VS SERIES POLICE OPTIONS

ELECTRICAL SYSTEM

CAUTION:

This vehicle may be equipped w ith an AIRBAG. An AIRBAG is a Supplemental Restraint System (SRS).

Refer to CAUT IONS, Section 12M of the VS Series Service Supplement before performing any service

operation on or around SRS components, the steering mechanism or wiring.

Failure to follow the CAUTIONS could result in airbag deployment, resulting in possible personal

injury or unnecessary SRS system repairs.

1. GENERAL DESCRIPTION

This Service Manual Supplement describes the electrical wiring modifications for the Police Options Pack

production option 9C1, available with VS Series vehicles.

During vehicle production, the additional wiring harnes ses desc ribed in this Supplem ent are installed in the vehic le.

Each harness provides a specific function or enables the police department to add ancillary components such as

lights, sirens, etc., as required.

Also included with production option 9C1, but not included in this Supplement are:

- Heavy duty battery. Refer to Section 12A BATTERY & CABLES of the VS Series Service Information for

servicing of the battery.

- 100 amp generator (V6) or 120 amp generator (V8). Refer to Section 6D1-1 CHARGING SYSTEM - V6

ENGINE or Section 6D2-1 CHARGING SYSTEM - V8 ENGINE of the VS Series Service Information for

servicing of the generator.

- Revised over-speed warning module. Refer to Section 12C INSTRUMENT S, W IPERS/W ASHERS & HORN of

the VR Series Service Information for servicing of the over-speed warning module.

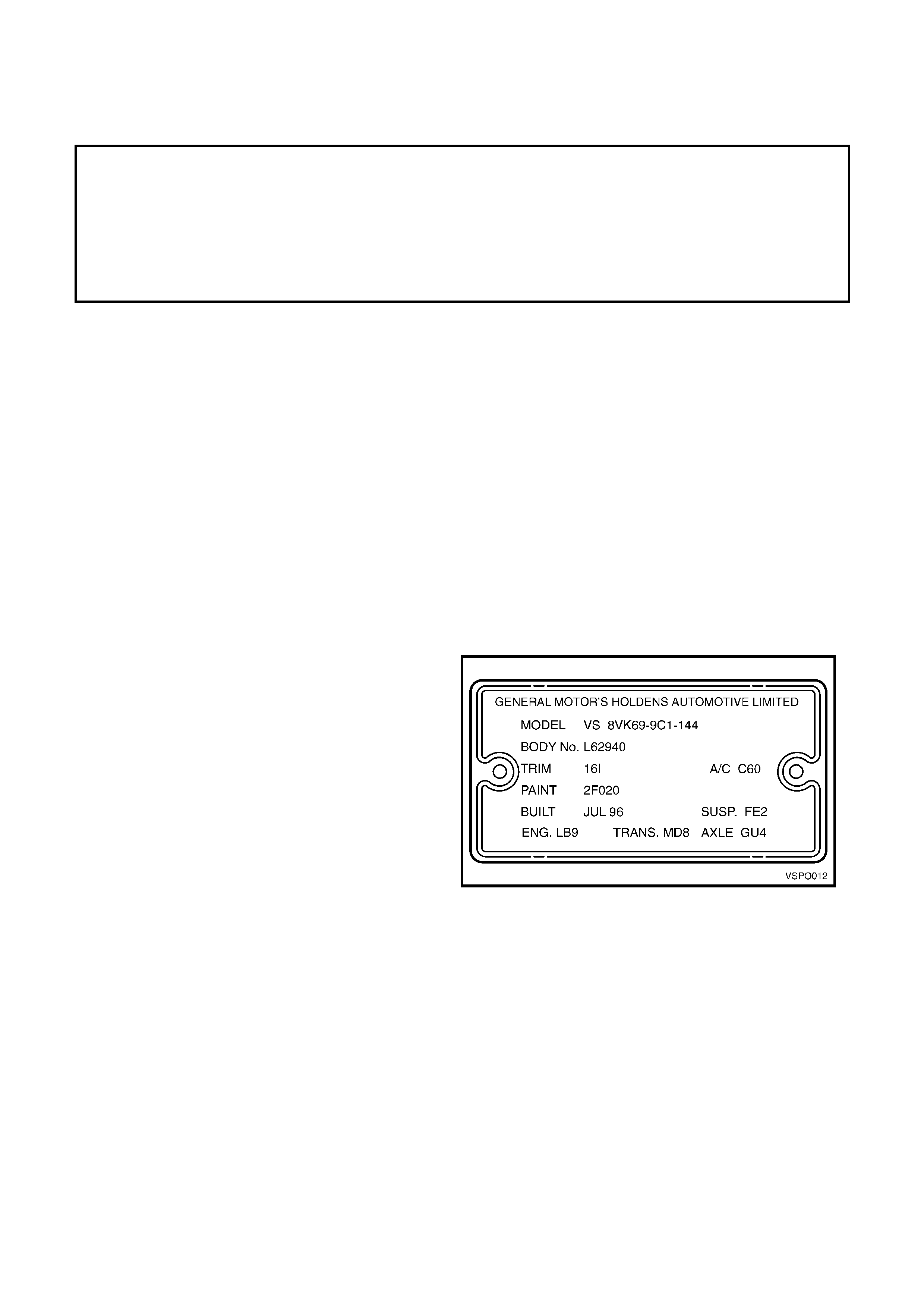

Vehicles f itted with Police Option 9C1 can be identif ied

by the body option identification plate mounted on the

upper dash panel in the engine compartment. Option

9C1 appears under the Model designation.

Figure 1A6-1

2. SERVICE OPERATIONS

2.1 SUPPRESSOR PATCH HARNESSES

The patch harnesses described in this Section provide additional interference noise suppression to the measures

undertaken to the standard vehicle.

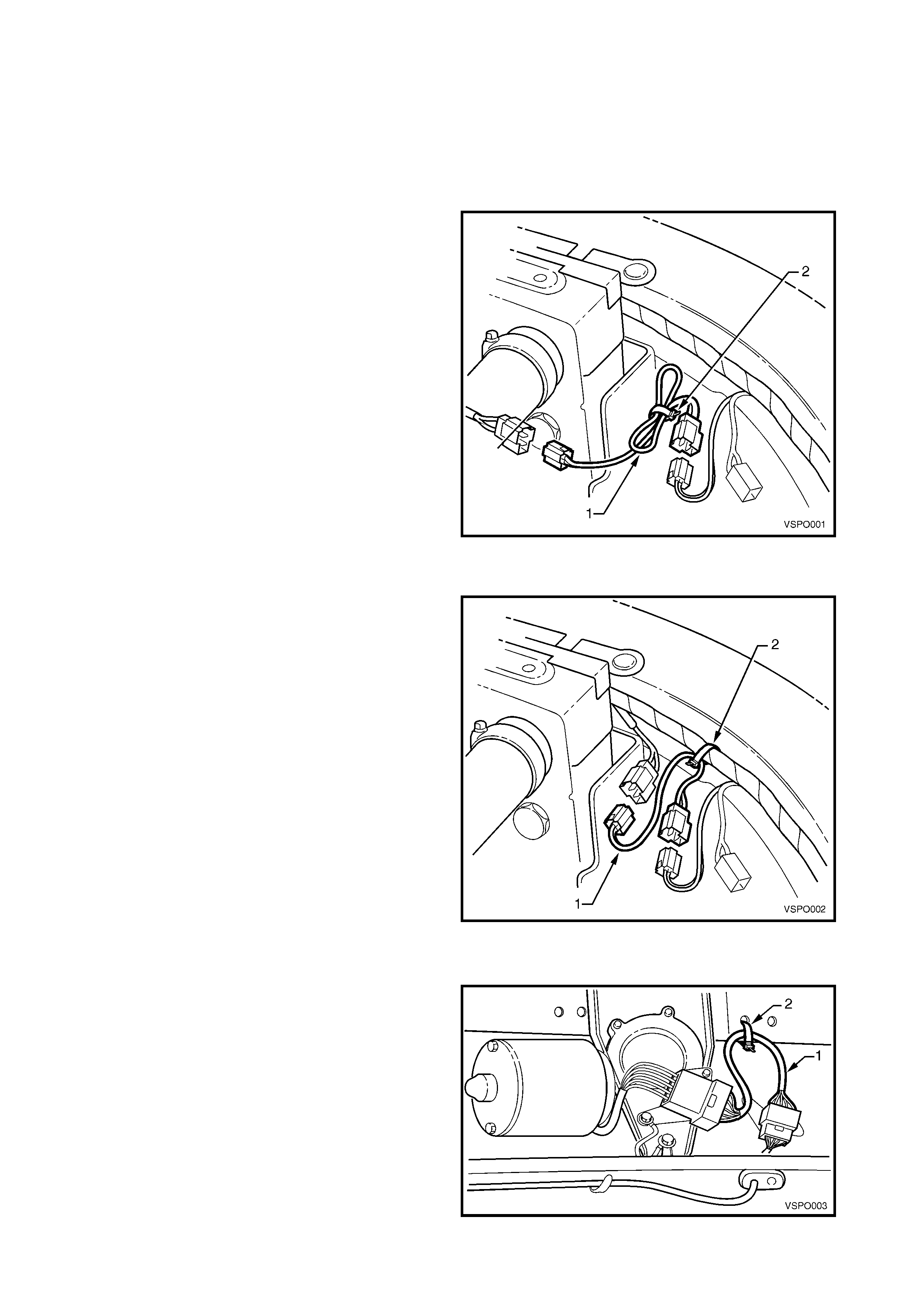

COOLING FAN MOTOR – V6

The c ooling fan motor s uppressor patch harnes s (1) is

installed between the engine cooling fan harness

connectors to the right of the radiator.

A tie-strap (2) is used to secure the patch harness to

the main harness.

Figure 1A6-2

COOLING FAN MOTOR – V8

The c ooling fan motor s uppressor patch harnes s (1) is

installed between the condenser cooling fan harness

connectors to the right of the radiator.

A tie-strap (2) is used to secure the patch harness to

the main harness.

Figure 1A6-3

WINDSCREEN WIPER MOTOR

The windscreen wiper motor suppressor patch

harness (1) is installed between the wiring connectors

at the wiper motor.

A tie-strap (2) is used to secure the patch harness to

the body.

NOTE: To access the patch harness, the wiper arm

assemblies and plenum chamber water deflector will

require removal. For further information refer to

Section 12C INSTRUMENTS, WIPERS/WASHERS &

HORN of the VR Series Service Information.

Figure 1A6-4

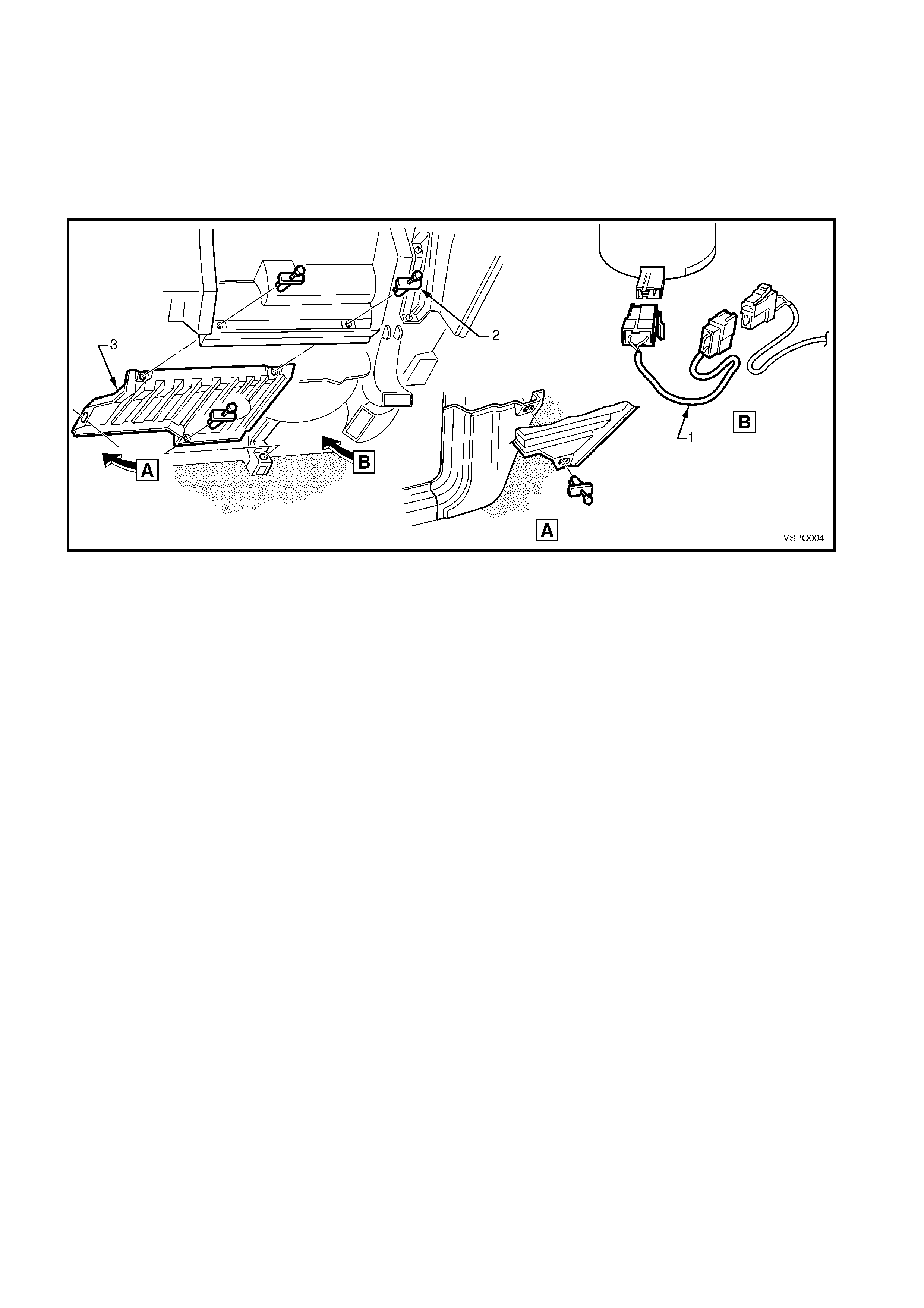

BLOWER FAN MOTOR

The blower fan motor suppressor patch harness (1) is

installed between the harness connectors at the blower

fan.

NOTE: To access the patch harness, remove the four

fasteners (2) and the LH instrument panel lower trim

(3). For further information refer to Section 1A3

INSTRUMENT PANEL of the VR Series Service

Information.

Figure 1A6-5

2.2 AUXILLIARY POWER HARNESS

An auxiliary power supply harness is fitted that provides constant 12V for ancillary components as required. Four

wiring connectors are attached to the auxiliary harness fuse box mounting bracket, rear of the LH strut tower,

providing c onnection of anc illary components. Two connectors c ontain individually fused positive c irc uit c onnections

and two contain negative circuit connections. Two fusible links are also provided in a holder which is tied back to the

auxiliary harness near the battery positive terminal.

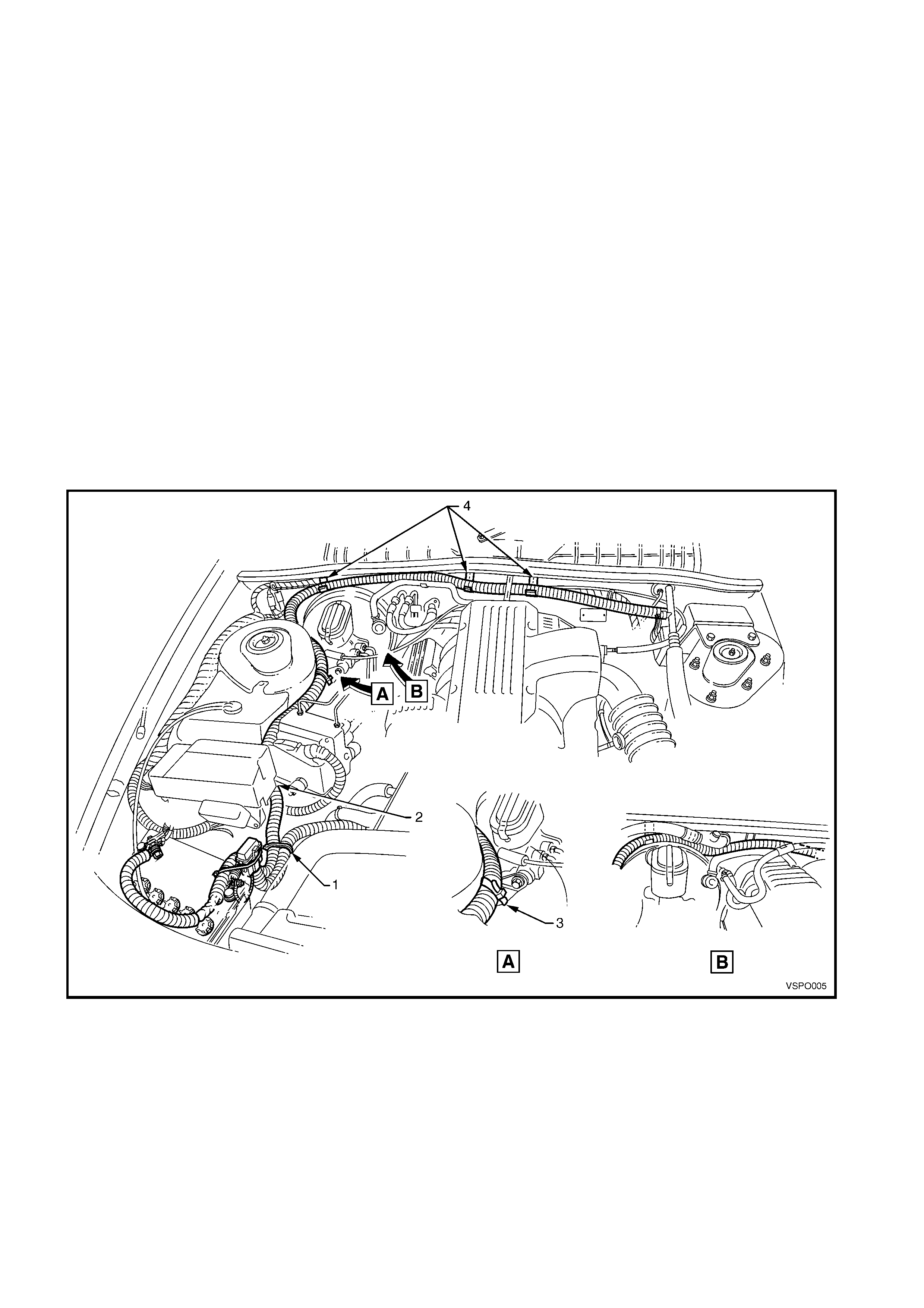

The auxiliary harness is routed from the battery along

the RH side and rear of the engine compartment as

shown in Fig. 1A6-6, noting the following points:

1. The auxiliary harness is tie-strapped around main

wiring harness near the battery (1).

2. The harness is routed under the relay panel and

between the coolant reservoir and ABS modulator

(2).

3. The harness is tie-strapped around the master

cylinder mounting bracket (3), View A.

4. Three cable clips (4) attach the harness along the

dash panel. The clips are hooked onto panel

flange under the seal.

NOTE: Ensure the harness is routed behind the brak e

booster vacuum line and throttle cable clip (V6) or

behind A/C pipe and over the booster (V8), View B.

Figure 1A6-6

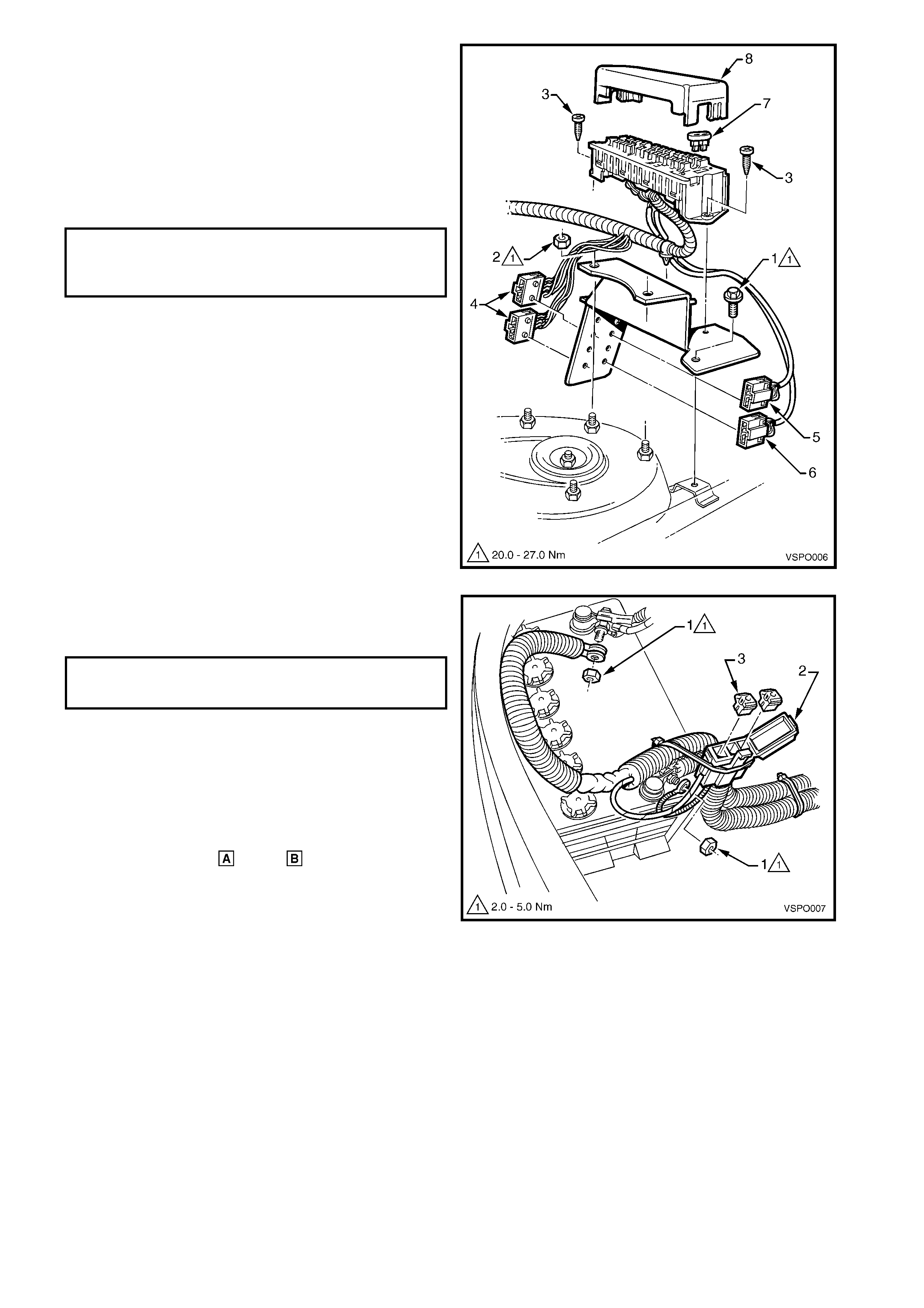

5. The auxiliary harness fuse panel and bracket

assembly is attached to the vehicle with a screw

(1), one place and two additional nuts (2) on the

suspension strut rear studs.

6. The auxiliary harness fus e panel is attached to the

mounting bracket with two screws (3).

7. The negative wiring connectors (4), positive wiring

connectors grey (5), white (6) and harness are

clipped to the bracket.

8. T o s ervice the f uses (7) the fus e panel cover (8) is

remove by unclipping.

Figure 1A6-7

9. The auxiliary harness is routed at the battery as

shown and is attached to the battery terminals with

additional nuts (1).

10. The fusible link holder (2) is tie-strapped back to

the auxiliary harness and contains two 50 amp

fusible links (3), one for each positive connector.

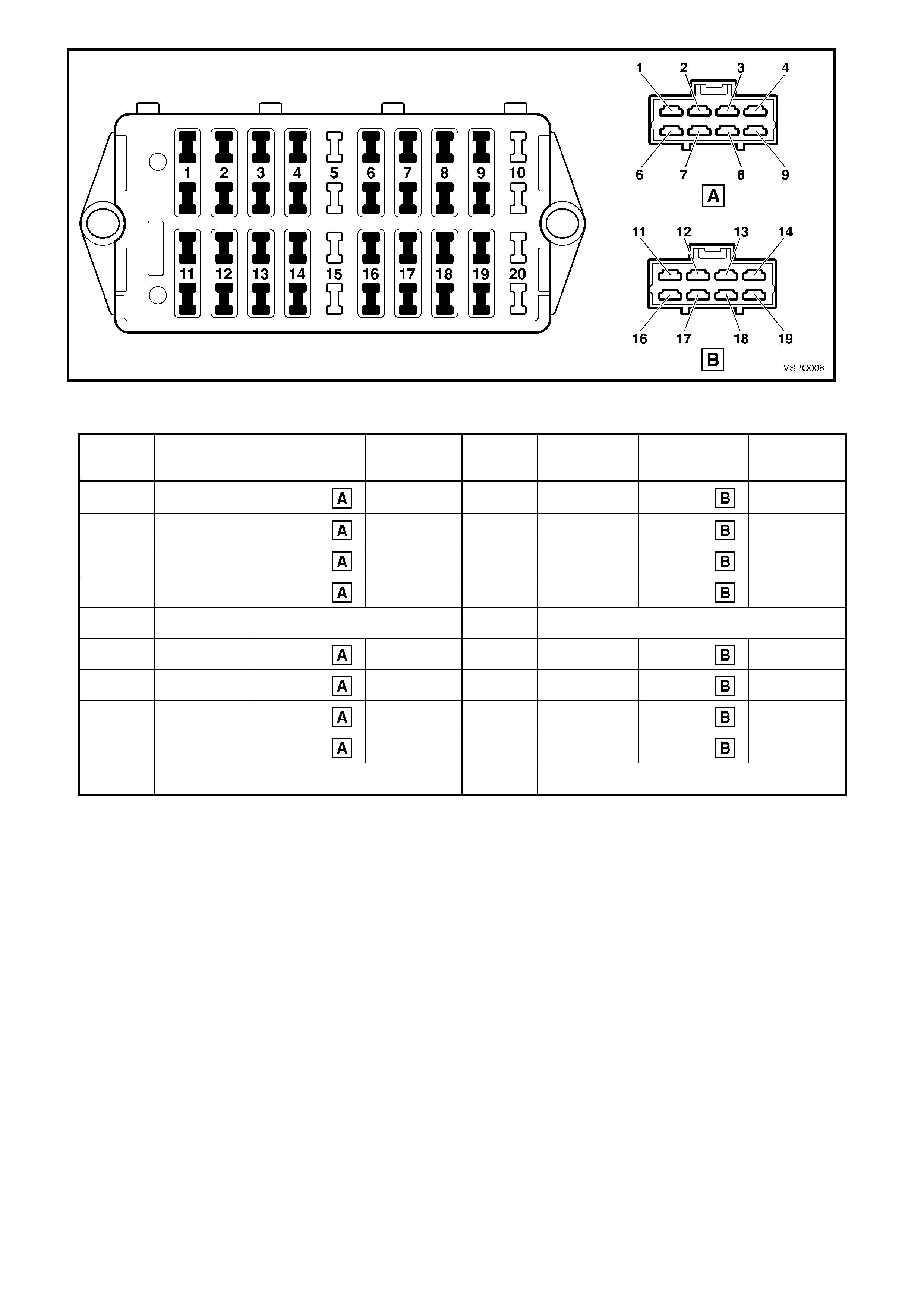

11. The auxiliary harness fuse box contains 16 fuses

(cavities 5, 10, 15 & 20 are not used). Each fuse

carries a unique am perage rating and relates to an

individual terminal in the positive wiring

connectors, white & grey , refer Fig 1A6-9.

12. If a device or circuit is (or is to be) connected to

the auxiliary power harness:

- the positive wire(s) of the device must be

connected to the terminal in either positive

connector that corresponds to a fuse of the

correct amperage, and

- the negative wire(s) of the device are to be

connected to any available pin in either of the

negative connectors.

Figure 1A6-8

AUXILIARY HARNESS FUSE BOX

MOUNTING BRACKET NUT & SCREW 20.0 – 27.0 Nm

TORQUE SPECIFICATION

AUXILIARY HARNESS TO BATTERY 2.0 – 5.0

TERMINAL TORQUE SPECIFICATION Nm

Figure 1A6-9

LEGEND

Fuse

No. Rating

(Amps) Connector /

Pin Wire

Colour Fuse

No. Rating

(Amps) Connector /

Pin Wire

Colour

1. 10 White / 1 Red / Black 11. 15 Grey / 11 Red / Black

2. 25 White / 2 Red / Blue 12. 20 Grey / 12 Red / Blue

3. 20 White / 3 Red / Yellow 13. 15 Grey / 13 Red / Yellow

4. 7.5 White / 4

Red / White 14. 10 Grey / 14 Red / White

5. NOT USED 15. NOT USED

6. 15 White / 6 Pink 16. 10 Grey / 16 Pink

7. 20 White / 7 Yellow 17. 25 Grey / 17 Yellow

8. 20 White / 8 Blue / Green 18. 20 Grey / 18 Blue / Green

9. 10 White / 9 Pink /White 19. 7.5 Grey / 19 Pink /White

10. NOT USED 20. NOT USED

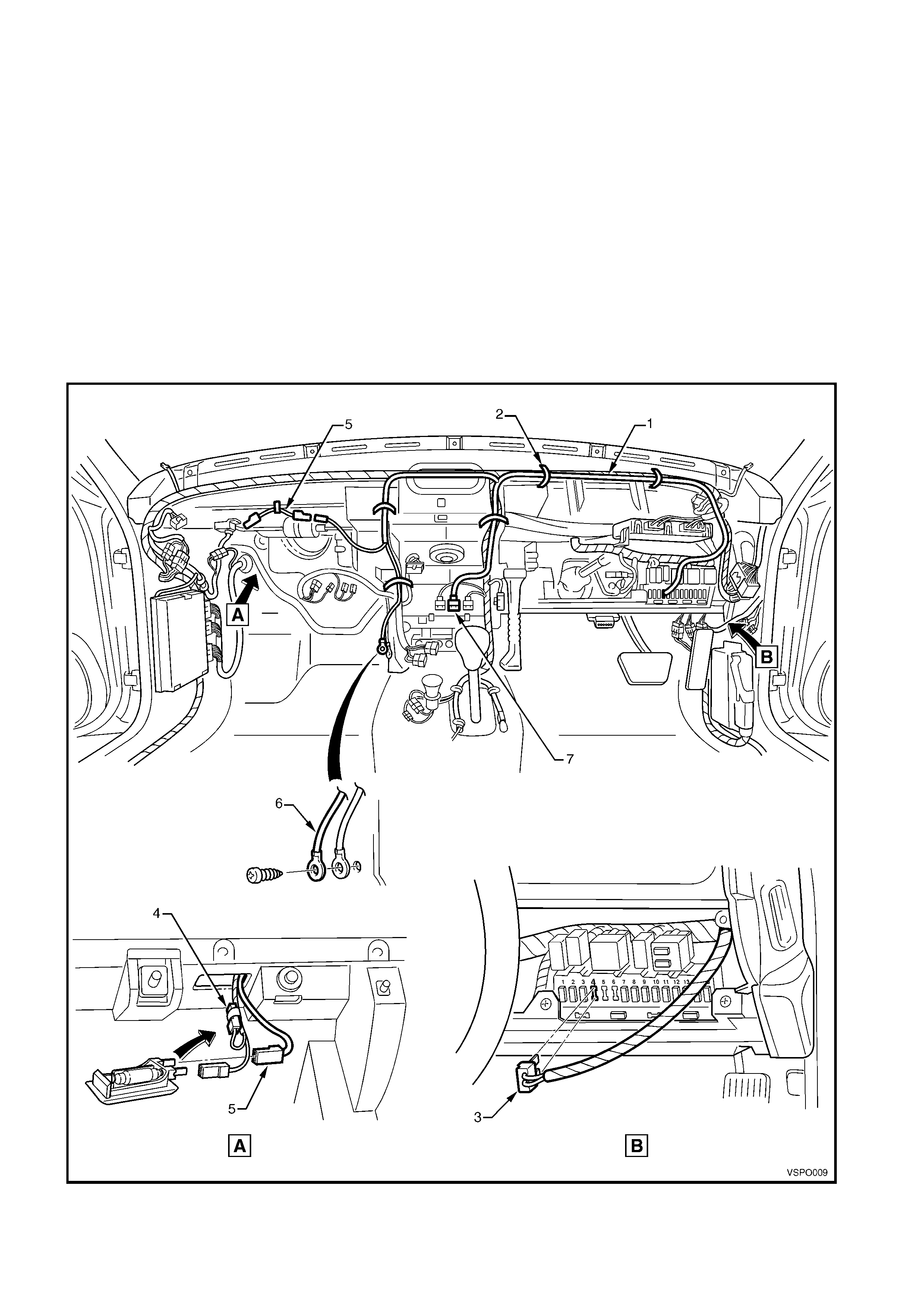

2.3 DOME LAMPS OVERRIDE HARNESS

The dome lamps override harness is used to provide manual override switching of the dome lamps, allowing the

doors to be opened without any lamps illuminating

1. The over ride har ness ( 1) is routed behind the das h

panel as shown and is tie-s trapped (2) to the m ain

harness, five places, refer Fig. 1A6-10.

2. Fuse No. 4 is removed (3) and the harness

installed into the fuse box cavity.

3. The existing orange/white glovebox lamp lead (4)

is taped back to the main wiring harness. A short

lead (5) is ins talled between the lamp and override

harness which is tie-strapped to the body.

4. An additional earth connection (6) is made at the

LH lower dash panel bracket.

5. The override switch wiring connector (7) is routed

to the rear of the centre escutcheon.

Figure 1A6-10

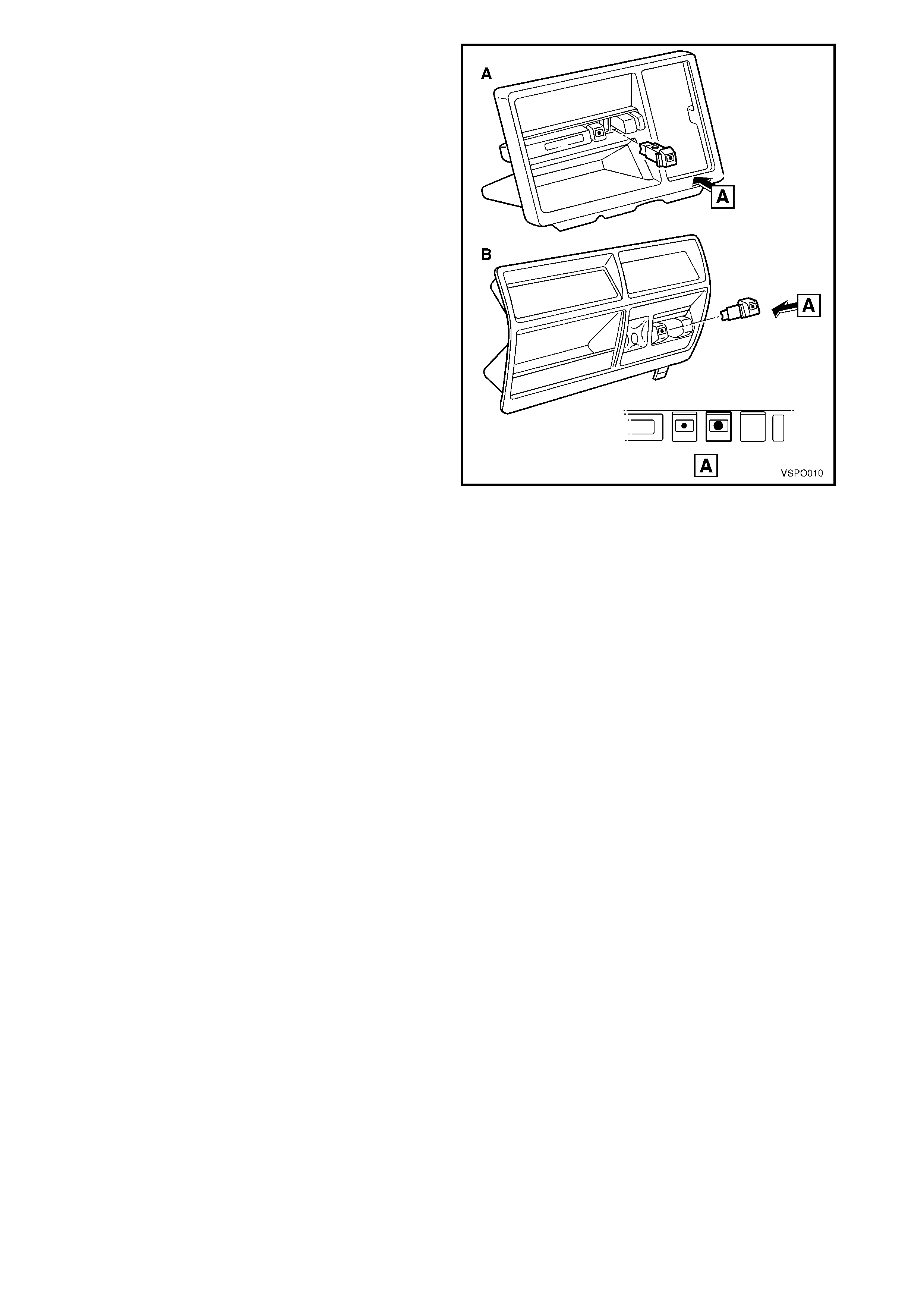

6. The override switch is added to the centre

escutcheon ‘A’ with bucket seats or ‘B’ with a

bench seat as shown.

7. For servicing of the override switch, refer to 2.11

DASH PANEL CENTRE FACIA ESCUTCHEON

SWITCHES in Section 12C INSTRUMENTS,

WIPERS/WASHERS & HORN of the VR Series

Service Information.

Figure 1A6-11

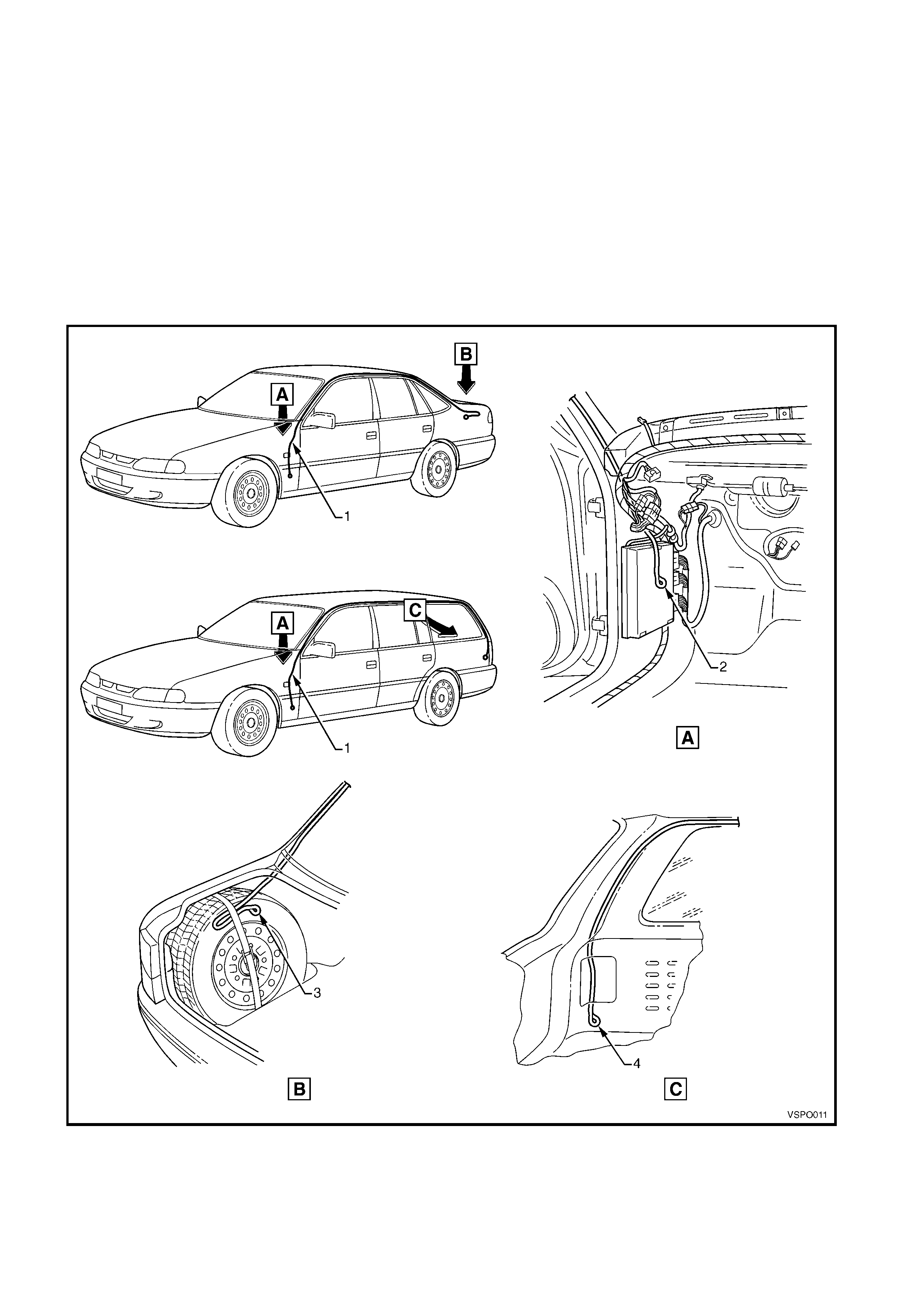

2.4 FEEDER WIRE

A feeder wire (1) is installed into the LH roof side rail,

down the A and D-pillars, refer Fig. 1A6-12.

The f eeder wire enables police dept. engineers to f eed

a wiring harness through the cavity to the rear of the

vehicle if required.

The front of the feeder wire is left to hang near the

engine / powertrain ECU (2).

For sedan models, the rear of the feeder wire is

secured to the spare wheel anchor strap (3).

For wagon models, the rear of the feeder wire is

located near the LH tail lamp, behind the rear

compartment trim (4).

Figure 1A6-12

3. TORQUE WRENCH SPECIFICATIONS

Nm

Auxiliary harness fuse box mounting bracket screw 20.0 – 27.0

Auxiliary harness fuse box mounting bracket nut 20.0 – 27.0

Auxiliary harness to battery terminal nut 2.0 – 5.0