General Information Page 0A–1

Page 0A–1

Section 0A

General Information

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Warnings, Cautions and Notes for correct workshop practices with regard to safety and / or property damage.

1 General Information............................................................................................................................... 2

1.1 Hoist Pad Locations...............................................................................................................................................3

2 Model Av ailab ility and Equipment ....................................................................................................... 4

3 Major Option Codes............................................................................................................................... 5

4 Powertrain .............................................................................................................................................. 6

5 Engine Data............................................................................................................................................ 7

6 Transmission Data.............................................................................................................. ................... 8

7 Transfer Case Data................................................................................................................................ 9

8 Exterior Dimensions............................................................................................................................ 10

9 Vehicle Weights ................................................................................................................................... 11

10 Fuel Consumption Label..................................................................................................................... 12

11 Serial Numbers..................................................................................................................................... 13

11.1 Location of Identification Plates.........................................................................................................................13

11.2 Safety Compliance Plate......................................................................................................................................14

11.3 Body and Option Identification Plate..................................................................................................................15

11.4 Vehicle Identif icati on Number.............................................................................................................................16

VIN Plates..............................................................................................................................................................16

VIN Body Stamping..............................................................................................................................................17

11.5 Vehicle Identification Numbering System..........................................................................................................18

11.6 Automatic Transmission Serial Number............................................................................................................19

11.7 Final Drive Assembly Serial Numbers................................................................................................................20

Front Final Drive...................................................................................................................................................20

Rear Final Drive....................................................................................................................................................20

11.8 Transfer Case Assembly Serial Number ............................................................................................................21

12 Special Tools........................................................................................................................................ 22

Transfer Case .......................................................................................................................................................23

Front Suspension.................................................................................................................................................24

Front Final Drive...................................................................................................................................................25

Techline

Techline

Techline

Techline

Techline

General Information Page 0A–2

Page 0A–2

1 General Information

The MY 2004 All Wheel Drive (AWD) Crewman Cross 8 Crew Cab is based upon the previously released 2WD Crewman

Crew Cab body style. Excluding the rear final drive assembly, it uses the same powertrain as that fitted to the MY 2004

AWD Wagon. Like the AWD Wagon, it is a constant AWD vehicle. It is available only with the GEN III V8 engine and

4L65-E heavy duty automatic transmission combination. The rear axle and rear suspension configuration is basically the

same as its 2WD equivalent although, the rear differential is a not a limited slip type.

The main features and changes for the MY 2004 AWD Crewman Cross 8 Crew Cab are summarised in the following list:

• Constant AWD powertrain.

• Heavy duty suspension to suit the AWD application.

• Heavy duty engine cooling fan system.

• Specific traction control system to suit the AWD application.

• Restyled front fascia incorporating fog lamps (as fitted to AWD Wagon).

• Extension mouldings on front and rear wheelhouses.

• Exterior colour range of five colours from MY 2004 VY Series.

• Front mounted aluminium plate and aluminium rocker panel inserts.

• Air conditioning as standard.

• Automatic air conditioning (Single zone Occupant Climate Control) optional as part of leather interior package.

• Inclinometer gauge assembly located on top centre of instrument panel (similar to AWD Wagon).

• Sports profile leather wrap steering wheel and alloy pedals.

• Leather wrap satin chrome gear knob and park brake lever.

• Additional badging to denote AWD model.

• Five spoke 17" alloy wheels and tyres (as fitted to AWD Wagon).

• Front tow attaching point and 'towing eye’ (as fitted to AWD Wagon).

• Driver, passenger and side aibags.

• Triple-window instrument cluster (as fitted to LX8 AWD Wagon).

• ‘In-dash’ cup holders (as part of optional leather interior package).

• ‘In-dash’ 6 disc CD changer as part of audio system.

General Information Page 0A–3

Page 0A–3

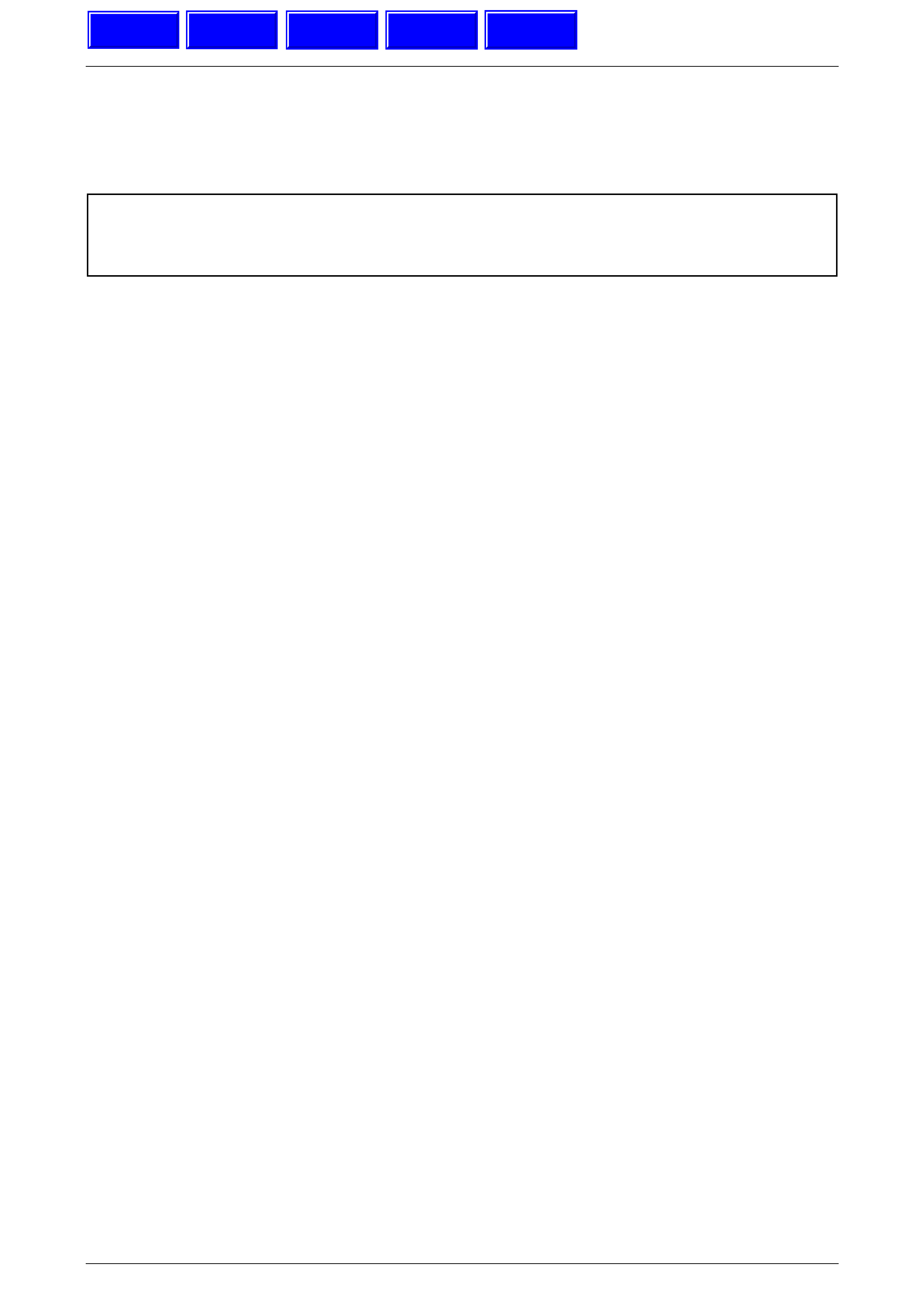

1.1 Hoist Pad Locations

When using a trolley jack to raise the vehicle, it is important that the jack be positioned under the suspension cross

member or hoist pad (1) locations. The vehicle should always be supported by jack stands at the hoist pad locations

when raised.

Figure 0A – 1

General Information Page 0A–4

Page 0A–4

2 Model Availability and

Equipment

NOTE

For tyre and wheel information, refer to

Section 10 Wheels and Tyres in this Service

Information.

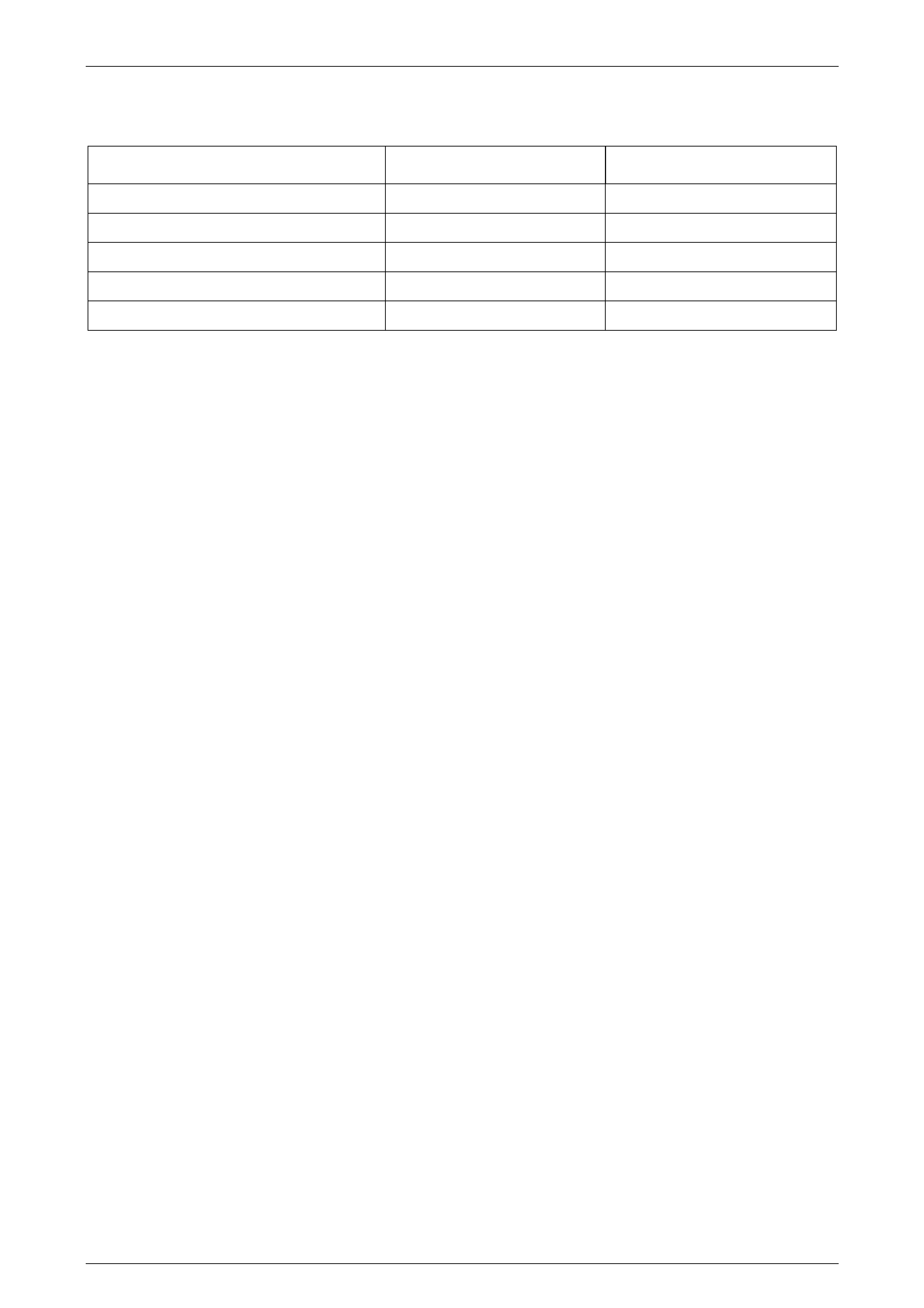

Model Name Luxury Level

(Description) Model Code. Bod y Style

(Doors) Engine

Crewman

Cross 8

Level 1 or 2

(Sport) –

dependent on

options fitted

8VM43 Cab (4) V8

General Information Page 0A–5

Page 0A–5

3 Major Option Codes

Option Code Description Option Code Description

81I Anthracite Interior Trim JL9 Anti-Lock Brake System

A31 Power Windows (Front and Rear) MD6 4 Speed Auto Trans. H/Duty AWD

AH6 Driver’s Seat, 4-Way N88 7.5 JJ x17" Alloy wheel

AJ7 Driver, Passenger and Side Airbag N40 Power Steering

AQ9 Front Seat, Reclining Bucket NK4 Sports Leather Stee ring Wheel

AX2 Keys, 2 Key Set NW9 Traction Control (with ABS)

C61 Automatic Air Conditioning (OCC) QBB 225/55 R17 97H Tyre

C60 Manual Air Conditioning R5C Bridgestone Hybrid Tyre Design

DL6 Exterior Mi rrors Body Colour Scalp U1V Audio System, 60W 6 Disc CD

E18 Satin Chrome Interior Door Handles U75 Antenna, Power

F46 AWD Powertrain UE1 Holden Assist (Telematics)

FE1 Suspension – Soft Ride UJ8 Instrument Cluster

GS9 Axle, 3.46:1 Ratio Rear U08 Dual Note Horns

K30 Cruise Control UY4 Satellite Navigation System

K69 Keys, Additional Set W1Y Steering Wheel Radio Controls

LS1 225KW, 5.7 V8 EFI Petrol Engine XS4 Roo Bar

JF5 Alloy Pedals XW 6 Paint, Metallic Finish

General Information Page 0A–6

Page 0A–6

4 Powertrain

Component Designation / ID Code Type

Engine GEN III V8 V8 5.7 litre OHV PFI

Transmission 4L65-E 4 speed with Overdrive

Transfer Case NV124 Full time AWD, Gear Drive

Final Drive – Front DY Conventional, Ratio – 3.46:1

Final Drive – Rear STD AWD Conventional, Ratio – 3.46:1

General Information Page 0A–7

Page 0A–7

5 Engine Data

Engine Designation GEN III V8

Piston Displacement

Nominal – cm3 5667

Compression Ratio 10.1:1

Number of Cylinders 8

Bore x Stroke – mm 99 x 92

Taxable H.P.

RAC OR SAE 48.6

Power kW

ECE @ RPM 225 kW @ 5200

Torque N.m

ECE @ RPM 460 N.m @ 4000

General Information Page 0A–8

Page 0A–8

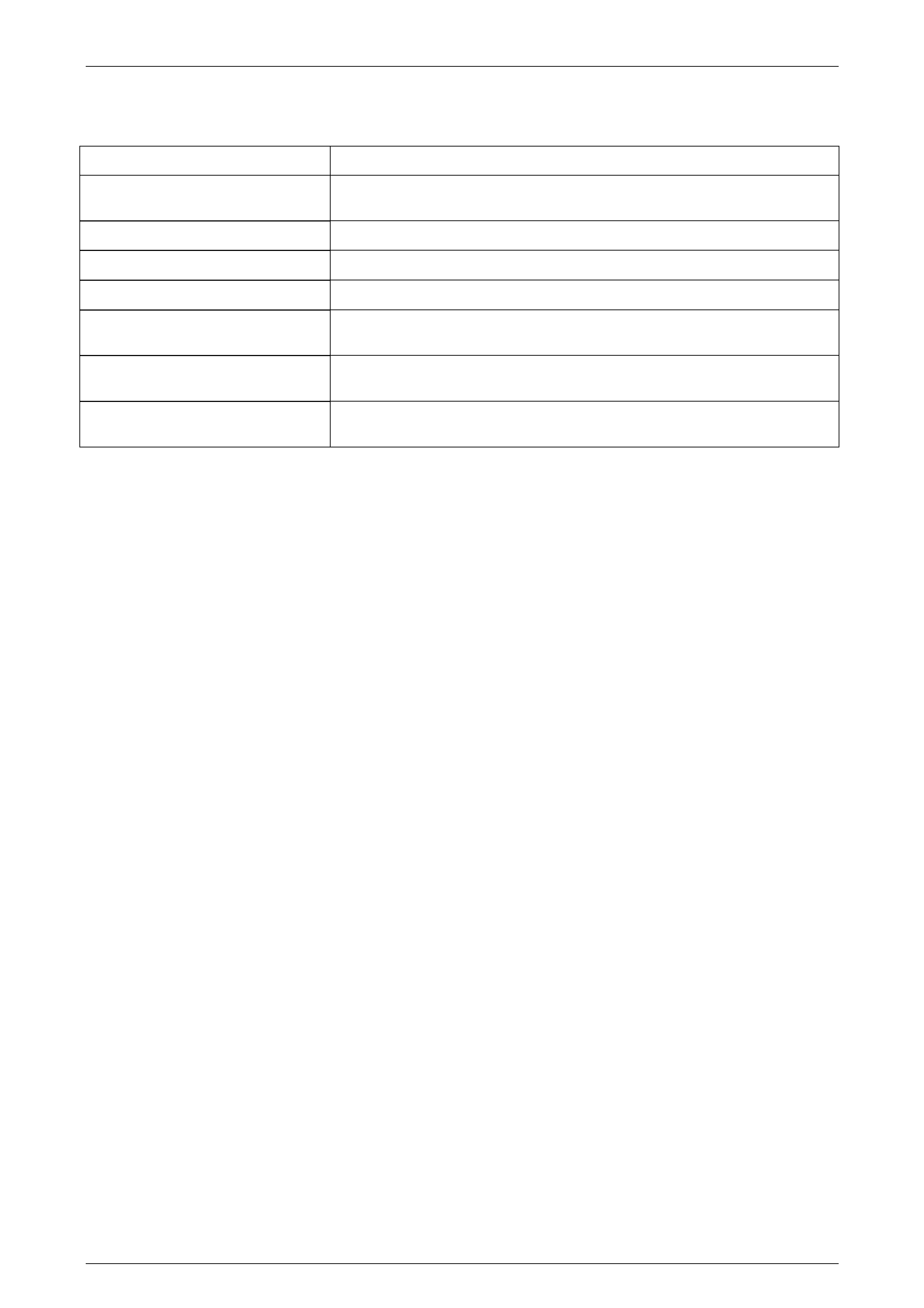

6 Transmission Data

Model 4L65-E

Torque converter 4 element (including lock-up clutch)

Pump 13 Vane, variable displacement

No. of clutch packs 5

No. of bands 1

No. of planetary gear sets 2

No. of solenoids 6

No. of electrical sensors 3

Ratios:

1st

2nd

3rd

4th

Reverse

3.06:1

1.63:1

1.00:1

0.70:1

2.29:1

General Information Page 0A–9

Page 0A–9

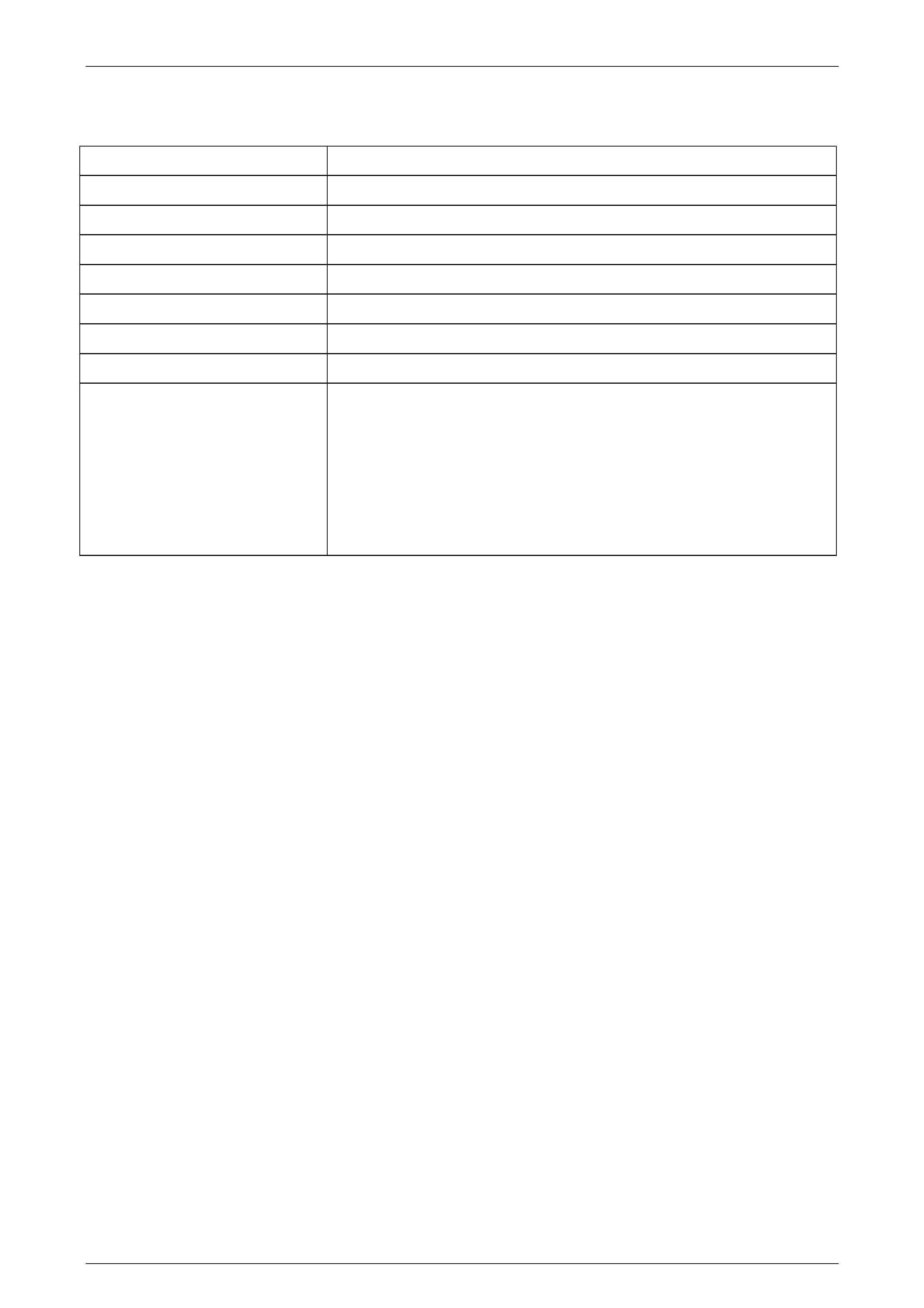

7 Transfer Case Data

Manufacturer New Venture Gear (NVG)

Model NV124

Type Full Time AWD

Torque Split 38 / 62 per cent, front to rear

General Information Page 0A–10

Page 0A–10

8 Exterior Dimensions

Dimension mm

Vehicle length 5323

Vehicle width 1954

Vehicle height (from kerb groundline) 1542

Wheelbase 3207

Overhang – front 944

Overhang – rear 1172

Track – front 1620

Track – rear 1623

Ground clearance 188

General Information Page 0A–11

Page 0A–11

9 Vehicle Weights

Weight kg

Kerb mass (Estimated including fluids) 1947

Gross Vehicle Mass (GVM) 2685

Front axle load 1230

Rear axle load 1460

Payload Refer Owner’s Handbook

NOTE

Payload figures include luggage, goods,

passengers and a full tank of fuel. When towing,

the weight on the tow bar ball must also be

included.

NOTE

Maximum rear axle load is the maximum for all

conditions.

General Information Page 0A–12

Page 0A–12

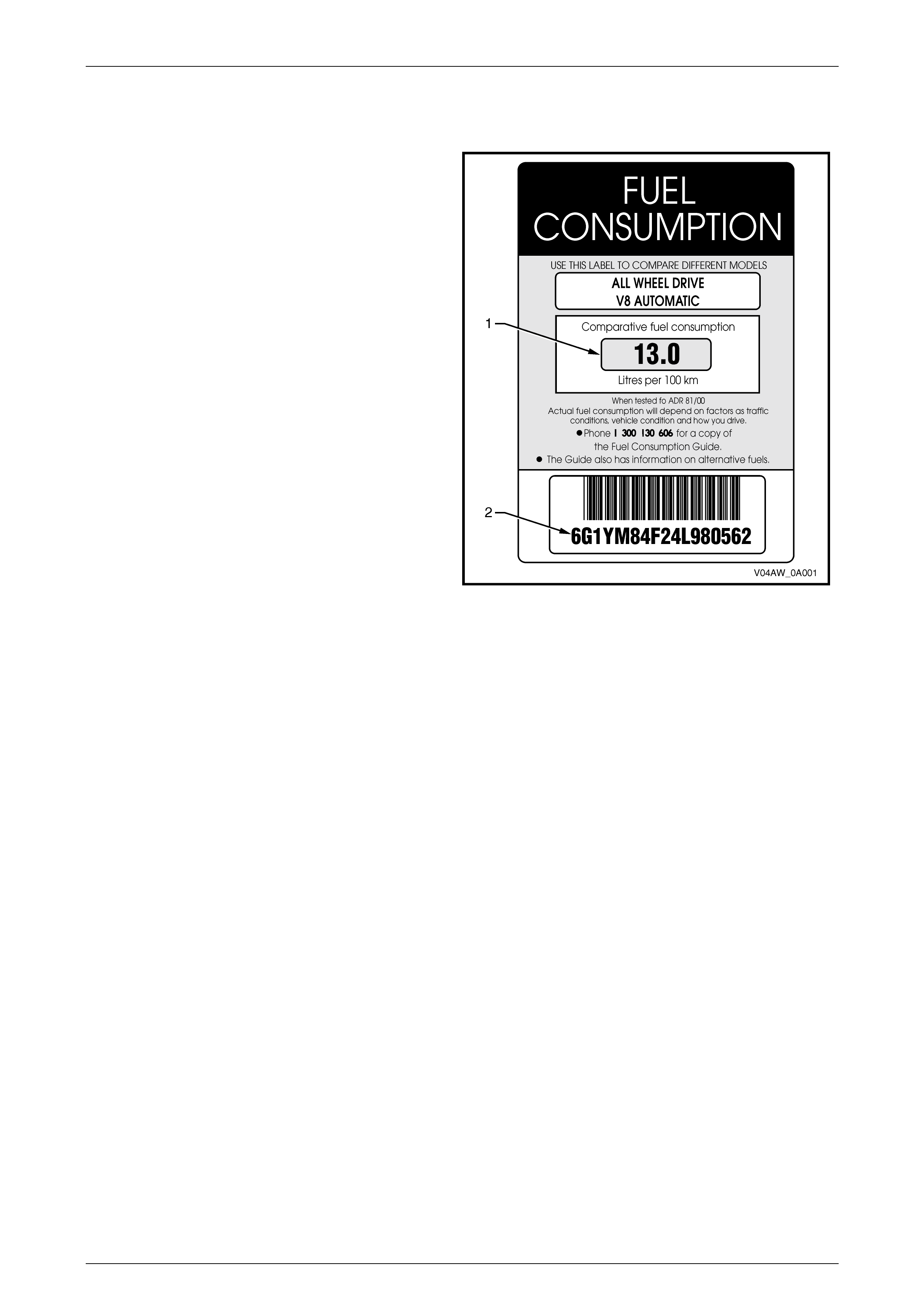

10 Fuel Consumpti on Label

ADR 81/00 required that from 1 January 2001, a label

similar to that show n in Figure 0A – 2, is attached to the

windscreen of any new domestic vehicle which is displayed

for sale.

The fuel consumption label figures (1) quoted are the

results of tests carried out in accordance with the City

Cycle test procedure of AS2877 – 1986, an Australian

standard for fuel consumption testing. Each vehicle is

tested under identical conditions. The tests therefore

enable a comparison to be made between vehicles.

The label should be removed from the windscreen

immediately prior to the vehicle being delivered to the

owner.

The number on the lower portion of the label (2) should

match the Vehi cle Identification Number.

Figure 0A – 2

General Information Page 0A–13

Page 0A–13

11 Serial Numbers

The complete vehicle and various components of the vehicle are identified by number plates or numbers stamped into

the body. It is essential that when compiling warranty claims or product and field reports, that the Vehicle Identification

Number (VIN) is quoted in conjunc tion w ith the identifi cat ion numb er of the compo nent affected.

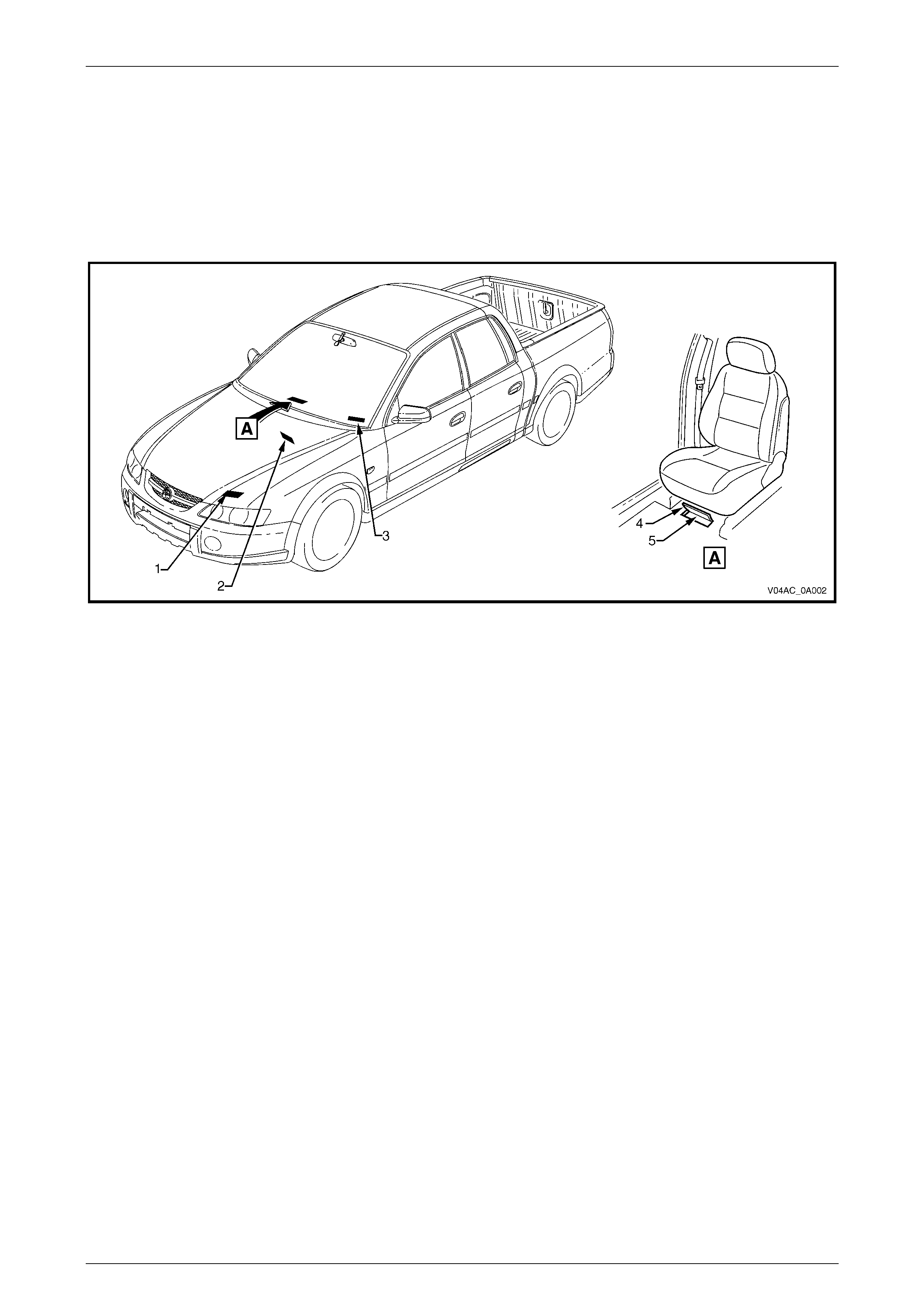

11.1 Location of Identification Plates

Figure 0A – 3

Legend

1 Body And Option Identification Plate – Left-hand

Side of the Front Panel Upper

2 Safety Compliance Plate – Dash Panel Assembly

3 Vehicle Identification Number Plate – Under

Windscreen

4 Carpet Flap

5 Vehicle Identification Number – Under Carpet Flap

Forward of Right-hand Side Front Seat.

General Information Page 0A–14

Page 0A–14

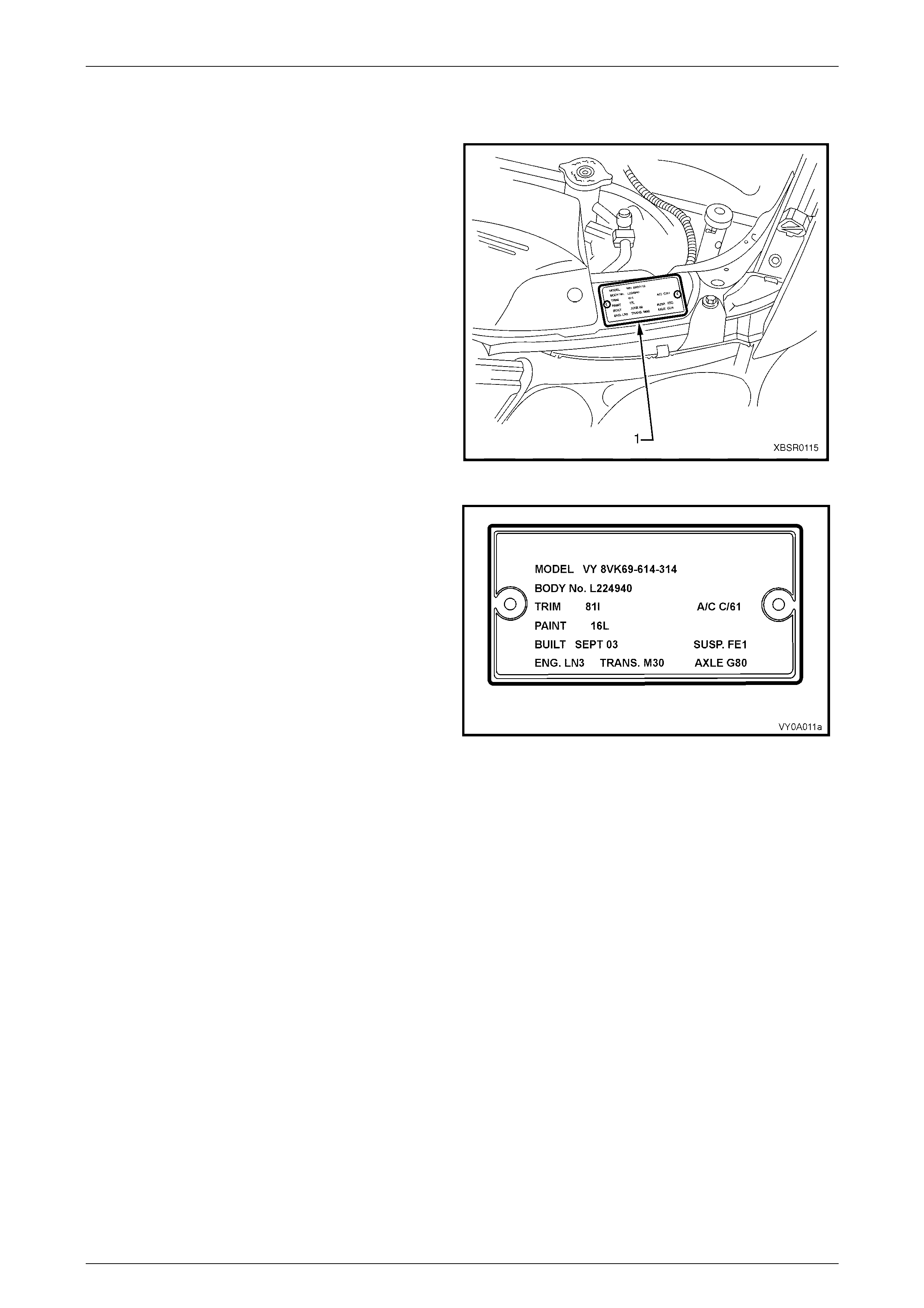

11.2 Safety Compliance Plate

The safety compliance plate (1) is located on the dash

panel assembly within the engine compartment.

Figure 0A – 4

The safety compliance plate is stamped with the following

information:

• Compliance plate approval number.

• Vehicle category code.

• Name appearing on compliance plate approval.

• Make / Model .

• Gross vehicle mass. This is the maximum loaded

mass at which the vehicle complies with the

approved design rules. Not required for passenger

vehicles. (Required for commercial vehicles.)

• Seating capacity.

• Number of adult positions for which seat belts are

provided.

• Date of manufacture.

• The day, month and year that the vehicle is

manufactured.

• Vehicle Identification Number (VIN).

Figure 0A – 5

General Information Page 0A–15

Page 0A–15

11.3 Body and Option Identification Plate

The Body and Option Identification Plate (1) is located on

the front panel assembly and is stamped with the following

information.

Model

Combination of letters and numbers identifying the body

style, the mechanical pack and smart pack options.

A listing of production and smart pack option numbers can

be found by referring to the latest spare parts information

for the applicable model.

Body

Production build number; run in continuous sequence

regardless of model, body type and series.

Trim

Trim combination.

Paint

Exterior paint material and colour identification.

Built

The date of manufacture by calendar month and year in

which the body shell and power train are conjoined and the

vehicle is driven or moved from the production line.

Susp

Suspension option code identification:

FE1 identifies vehicles with standard suspension.

FE2 identifies vehicles with sport suspension.

FR1 identifies vehicles with country pack suspension.

Engine, Transmission and Axle.

Identification option codes for specific engine, transmission

and rear axle (final drive).

A/C

C60 identifies vehicles fitted with air conditioning.

C61 Identifies vehicles fitted with single zone automatic

climate control air conditioning.

CJ2 identifies vehicles fitted with dual zone automatic

climate control air conditioning.

Figure 0A – 6

Figure 0A – 7

General Information Page 0A–16

Page 0A–16

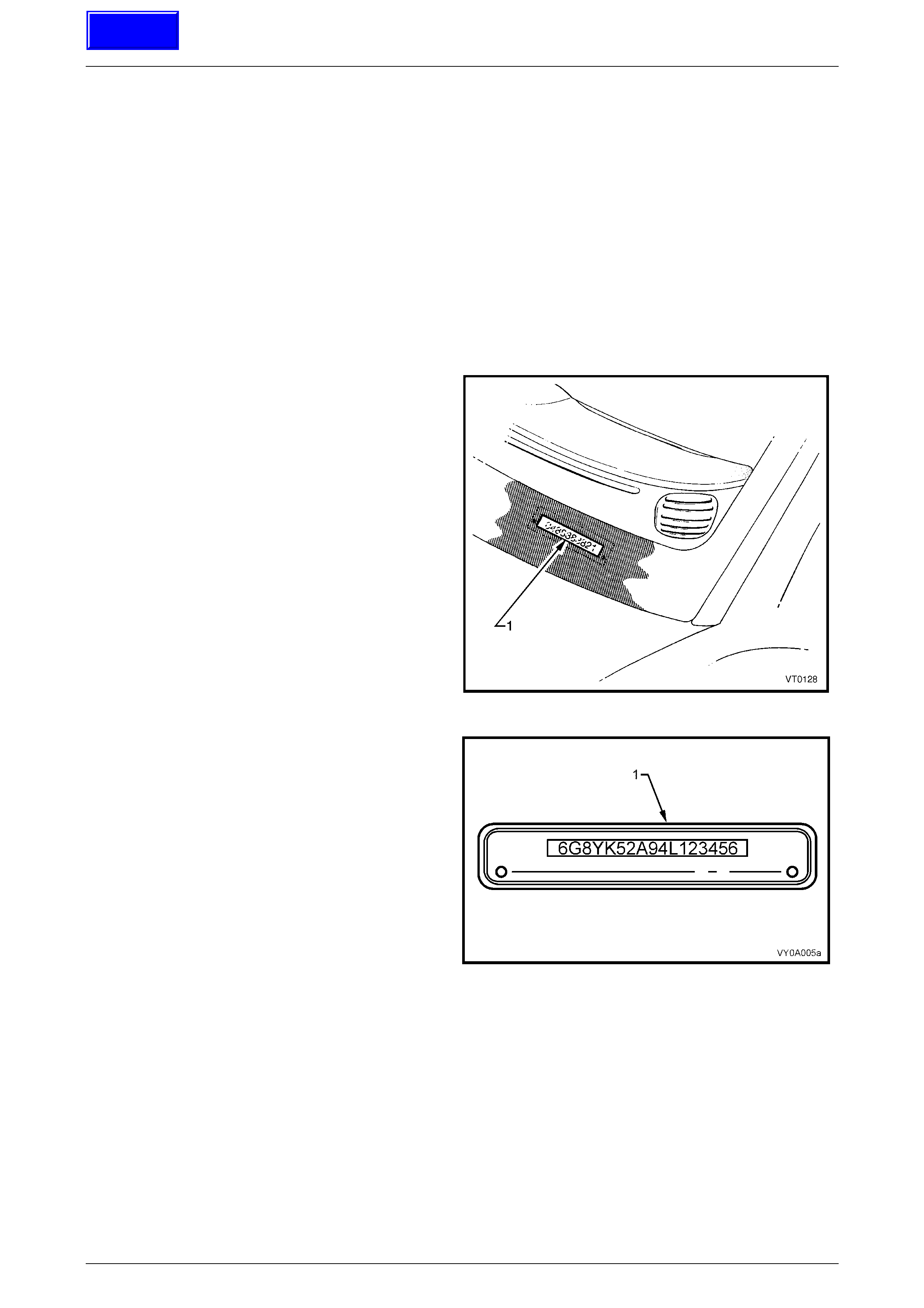

11.4 Vehicle Identification Number

The Vehicle Identification Numbering (VIN) system is based on the uniform Car Model Designation System. This

identifies the vehicle in one coded series of characters.

The Vehicle Identification Number is positioned in the following locations.

1 VIN plate under the windscreen – viewed through the windscreen aperture.

2 Body and option identification plate – left-hand side of the front panel upper.

3 Safety compliance plate – dash panel.

4 Stamping in the front floor panel under the front right-hand seat.

VIN Plates

The VIN Plate (1) is located under the windscreen and is

viewed through the windscreen aperture.

Figure 0A – 8

Figure 0A – 9 shows the VIN plate (1) that is located under

the windscreen aperture and is attached to the dash panel

assembly with unique rosette headed rivets.

Figure 0A – 9

Techline

General Information Page 0A–17

Page 0A–17

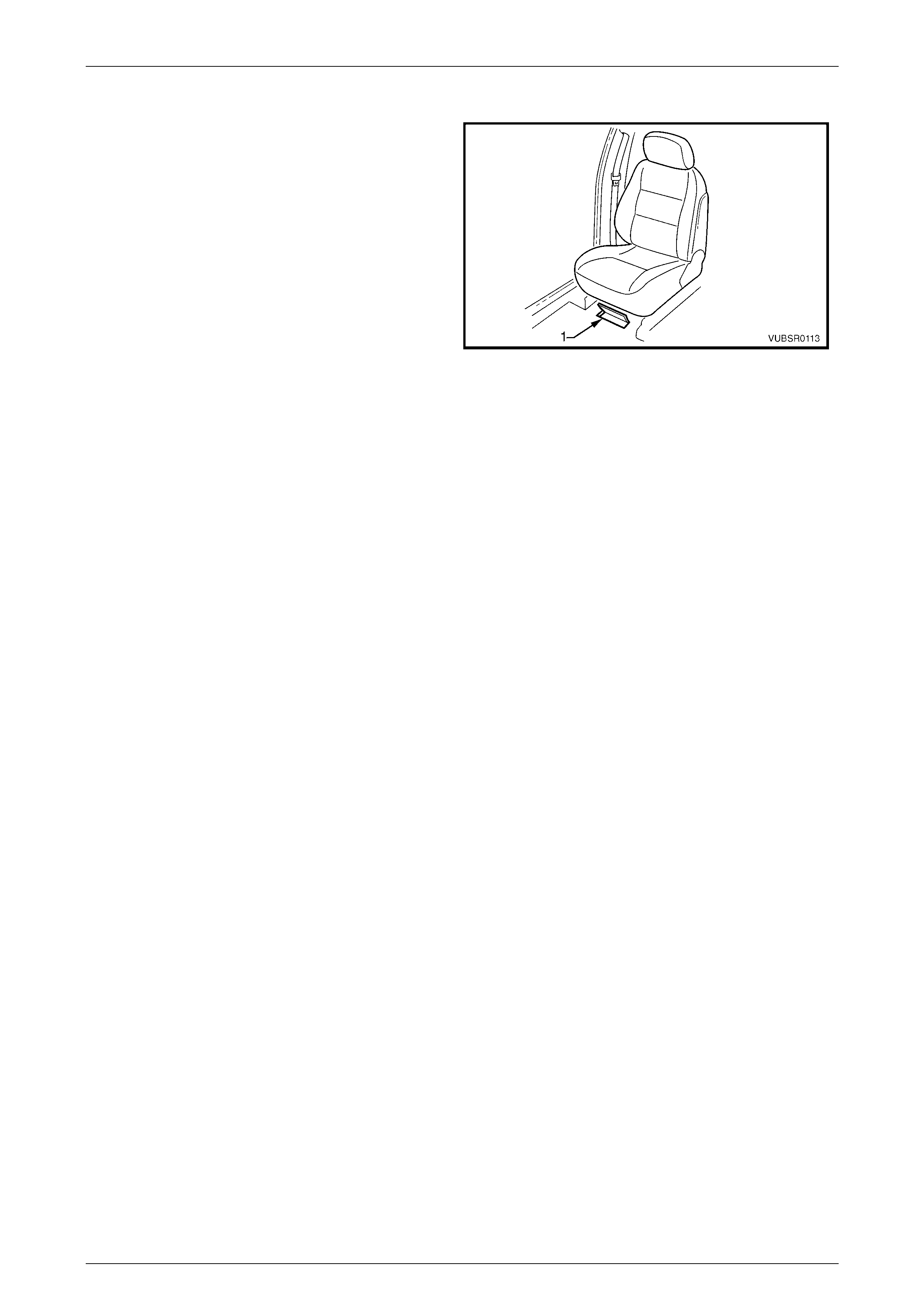

VIN Body Stamping

The VIN is stamped into the front floor panel under the

right-hand front seat. The VIN (1) is visible by lifting the

carpet flap.

NOTE

If the front floor panel assembly is to be

replaced, the VIN will be lost. Contact your local

Road Traffic Authority prior to replacing the

panel to obtain the correct procedure for

renumbering the vehicle.

NOTE

A replacement body shell assembly is stamped

during manufacture with a unique VIN that

identifies it as a replacement part.

NOTE

If an error is made to the VIN stamping during

manufacture, it is lined out so that it remains

legible and the correct number is stamped

underneath.

Figure 0A – 10

General Information Page 0A–18

Page 0A–18

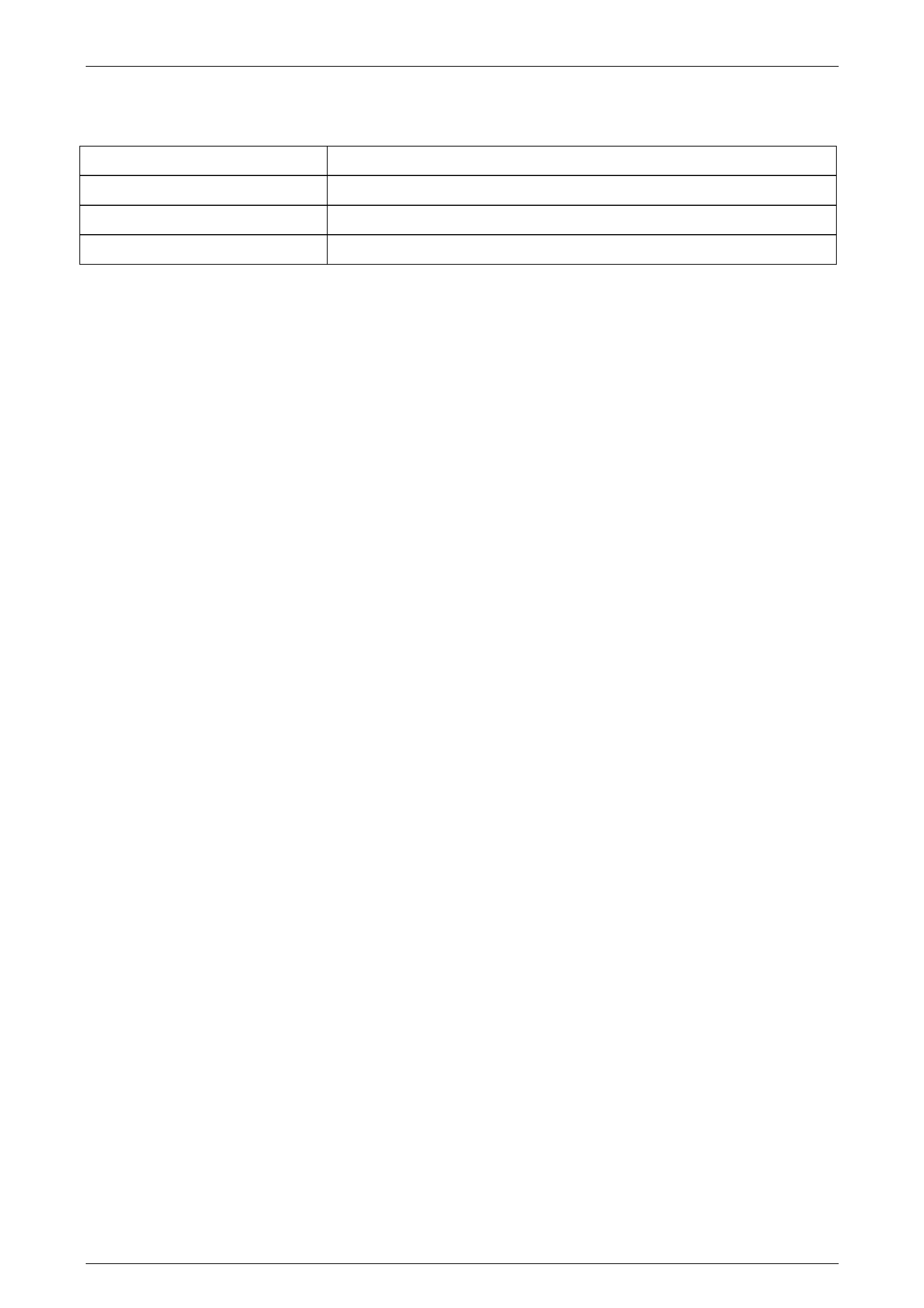

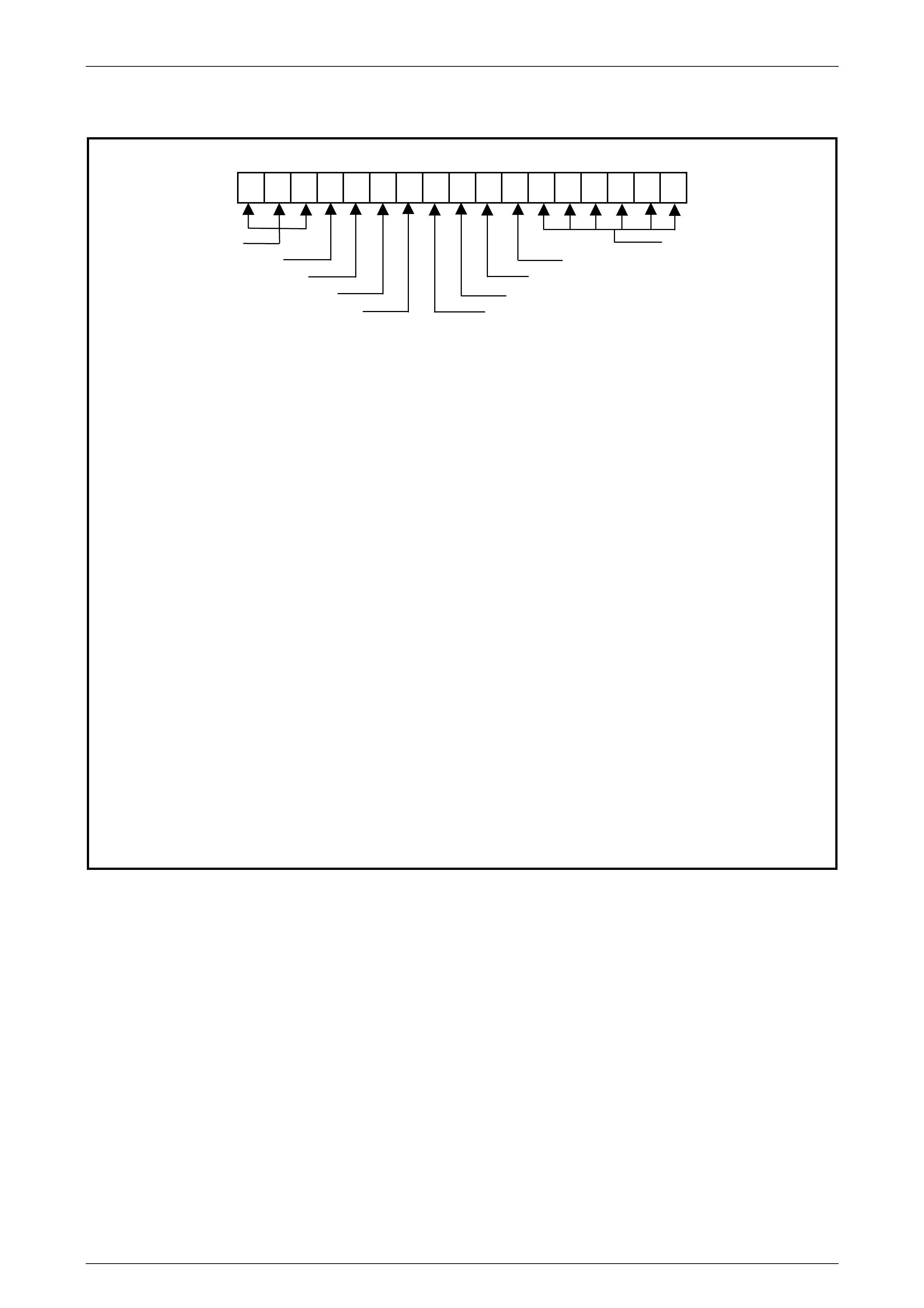

11.5 Vehicle Identification Numbering System

6 G 1 Y K 3 4 F 0 4 L 1 2 3 4 5 6

WMI CODE PRODUCTION

CARLINE PLANT SEQUENCE NUMBER

LUXURY LEVEL MODEL YEAR

BODY STYLE VIN CHECK DIGIT

RESTRAINT CODE ENGINE TYPE

WMI CODE: 6 – Oceania

G – Australia

1 – Holden

CARLINE: Y – VY Series

LUXURY LEVEL: K – SS

BODY STYLE: 3 – 4 door crew cab)

RESTRAINT CODE: 4 – Active (manual) seat belts with driver and passenger infl a table restrain t

system – frontal and side

ENGINE TYPE: F – 5.7 litre GEN III V8 engine

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 4 – 2004

5 – 2005

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUM BER:

123456 – Sequential Production Serial Number

NOTE

The production sequence number is sequentially allocated to each vehicle, regardless of vehicle type.

Figure 0A – 11

General Information Page 0A–19

Page 0A–19

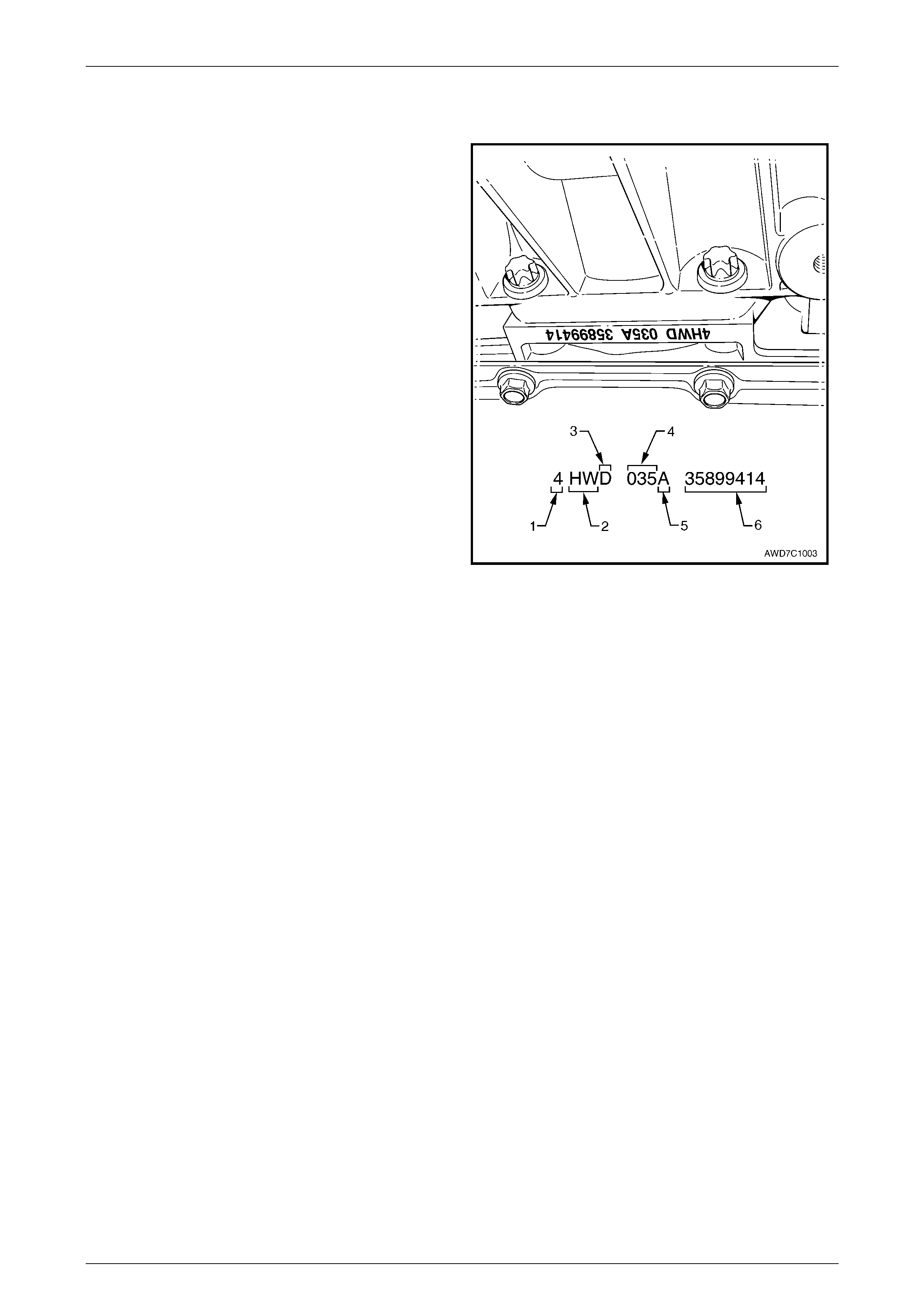

11.6 Automatic Transmission Serial Number

The automatic transmission serial number is stamped into

a machined surface located at the rear underside of the

transmission centre case, between the rear extension

housing and the tran smi ssion fluid pan.

Legend

1 Model Year (‘4’ = 2004)

2 Model: AWD and 5.7 litre GEN III V8 – 'HW'

3 Transmission Model Identifier (‘DR’ = 4L65-E)

4 Julian Date (Day of the Year)

5 Shift Build ‘A’, ‘B’, ‘J’ = First Shift;

‘C’, ‘H’, ‘W’ = Second Shift

6 Individual Transm is sion Serial Number

Figure 0A – 12

General Information Page 0A–20

Page 0A–20

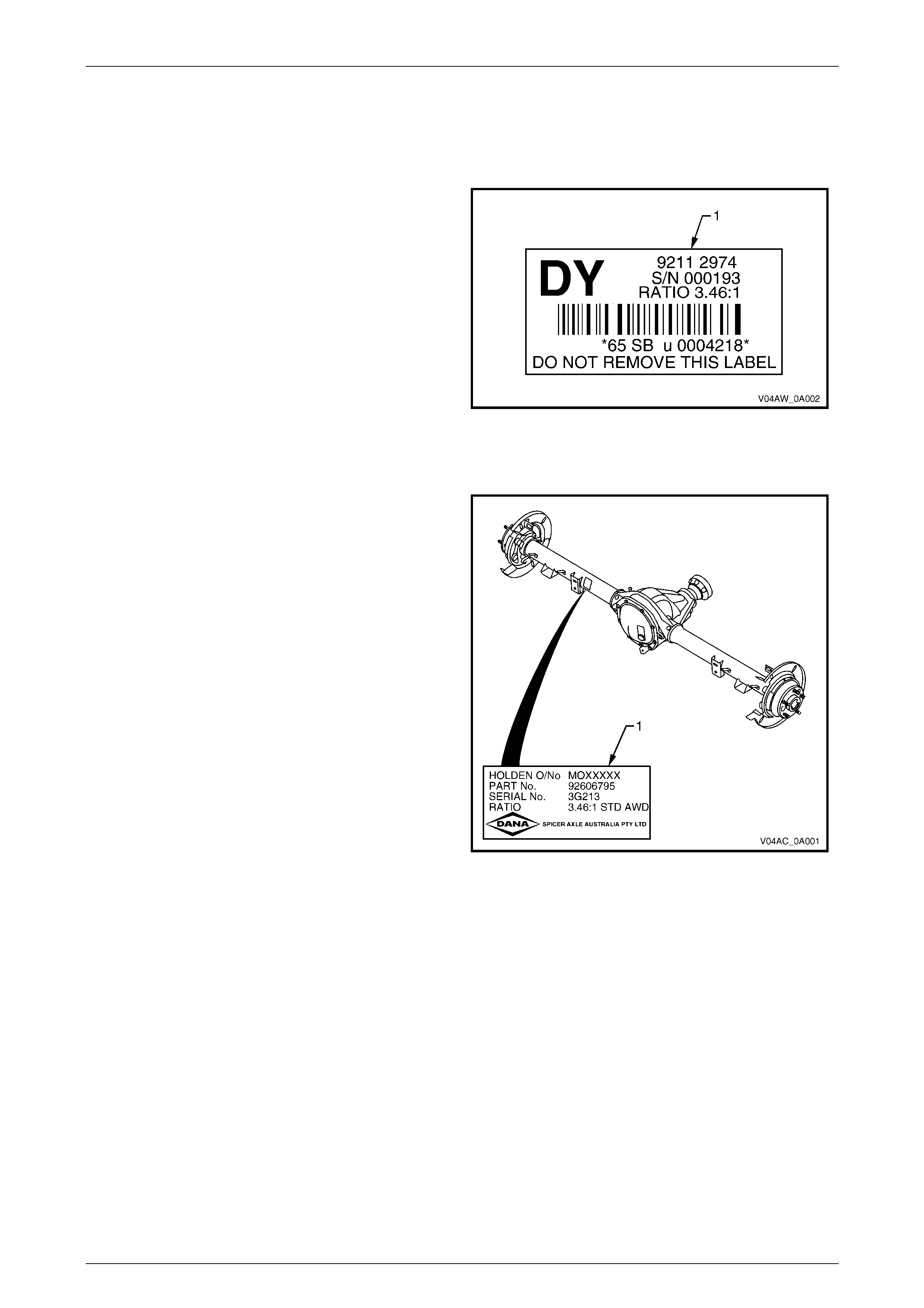

11.7 Final Drive Assembly Serial Numbers

Front Final Drive

An identification label (1) is adhered to the front final drive

assembly on the left side towards the rear of the housing.

The label contains the Holden Part Number for the

assembly, the serial number of the assembly as well as

the final drive ratio.

The front final drive assembly is attached to the left-hand

side of the engine oil pan.

Figure 0A – 13

Rear Final Drive

An identification label is adhered to the rear axle

assembly adjacent to the to left-hand side sway bar

mount. The label carries the Holden Part Number for the

assembly, the final drive ratio and the serial number of

the assembly.

Figure 0A – 14

General Information Page 0A–21

Page 0A–21

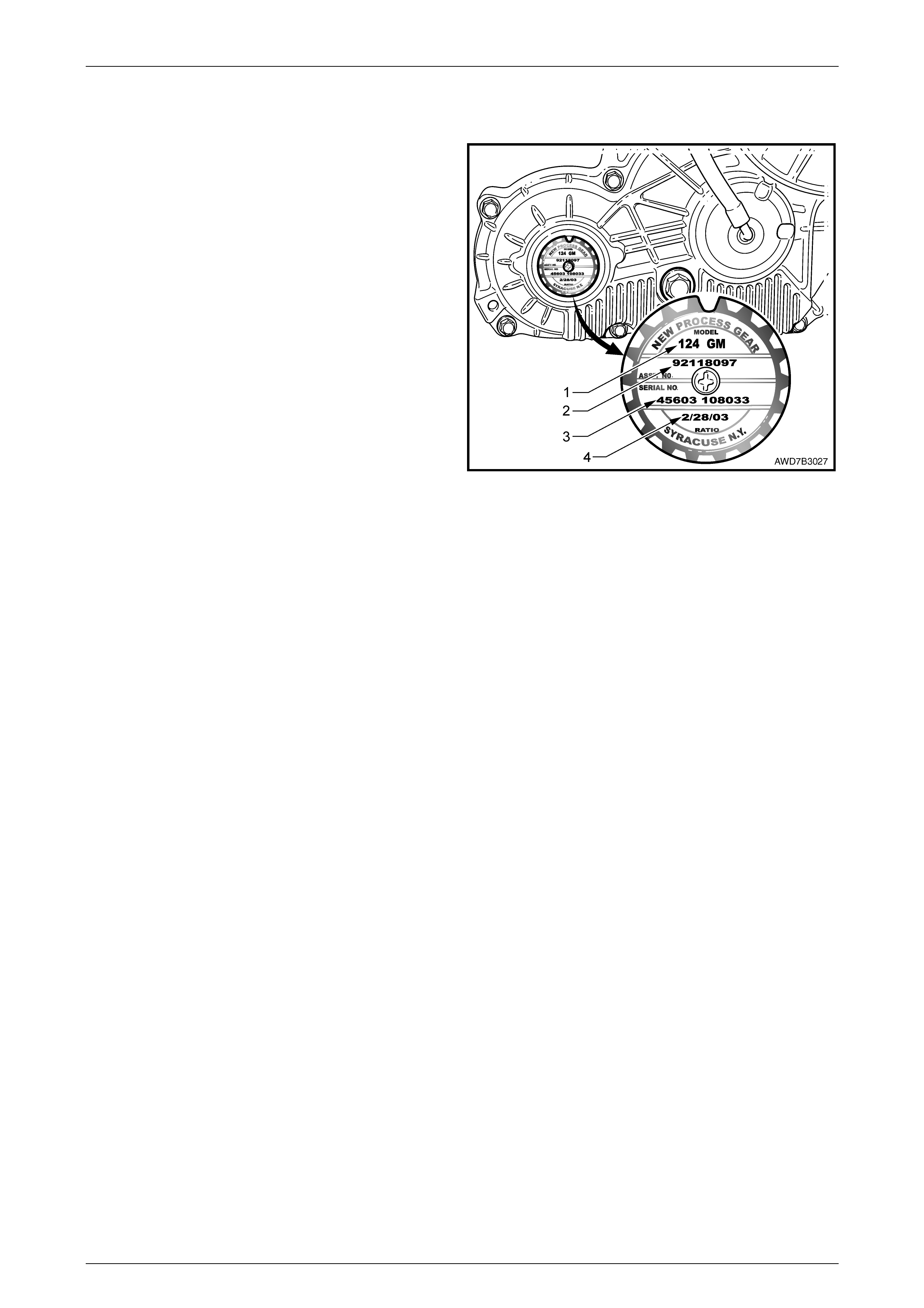

11.8 Transfer Case Assembly Serial Number

A

n identification tag is attached to the rear of the transfer

case housing, refer Figure 0A – 15. The information

contained on the tag provides the transfer case serial

number, build date and other information that may be

required for the correct procurement of service parts.

If the tag is removed or is dislodged during service

operations, the item is to be kept with the assembly.

Legend

1 Model Number ('124' )

2 Assembly Part Number

3 Serial Number

4 Build Date

Figure 0A – 15

General Information Page 0A–22

Page 0A–22

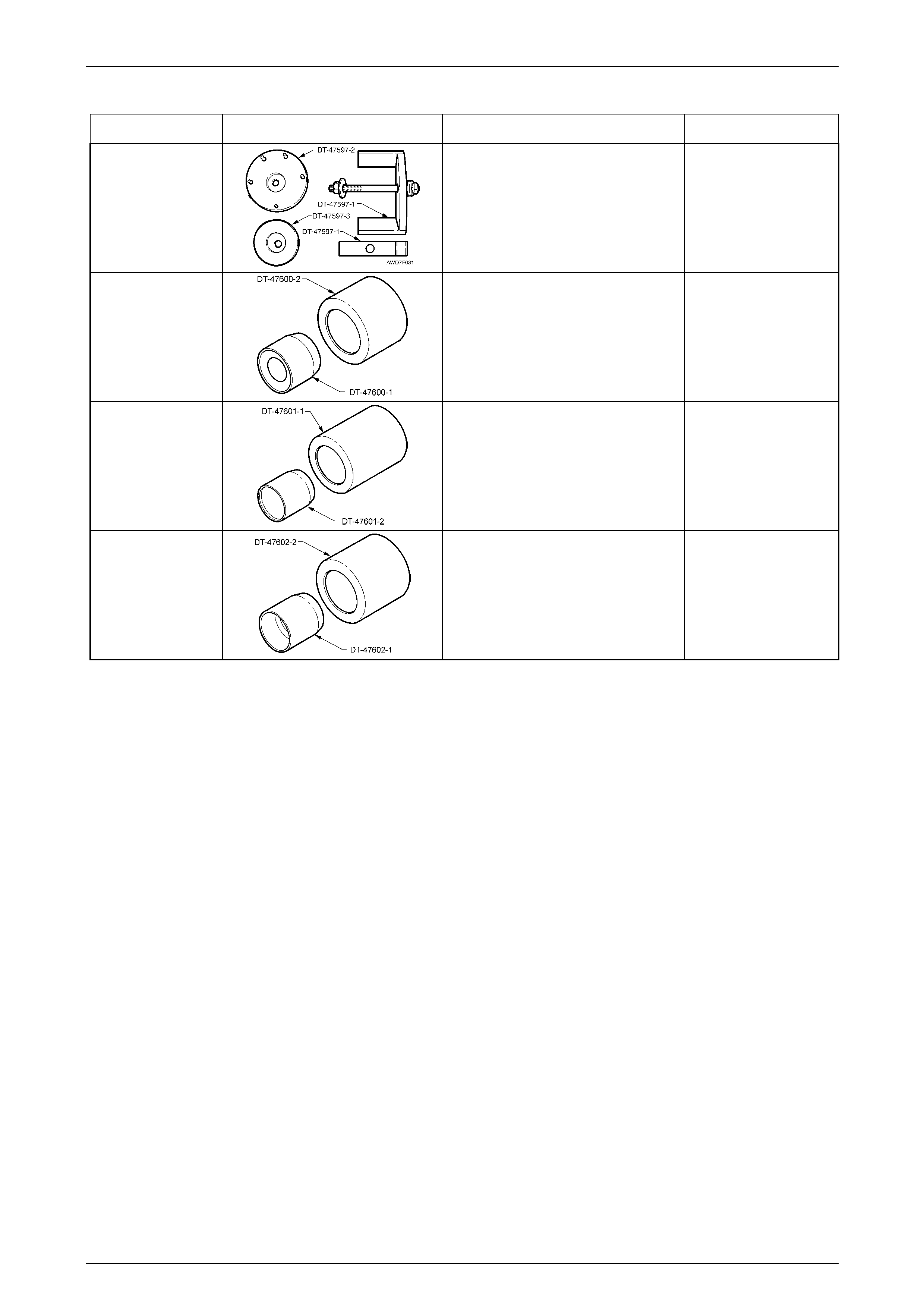

12 Special Tools

The following information lists the new Special Service Tools required for use on the MY 2004 AWD Crew Cab vehicles.

All other remaining Special Service Tools for us e on MY 2004 AWD Crew Cab vehicles carry over from the MY 2003 VY

and V2 Series. For all other Special Service Tools not listed in this Section, refer to Section 0A, 16 Consolidated Tool List

in the MY 2003 VY and V2 Series Service Information.

These new tools are grouped according to application (transfer case, front suspension and front final drive) and within

each group, are listed in tool number alphabetical / numerical order. They are also classified into the following categories:

• Mandatory: When required to perform routine maintenance operations and adjustments, or are required to carry

out fault diagnosis procedures.

• Desirable: These tools should be considered for purchase since their use will greatly facilitate performing

designat ed tas ks and perm it achieve ment of standard times.

• Unique: These tools are those that must be employed when overhauling major assemblies or performing relatively

large tasks.

• Available: Are those tools that are of general nature for which commercially available equivalents exists, or tools,

which have had previous application.

Unless otherwise specified, all Special Service Tools are availabl e from:

SPX Australia Pty. Ltd.

Service Solutions

28 Clayton Road

Notting Hill, Victoria, 3168

Telephone: (03) 9544 6222

Facsimile: (03) 9544 5222

Email: sales@spx.com.au

General Information Page 0A–23

Page 0A–23

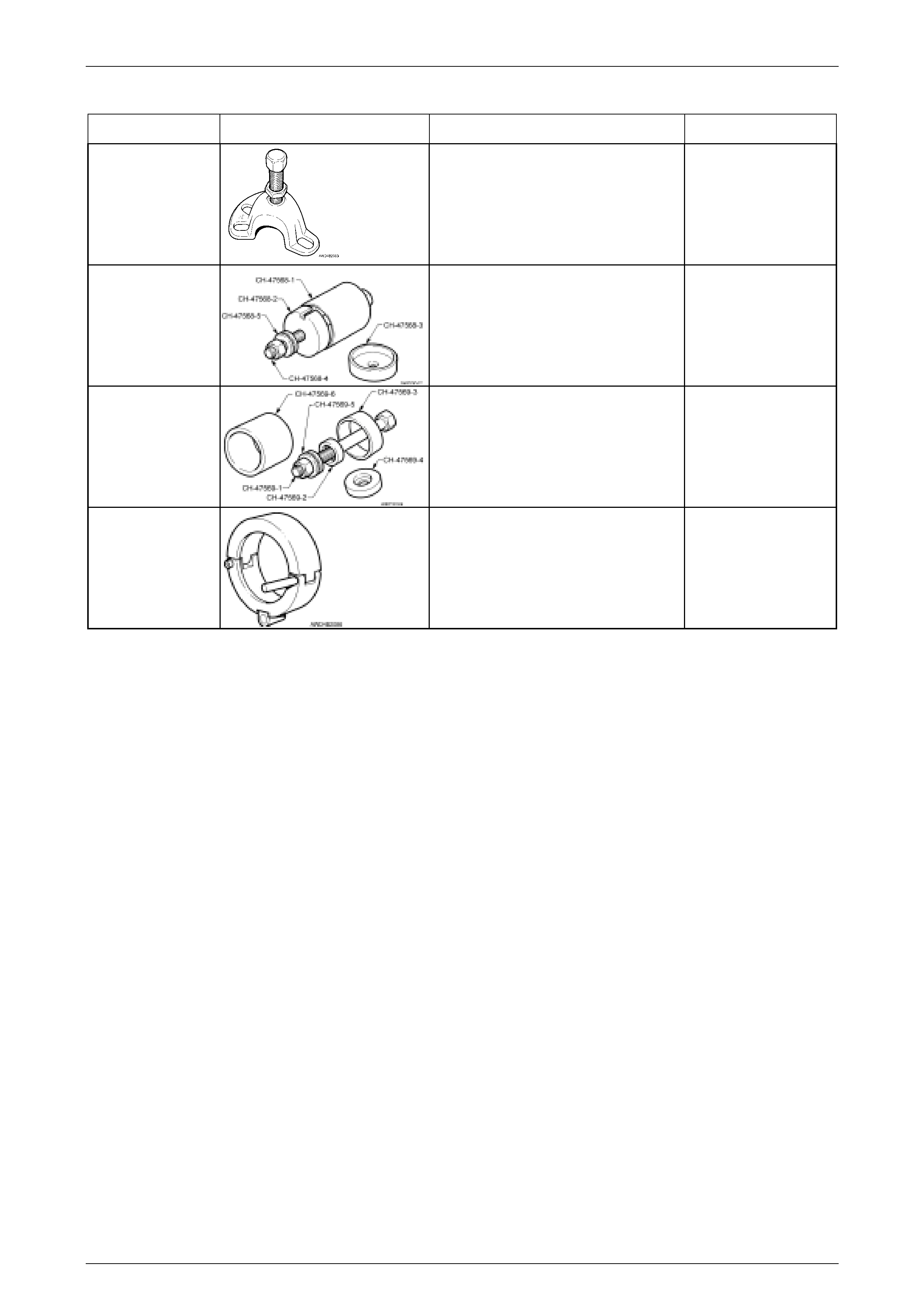

Transfer Case

Tool Number Illustration Description Tool Classification

DT-47597

Rear Mount Remover / Installer

Used to remove and install the rear

support mount from/to the tran sfer

case.

New release for AWD vehicles

Available

DT-47600

Seal Protector and Installer

Used to protect and install the front

input shaft oil seal to the transfer

case.

New release for AWD vehicles

Available

DT-47601

Seal Protector and Installer

Used to protect and install the rear

output shaft oil seal to the transfer

case.

New release for AWD vehicles

Available

DT-47602

Seal Protector and Installer

Used to protect and install the front

output shaft oil seal to the transfer

case.

New release for AWD vehicles

Available

General Information Page 0A–24

Page 0A–24

Front Suspension

Tool Number Illustration Description Tool Classification

7208

Hub Puller

Used to press the front driveshaft from

the front hub. Also used to check LSD

breakaway torque on final drives so

equipped.

Previously released

Mandatory

CH-47568 Remover / Installer Control Arm,

Front Isolator Bush

Used to remove and install the front

control arm, front hydraulic bushing

from/to the front suspension

crossmember cradle.

New release

for AWD vehicles

Available

CH-47569 Remover / Installer Control Arm,

Rear Bush

Used to remove and install the rear

bushing, from/to the front control arm.

New release for AWD vehicles

Available

DT-47570 Remover / Installer, Front

Driveshafts

Used in conjunction with slide hammer

J 6125-1B (and adaptor), or J 23907

slide hammer to remove and reinstall

the front driveshafts.

New release

for AWD vehicles

Mandatory

General Information Page 0A–25

Page 0A–25

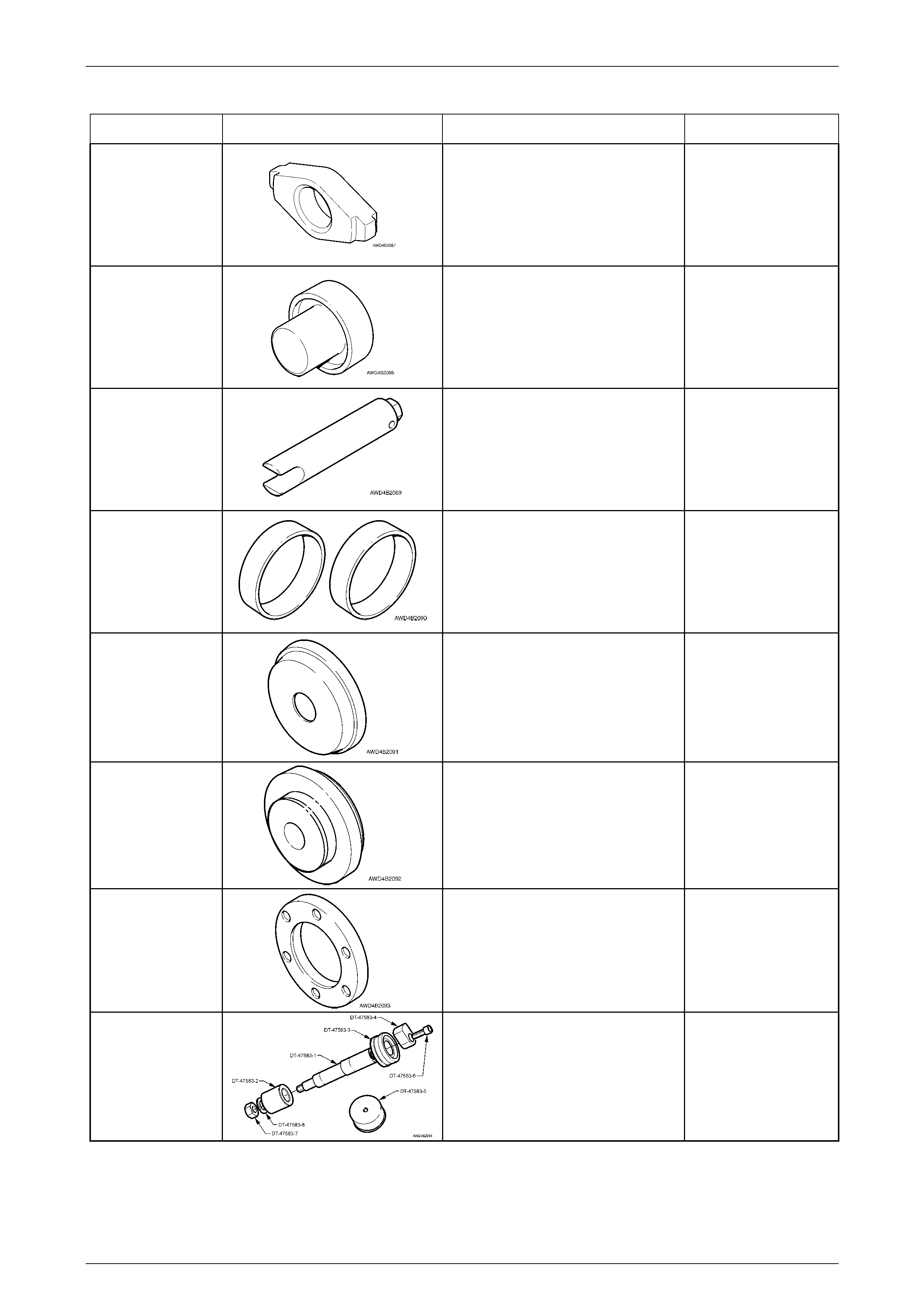

Front Final Drive

Tool Number Illustration Description Tool Classification

DT-47571

Cup Removal Adaptor

Used in conjunction with E9293 to

remove both pinion bearing cups from

the carrier housing.

New release for AWD vehicles

Available

DT-47572

Side Bearing Installer

Used with a hydraulic press to install

the differential carrier bearing cones.

New release for AWD vehicles

Available

DT-46573

Ring Gear Rotation Tool

Used to rotate differential housing to

measure bearing preload.

New release for AWD vehicles

Mandatory

DT-47577

Dummy Bearing Cups

Used when determining the

differential bearing preload and

position.

New release for AWD vehicles

Available

DT-47578

Bearing Cup Installer

Used in conjunction with bearing cup

alignment tool, DT-47579, to install

the ring gear carrier bearing cups to

the carrier and cover housings.

New release for AWD vehicles

Available

DT-47579

Bearing Cup Alignment Tool

Used in conjunction with bearing cup

installer, to ensure that bearing cups

are installed correctly.

New release for AWD vehicles

Available

DT-47580

Spacer Ring

Fitted into the pinion flange to act as a

spacer for holding tool J8614-01.

New release for AWD vehicles

Available

DT-47583

Dummy Pinion

Used to determine the pinion bearing

preload and position.

New release for AWD vehicles

Available