SECTION 2A - HEATER AND AIR CONDITIONING

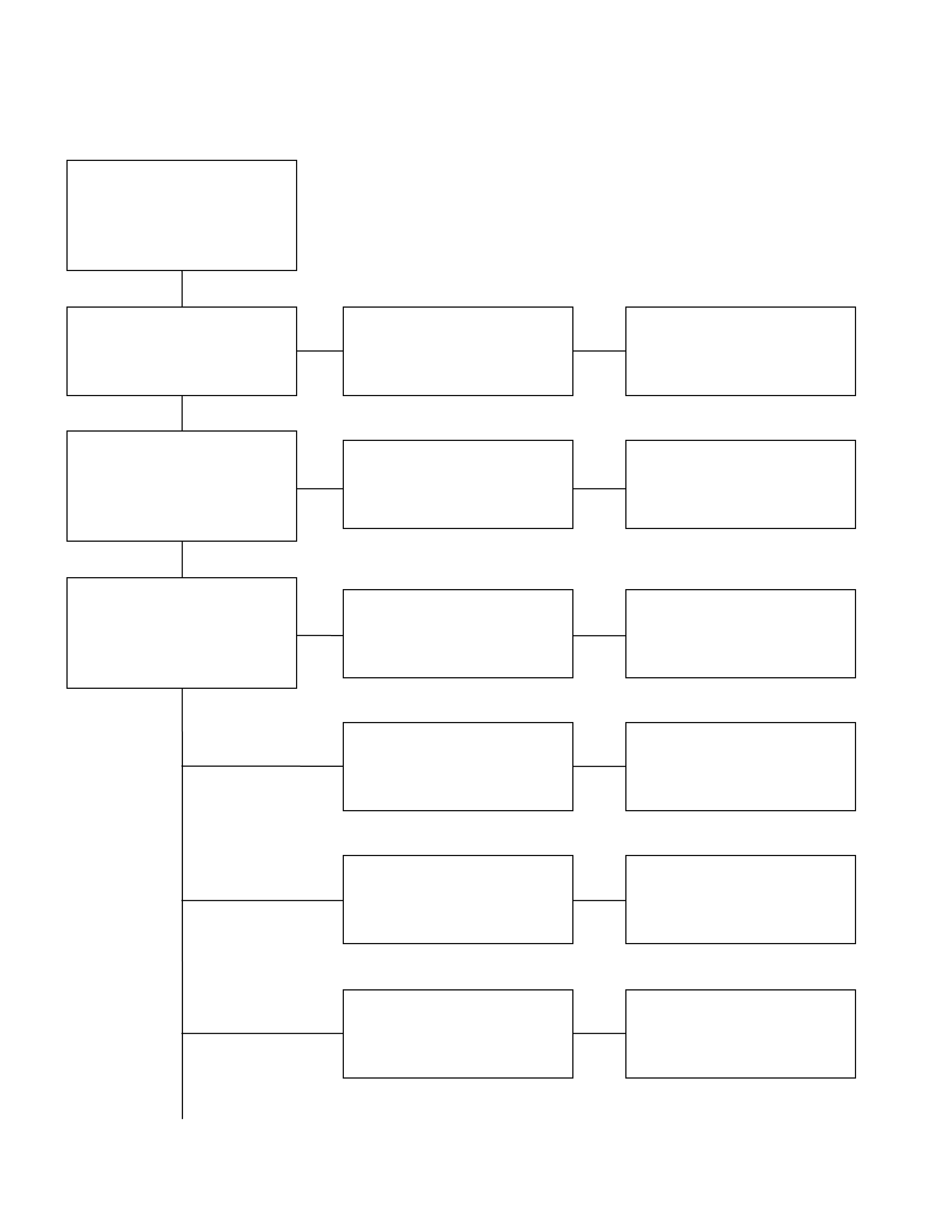

GENERAL DESCRIPTION

SYSTEM COMPONENTS

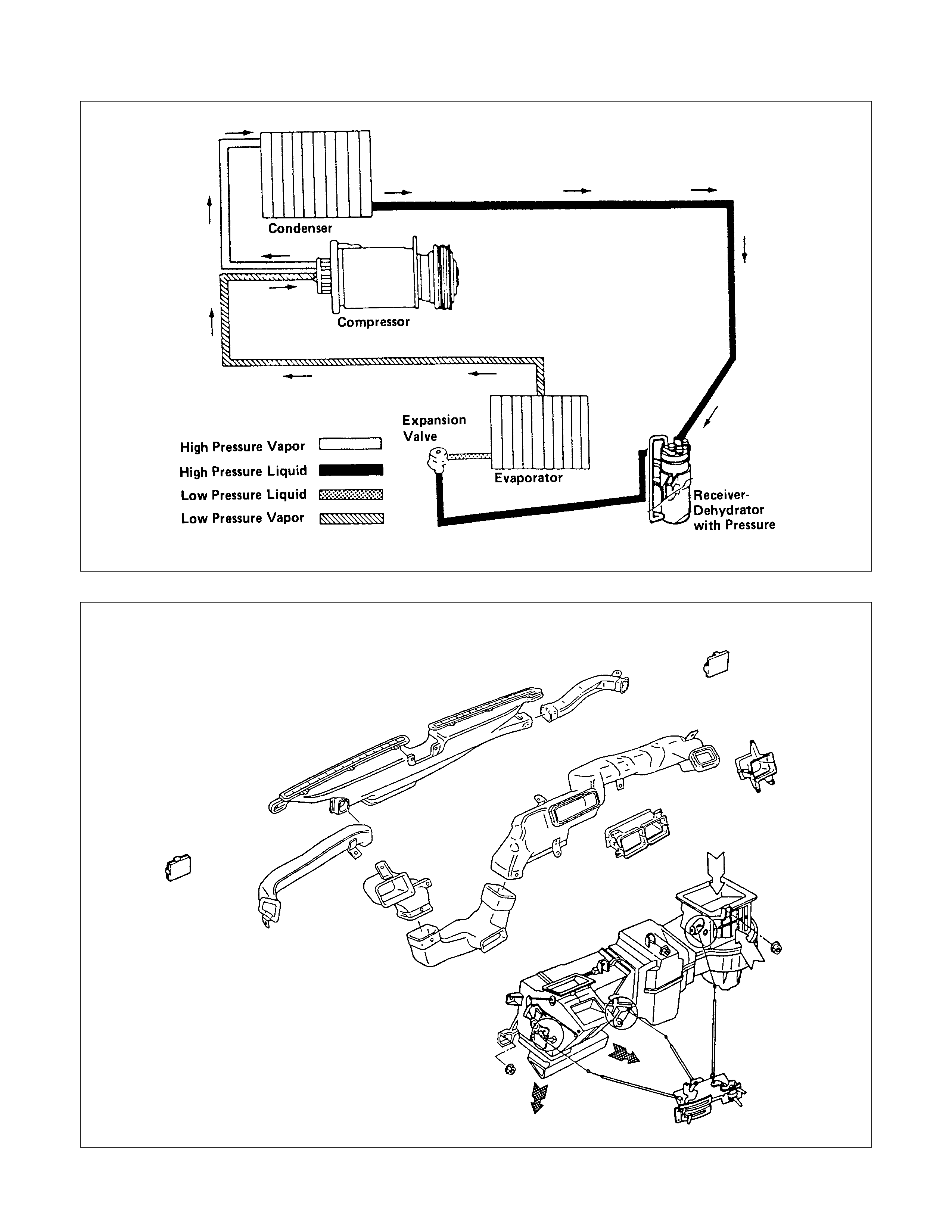

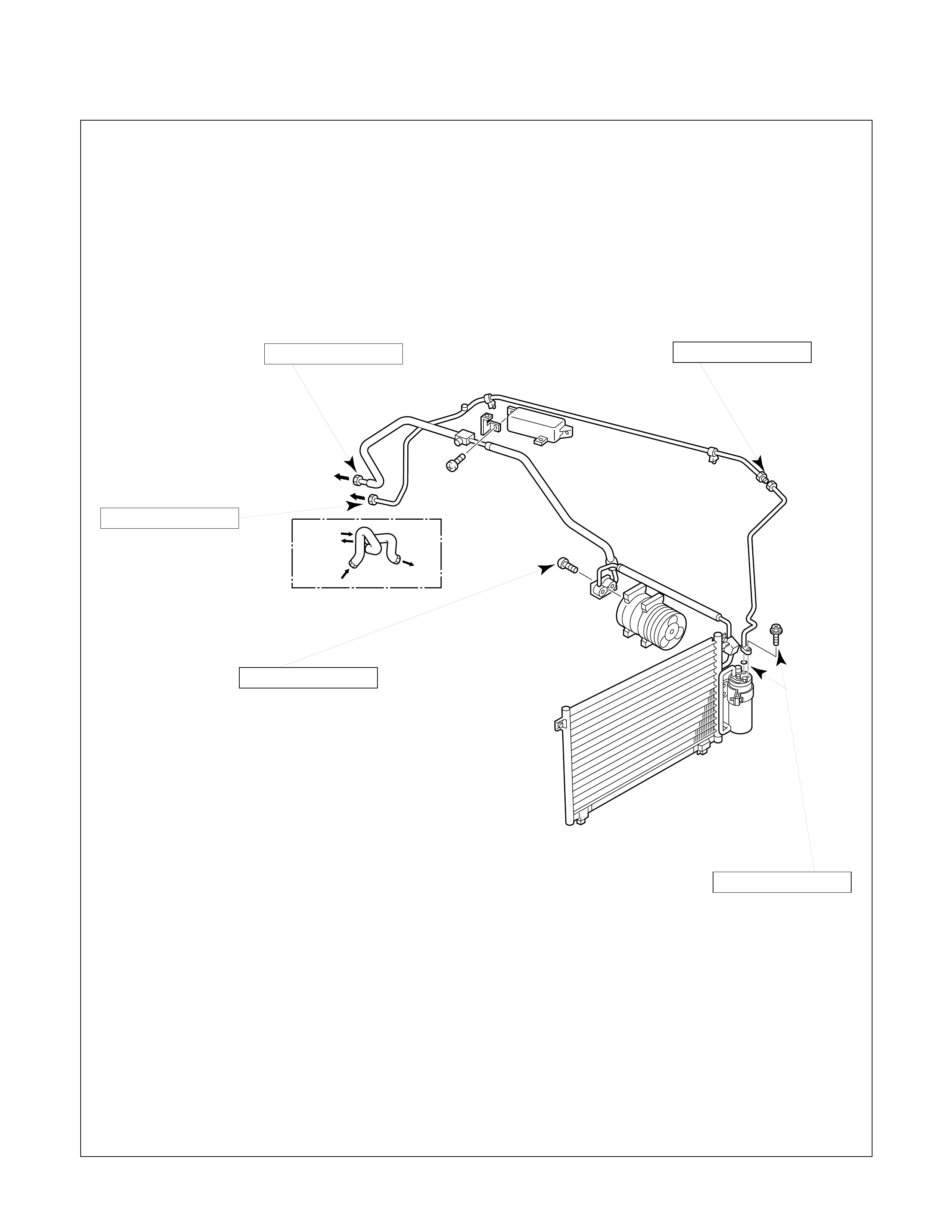

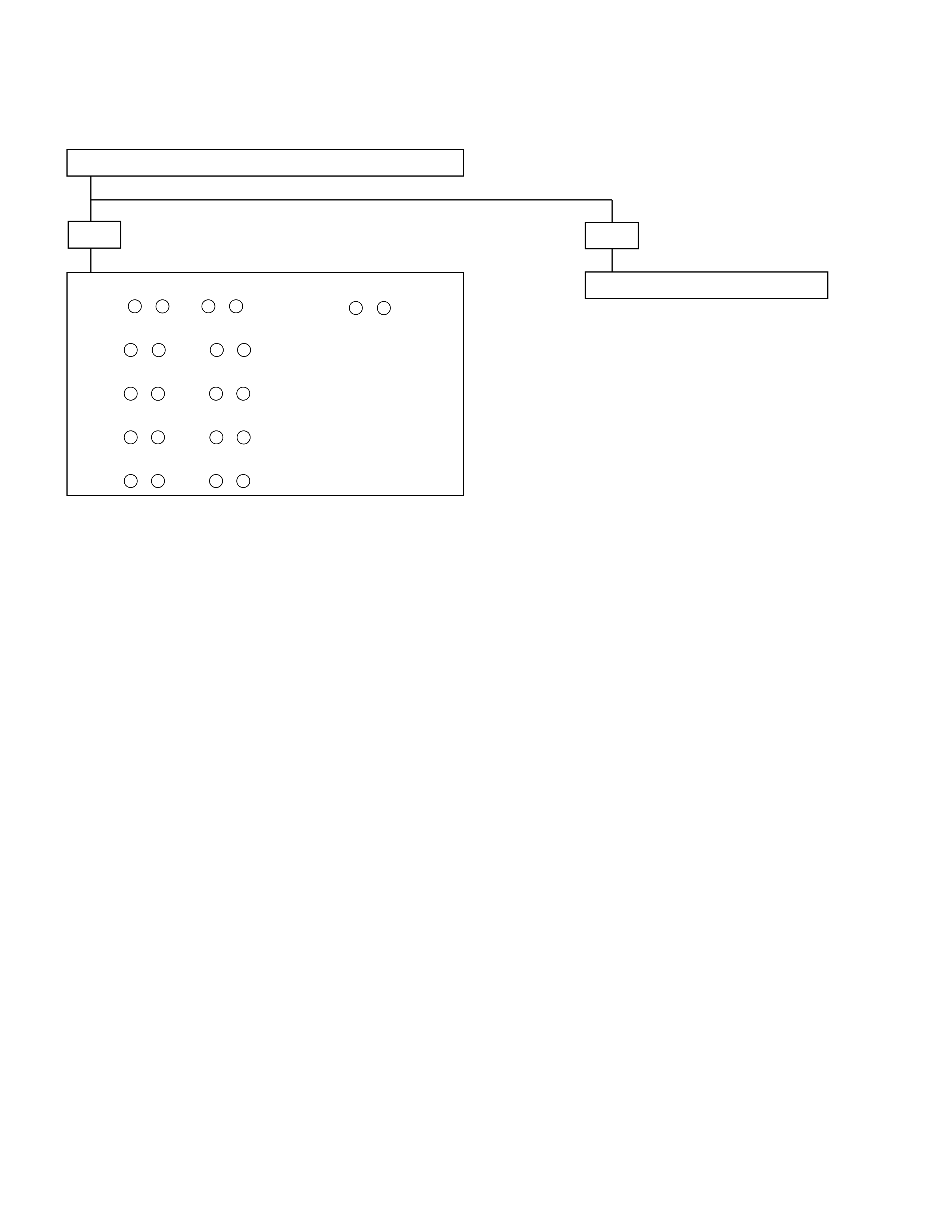

SYSTEM COOLING LINE

UNIT

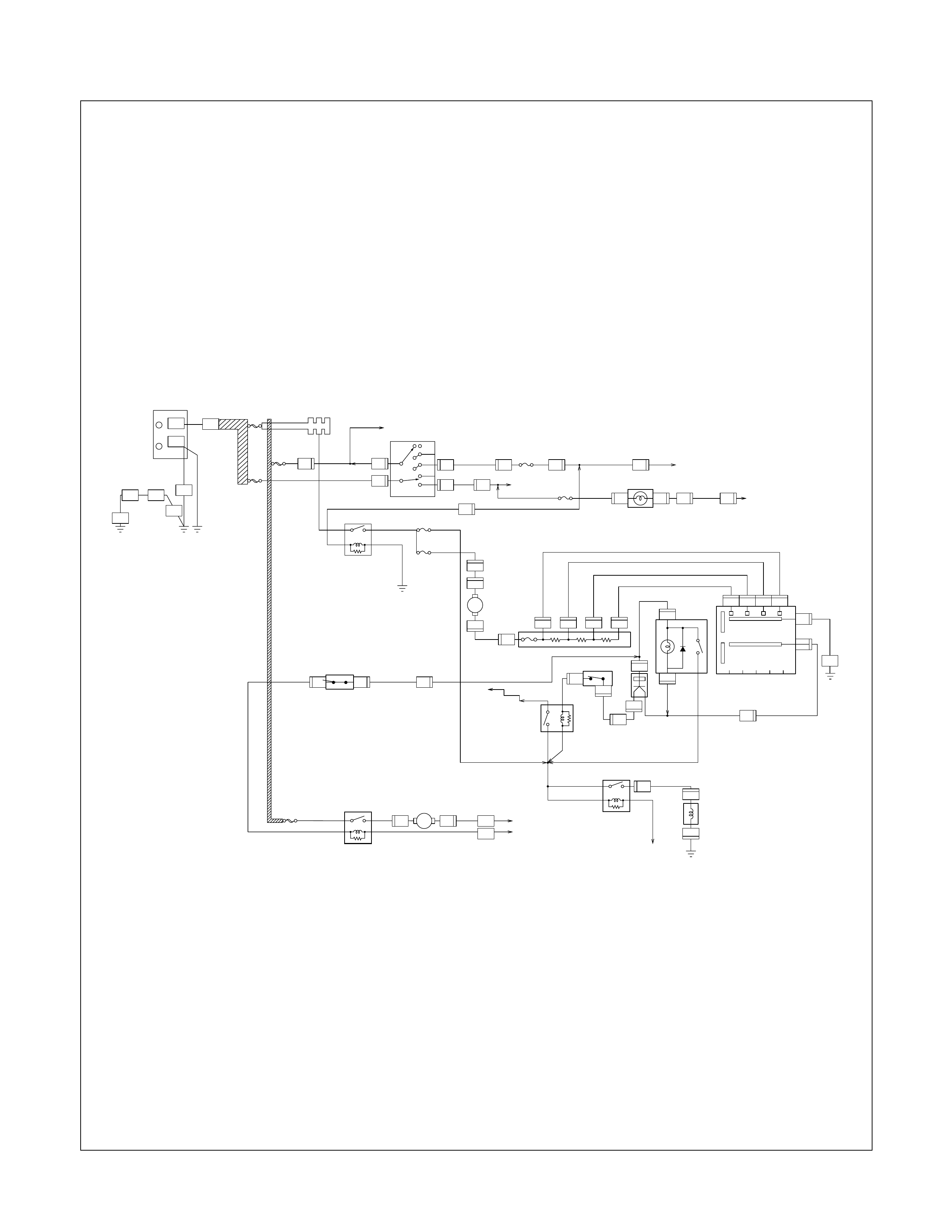

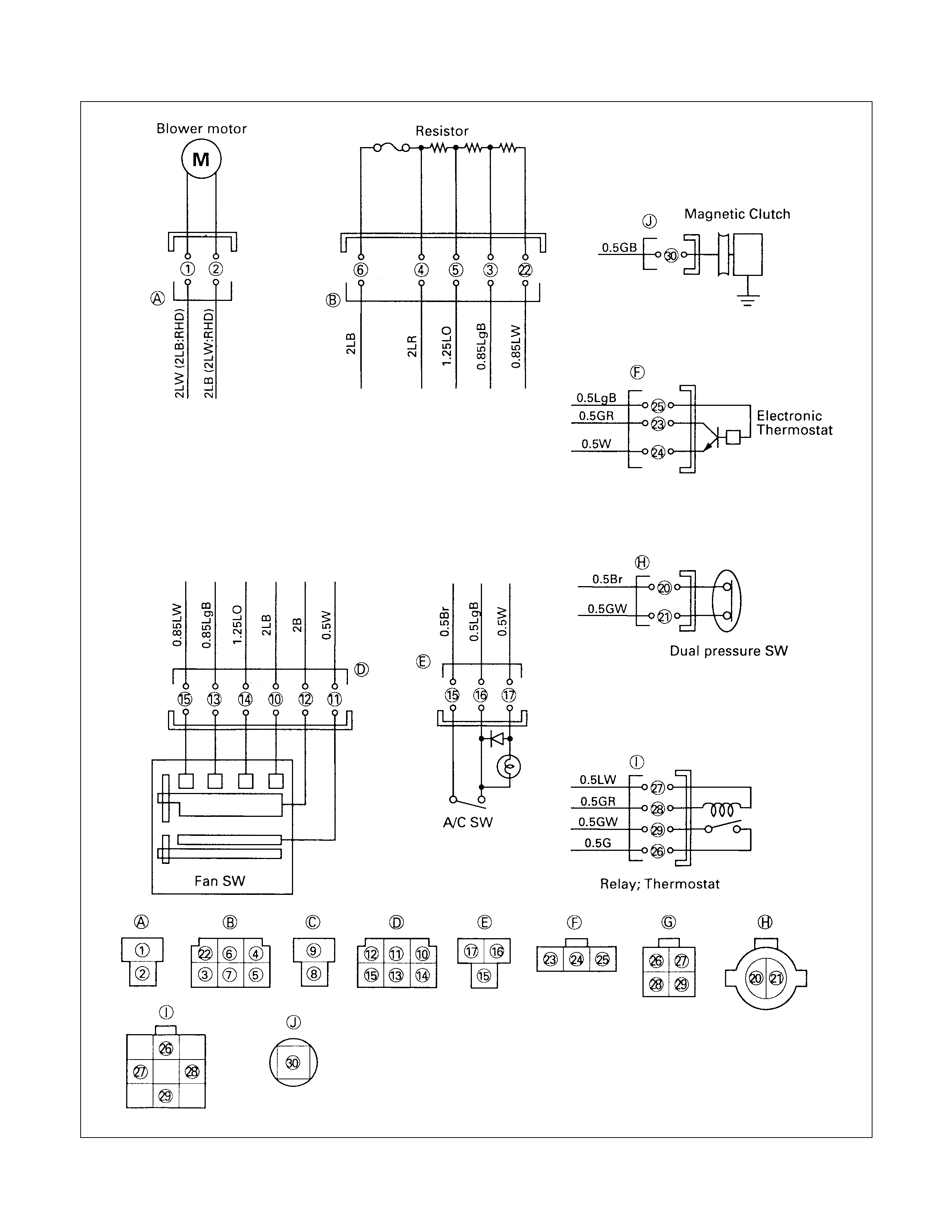

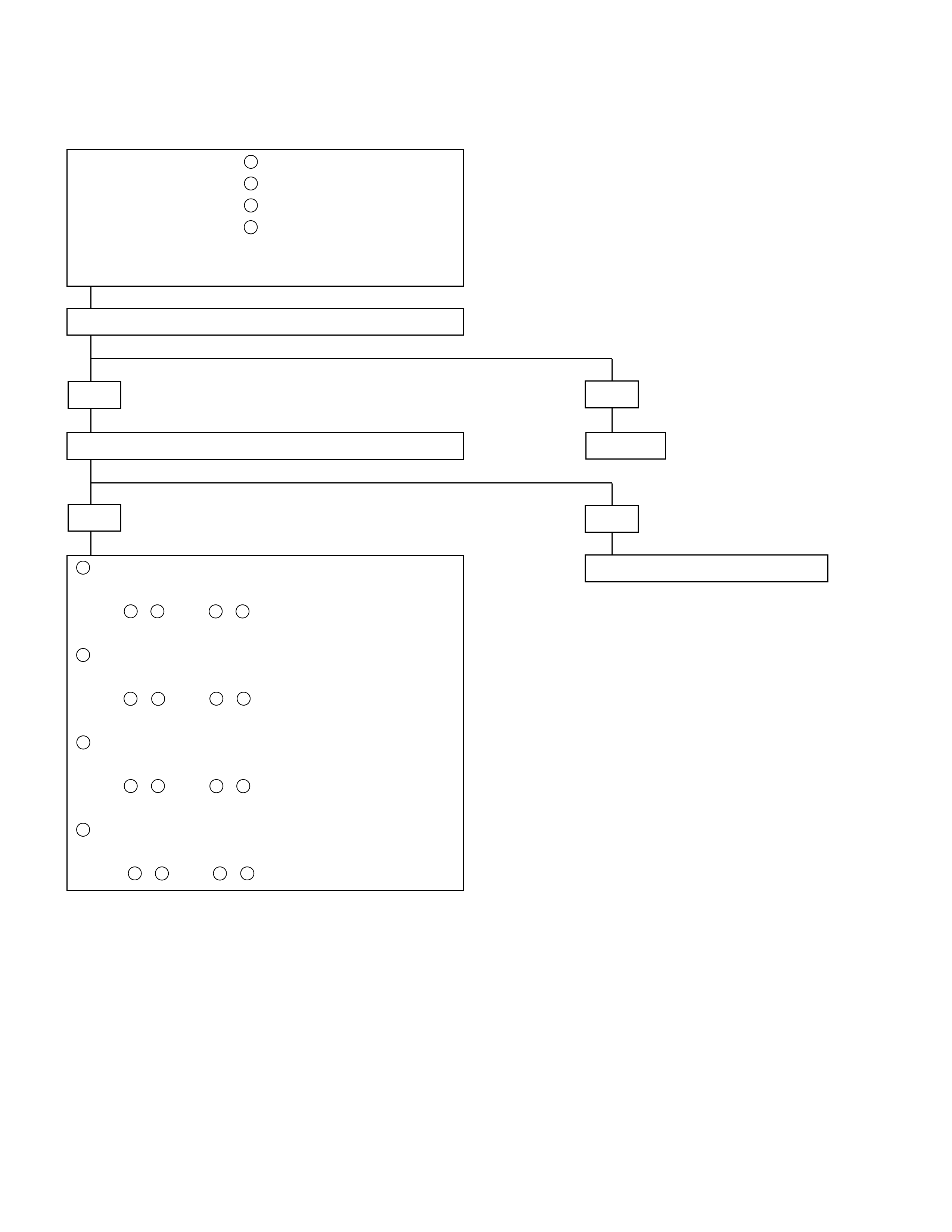

WIRING DIAGRAM

WIRING HARNESS TERMINAL POSTIONS

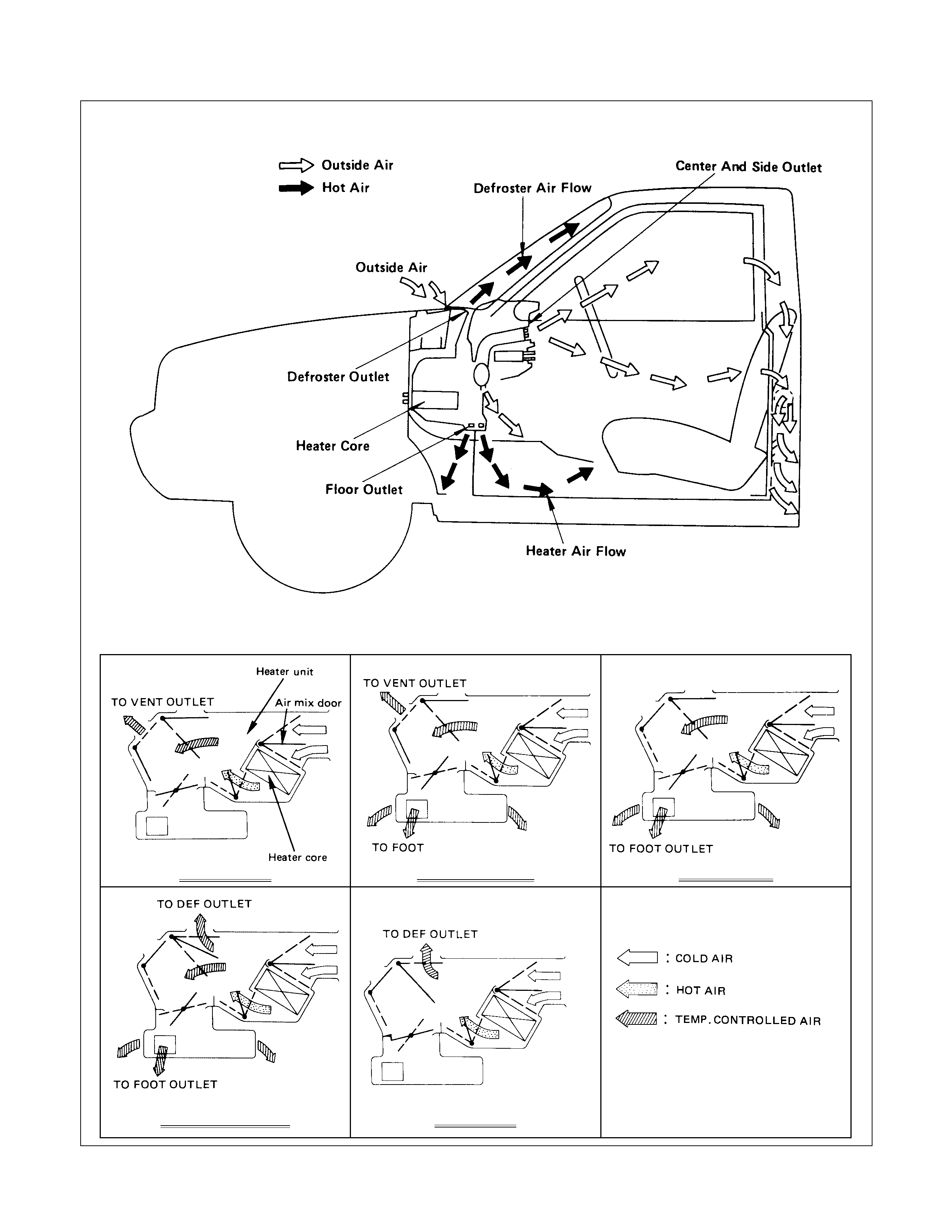

VENTILATION

MAIN DATA AND SPECIFICATIONS

SPECIAL PARTS FIXING NUTS AND BOLTS

COMPRESSOR ASSEMBLY

REFRIGERATION SYSTEM (RHD MODEL)

SERVICING

PRECAUTIONS FOR REFRIGERANT - 134A (R-134A) AIR CONDITIONING SYSTEM

REPAIR OF REFRIGERANT LEAKS

LEAK AT REFRIGERANT LINE CONNECTIONS

LEAK IN THE HOSE

COMPRESSOR LEAKS

REPLACEMENT OF COMPONENT PARTS

RECOVERY, RECYCLING, EV ACUATION AND CHARGING

REFRIGERANT RECOVERY

REFRIGERANT RECYCLING

EVACUATION OF THE REFRIGERANT SYSTEM

CHARGING THE REFRIGERANT SYSTEM

CHARGING P ROCE DURE

CONDENSER

REMOVAL AND INSTALLATION

RECEIVER DE HYDRATOR

REMOVAL AND INSTALLATION

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

COMPRESSOR

REMOVAL AND INSTALLATION

GENERAL REPAIR PROCEDURE

DISASSEMBLY

REASSEMBLY

HEATER UNIT

REMOVAL AND INSTALLATION

DISASSEMBLY AND REASSEMBLY

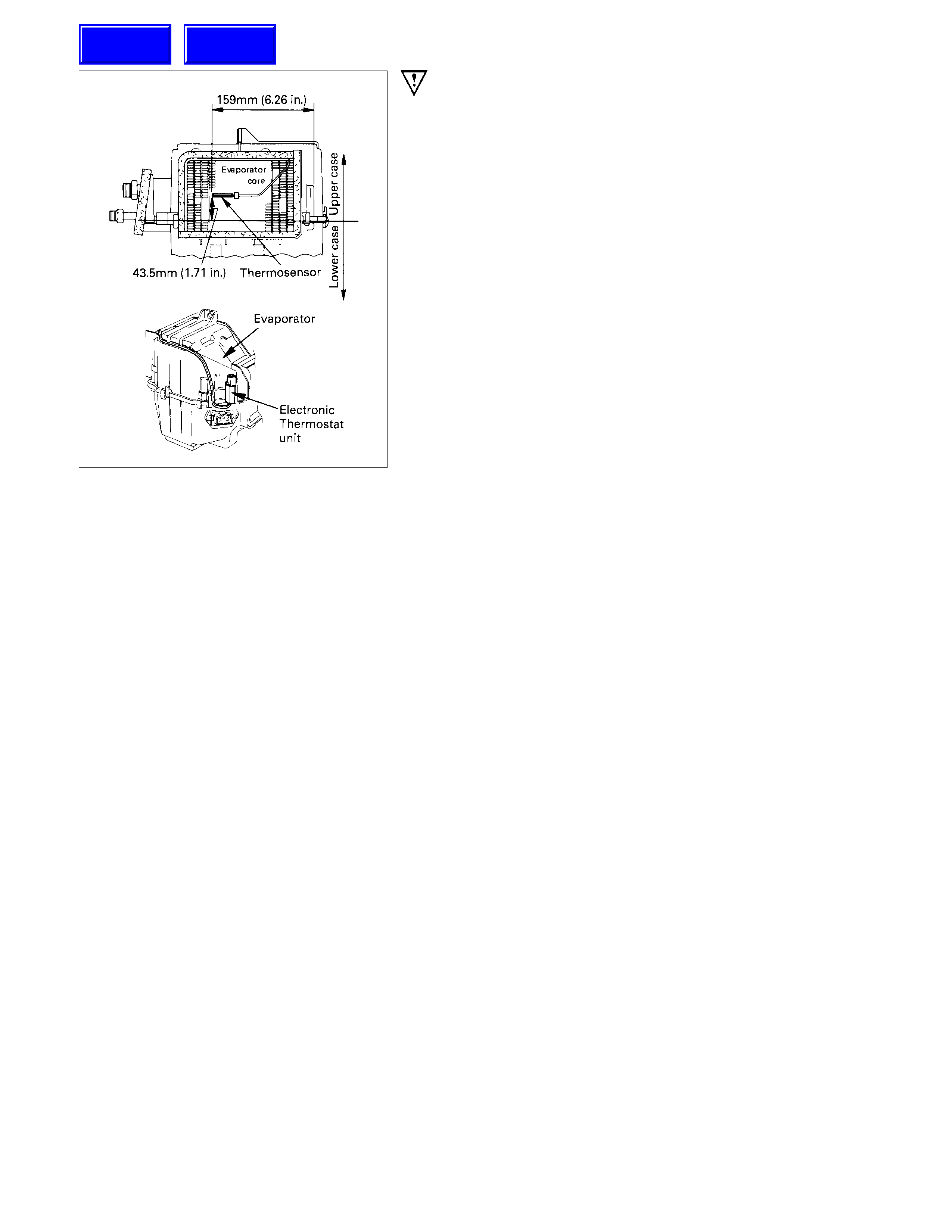

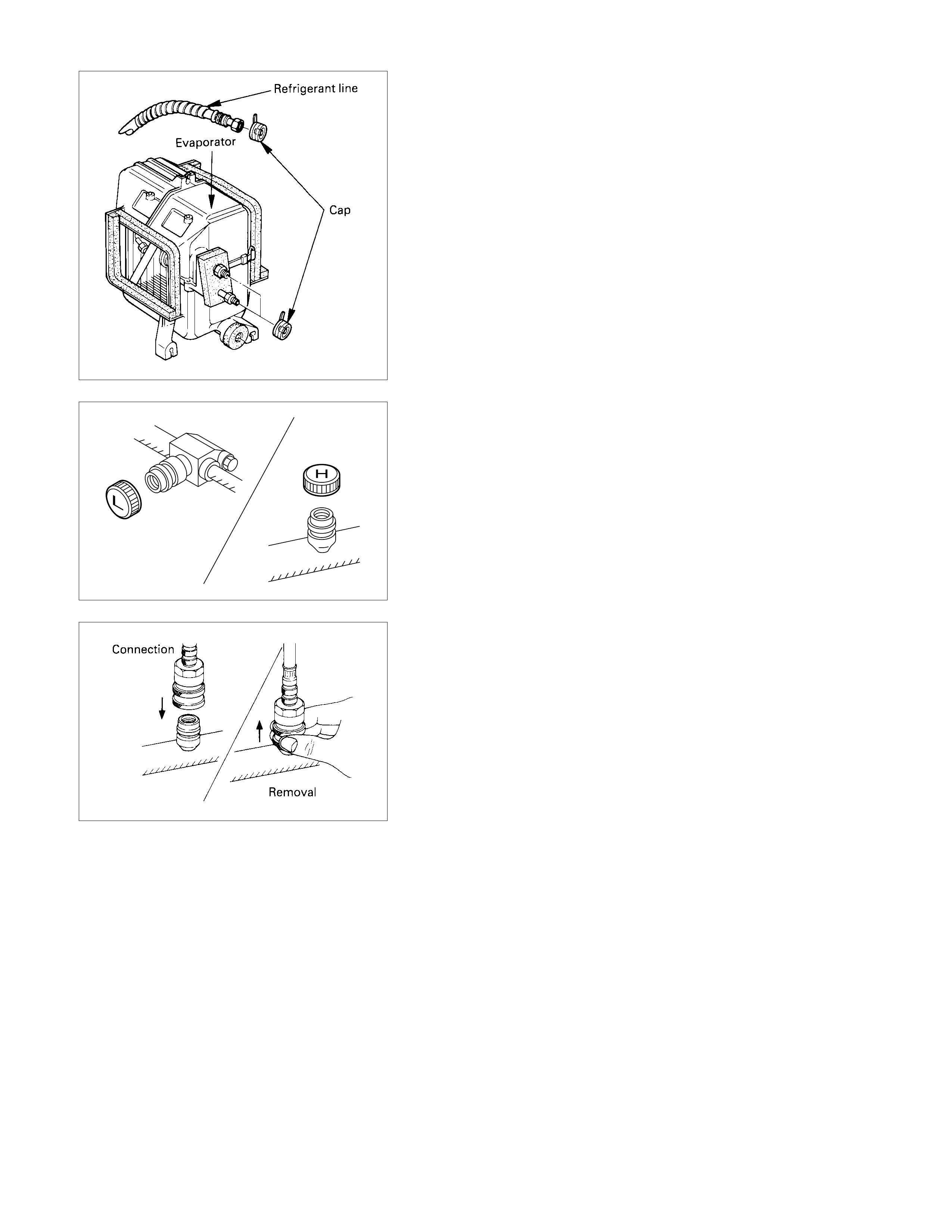

EVAPORATOR

REMOVAL AND INSTALLATION

DISASSEMBLY AND REASSEMBLY

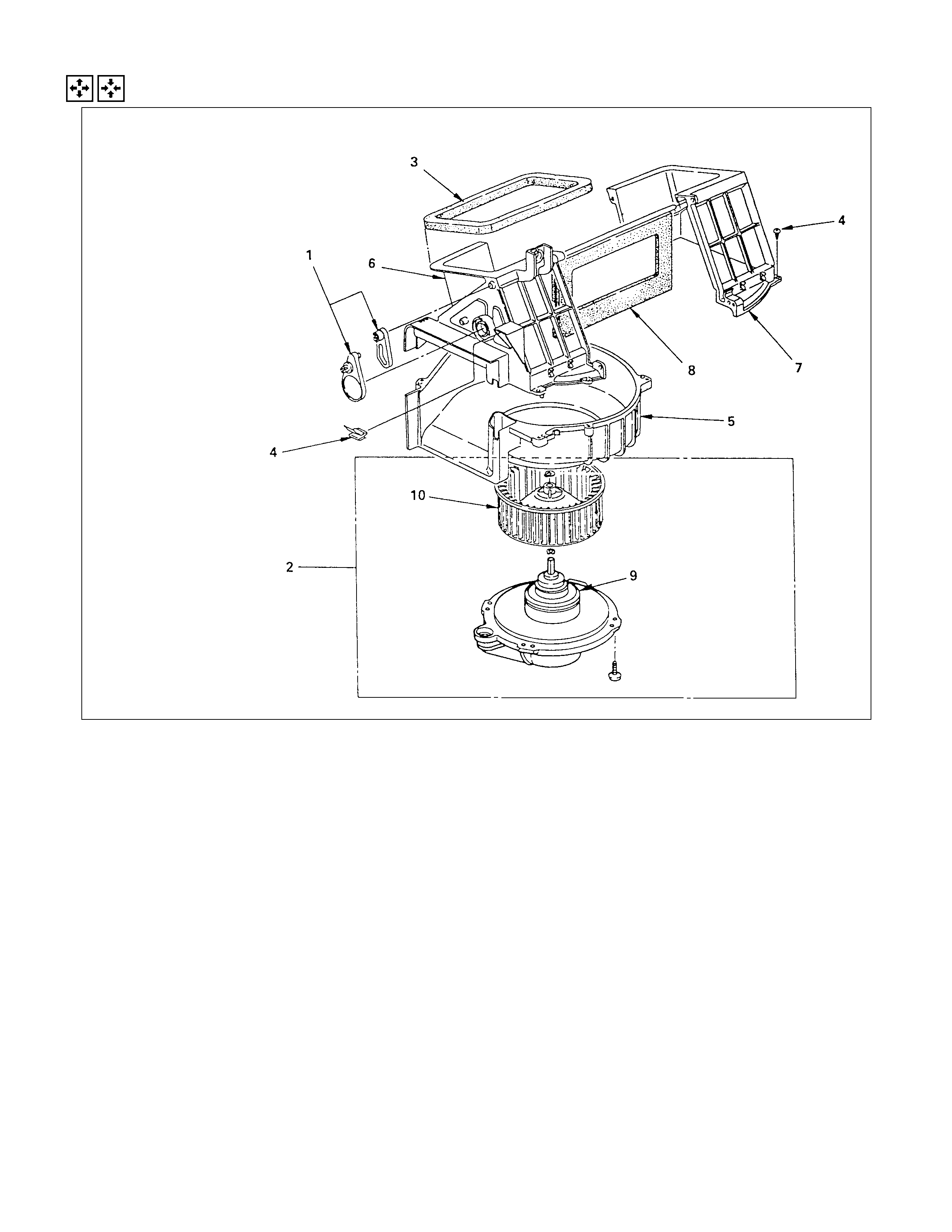

BLOWER UNIT ASSEMBLY

REMOVAL AND INSTALLATION

DISASSEMBLY AND REASSEMBLY

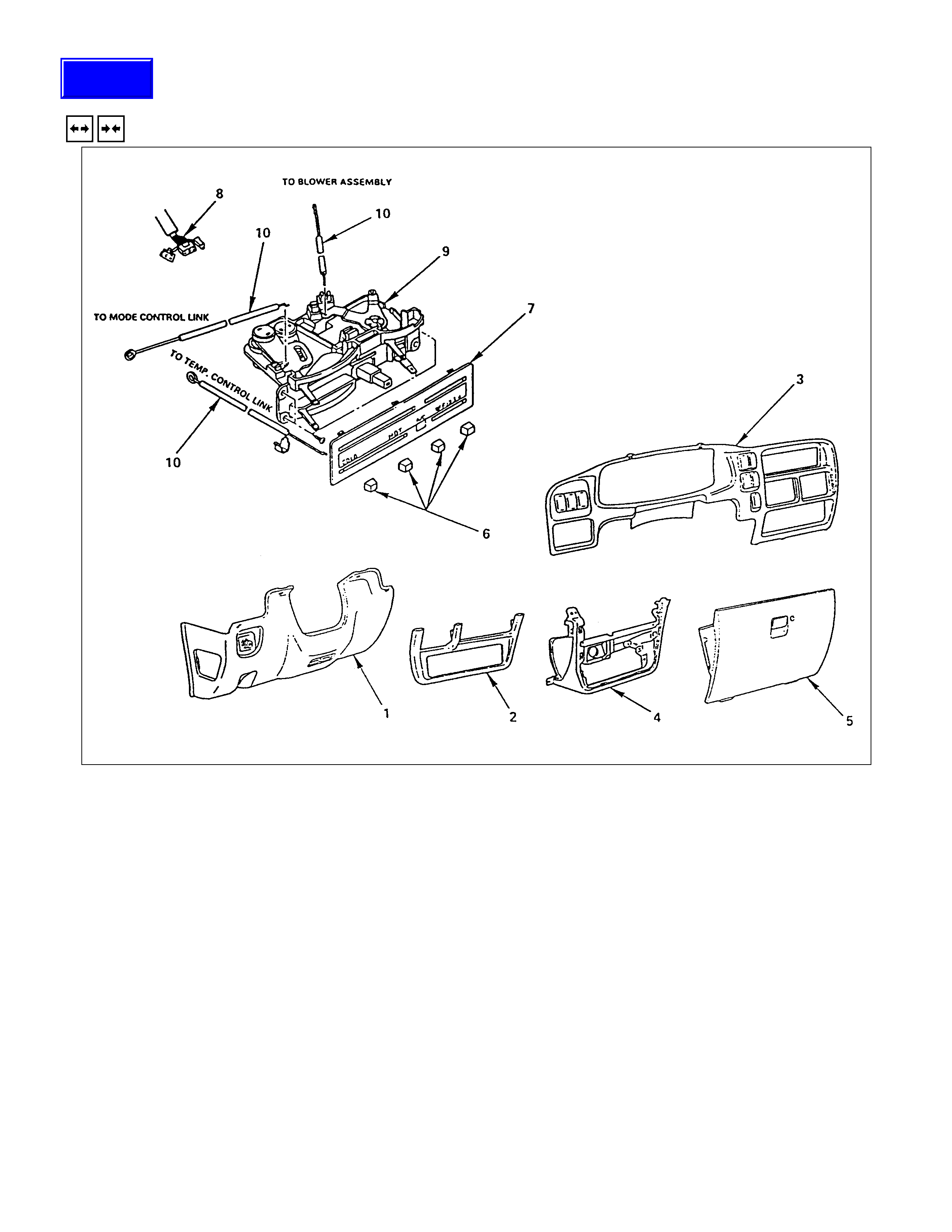

CONTROL LEVER ASSEMBLY

REMOVAL AND INSTALLATION

INSPECTION AND REPAIR

CONDENSER FAN MOTOR

REMOVAL

INSTALLATION

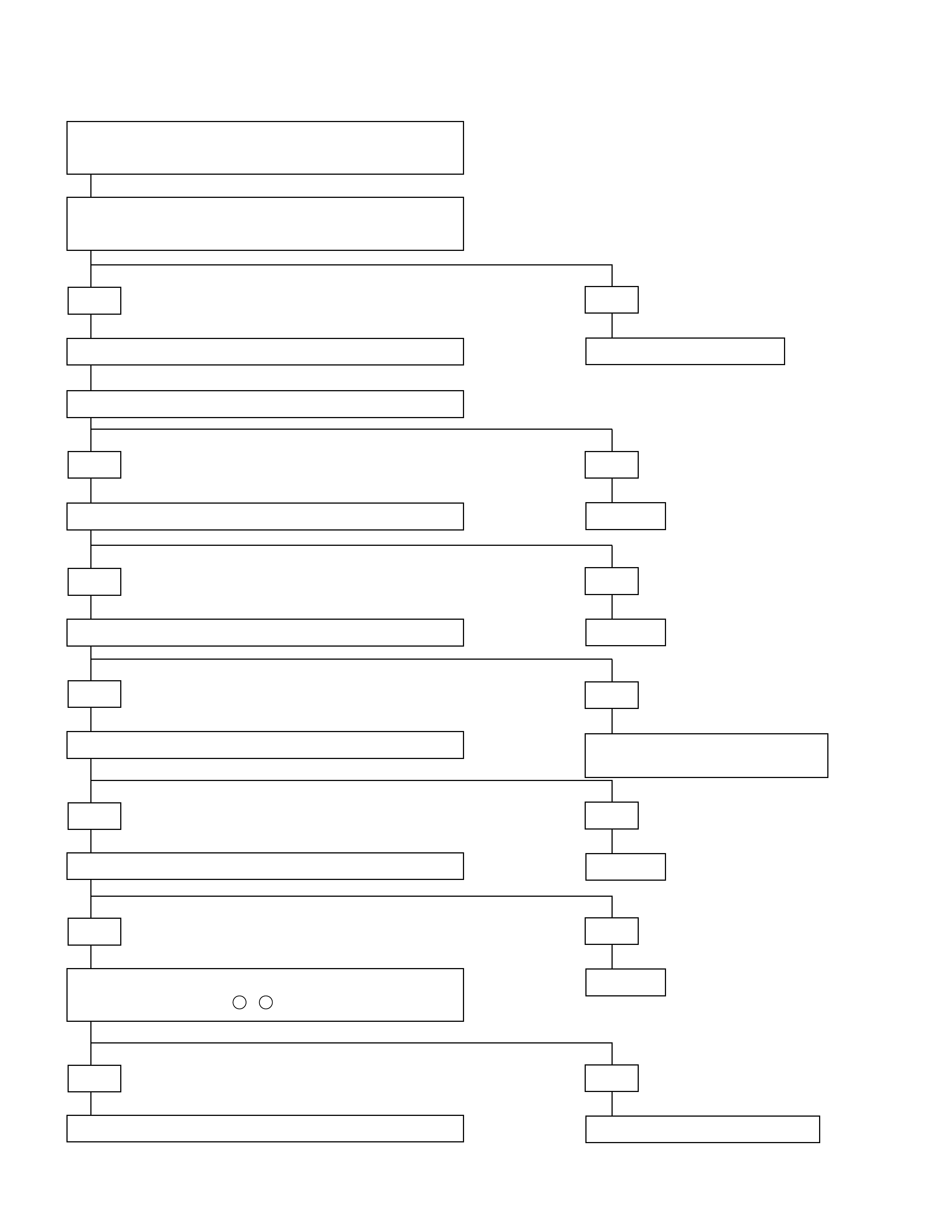

TROUBLESHOOTING

SPECIAL SERVICE TOOL

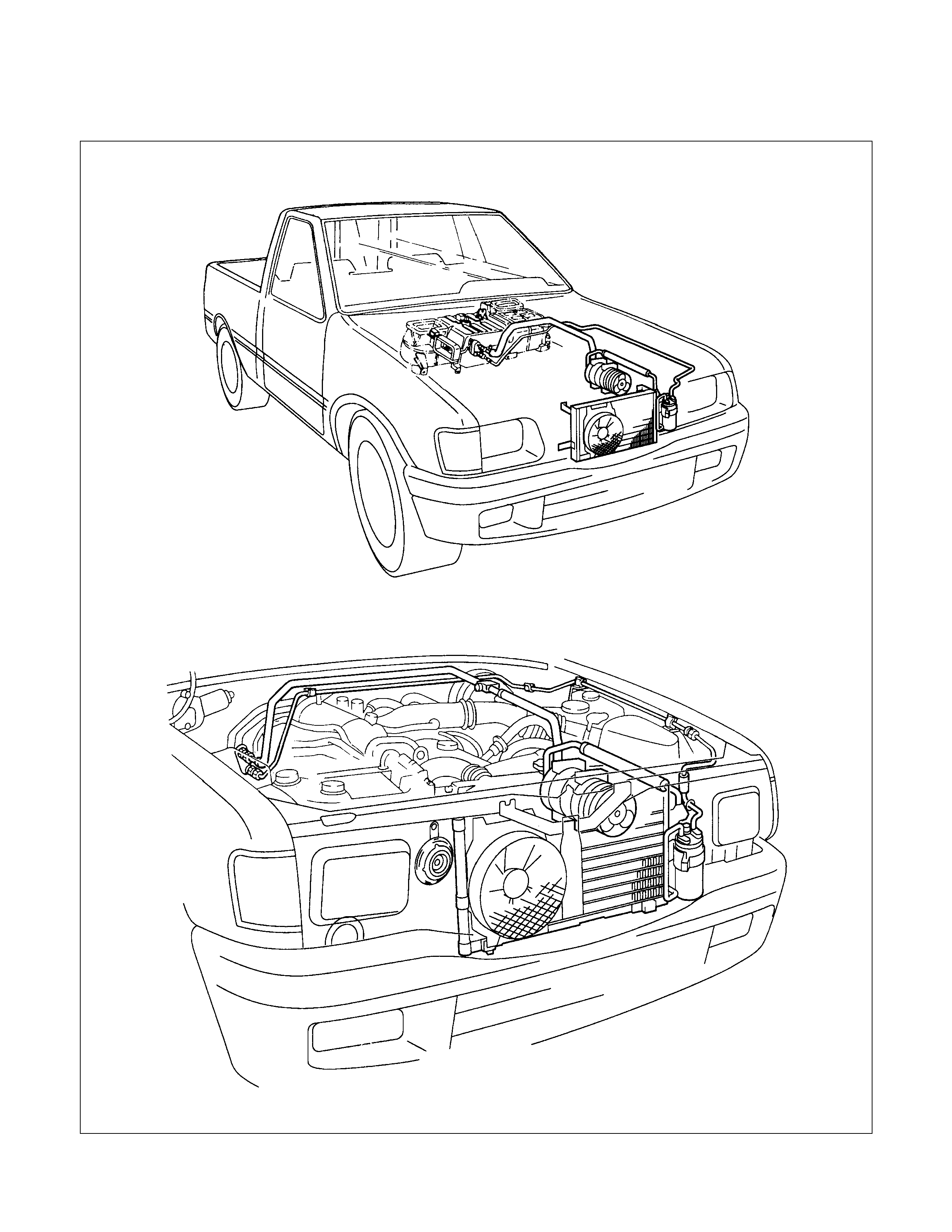

GENERAL DESCRI PTION

SYSTEM COMPO NENTS

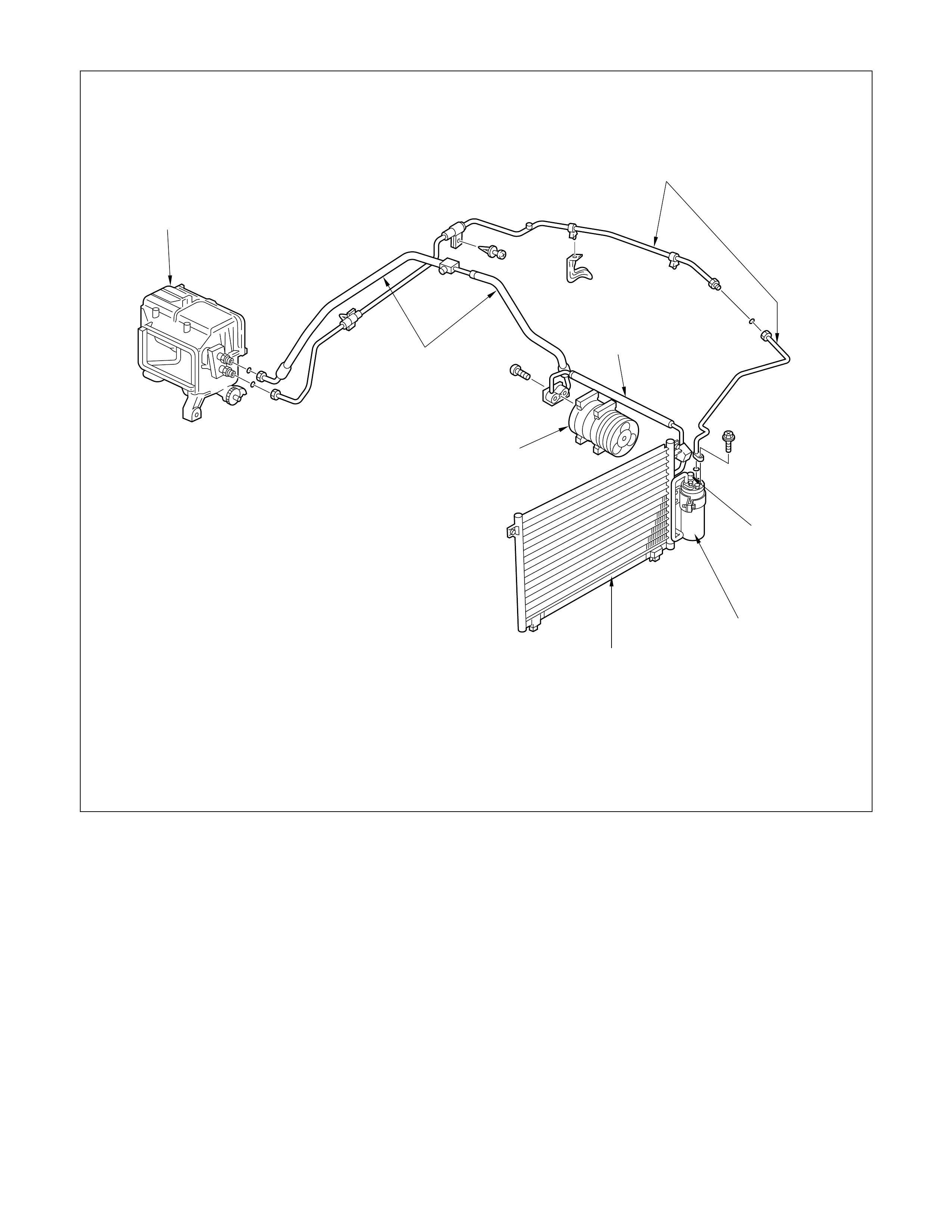

These illustrations are based on the LHD model.

SYSTEM COOLI NG LINE

UNIT

This illustration is based on the LHD model.

WIRI NG DIAGRAM

8B

20B

+

-

6V

2B

8BR

SW;IGNITION

OFF

IG1

ST

IG2

ACC BACK TURN

15A

EB-5

A/C

10A

EB-5

A/C

10A

CB-7

METER

15A

3W

3B 3L/R 1.25BR

2L/W

2L/B

0.5B

FRAME

ENG

BODY

0.85W

3W

3W/B

IGN

B-1

50A

IGN B-2

40A

MAIN

80A

3

H-7 C-41

1

C-41

8

H-7

6

H-8

8

B-24

2

B-23

13

H-8

15

H-1

1

H-5

3

C-41

6

H-7

2

C-41

3

3B/R

3B/Y 0.85W

0.85Y 0.85W/L

3B/R

FUSE;ENGINE

FUSE;CHARGE

SW;BACK UP

METER

CHARGE W/L

RELAY;

HEATER

RELAY;

CONDENSER

FAN

RELAY;

A/C COMP

RELAY;

THERMO

EARTH

H-8

10

B-13

4

B-3

1

B-3

2

M

B-1

2

OFF L M3M2H

CONTROL LEVER

B-13

5

B-13

6

B-13

3

C-2

B-13

1

B-13

2

2L/R

1.25L

0.85L/Y

0.85L/W

B-1

3

B-1

6

B-1

4

B-1

1

RESISTOR

2B

EARTH

B-2

20.5W

B-12

2

B-2

3

B-12

3

0.5W/B

SW;A/C

0.5W

0.5G/R

0.5G/W0.5BR

0.5GR/R

MAGNET

CLUTCH

1.25BR

BUS BAR NO.2

(MICRO ISO)

THERMO

B-2

1

C-24

1

H-8

13

C-24

4

H-6

19

C-24

2

C-24

3

C-92

1

C-92

2

C-95

C-95

SW;

PRESSURE

2G/B

TO ECM

(B10)

0.5BR

1.25BR 1.25BR/L

0.5BR

1.25BR

3L/R 2L 1.25B

0.5R/Y

0.5R/Y 0.5W/B

(MINI ISO)

TO ECM(A16)

H-20

14

EARTH

EARTH

CONDENSER

FAN

30A

M

CONDENSER

FAN

0.5B

B2

B1

BLOWER

H-5

3

SW;

PRESSURE

E-6

1

E-6

2

P-10

P-10

P-1

P-5

P-7

B-28 C-95

P-12

WIRI NG HARNESS TERMINAL POSITIONS

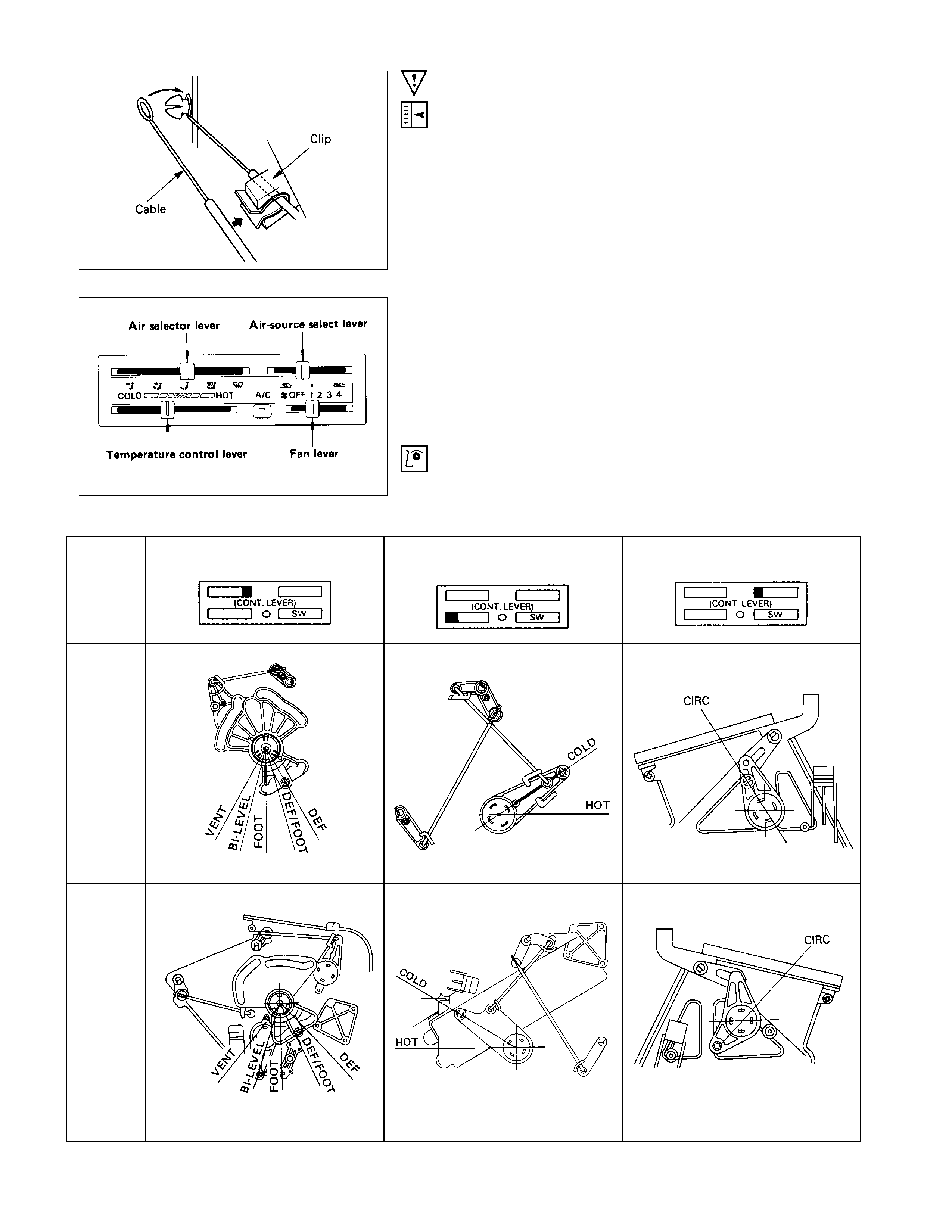

VENTILATION

VENT MODE BI⋅LEVEL MODE FOOT MODE

DEF/FOOT MODE DEF MODE

MAIN DATA AND SPECIFICATIONS

AIR COMPRESSOR

Type 6 cylinder swash plate type

Displacement cc (lmp fl oz) 147 (4.2)

Oil type ZXL-100PG

(ISUZU PART NO. 8-97101-338-0)

Oil capacity cc (lmp fl oz) 150 (4.2)

Magnetic clutch Type: Dry double disc dia. 135 mm (5.3 in.) (Gasoline)

125 mm (4.9 in.) (4J engine)

HEATING UNIT

Type Air mix type

Core dimension mm (in.) (L×H×W) 161 (6.34) ×163 (6.42) ×45 (1.77)

Capacity (kcal./hr.) 3700 kcal./hr. (280 m3/hr.)

BLOWER UNIT

Type Sirocco fan type

COOLING UNIT

Type Fin and tube evaporator

Evaporator element dimensions mm (in.) (L×H×W) 235 (9.25) ×224 (8.82) ×74 (2.91)

Evaporator capacity (kcal./hr.) 4200 kcal./hr. (470 m3/hr.)

CONDENSER

Type Aluminium louvered fins

Capacity (kcal./hr.) 9400 kcal./hr.

RECEIVER-DEHYDRATOR Assembly includes sight glass

and temperature sensitive device

REFRIGERANT Type: R-134a Capacity: 0.65 kg (1.43 lbs.)

IDLE SPEED-UP CONTROL Idle speed controlled by solenoid switch

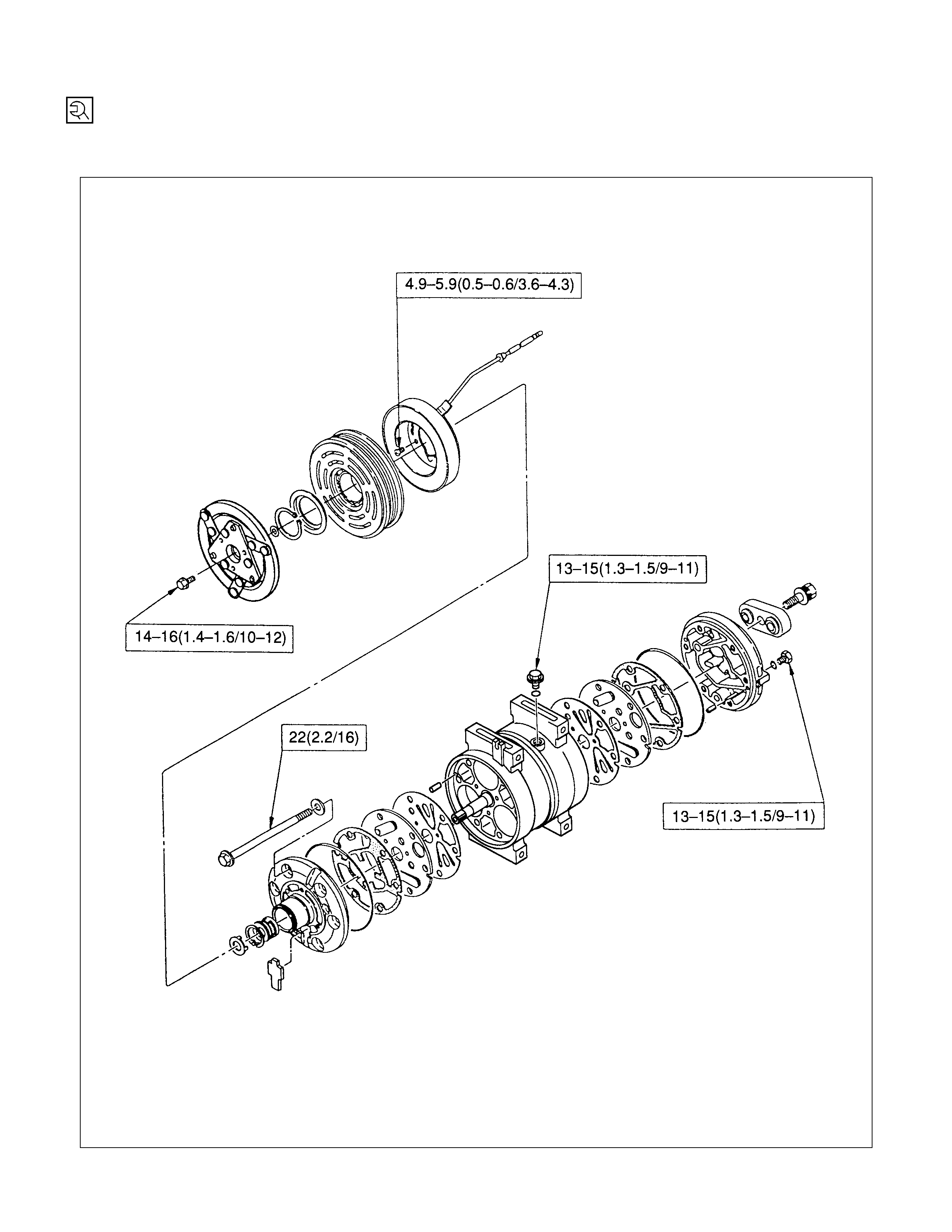

SPECIAL PARTS FIXING NUTS AND BOLTS

COMPRESSO R ASSEMBLY

N⋅

⋅⋅⋅m (kgf⋅

⋅⋅⋅m/lb⋅

⋅⋅⋅ft)

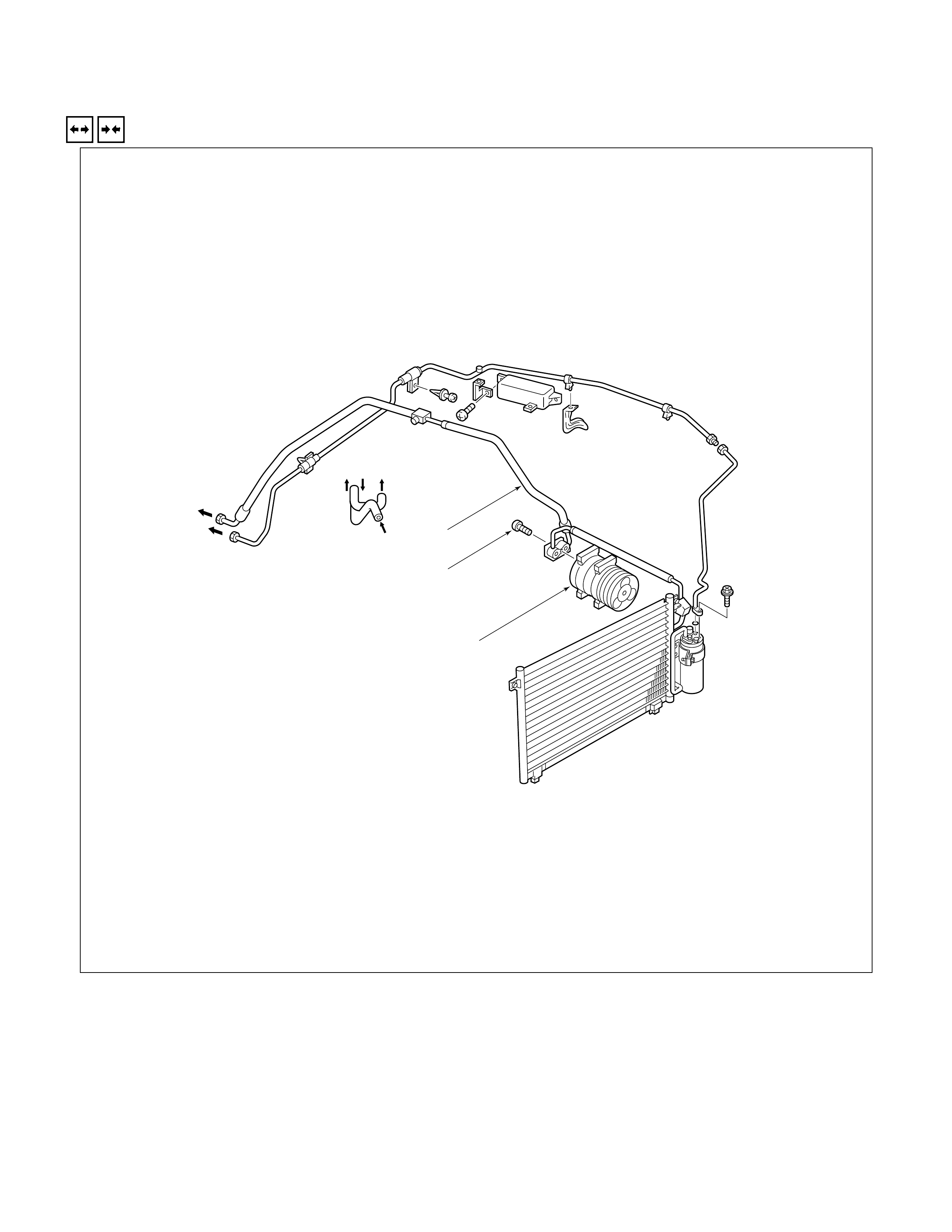

REFRIGERATION SYSTEM ( RHD MODEL)

N⋅

⋅⋅⋅m (kgf⋅

⋅⋅⋅m/lb⋅

⋅⋅⋅ft)

H/U

EVAPO

ENG.ENG.

20-29 (2.0-3.0/14-22) 10-20 (1.0-2.0/7.2-14)

10-20 (1.0-2.0/7.2-14)

27-34 (2.8-3.5/20-25)

4-8 (0.4-0.8/3-6)

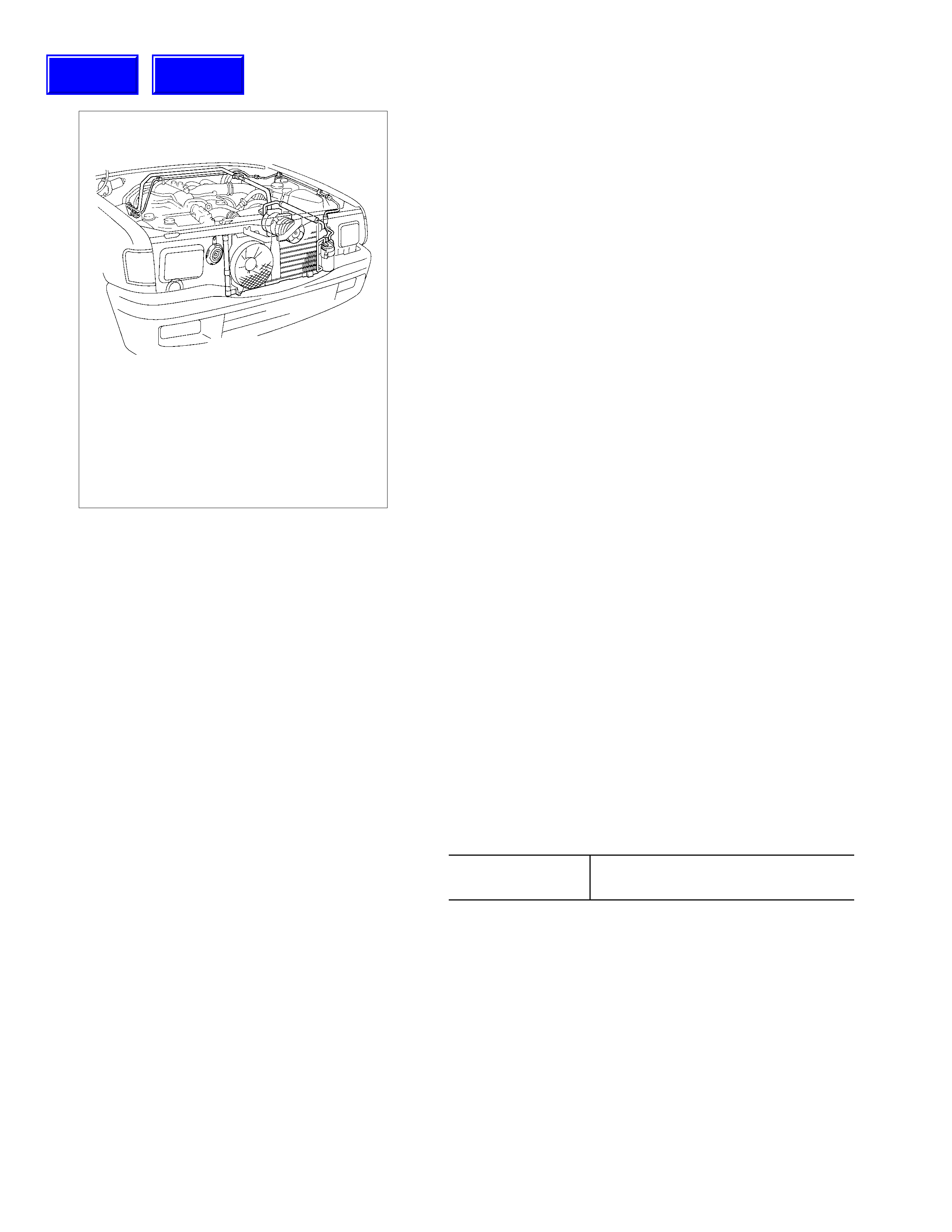

SERVICING

This illustration is based on the LHD

model.

PRECAUTIO NS FO R REFRIGERANT-134A (R-134A)

AIR CONDITIONING SYSTEM

Vehicles that use Refrigerant-134a (R-134a) in the air

conditioning system have a caution plate fixed to the rear wall

of the engine compartment. Also, components designed solely

for use with R-134a are so marked, to distinguish them from

components designed solely for use with Refrigerant-12 (R-

12).

R-12 and R-134a systems require different types of lubricating

oil. components designed solely for use with one refrigerant

and oil type must never by interchange with components

designed solely for use with another refrigerant and oil type.

R-134A REFRIGERANT:

•R-134a differs entirely from R-12 in its composition and,

therefore, the two should never by mixed. Always charge

the specified amount of R-134a.

•The pressure characteristics of R-134a differ from those o

f

R-12. The low pressure is lower, and the high pressure is

higher.

R-134A COMPRESSO R OIL:

•The R-134a s ystem requires a synthetic (PAG) com presso

r

oil whereas the R-12 system requir es a mineral compr ess o

r

oil. The two oils must never be mixed.

•Compressor (PAG) oil varies according to compresso

r

model. Be sure to use oil specified for the model o

f

compressor.

Oil Specification ZXL-100PG

(ISUZU PART NO. 8-97101-338-0)

Techline

Techline

•The PAG compressor oil for the R-134a system tends to

absorb moisture more quickly than mineral oil. When ai

r

conditioning parts are removed for servicing, all the open

ends of parts and com ponents must be s ealed with caps to

keep out contaminants.

•The PAG compressor oil must be stored in metal

containers, not in plastic containers.

R-134a

SERVICE CHARGE VALVE:

•The diameter of the service charge valve for the R-134a

system is made larger than that for the R-12 system to

prevent cross-contamination. In addition, the screw-in type

joint of the R-12 sys tem Is replaced with a quick joint type in

the R-134a system.

•To pr event refrigerant f rom esc aping during installation and

removal of charging hoses from the service charge valves,

quick-joint type fittings are used.

Connection: Push on firmly until locked (a "click" will be

heard).

Removal : Hold the grip-ring and pull to remove.

•

A

ir conditioning m anifold gauges , charging hoses and othe

r

service tools designed exclusively for the R-134a system

must be used with this vehicle.

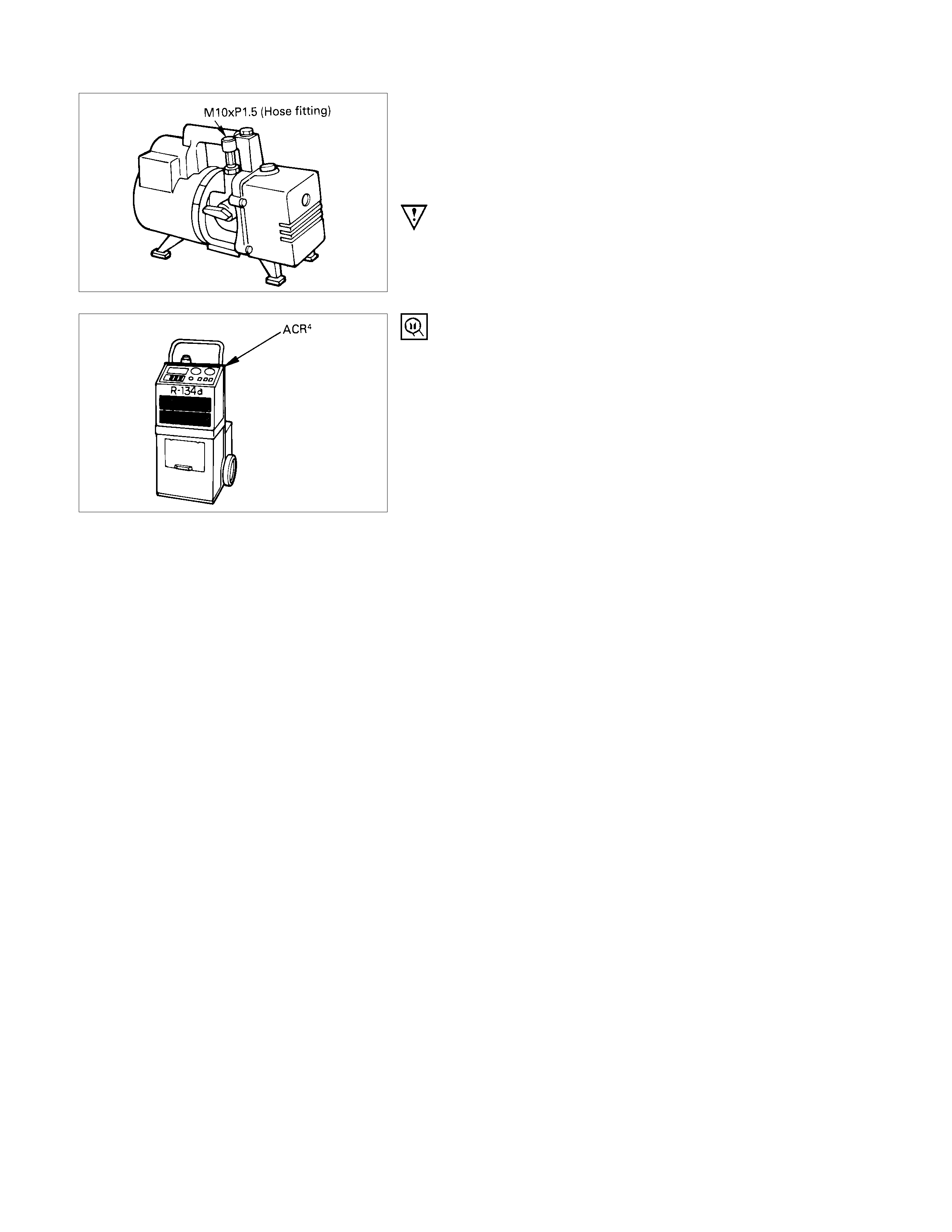

•Do not use the same vacuum pump for evacuating the R-

134a and R-12 systems interchangeably (The vacuum

pump hose fitting is a M10×1.5).

•R-134a vacuum pumps must have a positive shutoff valve.

CAUTION:

Never use the same vacuum pump for both R-134a and R-

12 systems, as cross contamination of compressor oil

may occur.

REFRIGERANT RECOVERY, RECYCLING AND

CHARGING

•R Avoid releasing the R-134a into the atmosphere.

Use the ACR4 (R-134a Refrigerant Recovery/Recycling/

Recharging/System) or equivalent to r ec over and r ec ycle R-

134a. Note that the ACR4 (or equivalent) is not

interchangeable between the R-134a and R-12 systems.

ACR4 (115V 60 Hz) : 5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60 Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR4 (220-240V 50/60 Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

REFRIGERANT LEAK INSPECTION

•The flame type gas leak detector for the R-12 system

cannot be used with the R-134a system.

•The electric leak detector for the R-12 cannot be used with

the R-134a system as the R-134a particles are far smalle

r

than the R-12 molec ules and, therefore, m ay not be always

detected. Use leak detectors designed exclusively for the

R-134a system.

Refrigerant liquid line

Pressure switch

Refrigerant discharge line

Refrigerant suction line

Evaporator

Compressor

Receiver/drier

Condenser

PRECAUTIO NS FOR REPLACEMENT OR REPAIR OF

R-134A AIR CONDITIONING PARTS

There are certain procedures, practices and precautions that

should be followed when servicing air conditioning systems:

•Keep your work area clean.

•Always wear safety goggle and protective gloves when

working on refrigerant systems.

•Beware of the danger of c ar bon monoxide f umes caus ed by

running the engine.

•Beware of discharged refrigerant in enclosed or improperly

ventilated garages.

•Always disconnect the negative battery cable and discharge

and recover the refrigerant whenever repairing the ai

r

conditioning system.

•When discharging and recovering the refrigerant, do not

allow refrigerant to discharge too fast; it will dra

w

compressor oil out of the system.

•Keep moisture and contaminants out of the system. W hen

disconnecting or removing any lines or parts, use plugs o

r

caps to close the fittings immediately.

Never remove the caps or plugs until the lines o

r

reconnecting the lines, use two wrenches to s upport the line

fitting, to prevent from twisting or other damage.

•Always install new O-rings whenever a connection is

disassembled.

•Before connecting any hoses or lines, apply new specified

compressor oil to the O-rings.

•When removing and replacing any parts which require

discharging the refrigerant circuit, the operations described

in this section must be performed in the following sequence:

1) Using the ACR4 (R-134a Refrigerant Recovery/

Recycling/Recharging/System) or equivalent to

thoroughly discharge and recover the refrigerant.

ACR4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

2) Remove and replace the defective part.

3) After evac uation, charge the air conditioning s ystem and

check for leaks.

REPAIR OF REFRIGERANT LEAKS

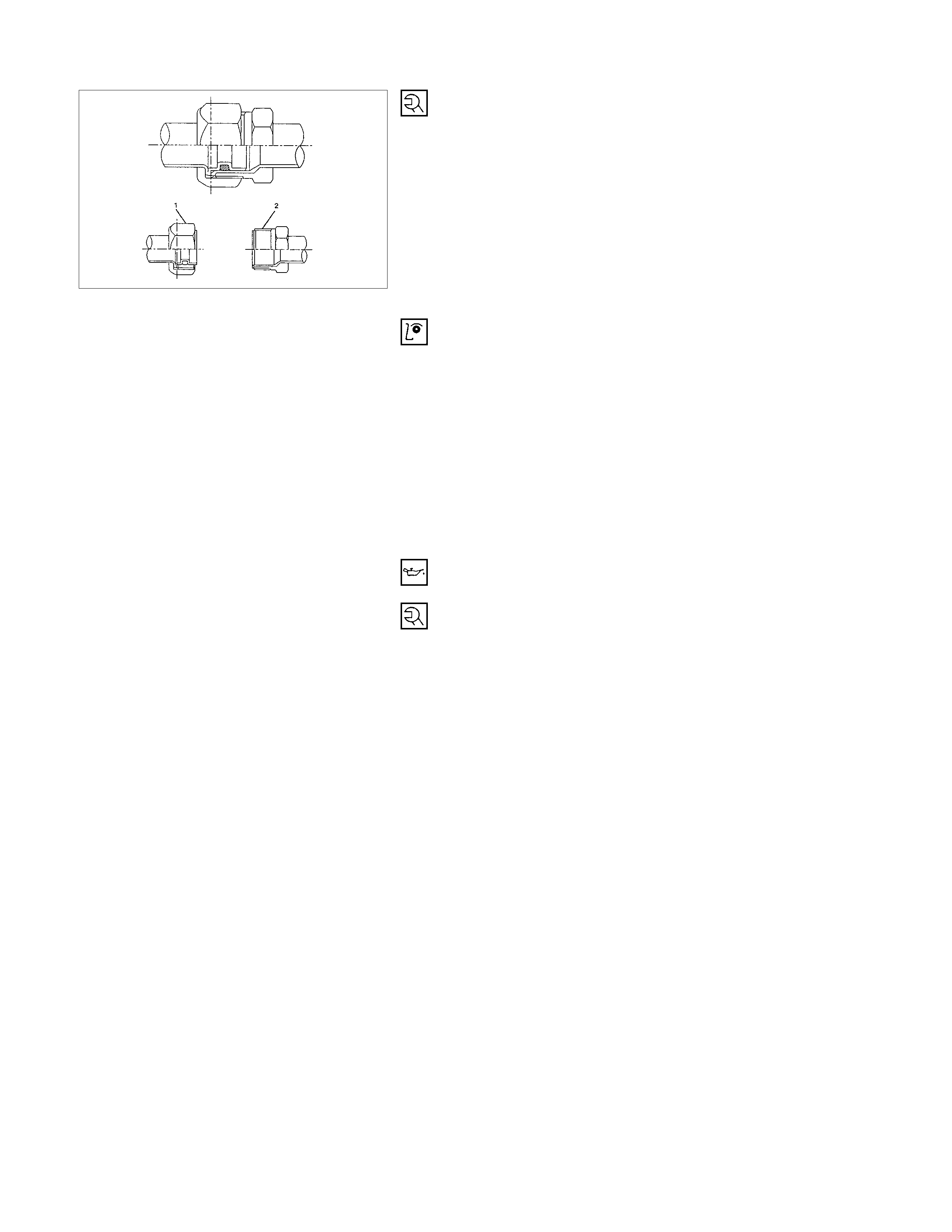

REFRIGERANT LINE CONNECTIONS

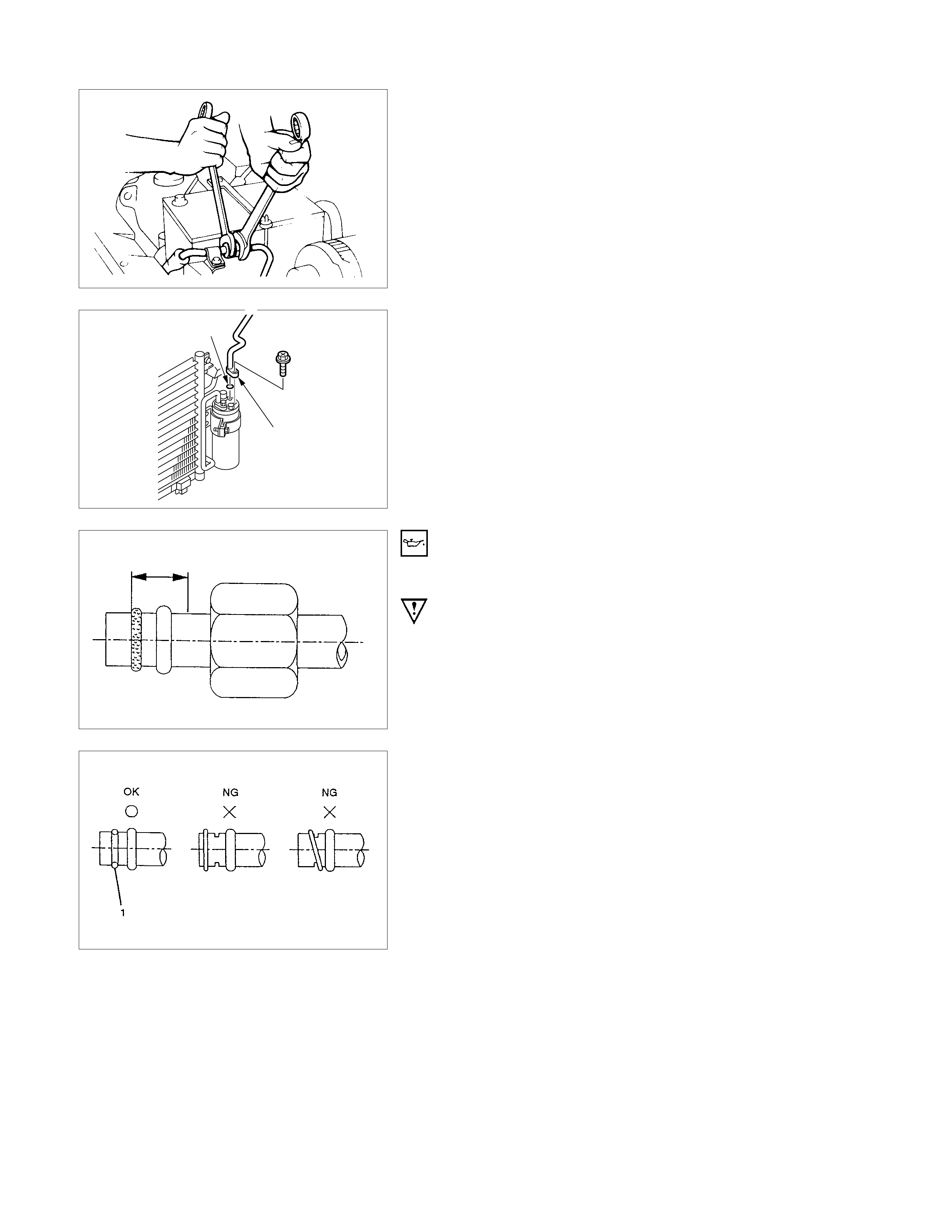

Install new O-ring, if required. When disconnecting or

connecting lines, use two wrenches to prevent the connecting

portion from twisting or becoming damaged.

O-ring

Block joint

When connecting the refrigerant line at the block joint, securely

insert the projecting portion of the joint portion into the

connecting hole on the unit side and secure with a bolt.

Apply specified compressor oil to the O-rings prior to

connecting.

CAUTION:

Compressor (PAG) oil to be used varies according to

compressor model. Be sure to apply oil specified for the

model of compressor.

O-rings must be fitted in the groove (1) of refrigerant line.

Insert the nut into union. First tighten nut by hand as much as

possible. Then, tighten nut to specified torque.

(Refer to "Special Parts Fixing Nuts and Bolts" in this

section)

LEAK AT REFRIGERANT LINE CONNECTIONS

1) Check the torque on the refrigerant line fitting and, if too

loose, tighten to the specified torque.

•Use two wrenches to prevent twisting and damage to the

line.

•Do not over tighten.

2) Perform a leak test on the refrigerant line fitting.

3) If the leak is still present, discharge and recover the

refrigerant from the system.

4) Replace the O-rings.

•O-rings cannot be reused. Always replace with ne

w

ones.

•Be sure to apply specified compressor oil to the new O-

rings.

5) Retighten the refrigerant line fitting to the specified torque.

•Use two wrenches to prevent twisting and damage to the

line.

6) Evacuate, charge and retest the system.

LEAK IN THE HOSE

If the compressor inlet or outlet hose is leaking, the entire hose

must be replaced. Refrigerant hose must not be cut or spliced

for repair.

1) Locate the leak.

2) Discharge and recover the refrigerant.

3) Remove the hose assembly.

•cap the open connections at once.

4) Connect the new hose assembly.

•Use two wrenches to prevent twisting or damage to the

hose fitting.

•Tighten the hose fitting to the specified torque.

5) Evacuate, charge and test the system.

COMPRESSO R LEAKS

If leaks are located around the compressor shaft seal or shell,

replace the compressor.

REPLACEM ENT O F COMPONENT PARTS

When replacing system component parts, supply the following

amount of oil to the component parts to be installed.

cc (lmp fl oz)

Component parts to be installed Amount of oil

Evaporator 50 (1.4)

Condenser 30 (0.8)

Receiver /drier 30 (0.8)

Refrigerant line (one piece) 10 (0.3)

RECOVERY, RECYCLI NG, EVACUATION AND

CHARGING

HANDLING REFRIG ERANT 134A

Air conditioning systems contain R-134a.

This is a chemical mixture which requires special handling

procedures to avoid personal injury.

•Always wear safety goggles and protective gloves.

•Always work in a well-ventilated area. Do not weld or steam

clean on or near any vehicle-installed air conditioning lines

or components.

•If R-134a s hould come in contac t with any part of the body,

flush the exposed area with cold water and immediately

seek medical help.

•If it is necessary to transport or carry any container of R-

134a in a vehicle, do not carry it in the passenge

r

compartment.

•If it is necessary to a fill a small R-134a container from a

large one, never f ill the container c ompletely. Space s hould

always be allowed above the liquid for expansion.

•R-134a and R-12 should never by mixed as thei

r

compositions are not the same.

•R-134a PAG oil tends to absor b m oisture m or e quick ly than

R-12 mineral oil and, therefore, should be handled more

carefully.

•Keep R-134a containers stored below 40°C (100°F).

WARNING:

•

••

•SHOULD R-134a CONTACT YOUR EYE(S), CONSULT A

DOCTOR IMMEDIATELY.

•

••

•DO NOT RUB THE AFFECTED EYE(S). INSTEAD,

SPLASH QUANTITIES OF FRESH COLD WATER OVER

THE AFFECTED AREA TO GRADUALLY RAISE THE

TEMPERATURE OF THE REFRIGERANT ABOVE THE

FREEZING POINT.

•

••

•OBTAIN PROPER MEDICAL TREATMENT AS SOON AS

POSSIBLE. SHOULD THE R-134a TOUCH THE SKIN,

THE INJURY MUST BE TREATED THE SAME AS SKIN

WHICH HAS BEEN FROSTBITTEN OR FROZEN.

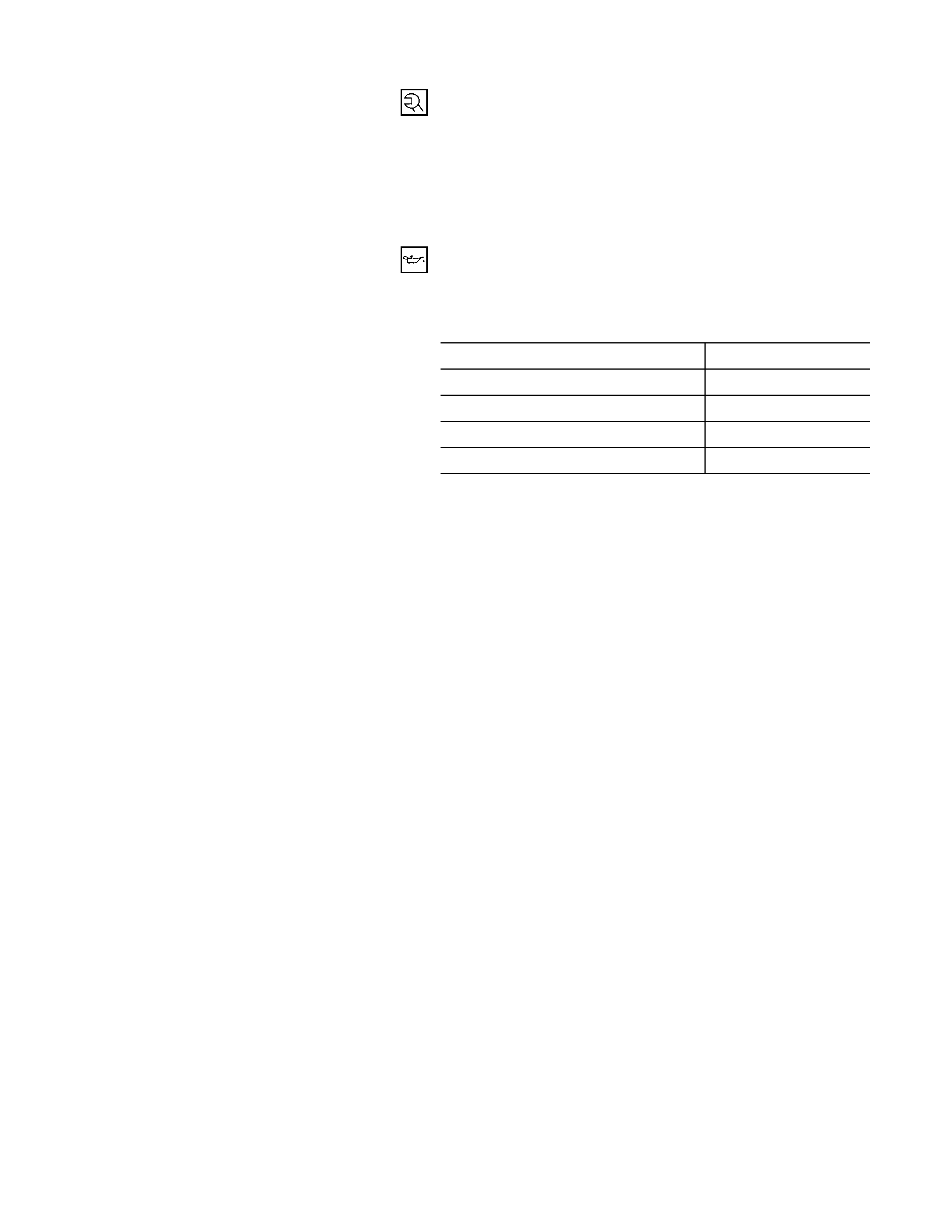

REFRIGERANT RECOVERY

The refrigerant must be discharged and recovered by using the

ACR4 (R-134a Refrigerant Recovery/Recycling/Recharging/

System) or equivalent before removing or installing air

conditioning parts.

ACR4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

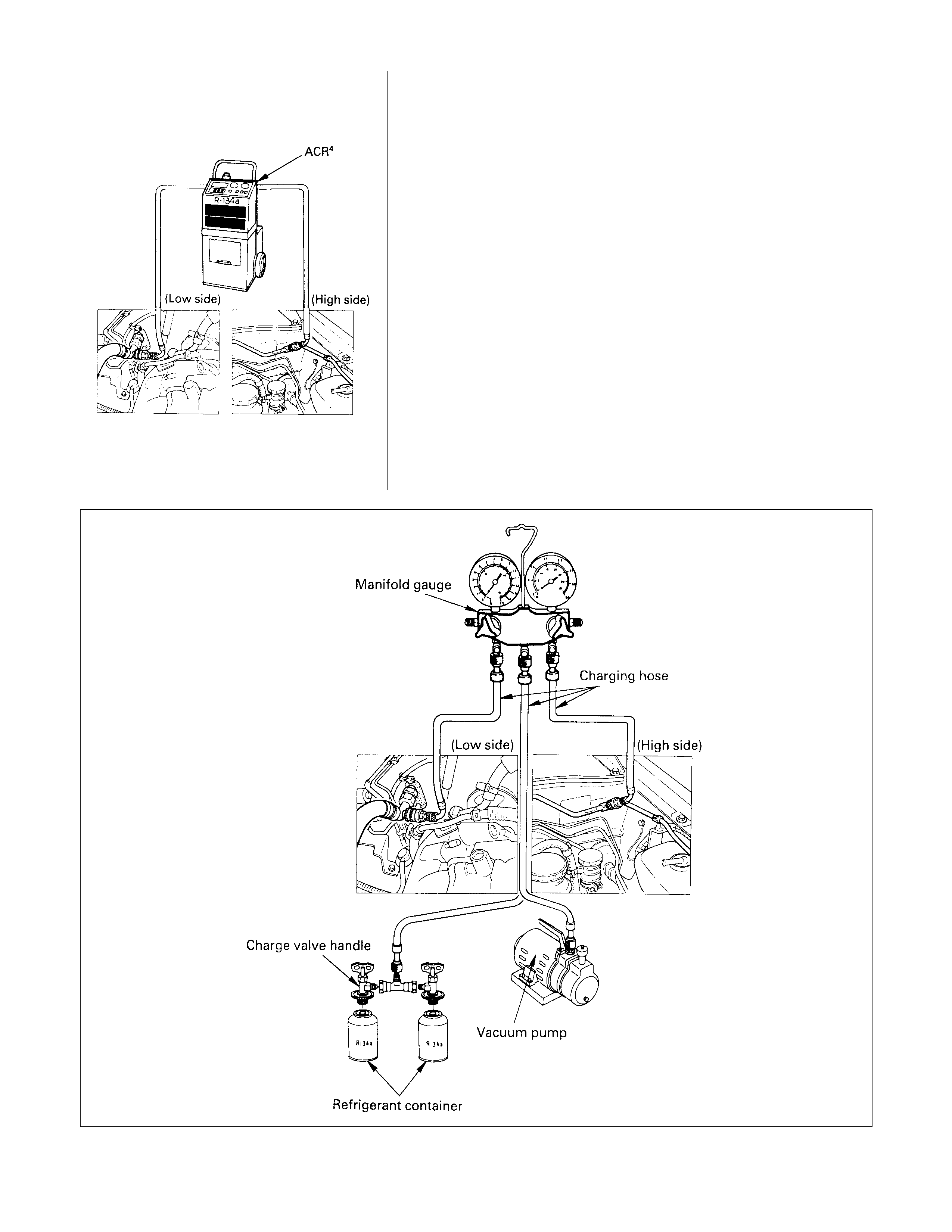

1) Connect the high and low charging hoses of the ACR4(o

r

equivalent) as shown.

2) Recover the refrigerant by following the ACR4

Manufacturer's Instructions.

3) When a part is removed, put a cap or a plug on the

connecting portion so that dust, dirt or moisture cannot get

into it.

REFRIGERANT RECYCLING

Recycle the refrigerant recovered by the ACR4 or equivalent.

For the details of the actual operation, follow the steps in the

ACR4 Manufacturer's Instructions.

ACR4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

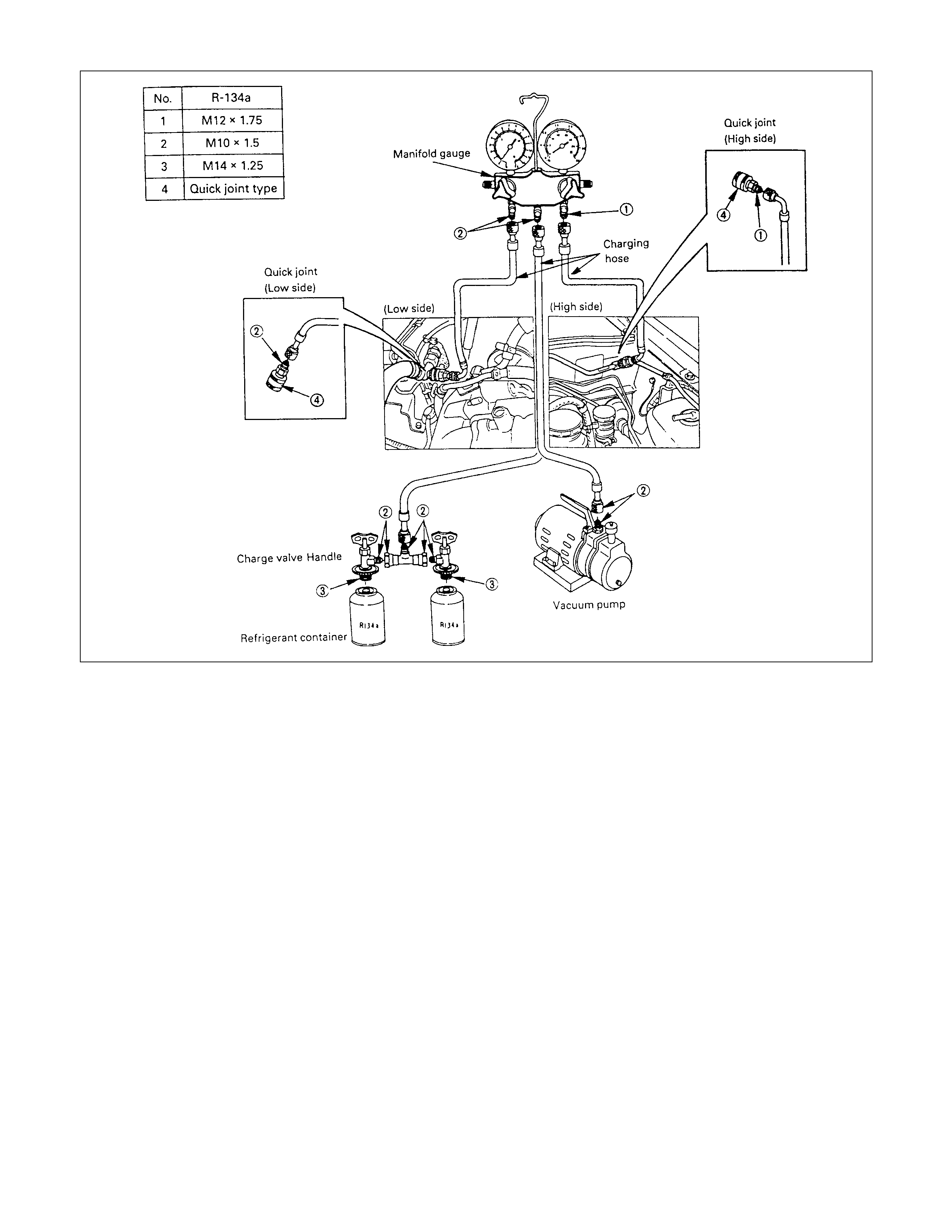

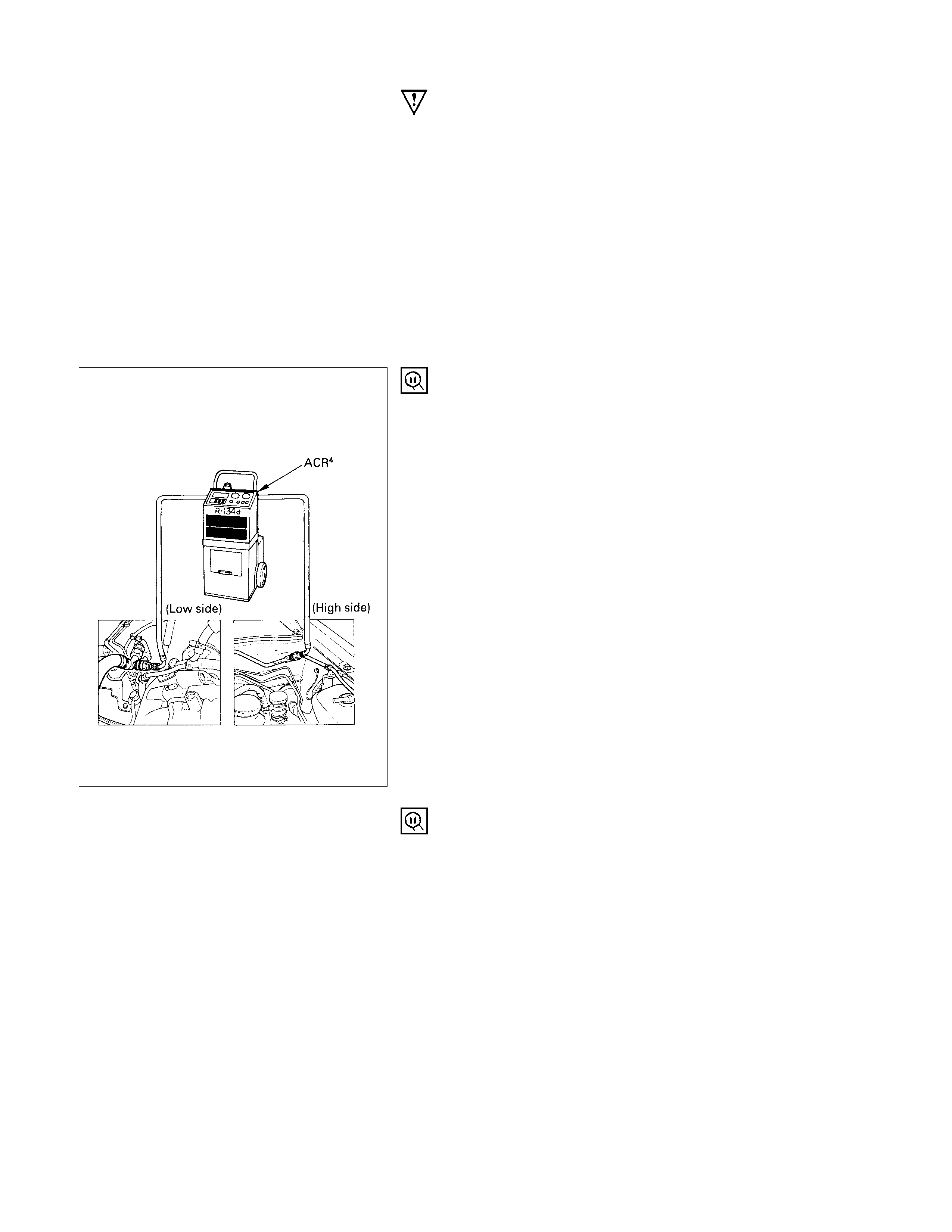

EVACUATION OF THE REFRIGERANT SYSTEM

Note:

Explained below is a method using a vacuum pump. Refer

to the ACR4 (or equivalent) Manufacturer's Instructions

when evacuating the system with ACR4 (or equivalent).

Air and moisture in the refrigerant will cause problems in the air

conditioning system.

Therefore, before charging the refrigerant, be sure to evacuate

air and moisture thoroughly from the system.

1) Connect the gauge manifold.

•

••

•High-pressure valve (HIGH)-Discharge-side

•

••

•Low-pressure valve (LOW)-Suction-side

2) Discharge and recover the refrigerant.

3) Connect the center hose of the gauge manifold set to the

vacuum pump inlet.

4) Operate the vacuum pump, open shutoff valve and then

open both hand valves.

5) W hen the low-pressure gauge indicates approx. 750 m m Hg

(30 ln.Hg), continue the evacuation for 5 minutes or more.

6) Close both hand valves and stop the vacuum pump.

7) Check to ensur e that the pres s ure does not c hange af ter 10

minutes or more.

•

••

•If the pressure changes, check the system for leaks.

•

••

•If leaks occur, retighten the refrigerant line connections

and repeat the evacuation steps.

8) If no leaks are found, again operate the vacuum pump fo

r

20 minutes or more. After confirming that the gauge

manifold pressure is at 750 mmHG (30 ln.Hg), close both

hand valves.

9) Close positive shutoff valve.

Stop the vacuum pump and disconnect the center hose

from the vacuum pump.

CHARGING THE REFRIGERANT SYSTEM

There are various methods of charging refrigerant into the air

conditioning system.

These include using the ACR4 (R-134a Refrigerant Recovery/

Recycling/Recharging/System) or equivalent and direct

charging with a manifold gauge charging station.

ACR4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

Techline

CHARGING PROCEDURE

•

••

•ACR4 (or equivalent) method

For the charging of refrigerant recovered by ACR4, follow the

Manufacturer's Instruction.

•

••

•Direct charging with a manifold gauge charging

station method.

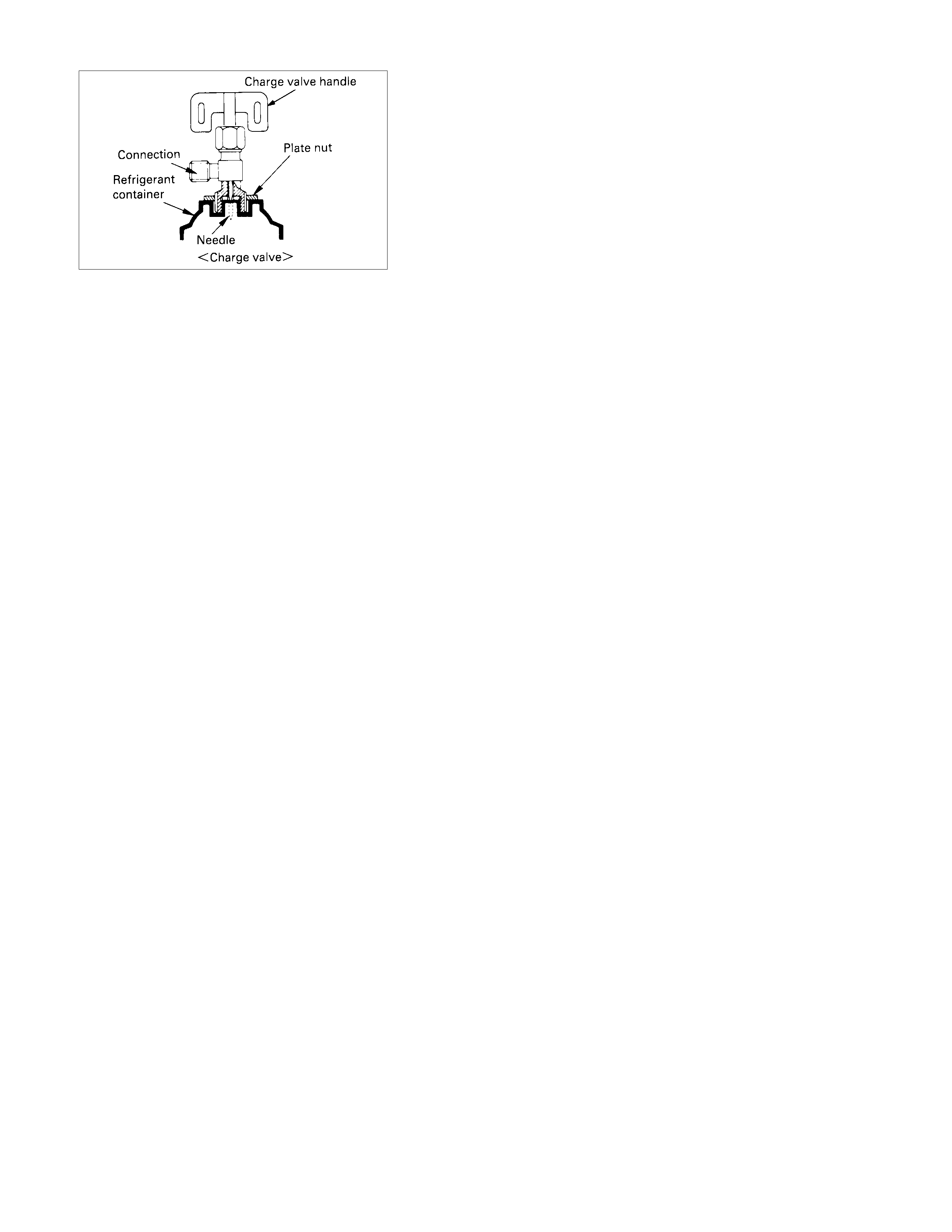

Handling the charge valve handle when installing refrigerant

container.

1) Before attaching the charge valve to the refrigerant

container, turn the charge valve handle counterclockwise

until the needle is fully retracted.

2) Turn the plate nut counterclockwise until it reaches its

highest position relative to the charge valve.

3) Install the charge valve onto the refrigerant container.

4) Turn the plate nut clockwise and connec t the c enter hos e o

f

the manifold gauge to the charge valve.

5) Tighten the plate nut sufficiently by hand. Then turn the

charge valve handle cloc kwise to lower the needle and bor e

a hole in the refrigerant container.

6) Turn the charge valve handle counterclockwise to raise the

needle. The refrigerant in the refrigerant container is

charged into the air c onditioning sys tem by the operation o

f

the manifold gauge.

•

••

•Be absolutely sure not to reuse the emptied refrigerant

container.

1) Make sure the evacuation process is correctly completed.

2) Connect the center-hose of the manifold gauge to the

refrigerant container.

•

••

•Turn the charge valve handle counterclock wise to purge

to charging line and purge any air exiting in the center-

hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the

refrigerant about 200 g (0.44 lbs.).

•

••

•Make sure the high-pressure hand valve is closed.

•

••

•Avoid charging the refrigerant by turning the refrigerant

container upside down.

4) Close the low-pressure hand valve of the manifold gauge.

•

••

•Check to ensure that the degree of pressure does not

change.

5) Check the refrigerant leaks by using a R-134a leak

detector.

•

••

•If a leak occurs, repair the leak connection, and start all

over again from the first step of evacuation.

6) If no leaks are found, open the low-pressure hand valve o

f

the manifold gauge. Then continue charging refrigerant to

the system.

•

••

•When charging the system becomes difficult:

(1) Run the engine at 1,300∼1,500 rpm and open the all

vehicle doors.

(2)A/C switch is "ON".

(3) Set the fan control knob (fan switch) to its highest

position.

WARNING:

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE REFRIGERANT

CONTAINER TO BURST.

7) W hen the refr igerant container is em ptied, use the f ollowing

procedure to replace it with a new refrigerant container.

(1) Close the low-pressure hand valve.

(2) Raise the needle upward and remove the charge valve.

(3) Reinstall the charge valve to the new refrigerant

container.

(4) Purge any air exis ting in the center hose of the m anifold

gauge.

8) Charge the system to the specified amount and then close

the low-pressure hand valve.

Refrigerant Specified Amount g(lbs.)

650 (1.43)

•

••

•A fully charged system is indicated by the sight glass on

the receiver/drier being free of any bubbles (Refer to

"Reading Sight Glass").

•

••

•Check the high and low pressure value of the manifold

gauge.

•

••

•Check for refrigerant leaks by using a R-134a leak

detector.

Immediately after charging refrigerant, both high and low

pressures are slightly high and to the left of the gauge, but they

settle down to the guide pressure valves as shown below:

•

••

•Ambient temperature; 30∼35°C (86∼95°F)

•

••

•Guide pressure

High-pressure side;

Approx. 1373∼167 kPa (14∼17 kg⋅cm2/199∼242 PSI)

Low-pressure side;

Approx. 127∼245 kPa (1.3∼2.5 kg⋅cm2/18∼36 PSI)

9)Close the low pressur e hand valve and charge valve of the

refrigerant container.

10)Stop the air conditioning and the engine.

11)Disconnect the high and low pressure hoses from the

manifold gauge fittings.

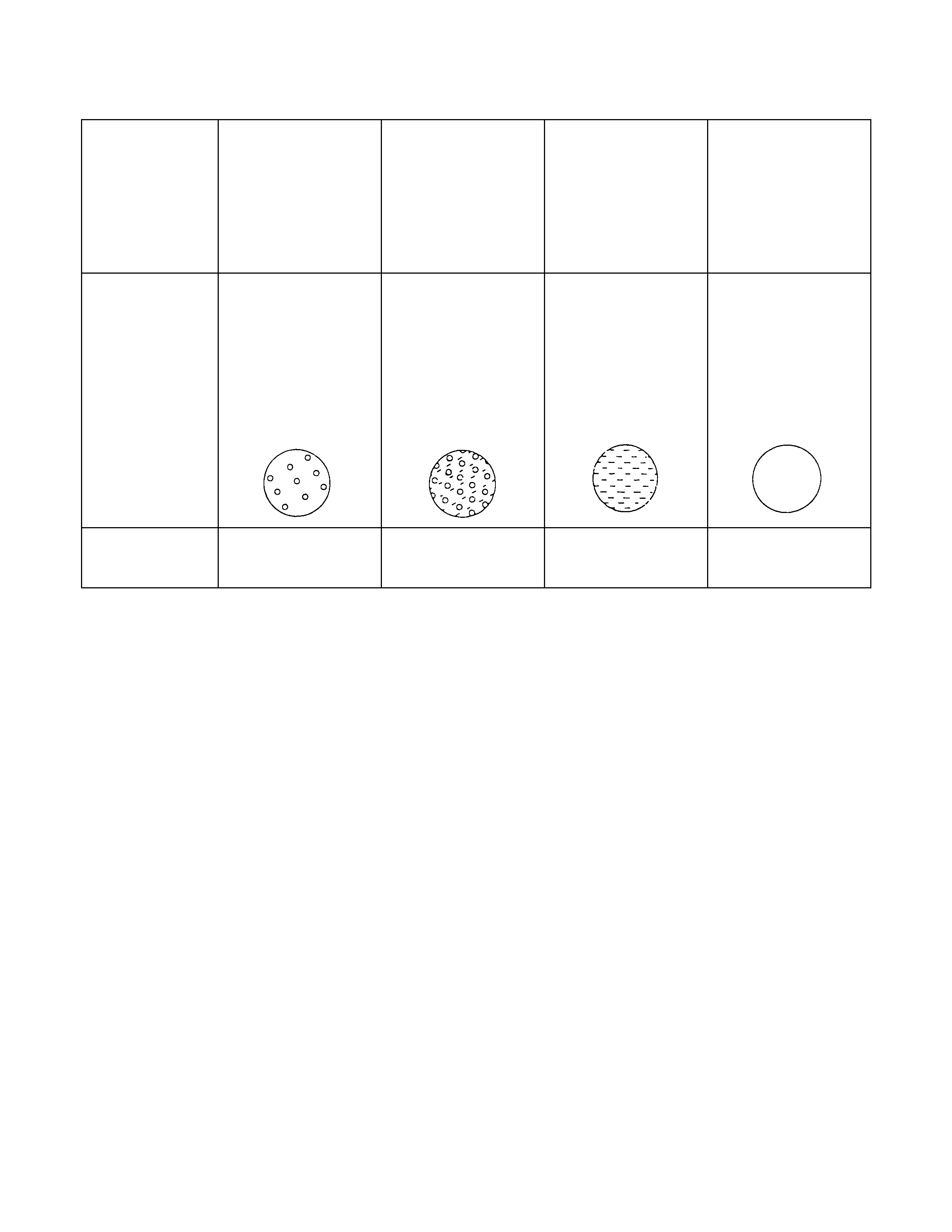

READING SIGHT GLASS

High and low

pressure pipe

temperature

The high pressure

pipe is hot and the

low pressure pipe

is cold. There is a

distinct difference

in temperature

between them.

The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great

difference in

temperature

between them.

There is little

difference in

temperature

between the high

pressure pipe and

the low pressure

pipe.

The high pressure

pipe is hot and the

low pressure pipe

is slightly warm.

There is a

difference in

temperature

between them.

Sight glass

condition Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

A flow of bubbles

always can be

seen. It appears

sometimes

transparent, and

sometimes frothy.

Something like fog

faintly can be seen. Evan at idle with

the fan at "HI" (with

the window fully

open), the bubbles

cannot be seen.

Air conditioning

cycle condition OK NG

(Not enough

refrigerant)

NG

(Almost no

refrigerant)

NG

(Too much

refrigerant)

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the chart

* Engine speed 1,500 RPM

* A/C switch "ON"

* Blower fan operating at highest speed

* Air source selector lever at "RECIRC"

* Temperature control lever at coldest position

* Ambient temperature below 35°C (95°F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1667 kPa (17 kg⋅cm2/242 PSI) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass cannot be used

for diagnosis. You must discharge and recover the refrigerant, then recharge the system with the specified amount of

refrigerant.

Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must discharge and

recover the refrigerant, then recharge the system with the specified amount of refrigerant.

Then continue checking system performance.

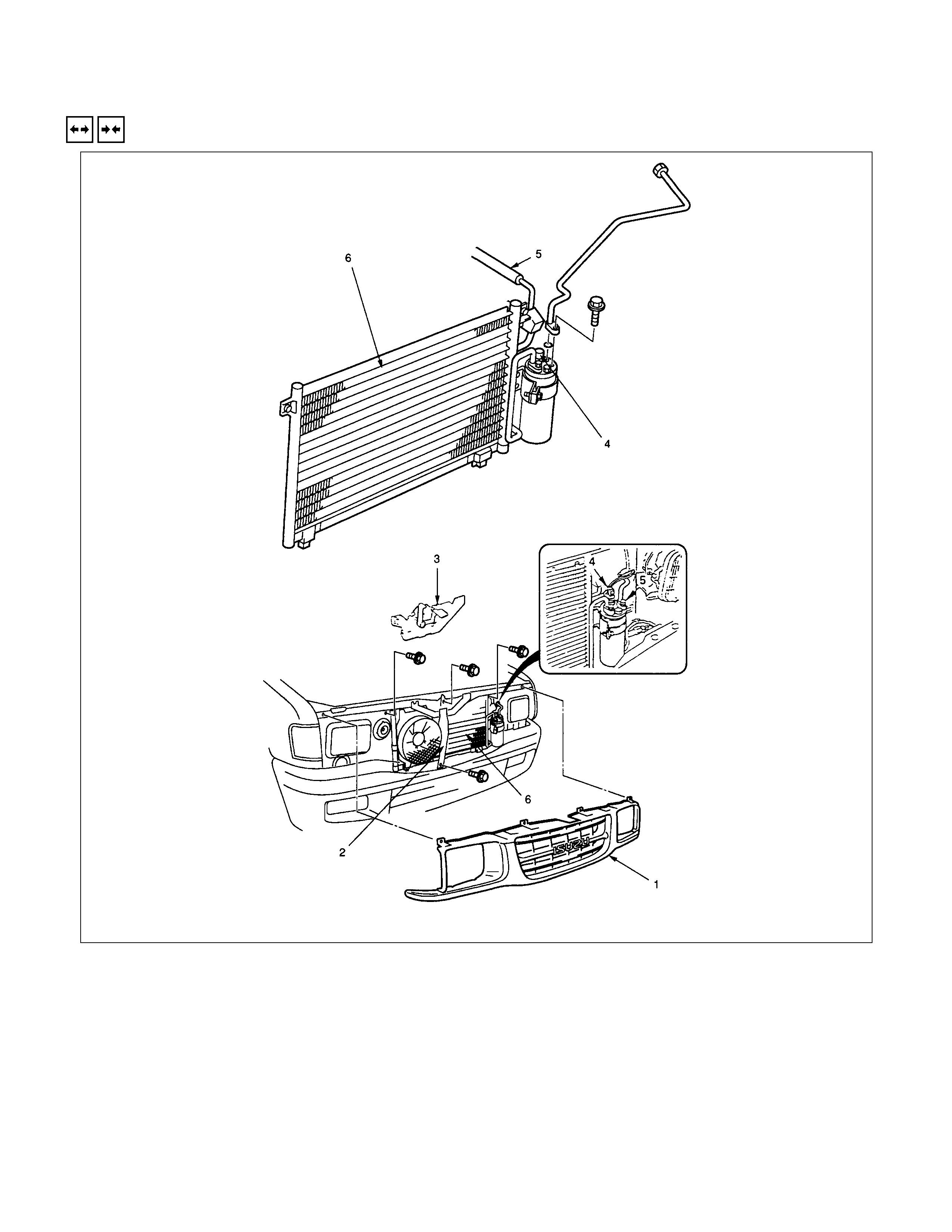

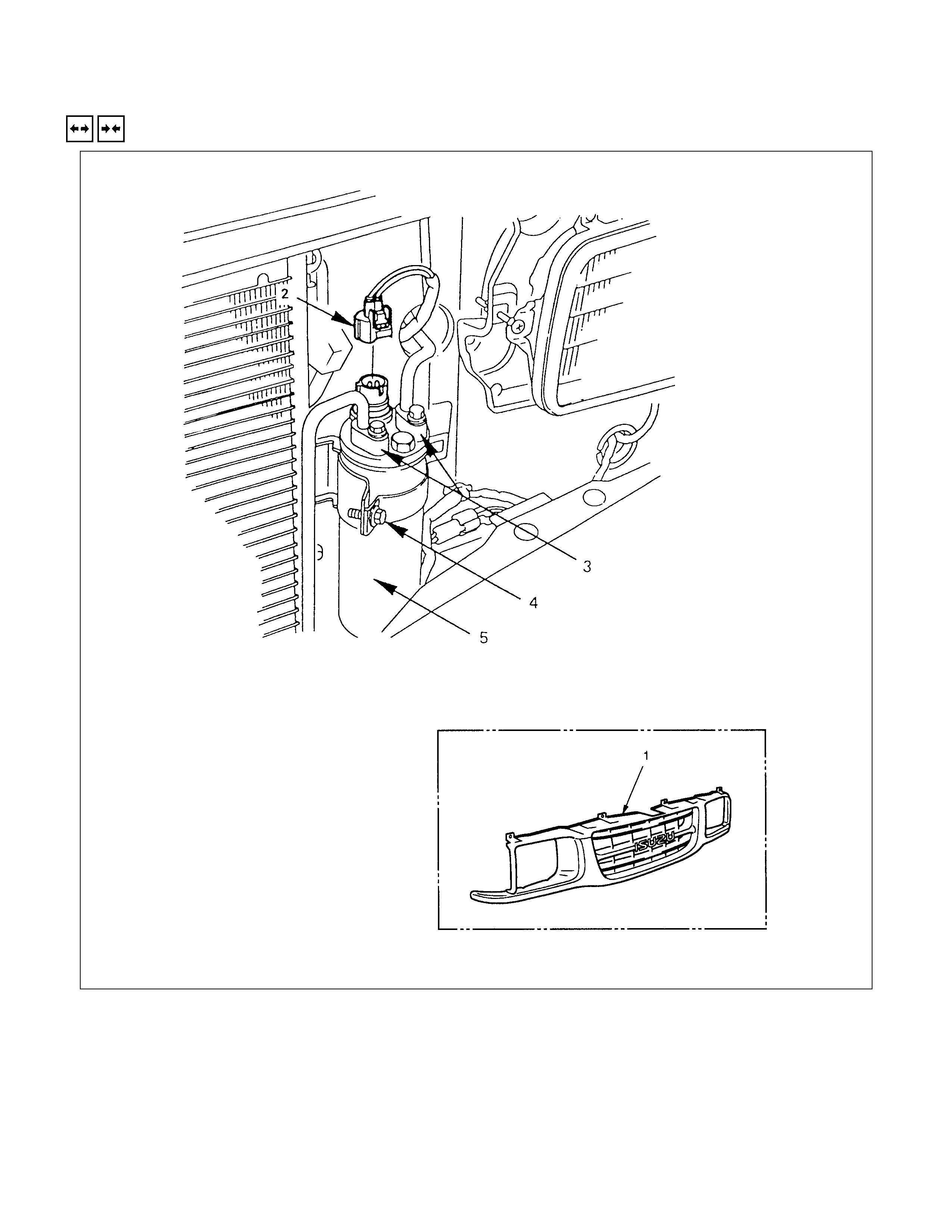

CONDENSER

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Radiator grille

2. Engine hood front end stay

3. Engine hood lock

4. Pressure switch connector

5. Refrigerant line

6. Condenser

INSTALLATION STEPS

To install, follow the removal procedure in

reverse order.

RECEIVER DEHYDRATOR

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Radiator grille

2. Dual pressure switch connector

3. Refrigerant line

4. Bracket bolt

5. Receiver dehydrator

INSTALLATION STEPS

To install, follow the removal procedure in

reverse order.

COMPRESSOR

REMOVAL AND INSTALLATION

EVAPO

H/U

ENG.

This illustration is based on the LHD gasoline engine model.

ENG.

1

2

3

REMOVAL STEPS

1. Compressor flex/hose

2. Bolt; compressor to bracket

3. Compressor assembly

INSTALLATION STEPS

3. Compressor assembly

▲2. Bolt; compressor to bracket

▲1. Compressor flex/hose

IMPORTANT OPERATIONS - INSTALLATION

2. Bolt; Compressor to Bracket N⋅m (kgf⋅m/lb⋅ft)

Torque 54-64 (5.5-6.5/40-47)

1. Compressor Flex/Hose N⋅m (kgf⋅m/lb⋅ft)

Torque 27-34 (2.8-3.5/20-25)

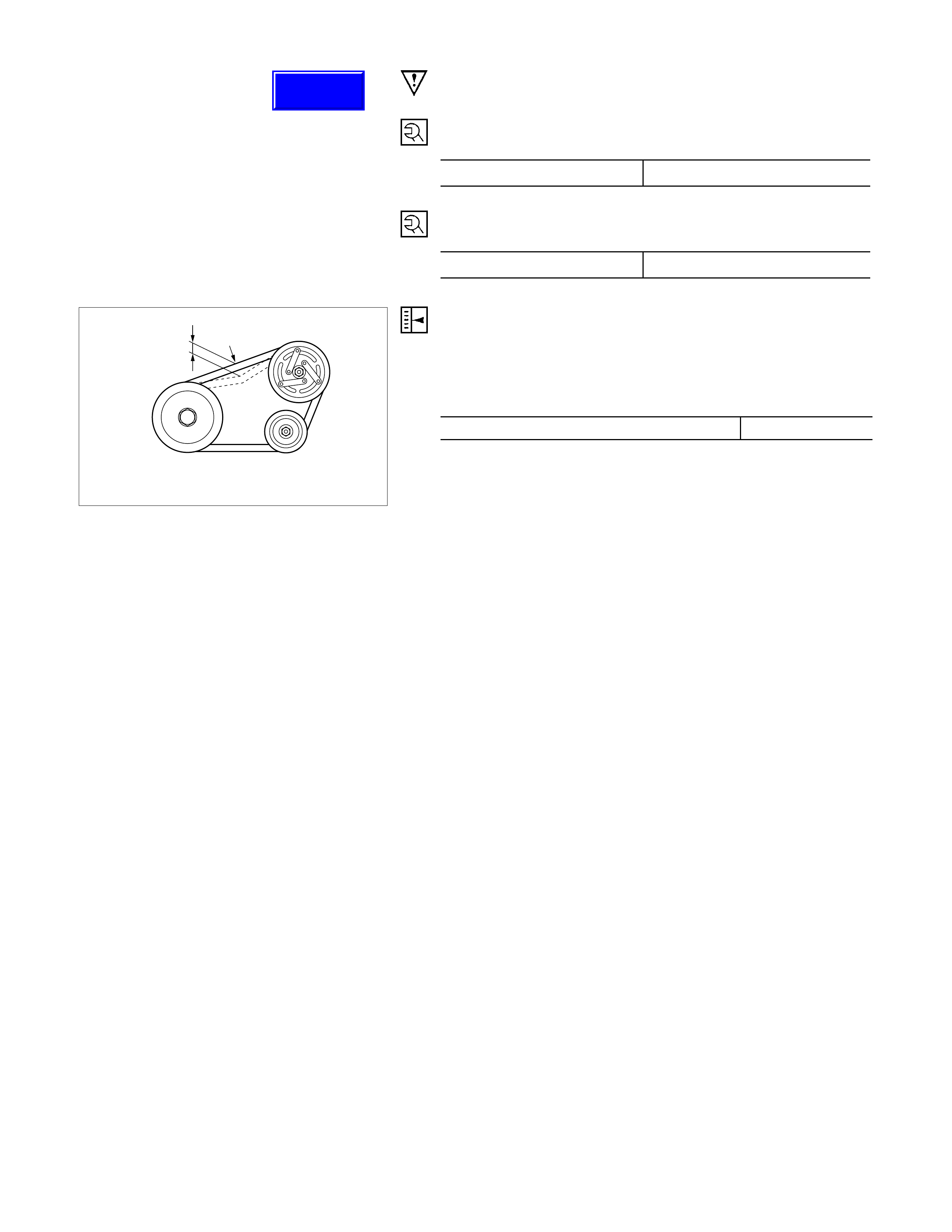

Compressor pulley

Crank pulley

10mm(0.4in)

Idler pulley

Compressor Belt

Check the drive belt tension.

Depress the drive belt mid-portion with a 98N (10kg/22Ib)

force.

Gasoline Engine mm(in.)

Standard deflection 10 (0.4)

Techline

GENERAL REPAIR PROCEDURE

OIL SPECIFICATION

•The R-134a system requires a synthetic (PAG)

compressor oil

•Compressor (PAG) oil varies according to compresso

r

model. Be sure to use oil specified for the model o

f

compressor.

Specified Compressor Oil

ZXL-100PG

(ISUZU PART NO.8-97101-338-0)

HANDLING OF OIL

•The oil should be free from moisture, dust, metal powder,

etc.

•Do not mix with other oil.

•The water content in the oil incr eases when exposed to the

air. After use, seal oil from air immediately.

(R-134a PAG Com pressor Oil absorbs m oisture ver y easily

than R-12.)

•The compressor oil must be stored in steel containers, not

in plastic containers.

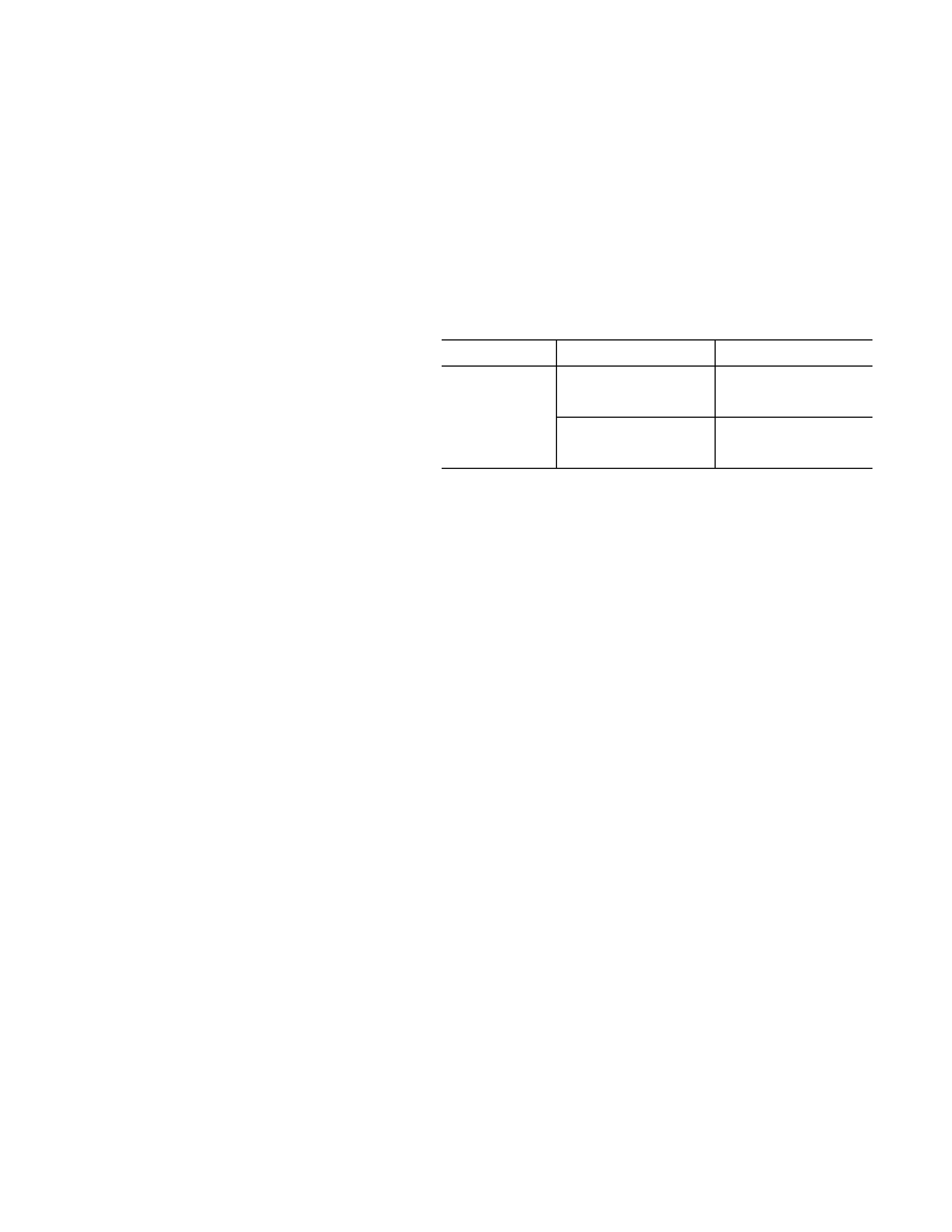

COMPRESSOR OIL CHECK

The Oil used to lubricate the compressor is circulating with the

refrigerant.

Whenever replacing any component of the system or a large

amount of gas leakage occurs, add oil to maintain the original

amount of. oil.

Oil Capacity

Capacity total in

system DKS 15 CH 150 cc (5.0 fl.oz.)

Compressor

(Service parts)

charging amount DKS 15 CH 150 cc (5.0 fl.oz.)

CHECKING AND ADJUSTING FOR USED

COMPRESSOR

(1)Perform Oil return operation.

(Refer to "Oil Return Operation" in this section.)

(2)Discharge refrigerant and remove the compressor.

(3)Drain the compressor oil and measure the extracted oil with

a measuring cylinder.

(4)Check the compressor oil for contamination.

(Refer to "Contamination of Compressor Oil" in this

section.)

(5)Adjust oil level following the procedure below.

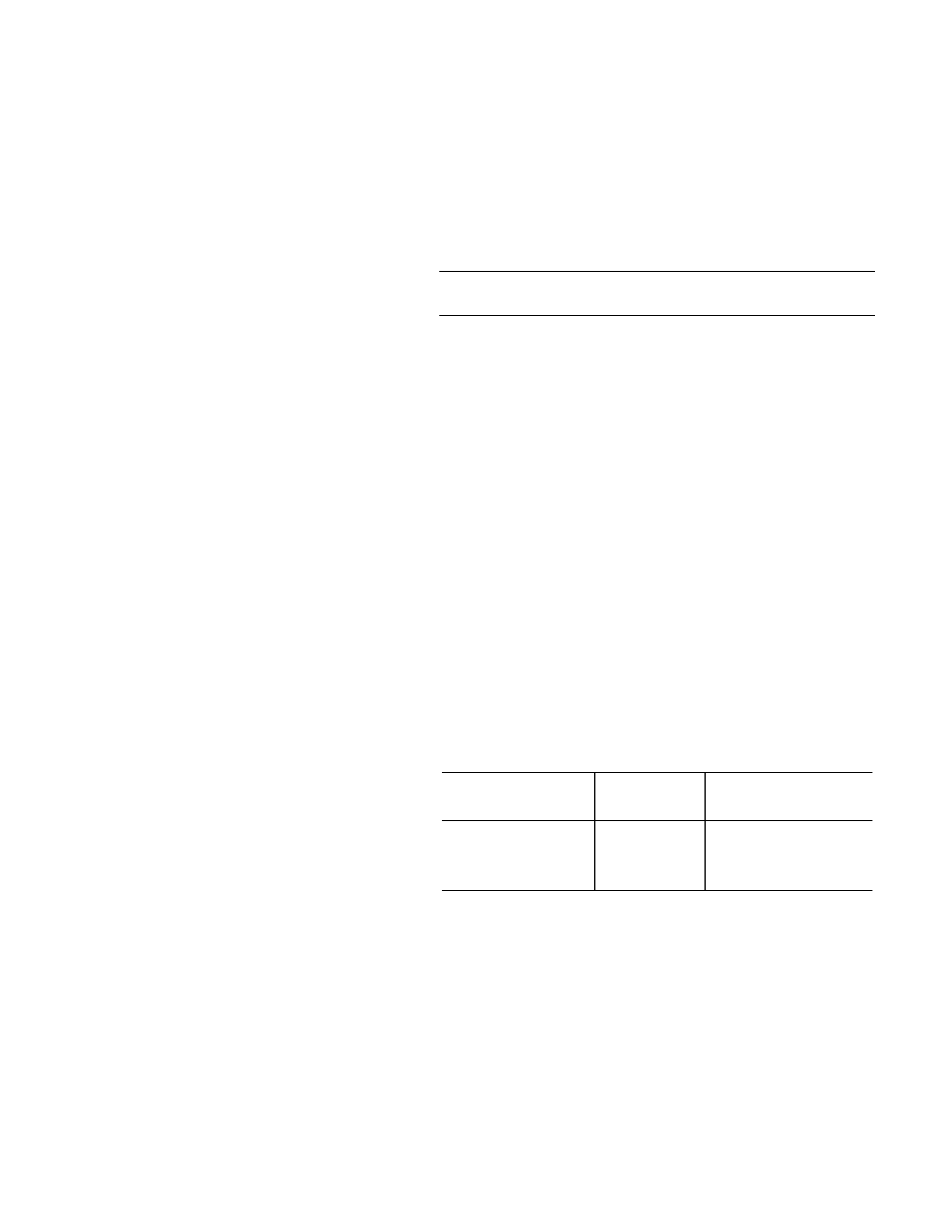

Type Collected Amount Charging Amount

more than 90 cc

(3.0 fl.oz.) same as collected

amount

less than 90 cc

(3.0 fl.oz.) 90 cc (3.0 fl.oz.)

DKS-15 CH

(6)Install the com pressor, then evacuate, charge and perform

oil return operation.

(7)Check system operation.

When it is impossible to pe rform oil return operation, the

compressor oil should be checked in the following order:

(1)Discharge refrigerant and remove the compressor.

(2)Drain the compressor oil and measure the extracted oil with

a measuring cylinder.

(3)Check the oil for contamination.

(4)If more than 90 cc (3.0 fl.oz.) for DKS-15 CH type is

extracted from the compressor, supply same amount of oil

to the compressor to be installed.

If the amount of oil extracted is less than 90 cc (3.0 fl.oz.)

for DKS-15 CH type recheck the compressor oil in the

following order:

(5)Supply 90 cc (3.0 fl.oz.) for DKS-15 CH type oil to the

compressor and install it onto the vehicle.

(6)Perform oil return operation.

(7)Remove the compressor and recheck the amount of oil.

(8)Adjust the compressor oil.

CHECKING AND ADJUSTING FOR COMPRESSOR

REPLACEMENT

150 cc (5.0 fl.oz.) for DKS-15 CH type of oil is charged in

compressor (serv ice parts).

So it is necessary to drain the proper amount of oil from new

compressor.

(1)Perform oil return operation.

(2)Recover refrigerant and remove the compressor.

(3)Drain the compressor oil and measure the extracted oil with

a measuring cylinder.

(4)Check the compressor oil for contamination.

(5)Adjust oil level following the procedure below.

Type Collected Amount Charging Amount

more than 90 cc

(3.0 fl.oz.) same as collected

amount

less than 90 cc

(3.0 fl.oz.) 90 cc (3.0 fl.oz.)

DKS-15 CH

(6)Evacuate, charge and perform oil return operation.

(7)Check system operation.

CONTAMINATION OF COMPRESSOR OIL

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even is the compressor runs for a long period

of time (approximately 1 season), the oil never becomes

contaminated as long as there is nothing wrong with the

compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

•The capacity of the oil has increased.

•The oil has changed color to red.

•Foreign substances, metal powder, etc., are present in the

oil.

If any of these conditions exists, compressor oil is

contaminated. Whenever contaminated compressor oil is

discovered, the receiver/drier must be replaced.

OIL RETURN OPERATION

There is close affinity betw een the oil and the refrigerant.

During normal operation, part of the oil recirculates with the

refrigerant in the system.

When checking the amount of oil in the system, or replacing

any component of the system, the compressor must be run in

advance for oil return operation. The procedure is as follows:

(1)Open the all doors and engine hood.

(2)Start the engine and A/C switch is "ON" and Set the fan

control knob at its highest position.

(3) Run the compressor for more than 20 minutes between

800 and 1,000 rpm in order to operate the system.

(4)Stop the engine.

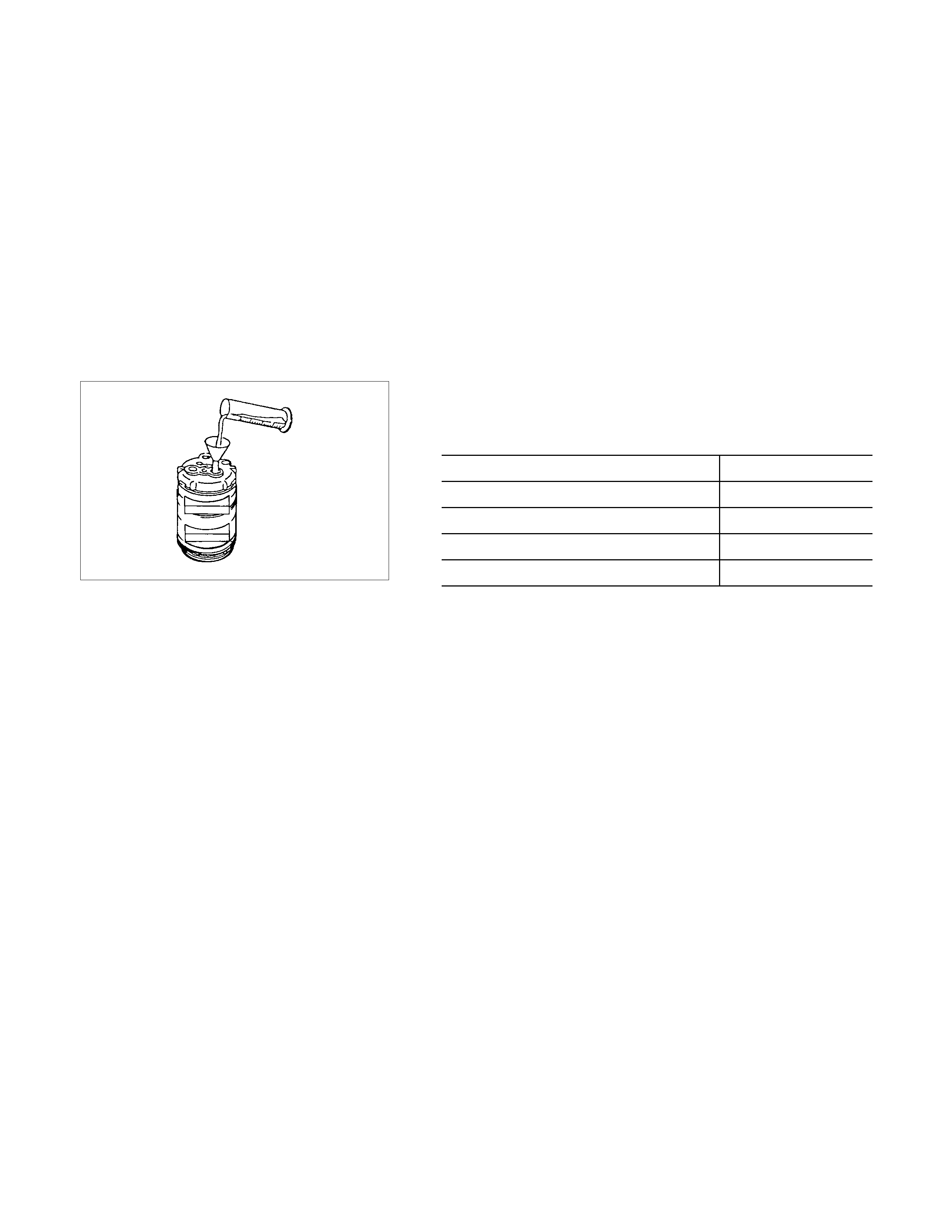

REPLACEM ENT O F COMPONENT PARTS

When replacing system component parts, supply the following

amount of oil to the component parts to be installed.

Component parts to be installed Amount of oil

Evaporator 50 cc (1.7 fl.oz.)

Condenser 30 cc (1.0 fl.oz.)

Receiver/drier 30 cc (1.0 fl.oz.)

Refrigerant line (One piece) 10 cc (0.3 fl.oz.)

Refrigeration oil must be replenished if more than two parts

are removed at the same time. After installing these

components, check compressor oil.

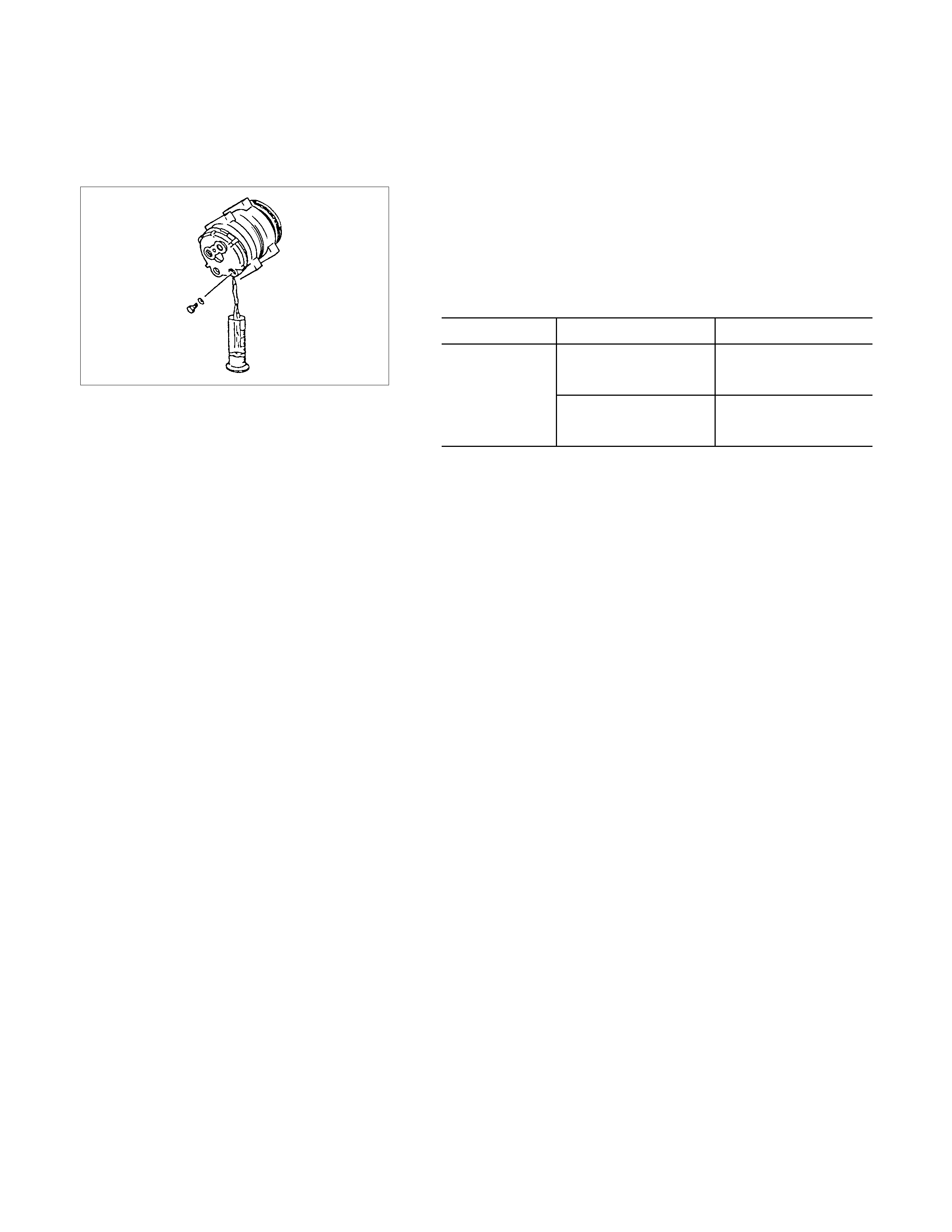

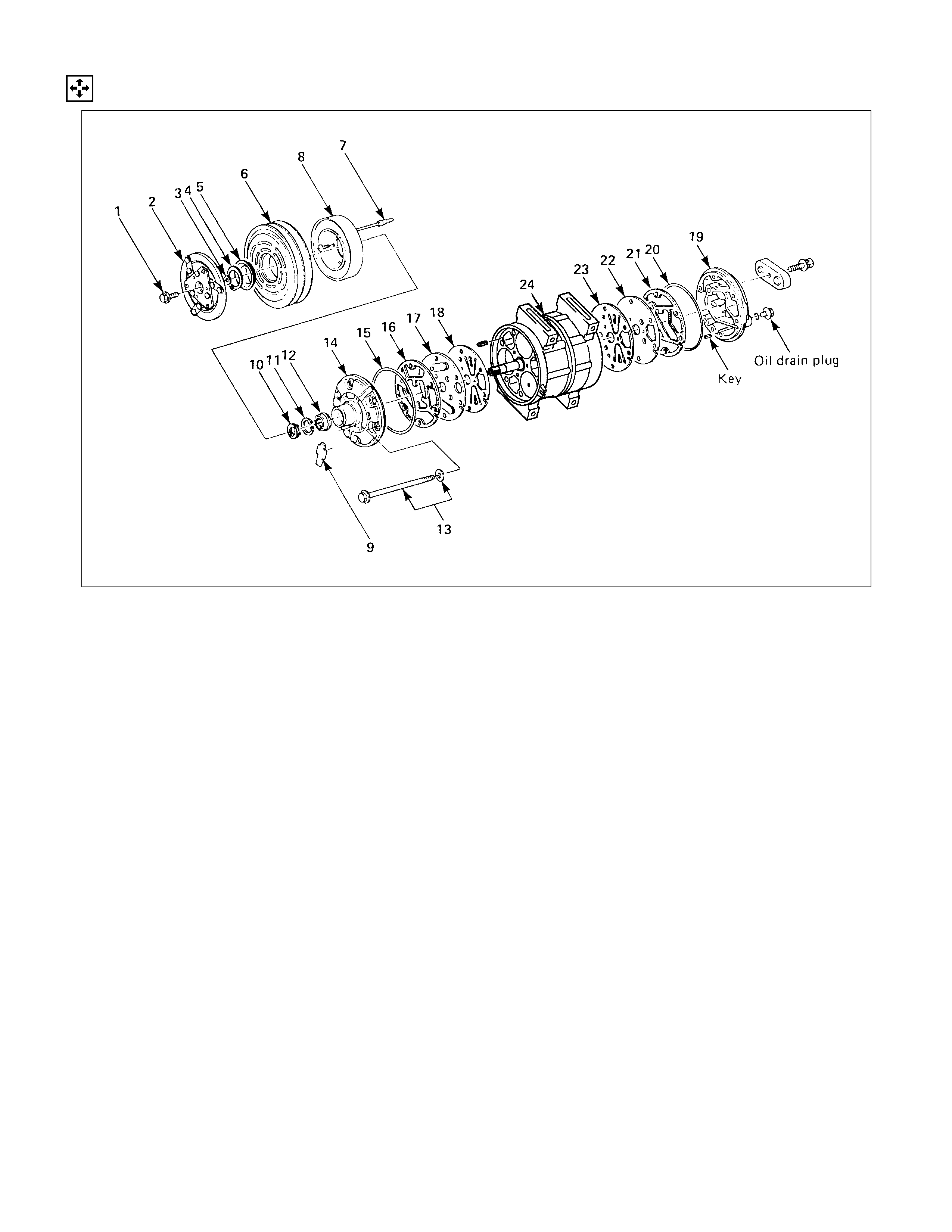

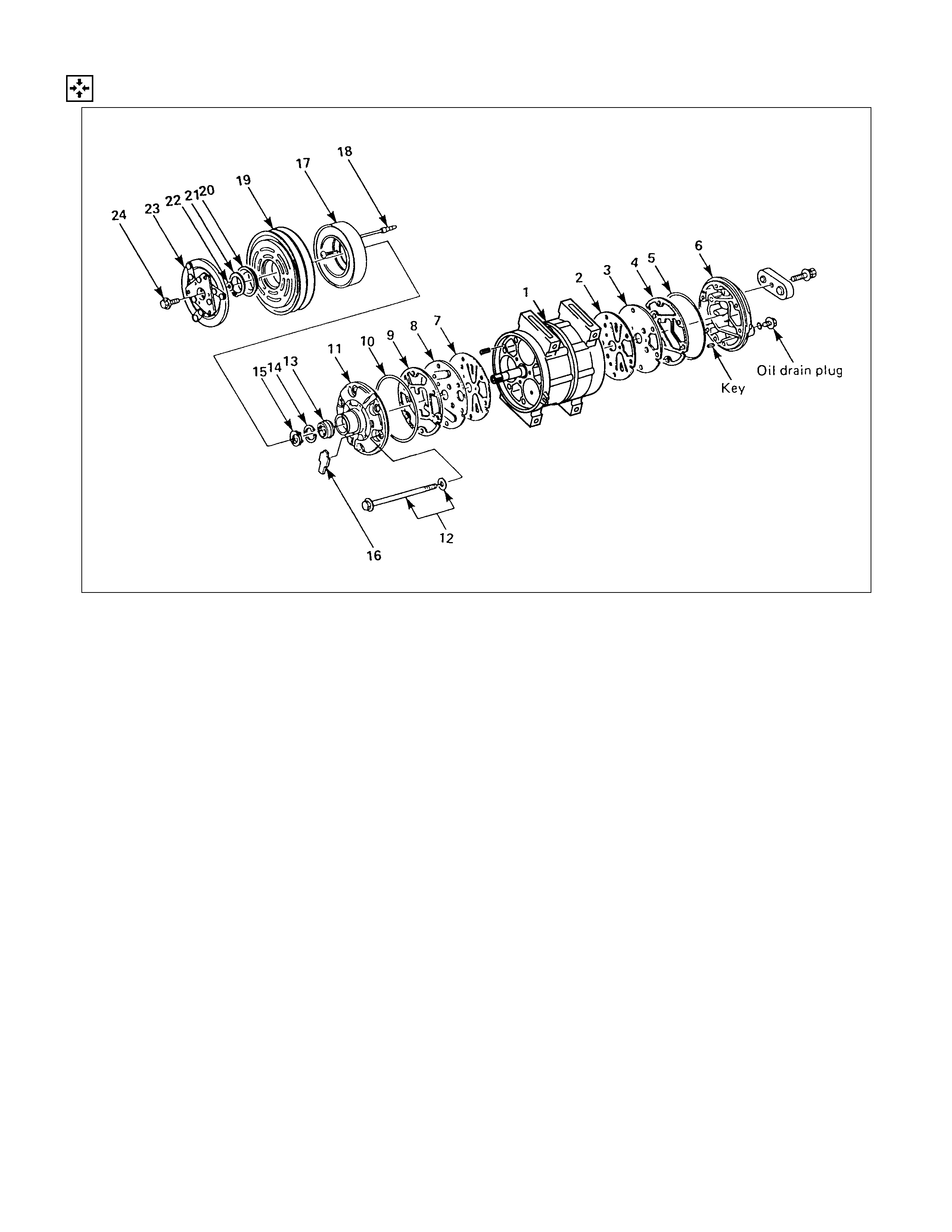

DISASSEMBLY

DISASSEMBLY STEPS

1. Drive plate bolt

2. Drive plate

3. Shim(s)

4. Snap ring

5. Cover (If so equipped)

6. Pulley assembly

7. Lead wire connector

8. Field coil

9. Felt (If so equipped)

10. Shaft seal cover (If so equipped)

11. Snap ring

12. Shaft seal assembly

13. Through bolt with gasket

14. Front cylinder head

15. O-ring

16. Gasket

17. Front valve plate

18. Front suction valve

19. Rear cylinder head

20. O-ring

21. Gasket

22. Rear valve plate

23. Rear suction valve

24. Cylinder and shaft assembly

IMPO RTANT OPERATIONS - DI SSASSEMBLY

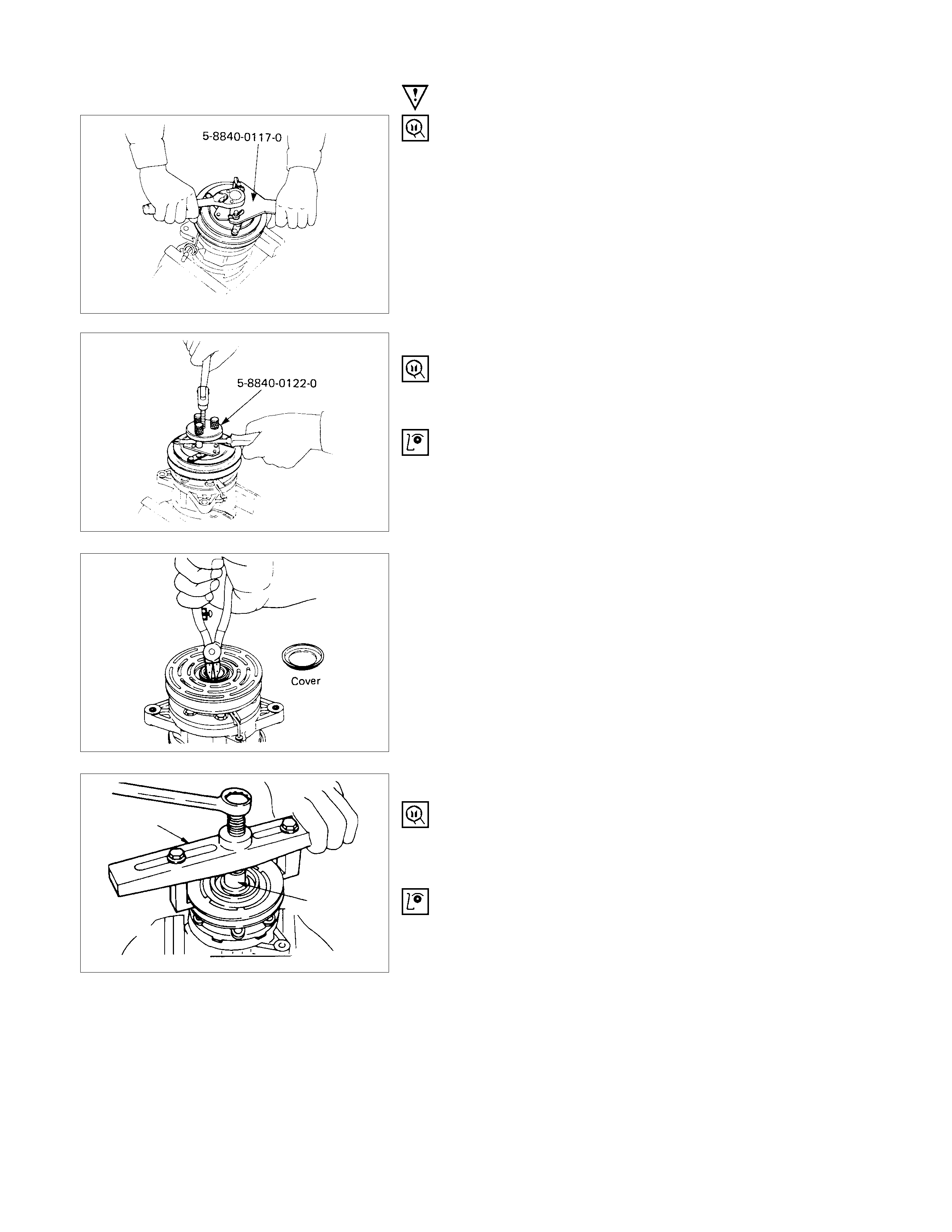

1. Drive Plate Bolt

Using drive plate holder to prevent the drive plate from

rotating, then remove the bolt.

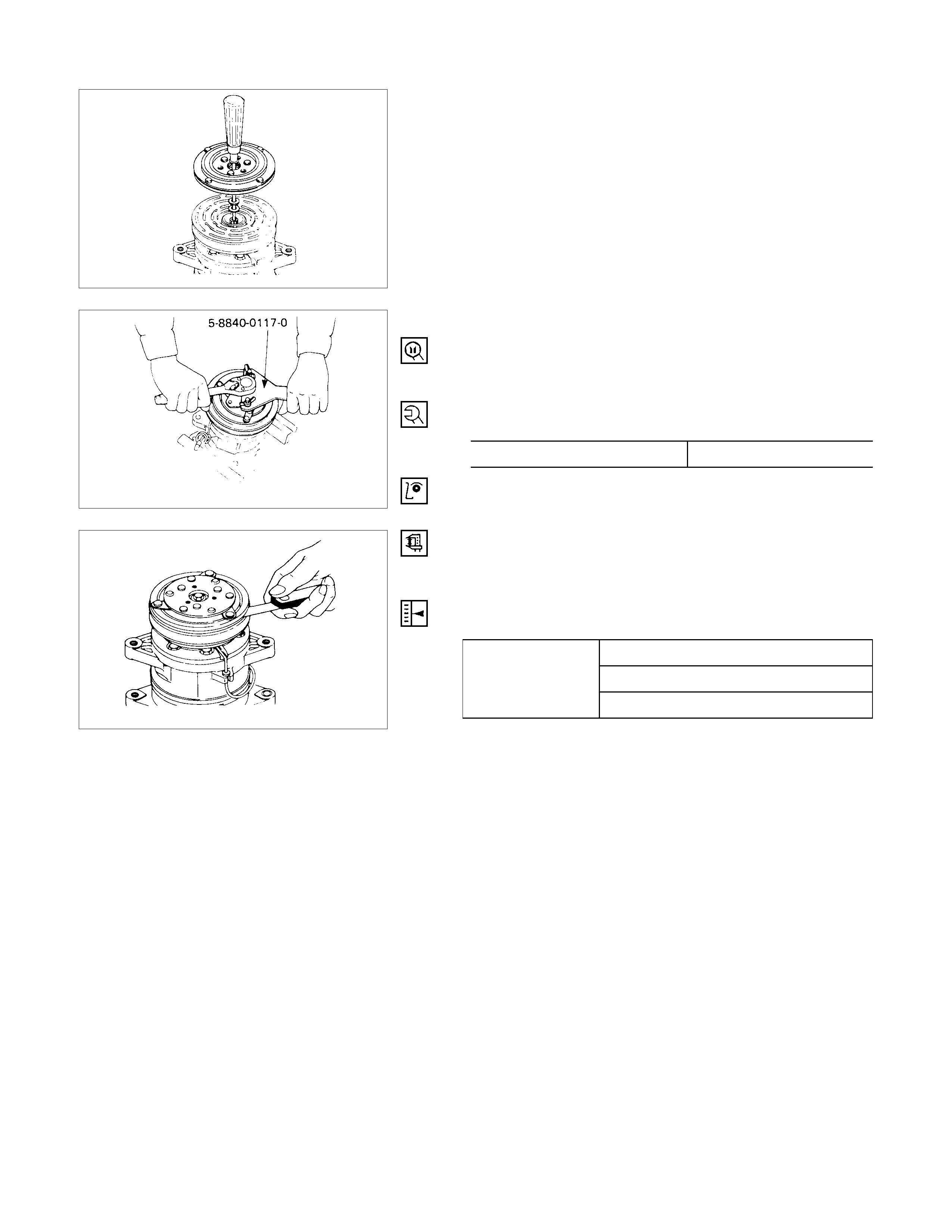

Drive Plate Holder: 5-8840-0117-0 (J-33939)

2. Drive Plate

Using drive plate puller and forcing screw to remove the

drive plate.

Drive Plate Puller: 5-8840-0122-0 (J-33944-A)

If the frictional surface shows signs of damage due to

excessive heat, the drive plate and pulley should be

replaced.

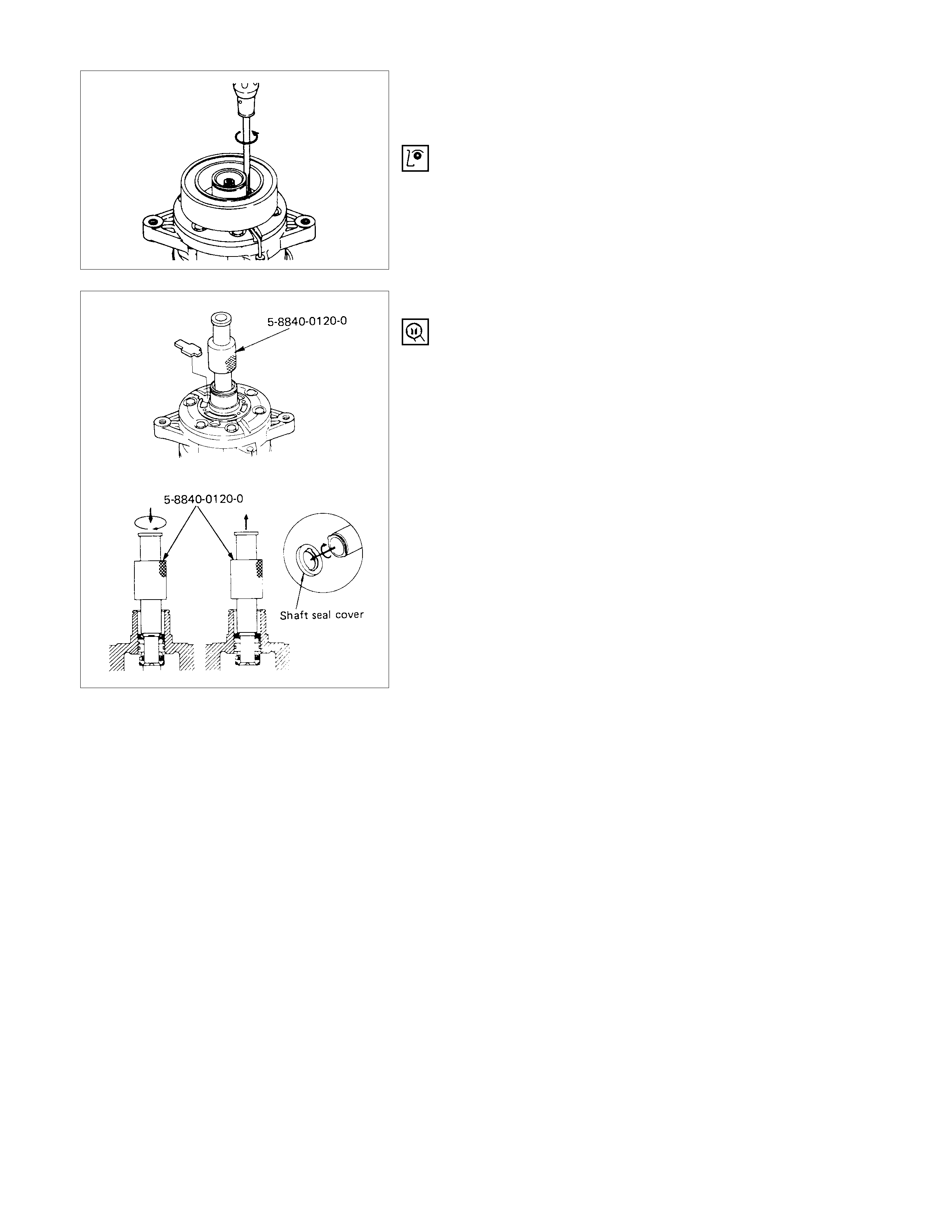

5. Cover (If so equipped)

Using snap ring pliers to remove the snap ring.

5-8840-0111-0

5-8840-0121-0

6. Pulley Assembly

Using pulley puller pilot and pulley puller to remove the

pulley assembly.

Pulley Puller Pilot: 5-8840-0121-0 (J-33943)

Pulley Puller: 5-8840-0111-0 (J-8433)

Check the appearance of the pulley assembly. If the

frictional surface of the pulley shows signs of excessive

grooving due to slippage, both the pulley and drive plate

should be replaced. The frictional surfaces of the pulley

assembly should be cleaned with a suitable solvent before

reinstallation.

8.Field Coil

Loosen three screws and remove the field coil with lead

wire.

Check coil for loose connector or cracked insulation.

10.Shaft Seal Cover (If so equipped)

Using shaft seal remover to remove the shaft seal cover.

Engage the remover hook with the shaft seal cover groove

and slowly draw the shaft seal cover out.

Shaft Seal Remover: 5-8840-0120-0 (J-33942)

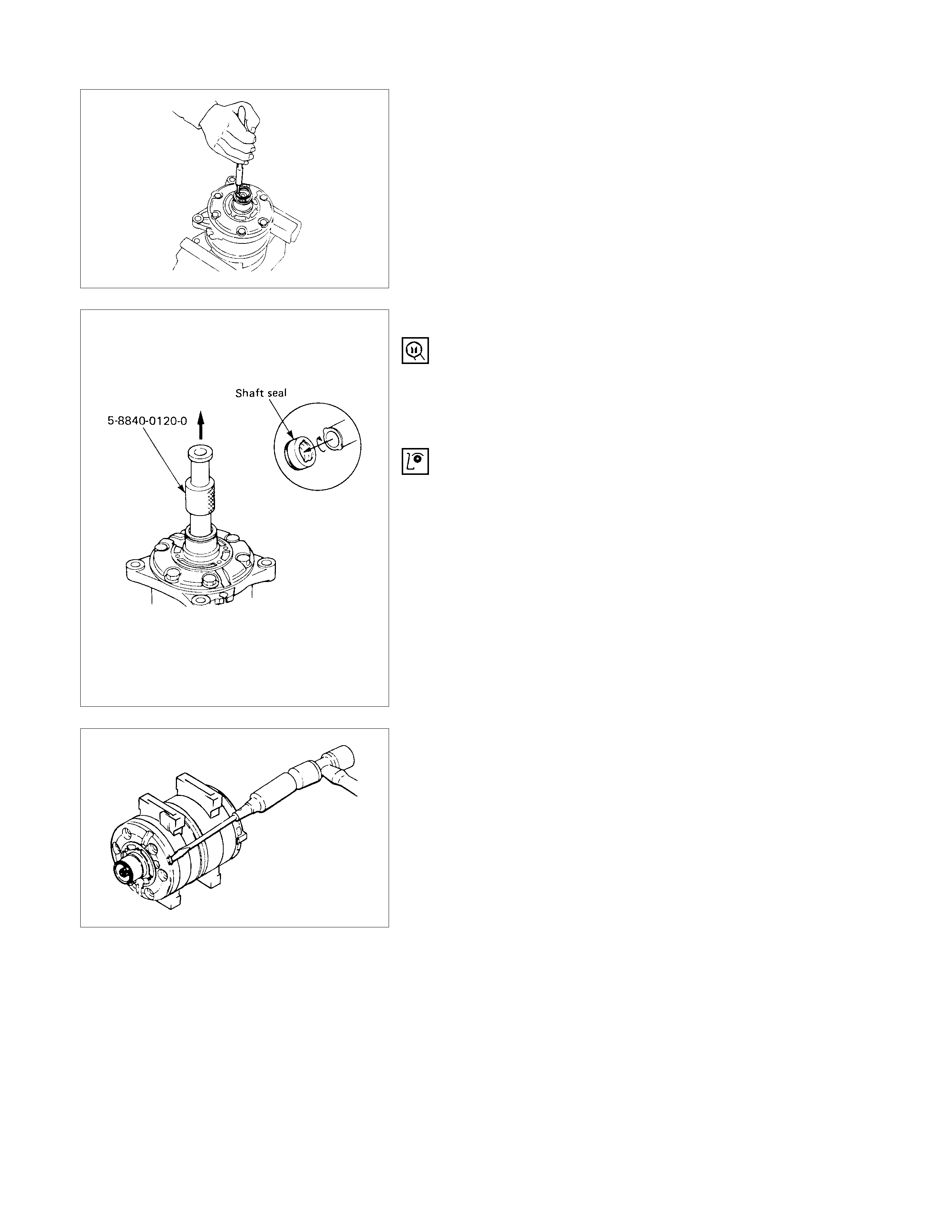

11.Snap Ring

Using snap ring pliers to remove the snap ring.

12.Shaft Seal Assembly

Using shaft seal remover to remove the shaft seal

assembly.

Engage the remover hook with the shaft seal assembly

groove and slowly draw the shaft seal assembly out.

Shaft Seal Remover: 5-8840-0120-0 (J-33942)

The shaft seal is precision-machined and its critical parts

are finished to extremely close tolerances. The assembly

must be handled with great care, it slips face demanding

particularly careful handling.

The shaft seal can not be reused. Install a new shaft seal

at reassembly.

Take care not to scratch or otherwise damage the shaft

seal face.

Keep the shaft seal free from lint and dirt.

14.Front Cy linder Head

15.O-ring

Alternately tap the projections on the circumference of the

front cylinder head with a screwdriver and a plastic hamme

r

to remove the front cylinder head.

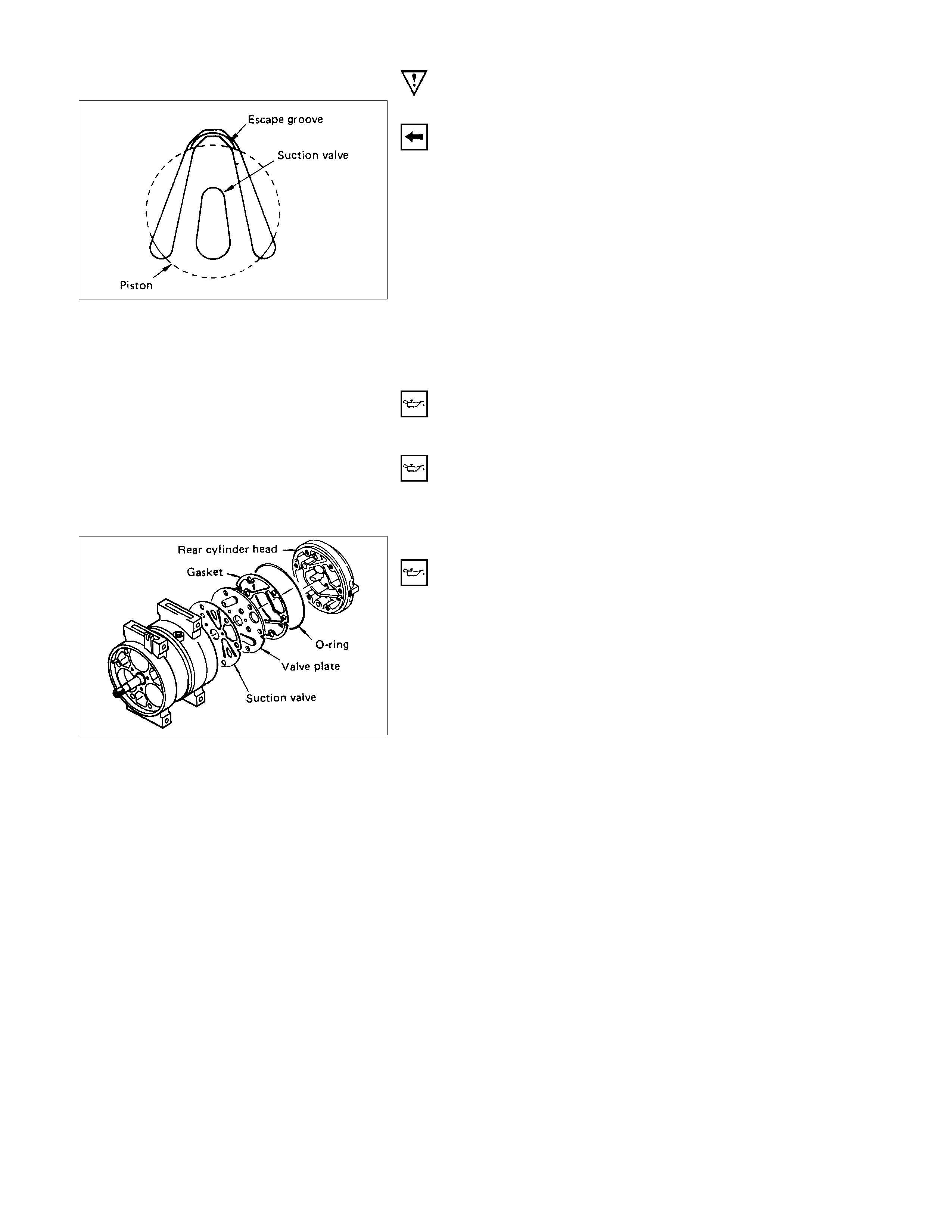

18.Front Suction Valve

Check the front valve plate for scratching and bending.

Check the front valve plate and the front cylinder head fo

r

nicks and burrs on the sealing surface.

Buff or replace the valve plate and cylinder head if nicks

and burrs are present.

Check that the front valve plate passage is free from

obstructions.

Check the front valve plate and the cylinder head fo

r

cracks.

Replace the valve plate and cylinder head if cracks are

present.

19.Rear Cylinder Head

20.O-ring

Alternately tap the projections on the circumference of the

rear cylinder head with a sc rewdriver and a plastic ham m e

r

to remove the rear cylinder head.

24.Cylinder and shaft assembly

Check the rear valve plate for scratching and bending.

Check the rear valve plate and the rear cylinder head fo

r

nicks and burrs on the sealing surface.

Buff or replace the valve plate and cylinder head if nicks

and burrs are present.

Check that the rear valve plate passage is free from

obstructions.

Check the rear valve plate and the cylinder head for cracks.

Replace the valve plate and cylinder head if cracks are

present.

REASSEM BLY

REASSEM BLY STEPS

1. Cylinder and shaft assembly

2. Rear suction valve

3. Rear valve plate

4. Gasket

5. O-ring

6. Rear cylinder head

7. Front suction valve

8. Front valve plate

9. Gasket

10. O-ring

11. Front cylinder head

12. Through bolt with gasket

13. Shaft seal assembly

14. Snap ring

15. Shaft seal cover (If so equipped)

16. Felt (If so equipped)

17. Field coil

18. Lead wire connector

19. Pulley assembly

20. Cover (If so equipped)

21. Snap ring

22. Shim(s)

23. Drive plate

24. Drive plate bolt

IMPO RTANT OPERATION - RESASSEMBLY

1. Cylinder and Shaft Assembly

Clamp the cylinder shaft assem bly in a vise. The rear side

of the cylinder shaft assembly must be facing up.

2. Rear Suction Valve

Install the suction valve by aligning it with the spring pin and

the cylinder valve relief grooves.

3. Rear Valve Plate

Install the valve plate to the suction valve by aligning it with

the spring pin.

Note:

Do not mix up the front and rear valve plates.

4. Gasket

1) Apply a coat of new compressor oil to the new gasket.

2) Install the gasket to the valve plate.

5. O-ring

6. Rear Cylinder Head

1) Apply a coat of new compressor oil to the new O-ring.

2) Install the O-ring to the rear cylinder head.

3) Install the rear cylinder head.

Tap the rear cylinder head into place with a plastic

hammer.

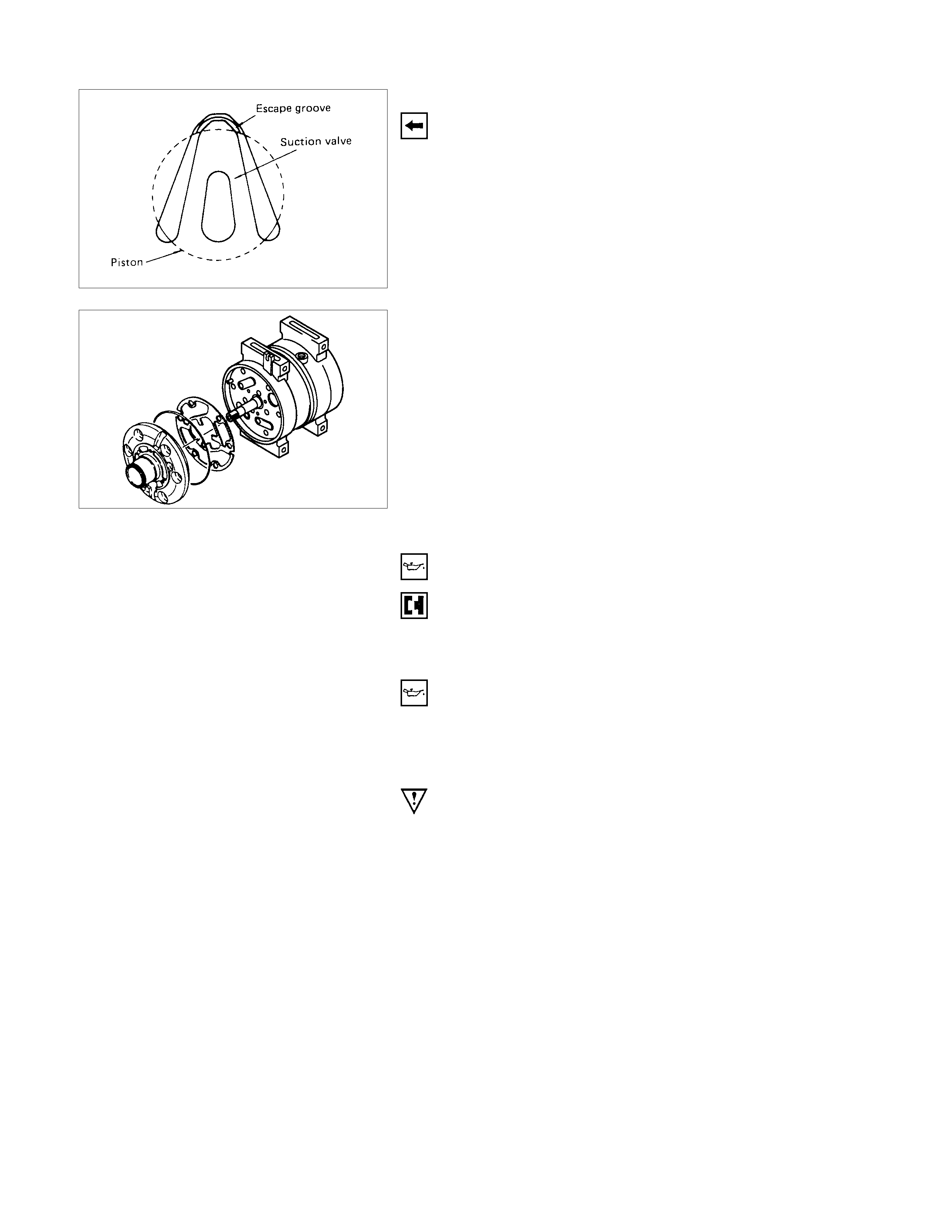

7. Front Suction Valve

Set the cylinder shaft assembly with the front side facing up.

Install the suction valve by aligning it with the spring pin and

the cylinder valve relief grooves.

8. Front Valve Plate

Install the valve plate to the suction valve by aligning it with

the spring pin.

Note:

Do not mix up the front and rear valve plates.

9. Gasket

Apply new compressor oil to the new gasket.

Install the gasket to the valve plate by aligning it with the

spring pin.

10.O-ring

11.Front Cy linder Head

Apply a coat of new compressor oil to the new O-ring.

Install the O-ring to the front cylinder head.

Install the front cylinder head.

Tap the front cylinder head into place with a plastic

hammer.

Note:

When installing the cylinder head, be careful that the

end of the drive shaft does not damage the shaft seal

assembly surface in the cylinder head.

12.Through Bolt with Gasket

Gaskets cannot reused. Always replace new ones.

Tighten the bolts to the specified torque a little at a time in

the sequence shown in the illustration.

Through Bolt Torque N⋅m (kg⋅m/lb⋅ft)

22 (2.2/16)

Rotate the compressor drive shaft two or three times to

make sure that it moves smoothly.

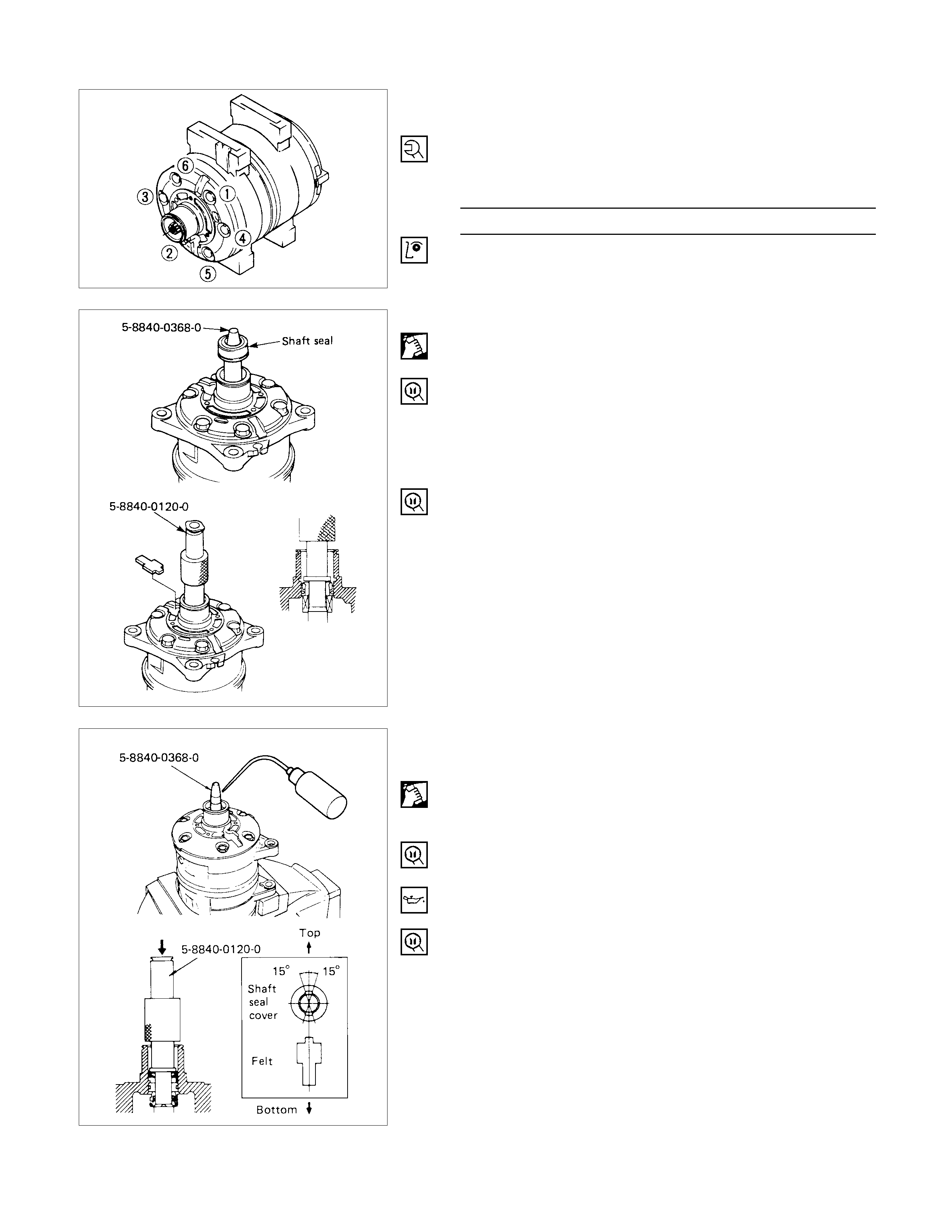

13.Shaft Seal Assembly

1) Clean the sealing portion of the compressor and shaft

seal.

2) Install the shaft seal guide onto the end of the drive

shaft.

3) Shaft Seal Guide: 5-8840-0368-0 (J-34614)

4) Apply new compressor oil to the shaft seal guide.

5) Install the shaft seal onto the compressor drive shaft

head by using shaft seal installer.

Shaft Seal Installer: 5-8840-0120-0 (J-33942)

15.Shaft Seal Cover (If so equipped)

16.Felt (If so equipped)

Clean the sealing portion of the compressor and shaft seal

cover.

Install the shaft seal guide onto the end of the drive shaft.

Shaft Seal Guide: 5-8840-0368-0 (J-34614)

Apply new compressor oil to the shaft seal guide.

Install the shaft seal cover onto the drive shaft by using

shaft seal installer.

The installation position of the shaft seal cover is shown in

the illustration.

Shaft Seal Installer: 5-8840-0120-0 (J-33942)

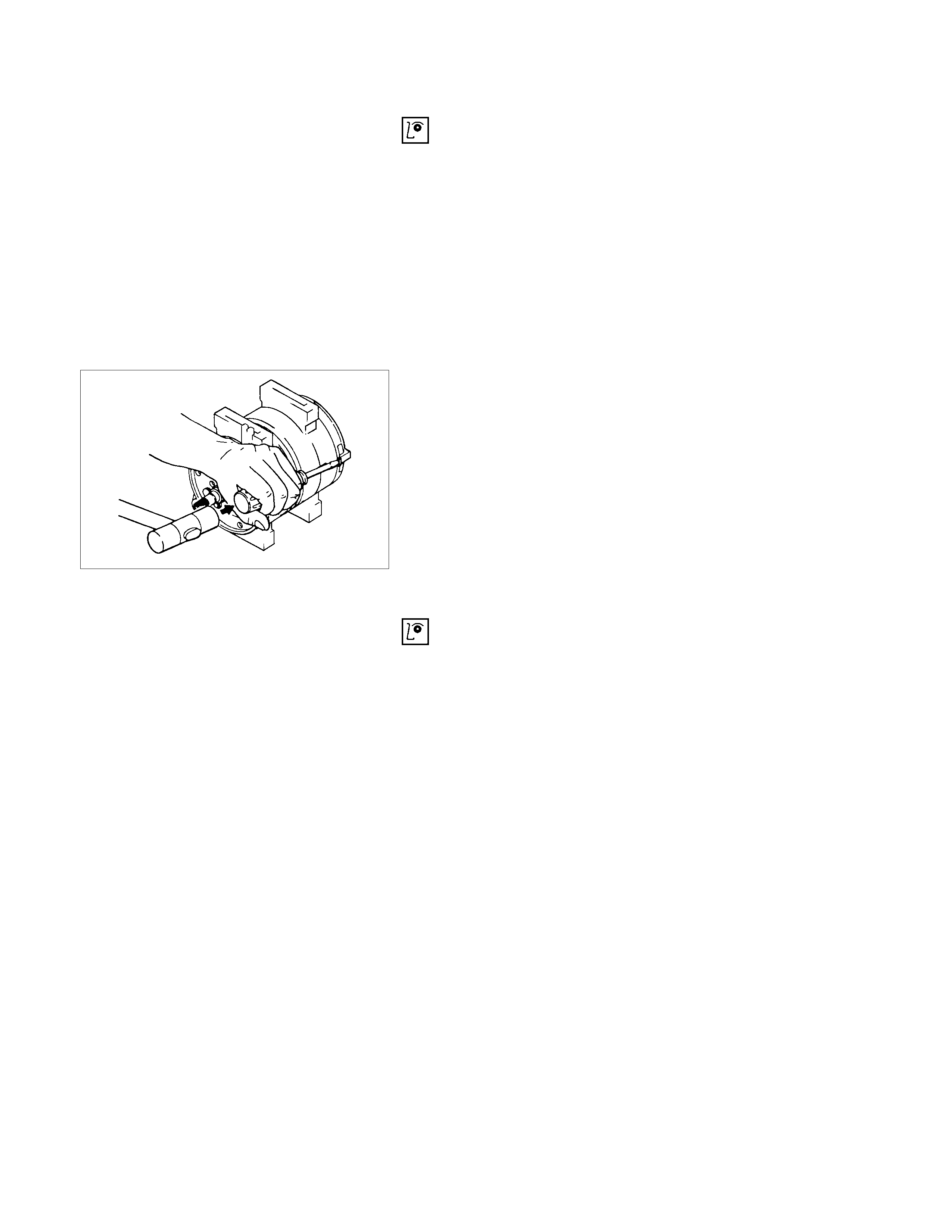

17.Field Coil

18.Lead Wire Connector

Install the field coil to the compressor.

Lead wire must be facing up.

Tighten the field coil fixing screws to the specified torque.

N⋅m (kgf⋅m/Ib⋅ft)

Torque 5.0 (0.5/3.6)

19.Pulley Asssembly

Using pulley installer and drive handle to install the pulley

assembly.

Pulley Installer: 5-8840-0118-0 (J-33940)

Drive Handle: 5-8840-0007-0 (J-8092)

20.Cover (If so equipped)

21.Snap Ring

Install the snap ring with the inside indented portion facing

out.

22.Shim(s)

23.Drive Plate

Install the drive plate to the com pres sor drive shaf t togethe

r

with the original shim(s).

Press the drive plate by hand.

24.Drive Plate Bolt

Using drive plate holder to prevent the drive plate from

rotating.

Drive Plate Holder: 5-8840-0117-0 (J-33939)

Tighten the bolt to the specified torque. N⋅m (kgf⋅m/Ib⋅ft)

Torque 15 (1.5/11)

After tightening the bolt, c heck to be s ure the pulley rotates

smoothly.

Check to be sure that the clutch clearance is between 0.3 -

0.6 mm (0.01 - 0.02 in).

If necessary, install adjusting shim(s).

Adjusting shims are available in the following thickness.

0.1 mm (0.0039 in)

Thickness 0.3 mm (0.0118 in)

0.5 mm (0.0197 in)

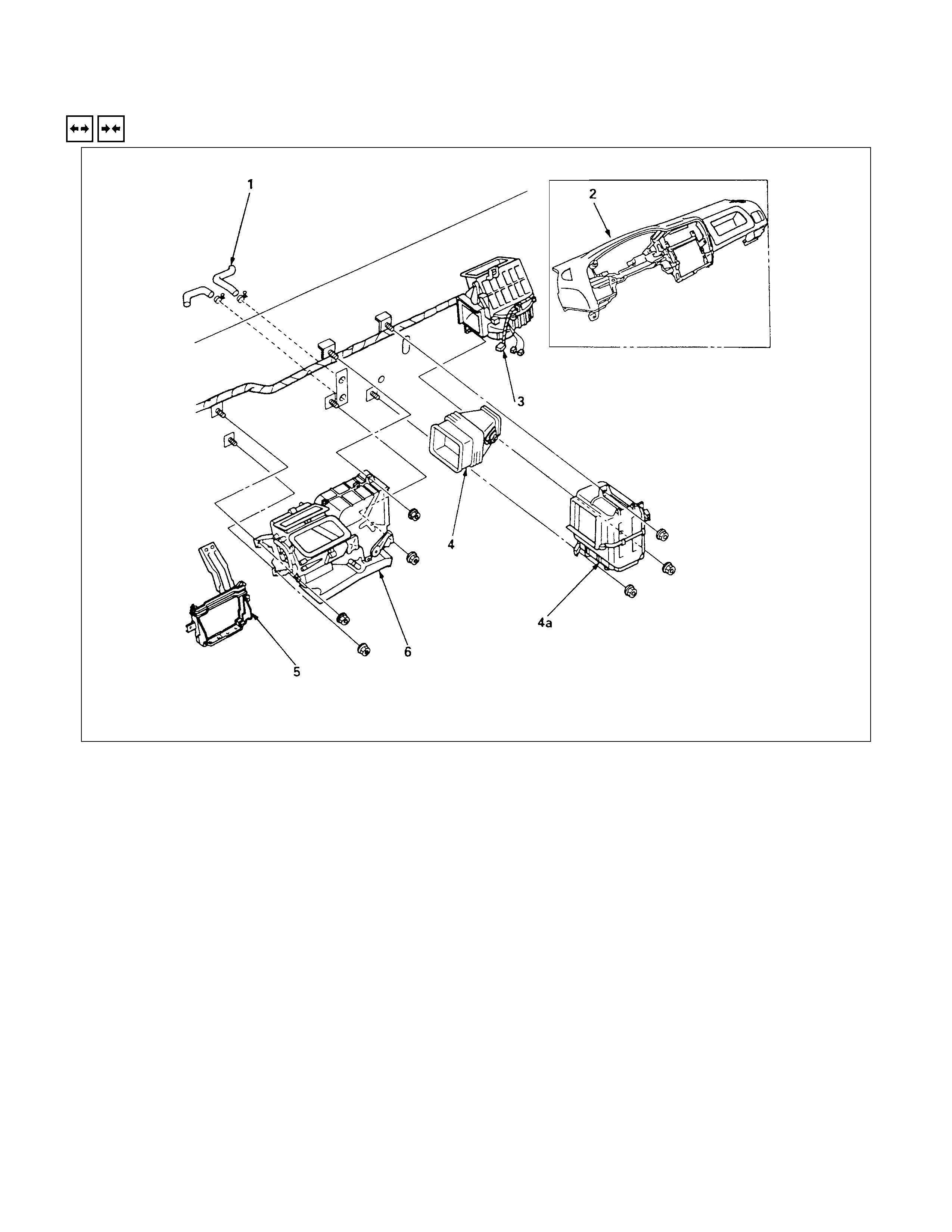

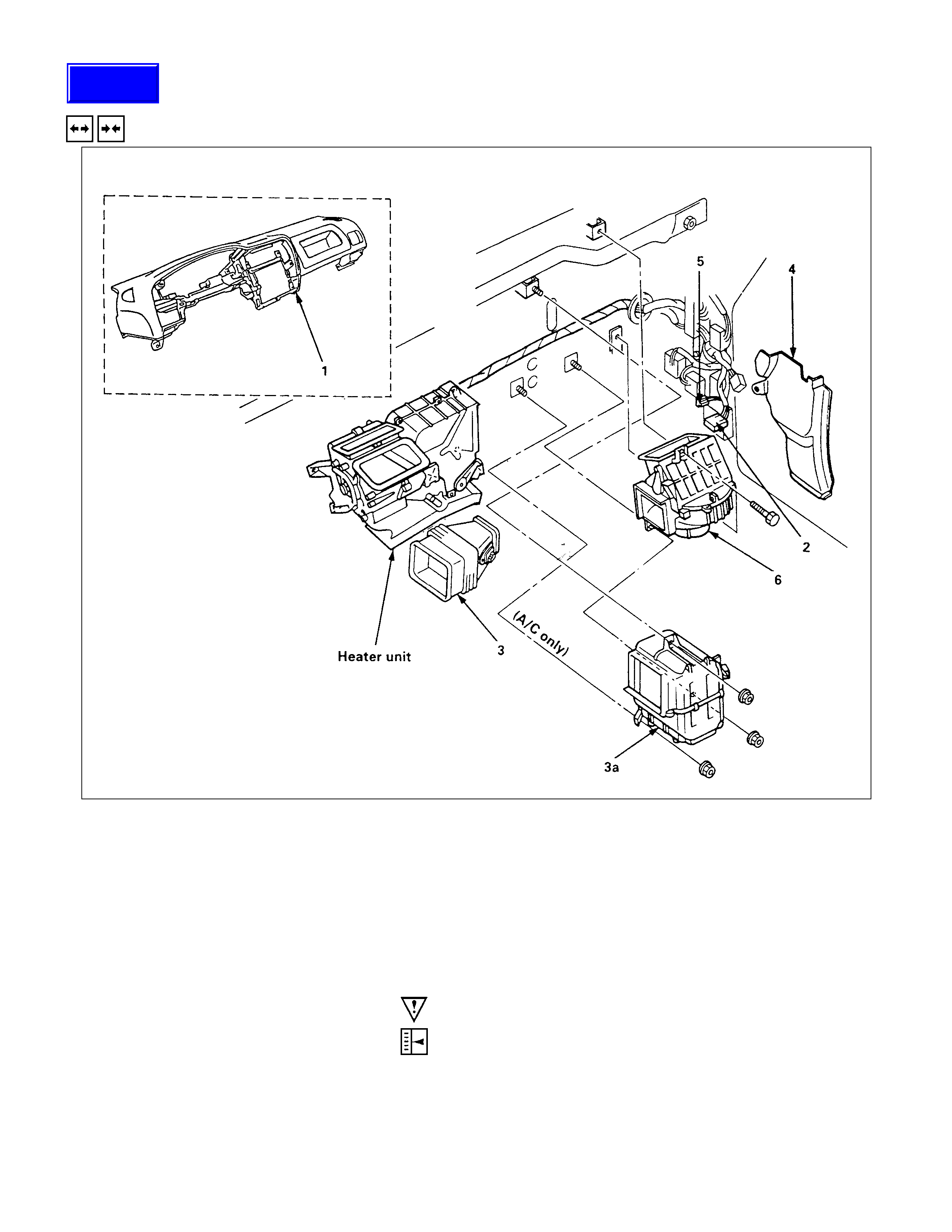

HEATER UNI T

REMOVAL AND INSTALLATION

This illustration is based on LHD model

REMOVAL STEPS

▲1. Heater hose

▲2. Instrument panel assembly

3. Resistor connector

4. Duct

4a. Evaporator (A/C only)

5. Instrument panel stay

6. Heater unit

INSTALLATION STEPS

6. Heater unit

5. Instrument panel stay

4a. Evaporator (A/C only)

4. Duct

3. Resistor connector

▲2. Instrument panel assembly

1. Heater hose

IMPO RTANT OPERATIONS - REM OVAL

1. Heater Hose

Disconnect the heater hoses at heater unit.

Place the drain pan under the vehicle.

2. Instrument Panel Assembly

Refer to section 1C "BODY" for instrument panel removal

procedure.

IMPORTANT OPERATION - INSTALLATION

2. Instrument Panel Assembly

Adjust the heater control cables.

Refer to "CONTROL LEVER ASSEMBLY" in this section.

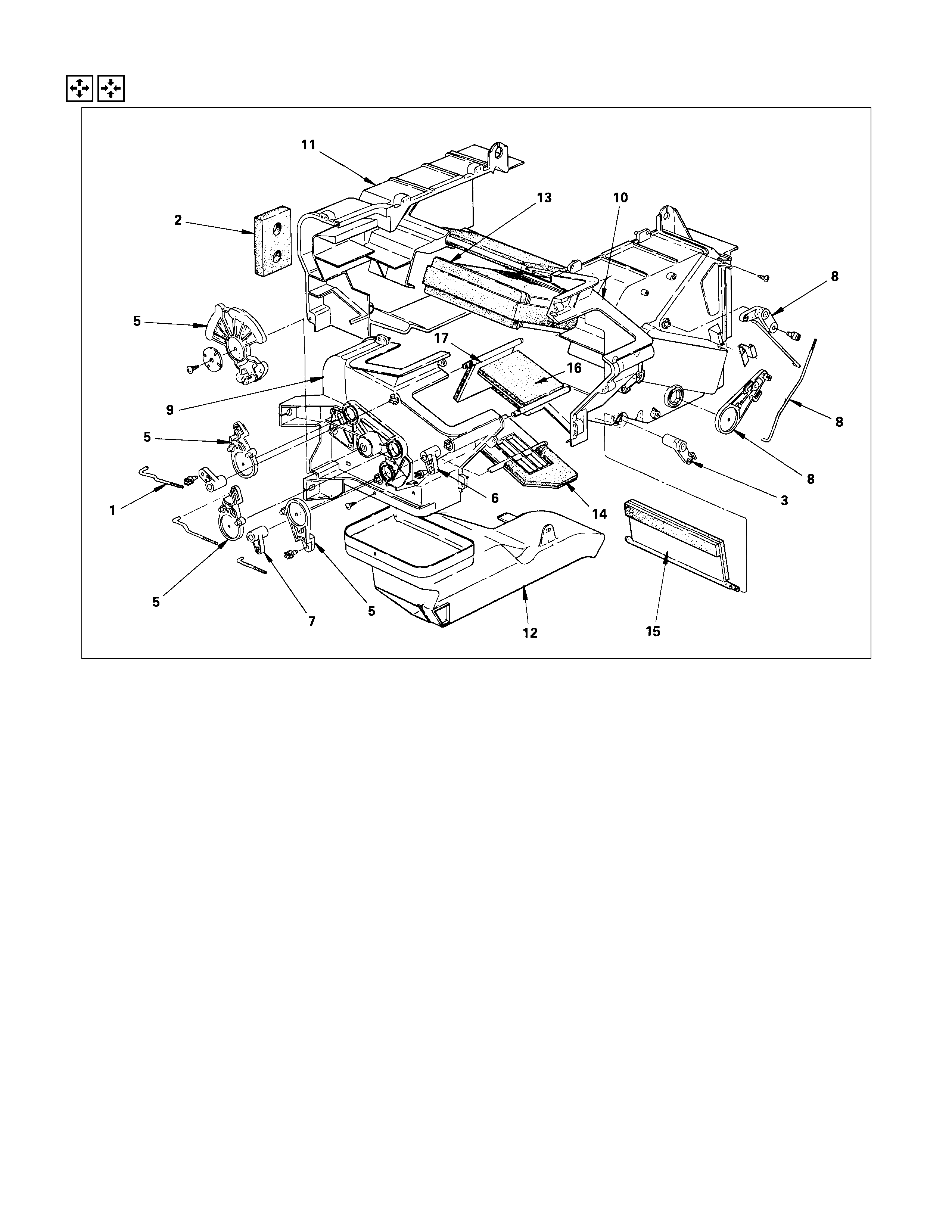

DISASSEMBLY AND REASSEMBLY

This illustration is based on the LHD model.

DISASSEMBLY STEPS

1. Rod and lever; defroster door

2. Plate and seal

3. Lever; mix door

4. Link; main model control

5. Relay link

6. Lever; vent door

7. Lever; heater door

8. Relay link mix door

9. Case; LH

10. Case; RH

11. Case; back

12. Duct

13. Core assembly

14. Door; heat foot

15. Door; heat mix

16. Door; side vent

17. Door; defroster

REASSEM BLY STEPS

To reassemble, follow the disassembly

procedure in reverse order.

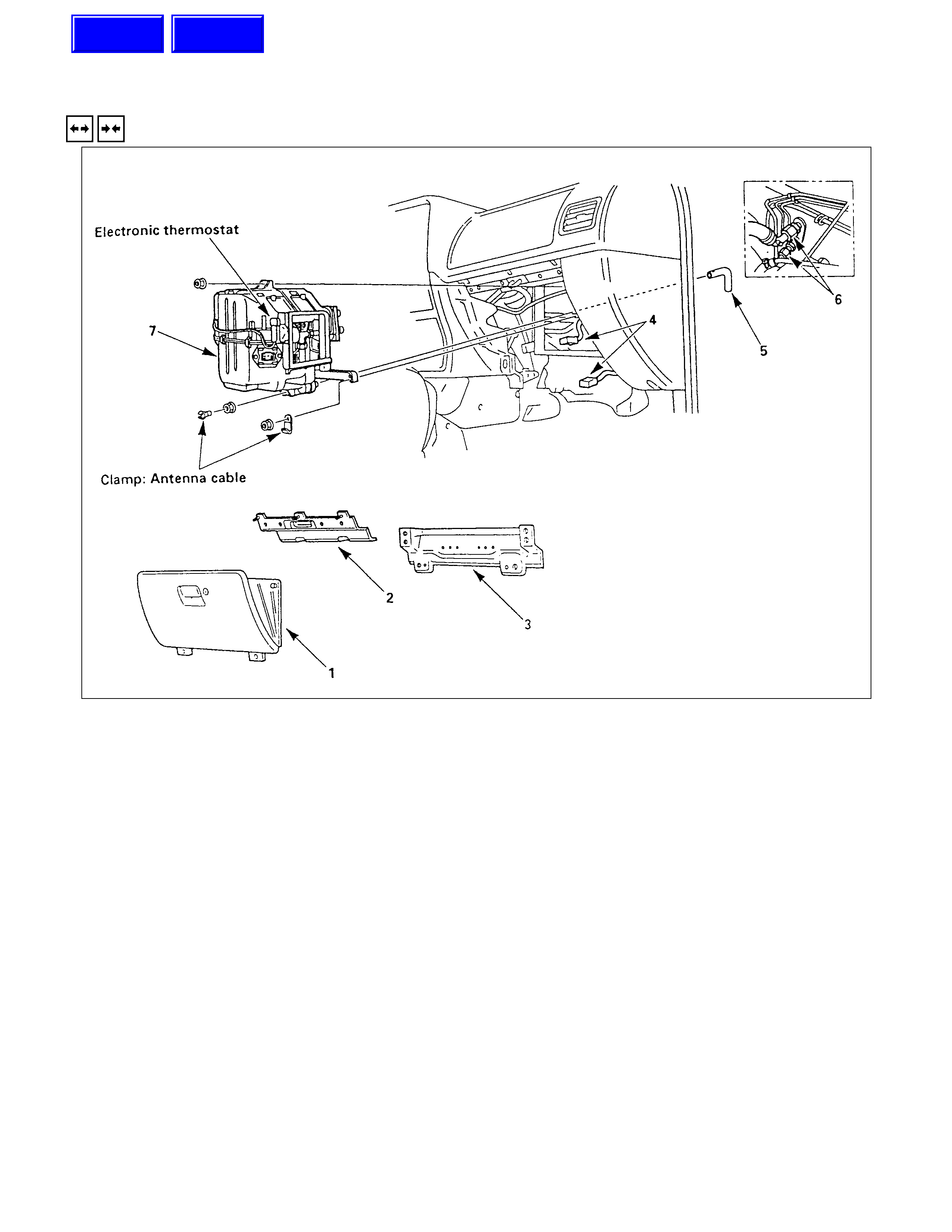

EVAPORATOR

REMOVAL AND INSTALLATION

This illustration is based on LHD model.

REMOVAL STEPS

1. Glove box

2. Glove box cover

3. Passenger knee bolster reintorcement

4. Resister and electronic thermostat

connector

5. Drain hose

6. Refrigerant line

7. Evaporator assembly

INSTALLATION STEPS

To install, follow the removal procedure in

reverse order.

Techline

Techline

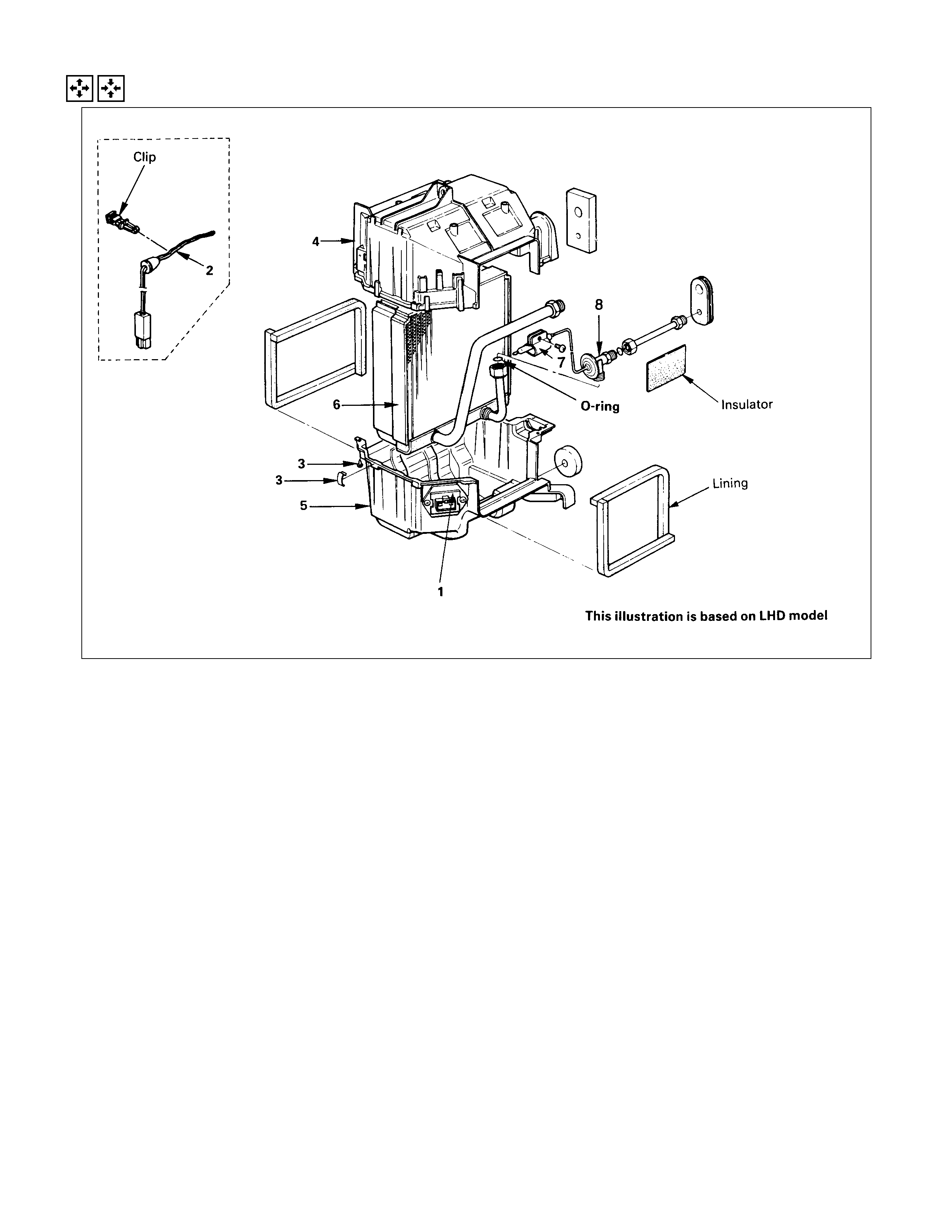

DISASSEMBLY AND REASSEMBLY

DISASSEMBLY STEPS

1. Resistor

2. Electronic thermostat (Clip type)

3. Attaching parts

4. Case; upper

5. Case; lower

6. Core assembly

7. Clip; sensing tube

8. Expansion valve assembly

REASSEM BLY STEPS

8. Expansion valve assembly

7. Clip; sensing tube

6. Core assembly

5. Case; lower

4. Case; upper

3. Attaching parts

▲2. Electronic thermostat (Clip type)

1. Resistor

BLOWER UNIT ASSEMBLY

REMOVAL AND INSTALLATION

This illustration is based on LHD model.

REMOVAL STEPS

1. Instrument panel assembly

2. Resistor connector

3. Duct

3a. Evaporator (A/C only)

4. Dash side trim panel

5. Blower motor connector

6. Blower unit assembly

INSTALLATION STEPS

6. Blower unit assembly

5. Blower motor connector

4. Dash side trim panel

3a. Evaporator (A/C only)

3. Duct

2. Resistor connector

▲1. Instrument panel assembly

IMPORTANT OPERATION - INSTALLATION

1. Instrument Panel Assembly

Adjust the blower control cable.

Refer to "CONTROL LEVER ASSEMBLY" in this section.

Techline

DISASSEMBLY AND REASSEMBLY

This illustration is

based on LHD model.

DISASSEMBLY STEPS

1. Lever; door

2. Blower motor assembly

3. Seal

4. Attaching parts

5. Case; lower

6. Case; LH

7. Case; RH

8. Door, blower unit

9. Fan; blower motor

10. Blower motor

REASSEM BLY STEPS

10. Blower motor

9. Fan; blower motor

8. Door, blower unit

7. Case; RH

6. Case; LH

5. Case; lower

4. Attaching parts

3. Seal

2. Blower motor assembly

1. Lever; door

CONTROL LEVER ASSEMBLY

REMOVAL AND INSTALLATION

REMOVAL STEPS

1. Instrument panel driver lower

2. Lower cluster assembly

3. Meter cluster assembly

4. Instrument panel lower center cover

assembly

5. Glove box

6. Knobs

▲7. Heater bezel

▲8. Fan control lever and / or A/C switch

connector

9. Control lever assembly

▲10. Cables cover assembly

INSTALLATION STEPS

10. Cables

9. Control lever assembly

8. Fan control lever and / or A/C switch connector

7. Heater bezel

▲6. Knobs

5. Glove box

4. Instrument panel lower center cover assembly

3. Meter cluster assembly

2. Lower cluster assembly

1. Instrument panel driver lower

Techline

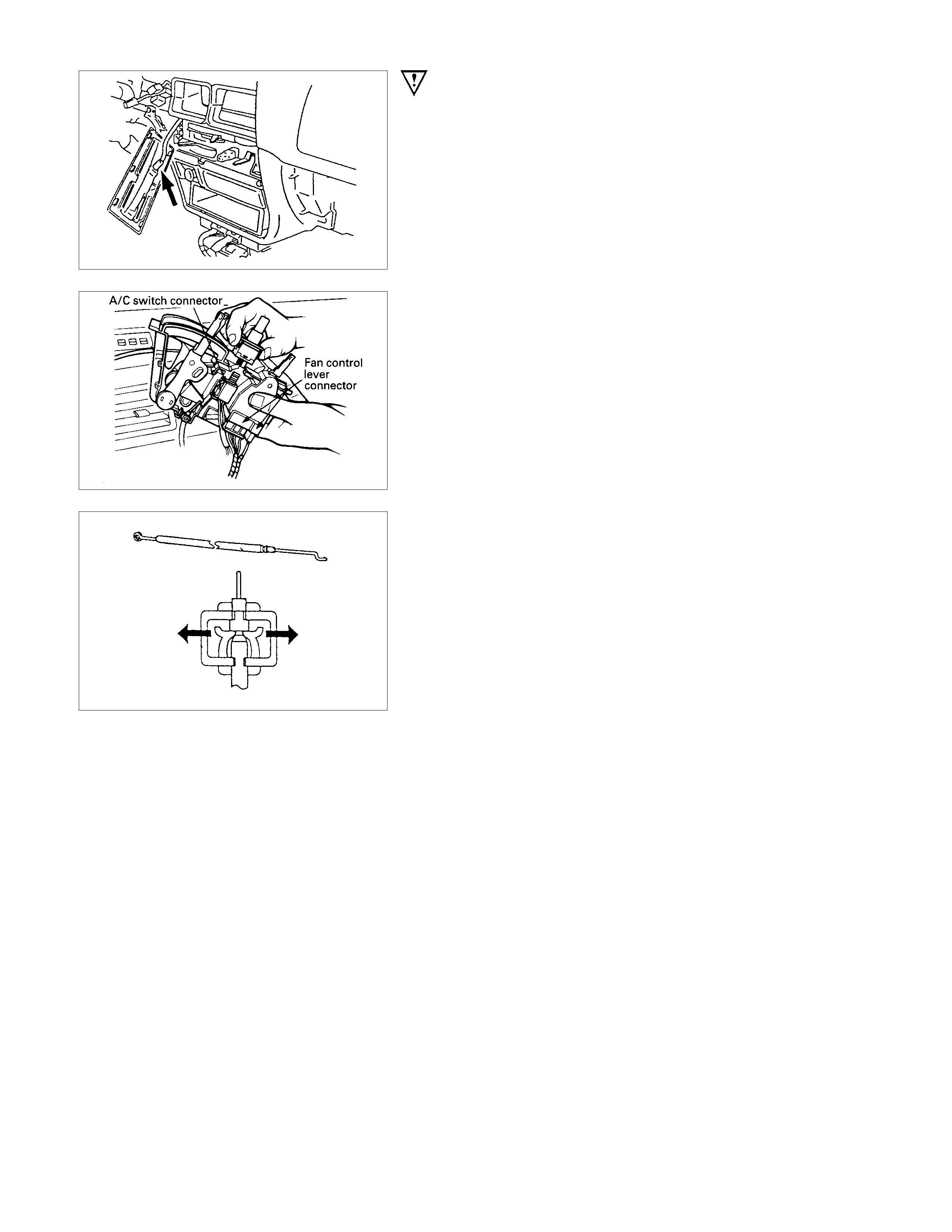

IMPORTANT OPERATION - REMOVAL

7. Heater Bezel

8. Fan and A/C Switch Connector

Pull the control lever assembly out and disconnect the

connectors.

10.Cables

IMPORTANT OPERATION - INSTALLATION

6. Control Lever Assembly

Adjust the control cables.

Air source control cable (Blower unit)

(1)Slide the control lever to the left.

(2)Connect the control cable at the "CIRC" position and fix it

with the clip.

Temperature control cable (Heater unit)

(1)Slide the control lever to the left.

(2)Connect the control cable at the "COLD" position and fix it

with the clip.

Air select control cable (Heater unit)

(1)Slide the control lever to the right.

(2)Connect the control cable at the "DEFROST" position and

fix it with the clip.

Check operation.

BEZEL

(AIR SELECTOR CABLE) (TEMPERATURE CONTROL

CABLE) (AIR SOURCE SELECT CABLE)

LHD

RHD

INSPECTION AND REPAIR

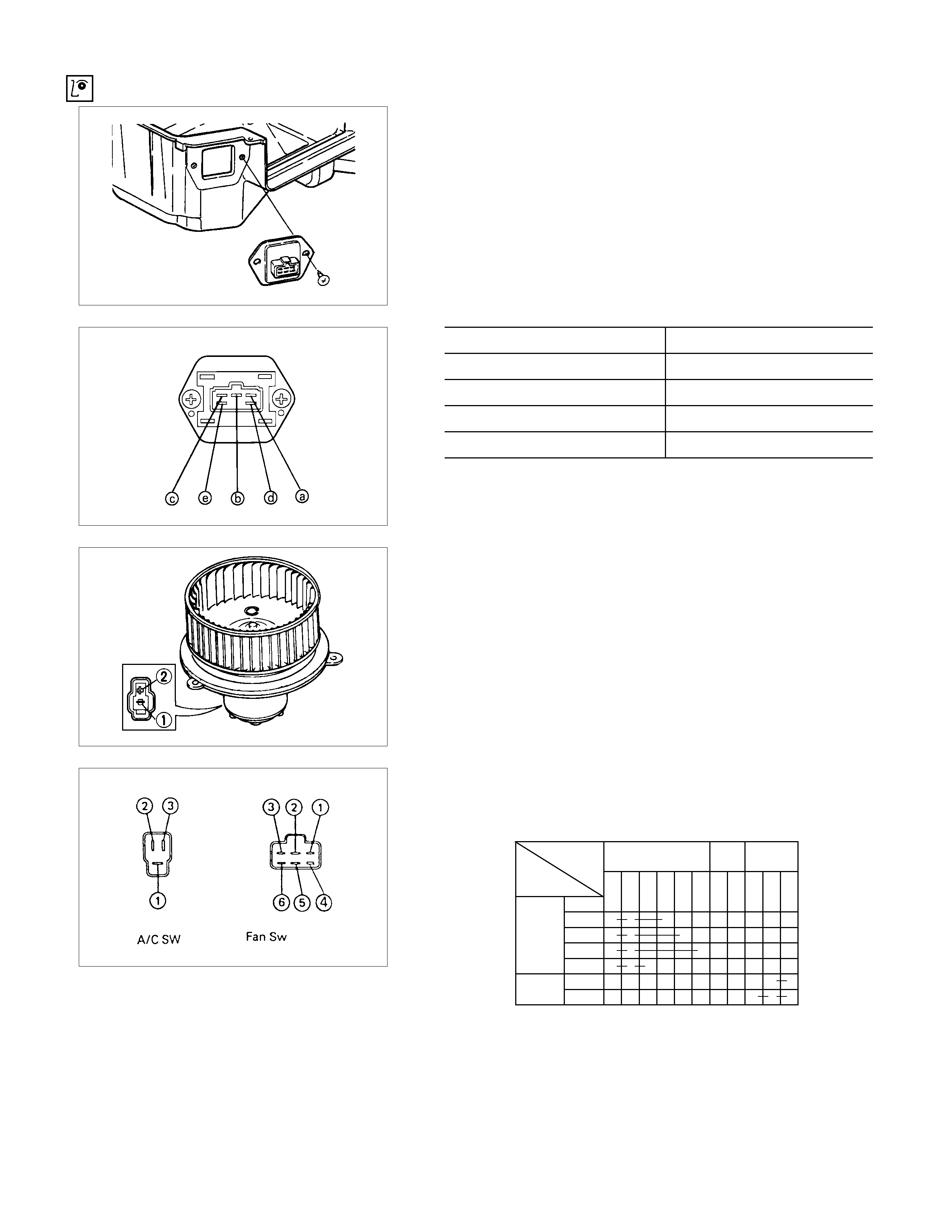

RESISTOR

As for air-conditioning model, fixed on right side of the

evaporator unit.

As for heater only model, fixed on right side of the duct placed

between blower unit and heater unit.

Replace the resistor with a new on if the coil is found to be

open or if the resistance value deviates from the specified

range.

Terminal Resistance

a - b 2.40Ω

b - d 0.90Ω

b - e 0.28Ω

b - c -

BLOWER MOTOR

Check blower motor for smooth rotation.

Connect the battery positive terminal to the No.1 (No.2: RHD)

terminal of the blower motor and negative to the No.2 (No.1:

RHD).

Be sure to check to see if the blower motor operates correctly.

FAN SW ITCH AND A/C SWITCH

Check for continuity between switch connector terminals.

Connector

No. FAN SW FAN

SW A/C

SW

SW Position 12345612123

OFF

1¡¡ ¡

2¡¡ ¡

3¡¡ ¡

4¡¡¡

OFF ¡¡

ON ¡¡¡

A/C

Blower

motor

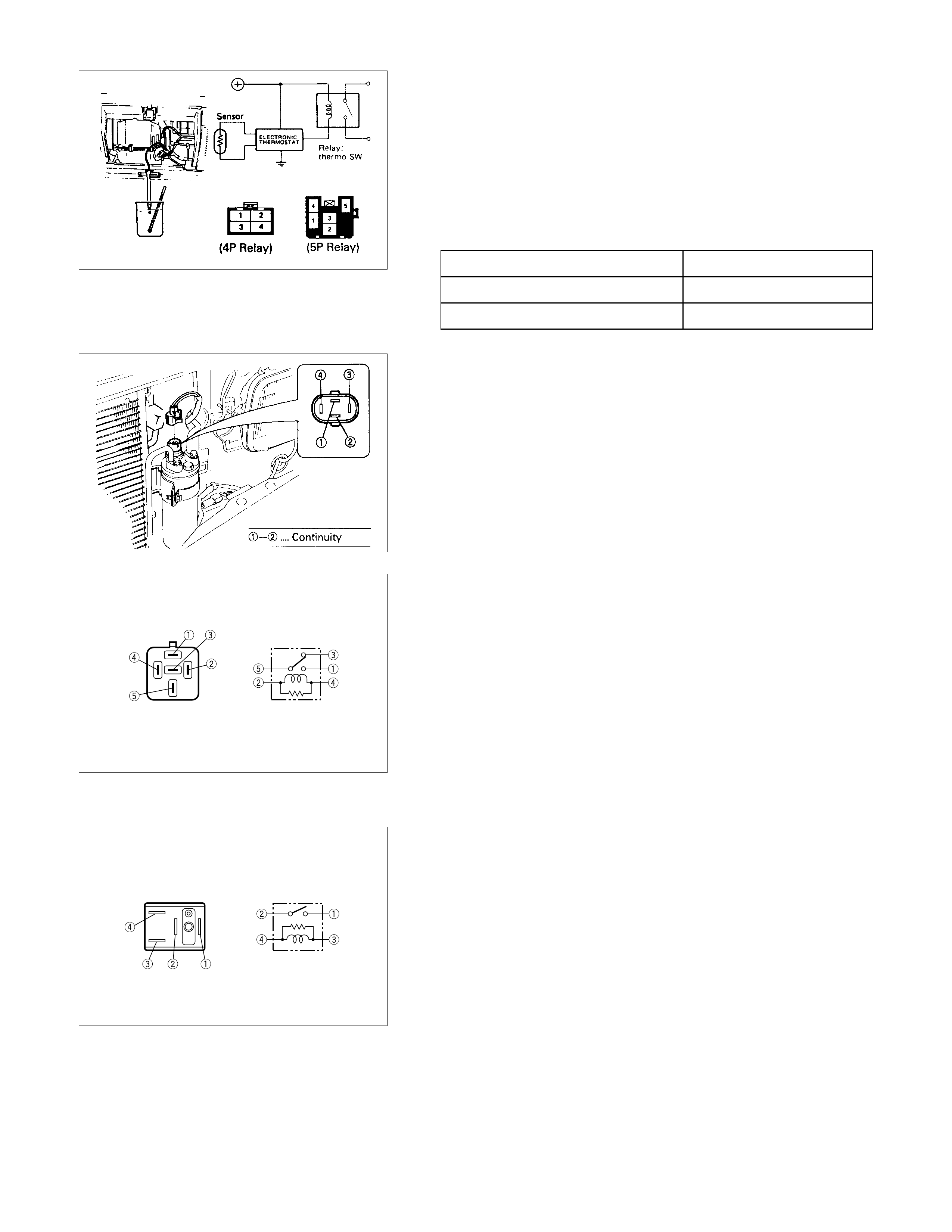

THERMO SWITCH

(1)Remove the thermosensor from the evaporator.

(2)A/C is "ON".

(3) Set the atmospheric temperature of the thermosensor to

the following condition.

(4)Confirm that the thermo switch relay is activated when the

condition is met.

Ambient Temperature Thermo switch relay

Below 3.5±0.5°C (38.3±0.9°F) OFF

Above 5.0±0.5°C (41.0±0.9°F) ON

PRESSURE SWITCH

Check for continuity between pressure switch side connector

terminals.

1. Disconnect the connector and check f or continuity between

pressure switch side connector terminals (1).

2 Reconnect the connector to activate the A/C switch, and

check to see if there is continuity between the chassis side

connector terminals (3) and (4) and the fan operates.

IT RELAY

HEATER AND THERMO SWI TCH RELAY.

Check for continuity between relay side connector terminals.

IT RELAY:

Rated voltage/Coil resistance

12V/Approx. 90Ω

Minimum operating voltage : 7V at 25°C (77°F)

There is continuity betw een the relay side connector terminals

(5) and (1) when the relay connects between terminals (2) and

(4).

CM RELAY

CM RELAY

Rated voltage/Coil resistance

12V/Approx. 130Ω

Minimum operating voltage : 7V at 25°C (77°F)

There is continuity betw een the relay side connector terminals

(2) and (1) when the relay connects between terminals (4) and

(3).

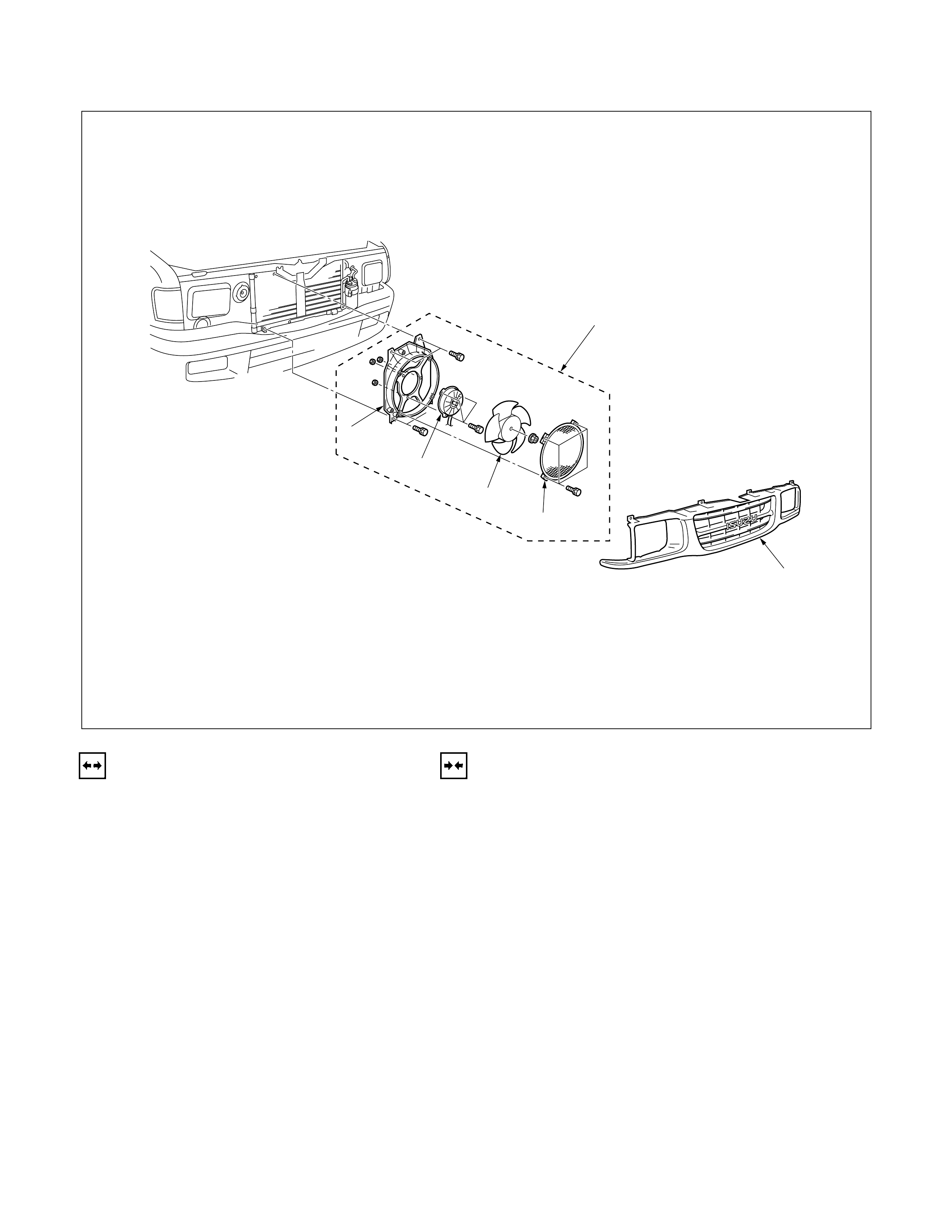

CONDENSER FAN MOTOR

1

2

3

4

5

6

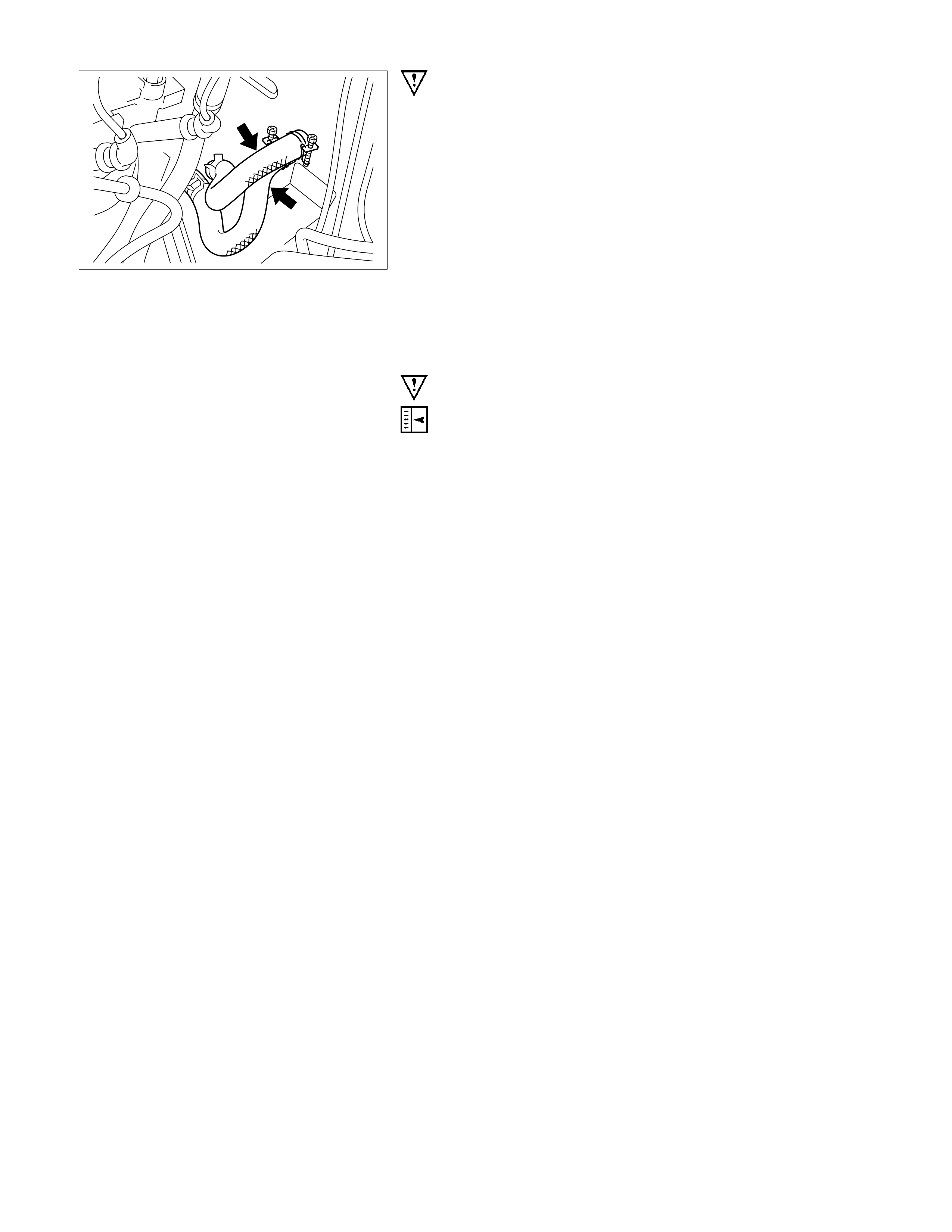

REMOVAL

Preparation: Battery ground cable

1. Radiator grille

2. Condenser fan assembly

•Disconnect the fan motor connector and

remove the 4 fixing bolts.

3. Cover

•Remove the 4 fixing screws.

4. Shroud

•Remove the 3 fixing nuts.

•Loosen the condenser fixing nut and

remove the fan motor connector from

bracket.

5. Fan

•Remove the fan fixing nut.

6. Condenser fan motor

•Disconnect the condenser connectors.

INSTALLATION

To install, follow the removal steps in the reverse order, noting

the following point.

1. Route the fan m otor har ness in its previous pos ition, and f ix

it securely with clip and bracket.

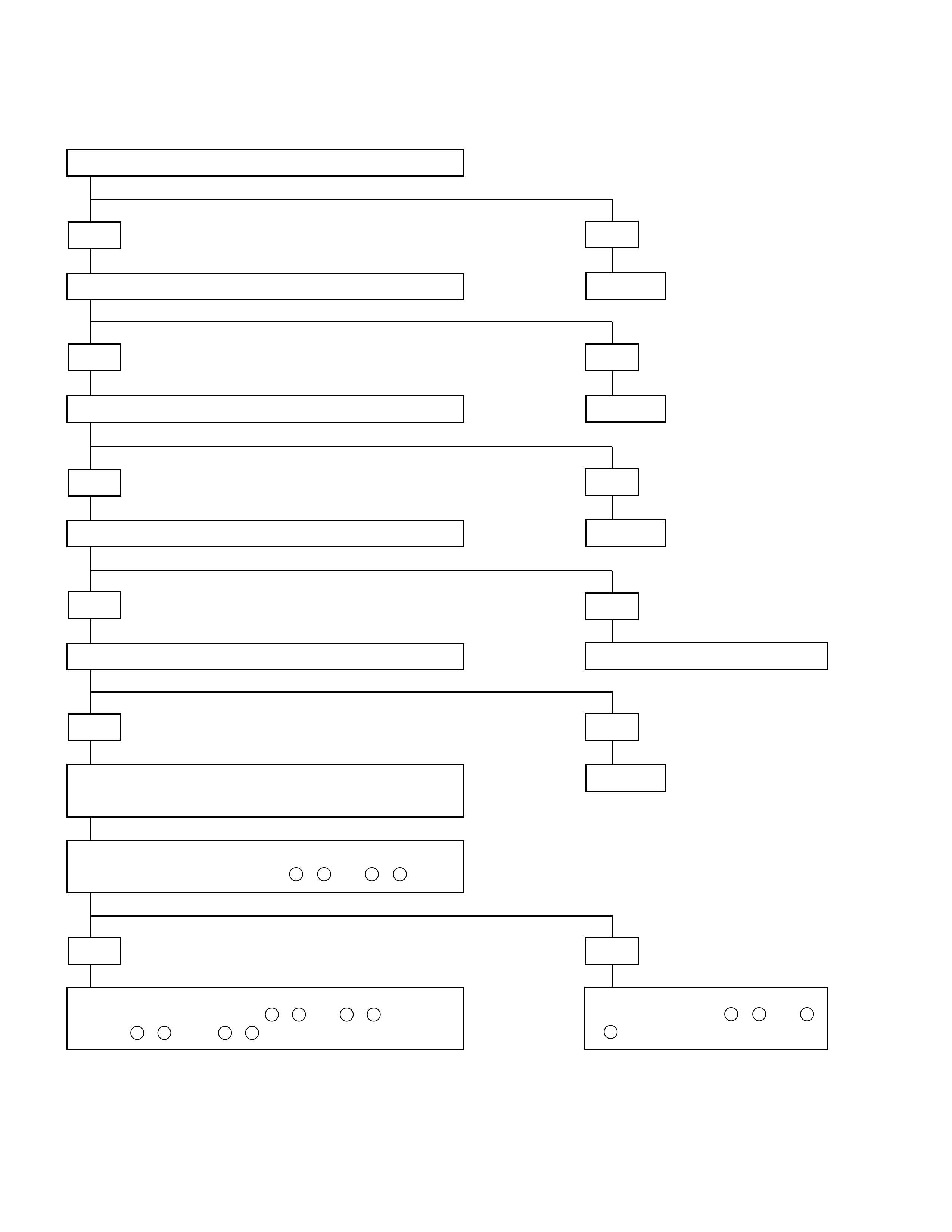

TROUBLESHOOTING

1. Trouble of Fan Control System

1-A Blower motor would not rotate totally.

1-B Blower motor does not rotate in certain position.

1-C Blower motor does no stop at "OFF" position.

2. Trouble of Air-Conditioning System

2-A Magnetic clutch would not engage.

2-B Refrigeration system defective.

1-A BLOWER MOTOR WO ULD NOT ROTATE TOTALLY

(REFER TO "WIRING HARNESS TERMINAL POSITIONS" IN THIS SECTION.)

Replace

YES

•Is heater fuse (20A) OK?

•Is heater relay OK?

YES

•Is resistor OK?

YES

•Is fan control knob (Fan switch) OK?

YES

YES

•Check to see if battery voltage is present at chassis

side connector terminal No.A - 1 (No.A - 2; RHD)

•Turn the ignition switch "ON" (Engine is running)

•Fan control knob (Fan switch) "ON"

•Is blower motor OK?

YES

Poor ground or open circuit either between chassis

side connector terminal No.A - 2 (No.A - 1; RHD)

and No.B - 6 or No.D - 12 and body ground

NO

Replace

NO

Replace

NO

NO

Replace control lever assembly

Replace

NO

NO

Open circuit between heater

fuse (20A) and No.A - 1 (No.A

- 2; RHD)

1-B BLOWER MOTOR DO ES NOT ROTATE IN CERTAIN POSI TION

(REFER TO "WIRING HARNESS TERMINAL POSITIONS" IN THIS SECTION.)

A1: (Low)

Blower motor does not B2: (Medium Low) Position

run at C3: (Medium Hi)

D4: (High)

* Checking is performed only when in the malfunction

mode.

•Is resistor OK?

YES

•Is fan control knob (Fan switch) OK?

YES

A Condition:

•Open circuit between chassis side connector terminal

No.B - 22 or No.D - 15

B Condition :

•Open circuit between chassis side connector terminal

No.B - 3 or No. D - 1

3

C Condition:

•Open circuit between chassis side connector terminal

No. B - 5 or No.D - 14

D Condition:

•Open circuit between chassis side connector terminal

No. B - 4 or No.D - 10

Replace

NO

NO

Replace control lever assembly

1-C BLOWER MOTOR DO ES NO T STOP AT "OFF" POSITION

(REFER TO "WIRING HARNESS TERMINAL POSITIONS" IN THIS SECTION.)

•Is fan control knob (Fan switch) OK?

YES

Short circuit between chassis side connector terminal

•No. A - 2 (No.A - 1; RHD) and No.B - 6

(or)

•No. B - 4 or No. D - 1

0

(or)

•No. B - 5 or No. D - 14

(or)

•No. B - 3 or No. D - 13

(or)

•No. B - 22 or No. D - 15

NO

Replace control lever assembly

2-A MAG NETIC CLUTCH WO ULD NOT ENGAGE

(REFER TO "WIRING HARNESS TERMINAL POSITIONS" IN THIS SECTION.)

Magnetic clutch deffective

NO

•Are A/C (10A) and heater (20A) fuses OK?

•Stop the engine

YES

•Are heater and thermo switch relays OK?

YES

•Is pressure switch (Dual pressure switch ) OK?

YES

YES

Check the A/C related harness and repair it as necessary

•Is thermo switch OK?

•Are A/C switch and fan control knob (Fan switch)

YES

Replace

NO

Replace

NO

NO

Switch defective or insufficient

refrigerant

Replace

NO

•Check to see if continuity between chassis side

connector terminal D - 12and ground

•Check to see if battery voltage is present at

magnetic clutch chassis side connector terminal

•Turn the ignition switch "ON" (Engine is running)

•A/C switch and fan switch "ON"

YES

YES

Replace

NO

Poor ground or open circuit

NO

2-B REFRIGERATION SYSTEM DEFECTIVE

Checkpoint Trouble Cause Countermeasure

Clean or replac e the

expansion v alv e

Clean or replac e the pipe line

Purge air from the

refrigeration system

Adjust the refriger ant gas

quantity

Expansion valve is c logged

Pipe line is c logged

Air exists in the system

The system is over-charged

Clean or replac e the

condenser

Charge the system with

ref r iger ant gas

Condenser is fouled or

clogged

The system is charged

unsufficiently

(Turn t he A /C swit c h on again)

Check to see if the pres s ur e

of high pr es s ur e s ide is 16

kg/cm2 (228 psi/ 15.7×102kPa)

or lower.

Check to see if bubbles c om e

out wit hin 5 seconds aft er

turning the A/C switch off from

5 minut es r unning

Continue d on the nex t page

NG

NG

NG

NG

NG

NG

OK

OK

Sight glas s for being clear or

not

First , tur n engine ( with engine

speed of about 1000 rpm) and

A/C s witch on, and set fan

switch to be at 1-4 position

Checkpoint Trouble Cause Countermeasure

Replace the expansion valveExpansion valve is defective

Repair or replace the

compressor

Compressor is faulty

Continued from the previous

page

NG

NG

OK

Check to see if the pressure

of low pressure side is about

2.1 kg/cm2 (30 psi/2.1 ×

102kPa)

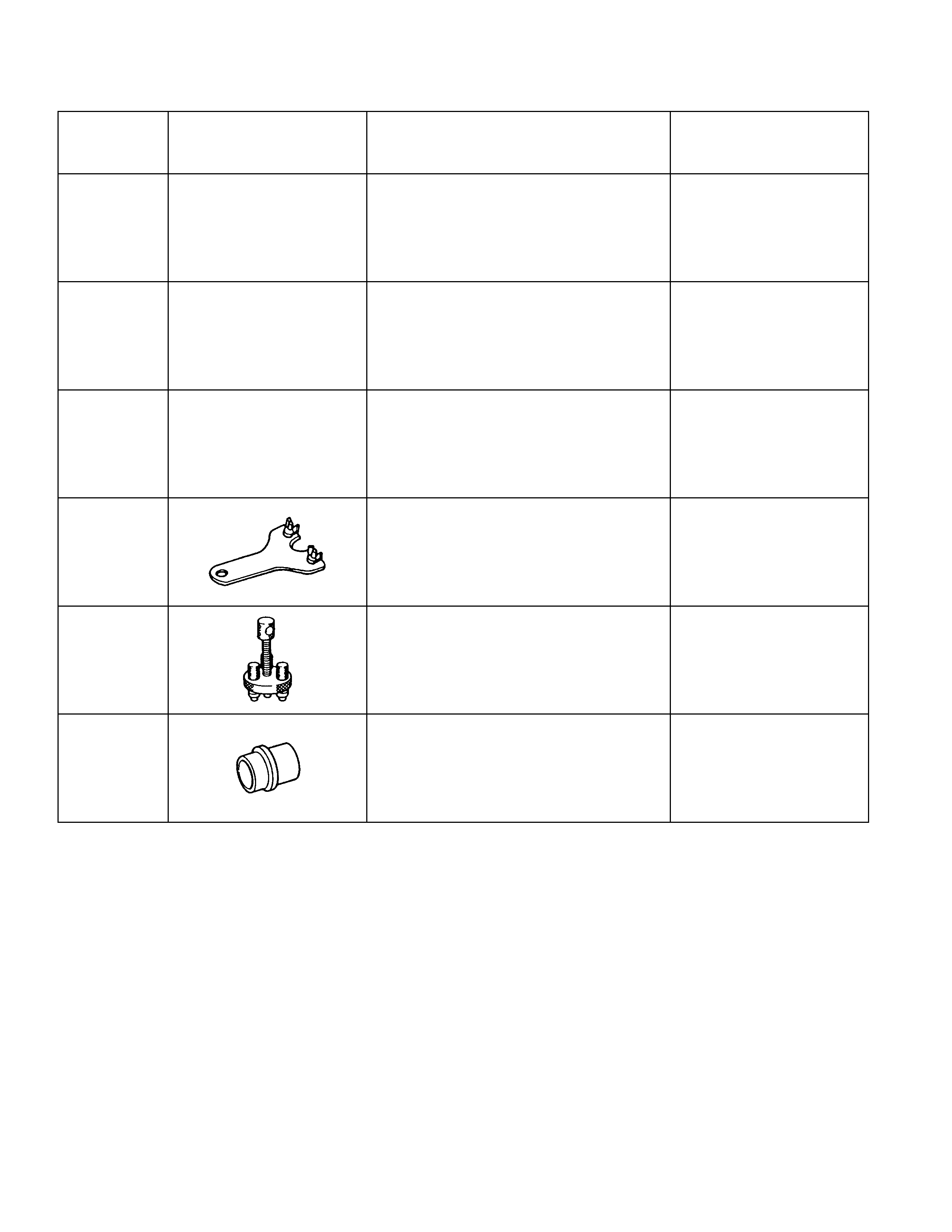

SPECIAL SERVICE TOOL

ITEM NO. ILLUSTRATION PART NO. PART NAME

5-8840-0629-0

(J-39500-A)

5-8840-0630-0

(J-39500-220A)

5-8840-0631-0

(J-39500-220ANZ)

ACL-2 5-8840-0117-0

(J-33939) Clutch hub holder

ACL-3 5-8840-0122-0

(J-33944-A) Clutch plate remover

ACL-4 5-8840-0121-0

(J-33943) Clutch pulley puller pilot

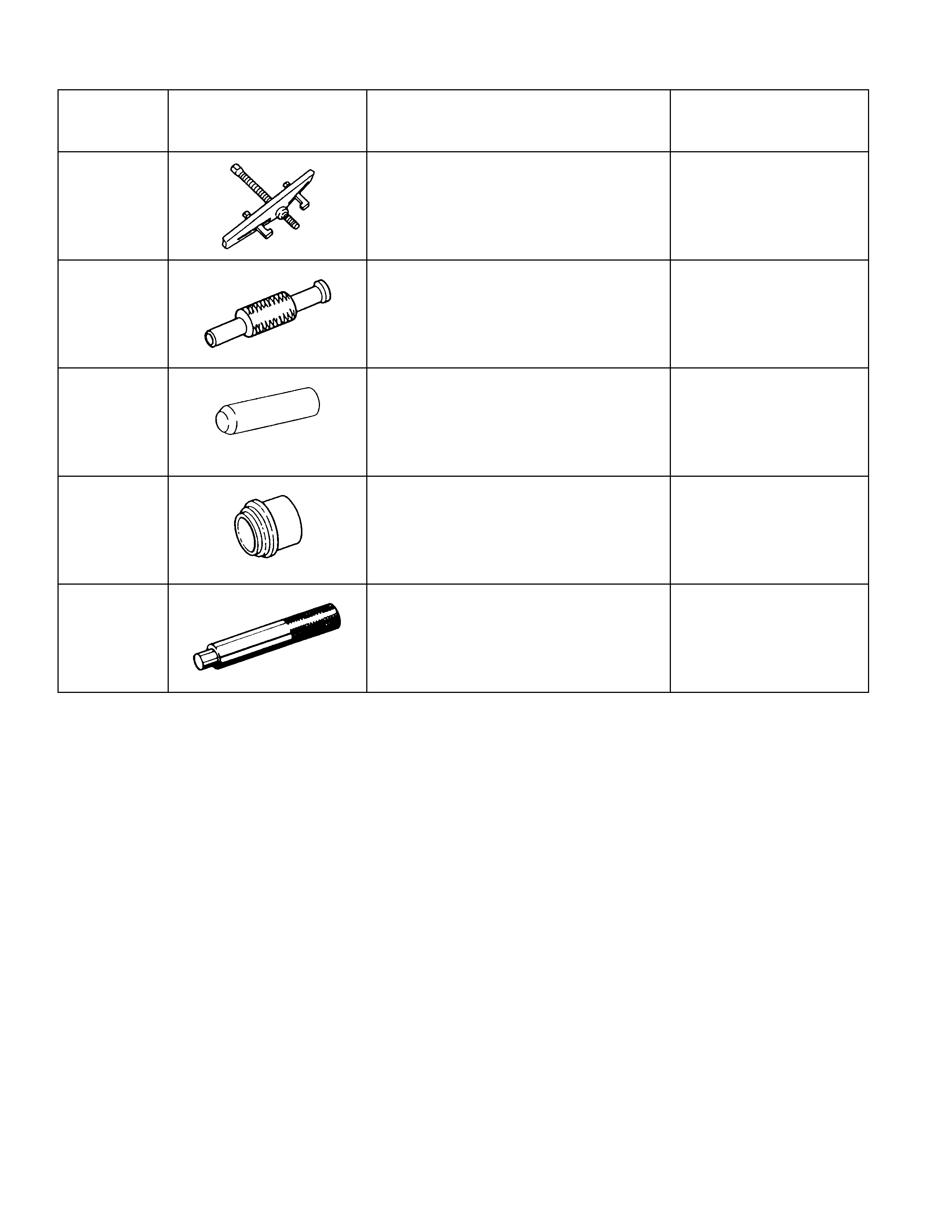

ITEM NO. ILLUSTRATION PART NO. PART NAME

ACL-5 5-8840-0111-0

(J-8433) Clutch pulley puller

ACL-6 5-8840-0120-0

(J-33942) Shaft seal cover remover

and installer

ACL-9 5-8840-0368-0

(J-34614) Shaft seal guide

CDL-10 5-8840-0118-0

(J-33940) Clutch pulley installer

OTL-1 5-8840-0007-0

(J-8092) Driver handle