Body Control Module Page 12J–1

Page 12J–1

Section 12J

Body Control Module

ATTENTION

Before performing any service operation or other procedure described in this section, refer to Section 00

Warnings, Cautions and Notes for correct w orkshop practices with regard to safety and/or property damage.

1 General Information.............................................................................................................................10

1.1 Abbreviations....................................................................................................................................................... 10

1.2 Body Control Module........................................................................................................................................... 11

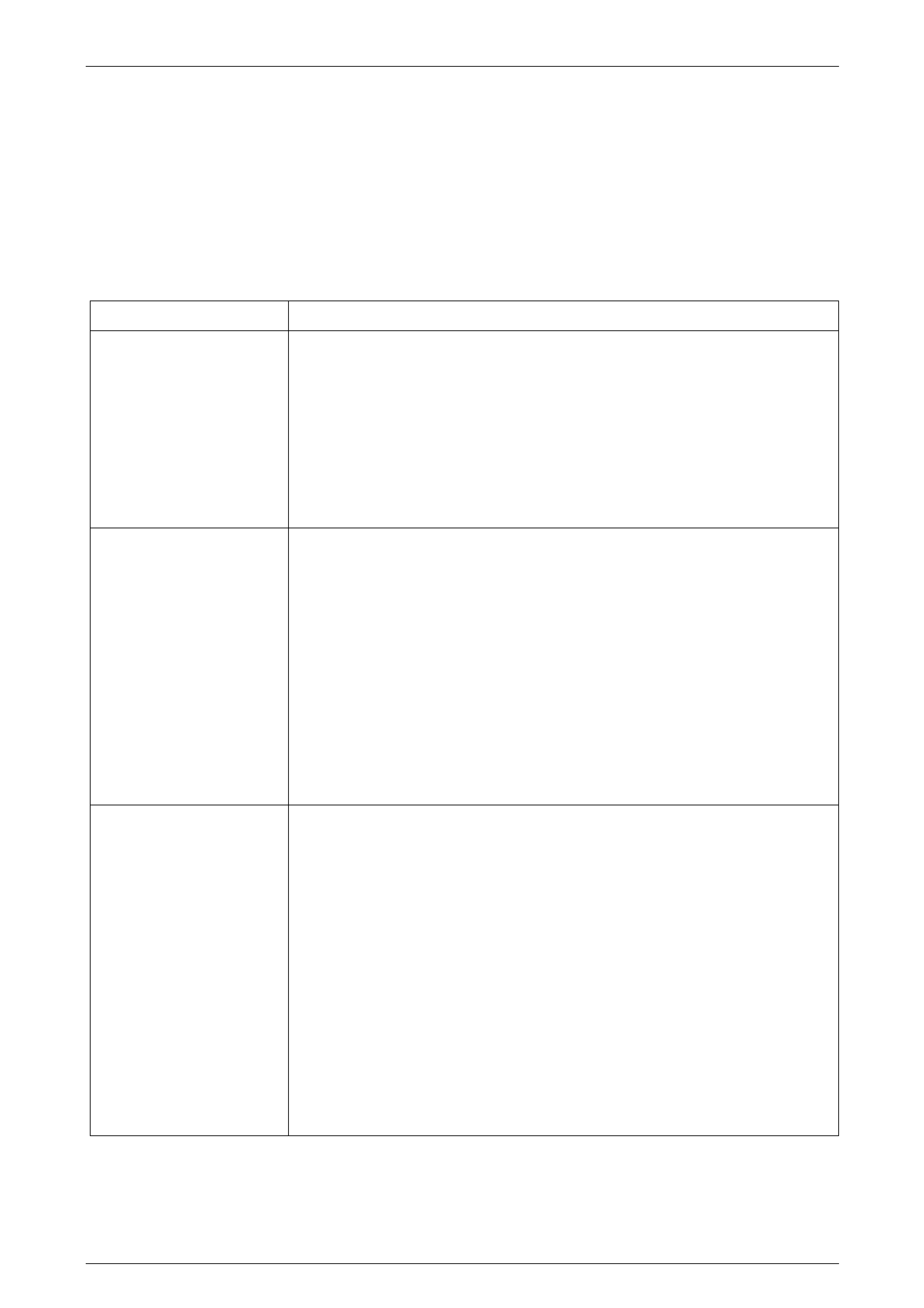

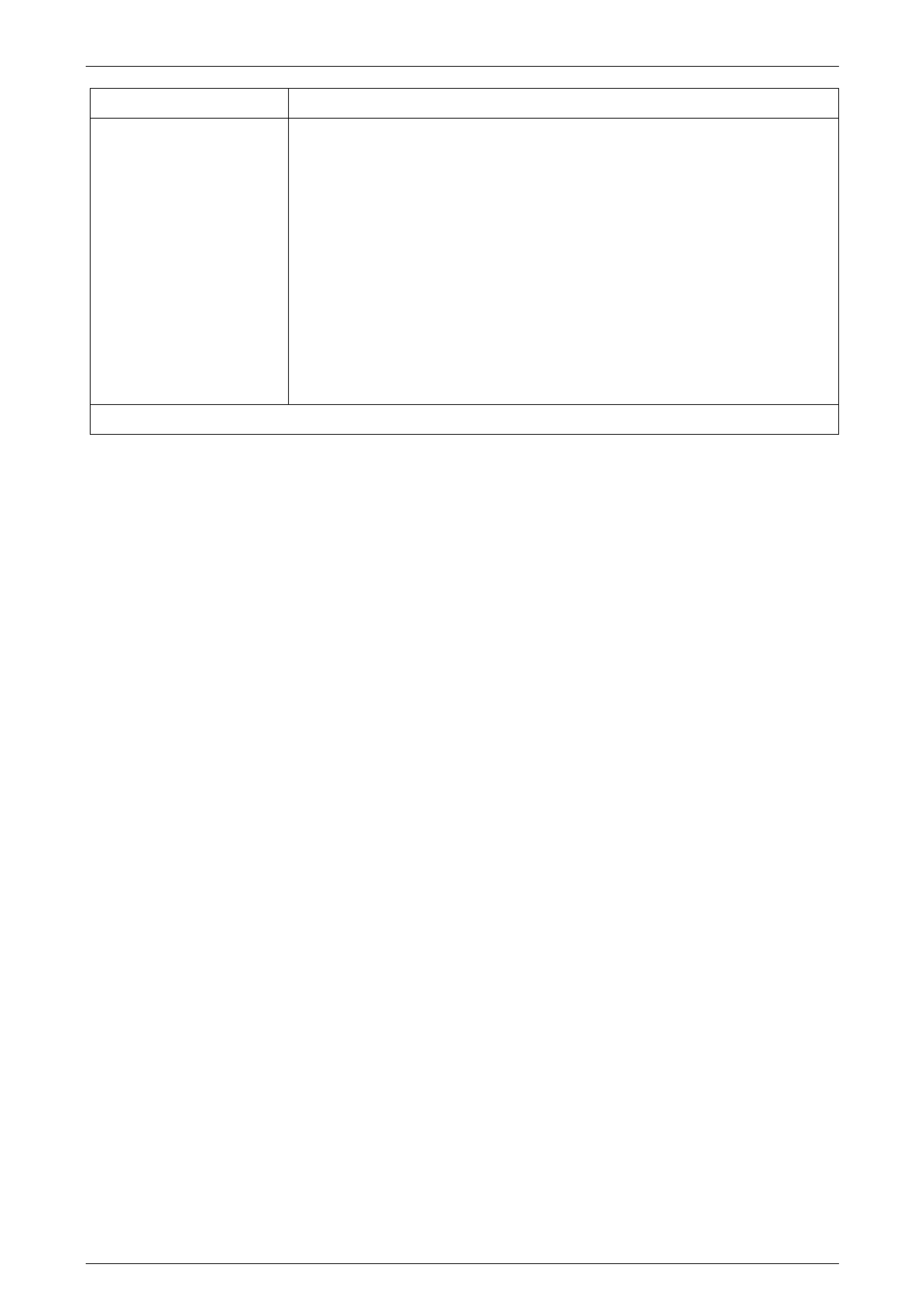

1.3 Body Control Module Models............................................................................................................................. 12

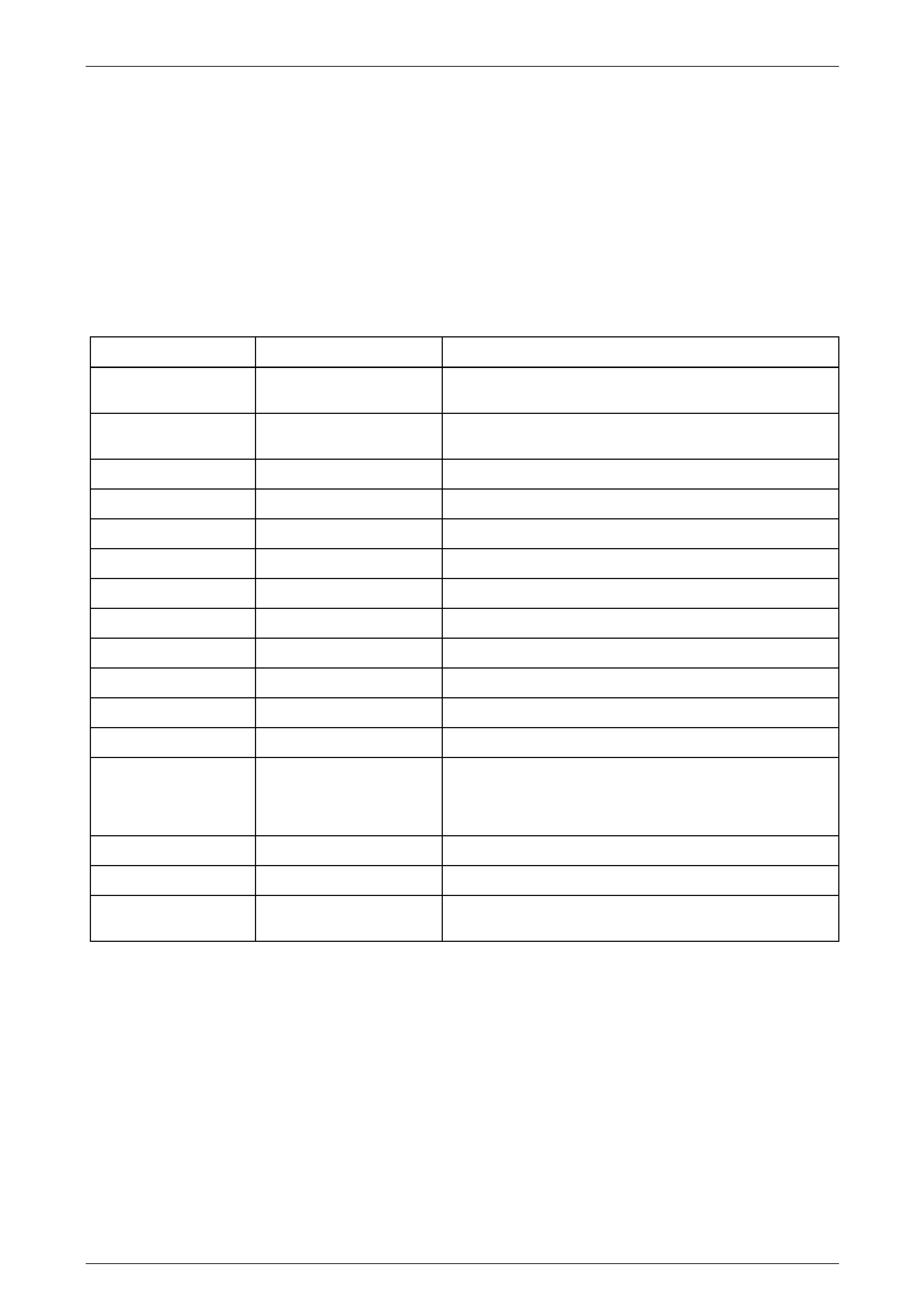

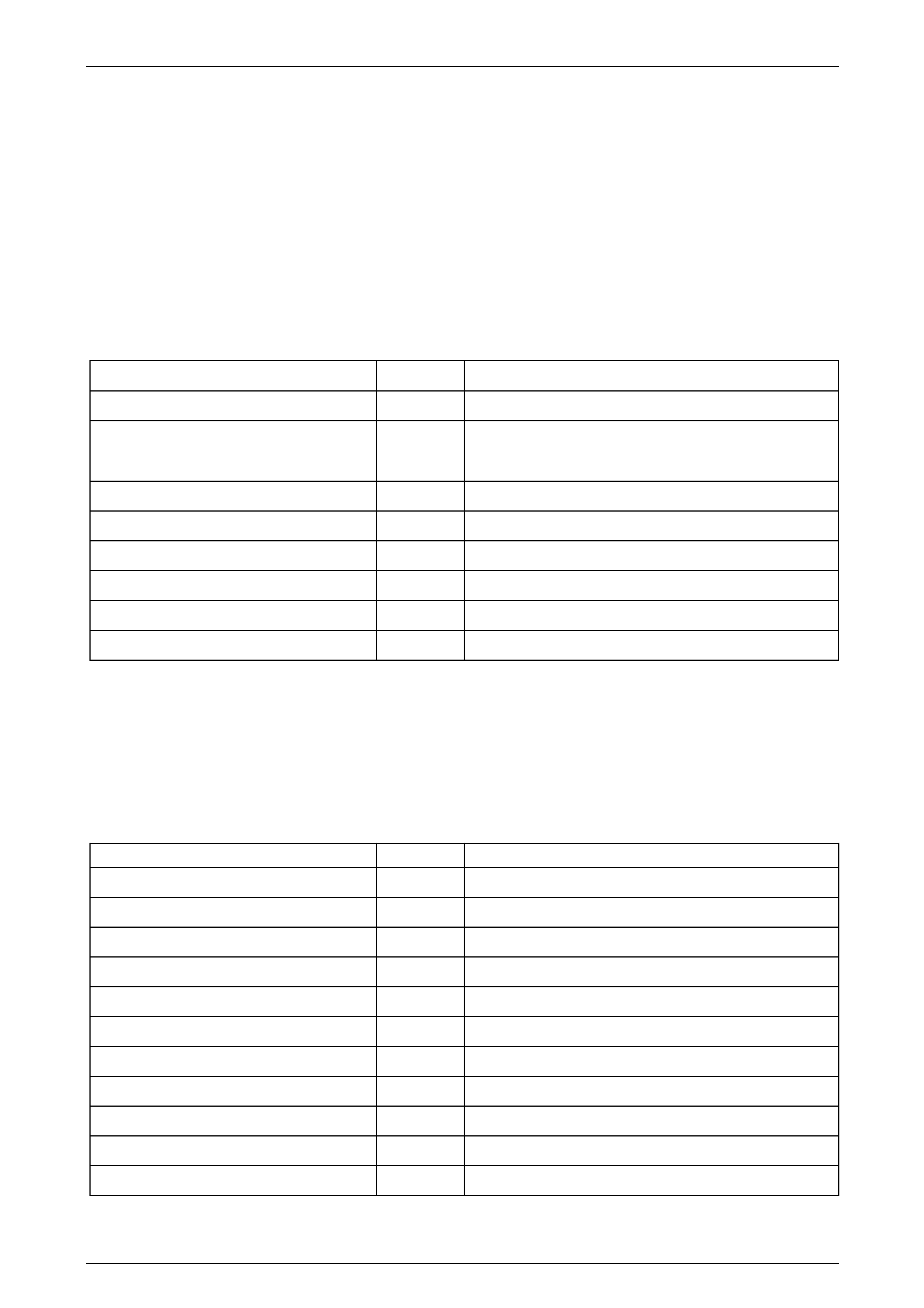

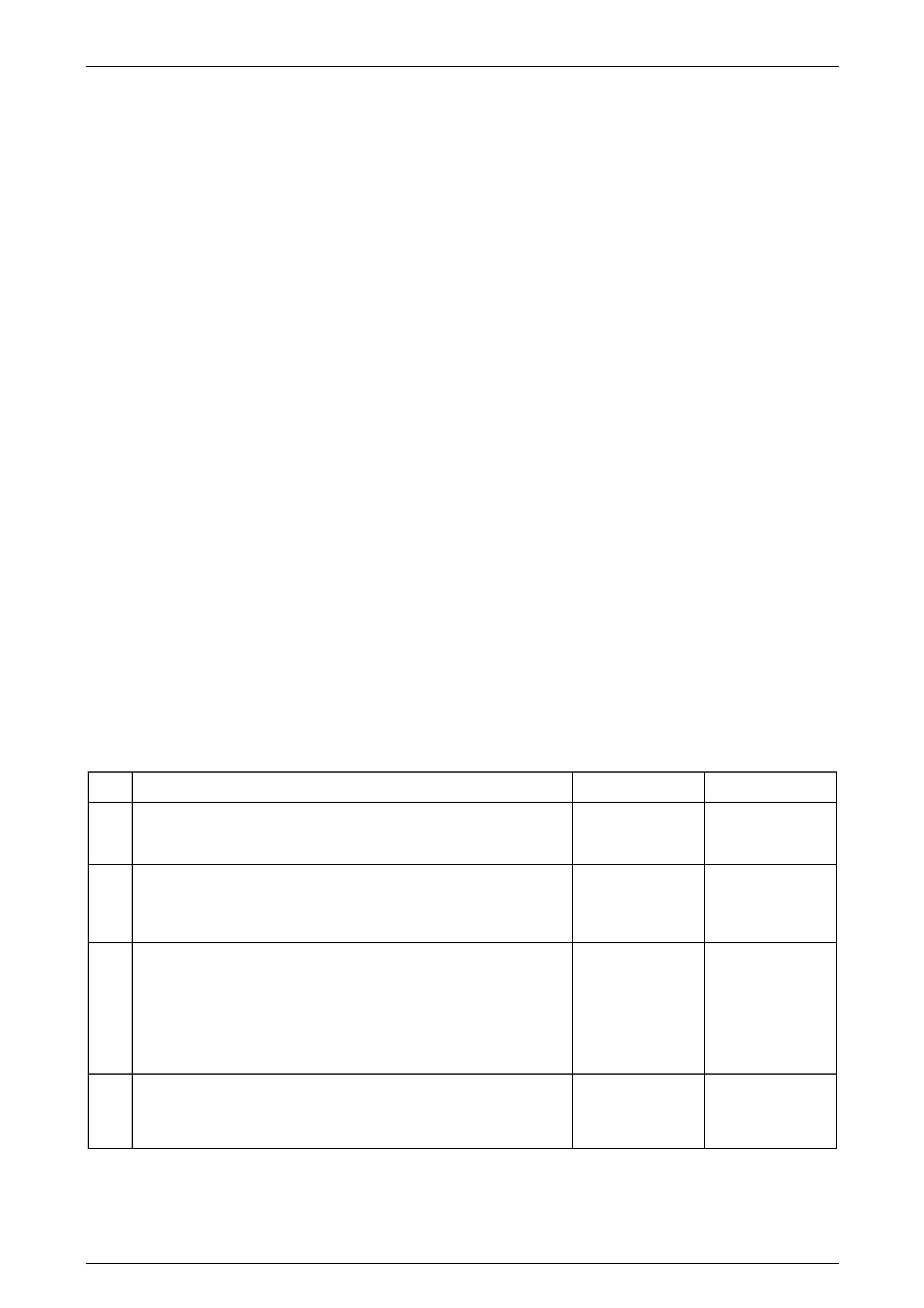

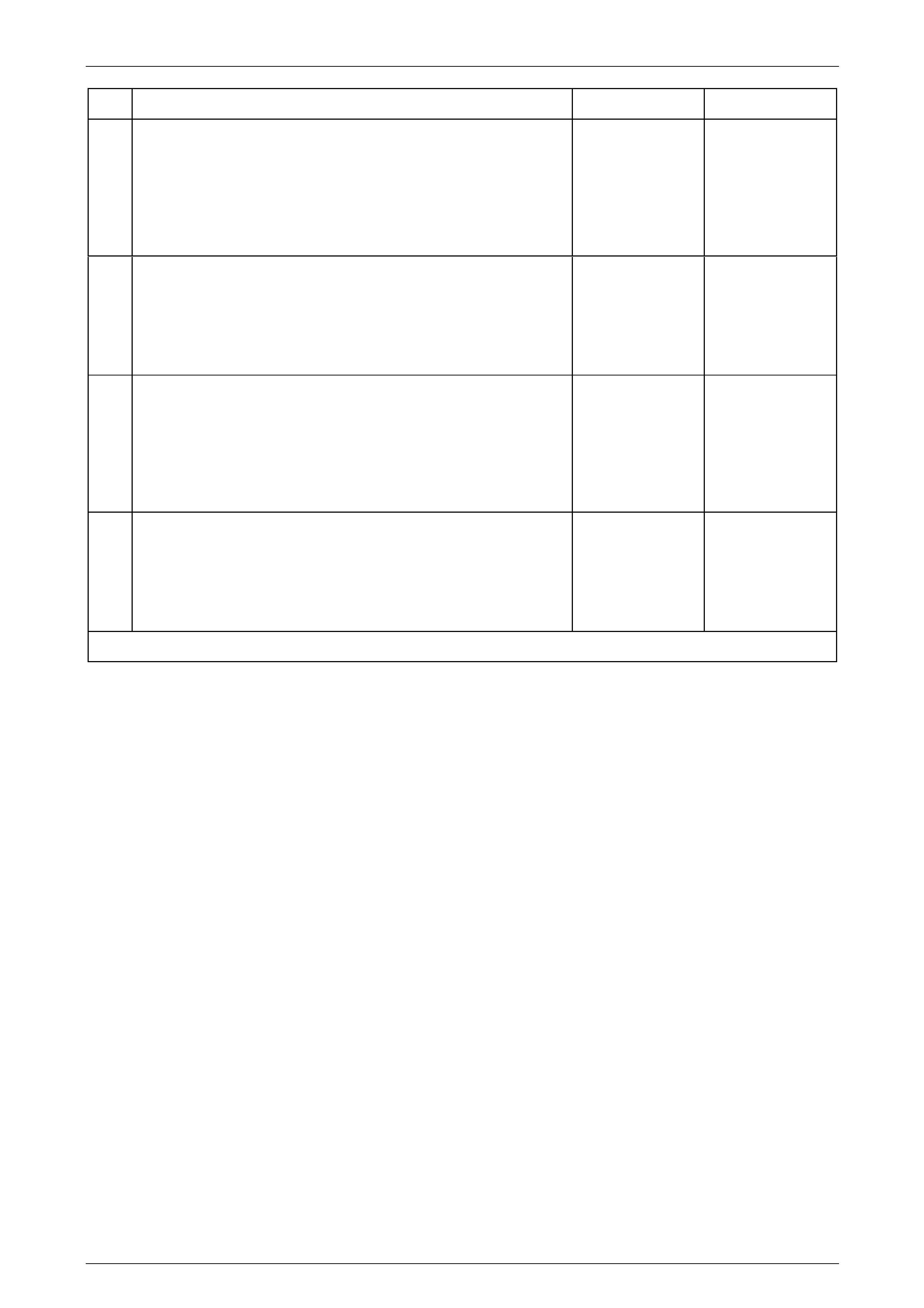

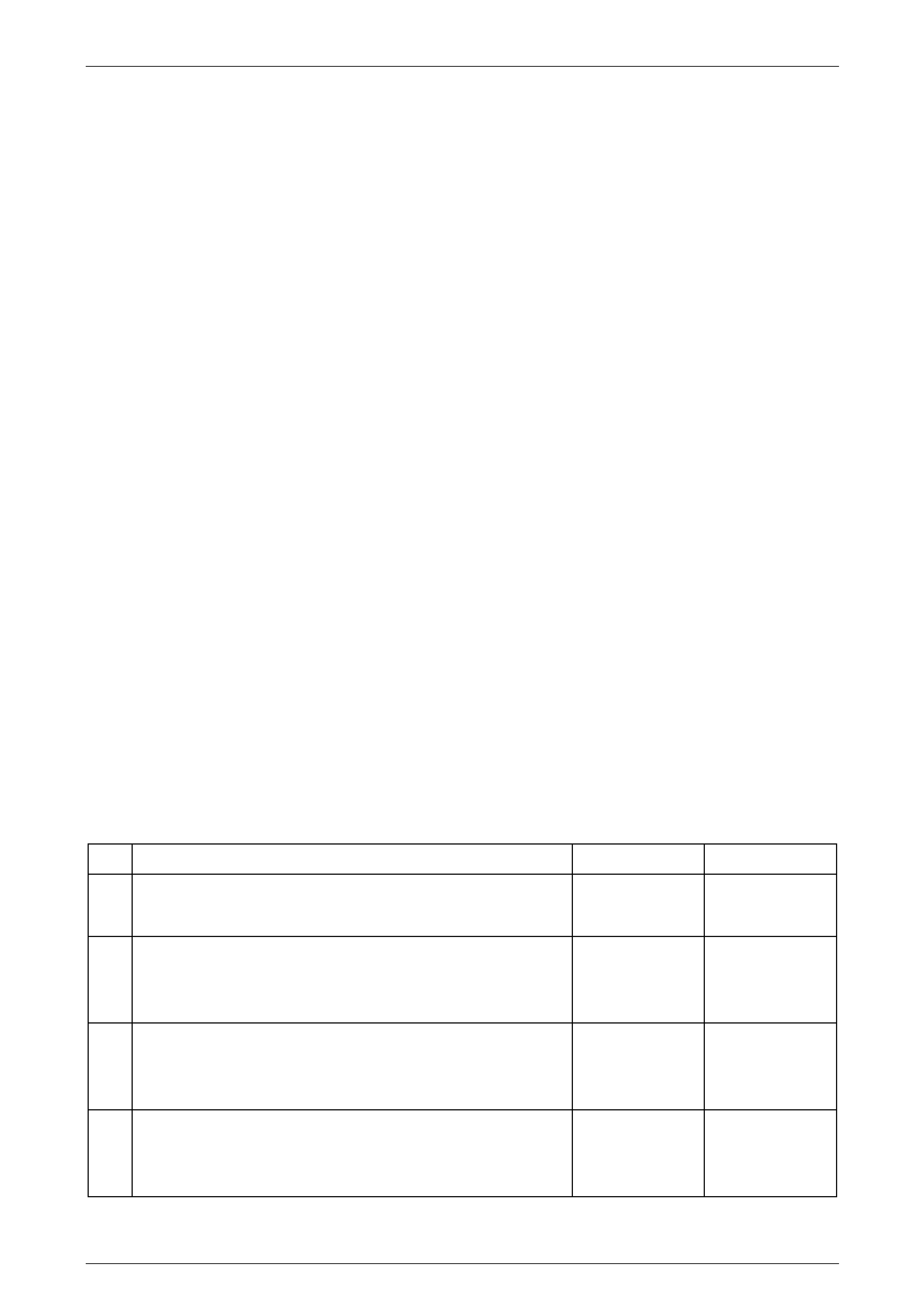

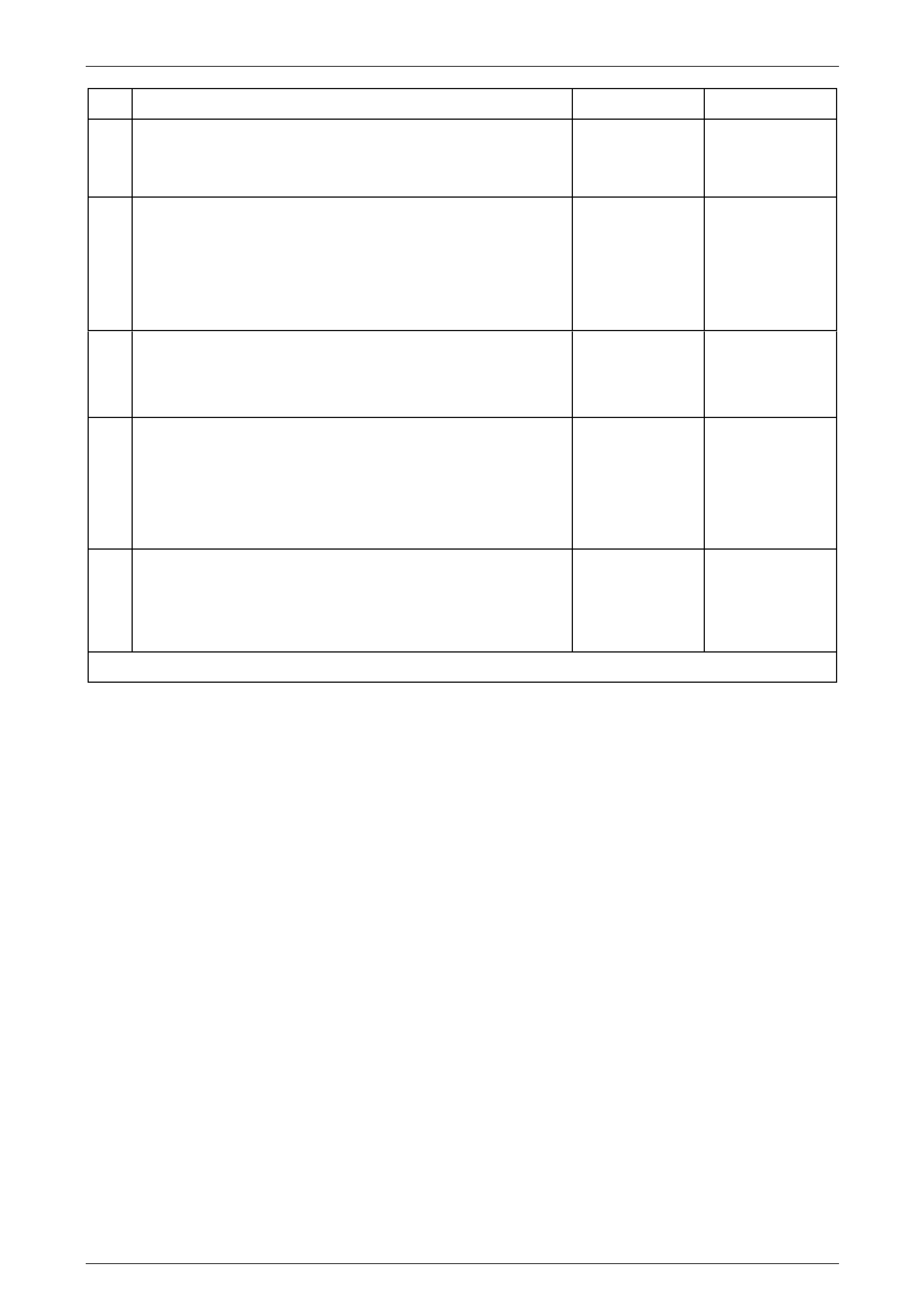

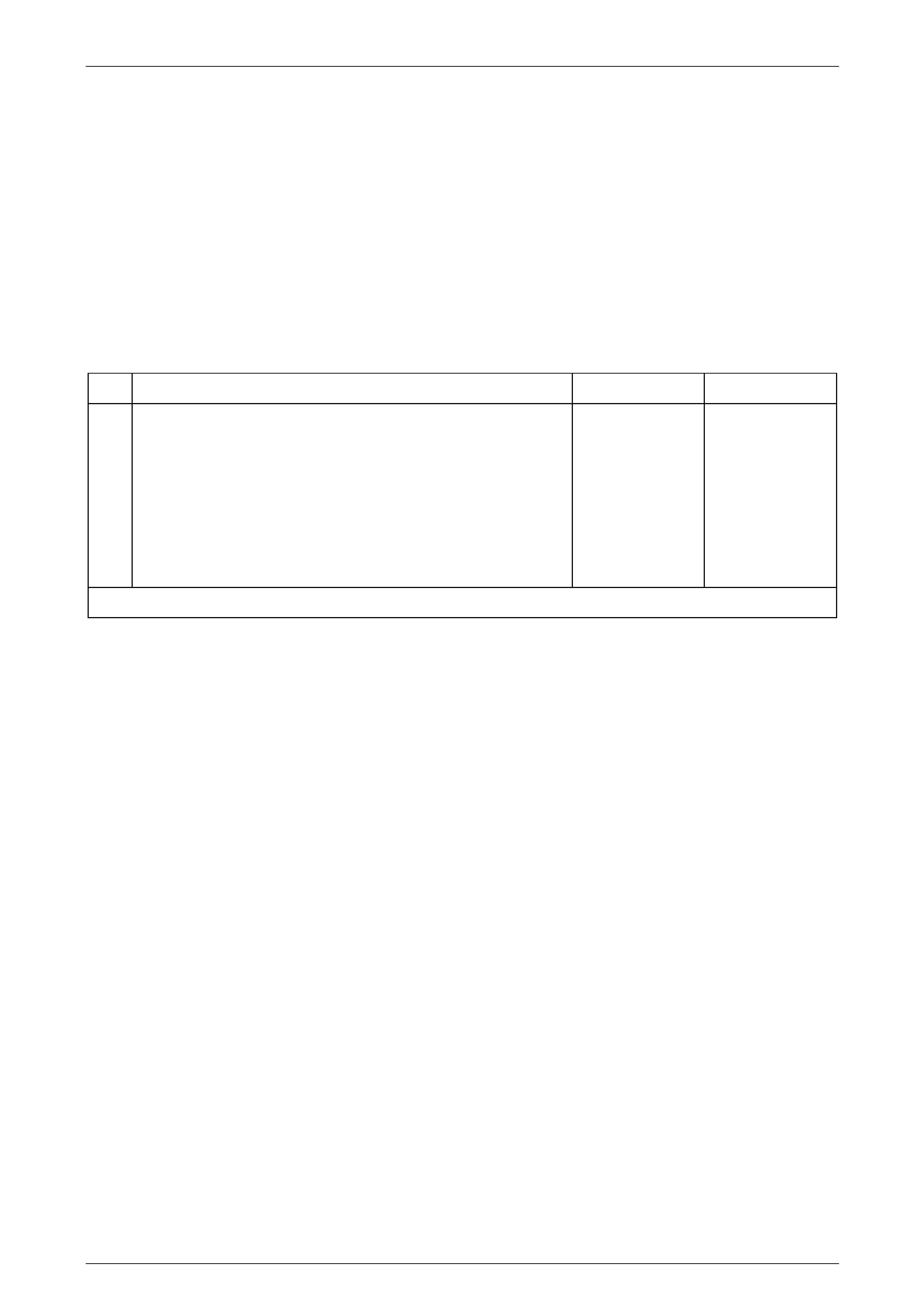

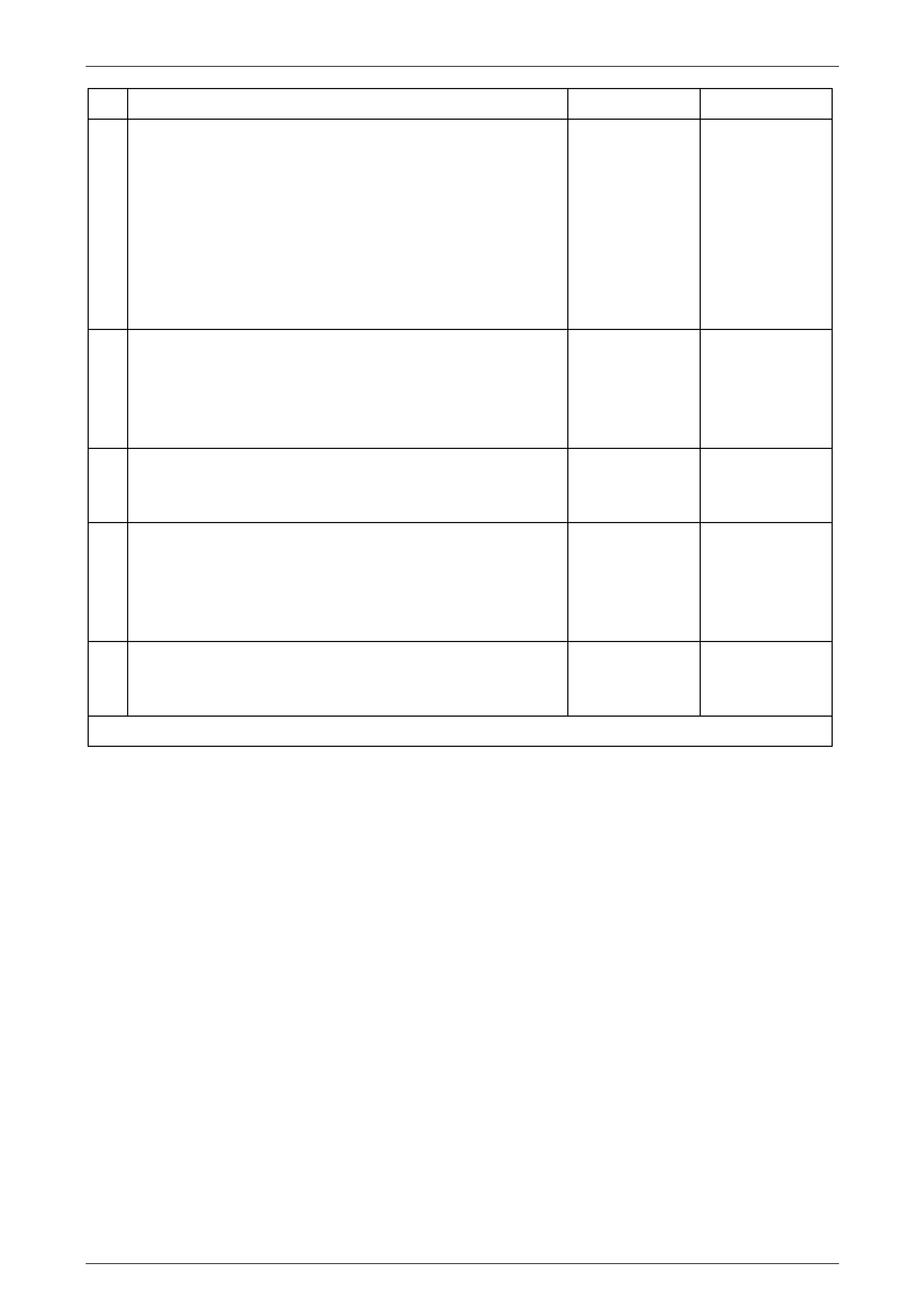

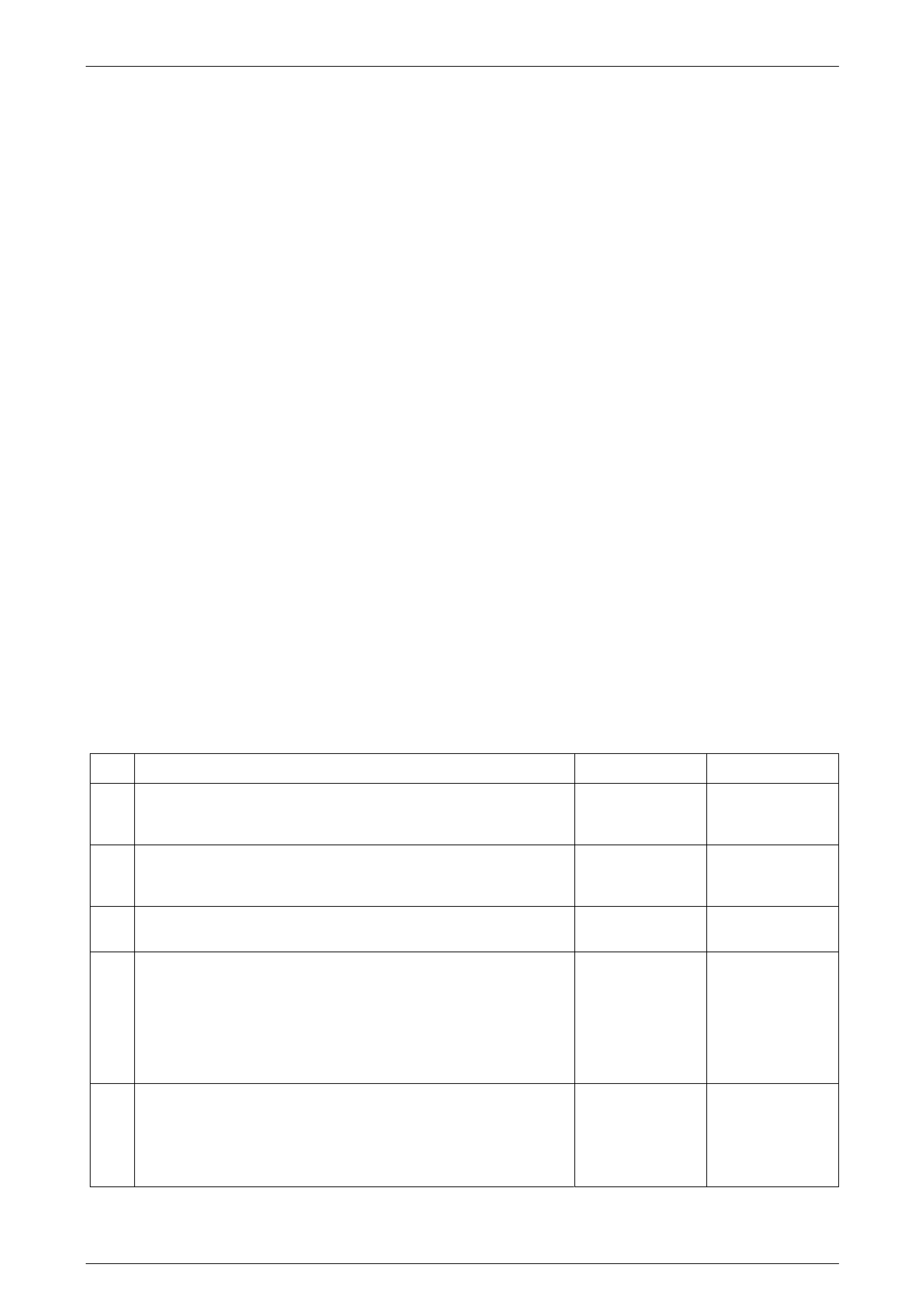

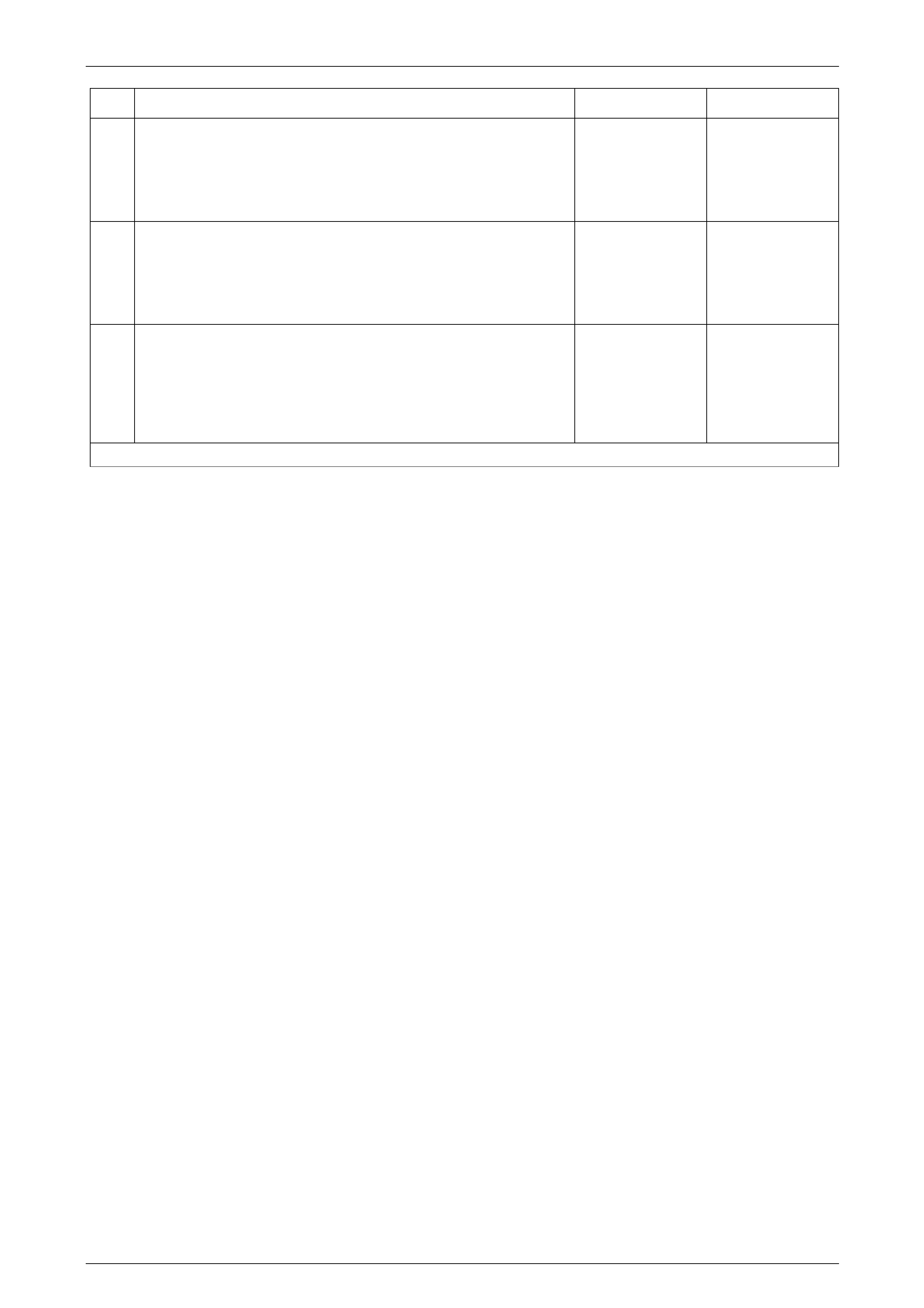

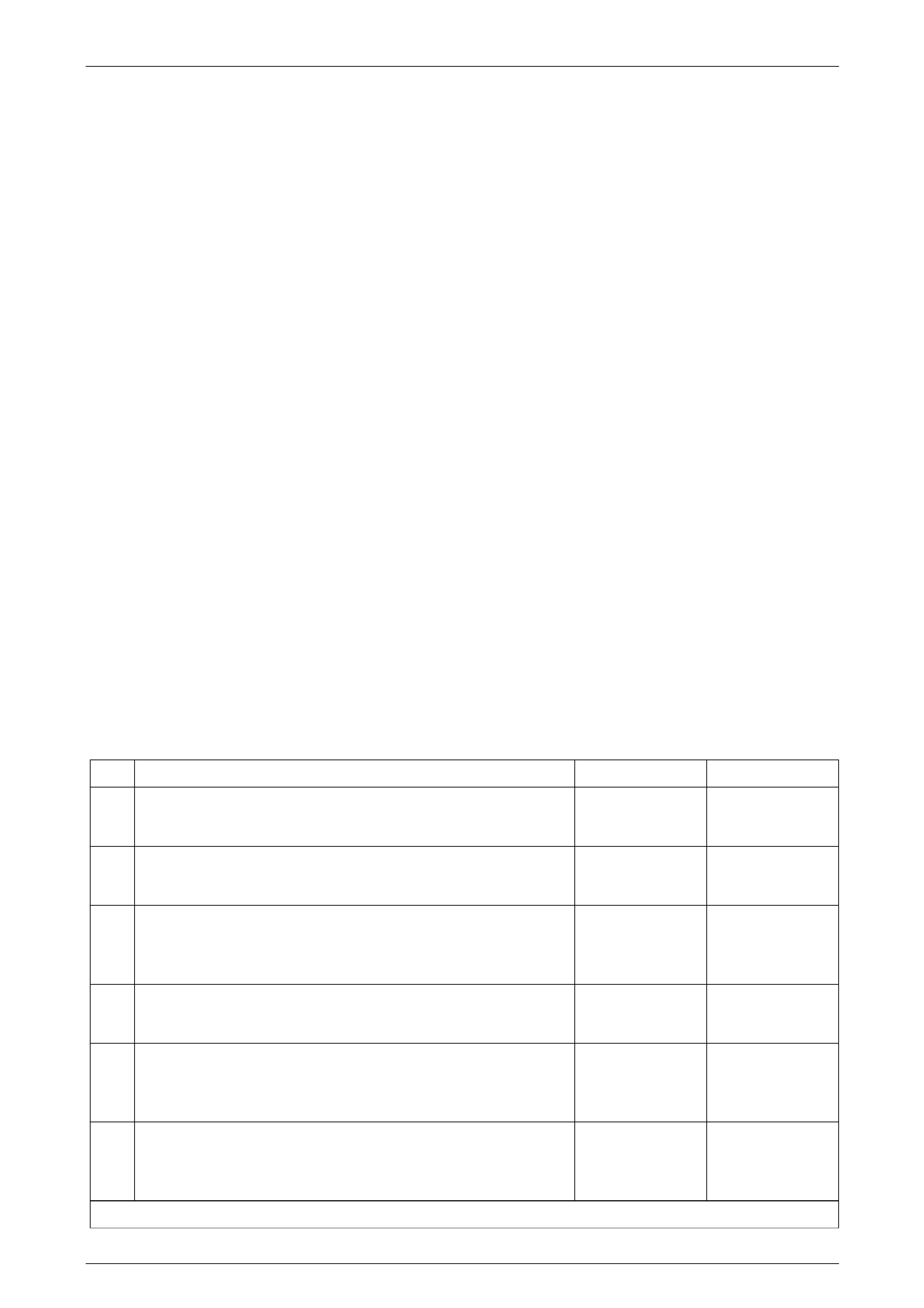

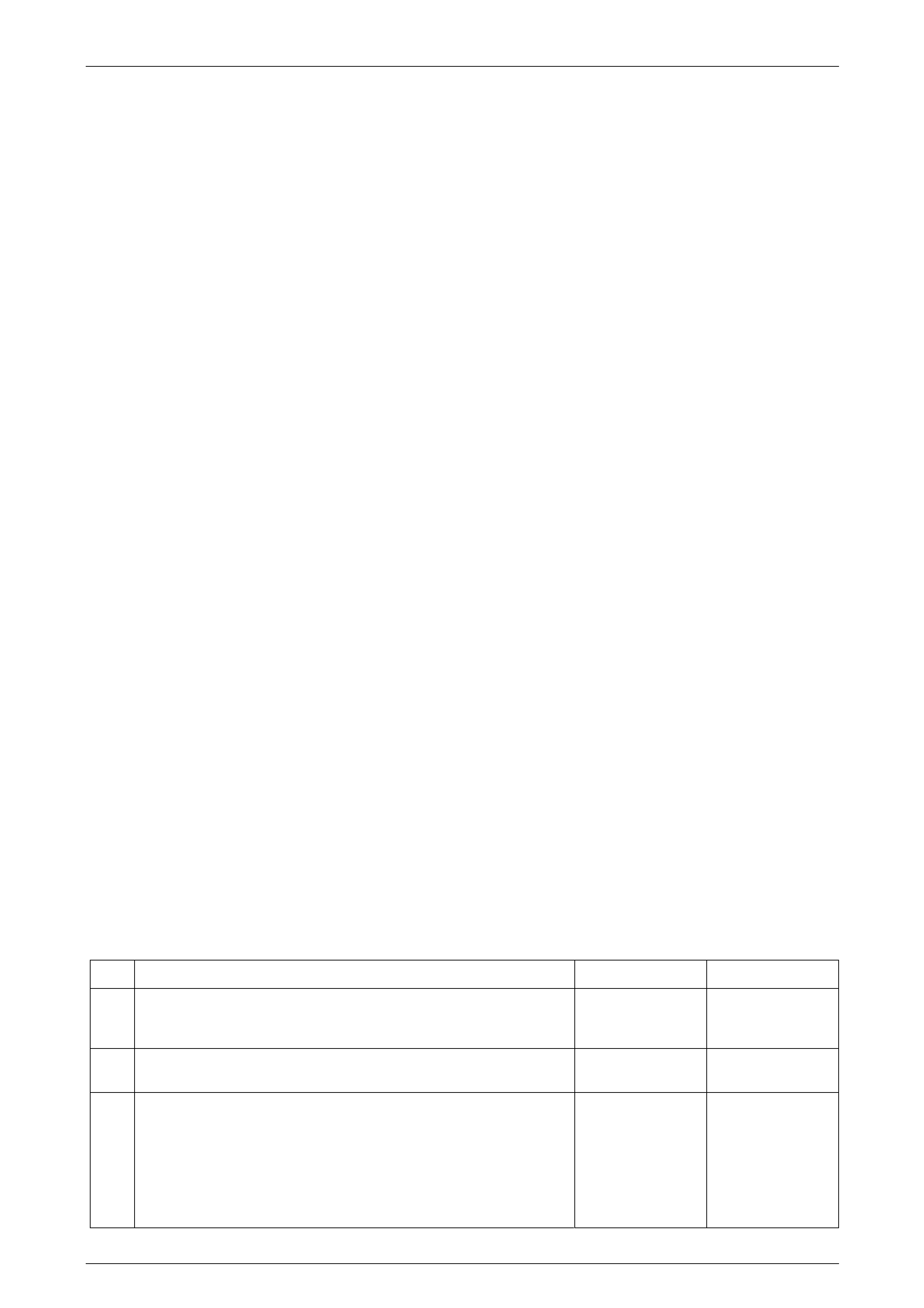

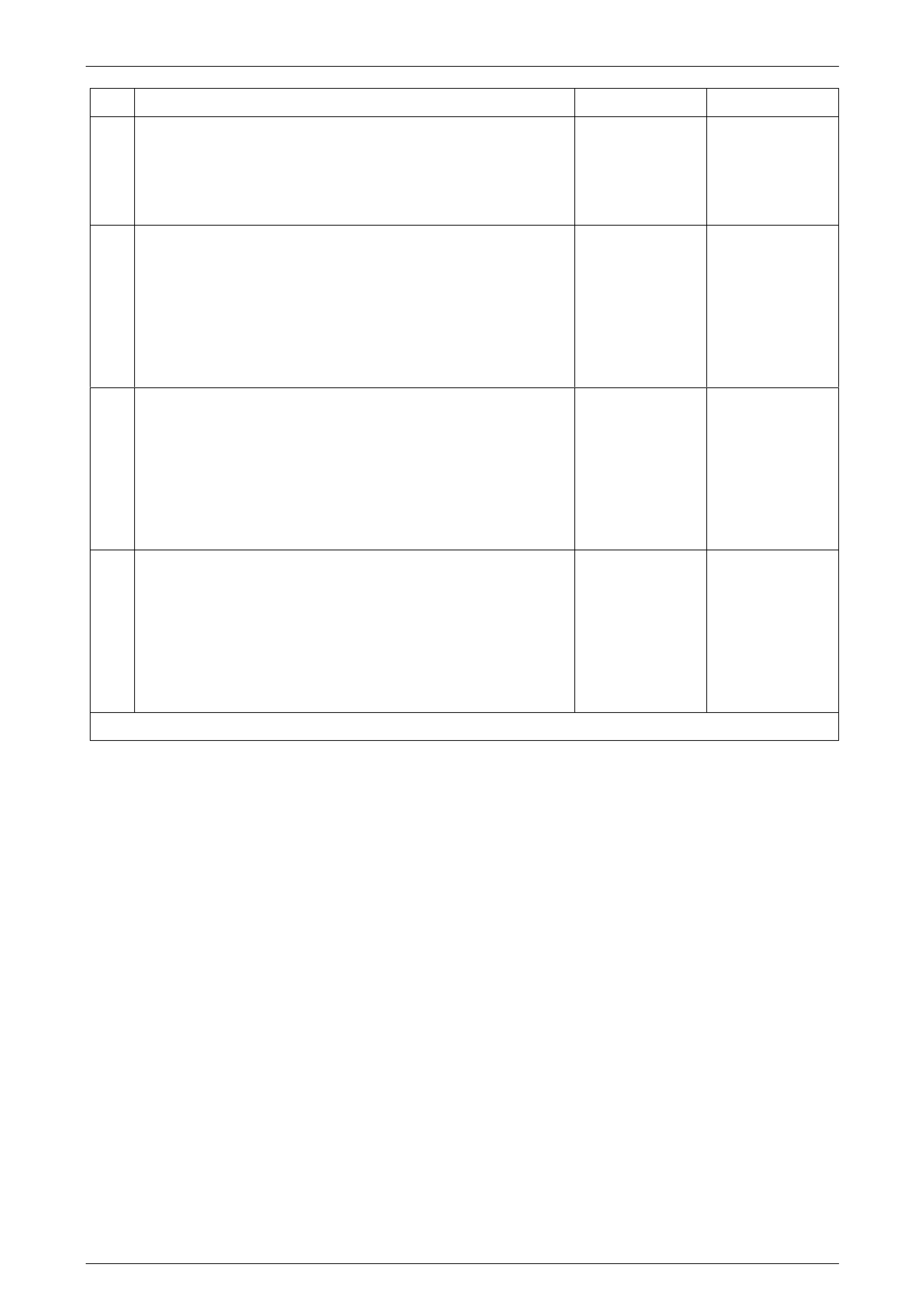

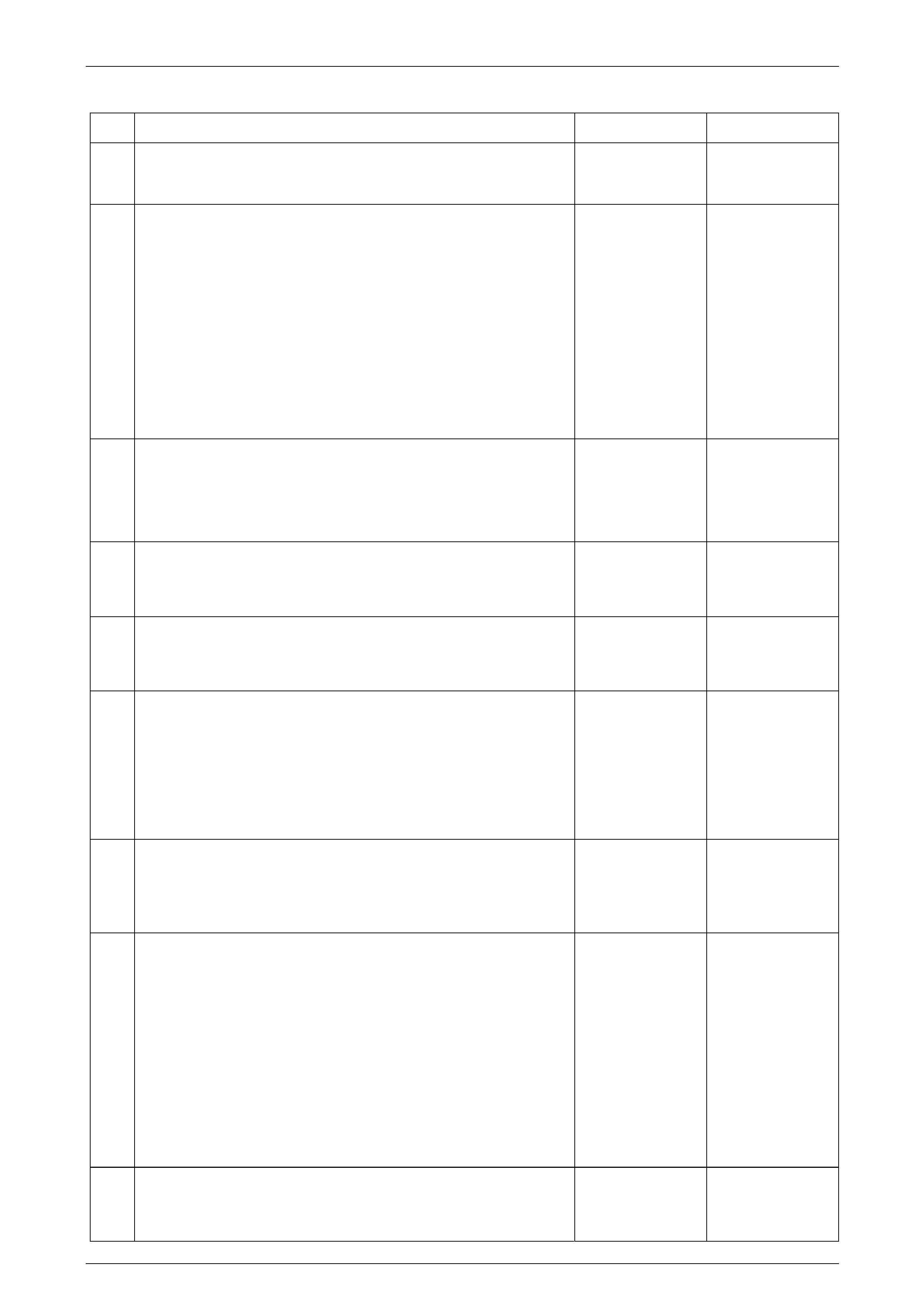

1.4 Body Control Module Features........................................................................................................................... 13

Feature Table Key................................................................................................................................................ 13

Feature Table........................................................................................................................................................ 13

2 System Operation.................................................................................................................................16

2.1 Body Control Module Operating Modes ............................................................................................................ 16

Battery Saver Mode.............................................................................................................................................. 16

Pre-delivery Mode................................................................................................................................................ 16

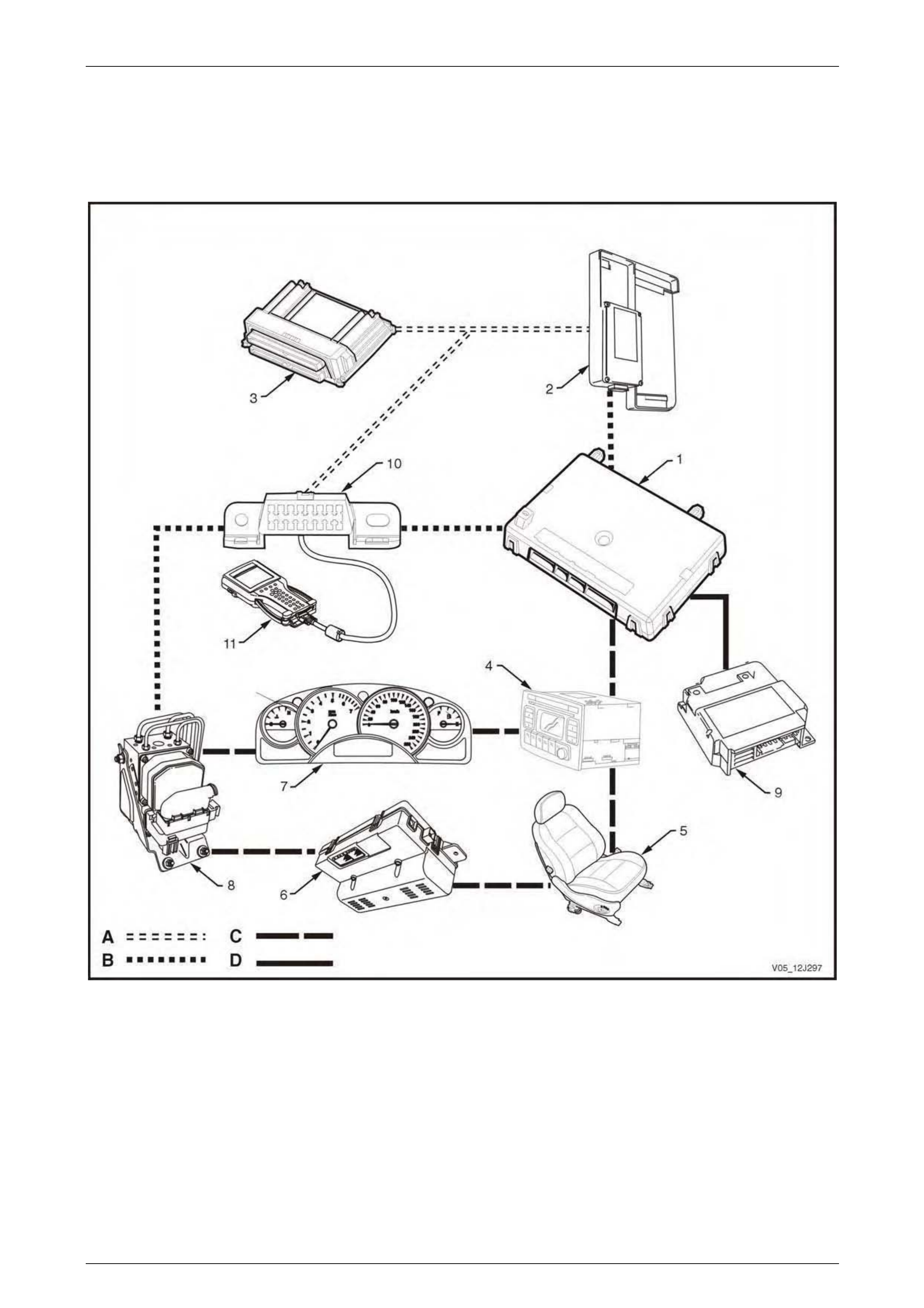

2.2 Serial Data Communication – V6........................................................................................................................ 17

System Overview ................................................................................................................................................. 17

V6 Serial Data Block Diagram.......................................................................................................................... 18

The GM LAN Bus System ................................................................................................................................ 19

UART Communications.................................................................................................................................... 19

Serial Data Bus ................................................................................................................................................ 19

Data Bus Device Polling................................................................................................................................... 20

Tech 2 and the Data Link Connector................................................................................................................ 20

Inputs and Outputs.............................................................................................................................................. 21

GM LAN Data Bus............................................................................................................................................ 21

Serial Data Signal – Primary UART.................................................................................................................. 21

Serial Data Signals – Secondary and Tertiary UART....................................................................................... 21

Data Bus Device Polling................................................................................................................................... 21

Data Messages ................................................................................................................................................ 21

Pow ertrain Interface Module............................................................................................................................... 21

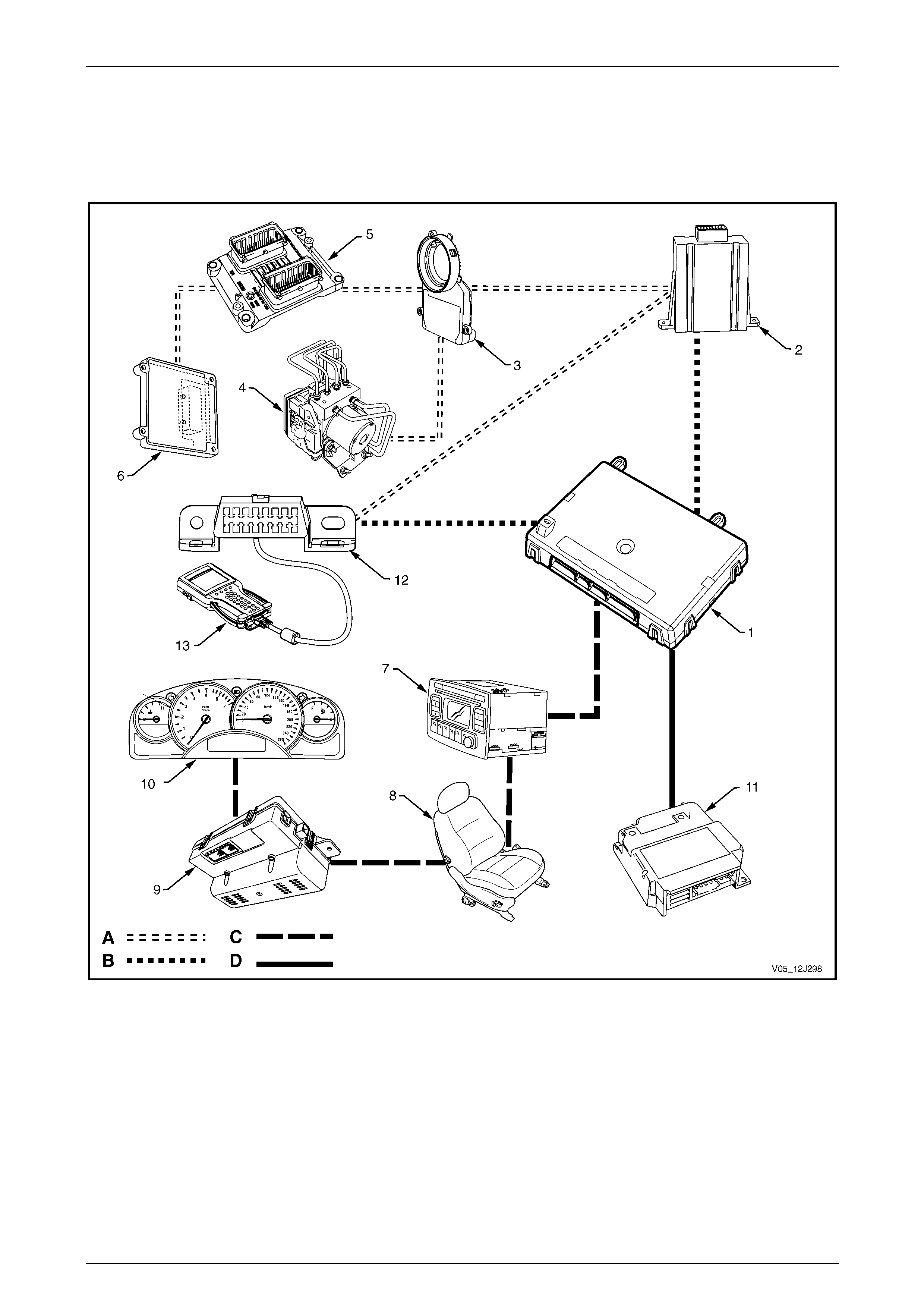

2.3 Serial Data Communication – GEN III V8........................................................................................................... 22

System Overview ................................................................................................................................................. 22

GEN III V8 Serial Data Block Diagram............................................................................................................. 23

UART and Class 2 Serial Data Bus.................................................................................................................. 24

Data Bus Device Polling................................................................................................................................... 24

Tech 2 and the Data Link Connector................................................................................................................ 25

Inputs and Outputs.............................................................................................................................................. 25

Class 2 Serial Data Signal................................................................................................................................ 25

Serial Data Signal – Primary UART.................................................................................................................. 25

Serial Data Signals – Secondary and Tertiary UART....................................................................................... 25

Data Bus Device Polling................................................................................................................................... 25

Data Messages ................................................................................................................................................ 25

Pow ertrain Interface Module............................................................................................................................... 26

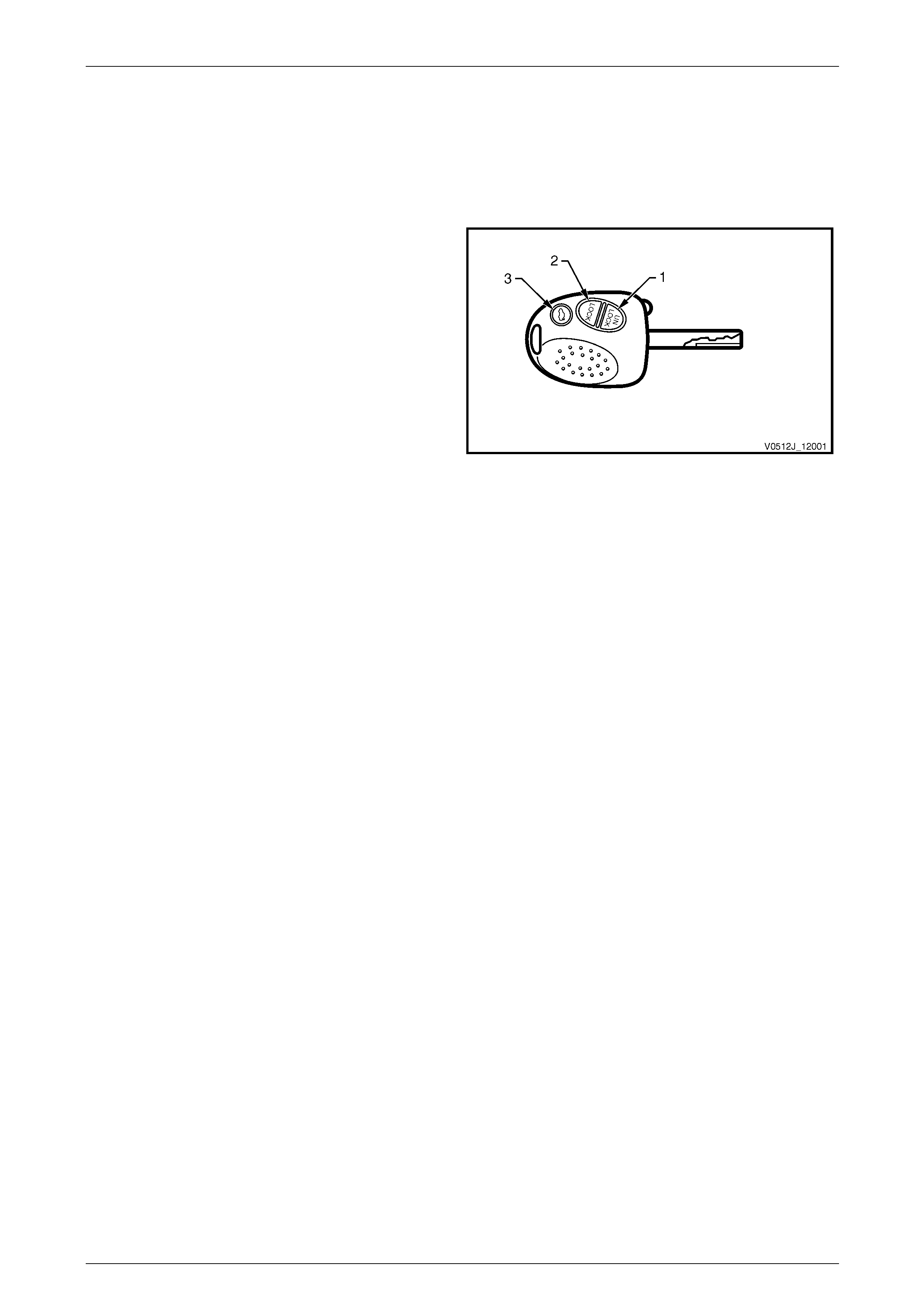

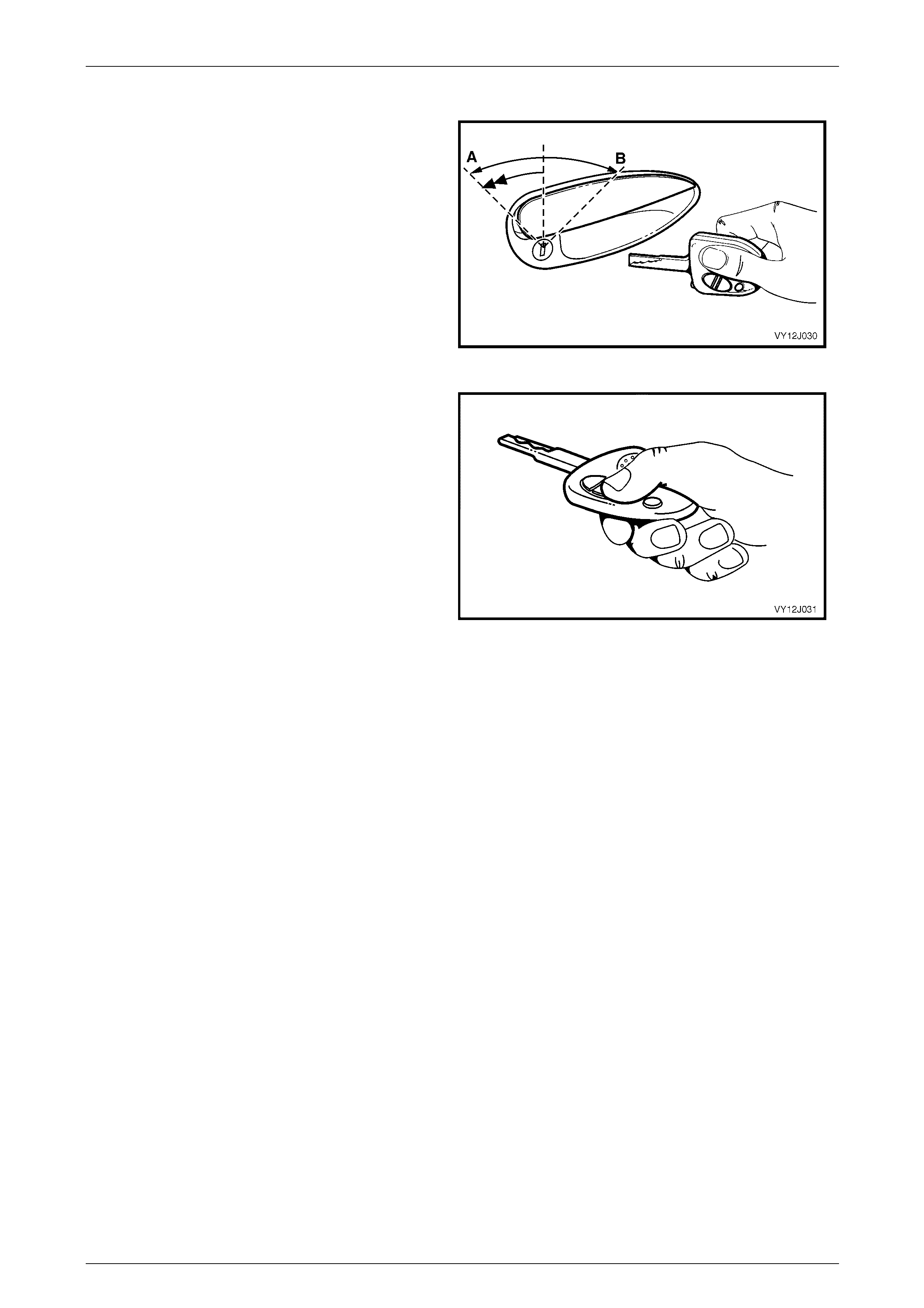

2.4 Remote Receiver / Key ........................................................................................................................................ 27

System Operation ................................................................................................................................................ 27

Unlocking.......................................................................................................................................................... 27

Locking............................................................................................................................................................. 27

Rear Compartment Lid Release....................................................................................................................... 27

Remote Coded Key Battery Failure.................................................................................................................. 27

Circuit Operation.................................................................................................................................................. 28

Techline

Techline

Techline

Techline

Body Control Module Page 12J–2

Page 12J–2

2.5 Accessory Power Control ................................................................................................................................... 29

System Operation ................................................................................................................................................ 29

Accessory Relay Shutdown Options................................................................................................................. 29

Wiper Control of the Accessory Relay.............................................................................................................. 29

Circuit Operation.................................................................................................................................................. 29

Radio On and Ignition Switch Input.................................................................................................................. 29

2.6 Central Door Locking .......................................................................................................................................... 31

System Operation ................................................................................................................................................ 31

Door Locking.................................................................................................................................................... 31

Door Unlocking................................................................................................................................................. 31

Deadlocking...................................................................................................................................................... 31

Single-stage and Two-stage Unlocking............................................................................................................ 32

System Check ...................................................................................................................................................... 33

Key Locking...................................................................................................................................................... 33

Remote Coded Key Check............................................................................................................................... 33

Deadlocking Check .......................................................................................................................................... 33

Door-lock Failure Warning................................................................................................................................ 33

Auto Door-lock in Drive .................................................................................................................................... 33

Overheating Prevention.................................................................................................................................... 34

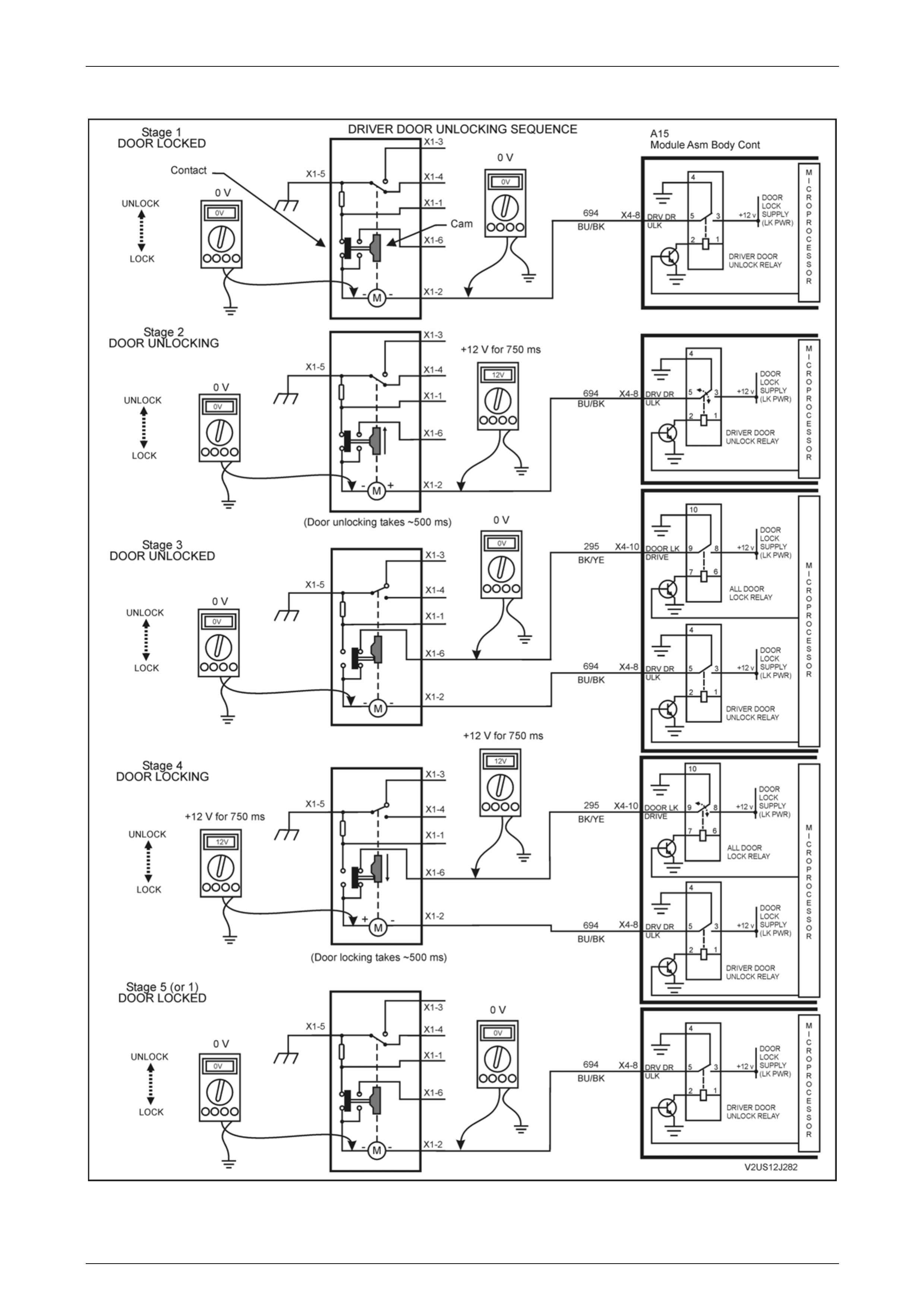

Functional Description of Door Locking/Unlocking Operation........................................................................... 34

Functional Diagram of Door Locking/Unlocking Operation............................................................................... 35

Circuit Operation.................................................................................................................................................. 36

Unlocking.......................................................................................................................................................... 36

Locking............................................................................................................................................................. 37

Door Input Signals............................................................................................................................................ 37

2.7 Rear Compartment Lid Release.......................................................................................................................... 38

System Operation ................................................................................................................................................ 38

Circuit Operation.................................................................................................................................................. 38

Battery Power................................................................................................................................................... 38

Inputs ............................................................................................................................................................... 38

Outputs............................................................................................................................................................. 39

2.8 Theft Deterrent System........................................................................................................................................ 40

System Operation ................................................................................................................................................ 40

V6 Engine......................................................................................................................................................... 40

GEN III V8 Engine............................................................................................................................................ 40

Battery.............................................................................................................................................................. 41

Security Status Indicator................................................................................................................................... 41

Circuit Operation.................................................................................................................................................. 41

Battery Power................................................................................................................................................... 41

Turn Signal Lamp Power.................................................................................................................................. 41

Inputs ............................................................................................................................................................... 42

Outputs............................................................................................................................................................. 42

2.9 Entry Deterrent System....................................................................................................................................... 43

System Operation ................................................................................................................................................ 43

Arming the System........................................................................................................................................... 43

Triggered Operation......................................................................................................................................... 43

Disarming Procedure........................................................................................................................................ 44

Multi-function Display (MFD) Trigger Point Displays ........................................................................................ 44

Remote Rear Compartment Release ............................................................................................................... 44

Loss of Vehicle Battery Power .......................................................................................................................... 44

Circuit Operation.................................................................................................................................................. 45

Power Supplies ................................................................................................................................................ 45

Inputs ............................................................................................................................................................... 45

Outputs............................................................................................................................................................. 46

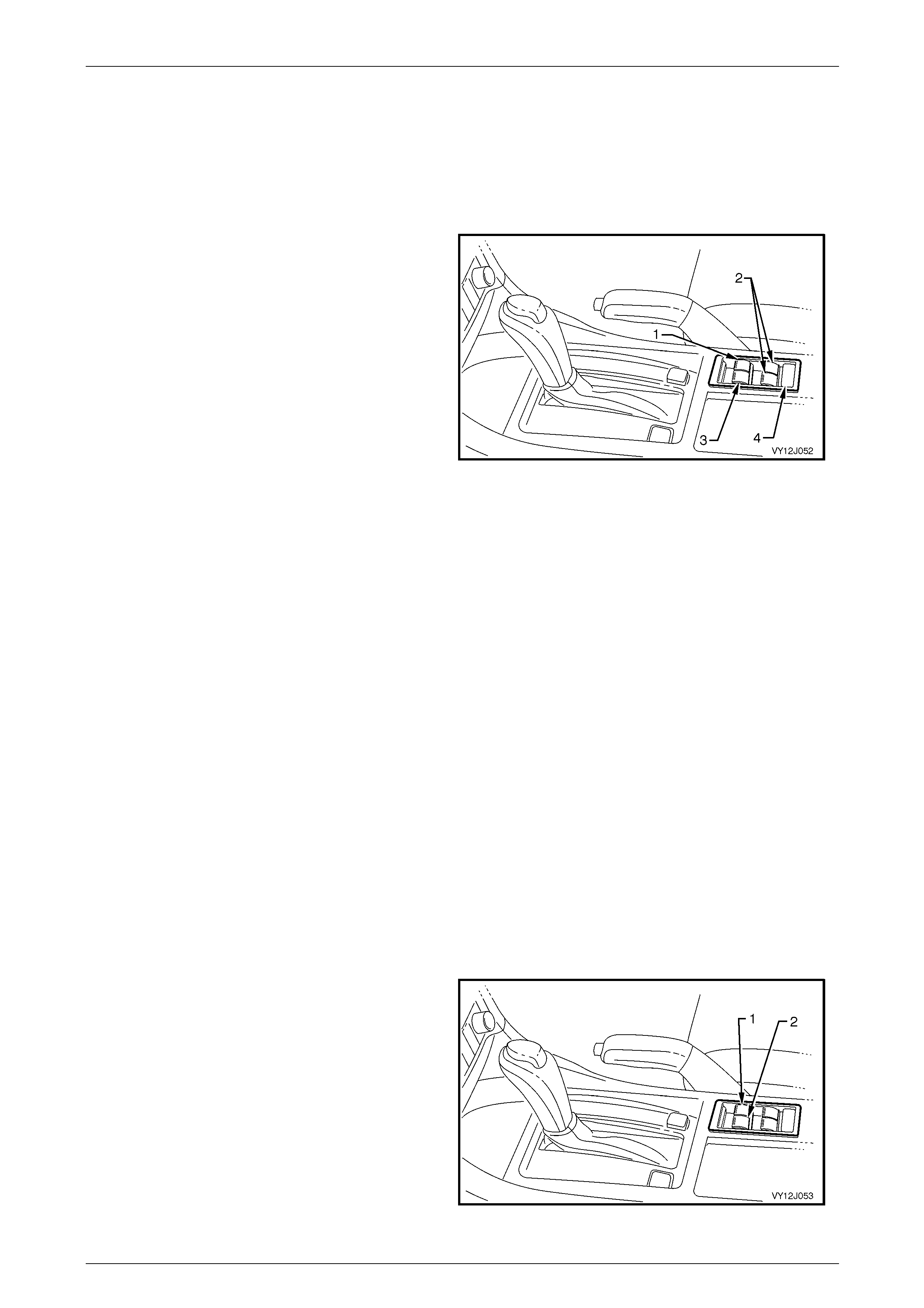

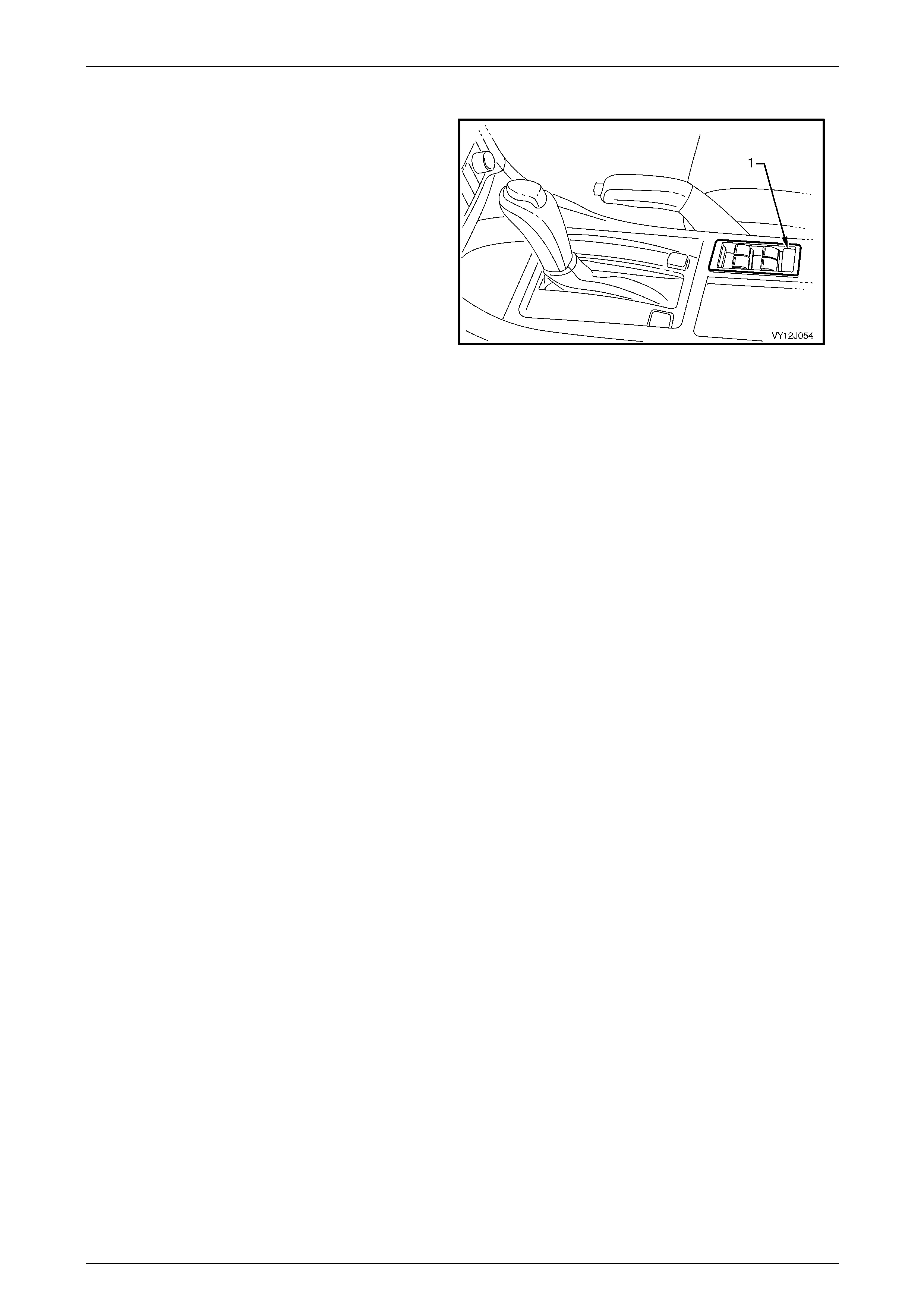

2.10 Power Window System ....................................................................................................................................... 47

System Operation ................................................................................................................................................ 47

System Active................................................................................................................................................... 47

System Inactive................................................................................................................................................ 47

Automatic Down Operation of Front Windows.................................................................................................. 47

Lockout Switch................................................................................................................................................. 48

Body Control Module Page 12J–3

Page 12J–3

Circuit Operation.................................................................................................................................................. 48

Ignition ON Input Signal ................................................................................................................................... 48

Driver and Front Passenger Window-down Circuit........................................................................................... 48

Driver and Front Passenger Window-up Circuit................................................................................................ 49

Rear Passenger Window Operation................................................................................................................. 49

2.11 Wiper System Intermittent Function .................................................................................................................. 50

System Operation ................................................................................................................................................ 50

Circuit Operation.................................................................................................................................................. 50

Intermittent Wiper Switch.................................................................................................................................. 50

Wiper Dwell Controller...................................................................................................................................... 51

Vehicle Speed and Reverse Gear.................................................................................................................... 51

Window Washer Switch.................................................................................................................................... 51

2.12 Dome Lamp Delay Control.................................................................................................................................. 52

System Operation ................................................................................................................................................ 52

Circuit Operation.................................................................................................................................................. 52

Inputs ............................................................................................................................................................... 52

2.13 Automatic Lamp Control..................................................................................................................................... 54

System Operation ................................................................................................................................................ 54

Automatic Lights On......................................................................................................................................... 54

Automatic Lights Off......................................................................................................................................... 54

Approach Illumination....................................................................................................................................... 55

Circuit Operation – Lights On............................................................................................................................. 55

Inputs ............................................................................................................................................................... 55

Power Supplies ................................................................................................................................................ 55

Ground Circuits ................................................................................................................................................ 56

Circuit Operation – Lights Off............................................................................................................................. 56

Inputs ............................................................................................................................................................... 56

Power Supplies ................................................................................................................................................ 56

Ground Circuits ................................................................................................................................................ 57

2.14 Instrument Dimming Control .............................................................................................................................. 58

System Operation ................................................................................................................................................ 58

Circuit Operation.................................................................................................................................................. 58

Inputs ............................................................................................................................................................... 59

2.15 Occupant Protection System Deployment Vehicle Shutdown......................................................................... 60

System Operation ................................................................................................................................................ 60

OPS Deployment Signals................................................................................................................................. 60

2.16 Priority Key System............................................................................................................................................. 61

Operating Parameters ......................................................................................................................................... 61

Parameter Checks............................................................................................................................................ 61

Circuit Operation.................................................................................................................................................. 62

2.17 Pow er Antenna Control....................................................................................................................................... 63

System Operation ................................................................................................................................................ 63

Power Antenna................................................................................................................................................. 63

Circuit Operation.................................................................................................................................................. 64

Antenna Up Switch Input Signal....................................................................................................................... 64

Antenna Up Memory Height............................................................................................................................. 64

Antenna Down.................................................................................................................................................. 64

Antenna Auto Down.......................................................................................................................................... 64

2.18 Rear Lamp Failure Warning System................................................................................................................... 65

System Operation ................................................................................................................................................ 65

Components Monitored.................................................................................................................................... 65

Circuit Operation.................................................................................................................................................. 66

Ground Circuit Monitoring................................................................................................................................. 66

Rear Lamp Failure Warning Lamp ................................................................................................................... 66

Inputs ............................................................................................................................................................... 66

2.19 Hazard Lamp Control........................................................................................................................................... 67

System Operation ................................................................................................................................................ 67

Circuit Operation.................................................................................................................................................. 67

Body Control Module Page 12J–4

Page 12J–4

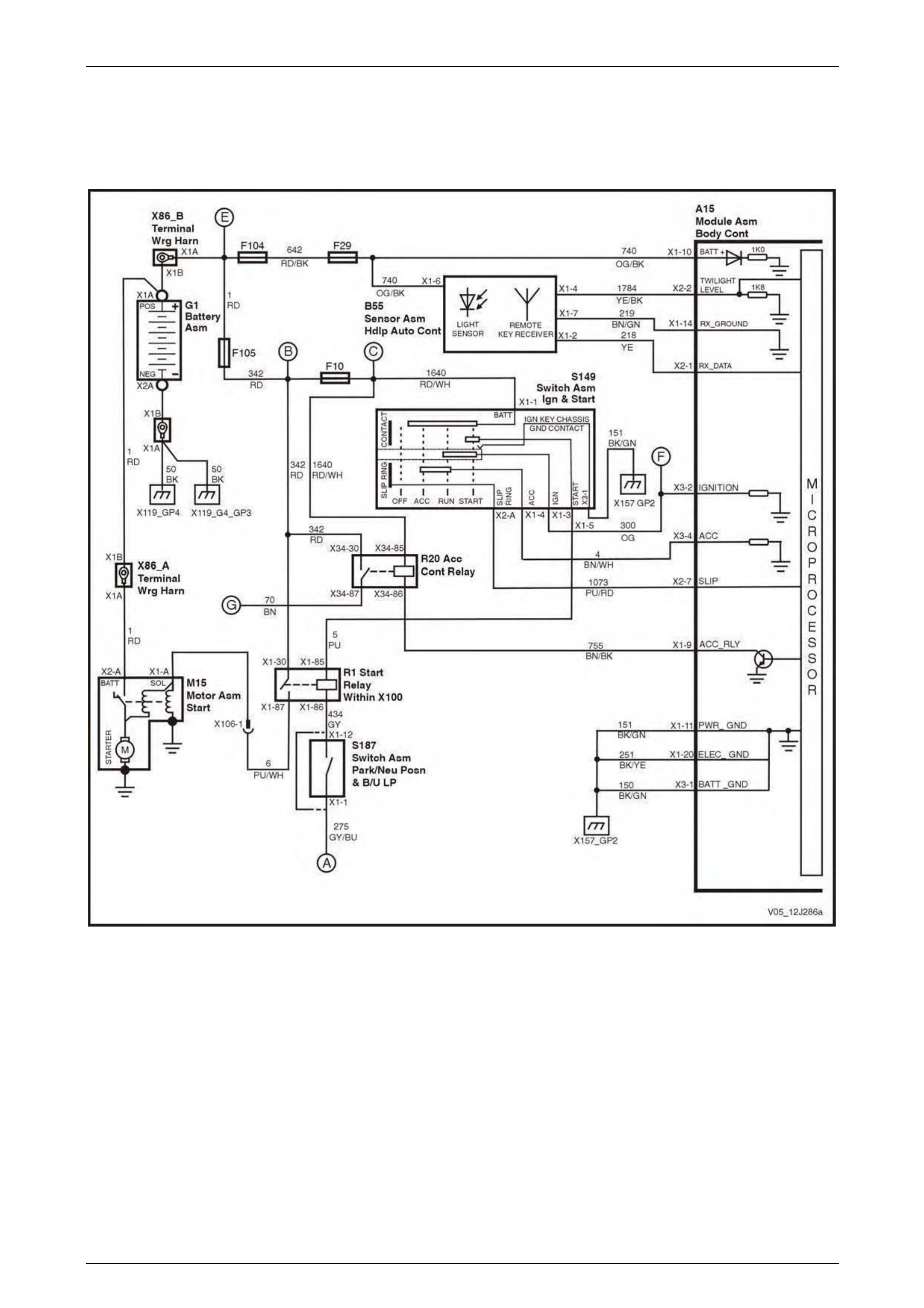

3 Wiring Diagrams and Connector Charts............................................................................................68

3.1 Wiring Diagrams – V6.......................................................................................................................................... 68

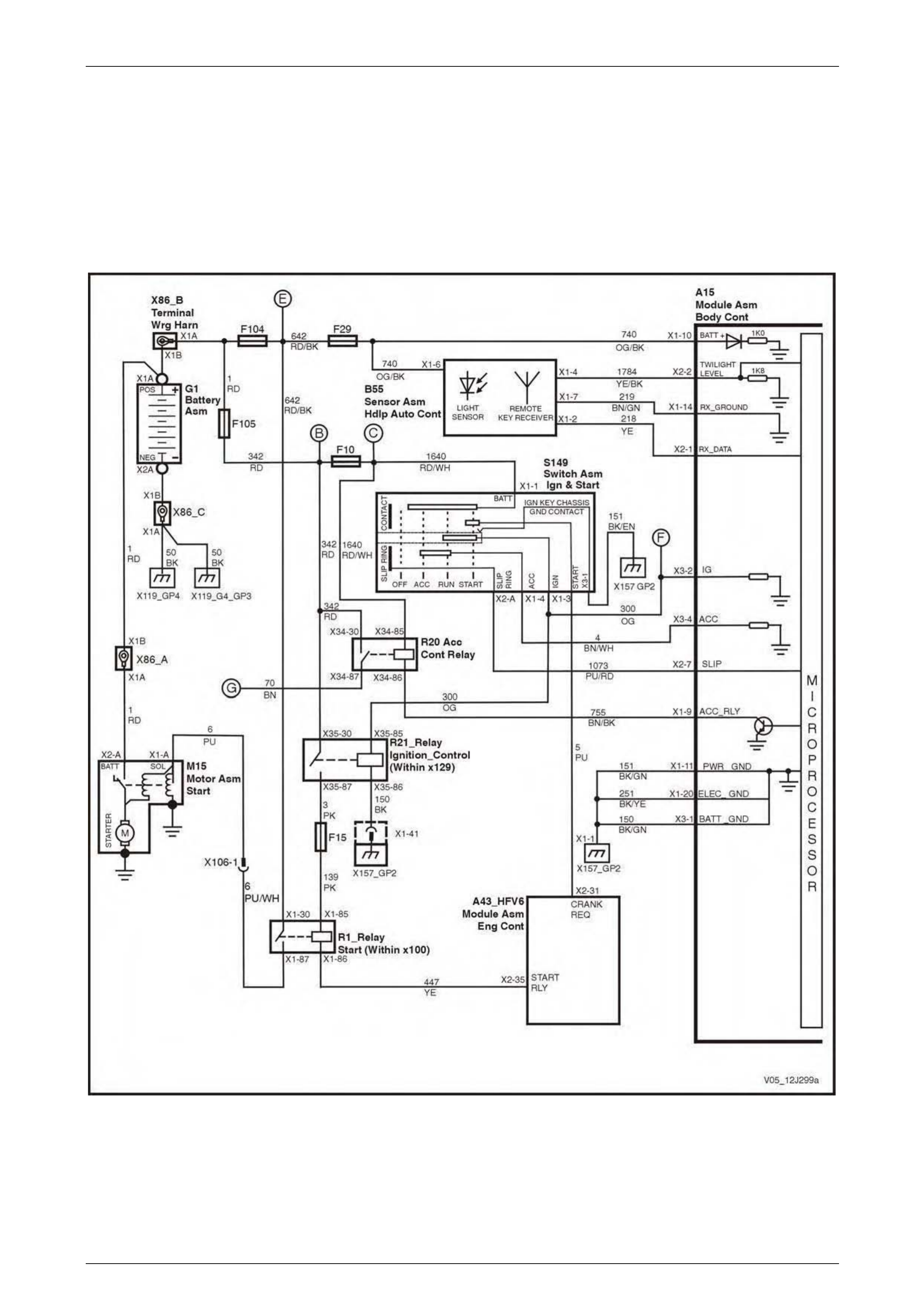

Ignition Key, RX Sensor, Common Power and Grounds.................................................................................. 68

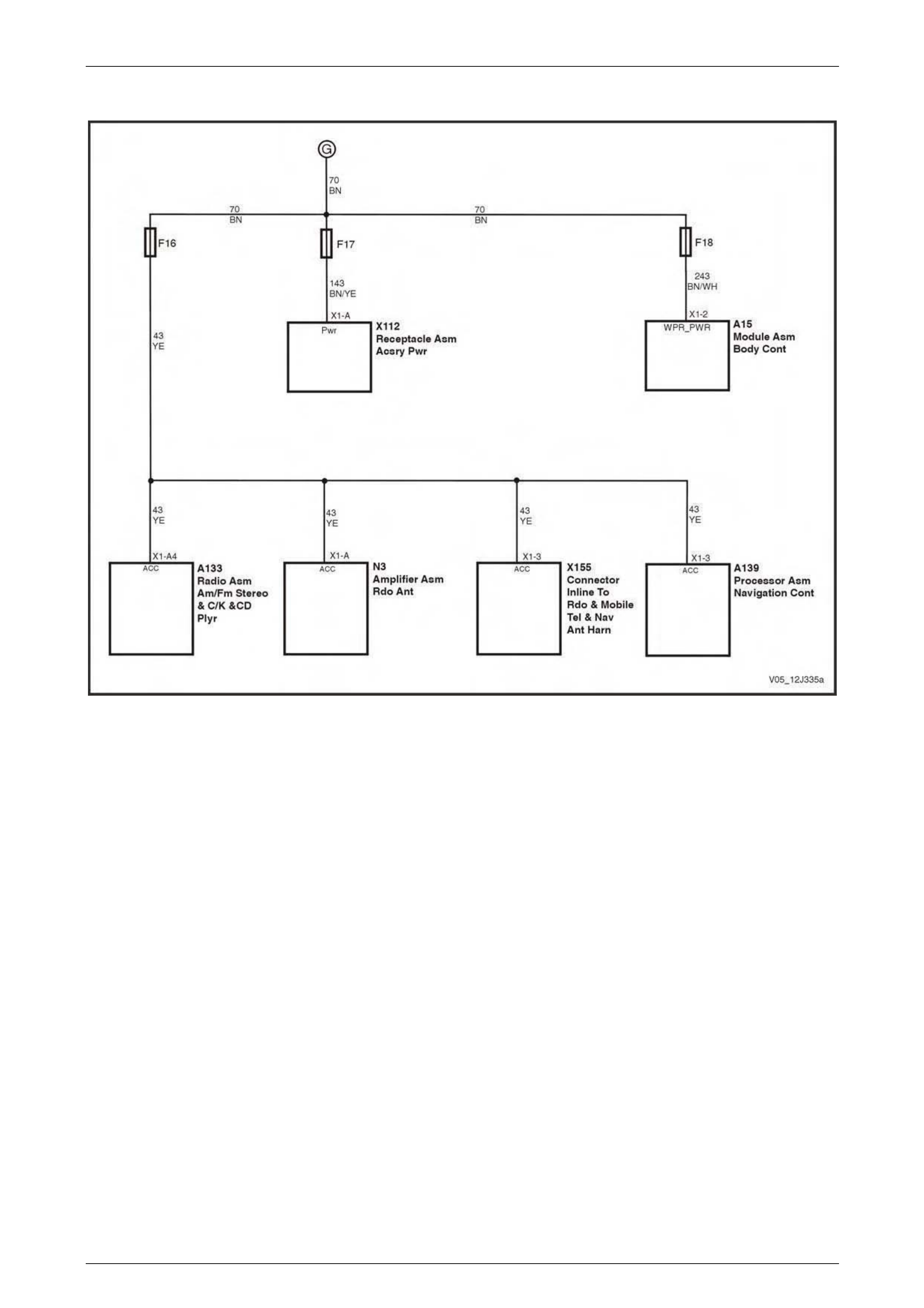

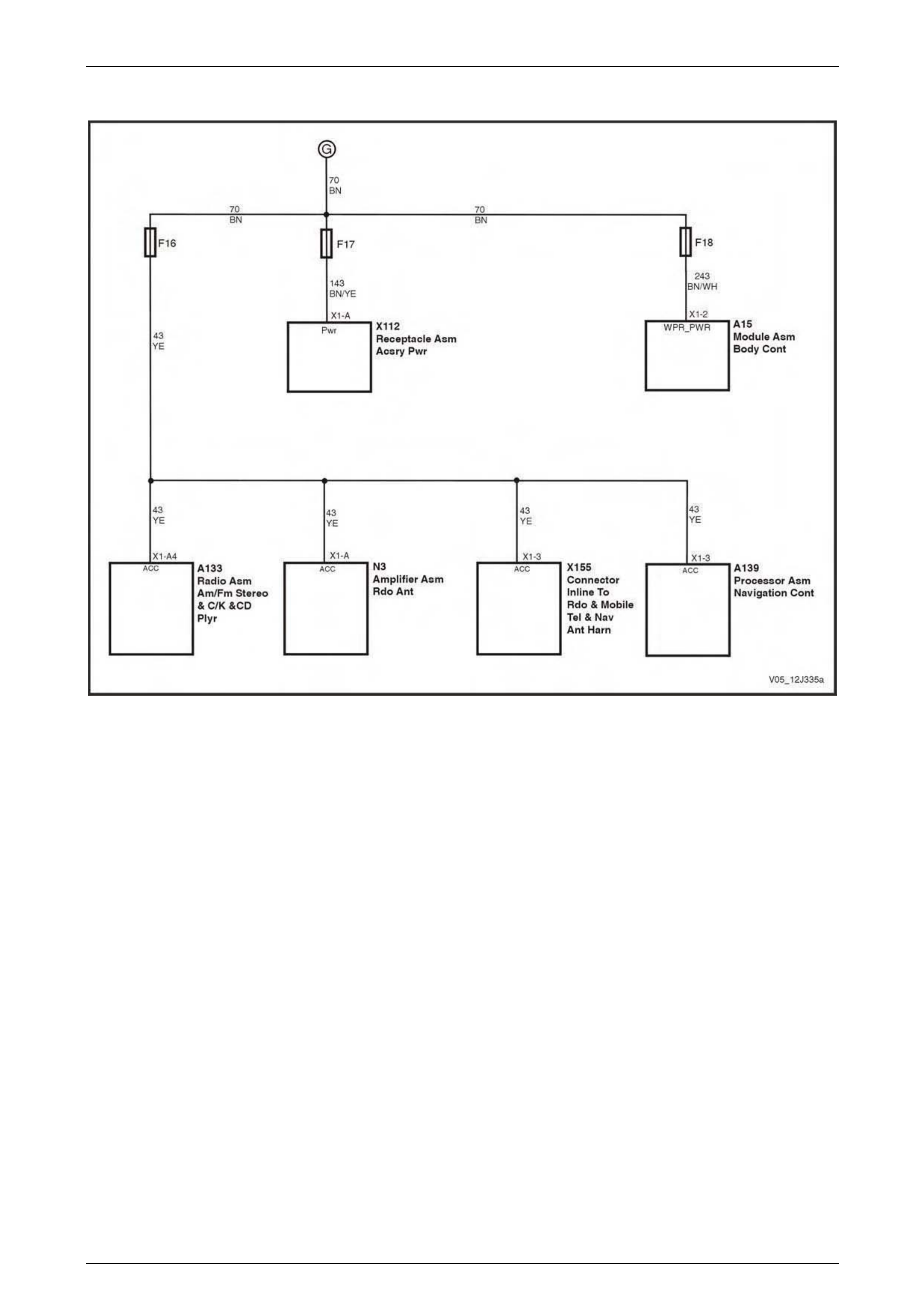

Accessory Power Circuit..................................................................................................................................... 69

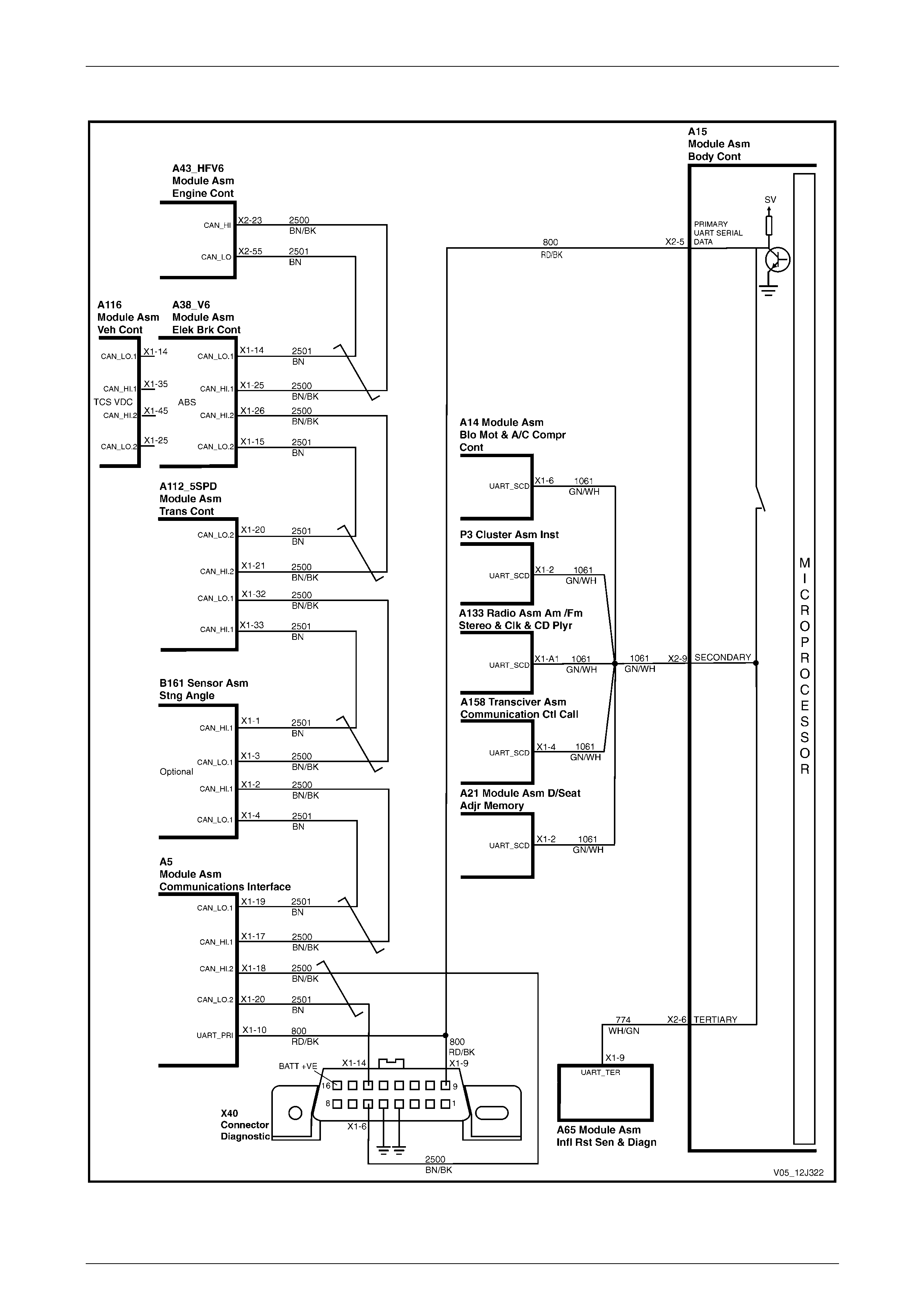

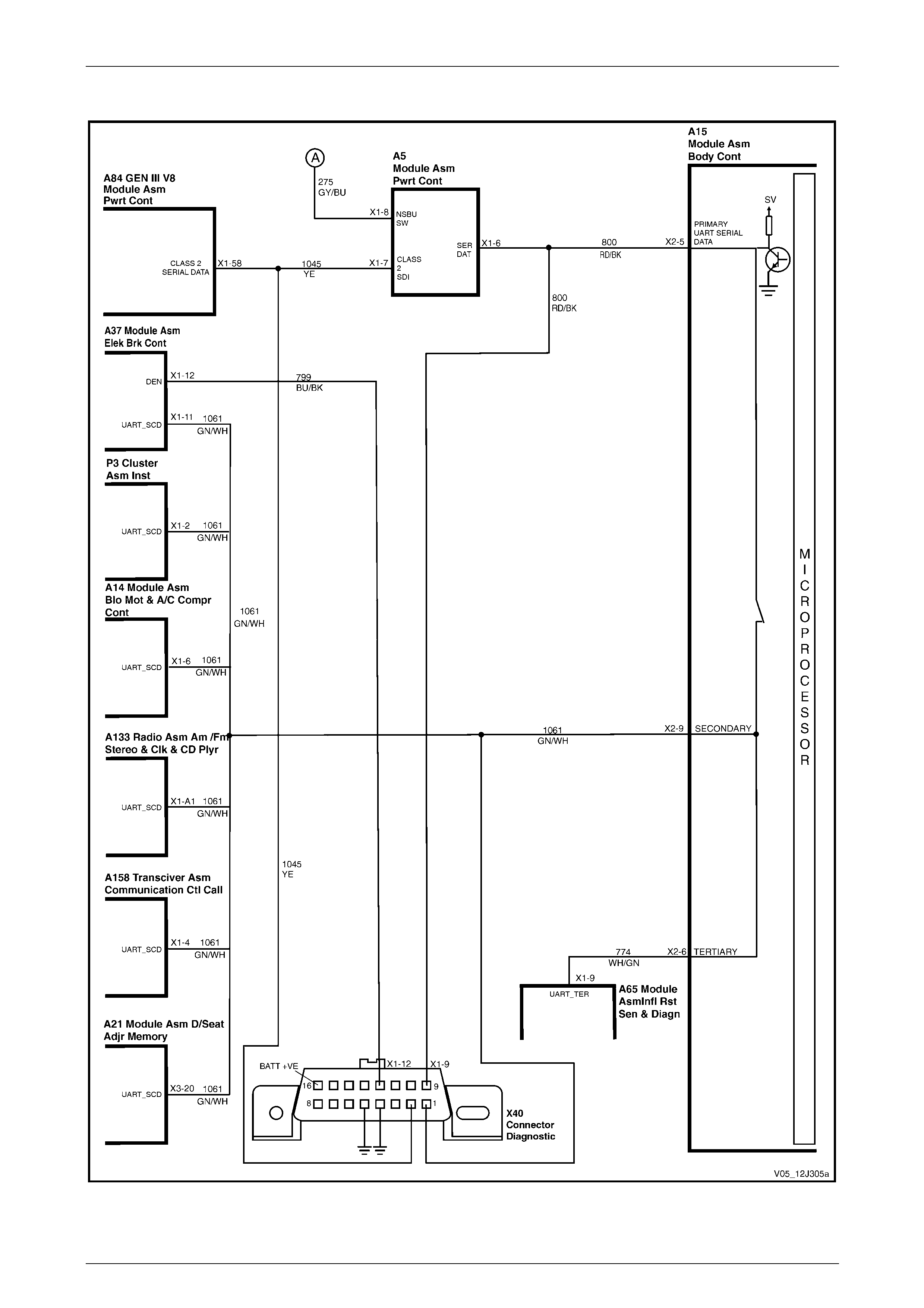

UART and GM LAN Communications................................................................................................................. 70

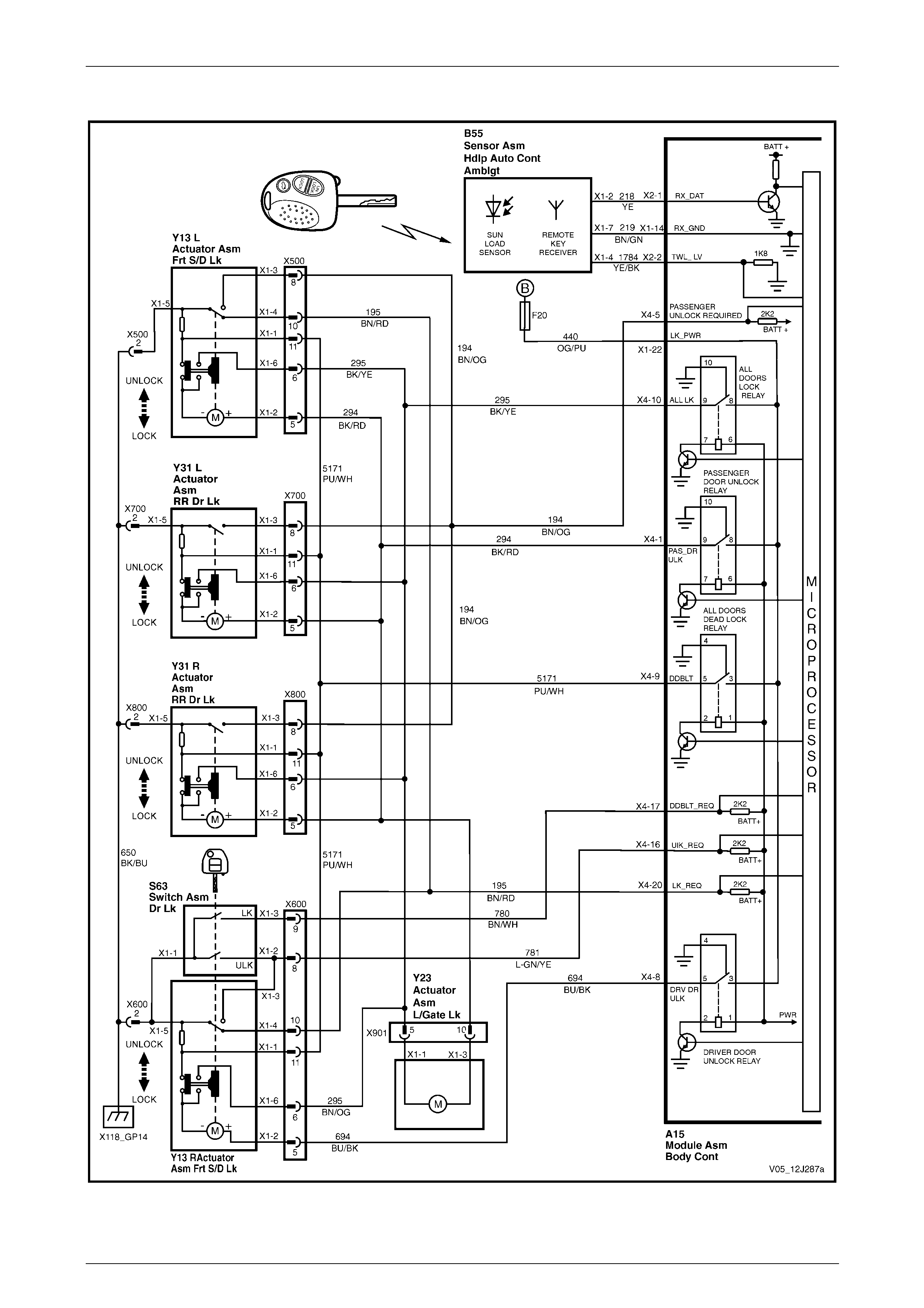

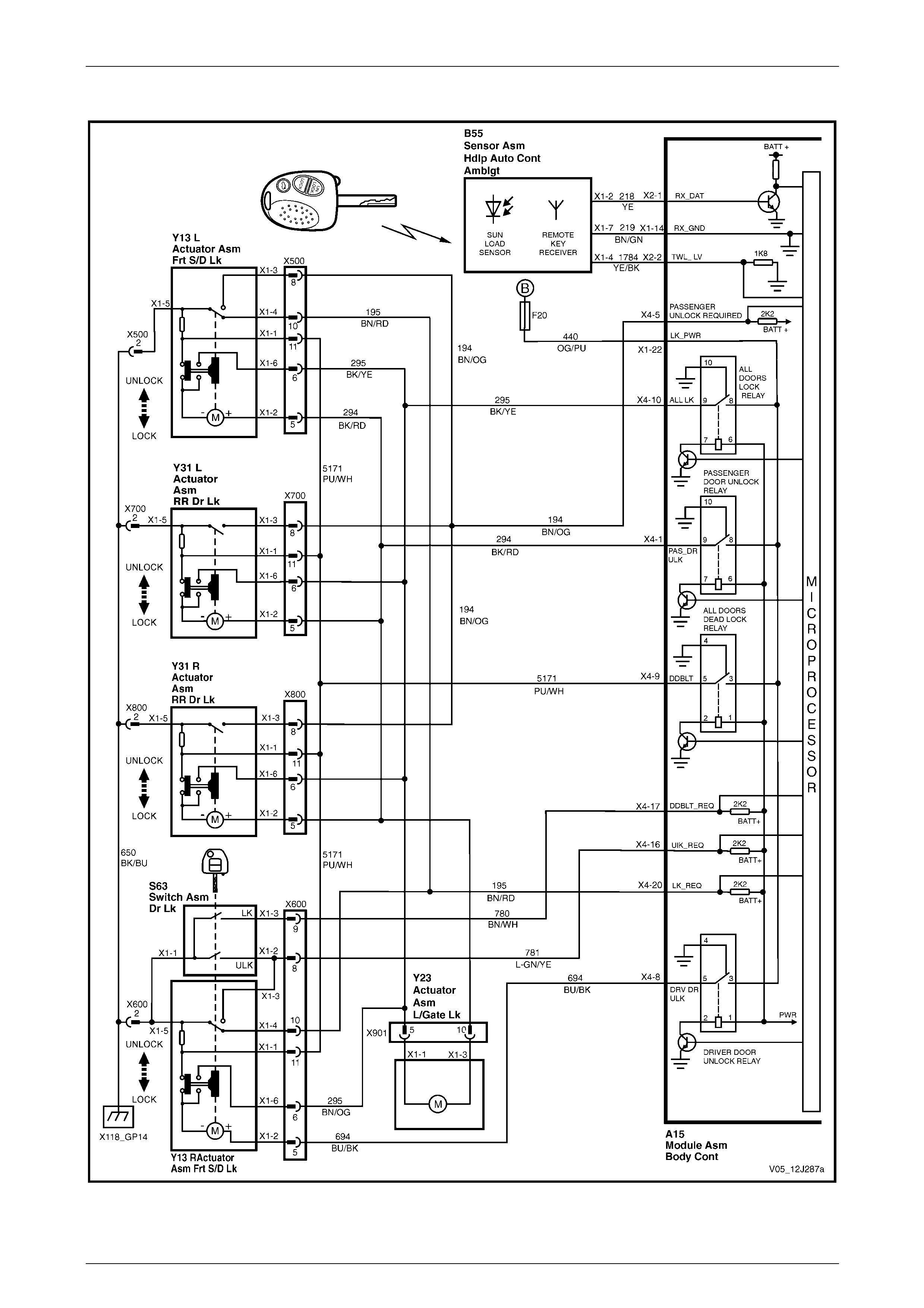

Central Door Locking .......................................................................................................................................... 71

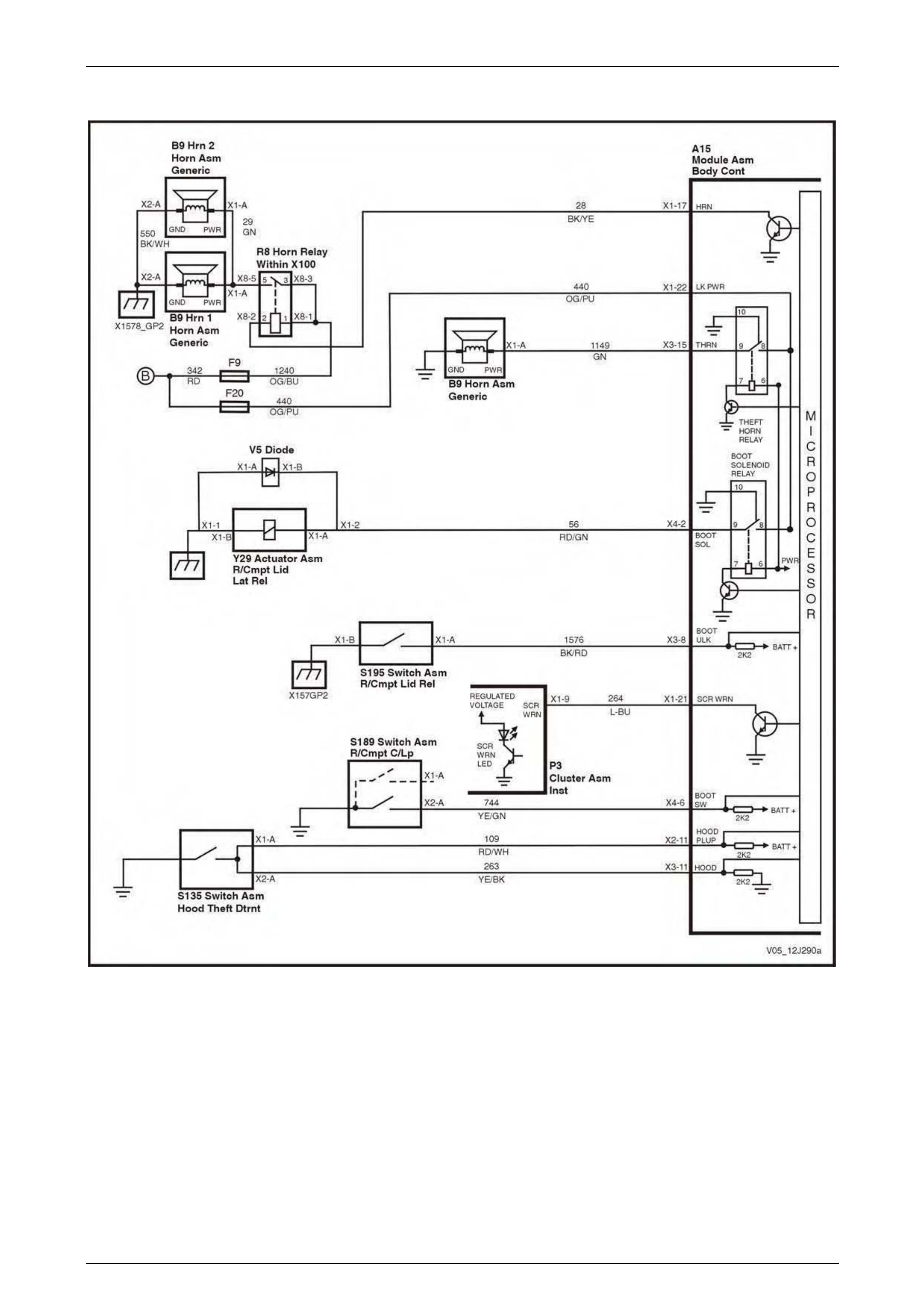

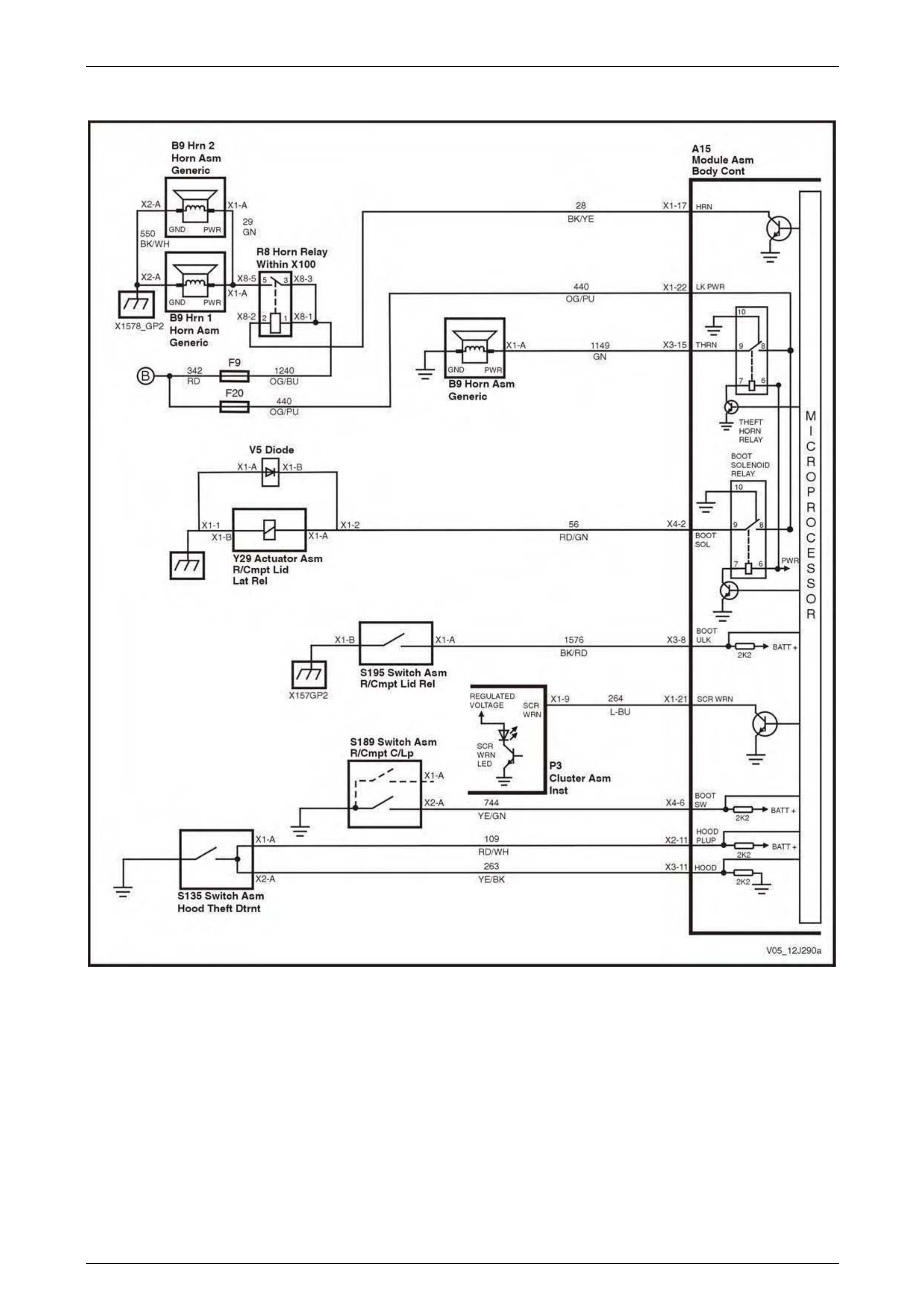

Entry Deterrent, Warning Horns and Rear Compartment Solenoid................................................................. 72

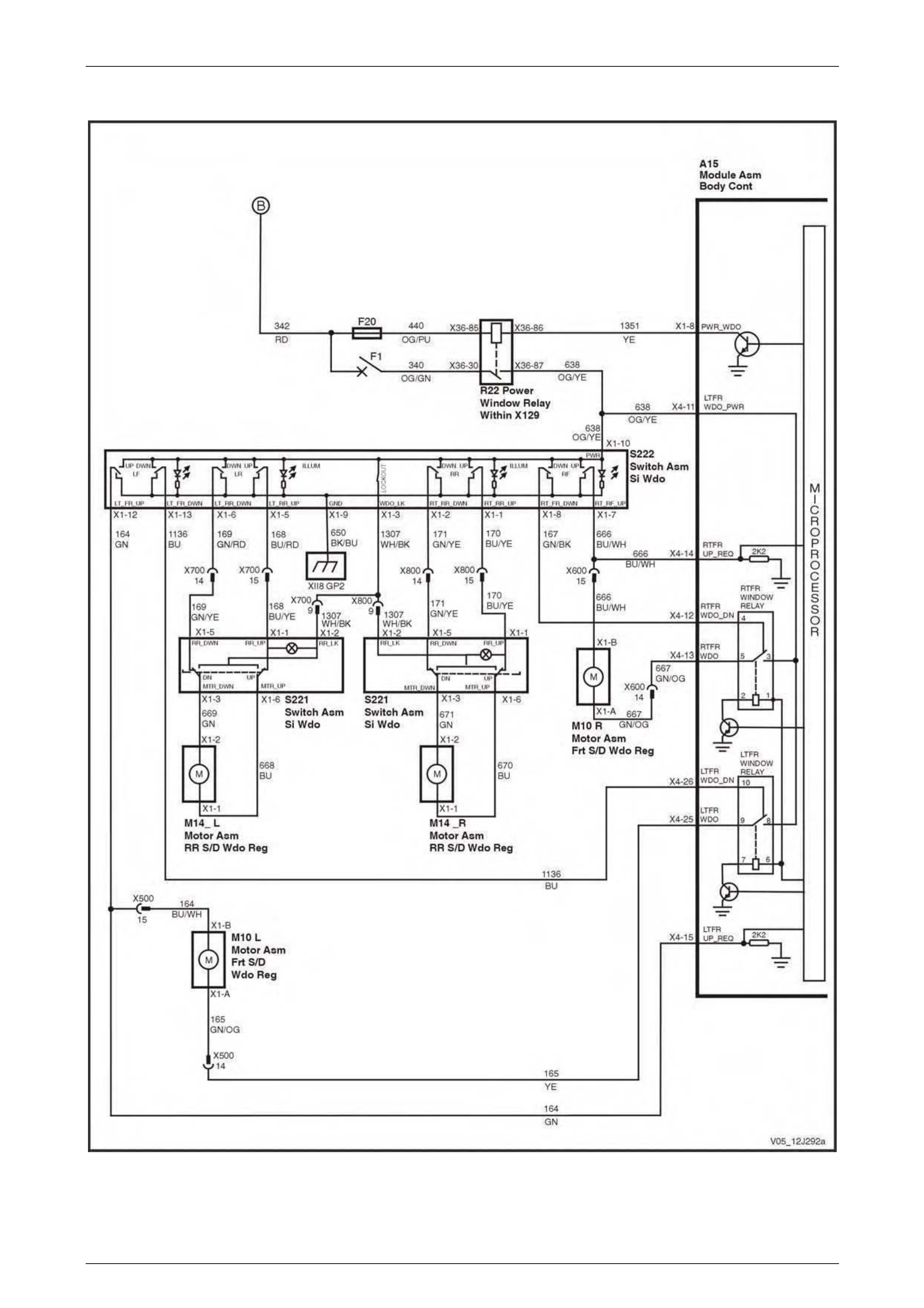

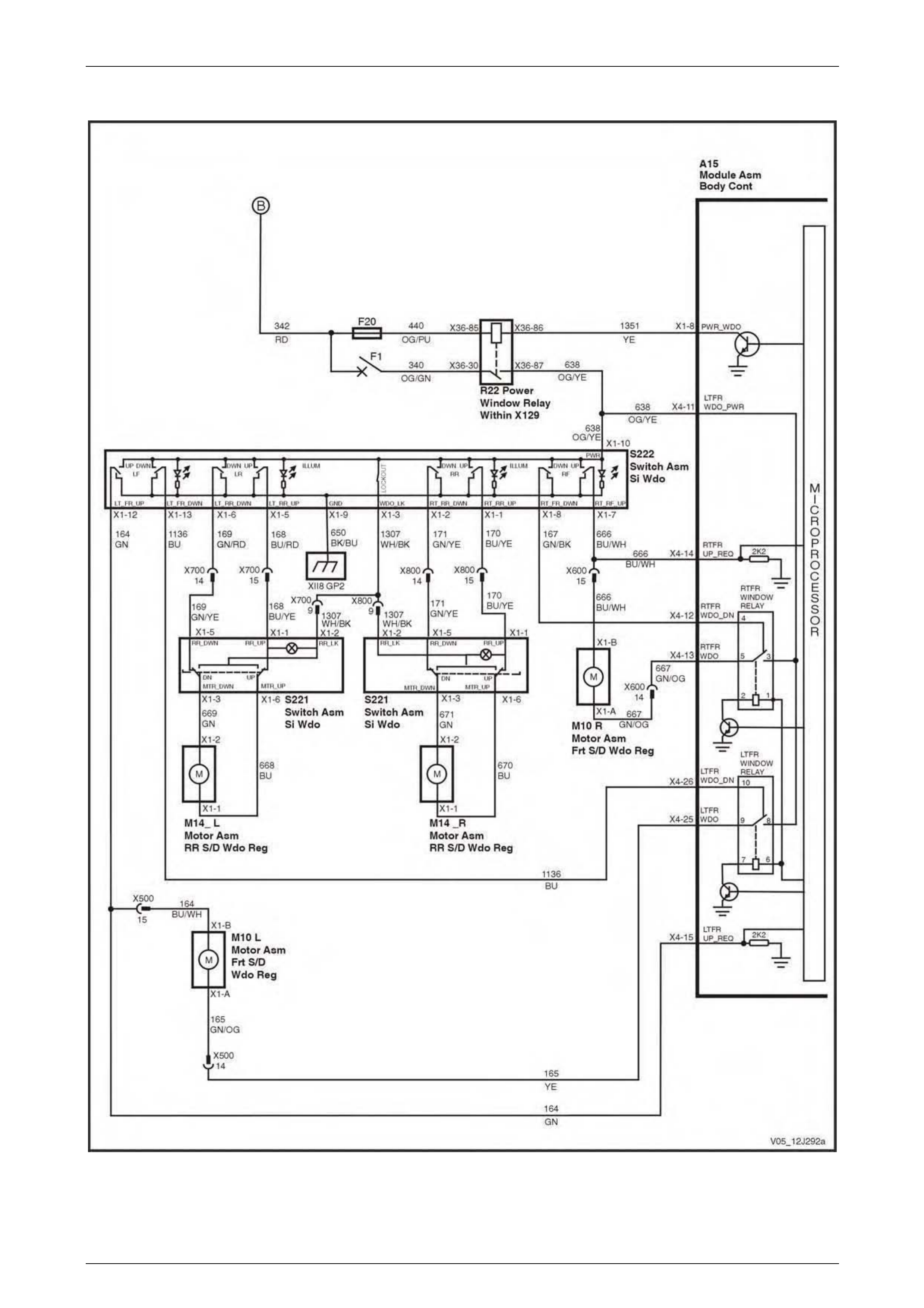

Power Windows................................................................................................................................................... 73

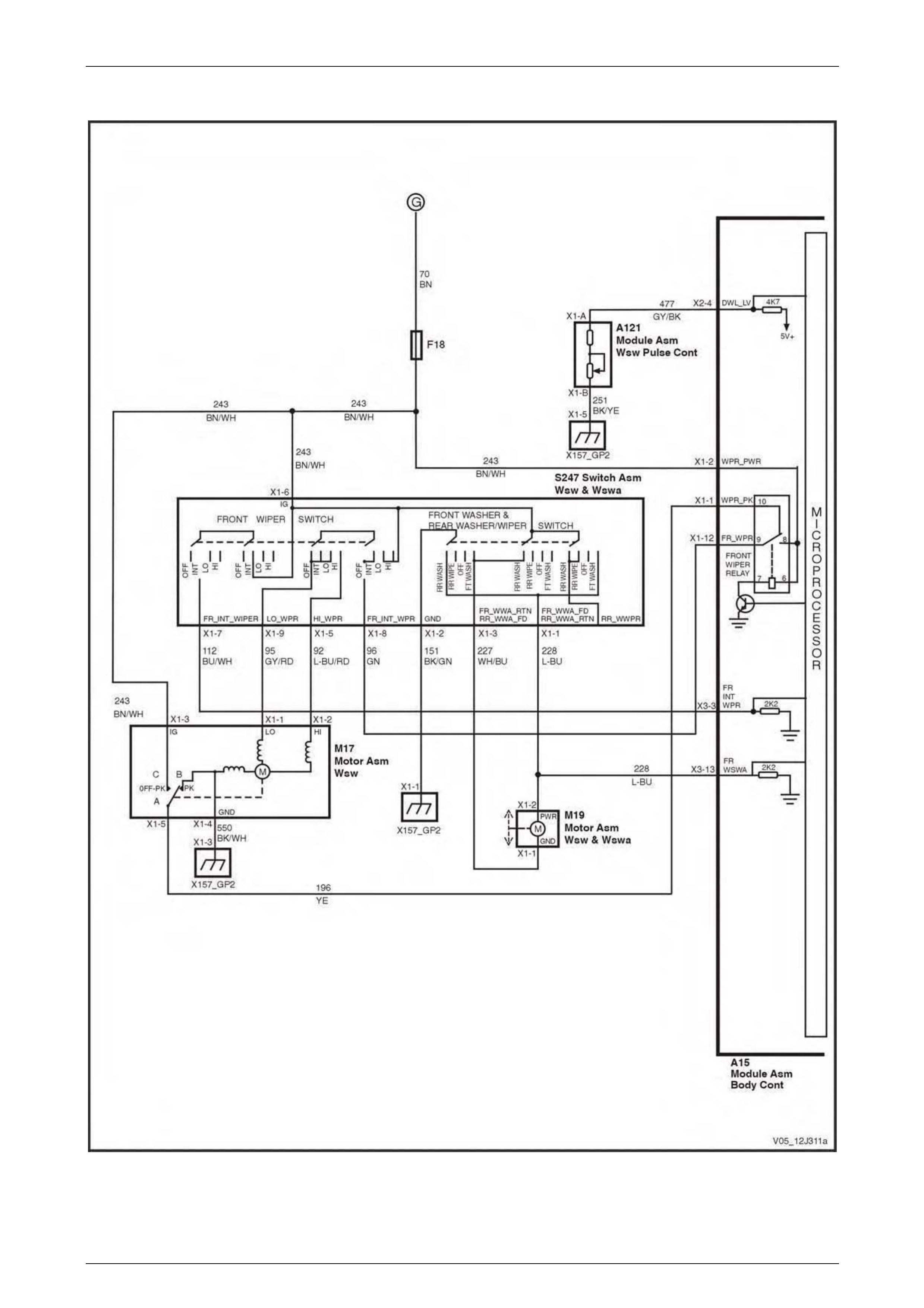

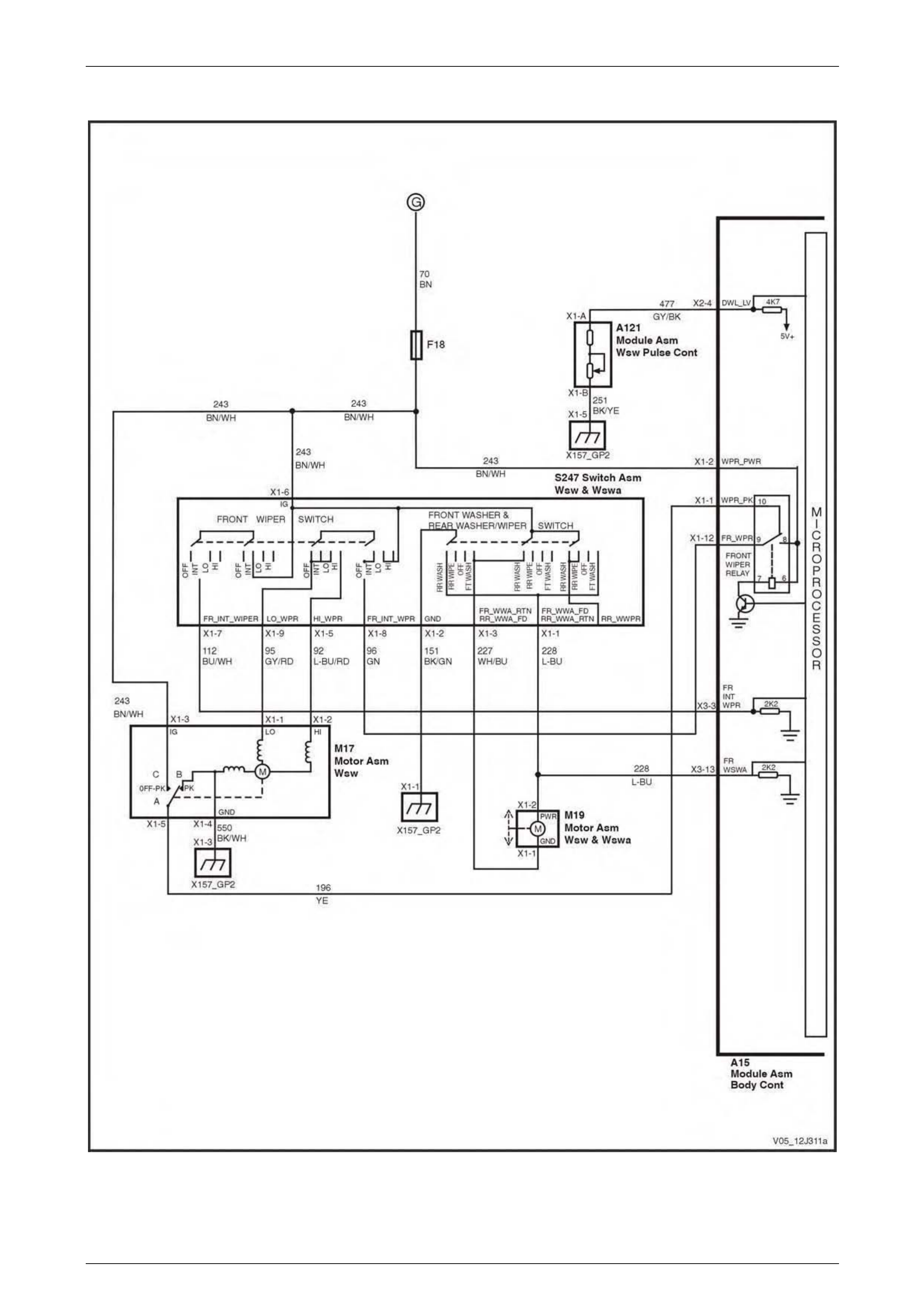

Wiper Systems Intermittent Function ................................................................................................................ 74

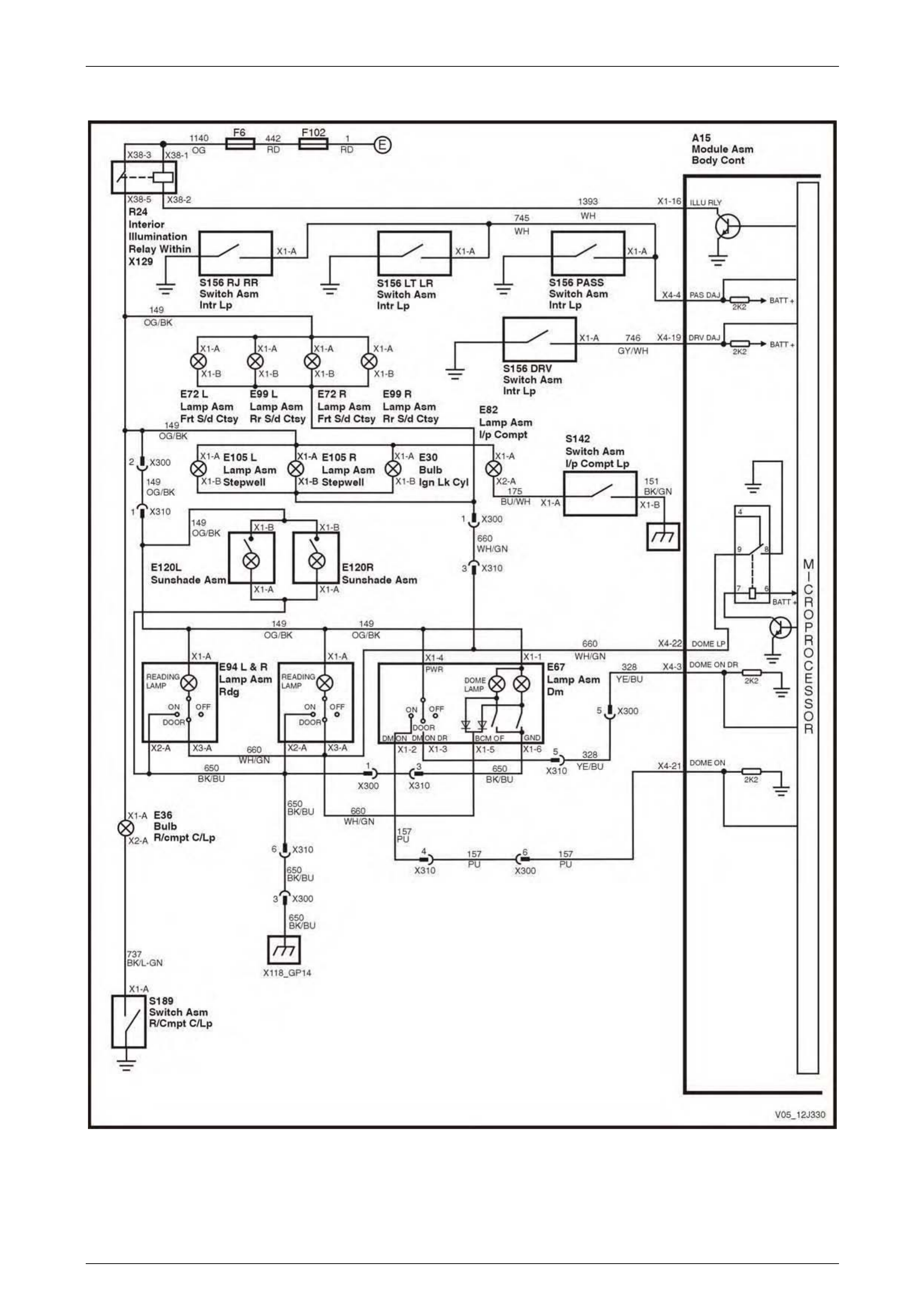

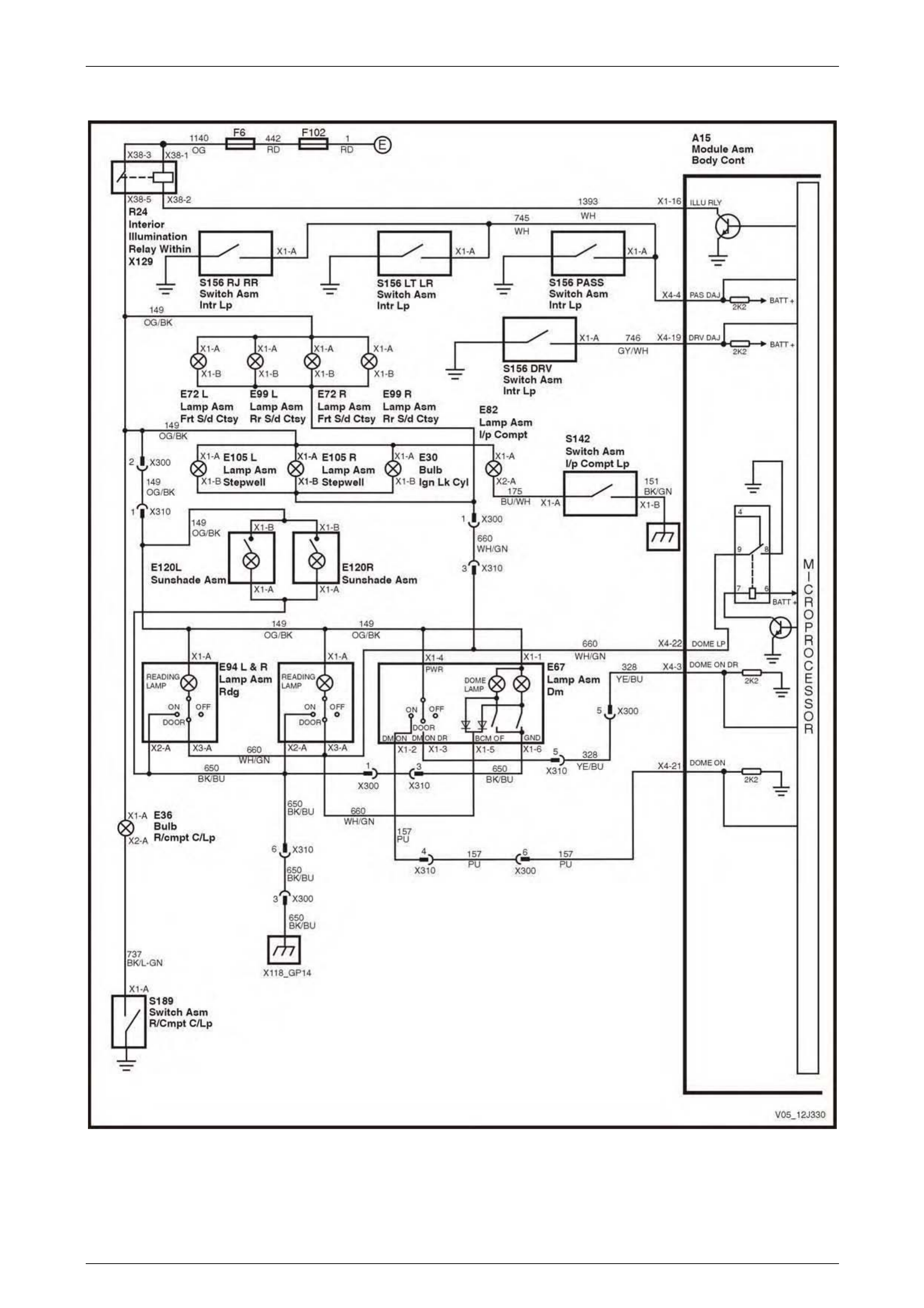

Dome Lamp Delay Control.................................................................................................................................. 75

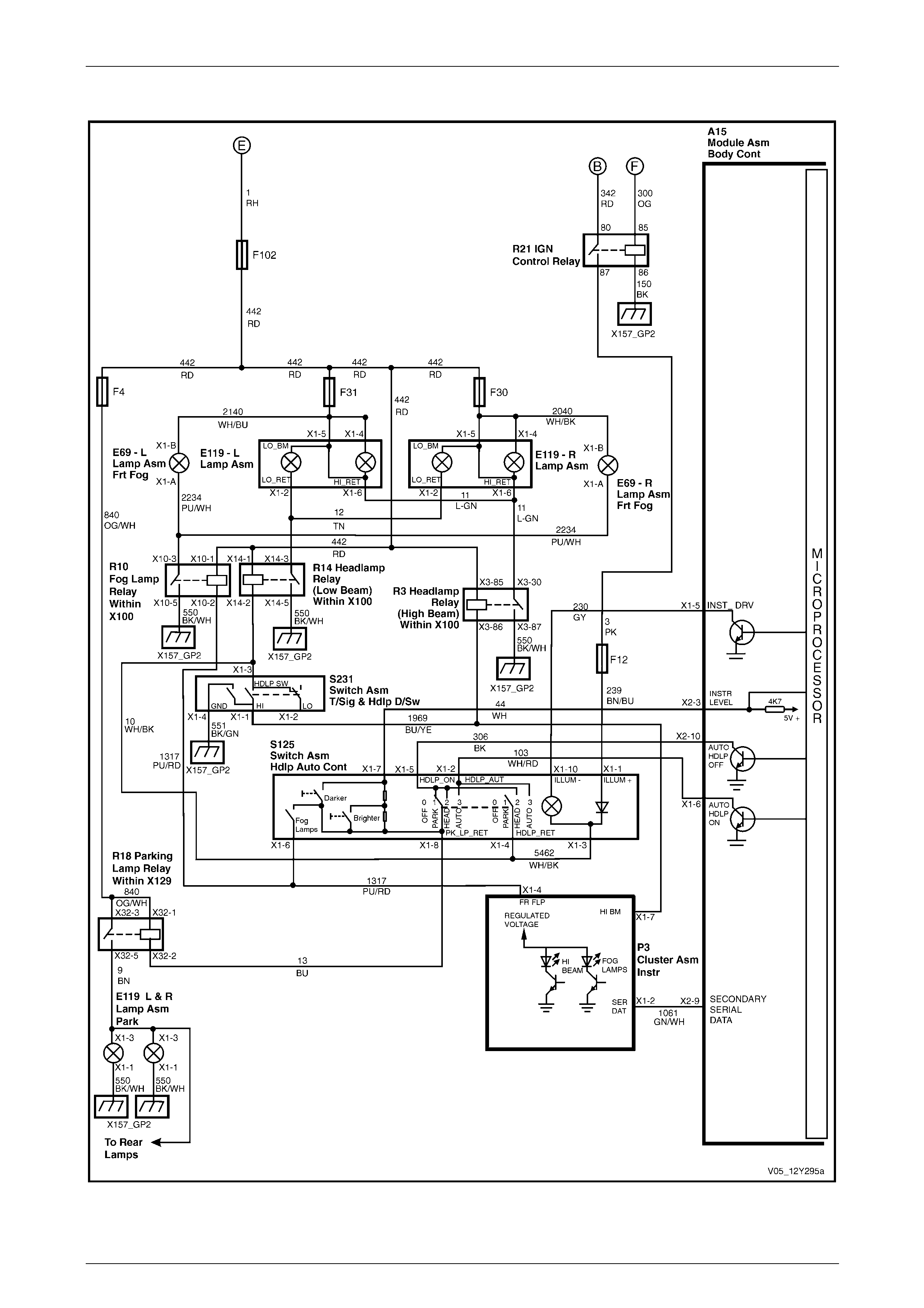

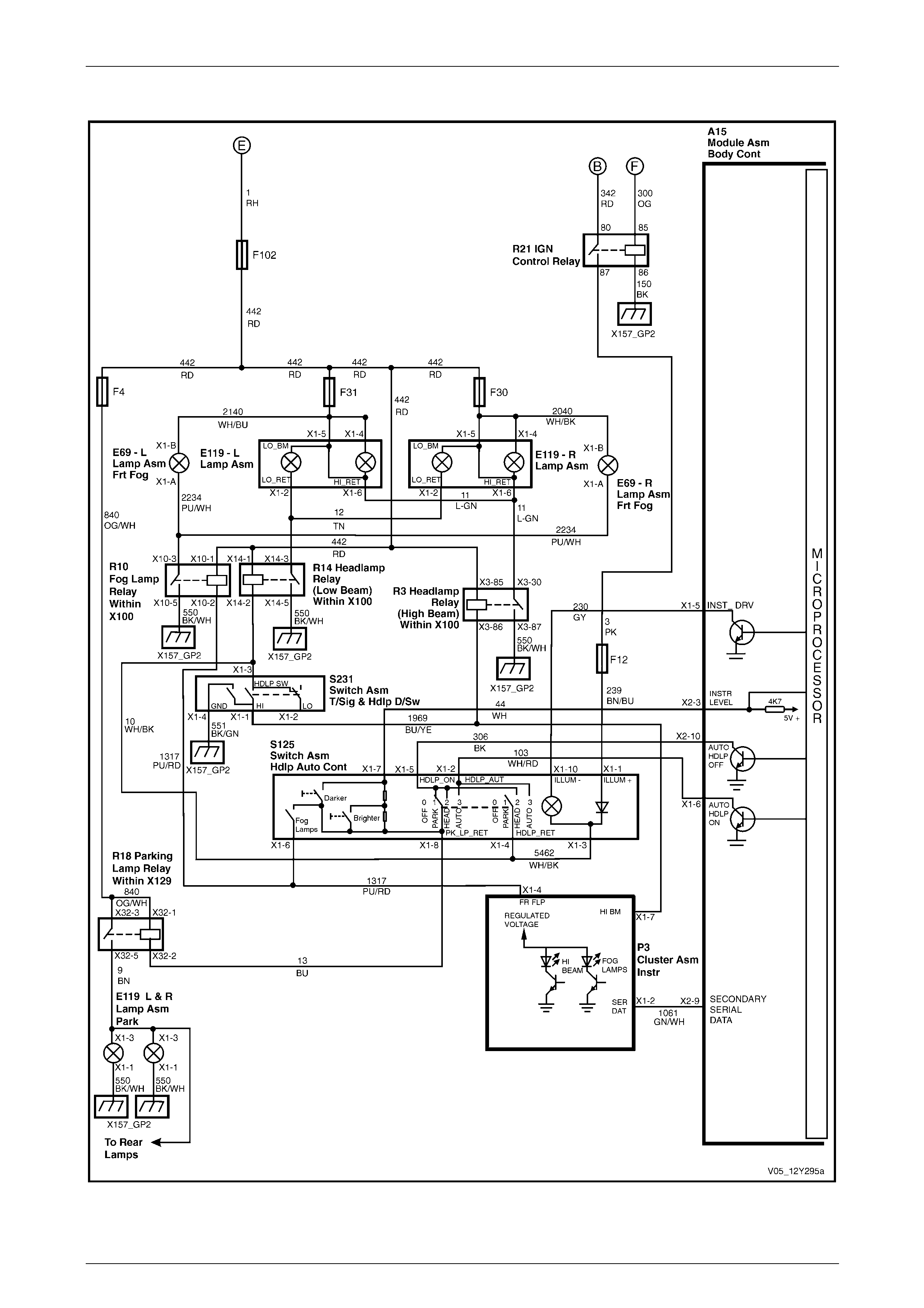

Automatic Lamp Control..................................................................................................................................... 76

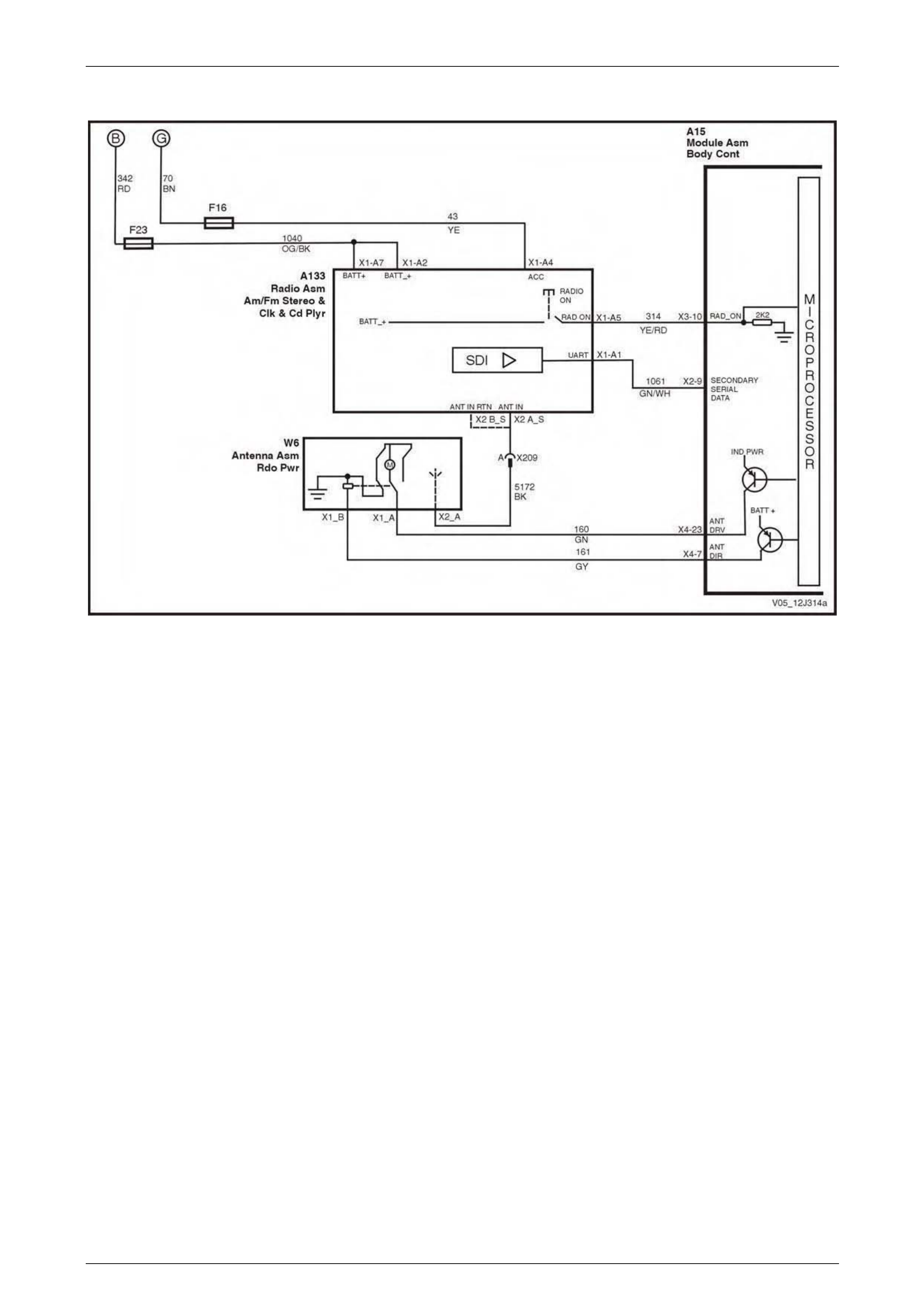

Pow er Antenna Control....................................................................................................................................... 77

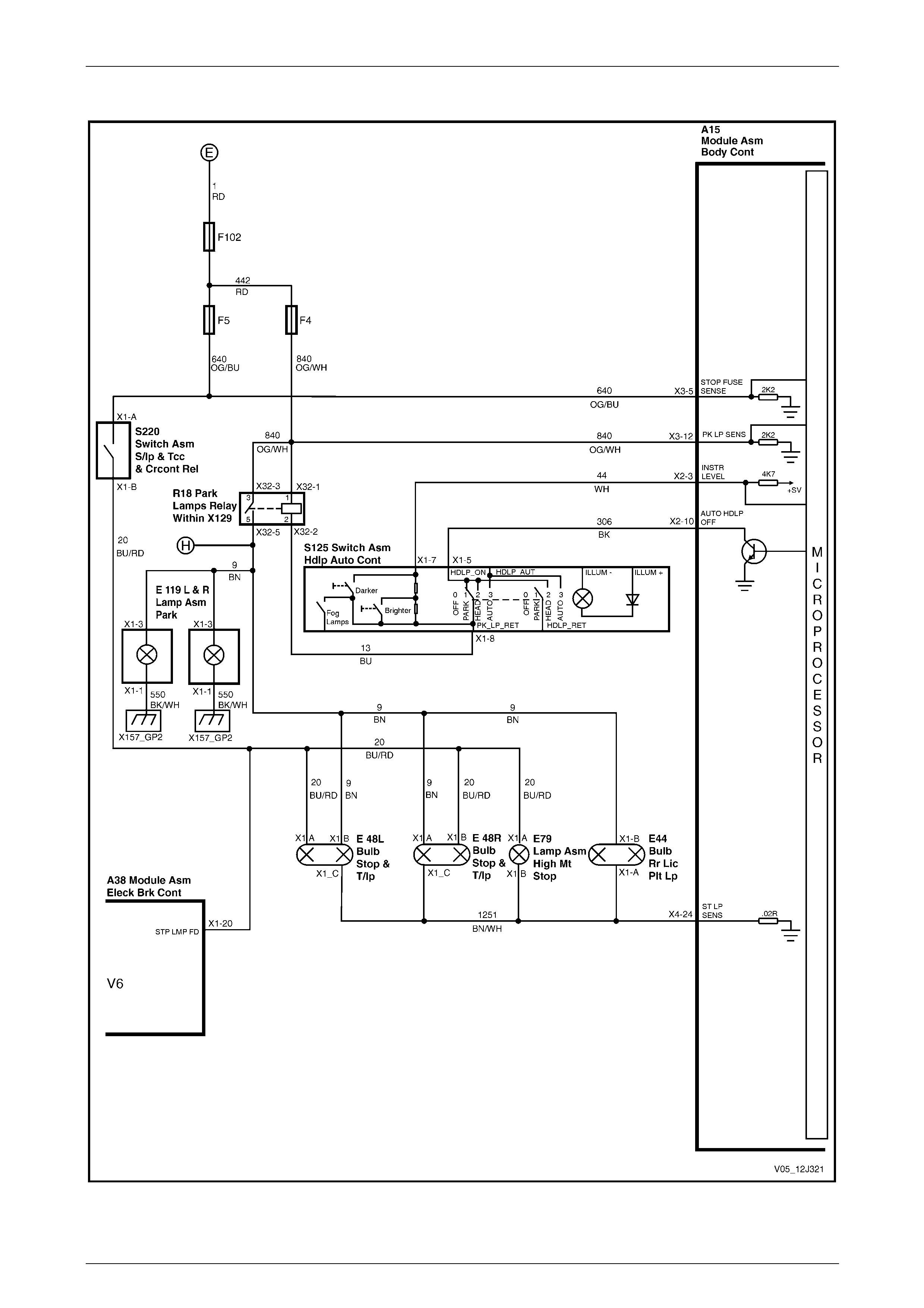

Rear Lamp Failure System.................................................................................................................................. 78

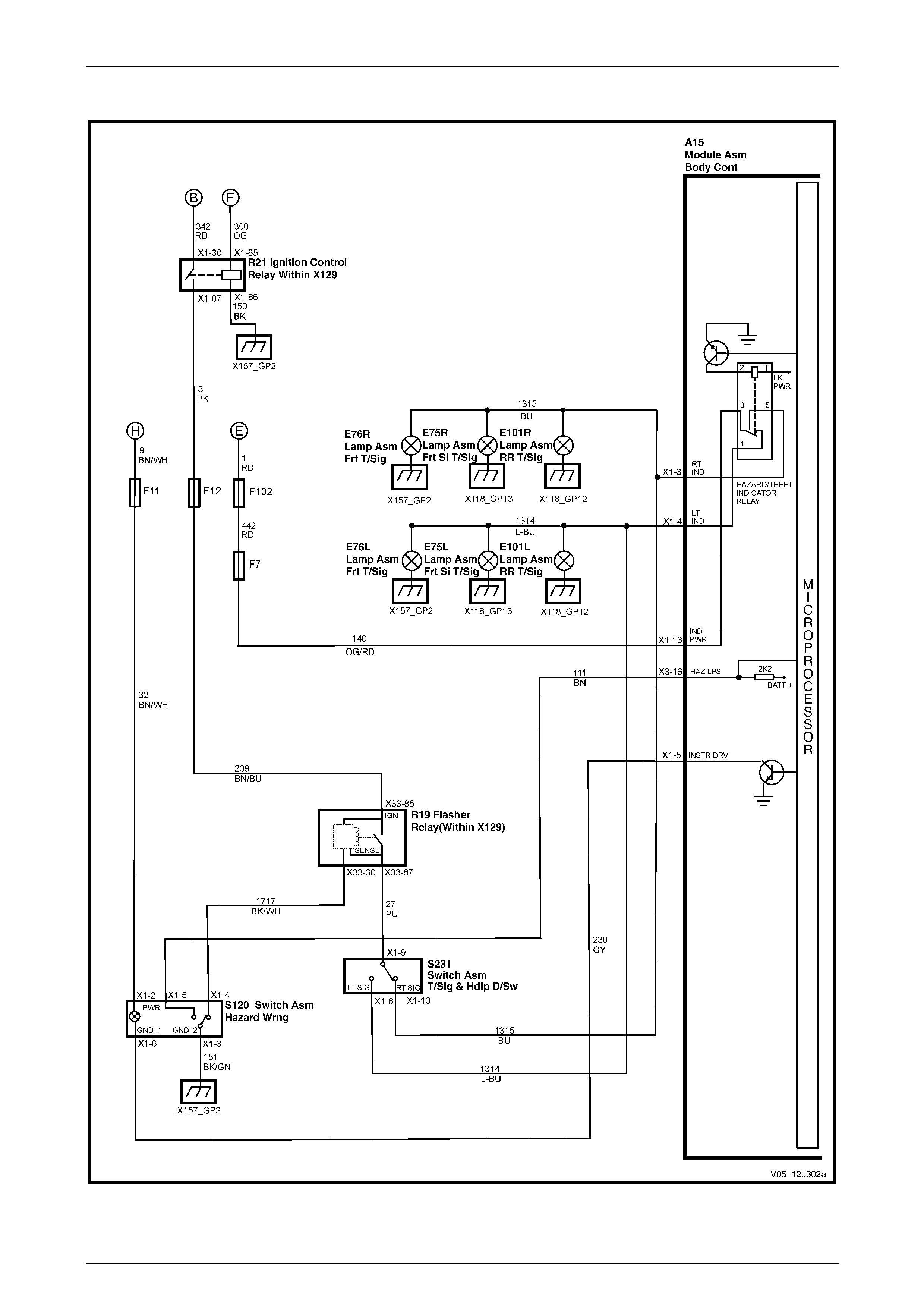

Hazard Lamp Control, Theft / Turn Signal Lamp Flasher................................................................................. 79

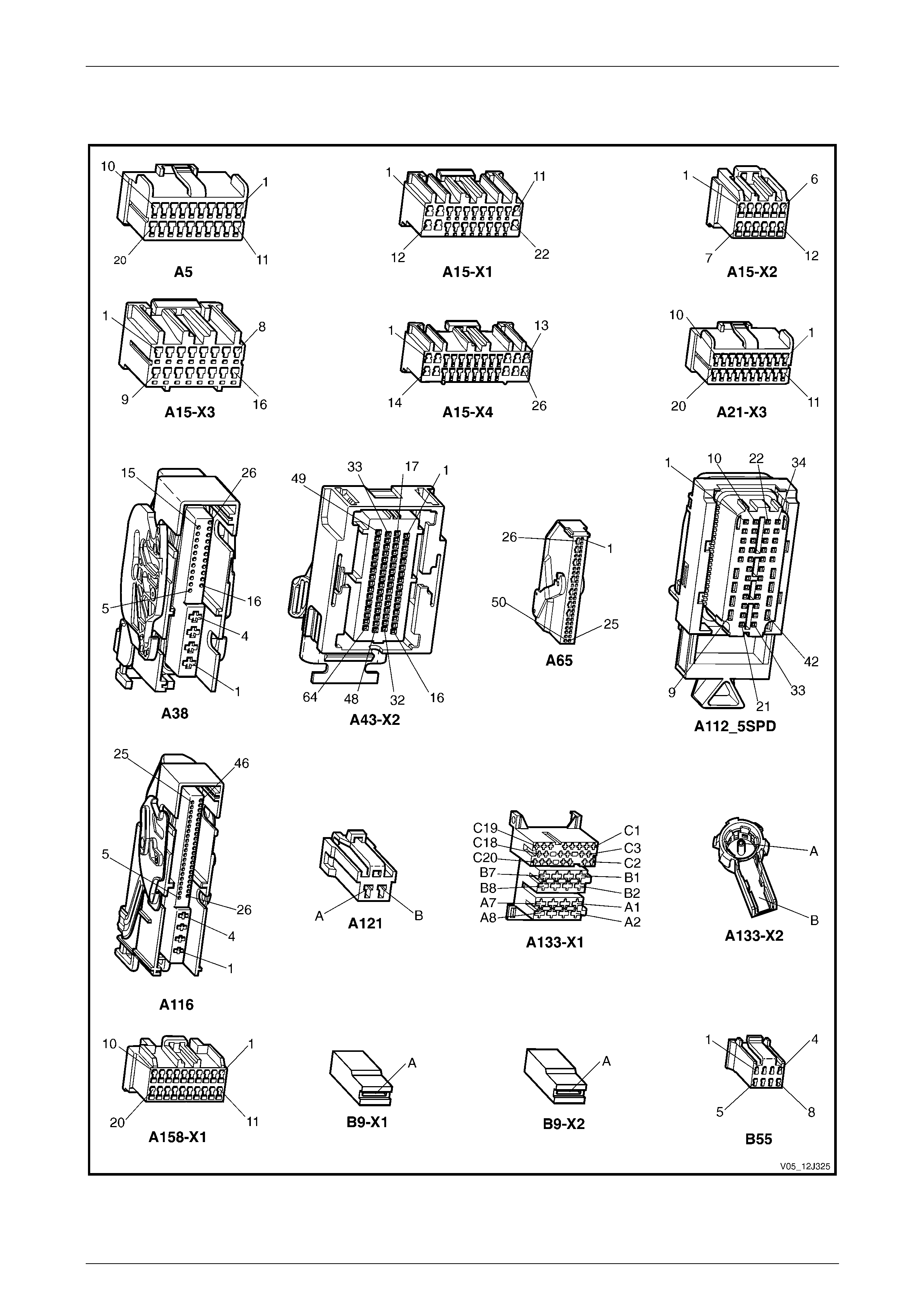

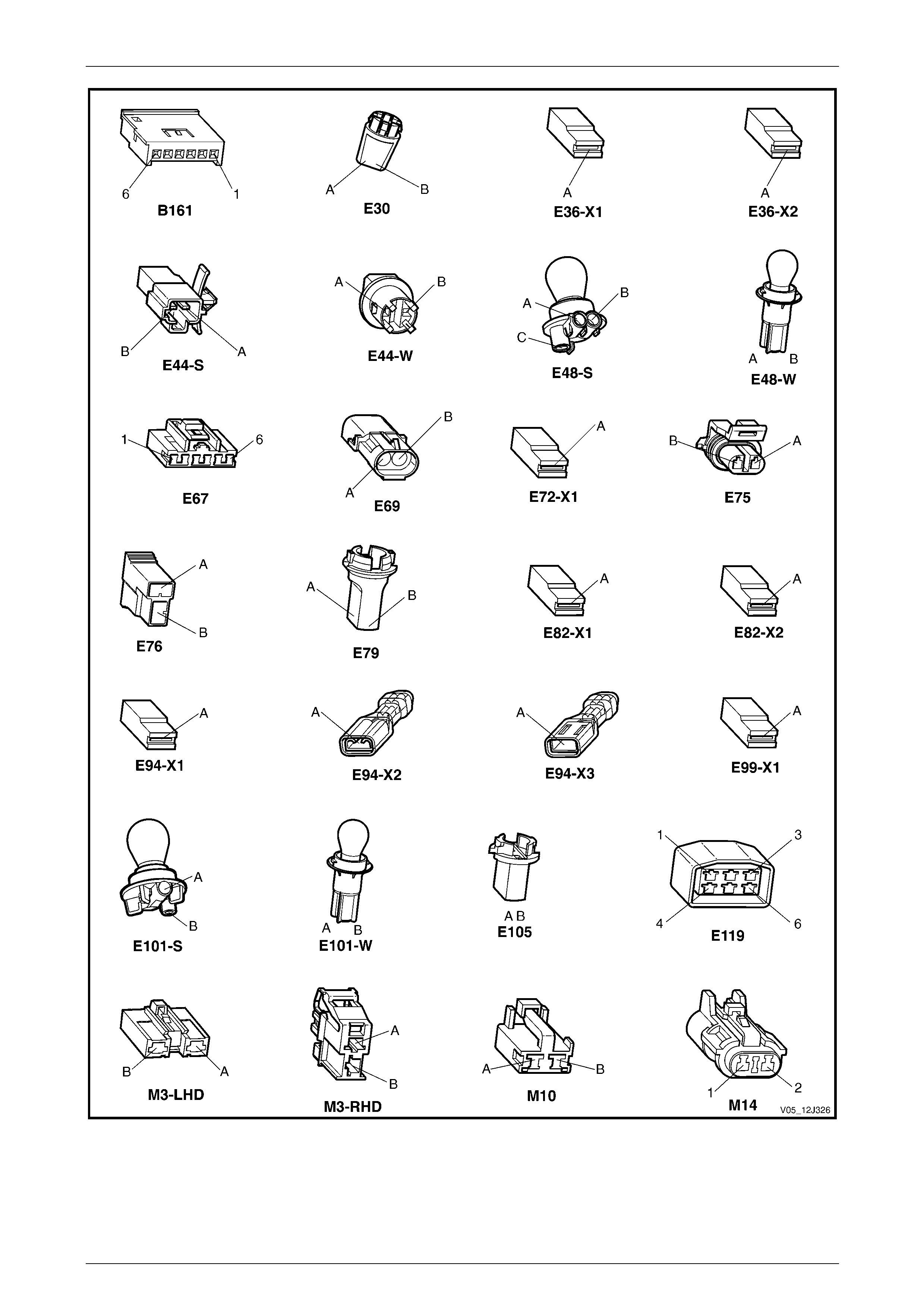

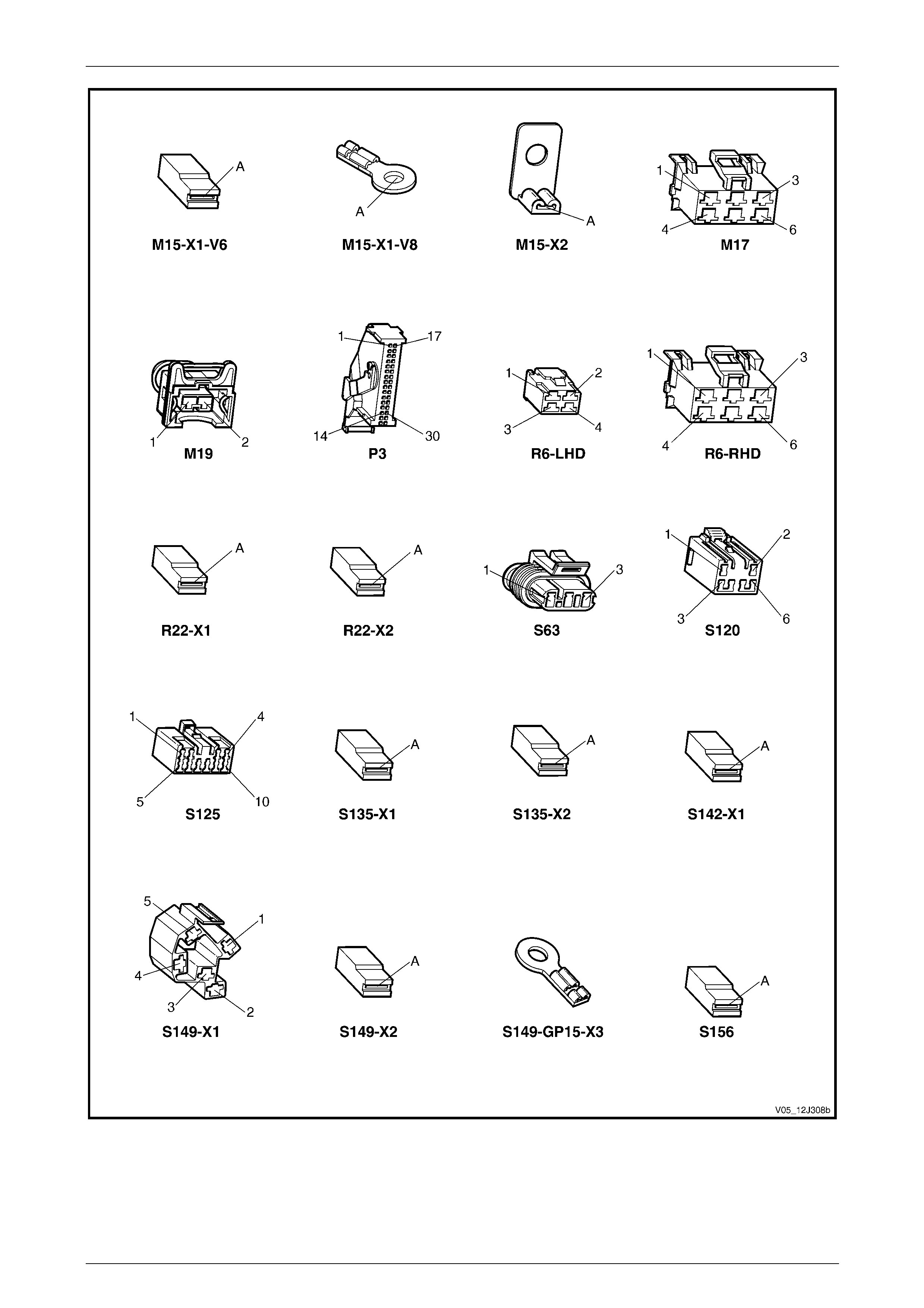

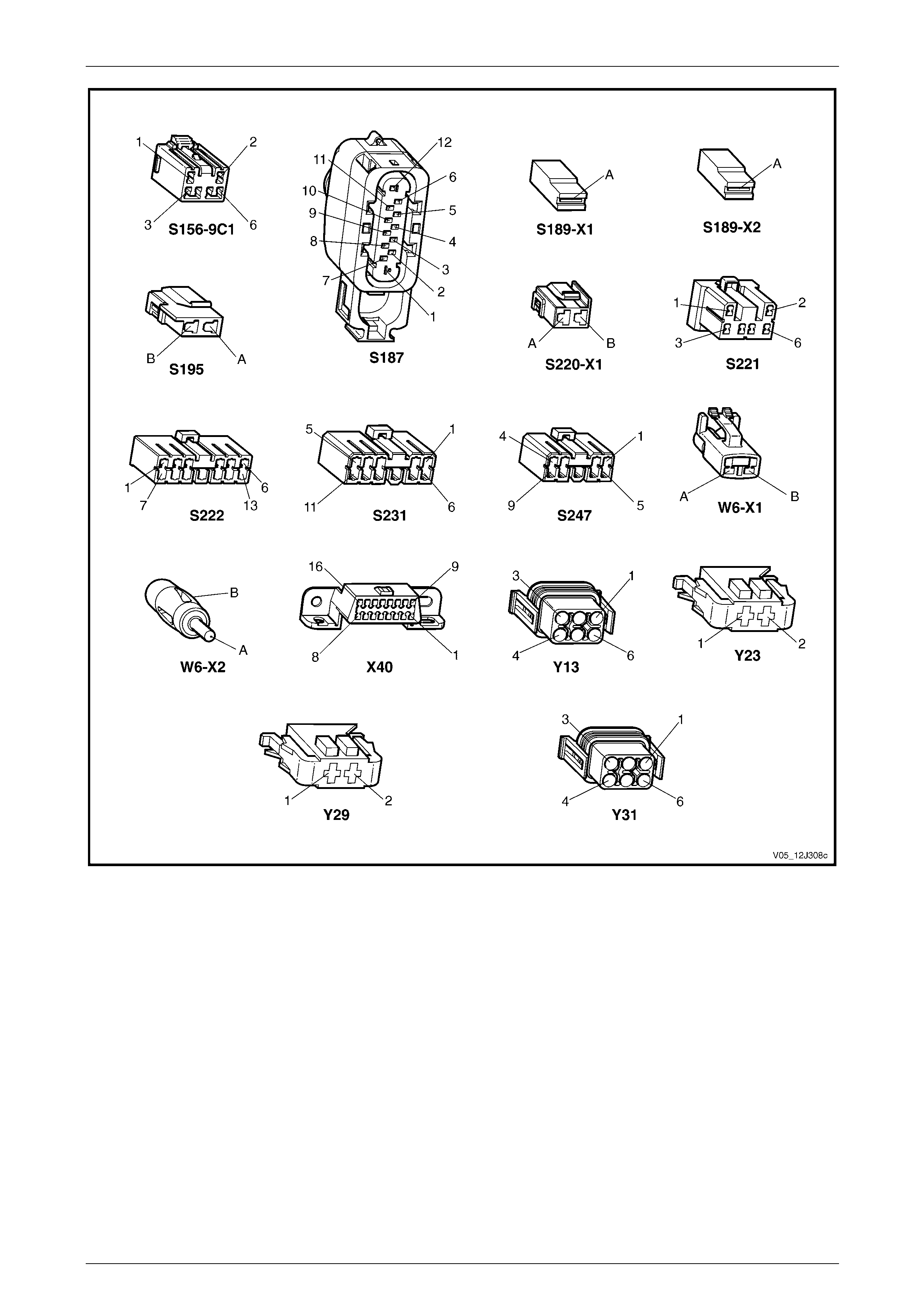

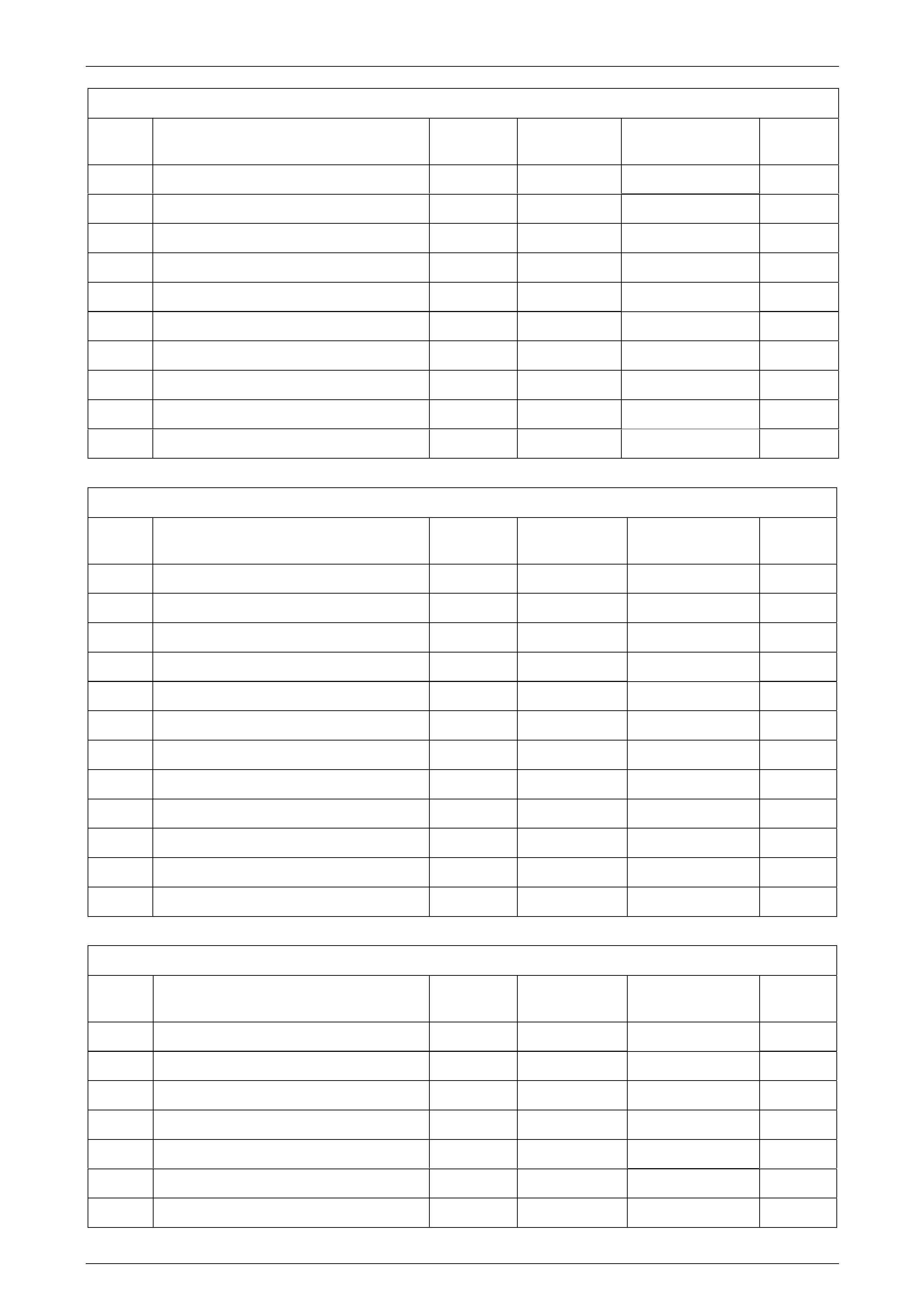

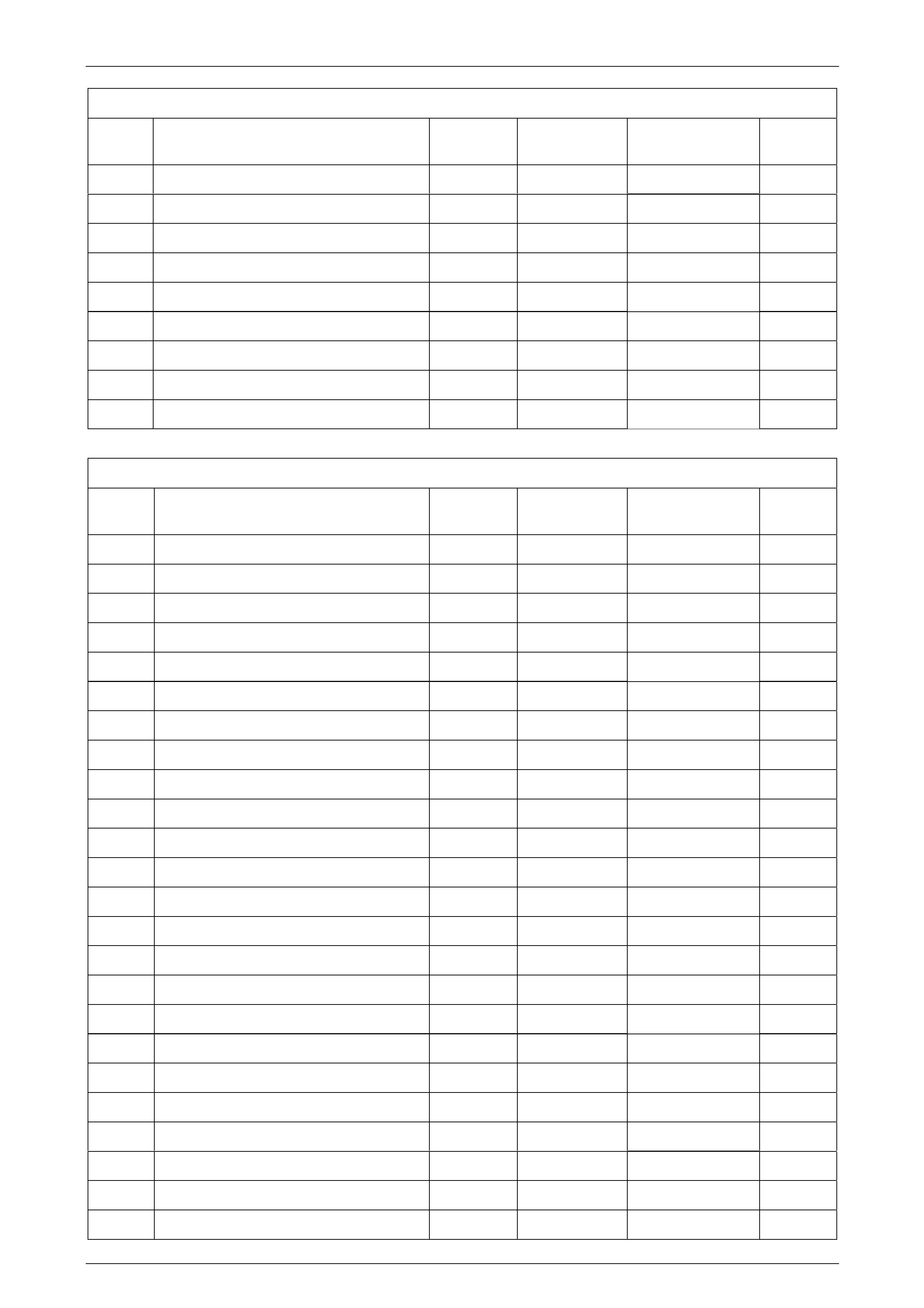

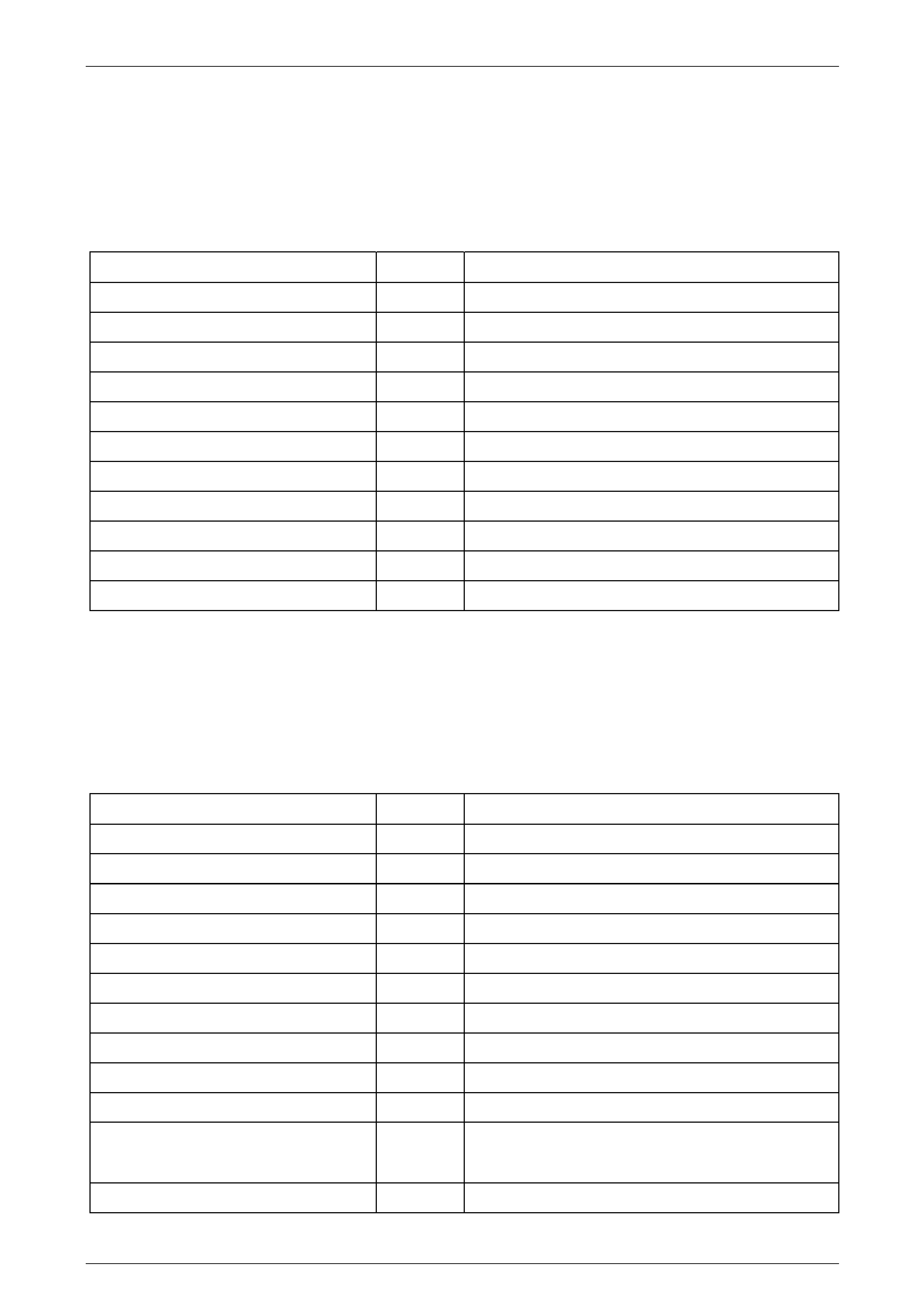

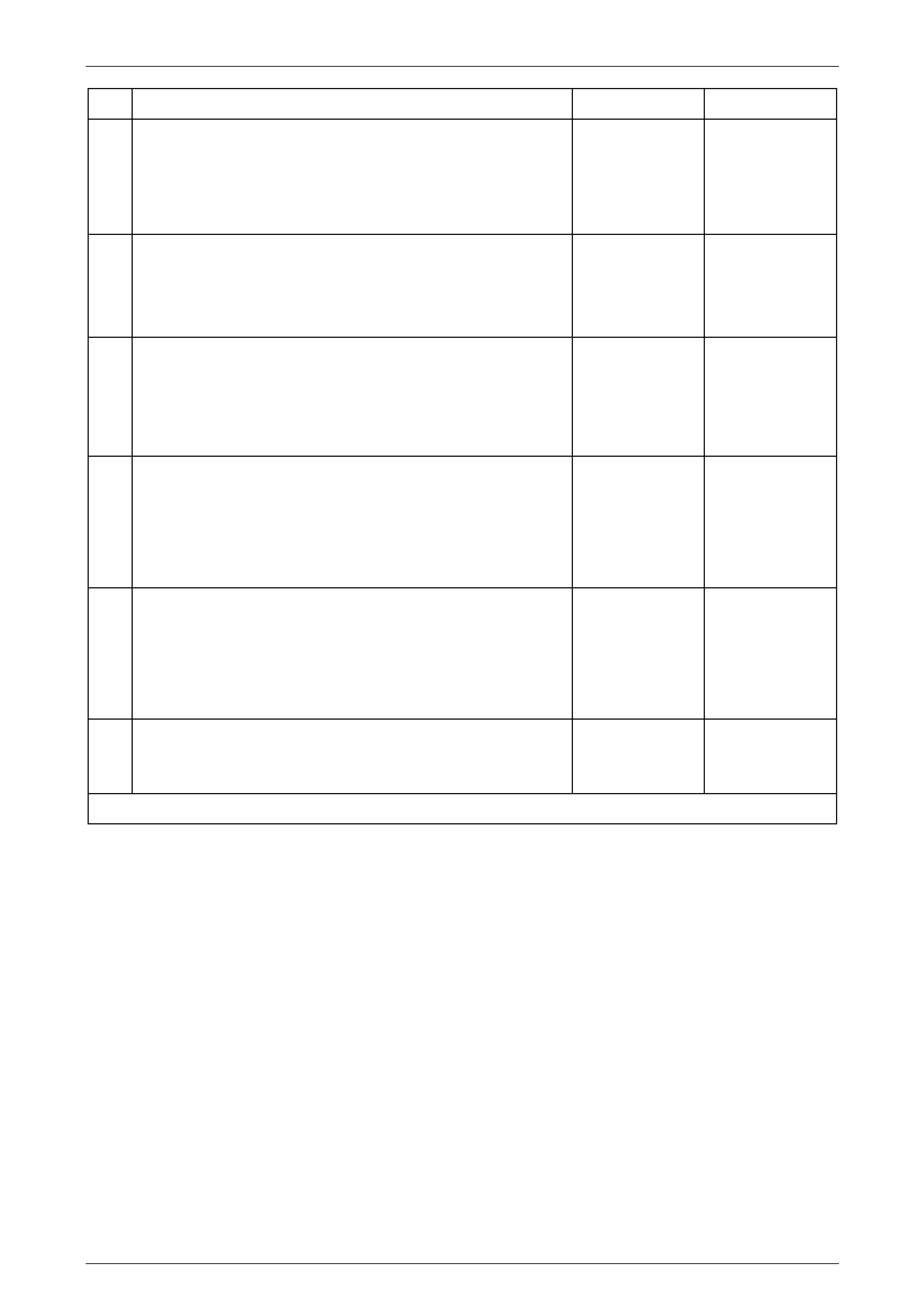

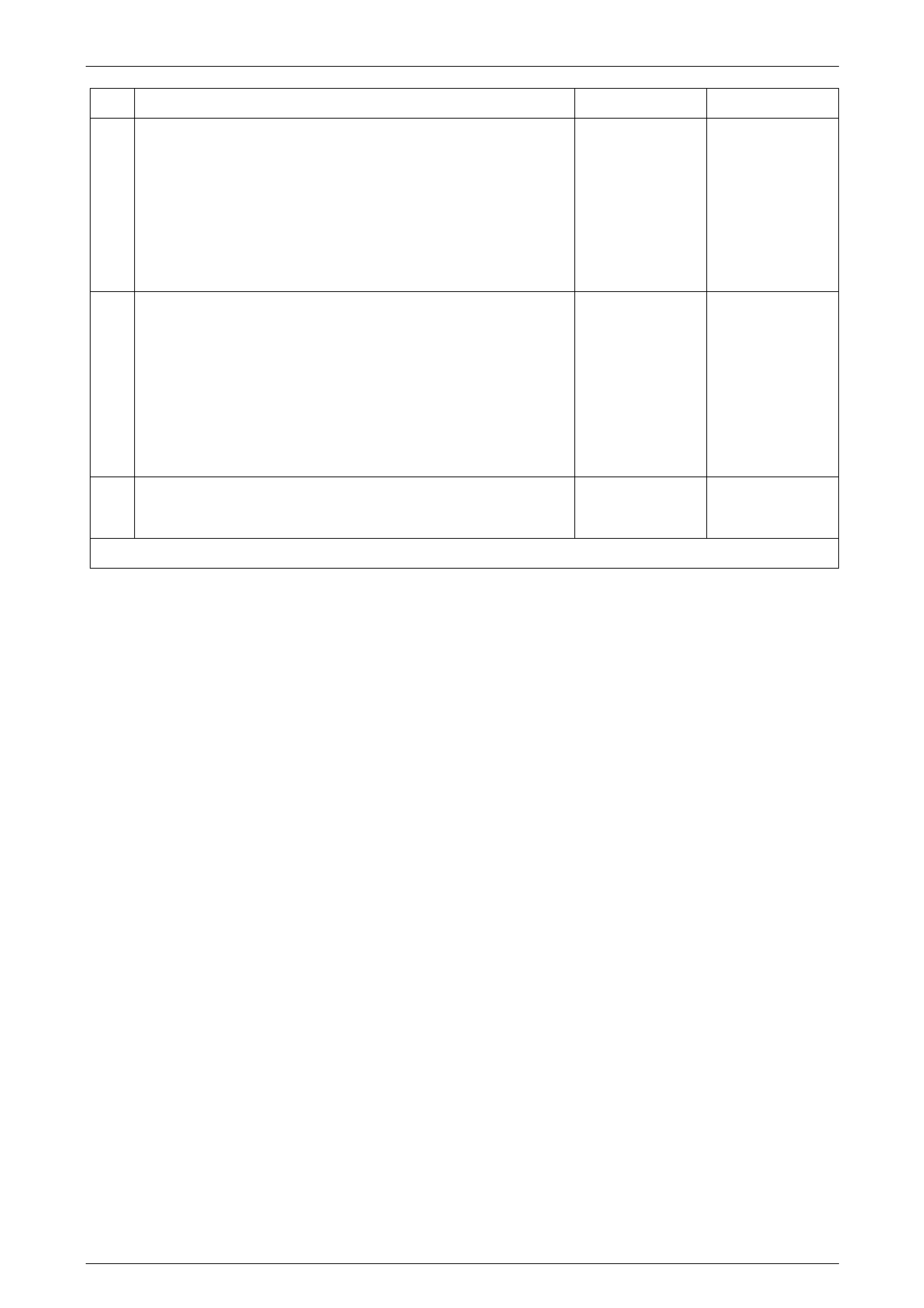

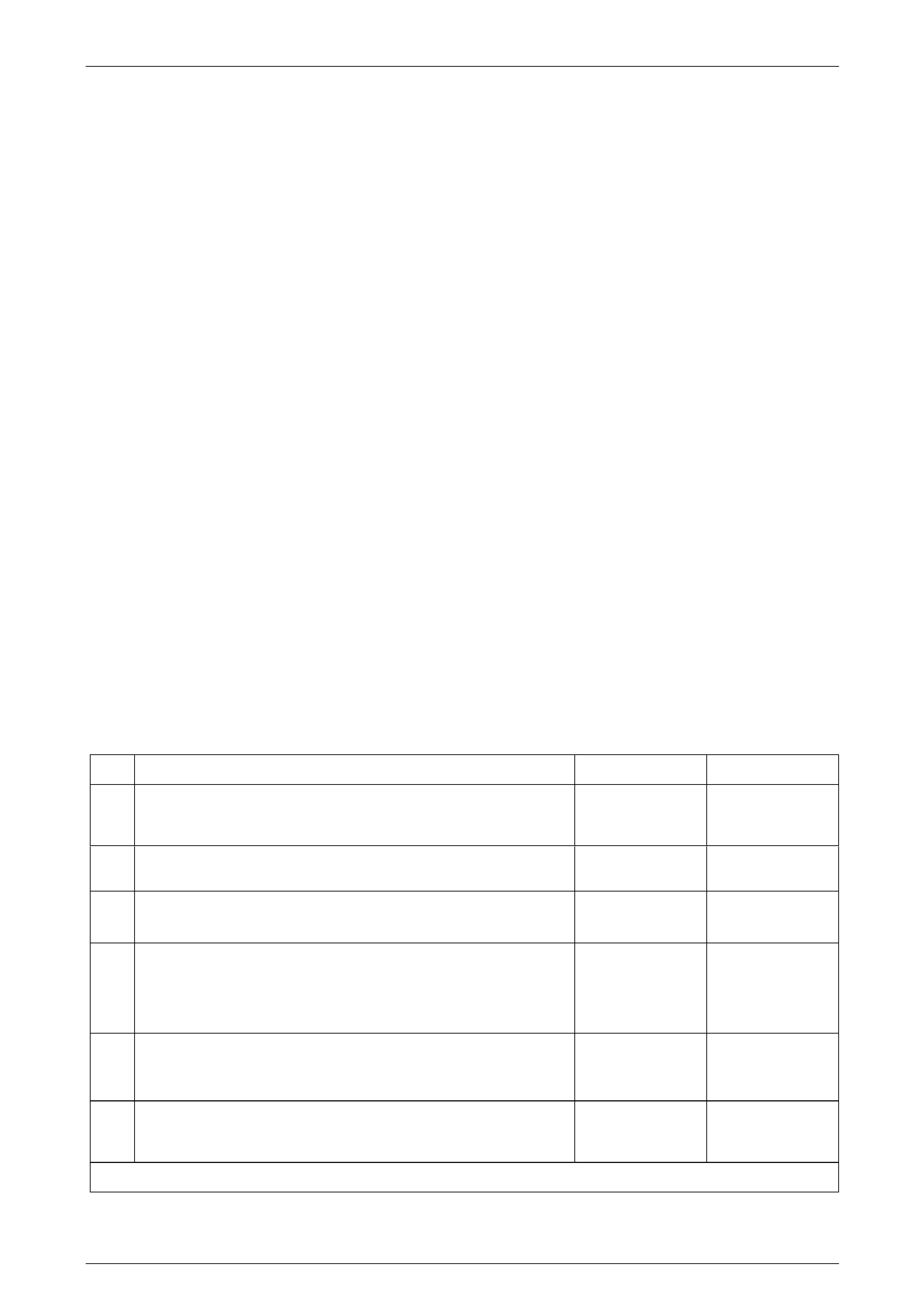

3.2 Connector Charts – V6 ........................................................................................................................................ 80

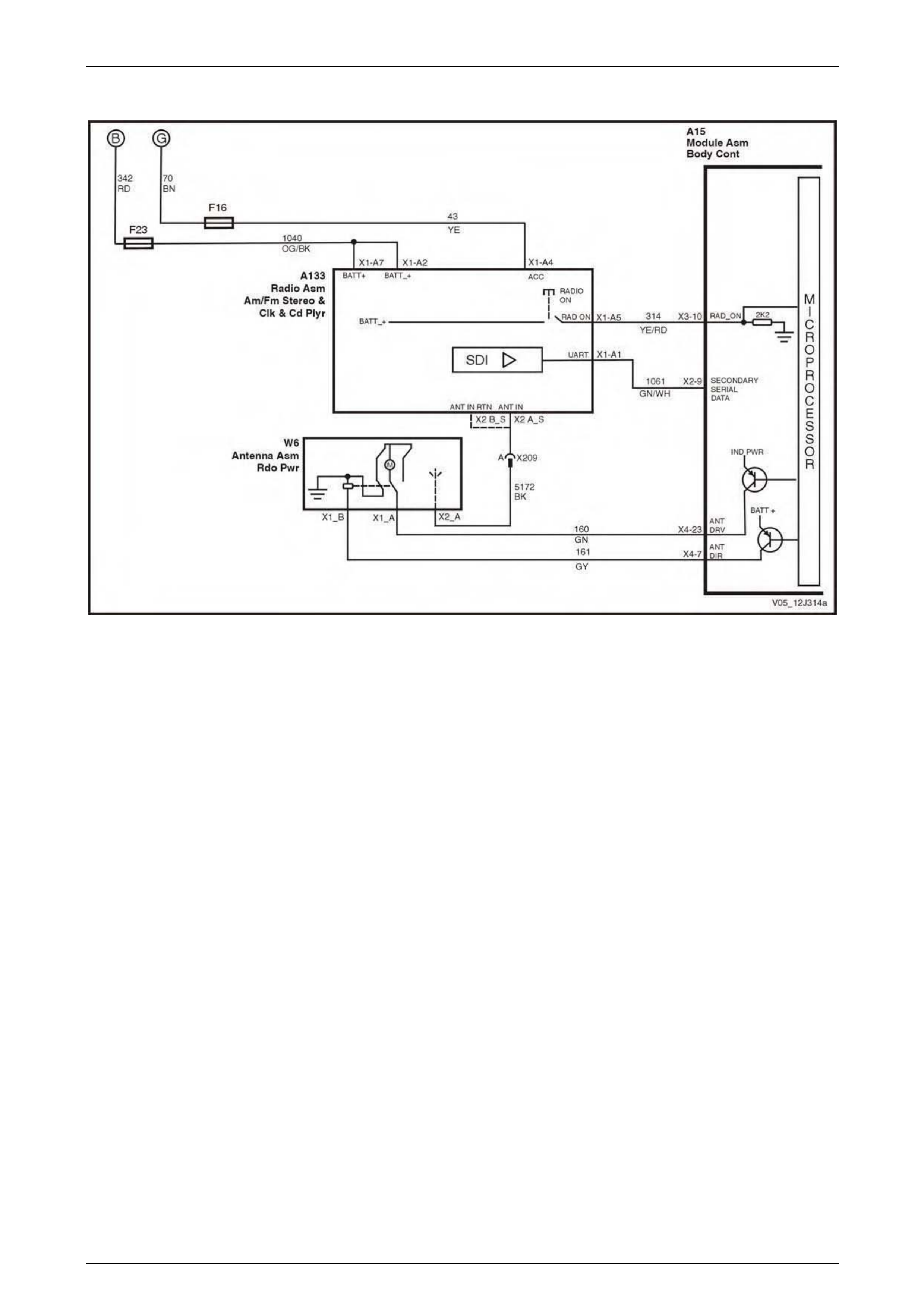

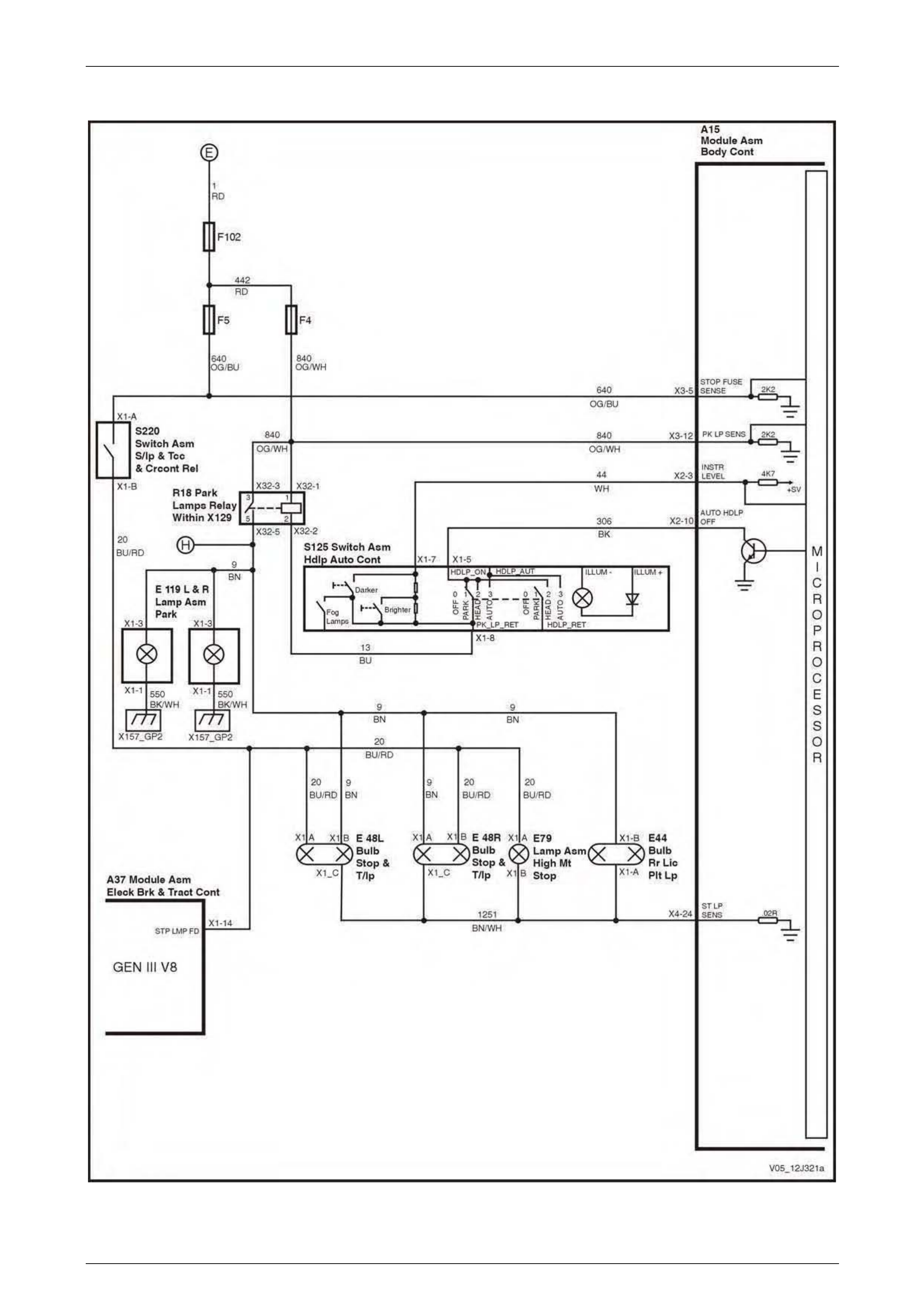

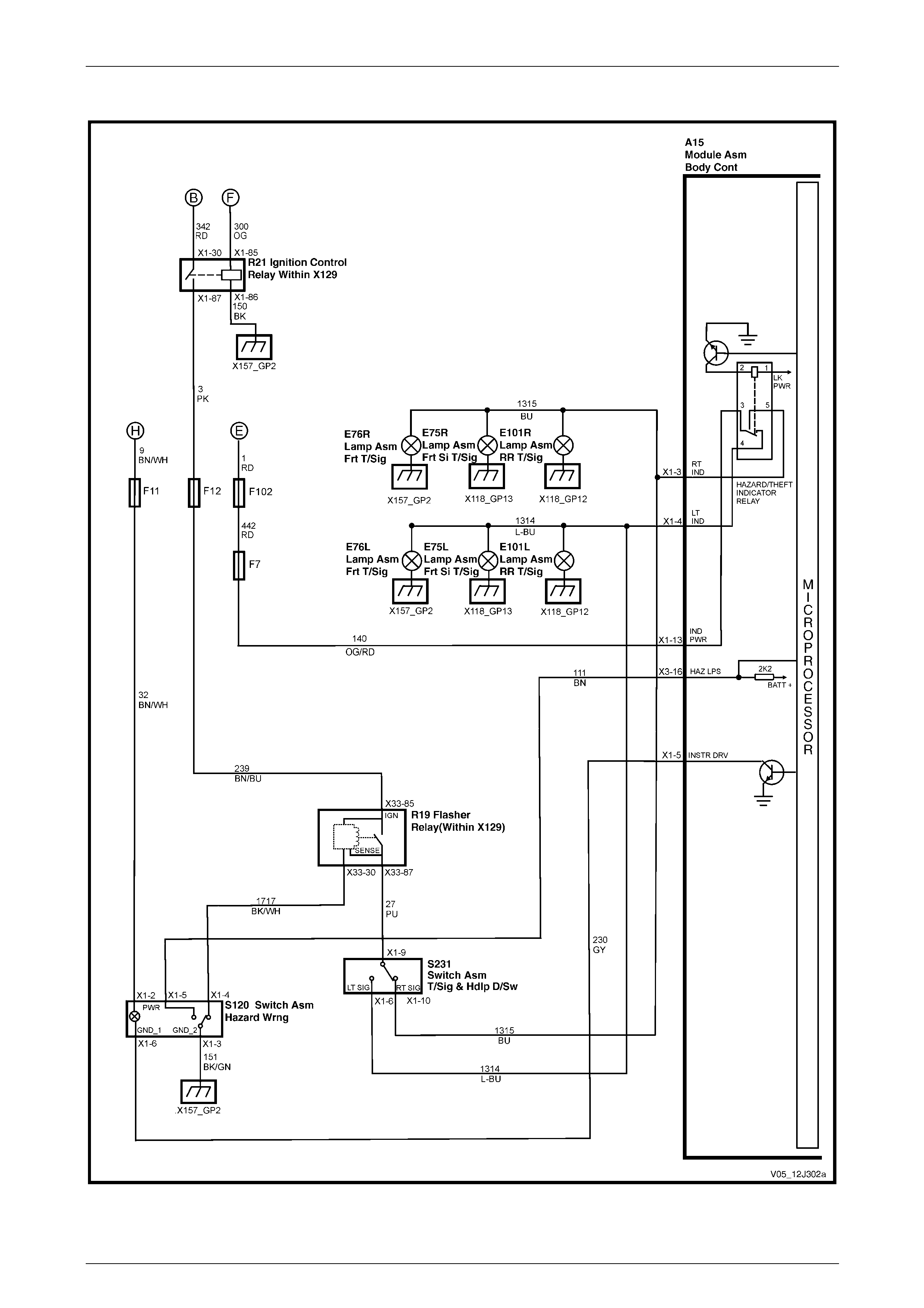

3.3 Wiring Diagrams – GEN III V8 ............................................................................................................................. 84

Ignition Key, RX Sensor, Common Power and Grounds.................................................................................. 84

Accessory Power Circuit..................................................................................................................................... 85

UART and Class 2 Communications.................................................................................................................. 86

Central Door Locking .......................................................................................................................................... 87

Entry Deterrent, Warning Horns and Rear Compartment Solenoid................................................................. 88

Power Windows................................................................................................................................................... 89

Wiper Systems Intermittent Function ................................................................................................................ 90

Dome Lamp Delay Control.................................................................................................................................. 91

Automatic Lamp Control..................................................................................................................................... 92

Pow er Antenna Control....................................................................................................................................... 93

Rear Lamp Failure System.................................................................................................................................. 94

Hazard Lamp Control, Theft / Turn Signal Lamp Flasher................................................................................. 95

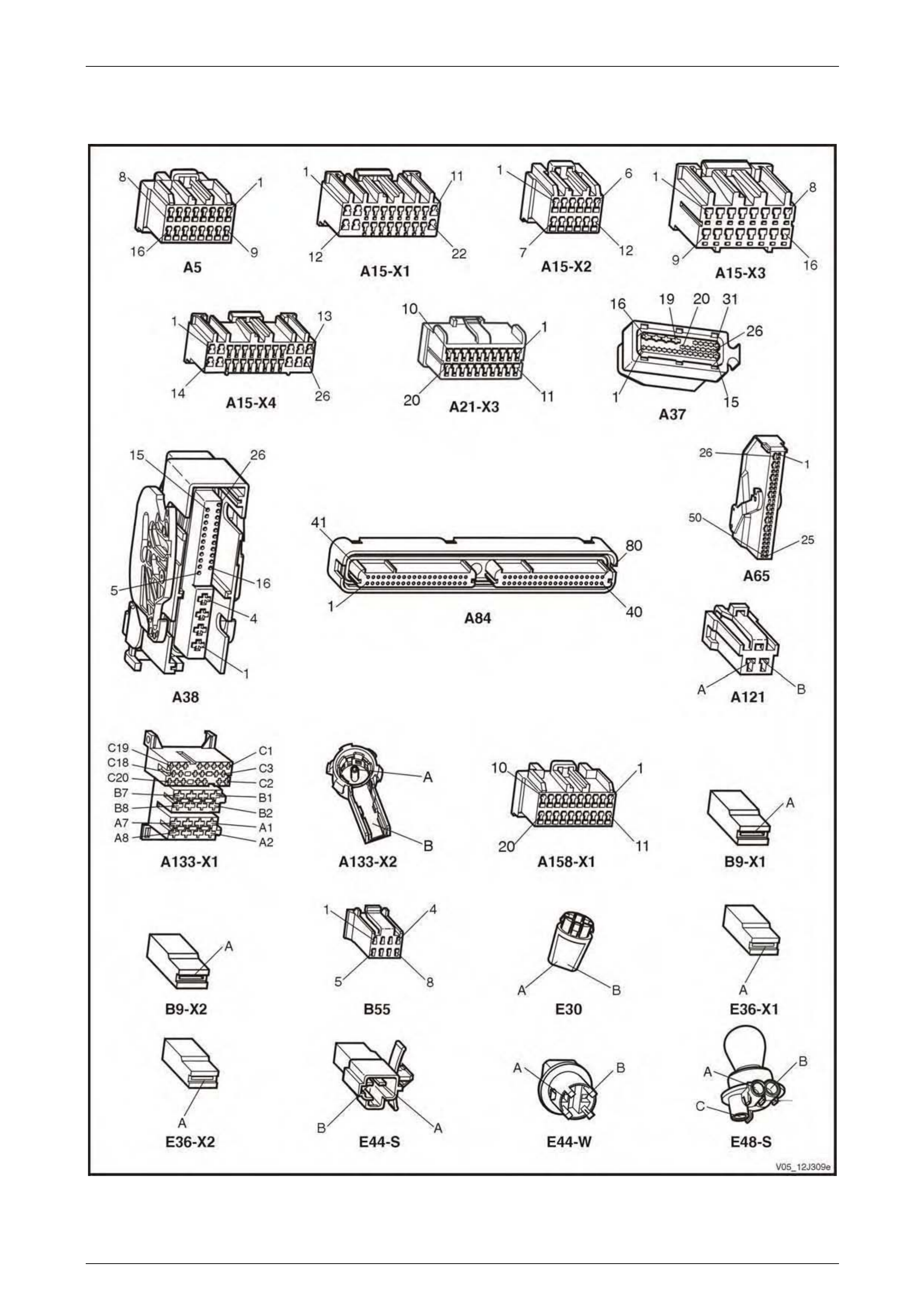

3.4 Connector Charts – GEN III V8............................................................................................................................ 96

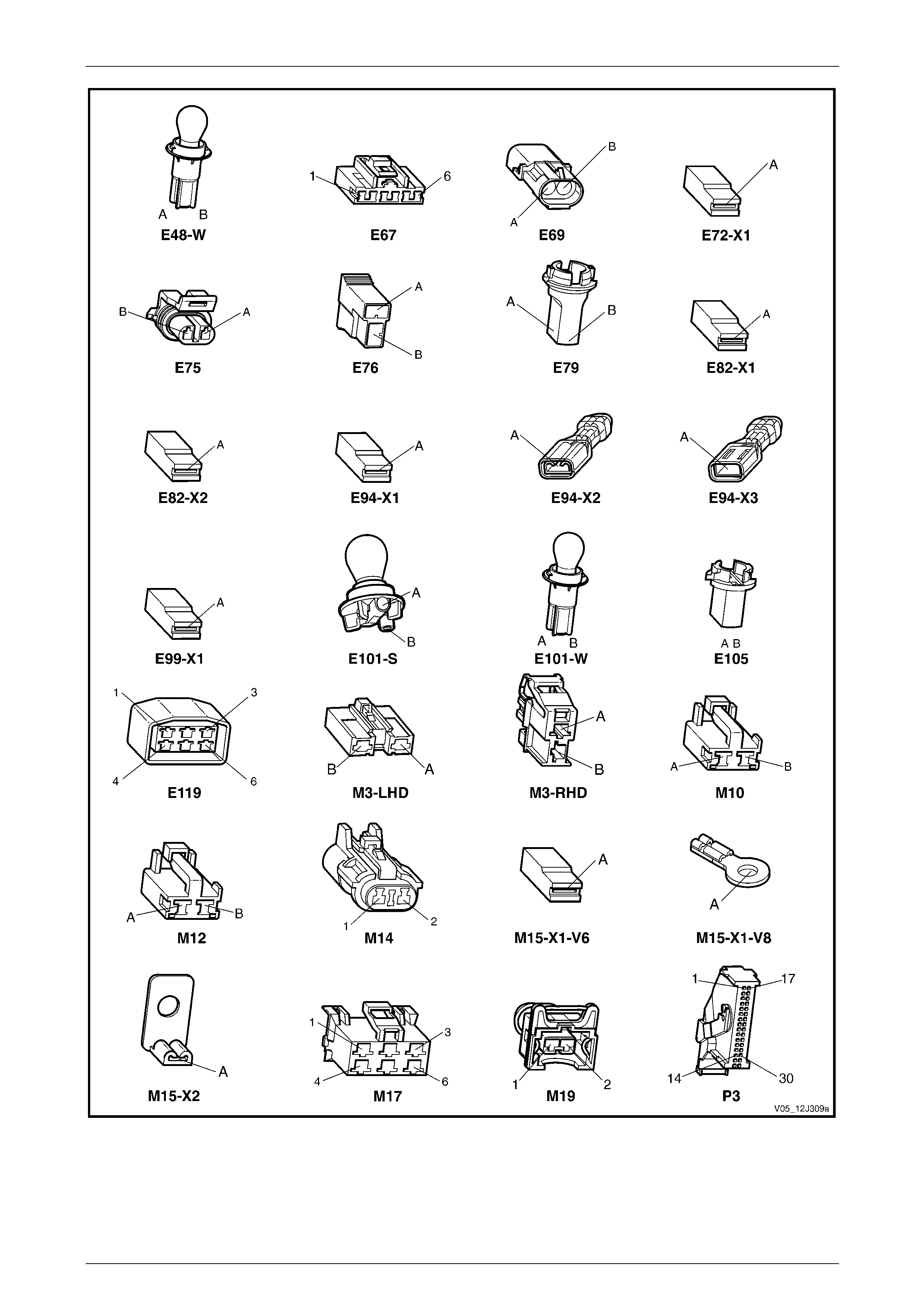

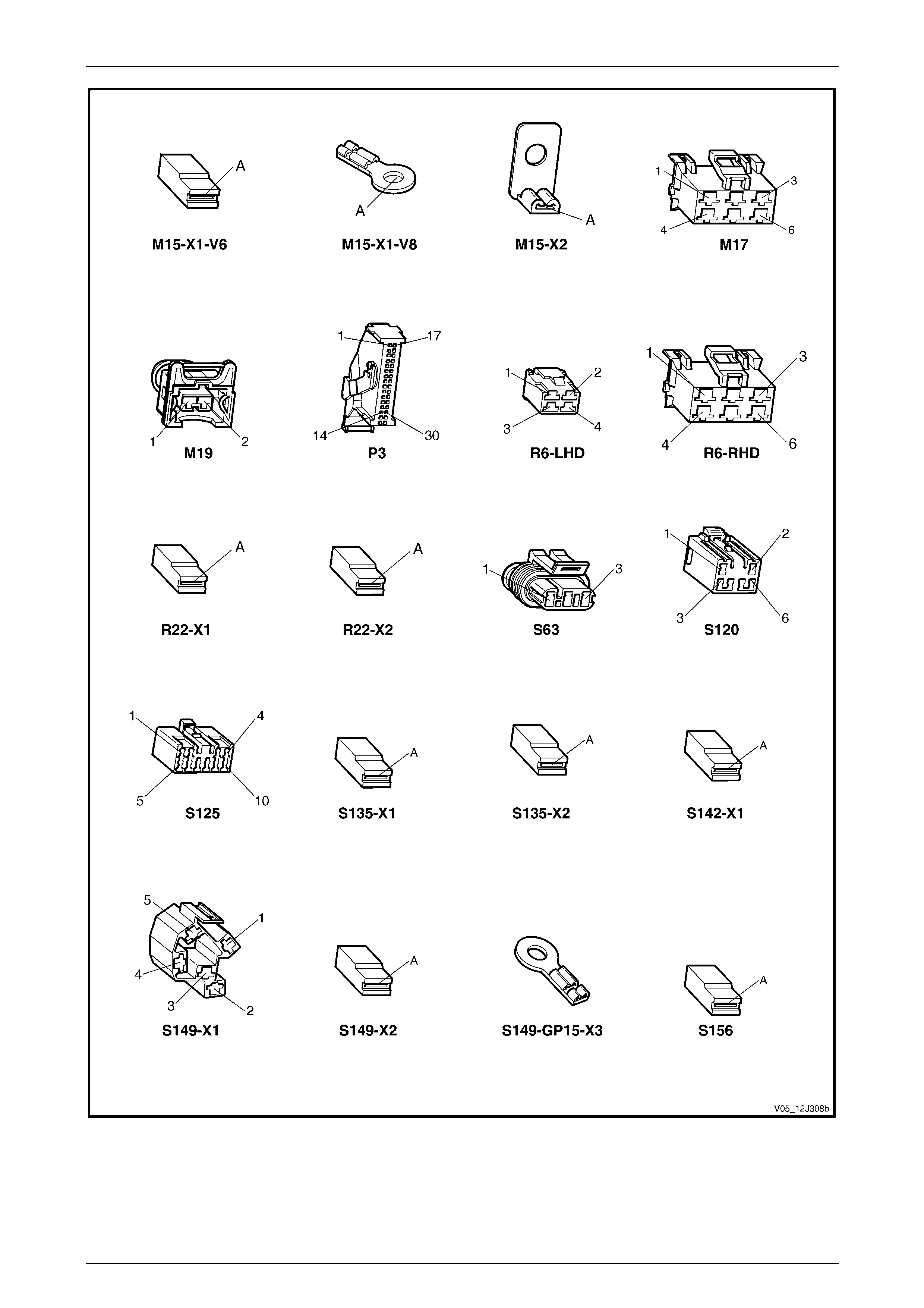

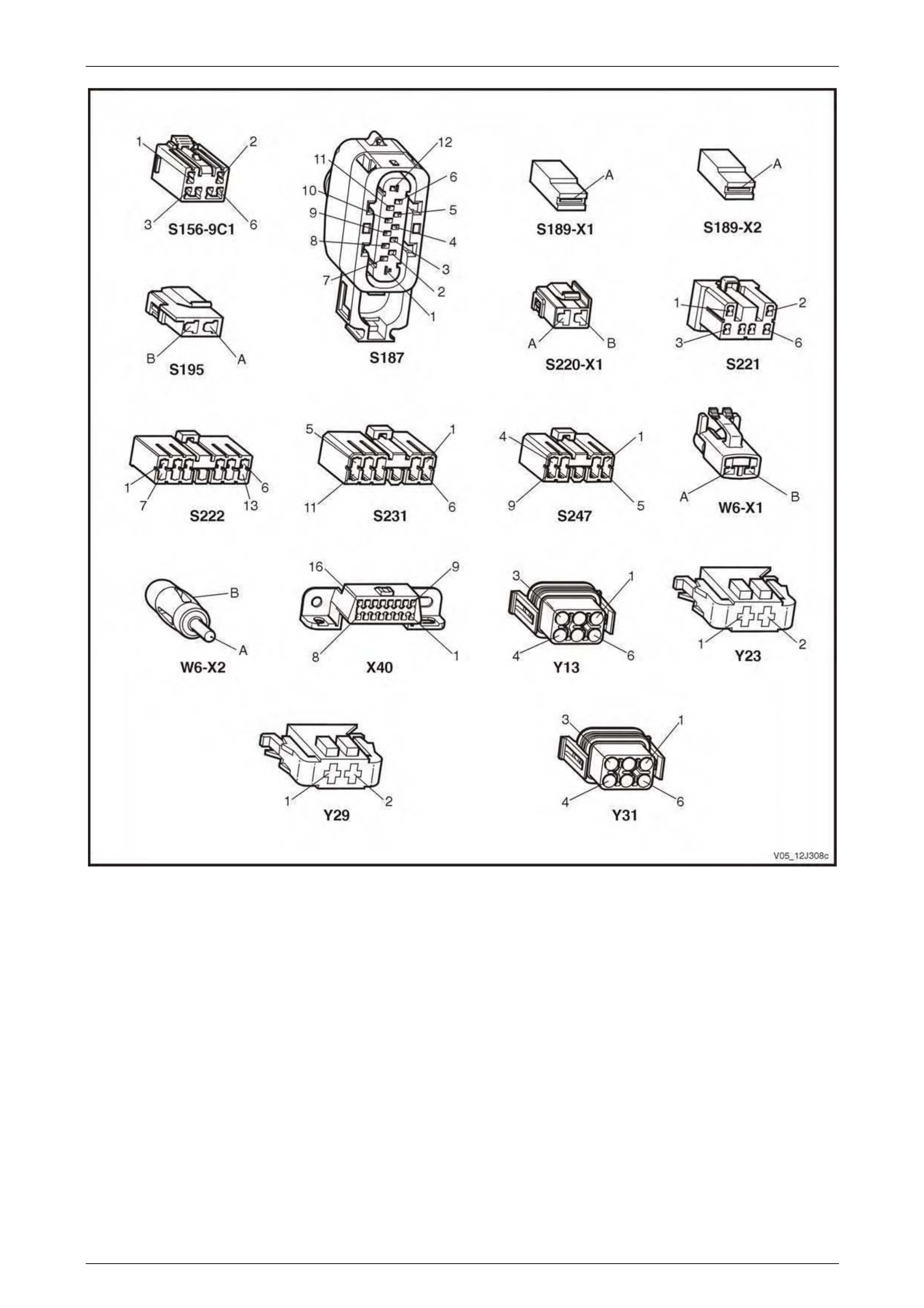

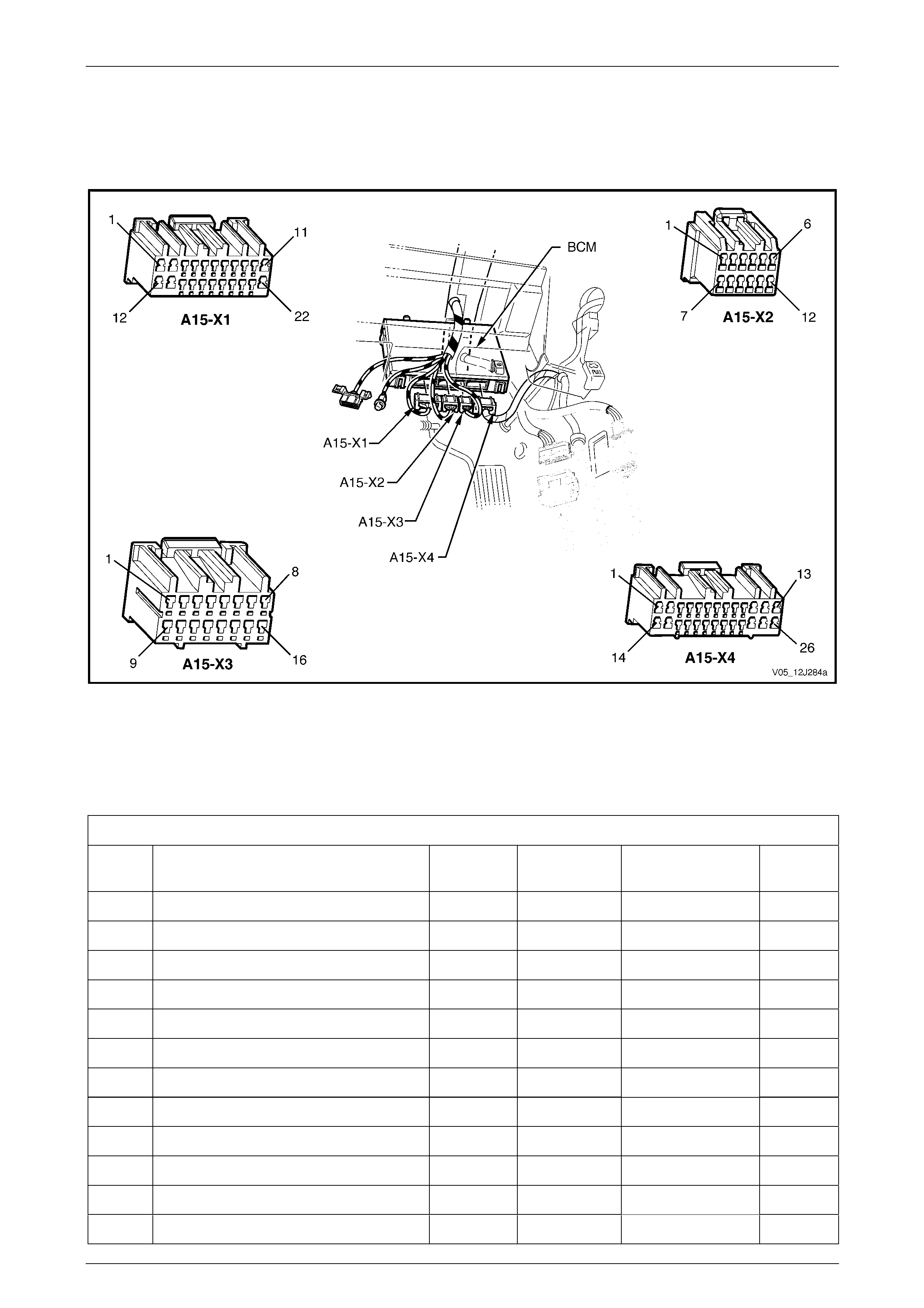

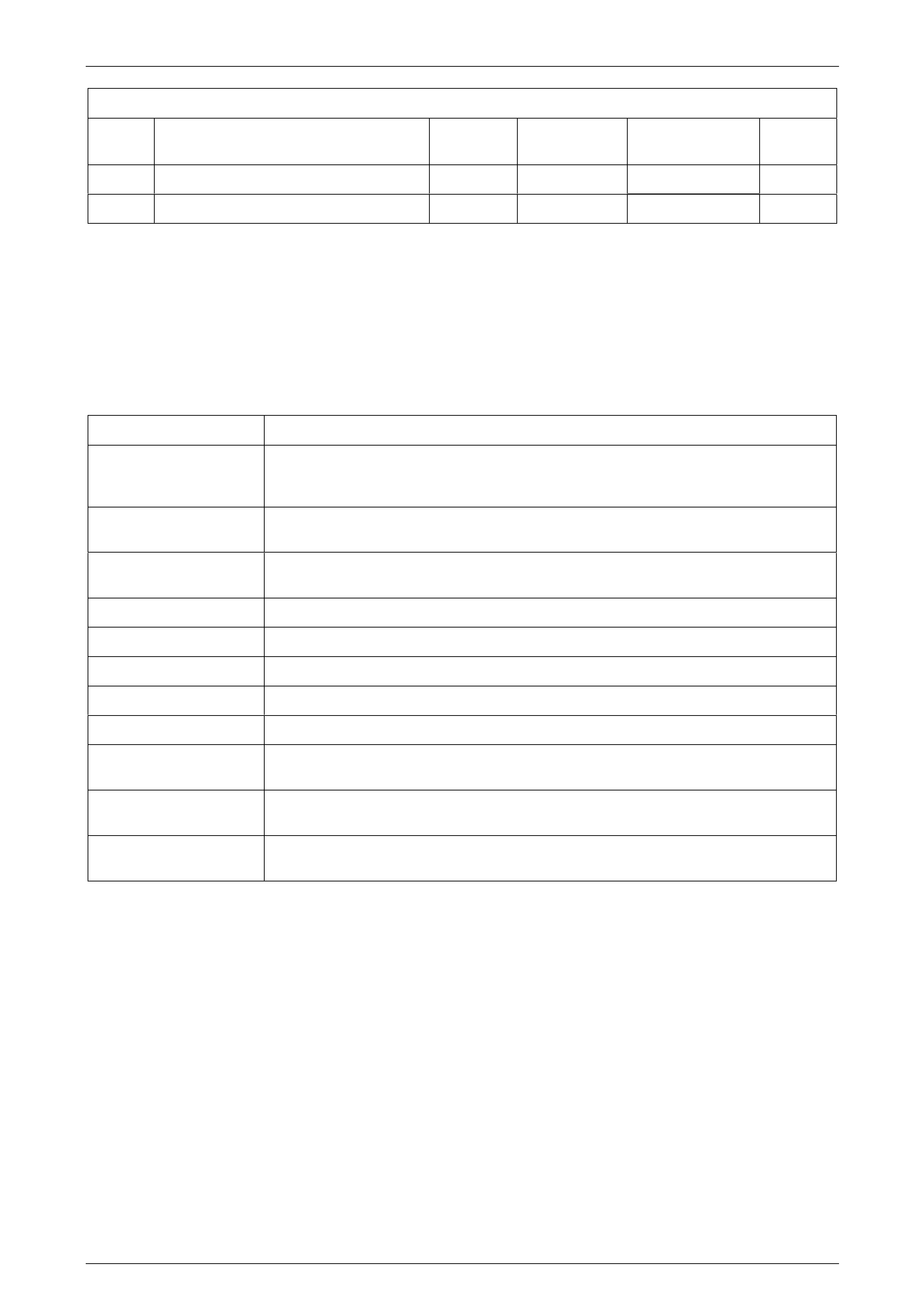

3.5 Connector Information ...................................................................................................................................... 100

BCM Location and Wiring Connectors ............................................................................................................ 100

BCM Connector Pin Identification.................................................................................................................... 100

Legend – Circuit Type .................................................................................................................................... 103

Explanation of Terms ..................................................................................................................................... 103

4 Tech 2 Information .............................................................................................................................104

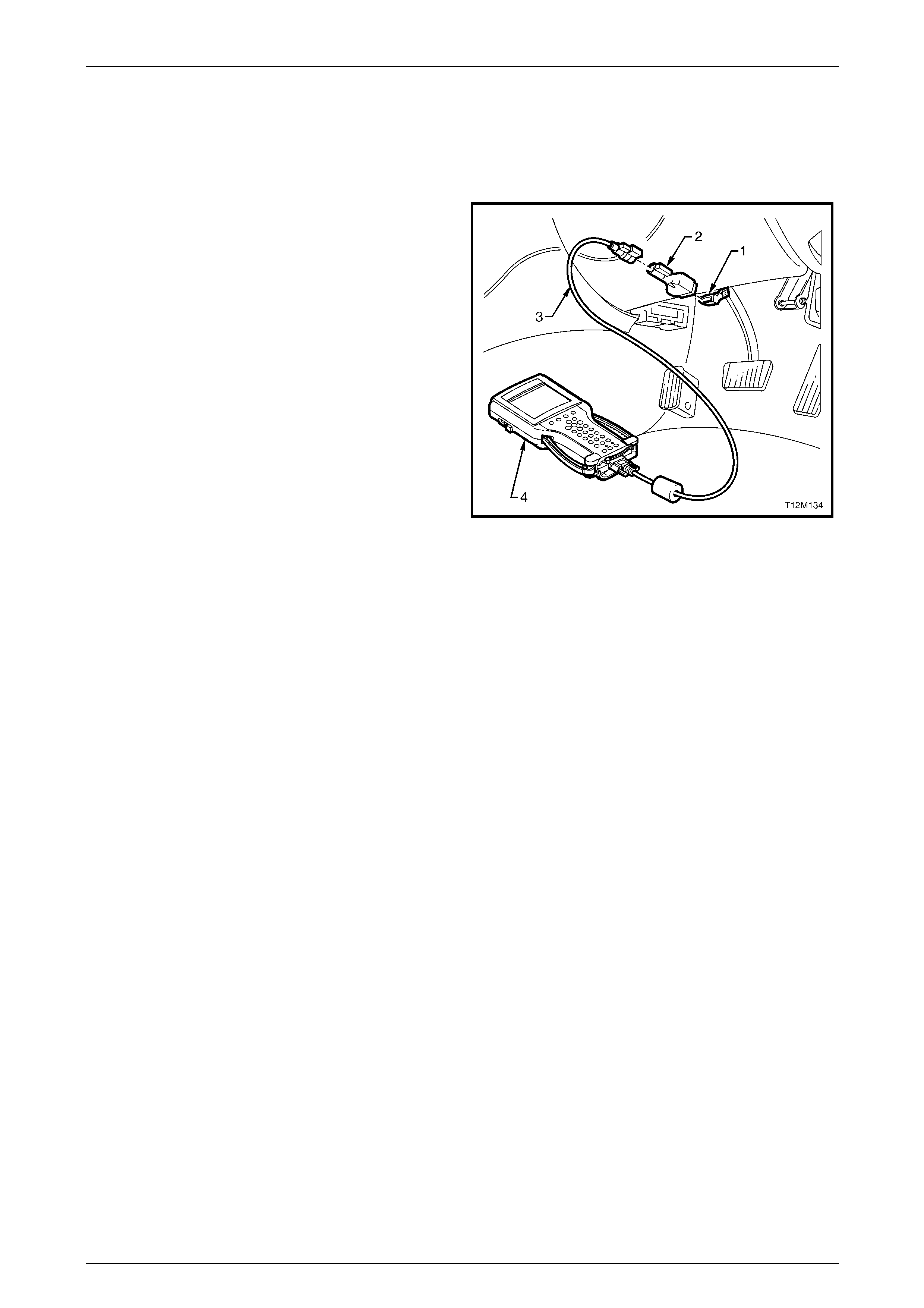

4.1 Connecting Tech 2 for System Diagnosis ....................................................................................................... 104

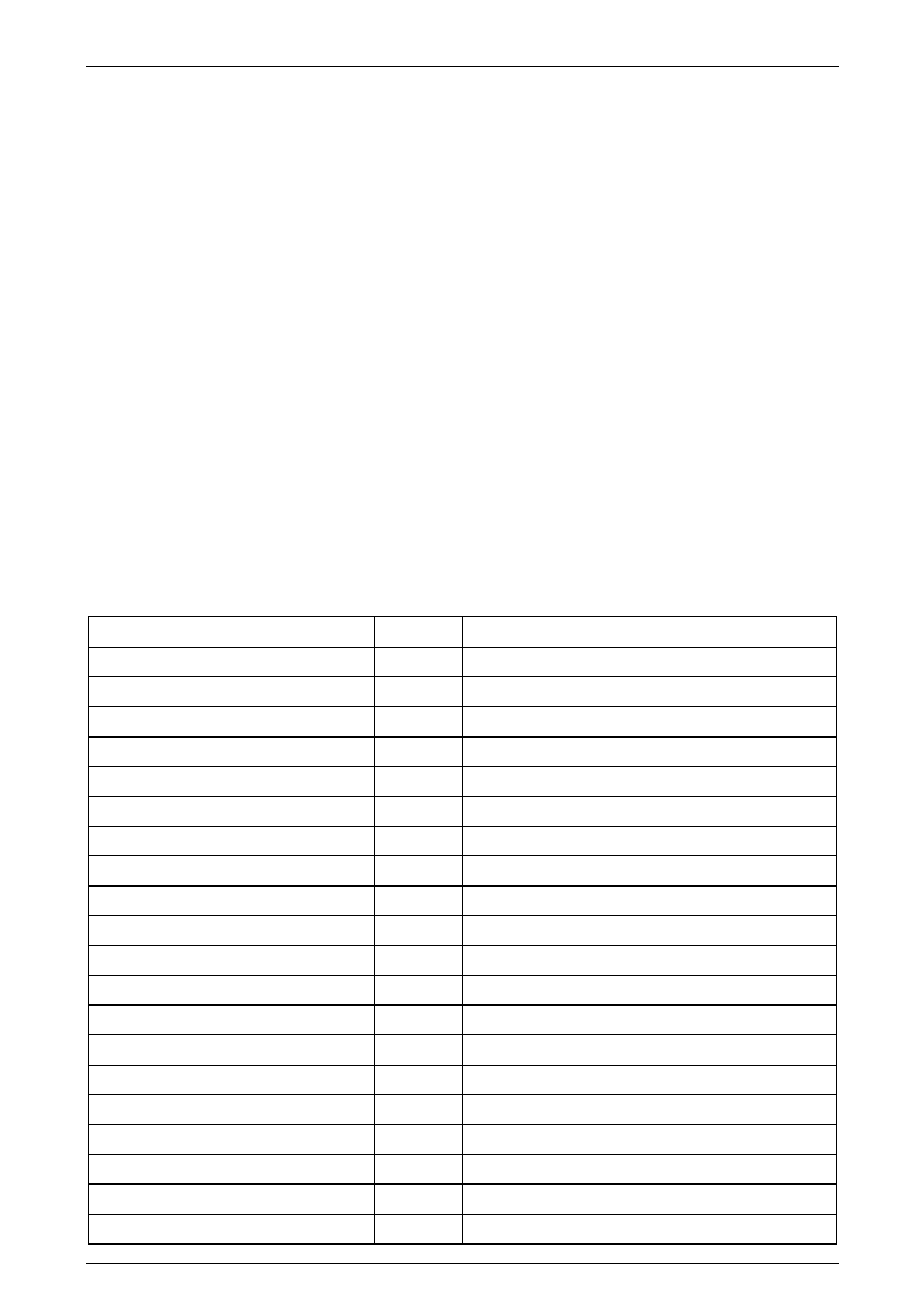

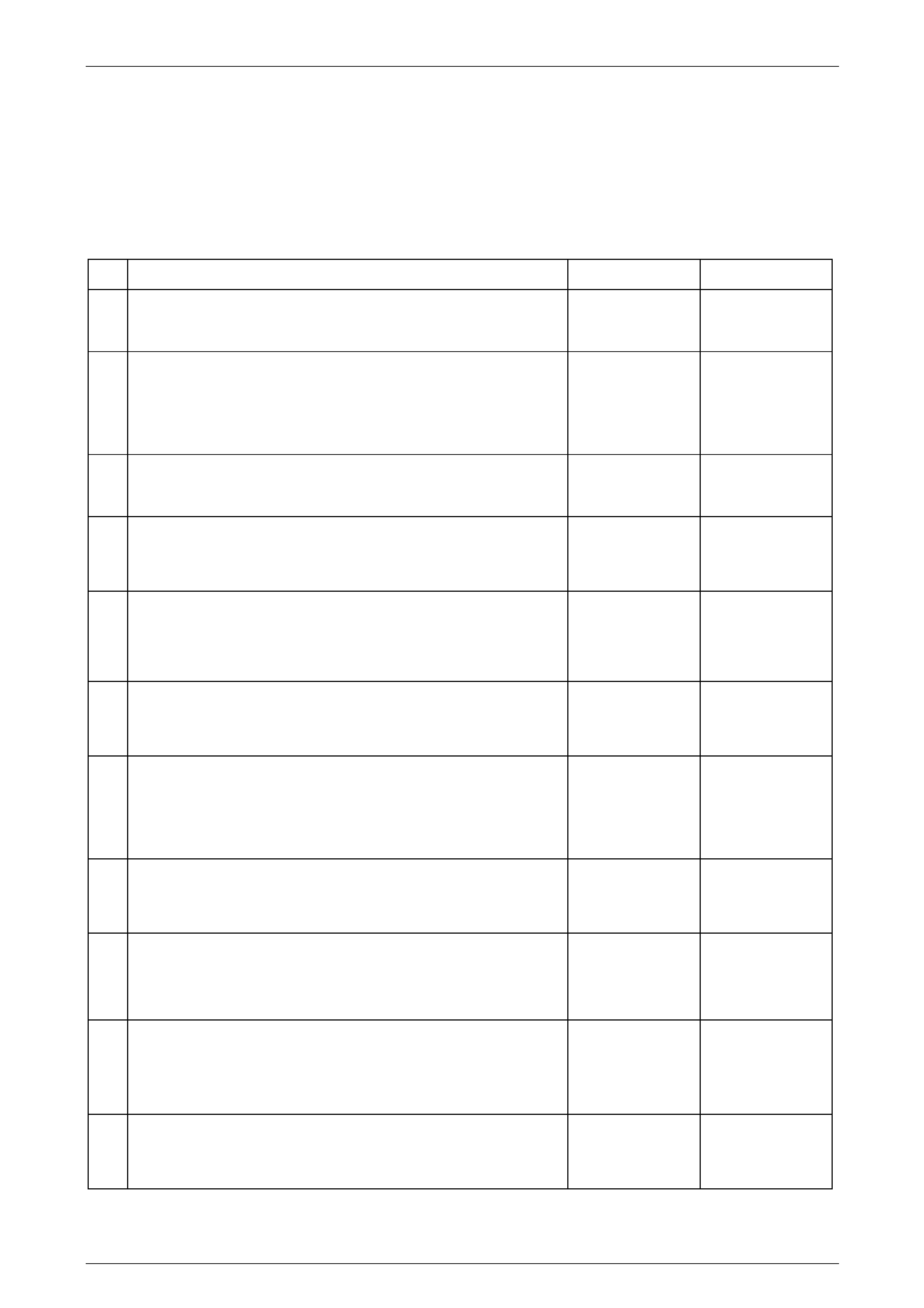

4.2 Tech 2 Test Modes and Displays...................................................................................................................... 105

4.3 Normal Mode...................................................................................................................................................... 106

4.4 Diagnostic Trouble Codes ................................................................................................................................ 107

Read DTC Information....................................................................................................................................... 107

Read Alarm Codes............................................................................................................................................. 107

Clear DTC and Alarm Codes ............................................................................................................................. 107

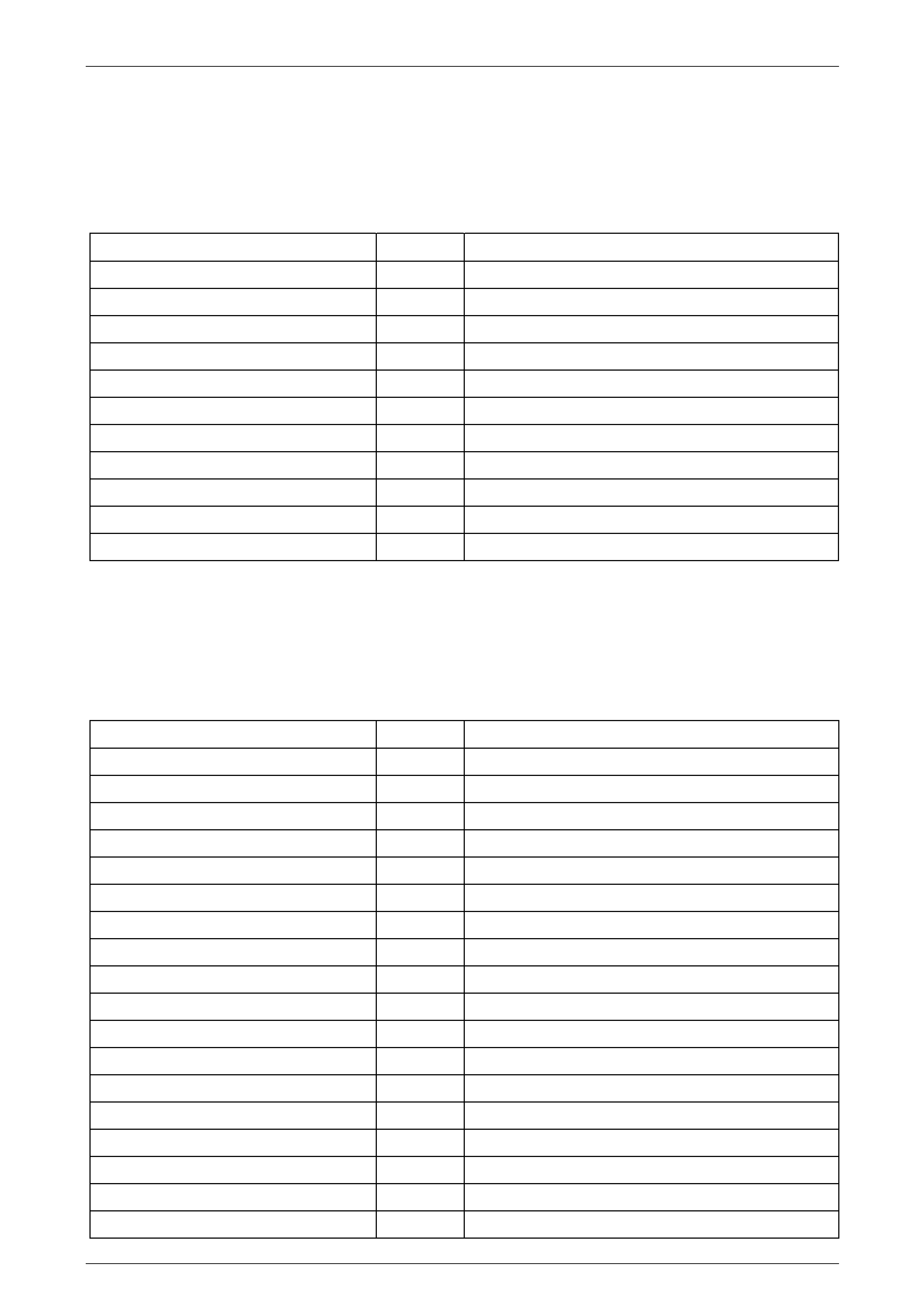

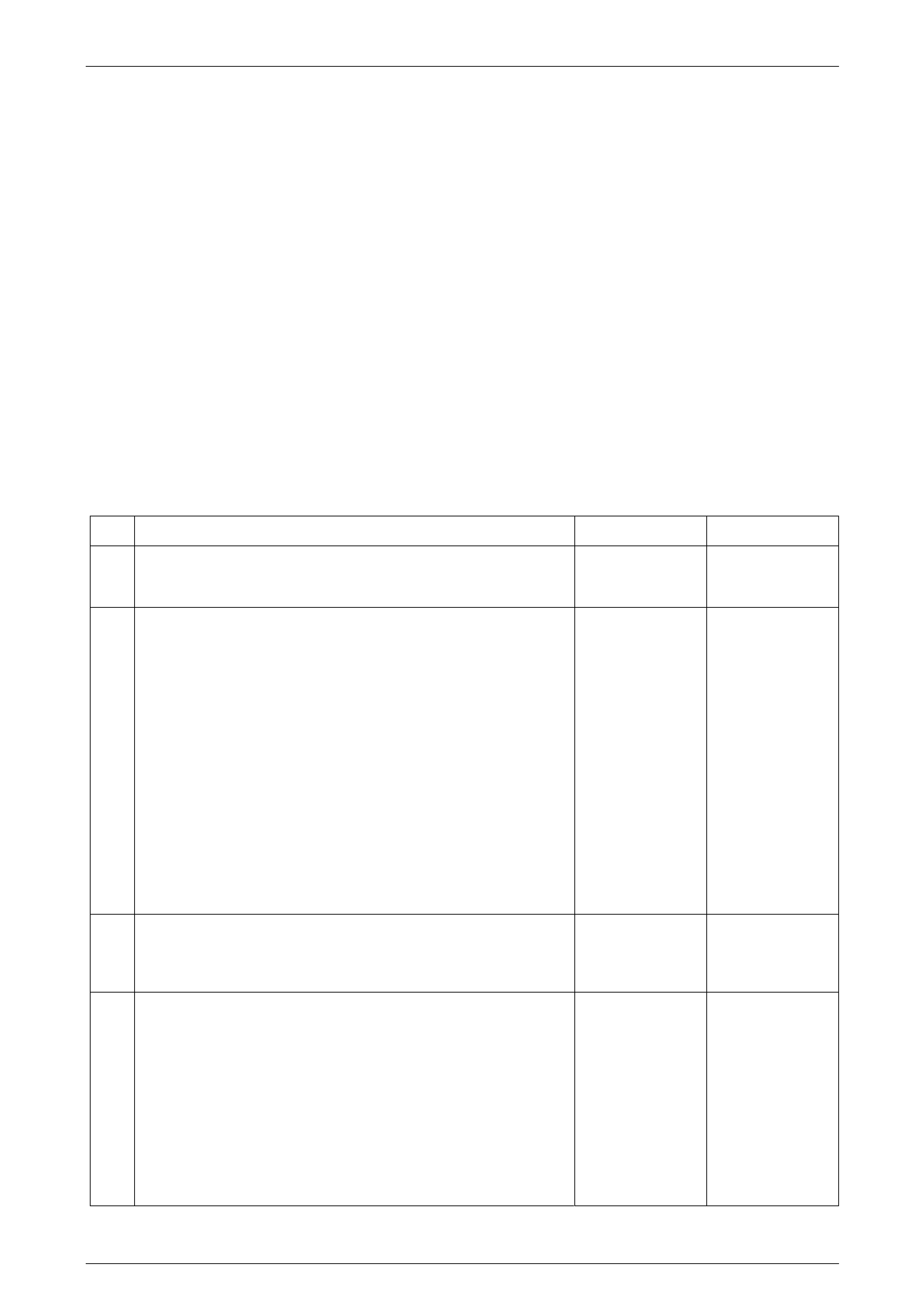

4.5 Data Display ....................................................................................................................................................... 108

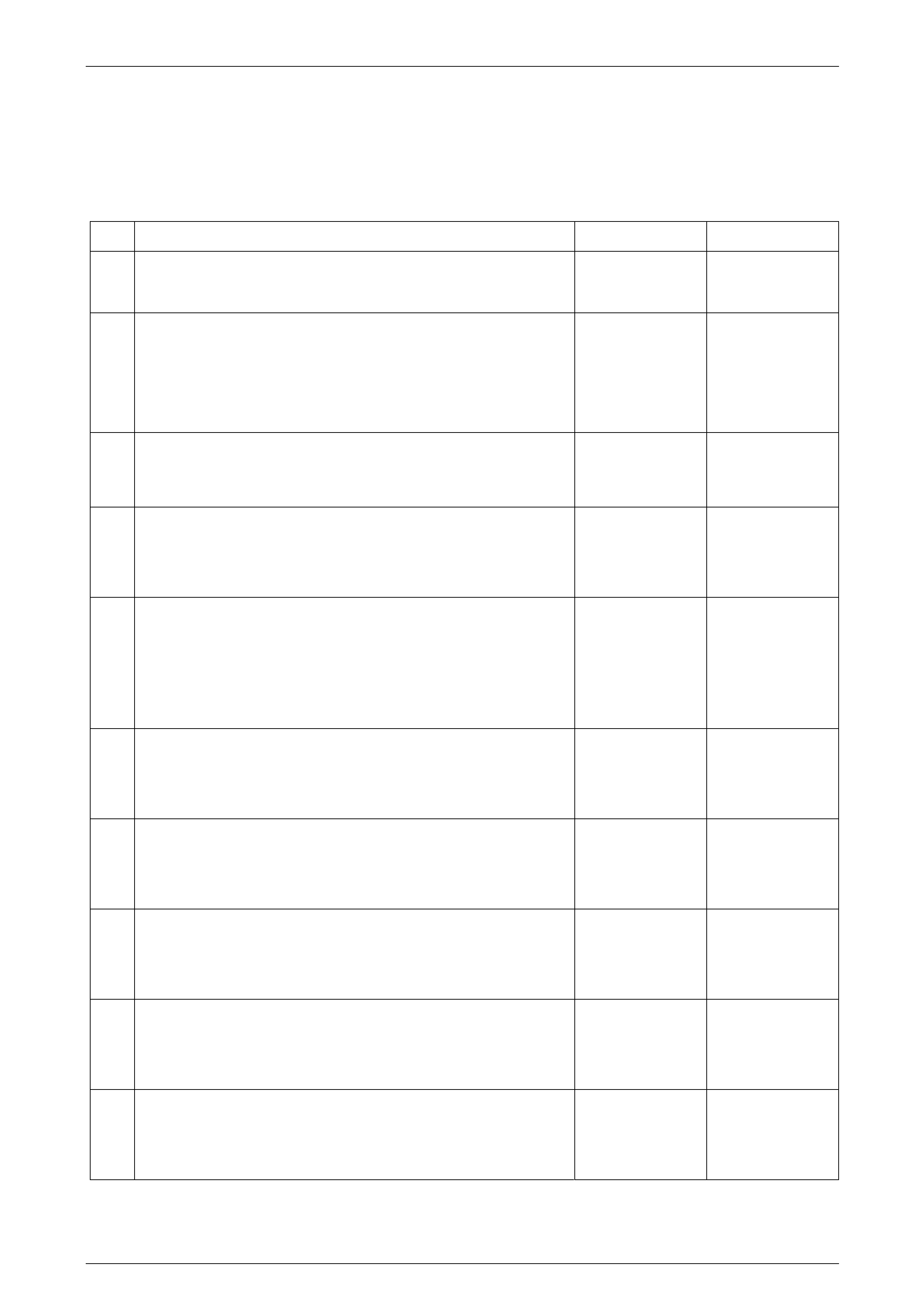

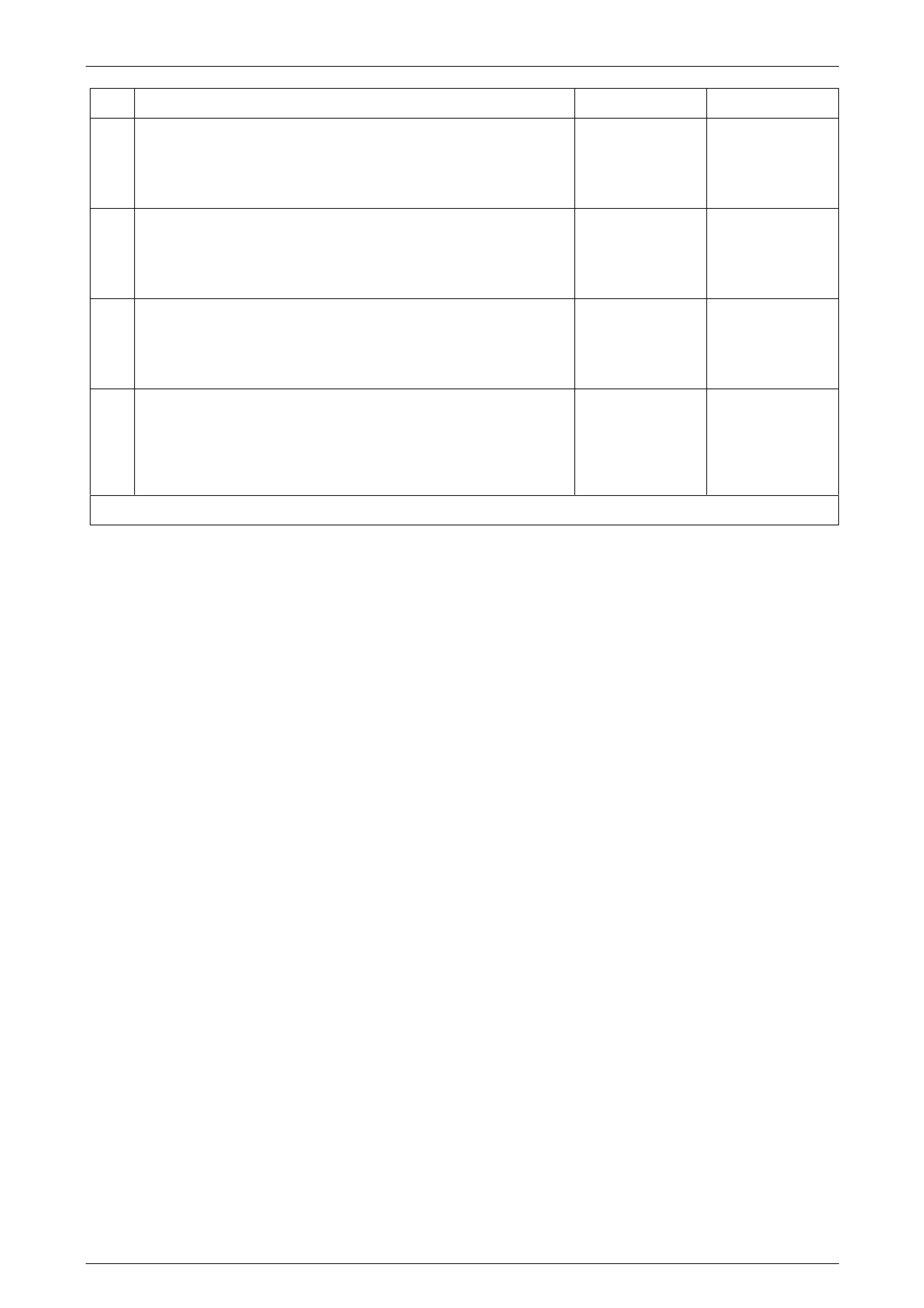

Inputs and Outputs............................................................................................................................................ 108

BCM Internal Status........................................................................................................................................... 110

Serial Data Inputs............................................................................................................................................... 111

Priority 1 User Settings ..................................................................................................................................... 111

Priority 2 User Settings ..................................................................................................................................... 112

Alarm / Theft Deterrent...................................................................................................................................... 112

Central Door Locking ........................................................................................................................................ 113

Power Windows................................................................................................................................................. 114

Wipers................................................................................................................................................................. 114

Headlamps.......................................................................................................................................................... 115

Instrument Illumination..................................................................................................................................... 115

Interior Illumination ........................................................................................................................................... 116

Rear Lamp Failure.............................................................................................................................................. 116

Antenna............................................................................................................................................................... 117

System Identification......................................................................................................................................... 117

4.6 Snapshot ............................................................................................................................................................ 118

Body Control Module Page 12J–5

Page 12J–5

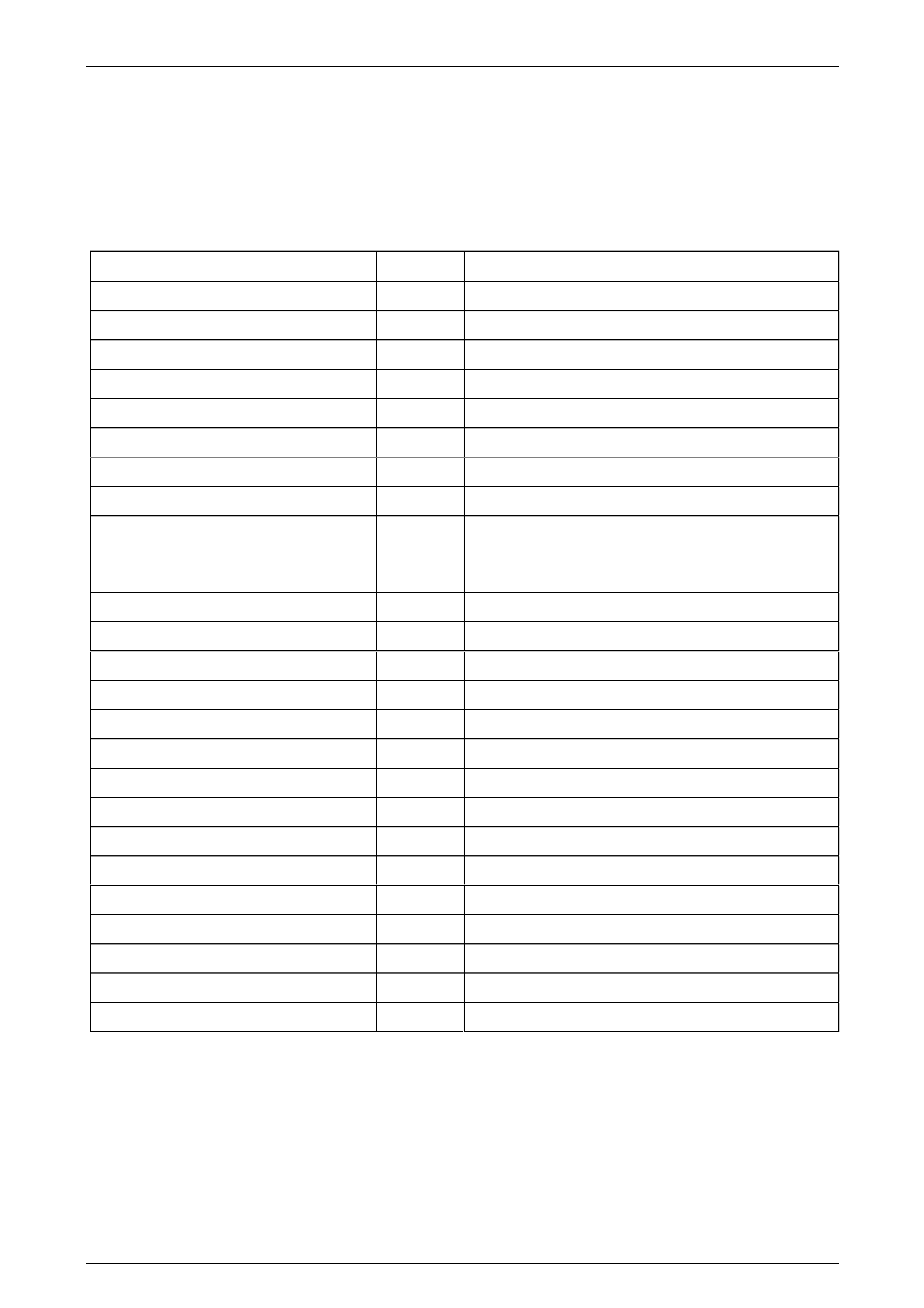

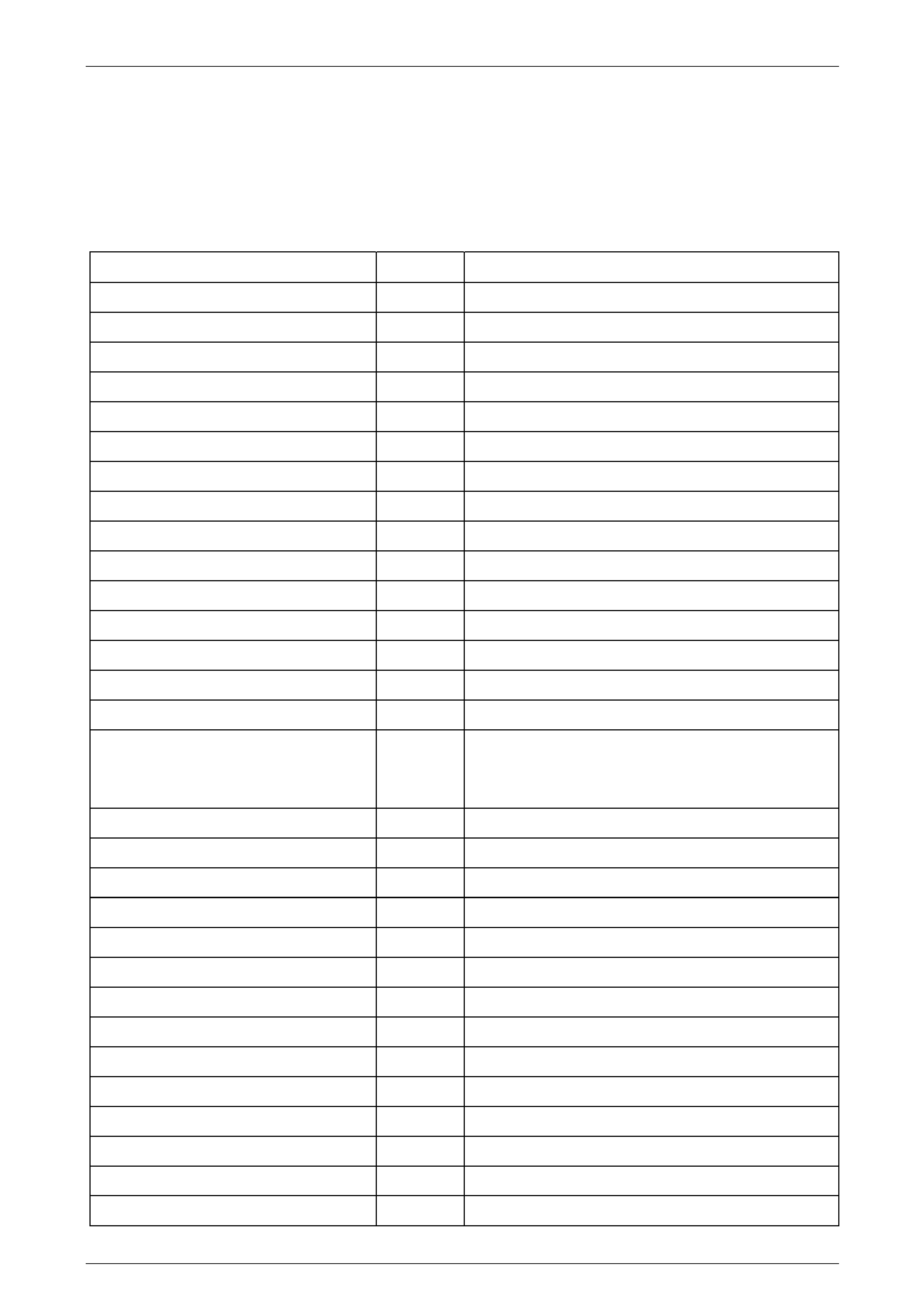

4.7 Miscellaneous Tests.......................................................................................................................................... 119

Lamps ................................................................................................................................................................. 119

Interior Lamp.................................................................................................................................................. 119

Headlamps..................................................................................................................................................... 120

Indicators........................................................................................................................................................ 120

Instrument Illumination................................................................................................................................... 120

Auto Lights On................................................................................................................................................ 120

Rear Lamp Bulb Fail....................................................................................................................................... 121

Rear Stop Lamp Bulb Fail .............................................................................................................................. 121

Rear Lamp Fuse Fail...................................................................................................................................... 121

Data Bus Isolator ............................................................................................................................................... 122

Central Locking.................................................................................................................................................. 122

Rear Compartment............................................................................................................................................. 122

Wipers................................................................................................................................................................. 123

Front Wipers................................................................................................................................................... 123

Power Windows................................................................................................................................................. 123

Driver’s Window Auto down............................................................................................................................ 123

Front Passenger’s Window Auto down........................................................................................................... 124

Power Window Relay ..................................................................................................................................... 124

Antenna............................................................................................................................................................... 124

Horn .................................................................................................................................................................... 125

Interior Illumination Relay................................................................................................................................. 125

Accessory Relay ................................................................................................................................................ 125

Security System................................................................................................................................................. 126

Security LED .................................................................................................................................................. 126

Theft Deterrent Horn ...................................................................................................................................... 126

Key Priority..................................................................................................................................................... 126

4.8 Program.............................................................................................................................................................. 127

User Settings...................................................................................................................................................... 127

Instrument Illumination................................................................................................................................... 127

Options............................................................................................................................................................... 127

Antenna Height Memory................................................................................................................................. 128

Set Key to Priority 1........................................................................................................................................... 128

Learn BCM Settings........................................................................................................................................... 128

Program Learnt BCM Settings.......................................................................................................................... 128

4.9 Security............................................................................................................................................................... 129

BCM Link to ECM/PCM/PIM............................................................................................................................... 129

Security Information.......................................................................................................................................... 129

Program.............................................................................................................................................................. 130

5 Diagnostics.........................................................................................................................................131

5.1 Introduction........................................................................................................................................................ 131

5.2 Prerequisites to Diagnosis and Troubleshooting........................................................................................... 132

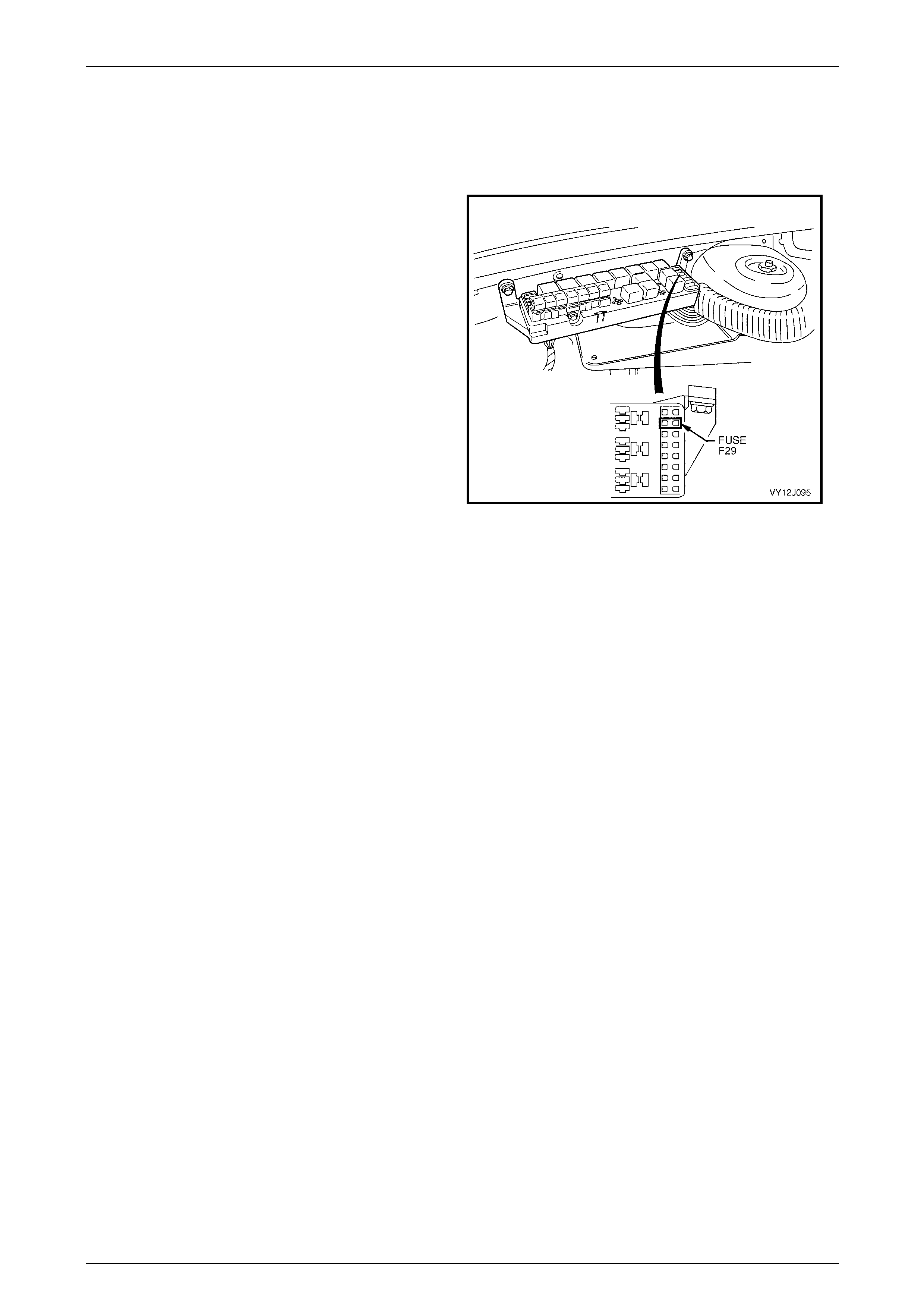

Preliminary System Requirements................................................................................................................... 132

Pre-delivery Mode.............................................................................................................................................. 132

Safety Requirements ......................................................................................................................................... 132

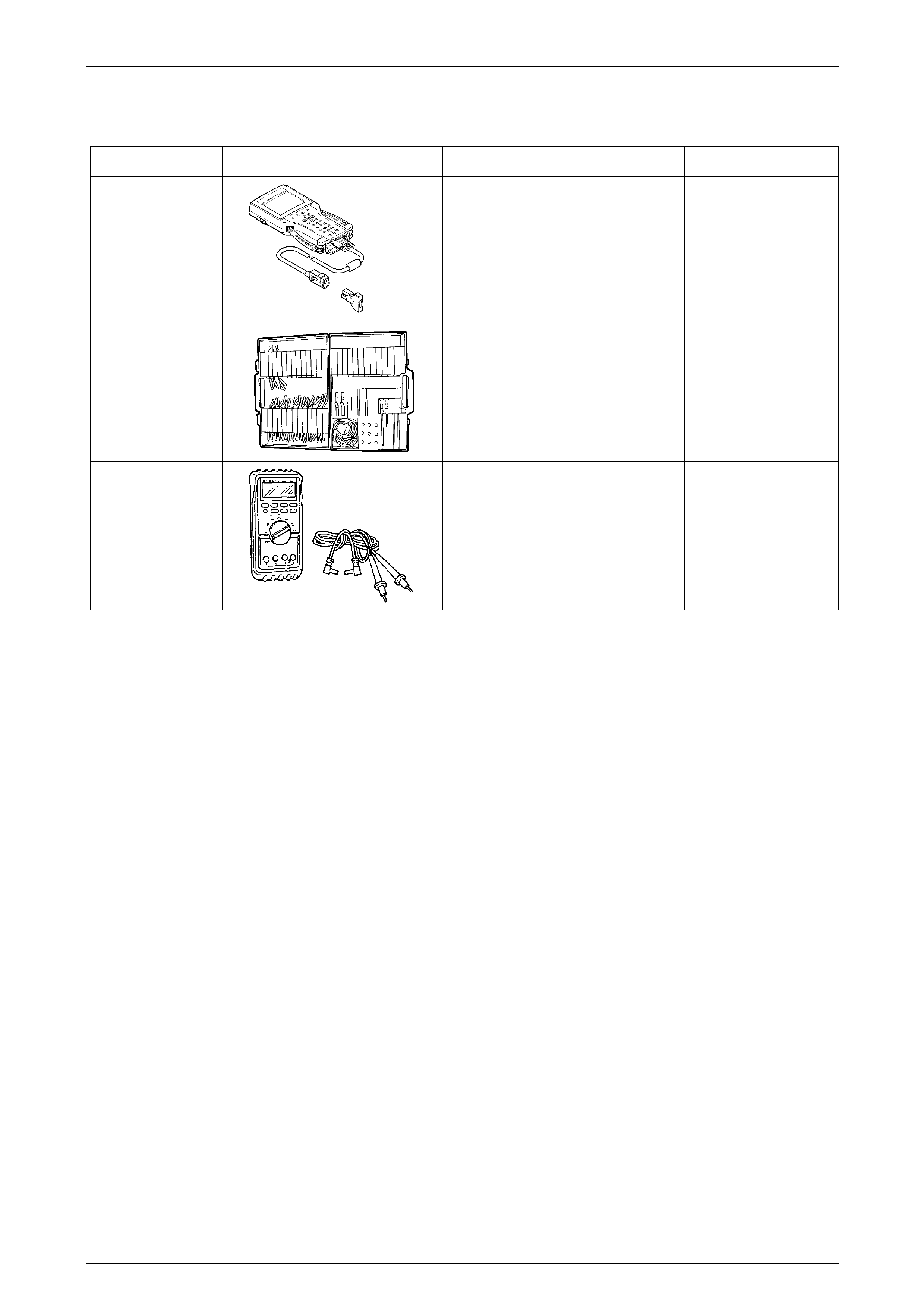

Equipment and Checking.................................................................................................................................. 132

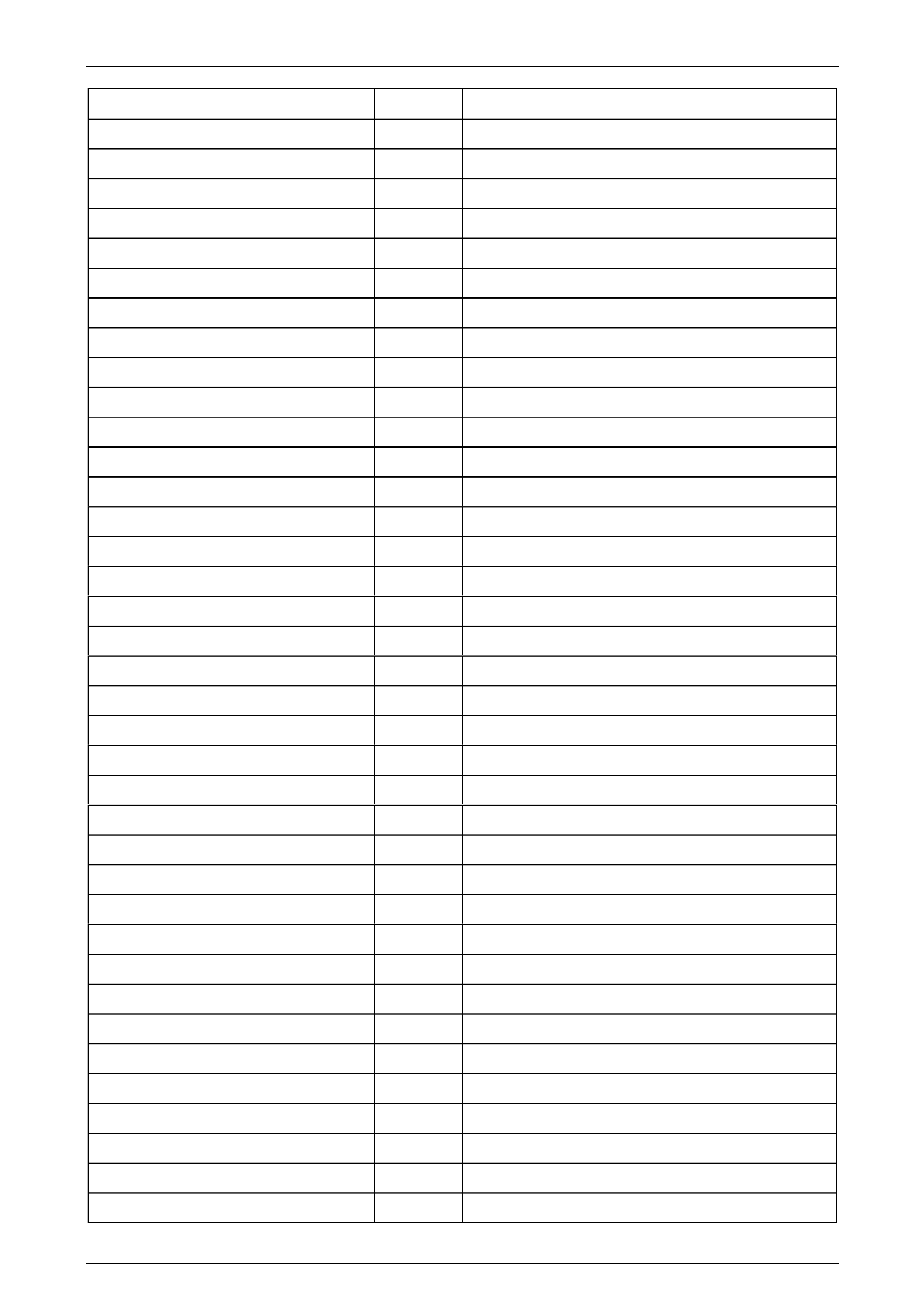

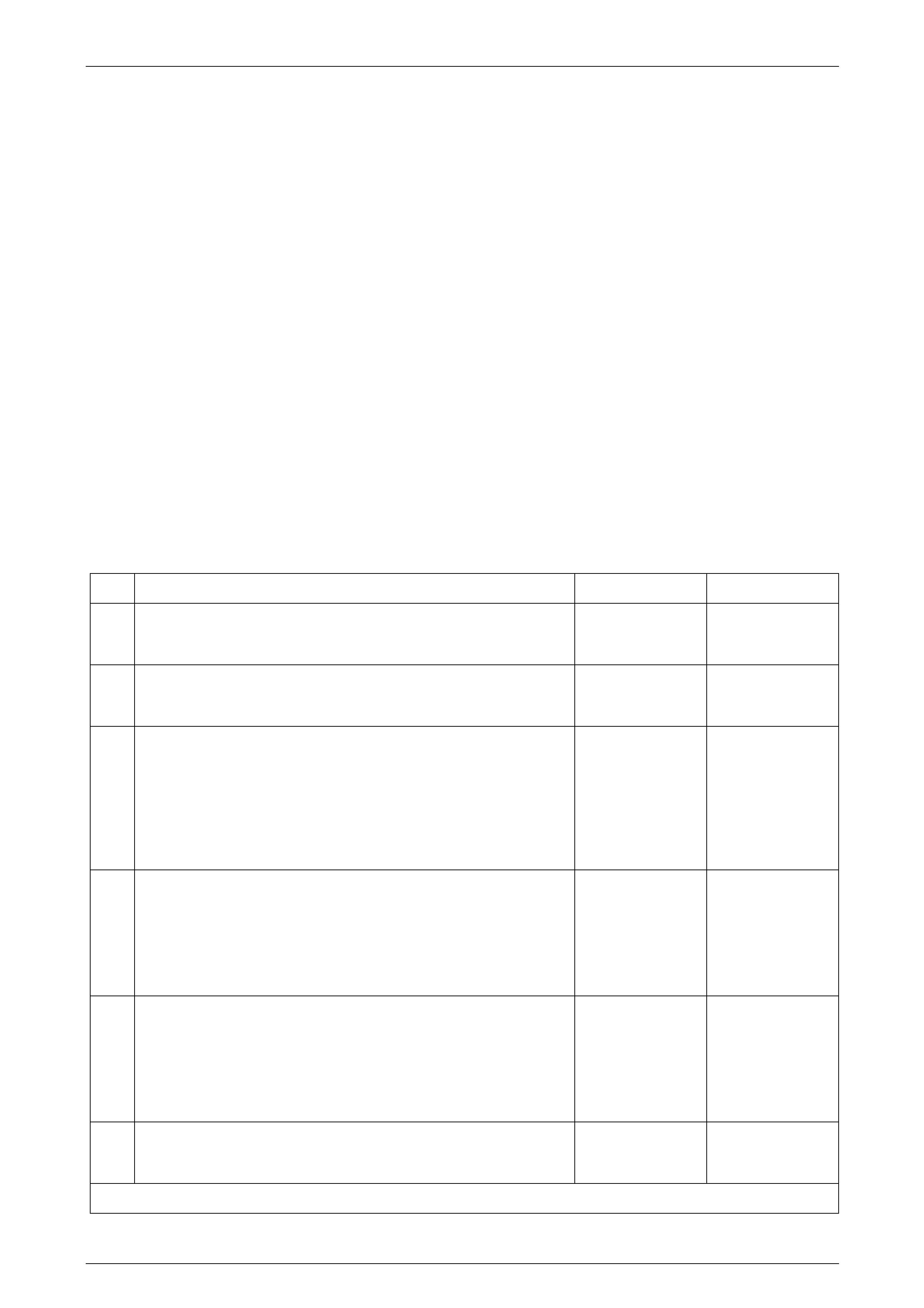

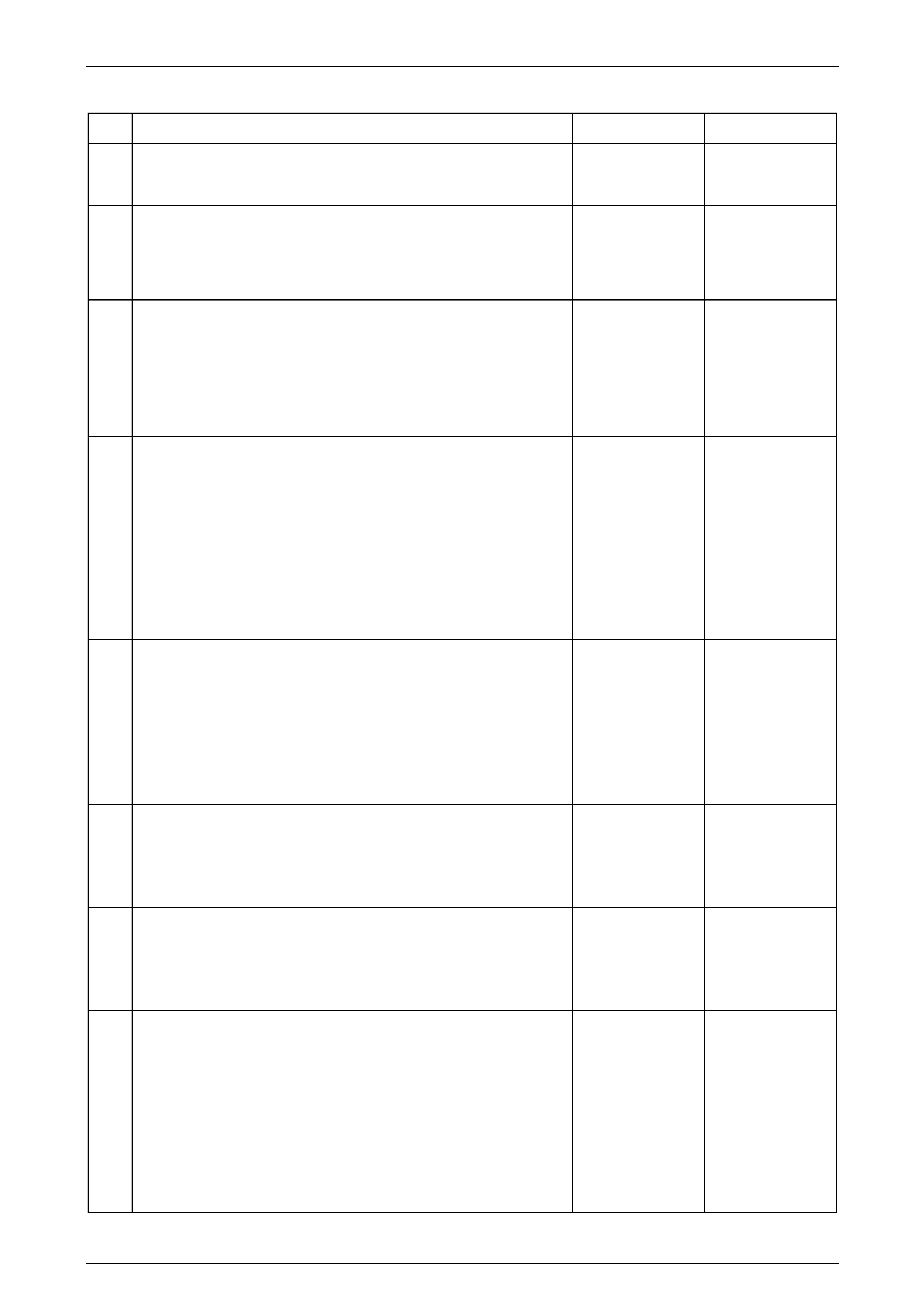

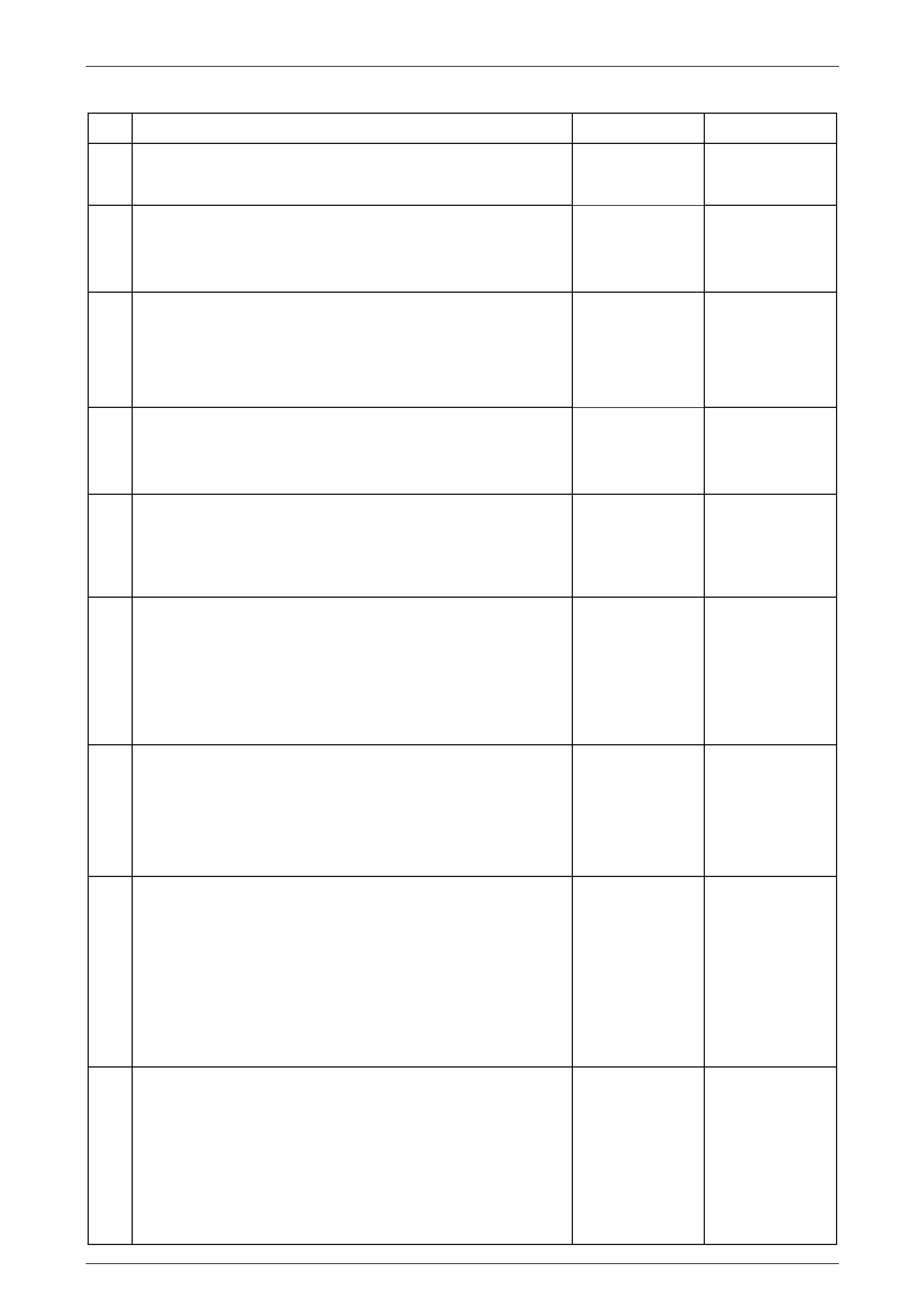

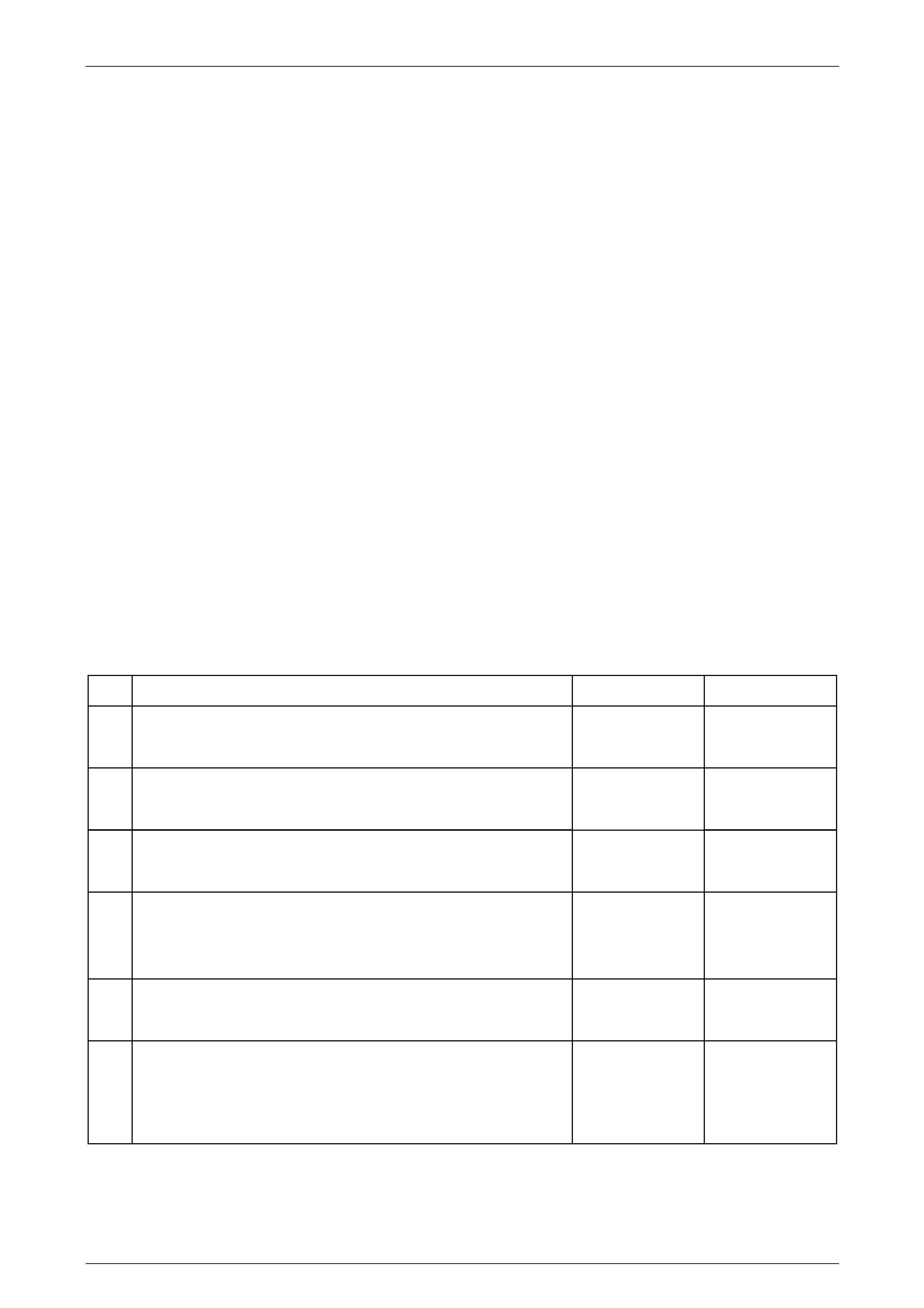

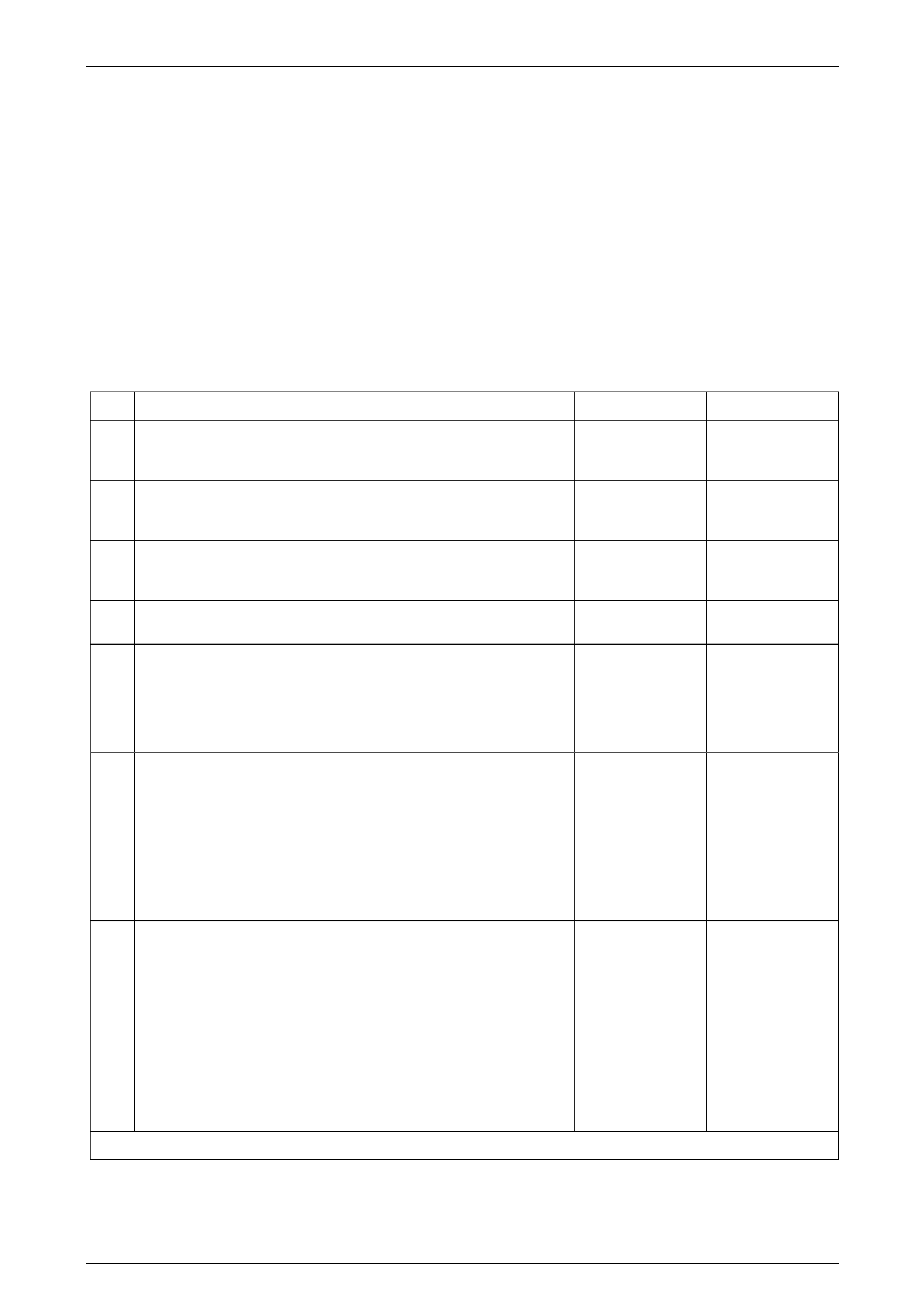

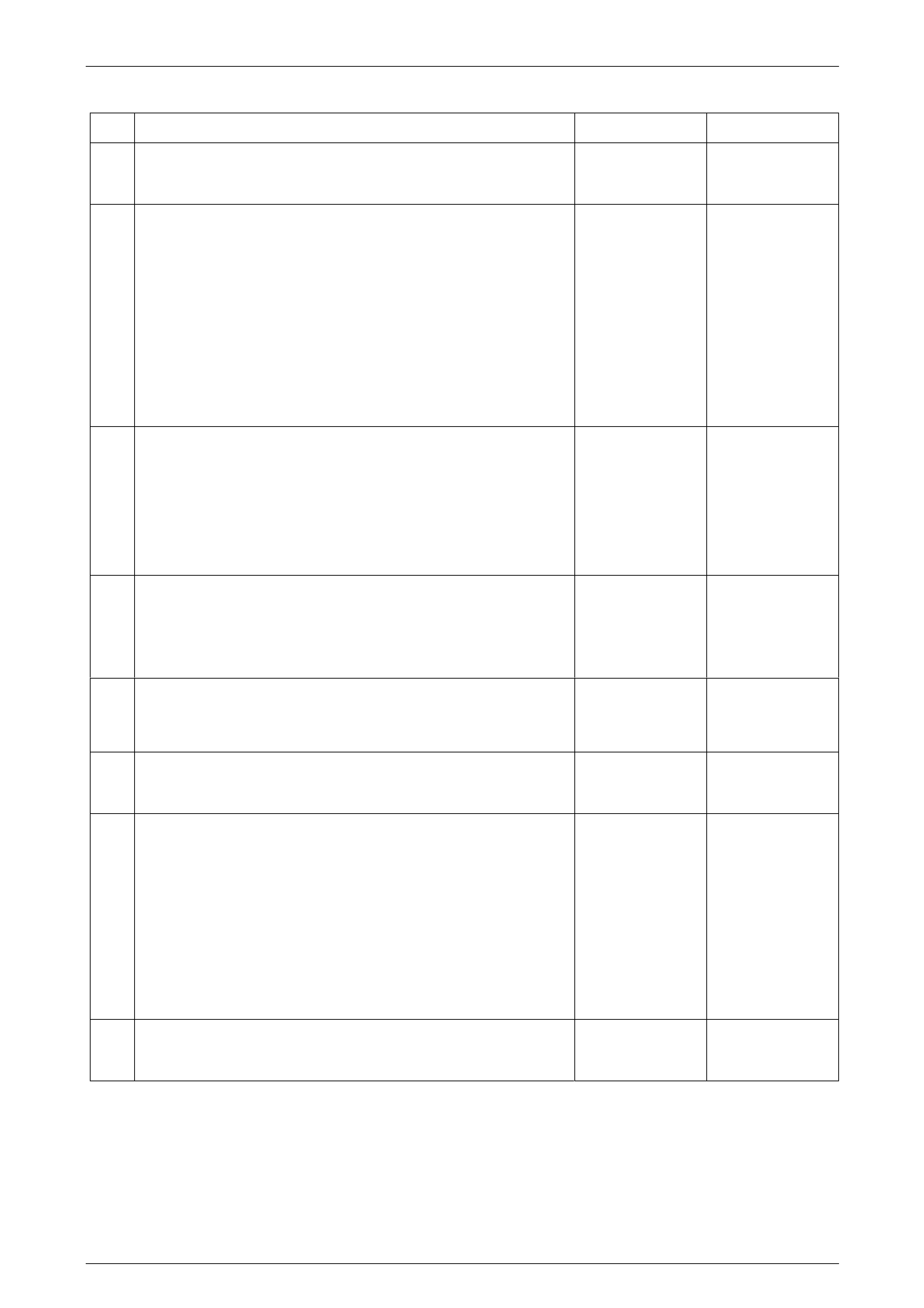

5.3 Diagnostic Trouble Code Definitions............................................................................................................... 134

Current Diagnostic Trouble Codes................................................................................................................... 134

History Diagnostic Trouble Codes................................................................................................................... 134

5.4 Description of Diagnostic Trouble Codes ....................................................................................................... 135

Multiple Diagnostic Trouble Code Fault Condition......................................................................................... 135

5.5 Intermittent Fault Conditions............................................................................................................................ 136

Description......................................................................................................................................................... 136

5.6 Diagnostic System Check................................................................................................................................. 138

Description......................................................................................................................................................... 138

Test Description ............................................................................................................................................. 138

Diagnostic Table............................................................................................................................................. 138

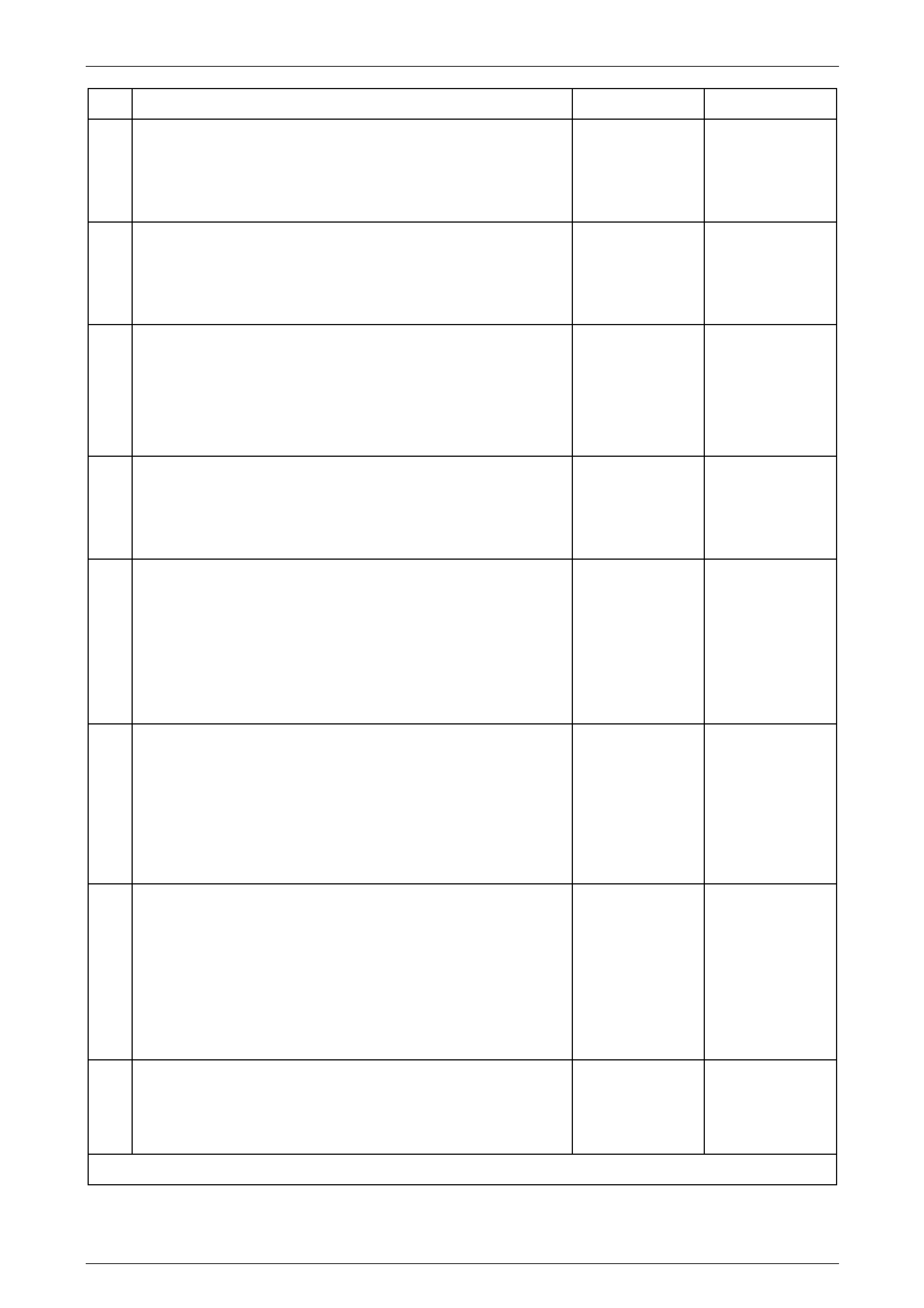

5.7 Symptoms Diagnostics Table........................................................................................................................... 139

Body Control Module Page 12J–6

Page 12J–6

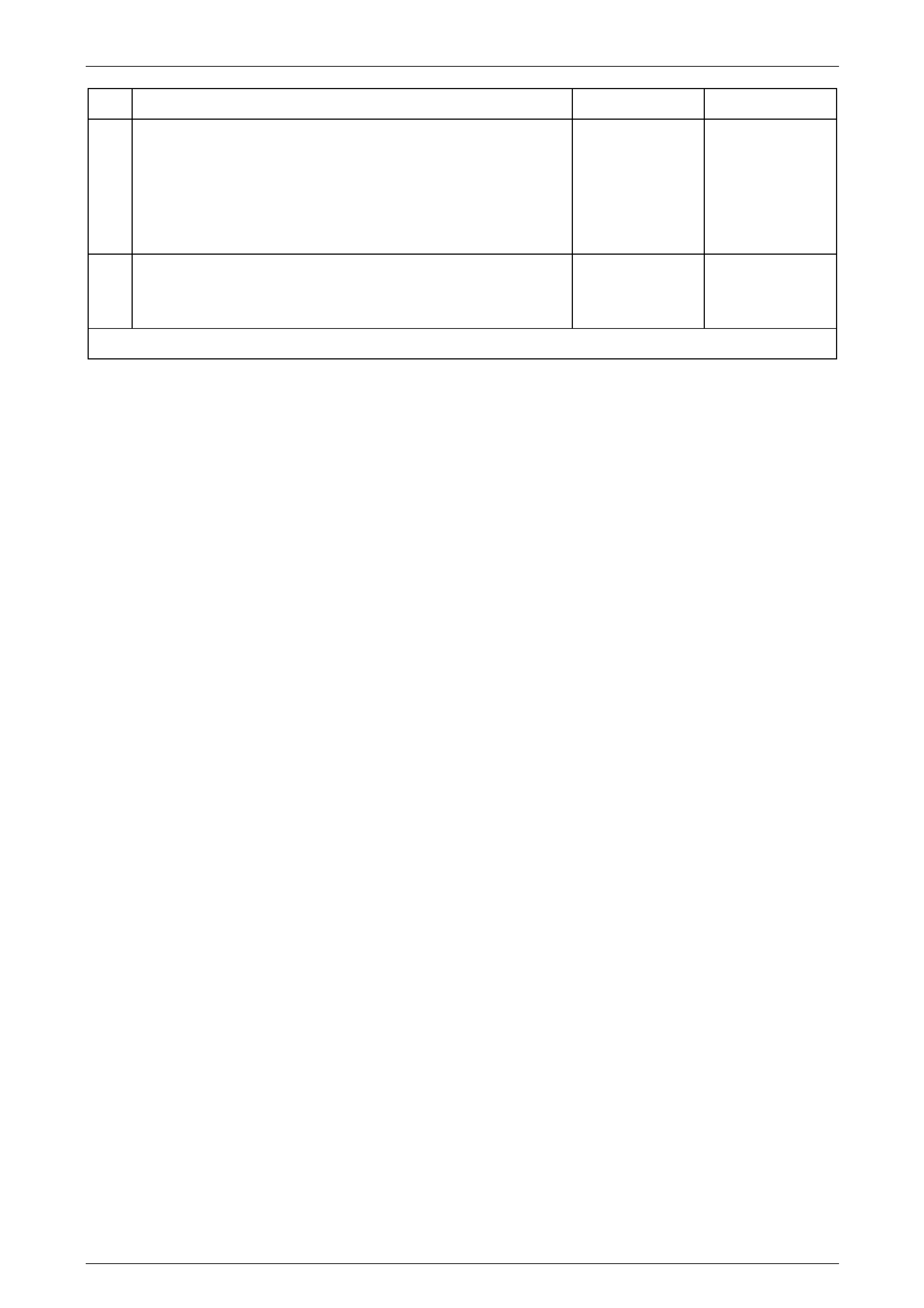

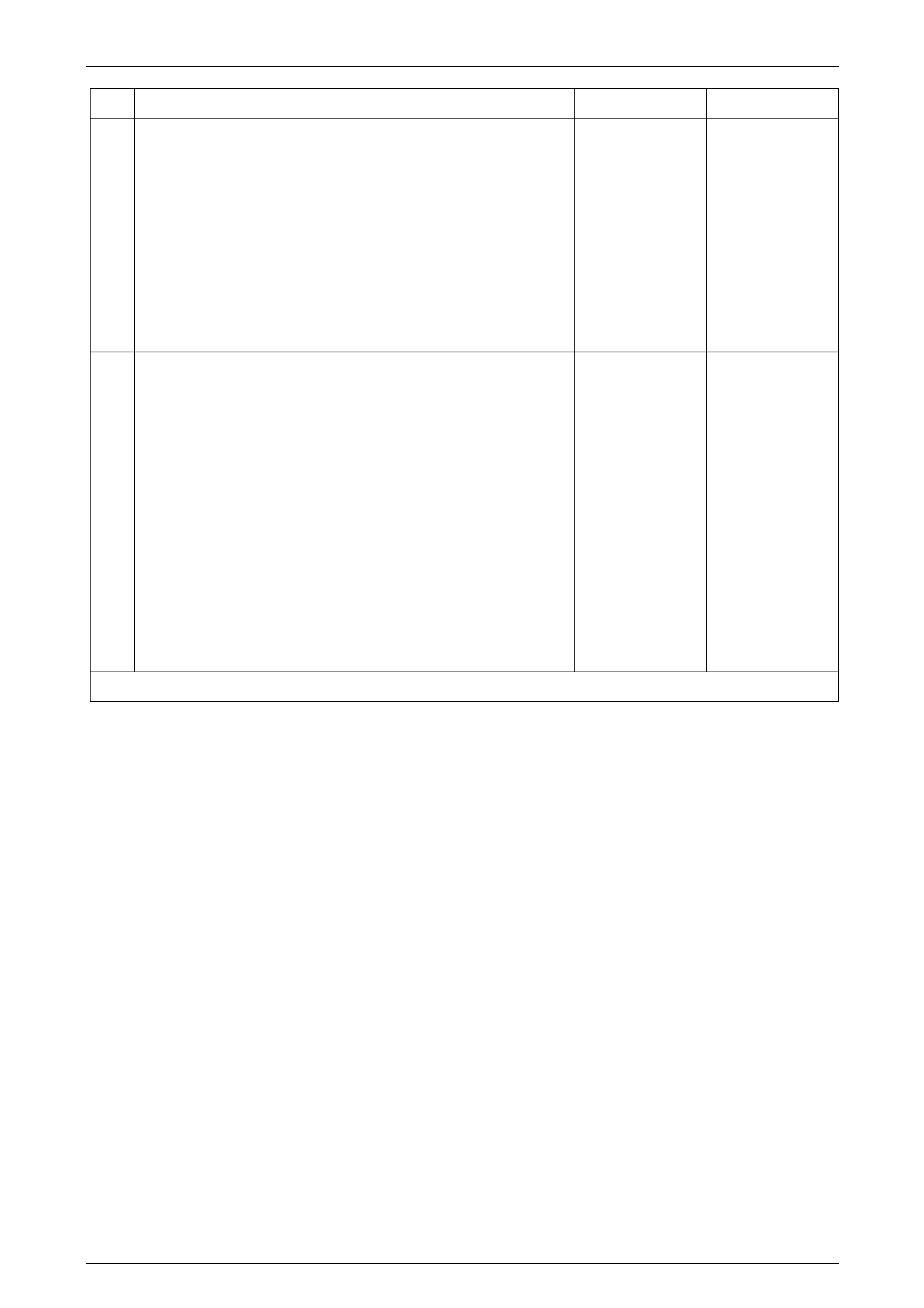

5.8 Diagnostic Trouble Code List........................................................................................................................... 140

5.9 Serial Data Communications ............................................................................................................................ 142

DTC Description................................................................................................................................................. 142

Circuit Description............................................................................................................................................. 142

Diagnostic Table................................................................................................................................................ 142

Test Description ............................................................................................................................................. 142

Diagnostic Table Notes .................................................................................................................................. 142

Diagnostic Table............................................................................................................................................. 143

5.10 Remote Receiver / Key ...................................................................................................................................... 146

Circuit Description............................................................................................................................................. 146

Remote Coded Key Battery Failure................................................................................................................ 146

Preliminary Diagnostic Table............................................................................................................................ 146

Test Description ............................................................................................................................................. 146

Diagnostic Table Notes .................................................................................................................................. 146

Diagnostic Table............................................................................................................................................. 146

Main Diagnostic Table....................................................................................................................................... 147

Test Description ............................................................................................................................................. 147

Diagnostic Table Notes .................................................................................................................................. 147

Diagnostic Table............................................................................................................................................. 148

5.11 Accessory Power Control ................................................................................................................................. 149

Circuit Description............................................................................................................................................. 149

Diagnostic Table................................................................................................................................................ 149

Test Description ............................................................................................................................................. 149

Diagnostic Table Notes .................................................................................................................................. 149

Diagnostic Table............................................................................................................................................. 150

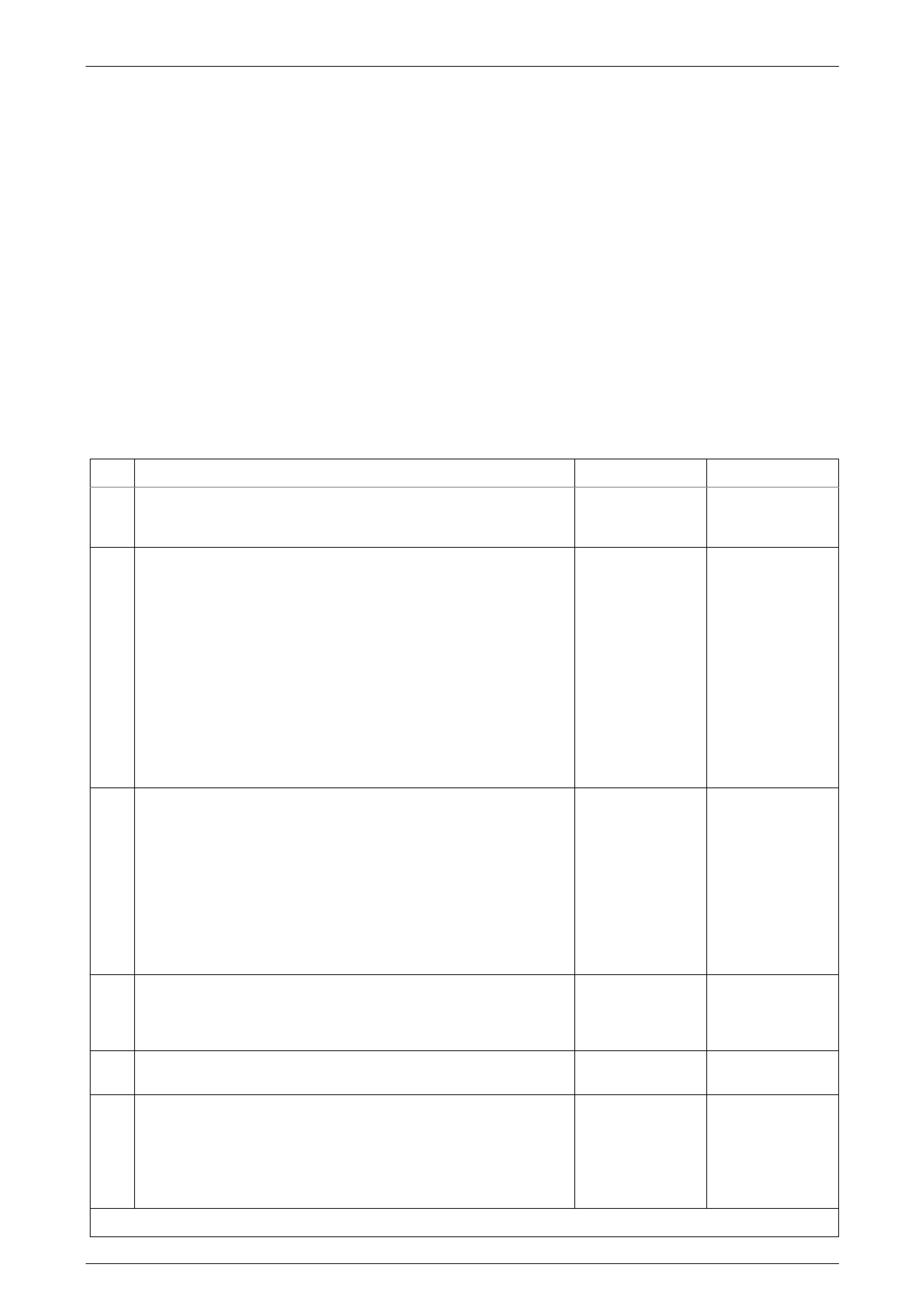

5.12 Central Door Locking ........................................................................................................................................ 152

System Overview ............................................................................................................................................... 152

Unlocking the Doors Using the Driver’s Door Microswitch.............................................................................. 152

Locking the Doors Using the Driver’s Door Microswitch................................................................................. 152

Door Locking System Test Overview............................................................................................................... 152

Diagnostic Trouble Codes ................................................................................................................................ 153

Conditions for Setting the DTC....................................................................................................................... 153

Conditions for Clearing the DTC..................................................................................................................... 153

Preliminary Diagnostic Table............................................................................................................................ 153

Test Description ............................................................................................................................................. 153

Diagnostic Table Notes .................................................................................................................................. 153

Diagnostic Table............................................................................................................................................. 154

Unlocking the Driver’s Door Using the Door Lock Diagnostic Table............................................................ 155

Test Description ............................................................................................................................................. 155

Diagnostic Table Notes .................................................................................................................................. 155

Diagnostic Table............................................................................................................................................. 155

Unlocking the Driver’s Door Using the Door Snib Diagnostic Table............................................................. 157

Test Description ............................................................................................................................................. 157

Diagnostic Table Notes .................................................................................................................................. 157

Diagnostic Table............................................................................................................................................. 157

Unlocking / Locking the Front Passenger’s Doors Using the Door Snib Diagnostic Table........................ 158

Test Description ............................................................................................................................................. 158

Diagnostic Table Notes .................................................................................................................................. 158

Diagnostic Table............................................................................................................................................. 158

Deadlocking the Vehicle’s Doors Diagnostic Table........................................................................................ 160

Test Description ............................................................................................................................................. 160

Diagnostic Table Notes .................................................................................................................................. 160

Diagnostic Table............................................................................................................................................. 160

Auto Door Locking (Gearshift In and Out of Park Position) Diagnostic Table............................................. 161

Test Description ............................................................................................................................................. 161

Diagnostic Table Notes .................................................................................................................................. 161

Diagnostic Table............................................................................................................................................. 161

Body Control Module Page 12J–7

Page 12J–7

Door Ajar Switches Diagnostic Table .............................................................................................................. 162

Test Description ............................................................................................................................................. 162

Diagnostic Table Notes .................................................................................................................................. 162

Diagnostic Table............................................................................................................................................. 162

Rear Compartment Release Diagnostic Table................................................................................................. 163

Test Description ............................................................................................................................................. 163

Diagnostic Table Notes .................................................................................................................................. 163

Diagnostic Table............................................................................................................................................. 164

5.13 Theft Deterrent System...................................................................................................................................... 166

Circuit Description............................................................................................................................................. 166

V6 Engines..................................................................................................................................................... 166

GEN III V8 Engine.......................................................................................................................................... 166

Diagnostic Table................................................................................................................................................ 167

Test Description ............................................................................................................................................. 167

Diagnostic Table Notes .................................................................................................................................. 167

Diagnostic Table............................................................................................................................................. 167

5.14 Entry Deterrent System..................................................................................................................................... 170

Circuit Description............................................................................................................................................. 170

Preliminary Diagnostic Table............................................................................................................................ 170

Test Description ............................................................................................................................................. 170

Diagnostic Table Notes .................................................................................................................................. 170

Diagnostic Table............................................................................................................................................. 170

Main Diagnostic Table....................................................................................................................................... 172

Test Description ............................................................................................................................................. 172

Diagnostic Table Notes .................................................................................................................................. 172

Diagnostic Table............................................................................................................................................. 173

Horn Diagnostic Table....................................................................................................................................... 174

Test Description ............................................................................................................................................. 174

Diagnostic Table Notes .................................................................................................................................. 174

Diagnostic Table............................................................................................................................................. 175

5.15 Power Window System ..................................................................................................................................... 176

Circuit Description............................................................................................................................................. 176

Introduction........................................................................................................................................................ 176

Preliminary Diagnostic Table............................................................................................................................ 176

Test Description ............................................................................................................................................. 176

Diagnostic Table Notes .................................................................................................................................. 176

Diagnostic Table............................................................................................................................................. 177

Main Power Diagnostic Table........................................................................................................................... 178

Test Description ............................................................................................................................................. 178

Diagnostic Table Notes .................................................................................................................................. 178

Diagnostic Table............................................................................................................................................. 178

Front Window Diagnostic Table....................................................................................................................... 180

Test Description ............................................................................................................................................. 180

Diagnostic Table Notes .................................................................................................................................. 181

Diagnostic Table............................................................................................................................................. 181

Rear Windows Diagnostic Table ...................................................................................................................... 183

Test Description ............................................................................................................................................. 183

Diagnostic Table Notes .................................................................................................................................. 183

Diagnostic Table............................................................................................................................................. 184

5.16 Wiper Systems Intermittent Function .............................................................................................................. 187

Circuit Description............................................................................................................................................. 187

Introduction........................................................................................................................................................ 187

Preliminary Diagnostic Table............................................................................................................................ 187

Test Description ............................................................................................................................................. 187

Diagnostic Table............................................................................................................................................. 187

Intermittent Diagnostic Table............................................................................................................................ 188

Test Description ............................................................................................................................................. 188

Diagnostic Table Notes .................................................................................................................................. 188

Diagnostic Table............................................................................................................................................. 189

Body Control Module Page 12J–8

Page 12J–8

Road Speed Diagnostic Table........................................................................................................................... 191

Test Description ............................................................................................................................................. 191

Diagnostic Table Notes .................................................................................................................................. 191

Diagnostic Table............................................................................................................................................. 191

5.17 Dome Lamp Delay Control................................................................................................................................ 192

Circuit Description............................................................................................................................................. 192

Battery Saver Mode........................................................................................................................................ 192

Preliminary Diagnostic Table............................................................................................................................ 193

Test Descriptions............................................................................................................................................ 193

Diagnostic Table Notes .................................................................................................................................. 193

Diagnostic Table............................................................................................................................................. 193

Main Diagnostic Table....................................................................................................................................... 194

Test Description ............................................................................................................................................. 194

Diagnostic Table Notes .................................................................................................................................. 195

Diagnostic Table............................................................................................................................................. 195

5.18 Automatic Lamp Control................................................................................................................................... 197

Circuit Description............................................................................................................................................. 197

Automatic Lamps Off...................................................................................................................................... 197

Automatic Lamps On...................................................................................................................................... 197

Adjustment ..................................................................................................................................................... 197

Approach Illumination..................................................................................................................................... 197

Preliminary Diagnostic Table............................................................................................................................ 198

Test Description ............................................................................................................................................. 198

Diagnostic Table............................................................................................................................................. 198

Sunload Sensor Diagnostic Table.................................................................................................................... 199

Test Description ............................................................................................................................................. 199

Diagnostic Table Notes .................................................................................................................................. 199

Diagnostic Table............................................................................................................................................. 199

Lamps On / Lamps Off Diagnostic Table......................................................................................................... 200

Test Description ............................................................................................................................................. 200

Diagnostic Table Notes .................................................................................................................................. 200

Diagnostic Table............................................................................................................................................. 201

5.19 Instrument Dimming Control ............................................................................................................................ 203

Circuit Description............................................................................................................................................. 203

Preliminary Diagnostic Table............................................................................................................................ 203

Test Description ............................................................................................................................................. 203

Diagnostic Table............................................................................................................................................. 203

Main Diagnostic Table....................................................................................................................................... 204

Test Description ............................................................................................................................................. 204

Diagnostic Table Notes .................................................................................................................................. 204

Diagnostic Table............................................................................................................................................. 204

5.20 OPS Deployment Vehicle Shutdown................................................................................................................ 205

Circuit Description............................................................................................................................................. 205

Diagnostic Table................................................................................................................................................ 205

Test Description ............................................................................................................................................. 205

Diagnostic Table Notes .................................................................................................................................. 205

Diagnostic Table............................................................................................................................................. 205

5.21 Priority Key System........................................................................................................................................... 207

Circuit Description............................................................................................................................................. 207

Diagnostic Table................................................................................................................................................ 207

Test Description ............................................................................................................................................. 207

Diagnostic Table Notes .................................................................................................................................. 207

Diagnostic Table............................................................................................................................................. 208

5.22 Pow er Antenna Control..................................................................................................................................... 210

Circuit Description............................................................................................................................................. 210

Diagnostic Table................................................................................................................................................ 210

Test Description ............................................................................................................................................. 210

Diagnostic Table Notes .................................................................................................................................. 210

Diagnostic Table............................................................................................................................................. 210

Body Control Module Page 12J–9

Page 12J–9

5.23 Rear Lamp Failure Warning System................................................................................................................. 211

Circuit Description............................................................................................................................................. 211

Preliminary Diagnostic Table............................................................................................................................ 211

Test Descriptions............................................................................................................................................ 211

Diagnostic Table............................................................................................................................................. 211

Main Diagnostic Table....................................................................................................................................... 212

Test Descriptions............................................................................................................................................ 212

Diagnostic Table Notes .................................................................................................................................. 212

Diagnostic Table............................................................................................................................................. 213

5.24 Hazard Lamp Control......................................................................................................................................... 215

Circuit Description............................................................................................................................................. 215

Preliminary Diagnostic Table............................................................................................................................ 215

Test Descriptions............................................................................................................................................ 215

Diagnostic Table............................................................................................................................................. 215

Main Diagnostic Table....................................................................................................................................... 216

Test Descriptions............................................................................................................................................ 216

Diagnostic Table Notes .................................................................................................................................. 216

Diagnostic Table............................................................................................................................................. 216

6 Service Operations.............................................................................................................................218

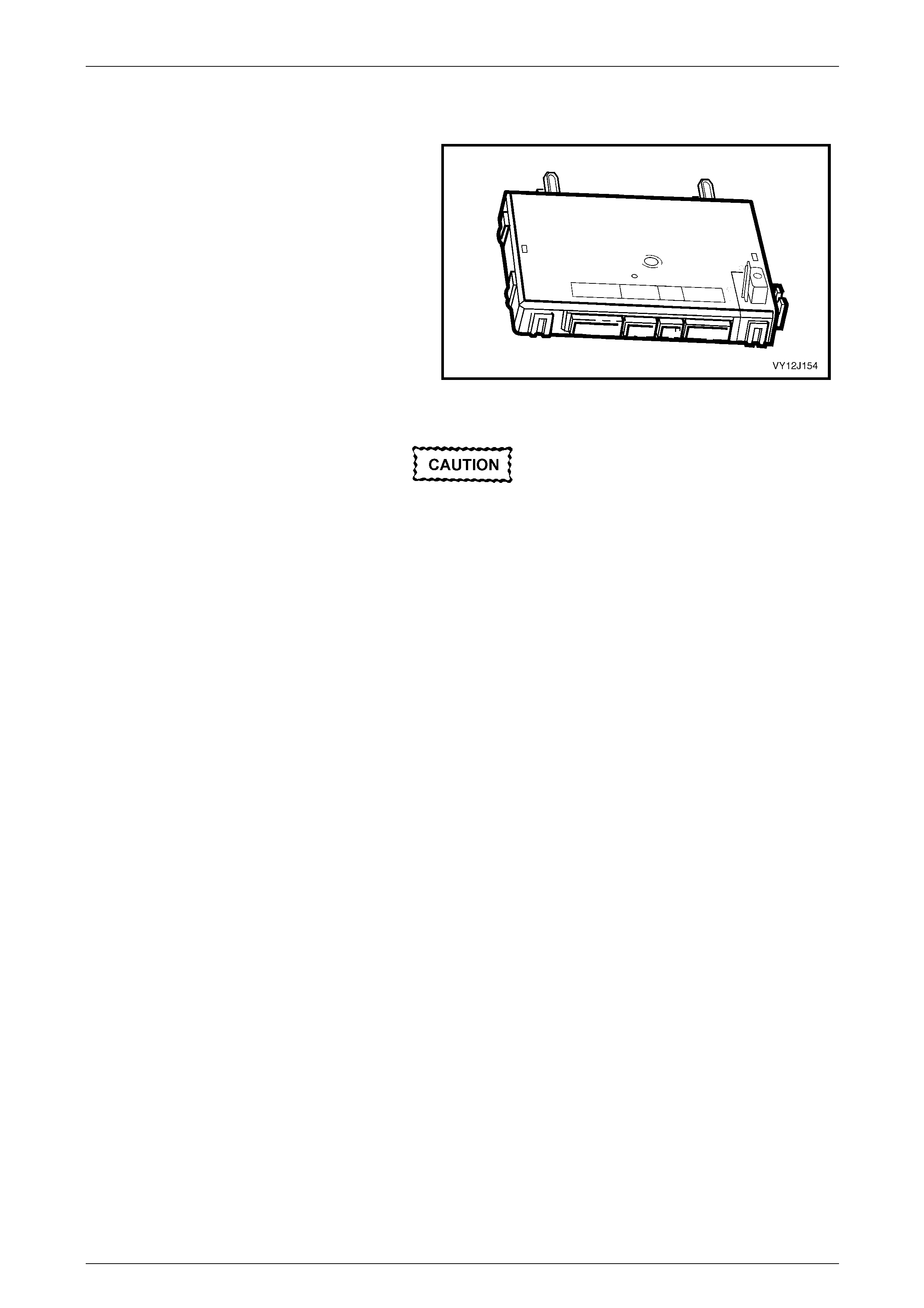

6.1 Body Control Module......................................................................................................................................... 218

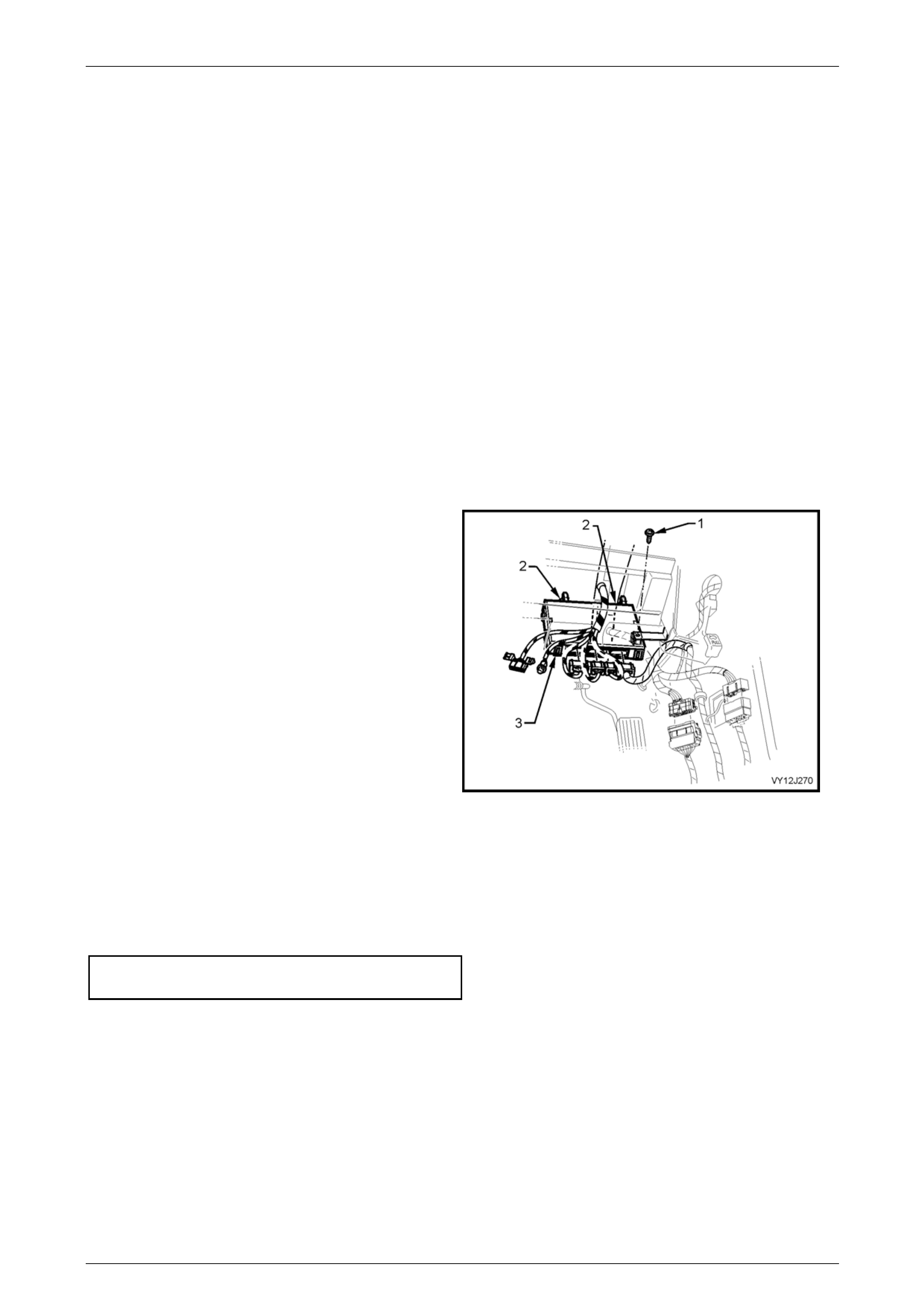

Mounting Location............................................................................................................................................. 218