SECTION 4B - FINAL DRIVE AND DRIVE SHAFTS

CAUTION:

This v ehicle will be equipped w ith a Supplemental Restraint System (SRS). An SRS w ill consist of either

seat belt pre-tensioners and a driver's side air bag, or seat belt pre-tensioners and a driver's and front

passenger's side air bags. Refer to CAUTIONS, Section 12M, of the VT Series I Service Information

before performing any service operation on or around any SRS components, the steering mechanism or

wiring. Failure to follow the CAUTIONS could result in SRS deployment, resulting in possible personal

injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, of the

VT Series I Service Information.

1. GENERAL INFORMATION

Independent rear suspension is fitted as standard equipment on all VT Series vehicles and all are f itted with a final

drive asse mbly, Production Option (P.O.) G U4. Additionally, P.O. G80, Limited Slip Dif f er ential ( LSD), (als o r ef er re d

to as Spin Resistant Differential - SRD) comes standard on all Models with P.O. 9C1 and A8V.

The type of diff erential f itted to the final drive as sem bly can be identified by referring to either the identif ication label

attached to the RHS of the c arr ier hous ing or f rom the lubr ication tag under the f iller plug on the rear cover . Ref er to

1.1 FINAL DRIVE ASSEMBLY IDENTIFICATION in this Section for additional information.

All information relating to the final drive and drive shafts fitted to VT Series vehicles with P.O. 9C1 and A8V, is as

detailed in Section 4B FINAL DRIVE AND DRIVE SHAFTS, of the VT Series I Service Information, noting the

following:

Due to omitted specifications for the 3.46:1 final drive assembly, specifications for this final drive assembly have

been published in full in this Section.

1.1 FINAL DRIVE ASSEMBLY IDENTIFICATION

The following chart provides a summary of the type of final drive assembly fitted to VT Series Models with

Production Options 9C1 and A8V.

Engine Body style Transmission Broadcast

code Ratio Type

Sedan All

Automatic EE 3.08:1 LSD

3.8 Lt V6 Wagon Manual

5.0 Lt V8 All All

All Automatic

EH 3.07:1 LSD

5.7 Lt

GEN III V8 Sedan Manual EP 3.46:1 LSD

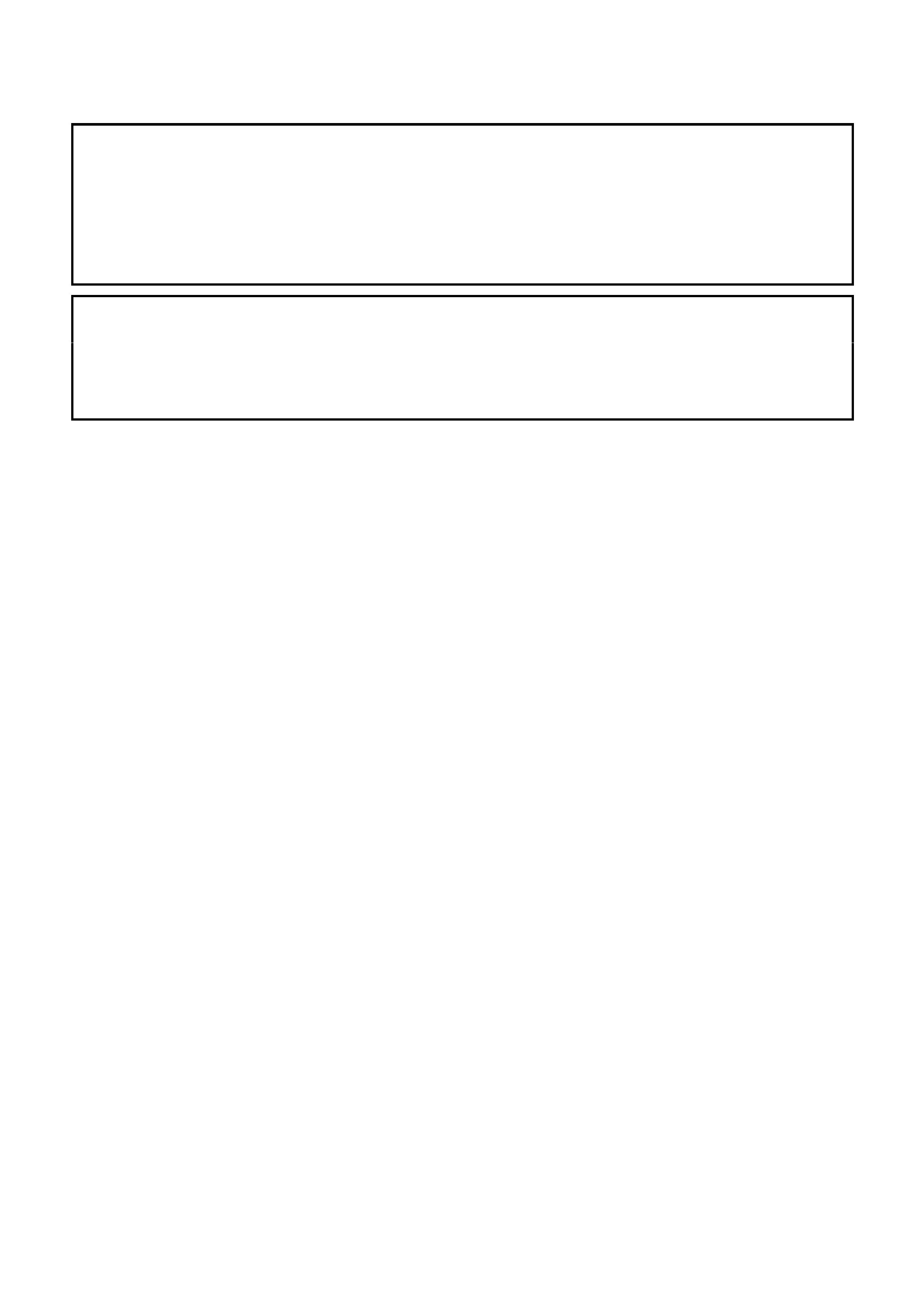

To identify the type of differential fitted to the final

drive assembly, refer to either the identification

label attached to the RHS of the carrier housing

(refer Fig. 4B-1) or from the lubrication tag under

the filler plug on the rear cover (refer Fig. 4B-2).

The identification tag carries the Holden part

number for the final drive assem bly, final drive ratio

and the serial number of the assembly.

The code number and bar code is used for

production identification of the final drive assembly.

Figure 4B-1

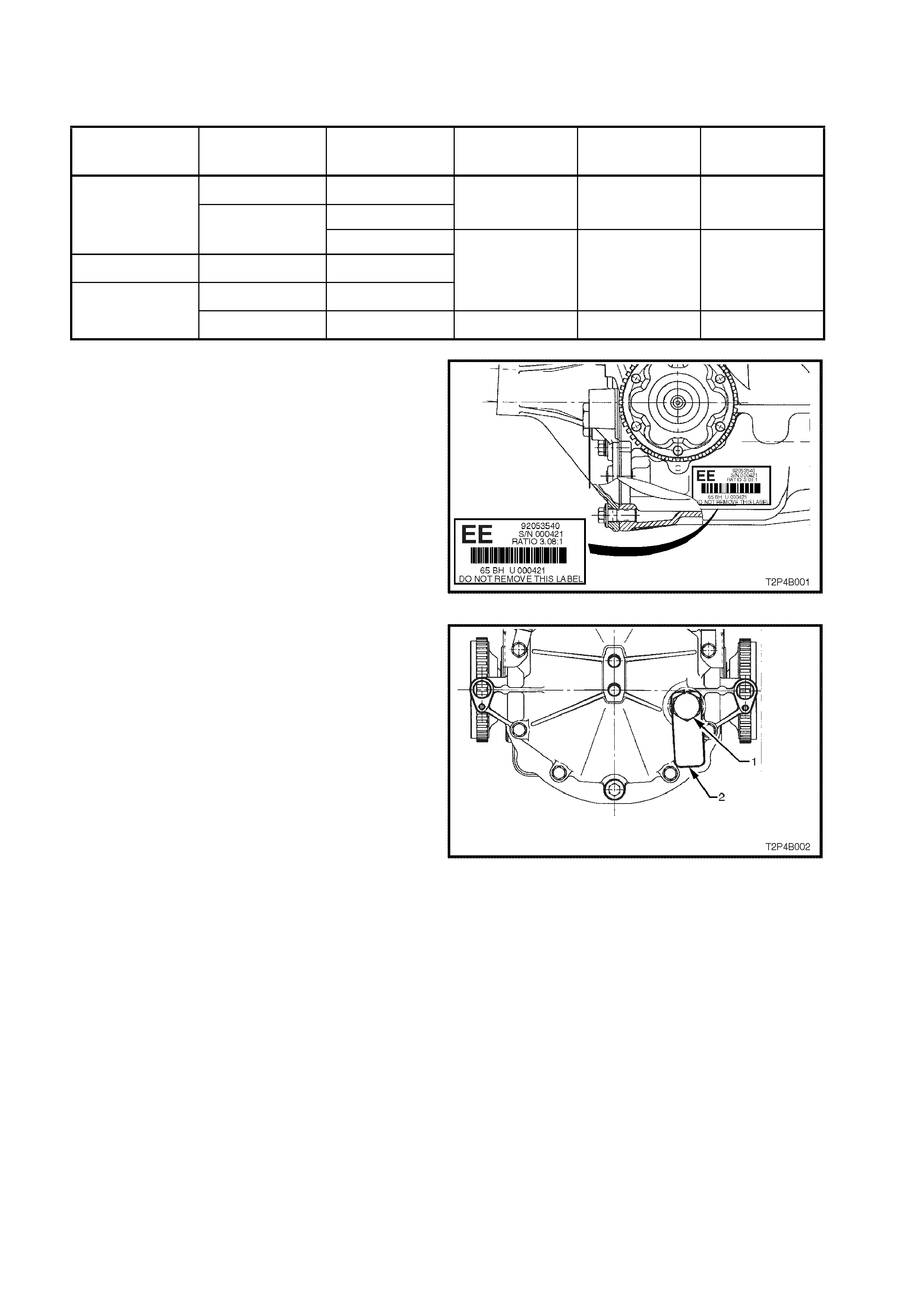

When fitted, the information on the lubrication tag

(2) under the filler plug (1), (refer Fig. 4B-2), will be;

• With V6 and LSD;

“SPIN RESISTANT DIFF. USE APPROVED

LUBRICANT ONLY”

• With V8 and LSD;

“LSD - HIGH PERFORMANCE. USE

APPROVED LUBRICANT ONLY”

Figure 4B-2

2. SPECIFICATIONS

NOTE: The following final drive specifications apply to vehicles with the GEN III V8 engine and 6 speed manual

transm iss ion only. Refer to Section 4B FINAL DRIVE AND DRIVE SHAFT S of the VT Series I Service Inf orm ation

for final drive specifications on other VT Series Models.

GENERAL

Rear Axle Assembly................................................................... BTRA - 80 Series

Axle Type ................................................................................... Independent Housing

STANDARD AND LSD AXLES

Gear Type .................................................................................. Hypoid

Gear Ratio.................................................................................. 3.46:1. (See I.D. tag attached to the carrier)

No. of Teeth: Ring Gear................................................. 45

Drive Pinion Gear..................................... 13

Ring Gear Diameter 203mm

LUBRICANT

Capacity..................................................................................... 1.6 litres

Type: ........................................................................................ Synthetic Hypoid Gear Oil to Holden Specification

HN2040.

DIFFERENTIAL GEARS

Type Straight Bevel

No. Teeth: Pinion Gears............................................. 10

Side Gears ............................................... 15

FINAL DRIVE PINION GEAR BEARINGS

Bearing Type.............................................................................. Adjustable Taper Roller

Bearing Adjustment.................................................................... Collapsible Spacer

Bearing Pre-Load Dummy pinion - New bearings ................. 1.4 - 2.0 Nm

Dummy pinion - Used bearings................ 0.7 - 1.0 Nm

New with oil seal....................................... 1.4 - 2.4 Nm

New without oil seal.................................. 1.4 - 2.0 Nm

Used with oil seal ..................................... 0.7 - 1.2 Nm

Used without oil seal ................................ 0.7 - 1.2 Nm

DIFFERENTIAL CARRIER SIDE BEARINGS

Type Adjustable Taper Roller

Adjustment................................................................................. Screw adjusters on each side of the carrier.

Bearing Pre-Load New Bearings........................................... 15 - 35 N Torque measured at the differential case,

Used Bearings.......................................... 8 - 18 N without inner axle shafts or final drive pinion

installed.

RUN-OUT SPECIFICATIONS

Trunnion Assembly Hub............................................................. 0.06 mm Total Indicated Run-out

Case Assembly (without ring gear attached).............................. 0.05 mm (maximum)

Ring Gear Rear Face (assembled onto case assembly) ........... 0.13 mm (maximum)

BACKLASH SPECIFICATIONS

Ring Gear to Drive Pinion...................................................... 0.10 - 0.18 mm (at the tightest point)

LSD TORQUE CHECK

Torque Check Specification................................................... 45 Nm (minimum)

ABS SENSOR

Air Gap (non-adjustable)....................................................... 0.4 - 1.5 mm

SEALANTS

Drive Shaft Dust Caps/Shield ..................................................... RTV 732 Sealant, to Holden Specification HN1373

Rear Cover to Carrier Housing................................................... Loctite 587 (‘Ultra Blue’) or equivalent, to Holden

Specification HN1973

As Required ............................................................................... Loctite 243 or equivalent, to Holden Specification HN1256,

Class 2, Type 1

LUBRICANTS

As Specified in Text.................................................................... Molybond HE50 or equivalent, to Holden Specification

HN1326

As Specified in Text.................................................................... Lithium Soap Based Grease to Holden Specification

HN1147