4L60-E

HYDRA-MATIC

2

CONTENTS

INTRODUCTION..................................................................................... 3

HOW TO USE THIS BOOK ...................................................................... 4

UNDERSTANDING THE GRAPHICS ....................................................... 6

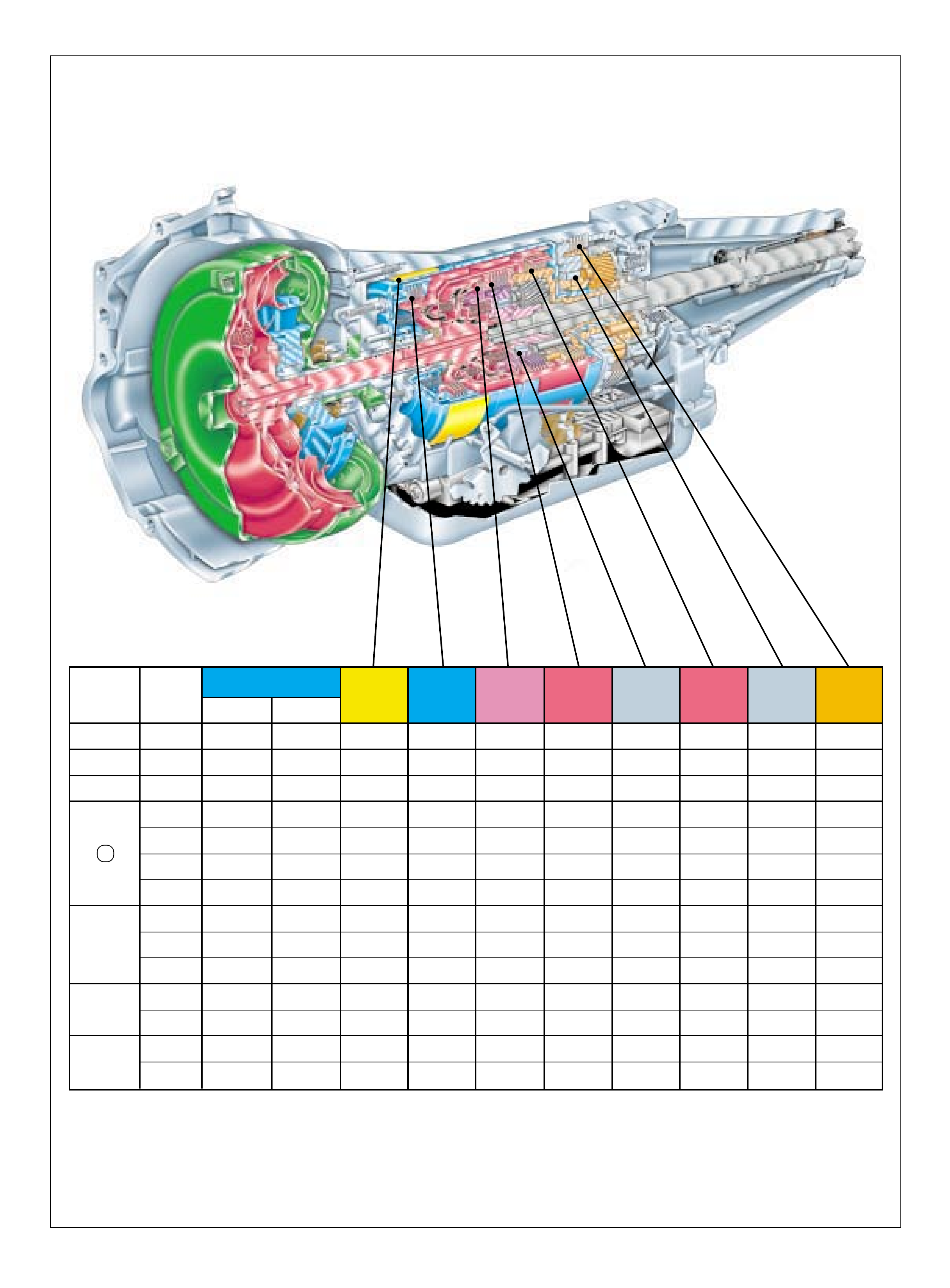

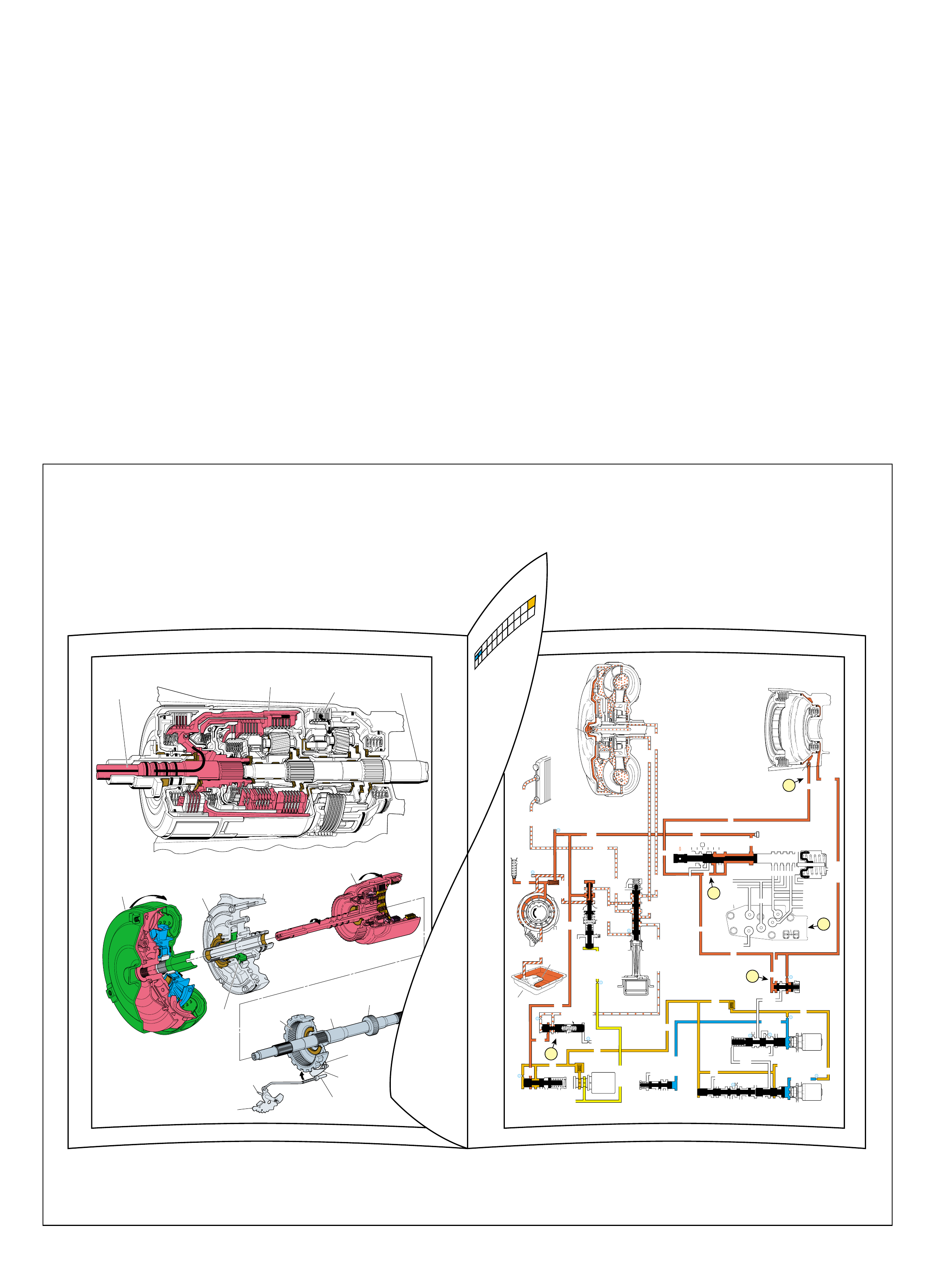

TRANSMISSION CUTAWAY VIEW (FOLDOUT) ....................................... 8

GENERAL DESCRIPTION ....................................................................... 9

PRINCIPLES OF OPERATION ............................................................... 9A

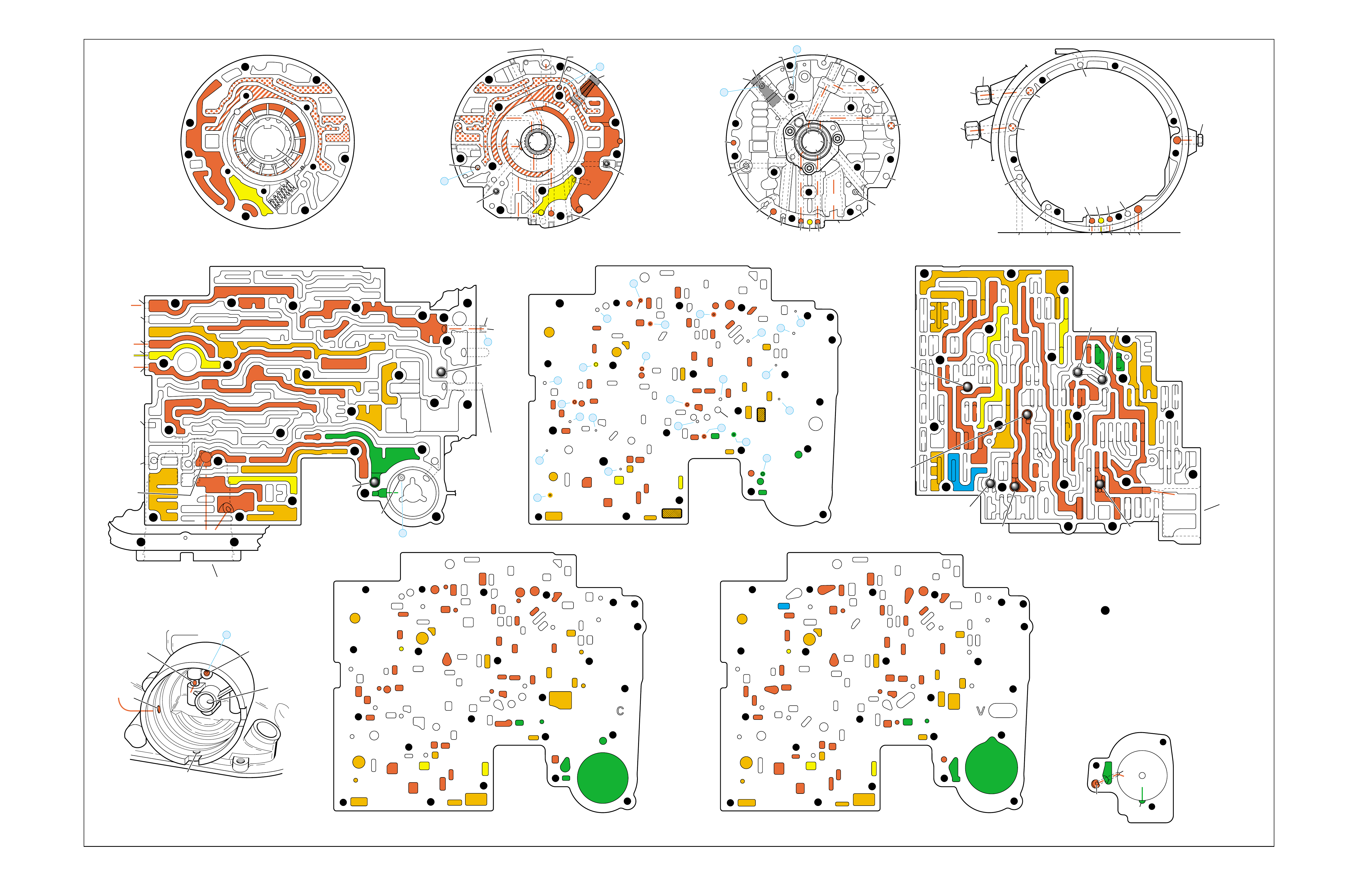

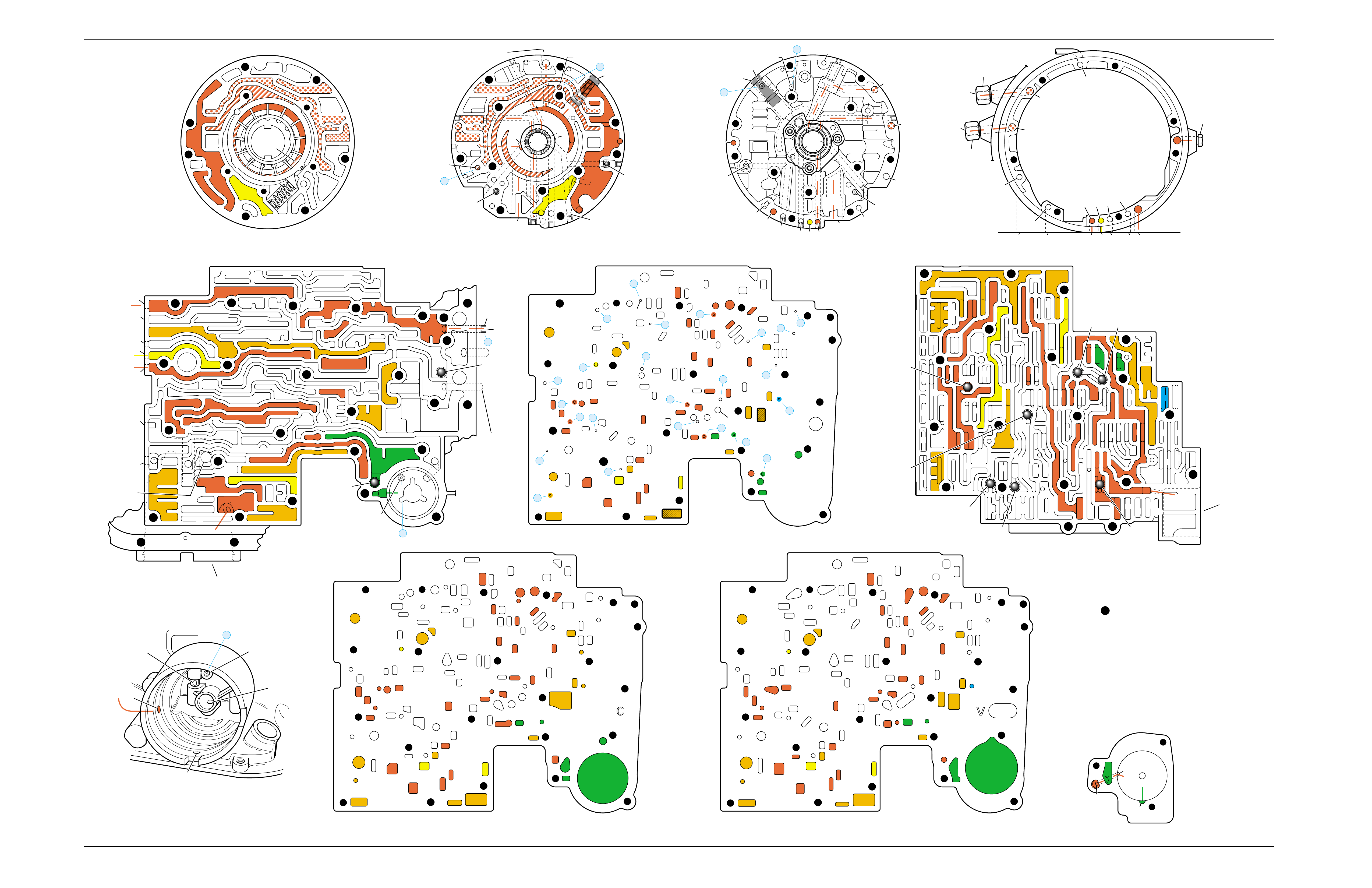

MAJOR MECHANICAL COMPONENTS (FOLDOUT) ...................... 10

RANGE REFERENCE CHART ......................................................... 11

TORQUE CONVERTER .................................................................. 12

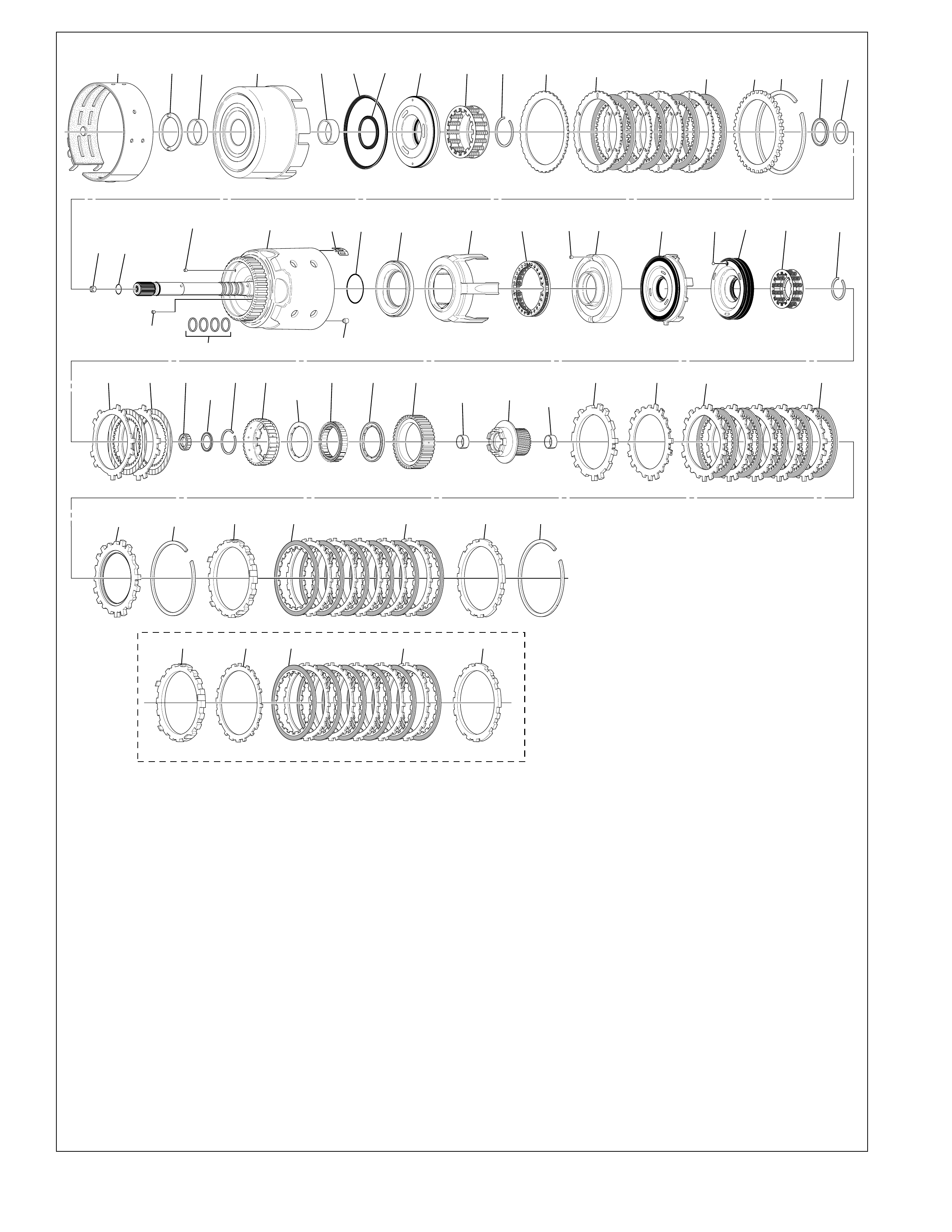

APPLY COMPONENTS ................................................................. 15

PLANETARY GEAR SETS ............................................................. 24

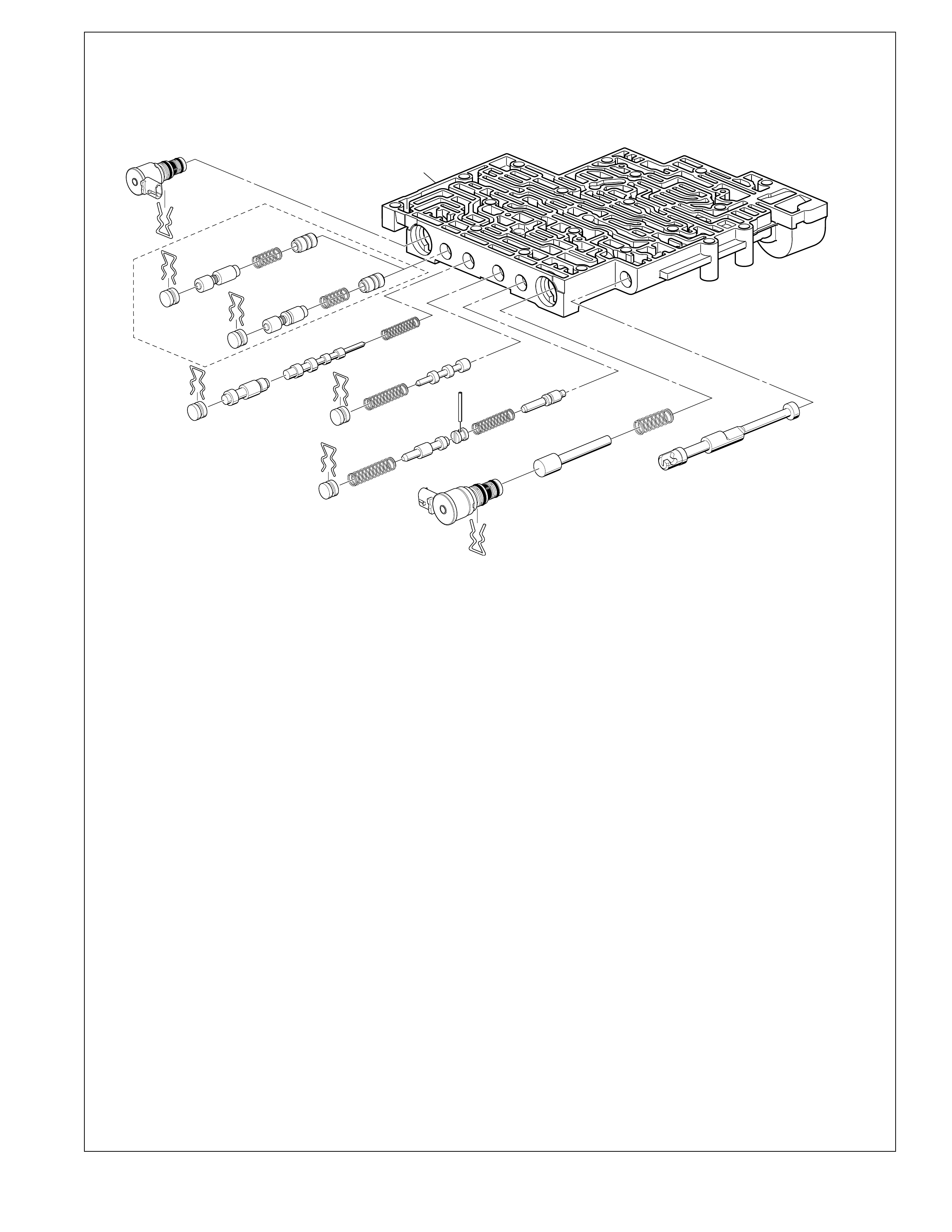

HYDRAULIC CONTROL COMPONENTS........................................ 26

ELECTRICAL COMPONENTS ........................................................ 36

POWER FLOW ...................................................................................... 45

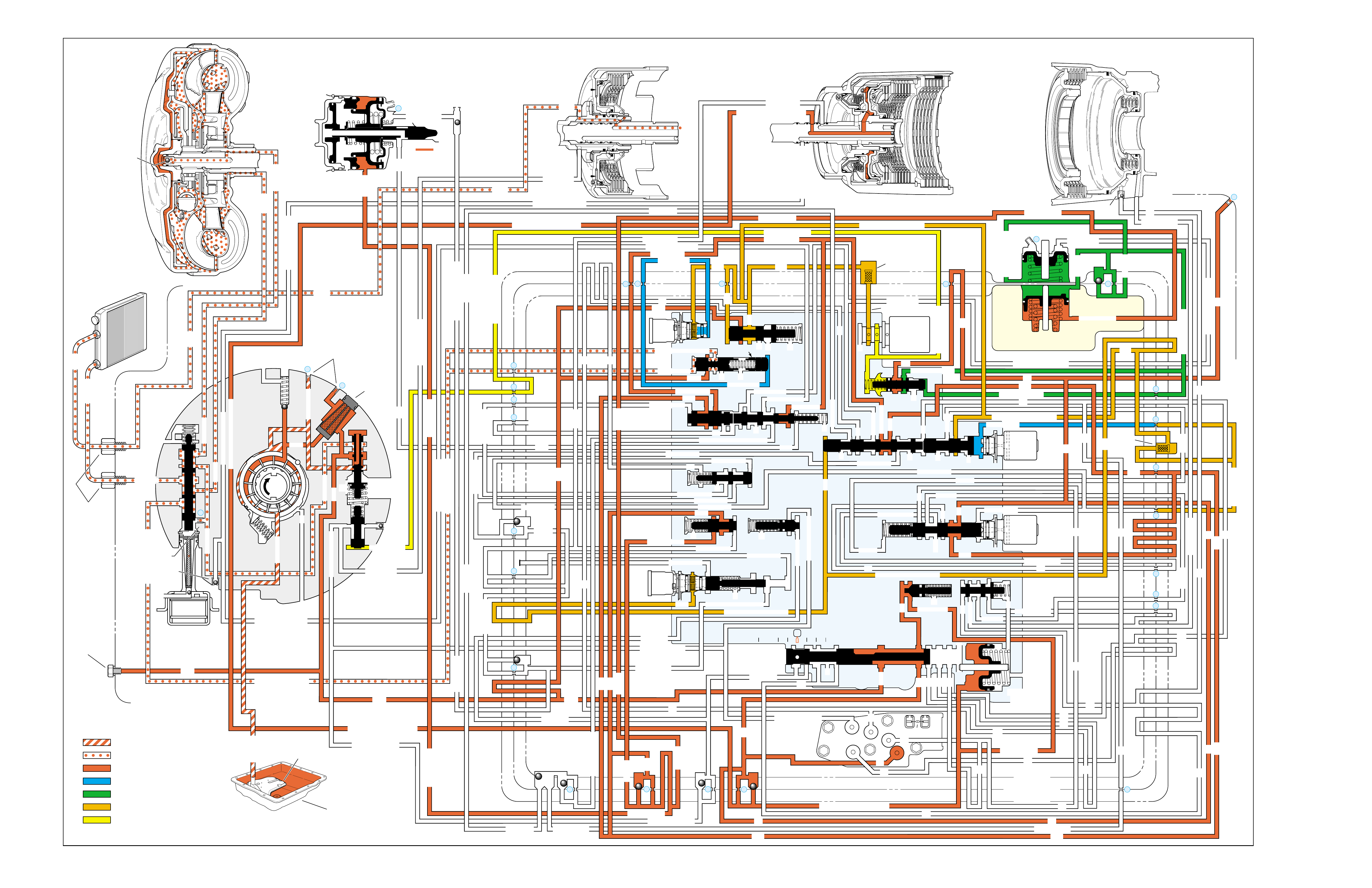

COMPLETE HYDRAULIC CIRCUITS ..................................................... 73

LUBRICATION POINTS......................................................................... 98

BUSHING AND BEARING LOCATIONS................................................. 99

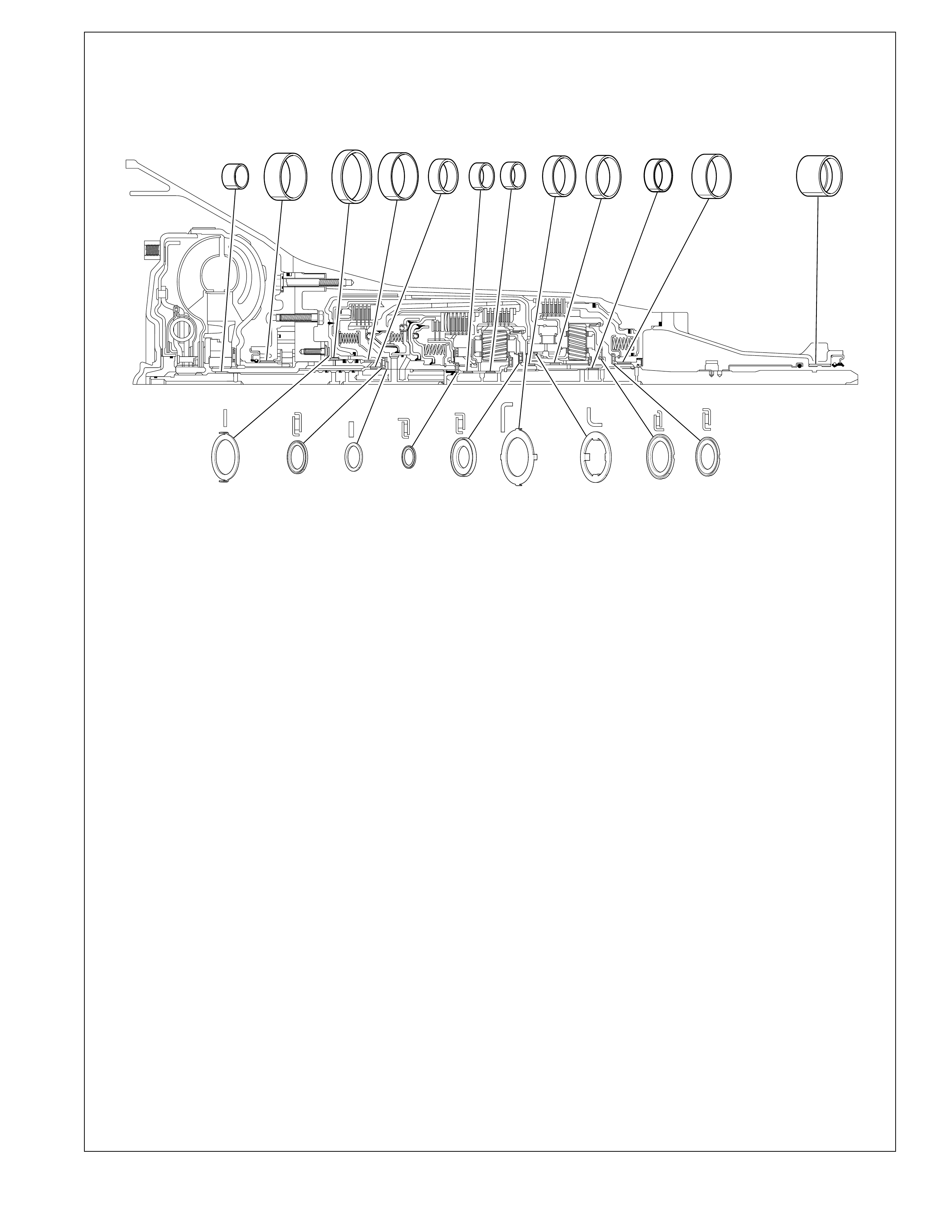

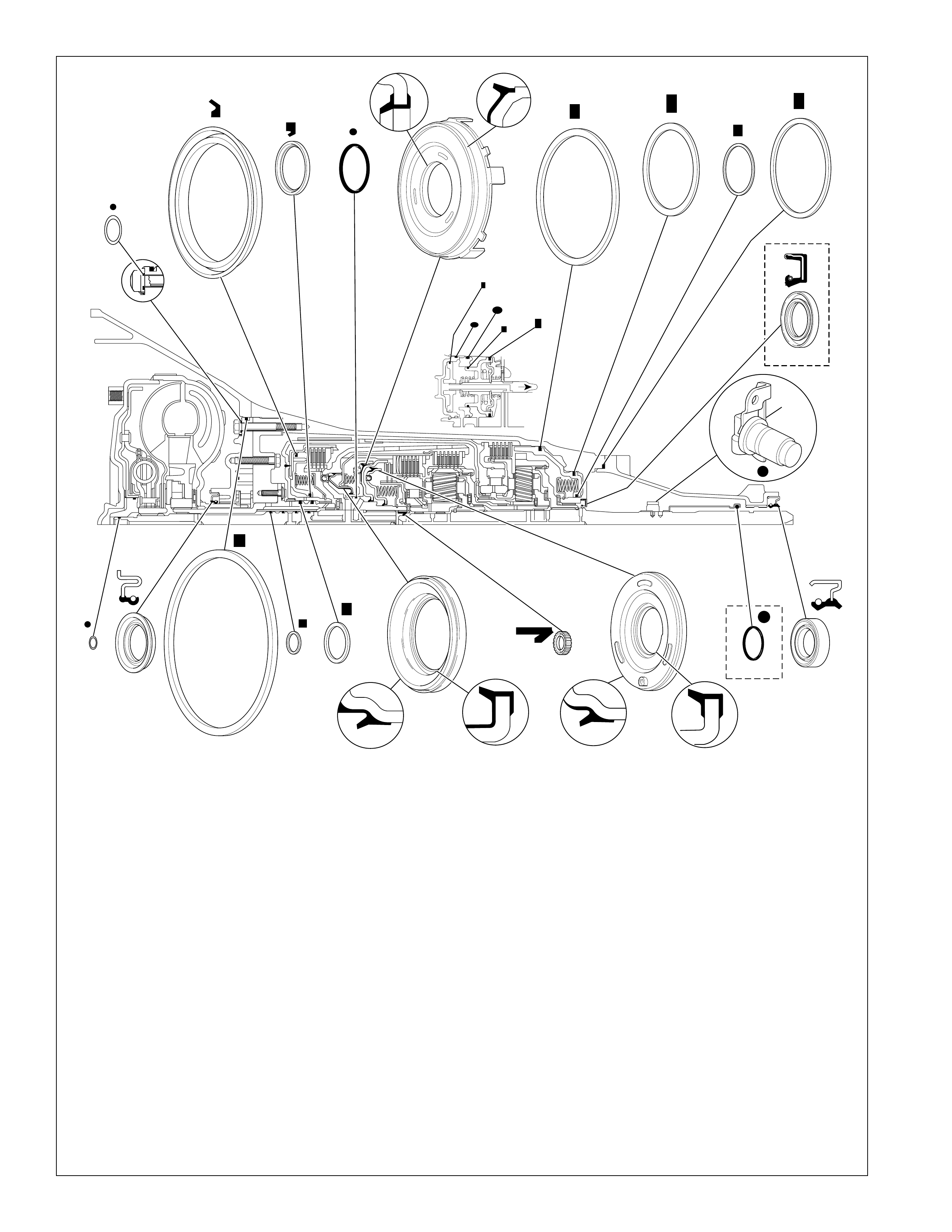

SEAL LOCATIONS.............................................................................. 100

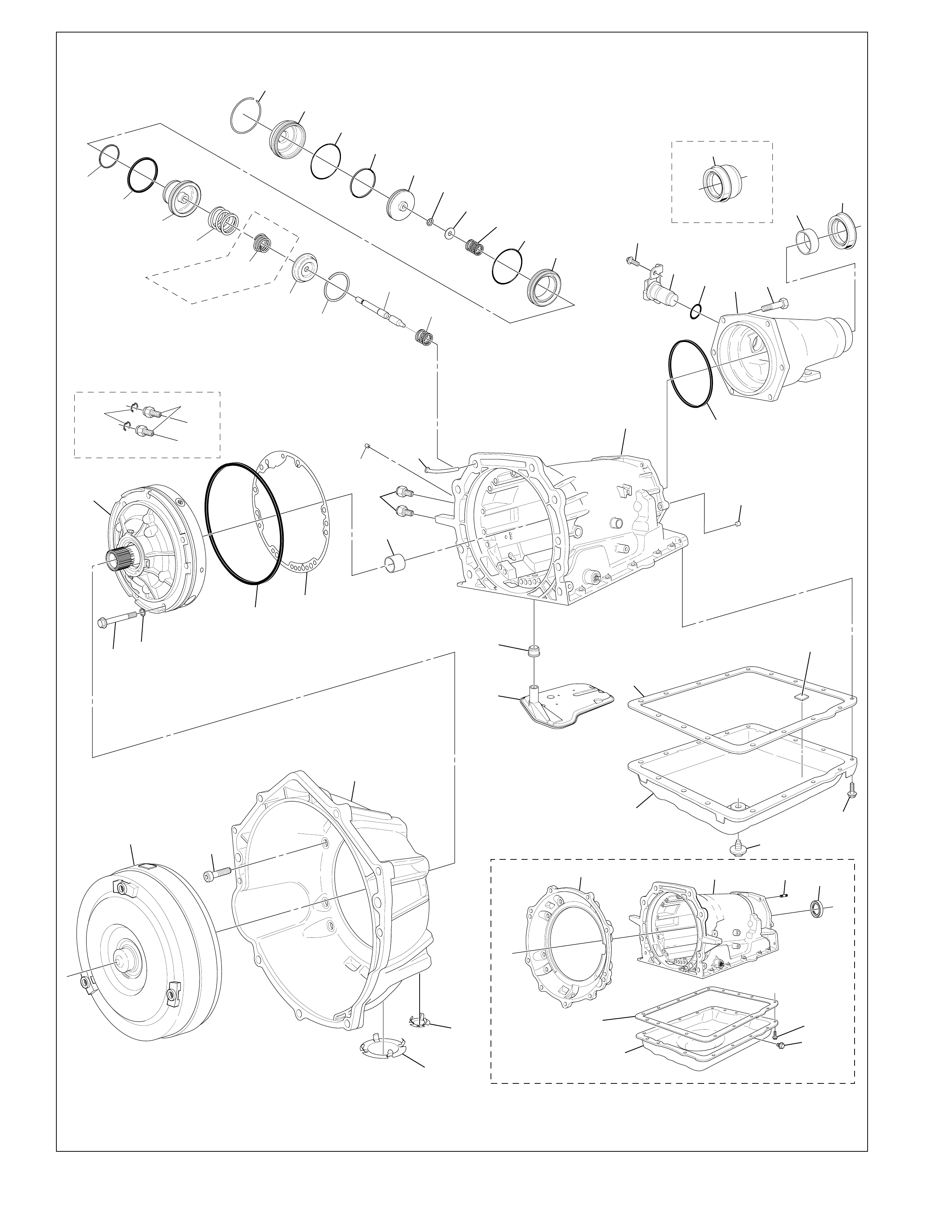

ILLUSTRATED PARTS LIST ................................................................ 101

BASIC SPECIFICATIONS .................................................................... 112

PRODUCT DESIGNATION SYSTEM ................................................... 113

GLOSSARY ........................................................................................ 114

ABBREVIATIONS ............................................................................... 116

INDEX................................................................................................ 117

PREFACE

All information contained in this book is based on the latest data available

at the time of publication approv al. T he right is reserved to mak e product or

publication changes, at any time, without notice.

No part of any GM Powertrain publication may be reproduced, stored

in any retrieval system or transmitted in any form or by any means,

including but not limited to electronic, mechanical, photocopying,

recording or otherwise, without the prior written permission of

Powertrain Group of General Motors Corporation. This includes all

text, illustrations, tables and charts.

© COPYRIGHT 2000 POWERTRAIN GROUP

General Motors Corporation

ALL RIGHTS RESERVED

The Hydra-matic 4L60-E Technician’s Guide is intended for automotive

technicians that are familiar with the operation of an automatic transaxle or

transmission. Technicians or other persons not having automatic transaxle

or transmission know-how may find this publication somewhat technically

complex if additional instruction is not provided. Since the intent of this

book is to explain the fundamental mechanical, hydraulic and electrical

operating principles, technical terms used herein are specific to the

transmission industry. However, words commonly associated with the

specific transaxle or transmission function have been defined in a Glossary

rather than within the text of this book.

The Hydra-matic 4L60-E Technician’s Guide is also intended to assist

technicians during the service, diagnosis and repair of this transaxle.

However, this book is not intended to be a substitute for other General

Motors service publications that are normally used on the job. Since there

is a wide range of repair procedures and technical specifications specific to

certain vehicles and transmission models, the proper service publication

must be referred to when servicing the Hydra-matic 4L60-E transmission.

1

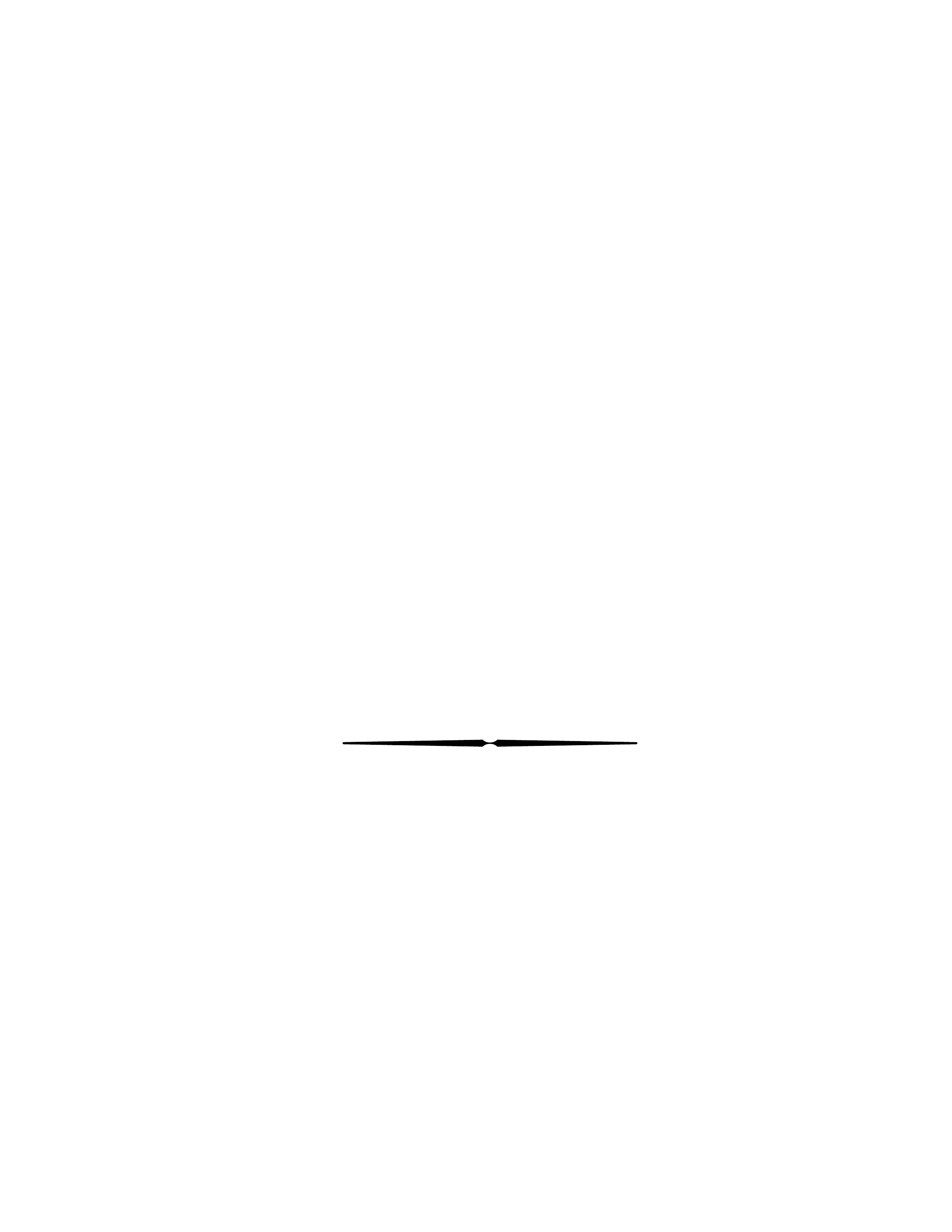

The Hydra-matic 4L60-E Technician’s Guide is

another Po wertrain publication from the Technician’s

Guide series of books. The purpose of this

publication, as is the case with other Technician’s

Guides, is to provide complete information on the

theoretical operating characteristics of this

transmission. Operational theories of the mechanical,

hydraulic and electrical components are presented in

a sequential and functional order to better explain

their operation as part of the system.

In the first section of this book entitled “Principles

of Operation”, exacting explanations of the major

components and their functions are presented. In

every situation possible, text describes component

operation during the apply and release cyc le as well

as situations where it has no effect at all. The

descriptive text is then supported by numerous

graphic illustrations to further emphasize the

operational theories presented.

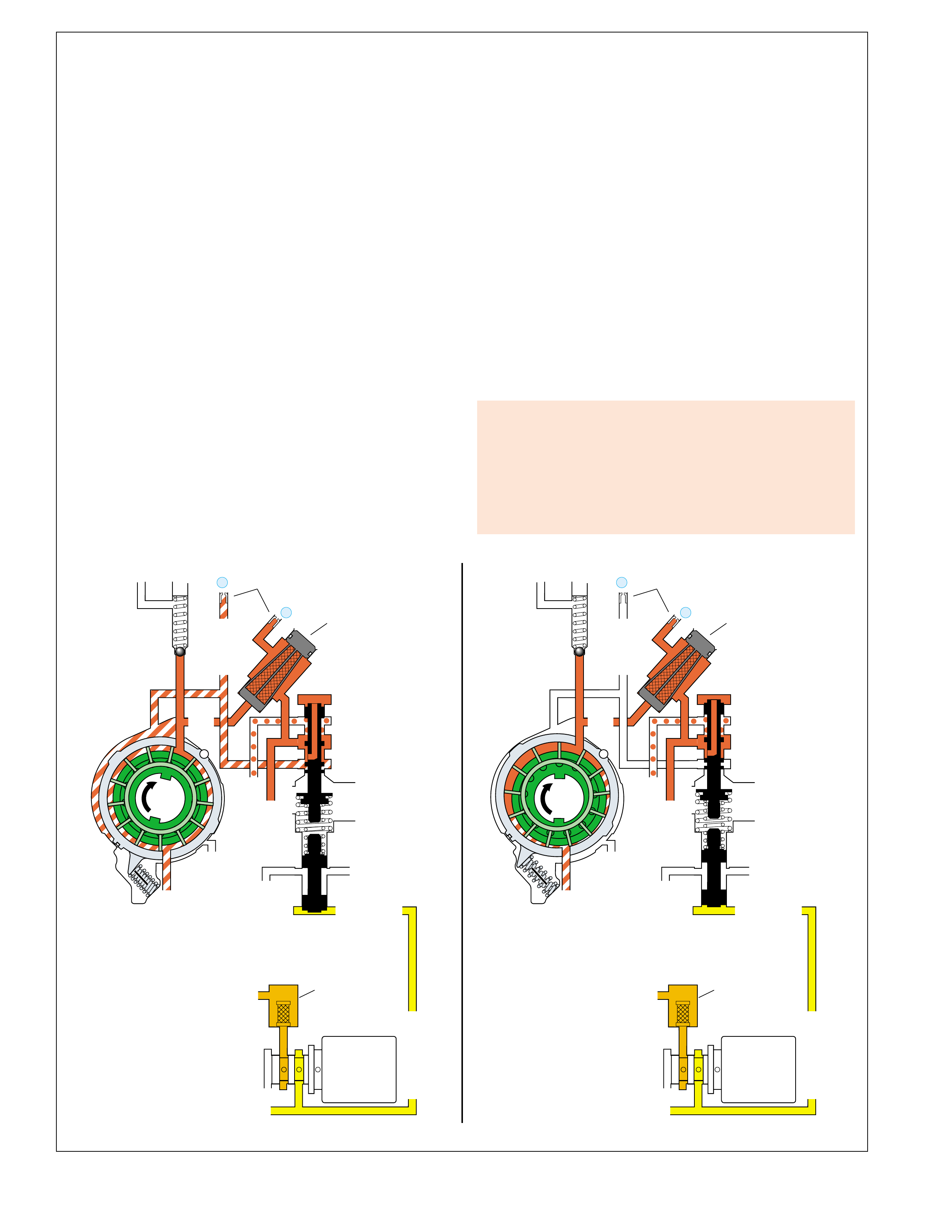

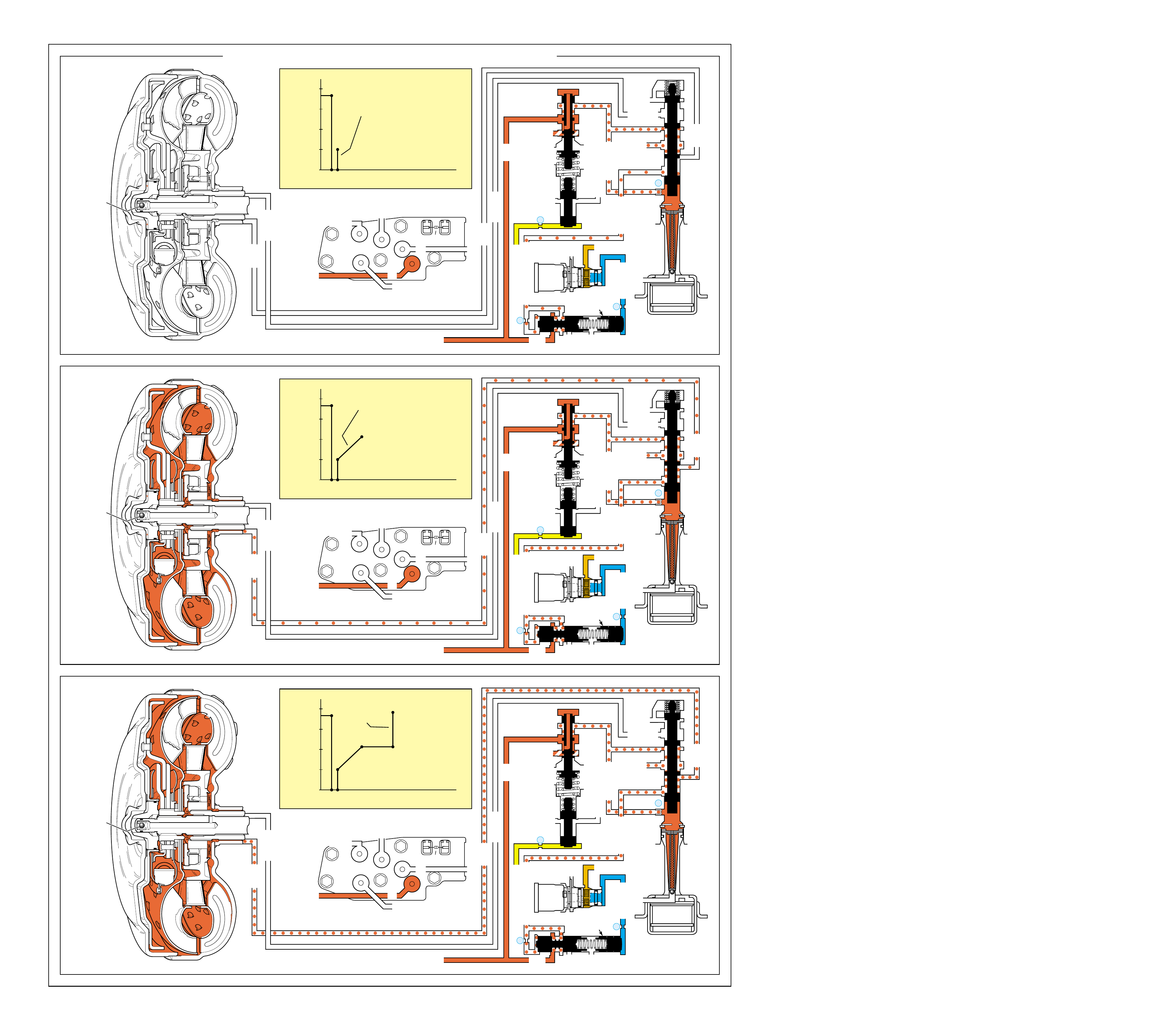

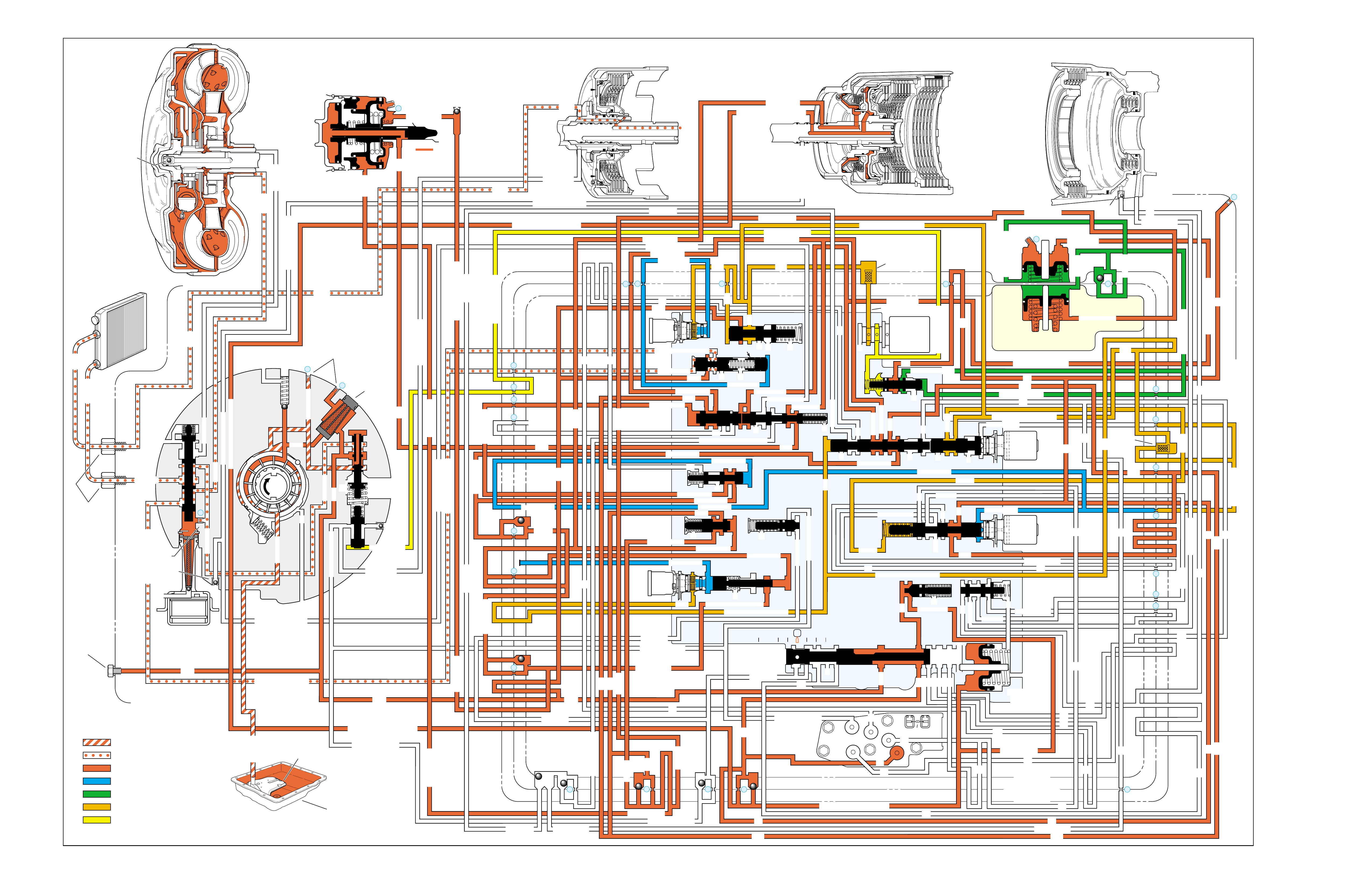

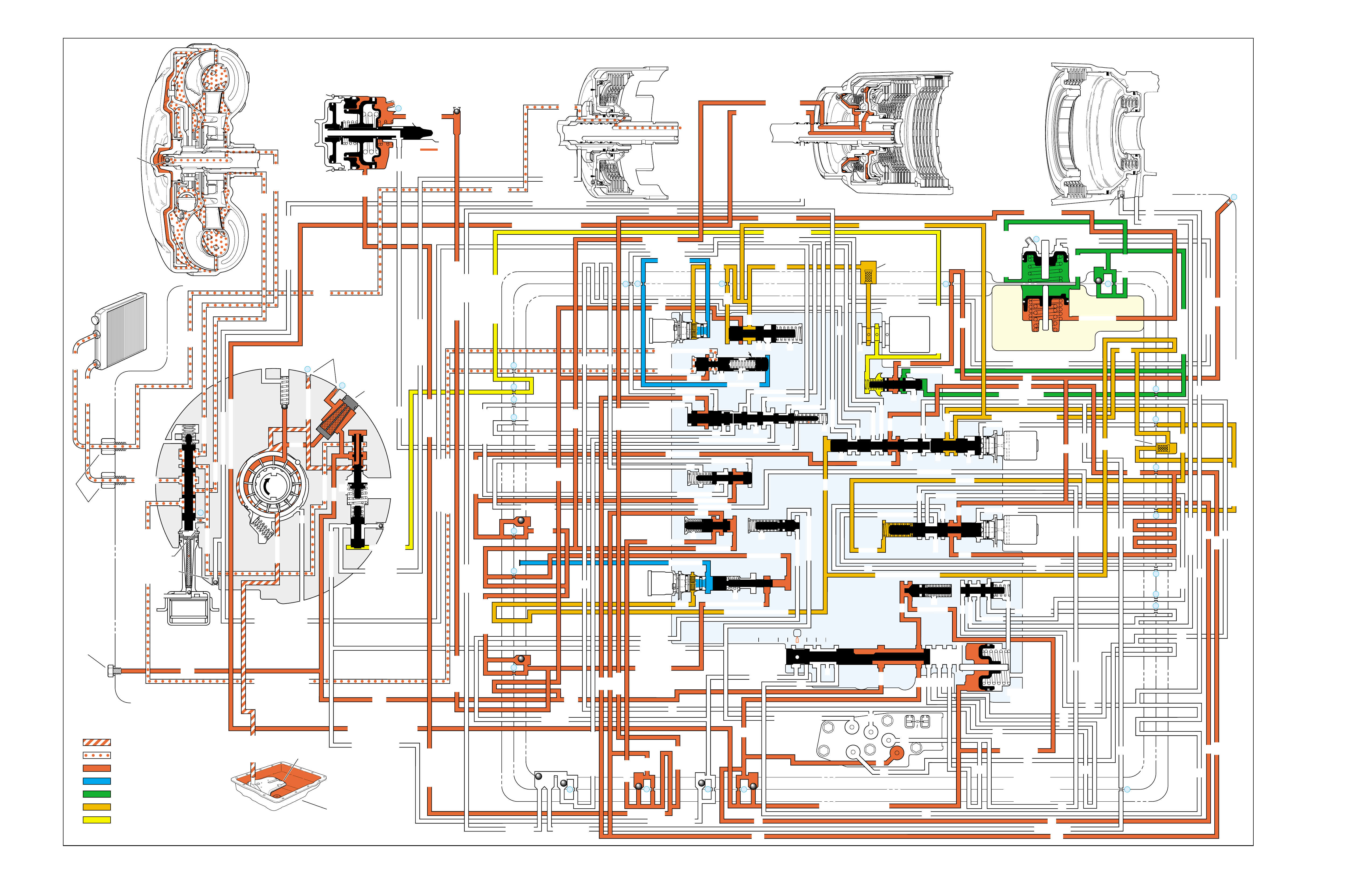

The second major section entitled “Power Flow”,

blends the information presented in the “Principles

of Operation” section into the complete transmission

assembly. The transfer of torque from the engine

through the transmission is graphically displayed on

a full page while a narrative description is provided

on a facing half page. The opposite side of the half

page contains the narrative description of the

hydraulic fluid as it applies components or shifts

valves in the system. Facing this partial page is a

hydraulic schematic that sho ws the position of v alv es,

ball check valves, etc ., as they function in a specific

gear range.

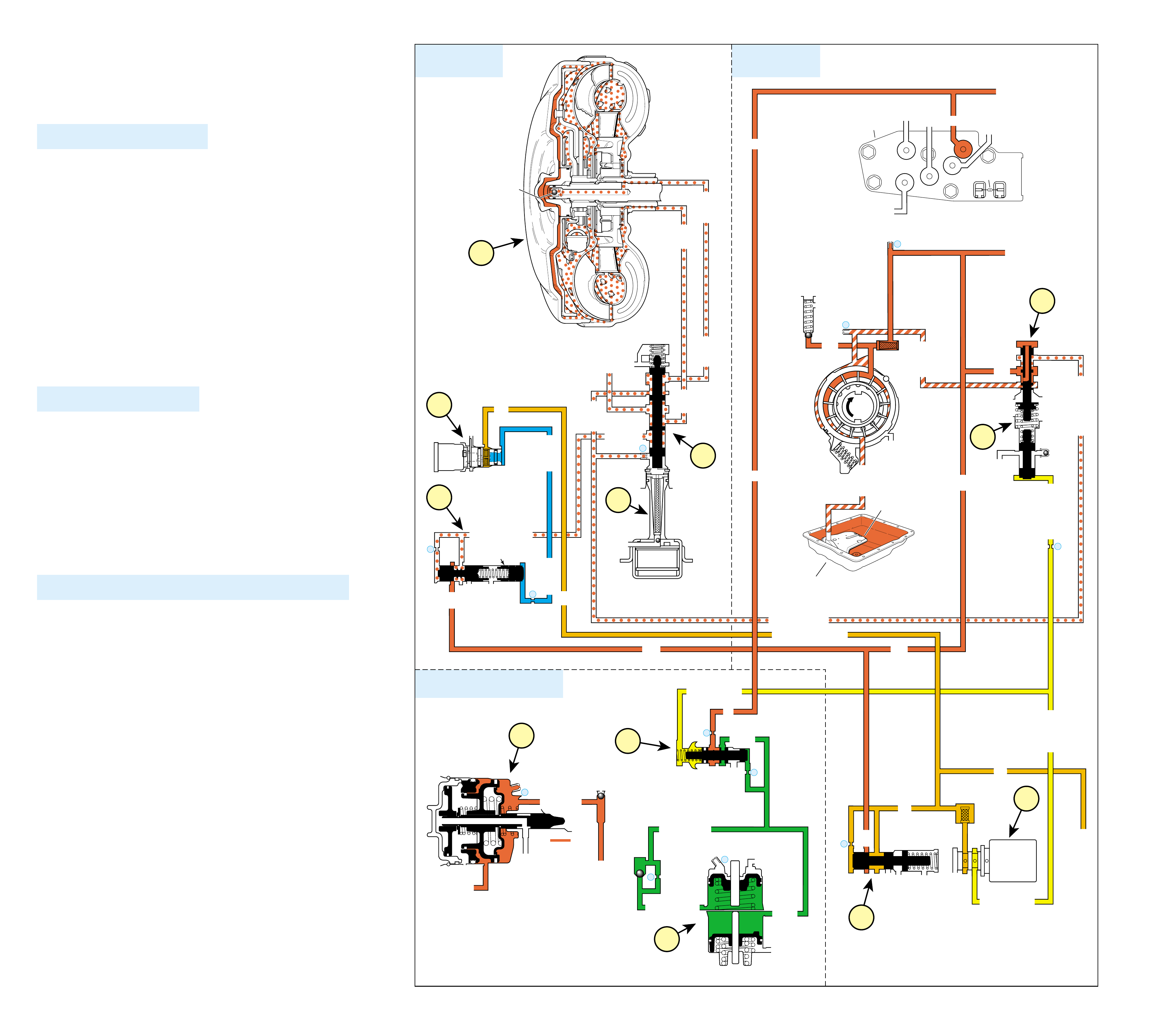

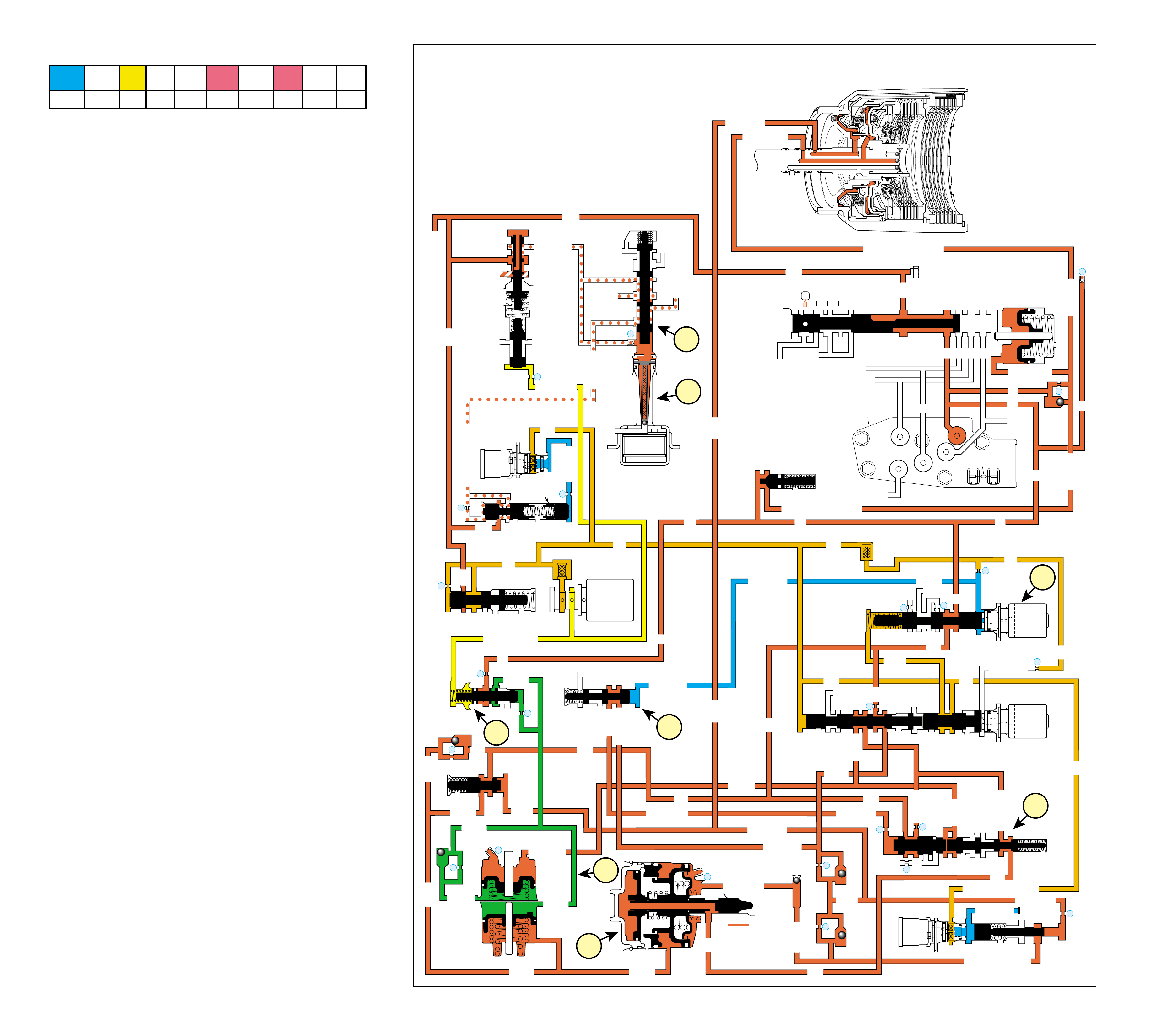

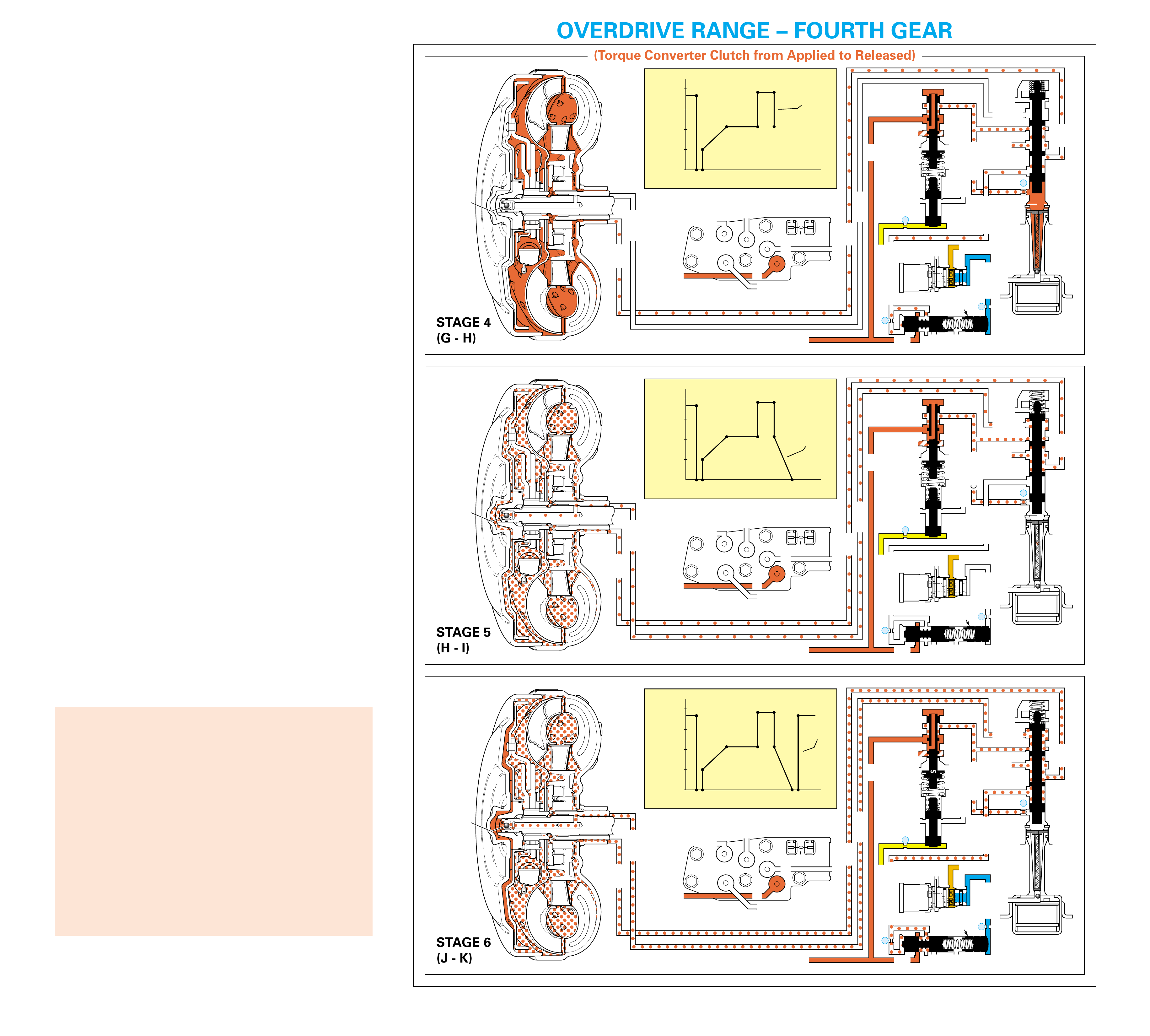

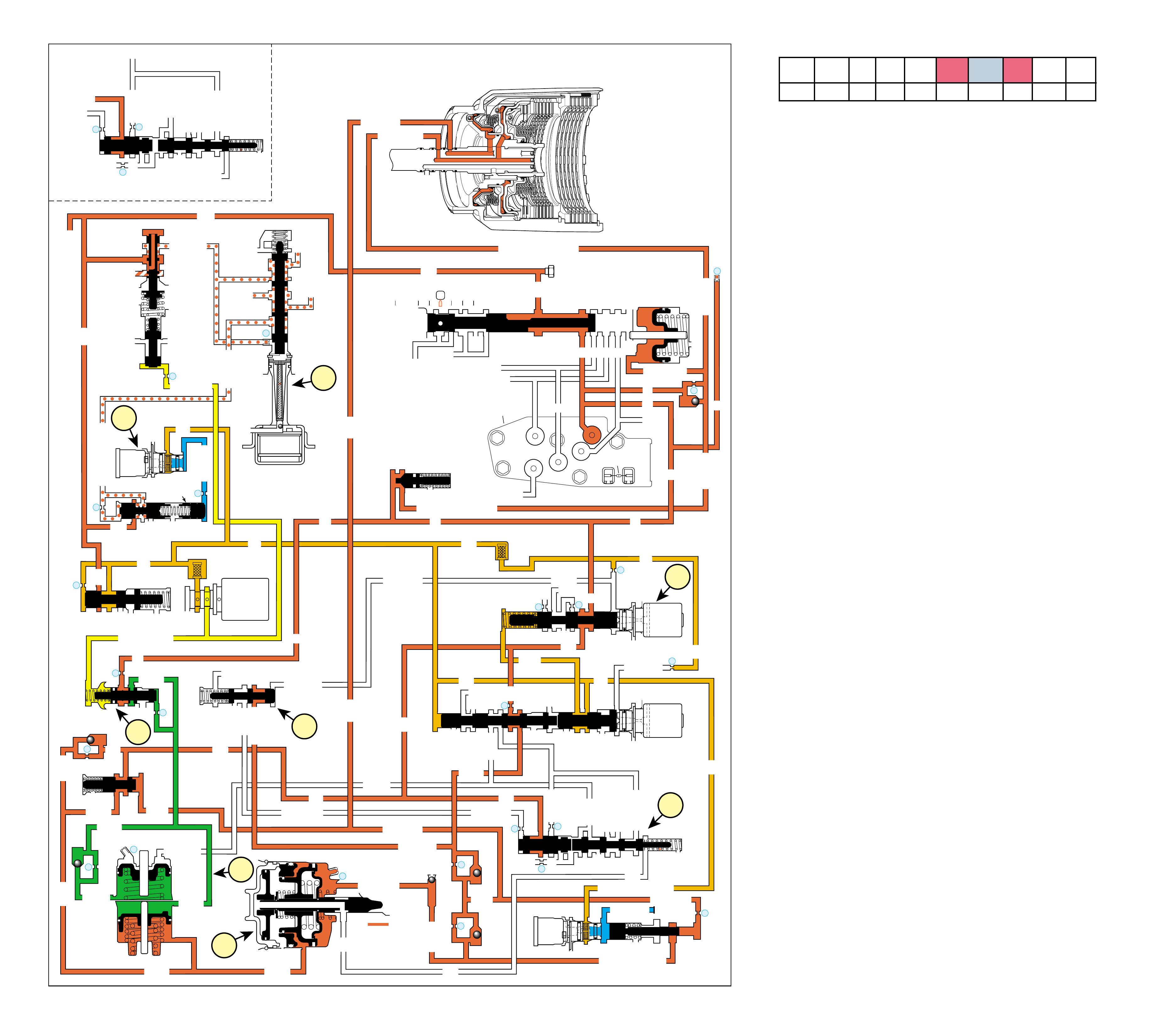

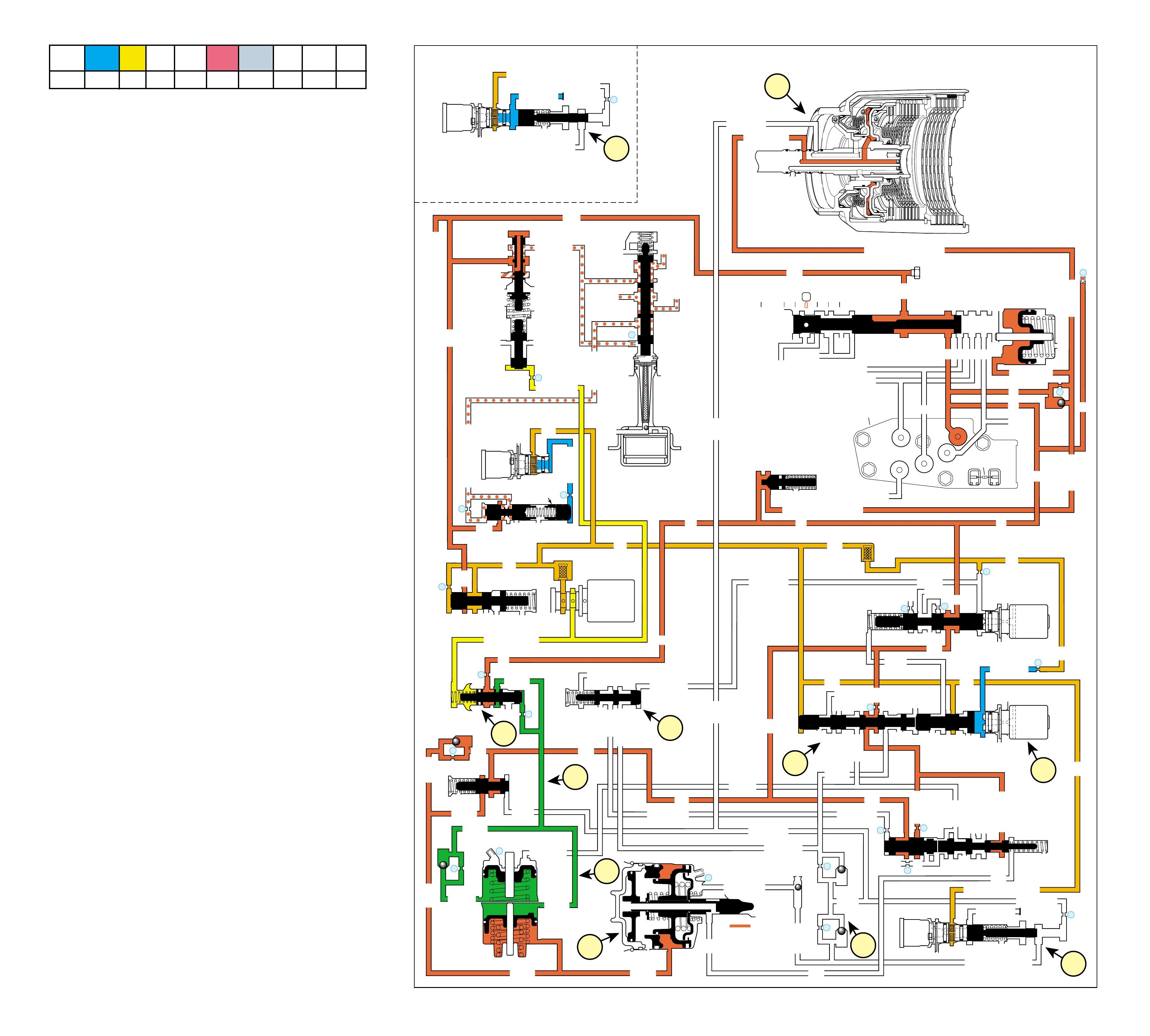

The third major section of this book displays the

“Complete Hydraulic Circuit” for specific gear

ranges. Foldout pages containing fluid flow

schematics and two dimensional illustra tions of major

components graphically display hydraulic circuits.

This information is extremely useful when tracing

fluid circuits for learning or diagnosis purposes.

The “Appendix” section of this book provides

additional transmission information regarding

lubrication circuits, seal locations, illustrated parts

lists and more. Although this information is available

in current model year Service Manuals, its inclusion

provides for a quick reference guide that is useful to

the technician.

Production of the Hydra-matic 4L60-E Technician’s

Guide was made possible through the combined efforts

of many staf f areas within the General Motors Powertrain

Group. As a result, the Hydra-matic 4L60-E Technician’s

Guide was written to provide the user with the most

current, concise and usable information available

reg arding this pr oduct.

3

INTRODUCTION

HOW TO USE THIS BOOK

specific fluid circuits that enable the mechanical

components to operate. The mechanical power

flow is graphically displayed on a full size page

and is followed b y a half page of descripti ve te xt.

The opposite side of the half page contains the

narrative description of the hydraulic fluid as it

applies components or moves valves in the system.

Facing this partial page is a hydr aulic schematic

which shows the position of valves, ball check

valves, etc., as they function in a specific gear

range. Also, located at the bottom of each half

page is a reference to the Complete Hydraulic

Circuit section that follows.

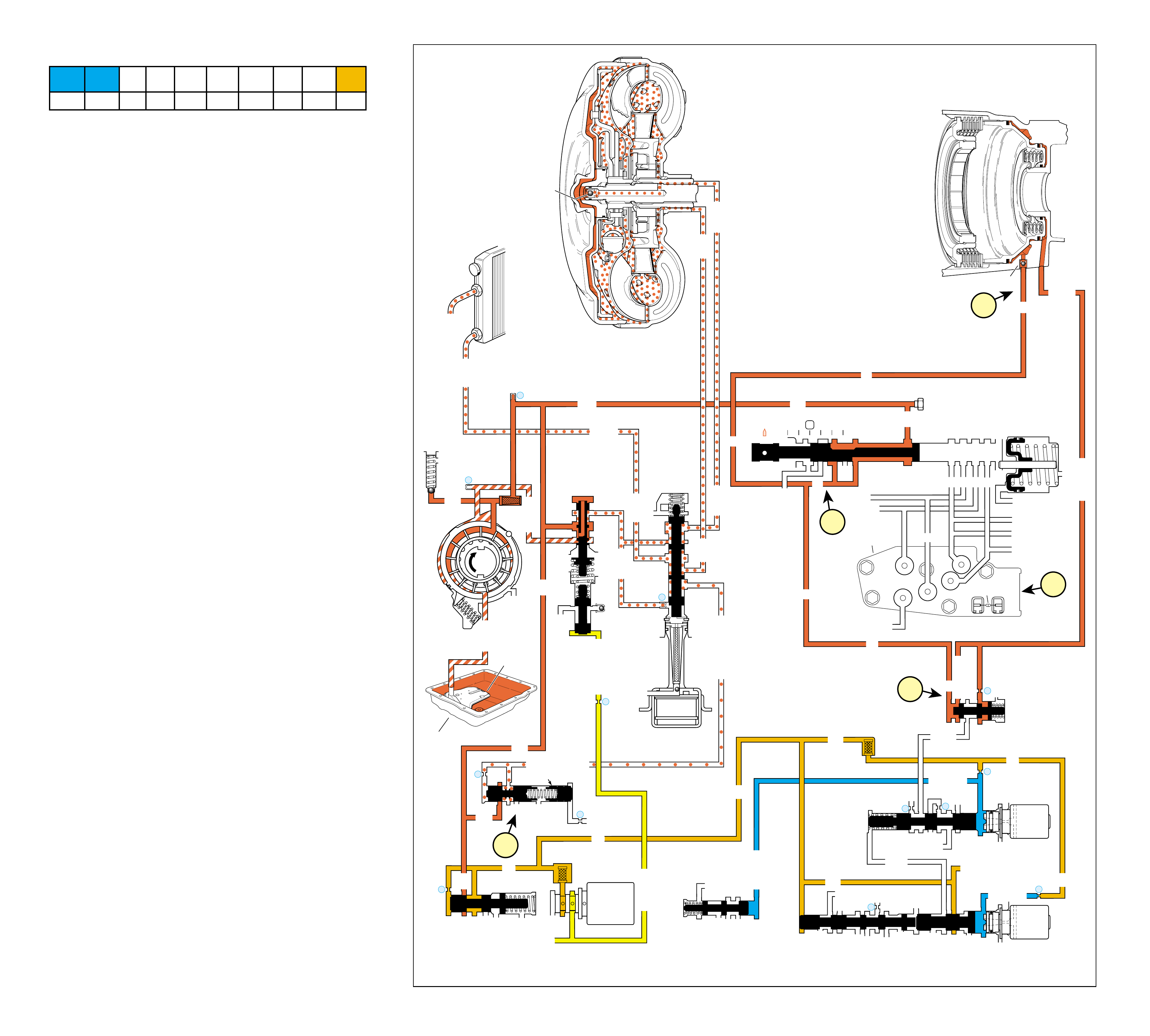

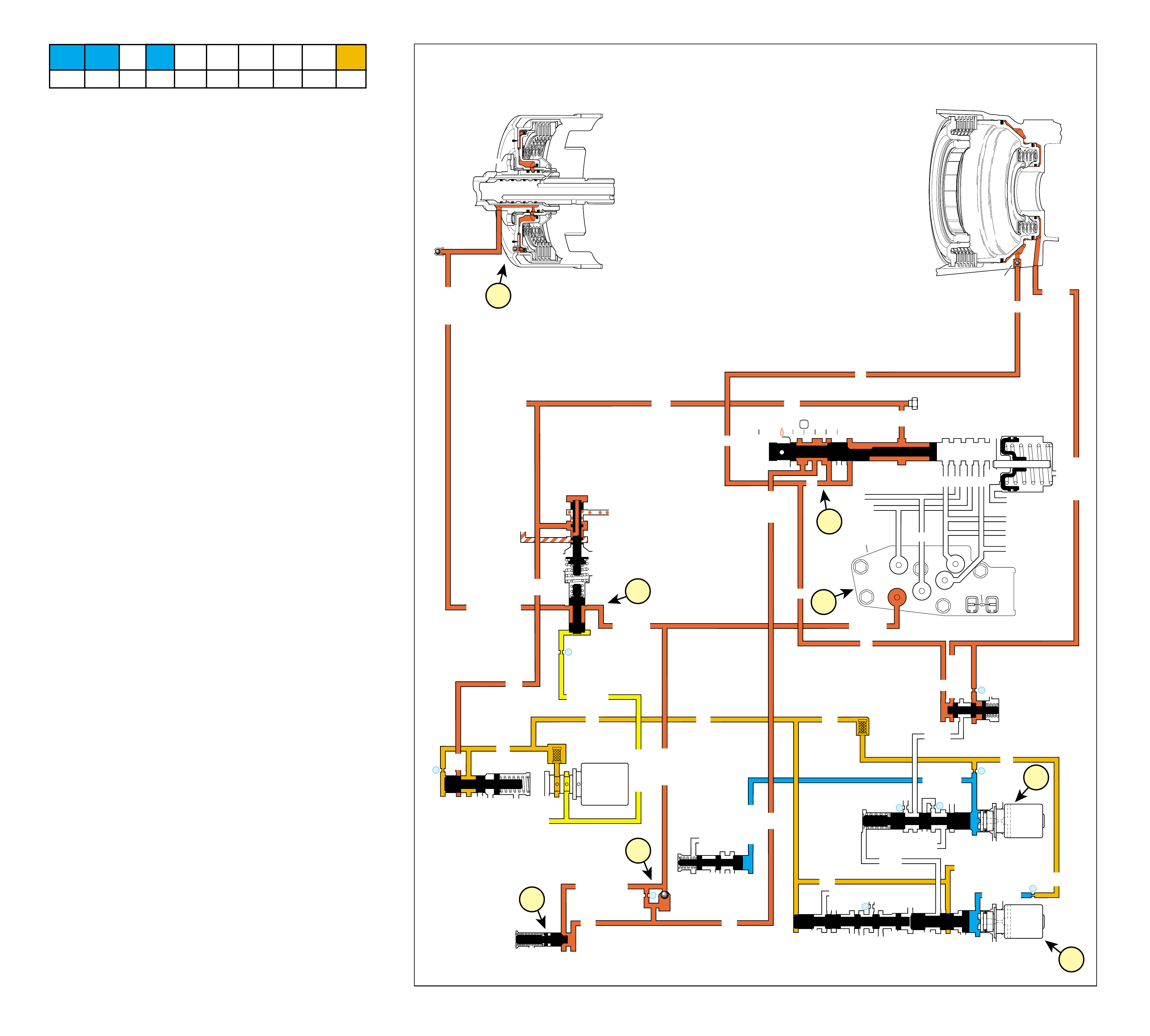

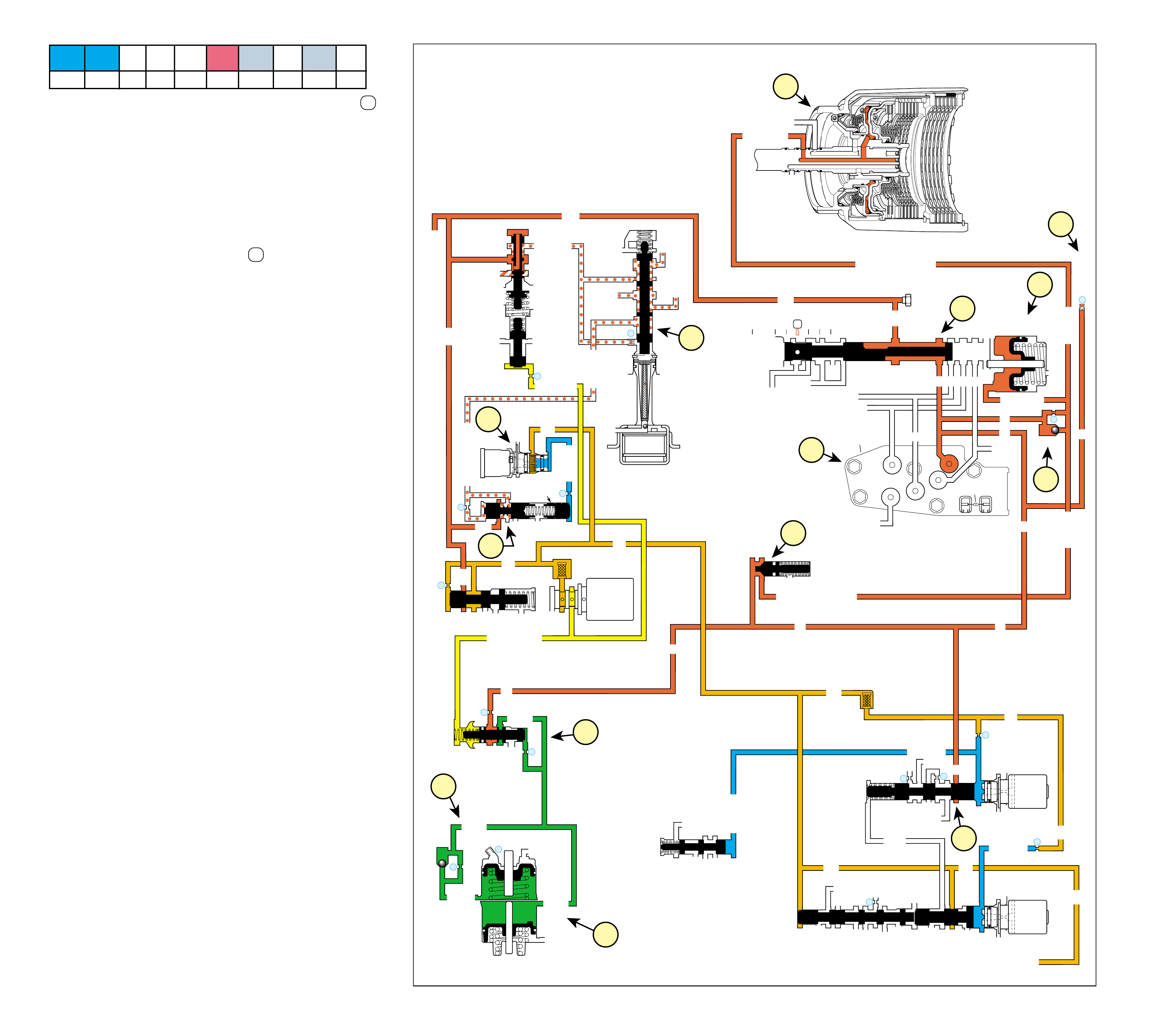

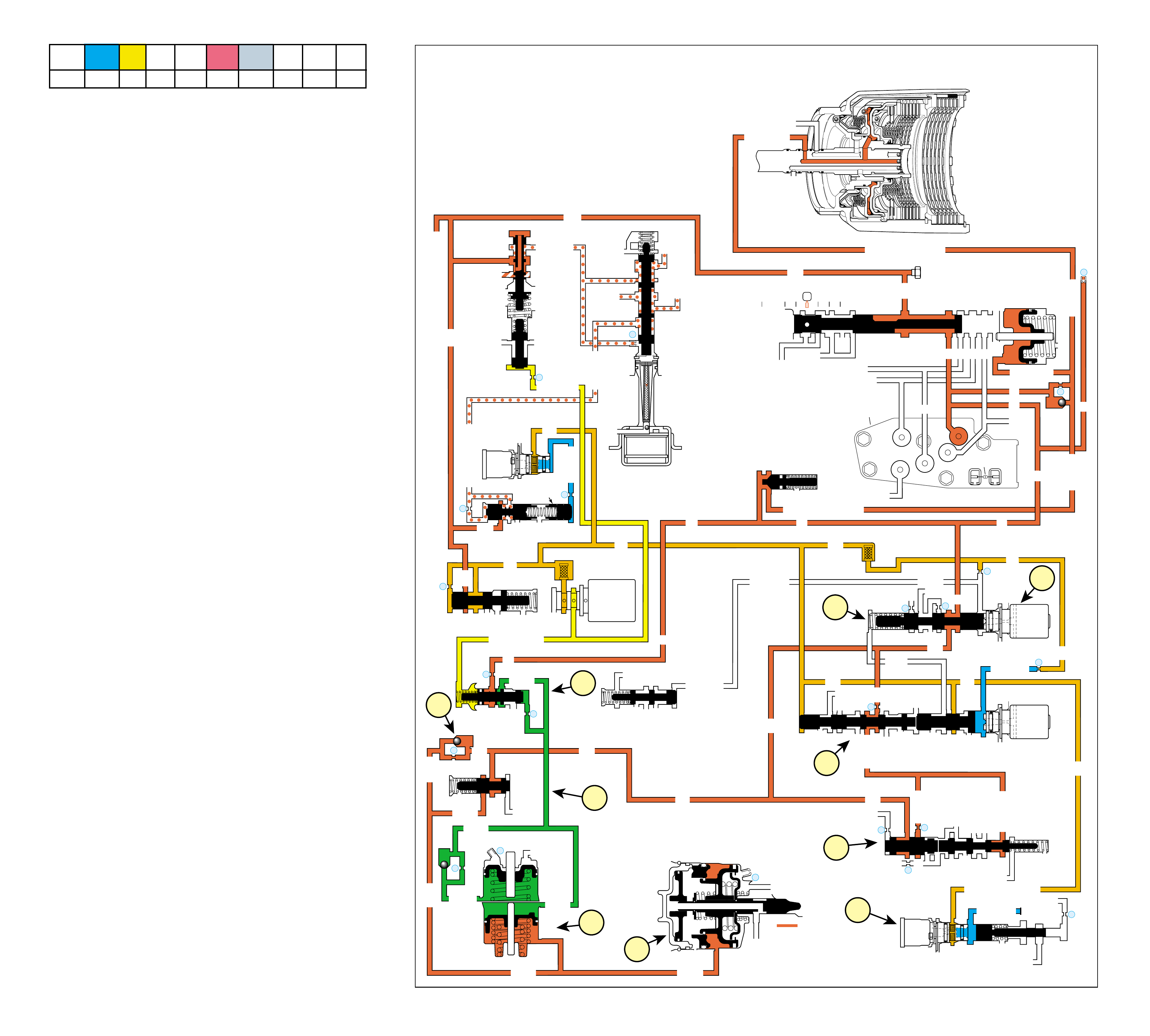

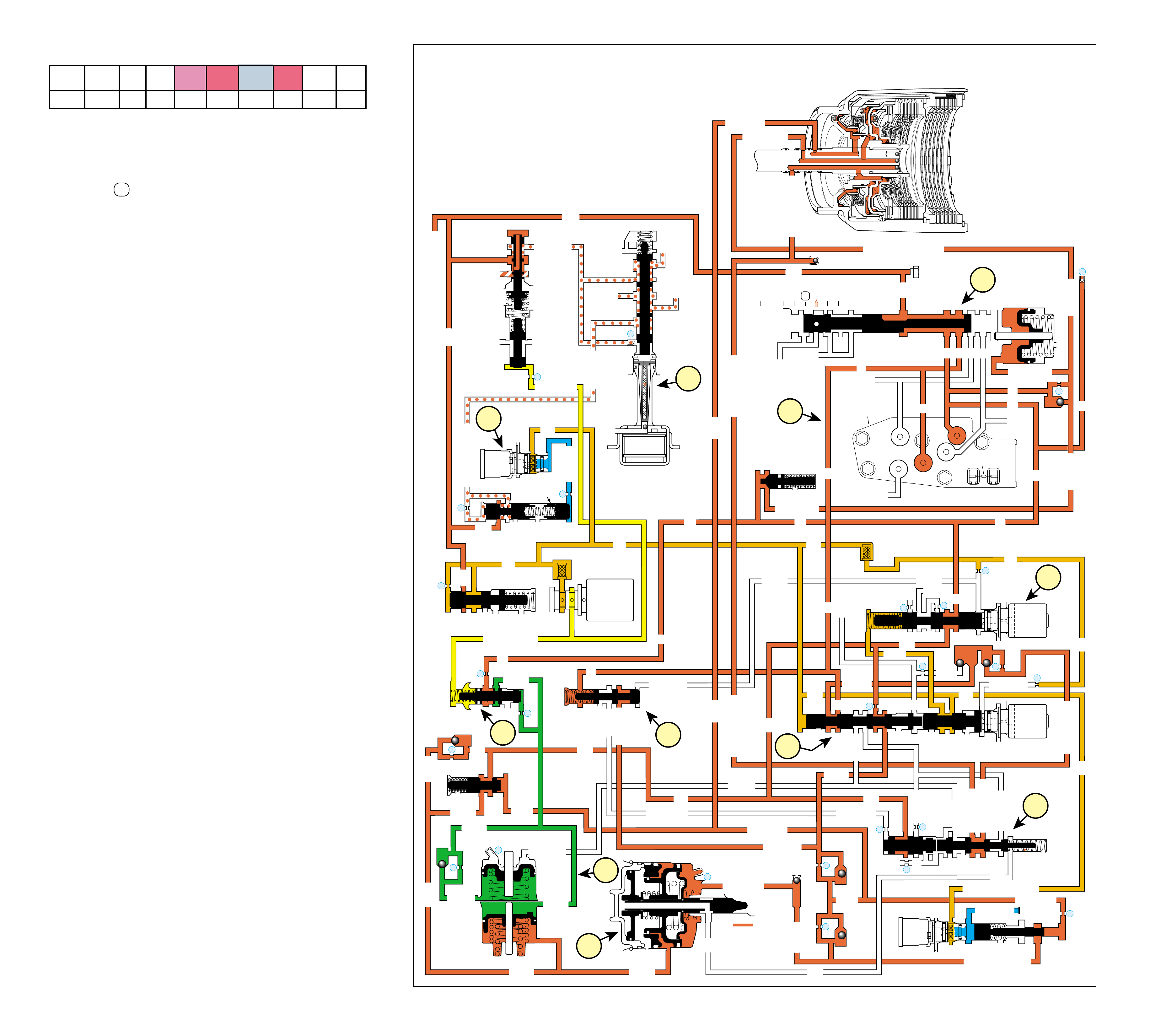

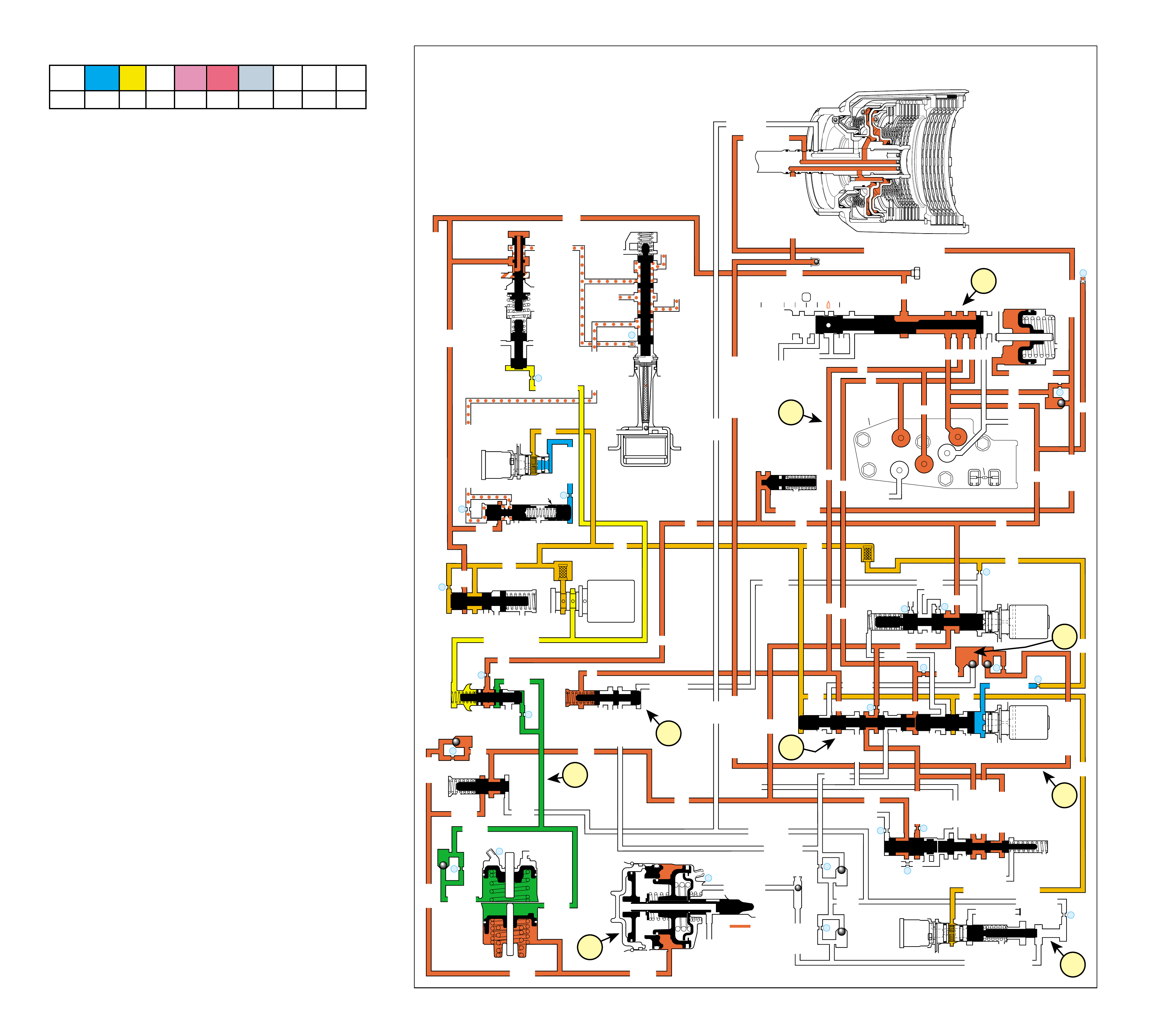

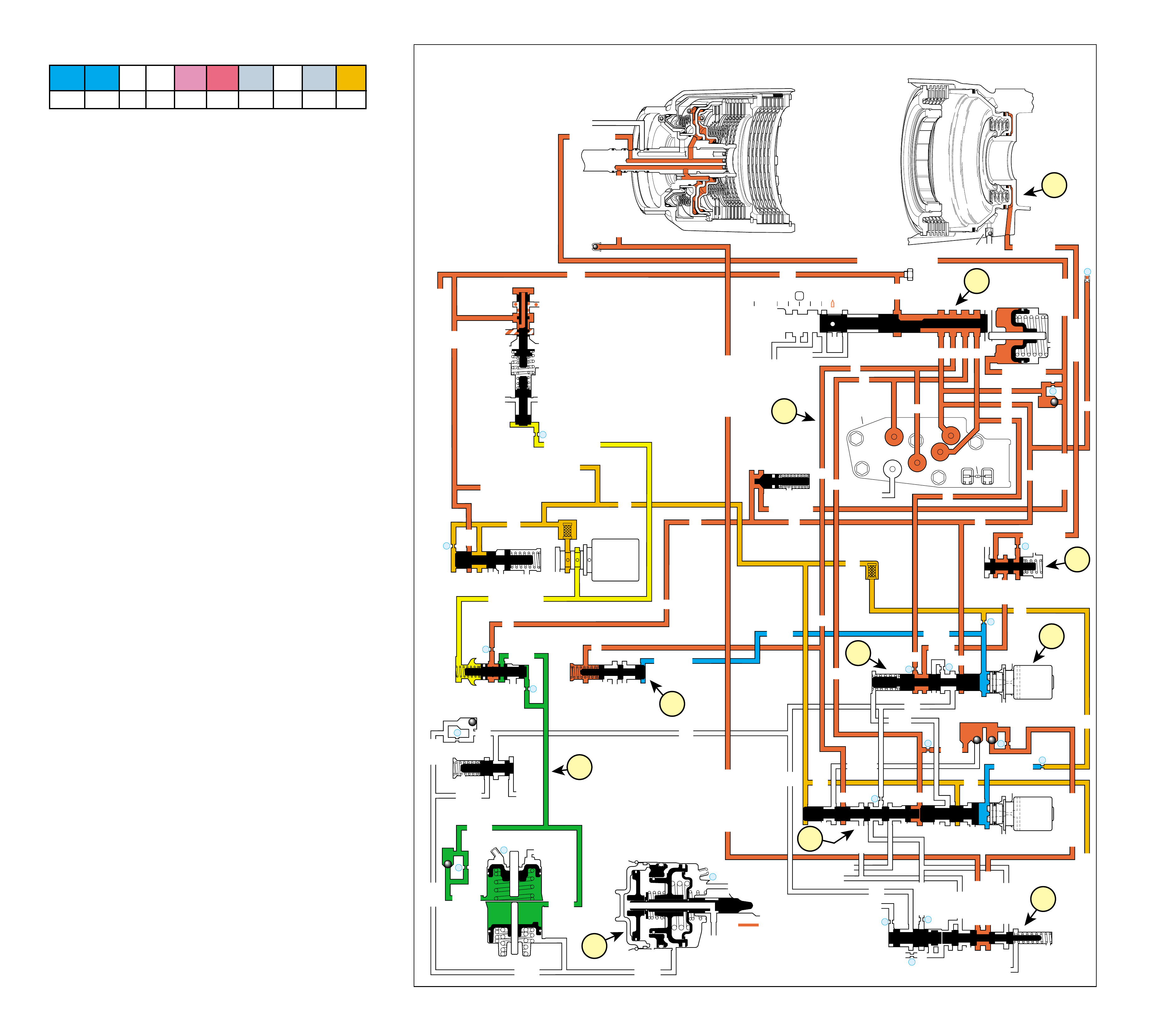

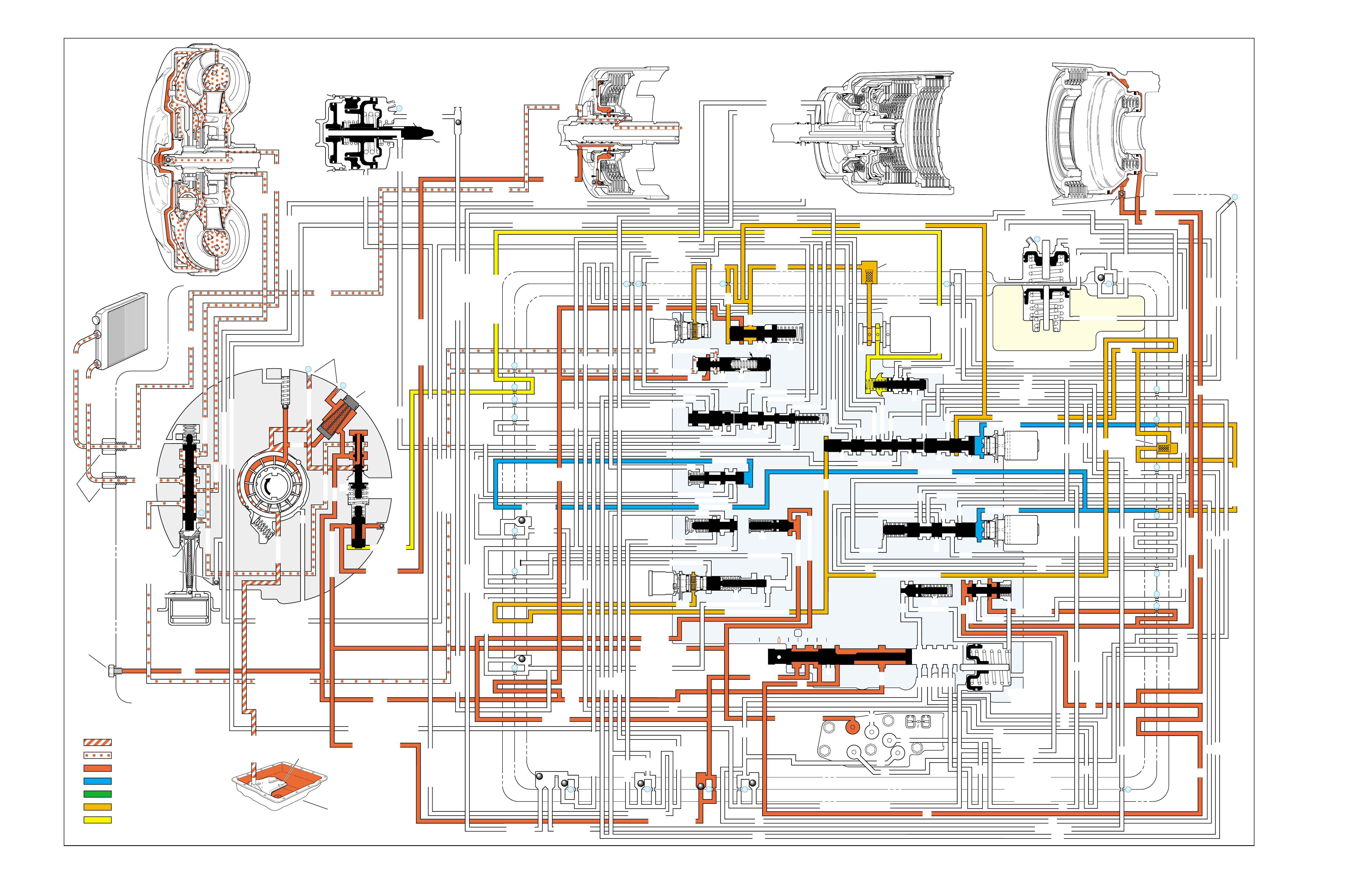

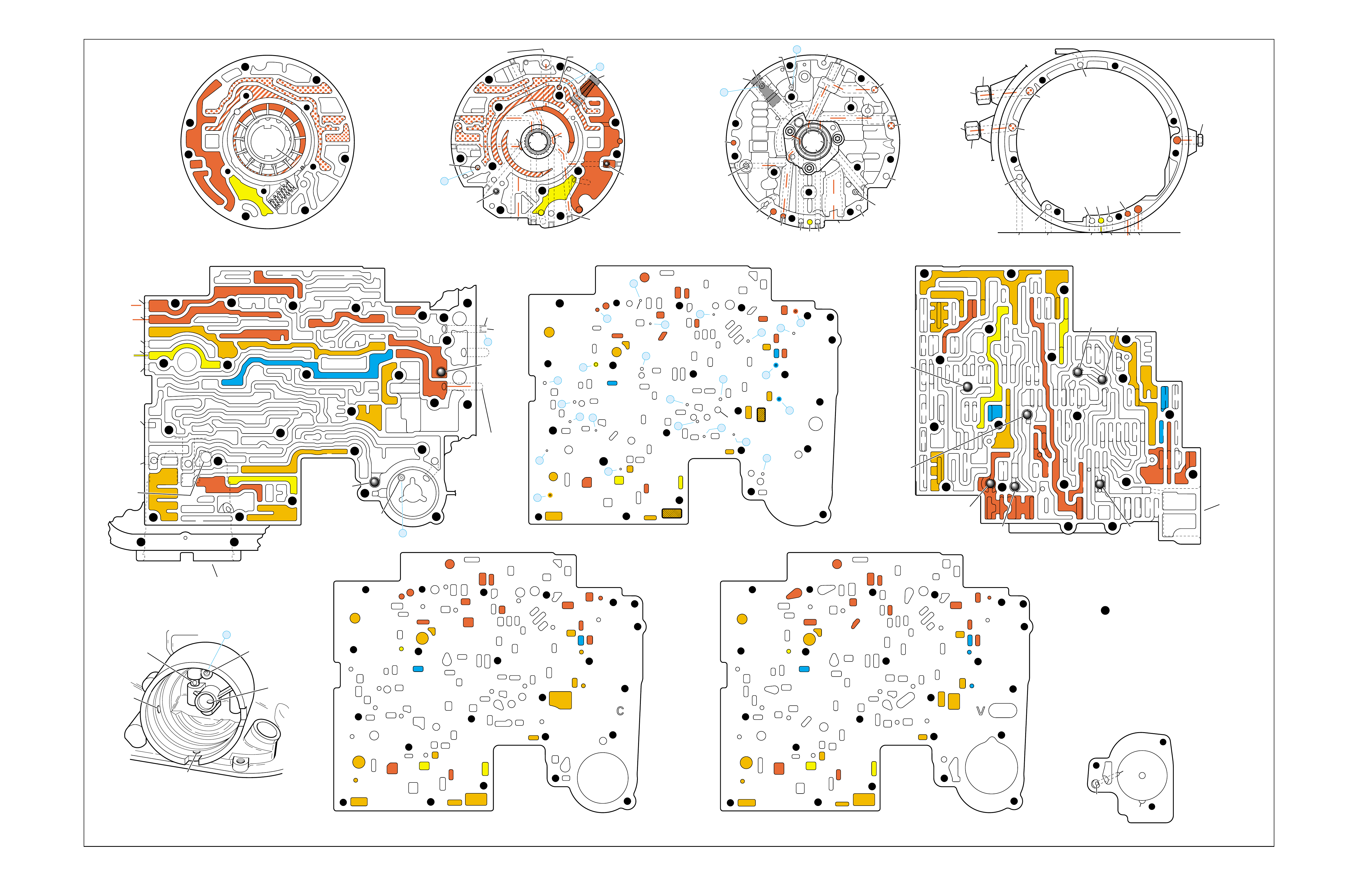

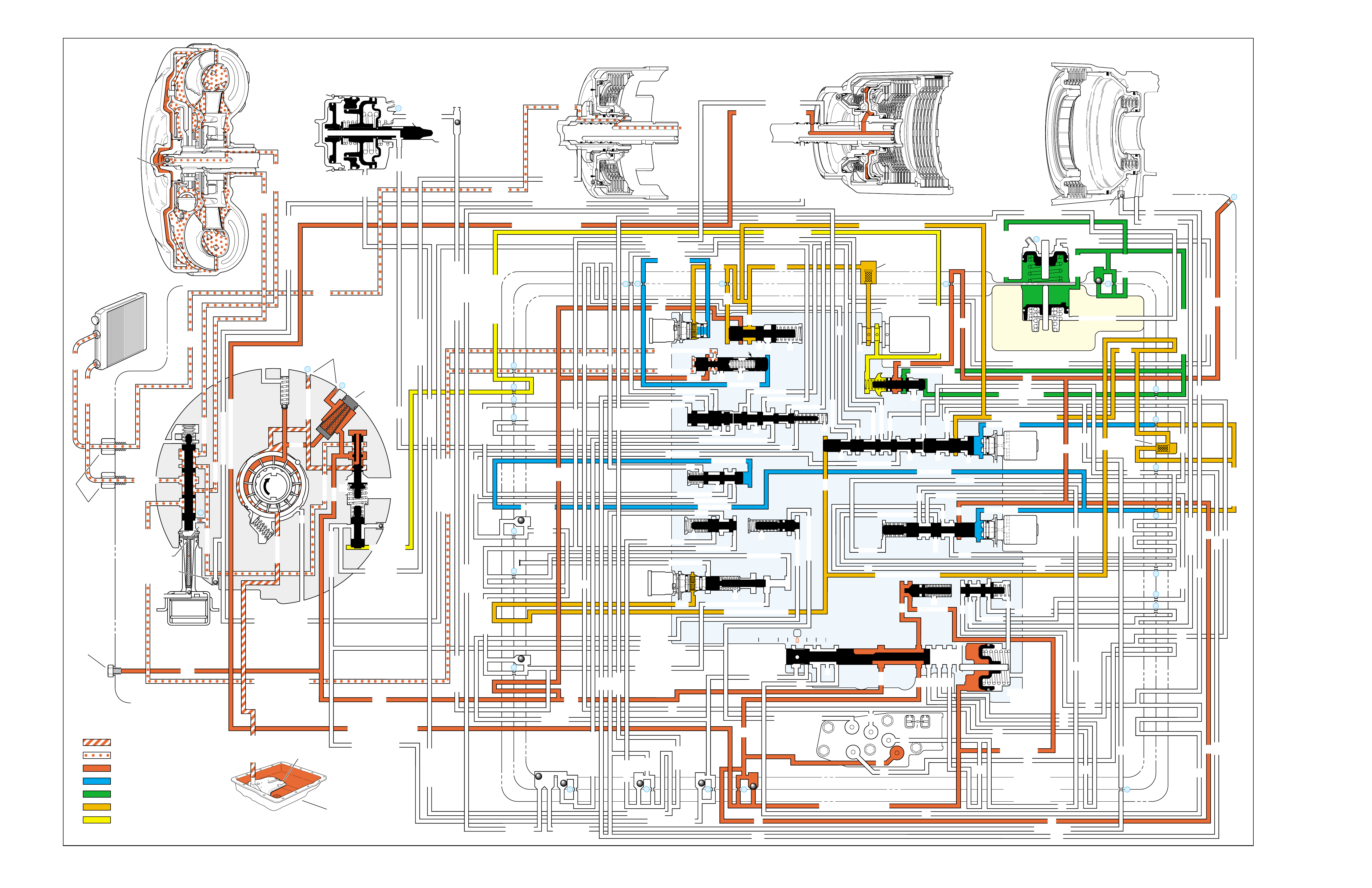

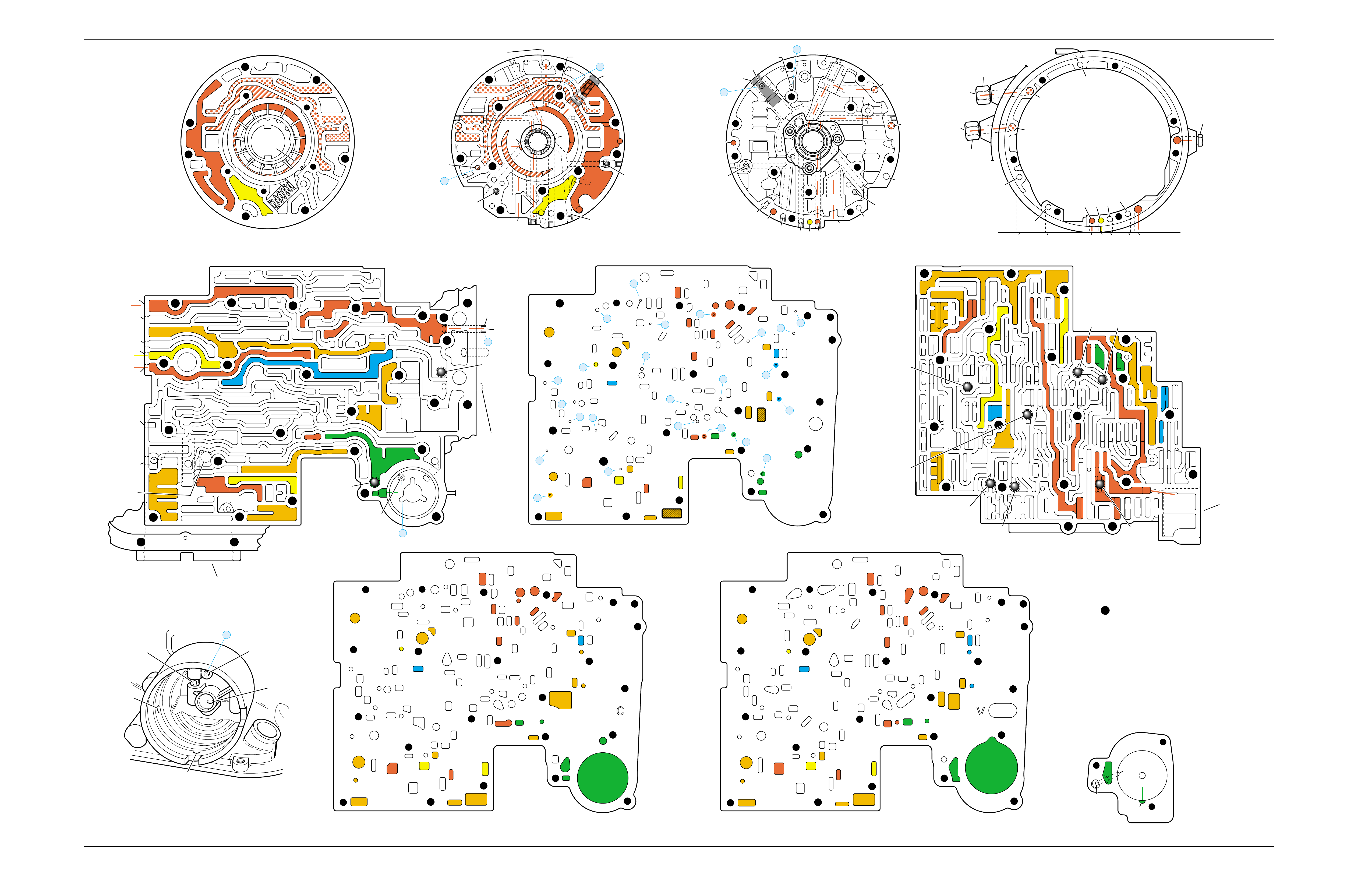

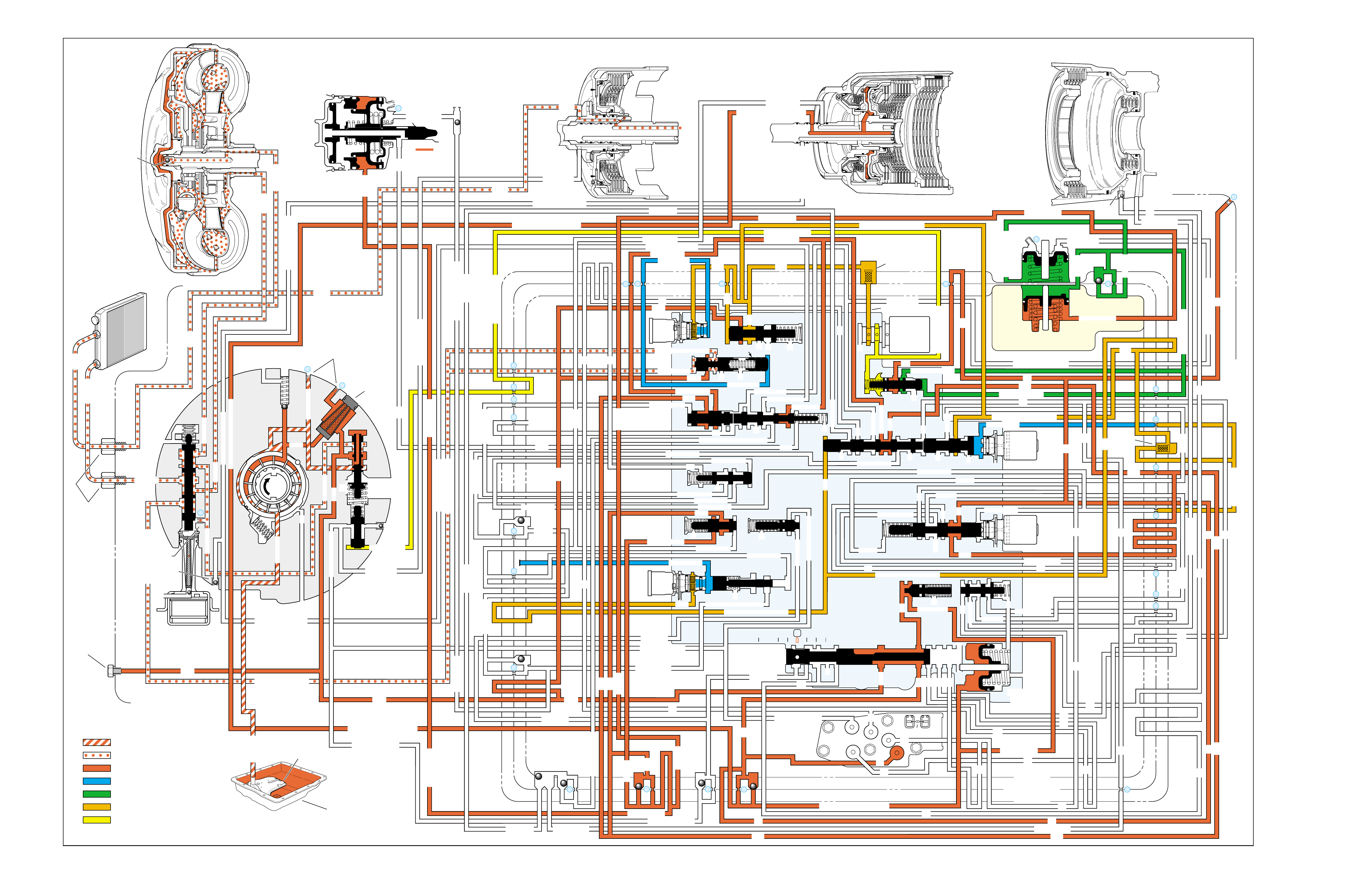

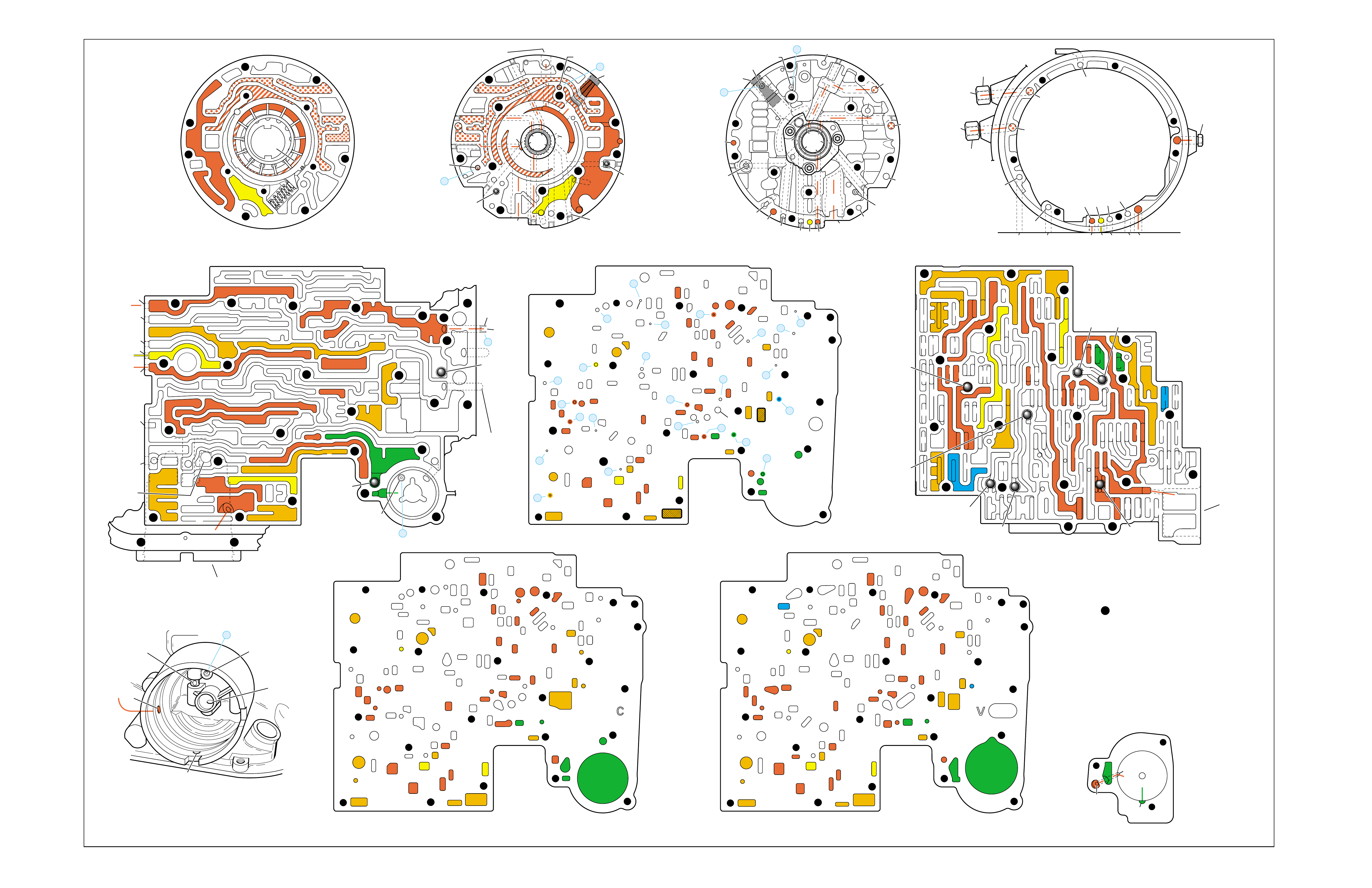

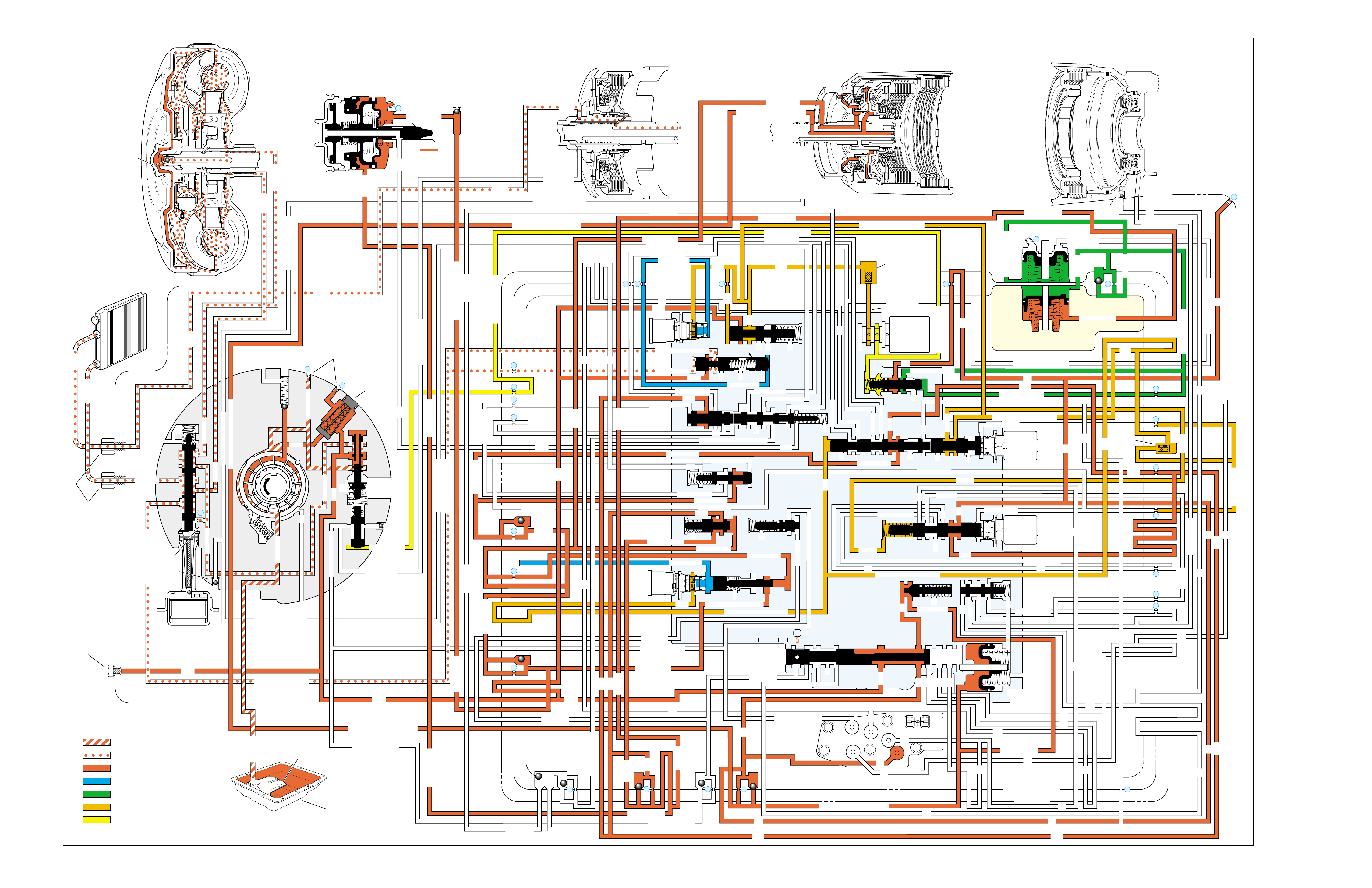

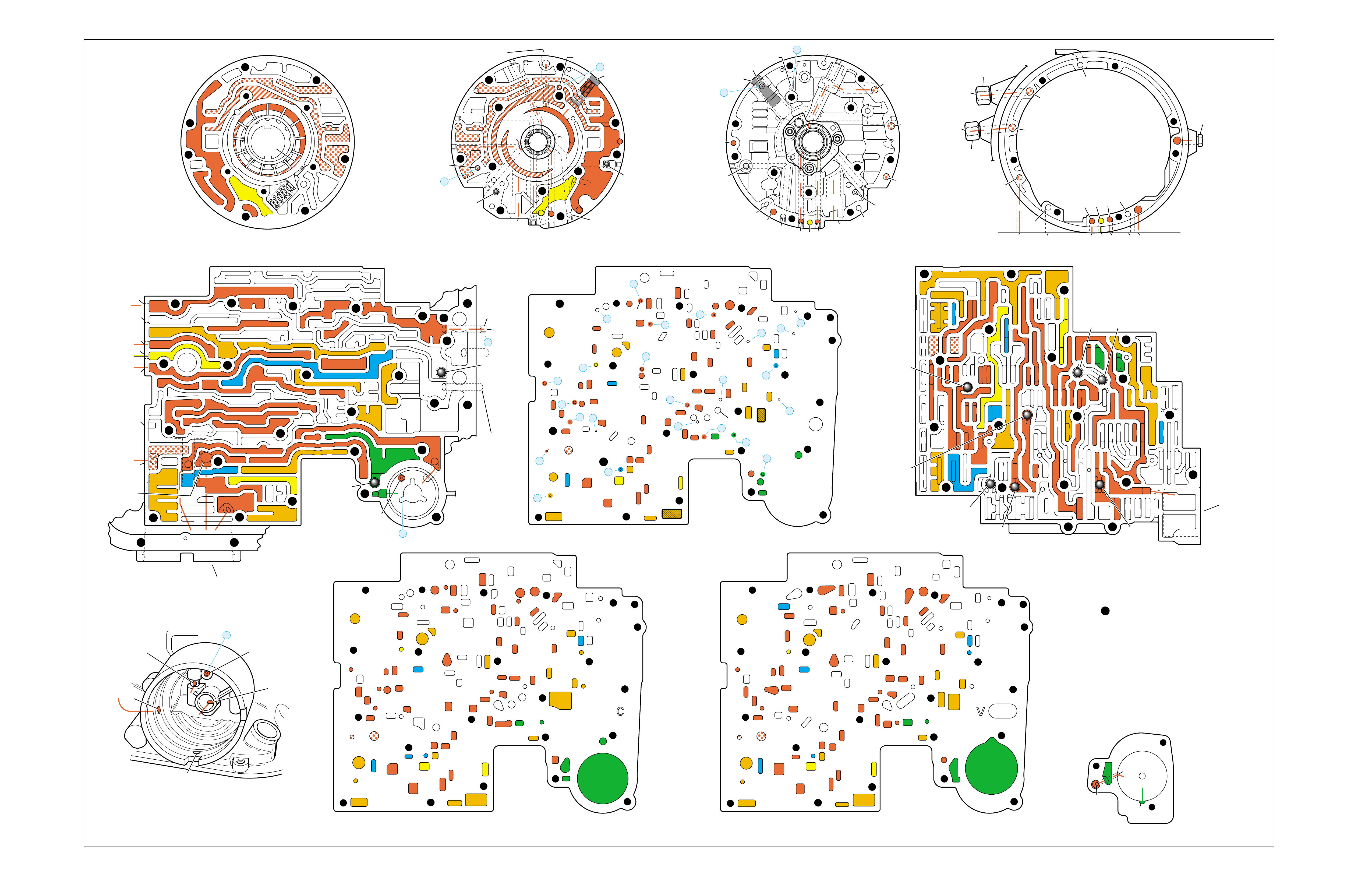

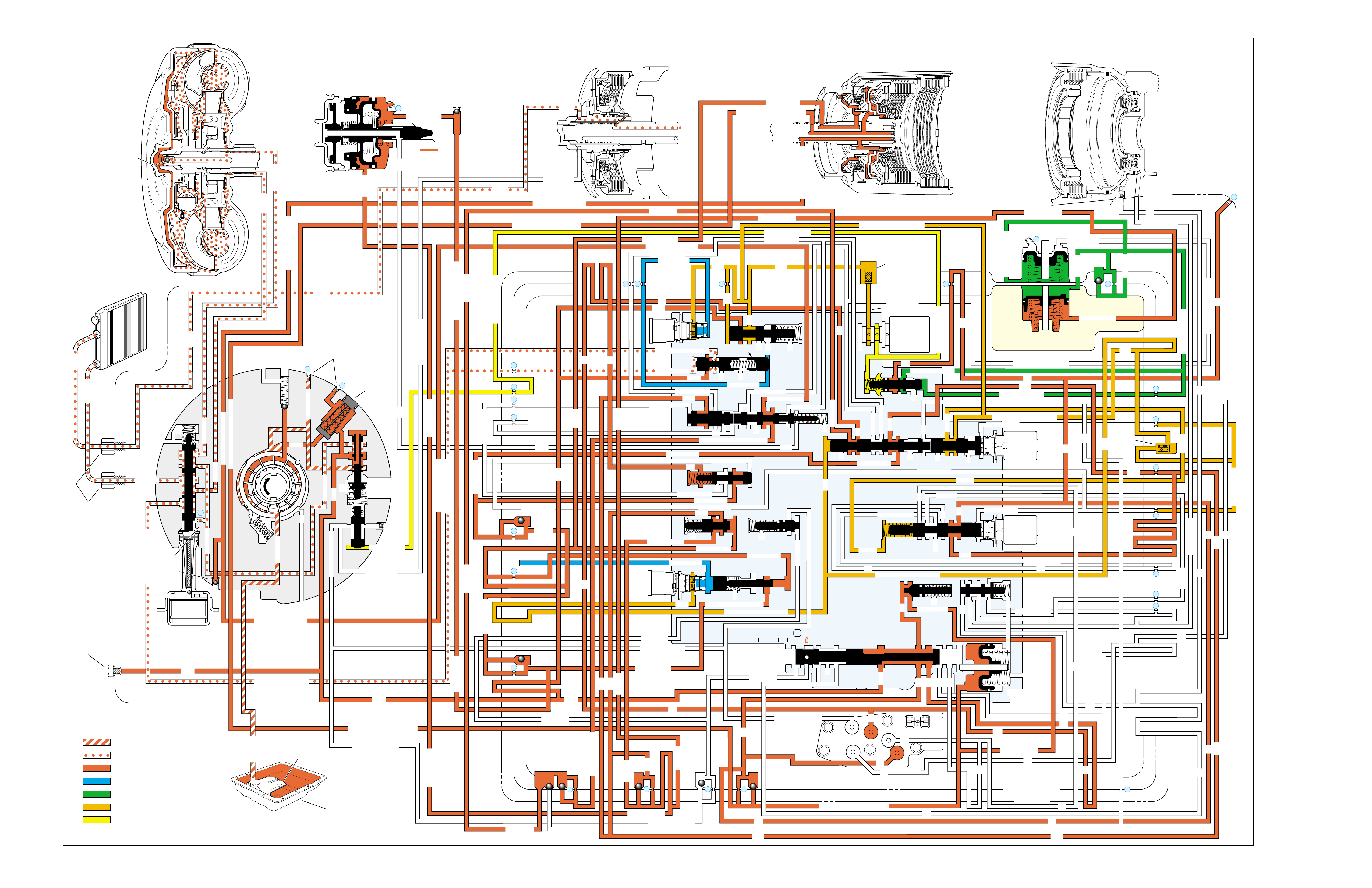

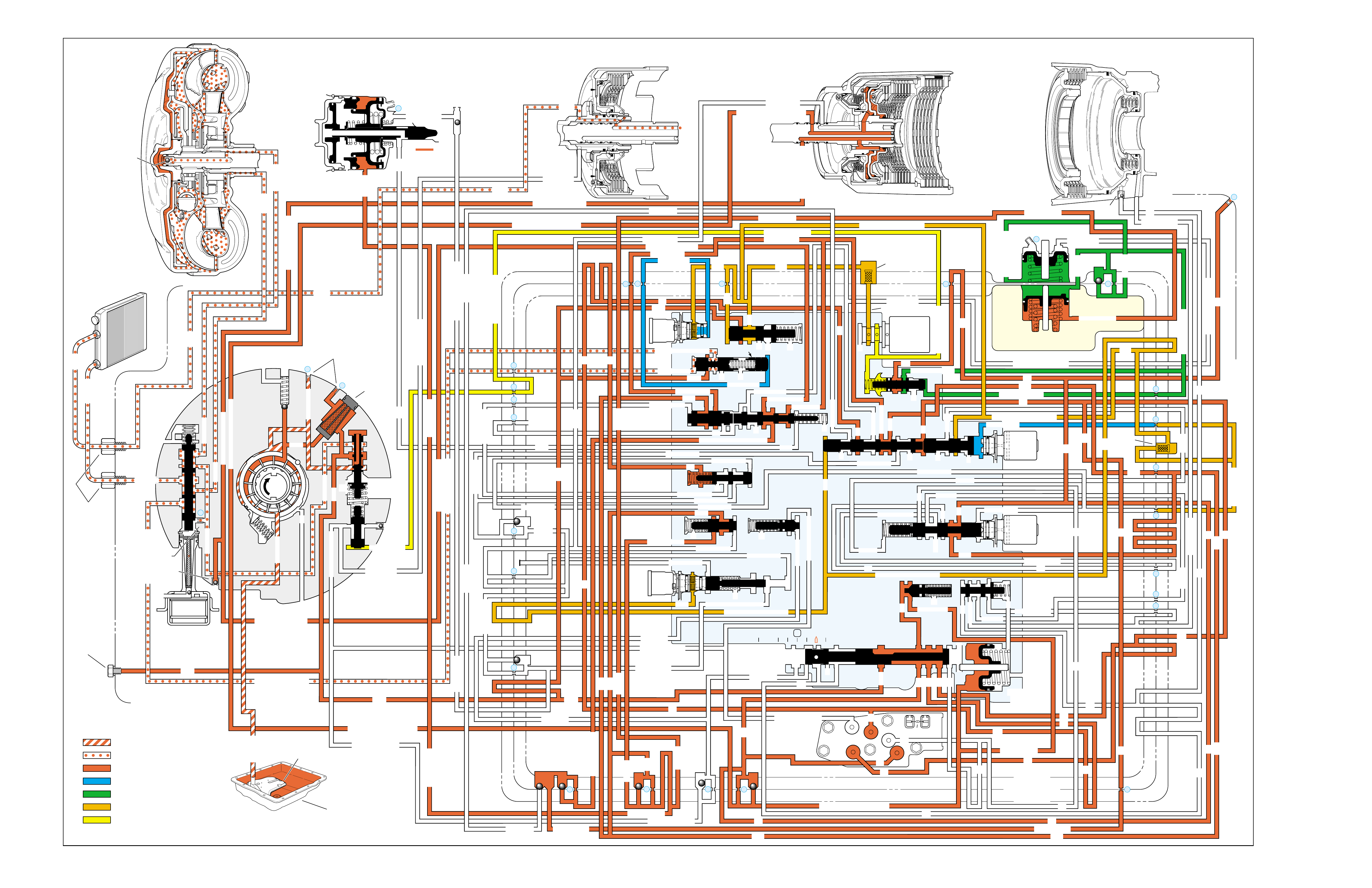

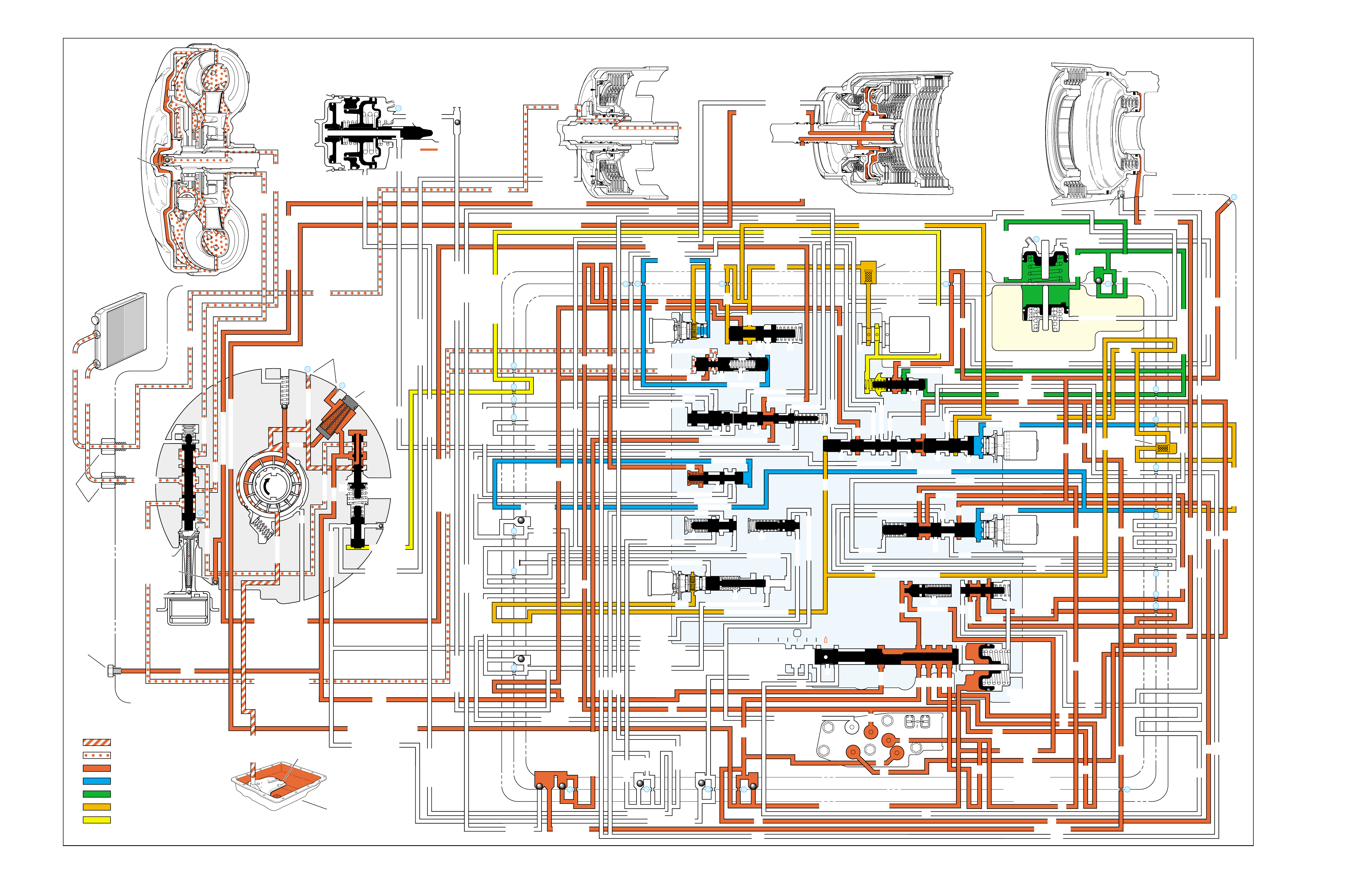

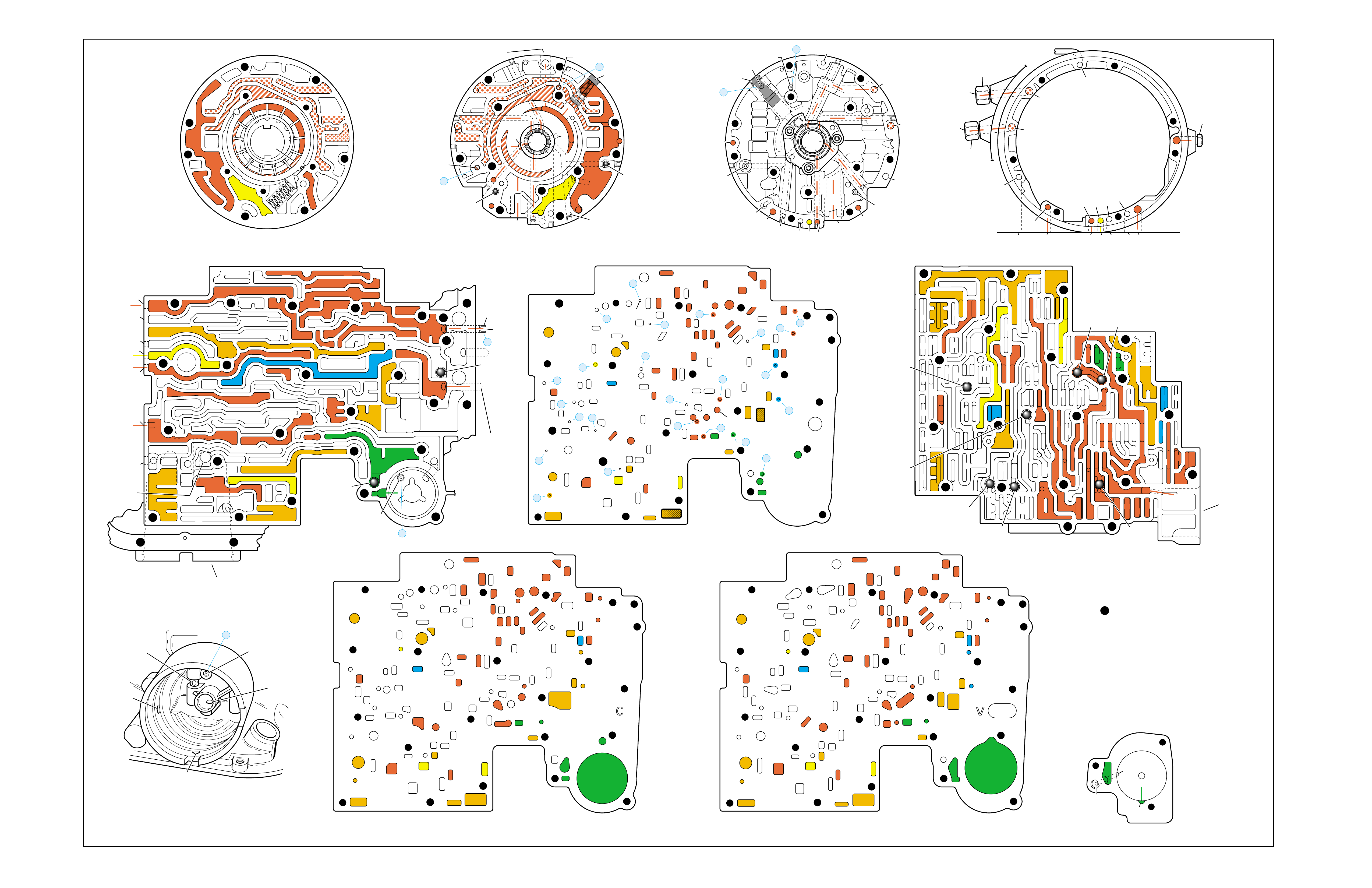

•The Complete Hydraulic Circuits section

(beginning on page 73) details the entire hydraulic

system. This is accomplished by using a foldout

circuit schematic with a facing page two

dimensional foldout drawing of each component.

The circuit schematics and component drawings

display only the fluid passages for that specific

operating range.

•Finally , the Appendix section contains a schematic

of the lubrication flow through the transmission,

disassembled view parts lists and transmission

specifications. This information has been included

to provide the user with convenient reference

information published in the appropriate vehicle

Service Manuals. Since component parts lists

and specifications may change over time, this

information should be verified with Service

Manual information.

First time users of this book may f ind the page layout

a little unusual or perhaps confusing. Ho wever, with

a minimal amount of exposure to this format its

usefulness becomes more obvious. If you are

unfamiliar with this publication, the following

guidelines are helpful in understanding the functional

intent for the various page layouts:

•Read the following section, “Understanding the

Graphics” to know how the graphic illustrations

are used, particularly as they relate to the

mechanical power flow and hydraulic controls

(see Understanding the Graphics page 6).

•Unfold the cutaway illustration of the Hydra-

matic 4L60-E (page 8) and refer to it as you

progress through each major section. This

cutaw ay provides a quick reference of component

location inside the transmission assembly and

their relationship to other components.

•The Principles of Operation section (beginning on

page 9A) presents information regarding the major

apply components and hydraulic control

components used in this transmission. This section

describes “how” specific components work and

interfaces with the sections that follow.

•The Power Flow section (beginning on page 45)

presents the mechanical and hydraulic functions

corresponding to specific gear ranges. This section

builds on the information presented in the

Principles of Operation section by showing

4

5

HOW TO USE THIS BOOK

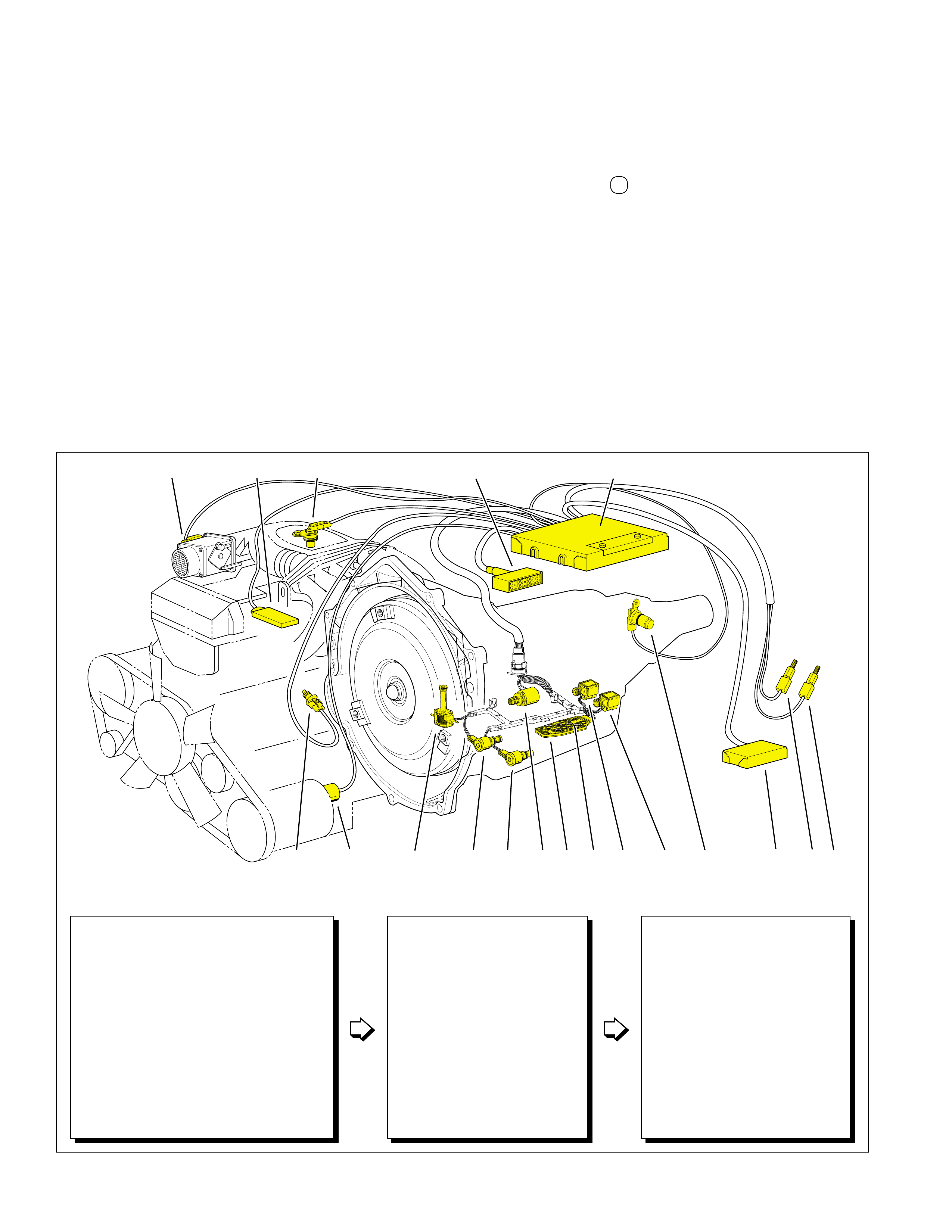

Figure 1

TORQUE

CONVERTER

ASSEMBLY

(1)

PUMP

ASSEMBLY

(4)

TRANSMISSION

CASE

(8)

INPUT HOUSING

& SHAFT ASSEMBLY

(621)

OUTPUT

SHAFT

(687)

HELD

SPEED SENSOR

ROTOR

(699)

PARKING PAWL

RETURN SPRING

(80)

PARKING BRAKE

PAWL (81)

ENGAGED

PARKING LOCK

ACTUATOR

ASSEMBLY

(85)

INSIDE

DETENT

LEVER

(88)

MANUAL

SHAFT

(84)

REACTION

INTERNAL

GEAR

(684)

HELD

OIL

PUMP

ROTOR

(212)

➤

➤

1

POWER FROM

TORQUE

CONVERTER

(1)

NO POWER

TRANSMITTED TO

OUTPUT SHAFT

(687)

2

POWERFLOW

TERMINATED LO & REVERSE

CLUTCH

APPLIED

PARK

(Engine Running)

Figure 39

42

42B

Engine Running

COMPLETE HYDRAULIC CIRCUIT

PAGE 68

With the selector lever in the Park (P)

position, line pressure from the oil

pump is directed to the following:

Pressure Regulator Valve(218): Reg-

ulates pump output (line pressure)

according to the transmission

requirements. When pump

output exceeds the demand

of line pressure, fluid from

the pressure regulator

PARK

H

Y

D

R

A

-

M

A

T

I

C

4

L

6

0

-

E

BOTTOM

PAN

(SUMP)

➤

➤➤

3-4 SHIFT VALVE

LO OVERRUN

ACTUATOR FEED LIMIT

➤

FILTER

➤

LINE

LINE

COOLER

D4

REVERSE

PR

D3

D2

LO

PR

D2

D3

D3

LO

D4

D4

FWD CL FEED

PR

PR

REV INPUT

LO/REVERSE

LO/1ST

TORQUE SIGNAL

D3

EX

EX

EX

EX

AFL

AFL

AFL

1-2 SIGNAL

AFL

LINE

PR

LO/REVERSE

AFL

AFL

PR

RELEASE

APPLY

DECREASE

LINE

LINE

LINE

LINE

COOLER

COOLER

EX

FILTER (50)

FILTER

(232)

EX

EX

AIR

BLEED

AIR

BLEED LINE

PRESSURE

TAP

FILTER

(49)

➤

➤➤

➤

➤

➤➤

➤

➤➤

➤

➤

➤

➤

➤

➤➤ ➤➤➤

➤

➤

➤

➤

➤

➤➤

➤➤

➤➤

➤

➤➤

➤➤ ➤ ➤

➤➤

➤➤

➤

➤

➤

➤

➤

➤

➤

➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤➤

➤

➤

➤

➤

➤➤➤

➤

➤

➤➤

➤

➤

➤➤

➤

➤➤➤

➤➤

➤

➤

➤➤➤

PRESSURE

RELIEF

VALVE

PUMP

ASSEMBLY

D2-N.C.

REV-N.O.

D3-N.C.

LO-N.O.

D4-N.O.

TEMP

SENSOR

➤

TFP

SWITCH

ASSEMBLY

➤

PARK

(Engine Running)

➤

➤

3-4 SIG

➤

AFL

➤

➤

➤

LO/REV

PR

➤

1-2 SIGNAL

4TH SIG

TORQUE SIG

➤

➤

➤

➤

➤

➤

➤

➤

➤➤

RELEASE

APPLY

➤

➤

➤

FORWARD CLUTCH

ACCUMULATOR

AFL (To 3-2 Control Solenoid)

➤

1c

2

TORQUE

CONVERTER

ASSEMBLY

#9

➤➤

#10

➤

LOW AND REVERSE

CLUTCH ASSEMBLY

1

2

COOLER

LUBE

➤

➤➤

➤➤

➤

➤

➤

4

10

TCC

SOLENOID

N.O.

OFF

EX

➤

EX

➤

➤

➤

➤

REGULATED APPLY

SUCTION

EX

➤➤

BOOST VALVE PRESS REG

EX

TORQUE SIGNAL

EX

CONV FD

EX

REVERSE INPUT

➤

➤

CONVERTER CLUTCH VALVE

EX

LINE

REGULATED APPLY

EX

EX

CC SIGNAL

ISOLATOR

REG APPLY

PRESSURE

CONTROL

SOLENOID

VALVE

8

32

9

25

23

26

27

29

2-3 SHUTTLE 2-3 SHIFT VALVE

EX

EX

EX

EX

D2

OVERRUN

D3

2ND

3-4 SIGNAL

EX

2-3 SIGNAL

SERVO FD

3-4 ACC

➤

➤

➤

2-3 SHIFT

SOLENOID

VALVE

N.O. ON

1-2 SHIFT VALVE

LO

D4

D4-3-2

2ND

EX

EX

1-2 SHIFT

SOLENOID

VALVE

N.O. ON

28

EX

PRND321

EX

EX

MANUAL VALVE

1a

1b

Figure 40

43

➤

➤➤

➤➤

➤

➤

➤

➤➤

➤

➤

➤

➤

➤➤

➤

➤

➤

➤

INPUT CLUTCH

HOUSING ASSEMBLY

24

REAR LUBE

FILTER

(49)

➤

➤

➤

➤

➤

➤

➤

RELEASE

APPLY

LO/REVERSE

PR

BOOST VALVE PRESS REG

BOTTOM

PAN

(SUMP)

(75)

FILTER

(72) REVERSE INPUT

REV INPUT

DECREASE

LINE

EX

FILTER

(232)

AIR

BLEED

(240)

1

SUCTION

LINE

EX

PRESSURE

RELIEF

VALVE

PUMP

ASSEMBLY

(4)

➤

➤➤

4

TCC

SOLENOID

(66)

N.O.

COOLER

LUBE

COOLER

SUCTION

CONVERTER & LUBE

MAINLINE

SOLENOID SIGNAL

ACCUMULATOR

ACTUATOR FEED LIMIT

TORQUE SIGNAL

FLUID PRESSURES

REVERSE INPUT

FORWARD CLUTCH FEED

#1

ACCUMULATOR

ORF ACC

2ND CLUTCH

3-4 ACCUMULATOR

1-2 ACCUMULATOR

19 3-4 ACCUM

ACCUM

EX

ORIFICED ACCUM

3-4 ACCUMULATOR

3-4 ACCUM

2ND CLUTCH

2ND CLUTCH

D3

REVERSE INPUT

D2-N.C.

REV-N.O. D3-N.C.

LO-N.O.

D4-N.O.

LO

TEMP

SENSOR

➤

TFP

SWITCH

ASSEMBLY

D2

D4

D3

D3

D3

EX

FORWARD ABUSE

FWD CL FD

3RD ACCUMULATOR EX

#7

11 3RD ACCUM

4TH

EX

EX

➤

4TH

2ND & 4TH

SERVO

REV ABUSE

EX

REVERSE

REVERSE INPUT

#12

D4

22

D4

D4

#4

13

3-4 SIGNAL

3-4 CL

3-4 CLUTCH

#2

12

3-4 CLUTCH

3RD ACCUM

3-4 CL

#8

16

2ND

2ND CL 2ND CL

2ND CL

2ND CL

2ND CLUTCH2ND CLUTCH

TORQUE SIG

FORWARD CLUTCH FEED

FORWARD

CLUTCH

ACCUMULATOR

EX

PR LO

LO

LO

FORWARD CLUTCH FEED

FORWARD CLUTCH FEED

FWD CL FEED

D3

D3

D3

14

3-4 CLUTCH

3RD ACCUMULATOR

3RD ACCUM

EX

AFL

3-2 SIGNAL

2ND

2ND

LINE

REGULATED APPLY

8REG APPLY

1-2 SHIFT VALVE

26

LO

D4

O’ EX

D4-3-2 2ND

25

1-2 SIGNAL

LO/1ST

27

1-2 SIGNAL

EX

ORIFICED EX

ORIFICED EX

EX

LO/1ST D4-3-2

D4

D4

2

➤

➤

➤

➤➤

➤

EX

CONV FD

EX

EX

EX

LINE LINE

LINE

PRESSURE

TAP

(39)

➤

➤

REGULATED APPLY

➤

➤

LUBE

LUBE

LUBE

LUBE

CASE (8)

CASE (8)

GASKET (47)

SPACER PLATE (48)

GASKET (52)

VALVE BODY (60)

SUCTION

LINE

LINE

3a

3b

3c

➤

➤

➤

➤

➤

➤➤

➤

➤

➤

➤

➤

➤

➤

D3

EX

3-4 SIGNAL

1-2 SIGNAL

4TH SIGNAL

3-4 SHIFT VALVE

1-2 SIGNAL

3-4 CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

12a

12b

12c

12d

12e

EX

EX

EX

32

AFL

AFL

30

D4

EX

31

ACCUMULATOR

ACCUMULATOR

EX

TORQUE SIGNAL

FILTERED AFL

D4

AFLAFL FILTER

(50)

10

43a

43b 44

11b

11c

11a

14b

14a

14c

LO OVERRUN

23

PR

LO/REV

LO/1ST LO/REVERSE

LO/REVERSE

PR PR

EX

22 10c

23 10b

9n

9o

22b

22a

10a

➤

10 9k

9g

9m

44a

43c 44

41a

41b

41c

41d

42b

42a

13a

13b

OIL

COOLER

PIPE

CONNECTOR

(10)

➤

➤

18a

18b

18c

18 17a

18 17b

20b

48b

48a

REGULATED APPLY

30a

30b

32a

37a

9b

9e

10 9d

9c

9a

9f

9h

31a

31b

31c

OVERRUN CLUTCH FEED

3-4 ACCUM

SERVO FEED

SERVO FEED

6

7

4TH4TH

OVERRUN CL

4TH SIGNAL2ND

EX

EX

3-4 RELAY 4-3 SEQUENCE VALVE

5

EX

SERVO FD

ORF EX

CASE (8)

REV INPUT

EX

(237)

17d

17c

17e

17f

17g

21

21

20d

20e

21a

20a

20c

1-2 ACCUMULATOR COVER (57)

25g

33c

33a

33b

27d

27c

27b

29

29

27a

28a

29b

29a

29d

40

29c

29e

29g28

28

29f

24a

24b

24c

24d

24e

24f

24g

24h

25a

25b

25d

25e

25f

25

25

24m

24k

REVERSE INPUT

#3

17

REVERSE INPUT

15c

15b

16

16

REVERSE

REVERSE INPUT

16a

15d

15a REVERSE

34f

34e

34d

34c

34a

34b

#6

OVERRUN CL FD

21

ORIFICED D2

#5

OVERRUN

OVERRUN OVERRUN

OVERRUN

36

36

35e

35d

39

35b

35c

36a

35a

38d

38e39

38c

38b

38a

EX

TORQUE SIGNAL

2ND CL

➤

➤

➤➤

➤

20

18

2-3 SHUTTLE 2-3 SHIFT VALVE

28

29

EX

EX

EX

EX

D2

OVERRUN

D3

D3

2ND

3-4 SIGNAL

EX

D4-3-2

2-3 SIGNAL

ACTUATOR FEED LIMIT

AFL

SERVO FD

3-4 ACC

FILTERED AFL

AFL

ACTUATOR FEED LIMIT

ACTUATOR FEED LIMIT

AFL

D2

2ND

2ND

2ND

2ND

D2

D2

D2

D2

ORIFICED D2

D2

D2

D2

VALVE BODY (60)

3-4 SIGNAL

➤

2ND

D4

PR 3-4 ACCUMULATOR

D4

EX

D4-3-2

LO

D4

2ND CLUTCH

D3

D3

FORWARD CLUTCH FEED ACTUATOR FEED LIMIT

TORQUE SIGNAL

SERVO FEED

➤

OVERRUN CLUTCH

LINE

9p

26a

➤

➤

➤➤

➤

➤

➤

➤

➤

➤➤➤

➤➤➤

➤

➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤

➤

➤

➤➤➤

➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤

➤➤ ➤

➤

➤

➤➤➤

➤➤

PR

➤➤

➤

➤➤

➤

➤➤

➤➤➤➤➤

➤

➤

➤

➤

➤➤

➤

➤➤➤➤➤

➤➤

➤

➤

➤➤➤

OFF

CONVERTER CLUTCH VALVE

COOLER

RELEASE

APPLY

EX

➤

➤

➤

➤

➤

➤

EX

➤➤

➤

➤➤

➤

CONV FD

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

REGULATED APPLY

3-2 CONTROL

EX

EX

CC SIGNAL

CC SIGNAL

ISOLATOR

REG APPLY

ACTUATOR FEED LIMIT

9

26b

TCC PWM

SOLENOID

VALVE

N.C.

1-2 SIGNAL

2ND

4TH SIGNAL

3-2

CONTROL

SOLENOID

VALVE

N.C.

OFF

#10

➤

LOW AND REVERSE

CLUTCH ASSEMBLY

REVERSE INPUT

CLUTCH ASSEMBLY

TORQUE

CONVERTER

ASSEMBLY

#9

➤➤

(237)

➤

(238)

➤

EX

2ND CLUTCH 3-4 CLUTCH

2ND

PRESSURE

CONTROL

SOLENOID

VALVE

2-3 SHIFT

SOLENOID

VALVE

N.O. ON

EX

1-2 SHIFT

SOLENOID

VALVE

N.O. ON

ACCUM VALVE

PRND321

D4

D4

REVERSE

D3

D2

LO EX

EX

LINE

➤

➤

➤

➤

➤

➤➤➤➤

➤

➤

➤

➤

➤

➤

➤➤➤ ➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

MANUAL VALVE

PR

EXEX

3-2 DOWNSHIFT

Engine Running

With the selector lever in the Park (P)

position, line pressure from the oil

pump is directed to the following:

Pressure Regulator Valve(218): Reg-

ulates pump output (line pressure)

according to the transmission

requirements. When pump

output exceeds the demand

of line pressure, fluid from

the pressure regulator

PARK

PARK

Engine Running

68

Figure 64

D4

PR

3

2

4

T

H

3

3

3

-

4

A

C

C

U

M

3

7

O

V

E

R

R

U

N

C

L

U

T

C

H

3

8

D

2

4

0

3

-

2

S

I

G

N

A

L

Engine Running

FOLDOUT ➤ 69

Figure 65

;

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤ ➤

➤

➤

➤

➤

➤

➤

;;;

;;;

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

➤ ➤

;;

;;

;;

;;

;;

➤

➤

➤

➤➤

➤➤

➤

➤

;;

;;

;;;;

;;;;

;;;

;;;;

;;;;

;

;

PUMP BODY (200)

(Pump Cover Side) PUMP COVER (215)

(Pump Body Side) PUMP COVER (215)

(Case Side) CASE (103)

(Pump Cover Side)

CASE (103)

(Control Valve Body Side) SPACER PLATE (48)

(Case/Control Valve Body) CONTROL VALVE BODY (60)

(Case Side)

12 38

312

34

18

15

16

38

29

16

47 47

29 15 29

9

9

29

12

38 41 17

24

18

9

30

34

25 24

25 43 37

33

24

25

30 27 22 27

34

34

13

35

34

36

31 31

33

33

48

9

9

26 3

25

11

99

925

28 32

11

26

17 20 20

9

25

20

21 21

24

36 35

39

24

27

24

13

9

10

24 10

14

22

912 42

41 44

42

17

18

34

17

12 14

41

38

41

11

3

25

39

24 10

18

18

29

29

29

16

48

43

9

14

44

26

25

31

20

GASKET (47)

(Case/Spacer Plate) GASKET (52)

(Spacer Plate/Control Valve Body)

CASE (103)

(2-4 Servo Bore)

1-2 ACCUMULATOR COVER (57)

NOTE:

- INDICATES BOLT HOLES

- NON-FUNCTIONAL HOLES

HAVE BEEN REMOVED FROM

COMPONENT DRAWINGS TO

TO SIMPLIFY TRACING FLUID

FLOW.

- EXHAUST FLUID NOT SHOWN

21

25

25

20

28

#7/(40) 44

(11)

25

43

32

3

16

(237)

18

43

3

(240)

37

(237)

43

47

45

43

43

48

11

29

16

3

16 29 18

2

(240)

8

85

37

37

1

47

(232)

7

46

;

;;

45 47

3

3

8

43

5

4

2

4

4

48

43

3

6

1

43

2

7

47 46

43 11

3

16

37

37

5

37 8

29

18

29

1

(232)

2

43

47

16

(237)

37

(237)

4

(238)

2

(240)

PRESSURE RELIEF

VALVE BORE

➤

16

45

8

7

48

37

11 29 16

3

18

3

(39)

8

7

(10)

(10)

48 37 316291118

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

;;;;;;;

47 45

8

43

5

4

4

4

3

3

3

2

43

16

11

29

43

43

4637 47

48

7

4

2

3

1

3

13V

12a 38b

3a

12b

34b

18b

38d

18c

13b

15d

16a

38c

15a

9m

9n

11c

29e

29d

9o

27b/29

29a

29f/28

15b/16

35a

22b

27d

30a

30b

34f

25a 24h

31c

25b

33c

24g 34e

31b

31a

27a

33a

33b

32a

37a

36a

3c

26b

11b

9c

25f

28a

9e

9p

9b

9d/10

(50)

48b

43a

25d

3b 11a

20c

25g

21a

9f

20e/21

17f 20a

9g

10a

35c/39

35b

35d/36

24f

24d 24c 13a

24a24b

41d

17c

41c

12c

17b/18 18a17d

42a

43c/44 9h 12e

22a 14b

10c/22

42b

14a

12d

17e

34a 41a

41b 38a

24m/25

47

9k/10

(49)

10b/23

20b

24e

17g

20d/21

25e

9a

48a

26a

43b/44

24k/25

34c

34d

29c

29b

29g/28

15c/16

17a/18 14c

44a

38e/39

27c/29

35e/36

➤

7

➤

5

➤

6

➤

16

➤

17

➤

8

➤

9

➤

32

➤

10

➤

12

➤

18

➤

20

➤

21

➤

22

➤

13

➤

14

➤

23

➤

25

➤

29

➤

30

➤

31

➤

26

➤

27

➤

28

➤

24

➤➤

1

➤➤

2

➤➤

2

➤➤

4

➤➤

11

12 38

3

18

38

16

28

29

15

34

29

9

9

15

29

11

929

40

15 43

35 34

31

31 33 33

22

27

30

34

30

25 24 24

2431

25 43

48

26

33 37

36 32

25

28

9

26

9

311

25 25 3

910

11 21 20

25

9

10

17 20

35 35/39

24

27 24 24

13

13

22

14

22

912 42

14

12

24

24

18

38 41 17

41

12 42

17

17

34

12 34 41

38

17

44

47

923

20

17

9

9

48 44

34

29

29 18

24

14

43

10

25

41

38

34

9

9

947

9

9

3

3

25

25

11

11

26

47

26

47

25

47

3

10

43

47 11

43

33

31

24

30

37 36

28

11

34

25 24

22

24

35

34

30 27

31 32

47 25

29

9

15

40

28 29 29 16

15

43

15 12

38

3

341 47

17 34 38 41

34

18

12

17

42

43

12

18

47

47

14

43

14 42

922

23

10

9

17

17

24

38

13 24

43

42

41

3

33

31 24 24

17 47

13

17 20 20

27

#8

#6 #5

#3

#2 #12

#4

FORWARD

CLUTCH

ACCUMULATOR

BORE

➤

17

47

47

35

47

43

47

47

47 48

48

47

47

47

47 9

26

47 12 38

3

3

29

38

16

47 29

15

29

11

18

30 27 27

18

34

47

34

25 24

31

33

43

37 37

48

47

47

47

47

47 47

9

25

311

32 28 32

25

21

20

33

33

25

9

39

35

35 24 47

24 22

22 10 47

14

12

9

99

44

17 47 42

41

17

14

12

12

18

34

34

41

9

9

9

36

9

17

17

12

14

11

9

11

34

16 16

22

13 13

#10

#1

#7

(40)

37

18

11

29

16

3

29

341

38

44

(38)

28

47

43

47

48

36

33

9

33

38

19

26

47

47

2-4 SERVO BORE

➤

REAR

LUBE

TO

LOW AND

REVERSE

CLUTCH

➤➤

19

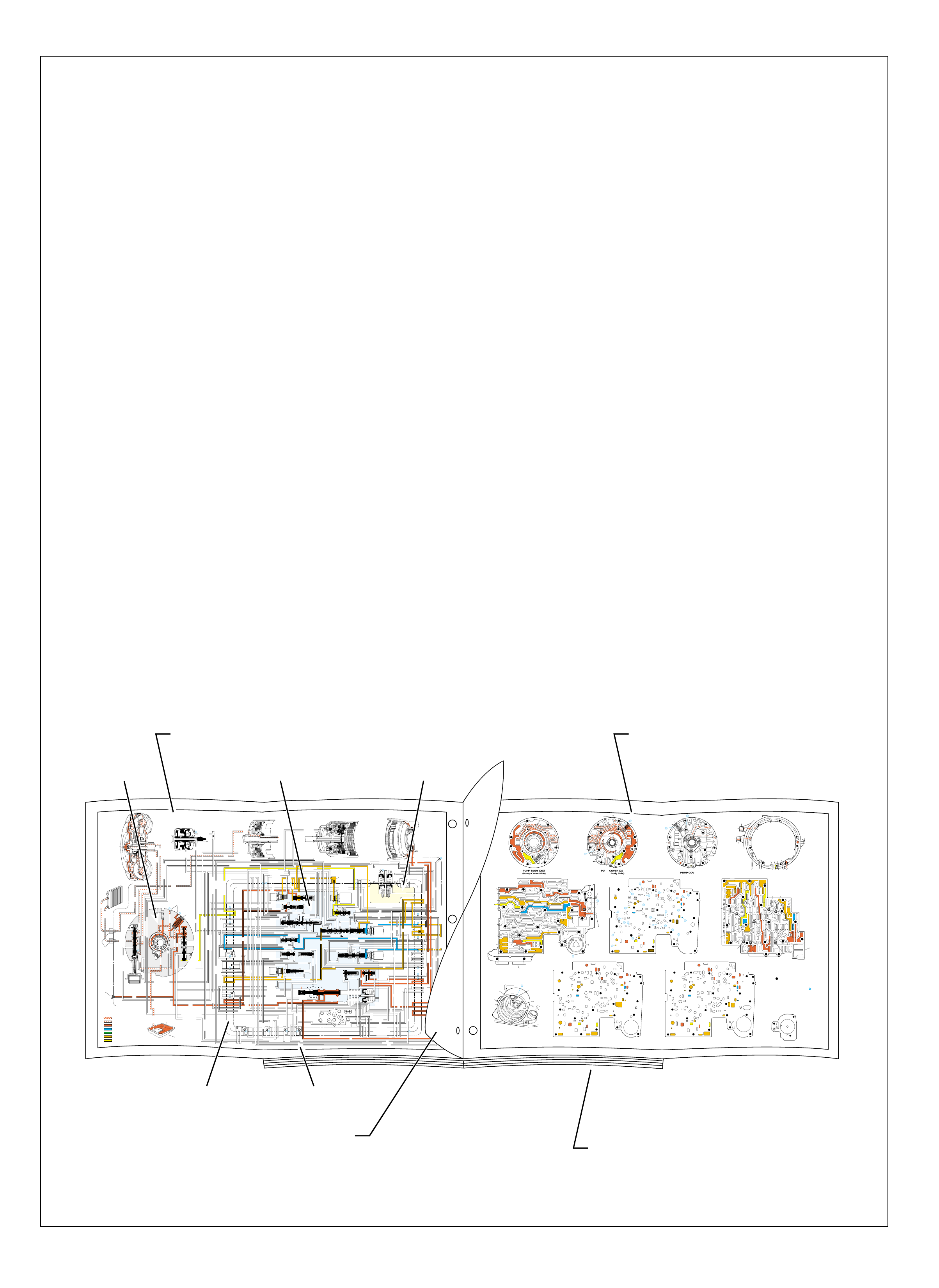

RANGE REFERENCE CHARTLARGE CUTAWAY VIEW

OF TRANSMISSION

(FOLDOUT)

HALF PAGE TEXT FOR EASY

REFERENCE TO BOTH PAGES

FLUID FLOW THROUGH

COMPONENTS (FOLDOUT)

COMPLETE ILLUSTRATED

PARTS LIST

FLUID FLOW SCHEMATIC —

(FOLDOUT)

HALF PAGE TEXT AND LEDGEND

PAGE NUMBER —

FOR REFERENCE TO

FLUID FLOW SCHEMATIC

➤

➤

➤

➤

➤

➤

➤

➤

CASE

ASSEMBLY REVERSE

INPUT CLUTCH INPUT CLUTCH

HOUSING OVERRUN

CLUTCH FORWARD

CLUTCH FORWARD

SPRAG CL

ASSEMBLY

3-4

CLUTCH INPUT

PLANETARY

GEARSET

LO AND

REVERSE

CLUTCH

TORQUE

CONVERTER

ASSEMBLY

STATOR

ROLLER

CLUTCH PUMP

ASSEMBLY

LO ROLLER

CLUTCH

ASSEMBLY

REACTION

PLANETARY

GEARSET

TURBINE

SHAFT

2-4

BAND

ASSEMBLY INSIDE

DETENT LEVER MANUAL

SHAFT CONTROL VALVE

ASSEMBLY PARKING LOCK

ACTUATOR ASSEMBLY SPEED

SENSOR

PARKING

PAWL

OUTPUT

SHAFT

➤

➤

➤

➤

➤

➤

➤

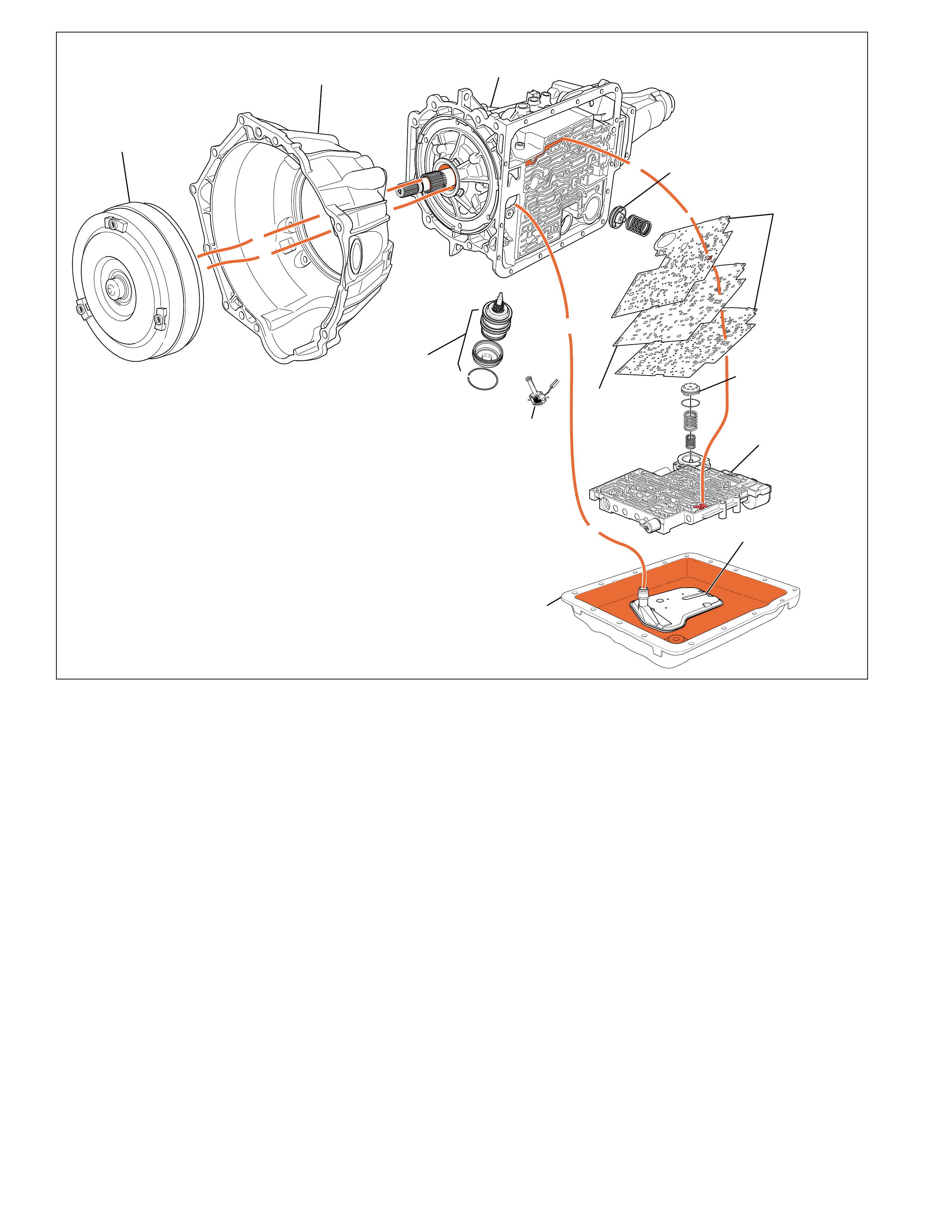

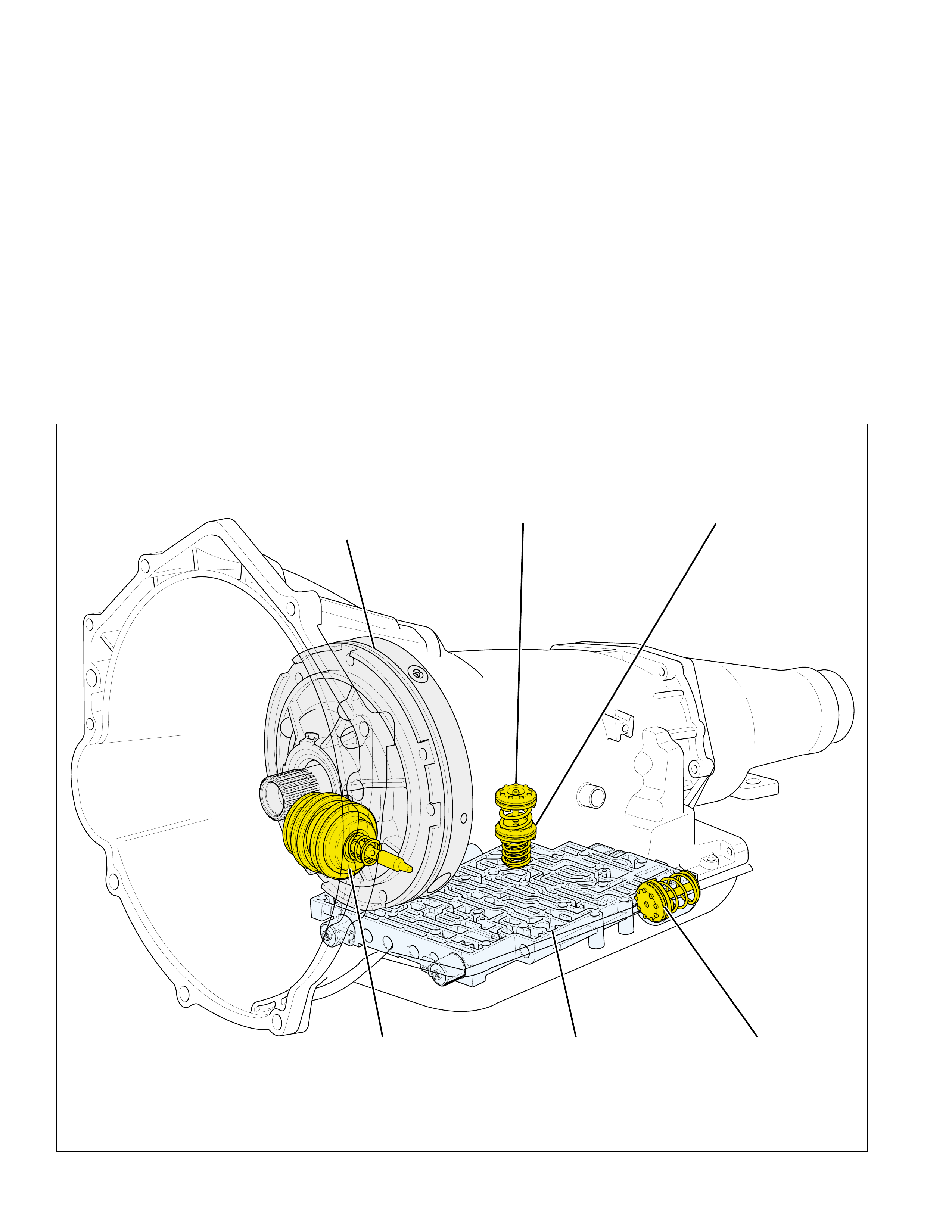

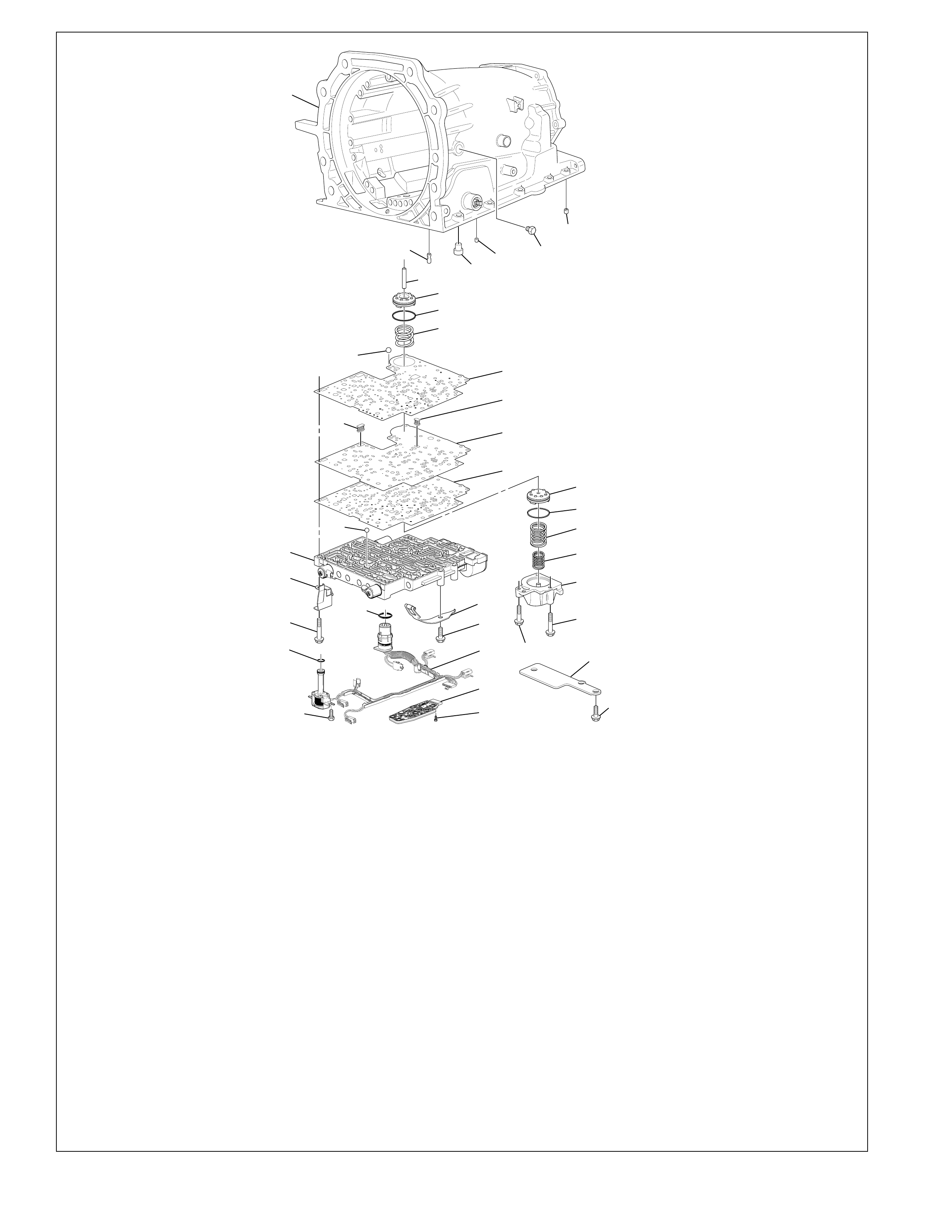

CASE

ASSEMBLY

(103)

CONVERTER

HOUSING

(102)

TORQUE

CONVERTER

(1)

SERVO

ASSEMBLY

(12-29)

TCC

SOLENOID

(66)

SPACER

PLATE

(48)

BOTTOM

PAN

(75)

FILTER

(72)

CONTROL

VALVE

ASSEMBLY

(60)

1-2 ACCUMULATOR

PISTON

(56)

SPACER PLATE

GASKETS

(47 & 52)

3-4 ACCUMULATOR

PISTON

(44)

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

UNDERSTANDING THE GRAPHICS

6

Figure 2

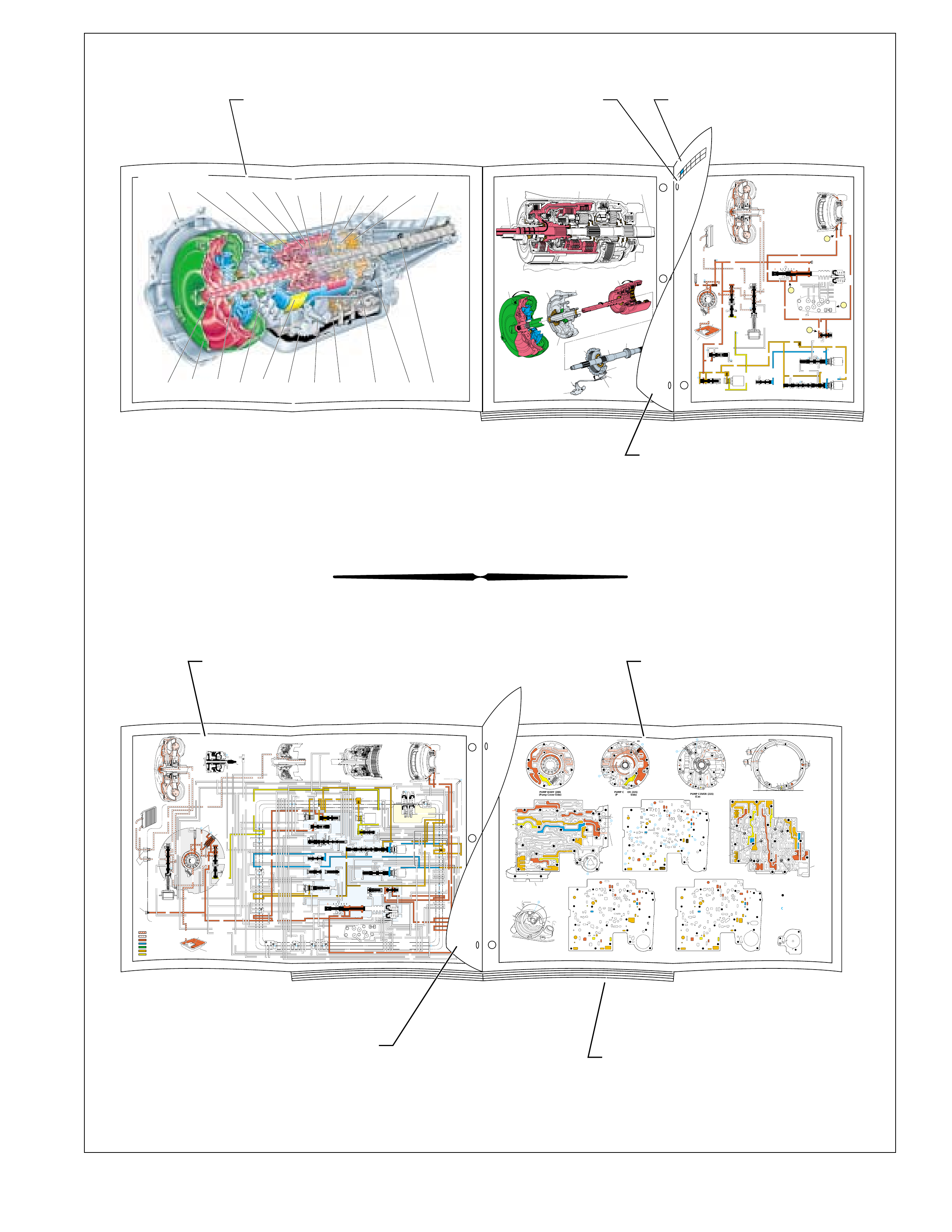

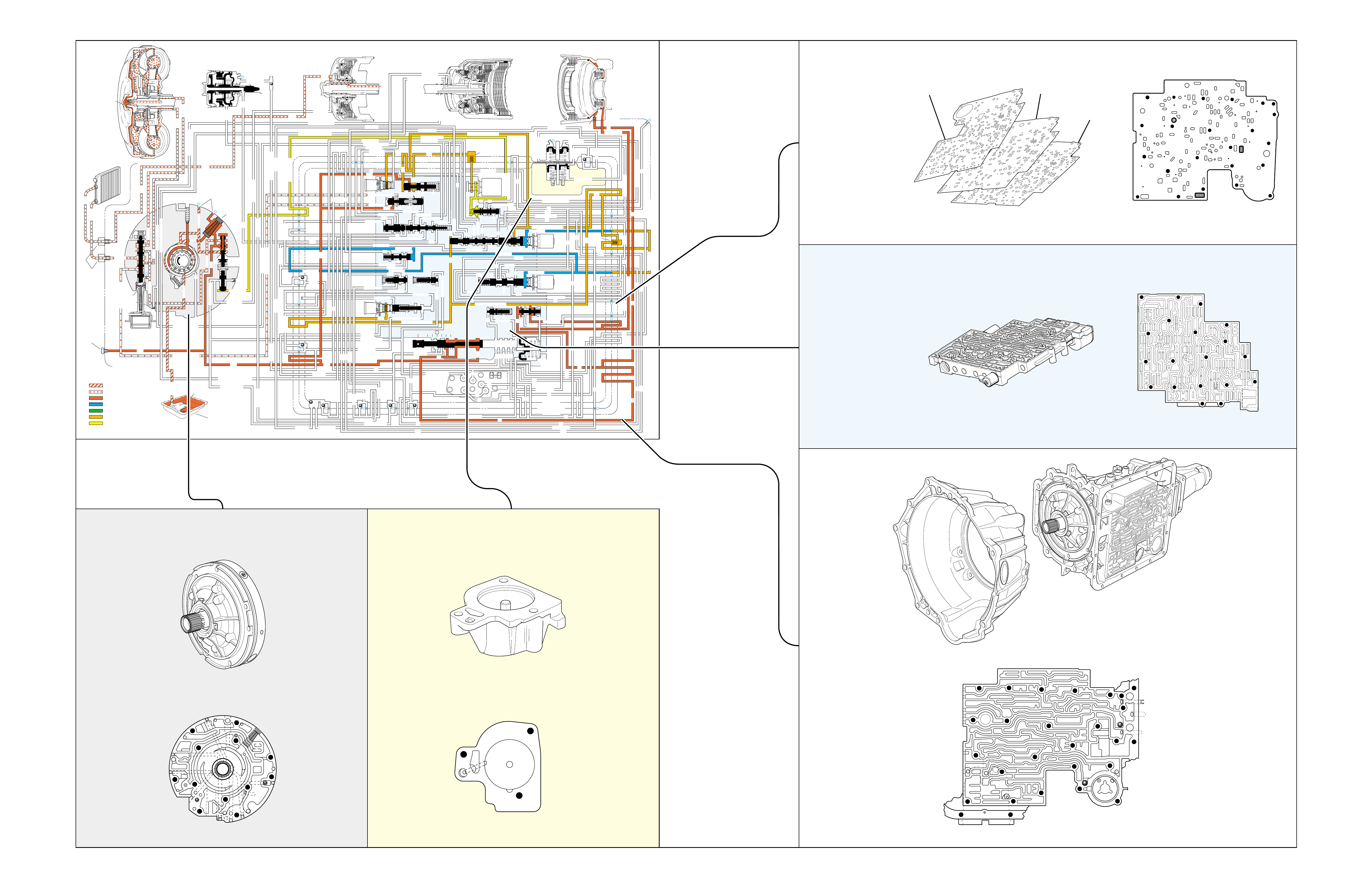

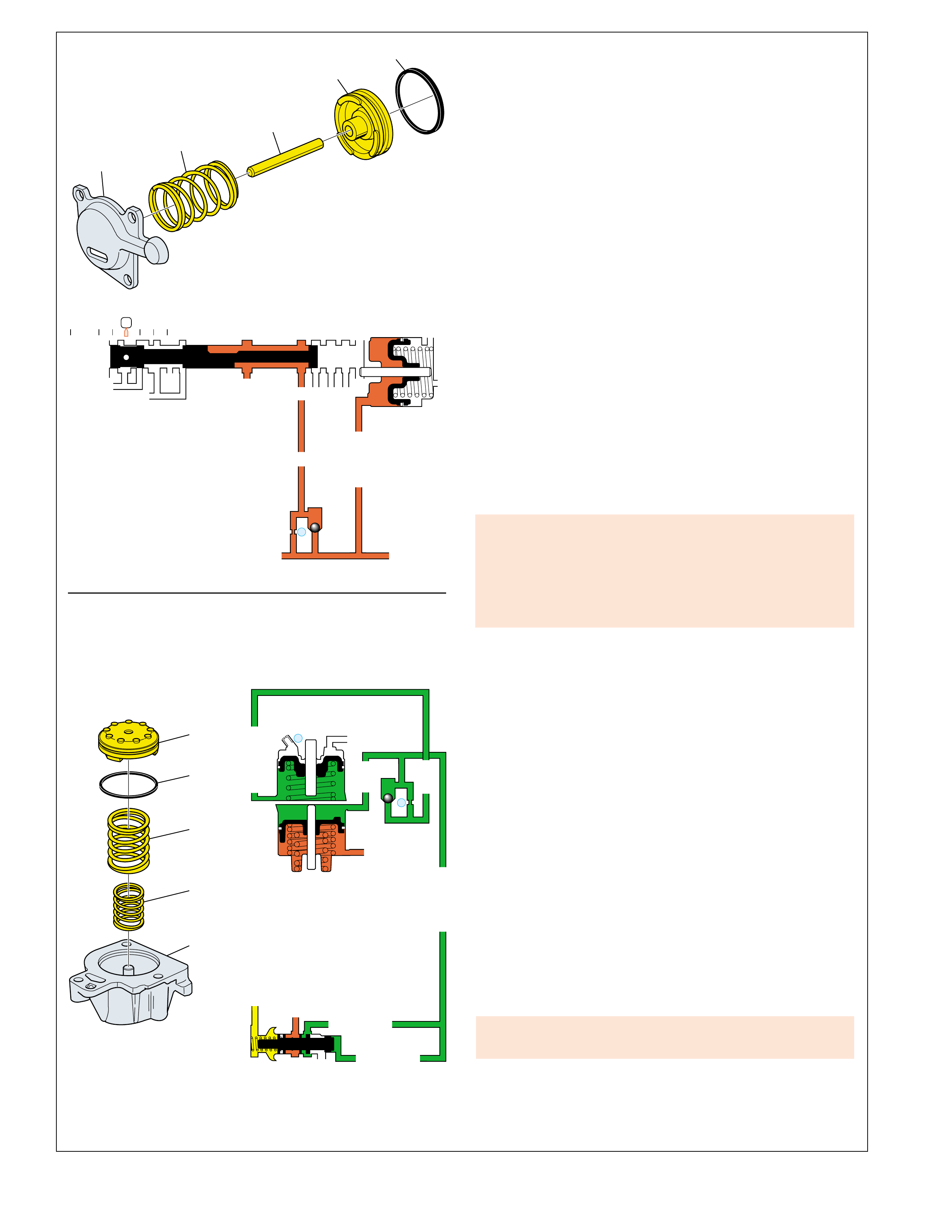

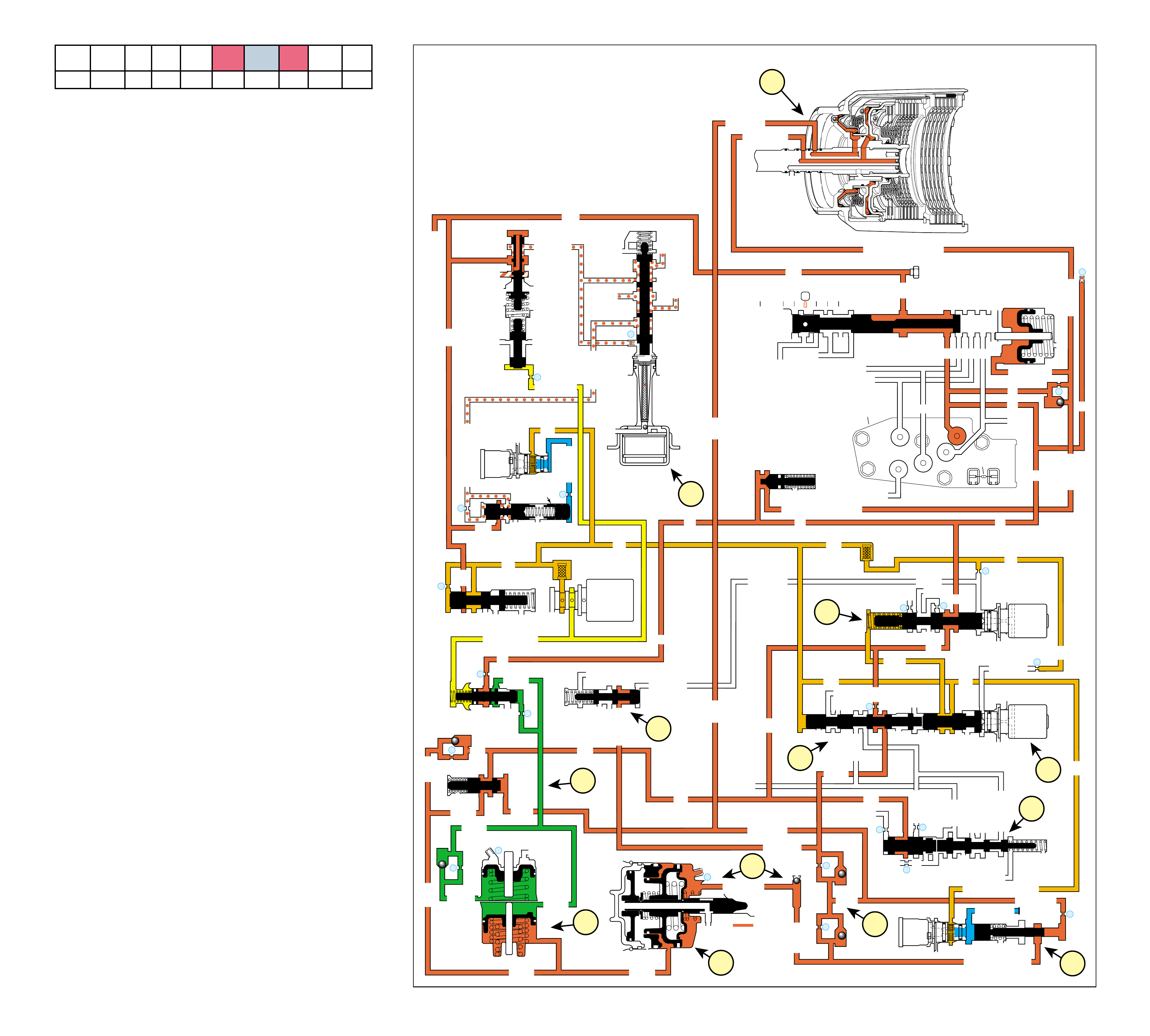

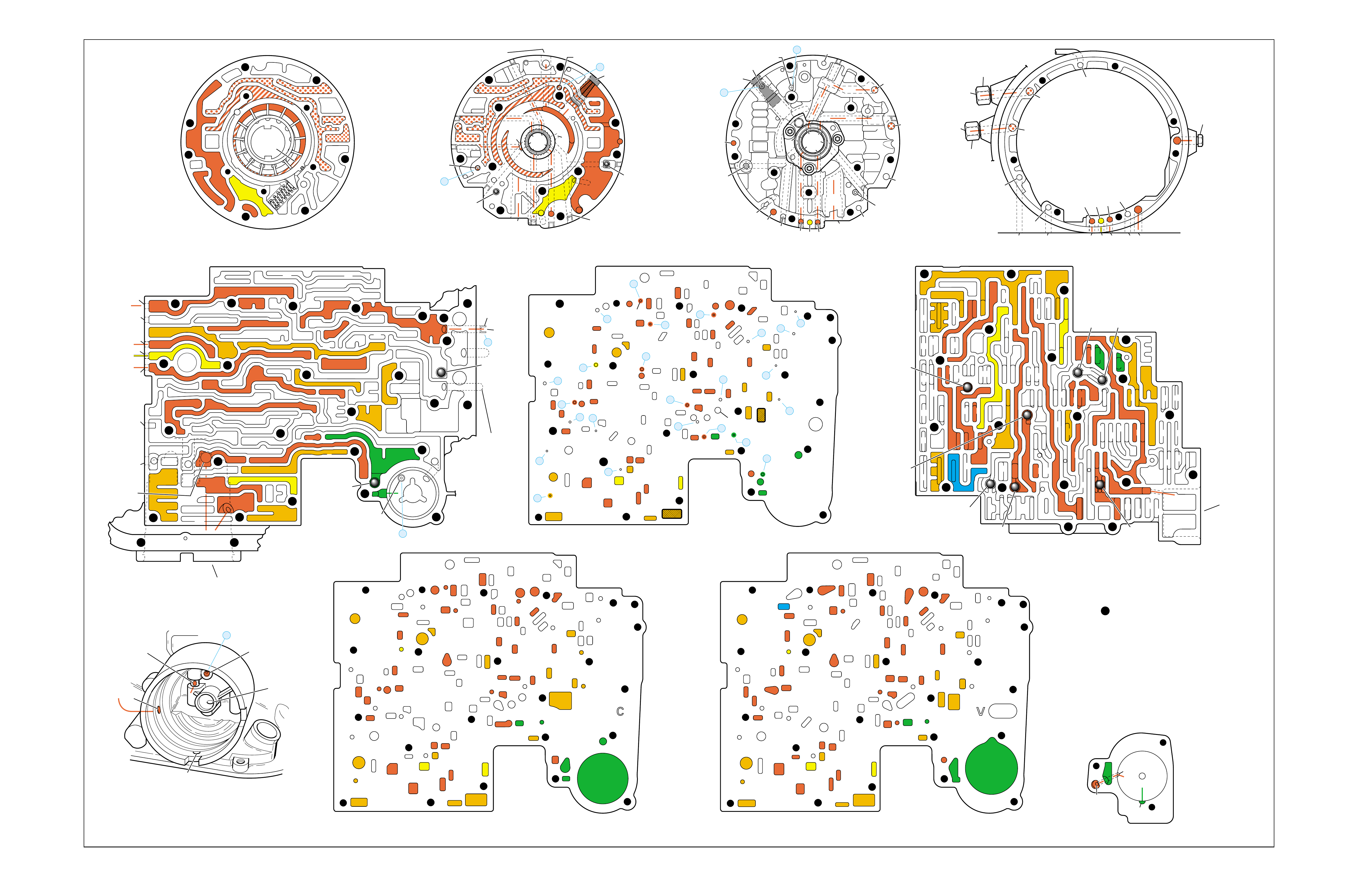

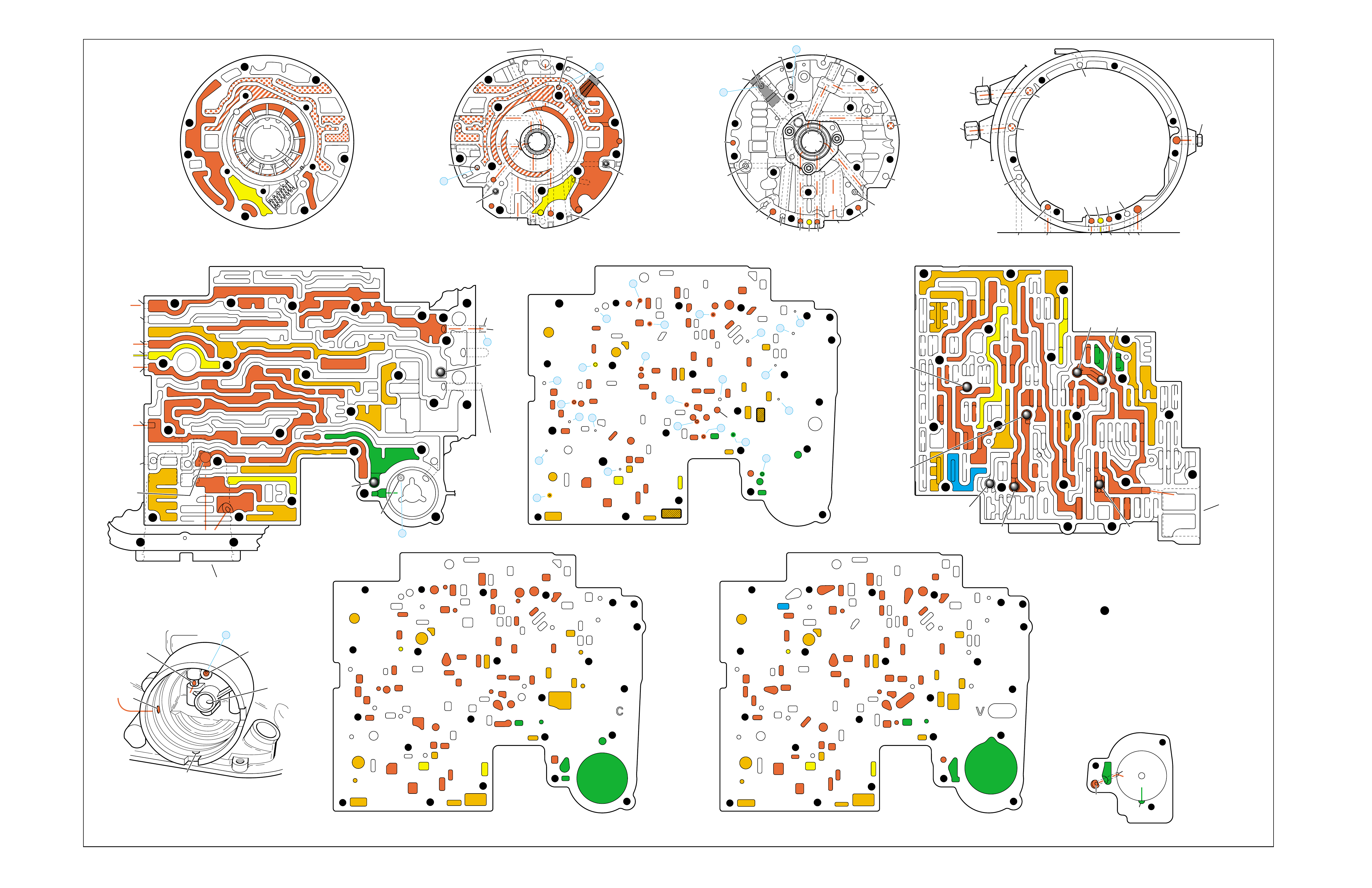

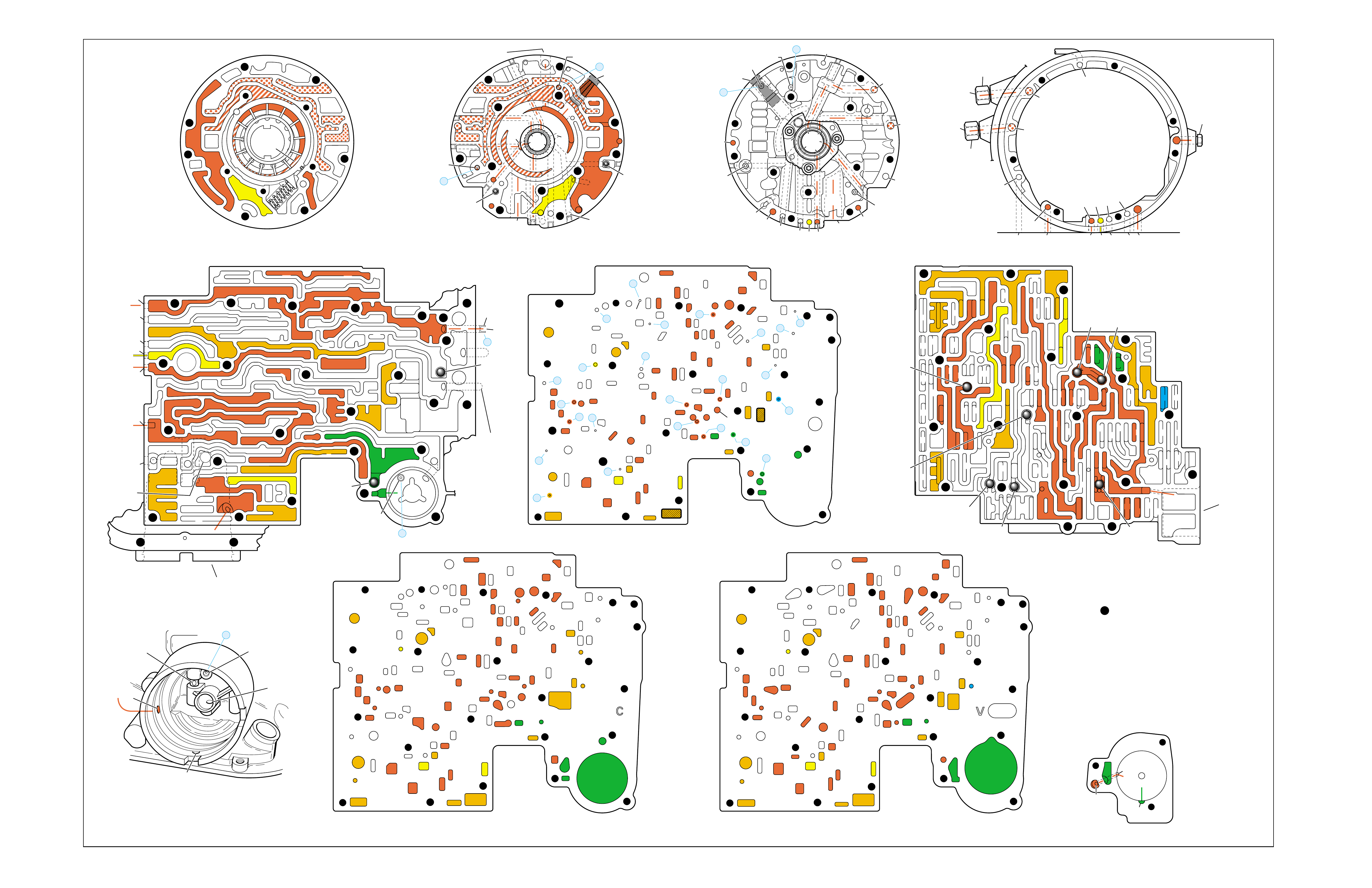

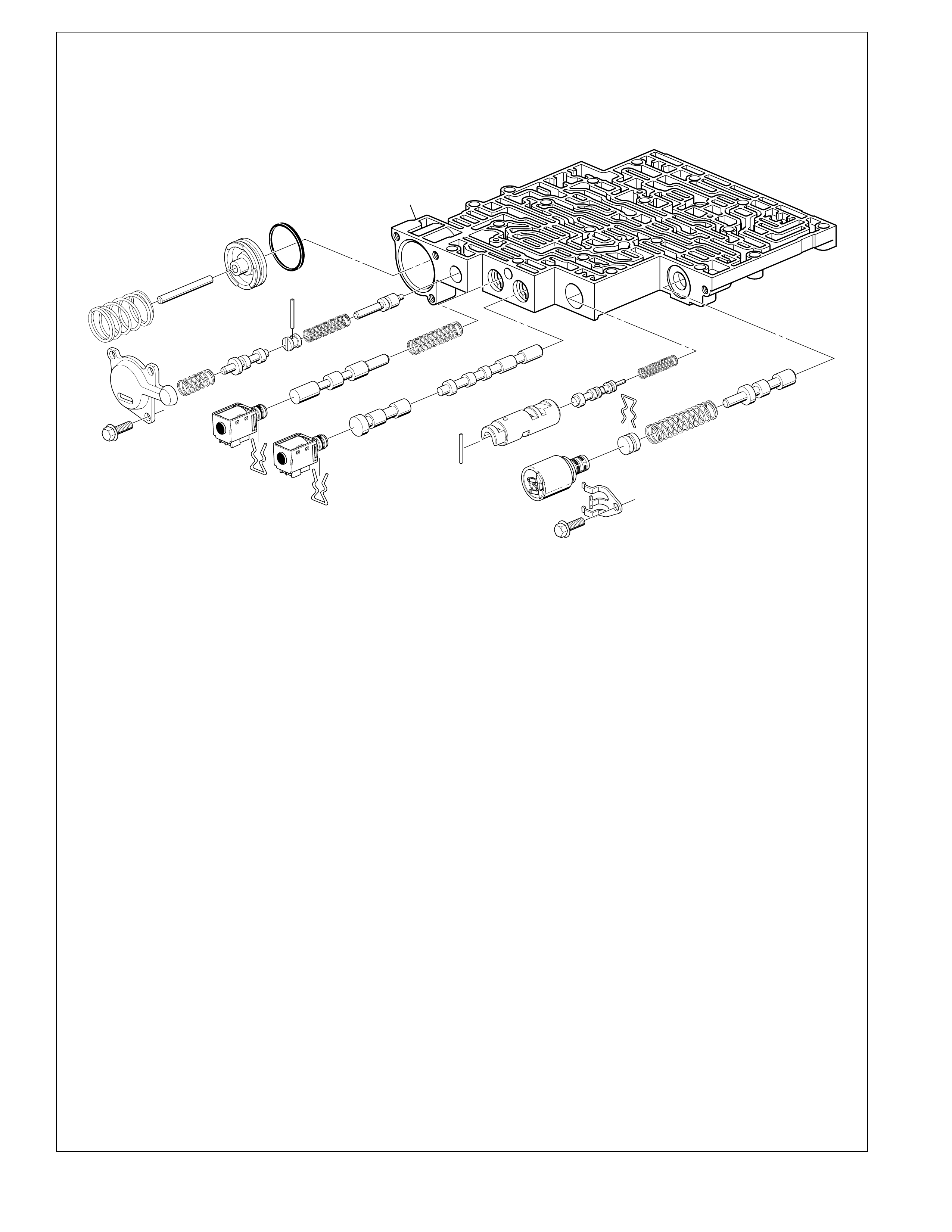

•A graphic schematic representation that displays

valves, checkballs, orif ices and so for th, required

for the proper function of transmission in a specific

gear range. In the schematic drawings, fluid

circuits are represented by straight lines and

orifices are represented by indentations in a circuit.

All circuits are labeled and color coded to provide

reference points between the schematic drawing

and the two dimensional line drawing of the

components.

•Figure 4 (page 7B) provides an illustration of a

typical valve, bushing and valve train components.

A brief description of valve operation is also

provided to support the illustration.

•Figure 5 (page 7B) provides a color coded chart

that references different fluid pressures used to

operate the hydraulic control systems. A brief

description of how fluid pressures affect valve

operation is also provided.

The flow of transmission fluid starts in the bottom

pan and is drawn through the filter, main case valve

body, transmission case, the oil pump assembly, and

into the torque converter. This is a general route for

fluid to flow that is more easily understood by

reviewing the illustrations provided in Figure 2.

However, fluid may pass between these and other

components many times before reaching a valve or

applying a clutch. For this reason, the graphics are

designed to show the e xact location where fluid passes

through a component and into other passages for

specific gear range operation.

To provide a better understanding of fluid flo w in the

Hydra-matic 4L60-E transmission, the components

involved with hydraulic control and fluid flow are

illustrated in three major formats. Figure 3 provides

an example of these formats which are:

•A three dimensional line drawing of the

component for easier part identification.

•A two dimensional line drawing of the component

to indicate fluid passages and orifices.

➤

➤➤

➤➤

➤

➤

➤

➤➤

➤

➤

➤

➤

INPUT CLUTCH

HOUSING ASSEMBLY

24

REAR LUBE

FILTER

(49)

➤

➤

➤

➤

➤

➤

➤

RELEASE

APPLY

LO/REVERSE

PR

BOOST VALVE PRESS REG

BOTTOM

PAN

(SUMP)

(75)

FILTER

(72) REVERSE INPUT

REV INPUT

DECREASE

LINE

EX

FILTER

(232)

AIR

BLEED

(240)

1

SUCTION

LINE

EX

PRESSURE

RELIEF

VALVE

PUMP

ASSEMBLY

(4)

➤

➤➤

4

TCC

SOLENOID

(66)

N.O.

COOLER

LUBE

COOLER

SUCTION

CONVERTER & LUBE

MAINLINE

SOLENOID SIGNAL

ACCUMULATOR

ACTUATOR FEED LIMIT

TORQUE SIGNAL

FLUID PRESSURES

REVERSE INPUT

FORWARD CLUTCH FEED

#1

ACCUMULATOR

ORF ACC

2ND CLUTCH

3-4 ACCUMULATOR

1-2 ACCUMULATOR

19

3-4 ACCUM

ACCUM

EX

ORIFICED ACCUM

3-4 ACCUMULATOR

3-4 ACCUM

2ND CLUTCH

2ND CLUTCH

D3

REVERSE INPUT

D2-N.C.

REV-N.O. D3-N.C.

LO-N.O.

D4-N.O.

LO

TEMP

SENSOR

➤

TFP

SWITCH

ASSEMBLY

D2

D4

D3

D3

D3

EX

FORWARD ABUSE

FWD CL FD

3RD ACCUMULATOR EX

#7

11

3RD ACCUM

4TH

EX

EX

➤

4TH

2ND & 4TH

SERVO

REV ABUSE

EX

REVERSE

REVERSE INPUT

#12

D4

22

D4

D4

#4

13

3-4 SIGNAL

3-4 CL

3-4 CLUTCH

#2

12

3-4 CLUTCH

3RD ACCUM

3-4 CL

#8

16

2ND

2ND CL 2ND CL

2ND CL

2ND CL

2ND CLUTCH2ND CLUTCH

TORQUE SIG

FORWARD CLUTCH FEED

FORWARD

CLUTCH

ACCUMULATOR

EX

PR LO

LO

LO

FORWARD CLUTCH FEED

FORWARD CLUTCH FEED

FWD CL FEED

D3

D3

D3

14

3-4 CLUTCH

3RD ACCUMULATOR

3RD ACCUM

EX

AFL

3-2 SIGNAL

2ND

2ND

LINE

REGULATED APPLY

8

REG APPLY

1-2 SHIFT VALVE

26

LO

D4

O’ EX

D4-3-2 2ND

25

1-2 SIGNAL

LO/1ST

27

1-2 SIGNAL

EX

ORIFICED EX

ORIFICED EX

EX

LO/1ST D4-3-2

D4

D4

2

➤

➤

➤

➤➤

➤

EX

CONV FD

EX

EX

EX

LINE LINE

LINE

PRESSURE

TAP

(39)

➤

➤

REGULATED APPLY

➤

➤

LUBE

LUBE

LUBE

LUBE

CASE (8)

CASE (8)

GASKET (47)

SPACER PLATE (48)

GASKET (52)

VALVE BODY (60)

SUCTION

LINE

LINE

3a

3b

3c

➤

➤

➤

➤

➤

➤➤

➤

➤

➤

➤

➤

➤

➤

D3

EX

3-4 SIGNAL

1-2 SIGNAL

4TH SIGNAL

3-4 SHIFT VALVE

1-2 SIGNAL

3-4 CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

OVERRUN CLUTCH

12a

12b

12c

12d

12e

EX

EX

EX

32

AFL

AFL

30

D4

EX

31

ACCUMULATOR

ACCUMULATOR

EX

TORQUE SIGNAL

FILTERED AFL

D4

AFLAFL FILTER

(50)

10

43a

43b 44

11b

11c

11a

14b

14a

14c

LO OVERRUN

23

PR

LO/REV

LO/1ST LO/REVERSE

LO/REVERSE

PR PR

EX

22 10c

23 10b

9n

9o

22b

22a

10a

➤

10 9k

9g

9m

44a

43c 44

41a

41b

41c

41d

42b

42a

13a

13b

OIL

COOLER

PIPE

CONNECTOR

(10)

➤

➤

18a

18b

18c

18 17a

18 17b

20b

48b

48a

REGULATED APPLY

30a

30b

32a

37a

9b

9e

10 9d

9c

9a

9f

9h

31a

31b

31c

OVERRUN CLUTCH FEED

3-4 ACCUM

SERVO FEED

SERVO FEED

6

7

4TH4TH

OVERRUN CL

4TH SIGNAL2ND

EX

EX

3-4 RELAY 4-3 SEQUENCE VALVE

5

EX

SERVO FD

ORF EX

CASE (8)

REV INPUT

EX

(237)

17d

17c

17e

17f

17g

21

21

20d

20e

21a

20a

20c

1-2 ACCUMULATOR COVER (57)

25g

33c

33a

33b

27d

27c

27b

29

29

27a

28a

29b

29a

29d

40

29c

29e

29g28

28

29f

24a

24b

24c

24d

24e

24f

24g

24h

25a

25b

25d

25e

25f

25

25

24m

24k

REVERSE INPUT

#3

17

REVERSE INPUT

15c

15b

16

16

REVERSE

REVERSE INPUT

16a

15d

15a

REVERSE

34f

34e

34d

34c

34a

34b

#6

OVERRUN CL FD

21

ORIFICED D2

#5

OVERRUN

OVERRUN OVERRUN

OVERRUN

36

36

35e

35d

39

35b

35c

36a

35a

38d

38e39

38c

38b

38a

EX

TORQUE SIGNAL

2ND CL

➤

➤

➤➤

➤

20

18

2-3 SHUTTLE 2-3 SHIFT VALVE

28

29

EX

EX

EX

EX

D2

OVERRUN

D3

D3

2ND

3-4 SIGNAL

EX

D4-3-2

2-3 SIGNAL

ACTUATOR FEED LIMIT

AFL

SERVO FD

3-4 ACC

FILTERED AFL

AFL

ACTUATOR FEED LIMIT

ACTUATOR FEED LIMIT

AFL

D2

2ND

2ND

2ND

2ND

D2

D2

D2

D2

ORIFICED D2

D2

D2

D2

VALVE BODY (60)

3-4 SIGNAL

➤

2ND

D4

PR 3-4 ACCUMULATOR

D4

EX

D4-3-2

LO

D4

2ND CLUTCH

D3

D3

FORWARD CLUTCH FEED ACTUATOR FEED LIMIT

TORQUE SIGNAL

SERVO FEED

➤

OVERRUN CLUTCH

LINE

9p

26a

➤

➤

➤➤

➤

➤

➤

➤

➤

➤➤➤

➤➤➤

➤

➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤

➤

➤

➤➤➤

➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤

➤➤ ➤

➤

➤

➤➤➤

➤➤

PR

➤➤

➤

➤➤

➤

➤➤

➤➤➤➤➤

➤

➤

➤

➤

➤➤

➤

➤➤➤➤➤

➤➤

➤

➤

➤➤➤

OFF

CONVERTER CLUTCH VALVE

COOLER

RELEASE

APPLY

EX

➤

➤

➤

➤

➤

➤

EX

➤➤

➤

➤➤

➤

CONV FD

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

REGULATED APPLY

3-2 CONTROL

EX

EX

CC SIGNAL

CC SIGNAL

ACTUATOR FEED LIMIT

9

26b

TCC PWM

SOLENOID

VALVE

N.C.

1-2 SIGNAL

2ND

4TH SIGNAL

3-2

CONTROL

SOLENOID

VALVE

N.C.

OFF

#10

➤

LOW AND REVERSE

CLUTCH ASSEMBLY

REVERSE INPUT

CLUTCH ASSEMBLY

TORQUE

CONVERTER

ASSEMBLY

#9

➤➤

(237)

➤

(238)

➤

EX

2ND CLUTCH 3-4 CLUTCH

2ND

PRESSURE

CONTROL

SOLENOID

VALVE

2-3 SHIFT

SOLENOID

VALVE

N.O.

ON

EX

1-2 SHIFT

SOLENOID

VALVE

N.O.

ON

ACCUM VALVE

PRND321

D4

D4

REVERSE

D3

D2

LO

EX

EX

LINE

➤

➤

➤

➤

➤

➤➤➤➤

➤

➤

➤

➤

➤

➤

➤➤➤ ➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤➤➤➤➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

MANUAL VALVE

PR

EXEX

3-2 DOWNSHIFT

ISOLATOR VALVE

REG APPLY

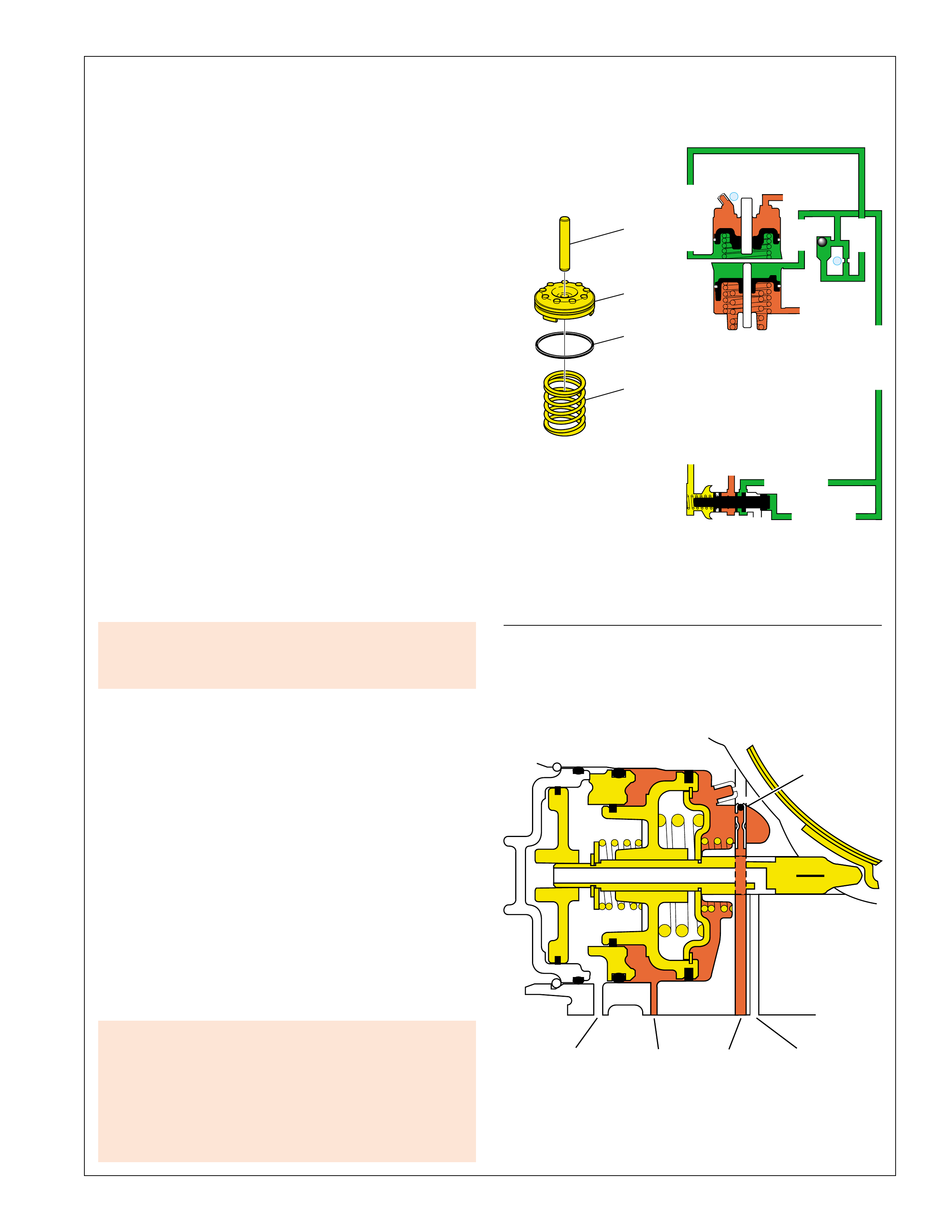

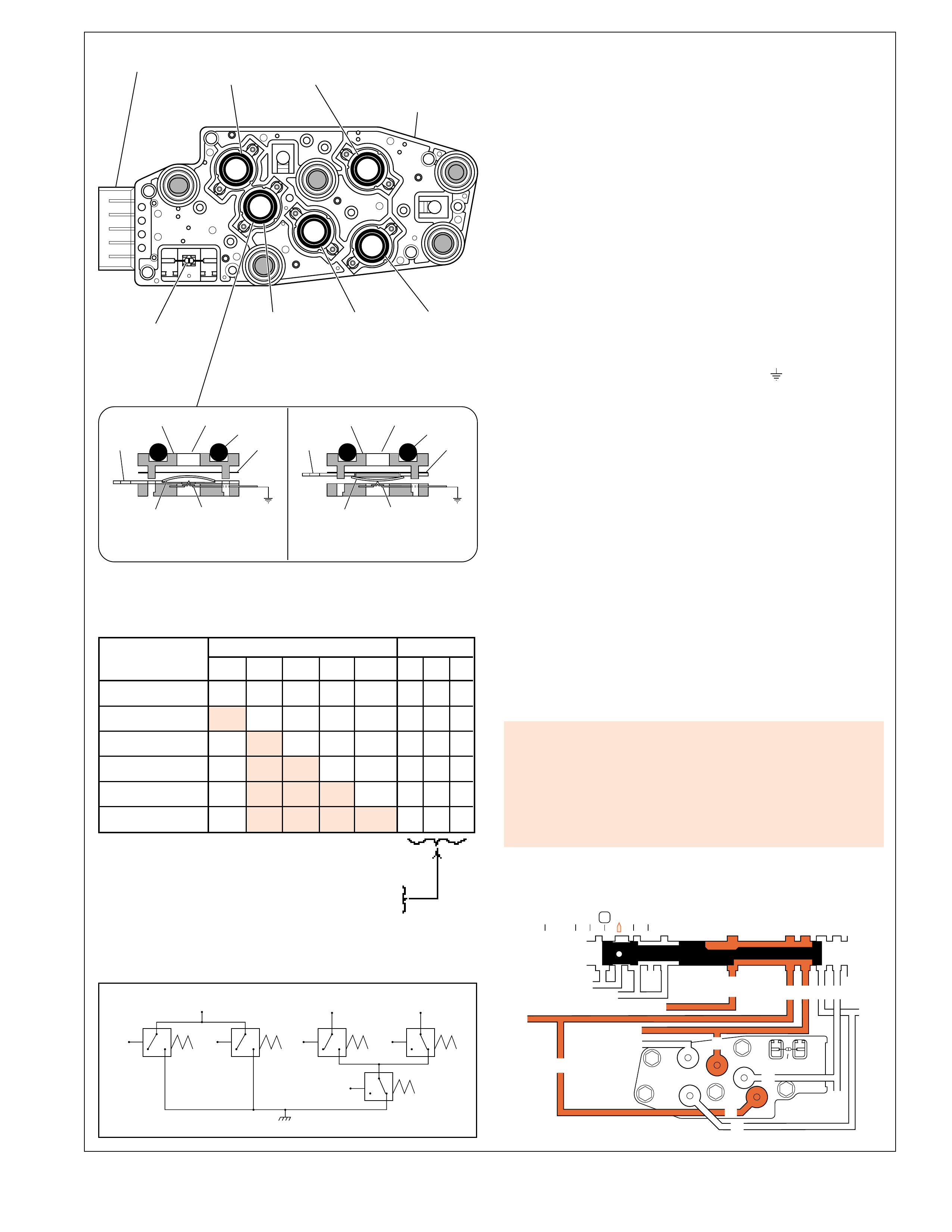

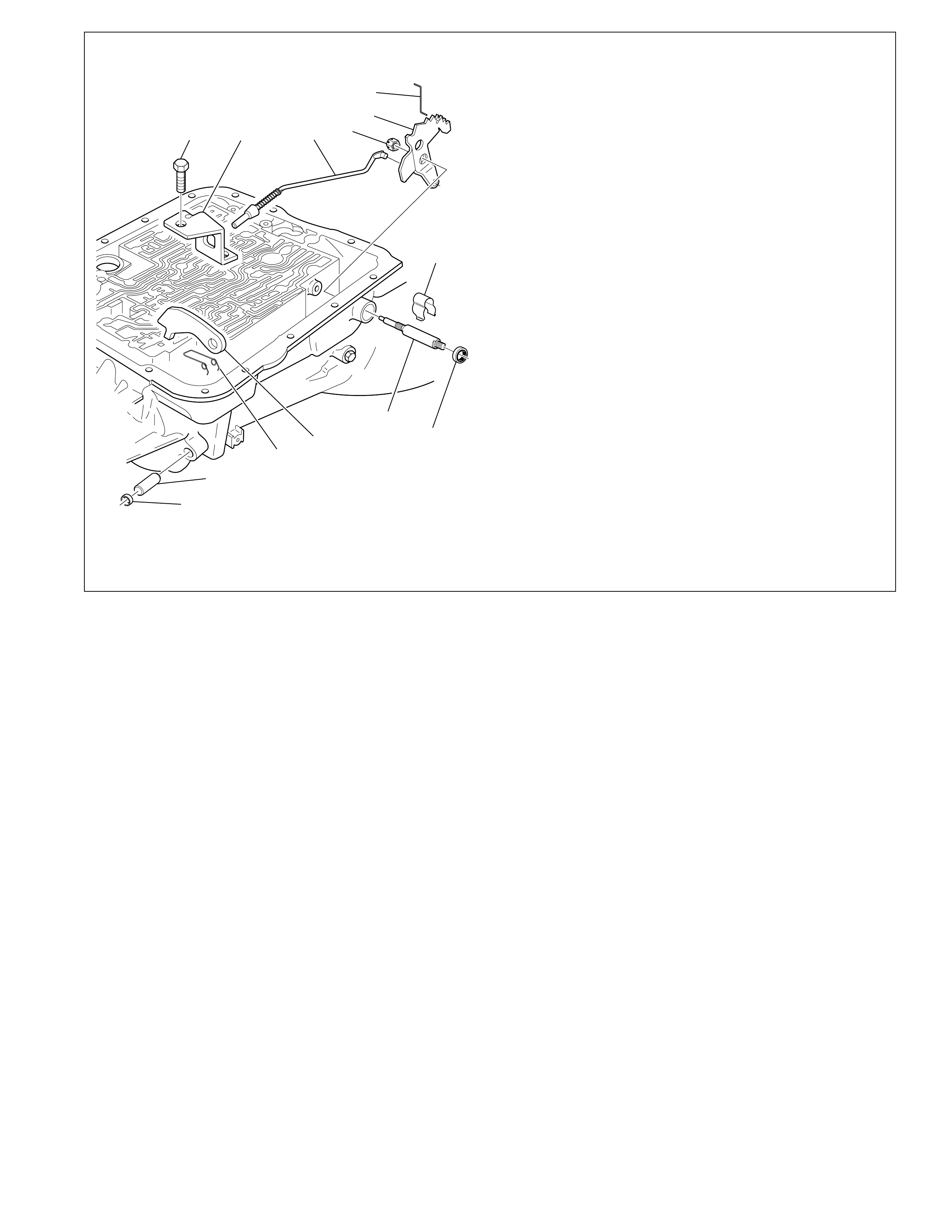

UNDERST ANDING THE GRAPHICS

Figure 3

PUMP COVER

CASE SIDE

THREE DIMENSIONAL

THREE DIMENSIONAL

TWO DIMENSIONAL

THREE DIMENSIONAL

TWO DIMENSIONAL

TWO DIMENSIONAL

GRAPHIC

SCHEMATIC

REPRESENTATION

TWO DIMENSIONAL

VALVE BODY SIDE

THREE DIMENSIONAL

TWO DIMENSIONAL

THREE DIMENSIONAL

CONTROL

VALVE BODY

ASSEMBLY (60)

CASE

ASSEMBLY

(103)

OIL PUMP

ASSEMBLY

(4)

1-2 ACCUMULATOR

COVER

(57)

VALVE BODY

SPACER

PLATE

(48)

FOLDOUT ➤ 7AFOLDOUT ➤ 7

GASKET

(47)

GASKET

(52)

SPACER

PLATE

(48)

CASE SIDE

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

7B

FLUID PRESSURES

SUCTION

CONVERTER & LUBE

MAINLINE

SOLENOID SIGNAL

ACCUMULATOR

ACTUATOR FEED LIMIT

TORQUE SIGNAL

EXHAUST

DIRECTION OF FLOW

➤➤➤

➤

➤

AB

➤

➤

➤

➤

AB

➤

WITH EQUAL SURFACE AREAS

ON EACH END OF THE VALVE,

BUT FLUID PRESSURE "A"

BEING GREATER THAN FLUID

PRESSURE "B", THE V ALVE

WILL MO VE T O THE RIGHT.

WITH THE SAME FLUID PRESSURE

ACTING ON BOTH SURFACE "A"

AND SURFACE "B" THE VALVE

WILL MO VE T O THE LEFT. THIS

IS DUE TO THE LARGER SURFACE

AREA OF "A" THAN "B".

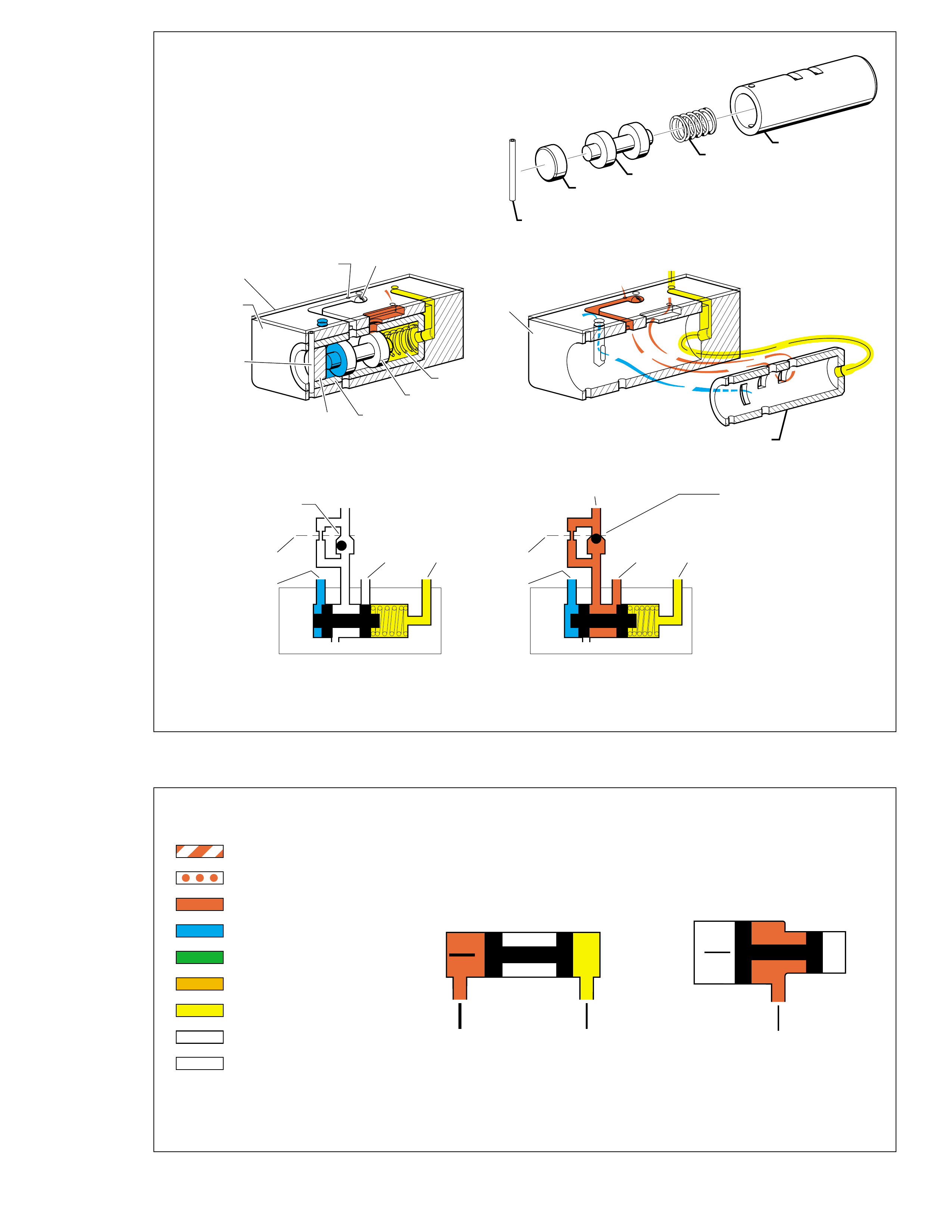

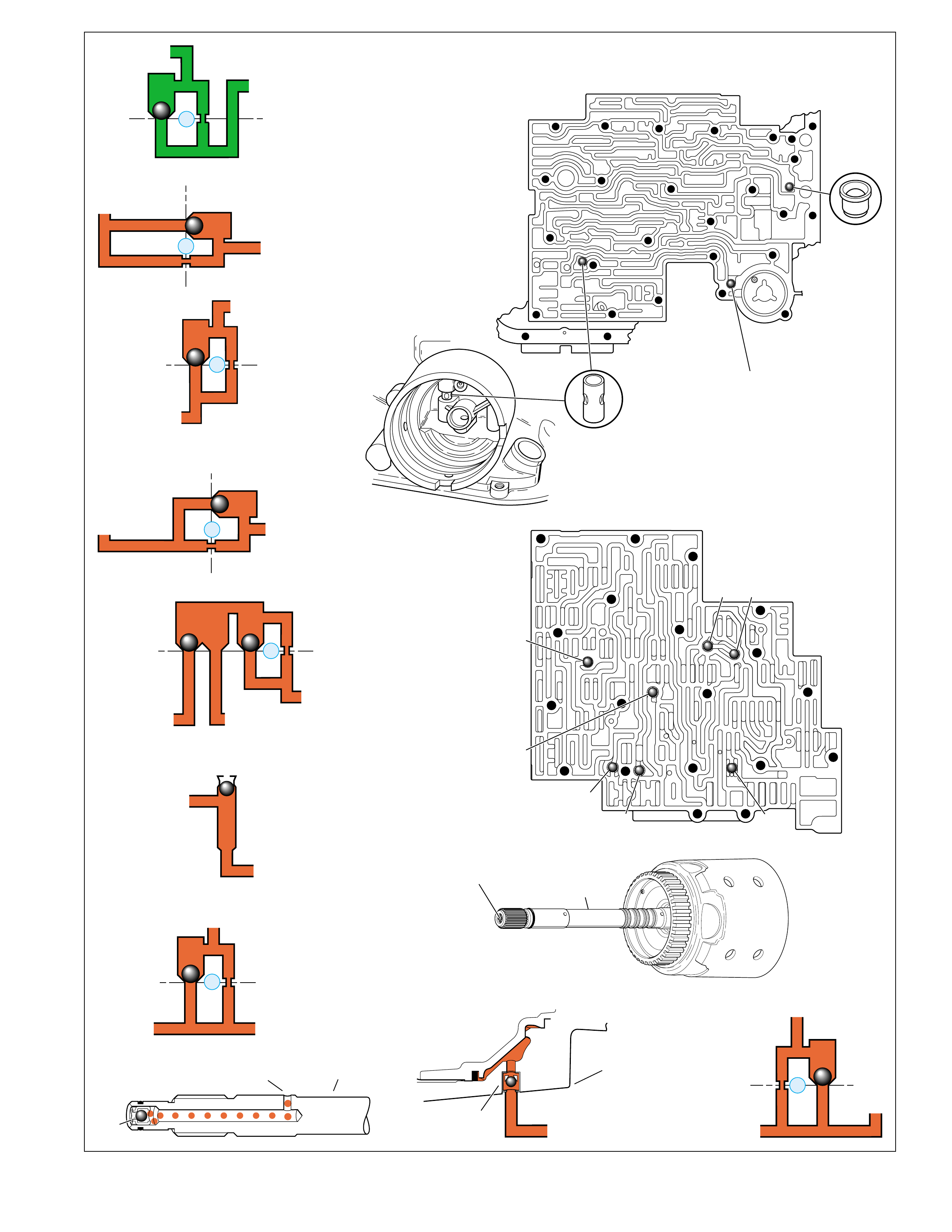

UNDERST ANDING THE GRAPHICS

TYPICAL BUSHING AND VALVE

Figure 4

Figure 5

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

SPRING

RETAINING

PIN

BORE

PLUG

VALVE

BUSHING

EXHAUST FROM THE

APPLY COMPONENT

UNSEATS THE

BALL CHECK VALVE,

THEREFORE CREATING

A QUICK RELEASE.

TO APPLY

COMPONENT APPLY FLUID SEATS

THE BALL CHECK VALVE

FORCING FLUID THROUGH

AN ORIFICE IN THE SPACER

PLATE, WHICH CREATES

A SLOWER APPLY.

WITH SIGNAL FLUID PRESSURE

GREATER THAN SPRING AND

SPRING ASSIST FLUID PRESSURE

THE VALVE MOVES OVER.

WITH SIGNAL FLUID PRESSURE

EQUAL TO OR LESS THAN

SPRING AND SPRING ASSIST

FLUID PRESSURE THE V ALVE

REMAINS IN CLOSED POSITION.

BUSHING

➤

VALVE

BODY

SPACER

PLATE

RESTRICTING

ORIFICE

BALL

CHECK

VALVE

RETAINING

PIN

BORE

PLUG

SPRING

VALVE

BUSHING

VALVE

BODY

➤

➤

➤

➤

➤

➤

➤

➤➤

➤

➤

➤➤

➤

➤

➤

SPACER

PLATE

SIGNAL

FLUID

APPLY

FLUID

SPRING

ASSIST

FLUID

EX

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

SPACER

PLATE

SIGNAL

FLUID

APPLY

FLUID

SPRING

ASSIST

FLUID

EX

➤

➤

➤

➤

➤

➤

➤

NOTE: NOT ALL VALVES ARE

USED WITH A BUSHING

HYDRA-MATIC 4L60-E

8

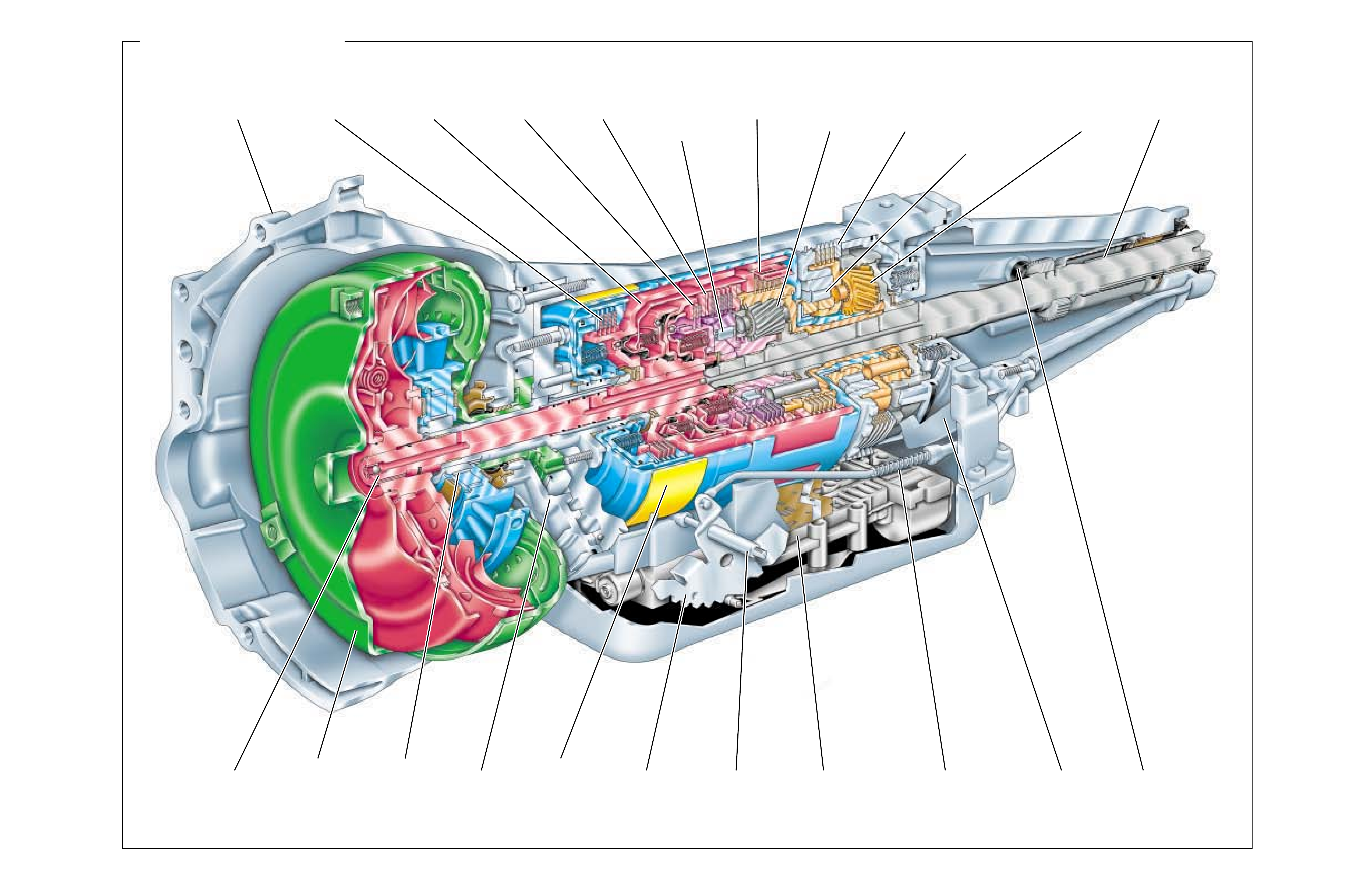

Figure 6

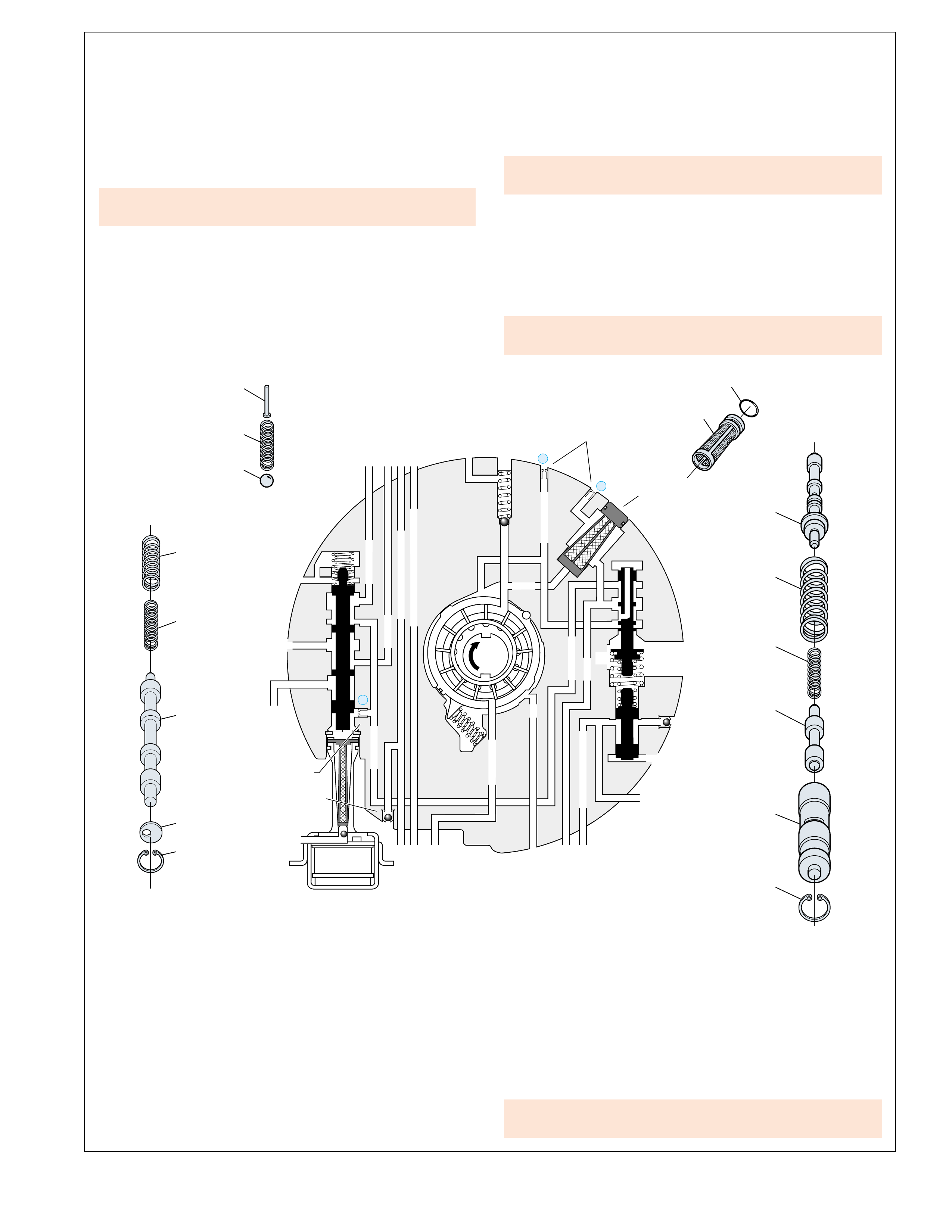

CASE

ASSEMBLY REVERSE

INPUT CLUTCH INPUT CLUTCH

HOUSING OVERRUN

CLUTCH FORWARD

CLUTCH FORWARD

SPRAG

CLUTCH

ASSEMBLY

3-4

CLUTCH INPUT

PLANETARY

GEARSET

LOW AND

REVERSE

CLUTCH

TORQUE

CONVERTER

ASSEMBLY

STATOR

ROLLER

CLUTCH PUMP

ASSEMBLY

LOW AND

REVERSE

ROLLER

CLUTCH

ASSEMBLY

REACTION

PLANETARY

GEARSET

TURBINE

SHAFT

2-4

BAND

ASSEMBLY INSIDE

DETENT LEVER MANUAL

SHAFT CONTROL VALVE

ASSEMBLY PARKING LOCK

ACTUATOR ASSEMBLY SPEED

SENSOR

PARKING

PAWL

OUTPUT

SHAFT

8A

Figure 7

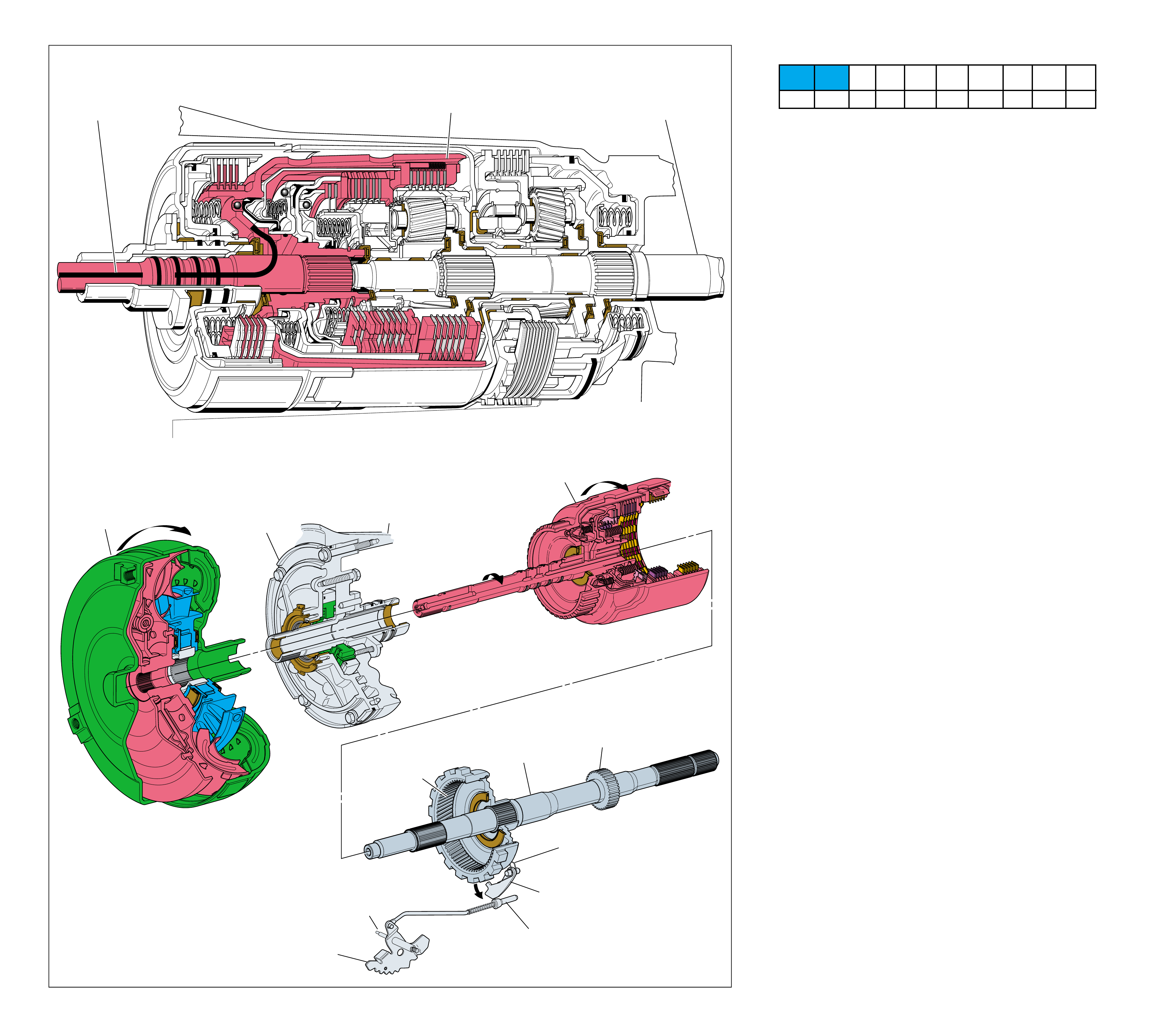

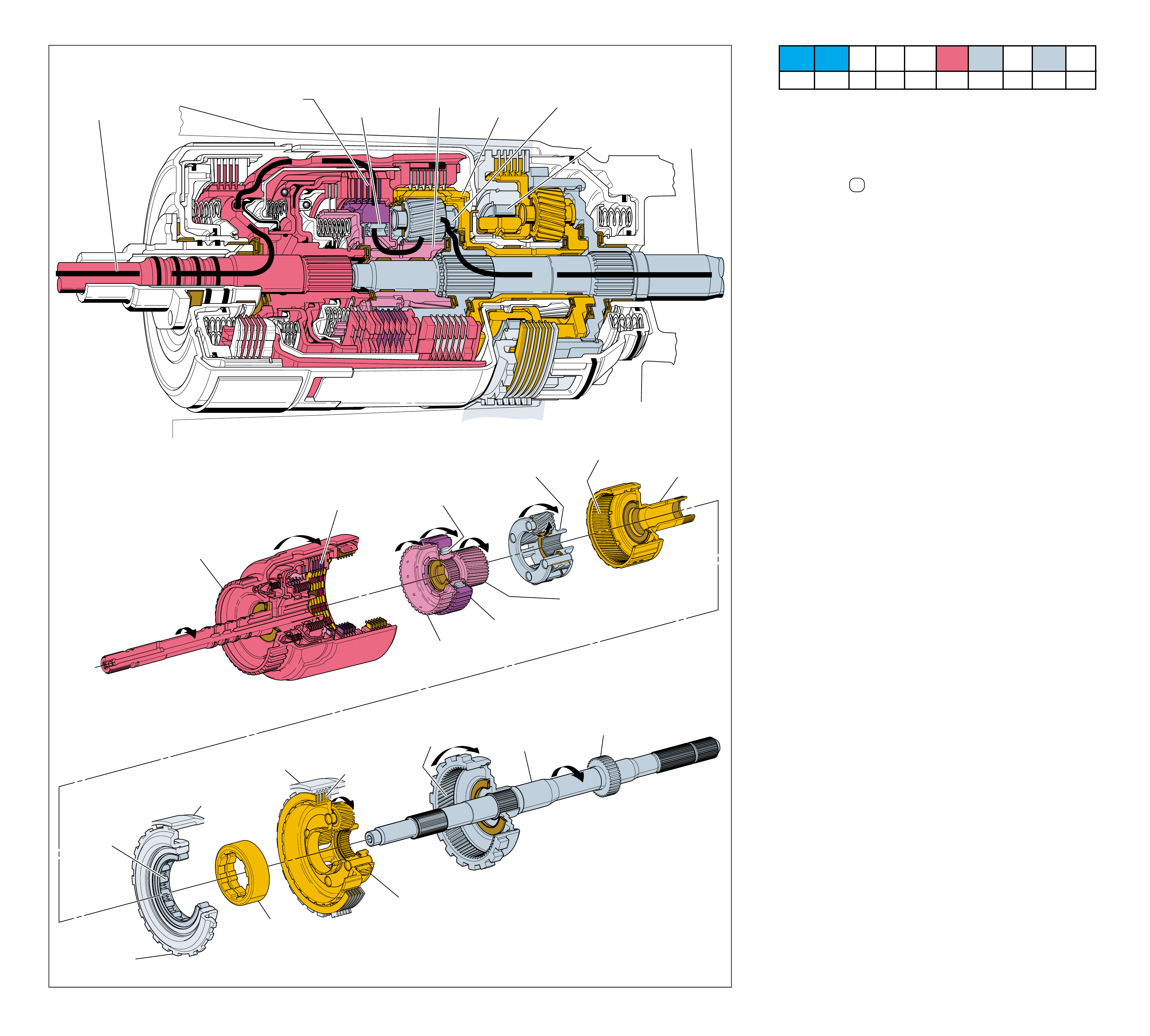

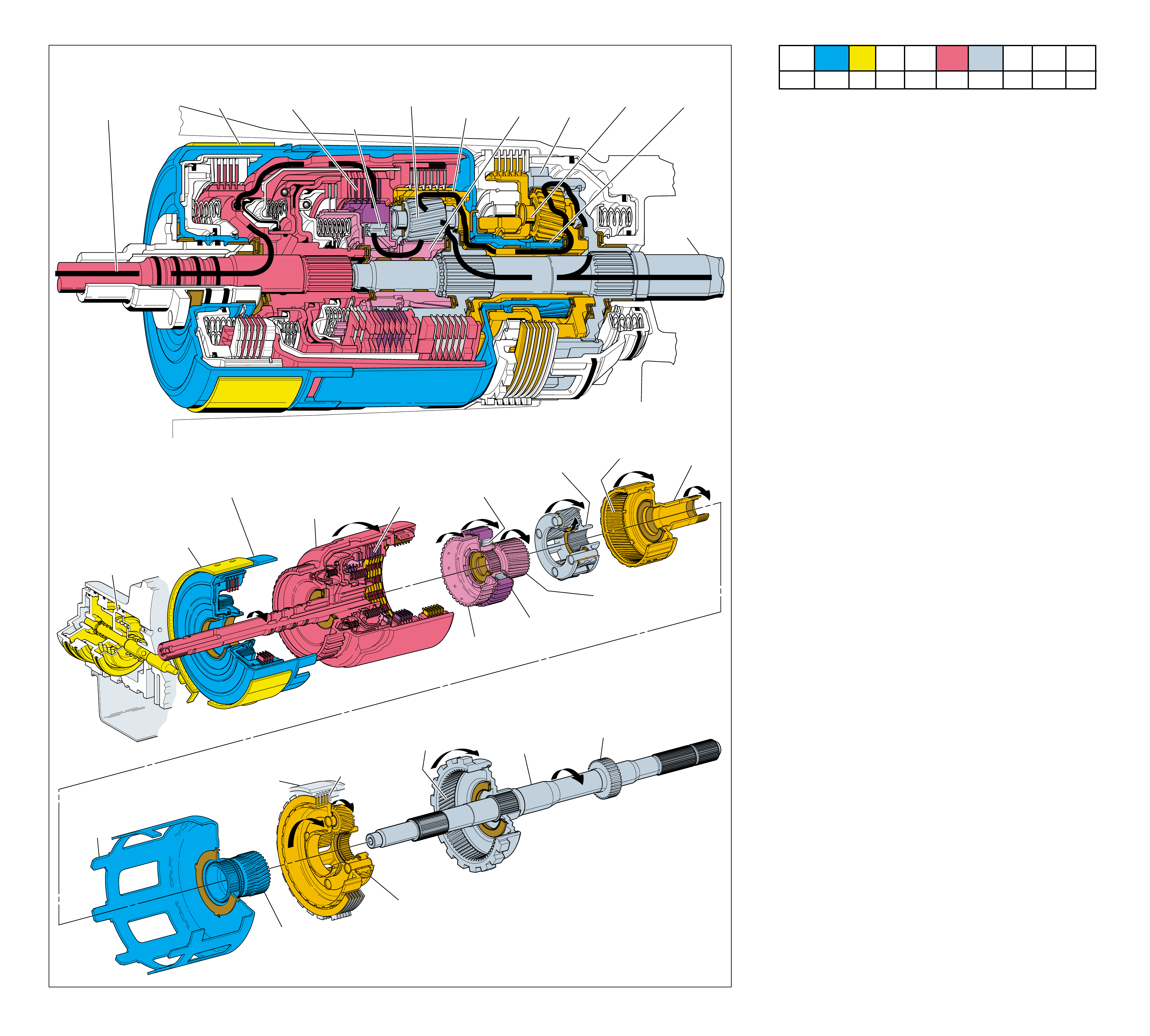

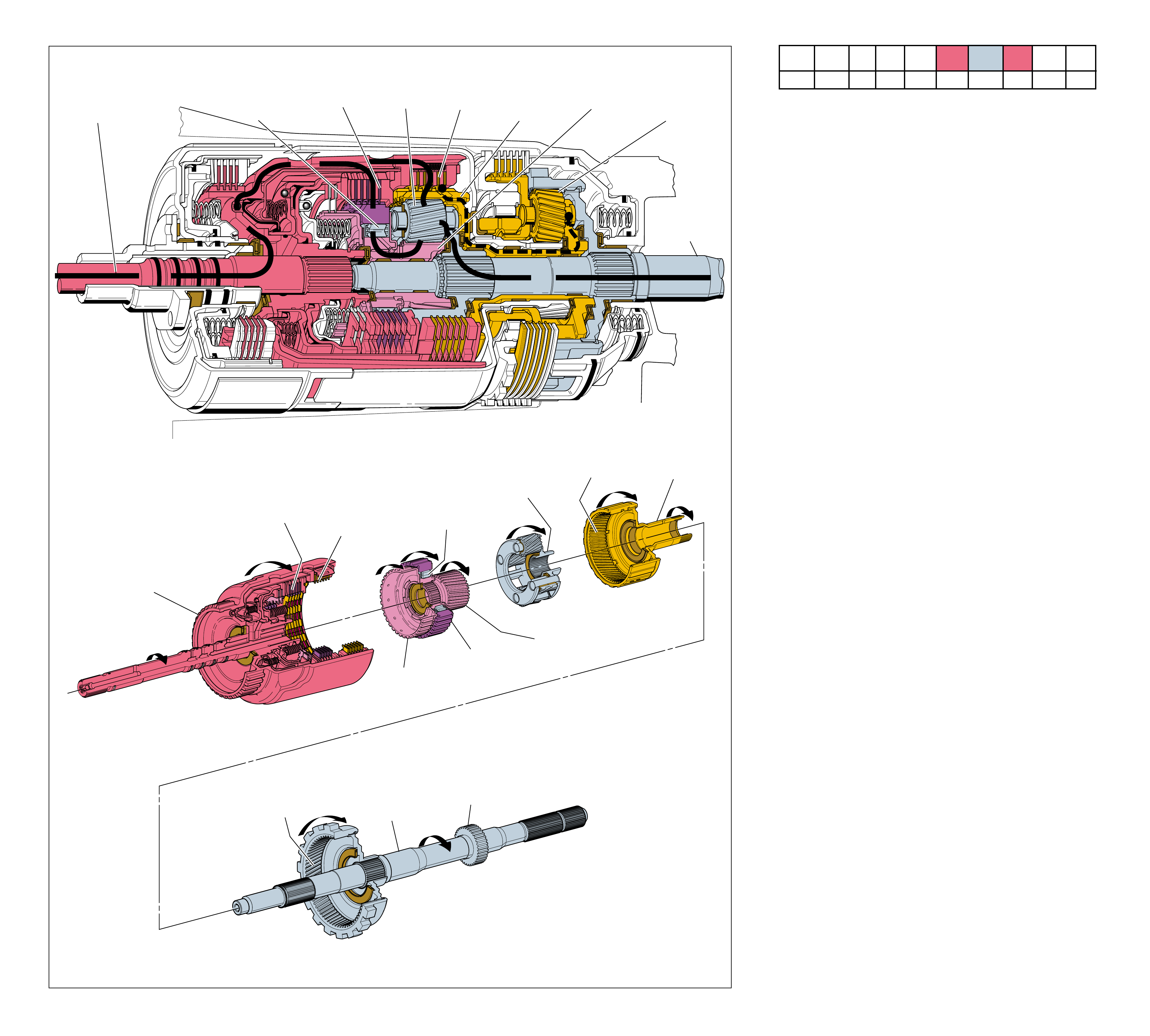

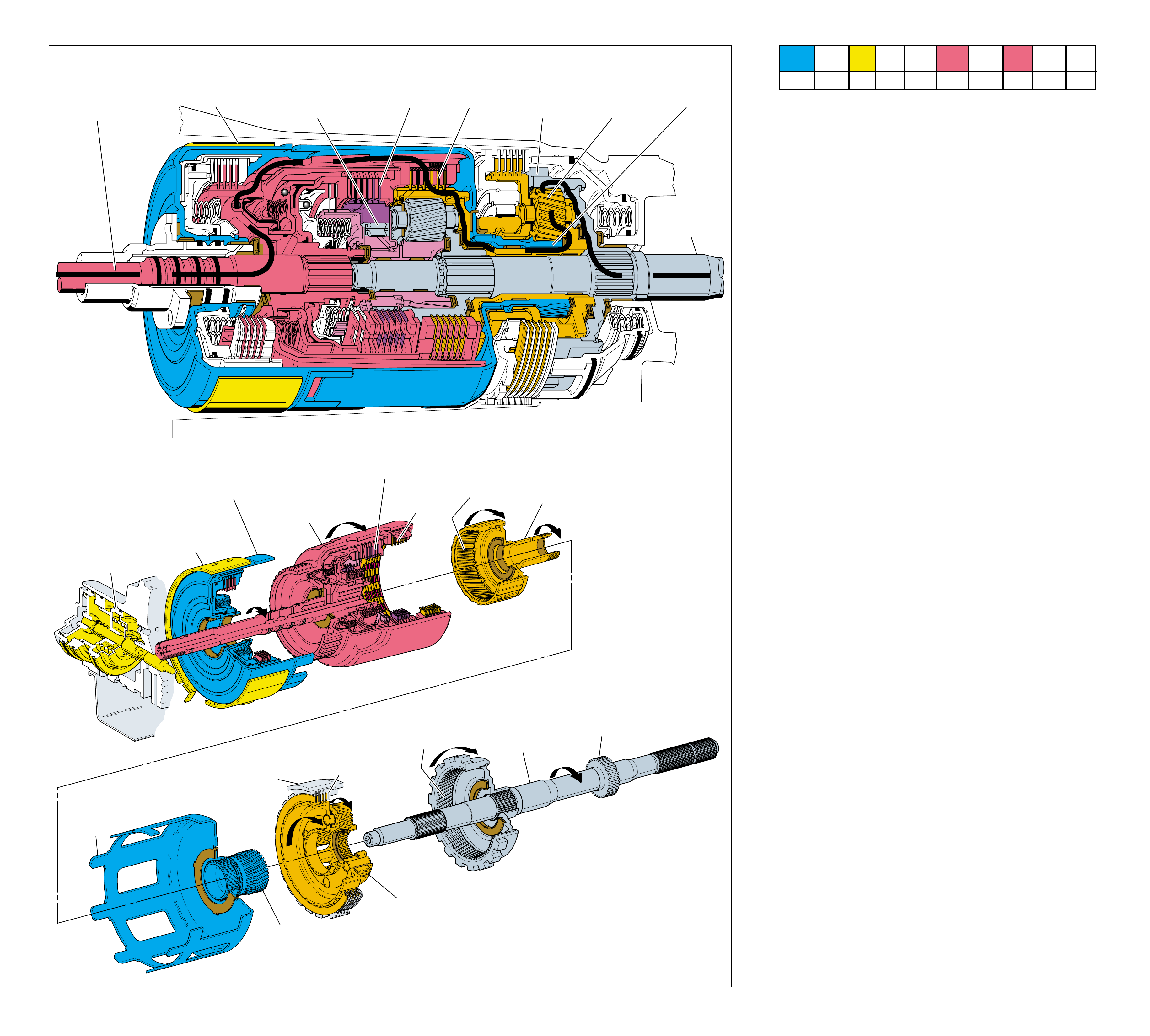

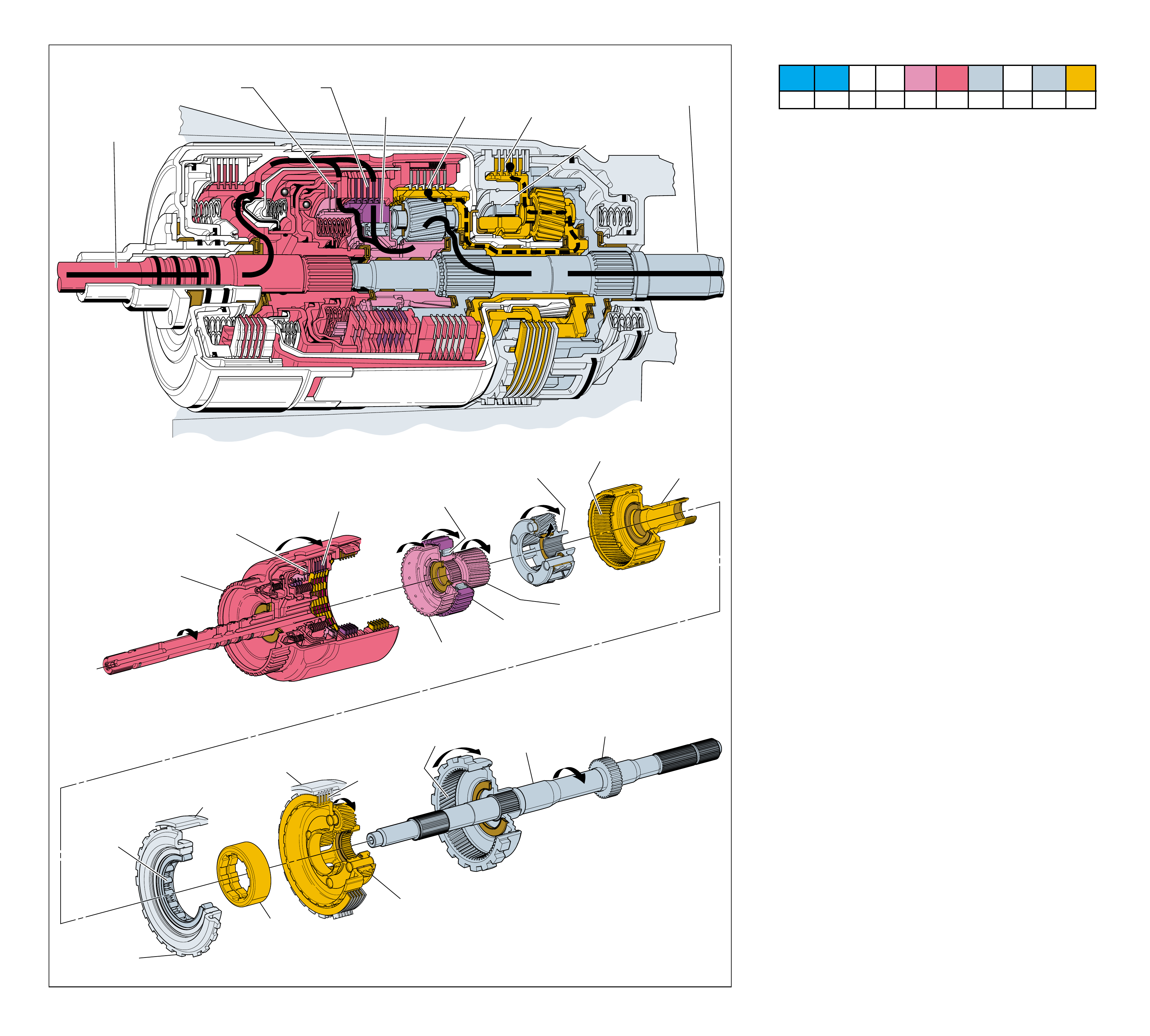

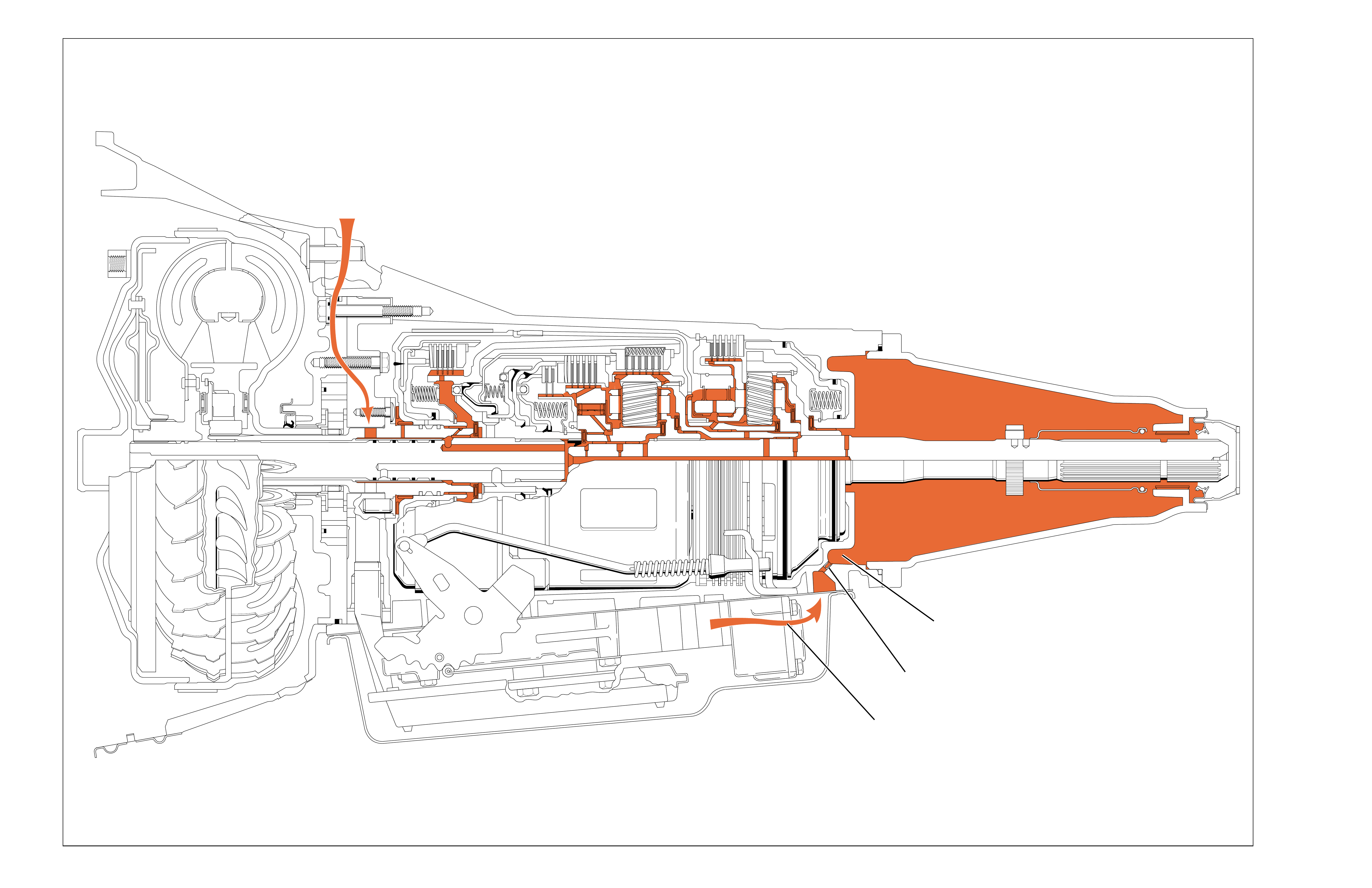

A cross sectional line drawing is typically the standard

method for illustrating either an individual mechanical

component or a complete transmision assembly.

However, unless a person is familiar with all the

individual components of the transmission,

distinguishing components may be diff icult in this type

of drawing. For this reason, a three dimensional

perspectiv e illustration (sho wn on page 8) is the primary

drawing used thr oughout this book.

The purpose for this type of illustration is to provide a

more e xacting graphic repr esentation of eac h component

and to show their relationship to other components

within the transmission assembly. It is also useful for

HYDRA-MATIC 4L60-E

CROSS SECTIONAL DRAWING

understanding the cross sectional line drawing by

comparing the same components from the three

dimensional perspective illustration. In this regard it

becomes an excellent teaching instrument.

Additionally, all the illustrations contained in this book

use a color scheme that is consistent throughout this

book. In other words, regardless of the type of

illustration or drawing , all components hav e an assigned

color and that color is used whenever that component

is illustrated. This consistenc y not only helps to provide

for easy component identification but it also enhances

the graphic and color continuity between sections.

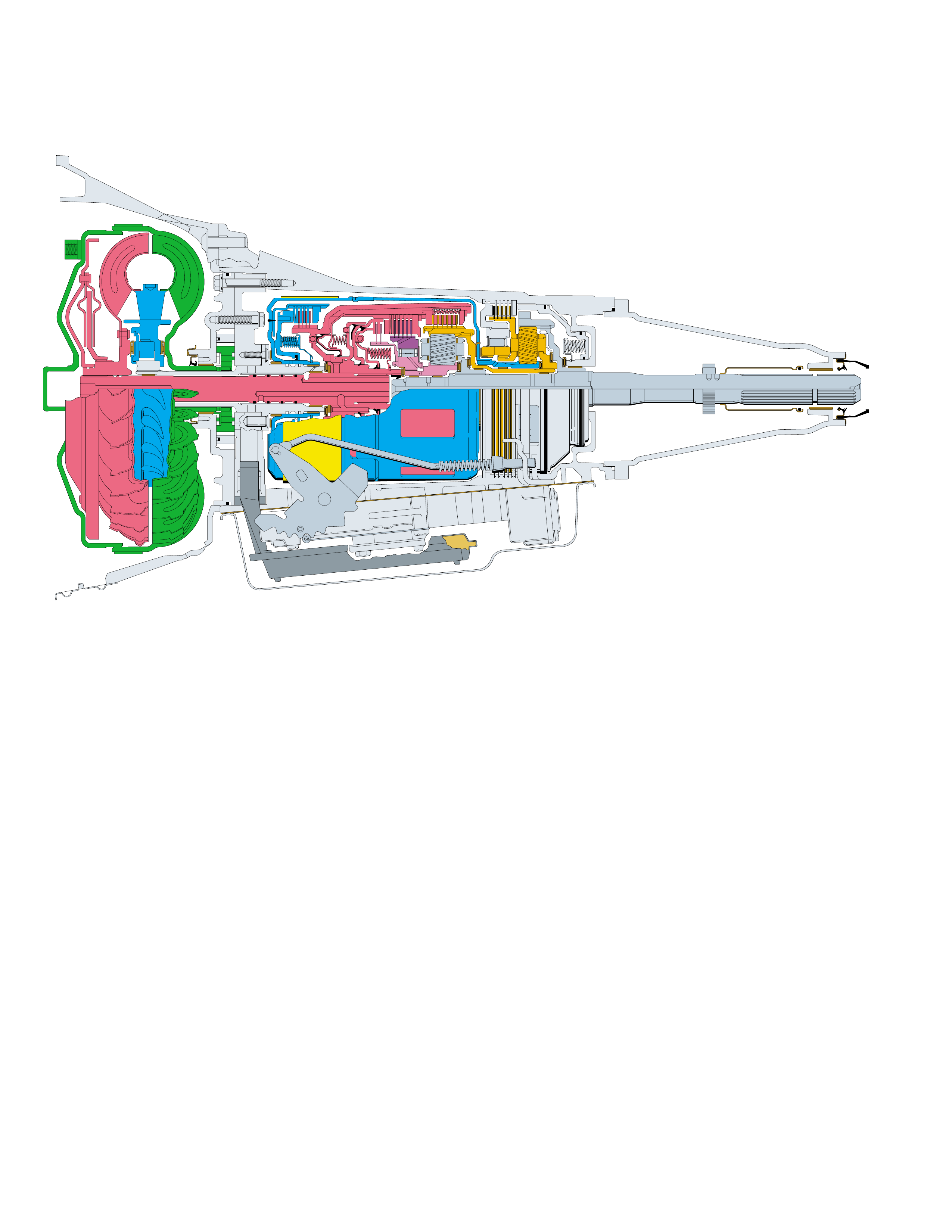

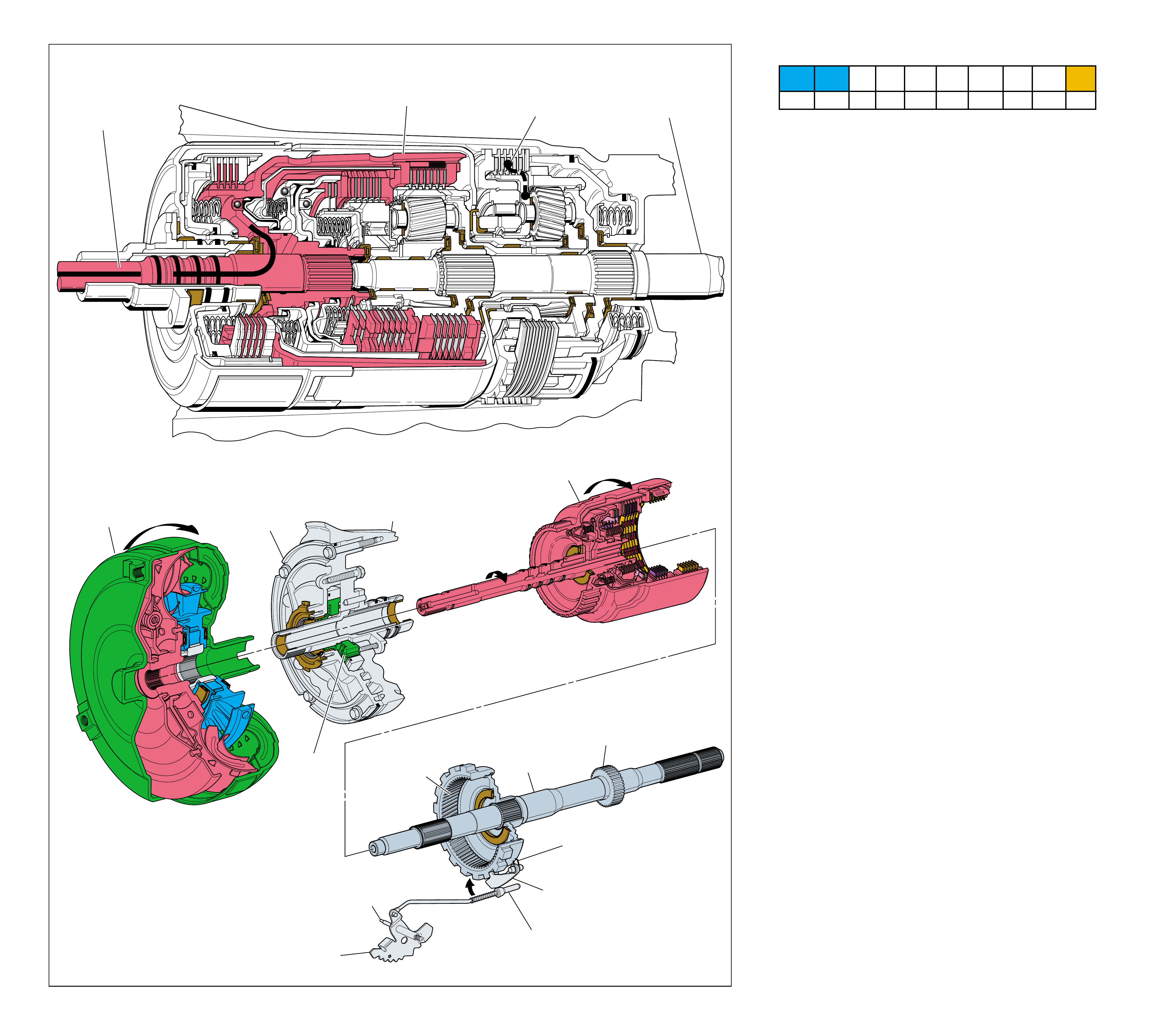

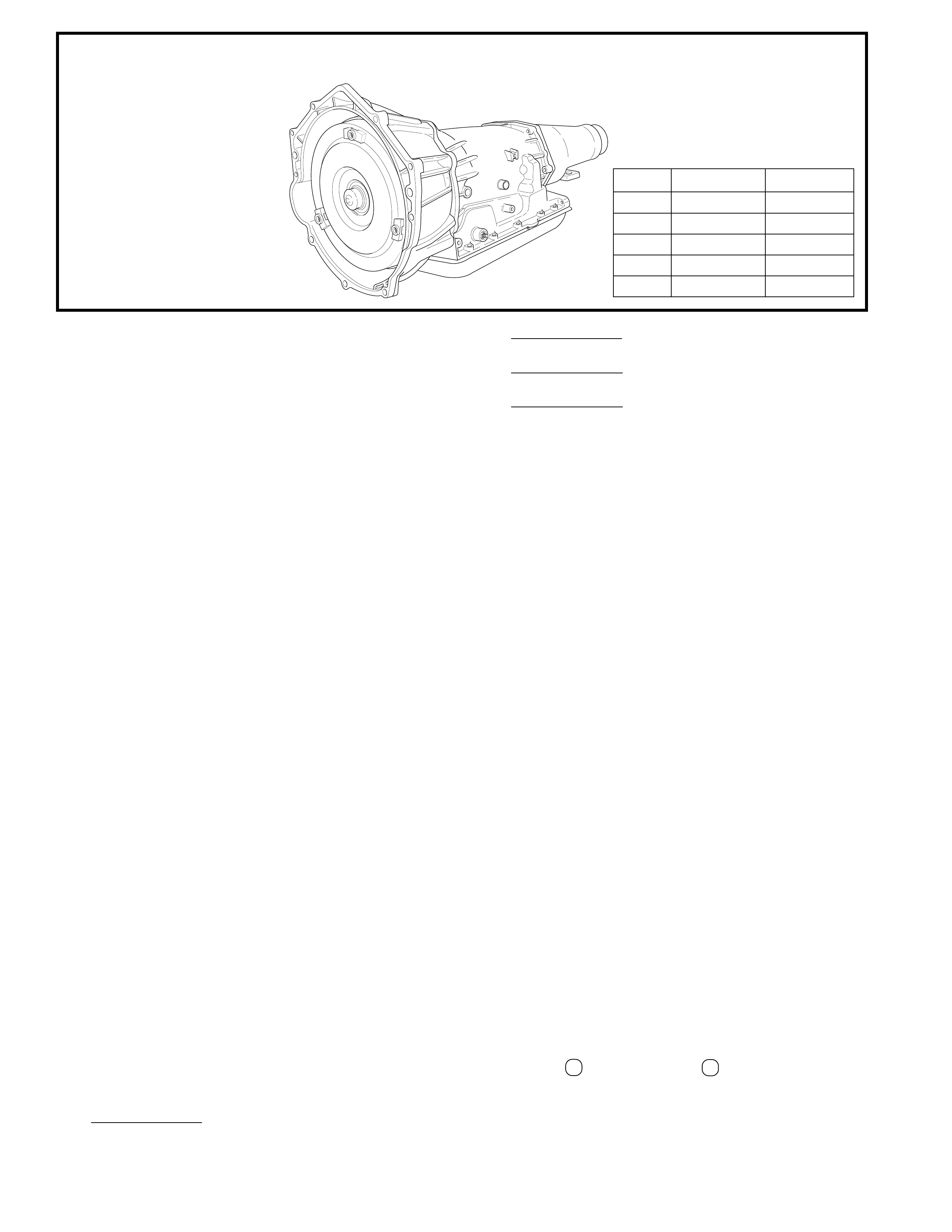

The Hydra-matic 4L60-E is a fully automatic, four

speed, rear wheel drive, electronically controlled

transmission. It consists primarily of a four-element

torque converter, two planetary gear sets, friction and

mechanical clutches and a hydraulic pressur ization and

control system.

The four-element torque converter contains a pump, a

turbine, a pressure plate splined to the turbine, and a

stator assembly. The torque converter acts as a fluid

coupling to smoothly transmit power from the engine

to the transmission. It also hydraulically provides

additional torque multiplication when required. The

pressure plate, when applied, provides a mechanical

“direct dri v e” coupling of the engine to the transmission.

The two planetary g ear sets provide the f our forward gear

ratios and re v erse. Changing gear ratios is fully automatic

and is accomplished through the use of a Powertrain

Control Module (PCM). The PCM recei v es and monitors

v ar ious electronic sensor inputs and uses this infor mation

to shift the transmission at the optimum time.

The PCM commands shift solenoids, within the

transmission, on and off to control shift timing. The

PCM also controls the apply and release of the torque

converter clutch which allows the engine to deliver the

maximum fuel efficiency without sacrificing vehicle

performance.

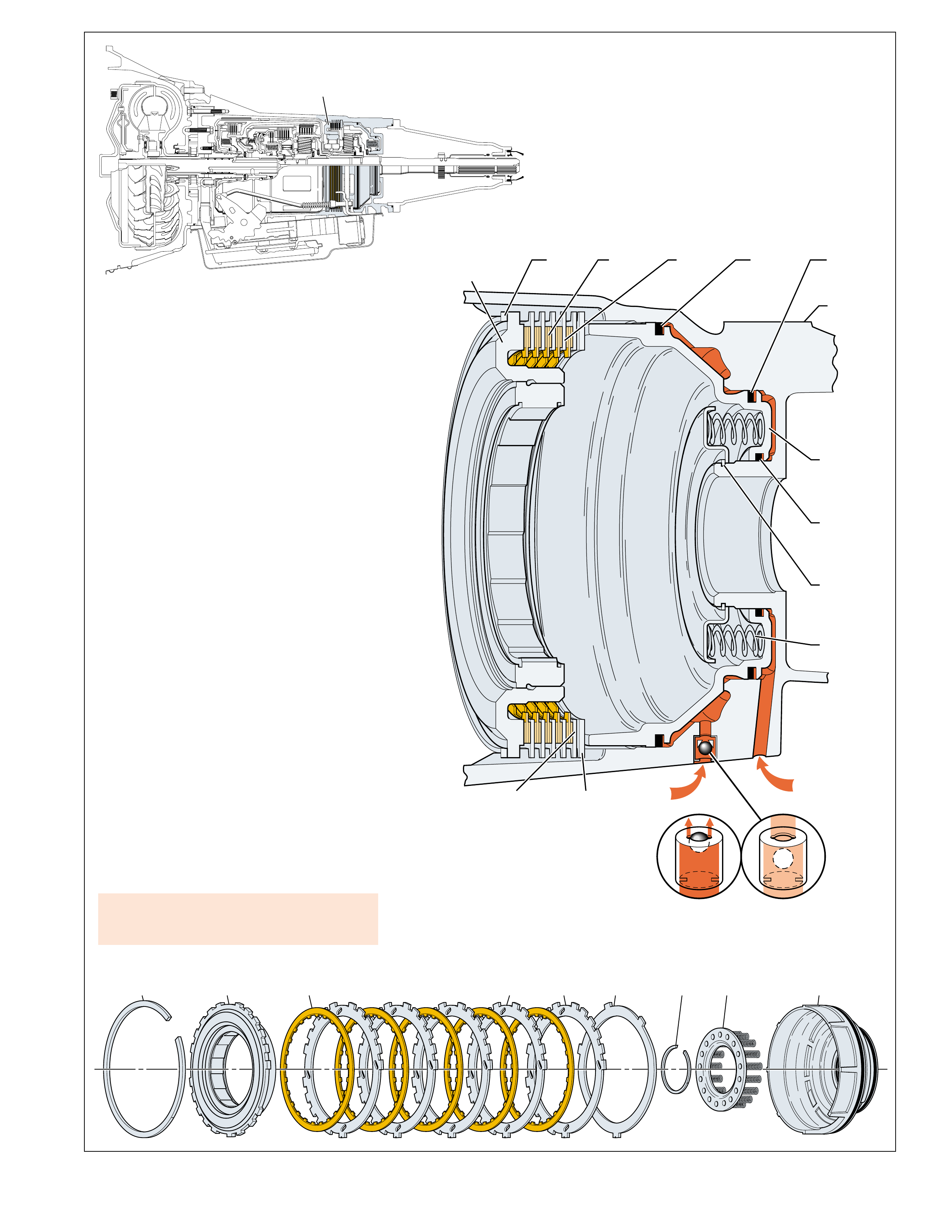

The hydraulic system primarily consists of a vane type

pump, control v alve body and case. The pump maintains

the working pressures needed to stroke the servo and

clutch pistons that apply or release the friction

components. These friction components (when applied

or released) support the automatic shifting qualities of

the transmission.

The friction components used in this transmission

consist of five multiple disc clutches and one band.

The multiple disc clutches combine with two

mechanical components, one roller clutch and one sprag

clutch, to deliver five different gear ratios through the

gear sets. T he gear sets then transfer torque through the

output shaft.

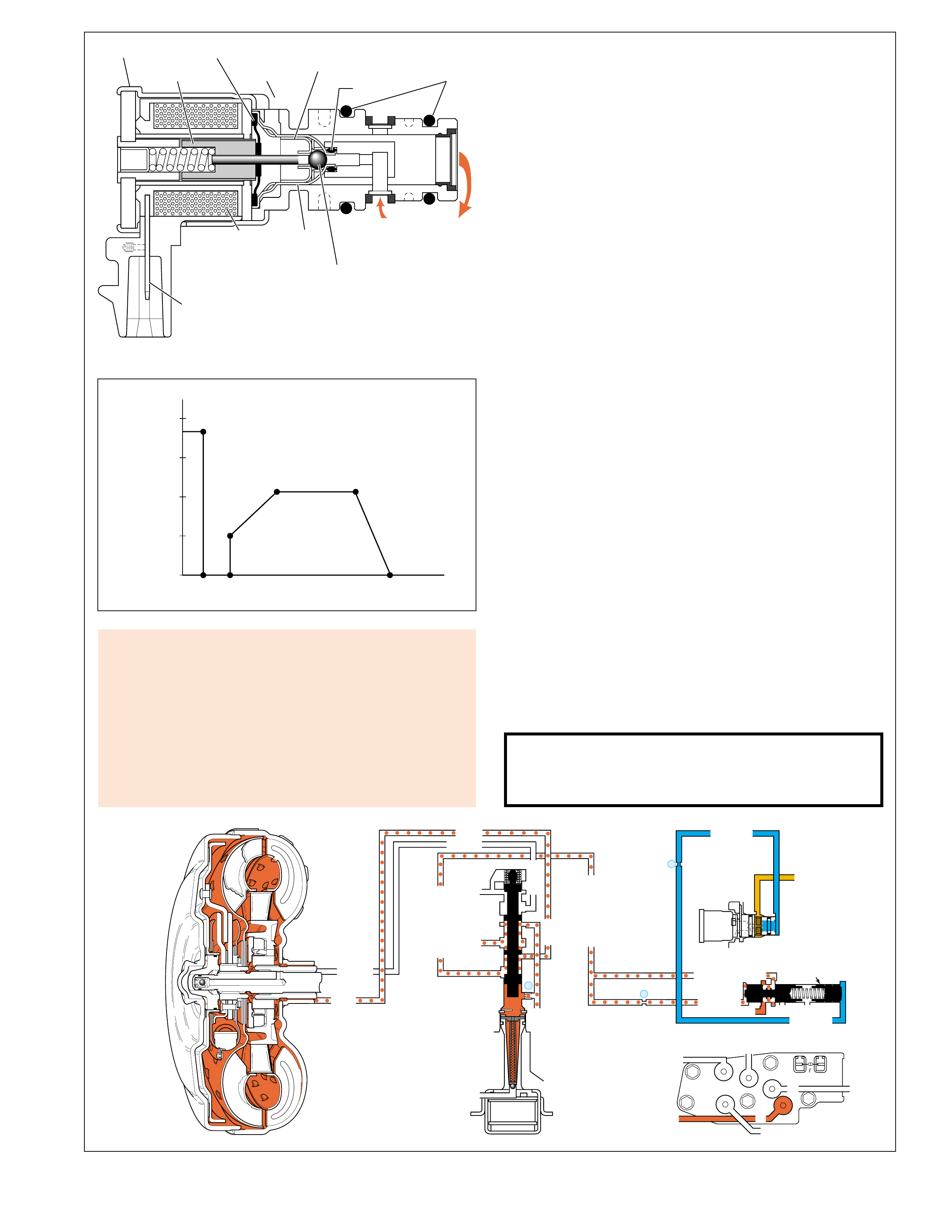

for safe passing by depressing the accelerator or by

manually selecting a low er gear with the shift selector.

The transmission should not be operated in Overdrive

towing a trailer or driving on hilly terrain. Under such

conditions that put an extra load on the engine, the

transmission should be driven in a lower manual gear

selection for maximum efficiency.

D–Manual Third can be used for conditions where it

may be desirable to use only three gear ratios. These

conditions include towing a trailer and driving on hilly

terrain as described above. This range is also helpful

for engine braking when descending slight grades.

Upshifts and downshifts are the same as in Overdrive

range for first, second and third gears except that the

transmission will not shift into fourth gear.

2–Manual Second adds more performance for con-

gested traffic and hilly terrain. It has the same starting

ratio (first gear) as Man ual Third b ut pre vents the tr ans-

mission from shifting abov e second gear. Thus, Manual

Second can be used to retain second gear for accelera-

tion and engine braking as desired. Manual Second

can be selected at any v ehicle speed but will not do wn-

shift into second gear until the vehicle speed drops

below approximately 100 km/h (62 mph).

1–

Manual First can be selected at any vehicle speed.

If the transmission is in third or fourth gear it will

immediately shift into second gear. When the vehicle

speed slows to below approximately 48 to 56 km/h (30

to 35 mph) the transmission will then shift into first

gear . This is particularly beneficial for maintaining maxi-

mum engine braking when descending steep grades.

Figure 8

EXPLANATION OF GEAR RANGES

FOLDOUT ➤ 9

PRINCIPLES OF OPERATION

An automatic transmission is the mechanical

component of a vehicle that transfers power

(torque) from the engine to the wheels. It

accomplishes this task by providing a number

of forward gear ratios that automatically change

as the speed of the vehicle increases. The

reason for changing forward gear ratios is to

provide the performance and economy expected

from vehicles manufactured today. On the

performance end, a gear ratio that develops a

lot of torque (through torque multiplication) is

required in order to initially start a vehicle

moving. Once the vehicle is in motion, less

torque is required in order to maintain the

vehicle at a certain speed. When the vehicle

has reached a desired speed, economy becomes

the important factor and the transmission will

shift into overdrive. At this point output speed

is greater than input speed, and, input torque

is greater than output torque.

Another important function of the automatic

transmission is to allow the engine to be started

and run without transferring torque to the

wheels. This situation occurs whenever Park

(

P

) or Neutral (

N

) range has been selected.

Also, operating the vehicle in a rearward

direction is possible whenever Reverse (

R

)

range has been selected (accomplished by the

gear sets).

The variety of gear ranges in an automatic

transmission are made possible through the

interaction of numerous mechanically,

hydraulically and electronically controlled

components inside the transmission. At the

appropriate time and sequence, these

components are either applied or released and

operate the gear sets at a gear ratio consistent

with the driver’s needs. The following pages

describe the theoretical operation of the

mechanical, hydraulic and electrical

components found in the Hydra-matic 4L60-E

transmission. When an understanding of these

operating principles has been attained, diagnosis

of these transmission systems is made easier.

9A

GENERAL DESCRIPTION

P

R

N

D

D

2

1

The transmission can be operated in any one of the

seven different positions shown on the shift quadrant

(Figure 8).

P–Park position enables the engine to be started while

preventing the vehicle from rolling either forward or

backward. For safety reasons, the vehicle’s parking

brake should be used in addition to the transmission

“Park” position. Since the output shaft is mechanically

locked to the case through the parking pawl and reac-

tion internal gear, Park position should not be selected

until the vehicle has come to a complete stop.

R–Reverse enables the vehicle to be operated in a

rearward direction.

N–Neutral position enables the engine to start and

operate without driving the vehicle. If necessary, this

position should be selected to restart the engine while

the vehicle is moving .

D –Overdrive range should be used for all normal

driving conditions for maximum efficiency and fuel

economy. Overdrive range allows the transmission to

operate in each of the four forward gear ratios. Down-

shifts to a lower gear, or higher gear ratio are available

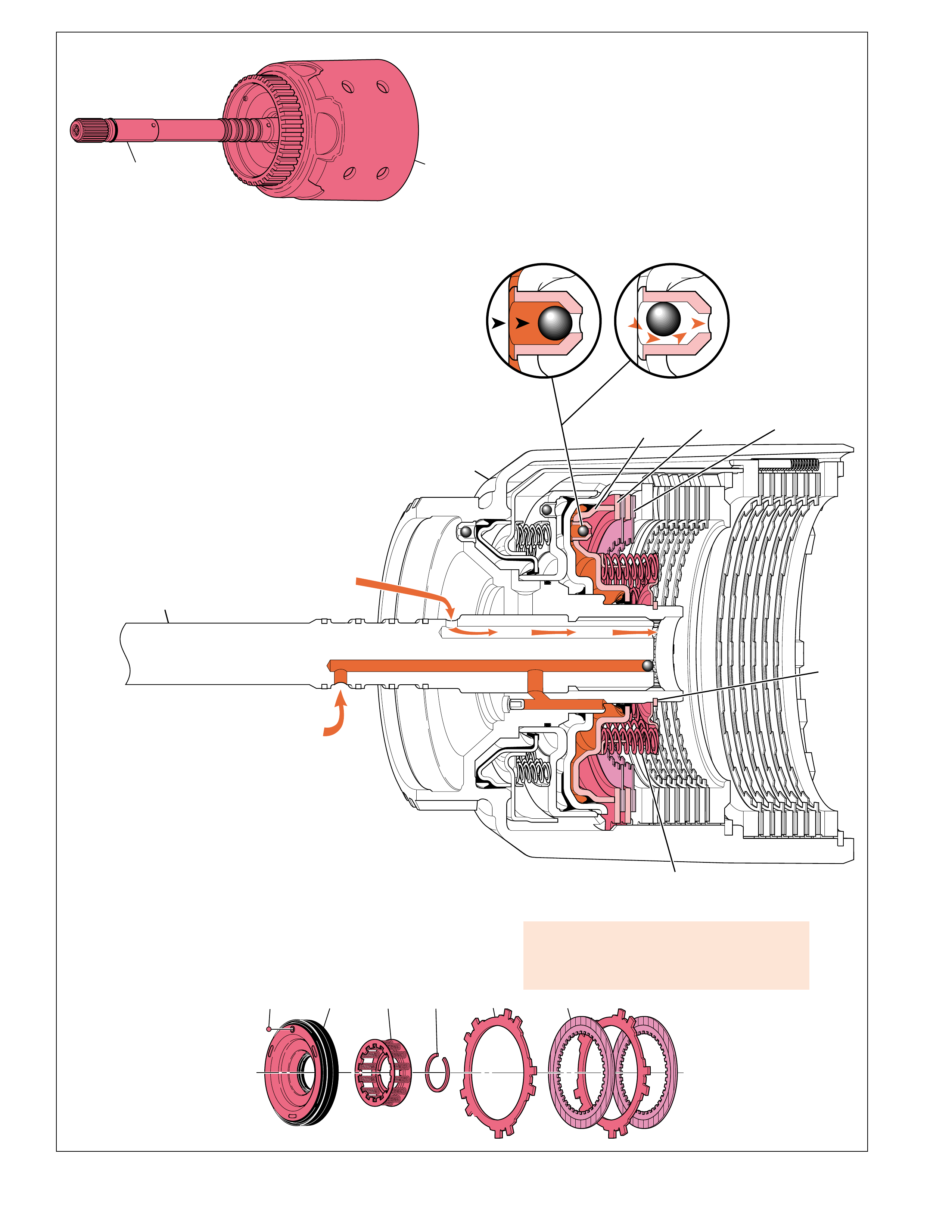

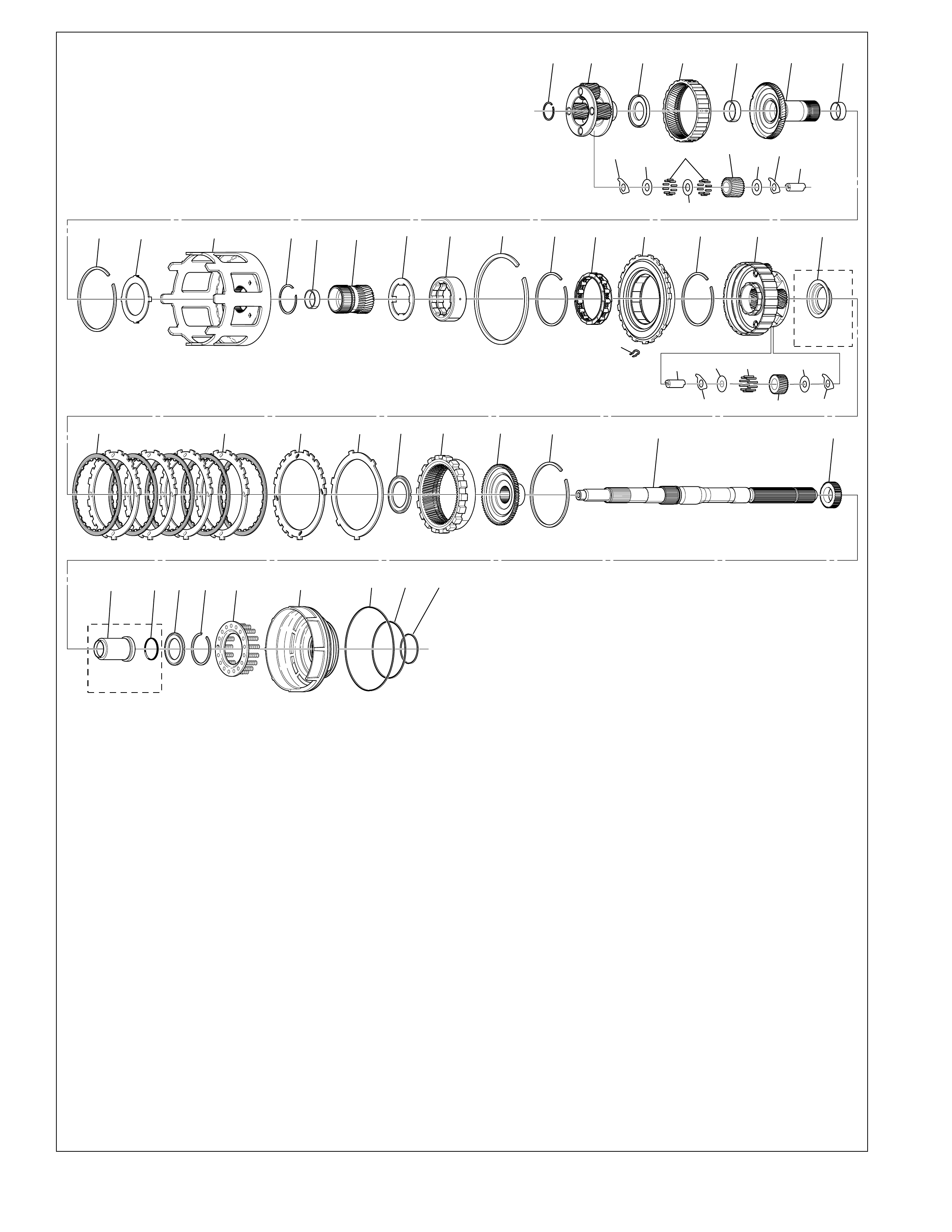

MAJOR MECHANICAL COMPONENTS

SPLINED

TOGETHER

SPLINED

TOGETHER

SPLINED

T O TORQ UE

CONVERTER TURBINE

SPLINED

TOGETHER SPLINED

TOGETHER

SPLINED

TOGETHER

SPLINED T O

OUTPUT SHAFT

(687)

SPLINED T O

REACTION

CARRIER

ASSEMBLY

(681)

LOCKS T OGETHER WITH

REVERSE INPUT

CLUTCH HOUSING

(605)

SPLINED

TOGETHER

SPLINED T O

REACTION

CARRIER

SHAFT

(666)

SPLINED T O

INPUT

CARRIER

ASSEMBLY

(662)

SPLINED

TOGETHER

TORQUE

CONVERTER

ASSEMBLY

(1)

PUMP

ASSEMBLY

(4)

MAIN

CASE

(103)

SERVO

ASSEMBLY

2-4 BAND

ASSEMBLY (602)

REVERSE INPUT

CLUTCH HOUSING

(605)

BAND

ANCHOR

PIN (41)

INPUT HOUSING

& SHAFT ASSEMBLY

(621)

FORWARD SPRAG

ASSEMBLY

(642)

OVERRUN

CLUTCH HUB

(639)

FORWARD CLUTCH

OUTER RACE

(644)

FORWARD

SPRAG CLUTCH

INNER RACE

AND INPUT

SUN GEAR

ASSEMBLY

(640)

INPUT CARRIER

ASSEMBLY

(662)

INPUT

INTERNAL

GEAR

(664)

REACTION

CARRIER

SHAFT

(666)

REACTION

SUN SHELL

(670)

REACTION

SUN GEAR

(673)

LOW AND REVERSE

CLUTCH SUPPORT

ASSEMBLY

(679)

LOW AND REVERSE

ROLLER CLUTCH

ASSEMBLY

(678)

LOW AND REVERSE

ROLLER CLUTCH

RACE

(675)

LOW AND REVERSE

CLUTCH PLATE

ASSEMBLY

(682)

REACTION

CARRIER

ASSEMBLY

(681)

OUTPUT

SHAFT

(687)

SPEED SENSOR

ROTOR

(699)

PARKING PAWL

RETURN SPRING

(80)

PARKING BRAKE

PAWL (81)

PARKING LOCK

ACTUATOR

ASSEMBLY

(85)

INSIDE

DETENT

LEVER

(88)

MANUAL

SHAFT

(84)

REACTION

INTERNAL

GEAR

(684)

MAIN

CASE

(103)

MAIN

CASE

(103)

LOCKS T OGETHER WITH

REACTION

SUN SHELL

(670)

10 Figure 9

COLOR LEGEND

MAJOR MECHANICAL COMPONENTS

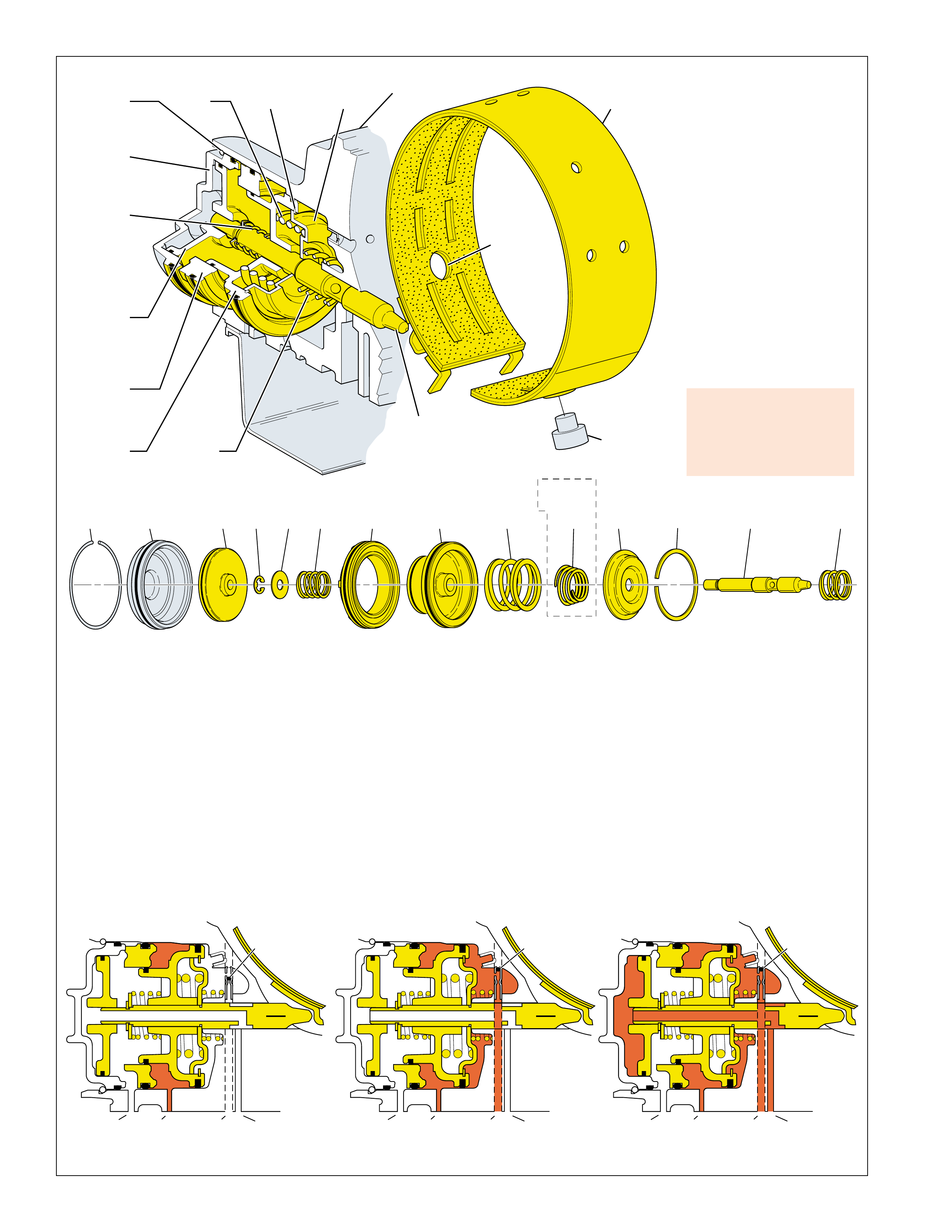

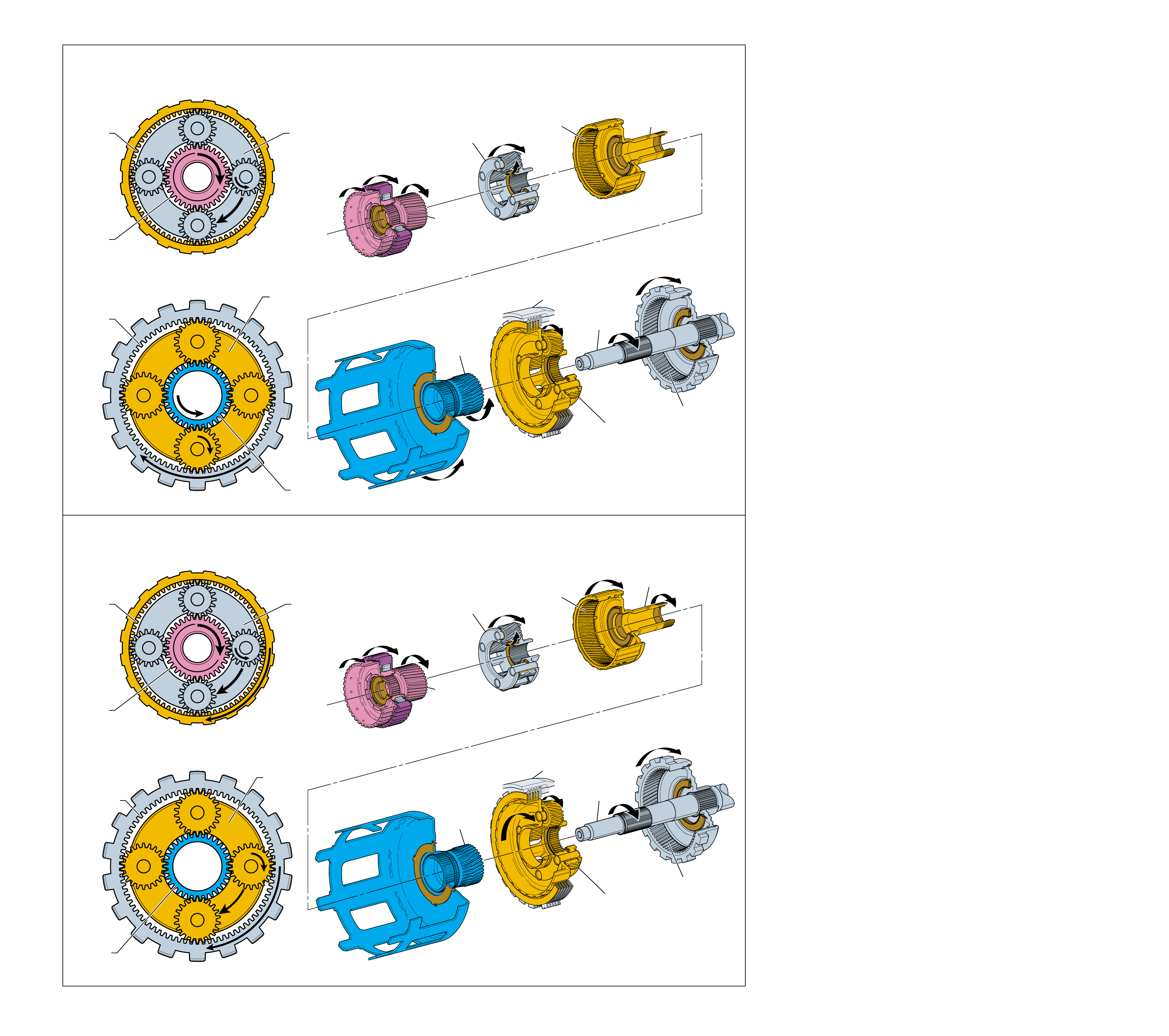

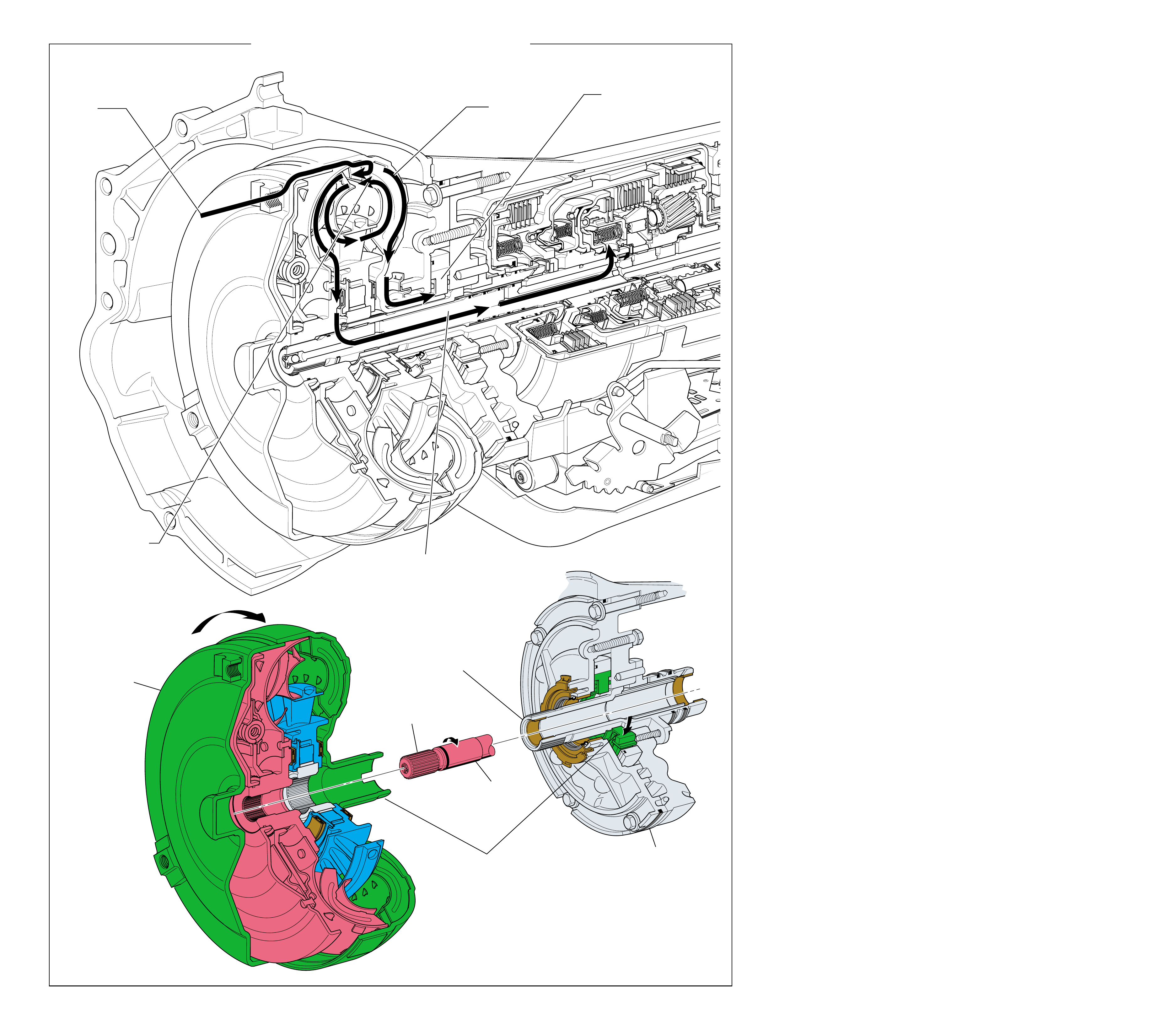

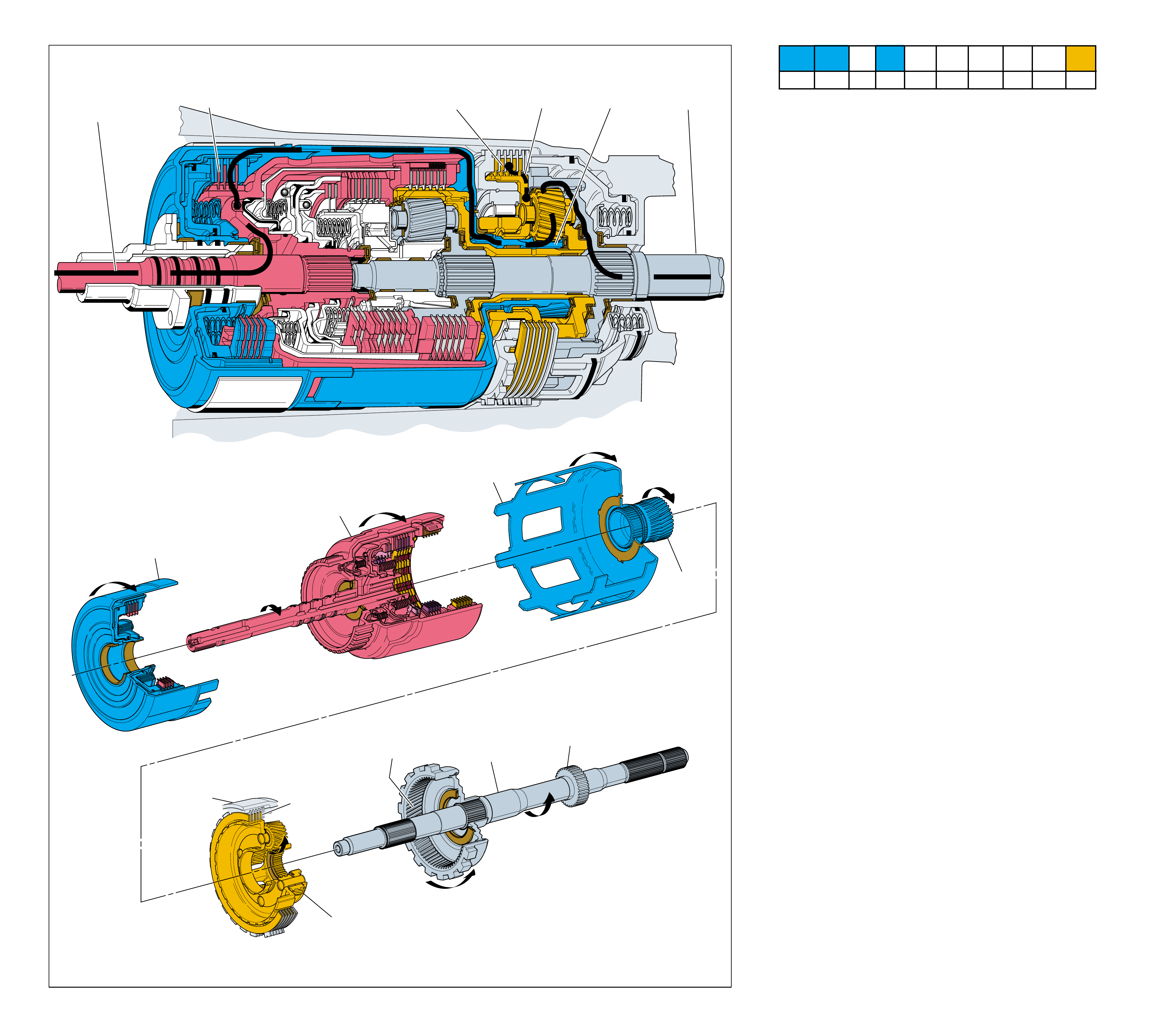

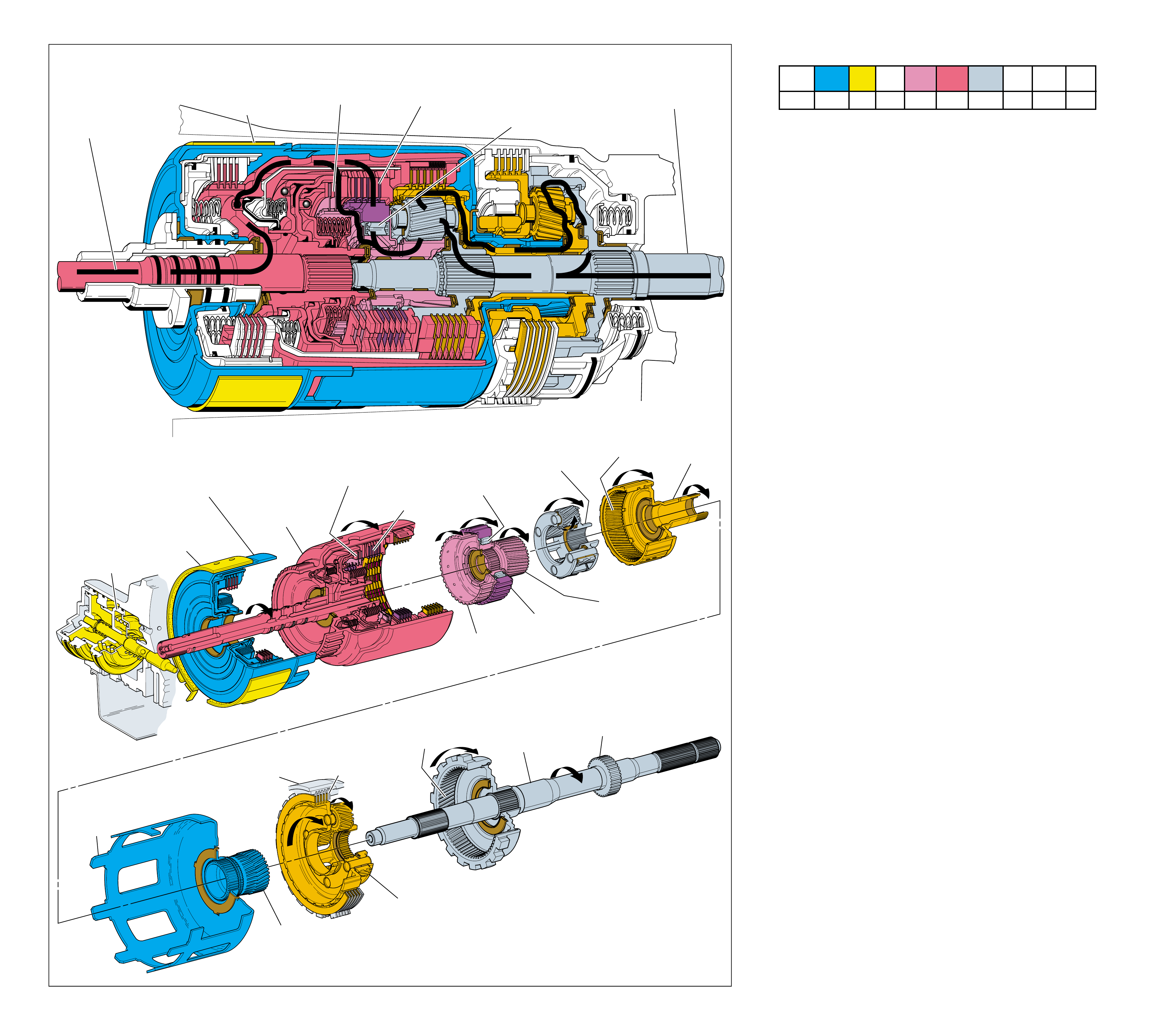

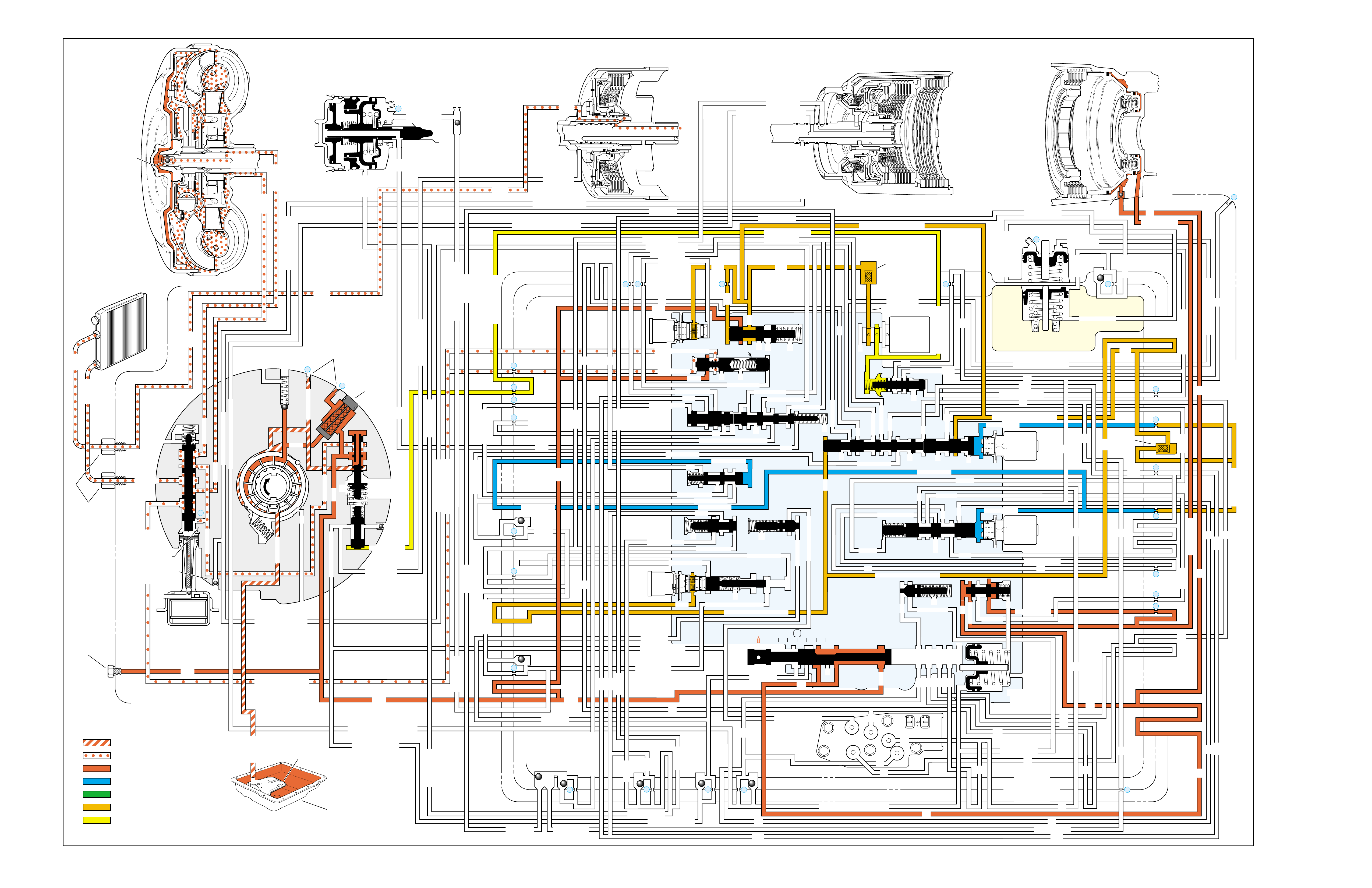

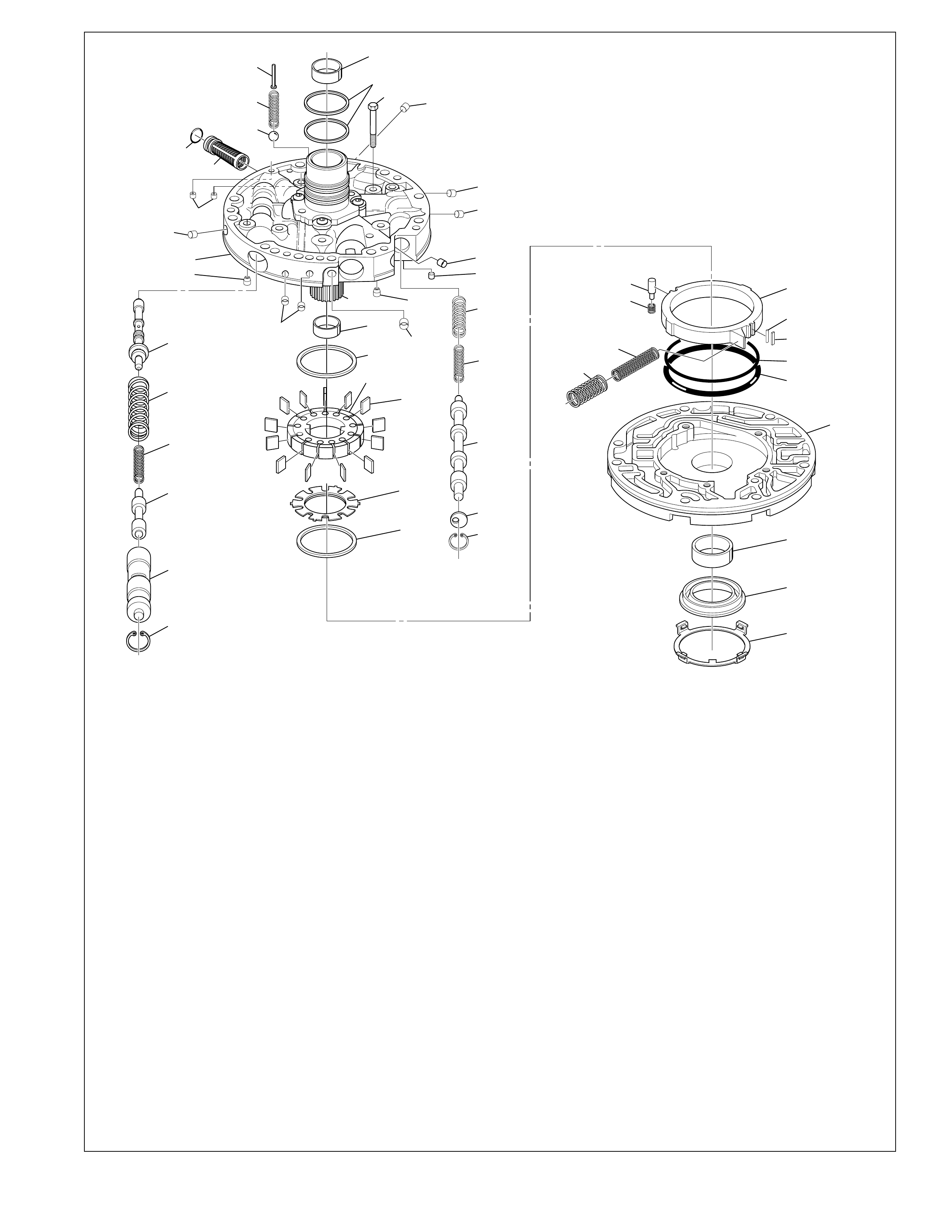

The foldout graphic on page 10 contains a disassembled drawing

of the major components used in the Hydra-matic 4L60-E

transmission. This drawing, along with the cross sectional

illustrations on page 8 and 8A, show the major mechanical

components and their relationship to each other as a complete

assembly. Therefore, color has been used throughout this book

to help identify parts that are splined together, rotating at engine

speed, held stationary, and so forth. Color differentiation is

particularly helpful when using the Power Flow section for

understanding the transmission operation.

The color legend below provides the “general” guidelines that

were followed in assigning specific colors to the major

components. However, due to the complexity of this transmission,

some colors (such as grey) were used for artistic purposes rather

than based on the specific function or location of that component.

Components that are stationary.

Examples: Converter Housing (102), Main Case

(103), Oil Pump Assembly (4), Low and Reverse

Clutch Support (679), Extension Housing (31).

Components that rotate at engine speed.

Examples: Torque Converter Cover and Pump, and

the Oil Pump.

Components that rotate at turbine speed. Examples:

Converter Turbine, Pressure Plate, Turbine Shaft and

Input Housing Assembly (621).

Components that rotate at transmission output speed

and other components. Examples: Reaction Internal

Gear (684), Output Shaft (687), Speed Sensor Rotor

(699), Forward Sprag Assembly (642), and Low and

Reverse Roller Clutch Assembly (678).

Components such as the Stator in the Torque

Converter (1), the Reverse Input Clutch Housing

(605) and the Reaction Sun Shell (670).

Components such as the Reaction Carrier Assembly

(681) and the Input Internal Gear (664).

Components such as the Overrun Clutch Hub (639)

and the Forward Sprag Clutch Inner Race and Input

Sun Gear Assembly (640).

All bearings, bushings, gaskets and spacer plates.

All seals

10A

COLOR LEGEND

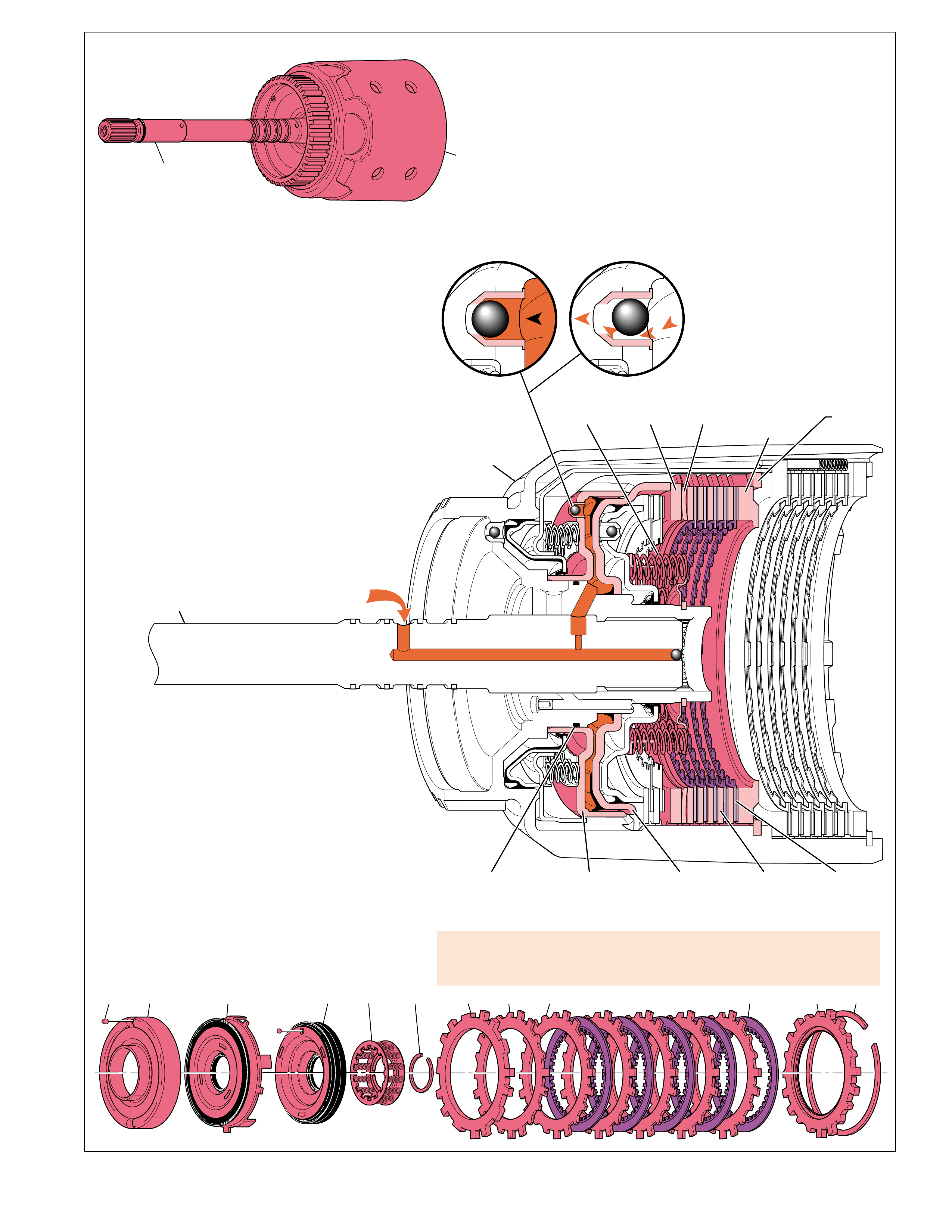

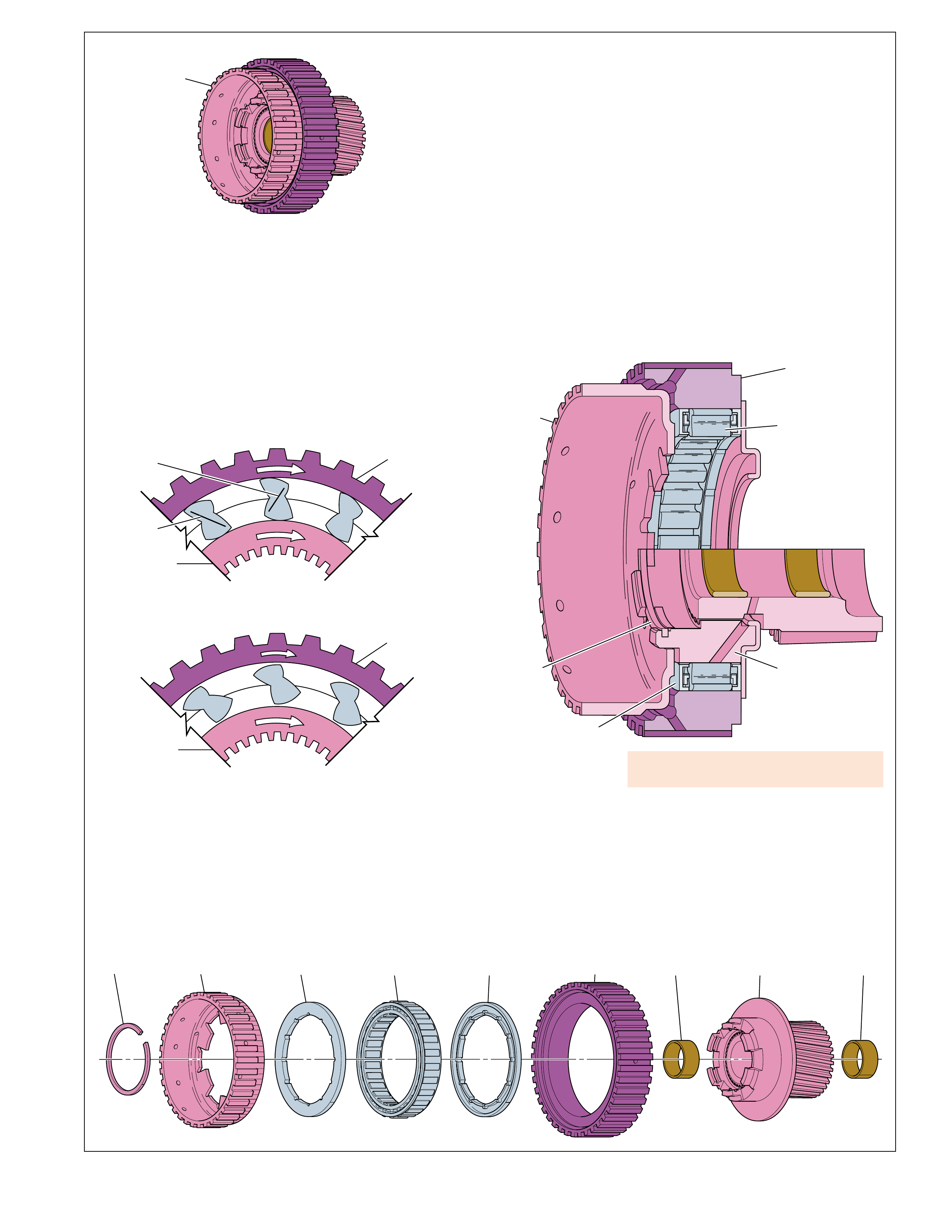

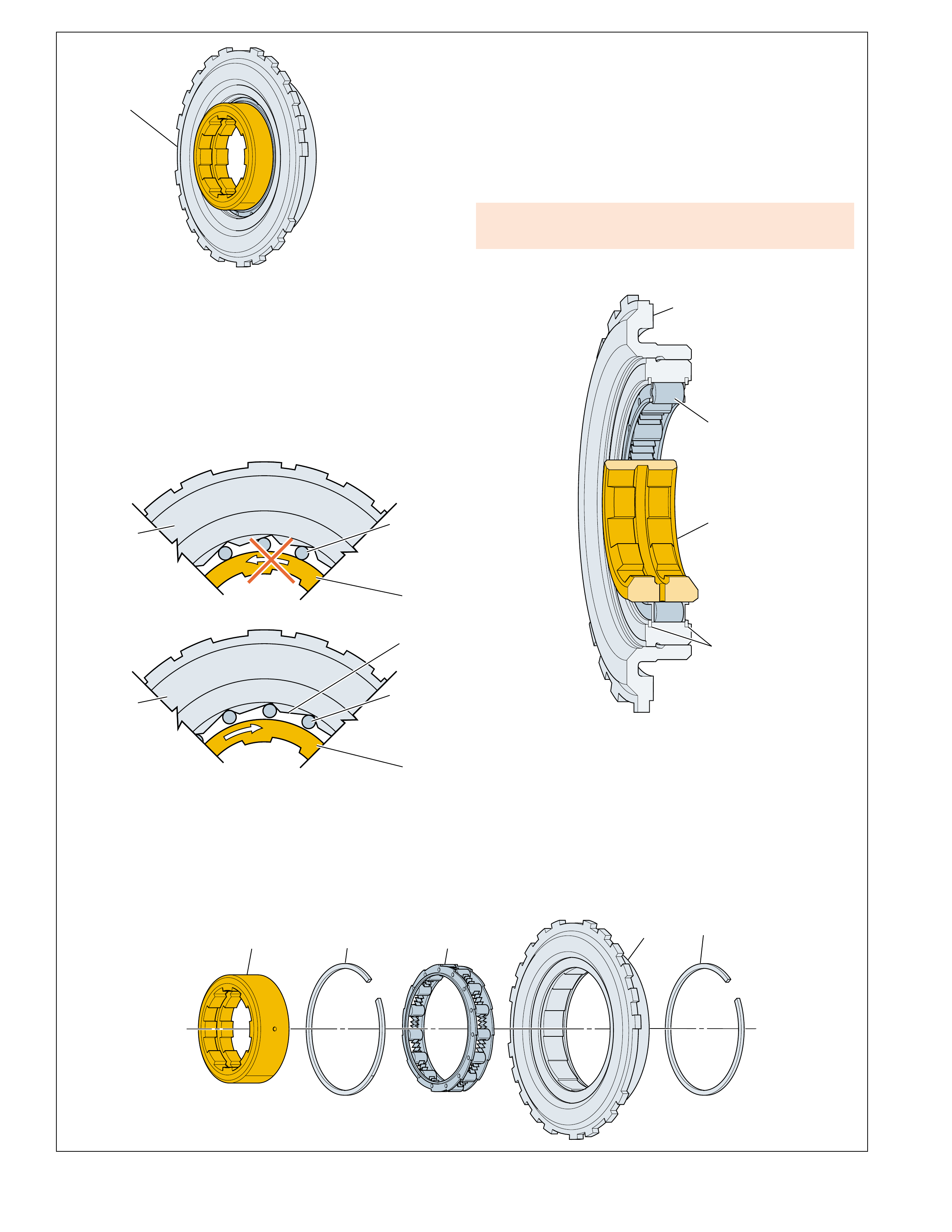

APPLY COMPONENTS

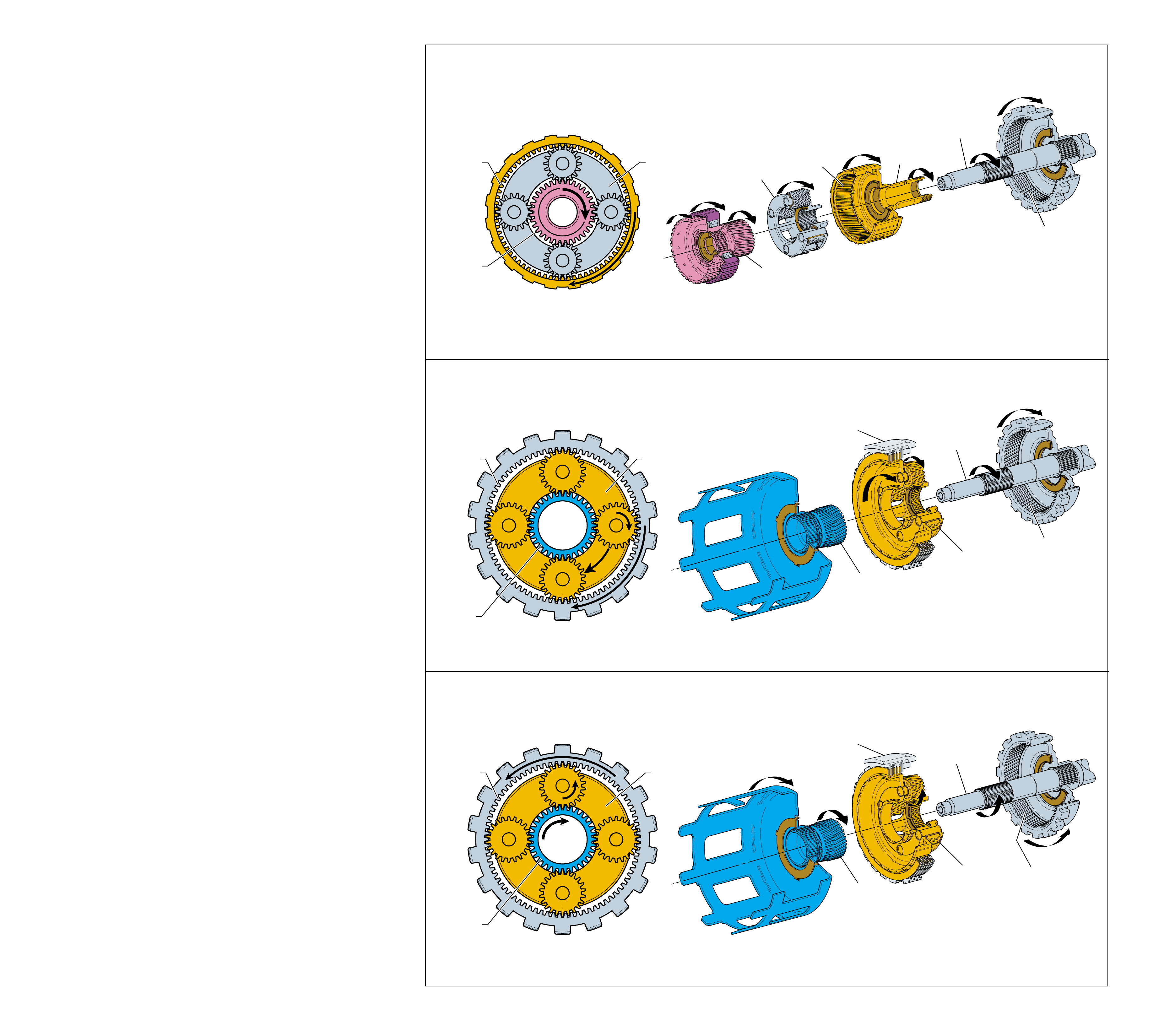

The Range Reference Chart on page 11, provides another

valuable source of information for explaining the overall function

of the Hydra-matic 4L60-E transmission. This chart highlights

the major apply components that function in a selected gear

range, and the specific gear operation within that gear range.

Included as part of this chart is the same color reference to each

major component that was previously discussed. If a component

is active in a specific gear range, a word describing its activity

will be listed in the column below that component. The row

where the activity occurs corresponds to the appropriate

transmission range and gear operation.

An abbreviated version of this chart can also be found at the top

of the half page of text located in the Power Flow section. This

provides for a quick reference when reviewing the mechanical

power flow information contained in that section.

10B

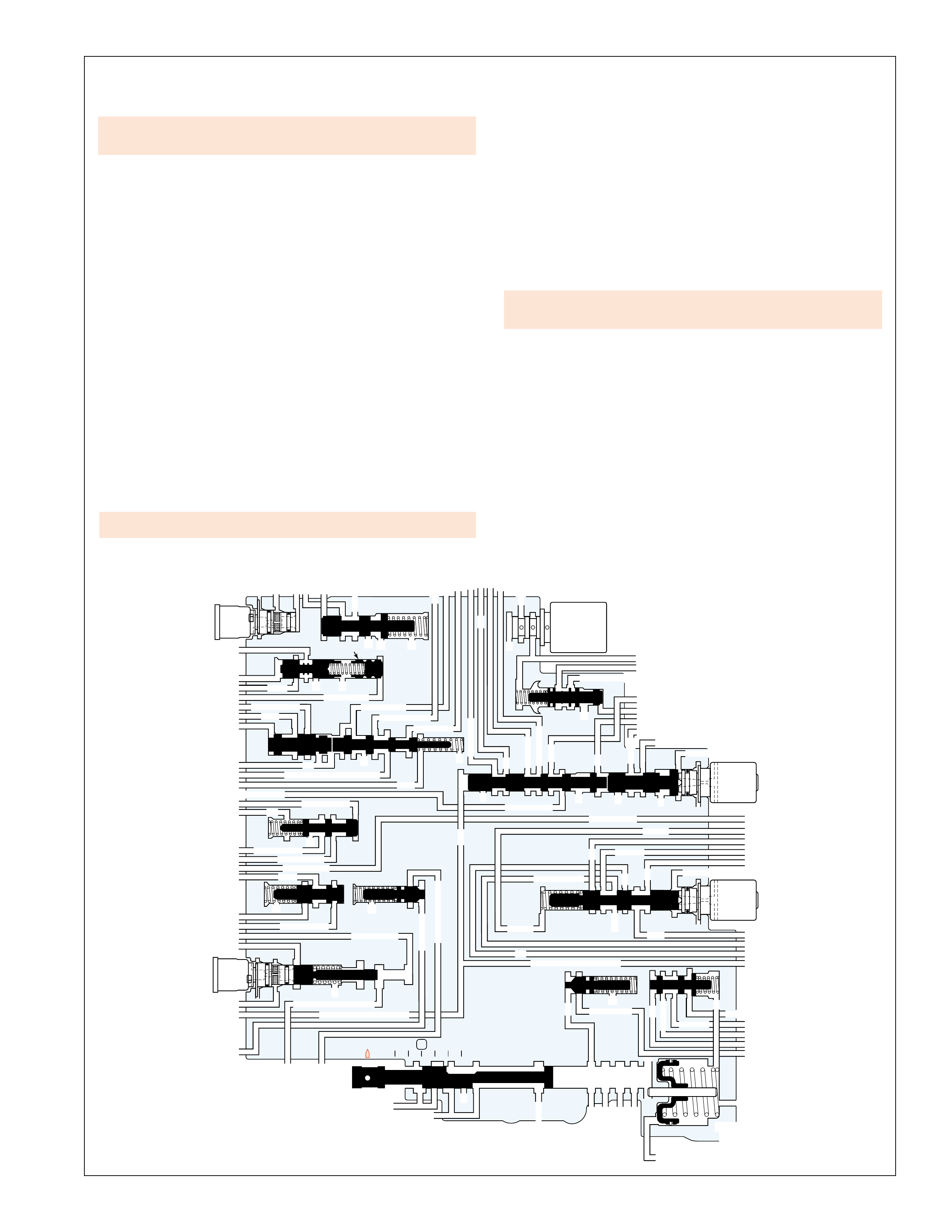

SHIFT SOLENOID VALVES 2-4 REVERSE OVERRUN FORWARD FORWARD 3-4 LO ROLLER LO/REV.

RANGE GEAR

1-2 2-3 BAND INPUT CLUTCH CLUTCH SPRAG CL. CLUTCH CLUTCH CLUTCH

CLUTCH ASSEMBLY

PARK

ON*ON*APPLIED

REVERSE

ON*ON*APPLIED APPLIED

NEUTRAL

ON*ON*

1st ON ON APPLIED HOLDING HOLDING

2nd OFF ON APPLIED APPLIED HOLDING

D

3rd OFF OFF APPLIED HOLDING APPLIED

4th ON OFF APPLIED APPLIED APPLIED

1st ON ON APPLIED HOLDING HOLDING

3

2nd OFF ON APPLIED APPLIED HOLDING

3rd OFF OFF APPLIED APPLIED HOLDING APPLIED

2

1st ** ON ON APPLIED APPLIED HOLDING HOLDING

*** 2nd OFF ON APPLIED APPLIED APPLIED HOLDING

1

1st ON ON APPLIED APPLIED HOLDING HOLDING APPLIED

*** 2nd OFF ON APPLIED APPLIED APPLIED HOLDING

*1-2 AND 2-3 SHIFT SOLENOID OPERATION AND THE SHIFT VALVE POSITIONING IN P, R, N RANGES ARE A FUNCTION OF THE

INPUT TO THE SOLENOIDS FROM THE VSS. UNDER NORMAL OPERATING CONDITIONS THE SOLENOIDS ARE ON IN P, R, N.

** A MANUAL SECOND - FIRST GEAR CONDITION IS ONLY AVAILABLE ON SOME MODELS. OTHERWISE, THIS CONDITION IS

ELECTRONICALLY PREVENTED.

*** IN MANUAL SECOND AND MANUAL FIRST, SOLENOID OPERATION IS A RESULT OF PCM CALIBRATION.

SOME CALIBRATIONS WILL ALLOW ALL THREE GEARS UNDER EXTREME CONDITIONS.

Figure 10 11

RANGE REFERENCE CHART

COLOR LEGEND

APPLY COMPONENTS

The Range Reference Chart on page 11, provides another

valuable source of information for explaining the overall function

of the Hydra-matic 4L60-E transmission. This chart highlights

the major apply components that function in a selected gear

range, and the specific gear operation within that gear range.

Included as part of this chart is the same color reference to each

major component that was previously discussed. If a component

is active in a specific gear range, a word describing its activity

will be listed in the column below that component. The row

where the activity occurs corresponds to the appropriate

transmission range and gear operation.

An abbreviated version of this chart can also be found at the top

of the half page of text located in the Power Flow section. This

provides for a quick reference when reviewing the mechanical

power flow information contained in that section.

10B

COLOR LEGEND

MAJOR MECHANICAL COMPONENTS

The foldout graphic on page 10 contains a disassembled drawing

of the major components used in the Hydra-matic 4L60-E

transmission. This drawing, along with the cross sectional

illustrations on page 8 and 8A, show the major mechanical

components and their relationship to each other as a complete

assembly. Therefore, color has been used throughout this book

to help identify parts that are splined together, rotating at engine

speed, held stationary, and so forth. Color differentiation is

particularly helpful when using the Power Flow section for

understanding the transmission operation.

The color legend below provides the “general” guidelines that

were followed in assigning specific colors to the major

components. However, due to the complexity of this transmission,

some colors (such as grey) were used for artistic purposes rather

than based on the specific function or location of that component.

Components that are stationary.

Examples: Converter Housing (102), Main Case

(103), Oil Pump Assembly (4), Low and Reverse

Clutch Support (679), Extension Housing (31).

Components that rotate at engine speed.

Examples: Torque Converter Cover and Pump, and

the Oil Pump.

Components that rotate at turbine speed. Examples:

Converter Turbine, Pressure Plate, Turbine Shaft and

Input Housing Assembly (621).

Components that rotate at transmission output speed

and other components. Examples: Reaction Internal

Gear (684), Output Shaft (687), Speed Sensor Rotor

(699), Forward Sprag Assembly (642), and Low and

Reverse Roller Clutch Assembly (678).

Components such as the Stator in the Torque

Converter (1), the Reverse Input Clutch Housing

(605) and the Reaction Sun Shell (670).

Components such as the Reaction Carrier Assembly

(681) and the Input Internal Gear (664).

Components such as the Overrun Clutch Hub (639)

and the Forward Sprag Clutch Inner Race and Input

Sun Gear Assembly (640).

All bearings, bushings, gaskets and spacer plates.

All seals

10A

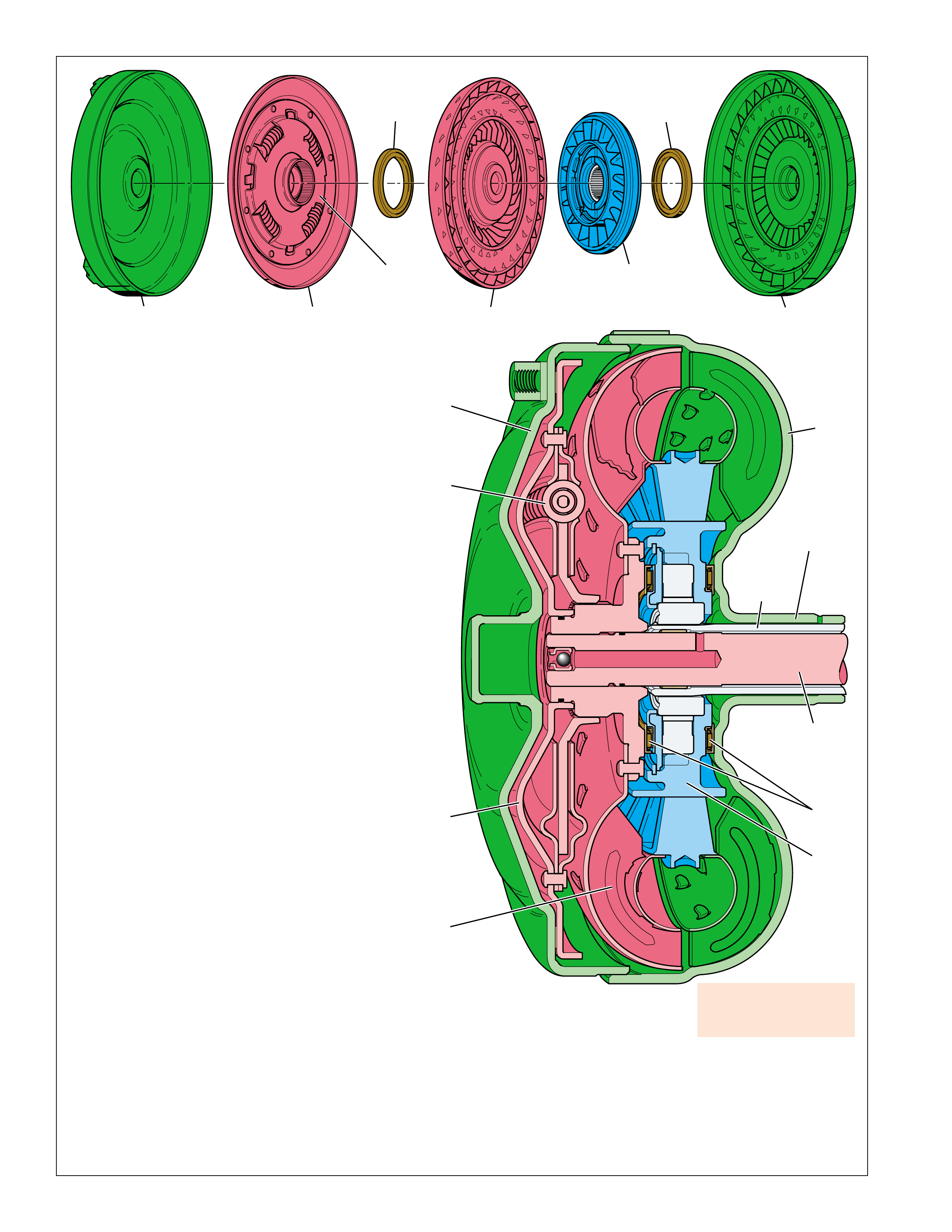

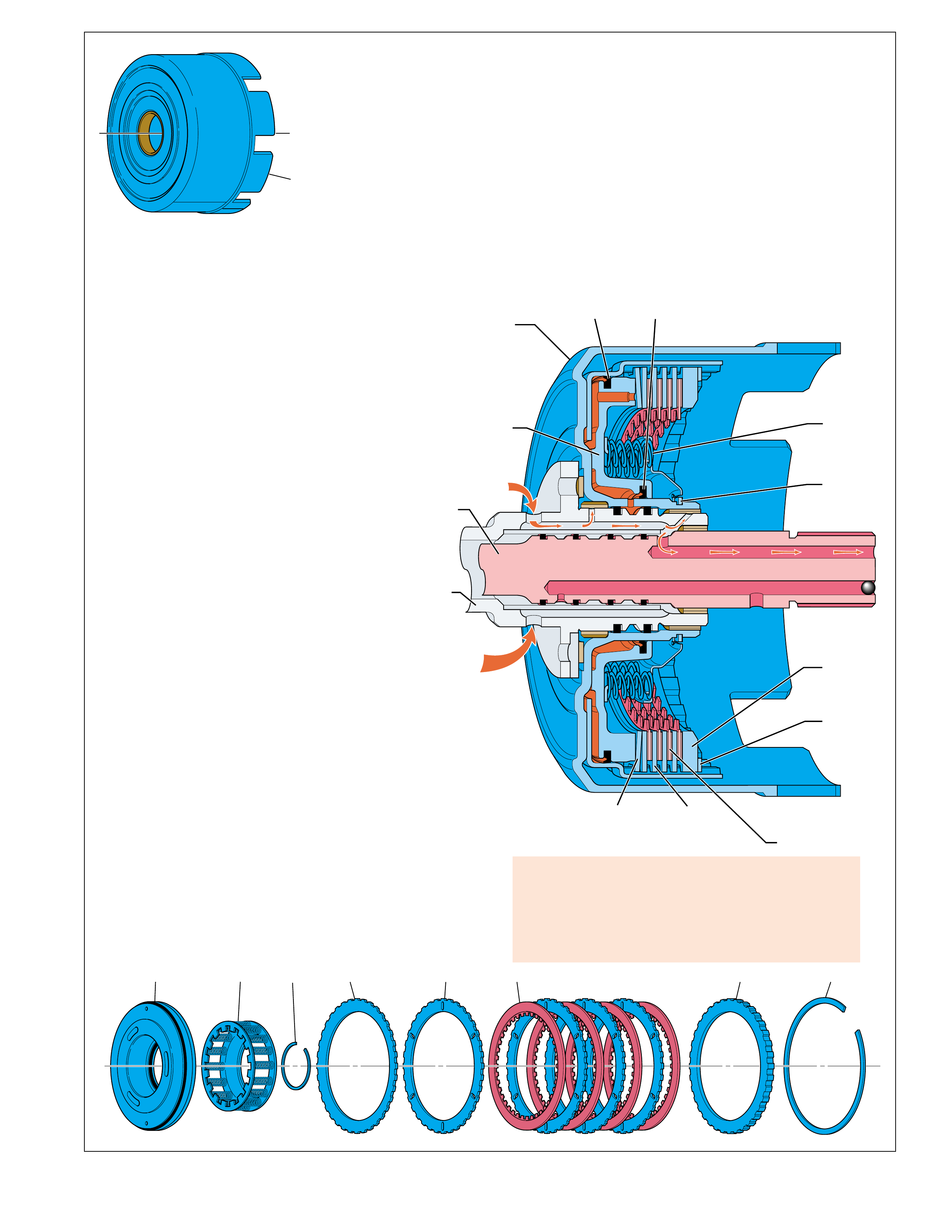

12

CONVERTER HOUSING

COVER ASSEMBLY

(A)

PRESSURE PLATE

ASSEMBLY

(B)

DAMPER

ASSEMBLY

(C) TURBINE

ASSEMBLY

(D)

STATOR

ASSEMBLY

(E) CONVERTER PUMP

ASSEMBLY

(G)

THRUST

BEARING

ASSEMBLY

(F)

THRUST

BEARING

ASSEMBLY

(F)

B

A

D

G

C

TURBINE

SHAFT

STATOR

SHAFT

(216)

CONVERTER

HUB

F

E

Figure 11

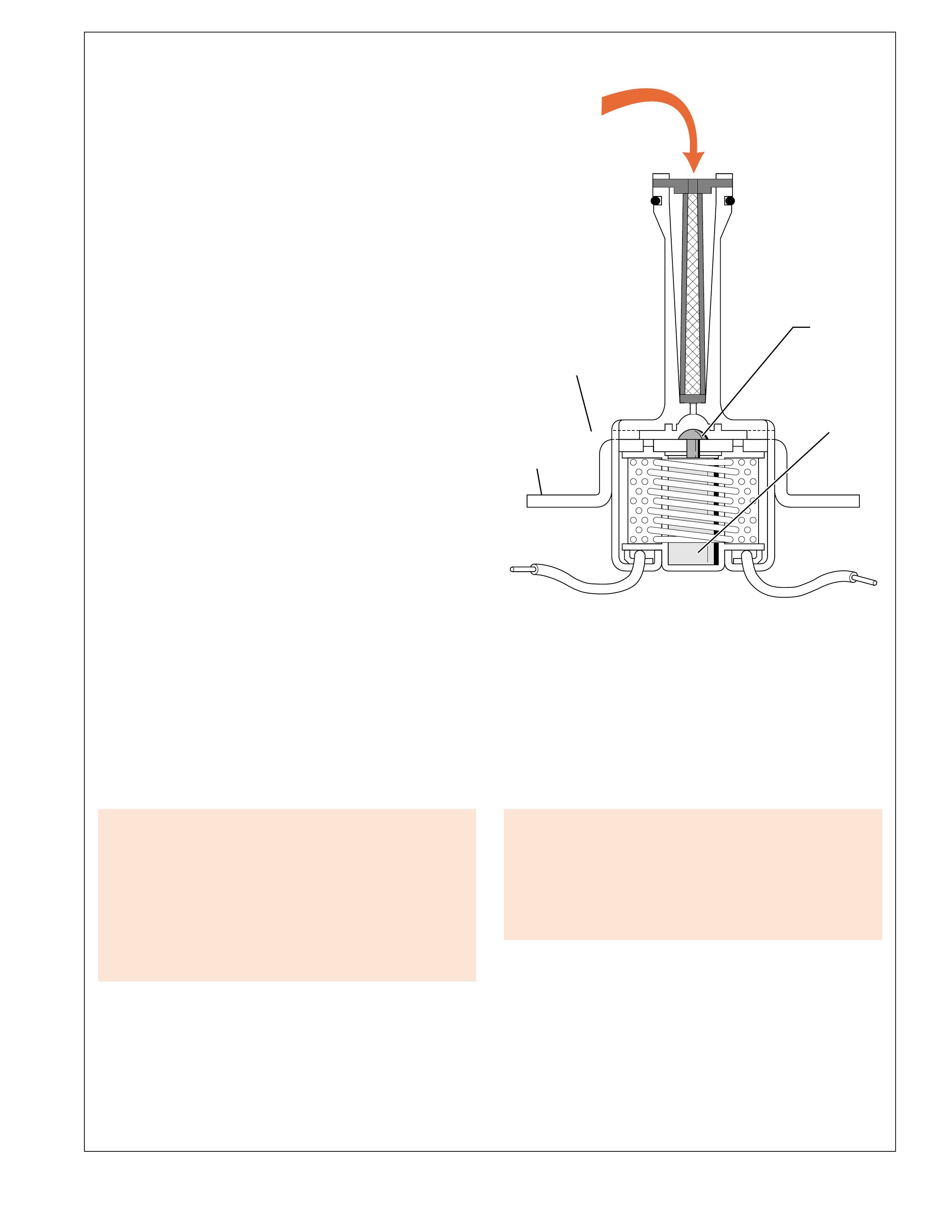

TORQUE CONVERTER

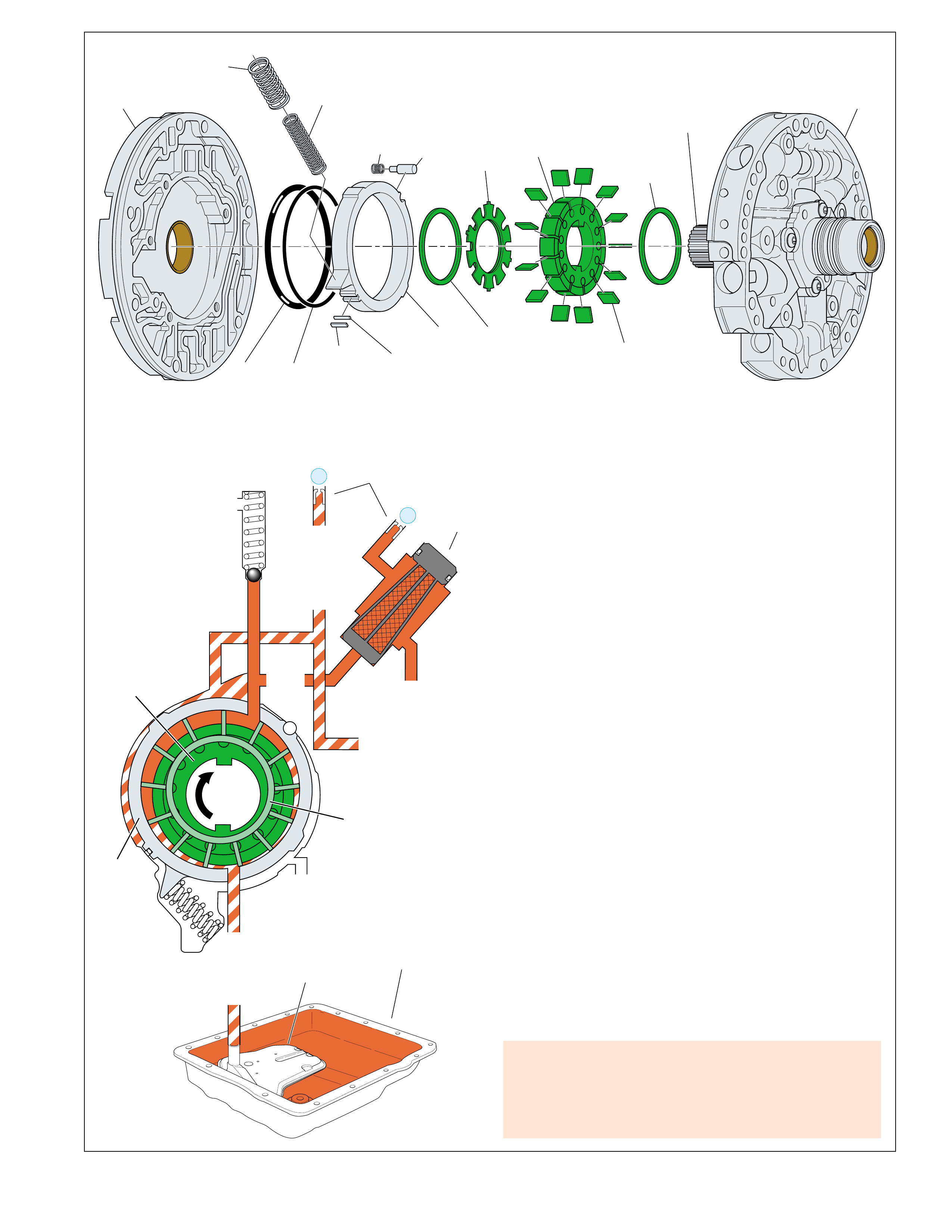

TORQUE CONVERTER:

The torque converter (1) is the primary component for

transmittal of power between the engine and the

transmission. It is bolted to the engine flywheel (also known

as the flexplate) so that it will rotate at engine speed.

Some of the major functions of the torque converter are:

•to provide for a smooth conversion of torque from the

engine to the mechanical components of the transmission.

•to multiply torque from the engine that enables the

vehicle to achieve additional performance when required.

•to mechanically operate the transmission oil pump (4)

through the converter hub.

•to provide a mechanical link, or direct drive, from the

engine to the transmission through the use of a torque

converter clutch (TCC).

The torque converter assembly is made up of the following

five main sub-assemblies:

•a converter housing cover assembly (A) which is welded

to the converter pump assembly (G).

•a converter pump assembly (G) which is the driving

member.

•a turbine assembly (D) which is the driven or output

member.

•a stator assembly (E) which is the reaction member

located between the converter pump and turbine

assemblies.

•a pressure plate assembly (B) splined to the turbine

assembly to enable direct mechanical drive when

appropriate.

CONVERTER PUMP ASSEMBLY AND TURBINE

ASSEMBLY

When the engine is running the converter pump assembly

acts as a centrifugal pump by picking up fluid at its center

and discharging it at its rim between the blades (see Figure

12). The force of this fluid then hits the turbine blades

and causes the turbine to rotate. As the engine and

converter pump increase in RPM, so does the turbine.

PRESSURE PLATE, DAMPER AND

CONVERTER HOUSING ASSEMBLIES

The pressure plate is splined to the turbine hub and applies

(engages) with the converter cover to provide a mechanical

coupling of the engine to the transmission. When the

pressure plate assembly is applied, the amount of slippage

that occurs through a fluid coupling is reduced (but not

eliminated), thereby providing a more efficient transfer of

engine torque to the drive wheels.

Torque converter failure

could cause loss of drive

and or loss of power.

To reduce torsional shock during the apply of the pressure plate to the

converter cover, a spring loaded damper assembly (D) is used. The

pressure plate is attached to the pivoting mechanism of the damper

assembly which allows the pressure plate to rotate independently of

the damper assembly up to approximately 45 degrees. During

engagement, the springs in the damper assembly cushion the pressure

plate engagement and also reduce irregular torque pulses from the

engine or road surface.

13

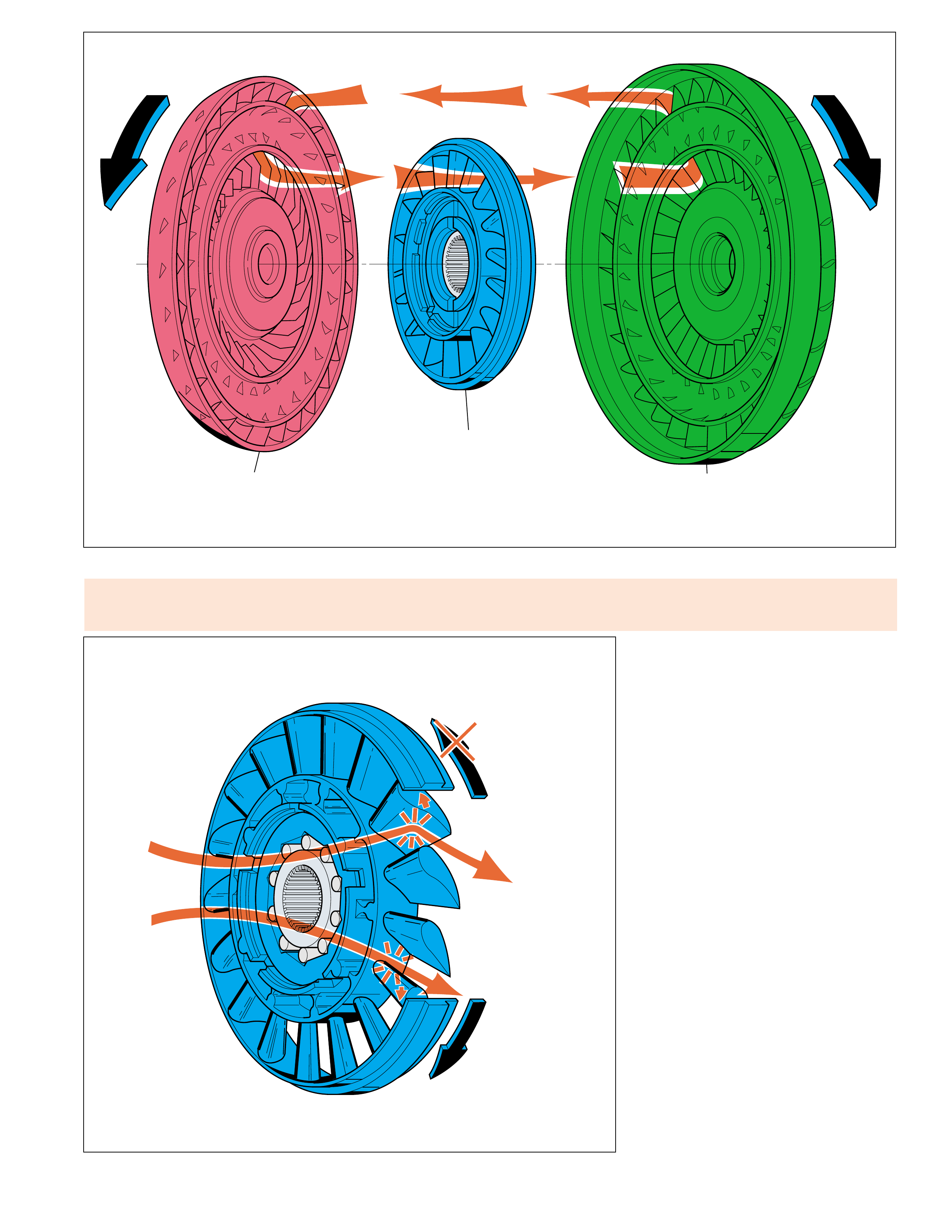

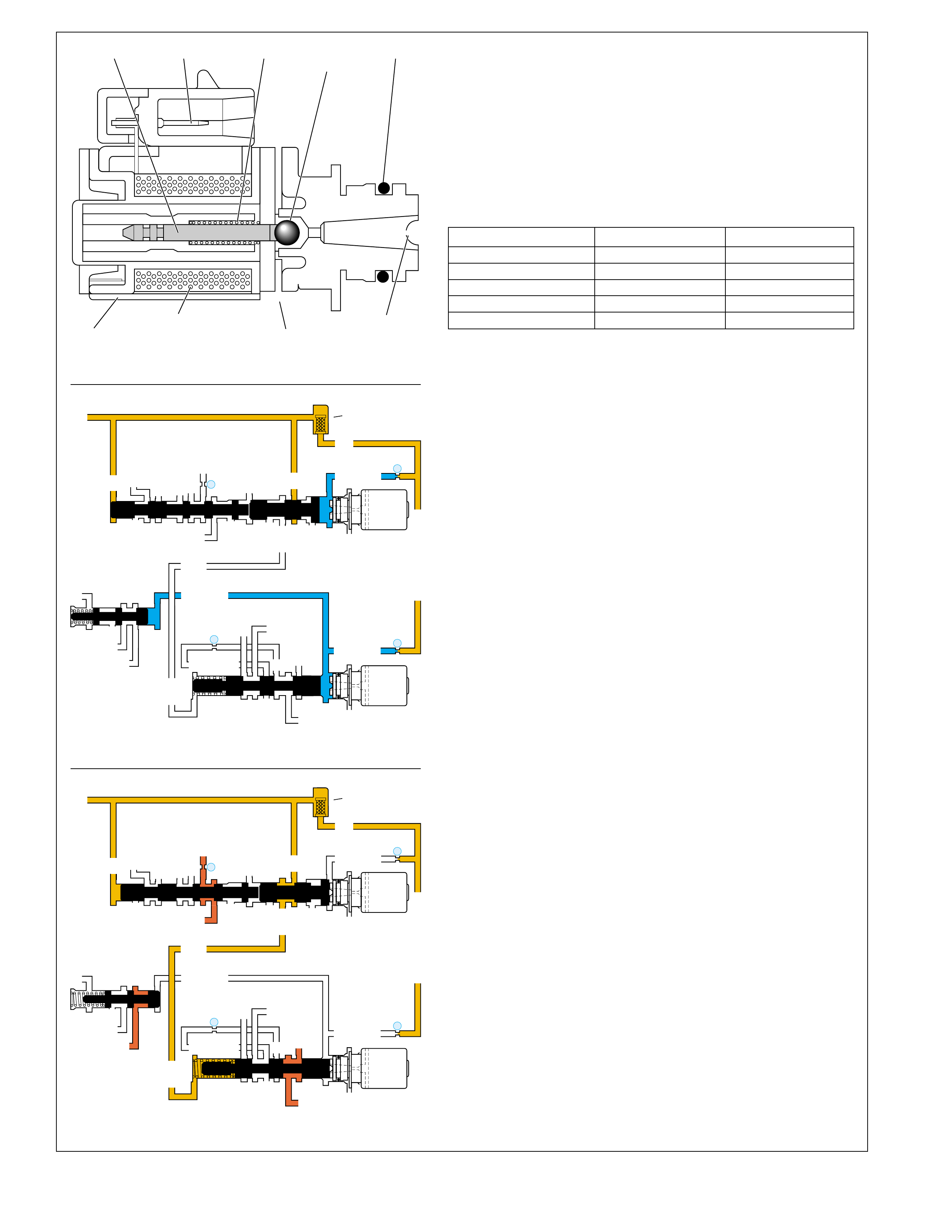

STATOR

STATOR ROTATES

FREELY

STATOR HELD

FLUID FLOW REDIRECTED

CONVERTER AT

COUPLING SPEED

FLUID FLOW

FROM TURBINE

CONVERTER

MULTIPLYING

FLUID FLOW

TURBINE

ASSEMBLY

(D)

CONVERTER PUMP

ASSEMBLY

(G)

STATOR

ASSEMBLY

(E)

Figure 13

TORQUE CONVERTER

Stator roller clutch failure

•roller clutch freewheels in both directions can

cause poor acceleration at lo w speed. •roller clutch locks up in both directions can

cause poor acceleration at high speed. •Overheated f luid.

Figure 12

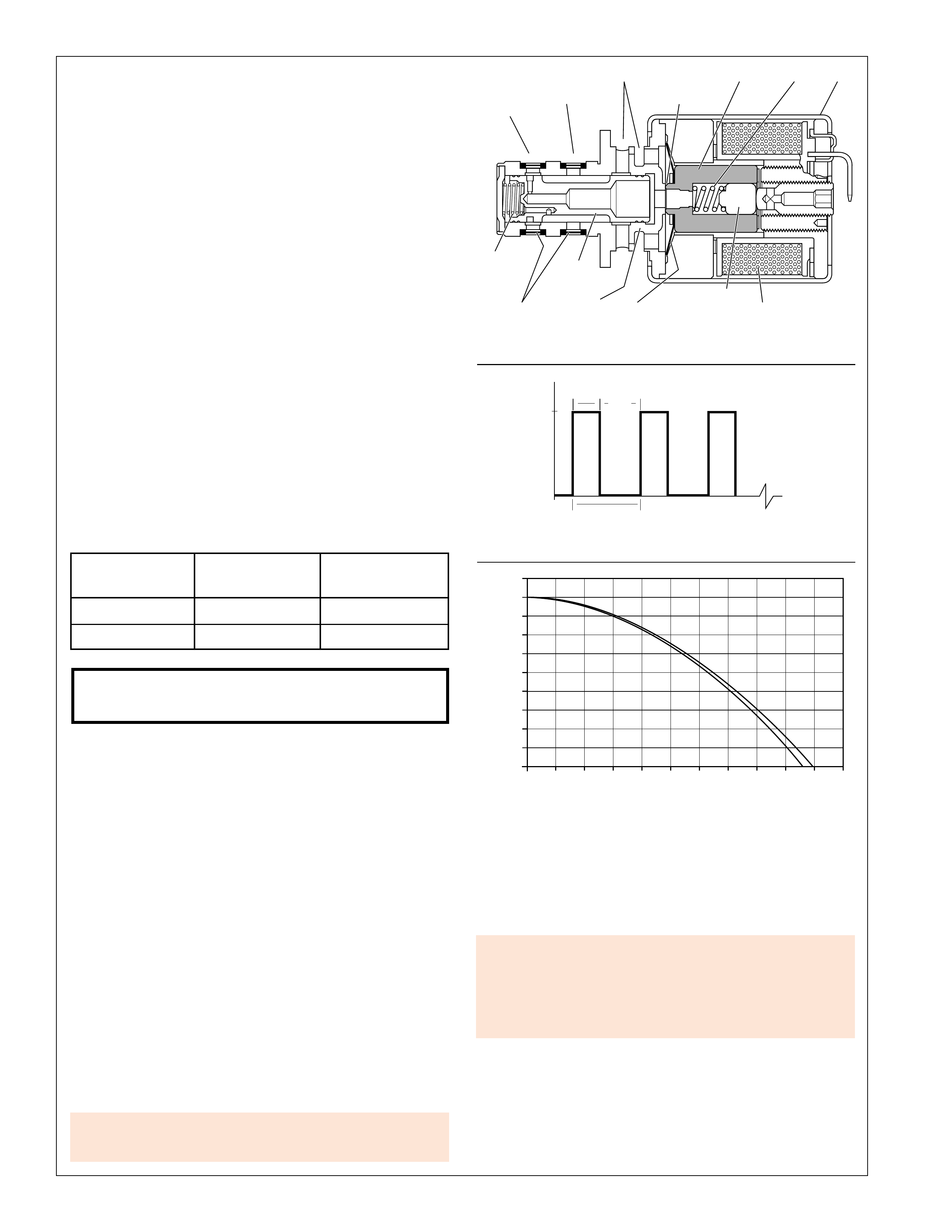

STATOR ASSEMBLY

The stator assembly is located between the

pump assembly and turbine assembly, and is

mounted on a one-way roller clutch. This one-

way roller clutch allows the stator to rotate in

one direction and prevents (holds) the stator

from rotating in the other direction. The

function of the stator is to redirect fluid

returning from the turbine in order to assist the

engine in turning the converter pump assembly.

At low vehicle speeds, when greater torque is

needed, fluid from the turbine hits the front

side of the stator blades (the converter is

multiplying torque). At this time, the one-way

roller clutch prevents the stator from rotating

in the same direction as the fluid flow, thereby

redirecting fluid to assist the engine in turning

the converter pump. In this mode, fluid leaving

the converter pump has more force to turn the

turbine assembly and multiply engine torque.

As vehicle speed increases and less torque is

required, centrifugal force acting on the fluid

changes the direction of the fluid leaving the

turbine such that it hits the back side of the

stator blades (converter at coupling speed).

When this occurs, the roller clutch overruns

and allows the stator to rotate freely. Fluid is

no longer being redirected to the converter

pump and engine torque is not being multiplied.

14

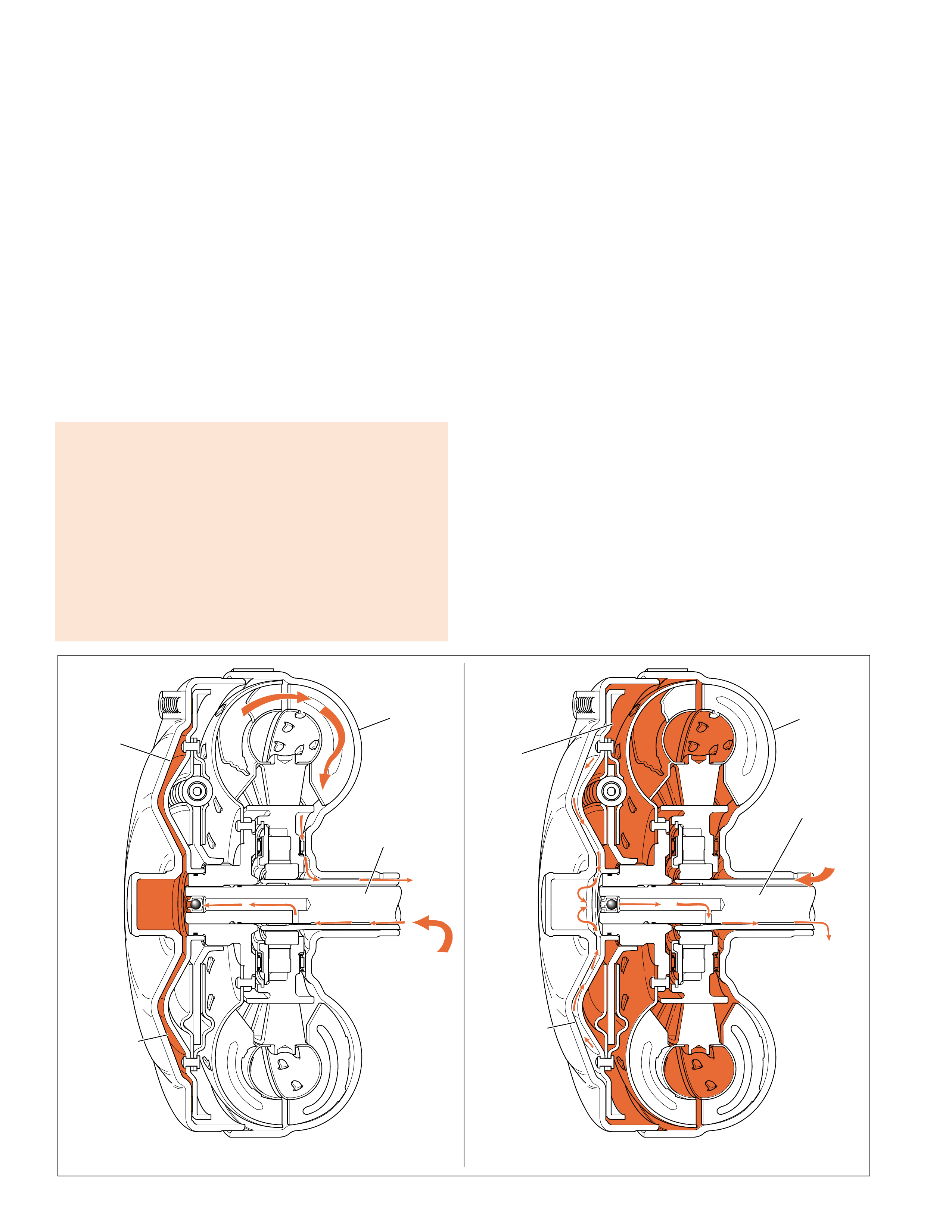

TORQUE CONVERTER

APPLY

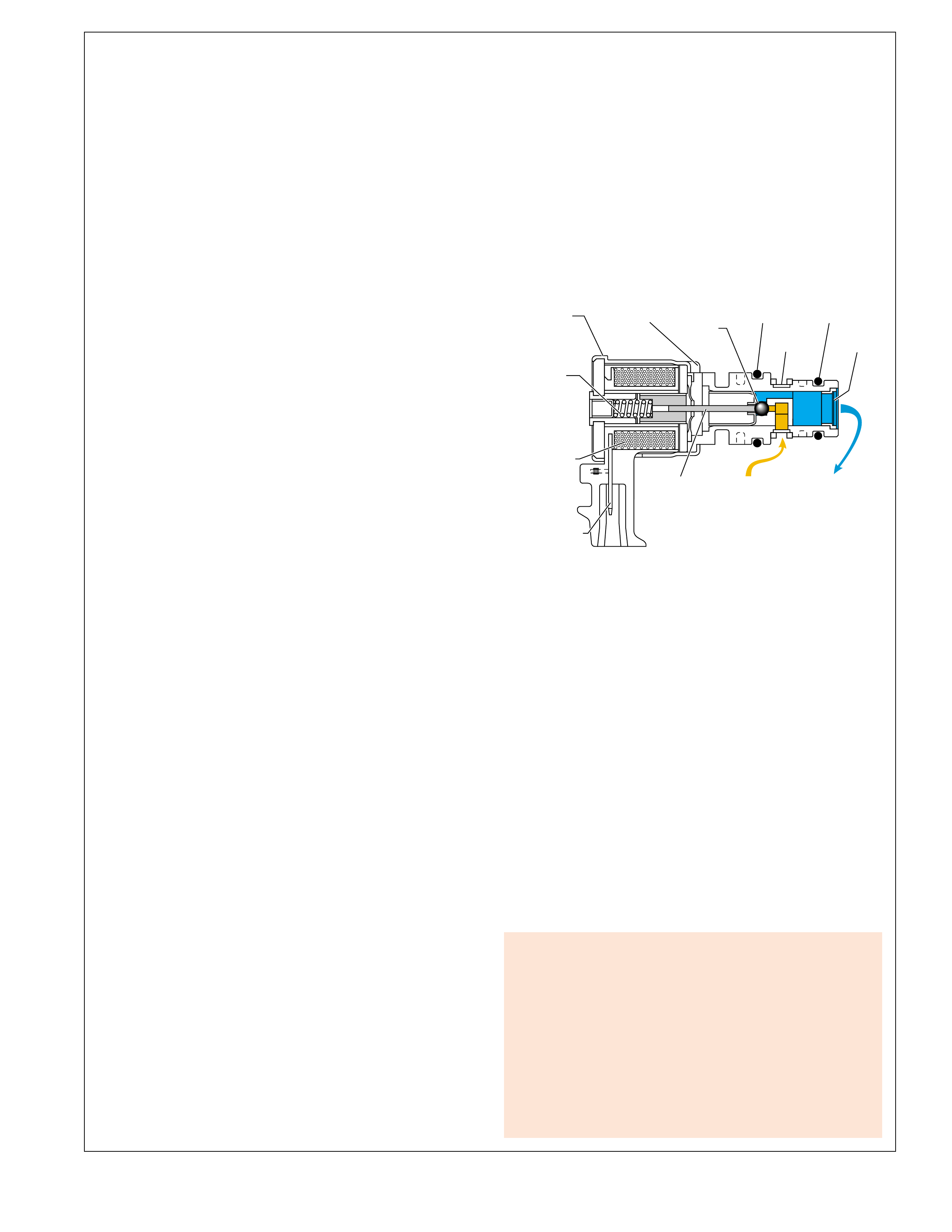

When the PCM determines that the vehicle is at the

proper speed for the torque converter clutch to apply

it sends a signal to the TCC (PWM) solenoid valve.

The TCC (PWM) solenoid valve then regulates line

fluid from the pump into the re gulated apply passag e.

The regulated apply fluid then feeds the apply fluid

passage and applies the torque converter. The apply

passage is located between the turbine shaft and the

stator shaft. T he fluid flo ws between the shafts, then

passes into the torque converter on the apply side of

the pressure plate assembly. Release fluid is then

routed out of the torque converter between the turbine

shaft and the stator shaft.

Apply fluid pressure forces the pressure plate against

the torque converter cover to provide a mechanical

link between the engine and the turbine.

The TCC apply should occur in fourth gear (also

third gear in some applications), and should not apply

until the transmission fluid has reached a minimum

operating temperature of 8°C (46°F) and the engine

coolant temperature reaches 50°C (122°F).

For mor e information on TCC apply and release, see

Overdrive Range – Fourth Gear TCC Released and

Applied, pages 62–63.

RELEASE

When the torque converter clutch is released, fluid is

fed into the torque converter by the pump into the

release fluid passage. The release fluid passage is

located between the stator shaft (214) and the turbine

shaft (621). Fluid tra vels between the shafts and enter s

the release side of the pressure plate at the end of the

turbine shaft. The pressure plate is forced away from

the converter cover and allows the torque converter

turbine to rotate at speeds other than engine speed.

The release fluid then flows between the friction

element on the pressure plate and the con v erter co ver