HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–1

Page 2E–1

Section 2E

HVAC Occupant Climate Control (Auto A/C) –

Diagnostics

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information ...............................................................................................................................5

1.1 Introduction............................................................................................................................................................ 5

2 Wiring Diagrams and Connector Charts..............................................................................................6

2.1 Wiring Diagram V6................................................................................................................................................. 6

2.2 Wiring Diagram V8................................................................................................................................................. 8

2.3 Connector Chart................................................................................................................................................... 10

2.4 Serial Databus Diagram V6 ................................................................................................................................. 12

2.5 Serial Databus Diagram V8 ................................................................................................................................. 13

2.6 Connector Information ........................................................................................................................................ 14

OCC Control Module............................................................................................................................................ 14

Module Side — A14 – X1................................................................................................................................. 14

Module Side — A14 – X2................................................................................................................................. 15

3 Tech 2 Information ...............................................................................................................................16

3.1 Tech 2 Diagnostics.............................................................................................................................................. 16

Test Modes........................................................................................................................................................... 16

Normal Mode.................................................................................................................................................... 16

Diagnostic Trouble Codes................................................................................................................................ 16

Data Display..................................................................................................................................................... 16

Snapshot.......................................................................................................................................................... 17

Miscellaneous Tests......................................................................................................................................... 17

Programming.................................................................................................................................................... 17

3.2 Normal Mode........................................................................................................................................................ 18

Normal Mode Parameters.................................................................................................................................... 18

3.3 Data Display ......................................................................................................................................................... 19

Data List................................................................................................................................................................ 19

Data List Parameters........................................................................................................................................ 19

Switch Data........................................................................................................................................................... 20

OCC Switch Data Parameters.......................................................................................................................... 20

System Identification........................................................................................................................................... 21

System Identification Parameters..................................................................................................................... 21

Air Mix Door Calibration Positions..................................................................................................................... 21

Air Mix Door Calibration Positions Parameters ................................................................................................ 21

3.4 Miscellaneous Tests............................................................................................................................................ 22

3.5 Program................................................................................................................................................................ 25

Calibrate Air Mix Door......................................................................................................................................... 25

Program Code Index............................................................................................................................................ 26

Code Index Details........................................................................................................................................... 26

4 Diagnostics...........................................................................................................................................27

4.1 Introduction.......................................................................................................................................................... 27

4.2 Precautions .......................................................................................................................................................... 28

Techline

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–2

Page 2E–2

4.3 Diagnostic Trouble Code Tables........................................................................................................................ 29

Multiple DTCs Fault Condition............................................................................................................................ 29

4.4 DTC Overview....................................................................................................................................................... 30

4.5 Intermittent Faults................................................................................................................................................ 31

4.6 Diagnostic System Check................................................................................................................................... 32

Circuit Description............................................................................................................................................... 32

Test Description................................................................................................................................................... 32

Diagnostic Table Notes ....................................................................................................................................... 32

Diagnostic Table.................................................................................................................................................. 33

4.7 OCC System Does Not Power Up....................................................................................................................... 34

Circuit Description............................................................................................................................................... 34

Test Description................................................................................................................................................... 34

Diagnostic Table Notes ....................................................................................................................................... 34

OCC System Does Not Power Up Diagnostic Table ......................................................................................... 34

4.8 Rear Demist Function Inoperative...................................................................................................................... 35

Circuit Description............................................................................................................................................... 35

Test Description................................................................................................................................................... 35

Diagnostic Table Notes ....................................................................................................................................... 35

Rear Demist Function Inoperative Diagnostic Table........................................................................................ 35

4.9 OCC Module Illuminati on In ope ra tive ................................................................................................................ 37

Circuit Description............................................................................................................................................... 37

Test Description................................................................................................................................................... 37

Diagnostic Table Notes ....................................................................................................................................... 37

OCC Module Illumination Inoperative Diagnostic Table................................................................................... 37

4.10 Rear Remote Control Inoperative....................................................................................................................... 39

Circuit Description............................................................................................................................................... 39

Test Description................................................................................................................................................... 39

Diagnostic Table Notes ....................................................................................................................................... 39

Rear Remote Control Inoperative Diagnostic Table ......................................................................................... 39

4.11 Diagnostic Trouble Code List............................................................................................................................. 41

4.12 DTC 13 – Ambient Temperature Sensor Voltage Too High.............................................................................. 42

Circuit Description............................................................................................................................................... 42

Test Description................................................................................................................................................... 42

Diagnostic Aids.................................................................................................................................................... 42

Diagnostic Table Notes ....................................................................................................................................... 42

DTC 13 Diagnostic Table..................................................................................................................................... 42

4.13 DTC 14 – Ambient Temperature Sensor Voltage Too Low............................................................................... 44

Circuit Description............................................................................................................................................... 44

Test Description................................................................................................................................................... 44

Diagnostic Aids.................................................................................................................................................... 44

Diagnostic Table Notes ....................................................................................................................................... 44

DTC 14 Diagnostic Table..................................................................................................................................... 44

4.14 DTC 15 – In-car Temperature Sensor Voltage Too High................................................................................... 46

Circuit Description............................................................................................................................................... 46

Test Description................................................................................................................................................... 46

Diagnostic Aids.................................................................................................................................................... 46

Diagnostic Table Notes ....................................................................................................................................... 46

DTC 15 Diagnostic Table..................................................................................................................................... 46

4.15 DTC 16 – In-car Temperature Sensor Voltage Too Low ................................................................................... 48

Circuit Description............................................................................................................................................... 48

Test Description................................................................................................................................................... 48

Diagnostic Aids.................................................................................................................................................... 48

Diagnostic Table Notes ....................................................................................................................................... 48

DTC 16 Diagnostic Table..................................................................................................................................... 48

4.16 DTC 17 – Evaporative Temperature Sensor Voltage Too High........................................................................50

Circuit Description............................................................................................................................................... 50

Test Description................................................................................................................................................... 50

Diagnostic Aids.................................................................................................................................................... 50

Diagnostic Table Notes ....................................................................................................................................... 50

DTC 17 Diagnostic Table..................................................................................................................................... 50

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–3

Page 2E–3

4.17 DTC 18 – Evaporative Temperature Sensor Voltage Too Low.........................................................................52

Circuit Description............................................................................................................................................... 52

Test Description................................................................................................................................................... 52

Diagnostic Aids.................................................................................................................................................... 52

Diagnostic Table Notes ....................................................................................................................................... 52

DTC 18 Diagnostic Table..................................................................................................................................... 52

4.18 DTC 19 – Sun Load Sensor Error ....................................................................................................................... 54

Circuit Description............................................................................................................................................... 54

4.19 DTC 35 and 36 – Serial Data Error...................................................................................................................... 55

DTC Descriptor..................................................................................................................................................... 55

Circuit Description............................................................................................................................................... 55

Test Description................................................................................................................................................... 55

Diagnostic Aids.................................................................................................................................................... 55

Diagnostic Table Notes ....................................................................................................................................... 55

DTC 35 and 36 Diagnostic Table......................................................................................................................... 56

4.20 DTC 37, 38 and 39 – OCC Memory Error............................................................................................................ 57

DTC Descriptor..................................................................................................................................................... 57

Circuit Description............................................................................................................................................... 57

DTC 37............................................................................................................................................................. 57

DTC 38............................................................................................................................................................. 57

DTC 39............................................................................................................................................................. 57

Test Description................................................................................................................................................... 57

Diagnostic Aids.................................................................................................................................................... 57

Diagnostic Table Notes ....................................................................................................................................... 57

DTC 37, 38 and 39 Diagnostic Table................................................................................................................... 58

4.21 DTC 40 – Air Mix Door Motor Driver Error ......................................................................................................... 59

Circuit Description............................................................................................................................................... 59

Test Description................................................................................................................................................... 59

Diagnostic Aids.................................................................................................................................................... 59

Diagnostic Table Notes ....................................................................................................................................... 59

DTC 40 Diagnostic Table..................................................................................................................................... 60

4.22 DTC 41 – Solenoid Driver Error .......................................................................................................................... 62

Circuit Description............................................................................................................................................... 62

Test Description................................................................................................................................................... 62

Diagnostic Table Notes ....................................................................................................................................... 62

DTC 41 Diagnostic Table..................................................................................................................................... 62

4.23 DTC 43 and 44 – Driver’s Air Mix Door Motor Feedback Circuit Voltage Error .............................................. 66

DTC Descriptor..................................................................................................................................................... 66

Circuit Description............................................................................................................................................... 66

Test Description................................................................................................................................................... 66

Diagnostic Aids.................................................................................................................................................... 66

Diagnostic Table Notes ....................................................................................................................................... 67

DTC 43 and 44 Diagnostic Table......................................................................................................................... 67

4.24 DTC 45 and 46 – Passenger Air Mix Door Motor Feedback Circuit Voltage Error.......................................... 70

DTC Descriptor..................................................................................................................................................... 70

Circuit Description............................................................................................................................................... 70

Test Description................................................................................................................................................... 70

Diagnostic Aids.................................................................................................................................................... 71

Diagnostic Table Notes ....................................................................................................................................... 71

DTC 45 and 46 Diagnostic Table......................................................................................................................... 71

4.25 DTC 47 and 48 – Driver Air Mix Calibration Error.............................................................................................. 74

DTC Descriptor..................................................................................................................................................... 74

Circuit Description............................................................................................................................................... 74

Test Description................................................................................................................................................... 74

Diagnostic Aids.................................................................................................................................................... 74

Diagnostic Table Notes ....................................................................................................................................... 74

DTC 47 and 48 Diagnostic Table......................................................................................................................... 75

4.26 DTC 49 and 50 – Passenger Air Mix Calibration Error...................................................................................... 76

DTC Descriptor..................................................................................................................................................... 76

Circuit Description............................................................................................................................................... 76

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–4

Page 2E–4

Test Description................................................................................................................................................... 76

Diagnostic Aids.................................................................................................................................................... 76

Diagnostic Table Notes ....................................................................................................................................... 76

DTC 49 and 50 Diagnostic Table......................................................................................................................... 77

5 Electrical Specifications......................................................................................................................78

5.1 In-car Air Temperature Sensor Resistance Chart............................................................................................. 78

5.2 Ambient Air Temperature Sensor Resistance Chart......................................................................................... 79

5.3 Evaporative Temperature Sensor Resistance Chart......................................................................................... 80

6 Special Tools ........................................................................................................................................81

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–5

Page 2E–5

1 General Information

1.1 Introduction

This Section contains the diagnostic ch arts for all DTCs associated with the occupant climate control (OCC) module

and the components that it controls. This should not be the starting point for diagnosing the OCC, refer to

Section 2B HVAC Climate Control (Auto A/C) – Service and Diagnosis.

Along with the diagnostic charts, details of the Tech 2 function and wiring diagrams with connector charts for the OCC

are also included

When starting diagnosis in this Section, always start with the diagnostic system check, 4.6 Diagnostic System Check

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–6

Page 2E–6

2 Wiring Diagrams and Connector

Charts

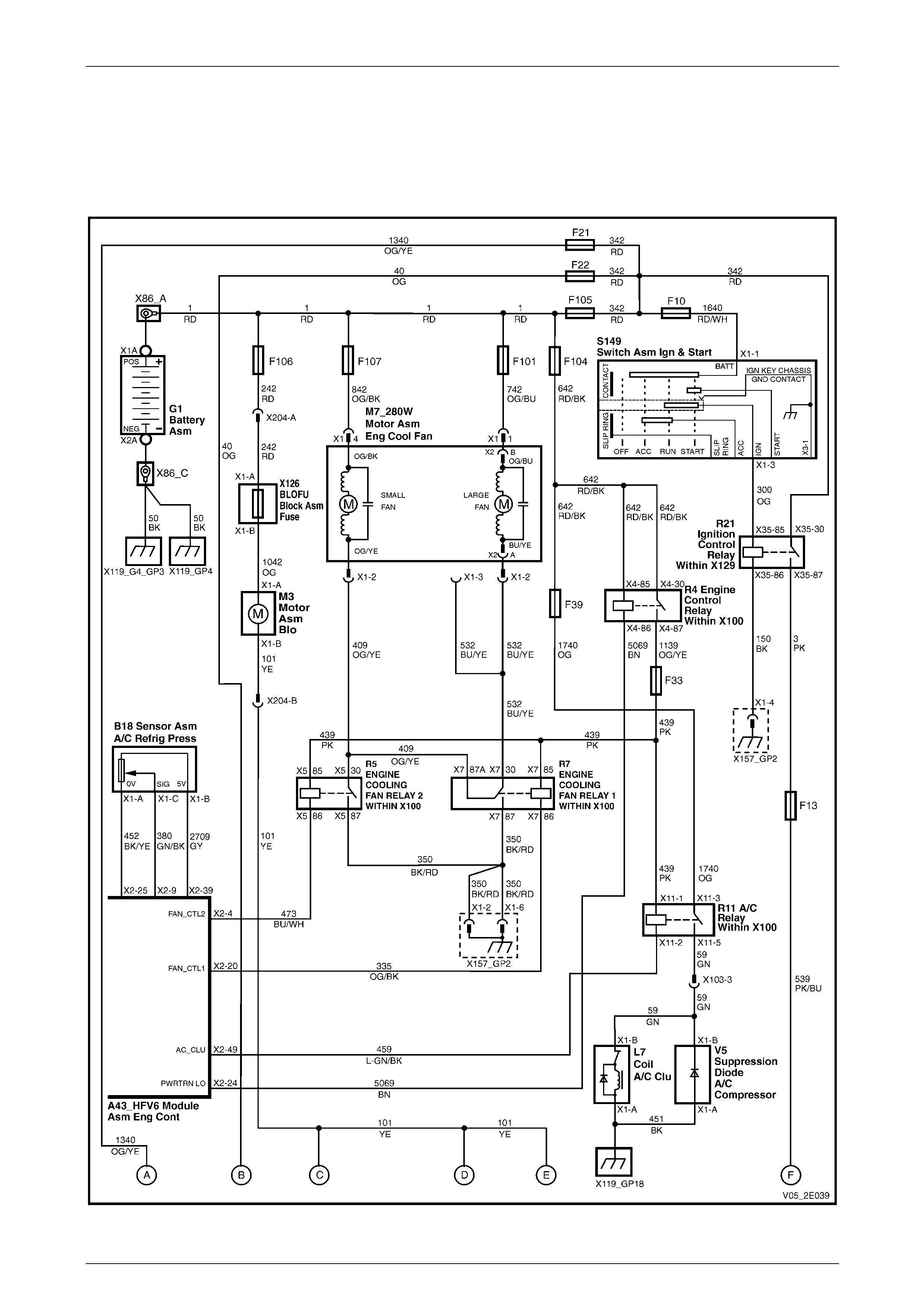

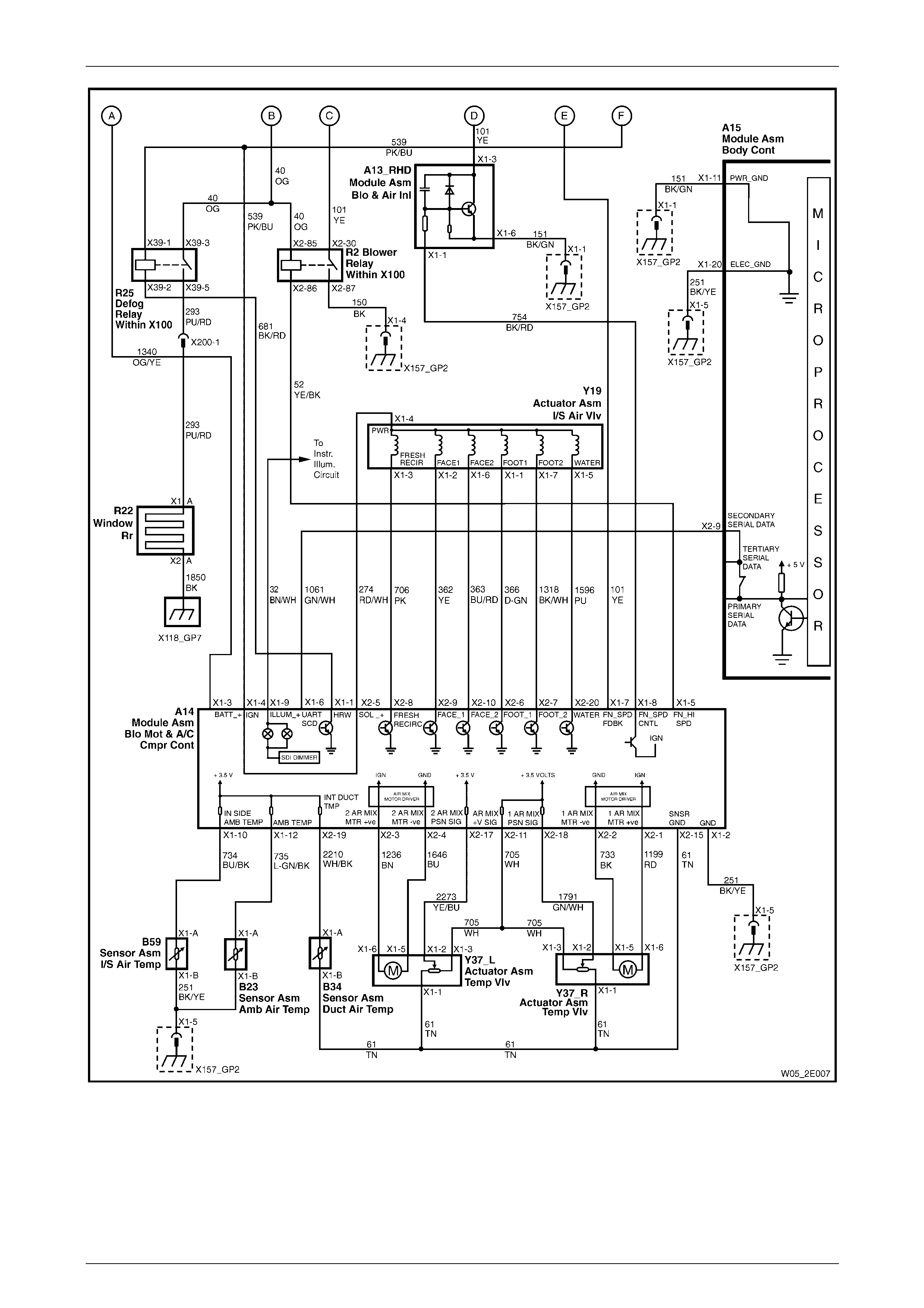

2.1 Wiring Diagram V6

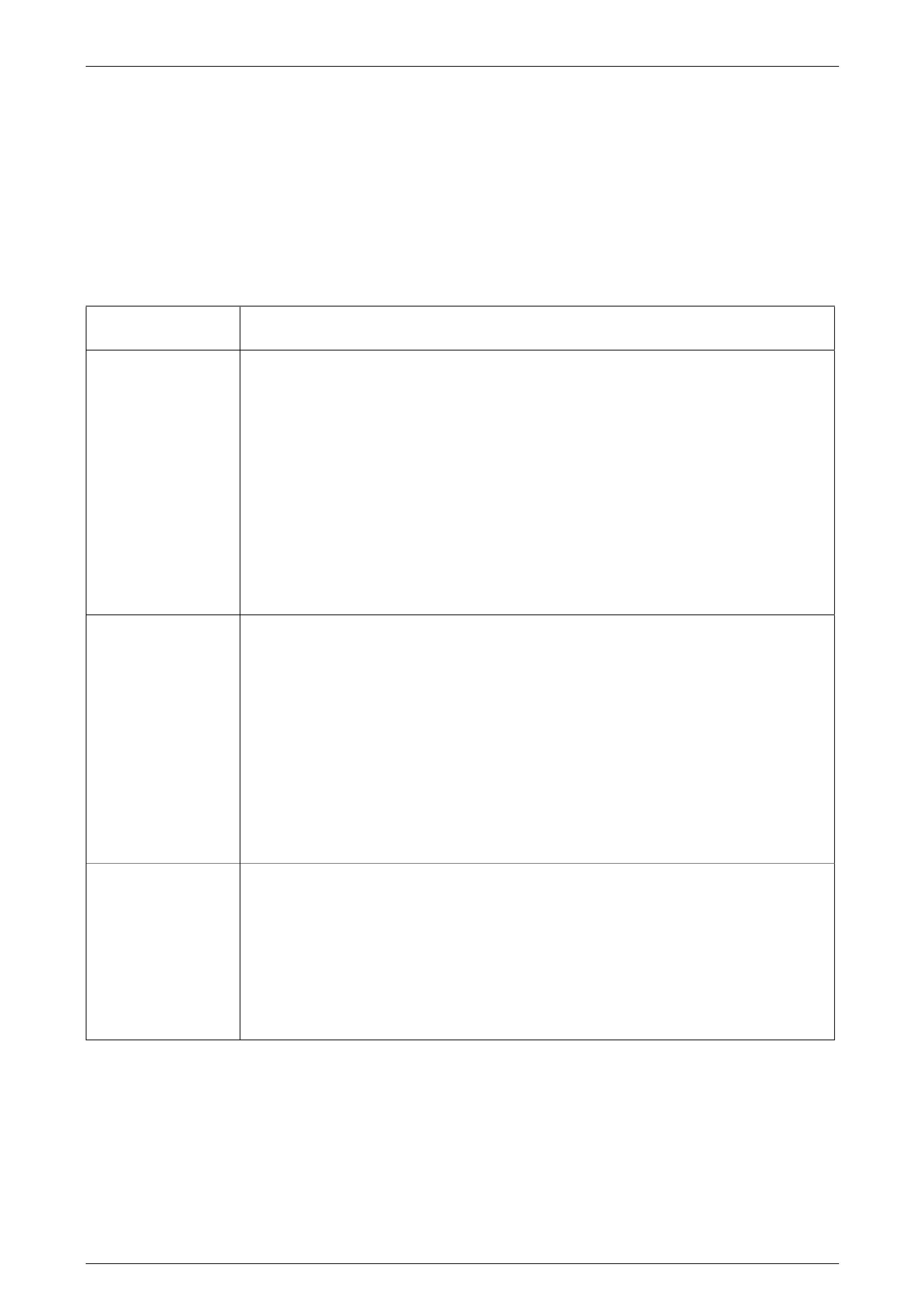

Figure 2E – 1

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–7

Page 2E–7

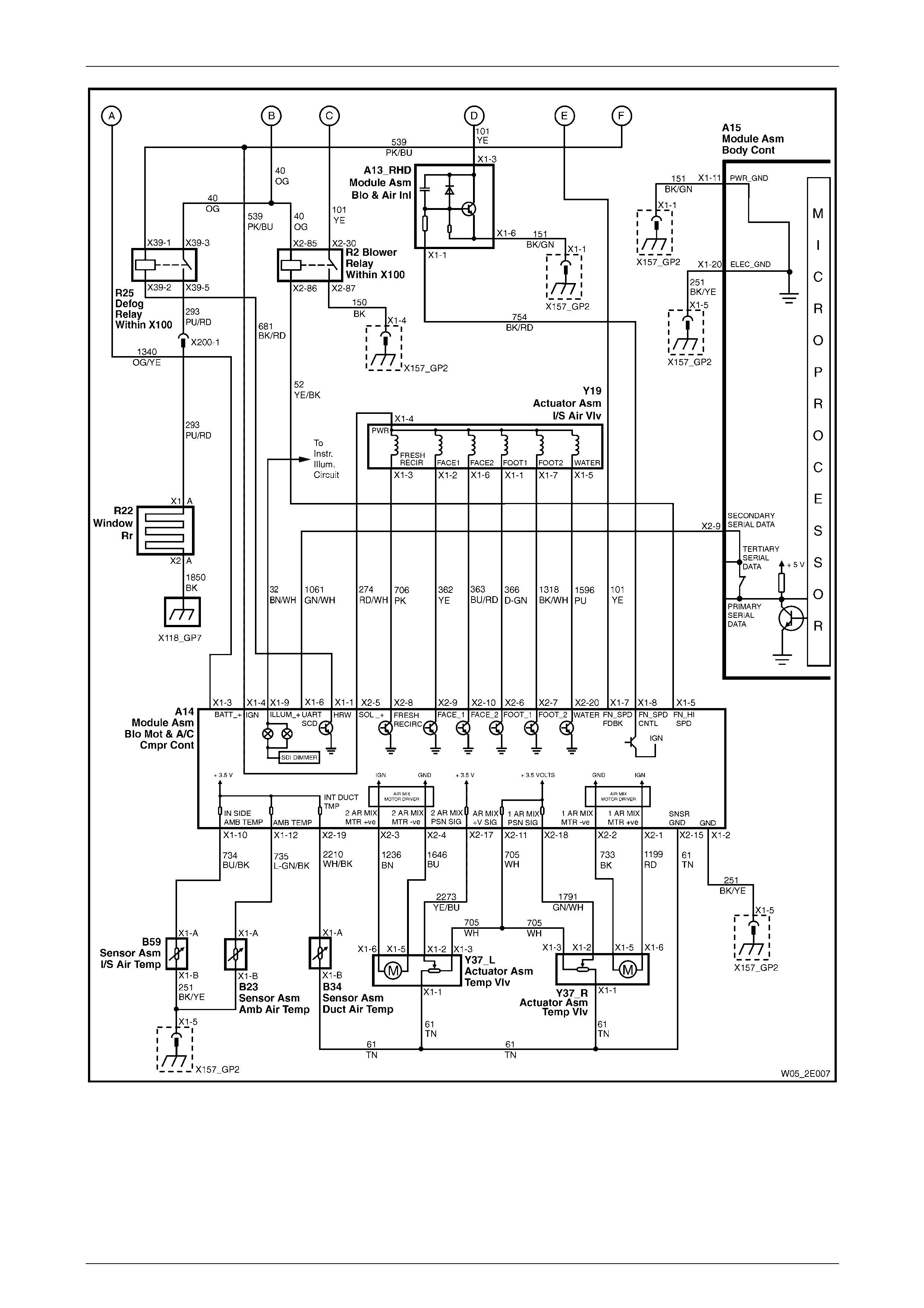

Figure 2E – 2

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–8

Page 2E–8

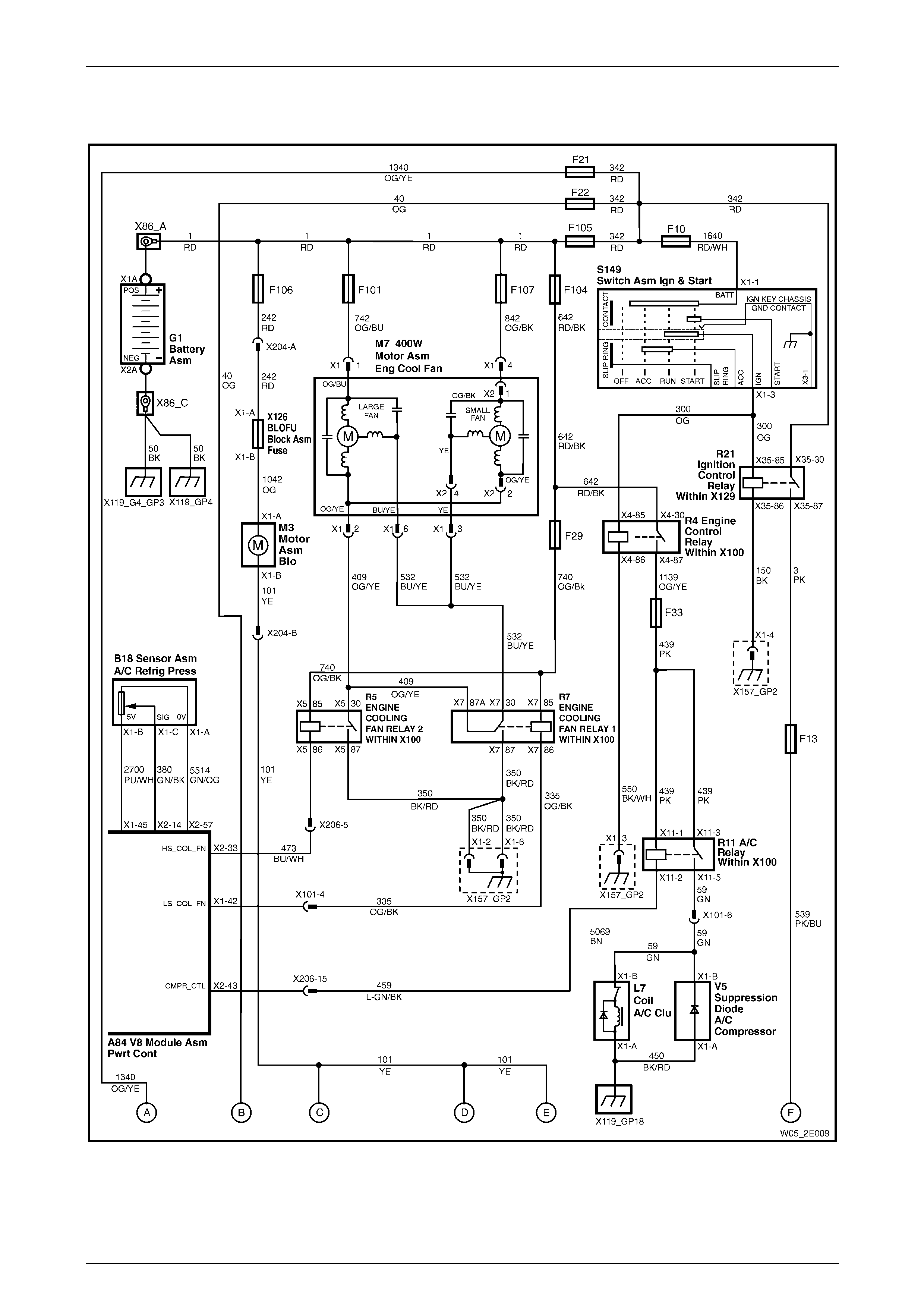

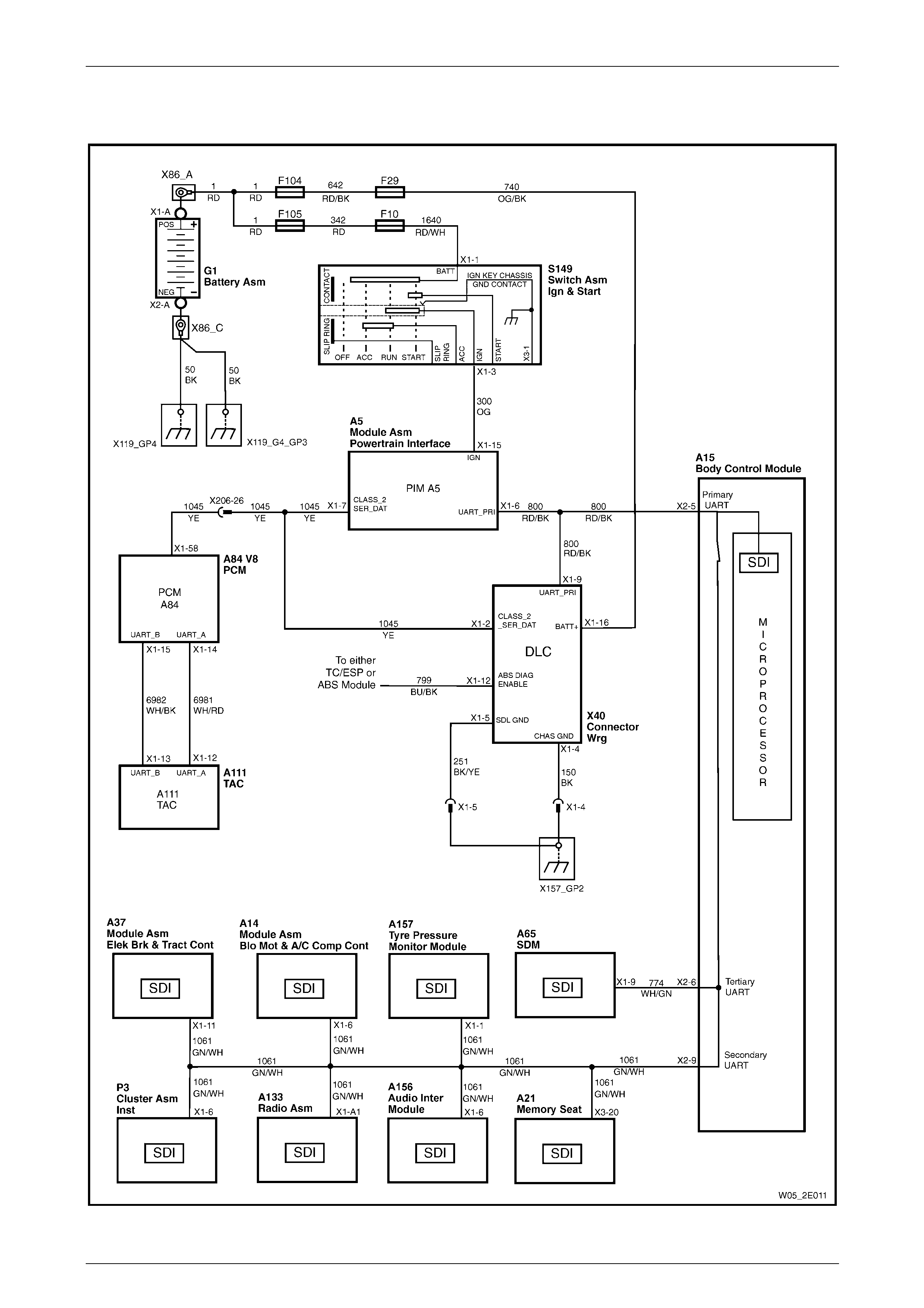

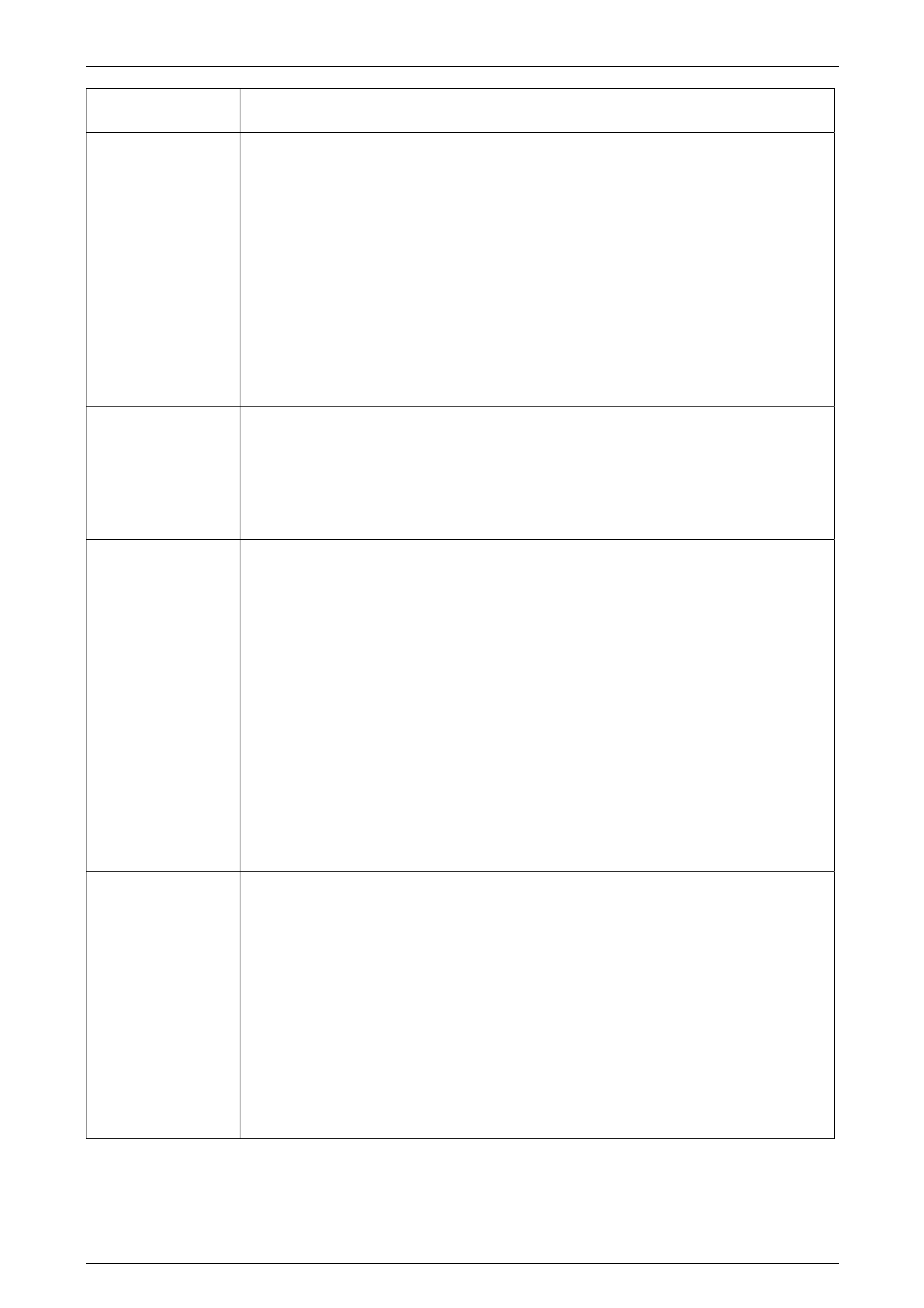

2.2 Wiring Diagram V8

Figure 2E – 3

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–9

Page 2E–9

Figure 2E – 4

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–10

Page 2E–10

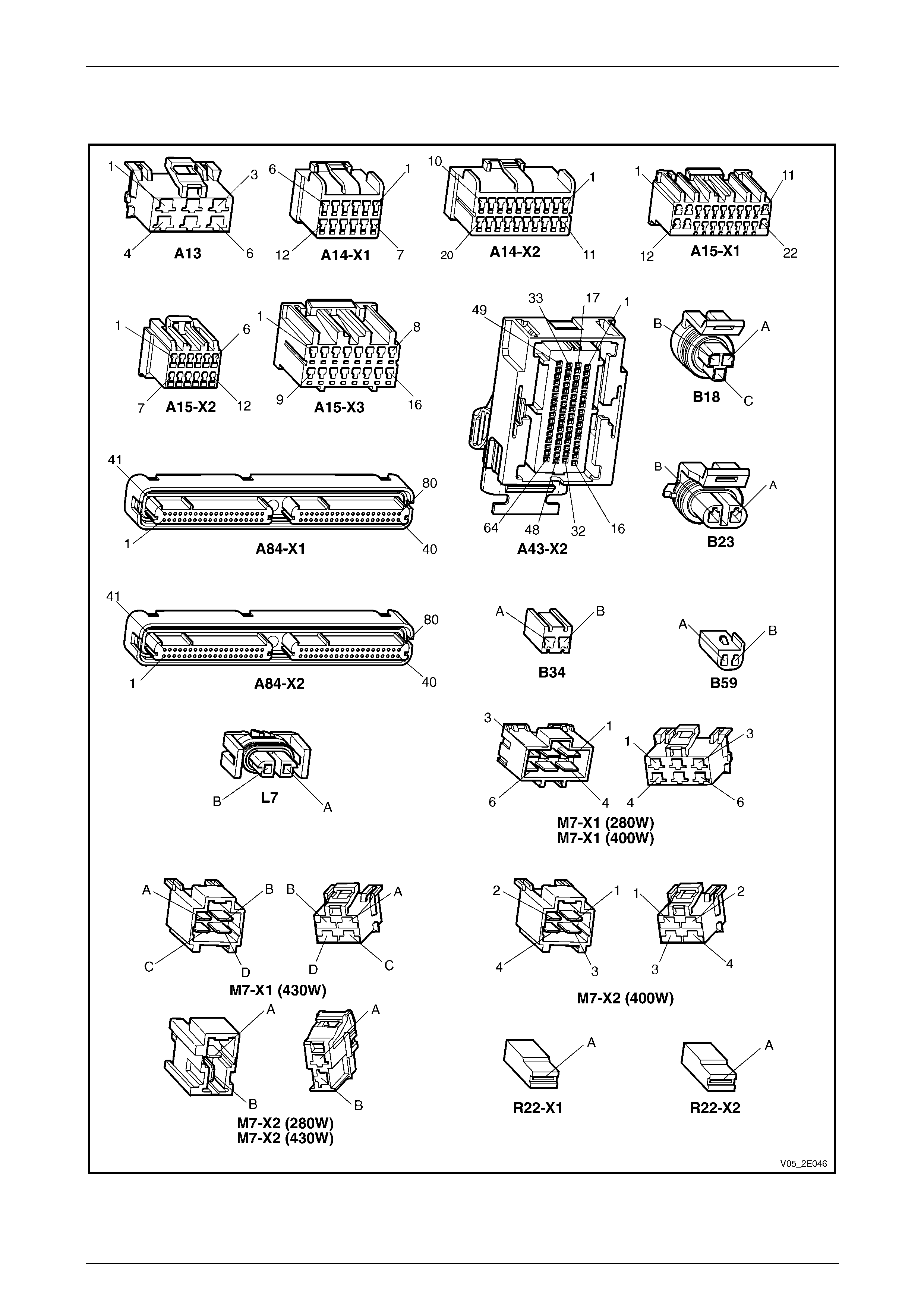

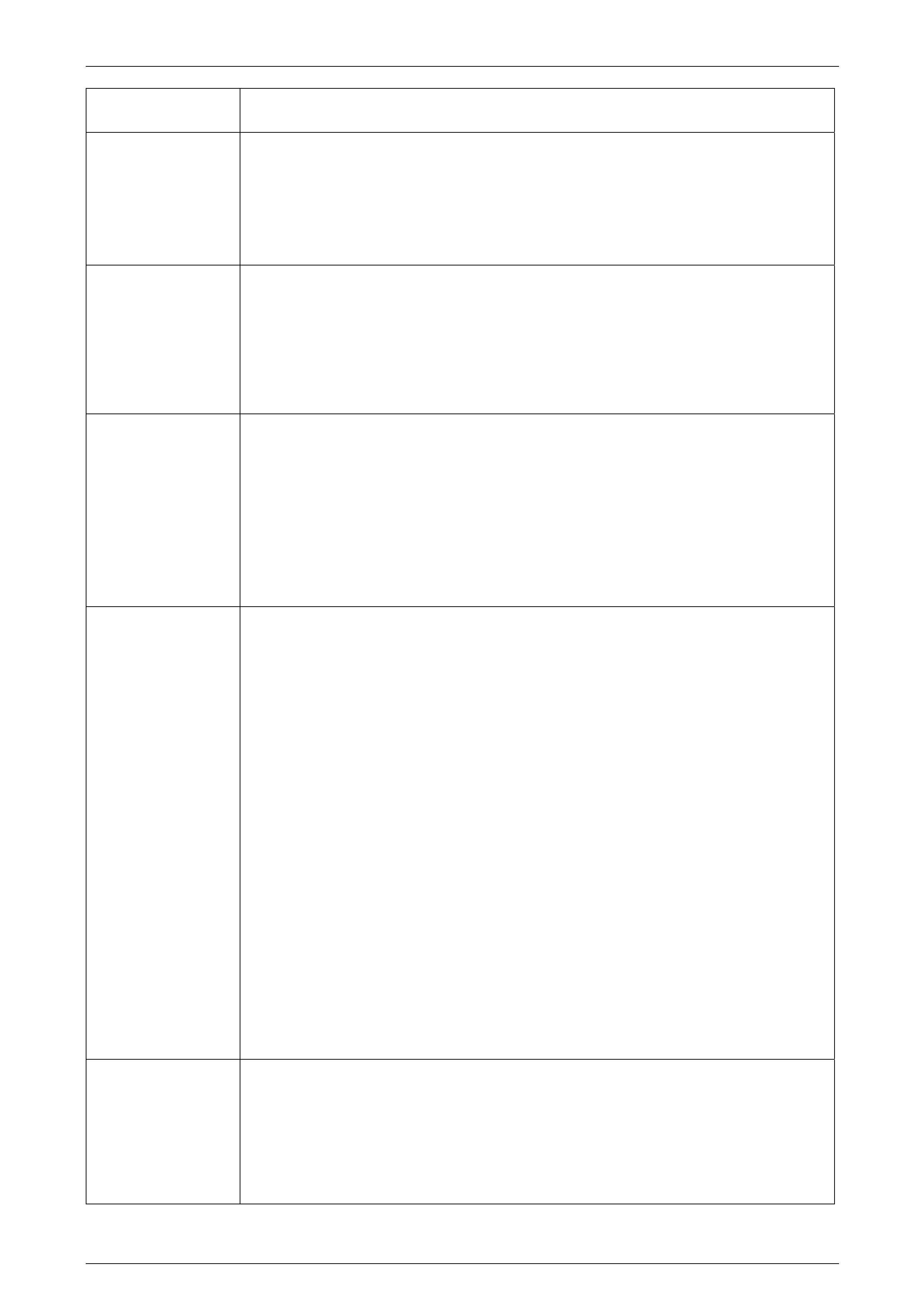

2.3 Connector Chart

Figure 2E – 5

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–11

Page 2E–11

Figure 2E – 6

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–12

Page 2E–12

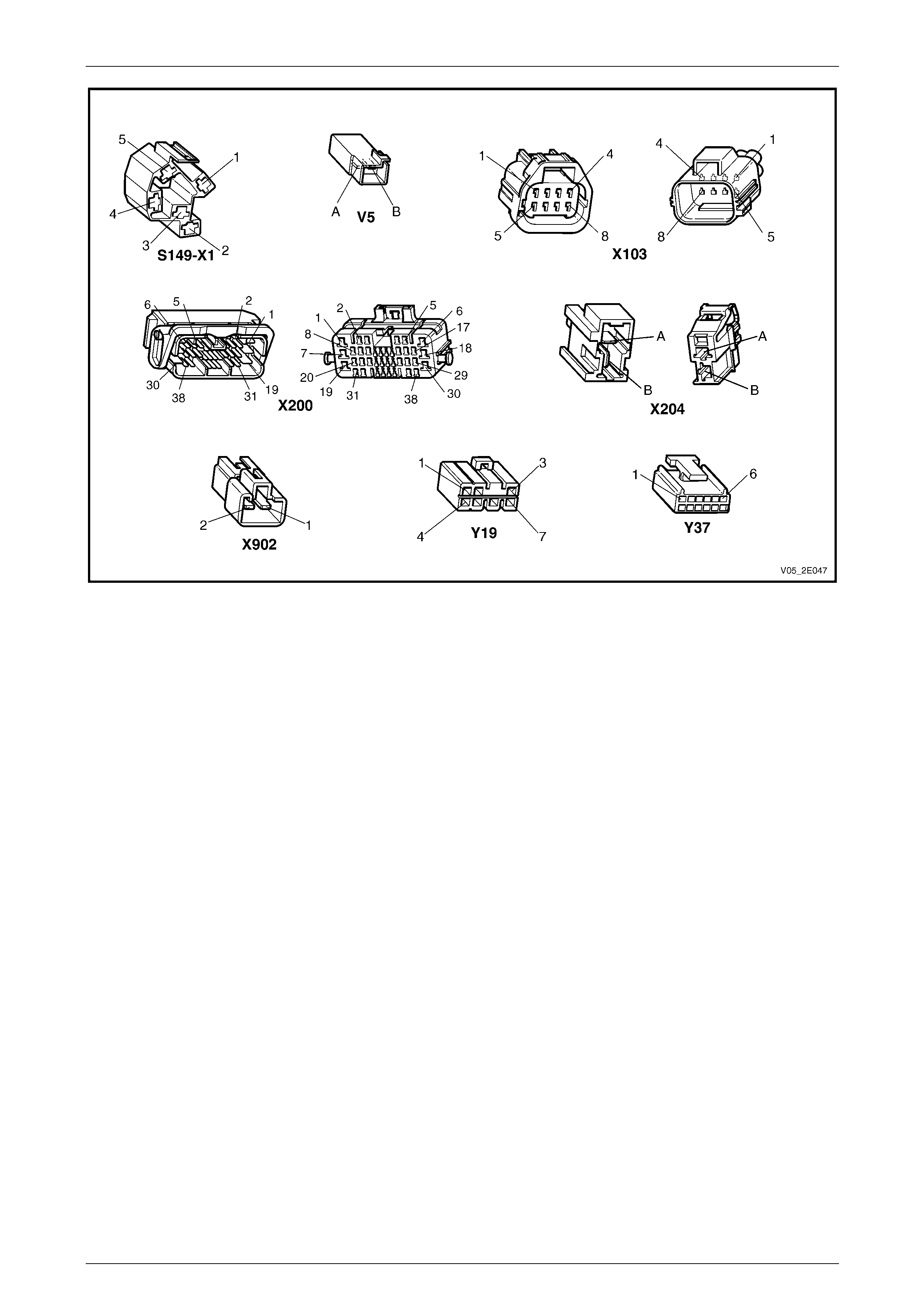

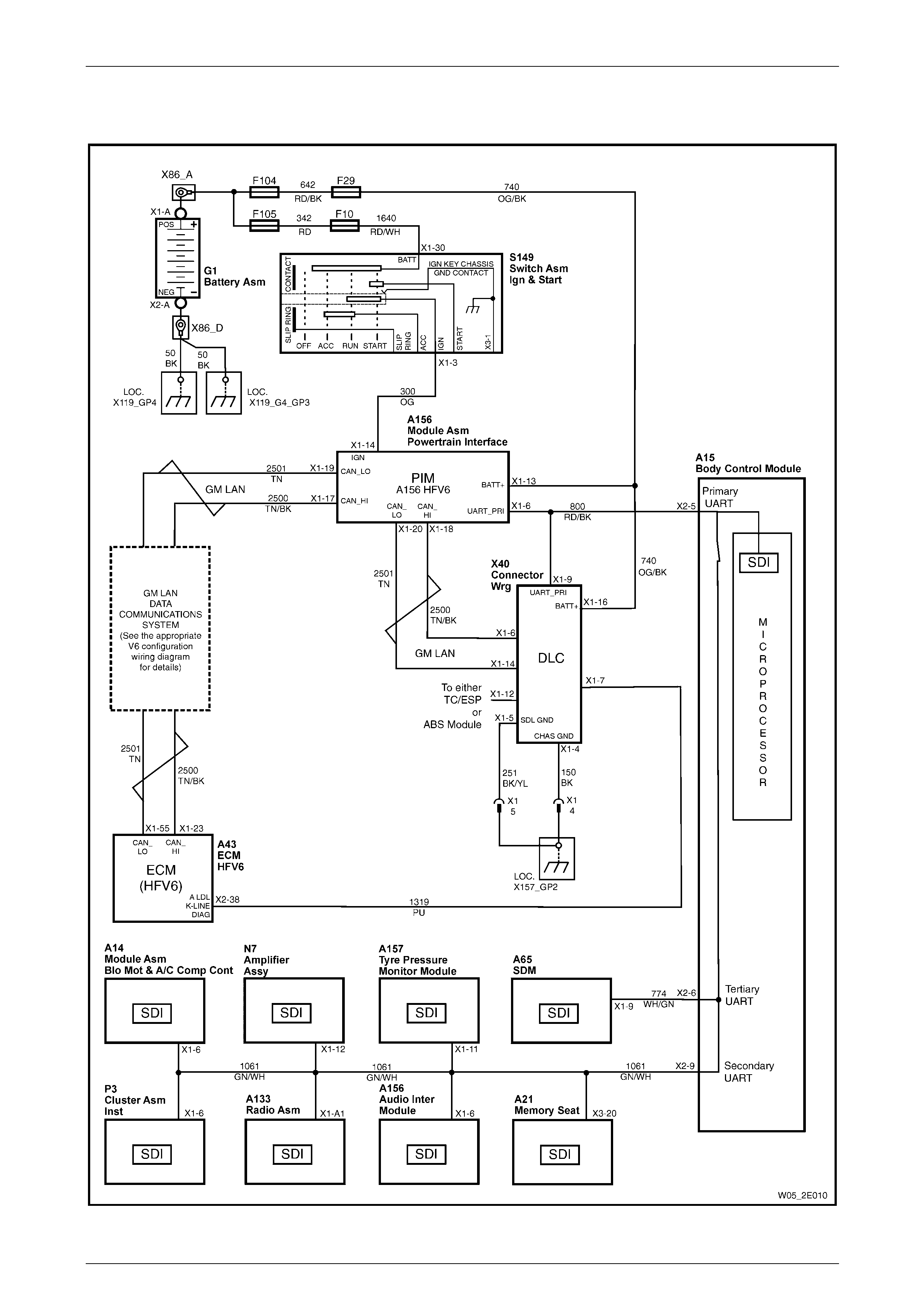

2.4 Serial Databus Diagram V6

Figure 2E – 7

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–13

Page 2E–13

2.5 Serial Databus Diagram V8

Figure 2E – 8

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–14

Page 2E–14

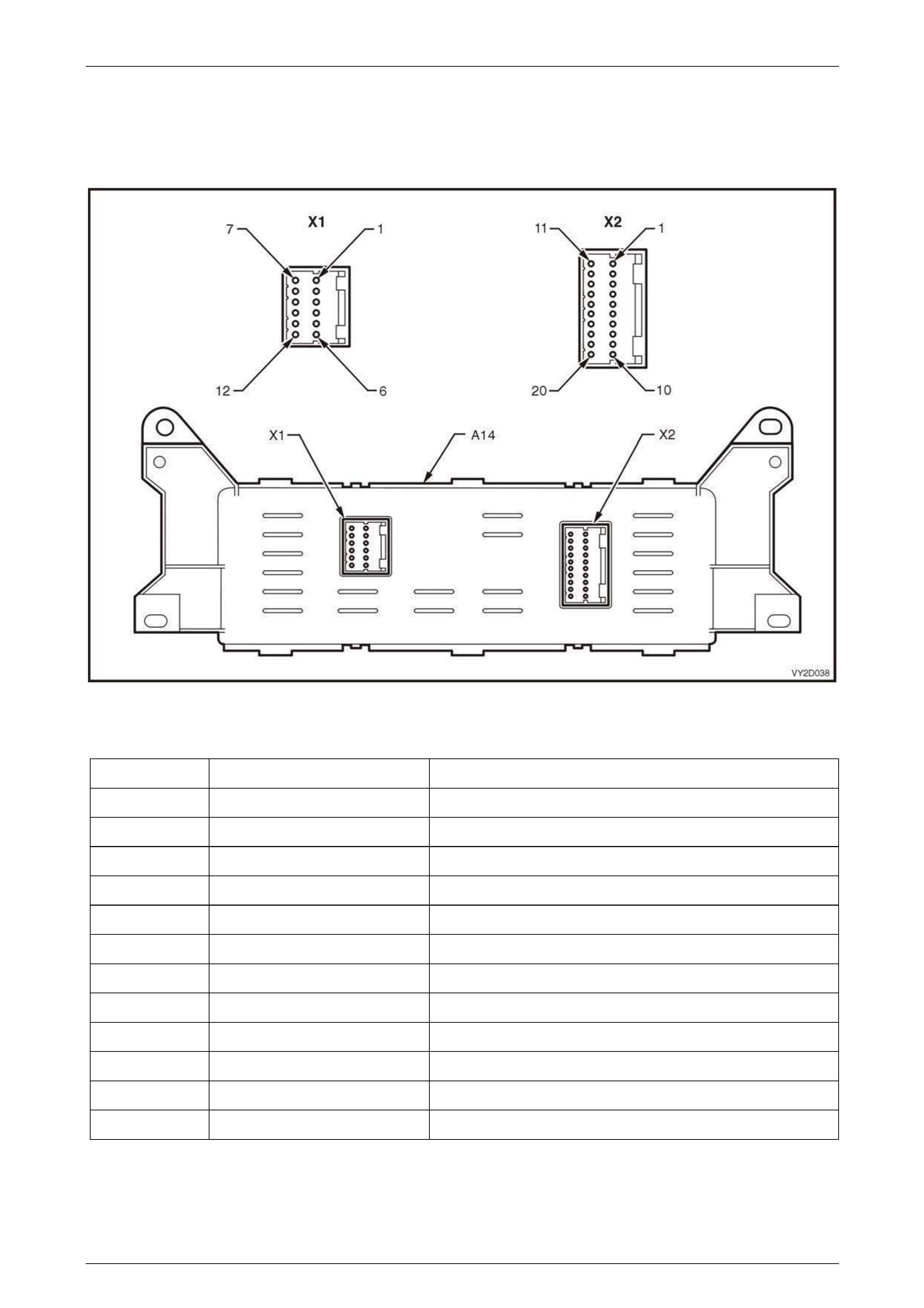

2.6 Connector Information

OCC Control Module

Figure 2E – 9

Module Side — A14 – X1

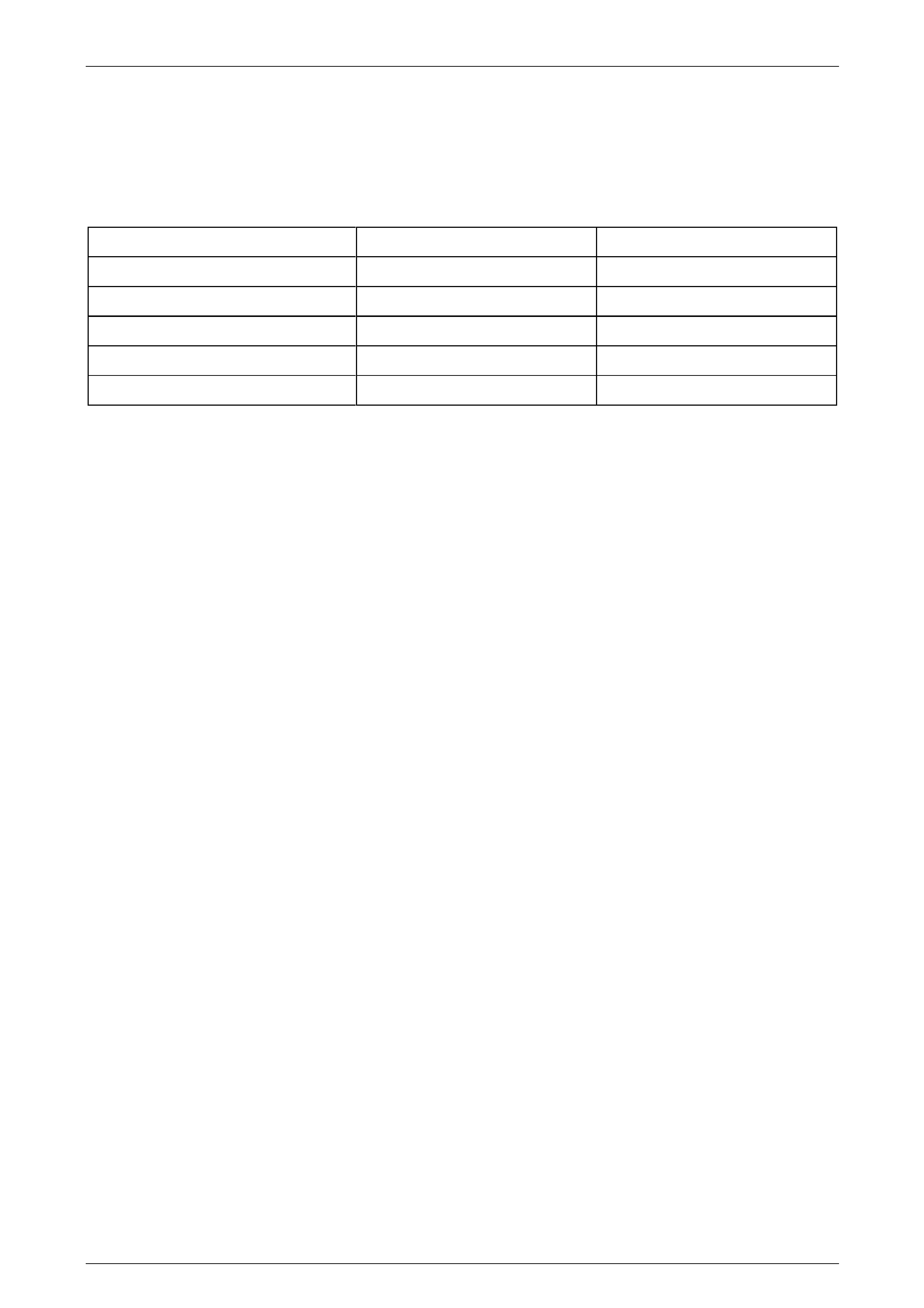

Pin Number Wire Colour Function

X1-1 BK/RD Rear Window Demister

X1-2 BK/YE Ground

X1-3 OG/YE Battery Voltage

X1-4 PK/BU Ignition Voltage

X1-5 YE/BK Fan Speed High – Blower Relay

X1-6 GN/WH UART Serial Databus

X1-7 YE Fan Speed Feedb ack

X1-8 BK/RD Fan Speed Control

X1-9 BN/WH Instrument Illumination

X1-10 BU/BK In-car Temperature Signal

X1-11 – Not Used

X1-12 L-GN/BK Ambient Air Temperature Signal

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–15

Page 2E–15

Module Side — A14 – X2

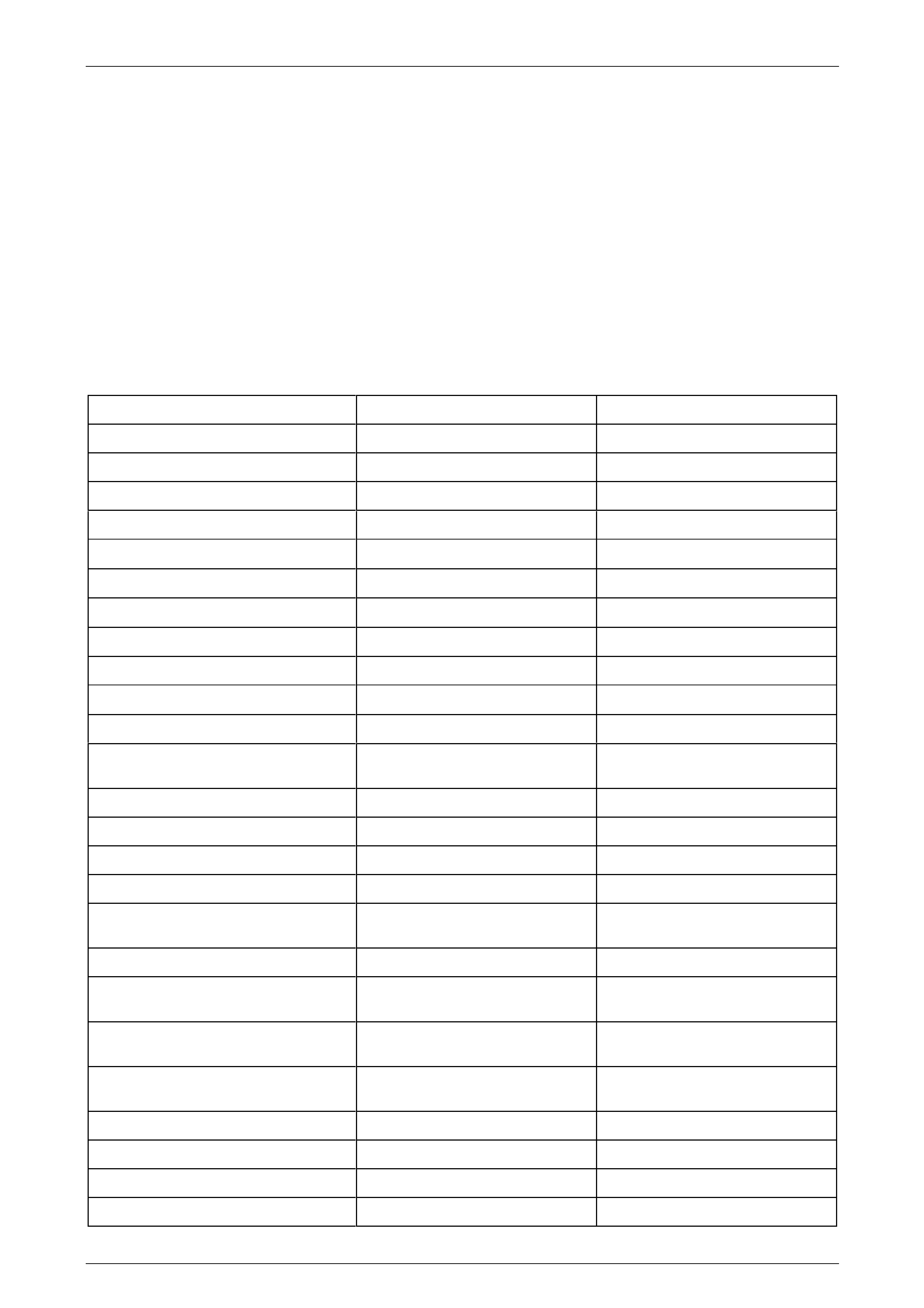

Pin Number Wire Colour Function

X2-1 RD Left Air Mix Door Motor + ve

X2-2 BK Right Air Mix Door Motor – ve

X2-3 BN Left Air Mix Door Motor + ve

X2-4 BU Right Air Mix Door Motor – ve

X2-5 RD/WH Solenoid Supply Voltage

X2-6 D-GN Foot 1 Select – No. 1 Solenoid

X2-7 BK/WH Foot 2 Select – No. 2 Solenoid

X2-8 PK Fresh / Recirc Select – No. 5 Solenoid

X2-9 YE Face 1 Select – No. 4 Solenoid

X2-10 BU/RD Face 2 Select – No. 3 Solenoid

X2-11 WH Air Mix Motor Position Sensor Supply Voltage

X2-12 – Not Used

X2-13 – Not Used

X2-14 – Not Used

X2-15 TN Sensor Ground

X2-16 – Not Used

X2-17 YE/BU Air Mix Motor Position Signal

X2-18 GN/WH Air Mix Motor Position Signal

X2-19 WH/BK Evaporative Temperature Sens or Signal

X2-20 PU Water Select – No. 6 Solenoid

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–16

Page 2E–16

3 Tech 2 Information

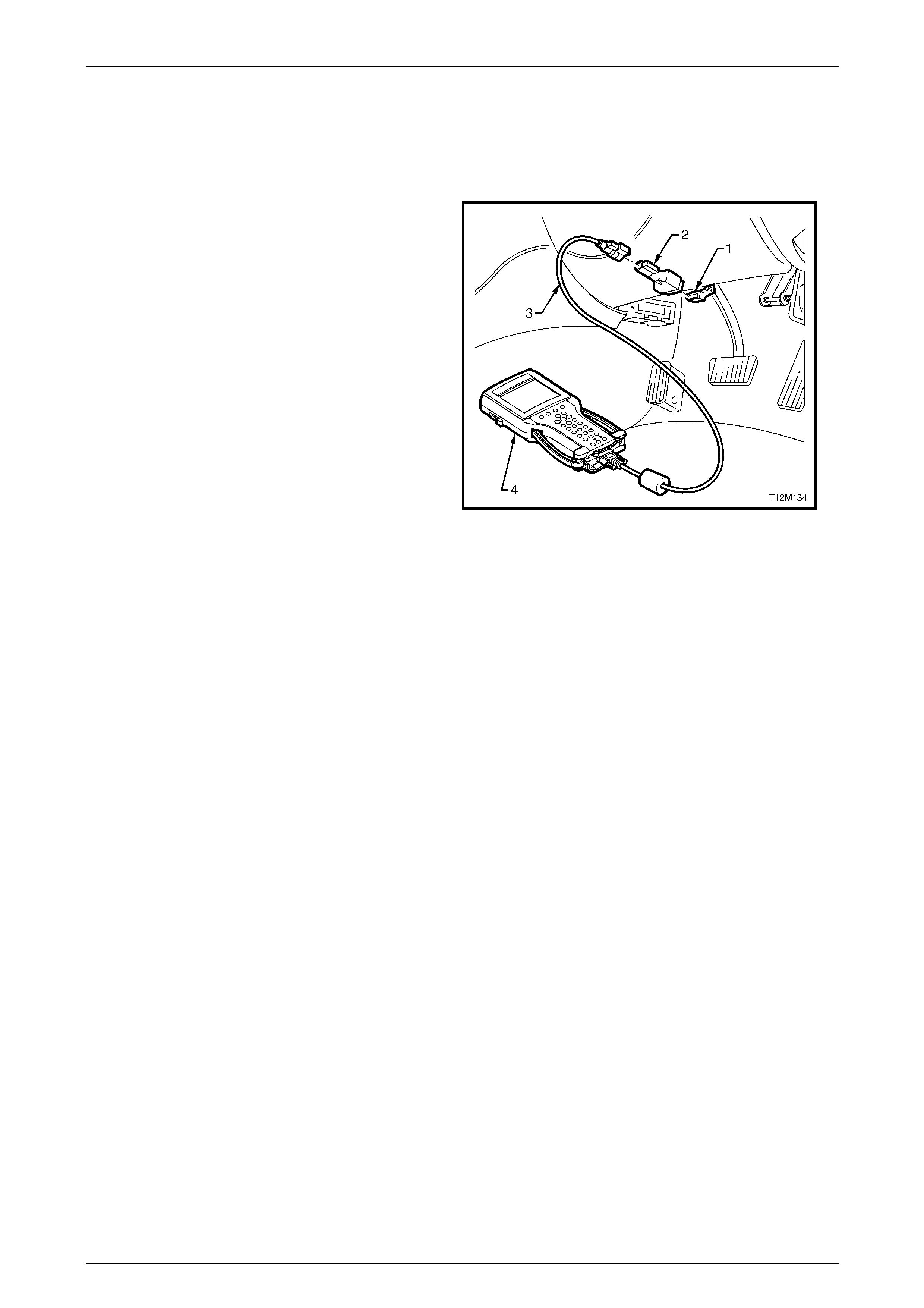

3.1 Tech 2 Diagnostics

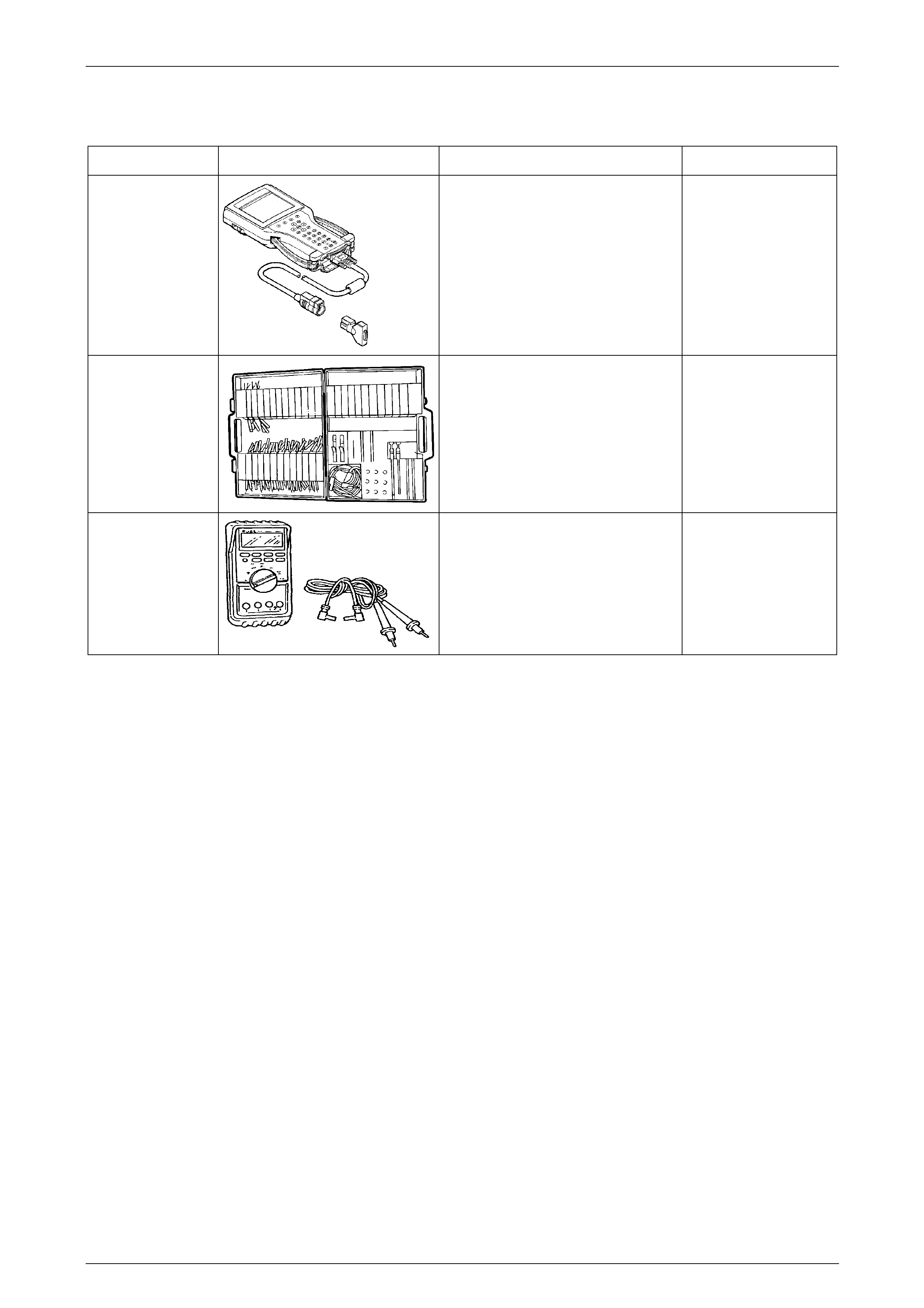

Tech 2, with appropriate software, cable and ada pters,

when connected to the Serial Data Link Connector (DL C),

can read occupant climate control (OCC) data. The DLC is

attached to the instrument panel trim retainer beneath the

steering wheel

Legend

1 Data Link Connector (DLC)

2 DLC Adaptor

3 DLC Cable

4 Tech 2 diagnostic tool.

For additional general information on connecting and

operating Tech 2, refer to Section 0C Tech 2.

Figure 2E – 10

Test Modes

Tech 2 has five test modes for diagnosing the OCC. To navigate to these various test modes, on T ech 2 select:

Diagnostics / Model Year / Model / Body / Occupant Climate Control

and follow Tech 2’s prompts. Tech 2 will then display the following Menu options:

Normal Mode

In this mode, the Tech 2 monitors the communic ation between control modules on the serial d atabus. T he information

displayed on the Tech 2 screen in this mode is what the OCC is communicating to the other modules via the seria l data

line. For further detail, refer to 3.2 Normal Mode.

Diagnostic Trouble Codes

If Diagnostic Trouble Codes is selected, a list is displayed which contains:

• Read DTC Information – Once selected, both current and history Diagnostic Trouble Codes (DTCs) stored will be

displayed.

• Clear DTC Information – Once selected, stored DTCs can be cleared from memory by following the Tech 2

prompts.

NOTE

For a complete list of OCC DTCs. For further

information on Tech 2 and its functions, refer to

Section 0C Tech 2.

Data Display

If Data Display is selected, a selection list is displayed which contains:

• Data List – Once selected, a list of OCC inputs and outputs are displayed a long with their status.

• Swit ch Dat a – Once selected, Tech 2 displays the status of the OCC switches.

• System Identification – Once selected, Tech 2 displa ys the OCC system control module identification data which

contains, Software Version, Manufacturer Hard ware, EEPROM Version, Production Date, Identifier and Part

number.

• Air Mix Door Calibration Positions – Once selected, Tech 2 will display the parameters associated with the mix

door calibration and associated voltages.

For further detail, refer to 3.3 Data Display.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–17

Page 2E–17

Snapshot

In this test mode, Tech 2 captures OCC data before and after a forced trigger

Miscellaneous Tests

If Miscellaneous Tests is selected, a selection list is displayed which contains:

• Drivers Air Mix Door – Tech 2 can command the driver’s air mix door open and closed in percentage in crements

thus controlling the temperature e xhausted from the driver’s centre air vent.

• Passengers Air Mix Door – Tech 2 can command the passengers air mi x door open and closed in percentage

increments thus controlling the temperatur e ex ha usted from the driver’s centre air vent.

• Blower Speed – T ech 2 can control the blower fan in 10 percent increments from 0 to 100% (0% being off and

100% being full speed)

• Maximum Fan Relay – Tech 2 can command the maximum fan relay on and off.

• LCD Display Test – Tech 2 can command all the HVAC symbols on the multi-function display (MFD) on and off.

• Outlet Mode – With the blower fan at 60%, Tech 2 can toggle through the various o utlet modes of the OCC module

and therefore change the p osition of where the air is exhausted. These are Demist, Face, Bi-Level, Blen d and F oot.

• Illumination – Tech 2 can command the illumination of the OCC module control buttons to increase and decrease.

• Front Demist LED – Tech 2 can command the front demist LED on and off.

• Rear Demist LED – Tech 2 can command the rear demist LED on and off.

• Rear Demist Relay – Tech 2 can command the rear demist relay on and off.

• A/C Request – Tech 2 can command the A/C request on and off thus engaging/disengaging the compressor clutch

• Solenoids – On selected, Tech 2 can command the following solenoids to energise and de-energise:

• Face 1 Solenoid

• Face 2 Solenoid

• Foot 1 Solenoid

• Foot 2 Solenoid

• Fresh / Recirculate Solen oid

• Water Valve Solenoid

For further detail, refer to 3.4 Miscellaneous Tests.

Programming

If Programming is selected, a selection list is displayed which contains:

• Calibrate Air Mix Door – Tech 2 can be used to calibrate the air mix do ors so they are driven to full open and

close

• Program Code Index – Tech 2 can program the OCC depending of what type (i.e. single zone, dual zone, right-

hand or left-hand drive) OCC is fitted to the vehicle.

For further detail, refer to 3.5 Program.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–18

Page 2E–18

3.2 Normal Mode

In the Normal Mode, information the OCC module is communicating to other control modules, via the s erial data line, is

displayed. In this mode the foll owing is displayed.

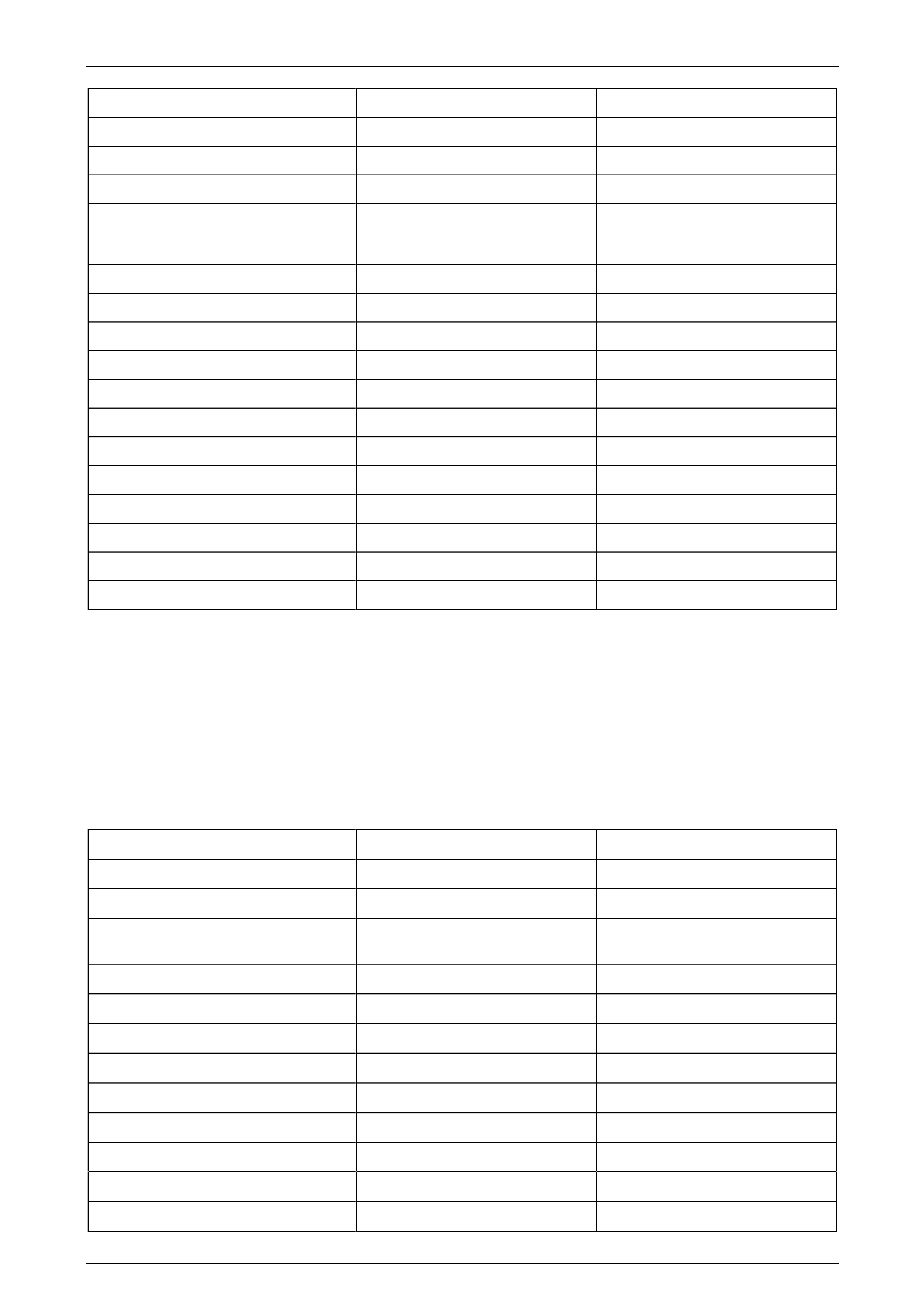

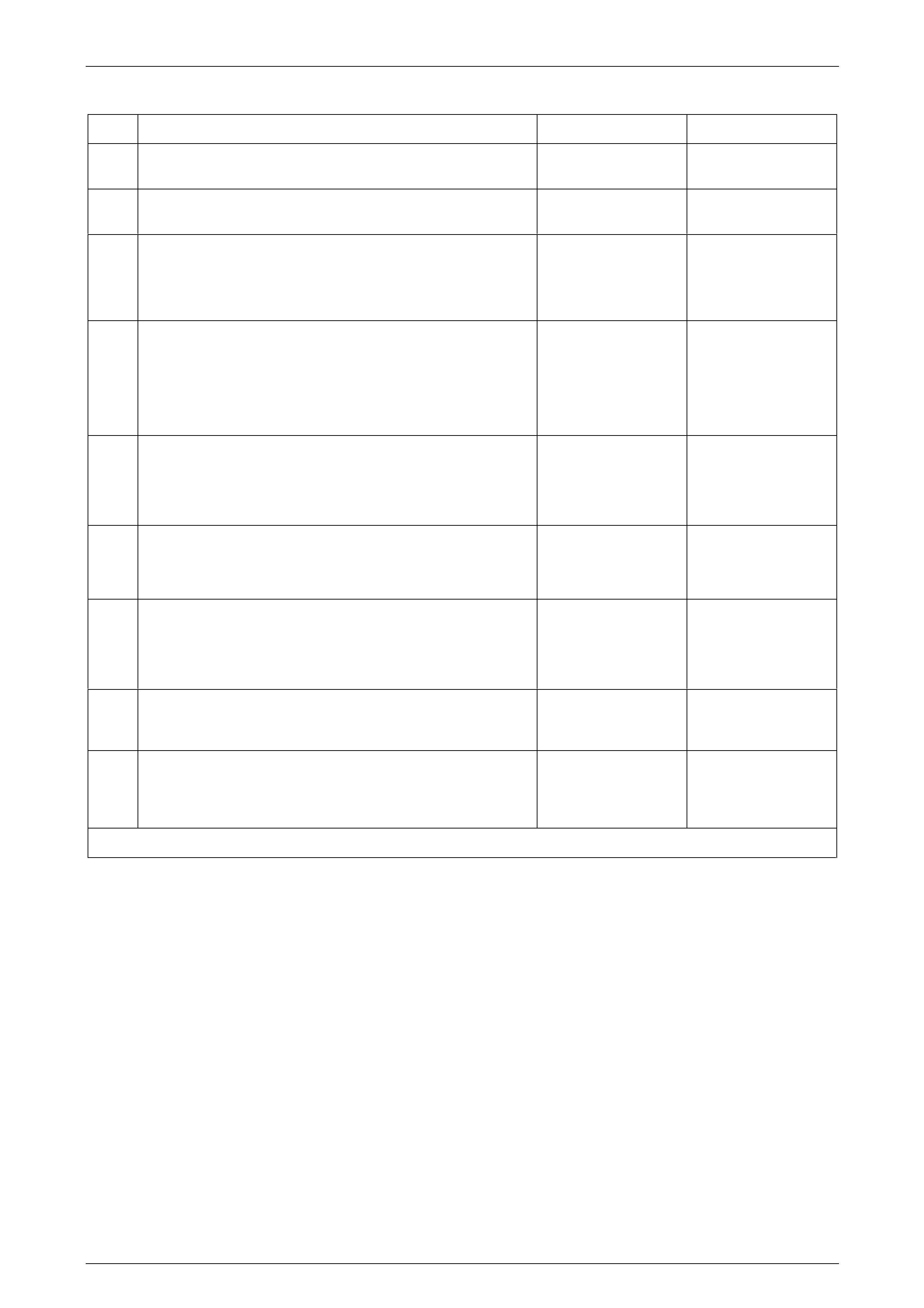

Normal Mode Parameters

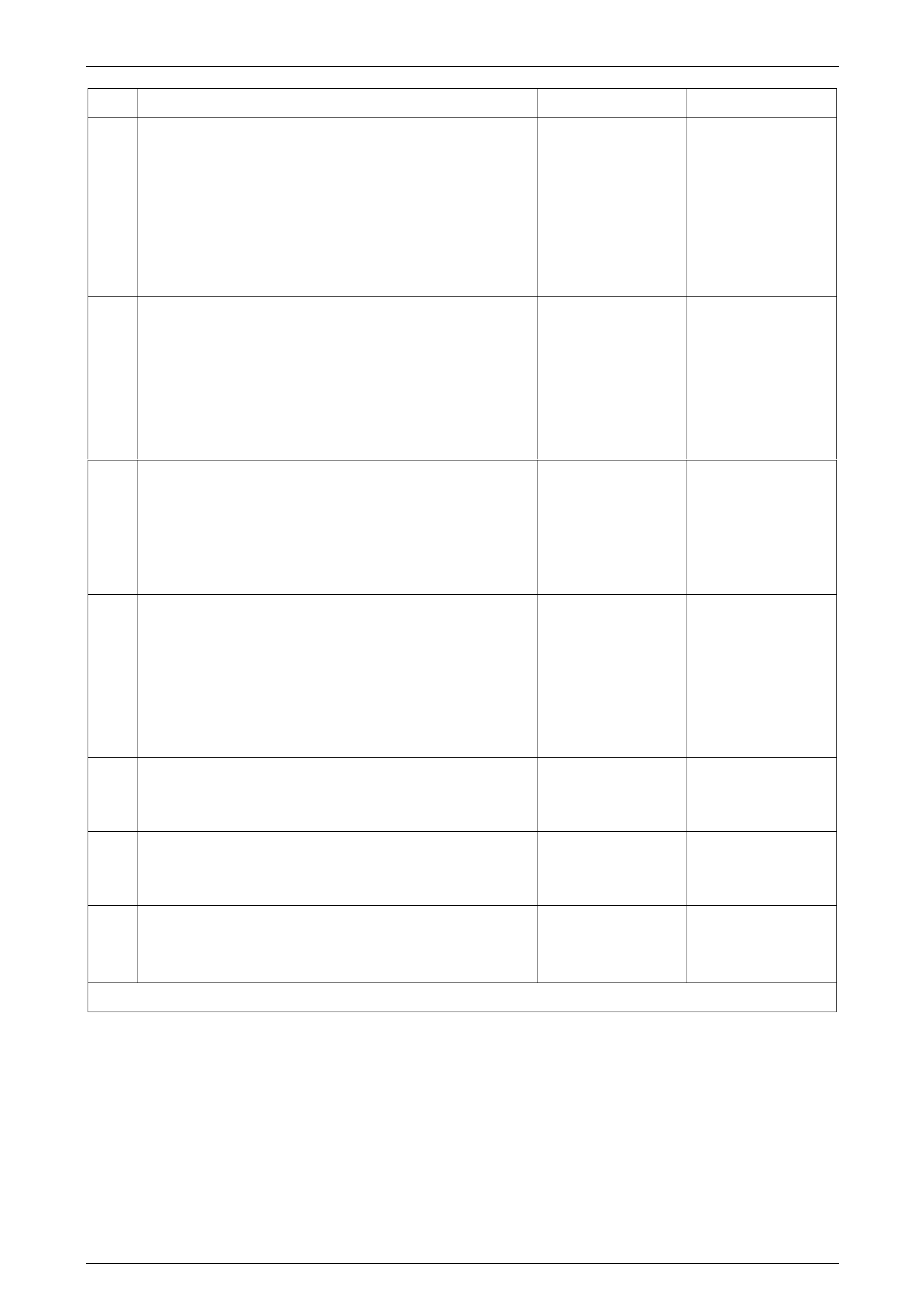

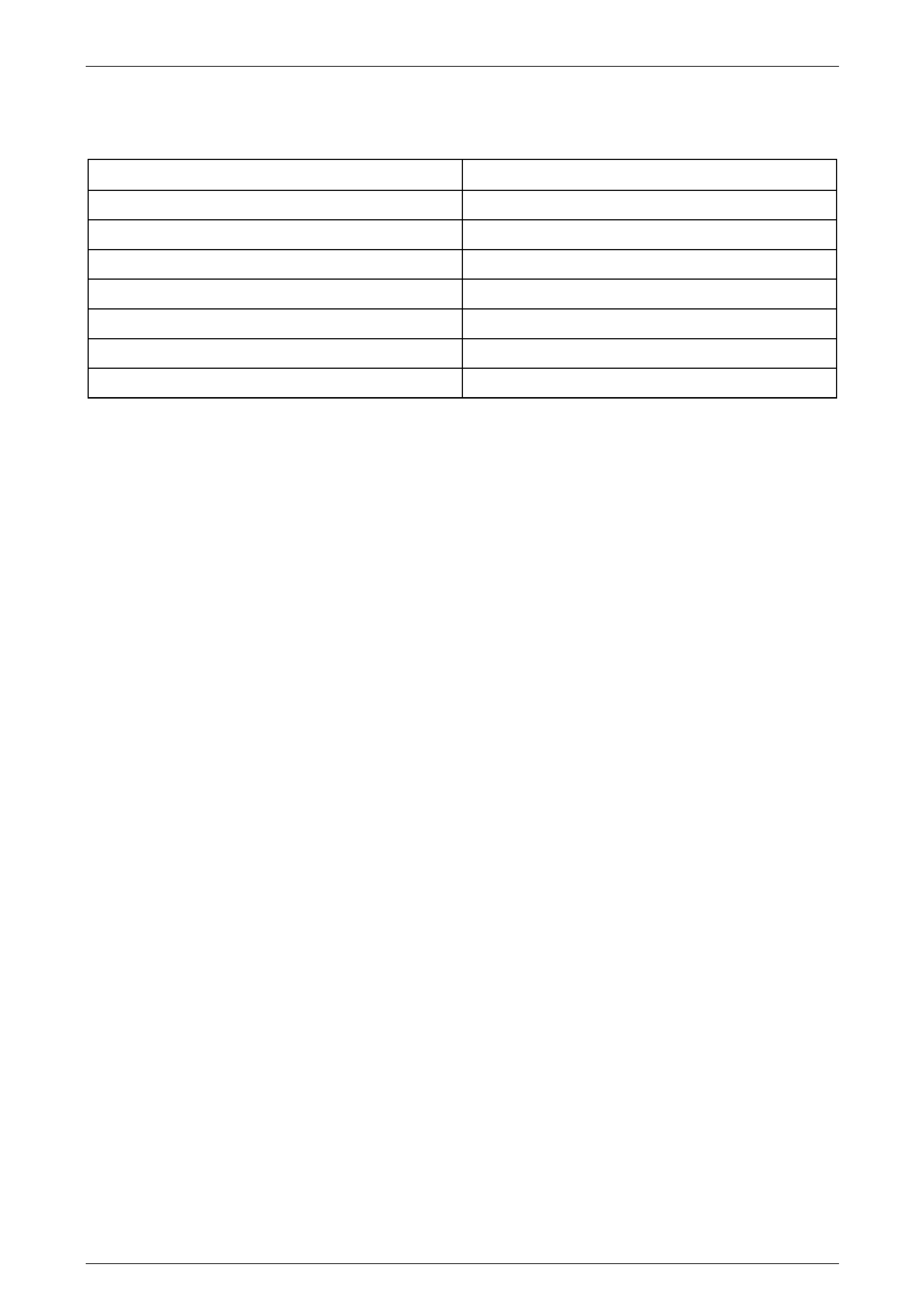

Tech 2 Parameter Units Displayed Typical Data Value

MFD Message (Multi Func Yes / No Varies

A/C Request (Air Condit On / Off Varies

Rear Window Heater Stat Volts Varies

DTC Set Yes / No Varies

Ambient Temperature °C Varies

For example: As displayed, the A/C request status is ‘(Air Condit off’. This means the OCC module is communicating

with the BCM, informing the air conditioning compressor is currently turned off.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–19

Page 2E–19

3.3 Data Display

If the Data Display mode is selected, an additional menu will appear giving the operator the optio n of selecting:

• Data List,

• Switch Data,

• System Identification, or

• Air Mix Door Calibration Positions.

Data List

Once in this mode, a list of OCC related compon ents, input and outputs and the associated values or status

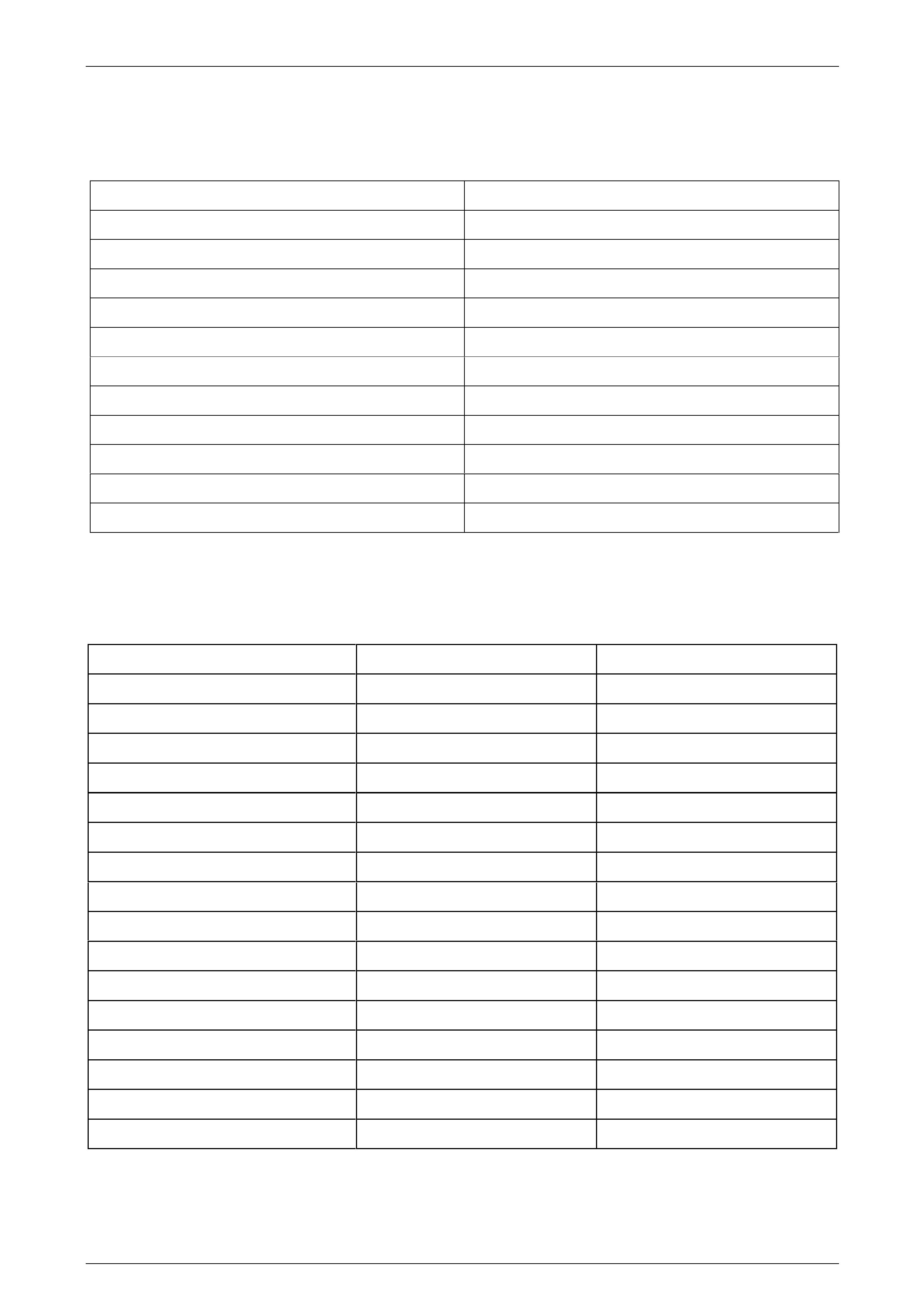

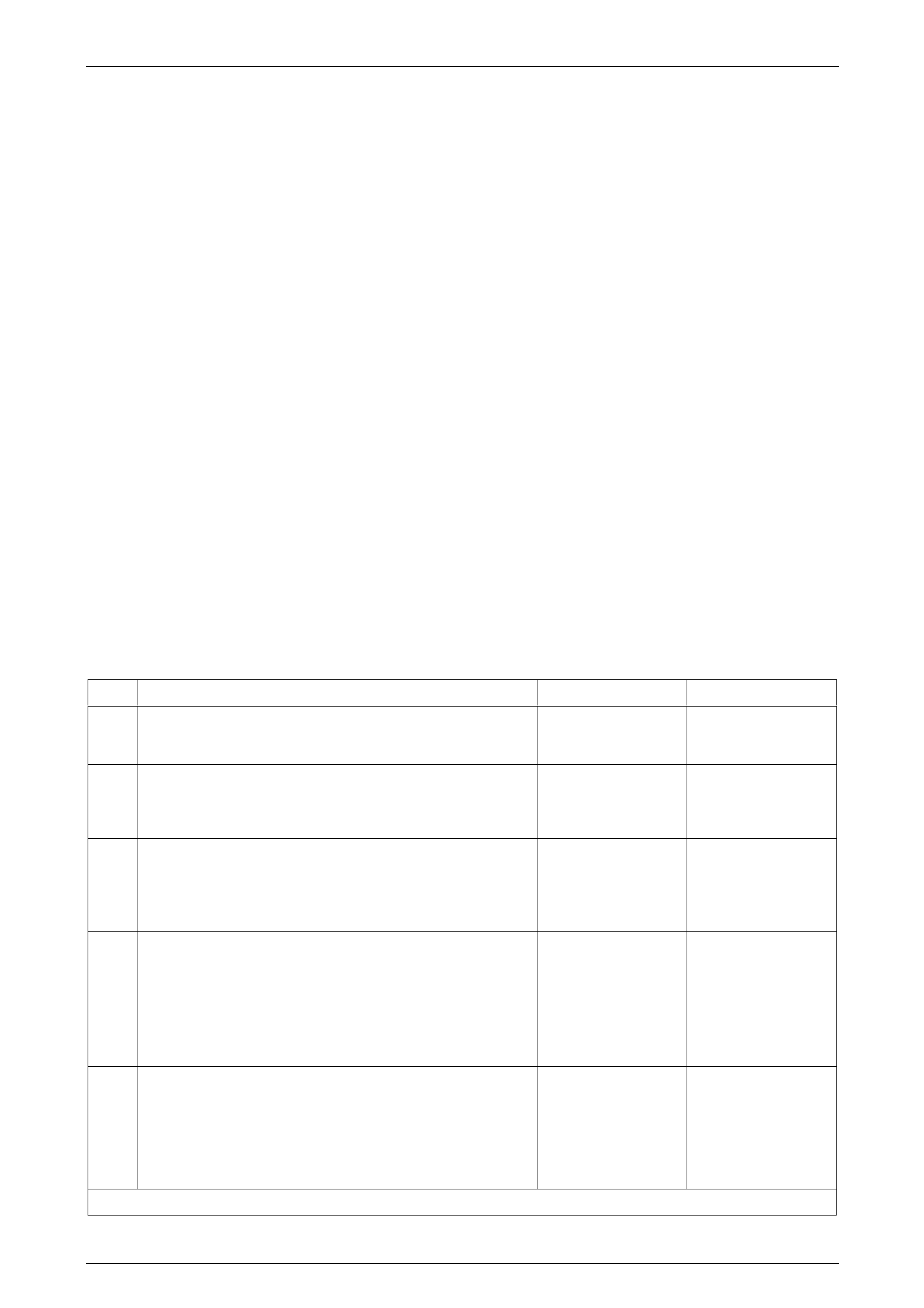

Data List Parameters

Tech 2 Parameter Units Displayed Typical Data Value

System Status On / Off Varies

Battery Voltage Volts Approx 13.5 V

Ignition Status On / Off Varies

Air Conditioning Request Yes / No Varies

Evaporative Temperatur e Sensor Volts 0 to 3.5 ± 0.2 V

Evaporative Temperatur e °C Varies

Ambient Temperature Sensor Volts 0 to 3.5 ± 0.2 V

Ambient Temperature °C Varies

Dampened Ambient Temperature °C Varies

In Car Temperature Sensor Volts 0 to 3.5 ± 0.2 V

In Car Temperature °C Varies

Blower Fan Speed Manual: 1234 and HIGH, Auto: Low,

Mid and High Varies

Desired Blower Fan Spee d Percent Varies

Blower Fan Speed Control Percent Varies

Blower Fan Speed Feedback Voltag e Volts Varies

Drivers Air Mix Motor Position Desired Percent Varies

Passengers Air Mix Motor Position

Desired Percent Varies

Drivers Air Mix Motor Position Feedback Percent Varies

Passengers Air Mix Motor Position

Feedback Percent Varies

Drivers Air Mix Motor Position Feedback

Voltage Volts 0 to 3.5 ± 0.2 V

Passengers Air Mix Motor Position

Feedback Voltage Volts 0 to 3.5 ± 0.2 V

Engine Coolant Temperature °C Varies

Sun Load Steps 0 – 255

Driver Set Temperature °C Varies

Passenger Set Temperature °C Varies

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–20

Page 2E–20

Tech 2 Parameter Units Displayed Typical Data Value

Operating Mode Manual/auto Varies

Outlet Mode Face / foot / blend / bi-level Varies

Inlet Mode Fresh / Recirc Varies

Startup Strategy None, Recirc / Delay, Demist /

Delay, Purge, A/C Purge, Fresh /

Delay

Varies

Fresh / Recirculation Solenoid Off / On Varies

Water Valve Solenoid Off / On Varies

Water Valve Closed / Open Varies

Face 2 Solenoid Off / On Varies

Face 1 Solenoid Off / On Varies

Foot 2 Solenoid Off / On Varies

Foot 1 Solenoid Off / On Varies

High Fan Rela y Inactive: 12 V Active: 0 V Varies

Rear Demist Relay Off / On Varies

Park Lamp Input Off / On Varies

Front Demist LED Off / On Varies

Rear Demist LED Off / On Varies

Switch Data

NOTE

The OCC module buttons will need to be held on

when checking the functionality with Tech 2 due

to a normal delay in information transfer.

Once this mode is selected, Tech 2 will display the status of the OCC module switches.

OCC S witch Data Parameters

Tech 2 Parameter Units Displayed Typical Data Value

Off Switch Off / On Varies

Auto Switch Off / On Varies

Driver Temp. Down Switch

(Temperature) Off / On Varies

Driver Temp. Up Switch (Temperature) Off / On Varies

Recirculation Switch Off / On Varies

Front Demist Switch Off / On Varies

Rear Demist Switch Off / On Varies

Fan Down Switch Off / On Varies

Fan Up Switch Off / On Varies

Mode Switch Off / On Varies

Outside Temperature Switch Off / On Varies

Air Conditioning Switch Off / On Varies

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–21

Page 2E–21

System Identification

Once this mode is selected the system identification informa tion will be displayed.

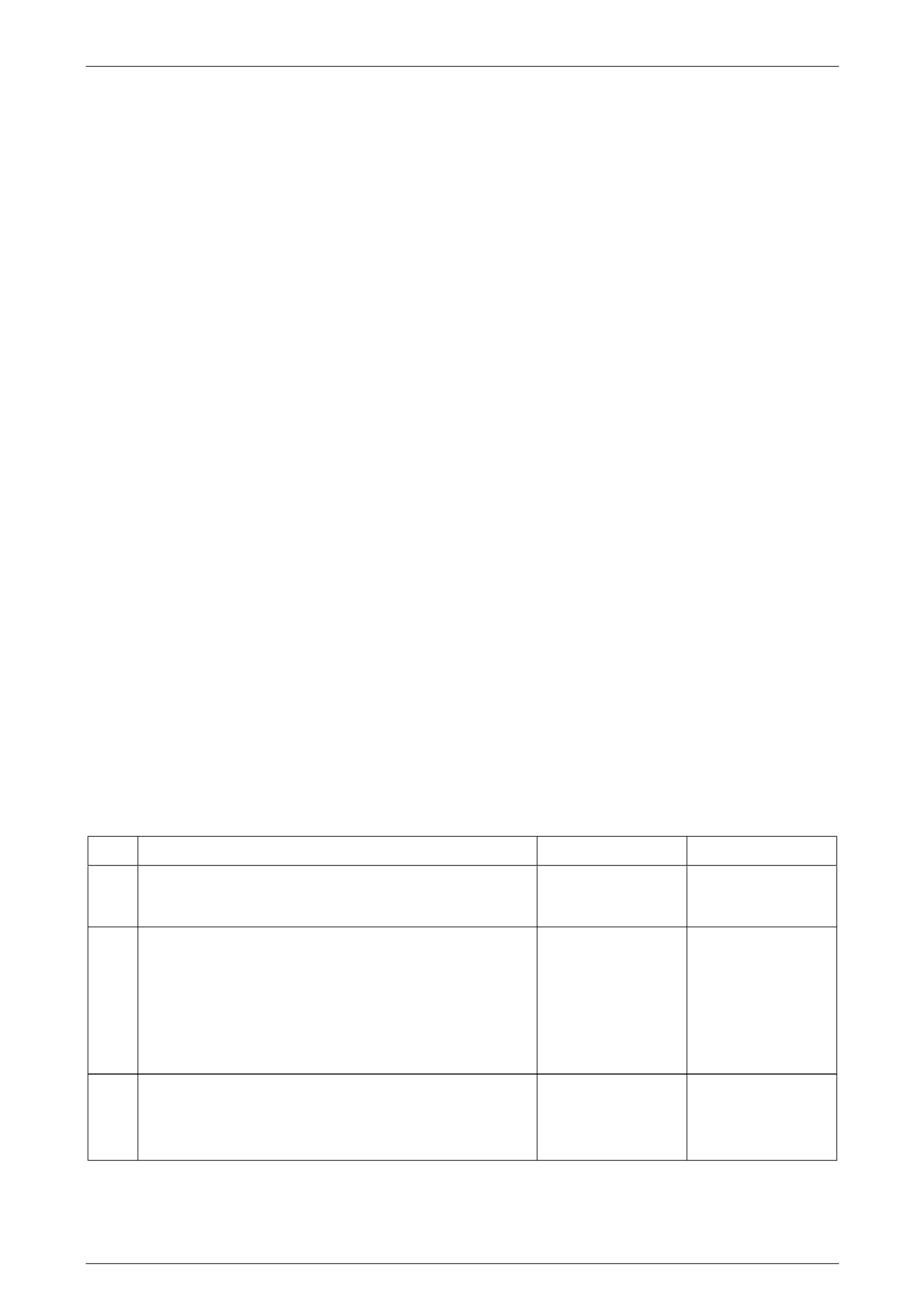

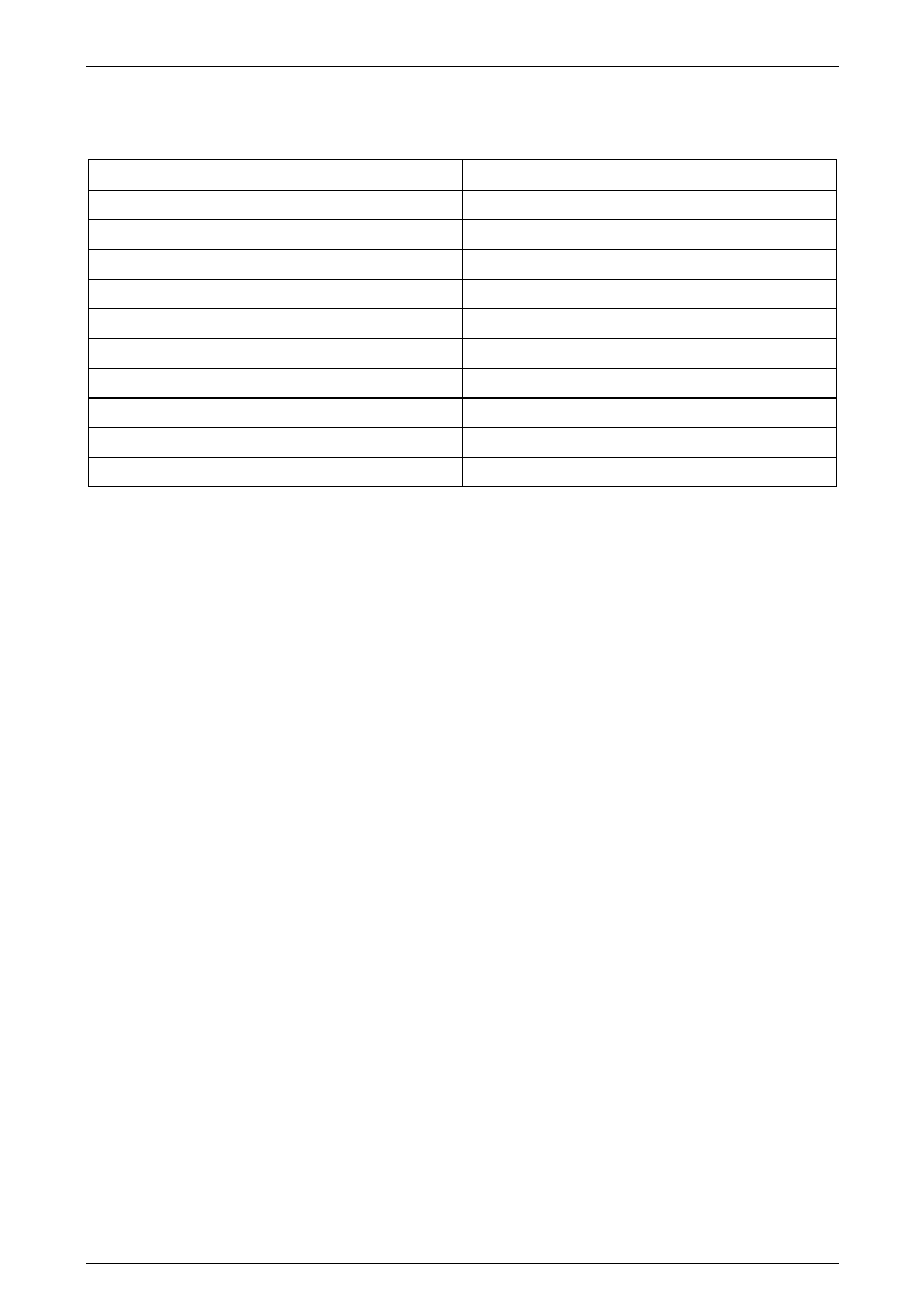

System Identification Parameters

Tech 2 Parameter Typical Data Value

Software Version Varies

Manufacturer Hardware V Varies

EEPROM Version Varies

Production Date Varies

Identifier Varies

Part number Varies

VIN Varies

Code Index 1, 2 or 3

Code Version Varies

Zone Configuration Single or Dual Zone

Drive Configuration Right or Left Hand Drive

Air Mix Door Calibration Positions

Once this mode is selected, Tech 2 displays the position of the air mix d oor as a voltage.

Air Mix Door Calibration Positions Parameters

Tech 2 Parameter Units Displayed Typical Data Value

Drivers Minimum Low Volts Varies

Passengers Minimum Low Volts Varies

Drivers Minimum High Volts Varies

Passengers Minimum High Volts Varies

Drivers Minimum Value Achieved Volts Varies

Passengers Minimum Value Achieved Volts Varies

Drivers Minimum Calibrated Value Volts Varies

Passengers Minimum Calibrated Value Volts Varies

Drivers Maximum Low Volts Varies

Passengers Maximum Low Volts Varies

Drivers Maximum High Volts Varies

Passengers Maximum High Volts Varies

Drivers Maximum Value Achieved Volts Varies

Passengers Maximum Value Achieved Volts Varies

Drivers Maximum Calibrated Value Volts Varies

Passengers Maximum Calibrated Val ue Volts Varies

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–22

Page 2E–22

3.4 Miscellaneous Tests

In the Miscellaneous Test mode, tests can be carried out to the OCC system that will test for proper operation of the

various OCC functions. In this mode, testing and observing the results can confirm correc t operation or identify error

conditions.

NOTE

During the Miscellaneous Tests, the blower fan

will be driven at approximately 60% for all tests

excluding the Blower Speed test.

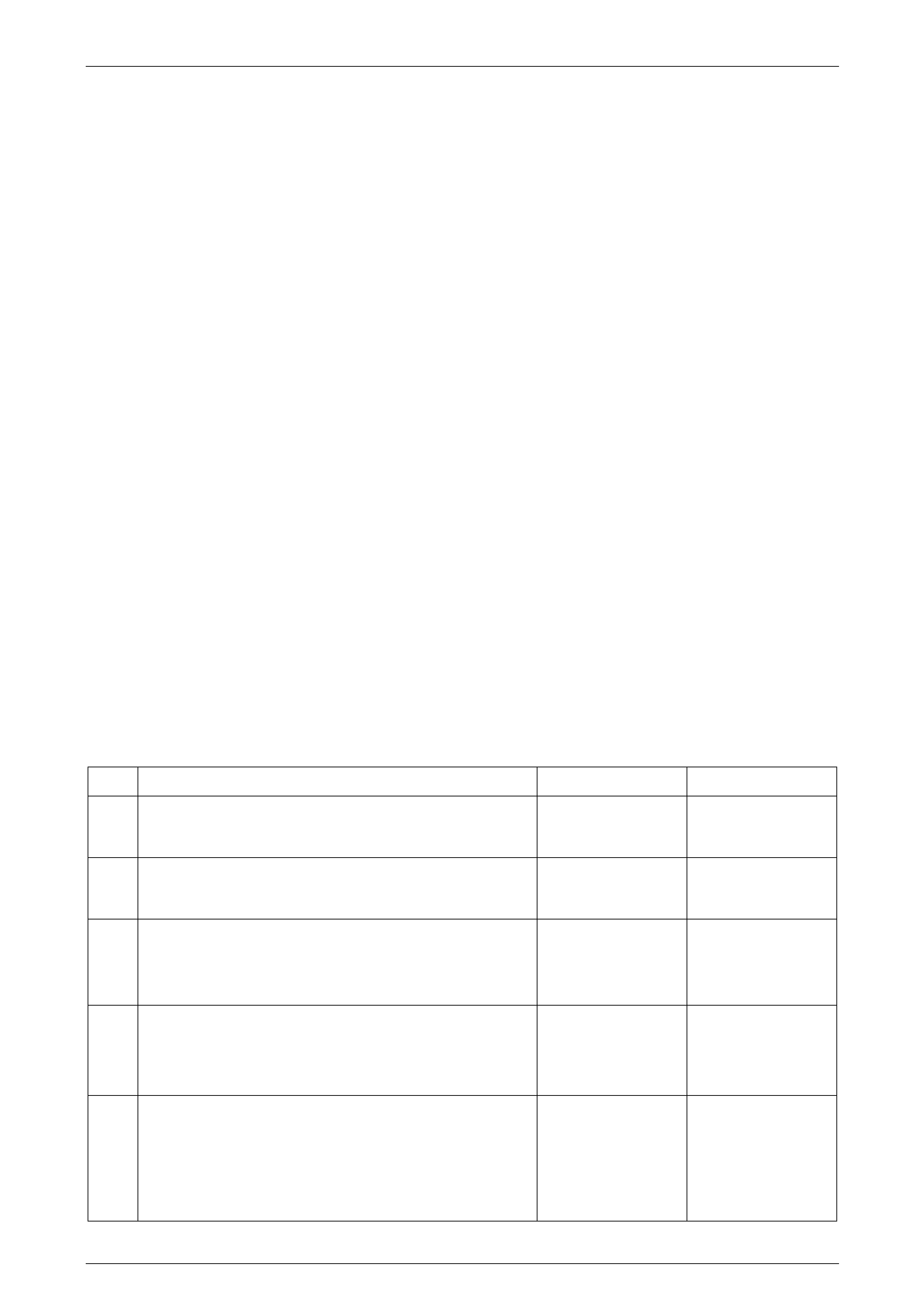

Tech 2

Miscellaneous Tests Description

Drivers Air Mix Door

• The OCC commands the driv ers air mix door open and closed to adjust the temperature

exhausted at the outlet vents.

• In this test, the engine must be running and at operating temperature. The blower fan

speed must be above 60%.

• Tech 2 can manually position the drivers air mix door open and closed using the

Increase and Decrease soft keys.

• Using the Increase soft key will open the door thus increasing the temperature

exhausted.

• Using the Decrease soft key will close the door thus decreasing the temperature

exhausted.

• A thermometer placed in the right-hand centre vent outlet can confirm the doors

operation.

Passengers Air Mix

Door

• The OCC commands the passeng ers air mix door open and closed to adjust the

temperature exhausted at the outlet vents.

• In this test, the engine must be running and at operating temperature. The blower fan

speed must be above 60%.

• Tech 2 can manually position the passenger s air mix door open and close d using the

Increase and Decrease soft keys.

• Using the Increase soft key will open the door thus increasing the temperature

exhausted.

• Using the Decrease soft key will close the door thus decreasing the temperature

exhausted.

• A thermometer placed in the left-hand centre vent outlet can confirm the doors oper ation.

Blower Speed

• The OCC controls the blower speed either automatically or manually when the operator

overrides the automatic function of the OCC.

• In this test, the engine must be running.

• Tech 2 can manually contro l the sp eed of the blower fan using the Increase and

Decrease soft keys.

• Tech 2 displays the blower fan speed as a percentage; 0% being off and 100% bein g the

maximum speed. Tech 2 will increase or decrease the fan speed in 10% increments

between the minimum and maximum values.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–23

Page 2E–23

Tech 2

Miscellaneous Tests Description

Maximum Fan Relay

• The OCC controls the maximu m blower fan speed by providing a ground cir cuit for the

blower relay (R2) which is located on the engine compartment fuse and relay panel

assembly. Refer to 12O Fuses, Relays and Wiring Harnesses for the location of the

blower relay.

• During normal oper ation, the relay will be open at all b lower fan speeds less than

maximum.

• In this test, the ignition must be in the On position.

• Tech 2 can manually turn the blower relay on and off using the Off and On soft keys.

NOTE

The blower fan will operate at 100% speed when the blower relay is turned on.

• When the relay is toggled from off to on or visa versa, an audi ble click should be heard

from the relay.

LCD Display Test

• The OCC module and the multi-function display (MFD) are connected via a serial

databus. Depending in what automatic mode or manual conf iguration the OCC module is

in, the module will inform the MFD to turn on and off certain symbols.

• In this test, the ignition must be in the On position.

• Tech 2 can manually turn on all the MF Ds HVAC symbols on and off using the Off and

On soft keys.

Outlet Mode

• The multiple solenoids that control which vents are used to exhaust the air, are controlled

by the OCC module. When in automatic mode, the OCC module sel ects which vents are

to be used and energises the correct solenoi ds. This can be over ridden by the operator

by pressing either the mode or front demist buttons. The OCC module will then use the

vents which the operator has selected.

• In this test, the engine must be running.

• Tech 2 can manually select the outlet modes of the OCC module by using the Previous

Mode and Next Mode soft keys. Tech 2 will toggle through the follo wing modes:

• Demist (demister vents only)

• Face (face level vents only)

• Bi-Level (face and foot level vents)

• Blend (demist and foot level vents), and

• Foot (foot level vents only)

• While this test is in operation, the blower fan speed will be above 60%.

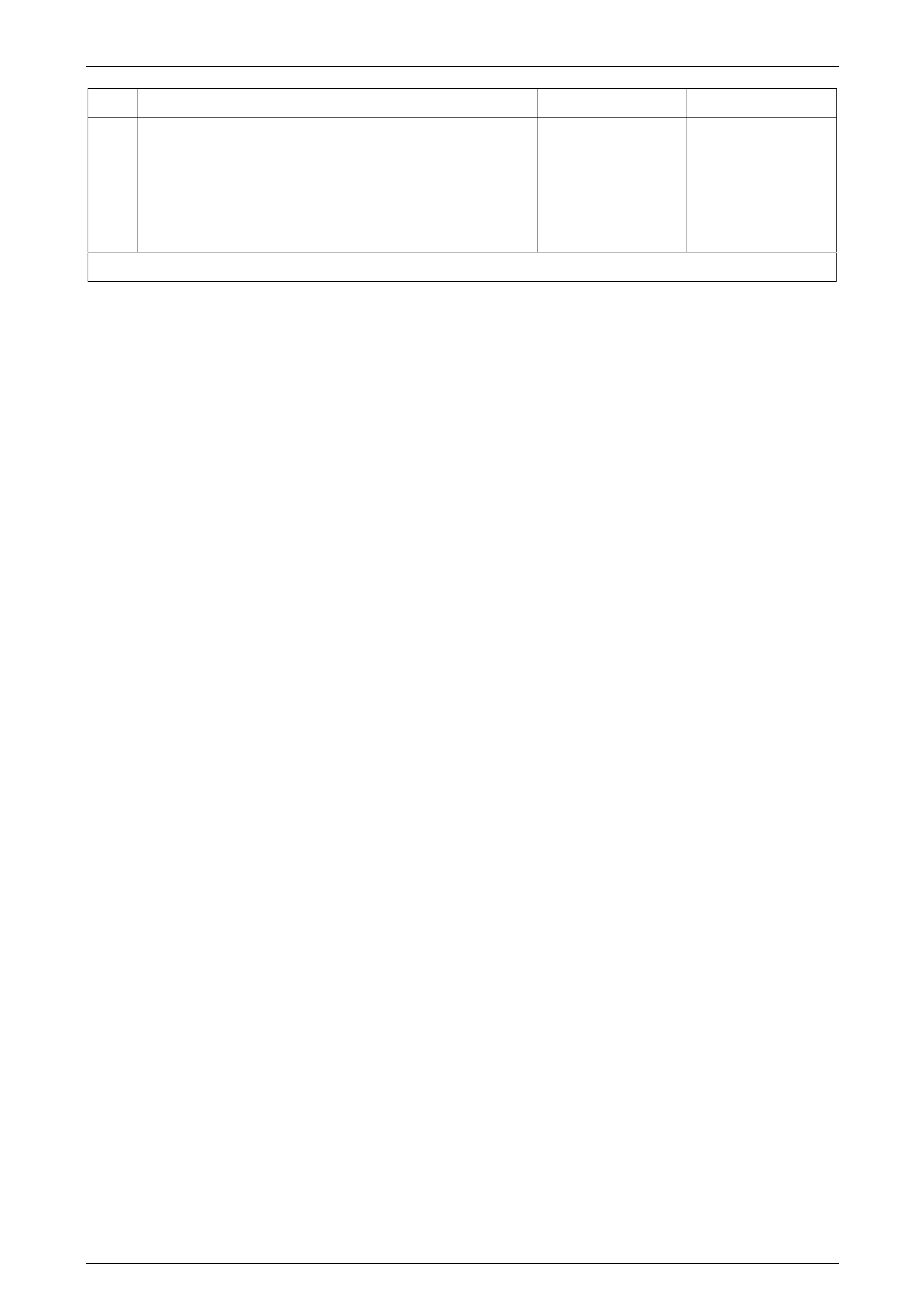

Illumination

• Along with all other switches and instrument cluster, the illumination level of the OCC

module buttons is controlled by the body control module (BCM). The BCM receives the

illumination level input from the slider on the headlamp switch assembly and then

broadcasts this level through the UART serial databus. For further information on the

BCM, refer to 12J Body Control Module.

• In this test, the ignition must be in the On position.

• Tech 2 can command the illumination of the OCC module control buttons to increase or

decrease using the Increase and Decrease soft keys. The illumi nation has a range of

0 to 100% with 100% percent being the brightest setting. Tech 2 increases or decreases

the illumination in 10% increments.

NOTE

This test only affects the OCC module’s control buttons. None of the other

components illumination is tested.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–24

Page 2E–24

Tech 2

Miscellaneous Tests Description

Front Demist LED

• Front demist is a function of the OCC module. With the engine running and pressing the

front demist button, the OCC module changes the outlets to demist and turns on the air

conditioning. The front demist button LED sh ould illuminate.

• In this test, the ignition must be in the On position.

• Tech 2 can manually turn the front demist button LED on and off using the Off and On

soft keys.

Rear Demist LED

• Rear demist is a function of the OCC module. Pressing the r ear demist button supplies a

ground circuit for the defog relay (R25) thus energisi ng it. With the relay energised, power

will be supplied to the rear demist heater element. T he rear demist button LED should

illuminate.

• In this test, the ignition must be in the On position.

• Tech 2 can manually turn the rear demist button LED on and off using the Off and On

soft keys.

Rear Demist Relay

• Rear demist is a function of the OCC module. Pressing the r ear demist button supplies a

ground circuit for the defog relay (R25) thus energisi ng it. With the relay energised, power

will be supplied to the rear demist heater element. T he rear demist relay is located on the

instrument panel fuse and relay panel assembly. Refer to 12O Fuses, Relays and Wirin g

Harnesses for the location of the rear demist relay.

• In this test, the ignition must be in the On position.

• Tech 2 can manually turn the rear demist relay on and off using the Off and On soft keys.

• When the relay is toggled from off to on or visa versa, an audi ble click should be heard

from the relay.

A/C Request

• The OCC module controls the airconditioning function. If in the automatic mode, the OCC

will turn on the air conditioni ng as required. In manual, pressing the air conditioner button

will toggle the air conditioning on and off.

• When the OCC module requests the airconditioning to turn on or off, the request is sent

by serial data to the engine control module (ECM). The ECM then provides a ground

circuit for the A/C relay (R11) which energise s. With the A/C relay energised, power is

supplied to the A/C clutch coil which engages the compressor clutch. Refer to 12O Fuses,

Relays and Wiring Harness for the location of the A/C relay.

NOTE

In this test a blower fan speed is automatically selected.

NOTE

A three second delay will occur until the compressor clutc h has engaged. This is a

normal condition.

• In this test, the engine must be running.

• Tech 2 can command the OCC to send a A/C request by using the Off and On soft keys.

• When a A/C request to turn on the air conditioning is sent, there should be an audib le

click heard from the A/C relay and the compressor should engage. The Air Conditioning

Request para m eter on Tech 2 will display Yes.

• When a A/C request to turn off the airconditio ning is sent, there should be an audible click

heard from the A/C relay and the compressor should disengage. The Air Conditioning

Request para m eter on Tech 2 will display No.

Solenoids

• The OCC module controls the HVAC solenoids either automatically when the module is in

automatic mode, or manually when a manual input is detected from the operator.

• The OCC supplies a ground circuit to the specific solenoid thus energis ing it.

• In this test, the ignition must be in the On position.

• Tech 2 has six individual tests for the solenoids. Each test is controlled by the Off and On

soft key which will de-energise and energise the selected solenoid respectively.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–25

Page 2E–25

3.5 Program

In this mode, Tech 2 allows the programming of the OCC module.

When the Program option is selected, the following two choices will be availabl e:

• Calibrate Air Mix Door

• Program Code Index

Calibrate Air Mix Door

In this mode, the air mix doors may be recalibrated / programmed so they drive to the full hot and full cold stops.

NOTE

During the calibration procedure, Tech 2

describes the air mix door function as, Driv ers Air

Mix Door and not as, Air Mix Door.

The calibration mode looks at the full movement in both directions (open and closed) of the air mix doors/motors and

compares the actual voltage values to known base values. If they are different, the OCC software will compensate.

1 To calibrate the air mix door, connect Tech 2 to the DLC and with the engine running, select:

Body / Occupant Climate Control / Program / Calibrate Air Mix Door.

2 Press the Calibrate soft key on Tech 2.

NOTE

While an air mix door is performing the

recalibration process, Tech 2 will display a

momentary Calibration Active screen showing

two percentage bar filling from left to right. This

symbolises the air mix door being driven from

closed to open and back to closed again.

3 When the air mix doors have been successfully recalibrated, Tech 2 will display the percentage of variati on

between the base value and the pre-c alibration value. If this variation is greater than 5%, a noticeabl e difference

should be felt and could have contributed to a customer complaint.

4 If the recalibration programming is unsuccessful, repeat the program again, as the system may have ‘crashed’

during this process.

5 During programming, a DTC 47, 48, 49 or 50 could be set. On Tech 2 sele ct:

Body / Occupant Climate Control / Diagnostic Trouble Codes / Clear DTC Information.

Follow the Tech 2 prompts and clear the DT Cs.

NOTE

If the recalibration programming of the air mix

door continues to be unsuccessful, Tech 2 will

display a Programming Failed! screen. The

message ‘Driver Error in Maximum Position’

defines the problem sector of air mix door

movement. This example means the air mix door

had difficulty in the maximum (fully open) sector

of door movement.

This may caused by a variet y of reasons such as

the air mix door fouling within the HVAC case,

damaged or sticking external linkages between

the air mix door and air mix d oor motor.

Press the Confirm key to view the results of the

air mix door calibration.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–26

Page 2E–26

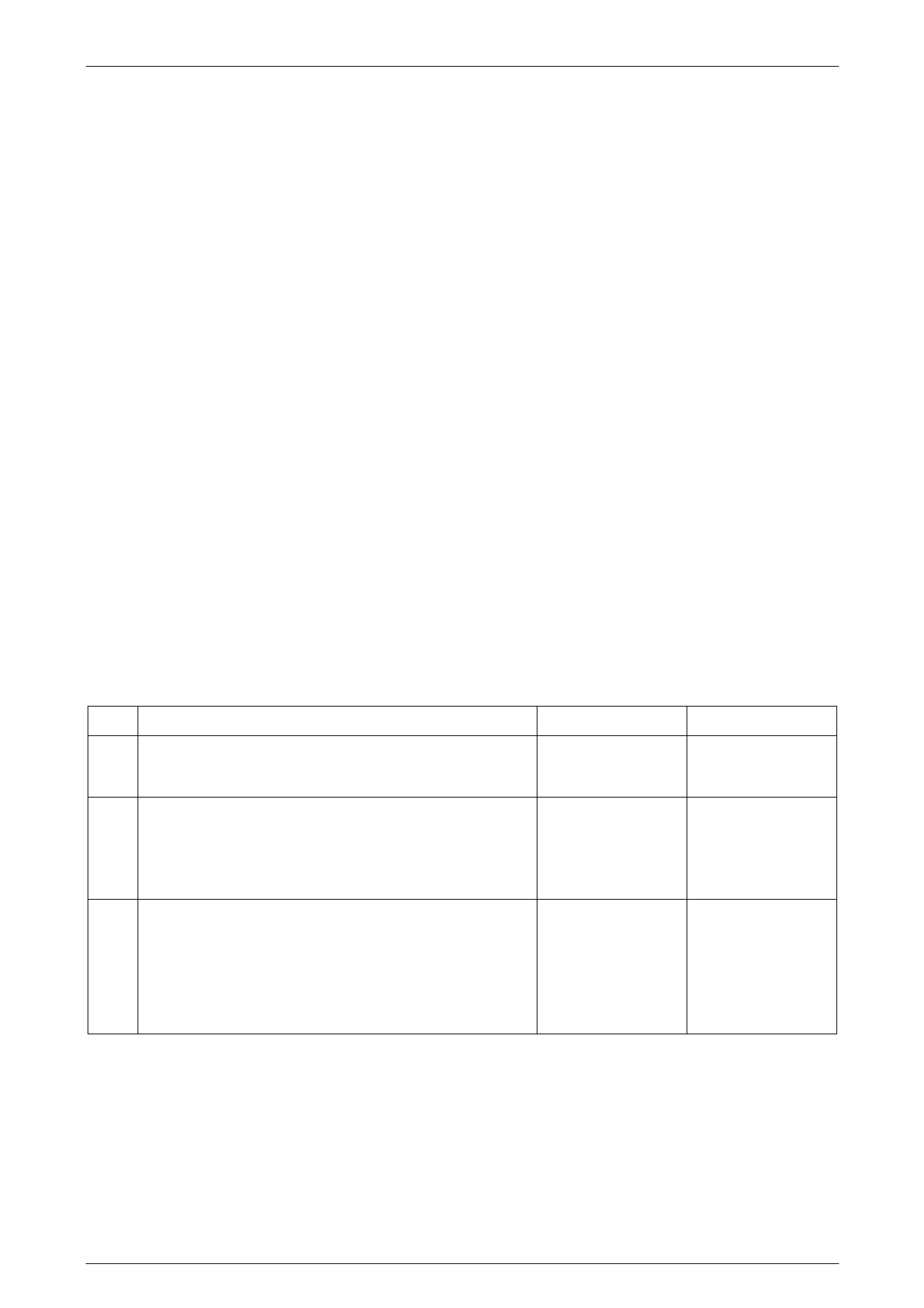

Program Code Index

In this mode, the code index and programmed code version are displayed, as well as providing the operator the option of

reprogramming the code version of the OCC system to the latest level.

The code index screen will display the current code version (software calibration) loaded into the OCC module. The code

version identifies the programmed level of OCC calibration. A higher number indicates a later version of calibr ation

loaded into the OCC module. This calibration can be updated, if necessary, by using Tech 2.

In the centre of the screen, a Code Index will be disp layed indicating th e application of the software. This will be one of

the following:

Code Index Details

Application Index

Dual Zone 2

The Code Index must match the vehicle type and OCC system configuration.

1 To update the calibration pres s the Modify Soft key on Tech 2.

2 A momentary Calibrati on Active screen will be displayed on Tech 2 sho wing a percentage bar filling from left to

right. This symbolises that recalibrating of the OCC module is taking place.

NOTE

If programming is unsuccessful, repeat the

program again, as the reprogramming procedure

may have ‘crashed’ during this process.

3 After the OCC module has been successfully reprogrammed, Tech 2 will display a Programming Completed

screen.

4 Follow any Tech 2 screen prompts when programming is completed.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–27

Page 2E–27

4 Diagnostics

4.1 Introduction

The OCC diagnostic proced ure is organised in a logical structure that begins with the Diagnostic S ystem Check and as

such must always be used as the starting point. The Diag nostic System Check direct the technician to the logical steps

necessary to diagnosing the OCC mod ule.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–28

Page 2E–28

4.2 Precautions

When tests are required on connector

terminals, use the adapters in connector

adaptor kit KM609 to prevent damage to

terminals.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–29

Page 2E–29

4.3 Diagnostic Trouble Code Tables

The Diagnostic System Check and the DTC list, directs the technician to the appropriate d iagnostic trouble code (DTC)

tables if there is a DTC currently stored in the TCM.

The diagnostic tables locate a faulty circuit or component through a logic based on the process of elimination. These

diagnostic tables are developed with the following assumptions:

• the vehicle functioned correctly at the time of assembly,

• there are no multiple faults, and

• the problem currently exists.

Understanding and the correct use of the diagnostic tables are essential to reduce d iagnostic time and to prevent

misdiagnosis.

Multiple DTCs Fault Condition

Some fault conditions trigger multiple comp onent DTCs even if the fault condition exists only on a single component. If

there are multiple DTCs stored in the BCM, the service tech nician must view and record all DTCs logge d.

Relationship between the logged DTCs can then be analysed to determine the source of the fault condition. Always

begin the diagnostic process with the DTC table of the fault condition that may trigger other DTCs to set.

The following fault conditions ma y trigger multiple DTCs:

• A fault in the serial data communication circuit.

• A system voltage that is too low may cause incorrect OCC operation.

• A system voltage that is too high may damage the OCC and/or other components.

• Fault condition in the OCC Read Only Memory (ROM) or Random Access Memory (RAM).

• Fault condition in the OCC internal circuitry or programming.

• Improperly connected sensor or component wiring connector.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–30

Page 2E–30

4.4 DTC Overview

The maximum number of individual DTCs associated with the OCC system is 21. The five most recent DTCs that have

occurred will be logged into EEPROM in the BCM into a table known as the DTC List. The DTC List only has space

allocated for five entries. Therefore, if more than five DTCs are logged, only the last five will be tracked. That is, the

oldest DTC will be removed from the list regardless of its position within the list.

The format of the DTC List is as follows:

List Position Position within the list numbered from 1 to 5.

DTC Number The DTC number is the number use d to identif y a particular fault conditi on.

Occurrence Count (0 to

255) The Occurrence Count is the number of times the particular fault condition has been

detected.

History Count

(0 to 255) The History Count is the number of ignitio n cycles that have occurred since the fault was

last detected. A count of 0 indicates the fault has occurred on the current ignition cycle,

while a count of 255 indicates the fault occurred 255 or more ignition cycles ago.

Algorithms for detecting each fault condition and setting the corresponding DTC vary. However, a particular DTC is only

set once per ignition cycle. When a DT C is set, the following occurs:

• If the DTC does not exist in the DTC List, it is inserted into the list at the first vacant location with the Occurrence

Count set to 1 and the History Count set to 0. In the event of the DTC List being full, the oldest DTC will be

removed from the list. The History Count determines the age of a DTC List entry. The item in the list with the

highest History Count will be remove d to make space for the new DTC.

• If the DTC already exists in the DTC List, then the Occurrence Count will be incremented (up to 255, at which point

it is no longer incremented). Each time the DTC is set, the History Count is cleared.

This procedure ensures the five most recent fault conditions are tracked. The Occurrence and History Counters provide a

means of determining how often the fault has occurred, and how long it has been since the fault last occurred. F or

instance, if the DTC Occurrence Count is 1, and the History Count is 201, then it can be determined the fault condition

existed only once, and it happened 201 ignition cycles ago (and has not been detected sinc e). Another example would

be an Occurrence Count of 4 and a History Count of 0. This would indicate the fault has been detected a total of four

times, and that it was detected on the current ignition c ycle.

The DTCs are not removed from the list unless five newer fault conditions occur pushing the oldest fault off the list, or

they are cleared using Tech 2.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–31

Page 2E–31

4.5 Intermittent Faults

Problems may or may not store a DTC, indicating an intermittent problem. DO NOT use the diagnostic code charts for

intermittent problems. When using the code charts the fault must be present to locate the problem. If a fault is

intermittent, use of diagnostic trouble code charts may result in replacement of good parts.

Most intermittent problems are caused by faulty electrical connections or wiring. Perform careful visual/ph ysic al checks of

the applicable circuit.

Check for:

a Poor mating of the connector halves or a terminal not fully seated in the connector body (backed out).

b Improperly formed or damaged termin al. All connector terminals in the suspect circuit shou ld be carefully reformed

or replaced to insure proper contact tensi on.

c Poor terminal to wire connection. This requires removi ng the terminal from the conn ector body to check as outlined

in service operations.

d Loose OCC ground circuit terminals.

NOTE

• If a visual / physical check does not find the

cause of the problem, the car can be driven

with a multimeter connected to a suspected

circuit. Tech 2 can also be used to help dete ct

intermittent conditions. An abnormal voltage,

or Tech 2 reading, when the problem occurs,

indicates the probl em may be in that circuit. If

the wiring and connectors are serviceable,

and a diagnostic trouble code was stored for a

circuit having a sensor, substitute a known

good sensor and recheck.

• Loss of diagnostic code memory. To check,

disconnect Ambient Air Temperature sensor

and turn the ignition on until the ‘X’ symbol is

displayed on the multi-fu nction display (MFD).

DTC 13 should be stored and kept in memory

when ignition is turned off. If not, the OCC

module is faulty.

• Check for electrical system interference

caused by a defective relay, OCC driven

solenoid, or switch. They can cause a sharp

electrical surge. Normally, the problem will

occur when the faulty component is oper ated.

• Check for improper installation of non-factory

installed electrical options such as lights,

2-way radios, etc.

• Refer to Section 12P Wiring Diagrams for

further information.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–32

Page 2E–32

4.6 Diagnostic System Check

Circuit Description

When investigating any complaint of an OCC problem or malfunction, always be gin diagnosis with the follo wing

diagnostic system check. T his check is a prel iminary procedure that checks to ensure the OCC is communicating on the

serial data line as well as helping to identify a problem or malfunction and directing the reader to the appropriate

diagnostic chart in this Section.

With Tech 2 connected to the DLC and the ignition switched on, Tech 2 should display se rial data communication. If

Tech 2 does not display serial data, the serial data circuit may be open or shorted.

In addition to the OCC module, there are several other control modules th at are connected to the serial data lin e (AHU,

BCM, instruments and SDM). Any one of these control modules could cause a fault on the serial data line. This fault

could result in Tech 2 not being able to display serial data.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 This test checks if the OCC module is being powered up.

5 Checks if Tech 2 can communicate with the OCC module. Confirms if the OCC module has power, ground and

serial data communications.

6 This test checks if the OCC module has stored a current Diagnostic Trouble Code.

7 Check if the air mix door is within calibration.

8 Check if there is a rear demist function problem.

9 Checks if there is an OCC module button problem. Completes the check of the OCC module and refers to an

overall air conditioning s ystem check..

Diagnostic Table Notes

1 For all wiring fault diagnoses, refer to Section 12P Wiring Diagrams.

2 For wiring repairs, refer to Section 12 P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If a fault is deemed intermittent, refer to 4.5 Intermittent Faults.

5 For information on Tech 2, refer to 3.1 Tech 2 Diagnostics.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–33

Page 2E–33

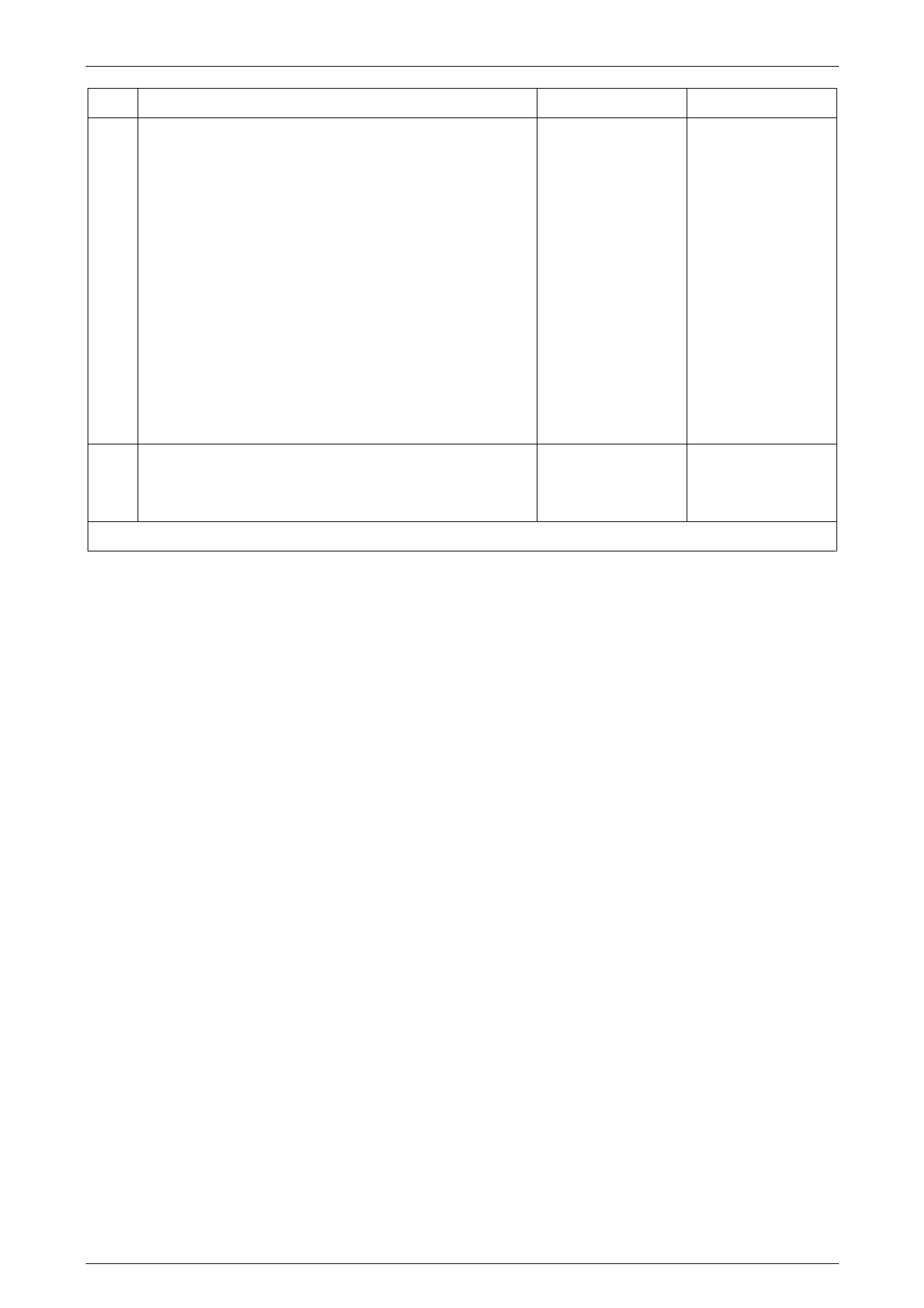

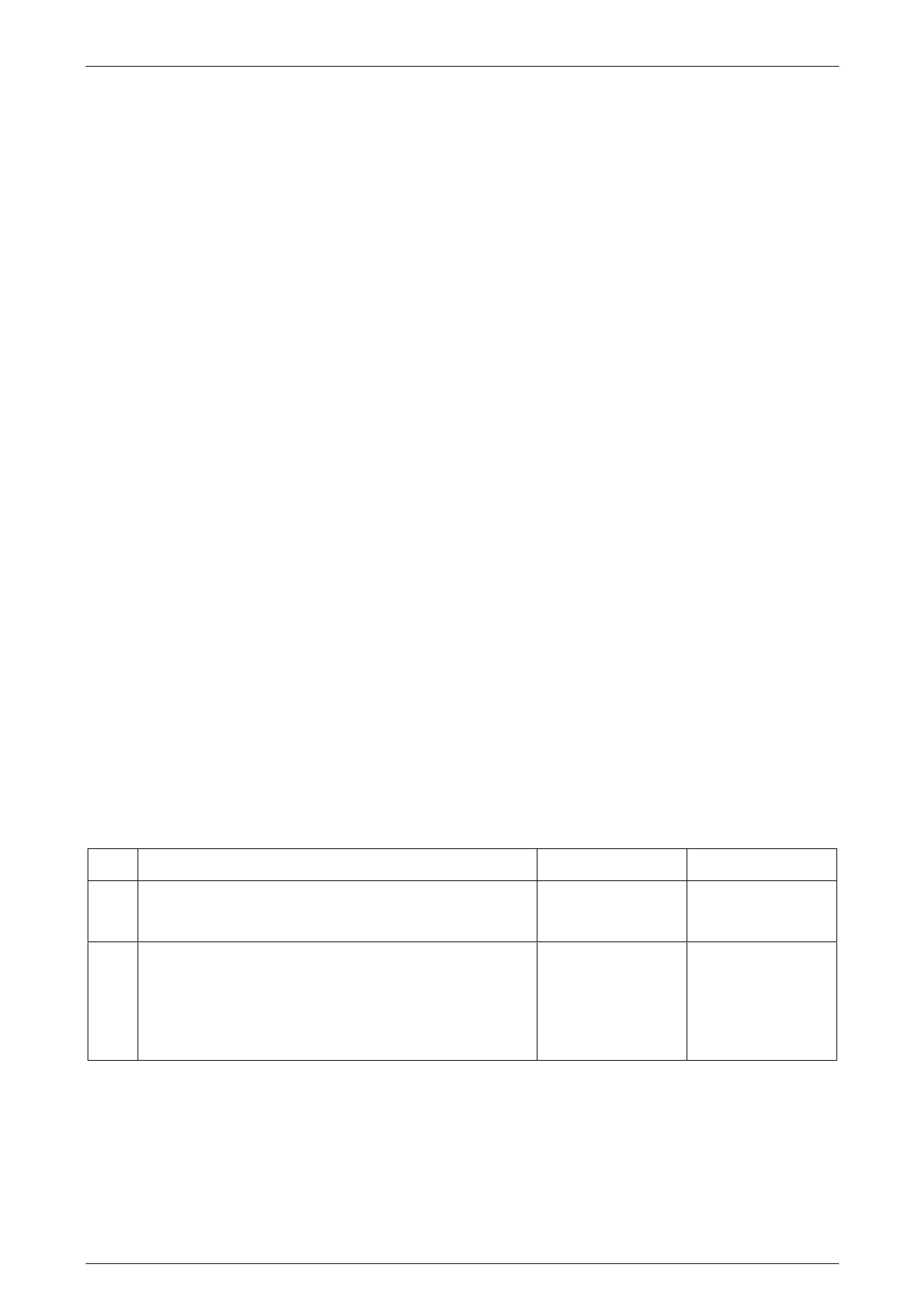

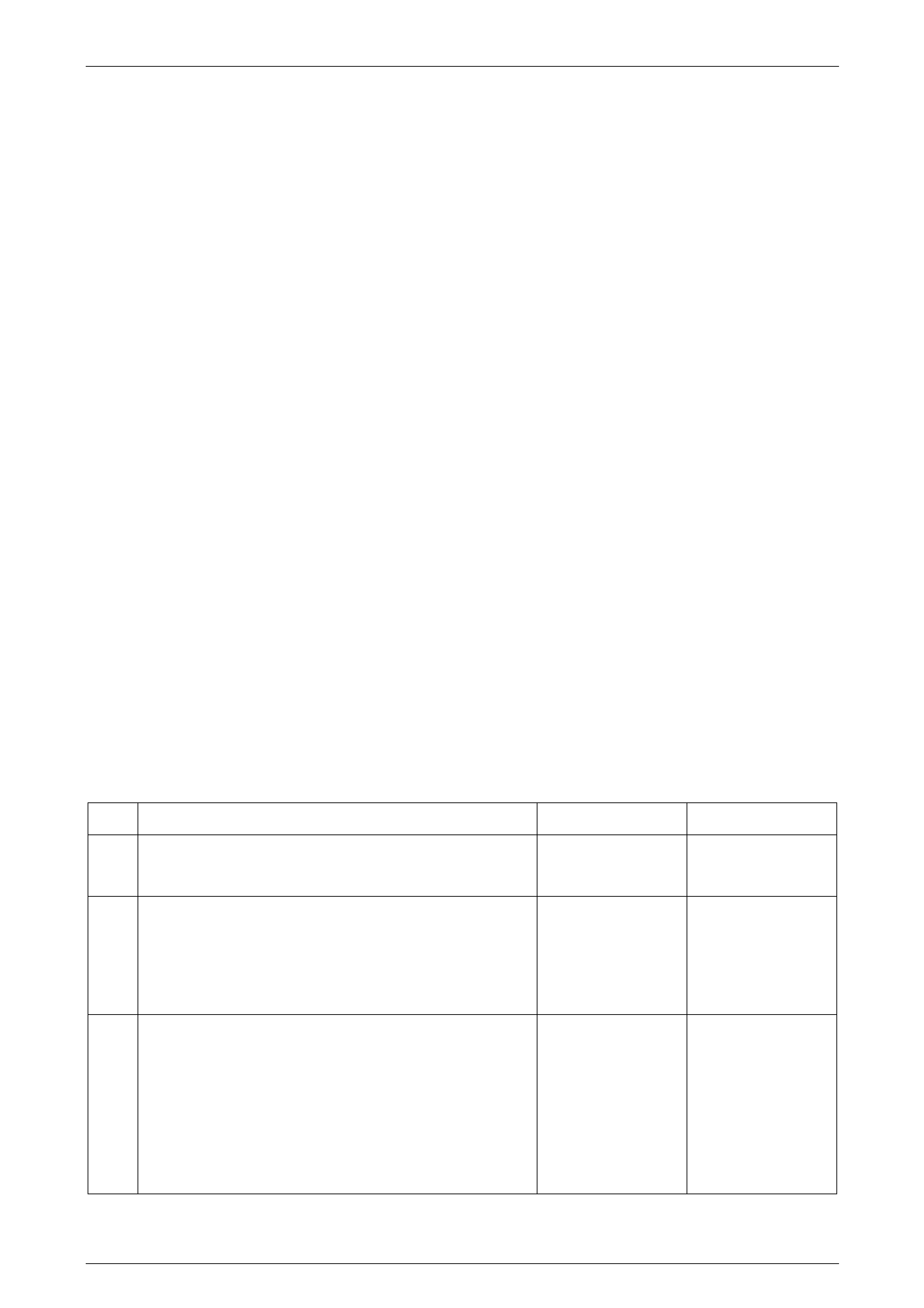

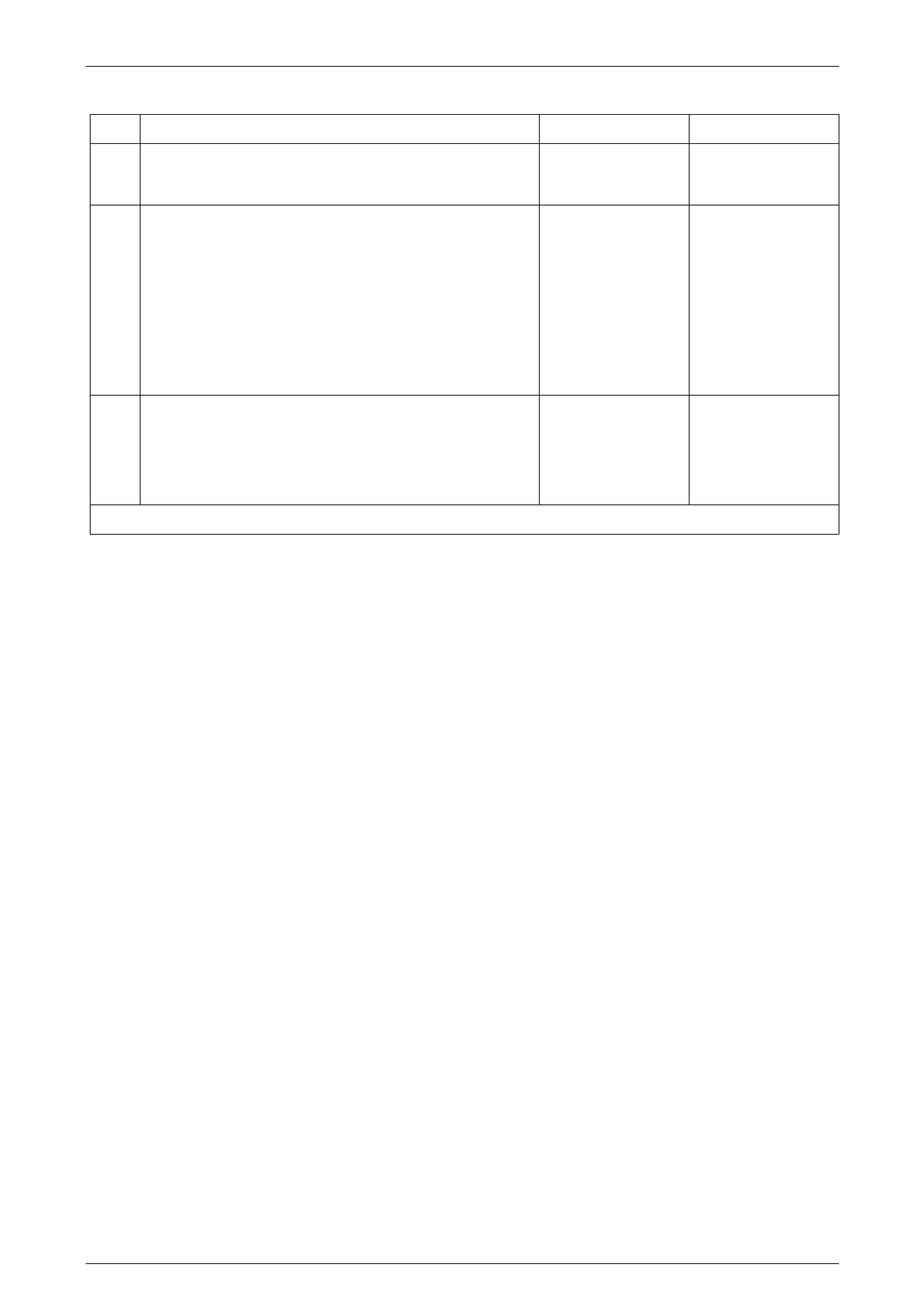

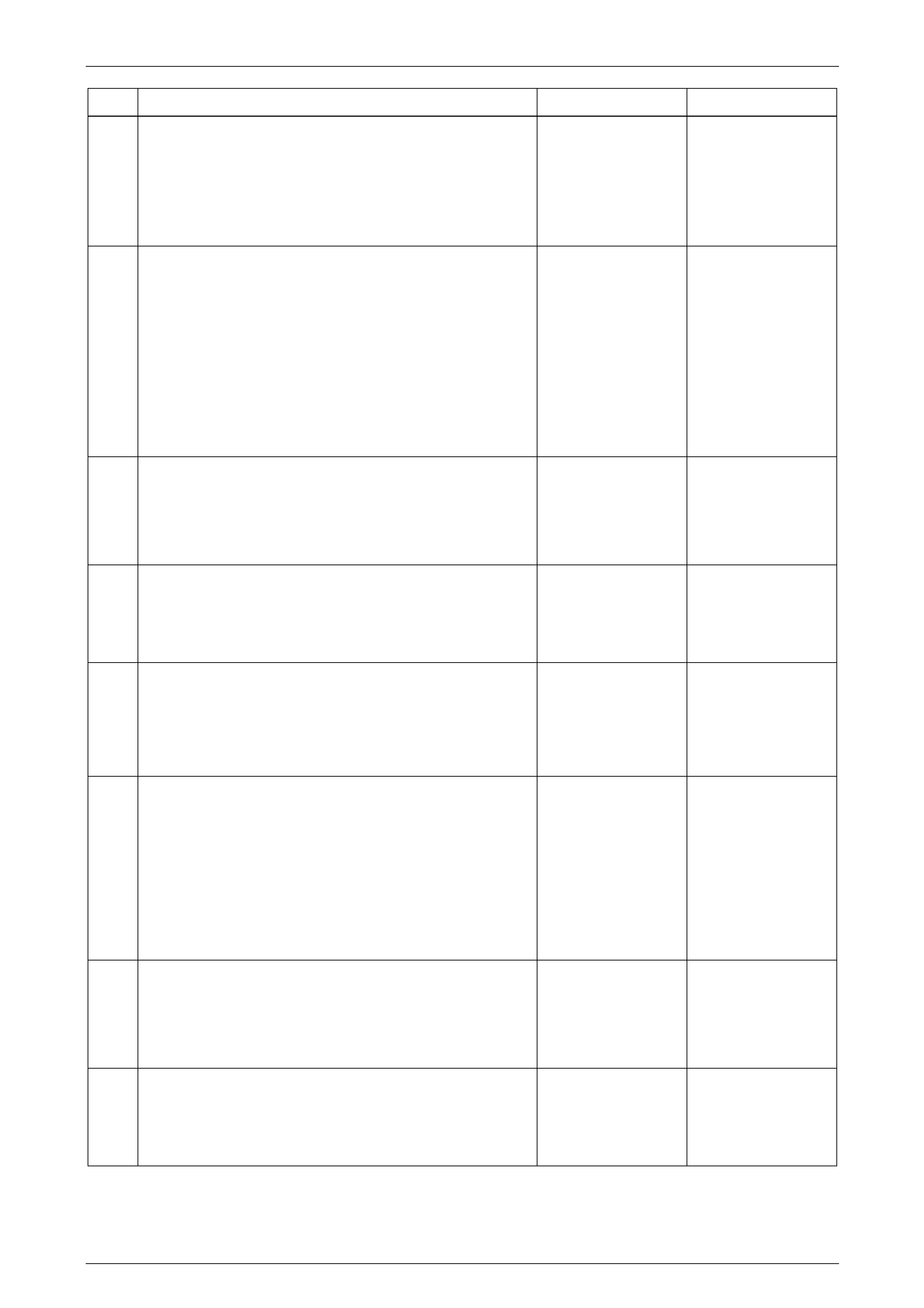

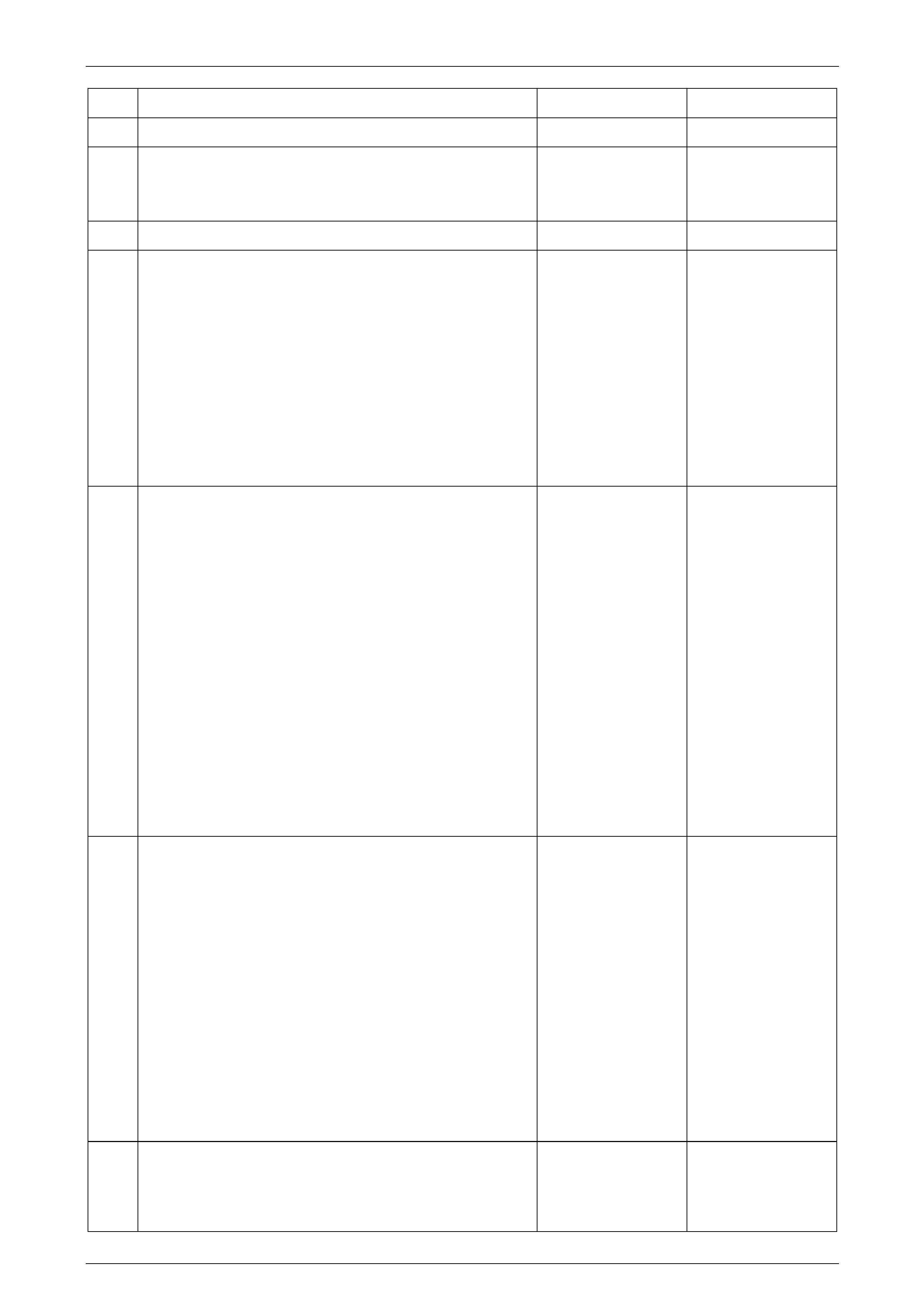

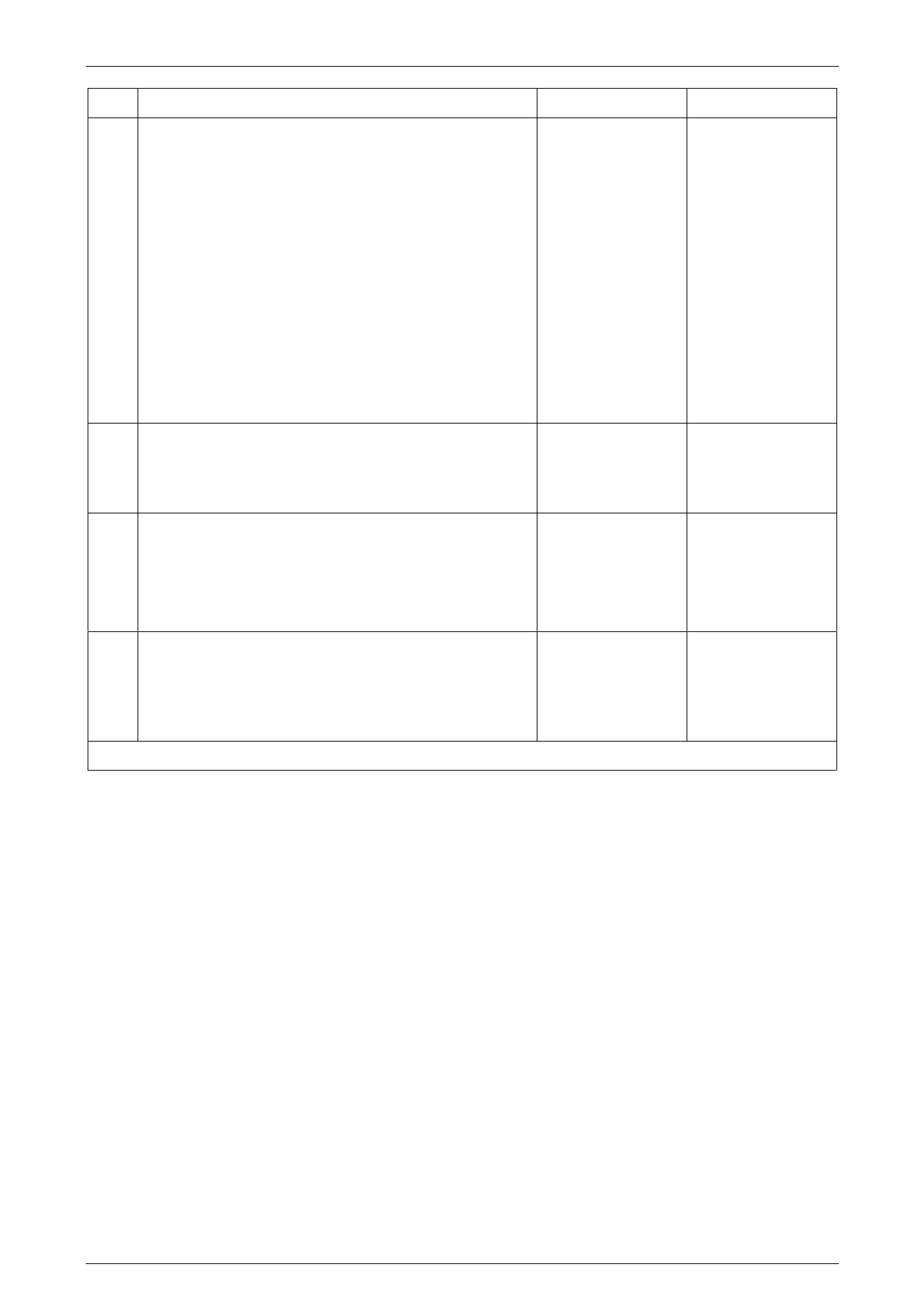

Diagnostic Table

Step Action Yes No

1 Is the fault specifically isolated to this system / module? Go to Step 2 Refer to

0D Vehicle Diagnostics

2 Have you read the Basic Diagnostic Requirements, Diagnostic

Precautions and Preliminar y Checks? Go to Step 3 Refer to

0D Vehicle Diagnostic

3 1 Turn the ignition on.

2 Turn on the OCC system.

Does OCC module LCD screen activate? Go to Step 4

Refer to

4.7 OCC System

Does Not Power Up

4 1 Connect Tech 2 to the DLC.

2 Turn the ignition on.

3 Push power button on Tech 2.

Does Tech 2 power up? Go to Step 5 Refer to 0C Tech 2

5 On Tech 2 select:

Body / Occupant Climate Control.

Does Tech 2 display OCC System Identification Screen

information (i.e. part number etc.)? Go to Step 6 Refer to 12J Body

Control Module

6 With Tech 2 connected and the ignition on, select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs? Go to Step 7

7 With Tech 2 connected the ignition on and OCC system

selected, select:

Program / Calibrate Air Mix Door / Calibrate.

Does Tech 2 display a value greater than 5%? Go to Step 8

8 Has the customer complained the rear demist function does not

operate correctly? Refer to

4.8 Rear Demist

Function Inoperative Go to Step 9

9 Has the customer complained the OCC module buttons do not

illuminate? Refer to

4.9 OCC Module

Illumination Inoperative

Refer to

2B HVAC Climate

Control (Manual A/C) –

Service and Diagnosis

When all diagno sis an d repairs are completed, check the system for correct operation.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–34

Page 2E–34

4.7 OCC System Does Not Power Up

Circuit Description

Battery power is supplied to the OCC module, terminal X1 pin 4, with the ignition switch in the ignition or start positions

through fuse F13 (located in the pass en ger compartment fuse panel).

Refer to 2 Wiring Diagrams and Connector Charts to aid i n diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 The diagnostic circuit test is the beginning of all diagnostics and should be performed whenever diagnosing an

OCC system complaint.

2 This test checks if the fuse F13 is serviceable.

3 This test determines if power is being su pplied to fuse F13.

4 Checks if there is power to the OCC module. Isolates whether circuit 539 is faulty.

5 Checks if there is a ground circuit. Isolates whether circuit 251 or the OCC module is faulty.

Diagnostic Table Notes

1 For all wiring fault diagnoses, refer to Section 12P Wiring Diagrams.

2 For wiring repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If a fault is deemed intermittent, refer to 4.5 Intermittent Faults.

5 For information on Tech 2, refer to 3.1 Tech 2 Diagnostics.

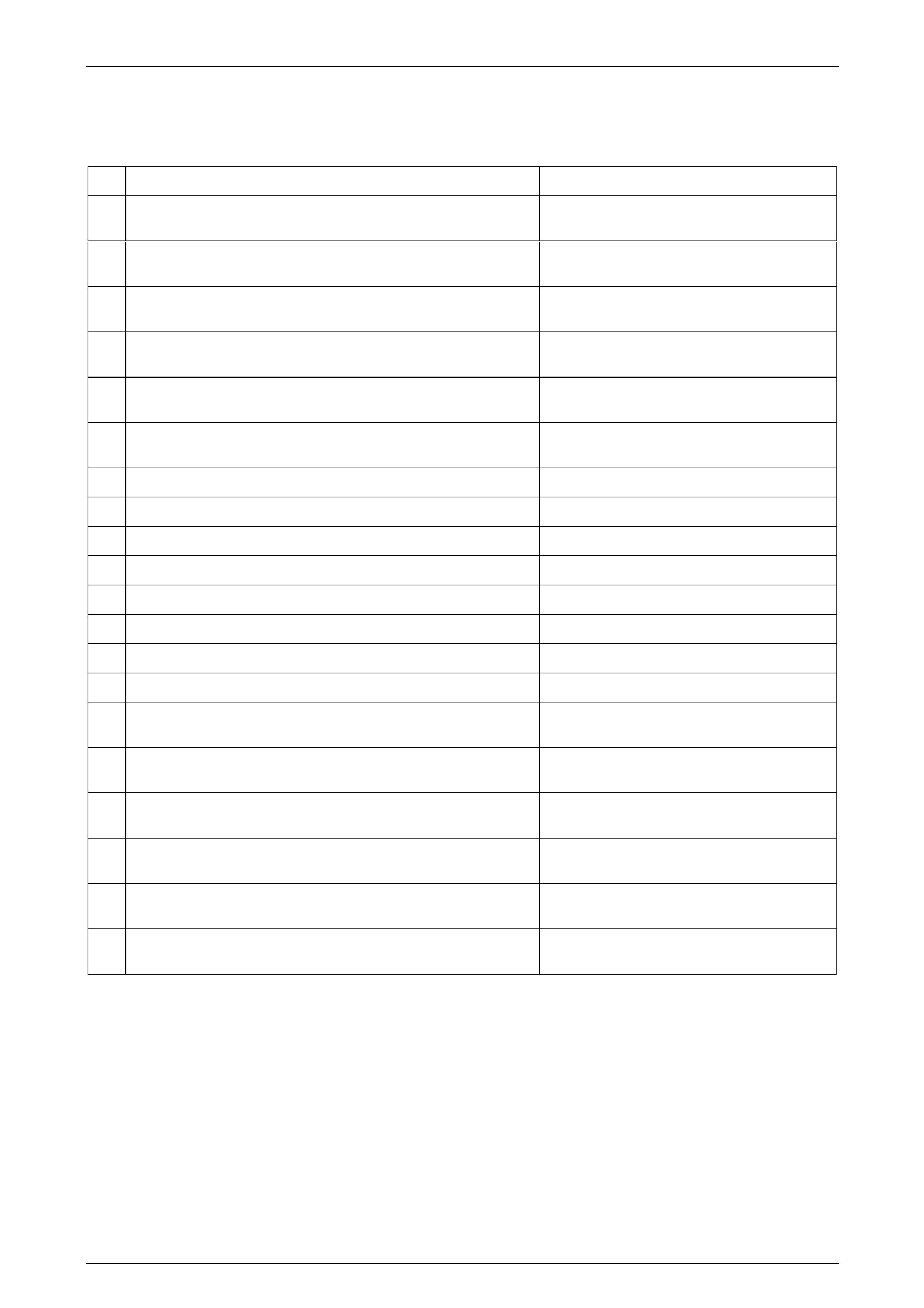

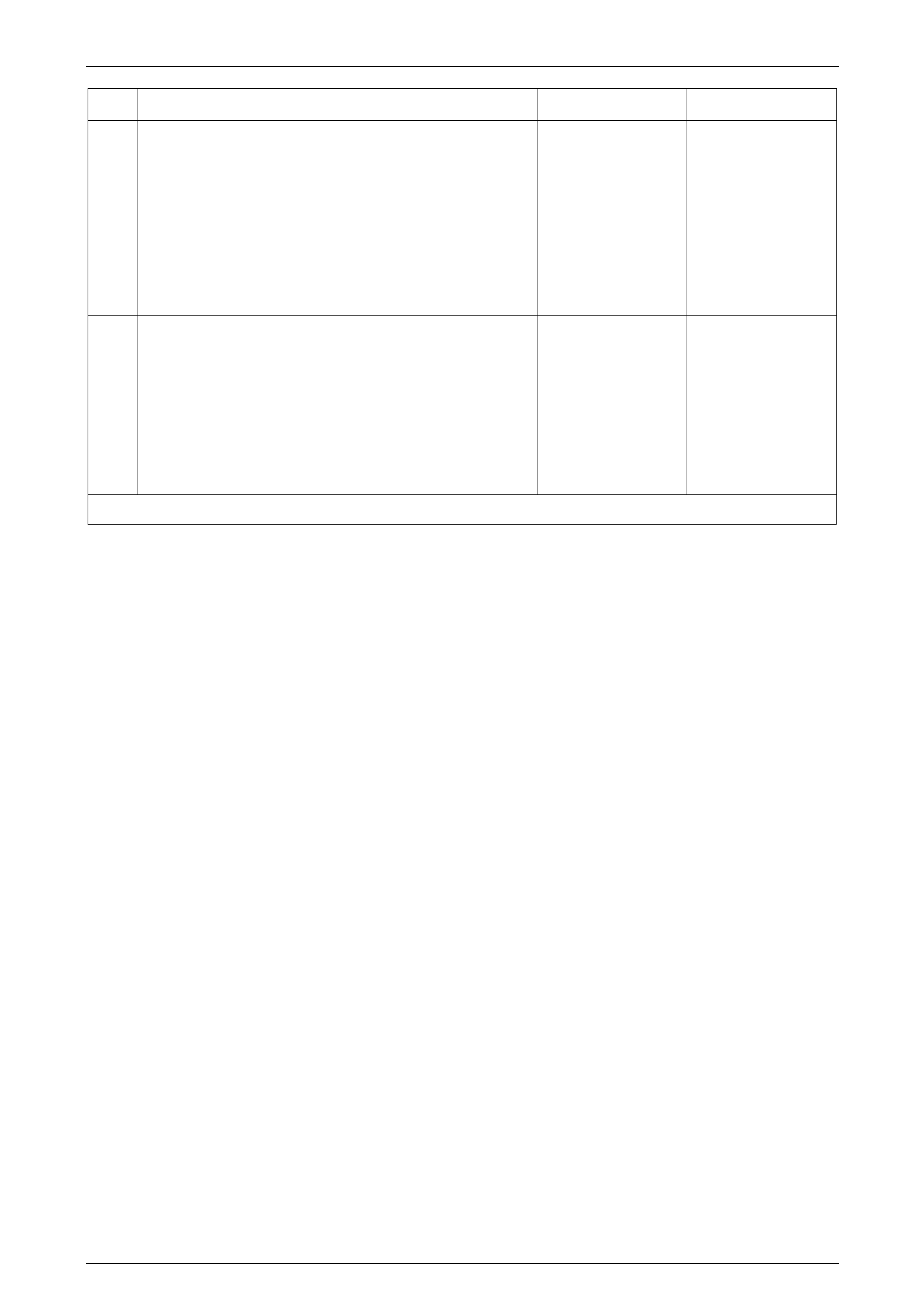

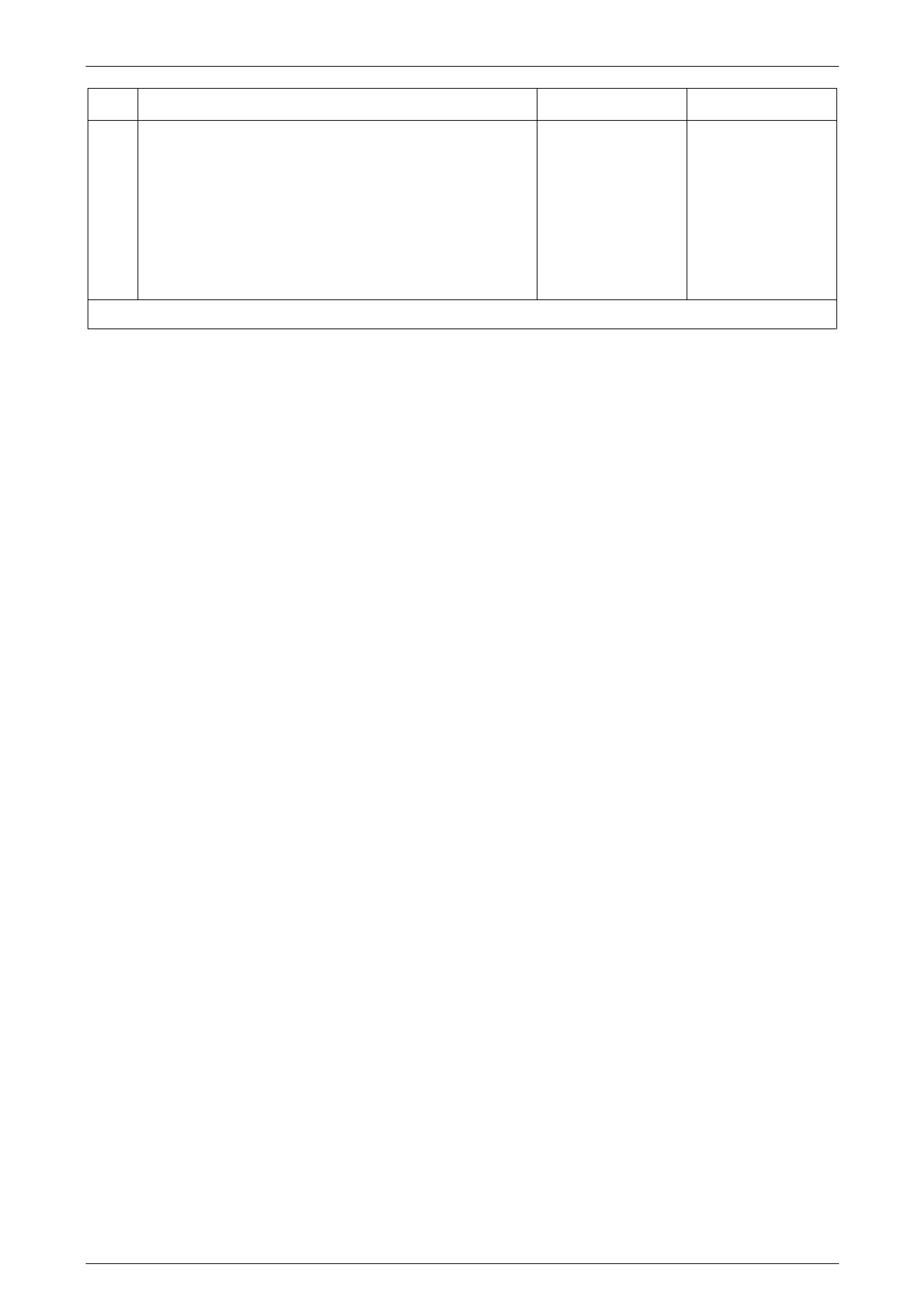

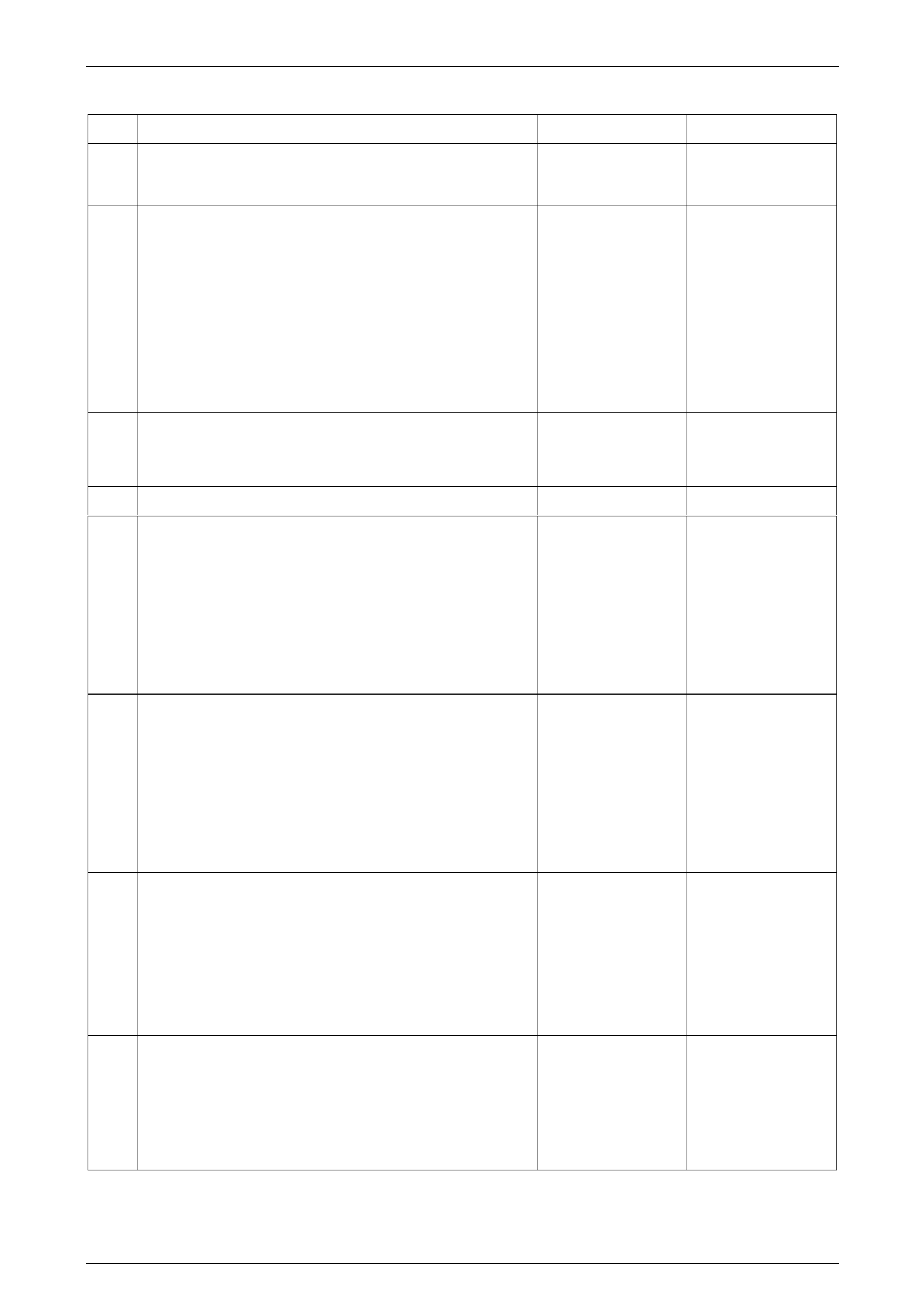

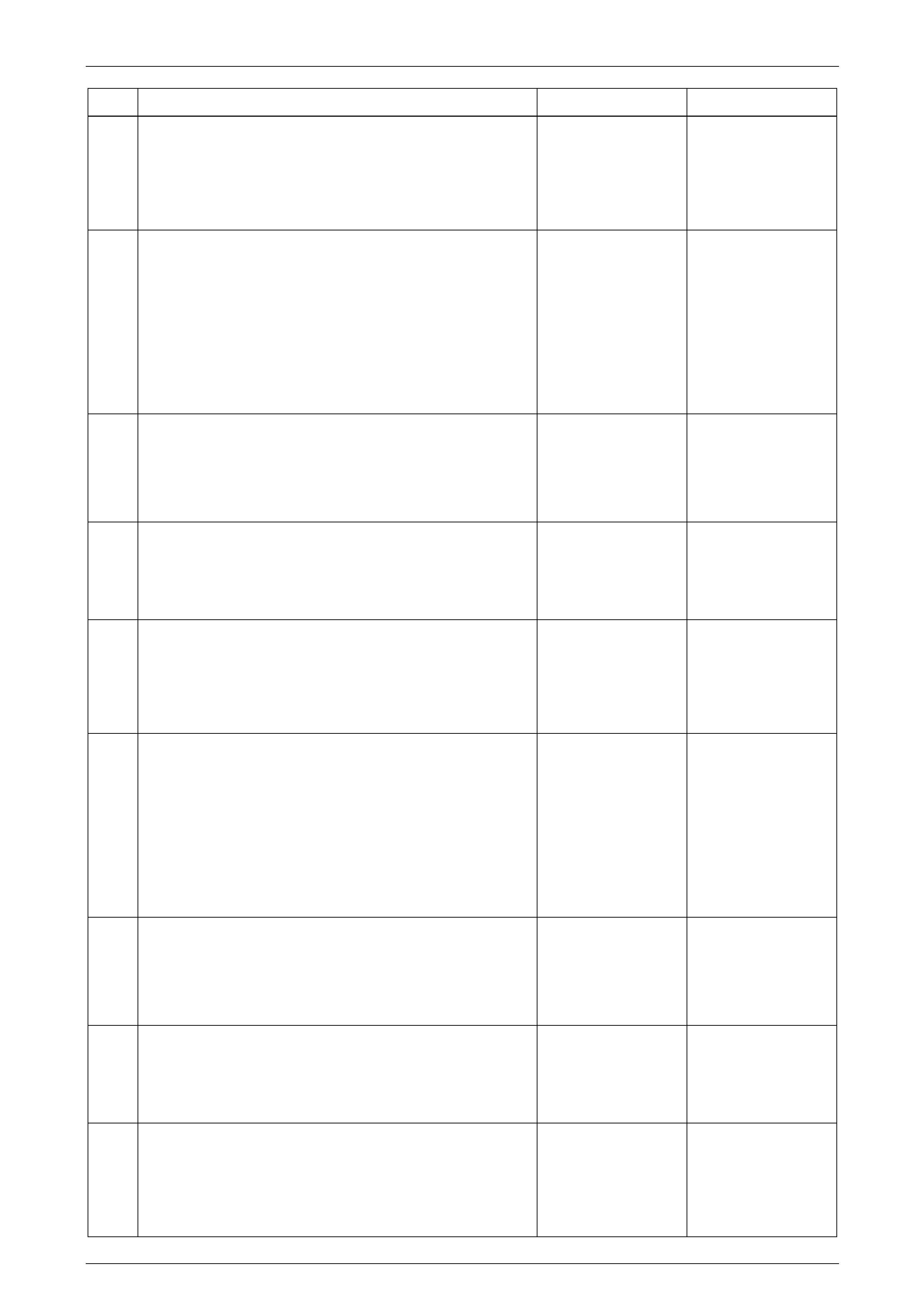

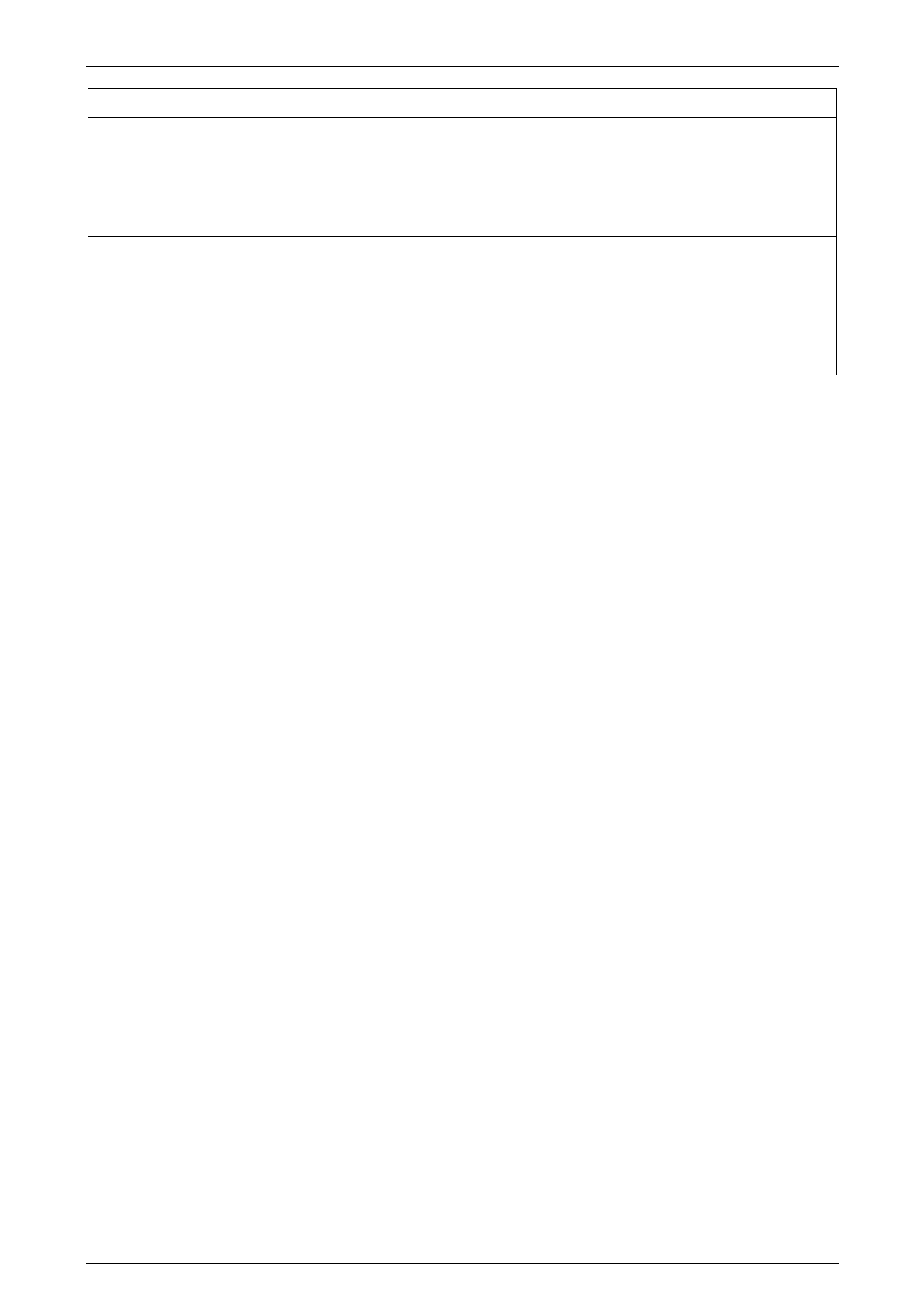

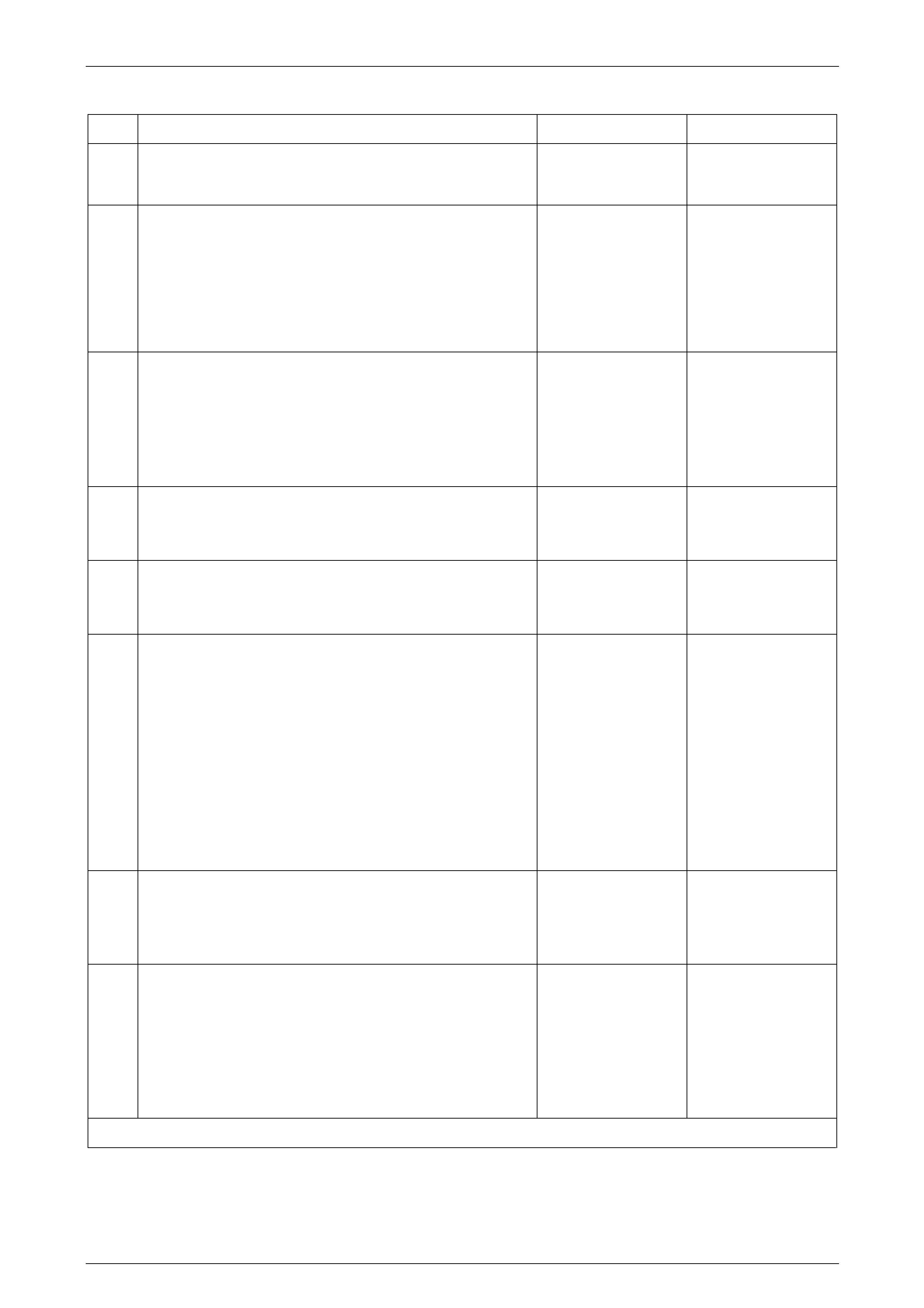

OCC System Does Not Power Up Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.6 Diagnostic

System Check

2 Check fuse F13.

Is the fuse blown?

Replace the fuse. If it

blows again, test its

circuit for a short to

ground Go to Step 3

3 1 Turn the ignition on.

2 Using a multimeter set to measure voltage, probe

between the front of fuse F13 and a kn own ground

Does the multimeter display battery voltage? Go to Step 4 Repair or replace

circuit 3

4 1 Remov e the OCC mod ule, refer to 2F HVAC Occupant

Climate Control (Auto A/C) – Removal and Installation.

2 Turn the ignition on and ensure the OCC is off.

3 Using a multimeter set to measure voltage, probe

between the A14 – X1 pin 4 and a known ground.

Does the multimeter display battery voltage? Go to Step 5 Repair or replace

circuit 539

5 Using a multimeter set to measure resistance, probe between

the A14 – X1 pin 2 and a known ground.

Does the multimeter display continuity?

Replace the OCC

module, refer to

2F HVAC Occupant

Climate Control

(Auto A/C) –

Removal and

Installation Repair or replace

circuit 251

When all diagno sis an d repairs are completed, check the system for correct operation.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–35

Page 2E–35

4.8 Rear Demist Function Inoperative

Circuit Description

The rear demist function is activated by a button on th e OCC module. When pressed, the OCC module supplies a

ground circuit for the defog relay R25, thus energisin g the relay. The relay then applies battery voltage to the rear demist

element.

Refer to 2 Wiring Diagrams and Connector Charts to aid i n diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 Checks if the relay R25 energises when the rear demist button is pressed. Confirms the controlling circuit for the

relay is serviceabl e

3 Check if the relay is at fault.

4 Checks if there is power supplied to the coil side of the relay. Isolates whether circuit 539 is faulty.

5 Checks if the relay energises when the control circuit is shorted to ground. Isolates whether the OCC module or

circuit 539 is faulty.

6 Checks if there is power to the switch side of the relay. Isolates whether circuit 40 is faulty.

7-8 Checks if circuit 293 is open circuit or shorted to ground.

9 Check if the ground circuit for the rear window heater element is serviceable. Isolates whether circuit 1850 is faulty.

10 Visually inspect the element for nicks or breaks.

Diagnostic Table Notes

1 For all wiring fault diagnoses, refer to Section 12P Wiring Diagrams.

2 For wiring repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If a fault is deemed intermittent, refer to 4.5 Intermittent Faults.

5 For information on Tech 2, refer to 3.1 Tech 2 Diagnostics.

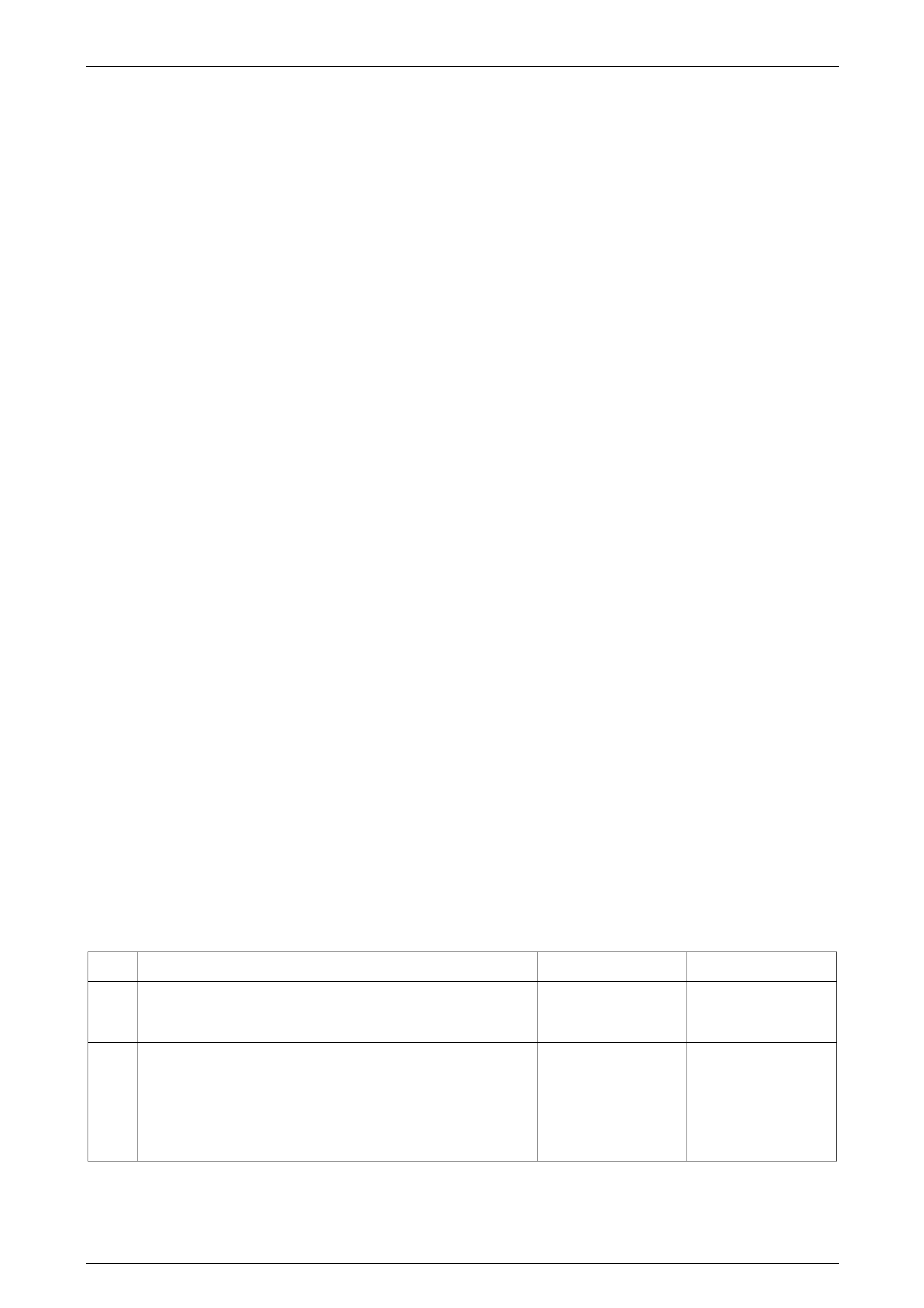

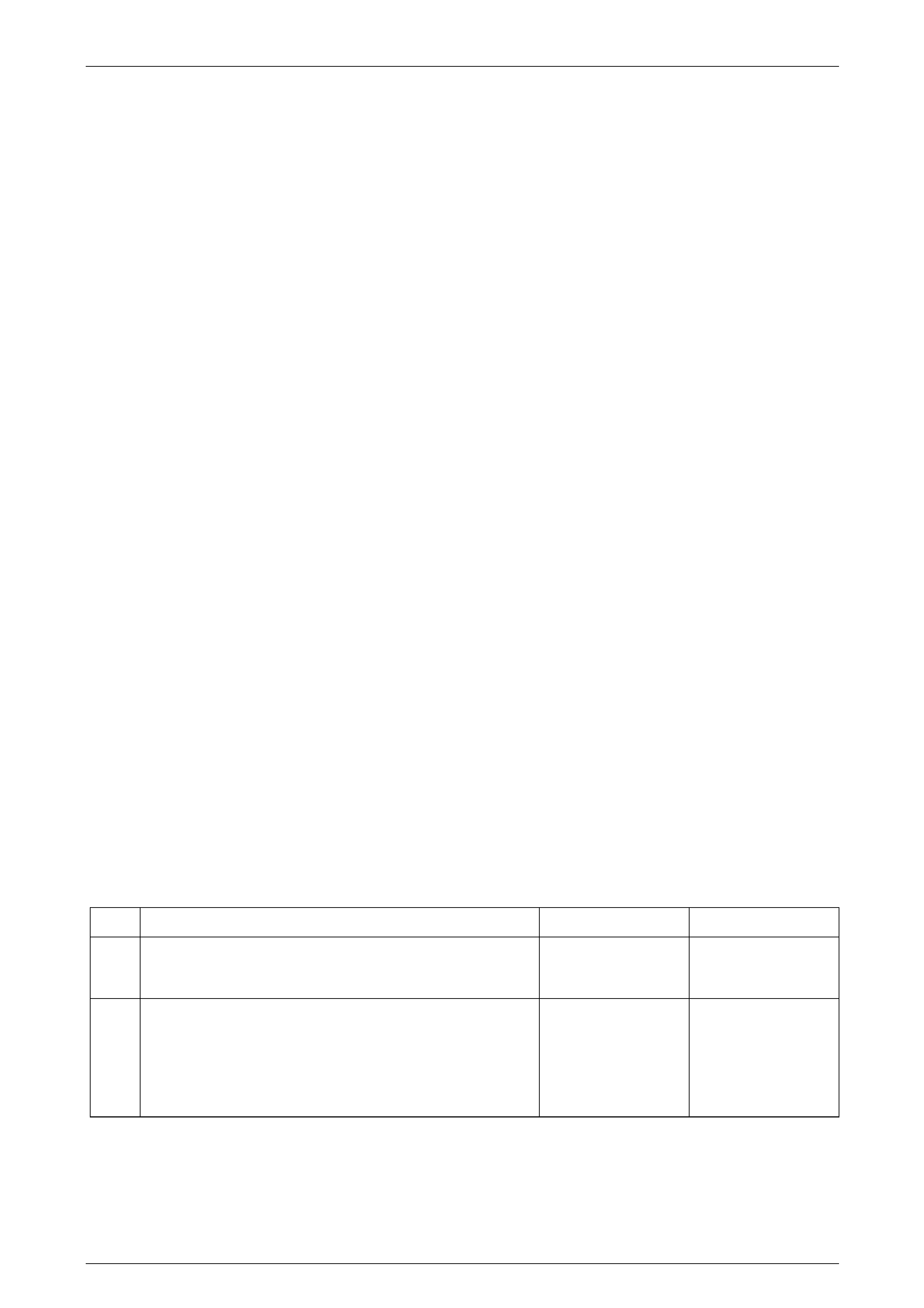

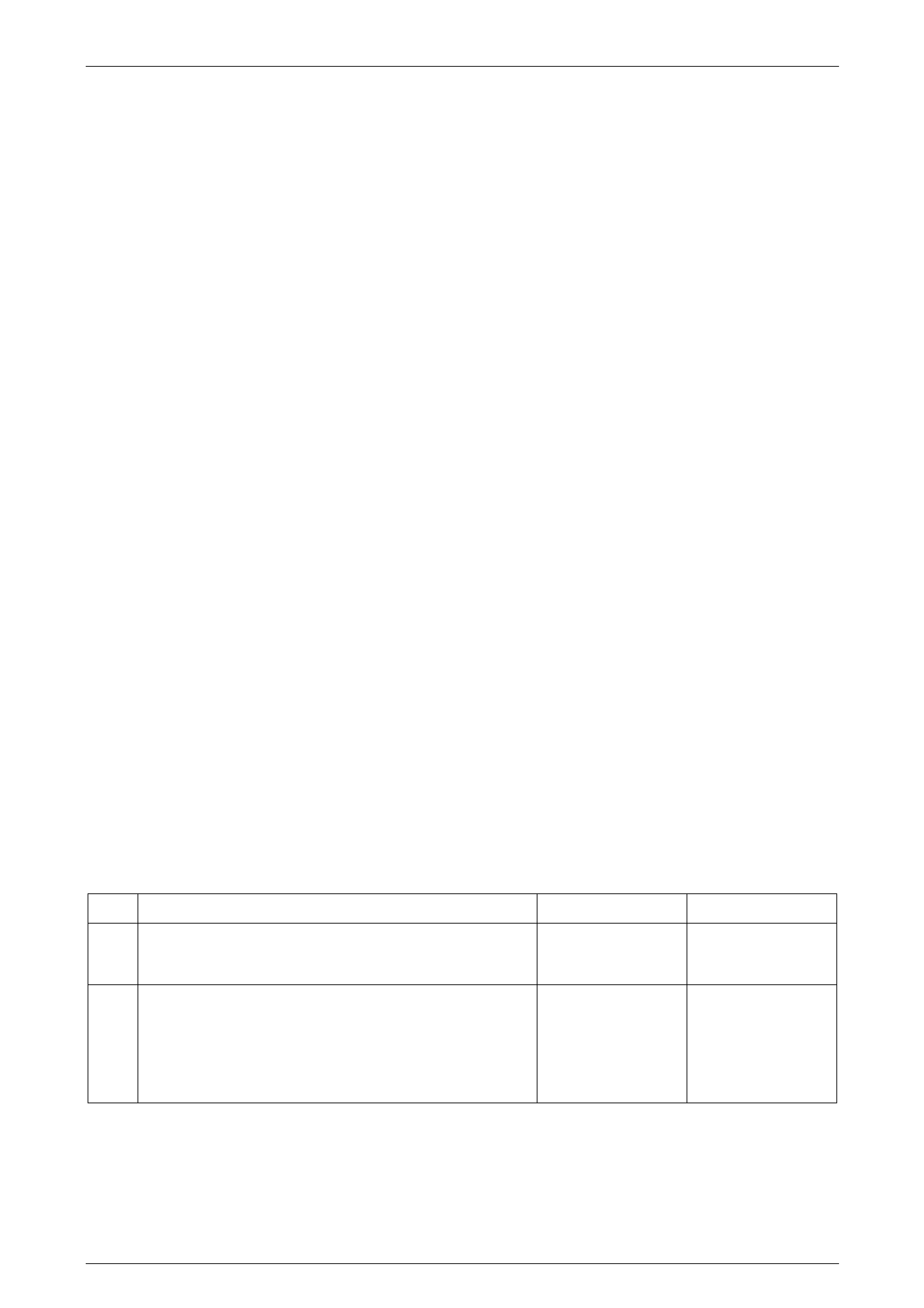

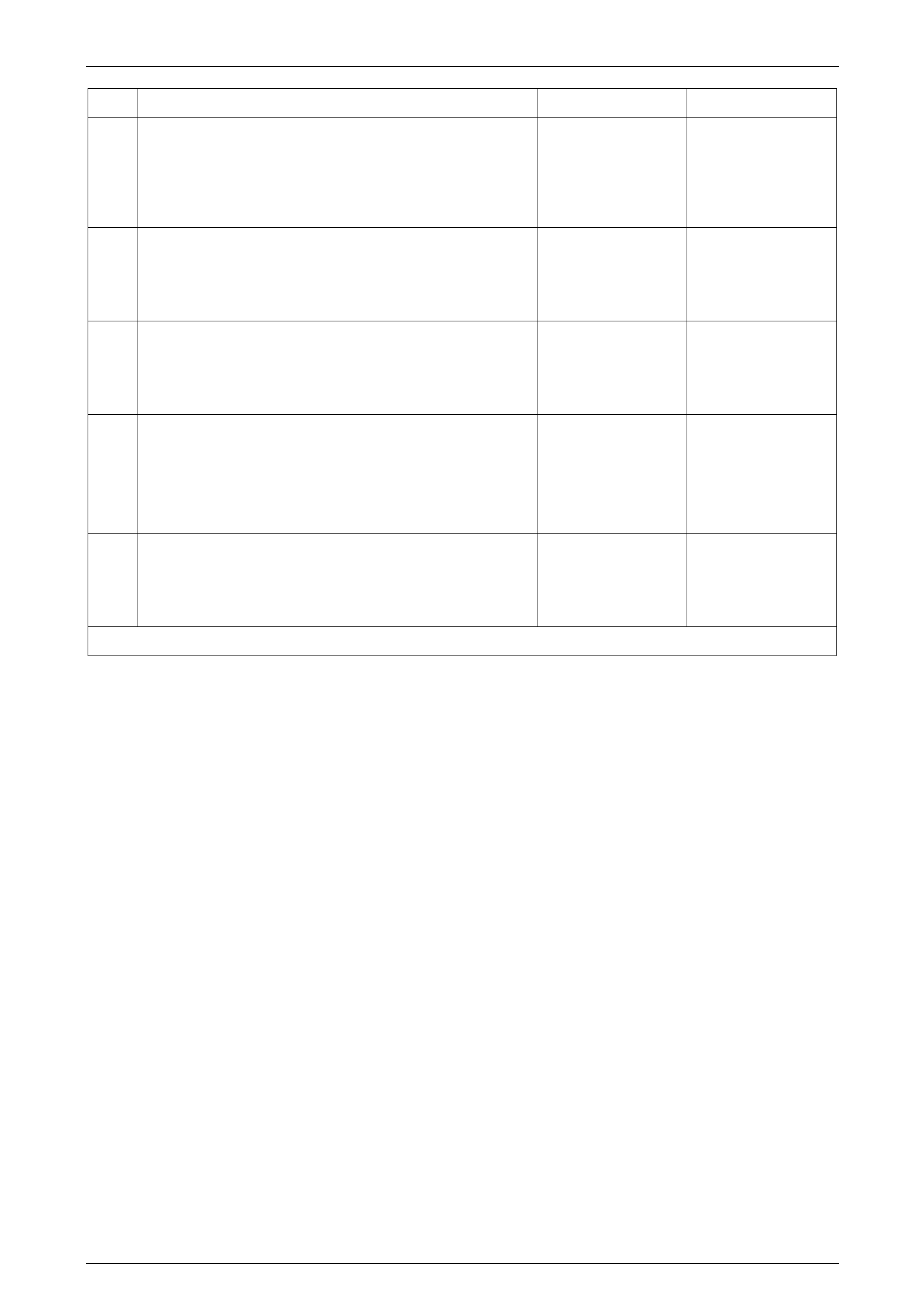

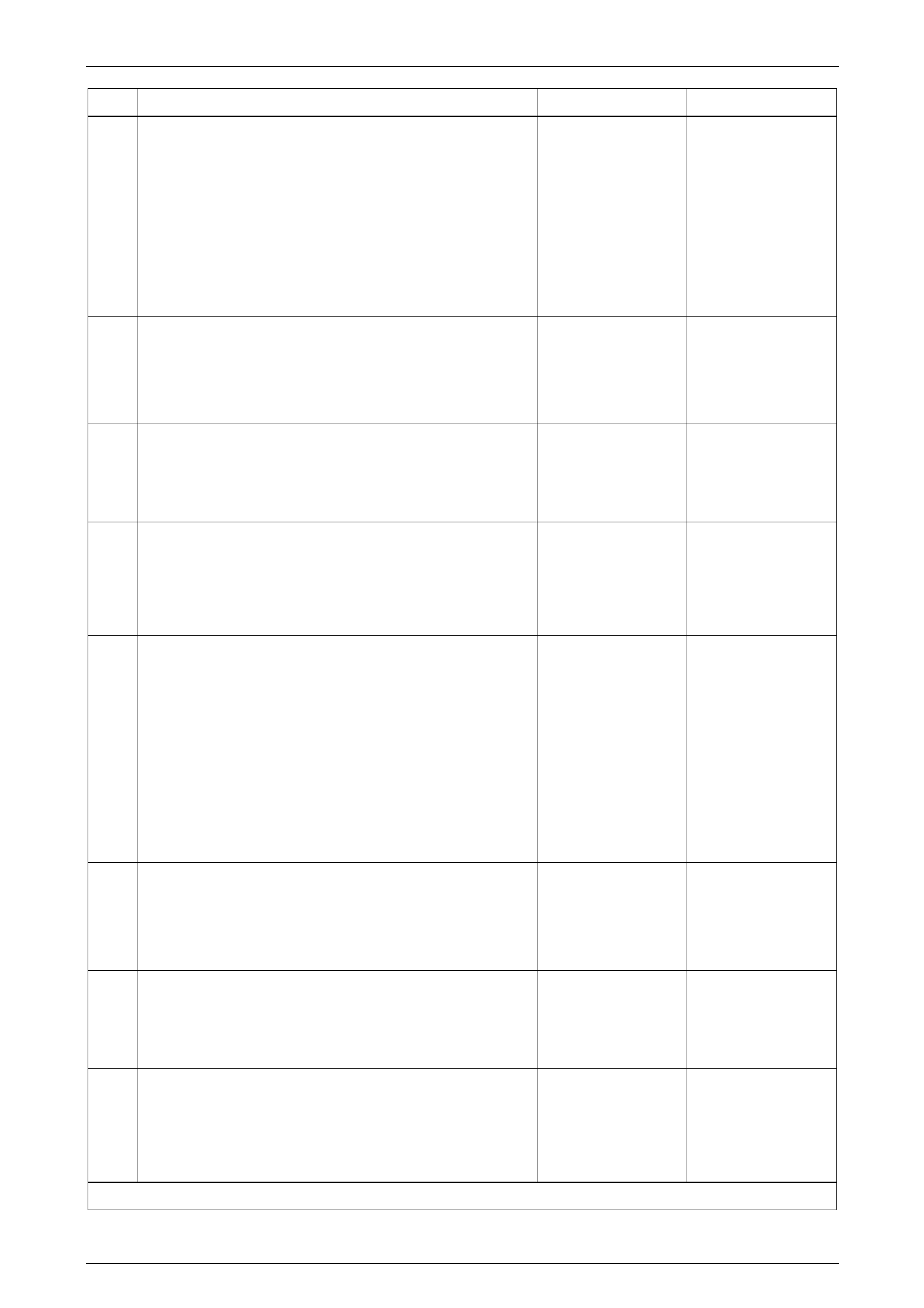

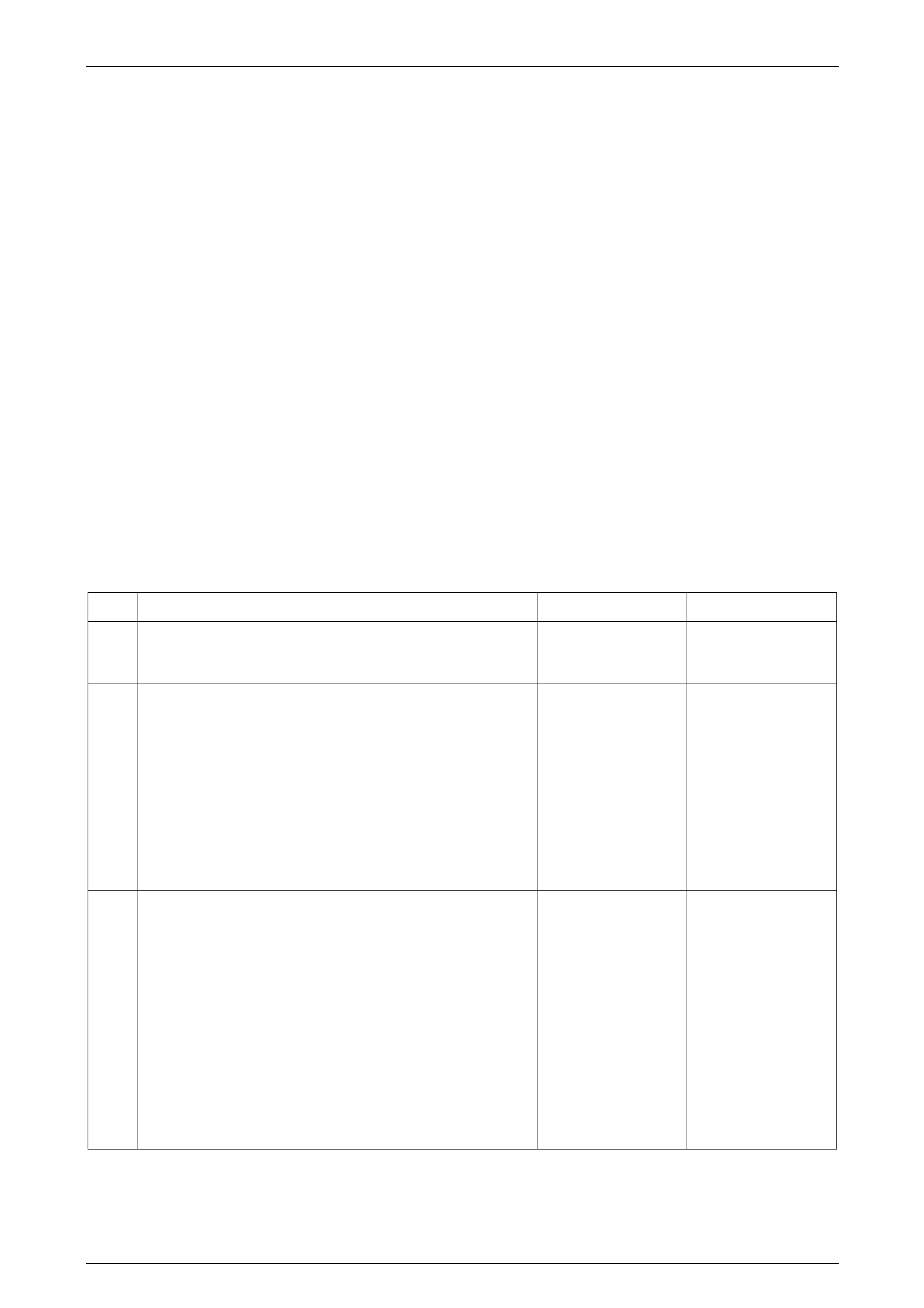

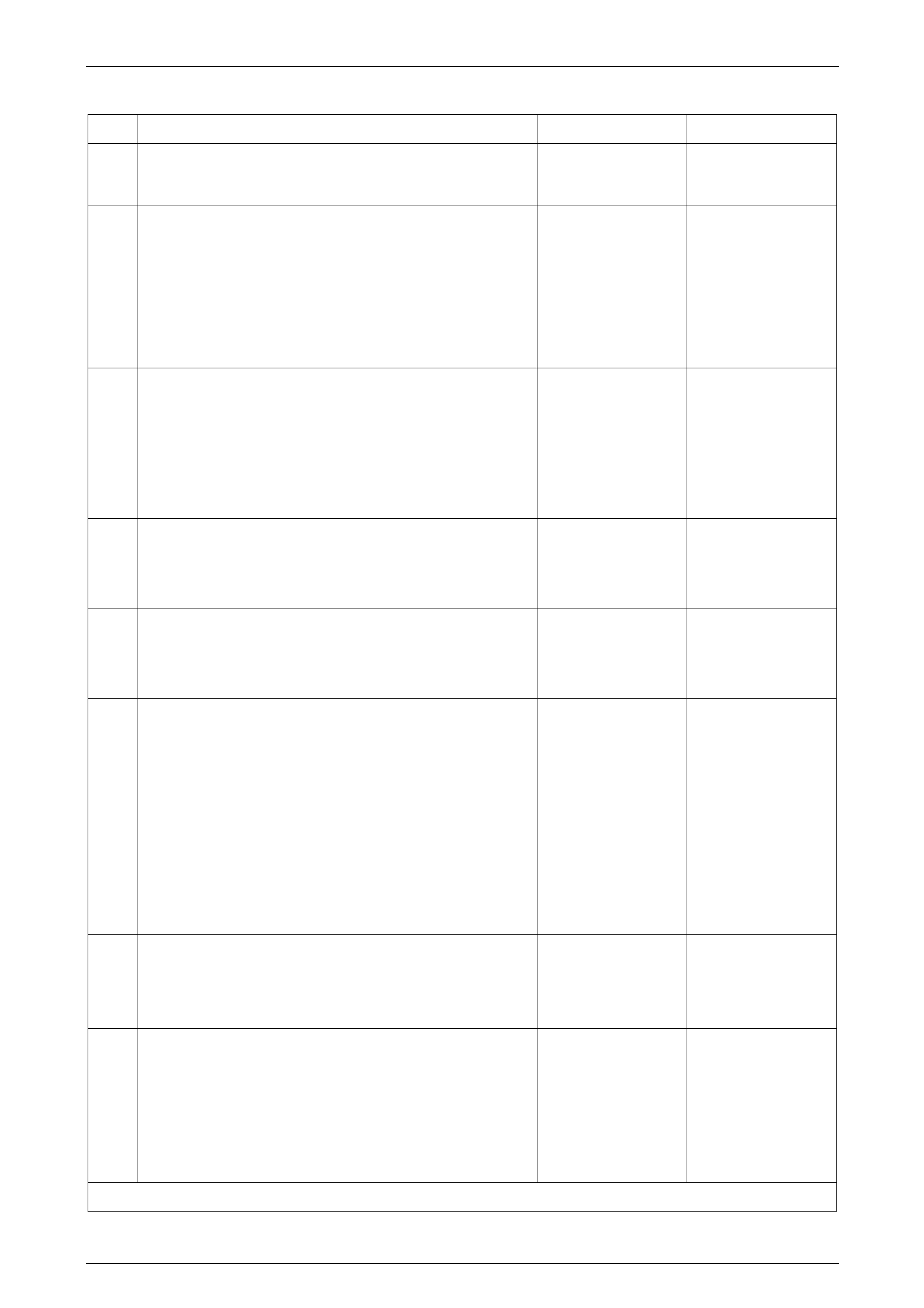

Rear Demist Function Inoperative Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.6 Diagnostic

System Check

2 1 Gain access to the instrument panel fuse and relay

panel assembly X100, refer to 12O F uses, Relays and

Wiring Harnesses.

2 Turn the ignition on.

3 Press the rear demist button on the OCC module.

Was an audible click heard from relay R3? Go to Step 6 Go to Step 3

3 1 Replace relay R3 with a known good relay.

2 Press the rear demist button on the OCC module.

Was an audible click heard from relay R 3? Leave the known

good relay in place

Replace with original

relay.

Go to Step 4

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–36

Page 2E–36

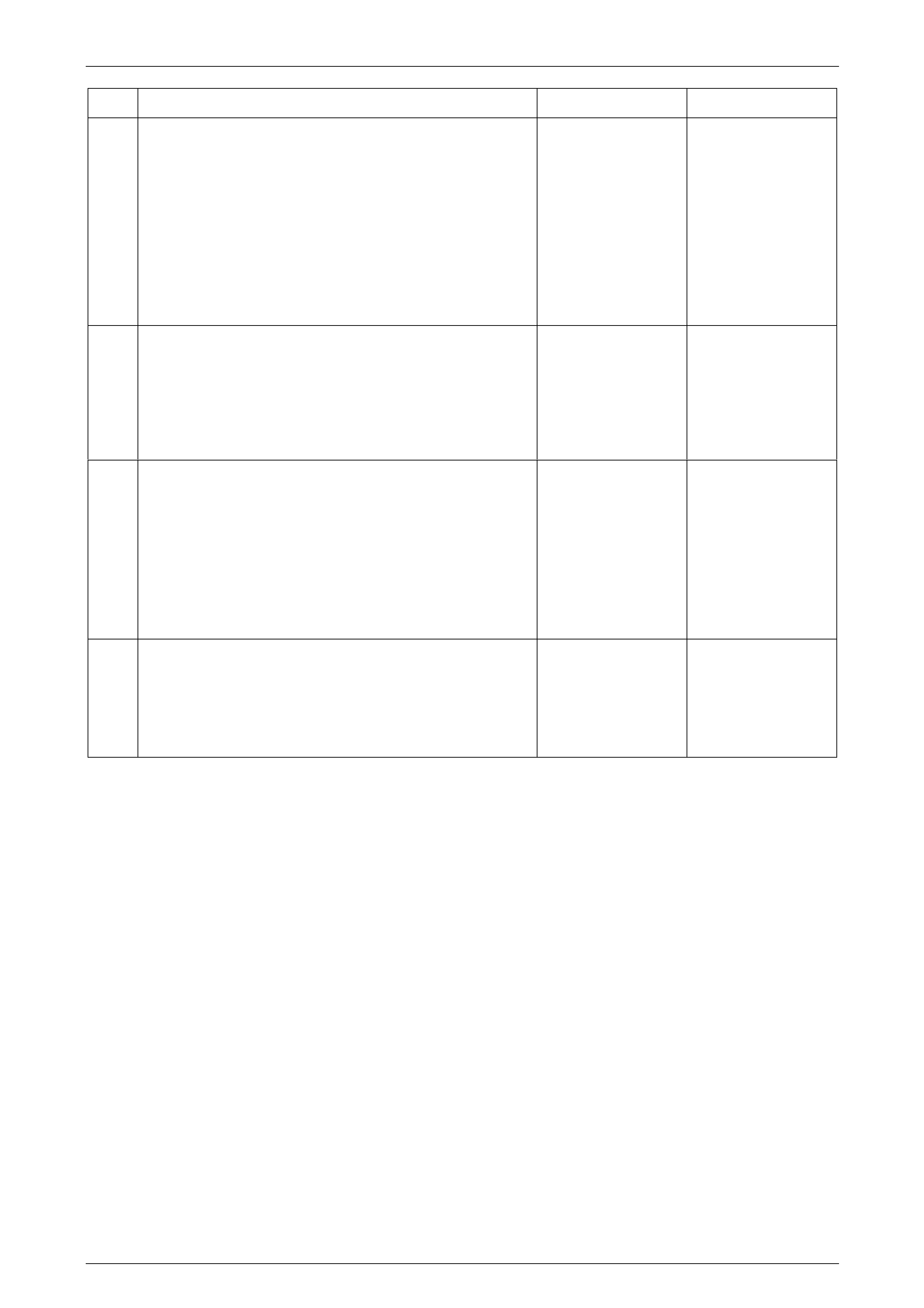

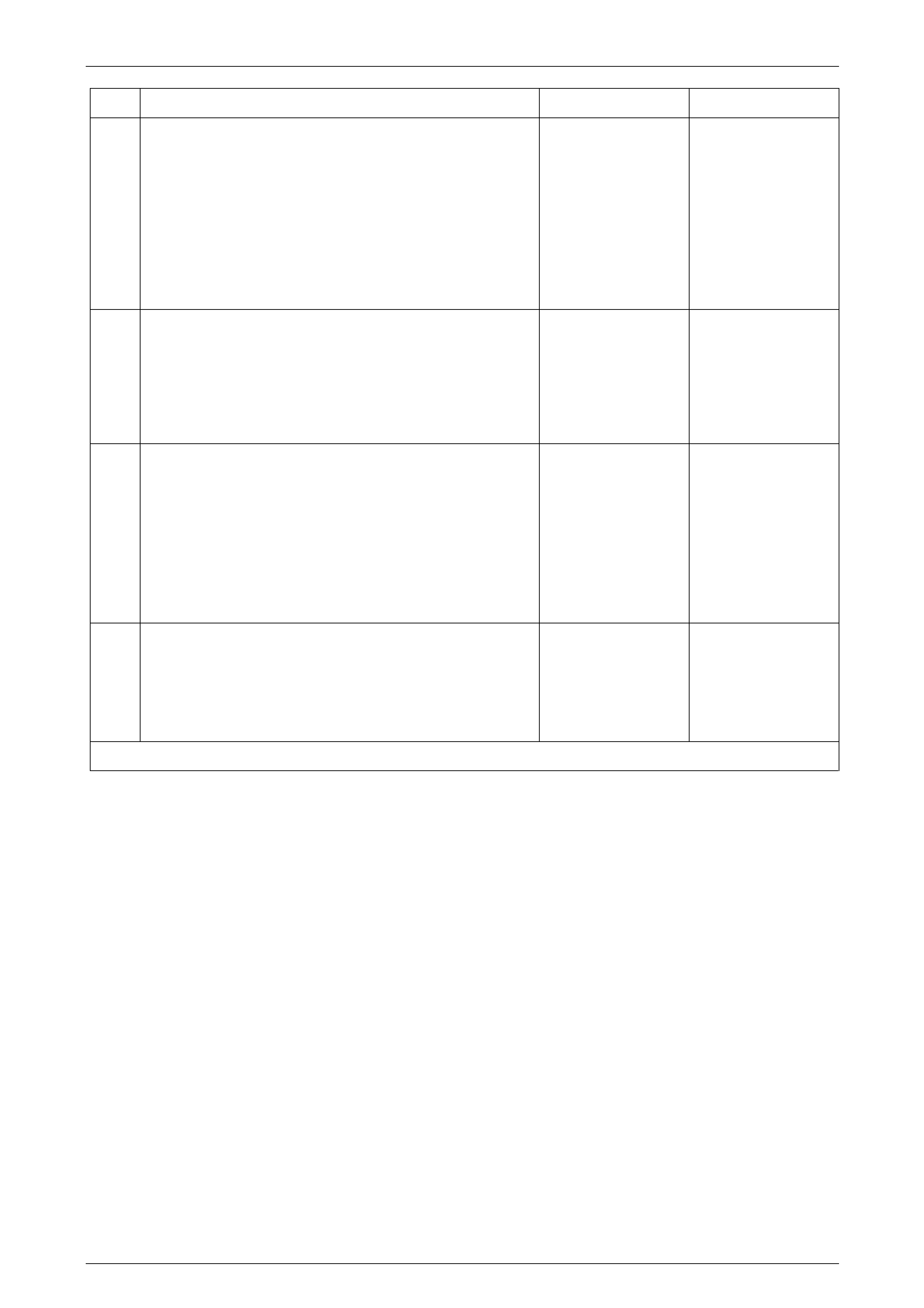

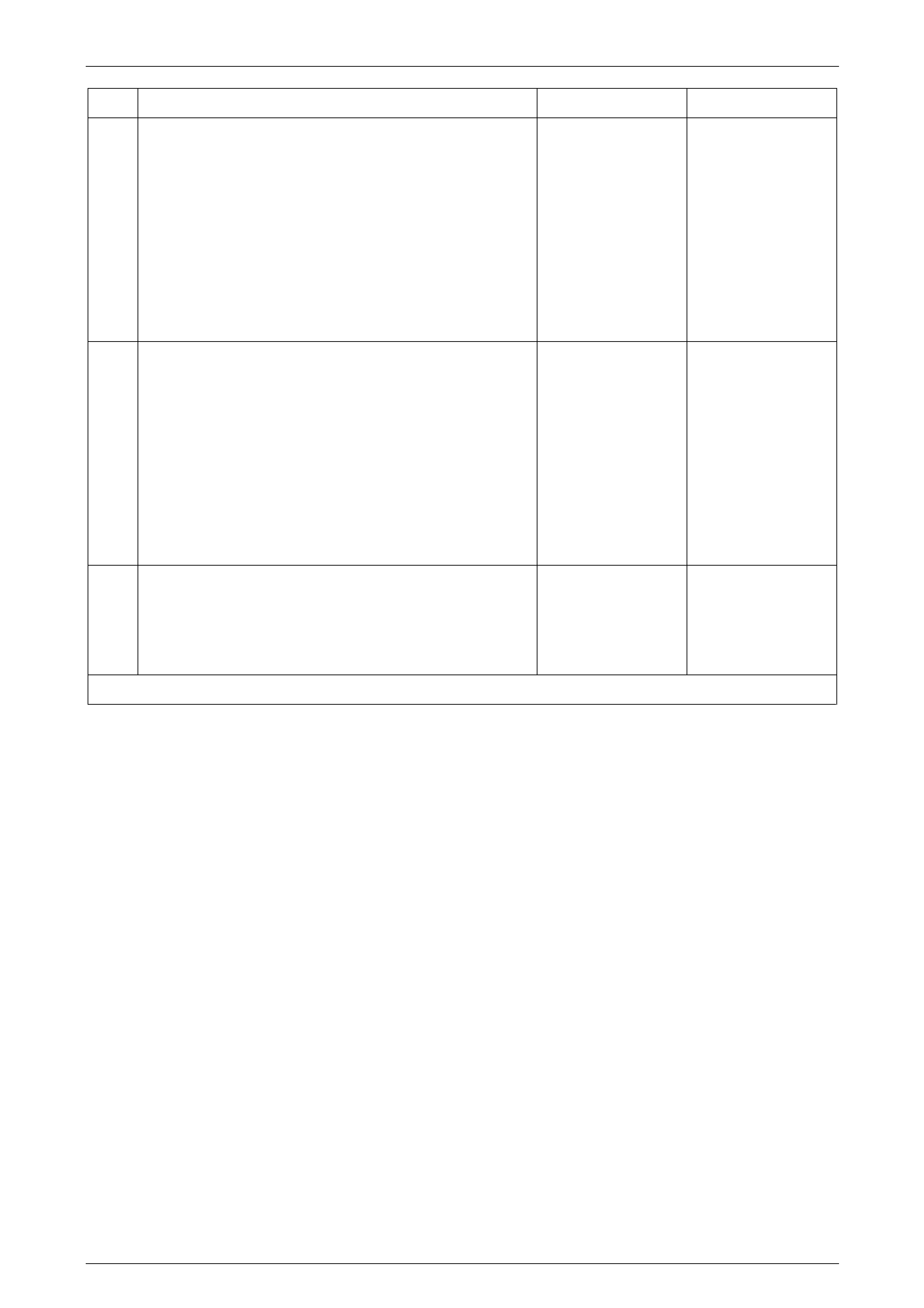

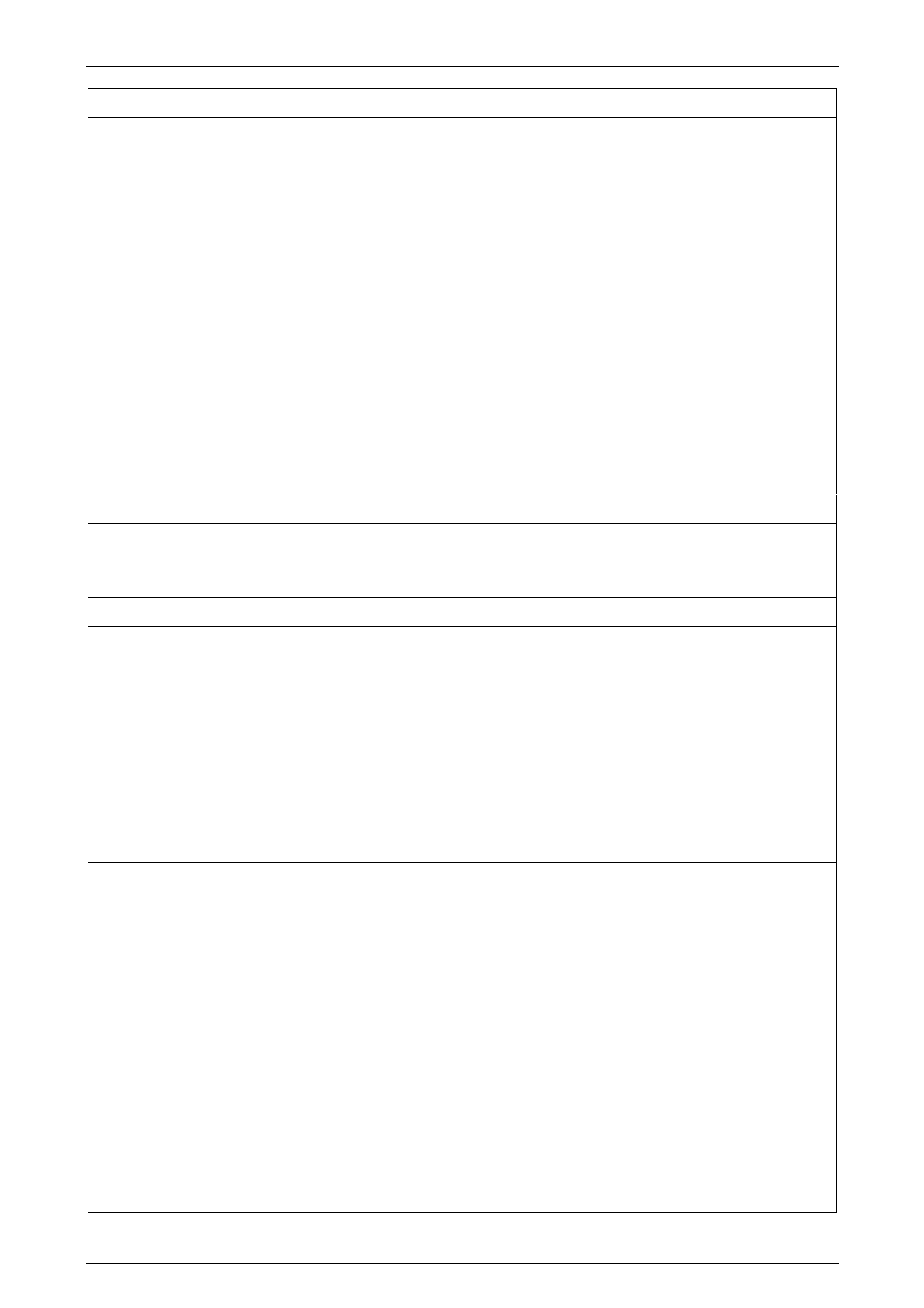

Step Action Yes No

4 1 Remov e relay R3 from the instrument panel fuse and

relay panel assembl y X100, refer to 12O Fuses, Relays

and Wiring Harnesses.

2 Turn the ignition on.

3 Using a multimeter set to measure voltage, probe

between connector X3 pin 85 and a known ground,

refer to 12O Fuses, Relays and Wiring Harnesses.

Does the multimeter display battery voltage? Go to Step 5 Repair or replace

circuit 539

5 1 Insert relay R3

2 Gain access to the OCC module, refer to 2F HVAC

Occupant Climate Control (Aut o A/C) – Removal and

Installation.

3 Using a fused jumper lead, ba ckprobe between A14 –

X1 pin 1 and a known ground.

Was an audible click heard from relay R 3?

Replace the OCC

module, refer to

2F HVAC Occupant

Climate Control

(Auto A/C) –

Removal and

Installation Repair or replace

circuit 681

6 1 Remov e relay R3 from the instrument panel fuse and

relay panel assembly.

2 Using a multimeter set to measure voltage, probe

between connector X3 pin 30 and a known ground,

refer to 12O Fuses, Relays and Wiring Harnesses.

Does the multimeter display battery voltage? Go to Step 7 Repair or replace

circuit 40

7 1 Gain access to the rear demist connector L4 – X2 pin A,

refer to 1A8 Headlining and Interior Trim.

2 Disconnect connector L4 – X2pin A.

3 Using a multimeter set to measure resistance probe

between connector R3 – X3 pin 87 (on fuse and relay

panel assembly) and L4 – X2 pin A.

Does the multimeter display continuity? Go to Step 8 Repair or replace

circuit 293

8 Using a multimeter set to measure resistance probe between

harness connector L4 – X2 pin A and a known ground.

Does the multimeter display continuity? Go to Step 9 Repair or replace

circuit 293

9 Using a multimeter set to measure resistance probe between

harness connector L4 – X3 pin A and a known ground.

Does the multimeter display continuity? Go to Step 10 Repair or replace

circuit 1850

10 Visually inspect the rear window heater element.

Are there any noticeable breaks in the element? Repair the element

with a commercially

available kit

Replace the rear

window assembly,

refer to 1A5

Stationary Windows

When all diagno sis an d repairs are completed, check the system for correct operation.

HVAC Occupant Climate Control (Auto A/C) – Diagnostics Page 2E–37

Page 2E–37

4.9 OCC Module Illumination Inoperative

Circuit Description

The OCC module buttons will illumi nate when the park lamps are turned on. The level of i llumination is controlled by the

BCM through serial data to the OCC module. When BCM receives an input from the illumination slider on the headlamp

assembly switch, it will broadcast the request to either increase or decrease the illumination level of various internal

components including the OCC module buttons and instrument cluster.

Refer to 2 Wiring Diagrams and Connector Charts to aid i n diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 The OCC module receive illumination levels via serial data from the BCM. Checks if there are any serial data faults.

3 Checks if the OCC module buttons illuminate when the park lamps are turned on.

4 Checks if the OCC module buttons increase and decrease illumination intensity when controlled by the headlamp

switch assembly.

5 Checks if any other module’s illumination was increased or decreased. Isolates whether it is an OCC module or

BCM fault.

6 Provides a ground for the OCC module illumination circuit. Isolates whether the module or circuit 32 is at fault.

Diagnostic Table Notes

1 For all wiring fault diagnoses, refer to Section 12P Wiring Diagrams.

2 For wiring repairs, refer to Section 12P Wiring Diagrams.

3 Refer to Section 12O Fuses, Relays and Wiring Harnesses for harness routeing.

4 If a fault is deemed intermittent, refer to 4.5 Intermittent Faults.

5 For information on Tech 2, refer to 3.1 Tech 2 Diagnostics.

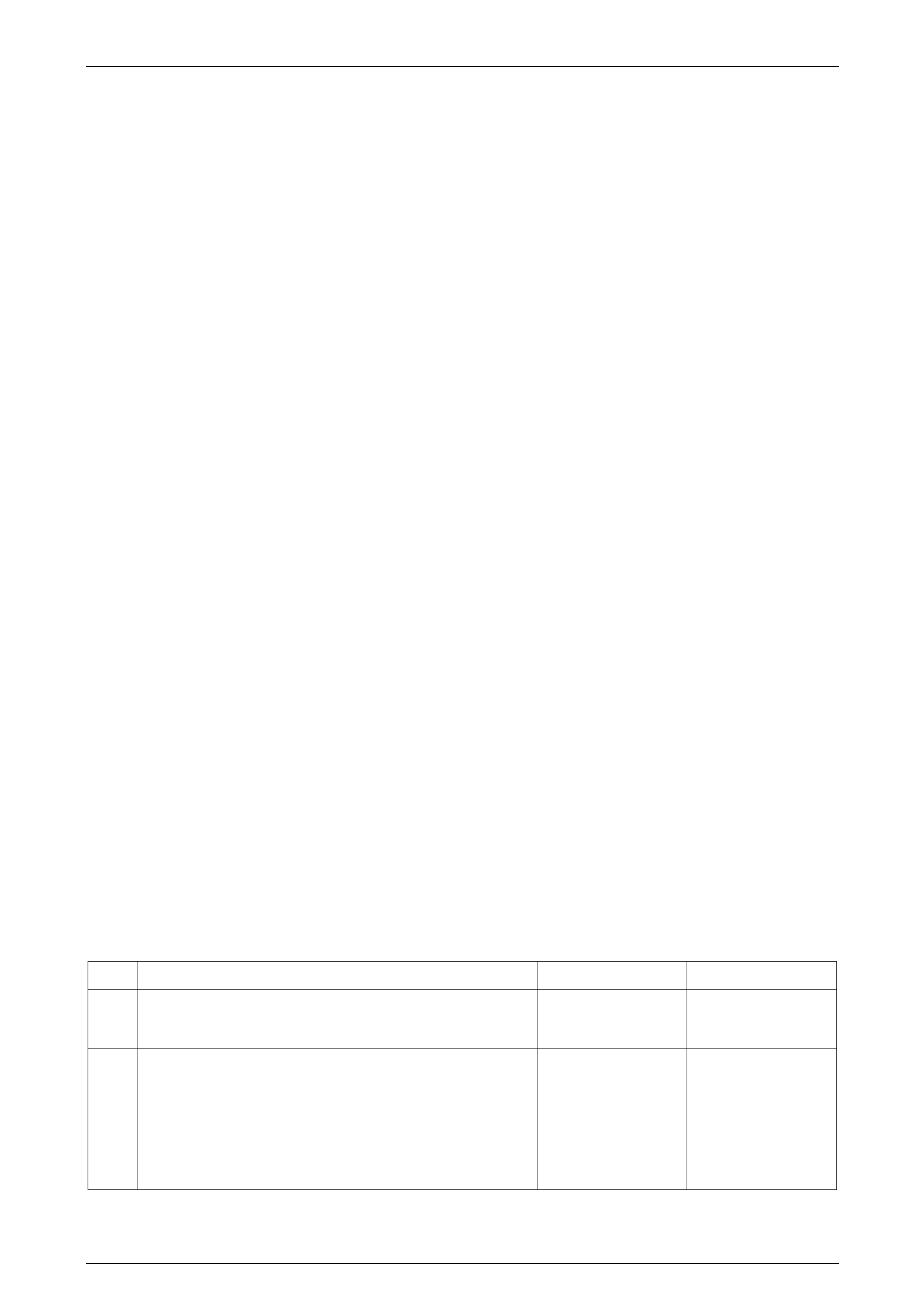

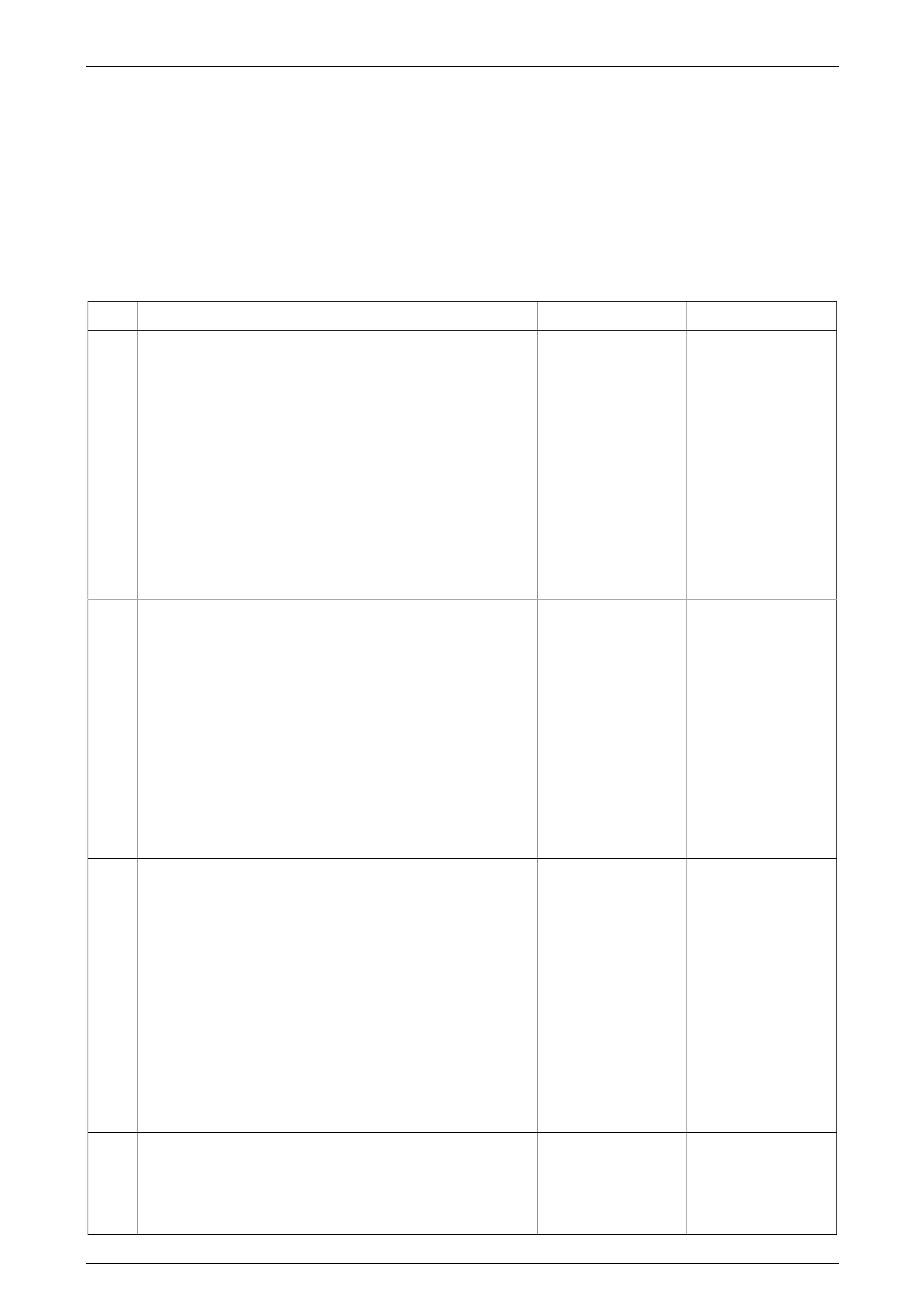

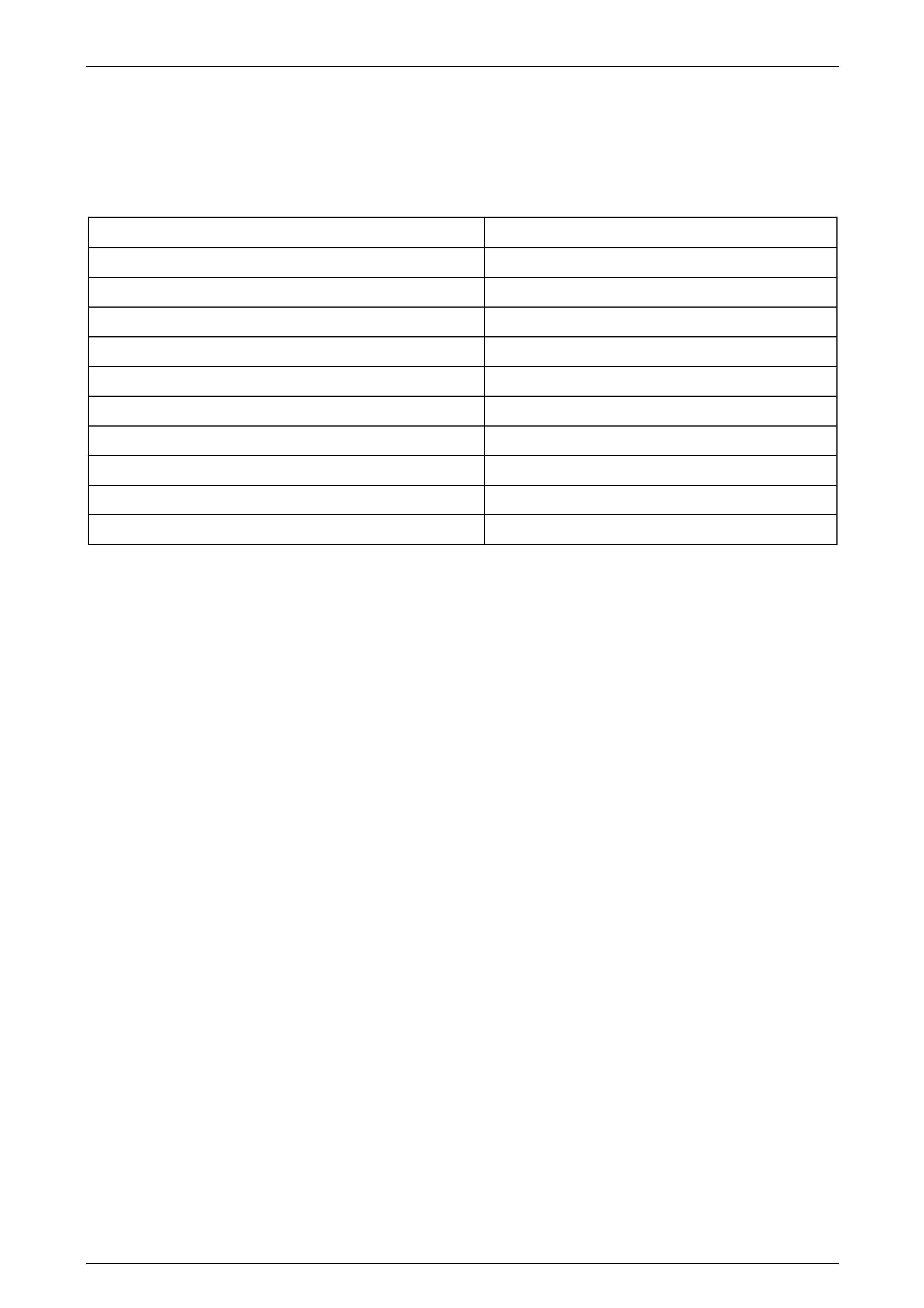

OCC Module Illumination Inoperative Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.6 Diagnostic

System Check

2 During the Di agnostic System Check, was DTC 35 or 36 set? Refer to

4.19 DTC 35 and 36

– Serial Data Error Go to Step 3

3 1 Turn on the OCC.

2 Turn on the park lamps