MAIN DATA AND SPECIFICATIONS

Models Standard Have-duty

Suspension Flat Deck

Items 4 × 2

(except

Sporty) 4 × 4 4 × 2

Sporty

4 × 2

(except

Sporty)

4 × 4

and

4 × 2

Sporty

4 × 24 × 4

Type Semi-elliptic, rubber bushed, leaf type springs and direct

double acting shock absorbers.

Main spring

No. of leaves 4 6 4

Leaf thickness - Numbered 7(0.276); No.1-2 7(0.276)

; No.1 7(0.276); No.1-4 8(0.315); No.1-2

(Top to bottom) mm(in) 6 (0.236); No. 3 6(0.236)

;No.2-3 7 (0.709); No. 3

15(0.591); No.4 12(0.472); No.5-6 18(0.709); No.4

Spring eye type Berlin eye type

Bushing outside dia. mm(in) Front; 40 (1.575), Rear; 30 (1.181)

Length mm(in) 1200 (47.244)

Width mm(in) 60 (2.362)

Rate - Unclamped kg/mm 2.61/7.96 2.23/

8.13 3.91/8.34 3.95/12.8

(lb/in) (146.0/445.4) (124.8/

454.9) (218.8/466.7) (221.0/716.2)

Clamped kg/mm 2.87/8.75 2.47/8.72 4.30/9.17 4.37/14.2

(lb/in) (160.6/489.6) (138.3/487.9

)

(240.6/513.1) (244.5/794.6)

Rear spring capacity N(kg/Ib) 768 763 701 760 755 715 720

(7532/1693) (7483/1682) (1545/6877) (7423/1676) (7404/1664) (7012/1576) (7061/1587)

Weight N(kg/lb) 153 (15.6/34.4) 16.2

(35.7/

158.9) 196 (20.0/44.1) 180 (18.4/40.6)

Rear shock absorbers

Type Hydraulic, double acting, telescopic

Gas-sealed Hydraulic, double acting telescopic

(For Australia)

Mean stroke mm(in) 245 (9.65)

Compressed length mm(in) 353 (13.90)

Extended length mm(in) 598 (23.54)

Bump rubber

Height mm(in) 69 (2.72) 84 (3.31) 69 (2.72) 84 (3.31) 84 (3.31) 84 (3.31)

For Australia mm(in) 69 (2.72) 99 (3.90) 69 (2.72) 99 (3.90) - -

TORQUE SPECIFICATIONS

SPECIAL PARTS FI XING NUTS AND BOLTS

REAR SUSPENSIO N N⋅

⋅⋅⋅m(kgf⋅

⋅⋅⋅m/lb⋅

⋅⋅⋅ft)

29.4±1.96(3.0±0.2/21.7±1.4)

152.0±14.7(15.5±15/112.1±10.8

98.0±19.6(10.0±2.0/72.3±14.4)

65.7±5.8(6.7±0.6/48.5±4.3)

39.2±1.9(4.0±0.2/28.9±1.4)

14.7(1.5/10.8)

39.2±4.9(4.0±0.5/28.9±3.6)

37.2±8.8(3.8±0.9/27.5±6.5)

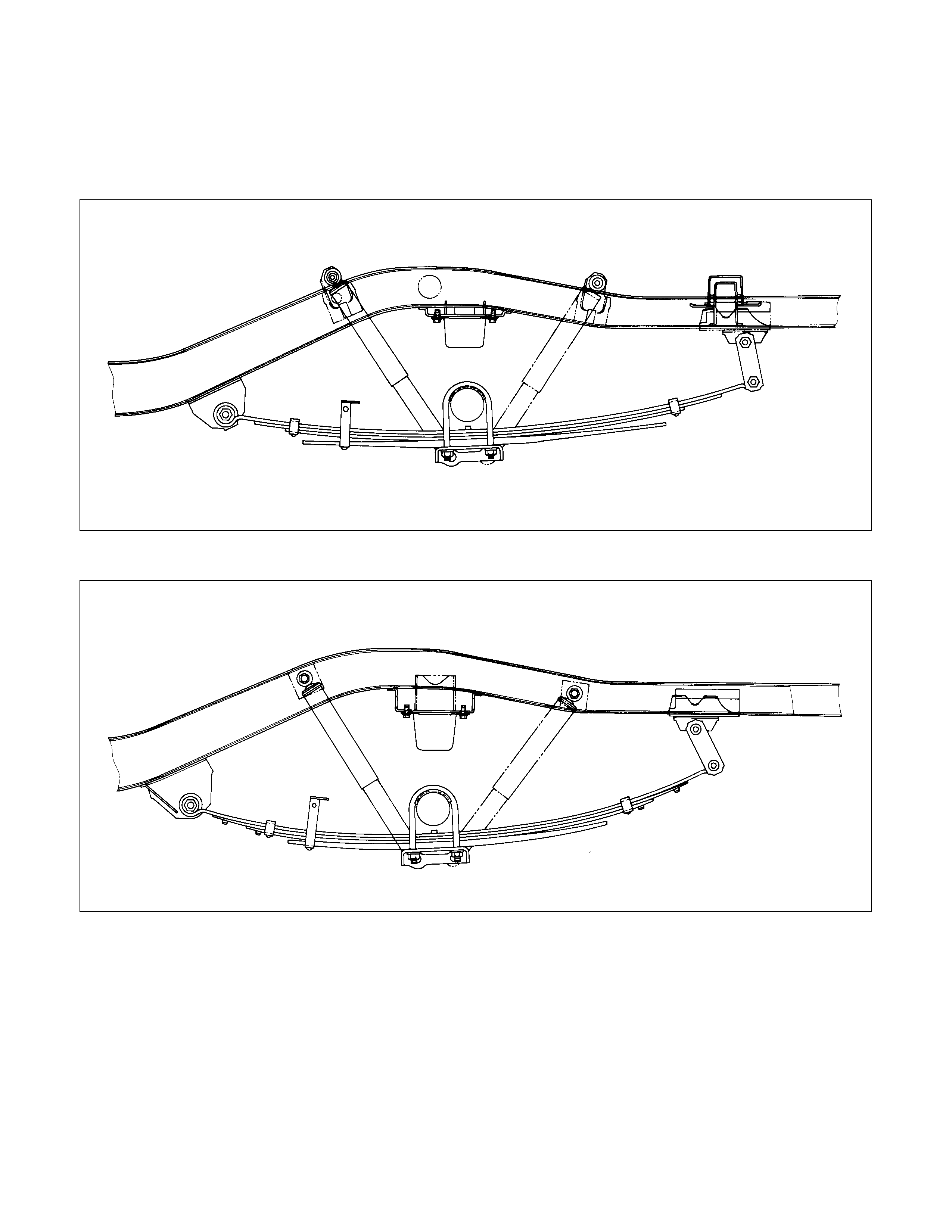

REAR SUSPENSION

GENERAL DESCRI PTION

4×

××

×2 MODEL ( EXCEPT SPORTY)

4×

××

×4 AND 4×

××

×2 SPORTY MODEL

Rear suspension absorbs vibration from the road surface thus preventing vehicle damage, as well as providing a

good ride.

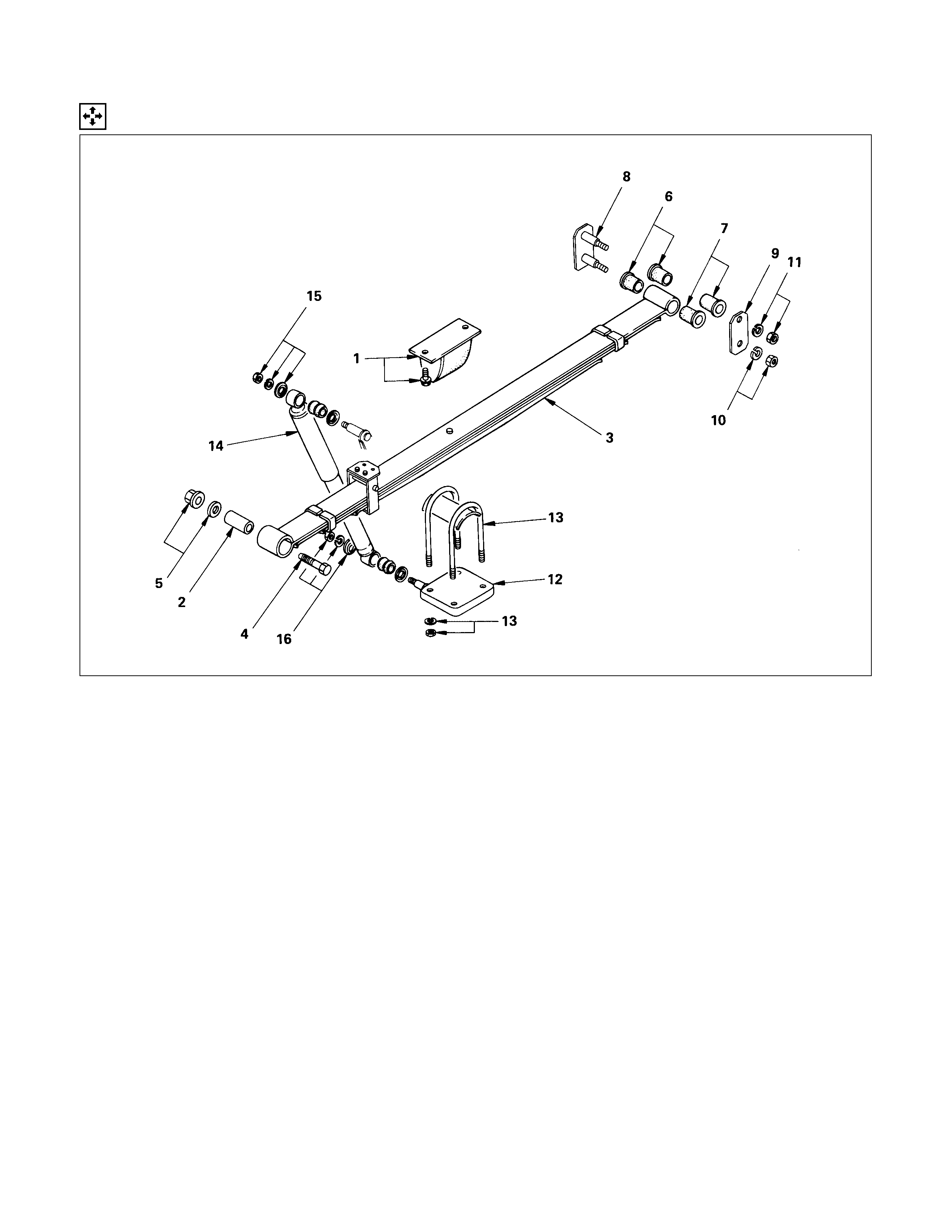

COMPONENTS PARTS

•Spring between the body and the axle case

•Spring shackle connecting the spring to the body

•Clamp and U-bolt fixing the axle case to the spring

•Shock absorber as a countermeasure for vibration

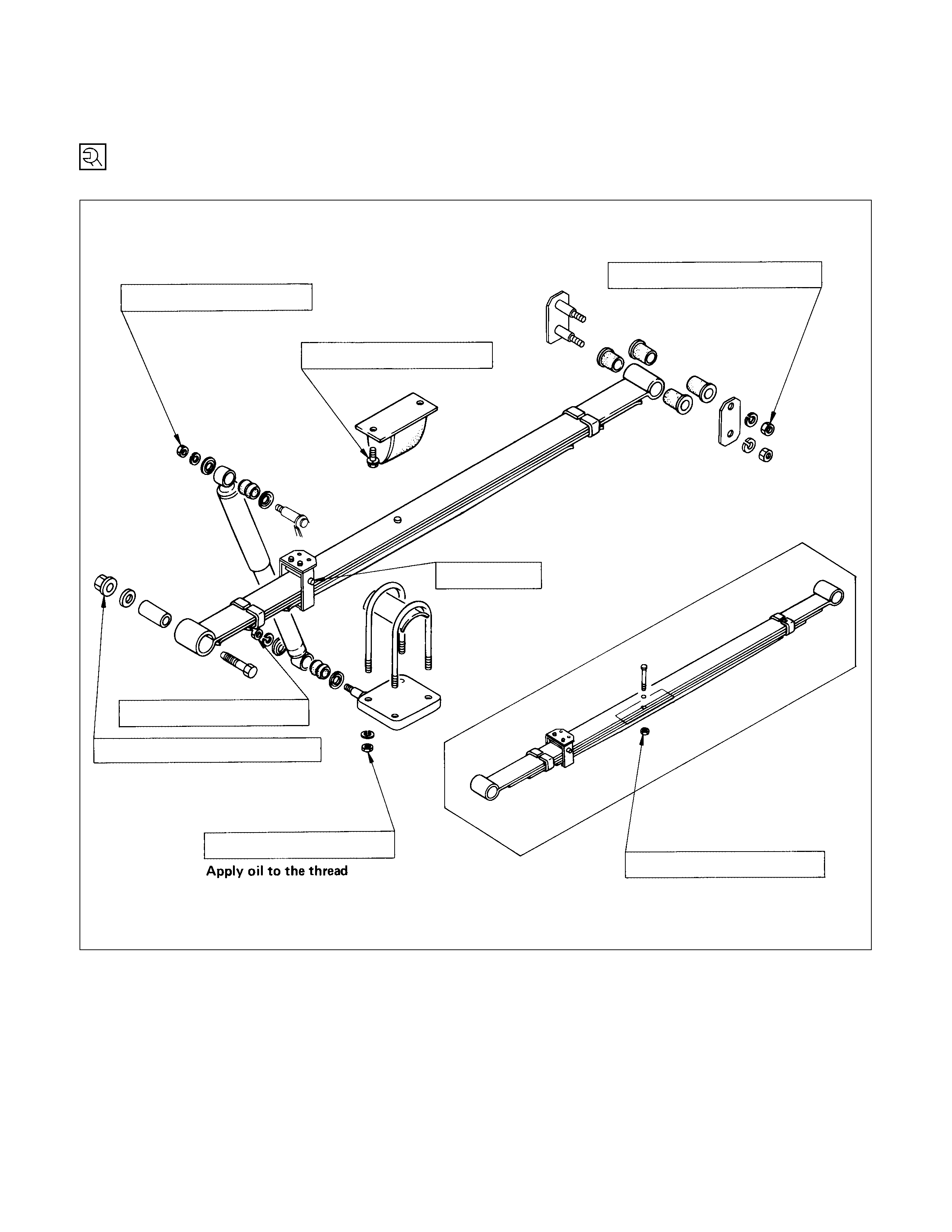

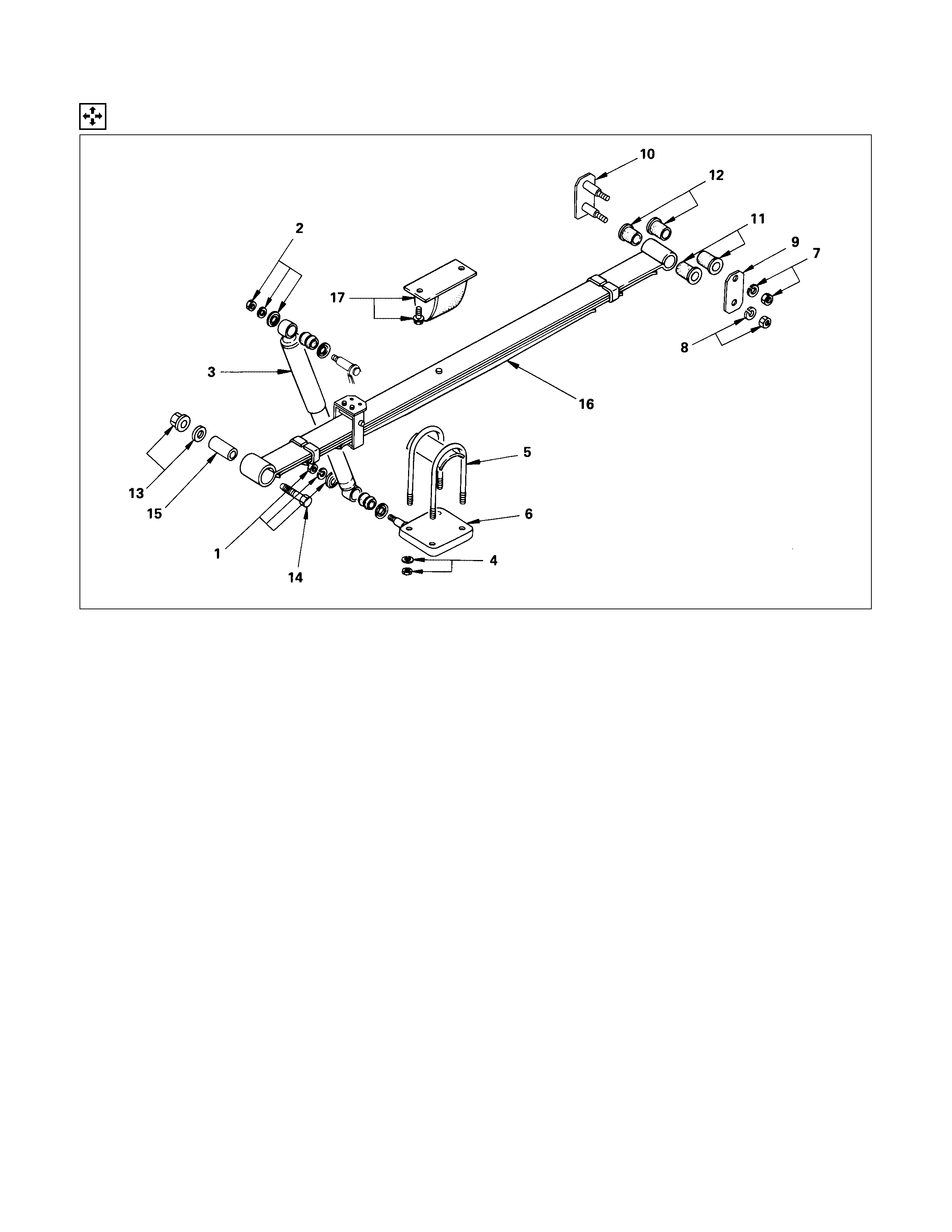

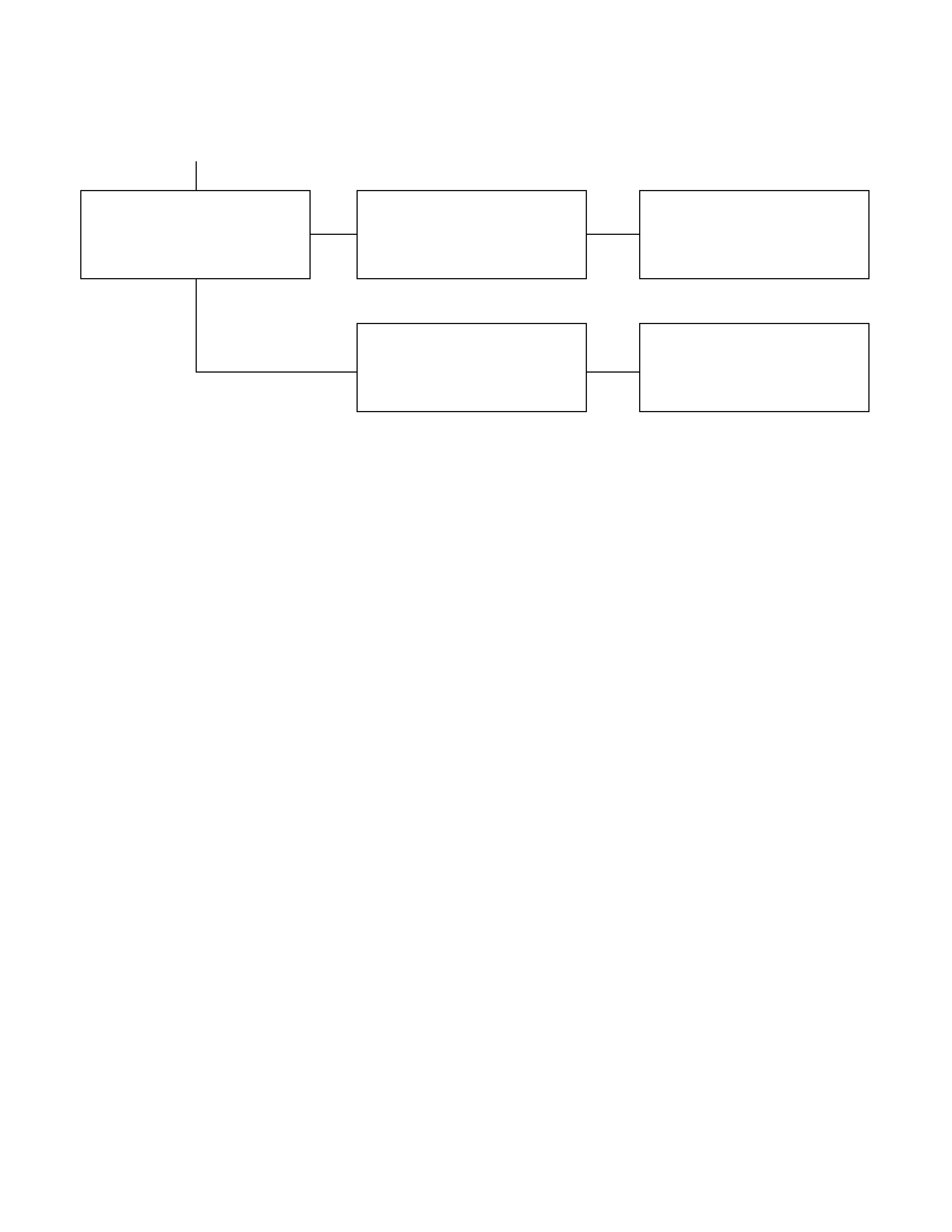

DISASSEM BLY

DISASSEM BLY STEPS

▲1. Nut and washer

▲2. Nut and washer

3. Shock absorber

▲4. Nut and washer

▲5. U-bolt

6. Lower clamp

▲7. Nut and washer

▲8. Nut and washer

▲9. Shackle plate

▲10. Shackle

11. Rubber bushing

12. Rubber bushing

▲13. Nut and washer

▲14. Bolt, washer and spring pin

▲15. Bushing

16. Leaf spring assembly

17. Bolt and dump rubber

IMPORTANT OPERATIONS

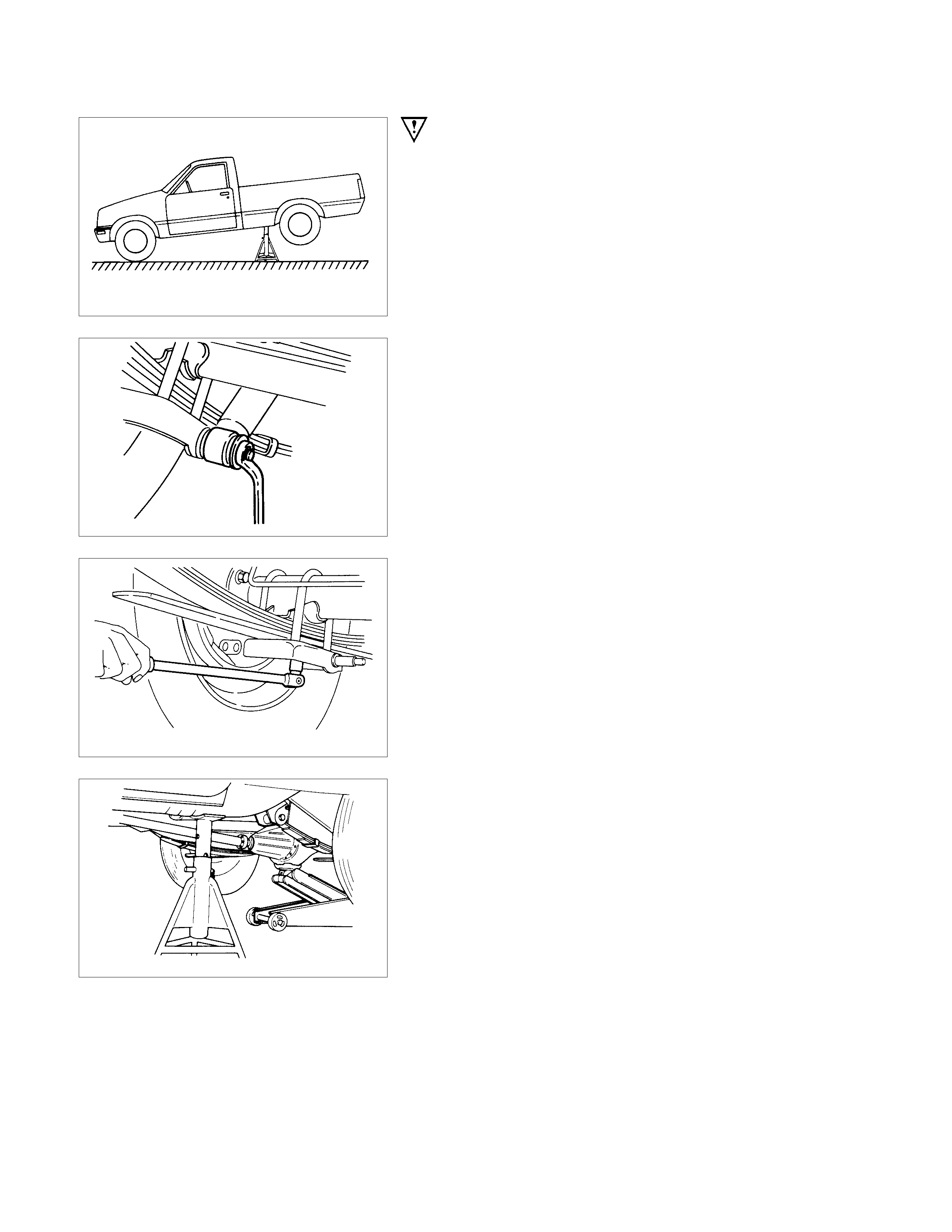

Jack up the rear axle and place chassis stands under the

frame near the front end of the rear spring brackets.

1. 2. Nut and Washer

Caution (Australia only):

The shock absorbers have been charged with gas at the

factory. Exposure to high temperatures or an open flame

can result in a dangerous explosion.

Keep the shock absorbers away from high temperatures

and open flames.

4. Nut and Washer

5. U-bolt

Jack up the rear axle case slightly to separate it from the leaf

spring assemblies.

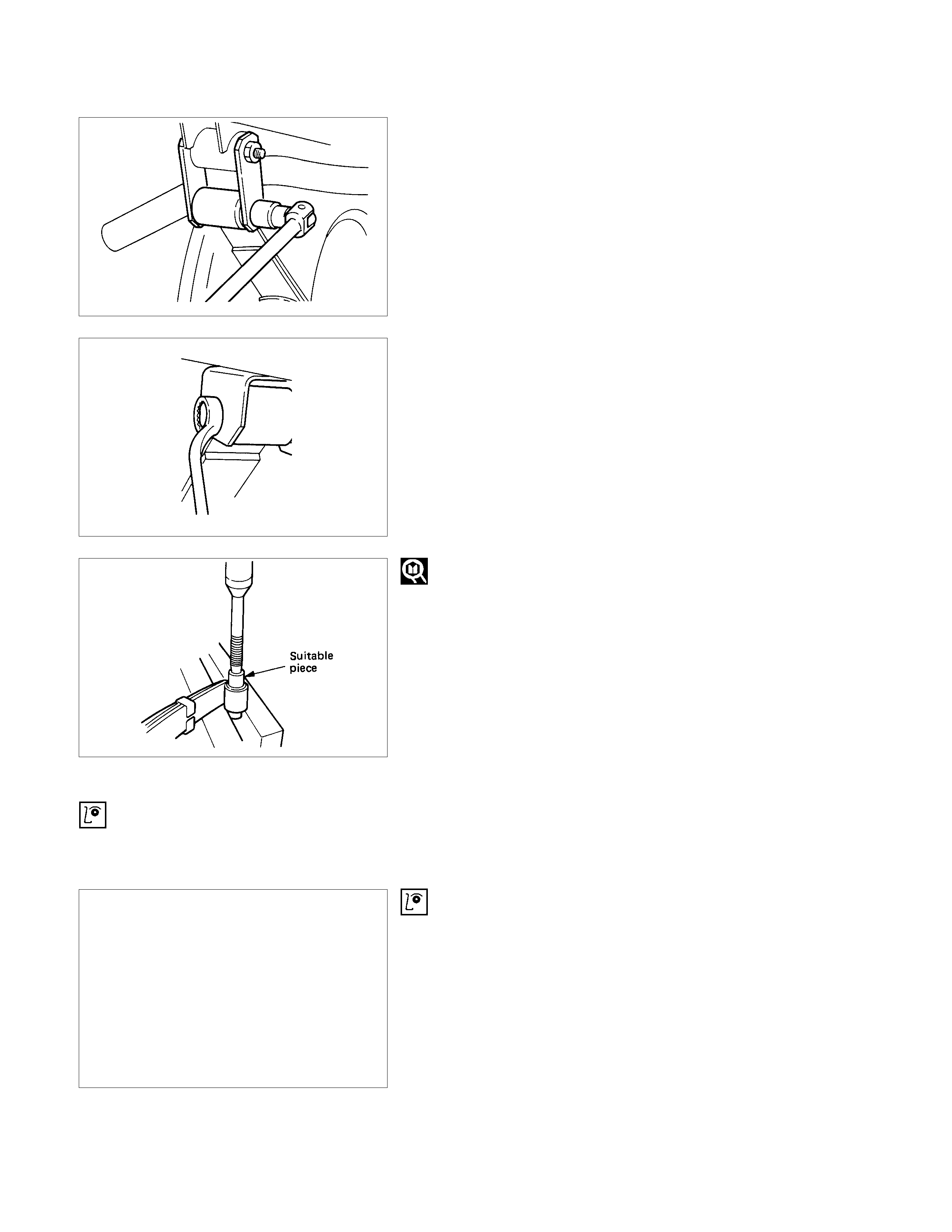

7. 8. Nut and Washer

9. 10. Shackle

Remove the nut and drive out the shackle with a hammer using

a brass bar.

13.14. Nut, Washer, Bolt and Spring Pin

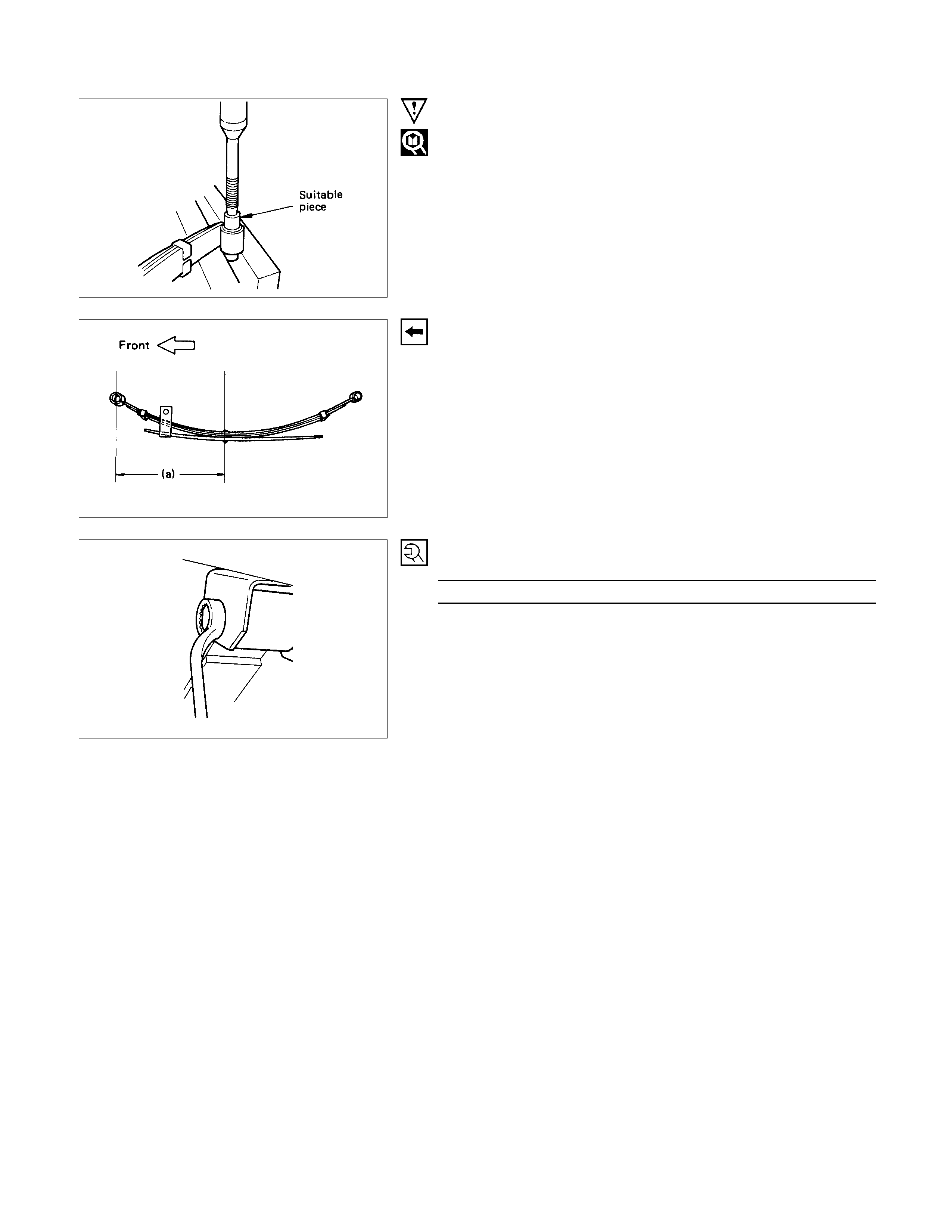

Remove the nut and drive out the spring pin with a hammer

using a brass drift.

15.Bushing

Remove the bushing using a bench press.

INSPECTION AND REPAIR

Make correction or parts replacement if wear, damage or their abnormal conditions are found through inspection.

• Leaf spring assembly

• Clip

• Center bolt

• U-bolt

• Spring pin

• Shackle pin

• Shock absorber

• Bump rubber

• Rubber bushing

• Bump rubber seat

VISUAL CHECK

Inspect the following parts for wear, damage or other abnormal

conditions.

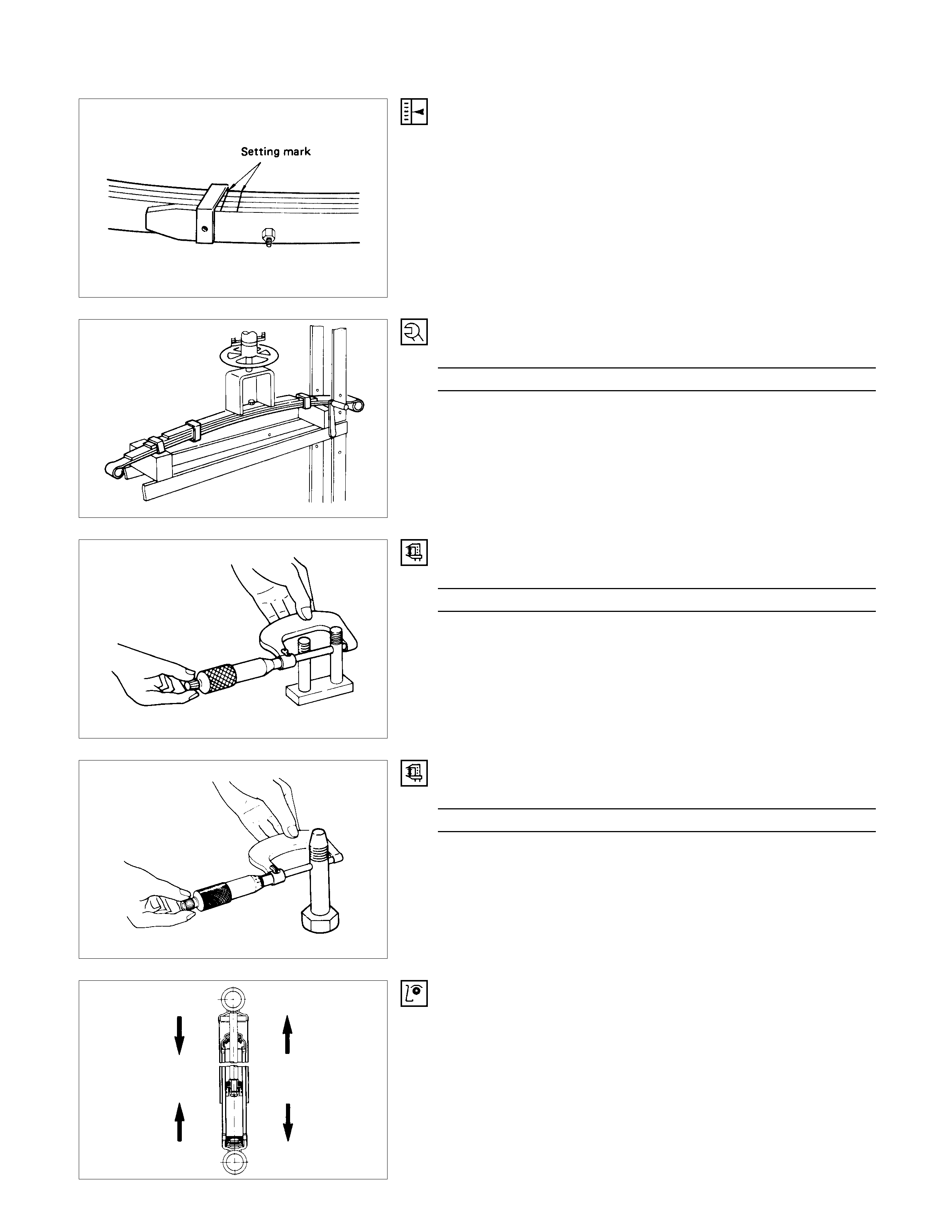

LEAF SPRING ASSEMBLY REPLACEMENT

•Apply a setting mark across the springs before

disassembling the leaf spring assembly.

•Apply grease to both faces of each leaf spring at assembly.

•Use a bench press for disassembly and reassembly.

•Discard center bolt and install a new one.

CENTER BOLT

Center Bolt Torque N⋅m(kgf⋅m/lb⋅ft)

29.4 ± 19.6 (3.0 ± 0.2 / 21.7 ± 1.4)

SHACKLE PIN

Shackle Pin diameter mm(in)

17.93 - 18.00 (0.706 - 0.709)

SPRING PIN

Spring Pin Diameter mm(in)

13.8 - 14.0 (0.543 - 0.551)

SHOCK ABSORBER

Inspection operation of shock absorber

If no resistance is felt while expanding the shock absorber, that

indicates the absorber is faulty.

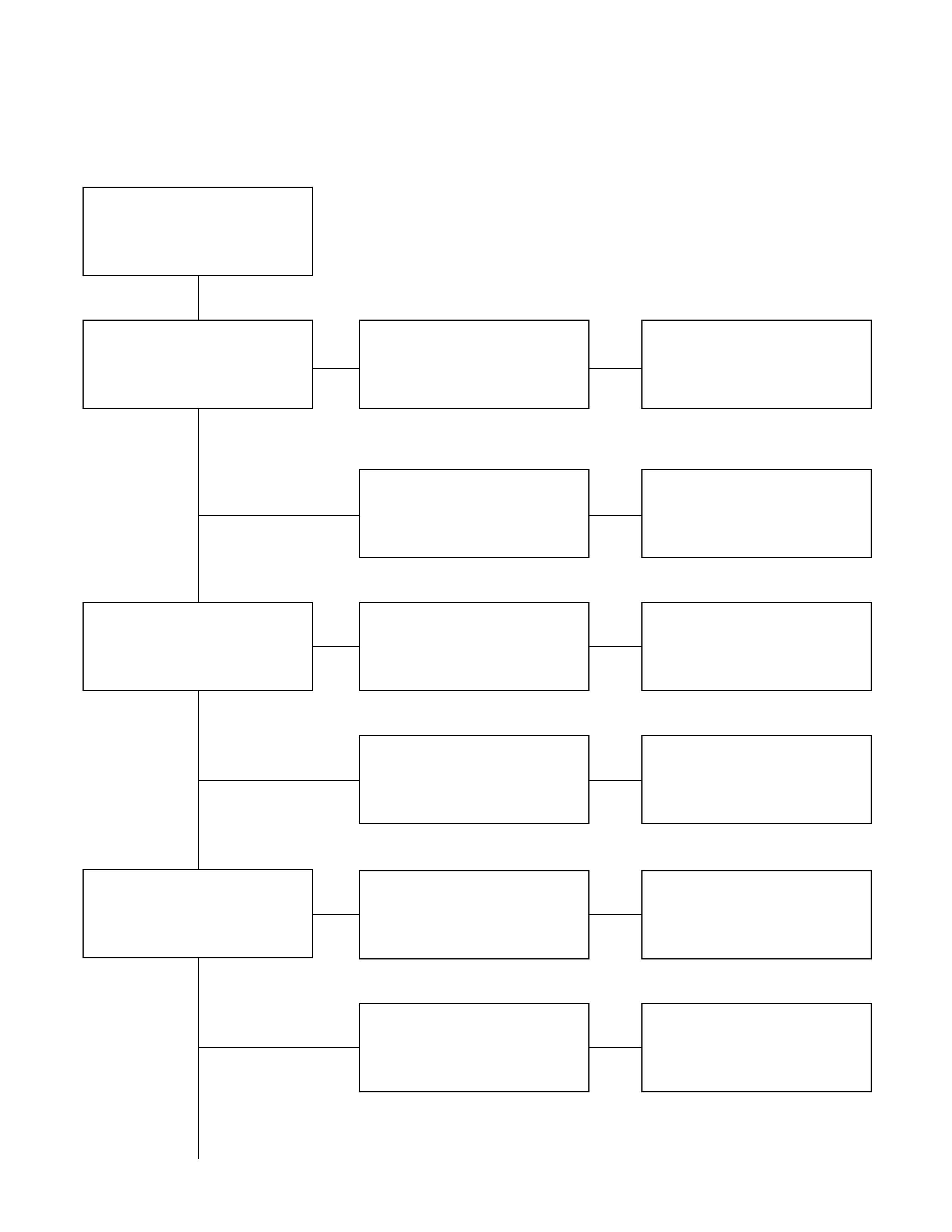

REASSEMBLY

REASSEMBLY STEPS

1. Bump rubber

▲2. Bushing

▲3. Leaf spring assembly

4. Spring pin, bolt and washer

▲5. Nut and washer

▲6. Rubber bushing

▲7. Rubber bushing

▲8. Shackle

▲9. Shackle plate

▲10. Nut and washer

▲11. Nut and washer

12. Lower clamp

▲13. U-bolt and nut

▲14. Shock absorber

▲15. Nut and washer

▲16. Nut and washer

IMPORTANT OPERATIONS

2. Bushing

Install the bushing using a bench press.

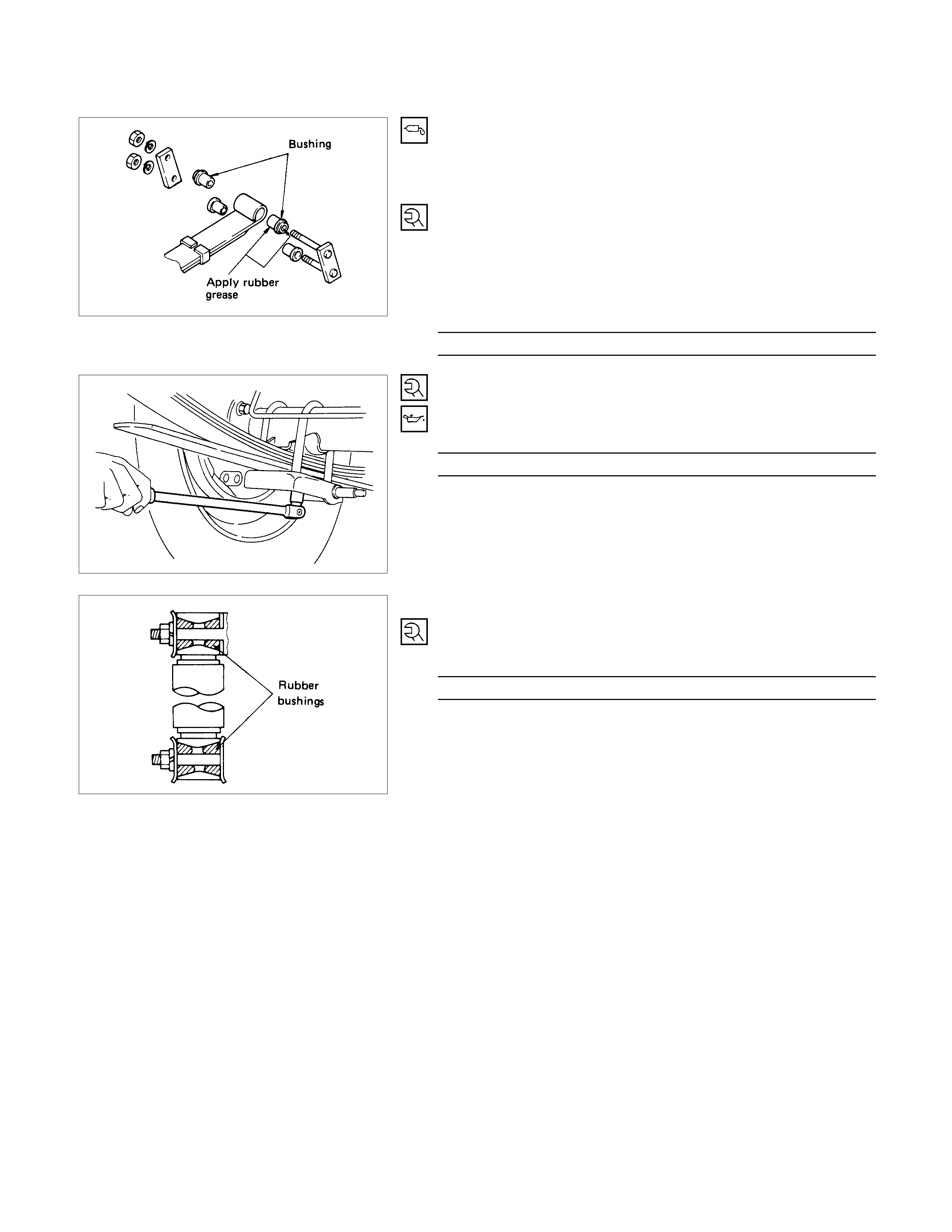

3. Leaf Spring Assembly

The leaf spring assembly should be installed so that the

shorter length (a) (distance between center bolt and center of

spring eye) is toward the front.

5. Nut and Washer

Spring Pin Torque N⋅m(kgf⋅m/lb⋅ft)

152.0 ± 14.7 (15.5 ± 1.5 / 112.1 ± 10.8)

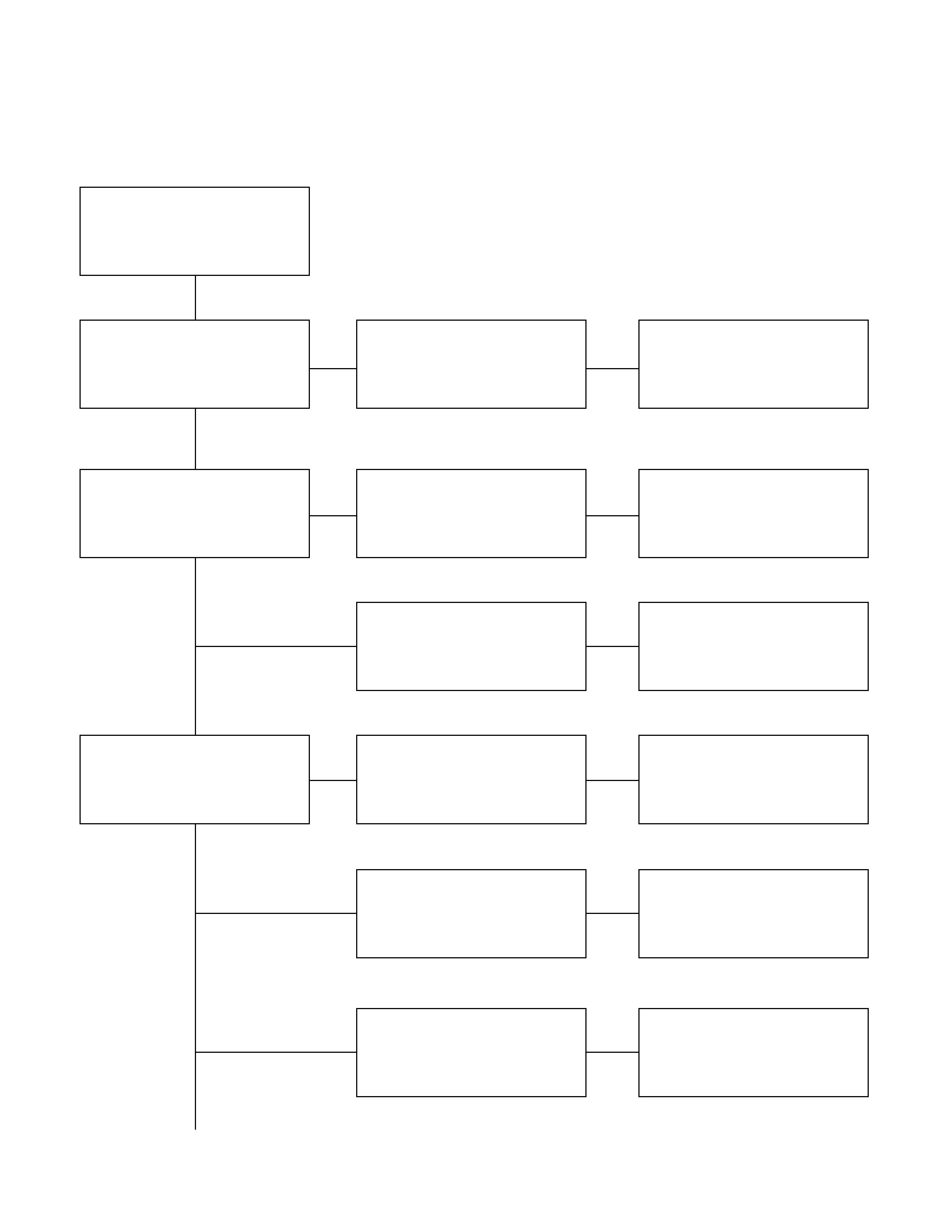

6. 7. Rubber Bushing

Apply rubber grease to inside and outside of the rubber

bushing.

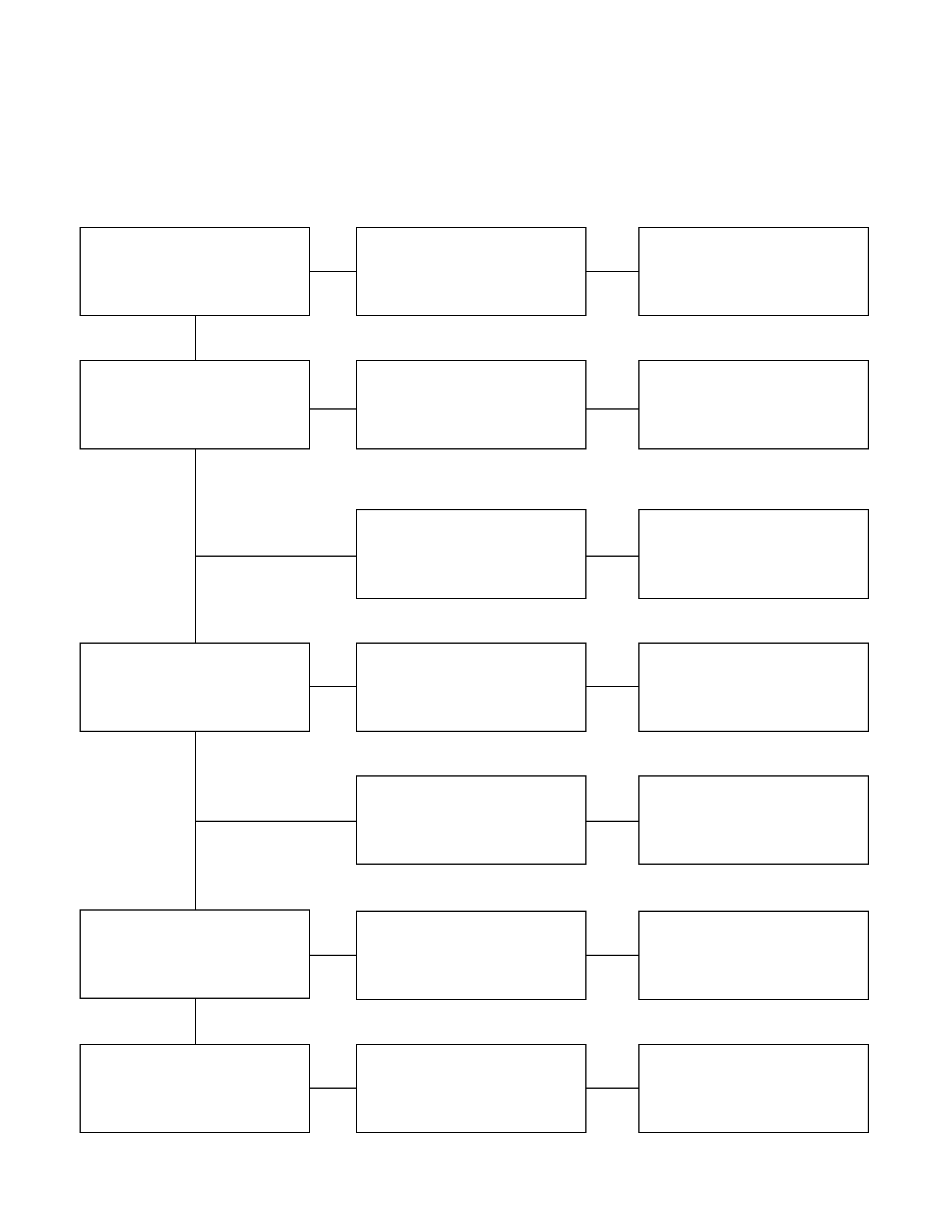

8. 9. Shackle

10.11. Nut and Washer

Install bushing with collar on the leaf spring, then install and

tighten the nut.

Note :

Tighten the nuts to the specified torque with the vehicle

empty.

Shackle Nut Torque N⋅m(kgf⋅m/lb⋅ft

)

98.0 ± 19.6 (10.0 ± 2.0 / 72.3 ± 14.4)

13.U-bolt and Nut

When tightening the nuts apply oil as necessary to prevent

damaging the threads.

U-bolt Nut Torque N⋅m(kgf⋅m/lb⋅ft)

65.7 ± 5.8 (6.7 ± 0.6 / 48.5 ± 4.3)

14.Shock Absorber

15.16. Nut and Washer

Refer to the drawing for parts installation.

Shock Absorber Nut Torque N⋅m(kgf⋅m/lb⋅ft)

39.2 ± 4.9 (4.0 ± 0.5 / 28.9 ± 3.6)

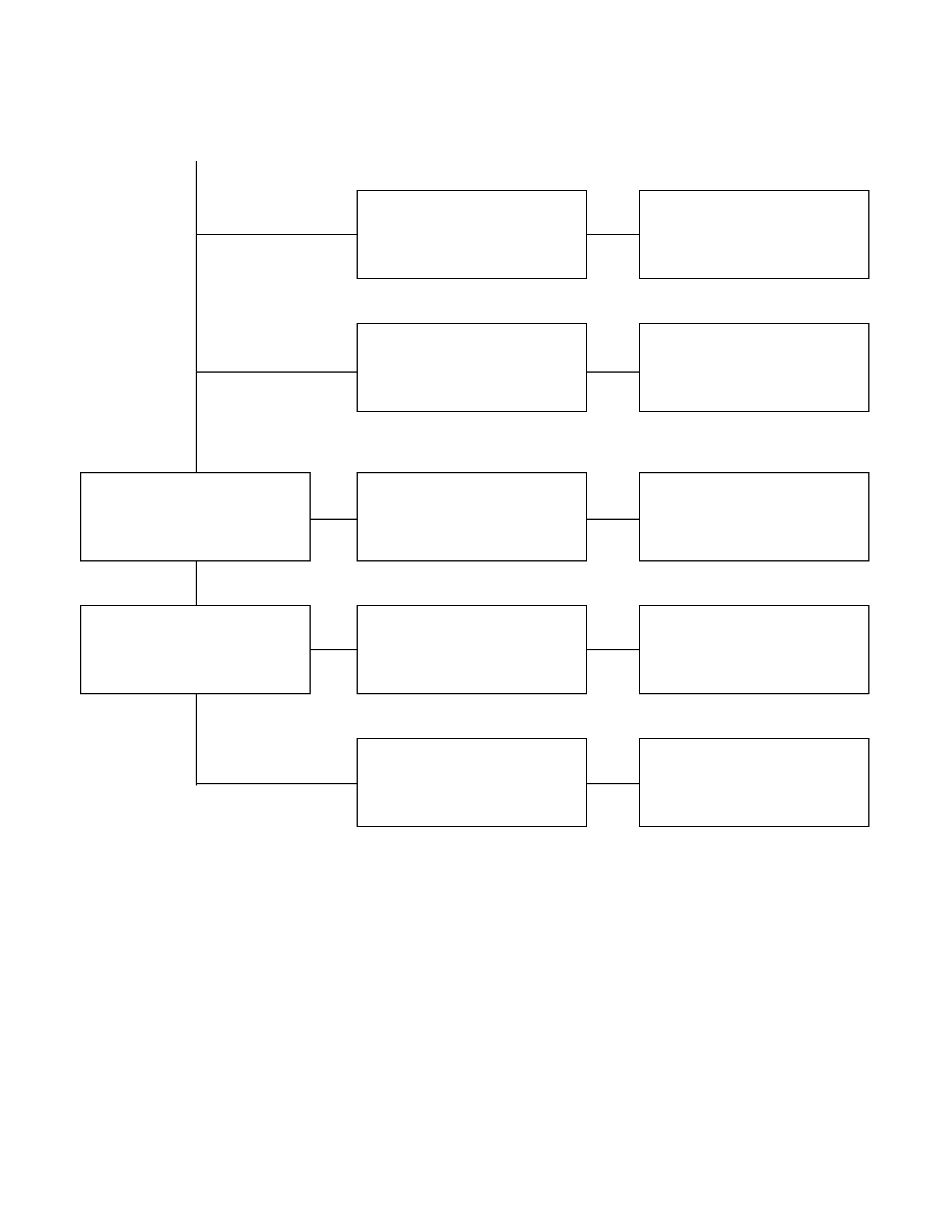

TROUBLESHOOTING

1. BODY INCLINATION

Checkpoint Trouble Cause Countermeasure

Replace

Bushings worn or

disintegrated

NG

Mounting brackets

Shock absorbers

ReplaceDefective

Spring brackets and U-bolts

Shackle pins and bushings

Replace

Retighten

Replace

Cracked

Bolt loosened

Worn or disintegrated

Regrease

Replace

Poorly lubricated

Weak or broken

OK

OK

OK

NG

NG

NG

NG

NG

NG

OK

Spring

2. REDUCTION G ROUND CLEARANCE

Checkpoint Trouble Cause Countermeasure

Bushings

Leaf springs

Regrease

Replace

Retighten

Replace

Poorly lubricated

Deteriorated or disintegrated

Loosened

Broken

Springs clip bands ReplaceWorn or broken

Continued on the next page

OK

NG

NG

NG

NG

NG

OK

OK

Condition of load

Wipe off excess greaseOver lubricated

NG

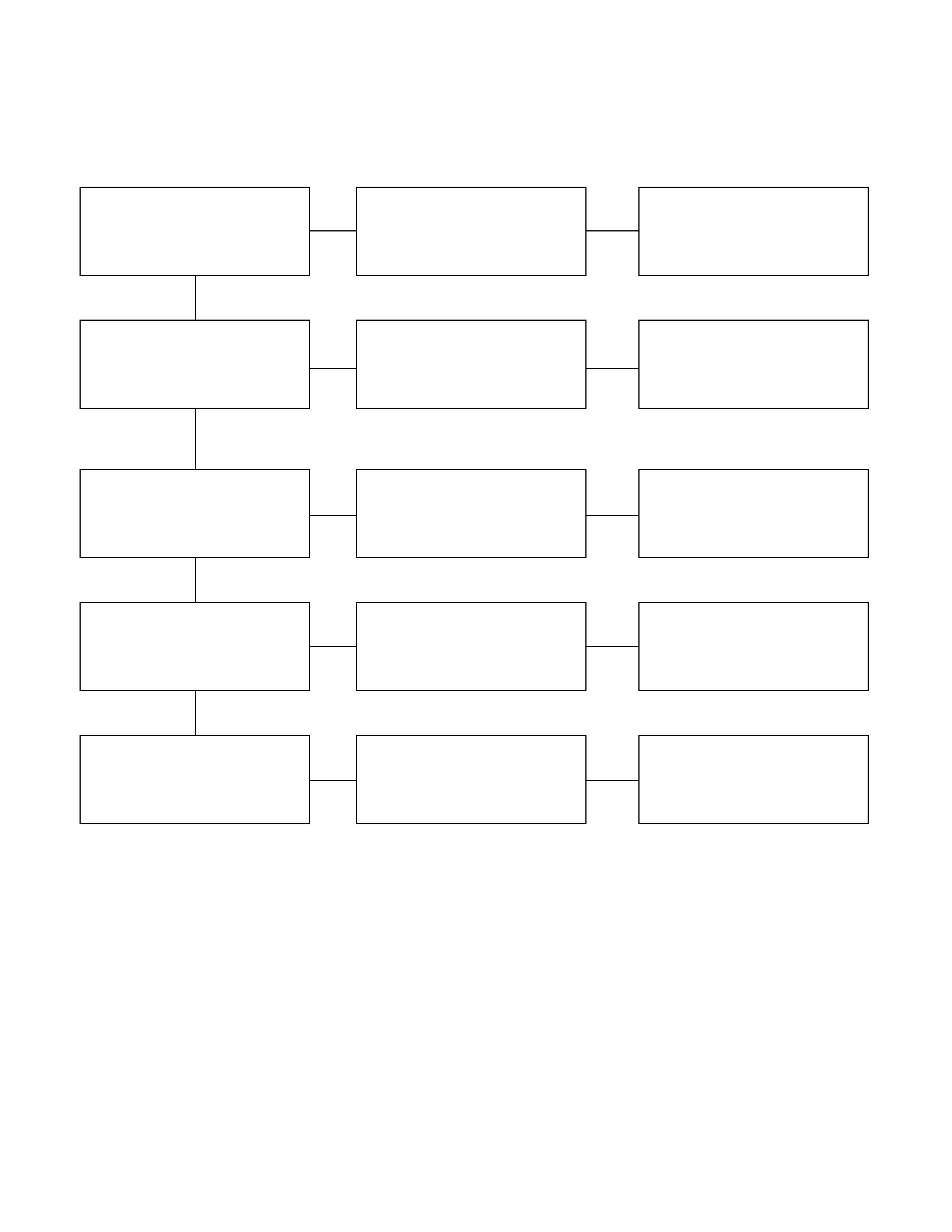

Checkpoint Trouble Cause Countermeasure

ReplaceCracked or damaged

RetightenLoose

OK

NG

NG

Parts for looseness

Continued from the previous page

3. SPRING BREAKAGE

Checkpoint Trouble Cause Countermeasure

ReplaceOil leakage

NG

Shock absorber

ReplaceBushing worn

U-bolts

Shackle pins and pivot pins

Replace

Retighten

Retighten

Damaged

Bolts and nuts for loosening

Bolts and nuts for loosening

ReplaceWorn or damaged

OK

OK

NG

NG

NG

NG

NG

OK

Condition of loading

Continued on the next page

Checkpoint Trouble Cause Countermeasure

Center bolts

Replace

Retighten

Replace

Damaged

Loosened

Defective

Spring bushing Replace

Replace

Worn or disintegrated

Brackets cracked

OK

NG

NG

NG

NG

NG

OK

Continued from the previous page

4. HARSHNESS

Checkpoint Trouble Cause Countermeasure

Bushings in suspension

system

Bushings in suspension

System

Tire inflation pressure

Retighten or replace

Replace

Adjust

Loosen or broken

Defective

Incorrect

Tires for out of balance Adjust or replace

Replace tires

Incorrect

Noise does not have any

specific pattern

OK

OK

NG

NG

NG

NG

NG

OK

OK

Road test vehicle(Noise has a

certain pattern)