SECTION 0B - LUBRICATION AND SERVICING

Maintenance Schedule List

Maintenance Schedule

Extreme Operating Conditions

Recomm ended Fluids and Lubricants

Recomm ended Liq uid Gask et

Recomm ended Th read Loc king Ag ents

Maintenance Service Data

MAINTENANCE SCHEDULE LIST

NORMAL VEHICLE USE

The maintenance instructions in this Maintenance Schedule are based on the assumption that the vehicle will be used

as designe d:

1. to carry passengers and cargo wit hin the limitations specified on the tyre placard located on the inside of the glove

compartment doo r;

2. to be driven on reasonable road surfaces wit hin legal operating limit s;

3. to be driven on a daily basis, as a general rule, for at leas t several kilometers;

4. to be driven on unleaded fuel

Unusual or severe operating conditions wi ll require more frequent vehicle maintenance, as specified in the following

sections.

Techline

Techline

Techline

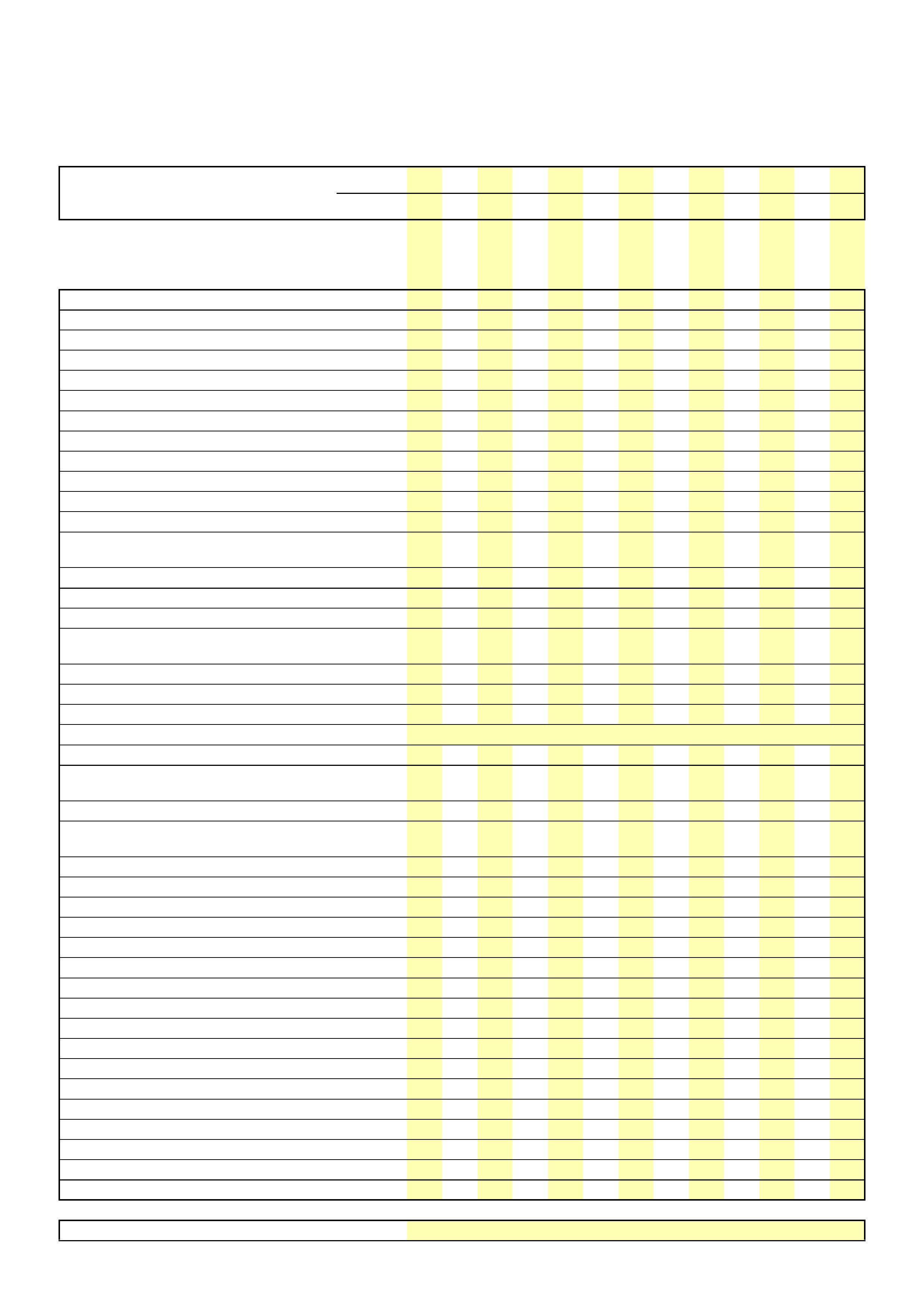

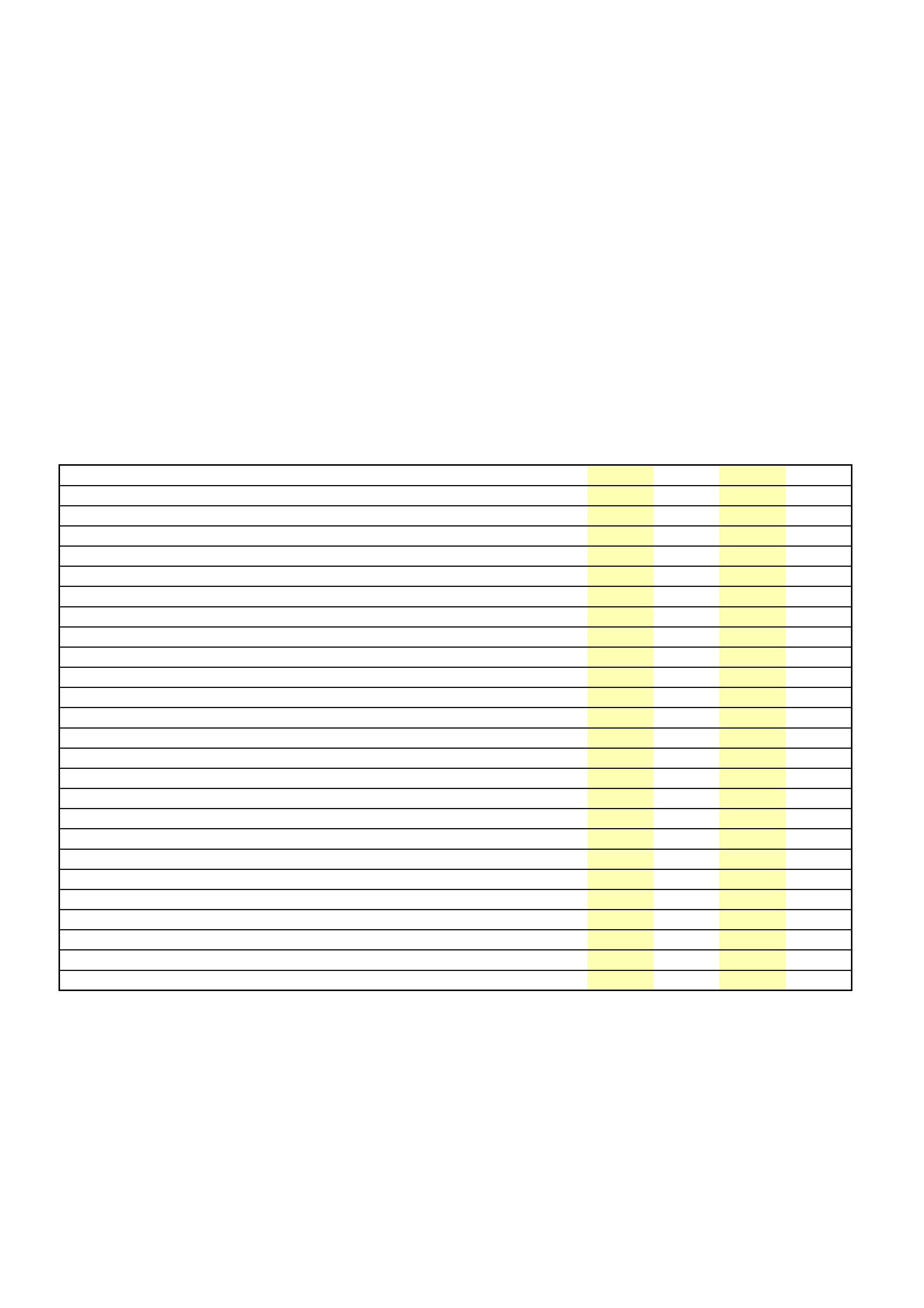

MAINTENANCE SCHEDULE

Use odome ter readings or years, whi c h ever

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or years .25 .5 11.522.533.544.555.56

UNDERBONNET

Engine oil - 6VD1, C22NE #RRRRRRRRRRRRR

Engine oil filter - 6VD1 #RRRRRR

Engine oil filter - C22NE #RRRRRRRRRRRRR

Engine oil - 4JB1T, 4JH1-TC #RRRRRRRRRRRRR

Engine oil filter - 4JB1T, 4JH1-TC #RRRRRR

Oil l eakage & contamin ati on IIIIIIIIIIIII

Flui d level s: power steeri ng, brak e, clutch,

washer, battery IIIIIIIIIIIII

Coolant Level IIIIIIIIIIRI I

Radiator cap and cooling system pressure

test I I I I I I

Timing Belt - C22NE R

Timing belt - 6VD1 Replace every 160, 000 km or 8 years

All hoses and pipes in t he engine compart-

ment for leaks and deterioration IIIIIIIIIIIII

Clean front of ra diator core and A/C con-

denser I I I I I I

Fuel filter RRRRRR

Air cleaner element # IIIIRI IIRI IIR

Pre-air cleaner #IIIIIIIIIIIII

Accessory-drive belt condition IIIIIIIIIIIII

Valve clearances - 6VD1 A

Valve clearances - 4JB1T, 4JH1- TC AAAAAAA

Spark plugs - 6VD1 R

Spark plugs - C22NE R R R

Oxygen Sensors Replace ever y 150,000 km or 7. 5 years

I: Inspect and correct or replace as necessary

R: Replace or change

T: Tighten to specified torque

L: Lubricate

A: Adjust

# : Under extreme conditions, more frequent maintenance is required. Refer to ‘Extreme Operating Conditions” in this Section.

Power steering fluid IIIIRI IIRI IIR

Use odome ter readi ngs or years, whi c h ev er

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or year s .25 .5 11.522.533.544.555.56

UNDER VEHICLE

Clut ch fl uid I R R R

Brake fluid I R R R

Manua l transmission oil #I I R I R I R

Automati c transmission fluid #IIIIIII

Transfer case fluid/oil #I I I I R I I

Universal j oints and spli nes for wear #IIIIIII

Universal j oints and sliding sleeve #LLLLLLLLLLLLL

Diffe r en t ia l gea r oil - fron t #I I I I R I I

Differential gear oil - rear I I R I R I R

Disc brake p ads and disc / dr um wear I I I I I I

Wheel nuts TTTTTTTTTTTTT

Front wheel bearing and locking hubs -

grease #R R

Front and rear hubs bearing for looseness IIIIIII

Vehicle ride height AAAAAAAAAAAAA

Tyre pressure and wheels for damage I I I I I I I I I I I I I

Tyre rotation Rotate as necessary

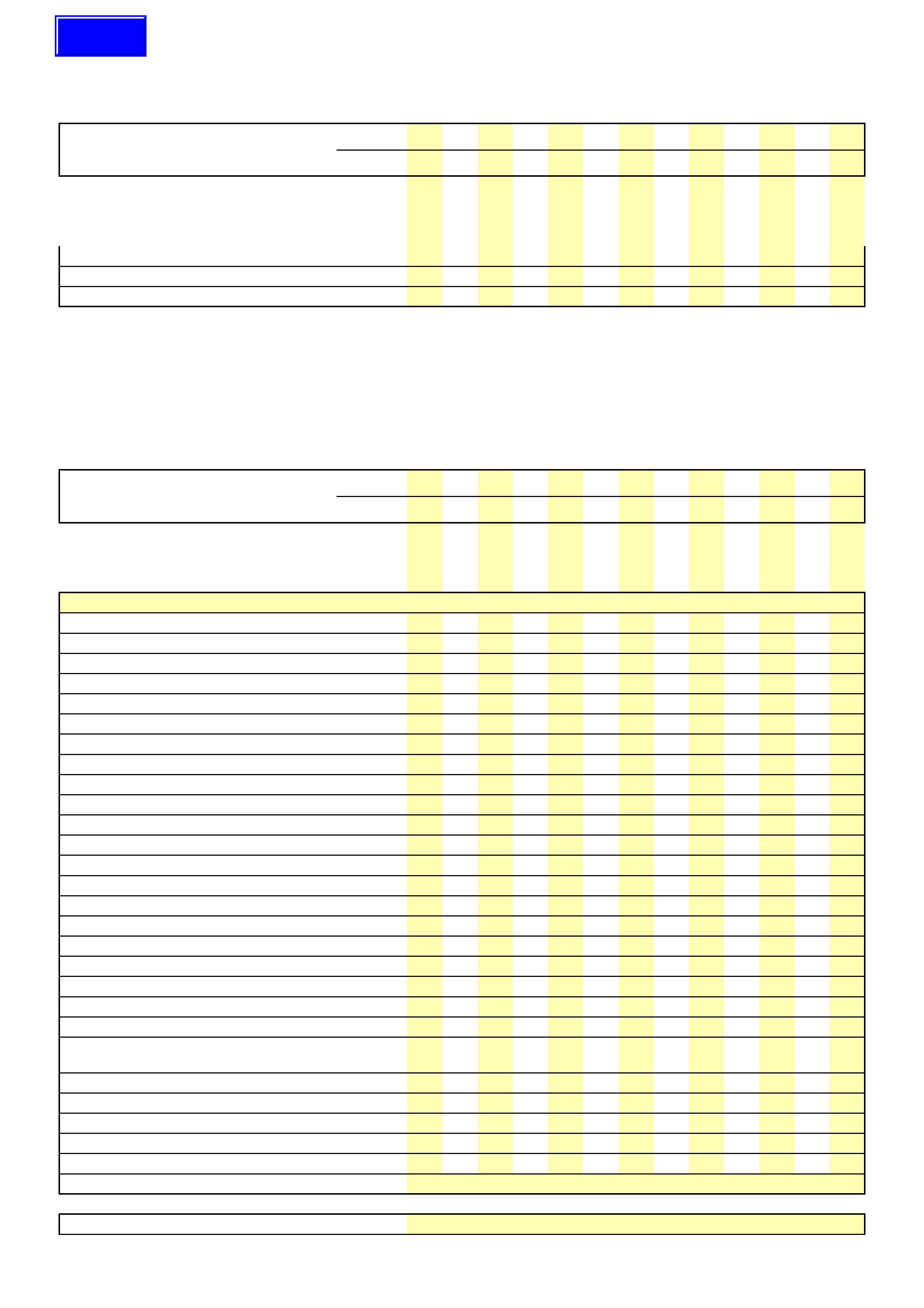

Use odome ter readi ngs or years, whi c h ev er

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or year s .25 .5 11.522.533.544.555.56

UNDERBONNET

Techline

I: Inspect and correct or replace as necessary

R: Replace or change

T: Tighten to specified torque

L: Lubricate

A: Adjust

# : Under extreme conditions, more frequent maintenance is required. Refer to ‘Extreme Operating Conditions” in this Section.

General underbody check: steering and

suspension components (inc. shock

absorbers, rubber bushes and boots, ball

joints and connections) park brake cables,

fuel sytem, exhaust system, brake system,

bolts, nuts, hoses, pipes and check for

leaks.

I I I I I I

Use odome ter readi ngs or years, whi c h ev er

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or year s .25 .5 11.522.533.544.555.56

INSIDE VEHICLE

Clutch pedal and fr ee trave l IIIIIIIIIIIII

Steering wheel play IIIIIIIIIIIII

Brake pedal and f ree travel IIIIIIIIIIIII

Park brake lever t ravel IIIIIII

Park brake ratchet for wear or dam age I I I I I I

ROAD TEST

Check vehicle on the road for braking,

steering, engine response,and transmis-

sion operation. Check cruise control, park

pawl operation, A/C performance and neu-

tral star t swi tch.

IIIIIIIIIIIII

Use odome ter readi ngs or years, whi c h ev er

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or year s .25 .5 11.522.533.544.555.56

Use odome ter readi ngs or years, whi c h ev er

occurs first.

x1000km 51020 30 40 50 60 70 80 90 100 110 120

or year s .25 .5 11.522.533.544.555.56

UNDER VEHICLE

SERVICE TI MES

Hours -1.91.7 1.0 2.2 1.0 1.7 1.9 2.2 1.0 3.3 1.0 2.2

- add for 4wd 0.4 0.4 0.2

- add for C22NE 0.5 0.7 0.5 0.7 0.7

- add for 4JB1T, 4JH1TC 0.5 0.7 0.5 0.5 0.7 0.4 0.7

- add for 6VD1 3.4

EXTREME OPERATING CONDITIONS

If the vehicle operates under any of the extreme conditions listed below, it is recommended that some items be

serviced more frequently than the intervals specified in the maintenance plan.

The extra services listed below need only be carried out if the vehicle operates continuosly under the conditions

specified.

If the vehicle is operated un der any of these conditions on a one-off basis, e.g. a holiday trip, then the extra service

should only be applied for that period of time.

As a guide, if operating under any of these extreme conditions for a period of one month or 1500k m, then the vehicle

would qualify for additional services.

A: Repeated short trips

B: Driving on rough roads

C: Driving on dust y roads

D: Driving in extremely cold weather and/or on salted roads.

Change engine oil every 5000km ACD

Change oil filter every 5000k m (exc. 6VD1) ACD

Change oil filter every 10000km - 6VD1 ACD

Change air cleaner element every 5000km C

Inspect air cleaner element every 2500km (Diesel) CD

Inspect pre-cleaner weekly C

Inspect steering system f or looseness and damage every 5000km B C

Inspect universal joints and sleeve for wear every 5000km B C

Change manua l transm ission and transfer case oil every 5000km B C

Change auto trans fluid and strainer every 40000 ABCD

Replace front wheel bearing and locking hub grease every 10000km B C

Change diff erential oil ev ery 20000km B C

Inspect brake pads and linings every 10000km ABC

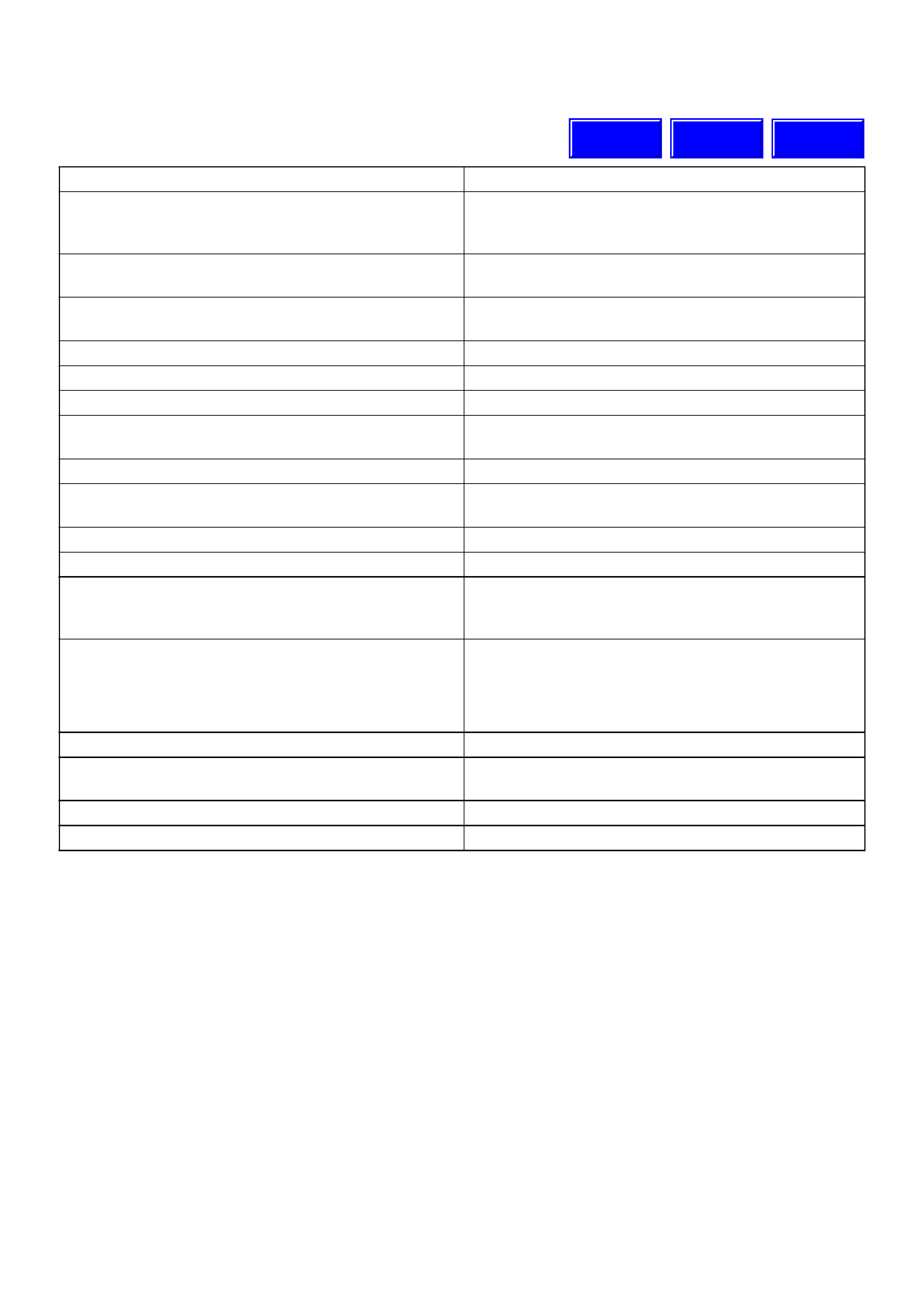

RECOMMENDED FLUIDS AND LUBRICANTS

B00RW003

USAGE FLUID/LUBRICANT

Engine Oil - C22NE, 6VD1

Normal use

Prolonge d use in snow areas API SG or SH Engine oil with a viscosity of 20W/50

API SG or SH Engine oil with a viscosity of 15W/40

Engine Oil - 4JB1T, 4JH1-TC API Minimum CG-4 rating (ACEA B1 or B3), with a

viscocity of 10W/30 or 15W/ 40

Engine Coolant 50% water and 50% coolant conforming to Holden

Sp ecific ati on HN2217 .

Brake System Heavy Duty Brake Fluid DOT-3, SAE Spe c J1703.

Power S teering System DEXRON® -III Automatic trans mission fluid.

Automatic Transmission DEXRON® -III Automatic transmission fluid.

MUA5C Type Manual Transmission - (6VD1, 4JB1T,

4JH1-TC) Same oil as engine or 5W/30 synthetic engine oil or gear

oil 75W/85

MUA5 S Type Ma nual Transmission (C22NE) Same oil as engine or 5W/30 synthetic engine oil

T ransfer case Same oil as engine or 5W/30 synthetic engine oil or gear

oil 75W/85

Front Axle API-GL5 85W/140 Gear Oil

Shift On the Fly (SO F) System API-GL5 85W/140 Gear Oil

Rear Axle - Standard Differential

Rear Axle - Limited Slip Differential API-GL5 85W/140 Gear Oil

API-GL5 85W/140 LSD Gear Oil + one bottle additive

pa rt number 1052358

Clutch System

Pivot points & Clutc h fork joint NLGI No.2 Lithium Grease wit h 10% Molydenum

Disulphide

Master cylinder Heavy Duty Brake Fluid DOT-3, SAE Spec J1703.

Parking brake cables Multipurpose grease

Door hinge pins, check straps, fuel door & hood hinges,

hood catch, seat adjusters NLGI No. 2 Lithium Grease with 9% Zinc Oxide

Windshield Washer Washe r fluid & water

Door and ignition key lock cylinders Powdered Graphite - Do Not Oil

Techline

Techline

Techline

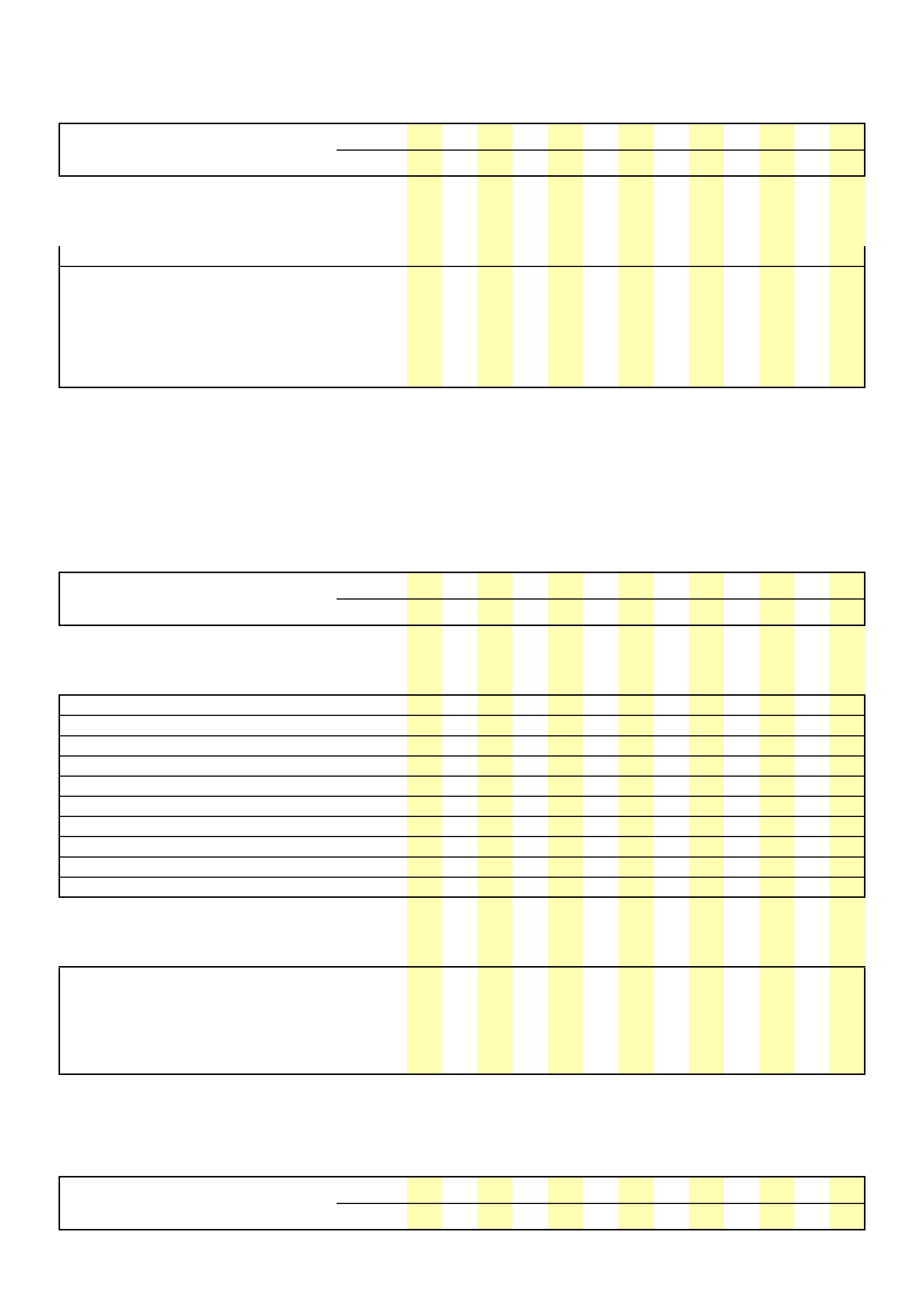

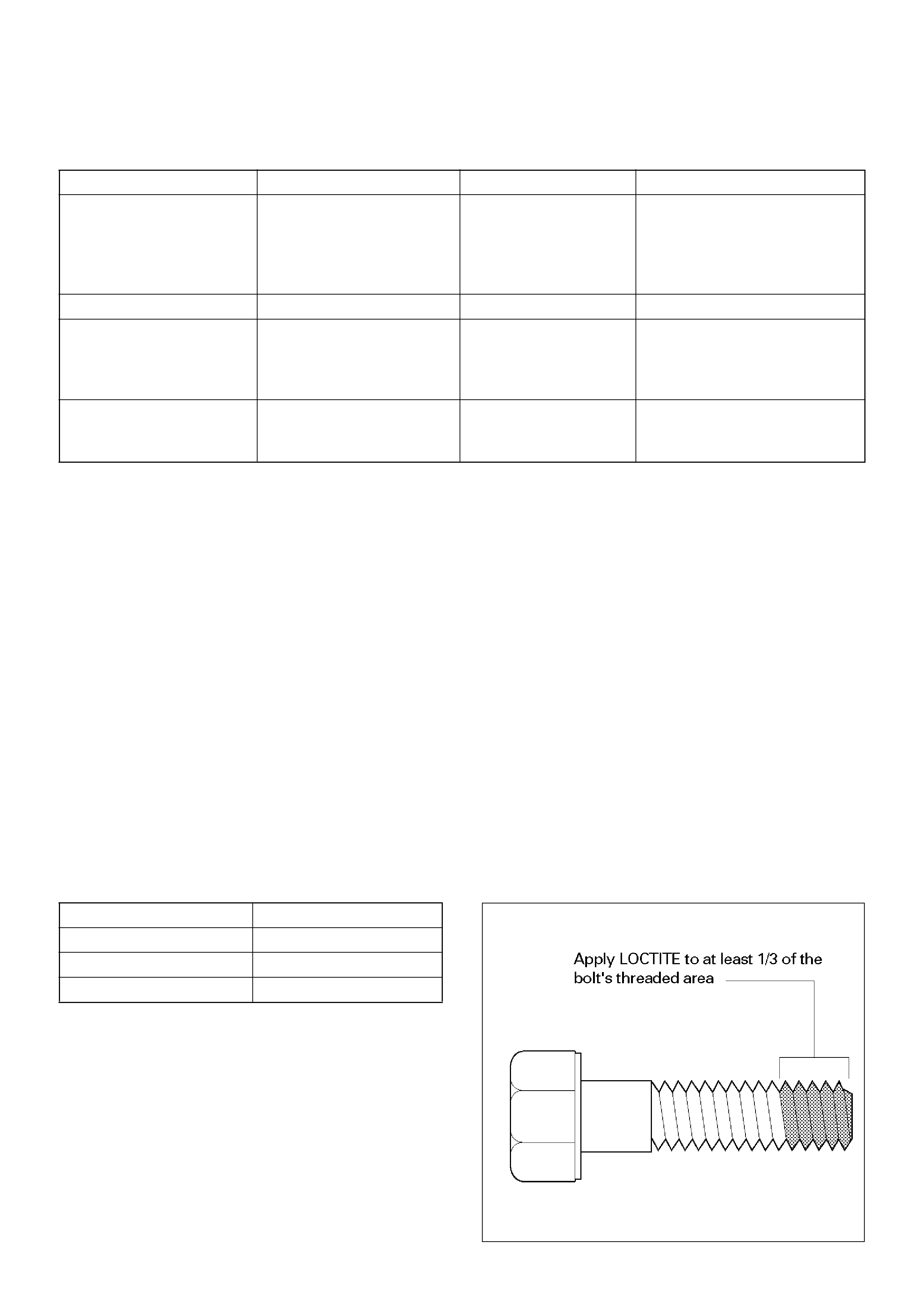

RECOMMENDED LIQUID GASKET

NOTE:

1. It is very important that the liquid gaskets listed

above or their exact equivalent be used on the

vehicle.

2. Be careful to use the specified amount of liquid

gasket.

3. Follow the manufacturer's ins tructions at all times.

4. Be absolutely sure to remove all lubricants and

moisture from the connecting surfaces before

applying the liquid gasket.

5. The connecti ng surfaces must be perfectly dry.

6. Do not apply LOCTITE 17430, LOCTITE 515 and

LOCTITE 518 bet ween two metal surfaces having a

clearance of greater than 0.25 mm (0.01 in). Poor

adhes ion will r e s ult .

* RTV: Room Temperature Vulcanizer

RECOMMENDED THREAD LOCKING

AGENTS

Ap pl icatio n Steps

1. Completely remove all lubricant and moisture from

the bolts and the female-threaded surfaces of the

parts to be joined.

2. The surfaces must be perfectly dry.

3. A pply LOCT ITE to the bolts.

4. Tighten the bolts to t he specified torque.

5. After tightening, be sure to keep the bolts free from

vibration and torque for at least an hour until

LOCTITE hardens.

Type B rand Nam e Manufacturer Remark s

RTV*

Silicon Base Three B ond 1207B

Three B ond 1207C

Three B ond 1215

Three B ond 1280

Three B ond 1281

Three Bond

Three Bond

Three Bond

Three Bond

Three Bond

For Engine Repairs

For A x le Case

Repairs T/M

Repairs T/M

Water Base Three B ond 1141E Three Bond For Engine Repairs

Solvent Three B ond 1104

Belc o Bond 4

Belc o Bond 401

Belc o Bond 402

Three Bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobi c LOCTI TE 515

LOCTITE 518

LOCTITE 17430

Loctite

Loctite

Loctite

All

LOCTITE Type LOC TITE Color

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 271 Red

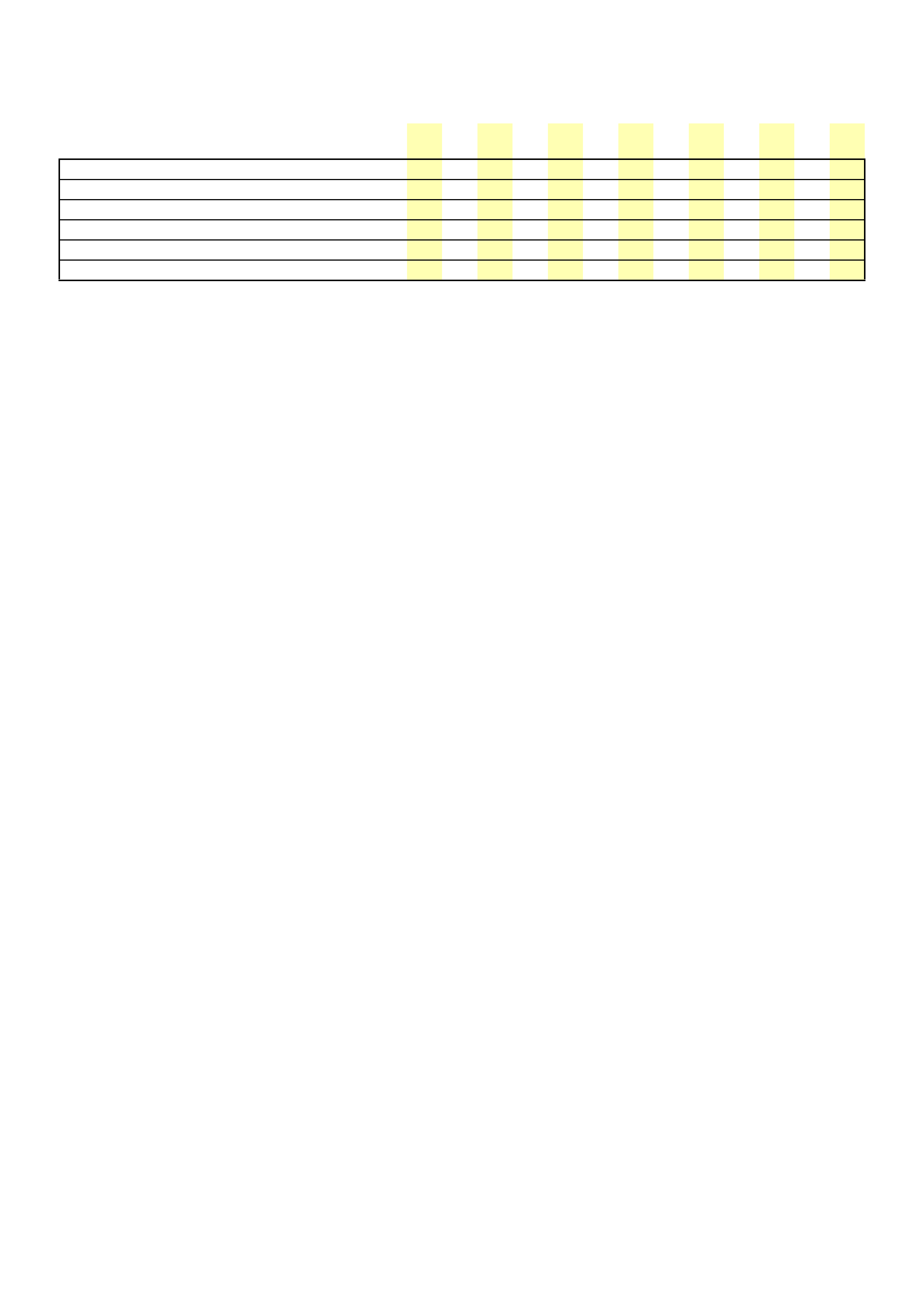

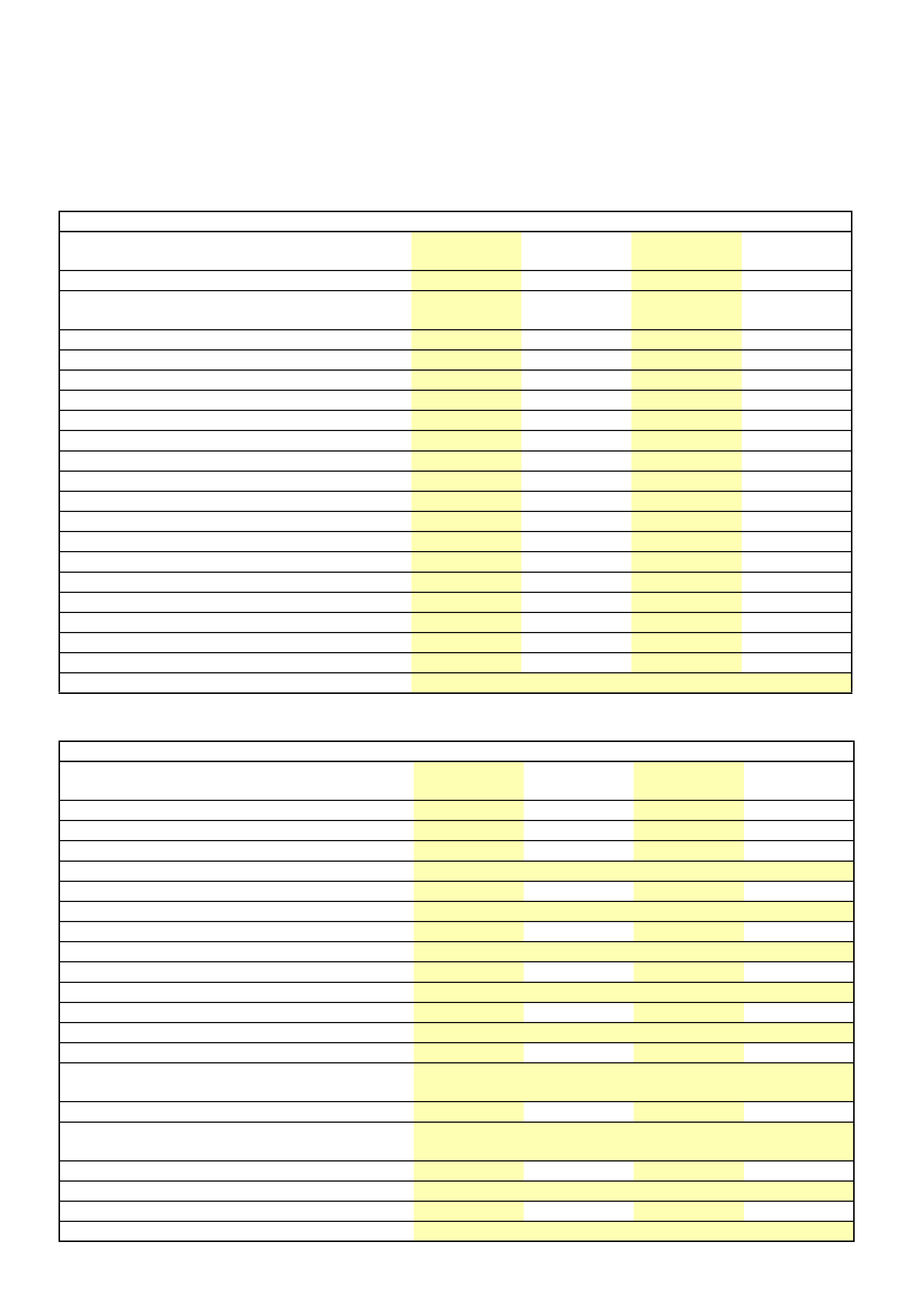

MAINTENANCE SERVICE DATA

.

APPROXIMATE CAPACITIES (LITRES) C22NE 6VD1 4JB1T 4JH1-TC

Engine Oil Capacity - w/filter 4.5 5.3 6.5 6.5 (4x2)

7.3(4x4)

Coolant capacity 6.9 11.2 (Man.)

11.0 (Auto) 9.5 9.9

Manual Transmission 2.95 2.95 2.95 2.95

Automatic Transmission —8.6 —8.7

Transfer Case —1.45 1.45 1.45

Manual Steering 0.4 —0.4 —

Power S teeri ng —1.0 1.0 1.0

Front Axle —1.4 1.4 1.4

Rear Axle 1.8 1.8 1.8 1.8

Shift On the Fly System —0.12 0.12 0.12

Air con ditioning syst e m 150cc Zexel -1 00PG oil

Service Data and Specifications C22NE 6VD1 4JB1T 4JH1-TC

Valve Clearance - Inlet (mm)

Valve Clearance - Exhaust (mm) —

—0.28 ± 0.05

0.30 ± 0.05 0.40

0.40 0.40

0.40

Spark Plug Gap (mm) 1.0- 1.1 1.0 - 1.1 — —

Clutch Pedal Free-play 5 - 15mm

Brake Pedal Free-play 6 - 10mm

Park Brake Lever Free-travel 7 - 10 notches

Toe-in 2.0 ± 2.0m m

Caster 30’ ± 60’

Camber 1° 50’ ± 45’(2WD)

2° 10’ ± 45’(4WD)

T ri m Height 56mm (2WD exc. 6VD 1)

130mm (4WD inc. all 6VD1)

Wheel nut torque 118 Nm

Tyre Pressure Refer Tyre Placard