Rear Propeller Shaft and Universal Joints Page 4C1 – 1

Page 4C1 – 1

Section 4C1

Rear Propeller Shaft & Universal Joints

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................2

2 Service Operations.................................................................................................................................4

2.1 Propeller Shaft ....................................................................................................................................................... 4

Remove................................................................................................................................................................... 4

Front Coupling Attached to the Transmission Output Flange............................................................................. 4

For WL Models with a Sliding Front Yoke .......................................................................................................... 6

Reinstall.................................................................................................................................................................. 6

For WL Models with Front Coupling Attached to the Transmission Output Flange ............................................ 6

For WL Models with a Sliding Front Yoke .......................................................................................................... 7

2.2 Rubber Coupling.................................................................................................................................................... 8

Replace................................................................................................................................................................... 8

2.3 Centre Bearing Assembly ................................................................................................................................... 10

Remove................................................................................................................................................................. 10

Reinstall................................................................................................................................................................ 12

3 Specifications.......................................................................................................................................14

4 Torque Wrench Specifications............................................................................................................15

5 Special Tools ........................................................................................................................................16

Rear Propeller Shaft and Universal Joints Page 4C1 – 2

Page 4C1 – 2

1 General Information

The propeller shaft assembly is a two piece tubular design, incorporating a sealed for life centre support bearing. The

centre support bearing is a fully sealed ball bearing, mounted in a reinforced rubber cup. This centre bearing rubber cup

is supported in a cup guide and attache d to a carrier, which is bolted to the vehicle underbod y brace. Should a specific

tow bar package be fitted, a heat shield may also be fitted to the centre bearing carrier. No periodic servicing of the

centre bearing nor any u niversal joint, is required.

For those MY2005 WL vehicles with the GEN III V8 engine and 4 speed 4L60-E automatic transmission, servicing of the

centre bearing is not possible. The reason is that the interference fit of the splined joint between the front and rear

propeller shaft halves is such that special tools and high press forces are required to separate the two shafts. As this

operation would also re quire the re-balancing of the propeller shaft assembly, the centre bearing assembly and/or slinger

are also non-serviceable.

On those MY2005 WL vehicles fitted with the V6 engine and the 5 speed 5L40-E automatic transmission however, the

centre bearing and boot are s erviceable items.

Front Coupling Joint: While al l propeller shafts have a rubber coupling in this location, dep endent upon the transmission,

the coupling may be attached to the transmission output shaft flange by a bolt and nut (V6 5L4 0-E – automatic

transmission) or by being bolted to a slip yoke that is splined to the output shaft (GEN III V8 – 4L60-E automatic

transmission).

Centre Universal Joint: This is a conventional cross type universal joint (Hooke’s joint) mounted behind the centre

bearing. The cross t ype universal joint type is non-serviceable, as the bearing cups are set and retained by staking. This

requires sophisticated equi pment to ensure concentricity of the installed universal joint.

Rear Coupling Joint: The rear coupling is fixed to the rear final drive pinion flange by three, T orx headed special thread

formed bolts.

Rear Propeller Shaft and Universal Joints Page 4C1 – 3

Page 4C1 – 3

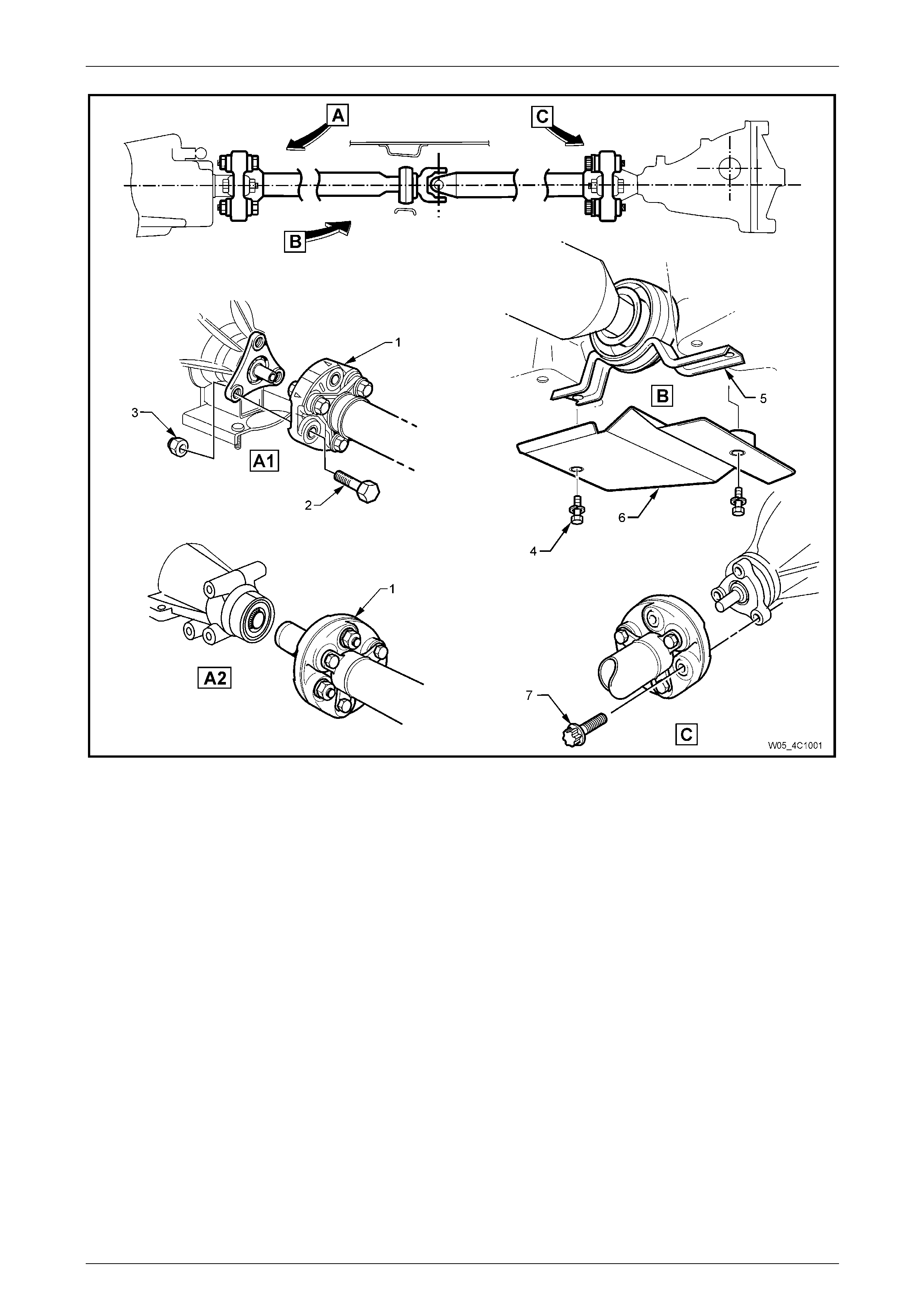

Figure 4C1 – 1

Legend

A1 Front Coupling – V6/5L40-E Automatic Transmission

A2 Front Coupling – GEN III V8/4L60-E Automatic Transmission

B Centre Bearing

C Rear Coupling to Final Drive Pinion Flange

1 Front Rubber Coupling

2 Coupling to Transmission Flange Bolt (3 Places)

3 Coupling to Transmission Flange Nut (3 Places)

4 Centre Bearing Cup Guide to Underfloor Bolt (2 Places)

5 Centre Bearing Cup Guide

6 Heat Shield – Centre Bearing (Where Fitted)

7 Rear Coupling To Final Drive Opinion Flange Bolt (3 Places)

Rear Propeller Shaft and Universal Joints Page 4C1 – 4

Page 4C1 – 4

2 Service Operations

ATTENTION

All fasteners are important attaching parts as they affect the performance of vital components and/or could

result in major repair expense. W here specified in this Section, fasteners MUST be replaced w ith parts of the

same part number or an approved equivalent. Do not use fasteners o f an inferior quality or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all components.

Throughout this Section, fastener torque wrench specifications may be accompanied with the following

identification marks:

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one or more of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 Propeller Shaft

Remove

1 Raise the vehicle and suppor t in a safe manner. Refer to Section 0A General Information for location of jacking and

support points.

2 To provide access to the propeller shaft fasteners, it is recommend ed that the intermediate exhaust pipe,

intermediate and rear muffler assemblies be removed. For information regarding the removal and installation

procedures for these components, refer to Section 8B Exhaust System.

Front Coupling Attached to the Transmission Output Flange

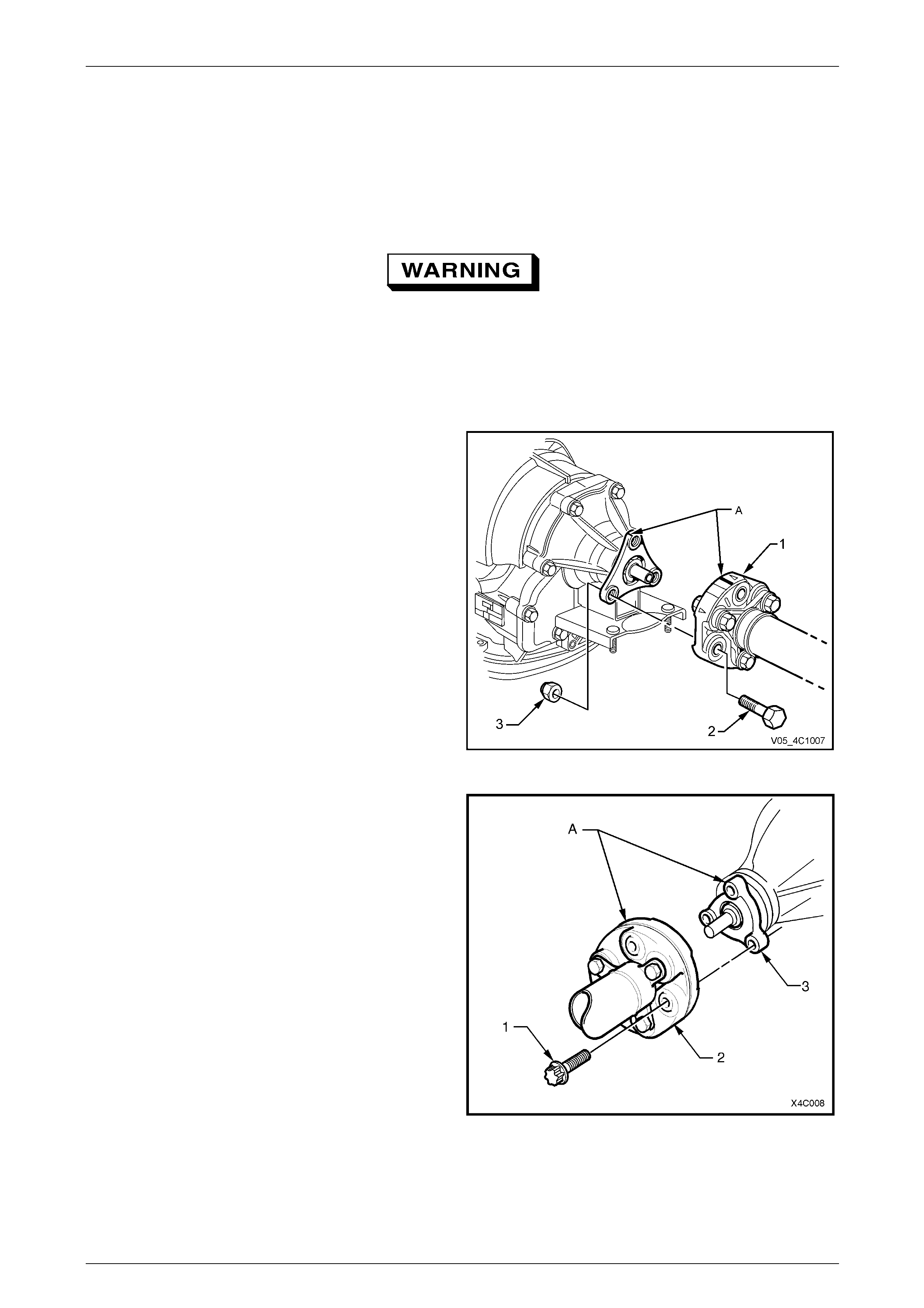

A number of different methods of attaching

the front coupling to the transmission output

flange may be observed:

• Hexagon headed bolts into threaded

flange holes. With this method, the output

flange threads are of the 'Spiralock' form

that can only be loosened/tightened a

maximum of ten times. Because of the

safety factor involved, if the complete

vehicle service history is not known, then

both the flange and the bolts MUST be

replaced on reassembly.

• Studs installed into the transmission

output flange facing rearward, with the

flange being secured by nuts.

• Hexagon headed bolts and nuts. Figure

4C1 – 2 shows this method.

Rear Propeller Shaft and Universal Joints Page 4C1 – 5

Page 4C1 – 5

NOTE

If the reason for removing the propeller shaft is

not related to the front rubber coupling, then it is

recommended that the three bolts and nuts

securing the propeller shaft to the front coupling

be removed, leaving the coupling attached to the

transmission output shaft flange.

Release the park brake to relax any ‘wind-up’

in the flexible rubber coupling. Otherwise,

when the propeller shaft bolts are released

from the final drive pinion flange, personal

injury may result.

3 Select the Park position with the transmission selector lever.

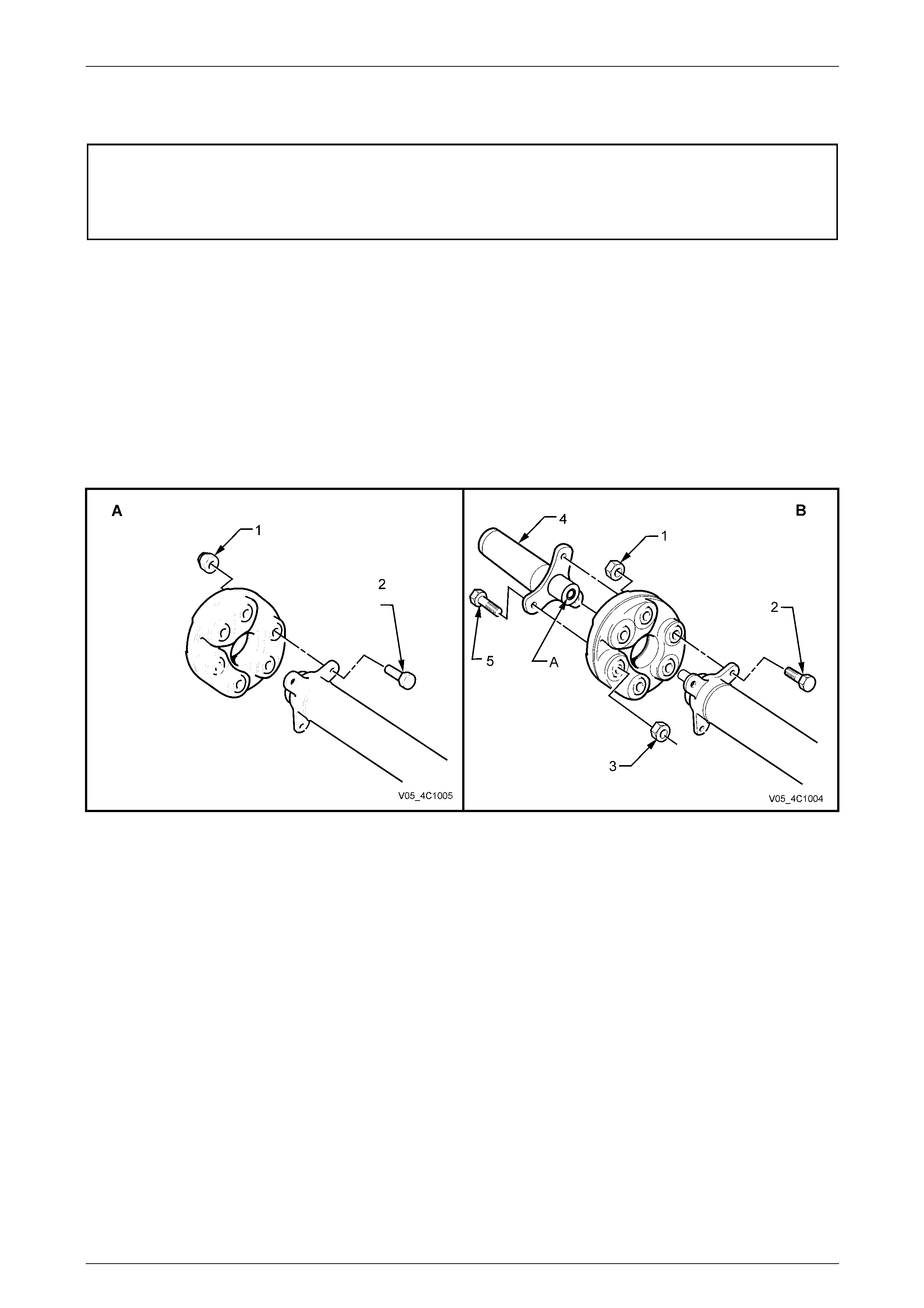

4 To enable the propell er shaft to be reinsta lled in the

original position relative to the transmissi on output

shaft flange, use a felt tipped pen or similar t o ide ntify

the relationship (‘A’) of the t wo components.

5 Using suitable socket equipment, loosen the three

bolts (2) and nuts (3) and securing the front coupling

(1) to the transmission output flange

6 With the transmission shift lever in the Neutral position

and the park brake released, remove the three Torx

headed bolts.

Figure 4C1 – 2

7 To enable the propell er shaft to be reinsta lled in the

original position relative to the final drive pinion flange,

use a felt tipped pen or similar to identify the

relationship (‘A’) of the two components.

8 With the transmission in the Park position, check that

the park brake is firmly applied.

9 Use Torx socket K04425E20 or a commercially

available E20 Torx equivalent to loosen the three Torx

headed bolts (1) securing the propeller shaft rear

rubber coupling (2) to the pini on flange (3).

10 Release the park brake to relieve any torque loading

on the rubber coupling, then remove the three Torx

headed bolts (1)

Figure 4C1 – 3

Rear Propeller Shaft and Universal Joints Page 4C1 – 6

Page 4C1 – 6

11 Remove the two centre bearing carrier (1) to

underbody reinforcement bolts (2).

12 While supporting the centre beari ng section, slide the

propeller shaft assembly forward to disengage from

the final drive pinion support pin, then lower the

assembly at the rear, sliding rearward to disengage

the front coupling.

13 Remove the propeller shaft assembly from the vehicle.

Figure 4C1 – 4

For WL Models with a Sliding Front Yoke

14 After completing all Steps except 4 to 6 inclusive, slide the propeller shaft assemb ly rearward to disengage the front

yoke from the transmission output shaft splines. Durin g this process:

a Locate a clean drain tray under the rear of the transmission to catch any spilled lubricant when the propeller

shaft is removed.

b Take care to protect the outer diameter of the front yoke. Nicks or abrasions will damage the transmission

extension seal during reassembly and result in subsequ ent lubricant leakage from this area.

c Insert a suitable plug in the end of the transmission re ar extension to prevent loss of transmission lubric ant.

Reinstall

Reinstallation is the reverse of removal procedures, except for the following items:

For WL Models with Front Coupling Attached to the Transmission Output Flange

1 Lubricate the transmission rear output shaft and final drive pinion spigots with a molybdenum disulphide grease

such as an NLGI No. 2 lithium soap based EP grease with molybdenum disulphide, such as Shell Retinax HDX2

grease or BP Energrease LMS-EP 23 (or eq uivalent).

2 Reinstall the front of the propeller shaft assembly first, supporting the centre and rear sections.

3 Align the marks made before removal (refer to Figure 4C1 – 2) and temporarily install either a coupling to flange

bolt and nut or nut to secure the propeller shaft in this position.

4 Install the rear coupling over the final drive pinion spigot, align the marks made before removal (refer to

Figure 4C1 – 3) and temporari ly install one of the Torx headed bolts to secure the coupl in g.

5 Raise the centre bearing assembly and install the bolts and spring washers to secure to the underbody

reinforcement. Tighten both bolts to the correct torque specification.

Centre bearing carrier to underbody

reinforcement bolt torque specification ................22 N.m

6 Provided no thread damage is evident, reinstall the original rear propeller shaft coupling to the final drive pinion

flange, Torx headed bo lts, tightening to the correct torque specification.

Propeller shaft rear coupling to pinion

flange bolt torque specification...........................115 N.m

Rear Propeller Shaft and Universal Joints Page 4C1 – 7

Page 4C1 – 7

7 If bolts are used to secure the coupling to the transmission output flange, provid ed no thread damage is evident,

the original front propeller shaft coupling bolts may be re-used up to a maximum of ten times:

a Reinstall the three bolts and tighten to the correct torque specification.

Front coupling to transmission output

flange bolt torque specification...........................115 N.m

b If bolts and nuts are used to secure the coupling to the tran smission output flange, install NEW bolts and nuts

and tighten to the correct torque specification.

Front coupling to transmission output

flange bolt and nut torque specification..............115 N.m

c If nuts are used to secure the front coupling to the transmission output flange studs, insta ll NEW nuts and

tighten to the correct torque specification.

Front coupling to transmission output

flange nut torque specification .............................85 N.m

8 Reinstall the exhaust system, refer to Section 8B Exhaust System, for the procedures an d clearances.

9 Lower the vehicle to the ground an d road test to check for correct operation.

For WL Models with a Sliding Front Yoke

1 Clean the sliding yoke bearing surface, inspect for nicks or other damage.

2 If considered serviceable, lubricate the sli ding yoke with the recommended transmission lubricant, reinstall to the

transmission output shaft splines.

3 Lubricate the final drive pinion spigot with a molybdenum disulp hide grease such as an NLGI No. 2 lithium soap

based EP grease with molybdenum disulph id e, such as Shell Retinax HDX2 grease or BP Energrease LMS-EP 23

(or equivalent).

4 While supporting the centre beari ng offer the rear coupling up to the final drive pinion flange and temporarily install

one of the retaining bolts to secure in this position.

5 Raise the centre bearing assembly and install the bolts with spring washers to secure to the underbody

reinforcement. Tighten both bolts to the correct torque specification.

Centre bearing carrier to underbody

reinforcement bolt torque specification ................22 N.m

6 Before installing the rear coupling to fin al drive flange bolts, align the marks made before remova l, refer to

Figure 4C1-3.

7 Provided no thread damage is evident, reinstall the original rear propeller shaft coupling to the final drive pinion

flange, Torx headed bo lts, tightening to the correct torque specification.

Rear coupling to pinion flange

bolt torque specification.....................................115 N.m

8 Reinstall the exhaust system, refer to Section 8B Exhaust System, for the procedures an d clearances.

9 Road test the vehicle to check for correct operation.

Rear Propeller Shaft and Universal Joints Page 4C1 – 8

Page 4C1 – 8

2.2 Rubber Coupling

ATTENTION

The following fasteners MUST be replaced when performin g these operations:

Front or rear rubber coupling to propeller shaft flange bolts and nuts.

Replace

1 Remove the propeller shaft. Refer to 2.1 Propeller Shaft in this Section.

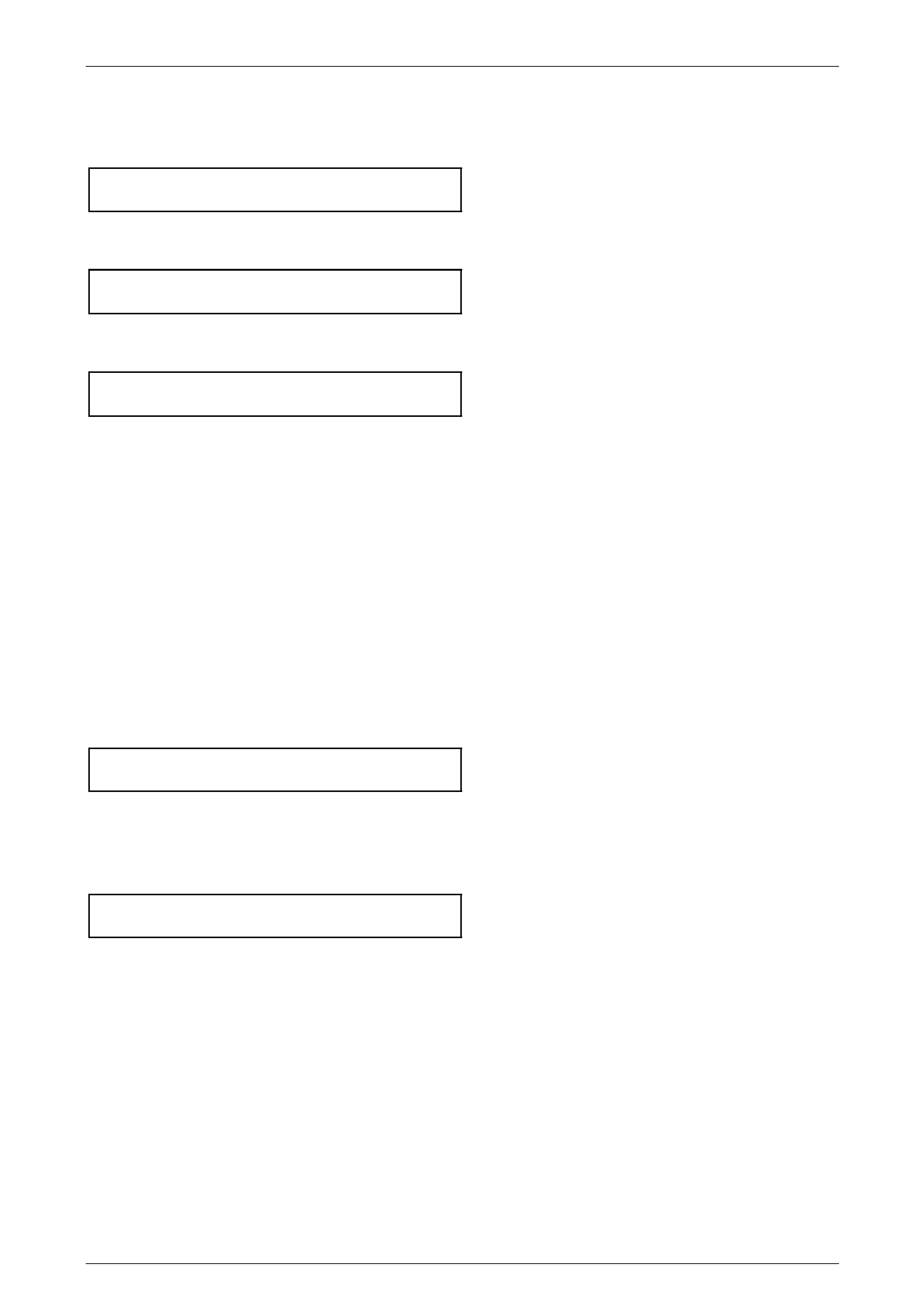

2 Using a back-up spanner on each of the three propeller shaft to coupling bolts (2), loosen then remove the nuts (1).

Discard the removed bolts and nuts. Remove the coupling from the front of the propeller shaft.

NOTE

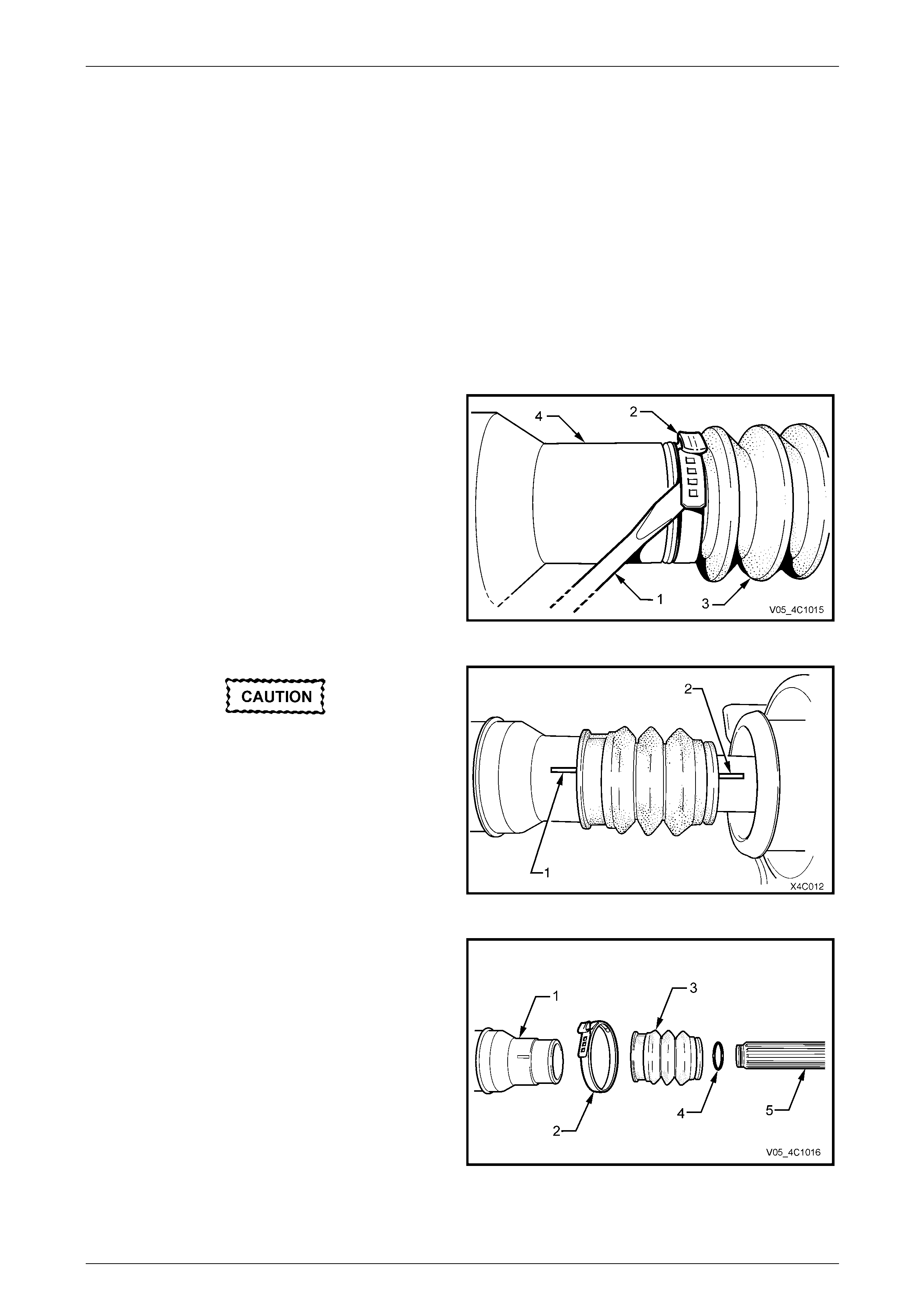

View ‘A’ shows the rubber coupling to flange

arrangement (front or rear) while view ‘B’ shows

the front coupling arrangement when a slip yoke

is utilised.

Figure 4C1 – 5

Legend

1 Nut – Coupling to Propeller Shaft (3 Places)

2 Bolt – Coupling to Propeller Shaft (3 Places)

3 Nut – Coupling to Slip Yoke (3 Places)

4 Slip Yoke Flange

5 Bolt – Coupling to Slip Yoke (3 Places)

A Spigot Bush Requiring Lubrication

3 Referring to view ‘B’, use a back-up spanner on each of the three, propeller shaft slip yoke bolts (5), loosen then

remove the nuts (3). Discard the removed bolts and nuts. Remove the sliding yoke from the coupling.

Rear Propeller Shaft and Universal Joints Page 4C1 – 9

Page 4C1 – 9

4 Install a replacement rubber coupling onto the end of

the propeller shaft, aligning the holes in such a way

that the triangular shape (‘A’) on the coupling ‘points’

to the propeller shaft flange lug (1), as shown.

5 Install NEW bolts and nuts to secure the couplin g to

the propeller shaft flange and tighten to the correct

torque specification, using a back-up sp anner on the

bolt head and angle wrench E 7115 to measure the

turn angle.

( ) Propeller shaft to rubber coupling

nut torque specification.......................................20 N.m,

then 55° turn angle

6 Lubricate the spigot bush in the propeller shaft end (or

the slip yoke bushing) with 0.5 gm of a molybdenum

disulphide grease such as an NLGI No. 2 lithi um soap

based EP grease with molybdenum disulph id e, such

as Shell Retinax HDX2 grease or BP Energrease

LMS-EP 23 (or equivalent). Figure 4C1 – 6

7 Reinstall the sliding yoke bush onto the propeller shaft spigot and align the three bolt holes.

NOTE

If the rear bolts were placed correctly (refer to

Step 4), the triangular shapes (’A’) will ‘point’ to

the sliding yoke flange bo lt holes.

8 Install NEW bolts and nuts to secure the couplin g to the slip yoke flange and tighten to the correct torque

specification, using a back-up spanner on the bolt head and angle wrench E 7115 to measure the turn a ngle.

Propeller shaft to rubber coupling

nut torque specification.......................................20 N.m,

then 55° turn angle

9 Reinstall the propeller shaft, Refer to 2.1 Propeller Shaft in this Sectio n.

Rear Propeller Shaft and Universal Joints Page 4C1 – 10

Page 4C1 – 10

2.3 Centre Bearing Assembly

NOTE

• This operation is not possible with the

propeller shaft fitted to GEN III V8 vehicles.

Refer to 1 General Information, in this Section

for further information.

• During the removal process described, the

rubber bearing support will be damaged,

resulting in the requirement for the complete

centre bearing assembl y to be replaced.

Remove

1 Remove the propeller shaft. Refer to 2.1 Propeller Shaft in this Section.

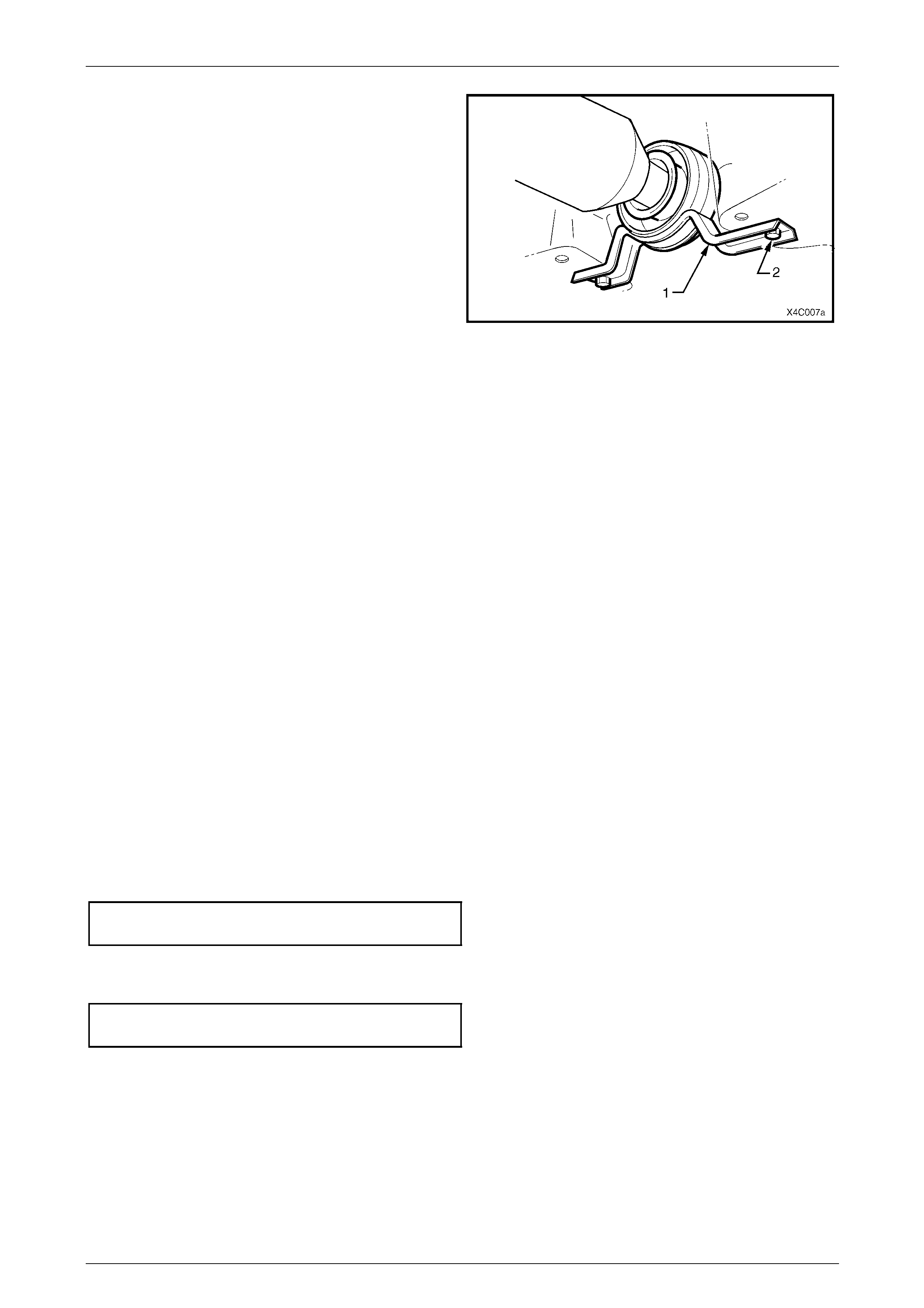

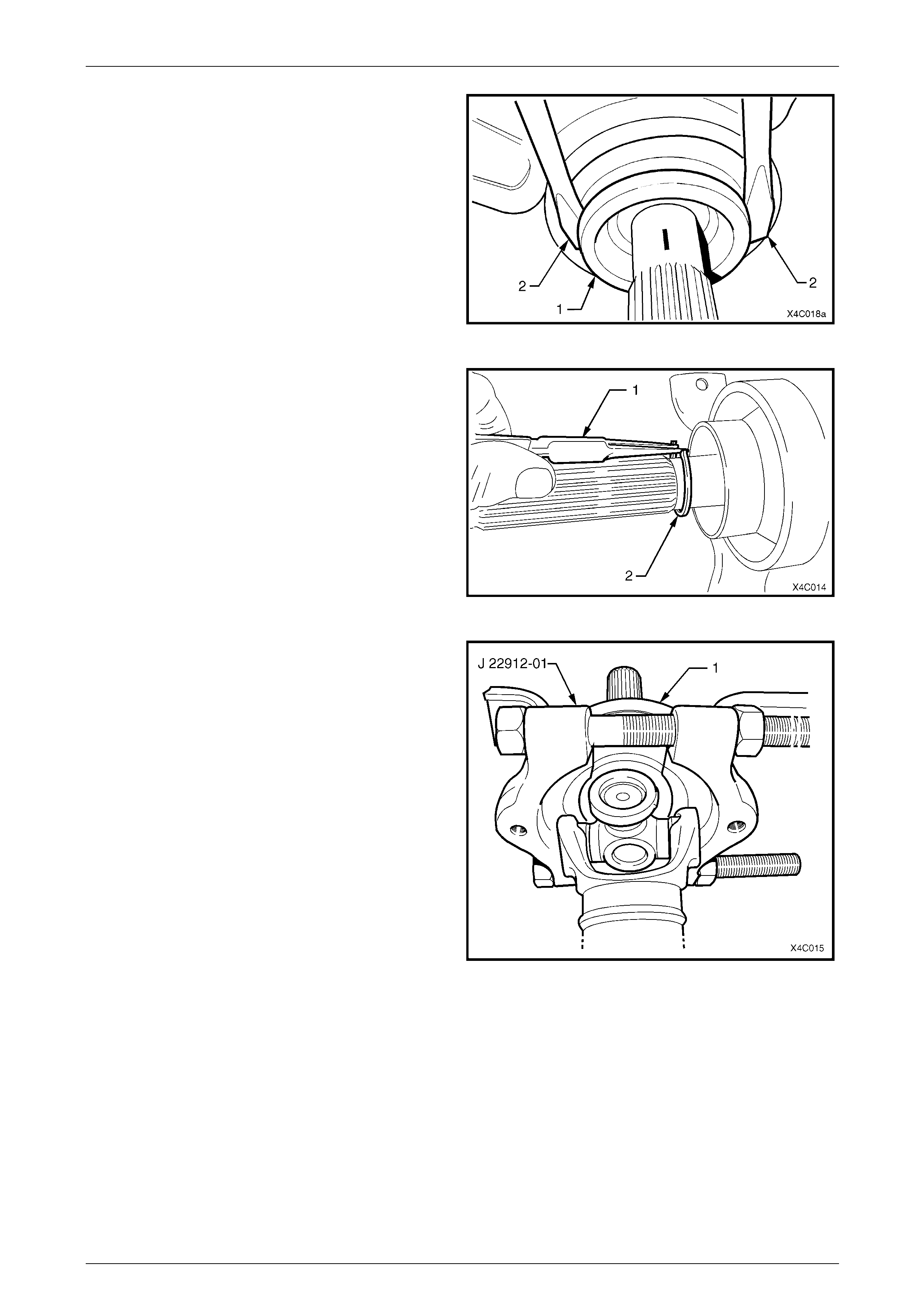

2 With the propeller shaft assembly (4) laying on a

workbench, use a screwdriver (1) or similar a nd lever

up on the boot clamp (2) releasing the te nsion.

Figure 4C1 – 7

This is a critical operation, as propeller shaft

phasing and balance will be affected if the

two propeller shaft halves are not aligned

correctly on reassembly.

3 Extend the sliding joint until a slight resistance is felt.

4 Using a felt tipped pen or similar, mark align m ent

marks on the front propeller shaft section (1) and the

rear (2)

Figure 4C1 – 8

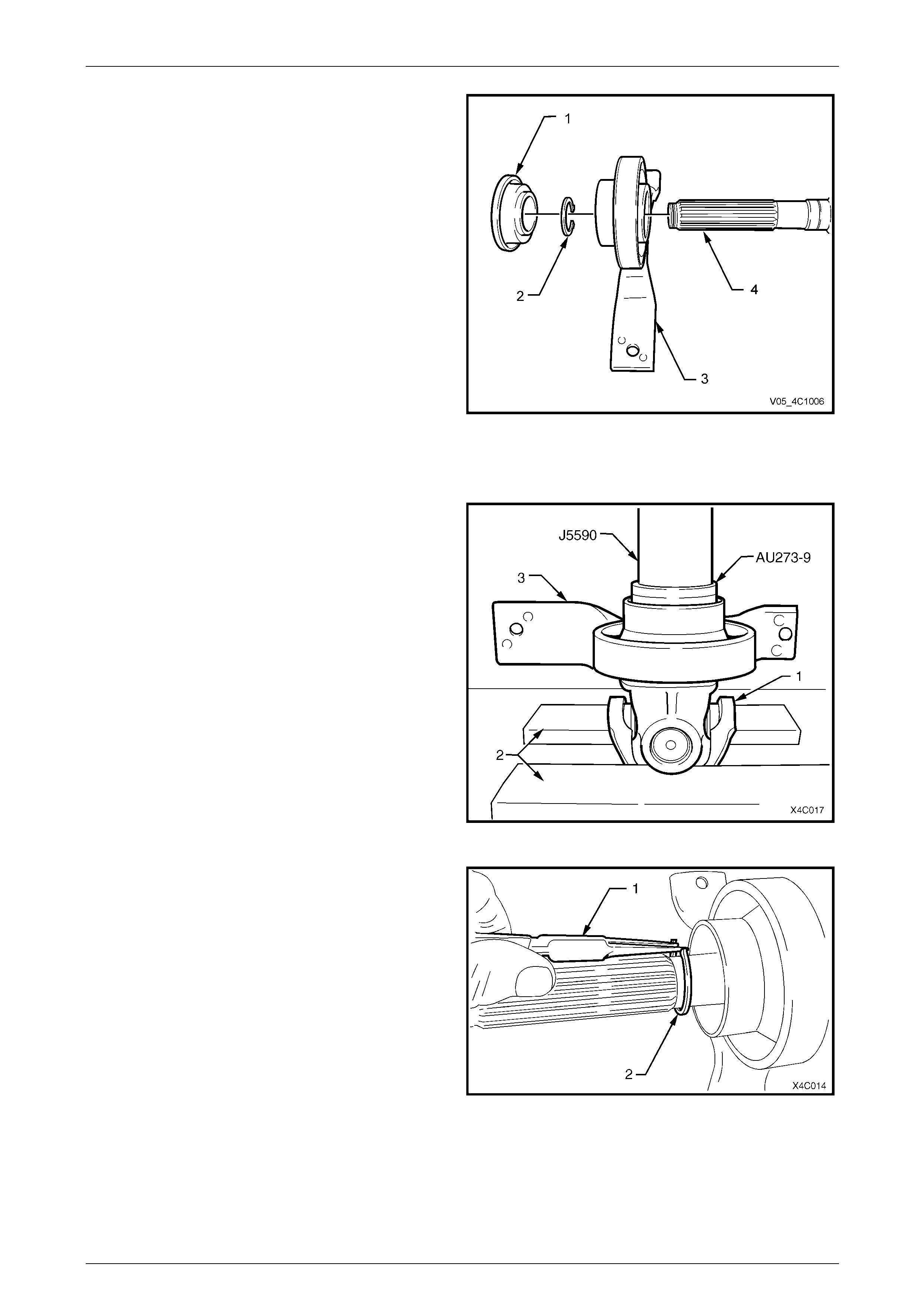

5 With the two propeller shaft halves extended, a snap

action is required to separate them, because of the O-

ring seal (3) mounted on the end of the re ar shaft (1).

6 Once separated, the ribbed boot (4) and O-ring seal

(3) are released.

NOTE

Once separated, the O-ring seal (3) may be

retained in the propeller shaft front half (2).

Retrieve by inserting a hooked piece of wire.

Figure 4C1 – 9

Rear Propeller Shaft and Universal Joints Page 4C1 – 11

Page 4C1 – 11

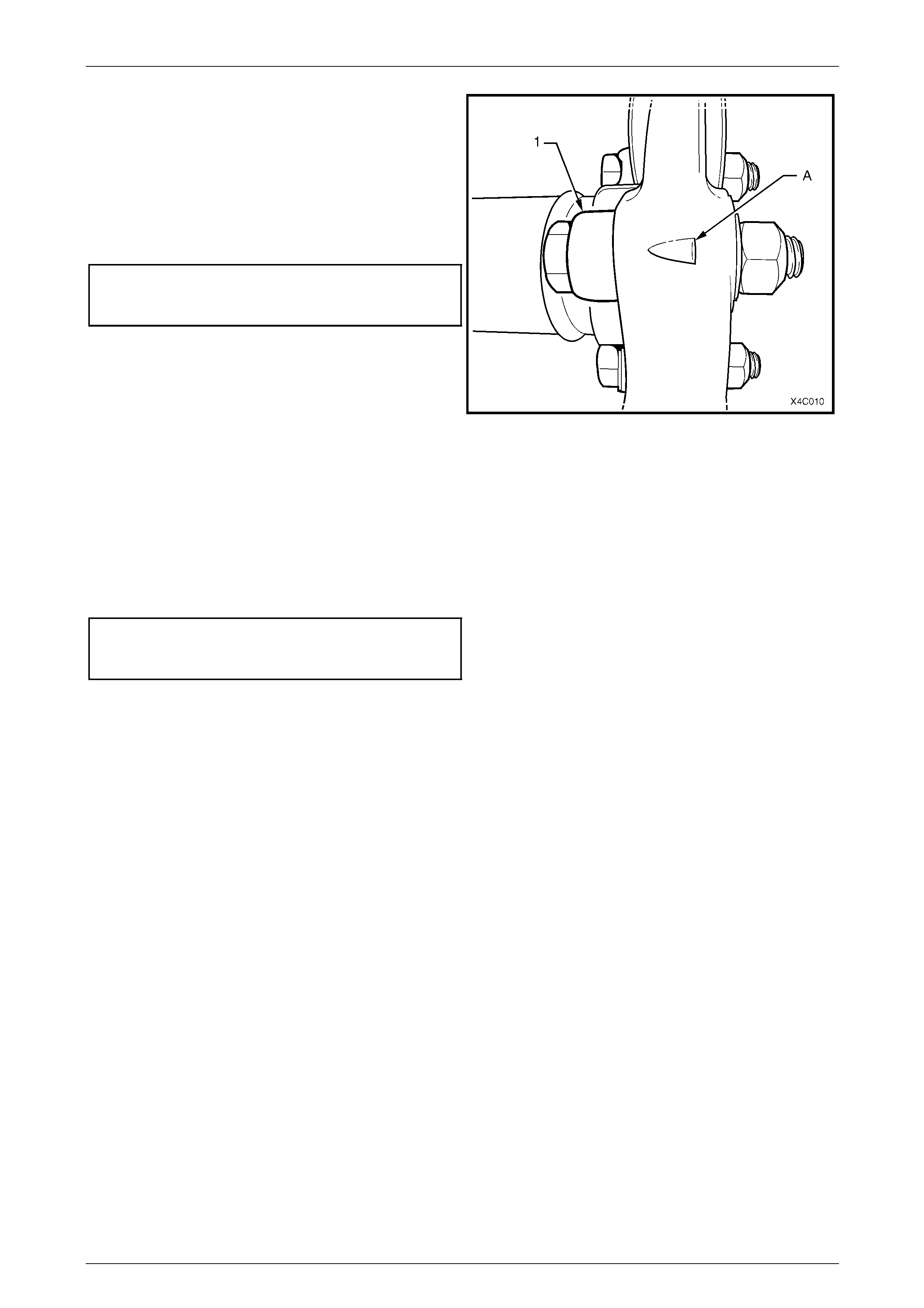

7 Remove the slinger (1), by levering off, using two

similar sized screwdrivers (2) or similar, as sho wn.

NOTE

Removal of the slinger is requir ed to gain access

to a circlip underneath.

8 Discard the removed slinger, as it will be dist orted

during the removal process.

Figure 4C1 – 10

9 Using suitable, commercial ly available circlip pliers (1),

remove the circlip (2) securing the centre bearing.

Figure 4C1 – 11

10 Install suitable press plates such as J 22912-01 under

the centre bearing, carrier (1) and rubb er support, with

the flat face towards the bearing and carrier (1).

11 Tighten the clamp nuts on the press plates until the

two halves are firmly secure around the bearing.

12 Support the press plates on the bed of an hydraulic

press and press the rear propeller shaft, splined shaft

from the centre bearing.

NOTE

This operation will damage the rubber bearing

support, requiring the cent re bearing, rubber and

carrier assembly to be replaced.

Figure 4C1 – 12

Rear Propeller Shaft and Universal Joints Page 4C1 – 12

Page 4C1 – 12

13 Shown is the relationship of the centre bear ing

assembly (3) to the rear propeller shaft (4) front half,

together with the slinger (1) and the retaining circlip

(2).

Figure 4C1 – 13

Reinstall

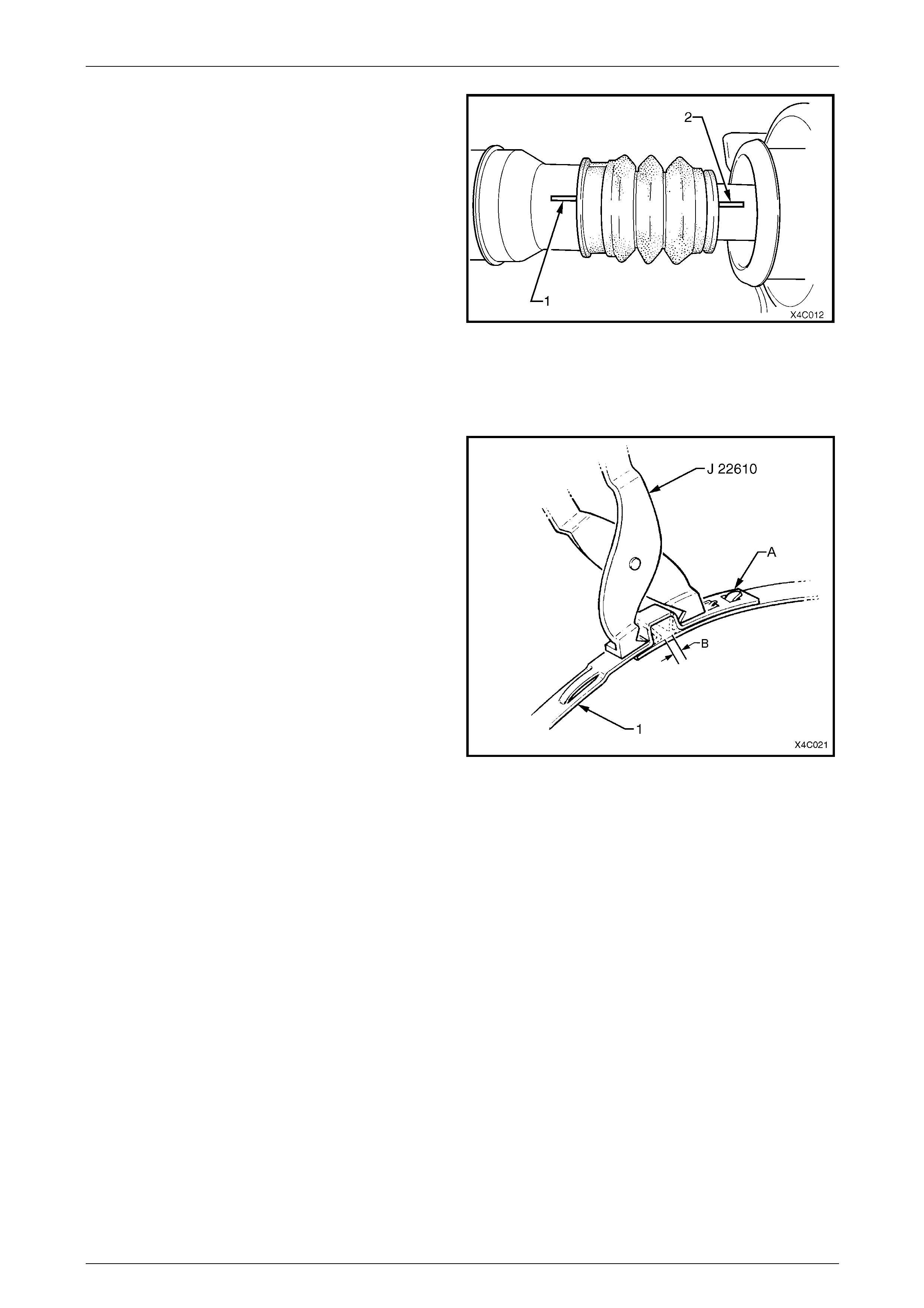

1 With the front universal joint ‘ears’ (1) supported on

press plates (2), press a NEW centre bearing

assembly (3) onto the front section of the rear

propeller shaft, using press tube J 5590 and adaptor

AU 273-9.

NOTE

If these tools are not available, then a 150 mm

length of pipe with an ID of 30 mm (and a wall

thickness of 5 mm), can be used as a substitute.

Figure 4C1 – 14

2 Install a NEW centre bearing retaining circlip (2), using

commercially available circlip pliers (1), taking care not

to over-stretch the circlip.

3 Install a NEW slinger, using press tube J 5590.

Figure 4C1 – 15

Rear Propeller Shaft and Universal Joints Page 4C1 – 13

Page 4C1 – 13

4 Install a NEW boot and ring assembly over the splines

of the rear propeller shaft.

5 Lubricate the splines of the rear prop eller shaft with

approximately 1 – 2 gm of molybdenum disulphide

grease with an NLGI No. 2 lithium soap based EP

grease with molybdenum disulphide, such as Shell

Retinax HDX2 grease or BP Energrease LMS-EP 23

(or equivalent).

6 Install a NEW O-ring seal onto the nos e of the rear

propeller shaft.

7 Taking care to align the two propeller shaft halves with

the marks made before disassembly (1 and 2), push

the two halves together until the O-ring seal clears the

inner splines of the front half.

NOTE

At this time it should be possi ble to slide the two

halves back and forth with little resistance.

Figure 4C1 – 16

8 With the boot and ring assembly located correctly in

the grooved section of the front propeller shaft, install

a NEW retaining clamp to secure.

9 After installing a new clamp around the boot and ring

assembly bend the tab over as shown by ‘A’ in Figure

4C1-17.

10 Using keystone clamp pliers such as J 22610 or

commercial equivalent, tighten the clamp (1) until the

gap ‘B’ is from 1 – 2 mm.

11 Reinstall the propeller sh aft assembly. Refer

2.1 Propeller Shaft, in this Section.

Figure 4C1 – 17

Rear Propeller Shaft and Universal Joints Page 4C1 – 14

Page 4C1 – 14

3 Specifications

Propeller Shaft Identification

Refer to the digit identification letters on the tag attached to the rear propeller shaft tube and the following table.

Body Style Engine Transmission I.D. Code

WL Alloytec 190 (LY7) 5L40-E Automatic Transmission (M82) NY

WL GEN III V8 (LS1) 4L60-E Automatic Transmission (M30) NF

Centre Bearing

Type.........................................................................Rubber Mounted – Single Row Ball Race

Lubrication.........................................................................................................Sealed for Life

Universal Joints

Front..............................................................................................................Rubber Coupling

Centre.........................................................................................Non-Serviceable Cross Type

Rear...............................................................................................................Rubber Coupling

Rear Propeller Shaft and Universal Joints Page 4C1 – 15

Page 4C1 – 15

4 Torque Wrench Specifications

ATTENTION

Fasteners must be repl aced after loosening.

Vehicle must be at curb height before final tightening.

Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

Centre Bearing Carrier to Underbody Reinforcement Bolt............................22 N.m

Front Rubber Coupling to Transmission Output Flange Nut.........................85 N.m

Front Rubber Coupling to Transmission Output Flange Bolt......................115 N.m

Front Rubber Coupling to Transmission Output Flange Bolt and Nut.........115 N.m

Propeller Shaft To Rubber Coupling Bolt and Nut...... 20 N.m , then 55° turn angle

Rear Rubber Coupling to Pinion Flange Torx Bolt......................................115 N.m

Rear Propeller Shaft and Universal Joints Page 4C1 – 16

Page 4C1 – 16

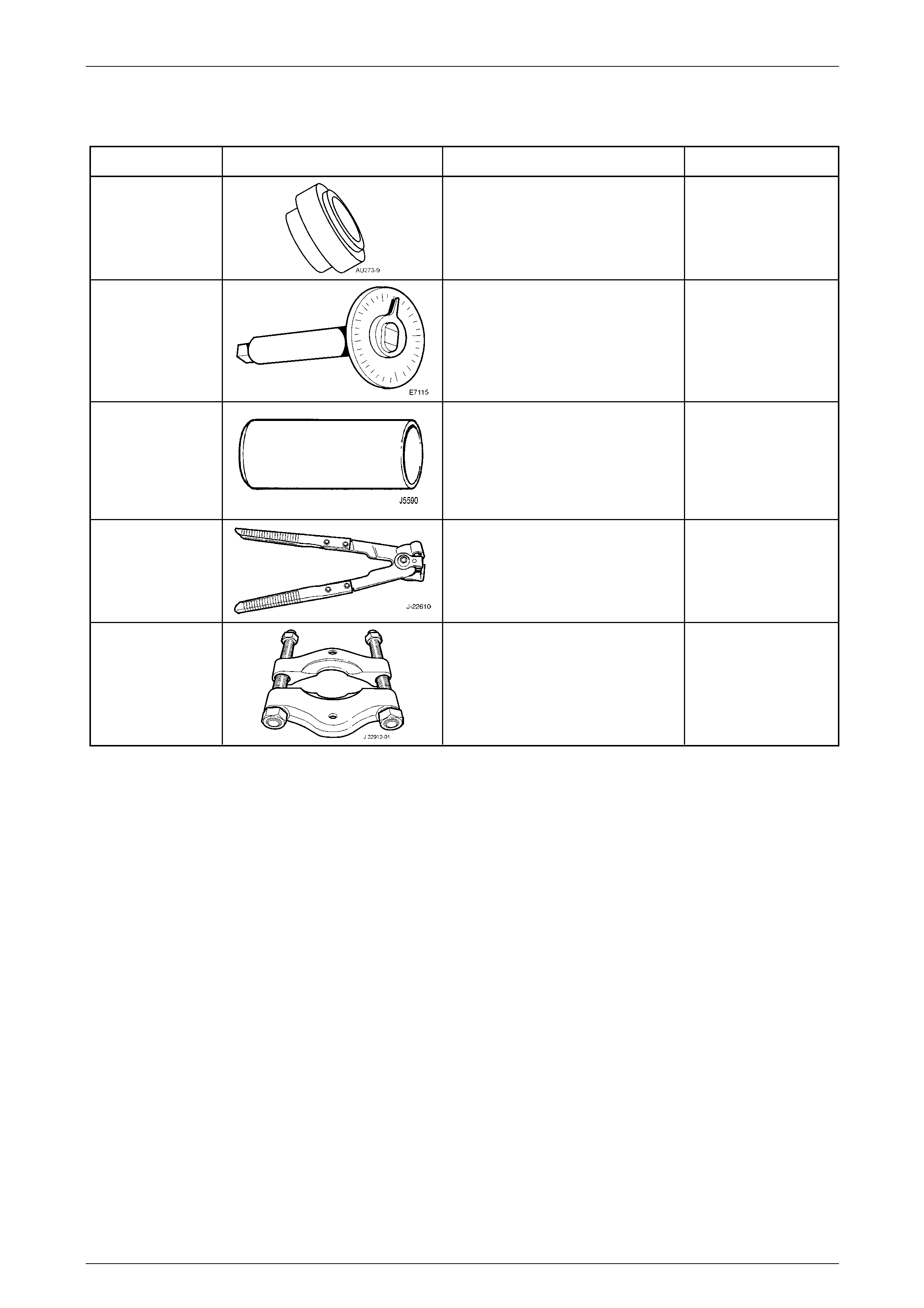

5 Special Tools

Tool Number Illustration Description Tool Classification

AU 273-9

Installer Adaptor

Used with J 5590 to install the centre

bearing to the rear propeller shaft.

Previously released.

Unique

E 7115

Angle Wrench

Used to tighten fasteners when an

angle torque is specified. Also

released as BT 8653-A

Previously released.

Unique

J 5590

Press Tube

Used to install centre bearing and the

slinger.

Previously released.

Unique

J 22610

Keystone Clamp Pliers

Used to tighten the constant velocity

joint boot clamps.

Previously released

Desirable

J 22912-01

Press Plates

Used for various pressing operations

Previously released.

Desirable