ALIGNMENT

•Tire pressure and abnormal wear

•Front hub bearings for axial play

•Ball joints on steering linkage for

play

•Suspension ball joint

•Operation of shock absorber

•Tightness of suspension parts

INSPECTION OF WHEEL ALIGNMENT

The points listed in table at left must be checked prior to

inspecting front wheel alignment.

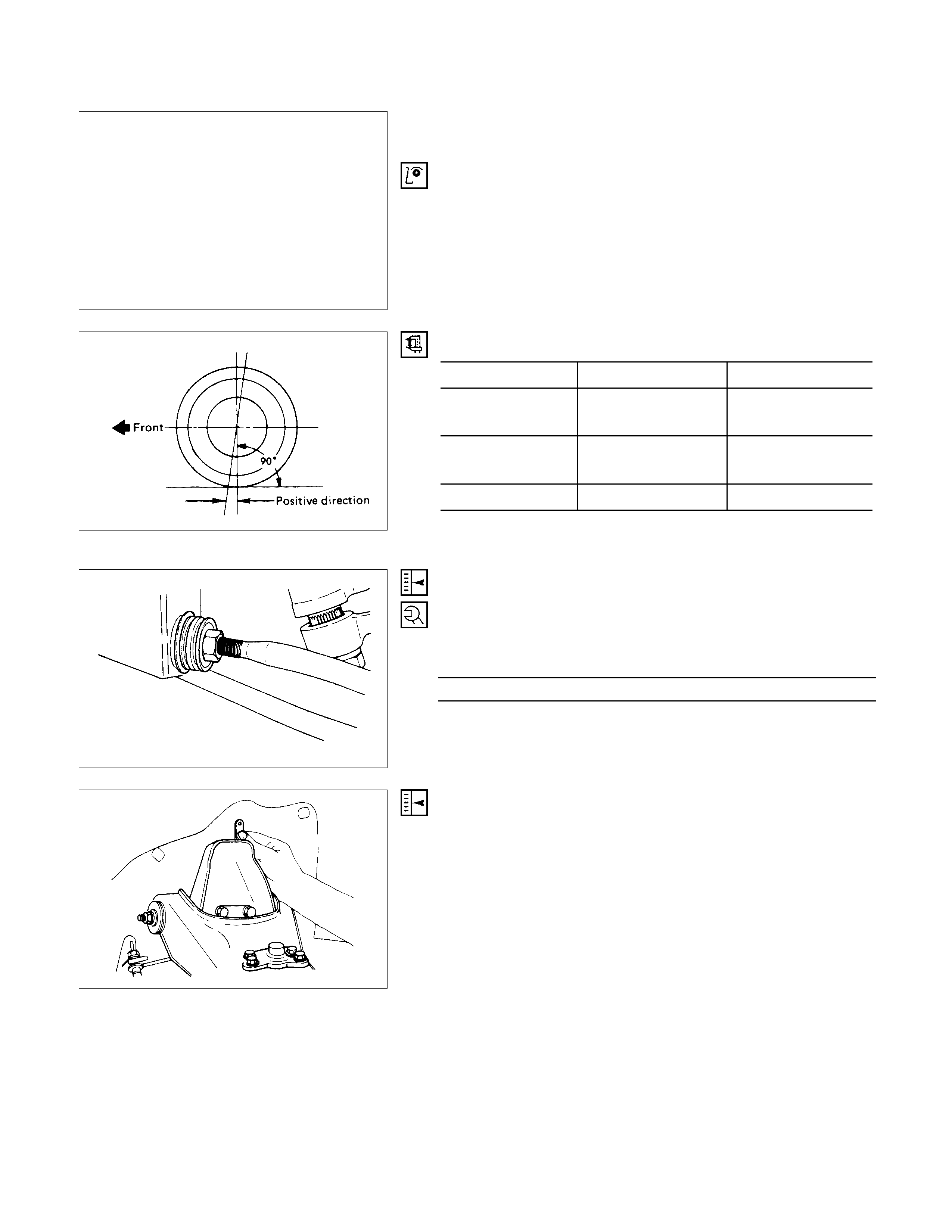

CASTER

Short wheel base Long wheel base

4×2 model

(except TFR25) 1°35'±45' 1°50'±45'

4×4 model and

TFR25 1°55'±45' 2°10'±45'

4×2 Flat Deck - 1°10'±45'

Note:

Left and right side to be equal within 35'.

[4×

××

×2 MODEL (EXCEPT TFR25)]

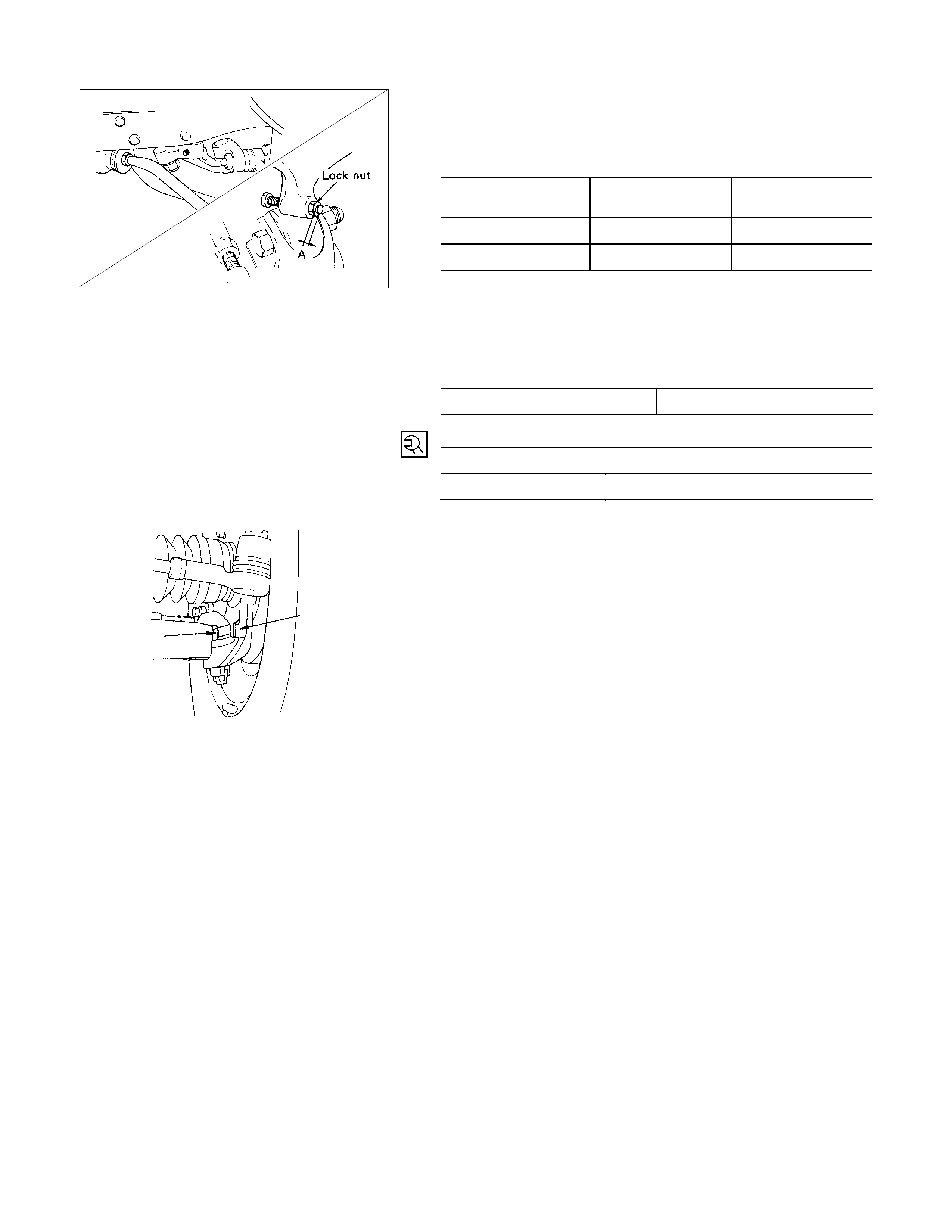

The caster angle can be adjusted by varying length of the strut

bar (adjust with lock nut) and shims should not be used for

adjustment.

Lock Nut Torque N⋅m

127.5±12.8

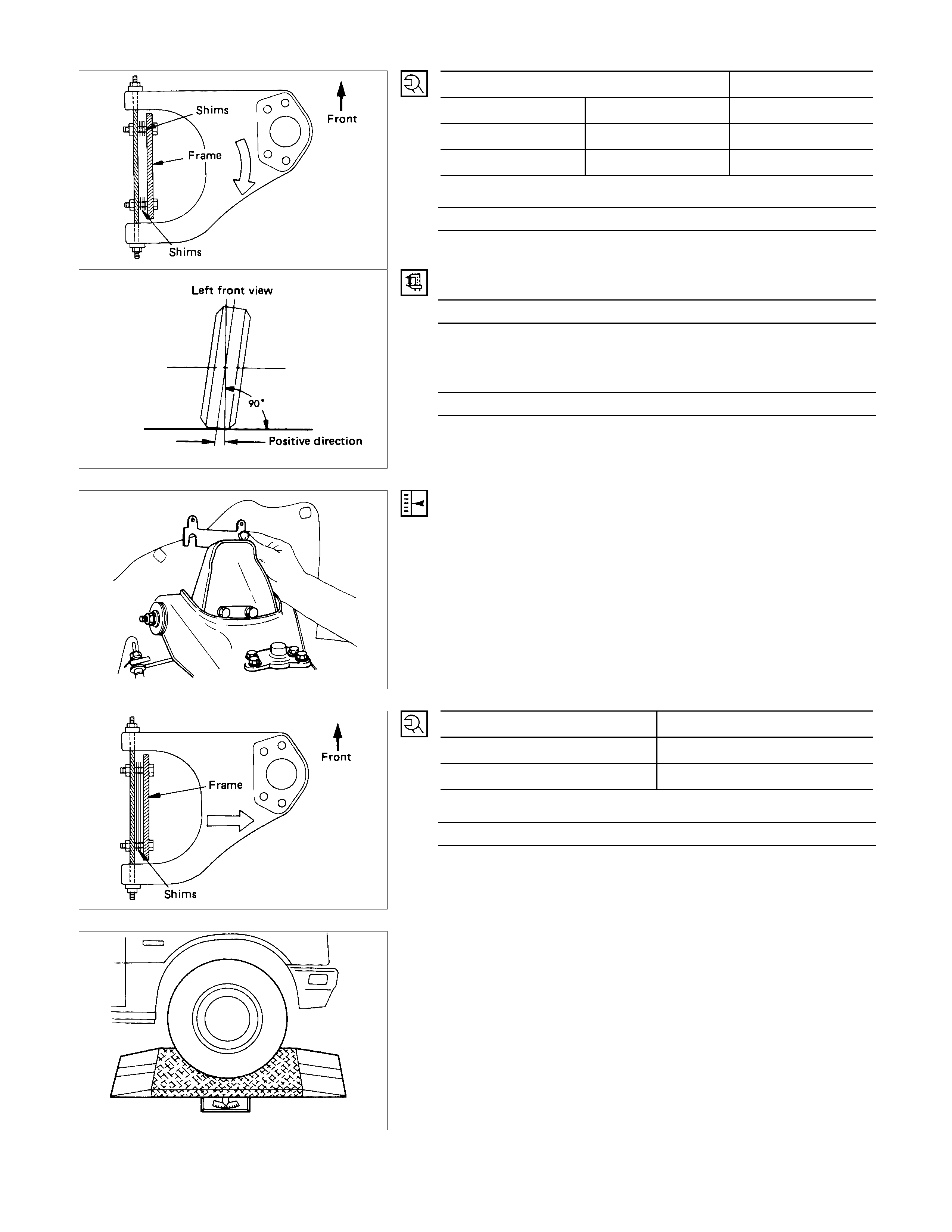

[4×

××

×4 MODEL AND TFR25]

The caster angle can be adjusted by means of the caster

shims installed in position between the chassis frame and

fulcrum pins.

Note:

Difference of the caster shim front/rear thickness shall be

3.2 mm (0.126 in) or less. Overall thickness of caster shim

and camber shim shall be 10.8 mm (0.426 in) or less.

Position of shims Caster angle

Front side Rear side

When added When removed Decreases

When removed When added Increases

Fulcrum Pin Bolt Torque N⋅m

152.0±14.7

CAMBER

30'±60’

Note:

Left and right side to be equal within 45'.

KING PIN INCLINATION 10°±60'

[4×

××

×4 MODEL AND TFR25 ONLY]

The camber angle can be adjusted by means of the camber

shims installed in position between the chassis frame and

fulcrum pins.

Note:

Overall thickness of caster shim and chamber shim shall

be 10.8 mm (0.425 in) or less.

Position of shims Camber angle

When added Decreases

When removed Increases

Fulcrum Pin Bolt Torque N⋅m

152.0±14.7

MEASUREMENT OF SIDE SLIPPAGE

When inspection and adjustments of toe-in, camber, caster

and kingpin inclination are completed, check for side slippage

using a side slip tester.

Roll the wheels over the side tester as slowly as possible and

take reading on the tester. If the amount of side slippage is in

excess of 5 mm per 1 m, recheck the wheel alignment.

TOE-IN

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at

front end.

3. Apply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks

reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with next formula.

Toe-in = B - A

Toe-in mm (in)

4×2 (except TFR25) 2±2 ( 0.08±0.08)

4×4 and TFR25 2±2 ( 0.08±0.08)

To adjust the toe-in angle, loosen the lock nut on the outer

track rod and turn the outer track rod with the same degree as

right and left.

Lock Nut Torque N⋅m

98.1±9.8

4×

××

×2 Model (except TFR25)

4×

××

×4 Model and TFR25

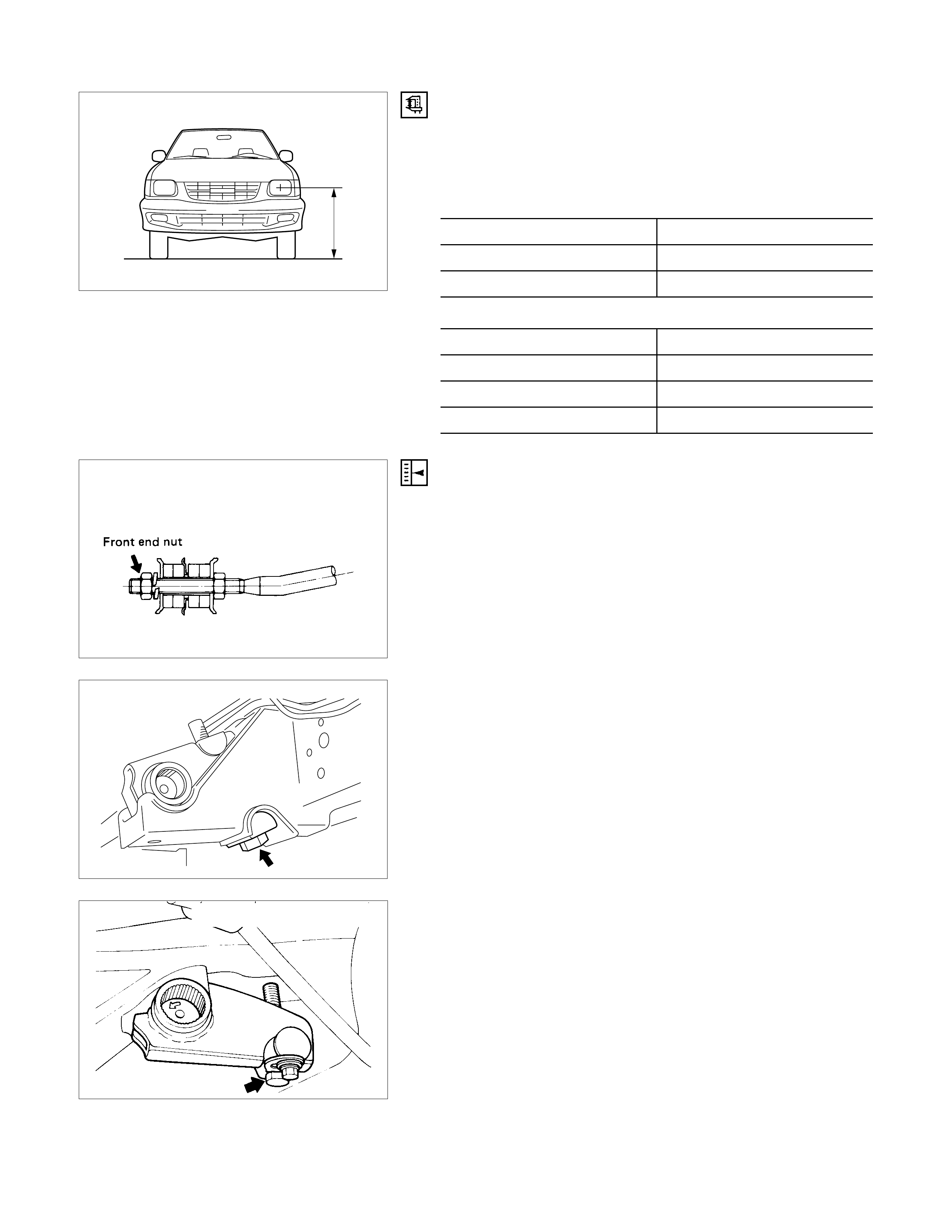

TRIM HEIGHT OR VEHICLE HEIGHT

Trim Height : at Curb Weight

Trim height (Z) = A - B

Front mm (in)

Model Z

4×2 (except TFR25) 56 (2.20)

4×4 and TFR25 130 (5.12)

Note:

Trim height and vehicle height measurements are

interchangeable.

Techline

VEHICLE HEIGHT

Measure the height from the center of the headlights to the

ground. Height should be as specified; there must be no more

than 10 mm difference between the left-hand and right-hand

measurements.

2WD (except TFR25) mm (in

)

185R14 735 (28.9)

6.50-14 760 (29.9)

P205/75R14 740 (29.1)

4WD and TFR25 mm (in)

205R16 835 (32.9)

6.50-15 835 (32.9)

215R15 825 (32.5)

P225/75R15 823 (32.5)

4×

××

×2 Model (except TFR25)

ADJUSTMENT

Adjust the trim height by means of the adjusting bolt on the

height control arms.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on a level ground and move the f r ont of the

vehicle up and down several times to settle the suspension.

3. Loosen the nuts on the front end of the strut bar. (For 4×2

model (except TFR25) only ).

C22, C20 Series Engine Model

4. Make necessary adjustment with the adjusting bolt on the

height control arms.

4J Series, 6VD1 E ngine Model

Reference Data mm(in)

4×4 and TFR25

4JB1T & 6VD1

Engine model only

Standard 90 (3.54) 95 (3.74)

Heavy Duty

Sus. 90 (3.54) -

Flat Deck 65( 2.56) -

4×2

(except TFR25)

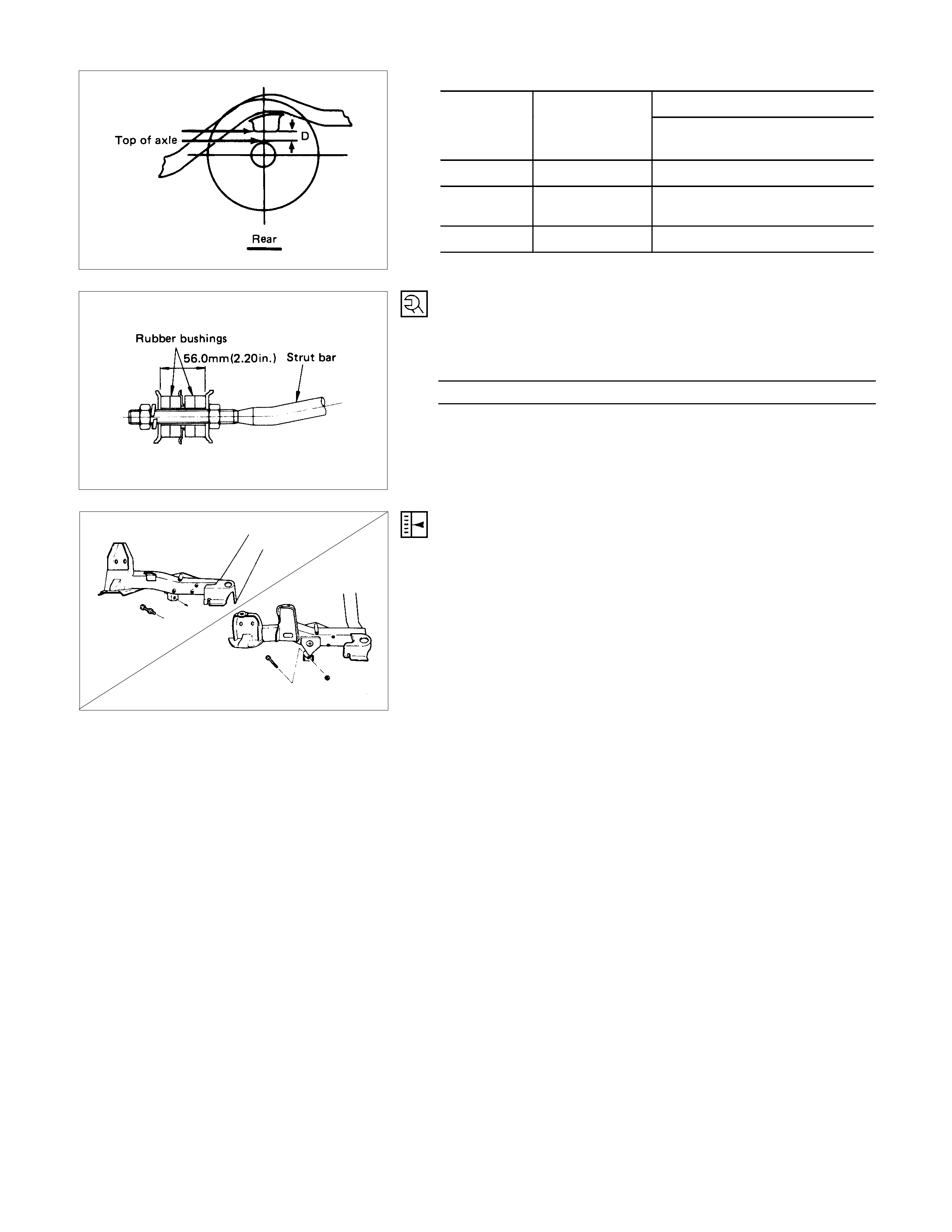

STRUT BAR

Securely Tighten the Strut Bar Nuts

(4×

××

×2 Model (except TFR25) Only)

Strut Bar Torque N⋅m

127.5±12.8

4×

××

×4 Model and TFR25

4×

××

×2 Model (except TFR25) MAXIM UM STEERING ANGLE ADJUSTMENT

The maximum steering angle of the front wheels can be

adjusted with the stopper bolts under the frame side members.

1. Position each front wheel on the turning radius gauge in a

straight-ahead position.

2. Set the parking brake firmly.

4×

××

×4 Model and TFR25

4×

××

×2 Model (except TFR25) 3.

A

djust the inside wheel angle of each side with the stoppe

r

bolts.

4. Similar ly adjust the inside wheel angle of the other side with

stopper bolt. 4×2

(except TFR25) 4×4 and TFR25

Outside wheel 33°33°

Inside wheel 37°+0°

-2°35°+0°

-2°

Note:

Maximum steering angles should be set after adjusting

front wheel alignment.

4×4 Model and TFR25 Only mm (in)

A 0 - 8.5 (0 - 0.33)

Stopper Bolt Lock Nut Torque N⋅m

4×2 (exc. TFR25) 44.1±9.8

4×4 and TFR25 22.5±2.9

Stoppe

r

Stopper

4×

××

×4 MODEL AND TFR25 ONLY

If the stopper (non-adjustable) between the lower link end and

the knuckle comes ahead of the stopper bolt, adjust the

stopper bolt so that the inner-side stopper bolt touches the

drop arm (relay lever).