SECTION 0A - GENERAL INFORMATION

General Repair Instruction

Illustration Arrows

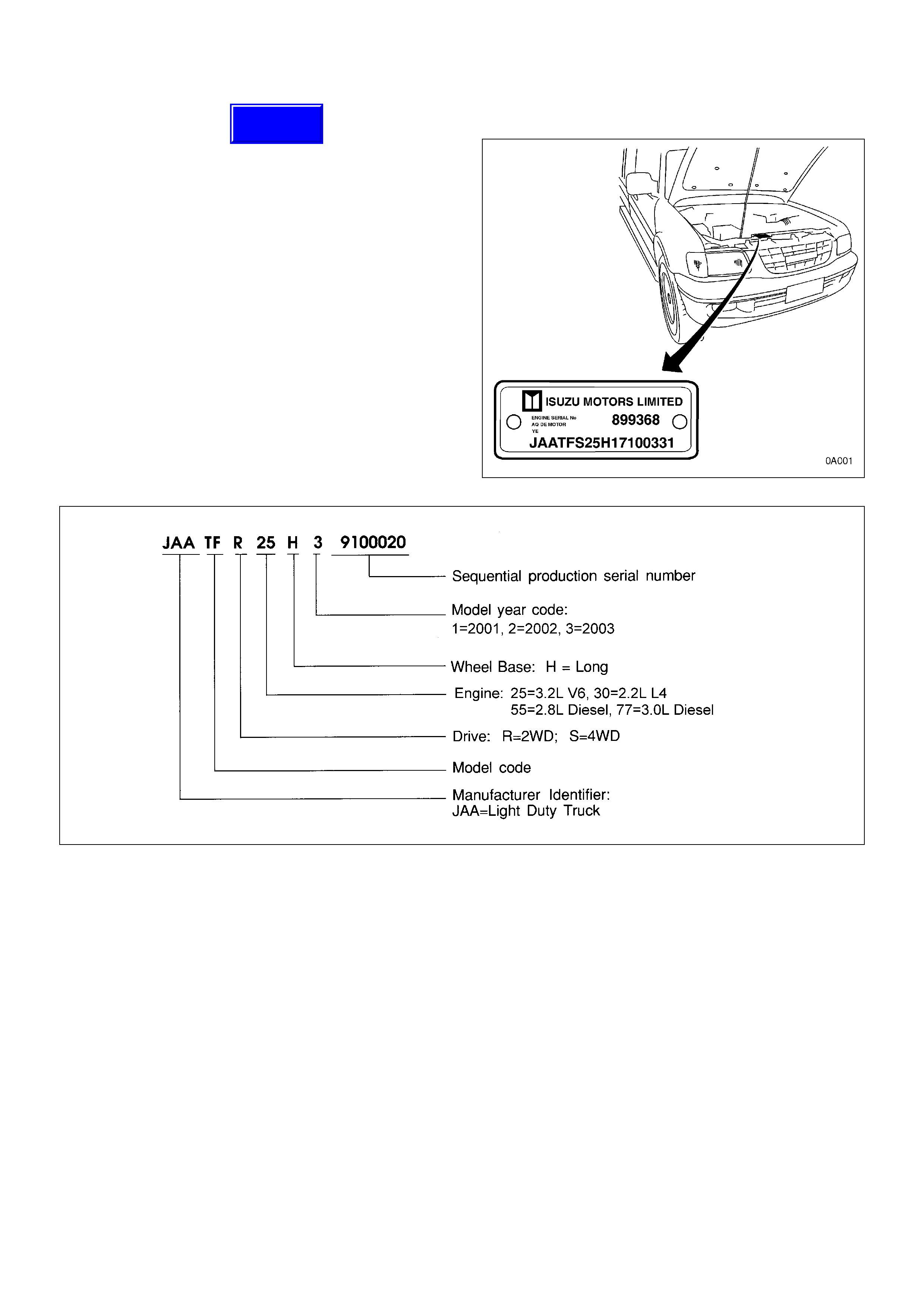

Identification

Lifting Instructions

Loading & Towing

Standard Bo lts Torque Specifications

Abbreviation s Charts

GENERAL REPAIR INSTRUCTION

1. If a floor jack i s used, the following precautions are

recommended.

• Park vehicle on level ground , “block" front or rear

wheels, set jack against the recommended lifting

points (see “Lifting Instructions" in this section),

raise vehicle and support with chassis stands and

then perform the service operations.

2. Before performing service operations, disconnect

ground c able from the bat tery to reduce the chance

of cable damage and burning due to short circuiting.

3. Use a cover on body, seats and floor to protect them

against dam age and contamina tion.

4. Brake fluid and anti–freeze solution must be

handled with reasonable care, as they can cause

paint damage.

5. The use of proper t ools and recommended essential

and available tools, where specified, is important for

efficient and reliable performance of service repairs.

6. Use genuine H olden parts.

7. Used cotter pins, plastic cl ips, gaskets, O–rings, oil

seals, lock was hers and s elf–locking n uts should b e

discarded and new ones should be installed, as

normal funct ion of the parts cannot be m aintained if

these parts are reused.

8. To facilitate proper and smooth reassembly

operation, keep disassembled parts neatly in

groups. Keeping fixing bolts and nuts separate is

very important, as they v ary in ha rdnes s and desig n

depending on position of installation.

9. Clean the parts before inspection or reassembly.

Also clean oil ports, etc. using compressed air, and

make certain they are free from restrictions.

10. Lubricate rotating and sliding faces of the parts with

oil or grease before installation.

11. When necessary, use a sealer on gaskets to

prevent leakage.

12. Carefully observe all specifications for bolt and nut

torques.

13. When removing or replacing parts that require

refrigerant to be discharged from the air

conditioning system, be sure to use the Vehicle

Refrigerant Recovery and Recycling Equipment

(VRRRE) to recover and recycle Refrigerant–134a.

14. When a service operation is completed, make a final

check to be sure the service has been done

properly and the problem has been corrected.

15. SUPPLEMENTAL REST RAINT SYSTEM

• The vehicle is equipped with a Supplemental

Restraint System (SRS) – Air Bags. Th is system

is not to be serviced without consulting the

appropriate service information. Consult Section

12M if work is to be done on the front of the

vehicle such as bumper, sheet metal, seats,

wiring, steering wheel or column. Also review

SRS system information if any arc welding is to

be done on the vehicle. The SRS system

equipped vehicle can be identified by:

1.“A IR BAG" warning light on the instrument

cluster.

2.“S RS” embossed on the steering wheel horn

pad.

3.SRS warning labeling on the interior sunvisor.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

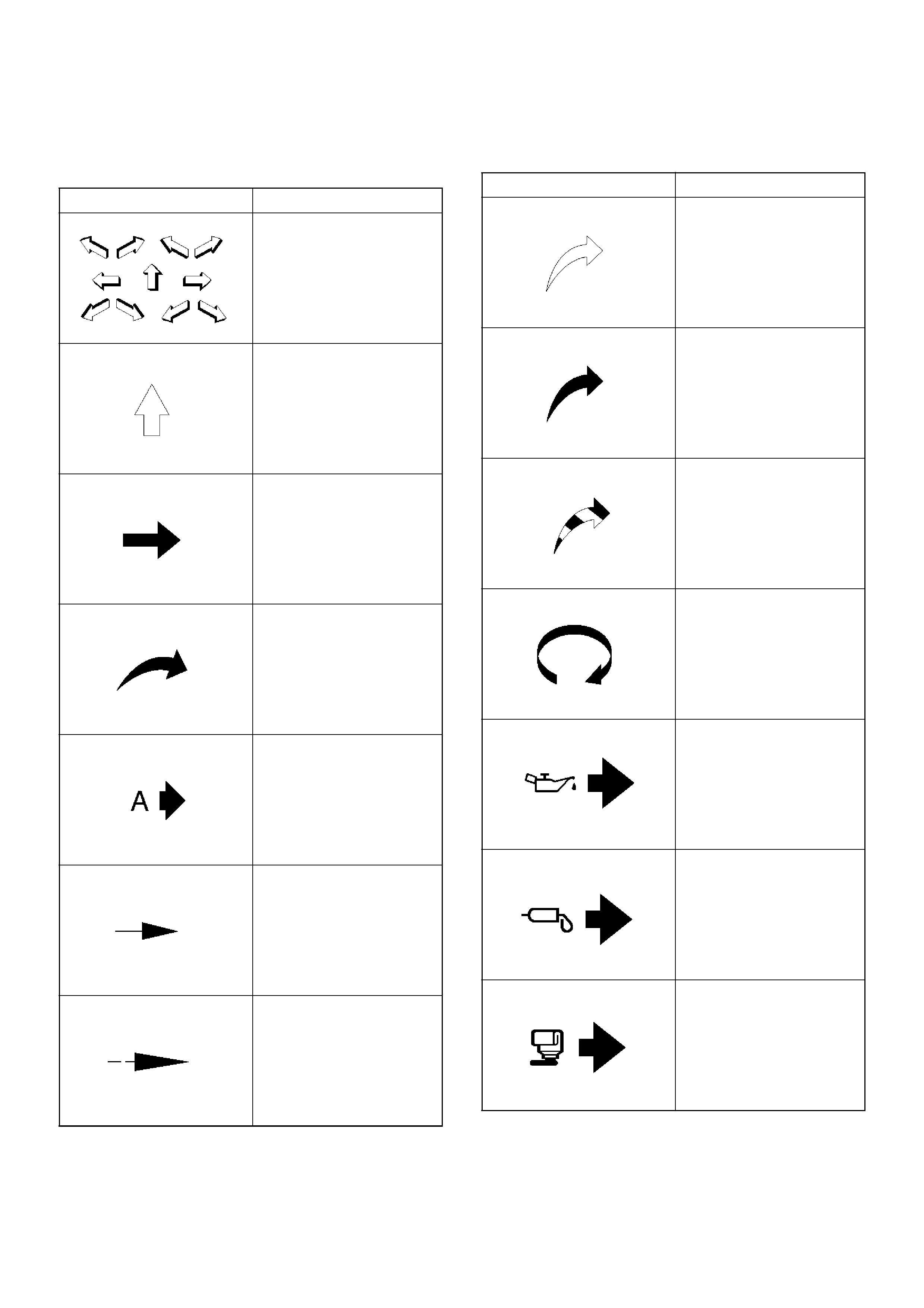

ILLUSTRATION ARROWS

Arrows are designed for specific purposes to aid your understanding of technical illustrations.

Arrow Type Application

Front of vehicle

Up Side

Task Relate d

View Detail

View Angle

Dimension (1:2)

Sectioning (1:3)

• Ambient/Clean air flow

• Cool air flow

• Gas other than

ambient air

• Hot air flow

• Ambient air mixed with

another gas

• Can indicate

temperature change

Motion or direction

Lubrication point oil or

fluid

Lubrication point grease

Lubrication point jelly

Arrow Type Application

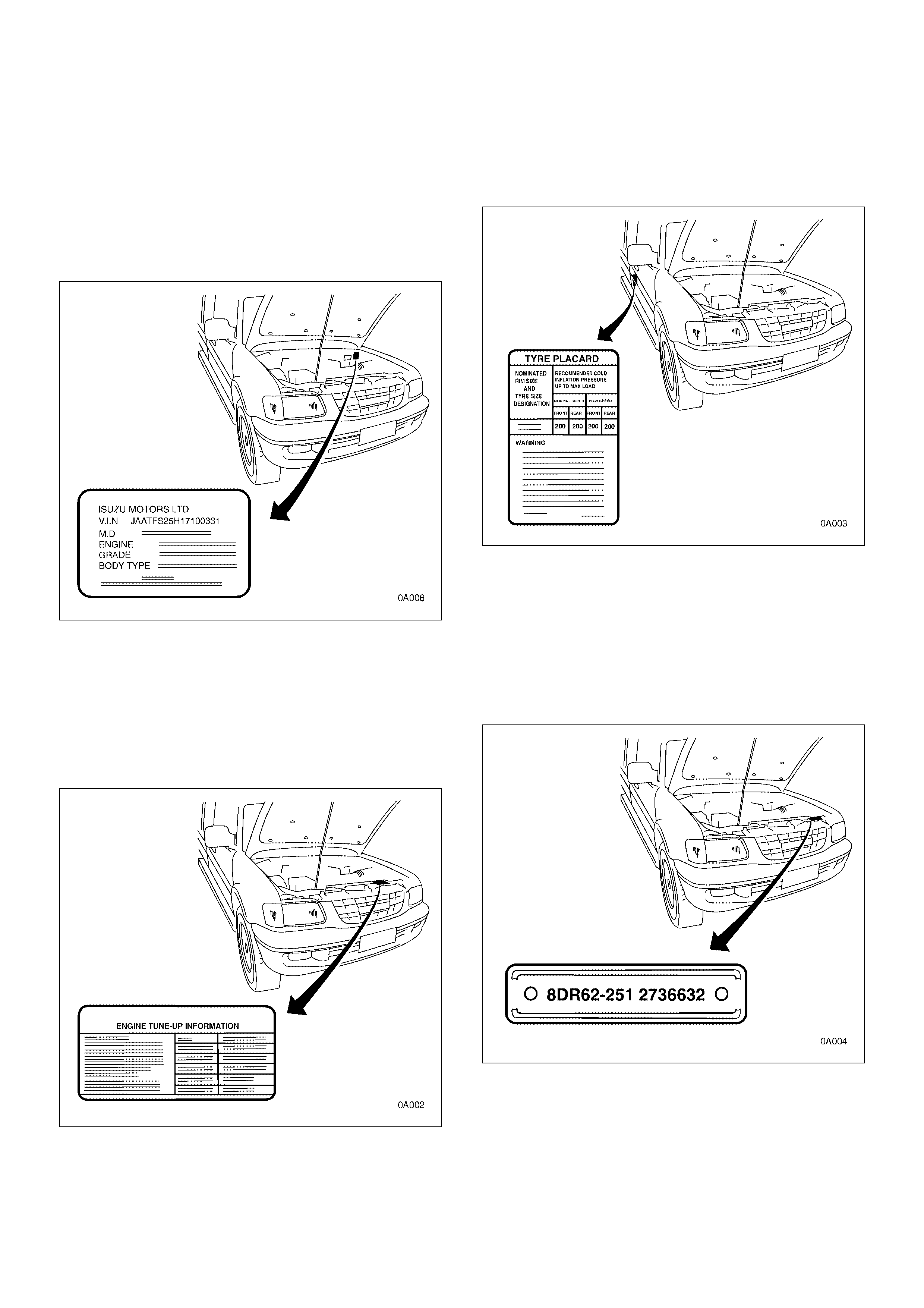

BODY AND OPTIONS PLATE

The Body and Options plate is located on the passenger

side of the dash panel in the engine compart men t.

It displays the VIN and codes for options that have been

built into t he ve hicle. F orr exam ple, t he body type , body

paint colour, trim level, engine and transmission codes

and model designation.

EMISSION LABEL

The Emiss ion label is located on the driver ’s side of the

dash panel in the engine compartment.

It shows the relevant tune-up information required to

maintain the minimum exhaus t emissions.

TYRE PLACARD

The Tyre Placard is located on the driver’s door lock

pillar, and is visible when the door is open.

HOLDEN IDENTIFICATION PLATE

The Holden identification Plate is riveted to the centre of

the radiator support panel in the engine compartment

It is used for warranty identification, roadside assist ance

identification etc.

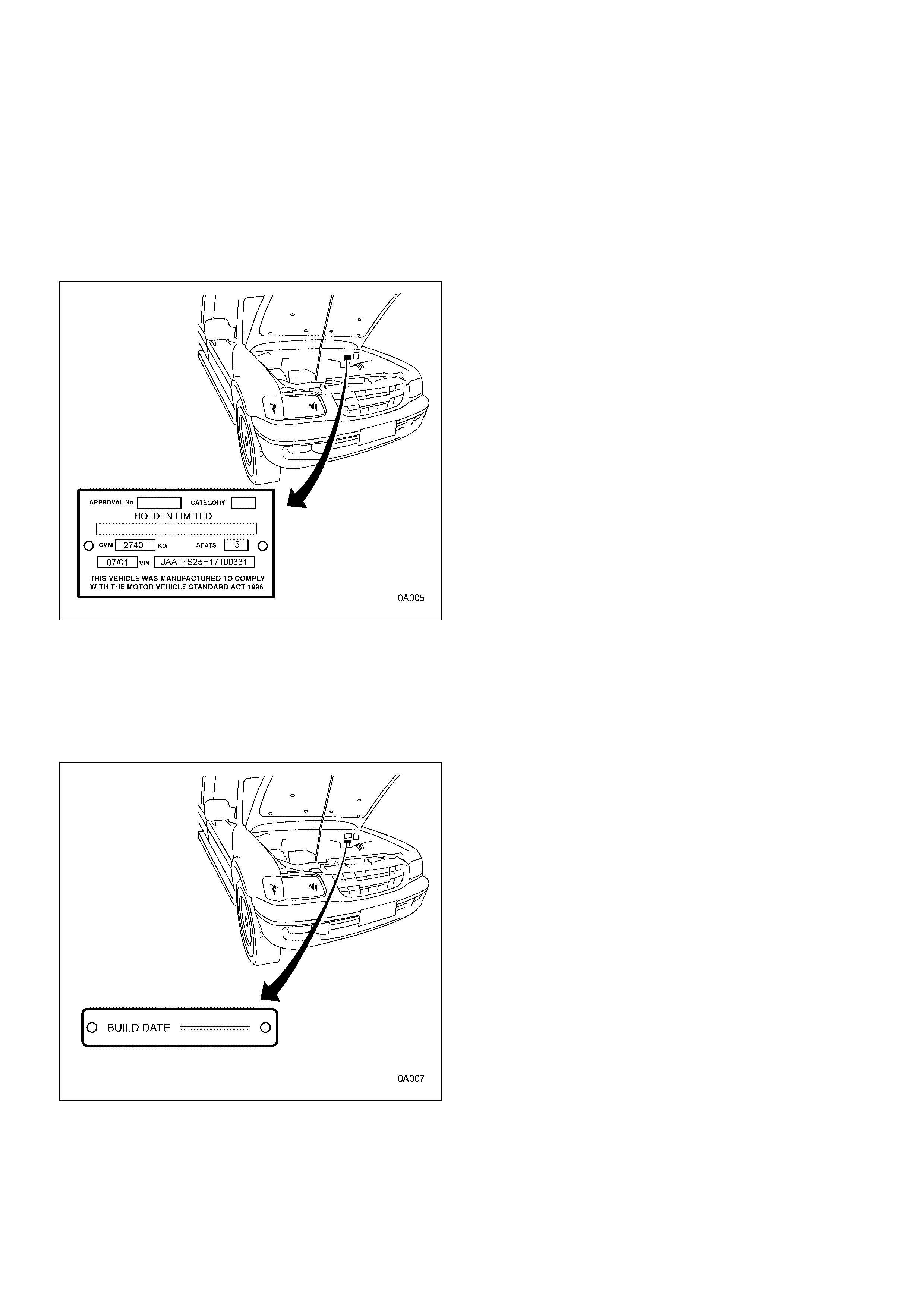

SAFETY COMPLIANCE (ADR) PLATE

The ADR plate is riveted to the passenger side of the

dash panel in the engine compartment.

It displays the approval numbers, category,

manufacturers name, model name and code, Gross

Vehicle Mass (GVM), seating capacity, build date and

VIN.

BUILD DATE PLATE

The B uild Date Plate is riveted to the passenger side of

the dash panel in the engine compartment, below the

Safety Com plianc e Plate.

It displays the date upon which the vehicle was built.

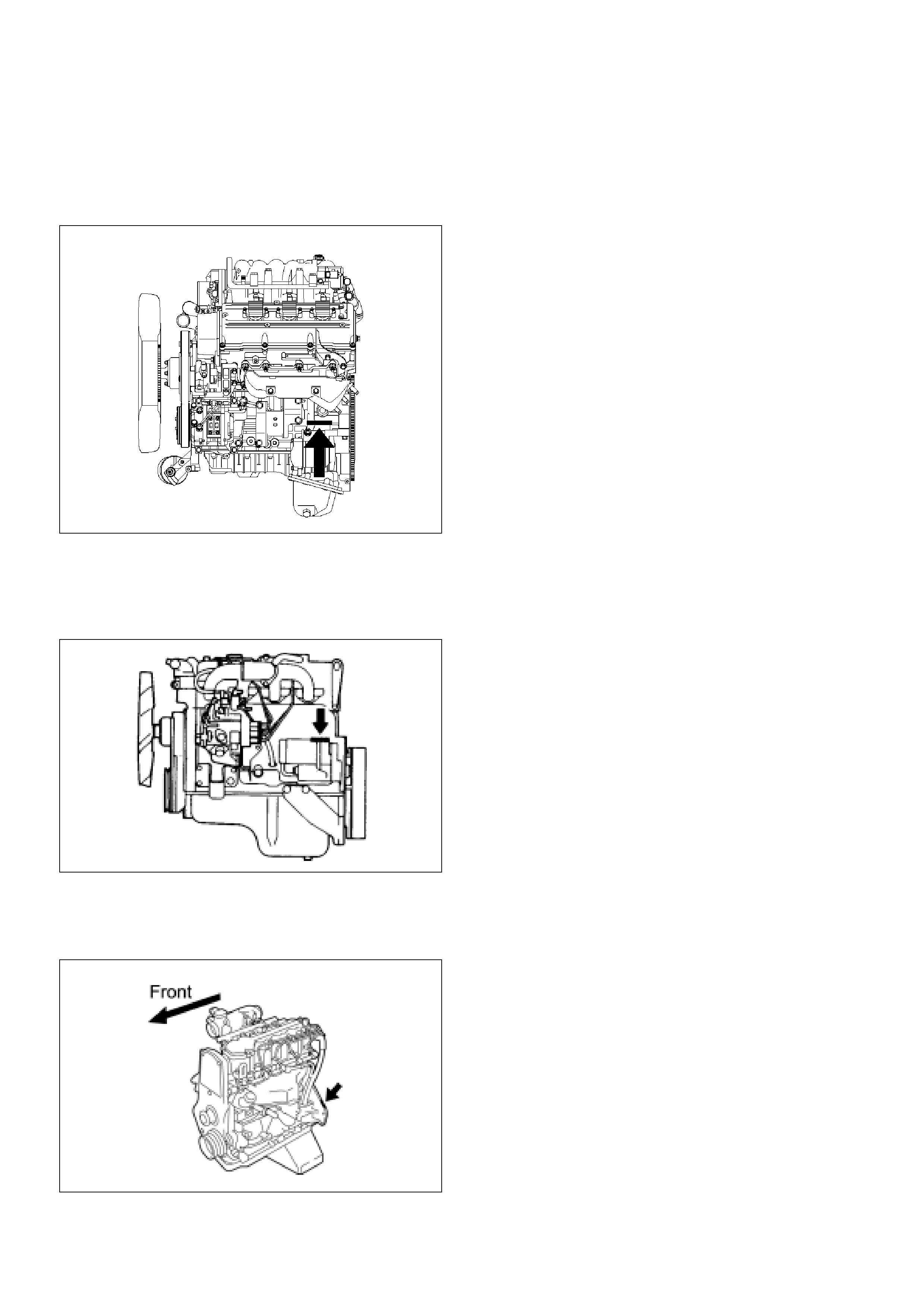

ENGINE SERIAL NUMBER

• 6VD1 Engine

Stamped on the left rear lower area of the cylinder block

above the starter.

F00R100002

• 4JB1T & 4JH1-TC Engines

On the left rear area of the cylinder block above the

starter.

• C22NE Engi ne

On the protrusion at the left rear of the cylinder block.

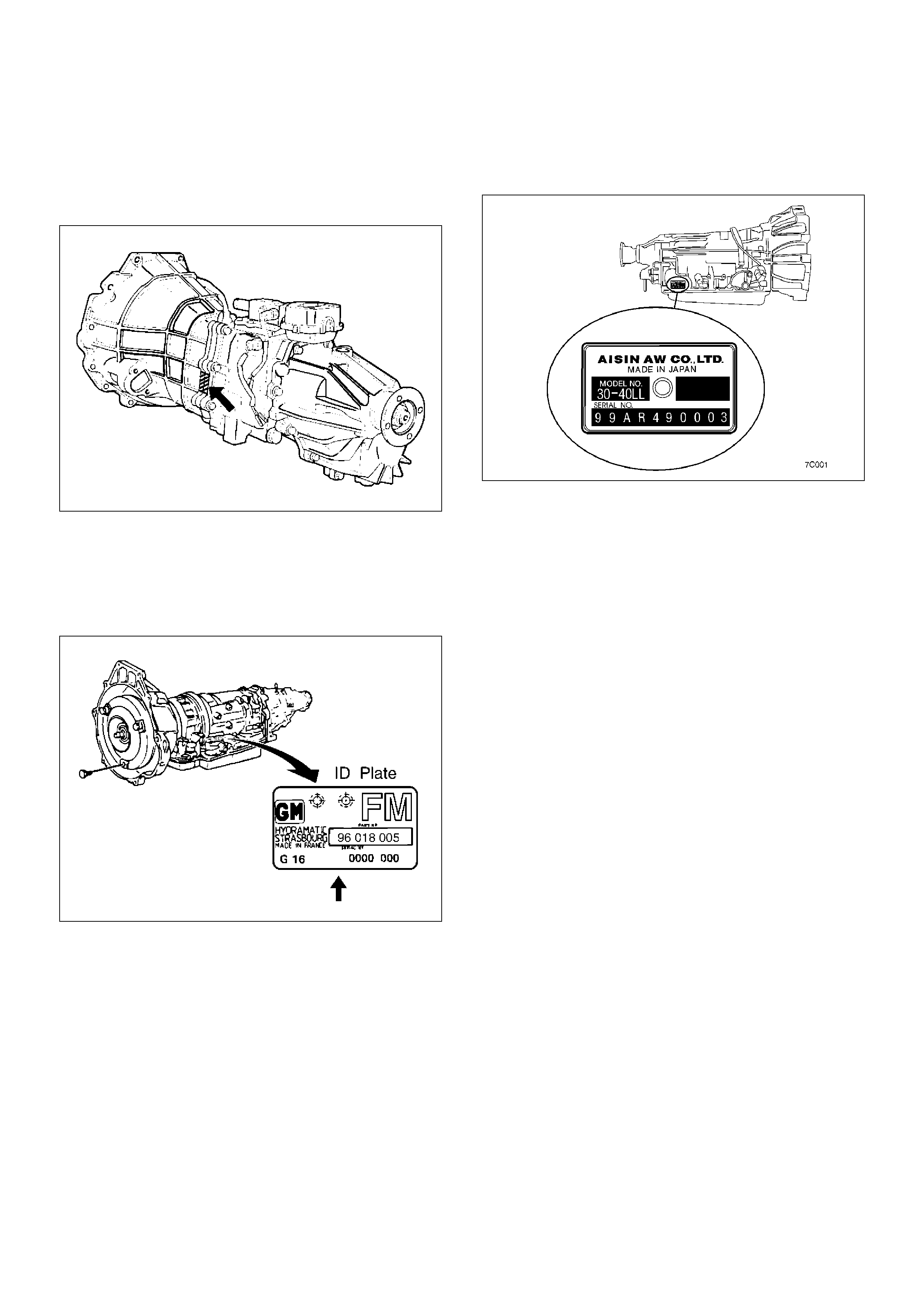

TRANSMISSION SERIAL NUMBER

• Manual - MUA Series

Stamped on the passenger side of the transmission

intermedia te plate.

220RS025

• Aut om at i c - TH M 4L 30E

Stamped on the identification plate, located on the

passenger side of the transmission above the mode

switch.

• Automati c - AW 30-40 LE

Stamped on the identification plate, l ocated on the driver

side of the transmission to the rear of the mode switch.

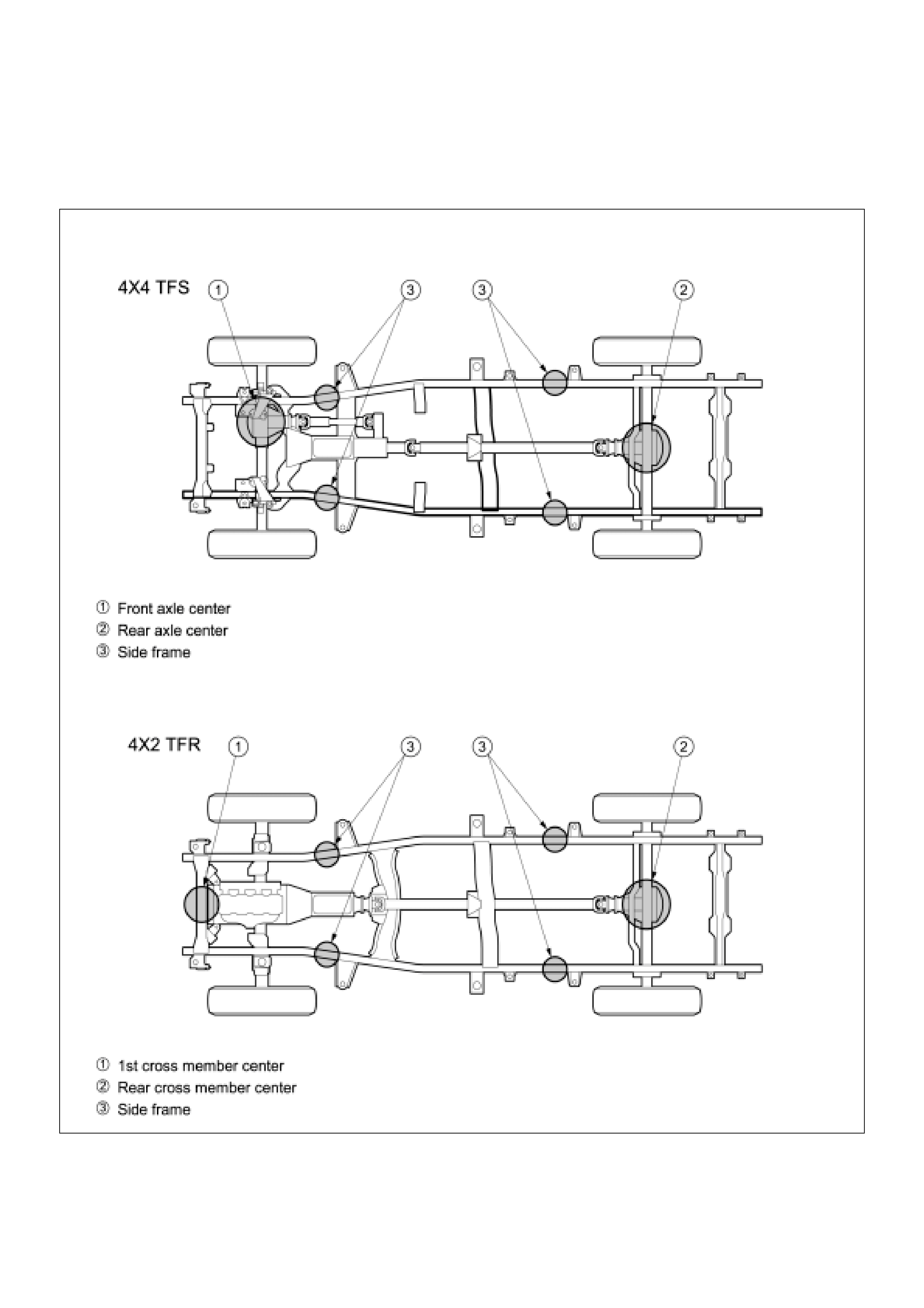

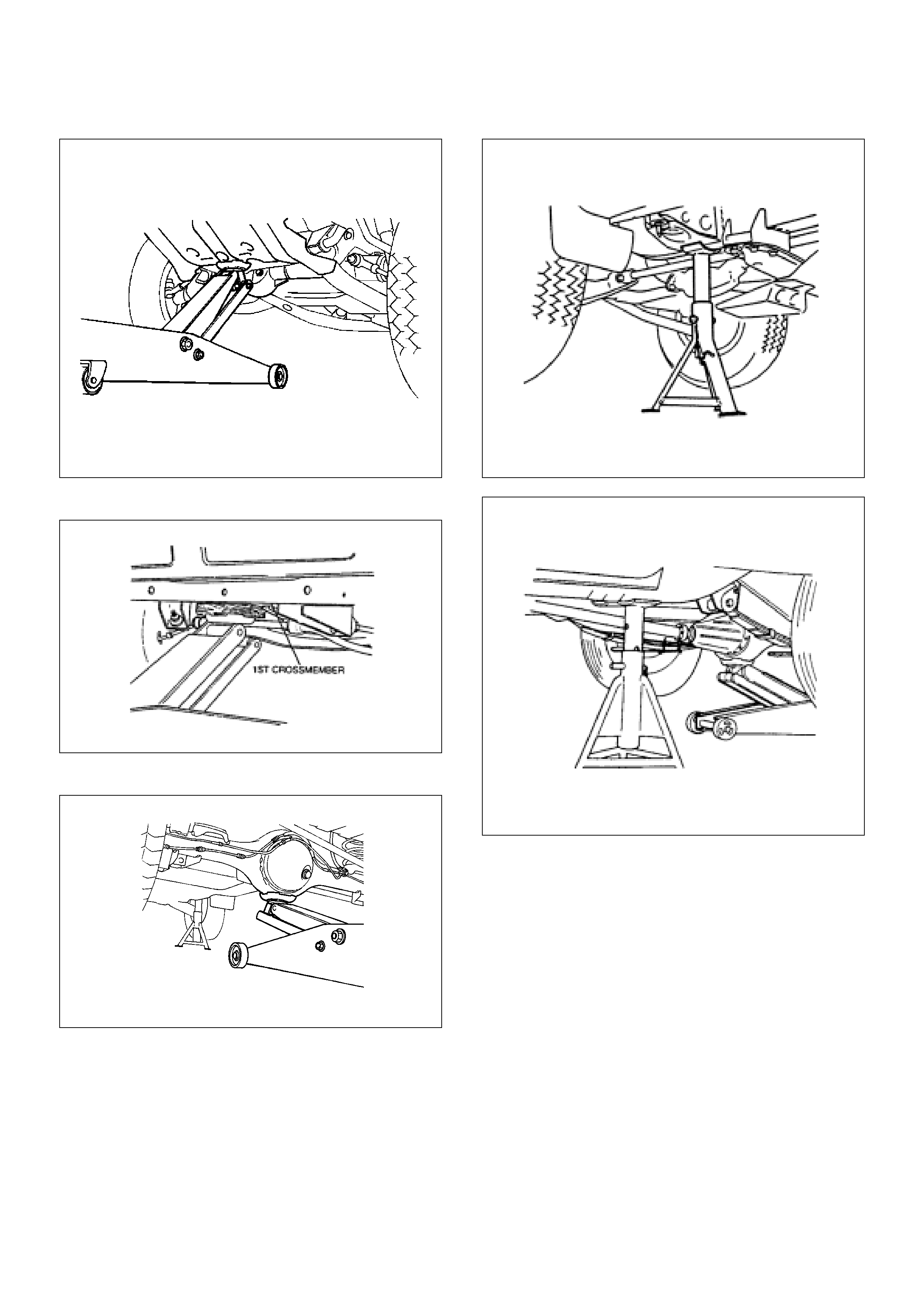

LIFTING INSTRUCTIONS

LIFTING POINTS AND SUPPORTABLE POINT LOCATIONS

CAUTION: IF A LIFTING DEVICE OTHER THAN THE OEM JACK IS USED, RAISING THE VEHICLE FROM ANY

OTHER POINT OTHER THAN THOSE SHOWN MAY RESULT IN SERIOUS DAMAGE.

C00RX002

• Lift Point: Front (4x4)

• Lift Point: Front (4x2)

•Lift Point: Rear

420RS002

•Su pport Po in t : Front

• Support Po int : Rear

LOADING & TOWING

Trailers

The word “trailer” is used throughout this section. The word “trailer” is intended to include all types of towed vehicle,

such as a caravan, boat trailer or any other special purpose trailer, etc.

Overloading

Ove rloading is a s afet y hazard and could al so s horte n the life of t he v ehicle . Neve r exce ed the loads sp ecified for th e

vehicle or trailer, as specifi ed below.

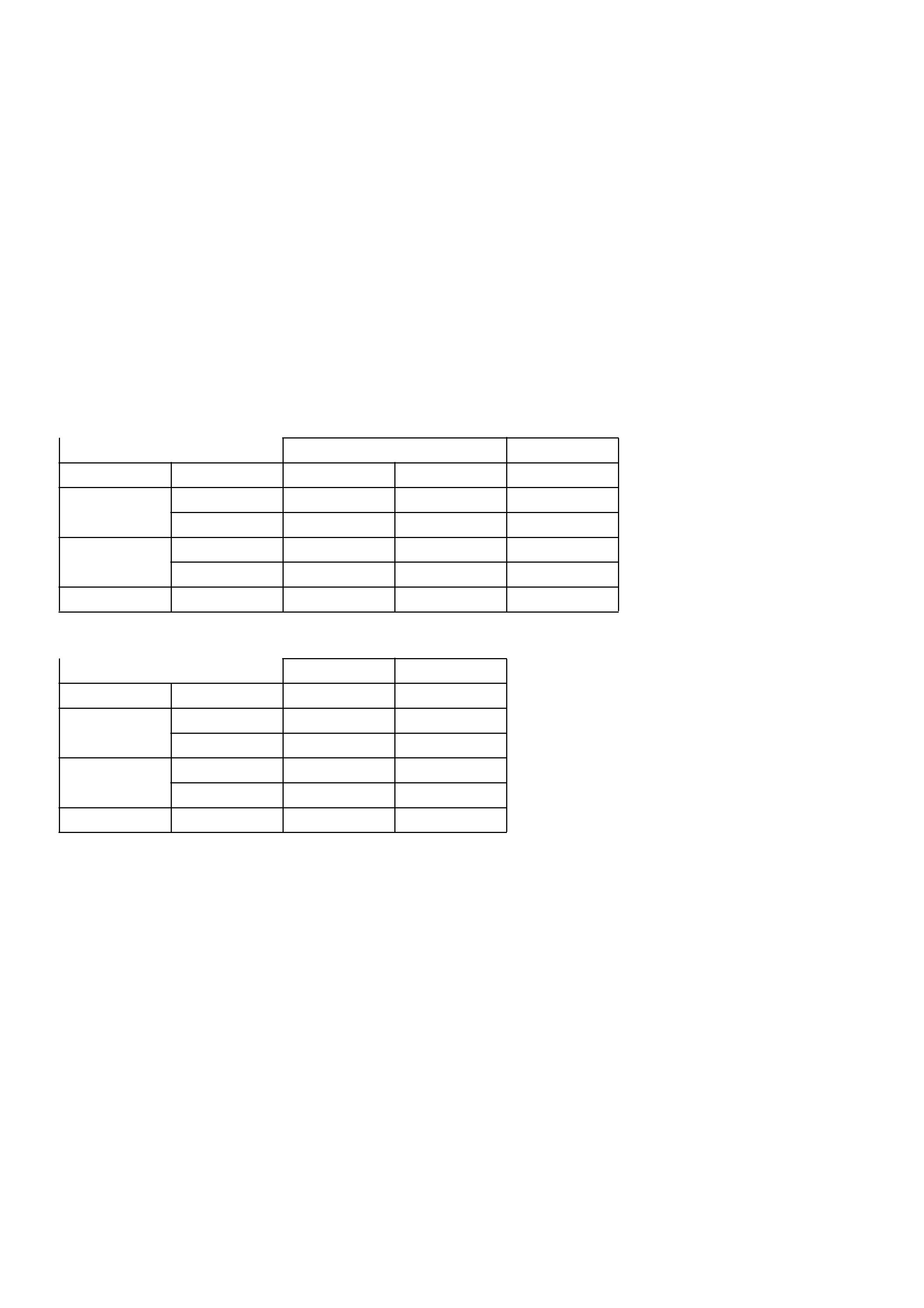

Vehicle Capacities

Unladen Mass – the mass of the vehicle in running order, unoccupied and unladen with all fluid reservoirs filled to

nomin al capacity (including fuel) and with all standard equipment fitted. Refer to the following table.

TFR 4x2 Unladen Mass (kg)

TFS 4x4 Unladen Mass (kg)

* excludes rear body mass

NOTE: Add 15kg to the above weights if the vehicle is fitted with automatic transmissi on.

Gross Vehicle Mass Rating (GVMR) – the maximum allowable laden mass of the vehicle. Refer to the following

table.

Gross Combination Mass Rating (GCMR) – the maximum allowable sum of the masses of the towing vehicle and

the towed trailer. Refer to the following table.

Gross To wed Mass Rating (GTMR) – the maximum allowable mass of a trailer (including load) that may be towed by

the vehicle. Refer to the following table.

Front A xle Capacity and Rear Axle Capacity – the maximum allowable loads on the ground at the front and rear

axles. Refer to the following table.

PETROL DIESEL

CAB REAR BODY DX LX LX

Single Pick-up 1345 1513

Cab-chassis* 1200 1368 1295

Space Pick-up 1530

Cab-chassis* 1410

Crew Pick-up 1410 1583

PETROL DIESEL

CAB REAR BODY LX LX

Single Pick-up 1635 1635

Cab-chassis* 1490 1485

Space Pick-up 1640 1685

Cab-chassis* 1540

Crew Pick-up 1705 1715

Note: It may not be possible to tow a fully laden trailer (total trailer mass near or equal to the GTMR) with a fully

laden vehicle (total vehicle mass near or equal to the GVMR), because the total combined weight of the vehi-

cle–trailer combination may exceed the Gross Combination Mass Rating (GCMR). In such cases it is neces-

sary to reduce the load in either or both the towing vehicle and the trailer so that the combined mass of the

towing vehicle and trailer is less than the GCMR.

When towing, the driver must take into account the additional load the trailer puts on the vehicle. Particular

attention must be given to how the trailer changes the loads at the vehicle’s front and rear axles.

When the vehicle and trailer are at or near full load, it may be necessary to use a public weighbridge to check

that none of the vehicle’s, trailer’s or towing equipment’s capacities have been exceeded.

Handling, durability and economy may be affected by towing a trailer.

Country/State Regulations

Note that there are various regulations related to towing, and that these can vary between the different countries/

states. These regulations normally cover the maximum allowable mass of the trailer and the maximum allowable driv-

ing speeds. You must be familiar with the regulations for towing for each of the states in which you intend to tow.

Details of the regulations are available from the relevant state road traffic authorities or motoring associations.

Towing Equipment

The following table shows which towing equipment is essential, according to the total mass to be towed.

For occupant safety and the vehicle’s durability, all equipment marked “Essential” must be correctly installed and used.

Otherwise you may void the New Vehicle Warranty, to the extent that Holden considers the overloading, missing

equipment or misuse to have affected the specifications or quality of the vehicle.

The Holden Dealer can supply and install towing equipment to suit the towing needs.

The Holden towing package for TFR/S Rodeo includes the tow bar, tow bar “tongue” and wiring harness. A Load

Equalising Hitch if required, is sold separately.

Caution: Holden towing equipment is recommended where it is available. Where it is not available, no recommenda-

tion is made as to the make of equipment to be used. Holden will not accept liability for defects occurring in

towing equipm ent not marketed by Holden or for defects in the vehicle arising from the use of such equi p-

ment. T he use of such equipment m ay vo id the New Vehicle Wa rranty, to the e xtent that H olden con siders

the overloadi ng or missing equipme nt to have affected the spe cifications or quality of the vehicle.

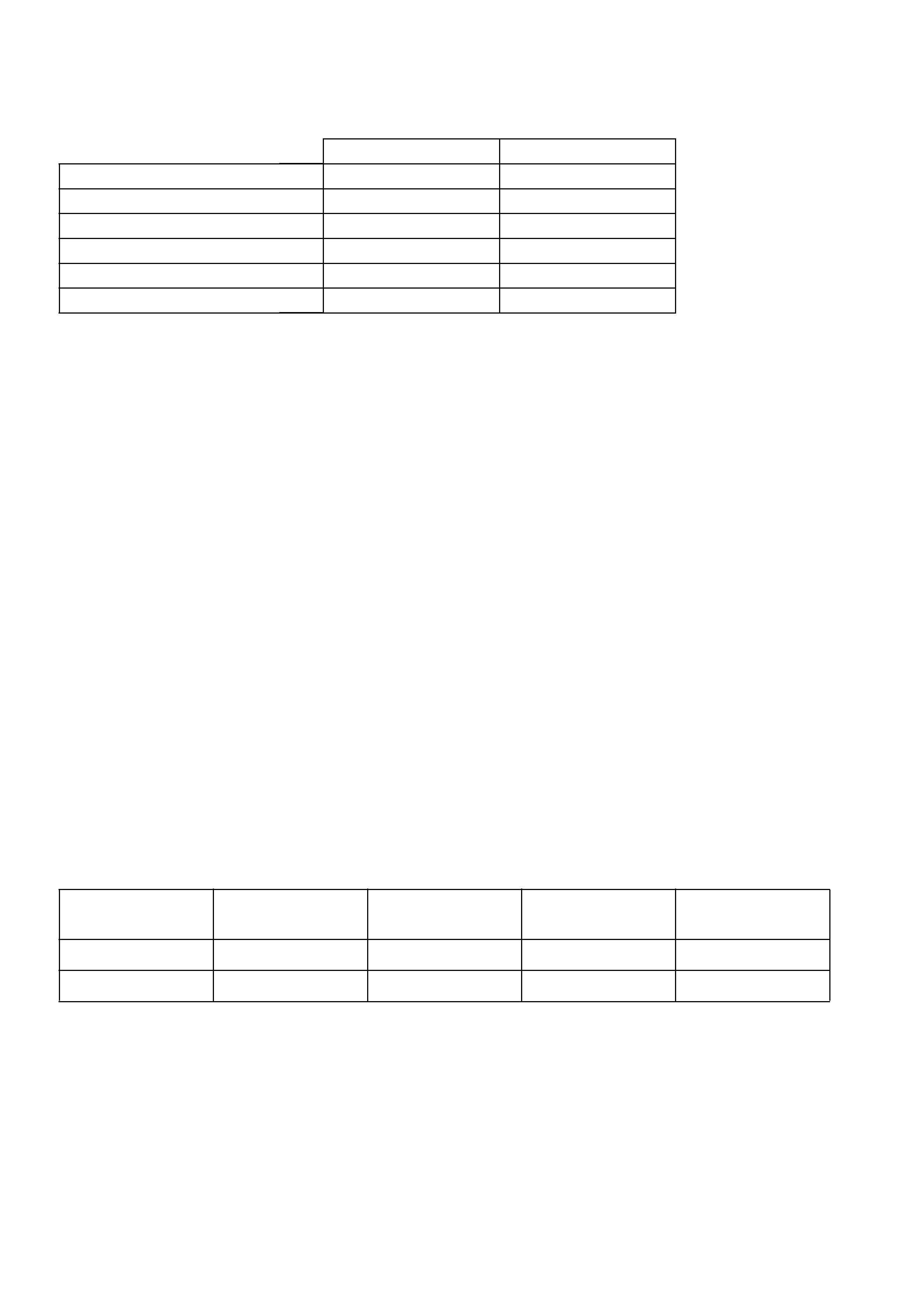

4x2 TFR 4x4 TFS

GVMR (kg) 2730 2740

GCMR (kg) 3730 3740

GTMR (kg) 1800 1800

Max. Ball Load (kg) 180 180

Fr ont A xl e Ca pacit y (kg) 1050 1150

Rear Axle Capacity (kg) 1680 1680

Total Trai ler Mass 1800 kg Tow Bar Trailer Wiring Har-

ness Trailer Brakes Load Dist ribution

Hitch

Up to 900kg Essen ti al Essentia l Check State Laws -

Above 900 kg Essential Essential Essential Essential

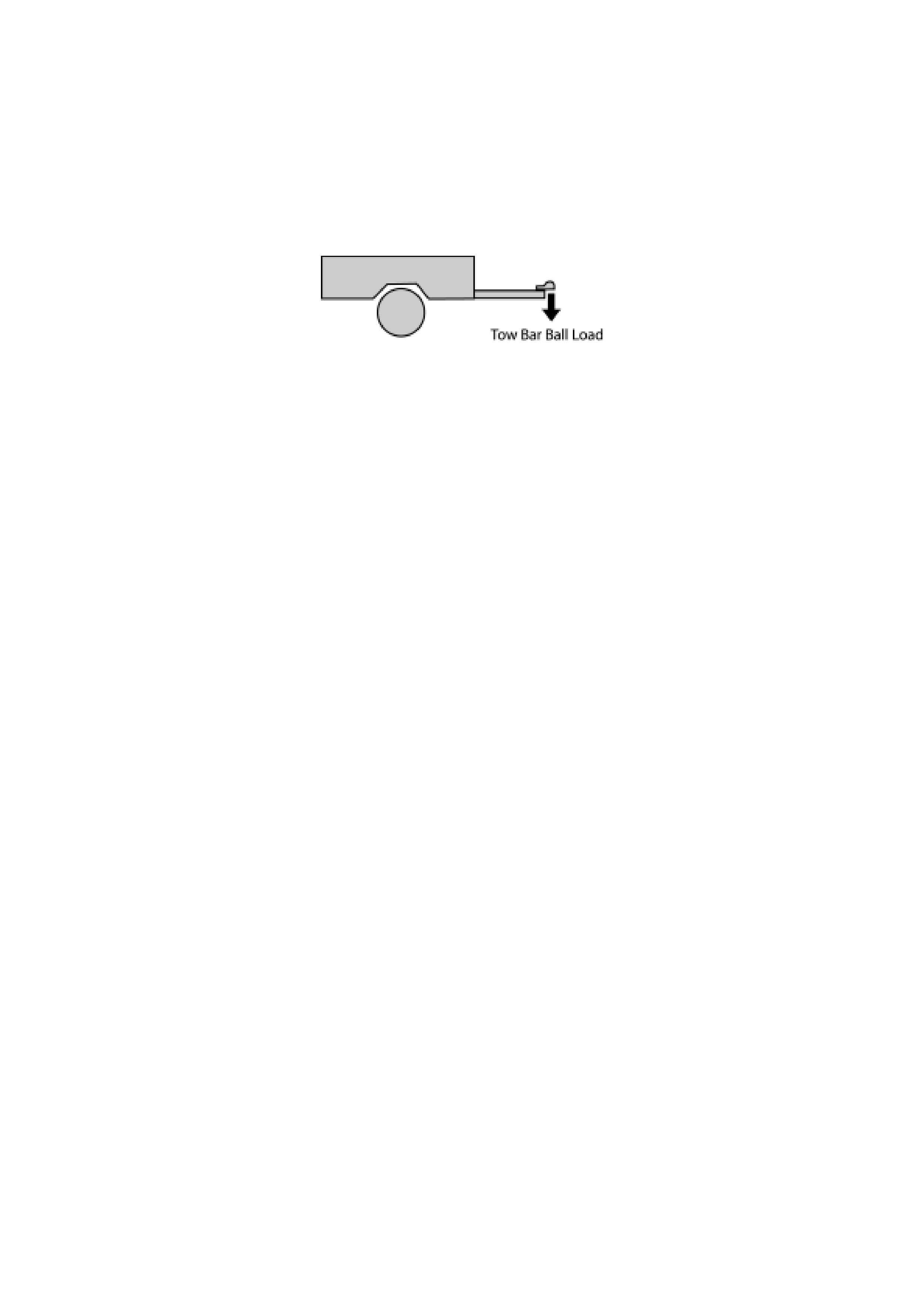

Tow Bar Ball Load

W hen a trailer is connecte d to the towing vehicle , some of the weight of the trailer is applied through the tow “b all” to

the tow bar and t owin g vehicle. T his wei ght is called t he “to w bar ball weight” or “ball load”. T he m ax imum ball load is

180kg.

If the “ball load” is too light or too heavy the steering, handli ng and ride characteristics of the vehicle can be adv ersely

affected.

As a general guideline , for singl e axle trailers, the “ball load” shoul d be appro ximately 10 % of the loaded t rail er mass.

For heavy trailers with more than one axle, the “ball load” should be in the range 5% - 10% of the loaded trailer mass.

Check the “ball load” capacity of the towing equipment. This may be called the “Maximum Down Load”, “Maximum

Vertical Load”, “M ax imum Ball Load” or similar a nd will be s pecifi ed on the tow ba r.

Establish a target “ball load” that is in accordance with the recommendations (above) and within the capacity of the

towing equipment.

Check the “ball load” (compare with the target) before coupling the trailer to the towing vehicle.

The “bal l lo ad” can be adj usted by redistributing the conte nts of th e trailer ie. by moving the co ntents of the trailer for-

ward or backward within the trailer so as to change the trailer ’s balance.

For further information contact the roads authority in the relevant country/state.

Load Equa l isin g Hitch

A Lo ad Distribution Hitch (sometim es called a “Load E qualising Hitch”) is designed to tra nsfer som e of the load f rom

the vehicle’s rear axle to the vehicle’s front axle and the axle(s) of the trailer.

A load distri bution hitch can also be used to restore the towing vehicle to a more normal (level) “attitude”. This reduces

the need to adjust headlight alignment and should provide the towing vehicle with more “normal” ride and handling.

For these reasons, the use of load distributing devices can make towing safer, more comfortable and more conve-

nient.

Adjust the load distribution hitch so that the vehicle is has about the same “attitude” (“stance” or “angle to the ground”)

as when it is unladen.

Roof Racks

For occupant safety, and to avoid damaging the vehicle’s roof, there is no released Holden approved roof rack system

for TF Rodeo.

Fitting Accessori es (Bull Bars , Driving Lamps, Insect Screens, etc.)

W hen fitting accessories take care not to restrict airflow through the air conditioner ’s condenser and the radiator, oth-

erwise engine overheating and/or poor air conditioning performance may result.

The mass of all accessories must be considered when ev aluating the vehicle’s overall loaded c ondition.

Remem ber that bull bars may affect air bag operation.

Running In Before Towing

Holden recommends driving the new vehicle for at least 1,500km before towing. If it is required to tow in the first 1,500

km of the vehicle’s life, the maximum vehicle speed should not exceed 80 km/h.

The same applies if the vehicle is equipped with a new or reconditioned engine, transmission or axle.

Off Road Loading And Towing

Driving the vehicle off-road may induce higher loads than normal on-road driving. To reduce the risk of damage to the

vehicle (and trailer) and improve safety when operating off-road, reduce the vehicle speed and minimise the load

being carried (and towed).

TOWING PRECAUTIONS

• The vehicle will handle differently when towing. It is a good idea to for the driver to make a couple of short-distance

trips with the trailer to become familiar with the handling characteristics of the vehicle when towing.

• The vehicle must be correctly maintained and serviced.

• Have the trailer maintained and serviced, with particula r attention to the condition of the brakes, tyres, suspension,

wheel bearings, lighting and the towing equipment.

• Driving speed should be reduced when towing.

• If the trailer has poor directional stability seek qualified advice eg. the trailer’s manufacturer or retailer. The use of

stabilising equipment should be considered.

• Ensure that all loads – in or on the towing vehicle and in the trailer - are properly secured.

• Use extended-arm rear vision mirrors when the trailer is wider than the towing vehicle.

• Headlights may need realignment after the loaded trailer has been hitched. The use of a load distribution hitch will

reduce the need for headlight realignment, making towing safer and more convenient.

• Slow the vehicle and select a lower gear before descending steep hills.

• When towing, inflate the vehicle’s tyres to the maximum recommended pressure.

• Be familiar with the regulations for towing for each of the states in which you intend to tow. Contact the road traffic

authority in each state for specific advice.

• The brakes on the trailer must be adequate for the braking needs of the trailer and must not adversely affect the

performance of the brakes of the towing vehicle.

• When a tow bar is removed, be certain to seal any mounting holes in the chassis frame or vehicle body to prevent

the possible entry of exhaust fumes, dust and water. Sealing mounting holes in the chassis frame will ensure that

the tow bar can be properly refitted at a later date.

• Ensure that no part of the tow bar (including the tongue or tow ball obscures the vehicle’s licence plate. If necessary,

remove the tow bar tongue when it is not in use.

• More frequent vehicle maintenance is required when using the vehicle to pull a trailer. Refer to

Section 0B - Lubrication and Servicing.

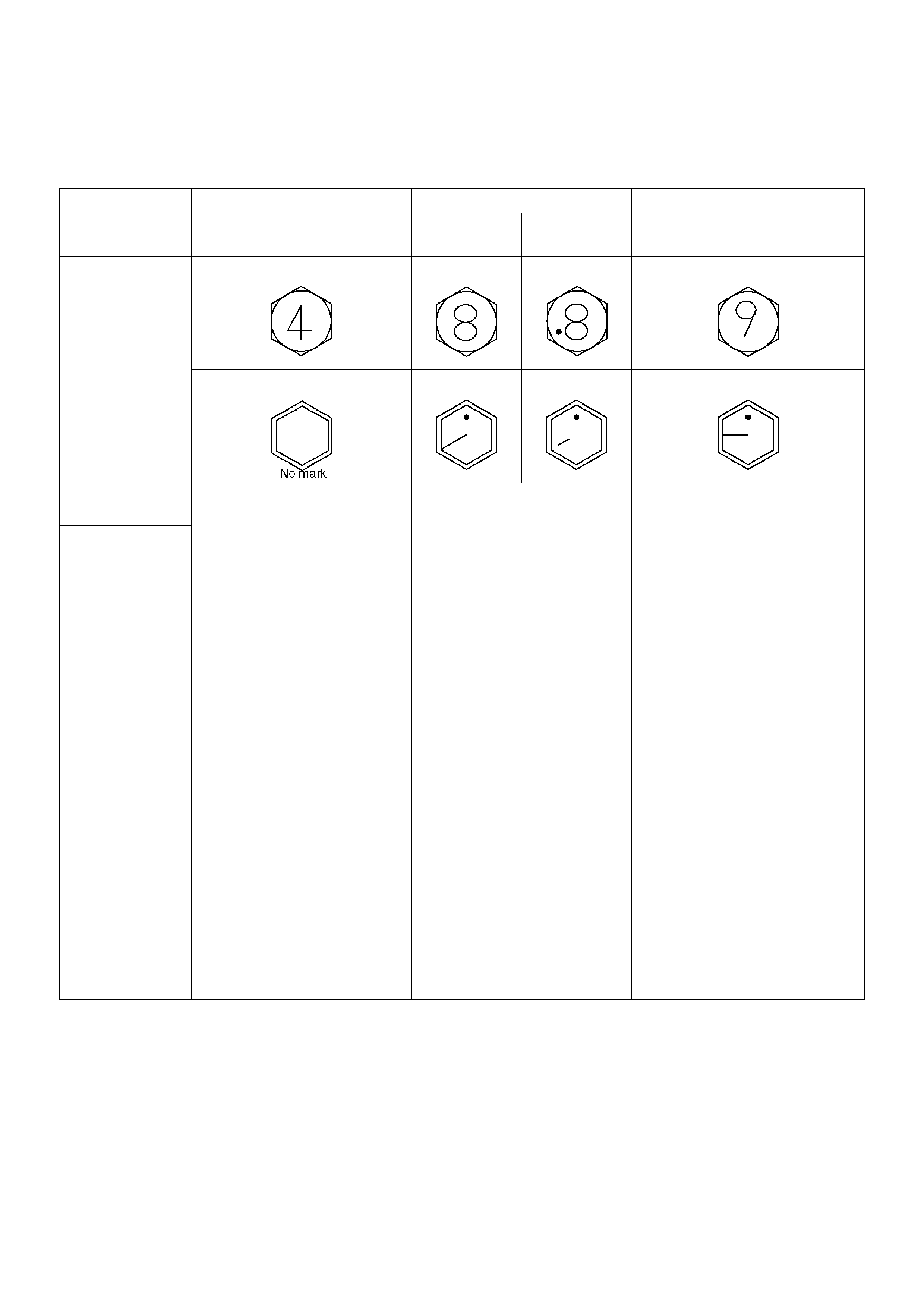

STANDARD BOLT TORQUE SPECIFICATIONS

NOTE: The torque values given in the following table should be applied where a particular torque is not specified.

The asterisk * indicates that the bolts are used for

female–threaded parts that are made of soft materials

such as castin g , etc.

1. Strength

Class 1. 4.8 1. 8.8 1. 9.8

1. Refined 1. Non-Refine

d

Bolt

Identification

Bolt Diameter ´

Pitch (mm)

2. M 6X1.0

3. M 8X1.25

4. M 10X1.25

5. * M10 X1.5

6. M12X1.25

7. * M12 X1.75

8. M14X1.5

9. * M14 X2.0

10. M16X1.5

11. * M16X2.0

12. M18X1.5

13. M20X1.5

14. M22X1.5

15. M24X2.0

16. 4 – 8 N·m (3 – 6 lb ft)

17. 8 – 18 N·m (6 – 13 lb ft)

18. 21 – 34 N·m (15 – 25 lb ft)

19. 20 – 33 N·m (14 – 25 lb ft)

20. 49 – 74 N·m (36 – 54 lb ft)

21. 45 – 69 N·m (33 – 51 lb ft)

22. 77 – 115 N·m (56 – 85 lb

ft)

23. 72 – 107 N·m (53 – 79 lb

ft)

24. 104 – 157 N·m (77 – 116

lb ft)

25. 100 – 149 N·m (74 – 110

lb ft)

26. 151 – 226 N· m (111 – 166

lb ft)

27. 206 – 310 N· m (152 – 229

lb ft)

28. 251 – 414 N· m (185 – 305

lb ft)

29. 359 – 539 N· m (265 – 398

lb ft)

30. 5 – 10 N·m (4 – 7 lb ft)

31. 12 – 23 N·m (9 – 17 lb ft)

32. 28 – 46 N·m (20 – 34 lb ft)

33. 28 – 45 N·m (20 – 33 lb ft)

34. 61 – 91 N·m (45 – 67 lb ft)

35. 57 – 84 N·m (42 – 62 lb ft)

36. 93 – 139 N· m (69 – 103 lb

ft)

37. 88 – 131 N·m (65 – 97 lb

ft)

38. 135 – 20 4 N·m (100 – 150

lb ft)

39. 130 – 194 N·m (95 – 143

lb ft)

40. 195 – 29 3 N·m (144 – 216

lb ft)

41. 270 – 40 5 N·m (199 – 299

lb ft)

42. 363 – 54 4 N·m (268 – 401

lb ft)

43. 431 – 711 N·m (318 – 524

lb ft)

44. –

45. 17 – 30 N·m (12 – 22 lb ft)

46. 37 – 63 N·m (27 – 46 lb ft)

47. 36 – 60 N·m (27 – 44 lb ft)

48. 76 – 114 N·m (56 – 84 lb ft)

49. 72 – 107 N·m (53 – 79 lb ft)

50. 114 – 171 N·m (84 – 126 lb

ft)

51. 107 – 160 N·m (79 – 118 lb

ft)

52. 160 – 240 N·m (118 – 177 lb

ft)

53. 153 – 230 N·m (113 – 169 lb

ft)

54. 230 – 345 N·m (169 – 255 lb

ft)

55. 317 – 476 N·m (234 – 351 lb

ft)

56. 425 – 637 N·m (313 – 469 lb

ft)

57. 554 – 831 N·m (409 – 613 lb

ft)

ABBREVIATIONS CHARTS

List of automotive abbreviations which may be used

in this ma nual

A — Ampere(s)

ABS — Antil ock Brake Sys te m

AC — A lternating C urrent

A/C — Air Conditioning

ACCEL — Accelerator

ACC — Accessory

ACL — A ir Cleaner

Adj — Adjust

A/F — Air Fuel Ratio

AIR — Secondary Air Injection Syste m

Alt — Altitude

AMP — Ampere(s)

ANT — Antenna

ASM — Assembly

A/T — A utomat ic Transmiss ion /Transaxle

ATDC — After Top Dead Center

ATF — Automatic Transmission Fluid

Auth — Authority

Auto — Automatic

BARO — Barometric Pressure

Bat — Batter y

B+ — Battery Positive Vo ltage

Bbl — Barrel

BHP — Brake Horsepowe r

BPT — Backpressure Transduc er

BTDC — Before Top Dead Center

° C — Degrees Celsius

CAC — Charge Air Cooler

Calif — California

cc — Cubic Centimeter

CID — Cubic Inch Displacement

CKP — Crankshaft Position

CL — Closed Loop

CLCC — Closed Loop Carburetor Control

CMP — Camshaft Position

CO — Carbon Monoxide

Coax — Coaxial

Conn — Connector

Conv — Converter

Crank — Crankshaf t

Cu. In. — Cubic Inch

CV — Constant Velo city

Cyl — Cylinder(s)

DI — Distributor Ignition

Diff — Differential

Dist — Distributor

DLC — Data Link Connector

DOHC — Double Overhead Camshaft

DTC — Diagnostic Trouble Code

DTM — Diagnostic Test Mode

DTT — Diag nostic Test Terminal

DVM — Digital Voltmeter (10 meg.)

DVOM — Digital Vol t Ohmmeter

EBCM — Electronic Brake Control Module

ECM — Engine Control Module

ECT — Engine Coolant Tempe rature

EEPROM — Electronically Erasable Programmable

Read Only Memory

EGR — Exhaust Gas Recirculation

EI — Electronic Ign ition

ETR — Electronically Tuned Receiver

EVAP — E vaporat ion Emission

Exh — Exhaust

° F — Degrees Fahrenheit

Fed — Federal (All States Except Calif.)

FF — Front Drive Front Engine

FL — Fusible Link

FLW — Fusib le Link Wire

FP — Fuel Pu mp

FRT — Fro nt

ft — Foot

FWD — Front Wheel Drive

4WD — Four Wheel Drive

4 x 4 — Four Wheel Drive

4 A/T — Four Sp eed Automa tic Transmission/Transaxle

Gal — Ga llon

GEN — Generat or

GND — Ground

Gov — Governor

g — Gram

Harn — Harness

HC — Hydrocarbons

HD — Heavy Duty

Hg — Hydrargyrum (Mercury)

HiAlt — High Altitude

HO2S — Heated Oxygen Sensor

HVAC — Heater–Vent–Air–Conditioning

IAC — Idle Air Con trol

IAT — In take Ai r Tem p era tu r e

IC — Integrated Circuit / Ignition Control

ID — Identification / Inside Diameter

IGN — Ignition

INJ — Injec tion

IP — Instrument Panel

IPC — Instrument Panel Cluster

Int — Intake

ISC — Idle Speed Control

J/B — Junction B lock

kg — Kilograms

km — Kilometers

km/h — Kilometer per Hour

kpa — Kilopascals

kV — Kilovolts (thousands of volts)

kW — Kilowatts

KS — Knock Sensor

L — Liter

lb ft — Foot Pounds

lb in — Inch Pounds

LF — Left Front

LH — Left Hand

LR — Left Rear

LS — Left Side

LWB — Lon g Wheel B ase

L–4 — In–Line Four Cylinde r Engine

MAF — Mass Air Flow

MAN — Manual

MAP — Manifold Absolute Pressure

Max — Maximum

MC — Mi xture Control

MFI — Mu ltiport Fuel Injection

MIL — Malfunction Indicator Lamp

Min — Minimum

mm — Millime ter

MPG — Miles Per Gallon

MPH — Miles Per Hour

M/T — Ma nual Transmission/Transaxle

MV — Millivo lt

N — Newtons

NA — Natural Aspirated

NC — Normally Closed

N·M — Newton Meters

NO — Normally Open

NOX — Nitrogen , Oxides of

OBD — On-Board Diagnostic

OD — Outside Diameter

O/D — Over Drive

OHC — Overhead Camshaft

OL — Open Loop

O2 — Oxygen

O2S — Oxygen Sensor

PAIR — Pulsed Secondary Air Injection System

P/B — Power Bra kes

PCM — Powertrain Control Module

PCV — Positive Crankcase Ventilation

PRESS — Pressure

PROM — P rogram mab le Read Only M emo ry

PNP — Park/Neutral Positi on

P/S — Power Steering

PSI — Pound s per Square Inch

PSP — Power Steer ing Pr e ssu re

Pt. — Pint

Pri — Primary

PWM — P ulse Width Modulate

Qt. — Quart

REF — Reference

RF — Right Front

RFI — Radio Frequency Interference

RH — Right Hand

RPM — Revolutions Pe r Minute

RPM Sensor — Engine Speed Sensor

RPO — Regular Production Option

RR — Right Rear

RS — Right Side

RTV — Room Temperature Vulcanizing

RWA L — Rear Whee l Antilock Brake

RWD — Rear Wheel Drive

SAE — Socie ty of Aut o mo tive Engineers

Sec — S ec ondary

SFI — S equential Multiport Fuel Inject ion

SI — System International

SIR — Supplemental Inflatable Restraint System

SOHC — Single Overhead Camshaft

Sol — Solenoid

SPEC — Specificati o n

Speedo — Speedometer

SRS — Supplemental Restraint System

ST — St art / Scan Tool

Sw — Switch

SWB — Short Wheel Base

SYN — Synchronize

Tach — Tac hom ete r

TB — Throttle Body

TBI — Throttl e Body Fuel Injection

TCC — Torque Converter Clutch

TCM — Transmission Control Mod ule

TDC — Top Dead Center

Term — Terminal

TEMP — Tem peratur e

TOD— Torque On Demand

TP — Throttle Position

TRANS — Transmission/Transaxle

TURBO — Turbocharger

TVRS — Televisio n & Radio Suppression

TVV — Th ermal Vacuum Valve

TWC — Three Way Cata l yt ic Converter

3 A/T — Three Speed Automatic Transmission/

Transaxle

2WD — Two Wheel Drive

4 x 2 — T wo Wheel Drive

U–jo int — U n iv er s al Join t

V — Volt ( s)

VAC — Vacuum

VIN — Vehi cle Identification Number

VRRRE — Vehicle Refrigerant Recovery and Recycling

Equipment

V–ref — ECM Reference V ol tage

VSS — Vehicle Speed Sensor

VSV — Vacuum Switch Valve

V–6 — Six Cylinder “V" Engine

V–8 — Eight Cylinder "V" Engine

W — Watt(s)

w/ — With

w/b — Wheel Base

w/o — Without

WOT — Wi de Open Th ro ttle