Powertrain Interface Module Page 6E4–1

Page 6E4–1

Section 6E4

Powertrain Interface Module – GEN IV V8

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to 00 Warnings,

Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................6

1.1 General Description............................................................................................................................................... 6

Serial Data Communication .................................................................................................................................. 6

Bus..................................................................................................................................................................... 6

Serial Data ......................................................................................................................................................... 7

Serial Data Communication Protocols................................................................................................................ 7

Serial Data Layout.................................................................................................................................................. 8

2 Component Location .............................................................................................................................9

2.1 Engine Compartment............................................................................................................................................. 9

2.2 Interior .................................................................................................................................................................. 10

3 Component Description and Operation.............................................................................................11

3.1 Powertrain Interface Module............................................................................................................................... 11

Communication Gateway.................................................................................................................................... 11

3.2 Powertrain Interface Module Gateway Components ........................................................................................ 12

Engine Control Module........................................................................................................................................ 12

ABS-TCS Electronic Control Unit....................................................................................................................... 12

Body Control Module........................................................................................................................................... 12

Automatic Transmission Control Module.......................................................................................................... 13

3.3 Powertrain Interface Module Direct Input Switches.......................................................................................... 14

Traction Control System Switch......................................................................................................................... 14

Cruise Control Switch ......................................................................................................................................... 14

4 Diagnostics...........................................................................................................................................15

4.1 Diagnostic General Descriptions........................................................................................................................ 15

Diagnostic Trouble Code (DTC) Tables ............................................................................................................. 15

Multiple DTCs................................................................................................................................................... 15

Diagnostic Trouble Codes (DTCs)...................................................................................................................... 16

Status of DTCs................................................................................................................................................. 16

Conditions for Clearing DTCs........................................................................................................................... 16

TECH 2 PIM Diagnostic Tests............................................................................................................................. 16

TECH 2 Intermittent Fault Tests....................................................................................................................... 16

TECH 2 Data List ............................................................................................................................................. 17

5 Powertrain Interface Module Diagnostic Starting Point...................................................................18

5.1 Diagnostic Requirements, Precautions and Preliminary Checks.................................................................... 18

Basic Knowledge Required................................................................................................................................. 18

Basic Diagnostic Tools Required....................................................................................................................... 18

Diagnostic Precautions....................................................................................................................................... 19

Preliminary Checks.............................................................................................................................................. 19

5.2 Main Diagnostic Table......................................................................................................................................... 20

5.3 Powertrain Interface Module – Module Presence Check Failure Diagnostic Table........................................ 22

Powertrain Interface Module Page 6E4–2

Page 6E4–2

6 Intermittent Fault Conditions..............................................................................................................23

6.1 Intermittent Conditions Diagnostic Table.......................................................................................................... 23

Description........................................................................................................................................................... 23

Diagnostic Table.................................................................................................................................................. 23

7 DTC Tables............................................................................................................................................25

7.1 DTC B1000, B1009, B1013 or B1014 – PIM Internal Fault................................................................................. 25

Circuit Description............................................................................................................................................... 25

DTC B1000, B1009, B1013 or B1014 Diagnostic Aids....................................................................................... 25

Additional Information....................................................................................................................................... 25

Conditions for Running the DTC B1000, B1009, B1013 or B1014................................................................... 25

Conditions for Setting the DTCs....................................................................................................................... 25

Action Taken When the DTCs Set.................................................................................................................... 25

Conditions for Clearing DTCs........................................................................................................................... 25

Test Description ............................................................................................................................................... 25

DTC B1000, B1009, B1013 or B1014 Diagnostic Table................................................................................... 26

7.2 DTC U1304 – Lost Communications with UART System.................................................................................. 27

Circuit Description............................................................................................................................................... 27

DTC U1304 Diagnostic Aids................................................................................................................................ 27

Additional information....................................................................................................................................... 27

Conditions for Running the DTC....................................................................................................................... 27

Conditions for Setting the DTC......................................................................................................................... 27

Action Taken When the DTC Sets.................................................................................................................... 27

Conditions for Clearing the DTC....................................................................................................................... 27

Test Description ............................................................................................................................................... 27

DTC U1304 Diagnostic Table........................................................................................................................... 28

7.3 DTC U2100 – No Communication With CAN Bus (High Speed)....................................................................... 29

Circuit Description............................................................................................................................................... 29

DTC U2100 Diagnostic Aids................................................................................................................................ 29

Additional Information....................................................................................................................................... 29

Conditions for Running the DTC....................................................................................................................... 29

Conditions for Setting the DTC......................................................................................................................... 29

Action Taken When the DTC Sets.................................................................................................................... 29

Conditions for Clearing the DTC....................................................................................................................... 30

Test Description ............................................................................................................................................... 30

DTC U2100 Diagnostic Table........................................................................................................................... 30

7.4 DTC U2105 – CAN Bus No Communication with Engine Control Module....................................................... 33

Circuit Description............................................................................................................................................... 33

DTC U2105 Diagnostic Aids................................................................................................................................ 33

Additional Information....................................................................................................................................... 33

Conditions for Running the DTC....................................................................................................................... 33

Conditions for Setting the DTC......................................................................................................................... 33

Action Taken When the DTC U2105................................................................................................................ 33

Conditions for Clearing the DTC....................................................................................................................... 33

Test Description ............................................................................................................................................... 33

DTC U2105 Diagnostic Table........................................................................................................................... 34

7.5 DTC U2106 – CAN Bus No Communication with Transmission Control Module........................................... 35

Circuit Description............................................................................................................................................... 35

DTC U2106 Diagnostic Aids................................................................................................................................ 35

Additional Information....................................................................................................................................... 35

Conditions for Running the DTC....................................................................................................................... 35

Conditions for Setting the DTC......................................................................................................................... 35

Action Taken When the DTC Sets.................................................................................................................... 35

Conditions for Clearing the DTC....................................................................................................................... 35

Test Description ............................................................................................................................................... 35

DTC U2106 Diagnostic Table........................................................................................................................... 36

7.6 DTC U2108 – CAN Bus No Communication with Steering Angle Sensor ....................................................... 38

Circuit Description............................................................................................................................................... 38

DTC U2108 Diagnostic Aids................................................................................................................................ 38

Powertrain Interface Module Page 6E4–3

Page 6E4–3

Additional Information....................................................................................................................................... 38

Conditions for Running the DTC....................................................................................................................... 38

Conditions for Setting the DTC......................................................................................................................... 38

Action Taken When the DTC Sets.................................................................................................................... 38

Conditions for Clearing the DTC....................................................................................................................... 38

Test Description ............................................................................................................................................... 39

DTC U2108 Diagnostic Table........................................................................................................................... 39

7.7 DTC P0565 – Cruise Control On Signal Malfunction......................................................................................... 41

Circuit Description............................................................................................................................................... 41

DTC P0565 Diagnostic Aids................................................................................................................................ 41

Additional Information....................................................................................................................................... 41

Conditions for Running the DTC....................................................................................................................... 41

Conditions for Setting the DTC......................................................................................................................... 41

Action Taken When the DTC Sets.................................................................................................................... 41

Conditions for Clearing the DTC....................................................................................................................... 41

Test Description ............................................................................................................................................... 41

DTC P0565 Diagnostic Table........................................................................................................................... 42

7.8 DTC P0567 – Cruise Control Resume Signal Malfunction................................................................................ 43

Circuit Description............................................................................................................................................... 43

DTC P0567 Diagnostic Aids................................................................................................................................ 43

Additional Information....................................................................................................................................... 43

Conditions for Running the DTC....................................................................................................................... 43

Conditions for Setting the DTC......................................................................................................................... 43

Action Taken When the DTC Sets.................................................................................................................... 43

Conditions for Clearing the DTC....................................................................................................................... 43

Test Description ............................................................................................................................................... 43

DTC P0567 Diagnostic Table........................................................................................................................... 44

7.9 DTC P0568 – Cruise Control Set Signal Malfunction........................................................................................ 45

Circuit Description............................................................................................................................................... 45

DTC P0568 Diagnostic Aids................................................................................................................................ 45

Additional Information....................................................................................................................................... 45

Conditions for Running the DTC....................................................................................................................... 45

Conditions for Setting the DTC......................................................................................................................... 45

Action Taken When the DTC Sets.................................................................................................................... 45

Conditions for Clearing the DTC....................................................................................................................... 45

Test Description ............................................................................................................................................... 45

DTC P0568 Diagnostic Table........................................................................................................................... 46

7.10 DTC P1611 – Wrong Security Code Entered...................................................................................................... 47

Circuit Description............................................................................................................................................... 47

DTC P1611 Diagnostic Aids................................................................................................................................ 47

Additional Information....................................................................................................................................... 47

Conditions for Running the DTC....................................................................................................................... 47

Conditions for Setting the DTC......................................................................................................................... 47

Action Taken When the DTC Sets.................................................................................................................... 47

Conditions for Clearing the DTC....................................................................................................................... 47

Test Description ............................................................................................................................................... 48

DTC P1611 Diagnostic Table........................................................................................................................... 48

7.11 DTC P1678 – Engine Control Module Identification Failed............................................................................... 49

Circuit Description............................................................................................................................................... 49

DTC P1678 Diagnostic Aids................................................................................................................................ 49

Additional Information....................................................................................................................................... 49

Conditions for Running the DTC....................................................................................................................... 49

Conditions for Setting the DTC......................................................................................................................... 49

Action Taken When the DTC Sets.................................................................................................................... 49

Conditions for Clearing the DTC....................................................................................................................... 49

Test Description ............................................................................................................................................... 49

DTC P1678 Diagnostic Table........................................................................................................................... 50

7.12 DTC B1019 – Transmission Control Module Configuration Mismatch............................................................ 51

Circuit Description............................................................................................................................................... 51

DTC B1019 Diagnostic Aids................................................................................................................................ 51

Powertrain Interface Module Page 6E4–4

Page 6E4–4

Additional Information....................................................................................................................................... 51

Conditions for Running the DTC....................................................................................................................... 51

Conditions for Setting the DTC......................................................................................................................... 51

Action Taken When the DTC Sets.................................................................................................................... 51

Conditions for Clearing the DTC....................................................................................................................... 51

Test Description ............................................................................................................................................... 51

DTC B1019 Diagnostic Table........................................................................................................................... 52

7.13 DTC B2745 – Traction Control Switch Signal Malfunction............................................................................... 53

Circuit Description............................................................................................................................................... 53

DTC B2745 Diagnostic Aids................................................................................................................................ 53

Additional Information....................................................................................................................................... 53

Conditions for Running the DTC....................................................................................................................... 53

Conditions for Setting the DTC......................................................................................................................... 53

Action Taken When the DTC Sets.................................................................................................................... 53

Conditions for Clearing the DTC....................................................................................................................... 53

Test Description ............................................................................................................................................... 53

DTC B2745 Diagnostic Table........................................................................................................................... 54

7.14 DTC B3924 – Wrong Environment Identifier Received from Body Control Module....................................... 55

Circuit Description............................................................................................................................................... 55

DTC B3924 Diagnostic Aids................................................................................................................................ 55

Additional Information....................................................................................................................................... 55

Conditions for Running the DTC....................................................................................................................... 55

Conditions for Setting the DTC......................................................................................................................... 55

Action Taken When the DTC Sets.................................................................................................................... 55

Conditions for Clearing the DTC....................................................................................................................... 55

Test Description ............................................................................................................................................... 56

DTC B3924 Diagnostic Table........................................................................................................................... 56

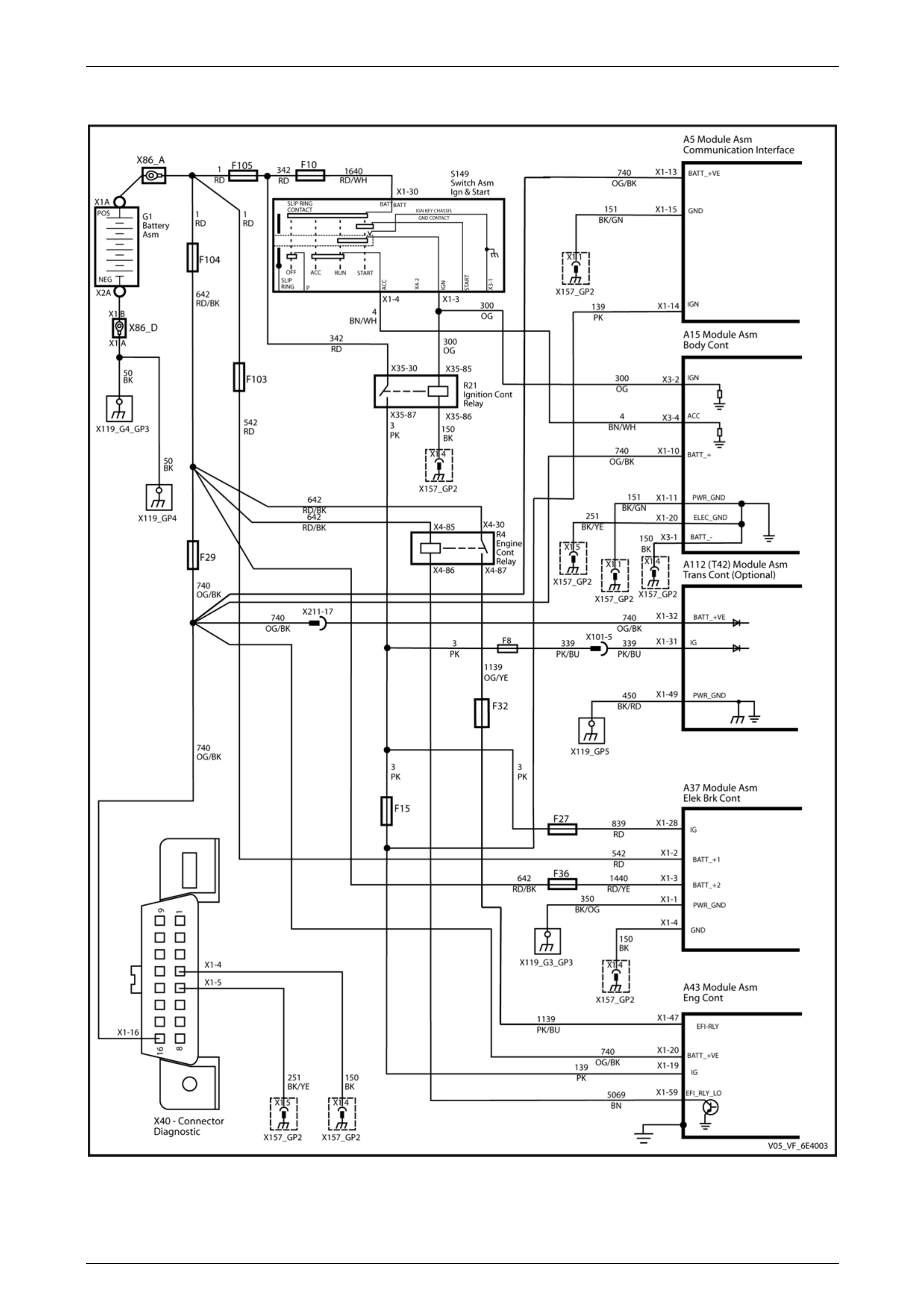

8 Electrical Circuit and Connector Views .............................................................................................57

8.1 PIM Electrical Circuit ........................................................................................................................................... 58

8.2 Power and Ground Distribution Circuit ............................................................................................................. 59

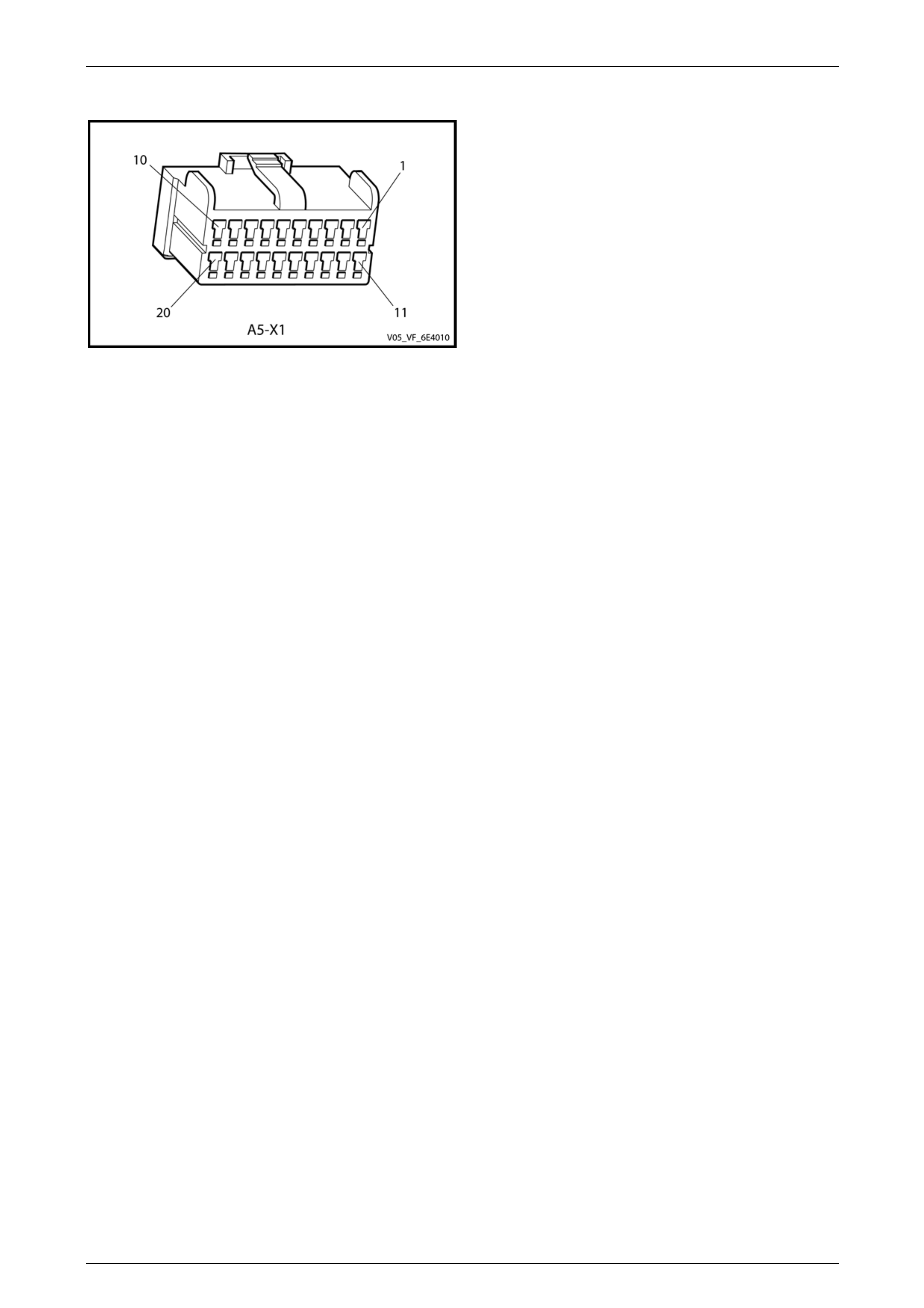

PIM Connector Pin Specifications...................................................................................................................... 60

Pin Description................................................................................................................................................. 60

8.3 Cruise Control Switch Assembly........................................................................................................................ 61

Cruise Control Switch Assembly Connector Pin Specifications.....................................................................61

Pin Description................................................................................................................................................. 61

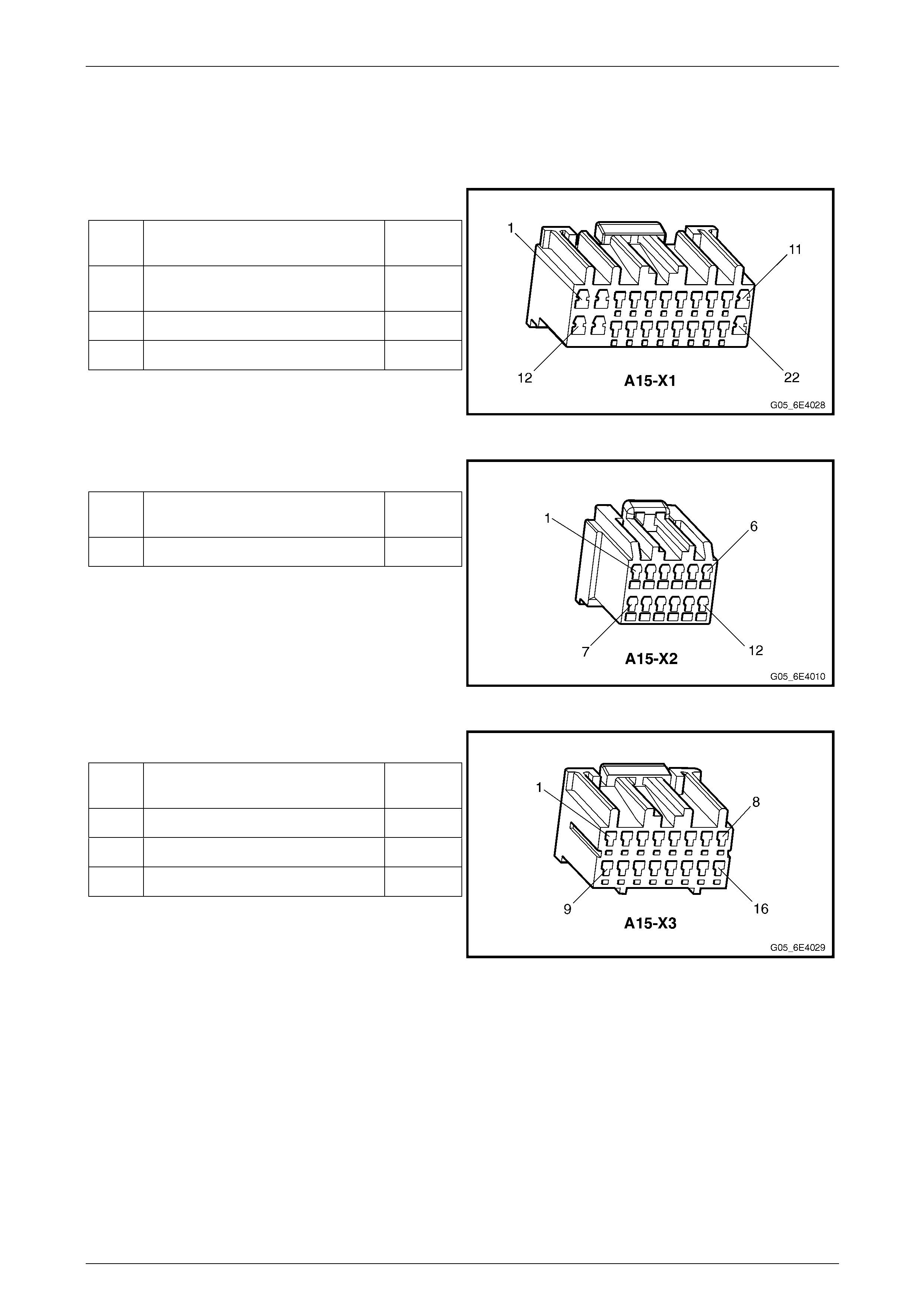

8.4 Body Control Module........................................................................................................................................... 62

Body Control Module Connector Pin Specification.......................................................................................... 62

Pin Description – Connector X1 ....................................................................................................................... 62

Pin Description – Connector X2 ....................................................................................................................... 62

Pin Description – Connector X3 ....................................................................................................................... 62

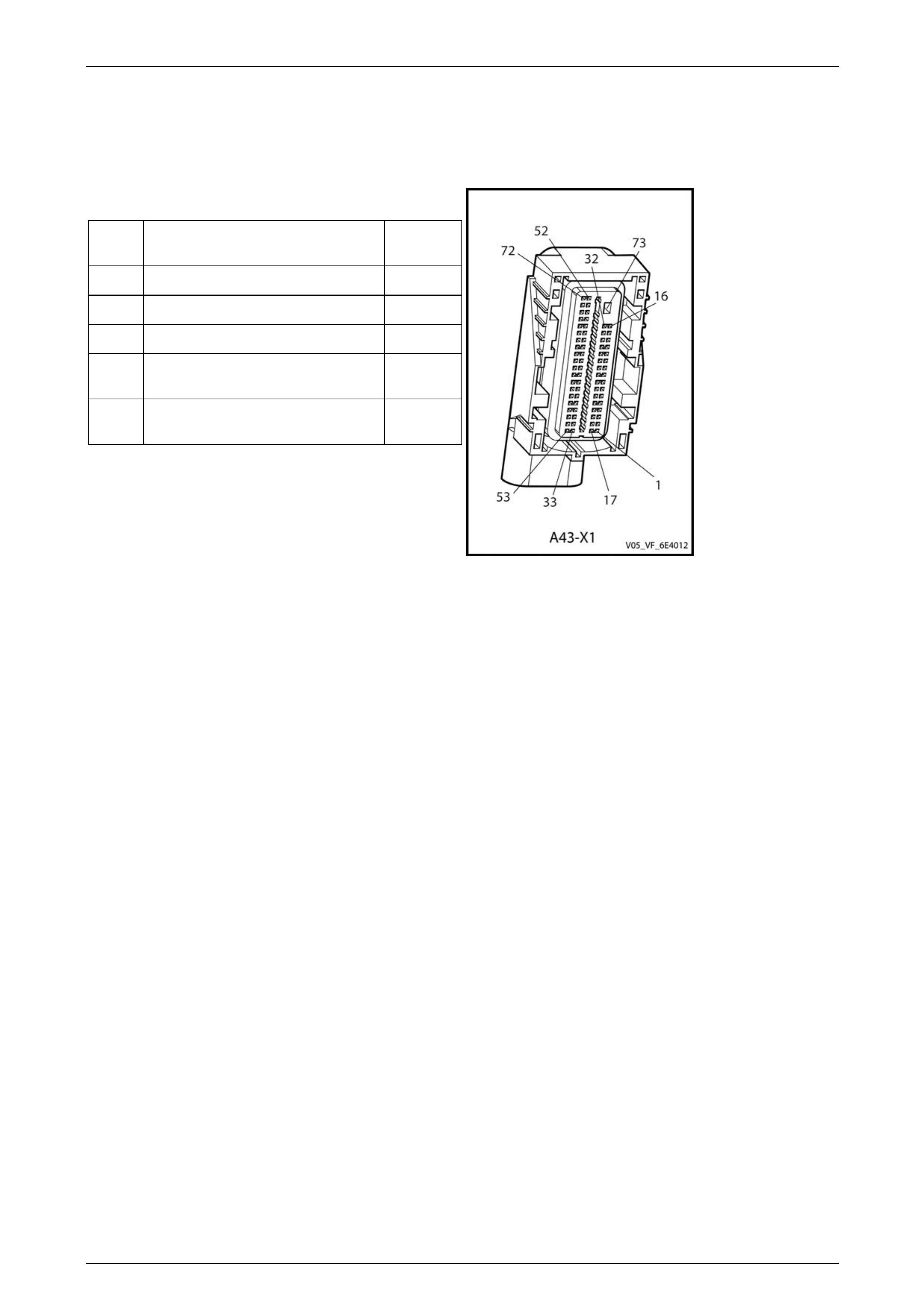

8.5 Engine Control Module........................................................................................................................................ 63

Engine Control Module Connector Pin Specifications..................................................................................... 63

Pin Description................................................................................................................................................. 63

8.6 Automatic Transmission Control Module.......................................................................................................... 64

Automatic Transmission Control Module Connector Pin Specifications ....................................................... 64

Pin Description................................................................................................................................................. 64

8.7 Ignition Switch ..................................................................................................................................................... 65

Ignition Switch Connector Pin Specification..................................................................................................... 65

Pin Description................................................................................................................................................. 65

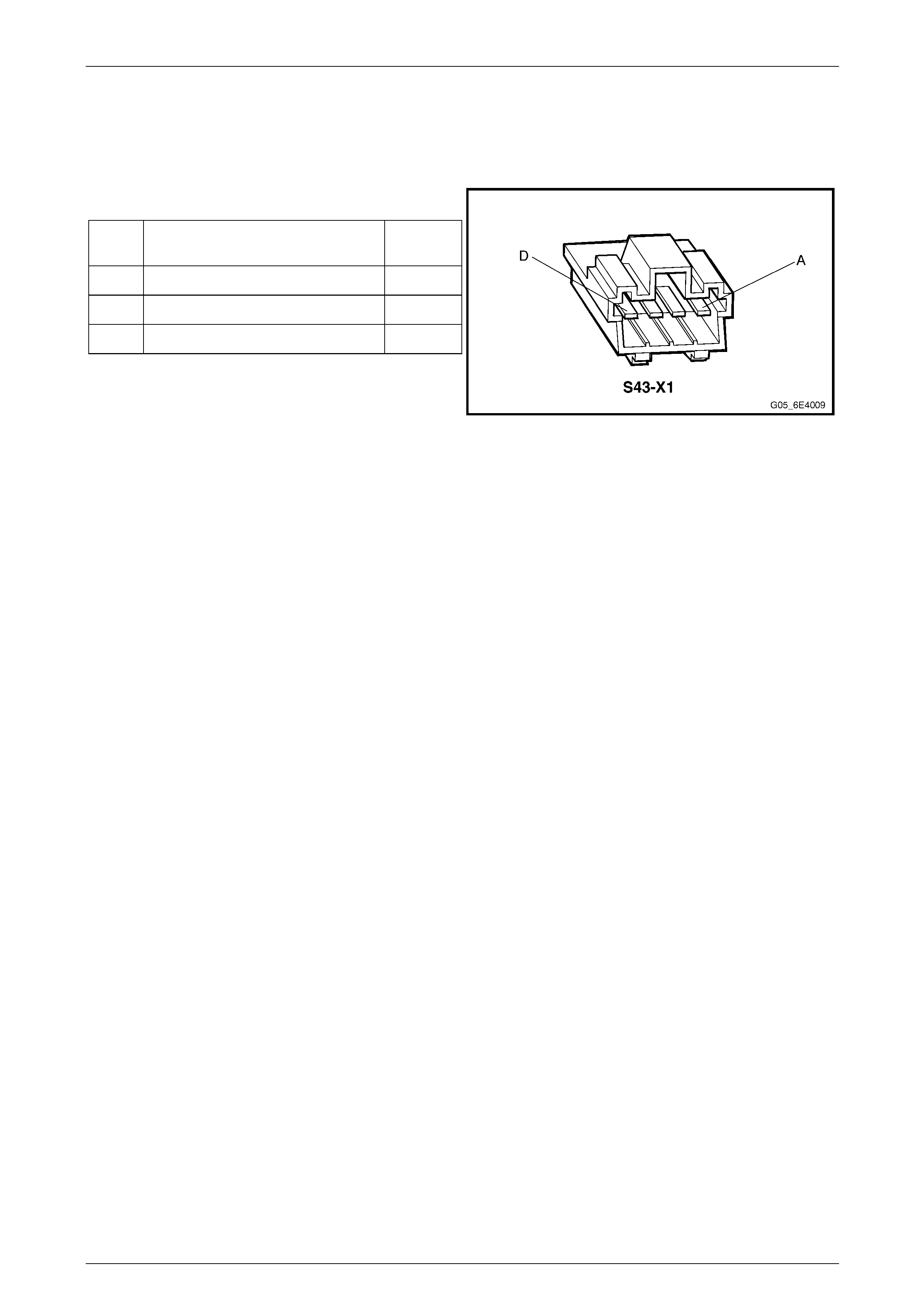

8.8 Traction Control Switch ...................................................................................................................................... 66

Traction Control Switch Connector Pin Specifications.................................................................................... 66

Pin Description................................................................................................................................................. 66

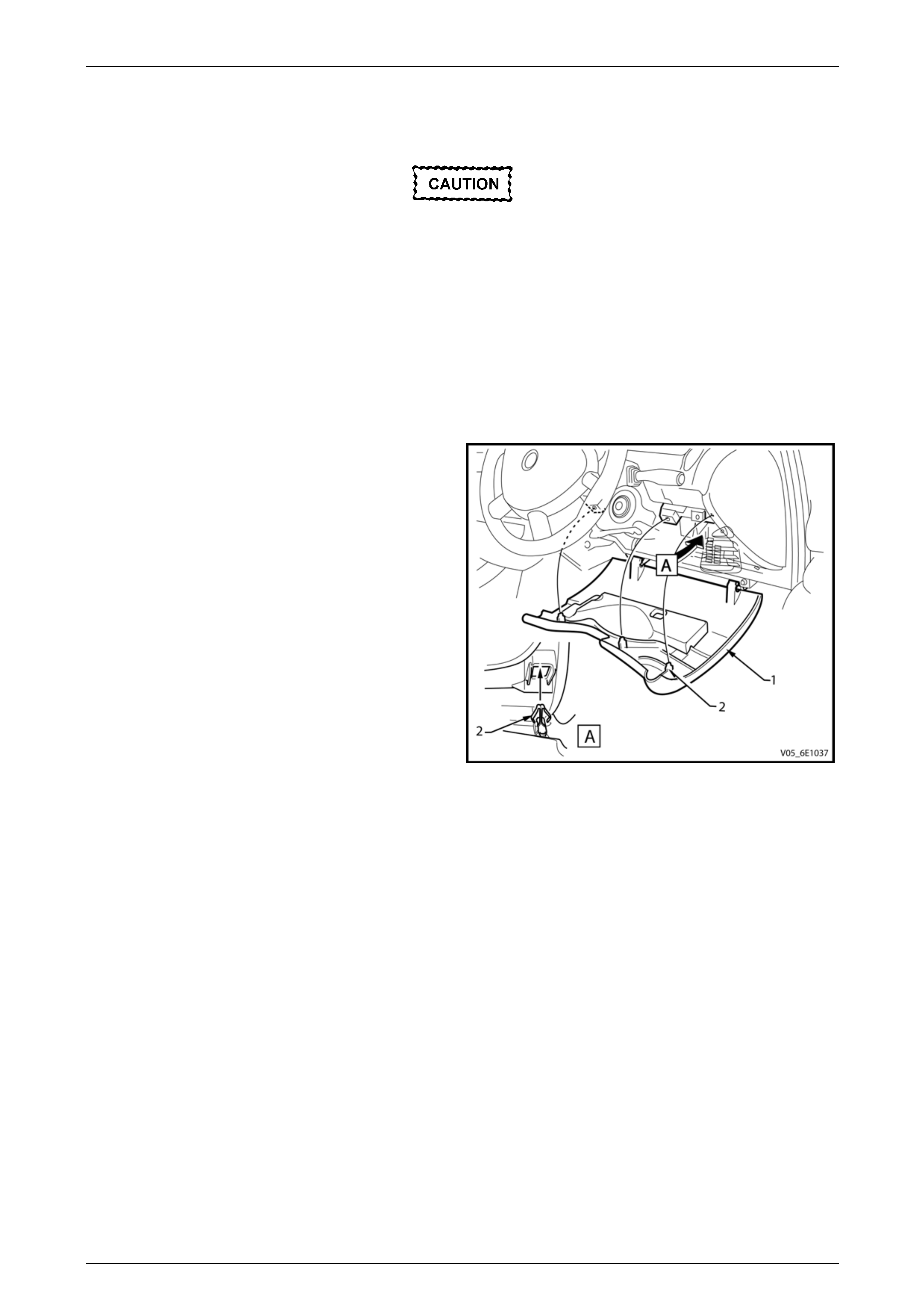

9 Service Operations...............................................................................................................................67

9.1 Safety and Precautionary Measures .................................................................................................................. 67

9.2 Powertrain Interface Module............................................................................................................................... 68

Remove................................................................................................................................................................. 68

Reinstall................................................................................................................................................................ 69

Powertrain Interface Module Page 6E4–5

Page 6E4–5

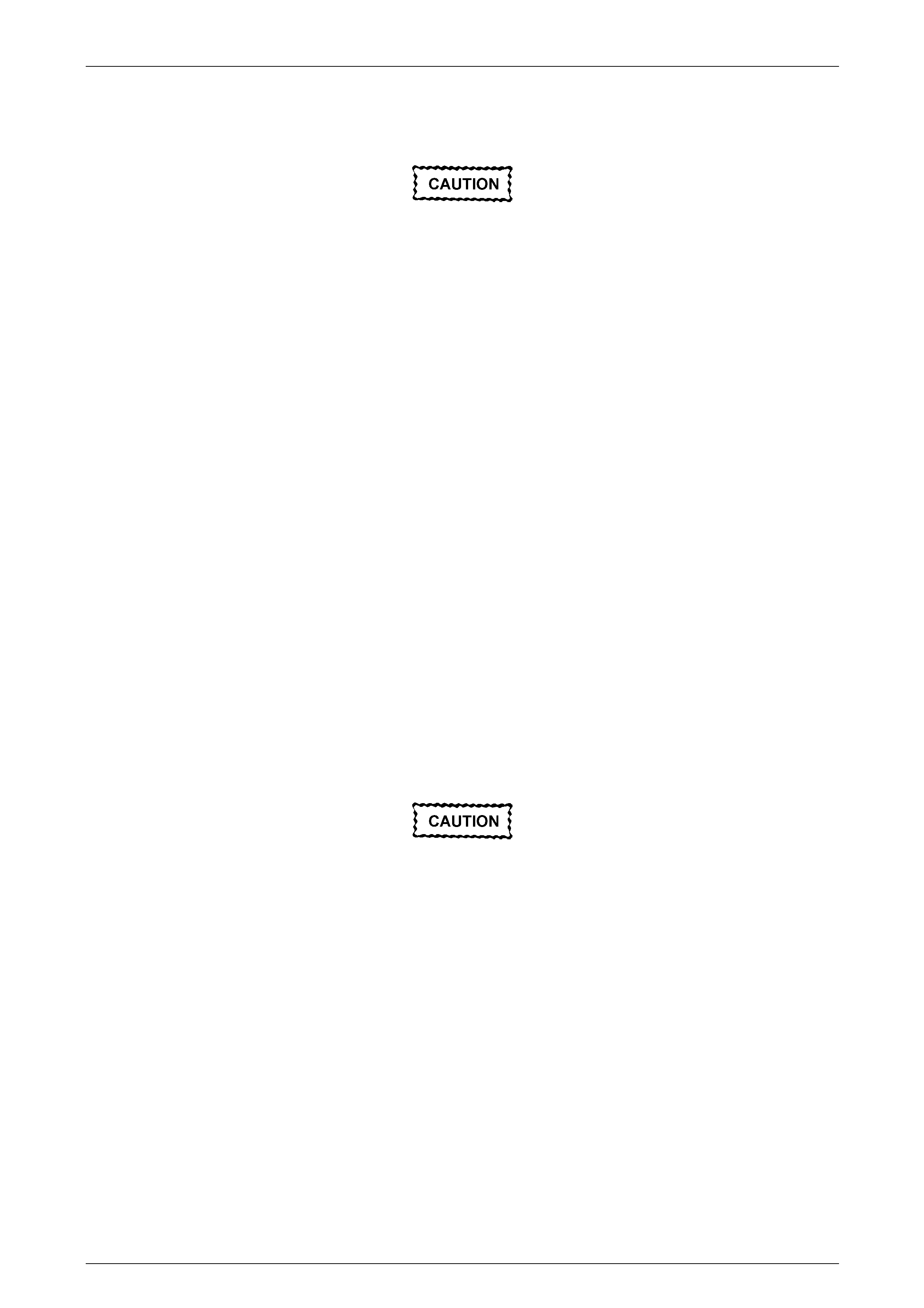

10 PIM Security and Programming................................................................................................... .......70

10.1 Security and Programming Information ............................................................................................................ 70

Vehicle Security Card.......................................................................................................................................... 70

Security Code....................................................................................................................................................... 70

TECH 2 PIM Security Information Data List....................................................................................................... 71

10.2 PIM Reset Procedure........................................................................................................................................... 72

10.3 PIM Configuration................................................................................................................................................ 73

Configuring a New PIM........................................................................................................................................ 73

Configuring an Existing PIM............................................................................................................................... 74

Programming the VIN.......................................................................................................................................... 74

10.4 BCM Link to ECM / PIM........................................................................................................................................ 75

11 Specifications.......................................................................................................................................76

12 Torque Wrench Specifications............................................................................................................77

13 Special Tools ........................................................................................................................................78

Powertrain Interface Module Page 6E4–6

Page 6E4–6

1 General Information

The MY 2006 WL is fitted with a new powertrain interface module (PIM). The most significant changes that have been

made to the PIM are as follows:

• Communication protocol between the engine control module (ECM), transmission control module (TCM) and the

Electronic Control Unit (ECU) of the Antilock Braking and Traction Control System, is General Motors Lo cal Area

Network (GM LAN) .

• ECM to PIM and PIM to body control module (BCM) authentication for vehicle security.

• Cruise control switch functions input directly into the PIM.

• Traction control enable/disable switch inputs directly into the PIM.

1.1 General Description

Serial Data Communication

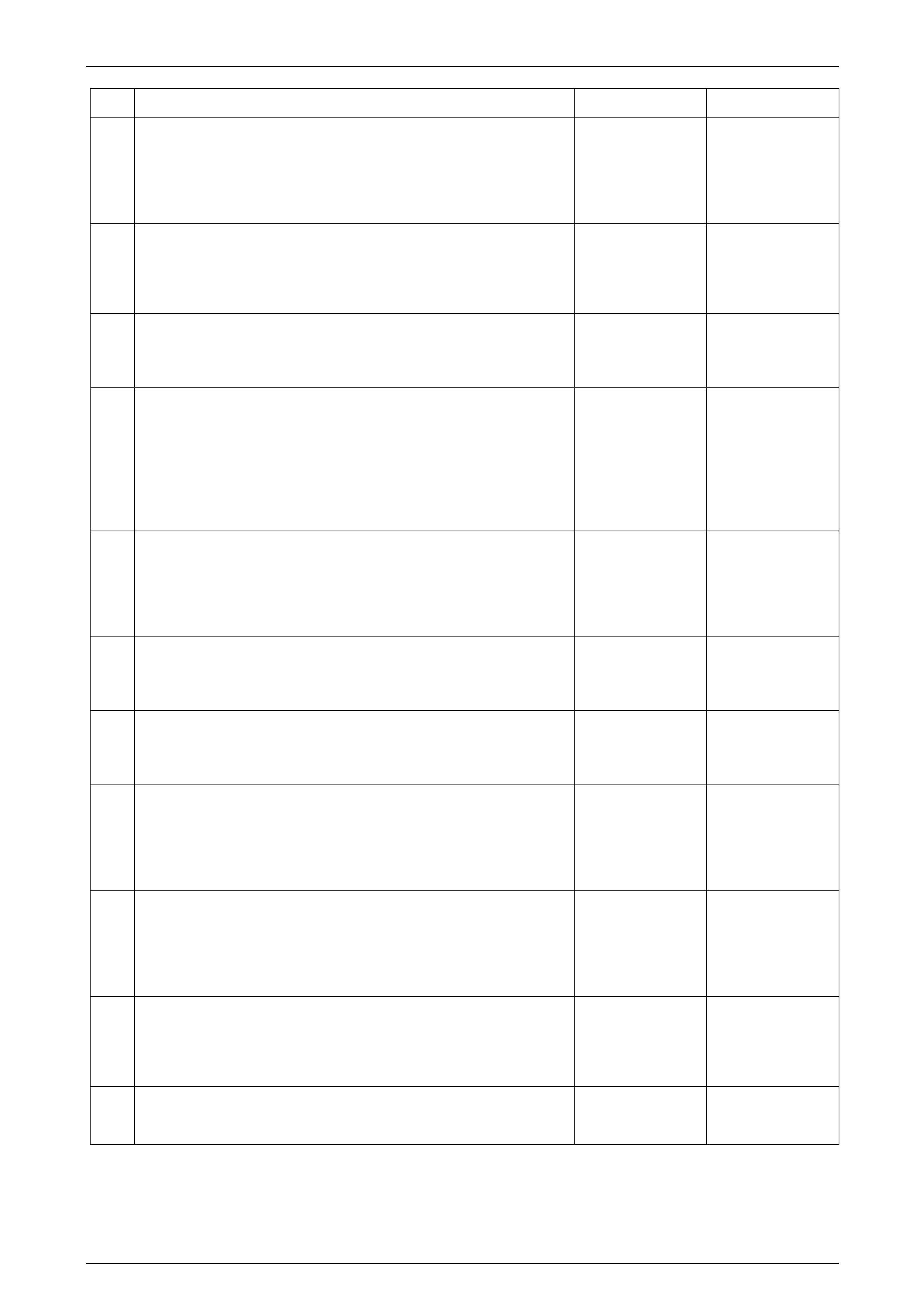

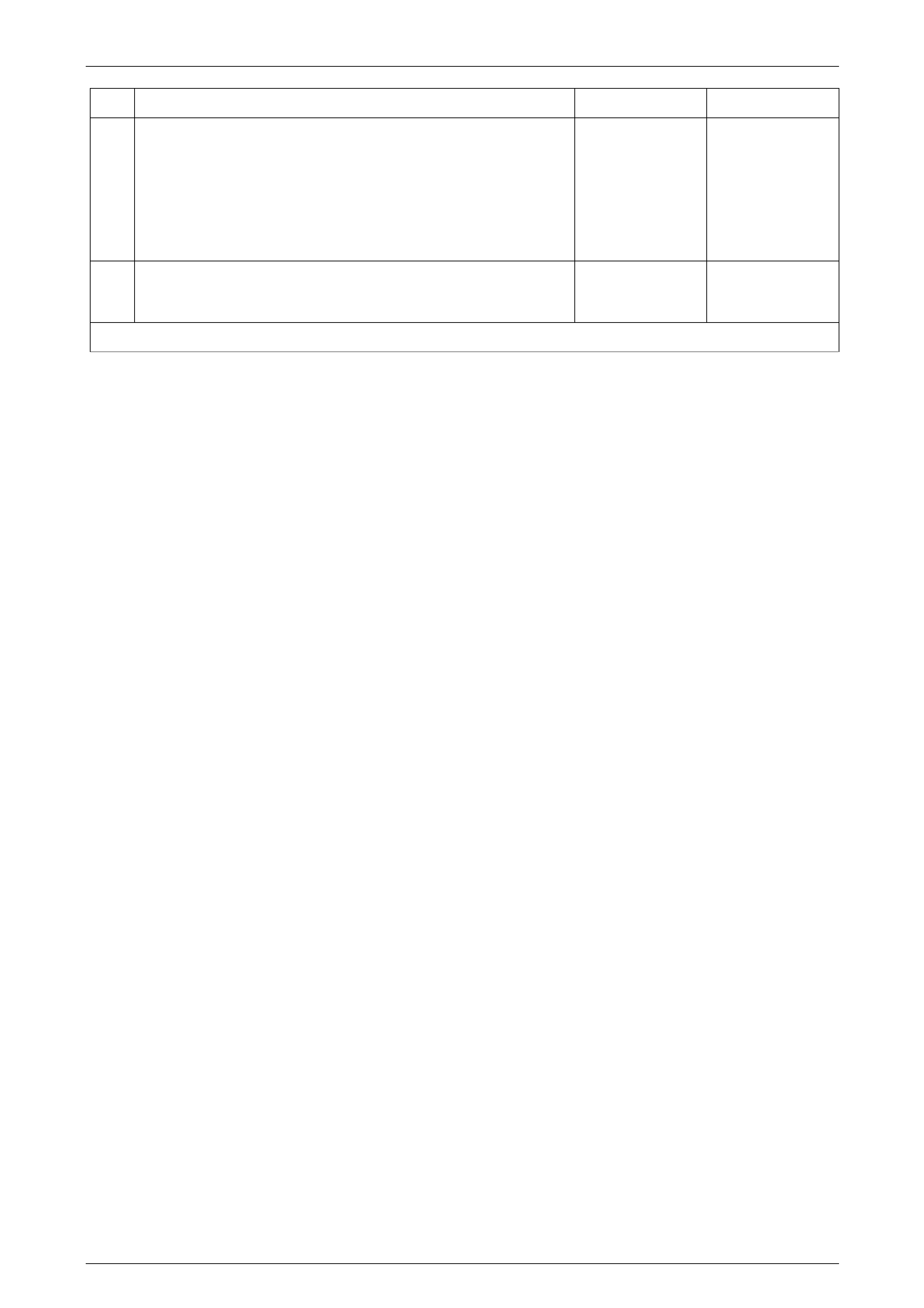

The various electronic control modules integrated into the MY2006 WL vehicle communicate with each other through the

serial data bus. The ECM, TCM and ABS-TCS ECU communicate on the serial data bus using the GM LAN

communication protocol, whilst the BCM communic ates with the instrument cluster, Audio Head Unit (AHU) and

Occupant Protection System Sensing and Diagnostic Module (SDM) using the Universal Asynchronous Receiv e and

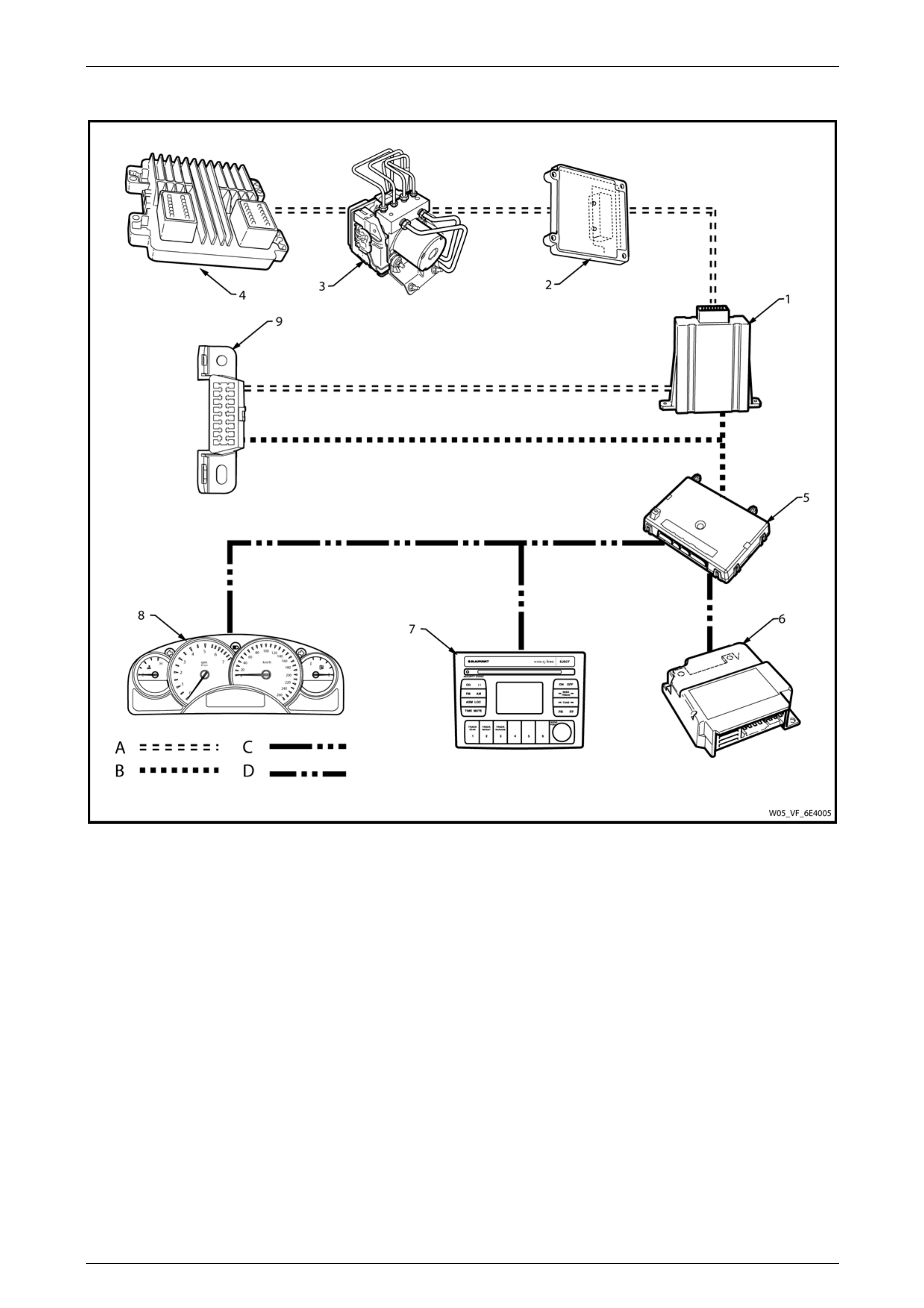

Transmit (UART) communicat ion protocol. Figure 6E4 – 2 shows the serial data layout.

The PIM is integrated into the serial dat a network and acts as a transparent bi-directional translation device that enables

the control modules on the GM LAN serial data bus to communicate with control modules on the UART serial data bus.

For further information on the UART serial data bus, refer to Section 12J Body Control Module.

Bus

A bus is a physical circuit or circuits which provides a communication path between two or more control modules.

UART Serial Data Bus

UART communication uses a single wire circuit. For further information on the UART serial data bus, refer to

Section 12J Body Control Module.

GM LAN Serial Data Bus

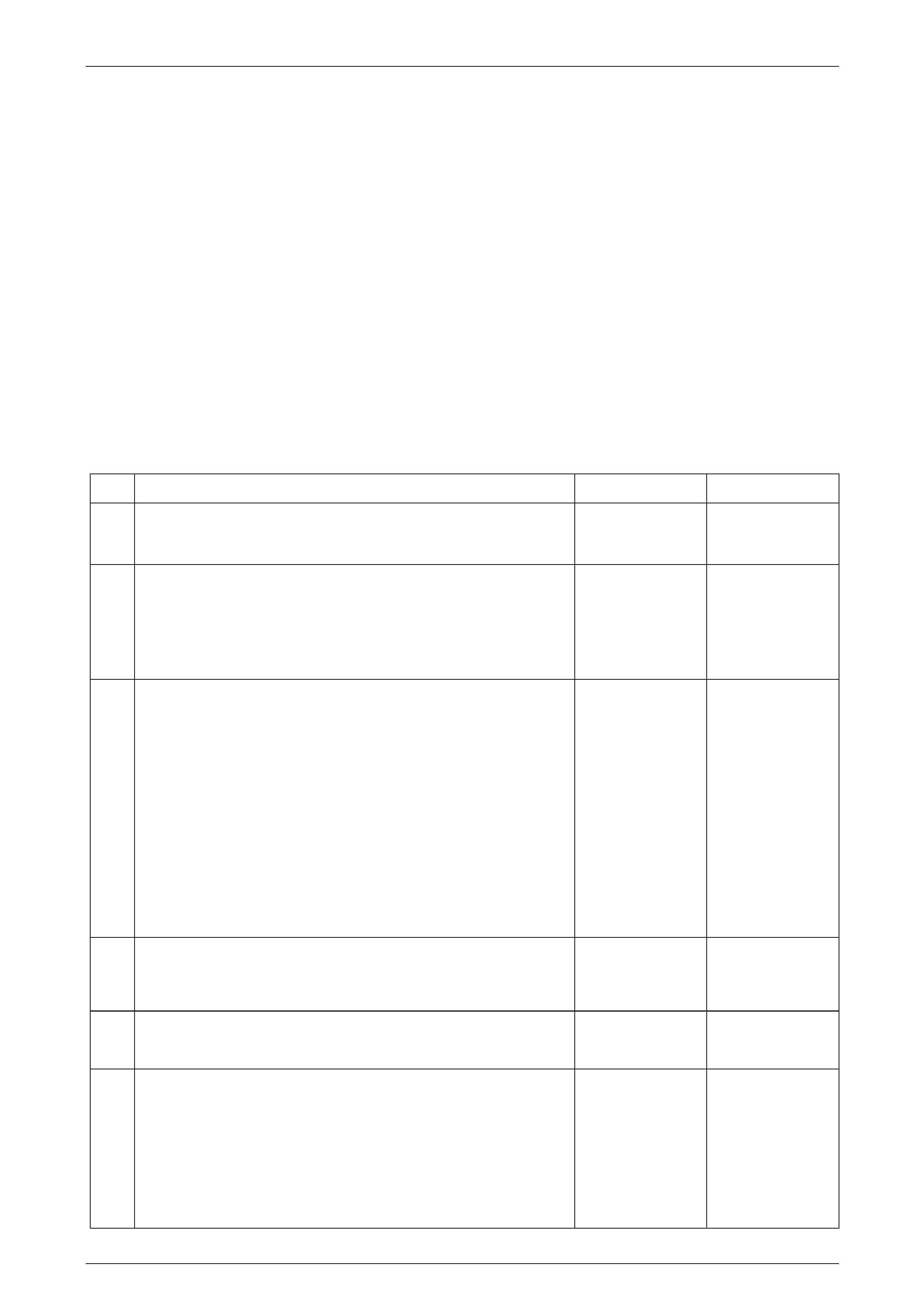

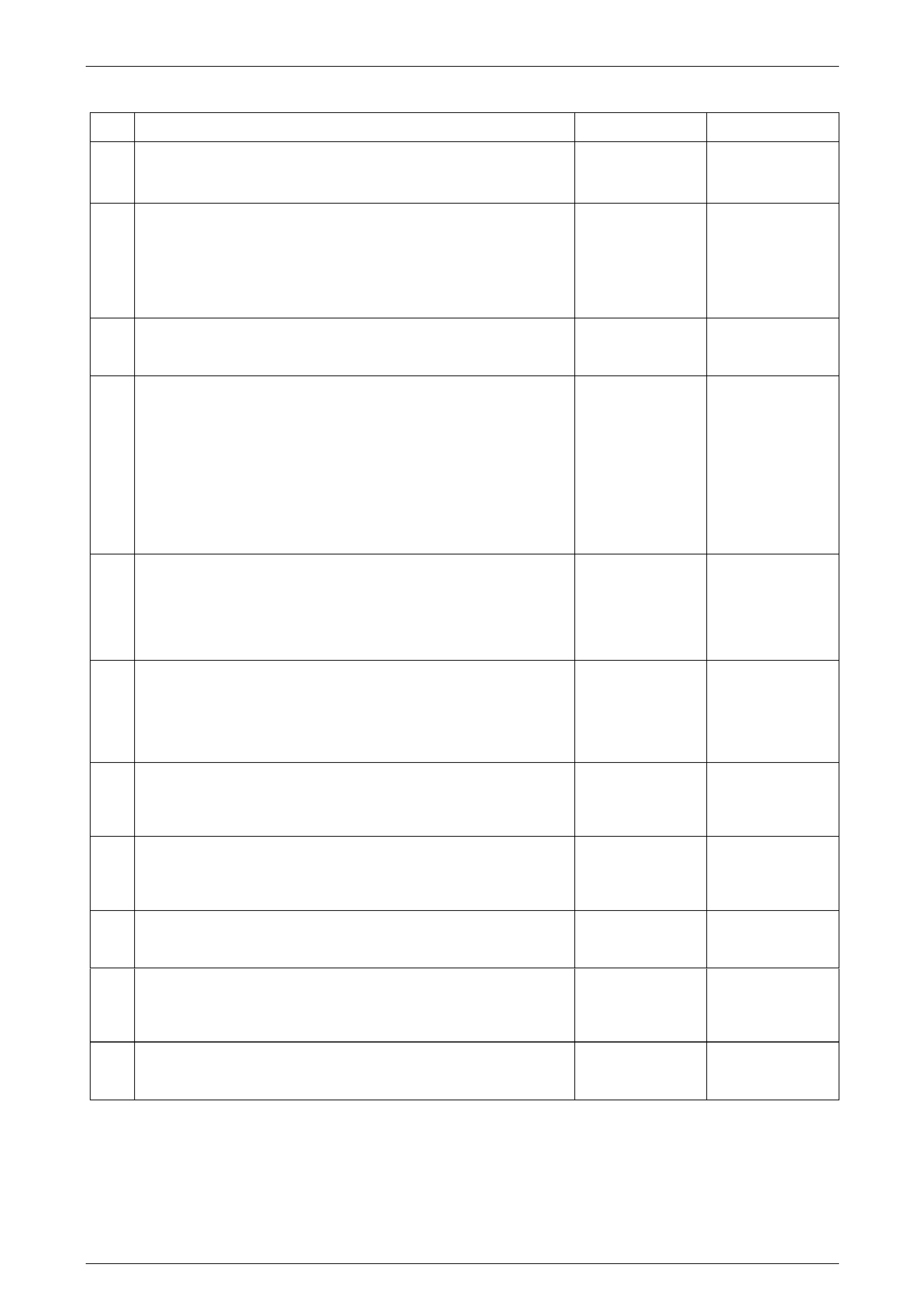

The GM LAN bus is a two wire circuit (1), refer to Figure 6E4 – 1. The GM LAN bus circuits are terminated with cut-off

resistors (2) which are locate d inside the two control modules at either end of the bus circuit. The purpose of these cut - off

resistors is to prevent data from returning as an echo after reaching the end of the GM LAN bus circu it.

NOTE

For illustration purposes, the cut-off resistors are

shown outside of the control modules.

The two control modules with the cut-off resistors

are the PIM and the ECM.

Powertrain Interface Module Page 6E4–7

Page 6E4–7

Figure 6E4 – 1

Legend

1 CAN Bus Lines

2 Cut-off Resistors (resistors are integrated into the PIM and

ECM)

3 Powertrain Interface Module (PIM)

4 Transmission Control Module (TCM)

5 ABS-TCS Electronic Control Unit (ECU)

6 Engine Control Module (ECM)

Serial Data

When information is sent from one control module to another via the serial data bus, the information sent is known as

serial data. Serial data in its electronic form, is made up of rapi dly changing high to lo w voltage pu lses strung together.

Each string of voltage pulses represents a message.

• GM LAN serial data has two data lines along which serial data is sent. These lines are kno wn as CAN HI and CAN

LO.

• CAN HI – The CAN HI data line is a 3.6 V data line that toggles the voltage between 2.5 V and 3.6 V

(referenced to ground). When there is no communication on the CAN HI data line, the system voltage

is 2.5 V.

• CAN LO – The CAN LO data line is a 2.5 V data line that toggles the voltage between 2.5 V and 1.4 V

(referenced to ground). When there is no communication on the CAN LO data line, the system voltage

is 2.5 V.

• UART serial data is a single 5 V data line that toggles the voltage to ground. When there is no communication on

the data line, the system voltage is 5 V.

Serial Data Communication Protocols

General Motors Local Area Network (GM LAN)

GM LAN is a communication protocol based on the Controller Area Network physical layer. The main difference between

GM LAN and CAN is the way in which the messages are structured. It is a broadcast communications channel, not

master / slave like UART.

Universal Asynchronous Receive and Transmit (UART)

UART is a communication pro t ocol that has a master module which controls the message traffic on the serial data bus.

The body control module (BCM) is the UART bus master in the MY 2006 WL. The main difference between

GM LAN and UART protocol is that UART relies on the bus master to control the messaging, where as with GM LAN, the

messaging is managed b y each of the control modules.

Powertrain Interface Module Page 6E4–8

Page 6E4–8

Serial Data Layout

Figure 6E4 – 2

Legend

1 Powertrain Interface Module (PIM)

2 Transmission Control Module (TCM)

3 ABS-TCS Electronic Control Unit (ECU)

4 Engine Control Module (ECM)

5 Body Control Module (BCM)

6 Occupant Protection System Sensing and Diagnostic

Module (SDM)

7 Audio Head Unit (AHU)

8 Instrument Cluster

9 Data Link Connector

A GM LAN Serial Data Circuit

B Primary UART Serial Data Circuit

C Secondary UART Serial Data Circuit

D Tertiary UART Serial Data Circuit

Powertrain Interface Module Page 6E4–9

Page 6E4–9

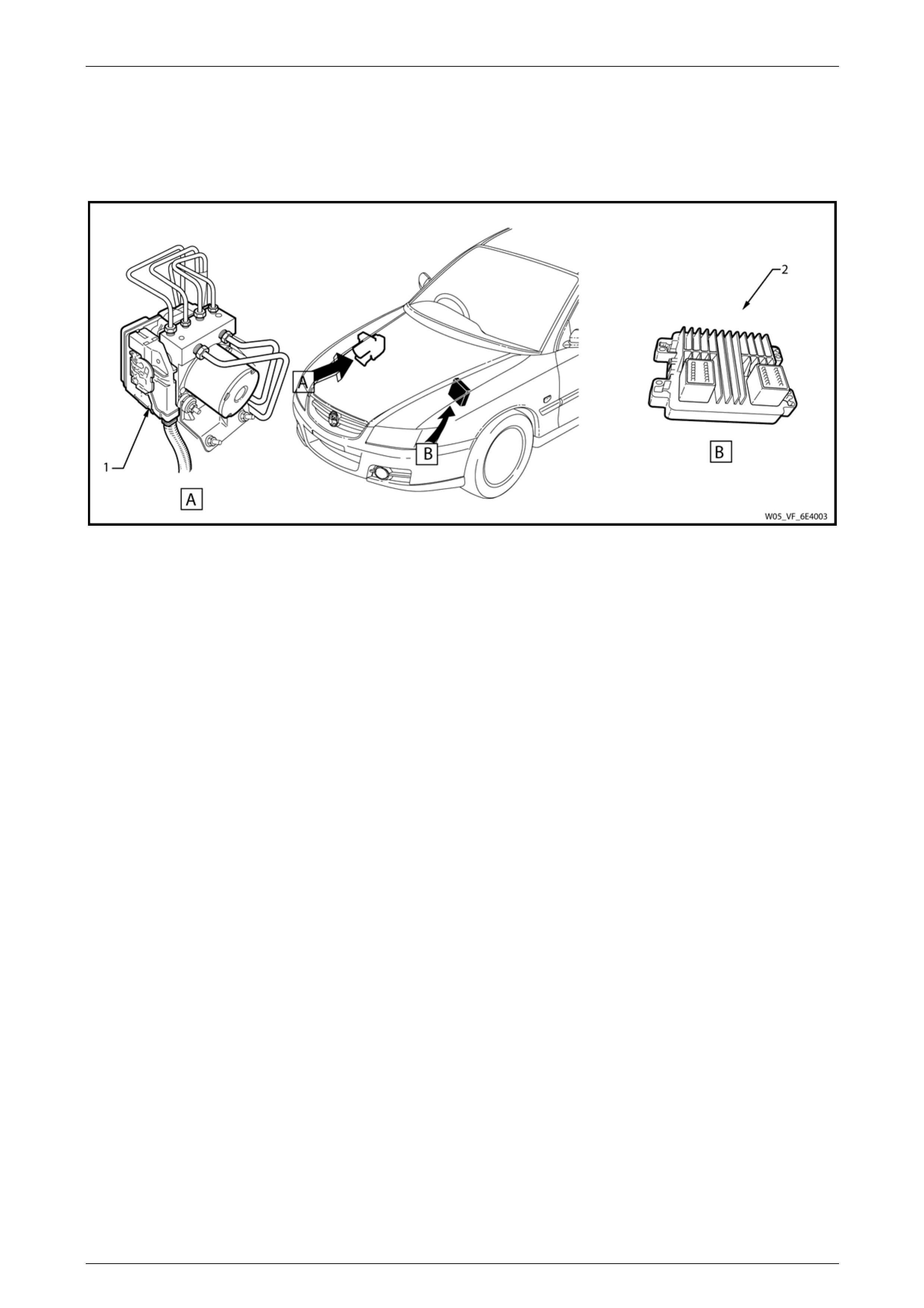

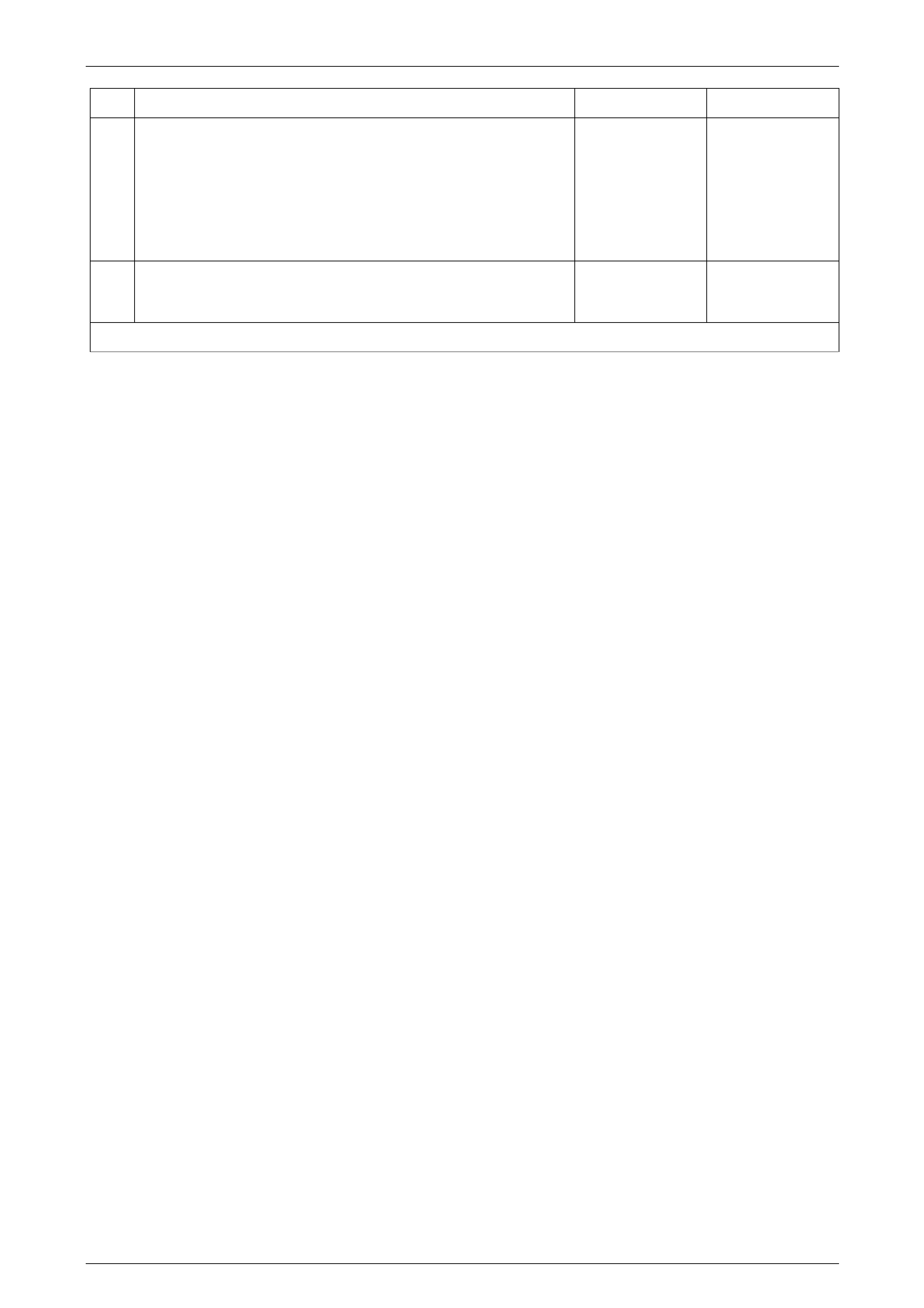

2 Component Location

2.1 Engine Compartment

Figure 6E4 – 3

Legend

1 ABS-TCS Electronic Control Unit (ECU) 2 Engine Control Module (ECM)

Powertrain Interface Module Page 6E4–10

Page 6E4–10

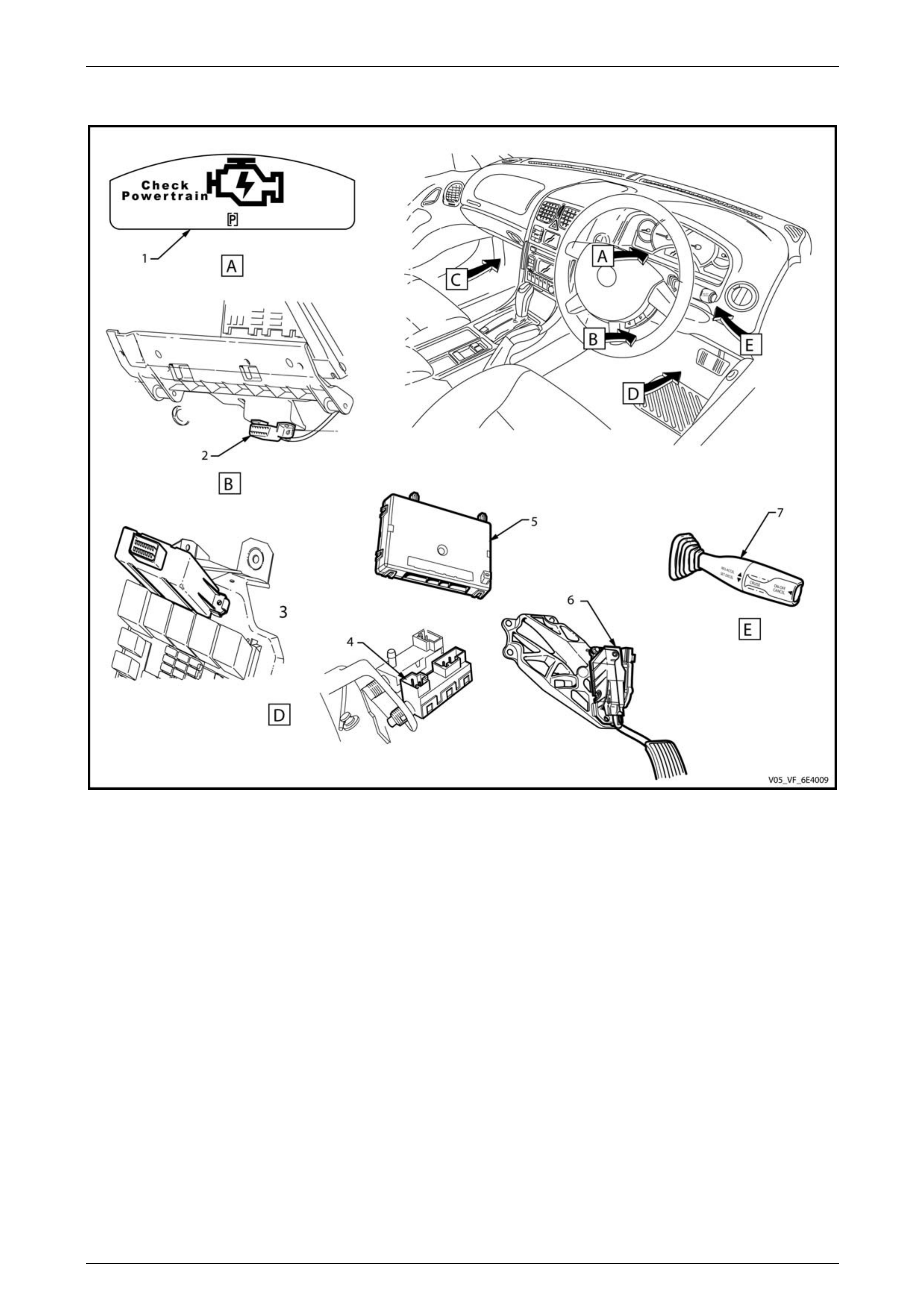

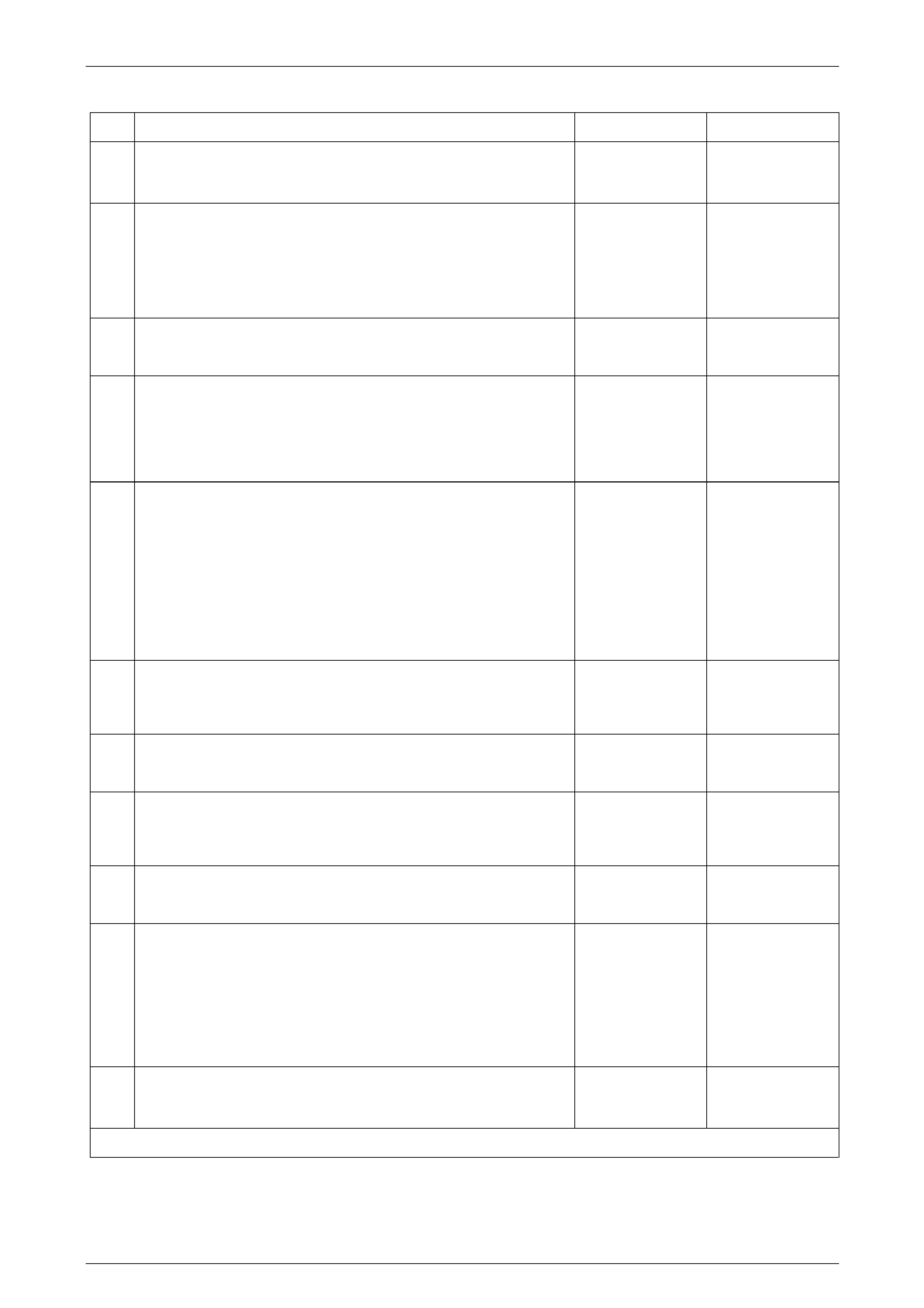

2.2 Interior

Figure 6E4 – 4

1 Check Powertrain Icon

2 Data Link Connector

3 Powertrain Interface Module (PIM)

4 Stop Lamp Switch

5 Body Control Module (BCM)

6 Accelerator Pedal Assembly

7 Cruise Control Switch Assembly

Powertrain Interface Module Page 6E4–11

Page 6E4–11

3 Component Description and

Operation

3.1 Pow ertrain Interface Module

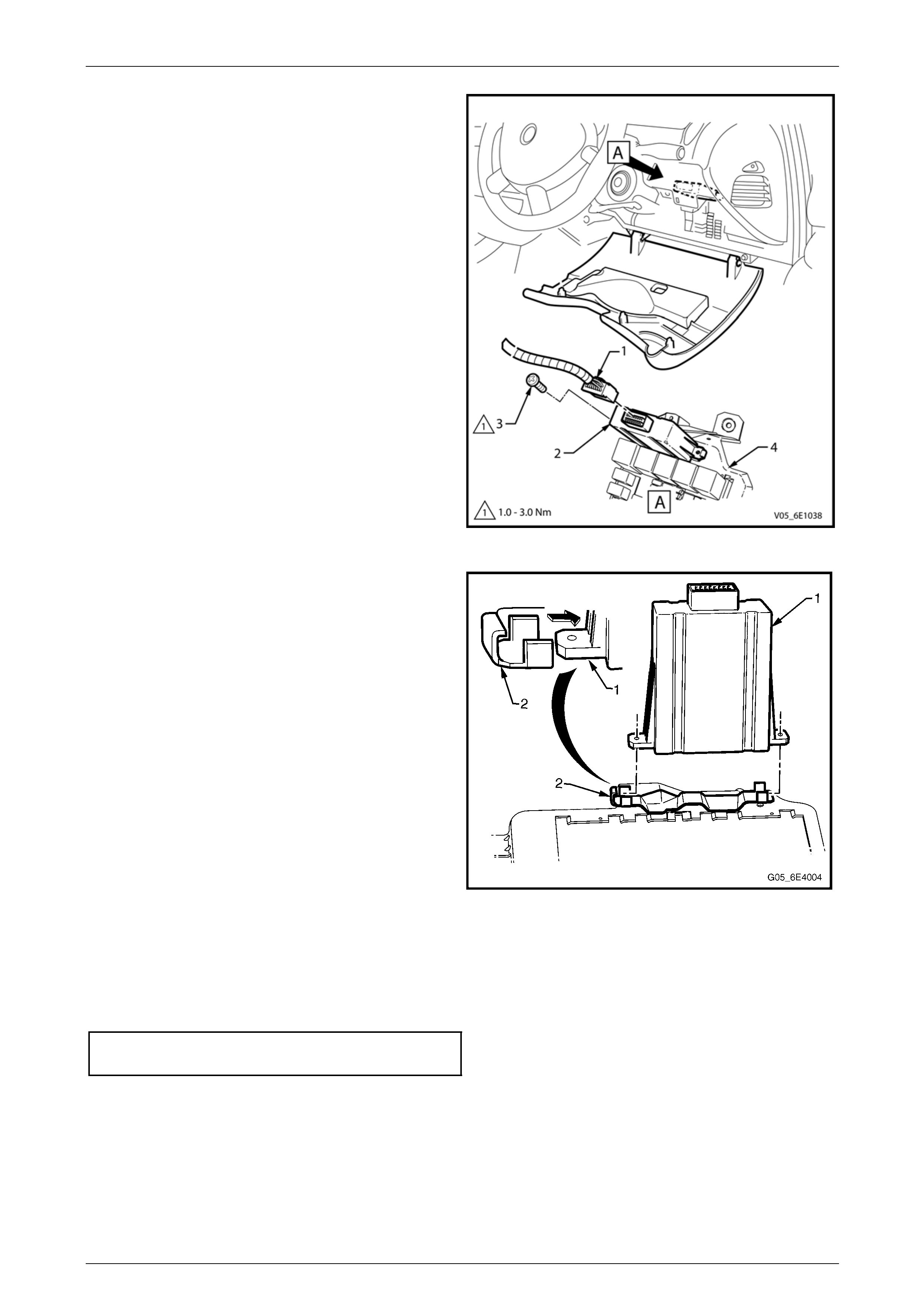

The powertrain interface module (PIM) is located on the

driver's instrument panel outer bracket and is accessible by

lowering the instrument panel lower trim panel assembly.

Figure 6E4 – 5

Communication Gateway

The PIM performs the following functions:

• The PIM Acts as the communication gate way between the GM LAN communications protocol and the Universal

Asynchronous Receive and Transmit (UART) protocol.

As the GM LAN protocol is not compatible with UART, the PIM is integrated into the serial data commu nication

system to enable bi-directional communication flow between control modules on the UART side and the GM LAN

side of the communication net work.

• The PIM converts analogue signals from the cruise control, traction control switches and crank request from the

ignition switch into digital serial data.

• The PIM is responsible for au thenticating the body control module (BCM) prior to the engine control module (ECM)

authenticating the PIM. If any of these authentication processes fail, the vehicl e will not start. For further information

on the theft deterrent system, refer to Section 12J Body Control Module.

• The PIM provides crank request to the ECM to allow cranking.

Powertrain Interface Module Page 6E4–12

Page 6E4–12

3.2 Pow ertrain Interface Module Gateway

Components

The following components use the PIM to communicate between the UART and GM LAN communication protocol:

Engine Control Module

The ECM is located in the engine com partment on the

left-hand front wheelhouse panel.

The ECM communicates directly with the transmission

control module (TCM), ABS-TCS ECU and PIM via the

serial data network. The ECM, via the PIM, also

communicates with the BCM and instrument cluster.

The ECM is also an integral part of the vehicle security

system. For further information on vehicle security, refer to

Section 12J Body Control Module.

Figure 6E4 – 6

ABS-TCS Electronic Control Unit

The ABS-TCS ECU is located in the engine compartment

adjacent to the right-hand front wheelho use liner.

The primary role of the ABS-TCS is to efficiently control the

vehicle's braking and traction control operation. To

effectively do this, the ECU of the ABS-TCS communicates

with other vehicle systems such as the engin e mana gement

and automatic transmission systems.

This information exchange is achieved by connecting the

various system control modules via the serial data network.

For further information on the serial data network, refer to

1 General Information.

Figure 6E4 – 7

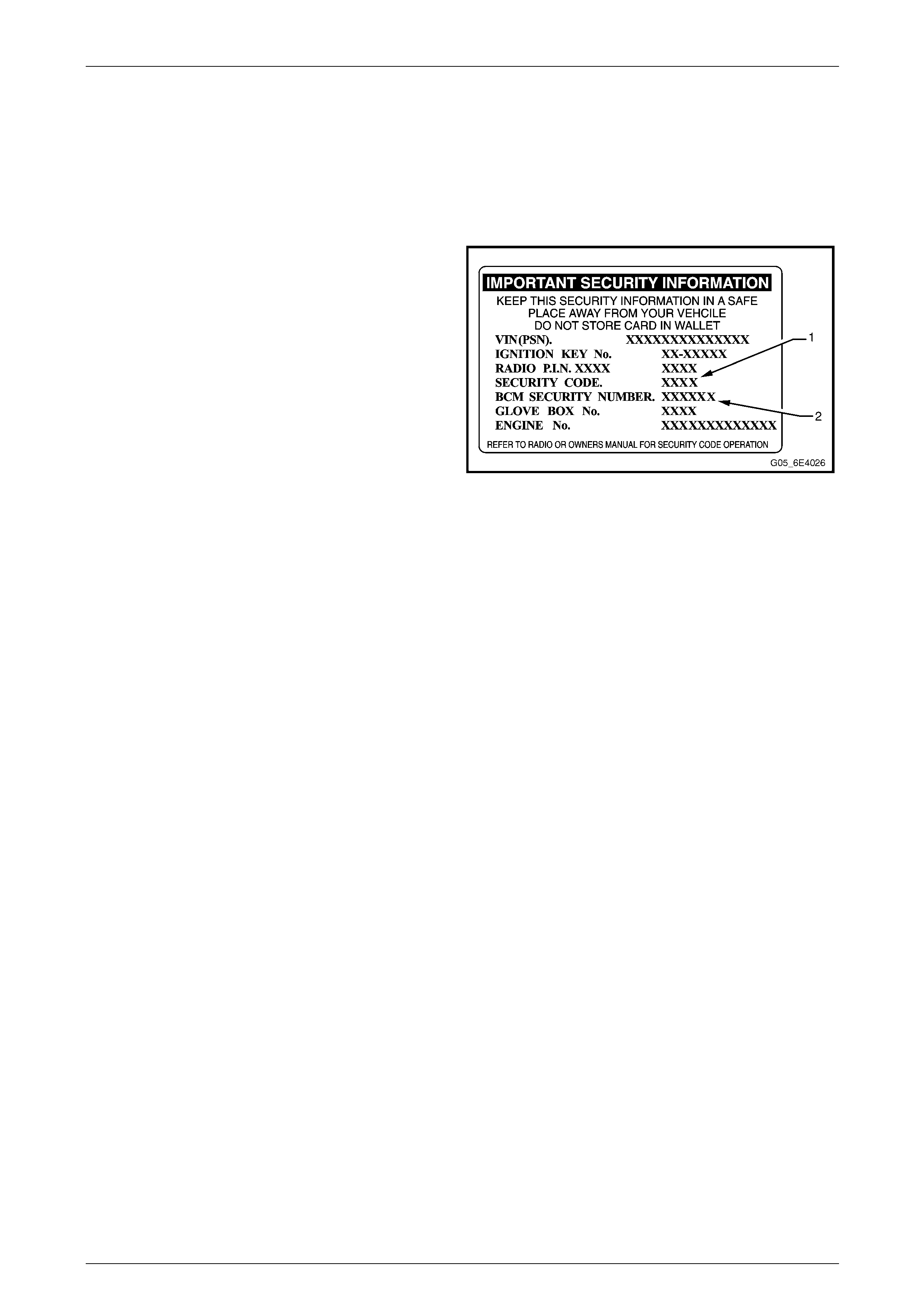

Body Control Module

The body control module (BCM) is mounted horizontally

behind the instrument panel compartment.

The BCM controls various vehicle electrica l systems, and is

an integral part of the serial data communication network.

The BCM communicates with other vehicle modules using

the Universal Asynchronous R eceive and Transmit (UART)

serial data protocol.

The BCM is connected to the PIM and the data link

connector (DLC) via the primary serial data circuit. The BCM

communicates via this circuit with the ECM, TCM and the

ABS-TCS ECU.

Refer to Section 12J Body Control Module for further

information on:

• serial data communication, a nd

• theft deterrent system.

Figure 6E4 – 8

Powertrain Interface Module Page 6E4–13

Page 6E4–13

Automatic Transmission Control Module

The transmission control module (T CM) is located behind

the left-hand lower hinge pillar trim.

The TCM's primary role is to efficientl y control transmission

shift points according to current driving and vehicle

operating conditions. To effectively do this, the TCM

requires information from other vehicl e systems such as the

engine management and automatic transmission systems.

This information exchanged is achieved by connecting the

various system control modules via the serial data network.

For further information on the serial data network, refer to

1 General Information.

Figure 6E4 – 9

Powertrain Interface Module Page 6E4–14

Page 6E4–14

3.3 Pow ertrain Interface Module Direct Input

Switches

The following switches are dir ect wired to the PIM. These switches use the PIM to convert their input signals into serial

data, which is then used by the various vehicle control modules to perform varying functions.

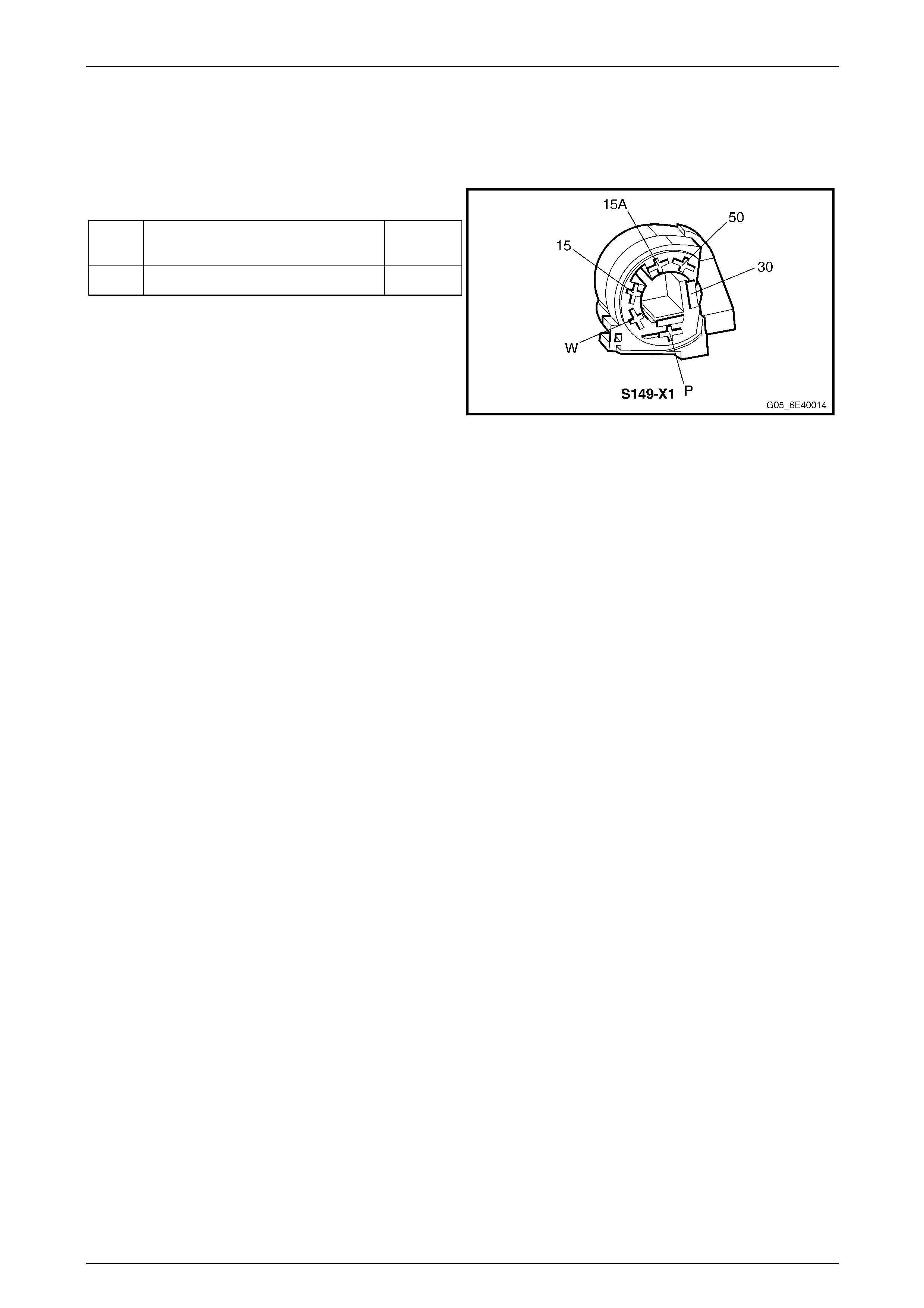

Traction Control System Switch

The traction control system (TCS) switch is located at the

rear of the floor console.

The TCS switch is a momentary contact switch that enables

or disables the traction control system. The TCS switch

inputs directly into the PIM. When the TCS switch is

pressed, the PIM sends a message on the serial data bus to

the ABS-TCS ECU. Refer to Section 5B ABS-TCS for

further information on the ABS-TCS.

Figure 6E4 – 10

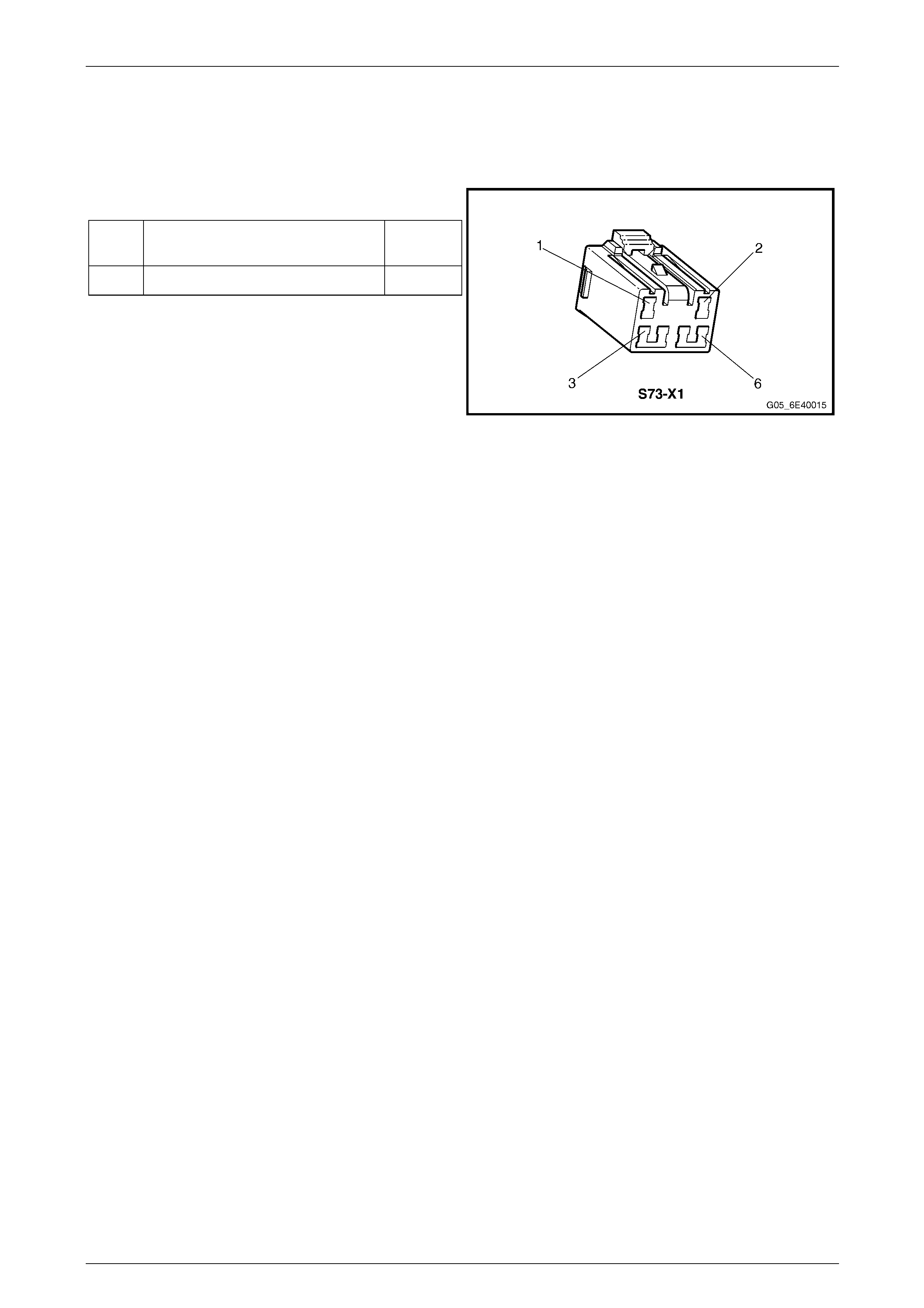

Cruise Control Switch

The cruise control switch is located on th e right-hand side of

the steering column.

The switch is comprised of three momentary contact

switches which control the follo wing function s:

• cruise control push button switch (ON / OFF /

CANCEL),

• cruise control resume – accelerate (RES–ACCEL),

and

• cruise control set – decelerate (SET–DECEL).

The cruise control ON / OFF / CANCEL switch directly

inputs into the PIM. For further information on the cruise

control system, refer to Section 12E Cruise Control. Figure 6E3 – 11

Powertrain Interface Module Page 6E4–15

Page 6E4–15

4 Diagnostics

4.1 Diagnostic General Descriptions

The powertrain interface module (PIM) diagnostic procedure is organised in a logical structure that beg ins with the PIM

Main Diagnostic Table. The Main Diagnostic T able directs the diag nostic procedure to the logical steps or appro priate

diagnostic table required to diagnose a PIM fault condition.

The diagnostic tables locate a faulty circuit or component through a logical based process of elimination. Correct use of

the diagnostic tables is essential to reduce di agnostic time and to prevent misdiagnosis.

In addition, the Main Diagnostic Table provides the following information:

• Identification of the PIM,

• condition of the diagnostic circuit, and

• identification and status of the DTCs if present.

Diagnostic Trouble Code (DTC) Tables

The diagnostic procedure is directed to a diagnostic trouble code (DTC) table if there are DTCs currently stored in the

PIM.

The diagnostic tables are designed to locate a faulty circuit or component through a logical based process of elimination.

The diagnostic tables are developed with the follo wing assumptions:

• the vehicle functioned correctly at the time of assembly,

• there are no multiple faults, and

• the problem currently exists.

Multiple DTCs

When performing a DTC check and there are multiple DTCs, the diag nostic process must begin with the most likely DTC

that may trigger other DTCs. The following situation is an exampl e of a DT C that may trigger other vehicle system DTCs

to set.

• If there is an open circuit condition with the CAN HI circuit between the ABS-TCS ECU and the engine control

module (ECM), DTC U2105 Loss of Communications from ECM may set. This condition may also cause the

following DTCs to set in other control modules:

• Instrument cluster – DTC 11 No Serial Data from the ECM.

• ABS-TCS – DTC U2105 Lost Communication with the ECM.

• Transmission Control Module (TCM) – DTC U2105 Lost Communicati on with the ECM.

• Body Control Module (BCM) – DTC 7 No Serial Data from the ECM.

Knowledge of the PIM and TECH 2 limitations are importa nt to reduce diagnostic time and to prevent misdiagnosis.

Refer to 5.1 Diagnostic Requirements, Prec autions and Preliminary Tests.

Powertrain Interface Module Page 6E4–16

Page 6E4–16

Diagnostic Trouble Codes (DTCs)

When the ignition s witch is turned on, the PIM performs an internal integrity check that detects and isolates any internal

faults. The PIM also monitors the cruise control and traction control switch circuit and the serial data bus for messages

from the control modules on the GM LAN bus and from the BCM on the UA RT bus. If a fault is detected by the PIM, it will

log a Diagnostic Trouble Code (DTC) that represents the fault detected. The DTCs stored in the PIM may be accessed

using TECH 2. Refer to Section 0C TECH 2 for further information on TECH 2.

Status of DTCs

The PIM designates the DT Cs logged into a Current or History DTC.

Current DTCs

If the fault condition that triggers the DTC is present during the last PIM self test, that DTC will be designated as a current

DTC.

History DTCs

If the fault condition that triggers the DTC is not present during the last PIM self test, that DTC will be designated as a

history DTC.

Conditions for Clearing DTCs

• If there is no DTC logged in the current PIM self test, the current DTC will be cleared.

• If there is no DTC logged after 100 consecutive drive cycles, the history DTC will be cleare d.

• Use of TECH 2 to clear the DTC.

TECH 2 PIM Diagnostic Tests

NOTE

Refer to Section 0C TECH 2 and the TECH 2

Users Manual for detailed information and

instructions regarding the use of TECH 2

Limitations

Some DTCs trigger other DTCs to set, which causes TECH 2 to display multiple DTCs. In those situations, TECH 2 may

display more DT Cs than is neede d to rectify a fault.

When TECH 2 displays an output function, it displays onl y the comma nd given by the PIM. If a connector is

disconnected, that fault will not register in the PIM output function. TECH 2 does not verify the command action.

The service technician must understand t he system being diagnosed as well as the correct use and limitations of TECH

2 to be able to perform diagnostic procedures efficiently and successfully.

TECH 2 Intermittent Fault Tests

The following are lists of TECH 2 diagnostic tests that ma y be used to diagnose intermittent faults:

• Wiggle test the suspected PIM wiring harness and connector while observing TECH 2 operating parameters of the

circuit being tested. If TECH 2 read-out fluctuates during this procedure, check the wiring harness circuit for loose

connection.

• Road test the vehicle in conditions that trigger the intermittent fault while an assistant observes the suspected

TECH 2 operating parameter data.

• Capture and store data in the Snapshot mode when the fault occurs. The stored data may be replayed at a slower

rate to aid in diagnostics. Refer to TECH 2 User Instructio ns for more information on the Snapshot function.

• Operate suspected components to test their operation using TECH 2 Output Control Data.

Powertrain Interface Module Page 6E4–17

Page 6E4–17

TECH 2 Data List

The TECH 2 PIM Data List contains the operating parameters that may be used to analyse the PIM.

The technician is able to compare the op erating parameter of the vehicle be ing diagnosed to the typical data value of a

known serviceable vehicle.

NOTE

The TECH 2 Data List Typical Data Values are

obtained from a correctly operating vehicle under

the following conditions;

• ignition switched on,

• engine not running, and

• vehicle is stationary.

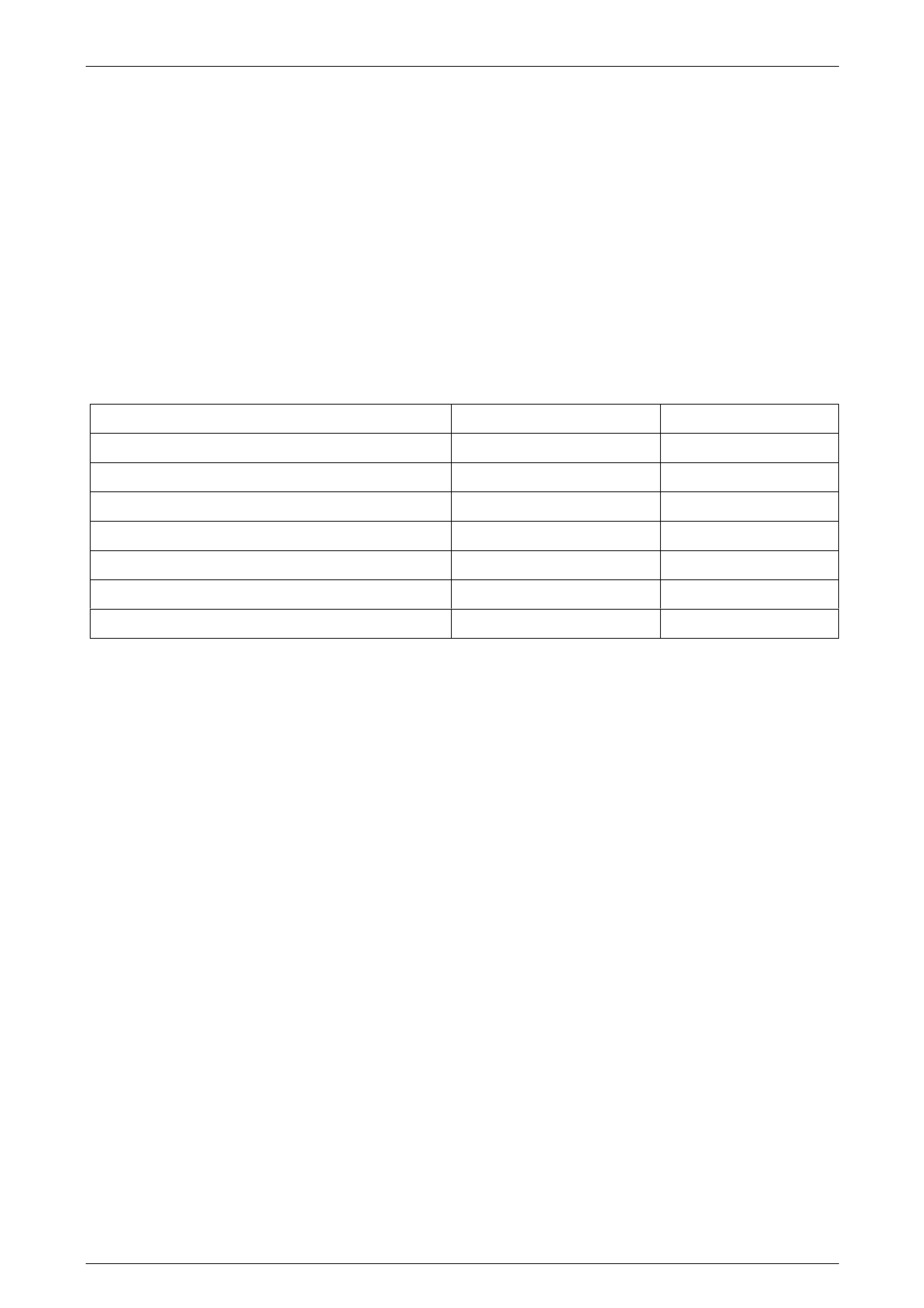

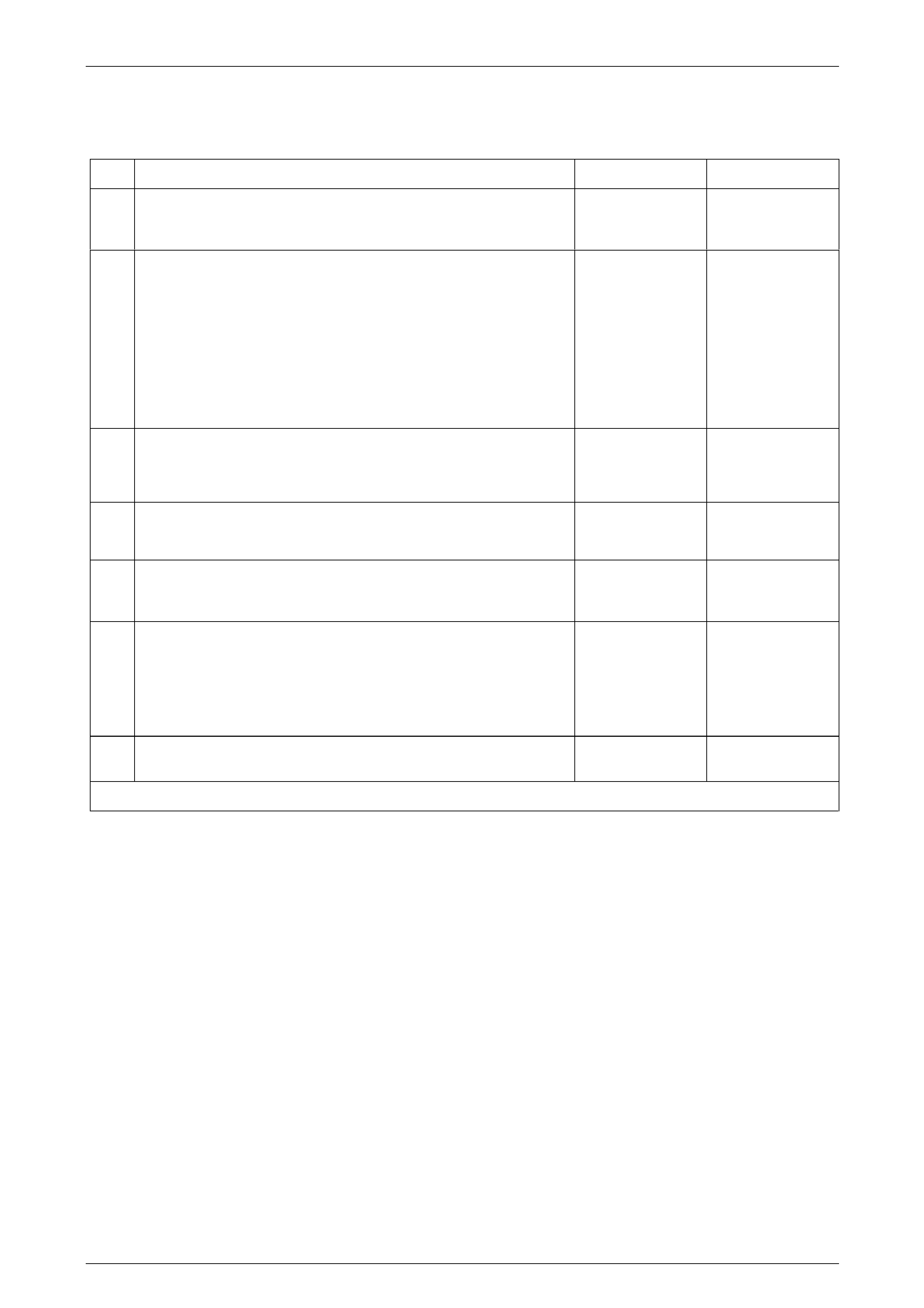

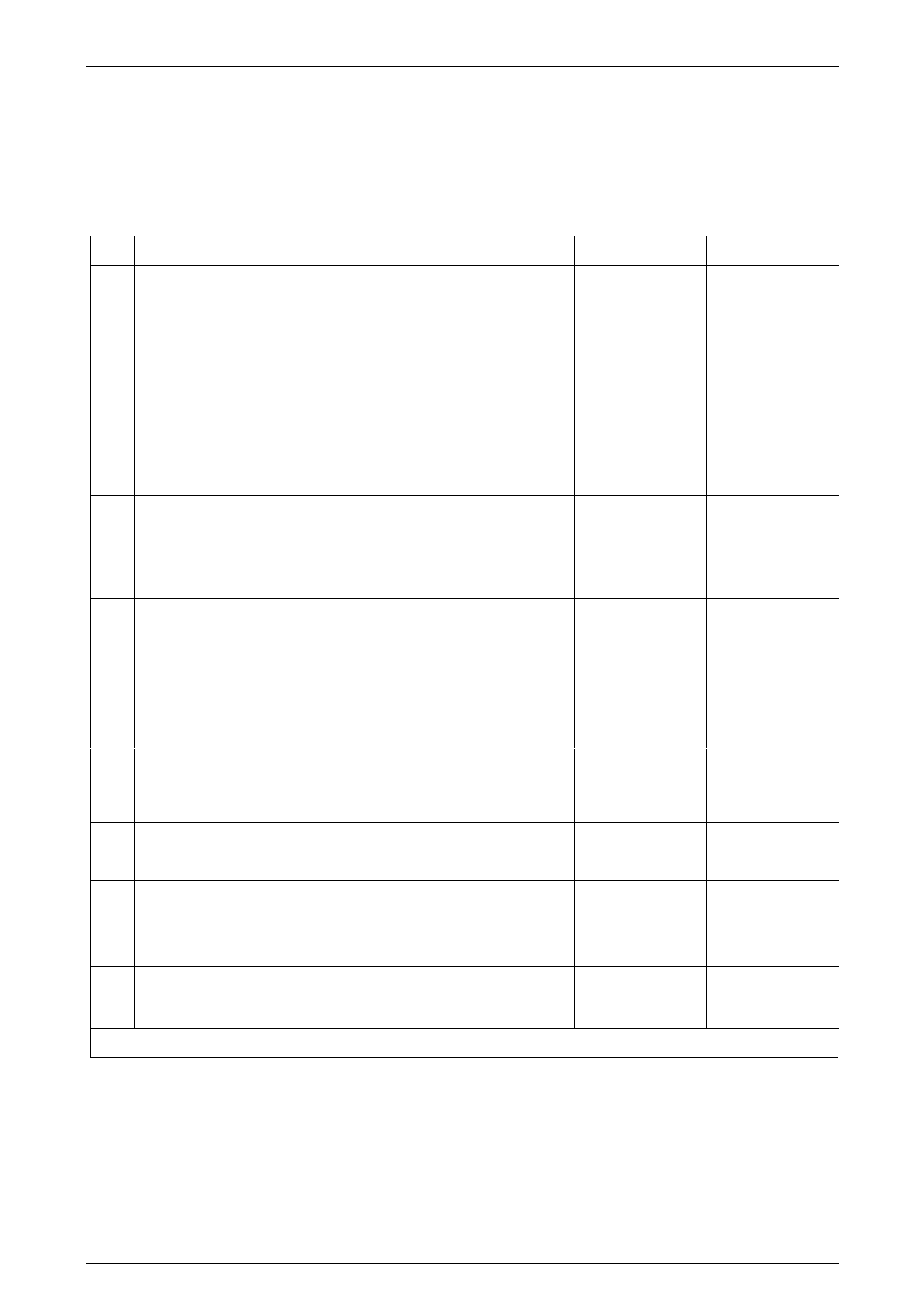

TECH 2 Data List Table

TECH 2 Parameter Units Displayed Typical Data Value

Battery Voltage V 12.8

Immobiliser Activated Yes / No No

Cruise Control Enable Switch Inactive / Active Inactive

Cruise Control Enabled / Disabled Disabled

Cruise Control Tip Switch Inactive / Active Inactive

Traction Control Disable Switch Inactive / Active Inactive

Crank Request Inactive / Active Inactive

Powertrain Interface Module Page 6E4–18

Page 6E4–18

5 Powertrain Interface Module

Diagnostic Starting Point

5.1 Diagnostic Requirements, Precautions

and Preliminary Checks

Basic Knowledge Required

A lack of basic understanding of electronics,

electrical wiring circuits and use of electrical

circuit testing tools when performing the PIM

diagnostic procedures could result in

incorrect diagnostic results or damage to

components.

In addition, a general understanding of the PIM and its component operation is essential to prevent misdiagnosis and

component damage.

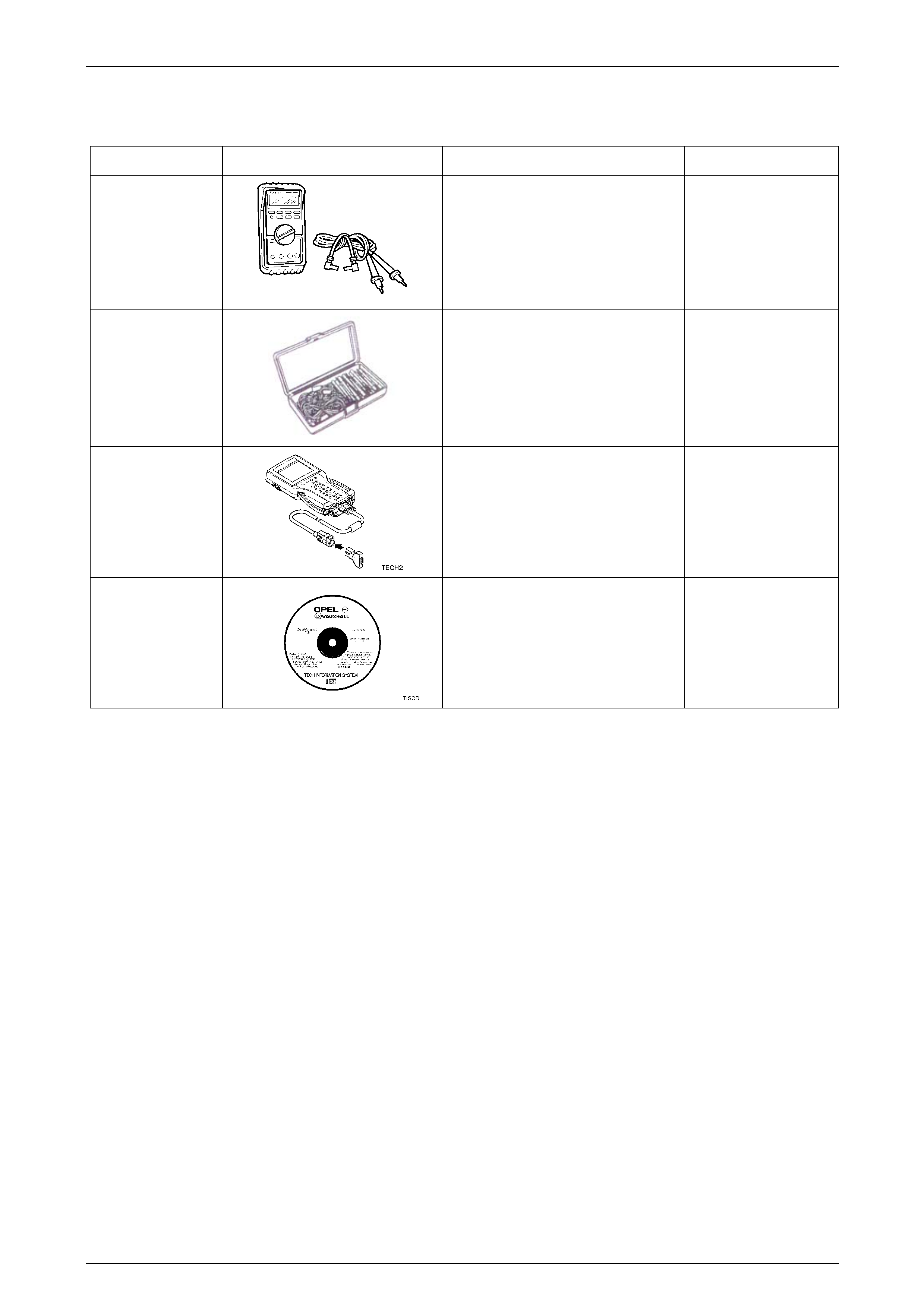

Basic Diagnostic Tools Required

Use of incorrect electrical circuit diagnostic

tools when performing the PIM diagnostic

procedures could result in incorrect

diagnostic results or damage to components.

The following electrical circuit testing tools are required to perform the diagnostic procedur es detailed in this Section:

• TECH 2, refer to Section 0C TECH 2 for further information.

• Test light, refer to Section 12P Wiring Diagrams for further information.

• Digital multimeter with 10 MΩ ohms impedance, refer to Section 12P Wiring Diagrams for further information.

• Connector test adapter kit Tool No. J35616-A.

Powertrain Interface Module Page 6E4–19

Page 6E4–19

Diagnostic Precautions

In addition to the safety and precautionary

measures listed in 9.1 Safety and

Precautionary Measures, the following

diagnostic precautions must be observed

when performing any PIM diagnostic

procedure:

• Use only the test equipment specified in the diagnostic tables. Other test equipment may either give incorrect

results or damage serviceable components.

• Do not clear any DTCs unless instructed.

• The fault must be present when using the DTC Diagnostic Tables. Otherwise, misdiagnosis or replacement of

serviceable parts may occur.

• Always use connector adapters such as those contained in connector test adapter kit Tool No. J35616-A to prevent

connector terminal damage.

• Thorough inspection of the wiring circuits and connectors listed in the diagnostic procedures must be performed,

otherwise misdiagnosis may occur.

• Inspect the electrical circuitry or connector terminals that are suspected to be causing the complaint for the

following conditions:

• backed-out connector terminals,

• improper wiring connector mating,

• broken wiring connector locks,

• damaged connector terminals, and

• physical damage to the wiring harness.

• Before replacing a component, inspect its connector terminal for corrosion or deformation that may cause the fault

condition.

Preliminary Checks

The PIM preliminar y check examines easily accessible components which may cause problems with the PIM. This visual

and physical inspection proc edure may quickly identif y the fault condition and eliminate the need for additional dia gnosis.

• Refer to Service Techlines for releva nt information regarding the fault condition.

• Ensure the battery is fully charged.

• Check the battery connections for corrosion or a loose terminal.

• Perform a visual and physical inspection of the following:

• PIM component wiring harness and terminals for proper connections, pinches or cuts, and

• PIM wiring harness routing which may b e positioned very close to a high voltage or high current devices such

as aftermarket audio systems.

NOTE

High voltage or high current devices may induce

electrical noise on a circuit, which can interfere

with normal circuit operation.

• The PIM is sensitive to Electro-magnetic Interference (EMI). Check for incor rect aftermarket theft deterrent

devices, lights or mobile phon e installations if an intermittent malfunction is suspected.

Powertrain Interface Module Page 6E4–20

Page 6E4–20

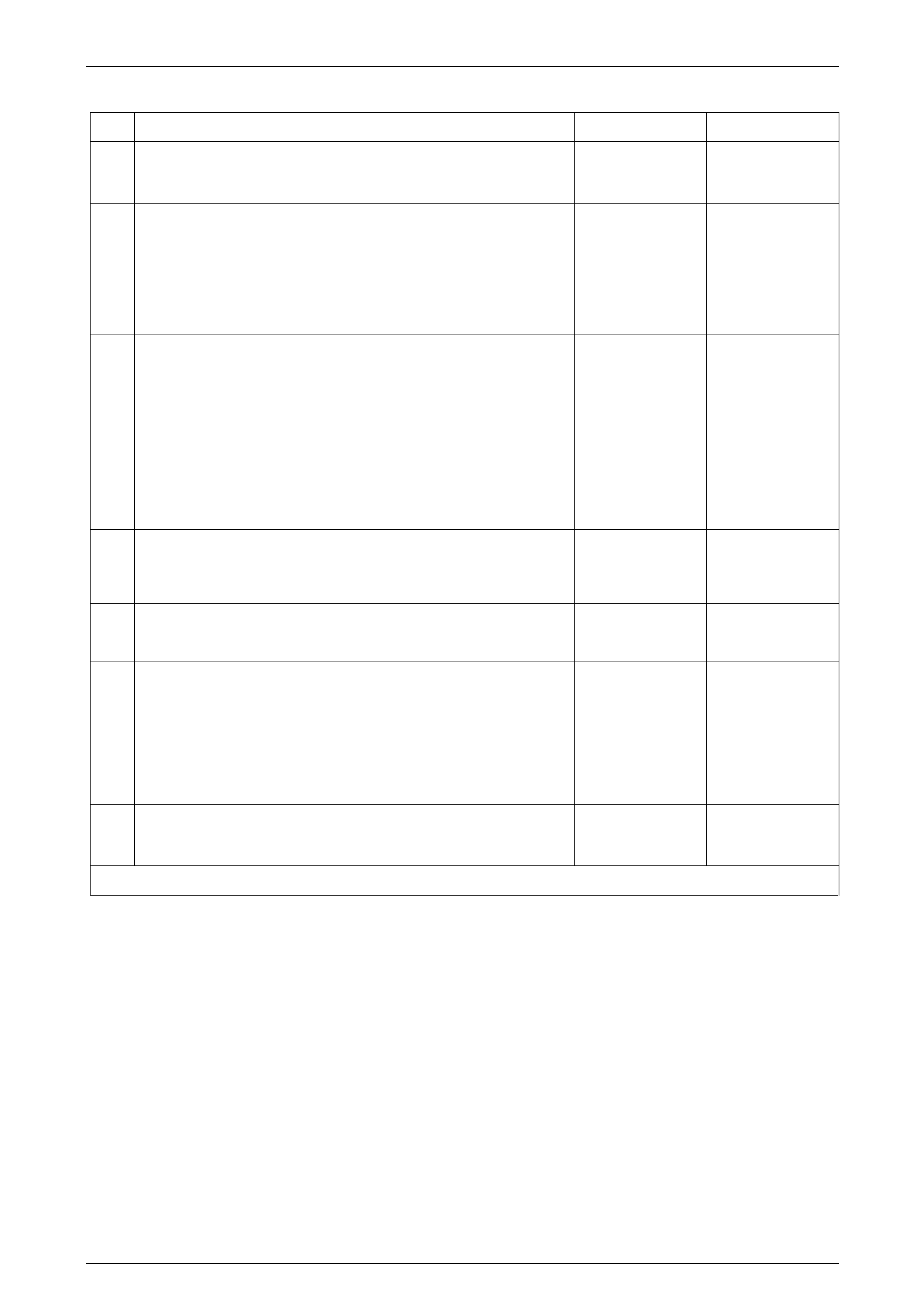

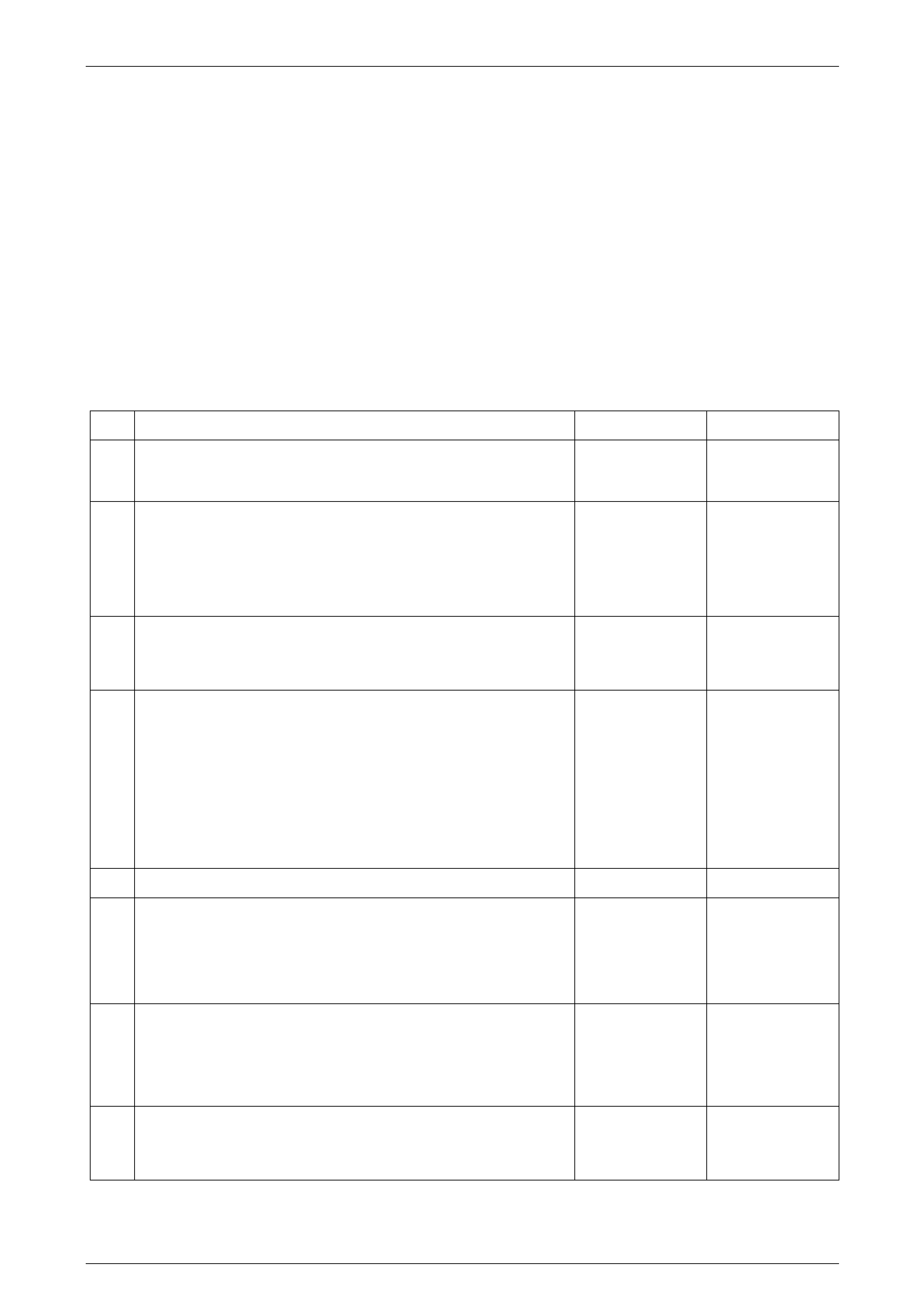

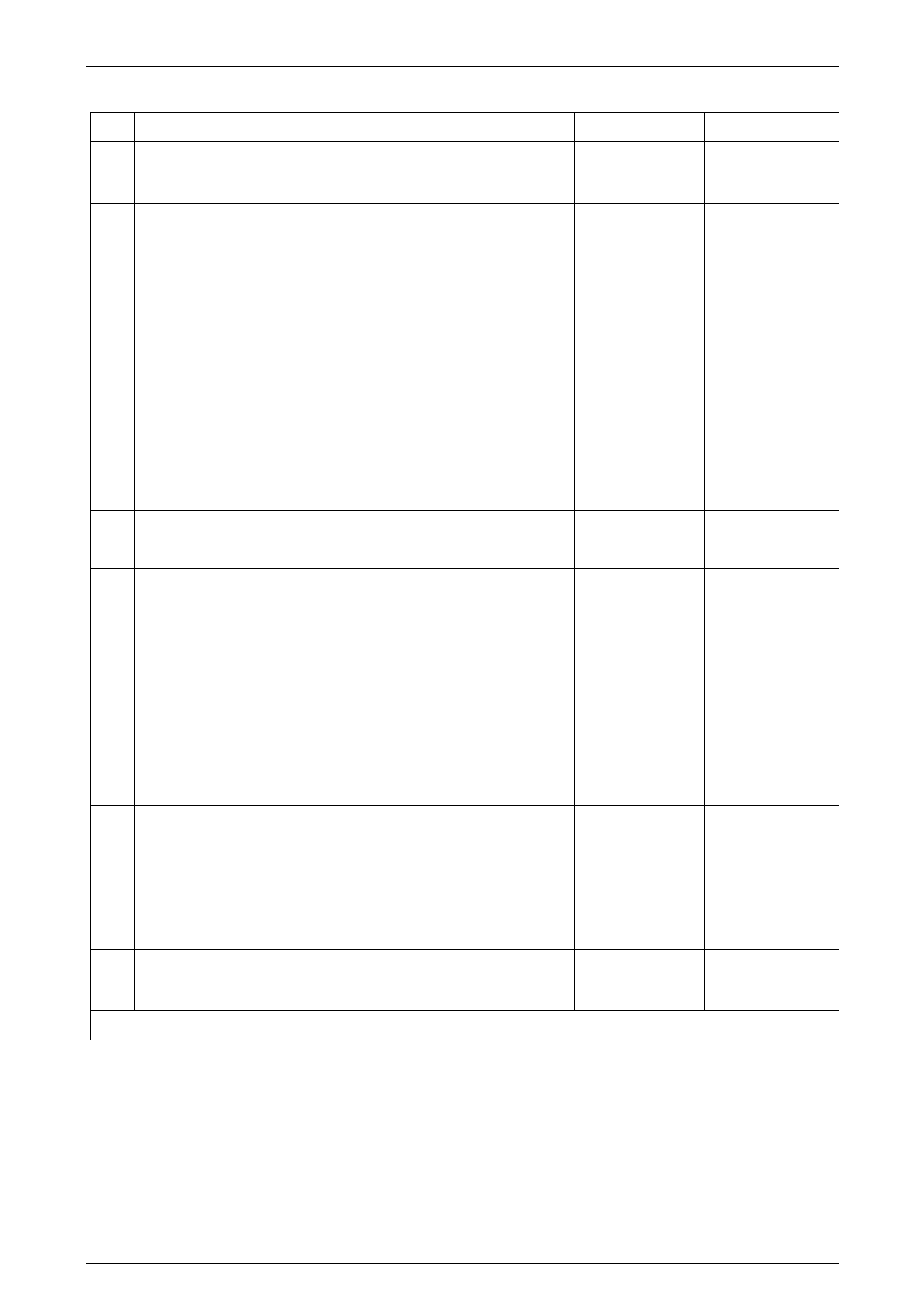

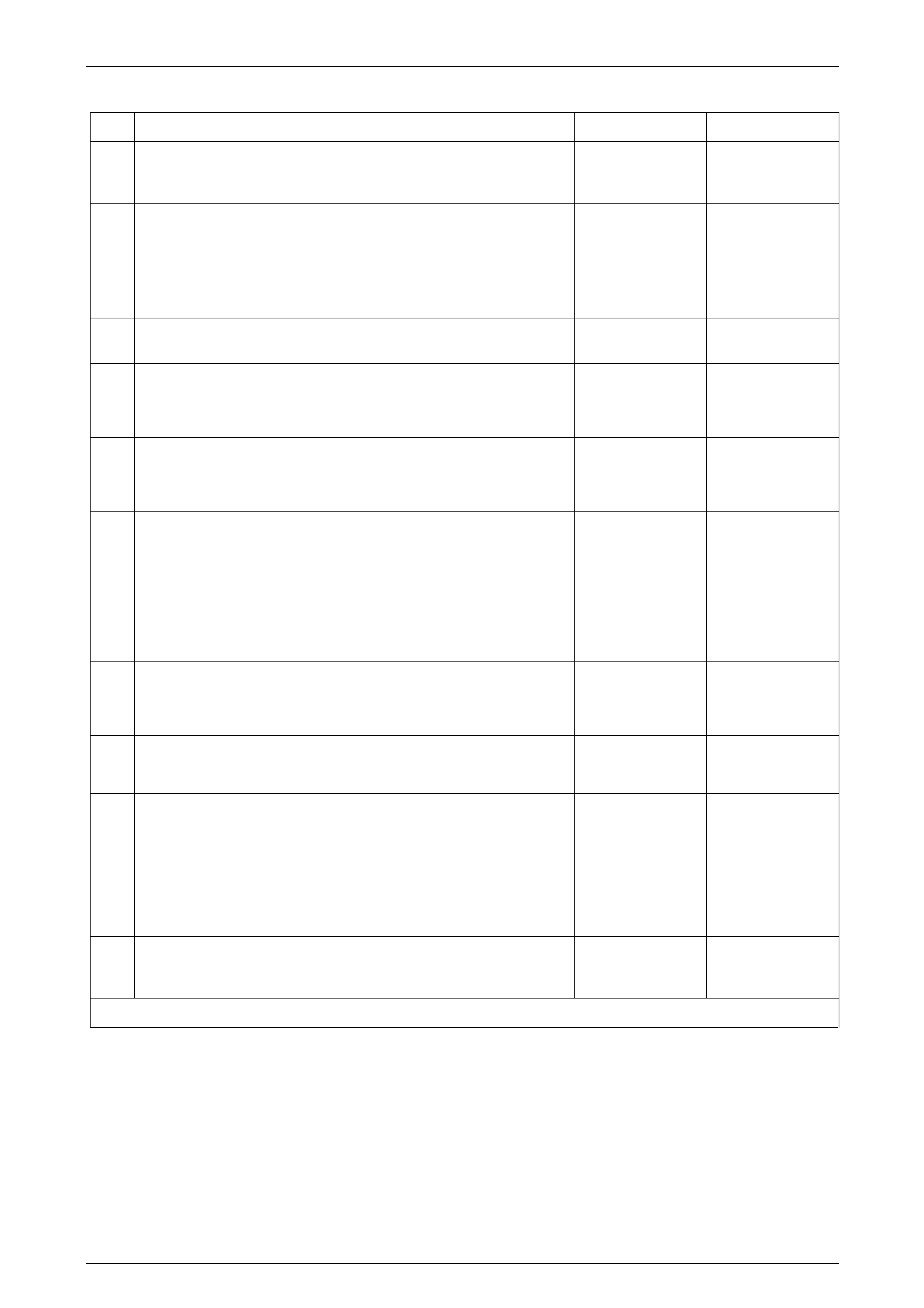

5.2 Main Diagnostic Table

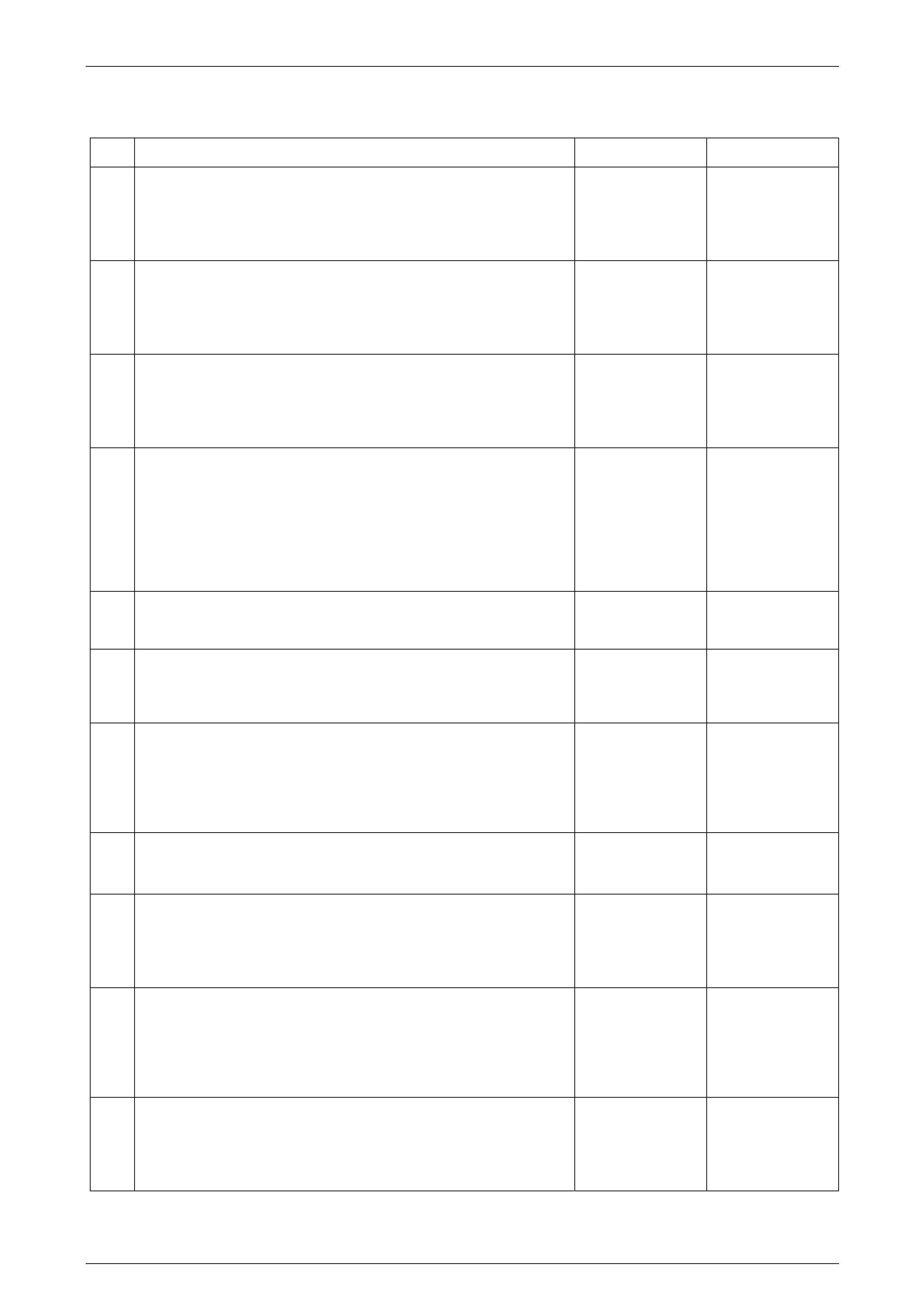

Step Action Yes No

1 Have you met the basic diagnostic requirements listed in the PIM

Diagnostic Starting Point?

Go to Step 2

Refer to

5.1 Diagnostic

Requirements,

Precautions and

Preliminary Ch ecks

2 Have you read the Diagnostic Precautions?

Go to Step 3

Refer to

5.1 Diagnostic

Requirements,

Precautions and

Preliminary Ch ecks

3 Have you performed the Preliminary Checks?

Go to Step 4

Refer to

5.1 Diagnostic

Requirements,

Precautions and

Preliminary Ch ecks

4 1 Switch off the ignition.

2 Connect TECH 2 to the Diagnostic Link Connector (DLC).

3 Switch on the ignition with the engine not running.

4 Press TECH 2 power button on.

Does TECH 2 screen illuminate and display TECH 2? Go to Step 5 Refer to 0C TECH 2

5 Using TECH 2, perform a Module/ECU Presence Check.

Does TECH 2 display the BCM as being Present? Go to Step 7 Go to Step 6

6 Refer to 12J Body Control Module to rectif y the BCM communication

fault.

Was the BCM communication fault rectified? Go to Step 7 –

7 Does TECH 2 display the PIM as bein g Present?

Go to Step 8

Refer to

5.3 Powertrain

Interface Module –

Module Presence

Check Failure

Diagnostic Table

8 Using TECH 2, view and record all DTCs.

Does TECH 2 display any DTCs? Go to Step 9

Refer to

6 Intermittent

Fault Conditions

9 Does DTC B1000, B1009, B1013, or B1014 fail this ignition cycle? Refer to 7.1 DTC

B1000, B1009,

B1013 or B1014 –

PIM Internal Fault

Diagnostic Table Go to Step 10

10 Does DTC U2100 fail this ignition cycle? Refer to 7.3 DTC

U2100 – No

Communication

With CAN Bus (High

Speed) Diagnostic

Table Go to Step 11

11 Does DTC U2106 fail this ignition cycle? Refer to 7.5 DTC

U2106 – CAN Bus

No Communication

with Transmission

Control Module Go to Step 12

Powertrain Interface Module Page 6E4–21

Page 6E4–21

Step Action Yes No

12 Does DTC U2108 fail this ignition cycle? Refer to 7.6 DTC

U2108 – CAN Bus

No Communication

with Diagnostic

Table Go to Step 13

13 Does DTC U2105 fail this ignition cycle? Refer to 7.4 DTC

U2105 – CAN Bus

No Communication

with Engine Control

Module Diagnostic

Table Go to Step 14

14 Does TECH 2 display multiple DTCs?

Go to Step 15

Refer to the DTC

Table of the DTC

displayed

15 Refer to the DTC Table of the fault condition that is most likely to

trigger multiple DTCs. Refer to 3.1 Diagnostic General Descriptions for

information on multiple DTCs fault condition. – –

When all diagno sis an d repairs are completed, clear all DTCs and check the system for correct operation.

Powertrain Interface Module Page 6E4–22

Page 6E4–22

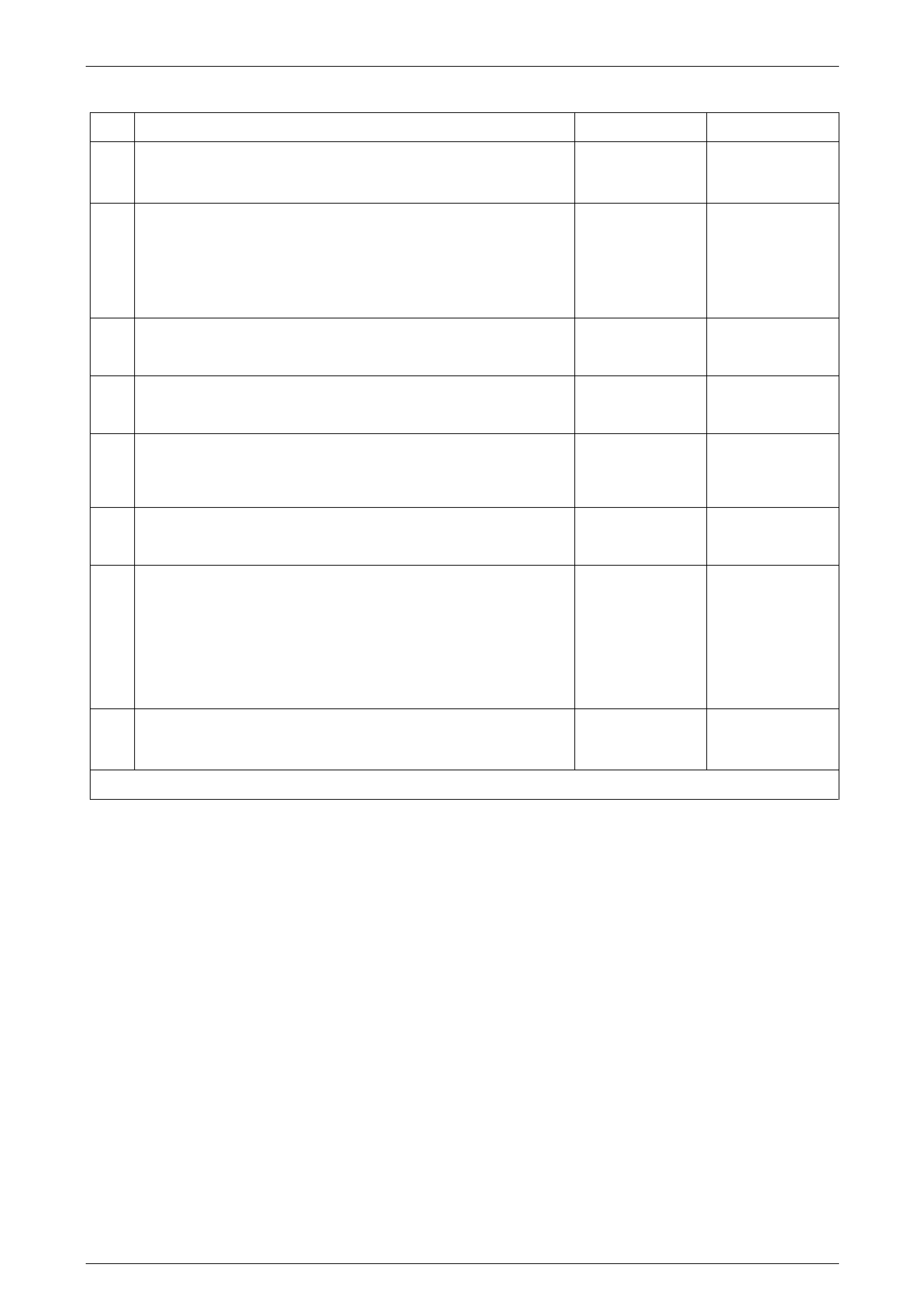

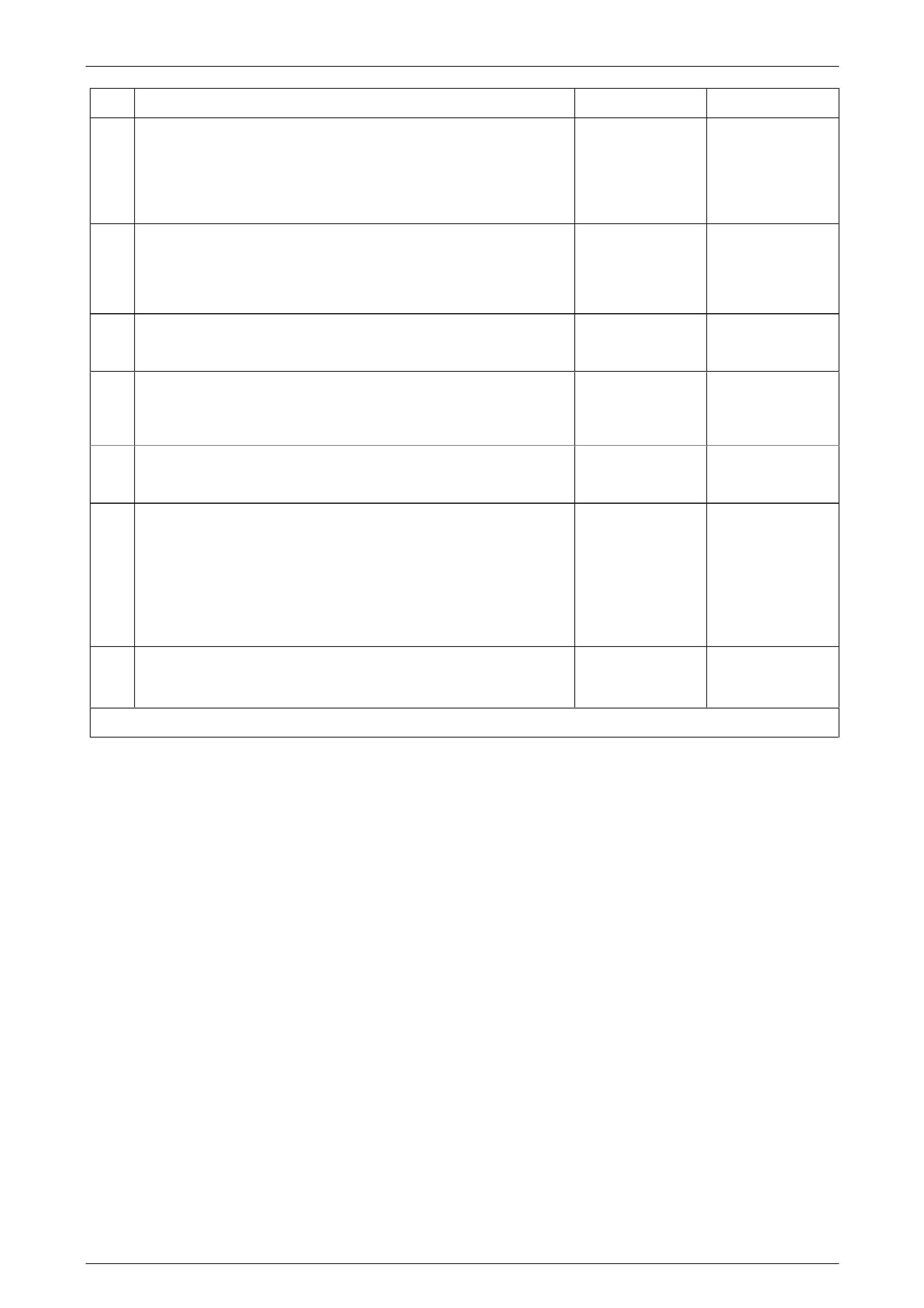

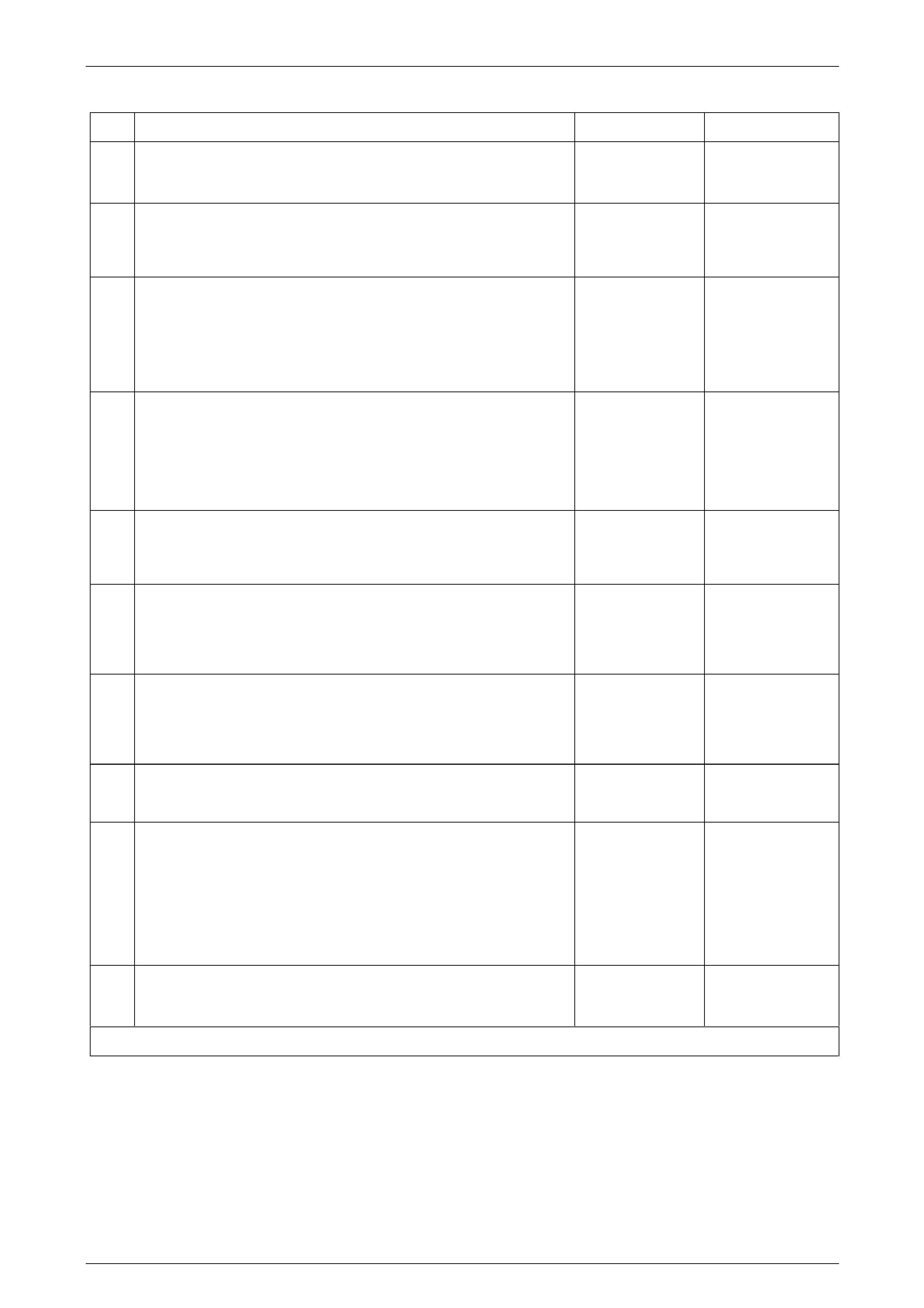

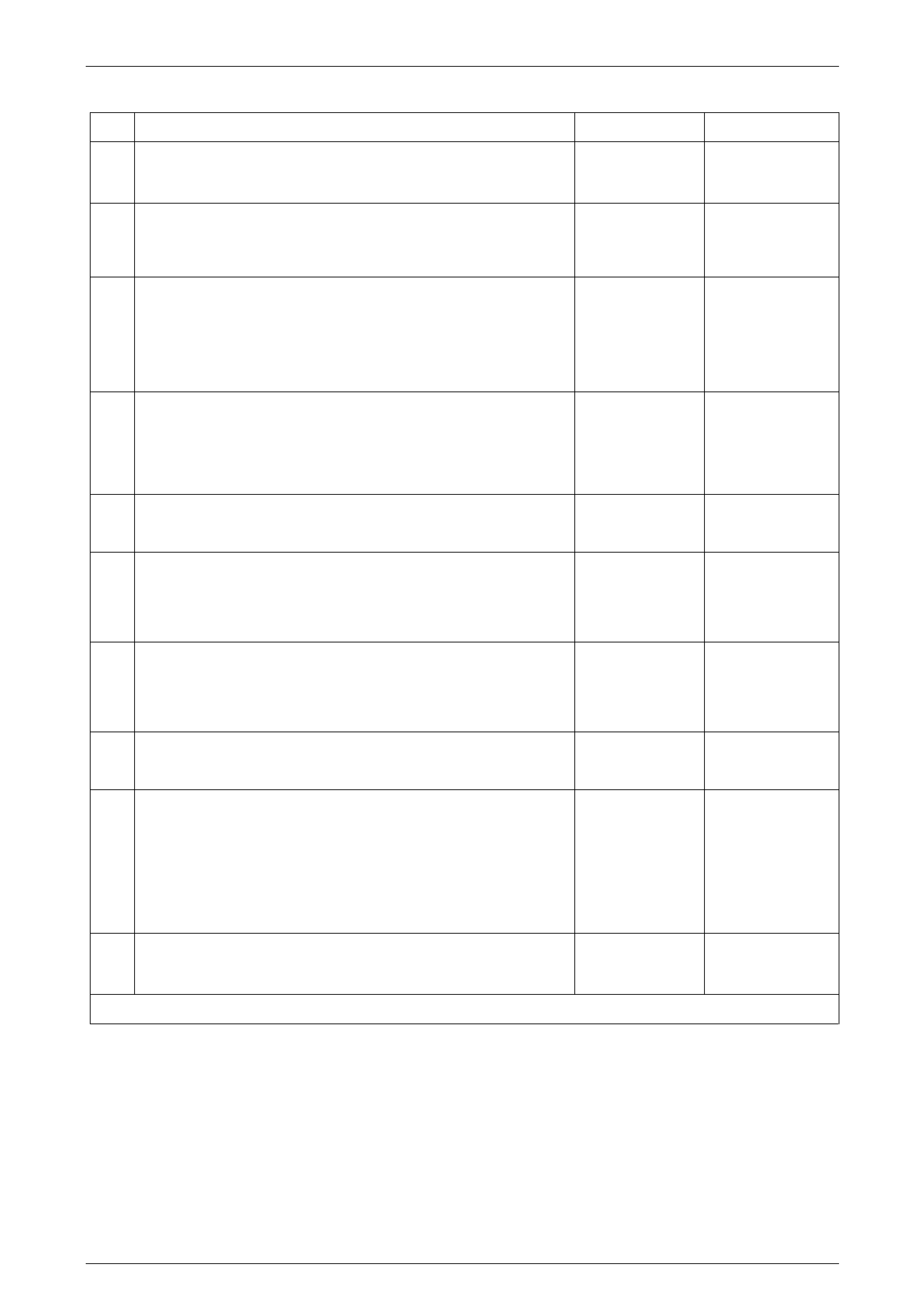

5.3 Powertrain Interface Module – Module

Presence Check Failure Diagnostic Table

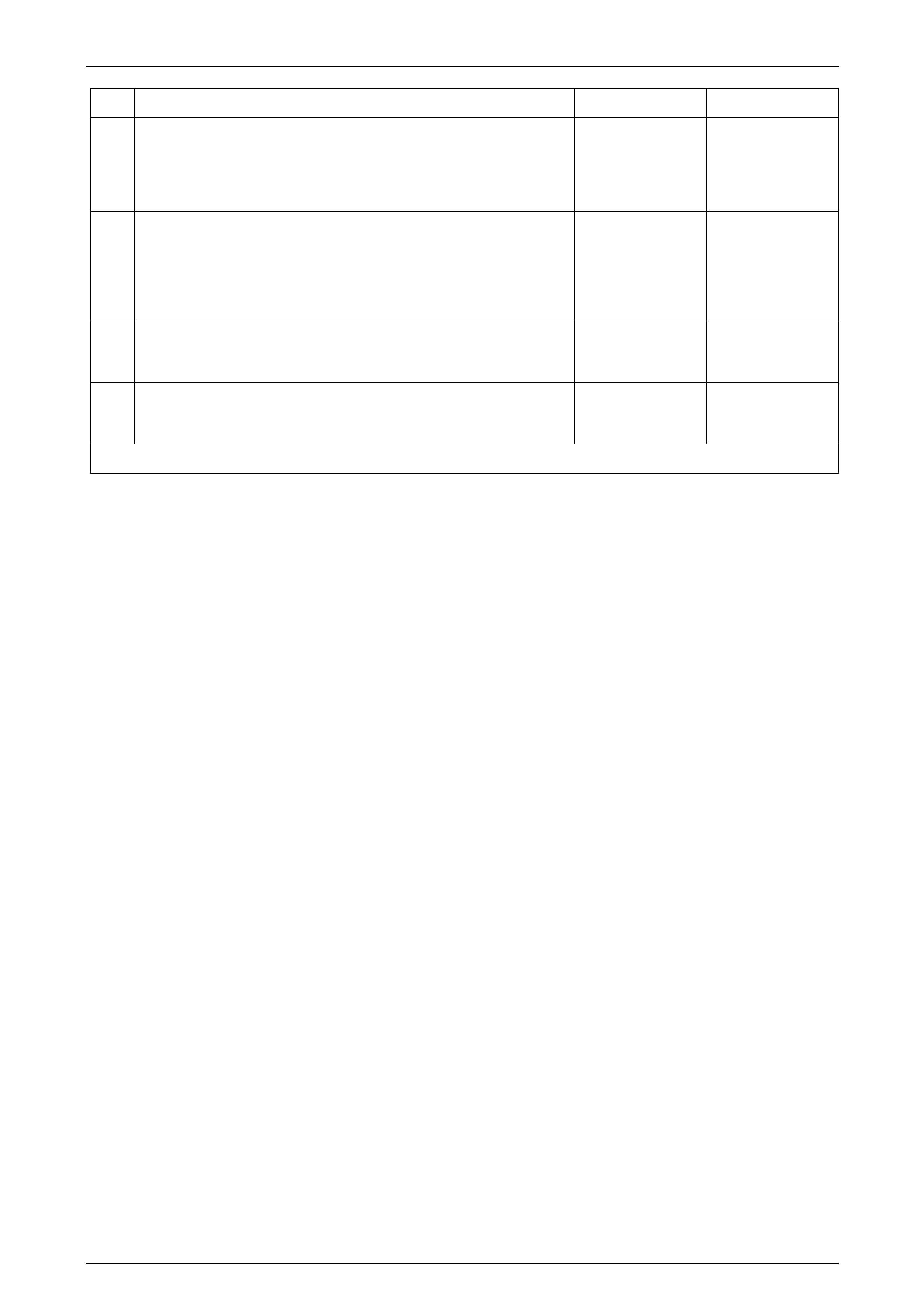

Step Action Yes No

1 Was the PIM Main Diagnostic Table performed?

Go to Step 2

Refer to

5.2 Main

Diagnostic Table

2 Test the following PIM circuits for a high resistance, open circuit or

short to ground fault condition. Refer to 12P W iring Diagrams for

information on electrical diagnosis:

• 12 V battery supply circuit 740 ,

• 12 V ignition circuit 300, and

• ground circuit 151

Has any fault been found and rectified? Go to Step 5 Go to Step 3

3 Test the UART serial data primary circuit 800 for a high resistance or

an open circuit fault condition

Has any fault been found and rectified? Go to Step 5 Go to Step 4

4 Replace the PIM. Refer to 9.2 Powertrain Interface Module.

Has the repair been completed? Go to Step 5 –

5 Using TECH 2, perform a Module/ECU Presence Check.

Does TECH 2 display the PIM as bein g Present? Go to Step 6

Refer to

5.2 Main

Diagnostic Table

6 1 Using TECH 2, clear all DTCs.

2 Switch off the ignition for 30 seconds.

3 Check for DTCs.

Are there any PIM DTCs displaye d?

Refer to

5.2 Main

Diagnostic Table Go to Step 7

7 Are there other DTCs displayed? Refer to the

appropriate Section System OK

When all diagno sis an d repairs are completed, clear all DTCs and check the system for correct operation.

Powertrain Interface Module Page 6E4–23

Page 6E4–23

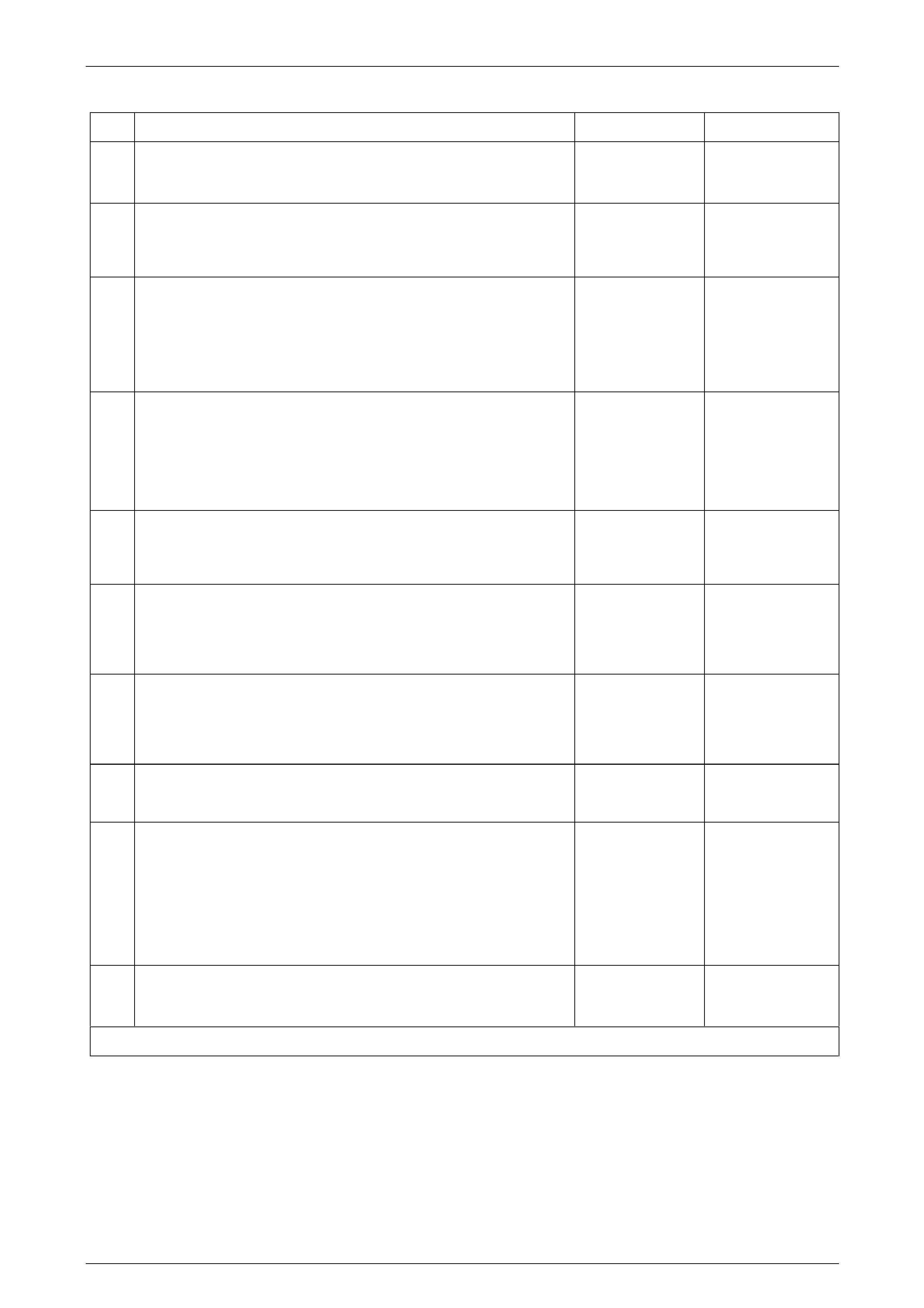

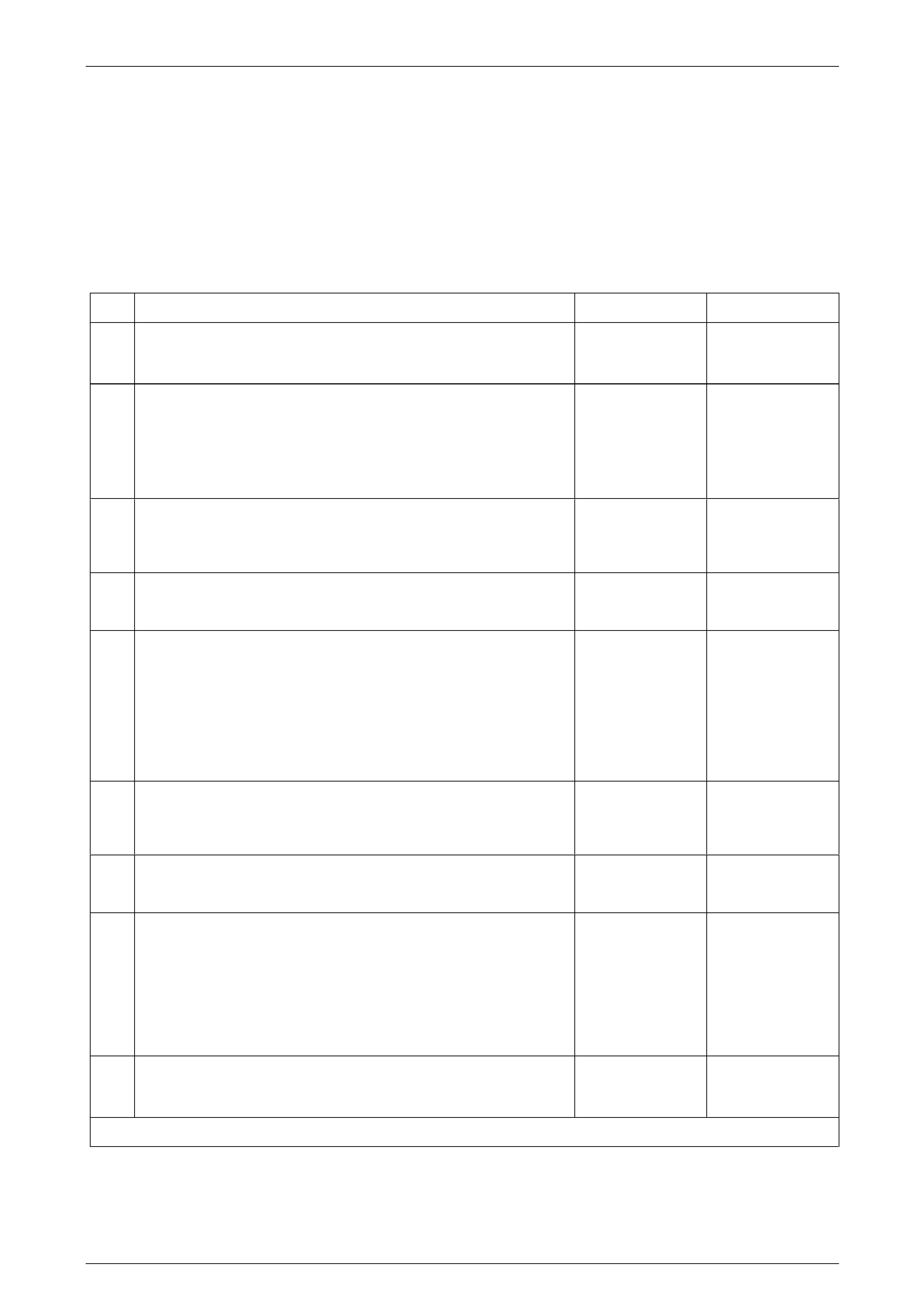

6 Intermittent Fault Conditions

6.1 Intermittent Conditions Diagnostic Table

Description

A fault condition is intermittent if one of the following conditions exists:

• The fault condition is not al ways present.

• The fault condition cannot be presently duplicated.

• There is no Current DTC but a Histor y DTC is stored.

Diagnostic Table

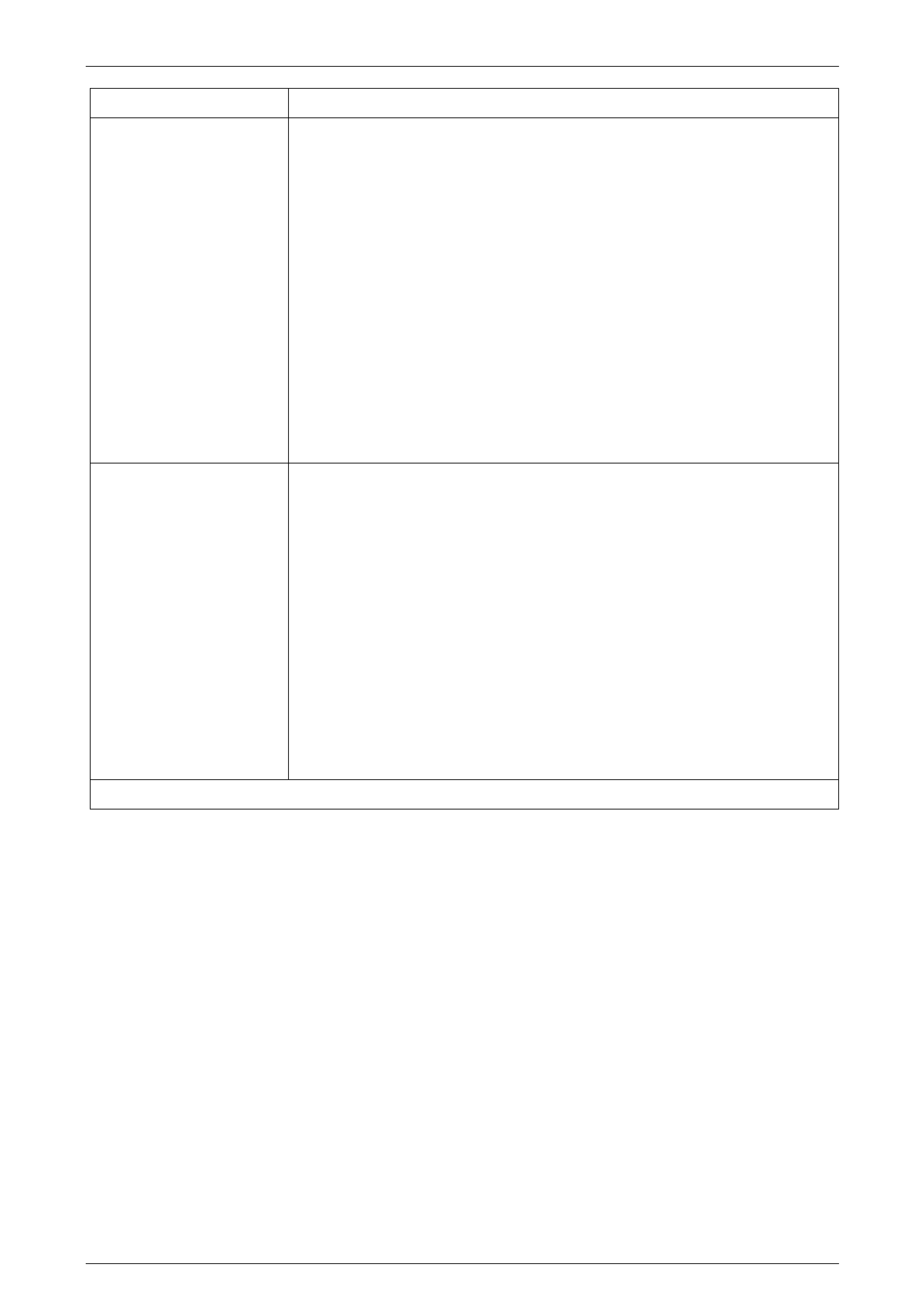

Checks Actions

Preliminary • Perform the Preliminary Checks, refer to 2.4 Preliminary Checks.

• Gather information from the customer regarding the conditions that trigger the

intermittent fault such as:

• At what engine or ambient temperature range do es the fault occur?

• Does the fault occur when operating aftermarket electrical equi pment inside

the vehicle?

• Does the fault occur on rough roads or in wet road conditions?

• If the intermittent fault is a start and then stall condition, check theft deterrent

system. Refer to 12J Body Control Module.

Harness/ Connector Install TECH 2 and perform the TECH 2 Intermittent Fault Tests. Refer to

4.1 Diagnostic General Descriptio ns for information on TECH 2 ECU diagnostic tests.

Warning Indicator The following conditions may cause an intermittent Malfunction Indicator Lamp fault with

no DTC listed:

• Electromagnetic Interference (EMI) caused by a faulty relay, ECM controlled

solenoid, switch or other external source.

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Loose PIM ground connections.

Powertrain Interface Module Page 6E4–24

Page 6E4–24

Checks Actions

Temperature Related The TECH 2 Freeze Frame/Failure Records or Snapshot data may be used if applicable

to the fault condition. Refer to 4.1 Diagnostic General Descriptions for information on

TECH 2 ECU diagnostic tests.

• If the intermittent fault is heat related, review the TECH 2 data in relations hip to

the following:

• high ambient temperature,

• under hood / engine gener ated heat,

• circuit generated heat due to a poor electrical connection or high e lectrical

load, and

• higher than normal load conditions (towing, etc.).

• If the intermittent fault is related to cold ambient or engine temperature, review the

TECH 2 data in relationship to the following:

• low ambient temperature, and

• the fault condition that occurs only on a cold start situation.

Additional Tests • Check for incorrect installation of aftermarket electrical equipment such as the

following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Check for electromagnetic Interference (EMI) caused by a faulty relay, ECM

controlled solenoid or switch. The fault is triggered when the relay or solenoid is

activated.

• Check the A/C compressor clutch and some rela ys that contain a clamping diode

or resistor for an open circuit.

• Check the generator for a faulty rectifier bridge that may allow A/C noise into the

PIM electrical circuit.

When all diagno sis an d repairs are completed, check th e engine management system for correct o peration.

Powertrain Interface Module Page 6E4–25

Page 6E4–25

7 DTC Tables

7.1 DTC B1000, B1009, B1013 or B1014 –

PIM Internal Fault

Circuit Description

The powertrain interface module (PIM) is the control centre for the communication language conversion between GM

LAN serial data and UART serial data. If there is an internal microprocessor integrity fault condition with the PIM, DTCs

B1000 and/or B1009, B1013 and B1014 sets.

DTC B1000, B1009, B1013 or B1014 Diagnostic Aids

Additional Information

• The following are descriptions of the DTCs:

• DTC B1000 – RAM Test Error

• DTC B1009 – EEPROM Checksum Error

• DTC B1013 – ROM Checksum Error

• DTC B1014 – Program ROM Checksum Error

• Refer to 8 Electrical Circuit and Connector Views, for the following information:

• PIM connector illustration and terminal assignment, and

• PIM wiring diagram.

• For intermittent fault conditions, refer to 6 Intermittent Fault Conditions.

• Always test the connectors related to this diagnostic procedure for shorted terminals or poor wiring connection

before replacing any component. Refer to Section 12P Wiring Diagrams for information on electrical fault diagnosis.

Conditions for Running the DTC B1000, B10 09, B1013 or B1014

Conditions for running the DTC are:

• The ignition is switched on.

• The ignition volt age is 10.0 – 16.0 V.

Conditions for Setting the DTCs

An internal PIM fault exists.

Action Taken When the DTCs Set

The action taken when any of these DTCs set will depend on the severit y of the error. This may vary from no visual or

audible warning messages to a Service Ve hicle Soon message displayed on the instrument cluster multi-function disp lay.

Conditions for Clearing DTCs

Refer to 4.1 Diagnostic General Descriptions for information on the conditions for clearing DTCs.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 This step checks if the DTC is current, and if so, indicates the PIM has an internal proble m.

3 This step checks the PIM ground and 12 V battery supply.

4 This step tests the PIM harness connector for servicea bility.

Powertrain Interface Module Page 6E4–26

Page 6E4–26

DTC B1000, B10 09, B1013 or B1014 Diagnostic Table

Step Action Yes No

1 Has the Main Diagnostic Table been performed?

Go to Step 2

Refer to

5.2 Main

Diagnostic Table

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for setting DTC B1000,

B1009, B1013 or B1014.

3 Using TECH 2, select the DTC display function.

Does DTC B1000, B1009, B1013 or B1014 fail this ignition c ycle? Go to Step 3

Refer to

DTC B1000, B1009,

B1013 or B1014

Diagnostic Aids

3 1 Test all ground circuits of the PIM for a high resistance or an

open circuit fault condition. Refer to 12P Wiring Diagrams for

information on electrical fault diagnosis.

2 Test the PIM fuses and replace as requ ired. Refer to

12O Fuses, Relays and Wiring Harnesses.

3 Test the PIM battery supply voltage circuit for a high resistance,

open circuit or short to ground fault condition. Refer to 12P

Wiring Diagrams for information on el ectrical fault diagnosis.

Has any fault been found and rectified? Go to Step 6 Go to Step 4

4 Inspect for poor connections at the PIM wiring connector. Refer to

12P Wiring Diagrams for information on el ectrical fault diagnosis.

Has any fault been found and rectified? Go to Step 6 Go to Step 5

5 Replace the PIM. Refer to 9.2 Powertrain Interface Module.

Has the repair been completed? Go to Step 6 –

6 1 Using TECH 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC B1000, B1009, B1013 or B1 014 fail this ignition cycle? Go to Step 2 Go to Step 7

7 Using TECH 2, select the DTC display function.

Does TECH 2 display any DTCs?

Go to the

appropriate DTC

Table System OK

When all diagno sis an d repairs are completed, clear all DTCs and check the system for correct operation.

Powertrain Interface Module Page 6E4–27

Page 6E4–27

7.2 DTC U1304 – Lost Communications with

UART System

Circuit Description

The transmission control module (T CM), ABS-TCS electronic control module (ECU) and eng ine control module (ECM)

transmit and receive data using the GM LAN serial data protocol, while the bod y control module (BCM) and other vehicle

control modules use the Universal Asynchronous Receive and Transmit (UART) serial data protocol.

As the GM LAN and UART protocols are not compatibl e, a powertrain interface module (PIM) is integrated into th e serial

data system to enable communication b etween the two different protocols.

The PIM monitors the UART serial data bus for traffic, and if the PIM does not detect any traffic on the UART serial data

bus, DTC U1304 sets.

DTC U1304 Diagnostic Aids

Additional information

For additional information refer to:

• 8 Electrical Circuit and Connector Views, for the following information:

• PIM connector illustration and terminal assignment, and

• PIM wiring diagram.

• Section 12J Body Control Module for BCM diagnosis.

• For intermittent fault conditions, refer to 6 Intermittent Fault Conditions.

• Always test the connectors related to this diagnostic procedure for shorted terminals or poor wiring connection

before replacing any component. Refer to Section 12P Wiring Diagrams for information on electrical fault diagnosis.

Conditions for Running the DTC

Conditions for running the DTC are:

• The ignition is switched on.

• The ignition volt age is 10.0 – 16.0 V.

Conditions for Setting the DTC

The PIM does not see any serial data communication on the UART serial data circu it 800 for greater than 10 seconds.

Action Taken When the DT C Sets

DTC U1304 sets when there is a communic ation failure on the UART serial data bus. TECH 2 accesses DTC information

via the UART serial data bus. If DTC U1304 is current, T ECH 2 will be unable to display any PIM DTC information. If

TECH 2 displays DT C U1304, this DTC will only be displayed as a history DT C.

NOTE

DTC U1304 may set as a current DTC if there is

a fault with the PIM.

Conditions for Clearing the DTC

Refer to 4.1 Diagnostic General Descriptions for information on the conditions for clearing DTCs.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 This step checks if TECH 2 can communicate with the BCM.

6 This step tests the PIM harness connector for servicea bility.

Powertrain Interface Module Page 6E4–28

Page 6E4–28

DTC U1304 Diagno stic Table

Step Action Yes No

1 Has the Main Diagnostic Table been performed?

Go to Step 2

Refer to

5.2 Main

Diagnostic Table

2 1 Switch off the ignition for 10 seconds.

2 Operate the vehicle within the conditions for setting DTC U1304.

3 Using TECH 2, select the DTC display function.

Does DTC U1304 fail this ignition cycle? Go to Step 3 Refer to DTC U1304

Diagnostic Aids

3 Using TECH 2, view the BCM identification information.

Does TECH 2 display the BC M identification information? Go to Step 4 Refer to 12J Body

Control Module

4 Using TECH 2, view the BCM Normal Mode Data.

Does TECH 2 display normal mode data? Go to Step 5 Refer to 12J Body

Control Module

5 Inspect for poor connections at the PIM wiring connector. Refer to 12P

Wiring Diagrams for information on electrical fault diagnosis.

Has any fault been found and rectified? Go to Step 7 Go to Step 6

6 Replace the PIM. Refer to 9.2 Powertrain Interface Module.

Has the repair been completed? Go to Step 7 –

7 1 Using TECH 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC U1304 fail this ignition cycle? Go to Step 2 Go to Step 8

8 Using TECH 2, select the DTC display function.

Does TECH 2 display any DTCs?

Go to the

appropriate DTC

Table System OK

When all diagno sis an d repairs are completed, clear all DTCs and check the system for correct operation.

Powertrain Interface Module Page 6E4–29

Page 6E4–29

7.3 DTC U2100 – No Communication With

CAN Bus (High Speed)

Circuit Description

The transmission control module (T CM), ABS-TCS electronic control unit (ECU) and engine control module (ECM)

transmit and receive data using the GM LAN serial data protocol, while the body co ntrol module (BCM) and other vehicle

control modules use the Universal Asynchronous Receive and Transmit (UART) serial data protocol.

As the GM LAN and UART protocols are not compatibl e, a powertrain interface module (PIM) is integrated into th e serial

data system to enable communication b etween the two different protocols.

The PIM will detect if a short to ground or a short to voltage conditio n occurs on the GM LAN circuits 2501 (CAN LO line)

and 2500 (CAN HI line). If either of these conditions occur, DTC U2100 sets.

DTC U2100 Diagnostic Aids

Additional Information

• Refer to 8 Electrical Circuit and Connector Views, for the following information:

• PIM connector illustration and terminal assignment, and

• PIM wiring diagram.

• For intermittent fault conditions, refer to 6 Intermittent Fault Conditions.

• Always test the connectors related to this diagnostic procedure for shorted terminals or poor wiring connection

before replacing any component. Refer to Section 12P Wiring Diagrams for information on electrical fault diagnosis.

Conditions for Running the DTC

Conditions for running the DTC are:

• The ignition is switched on.

• The ignition volt age is 10.0 – 16.0 V.

Conditions for Setting the DTC

The PIM detects a short to ground or short to voltage on the GM LAN circuits 2501 or 250 0 when the ignition is switched

on and the short condition exists for greater than five seconds.

NOTE

This DTC will only set when the ignition has

initially been turned to the On position, and will

not set when the vehicle is being driven.

Action Taken When the DT C Sets

NOTE

Depending on the severity of the fault, the

number of messages displayed ma y vary.

• When the DTC sets, the following messages may be displayed on the instrument cluster multi-function display:

• Service Vehicle Soon,

• Fuel Gauge Error – Contact Retailer, and

• TCS Fail.

• The instrument cluster will also display an ABS Off warning indicator.

Powertrain Interface Module Page 6E4–30

Page 6E4–30

Conditions for Clearing the DTC

Refer to 4.1 Diagnostic General Descriptions for information on the conditions for clearing DTCs.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 This step establishes if there is a fault with the ECM.

5 This step isolates whether the fault is between the ECM and the ABS-TCS ECU or with the ABS-TCS ECU.