Seat Assemblies Page 1A7–1

Page 1A7–1

Section 1A7

Seat Assemblies

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information .............................................................................................................................10

1.1 Front Seat General Description.......................................................................................................................... 10

Seat Covers.......................................................................................................................................................... 10

Electric Seat Operation ....................................................................................................................................... 11

Raise/Lower Movement.................................................................................................................................... 11

Fore/Aft Movement........................................................................................................................................... 11

Recline Movement............................................................................................................................................ 11

Eight-way Movement Control ........................................................................................................................... 12

Memory Seat Position System ......................................................................................................................... 12

Priority Keys (Level 5 Vehicles Only) ............................................................................................................... 13

Memory Buttons............................................................................................................................................... 13

Using the Exterior Mirrors................................................................................................................................. 13

Active Head Restraints........................................................................................................................................ 14

1.2 Rear Seat General Description ........................................................................................................................... 15

Seat Covers.......................................................................................................................................................... 15

2 Diagnostics – Front Seat, Non-memory.............................................................................................16

2.1 Prerequisites........................................................................................................................................................ 16

Safety Requirements ........................................................................................................................................... 16

Equipment ............................................................................................................................................................ 16

Testing Procedures ............................................................................................................................................. 16

2.2 Mechanical Diagnosis ......................................................................................................................................... 17

Lumbar Support Inoperative............................................................................................................................... 17

Introduction ...................................................................................................................................................... 17

Test Description ............................................................................................................................................... 17

Diagnostic Table............................................................................................................................................... 17

2.3 Electrical Diagnosis – Front Seat, Non-memory............................................................................................... 18

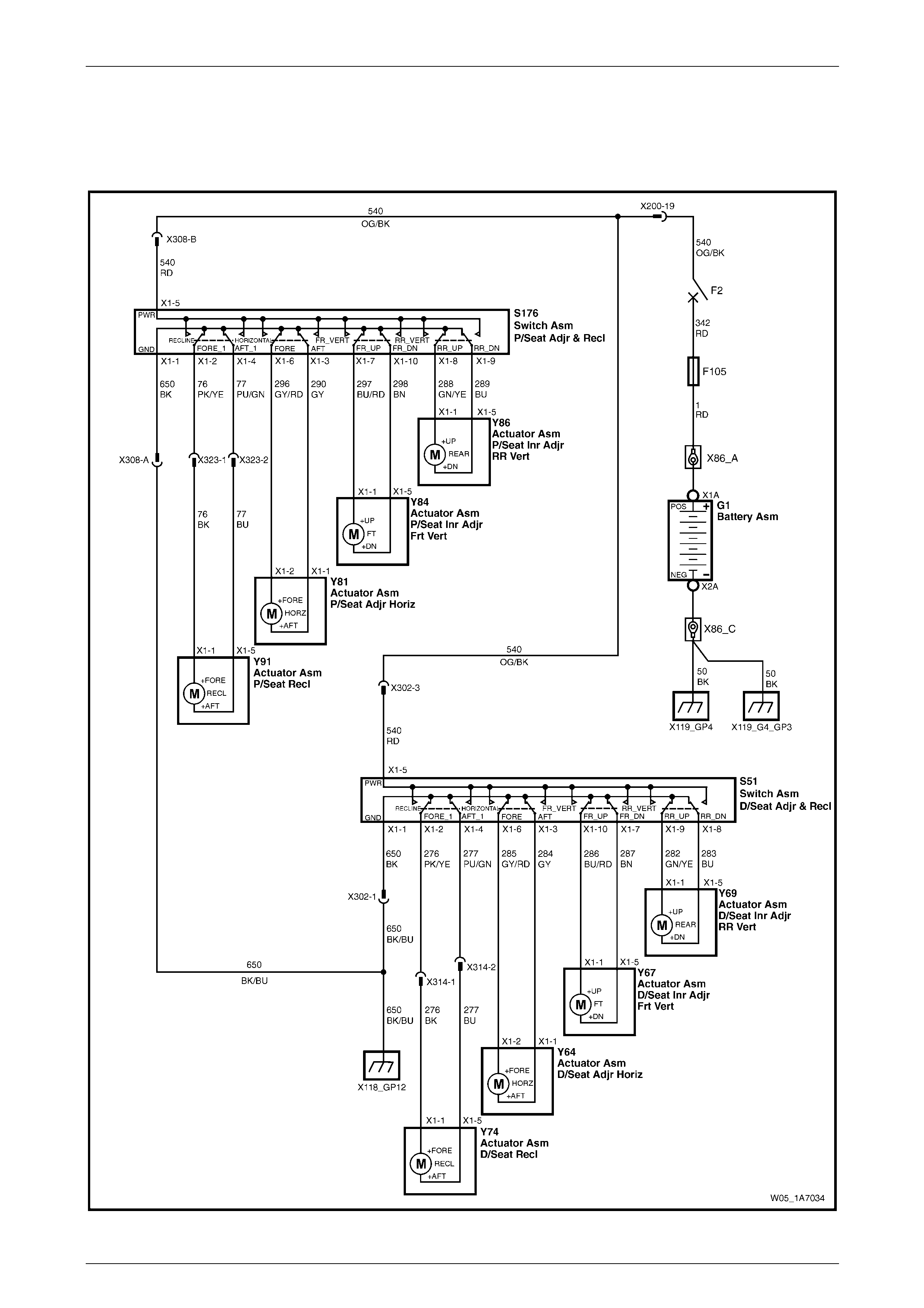

Wiring Diagram – Front Seat, Non-memory....................................................................................................... 18

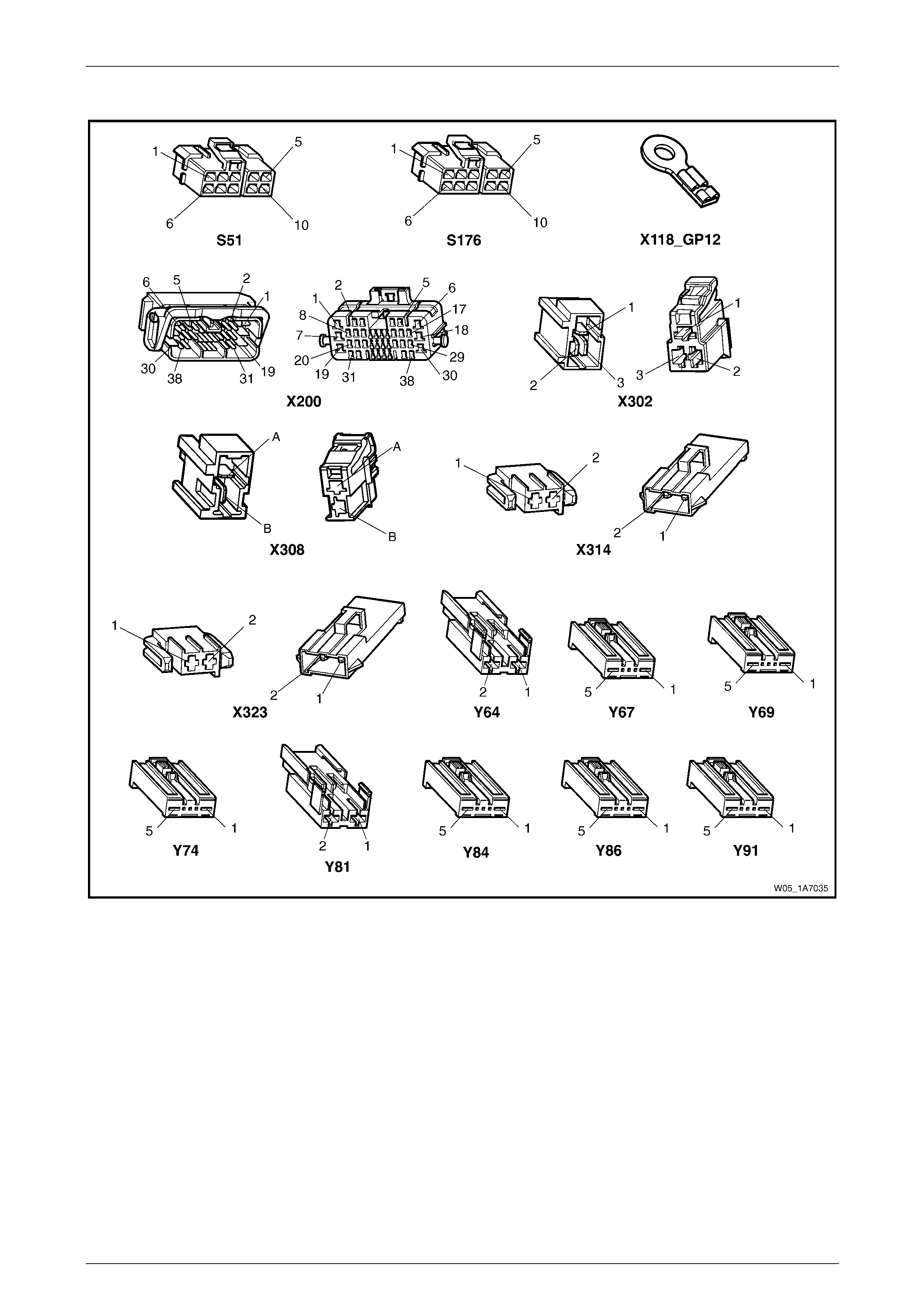

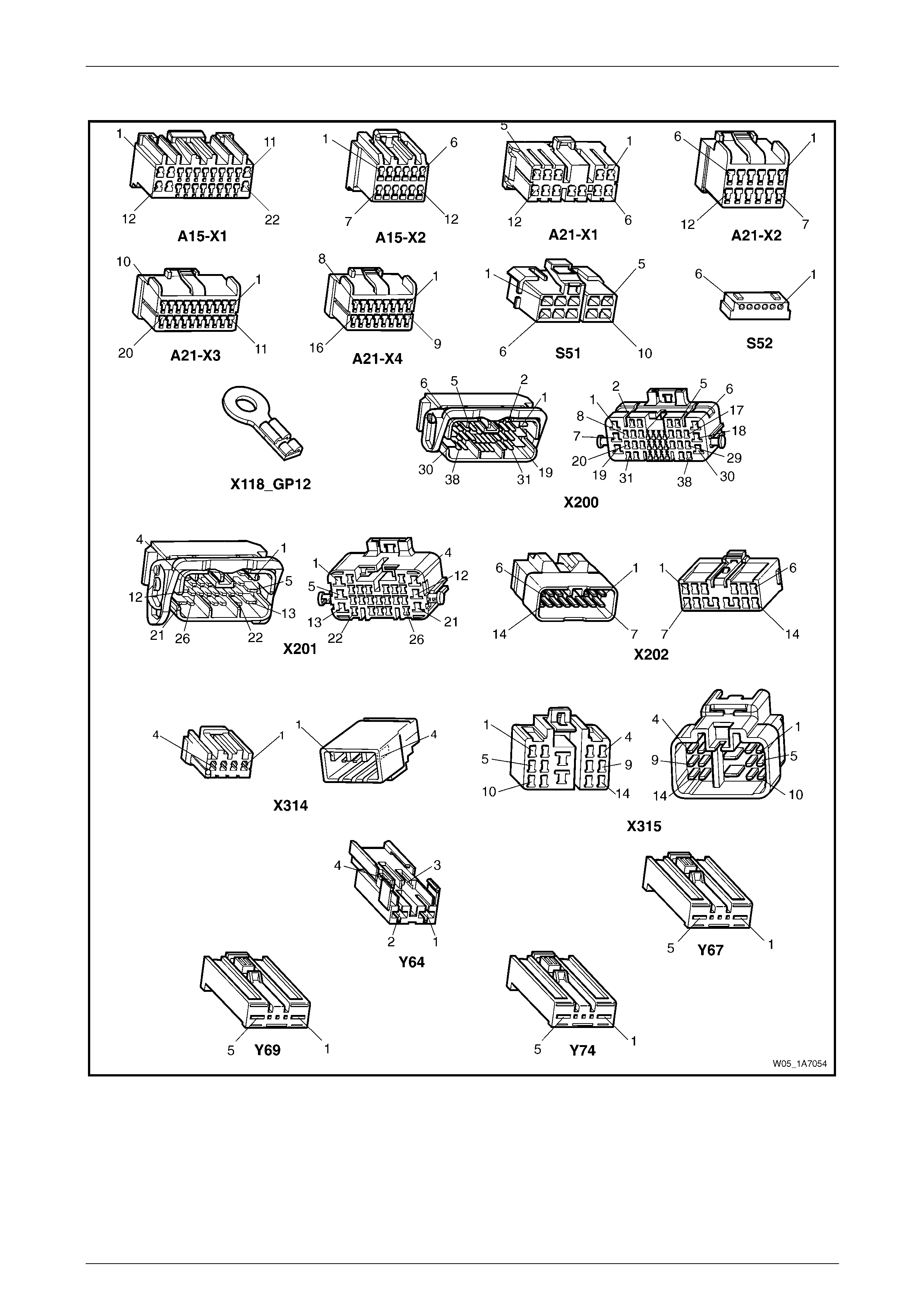

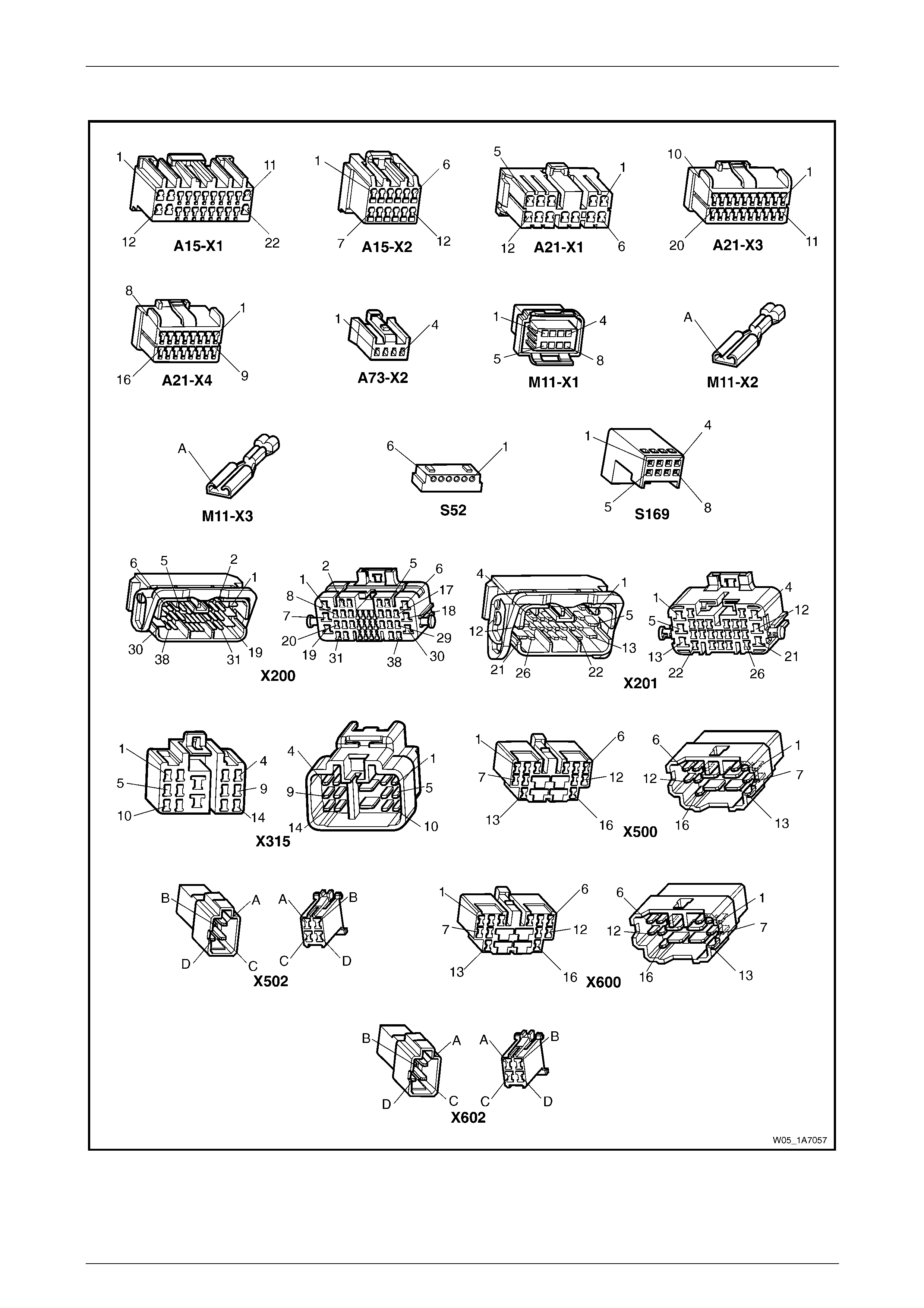

Connector Chart – Front Seat, Non-memory..................................................................................................... 19

Neither Seat Adjustment Switch Functions Operate........................................................................................ 20

Introduction ...................................................................................................................................................... 20

Test Description ............................................................................................................................................... 20

Diagnostic Table Notes .................................................................................................................................... 20

Diagnostic Table............................................................................................................................................... 21

None of the Driver’s Seat Adjustment Switch Functions Operate...................................................................22

Introduction ...................................................................................................................................................... 22

Test Description ............................................................................................................................................... 22

Diagnostic Table Notes .................................................................................................................................... 22

Diagnostic Table............................................................................................................................................... 23

Front/Rear of the Driver’s Seat Does Not Raise and/or Lower......................................................................... 24

Introduction ...................................................................................................................................................... 24

Test Description ............................................................................................................................................... 24

Diagnostic Table Notes .................................................................................................................................... 24

Diagnostic Table............................................................................................................................................... 25

Techline

Techline

Techline

Techline

Seat Assemblies Page 1A7–2

Page 1A7–2

Driver’s Seat Fore/Aft Movement Function is Inoperative or Not Smooth...................................................... 26

Introduction ...................................................................................................................................................... 26

Test Description ............................................................................................................................................... 26

Diagnostic Table Notes .................................................................................................................................... 26

Diagnostic Table............................................................................................................................................... 27

Driver’s Seat-back Recline Forw ard and/or Aft Function is Inoperative......................................................... 28

Introduction ...................................................................................................................................................... 28

Test Description ............................................................................................................................................... 28

Diagnostic Table Notes .................................................................................................................................... 28

Diagnostic Table............................................................................................................................................... 29

None of the Passenger’s Seat Adjustment Switch Functions Operate........................................................... 30

Introduction ...................................................................................................................................................... 30

Test Description ............................................................................................................................................... 30

Diagnostic Table Notes .................................................................................................................................... 30

Diagnostic Table............................................................................................................................................... 31

Front/Rear of the Passenger’s Seat Does Not Raise and/or Lower................................................................. 32

Introduction ...................................................................................................................................................... 32

Test Description ............................................................................................................................................... 32

Diagnostic Table Notes .................................................................................................................................... 32

Diagnostic Table............................................................................................................................................... 33

Passenger’s Seat Fore/Aft Movement Function is Inoperative or Not Smooth.............................................. 34

Introduction ...................................................................................................................................................... 34

Test Description ............................................................................................................................................... 34

Diagnostic Table Notes .................................................................................................................................... 34

Diagnostic Table............................................................................................................................................... 35

Passenger’s Seat-back Recline Forward and/or Aft Function is Inoperative................................................. 36

Introduction ...................................................................................................................................................... 36

Test Description ............................................................................................................................................... 36

Diagnostic Table Notes .................................................................................................................................... 36

Diagnostic Table............................................................................................................................................... 37

2.4 Seat Adjustment Switch Test.............................................................................................................................. 38

Test ....................................................................................................................................................................... 38

3 Diagnostics – Front Seat, Memory and Rear-v iew Mirror ................................................................39

3.1 Prerequisites........................................................................................................................................................ 39

Safety Requirements ........................................................................................................................................... 39

Equipment ............................................................................................................................................................ 39

Testing Procedures ............................................................................................................................................. 39

3.2 System Self Diagnosis ........................................................................................................................................ 40

Current DTCs........................................................................................................................................................ 40

History DTCs........................................................................................................................................................ 40

Clearing DTCs...................................................................................................................................................... 40

3.3 Tech 2 Diagnostics.............................................................................................................................................. 41

Test Modes........................................................................................................................................................... 41

Mode F0: Diagnostic Trouble Codes................................................................................................................ 41

Mode F1: Diagnostic Data Display................................................................................................................... 41

Mode F2: Snapshot.......................................................................................................................................... 41

Mode F3: Miscellaneous Tests......................................................................................................................... 41

Mode F4: Additional Functions......................................................................................................................... 41

Seat Assemblies Page 1A7–3

Page 1A7–3

3.4 Tech 2 Test Modes and Displays for Diagnosis................................................................................................ 42

System Select Menu............................................................................................................................................ 42

Body Application Menu....................................................................................................................................... 42

System Identification........................................................................................................................................... 42

Application Menu................................................................................................................................................. 42

F0: Diagnostic Trouble Codes............................................................................................................................ 43

F0: Read DTC Information ............................................................................................................................... 43

F1: Clear DTC Information ............................................................................................................................... 43

Diagnostic Trouble Codes................................................................................................................................... 43

F1: Diagnostic Data Display................................................................................................................................ 44

F0: Inputs and Outputs..................................................................................................................................... 44

F1: Memory...................................................................................................................................................... 48

F2: System Identification.................................................................................................................................. 49

F2: Snapshot........................................................................................................................................................ 49

F3: Miscellaneous Tests...................................................................................................................................... 50

F0: Chime......................................................................................................................................................... 50

F1: LED............................................................................................................................................................ 50

F2: Right Exterior Mirror................................................................................................................................... 50

F3: Left Exterior Mirror ..................................................................................................................................... 50

F4: Front Vertical Motor.................................................................................................................................... 50

F5: Rear Vertical Mirror.................................................................................................................................... 50

F6: Horizontal Motor......................................................................................................................................... 50

F7: Recline Motor............................................................................................................................................. 50

F4: Additional Functions..................................................................................................................................... 50

F0: Module Reset............................................................................................................................................. 50

3.5 Preliminary System Diagnosis............................................................................................................................ 51

3.6 Diagnostic Tables................................................................................................................................................ 52

Introduction.......................................................................................................................................................... 52

3.7 Mechanical Diagnosis ......................................................................................................................................... 53

Lumbar Support Inoperative............................................................................................................................... 53

Introduction ...................................................................................................................................................... 53

Test Description ............................................................................................................................................... 53

Diagnostic Table............................................................................................................................................... 53

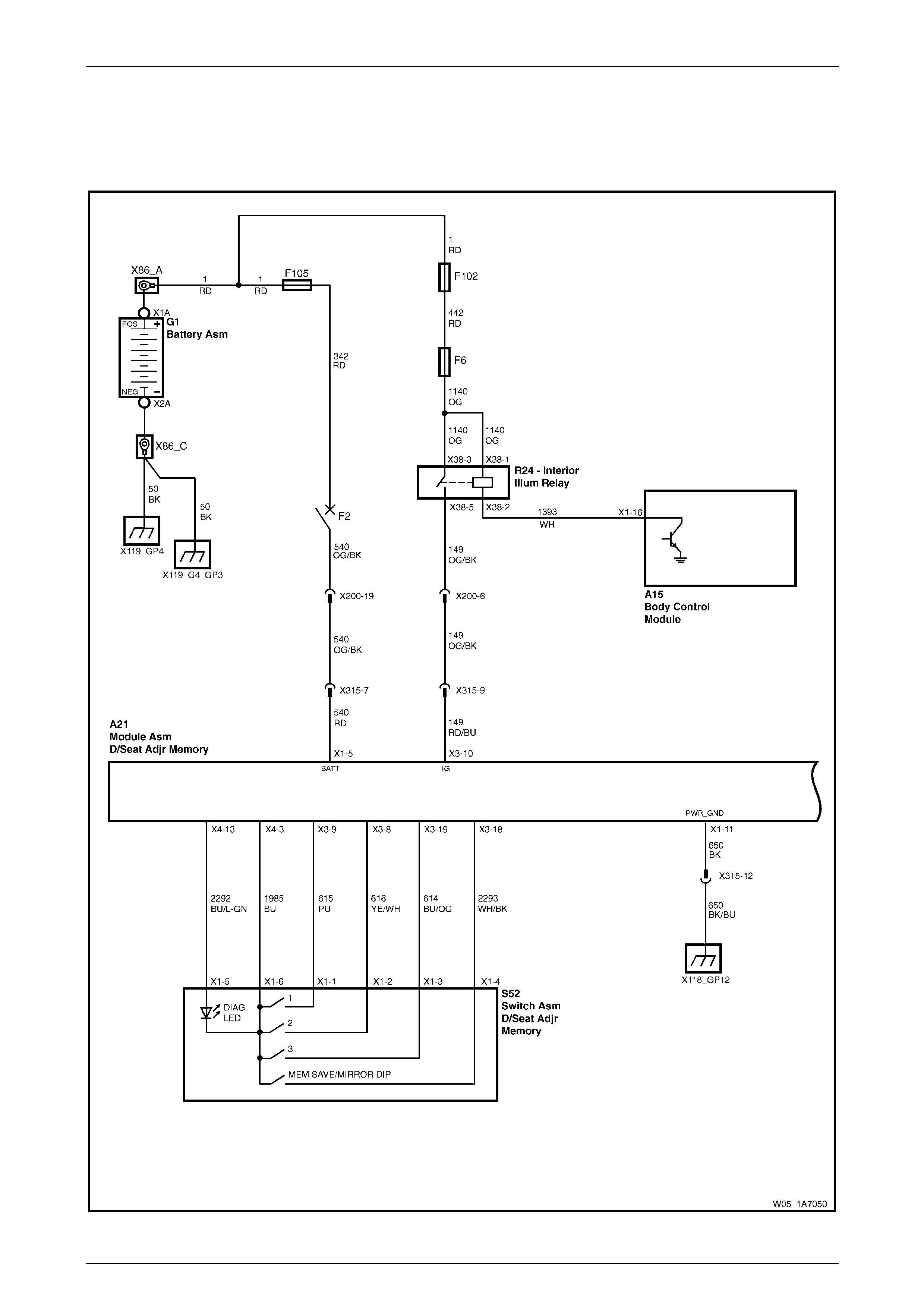

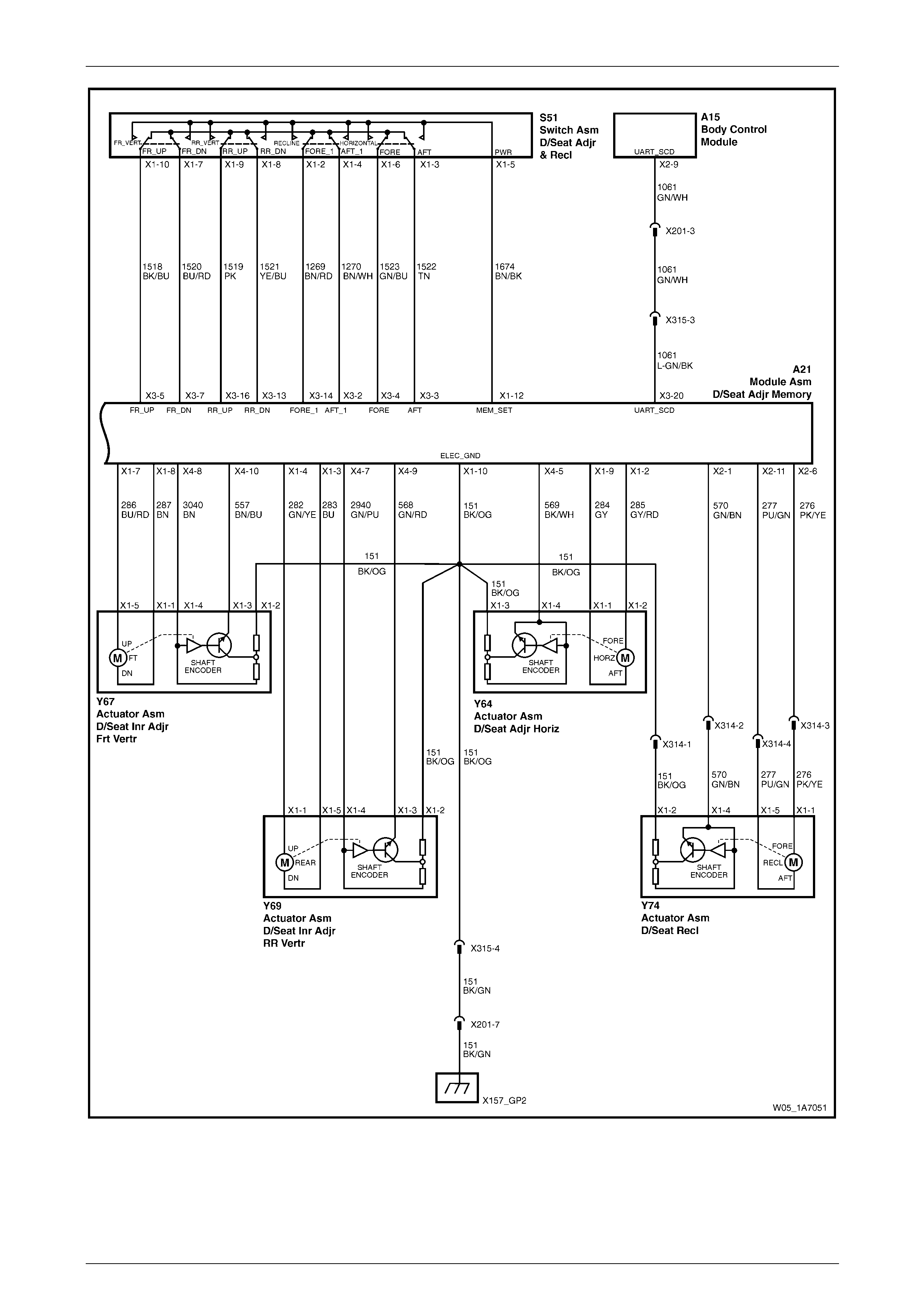

3.8 Electrical Diagnosis – Front Seat, Memory........................................................................................................ 54

Wiring Diagram – Front Seat, Memory............................................................................................................... 54

Connector Chart – Front Seat, Memory............................................................................................................. 56

Initial Check.......................................................................................................................................................... 57

Introduction ...................................................................................................................................................... 57

Test Description ............................................................................................................................................... 57

Diagnostic Table............................................................................................................................................... 58

No Serial Data Communications to the Seat Memory Module.........................................................................63

Introduction ...................................................................................................................................................... 63

Test Description ............................................................................................................................................... 63

Diagnostic Table Notes .................................................................................................................................... 63

Diagnostic Table............................................................................................................................................... 64

Seat Adjustment Switch Inoperative.................................................................................................................. 65

Introduction ...................................................................................................................................................... 65

Test Description ............................................................................................................................................... 65

Diagnostic Table Notes .................................................................................................................................... 65

Diagnostic Table............................................................................................................................................... 66

Seat Front Lift Motor Inoperative ........................................................................................................................ 67

Introduction ...................................................................................................................................................... 67

Test Description ............................................................................................................................................... 67

Diagnostic Table Notes .................................................................................................................................... 67

Diagnostic Table............................................................................................................................................... 67

Seat Assemblies Page 1A7–4

Page 1A7–4

Seat Rear Lift Motor Inoperative......................................................................................................................... 68

Introduction ...................................................................................................................................................... 68

Test Description ............................................................................................................................................... 68

Diagnostic Table Notes .................................................................................................................................... 68

Diagnostic Table............................................................................................................................................... 68

Seat Fore/Aft Movement Motor Inoperative....................................................................................................... 69

Introduction ...................................................................................................................................................... 69

Test Description ............................................................................................................................................... 69

Diagnostic Table Notes .................................................................................................................................... 69

Diagnostic Table............................................................................................................................................... 69

Seat-back Recline Motor Inoperative ................................................................................................................. 70

Introduction ...................................................................................................................................................... 70

Test Description ............................................................................................................................................... 70

Diagnostic Table Notes .................................................................................................................................... 70

Diagnostic Table............................................................................................................................................... 71

Memory Position Switch Inoperative ................................................................................................................. 72

Introduction ...................................................................................................................................................... 72

Test Description ............................................................................................................................................... 72

Diagnostic Table Notes .................................................................................................................................... 72

Diagnostic Table............................................................................................................................................... 72

Seat Front Lift Motor Hall-effect Sensor Check................................................................................................. 73

Introduction ...................................................................................................................................................... 73

Test Description ............................................................................................................................................... 73

Diagnostic Table Notes .................................................................................................................................... 73

Diagnostic Table............................................................................................................................................... 73

Seat Rear Lift Motor Hall-effect Sensor Check.................................................................................................. 74

Introduction ...................................................................................................................................................... 74

Test Description ............................................................................................................................................... 74

Diagnostic Table Notes .................................................................................................................................... 74

Diagnostic Table............................................................................................................................................... 74

Seat Fore/Aft Movement Motor Hall-effect Sensor Check................................................................................ 75

Introduction ...................................................................................................................................................... 75

Test Description ............................................................................................................................................... 75

Diagnostic Table Notes .................................................................................................................................... 75

Diagnostic Table............................................................................................................................................... 75

Seat-back Recline Motor Hall-effect Sensor Check.......................................................................................... 76

Introduction ...................................................................................................................................................... 76

Test Description ............................................................................................................................................... 76

Diagnostic Table Notes .................................................................................................................................... 76

Diagnostic Table............................................................................................................................................... 76

Priority Key Feature Inoperative......................................................................................................................... 77

Introduction ...................................................................................................................................................... 77

Test Description ............................................................................................................................................... 77

Diagnostic Table Notes .................................................................................................................................... 77

Diagnostic Table............................................................................................................................................... 77

DTC 1 – Front Vertical Up Switch Stuck ............................................................................................................ 78

Introduction ...................................................................................................................................................... 78

Test Description ............................................................................................................................................... 78

Diagnostic Table Notes .................................................................................................................................... 78

Diagnostic Table............................................................................................................................................... 78

DTC 2 – Front Vertical Down Switch Stuck........................................................................................................ 79

Introduction ...................................................................................................................................................... 79

Test Description ............................................................................................................................................... 79

Diagnostic Table Notes .................................................................................................................................... 79

Diagnostic Table............................................................................................................................................... 79

Seat Assemblies Page 1A7–5

Page 1A7–5

DTC 3 – Rear Vertical Up Switch Stuck.............................................................................................................. 80

Introduction ...................................................................................................................................................... 80

Test Description ............................................................................................................................................... 80

Diagnostic Table Notes .................................................................................................................................... 80

Diagnostic Table............................................................................................................................................... 80

DTC 4 – Rear Vertical Down Switch Stuck......................................................................................................... 81

Introduction ...................................................................................................................................................... 81

Test Description ............................................................................................................................................... 81

Diagnostic Table Notes .................................................................................................................................... 81

Diagnostic Table............................................................................................................................................... 81

DTC 5 – Horizontal Forward Switch Stuck......................................................................................................... 82

Introduction ...................................................................................................................................................... 82

Test Description ............................................................................................................................................... 82

Diagnostic Table Notes .................................................................................................................................... 82

Diagnostic Table............................................................................................................................................... 82

DTC 6 – Horizontal Back Switch Stuck .............................................................................................................. 83

Introduction ...................................................................................................................................................... 83

Test Description ............................................................................................................................................... 83

Diagnostic Table Notes .................................................................................................................................... 83

Diagnostic Table............................................................................................................................................... 83

DTC 7 – Recline Up Switch Stuck....................................................................................................................... 84

Introduction ...................................................................................................................................................... 84

Test Description ............................................................................................................................................... 84

Diagnostic Table Notes .................................................................................................................................... 84

Diagnostic Table............................................................................................................................................... 84

DTC 8 – Recline Down Switch Stuck.................................................................................................................. 85

Introduction ...................................................................................................................................................... 85

Test Description ............................................................................................................................................... 85

Diagnostic Table Notes .................................................................................................................................... 85

Diagnostic Table............................................................................................................................................... 85

DTC 9 – Memory Button 1 Stuck......................................................................................................................... 86

Introduction ...................................................................................................................................................... 86

Test Description ............................................................................................................................................... 86

Diagnostic Table Notes .................................................................................................................................... 86

Diagnostic Table............................................................................................................................................... 86

DTC 10 – Memory Button 2 Stuck....................................................................................................................... 87

Introduction ...................................................................................................................................................... 87

Test Description ............................................................................................................................................... 87

Diagnostic Table Notes .................................................................................................................................... 87

Diagnostic Table............................................................................................................................................... 87

DTC 11 – Memory Button 3 Stuck....................................................................................................................... 88

Introduction ...................................................................................................................................................... 88

Test Description ............................................................................................................................................... 88

Diagnostic Table Notes .................................................................................................................................... 88

Diagnostic Table............................................................................................................................................... 88

DTC 12 – Mirror DIP Button Stuck...................................................................................................................... 89

Introduction ...................................................................................................................................................... 89

Test Description ............................................................................................................................................... 89

Diagnostic Table Notes .................................................................................................................................... 89

Diagnostic Table............................................................................................................................................... 89

DTC 13 – No Serial Data ...................................................................................................................................... 90

DTC 14 – No Exterior Mirror Communications.................................................................................................. 90

DTC 20 – Front Vertical Position Sensor Fault.................................................................................................. 90

DTC 21 – Rear Vertical Position Sensor Fault................................................................................................... 90

DTC 22 – Horizontal Position Sensor Fault ....................................................................................................... 90

DTC 23 – Recline Position Sensor Fault............................................................................................................ 90

DTC 24 – System Voltage Out of Range ............................................................................................................ 90

Seat Assemblies Page 1A7–6

Page 1A7–6

3.9 Memory Position Switch Test............................................................................................................................. 91

Remove................................................................................................................................................................. 91

Reinstall................................................................................................................................................................ 91

Test ....................................................................................................................................................................... 91

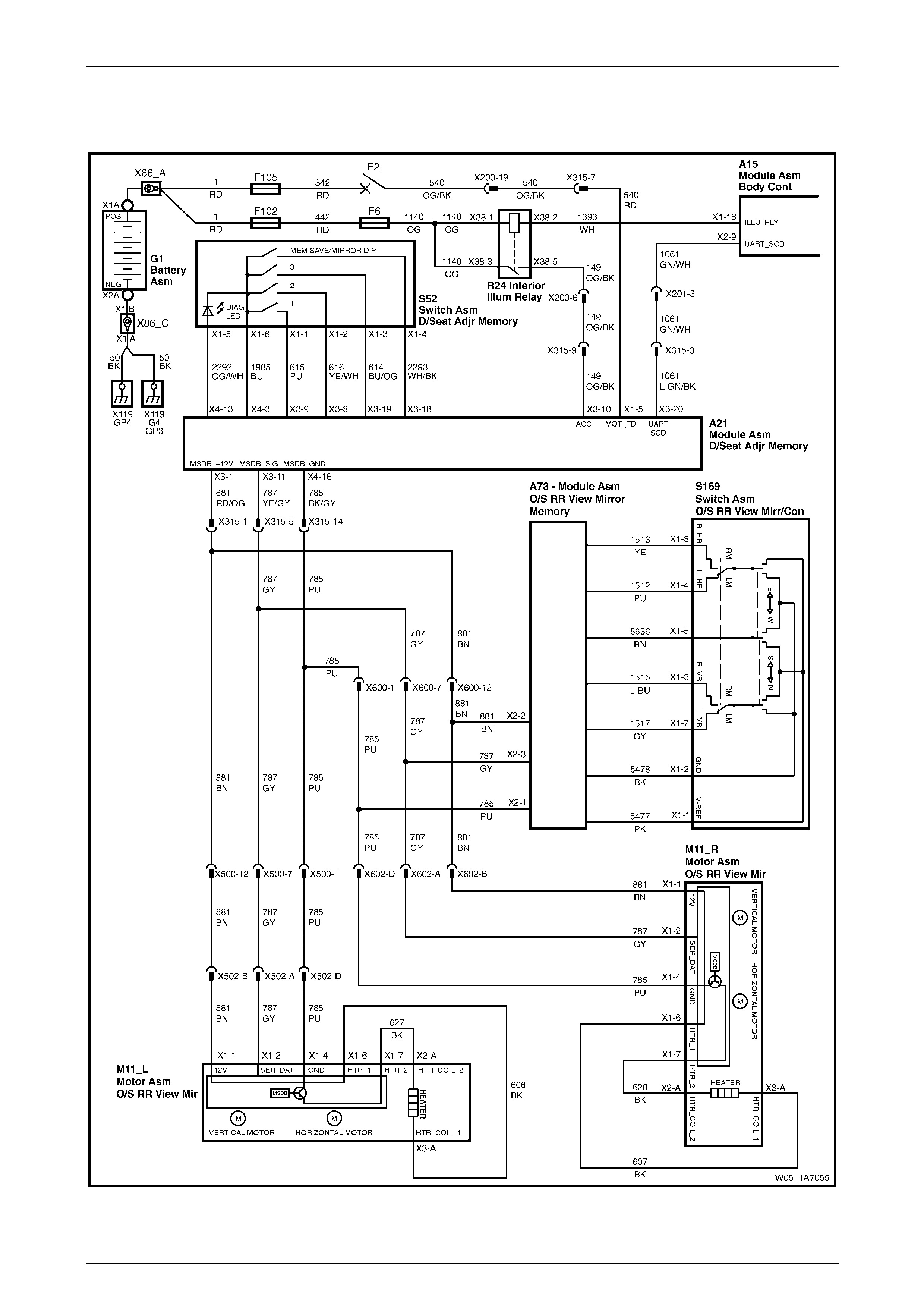

3.10 Electrical Diagnosis – Rear-view Mirrors........................................................................................................... 92

Wiring Diagram – Rear-view Mirrors.................................................................................................................. 92

Connector Chart – Rear-view Mirrors ................................................................................................................ 93

Initial Check.......................................................................................................................................................... 94

Introduction ...................................................................................................................................................... 94

Test Description ............................................................................................................................................... 94

Diagnostic Table............................................................................................................................................... 95

Mirror Dip Function Check.................................................................................................................................. 97

Introduction ...................................................................................................................................................... 97

Test Description ............................................................................................................................................... 97

Diagnostic Table............................................................................................................................................... 97

Mirror Heating Function Check........................................................................................................................... 98

Introduction ...................................................................................................................................................... 98

Test Description ............................................................................................................................................... 98

Diagnostic Table............................................................................................................................................... 98

No Serial Data from Exterior Rear-view Mirrors................................................................................................ 99

Introduction ...................................................................................................................................................... 99

Test Description ............................................................................................................................................... 99

Diagnostic Table Notes .................................................................................................................................... 99

Diagnostic Table............................................................................................................................................. 100

No Serial Data – Right-hand Exterior Rear-view Mirror.................................................................................. 101

Introduction .................................................................................................................................................... 101

Test Description ............................................................................................................................................. 101

Diagnostic Table Notes .................................................................................................................................. 101

Diagnostic Table............................................................................................................................................. 101

No Serial Data – Left-hand Exterior Rear-view Mirror..................................................................................... 102

Introduction .................................................................................................................................................... 102

Test Description ............................................................................................................................................. 102

Diagnostic Table Notes .................................................................................................................................. 102

Diagnostic Table............................................................................................................................................. 102

Mirror Control Switch Inoperative.................................................................................................................... 103

Introduction .................................................................................................................................................... 103

Test Description ............................................................................................................................................. 103

Diagnostic Table Notes .................................................................................................................................. 103

Diagnostic Table............................................................................................................................................. 104

4 Service Operations – Front Seat.......................................................................................................105

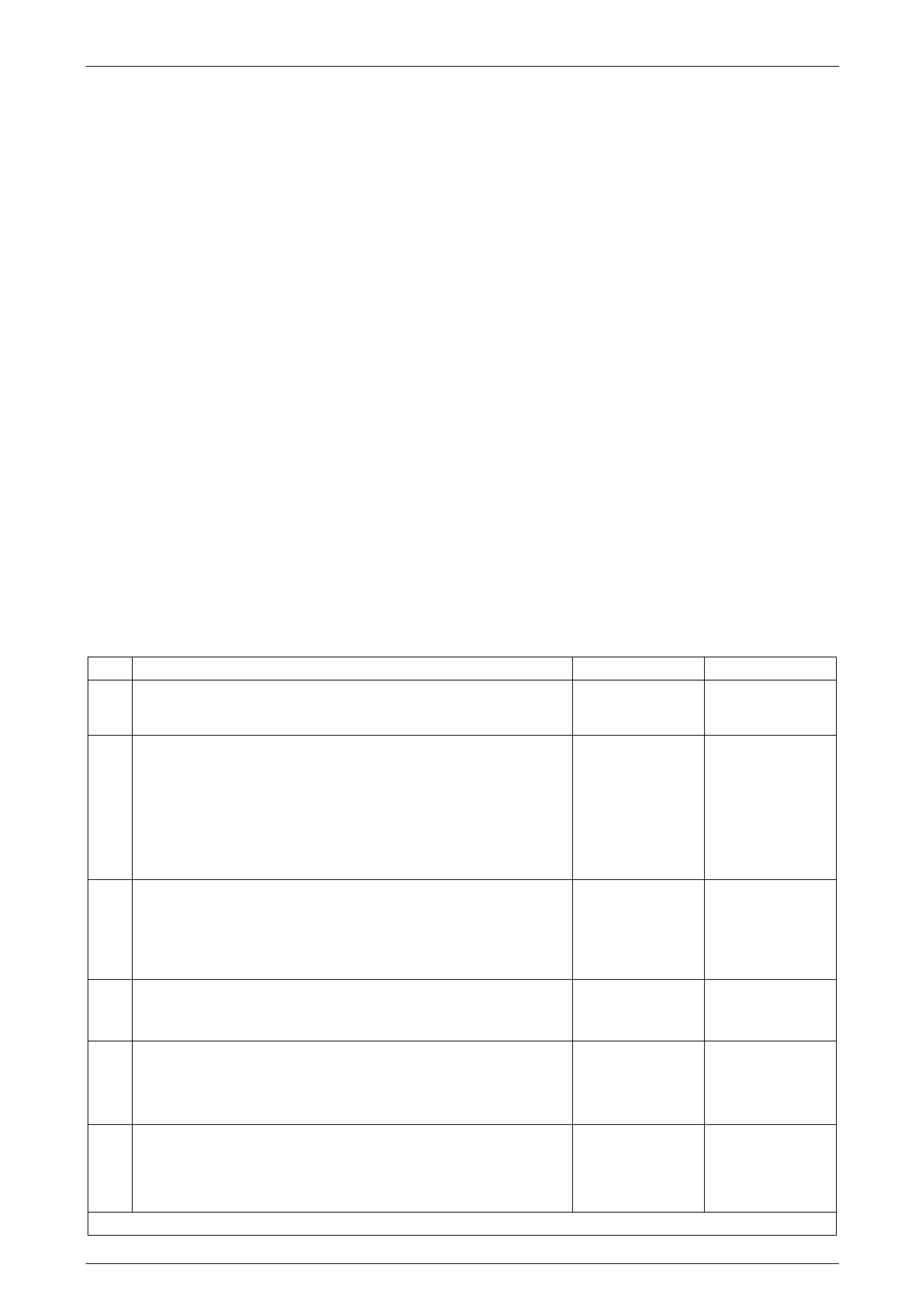

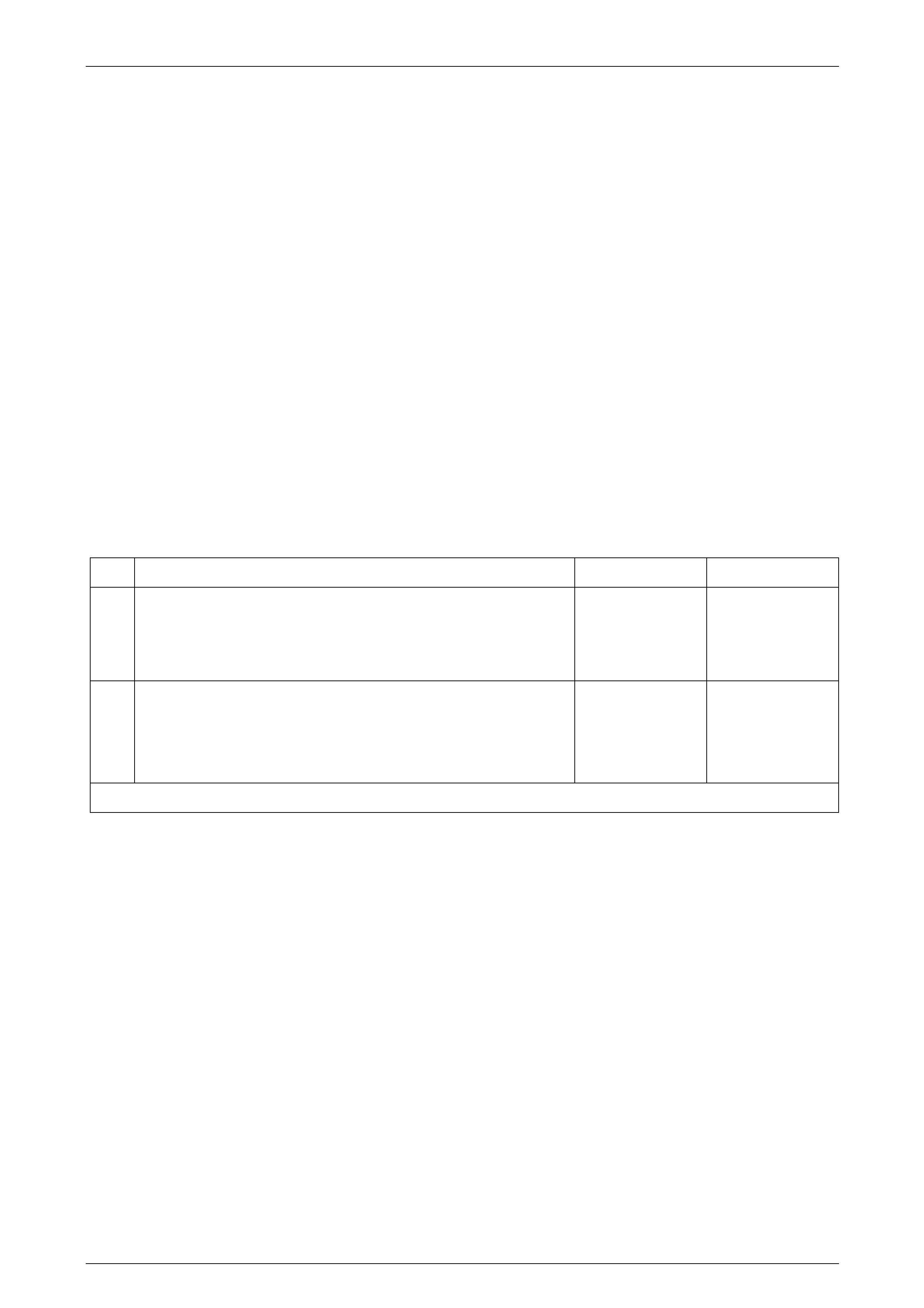

4.1 Usage Chart........................................................................................................................................................ 105

How to Use this Chart........................................................................................................................................ 105

Front Seat Type 1............................................................................................................................................... 106

Front Seat Type 2............................................................................................................................................... 108

Front Seat Type 3............................................................................................................................................... 110

Front Seat Type 4............................................................................................................................................... 112

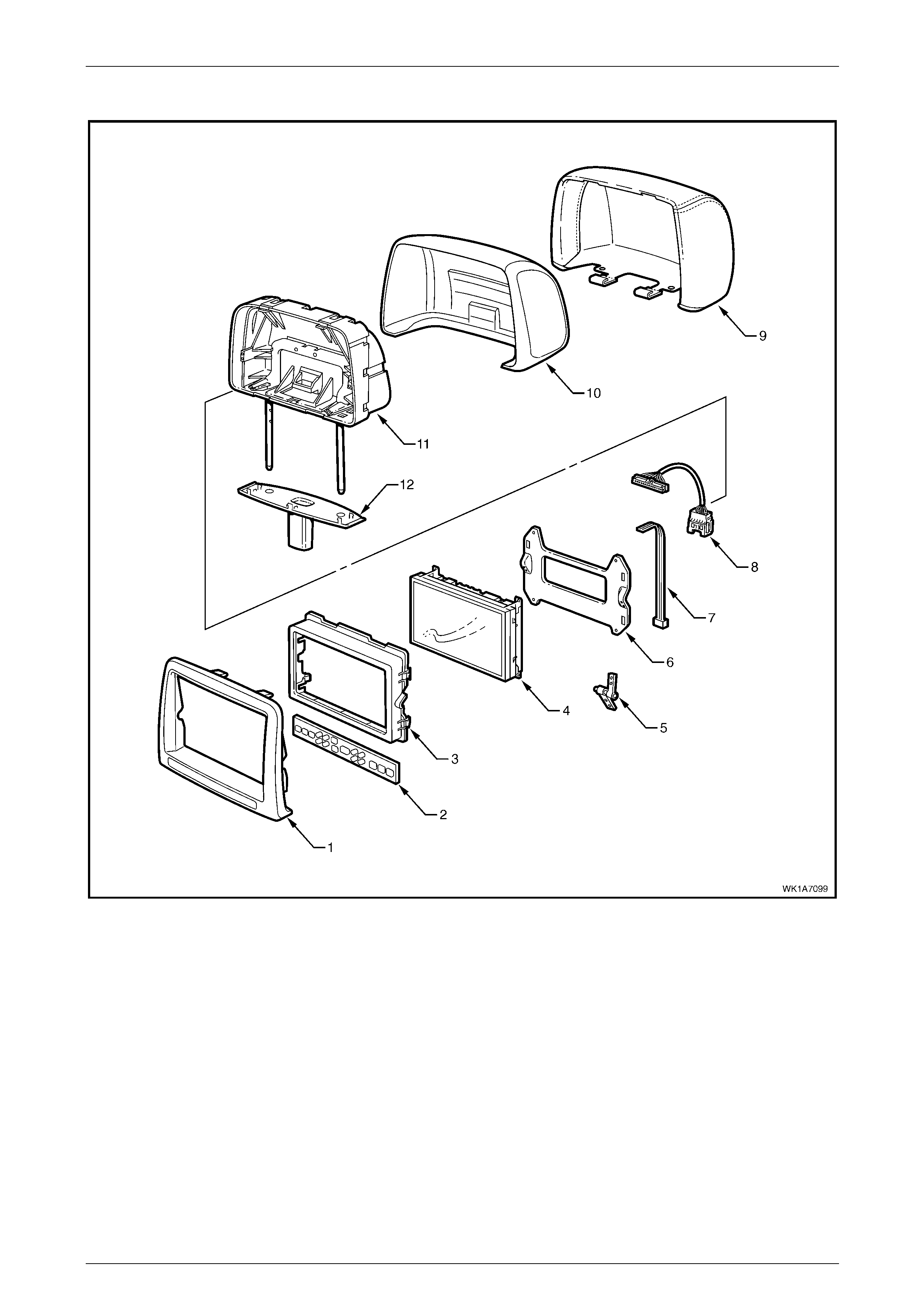

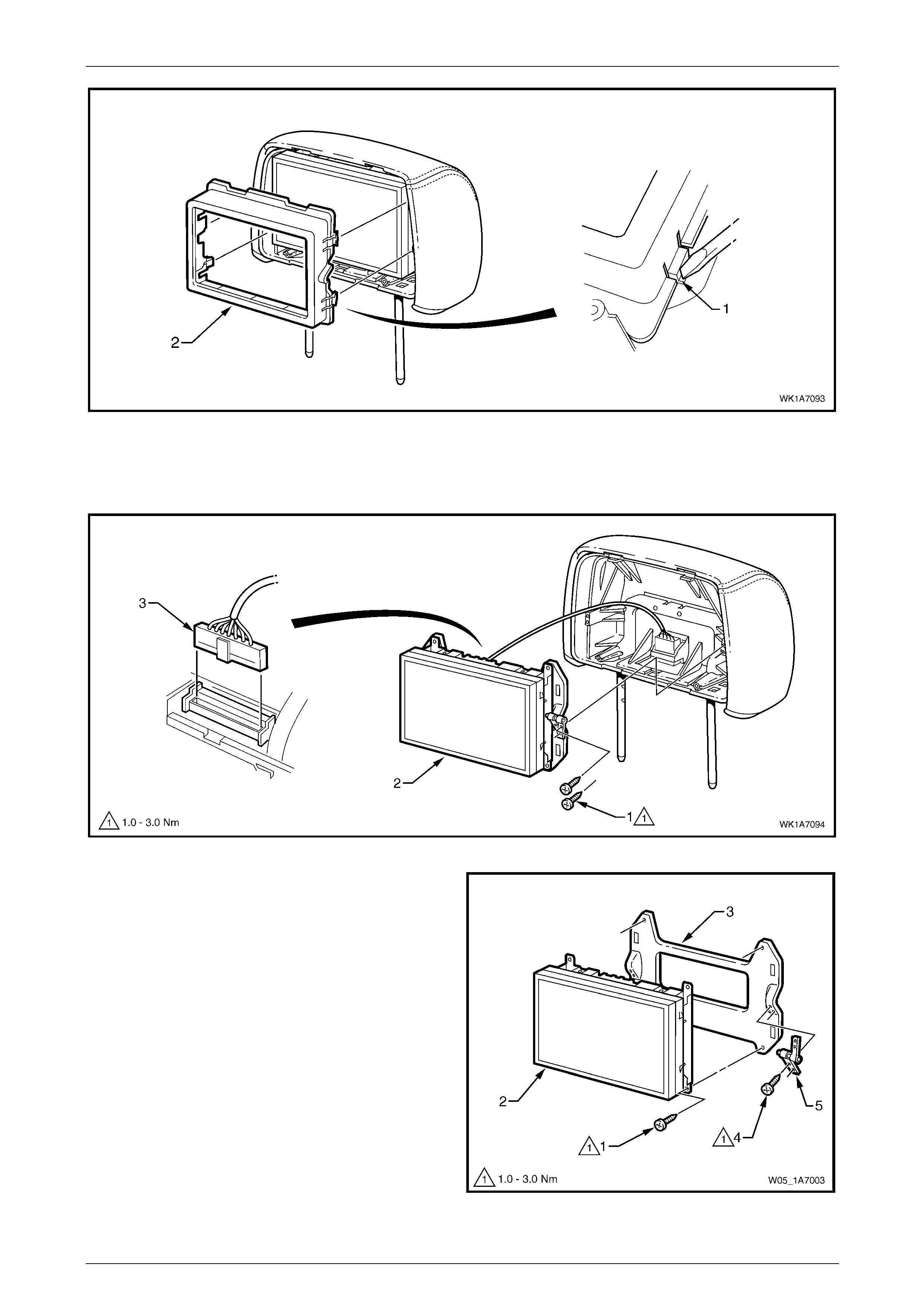

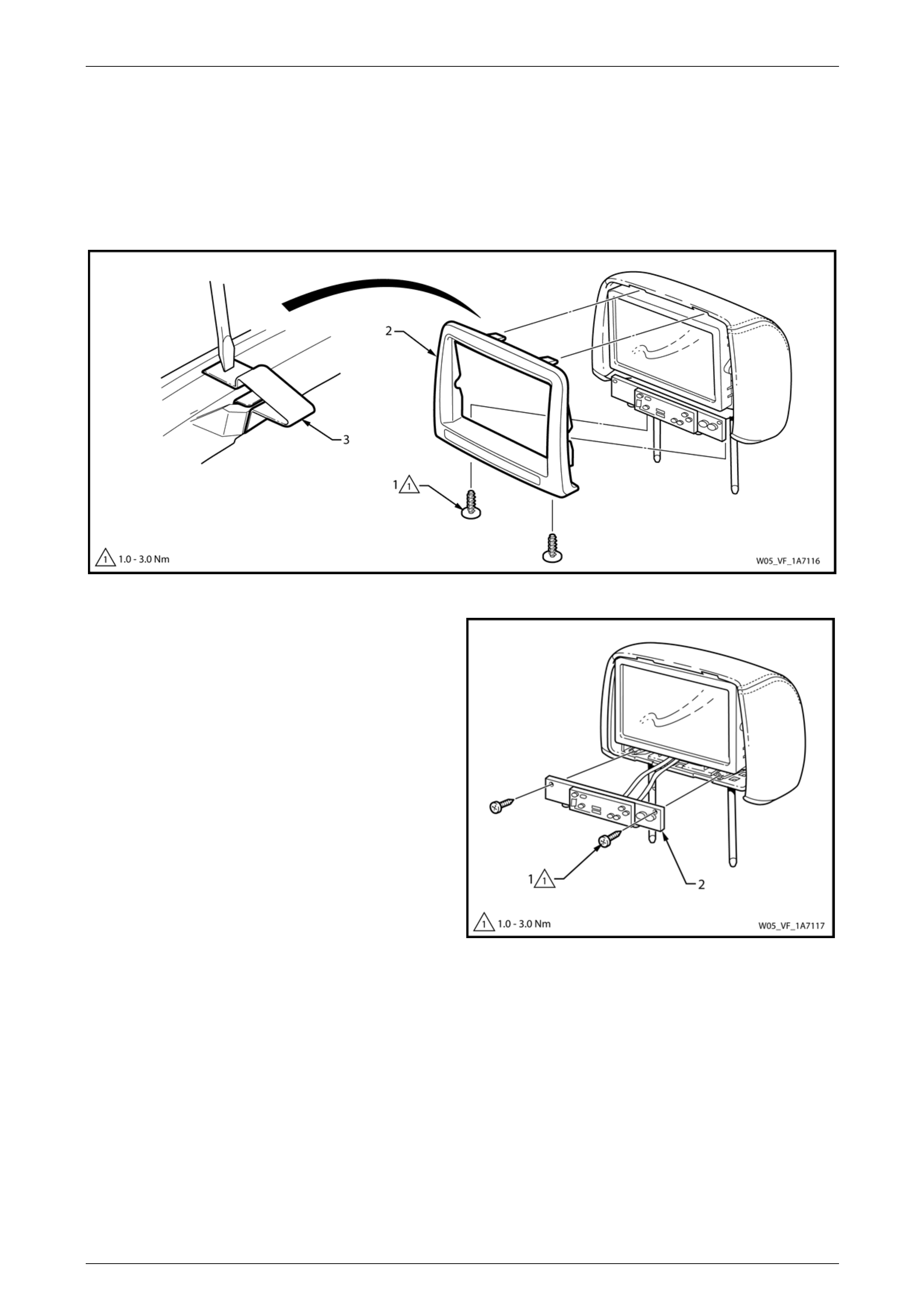

Front Seat Type 3 & 4 Head Restraint Assembly, Panasonic DVD................................................................ 114

Front Seat Head Restraint Assembly, Blaupunkt DVD................................................................................... 115

4.2 Front Seat Assembly......................................................................................................................................... 116

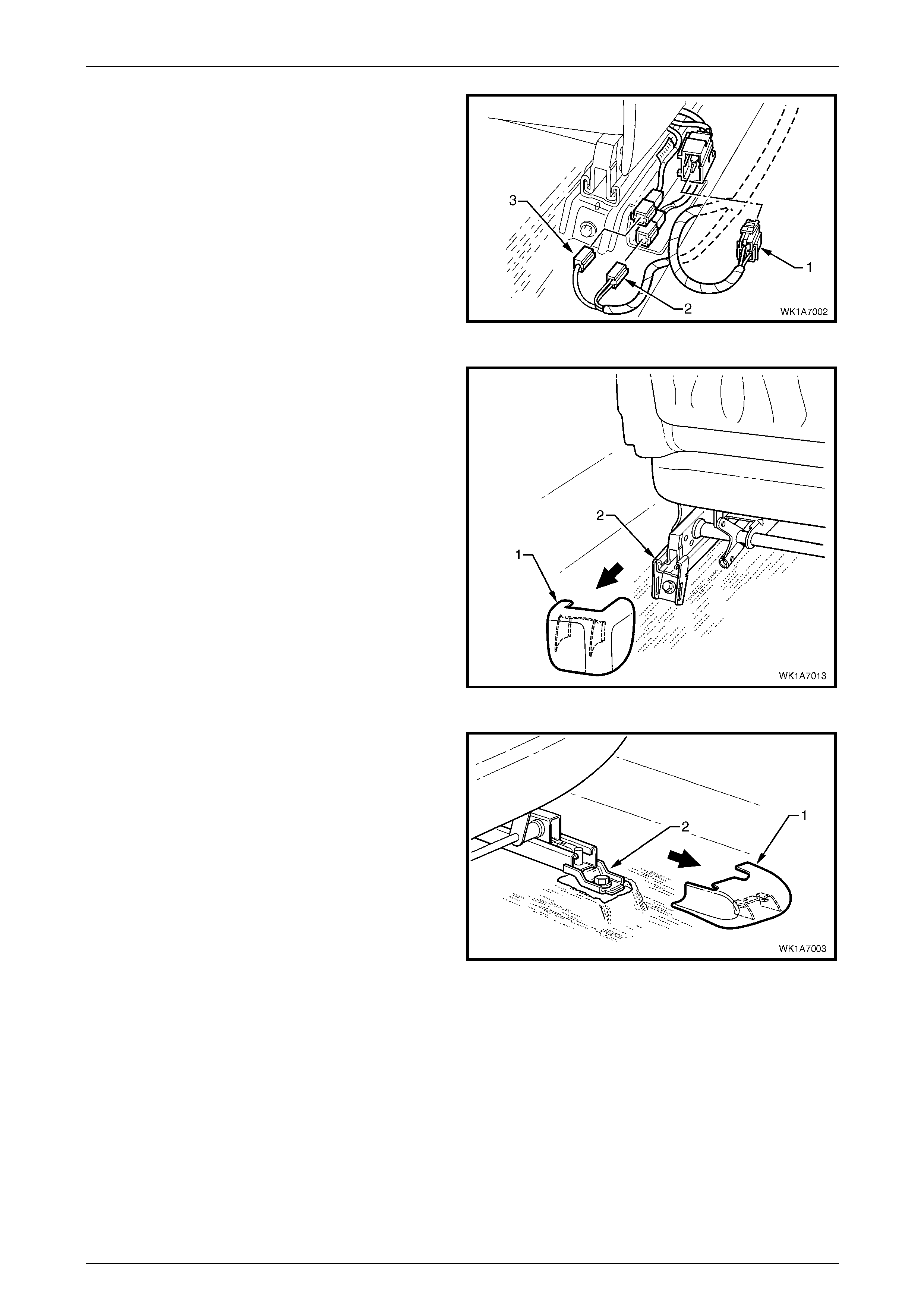

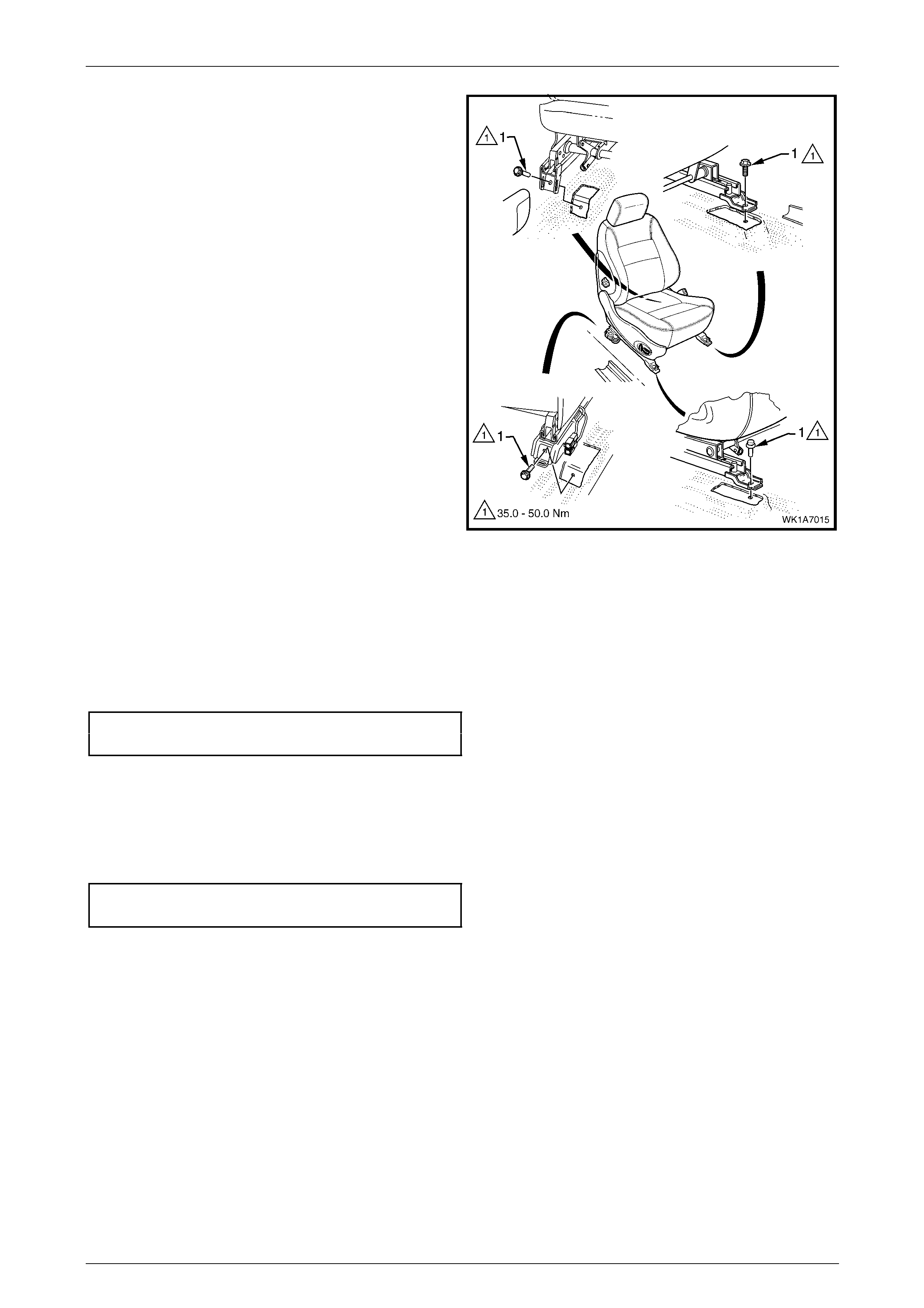

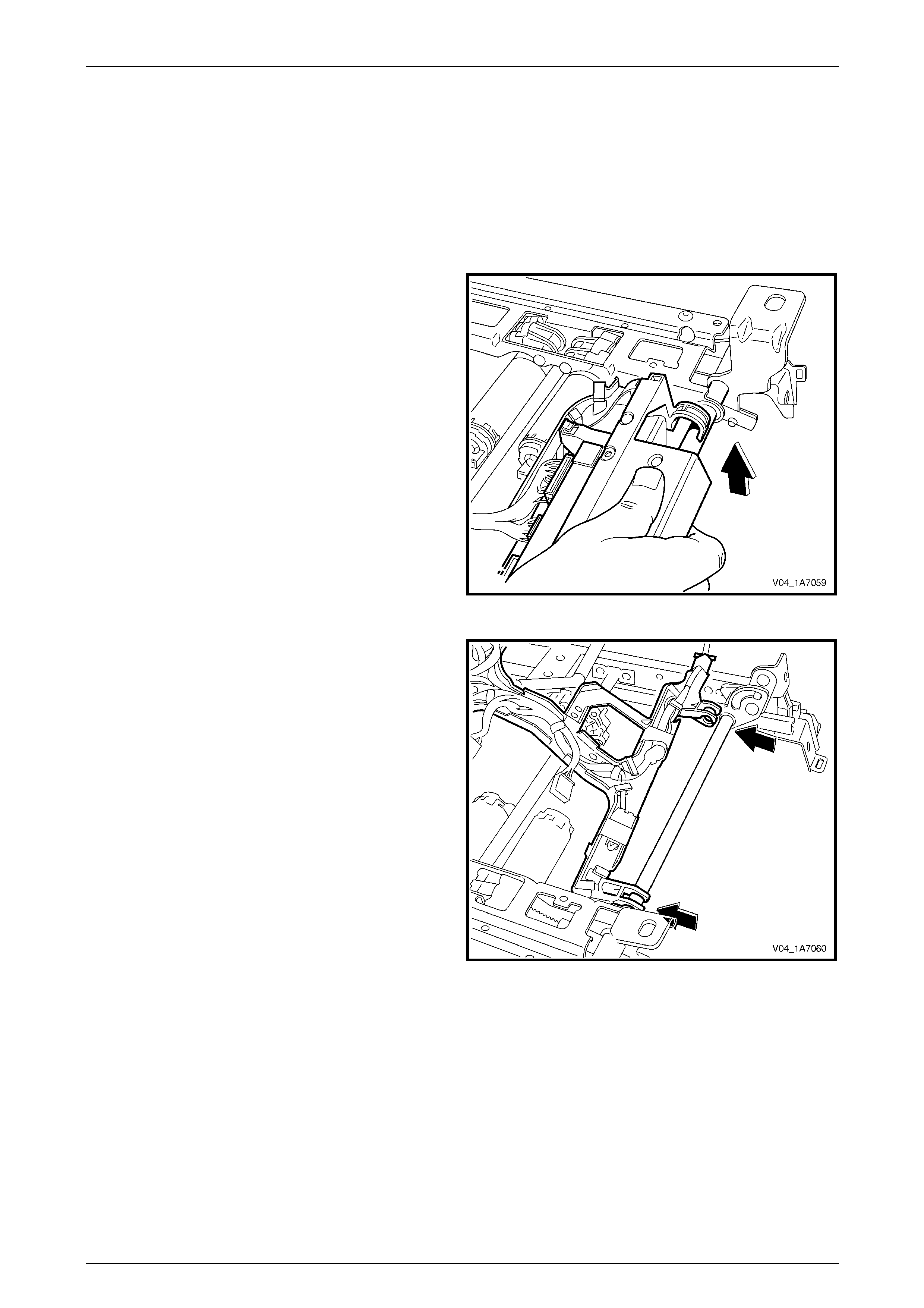

Remove............................................................................................................................................................... 116

Reinstall.............................................................................................................................................................. 118

Seat Memory Calibration................................................................................................................................... 119

Seat Assemblies Page 1A7–7

Page 1A7–7

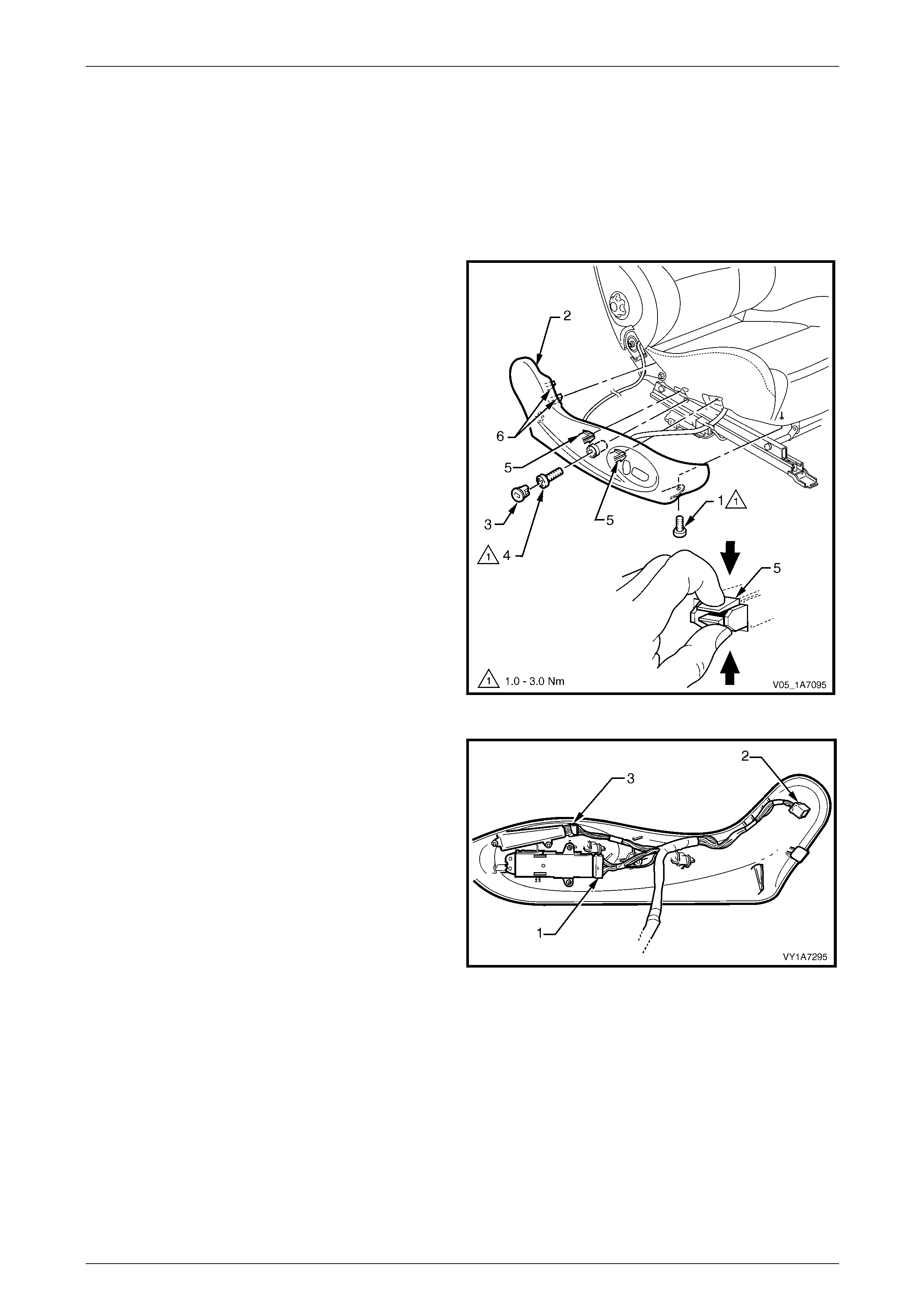

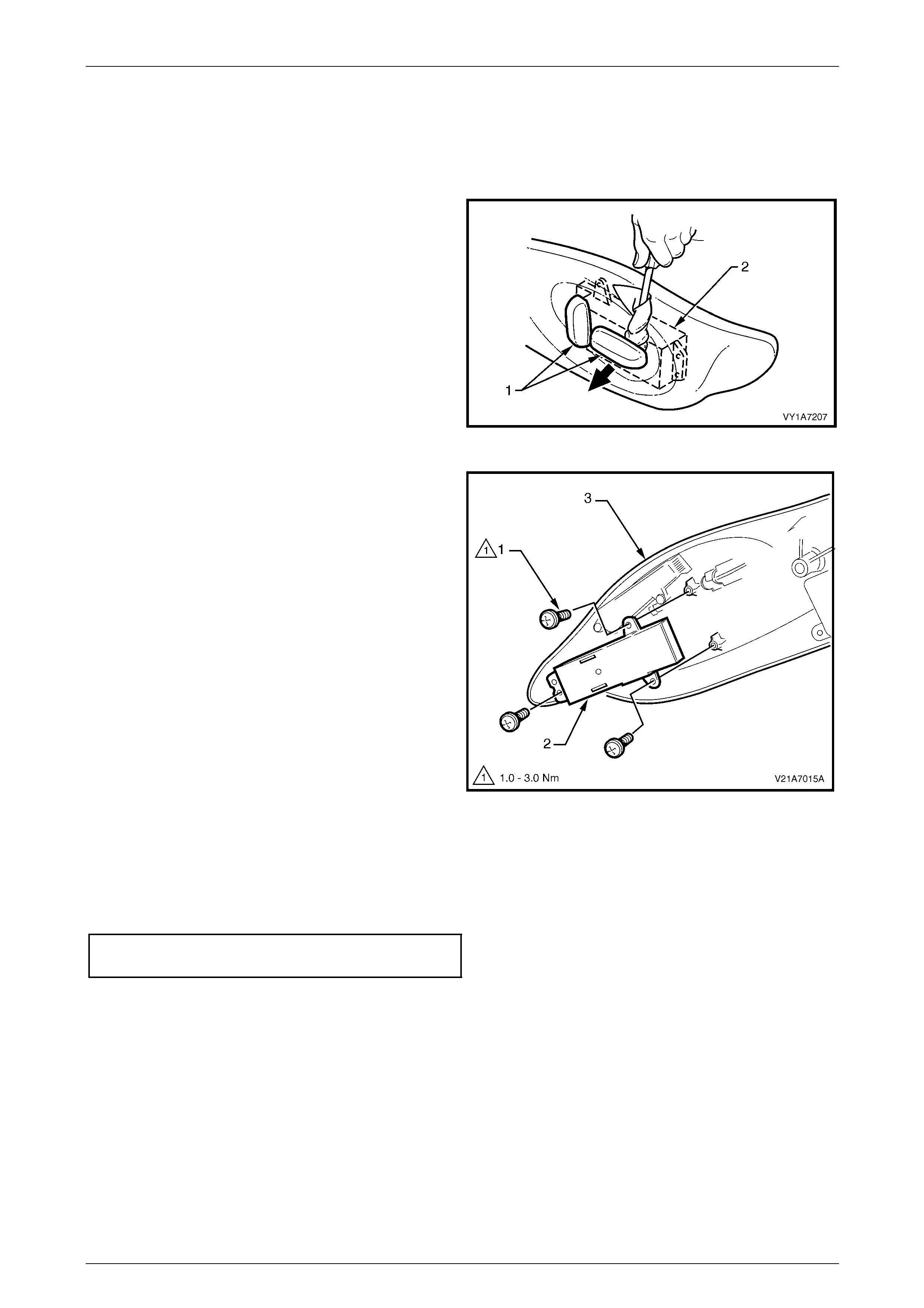

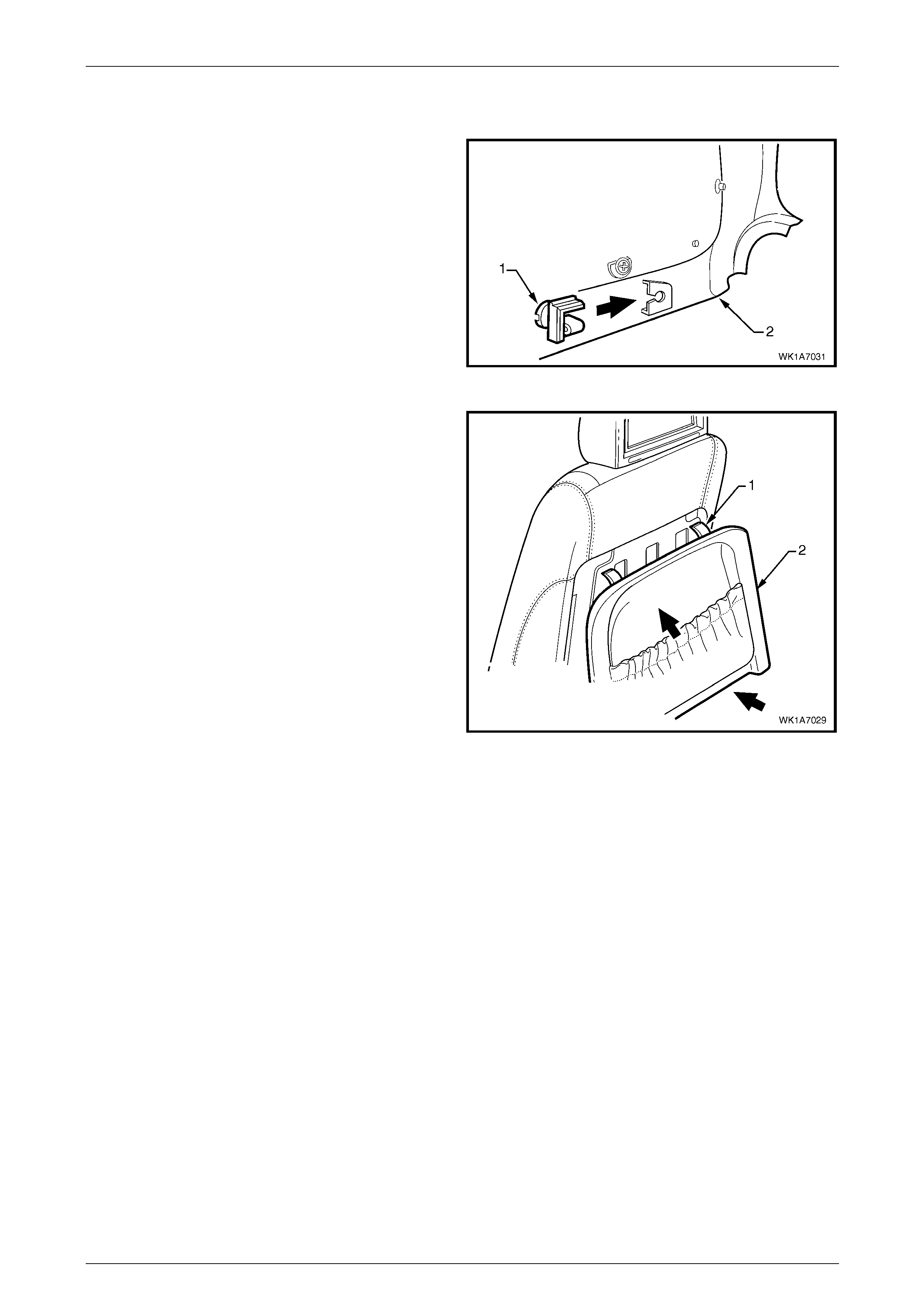

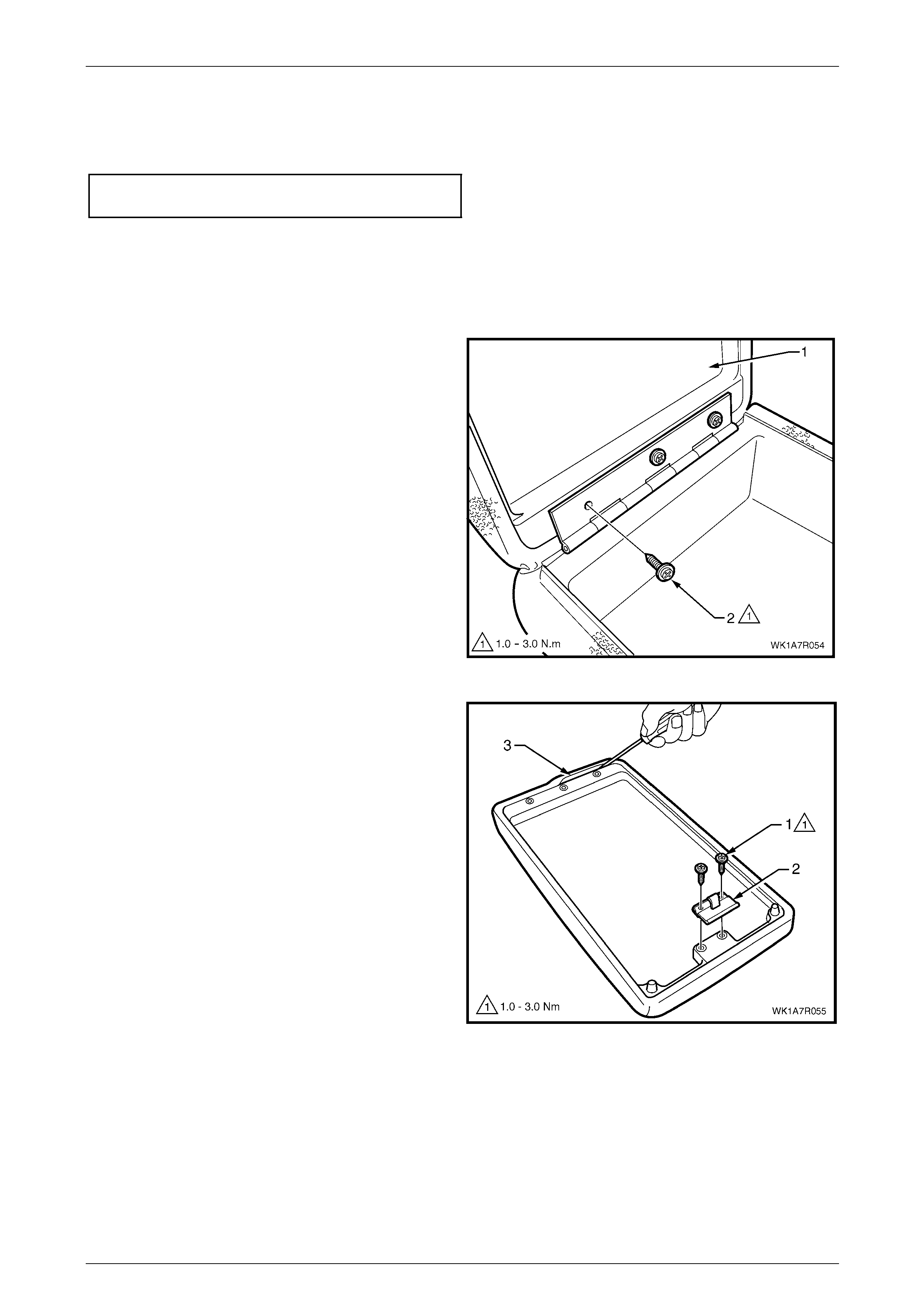

4.3 Front Seat Outer Side Cover Assembly........................................................................................................... 121

Remove............................................................................................................................................................... 121

Disassemble....................................................................................................................................................... 122

Front Seat Adjustment Switch........................................................................................................................ 122

Memory Position Switch Assembly................................................................................................................. 123

Reinstall.............................................................................................................................................................. 123

4.4 Front Seat Inner Side Cover.............................................................................................................................. 124

Remove............................................................................................................................................................... 124

Reinstall.............................................................................................................................................................. 124

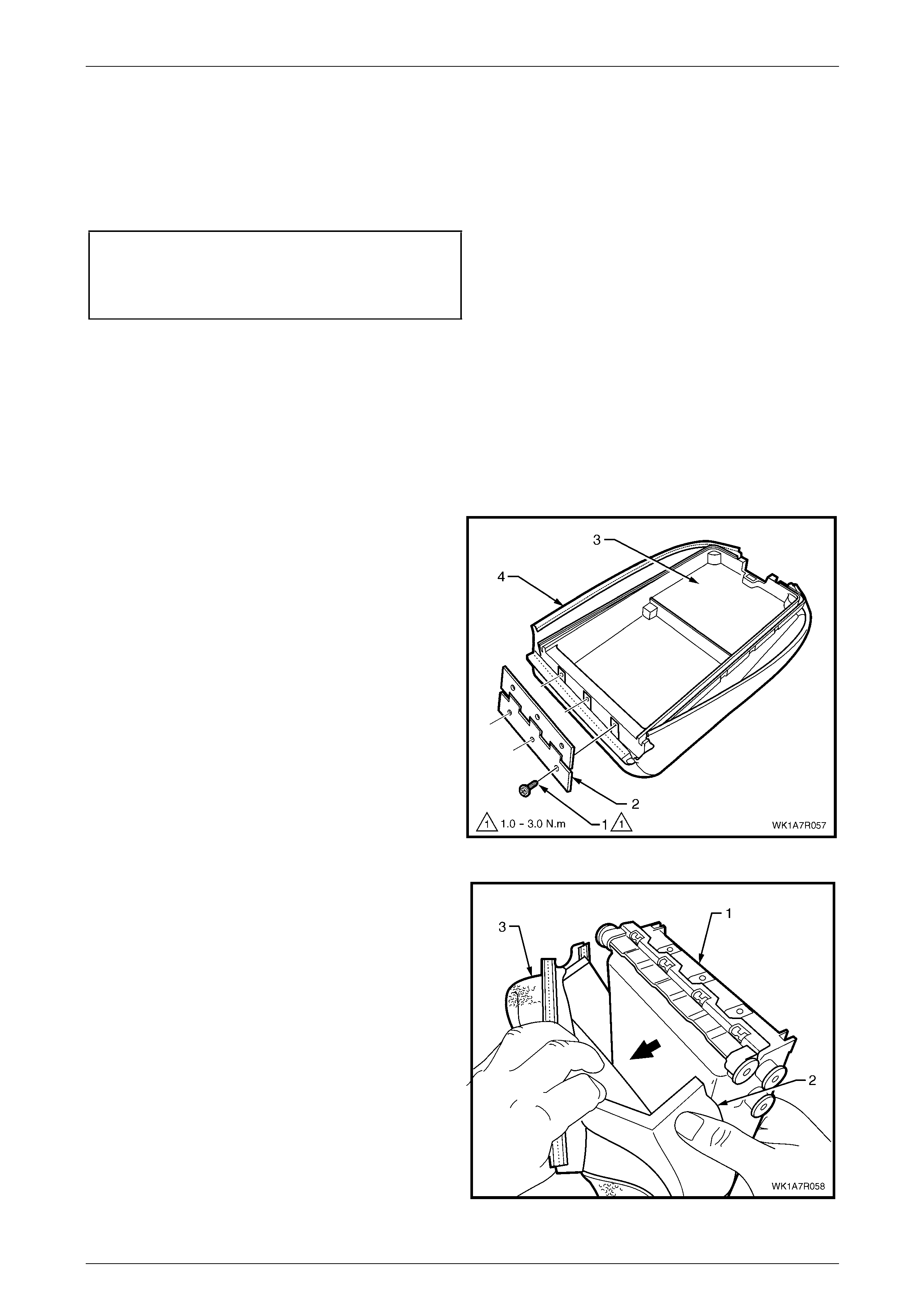

4.5 Front Seat-back Rear Cover Assembly............................................................................................................ 125

Remove............................................................................................................................................................... 125

Disassemble....................................................................................................................................................... 126

Reassemble........................................................................................................................................................ 126

Reinstall.............................................................................................................................................................. 127

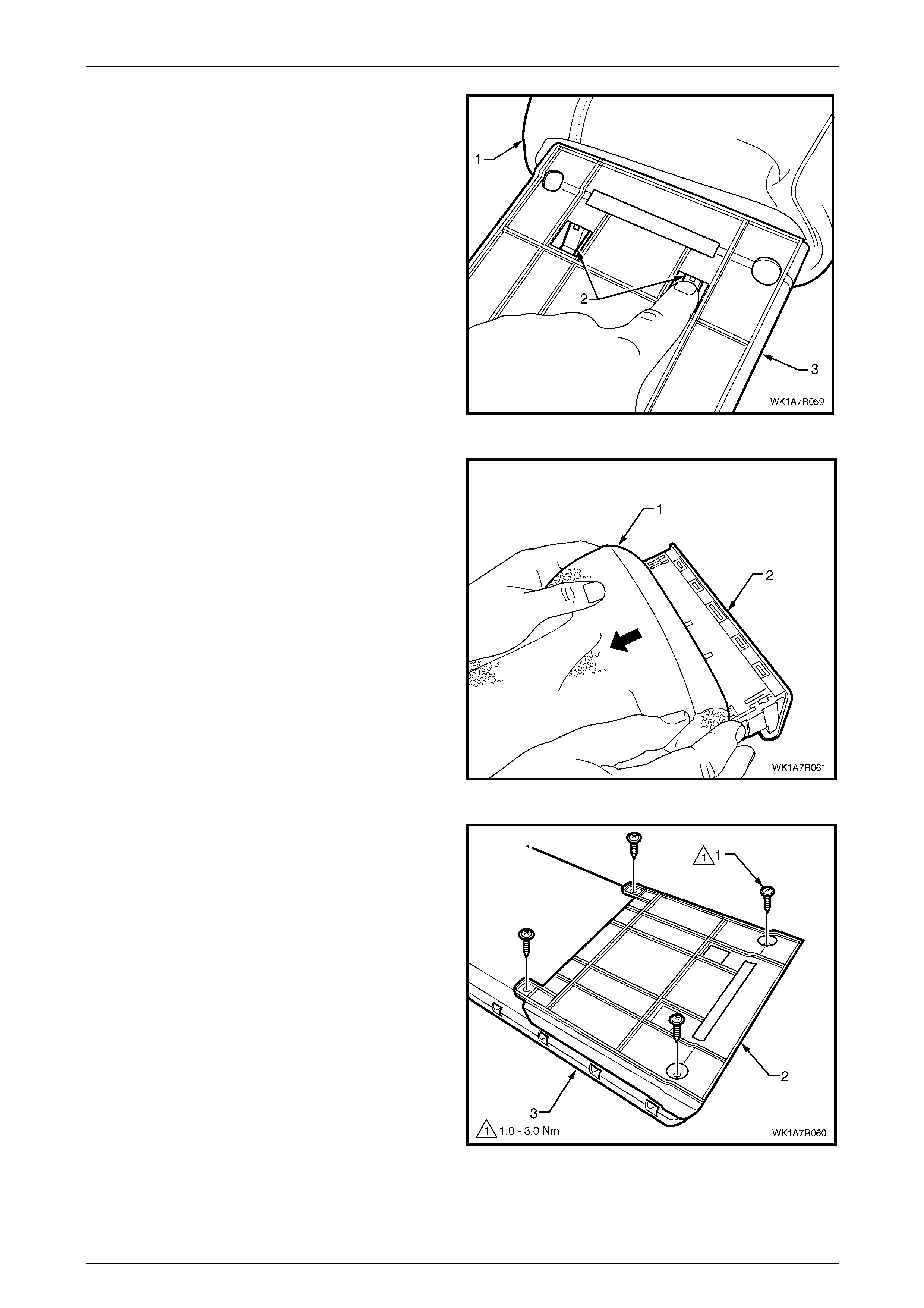

4.6 Front Seat Head Restraint Assembly............................................................................................................... 128

Front Seat Type 1 & 2........................................................................................................................................ 128

Remove.......................................................................................................................................................... 128

Disassemble................................................................................................................................................... 128

Reassemble ................................................................................................................................................... 128

Reinstall ......................................................................................................................................................... 128

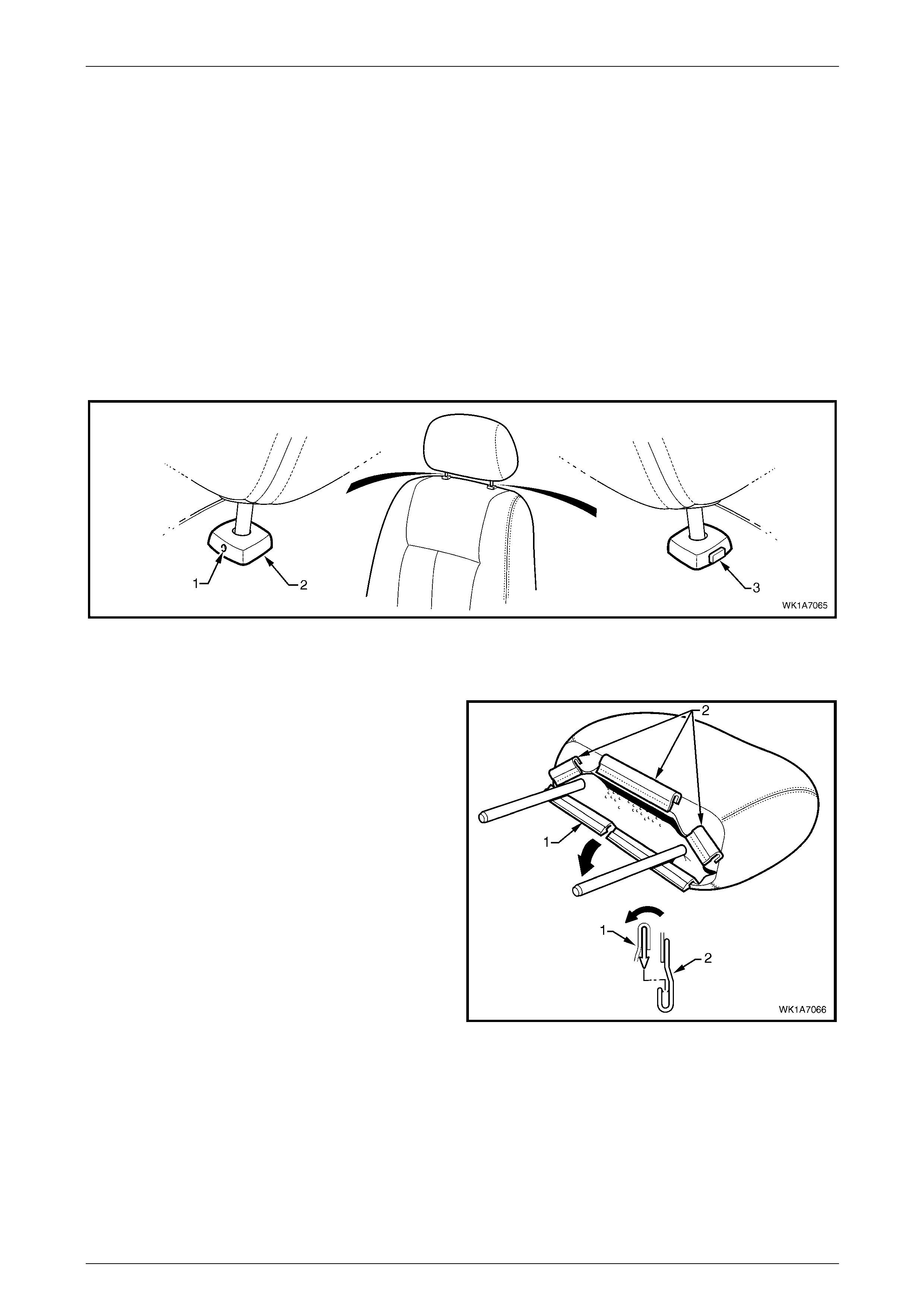

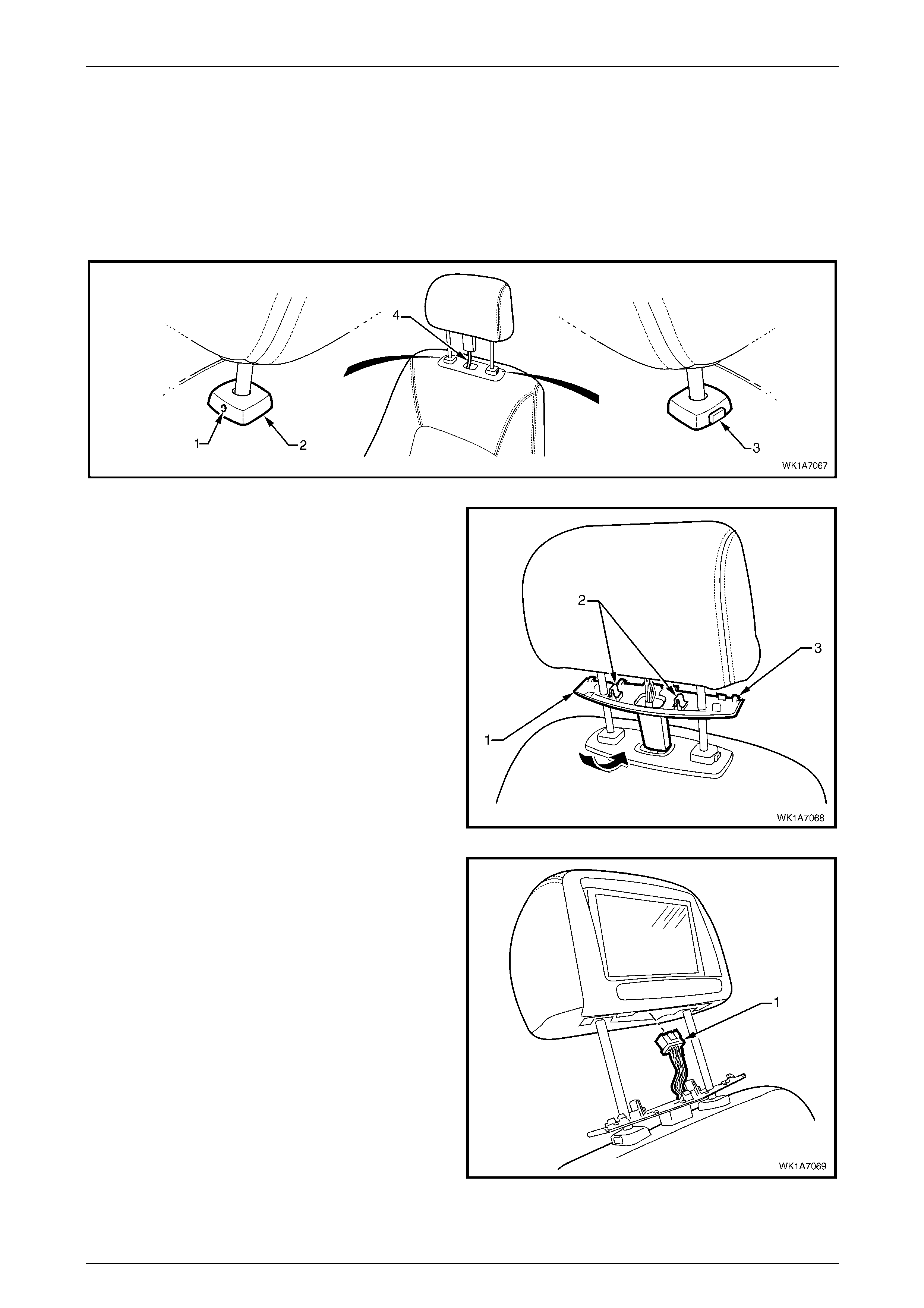

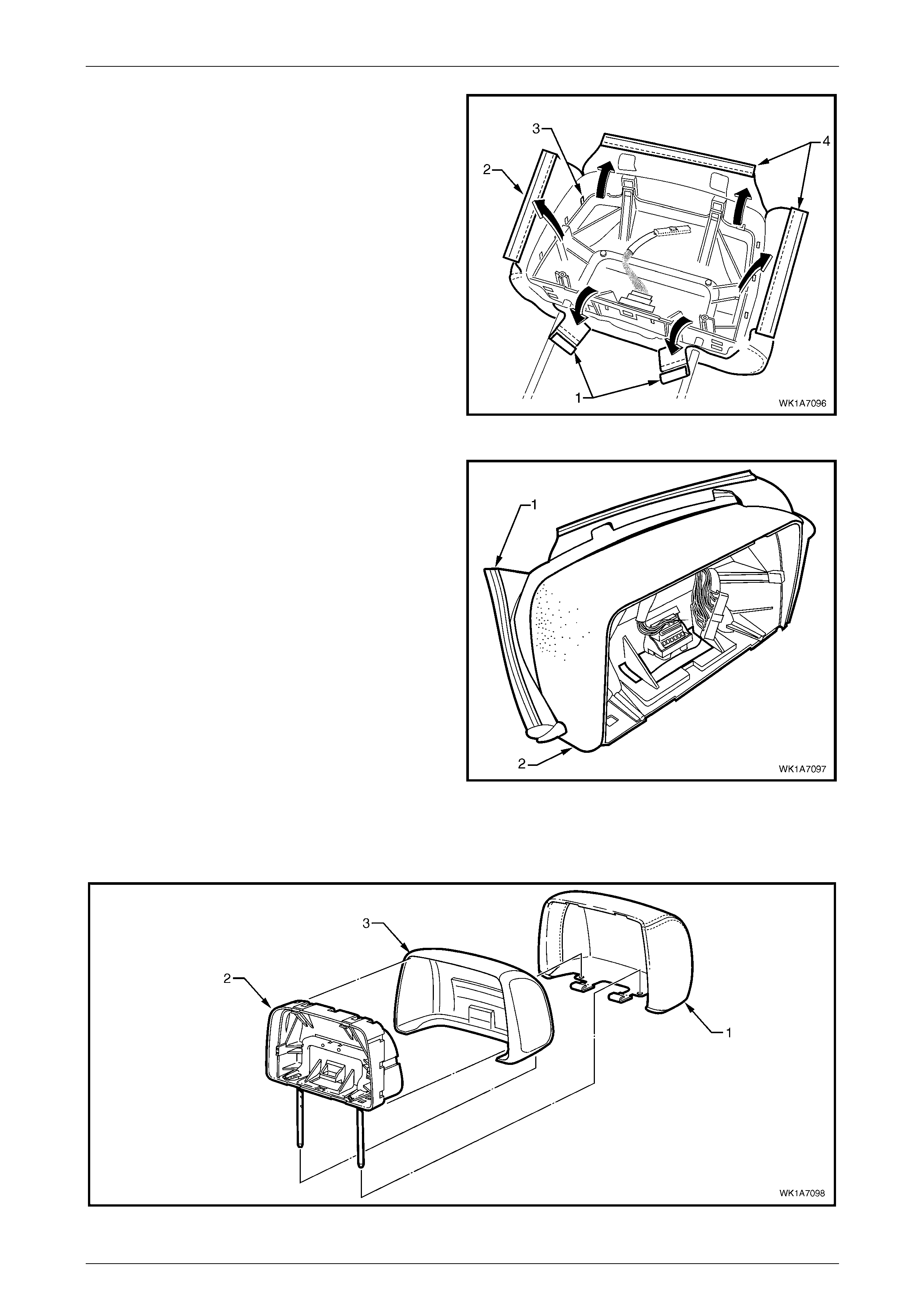

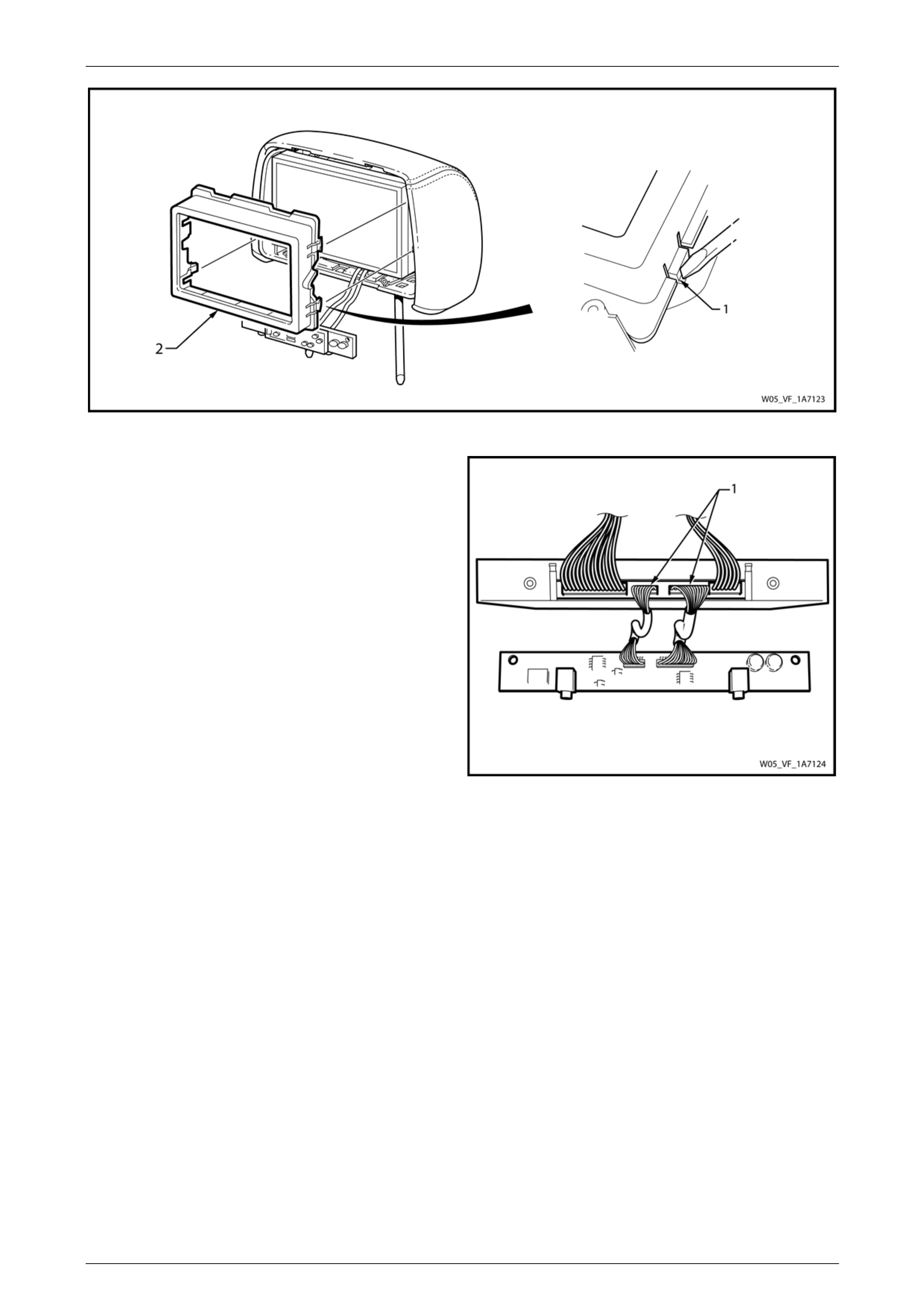

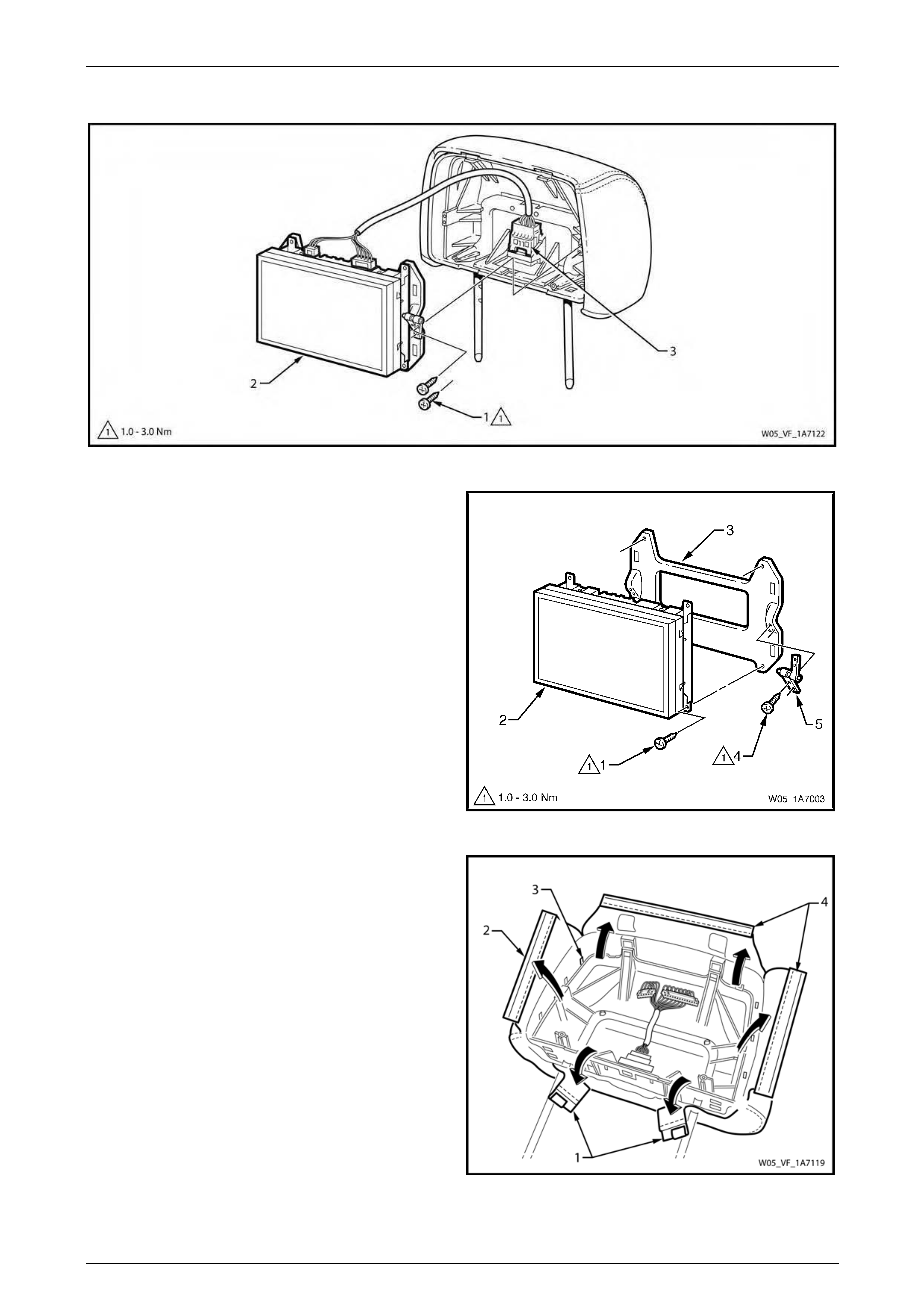

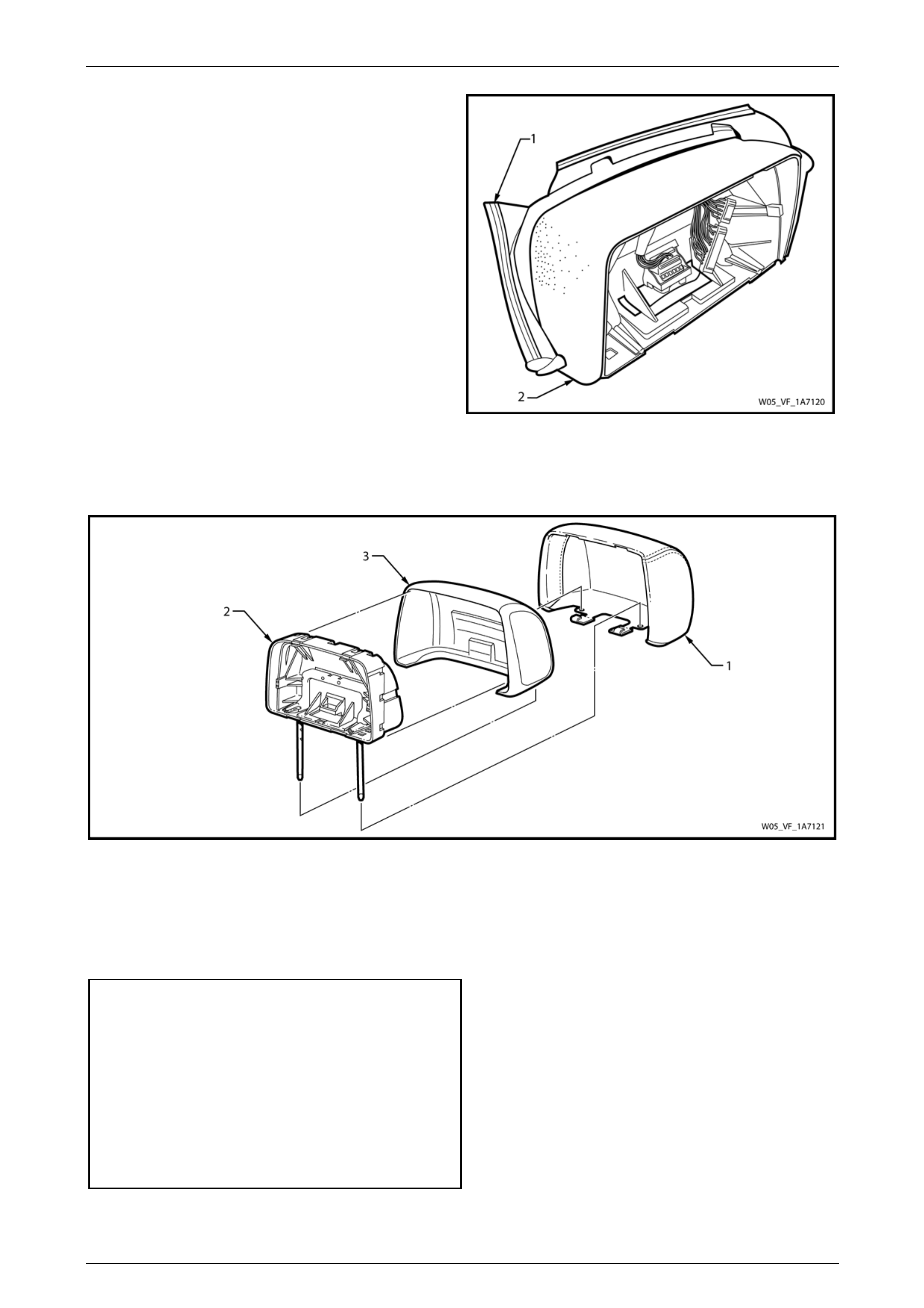

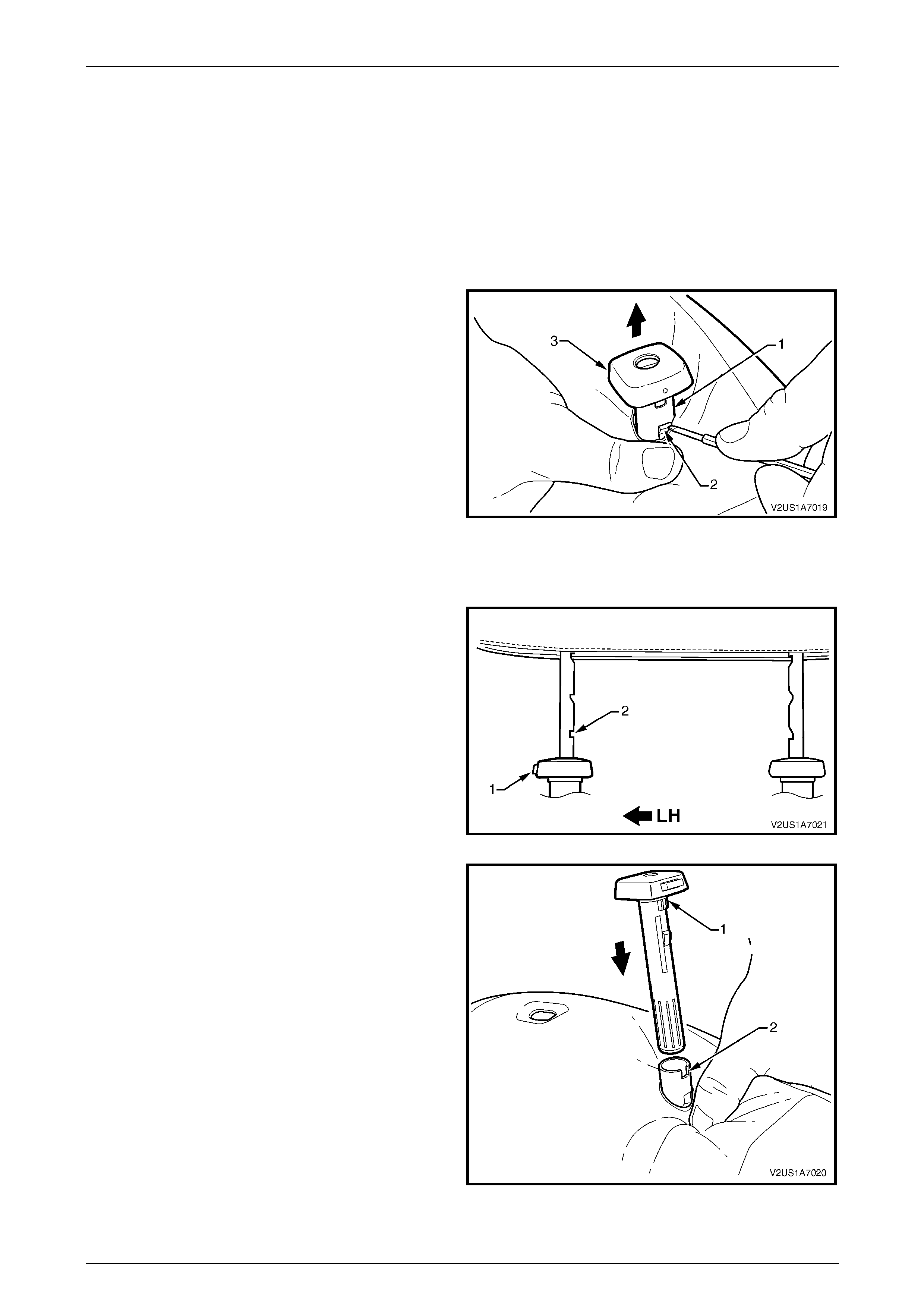

Front Seat Type 3 & 4, Panasonic DVD............................................................................................................ 129

Remove.......................................................................................................................................................... 129

Disassemble................................................................................................................................................... 130

Reassemble ................................................................................................................................................... 133

Reinstall ......................................................................................................................................................... 133

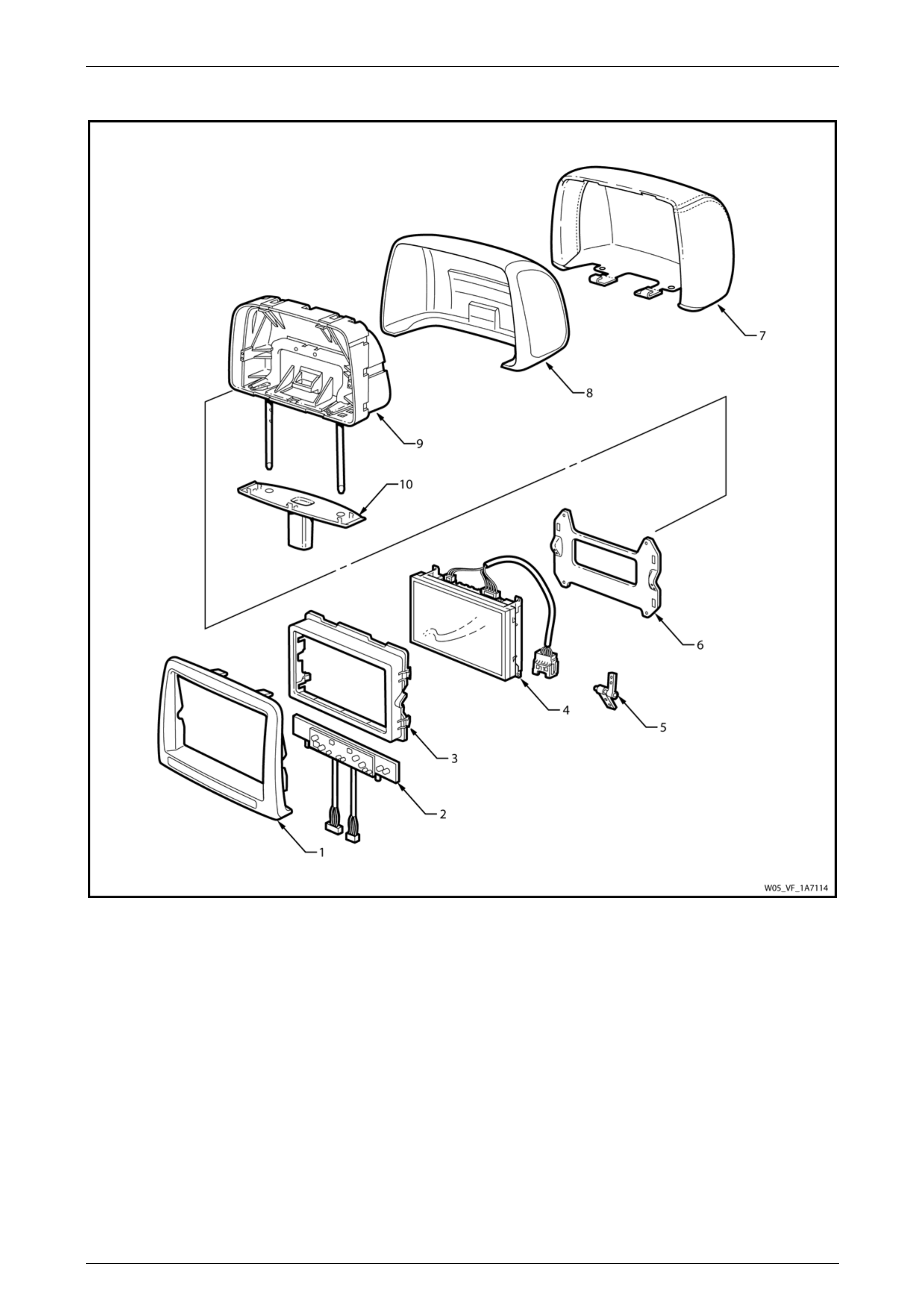

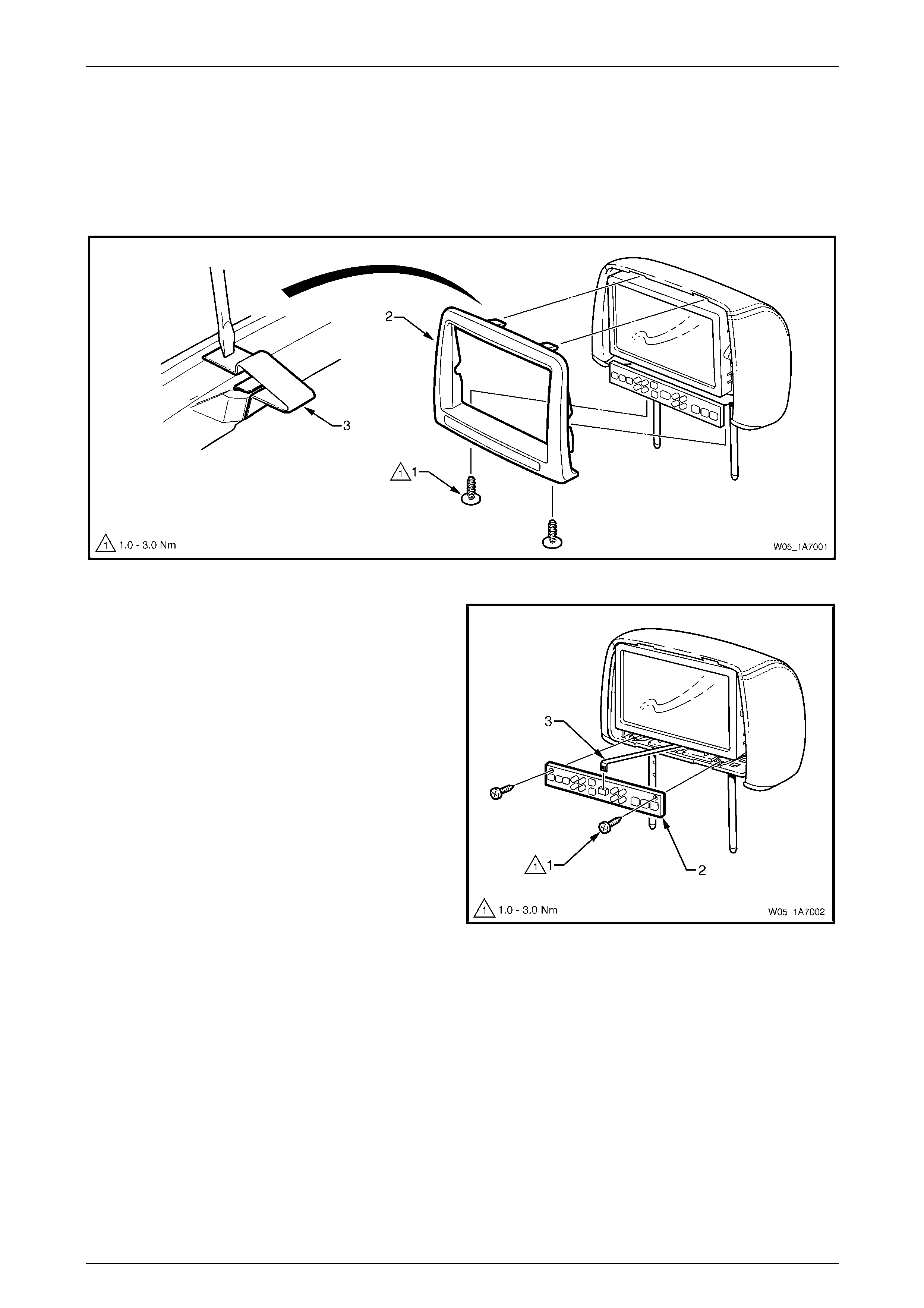

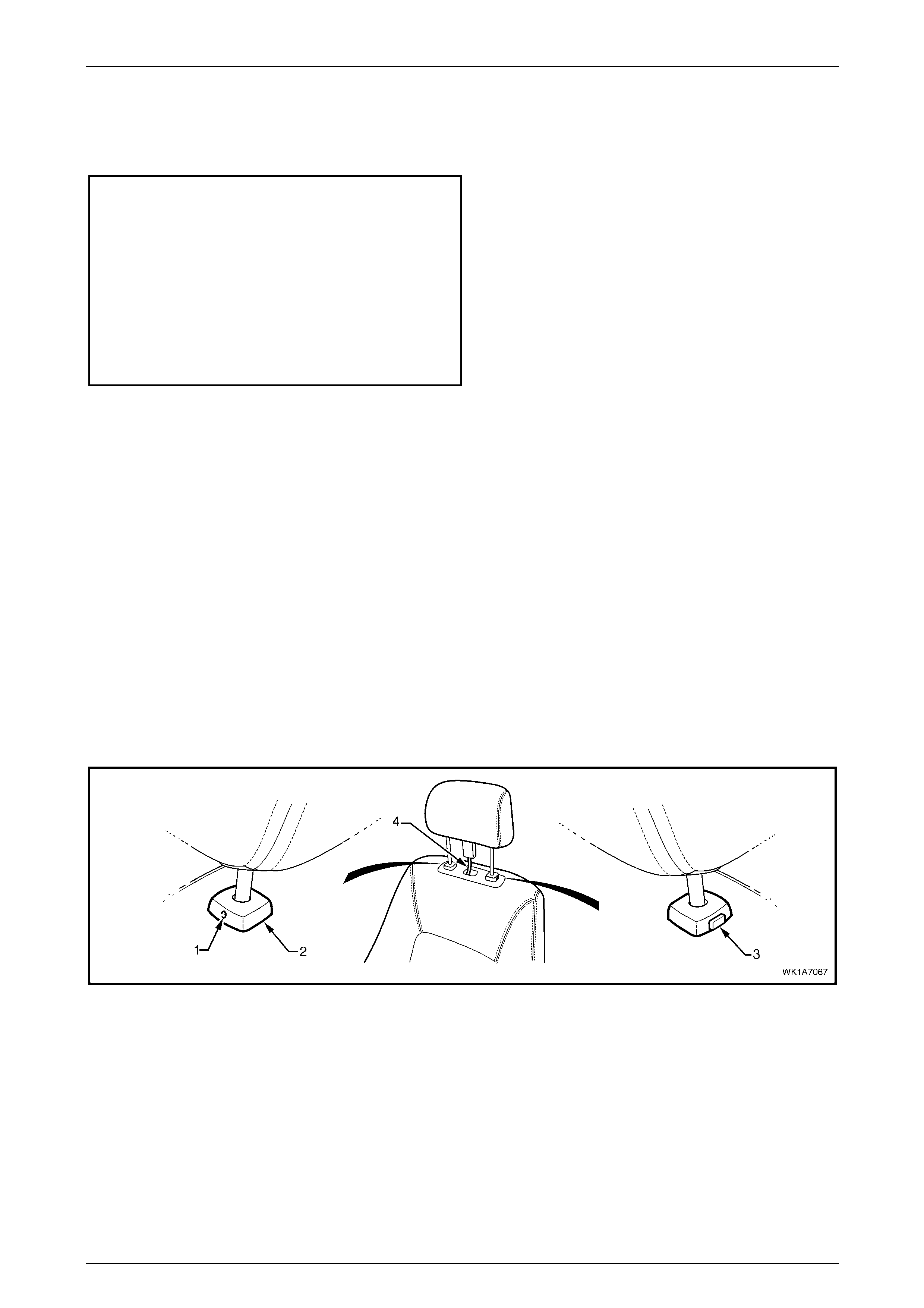

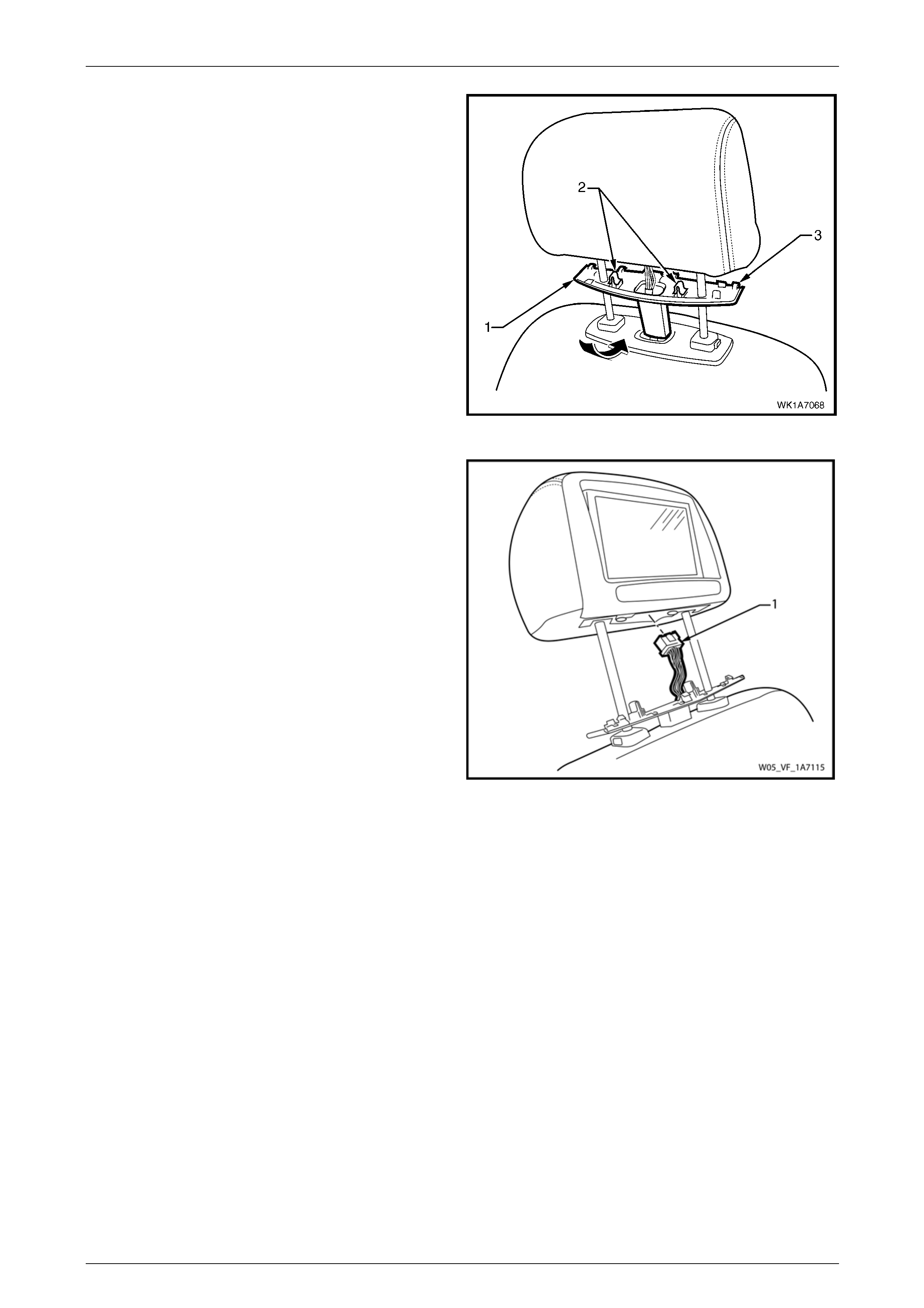

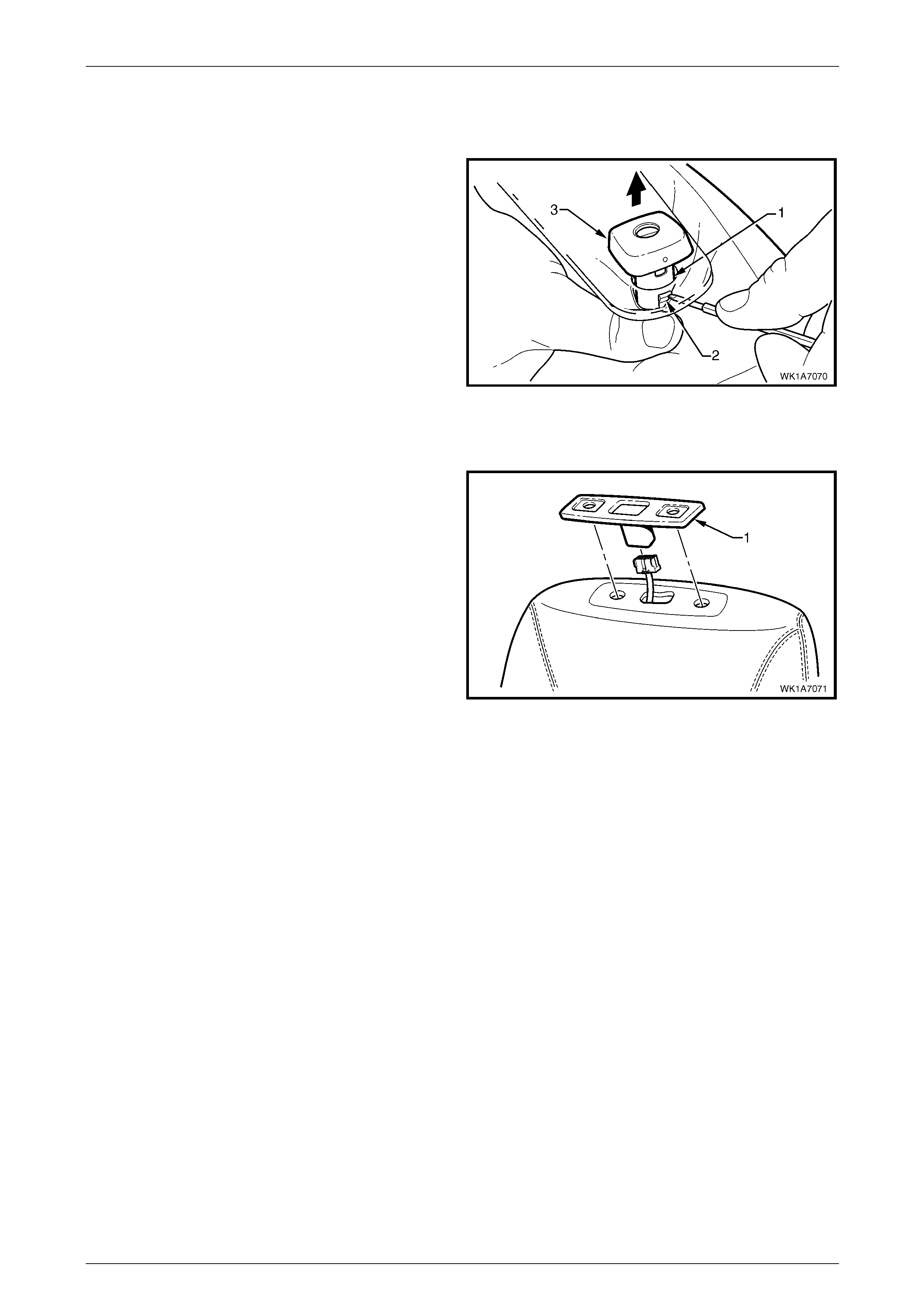

Front Seat Type 3 & 4, Baupunkt DVD............................................................................................................. 133

Remove.......................................................................................................................................................... 133

Disassemble................................................................................................................................................... 135

Reassemble ................................................................................................................................................... 138

Reinstall ......................................................................................................................................................... 139

4.7 Front Seat Head Restraint Sleeve..................................................................................................................... 140

Front Seat Type 1 & 2........................................................................................................................................ 140

Remove.......................................................................................................................................................... 140

Reinstall ......................................................................................................................................................... 140

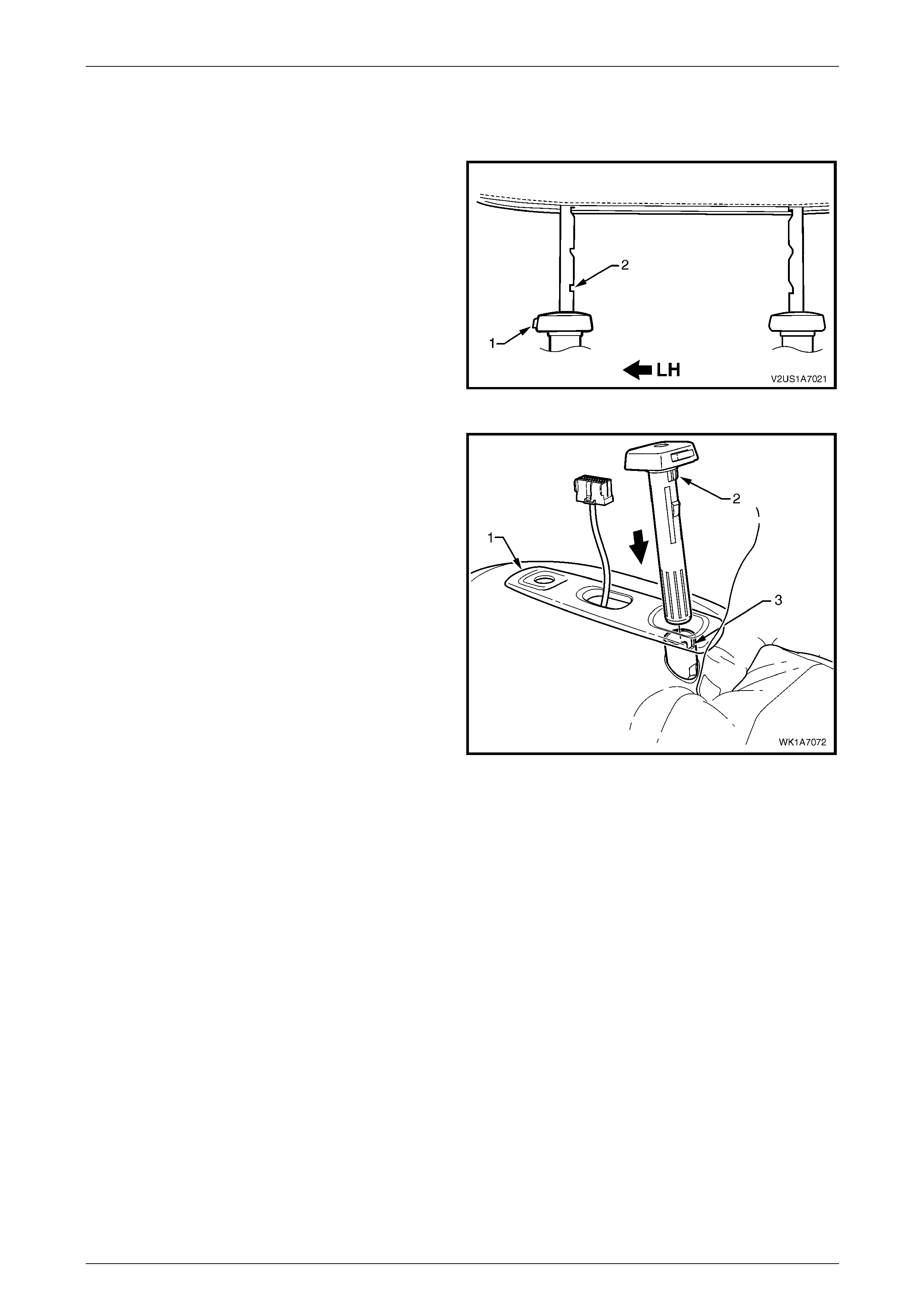

Front Seat Type 3 & 4........................................................................................................................................ 141

Remove.......................................................................................................................................................... 141

Reinstall ......................................................................................................................................................... 142

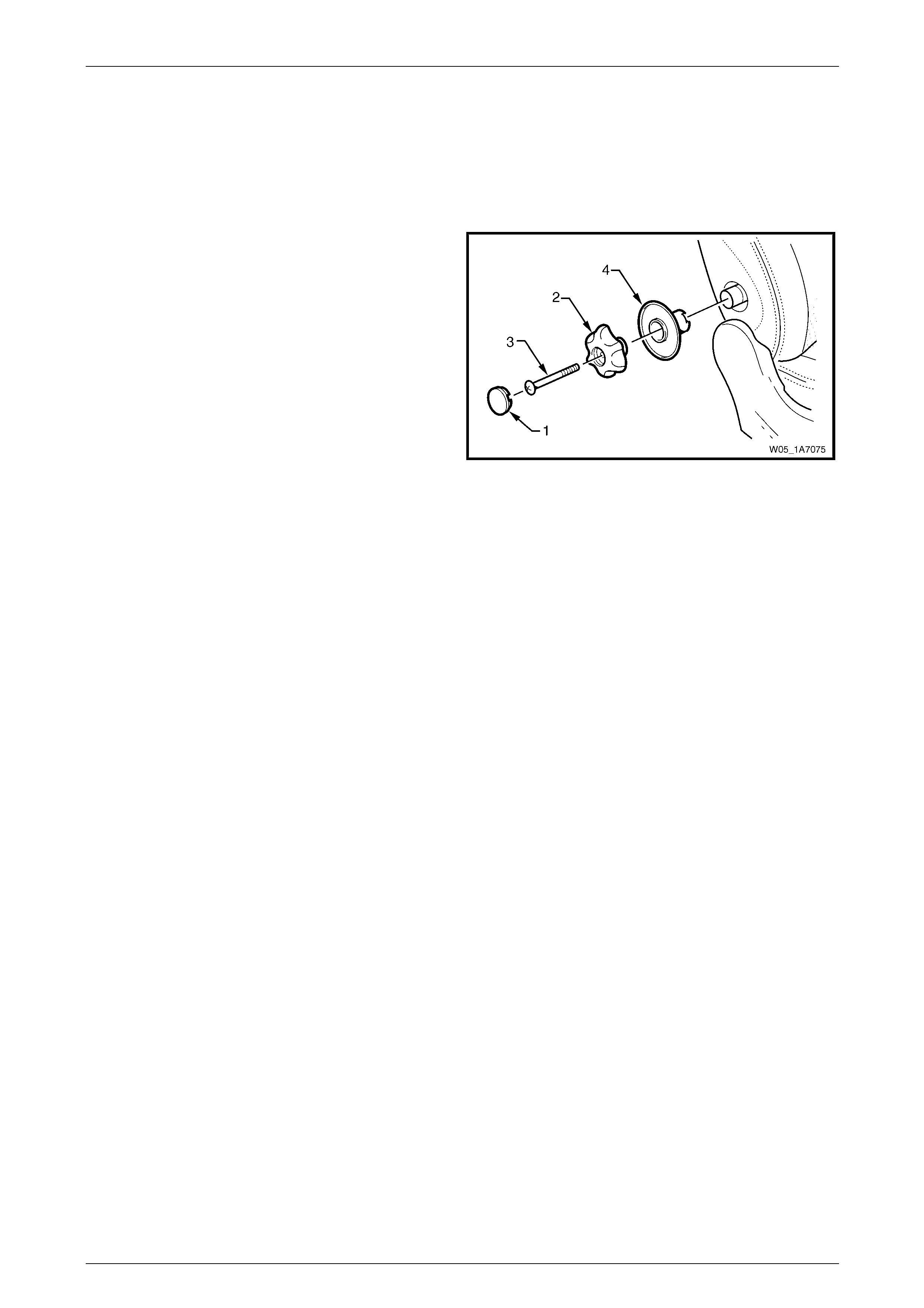

4.8 Lumbar Support Knob Assembly..................................................................................................................... 143

Remove............................................................................................................................................................... 143

Reinstall.............................................................................................................................................................. 143

4.9 Front Seat-back Pad and Cover Assembly...................................................................................................... 144

Remove............................................................................................................................................................... 144

Disassemble....................................................................................................................................................... 145

Reassemble........................................................................................................................................................ 146

Reinstall.............................................................................................................................................................. 146

4.10 Front Seat-back Frame Assembly.................................................................................................................... 147

Remove............................................................................................................................................................... 147

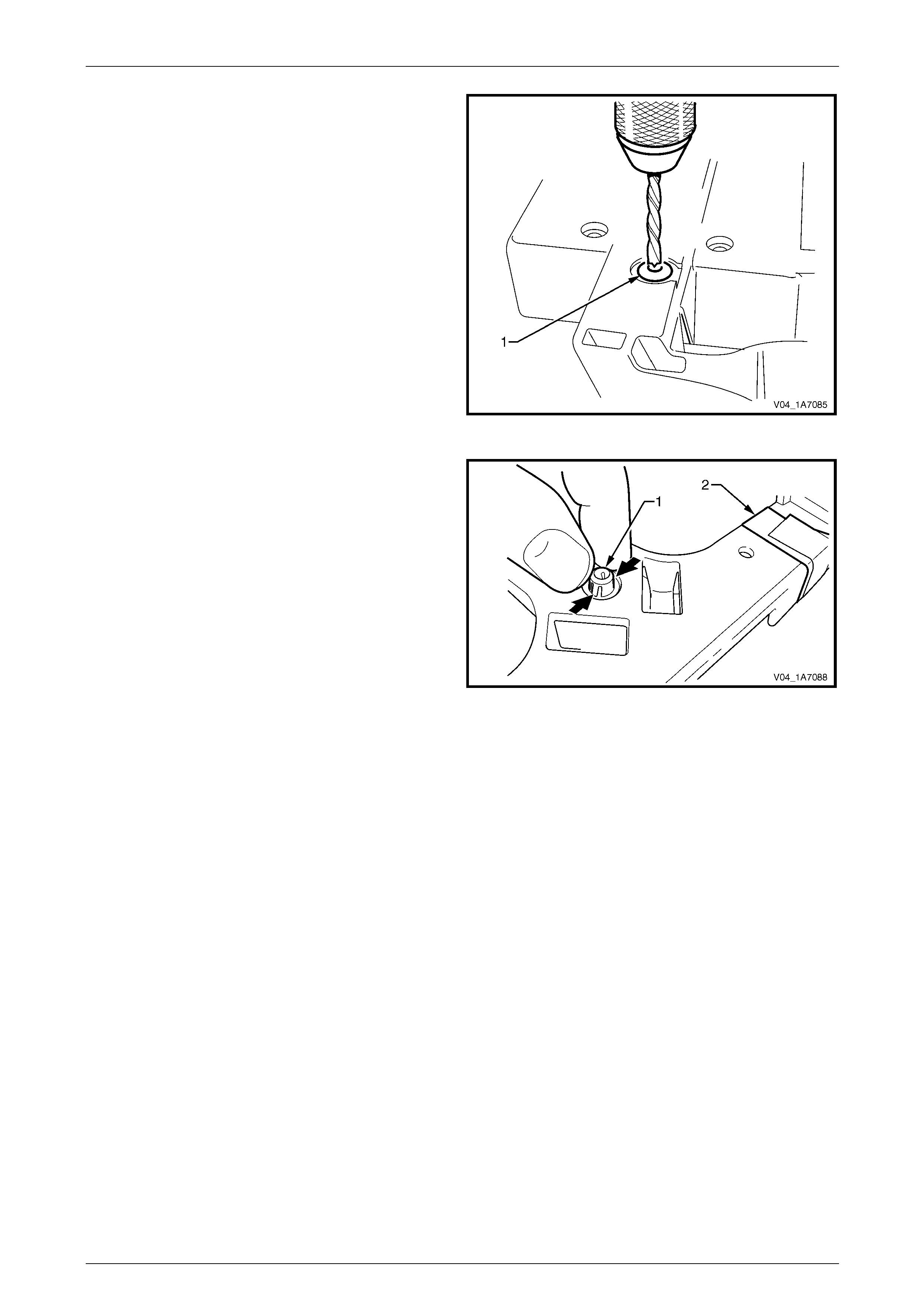

Disassemble....................................................................................................................................................... 148

Side Impact Airbag Assembly ........................................................................................................................ 148

Front Seat Dummy Block Insert Assembly..................................................................................................... 149

Lumbar Support Assembly............................................................................................................................. 149

Active Head Restraint Frame Assembly......................................................................................................... 151

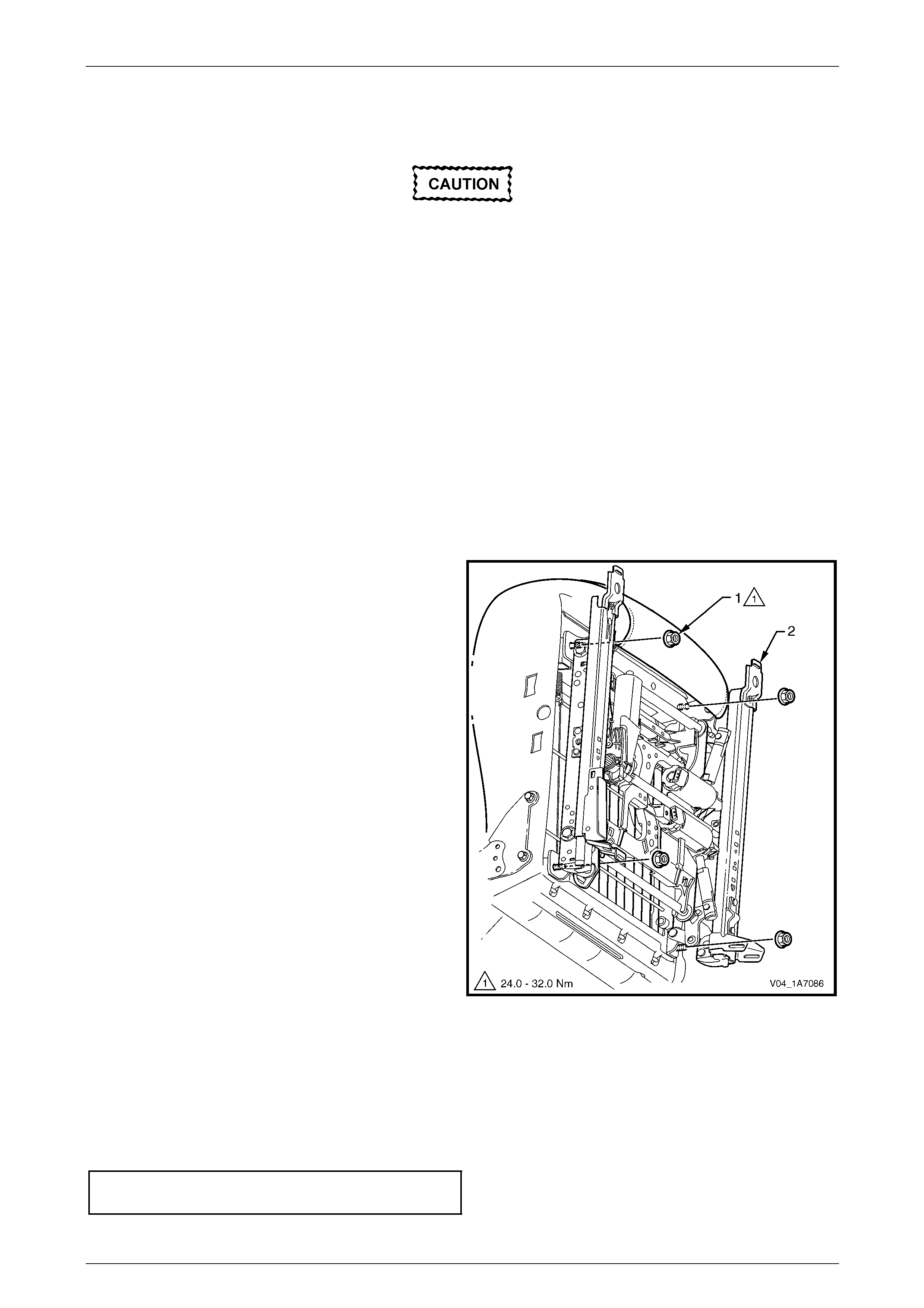

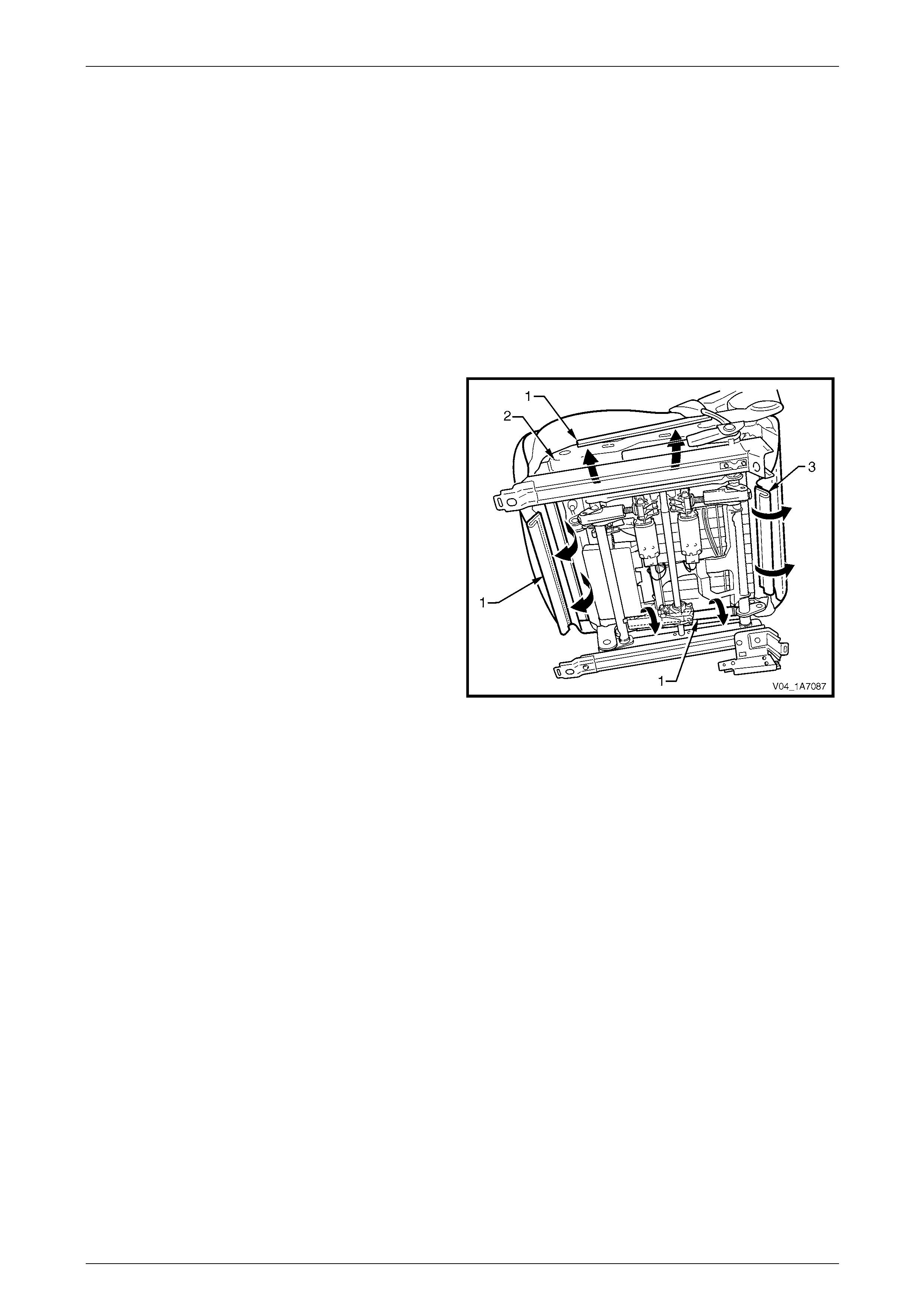

Reinstall.............................................................................................................................................................. 152

4.11 Seat Cable Tray and Memory Module .............................................................................................................. 153

Remove............................................................................................................................................................... 153

Reinstall.............................................................................................................................................................. 154

Seat Assemblies Page 1A7–8

Page 1A7–8

4.12 Track and Height Adjust Assembly.................................................................................................................. 155

Remove............................................................................................................................................................... 155

Reinstall.............................................................................................................................................................. 155

4.13 Front Seat Cushion Pad and Cover Assembly................................................................................................ 156

Remove............................................................................................................................................................... 156

Disassemble....................................................................................................................................................... 157

Reassemble........................................................................................................................................................ 158

Reinstall.............................................................................................................................................................. 158

4.14 Front Seat Cushion Frame Assembly.............................................................................................................. 159

Remove............................................................................................................................................................... 159

Disassemble....................................................................................................................................................... 159

Reassemble........................................................................................................................................................ 159

Reinstall.............................................................................................................................................................. 159

4.15 Front Seat Lift Motor Assemblies..................................................................................................................... 160

4.16 Front Seat Fore/Aft Movement Motor Assembly............................................................................................. 161

4.17 Front Seat-back Recline Motor Assembly ....................................................................................................... 162

4.18 Drive Motor Hall-effect Sensors........................................................................................................................ 163

5 Service Operations – Rear Seat........................................................................................................164

5.1 Usage Chart........................................................................................................................................................ 164

How to Use this Chart........................................................................................................................................ 164

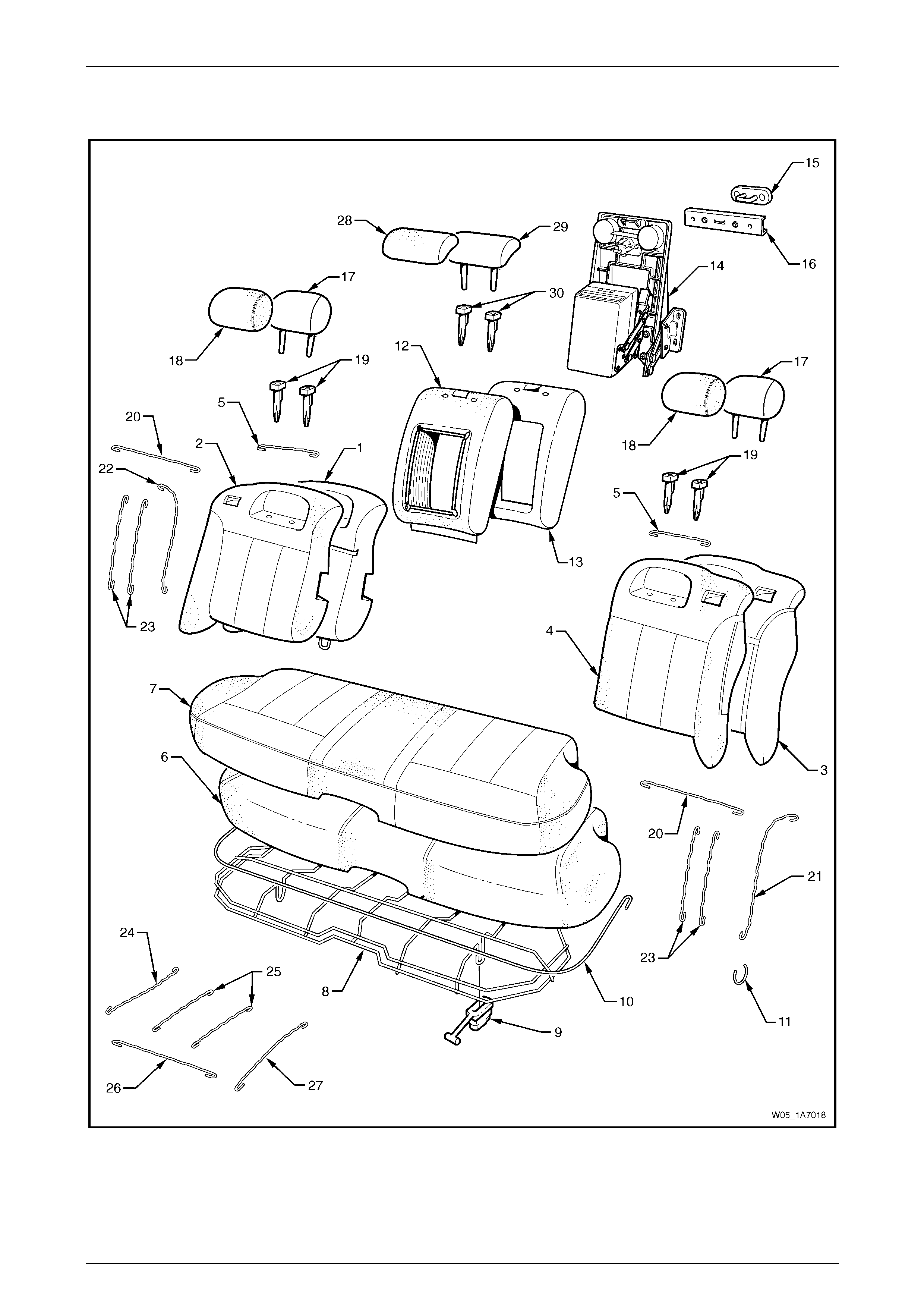

Rear Seat Type 1................................................................................................................................................ 165

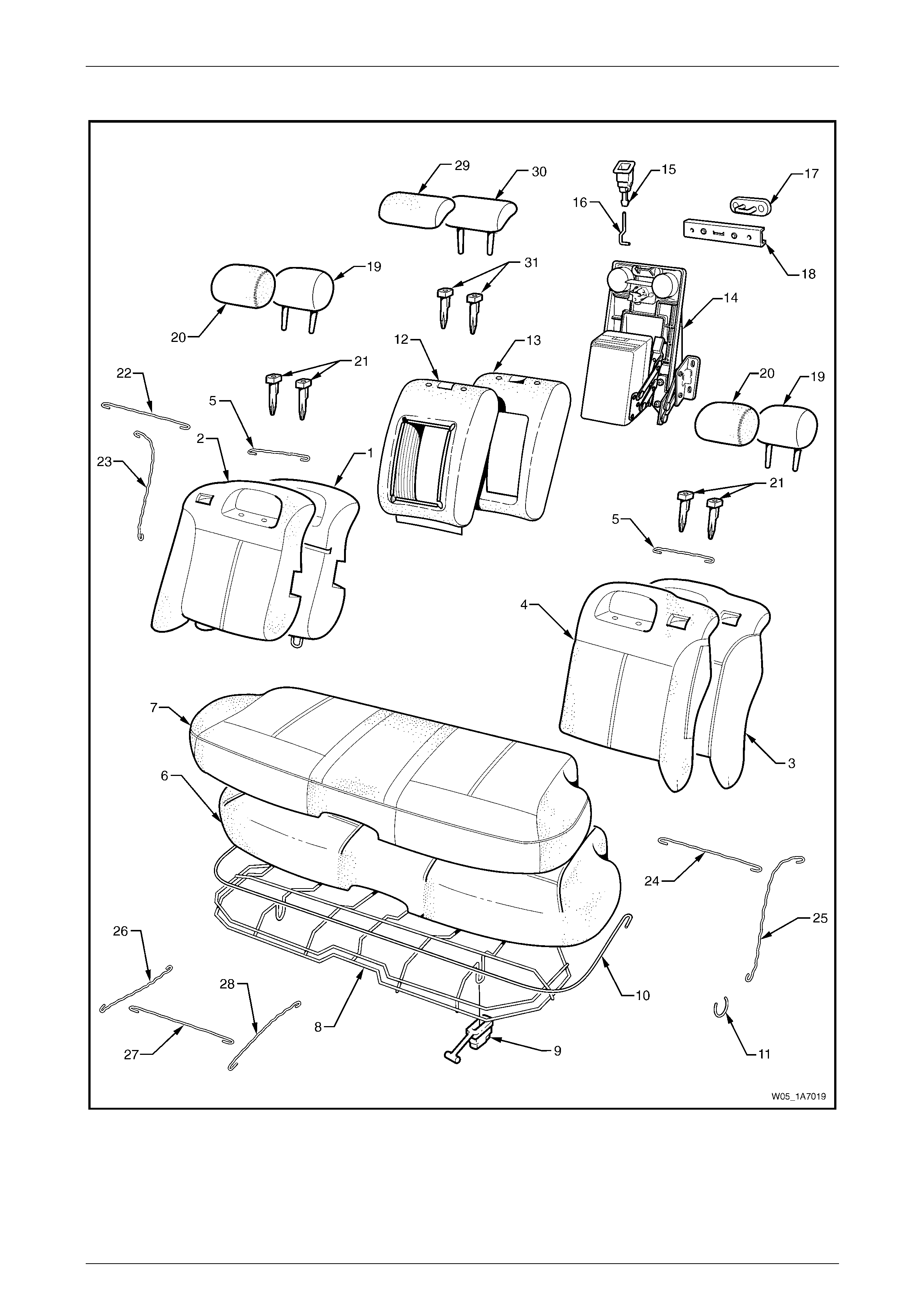

Rear Seat Type 2................................................................................................................................................ 167

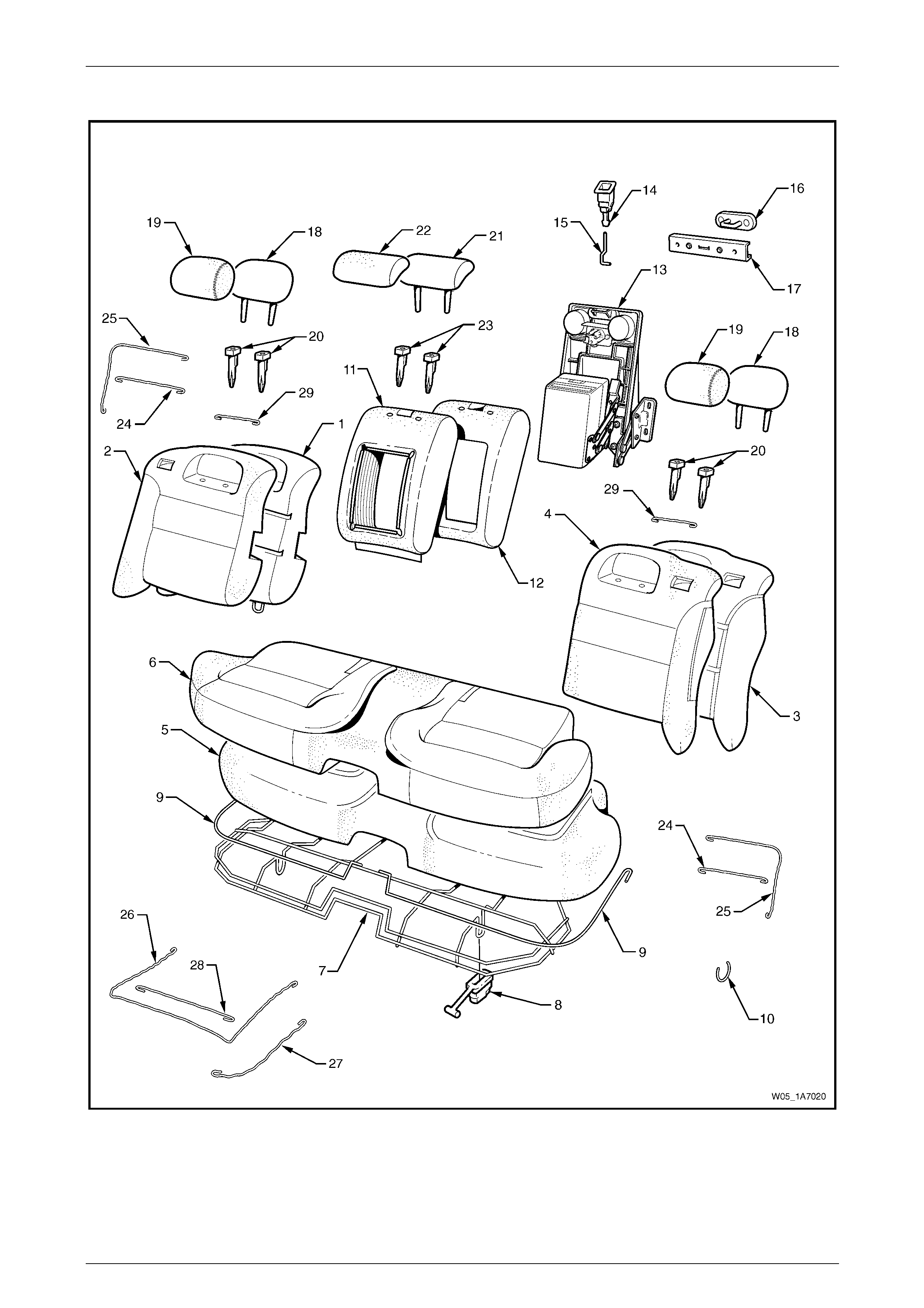

Rear Seat Type 3................................................................................................................................................ 169

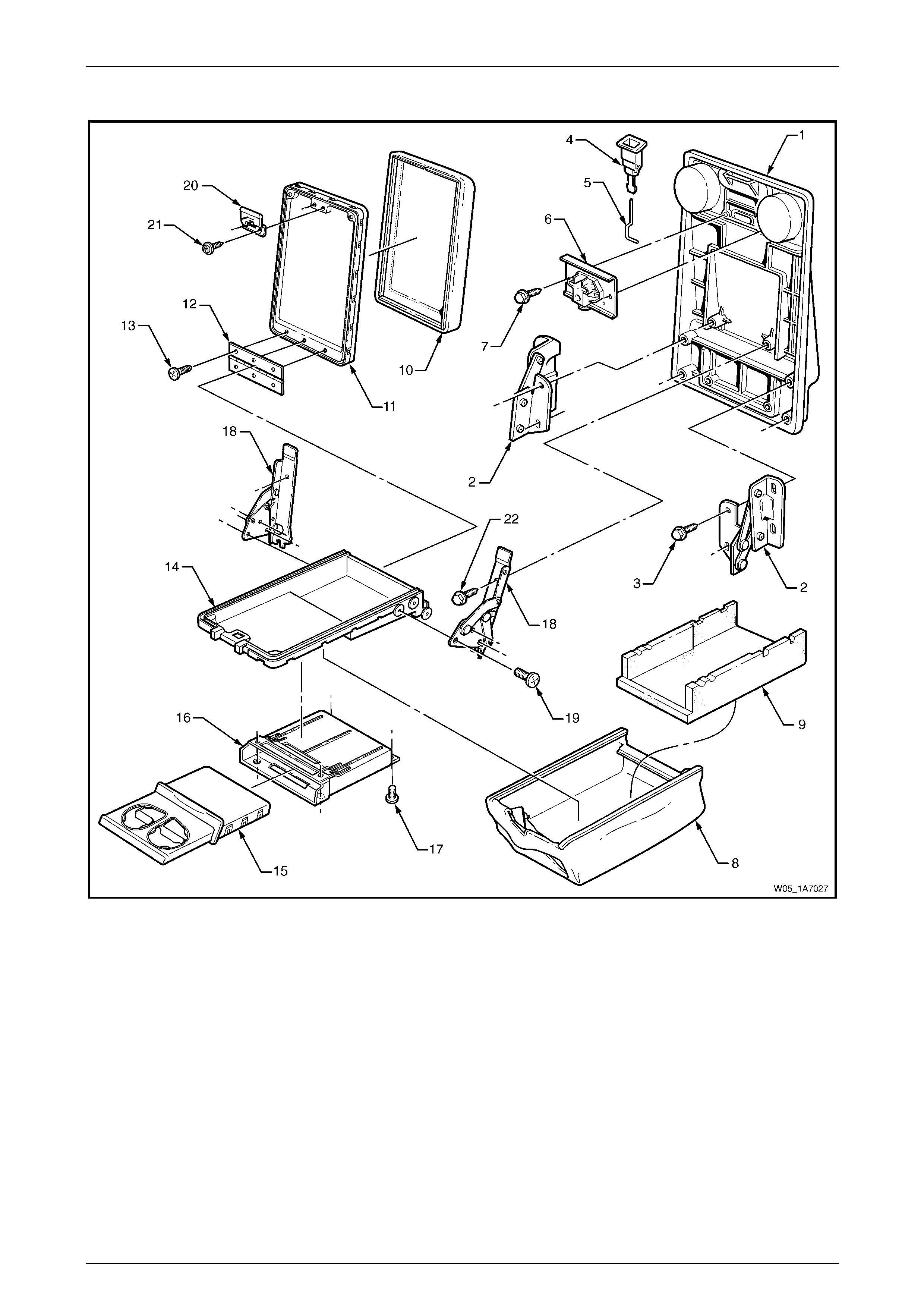

Rear Seat-back Centre Tray and Armrest Assembly With Compartment ..................................................... 171

5.2 Rear Seat Cushion Assembly........................................................................................................................... 172

Remove............................................................................................................................................................... 172

Disassemble....................................................................................................................................................... 172

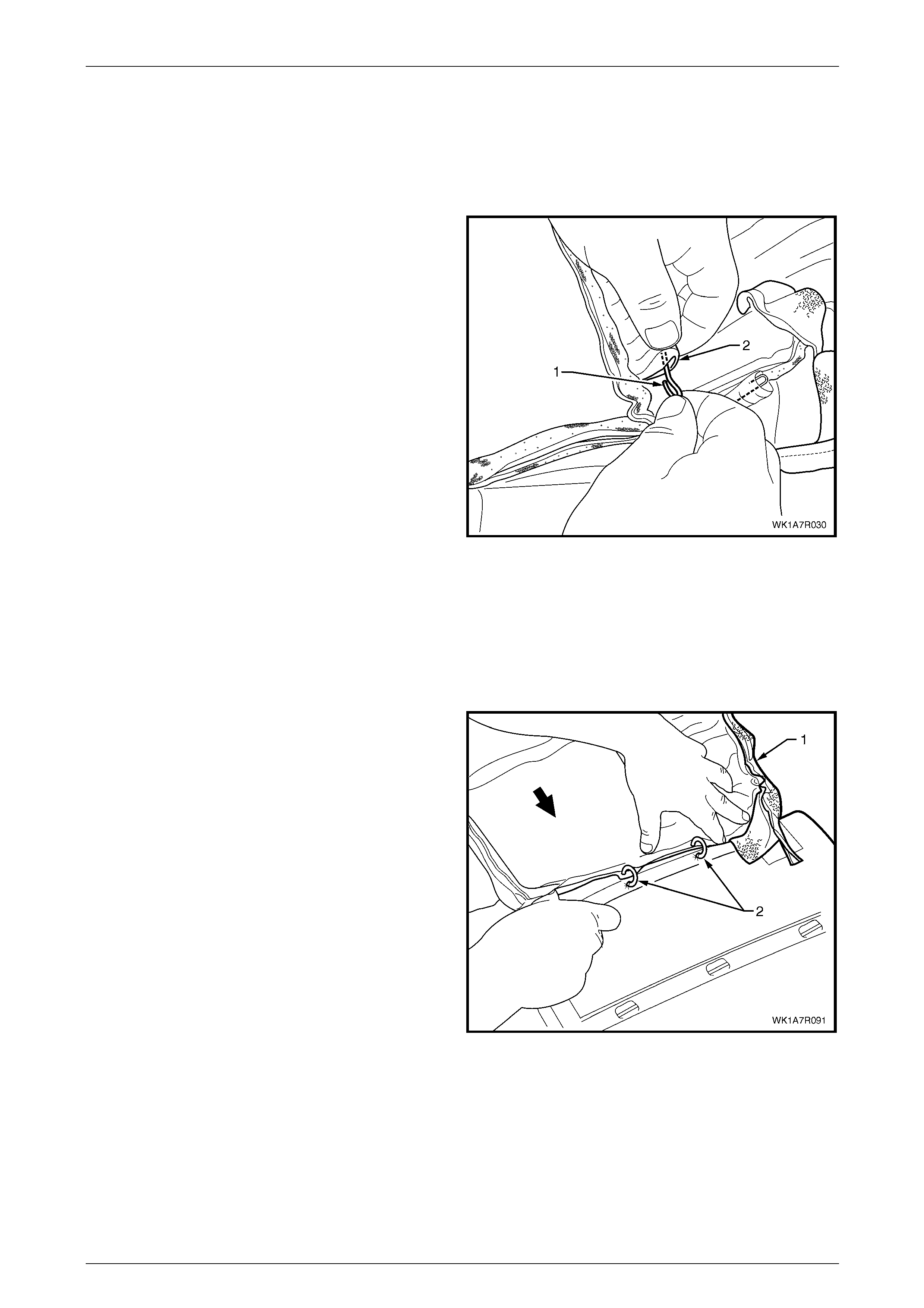

Rear Seat Cushion Release Handle............................................................................................................... 172

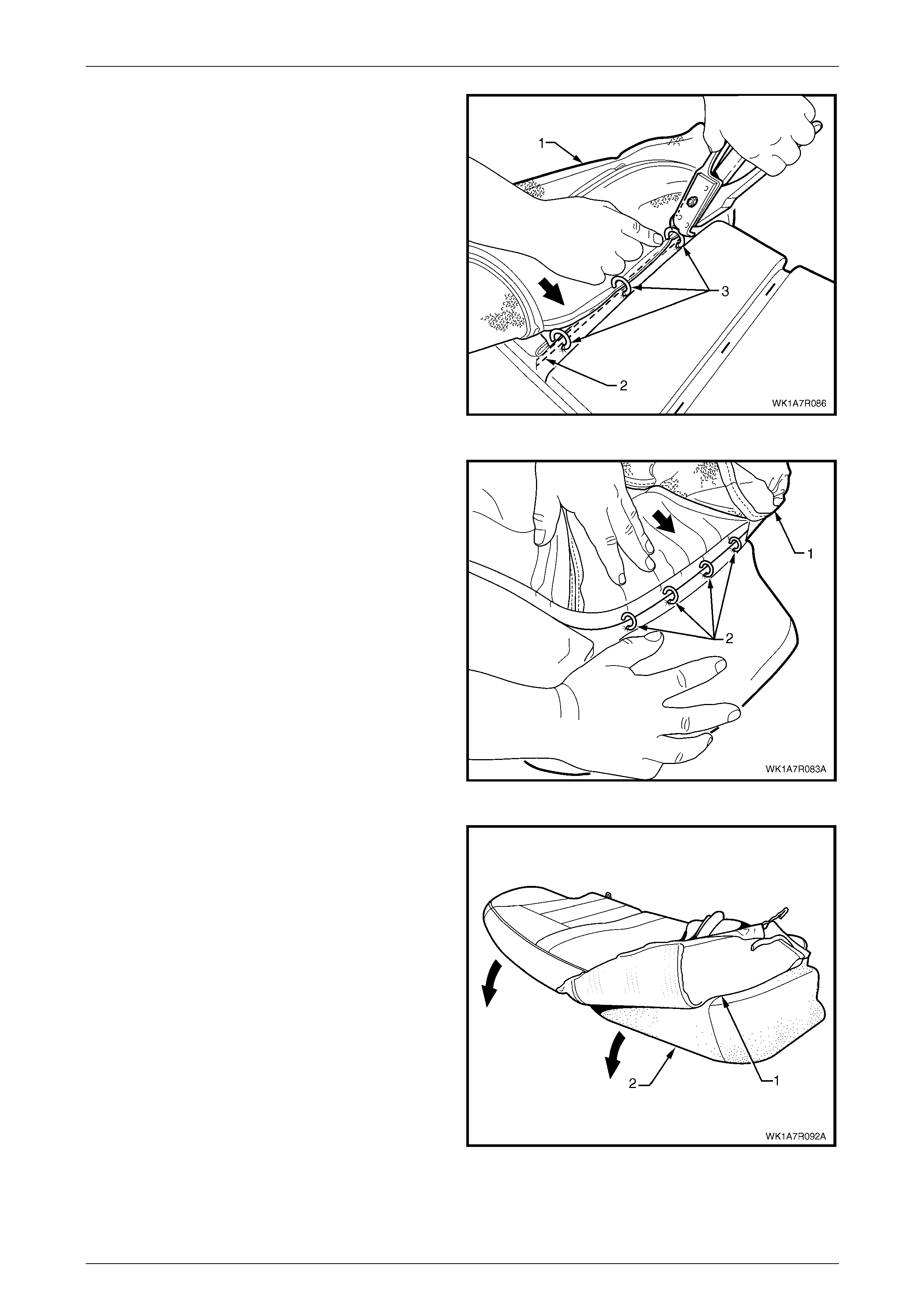

Rear Seat Cushion Frame.............................................................................................................................. 173

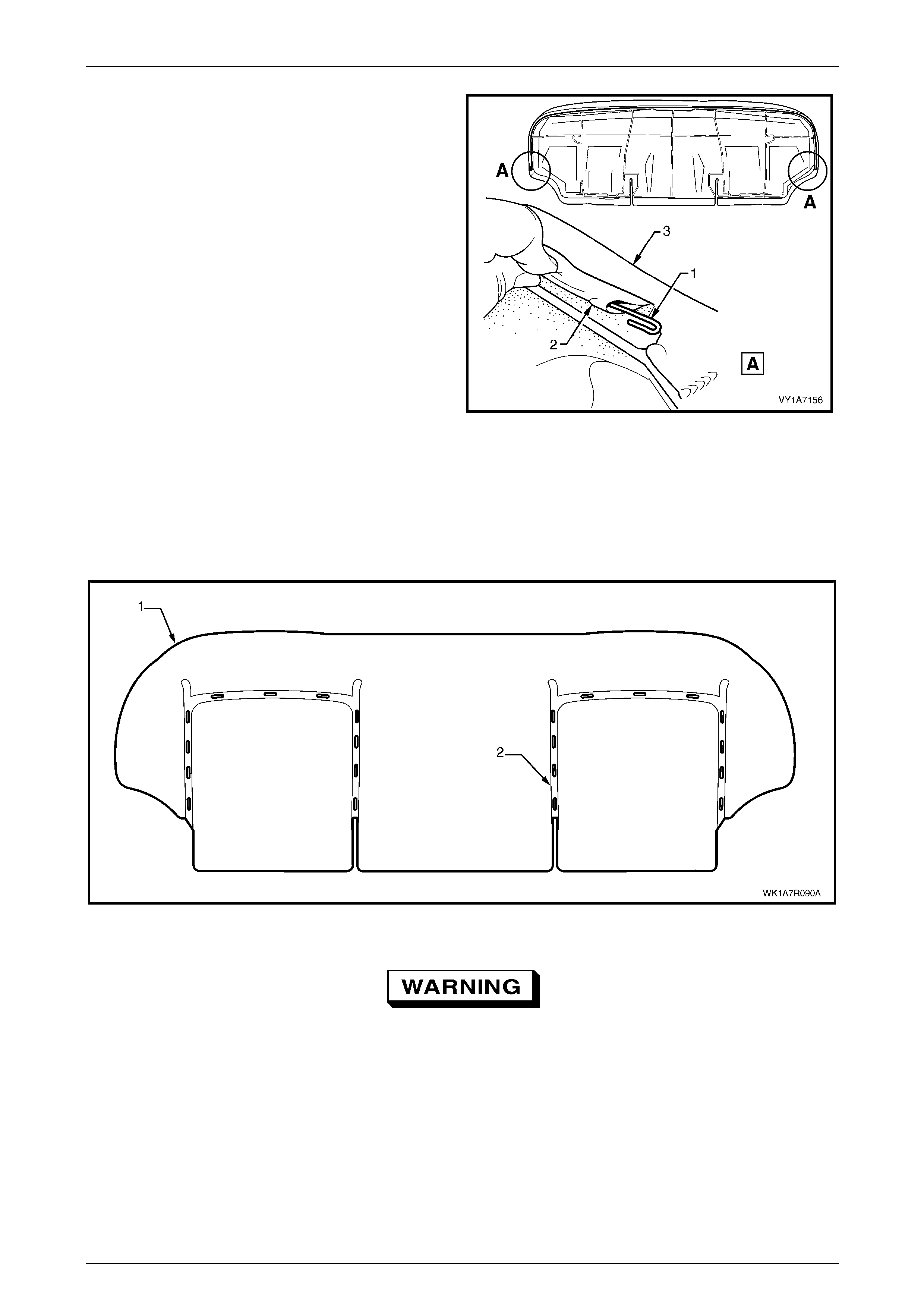

Cushion Cover Assembly ................................................................................................................................. 178

Rear Seat Type 1........................................................................................................................................... 178

Rear Seat Type 2........................................................................................................................................... 183

Rear Seat Type 3........................................................................................................................................... 188

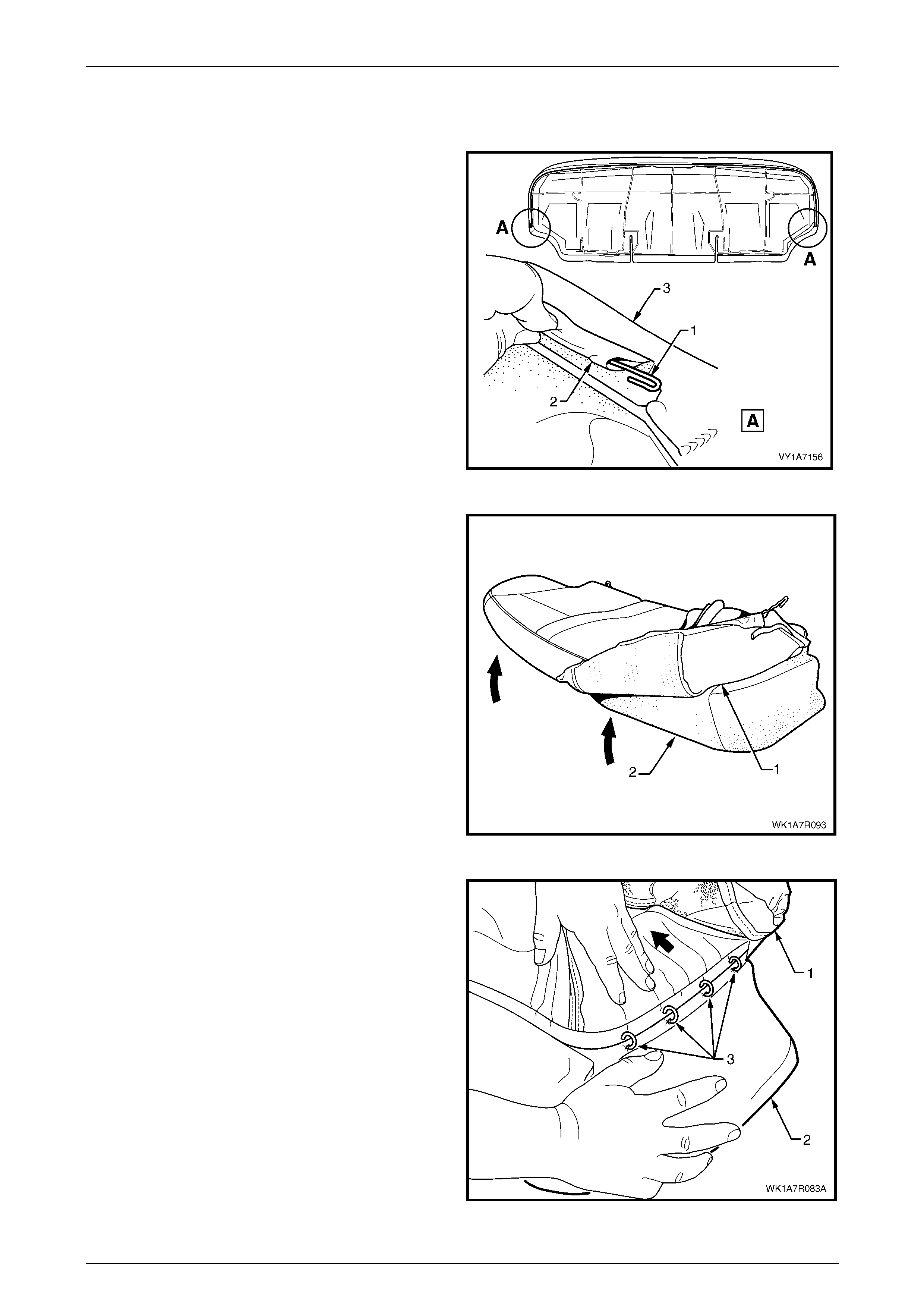

Reinstall.............................................................................................................................................................. 195

5.3 Rear Seat-back Head Restraint Assembly Right-hand and Left-hand Side.................................................. 196

Remove............................................................................................................................................................... 196

Reinstall.............................................................................................................................................................. 198

5.4 Rear Seat-back Assembly................................................................................................................................. 199

Remove............................................................................................................................................................... 199

Head Restraint Sleeve....................................................................................................................................... 200

Remove.......................................................................................................................................................... 200

Reinstall ......................................................................................................................................................... 200

Rear Seat-back Cover........................................................................................................................................ 201

Rear Seat Type 1........................................................................................................................................... 201

Rear Seat Type 2........................................................................................................................................... 208

Rear Seat Type 3........................................................................................................................................... 215

Reinstall.............................................................................................................................................................. 222

5.5 Rear Seat-back Centre Head Restraint Assembly........................................................................................... 223

Remove............................................................................................................................................................... 223

Disassemble....................................................................................................................................................... 224

Reassemble........................................................................................................................................................ 225

Reinstall.............................................................................................................................................................. 225

Seat Assemblies Page 1A7–9

Page 1A7–9

5.6 Rear Seat-back Centre Armrest Assembly...................................................................................................... 226

Remove............................................................................................................................................................... 226

Disassemble....................................................................................................................................................... 226

Rear Seat-back Centre Armrest Hinge........................................................................................................... 226

Rear Seat-back Centre Armrest Lid and Cover.............................................................................................. 227

Rear Seat-back Centre Armrest Deposit Box, Cover and Cup Holder ........................................................... 228

Reassemble........................................................................................................................................................ 231

Reinstall.............................................................................................................................................................. 231

5.7 Rear Seat-back Centre Assembly..................................................................................................................... 232

Remove............................................................................................................................................................... 232

Disassemble....................................................................................................................................................... 232

Pad Assembly, Cover and Head Restraint Sleeves ....................................................................................... 232

Rear Seat-back Centre Release Button......................................................................................................... 235

Rear Seat-back Centre Lock Actuator............................................................................................................ 235

Rear Seat-back Centre Hinge ........................................................................................................................ 236

Reinstall.............................................................................................................................................................. 236

5.8 Rear Seat-back Centre Lock Striker................................................................................................................. 237

Remove............................................................................................................................................................... 237

Reinstall.............................................................................................................................................................. 237

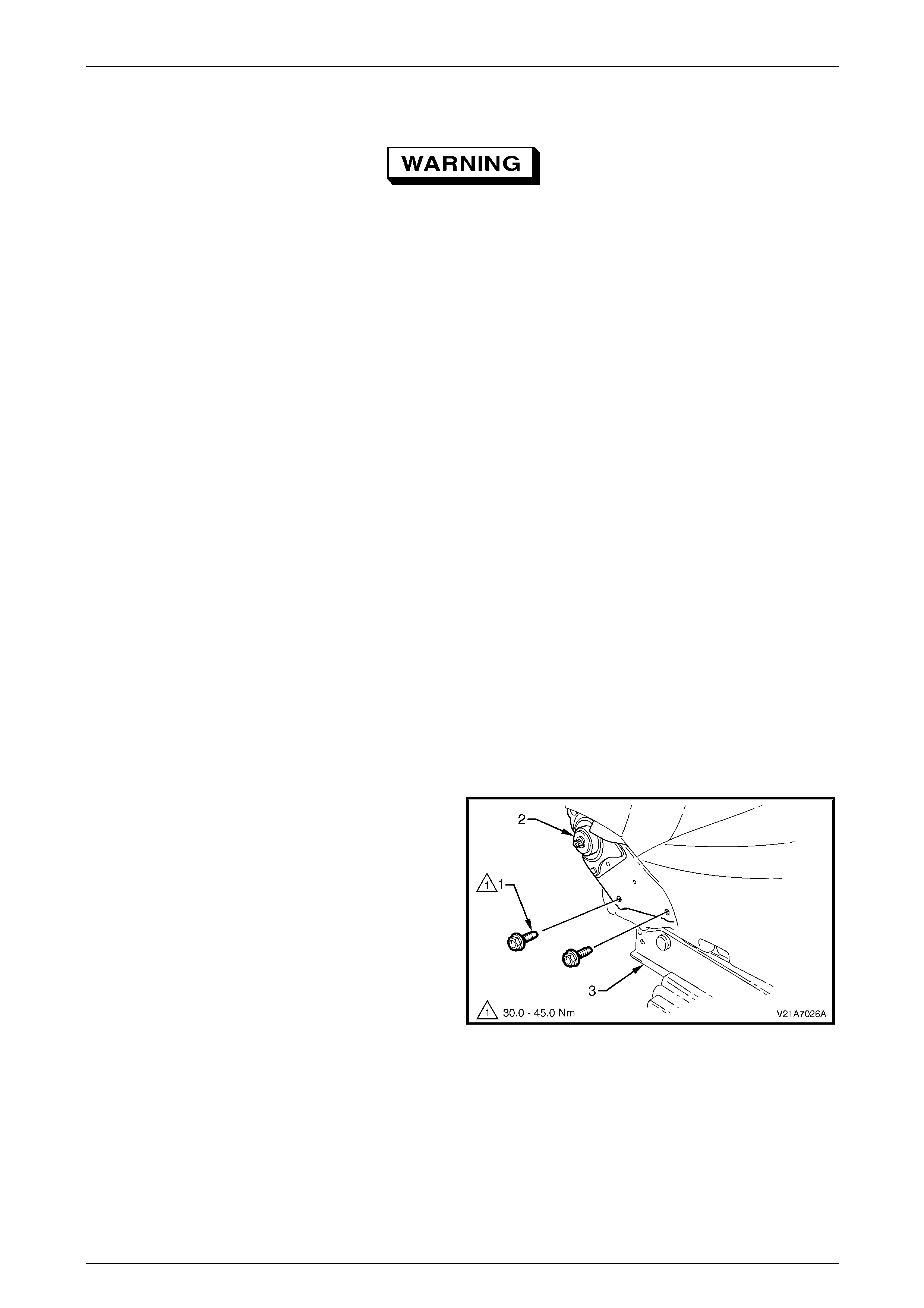

6 Torque Wrench Specifications..........................................................................................................238

Front Seat........................................................................................................................................................... 238

Rear Seat ............................................................................................................................................................ 238

Seat Assemblies Page 1A7–10

Page 1A7–10

1 General Information

This Section describes the service and dia gn o stic procedures for the seat assemblies.

For Diagnosis the section is di vided as follows:

• front seat, non-memory, and

• front seat, memory and rear-view Mirror.

For Service Operations the section is divided as follows:

• front seat assemblies, and

• rear seat assemblies.

1.1 Front Seat General Description

For reasons of personal safety, the vehicle

must only be driven after the seat has been

adjusted to the correct driving position. Do

not adjust the driver’s seat when the vehicle

is moving as the seat could move away from

the driving position, causing loss of control.

Accessory and after mar ket seat covers MUST

NOT be fitted to any vehicle with side impact

airbags unless app roved by the manu facturer.

Non-approved seat covers may inhibit the

operation of the side airbag, reducing the

protection otherwise provided to the

occupants during a side-impact collision.

The front seats fitted feature:

• eight-way electric movement functions,

• side impact airbag assembl ies,

• cloth or leather trim,

• active head restraints,

• rear seat entertainment screens in the b ack of the head restraints for Level 5 vehicles, and

• a driver's seat memory positio n system that integrates with other vehicle functions for Level 5 vehicles.

To identify the front seat type fitted, refer to 4.1 Usage Chart.

The front seatbelt buckle and pretens ioner assemblies are attached to the front seats. For service operations

refer to Section 12M Occupant Protection System.

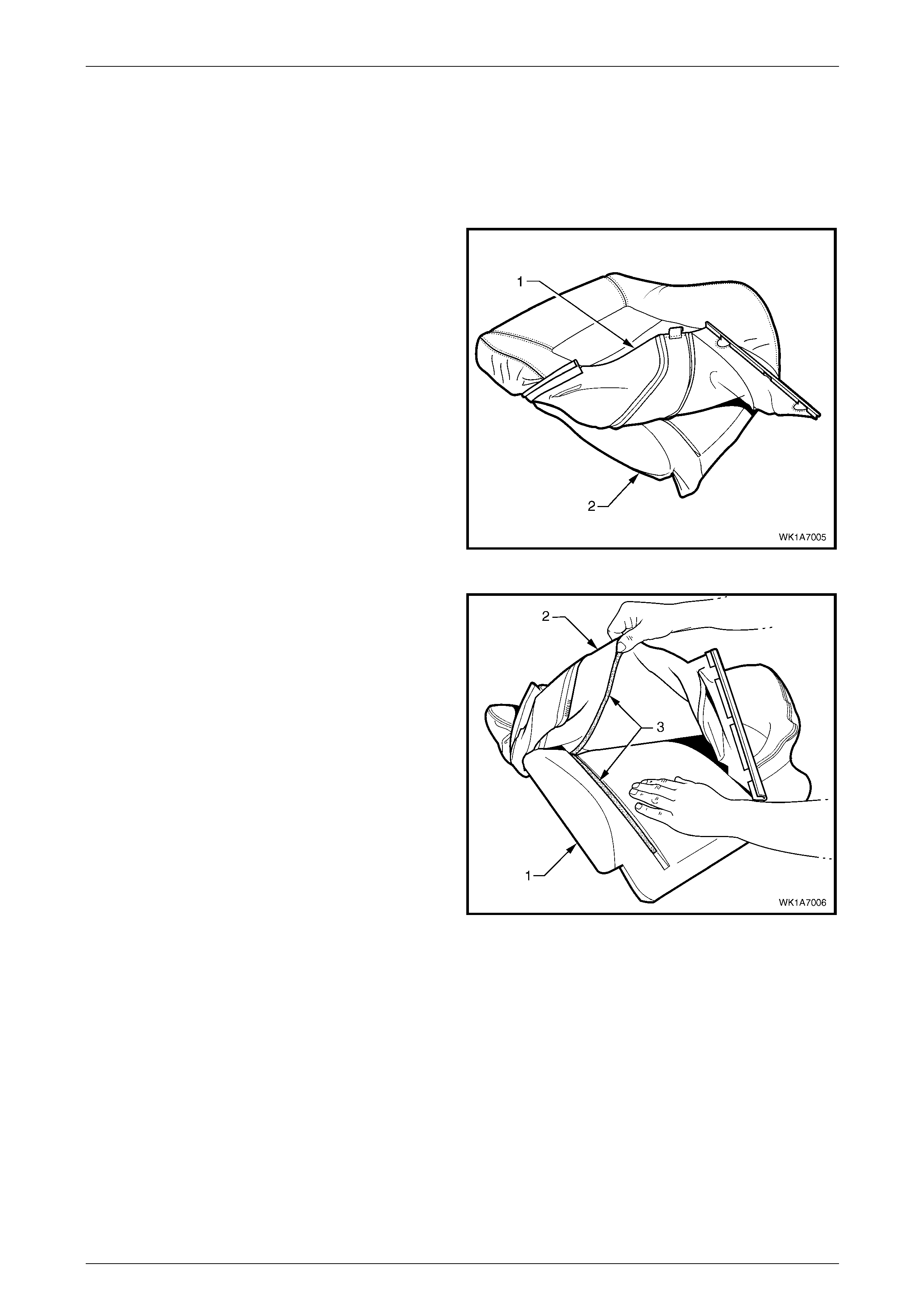

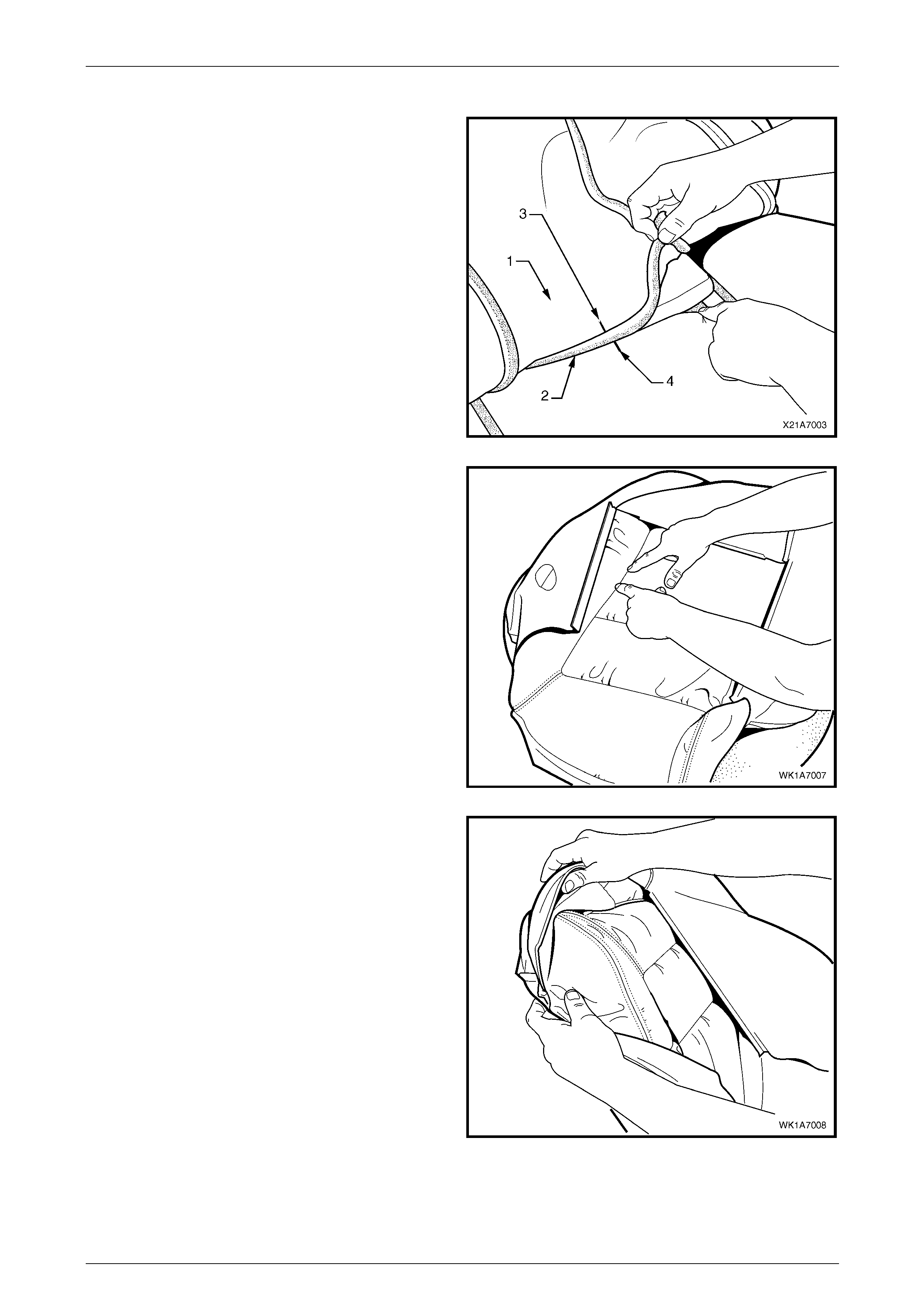

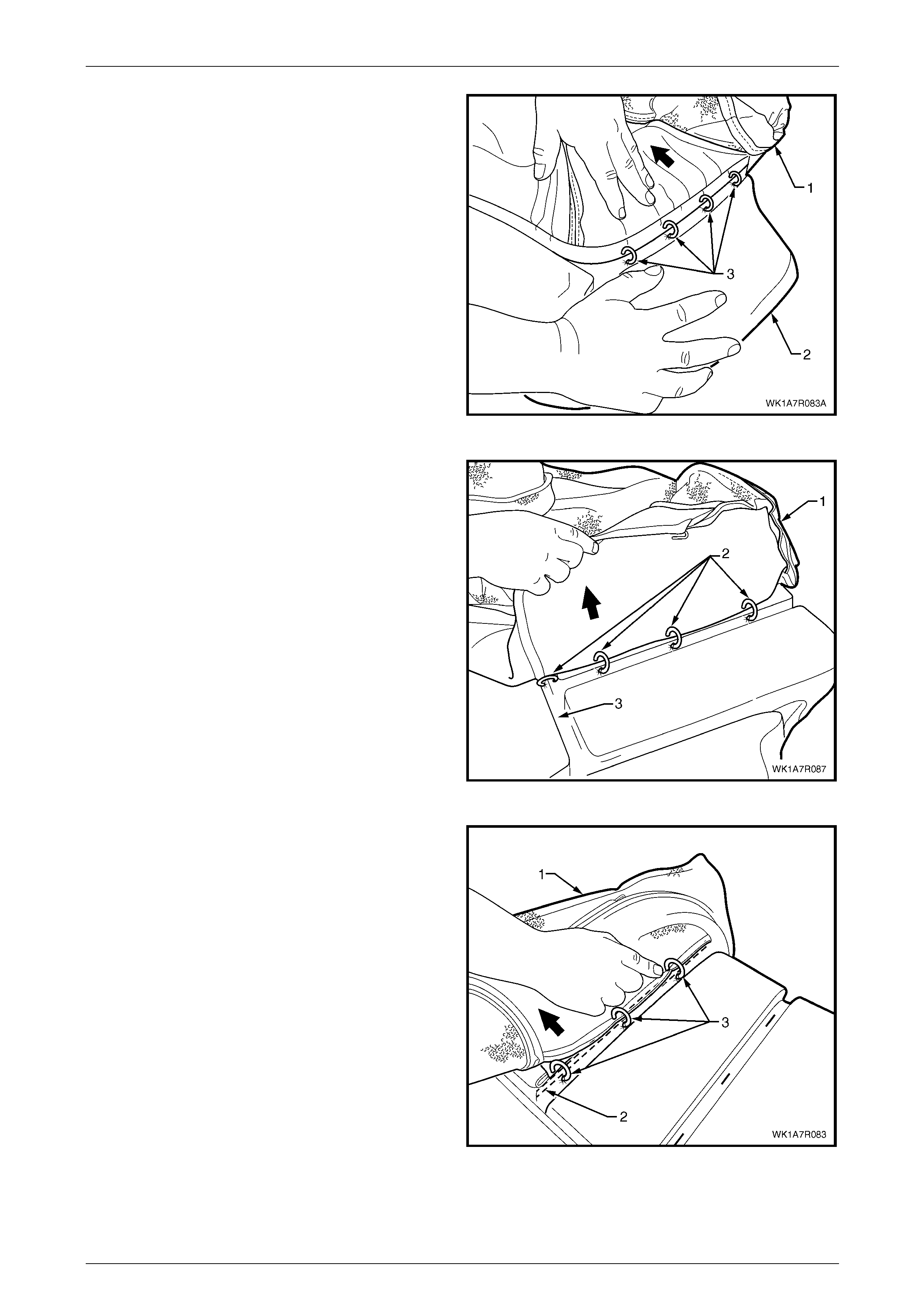

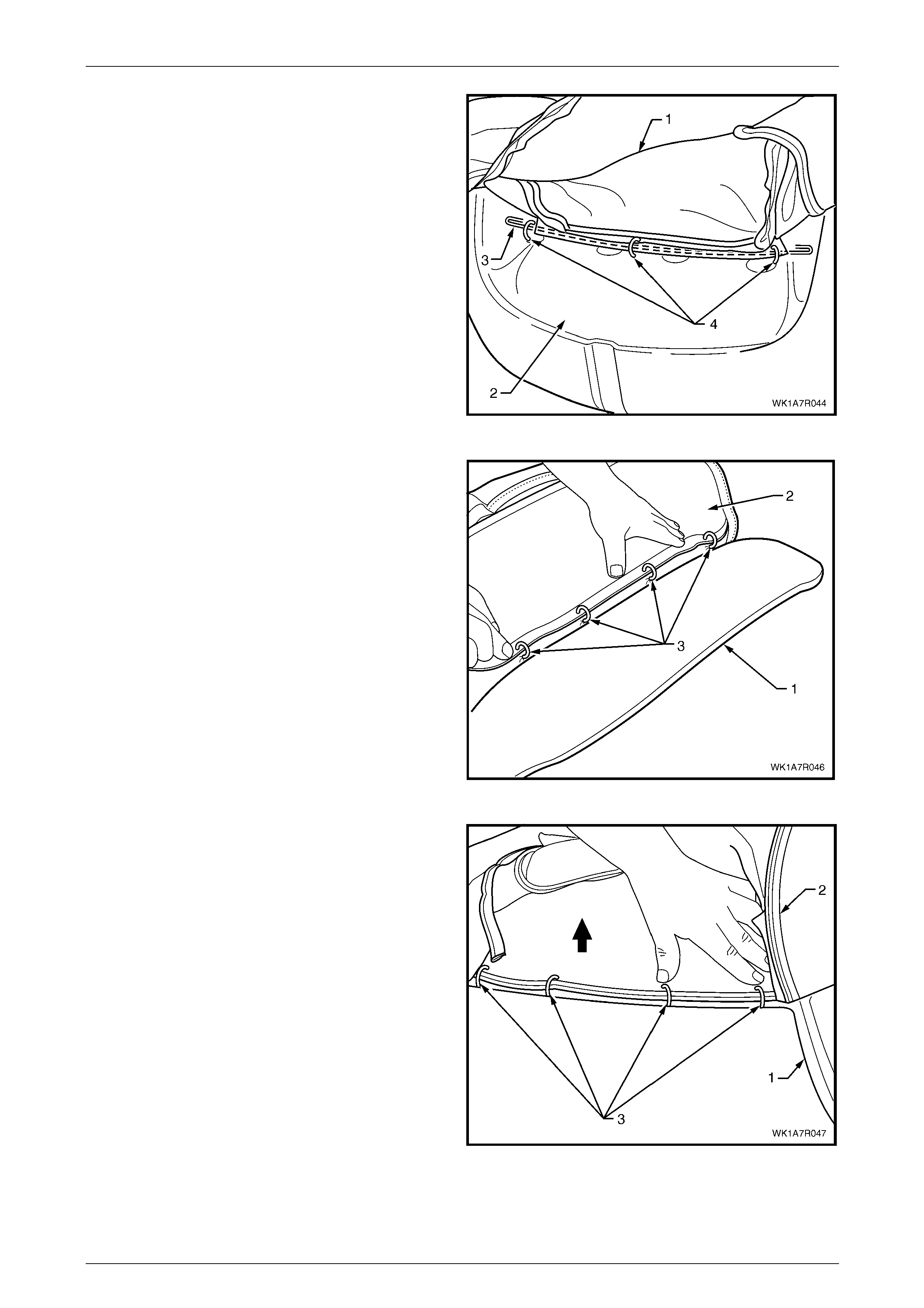

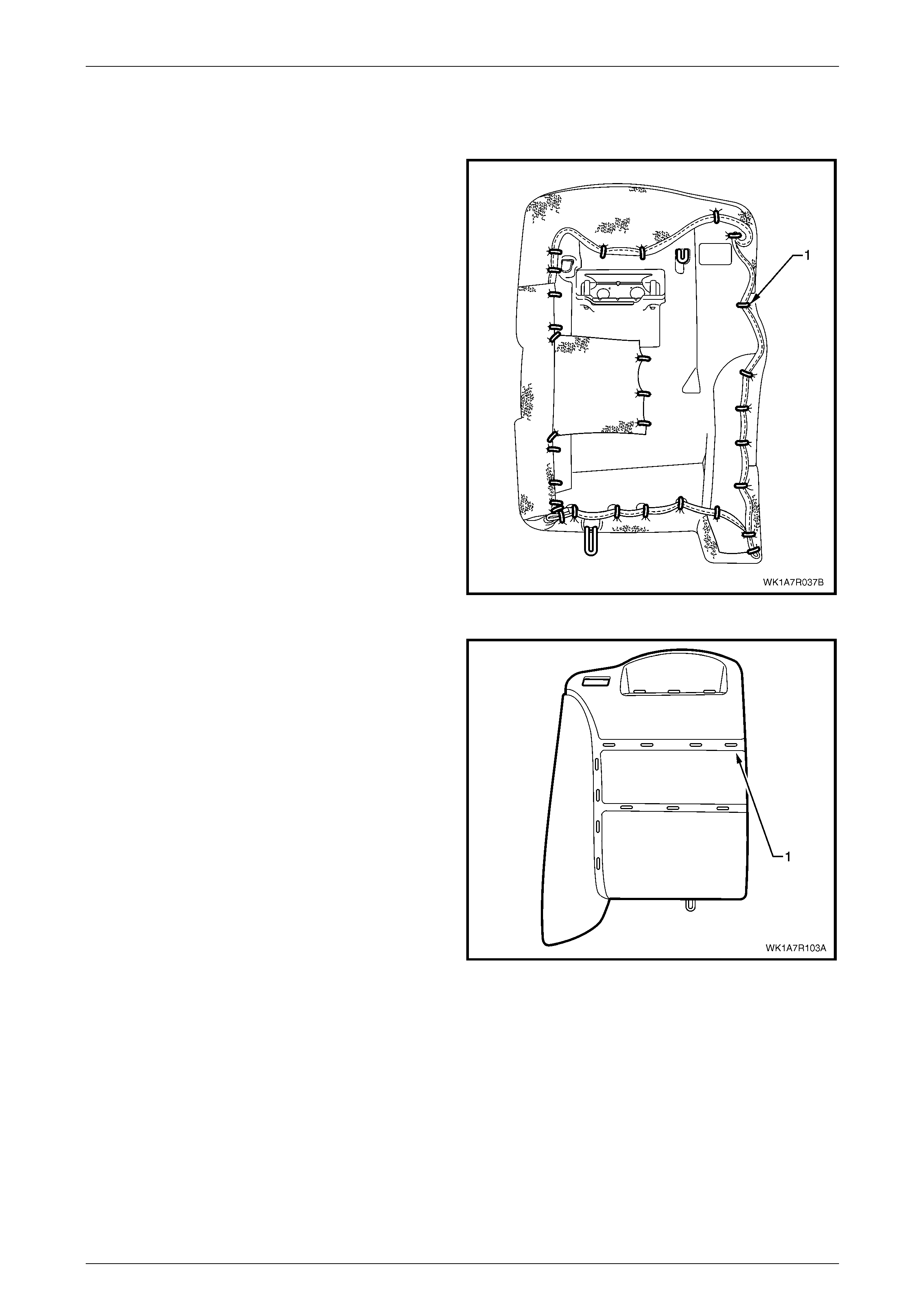

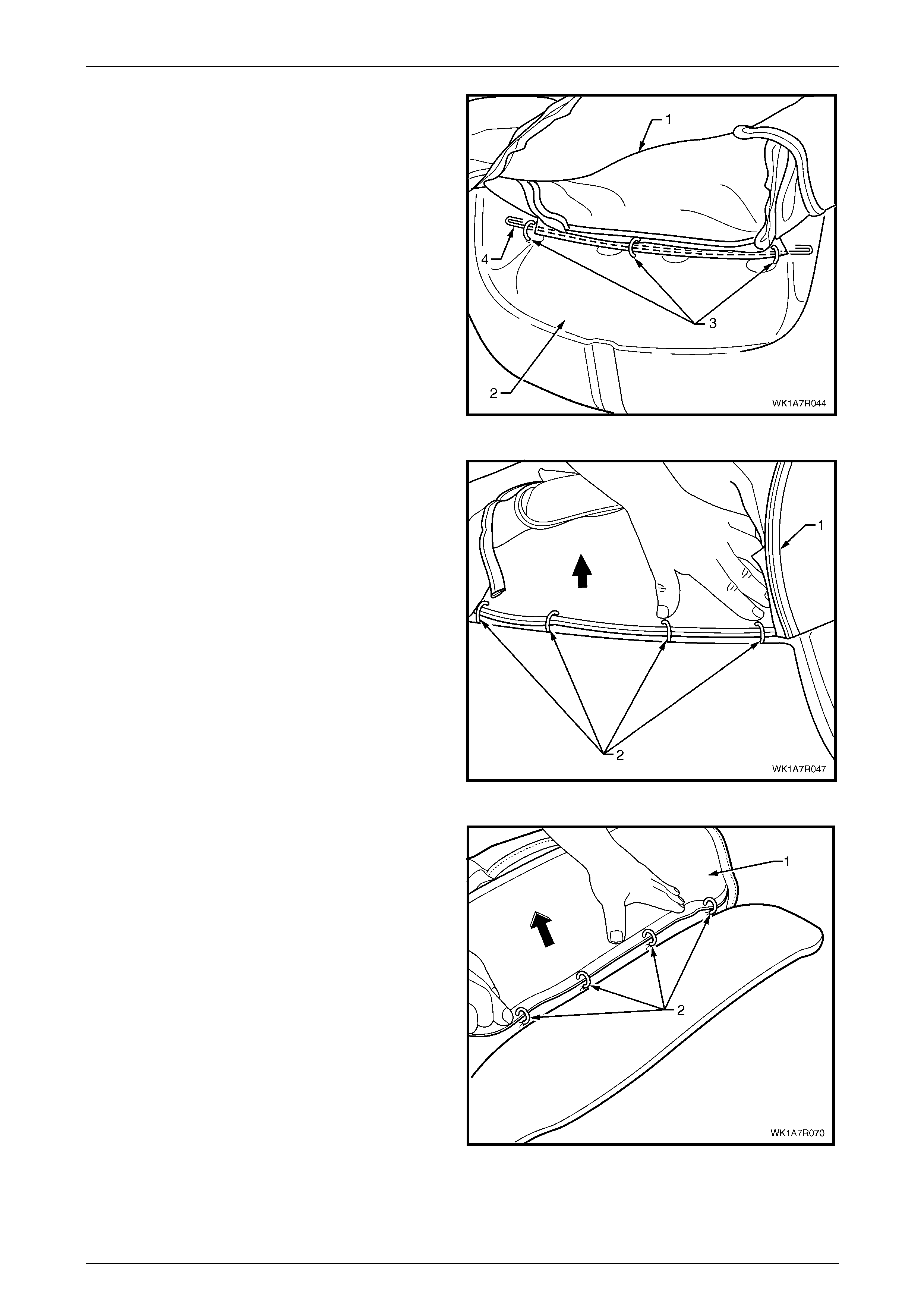

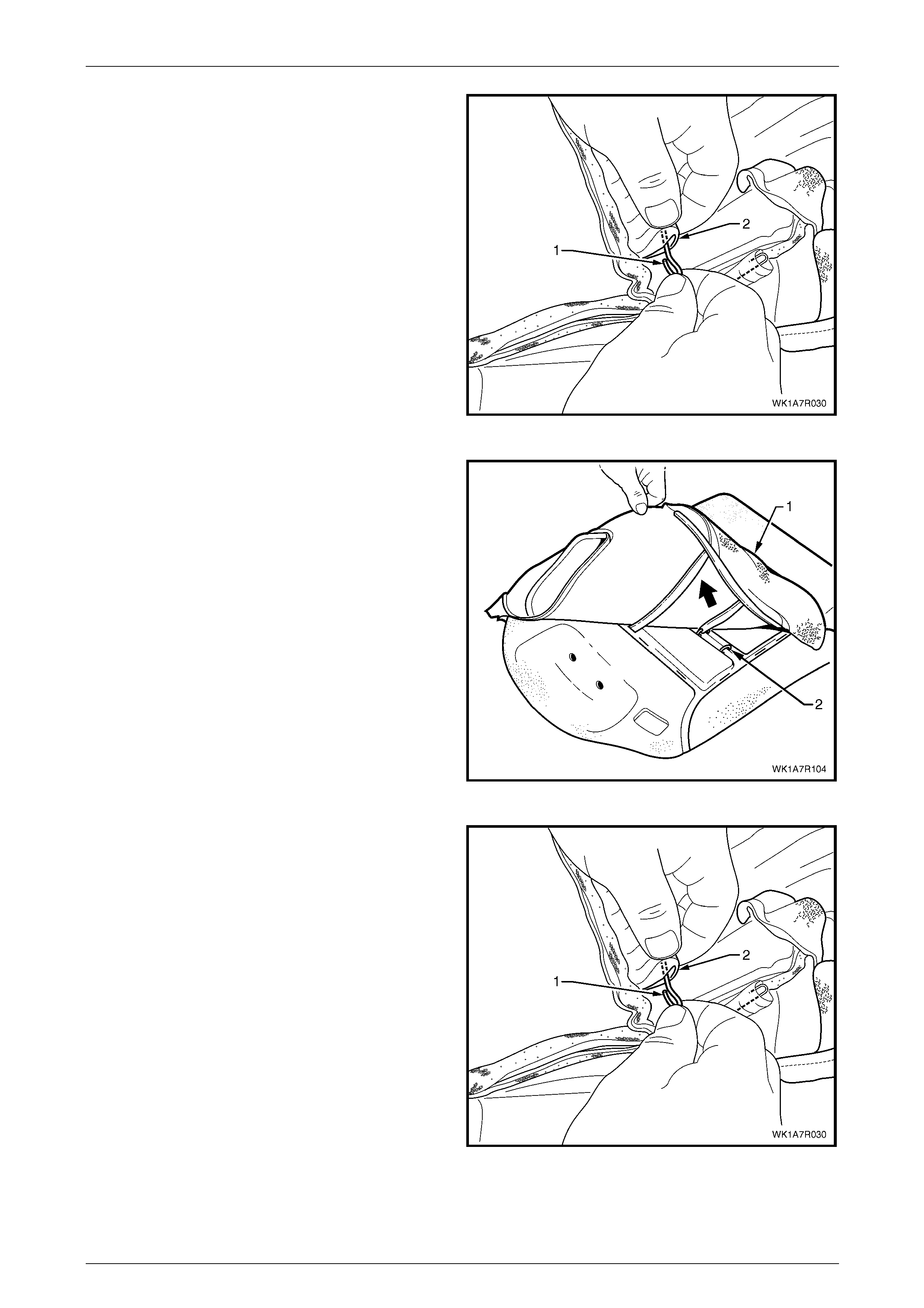

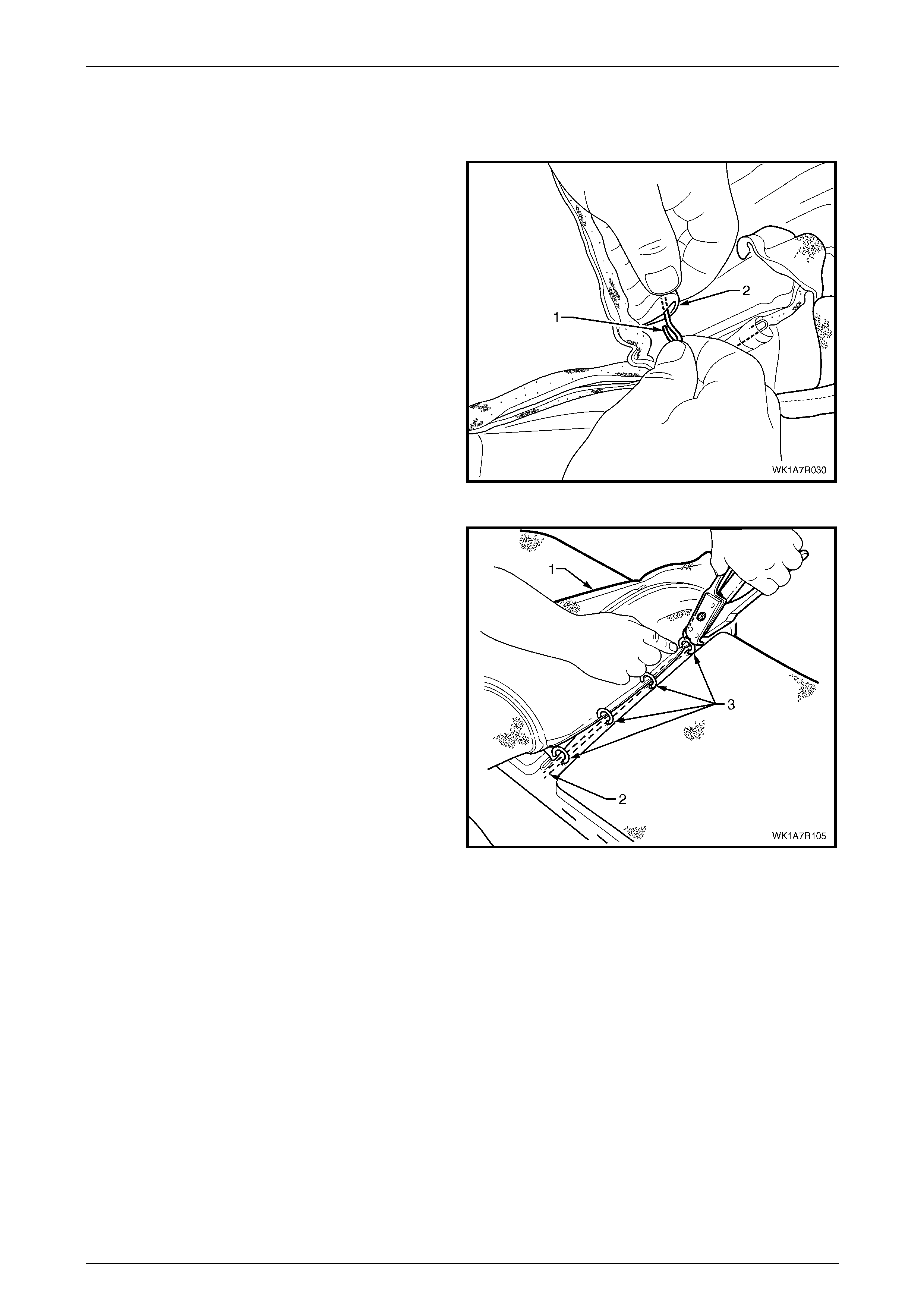

Seat Covers

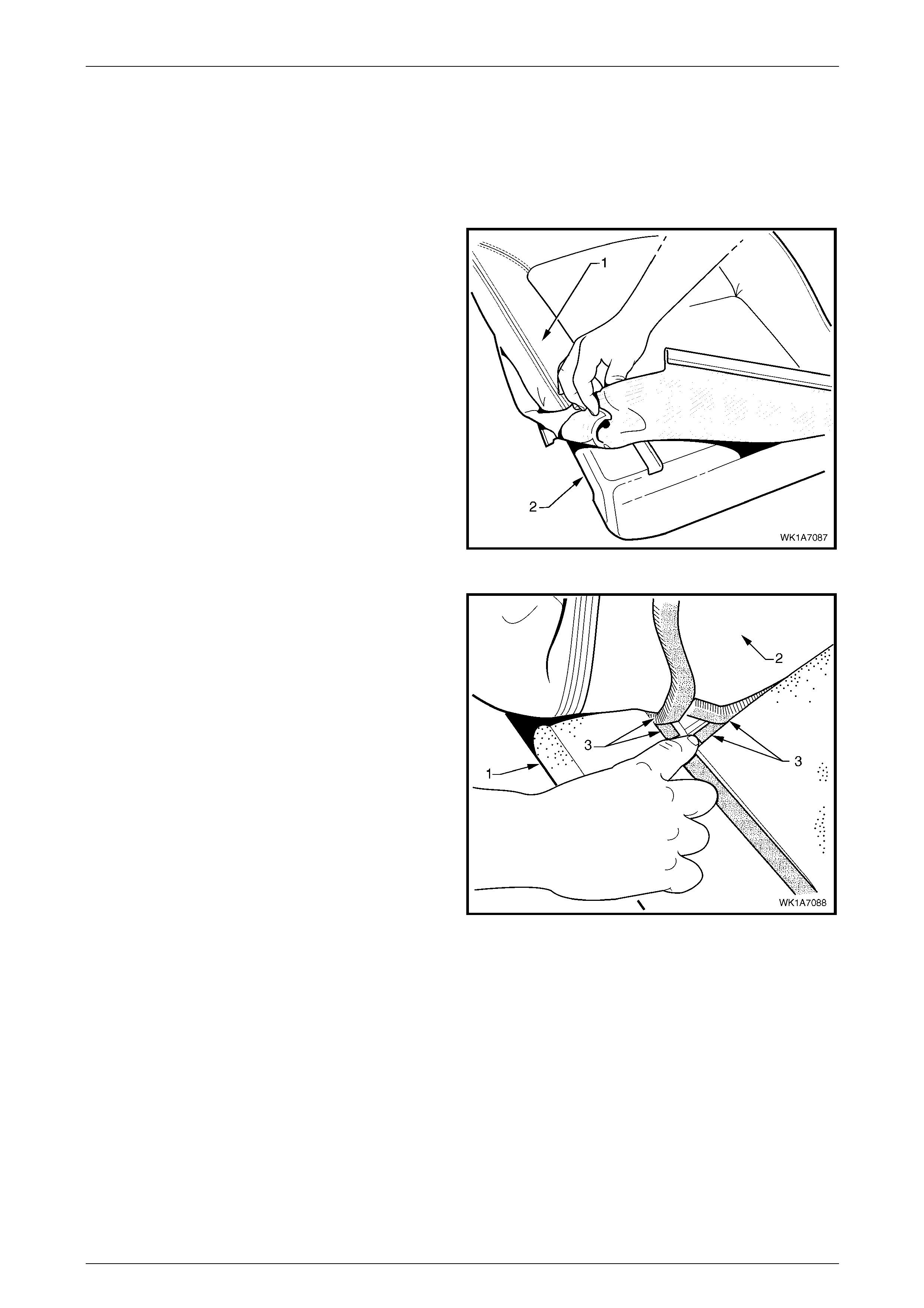

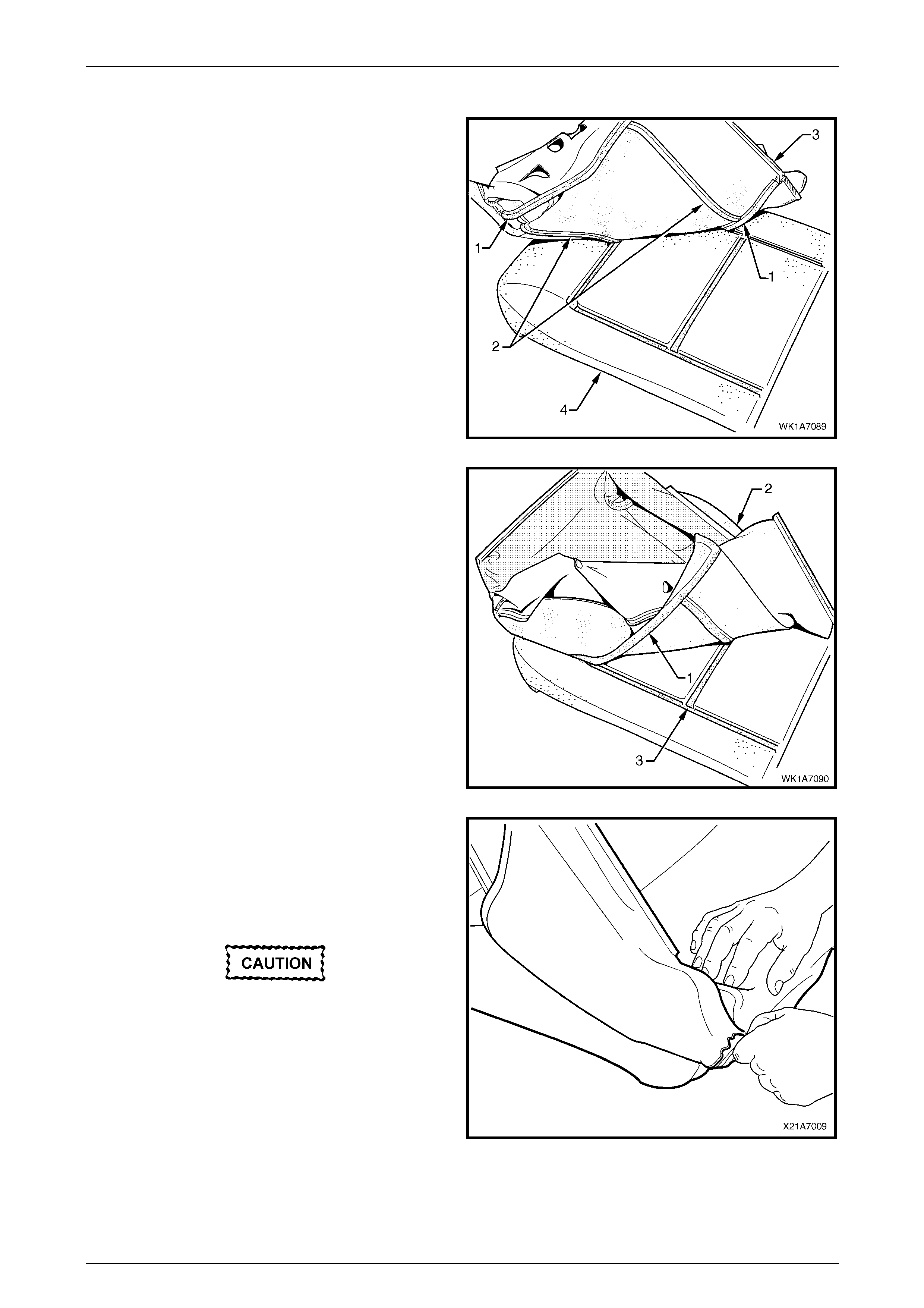

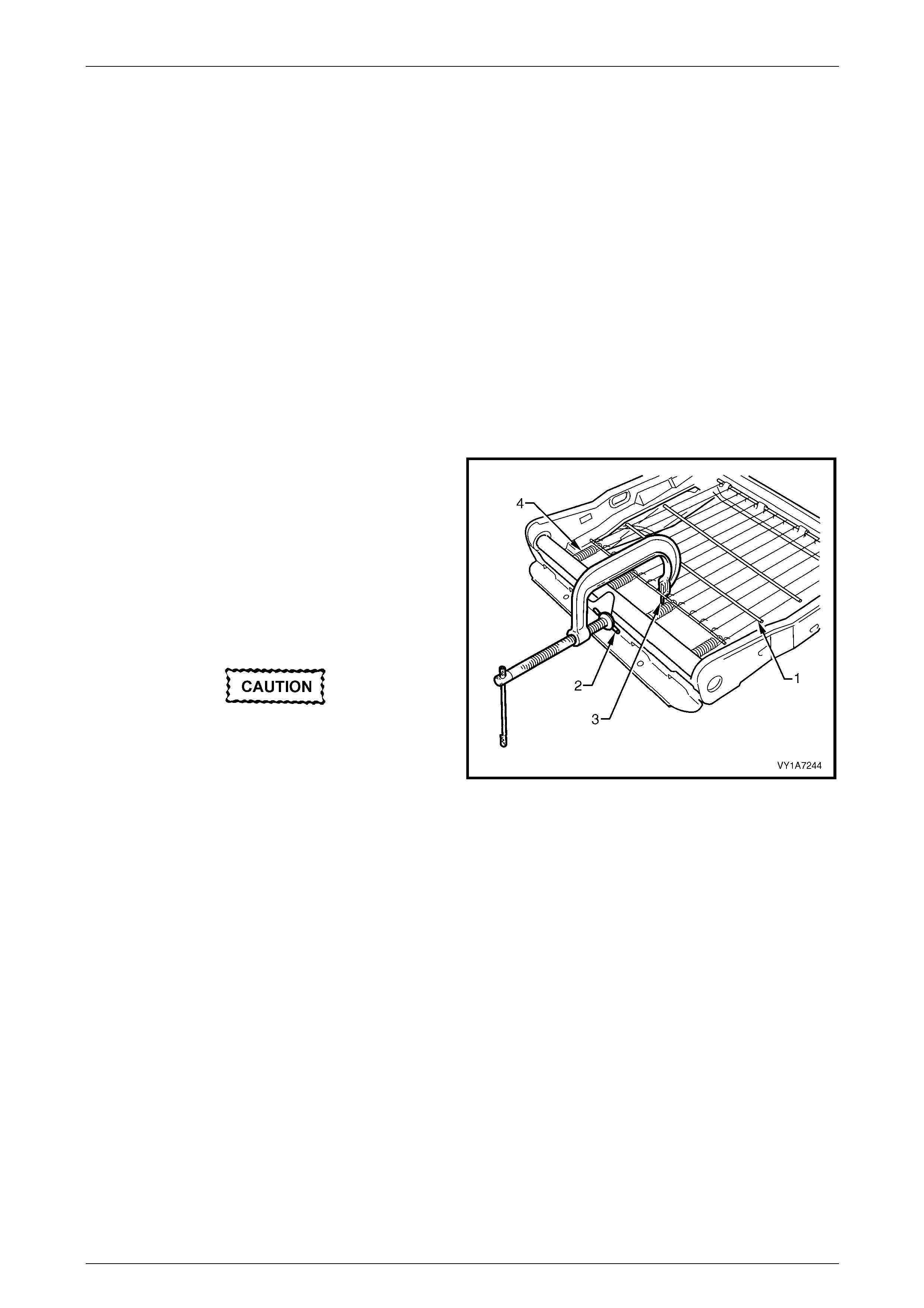

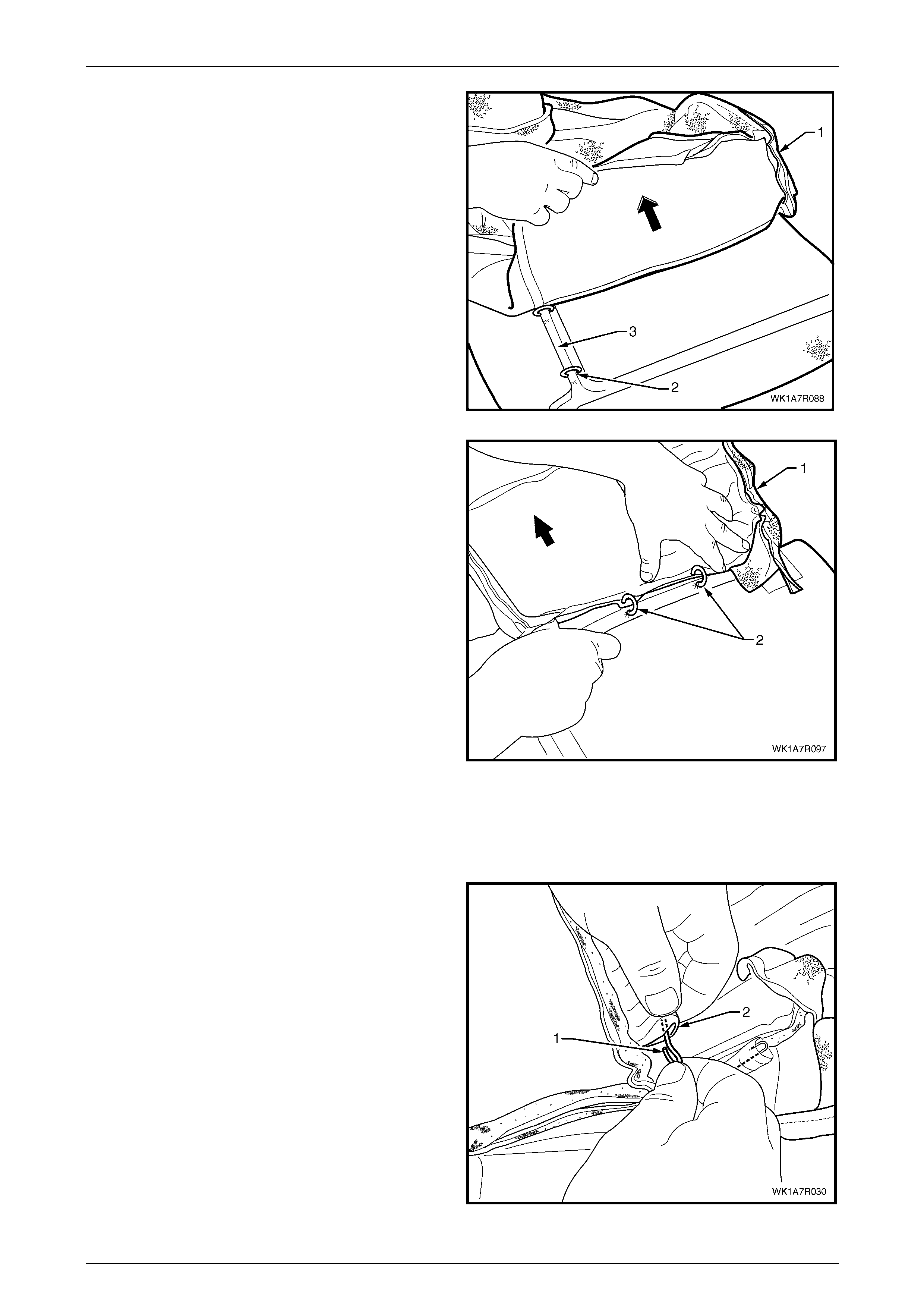

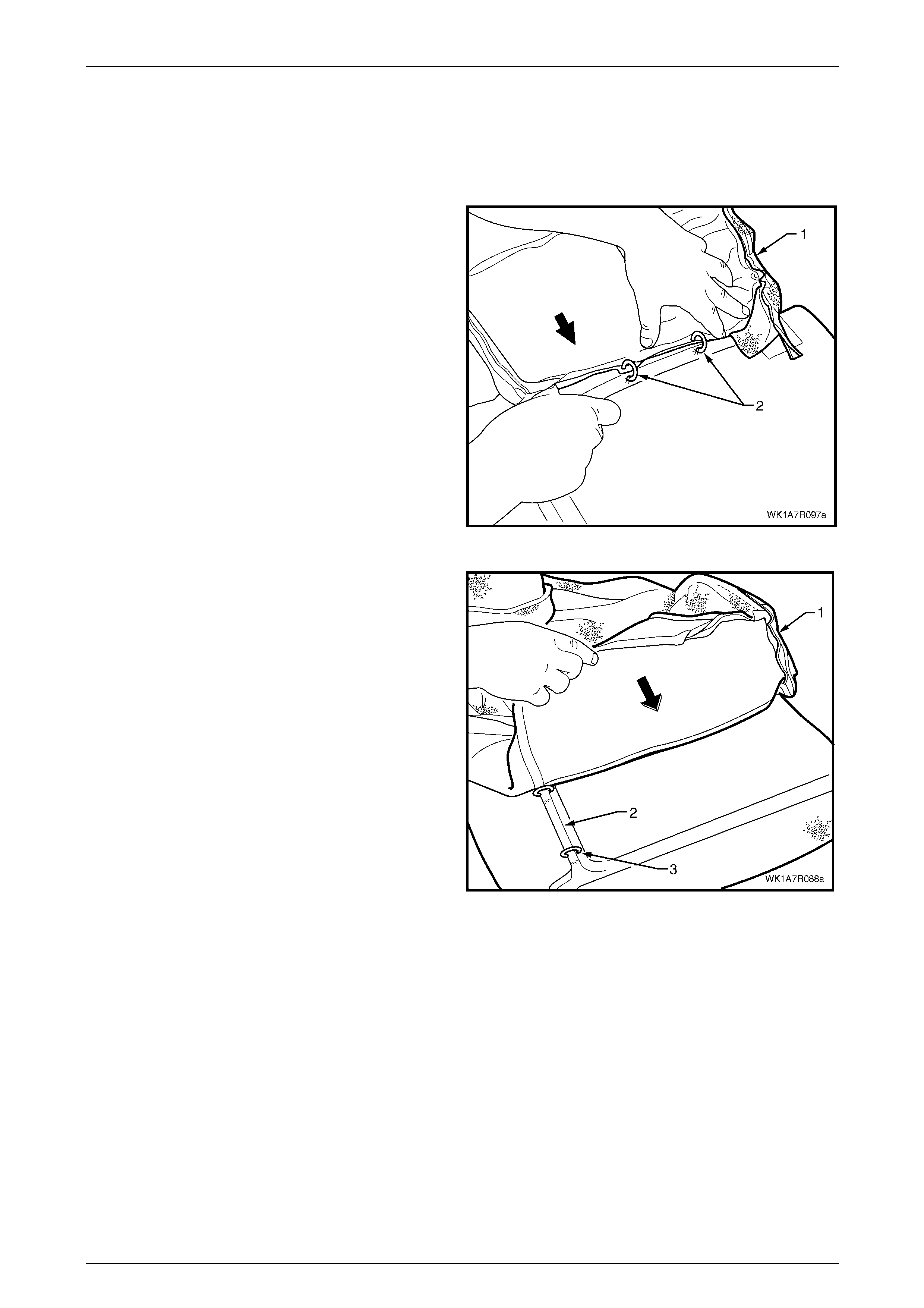

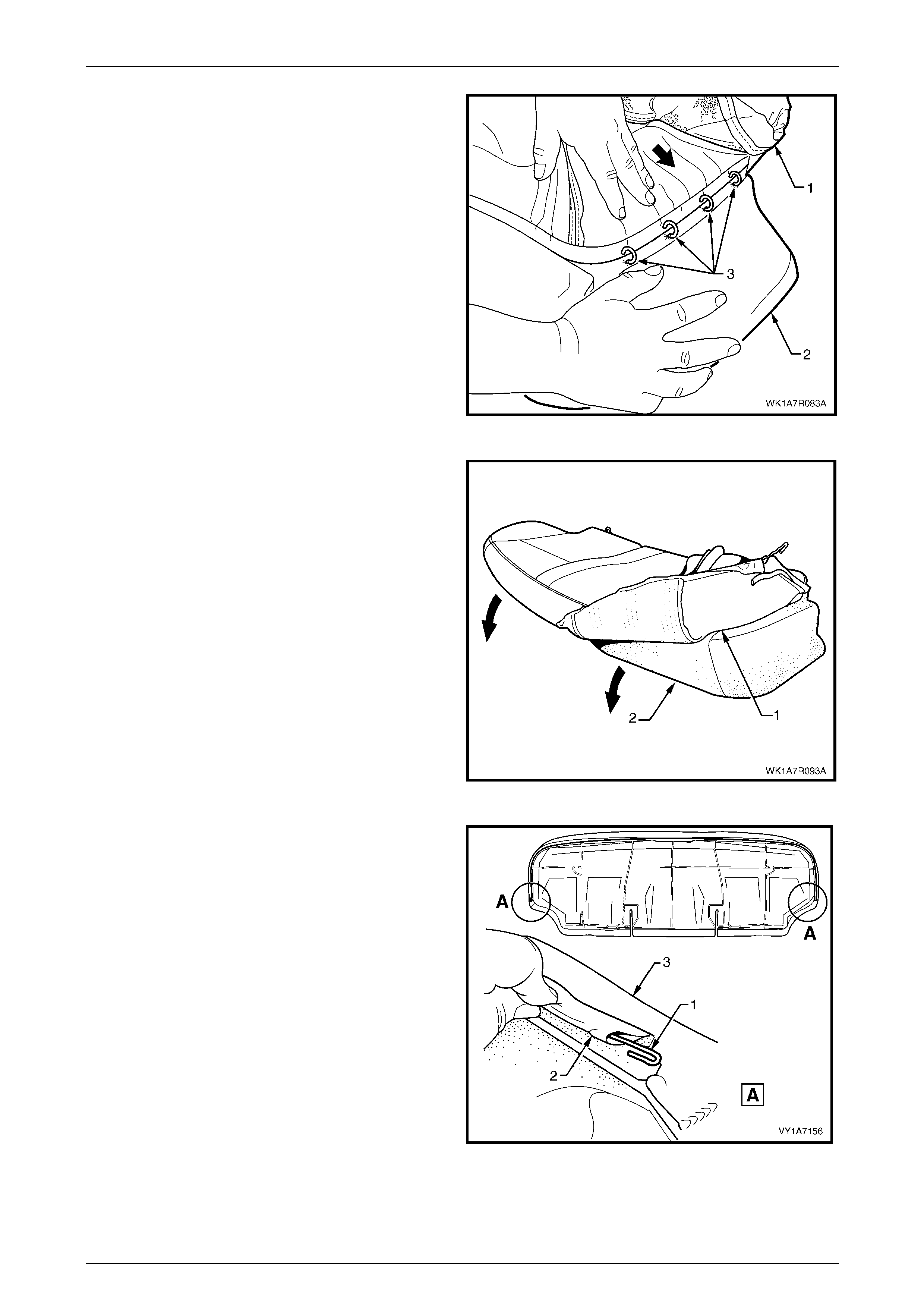

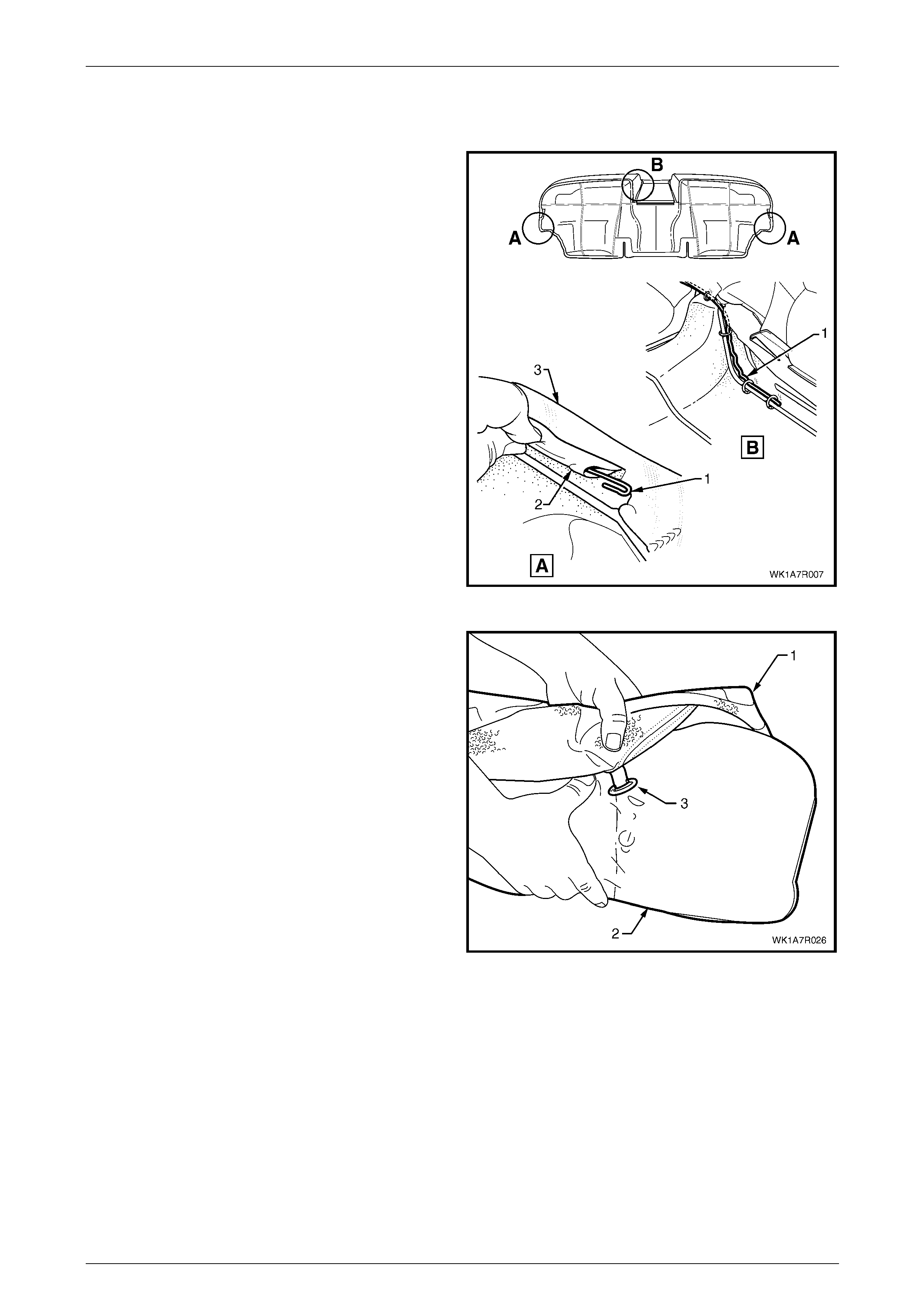

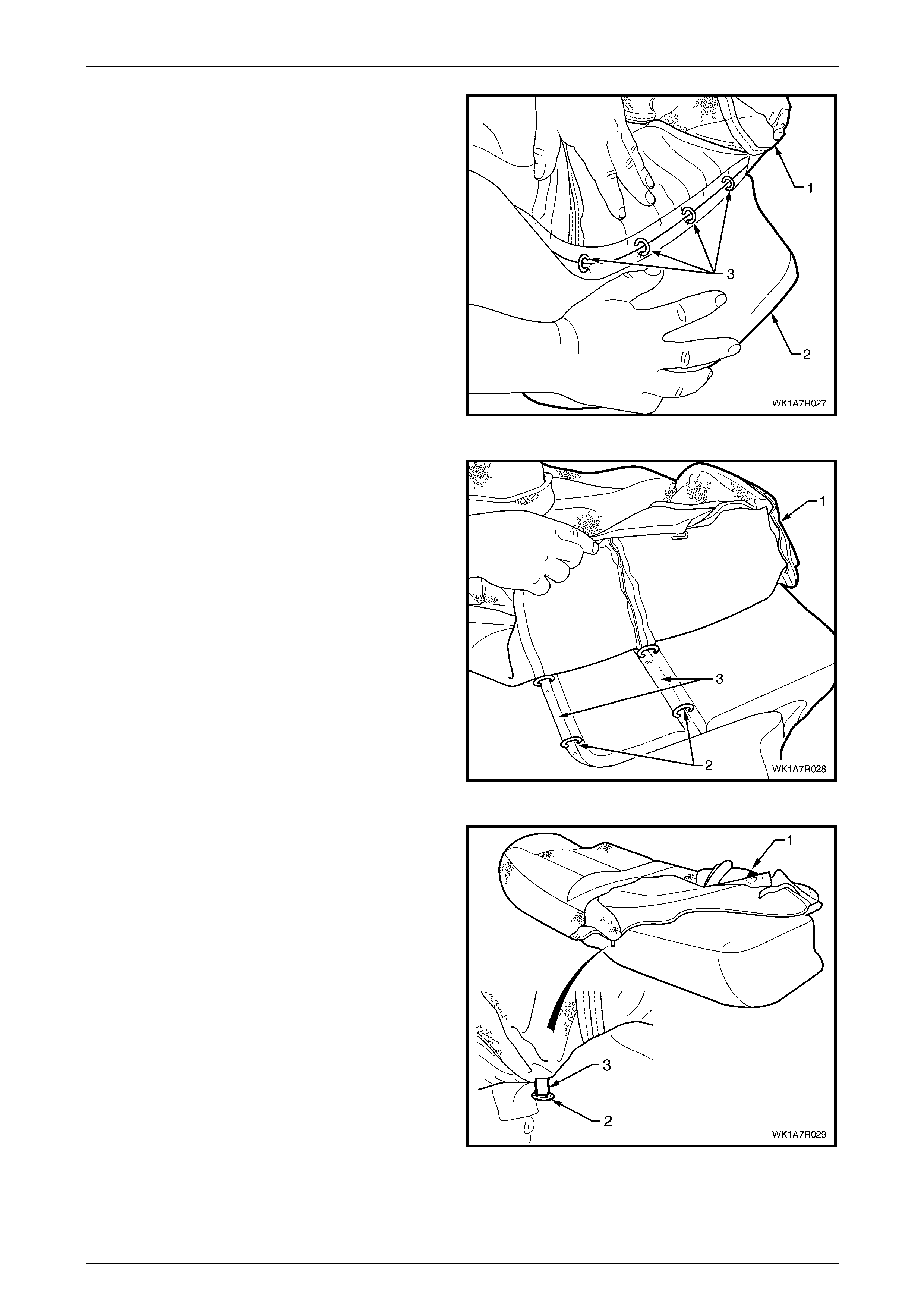

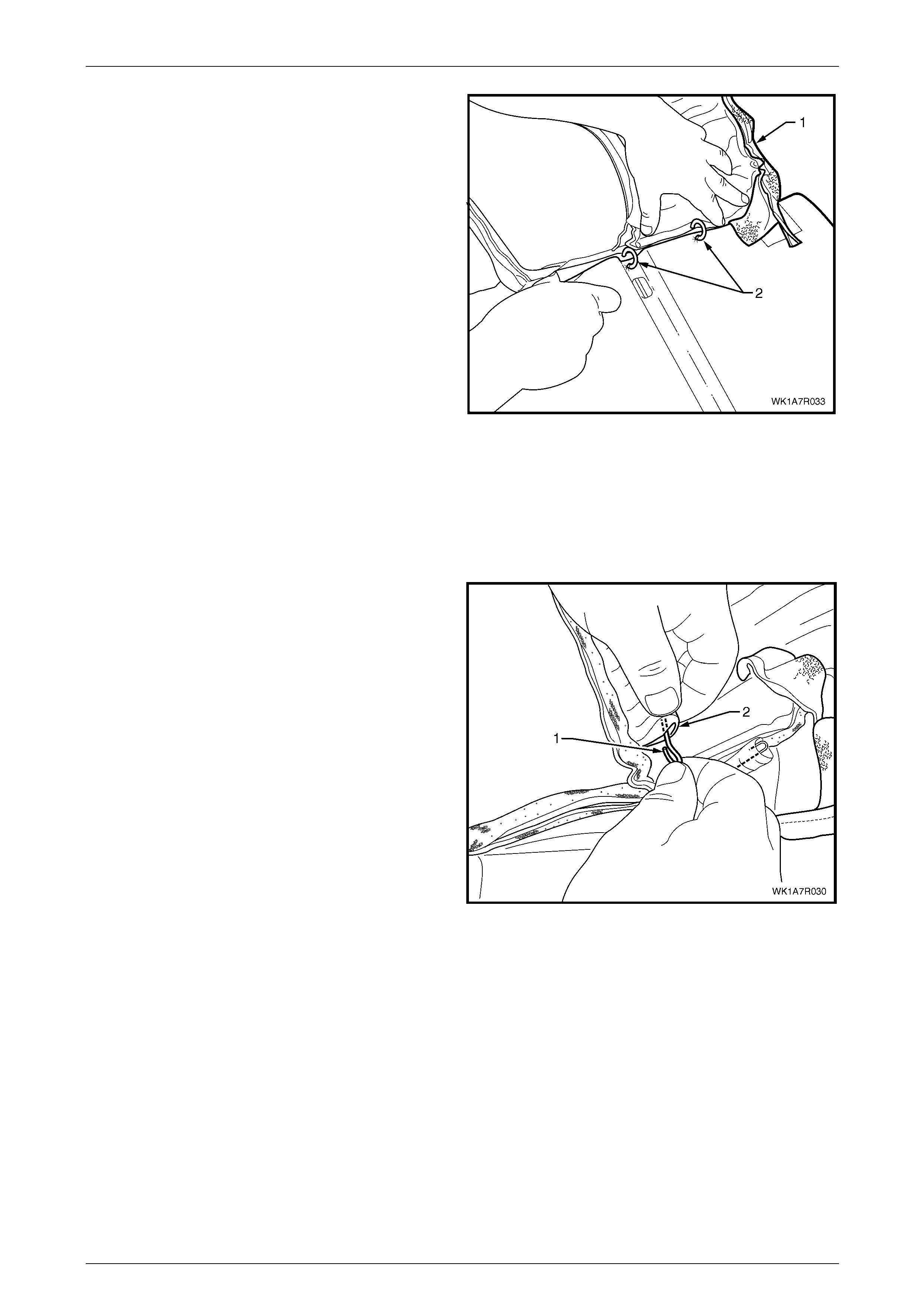

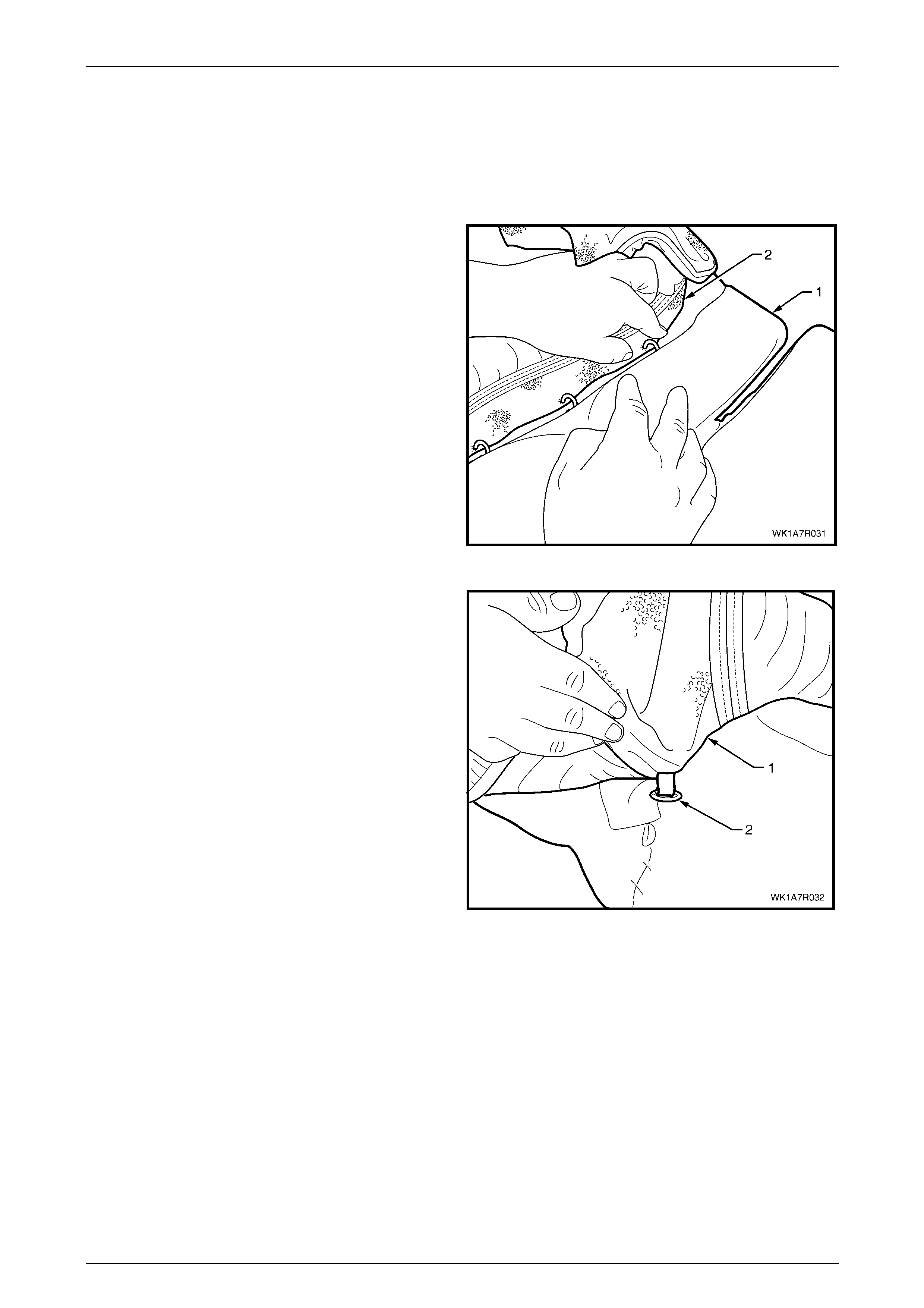

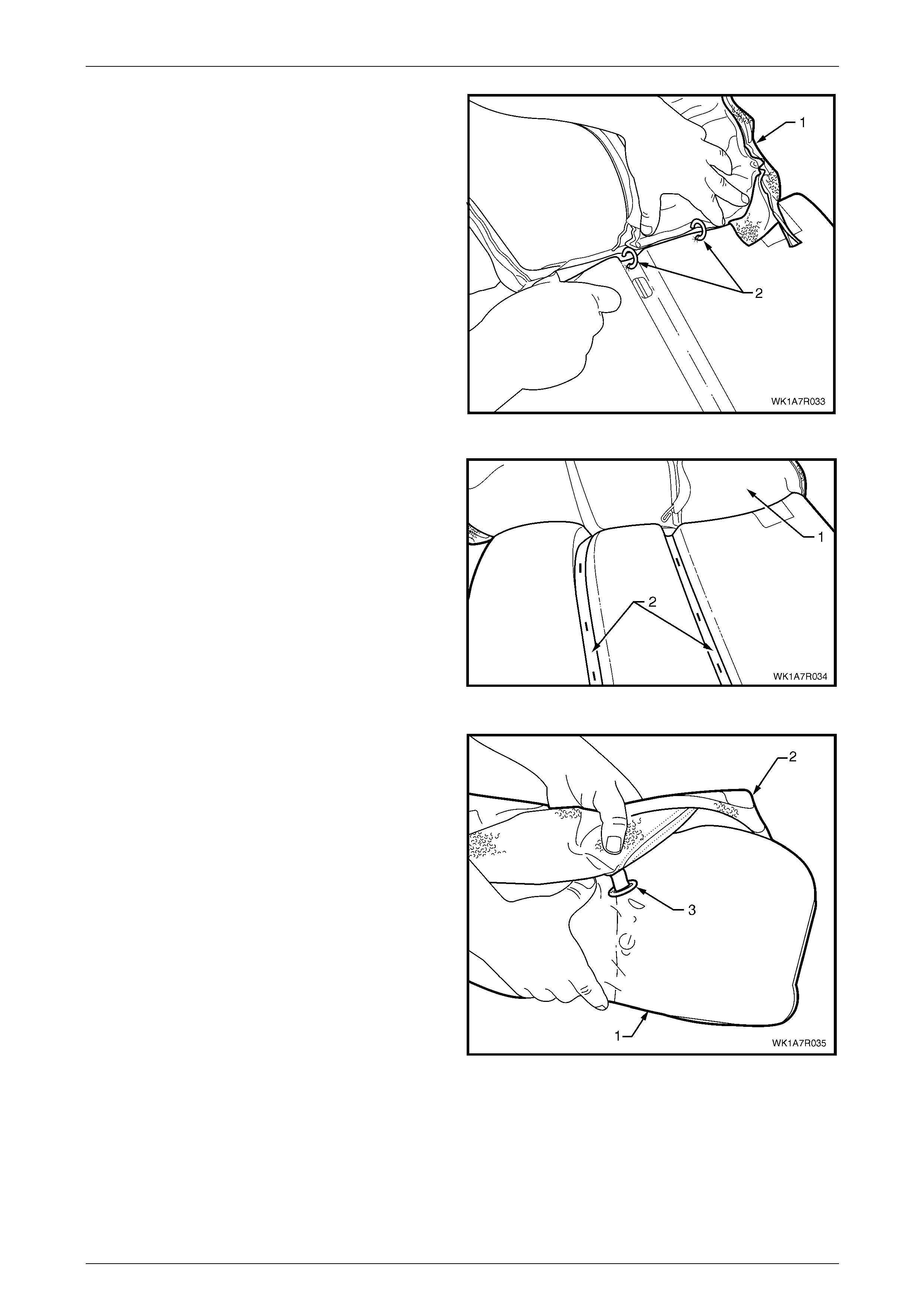

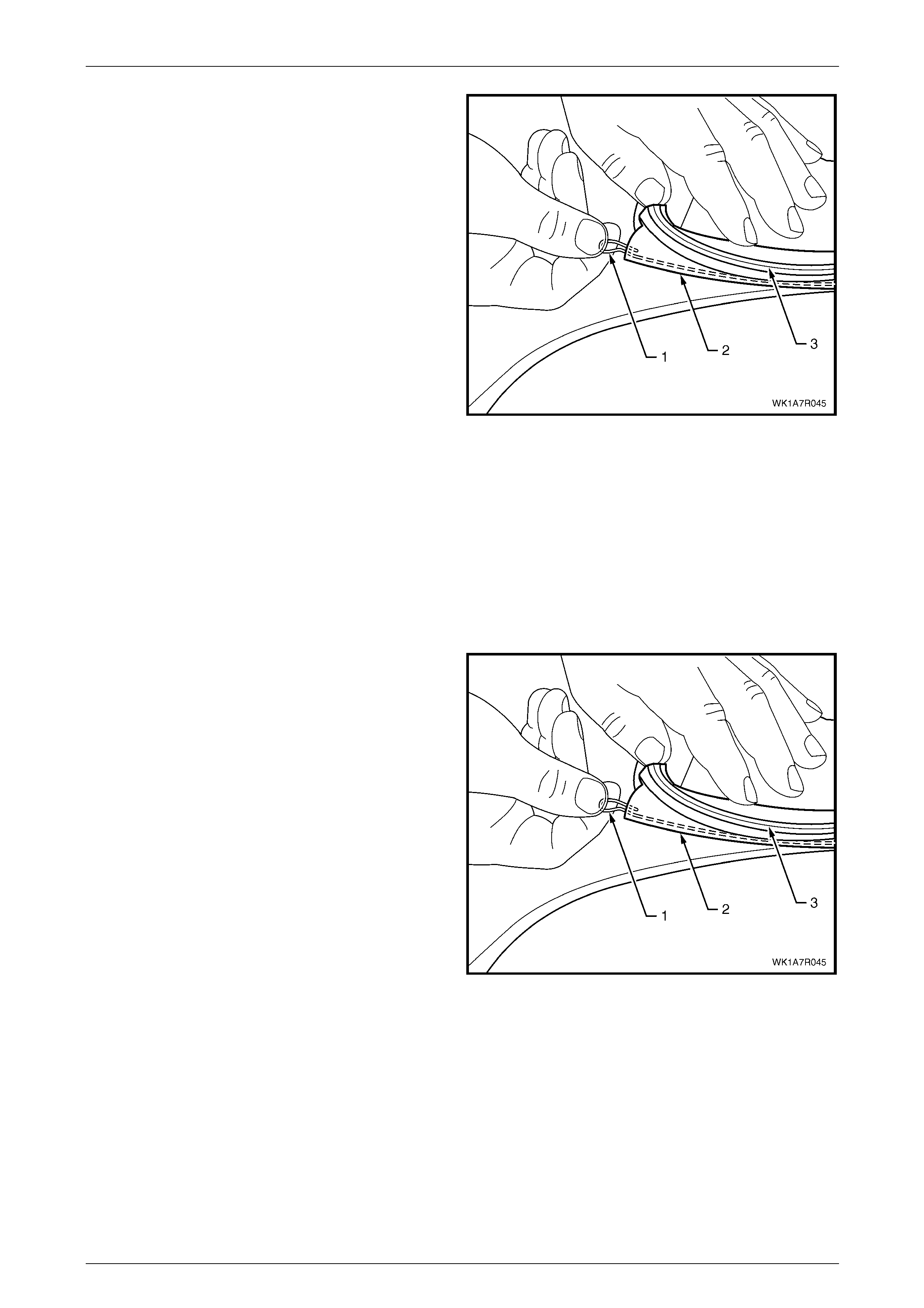

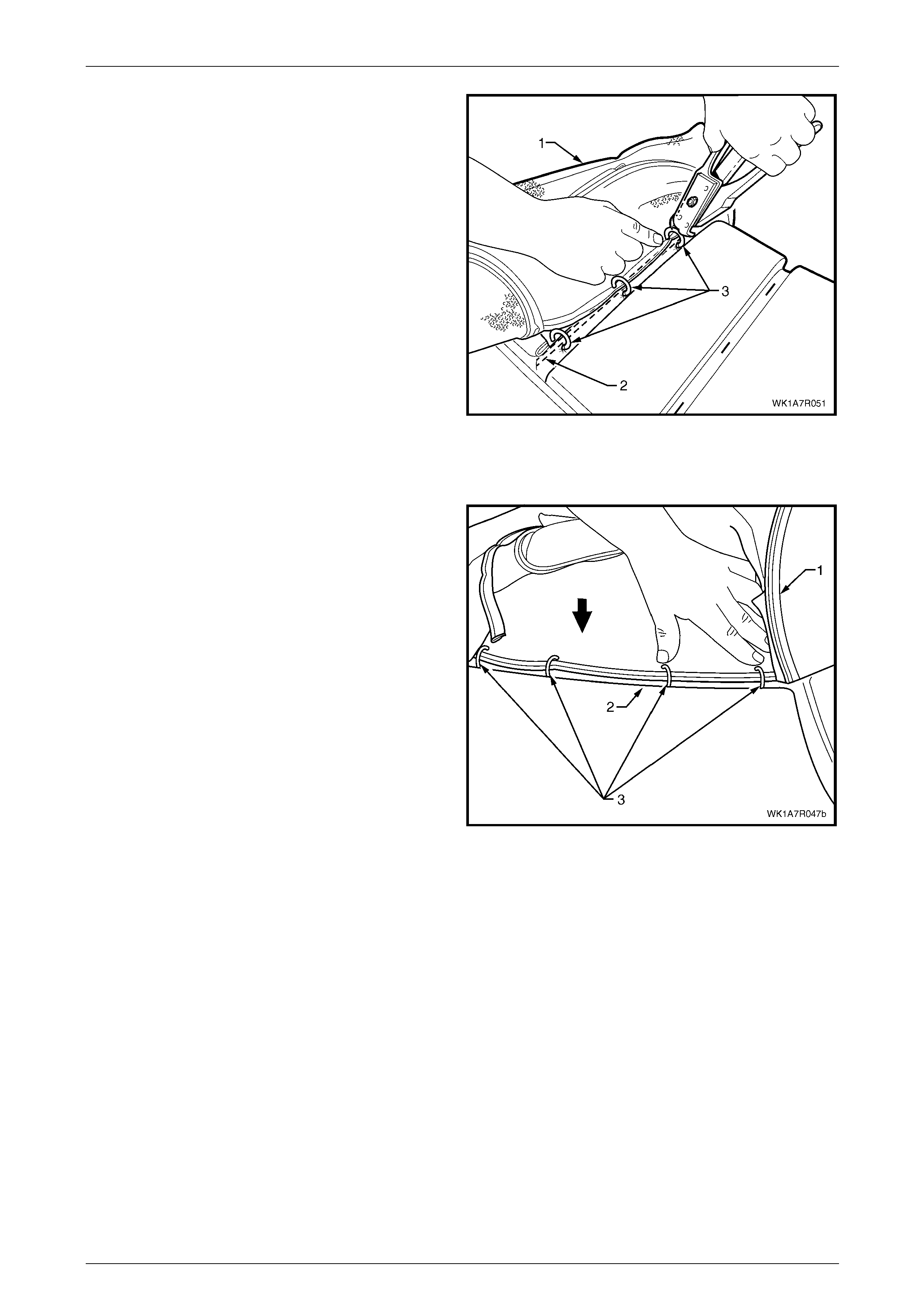

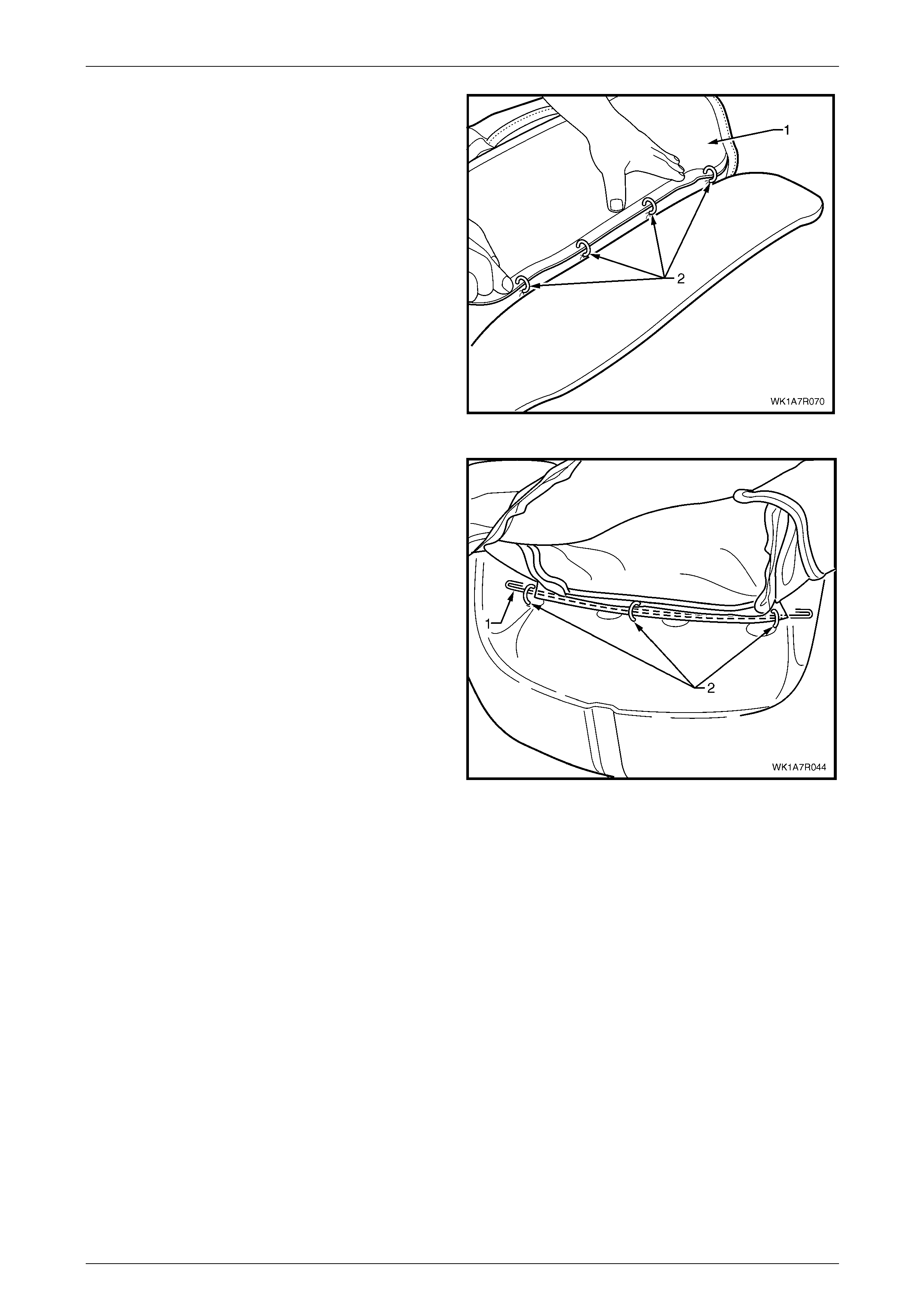

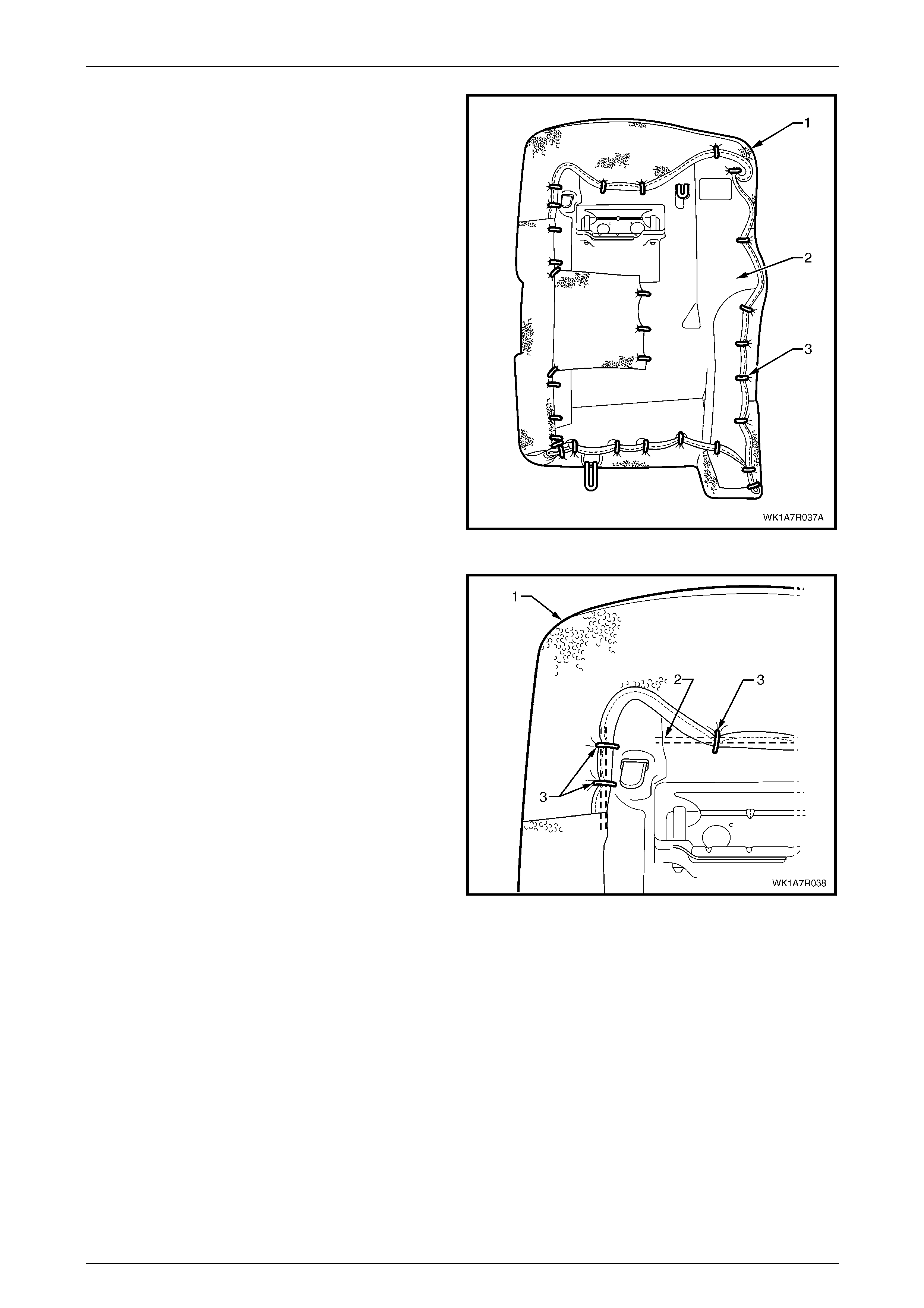

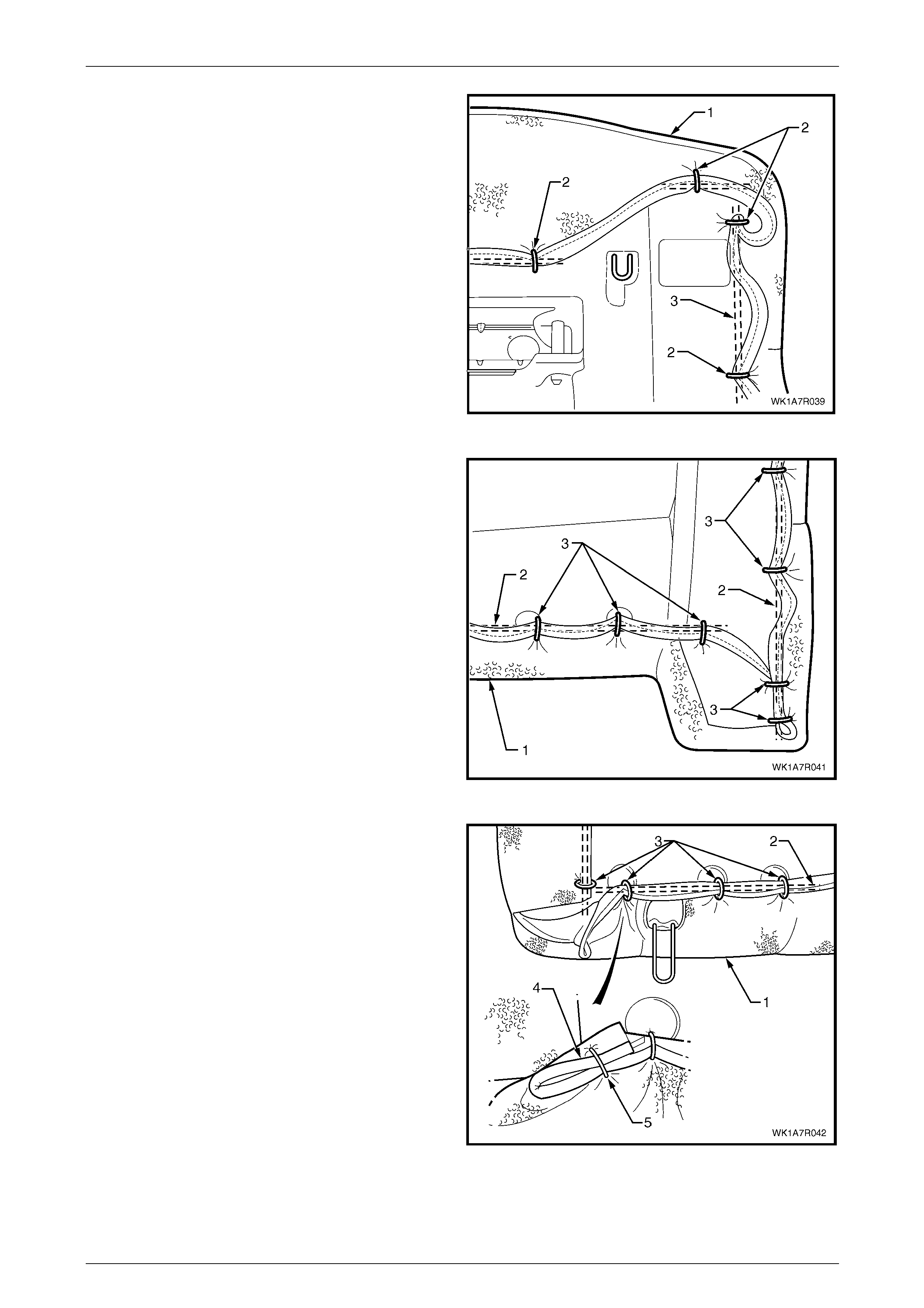

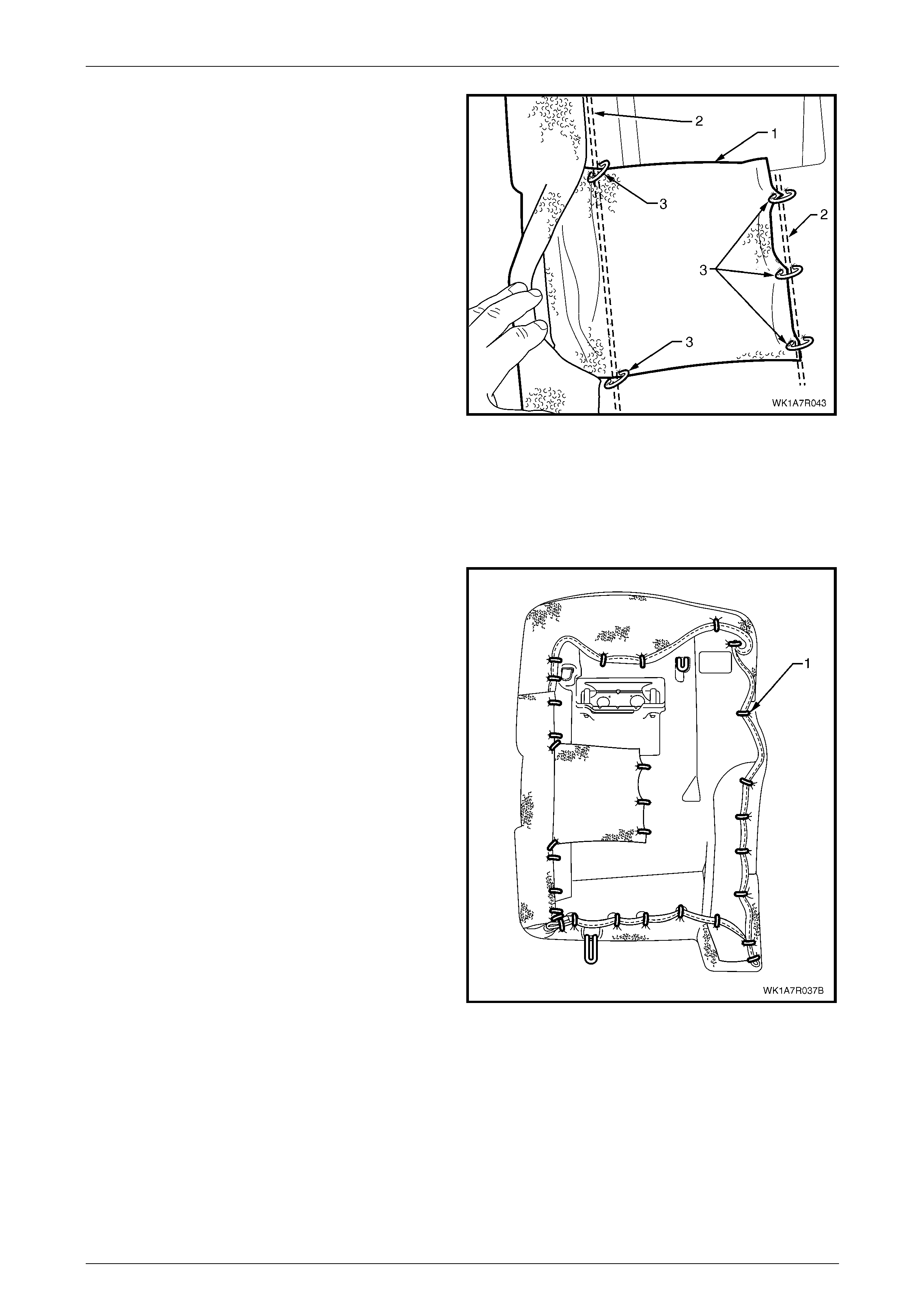

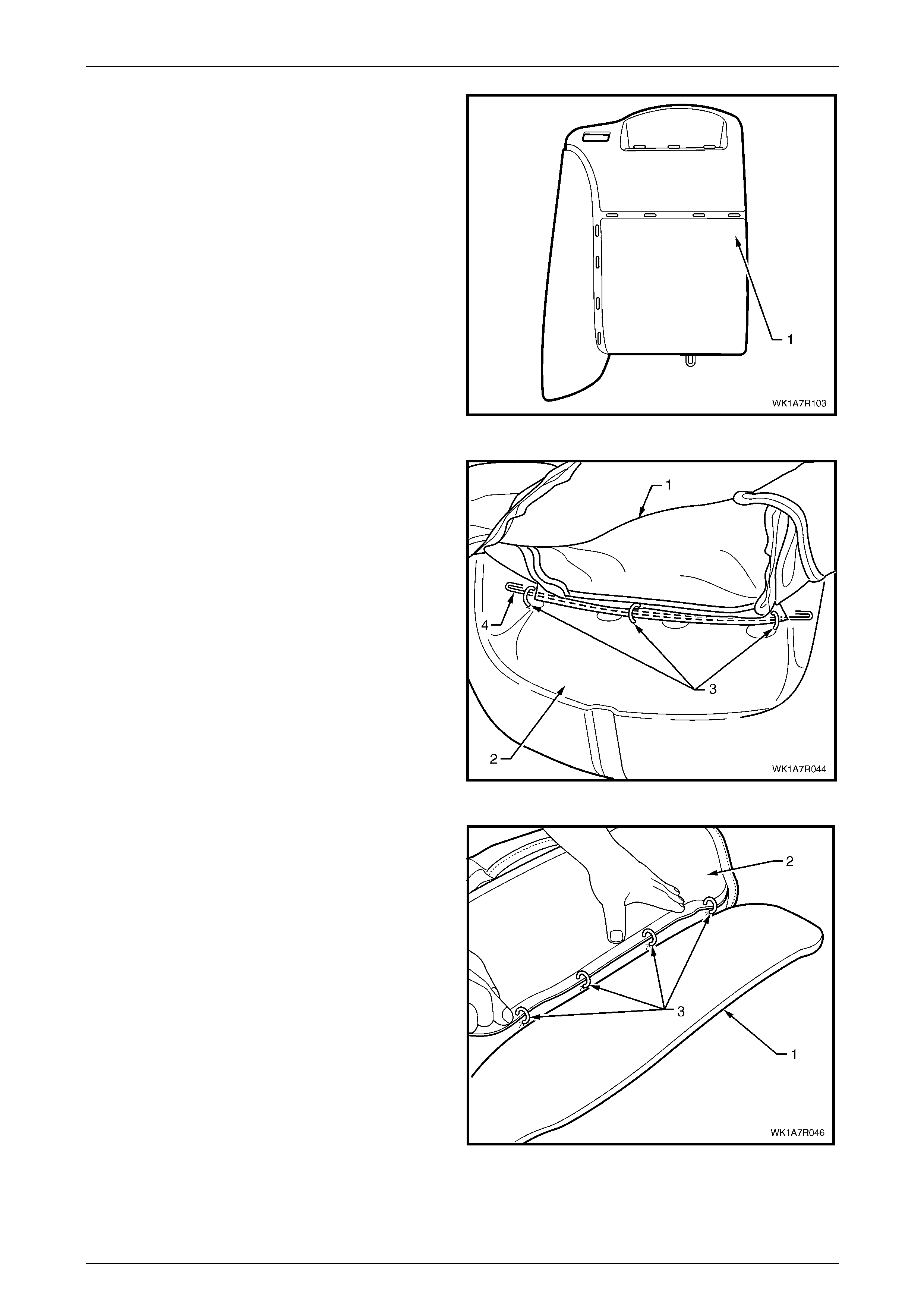

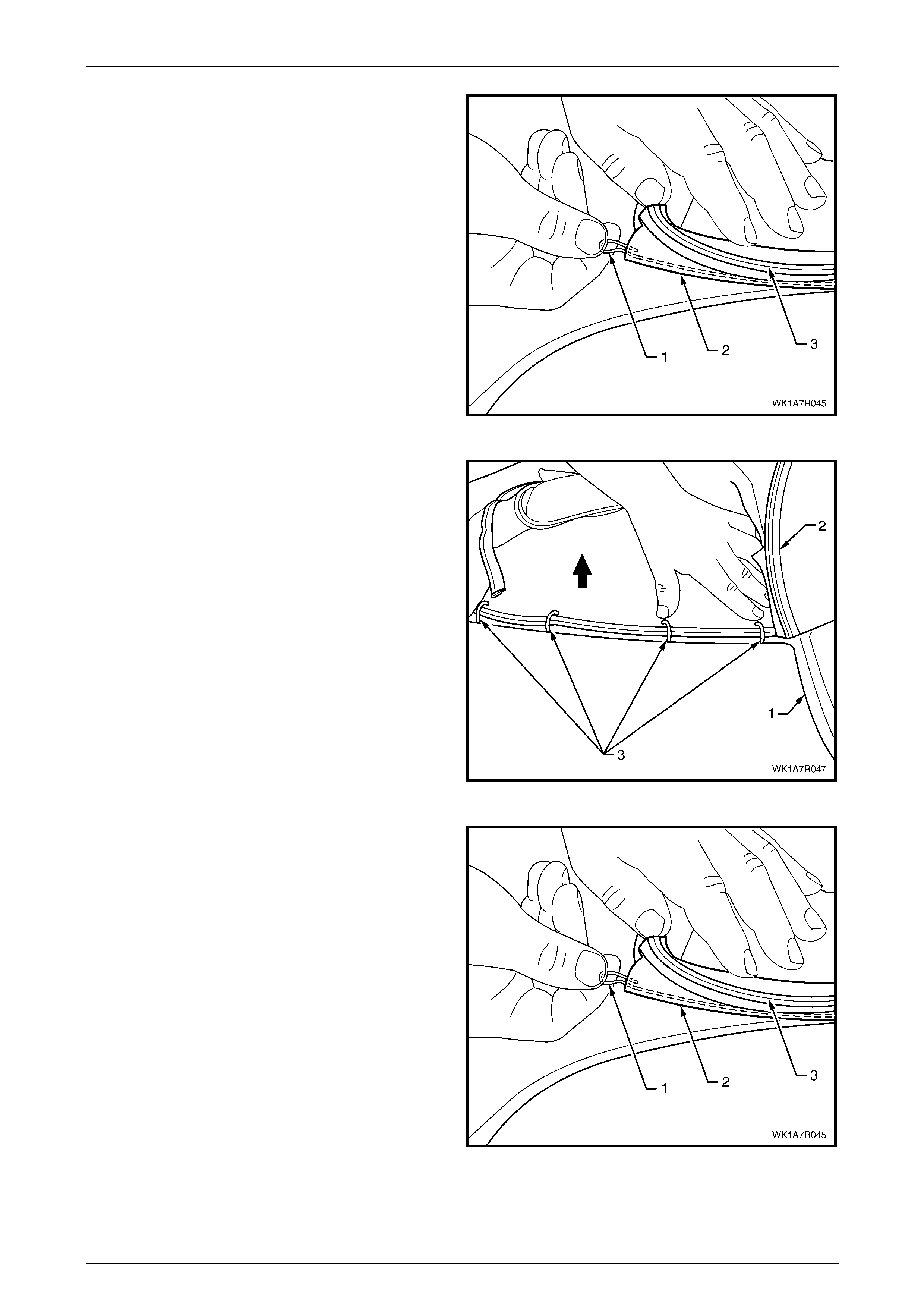

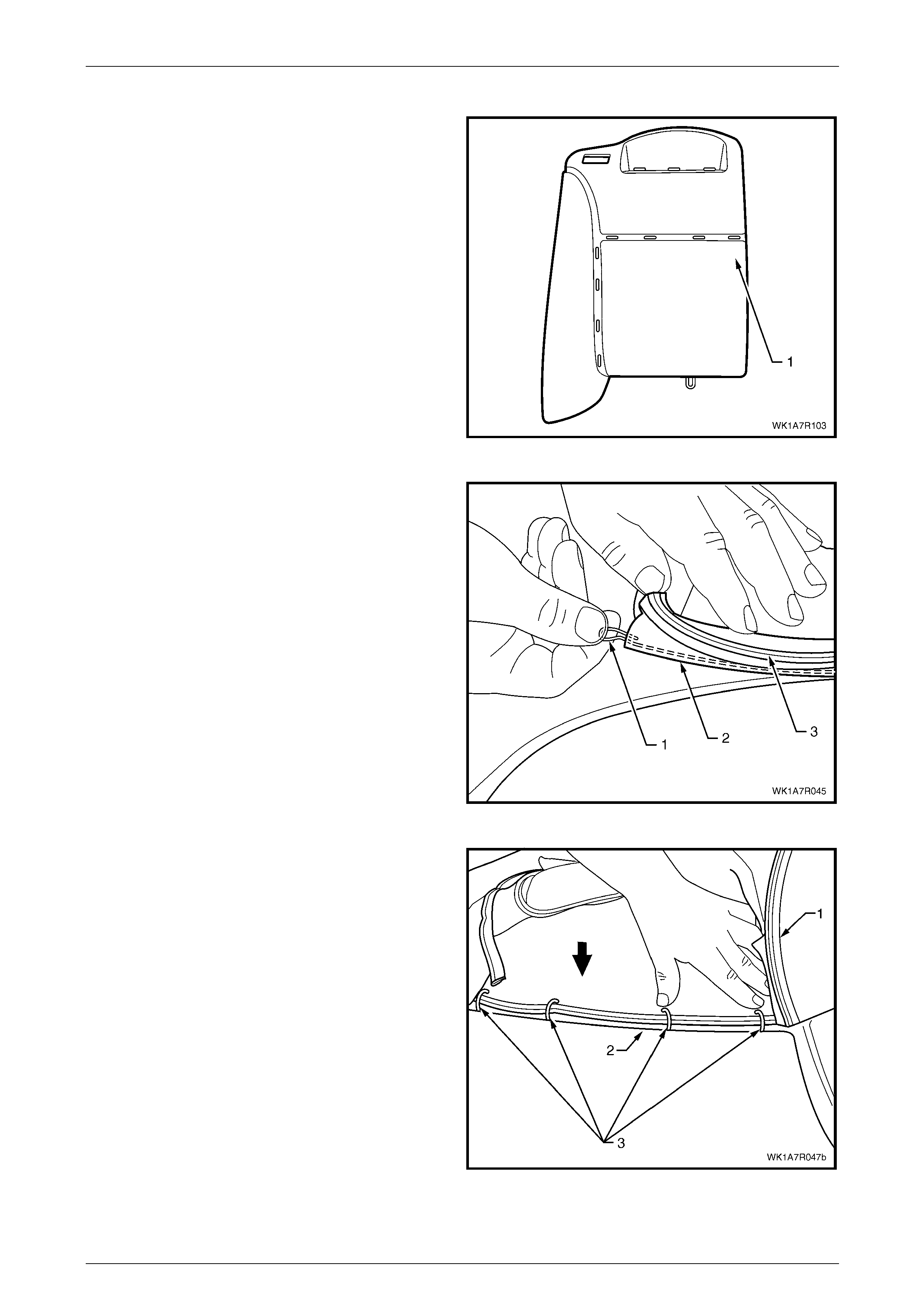

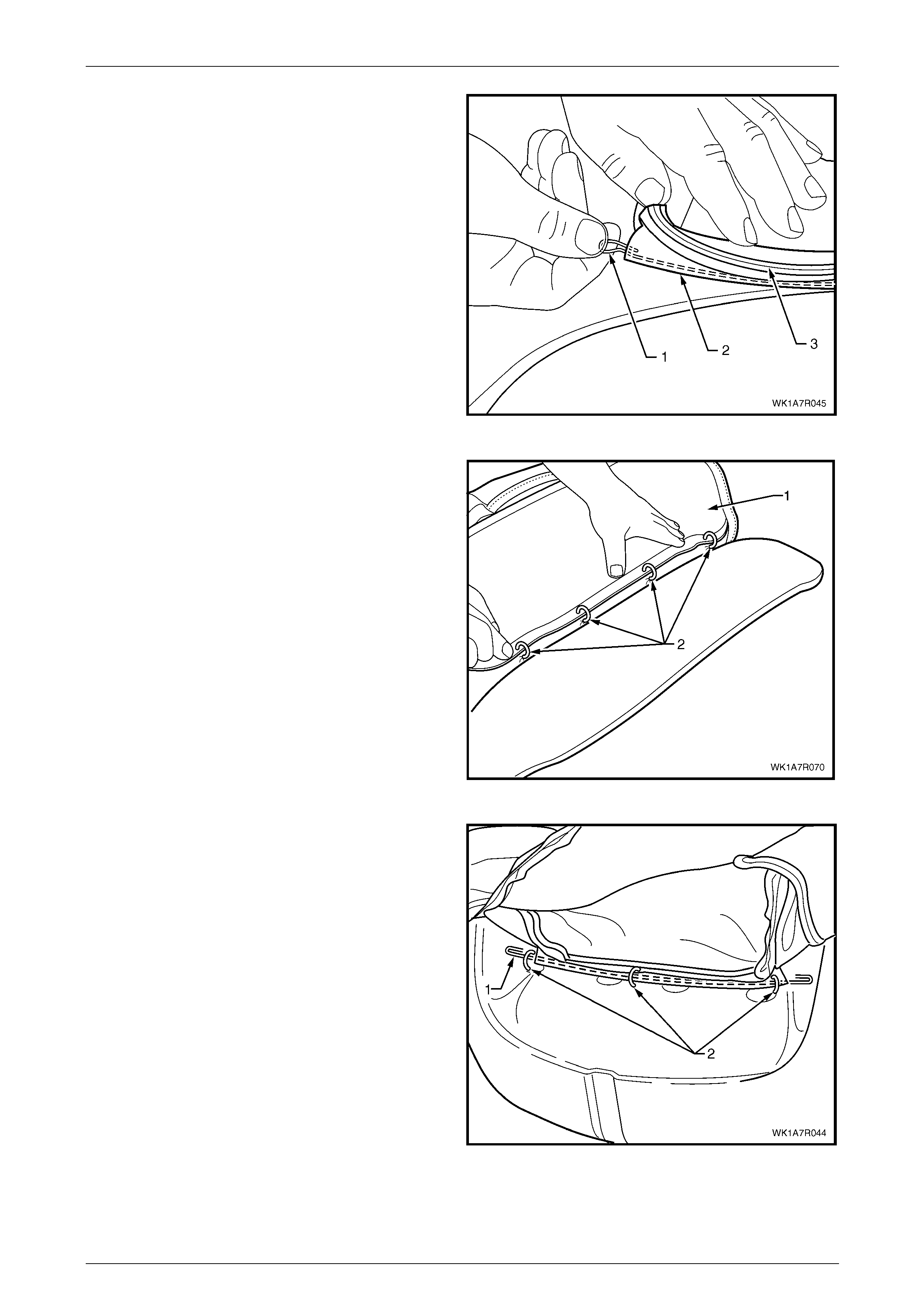

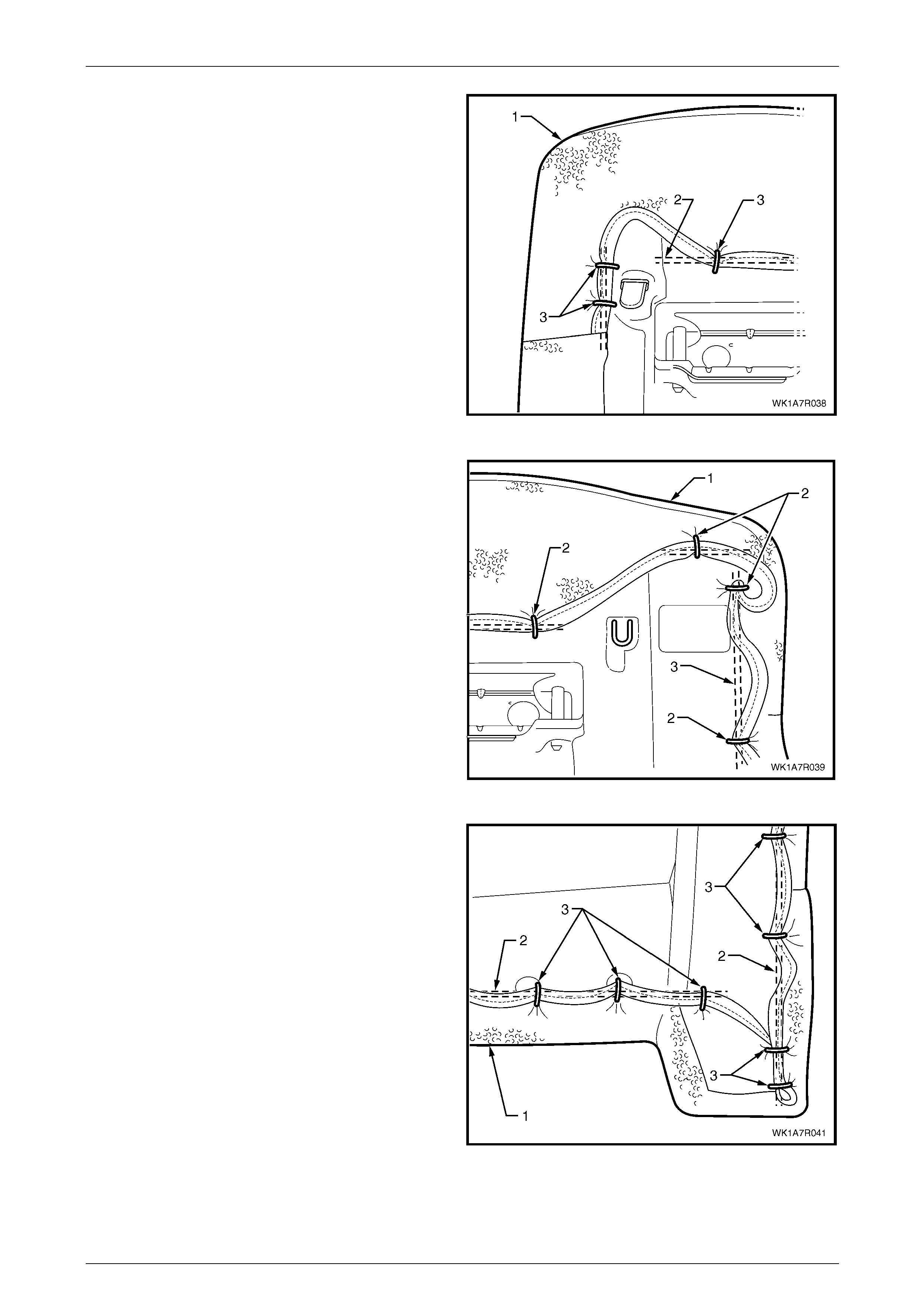

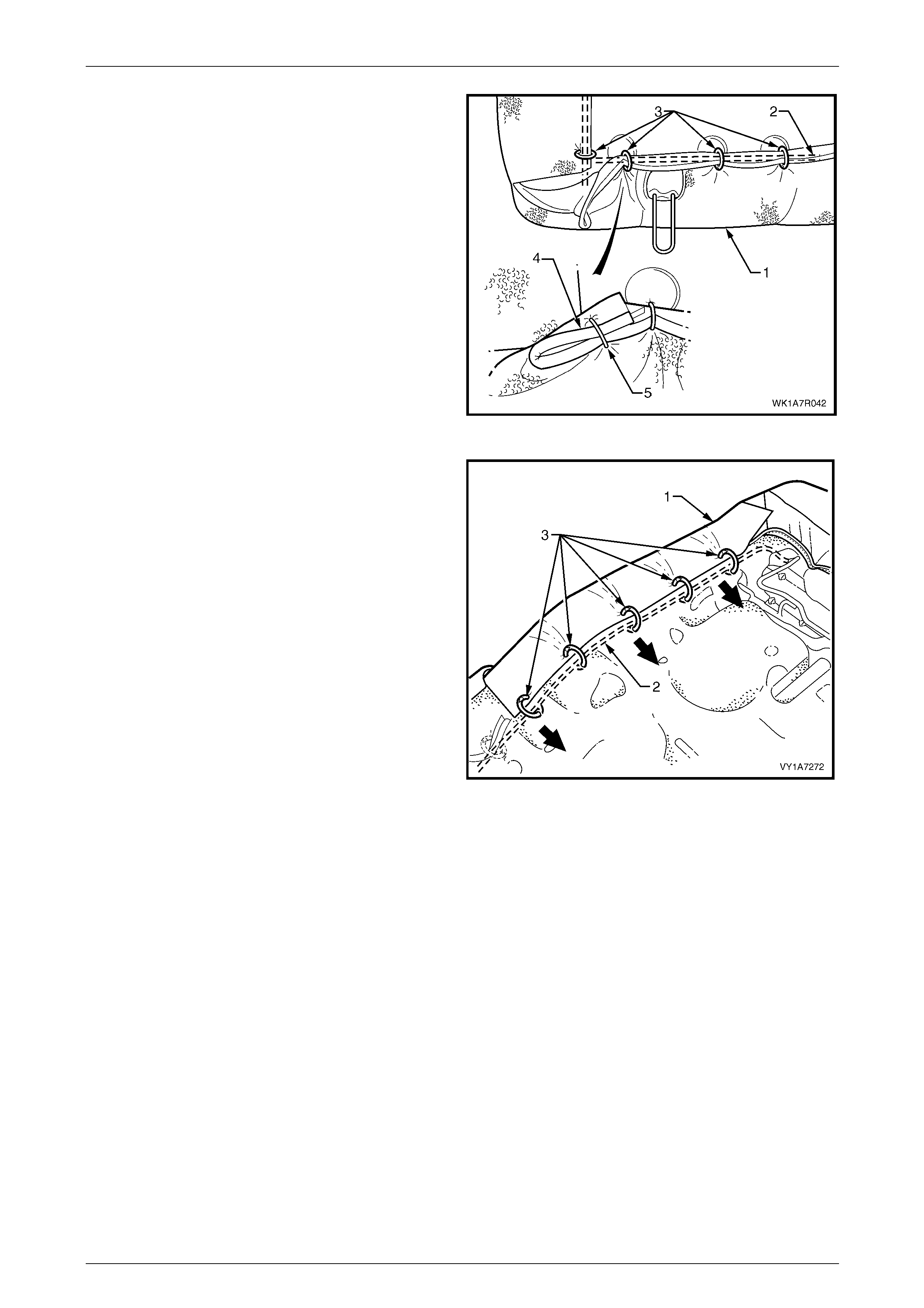

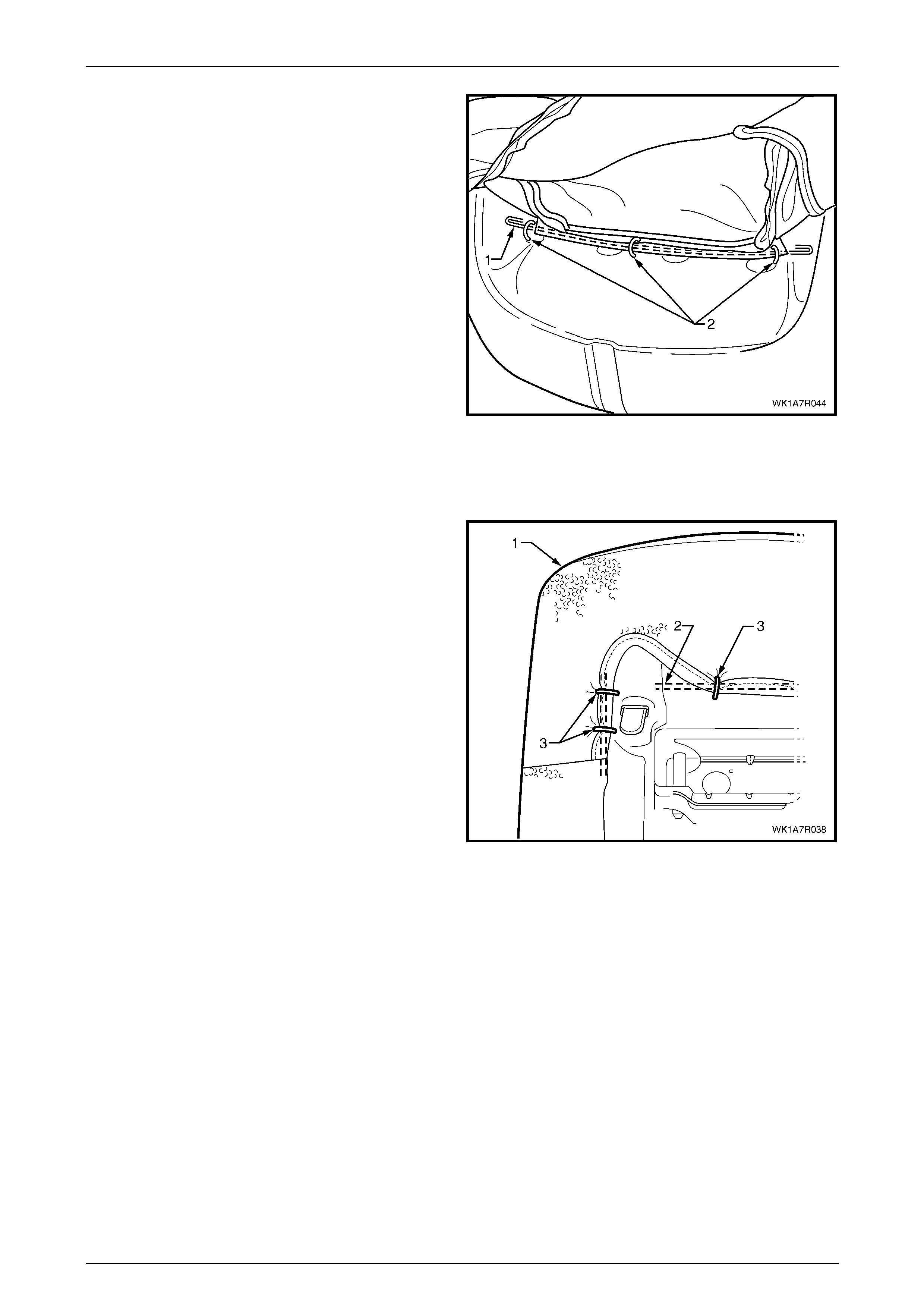

The seat cover construction method used for the front seat assemblies is a Hook and Loop type. Hook and Loop type

covers are fully serviceable as they are attached within the grooves of the seat pad with a Velcro type material.

Seat Assemblies Page 1A7–11

Page 1A7–11

Electric Seat Operation

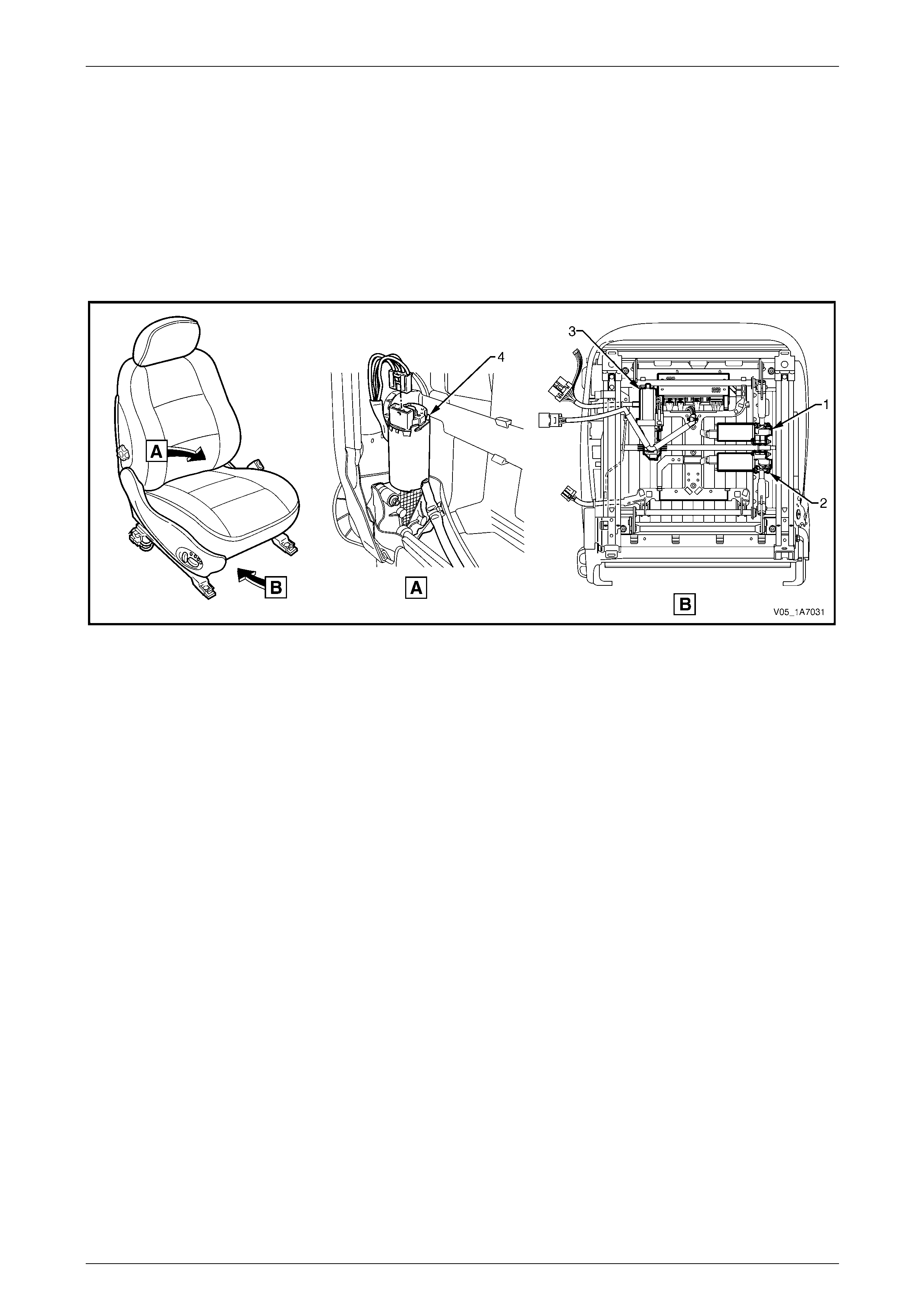

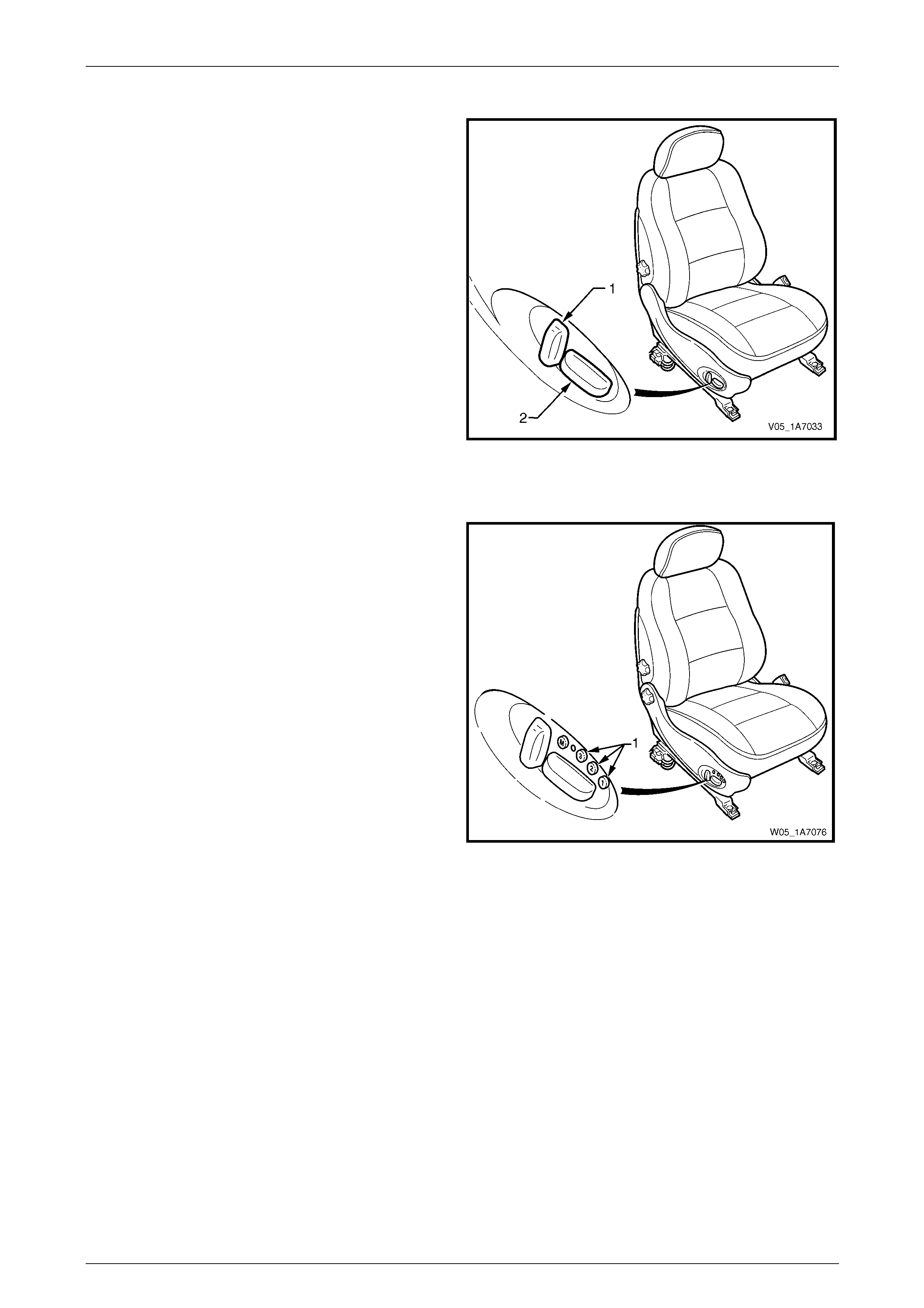

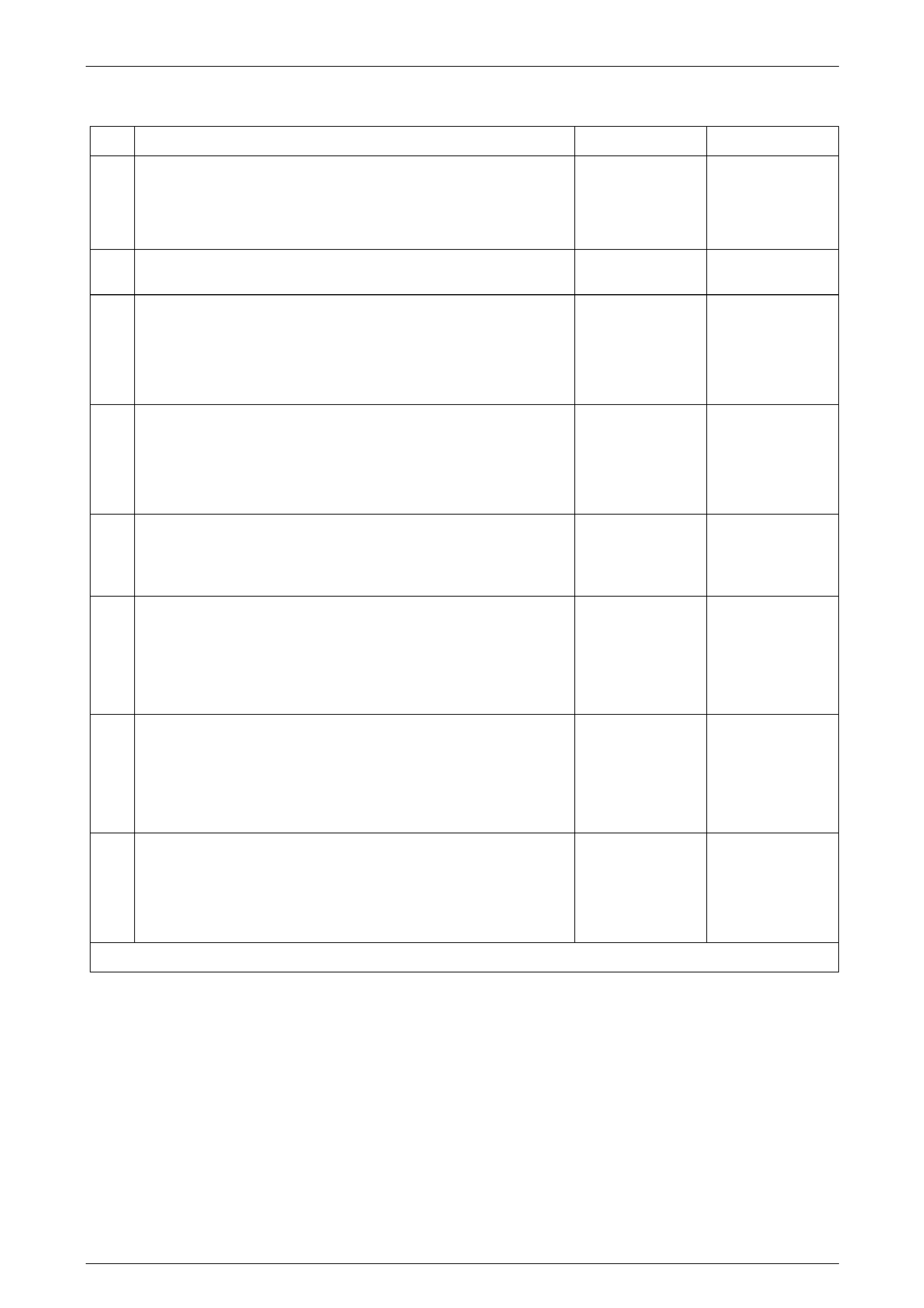

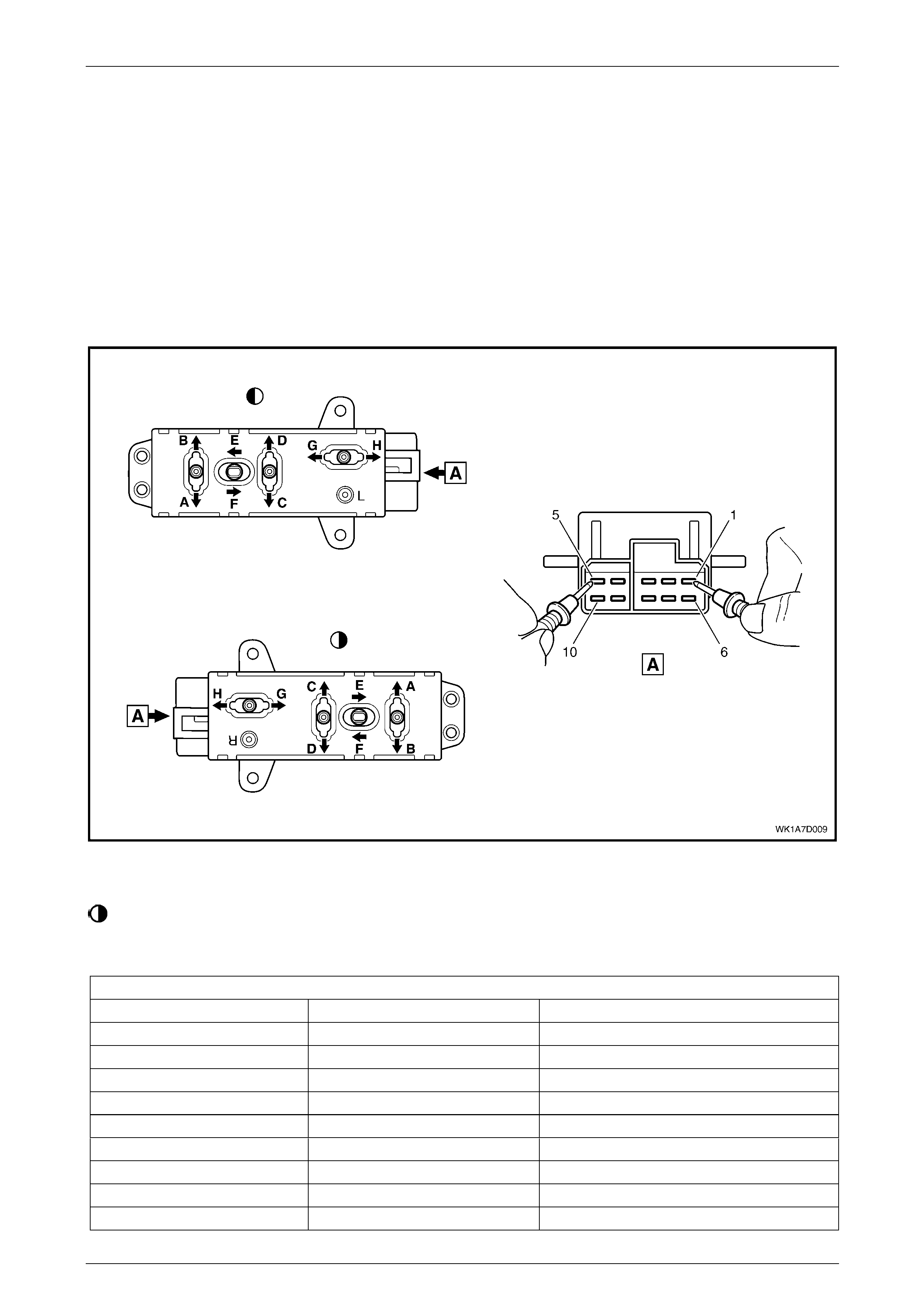

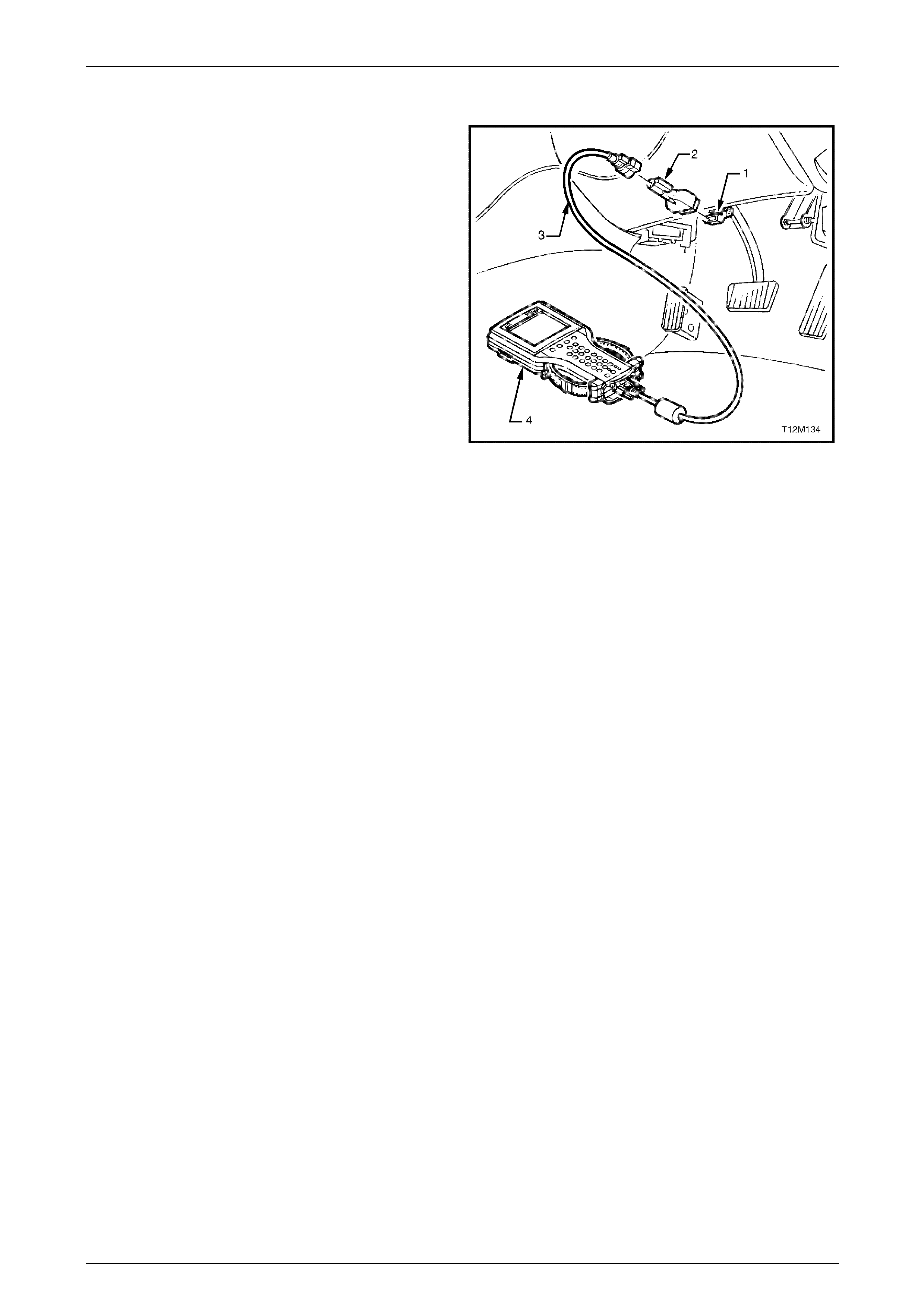

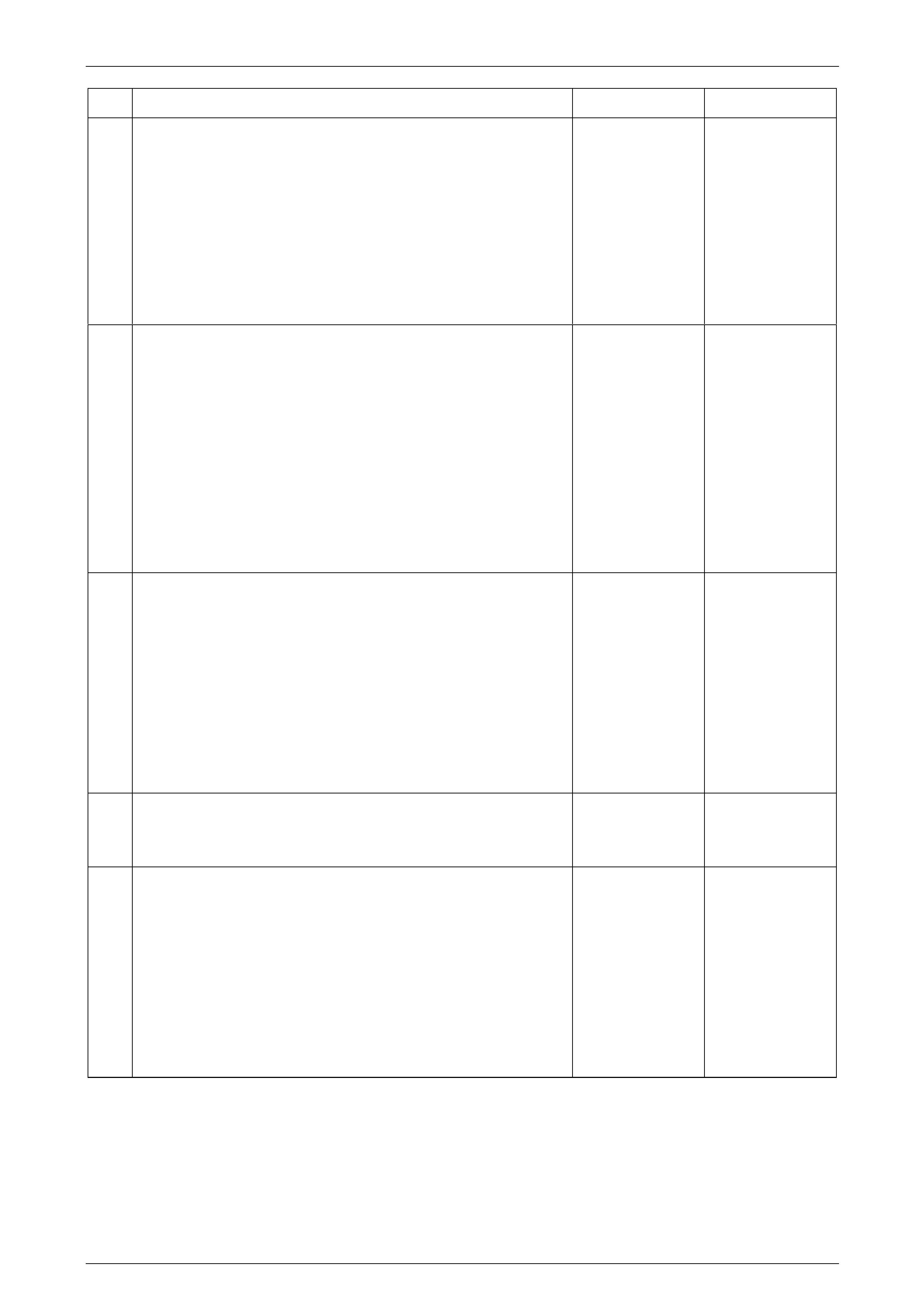

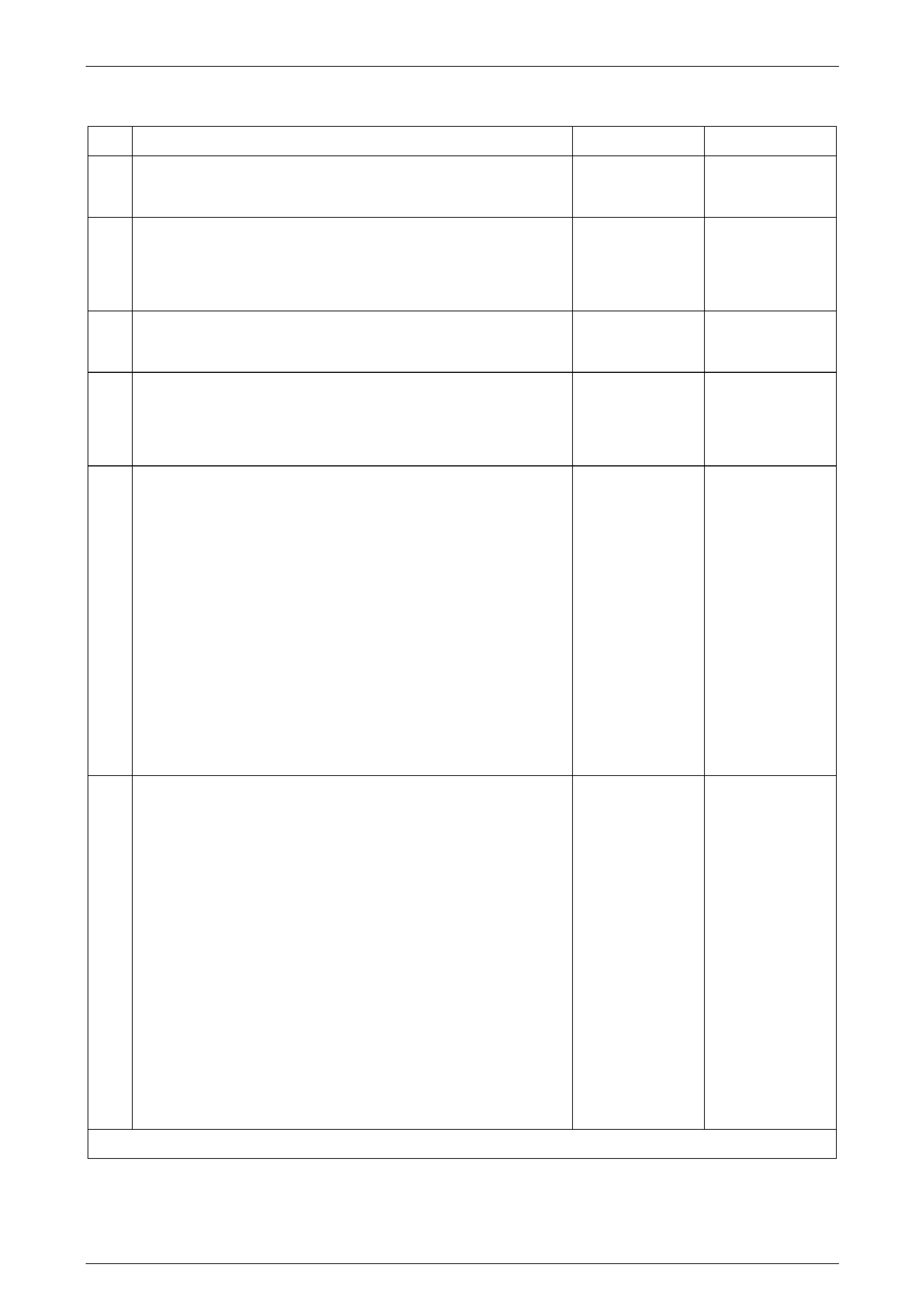

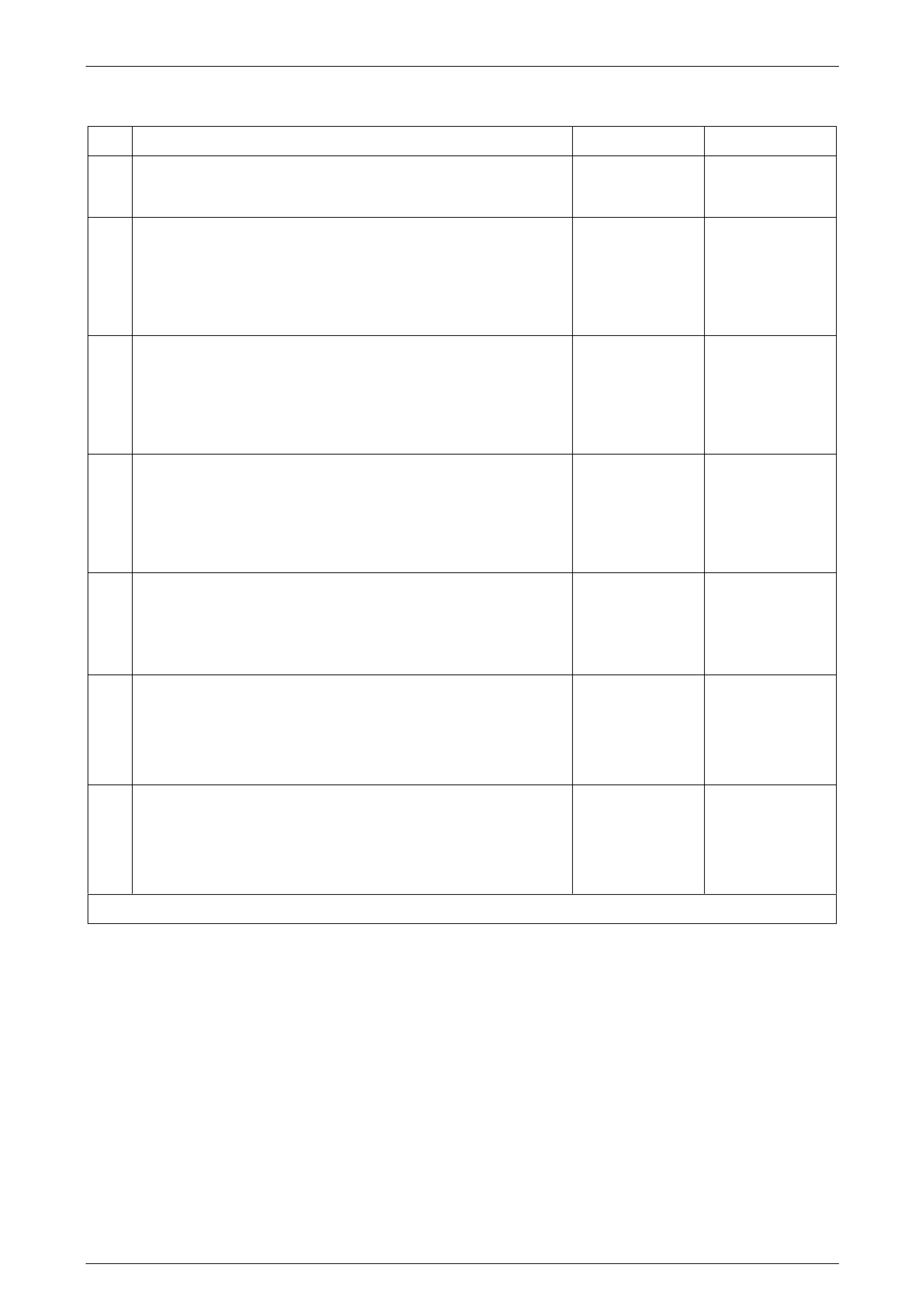

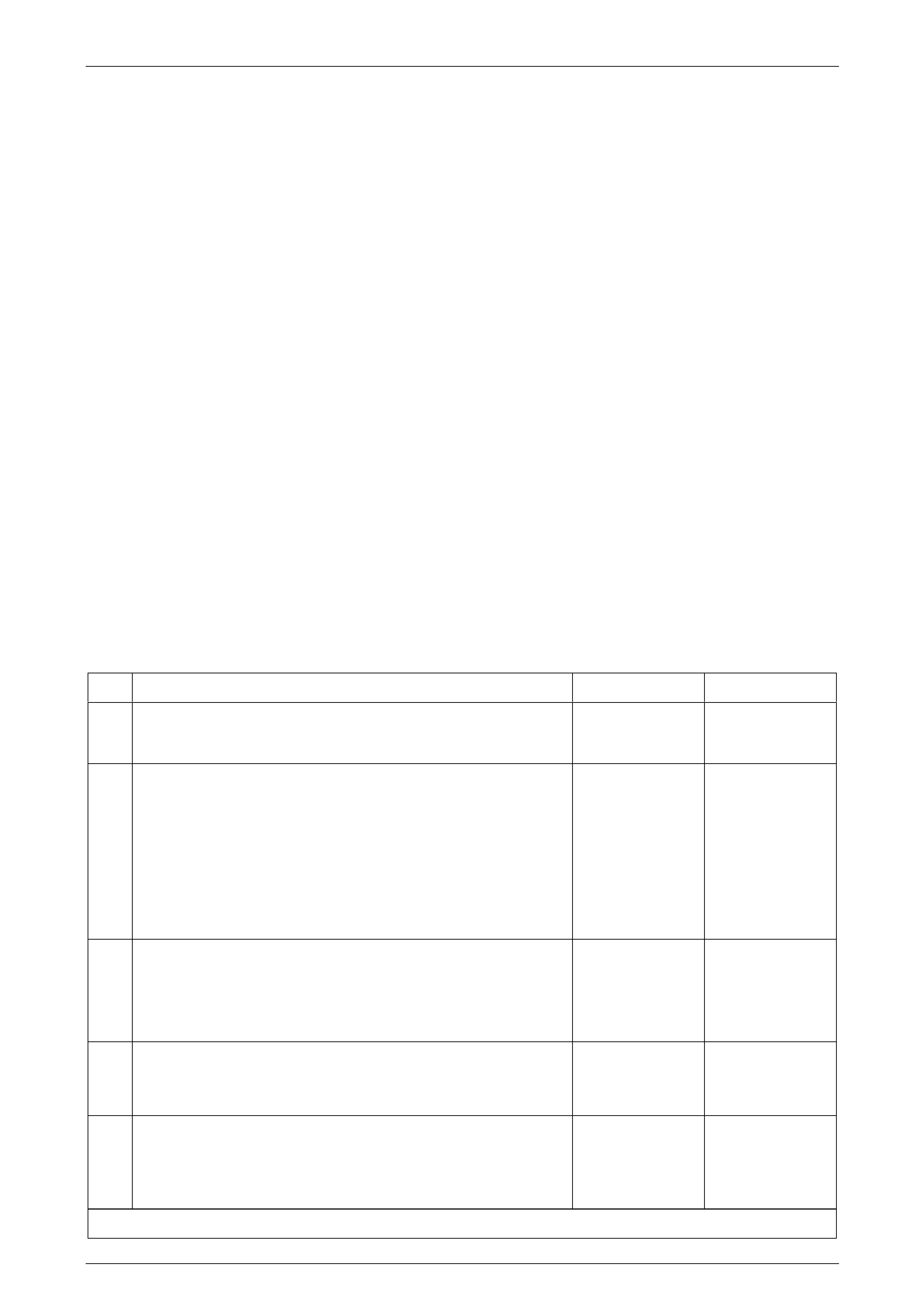

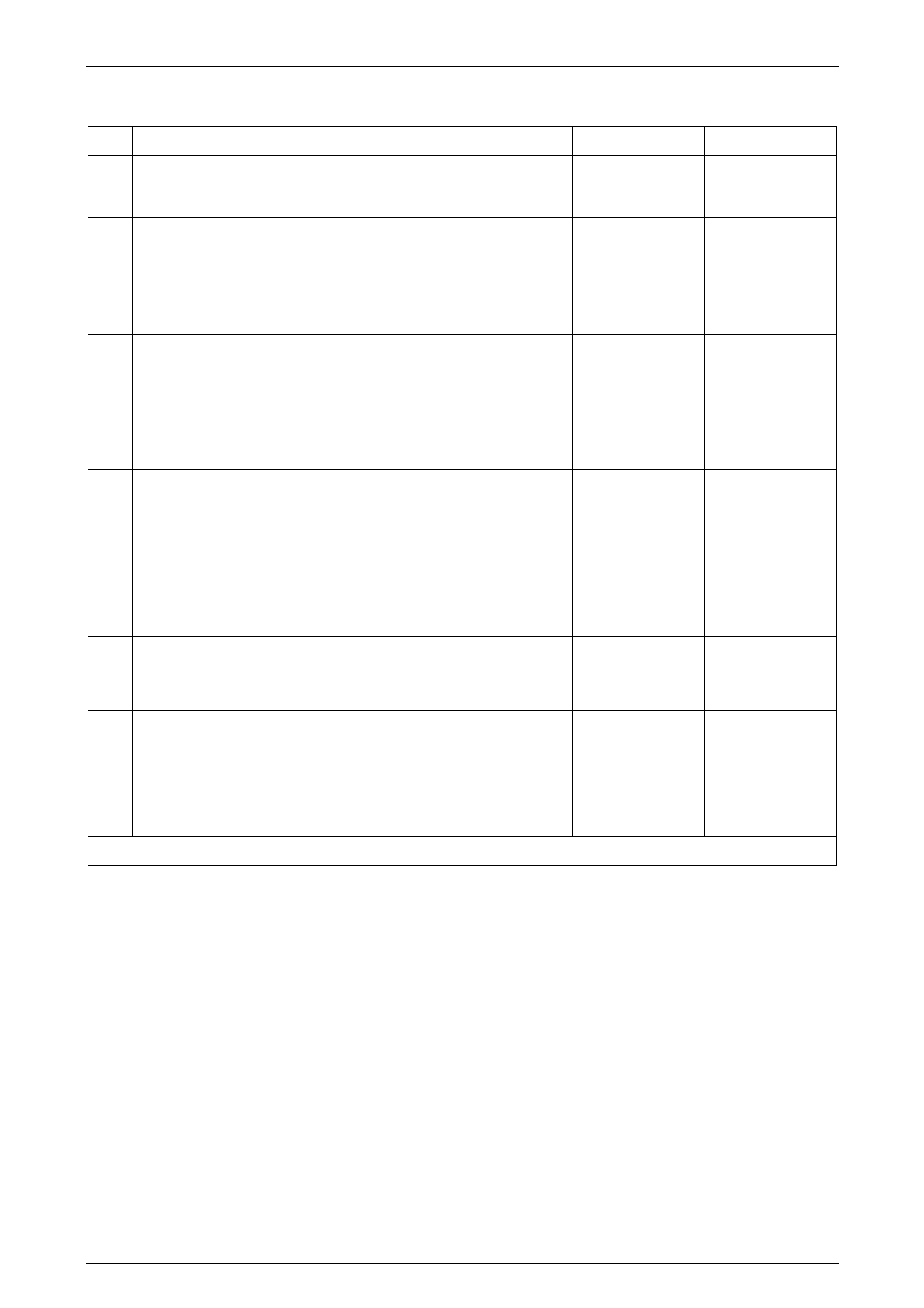

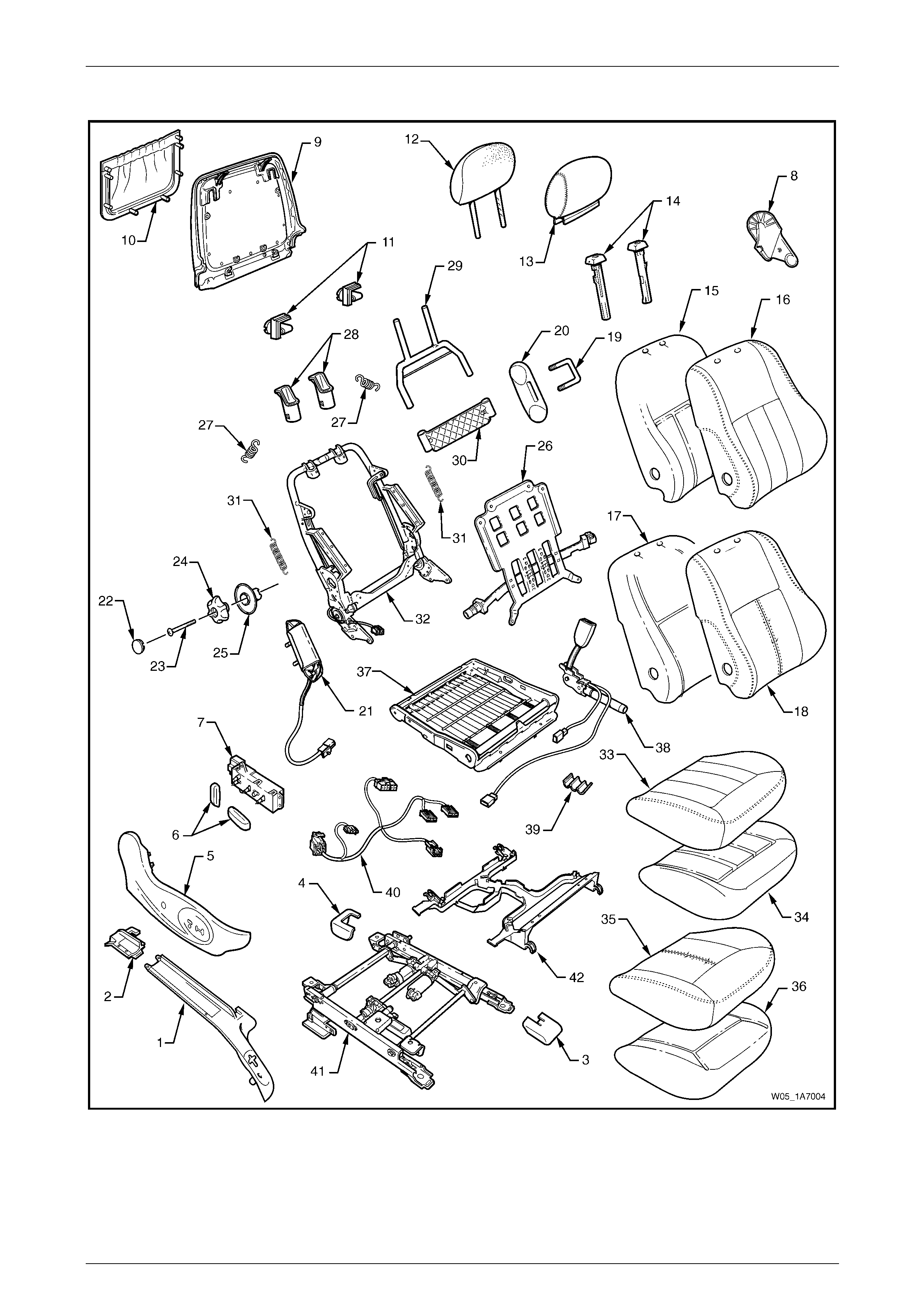

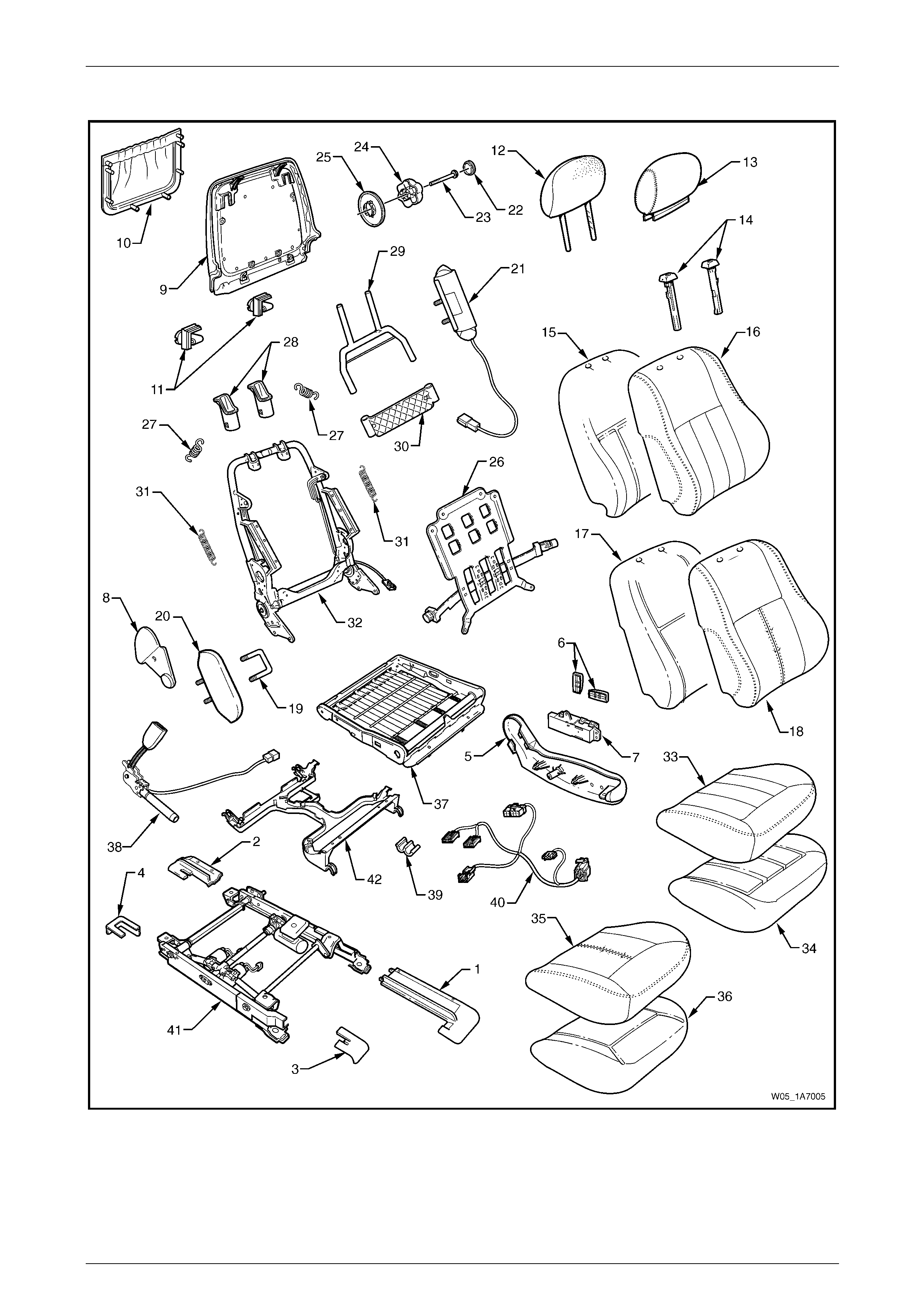

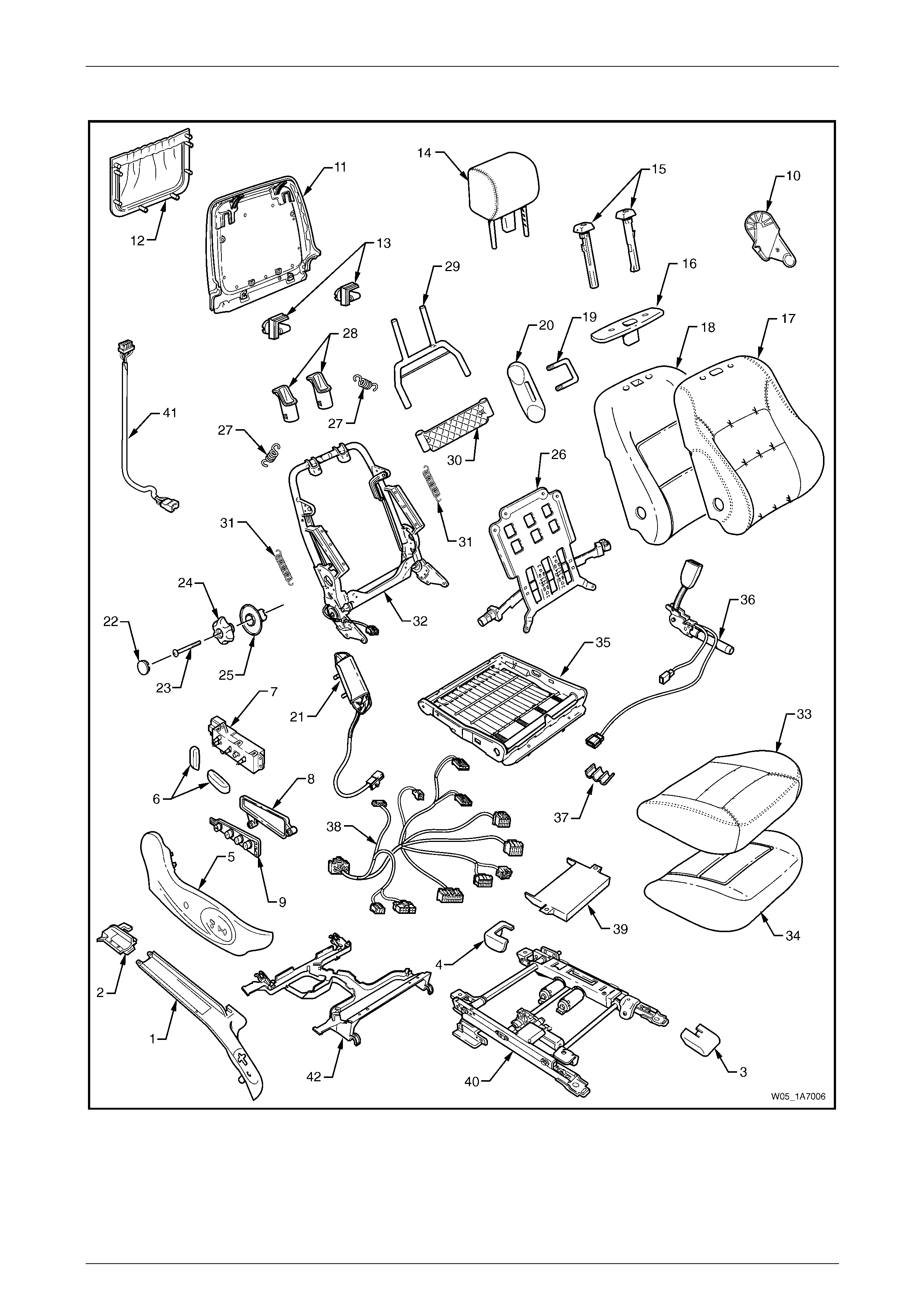

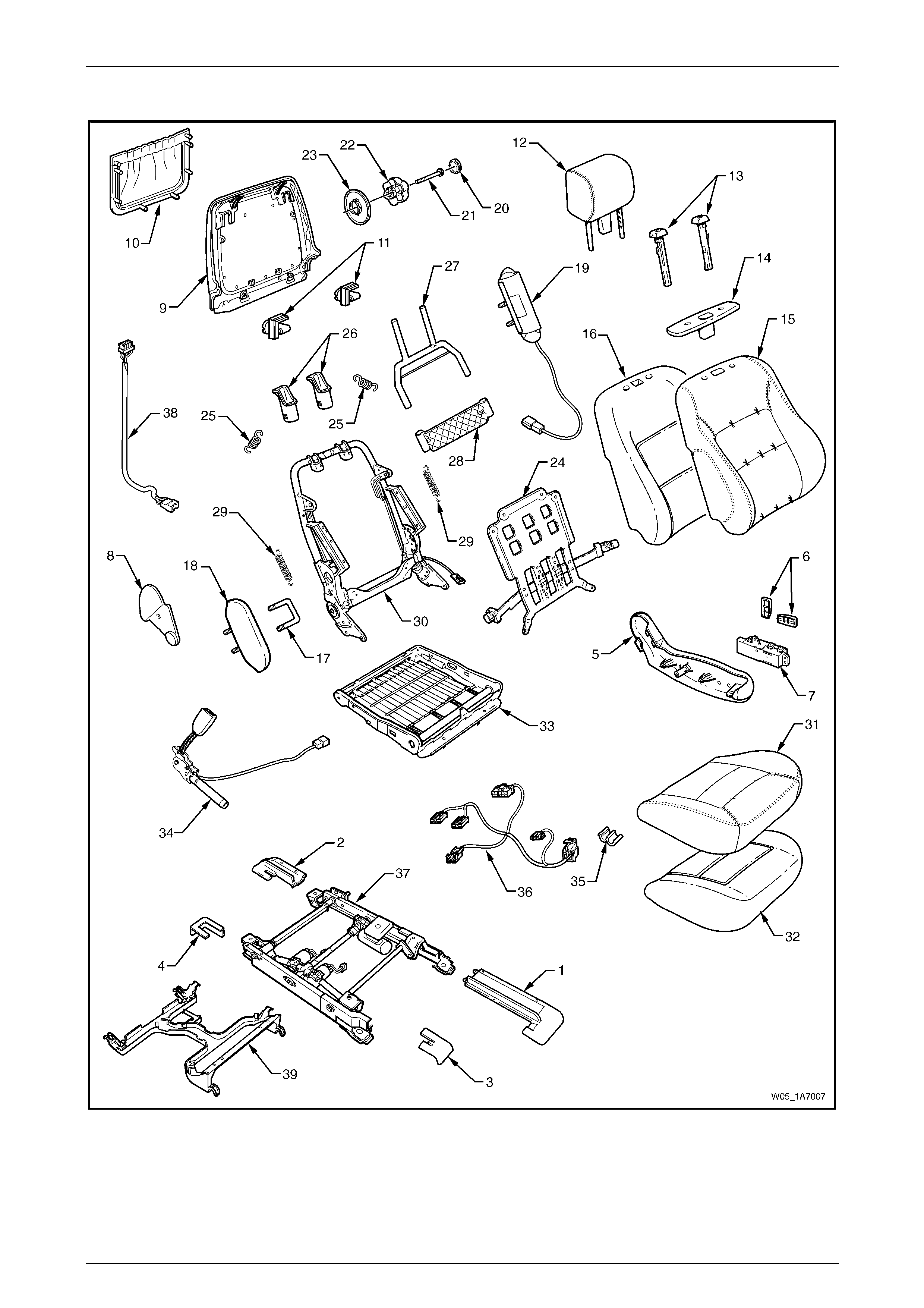

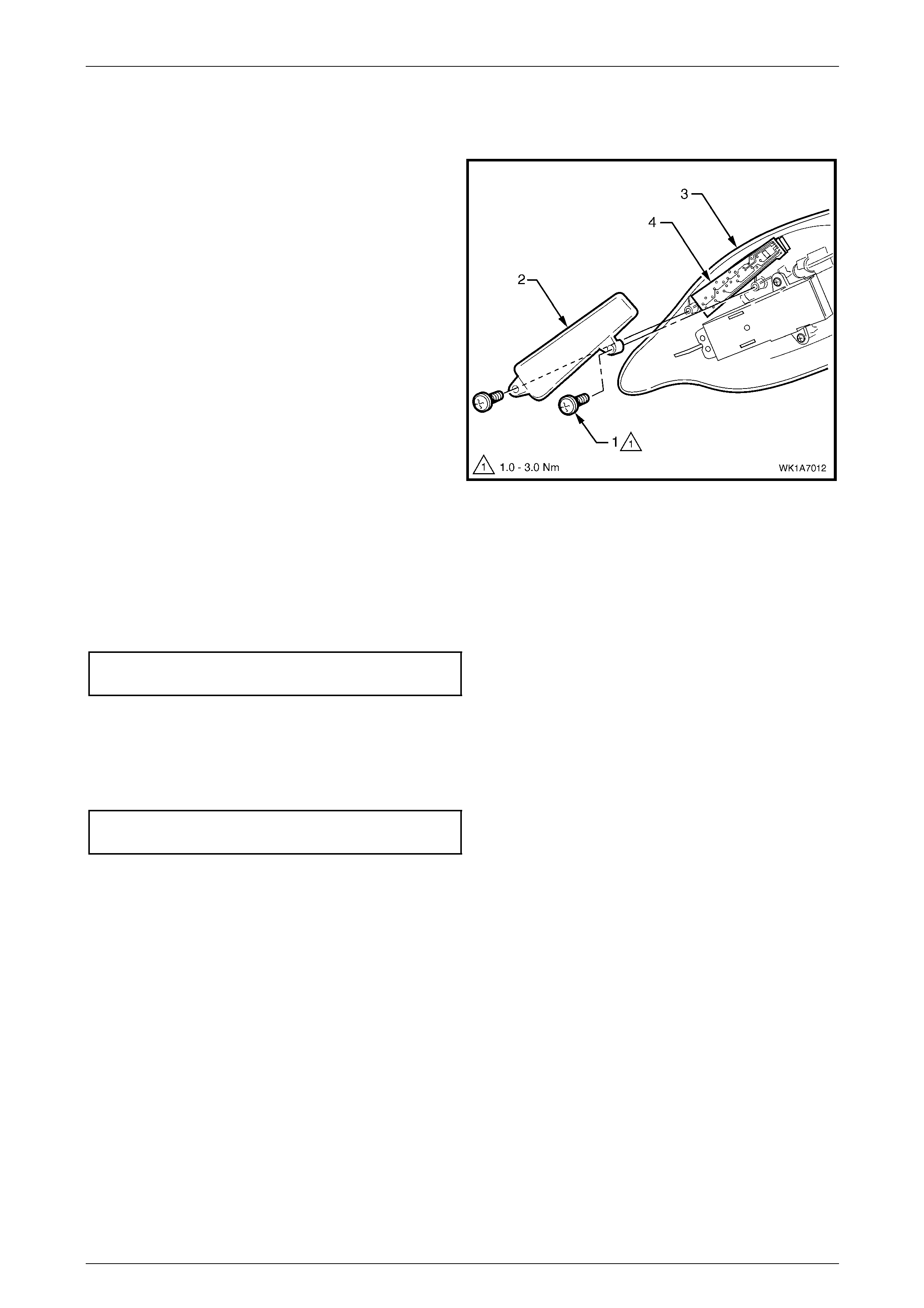

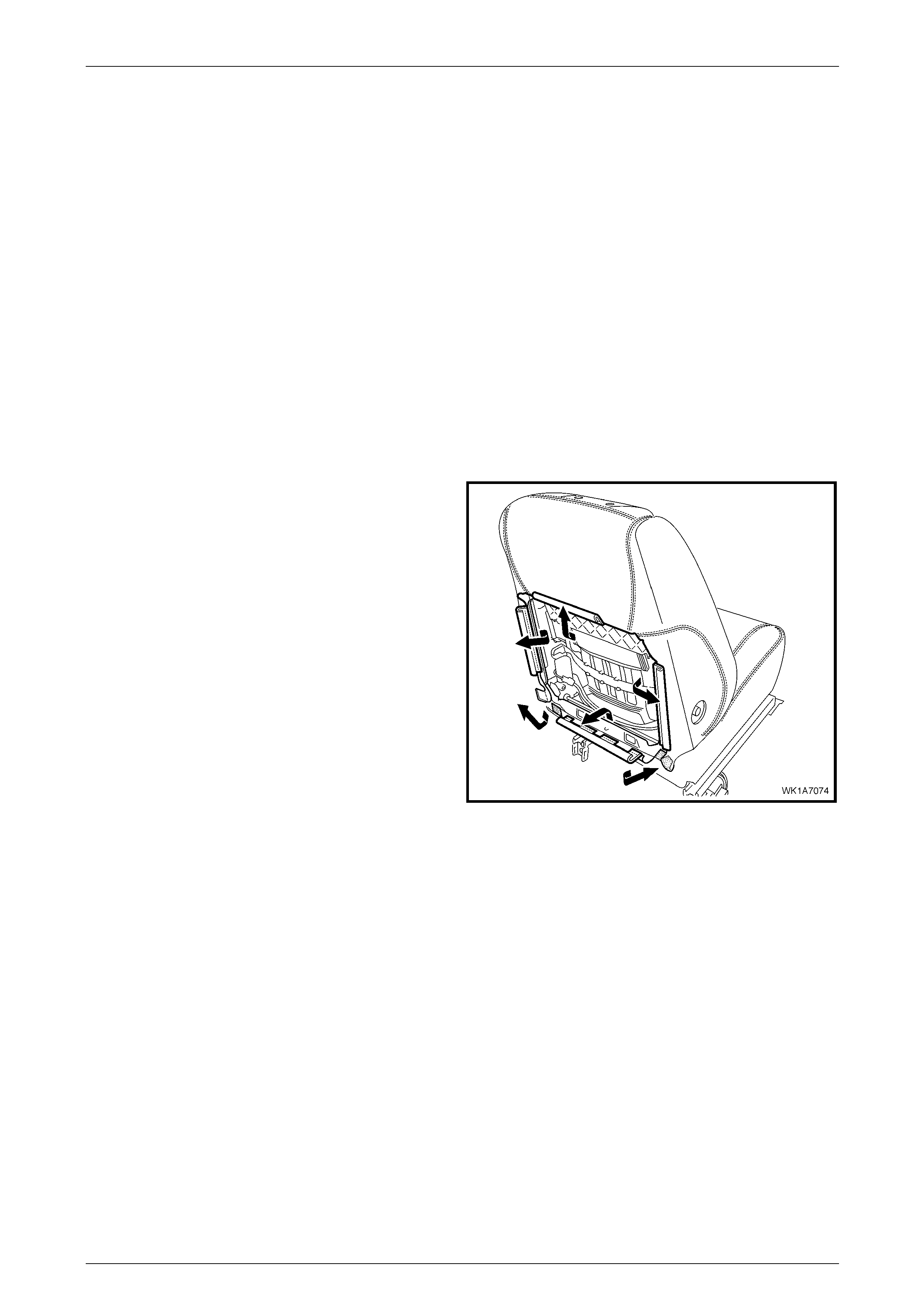

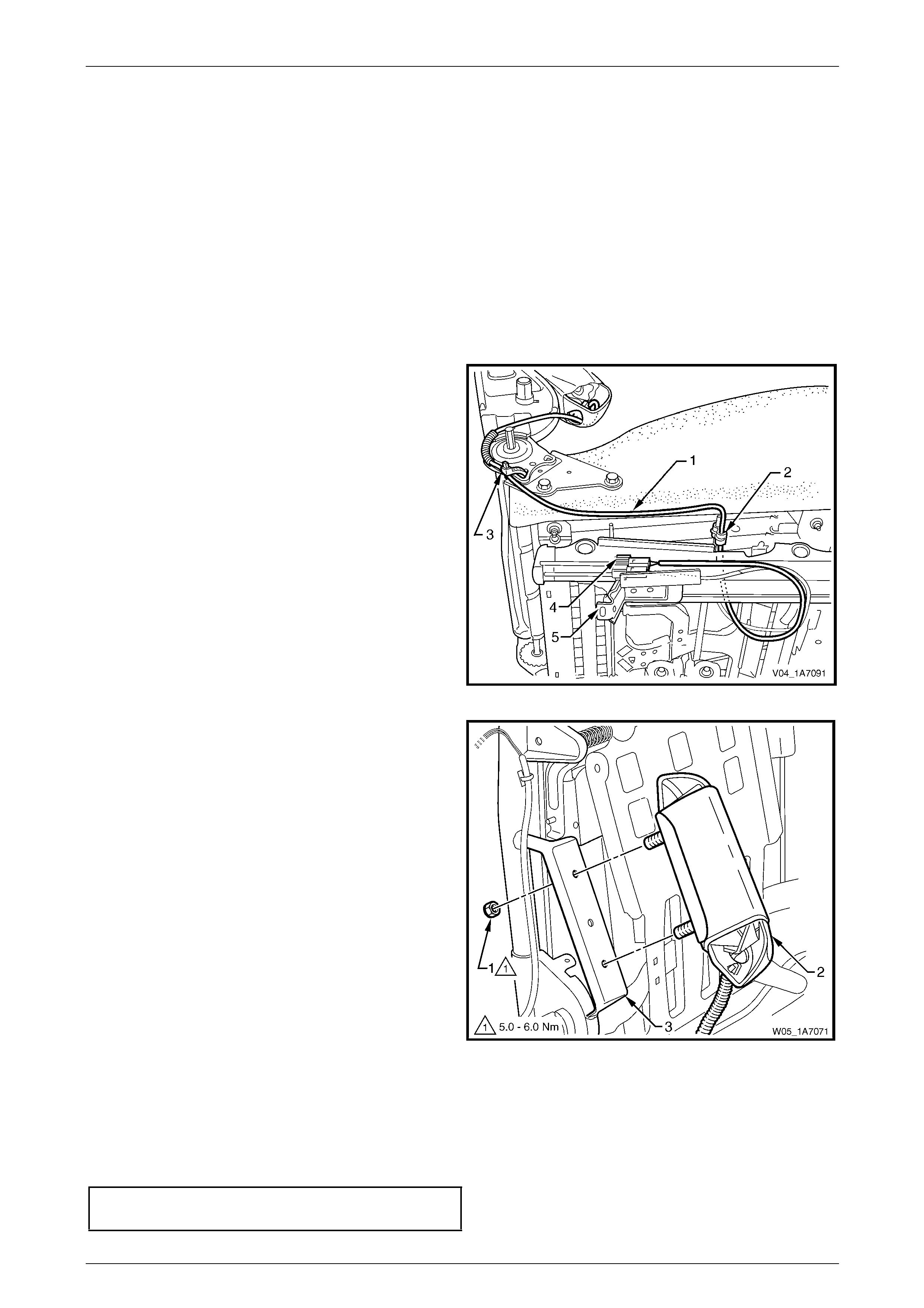

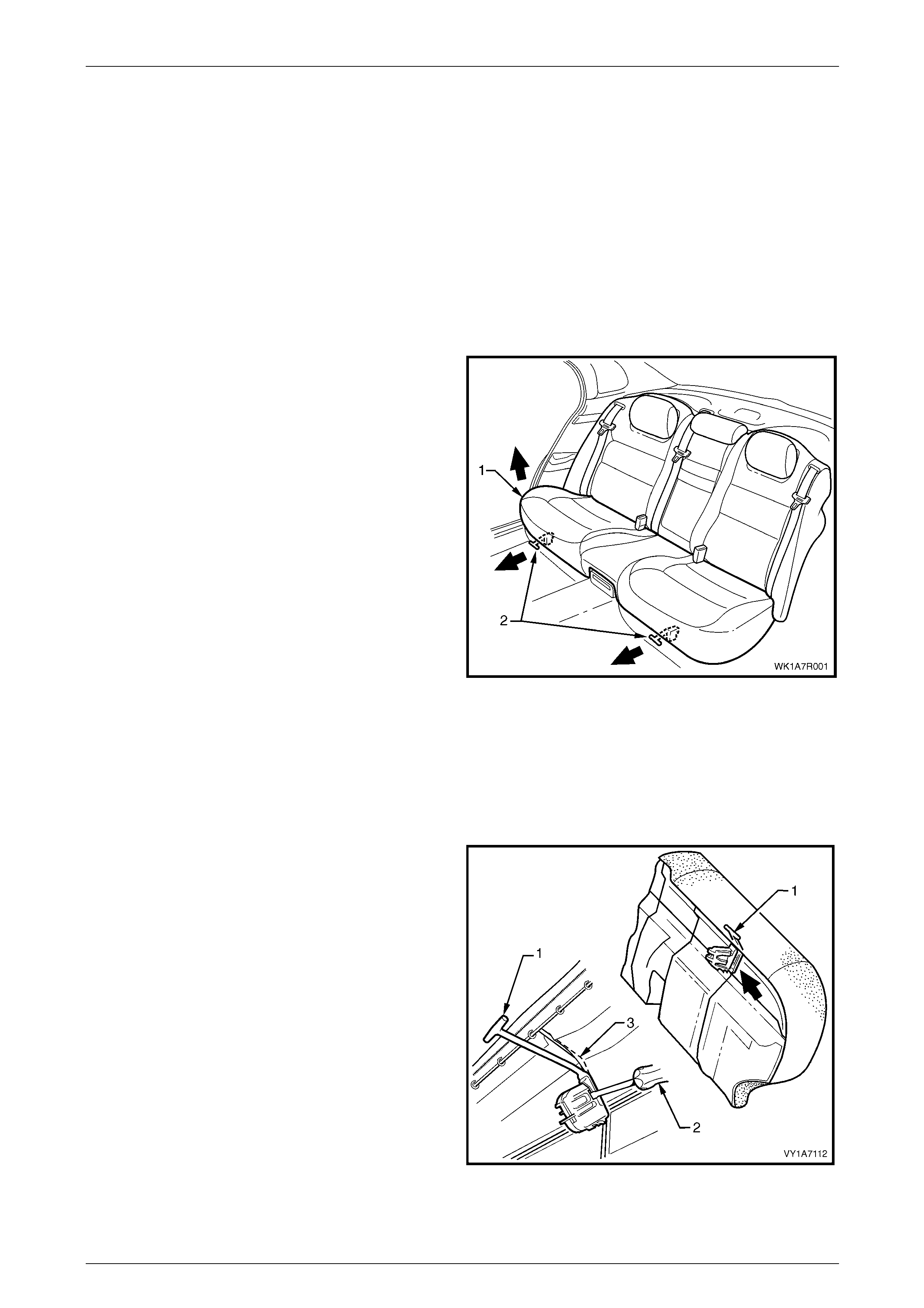

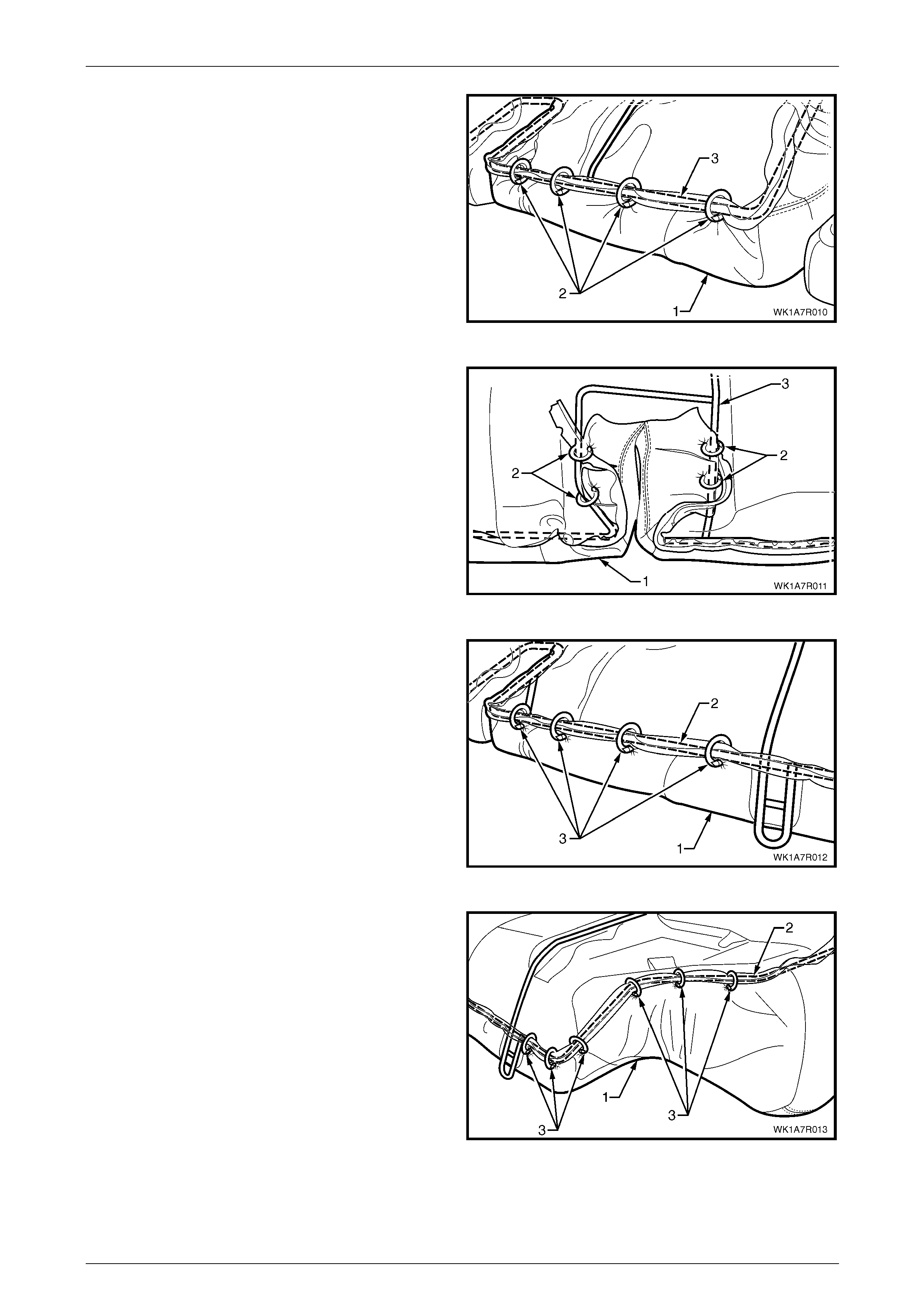

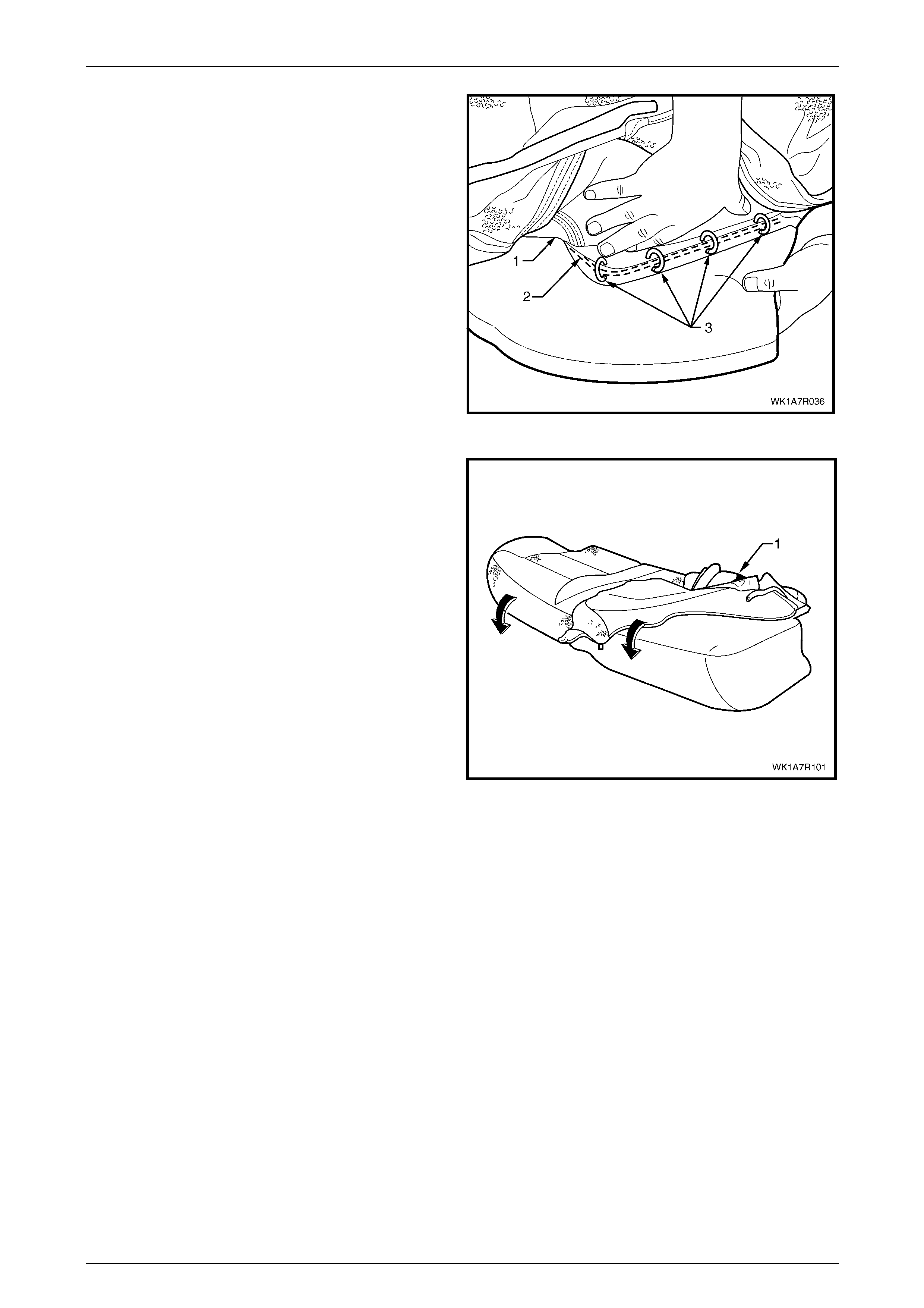

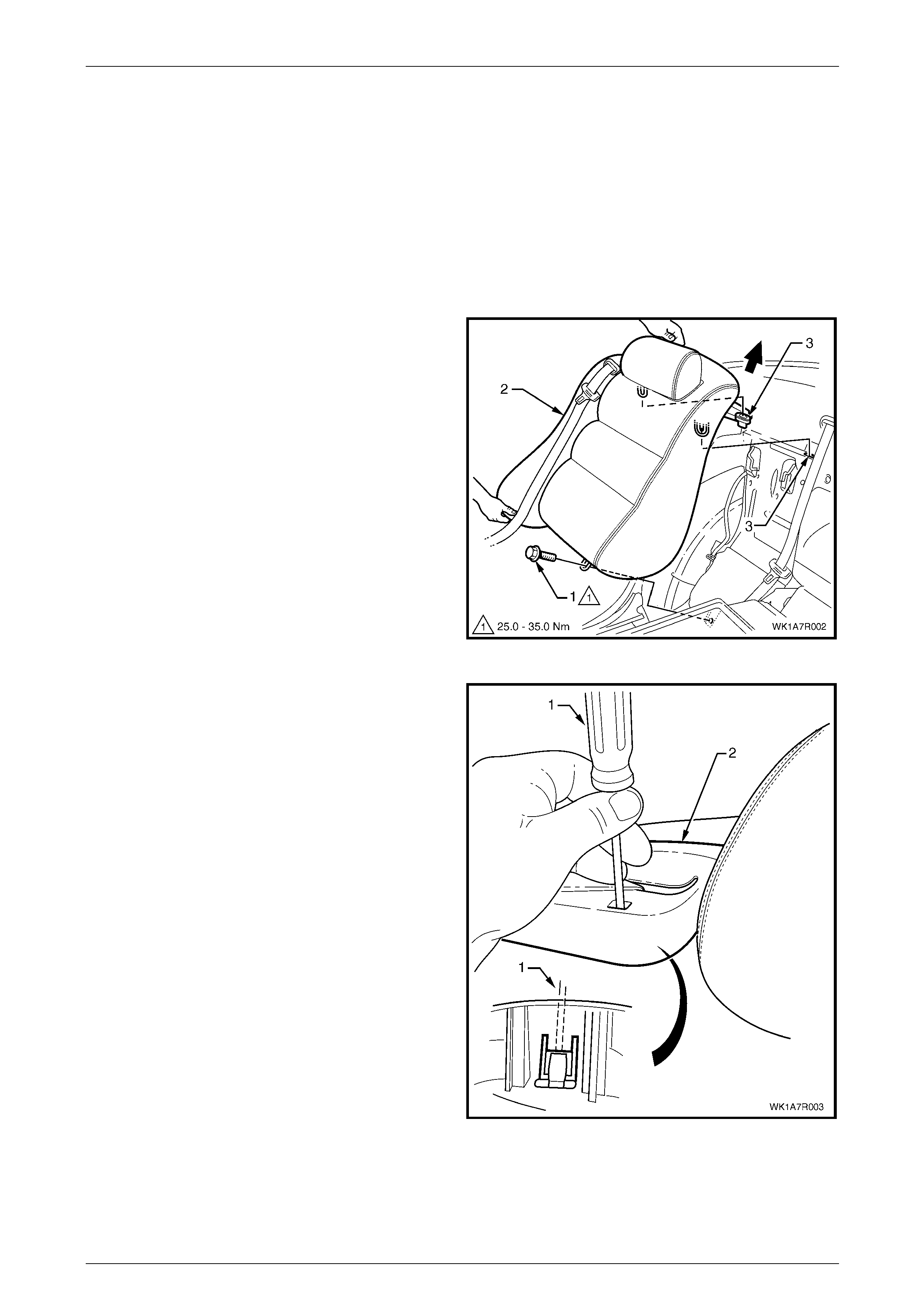

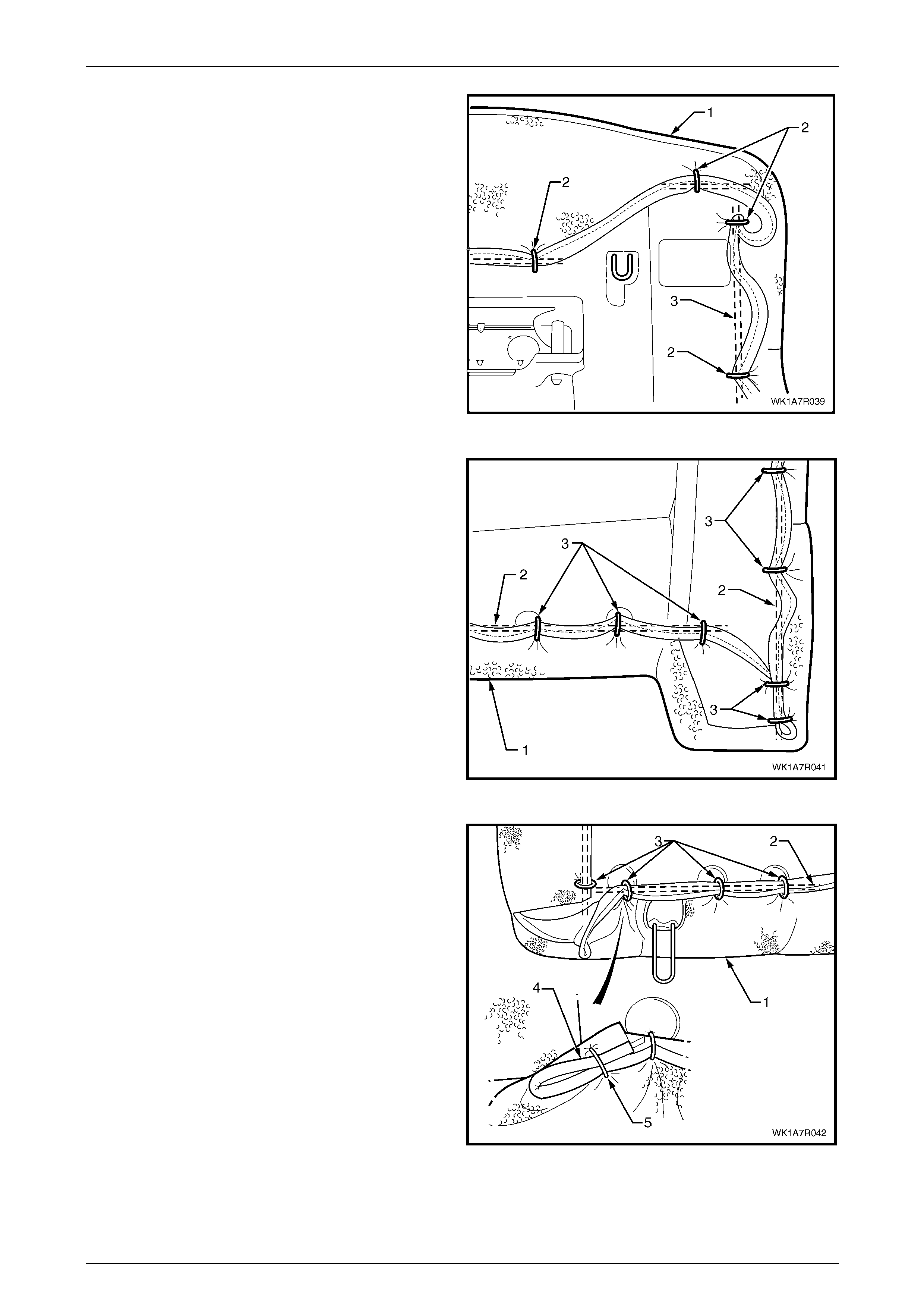

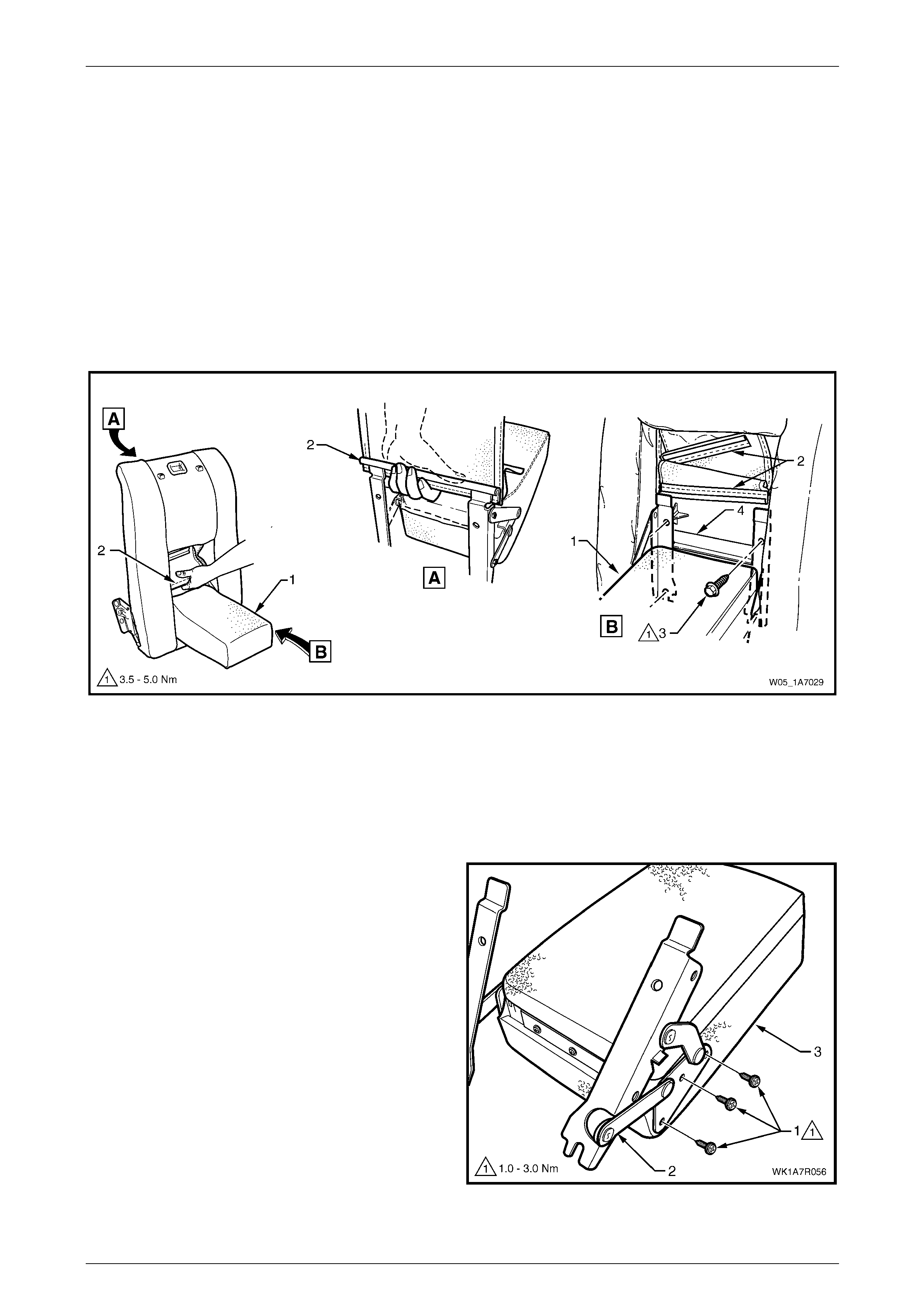

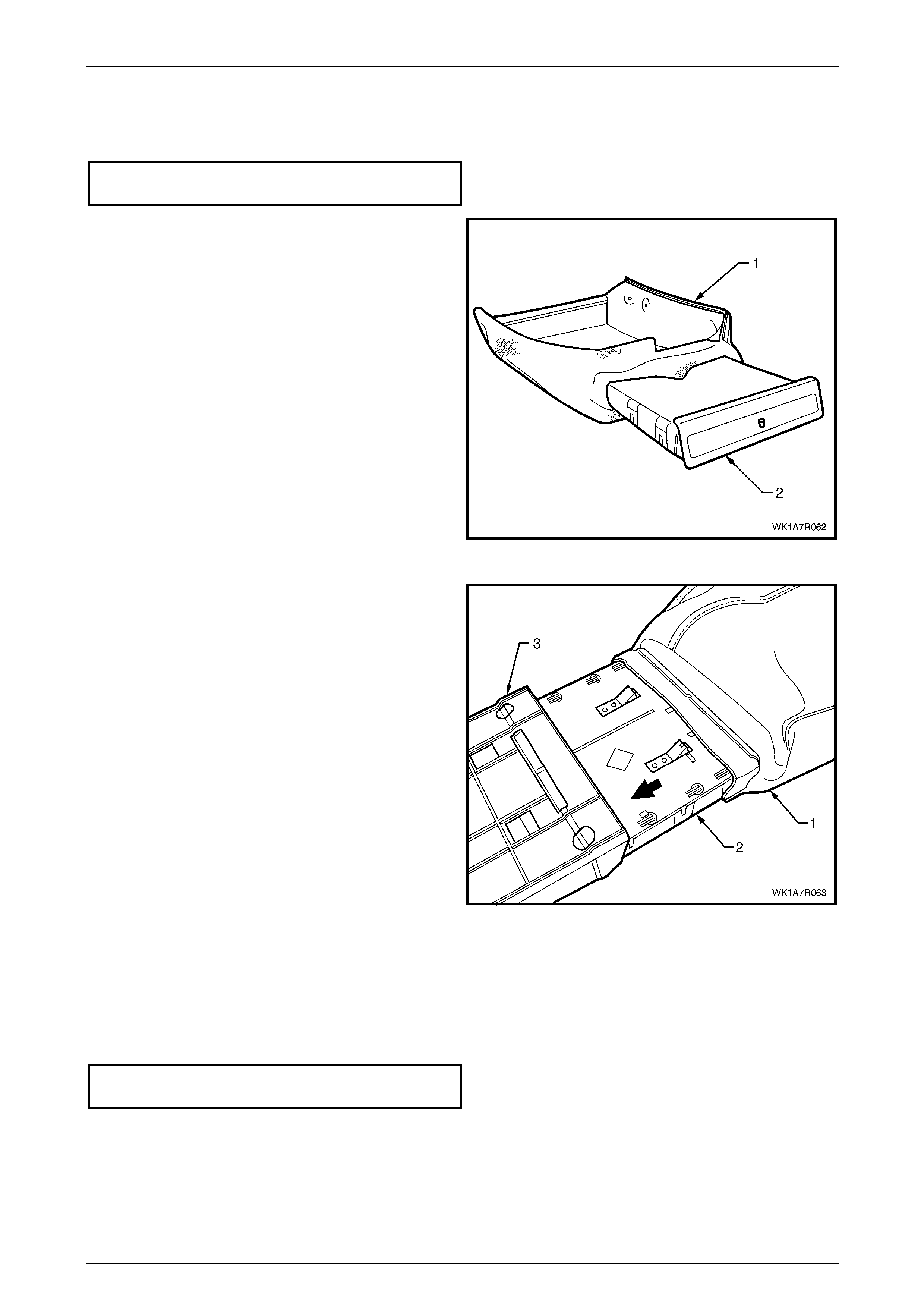

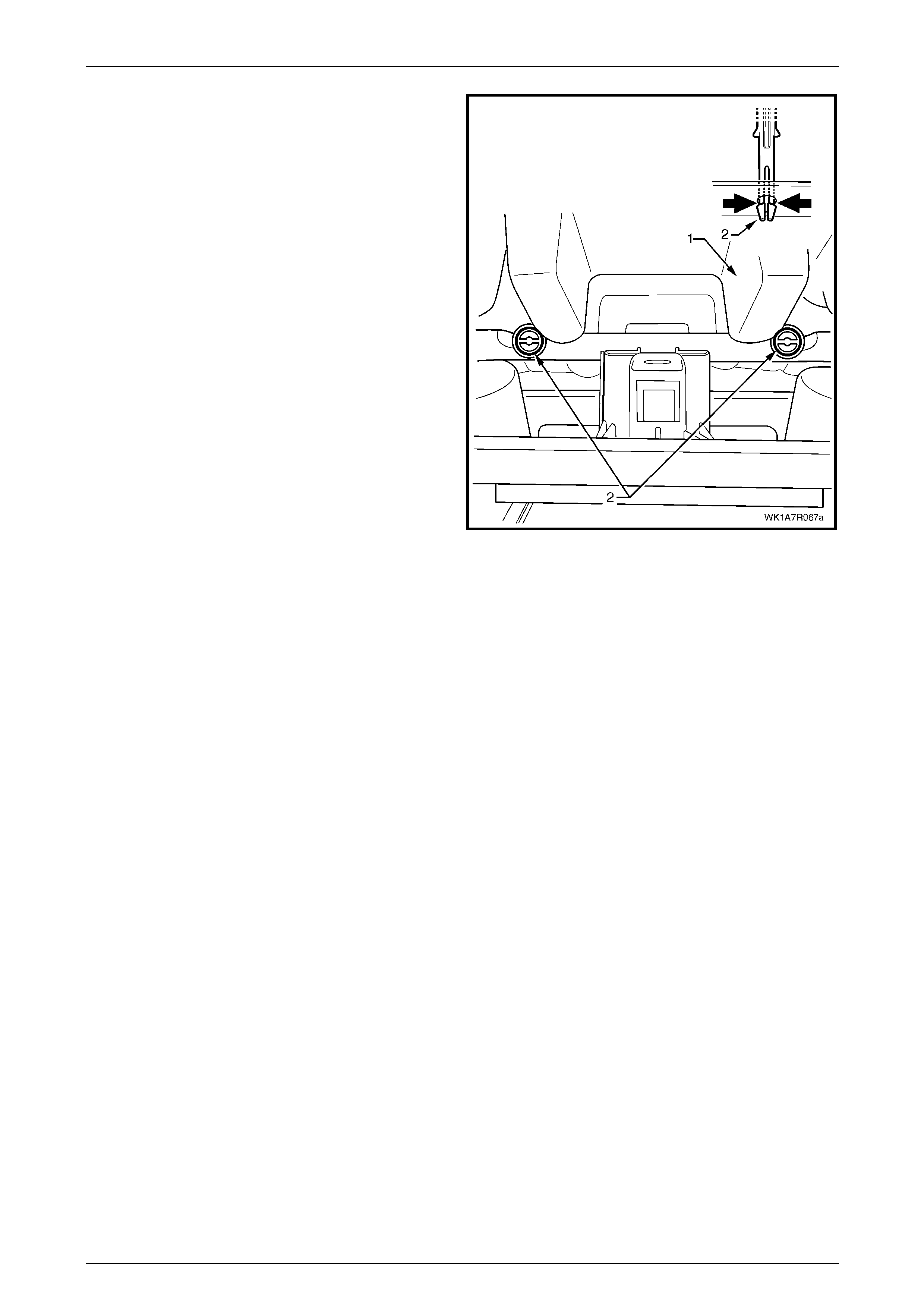

Referring to Figure 1A7 – 1, four electric motor and gearbox assemblies provide the mov ement of the front seat, one

each for:

• front raise/lower movement (1),

• rear raise/lower movement (2),

• seat fore/aft movement (3),

• seat-back recline (4).

Figure 1A7 – 1

Each function is independentl y controlled. Alternatively, if desired the front and rear raise/lower movement can be

performed together to raise or lower the complete seat.

Raise/Lower Movement

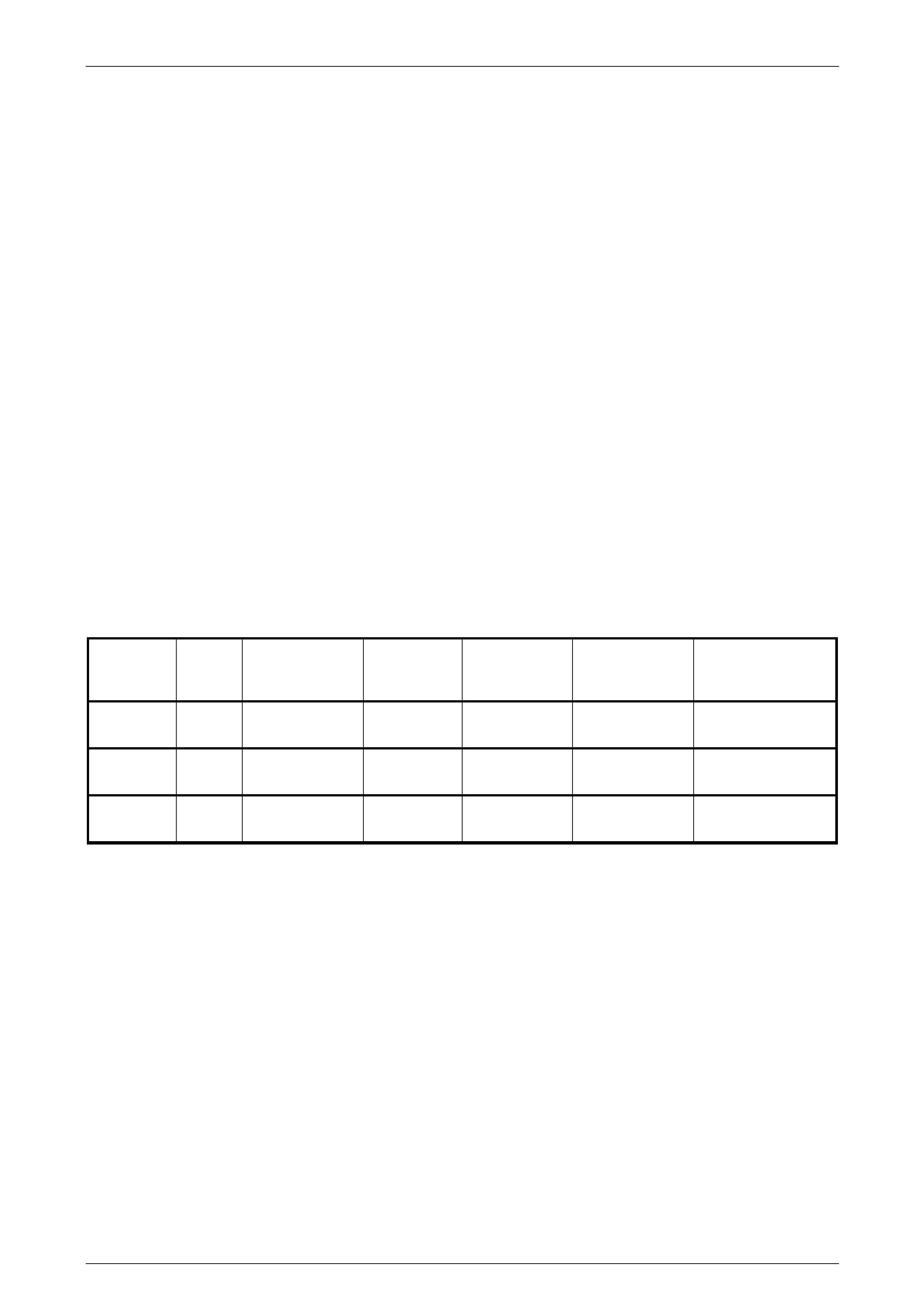

Two lift motor and gearbox assemblies (1 & 2, refer to Figure 1A7 – 1) are attached to th e inboard side of the track and

height adjust assembly: one for front and the other for rear raise/lo wer movement. When a lift motor is operating, it drive s

the gearbox which draws in or extends a mating worm shaft. This in turn operates on an arm and cross-shaft.

The cross-shaft is connected to another arm on the opposite side of the track and height adjust assembly and allows the

raising or lowering of that portion (front or rear) of the seat.

Fore/Aft Movement

To provide seat fore/aft movement, the motor and gearbox assembly (3, refer to Figure 1A7 – 1) is connected to a shaft

geared at each end. Within e ach seat track, the shaft gear is meshed upon a rack, providing fore/aft movement.

Recline Movement

Seat-back recline movement is provided by the recline motor and gearbo x assembly (4, refer to Figure 1A7 – 1), which is

attached to the seat-back frame. A shaft from the gearbox is fitted with a drive gear at each end and is meshed with a

driven gear attached to each seat-back fram e pivot. Motor oper ation causes rotation of the drive ge ar, which turns the

driven gear and seat-back frame, thereby altering the seat-back recline a ngle.

All motors reverse direction when the polarity at the wiring terminals is reversed, resu lting in seat movement in the

opposite direction. During seat position adjustment, the drive motors will cease operation at the end of their travel via an

internal thermal cut-out switch, even if the seat adjustment switch is held on.

Components making up the seat-back recline mechanism and track and height adjust asse mbly are not serviced.

Seat Assemblies Page 1A7–12

Page 1A7–12

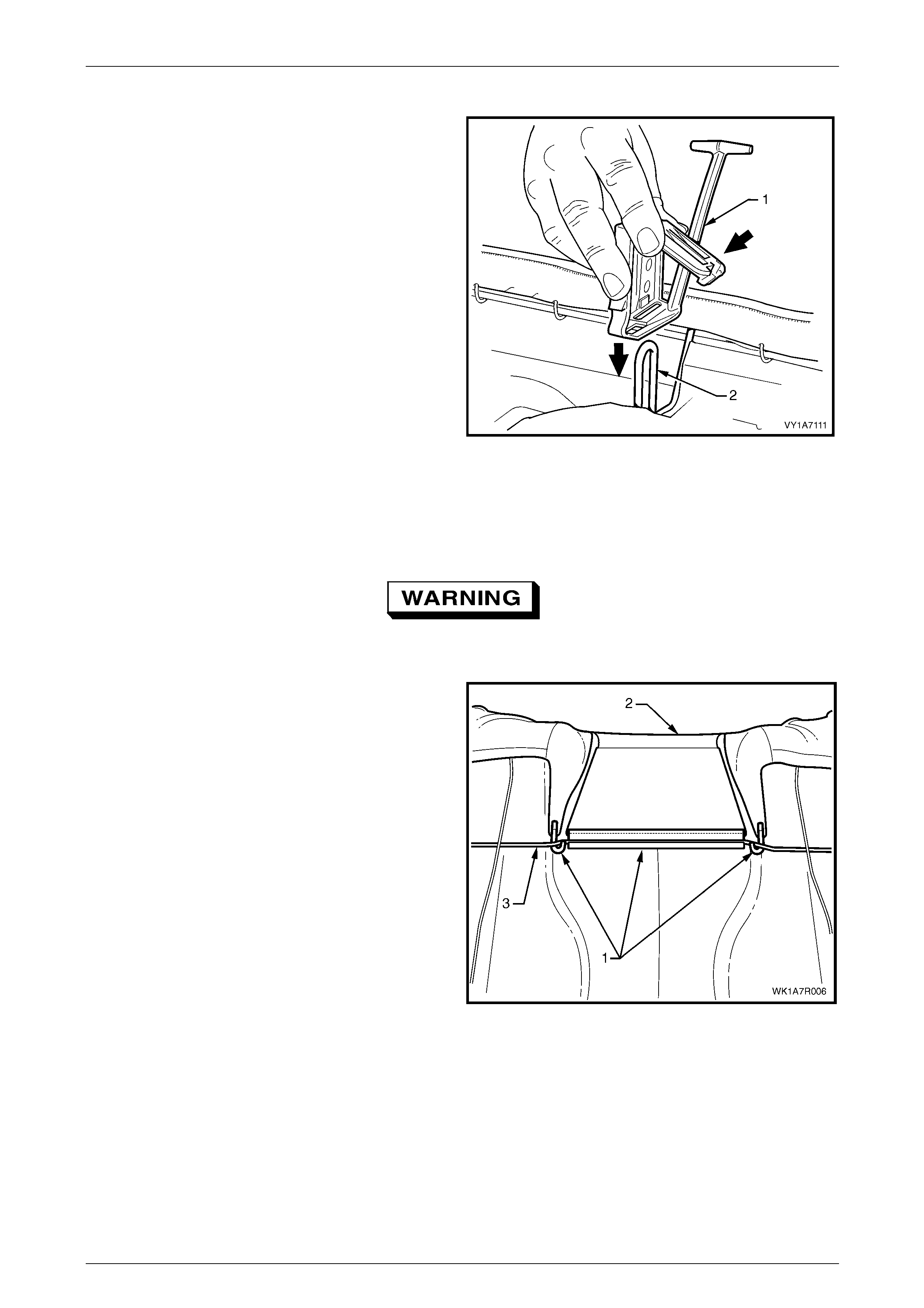

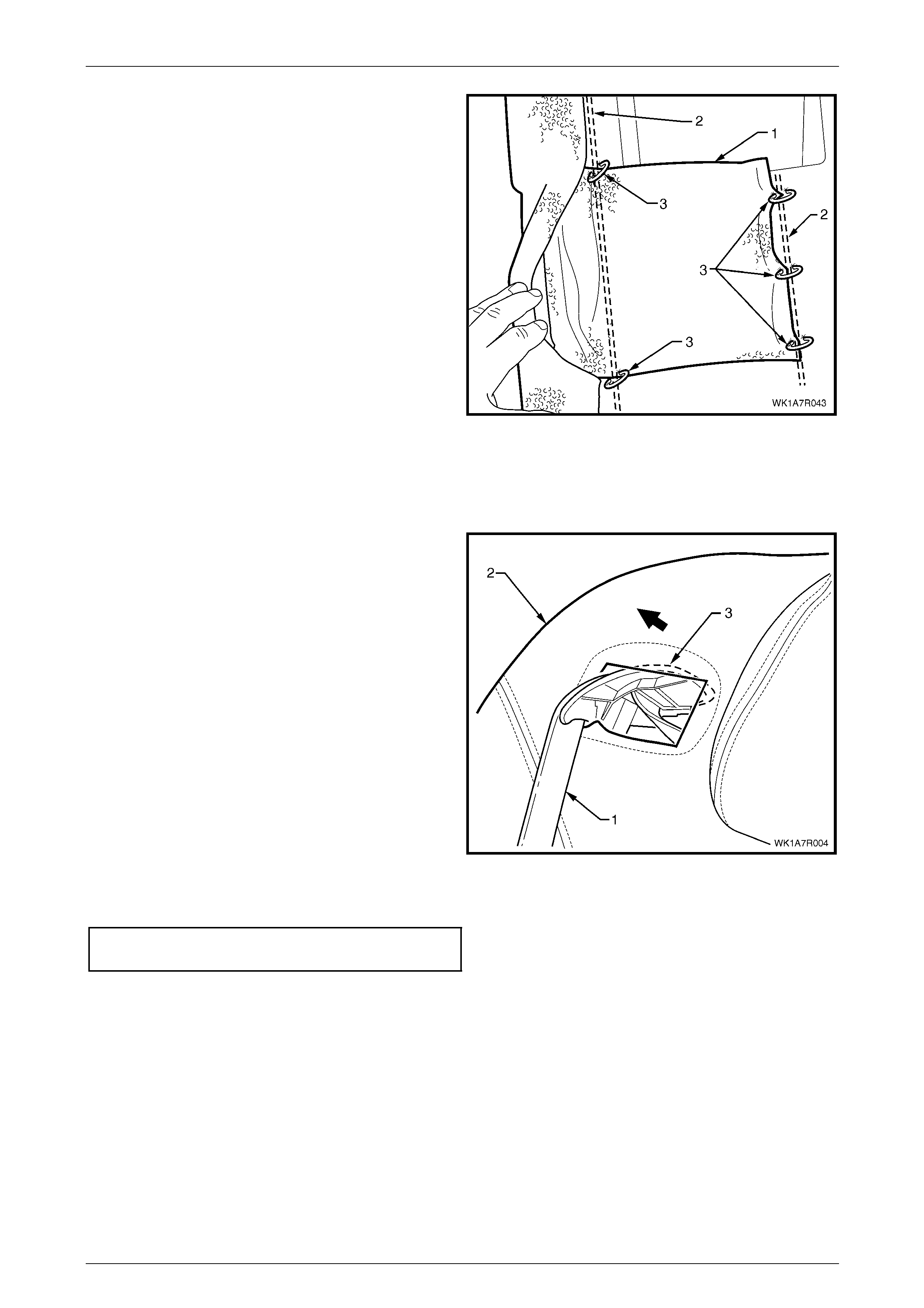

Eight-way Movement Control

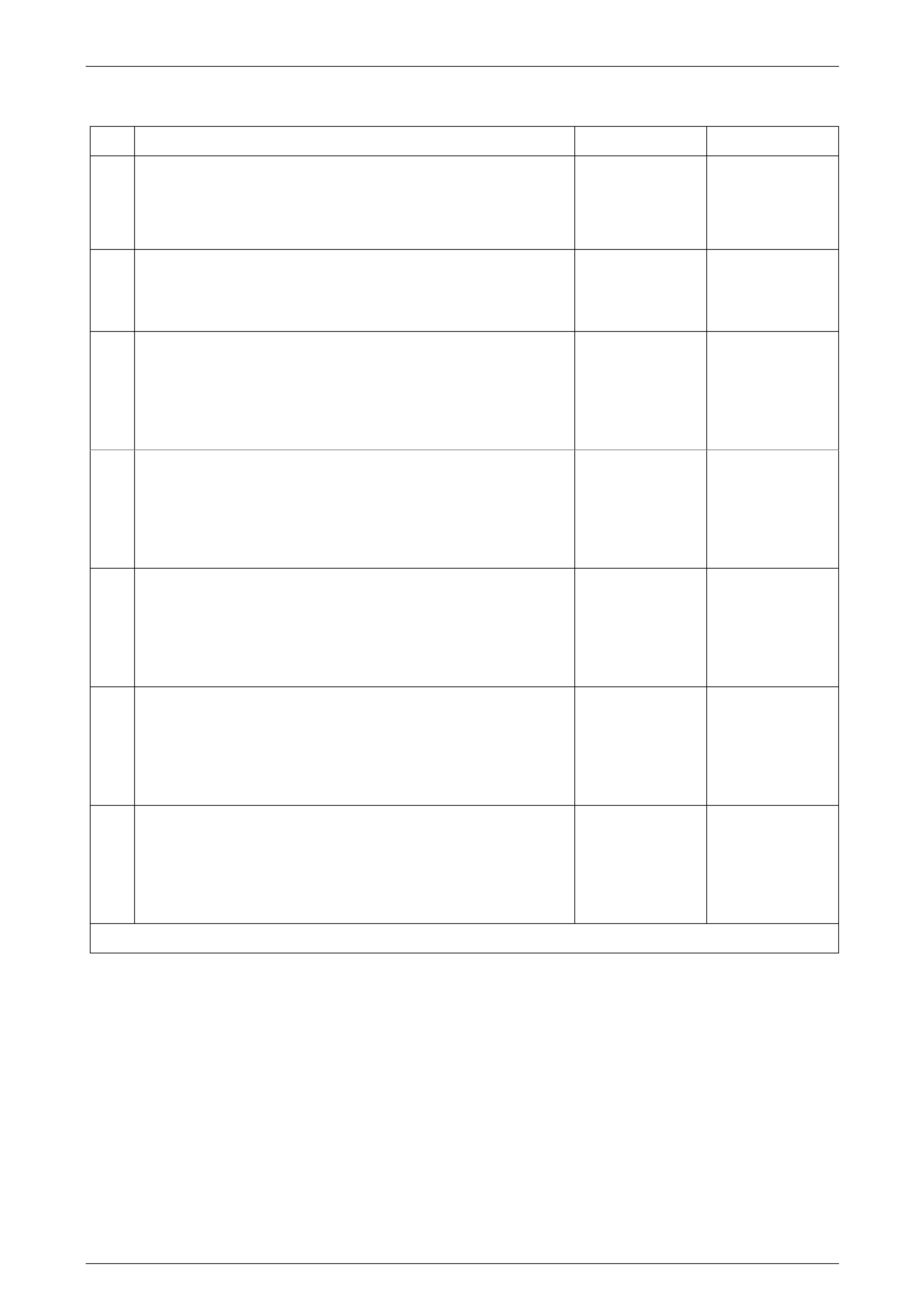

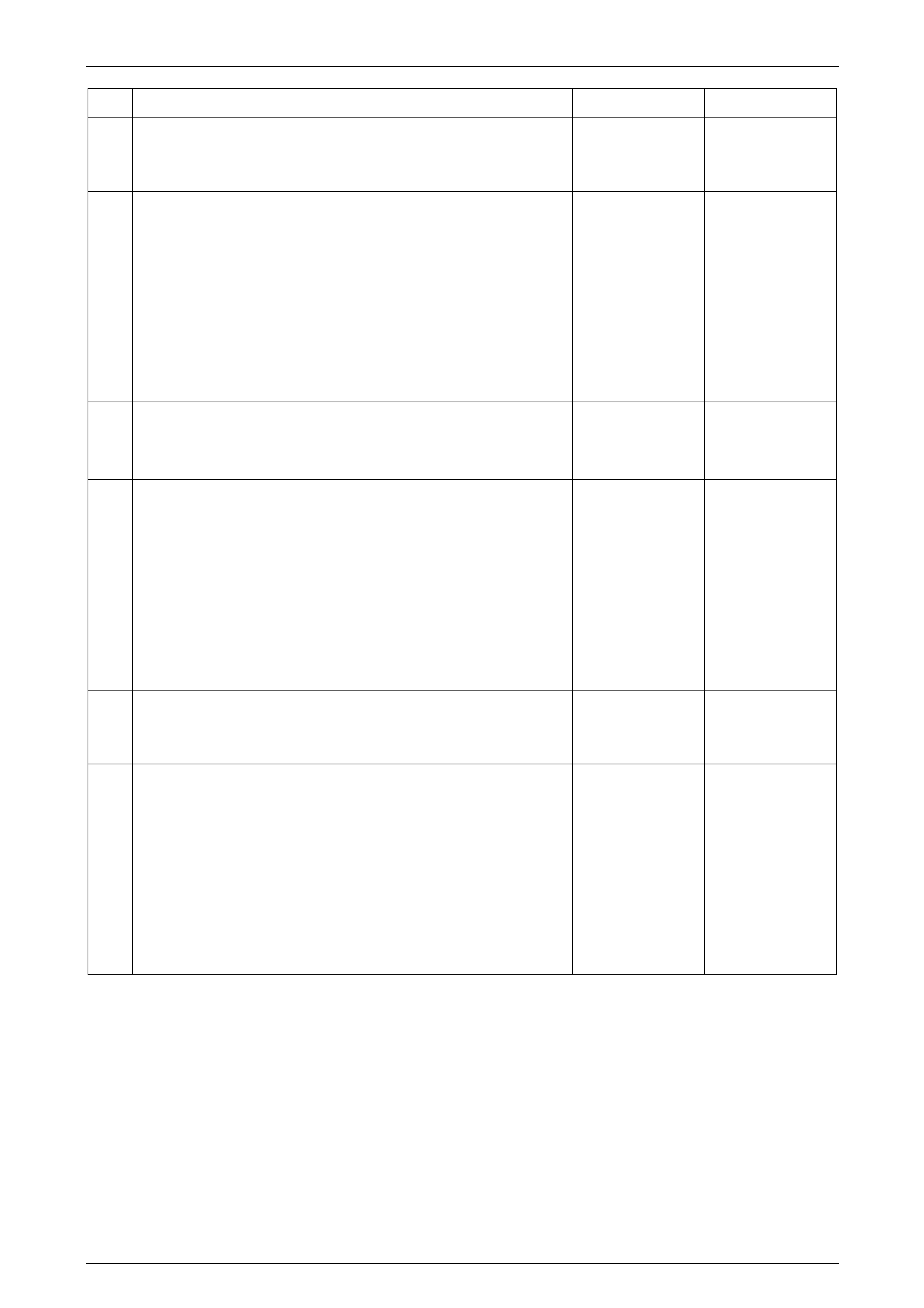

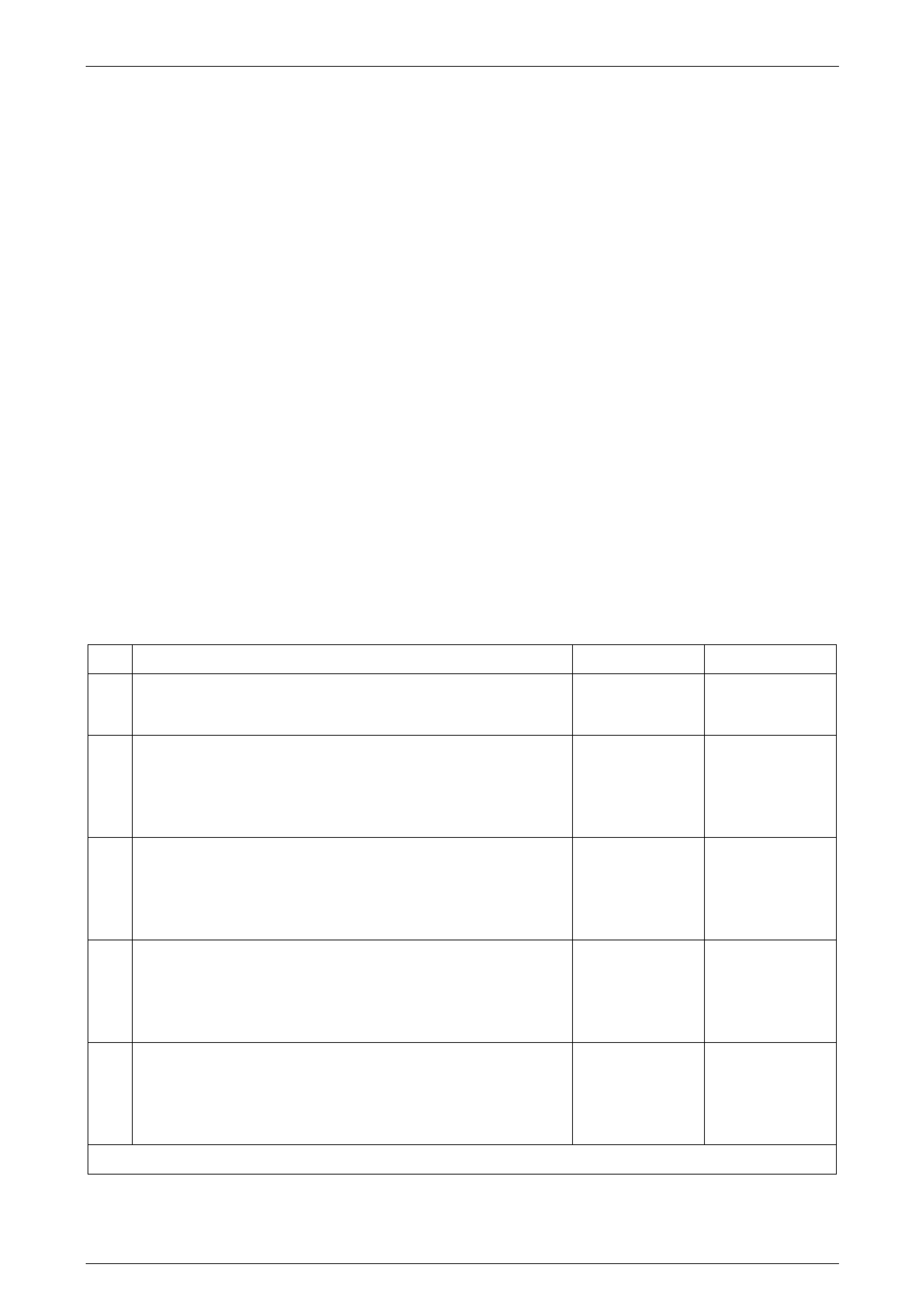

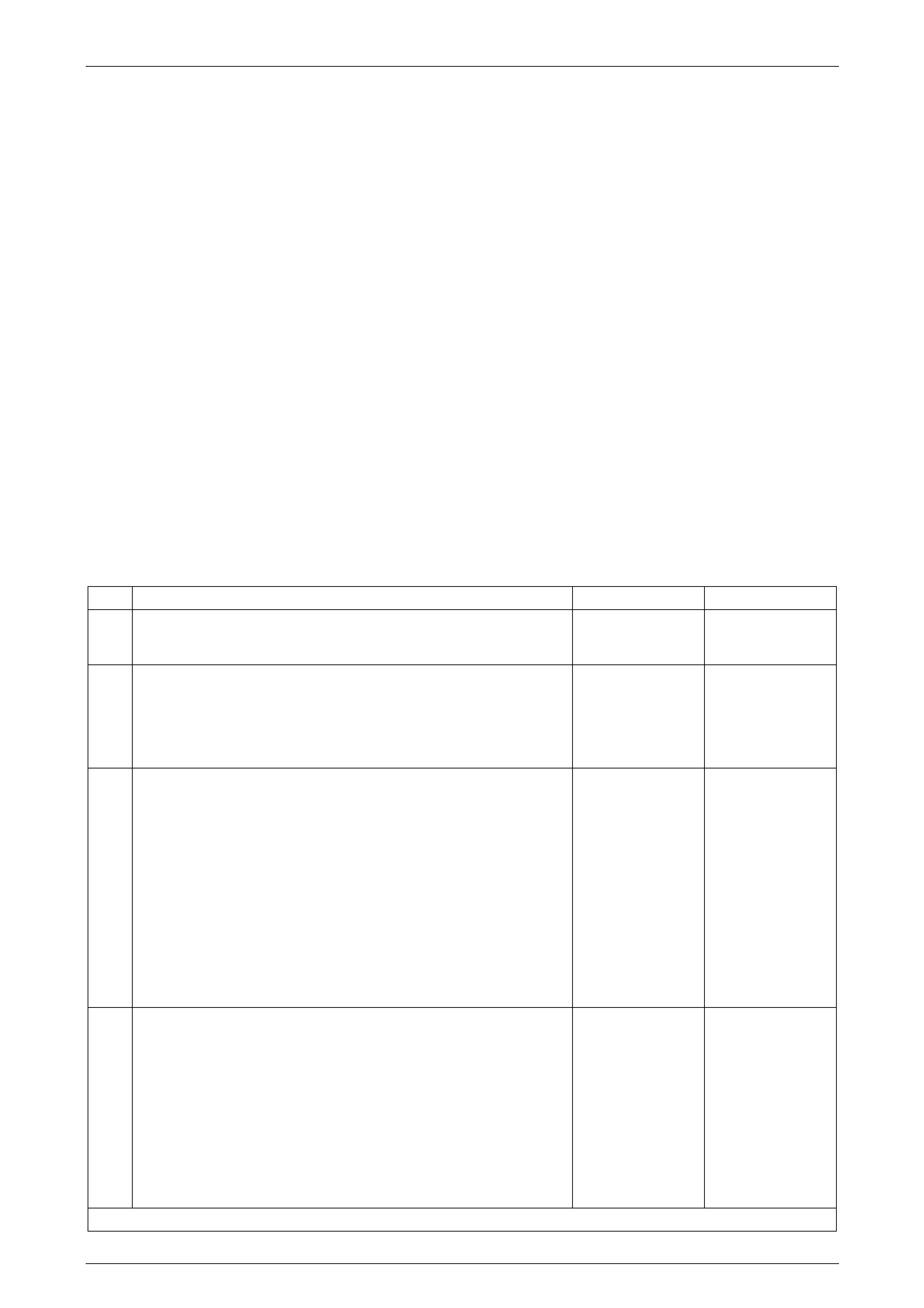

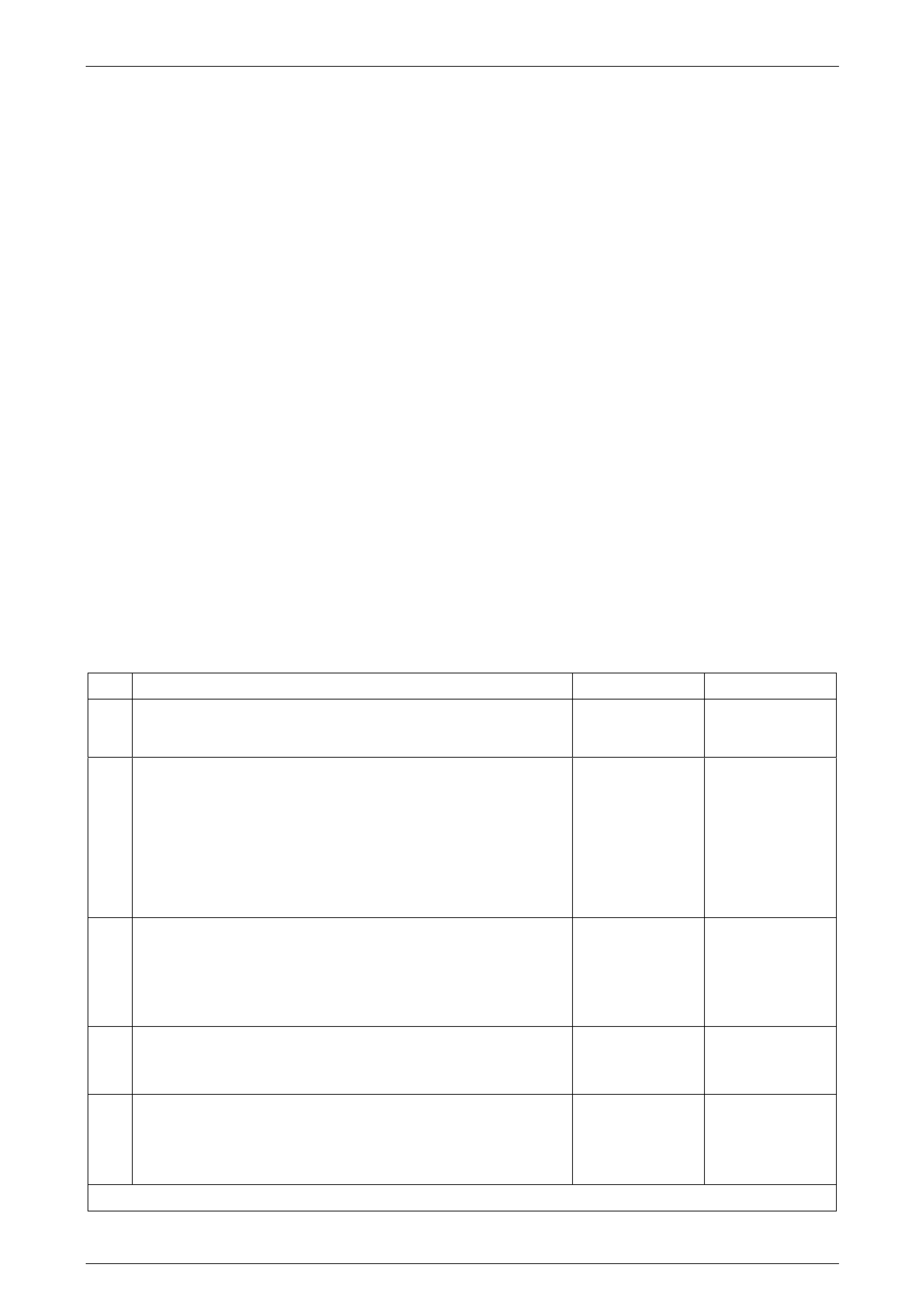

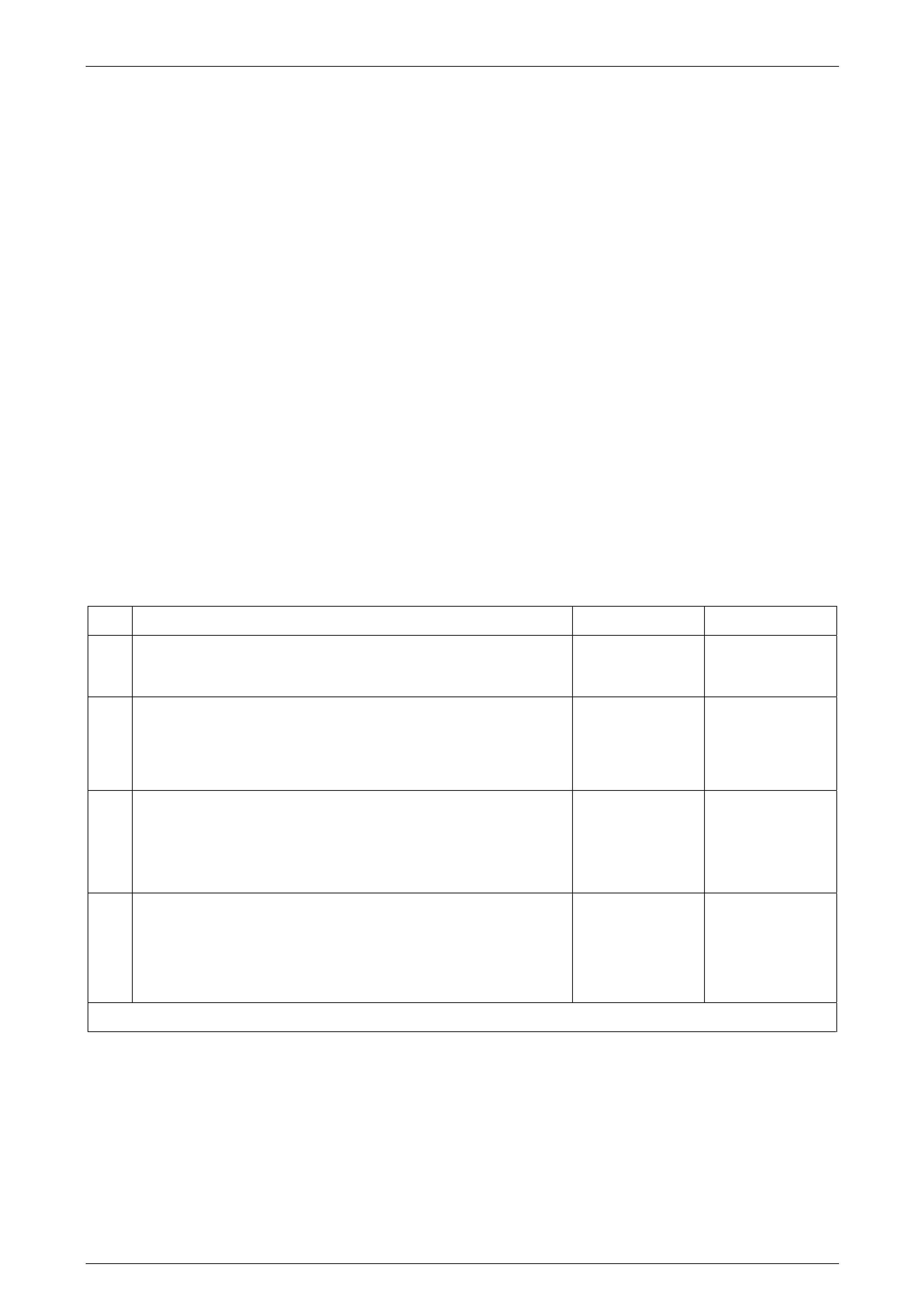

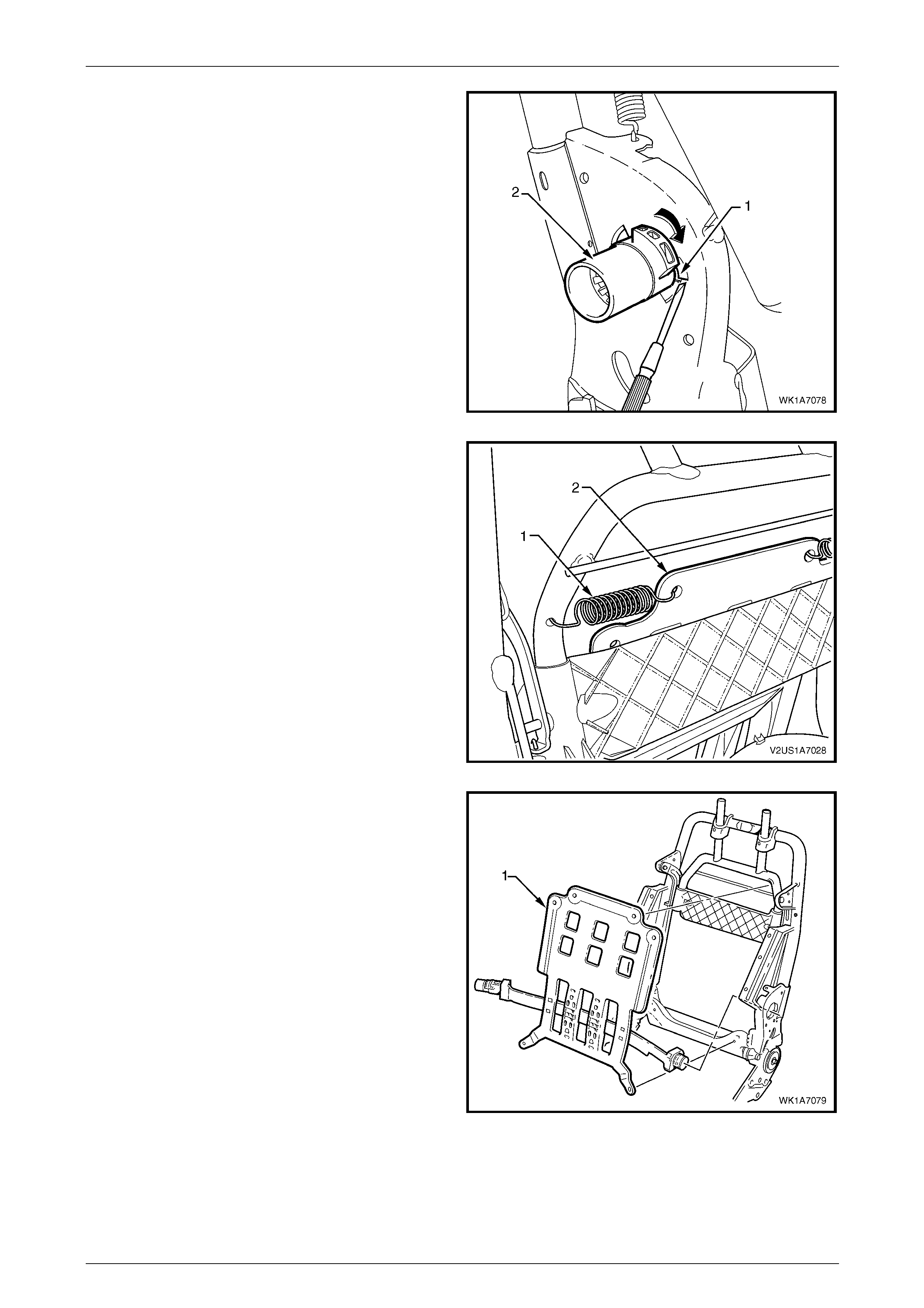

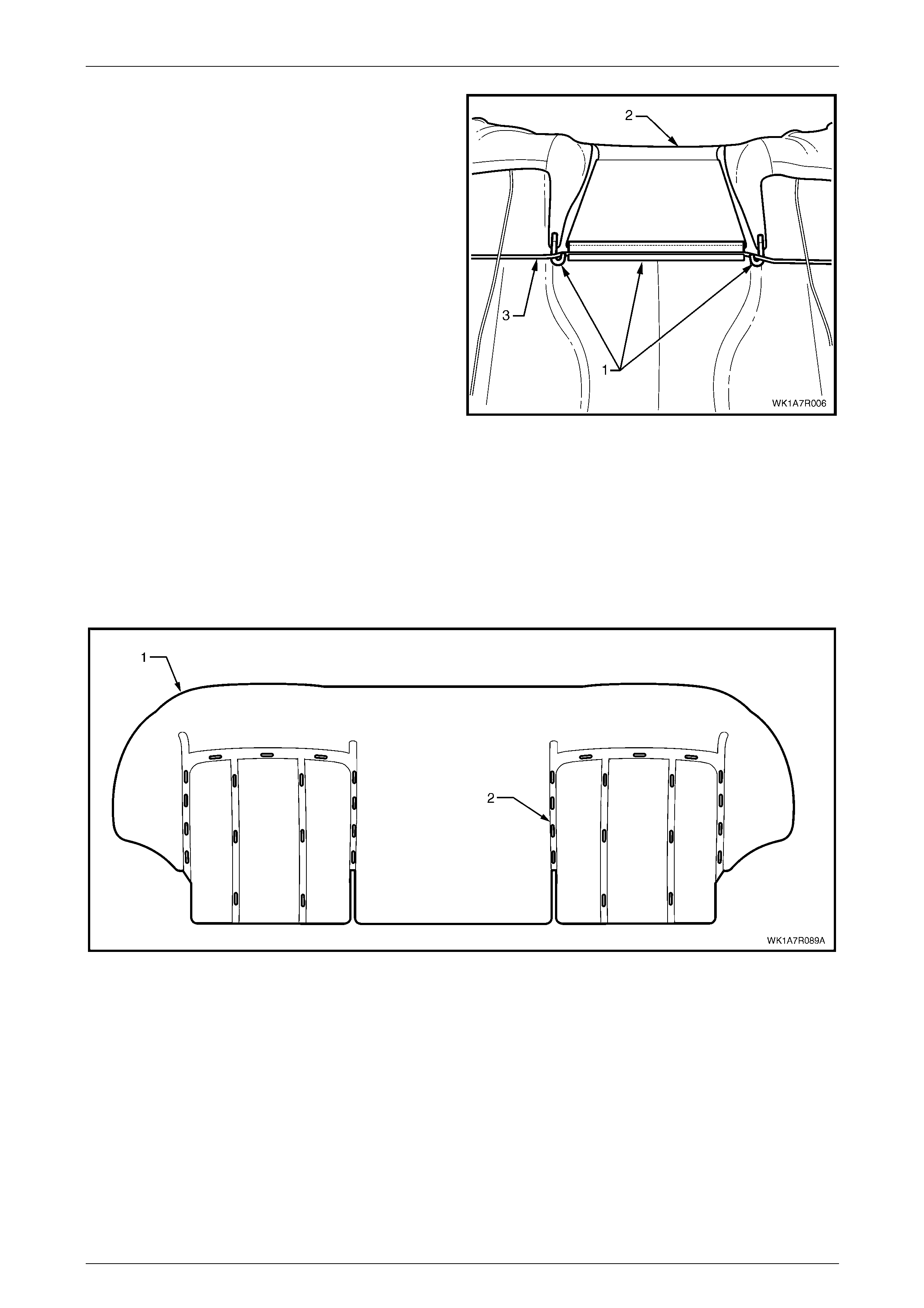

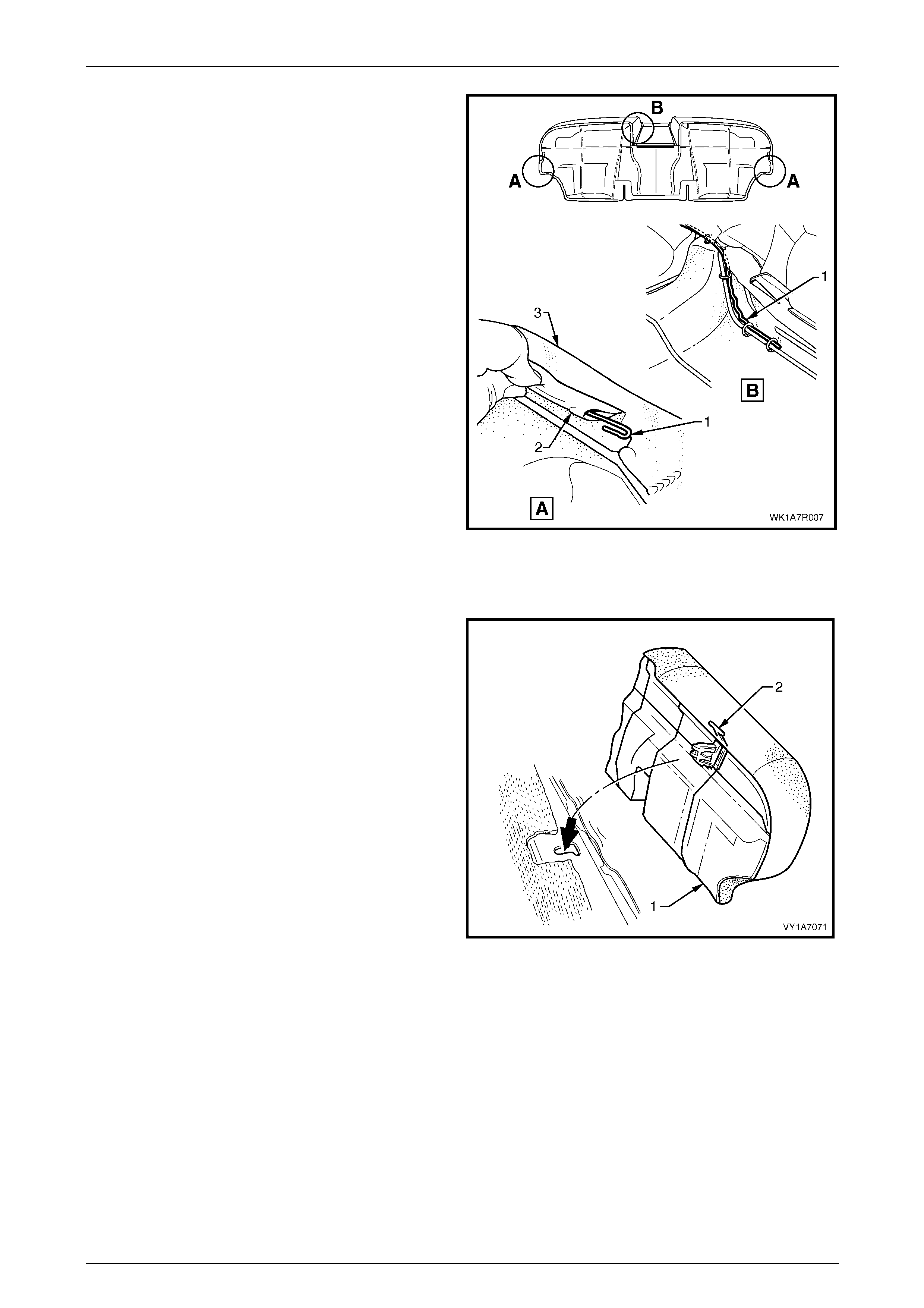

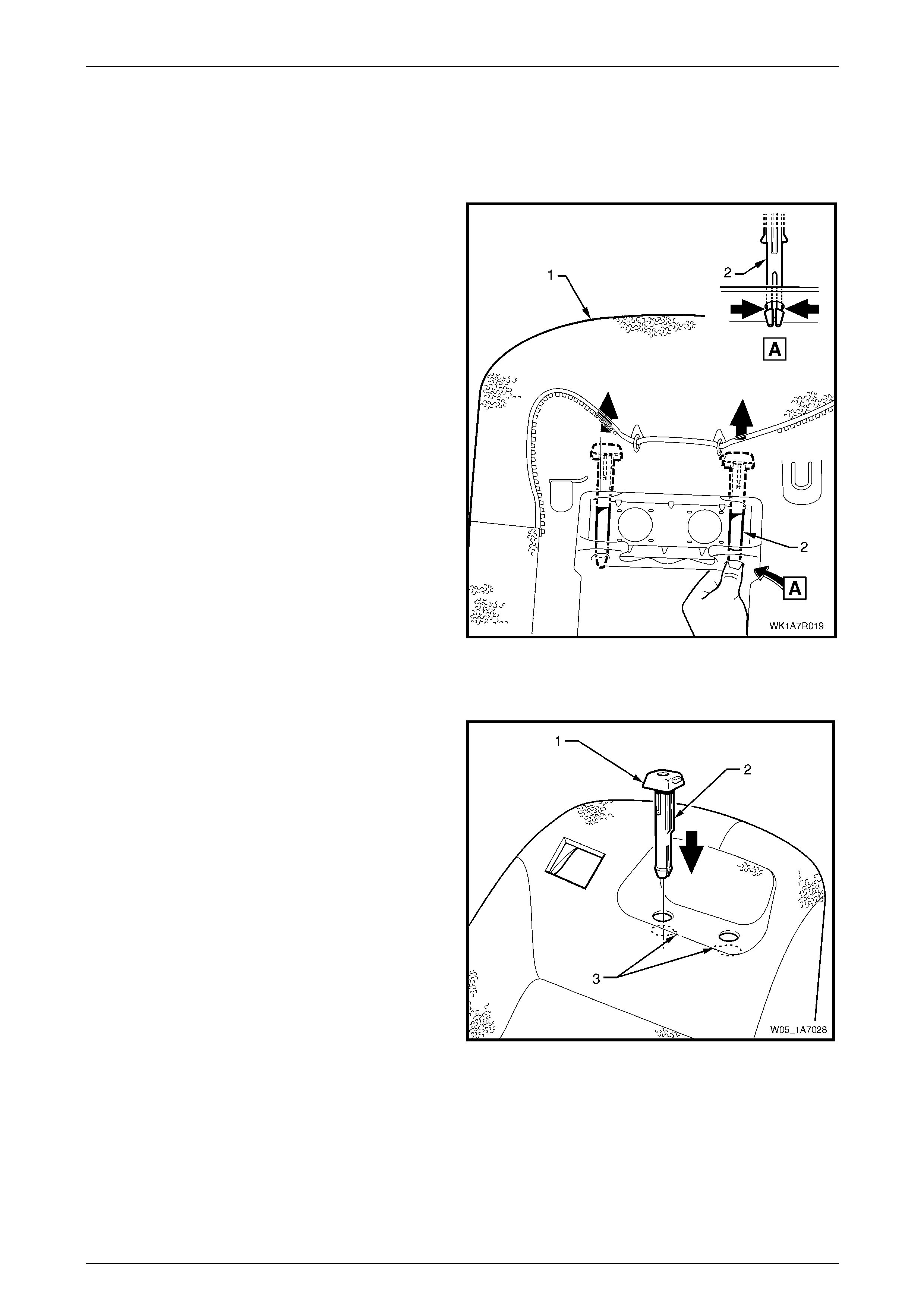

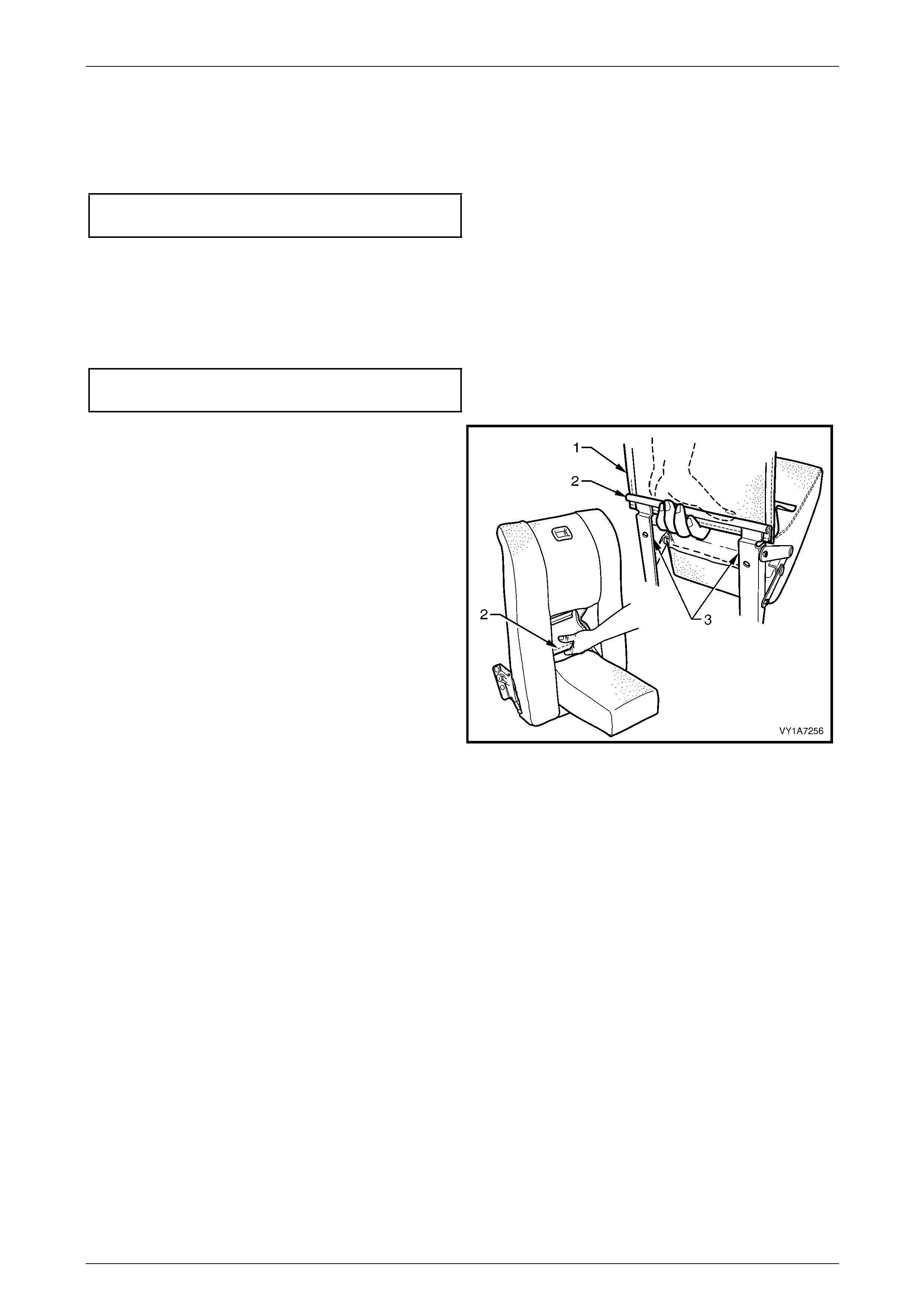

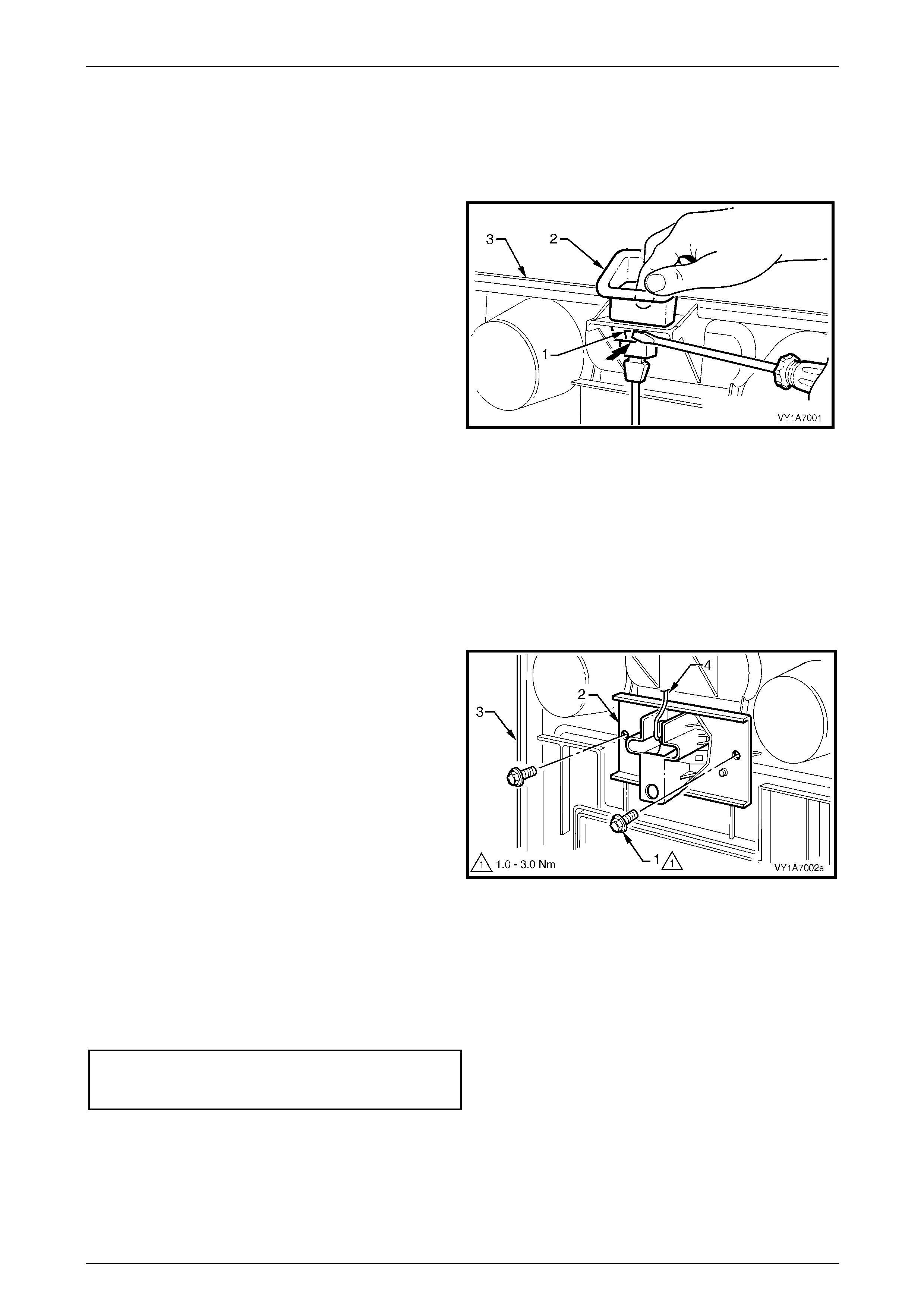

Movement is controlled by a seat control s witch attached to

the front seat outer side cover. Two adjustment knobs

provide independent control of:

• seat-back recline angle (1), and

• front cushion height, rear cushion height an d fore/ aft

seat movement (2).

For further information, refer to the Owner's Handbook.

Figure 1A7 – 2

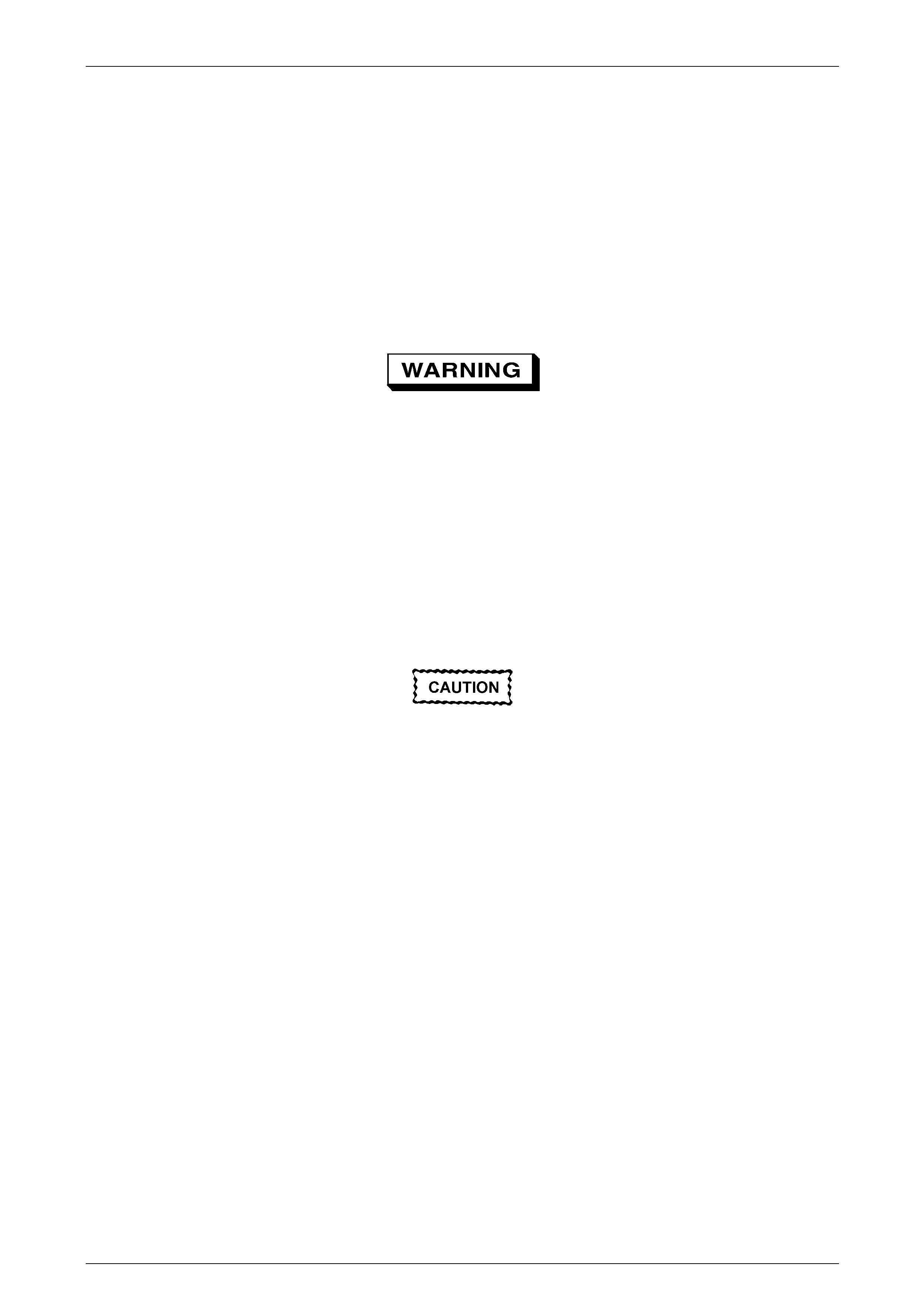

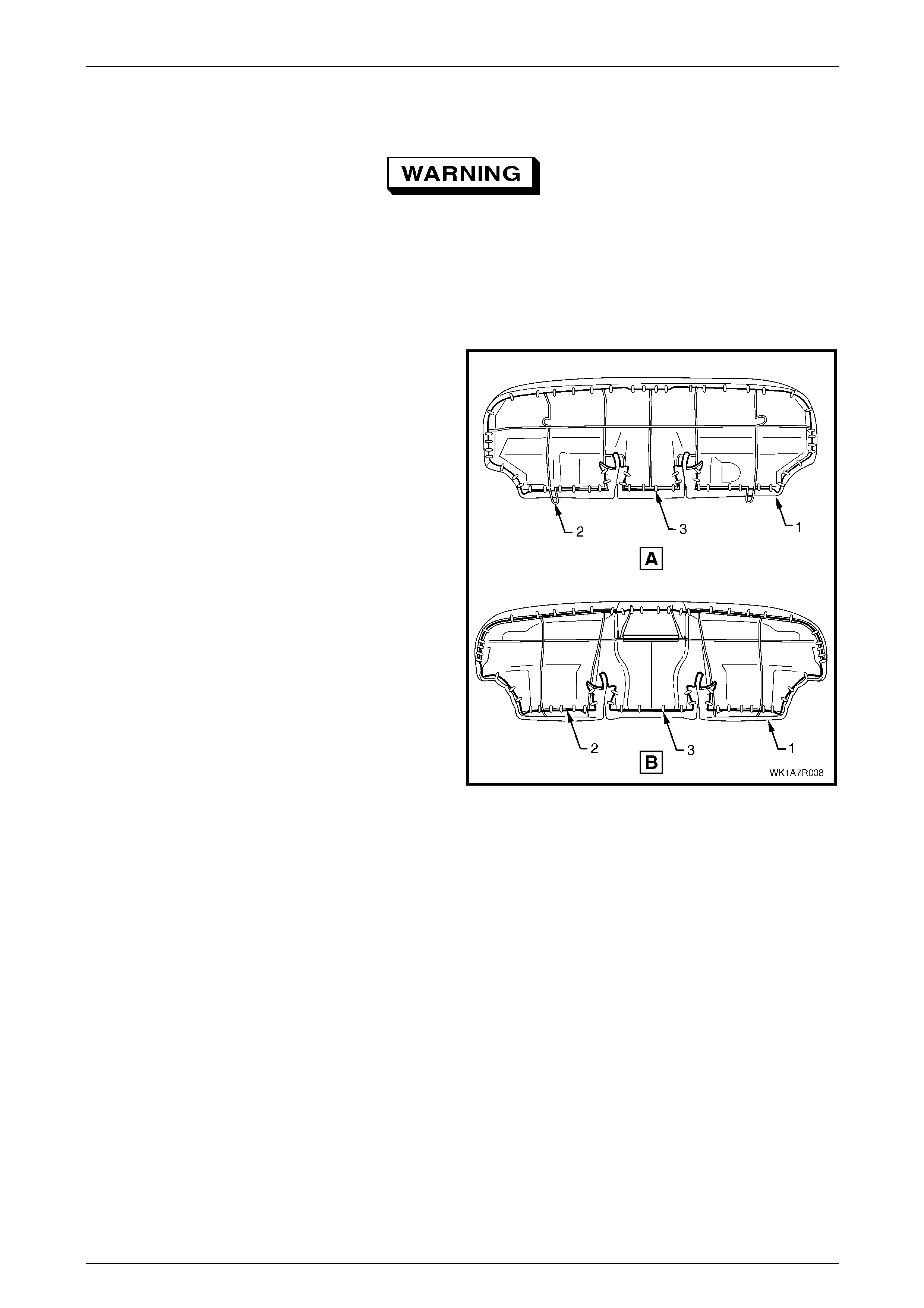

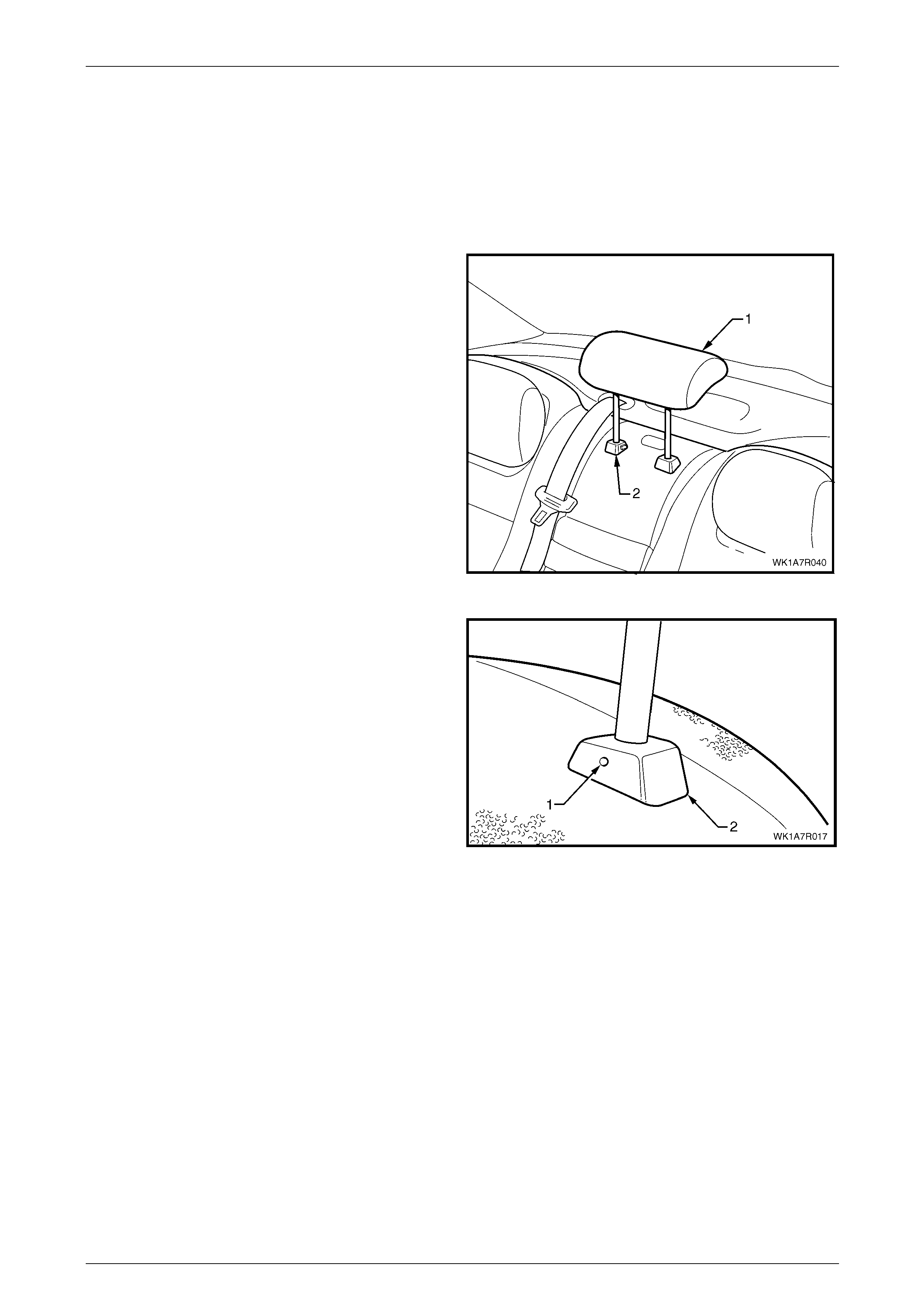

Memory Seat Position System

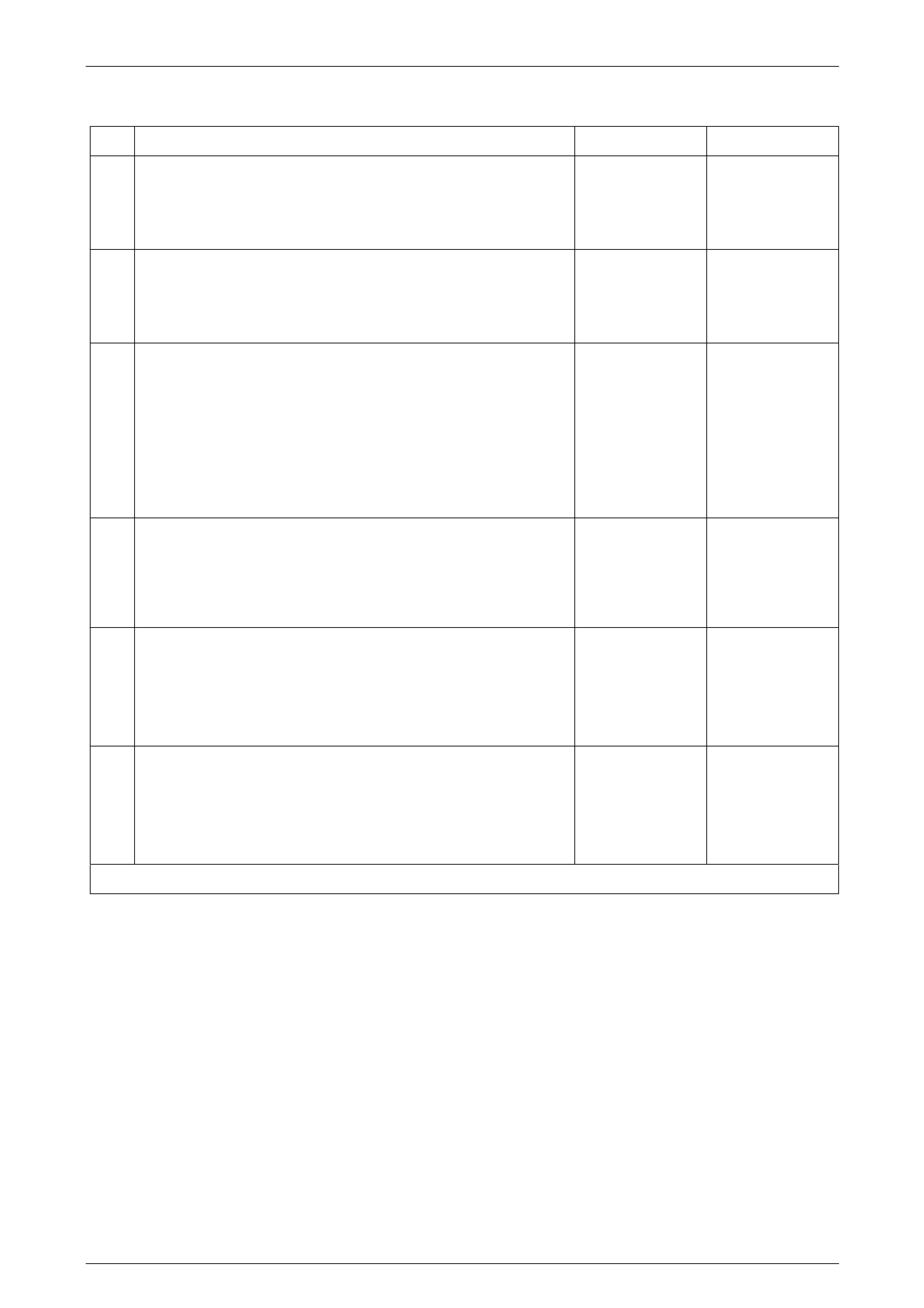

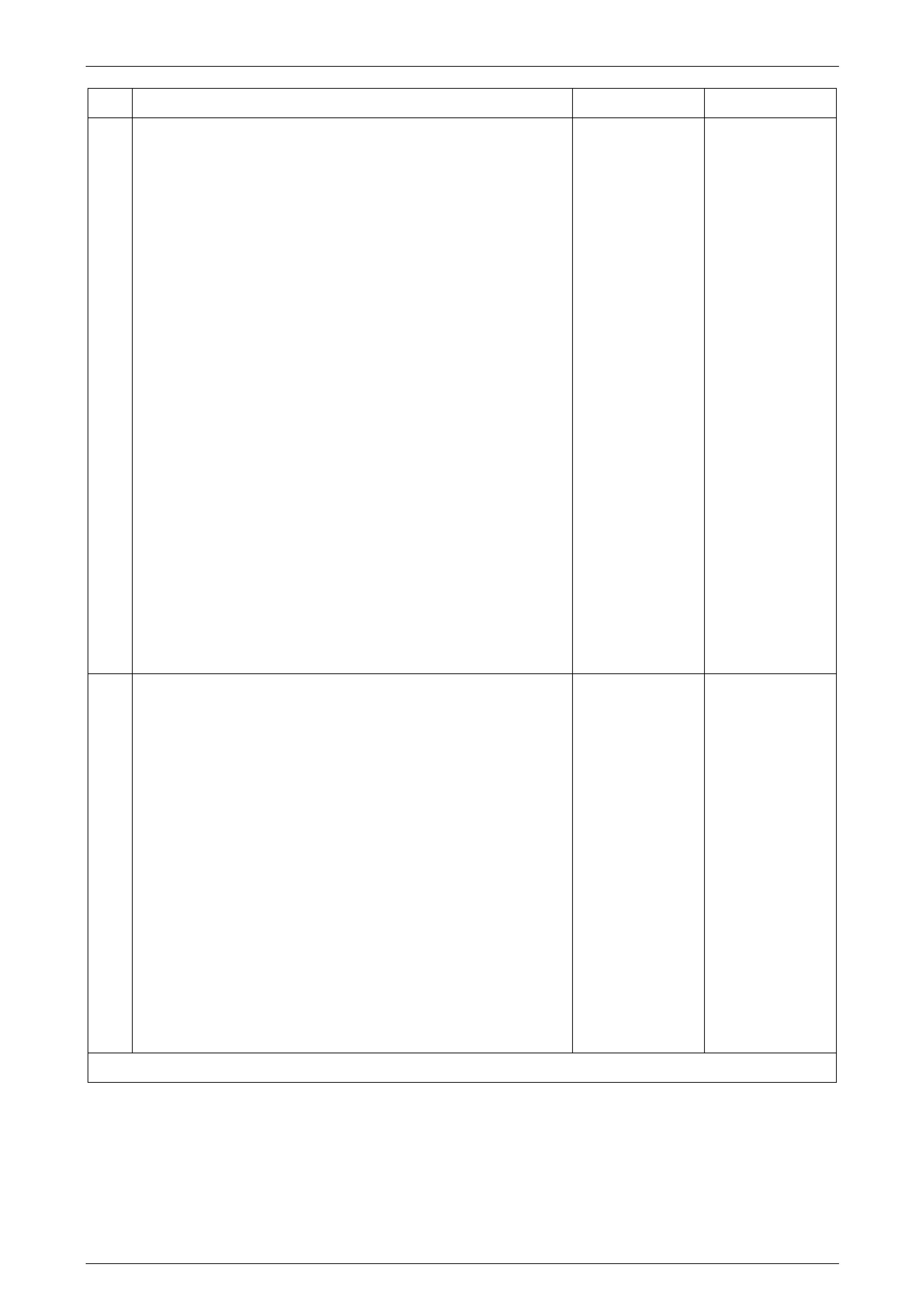

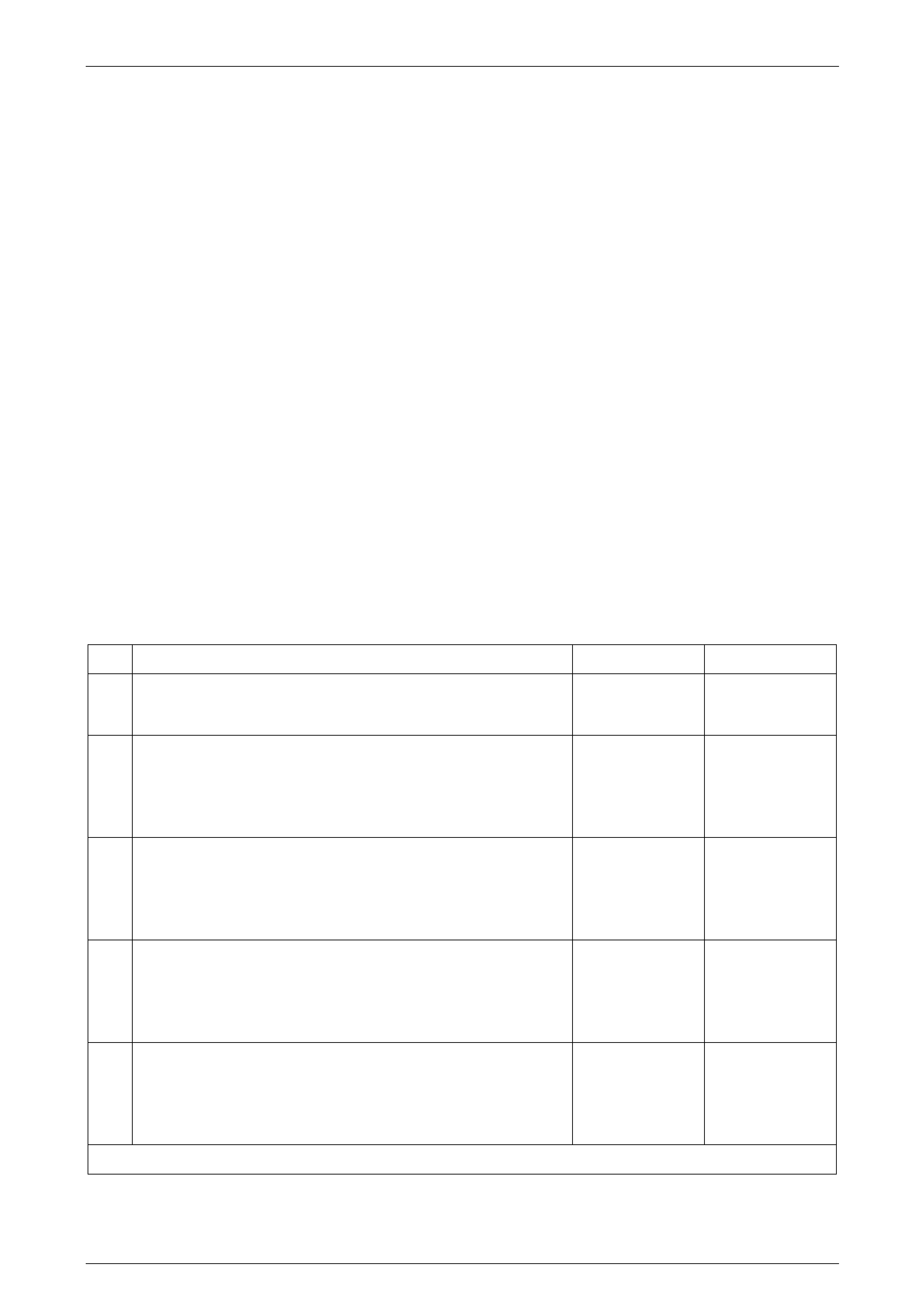

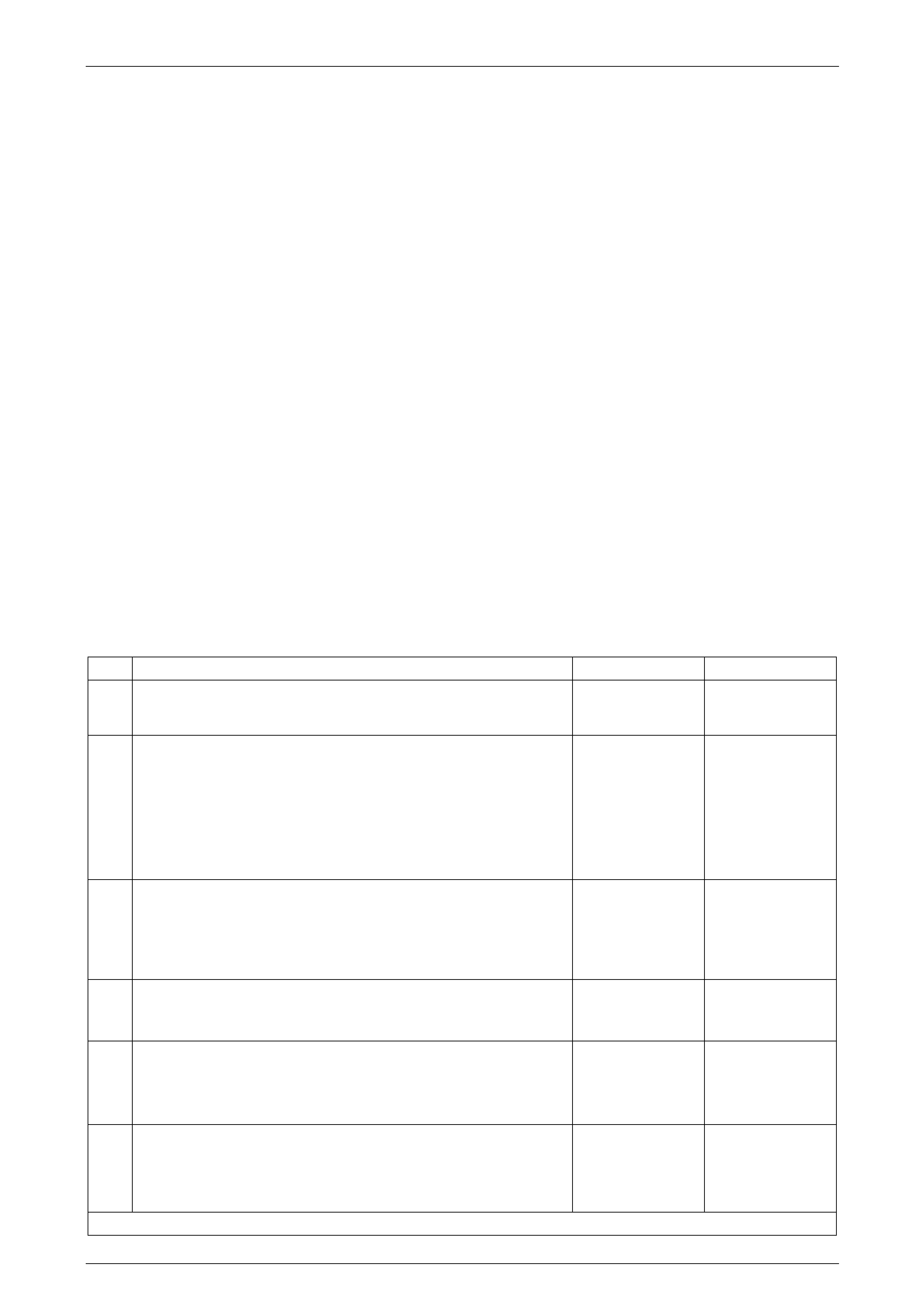

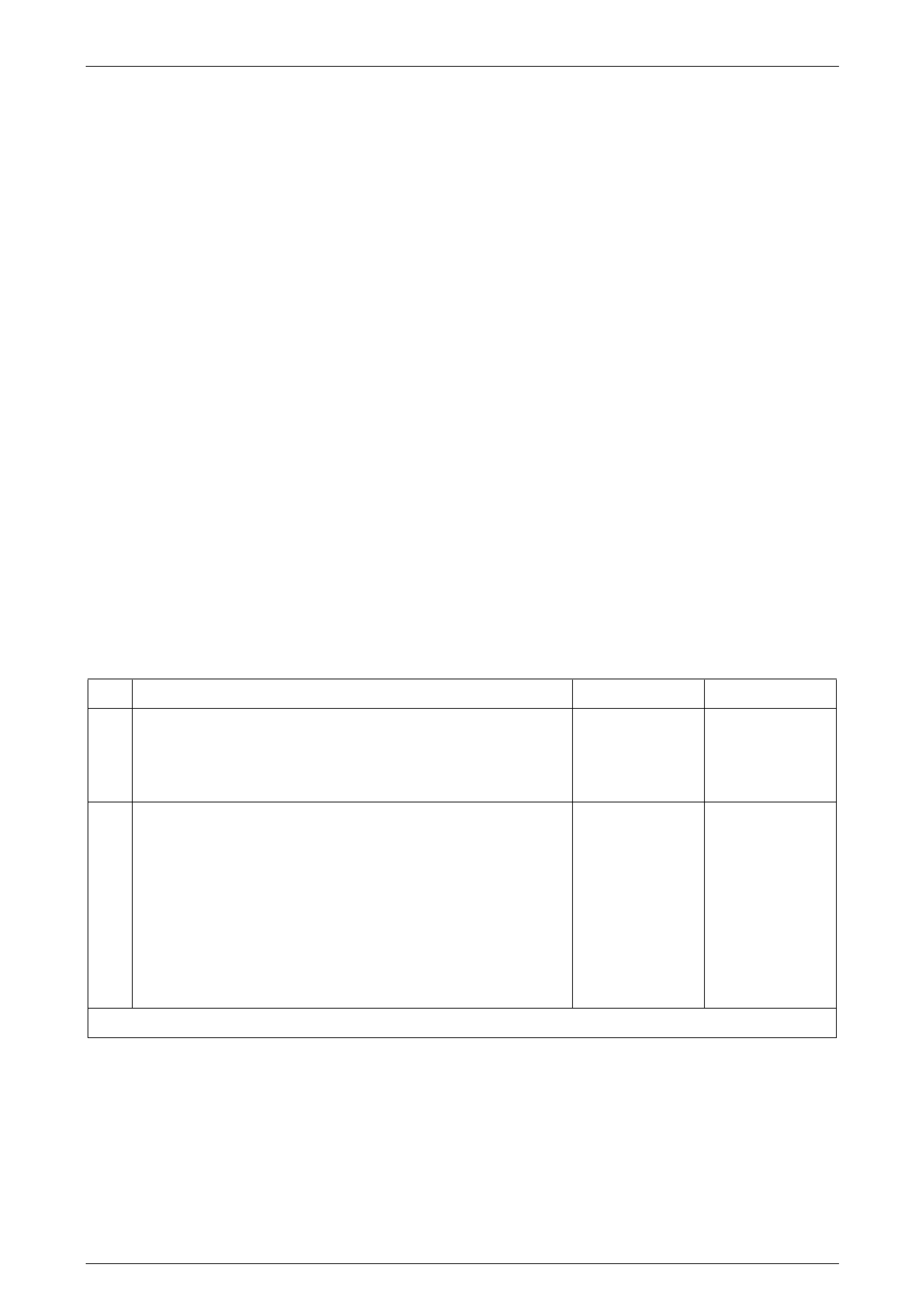

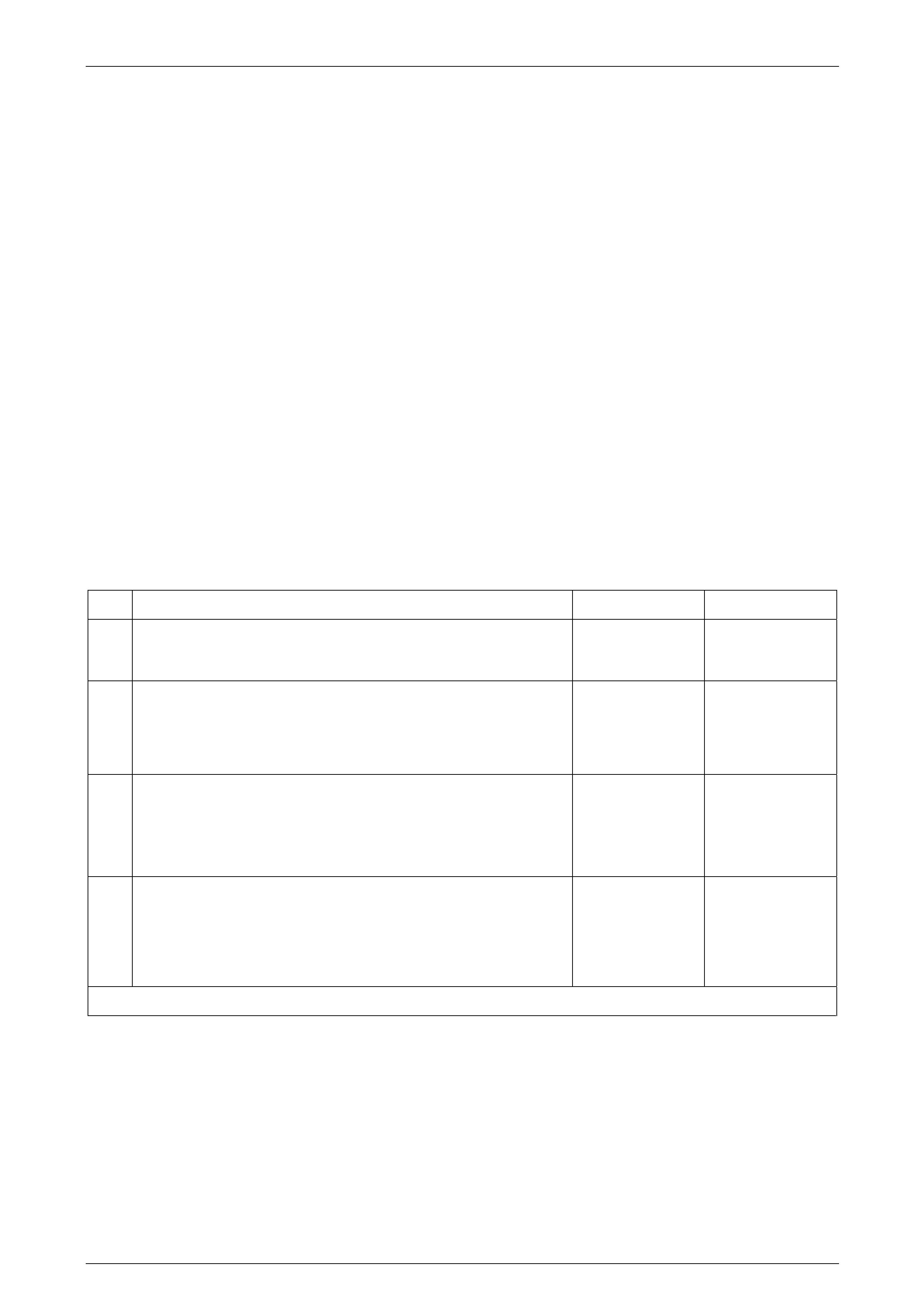

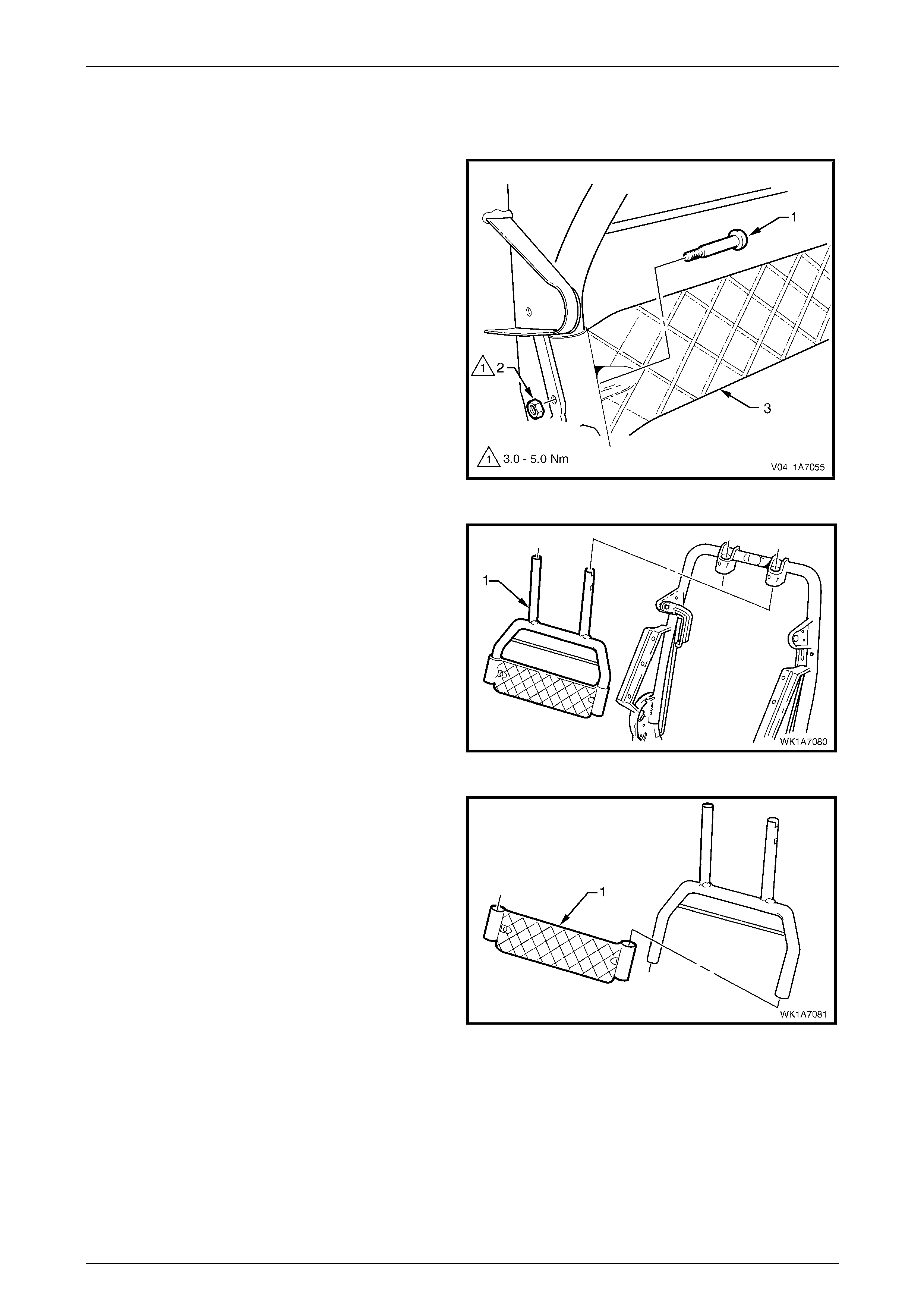

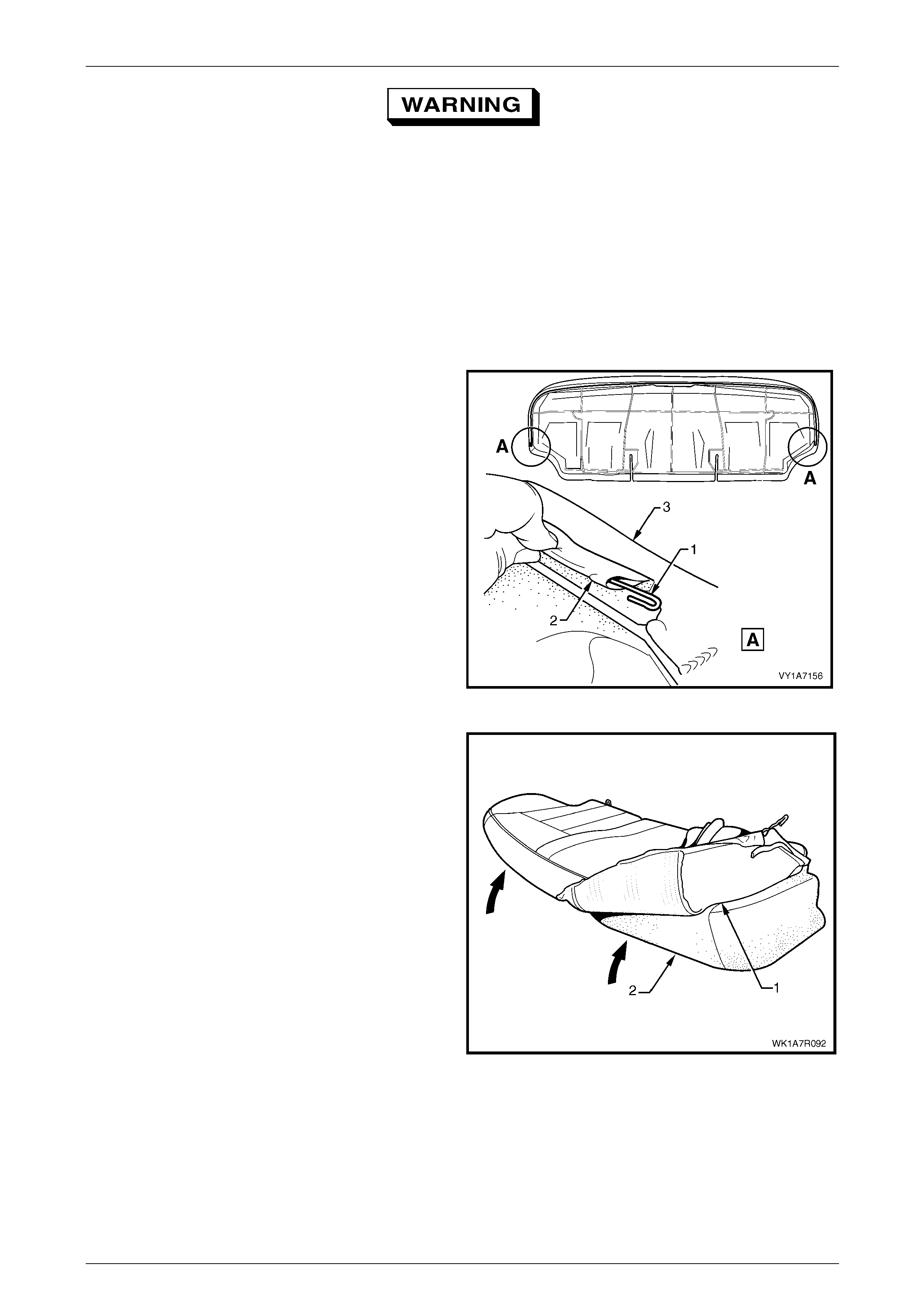

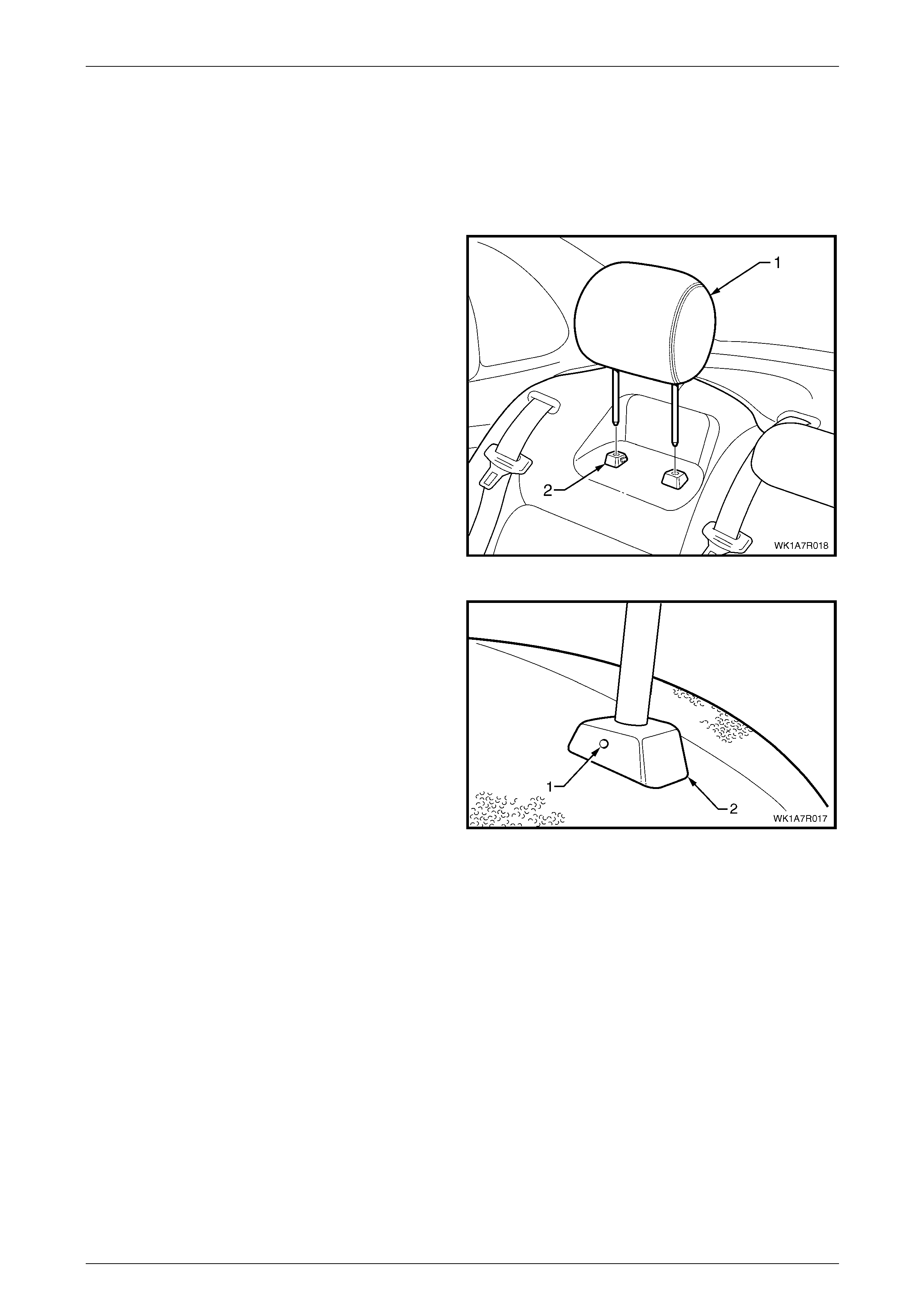

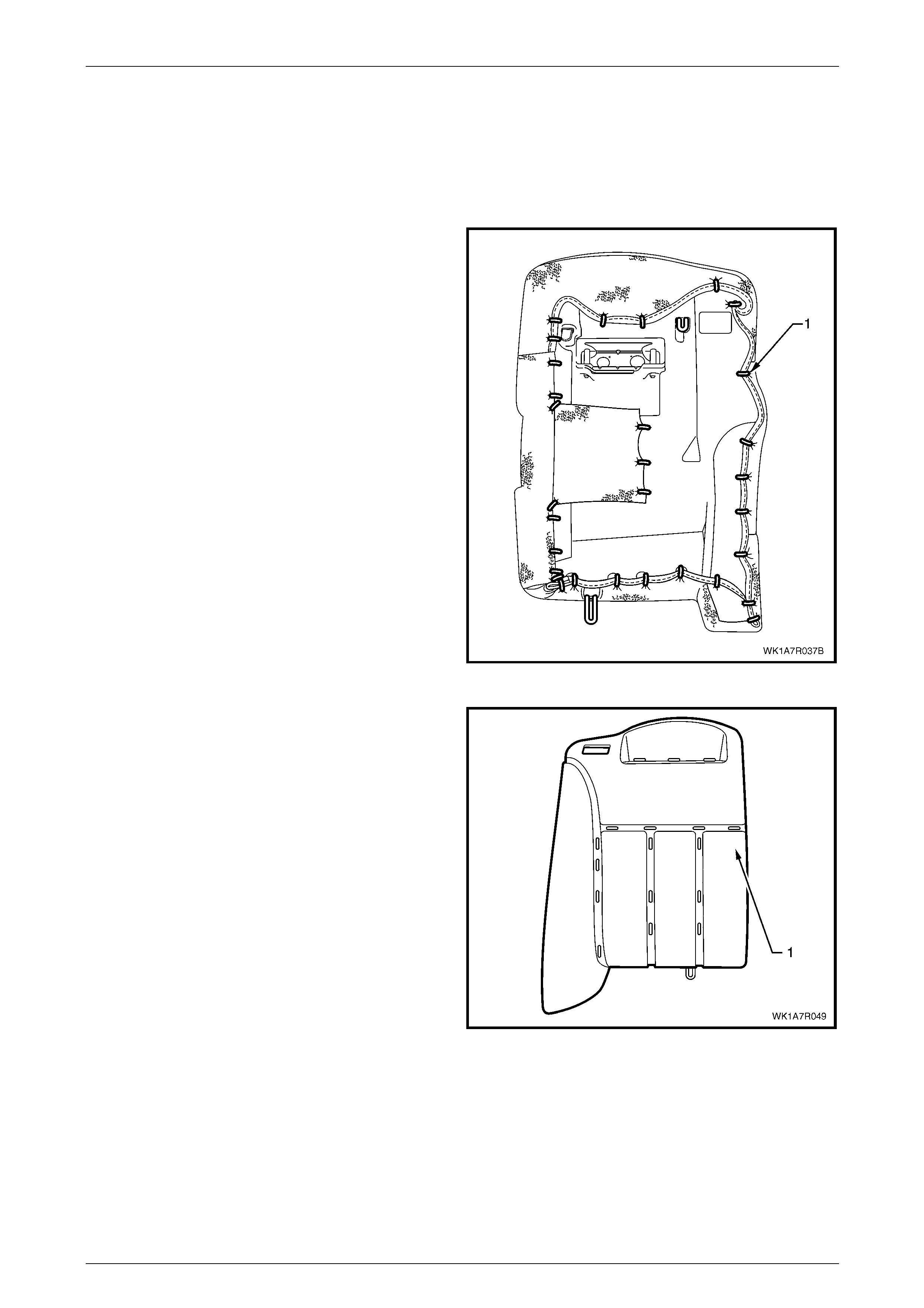

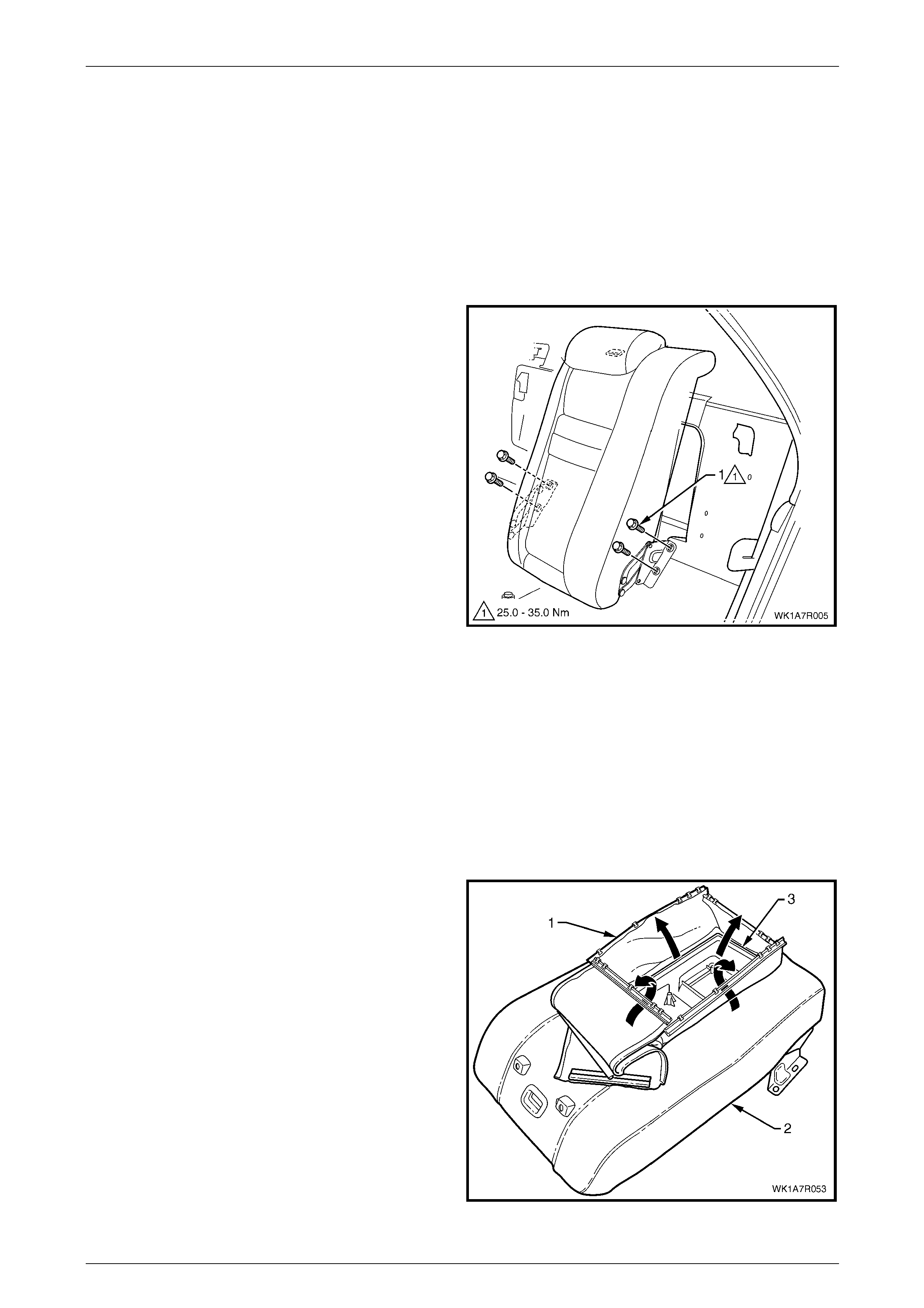

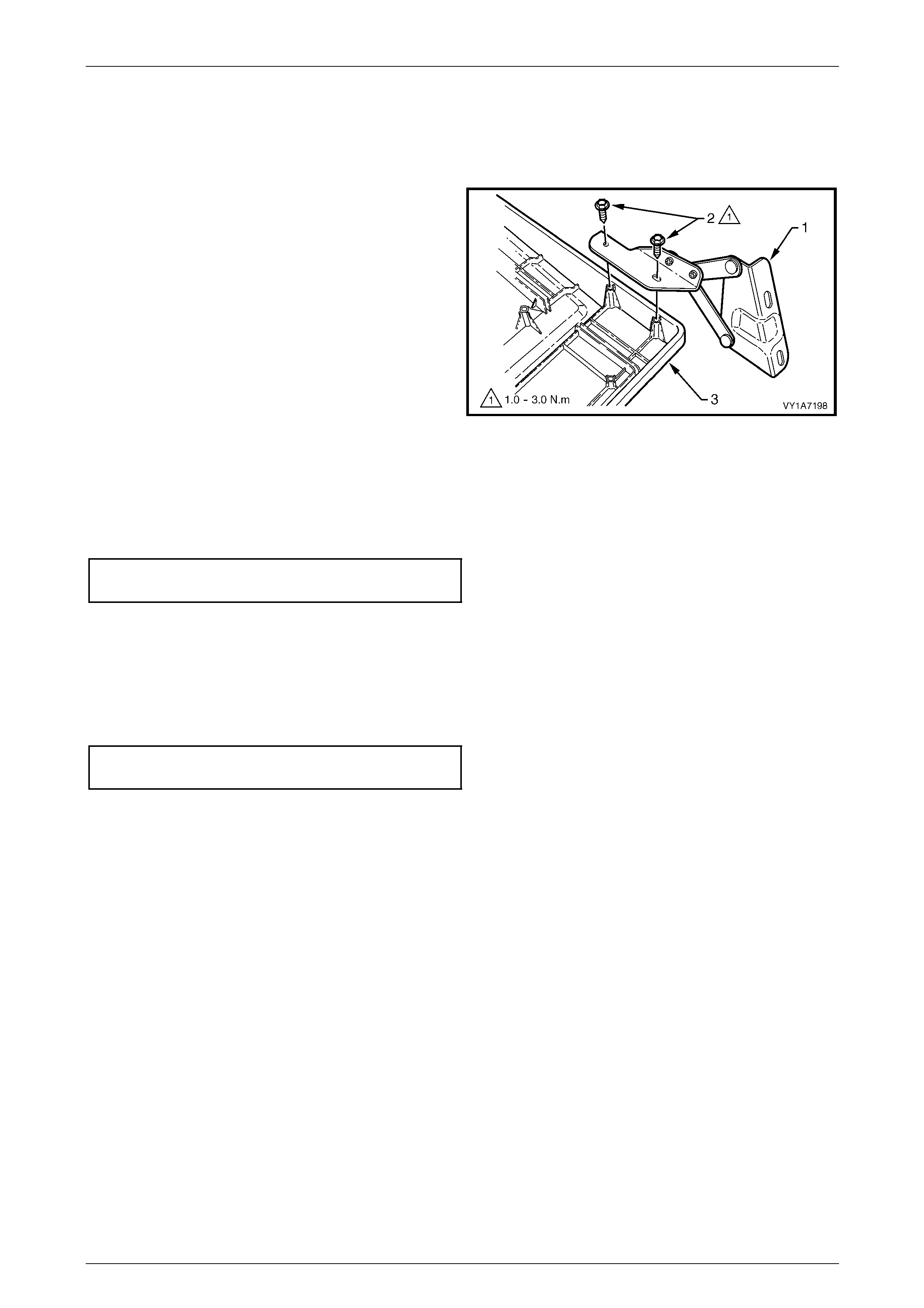

The driver’s seat in Level 5 vehicles is fitted with a memory

seat position system.

The memory seat position system allo ws the driver to adjust

the seat to any of the positions stored in memory by

pressing one of the three memory buttons (1).

In addition, on keyless entr y to the vehic le, the memory seat

position system through the Body Control Module (BCM),

recognises which ignition k ey has been used (Priority 1 or

Priority 2) and adjusts the seat position to the driver’s

preferred set position.

Audible and visual feedback for the various fu nctions of the

memory seat position system is provided. The s ystem has a

green LED and a chime which are used to i ndicate memory

saves, the recall of priority memory numbers and for seat

diagnostic procedures.

Hall-effect sensors integrated into each of the motor

assemblies are used to monit or the positi on of the seat.

Figure 1A7 – 3

The seat memory module, mounted under the front seat, has a non-volatile memory. While disconnecting the battery will

not erase the seat memory settings, the seat will require recalibrating to reset the sensor stop values within the memory