Powertrain Management GEN III V8 – General Information Page 6C3-1–1

Page 6C3-1–1

Section 6C3-1

Powertrain Management GEN III V8 –

General Information

ATTENTION

Before performing any service operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 General Information ...............................................................................................................................3

1.1 Introduction............................................................................................................................................................ 3

1.2 Emission Control................................................................................................................................................... 4

Euro 2 Emissions Standards ................................................................................................................................ 4

2 Component Locations ...........................................................................................................................5

2.1 Cylinder Numbering............................................................................................................................................... 5

2.2 Engine Compartment............................................................................................................................................. 6

2.3 Engine..................................................................................................................................................................... 7

2.4 Automatic Transmission....................................................................................................................................... 9

2.5 Interior .................................................................................................................................................................. 10

3 System Operation.................................................................................................................................11

3.1 Fuel Delivery System........................................................................................................................................... 12

Fuel System Modes of Operation....................................................................................................................... 12

Starting Mode................................................................................................................................................... 12

Clear Flood Mode............................................................................................................................................. 12

Run Mode......................................................................................................................................................... 13

Acceleration Mode............................................................................................................................................ 13

Power Enrichment Mode.................................................................................................................................. 13

Deceleration Mode........................................................................................................................................... 13

Fuel Shut-off Mode........................................................................................................................................... 13

Engine Protection Mode................................................................................................................................... 13

Battery Voltage Correction Mode..................................................................................................................... 14

Limp Mode ....................................................................................................................................................... 14

Speed Density Mode........................................................................................................................................ 14

Catalyst Protection Mode................................................................................................................................. 14

Short and Long Term Fuel Trim.......................................................................................................................... 14

3.2 Electronic Ignition (EI) System........................................................................................................................... 15

3.3 Throttle Actuator Control (TAC) System............................................................................................................ 16

Description........................................................................................................................................................... 16

Throttle Body Relearn Procedure..................................................................................................................... 17

3.4 Emission Control Systems.................................................................................................................................. 19

Evaporative Emission Control System .............................................................................................................. 19

Engine Ventilation System.................................................................................................................................. 19

3.5 Electric Cooling Fans.......................................................................................................................................... 20

3.6 Torque Management............................................................................................................................................ 21

4 System Components............................................................................................................................22

4.1 A/C Refrigerant Pressure Sensor....................................................................................................................... 22

4.2 Brake Pedal Switches.......................................................................................................................................... 23

Stop Lamp and BTSI Switch Assembly ............................................................................................................. 23

Cruise Control Release and Extended Brake Travel Switch Assembly.......................................................... 23

Powertrain Management GEN III V8 – General Information Page 6C3-1–2

Page 6C3-1–2

4.3 Cruise Control System ........................................................................................................................................ 24

4.4 Camshaft Position (CMP) Sensor....................................................................................................................... 25

4.5 Crankshaft Position (CKP) Sensor..................................................................................................................... 26

4.6 Engine Coolant Temperature (ECT) Sensor ...................................................................................................... 27

4.7 Engine Oil Pressure (EOP) Sensor..................................................................................................................... 28

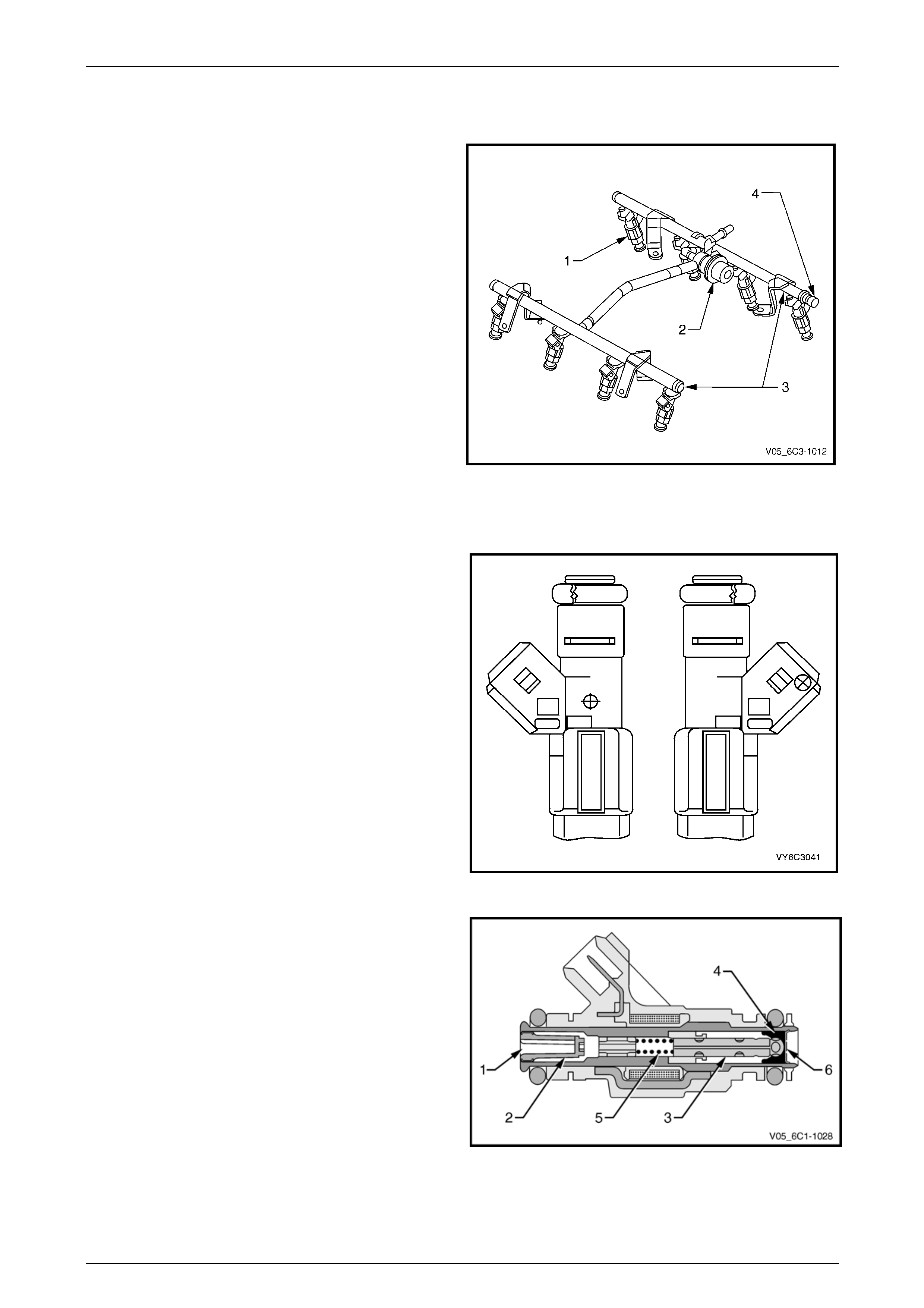

4.8 Fuel Rail Assembly.............................................................................................................................................. 29

Fuel Injectors........................................................................................................................................................ 29

4.9 Heated Oxygen Sensors (HO2S)......................................................................................................................... 30

4.10 Ignition Coils / Modules....................................................................................................................................... 32

4.11 Intake Air Temperature (IAT) Sensor.................................................................................................................. 33

4.12 Knock Sensors (KS) ............................................................................................................................................ 34

4.13 Manifold Absolute Pressure (MAP) Sensor....................................................................................................... 35

4.14 Air Intake System................................................................................................................................................. 36

Mass Air Flow (MAF) Sensor............................................................................................................................... 36

Intake Air Temperature (IAT) Sensor.................................................................................................................. 37

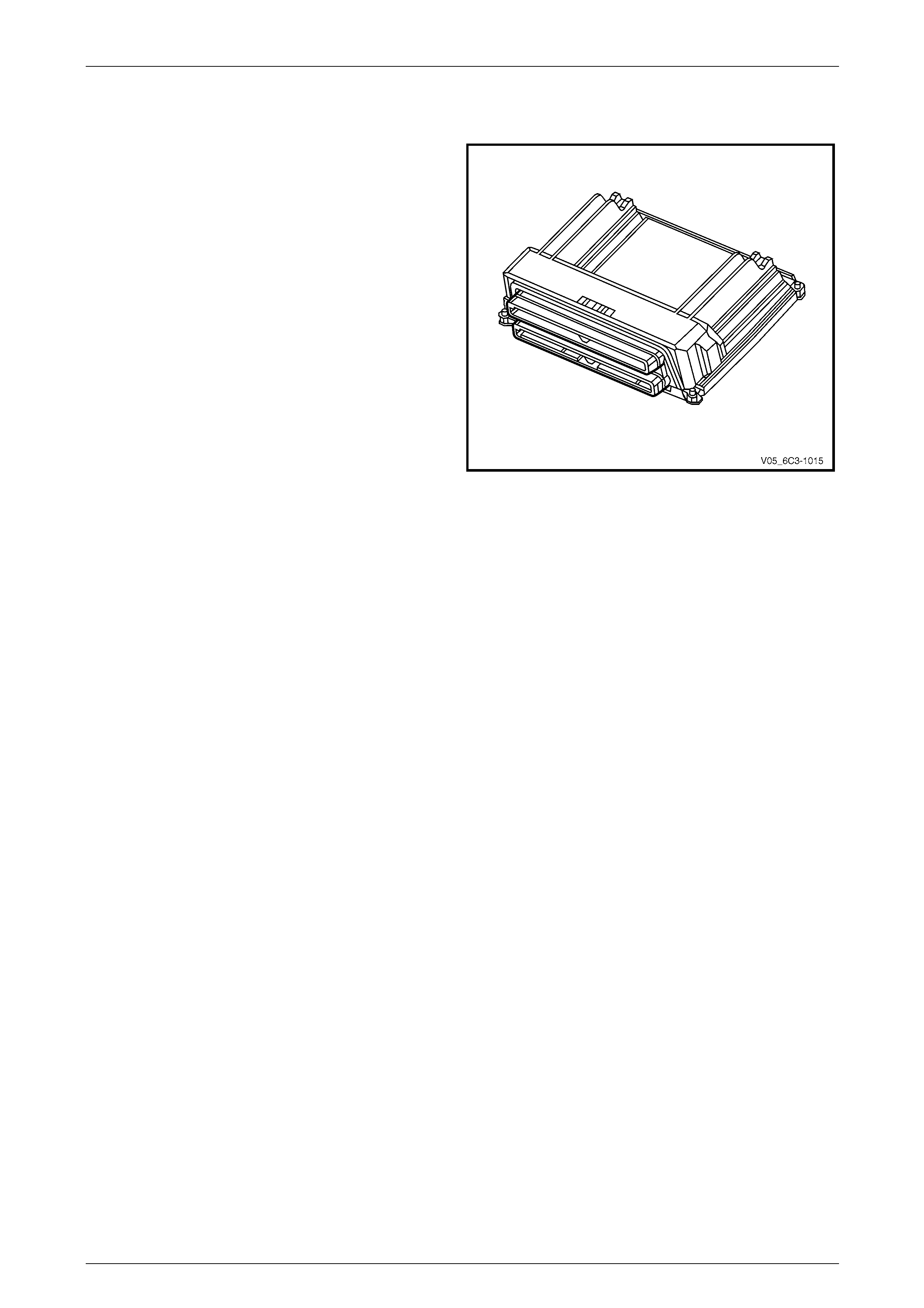

4.15 Powertrain Control Module (PCM)...................................................................................................................... 38

Self Diagnosis...................................................................................................................................................... 38

Programming........................................................................................................................................................ 38

4.16 Vehicle Speed Sensor (VSS)............................................................................................................................... 40

5 Automatic Transmission Components ..............................................................................................41

5.1 Range Switch (PRNDL)........................................................................................................................................ 41

Range Switch Valid Combination Table............................................................................................................. 41

5.2 1-2 (A) and 2-3 (B) Shift Solenoid Valves........................................................................................................... 42

5.3 3-2 Shift Solenoid Valve Assembly .................................................................................................................... 43

5.4 Pressure Control Solenoid.................................................................................................................................. 44

5.5 Torque Converter Clutch (TCC) Solenoid Valv e................................................................................................ 45

5.6 Torque Converter Clutch PWM Solenoid Valve................................................................................................. 46

5.7 Fluid Pressure Switch Assembly........................................................................................................................ 47

Pressure Switch Valid Combination Table........................................................................................................ 47

5.8 Fluid Temperature (TFT) Sensor......................................................................................................................... 49

6 Abbreviations and Glossary of Terms...............................................................................................50

Powertrain Management GEN III V8 – General Information Page 6C3-1–3

Page 6C3-1–3

1 General Information

The GEN III V8 powertrain management

system incorporates functions and

components that could cause personal injury

or vehicle damage. Refer to Section 6C3-2

GEN III V8 Powertrain Management –

Diagnostics, and Section 6C3-3 GEN III V8

Powertrain Management – Service

Operations, before attempting any diagnosis

or repairs.

1.1 Introduction

The GEN III V8 engine and transmission assembl y incorp orates an electronic powertrain management system. T his

Section describes the operation and lo cations of the various systems and components enc ompassed by the powertrain

management system.

The powertrain management system is controlled b y the powertrain control module (PCM) which is located on the left-

hand side of the engine compartment.

The PCM controls:

• the fuel injection system,

• ignition timing and dwell,

• engine throttling,

• automatic transmission functions,

• the engine cooling fans, and

• the air-conditioner compressor clutch ( where fitted).

The engine and transmission incorporate sensors that provide input to the PCM, and a range of components that perform

functions as commanded by the PCM, refer to Figure 6C3-1 – 7.

The powertrain management system has a self diagnostic capa bil ity, as well as connections to enable diagnosis of faults.

If the PCM recognises operational problems it can alert the driver via the check powertrain icon in the instrument cluster

multi-function display. The PCM also interfaces with other systems in the vehicle as required.

The vehicle incorporates a the ft deterrent system. When the ignition switch is turned from off to on, the body control

module (BCM) will transmit serial security data to the PCM via the powertrain interface module (PIM). If the data

matches, the PCM and PIM will enable the starter relay and fuel injection. For further infor m ation and diagnosis of the

theft deterrent system, refer to Section 12J Body Control Module.

For further information on the PIM, refer to Section 6E3 Powertrain Interface Module – GEN III V8.

For further information on the air-conditioni ng system, refer to Section 2A HVAC Climate Control – Description and

Operation.

For the location of fuses, fusible links and relays, refer to Section 12O Fuses, Relays, an d Wiring Harnesses.

Powertrain Management GEN III V8 – General Information Page 6C3-1–4

Page 6C3-1–4

1.2 Emission Control

Euro 2 Emissions Standards

The vehicle has been configured to comply with Euro 2 vehicle emissions standards. Euro 2 is a European standard

which sets vehicle emissions targets to compel vehicle manufacturers to reduce harmful vehicle emissio ns such as

carbon monoxide (CO), hydrocarbons (HC) and the various oxides of nitrogen (NOx).

Australian Design Rule 79/00 implements the Euro 2 exhaust and evaporative emissions requirements for light veh icles

to reduce air pollution. The following tests are prescribed:

• average tailpipe emissions after a cold start,

• carbon monoxide emission at idling speed,

• emission of crankcase gases,

• evaporative emissions, and

• durability of pollution-control d evices.

Powertrain Management GEN III V8 – General Information Page 6C3-1–5

Page 6C3-1–5

2 Component Locations

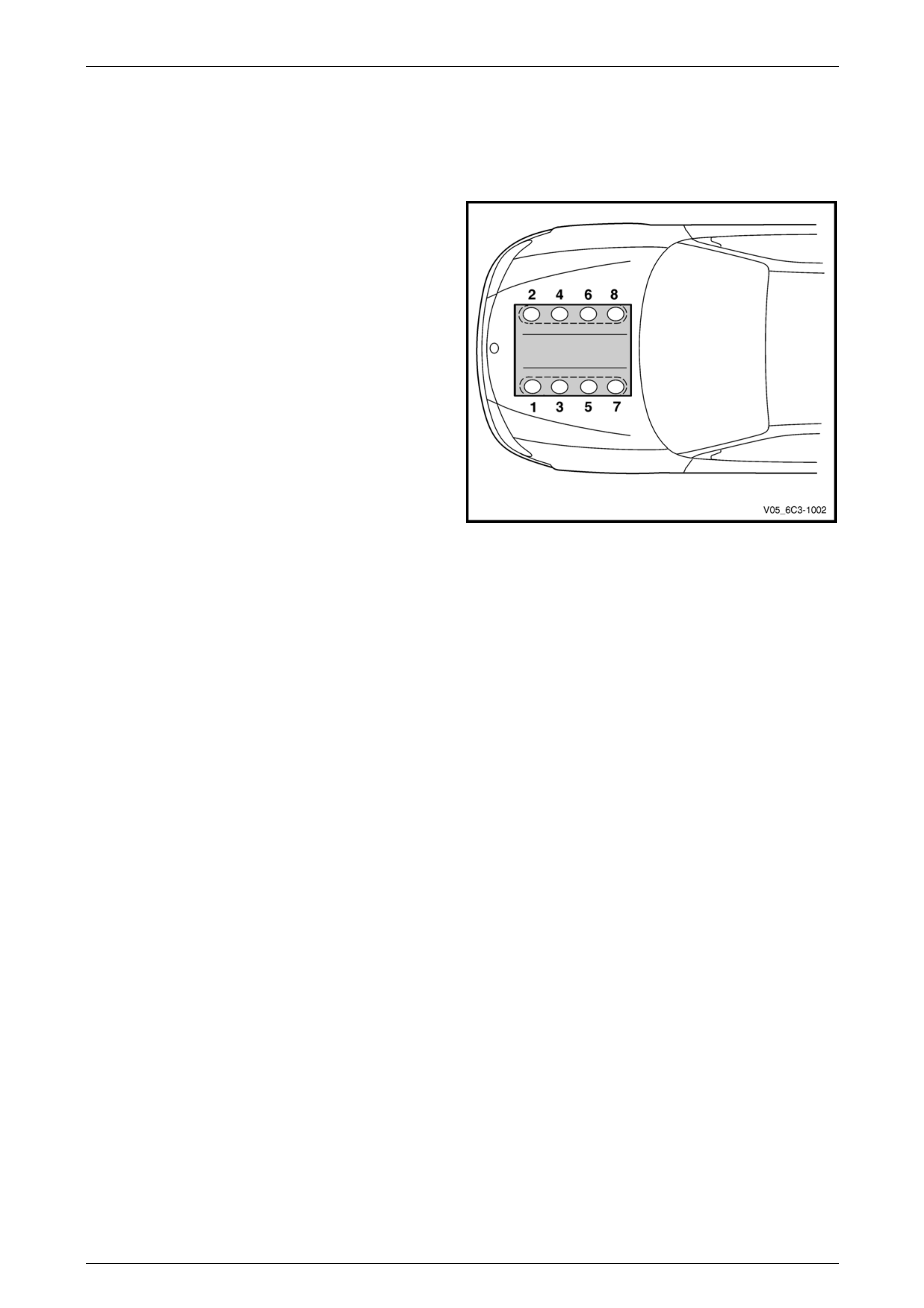

2.1 Cylinder Numbering

Engine cylinder identification follows the international

standard OBD II. This standard calls for the engine cylinder

bank number one to be identified by the location of cylinder

number one. Therefore the numbering for the GEN III V8

engine is:

• 1, 3, 5, 7 – Left-hand side (Bank 1),

• 2, 4, 6, 8 – Right-hand side (Bank 2).

The engine firing order is 1, 8, 7, 2, 6, 5, 4, 3.

Figure 6C3-1 – 1

Powertrain Management GEN III V8 – General Information Page 6C3-1–6

Page 6C3-1–6

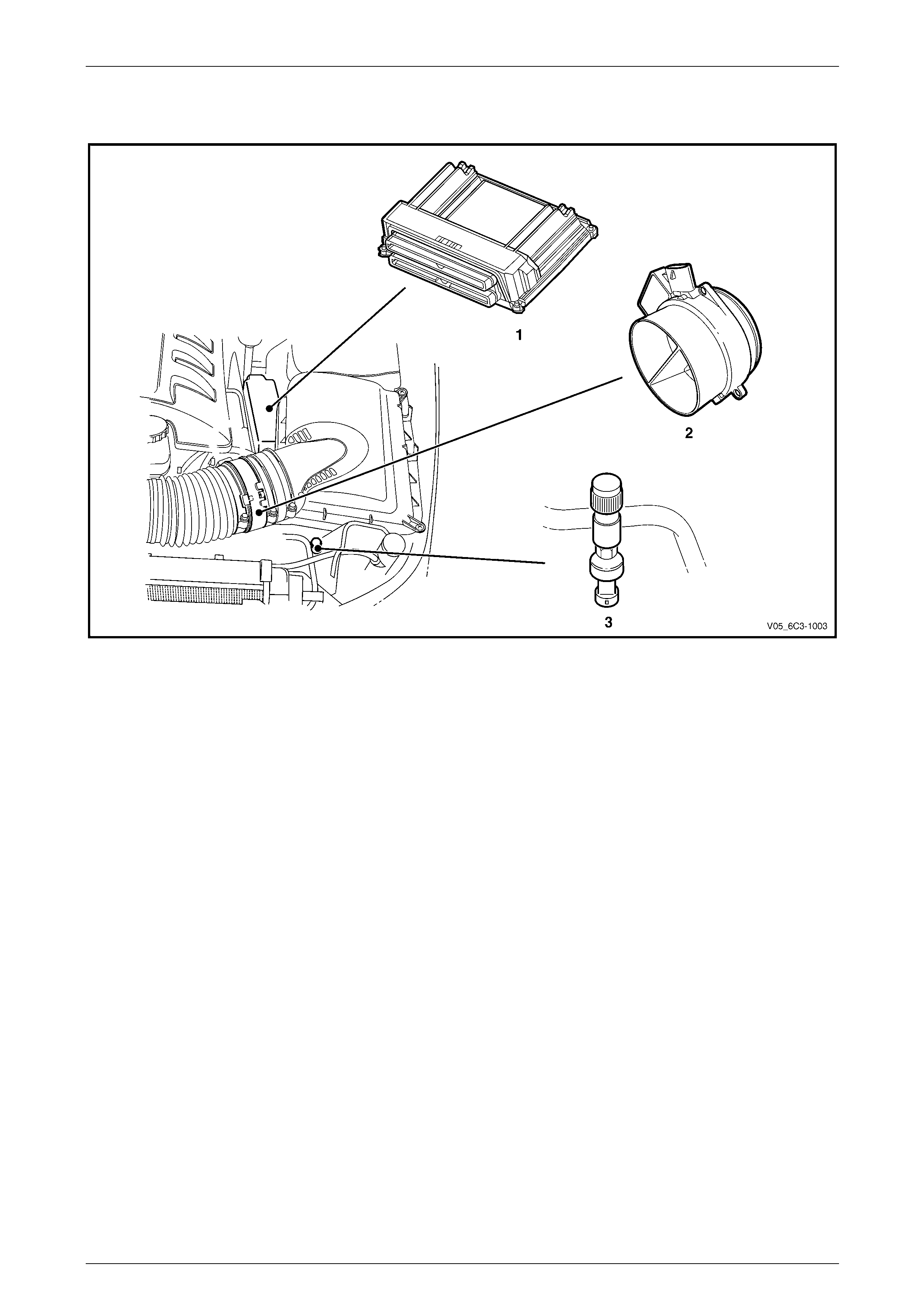

2.2 Engine Compartment

Figure 6C3-1 – 2

Legend

1 Powertrain Control Module (PCM)

2 Mass Air Flow (MAF) Sensor 3 Air-conditioner Refrigerant Pressure Sensor

Powertrain Management GEN III V8 – General Information Page 6C3-1–7

Page 6C3-1–7

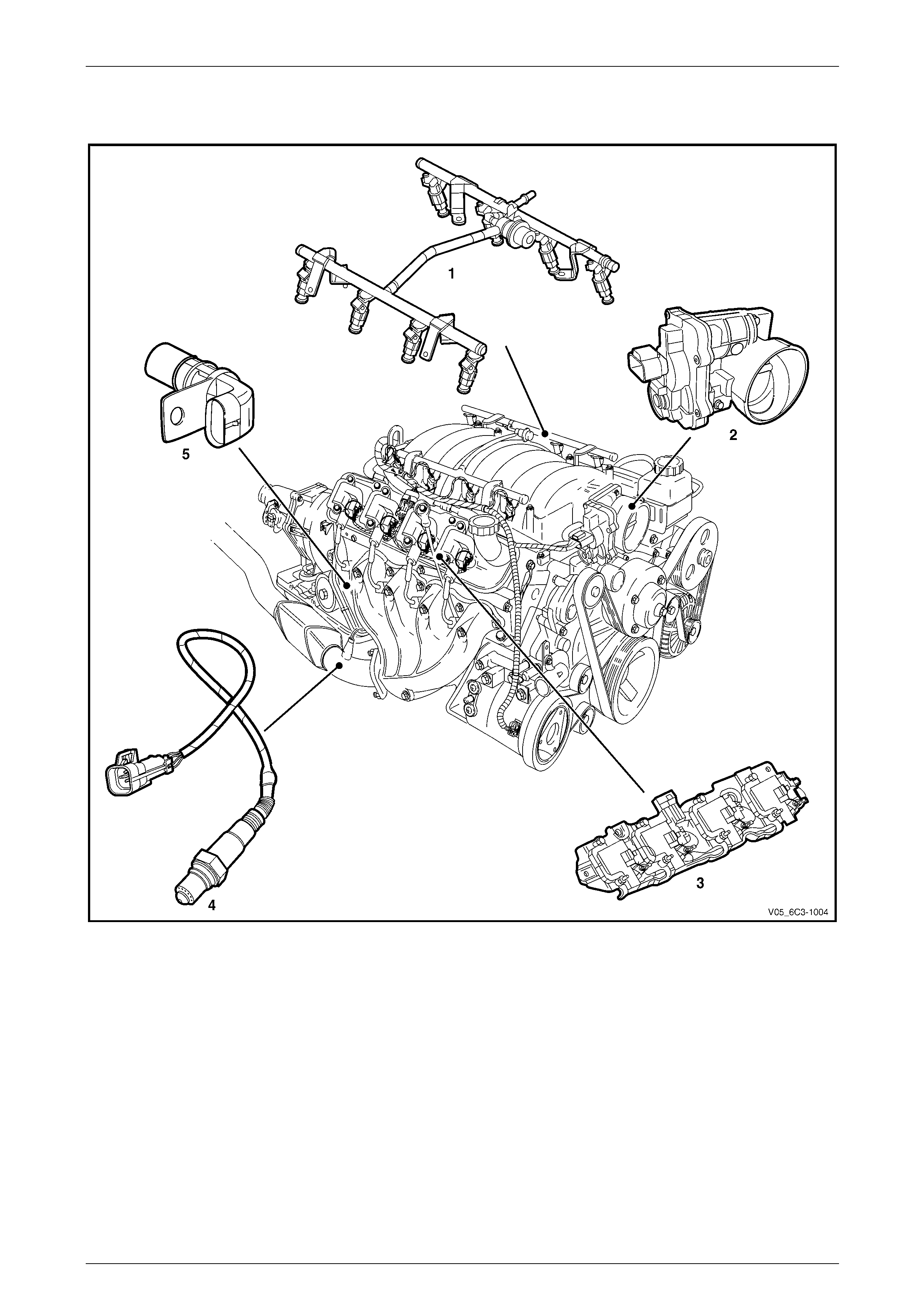

2.3 Engine

Figure 6C3-1 – 3

Legend

1 Fuel Rail Assembly (with fuel injectors)

2 Throttle Body

3 Ignition Coils/Modules Assembly, 2 Places

4 Heated Oxygen Sensor (HO2S), 2 places

5 Crankshaft Position (CKP) Sensor

Powertrain Management GEN III V8 – General Information Page 6C3-1–8

Page 6C3-1–8

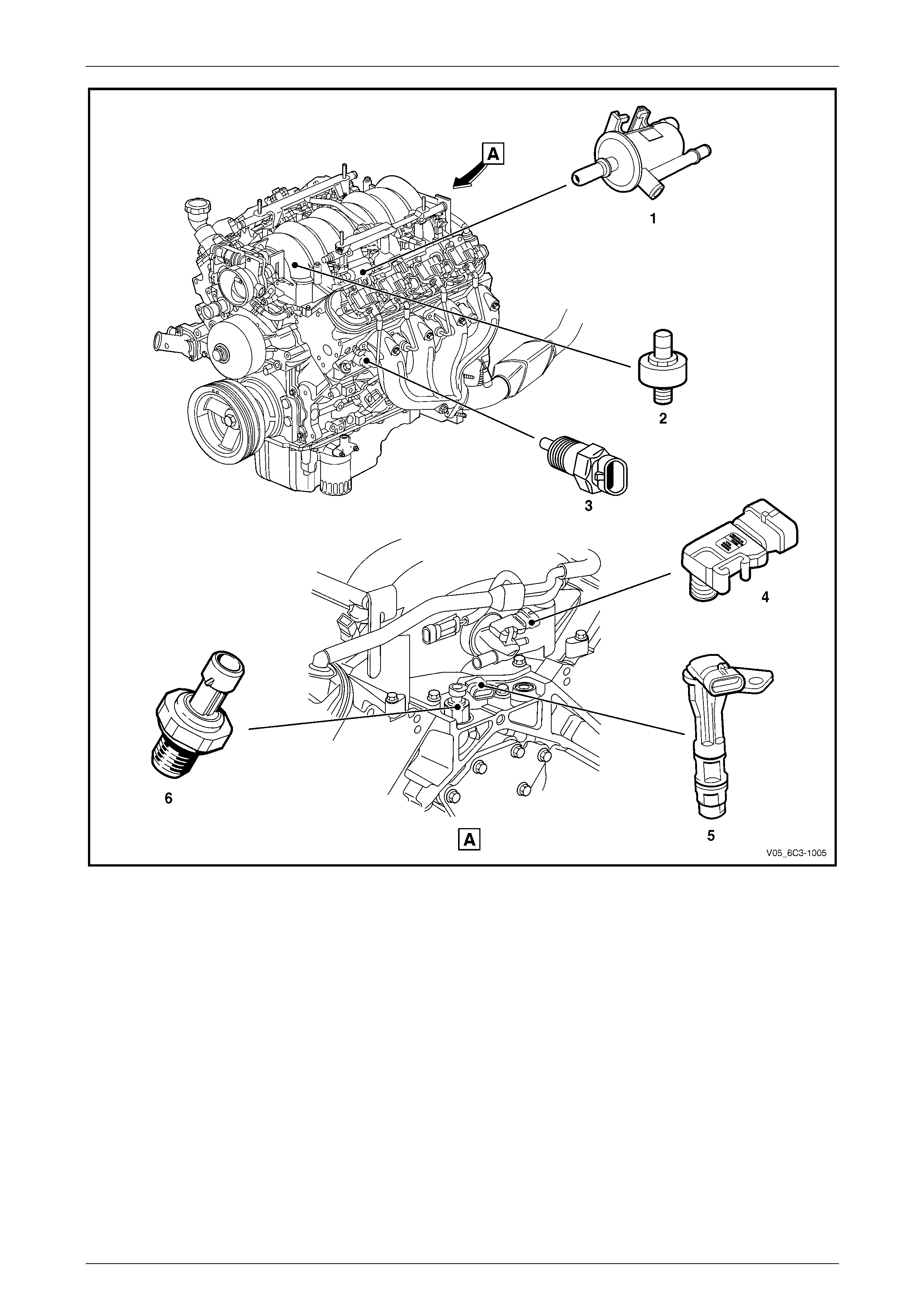

Figure 6C3-1 – 4

Legend

1 Evaporative Canister Purge Solenoid

2 Knock Sensor, 2 Places

3 Engine Coolant Temperature (ECT) Sensor

4 Manifold Absolute Pressure (MAP) Sensor

5 Camshaft Position (CMP) Sensor

6 Engine Oil Pressure (EOP) Sensor

Powertrain Management GEN III V8 – General Information Page 6C3-1–9

Page 6C3-1–9

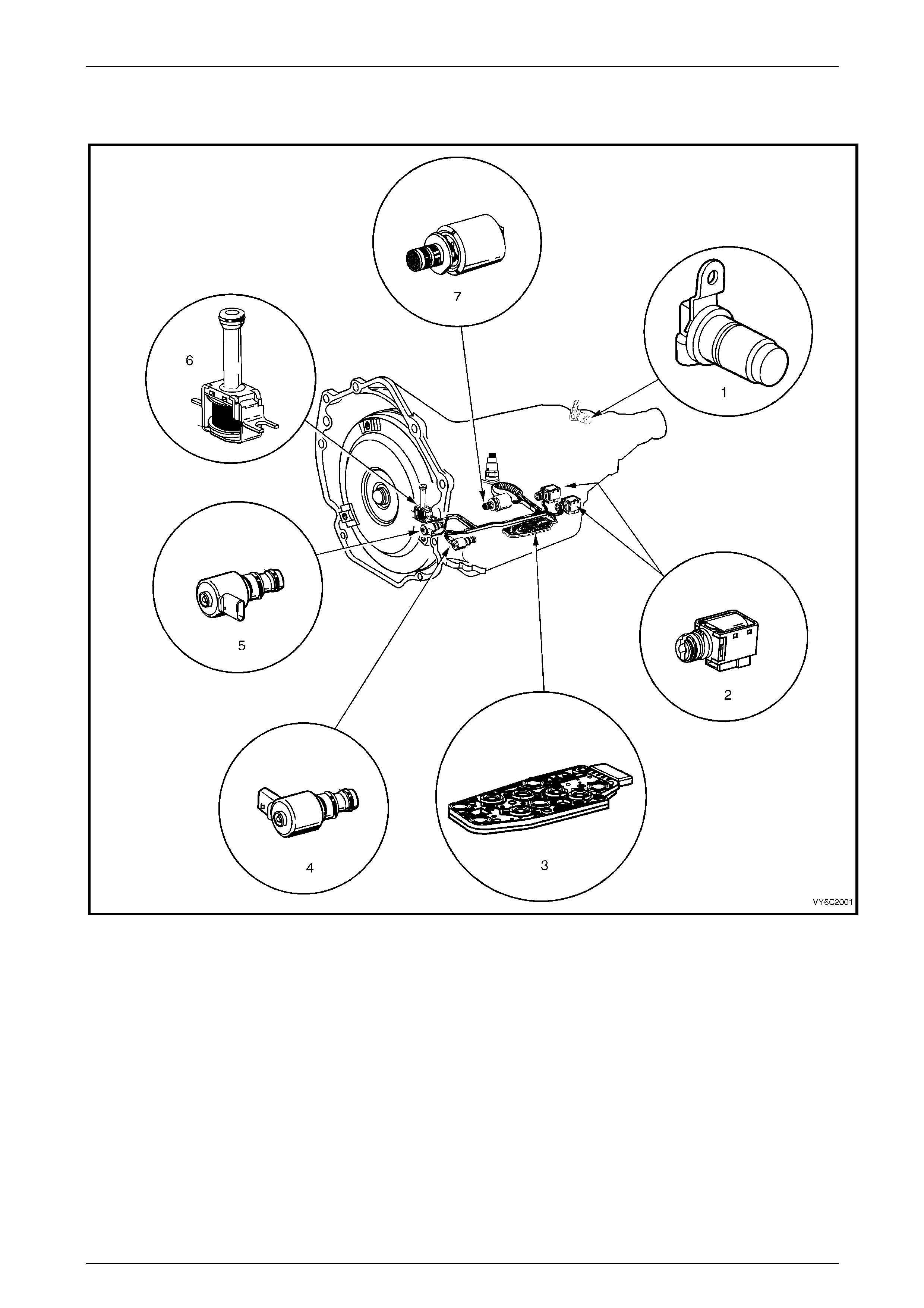

2.4 Automatic Transmission

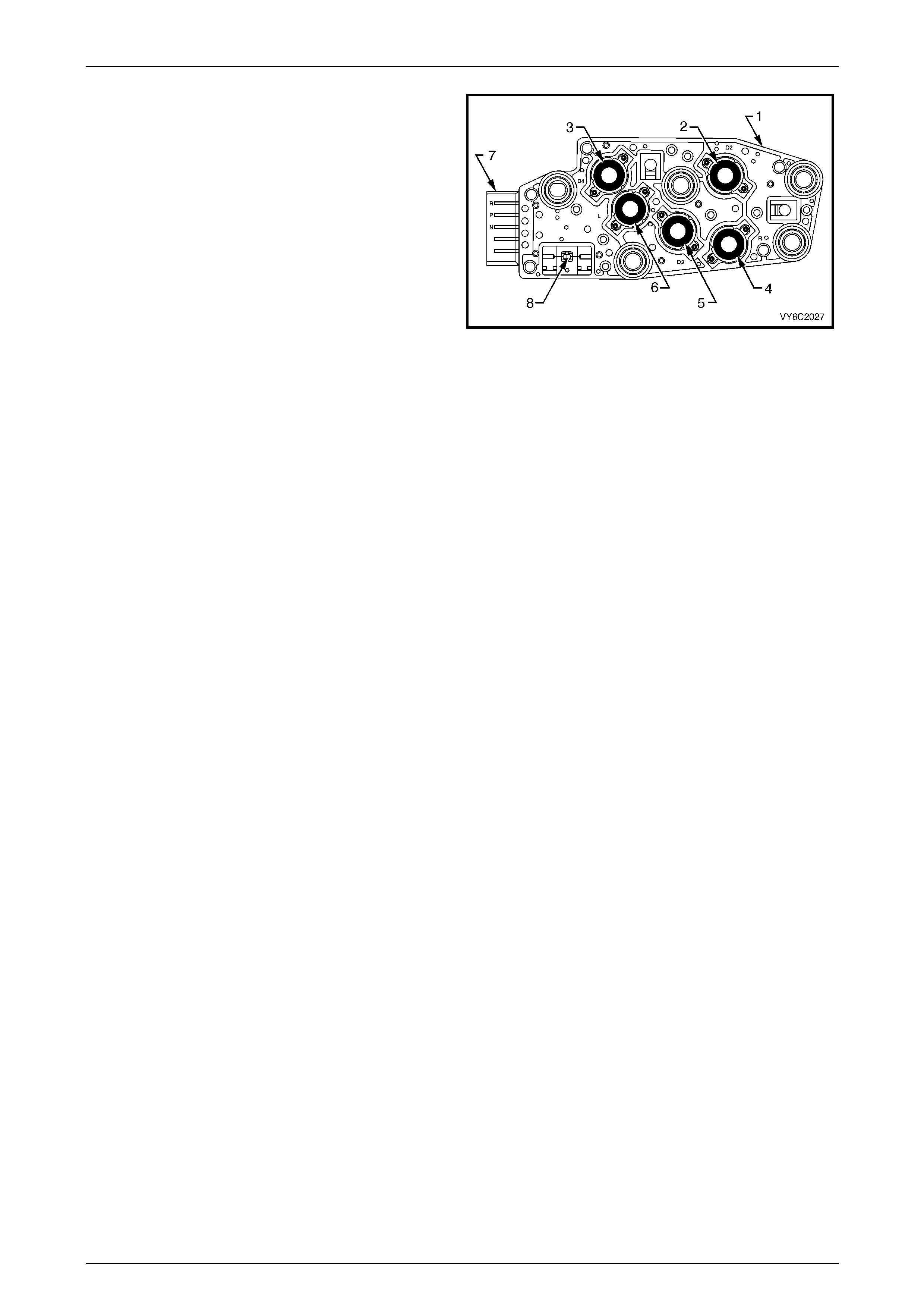

Figure 6C3-1 – 5

Legend

1 Vehicle Speed Sensor

2 1-2 Shift Solenoid A and 2-3 Shift Solenoid B

3 Automatic Transmission Fluid Pressure (TFP) Manual

Valve Position Switch

4 3-2 Downshift Control Solenoid

5 Torque Converter Clutch Pulse Width Modulation (TCC

PWM) Solenoid Valve

6 Torque Converter Clutch (TCC) Solenoid Valve

7 Pressure Control Solenoid (PCS) Valve

Powertrain Management GEN III V8 – General Information Page 6C3-1–10

Page 6C3-1–10

2.5 Interior

Figure 6C3-1 – 6

Legend

1 Check Powertrain Icon

2 Accelerator Pedal Assembly

3 Data Link Connector (DLC)

4 Extended Brake Pedal Travel and Brake Pedal Cruise

Control Cancel Switch

5 Stop Lamp and BTSI Switch Assembly

Powertrain Management GEN III V8 – General Information Page 6C3-1–11

Page 6C3-1–11

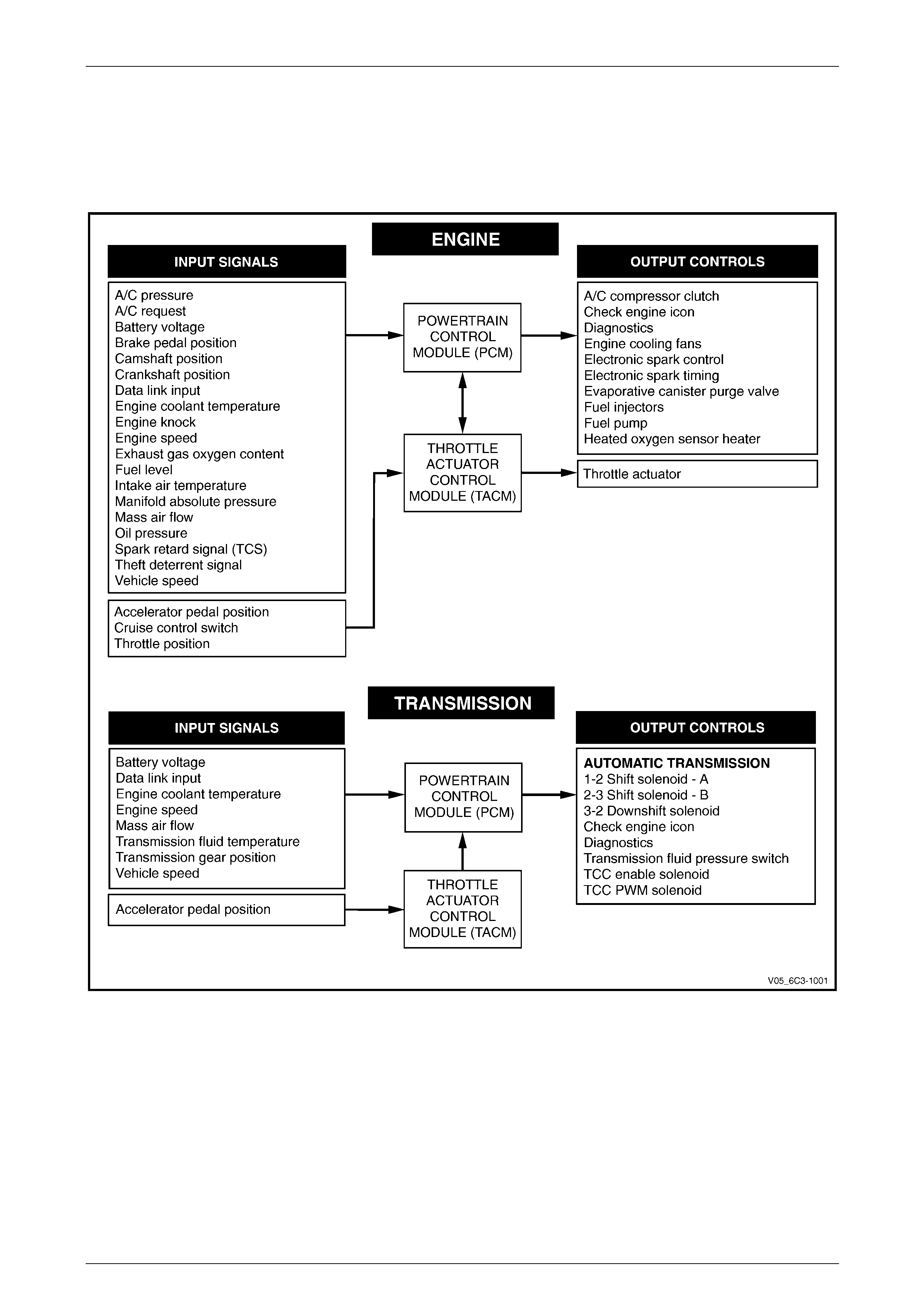

3 System Operation

The PCM is the control centre of the GEN III V8 powertrain management system and constantly monitors and evaluates

inputs from various sensors and switches. Based on these inputs, the PCM controls the operation of the powertrain

management system. Refer to Figure 6C3-1 – 7 for the illustration of the inputs and outputs of the PCM.

Figure 6C3-1 – 7

Powertrain Management GEN III V8 – General Information Page 6C3-1–12

Page 6C3-1–12

3.1 Fuel Delivery System

Unleaded fuel must be used to ensure correct emission parameters and engine operation. Leaded fuel can damage the

emission control system and can result in loss of emission warranty. Using unleaded fuel will also minimise any spark

plug fouling and e xtend engine oil life.

The function of the fuel and air control s yste m is to manage the delivery of fuel and air mixture to each cylinder,

optimising the performance and t he driveability of the engine und er all conditions. A modular fuel pump and sender

assembly delivers fuel from the fuel tank and provides infor mation on the fuel level.

The fuel supply system is a single lin e, on-demand design. With the fuel pressure regulator incorporated into the modular

fuel pump and sender assembly, the need for a return pipe from the engine is eliminated. Havin g a single line fuel supply

system reduces the internal temperature of the fuel tank by not returning hot fuel from the engine. In reducing the internal

temperature of the fuel tank, lower evaporative emissions are achieved.

An electric fuel pump contained in the modu lar fuel pump and sender assembly provides fuel at a pressure above the

regulated pressure which is supplied to the fuel rail. The fuel is then distributed through the fuel rail to six injectors

located directly above each cylind er’s two intake valves. A fuel pump relay allows the PCM to control the fuel pump.

The PCM controls each fuel in jector by energising the injector coil for a brief period once every other engine revolution.

The length of this brief period is carefully calculated by the PCM to deliver the correct amount of fuel for optimum engine

performance and emission control. The period of time when the injector is energised is called the pulse width and is

measured in milliseconds (thousandths of a second).

While the engine is running, the PCM is constantly monitoring the inputs and recalculating the appropriate pulse width for

each injector. The pulse width calculation is based on:

• the injector flow rate,

• mass of fuel passed by the energised injector per unit of time,

• the desired air/fuel ratio, and

• actual air mass in each cylinder.

The calculated pulse is timed to occur as each cylinder’s intake valve is closing to provide enough time for the fuel to

atomise completely and mix with the intak e air. Each injector is energised individually in the engine firing order, which is

known as sequential fuel injection.

Fuel System Modes of Operation

The PCM has several operati ng modes for fuel control, depending on the information received from the sensors.

Starting Mode

When the ignition s witch is turned on, the PC M energises the fuel pump circuit to operate the fuel p ump which builds

pressure in the fuel system. If the PCM does not receive reference pulses from the cranks haft position sensor, the fuel

pump circuit will be de-energised after 2 seconds. When the ignition switch is moved to the START position, the fuel

pump circuit will remain (or become) energised by the PCM once reference pulses are received from the crankshaft

position sensor.

As the engine begins to turn, a prime pulse may be injected to speed starting. As soon as the PCM can determine where

in the firing order the engine is, the PCM begins p ulsi ng the injectors. The PCM also monitors mass air flow, intake air

temperature, engine coolant temperature, and throttle position in order to determine the required injector pulse width for

starting.

Clear Flood Mode

If the engine is flooded with fuel during cranking and will not start, the clear flood mode can be manually selected by

depressing the accelerator pedal to wide open throttle (WOT). In this mode, the PCM will completely turn off the

injectors, and will maintain this state during engine cranking as long as th e PCM detects a WOT condition with engine

speed below 1,000 RPM.

Powertrain Management GEN III V8 – General Information Page 6C3-1–13

Page 6C3-1–13

Run Mode

The PCM changes to run mode when it reaches 480 RPM after being started. The run mode has two sub-modes called

Open Loop and Closed Loop.

Open Loop Mode

In open loop, the PCM ignores the signals from the heated oxygen sensors (HO2S), and calculates the required injector

pulse width based primarily on inputs from the mass air flow (MAF), Intake Air Temperature (IAT), and Engine Coolant

Temperature (ECT) sensors. In open loop the calculate d pu lse width may give an air/fuel ratio other than the ideal 14.7

to 1, for example when the engine is cold a richer mixture is needed. The system will stay in the open loop mode until the

HO2S produce a usable output.

Closed Loop Mode

Once the HO2S reaches operating temperature and starts producing its own signal voltage output, the PCM switches to

closed loop mode. In closed loop mode, the PCM initially calculates injector pulse width bas ed on the same sensors

used in open loop and ad ditionally, uses the oxyge n sensor signals to modify and fine tune the fuel pulse width

calculations to precisely maintain the ideal 14.7 to 1 air/fuel ratio.

Acceleration Mode

The PCM monitors changes in the acceler ato r pedal position (APP) and MAF sensor signals to determine when the

vehicle is being accelerated. The PCM will then increase the injector pulse width in order to provide more fuel

accordingly.

Power Enrichment Mode

Similar to Acceleration Mode, the PCM enters power enrichment mode when the PCM detects a large change in the

accelerator pedal position, providing extra fuel to the cylinders as required.

Deceleration Mode

The PCM monitors changes in the APP and MAF sensor signals to determine when the vehicle is being dece lerated. The

PCM will then decrease injector pulse width, or even shut the injectors off for short periods, to reduce exhaust emissions

and improve fuel econom y.

Fuel Shut-off Mode

The PCM has the ability to completely turn off some or all of the injectors when certain conditions are met. These fuel

shut-off modes allow the PCM to protect the engine from damage a nd to also improve the vehicle's drive ability.

The PCM will disable all eight injectors under the following conditions:

• ignition off – to prevent engine run-on,

• ignition on but no ignition refe rence signal – prevents flooding or backfiring,

• at high engine speed – above the red line (rev limiter),

• at high vehicle speed – above the rated tyre speed (vehicle speed limiter), or

• extended high speed closed throttle coast-do wn – reduc es engine emissions and increases engine braking.

The PCM will selectivel y disable the injectors under the following condition s :

• torque management enabled – transmission shifts or abusiv e maneouvres, or

• traction control enabled – in c onjunction with brake application.

Engine Protection Mode

Engine protection mode is en gaged to protect engine components from friction damage in the event of an engine over-

temperature condition being detected by the PCM.

When the PCM is in engine pr otection mode, fuel injectors are systematically disable d an d re-activated. The injectors

that have been shut down allow the air being drawn into the engine to assist with engine cooling.

Powertrain Management GEN III V8 – General Information Page 6C3-1–14

Page 6C3-1–14

Battery Voltage Correction Mode

The PCM can provide compensatio n to main tain acceptable vehicle driveabilit y when the PCM sees a low battery voltage

condition. The battery voltage adjustment is necessary since the changes in the voltage across the inj ector affect the

injector flow rate.

The PCM compensates by performing the following functions:

• increases the injector pulse width to maintain the correct amount of fuel being de livered, and

• increases the idle speed to increase the gen erator outp ut.

Limp Mode

In the event of a major internal problem, the PCM is equipped with a back-up fuel strategy for limp mode that will run the

engine until service can b e performed.

Speed Density Mode

If the PCM detects a malfunction with the MAF sensor circuit, the PCM will default to speed de nsity fuel management. In

speed density mode, the PCM will rely primarily on the MAP sensor instead of the MAF sensor si gnal to control engine

fuelling.

Catalyst Protection Mode

During sustained heav y loads, the PCM increases the pulse width to the injectors to provide extra fuel to prevent the

catalytic converters from overheating.

Short and Long Term Fuel Trim

Short term fuel trim (STFT) represents short term corrections to the fuel injector pulse width calculations based on the

HEGO sensor input signals to the PCM. STFT is not active until the HO2S sensor is at operational temperature.

By using the HO2S as the main reference point for control of engin e fuelling, the PCM can more accurately control the air

/ fuel ratio. This is because when using STFT the PCM reacts to actual results from combustion, and not expected

results (base settings). STFT is used by the PCM to make quick changes to the fuel injector pulse width over a short

period of time.

The values for STFT can be viewed as a percentage using Tech 2. Values greater than 0% indicate that the PCM is

increasing injector pulse width, and negative values (less than 0%) indicate reduced injector pulse widths.

Long term fuel trim (LTFT) represents long term corrections to the fuel injector pulse width calculatio ns based on the long

term trend of the STFT calculations. T he PCM monitors the STFT and will adjust the long term trend of the fuel injector

pulse width when the STFT has been at a particular value for a certain period of time. LT FT is not active until the HO2S

sensor is at operational temperature.

LTFT compensates for engi ne and component wear, condition of filters, and an y other system variations.

The LTFT function of the PCM is divided into 23 cells arranged by MAP sensor readings and engine RPM. Each cell

corresponds to a region on a MAP vs. RPM table. A value of 0% in a given cell indicates that no fuel adjustment is

needed for that engine load and speed condition. As the engine moves through its operating range, the LTFT changes to

the relevant cell. The PCM will read the LTFT value in each cell and adjust the fuel injector base pulse width accordin gly.

As the LTFT changes cell so does STFT, however STFT will only make short term corrections in the cell that the LTFT is

operating in. The ST FT adjustments occur after the LTFT correctio ns are made. In this way, the STFT can make minor

corrections to the injector pulse width in each cell quicker than if the corrections were made from 0% each time the PCM

changed cell.

If STFT and LTFT are both set at their maximum value limit, the fuel control system is out of the limits of control. This will

result in the system going into open loop op eration and a Diagnostic Trouble Code to be set.

The values for LTFT can be viewed as a percentage using Tech 2. Values greater than 0% ind icate that the PCM is

increasing injector pulse width, and negative values (less than 0%) indicate reduced injector pulse widths.

Tech 2 has the ability to reset all LTFT cells to 0%.

All LTFT cell values are reset to 0% when long term memory power to the PCM is removed.

Powertrain Management GEN III V8 – General Information Page 6C3-1–15

Page 6C3-1–15

3.2 Electronic Ignition (EI) System

The electronic ignition s ystem provides a sp ark to ignite the compressed air/fuel mixture at the correct time. The PCM

maintains correct spark timing and dwell for all driving conditions. The PCM calculates the optimum spark parameters

from information received from the various sensors and triggers the appropriate ignition modu le / coil to fire the spark

plug.

Powertrain Management GEN III V8 – General Information Page 6C3-1–16

Page 6C3-1–16

3.3 Throttle Actuator Control (TAC) System

Description

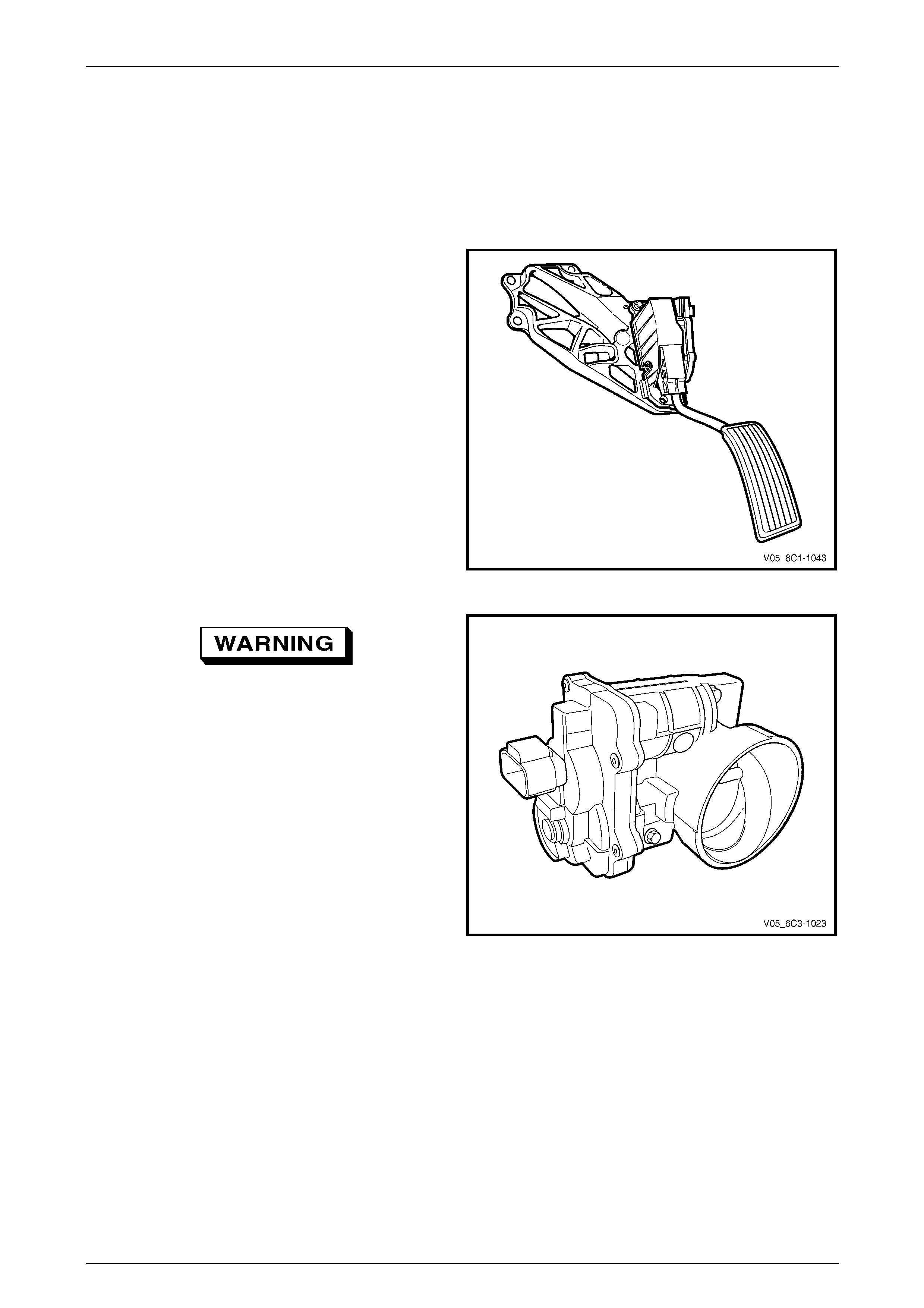

The throttle actuator control (TAC) system is used to impr ov e emissions, fuel economy and drive ability. The TAC system

deletes the mechanical link between the accelerator pedal and the throttle plate and eliminates the need for a cruise

control module and idle air co ntrol motor. The TAC system consists of:

• an accelerator pedal assembly which includes:

• accelerator pedal,

• accelerator pedal position (APP) sensor 1,

• accelerator pedal position (APP) sensor 2;

Figure 6C3-1 – 8

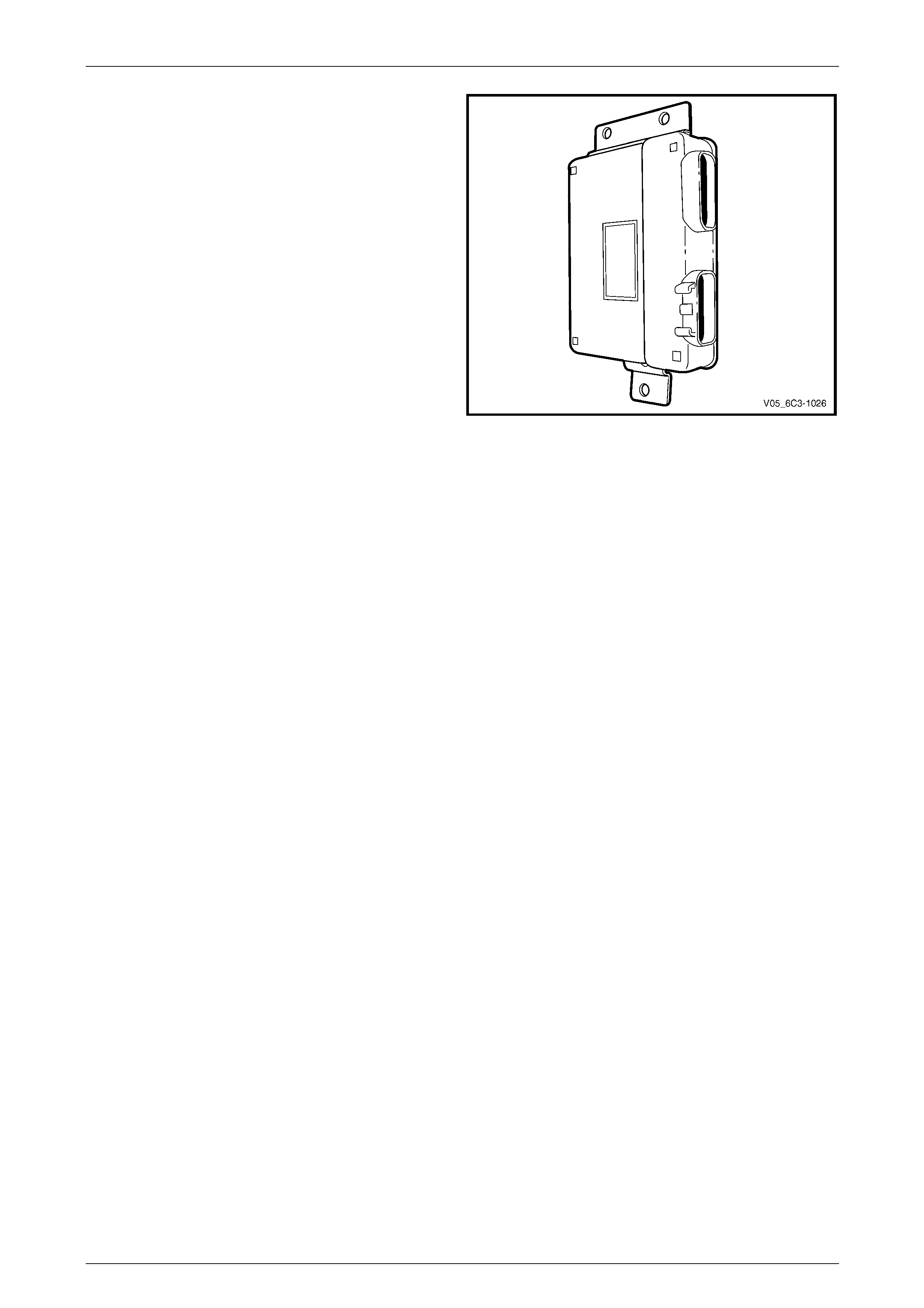

To avoid serious personal injury, never

attempt to rotate the throttle plate manually

whilst the throttle body harness connector is

connected to the throttle bod y.

• a throttle body assembly which includes:

• throttle position (TP) sensor 1,

• throttle position (TP) sensor 2,

• throttle actuator control motor, and

• throttle plate;

Figure 6C3-1 – 9

Powertrain Management GEN III V8 – General Information Page 6C3-1–17

Page 6C3-1–17

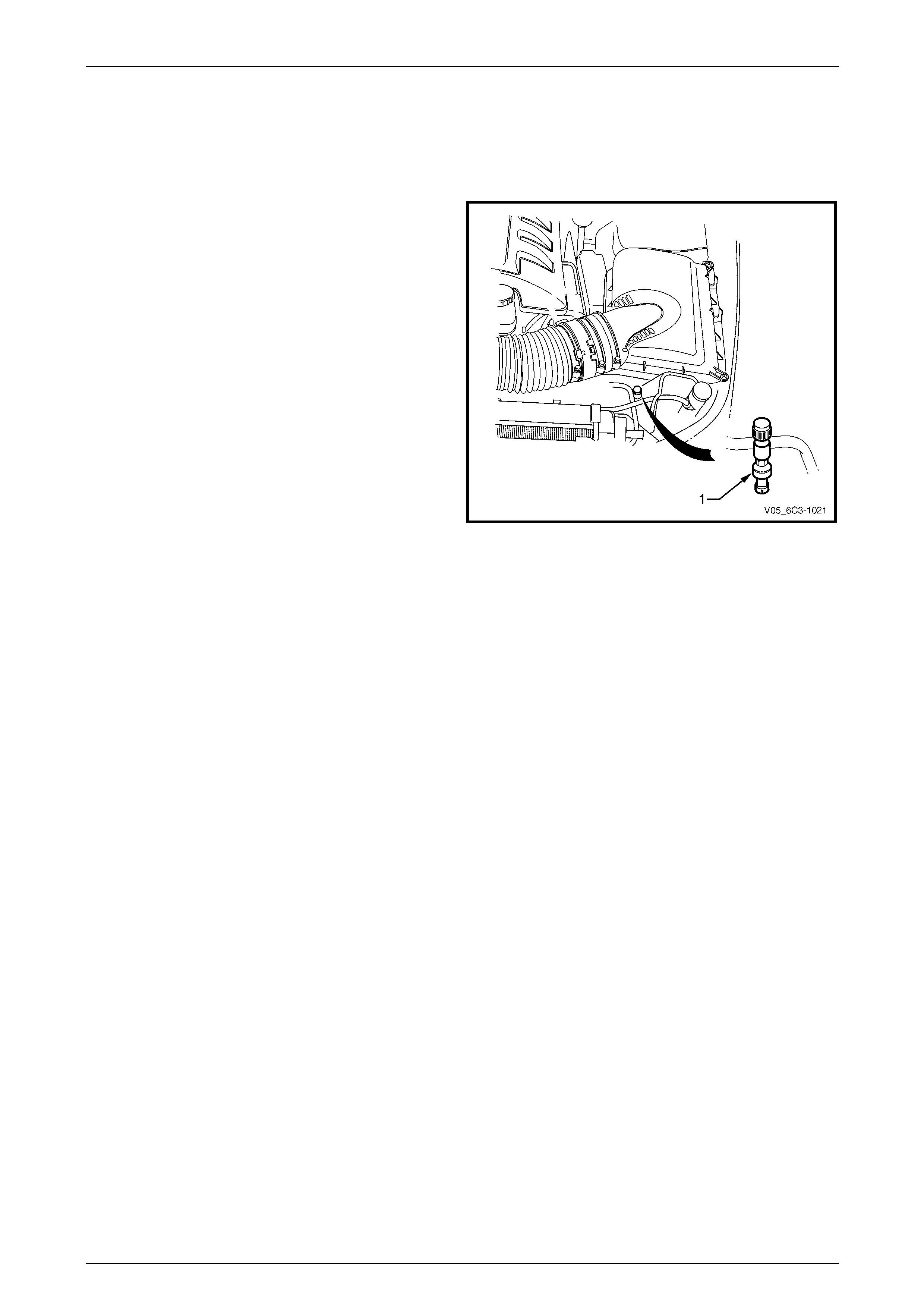

• a throttle actuator control module (TACM);

• a powertrain control module (PCM).

Figure 6C3-1 – 10

The TACM monitors the accelerator pedal position through the two APP sensors and forwards this signal to the PCM via

a dedicated serial data line. The PCM processes this information along with other system sensor inputs to command the

throttle plate to a certain position. T his throttle position requ est is sent back the TACM along the same serial data line,

and the TACM sends a pulse width modulated signal to the throttle body.

A direct current motor called the throttle actuator control motor controls the throttle plate. The TACM can operate this

motor in the forward or reverse direction by controlling battery voltage and/or grou nd to two internal drivers. When there

is no current flowing to the actuator motor, the throttle plate is held at a rest position of 7 percent open using a constant

force return spring.

The TACM monitors the throttle plate angle t hrough two TP sensors. Using this information, the TACM can precisely

adjust the throttle plate.

The TACM performs diagnostics that monitor the voltage levels of both APP sensors, both TP sensors and the throttle

actuator control motor circuit. It also monitors the spring return rate. T hese diagnostics are performed at different times

based on whether the engi ne is running, not running, or whether the TACM is currently in a throttle body relearn

procedure. This information is sent to the PCM for external diagnosis purposes.

Two sensors within the accelerator ped al assembly and throttle body assembly are used to provide redu ndancy. If a

malfunction is detected, the throttle plate is moved to a pre-determined po s ition.

Every ignition cycle, the TACM performs a quick throttle return spring test to ensure the throttle plate can return to the

7 percent rest position from the 0 percent position. This is to ensure that the throttle plate can be brought to the rest

position in case of an actuator motor circuit failure.

Throttle Body Relearn Procedure

The TACM stores values that inclu de the lowest possible TP sensor positions (0 percent), the rest positions (7 percent),

and the spring return rate. These values will only be erased or overwritten if the TACM is reprogrammed or if a throttle

body relearn procedure is performed.

NOTE

If the battery has been disconnected, the PCM

performs a throttle body relearn procedure once

the battery has been reconn ected and the ig nition

turned on.

The TACM performs a throttle body relearn procedure anytime the ign ition is turned on and the following conditions have

been met:

• the engine has been off for longer tha n 29 seconds,

• the engine speed is less than 40 RPM,

• the vehicle speed is 0 km/h,

• the engine coolant temperature (ECT) is between 5 – 60°C; if Tech 2 is used to perform the relearn procedure, the

ECT is between 5 – 100°C,

Powertrain Management GEN III V8 – General Information Page 6C3-1–18

Page 6C3-1–18

• the intake air temperature (IAT) is more than 5 – 60°C; if Tech 2 is used to perform the relearn procedure, the IAT

is between 5 – 100°C,

• the APP sensor angle is less than 15 percent, and

• ignition voltage is more than 10 volts.

The throttle body relearn procedure is performed 29 seconds after the ignition is turned on. The TACM commands the

throttle plate from the rest position (7 percent open) to full closed (0 percent), then to around 10 percent open. This

procedure takes about 6 – 8 seconds. If any faults occur in the TAC system, a DTC sets. At the start of this procedure,

the Tech 2 TAC Learn Counter parameter should display 0, then count up to 11 after the procedure is completed. If the

counter did not start at 0, or if the counter did not end at 11, a fault has occurred and a DTC should set.

Powertrain Management GEN III V8 – General Information Page 6C3-1–19

Page 6C3-1–19

3.4 Emission Control Systems

Evaporative Emission Control System

The evaporative emission con t rol system used is the

activated carbon (charcoal) canister storage method. Fuel

vapour is drawn from the fuel tank into the canister where it

is held by the activated carbon until the PCM commands the

Evaporative Emission (EVAP) purge solenoid valve to open.

Figure 6C3-1 – 11

The PCM energises the EVAP purge sole noid valve by

applying a Pulse Width Modulated (PWM) ground to the

EVAP purge solenoid valve control circuit.

When the PCM commands the EVAP valve (1) to open, the

fuel vapours are drawn from the canister line (2) into the

intake manifold where it is consumed in the normal

combustion process.

The PCM energises the EVAP valve when the appropriate

conditions have been met.

The EVAP purge PWM duty cycle varies according to

operating conditions determin ed by mass air flow, fuel trim

and intake air temperature. For further information on the

evaporative emission control system, refer to

Section 8A1 Fuel System.

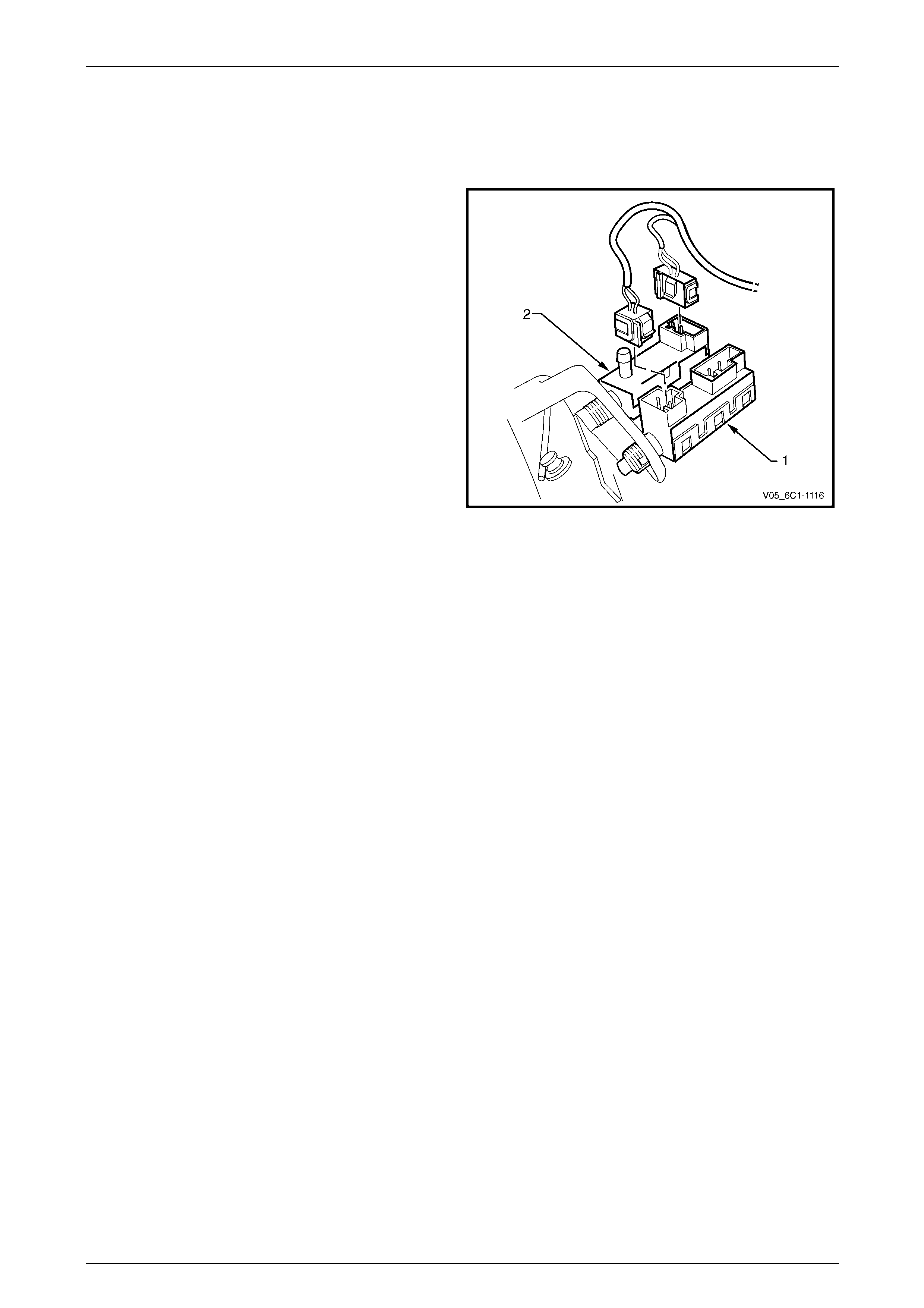

Figure 6C3-1 – 12

Engine Ventilation System

The engine ventilation system contains an oil separator (1)

and fixed internal flow-restricting orifice (2) located inside

the front right-hand corner of the valley cover. A hose is

routed from the valley cover to the intake manifold.

A breather pipe is routed from the intake manifold to the

right-hand camshaft cover and provides fresh filtered air

from the intake duct to the engine.

For further information of the engine ventilati on system,

refer to Section 6A3 Engine Mechanical – GEN III V8.

Figure 6C3-1 – 13

Powertrain Management GEN III V8 – General Information Page 6C3-1–20

Page 6C3-1–20

3.5 Electric Cooling Fans

The PCM controls the operation of two dual-speed electric engine cooling fans. The PCM operates the fans at either low

or high speed based on inputs from engine coolant temperature, vehicle speed and air-conditioner requ est. F or further

information on cooling fan ope ration, refer to Section 6B3 Engine Cooling – GEN III V8.

Powertrain Management GEN III V8 – General Information Page 6C3-1–21

Page 6C3-1–21

3.6 Torque Management

Torque management is a function of the PCM that reduces engine power during certain conditions.

Torque management is perform ed for the following reasons:

• to prevent over stressing the powertrain components,

• to prevent damage to the vehicle during certain abusive maneouvres, and

• to reduce the engine speed when the IAC is out of the normal operating range.

The PCM monitors the following sensors and engine parameters to calculate the engine output torque:

• air/fuel ratio,

• mass air flow,

• manifold absolute pressure,

• intake air temperature,

• spark advance,

• engine speed,

• engine coolant temperatur e, and

• A/C clutch status.

The PCM monitors the torque converter status, the transmission gear ratio, and the engine speed to determine if torque

reduction is required. T he PCM retards the spark as appropriate, to reduce the engine torque output if torque reduction is

required. The PCM also shuts off the fuel to certain injectors in order to reduce the engine power in the instance of an

abusive maneouvre.

The following are instances when an engine power reduction is likely to be experienced:

• during transmission up-shifts and do wnshifts,

• during heavy acceleration from a standing start,

• if the IAC is out of the normal operating range, or

• if the driver is performing harsh or abusive maneuvers, such as shifting into gear at high throttle angles or shifting

the transmission from reverse to drive in orde r to create a rocking motion.

The driver is unlikely to notice the torqu e mana gement actions in the first two instances. The engine power output will be

moderate at full throttle in the other two instances.

The PCM calculates the amount of spark retard that is necessary to reduce the engine power by the desired amount.

The PCM disables the fuel injectors for cylinders 1, 4, 6, and 7 if an abusive maneouvre occurs.

Powertrain Management GEN III V8 – General Information Page 6C3-1–22

Page 6C3-1–22

4 System Components

4.1 A/C Refrigerant Pressure Sensor

The PCM applies a positive 5 volts reference voltage and

ground to the air-conditioning (A/C) refrigerant pressure

sensor. The A/C pressure sensor provi des signal voltage to

the PCM that is proportional to the A/C refrigerant pressure.

The PCM monitors the A/C pressure sensor signal voltage

to determine the refrigerant pressure.

• The A/C pressure sensor volt age increases as the

refrigerant pressure increases.

• When the PCM detects that the refrigerant pressure

exceeds a predetermined value, the PCM activates

the cooling fans to reduce the refrigerant pre ssure.

• When the PCM detects that the refrigerant pressure is

too high or too low, the PCM disables the A/C clutch to

protect the A/C compressor from damage.

Figure 6C3-1 – 14

Powertrain Management GEN III V8 – General Information Page 6C3-1–23

Page 6C3-1–23

4.2 Brake Pedal Switches

Stop Lamp and BTSI Switch Assembly

The stop lamp and BTSI s witch assembly (1) is located o n

the brake pedal support.

The powertrain control module (PCM) uses the stop lamp

switch signal voltage to determine when the brake pedal is

depressed.

The PCM uses this input for torque management, for

cross-referencing the stop lamp s witch against the cruise

control cancel switch for correct operation, etc. For further

information on brake torque management, refer to

3.6 Torque Management.

The stop lamp switch is a normally open switch with the

brake pedal at rest.

Figure 6C3-1 – 15

Cruise Control Release and Extended Brake Travel Switch Assembly

The cruise control release and extended brake travel switch assembly (2) is located on the brake pedal support. Refer to

Figure 6C3-1 – 15

The powertrain control module (PCM) uses the cruise control release switch signal voltage to determine when the brake

pedal is depressed. T he PCM uses this input to cancel cruise control operation, for cross-referencing the cruise control

release switch against the stop lamp s witch for correct operation, etc.

The powertrain control module (PCM) uses the extended brake travel switch signal voltage to determin e when full brake

pedal travel has been achieved. The PCM uses this input to compensate for the air being used by the brake booster.

Both of these switches are normally closed when the brake pedal is in the rest position, opening when the pedal is

pressed. Activation of this switch removes the signal to the PCM.

For further information on the cruise control system, refer to 4.3 Cruise Control System.

Powertrain Management GEN III V8 – General Information Page 6C3-1–24

Page 6C3-1–24

4.3 Cruise Control System

The cruise control system inte grates with the powertrain control system through the po wertrain interface module (PIM),

throttle actuator control module (TACM), and the powertrain control module (PCM), to control the electronic throttle

actuator and maintain the vehicle at the spe ed set by the driver.

When the cruise ON-OFF button is pressed, the PIM, on receiving the input from the cruise control switch, outputs a

signal to the TACM. The TACM communicates with the PCM via the dedicated serial data link, and the PCM verifies the

signal then commands the TACM to engag e the cruise co ntrol. The PCM also prov ides a signal for the instrument

cluster, via the PIM, to inform the user that the cruise control is engaged.

The user activates the cruise control at a desired speed above 40 kph by rotating the cruise control switch assembly to

SET–DECEL. The TACM receives the i np ut from the cruise control switch, communicates with the PCM via the

dedicated serial data link, and the PCM verifi es the signal. The PCM then commands the TACM to set the desired

speed. The PCM receives all the various inputs required to maintain the correct speed and then controls the throttle

plate, through the TACM, depending on the load on the engine (ascending or descending hills, etc.).

The cruise control is deactivated b y either pressing the brake pedal or by the cruise control ON-OF F button. In each of

these instances, the TACM receives an input when any of these switches are activated.

For further information on the cruise control system, refer to Section 12E Cruise Control.

Powertrain Management GEN III V8 – General Information Page 6C3-1–25

Page 6C3-1–25

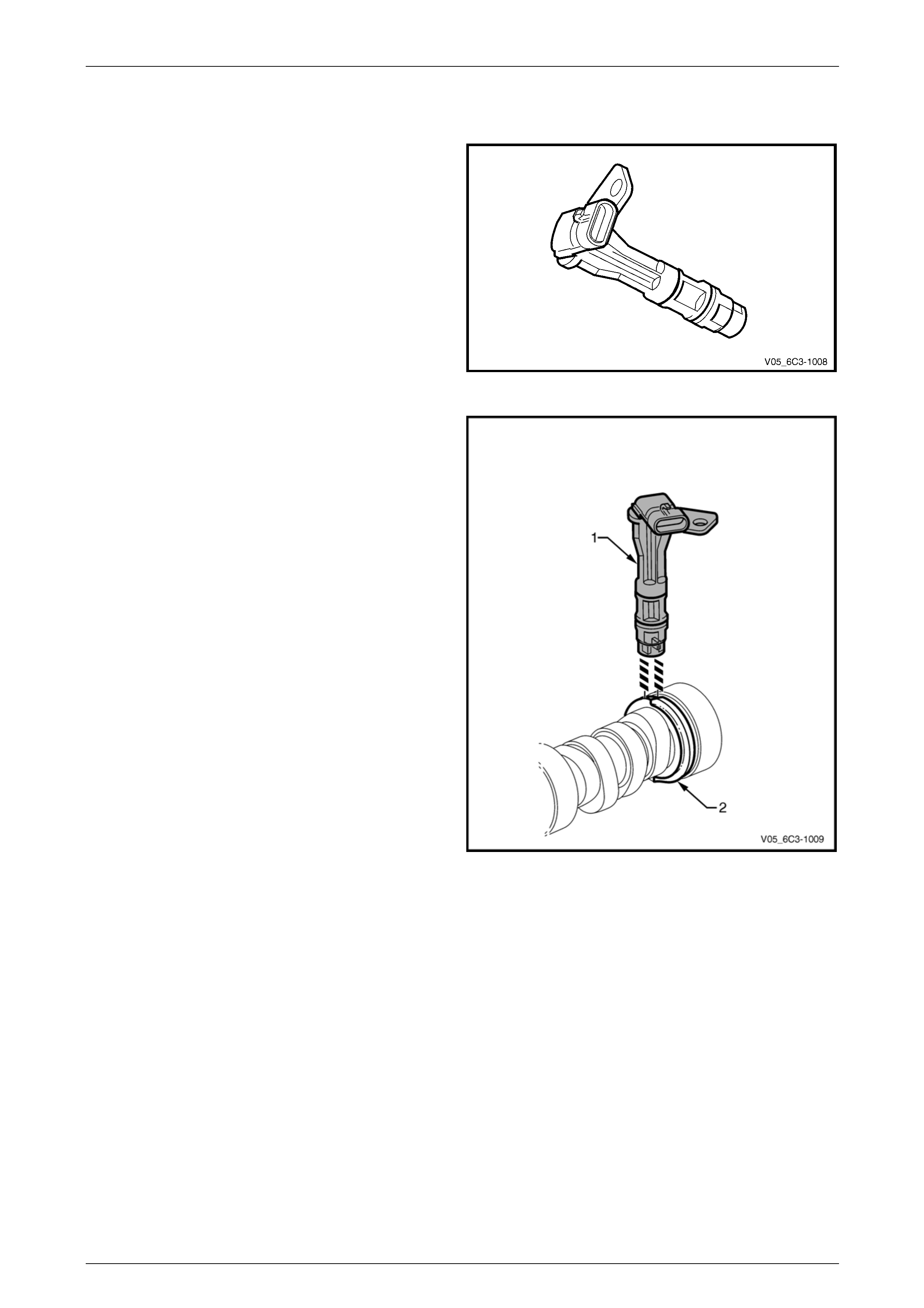

4.4 Camshaft Position (CMP) Sensor

The CMP sensor is used by the PCM to determine the

position of the camshaft. In conjunction with the crankshaft

position sensor, the CMP enables the PCM to determine

engine rotational position.

Figure 6C3-1 – 16

The CMP sensor operates on the dua l-Hall sensing

principle. The sensor contains two Hall elements (1) which

operate in conjunction with a two-track trigger wheel (2) on

the camshaft.

As the tracks on the trigger wheel pass the elements,

magnetic flux affects a voltage in the Hall elements. The

integrated circuit inside the sensor conditions the signal

generated by the Hall eleme nts to provide a rectangular

wave on / off signal to the PCM.

The PCM supplies the CMP sensors with a 12-volt

reference and a ground circui t.

Figure 6C3-1 – 17

Powertrain Management GEN III V8 – General Information Page 6C3-1–26

Page 6C3-1–26

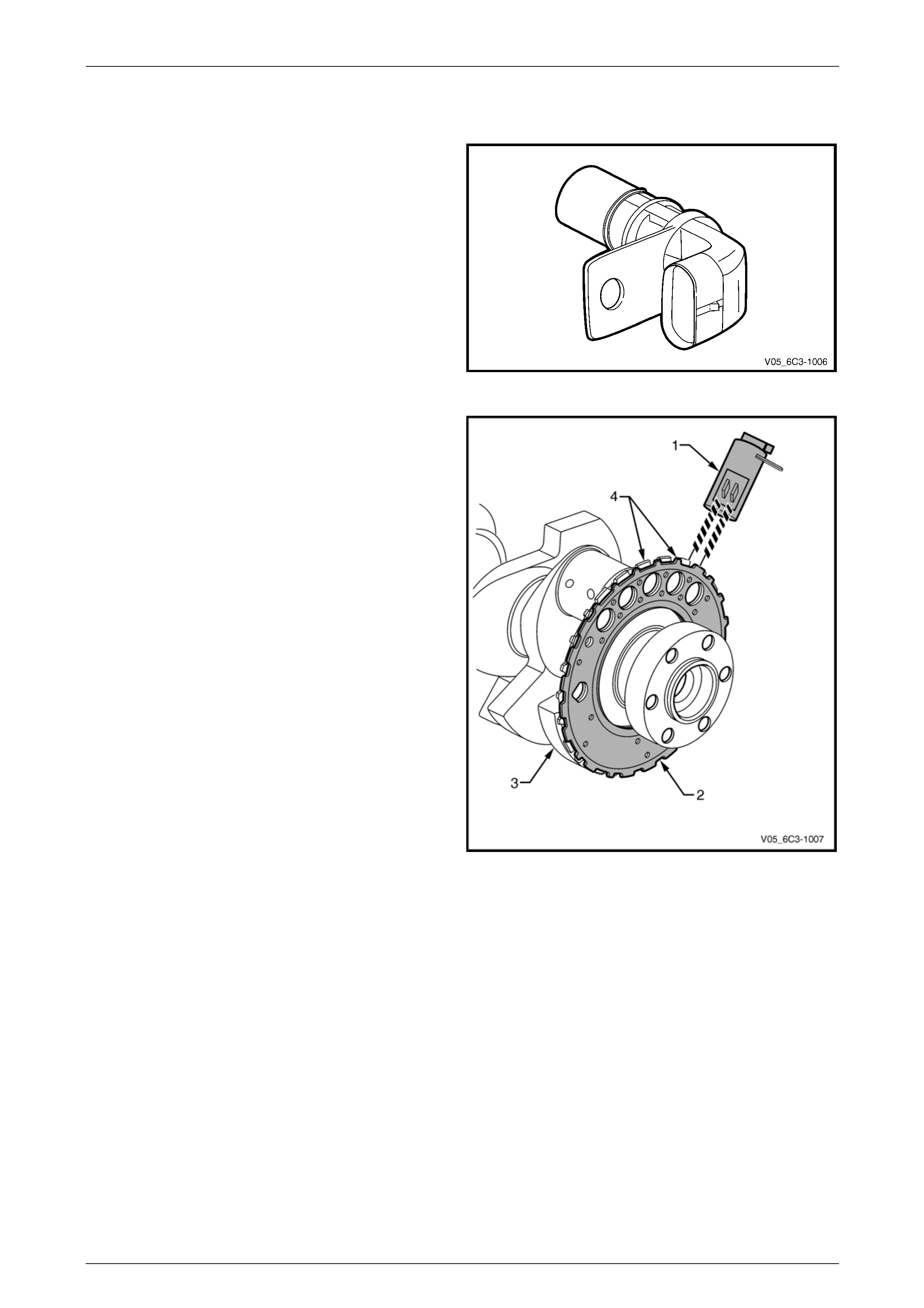

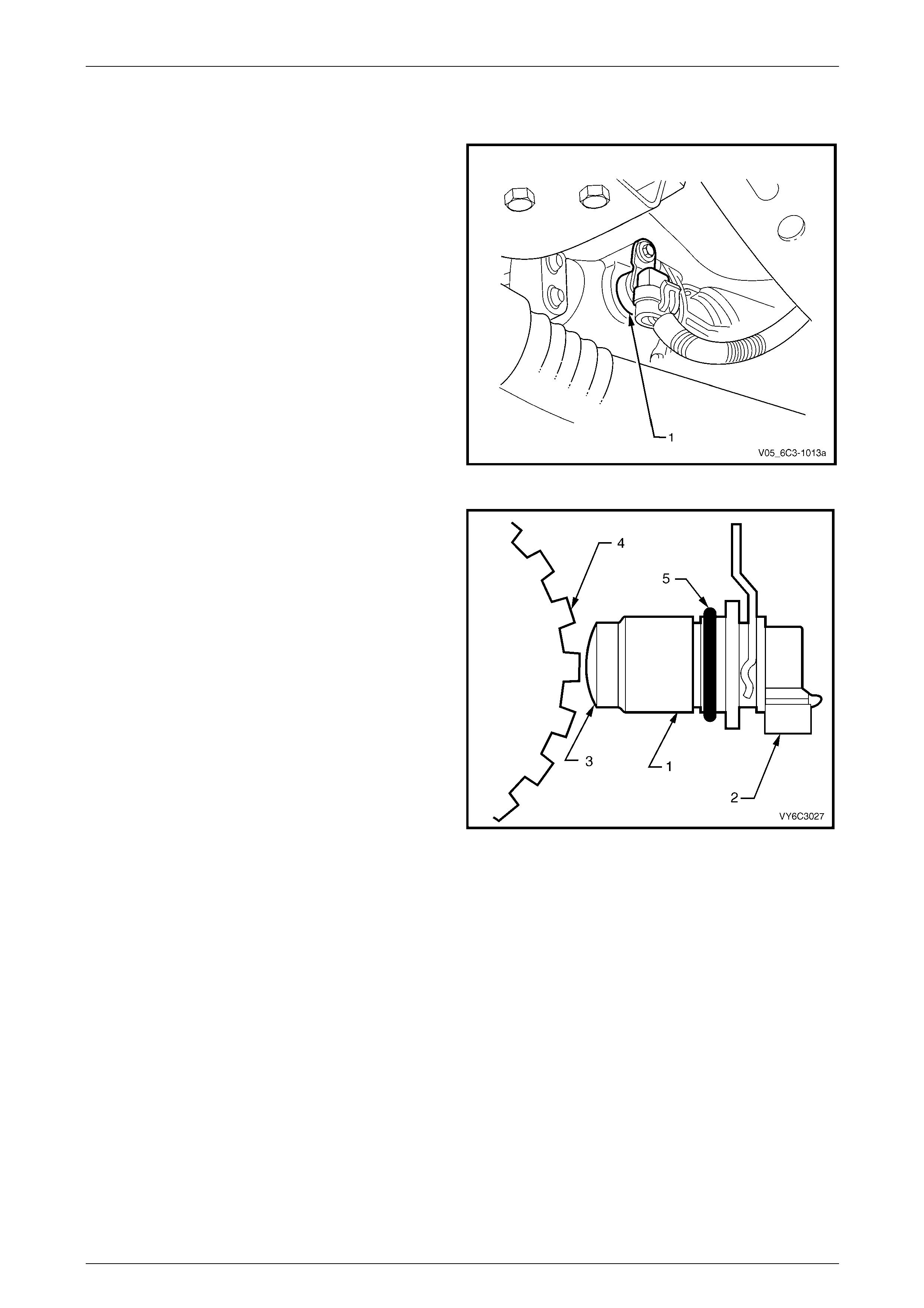

4.5 Crankshaft Position (CKP) Sensor

In conjunction with the camshaft position sensor, the

crankshaft position (CKP) sensor enables th e PCM to

determine engine rotational position. The CKP is also used

to determine engine speed (RPM).

Figure 6C3-1 – 18

The CKP sensor operates on the dual-Hall sensing

principle. The sensor contains two Hall elements (1) which

operate in conjunction with a two-track trigger wheel (2) on

the crankshaft (3).

As the tracks (4) on the trigger wheel pass the elements,

magnetic flux affects a voltage in the Hall elements. The

integrated circuit inside the sensor conditions the signal

generated by the Hall eleme nts to provide a rectangular

wave on / off signal to the PCM.

The PCM supplies the CKP sensors with a 12-volt reference

and a ground circuit.

Figure 6C3-1 – 19

Powertrain Management GEN III V8 – General Information Page 6C3-1–27

Page 6C3-1–27

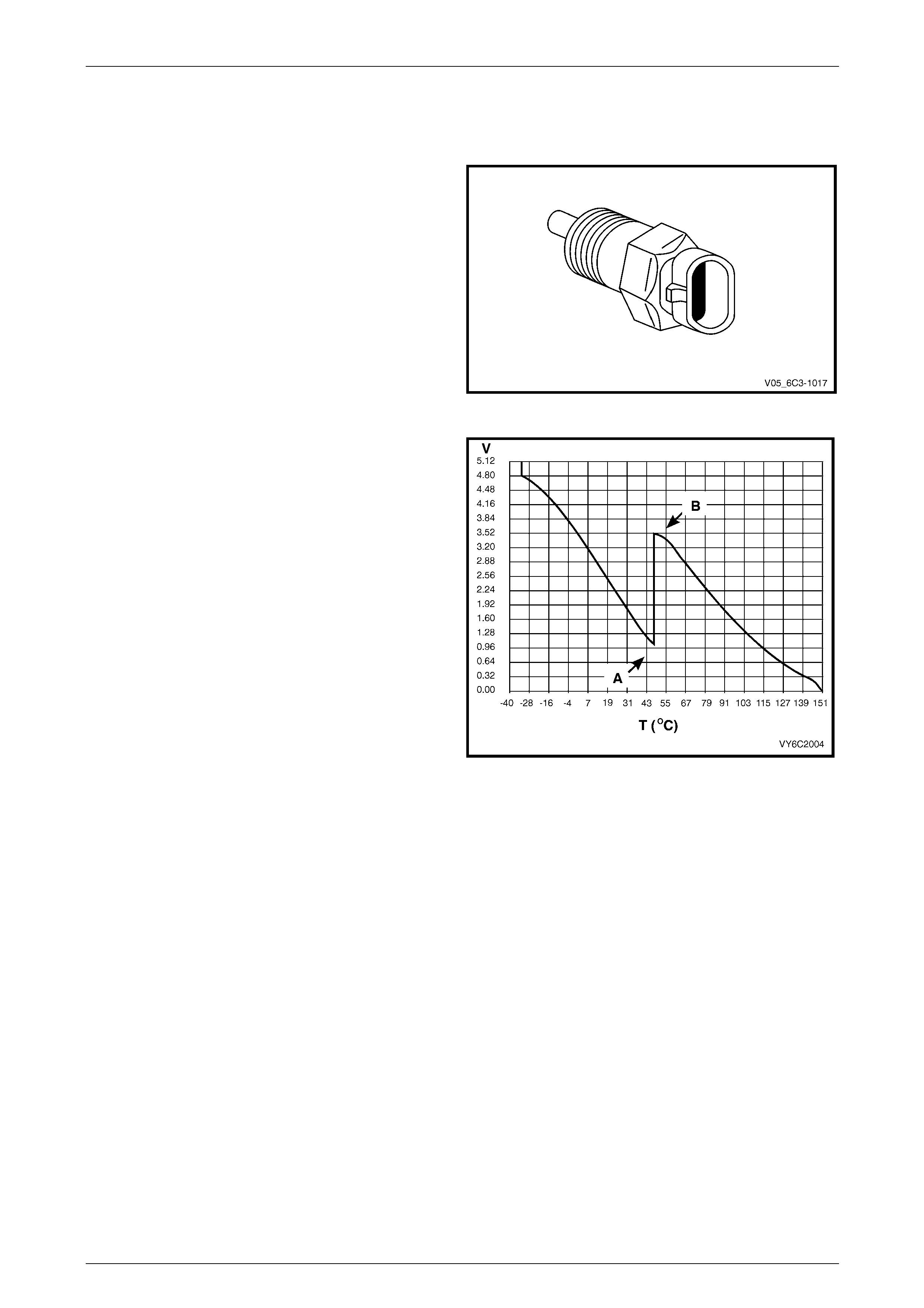

4.6 Engine Coolant Temperature (ECT)

Sensor

The engine coolant temperature (ECT) sensor is a

thermistor (a resistor that changes value based on

temperature) mounted in the engine coolant stream. Low

engine coolant temperature produces a high sensor

resistance (29 kΩ at –20° C) while high engine coolant

temperature causes low sensor resistance (180 Ω at

100° C).

Figure 6C3-1 – 20

The PCM uses a dual pull up resistor network to increase

the resolution through the entire operating range of engine

coolant temperature. When the coolant temp erature is less

than 51° C, both the 4K and 348 ohm resistors are used (A) .

When the coolant temperature reaches 51° C, the PCM

switches a short across the 4K resistor and only the 348

ohm resistor is used (B).

As the engine warms, the sensor resistance becomes less

and the voltage at the PCM coolant temper ature sensor

signal terminal should decrease from approximately 4.5

volts when cold to 0.9 volts at 51° C.

At this temperature the PCM switches the short across the

4k resistor, the voltage will then rise to 3.5 volts. The voltage

will again decrease as the coolant temperature increases

until at normal engine operating temperature (95° C), the

voltage should be less than 2.0 volts.

Figure 6C3-1 – 21

Powertrain Management GEN III V8 – General Information Page 6C3-1–28

Page 6C3-1–28

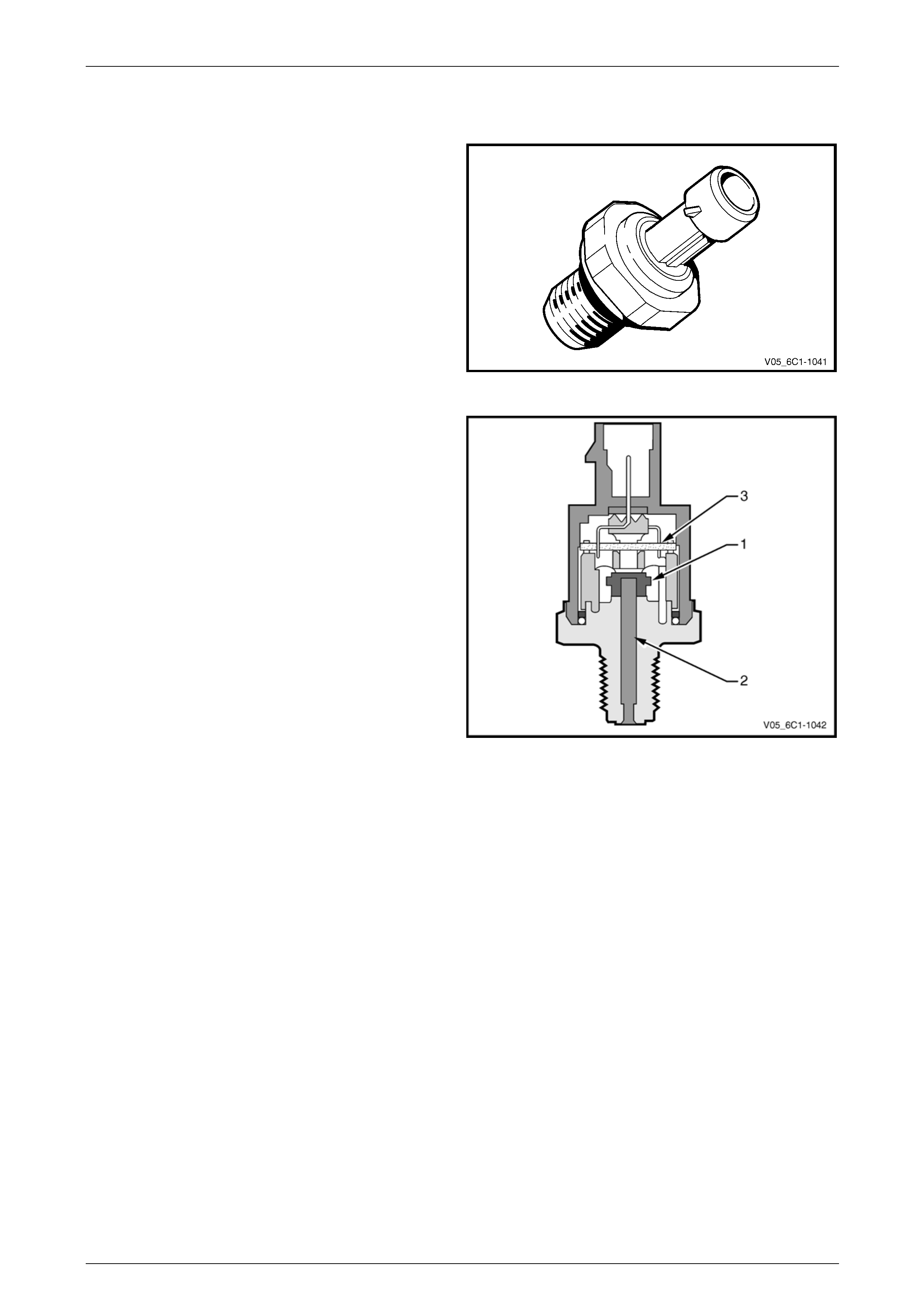

4.7 Engine Oil Pressure (EOP) Sensor

The engine oil pressur e (EOP) sensor measures engine oil

pressure. When the EOP sensor signal is below a certain

value, which increases with RPM, the PCM activates the

Check Oil warning icon in the i nstrument cluster multi-

function display (MFD).

Figure 6C3-1 – 22

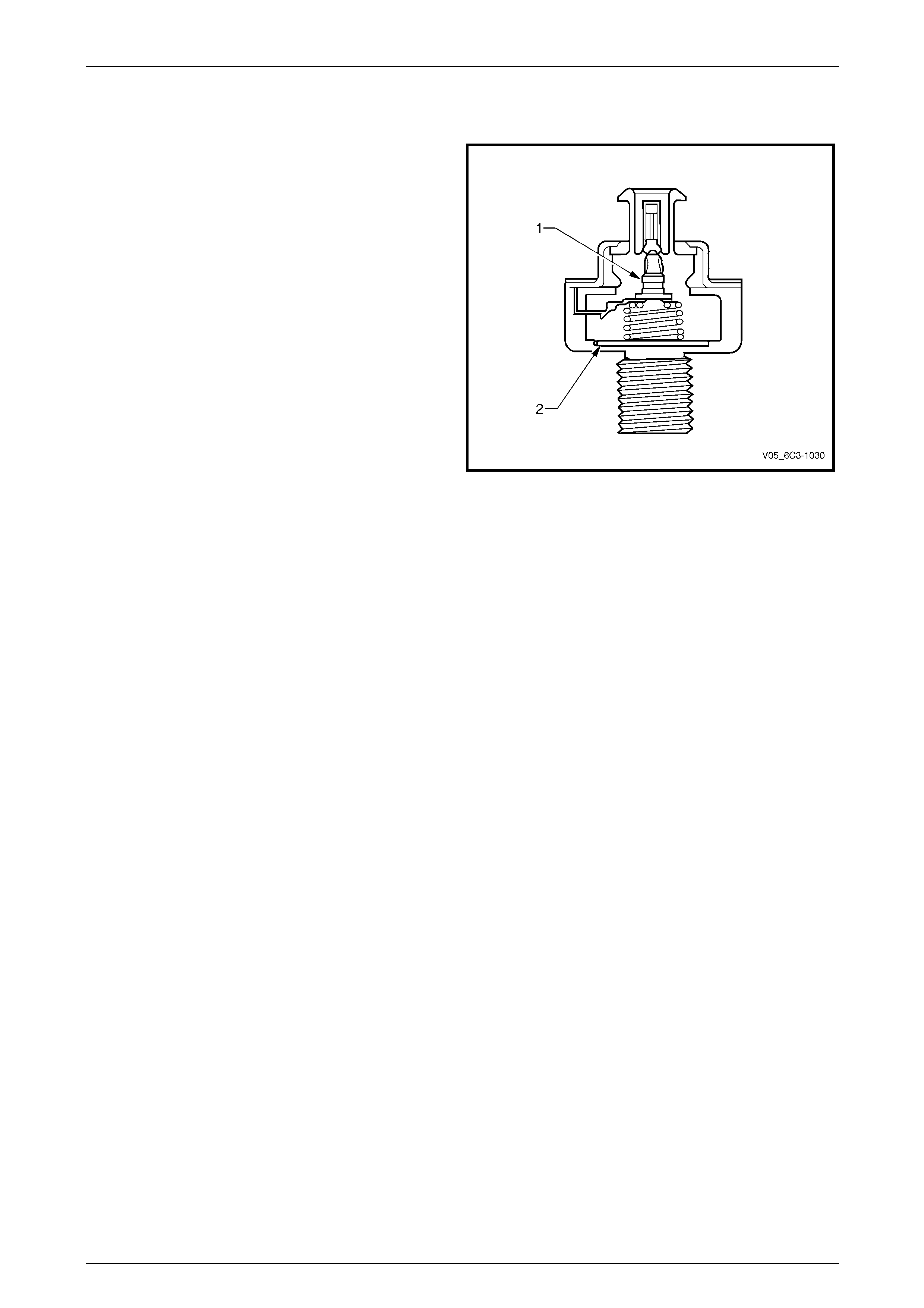

The EOP sensor provides a voltag e signal to the PCM that

is a function of engine oil pressure. It does this through a

series of deformation resistors (1), which change resistance

when a mechanical force is applied. This force is applied to

the resistors by a diaphragm on which the engine oil

pressure acts (2).

The sensor has an internal ev aluation circuit (3) and is

provided with a five volt reference voltage, a ground and a

signal circuit.

Figure 6C3-1 – 23

Powertrain Management GEN III V8 – General Information Page 6C3-1–29

Page 6C3-1–29

4.8 Fuel Rail Assembly

The fuel rail assembly is mou nted on th e lower intake

manifold and distributes fuel to each c ylinder through

individual fuel injectors. The fuel rail assembly consists of:

• eight individual fuel injectors (1),

• the fuel pulse dampener (2),

• the pipe (3) that carries fuel to each injector, and

• a fuel pressure test port (4).

Figure 6C3-1 – 24

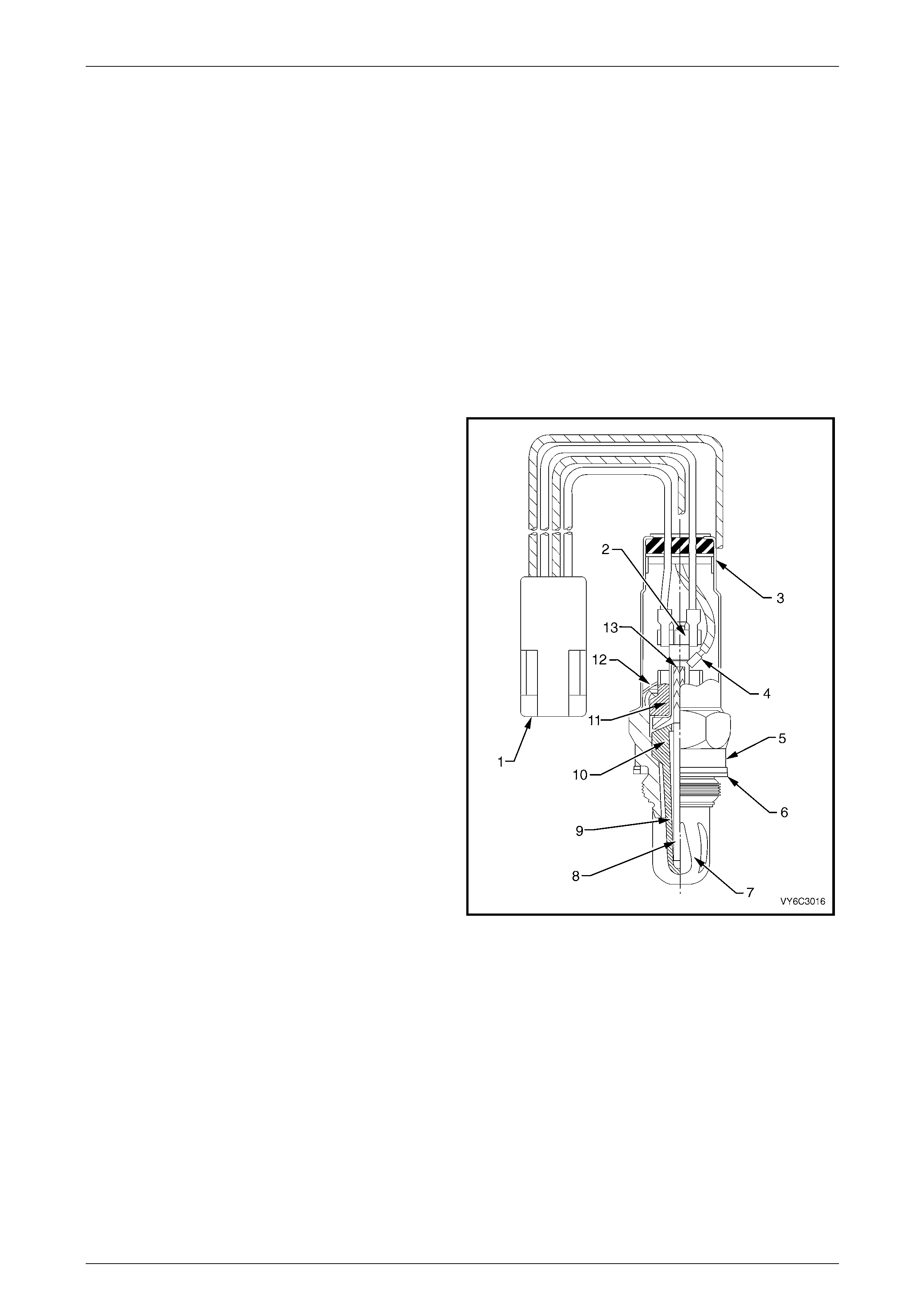

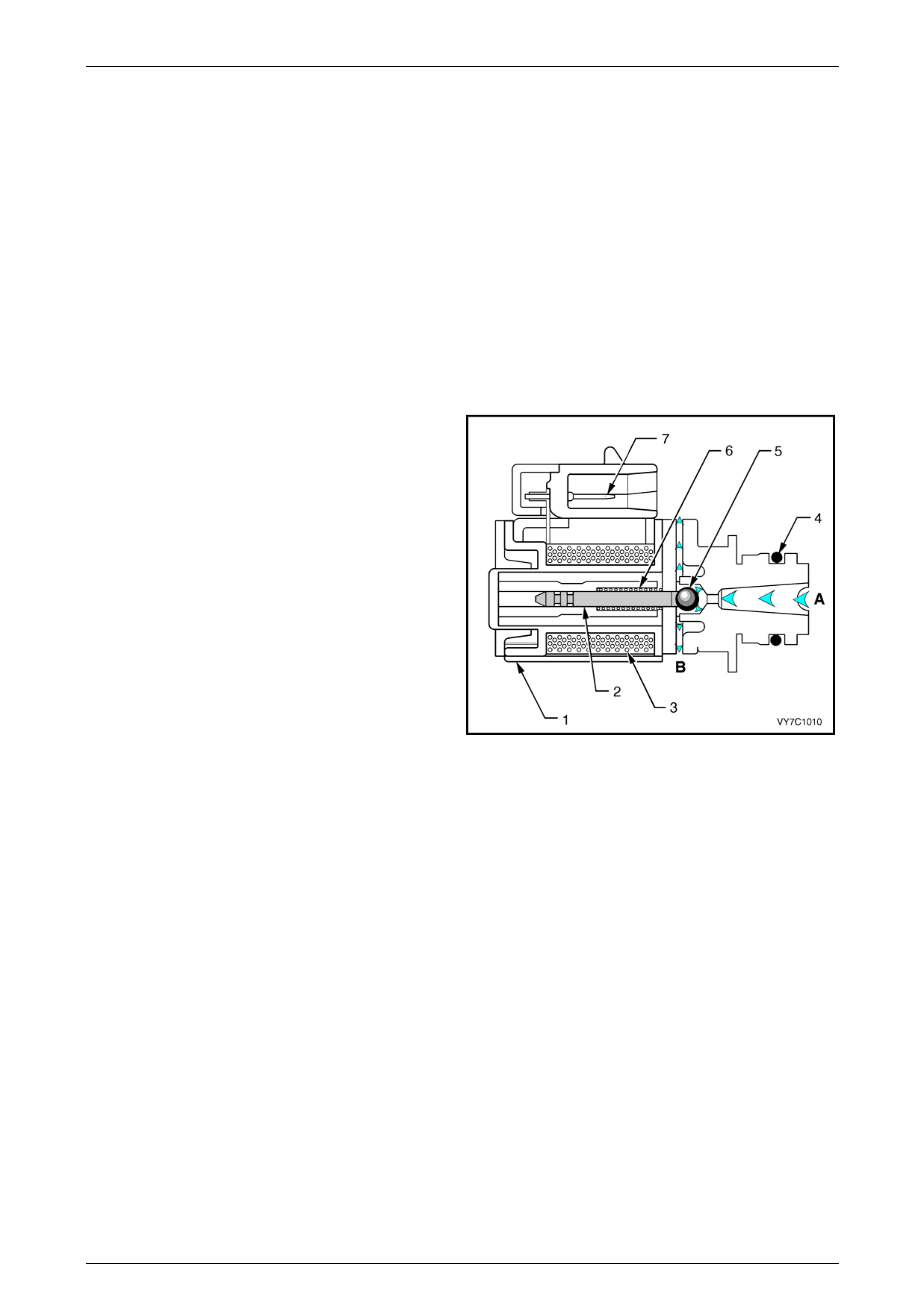

Fuel Injectors

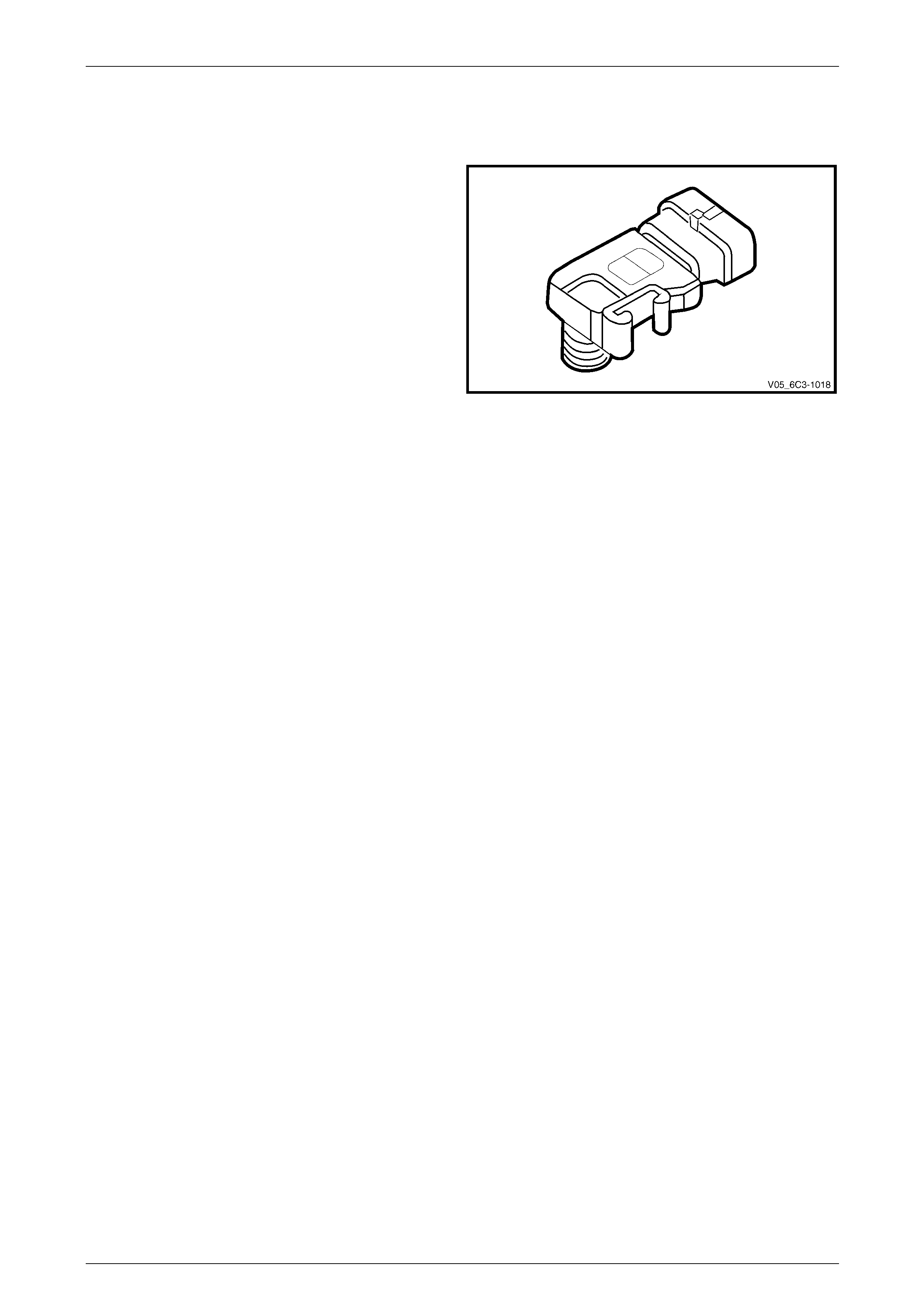

A fuel injector is a solenoid device that is cont rolled by the

PCM. The eight injectors deliver a precise amount of fuel

into the intake ports as requir ed by the engine. The injectors

are supplied with igniti on voltage through the EFI relay, and

are switched to ground by the PCM.

Figure 6C3-1 – 25

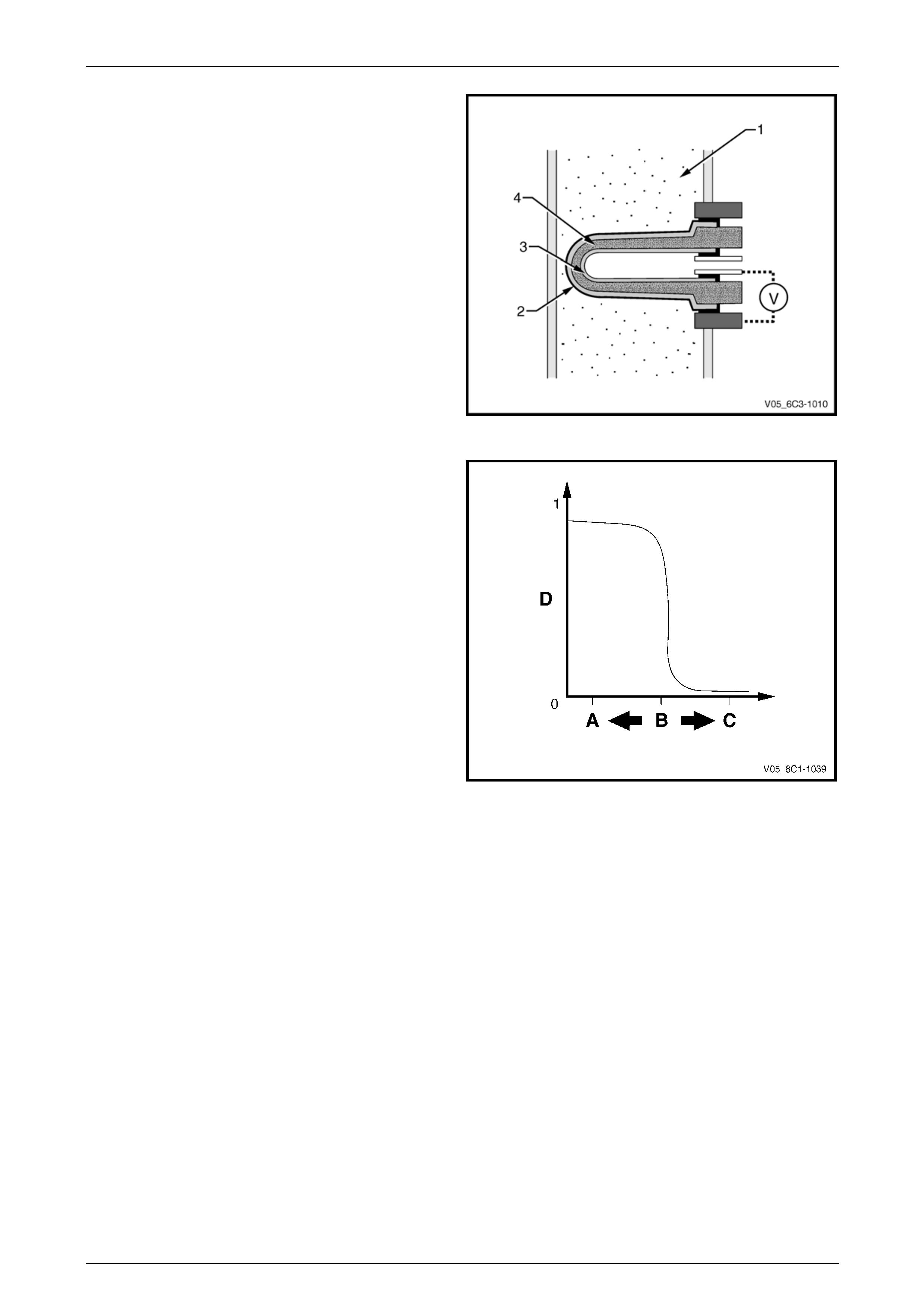

The fuel port (1) connects to the fuel rail. A strainer (2) is

provided in the port to protect the injector from fuel

contamination.

In the de-energised state (no voltage), the valve needle and

sealing ball assembly (3) are held against a cone-shaped

valve seat (4) by spring force (5) and fuel pressure.

When the injector is energise d by the PCM, the valve

needle, which has an integr al armature, is moved upward by

the injector solenoid’s magnetic field, un-seating the ball.

An orifice plate (6), located at the base of the injector has

several small holes which provide very fine atomisation of

the fuel. The plate is insensitive to fuel de posits ensuring

reliable fuel delivery.

The fuel is directed at each of the intake valves, causing the

fuel to become further vaporised before entering the

combustion chamber.

Figure 6C3-1 – 26

Powertrain Management GEN III V8 – General Information Page 6C3-1–30

Page 6C3-1–30

4.9 Heated Oxygen Sensors (HO2S)

The heated oxygen sensors (HO2S) are mounted in the exhaust pipe and enable the PCM to measure oxyge n conte nt in

the exhaust stream. The PCM uses this information to accurately control the air / fuel ratio, because the oxygen content

in the exhaust gas is indicative of the air / fuel ratio of engine combustion.

When the sensor is cold, it produces little or no signal voltage, therefore the PCM only reads the HO2S signal when the

HO2S sensor is warm. As soon as the HO2S are warm and outputting a usable signal, the PCM begins making fuel

mixture adjustments base d o n the HO2S signals. This is known as closed loop mode.

GEN III V8 engines have two HO2S, one HO2S upstream of the catalytic converter in each exhaust pipe.

NOTE

Some vehicles may be fitted with an additional

HO2S downstream of each catalytic converter.

These are fitted for production purposes but are

not used by the powertrain management s ystem.

The HO2S has four wires:

1 The internal heater element supply, which has 12 volts

continually applied whenever the ignition is on.

2 Heater element ground. When the sensors are cold,

the PCM applies maximum current (approximately four

amps) to the heater circuit, which graduall y reduces to

approximately 0.5 amps as the sensor reaches full

operating temperature.

3 Sensor signal to the PCM.

4 Sensor ground.

Legend

1 Four Wire In-line Connector

2 Heater Termination

3 Water Shield Assembly

4 Sensor Lead

5 Sensor Body

6 Seat Gasket

7 Outer Electrode and Protective Coating

8 Rod Heater

9 Inner Electrode

10 Zirconia Element

11 Insulator

12 Clip Ring

13 Gripper Figure 6C3-1 – 27

Powertrain Management GEN III V8 – General Information Page 6C3-1–31

Page 6C3-1–31

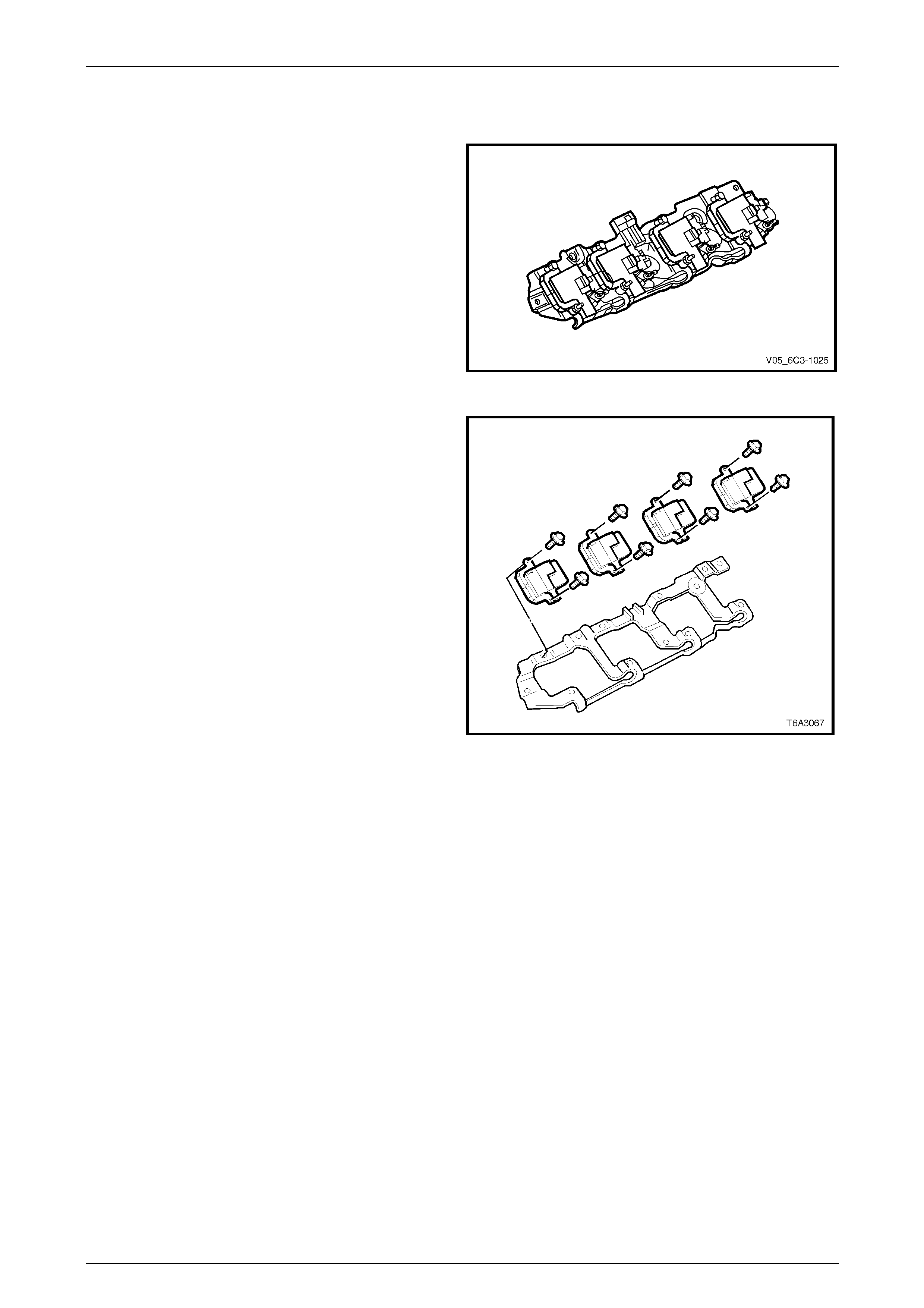

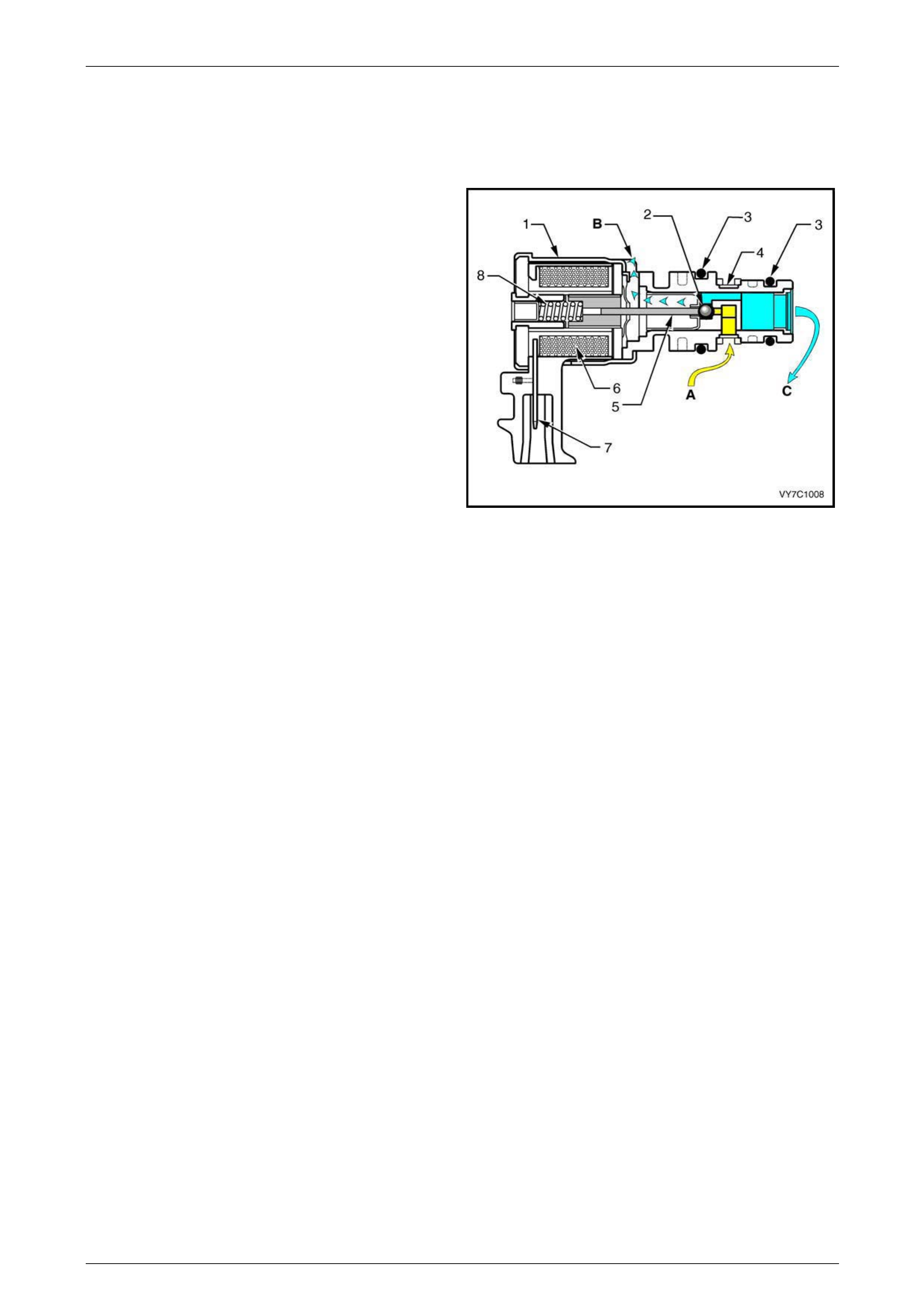

Measurement is achieved b y comparing the oxygen content

of the exhaust gas (1) to the oxygen content of a referenc e

gas (outside air) using the Nernst principle. Oxygen

molecules from the exhaust gas will accumu late on the

outer electrode (2), while oxygen molecules from the

reference gas will accumulate on the inner electrode (3).

This creates a voltage difference across the ceramic

element (4), between the two electrodes, which is the signal

voltage (V) to the PCM.

The PCM supplies a steady 450 millivolt, very low current

bias voltage to the oxygen sensor signal circuit. When the

sensor is cold and not produc ing any voltage, the PCM

detects only this steady bias voltage. As the sensor b egins

to become warm, its internal resistance decreases and it

begins produci ng a rapidly changing voltage that will

overshadow the steady bias voltage supplied by the PCM.

The PCM detects the changing voltage, and can begin

operating in closed lo op.

Figure 6C3-1 – 28

When the fuel system is correctly operating in closed loop

mode, the oxygen sensor voltage output is rapi dly changing

several times per second, fluctuating from approximately

100mV (high oxygen co ntent – lean mixture) to 900mV (low

oxygen content – rich mixture). The transition from rich to

lean occurs quickly at about 450-500 mV (A/F ratio 14.7:1,

or lambda = 1). Due to this, these HO2S are known as t wo-

step or switching type oxygen sensors.

Legend

A Rich Mixture

B A/F Ratio 14.7:1 (Lambda = 1)

C Lean Mixture

D Sensor Voltage

Figure 6C3-1 – 29

Powertrain Management GEN III V8 – General Information Page 6C3-1–32

Page 6C3-1–32

4.10 Ignition Coils / Modules

Eight ignition coils, four per cylind er ba nk, are individually

mounted to an ignition coil mountin g bracket that is bolted

to each rocker cover. Each coil has a short high tension

secondary ignit ion wire connecting it the relevant spark plug.

A printed circuit board, or driver module, is integrated with

each coil, and controls the firing of the coil based on in put

from the PCM.

Figure 6C3-1 – 30

The PCM is responsible for maintaining correct spark timing

and dwell for all driving conditions. The PCM calculates the

desired spark parameters from informatio n received from

the various sensors, and triggers the appropr iate ignition

module which then operates the coi l.

The ignition coil / modules are supplied with the following

circuits:

• Ignition feed circuit.

• Ignition control circuit.

• Ground circuit.

• Reference low circuit.

Figure 6C3-1 – 31

Powertrain Management GEN III V8 – General Information Page 6C3-1–34

Page 6C3-1–34

4.12 Knock Sensors (KS)

The knock sensor signal is used b y the PCM to provide

optimum ignition timing while minimising engine knock or

detonation.

The knock sensor is tuned to detect the frequency of the

vibration created by combustion knock. The vibration is

transferred through the cylinder block to the knock sensor.

Inside the sensor is a mass (1) that is excited by this

vibration, and the mass exerts a compressive force onto a

piezo-ceramic element (2). The compressive force causes a

charge transfer inside the element, so that an AC voltage

appears across the two outer faces of the element. The

amount of the AC voltage produced is proportional to the

amount of knock. This AC signal voltage to the PCM is

processed by a Digital Signal Noise Enhancement Filter

(DSNEF) module. This DSNEF module, an integral part of

the PCM, is used to determine if the AC signal coming in is

noise or actual detonation.

Figure 6C3-1 – 32

Powertrain Management GEN III V8 – General Information Page 6C3-1–35

Page 6C3-1–35

4.13 Manifold Absolute Pressure (MAP)

Sensor

The manifold absolute pressure (MAP) sensor is mounted to

the rear of inlet manifold so that its sensing element is

exposed to manifold pressure downstream of the throttle

body.

The PCM sends a 5-volt supply voltage to the MAP sensor.

As the manifold pressure varies, due to changes in engine

load, the output voltage of the sensor also chang es. By

monitoring the sensor output voltage, the control module

determines the manifold pressure.

The MAP sensor is used for the follo wing:

• ignition timing control, and

• speed density fuel manag ement default. Figure 6C3-1 – 33

Powertrain Management GEN III V8 – General Information Page 6C3-1–36

Page 6C3-1–36

4.14 Air Intake System

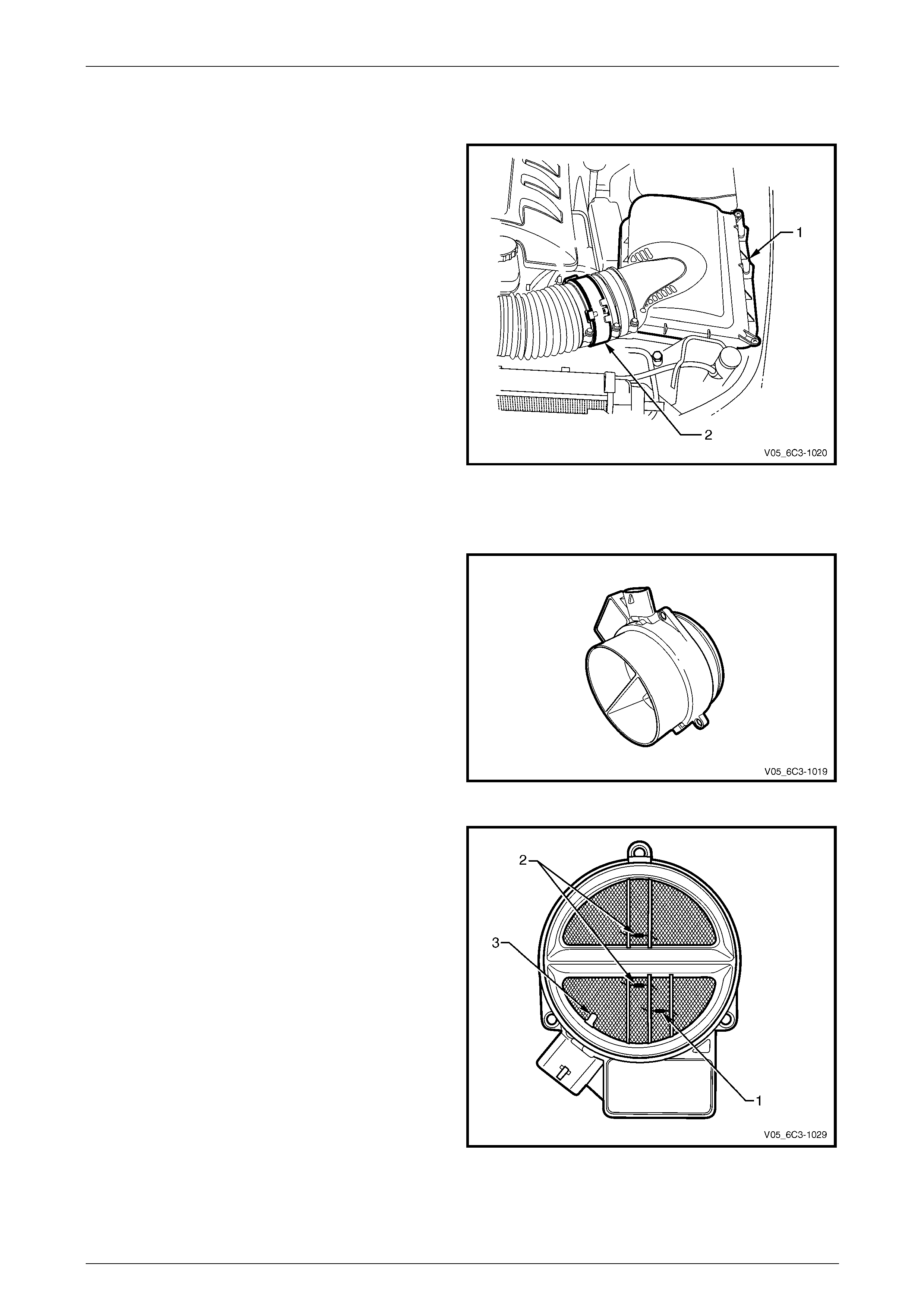

The air intake system draws outside air through the an air

cleaner assembly (1). The air is then routed throu gh a mass

air flow (MAF) sensor (2) and into the throttle body and

intake manifold. The air is then directed into the intake

manifold runners, through the c ylinder he ads and into the

cylinders.

An arrow marked on the body of the MAF sensor indicates

correct air flow direction. The arrow must point toward the

engine.

Figure 6C3-1 – 34

Mass Air Flow (MAF) Sensor

A heated element type mass air flow (MAF) sensor is

mounted in the air flow stream of the engine intake system.

The MAF sensor measures the mass of the air being

inducted into the engine, and is one of the key signals the

PCM uses to calculate the required fuel quantity to be

injected.

Figure 6C3-1 – 35

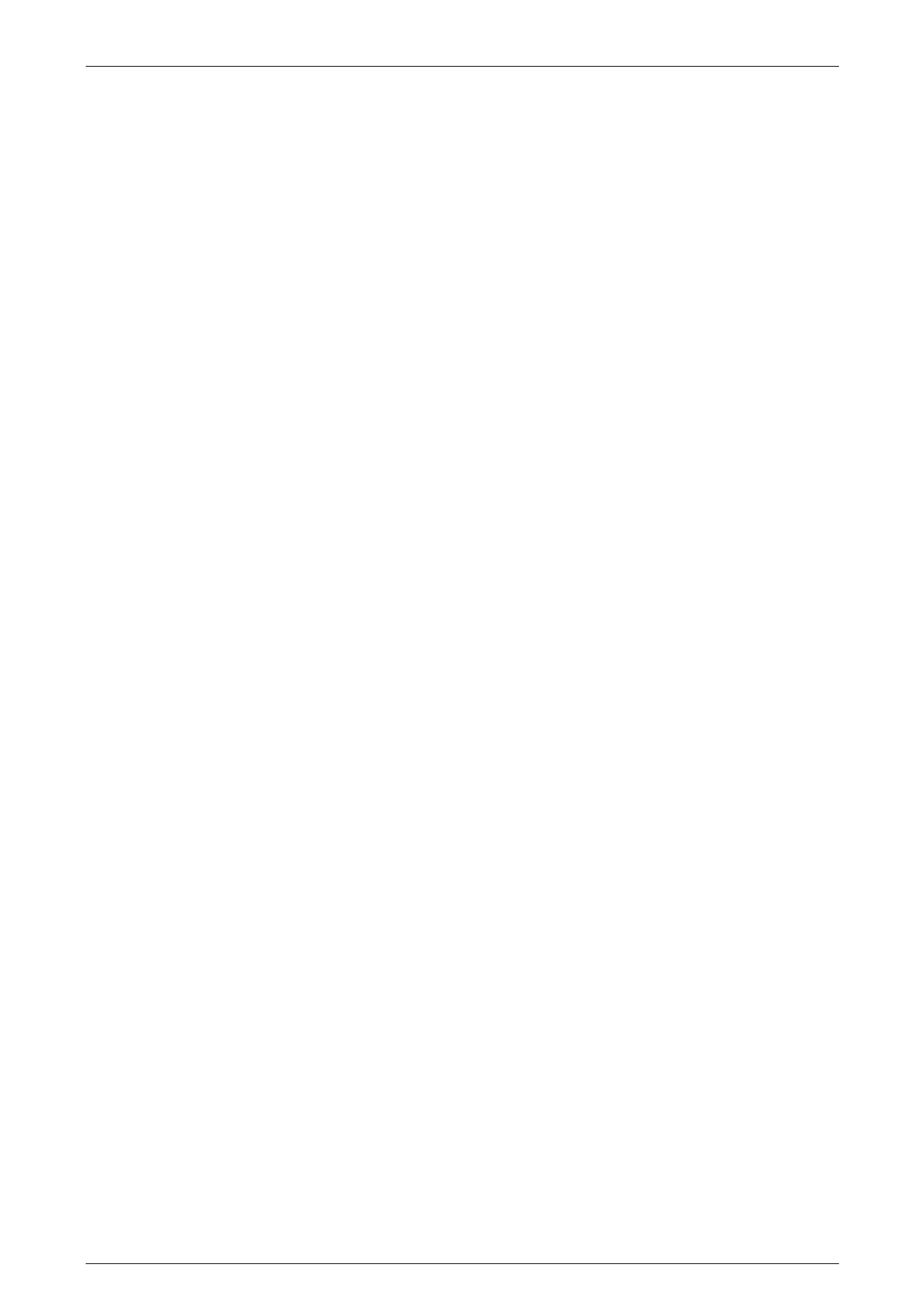

Three sensing elements are used in the MAF sensor. One

senses ambient air temperatur e (1) and is mounted in the

lower half of the sensor housing. The ambient temperature

sensor uses two calibrated resistors to establish a voltage

that is a function of ambient temperature.

The other two sensing elements (2) are heated to a

predetermined temperature that is significantly above

ambient air temperature. The t wo heated elements are

connected electrically in para llel and mounted directly in the

air flow stream of the sensor housing.

One sensor is in the top and the other sensor is in the

bottom of the sensor housing. This is done so that the air

meter is less sensitive to upstream airflo w variations that

could affect the flow of air through the housin g.

As air passes over the heated elements during engine

operation, they begin to cool. By measuring the amo unt of

electrical power required to maintain the heated elements at

the predetermined temperature above ambient temperature,

the mass air flow rate can be determined. Figure 6C3-1 – 36

Before being sent to the PCM, the small voltage signal generated in the mass air flow sensor is converted to a frequency

signal by a voltage oscill ator, to preserve the accuracy and resolution of the signal.

Powertrain Management GEN III V8 – General Information Page 6C3-1–37

Page 6C3-1–37

A large quantity of air passing through the se nsor (such as when accelerating) will be ind icated as a high frequency

output. A small quantity of air passi ng through the sensor will be indicated as a low frequency output (such as when

decelerating or at idle). T ech 2 displays MAF sensor information in frequency or in grams per second. At idle the

readings should be low and increase with engine RPM.

If a fault occurs in the MAF sensor circuit, the PCM will store a DTC in its memory, and will calculate a substitute mass

air flow signal based on speed density, using the engine speed, Manifo ld Absolute Pressure, and Intake Air Temperature

signals.

Intake Air Temperature (IAT) Sensor

The MAF sensor also incorporates the intake air temperature (IAT) sensor. The IAT sensor is a thermistor, (a resistor

that changes resistance with changes in temperature). Low intake air temperature produces high resistance in the

sensor, while high intake air temperature caus es low sensor resistance. The IAT sensor (3) is not serviced sep arately

from the MAF sensor, refer to Figure 6C3-1 – 36.

The PCM provides a 5 volt referenc e signal to the IAT and monitors the return signal which enables it to calculate the

intake air temperature. The PCM uses this signal to make corrections to the operating parameters of the system based

on changes in air intake temperature. The circuit voltage will vary dependin g on the resistance of the IAT sensor. The

voltage will be close to the 5 volt level when the sensor is cold, and will decrease as the sensor warms.

No field service adjustment is necessary or possible with the MAF or IAT sensors.

Powertrain Management GEN III V8 – General Information Page 6C3-1–38

Page 6C3-1–38

4.15 Powertrain Control Module (PCM)

Located at the left side of the engine compartment, the

powertrain control module (PCM) constantly monitors

information from various sensors and co ntrols the many

powertrain management functions, such as the fuel injection

and ignition systems, to provide optimal performance and

minimal emission output in all driving conditions.

The PCM also controls:

• electronic throttle actuation,

• on-board diagnostics,

• the engine cooling fans, and

• the A/C compressor clutch (where fitted).

Figure 6C3-1 – 37

The PCM supplies 5 volts to the various sensors through pull-up resistors to the internal r egulated power supplies.

The PCM controls output circuits such as the injectors, IAC, cooling fan relays, etc. b y controlling the ground circuits

through transistors or a device inside the PCM called a driver.

The exception to this is the fuel pump relay control circuit. The fuel pump r elay is the only PCM controlled circuit where

the PCM controls the +12 volts sent to the coil of the relay. The ground side of the fuel pump relay coil is connected to

engine ground.

The PCM also interfaces with other systems in the vehicle, such as automatic transmission, body control module

(through the PIM), anti-lock braking, traction control, etc.

Self Diagnosis

The PCM performs diagnostic tests on system components and constantly monitors the s ystem for faults.

When the PCM detects a malfunction, it also stores a diagnostic trouble code (DTC). A stored DTC will identify the

problem area(s) and is desig ned to assist the technician in rectifying the fault.

Depending on the type of DTC set, the PCM may command the instrument cluster multi-function displ ay check

powertrain icon to illuminate and warn the driver that there is a fault in the powertrain management system.

Communication to the Icon is through the controller area network (CAN) serial data communication line to the powertrain

interface module (PIM), and then universal asynchronous receive and transmit (UART) serial data to the instrument

cluster via the body control module (BCM). For further information on DTCs and the chec k powertrain icon, refer to

Section 6C3-2 Powertrain Management – GEN III V8 – Diagnostics.

Programming

The PCM features electronically erasable programmable read only memory (EEPROM) which contains program and

calibration information required to operate the po wertrain mana gement system. The service programming system (SPS)

has been incorporated with this PCM and enables a technician to directly update the data stored in the EEPROM. In

effect, the data in the memory matches the PCM to the vehicle to provide optimum performance, driveability and

emissions control.

Flash programming refers to the SPS used to transfer (or download) PCM data from a computer terminal and compact

disc-read only memory (CD-ROM) to the vehicle’s PCM. The system is designed so that the vehicle verification

procedures are required to eliminate EEPROM tampering that could increase engine emission levels.

There are three main flash pr ogramming techniques:

1 Direct programming (Pass Through). This is where the vehicle’s data link c onnector (DLC) is connected directly to

a computer terminal. On screen directions are then followed for downloadi ng.

2 Remote programming. Reprogramming information is downloaded from a computer terminal to Tech 2. Tech 2 is

then connected to the vehicle’s data link connector (DLC). On screen directions are then followed for downloading.

Powertrain Management GEN III V8 – General Information Page 6C3-1–39

Page 6C3-1–39

3 Off-board Programming. The off-board programming method is used when a re-programmable PCM must be

programmed while it is removed from the vehicle. For example, an independent repair facility may find it necessary

to replace a faulty PCM. On flash programming eq uipped vehicles, the replacement PCM must be programmed

with data for the specific vehicle identification number (VIN) or the vehicle may not operat e properly.

The vehicle is fitted with a theft deterrent system that interfaces with the PCM. If the PCM is replaced it must be

programmed with appropriate data to match the theft deterrent system.

For further information on the SPS, refer to Section 0C Tech 2.

Powertrain Management GEN III V8 – General Information Page 6C3-1–40

Page 6C3-1–40

4.16 Vehicle Speed Sensor (VSS)

The PCM receives vehicle speed i nformatio n from the

vehicle speed sensor (VSS) located on the rear of the

transmission.

Figure 6C3-1 – 38

The VSS consists of a magnetic core and a coil. Mounted

on the transmission output shaft is a toothed rotor which

revolves past the VSS, causing fluctuations in the magnetic

field inside the sensor. The magn etic flux increases and

then decreases as the teeth move in and out of the

magnetic field, inducing an AC voltage i nto th e coil. An

increase in speed will increase the output voltage and

frequency.

This AC voltage produced in the VSS sensor circuit is fed

into the PCM. The PCM measures the AC voltage and

frequency to determine the vehicle speed. T he PCM also

sends this information to the instrument cluster.

Legend

1 Sensor Body

2 Electrical Connector

3 Magnetic Pickup

4 Reluctor Wheel (Rotor)

5 O-Ring Figure 6C3-1 – 39

Powertrain Management GEN III V8 – General Information Page 6C3-1–41

Page 6C3-1–41

5 Automatic Transmission

Components

5.1 Range Switch (PRNDL)

The transmission range (TR) switch is part of the transmission park / neutral position switch mounted on the transmission

manual shaft. The four inputs from the four switches contained in the transmission range switch indicate to the

powertrain control module (PCM) which position is selected by the transmission select or lever. The input voltage level at

the PCM is high (B+) when the transmission range switch is open, and low when the switch is closed to ground. T he

various combinations of the four inputs are interpreted by the PCM to determine the gear position selected.

Range Switch Valid Combination Table

Gear Selector

Position

Switch P

Position /

PCM Input

Sw i tch A

Position /

PCM Input

Switch B

Position /

PCM Input

Switch C

Position /

PCM Input

Park (P) Closed / 0 V Closed / 0 V Open / 12 V Open / 12 V

Reverse (R) Open / 12 V Closed / 0 V Closed / 0 V Open / 12 V

Neutral (N) Closed / 0 V Open / 12 V Closed / 0 V Open / 12 V

D Open / 12 V Open / 12 V Closed / 0 V Closed / 0 V

3 Closed / 0 V Closed / 0 V Closed / 0 V Closed / 0 V

2 Open / 12 V Closed / 0 V Open / 12 V Closed / 0 V

1 Closed / 0 V Open / 12 V Open / 12 V Closed / 0 V

Powertrain Management GEN III V8 – General Information Page 6C3-1–42

Page 6C3-1–42

5.2 1-2 (A) and 2-3 (B) Shift Solenoid Valves

The 1-2 and 2-3 shift solenoid valves (also called A and B solenoids) are identical devices that control the movement of

the 1-2 and 2-3 shift valves (the 3-4 shift valve is not directly controlled by a shift solenoid). The solenoids are normally

open exhaust valves that work in four combinations to shift the transmission into different gears.

The PCM energises each solenoid by grounding the solenoid through an internal qu ad driver. This sends current through

the coil winding in the solenoid and moves the internal plunger out of the exhaust position. When on, the solenoid

redirects fluid to move a shift valve.

The shift solenoid should energise at a voltage of 7.5 volts or greater (measured across the terminals and de-energise

when the voltage is one volt or less. If both solenoids lose p ower, only third gear engages.

The manual valve can hydra ulically override the shift solenoids. Only in D4 do the shift solenoid states totally d etermine

what gear the transmission is in. In the other manual valve positions, the transmission shifts hydraulically and the shift

solenoid states catch up when the throttle position and the vehicl e speed fall into the correct ranges.

The PCM-controlled shift solenoids eliminate the need for throttle valve and governor pressures to control shift valve

operation.

Legend

1 Frame

2 Plunger

3 Coil Assembly

4 O-Ring

5 Metering Ball

6 Spring

7 Wiring Harness Connector Terminals

A Signal Fluid

B Exhaust

Figure 6C3-1 – 40

Powertrain Management GEN III V8 – General Information Page 6C3-1–43

Page 6C3-1–43

5.3 3-2 Shift Solenoid Valve Assembly

The 3-2 shift solenoid valve assembly is an on / off solenoid that is used to improve the 3-2 do wnshift. The solenoid

regulates the release of the 3-4 clutch and the 2-4 band apply.

Legend

1 Housing

2 Metering Ball

3 O-Ring

4 Fluid Screen

5 Plunger

6 Coil Assembly

7 Connector Terminals

8 Spring

A Pressure Apply

B Exhaust

C Pressure Control (3-2 Signal)

Figure 6C3-1 – 41

Powertrain Management GEN III V8 – General Information Page 6C3-1–44

Page 6C3-1–44

5.4 Pressure Control Solenoid

The transmission pressure control solenoid is an electronic pressure regu lator that controls pressure based on the

current flow through its coil winding. The magnetic field produced by the c oil moves the solenoid's internal valve which

varies pressure to the pressure regulator val v e.

The PCM controls the pressure control solenoid by commanding current between 100 and 1100 milliamps. This changes

the duty cycle of the solenoi d, which can range between 5 percent and 95 percent (typicall y less than 60 percent). 1100

milliamps corresponds to minimum line pressure, and 100 milliamps corresponds to maxi mum line pressure. If the

solenoid loses power, the transmission defaults to maximum line pressure.

The PCM commands the line pressur e valu es using inputs such as the throttle position sensor.

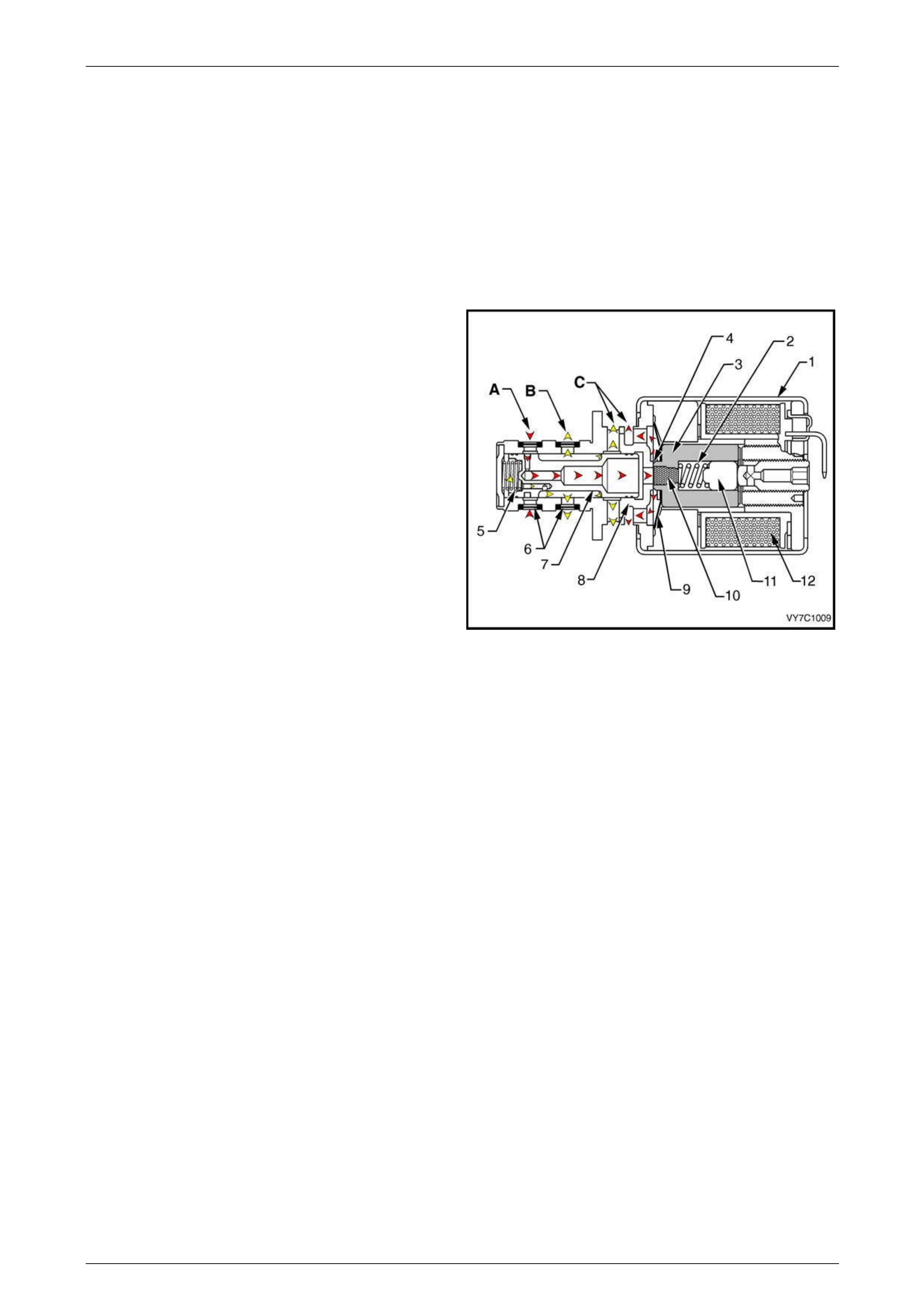

Legend

1 Frame

2 Spring

3 Armature

4 Variable Bleed Orifice

5 Spool Valve Spring

6 Fluid Screens

7 Spool Valve

8 Spool Valve Sleeve

9 Damper Spring

10 Restrictor

11 Push Rod

12 Coil Assembly

A Actuator Feed Limit (AFL) Fluid

B Torque Signal Fluid

C Exhausts Figure 6C3-1 – 42

Powertrain Management GEN III V8 – General Information Page 6C3-1–45

Page 6C3-1–45

5.5 Torque Converter Clutch (TCC) Solenoid

Valve

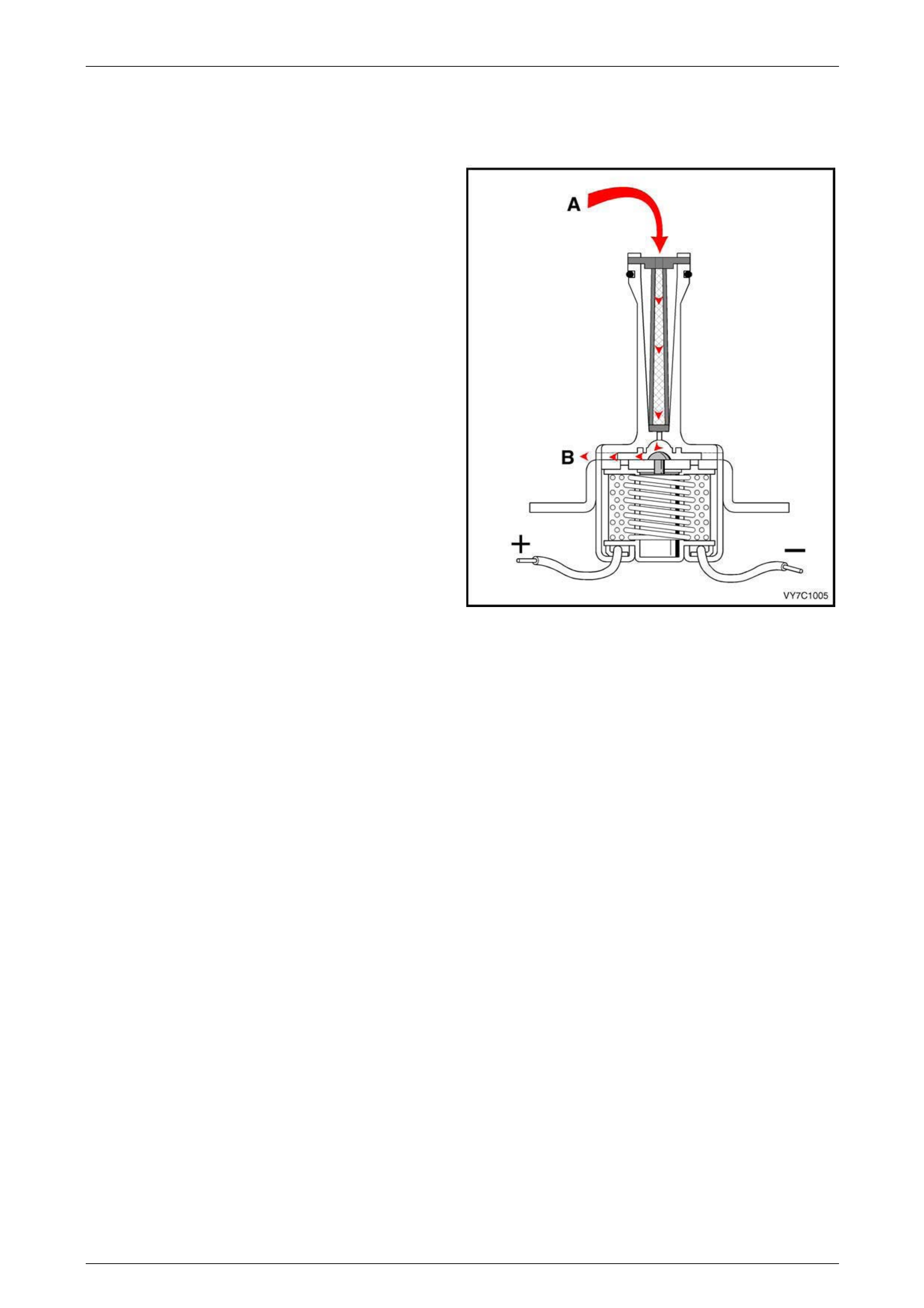

The torque converter clutch solenoid valve is a normally

open exhaust valve that is used to control tor que converter

clutch apply and release. W hen grounded (energised) by

the PCM, the TCC solenoid valve stops converter signal oil

from exhausting. This causes converter signal oil pressure

to increase and shifts the TCC solenoi d valve into the apply

position.

Legend

A Converter Feed Fluid

B Exhaust

Figure 6C3-1 – 43

Powertrain Management GEN III V8 – General Information Page 6C3-1–46

Page 6C3-1–46

5.6 Torque Converter Clutch PWM Solenoid

Valve

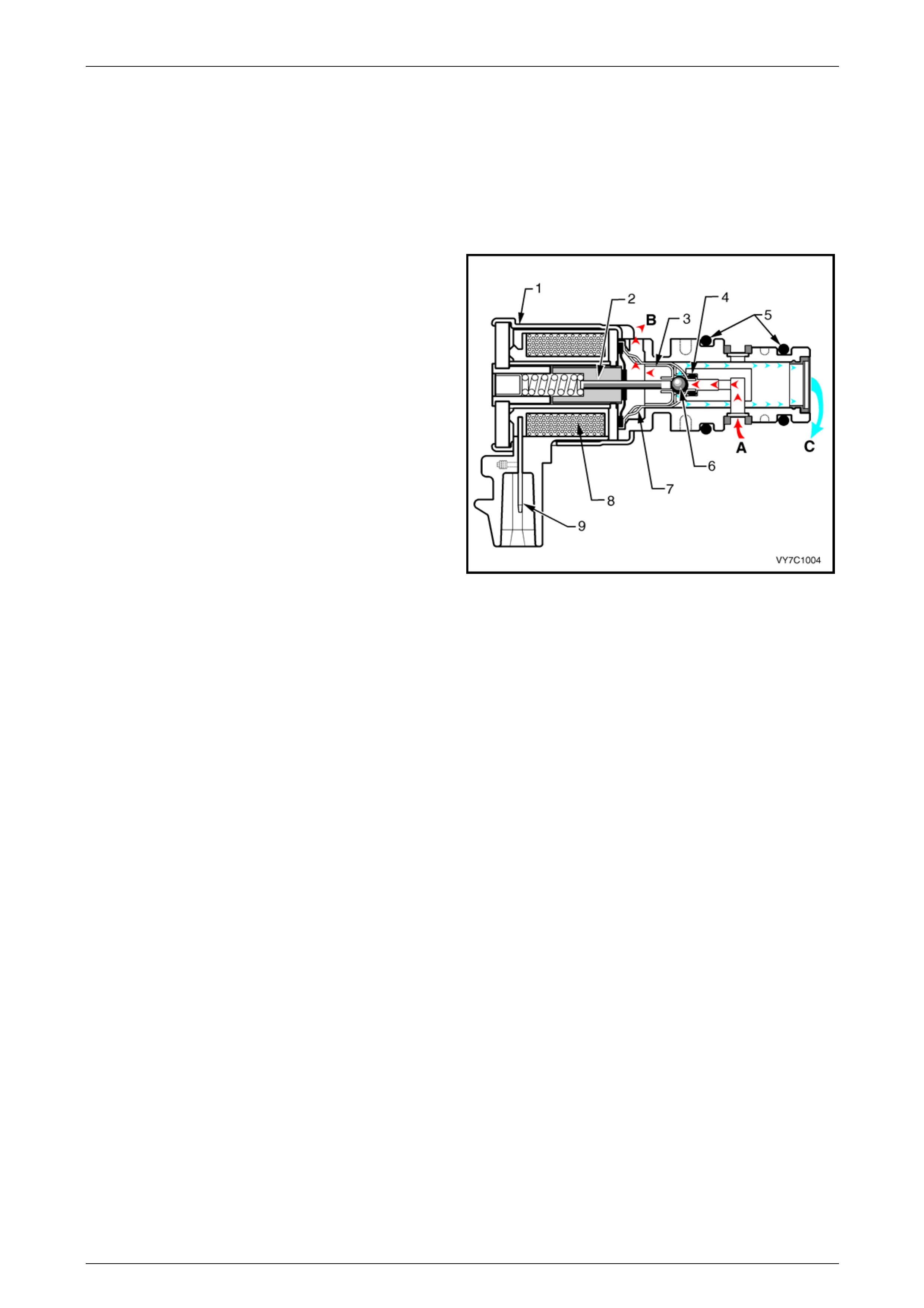

The torque converter clutch PWM solenoid valve controls the fluid acting on the converter clutch valve, which then

controls the TCC apply and release. This solenoid is attached to the control valve body assembly within the transmission.

The TCC PWM solenoid valve provides smooth engagement of the torque converter clutch by operating on a negative

duty cycle a variable percent of on time.

Legend

1 Housing

2 Armature

3 Exhaust Seat

4 Internal O-Ring

5 O-Rings

6 Metering Ball

7 Inlet Seat

8 Coil Assembly

9 Connector Terminal

A Actuator Feed Limit (AFL) Fluid

B Exhaust

C Converter Clutch Signal (CCS) Fluid

Figure 6C3-1 – 44

Powertrain Management GEN III V8 – General Information Page 6C3-1–47

Page 6C3-1–47

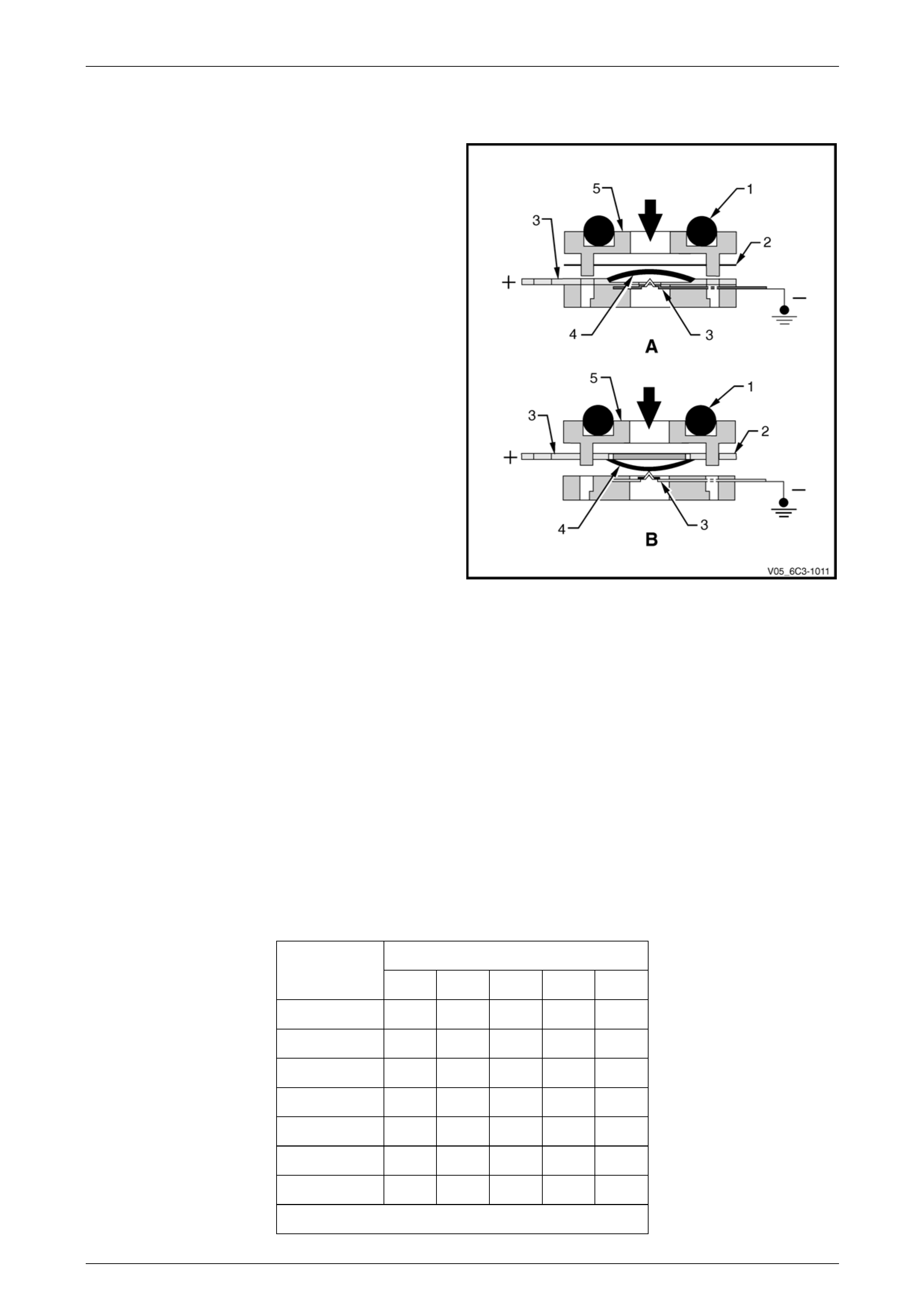

5.7 Fluid Pressure Switch Assembly

The transmission fluid pressure (TFP) manual valve position

switch assembly is used by the PCM to sense which gear

range has been selected by the driver. The TFP manual

valve position switch is located on the valve body and

consists of five pressure switches, two normall y closed and

three normally open, combined into one unit.

The normally open fluid pressure switches are the D4, LO

and Reverse fluid pressure s witches. They are normally

open and electrical current is stopped at these switches

when no fluid pressure is present. Fluid pressure moves the

diaphragm and contact element until the contact element

touches both the positive contact and the ground contact.

This creates a closed circuit and allows current to flow from

the positive contact, through the switch and to ground. The

normally closed fluid pressure switches are the D2 and D3

fluid pressure switches. T hey are normally closed and

electrical current is free to flow from the positive contact to

the ground contact when no fluid pressure is present. Fluid

pressure moves the diaphragm to disconnect the positive

and ground contacts. This opens the switch and stops

current from flowing through the s witch.

The PCM applies system voltage to the T F P manual valve

position switch assembly on three sep arate wires. An open

circuit measures 12 Volts while a grounded circuit measures

0 Volts. The switches are opened or closed by fluid

pressure. The combination of which switches are open and

closed is used by the PCM to determine actual manual

valve position. The TFP manual valve position switch

assembly cannot distinguish b etween Park and Neutral

because the monitored valve body pressures are identical in

both cases.

LO This switch will have hydraulic pressure applied to it in

manual 1st gear only and will be closed.

REV This switch will have hydraulic pressure applied to it in

reverse only and will be closed.

D2 This switch will have hydraulic pressure applied to it in

manual 1st and 2nd gear and will be open.

D3 This switch will have hydraulic pressure applied to it in

manual 1st, 2nd and 3rd gear and will be open.

D4 This switch will have hydraulic pressure applied to it in

all drive gears except revers e and will be closed.

Figure 6C3-1 – 45

Legend

1 O-Ring

2 Diaphragm

3 Contact

4 Contact Element

5 Body

A Normally Open

B Normally Closed

Pressure Switch Valid Combination Table

Fluid Pressure Switch

Range

Selected REV D4 D3 D2 LO

Park

Reverse X

Neutral

D X

3 X X

2 X X X

1 X X X X

X – Pressure Applied

Powertrain Management GEN III V8 – General Information Page 6C3-1–48

Page 6C3-1–48

These TFP manual valve position switch inputs are used to

help control line pressure, torque converter clutch apply and

shift solenoid operation. T o monitor TFP manual valve

position switch operation, the PCM compares the actual

voltage combination of the switches to a TFP manual valve

position switch combination table stored in its memory.

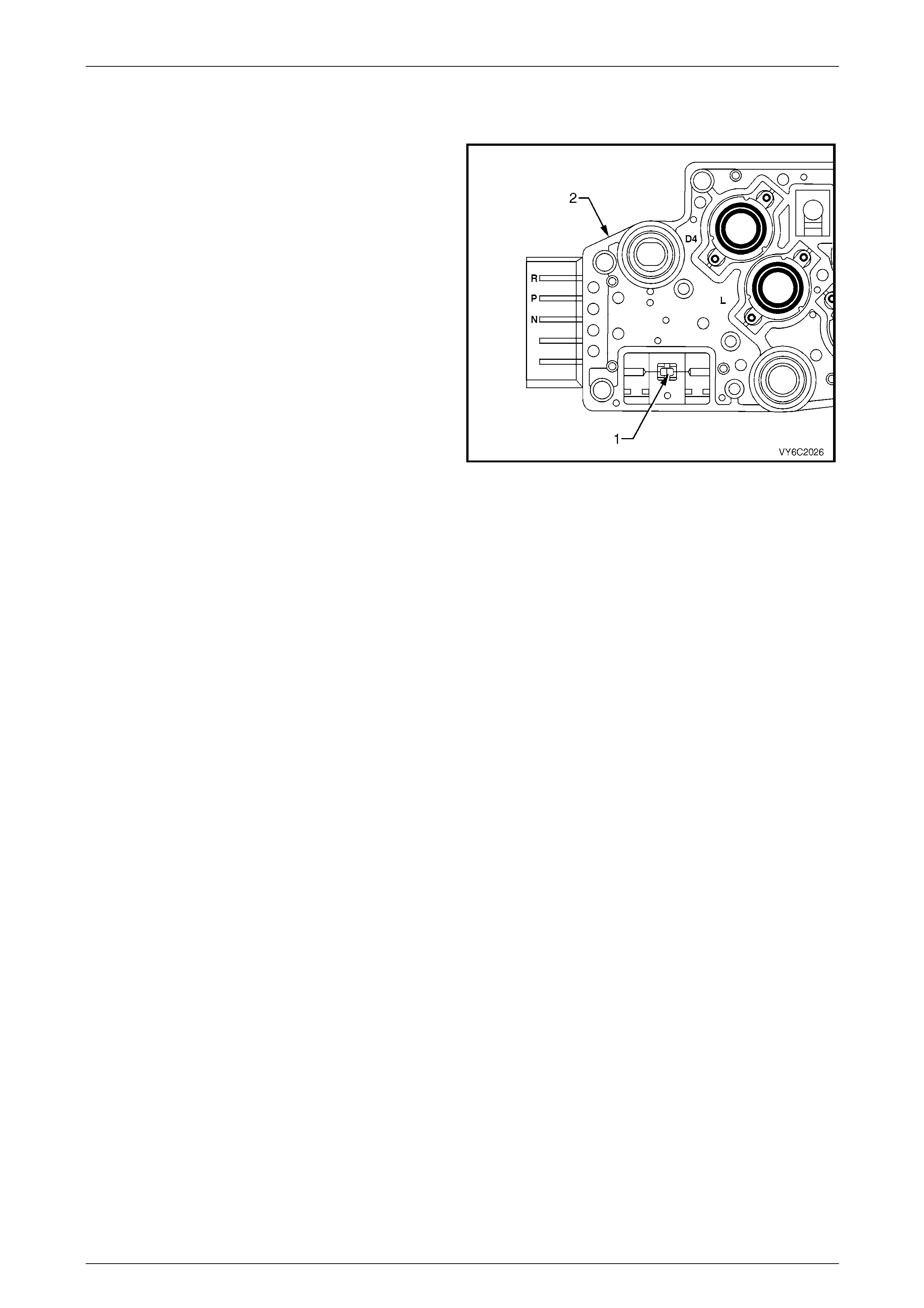

Legend

1 Transmission Fluid Pressure Manual Valve Position Switch

2 D2 Indicator Switch

3 D4 Indicator Switch

4 Reverse Indicator Switch

5 D3 Indicator Switch

6 LO Indicator Switch

7 Five Pin Connector Terminal

8 Transmission Fluid Temperature Sensor

Figure 6C3-1 – 46

Powertrain Management GEN III V8 – General Information Page 6C3-1–49

Page 6C3-1–49

5.8 Fluid Temperature (TFT) Sensor

The automatic transmission fluid temperature (TFT) Sensor

(1) is part of the automatic transmission fluid pressure (TFP)

manual valve position switch assembly (2). This sensor

helps control torque converter clutch ap ply and shift quality.