Engine Management GEN IV V8 – Diagnostics Page 6C4-2–1

Page 6C4-2–1

Section 6C4-2

Engine Management GEN IV V8 –

Diagnostics

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 00 Warnings,

Cautions and Notes for correct w o rkshop practices with regard to safety and/or property damage.

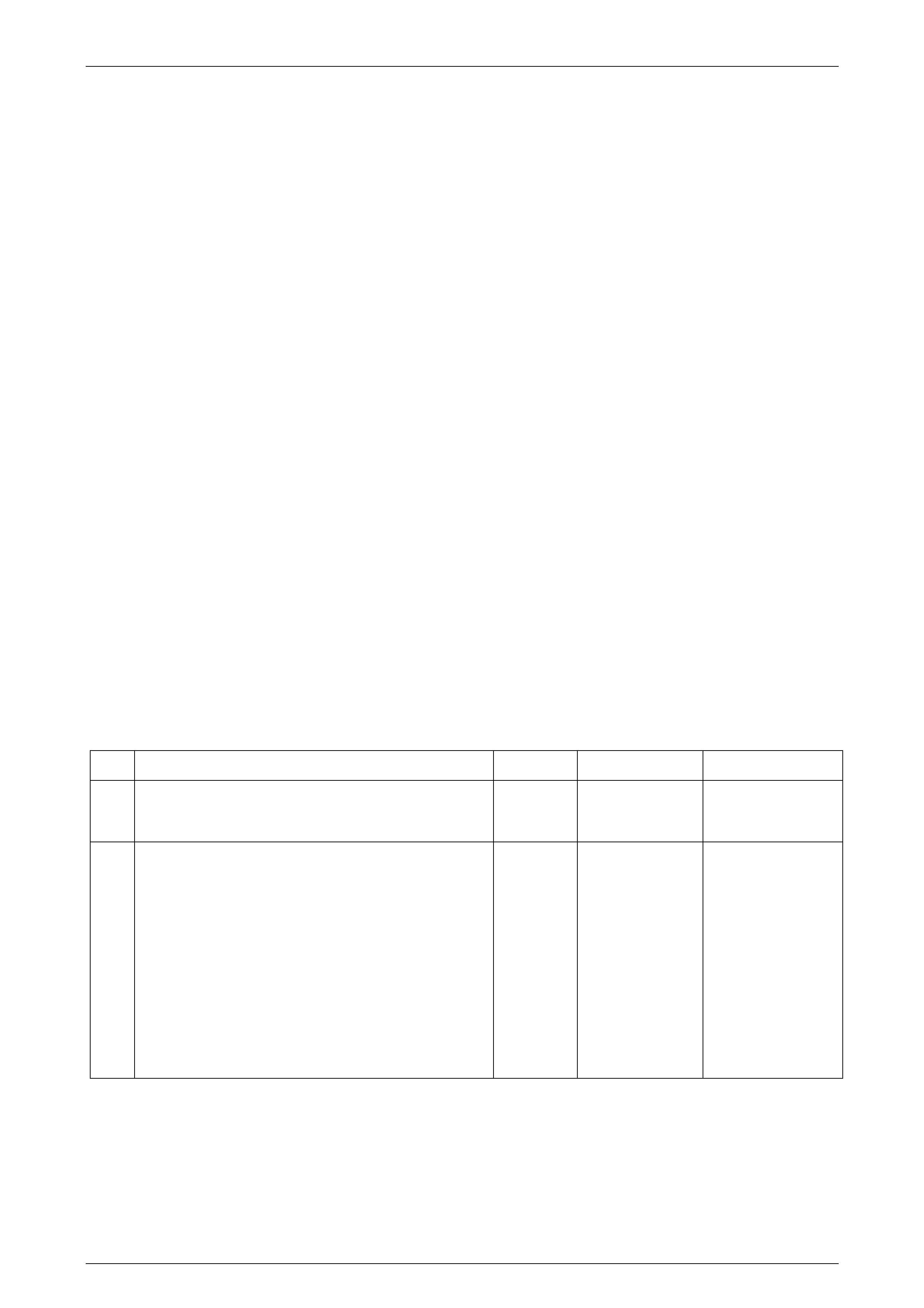

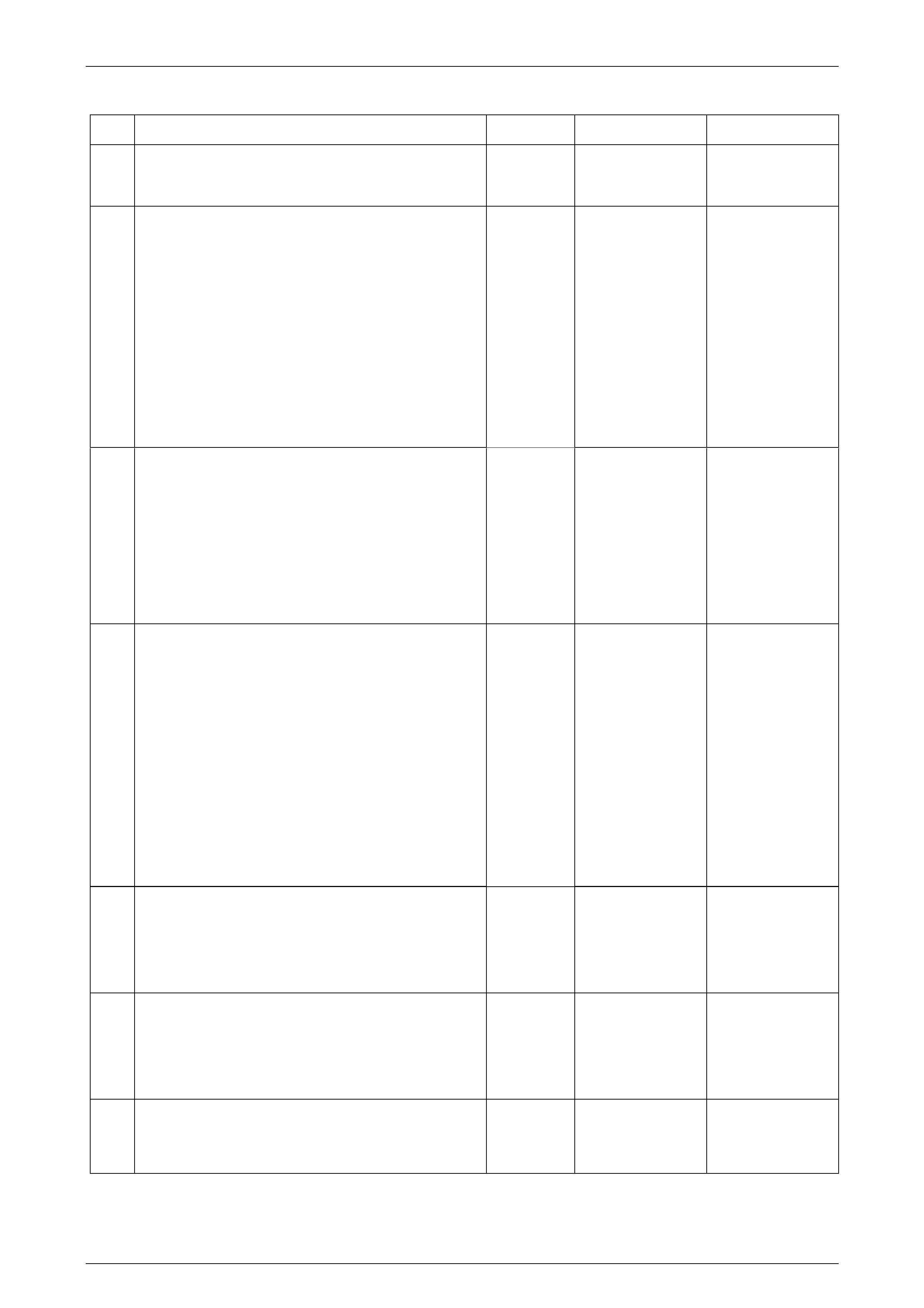

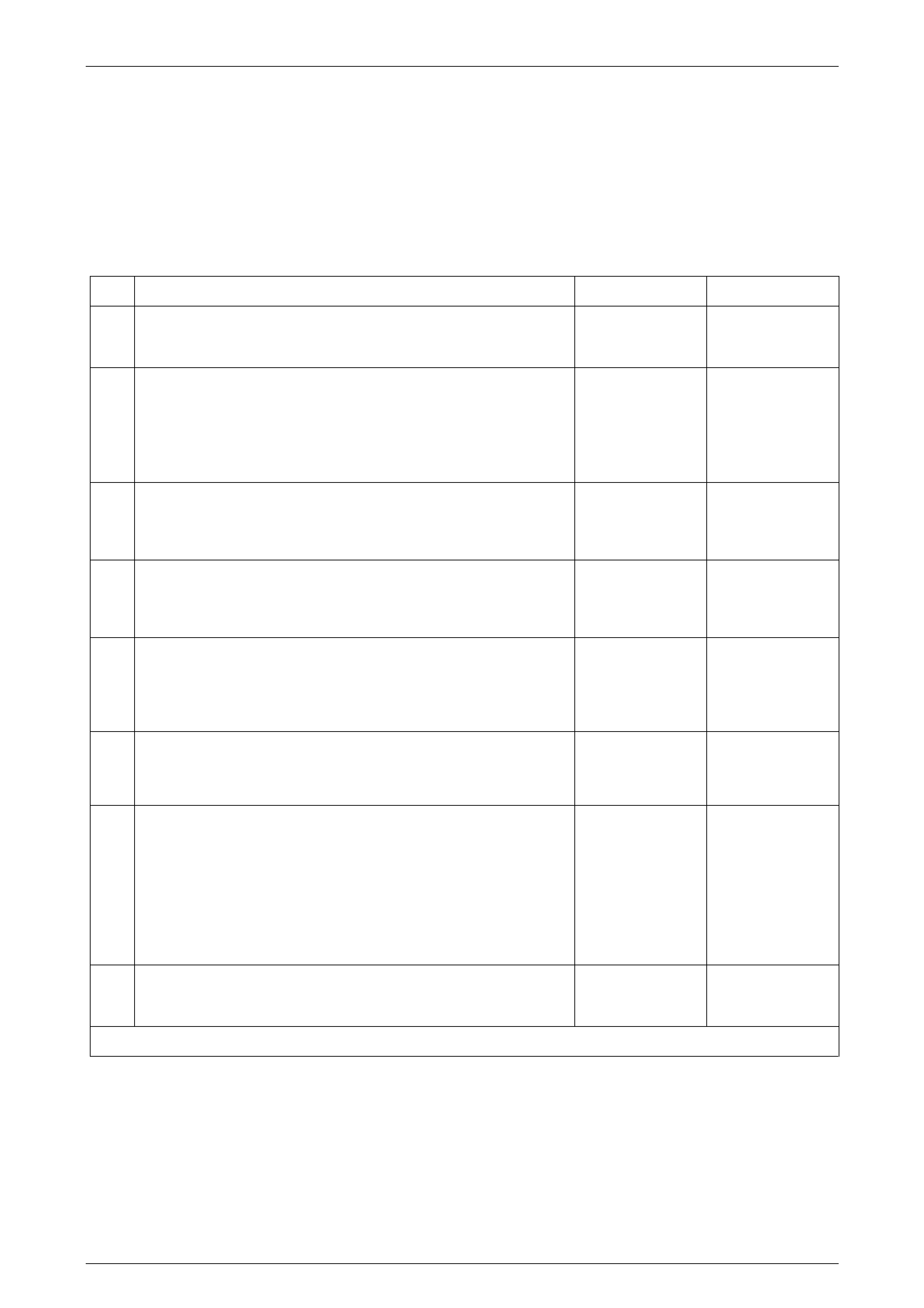

1 General Information.............................................................................................................................13

1.1 Diagnostic System Check................................................................................................................................... 13

1.2 Diagnostic Trouble Code Tables........................................................................................................................ 14

1.3 Multiple DTCs Fault Condition............................................................................................................................ 15

1.4 Symptoms Diagnostics ....................................................................................................................................... 16

1.5 Diagnostic Trouble Codes .................................................................................................................................. 17

Type A – Emission Related DTCs....................................................................................................................... 17

Type B – Emission Related DTCs....................................................................................................................... 17

Conditions for Clearing Type A or Type B DTCs.............................................................................................. 17

Type C – Non-Emission Related DTCs............................................................................................................... 18

Condition for Clearing the Type C DTCs.......................................................................................................... 18

Current DTCs........................................................................................................................................................ 18

History DTCs........................................................................................................................................................ 18

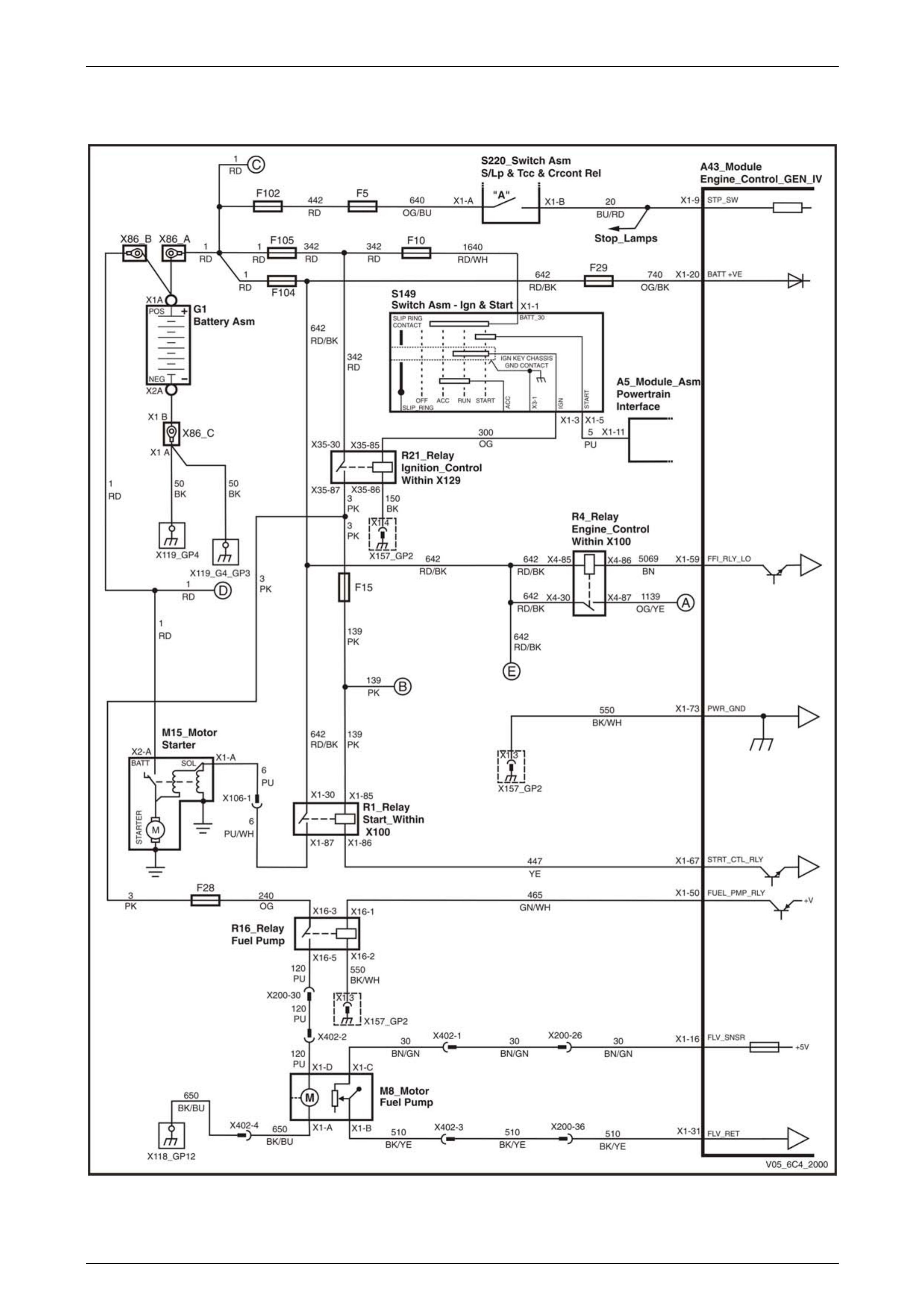

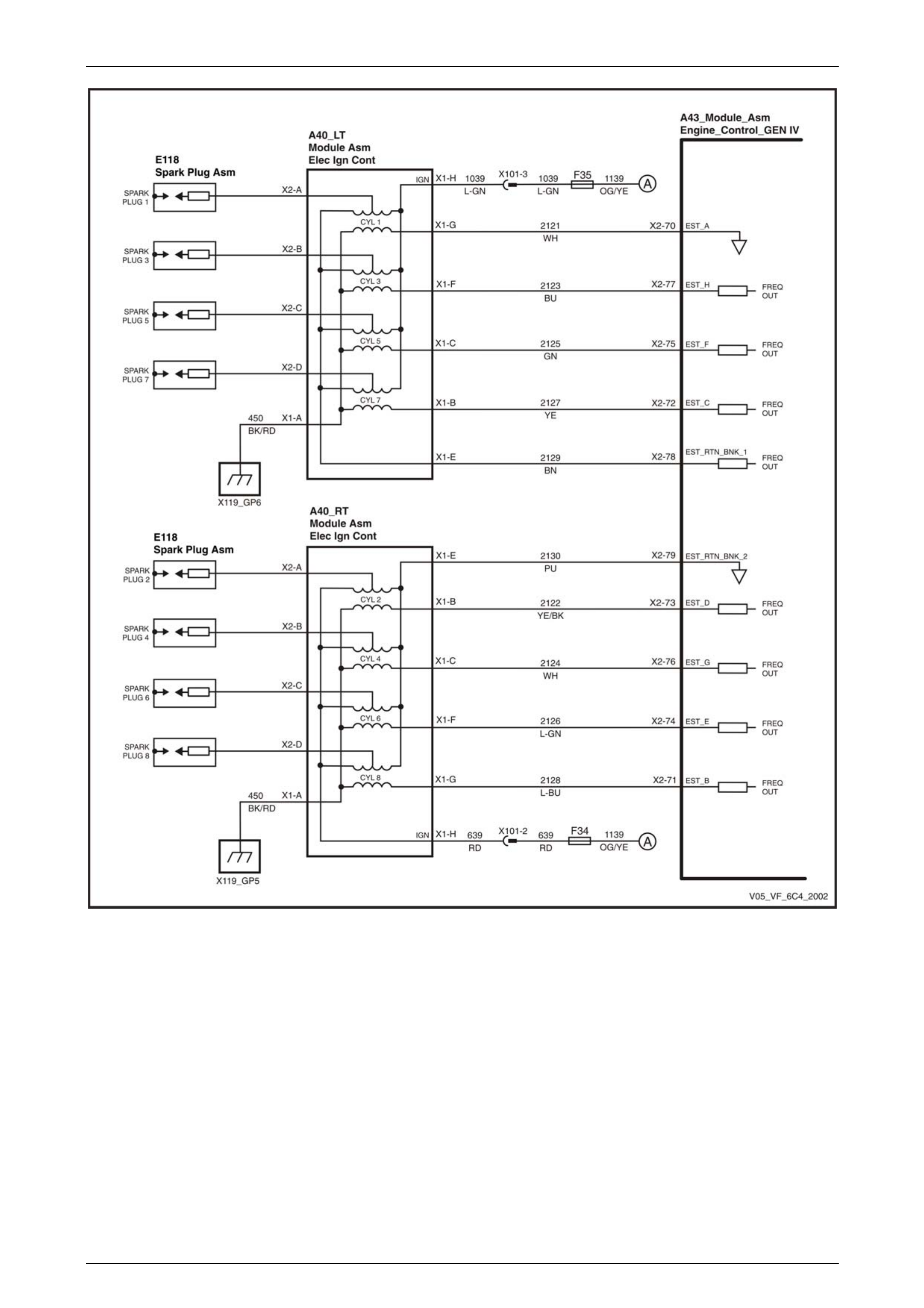

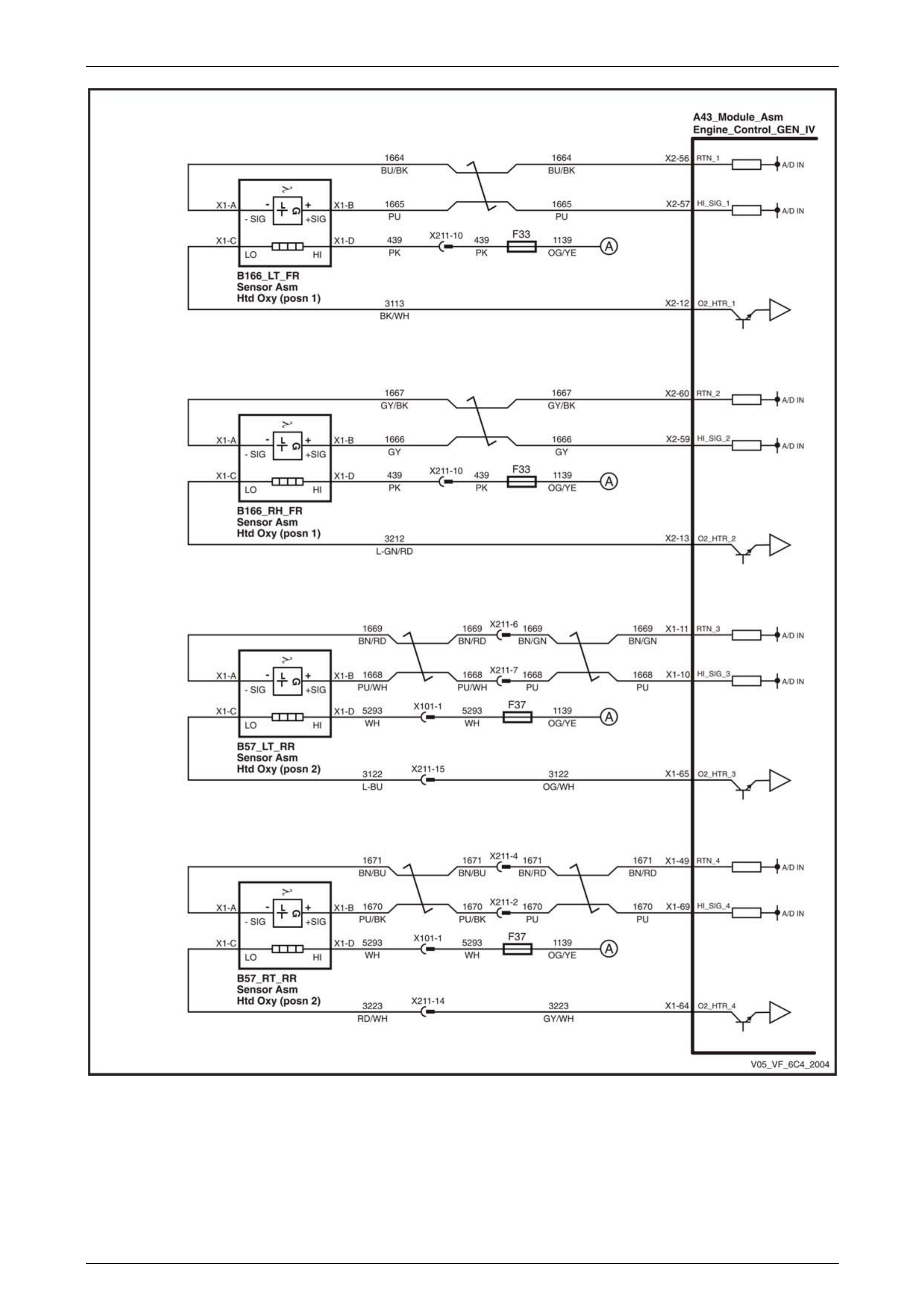

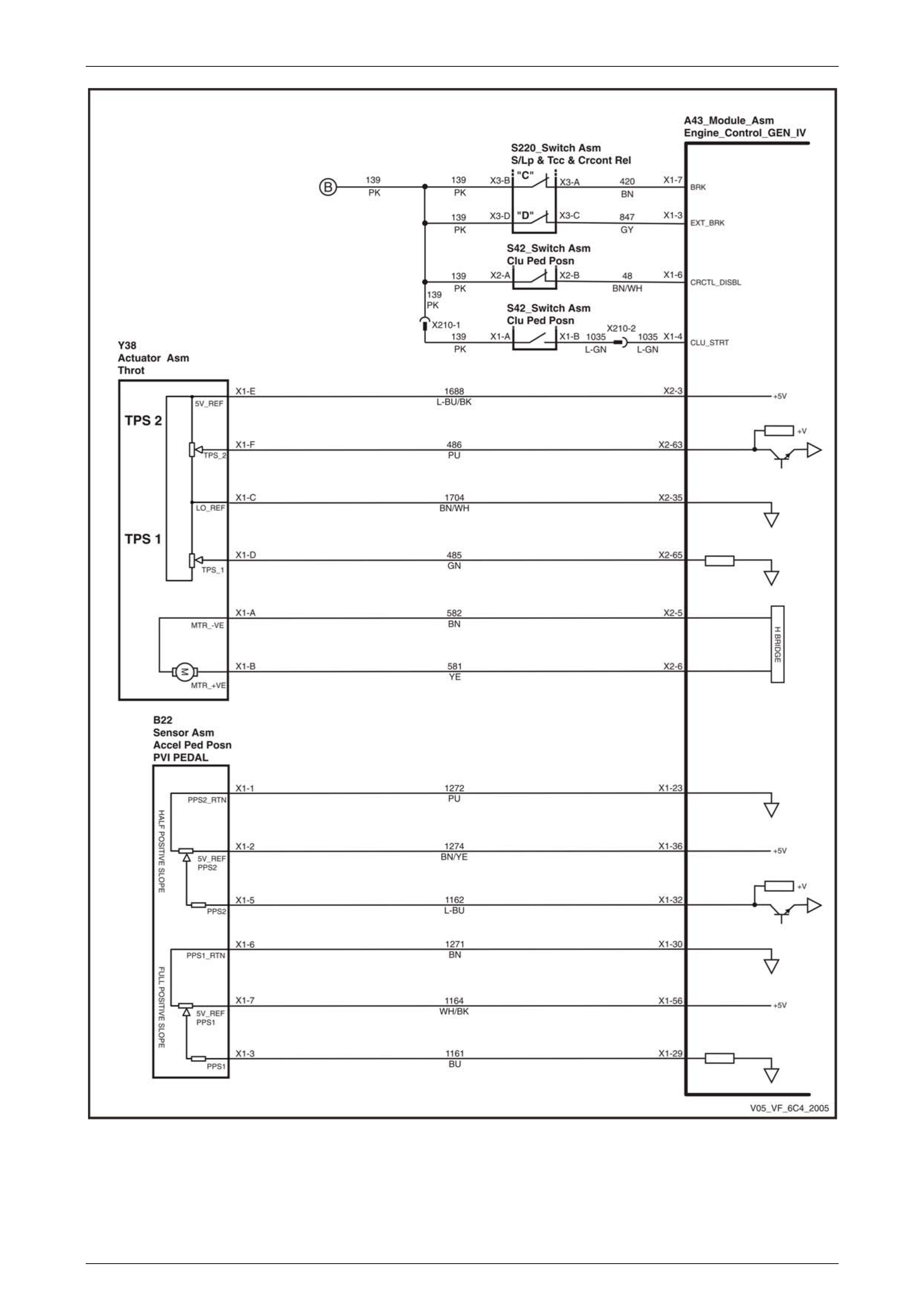

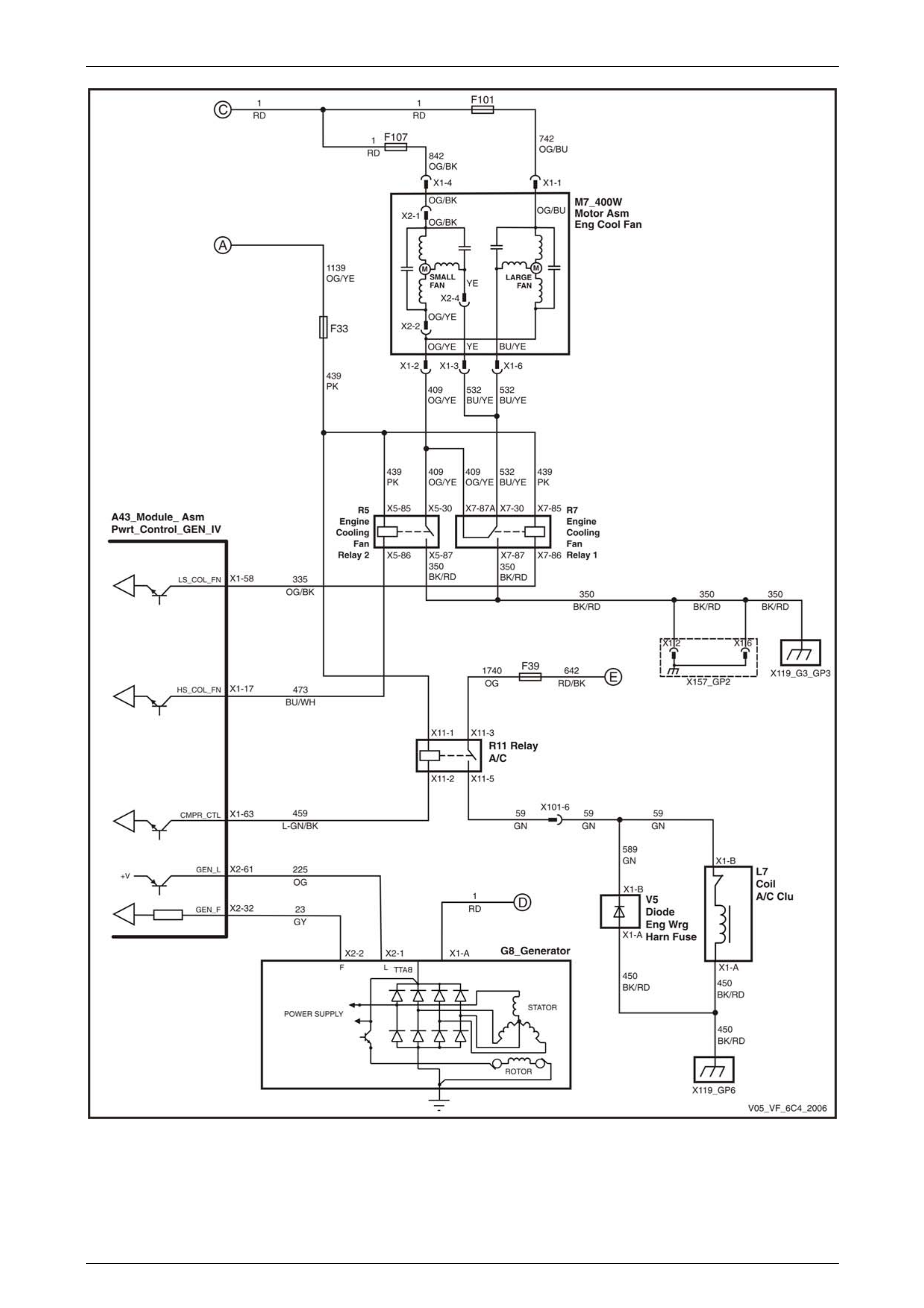

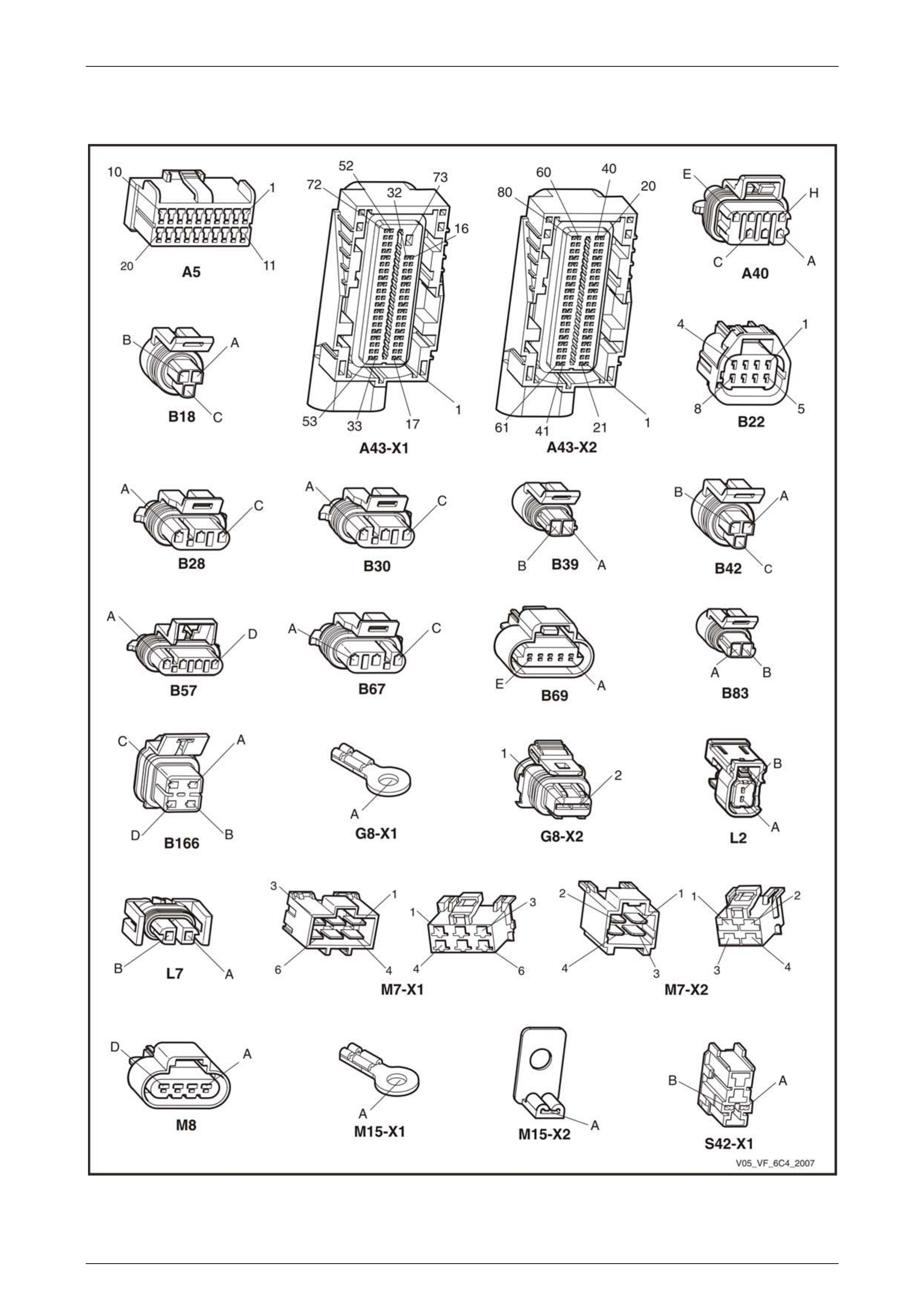

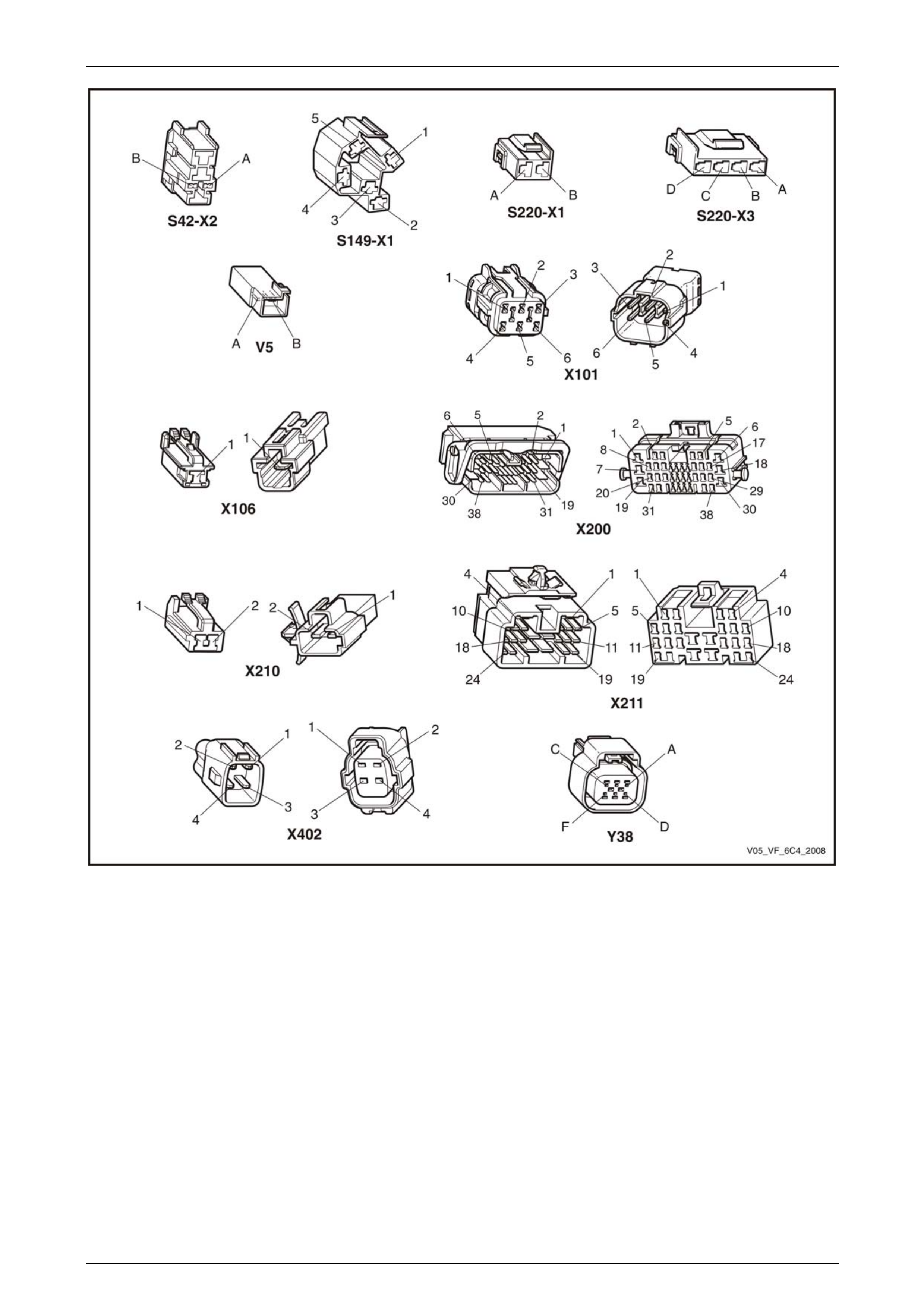

2 Wiring Diagrams and Connector Charts............................................................................................19

2.1 Wiring Diagrams .................................................................................................................................................. 20

2.2 Connector Chart................................................................................................................................................... 27

3 Diagnostic Starting Point ....................................................................................................................29

3.1 Basic Requirements ............................................................................................................................................ 29

Basic Know ledge Required................................................................................................................................. 29

Basic Tools Required .......................................................................................................................................... 29

3.2 Diagnostic Precautions....................................................................................................................................... 30

3.3 Preliminary Checks.............................................................................................................................................. 31

3.4 Diagnostic System Check................................................................................................................................... 32

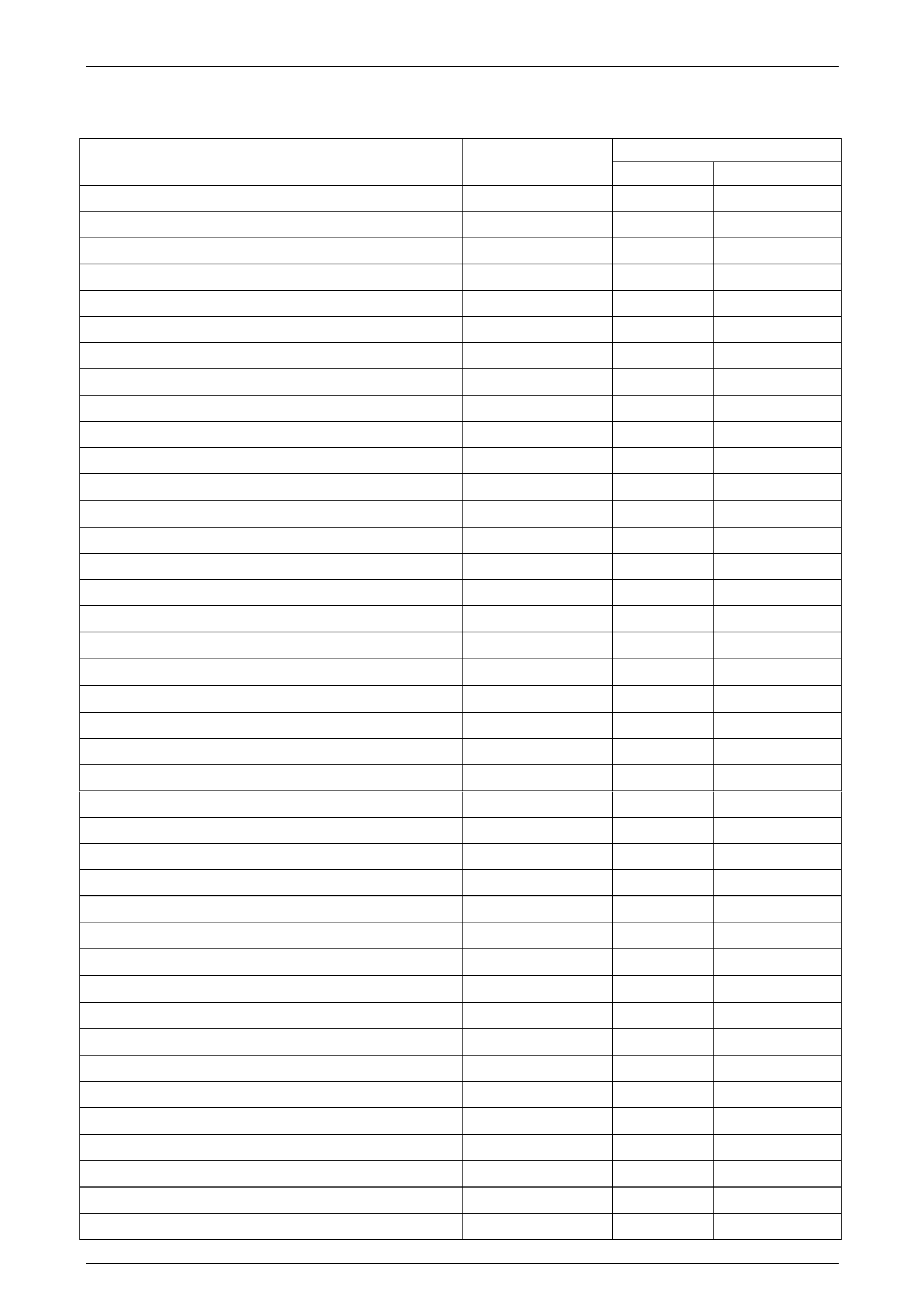

4 Symptom Diagnostics.................................................................................................................................33

4.1 Symptom Diagnosis Table.................................................................................................................................. 33

4.2 Intermittent Fault Conditions.............................................................................................................................. 34

Description........................................................................................................................................................... 34

Diagnostic Table.................................................................................................................................................. 34

4.3 Backfire................................................................................................................................................................. 36

Description........................................................................................................................................................... 36

4.4 Cranks but does not run ..................................................................................................................................... 38

Definition .............................................................................................................................................................. 38

4.5 Cuts Out, Misses.................................................................................................................................................. 39

Description........................................................................................................................................................... 39

4.6 Detonation/Spark Knock ..................................................................................................................................... 41

Description........................................................................................................................................................... 41

4.7 Dieseling, Running on......................................................................................................................................... 42

Description........................................................................................................................................................... 42

4.8 Hard Start.............................................................................................................................................................. 43

Definition .............................................................................................................................................................. 43

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–2

Page 6C4-2–2

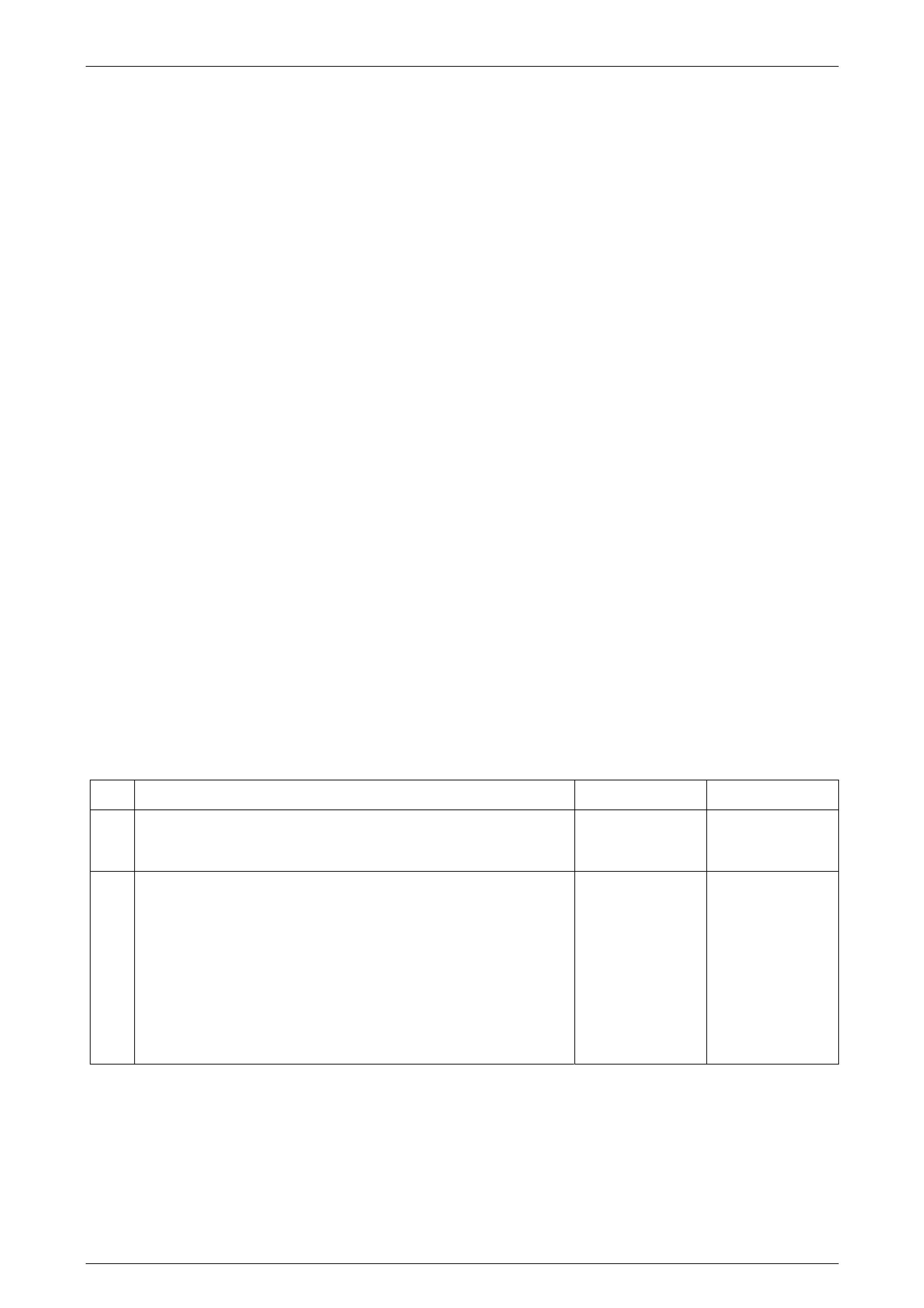

4.9 Hesitation, Sag and Stumble .............................................................................................................................. 44

Description........................................................................................................................................................... 44

4.10 Lack of Pow er, Sluggishness or Sponginess ................................................................................................... 45

Description........................................................................................................................................................... 45

4.11 Poor Fuel Economy............................................................................................................................................. 46

Description........................................................................................................................................................... 46

4.12 Rough, Unstable, Incorrect Idle or Stalling ....................................................................................................... 48

Description........................................................................................................................................................... 48

4.13 Surges / Chuggles ............................................................................................................................................... 50

Description........................................................................................................................................................... 50

4.14 Fuel Pump Not Operating.................................................................................................................................... 52

Circuit Description............................................................................................................................................... 52

Fuel Pump Not Operating Diagnostic Aids........................................................................................................ 52

Additional Information....................................................................................................................................... 52

Test Description ............................................................................................................................................... 52

Fuel Pump Not Operating Diagnostic Table...................................................................................................... 52

4.15 Fuel Pump Continuously Operating................................................................................................................... 55

Circuit Description............................................................................................................................................... 55

Fuel Pump Continuously Operating Diagnostic Aids....................................................................................... 55

Additional Information....................................................................................................................................... 55

Test Description ............................................................................................................................................... 55

Fuel Pump Continuously Operating Fault Condition Diagnostic Table.......................................................... 55

4.16 Automatic Transmission Functional Check procedure.................................................................................... 57

Description........................................................................................................................................................... 57

4.17 Automatic Transmission Power / Economy Switch.......................................................................................... 60

Circuit Description............................................................................................................................................... 60

Automatic Transmission Power / Economy Switch Diagnostic Aids.............................................................. 60

Additional Information....................................................................................................................................... 60

Automatic Transmission Power / Economy Switch Diagnostic Table............................................................ 60

5 Functional Checks ...............................................................................................................................62

5.1 General Information............................................................................................................................................. 62

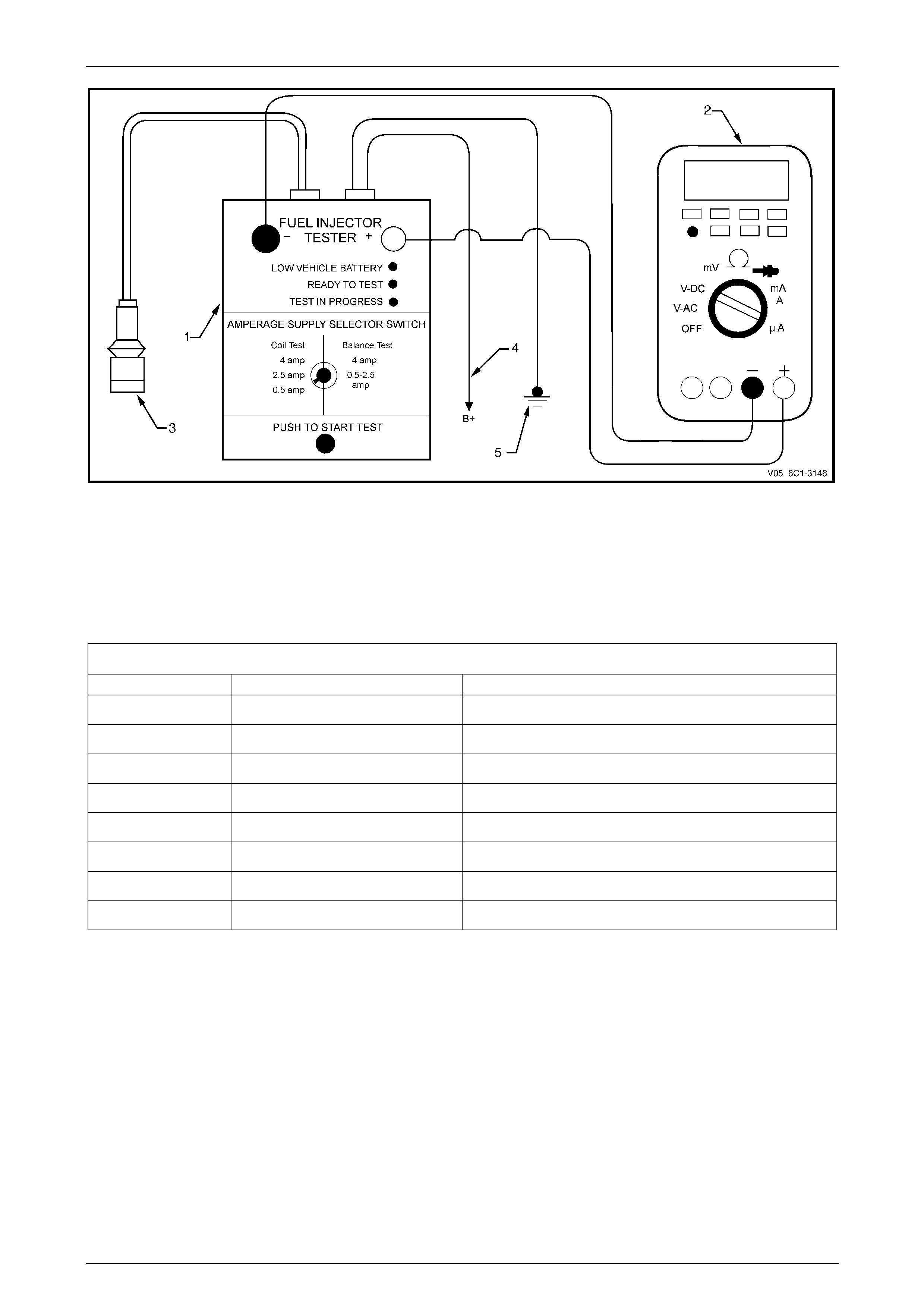

5.2 Fuel Injector Coil Test ......................................................................................................................................... 63

Engine Coolant Temperature Between 10 – 35°C............................................................................................ 63

Engine Coolant Temperature Outside 10 – 35°C ............................................................................................. 64

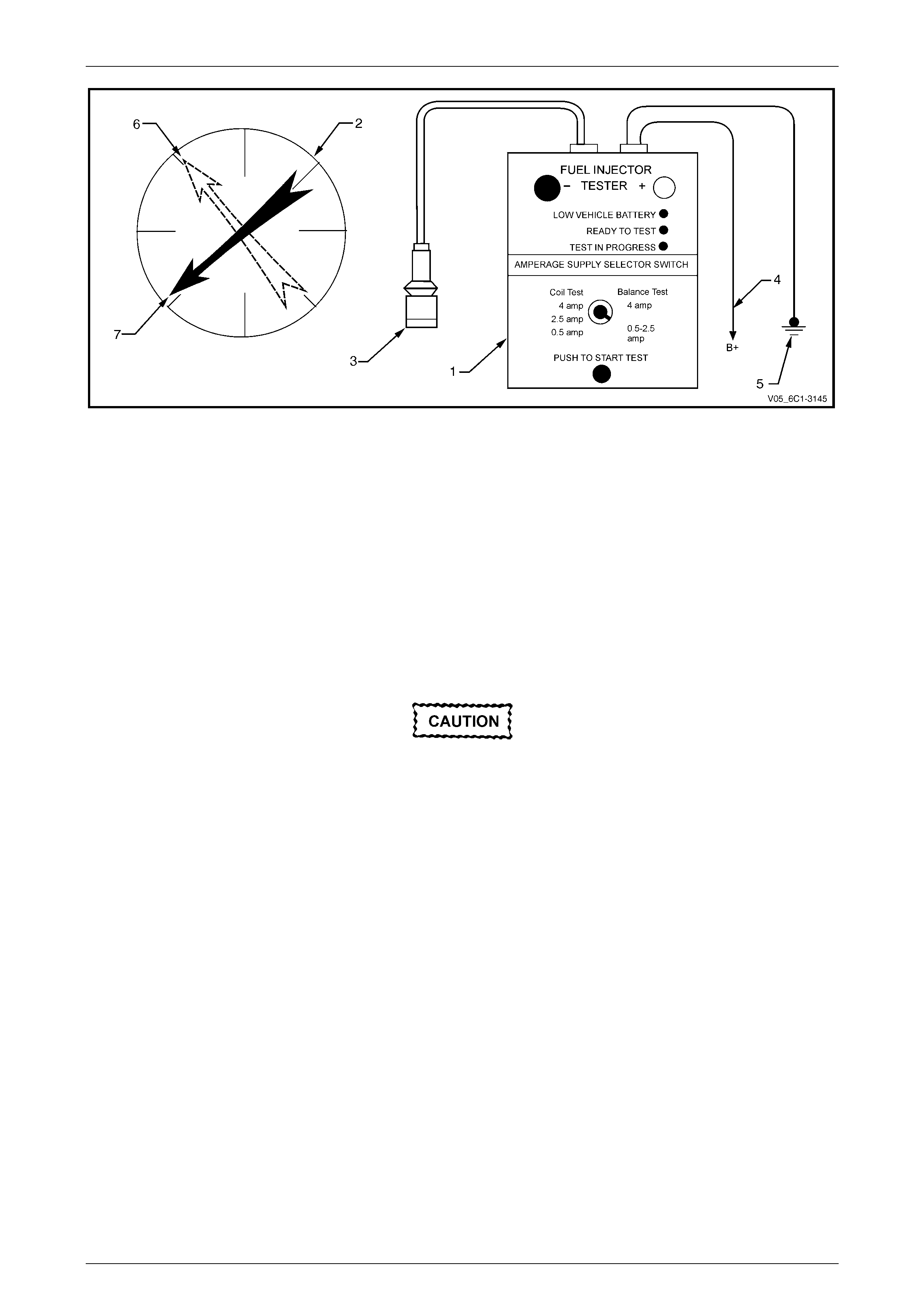

5.3 Fuel Injector Balance Test .................................................................................................................................. 67

Fuel Injector Balance Test – With Tech 2 .......................................................................................................... 67

Fuel Injector Balance Test – Without Tech 2..................................................................................................... 67

Fuel Injector Pressure Drop Calculation........................................................................................................... 69

Fuel Injector Pressure Drop Analysis ............................................................................................................... 69

5.4 Fuel Injector Leak Down Test ............................................................................................................................. 70

5.5 Alcohol/Contaminants in Fuel Diagnosis .......................................................................................................... 72

Without Special Tool ........................................................................................................................................... 72

Description ....................................................................................................................................................... 72

Alcohol in Fuel Testing Procedure.................................................................................................................... 72

Particulate Contaminants in Fuel Testing Procedure ....................................................................................... 72

With Special Tool................................................................................................................................................. 72

Description ....................................................................................................................................................... 72

Test Procedure................................................................................................................................................. 73

5.6 Crankshaft Position (CKP) System Variation Learn Procedure....................................................................... 74

Description........................................................................................................................................................... 74

5.7 Electronic Ignition (EI) System Diagnosis......................................................................................................... 75

Circuit Description............................................................................................................................................... 75

Additional Information......................................................................................................................................... 75

Test Description................................................................................................................................................... 75

Diagnostic Table.................................................................................................................................................. 75

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–3

Page 6C4-2–3

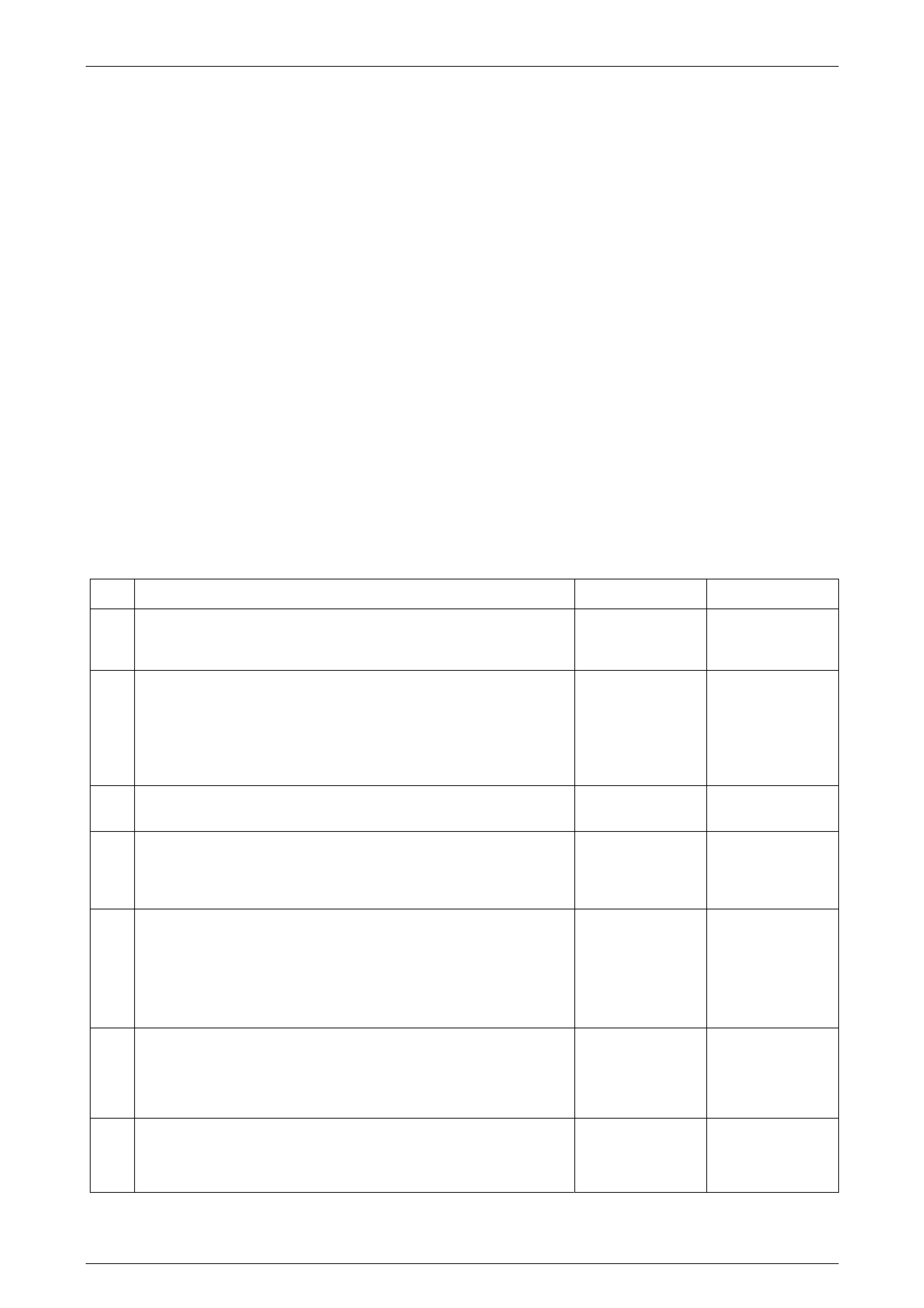

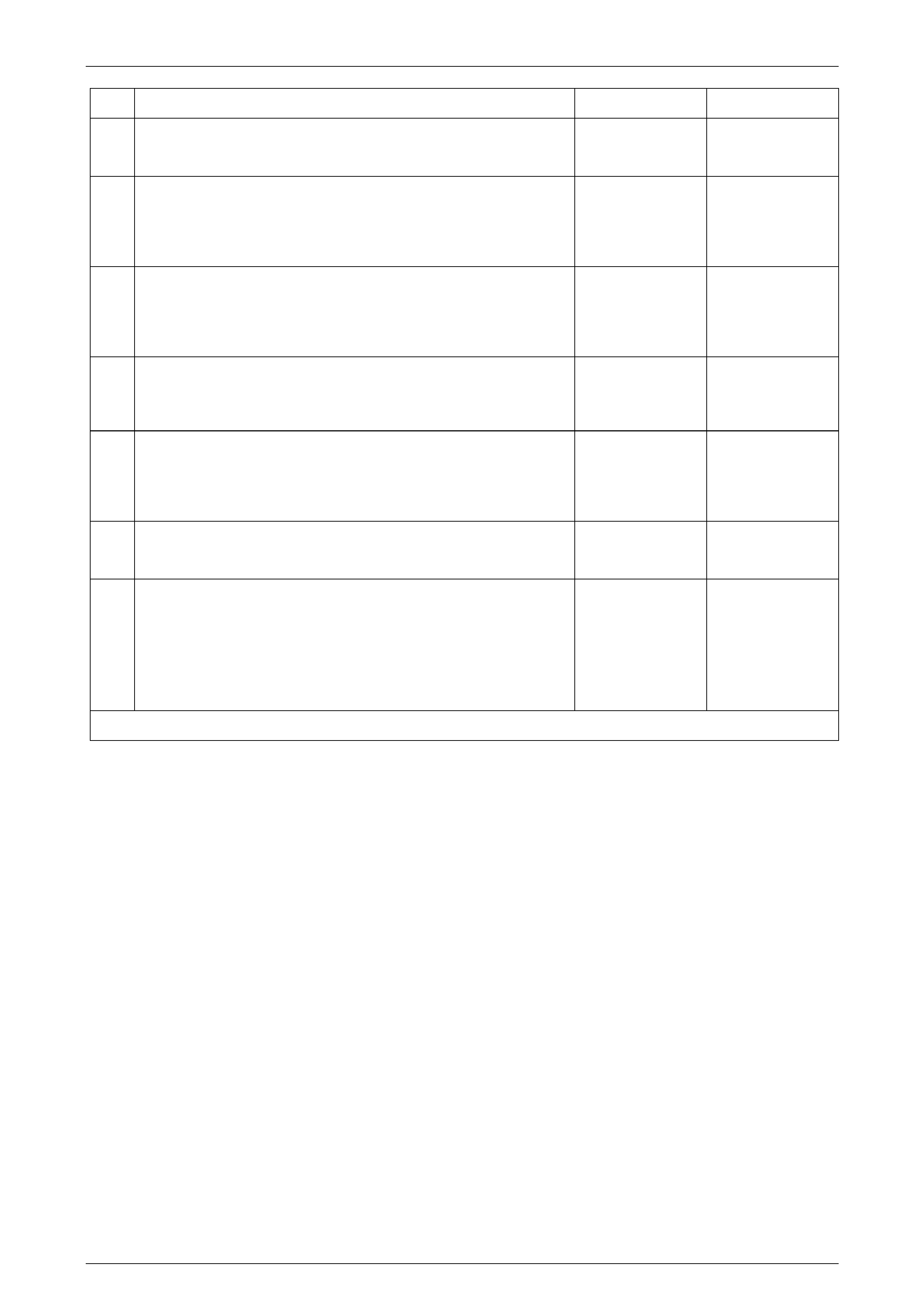

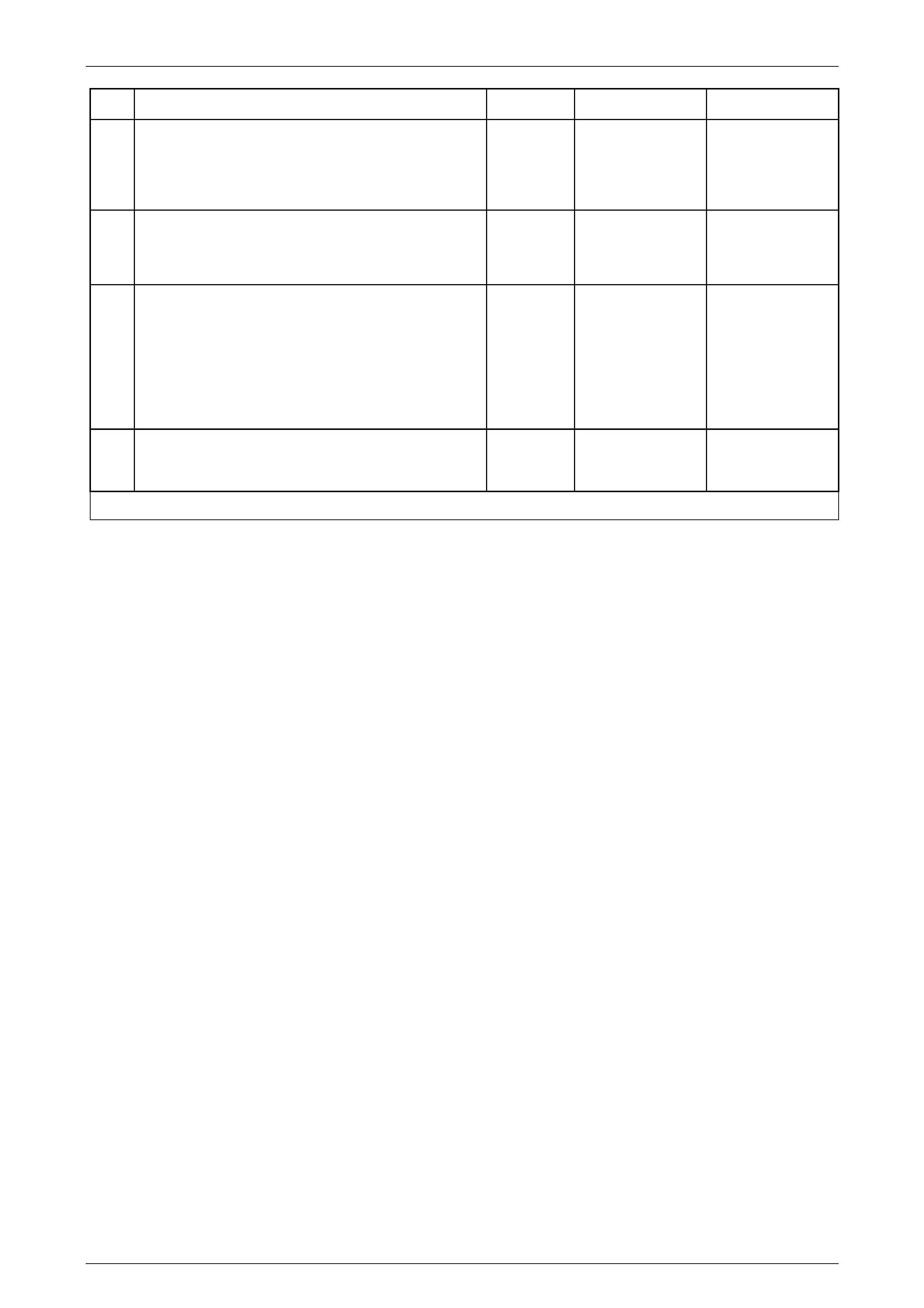

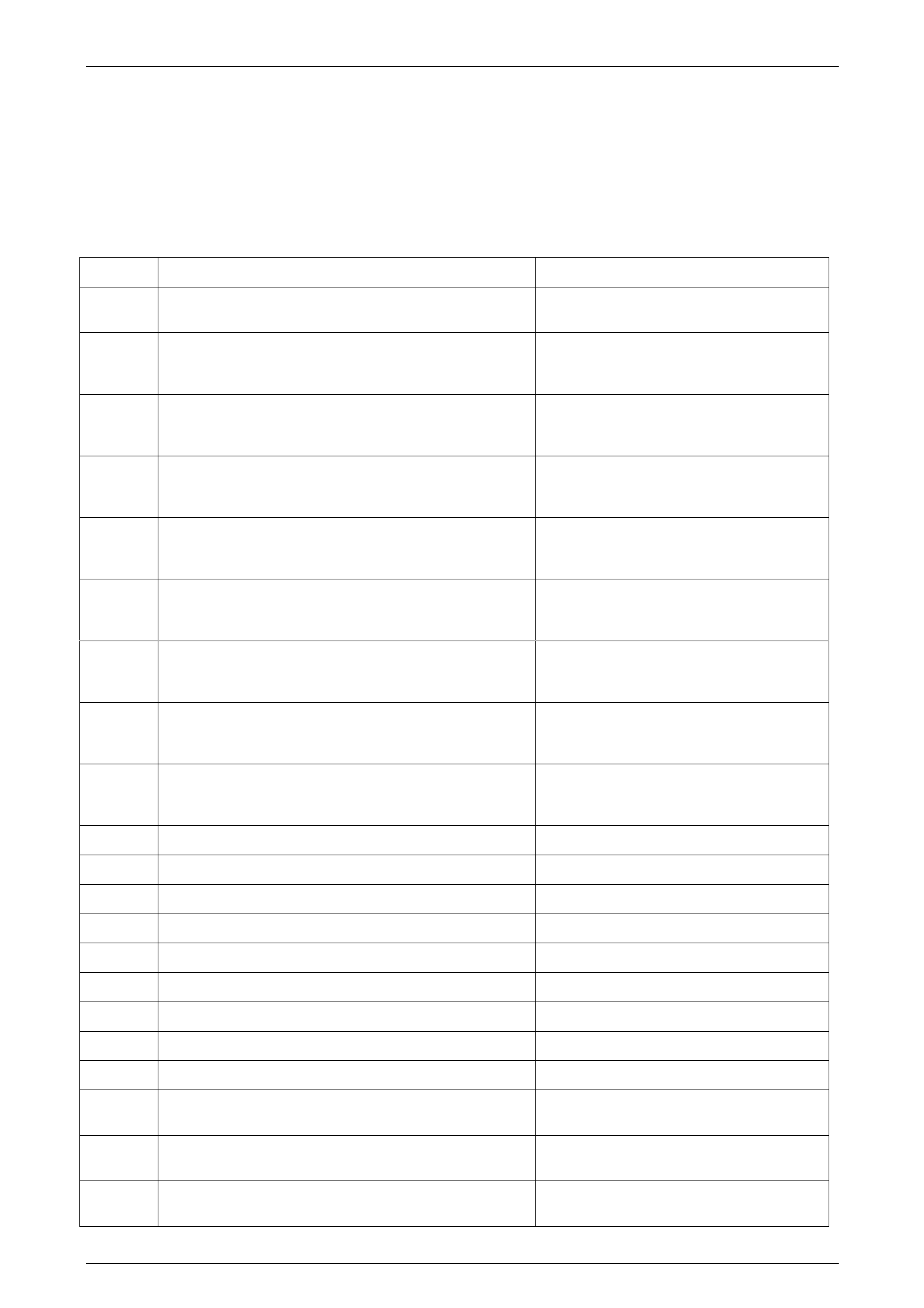

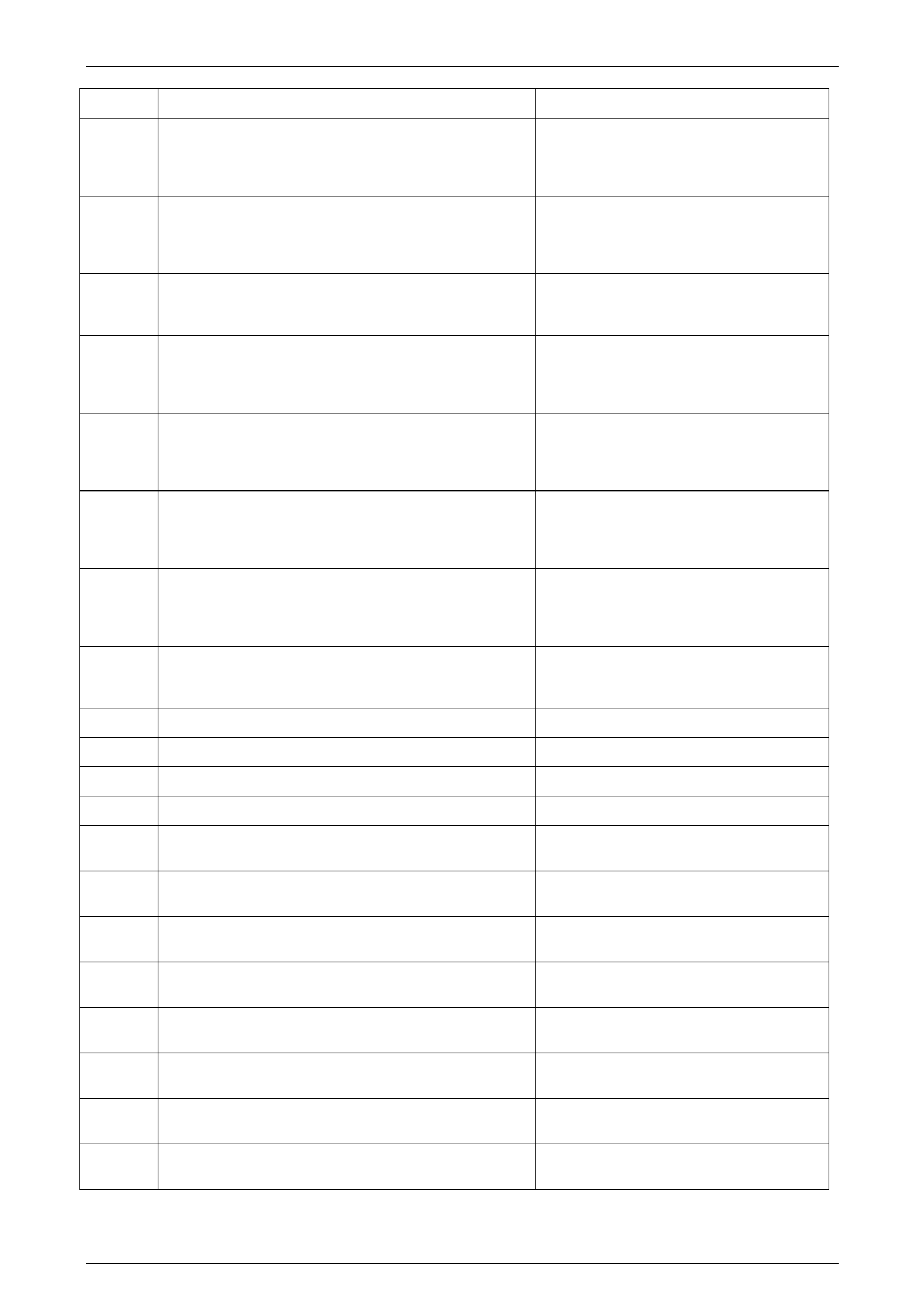

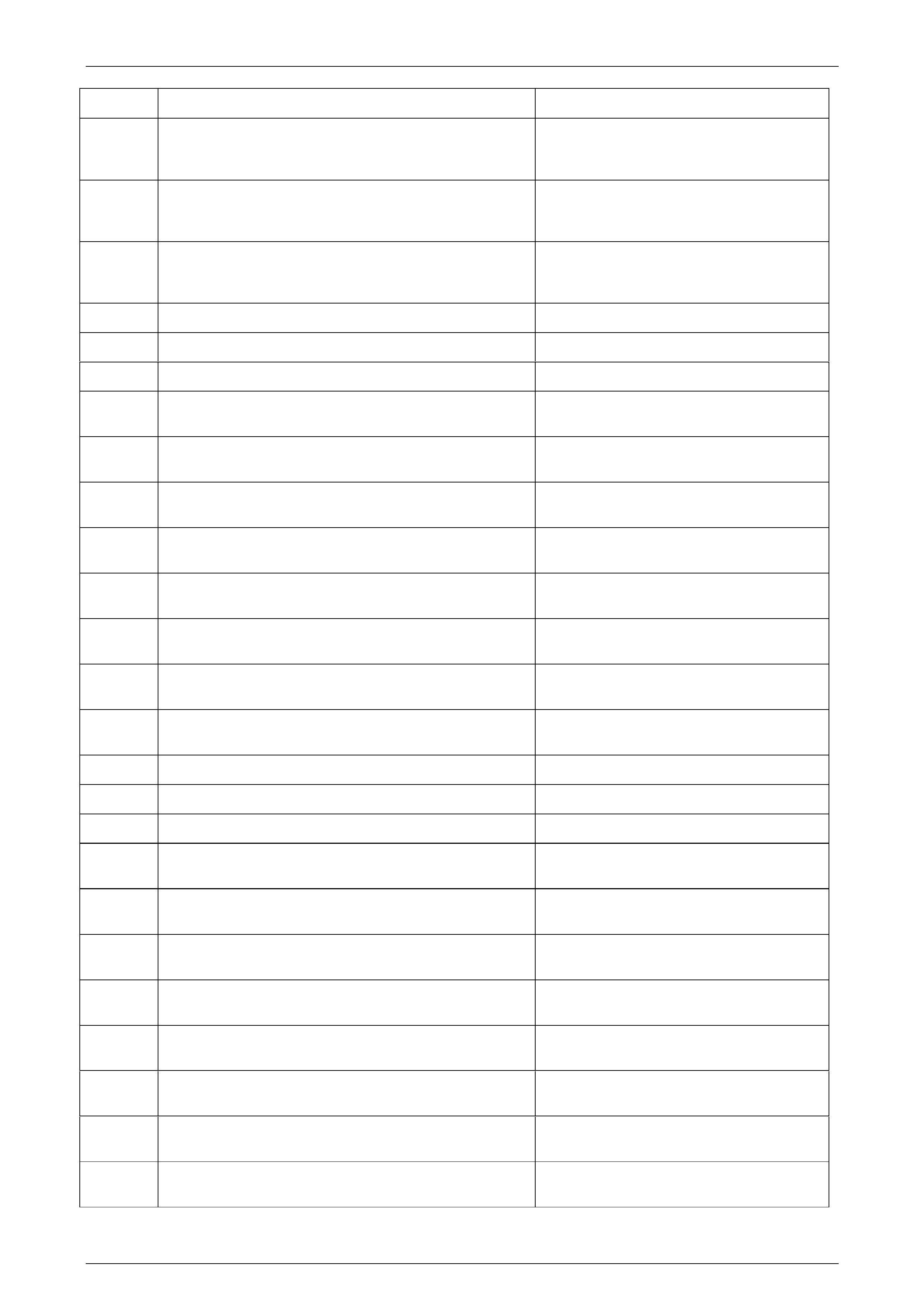

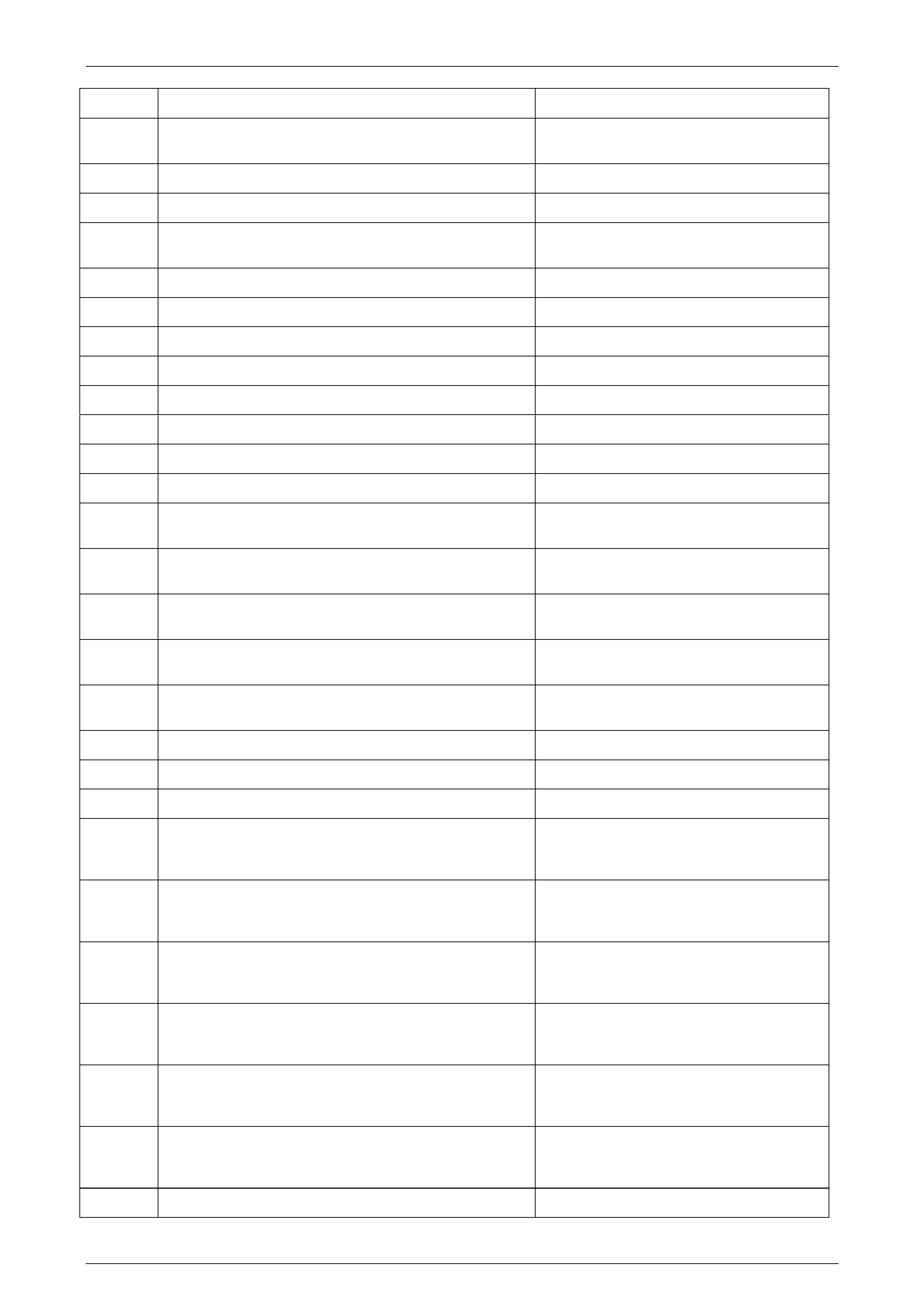

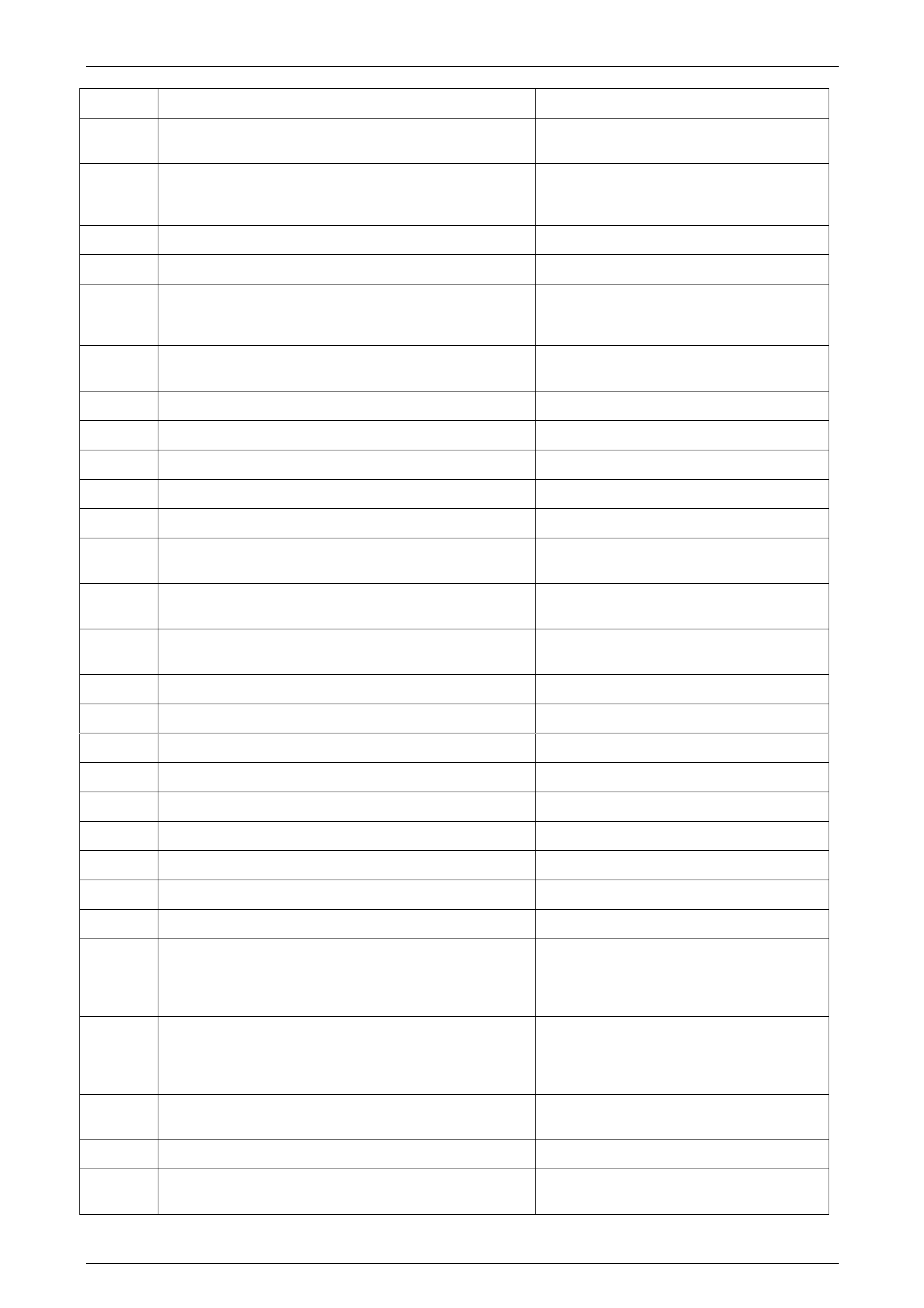

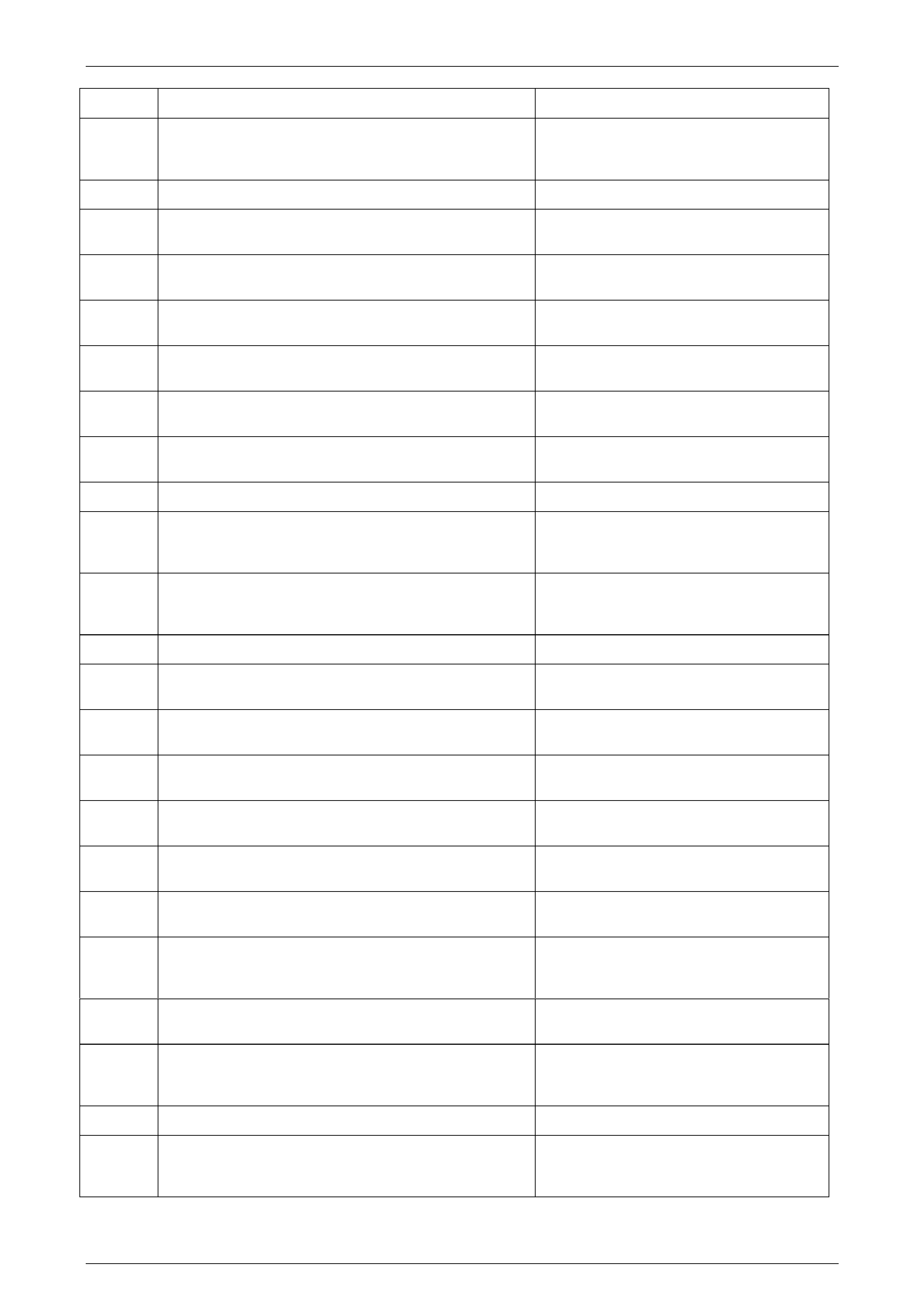

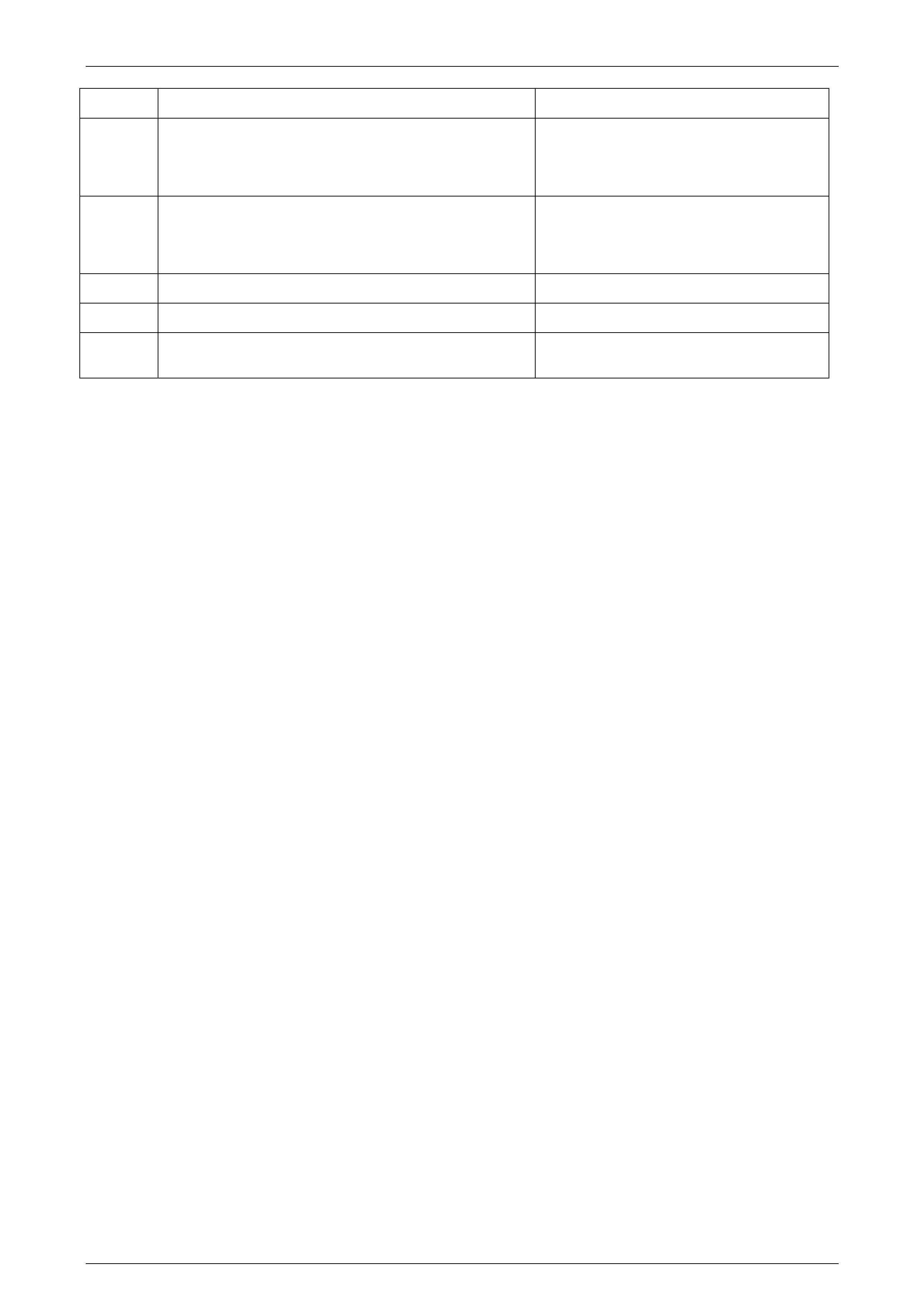

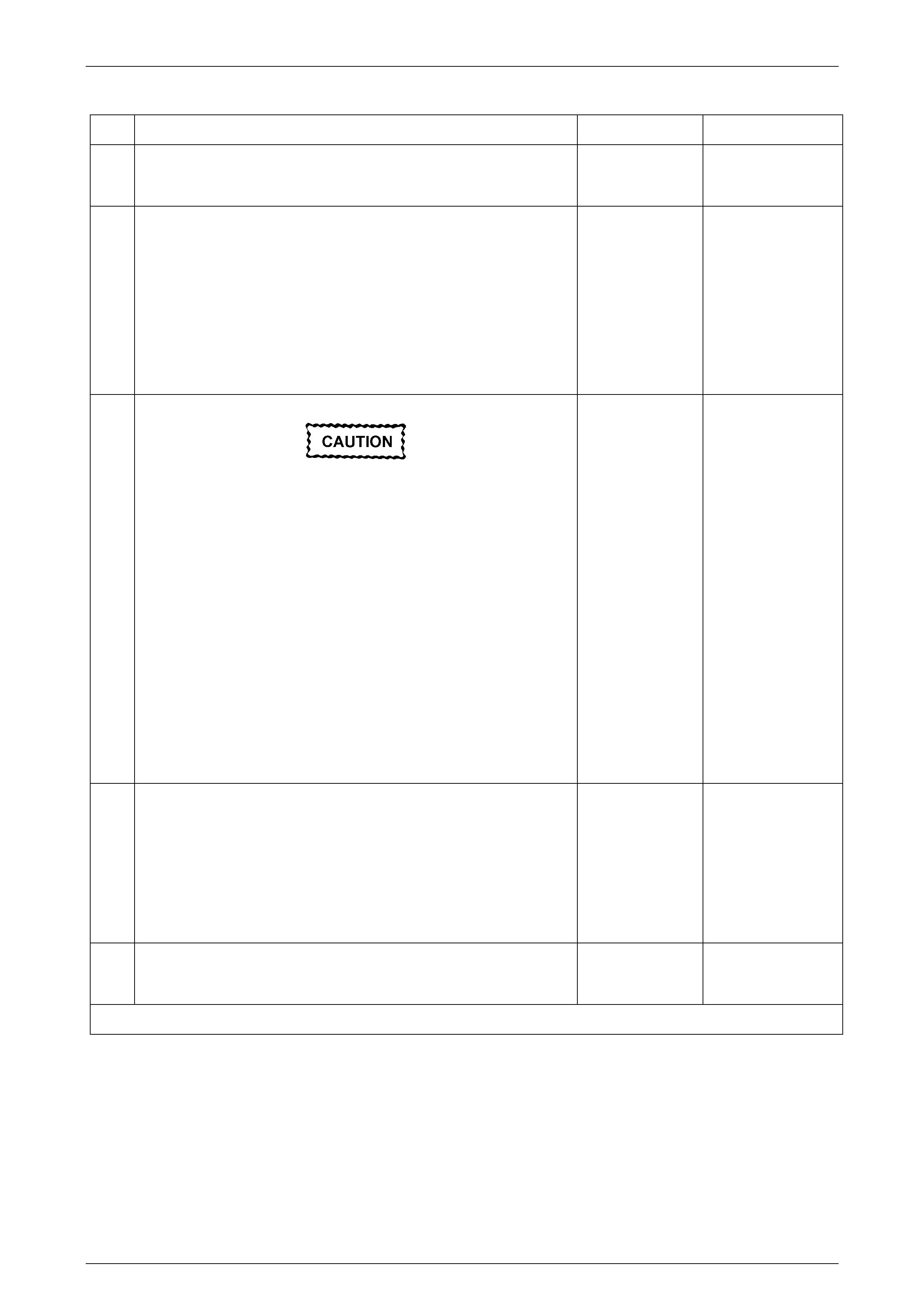

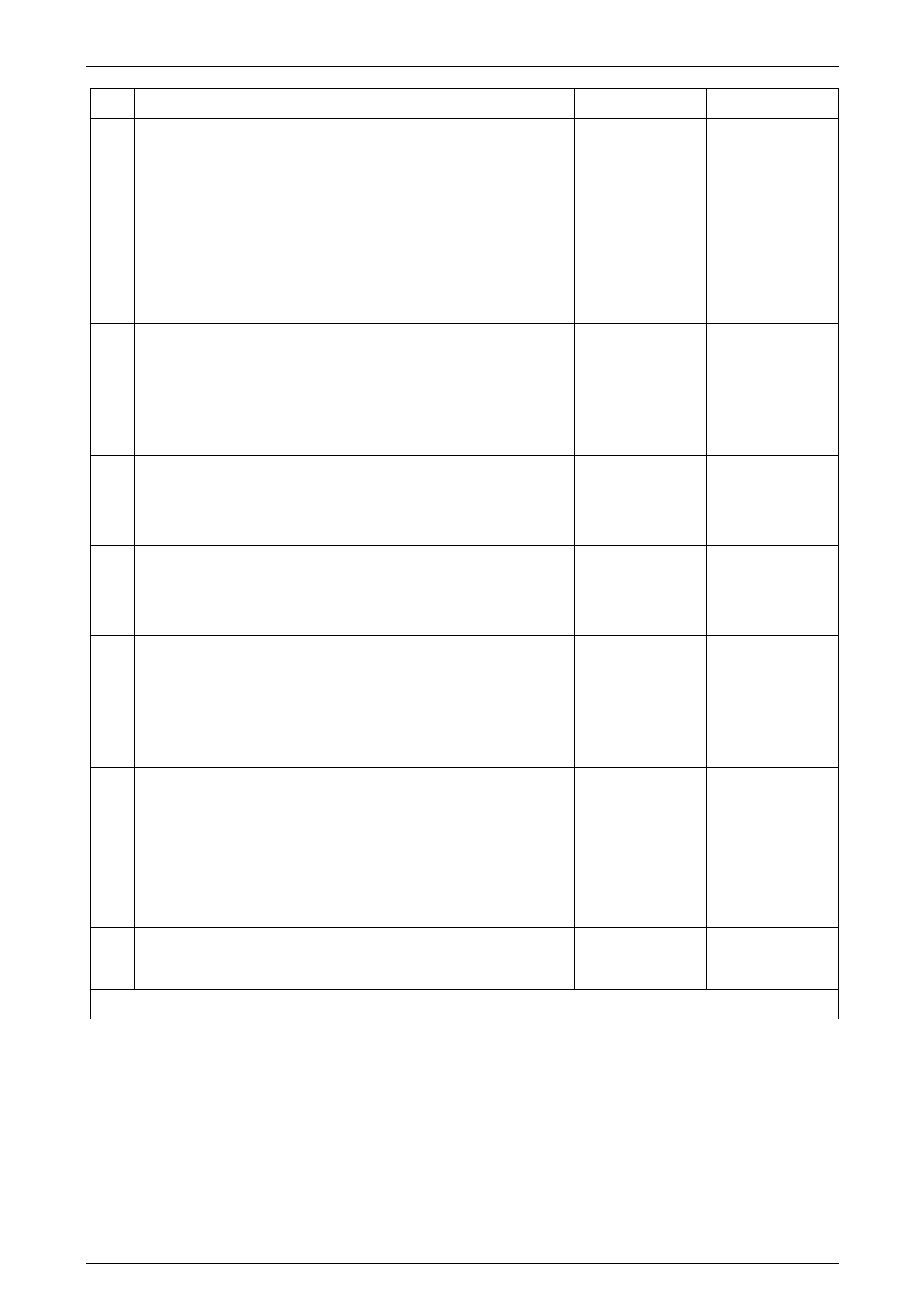

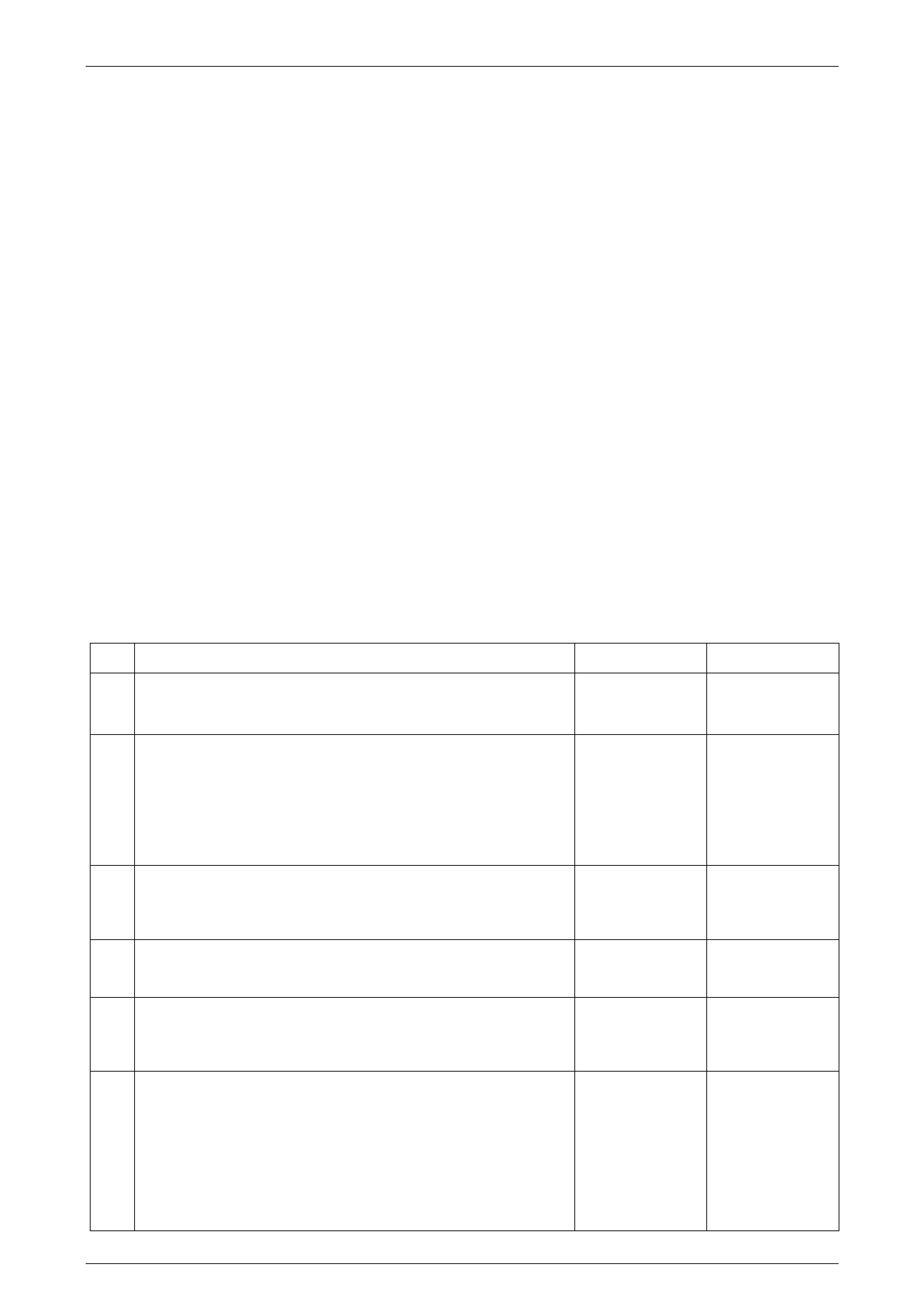

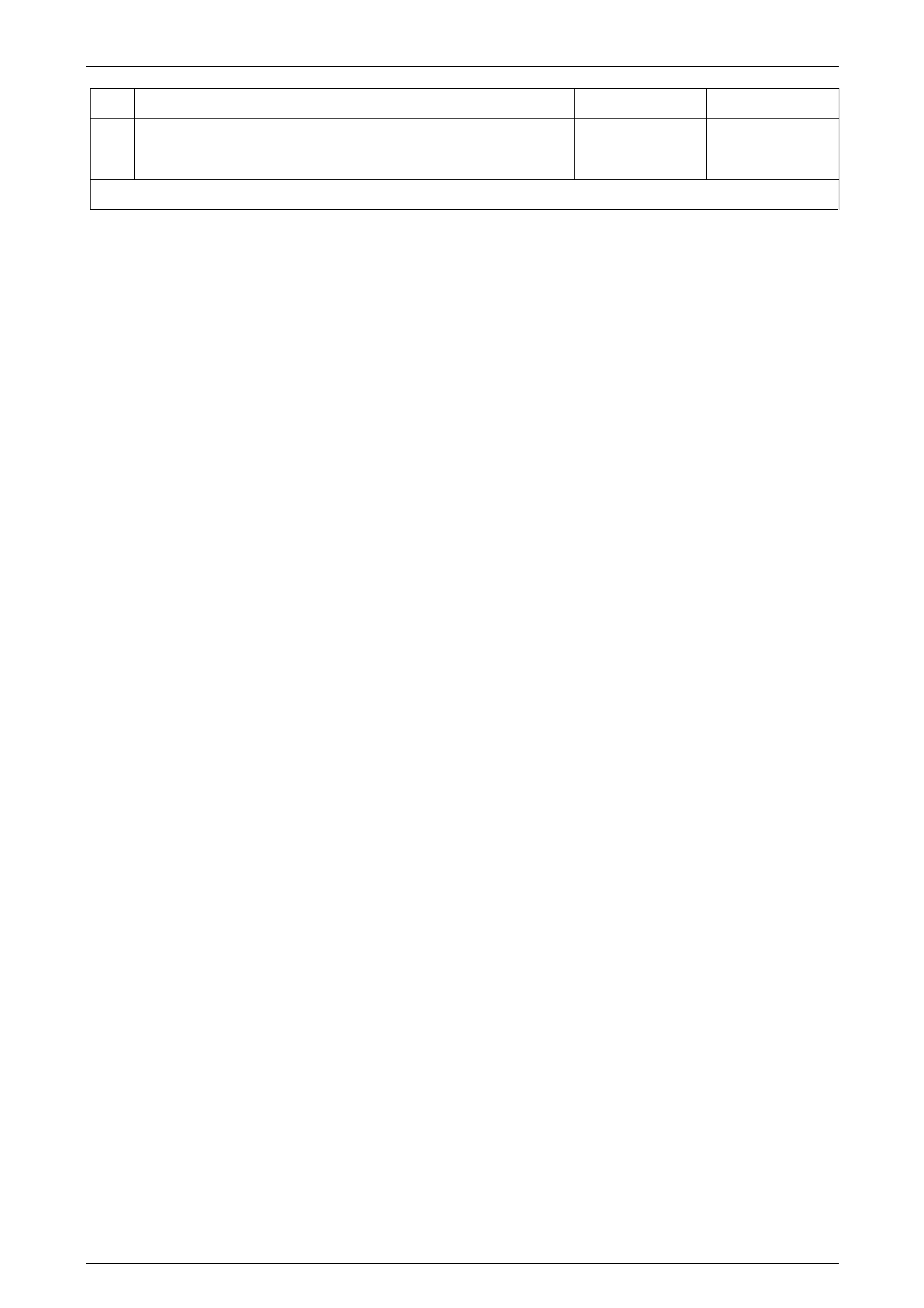

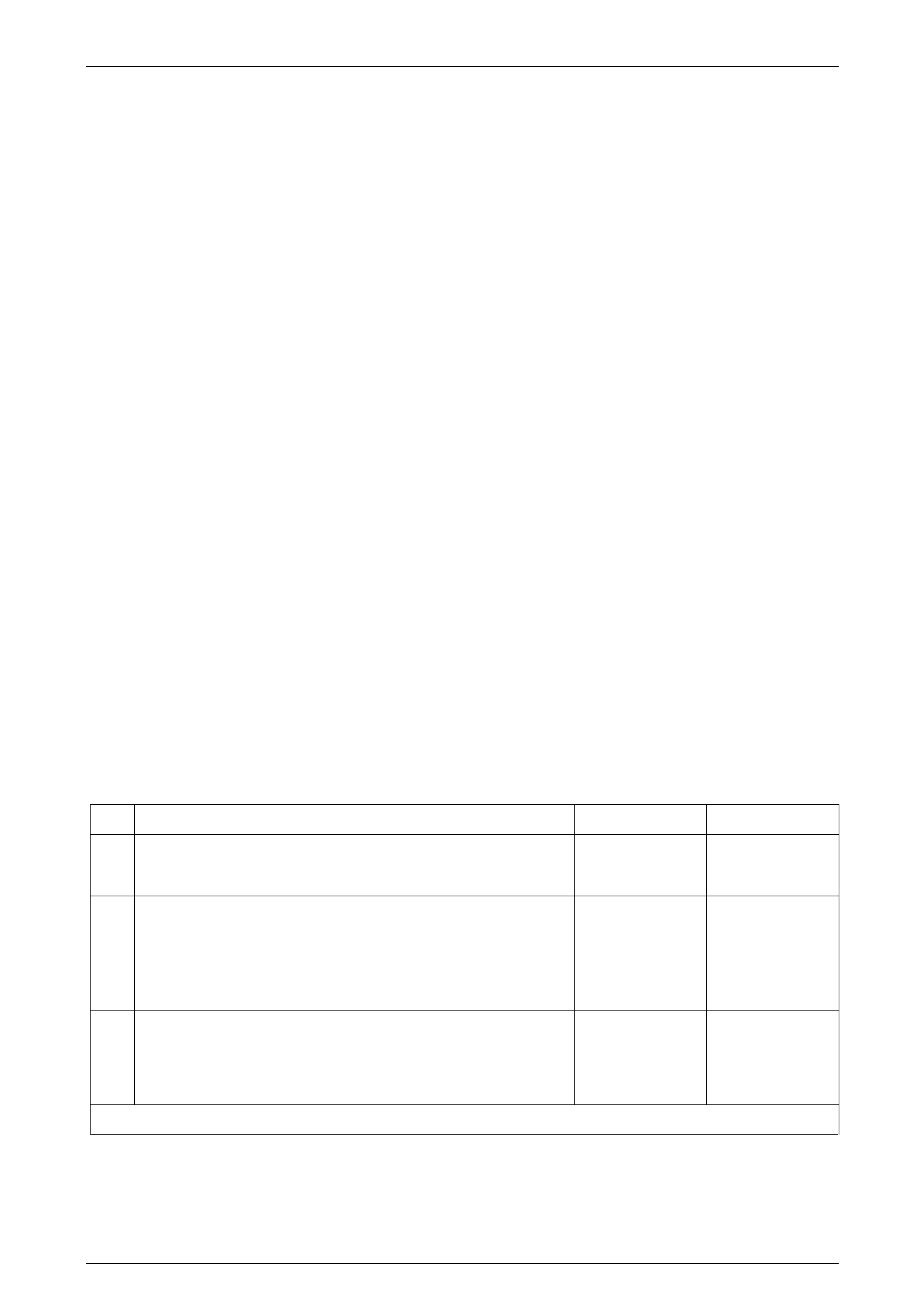

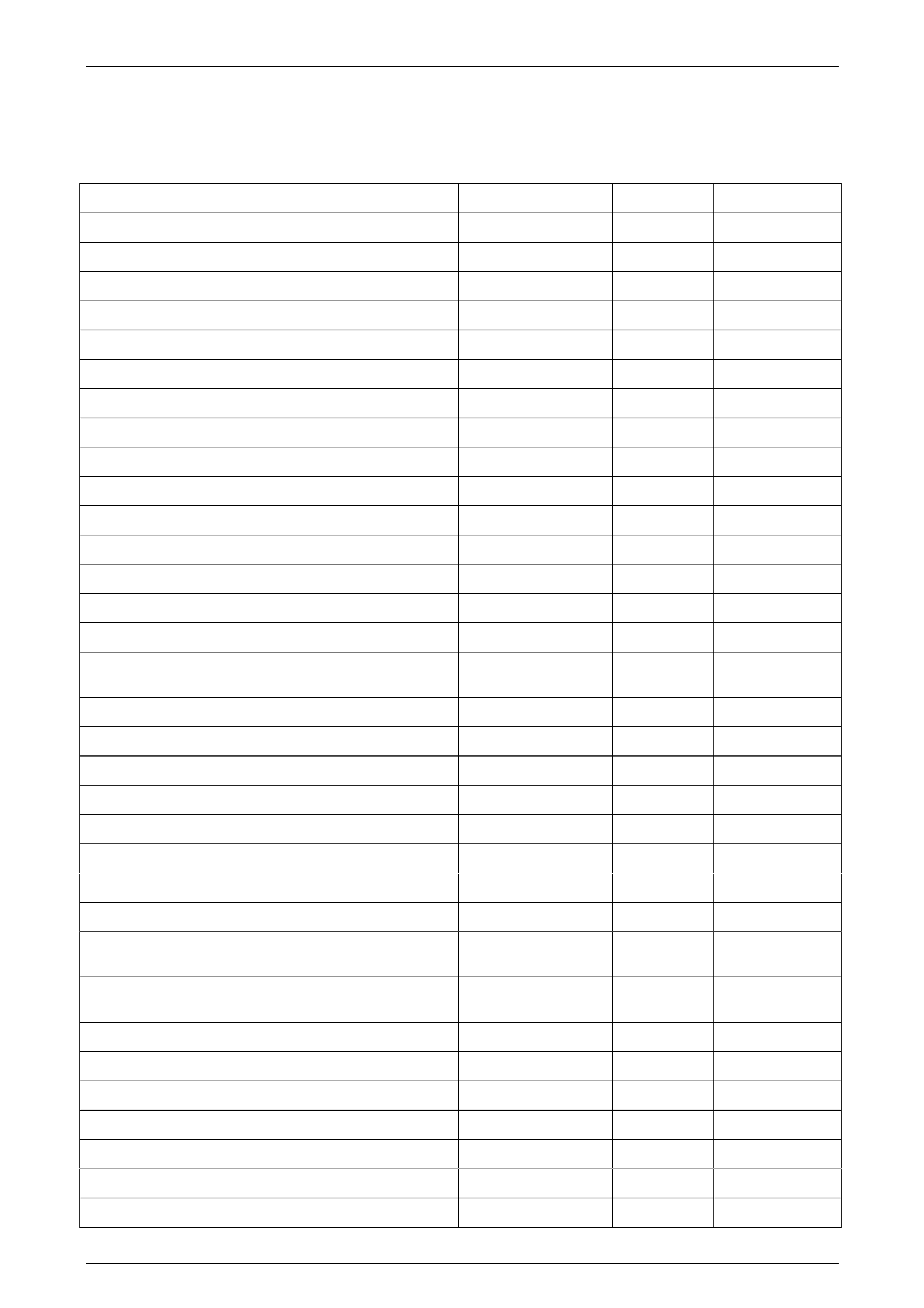

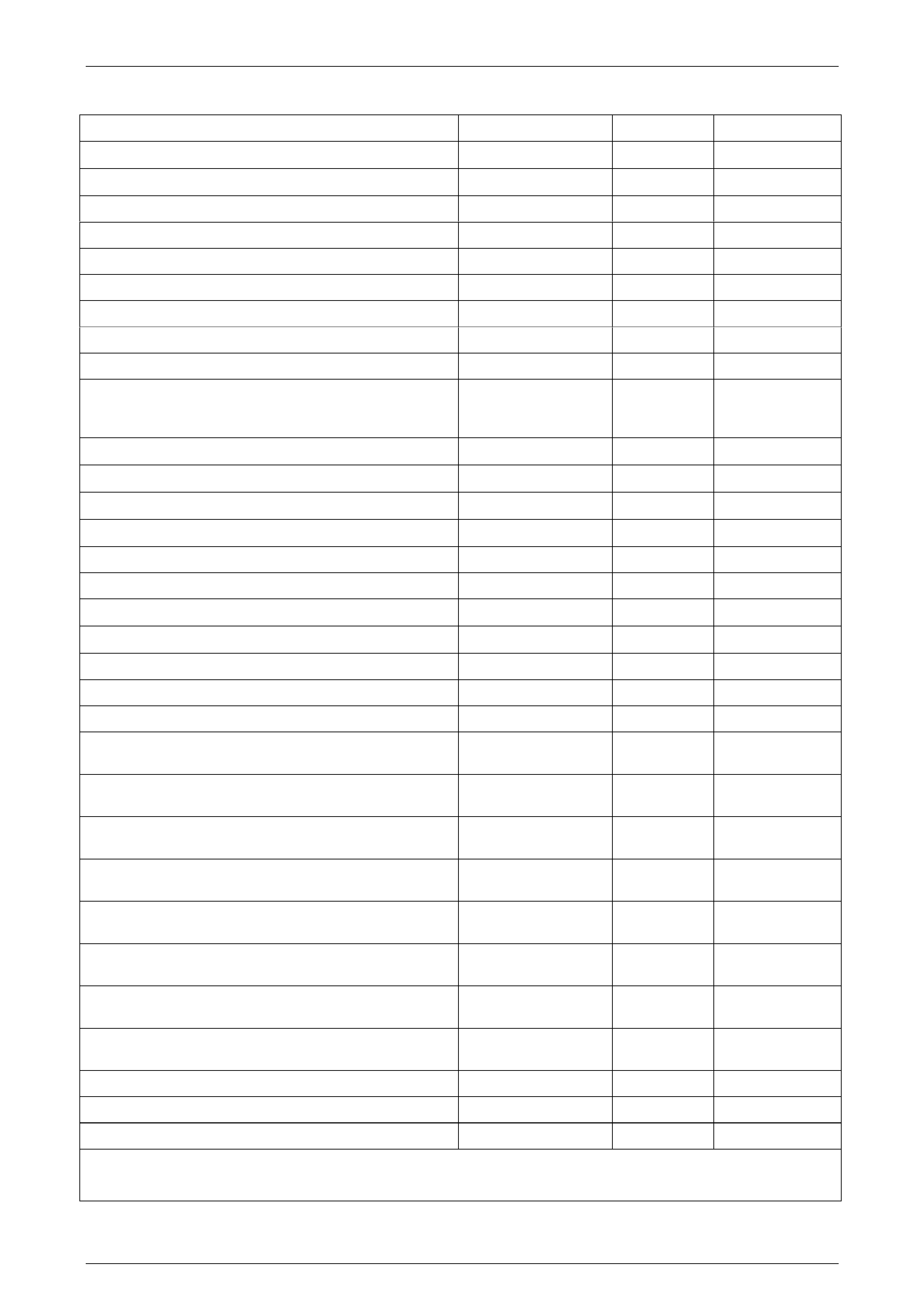

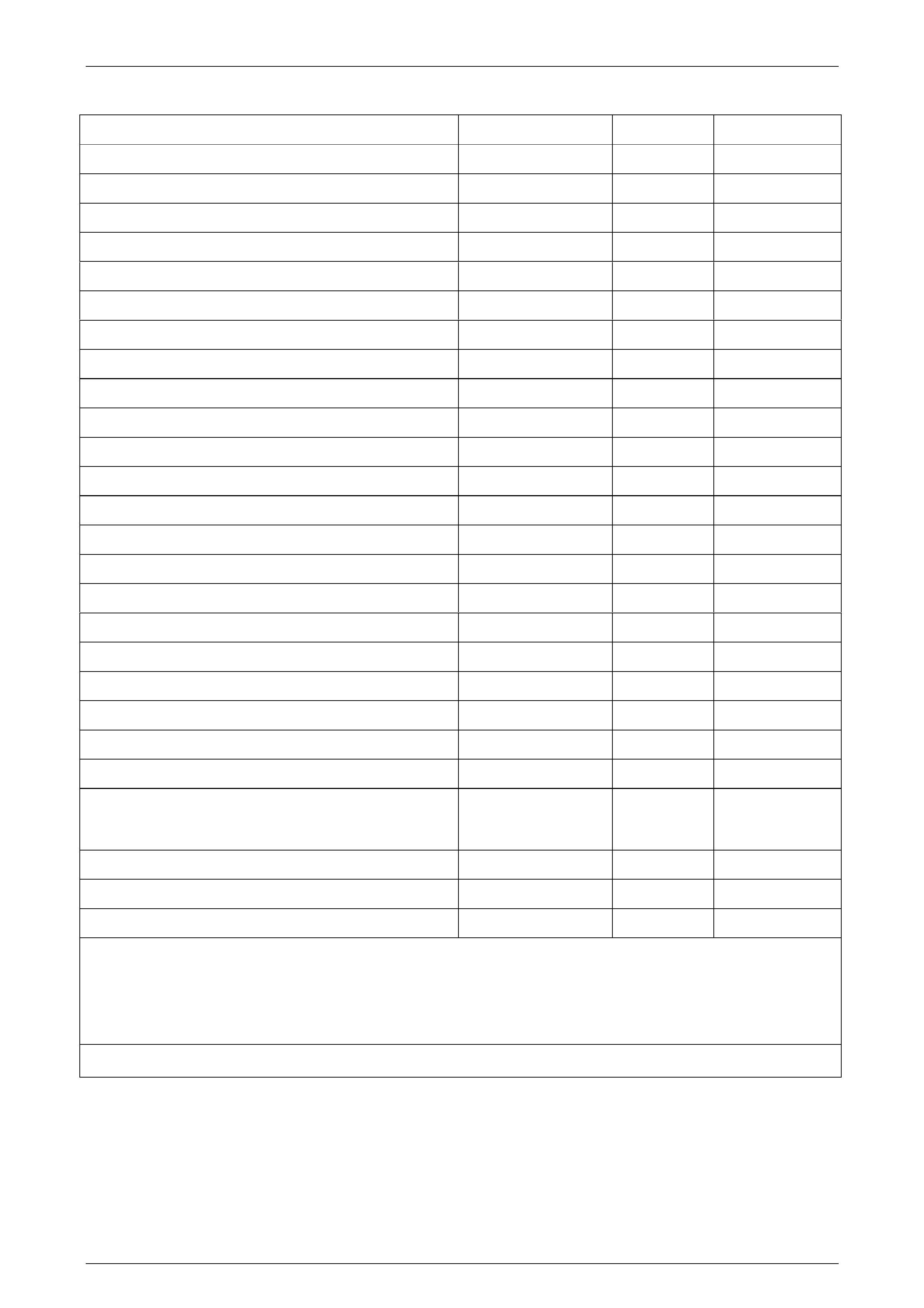

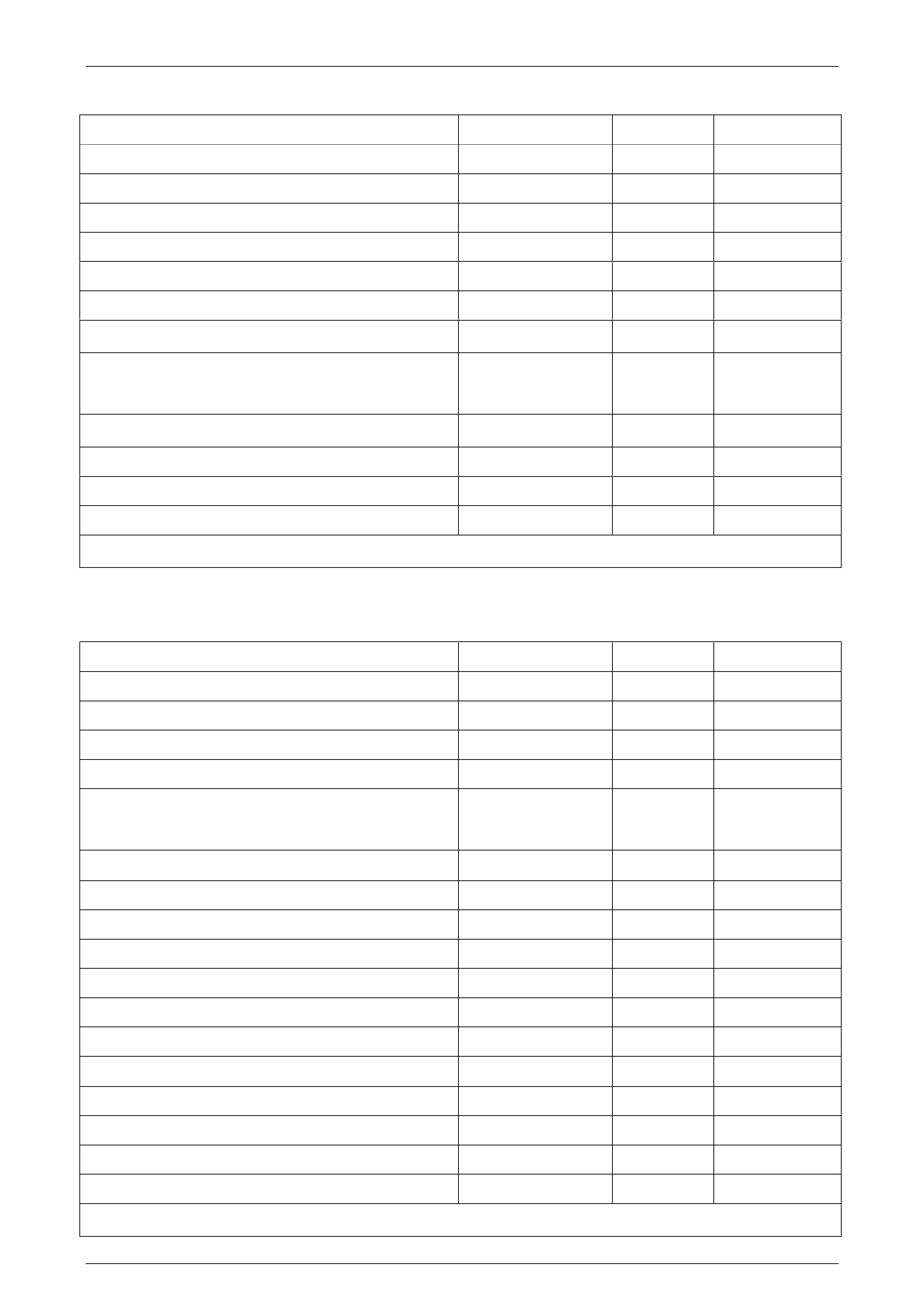

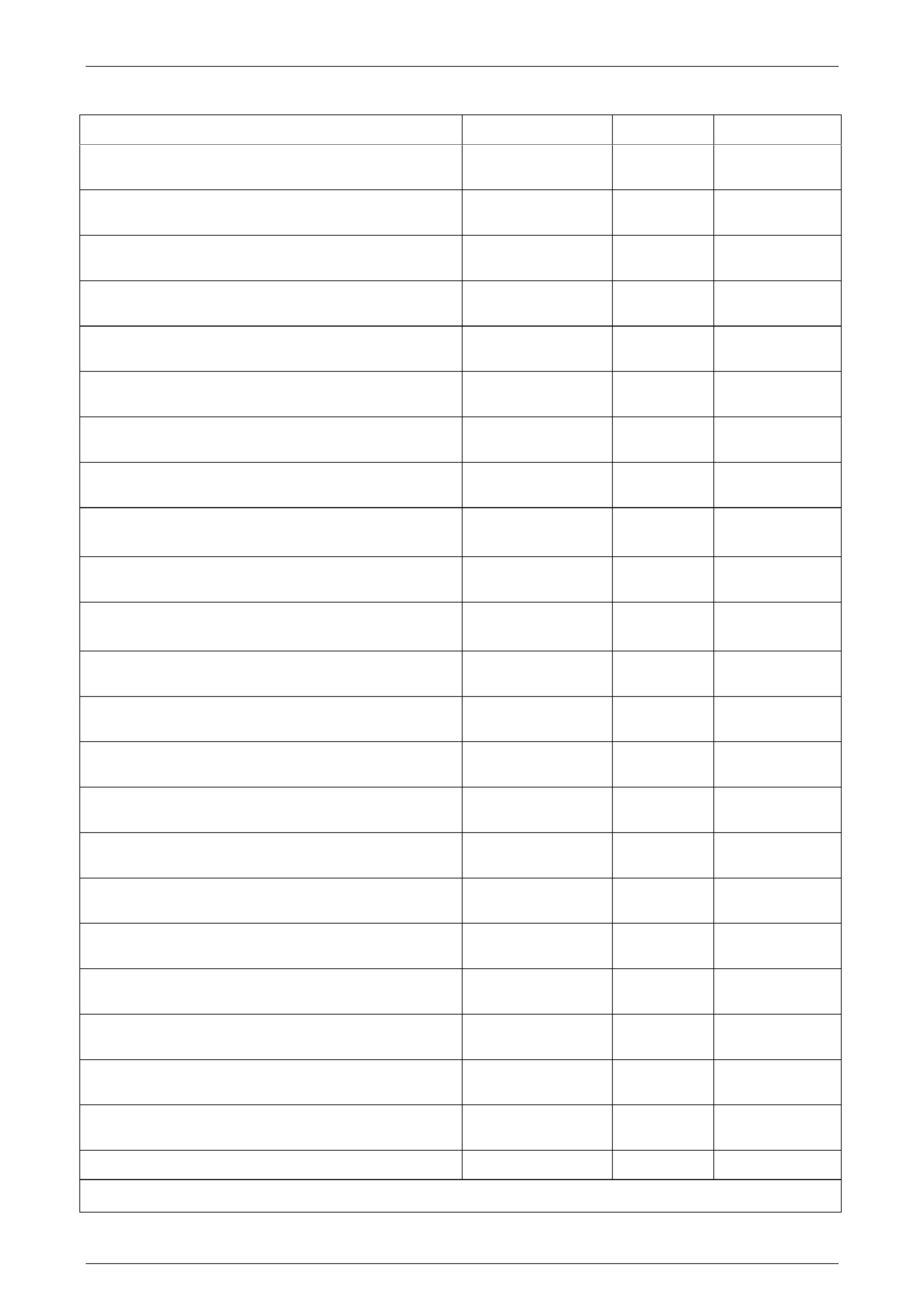

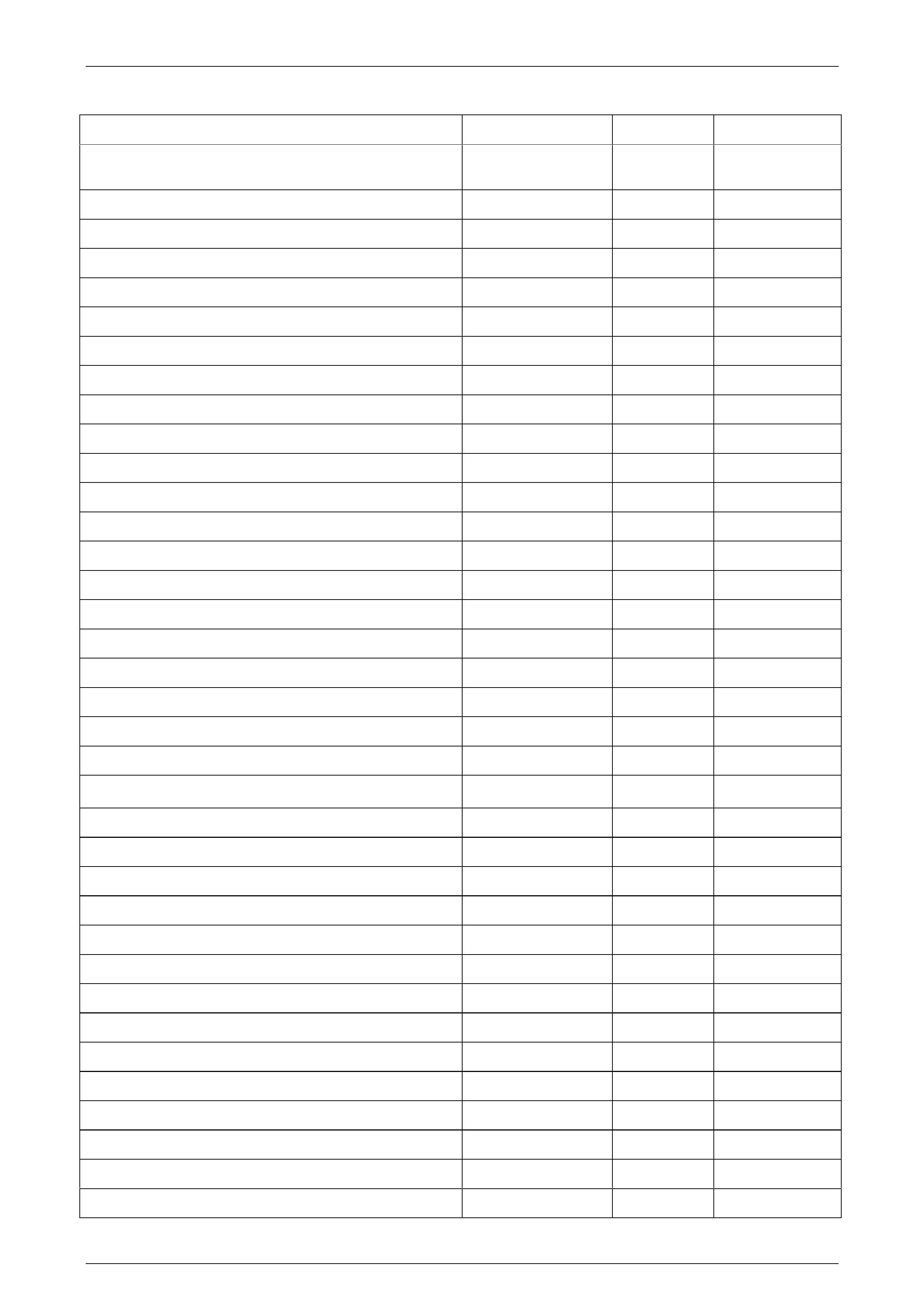

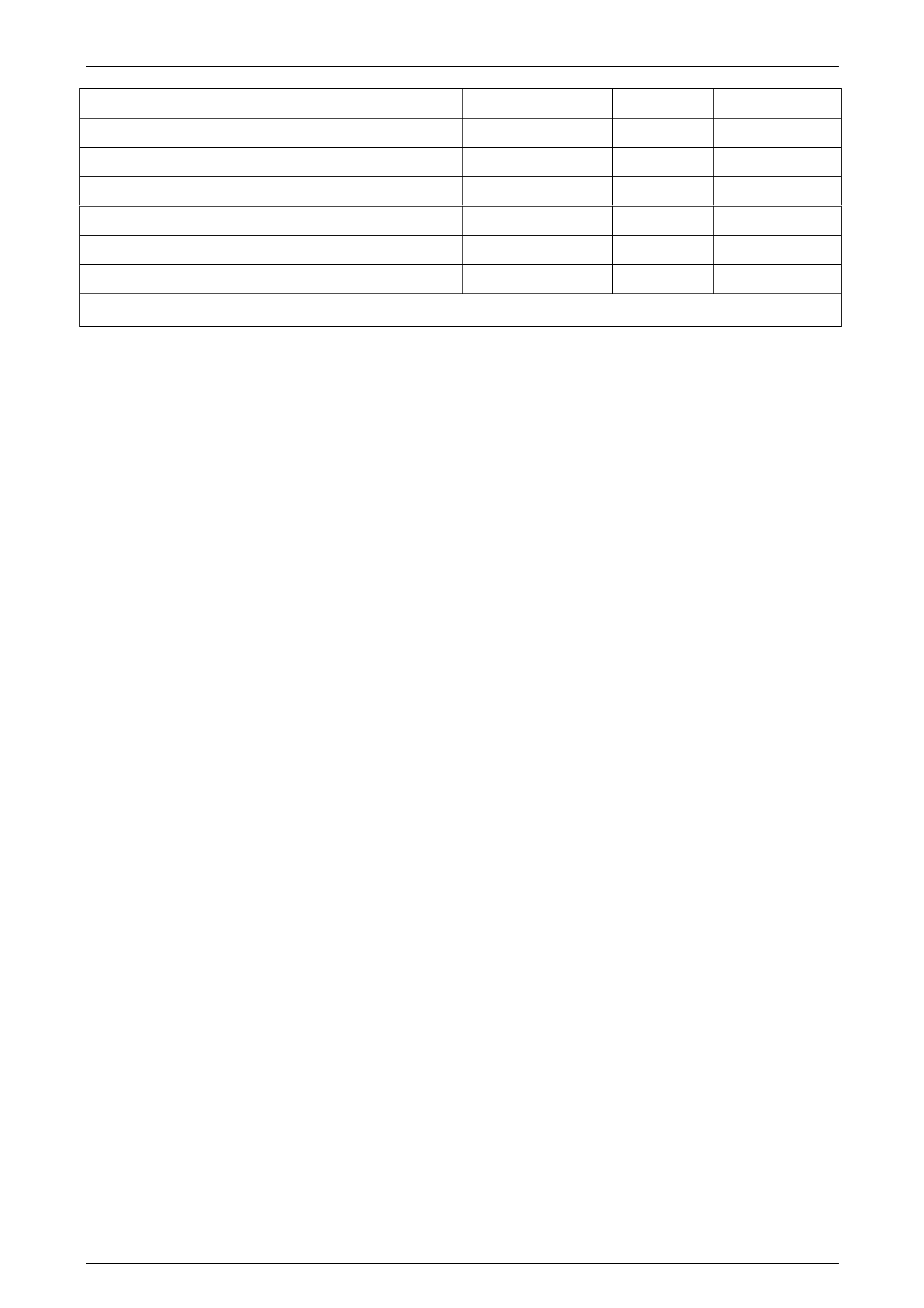

6 Diagnostic Trouble Code Tables........................................................................................................78

6.1 DTC List in Ascending Order.............................................................................................................................. 78

6.2 DTC P0016............................................................................................................................................................ 86

DTC Descriptor..................................................................................................................................................... 86

Circuit Description............................................................................................................................................... 86

Conditions for Running the DTC........................................................................................................................ 86

DTC P0016 ...................................................................................................................................................... 86

Conditions for Setting the DTC .......................................................................................................................... 86

Conditions for Clearing the DTC........................................................................................................................ 86

Additional Information......................................................................................................................................... 86

Test Description................................................................................................................................................... 86

DTC P0016............................................................................................................................................................ 87

6.3 DTC P0030, P0036, P0050 P0053, P0054, P0056, P0059, P0060, P0135, P0141, P0155, P0161...................... 88

DTC Description................................................................................................................................................... 88

Circuit Description............................................................................................................................................... 88

Additional Information......................................................................................................................................... 88

Conditions for Running the DTC........................................................................................................................ 89

Conditions for Setting the DTC .......................................................................................................................... 89

DTC P0030, P0036, P0050 or P0056 .............................................................................................................. 89

DTC P0053, P0054, P0059, P0060.................................................................................................................. 89

DTC P0135, P0141, P0155, P0161.................................................................................................................. 89

Conditions for Clearing the DTC........................................................................................................................ 89

Test Description................................................................................................................................................... 89

DTC P0030, P0036, P0050, P0053, P0054, P0056, P0059, P0060, P0135, P0141, P0155, P0161 Diagnostic

Table................................................................................................................................................................ 89

6.4 DTC P0068............................................................................................................................................................ 91

DTC Descriptor..................................................................................................................................................... 91

Circuit Description............................................................................................................................................... 91

Conditions for Running the DTC........................................................................................................................ 91

DTC P0068 ...................................................................................................................................................... 91

Conditions for Setting the DTC .......................................................................................................................... 91

DTC P0068 ...................................................................................................................................................... 91

Conditions for Clearing the DTC........................................................................................................................ 91

Additional Information......................................................................................................................................... 91

Test Conditions.................................................................................................................................................... 91

DTC P0068............................................................................................................................................................ 92

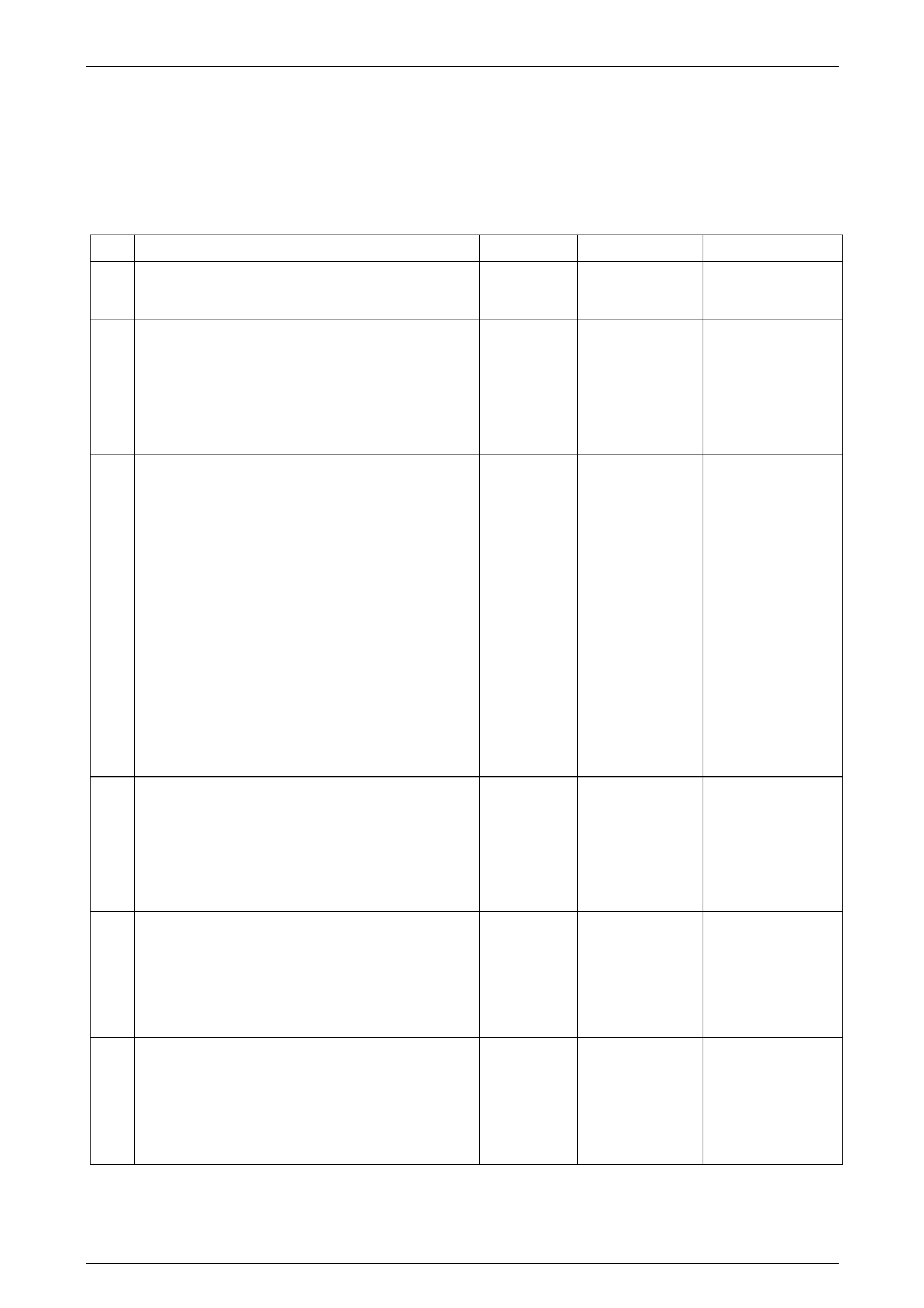

6.5 DTC P0101, P0102, P0103, P1101 ....................................................................................................................... 93

DTC Descriptors................................................................................................................................................... 93

Circuit Description............................................................................................................................................... 93

Conditions for Running the DTC........................................................................................................................ 93

DTC P0101 ...................................................................................................................................................... 93

DTC P0102 ...................................................................................................................................................... 93

DTC P0103 ...................................................................................................................................................... 93

DTC P1101 ...................................................................................................................................................... 94

Conditions for Setting the DTC .......................................................................................................................... 94

DTC P0101 ...................................................................................................................................................... 94

DTC P0102 ...................................................................................................................................................... 94

DTC P0103 ...................................................................................................................................................... 94

DTC P1101 ...................................................................................................................................................... 94

Additional Information......................................................................................................................................... 94

DTC P0101 to P0103 and P1101 Diagnostic Table............................................................................................ 95

6.6 DTC P0106, P0107, P0108.................................................................................................................................... 97

DTC Description................................................................................................................................................... 97

Circuit Description............................................................................................................................................... 97

Conditions for Running the DTC........................................................................................................................ 97

DTC P0106 ...................................................................................................................................................... 97

DTC P0107 ...................................................................................................................................................... 97

DTC P0108 ...................................................................................................................................................... 97

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–4

Page 6C4-2–4

Conditions for Setting the DTC .......................................................................................................................... 98

DTC P0106 ...................................................................................................................................................... 98

DTC P0107 ...................................................................................................................................................... 98

DTC P0108 ...................................................................................................................................................... 98

Conditions for Clearing DTCs ............................................................................................................................. 98

Additional Information......................................................................................................................................... 98

Test Description................................................................................................................................................... 98

Diagnostic Table for DTCs P0106, P0107 and P0108........................................................................................ 99

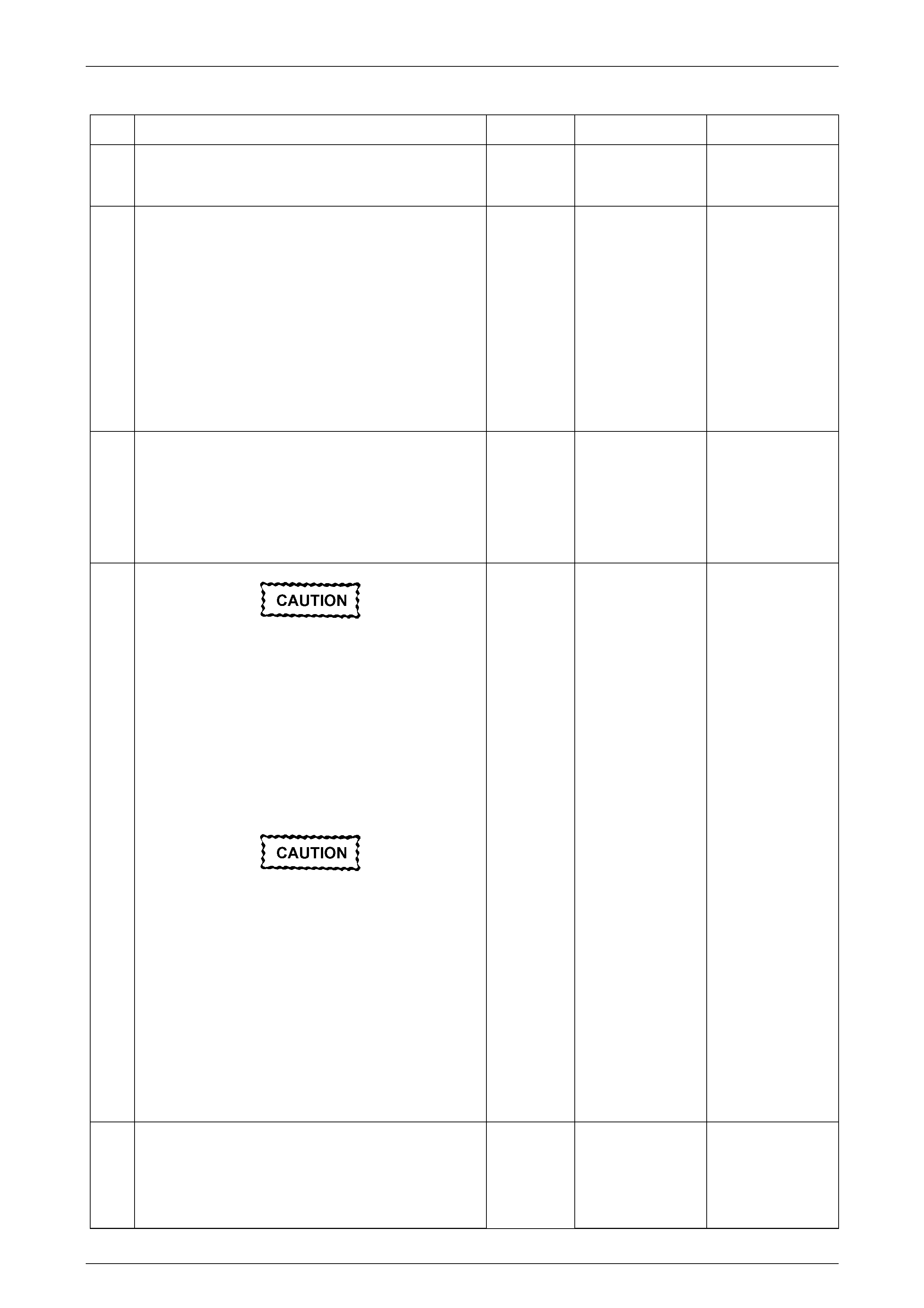

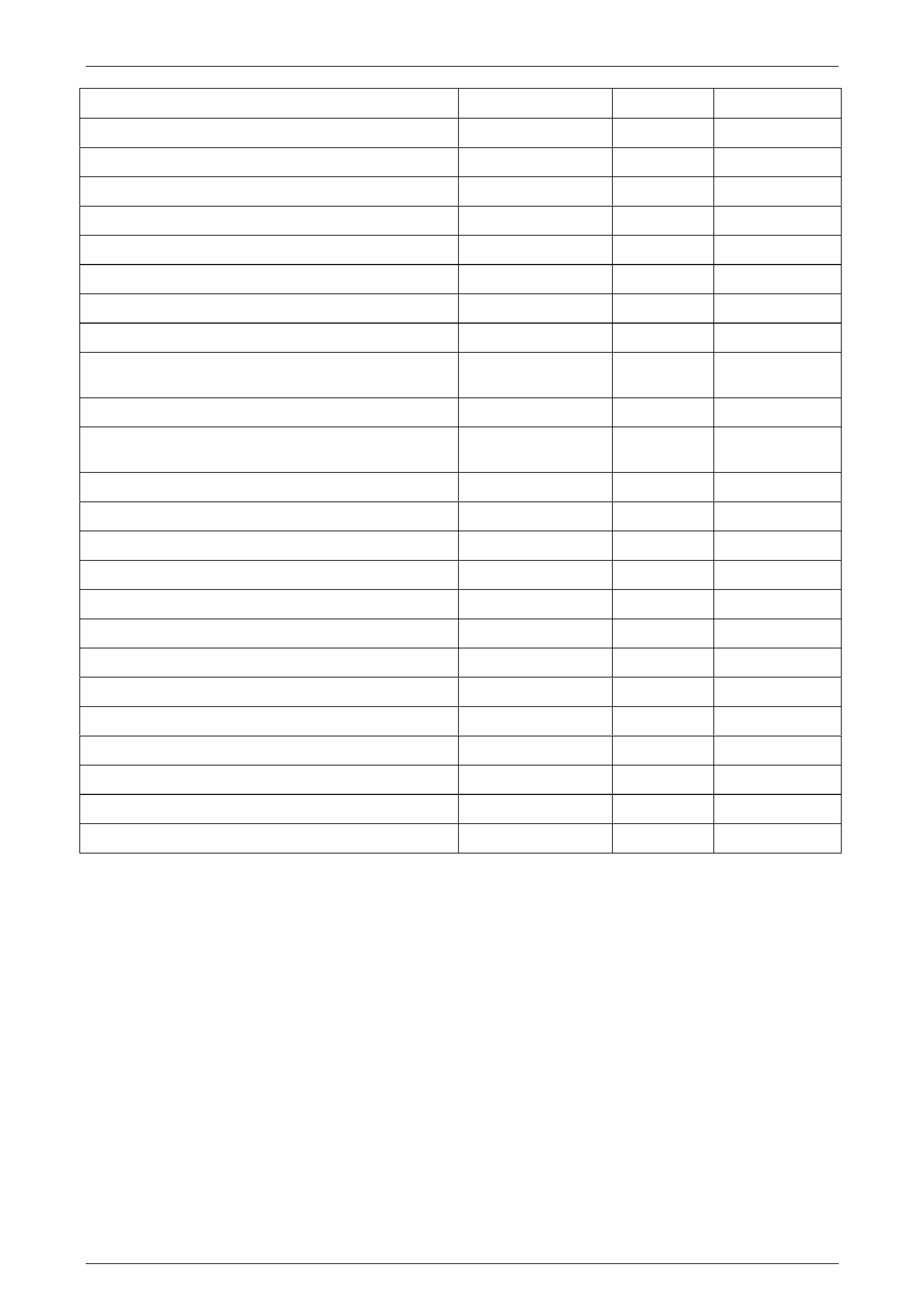

6.7 DTC P0112, P0113, P1101.................................................................................................................................. 101

DTC Description................................................................................................................................................. 101

Circuit Description............................................................................................................................................. 101

Conditions for Running the DTC...................................................................................................................... 101

DTC P0112 .................................................................................................................................................... 101

DTC P0113 .................................................................................................................................................... 101

Conditions for Setting the DTC ........................................................................................................................ 101

DTC P0112 .................................................................................................................................................... 101

DTC P0113 .................................................................................................................................................... 101

Conditions for Clearing the DTCs .................................................................................................................... 102

Additional Information....................................................................................................................................... 102

Test Description................................................................................................................................................. 102

Diagnostic Table for the Intake Air Temperature Sensor Circuit DTCs......................................................... 102

6.8 DTC P0116, P0117, P0118, P0128, P1258......................................................................................................... 104

DTC Descriptors................................................................................................................................................. 104

Circuit Description............................................................................................................................................. 104

Conditions for Running the DTC...................................................................................................................... 104

DTC P0116 .................................................................................................................................................... 104

DTC P0117, P0118 and P1258...................................................................................................................... 104

DTC P00128................................................................................................................................................... 104

Conditions for Setting the DTC ........................................................................................................................ 104

DTC P0116 .................................................................................................................................................... 104

DTC P0117 .................................................................................................................................................... 104

DTC P0118 .................................................................................................................................................... 104

DTC P0128 .................................................................................................................................................... 104

DTC P1258 .................................................................................................................................................... 104

Conditions for Clearing the DTC...................................................................................................................... 105

Additional Information....................................................................................................................................... 105

Test Description................................................................................................................................................. 105

DTC P0116, P0117, P0118, P0128 and P1258 Diagnostic Table..................................................................... 105

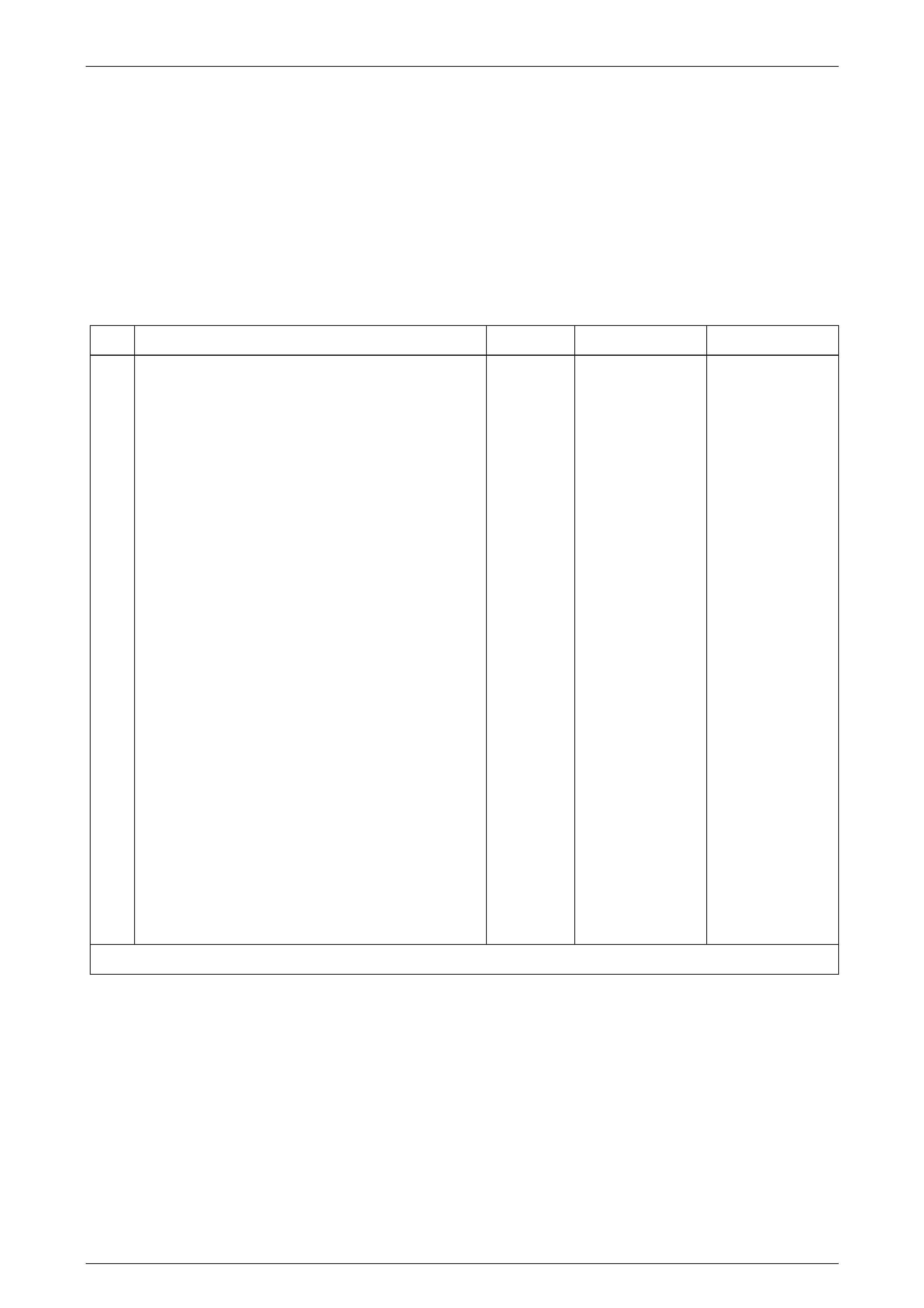

6.9 DTC P0120, P0121, P0122, P0123, P0220, P0222, P0223, P1516, P2101, P2135............................................ 107

DTC Descriptors................................................................................................................................................. 107

Circuit Description............................................................................................................................................. 107

Conditions for Running the DTC...................................................................................................................... 107

DTC P0120, P0121 or P0220......................................................................................................................... 107

DTC P0122, P0123, P0222 and P0223.......................................................................................................... 107

Conditions for Setting the DTC ........................................................................................................................ 107

DTC P0120 .................................................................................................................................................... 107

DTC P0121 .................................................................................................................................................... 108

DTC P0122 .................................................................................................................................................... 108

DTC P0123 .................................................................................................................................................... 108

DTC P0222 .................................................................................................................................................... 108

DTC P0223 .................................................................................................................................................... 108

DTC P1516 .................................................................................................................................................... 108

DTC P2101 .................................................................................................................................................... 108

DTC P2138 .................................................................................................................................................... 108

Conditions for Clearing the DTC...................................................................................................................... 108

Additional Information....................................................................................................................................... 108

Test Description................................................................................................................................................. 109

Diagnostic Table for the TP Sensor Circuit DTCs........................................................................................... 109

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–5

Page 6C4-2–5

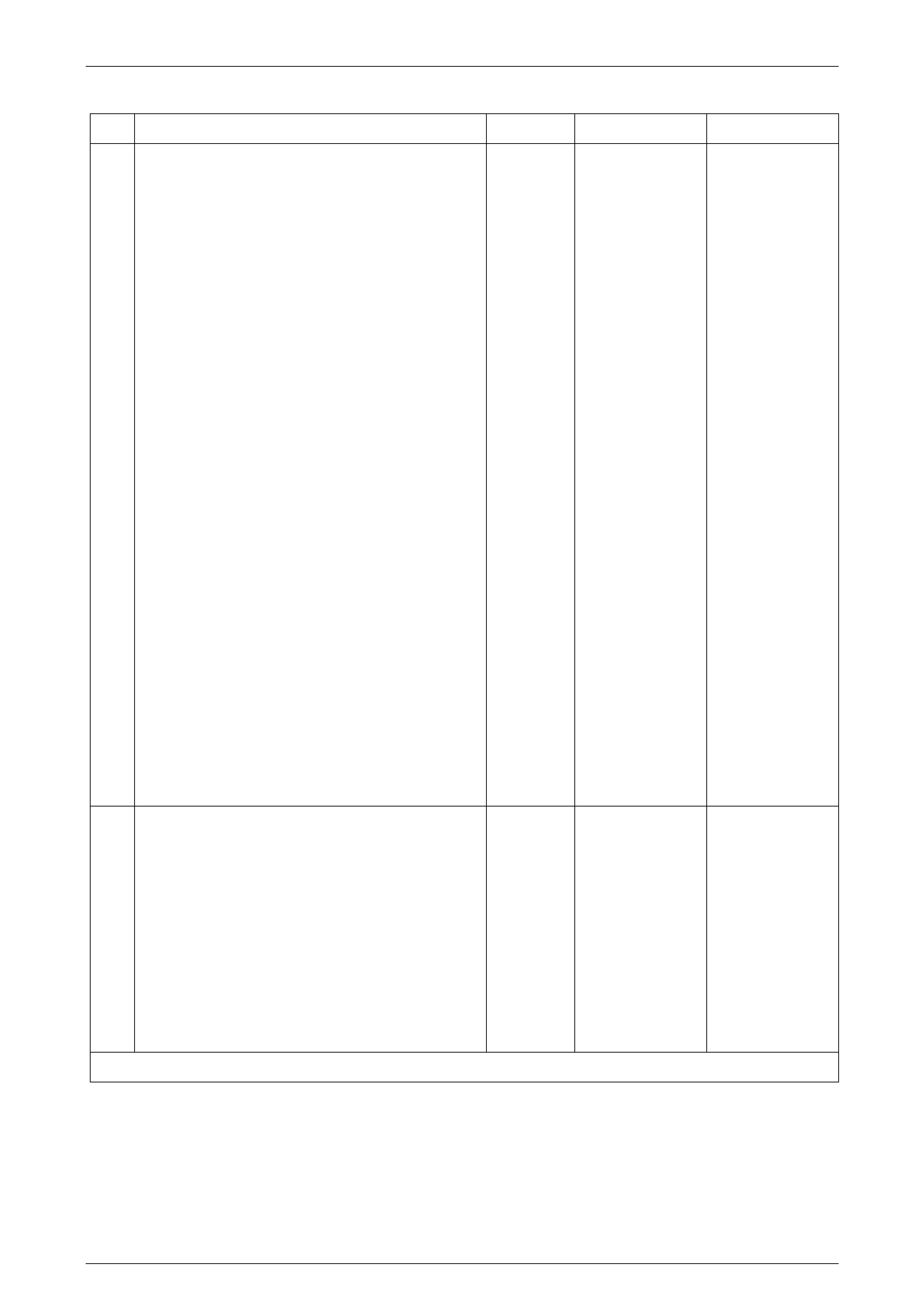

6.10 DTC P0131, P0132, P0133, P0134, P0137, P0138, P0140, P0151, P0152, P0153, P0154, P0157, P0158, P0160,

P1133, P1153, P2A01, P2A04............................................................................................................................. 111

DTC Descriptors................................................................................................................................................. 111

Circuit Description............................................................................................................................................. 111

Heated O2 Sensor.......................................................................................................................................... 111

Conditions for Running the DTC...................................................................................................................... 112

DTC P0131, P0137, P0151 or P0157 ............................................................................................................ 112

DTC P0132, P0138, P0152 or P0158 ............................................................................................................ 112

DTC P0133 or P0153..................................................................................................................................... 112

DTC P0134, P0140, P0154 or P0160 ............................................................................................................ 112

DTC P1133 or P1153..................................................................................................................................... 112

DTC P2A01 or P2A04.................................................................................................................................... 112

Conditions for Setting the DTC ........................................................................................................................ 113

DTC P0131, P0137, P0151 or P0157 ............................................................................................................ 113

DTC P0132, P0138, P0152 or P0158 ............................................................................................................ 113

DTC P0133 or P0153..................................................................................................................................... 113

DTC P0134, P0140, P0154 or P0160 ............................................................................................................ 113

DTC P1133 or P1153..................................................................................................................................... 113

DTC P2A01 or P2A04.................................................................................................................................... 113

Conditions for Clearing the DTC...................................................................................................................... 113

Additional Information....................................................................................................................................... 113

Diagnostic Table for the Heated Oxygen Sensor Reference Circuit DTCs................................................... 114

6.11 DTC P0171, P0172, P0174, P0175 ..................................................................................................................... 116

DTC Descriptors................................................................................................................................................. 116

Circuit Description............................................................................................................................................. 116

Conditions for Running the DTC...................................................................................................................... 116

DTCs P0171, P0172, P0174, and P0175....................................................................................................... 116

Conditions for Setting the DTC ........................................................................................................................ 116

DTCs P0171 and P0174 ................................................................................................................................ 116

DTCs P0172 and P0175 ................................................................................................................................ 116

Conditions for Clearing the DTC...................................................................................................................... 116

Additional Information....................................................................................................................................... 117

Diagnostic Table for the Fuel Trim Reference Circuit DTCs.......................................................................... 117

6.12 DTC P0201, P0202, P0203, P0204, P0205, P0206, P0207, P0208.................................................................... 119

DTC Descriptors................................................................................................................................................. 119

Circuit Description............................................................................................................................................. 119

Conditions for Running the DTC...................................................................................................................... 119

Conditions for Setting the DTC ........................................................................................................................ 119

DTC P0201, P0202, P0203, P0204, P0205, P0206, P0207 or P0208 ........................................................... 119

Conditions for Clearing the DTC...................................................................................................................... 119

Additional Information....................................................................................................................................... 119

Test Description................................................................................................................................................. 120

DTC P0201 to P0208, Diagnostic Table............................................................................................................ 120

6.13 DTC P0230.......................................................................................................................................................... 122

DTC Description................................................................................................................................................. 122

Circuit Description............................................................................................................................................. 122

Diagnostic Aids for the Fuel Pump Control Circuit DTCs.............................................................................. 122

Conditions for Running the DTC..................................................................................................................... 122

Conditions for Setting the DTC....................................................................................................................... 122

Conditions for Clearing the DTC..................................................................................................................... 122

Additional Information..................................................................................................................................... 122

Test Descriptions............................................................................................................................................ 122

Diagnostic Table for the Fuel Pump Control Circuit DTCs ............................................................................ 123

6.14 DTC P0300, P1380, P1381.................................................................................................................................. 125

DTC Descriptor................................................................................................................................................... 125

Circuit Description............................................................................................................................................. 125

Conditions for Running the DTCs.................................................................................................................... 125

Conditions for Setting the DTC ........................................................................................................................ 125

Action Taken When the DTC Sets .................................................................................................................... 125

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–6

Page 6C4-2–6

Conditions for Clearing the MIL/DTC............................................................................................................... 125

Additional Information....................................................................................................................................... 126

DTCs P0300 and P1380 ................................................................................................................................ 126

DTC P1381 .................................................................................................................................................... 126

Test Description................................................................................................................................................. 126

DTC P0300, P1380 and P1381 Diagnostic Table.............................................................................................. 126

6.15 DTC P0315, P0335, P0336 and P0654............................................................................................................... 128

DTC Description................................................................................................................................................. 128

Circuit Description............................................................................................................................................. 128

Conditions for Running the DTCs.................................................................................................................... 128

DTC P0315 .................................................................................................................................................... 128

DTC P0335 .................................................................................................................................................... 128

DTC P0336 .................................................................................................................................................... 128

Conditions for Setting the DTCs....................................................................................................................... 128

DTC P0315 .................................................................................................................................................... 128

DTC P0335 .................................................................................................................................................... 128

DTC P0336 .................................................................................................................................................... 128

Conditions for Clearing the DTCs .................................................................................................................... 129

Additional Information....................................................................................................................................... 129

Diagnostic Table for the CKP Sensor Circuit DTCs........................................................................................ 129

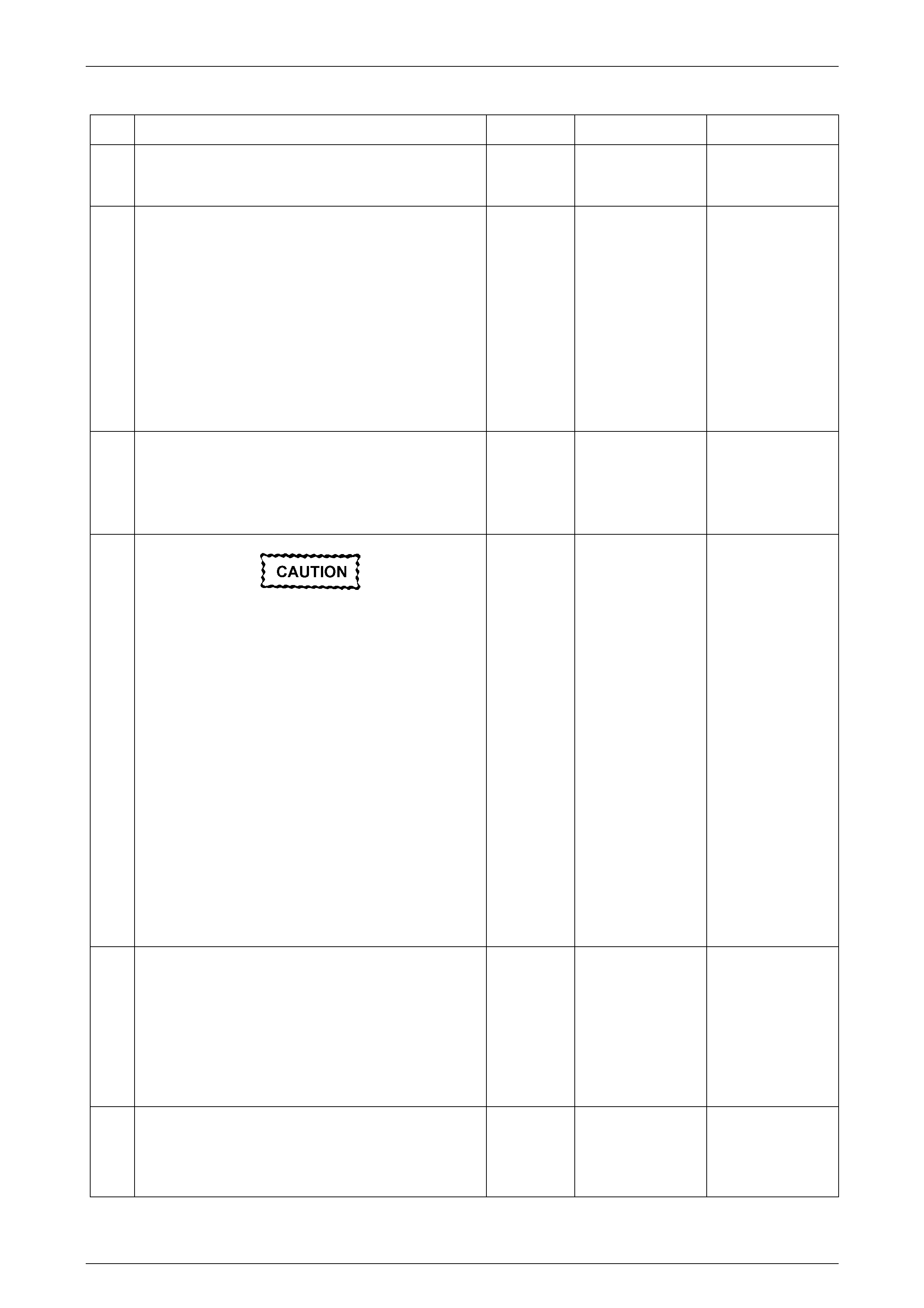

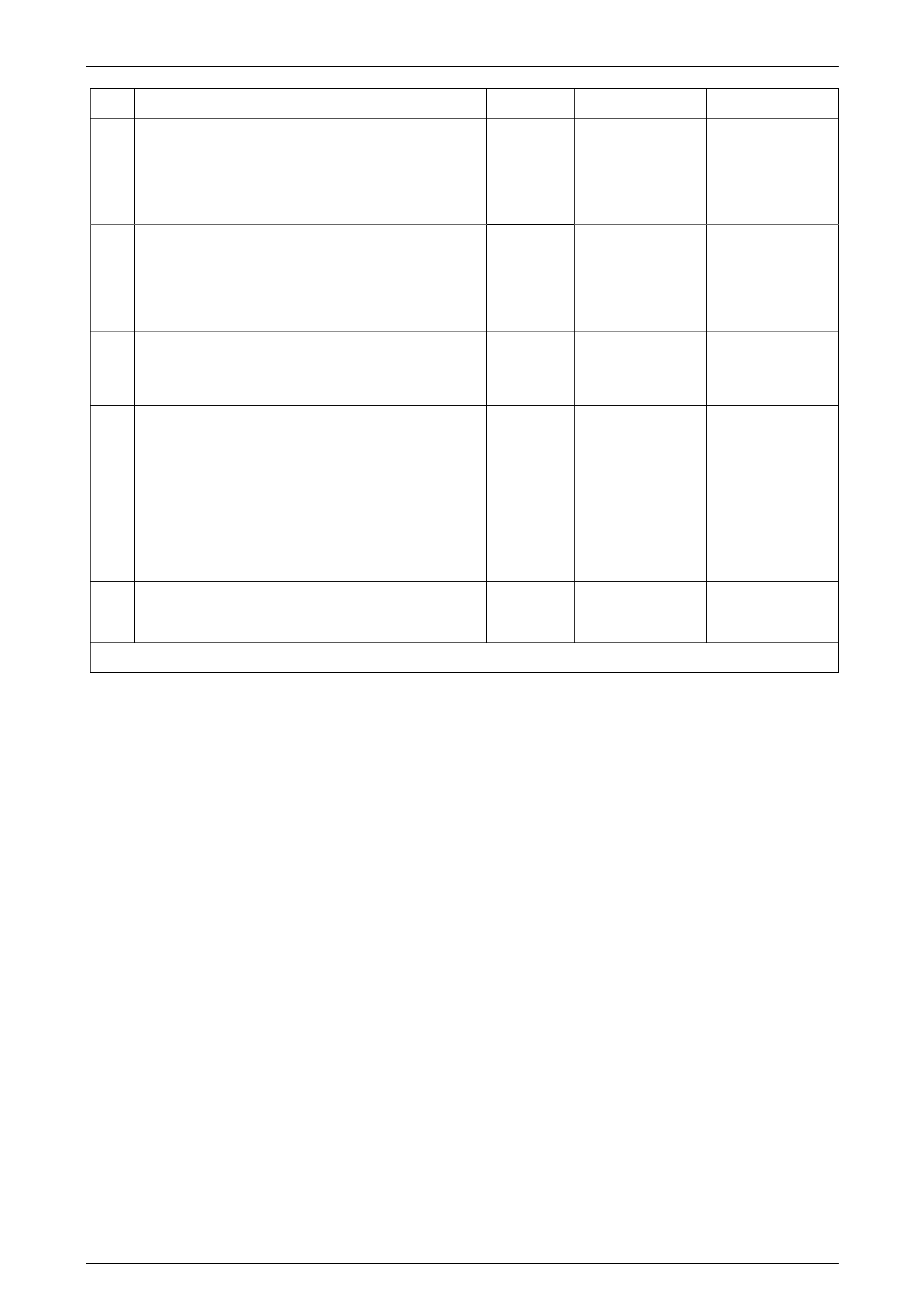

6.16 DTC P0324, P0325, P0326, P0327, P0328, P0330, P0332, P0333.................................................................... 133

DTC Descriptors................................................................................................................................................. 133

Circuit Description............................................................................................................................................. 133

DTC P0324 only............................................................................................................................................. 133

Test One ........................................................................................................................................................ 133

Test Two ........................................................................................................................................................ 133

Test Three...................................................................................................................................................... 133

Conditions for Running the DTC...................................................................................................................... 134

DTC P0324 .................................................................................................................................................... 134

Condition One ................................................................................................................................................ 134

Condition Two ................................................................................................................................................ 134

Condition Three.............................................................................................................................................. 134

DTC P0325 .................................................................................................................................................... 134

DTC P0326 .................................................................................................................................................... 134

DTC P0327 .................................................................................................................................................... 134

DTC P0328 .................................................................................................................................................... 135

DTC P0330 .................................................................................................................................................... 135

DTC P0332 .................................................................................................................................................... 135

DTC P0333 .................................................................................................................................................... 135

Conditions for Setting the DTC ........................................................................................................................ 135

DTC P0324 .................................................................................................................................................... 135

DTC P0325 .................................................................................................................................................... 135

DTC P0326 .................................................................................................................................................... 135

DTC P0327 .................................................................................................................................................... 135

DTC P0328 .................................................................................................................................................... 135

DTC P0330 .................................................................................................................................................... 135

DTC P0332 .................................................................................................................................................... 136

DTC P0333 .................................................................................................................................................... 136

Conditions for Clearing the DTC...................................................................................................................... 136

Additional Information....................................................................................................................................... 136

Test Description................................................................................................................................................. 136

Diagnostic Table for the Knock Sensor and Circuit DTCs............................................................................. 136

6.17 DTC P0340, P0341.............................................................................................................................................. 138

Circuit Description............................................................................................................................................. 138

Conditions for Running the DTCs.................................................................................................................... 138

Conditions for Setting the DTCs....................................................................................................................... 138

DTC P0340 .................................................................................................................................................... 138

DTC P0341 .................................................................................................................................................... 138

Conditions for Clearing the DTCs .................................................................................................................... 138

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–7

Page 6C4-2–7

Additional Information....................................................................................................................................... 138

Test Description................................................................................................................................................. 138

Diagnostic Table for the CMP Sensor Circuit DTCs ....................................................................................... 139

6.18 DTC P0351, P0352, P0353, P0354, P0355, P0356, P0357, P0358.................................................................... 141

DTC Description................................................................................................................................................. 141

Circuit Description............................................................................................................................................. 141

Conditions for Running the DTCs.................................................................................................................... 141

Conditions for Setting the DTCs....................................................................................................................... 141

Conditions for Clearing the DTCs .................................................................................................................... 141

Additional Information....................................................................................................................................... 141

Test Descriptions............................................................................................................................................... 142

Diagnostic Table for the Ignition Control Circuit DTCs.................................................................................. 142

6.19 DTC P0420 or P0430 .......................................................................................................................................... 144

DTC Descriptors................................................................................................................................................. 144

Circuit Description............................................................................................................................................. 144

Conditions for Running the DTC...................................................................................................................... 144

Conditions for Setting the DTC ........................................................................................................................ 144

Action Taken When the DTC Sets .................................................................................................................... 144

Conditions for Clearing the DTC...................................................................................................................... 145

P0420 or P0430 Diagnostic Table..................................................................................................................... 145

6.20 DTC P0443.......................................................................................................................................................... 146

DTC Description................................................................................................................................................. 146

Circuit Description............................................................................................................................................. 146

Conditions for Running the DTC...................................................................................................................... 146

Conditions for Setting the DTC ........................................................................................................................ 146

Conditions for Clearing the DTC...................................................................................................................... 146

Additional Information....................................................................................................................................... 146

Diagnostic Table for the Evaporative Emission Control System Purge Control Circuit DTCs ................... 146

6.21 DTC P0461, P0462 and P0463........................................................................................................................... 148

DTC Description................................................................................................................................................. 148

Circuit Description............................................................................................................................................. 148

Conditions for Running the DTCs.................................................................................................................... 148

Conditions for Setting the DTCs....................................................................................................................... 148

DTC P0461 .................................................................................................................................................... 148

DTC P0462 and DTC P0463.......................................................................................................................... 148

Conditions for Clearing the DTCs .................................................................................................................... 148

Additional Information....................................................................................................................................... 148

Diagnostic Table for the Fuel Tank Sensor DTCs........................................................................................... 149

6.22 DTC P0480, P0481.............................................................................................................................................. 151

DTC Description................................................................................................................................................. 151

Circuit Description............................................................................................................................................. 151

Conditions for Running the DTCs.................................................................................................................... 151

Condition for Setting the DTCs ........................................................................................................................ 151

Conditions for Clearing DTCs ........................................................................................................................... 151

Additional Information....................................................................................................................................... 151

Diagnostic Table for the Cooling Fan High Speed Relay Circuit DTCs......................................................... 151

6.23 DTC P0502.......................................................................................................................................................... 153

DTC Description................................................................................................................................................. 153

Circuit Description............................................................................................................................................. 153

Conditions for Running the DTC...................................................................................................................... 153

DTC P0502 .................................................................................................................................................... 153

Conditions for Setting the DTC ........................................................................................................................ 153

DTC P0502 .................................................................................................................................................... 153

Conditions for Clearing DTC............................................................................................................................. 153

Additional Information....................................................................................................................................... 153

Diagnostic Table for the Vehicle Speed Sensor Circuit DTCs....................................................................... 154

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–8

Page 6C4-2–8

6.24 DTC P0506, P0507 P2119................................................................................................................................... 156

DTC Descriptors................................................................................................................................................. 156

Circuit Description............................................................................................................................................. 156

Conditions for Running the DTC...................................................................................................................... 156

DTC P0506 and P0507 .................................................................................................................................. 156

DTC P2119 .................................................................................................................................................... 156

Conditions for Setting the DTC ........................................................................................................................ 157

DTC P0506 .................................................................................................................................................... 157

DTC P0507 .................................................................................................................................................... 157

DTC P2119 .................................................................................................................................................... 157

Conditions for Clearing the DTC...................................................................................................................... 157

Additional Information....................................................................................................................................... 157

Test Description................................................................................................................................................. 157

Diagnostic Table for.P0506, P0507 or P2119................................................................................................... 157

6.25 DTC P0513, P0633, P1629, P1632, P1648, P1677, P1678, P1679.................................................................... 160

DTC Descriptors................................................................................................................................................. 160

Circuit Description............................................................................................................................................. 160

Conditions for Running the DTC...................................................................................................................... 160

Conditions for Setting the DTC ........................................................................................................................ 160

P0513............................................................................................................................................................. 160

P0633............................................................................................................................................................. 160

P1629............................................................................................................................................................. 161

P1632............................................................................................................................................................. 161

P1677............................................................................................................................................................. 161

P1678............................................................................................................................................................. 161

P1679............................................................................................................................................................. 161

Conditions for Clearing the DTC...................................................................................................................... 161

Additional Information....................................................................................................................................... 161

Diagnostic Table for DTCs P0513, P0663, P1629, P1632, P1648, P1677, P1678, P1679............................... 161

6.26 DTC P0522, P0523.............................................................................................................................................. 163

DTC Description................................................................................................................................................. 163

Circuit Description............................................................................................................................................. 163

Conditions for Running the DTCs.................................................................................................................... 163

Conditions for Setting the DTCs....................................................................................................................... 163

Conditions for Clearing the DTCs .................................................................................................................... 163

Additional Information....................................................................................................................................... 163

Test Descriptions............................................................................................................................................... 163

Diagnostic Table for the Engine Oil Pressure Sensor Circuit DTCs ............................................................. 164

6.27 DTC P0532, P0533.............................................................................................................................................. 166

DTC Description................................................................................................................................................. 166

Circuit Description............................................................................................................................................. 166

Conditions for Running the DTC...................................................................................................................... 166

Conditions for Setting the DTC ........................................................................................................................ 166

DTC P0532 .................................................................................................................................................... 166

DTC P0533 .................................................................................................................................................... 166

Conditions for Clearing the DTC...................................................................................................................... 166

Additional Information....................................................................................................................................... 166

Test Description................................................................................................................................................. 167

DTC P0532 and P0533 Diagnostic Table.......................................................................................................... 167

6.28 DTC P0562, P0563.............................................................................................................................................. 169

DTC Descriptors................................................................................................................................................. 169

Circuit Description............................................................................................................................................. 169

Conditions for Running the DTC...................................................................................................................... 169

Conditions for Setting the DTC ........................................................................................................................ 169

DTC P0562 .................................................................................................................................................... 169

DTC P0563 .................................................................................................................................................... 169

Conditions for Clearing the DTC...................................................................................................................... 169

Additional Information....................................................................................................................................... 169

DTC P0562 or P0563 Diagnostic Table............................................................................................................. 170

Engine Management GEN IV V8 – Diagnostics Page 6C4-2–9

Page 6C4-2–9

6.29 DTC P0575.......................................................................................................................................................... 171

DTC Descriptor................................................................................................................................................... 171

Circuit Description............................................................................................................................................. 171

Conditions for Running the DTC...................................................................................................................... 171

Conditions for Setting the DTC ........................................................................................................................ 171

Conditions for Clearing the DTC...................................................................................................................... 171

Additional Information....................................................................................................................................... 171

Test Description................................................................................................................................................. 171

DTC P0575.......................................................................................................................................................... 171

6.30 DTC P0601, P0602, P0603, P0604, P0606, P0607, P062F, P1621, P1681, P2610 ........................................... 173

DTC Description................................................................................................................................................. 173

Circuit Description............................................................................................................................................. 173

Conditions for Running the DTC...................................................................................................................... 173

DTC P0601 .................................................................................................................................................... 173

DTC P0602,P0603 and P0606....................................................................................................................... 173

DTC P0604 .................................................................................................................................................... 173

DTC P0607 .................................................................................................................................................... 173

DTC P062F .................................................................................................................................................... 173

Conditions for Setting the DTC ........................................................................................................................ 173

DTC P0601 .................................................................................................................................................... 173

DTC P0602 .................................................................................................................................................... 173

DTC P0603 .................................................................................................................................................... 173

DTC P0604 .................................................................................................................................................... 174

DTC P0606 .................................................................................................................................................... 174

DTC P0607 .................................................................................................................................................... 174

DTC P062F .................................................................................................................................................... 174

Conditions for Clearing the DTC...................................................................................................................... 174

Additional Information....................................................................................................................................... 174

DTC P0601, P0602, P0603, P0604, P0606, P0607 and P062F Diagnostic Table ............................................ 174

6.31 DTC P0608.......................................................................................................................................................... 176

DTC Description................................................................................................................................................. 176

Circuit Description............................................................................................................................................. 176

Conditions for Running the DTC...................................................................................................................... 176

Conditions for Setting the DTC ........................................................................................................................ 176

Conditions for Clearing DTCs ........................................................................................................................... 176

Additional Information....................................................................................................................................... 176

Test Descriptions............................................................................................................................................... 176