SECTION 6D1-1 - CHARGING SYSTEM - V6 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air b ags o r seat b elt p re-t ension ers, driv er’s an d f ron t p asseng er’s air bag and left and righ t

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System

before performing any se rvice operation on, or around any S RS components, the steering mechanism or

wiring. Failure to follow the SAFETY PRECAUTIONS could result in SRS deployment, resulting in

possible personal injury or unnecessary SRS system repairs.

1. GENERAL INFORMATION

VT Series Models with V6 engine and Production Option (P.O.) 9C1 built prior to May 20 1998 have the standard

100 amp Bosch generator fitted. For all information regarding this generator, refer to Section 6D1-1 CHARGING

SYSTEM – V6 ENGINE of the VT Series I Service Information.

VT Series Models with V6 engine and P.O. 9C1 built from May 20 1998 (Vehicle Tag No. L335798) have a

Mitsubishi 120 amp generator fitted. All information regarding this generator can be found in this Section.

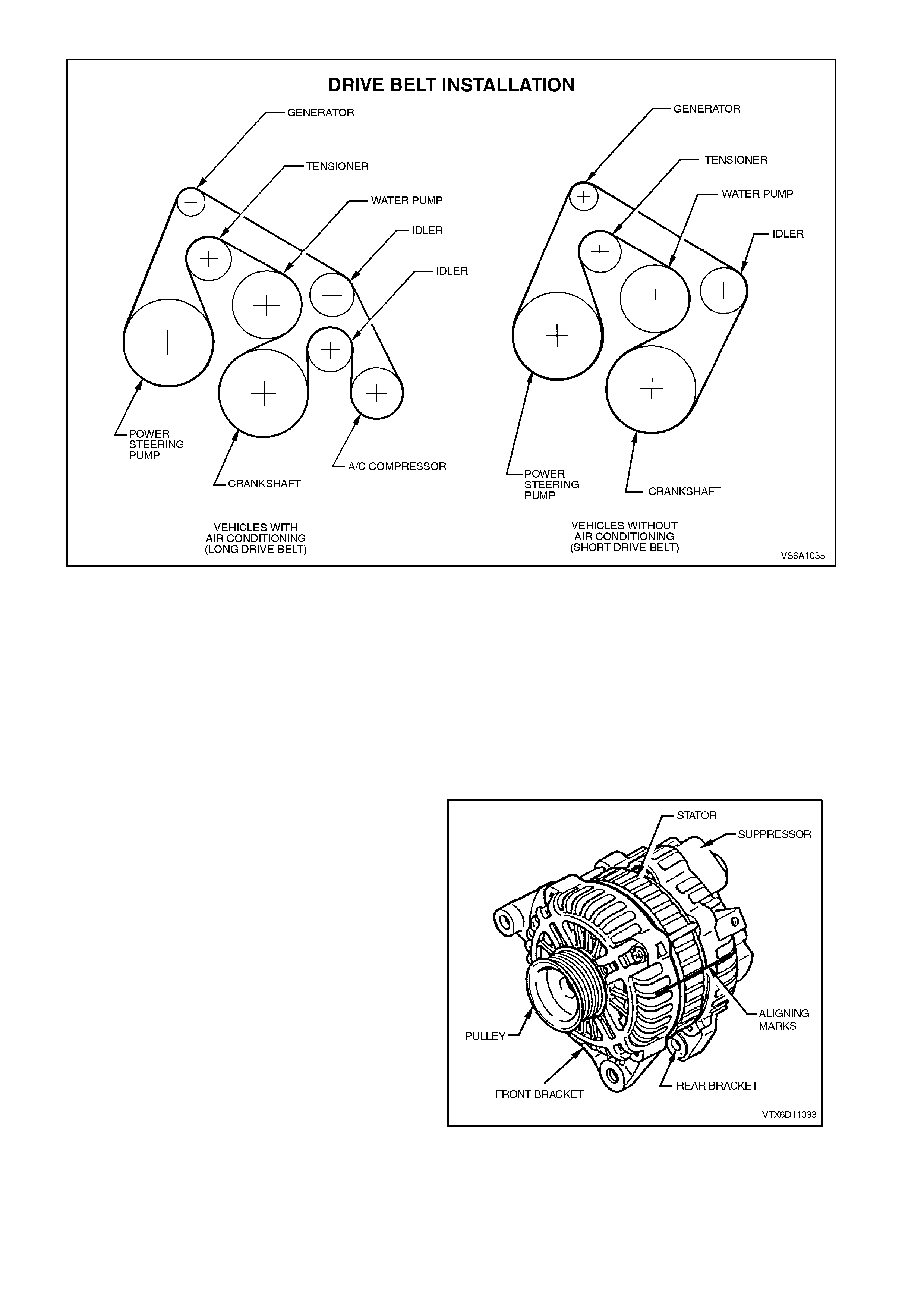

The Mits ubishi 120 amp generator c an be identified by its exter nal appearance in that it does not have an ex ternal

cooling fan.

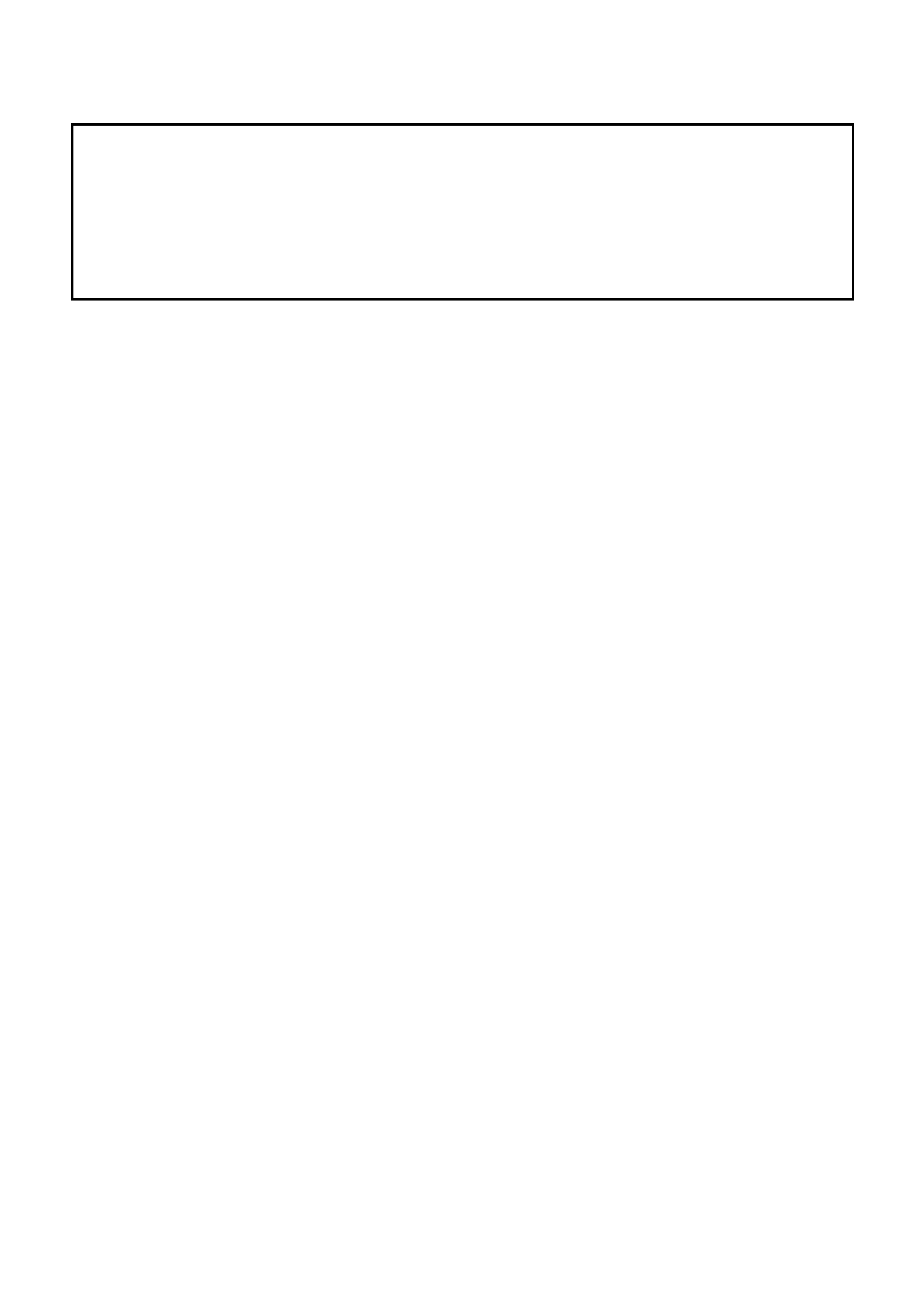

The generator is a 3-phase type, incorporating a rotor having six pole pairs fitted with two cooling fans, one on the

drive end and the other on the slip ring end. Rotor curr ent is conveyed to the rotor winding by a pair of s lip r ings and

carbon brushes via the voltage regulator. The r otor is supported by ball bearings in both the drive and slip ring end

housings. Surr ounding the rotor is a stator, which is of a three phas e star c onnected output winding constr uction on

a ring shaped lamination pack.

The output of the stator winding is rectified by six diodes which are contained within the slip ring end housing.

Excitation current is supplied to the rotor field coil via the voltage regulator, brushes and slip rings. The electronic

voltage regulator requires no adjustment in service.

The generator has four external connections; the ‘B+’ lead to the battery positive terminal, the ‘L’ lead to the

generator warning lamp (max. 2 watts), the ‘S’ lead for battery voltage sensing and an earth connection, refer to Fig.

6D1-1-1.

Figure 6D1-1-1

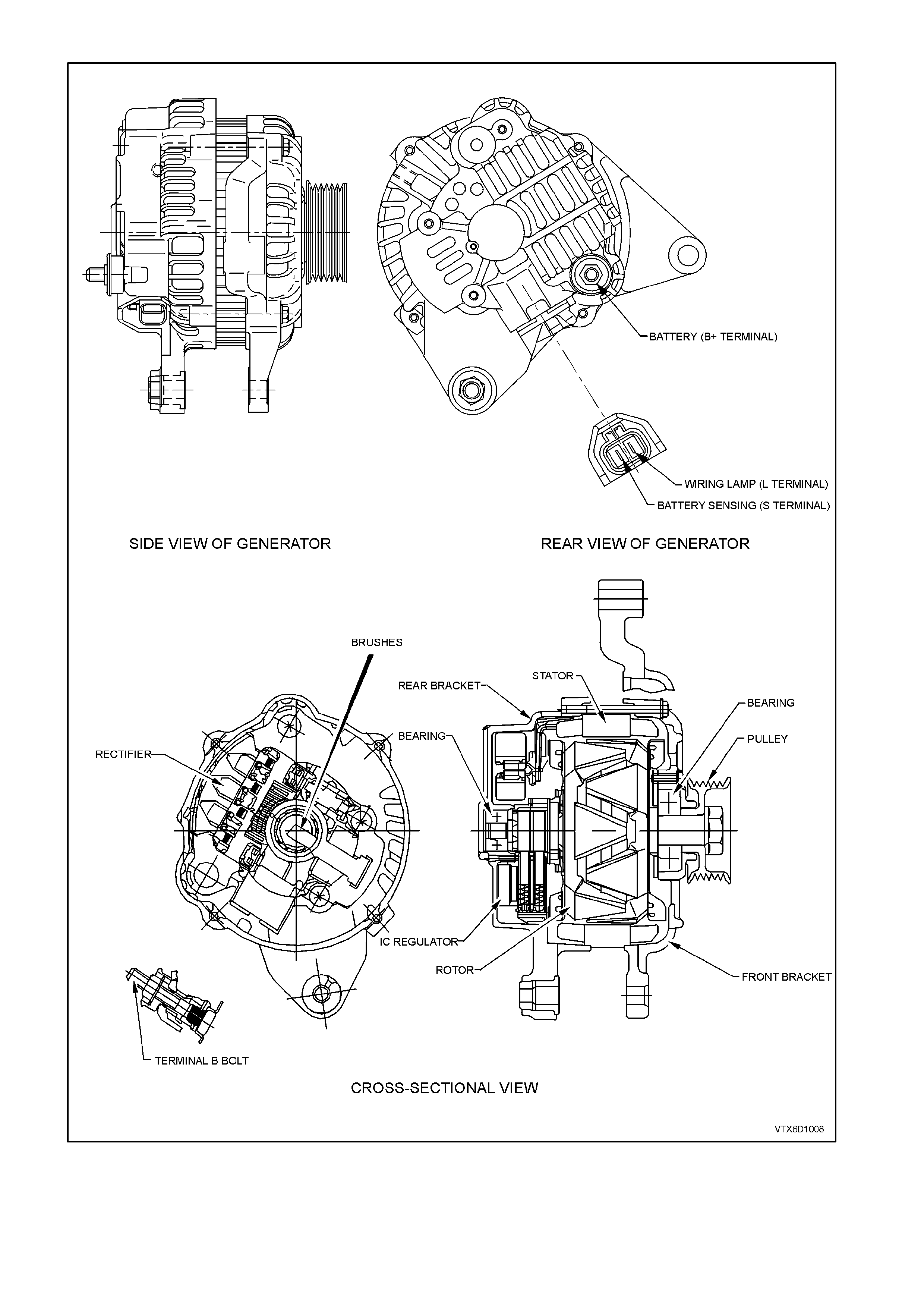

Figure 6D1-1-2

1 Through Bolt (4) 8 Rotor 15 Thrust Washer

2 Bearing Retaining Plate Screw (4) 9 Slip Ring End Bearing 16 Rectifier Assembly

3 Nut 10 Stator 17 Rear Bracket Assembly (Includes

4 Drive Pulley 11 Regulator and Brush Screws Items 11, 12, 13, 14, 15, 16, 17,

5 Front Bracket Assembly (Includes 12 Brush Retaining Plate 18 and 19)

Items 2, 5, 6 and 7) 13 Regulator 18 Terminal Cover Bush

6 Front Bearing 14 Brush 19 Nut

7 Bearing Retaining Plate

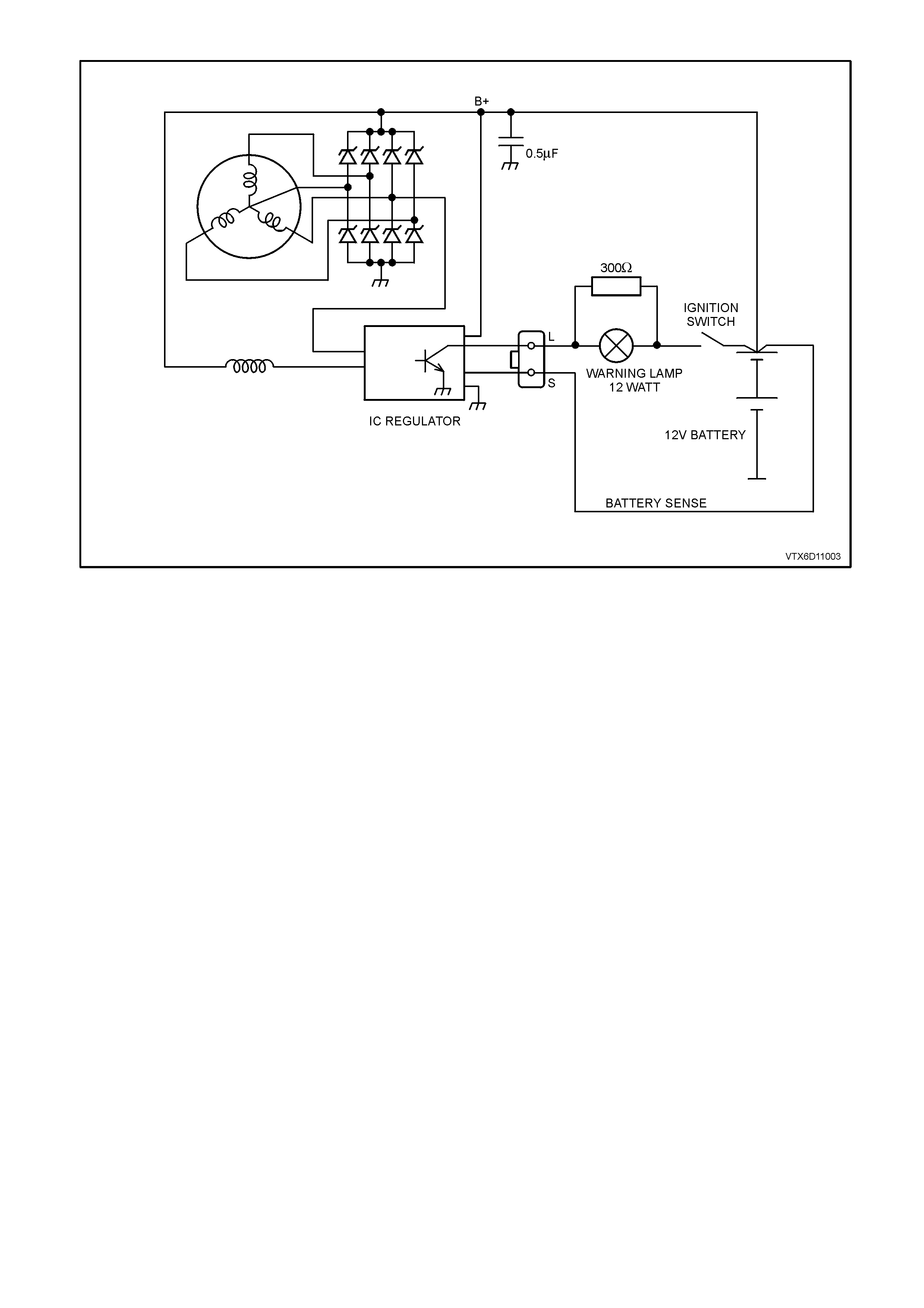

1.1 OPERATION

W ith the ignition switch turned to the on position, current is supplied via the warning lamp to the ‘L’ term inal of the

regulator. Current then flows from the ‘B+’ terminal through the rotor winding via the regulator brushes and the

collector emitter junction of the regulator switching transistor to earth, completing the circuit.

The c urrent in the rotor caus es a m agnetic field between adjacent poles to be created, this f ield is r otated and c uts

the windings of the stator at right angles inducing a voltage into them. As the speed is increased, this induced

voltage increases and results in current being rectified in the 3 phase diode bridge and supplied as DC to the B+

output and hence to the battery. When the voltage at the ‘B+’ terminal to the battery reaches approximately 14.2

volts, the ‘S’ term inal which is m onitoring this voltage, tur ns the regulator trans istor base c urrent off , rem oving rotor

current. T his results in a dec rease in output voltage to below the regulating voltage, turning the regulator tr ansistor

base current back on and the whole cycle is repeated very rapidly. An internal diode protects the transistor and the

regulator the against back voltage developed across the rotor winding when the regulator transistor turns off.

Should a situation arise where the m ain B+ c able or batter y sense wire (‘S’ ter m inal) bec om e dis connected or have

a high resistance, the regulator will limit the output voltage to a safe level (backup mode), approximately 1-3 volts

above the regulators normal setting.

When the ignition switch is turned on and the engine is not running, the current to the rotor is reduced by switching it

on and off at a 50% duty cycle (active stand by mode) , the frequenc y is approxim ately 4 kHz and may be audible at

times (this is normal). Once the engine is started, normal regulation commences.

Should the warning lamp fail, the generator will self excite by deriving a small current from the phase connection

allowing the voltage to build up to regulating level.

NOTE: No rotor winding current will flow when the engine is cranking.

The regulator incorporates internal diagnostics which will illuminate the warning lam p as a result of fault conditions

in the generator and/or external circuitry.

These conditions include:

1. An open circuit in the regulator battery sensing wire (‘S’ terminal).

2. An open circuit or excessive voltage drop in the B+ cable.

3. An open circuit in the generator phase connection.

4. Overcharging of the battery.

5. Regulator output stage short circuit.

6. Open circuit in the rotor winding.

The regulator com pares the voltage at the ‘B+’ term inal with the voltage sensed at the ‘S’ term inal connected to the

battery positive. If the voltage differential exceeds a predetermined threshold, the regulator will operate in backup

mode to limit the output voltage to a safe level. The warning lamp will remain illuminated as long as the fault

conditions prevail.

Sources of high resistance which will trigger the warning lamp are:

1. Poor contact in the wiring harness connectors.

2. Poor contact between the rectifier and the regulator.

3. High resistance in the fusible link assembly or battery terminals and cables.

Figure 6D1-1-3

2. MI NOR SERVICE OPERATIONS

2.1 SAFETY PRECAUTIONS

Since the generator and voltage regulator are designed for use only on a negative earth system, the following

precautions must be observed. Failure to observe these precautions will result in serious damage to the generator.

1. When installing a battery, first fit positive ( +) cable to battery positive (+) term inal and then f it negative ( –) cable

to battery negative (–) terminal.

2. When a slave battery is utilised for starting purposes, ensure both batteries are connected in parallel, ie.

positive terminals together and negative terminals together.

3. When charging battery, disconnect both battery cables, thus isolating generator from battery and external

charging equipment.

4. The generator must not be operated on open circuit (this is without battery in circuit), and battery must not be

disconnected while the generator is running.

5. Do not attempt to polarise generator.

6. Always ensure that generator warning lamp glows when ignition switch is turned to the ON position.

NOTE: As this circuit is related to and assists in the excitation of the rotor field windings, do not proceed until any

faults in the generator warning lamp circ uit have been rectified. Ensur e the warning lam p wattage does not exceed

2 watts.

7. The ‘L’ terminal of generator should never be connected to battery or ignition circuit (12 volts), as this will

damage generator warning lamp circuit.

8. Some batter y powered tim ing lights c an produce high tr ansient voltages when connec ted or dis connected. Only

disconnect or connect timing lights when the engine is switched off.

2.2 MAINTENANCE AND ON-VEHICLE TESTING

At regular intervals, inspect the terminals of the generator for corrosion, loose connectors and the wiring for

damaged insulation. Check the mounting bolts for tightness, check the drive belt for alignment and wear and the

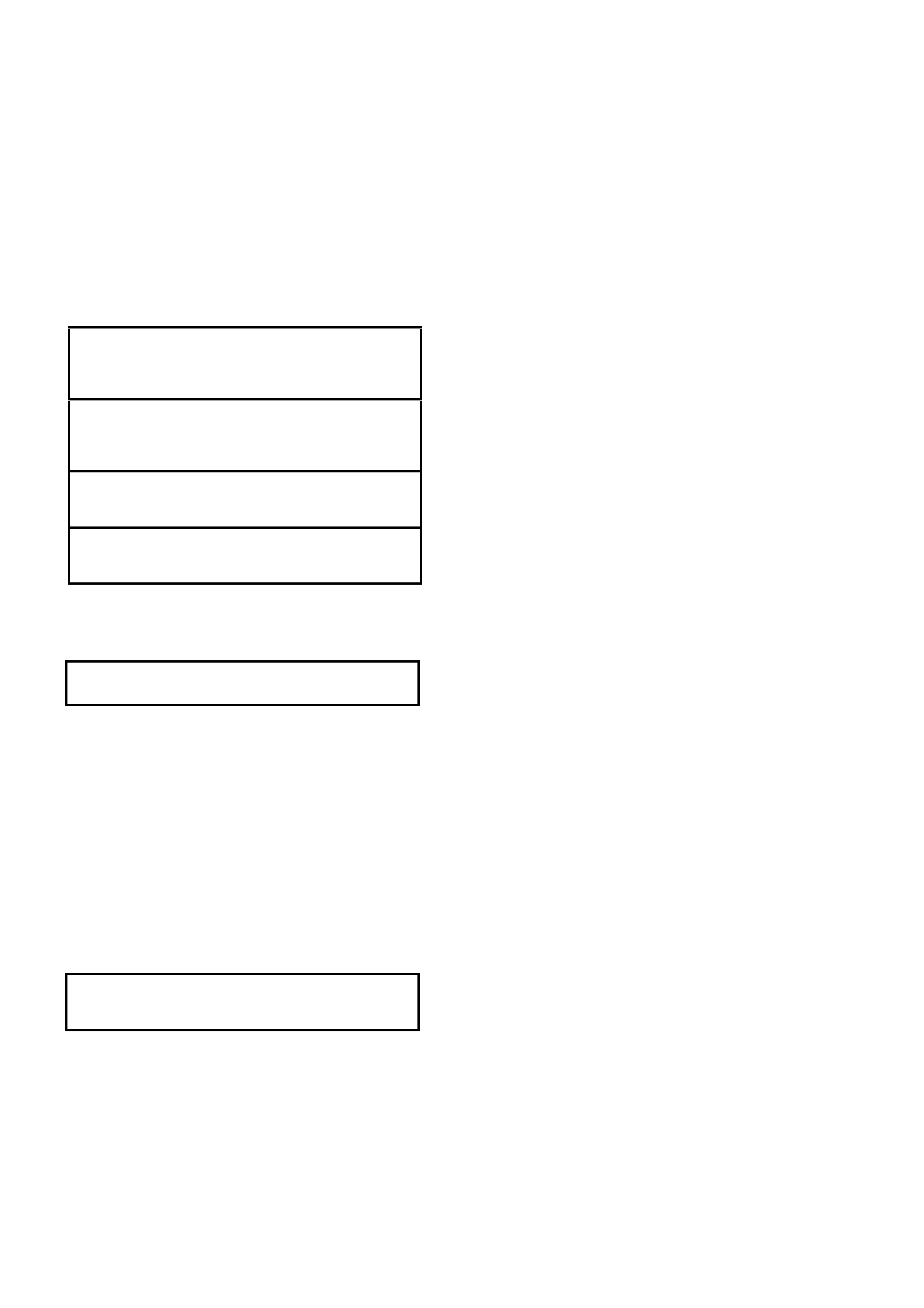

drive pulley for damage. The drive belt adj us tment f or the engine ancillar ies, s uc h as the generator and water pump

etc., is provided by a spring-loaded tensioner. The drive belt therefore, does not require any regular adjustment.

LUBRICATION

The ball bearings supporting the rotor shaf t ar e pr e-lubr icated and s ealed, ther ef or e no lubric ation is poss ible during

service.

The bearings used in this generator are high tolerance type. If the bearings are removed during the generator

disassembly, new bearings must be installed to restore the generator to original specification.

TESTING THE GENERATOR OUTPUT AND VOLTAGE REGULATOR

Testing Prerequisites

Before testing the generator output, m ake certain that the generator circuit is thoroughly check ed for loose or dirty

connections. The generator must always be connected to the battery during testing, otherwise damage to the

diodes could result.

The battery should be fully charged. Test the specific gravity of the individual cells. The readings should be within 10

points of each other. It is recommended that the average specific gravity should be 1.260 or higher.

A load test should be carried out to determine the ability of the battery to supply and accept c urrent. This is a good

indicator as to the general condition of the battery. Refer to Section 12A BATT ERY AND CABLES of the VT Series

I Service Information for details of battery testing.

The generator warning light, in addition to indicating that the generator is charging, is also nec essary for initial field

excitation.

Inspect drive belt and tensioner markings to determine if belt is within operating limits. Replace belt if it is

excessively worn or outside tensioner’s operating range, refer to Section 6A1 ENGINE MECHANICAL - V6

ENGINE of the VT Series I Service Information for details.

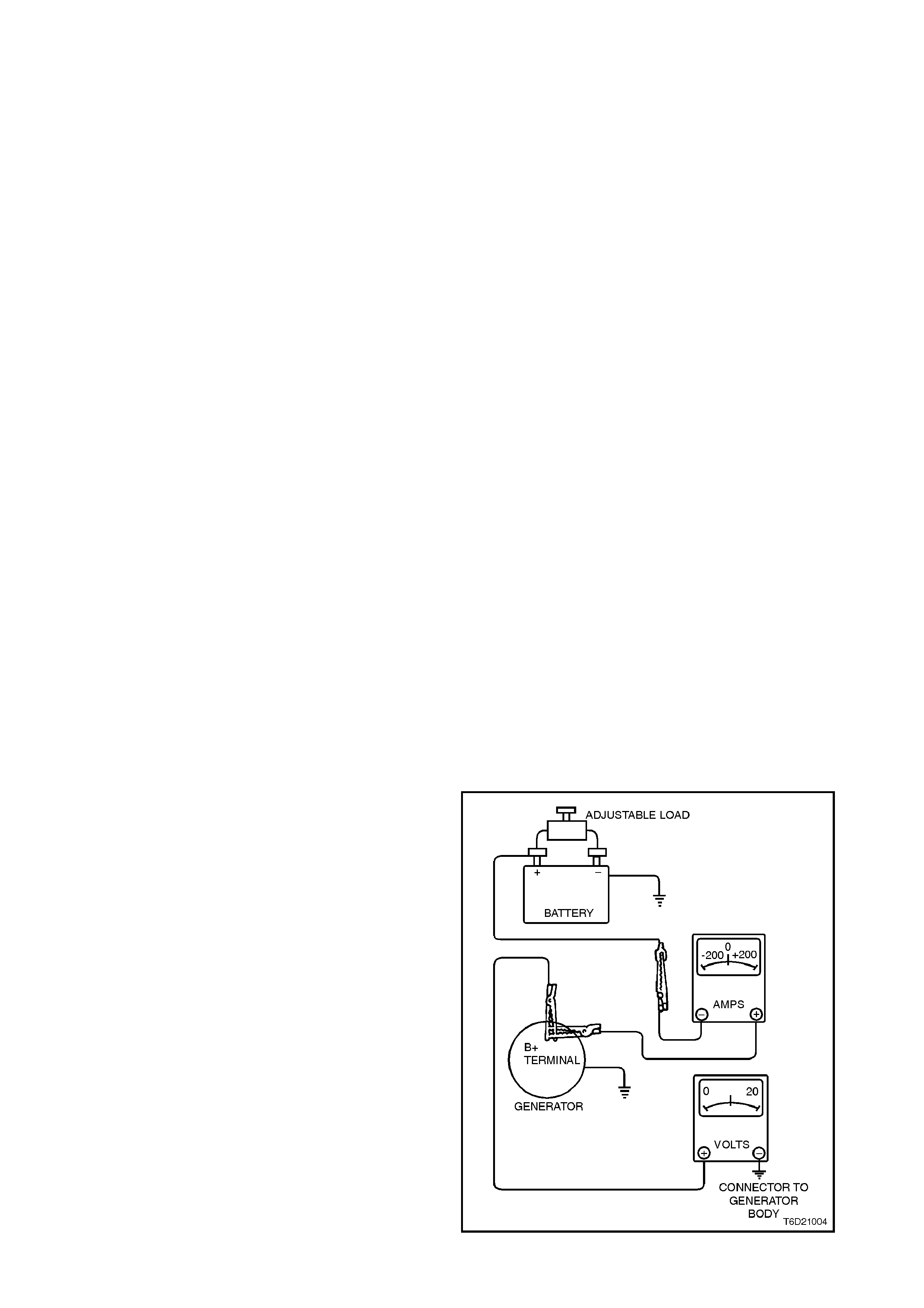

TESTING GENERATOR OUTPUT

Regulating Voltage Test On The Vehicle

1. Ensure that all the electrical equipment is

turned off, and the ignition switch is in the OFF

position.

2. Disconnect battery earth cable at battery.

3. Disconnect the generator positive lead (Red

wire) from the ‘B+’ generator terminal.

4. Connect the positive lead of an ammeter (0 –

100 amp scale) to the generator ‘B+’ terminal,

and the ammeter negative lead to the

disconnected generator positive lead (Red

wire).

5. Connect positive lead of a voltmeter (0 – 20

volt scale minimum) to the generator ‘B+’

term inal, and voltmeter negative lead to a good

earth connection on the generator housing.

CAUTION: INSULATE THE GENERATOR

POSITIVE LEAD (RED WIRE) TERMINAL TO

PREVENT CONTACT WITH ANY METAL PART

OF THE VEHICLE. IF THE TERMINAL IS

EARTHED, DAMAGE TO THE CHARGING

CIRCUIT WILL RESULT WHEN THE BATTERY

IS RECONNECTED.

6. Reconnect the battery earth cable. Fit a loading

device across battery terminals, i.e. an

adjustable carbon pile.

NOTE: Loading device must have a minimum

power consumption of 1000 watts.

Figure 6D1-1-4

7. Record the voltmeter reading before starting

the engine. This reading should increase

when the engine is running, indicating

generator output.

8. Start engine, raise rpm and adjust load

(ammeter reading) to that nominated in the

following chart. Check generator output

(voltmeter reading) against specification.

Load Regulation Test

With the voltmeter, ammeter and carbon pile connected as in previous test, increase engine speed to 2350 rpm

(approxim ately 5000 generator rpm ) and incr ease load to approxim ately 108 amps (90% of full output). A decr ease

in the regulating voltage should not exceed 0.5 volt of the readings obtained in the previous test.

If the decrease in the regulating voltage is greater than 0.5 volt, the regulator is defective and must be replaced.

Generator Output Test At Full Load

With the voltmeter, ammeter and carbon pile connected as in previous tests, increase engine speed to 2350 rpm

(approximately 5000 generator rpm) and increase load until the generator output voltage drops to 13.5 volts and

note ammeter reading.

Full output (120 am ps) should be obtained under thes e conditions. It may be necess ary to adj ust the throttle so as

to maintain the desired engine speed.

NOTE: Keep the time for this test to a minimum so as to avoid undue heating and high engine speeds.

If the generator does not provide rated output, it should be removed for repair, refer to 3.1 GENERATOR in this

Section.

CAUTION: ON COMPLETION OF THE GENERATOR OUTPUT TESTING, TO PREVENT EXCESSIVE BATTERY

DISCHARGE OCCURRING, THE ENGINE SHOULD BE RETURNED TO IDLE SPEED AND THE LOADING

DEVICE DISCONNECTED FROM BATTERY TERMINALS.

9. Disconnect the battery earth cable at battery. Remove the voltmeter and ammeter, then reconnect the

generator positive lead (Red wire) to the generator ‘B+’ terminal. Reconnect the battery earth cable to the

battery.

Charging Circuit Voltage Drop Test

With normal connections made at generator, charging circuit can be checked for voltage drop as follows:

1. Connect a low range voltmeter between generator positive terminal and battery positive post.

2. Switch on headlamps, start engine and increase engine speed to approximately 2500 rpm and note voltmeter

reading.

3. Reduce engine speed and trans fer voltm eter connec tions, negative to generator housing and positive to battery

negative post. Increase engine speed to approximately 2500 rpm and again note voltmeter reading.

4. If readings exceed 0.5 volt on positive side and 0.25 volt on negative side, there is a high resistance in the

charging circuit which must be traced and corrected.

ENGINE RPM

LOAD

VOLTMETER READING

1300

5 AMPS

14.4 ±0.3 VOLTS

3. MAJOR SERVICE OPERATIONS

3.1 GENERATOR

REMOVE

1. Disconnect battery earth lead.

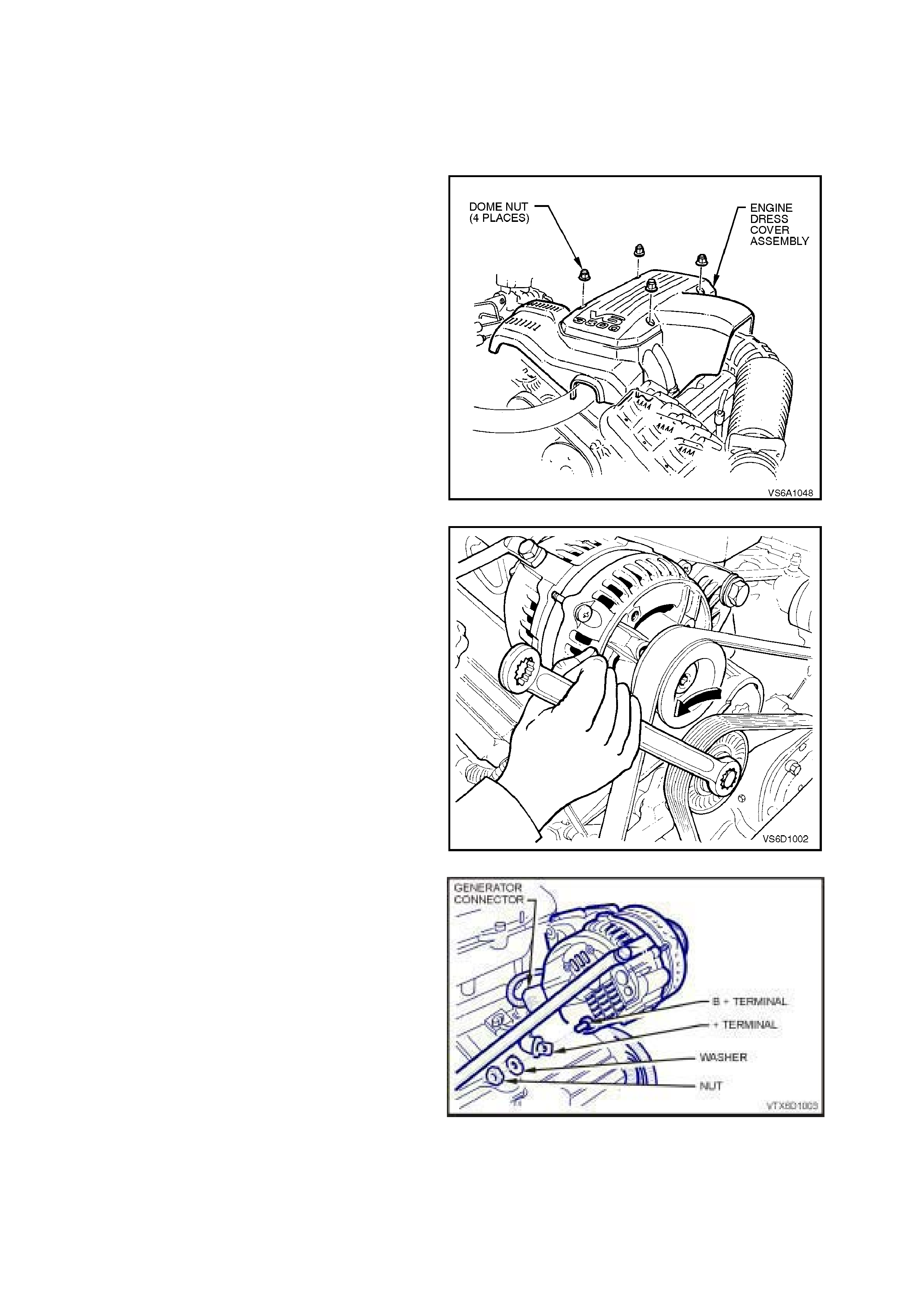

2. Remove four dome nuts securing the engine

dress cover assembly to the intake manifold

studs, lift off and remove the cover assembly .

Figure 6D1-1-5

3. Using a 15 mm ring spanner on drive belt

tensioner pulley pivot bolt, rotate tensioner

pulley assembly anti-clockwise and remove

drive belt from generator drive pulley. Release

drive belt tensioner.

Figure 6D1-1-6

4. Pull battery harness cap from ‘B+’ terminal,

remove nut, washer and positive lead (Red

wire).

Figure 6D1-1-7

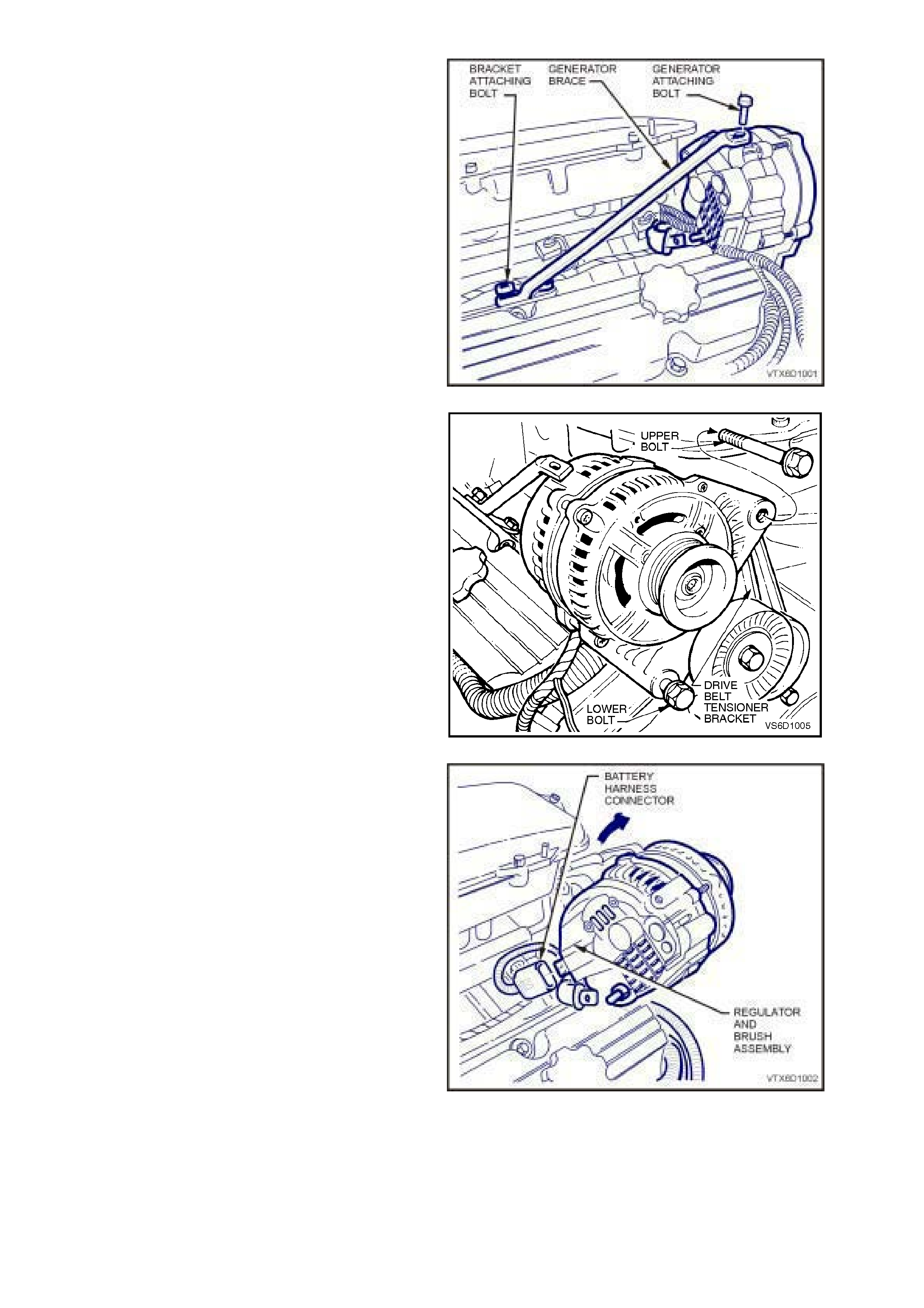

5. Remove generator brace to generator attaching

bolt and loosen brace to engine bracket

attaching bolt.

Figure 6D1-1-8

6. Remove generator to drive belt tensioner

bracket upper bolt and loosen lower bolt.

Figure 6D1-1-9

7. Swing generator away from the intake m anif old

and remove battery harness connector from

regulator and brush ass em bly terminal block by

depressing connector retainer and pulling

connector from generator.

8. Remove generator to drive belt tensioner

bracket lower bolt and remove generator

assembly.

Figure 6D1-1-10

REINSTALL

1. Assemble generator to drive belt tensioner

brack et and install lower m ounting bolt, leaving

it loose.

2. Install battery harness connector into

generator’s regular and brush assembly

terminal block, ensuring that connector’s

retainer locks into place.

3. Swing generator up toward intake m anif old and

install generator to drive belt tensioner bracket

attaching bolt.

4. Install generator brace onto generator housing

and install attaching bolt.

GENERATOR TO DRIVE BELT

TENSIONER LOWER

ATTACHING BOLT

TORQUE SPECIFICATION

40 - 50 Nm

GENERATOR TO DRIVE BELT

TENSIONER UPPER

ATTACHING BOLT

TORQUE SPECIFICATION

40 - 50 Nm

GENERATOR BRACE TO

GENERATOR ATTACHING

BOLT TORQUE SPECIFICATION 20 - 30 Nm

GENERATOR BRACE TO

ENGINE BRACKET ATTACHING

BOLT TORQUE SPECIFICATION 20 - 30 Nm

5. Install battery harness positive lead (Red wire),

washer and nut on ‘B+’ terminal. T ighten nut to

the correc t torque s pecif ication. Install c ap over

‘B+’ terminal.

‘B+’ TERMINAL NUT

TORQUE SPECIFICATION 5 - 12 Nm

6. W ith aid of a 15 mm ring spanner, rotate drive

belt tensioner anti-c lockwise and f it drive belt to

generator drive pulley. Release tensioner and

ensure that drive belt ribs are c orrec tly installed

into all accessory drive pulleys and crankshaft

balancer drive belt grooves.

7. Reconnect battery earth lead.

8. Start engine and check generator warning lamp

operation, drive belt alignment, generator

output and voltage regulator operation.

9. Install engine dress cover to intake manifold,

ensuring that stud grom m ets in the dress cover

remain in place. Install dome nuts and tighten

to the correct torque specifications.

ENGINE DRESS COVER TO

INTAKE MANIFOLD DOME NUT

TORQUE SPECIFICATION 4 - 6 NM

Figure 6D1-1-11

DISASSEMBLE

The following precautions must be noted before attempting to disassemble the generator and checking for faulty

components.

A. When testing the rectifier diodes with an AC type tester, the RMS output must not exceed 12.0 volts. It is

recommended that the stator should be disconnected before testing the diodes.

B. Insulation tests on the rotor and stator should use a voltage not exceeding 110 V for a series test lamp. The

rectifier must be disconnected from the stator prior to testing.

C. Due to the very low resistance value of the stator winding, it may not be possible to obtain accurate readings

using a conventional ohmmeter.

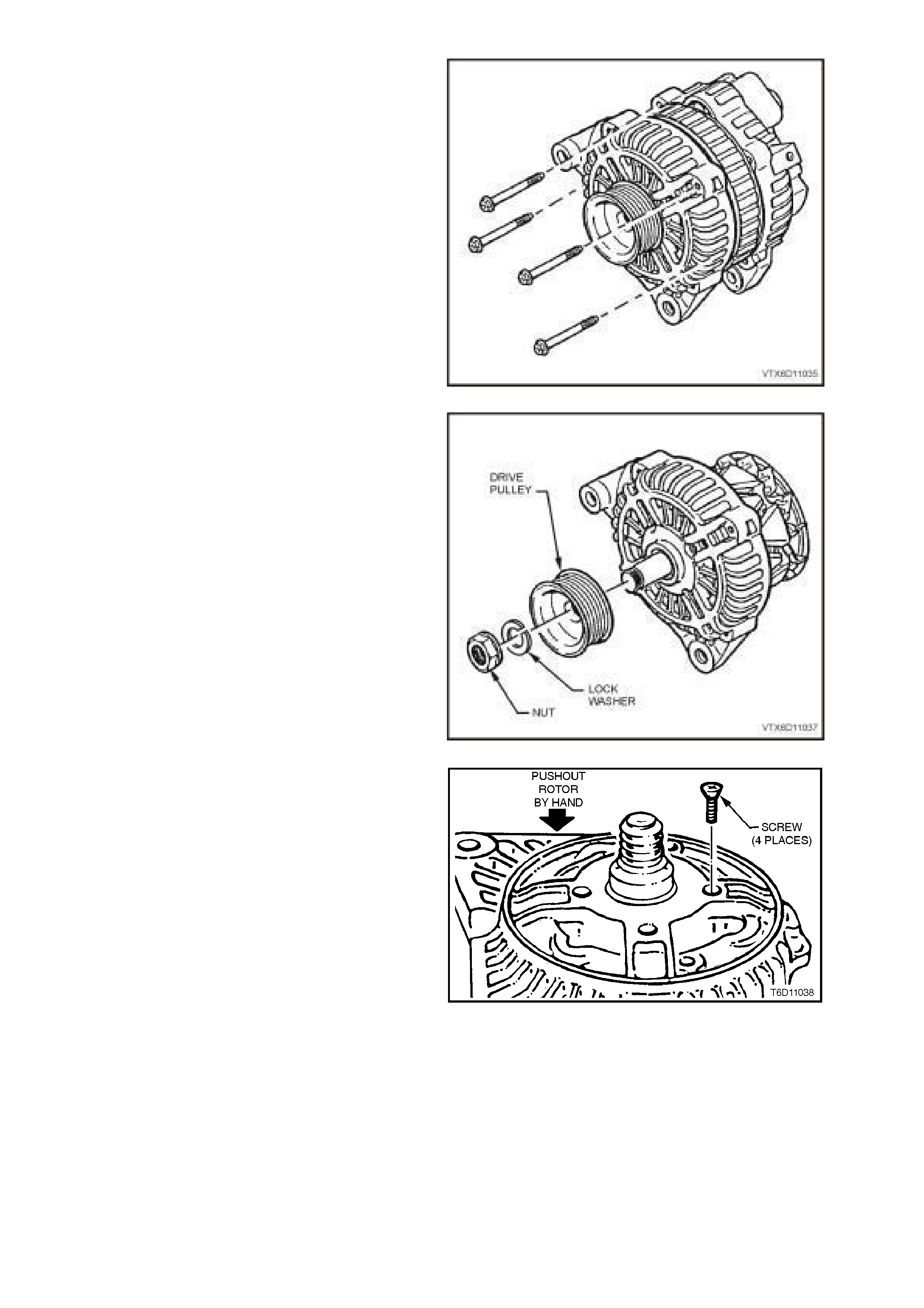

1. Mark relative positions of front bracket, stator

frame and rear bracket using a permanent

marking pen.

Figure 6D1-1-12

2. Remove four through bolts.

3. Using a screwdriver, carefully pry between the

stator and the front bracket, ensuring that the

screwdriver is not inserted too far or the stator

coil will be damaged. Separate the front

bracket, pulley and rotor assembly away from

the stator and rear bracket assembly.

Figure 6D1-1-13

4. Clamp rotor in a vise, ensuring that the rotor

poles are not distorted, and remove drive pulley

attaching nut, drive pulley and front bracket.

Figure 6D1-1-14

5. Remove four screws securing the bearing

retaining plate to front bracket.

6. Press the bearing from the front bracket with a

suitable socket.

NOTE: The bearing MUST be replaced with a new

bearing on assembly.

Figure 6D1-1-15

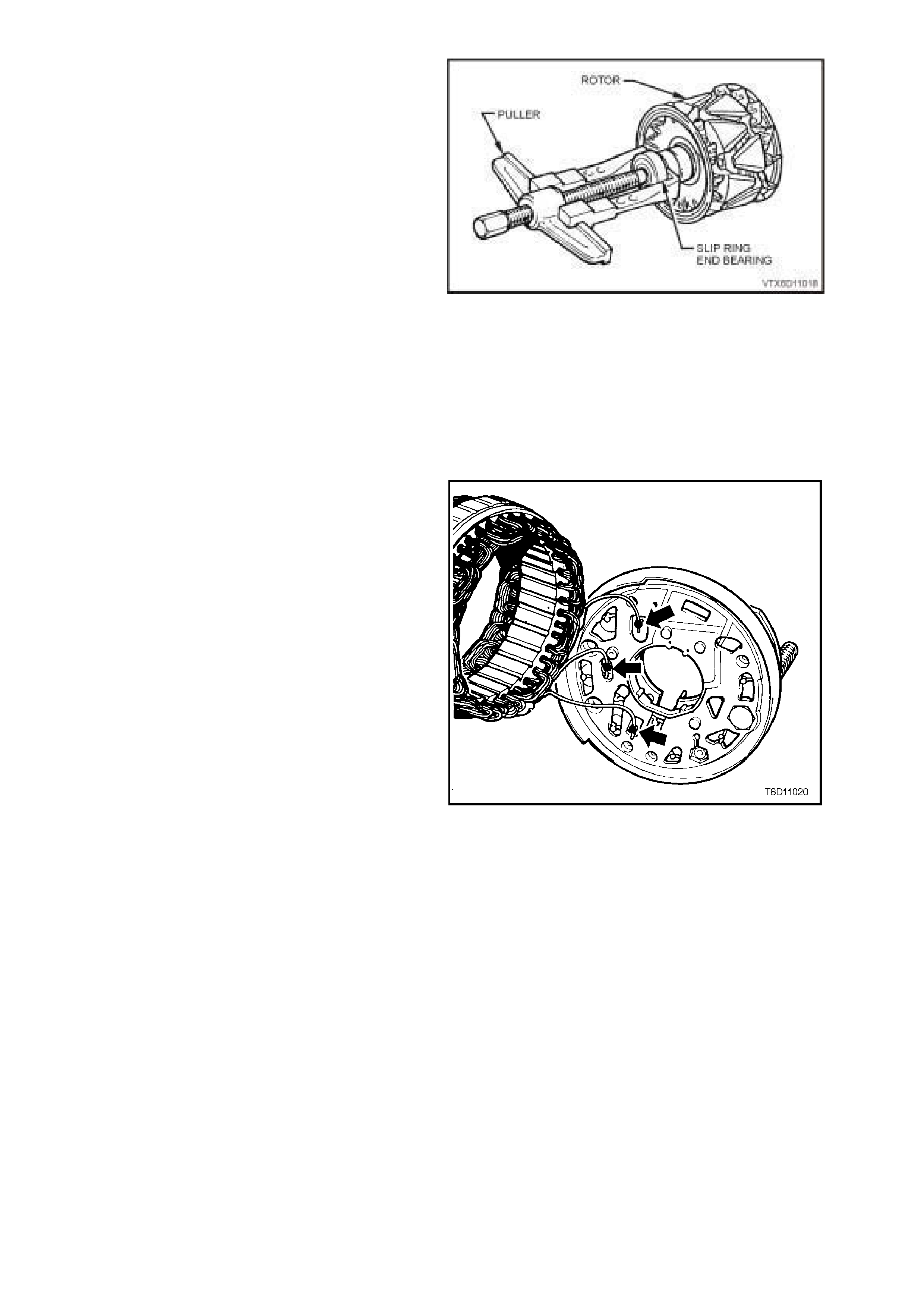

7. Using a bearing puller, remove slip ring end

bearing from rotor shaft, taking care not to

damage the plastic side of the slip ring or

distort the rear fan during the process.

NOTE: The bearing MUST be replaced with a new

bearing on assembly.

Figure 6D1-1-16

8. Remove nut, wave washer, flat washer and

insulating washer from the ‘B+’ terminal bolt.

9. Remove the rectifier retaining screw and two

brush holder retaining screws. Separate the

stator and rectifier assemblies as a unit from

the rear bracket.

10. Unsolder and remove each brush and spring

assembly.

11. Separate stator from rectifier assembly by

unsoldering the three s tator windings to r ec tif ier

connections.

CAUTION: USE ONLY AS MUCH HEAT AS

REQUIRED TO MELT THE SOLDER.

EXCESSIVE HEAT MAY DAMAGE THE DIODES.

NOTE: The rectifier assembly is serviced as an

assem bly only. Individual replacem ent parts ar e not

available.

Figure 6D1-1-17

12. Unsolder the two joints connecting the brush

holder and regulator assembly to the rectifier,

and remove the assembly from the rectifier.

CLEANING AND INSPECTION

With generator completely disassembled, components should be cleaned and inspected.

Wash all components except stator, rotor, rectifier and regulator in a suitable cleaning solvent.

Carefully clean rotor and stator with compressed air.

CAUTION: DO NOT CLEAN STATOR OR ROTOR WINDINGS WITH THE CLEANING SOLVENT OR DAMAGE

TO THE INSULA TION COULD RESULT.

CAUTION: CLEAN ALL PARTS OTHER THAN THOSE PREVIOUSLY NOMINATED USING A NON VOLATILE

OR LOW INFLAMMABLE AGENT IN A WELL VENTILATED AREA.

IT IS IM PORTANT THAT ALL PARTS ARE THOROUGHLY DRIED BEFORE ASSEMBLY, T AKING CARE NOT

TO BREATH IN ANY VAPOURS.

OBSERVE THE SAFETY REGULATIONS AND PRECAUTIONS ISSUED BY THE MANUFACTURER OF THE

CLEANING AGENT IN USE.

COMPONENT CHECKING

Brush Gear

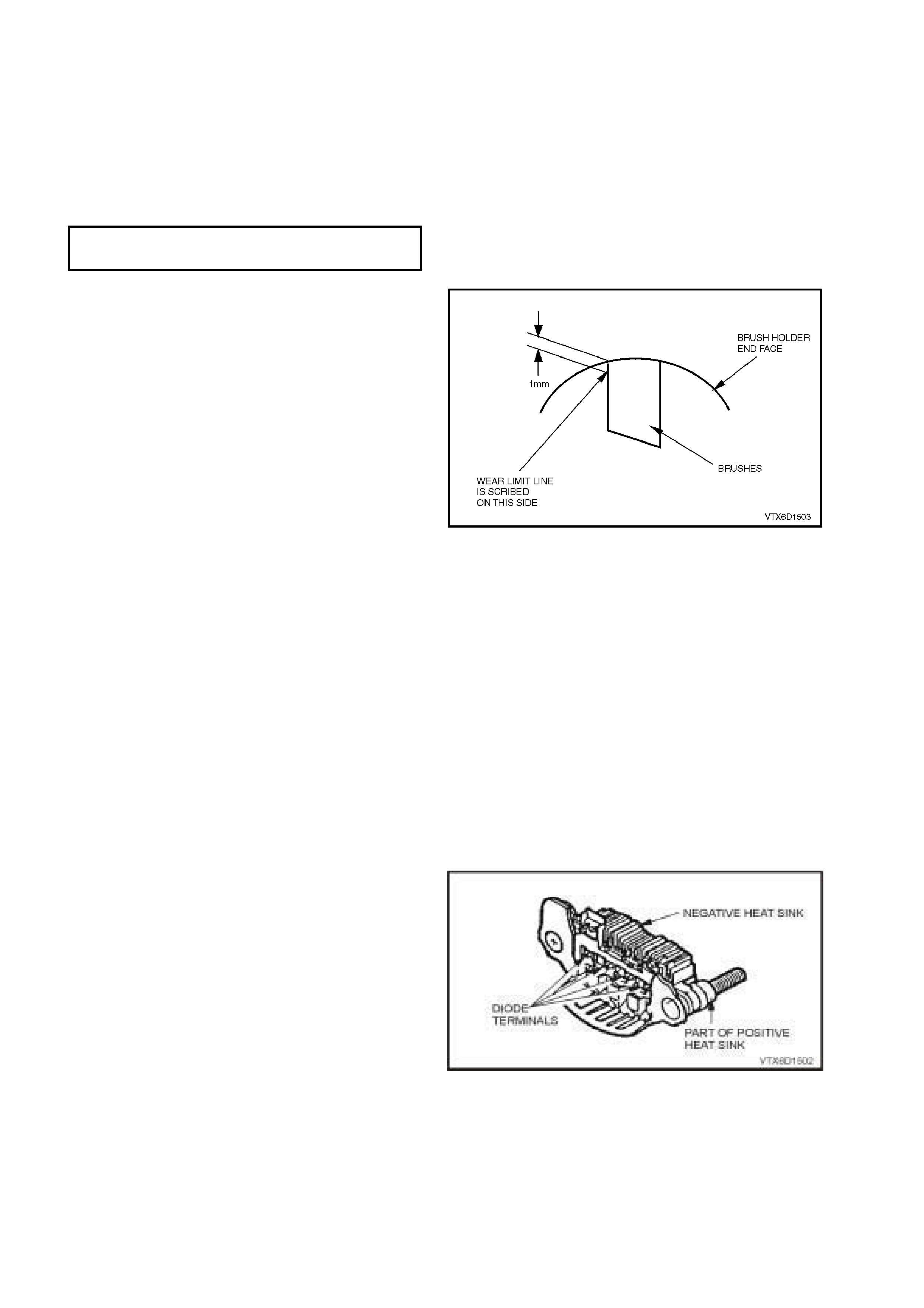

Check the length of the brushes protruding from

the brush holder. Replace the brush and spring

assembly if the brush is worn down to the wear

limit. Also replace if abnormal wear or cracks are

noticed.

MINIMUM BRUSH

LENGTH 5.0

mm

Clean the brushes and brush holder, removing

particles by wiping with a clean cloth. Ensure that

the brush moves smoothly in the brush holder.

Replace if necessary.

Check the brush spring function. Push the brush

into the brush holder until the wear limit line of the

brush protrudes 1 mm from the brush holder

moulding and check the spring is functioning

correctly. Replace if necessary.

Check that brushes move smoothly in and out of

holder by pushing on end of brushes, and then

releasing. Replace if necessary.

Figure 6D1-1-18

Diodes

NOTE: T he rectifier assem bly is not repairable and

should be replaced if any diodes proves to be

faulty.

The following commercially available test

equipment is essential for correctly testing the

diodes within the rectifier assembly.

A diode tester or multimeter with a diode test

feature where the DC output at the test pr obes

does not exceed 14 volts, or in the case of AC

testers, 12 volts RMS.

This is necessary so as to ensure that when

testing the diodes, the forward and reverse

voltage checks are completed and are not

masked by the diode turning on due to Zener

breakdown voltage.

NOTE: In Steps 1 and 2, ensure that the reverse

voltage applied is less than 14 volts DC, or 12 volts

RMS when using an AC tester.

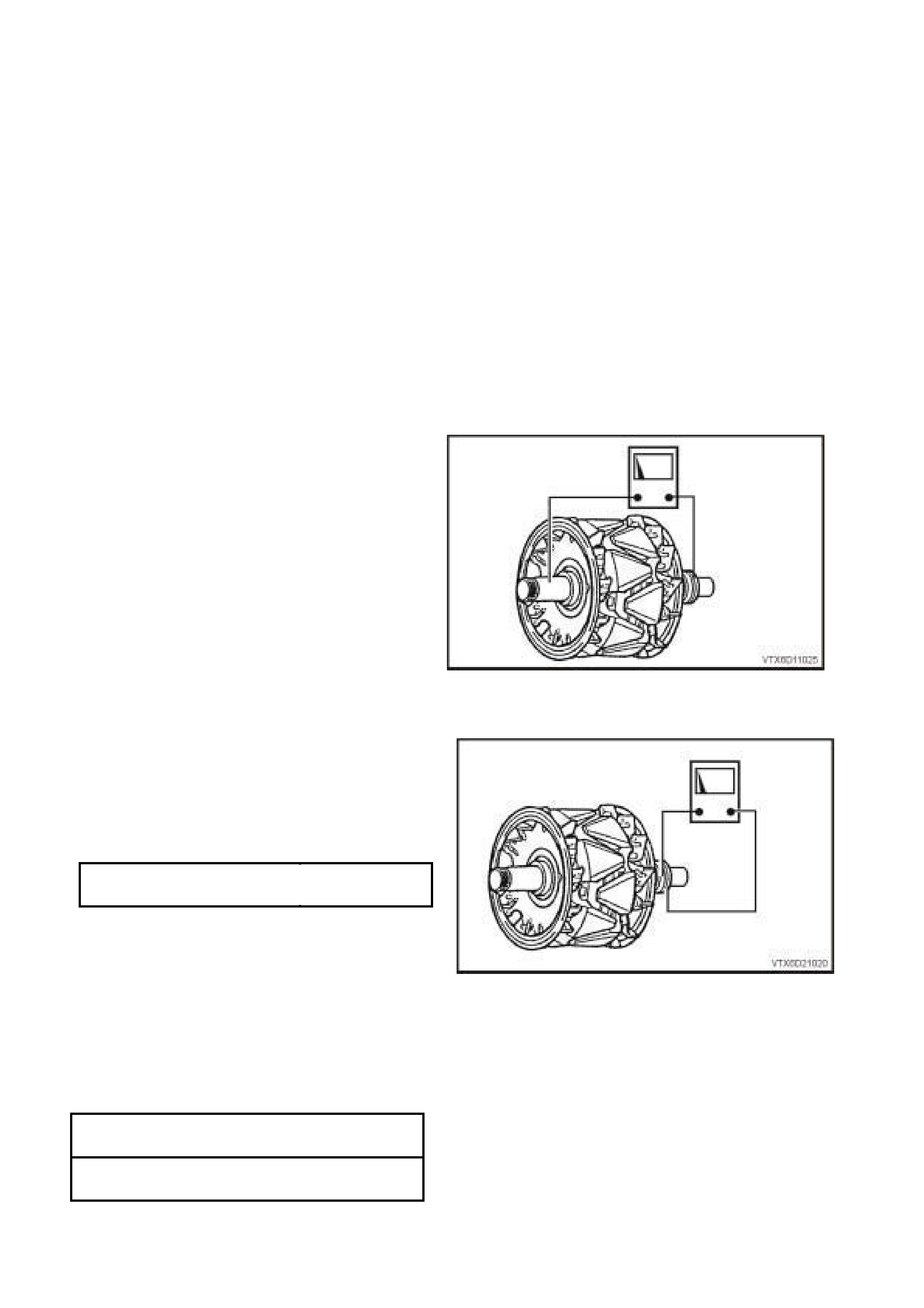

1. Attach negative test probe of diode tester or

multimeter with diode test function to the

positive heatsink of the rectifier assembly and

the positive probe alternatively to positive diode

connections.

A low resistance reading, or the forward

voltage drop across the diode should be

obtained.

Reverse probe connections and repeat test to

check that current is passed in one direction

only (high resistance reading or higher reverse

voltage should be obtained).

If necessary, replace the rectifier assembly.

Figure 6D1-1-19

2. Repeat procedure on negative heatsink by

attaching positive test probe to the negative

heatsink and the negative probe alternatively to

negative diode connections.

A low resistance reading, or the forward

voltage drop across the diode should be

obtained.

Reverse probe connections and repeat test to

check that current is passed in one direction

only (high resistance reading or higher reverse

voltage should be obtained).

If necessary, replace the rectifier assembly.

Rotor

Clean any dirt or particles from the rotor with

compressed air or a clean cloth.

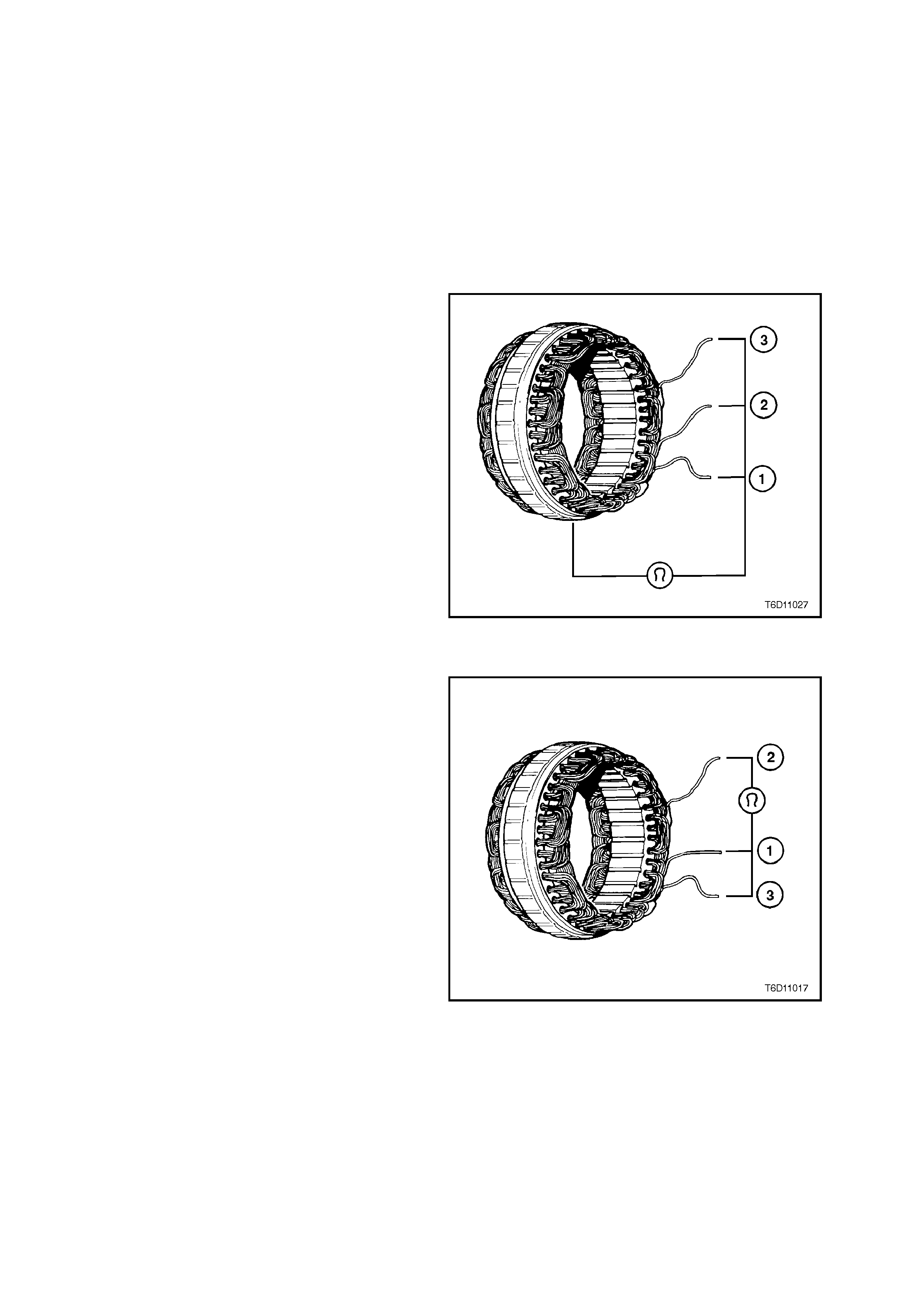

Insulation Test

Using an insulation test er, or a series tes t lam p (up

to 110 V), check insulation between slip rings and

rotor core or shaft. Test light should not glow or

insulation tester should indicate an open circuit

(greater than 1 Megaohm). If an open circuit does

not exist replace rotor.

Figure 6D1-1-20

Open Circuit Test

Slip Rings

Check slip rings for wear or damage. If the slip

rings are worn, damaged or out-of-round, the rotor

must be replaced.

SLIP RING

OUTER DIAMETER 22.7

mm

SLIP RING

SERVICE LIMIT 22.1

mm

Connect ohmmeter probes across slip rings and

measure resistance of rotor windings.

Rotor winding resistance values are given in the

following chart.

NOTE: If the resistance of the rotor winding is not to

specification, replace the rotor.

Figure 6D1-1-21

STATOR WINDING

RESISTANCE @ 20°C 1.7 - 2.1

ohms

Bearings

The bearings used in this generator are a high

tolerance type. Only genuine replacem ent bearings

are to be used. It is recommended that the

bearings be replaced during the reconditioning

process to restore the generator to original

specification.

Stator

Inspect stator for damage, loose connections or

discoloured windings. Replace if necessary.

Insulation Test

Connect a powered test lamp (up to 40 V) or an

ohmmeter between any stator lead and stator

frame. If test lamp glows or ohmmeter reading is

low indicating that an open circuit does not exist,

replace stator.

Figure 6D1-1-22

Open Circuit Test

1. Connect ohmmeter to any two stator leads.

Ohmmeter should not register any significant

resistance.

2. Repeat test on remaining stator leads. If

resistances are high, replace the stator.

Figure 6D1-1-23

REASSEMBLE

Reassembly of the alternator is the reverse of the

disassembly procedure, noting the following:

1. Do not lubricate the bearings as they are pre-

lubricated.

2. For rotor bearings with resin bands, grease

should not be applied. Remove oil com pletely if

found on the bearing box to prevent bearing

creep.

3. Use high temperature solder (melting point

230°C) and a 180 – 270 W soldering iron. Do

not used excessive heat as damage to the

rectifier may result.

4. As the rotor bearing and rear bracket fitting is

tight, heat the area around the rear bracket

bearing box to 50 – 60°C before installing the

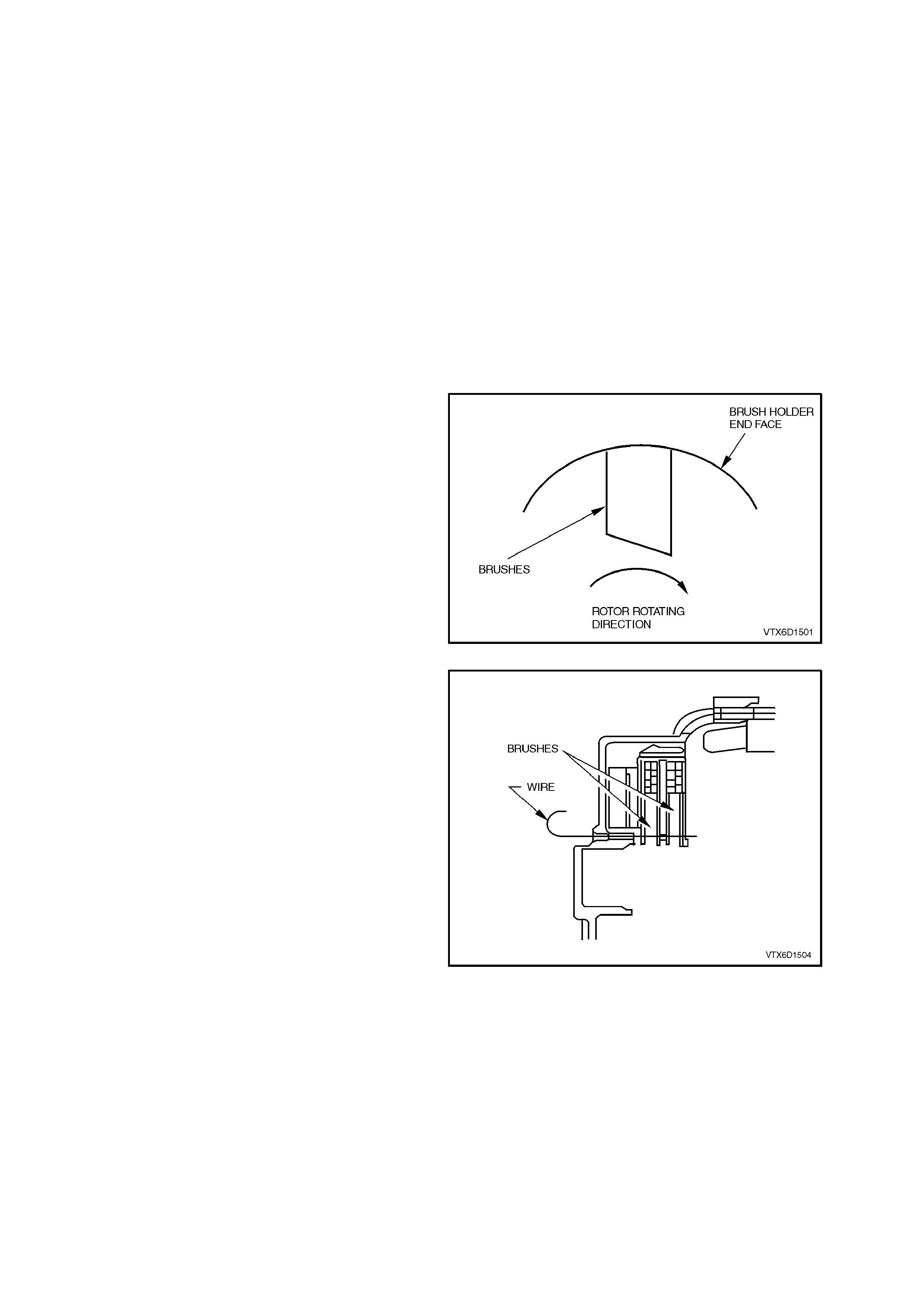

rotor into the rear bracket.

5. Position brushes in the brush holder as shown

in Figure 6D1-1-23.

Figure 6D1-1-24

6. Before installing the rotor, push brushes into

the brush holder and ins ert a wire to hold them

in the raised position. Install the rotor and

remove the w ire.

Figure 6D1-1-25

7. Do not over tighten the terminal ‘B+’ nut as

damage to the insulating washer will result.

8. After as s embly, rotate the pulley slowly by hand

to verify that the rotor turns smoothly.

9. Ensure all fasteners are tightened to the

correct torque specifications.

DRIVE PULLEY ATTACHING

NUT TIGHTENING TORQUE 99 – 137

Nm

THROUGH BOLTS

TIGHTENING TORQUE 3.5 – 5.3

Nm

BEARING RETAINER SCREWS

TIGHTENING TORQUE 2.0 – 5.3

Nm

BRUSH HOLDER RETAINING

SCREWS

TIGHTENING TORQUE

2.0 – 5.3

Nm

RECTIFIER RETAINING

SCREWS

TIGHTENING TORQUE

2.0 – 5.3

Nm

TERMINAL ‘B+’ NUT

TIGHTENING TORQUE 12.8 – 18.6

Nm

4. DIAGNOSIS

1. UNDERCHARGED BATTERY

a. Defective battery.

b. Loose connection in charging system.

c. Corroded connections in charging circuit.

d. Defective wiring.

e. Faulty generator.

f. Faulty voltage regulator.

2. OVERCHARGED BATTERY

a. Shorted battery cell.

b. Faulty voltage regulator.

c. Short circuit in rotor winding.

d. Voltage drop in sense wire.

3. FAULTY INDICATOR LIGHT OPERATION

(LIGHT DOES NOT GLOW)

a. Burnt out bulb.

b. Defective bulb socket.

c. Defective wiring.

d. Defective rectifier.

e. Defective regulator.

4. FAULTY INDICATOR LIGHT OPERATION

(LIGHT REMAINS ON)

a. Negative diode failure.

b. Defective voltage regulator.

c. Faulty generator.

d. ‘B+’ cable off or broken.

e. ‘S’ cable off or broken.

f. Battery overcharged.

g. Open circuit in rotor winding.

5. NOISY GENERATOR OPERATION

a. Normal magnetic hum.

b. Badly discharged battery.

c. Generator mounting brackets loose or bolts loose.

d. Worn or frayed drive belt.

e. Worn bearings.

f. Loose drive pulley attaching nut.

g. Open or shorted diodes.

h. Open or shorted stator winding.

5. SPECIFICATIONS

Earth Polarity......................................................................... Negative

Nominal Voltage.................................................................... 12 V

Nominal Output..................................................................... 120 Amps

Voltage Regulator Setting..................................................... 14.4 ±0.3 V

Stator Winding Resistance ................................................... 1.7 – 2.1 ohms

Slip Ring Outer Diameter...................................................... 22.7 mm

Slip Ring Service Limit.......................................................... 22.1 mm

Brush Length New ................................................................ 18.5 mm

Brush Length Service Limit................................................... 5.0 mm

Direction of Rotation (viewed from pulley)............................ Clockwise

6. TORQUE WRENCH SPECIFI CATIONS

Nm

Engine Dress Cover to Intake Manifold Dome Nut............... 4 – 6

Through Bolts........................................................................ 3.5 – 5.3

Drive Pulley Attaching Nut .................................................... 99 – 137

‘B+’ Terminal Nut .................................................................. 12.8 – 18.6

Battery Harness Terminal to ‘B+’ Terminal Nut .................... 5 – 12

Generator to Drive Belt Tensioner Attaching Bolts............... 40 – 50

Generator Support Brace Mounting Bolts............................. 20 – 30

Generator to Drive Belt Tensioner

Bracket Mounting Bolt........................................................... 20 – 34

Bearing Retainer Screws...................................................... 2.0 – 5.3

Brush Holder Retaining Screws............................................ 2.0 – 5.3

Rectifier Retaining Screws.................................................... 2.0 – 5.3