5L40–E General Information 7E1 – 1

7E1 – 1

Section 7E1

Hydra-Matic 5L40–E Automatic Transmission: –

General Information

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and/or property damage.

1 Section Descriptions..............................................................................................................................2

Section 7E1: Hydra–matic 5L40–E Automatic Transmission – General Information.......................................... 2

Section 7E2: Hydra–matic 5L40–E Automatic Transmission – Electrical Diagnosis .......................................... 2

Section 7E3: Hydra–matic 5L40–E Automatic Transmission – Hydraulic/Mechanical Dia gnosis....................... 2

Section 7E4: Hydra–matic 5L40–E Automatic Transmission – On–Vehic le Servicing ....................................... 2

Section 7E5: Hydra–matic 5L40–E Automatic Transmission – Unit Repair........................................................ 2

2 Transmission Operation – Overview....................................................................................................3

2.1 General Description............................................................................................................................................... 3

Transmission Component Summary ................................................................................................................... 3

Transmission Identification .................................................................................................................................. 5

Transmission Speed Ranges................................................................................................................................ 5

‘Active Select’ Shift Control.................................................................................................................................. 6

Transmission Range Reference Chart................................................................................................................. 6

Transmission Adaptive Functions ....................................................................................................................... 7

Safety Mode Description....................................................................................................................................... 8

Transmission Shift Mode Operation .................................................................................................................... 8

Normal Mode Operation..................................................................................................................................... 8

Power Mode Operation ...................................................................................................................................... 8

Cruise Control Mode Operation.......................................................................................................................... 8

Active Select Mode Operation............................................................................................................................ 8

3 Service Notes..........................................................................................................................................9

3.1 Fasteners................................................................................................................................................................ 9

3.2 General Workshop Practice................................................................................................................................ 10

4 Transmission Definitions and Abbreviations....................................................................................11

4.1 Definitions ............................................................................................................................................................ 11

4.2 Abbreviations....................................................................................................................................................... 14

Techline

Techline

Techline

5L40–E General Information 7E1 – 2

7E1 – 2

1 Section Descriptions

A multi–section approach to the service inform ation for the Hydra–matic 5L40–E automatic transmission has been

adopted for MY 2005 VZ and WL Series vehicles. The Section breakdown is as follows:

Section 7E1: Hydra–matic 5L40–E Automatic Transmission – General Information

The purpose of this Section is to provide an overview of the 5L40–E automatic transmission, by briefly d escribi ng what

each of the various sub–sections contain.

In addition, an overvie w of the transmission features is provided, that includes:

• A general description of the transmissi on, its operation and control, as well as transmission identification

information.

• Some notes that address safe workshop practices when dealing with automatic transmissions.

• Service notes relating to fasteners and consumable items used at various stages throughout these Sections.

Section 7E2: Hydra–matic 5L40–E Automatic Transmission – Electrical Diagnosis

As this automatic transmission uses a separate Transmission Control Module (TCM), the information in this Section

covers all aspects of the TCM control of the transmission. Information includ es component locatio ns, system operation,

active select (where fitted), diagnostic trouble codes and el ectrical fault finding charts.

Section 7E3: Hydra–matic 5L40–E Automatic Transmission – Hydraulic/Mechanical Diagnosis

As distinct from the previous Section, 7E3 contains information that will assist in the diagnosis of the mechanical and

hydraulic components in the 5L40 –E automatic transmission.

The type of diagnostic information in this Section i nclu des transmission functional test, shift speed and line pressure

information. Other material contained in this Section refers to the fluid flow and circuit descriptions, plus fluid passage

identification diagrams relating to this transmission.

Section 7E4: Hydra–matic 5L40–E Automatic Transmission – On–Vehicle Servicing

Information in this Section covers transmission fluid level checking and diagnosis, as well specific information for

servicing some components while the transmission remains installed in the vehicle.

This Section also contains the necessary procedures for the removal and installation of the transmission.

Section 7E5: Hydra–matic 5L40–E Automatic Transmission – Unit Repair

This Section contains the procedures necessary for the disassembly, inspection, overhaul an d assembly operations of

the mechanical components, once the tran smission is removed from the vehicle. Also included is information relating to

measurement of certain clearances, the correct use of special service tools and torque wrench specifications required

during overhaul.

5L40–E General Information 7E1 – 3

7E1 – 3

2 Transmission Operation –

Overview

2.1 General Description

The Hydra–matic 5L40–E a fu lly automatic, five speed, rear drive, electronically controlled transmission. It consists

primarily of a four–element torque converter, one planetary gear set, friction and mechanical clutch es and a hydraulic

pressurization and control system.

The four–element torque converter contains a pump, a turbine, a pressure plate splined to the turbine, and a stator

assembly. The torque converter acts as a flui d coupling to smoothly transmit power from the engine to the transmission.

It also hydraulically provides additional torque multiplication wh en required. The pressure plate, when applied, provid es a

mechanical ‘direct drive’ coupling of the engine to the transmission.

The planetary gear set provides the five forward gear ratios and reverse. C hanging gear ratios is fully automatic and is

accomplished through the use of a T r ansmission Control Module (TCM). The TCM receives and monitors various

electronic sensor inputs and uses this inform ation to shift the transmission at the optimum time.

The TCM commands shift solenoids, within the transmission, on and off to control shift timing. The TCM controls shift

feel through the pressure control sole noid. The TCM also controls the apply and release of the torque converter clutch

which allows the engine to deliver the maximum fuel efficiency without sacrificing vehicle performance.

The hydraulic system primarily consists of a vane type pump, two control valve bodies, two channel plates, converter

housing and case. The pump maintains the working pressures neede d to stroke the clutch pistons that apply the friction

components. These friction components (when applied or released) support the automatic shifting qualities of the

transmission.

The friction components used in this transmission consist of nine multiple disc clutch packs. The multiple disc clutches

combine with four mechanical sprag clutches, to deliver six different gear ratios through the gear set. The gear set then

transfers torque though the output shaft.

There are no brake bands within this transmission.

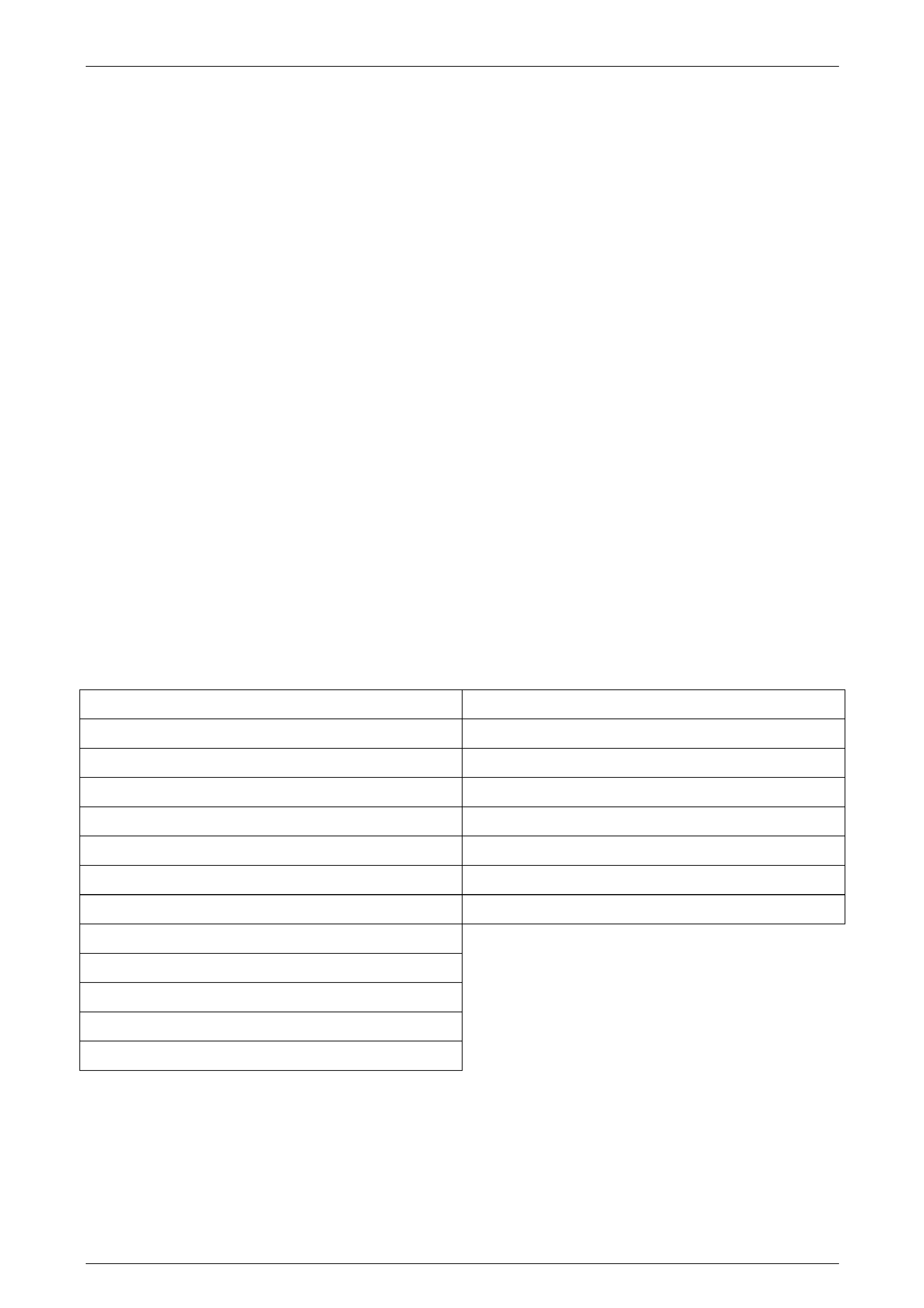

Transmission Component Summary

Mechanical / Hydraulic Components Electrical Components

Torque converter assembly 1–2, 2–3 and 4–5 shift solenoids

Direct and reverse clutch assembly Transmission manual shift shaft switch assembly

Forward and coast clutch assembly Transmission pressure control (PC) solenoid

Input sun gear shaft and forward sprag clutch assembly TCC pulse width modulatio n (PW M) solenoid valve

Output shaft assembly, with rear internal gear Transmission fluid temperature (TFT) sensor

Intermediate clutch sprag assembly Transmission input speed se nsor (TISS)

Overdrive clutch housing Transmission output speed sensor (TOSS)

Low clutch sprag

Centre support

Input and reaction carrier

Fluid pump assembly

Control valve body and accumulator ass embly

5L40–E General Information 7E1 – 4

7E1 – 4

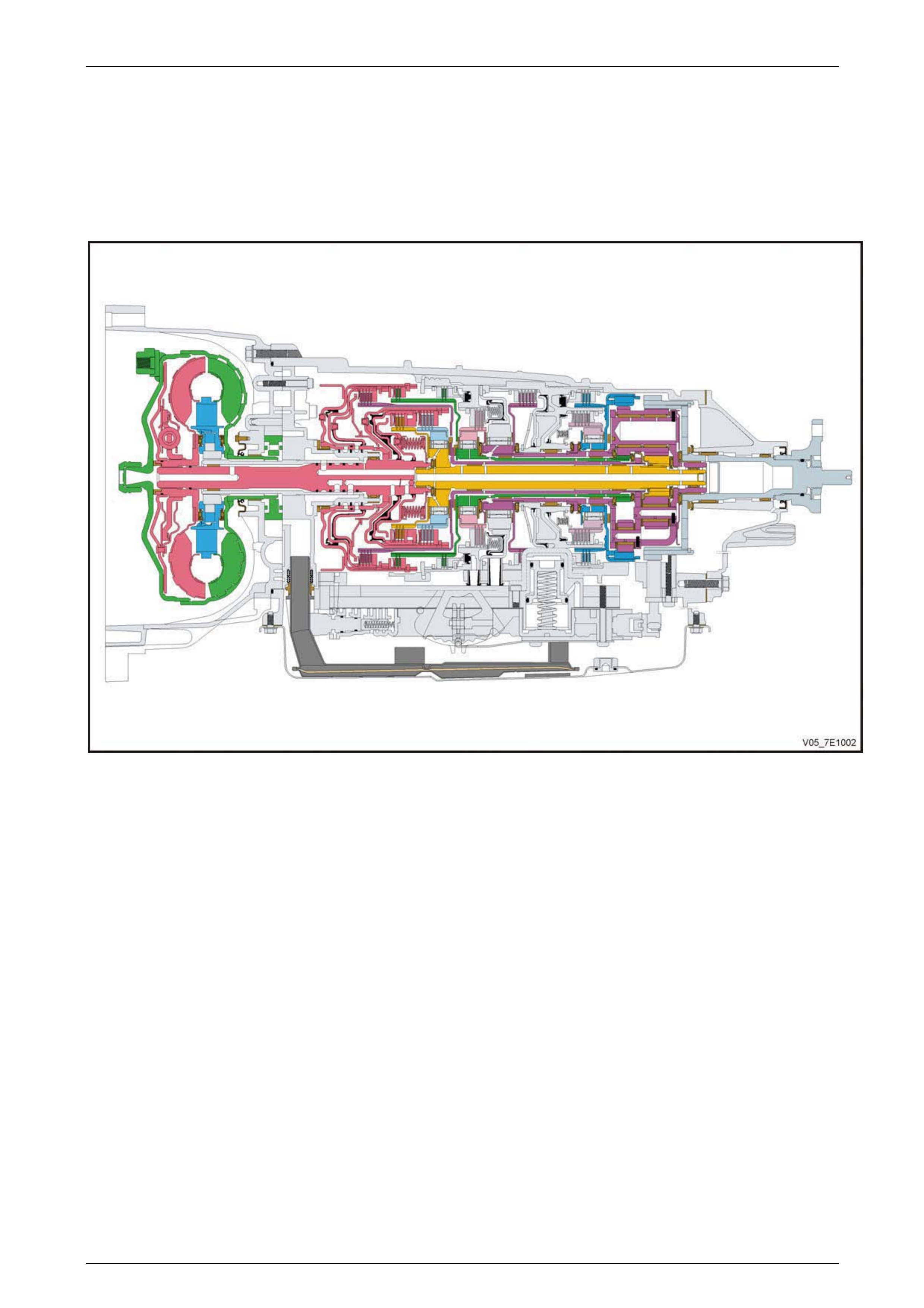

Figure 7E1 – 1 – Transmission Major Components & Assemblies

Legend

1 Stator Roller Clutch

2 Converter Pump

3 Torque Converter Housing/Pump

4 Direct Clutch

5 Coast Clutch

6 Reverse Clutch

7 Forward Clutch

8 Forward Sprag Clutch

9 Overdrive Clutch

10 Intermediate Sprag Clutch

11 Intermediate Clutch

12 Low/Reverse Clutch

13 Low Sprag Clutch

14 Second Coast Clutch

15 Second Clutch

16 Second Sprag Clutch

17 Output Shaft

18 Planetary Carrier

19 Rear Internal Gear

20 Front Internal Gear

21 Park Pawl Actuator

22 Input Sun Gear Shaft

23 Control Valve Body/Accumulatory

24 Transmission Manual Shaft Switch

25 Manual Valve

26 Transmission Fluid Pan

27 TOO PWM Solenoid Valve

28 Transmission Fluid Filter

29 Converter Stator

30 Converter Turbine

31 Pressure Plate

32 Forward/Coast Clutch Housing Shaft

33 Torque Converter

5L40–E General Information 7E1 – 5

7E1 – 5

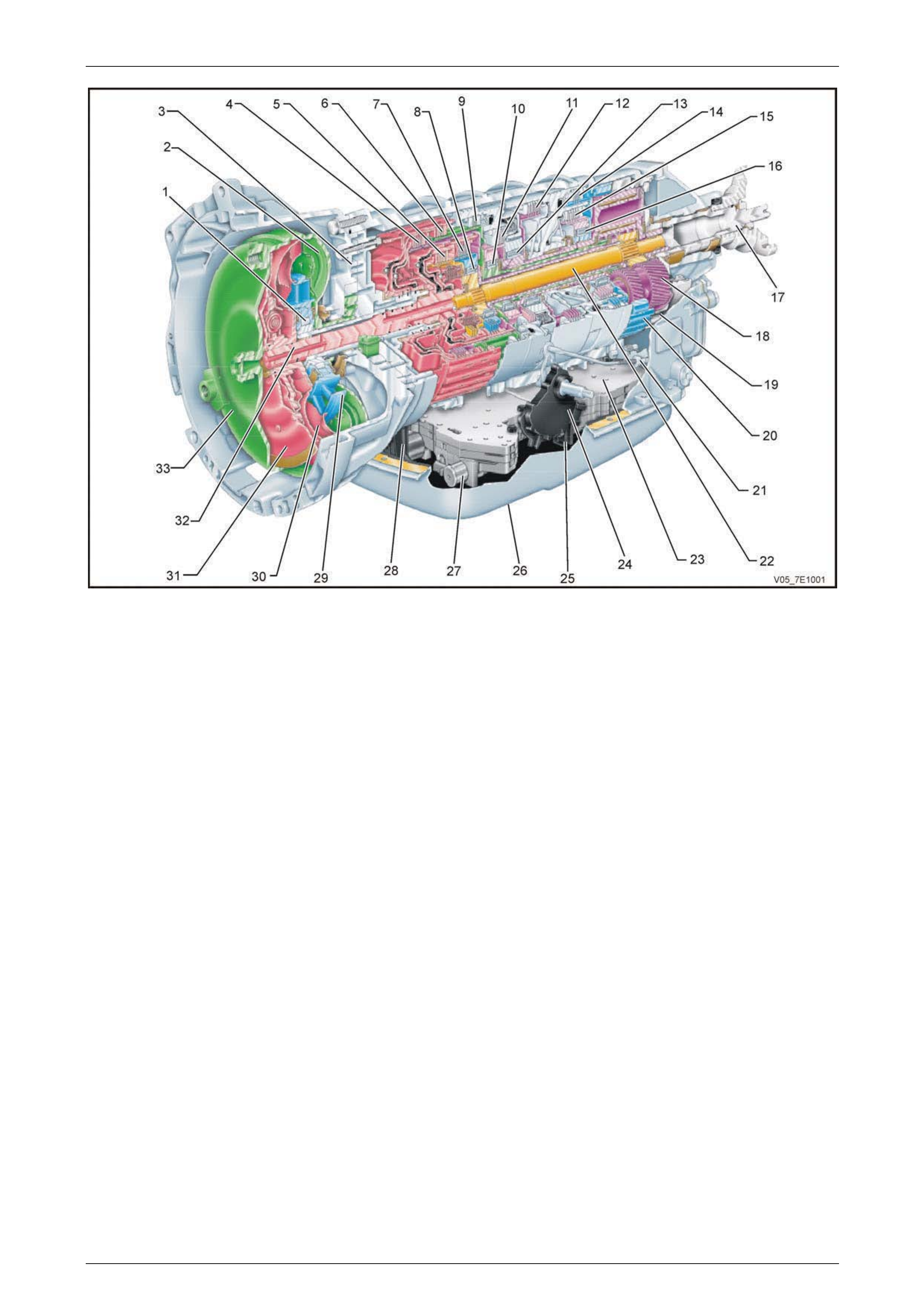

Transmission Identification

A transmission identification p late (item 9 in Figure 7E1 –2) is located on the left hand side rear of the transmission case.

Figure 7E1 - 2

Legend

1 Production Identification Plate 6 Serial Number

2 Transmission Family 7 Empty

3 Model Year 8 Calibration Code

4 Application – ‘HA’ = 3.6 litre V6 / ‘HB’ = V6 AWD / ‘HF’ = 2.8 litre V6 9 I.D. Tag Location

5 Part Number

Transmission Speed Ranges

The 5L40–E transmission can be operated in any one of the seven different positions shown on the shift quadrant.

P – Park position enables the engine to be started while preventing the vehicle from rolling either forward or backward.

For safety reason, the vehicle’s parkin g brake should be used in addition to the transmission ‘P ark’ position. Since the

output shaft is mechanically locked to the case through the parking pawl and rear internal gear, park position should not

be selected until the vehicle ahs come to a complete stop.

R – Reverse enables the vehicle to be operated in a rearward direction.

N – Neutral position enables t he engine to start and operated without driving the vehicle. If necessar y, this position

should be selected to restart the engine while the vehicle is moving.

D – Overdrive range should be used for all normal driving conditions for maximum efficie ncy and fuel economy.

Overdrive range allows the transmission to operate i n each of the five forward gear ratios. Downshifts to a lower gear, of

higher gear ratio are available for safe passing by depressing the accelerator or by manuall y selecting a lower gear with

the shift lever.

4 – Manual Fourth can be used for conditions where it may be desirable to use on ly four gear ratios. These conditions

include towing a trailer and driving on hilly terrain as previously described. This range is also helpful for engine braking

when descending slight grades. Upshifts and downshifts are the same as in Overdrive range for first, second, third and

fourth gears except that the transmission will not shift into fifth gear. Manual Fourth can be selected at any vehicle speed

but will downshift into fourth gear only at the road speed and throttle position calibrated within the TCM.

3 – Manual Third adds more performance for congested traffic and hilly terrain. It has the same starting ratio (first gear)

as Manual Fourth, but prevents the transmiss ion from shifting above third gear. Thus, Manual Third can be used to retain

third gear for acceleration and engine braking as desired. Manual Third can be selected at any vehicle speed but will

downshift into third gear only at the road speed an d throttle position calibrated within the TCM.

L – Manual Second again adds more performance for congested traffic and hilly terrain. It has the same starting ratio

(first gear) as Manual Third, but prevents the transmission from shifting above second gear. Thus, Manual Second can

be used to retain second gear for acceleration and engine braking as desired. Manual Second can be selected at any

vehicle speed but will downshift into second gear only at the road speed and throttle position calibrated within the TCM.

When the vehicle speed slows down, the transmission will shift into first gear, in the same way that a 2-1 downshift

occurs, when the shift selector is in the Drive range. Use of the ‘L’ range is particularly beneficial for maintaining

maximum engine braking when descending steep grades.

5L40–E General Information 7E1 – 6

7E1 – 6

‘Active Select’ Shift Control

When the momentary contact ‘A/S’ switch in the centre console cover is pressed and the Active Select mo de is

operational, the driver can change speed ratios either up or down, using the steering wheel mounted paddle shift pads

(marked ‘+’ for upshifts and – for downshifts), provided the vehicle is moving, the shift selector is in the ‘D’ position and

the shift desired, is within the TCM calibration.

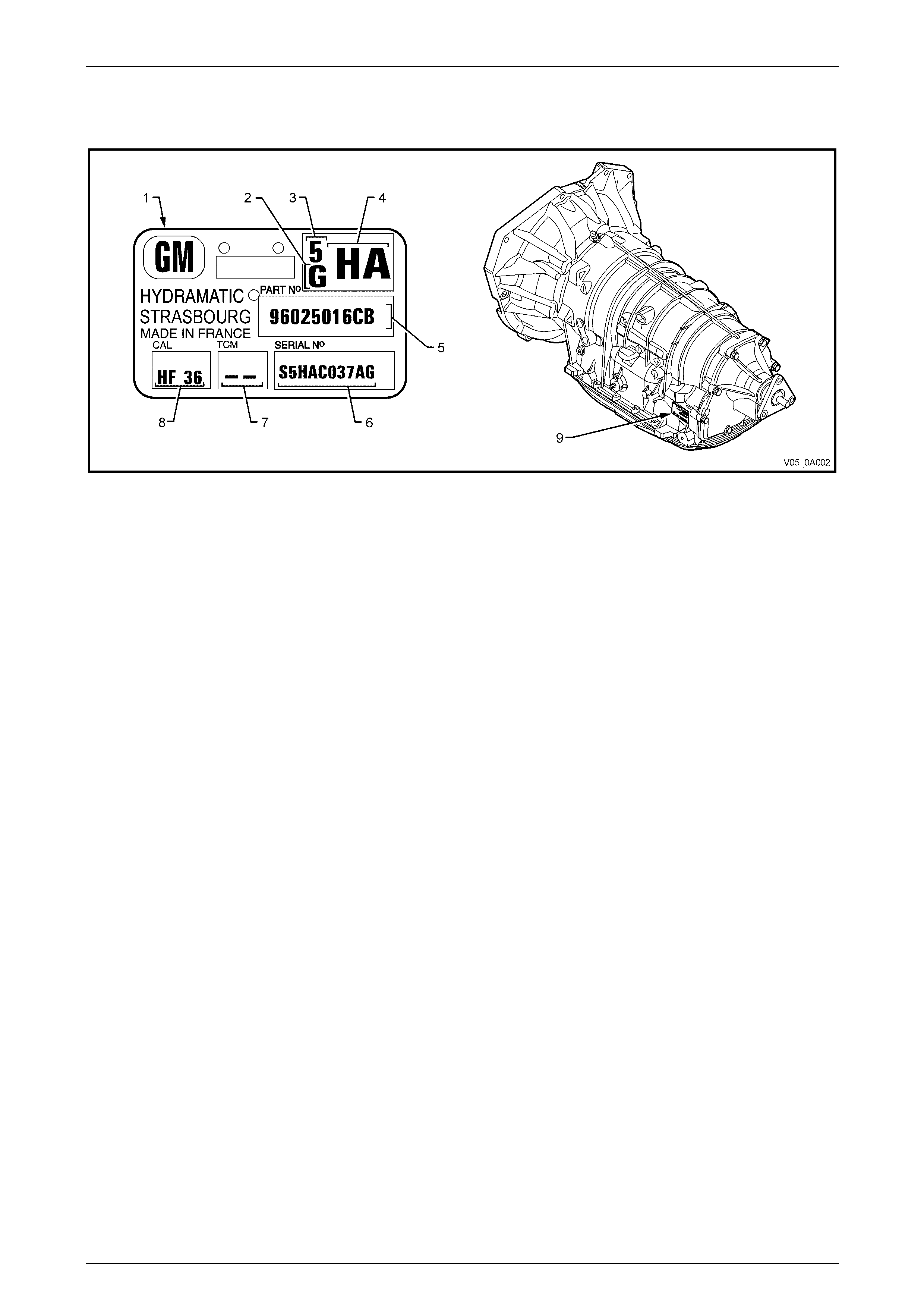

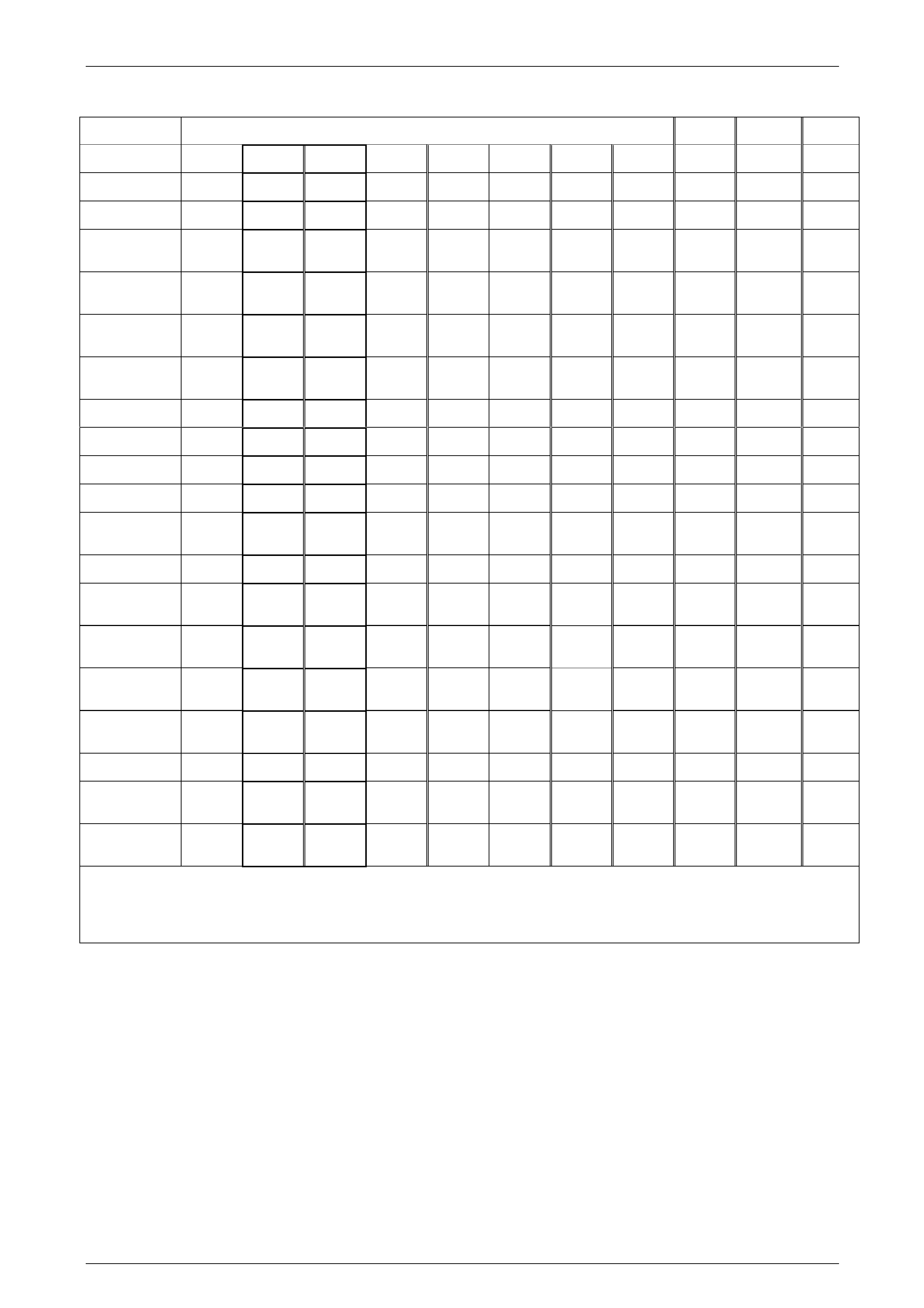

Transmission Range Reference Chart

Figure 7E1 - 3

5L40–E General Information 7E1 – 7

7E1 – 7

Range D / 4 / 3 / 2 Neutral Reverse Park

Gear 1 1 2 2 3 3 4 5 – R –

Engine Braking NO YES NO YES NO YES YES YES – YES –

Ratio 3.24 3.24 2.21 2.21 1.60 1.60 1.00 0.75 – 3.03 –

1–2 Shift

Solenoid Valve OFF OFF ON ON ON ON OFF OFF

ON/OFF

ON/OFF

ON/OFF

2–3 Shift

Solenoid Valve ON ON ON ON OFF OFF OFF OFF

ON/OFF

ON/OFF

ON/OFF

4–5 Shift

Solenoid Valve OFF ON OFF ON OFF ON ON OFF

ON/OFF

ON/OFF

ON/OFF

TCC Solenoid

Valve OFF OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

ON/OFF

OFF

Direct Clutch APPLIED APPLIED

Coast Clutch APPLIED APPLIED APPLIED APPLIED APPLIED APPLIED APPLIED

Reverse Clutch APPLIED

Forward Clutch APPLIED APPLIED APPLIED APPLIED APPLIED APPLIED APPLIED APPLIED

Forward Clutch

Sprag LD LD LD LD LD LD LD

Overdrive Clutch APPLIED APPLIED

Intermediate

Clutch Sprag LD LD

Intermediate

Clutch APPLIED APPLIED APPLIED APPLIED

Low Clutch

Sprag LD LD

Low and Reverse

Clutch APPLIED APPLIED

Second Clutch APPLIED APPLIED APPLIED APPLIED APPLIED APPLIED

Second Clutch

Sprag LD LD

Second Coast

Clutch APPLIED

LD = Locked in Drive ON = Solenoid Ene rgised OFF = Solenoid De-Ene rgised

The solenoids state follows a shift pattern that depends upon vehicle speed and throttle position. It does not depend upon the selected gear.

Engine braking is electronically controlled by the TCM and is available as a calibrated function.

Transmission Adaptive Functions

The Hydra-matic 5L40-E uses a line pressure control system which has the abilit y to adapt the s ystem line press ure in

order to compensate for normal wear of clutch fibre plates, seals, springs, etc. The adapt feature is similar in function to

fuel control (integrator/block learn).

The Hydra-matic 5L40-E transmission uses the adapt function for garage shifts, upshifts, and TCC application. The TCM

monitors the input shaft speed in order to determine if the shift is occurring too fast or too slow and adjusts the pressure

control solenoid in order to maintain the correct shift feel.

As this adaptive feature is unique to any given transmission, it should be noted that any two different vehicles fitted with

the Hydra-matic 5L40-E automatic transmission, cou ld e xhibit different shift characteristics and have a different ‘feel’.

This is a normal phenomena.

5L40–E General Information 7E1 – 8

7E1 – 8

Safety Mode Description

If a major electrical system failure occurs which could affect vehicle safety or damage the transmission during normal

operation, the TCM enters a default safety mode. In this mode, the transmission operates in the following manner:

• The pressure control solenoid is commanded off and the line pressure is at maximum to minimise clutch slippage.

• The TCC solenoid is commanded off. The converter clutch is disabled.

• All three of the shift solenoids are commanded off. The transmission will operate in fifth gear if the vehicle has

successfully completed a 1-2 upsh ift in the current ig nition cycle. If the vehicle has not completed a 1-2 upshift in

the current ignition cycle, the transmission will operate in fourth gear. If the transmission is operating in fifth gear,

fourth gear may be obtained if the engine is stopped briefly and re-started.

In safety mode, the gear selector lever is ineffective at selecting forward gear ranges. In fourth or fifth gear, heat builds

up in the transmission quickly, particularly in stop and go traffic. Excessive heat bu ild-up may cause transmission failure

if the vehicle is driven for extended distances in the safety mode.

Transmission Shift Mode Operation

Normal Mode Operation

During economy mode operation, drivers may notice increased powertrain brakin g after releasing the accelerator pedal.

The vehicle will not coast freel y when the accelerator pedal is released, but will start to gradually slow down as if the

brakes were lightly applied. This feels very similar to what is experienced when releasing the accelerator pedal on a

vehicle equipped with a manual transmission.

Power Mode Operation

The power mode was designed to simulate the performance driving of a manual transmission equipped vehicle. This

means that, given certain driving conditi ons, the vehicle will maintain specific gears longer than a traditional automatic

transmission would. No attempt should be m ade to change or alter these operating characteristics.

Cruise Control Mode Operation

When the driver activates the cruise control (where fitted), the ‘Power’ icon in the Instrument, Multi-Function Display

(MFD) will be deactivated (provided the vehicle was operating in ‘Power’ mode) and the transmission shift pattern will

switch to the cruise control mode.

Through the electronic progra mming of the logic processes contained in the Transmission Control Module (TCM), the

frequency of gear shifting and torque converter clutch application and release is minimised. The end result of these logic

processes, is that transmission 'busyness' (a quick series of upshifts and downshifts, such as a '4-3-4' shift pattern) is

minimised.

Active Select Mode Operation

When activated by the driver pressing the m omentary contact ‘A/S’ switch in the centre console, changes to the upshift

and downshift of the transmission can be effected by tapping either the ‘+’ (upshift) or ‘–‘ (downshift) paddles l ocate d at

the steering wheel.

Provided the shift select lever is in the ‘D’ position and the vehicle in motion, the transmission shift pattern can then be

governed by the selection command ed. That is, the transmission shift pattern can be selected by the driver controls,

within the TCM programmed parameters.

With Active Select operational and the vehicle is brought to a stop, the transmission will shift down to first gear.

5L40–E General Information 7E1 – 9

7E1 – 9

3 Service Notes

In the interests of safety to personnel, equipment and to the vehicle and its components, the following notes should be

read and adhered to whenever servicing operations are to be carried out on the H ydra–m atic 5L4 0–E automatic

transmission. In addition, some of this information also refers to the adher ence to sound workshop practices and, to

achieve the design life of affected components; it is also recommended that these points be taken into account.

3.1 Fasteners

1 Always reinstall fasteners in the same location as they were removed.

2 If a fastener requires replacement, al ways use a part of the correct part number or of equ al size and strength or

stronger.

3 Tighten fasteners to correct torque value when required. Torque values are specified for dry, unlubricated fastener

threads.

4 Additional notes regarding the tightening of fasteners is located in Section 00 Warning, Cautions and Notes.

5L40–E General Information 7E1 – 10

7E1 – 10

3.2 General Workshop Practice

• Machined surfaces on alloy castings have

extremely sharp edges that can easily

cause injury and blood loss, through

severe cuts. Take extreme care when

working under these conditions.

• Always wear eye protection when using

compressed ai r o n components.

• Keep work area and tools clean.

• To avoid unnecessar y conta mination, always clean the exterior of the transmission before removi ng any parts.

• Do not use wiping cloths or rags because of the risk of lint being trapped in the transmission.

• Do not use solvents on:

• neoprene seals.

• composition faced clutch plates.

• thrust washers.

• Blow out all passages with compressed air. Only probe small passages with soft, thin wire.

• Handle parts with care to avoid nicks and scratches.

• Do not remove Teflon oil seal rings and compress external snap rings to maximise retention and security.

• Lubricate all internal parts with transmission fluid (only use Dexron® III unless otherwise directed), as they are

installed.

• When installing cap screws into aluminium castings:

• always use a torque wrench.

• always dip screw threads in transmission fluid (only use Dexron® III).

• stripped or damaged threads in aluminium castings may be reconditioned by using commercially available

thread inserts.

• Once removed, replace all ga skets, seals and O–rings with new parts and:

• always use seal protectors when indicated and do not use gasket cement or sealant on a ny joined face

unless specified to do so.

5L40–E General Information 7E1 – 11

7E1 – 11

4 Transmission Definitions and

Abbreviations

The following definitions and abbreviations are provided to establish a common language and assist the user / technician

in describing transmission related conditions. The use of these terms and / or conditions can be found in the various

parts of the automatic transmission sections of this Service Information, but more particularly, in Section 7E3 Hydraulic /

Mechanical Diagnosis.

Besides the following definitio ns and abbreviations, there are some additional definitions and abbreviati ons used when

describing transmission related cond itions, refer to Section 7E3 Hydraulic / Mechanical Diagnosis,

1.3 Transmission Definitions and Ab breviations, for details.

4.1 Definitions

Accumulator: A component of the transmission that absorb s hydraulic pressure during the apply of a clutch or band.

Accumulators are designed to control the quality of a shift from one gear to another.

Adaptive Learning: Programming within the Transmission Control Module (TCM) that automatically adjusts hydraulic

pressure in order to compensate for changes in the transmission (i.e. component wear).

Applied: An apply component that is holding another component to which it is splined or assembled with. Also referred

to as ‘engaged’.

Apply Components: Hydraulic operated cl utches, servos, bands, and mechanical one–way roller or spr ag clutches that

drive or hold members of a planetary g ear set.

Backing Plate: A steel plate in a clutch pack that is usually the last plat e in that clutch assembly (farthest from the clutch

piston).

Ball Check Valve: A spherical hydraulically operated controlled component (usually made of steel) that either seals or

opens fluid circuits. It is also referred to as a check valve or checkball.

Band: An apply component that consists of a flexible strip of steel and friction material that wraps around a drum. When

applied, it tightens around the drum and prevents the drum from rotating.

Brake Switch: An electrical device that provides signals to the TCM based on the position of the brake pedal. The TCM

uses this information to apply or releas e the torque converter clutch.

Centrifugal Force: A force that is imparted on an object (due to rotation) that increases as that object moves further

away from a centre / point of rotation.

Clutch Pack: An assembly of compone nts generally consisting of clutch plates, an apply plate and a backing plate.

Component: Any physical part of the transmission.

Control Valve Body: A machined metal casting that contains valve trains, and other hydraulically controlled components

that shift the transmission.

Coupling Speed: The speed at which a vehicle is travelling and no longer requires torque multiplicatio n through the

torque converter. At this point the stator free wheels to allow fluid leaving th e turbine to flow directly to the pump.

De-energise(d): To interrupt the electrical current that flows to an electronically controlled device mak ing it electrically

inoperable.

Direct Drive: A condition in a gear set where the input speed and the input torque equals the output speed and torque.

The gear ratio through the gear set is 1:1.

Downshift: A change in a gear ratio where input speed a nd torque increases.

Driver Shift Control: A selector system variant which is configured to be shifted only manually, and allows for engine

braking in first, second, third and fourth gears.

Duty Cycle: In reference to an electronically controlled solenoid, it is the amount of time (expressed as a percentage)

that current flows through the solenoid coil.

5L40–E General Information 7E1 – 12

7E1 – 12

Engine Control Module (ECM): An electronic device that manages the electrical system of the engi ne.

Energise(d): To supply a curr ent to an electronically controlled device enabling it to perform its designed function.

Engine Compression Braking: A condition where compression from the engine is used with the transmission to

decrease vehicle speed. Braki ng (slowing of the vehicle) occurs when a lower gear ratio is manually selected by moving

the gear selector lever.

Exhaust: The release of fluid pressure from a hydraulic circuit. (The words exhausts and exhausting are also used and

have the same intended meanin g).

Fluid: In this Service Information, ‘fluid’ refers primarily to Automatic Transmission Fluid (or ATF) and, for the Hydra–

matic 5L40–E transmission, the only recommended fluid is Dexron III®.

Fluid Pressur e: A pressure that is consistent throughout its circuit.

Force: A measurable effort that is exerted on an object (component).

Freewheeling: A condition where power is lost through a driving or holding device (i.e. roller or sprag clutches).

Friction Material: A heat and wear resistant fibrous material bonded to clutch plates a nd bands.

Gear: A round, toothed device that is used for transmitting torque through other components.

Gear Range: A specific speed to torque ratio at which the transmission is operating (i.e. 1st gear, 2nd gear etc.).

Gear Ratio: Revolutions of an input gear as compared to the revolutions of an output gear. It can also be expressed as

the number of teeth on a gear that it is in mesh with.

Hydraulic Circuit: A fluid passage that often includes the mechanical components in that circuit designed to perform a

specific function.

Input: A starting point for torque, revolutions or energy into another component of the transmission.

Internal Gear: The outermost member of a gear set that has gear teeth in constant mesh with planetary pinion gears of

the gear set.

Internal Leak: Loss of fluid pressure in a hydraulic circuit.

Land (Valve Land): The larger diameters of a spool valve that contact the valve bo dy bore or bushing.

Line Pressure: The main fluid pressure in a hydraulic system created by the pump and pressur e regulator valve.

Manual Valve: A spool valve that distributes fluid to various hydraulic circuits and is mechanically linked to the gear

selector lever.

Orifice: A restricting device (usually a hole in the spacer plate) for controlling pressure build up into another circuit.

Overdrive: An operating condition in the gear set allowing output speed to be higher than inp ut speed and output torque

to be lower than input torque.

Overrunning: The function of a one–way mechanical clutch that allows the clutch to freewheel during certain operating

conditions of the transmission.

Pinion Gear: A small toothed gear that meshes with a larger gear.

Planet Pinion Gears: Pinion gears (housed in a carrier) that are in constant mesh with a circumferential internal gear

and centralised sun gear.

Planetary Gear Set: An assembly of gears that consists of an internal gear, planet pinion gears with a carrier, and a sun

gear.

Pressure: A measurabl e force that is exerted on an area and expressed as kilopascals (kPa).

Pulse Width Modulated (PWM): An electronic signal that continuousl y cycles the ON and OFF time of a device (such as

a solenoid) while var ying the amount of ON time.

5L40–E General Information 7E1 – 13

7E1 – 13

Race (Inner of Outer): A highly polished steel surface that contacts bearings or sprag or roller elem ents.

Reduction (Gear Reduction): An operating condition in the gear set allowing output speed to be lower than input speed

and output torque to be higher that input torque.

Residual Fluid Pressure: E xcess pressure contained within an area after the supply pressure has been terminated.

Roller Clutch: A mechanical clutch (holding device) consisting of roller bearings assembled between inner and outer

races.

Safety Mode: A condition whereby a compo nent (i.e. engine or transmission) will partially function even if its electrical

system is disabled.

Servo: A spring loaded device consisting of a piston in a bore that is operated (stroked) by hydraulic pressure to apply or

release a band.

Solenoid Valve: An electronic device used to control transmission shift patterns or regulate fluid pressu re.

Spool Valve: A cylindrical hydraulic control device having a variety of land and valley diameters, used to control fluid

flow.

Sprag Clutch: A mechanical clutch (holding devic e) consisting of figure eight like elements assembled between inner

and outer races.

Throttle Position: The trave of the throttle plate that is expressed in percentages and measured by the throttle position

(TP) sensor.

Torque: A measurable twisting force expressed in terms of Newton–meters (N.m).

Torque Converter: A component of an automatic transmission, (attached to the engine flywheel) that transfers torque

from the engine to the transmission through a fluid coupling.

Transmission Control Module (TCM): An electronic device that manages the electrical system of the transmission.

Variable Capacity Pump: The device that provid es fluid for operating the hydraulic circuits in the transmission. T he

amount of fluid supplied varie s depending on vehicle operating con ditions.

5L40–E General Information 7E1 – 14

7E1 – 14

4.2 Abbreviations

AC – Alternating Current

A/C – Air Conditioning

ACC or ACCM – Accumulator

AFL – Actuator Feed Limit

AMP – Amperage

ASM –Assembly

AT – Automatic Transmission

°C – Degrees Celsius

CC – Converter Clutch

CONT – Control

CONV – Converter

DC – Direct Current

D.C. – Duty Cycle

DLC – Diagnostic Link Connector

DTC – Diagnostic Trouble Co de

D2 – Drive 2 (circuit)

D3 – Drive 3 (circuit)

D4 – Drive 4 (circuit)

D432 – Drive 432 (circuit)

ECM – Engine Control Module

ECT – Engine Coolant Temperature

EX – Exhaust

FD – Feed

Hz – Hertz

ISS – Input Speed Sensor

Km/h – kilometres per hour

MAP – Manifold Absolute Pressure

N – Neutral

NC – Normally Closed

N.m – Newton Metres

NO – Normally Open

ORF – Orifice

ORUN – Overrun

OSS – Output Speed Sensor

P – Park

PC – Pressure Control (solenoid)

PR – Park Reverse (circuit)

PRESS REG – Pressure Regulator

PWM – Pulse Width Modulated

R – Reverse

RPM – Revolutions per Minut e

SEL – Selective

SIG – Signal

SOL – Solenoid

SS – Shift Solenoid

TCC – Torque Converter Clutch

TCM – Transmission Control Module

TFP – Transmission Fluid Pressure

TFT – Transmission Fluid Temperature

TP – Throttle Position (sensor)

TRANS – Transmission

V – Volts

VSS – Vehicle Speed Sens or

2WD – 2 Wheel Drive

4WD – 4 Wheel Drive

AWD – All Wheel Drive