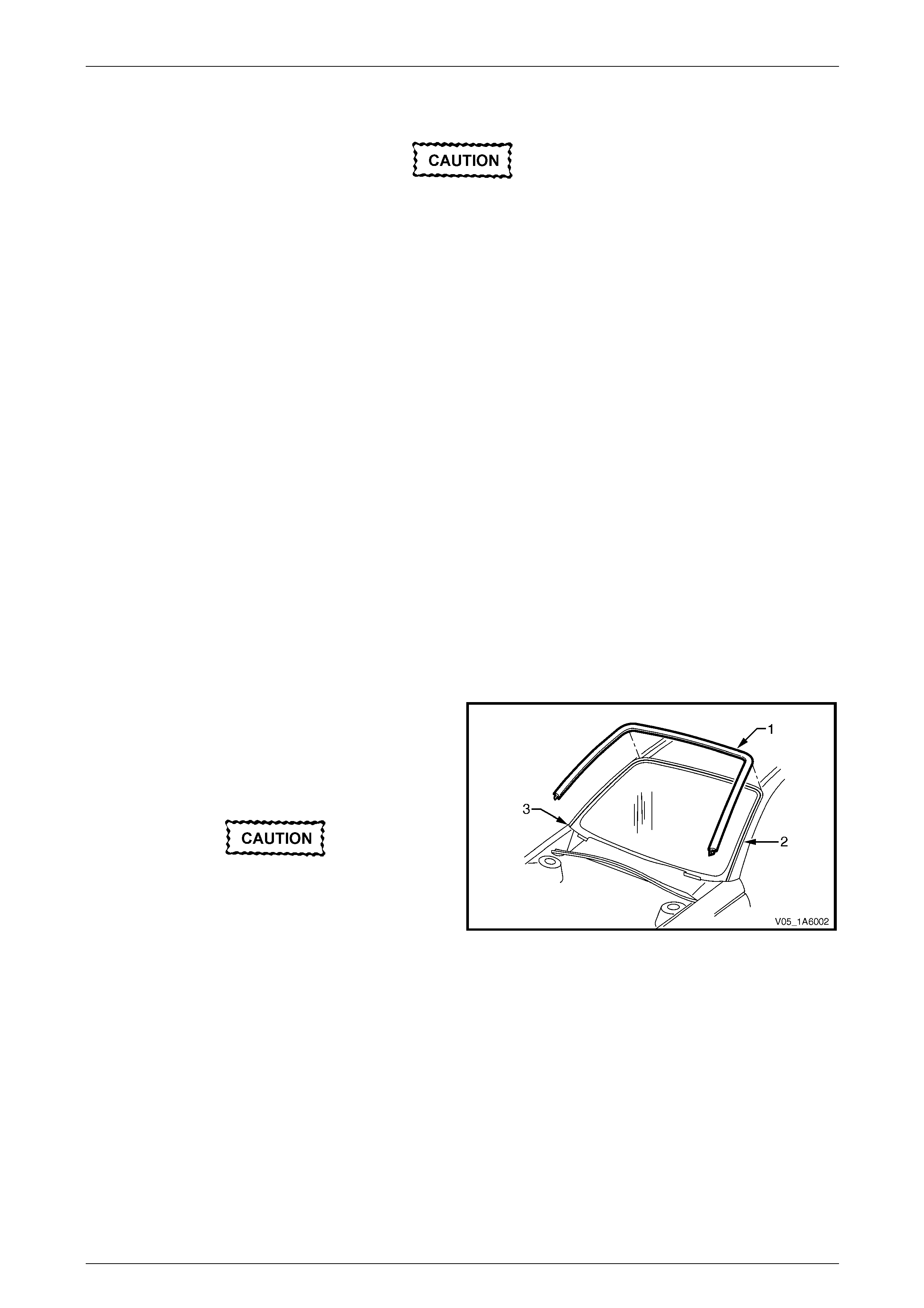

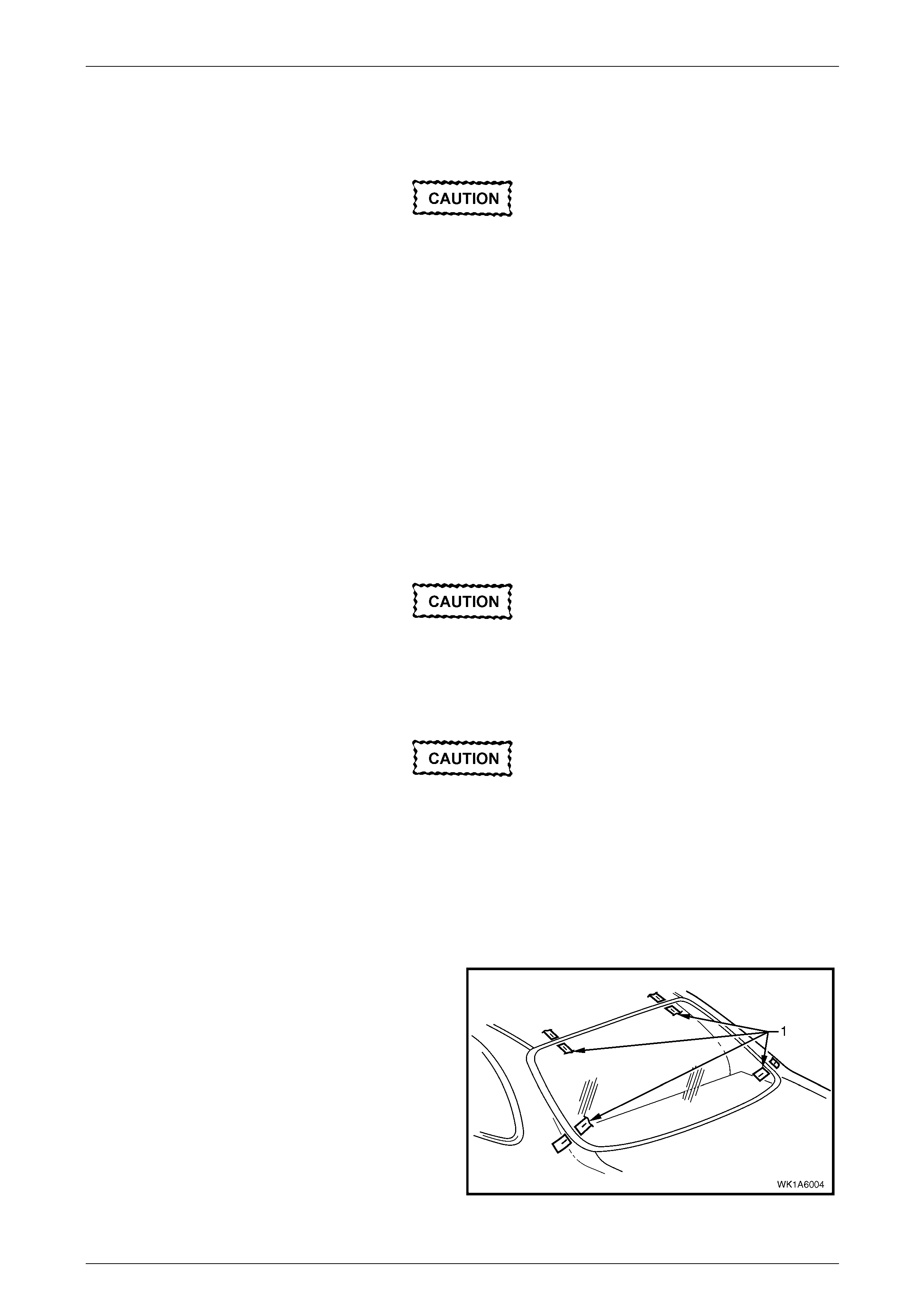

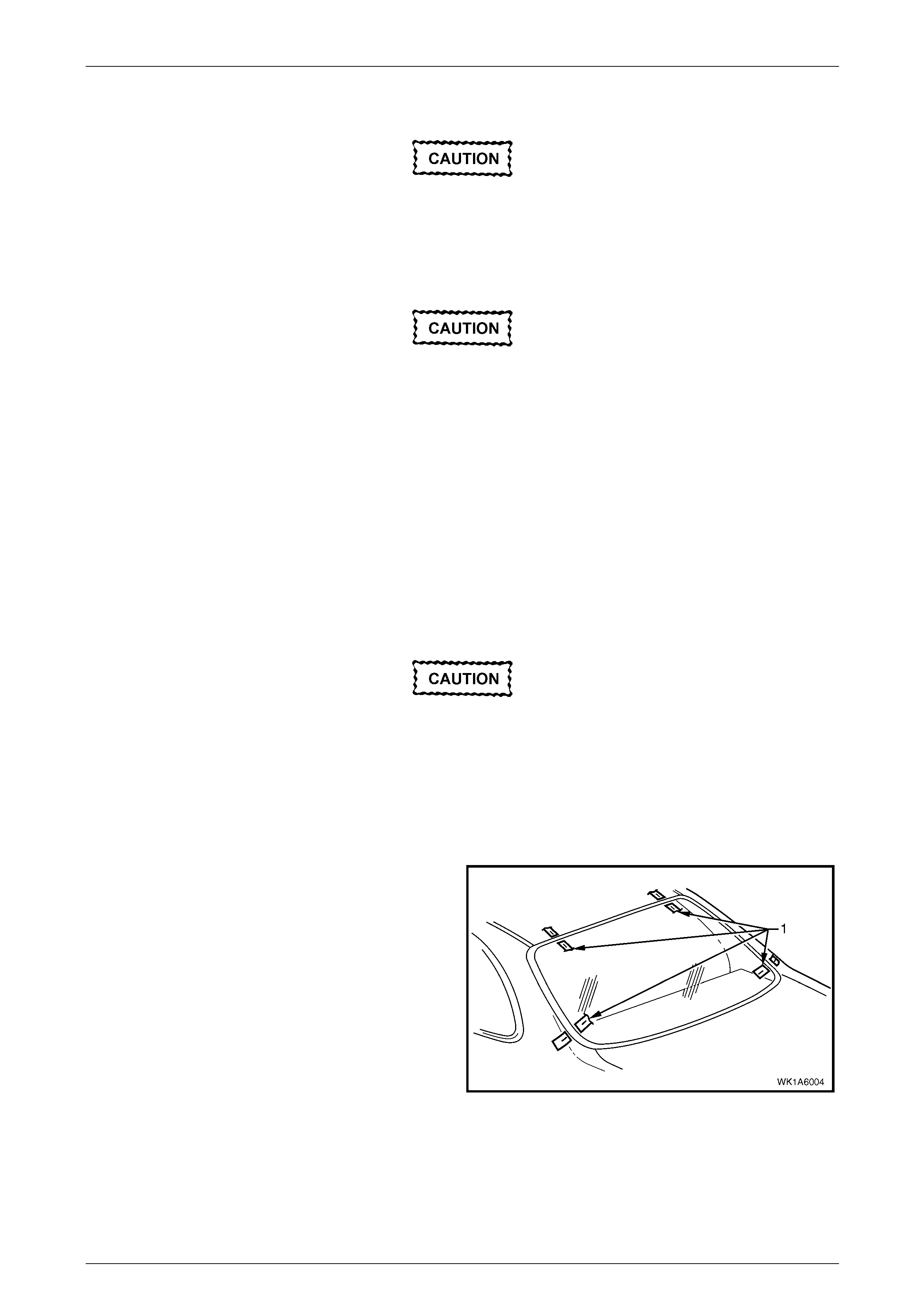

1 Remove the windshield reve al moulding (1) by pulling

the moulding from the windshield opening (2) . Start at

the lower corner (3) and work around the windshield.

2 If the windshield is broken, take care to remove all

fragments of glass from the windshield opening.

Ensure the headlining and other trim items

are not damaged while cutting the urethane.

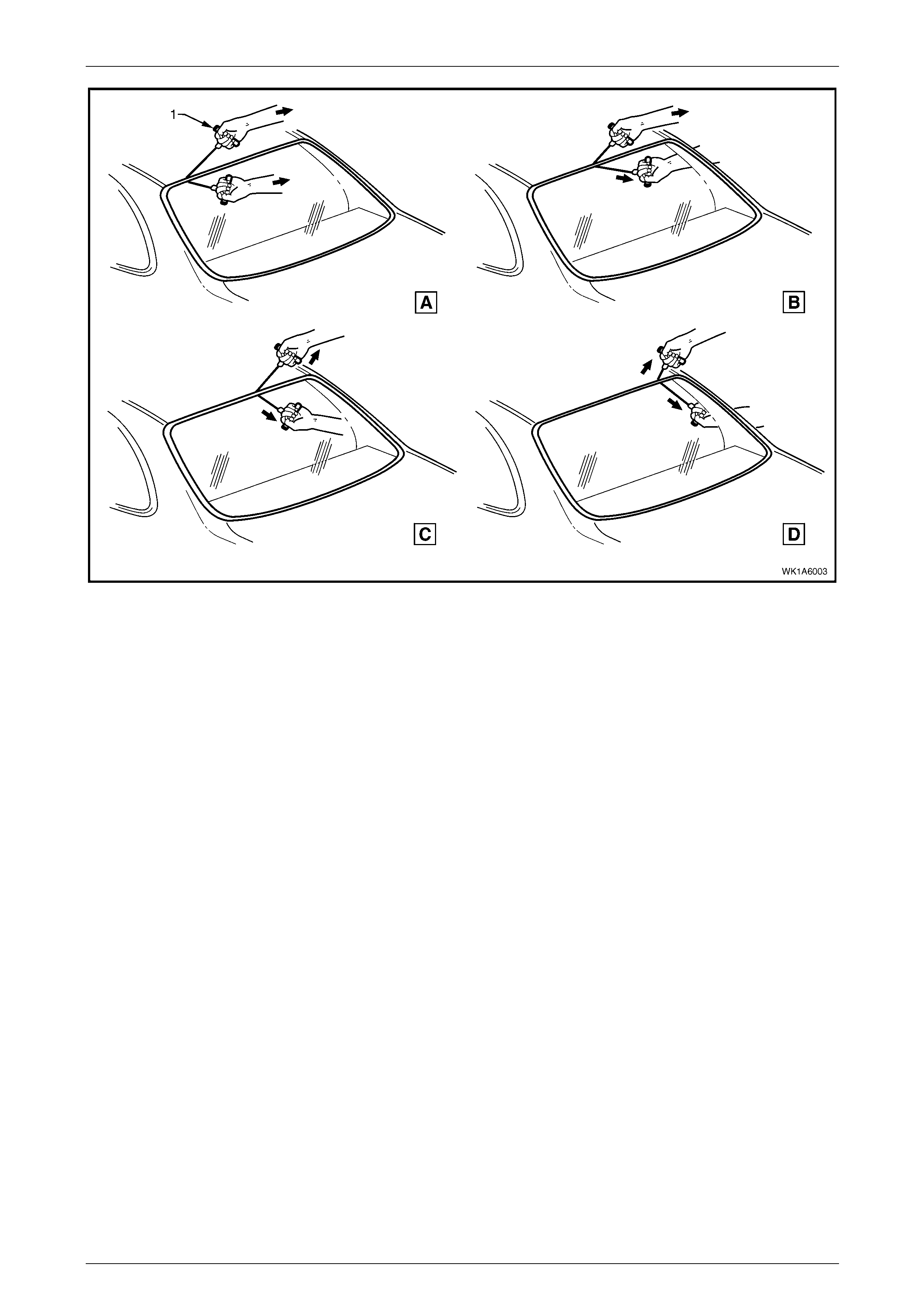

3 Use special tool J36020, or equiv alent, thread one end

of the piano wire through the urethan e, starting at the

windshield upper corner. Pull the end of the piano wire

through with pliers.

Figure 1A6 – 3

4 Connect the end of the piano wire to the other han dle of the special tool or equivale nt.

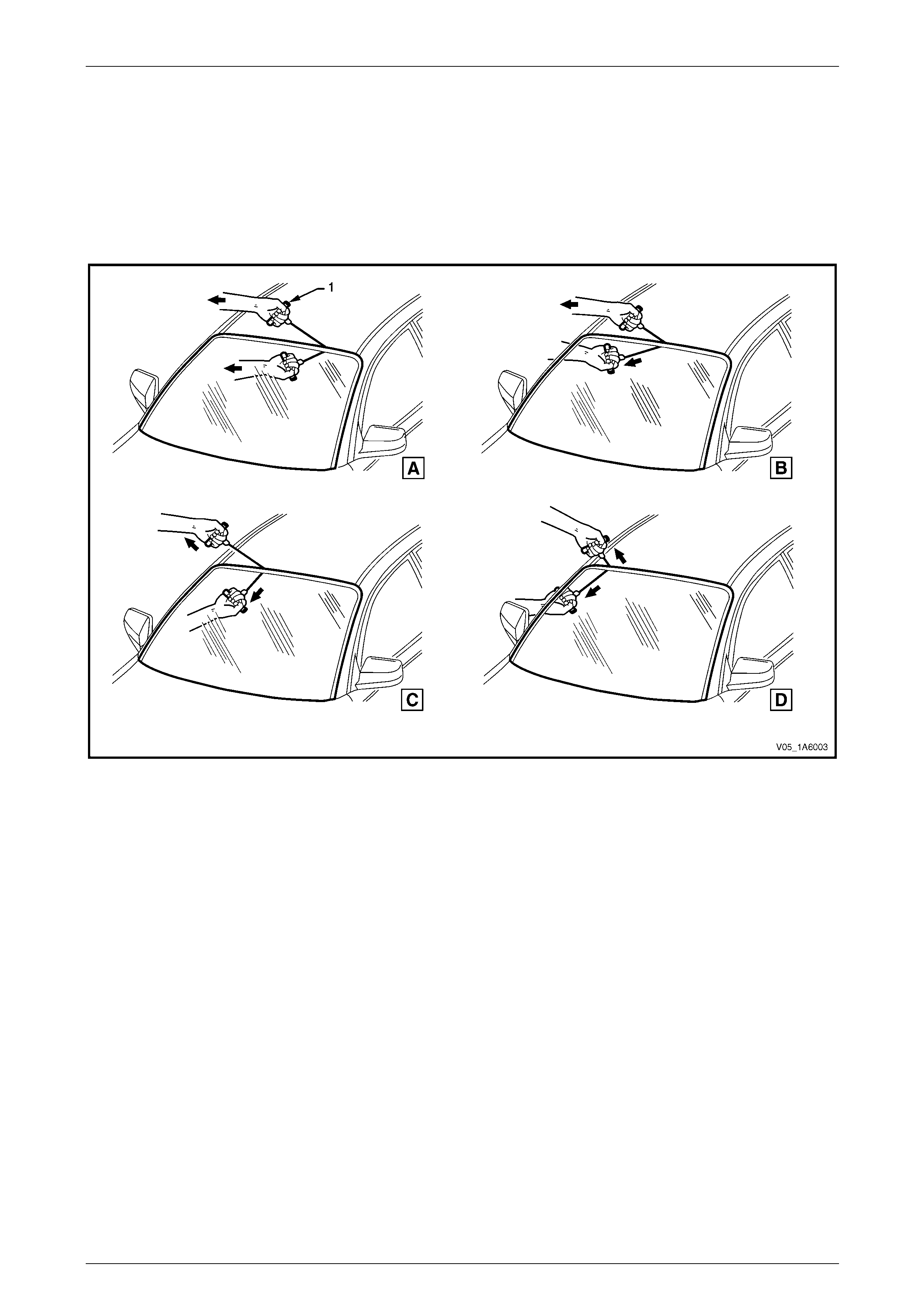

5 With the aid of an assistant, commence cutting the urethane bead. Keep the outsi de handle (1) parallel to the edge

of the windshield. Use the full len gth of the wire to prevent heat build up in the wire, refer to Figure 1A6 – 4.

Stationary Windows Page 1A6–6

Page 1A6–6

NOTE

To minimise the damage to the interior of the

vehicle, the operator inside th e vehicle should act

as an anchor point and hold the T-handle as

close as possible to the windshield at all times

(especially along the lower edge of the

windshield). The outside operator should pull the

wire up to the interior T-handle in a walking

motion.

Figure 1A6 – 4

6 Carefully lift the windshield o ut of the bod y opening. If there is evidence of the windshield adhering to the urethane,

cut the area again with the piano wire.

7 Remove the two windshield locators from the windshield reinforcing flange , refer to Figure 1A6 – 5. Retain for

reinstallation of the windshield.

8 If the original windshield is to be insta lled again, place the windshield on a clean protected surface or a holding

fixture.

NOTE

• The use of suction cu ps will greatly assist an y

handling of the windshield.

• All traces of urethane must be removed from

the windshield. It is not necessary to remove

all traces of the original urethane from the

body opening, unless the long method of

reinstallation is being used. However, any

original urethane remaining must be smooth

and firm.

Stationary Windows Page 1A6–7

Page 1A6–7

Reinstall – Short Method

Description

Throughout the curing period, ensure the

door windows are partially lowered to

eliminate pressure build-up which can be

caused by slamming doors. A curing time of

24 hours is recommended, although the

vehicle may be driven after five hours

providing it is driven only on a smooth road at

speeds not exceeding 80 km/h with the door

windows partially lowered.

• The short method is recommended when replacing a cracked or broken windshield, or a leak condition that cannot

be overcome by using minor water le ak repair procedures.

• The short method installation i nvolves leaving the maximum amount of the original urethane intact on the body

opening to form a sound base for the replacement urethane and windshield. Any original urethane remaining must

be smooth and firm.

• If material other than urethane has been used for previous servicing of the windshield, the long method installation

procedure (complete removal of adhesive) is mandatory to achieve an effective window to metal bond.

Preparation

Care should be taken to ensure the

windshield does not strike the windshield

opening or any other object. Chipped edges

can lead to subsequent breakage of the

windshield.

Do not use petro leum based sol vents to clean

any part of the window assembly or body

opening as the presence of oil in the solvent

will pre vent th e adhesion of the n ew urethane.

1 Use a sharp scraper to carefully remove an y origina l urethane from around the windshield. Clean the windshield to

be installed with a suitable o il free cleaning agent.

Stationary Windows Page 1A6–8

Page 1A6–8

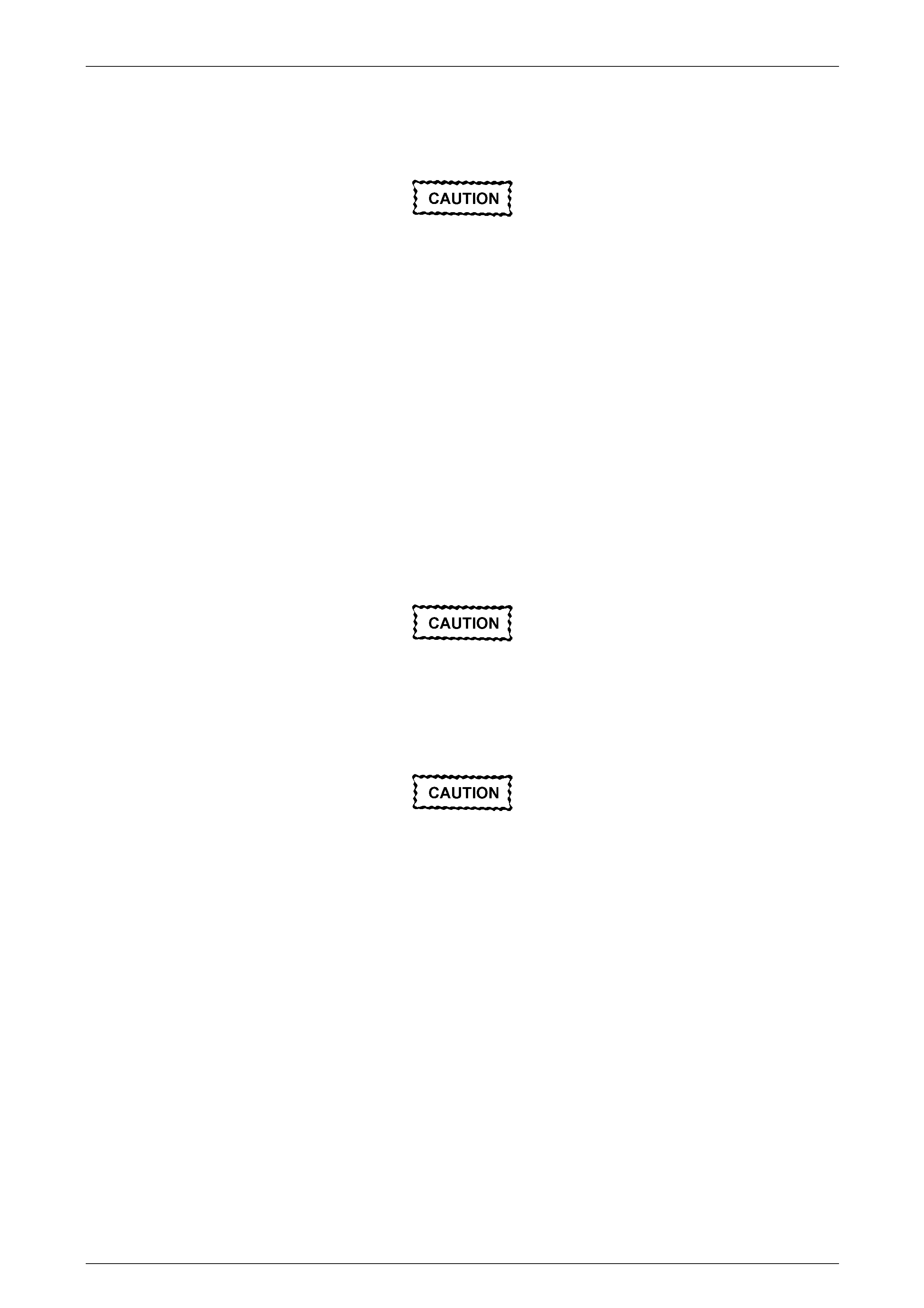

2 Check for correct alignment of the windshield by

temporarily pla c ing the windshield in the body

opening. Fit the windshield locator (1) between the

lower windshield edge (2) and the reinforcing flange

(3).

3 Ensure the windshield is centralised in the body

opening left to right by checking the gaps between the

windshield and body opening are eve n on both sides

of the vehicle.

4 With masking tape (4), mark the outer top and side of

the windshield pillar and the roof.

NOTE

This procedure will assist in the alignment of the

windshield in the correct horizontal and vertical

plane during final windshield installation.

5 Remove and place the windshield face down on a

clean protected surface or fixture.

Figure 1A6 – 5

Reinstall

Do not use petro leum based sol vents to clean

any part of the window assembly, or body

opening as the presence of oil in the solvent

will pre vent th e adhesion of the n ew urethane.

1 Thoroughly clean the inner surface and edges of the

windshield to which the ur ethane is to be applied. Use

a clean lint-free cloth and a suitable oil free cleaning

solvent.

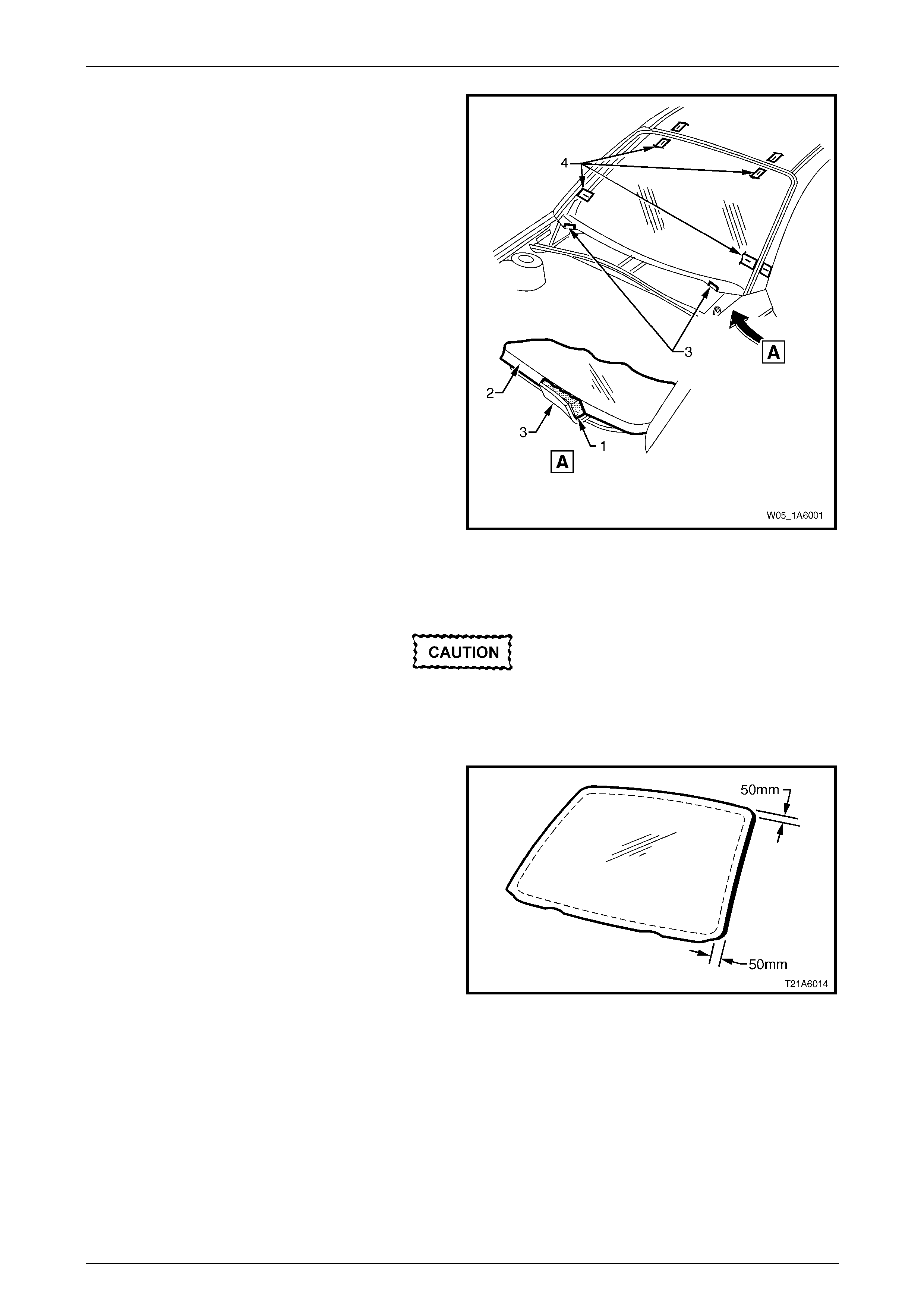

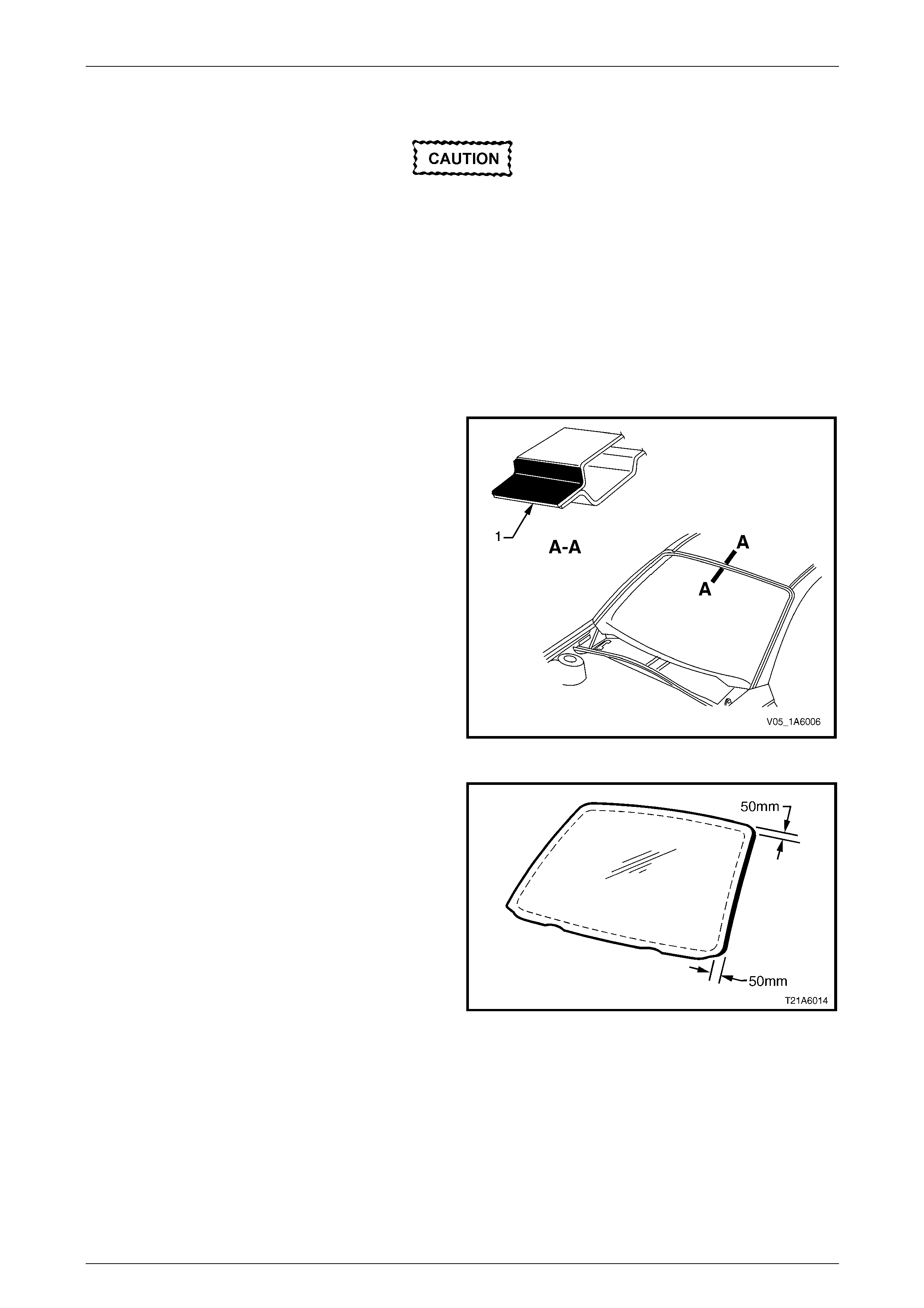

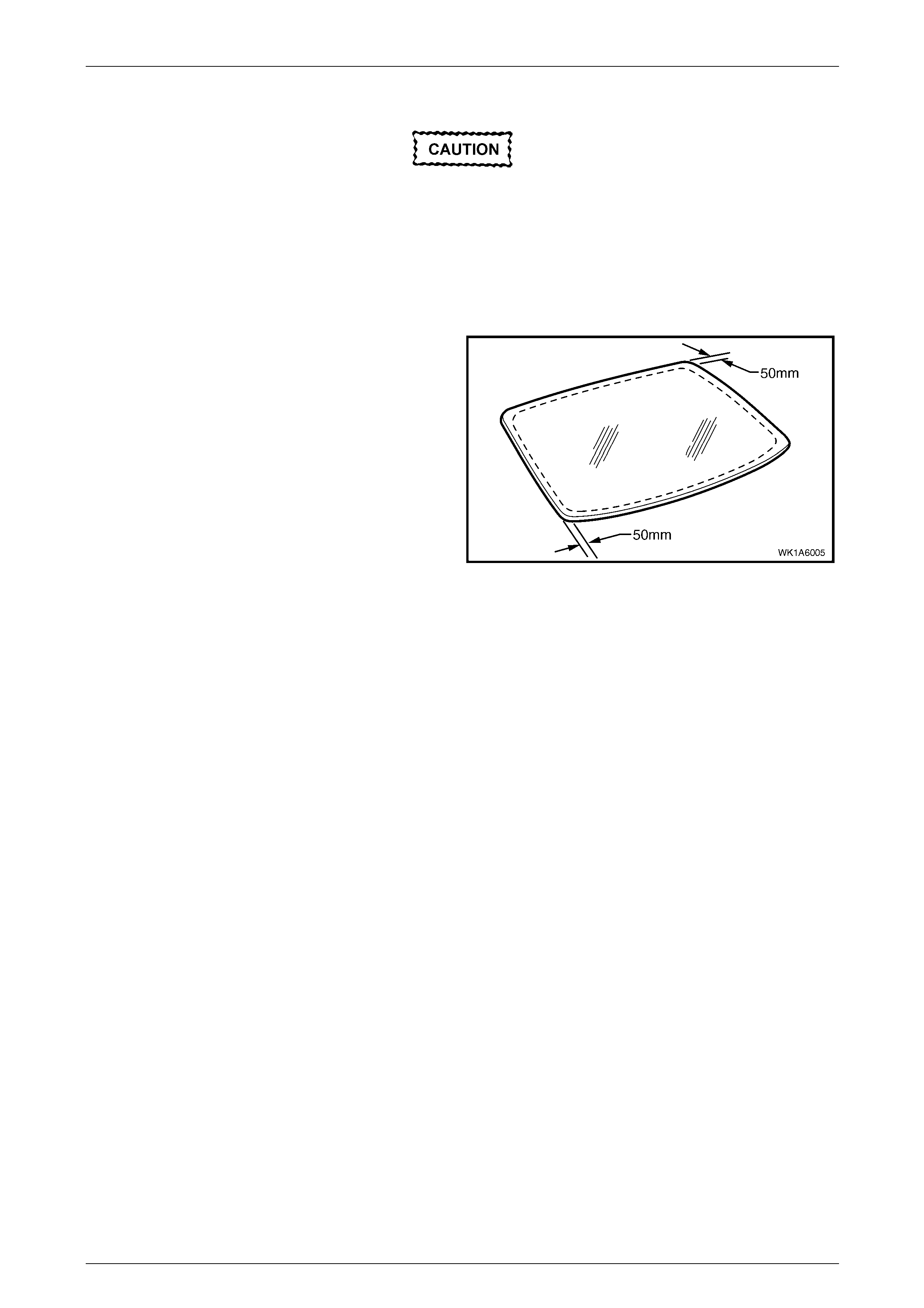

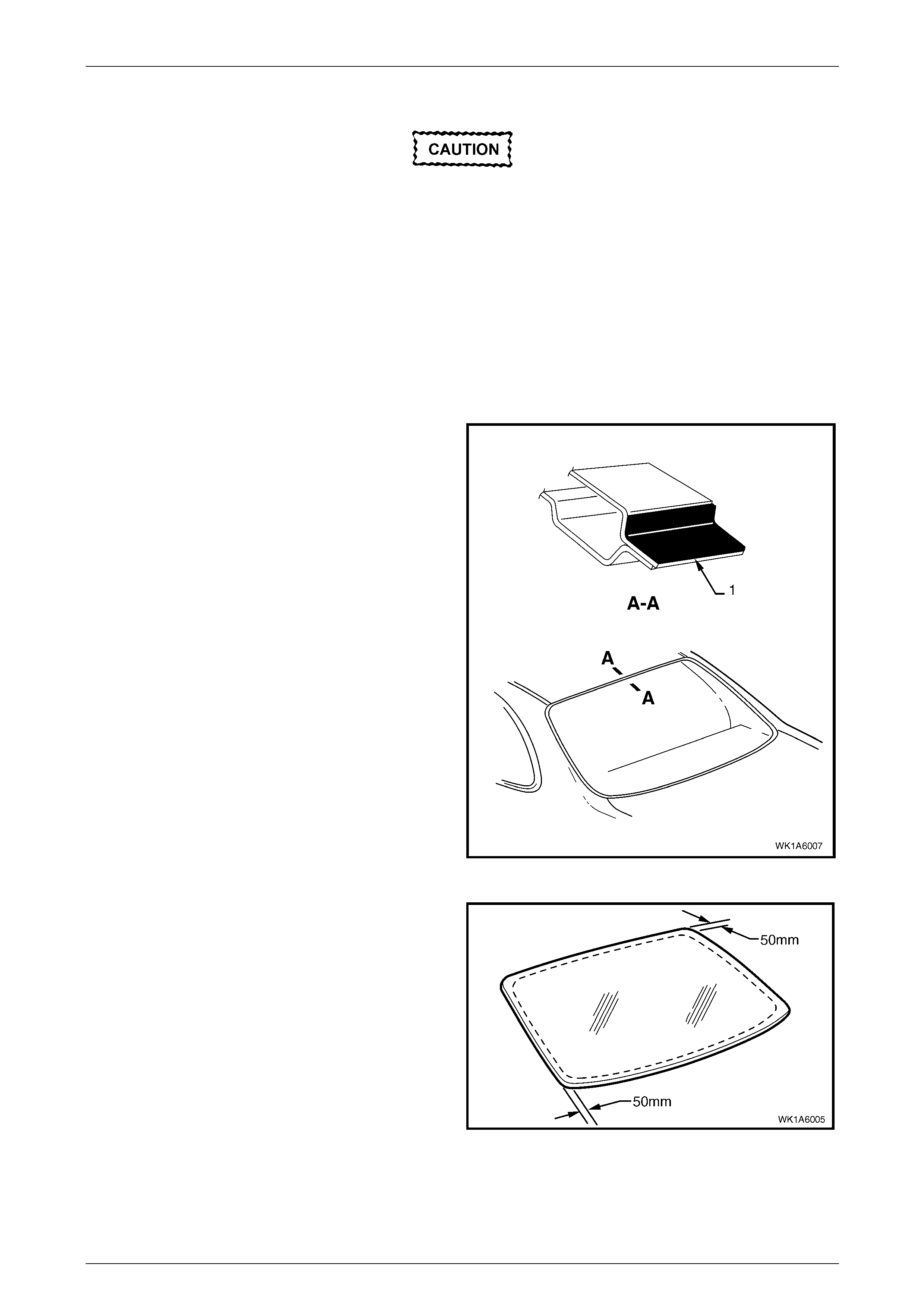

2 Apply a 50 mm wide layer of clear glass primer, to the

inner surface of the windshield's perimeter.

Immediately wipe off with a lint-free cloth.

Figure 1A6 – 6

Stationary Windows Page 1A6–9

Page 1A6–9

3 Check the condition of the windshiel d reveal moulding

assembly (1). Discard and replace with a new

moulding if damaged.

4 Fit the moulding to the sides and upper section of the

windshield. Ensure the notch of the moulding (2) is

aligned with the V locating mark (3) on the lower

portion of the right-hand and the left-hand side of the

windshield.

5 Check the condition of the original urethane around

the windshield opening flange for voids or looseness.

6 Cut away any loose pieces of urethane.

7 Using a suitable spatula, spre ad fresh urethane

smoothly into any voids or uneven sections.

Figure 1A6 – 7

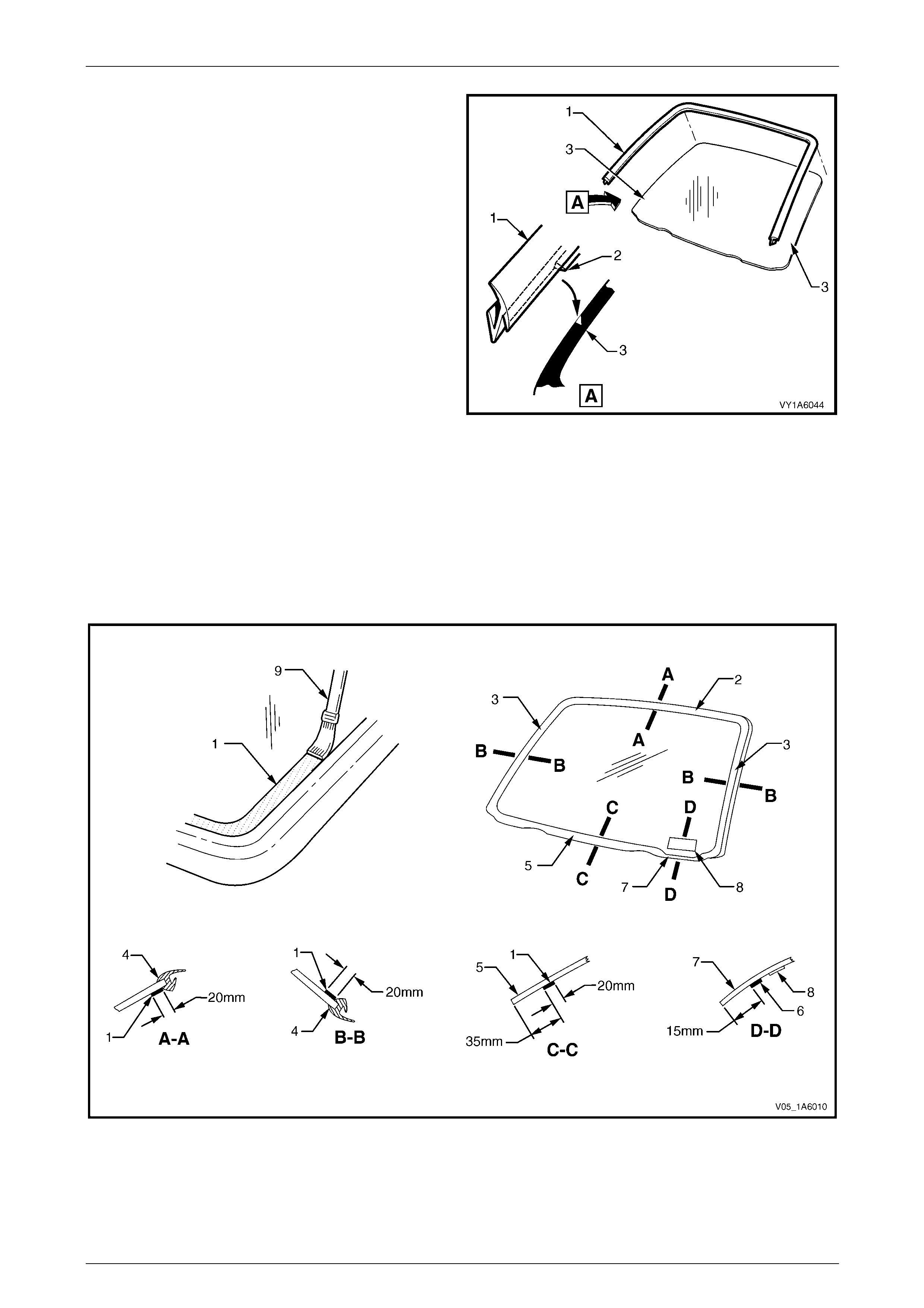

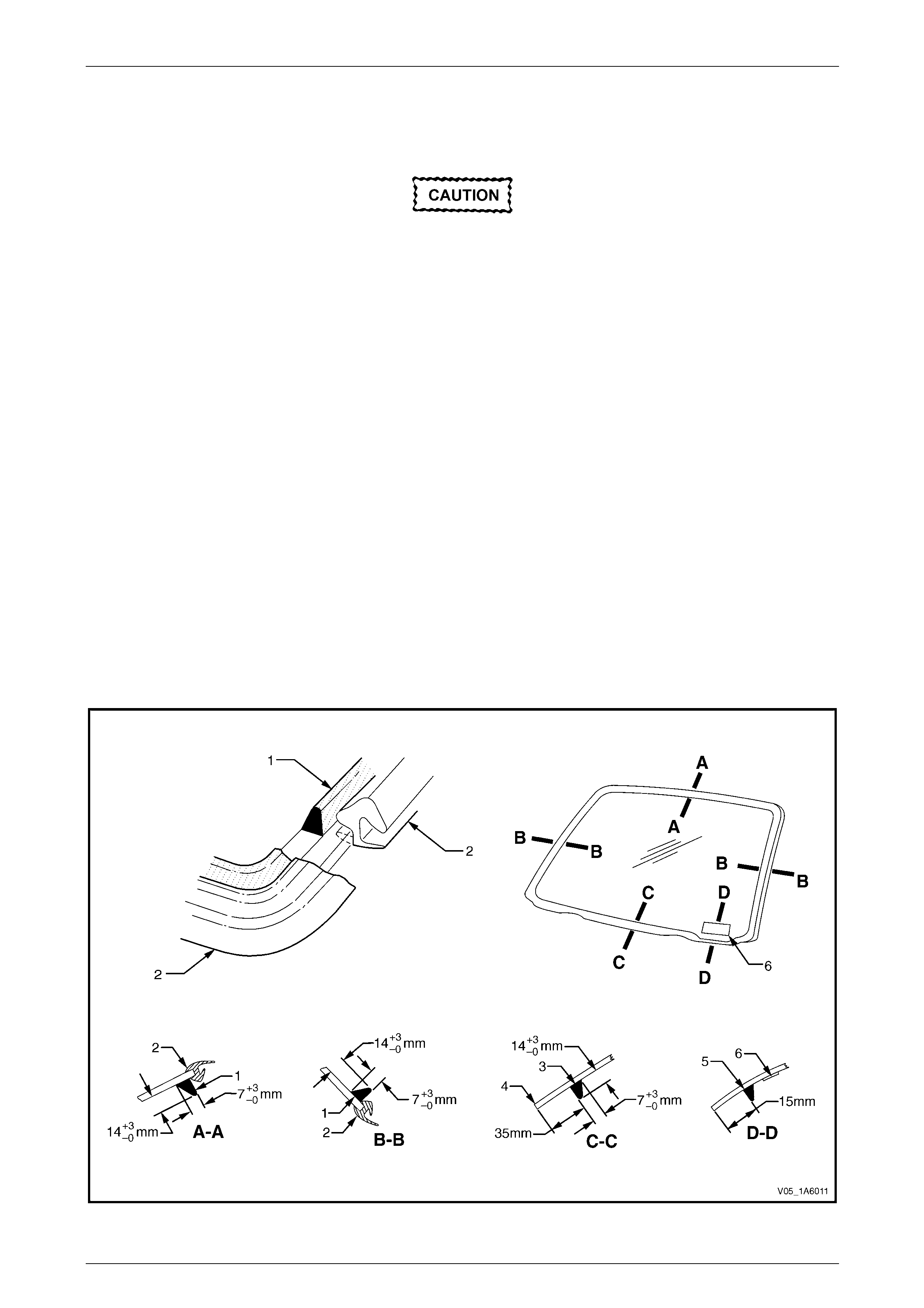

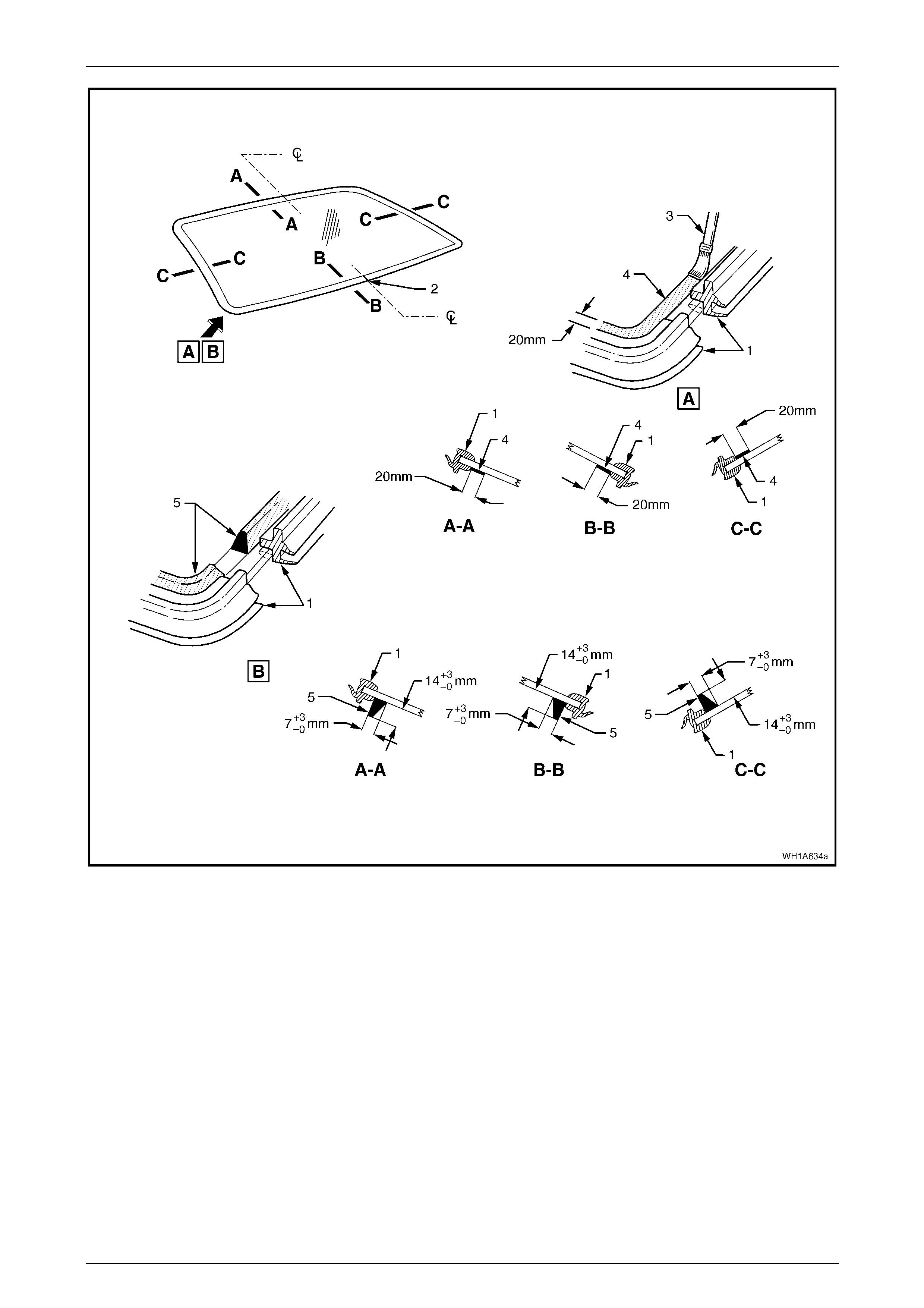

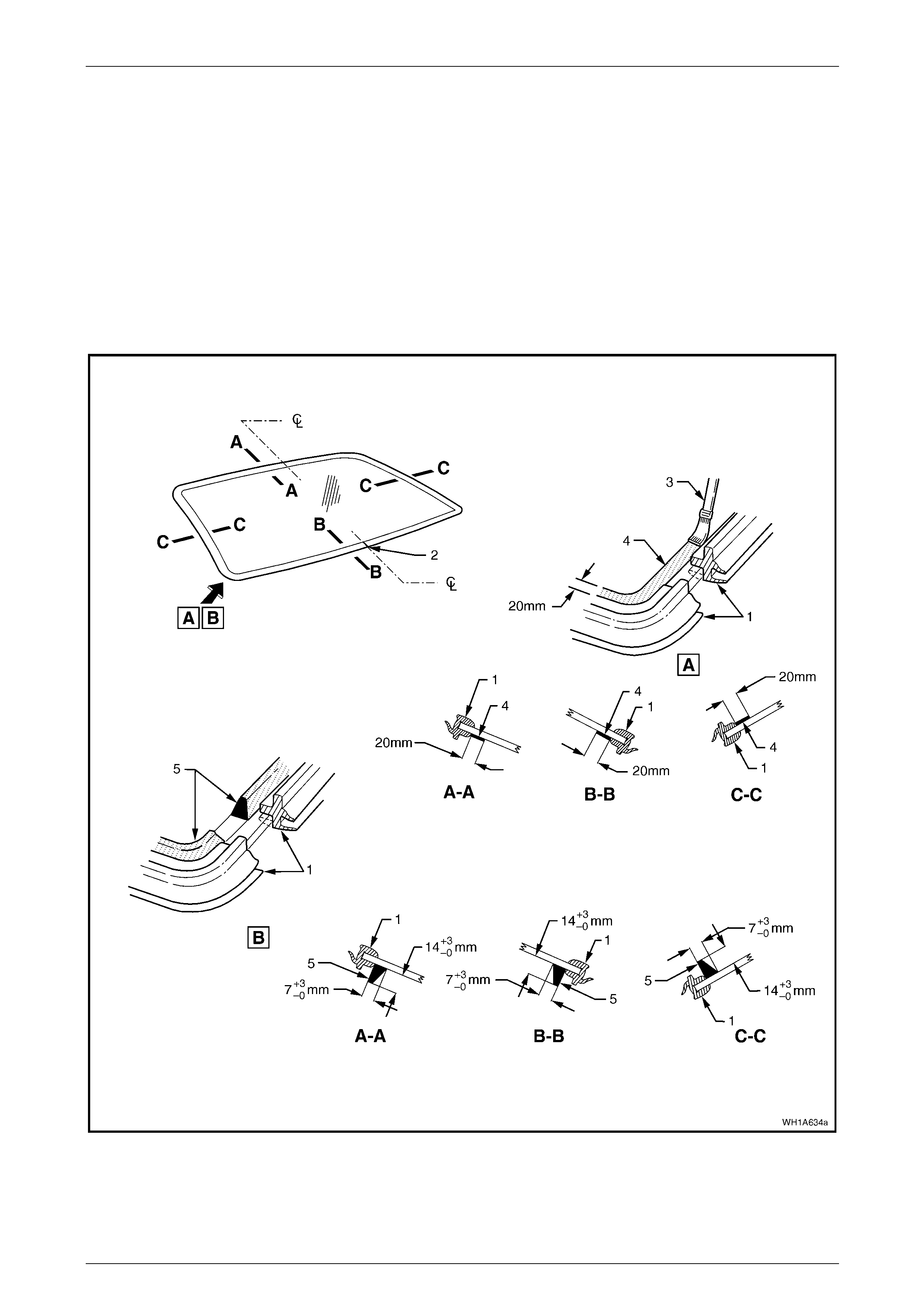

8 Referring to Figure 1A6 – 8, apply a 20 mm wide strip of black glass primer (1) with the app licator (9) included in

the service kit to the inside of the windshield along:

• The upper edge (2), adjacent to the moulding (4).

• The side edges (3), adjacent to the mould in g.

• The lower edge 35 mm from the bottom edge (5) of the windshield. Do not apply primer a cross the gap for

displaying the Vehicle Identification Number (VIN) (8). Here apply the primer (6) 15 mm from the lower edge

of the windshield (7).

Figure 1A6 – 8

9 For ease of installation and to avoid unnecessary stress on the freshly appli ed urethane, it is recommended the

interior mirror assembly be fitted to the windshiel d prior to installation of the windshield to the vehicle,

refer to Section 12H Rear-view Mirrors.

Stationary Windows Page 1A6–10

Page 1A6–10

On the lower section of the body opening,

care must be taken to ensure the urethane

bead diameter is such that when compressed

by the windshield installation, the Vehicle

Identification Number (VIN) plate is not

obscured.

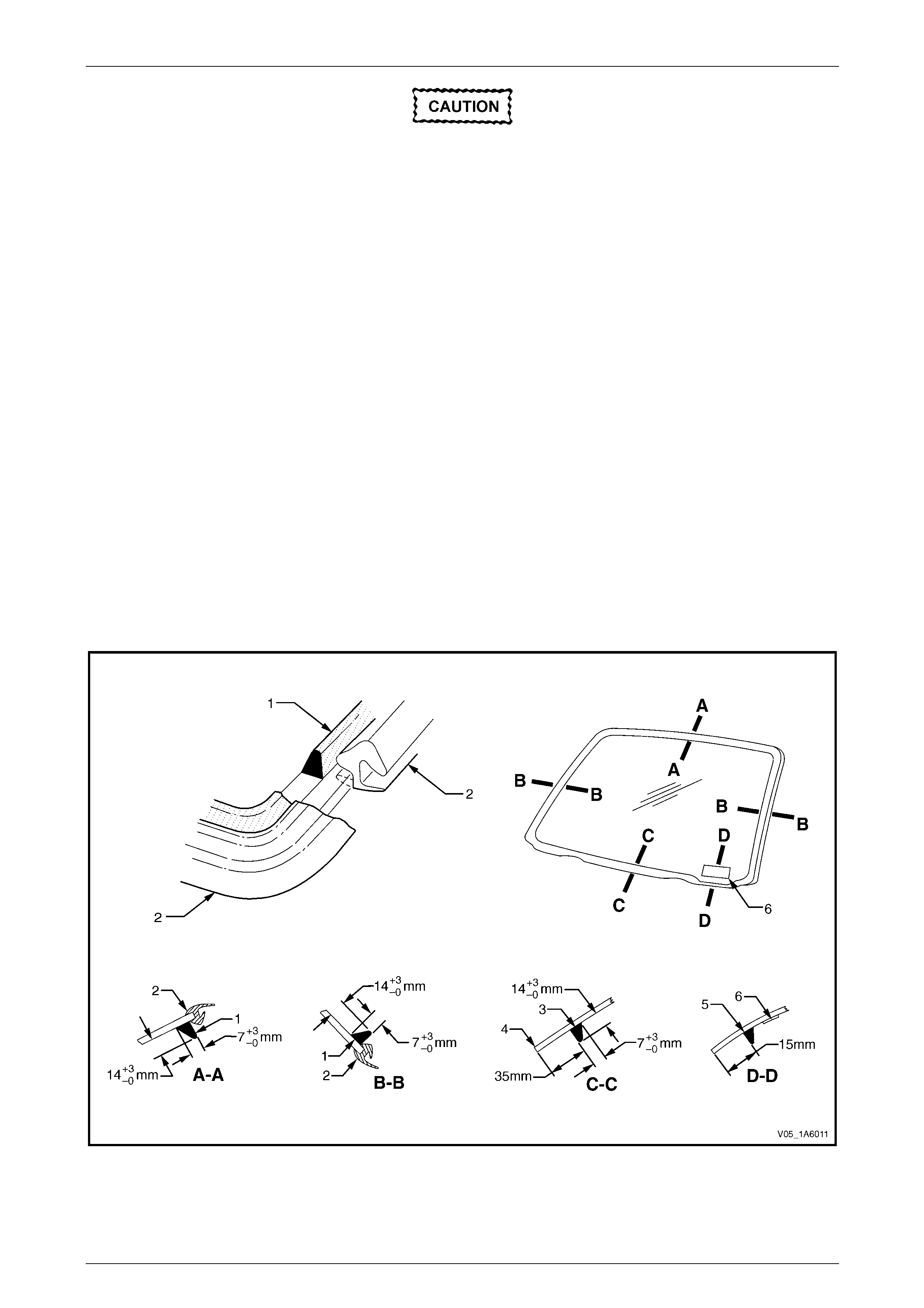

10 Use a hand or automatic applicator to apply a smooth and contin uous bead of urethane (1) to the inside of the

windshield (2).

Apply the urethane bead along:

• The upper edge, adjacent to the moulding.

• The side edges, adjacent to the moulding.

• The bottom edge (4) 35 mm inboard from the edge. Adjacent to the gap to display the VIN plate (6) apply a

suitably reduced amount of urethane (5) to ensure the VIN is not obscured when the windshield is installed.

Here apply the urethane 15 mm from the lower edge of the windshield.

The amount of new urethane applied should ensure the total amount of uret hane is within the recommended

dimensions. Refer to Figure 1A6 – 9.

NOTE

• Only use urethane adh esive such as Betaseal

15685 or equivalent.

• In cold weather, placing the urethane

cartridges adjacent to a source of warmth will

assist in the flow of urethane when using a

hand applicator.

Figure 1A6 – 9

Stationary Windows Page 1A6–11

Page 1A6–11

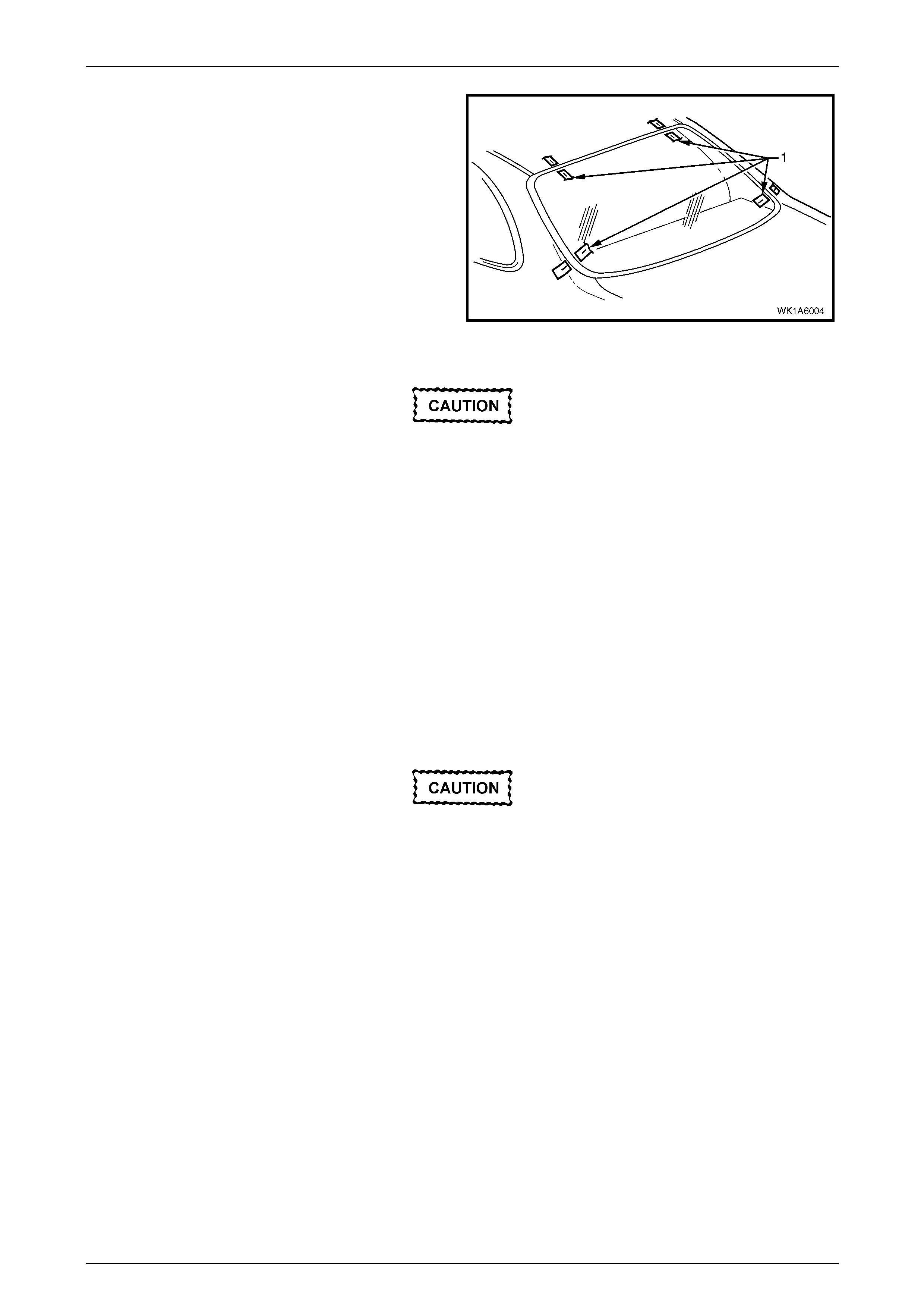

11 With the aid of an assistant, install the windshield

using the previously attached masking tape (1) on the

roof and windshield pi llar as a guide. Use a windshield

locator (2), between the lower windshield edge (3) and

the reinforcing flange (4), t wo places, to locate the

windshield verticall y i n the windshield opening.

12 Press the windshield firmly into positi on.

13 Check the effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps.

Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is

evident, apply addition al urethane to the leak

area, using a spatula to work the urethane

into the source of the leak.

14 Wait two hours and then water test the windshield

using a moderate spray of water.

15 Clean off any excess urethane using Prepsol or white

spirit.

16 Clean the windshield and then remove the masking

tape previously installed.

17 Reinstall the trim and hardware as required.

Figure 1A6 – 10

Reinstall – Long Method

Description

Throughout the curing period, ensure the

door windows are partially lowered to

eliminate pressure build-up, which can be

caused by slamming doors. A curing time of

24 hours is recommended, although the

vehicle may be driven after five hours

providing it is driven only on a smooth road at

speeds not exceeding 80 km/h with the door

windows partially lowered.

• The long method should be used on vehicles requiring metal or paint repair to the windshield opening or when the

original adhesive is compl etely removed and replaced with new urethane for the windshield installati on.

• This method for the windshield replacement is used when the original ur ethane adhesive material cannot serve as

a base for the replacement windsh ield.

• This method should also be u s ed when the windshield h as been previously replac ed using the short method. In

such instances, the build-up of urethane could position the windshield too high in the o pening.

Stationary Windows Page 1A6–12

Page 1A6–12

Preparation

Care should be taken to ensure the

windshield does not strike the windshield

opening or any other object. Chipped edges

can lead to subsequent breakage of the

windshield.

Do not use petro leum based sol vents to clean

any part of the window assembly or body

opening as the presence of oil in the solvent

will pre vent th e adhesion of the n ew urethane.

NOTE

Thoroughly check the windshield opening flange

for any irregularities before installing the

windshield.

1 Remove carefully, using a sha rp scraper all of the original urethane from around the windshield. Cle an the

windshield to be installed with a suitable oil free cleaning agent.

2 Remove carefully, using a knife or sharp scraper all the original urethane from around the entire perimete r of the

windshield opening flange. Take care to avoid the removal of paint when removi ng urethane from opening flange.

If any paintwork around the windshield

opening flange has been damaged, refinish

the paint before proceeding. Damaged paint

can lead to subsequent ru stin g.

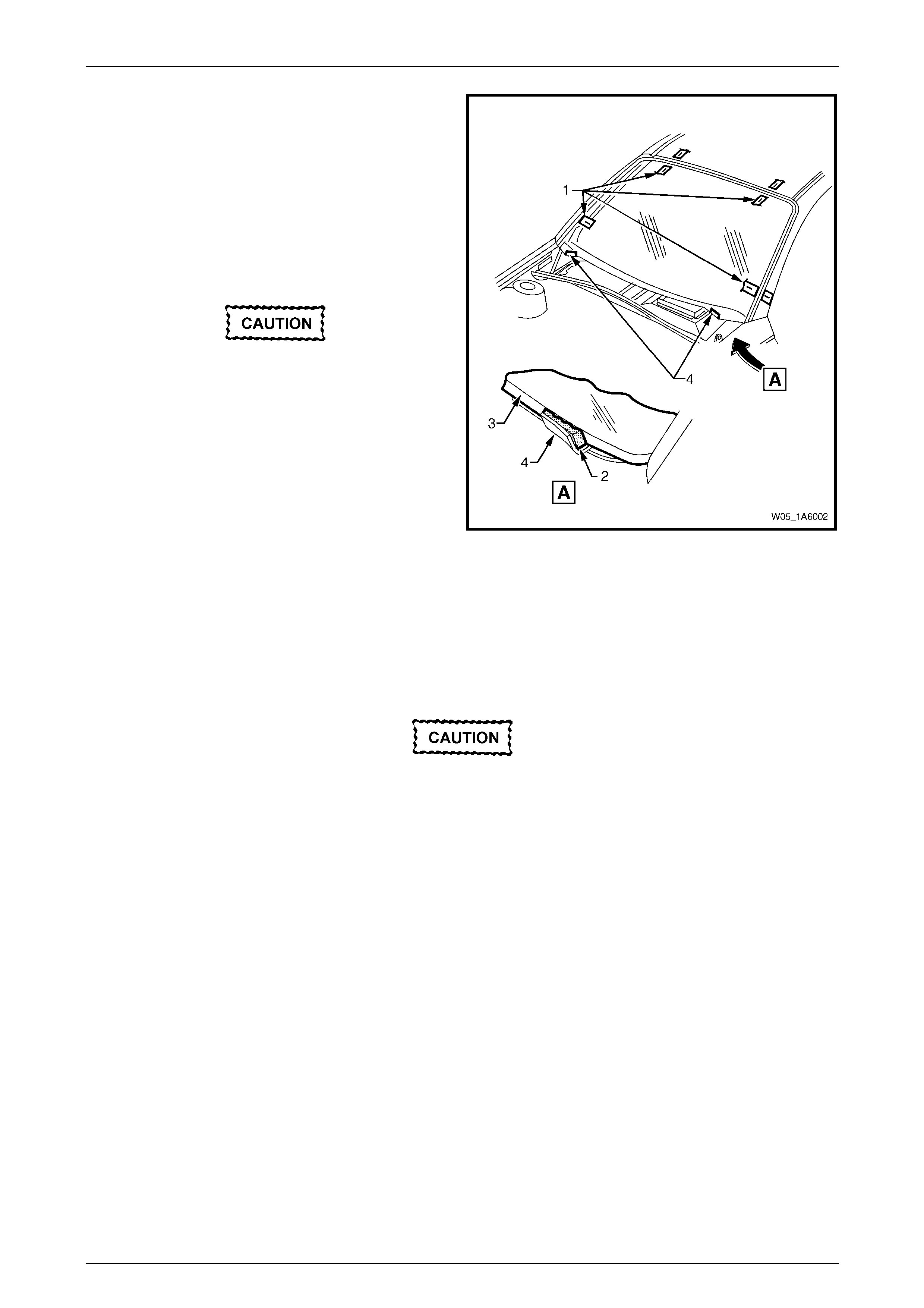

3 Check for correct alignment of the windshield by

temporarily pla c ing the windshield in the body

opening. Fit the windshield locator (1) between the

lower windshield edge (2) and the reinforcing flange

(3).

4 Ensure the windshield is centralised in the body

opening left to right by checking the gaps between the

windshield and body opening are eve n on both sides

of the vehicle.

5 With masking tape (5), mark the outer top and side of

the windshield pillar and the roof.

NOTE

This procedure will assist in the alignment of the

windshield in the correct horizontal and vertical

plane during final windshield installation.

6 Remove and place the windshield face down on a

clean protected surface or fixture.

Figure 1A6 – 11

Stationary Windows Page 1A6–13

Page 1A6–13

Reinstall

Do not use petro leum based sol vents to clean

any part of the window assembly, or body

opening as the presence of oil in the solvent

will pre vent th e adhesion of the n ew urethane.

NOTE

• Flange primer is not required if using the

recommended urethane adhesive Betaseal

15685.

• If using an equivalent to Betaseal 15685 refer

to technical data supplied by the supplier.

1 Only if required by the supplier of the urethane, apply

flange primer (1) to the region indicated.

2 Thoroughly clean the inner surface and edges of the

rear window assembly to which the urethane is to be

applied, using clean lint-free cloths and a suitable oil

free cleaning solvent.

Figure 1A6 – 12

3 Apply a 50 mm wide layer of clear glass primer, to the

inner surface of the windshield's perimeter.

Immediately wipe off with a lint-free cloth.

Figure 1A6 – 13

Stationary Windows Page 1A6–14

Page 1A6–14

4 Check the condition of the windshiel d reveal moulding

assembly (1). Discard and replace with a new

moulding if damaged.

5 Fit the moulding to the sides and upper section of the

windshield. Ensure the notch of the moulding (2) is

aligned with the V locating mark (3) on the lower

portion of the right-hand and the left-hand side of the

windshield.

Figure 1A6 – 14

6 Referring to Figure 1A6 – 15, apply a 20 mm wide strip of black glass primer (1) with the applicator (9) included in

the service kit to the inside of the windshield along:

• The upper edge (2), adjacent to the moulding. (4)

• The side edges (3), adjacent to the mould in g.

• The lower edge 35 mm from the bottom edge (5) of the windshield. Do not apply primer a cross the gap for

displaying the Vehicle Identification Number (VIN) (8). Here apply the primer (6) 15 mm from the lower edge

of the windshield (7).

Figure 1A6 – 15

Stationary Windows Page 1A6–15

Page 1A6–15

7 For ease of installation and to avoid unnecessary stress on the freshly appli ed urethane, it is recommended the

interior mirror assembly be fitted to the windshiel d prior to installation of the windshield to the vehicle,

refer to Section 12H Rear-view Mirrors.

On the lower section of the body opening,

care must be taken to ensure the urethane

bead diameter is such that when compressed

by the windshield installation, the Vehicle

Identification Number (VIN) plate is not

obscured.

8 Use a hand or automatic applicator to apply a smooth and contin uous bead of urethane (1) to the inside of the

windshield (2).

Apply the urethane bead along:

• The upper edge, adjacent to the moulding.

• The side edges, adjacent to the moulding.

• The bottom edge (4) 35 mm inboard from the edge (3). Adjacent to the gap to display the VIN plate (6) apply

a suitably reduced amount of urethane (5) to ensure the VIN is not obscured when the windshield is installed.

Here apply the urethane (5) 15 mm from the lower edge of the windshield

The amount of urethane applied should be within the recomm ended dimensions. Refer to Figure 1A6 – 16.

NOTE

• Only use urethane adh esive such as Betaseal

15685 or equivalent.

• In cold weather, placing the urethane

cartridges adjacent to a source of warmth will

assist in the flow of urethane when using a

hand applicator.

Figure 1A6 – 16

Stationary Windows Page 1A6–16

Page 1A6–16

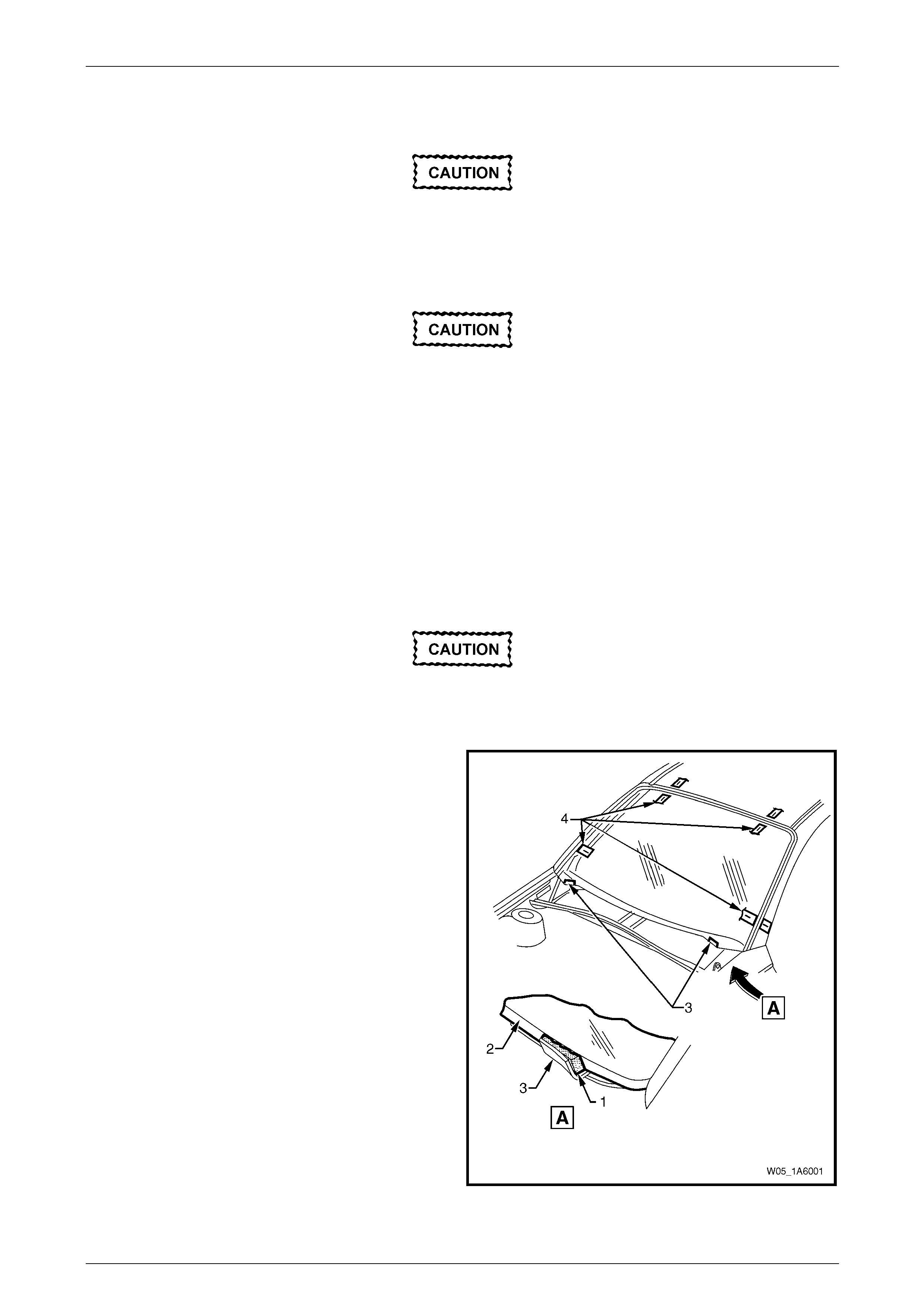

9 With the aid of an assistant, install the windshield

using the previously attached masking tape (1) on the

roof and windshield pillar to ensure accurate

installation. Use a windshield locator (2), between the

lower windshield edge (3) and the reinforcing

flange (4), two places, to locate the windshield

vertically in the windshield opening.

10 Press the windshield firmly into positi on.

11 Check effectiveness of sealing from inside the vehicle.

Should any gaps in the seali ng exist, apply additional

urethane to fill these gaps.

Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is

evident, apply addition al urethane to the leak

area, using a spatula to work the urethane

into the source of the leak.

12 Wait two hours and then water test the windshield

using a moderate spray of water.

13 Clean off any excess urethane using Prepsol or white

spirit.

14 Clean the windshield and then remove the masking

tape previously installed.

15 Reinstall the trim and hardware as required.

Figure 1A6 – 17

Stationary Windows Page 1A6–17

Page 1A6–17

4 Service Operations – Side

4.1 Quarter Window Assembl y

LT Section No. — 11–030

Safety glasses an d work glo ves must be w orn

at all times when operating with glass.

Care must be taken during any operation

involving the side glass removal or

installation, to not exert any load on the

window. Failure to observe this may result in

damage to the window.

NOTE

To retain a watertight seal the following

component will require replacement when

performing this operation.

• Quarter window nut (five required)

Preparation

As required, remove the body lock pillar garnish, refer to Section 1A8 Headlining and Interior T r im.

Remove

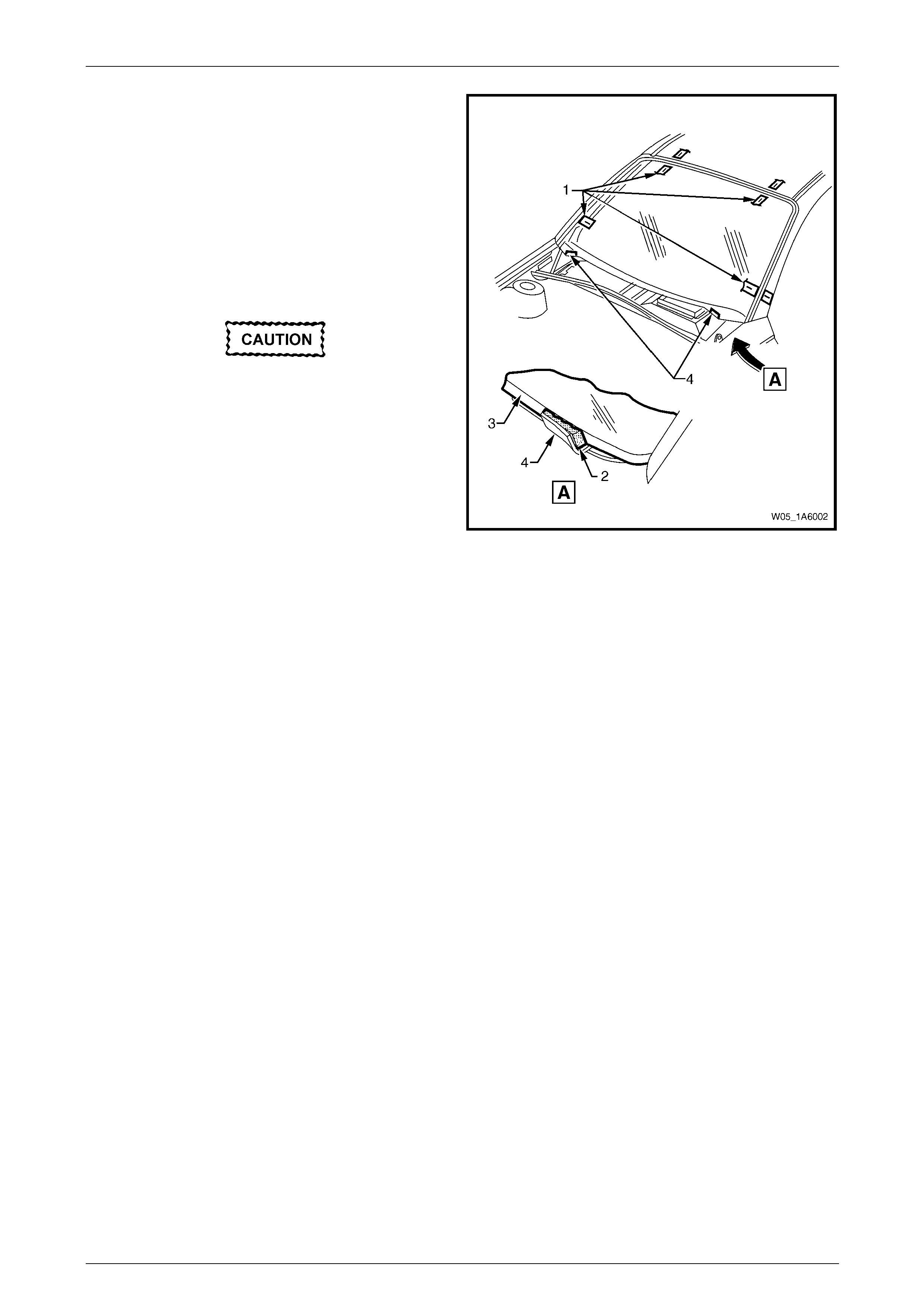

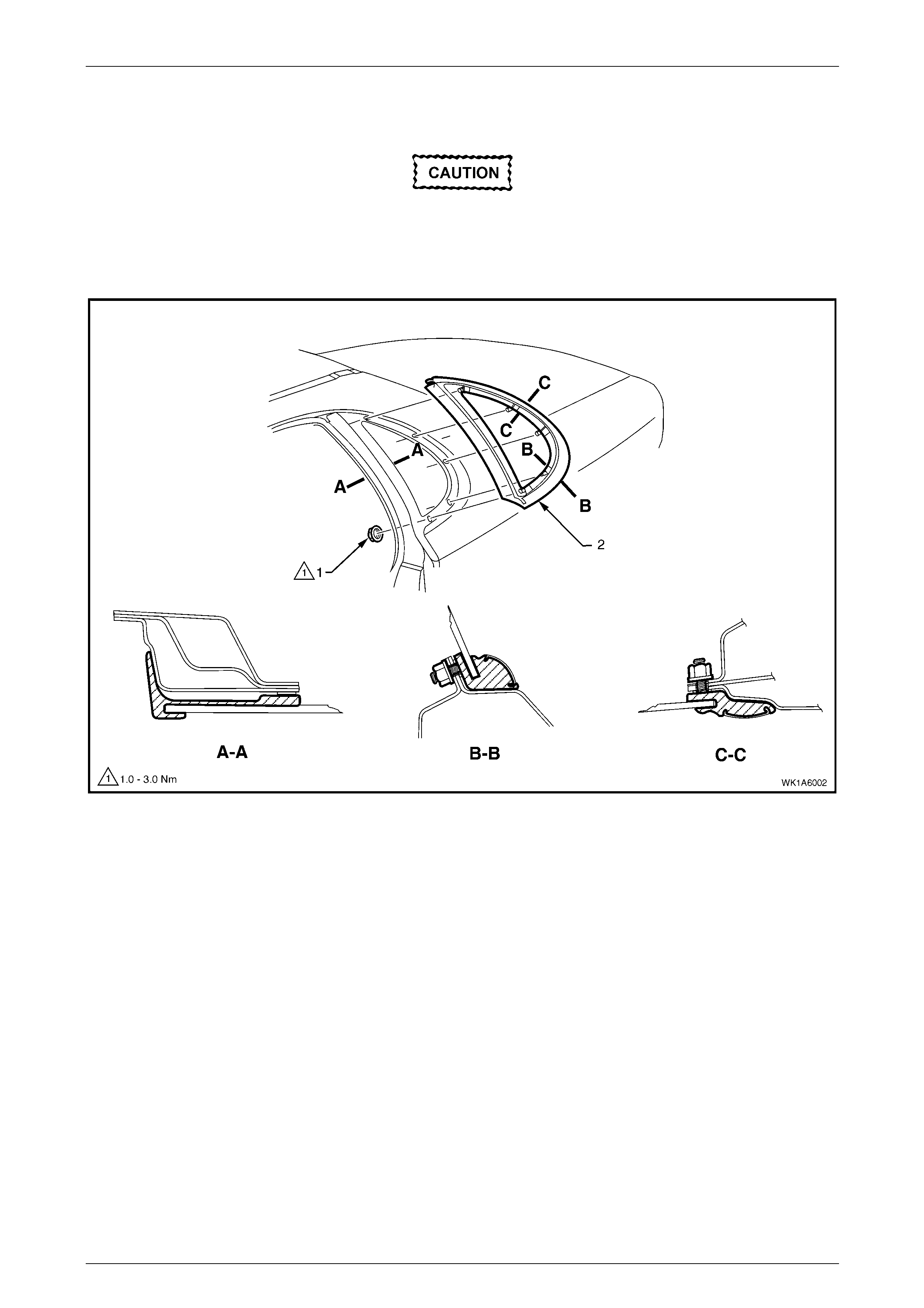

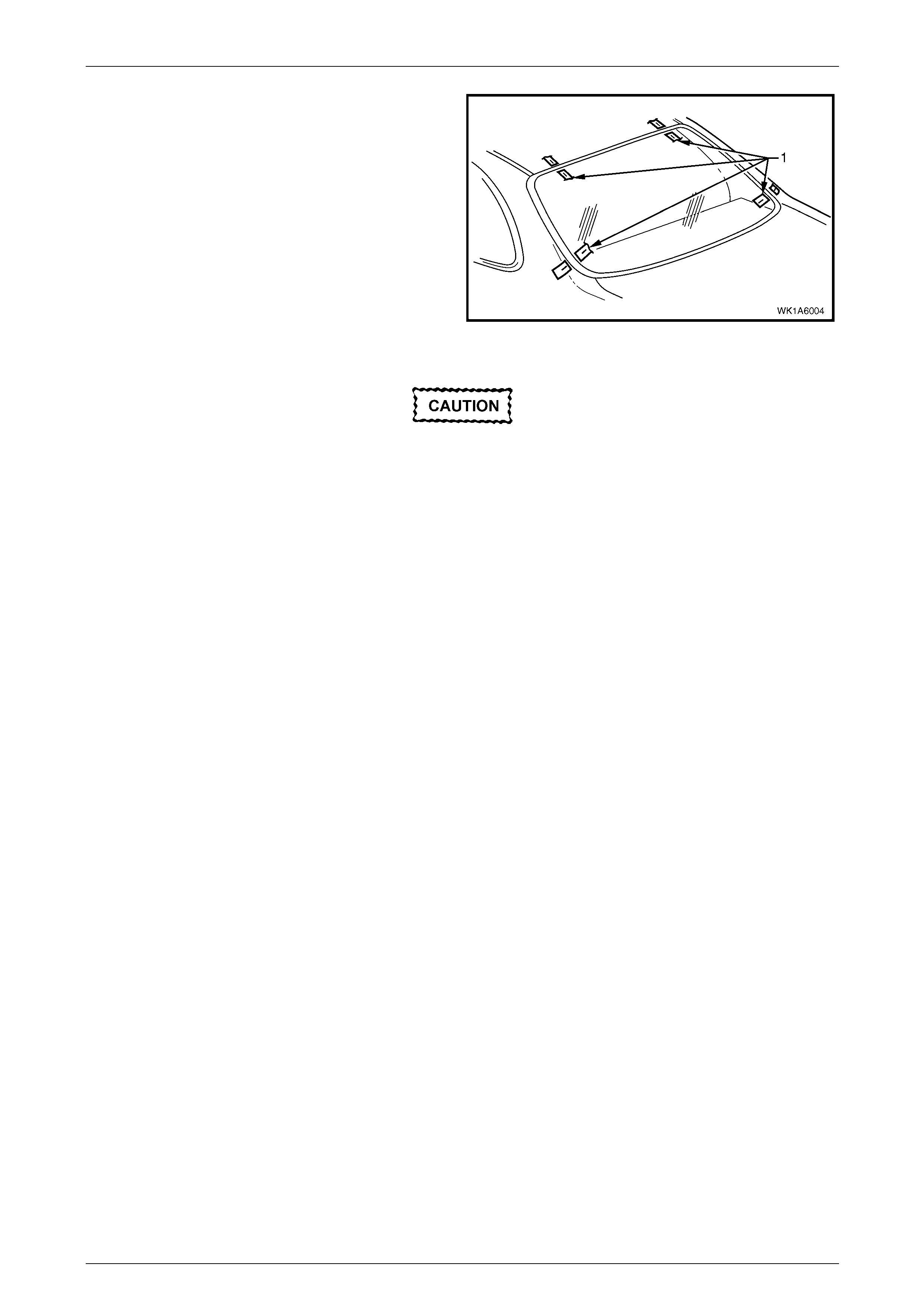

1 Remove the screw (1), three places, from the rear

door opening and partiall y remove the rear section of

the door opening moulding (2 ), disengaging it from the

quarter window assembly tab (3).

Figure 1A6 – 18

Stationary Windows Page 1A6–18

Page 1A6–18

2 Remove the quarter window nut (1), five places, securing the quarter window assembly (2) to the body opening,

refer to Figure 1A6 – 19.

Take care when removing the quarter window

from the body opening the attaching pins are

clear of the outer body.

3 Carefully lift the window from the vehicle.

Figure 1A6 – 19

Legend

1 Quarter Window Nut (five places) 2 Quarter Window Assembly

Stationary Windows Page 1A6–19

Page 1A6–19

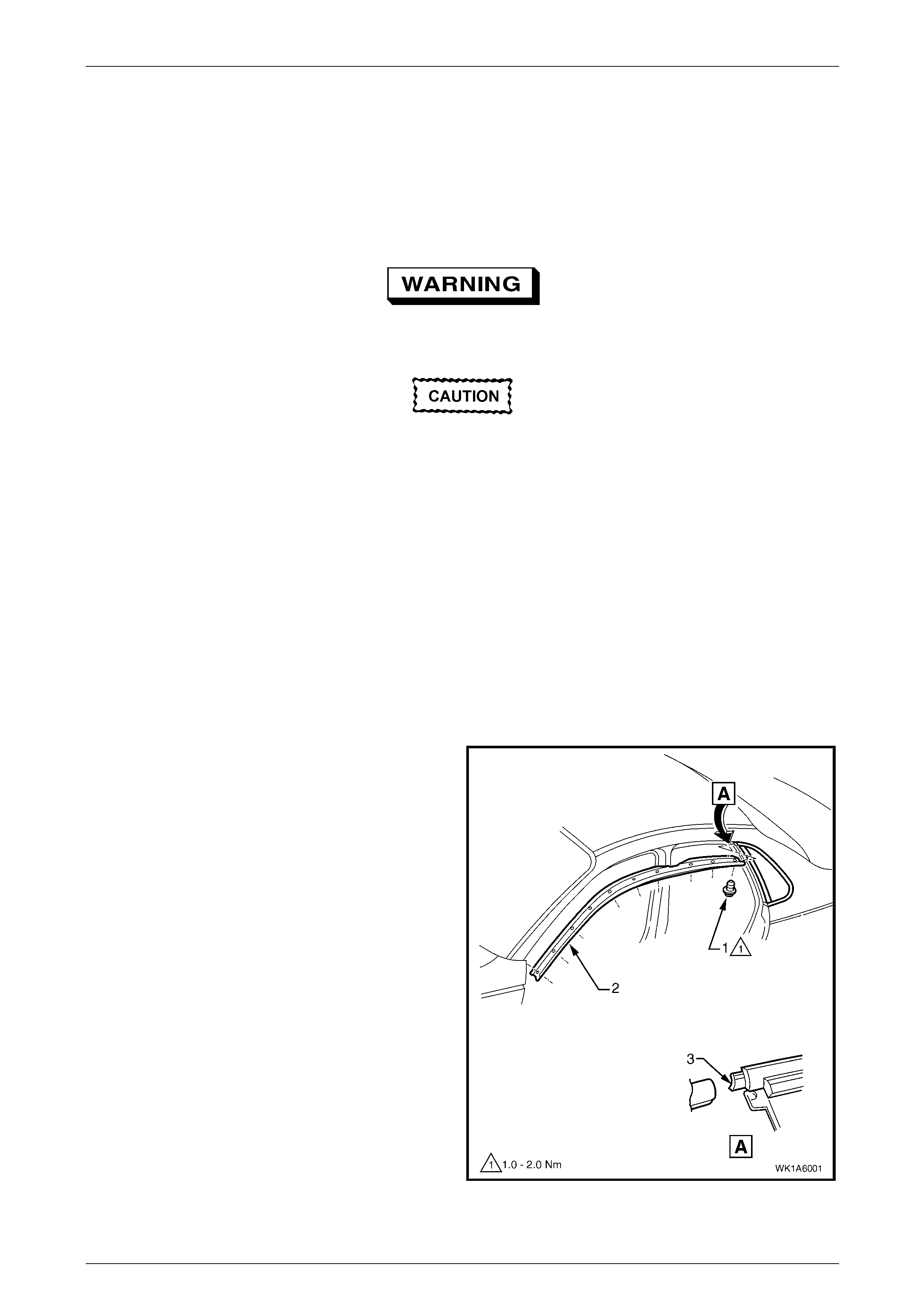

Reinstall

1 Ensure the seal is in sound condition.

2 Fit the quarter window into the body opening, ensuring the pins are correctly aligned i nto the holes in the body

opening.

NOTE

The quarter window nuts are encapsulated with a

wax sealer. It is recommended the nuts be

replaced once removed, however if this is not

possible apply a small amount of sealer to the

end of the thread.

3 Install new nuts attaching the quarter window to the body opening. Do not tighten.

4 Position the door opening mouldi ng and tighten the screws to the correct torque specification.

Door frame opening moulding attaching

screw torque specification...........................1.0 – 2.0 Nm

5 Tighten the quarter window nuts to the correct torque specification.

Quarter window assembly attaching

nut torque specification...............................1.0 – 3.0 Nm

6 Perform a water test of the window's sealing, using a moderate spray of water.

7 Reinstall the trim and hardware as required.

Stationary Windows Page 1A6–20

Page 1A6–20

5 Service Operations – Rear

5.1 Rear Window Assembly

LT Section No. — 11–020

Safety glasses an d work glo ves must be w orn

at all times when operating with glass.

Care must be taken during any operation

involving the rear window assembly removal

or installation not to exert any load on the

window. Failure to observe this may result in

damage to the window.

NOTE

• Only use urethane adh esive such as Betaseal

15685 or equivalent.

• Skinning (partial curing) of the urethane

commences after exposure to the

atmosphere. At 23 degrees Celsius and 50

percent relative humidity, skinning

commences after 30 minutes. Complete

curing of the urethane at this temperature an d

humidity takes 72 hours.

• Urethane service kits are available from most

windshield agents. Manufacturer’s instruction s

should always be foll owed.

• Window assemblies should be installed in the

window opening within five minutes of the

application of urethane.

• The rear window moulding may require

replacement when performing this operation.

Description

The rear window assembly removal procedure is the same for both the sh ort and long installation methods, with one

exception. If the short method installation is to be used, care must be taken during removal to ensure that an even

surface of the original urethane remains in the body opening. This will serve as a base for the new urethane bead and

the replacement rear window.

Preparation

Prevent damage to the paint finish and

minimise clean up by using protective covers

and masking tape over the regions adjacent

to the rear window .

As required, remove the following compo nents:

1 Roof joint moulding, refer to Section 1A9 Exterior Ornamentation.

2 Body lock pillar garnish, refer to Section 1A8 Headlining and Interior Trim.

Stationary Windows Page 1A6–21

Page 1A6–21

Remove

A high mount stop lamp assembly is installed

below the rear window trim panel assembly.

Care must be taken to avoid damage to the

lamp assembly during window removal

procedure. It is not necessary to remove the

lamp assembly, but to ensure that it is clear of

any debris before window installation.

NOTE

To remove the windshield or rear window special

tool J36020 is required. Alternately manufacture

an equivalent tool. Refer to 6 Special Tools.

1 Disconnect the rear window electrical demister connectors and ce llular telephone antenna if fitted.

2 If the rear window is broken, carefully remove all fragments of glass from the window opening.

Ensure the headlining and other trim items

are not damaged while cutting the urethane.

3 Use special tool J36020, or equiv ale nt, thread one end of the piano wire throu gh the urethane, starting at the rear

window upper corner. Pull the end of the wire through with pliers.

4 Connect the end of the piano wire to the other han dle of the special tool or equivale nt.

5 With the aid of an assistant commence cutting the urethane bead. Keep the outside handle (1) parallel to the edge

of the rear window. Use the full length of the wire to prevent heat build up in the wire, refer to Figure 1A6 – 20.

NOTE

To minimise damage to the interior of the vehicle,

the operator inside the vehicle should act as an

anchor point, holding the T-handle as close as

possible to the window at all times. The outside

operator pulls the wire up to the interior T-handle

in a walking motion.

Stationary Windows Page 1A6–22

Page 1A6–22

Figure 1A6 – 20

6 Carefully lift the rear window out of the rear opening. If there is evidence of the window adhering to the urethane,

cut the area again with the piano wire.

7 If the original rear window is to be installed a gain, place the window on a clean protected surface or a holding

fixture.

NOTE

• The use of suction cu ps will greatly assist an y

handling of the rear windo w.

• All traces of urethane must be removed from

the rear window. It is not necessary to remo ve

all traces of the original urethane from the

body opening, unless the long method of

reinstallation is being used. However, any

original urethane remaining must be smooth

and firm.

Stationary Windows Page 1A6–23

Page 1A6–23

Reinstall – Short Method

Description

Throughout the curing period, ensure the

door windows are partially lowered to

eliminate pressure build-up, which can be

caused by slamming doors. A curing time of

24 hours is recommended, although the

vehicle may be driven after five hours

providing it is driven only on a smooth road at

speeds not exceeding 80 km/h with the door

windows partially lowered.

• The short method is recommende d when replacing a cracked or broken rear window, or a leak condition that

cannot be overcome by using minor water leak repair procedures.

• The short method installation i nvolves leaving the maximum amount of the original urethane intact on the body

opening to form a sound base for the replacement urethane and rear window. Any original urethane remaining

must be smooth and firm.

• If material other than urethane has been used for previous servicing of the rear window, the long method

installation procedure (complete removal of adhesive) is mandator y to ac hieve an effective window to metal bond.

Preparation

Care should be taken to ensure the rear

window does not strike the rear window

opening or any other object. Chipped edges

can lead to subsequent breakage of the rear

window.

Do not use petro leum based sol vents to clean

any part of the window assembly or body

opening as the presence of oil in the solvent

will pre vent th e adhesion of the n ew urethane.

1 Using a sharp scraper, carefully remove all the original urethane from around the rear window. Clean the rear

window to be installed with a suitable oil free cleaning agent.

2 Check for correct alignment of the rear window by temporarily placing the rear windo w in the body opening.

3 Ensure the rear windo w is centralised in the body opening left to right by checking the gaps between the rear

window and body opening are even on both sides of the vehicle.

4 Use masking tape (1), to mark the outer top of the roof

and the rear quarter panel.

NOTE

This procedure will assist in the alignment of the

window in the correct horizontal and vertical

plane during final window installation.

5 Remove and place the rear window assembly face

down on a clean protected s urface or fixture.

Figure 1A6 – 21

Stationary Windows Page 1A6–24

Page 1A6–24

Reinstall

Do not use petro leum based sol vents to clean

the rear w indow assembly or th e rear openin g

flange as the presenc e of t he o il in th e sol vent

will pre vent th e adhesion of the n ew urethane.

1 As required, remove the rear window moulding.

2 Thoroughly clean the inner surface and edges of the rear window assembly to which the urethane is to be applied,

using clean lint-free cloths and a suitable oil free cleaning s olve nt.

3 Apply a 50 mm wide layer of clear glass primer, to the

inner surface of the rear window's perimeter.

Immediately wipe off with a lint-free cloth.

4 If using an existing rear windo w moul ding, check its

condition. If damaged discard and replace it.

Figure 1A6 – 22

5 Install the rear window moulding (1) over the edge of the window. Ensure the moulding is fitted correctly to the

glass with the moulding joint at the bottom middle (2) of the rear window, refer to Figure 1A6 – 23.

6 Check the condition of the original urethan e around the window opening flange for voids or looseness and cut away

any loose pieces.

7 Using a suitable spatula, spread fresh urethane smoothly into any voids or uneven sections.

8 Apply a 20 mm wide strip of black glass primer (4) with the applicator (3) included in the service kit adjacent to the

inside edge of the window moulding (1).

9 Use a hand or automatic applicator to appl y a smooth and continuo us bead of urethane (5) to the inside of the rear

window adjacent to the inside edge of the window moulding (1). The amount of new urethane applied should

ensure the total amount of urethane is within the recommended dimensions.

NOTE

• Only use urethane adh esive such as Betaseal

15685 or equivalent.

• In cold weather, placing the cartridges

adjacent to a source of warmth will assist in

the flow of urethane when using a hand

applicator.

Stationary Windows Page 1A6–25

Page 1A6–25

Figure 1A6 – 23

Legend

1 Moulding

2 Moulding Joint Position (on centre-line)

3 Applicator

4 Black Glass Primer

5 Urethane Adhesive

Stationary Windows Page 1A6–26

Page 1A6–26

10 With the aid of an assistant, install the rear window

assembly using the previously attached masking tape

(1) on the roof and the rear quarter panel as a guide.

NOTE

Ensure the rear window is centralised in the

body opening left to right by checking the gaps

between the windo w mouldin g an d body openin g

are even on both sides of the vehicl e.

11 Press the rear window firmly into position.

12 Check the effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps. Figure 1A6 – 24

Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is

evident, apply additional urethane to the leak

area, using a spatula to work the urethane

into the source of the leak.

13 Wait two hours and then water test the rear window using a moderate spray of water.

14 Clean off any excess urethane using Prepsol or white spirit. Clean the rear window and then remove the masking

tape previously installed.

15 Connect the electrical demist connectors and cell ular telephone antenna if fitted.

16 Reinstall the trim and hardware as required.

Reinstall – Long Method

Description

Throughout the curing period ensure the door

windows are partially lowered to eliminate

pressure build-up, which can be caused by

slamming doors. A curing time of 24 hours is

recommended, although the vehicle may be

driven after five hours providing it is driven

only on a smooth road at speeds not

exceeding 80 km/h with the door windows

partially lowered.

• The long method should be used on vehicles requiring metal or paint repair to the rear window opening, when the

original adhesive is completely removed and replaced with new urethane for the rear window installation.

• This method for the rear windo w replacement is used when the original urethane adh esive material cannot serve

as a base for the replacement rear window.

• This method is also used when the rear window has been previously replaced using the short method. In such

instances, the build-up of uret hane could position the rear window too high in the opening.

Stationary Windows Page 1A6–27

Page 1A6–27

Preparation

Care should be taken to ensure the rear

window does not strike the rear window

opening. Chipped edges can lead to

subsequent breakage of the window

assembly.

Do not use petro leum based sol vents to clean

the rear window or the rear o pening flange, as

the presence of the oil in the solvent will

prevent the adhesion of the new urethane.

NOTE

Thoroughly check the rear window opening

flange for any irregularities before installing the

rear window assembly.

1 Using a sharp scraper, carefully remove any original urethane from around the rear window. Clean the window to

be installed with a suitable o il free cleaning agent.

2 Using a knife or sharp scraper, remove the original urethane from around the entire perimeter of the windo w

opening flange. Take care to avoid the removal of paint when removing urethane from opening flange.

If any paintwork around the rear window

opening flange has been damaged, refinish

the paint before proceeding. Damaged paint

can lead to subsequent ru stin g.

3 Check for correct alignment of the rear window by temporarily placing the rear windo w in the body opening.

4 Ensure the rear windo w is centralised in the body opening left to right by checking the gaps between the rear

window and body opening are even on both sides of the vehicle.

5 With masking tape (1), mark the outer top of the roof

and the rear quarter panel.

NOTE

This procedure will assist in the alignment of the

window in the correct horizontal and vertical

plane during final window installation.

6 Remove and place the rear window assembly face

down on a clean protected s urface or fixture.

Figure 1A6 – 25

Stationary Windows Page 1A6–28

Page 1A6–28

Reinstall

Do not use petro leum based sol vents to clean

the rear window assembly, or the rear

opening flange as the presence of the oil in

the solvent will prevent the adhesion of the

new urethane.

NOTE

• Flange primer is not required if using the

recommended urethane adhesive Betaseal

15685.

• If using an equivalent to Betaseal 15685 refer

to technical data supplied by the supplier.

1 Only if required by the supplier of the urethane, apply

flange primer (1) to the region indicated.

2 If required remove the rear window moulding.

3 Thoroughly clean the inner surface and edges of the

rear window assembly to which the urethane is to be

applied, using clean lint-free cloths and a suitable oil

free cleaning solvent.

Figure 1A6 – 26

4 Apply a 50 mm wide layer of clear glass primer, to the

inner surface of the rear window's perimeter.

Immediately wipe off with a lint-free cloth.

5 If using an existing rear windo w moul ding, check its

condition. If damaged discard and replace it.

Figure 1A6 – 27

6 Install the rear window moulding (1) over the edge of the window. Ensure the moulding is fitted correctly to the

window with the moulding joint at the bottom middle (2) of the rear window, refer to Figure 1A6 – 28.

Stationary Windows Page 1A6–29

Page 1A6–29

7 Apply a 20 mm wide strip of black glass primer (4) with the applicator (3) included in the service kit adjacent to the

inside edge of the windo w moulding (1).

8 Use a hand or automatic applicator to appl y a smooth and continuo us bead of urethane (5) to the inside of the rear

window adjacent to the inside edge of the window moulding (1). The amount of urethane applied sho uld be within

the recommended dimensions.

NOTE

• Only use urethane adh esive such as Betaseal

15685 or equivalent.

• In cold weather, placing the urethane

cartridges adjacent to a source of warmth will

assist in the flow of urethane when using a

hand applicator.

Figure 1A6 – 28

Legend

1 Moulding

2 Moulding Joint Position (on centre line)

3 Applicator

4 Black Glass Primer

5 Urethane Adhesive

Stationary Windows Page 1A6–30

Page 1A6–30

9 With the aid of an assistant, install the rear window

assembly, using the previously attached masking tape

(1) on the roof and the rear quarter panel as a guide.

NOTE

Ensure the rear window is centralised in the

body opening left to right by checking the gaps

between the window moulding and the body

opening are even on both sides of the vehicle.

10 Press the rear window firmly into position.

11 Check effectiveness of sealing from inside the vehicle.

Should any gaps in the seali ng exist, apply additional

urethane to fill these gaps. Figure 1A6 – 29

Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is

evident, apply additional urethane to the leak

area, using a spatula to work the urethane

into the source of the leak.

12 Wait two hours then water test the rear windo w, using a moderate spray of water.

13 Clean off any excess urethane using Prepsol or white spirit. Clean the rear window, then remove the masking tape

previously installed.

14 Connect the electrical demist connectors and cell ular telephone antenna if fitted.

15 Reinstall the trim and hardware as required.

Stationary Windows Page 1A6–31

Page 1A6–31

5.2 Rear Window Lower Finisher

Remove

1 Remove the rear compartment lid weatherstrip (1) from around the lip flan ge of the rear compartment (2), refer to

Figure 1A6 – 30.

2 Starting from one end, carefully remove the rear window lower finisher (3) by pulling it out from under the rear

window weatherstrip (4).

Figure 1A6 – 30

Reinstall

1 Gently lift the rear window weatherstrip using a fine bladed screwdriver and insert the lower finisher underneath it.

2 Reinstall the rear compartment lid weatherstrip on the lip flange around the rear compartment.

Stationary Windows Page 1A6–32

Page 1A6–32

6 Special Tools

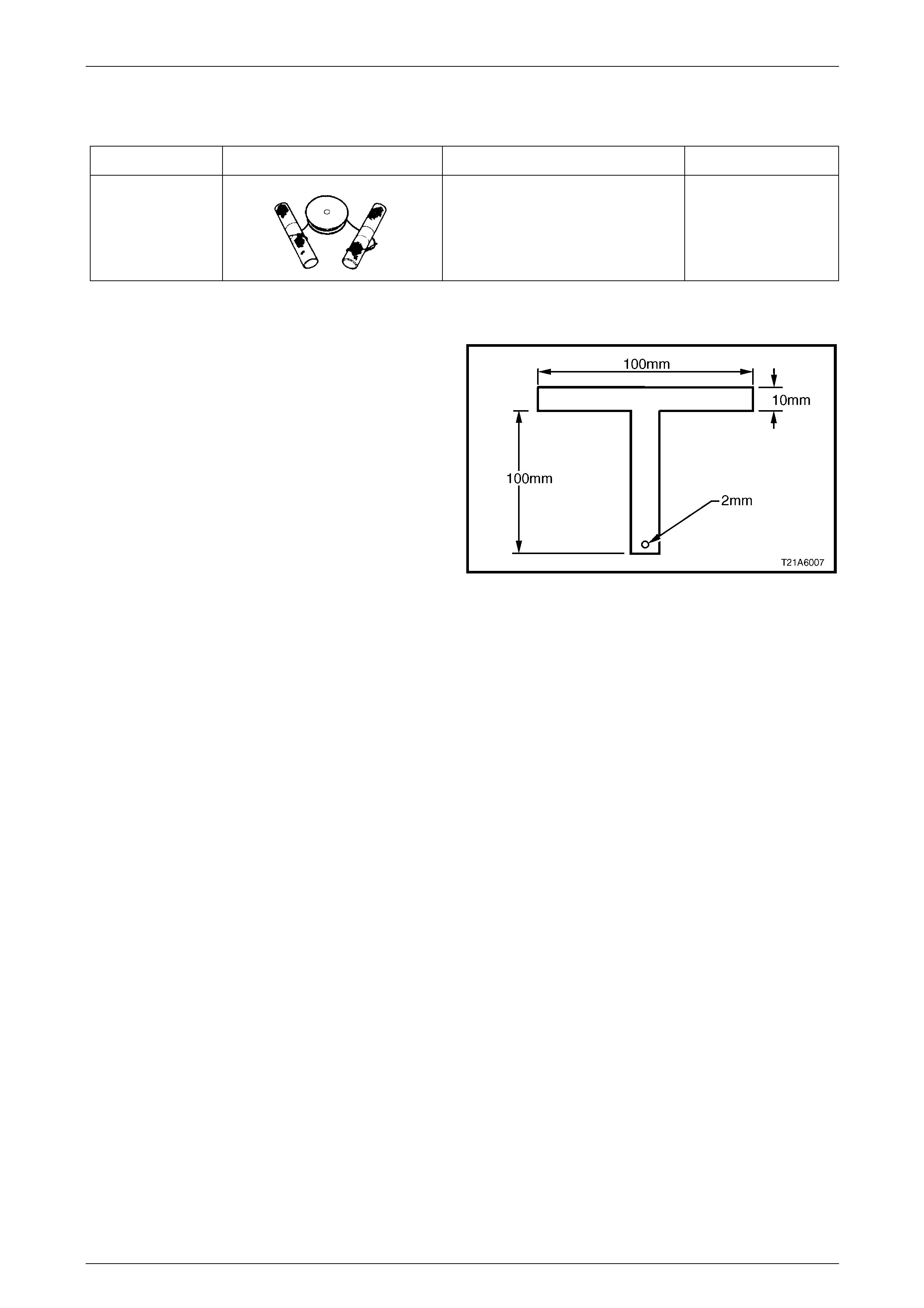

Tool Number Illustration Description Tool Classification

J36020

Windshield Removal Tool and

Piano Wire

Previously Released

Unique

Alternative:

Manufacture an equivalent tool.

1 Manufacture two T-handles to the dimensions shown.

2 Thread 700 mm of piano wire through the hole of one

handle.

Figure 1A6 – 31

Stationary Windows Page 1A6–33

Page 1A6–33

7 Torque Wrench Specifications

Door Opening Moulding Retaining Screw......................................1.0 – 2.0 Nm

Quarter Window Assembly Retaining Nut .....................................1.0 – 3.0 Nm