SECTION 1C - CAB

SERVICING

WINDSHIELD AND REAR WINDOW GLASSES

GENERAL DESCRIPTION

REMOVAL AND INSTALLATION

SLIDING REAR WINDOW ASSEMBLY

DISASSEMBLY

REASSEMBLY

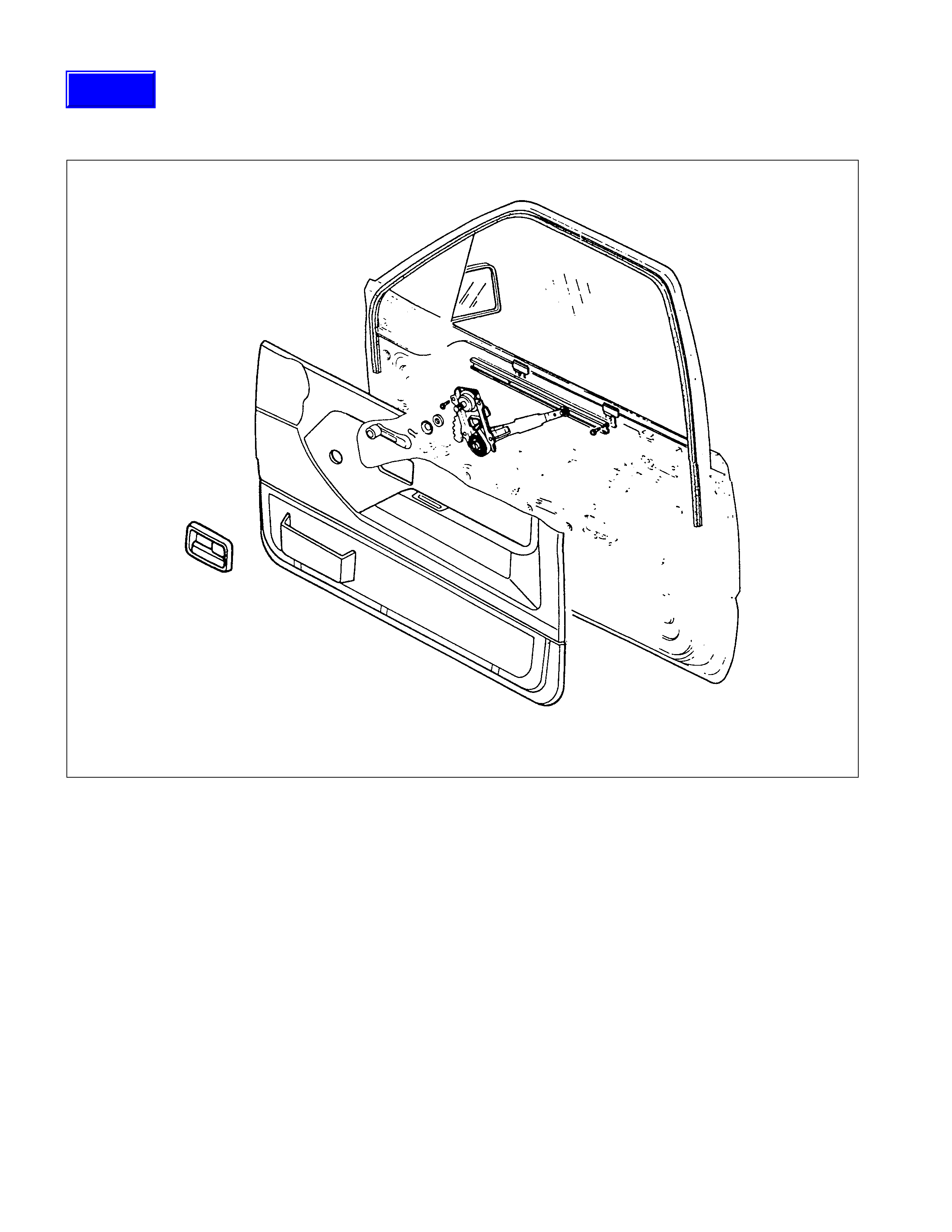

DOORS

GENERAL DESCRIPTION

REMOVAL AND INSTALLATION

DISASSEMBLY

DISASSEMBLY AND REASSEMBLY

ADJUSTMENT (FRONT AND REAR)

REASSEMBLY

ADJUSTMENT (FRONT AND REAR)

INSTRUMENT PANEL

REMOVAL

INSTALLATION

CONSOLE BOX

REMOVAL AND INSTALLATION (4X4 S MODEL)

REMOVAL AND INSTALLATION (4X4 & 4X2 LS MODEL)

HEAD LINING

GENERAL DESCRIPTION

REMOVAL AND INSTALLATION

Techline

Techline

FUEL FILLER LID OPENER LEVER/CABLE

REMOVAL (DOUBLE CAB)

REMOVAL (SPACE CAB)

REMOVAL (SINGLE CAB)

INSTALLATION (DOUBLE CAB)

INSTALLATION (SPACE CAB)

INSTALLATION (SINGLE CAB)

QUARTE R GLASS (SPACE CAB)

REMOVAL AND INSTALLATION

FRONT SEAT

REMOVAL AND INSTALLATION

REAR SEAT

REMOVAL AND INSTALLATION

FRONT SEAT BELT

REMOVAL AND INSTALLATION

REAR SEAT BELT

REMOVAL AND INSTALLATION

SERVICING

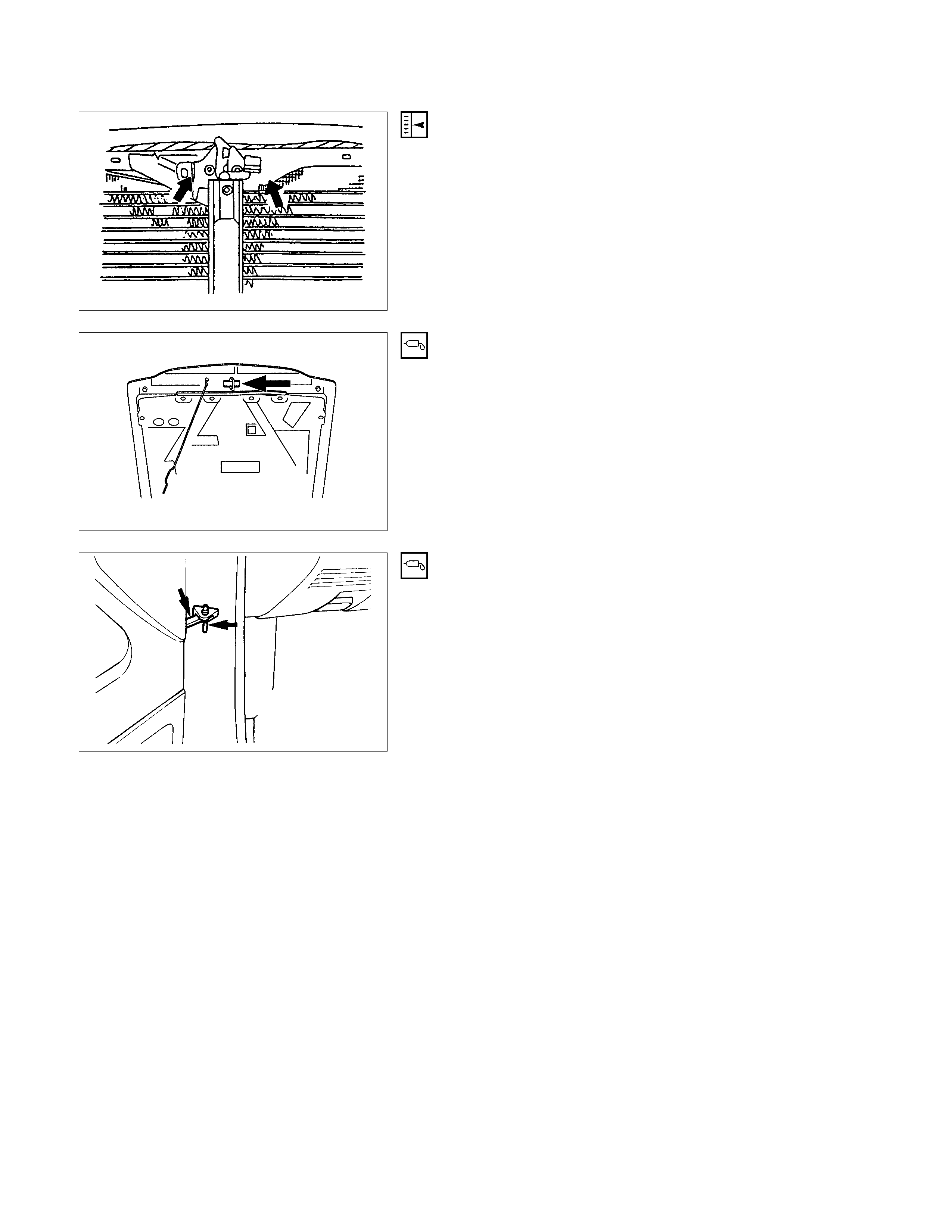

ENGINE HOOD LOCK

Align the engine hood lock with the installation holes.

ENGINE HOOD STRIKER

Apply a light coat of grease to the striker.

DOOR CHECKER ARM AND PI N

Apply a light coat of grease to the checker arm and pin.

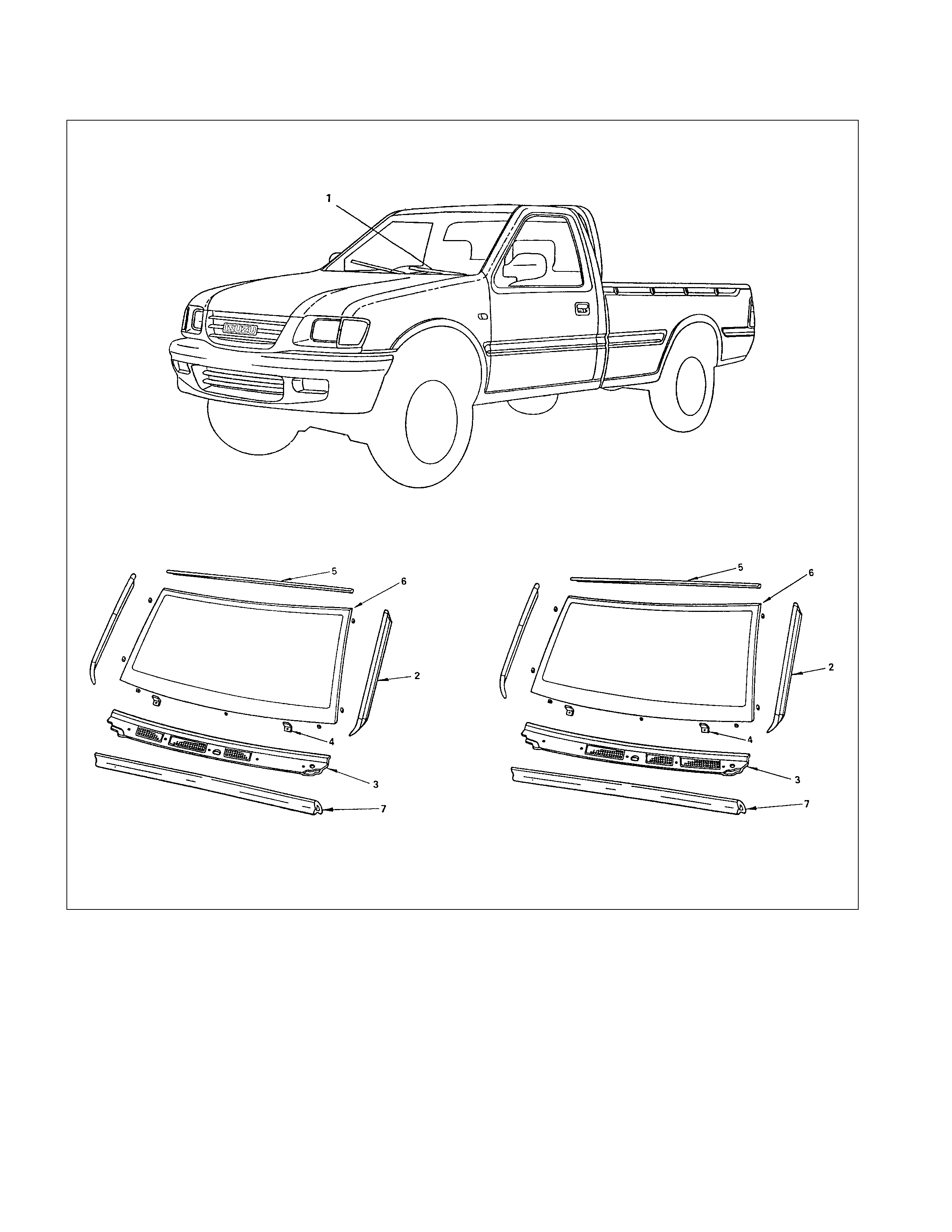

WINDSHIELD AND REAR WINDOW GLASSES

GENERAL DESCRIPTION

This vehicle uses two types of safety glass: (1) laminated safety plate, for the windshield, and (2) solid tempered safety

plate, for the rear window glass.

The windshield glass is one-piece and is directly retained in the windshield opening by the adhesive.

When replacing a cracked windshield glass, it is very important that the cause of the glass breakage is determined and

the condition corrected before a new glass is installed. Otherwise, it is possible that a small obstruction or high spot

somewhere around the windshield opening will continue to crack or break the newly installed windshield. This is

especially true when the strain on the glass caused by this obstruction is increased by such conditions as wind

pressures, extremes of temperature, motion of the vehicle, etc. The procedure for removal of the windshield applies to

the complete windshield assembly.

WINDSHIELD GLASS REAR WINDOW GLASS

Techline

REMOVAL AND INSTALLATION

For RHD model For LHD model

REMOVAL STEPS

1. Wiper arm assembly

2. Side moulding

3. Vent cowl cover

4. Windshield stopper

5. Upper moulding

▲6. Windshield glass

7. Engine hood rear seal

INSTALLATION STEPS

▲7. Engine hood rear seal

▲6. Windshield glass

▲5. Upper moulding

▲4. Windshield stopper

3. Vent cowl cover

▲2. Side moulding

1. Wiper arm assembly

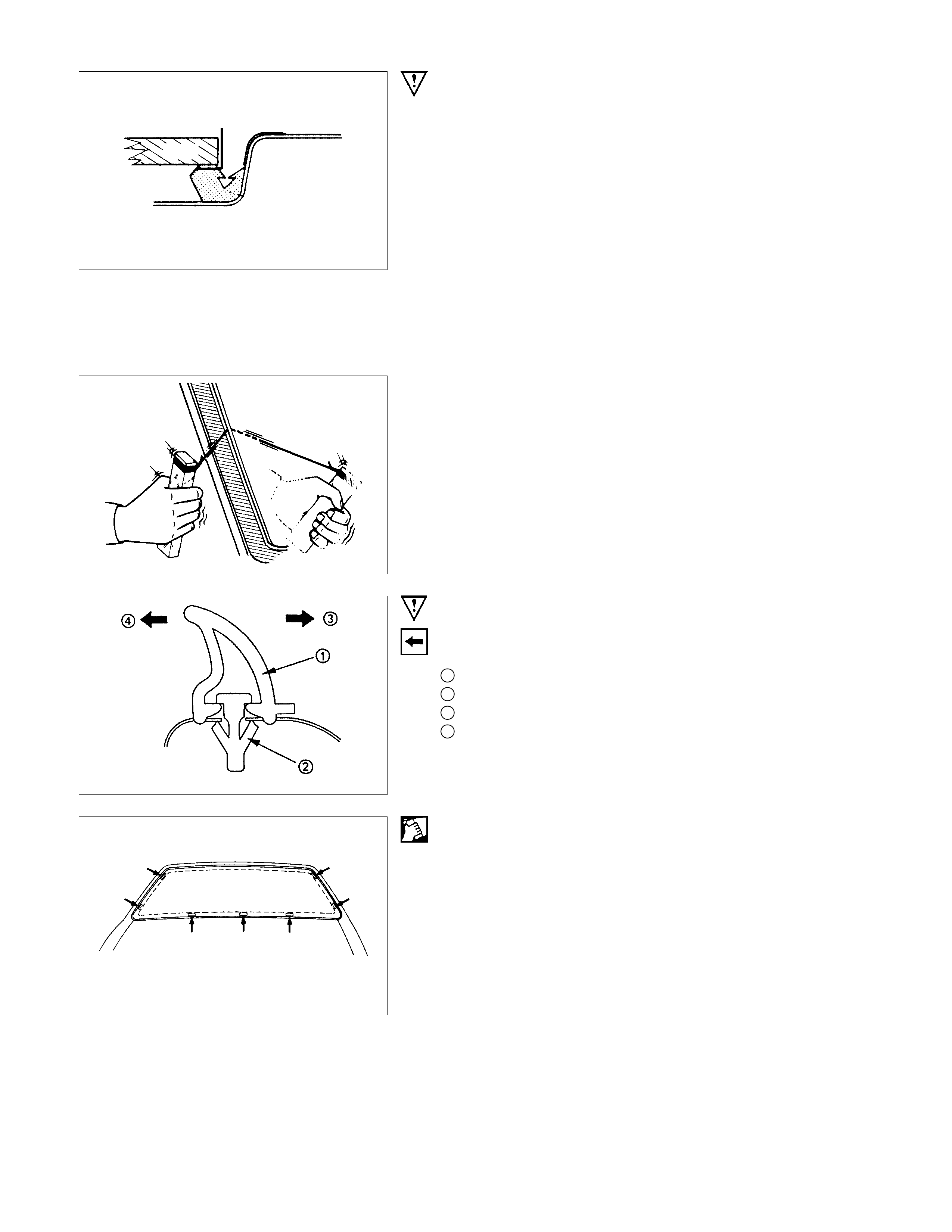

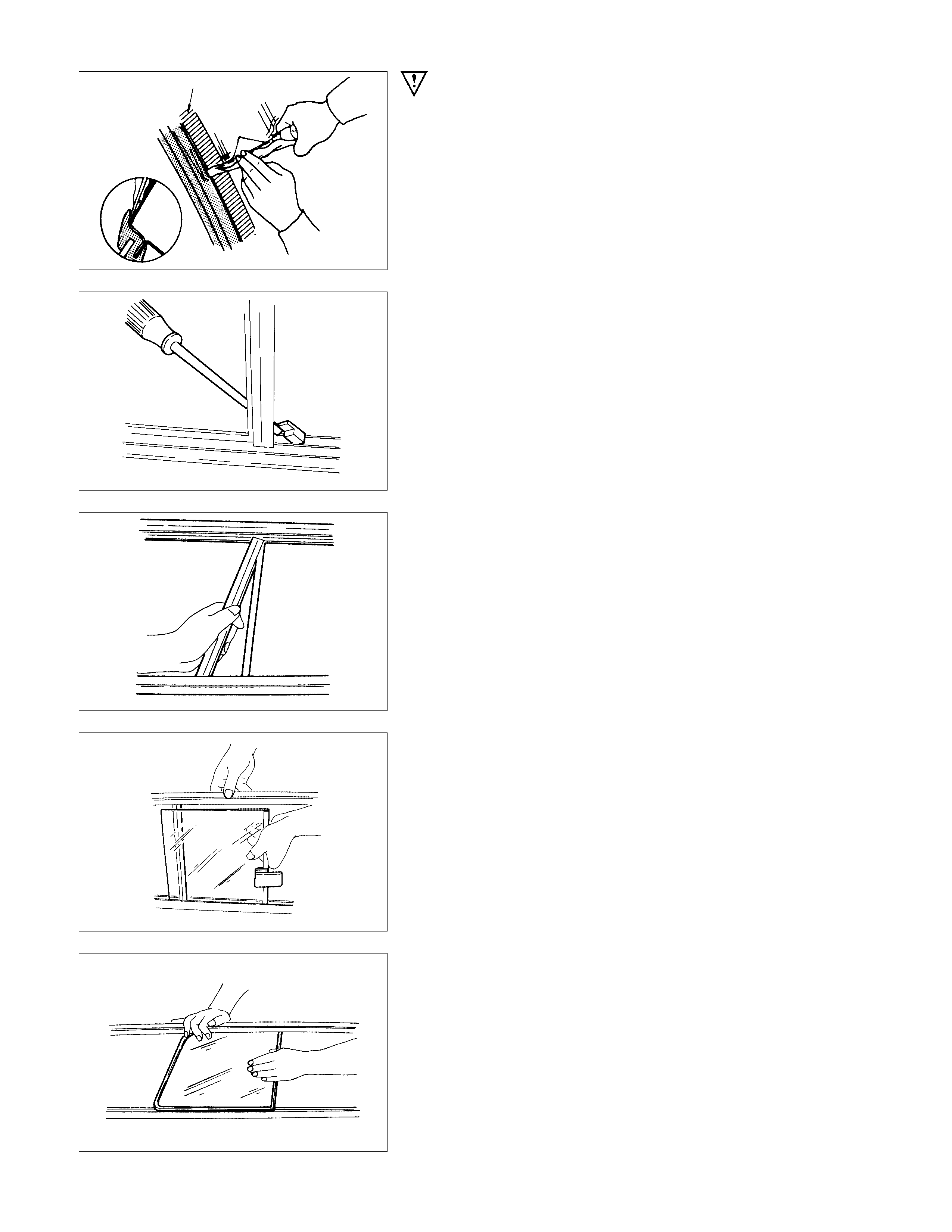

IMPORTANT OPERATION - REMOVAL

6. Windshield Glass

Remove the windshield glass, carefully following the steps

listed below :

1) Use a knife to cut through part of the adhesive caulking

material.

2) Secure one end of a piece of steel piano wire (0.02 inches

in diameter) to a piece of wood that can serve as a handle.

3) Use a pair of needle nose pliers to insert the other end o

f

the piano wire through the adhesive caulk ing m aterial at the

edge of the windshield glass.

4) Secure the other end of the piano wire to another piece o

f

wood.

5) With the aid of an assistant, carefully move the piano wire

with a sawing motion to cut through the adhesive caulking

material around the entire circumference of the windshield

glass.

6) Lift the windshield from the body.

7) Clean any remaining adhesive caulking material from the

area of the body, which holds the windshield.

8) Use a soft rag and unleaded gasoline to wipe off any

adhesive remaining on the windshield glass.

IMPORTANT OPERATIONS - INSTALLATION

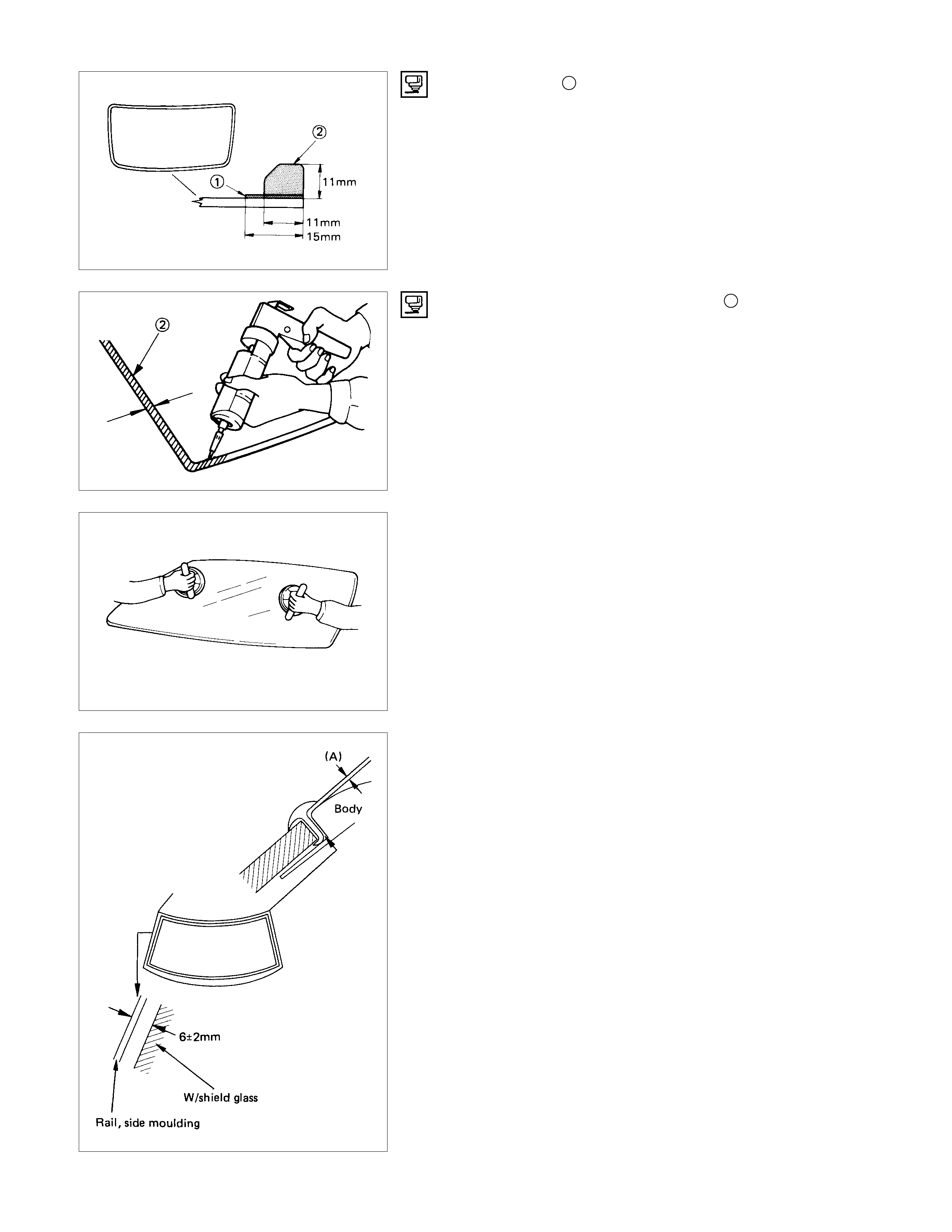

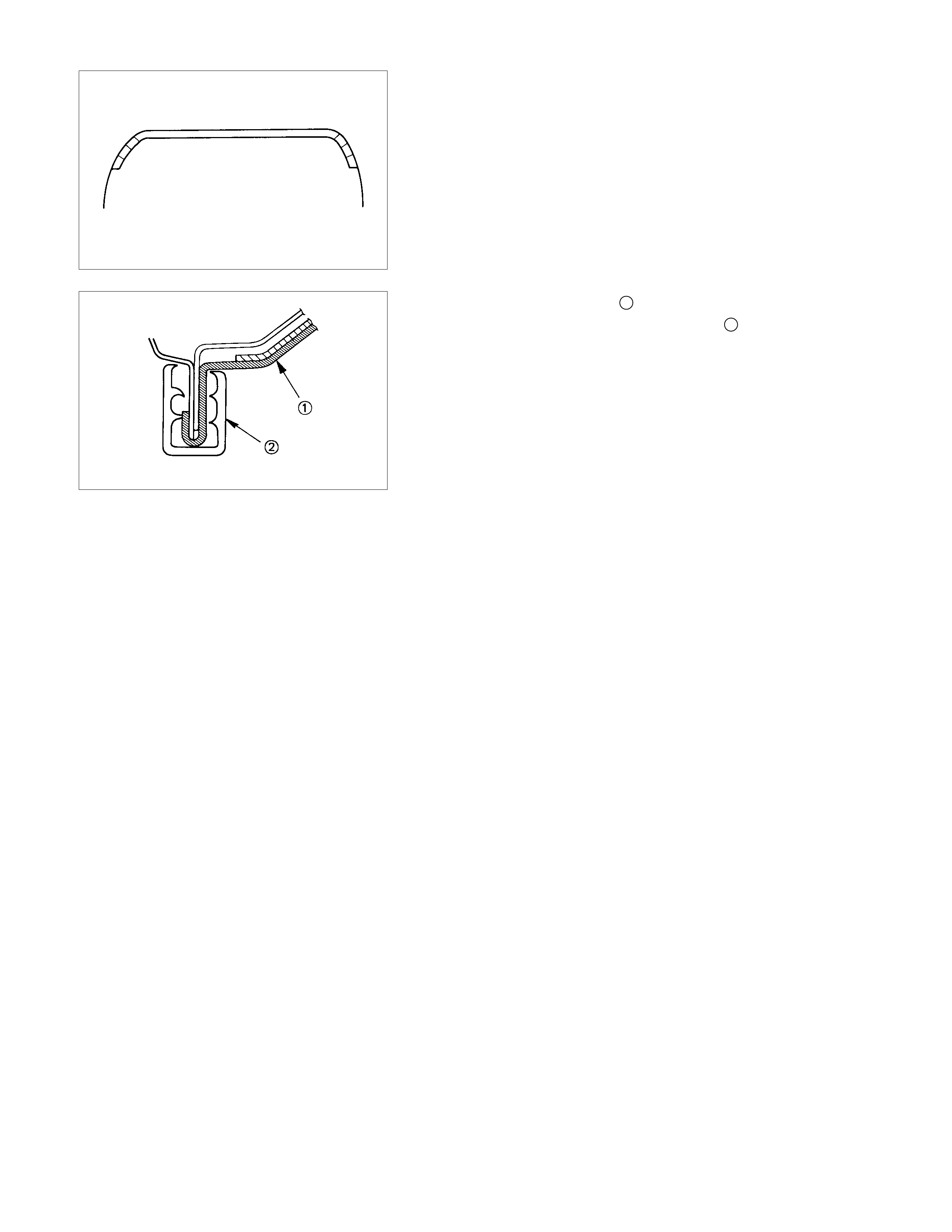

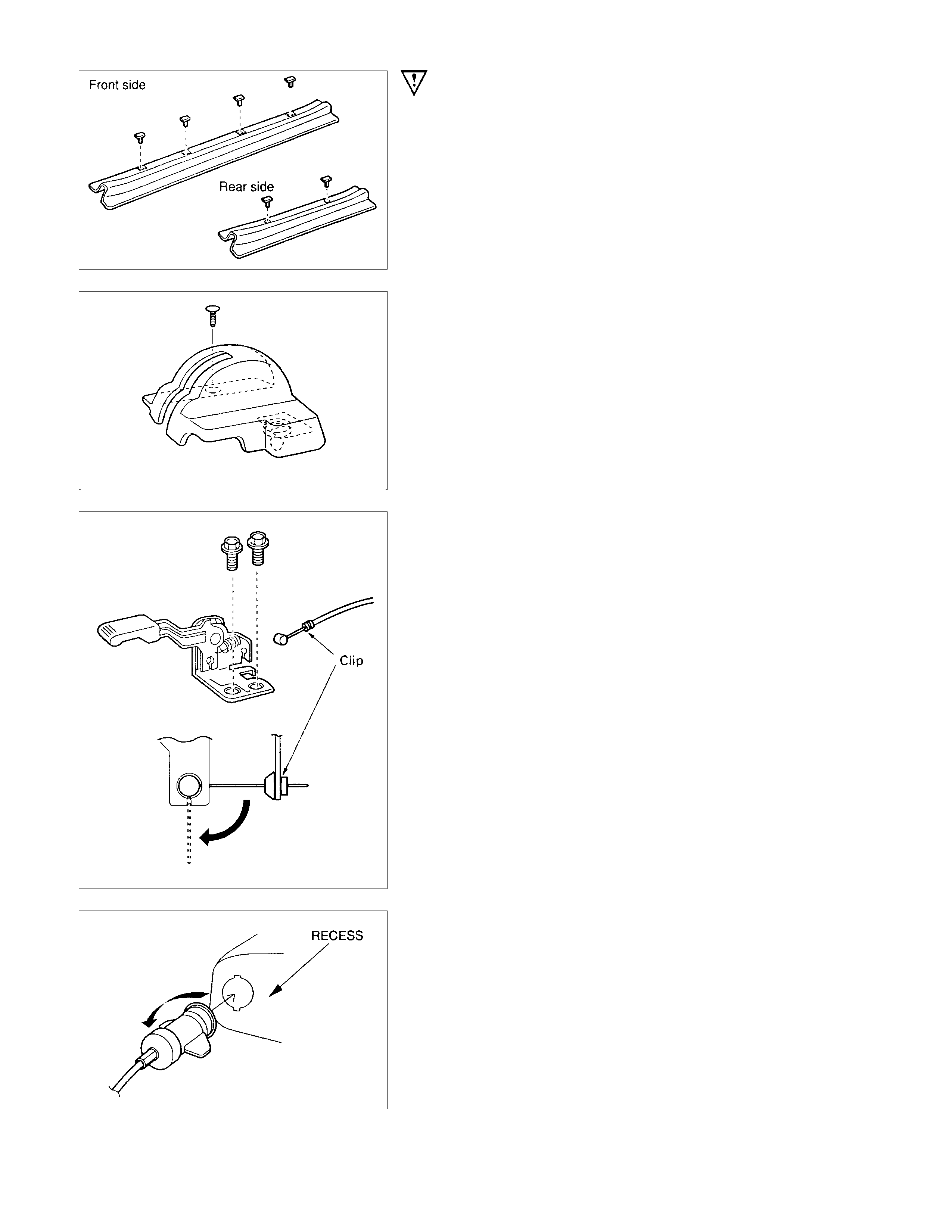

7. Engine Hood Rear Seal

Install the engine hood rear seal as shown in the illustration.

1 : Seal

2 : Clip

3 : Rear (windshield glass side)

4 : Front

6. Windshield Glass

1) Clean the windshield glass bonding surface.

2) Use a soft rag and unleaded gasoline to wipe off any

adhesive remaining on the body.

3) Mount the body window glass as shown in the illustration.

Attach spacers at seven (7) locations.

4) Apply primer 1 #435-95 or equivalent to the body side

bonding surface. The primer should extend 25 mm (1 in.).

Apply primer #435-40 or equivalent to the windshield glass

side bonding surface.

The primer should extend 15 mm (0.6 in.) from end of the

glass.

Apply the window glass sealing adhesive 2.

If you are using an air gun, air pressure should be maintained

at 147 - 294 kPa.

Note :

Open time (1 min. or more) should be set after application

of the primer.

Bonding shall be done within 5 minutes after the sealer

has been applied.

Adjust the setting of the windshield glass with suction discs.

The centre of the windshield glass should be in alignment with

the center of the windshield glass opening.

The clearance between body and upper moulding should be

within 0.5 mm (A).

Both of the clearance for RH and LH should be same. (6 mm ±

2 mm)

Note:

It is a good idea to perform the windshield installation

procedure from beginning to end without pausing. If you

allow time to elapse between steps, excessive amounts of

adhesive may be extruded from around the windshield.

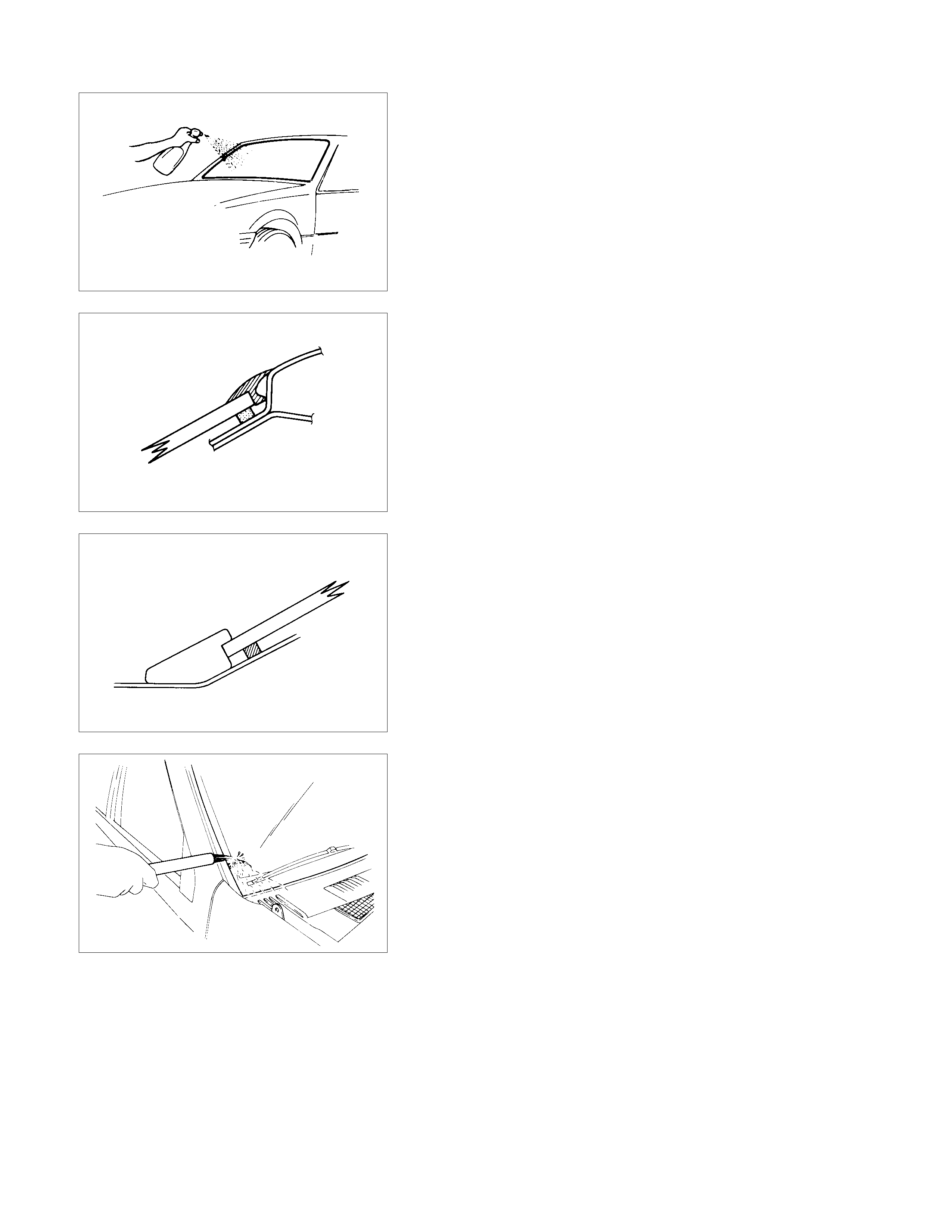

5. Upper Moulding

1) Before installing the windshield moulding (at the upper part

of the windshield), spray hot water at a temperature o

f

about 140°F (60°C) onto the windshield glass and the

adhesive. This will cause curing.

2) Install the upper moulding as soon as hot water has been

applied. Using a roller push moulding in until it bottoms.

4. Windshield Stopper

Do this immediately after completing the gap adjustment.

2. Side Moulding

Use unleaded gasoline and a soft cloth to wipe away any

excess adhesive.

Cure the bonding at a temperature of 68° - 86°F (20 ° - 30°C)

for twenty-four hours.

Check that the windshield does not leak water.

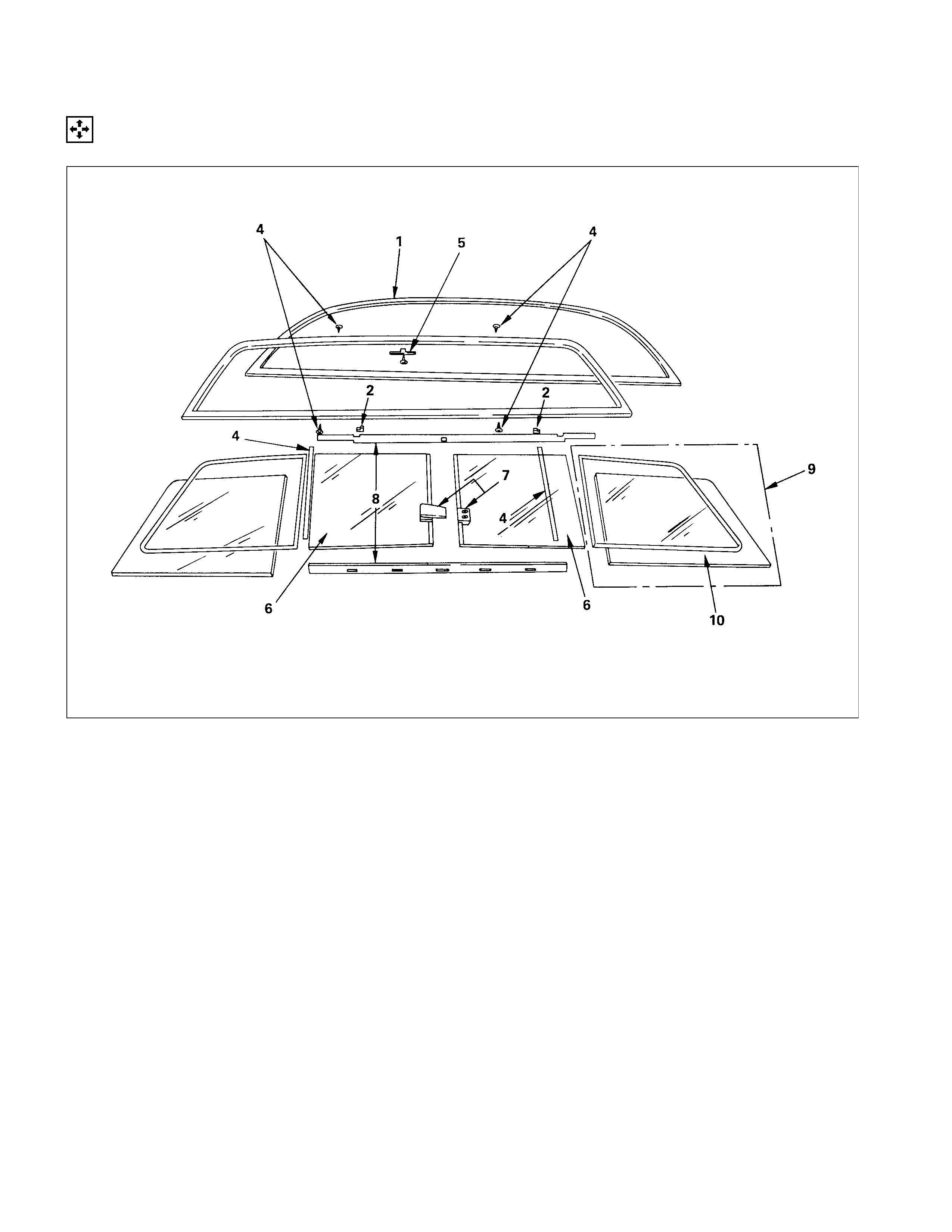

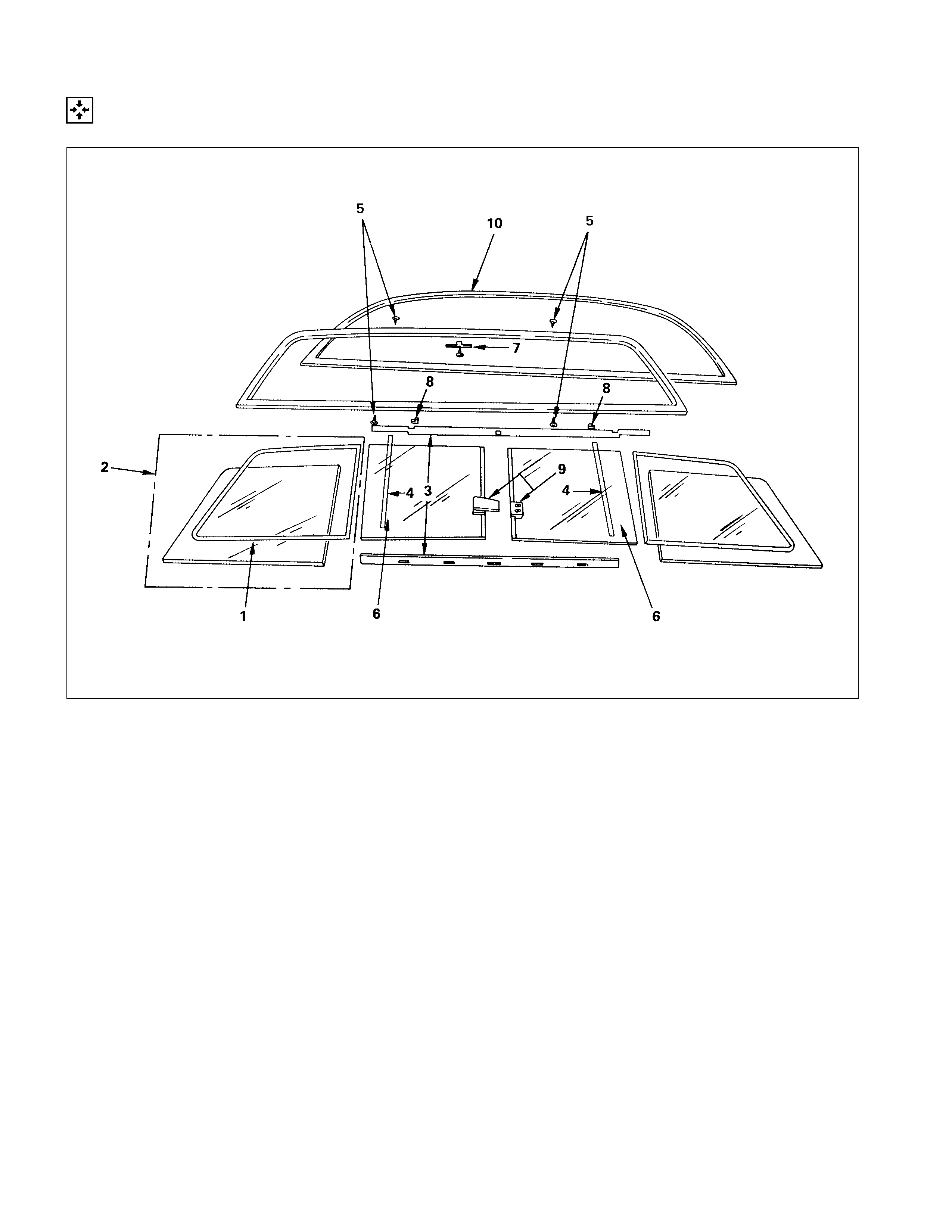

SLIDING REAR WINDOW ASSEMBLY

DISASSEMBLY

DISASSEMBLY STEPS

▲1. Weather strip

▲2. Packing ; rear window

3. Screw; binding

▲4. Frame ; rear window

5. Stopper

▲6. Rear window ; slide

7. Lock assembly with catchback window

8. Glass run

▲9. Glass ; rear window corner

1C. Weather strip ; rear window corner

IMPORTANT OPERATION - REMOVAL

1. Weather Strip

Remove the weather strip with a knife.

2. Packing ; Rear Window

With a screwdriver or similar tool, remove the window stop.

4. Frame ; Rear Window

Place the window channel in a vertical position and remove the

frame rear by pulling on one end of it with your hand.

6. Rear Window ; Slide

With the window channel held in a vertical position, remove the

rear window slide.

9. Glass ; Rear Window Corner

Stand the window channel up and remove the glass: rear

window corner.

REASSEMBLY

REASSEMBLY STEPS

▲1. Weather strip ; rear window corner

▲2. Glass ; rear window corner

▲3. Glass run

4. Frame ; rear window

5. Screw; binding

▲6. Rear window ; slide

7. Stopper

▲8. Packing ; rear window

9. Lock assembly with catchback window

1C. Weather strip

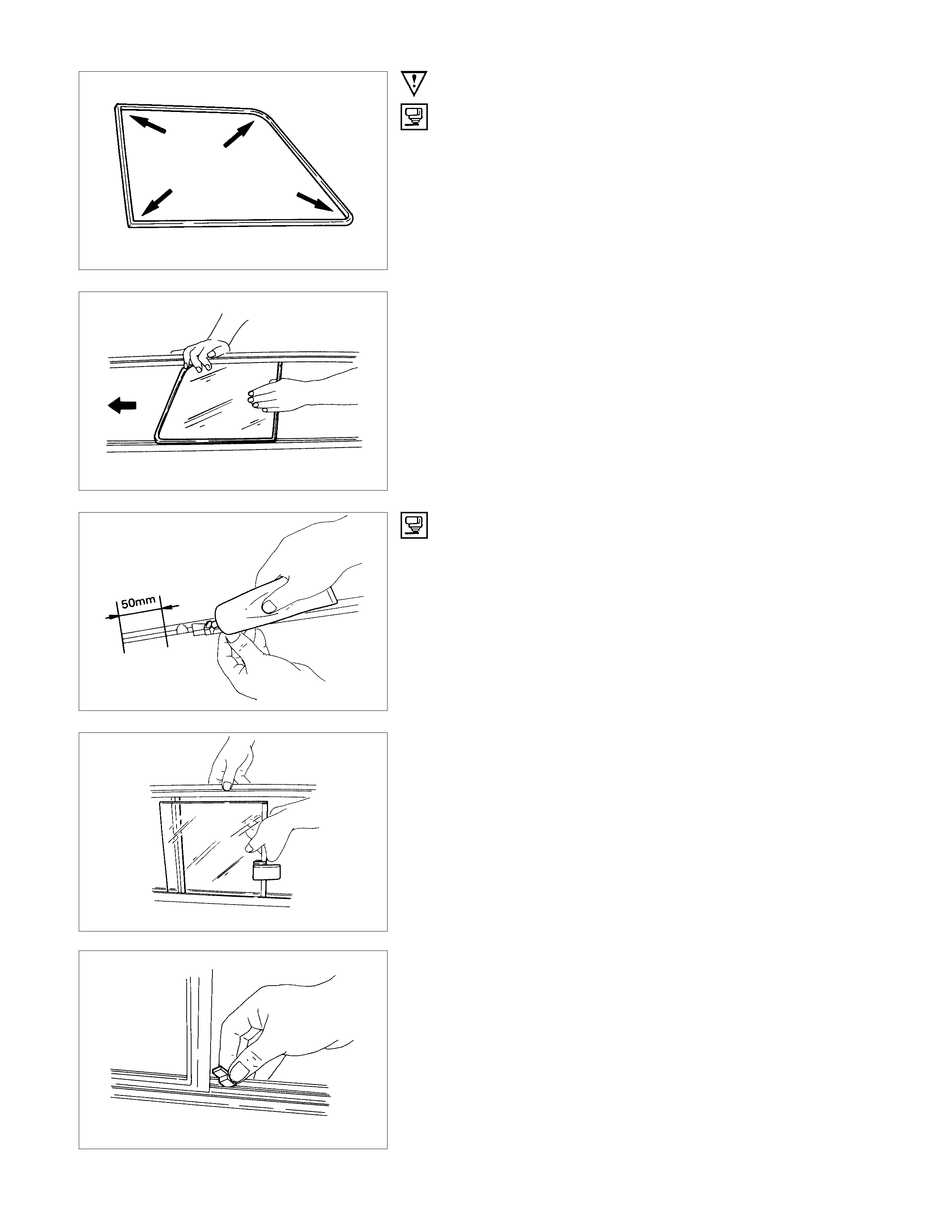

IMPORTANT OPERATION - INSTALLATION

1. Weather Strip ; Rear Window Corner

Using Cemedein #560 (or equivalent to HN1068 spec.)

adhesive, glue the weather strip to the complete circumference

of the frame, paying close attention to the corner areas.

2. Glass ; Rear Window Corner

Apply soap and water to the rim as a lubricant.

Place the channel in a vertical position. With your hand, apply

pressure to expand the channel. Insert the window glass in the

center of the channel.

3. Glass Run

Apply Cemedein #560 (or equivalent to HN1068 spec.)

adhesive to the entire length of both the upper window glass

and the weather strip.

Apply adhesive to both sides of the extreme ends of the lower

portion for a distance of about 50 mm.

There should be no gap between the weather strip rear window

glass channel and the channel.

6. Rear Window ; Slide

Hold the window vertically. Apply an upward pressure to the

channel and insert the rear window slide.

8. Packing ; Rear Window

Apply a fast setting adhesive agent to both sides of the window

atop and insert it into the channel.

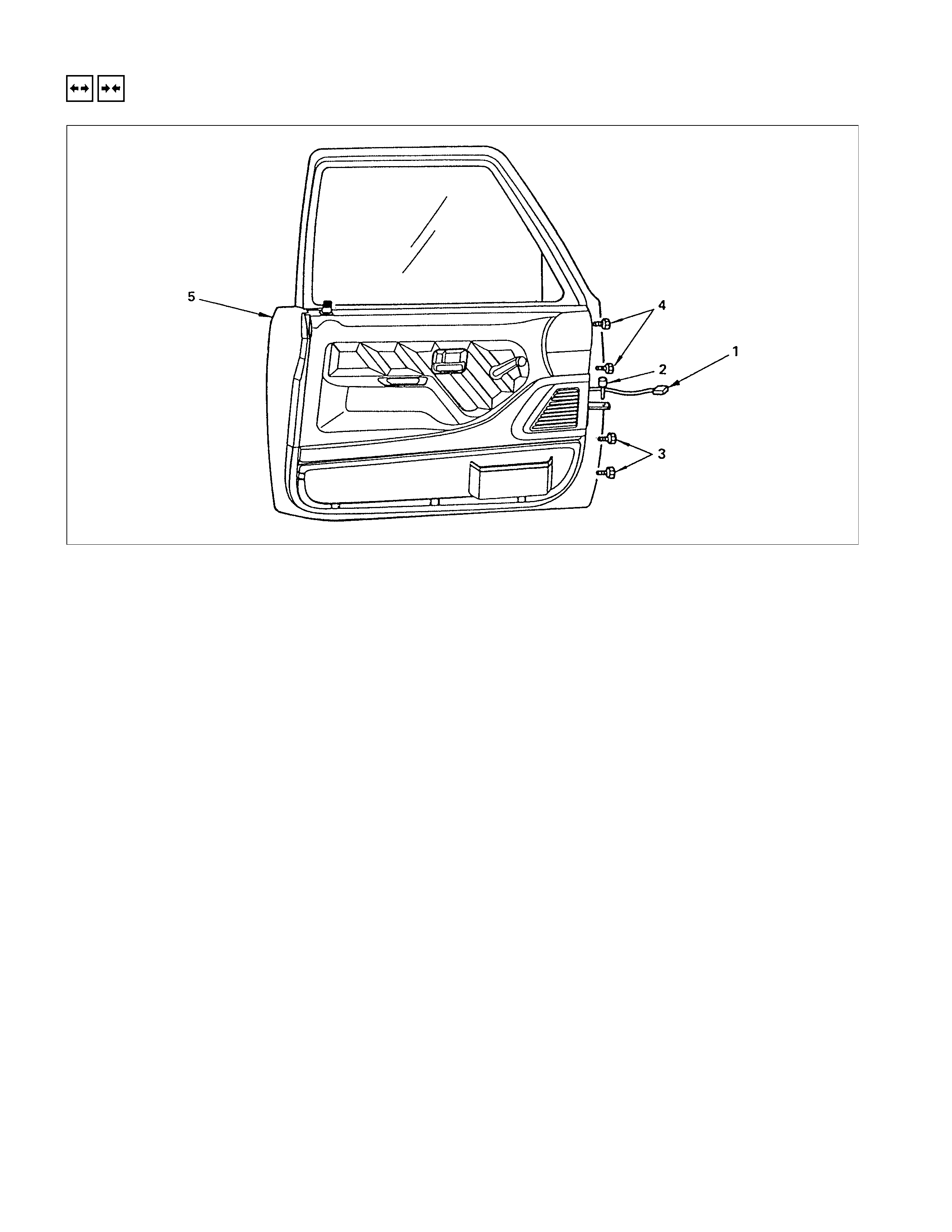

REMOVAL AND INSTALLATION

REMOVAL STEPS

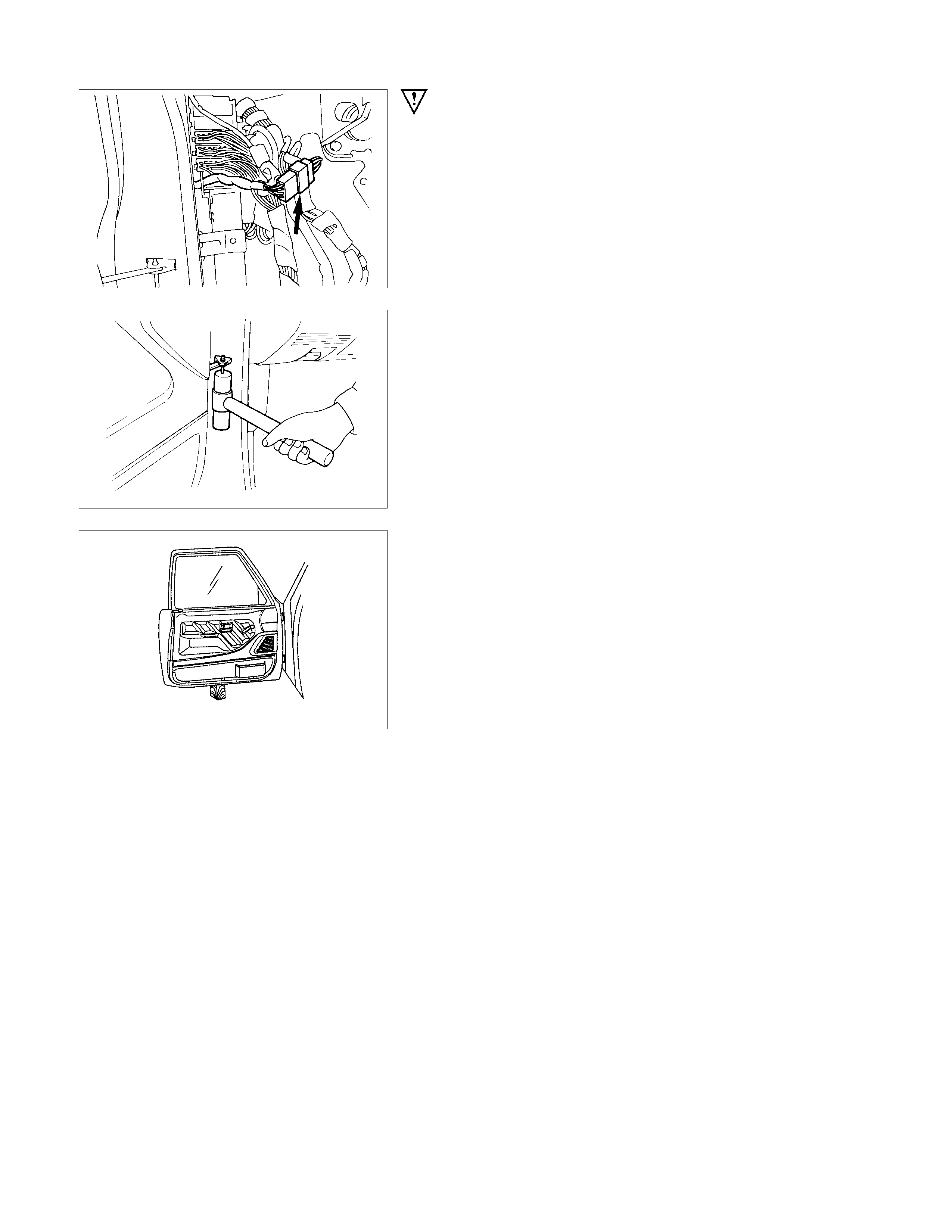

▲1. Door harness

▲2. Checker pin

▲3. Lower hinge

4. Upper hinge

5. Door assembly

INSTALLATION STEPS

5. Door assembly

4. Upper hinge

3. Lower hinge

2. Checker pin

1. Door harness

IMPORTANT OPERATION - REMOVAL

1. Door Harness

Disconnect the door harness.

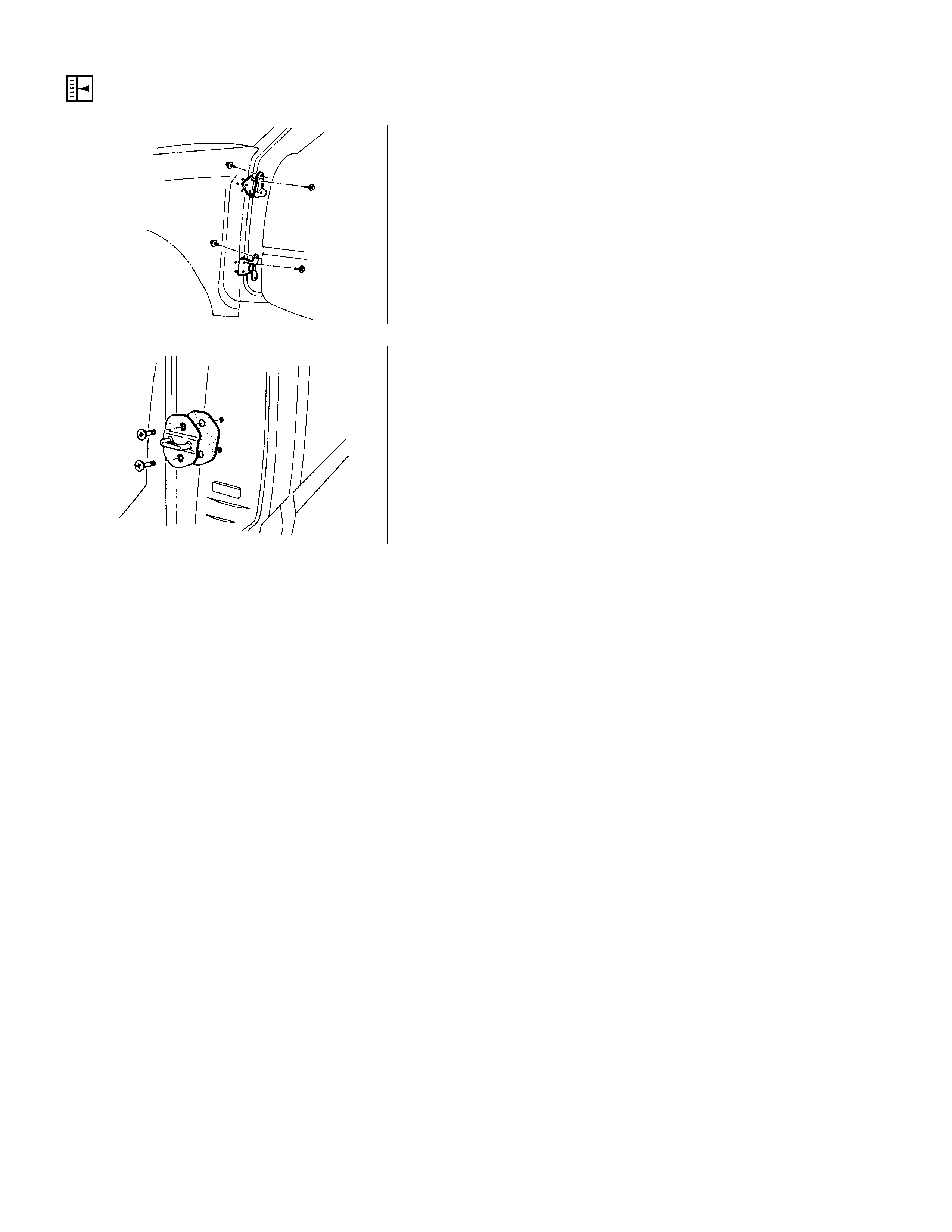

2. Checker Pin

3. Lower Hinge

Position a wood block under the door for protection and

support the door assembly with hands at removal or

installation.

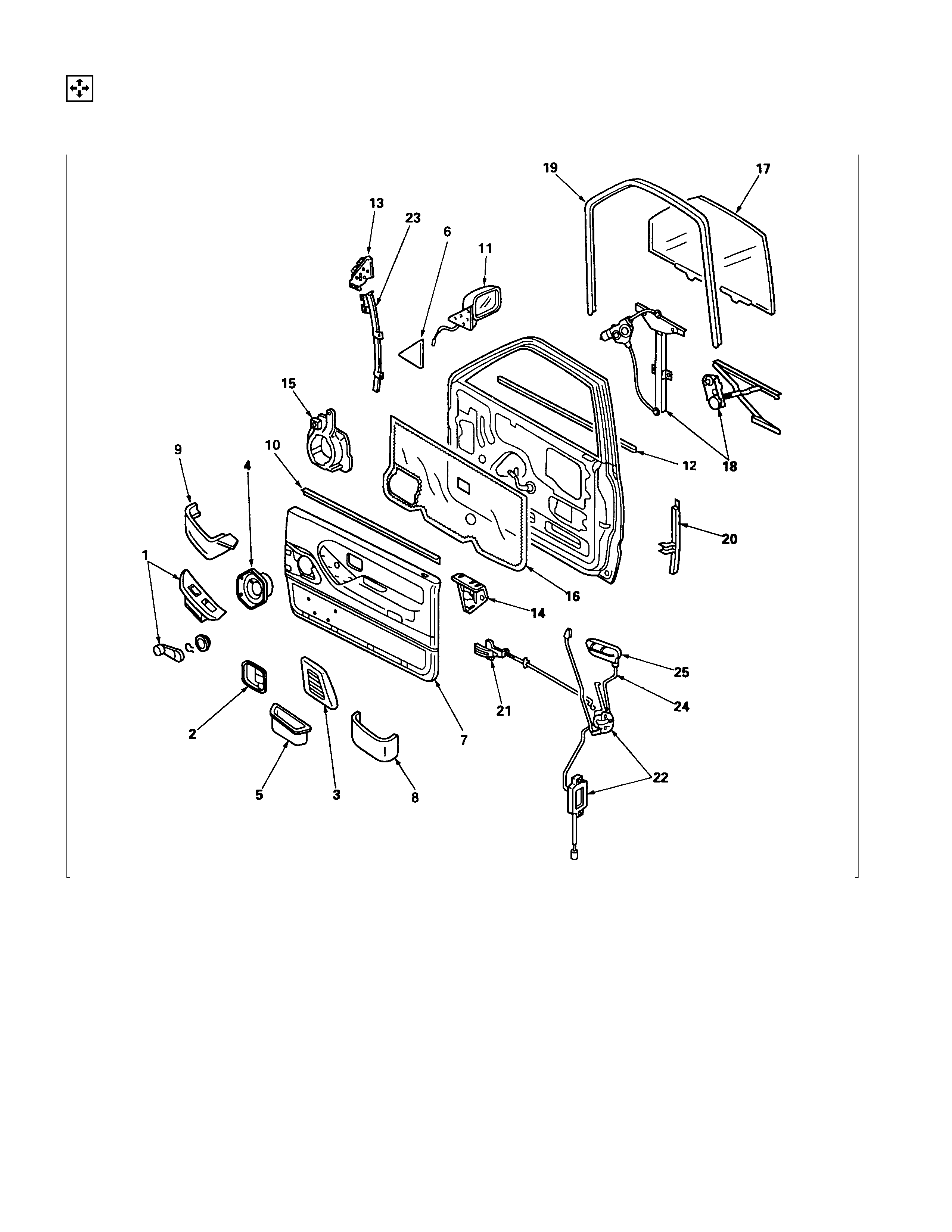

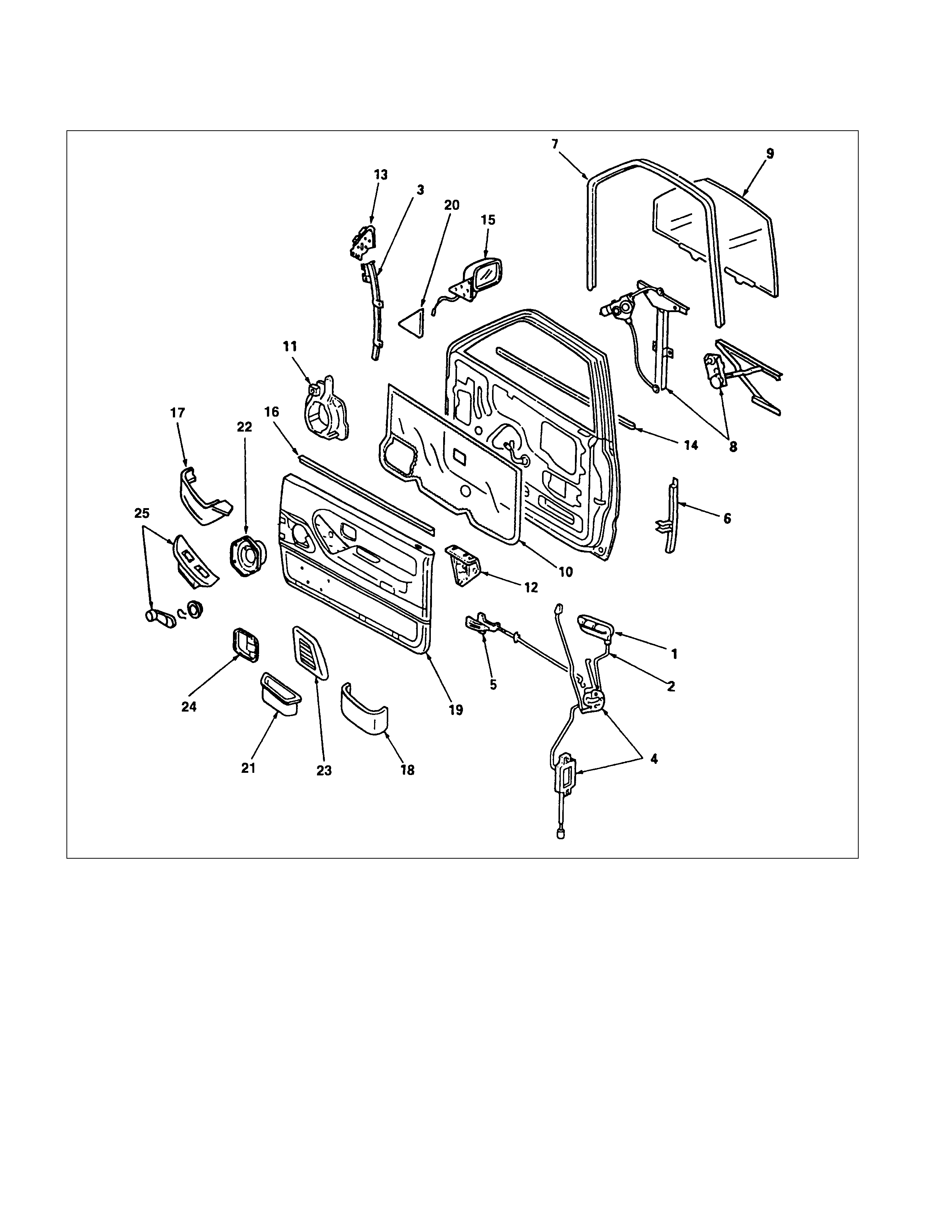

DISASSEMBLY

(FRONT DOOR)

DISASSEMBLY STEPS

▲1. Power window switch/Windows regulator handle

▲2. Bezel

▲3. Speaker grill

▲4. Speaker assembly

▲5. Door pull case

▲6. Door mirror cover

▲7. Door trim pad

▲8. Door pocket

▲9. Power window box

▲10. Inner waste seal

▲11. Door mirror assembly

▲12. Outer waste seal

▲13. Door mirror bracket

▲14. Bracket

▲15. Speaker box

▲16. Water-proof sheet

▲17. Window glass

▲18. Window regulator/Power window motor

▲19. Glass run

▲20. Glass run rear channel

▲21. Inside lever

▲22. Door lock assembly/Door lock actuator

▲23. Glass run front channel

▲24. Door lock cylinder

▲25. Outside handle

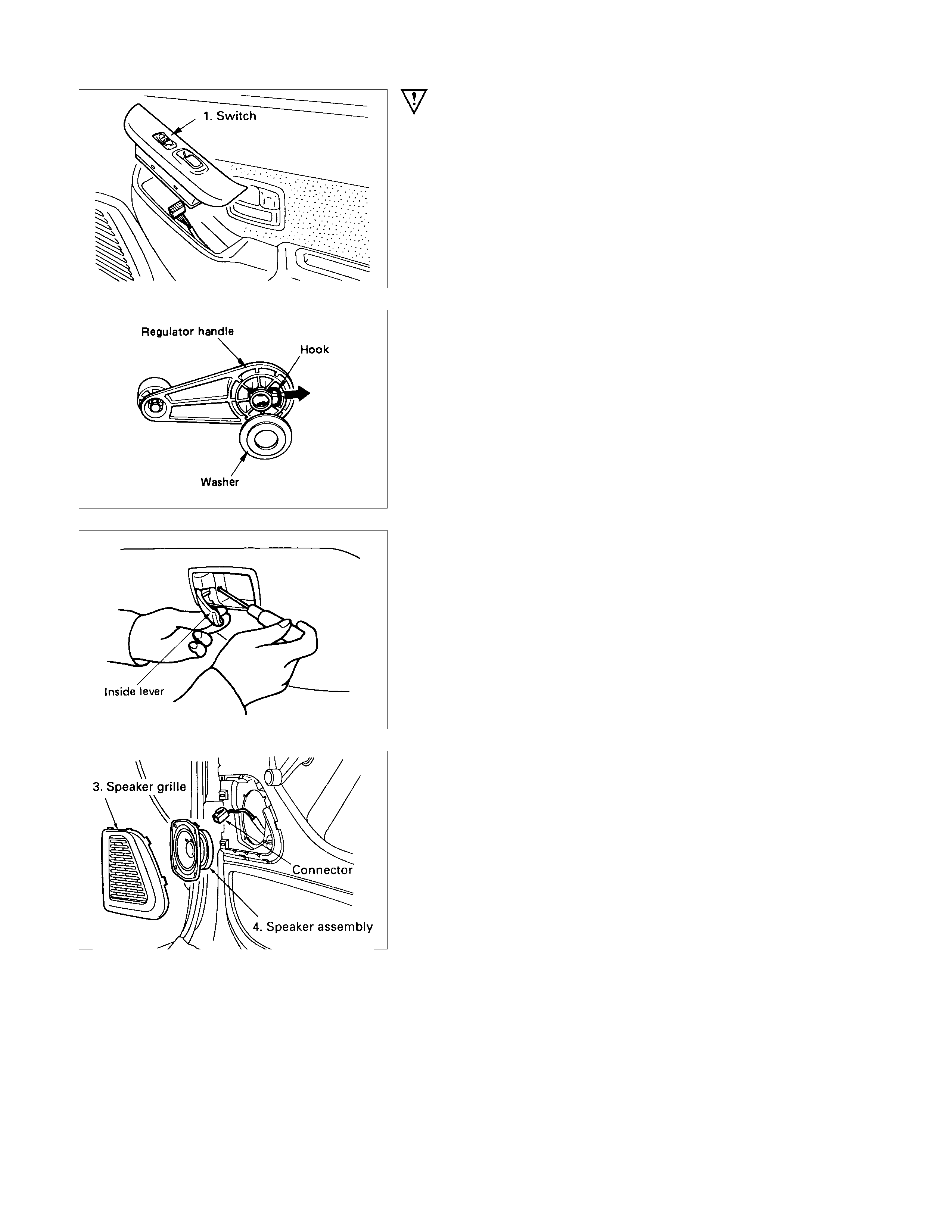

IMPORTANT OPERATIONS

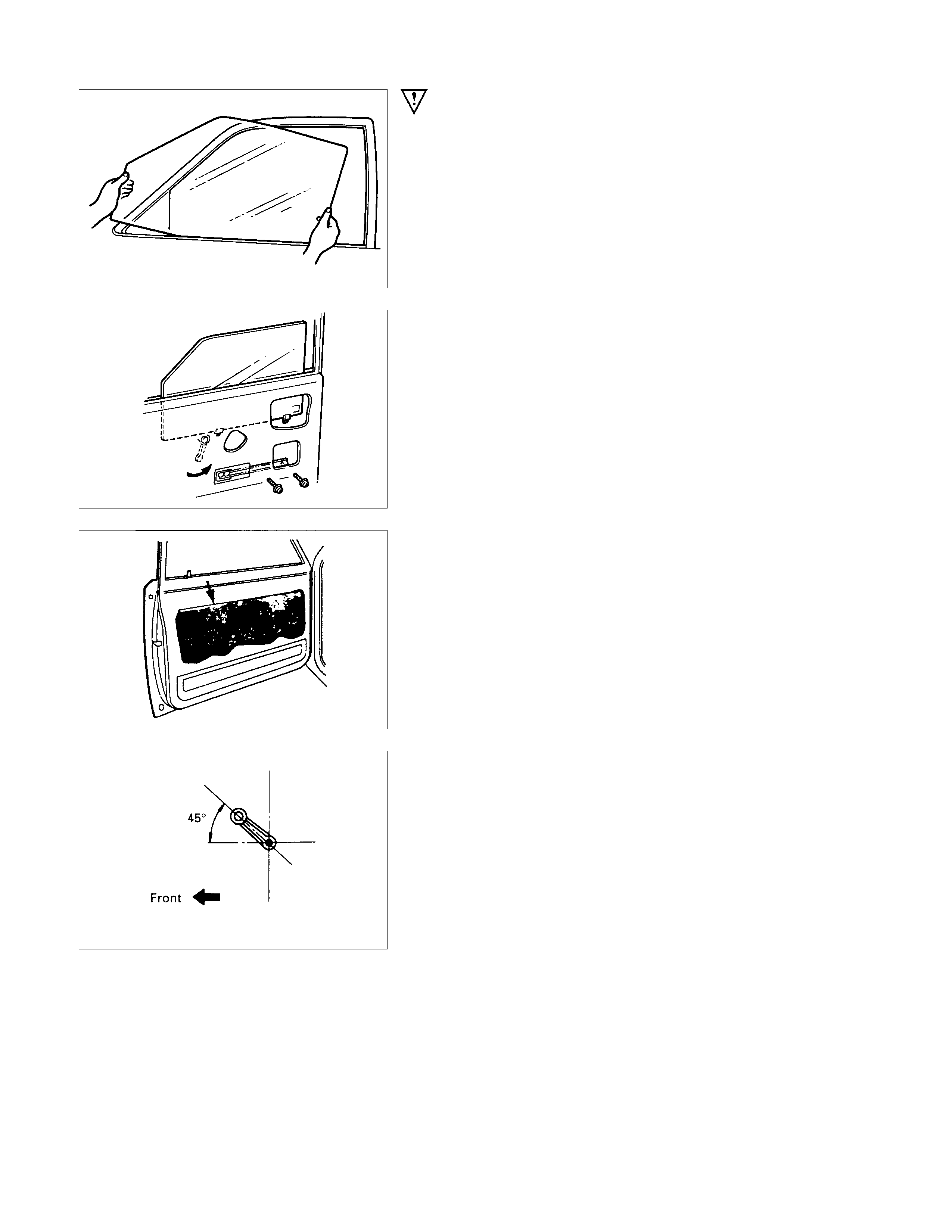

1. Power Window Switch/Window Regulator Handle

•Prise out the power window switch and remove the

connectors.

•To remove the regulator handle, remove the clip at the

root of the handle by using wire.

2. Bezel

•Remove the screw while pulling the inside lever toward

you.

3. Speaker Grill

•Pull out the clips.

4. Speaker Assembly

•Remove 4 screws and disconnect the speaker harness

connector.

5. Door Pull Case

•Remove the screw at the bottom of the case.

6.Door Mirror Cover

•Pull out the upper clip, and then tak e out the c atc h at the

lower section.

7.Door Trim Pad

•Remove the cover bottom of the trim pad (4 pcs), then

remove the screws.

8.Door Pocket

9.Power Window Box

10.Inner Waste Seal

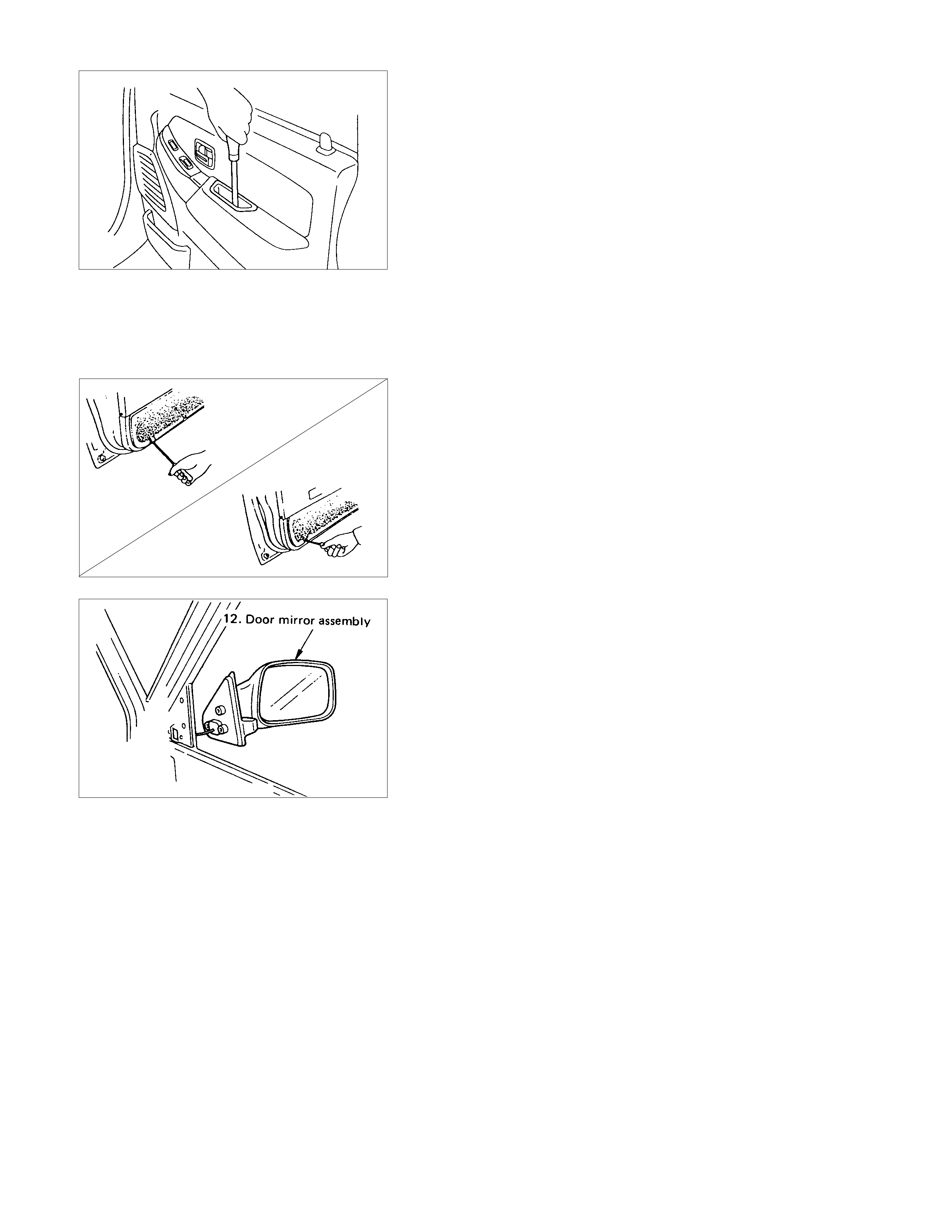

11.Door Mirror Assembly

•Remove 3 fixing bolts and then remove the connector.

12.Outer Waste Seal

13.Door Mirror Bracket

•Remove 2 bolts at the lower section, and then rem ove 2

screws in the weather strip.

14.Bracket

15.Speaker Box

•Remove 3 fixing bolts.

16.Water Proof Sheet

•Take care not to damage the sheet when peeling it off.

17.Window Glass

•Remove 2 screws through the access hole and pull out

the window glass upward.

18.Window Regulator/Power Window Motor

•Disconnect the power window motor connector.

19.Glass Run

•Pull it out of the door piller of the channel. (front/rear)

20.Glass Run Rear Channel

•Remove 2 screws.

21.Inside Lever

22.Door Lock Assembly/Door Lock Actuator

•Disconnect the linkage with the outside handle, the

inside lever and the lock cylinder.

23.Glass Run Front Channel

24.Door Lock Cylinder

•Remove the door lock cylinder by applying finge

r

pressure from inside while depressing the retaining clip.

25.Outside Handle

DISASSEMBLY AND REASSEMBLY

(REAR DOOR)

DISASSEMBLY STEPS

▲1. Power window switch/Window regurator

handle

▲2. Bezel/Speaker grill

3. Inside pull handole/Speaker

▲4. Door trim pad

5. Arm rest (W/Power window only)

6. Water proof sheet

7. Glass guide

8. Upper cover

▲9. Window regurator/Power window motor

▲10. Window glass

11. Bracket

12. Inside lever

13. Outside handle

▲14. Door lock cylinder

15. Outer waste seal

16. Glass run

REASSEMBLY STEPS

To reassemble, follow the disassembly steps

in the reverse order.

IMPORTANT OPERATIONS

1. Window Regulator Handle

•To remove the regulator handle, remove the clip at the

root of the handle by using wire.

2. Bezel

•Remove the screw while pulling the inside lever toward

you.

4. Door Trim Pad

•Remove the cover bottom of the trim pad (4 pcs), then

remove the screws.

9. Window Regulator

•Remove the 4 screws holding the regulator.

10.Window Glass

•First, align the height of regulator to the access hole.

Remove 2 screws attaching bottom channel and

regulator, then remove the glass.

•Remove the window glass by tilting it as necessary .

14.Door Lock Assembly

•Disconnect the linkage from the door outside handle,

inside lever and lock cylinder.

Remove the 2 bolts holding the outside handle from

inner side.

•Remove the 3 bolts holding the door lock assembly.

ADJUSTMENT (F RO NT AND REAR)

DOOR HINGE

Door alignment can be obtained by moving door hinges.

Prior to adjustment, remove the fender and set the door

temporarily.

Loosen hinge to door bolts when adjusting steps between the

door and body.

Loosen hinge to body bolts to adjust the clearance between the

door and body.

DOOR STRIKER

Loosen the striker screws and adjust the position of the striker

by holding a piece of wood against the striker and tapping it

with a hammer.

To obtain correct adjustment, move the position of the striker

vertically so that the lower face of the dovetail becomes parallel

to the striker.

Adjust the number of sheets to control engagement of the

striker with the door latch. One or two sheets are generally

used to obtain correct adjustment.

REASSEMBLY

(FRONT DOOR)

REASSEMBLY STEPS

1. Outside handle

2. Door lock cylinder

3. Glass run front channel

4. Door lock assembly/Door lock actuator

5. Inside lever

6. Glass run rear channel

7. Glass run

8. Window regulator/Power window motor

▲9. Window glass

▲10. Water proof sheet

11. Speaker box

12. Bracket

13. Door mirror bracket

14. Outer waste seal

15. Door mirror assembly

16. Inner waste seal

17. Power window box

18. Door pocket

19. Door trim pad

20. Door mirror cover

21. Door pull case

22. Speaker assembly

23. Speaker grill

24. Bezel

▲25. Power window sw itch/Windows regulator

handle

IMPORTANT OPERATIONS

9.Window Glass

•Insert the window glass into position by tilting it as

necessary, and then set it against the channel of the

window regulator.

•Attach the window glass to the window regulator with the

two screws.

10.Water Proof Sheet

•Place the butyl type on the door panel so as not to cove

r

the drain hole.

25.Regulator Handle

•Install the regulator handle as illustrated when closing

the window glass.

ADJUSTMENT (F RO NT AND REAR)

DOOR HINGE

Door alignment can be obtained by moving door hinges.

Prior to adjustment, remove the fender and set the door

temporarily.

Loosen hinge to door bolts when adjusting steps between the

door and body.

Loosen hinge to body bolts to adjust the clearance between the

door and body.

DOOR STRIKER

Loosen the striker screws and adjust the position of the striker

by holding a piece of wood against the striker and tapping it

with a hammer.

To obtain correct adjustment, move the position of the striker

vertically so that the lower face of the dovetail becomes parallel

to the striker.

Adjust the number of sheets to control engagement of the

striker with the door latch. One or two sheets are generally

used to obtain correct adjustment.

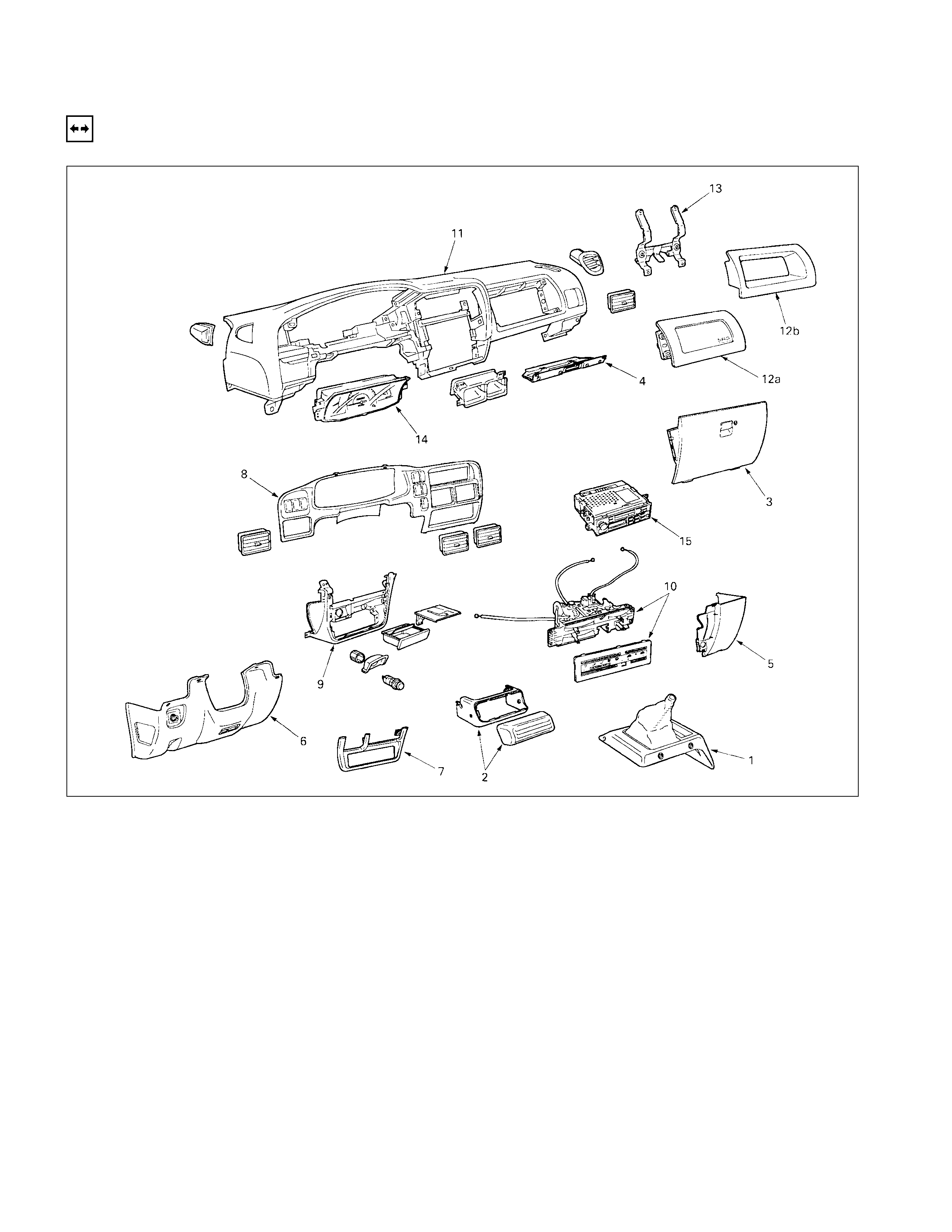

INSTRUMENT PANEL

REMOVAL

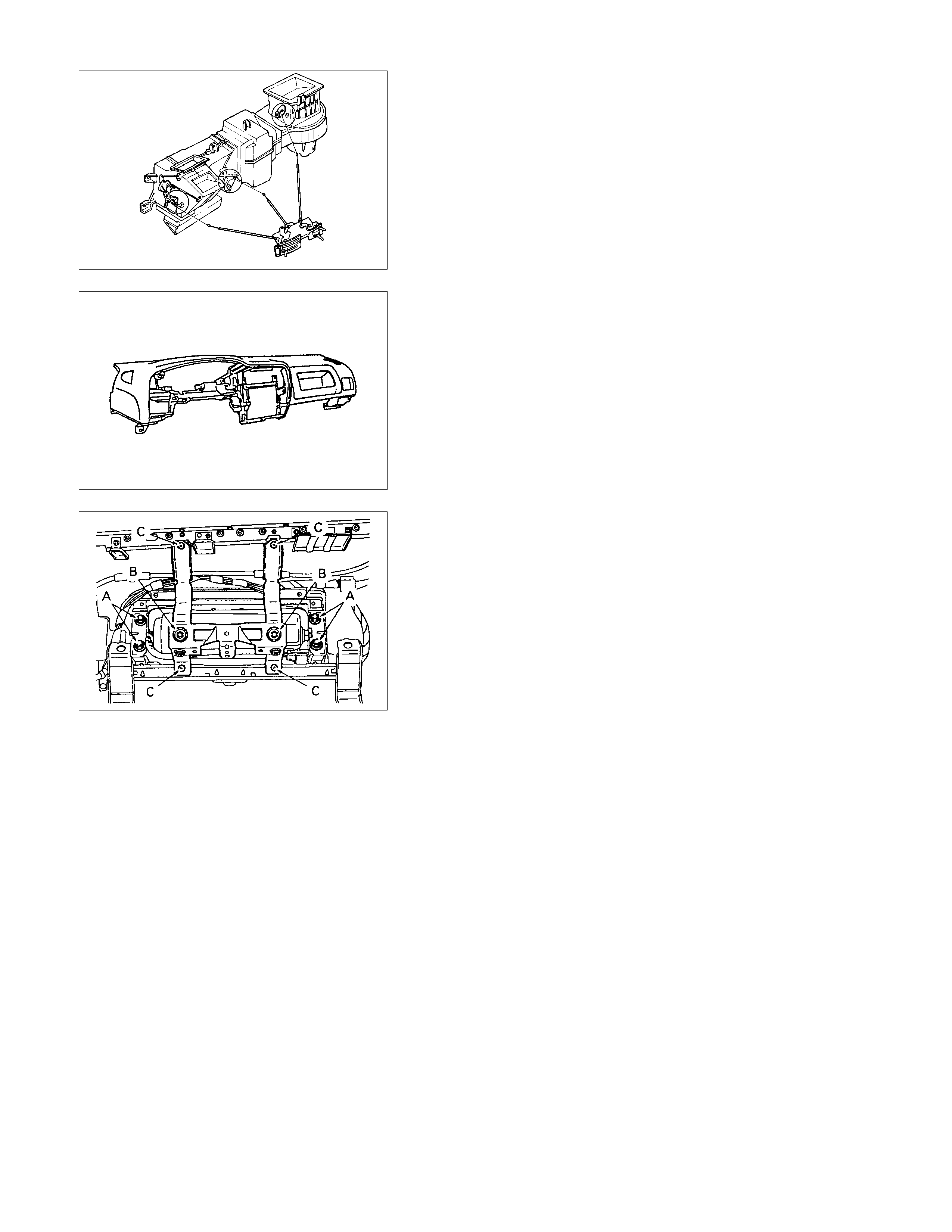

DISASSEMBLY STEPS

▲1. Center console assembly

▲2. Control unit cover

▲3. Glove box

▲4. Glove box cover

▲5. Instrument panel passenger lower cover

assembly

▲6. Instrument panel driver lower cover

assembly

▲7. Lower cluster assembly

▲8. Meter cluster assembly

▲9. Instrument panel lower center cover

assembly

▲10. Control lever assembly

▲11. Instrument panel assembly

▲12a. Passenger air bag (if so equipped)

12b. Utility box

▲13. Passenger air bag reinforcement

assembly (W/SRS)

14. Meter assembly

15. Radio assembly

IMPORTANT OPERATIONS

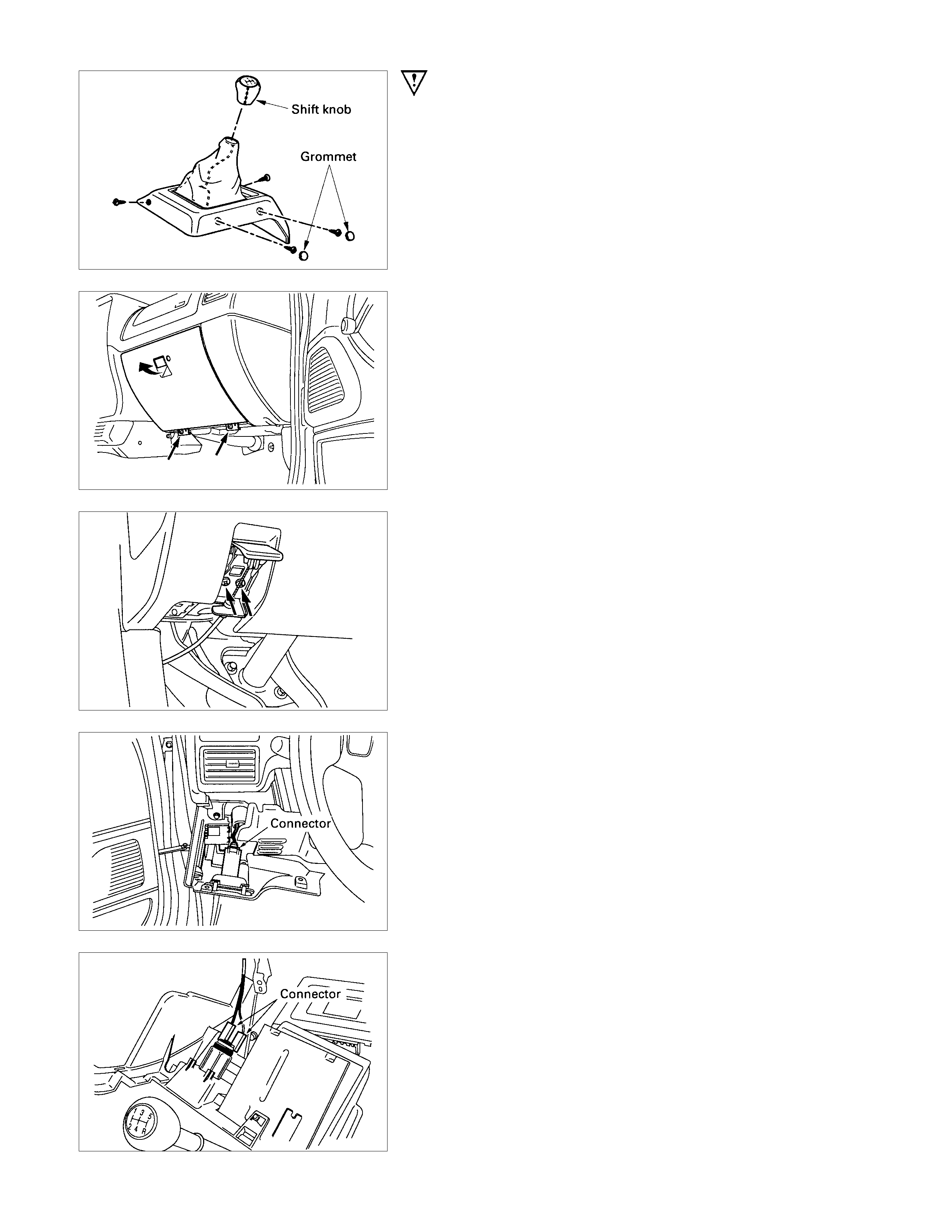

1. Center Console Assembly

•Remove shift knob and 2 fixing screws (front side).

Open the grommet and remove 2 fixing screws (rea

r

side).

2. Control unit cover

3. Glove Box

•Remove 2 fixing screws and pulling the handle.

4. Glove Box Cover

•Remove 4 fixing screws and pull the cover toward you

and remove the clips at 2 positions.

5. Instrument Panel Passenger Lower Cover Assembly

•Remove 3 fixing screws and 1 clip.

6. Instrument Panel Driver Lower Cover Assembly

•Remove the engine hood opener 2 fixing screws and 6

fixing screws.

•Disconnect the connector of the illumination.

7. Lower Cluster Assembly

•Remove 3 fixing clips.

8. Meter Cluster Assembly

•Remove 3 fixing screws, 7 clips and switch connectors.

9. Instrument Panel Lower Center Cover Assembly

•Remove 7 fixing sc r ews and disc onnect the c onnec tor o

f

the cigarette lighter.

10.Control Lever Assembly

1) Disc onnect the c ontr ol c able f rom heater unit and blowe

r

unit.

2) Remove the control lever assembly fixing screws.

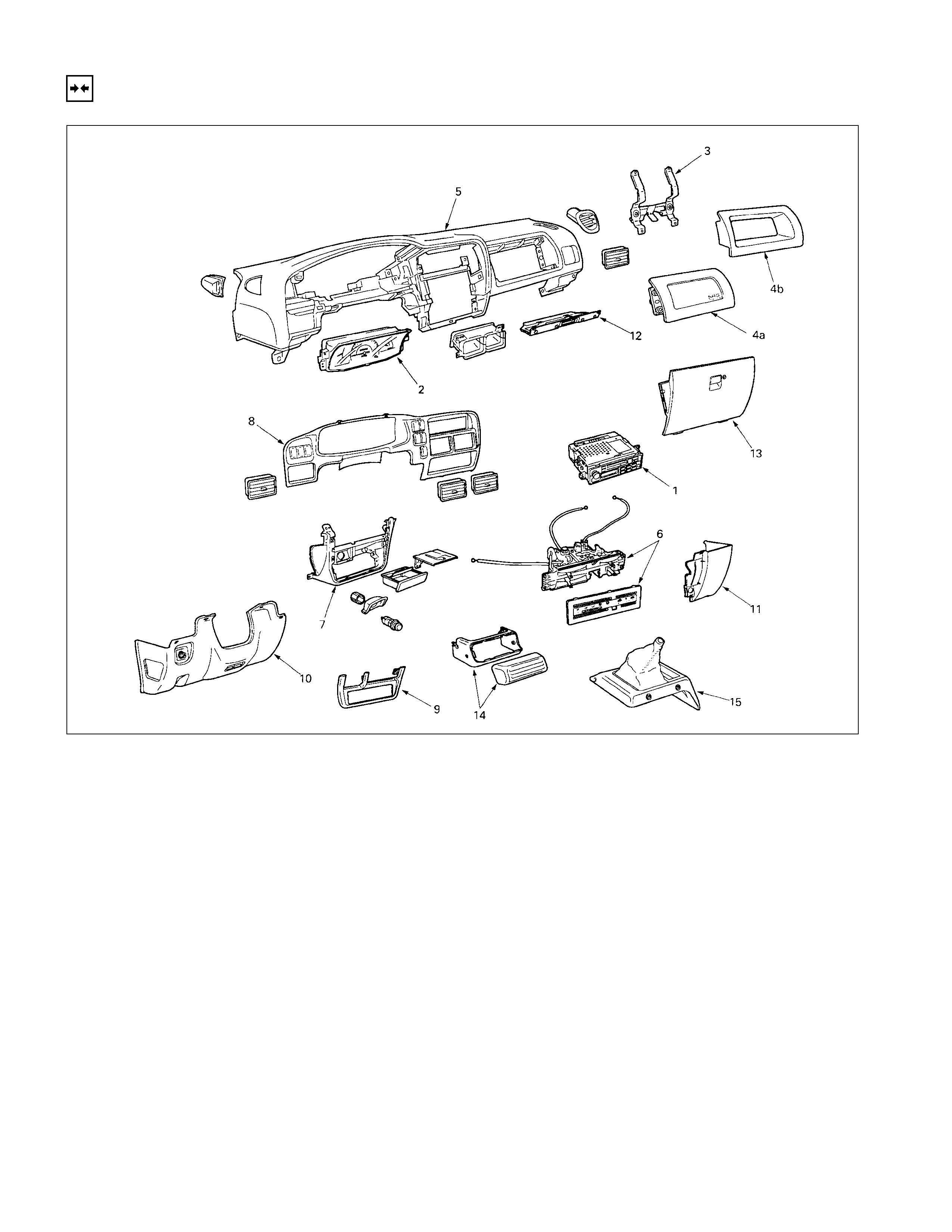

11.Instrument Panel

1) Remove the instrument panel fixing nuts and bolts.

2) Disconnect the instrument harness connectors.

3) Remove the instrument panel.

Caution:

For precautions on installation or removal of SRS-air bag

system, refer to Section 12M1 - AIR BAG.

12a. Passenger air bag assembly

•Remove 4 fixing bolts A and 2 nuts B.

Caution:

For precautions on installation or removal of SRS-air bag

system, refer to Section 12M1 - AIR BAG.

13.Passenger air bag reinforcement assembly (W/SRS)

•Remove 4 fixing screws C.

INSTALLATION

INSTALLATION STEPS

1. Radio assembly

2. Meter assembly

3. Passenger air bag reinforcement

assembly

4a. Passenger air bag

4b. Utility box

5. Instrument panel assembly

▲6. Control lever assembly

7. Instrument panel lower center cover

assembly

8. Meter cluster assembly

9. Lower cluster assembly

10. Instrument panel driver lower cover

assembly

11. Instrument panel passenger lower cover

assembly

12. Glove box cover

13. Glove box

14. Control unit cover

15. Center console assembly

IMPORTANT OPERATION - INSTALLATION

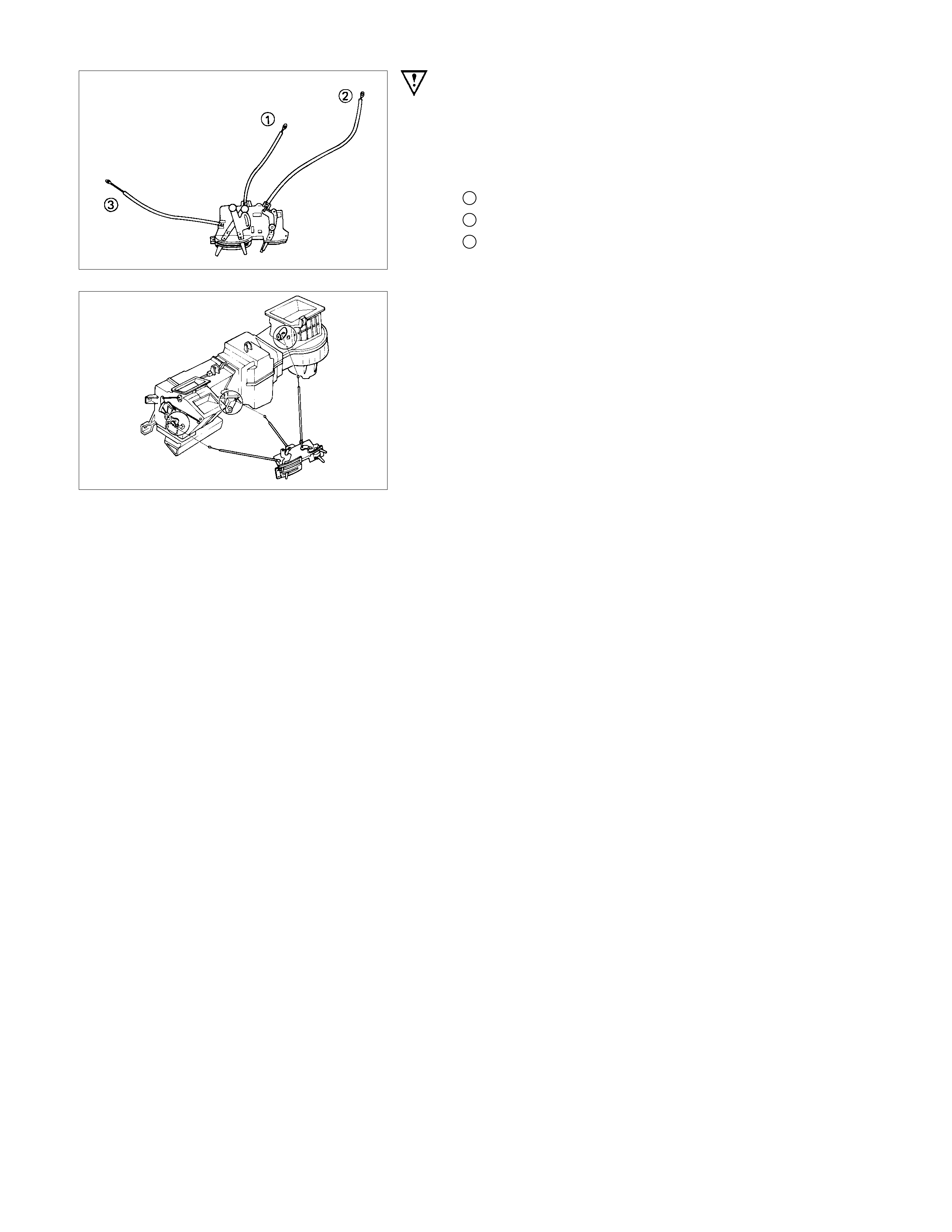

6. Control Lever Assembly

1) Set the temperature control lever and the airsource

select lever at the left-hand side end.

2) Set the air selector lever at the right-hand side end.

1 : Temperature control cable

2: Air source select cable

3: Air selector

3) Attach the cable, after the work 1) and 2) have been

completed.

CONSOLE BOX

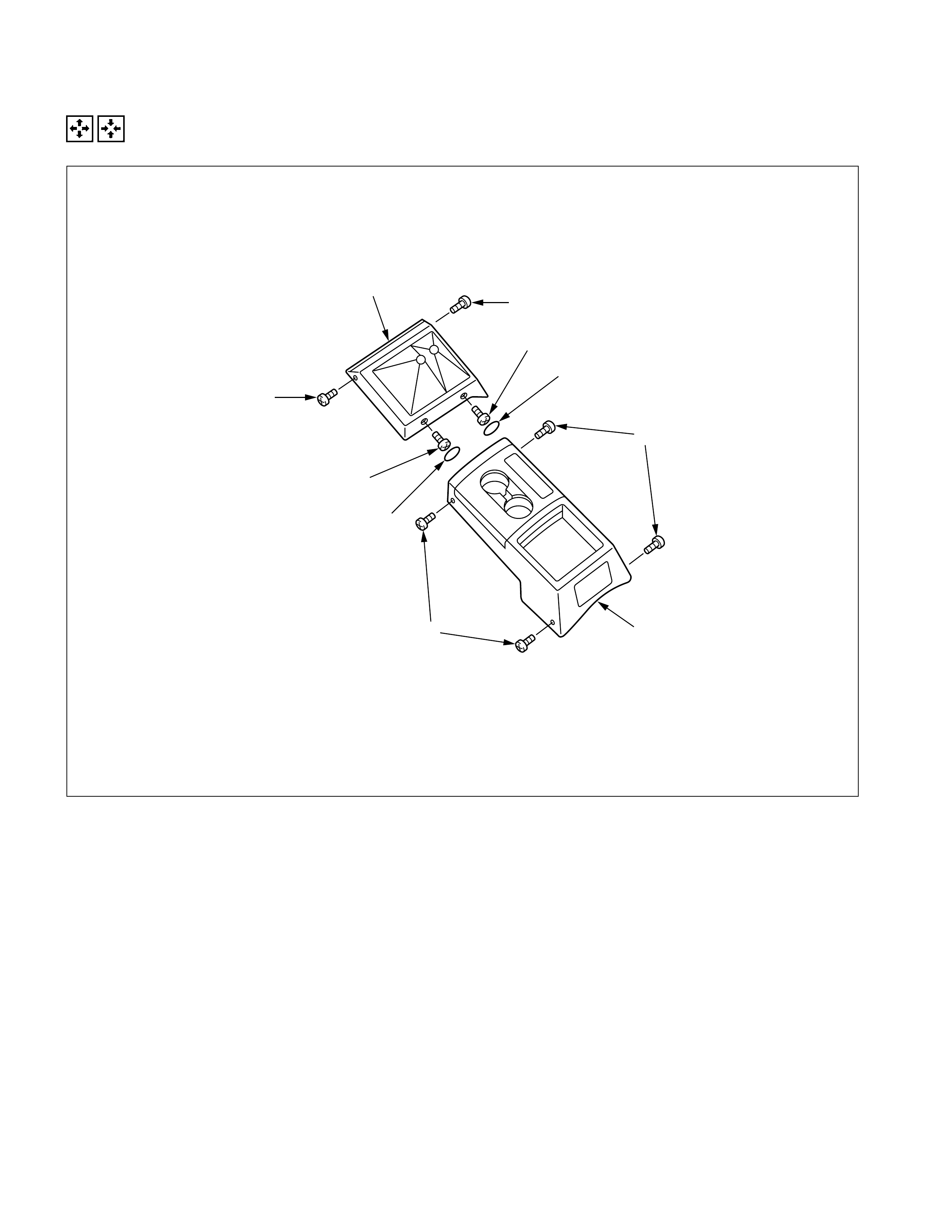

REMOVAL AND INSTALLATION (4×

××

×4 S MODEL)

1

1

2

2

3

3

4

5

5

6

REMOVAL STEPS

1. Hole cover ×2

2. Screw ×2

3. Screw ×2

4. Center console

5. Screw ×4

6. Rear console

INSTALLATION STEPS

6. Rear console

5. Screw ×4

4. Center console

3. Screw ×2

2. Screw ×2

1. Hole cover ×2

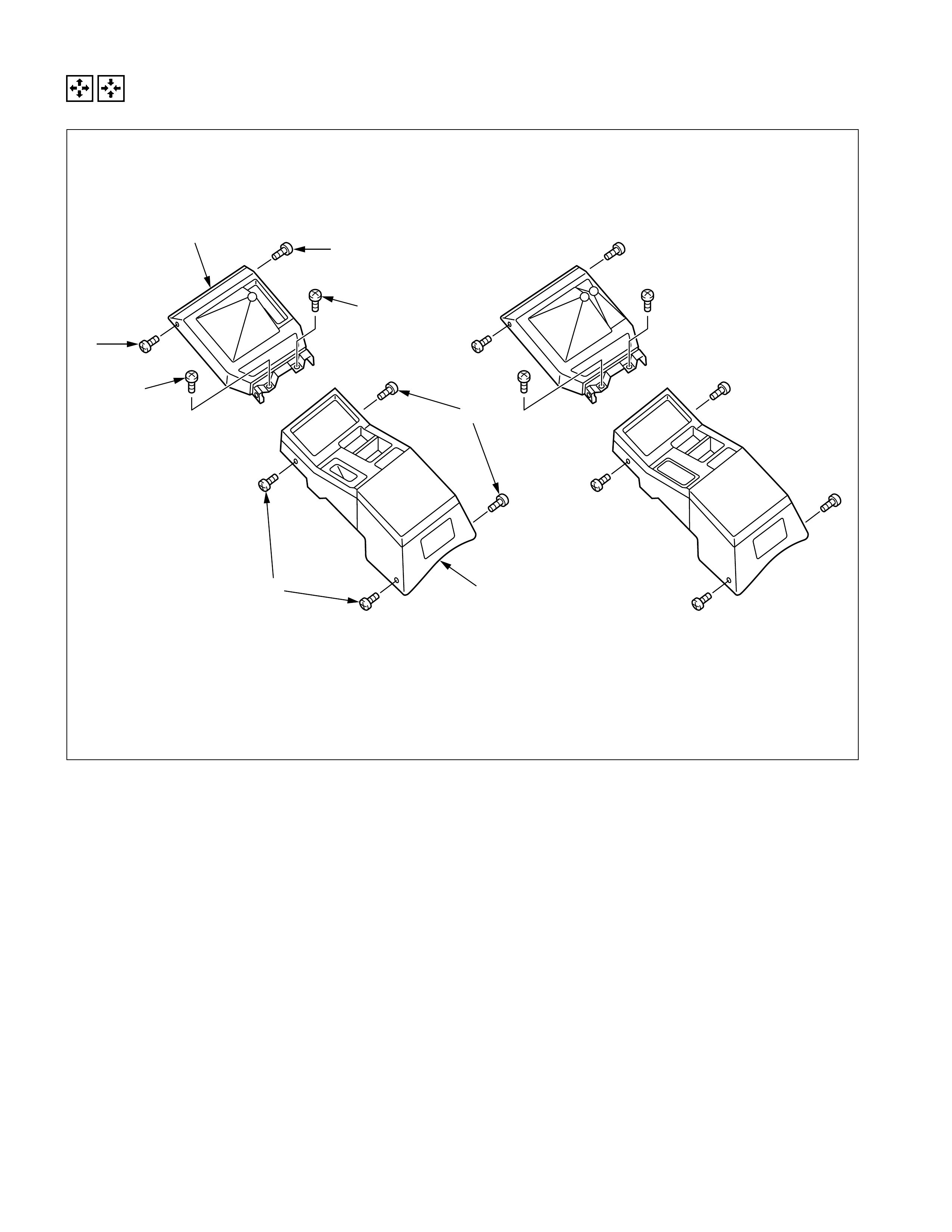

REMOVAL AND INSTALLATION (4X4 & 4X2 LS MODEL)

3

3

5

1

4x2 LS Model

1

2

4

4

4x4 LS Model

REMOVAL STEPS

1. Screw ×4

2. Rear console

3. Screw ×2

4. Screw ×2

5. Center console

INSTALLATION STEPS

5. Center console

4. Screw ×2

3. Screw ×2

2. Rear console

1. Screw ×4

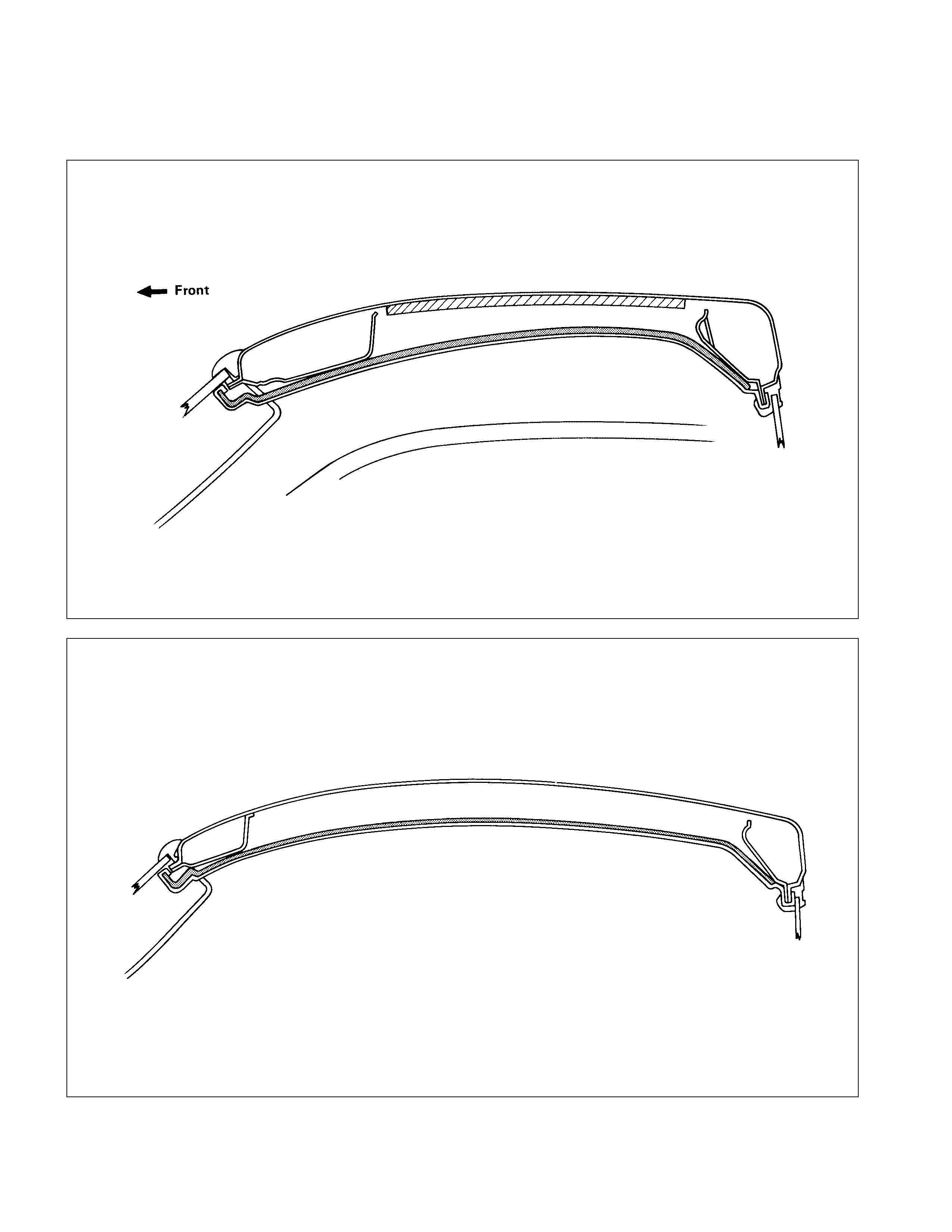

HEAD LINING

GENERAL DESCRIPTION

STANDARD CAB

SPACE CAB (SPORTS CAB)

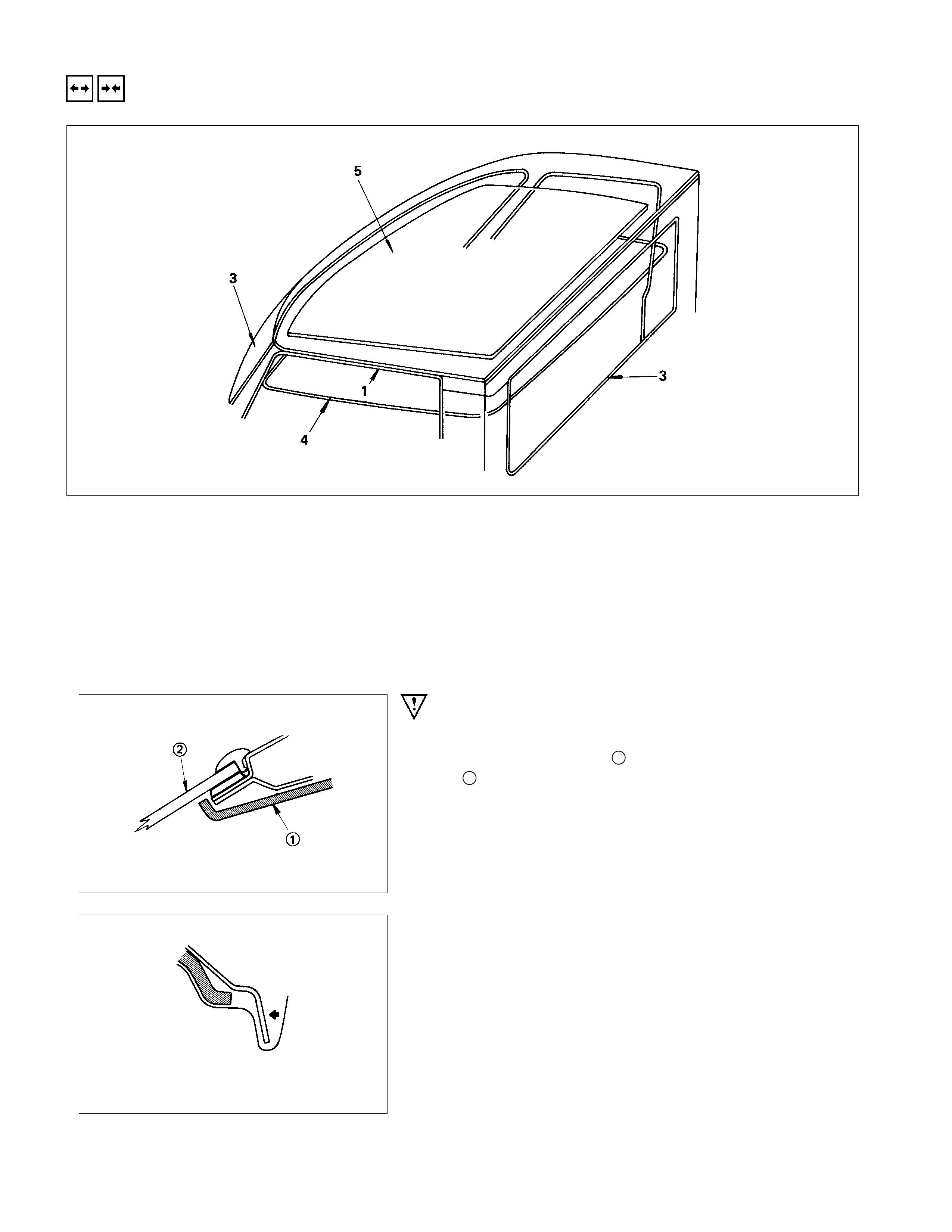

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Door finisher

2. Rear view mirror, sunvisor and dome

la mp assembly

3. Windshield and back light glass

4. Head lining

5. Insulation pad

INSTALLATION STEPS

5. Insulation pad

▲4. Head lining

3. Windshield and back light glass

2. Rear view mirror, sunvisor and dome

la mp assembly

1. Door finisher

IMPORTANT OPERATIONS - INSTALLATION

4. Head Lining

1) Install the head lining 1 to the body panel.

2 : Windshield glass

2) Roll up the head lining in the body side of the back light

glass and door opening.

3) Roll up the head lining provided with slits, in the corner.

4) Roll up the head lining 1 in the body side of door opening.

5) Fix to the door side, using the finisher 2.

FUEL FILLER LID OPENER VELER/CABLE

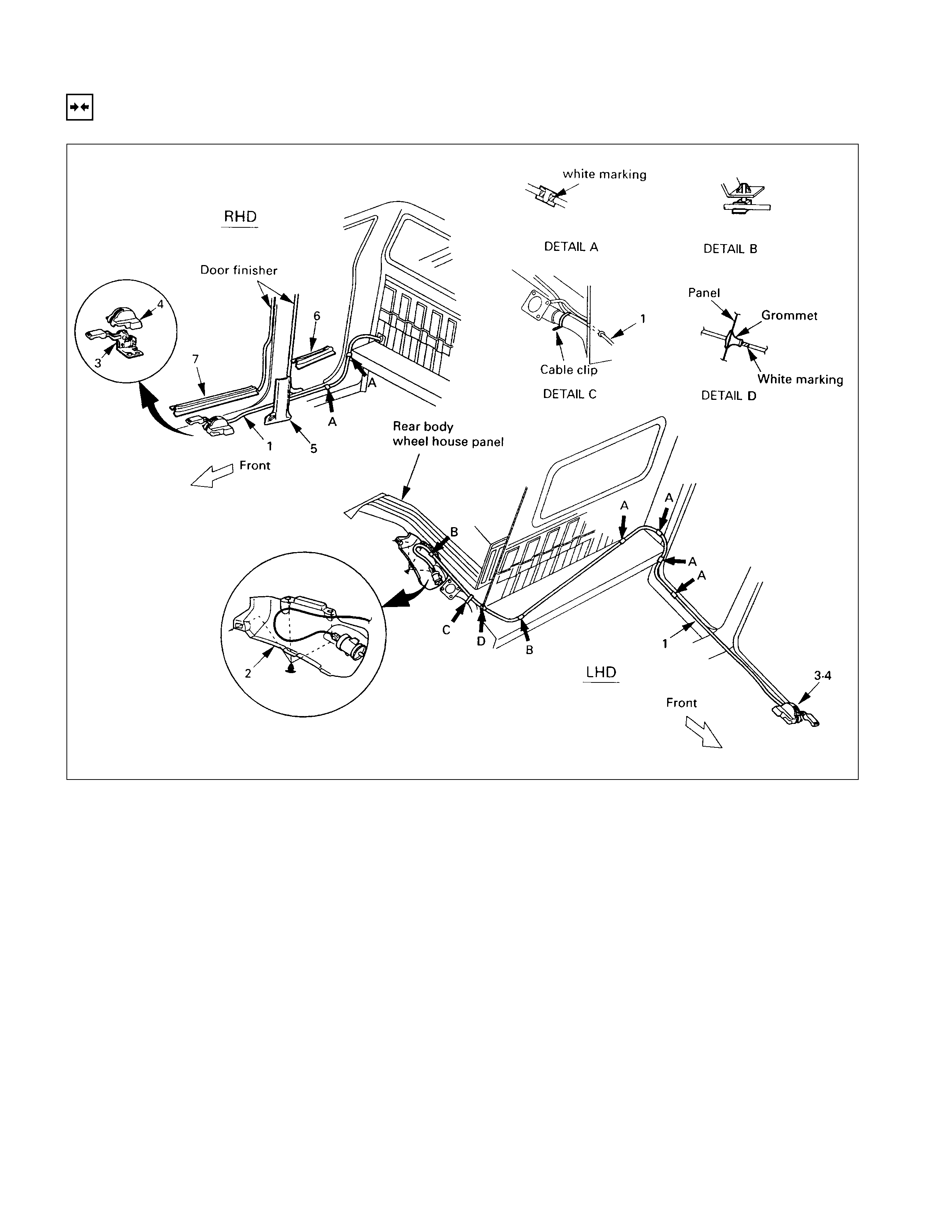

REMOVAL (DOUBLE CAB)

REMOVAL STEPS

▲1. Front sill plate

▲2. Rear sill plate

3. Center pillar inner trim cover

▲4. Fuel filler lid opener cover

▲5. Fuel filler lid opener lever

6. Cover

▲7. Fuel filler lid cable assembly

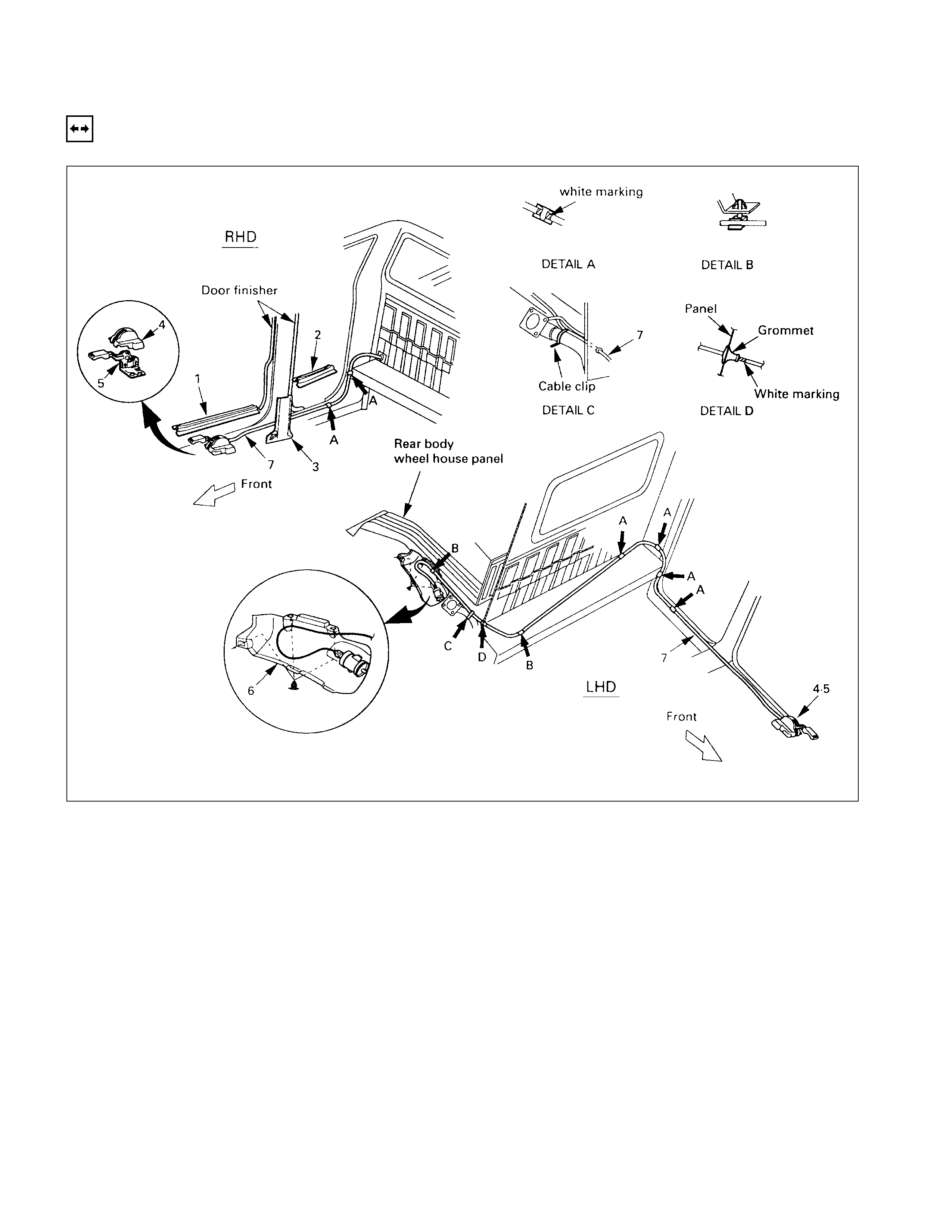

REMOVAL (SPACE CAB)

4

51

7

7

4,5

7

A

A

RHD

DETAIL C DETAIL D

Door finisher

Front

Cable clip

Panel Grommet

White marking

Cab mounting

White marking

DETAIL E

DETAIL BDETAIL A

Protector

Front

A

D

Rear body

wheel house panel

B

B

C

E

E

6

B

REMOVAL STEPS

▲1. Front sill plate

▲4. Fuel filler lid opener cover ▲5. Fuel filler lid opener lever

6. Cover

▲7. Fuel filler lid cable assembly

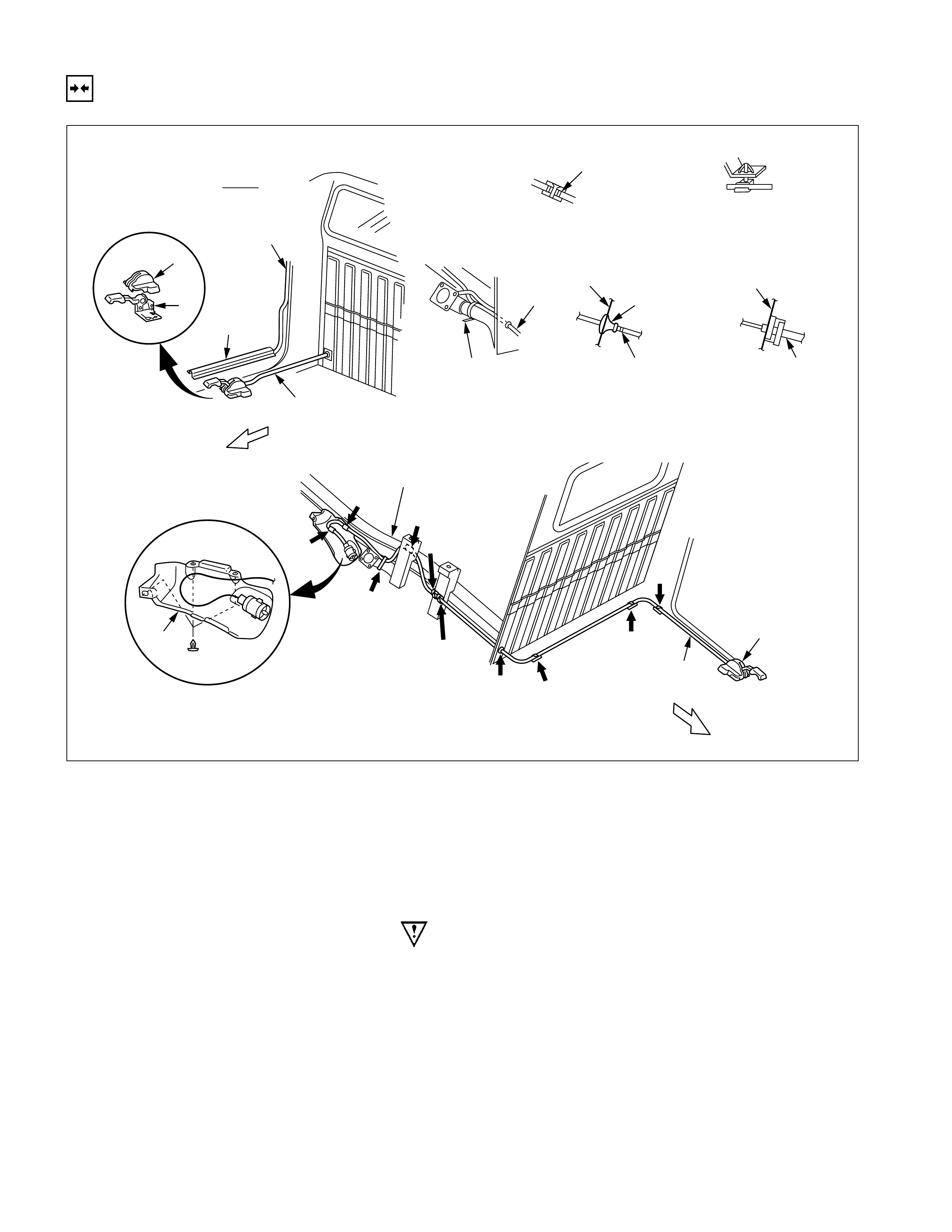

REMOVAL (SINGLE CAB)

Rear body

wheel house panel

B

B

C

E

E

6

B

4

51

7

7

RHD

DETAIL C DETAIL D

Door finisher

Front

Cable clip

Panel Grommet

White marking

Rear body mounting

White marking

DETAIL E

DETAIL BDETAIL A

Protector

4,5

7

A

A

Front

A

D

REMOVAL STEPS

▲1. Front sill plate

▲4. Fuel filler lid opener cover ▲5. Fuel filler lid opener lever

6. Cover

▲7. Fuel filler lid cable assembly

IMPO RTANT OPERATIONS - REMOVAL

1. Front Sill Plate

•Remove the 4 clips.

2. Rear Sill Plate (Double Cab)

•Remove the 2 clips.

4. Fuel Filler Lid Opener Cover

•Remove the clip and release the fixed point.

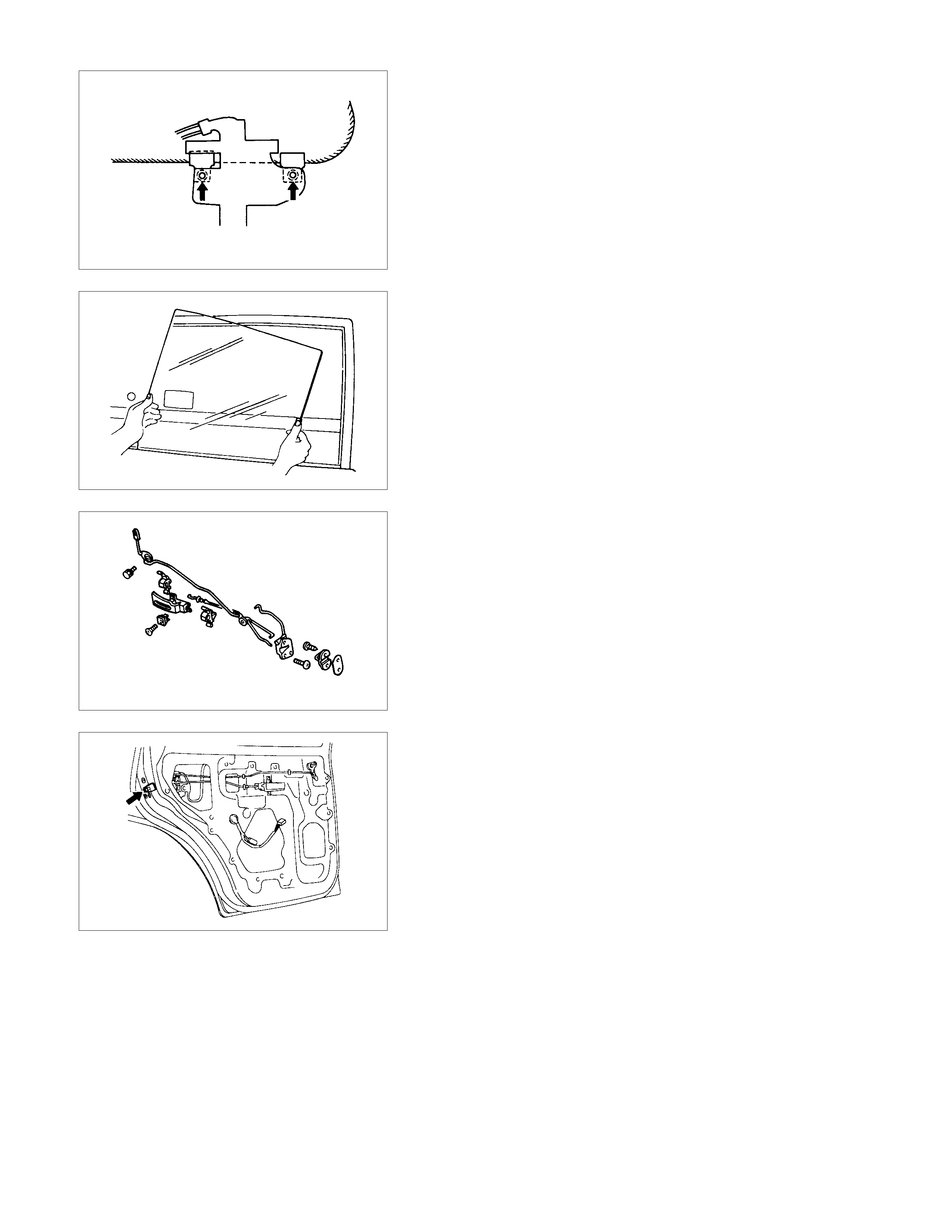

5. Fuel Filler Lid Opener Lever

•Remove the 2 opener fixing bolts and disconnect the

cable.

7. Fuel Filler Lid Cable Assembly

•Remove some fixing clips, turn the cable holder on the

side of recess in 90° counterclockwise and remove it

from the recess. Pull out the grommet to rearward o

f

vehicle and remove the cable assembly.

• In case of LHD, remove the rear seat assembly before

removing the fuel filler lid cable assembly.

(Refer to Rear Seat in this section)

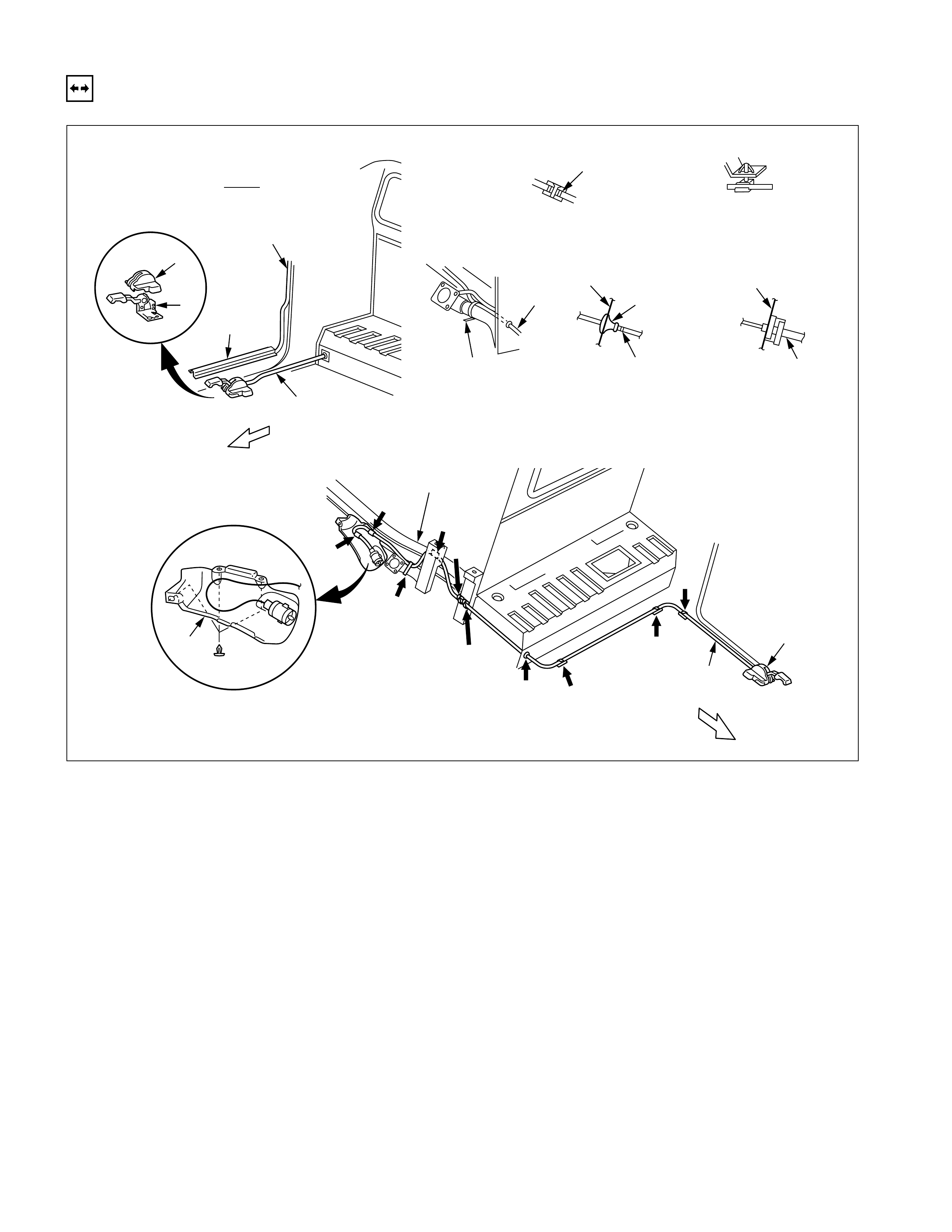

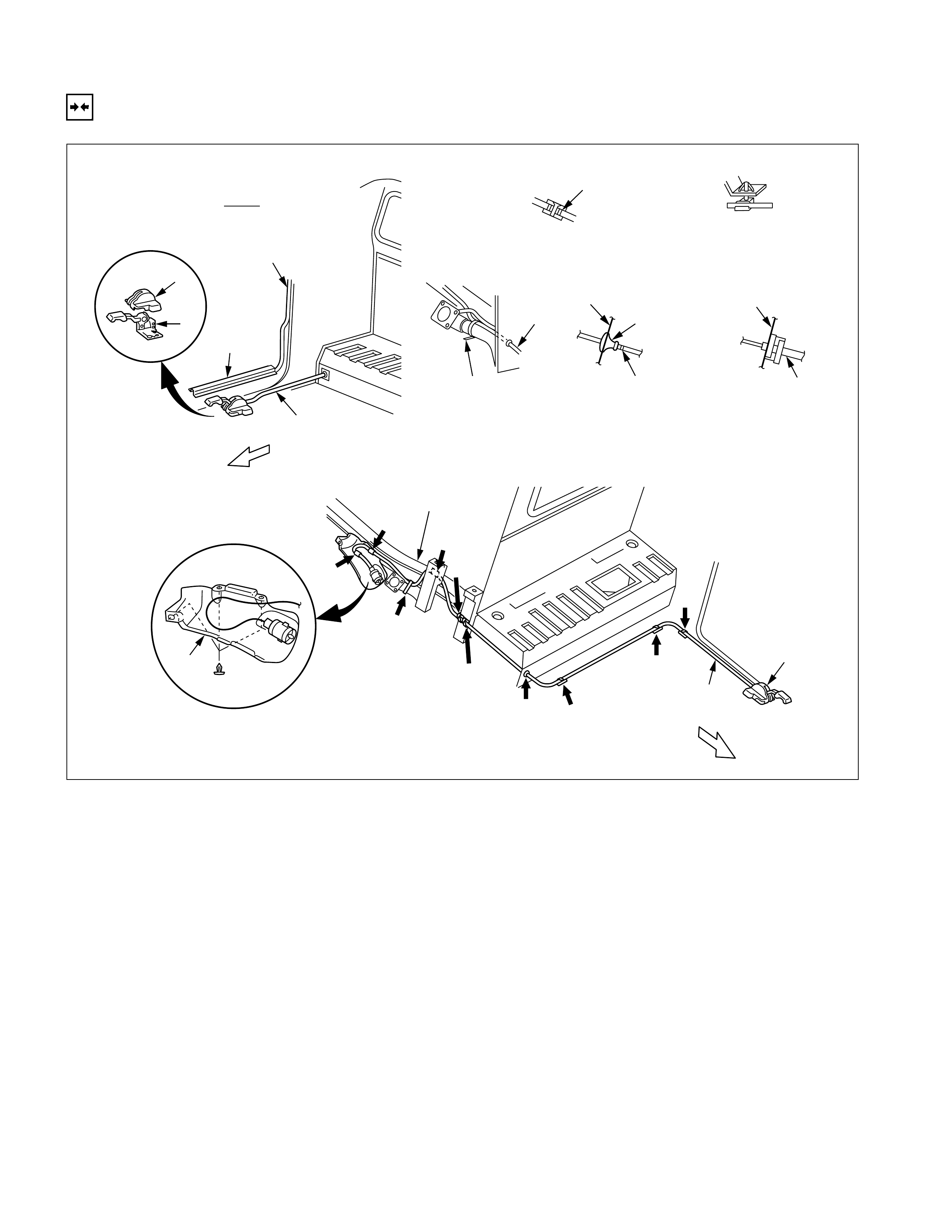

INSTALLATION (DOUBLE CAB)

INSTALLATION STEPS

▲1. Fuel filler lid cable assembly

2. Cover

3. Fuel filler lid opener lever

4. Fuel filler lid opener cover

5. Center pillar inner trim cover

6. Rear sill plate

7. Front sill plate

INSTALLATION (SPACE CAB)

4

37

1

1

1

A

A

RHD

DETAIL C DETAIL D

Door finisher

Front

Cable clip

Panel Grommet

White marking

Cab mounting

White marking

DETAIL E

DETAIL BDETAIL A

Protector

Front

A

D

Rear body

wheel house panel

B

B

C

E

E

2

B

3,4

INSTALLATION STEPS

▲1. Fuel filler lid cable assembly

2. Cover

3. Fuel filler lid opener lever

4. Fuel filler lid opener cover

7. Front sill plate

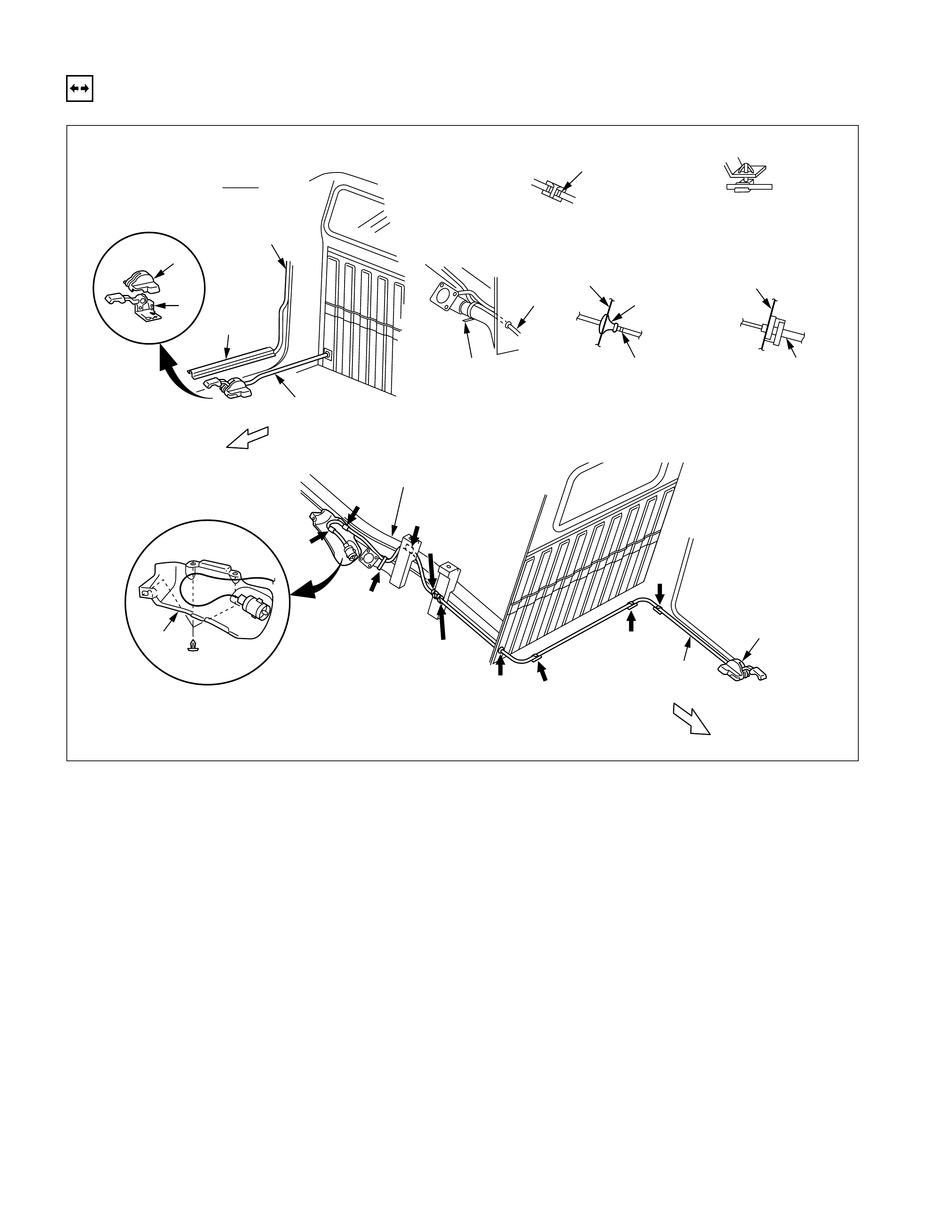

INSTALLATION (SINGLE CAB)

Rear body

wheel house panel

B

B

C

E

E

2

B

4

37

1

1

RHD

DETAIL C DETAIL D

Door finisher

Front

Cable clip

Panel Grommet

White marking

Rear body mounting

White marking

DETAIL E

DETAIL BDETAIL A

Protector

1

A

A

Front

A

D

3,4

INSTALLATION STEPS

▲1. Fuel filler lid cable assembly

2. Cover

3. Fuel filler lid opener lever

4. Fuel filler lid opener cover

7. Front sill plate

IMPORTANT OPERATIONS - INSTALLATION

1. Fuel Filler Lid Cable Assembly

•Install the cable holder of cable assembly to the recess

and push the grommet in to the back panel. Fix the

pointed places.

Note:

To install, follow the removal steps in the reverse order,

noting the following points.

•

••

•Do not make extreme curve on the cable.

•

••

•Install the cable from outside of the cab.

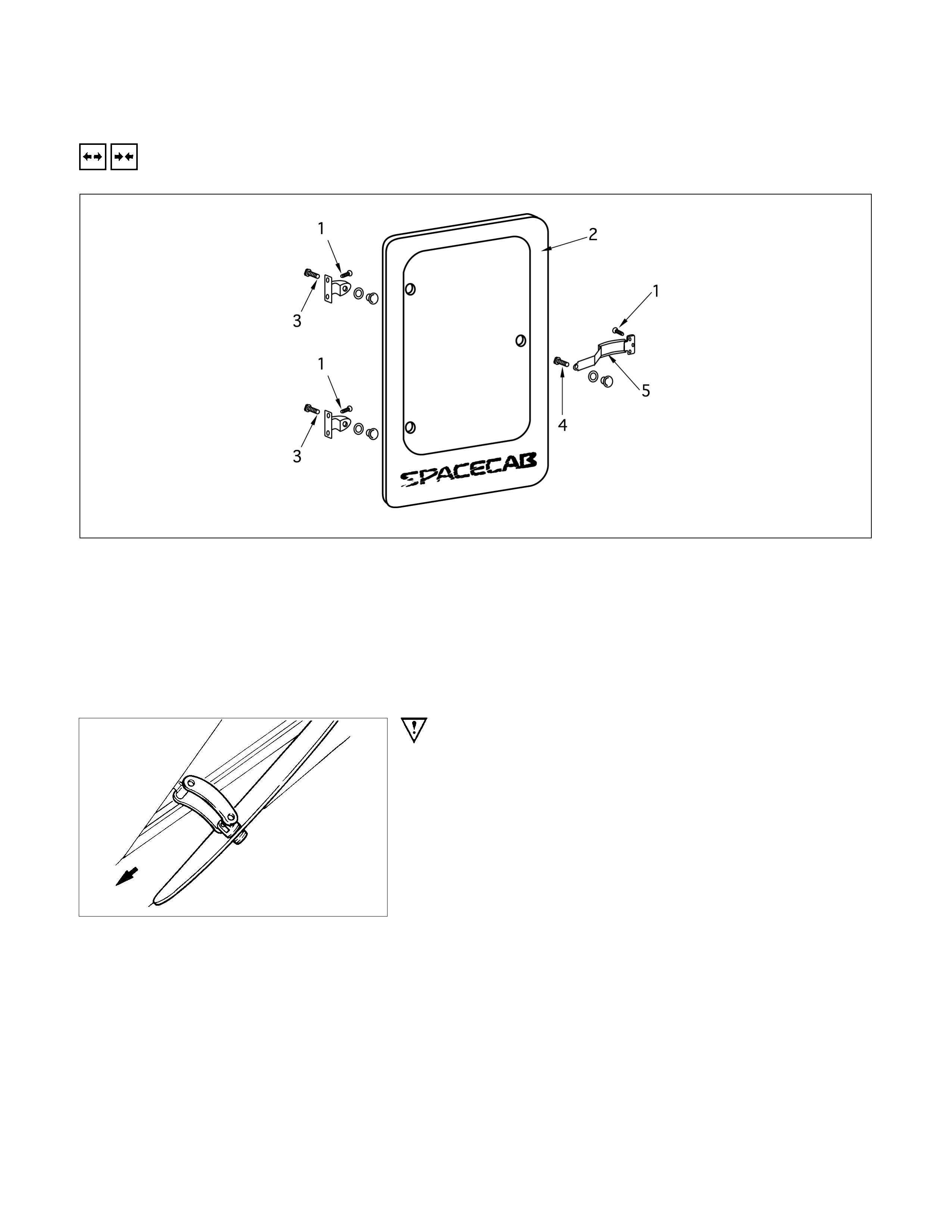

QUARTER GLASS (SPACE CAB)

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Screw bolt

▲2. Quarter glass

3. Screw bolt

4. Screw bolt

5. Fastener assembly

INSTALLATION STEPS

5. Fastener assembly

4. Screw bolt

3. Screw bolt

2. Quarter glass

1. Screw bolt

IMPO RTANT OPERATIONS - REMOVAL

2. Quarter Glass

Pull out the glass assembly towards the rear of the vehicle.

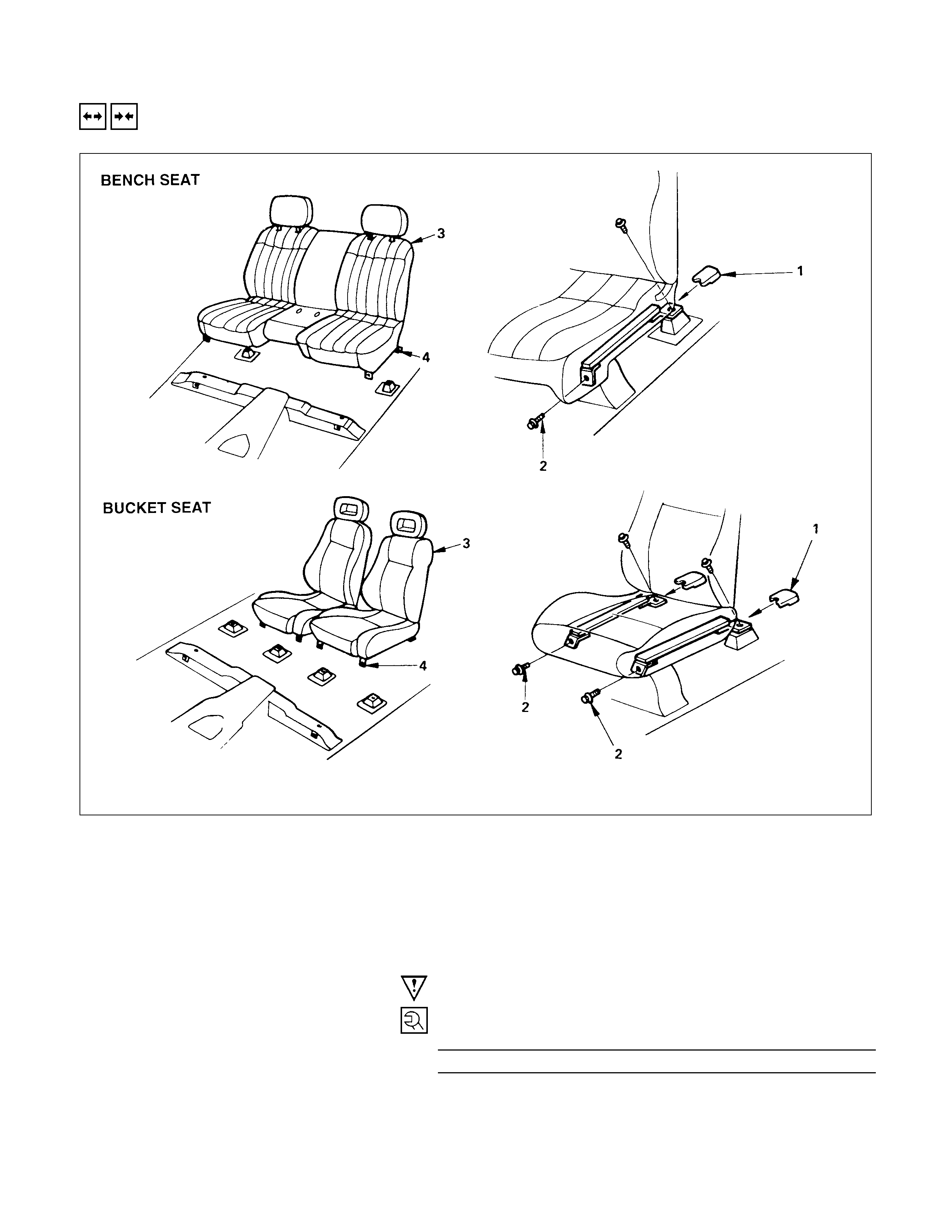

FRONT SEAT

SPECIAL PARTS FIXI NG BOLT N⋅

⋅⋅⋅m (kgf⋅

⋅⋅⋅m/lb⋅

⋅⋅⋅ft)

39.2±

±±

±9.8 (4±

±±

±1/28.9±

±±

±7.2)

39.2±

±±

±9.8 (4±

±±

±1/28.9±

±±

±7.2)

39.2±

±±

±9.8 (4±

±±

±1/28.9±

±±

±7.2)

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. A djust cover

2. Bolt

3. Seat assembly

4. Adjuster

INSTALLATION STEPS

4. Adjuster

3. Seat assembly

▲2. Bolt

1. A djust cover

IMPORTANT OPERATION - INSTALLATION

2. Bolt

Torque N⋅m(kgf⋅m/lb⋅ft)

40.2 ± 9.8 (4.1 ± 0.6 / 29.6 ± 4.3)

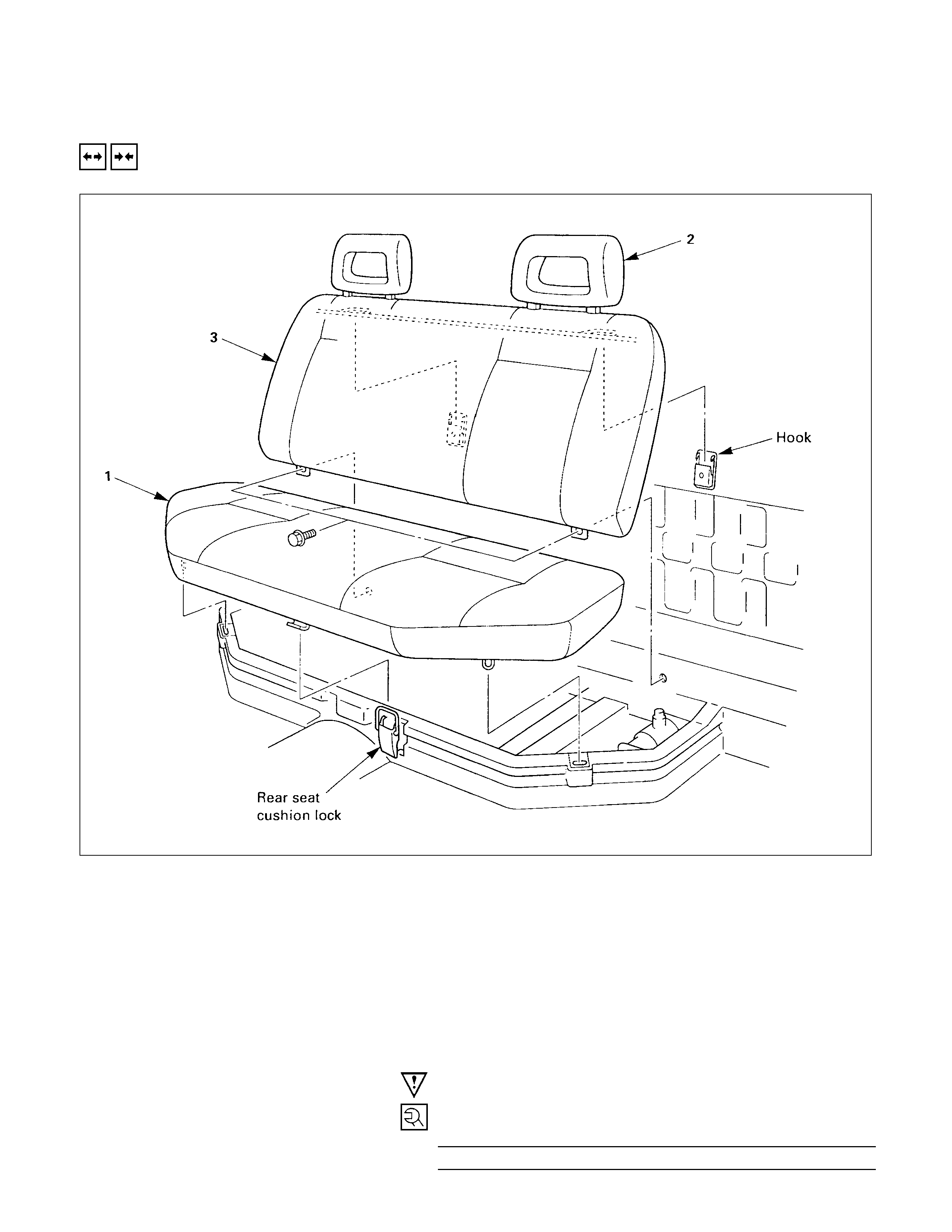

REAR SEAT

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Rear seat cushion assembly

•Release the lock, pull up the fixed

points.

2. Head rest

3. Rear seat back assembly

•After removing the 2 fixing bolts,

remove the wire of the back from the

hook.

INSTALLATION STEPS

▲3. Rear seat back assembly

2. Head rest

1. Rear seat cushion assembly

IMPORTANT OPERATION - INSTALLATION

3. Rear Seat Back Assembly

Bolt torque N⋅m(kgf⋅m/lb⋅ft)

19.6 ± 5 (2 ± 0.5 / 14.5 ± 3.6)

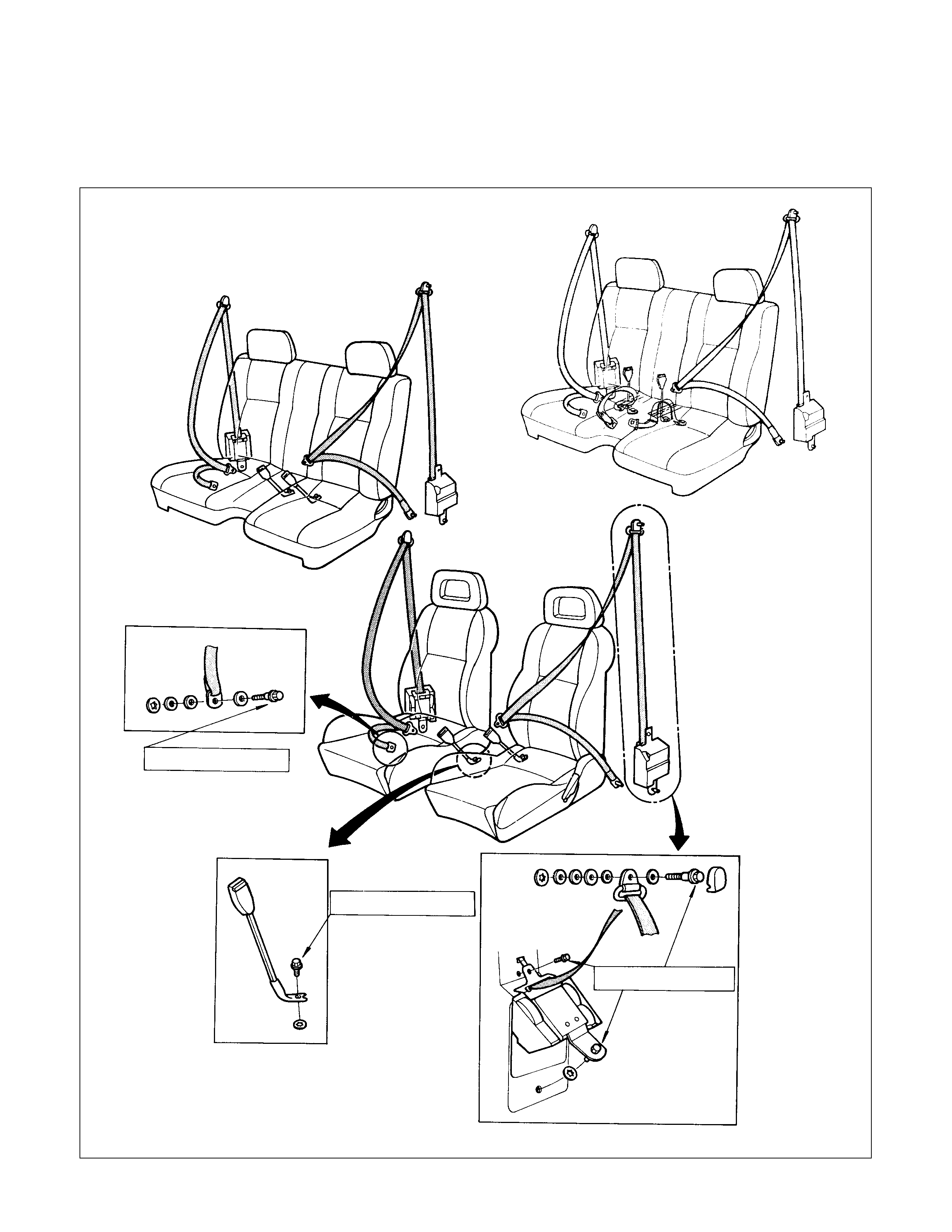

FRONT SEAT BELT

REMOVAL AND INSTALLATION

Removal Steps

1. Trim

2. Seat belt and retractor

Installation Steps

▲2. Seat belt and retractor

1. Trim

Important Oper ati on - Installati on

2. Seat Belt and Retractor

Bolt Torque N⋅m(kgf⋅m/lb⋅ft)

39.2 ± 9.8 (4 ± 1 / 28.9 ± 7.2)

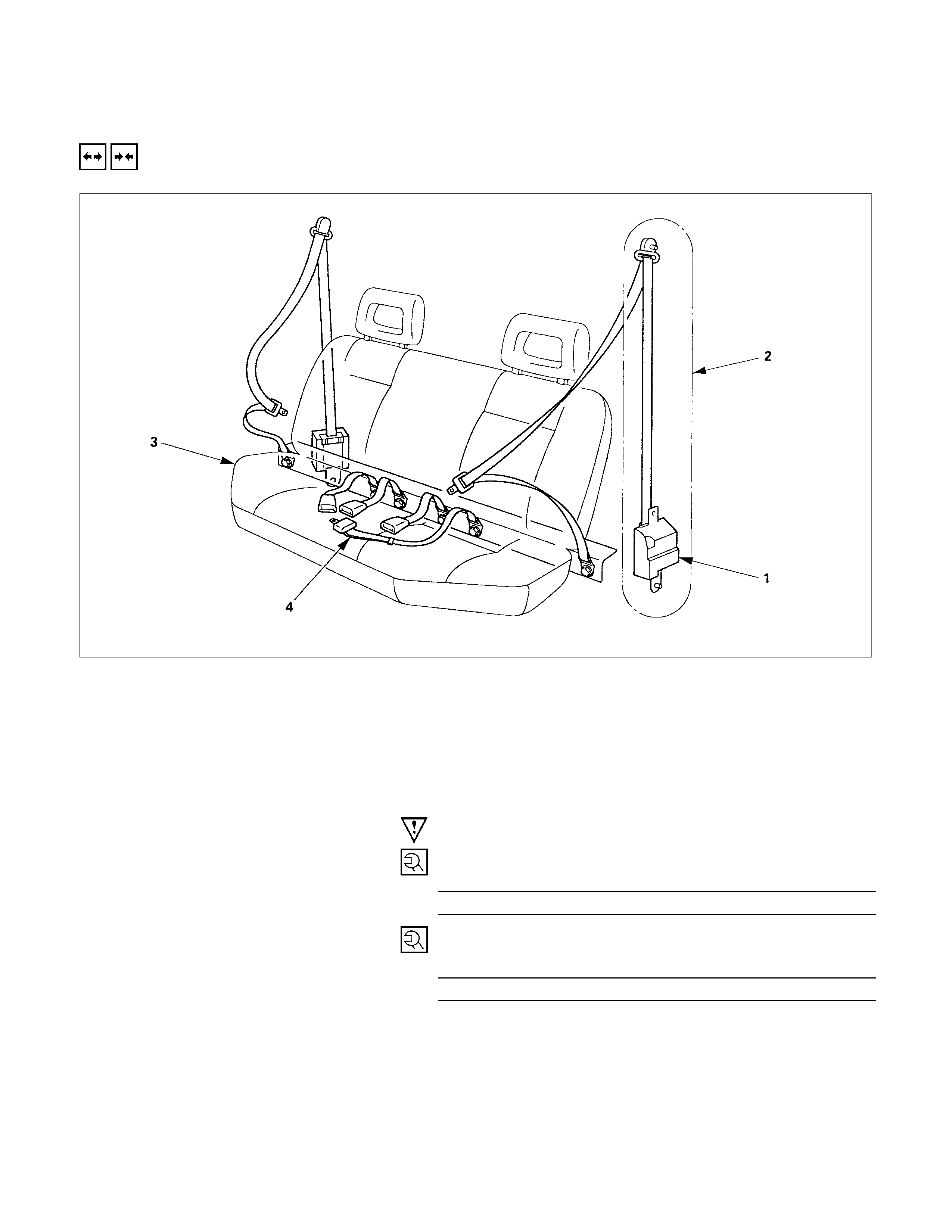

REAR SEAT BELT

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Trim

2. Rear seat belt and retractor

3. Rear seat cushion

4. Center belt and buckle

INSTALLATION STEPS

▲4. Center seat belt and buckle

3. Rear seat cushion

▲2. Rear seat belt and retractor

1. Trim

IMPORTANT OPERATION - INSTALLATION

2. Rear Seat Belt and Retractor

Bolt Torque N⋅m(kgf⋅m/lb⋅ft)

39.2 ± 9.8 (4 ± 1 / 28.9 ± 7.2)

4. Center back Belt and buckle

Bolt Torque N⋅m(kgf⋅m/lb⋅ft)

39.2 ± 9.8 (4 ± 1 / 28.9 ± 7.2)