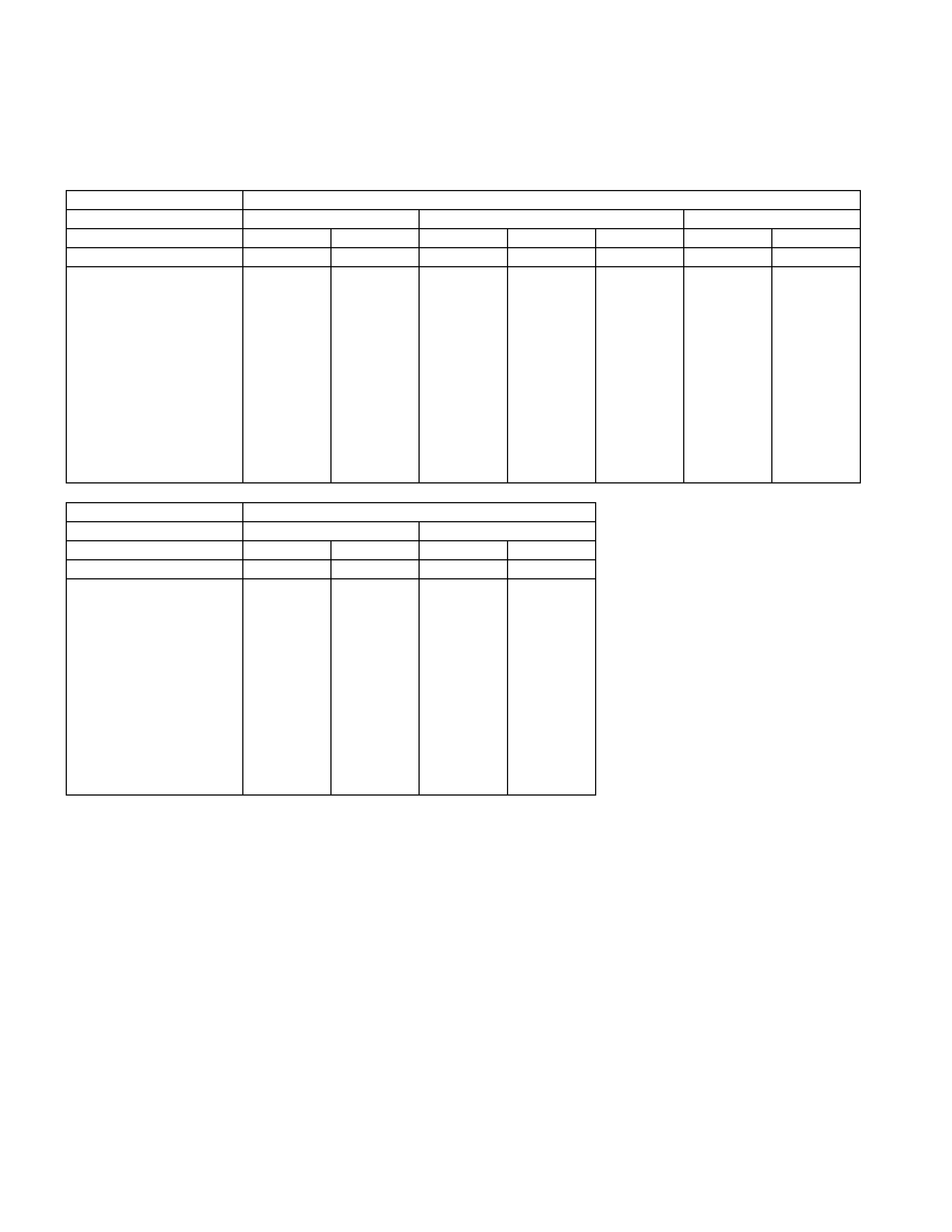

MAIN DATA AND SPECIFICATION

REAR PROPELLER SHAFT

4 ×

××

× 2 MODEL Long Wheel Base

Engine Model 4JA1 4JB1 4JG2

Transmission Type 5M/T ←←←4A/T 5M/T 4A/T

Rear Axle 194mm 220mm 194mm 220mm ←←←

Type OBS ←←←←←←

Outside Diameter mm 63.5 68.9 63.5 68.9 68.9 68.9 68.9

Inside Diameter mm 60.3 64.9 60.3 64.9 64.9 64.9 64.9

Length 1st mm 675.5 675.5 675.5 675.5 593.5 675.5 593.5

2nd mm 949 924 949 924 924 924 924

Spline Outside mm 29.87 29.87 29.87 29.87 30.48 29.87 30.48

Diameter

Fix Bolt Size M8 M10 M8 M10 M10 M10 M10

Long Wheel Base

Engine Model C22NE 6VD1

Transmission Type 5M/T ←←4A/T

Rear Axle 194mm 220mm ←←

Type OBS ←←IBS

Outside Diameter mm 63.5 68.9 68.9 68.9

Inside Diameter mm 60.3 64.9 64.9 64.9

Length 1st mm 720.5 720.5 695.5 737.5

2nd mm 949 924 924 924

Spline Outside mm 29.87 29.87 29.87 36.67

Diameter

Fix Bolt Size M8 M10 M10 M10

* OBS - Outboard Slip (Spline Engagement To T/M)

IBS - Inboard Slip (Spline Travel at Joint Center)

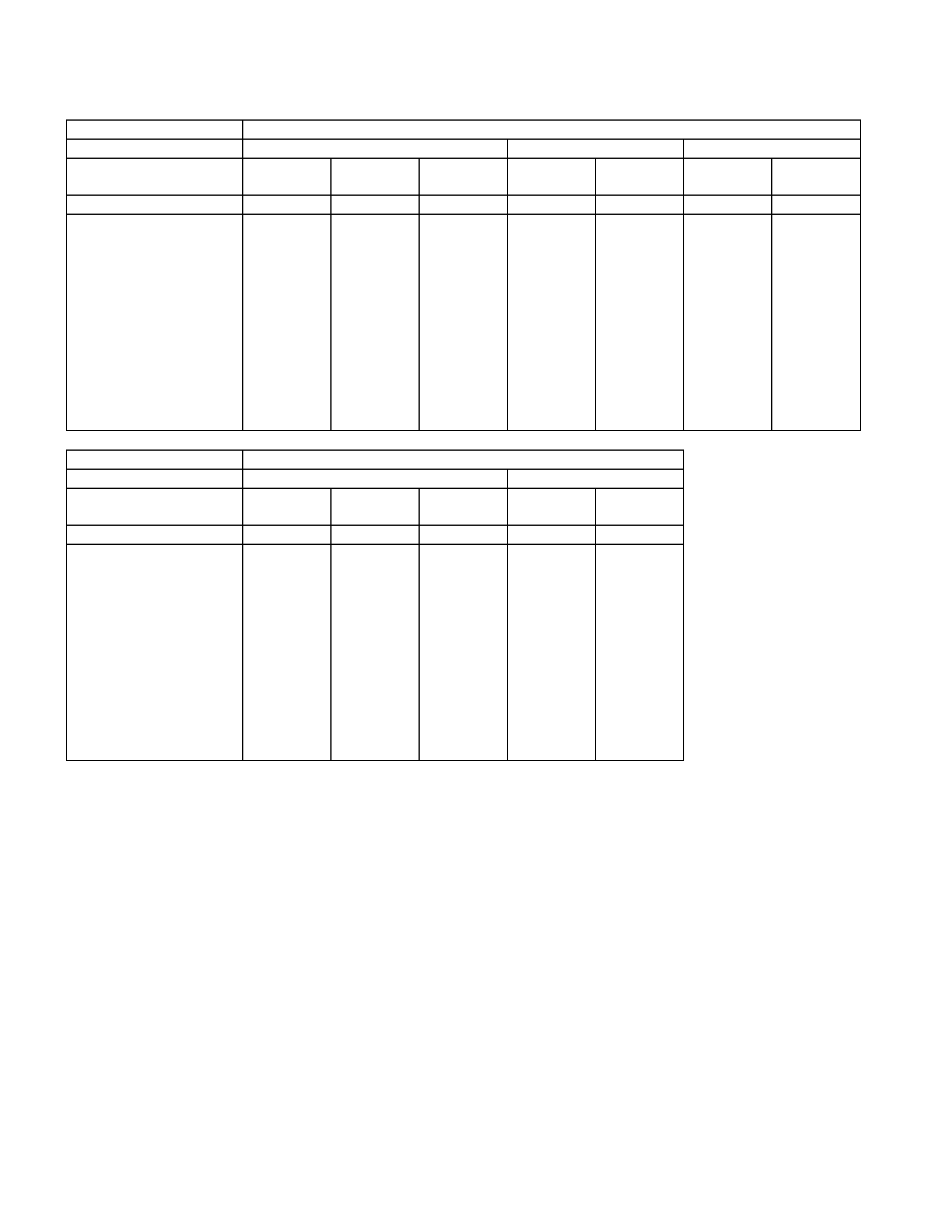

4 ×

××

× 4 MODEL

Long Wheel Base

Engine Model 4JA1 4JB1 4JG2

Transmission Type 5M/T ←←←4A/T 5M/T 4A/T

(MSG) ←(MUA) ←(MUA)

Rear Axle 194mm 220mm 220mm ←←←←

Type OBS ←←←IBS OBS IBS

Outside Diameter mm 63.5 68.9 68.9 68.9 68.9 68.9 68.9

Inside Diameter mm 60.3 64.9 64.9 64.9 64.9 64.9 64.9

Length 1st mm 541.5 541.5 482.5 482.5 627.5 482.5 627.5

2nd mm 949 924 924 924 670 924 670

Spline Outside mm 29.87 29.87 29.87 29.87 36.67 29.87 36.67

Diameter

Fix Bolt Size M8 M10 M10 M10 M10 M10 M10

Long Wheel Base

Engine Model C22NE 6VD1

Transmission Type 5M/T ←←←4A/T

(MSG) ←(MUA) ←

Rear Axle 194mm 220mm ←←←

Type OBS ←←←IBS

Outside Diameter mm 63.5 68.9 68.9 68.9 68.9

Inside Diameter mm 60.3 64.9 64.9 64.9 64.9

Length 1st mm 581.5 581.5 527.5 607.5 437.5

2nd mm 949 924 924 924 924

Spline Outside mm 29.87 29.87 29.87 36.67 36.67

Diameter

Fix Bolt Size M8 M10 M10 M10 M10

* OBS - Outboard Slip (Spline Engagement To T/M)

IBS - Inboard Slip (Spline Travel at Joint Center)

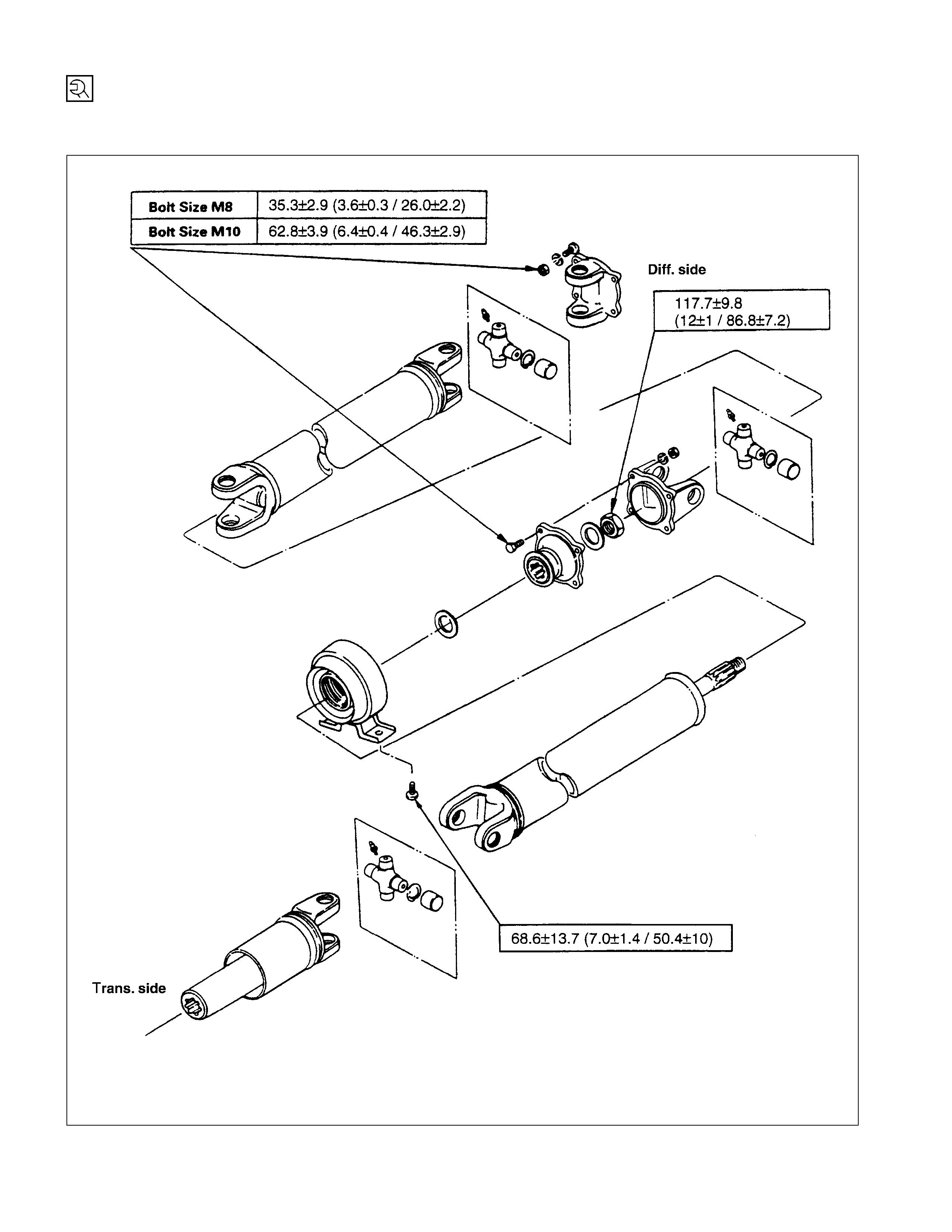

SPECIAL PARTS FI XING NUT AND BOLT

REAR PROPELLER SHAFT ( LONG WHEEL BASE MODEL) N⋅m (kgf⋅m/lb⋅ft)

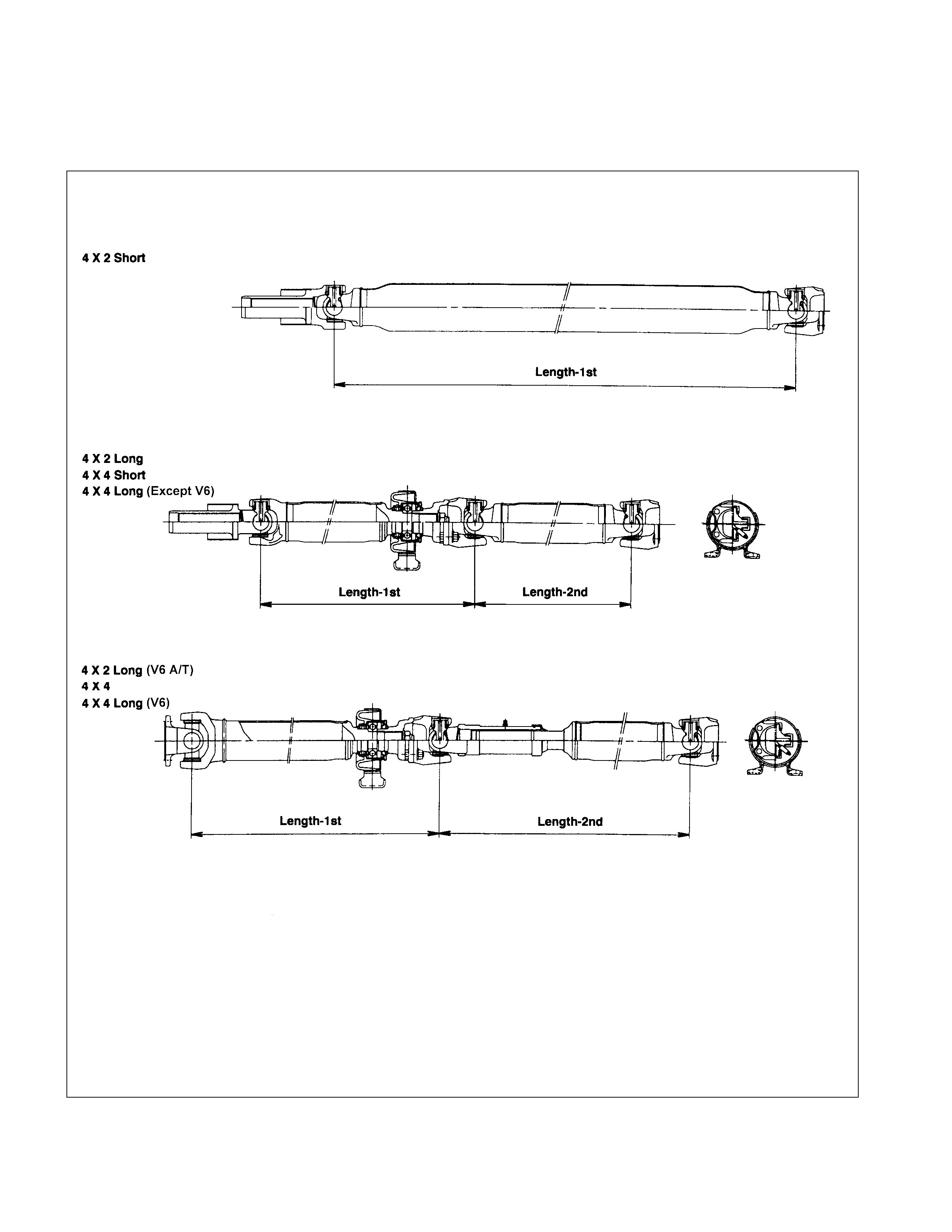

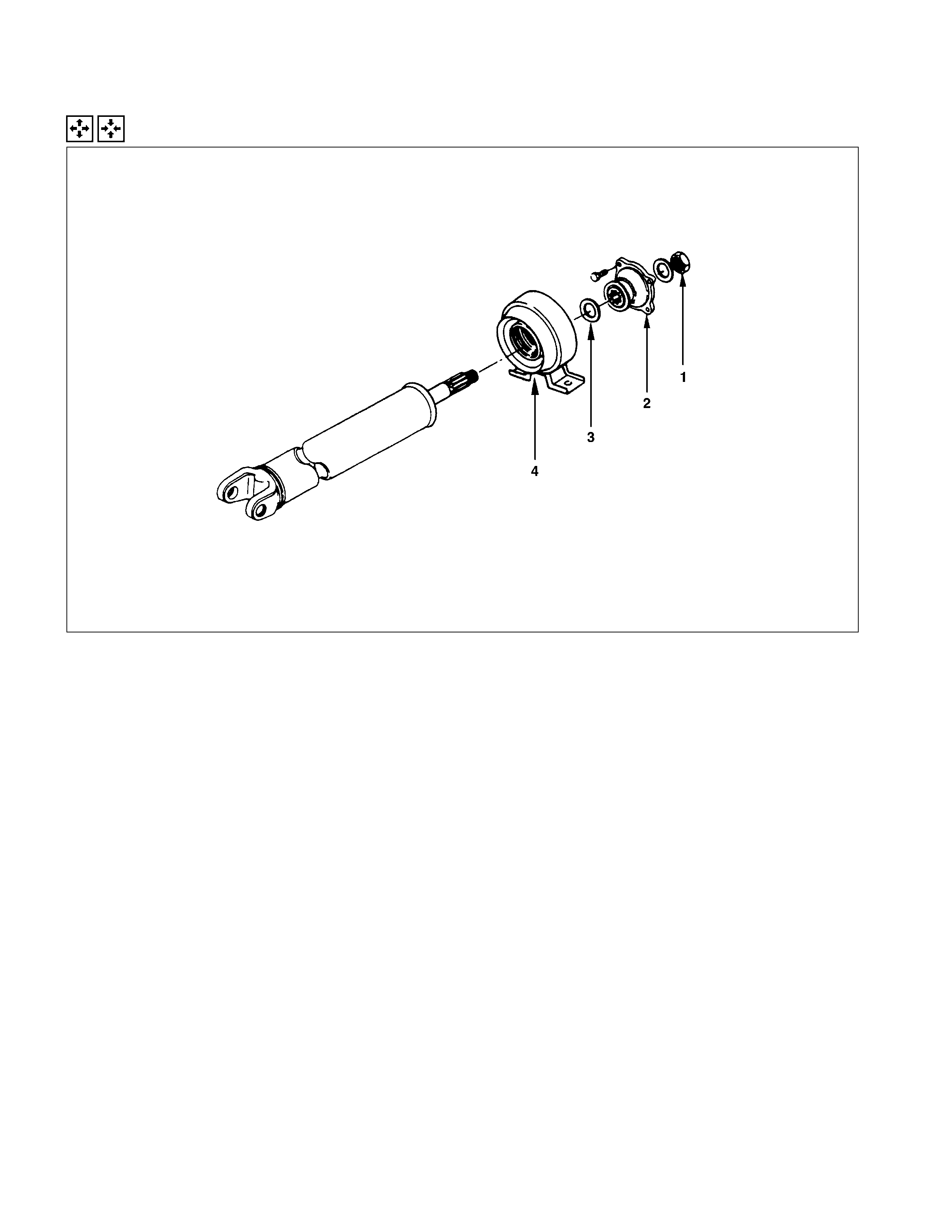

PROPELLER SHAFT ASSEMBLY

GENERAL DESCRI PTION

REAR PROPELLER SHAFT

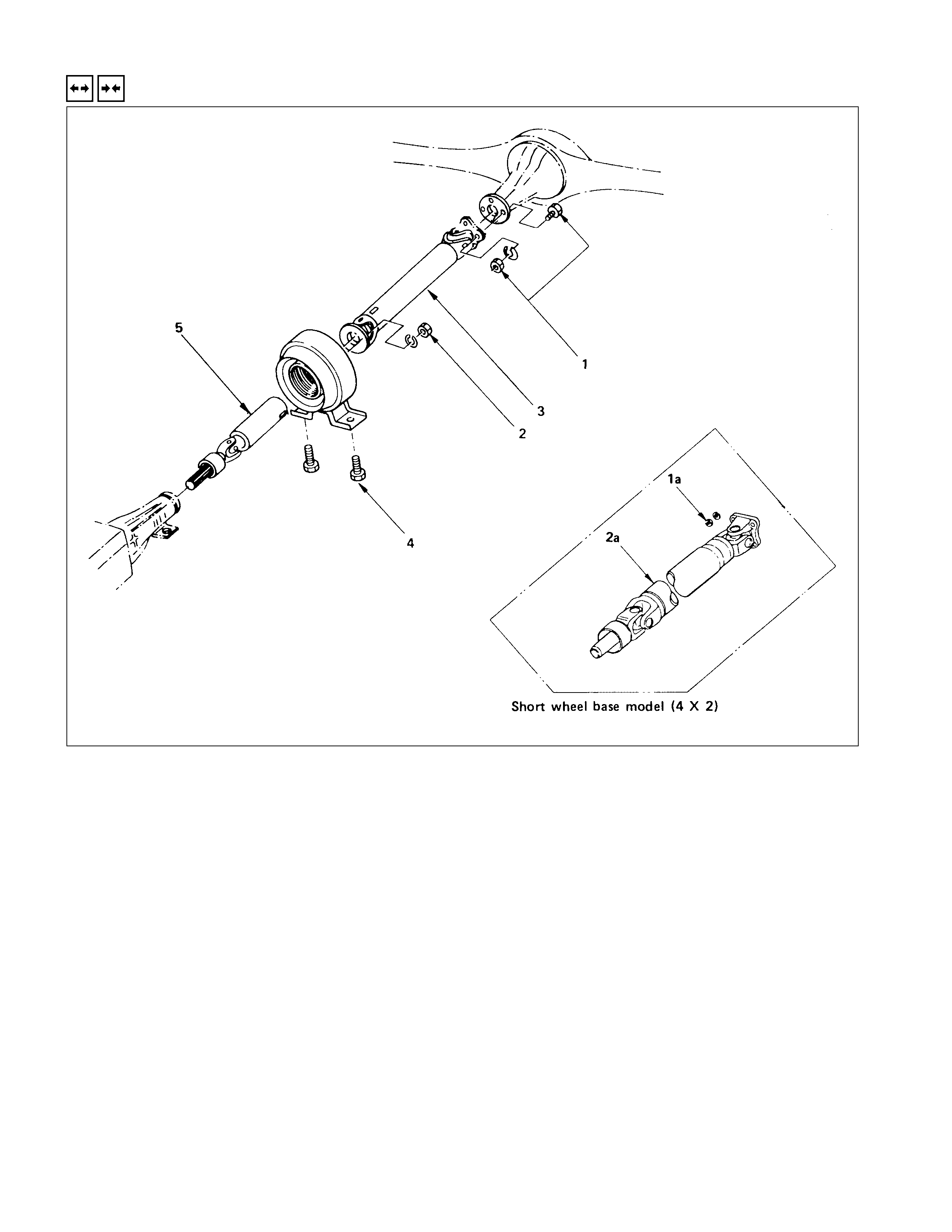

REMOVAL AND INSTALLATION

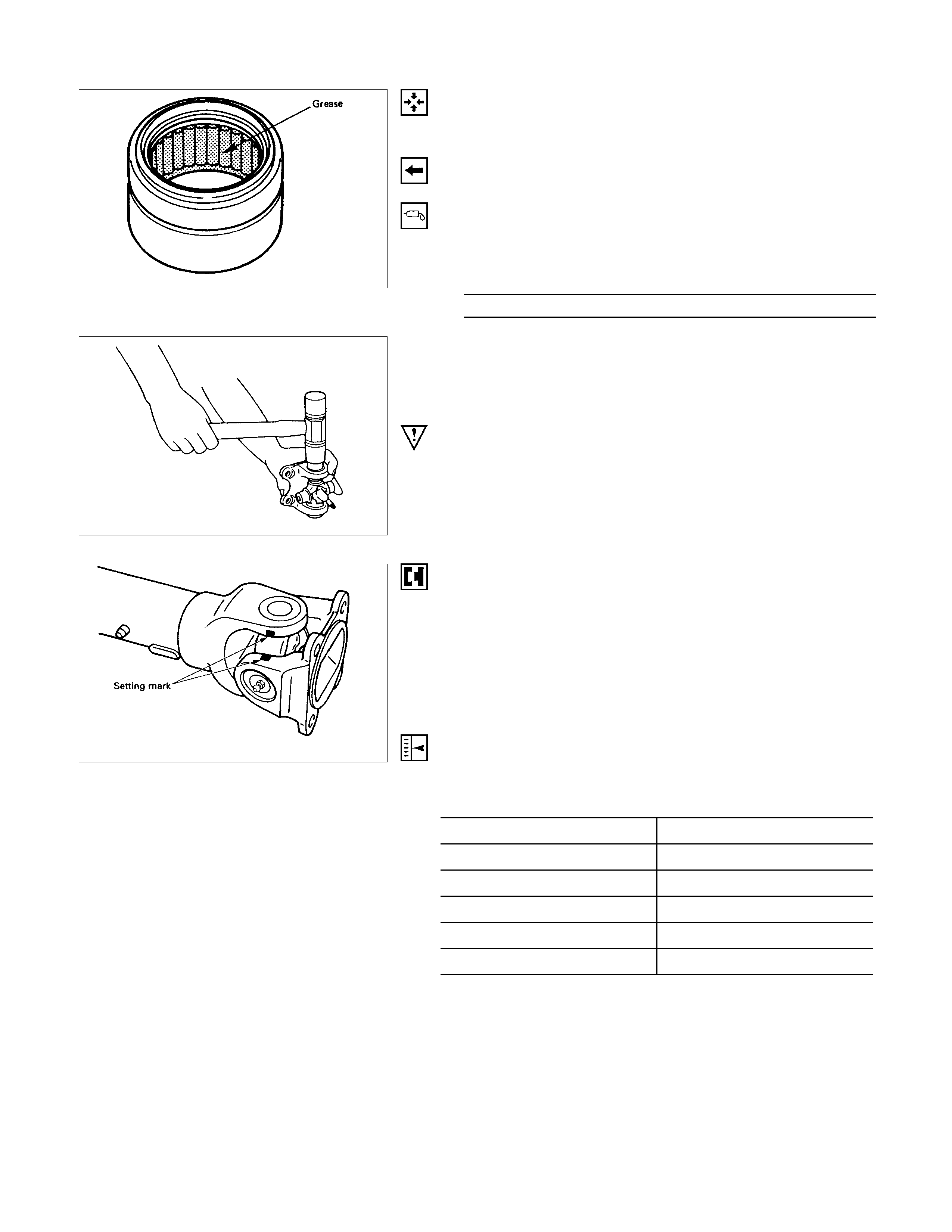

Since the propeller shaft assembly is carefully

balanced, a scribe mark should be made on

the flange before removal.

Install the parts by aligning scribe marks made

during removal.

REMOVAL STEPS

1. 1a. Bolt ; differential side

2. Bolt ; flange

▲2a. Propeller shaft assembly

3. Propeller shaft assembly ; 2nd

4. Bolt ; center bearing bracket

▲5. Propeller shaft assembly ; 1st

INSTALLATION STEPS

5. Propeller assembly ; 1st

▲4. Bolt ; center bearing bracket

3. Propeller shaft assembly ; 2nd

▲2. Bolt ; flange

2a. Propeller shaft assembly

▲1. 1a. Bolt ; differential side

IMPO RTANT OPERATIONS - REMOVAL

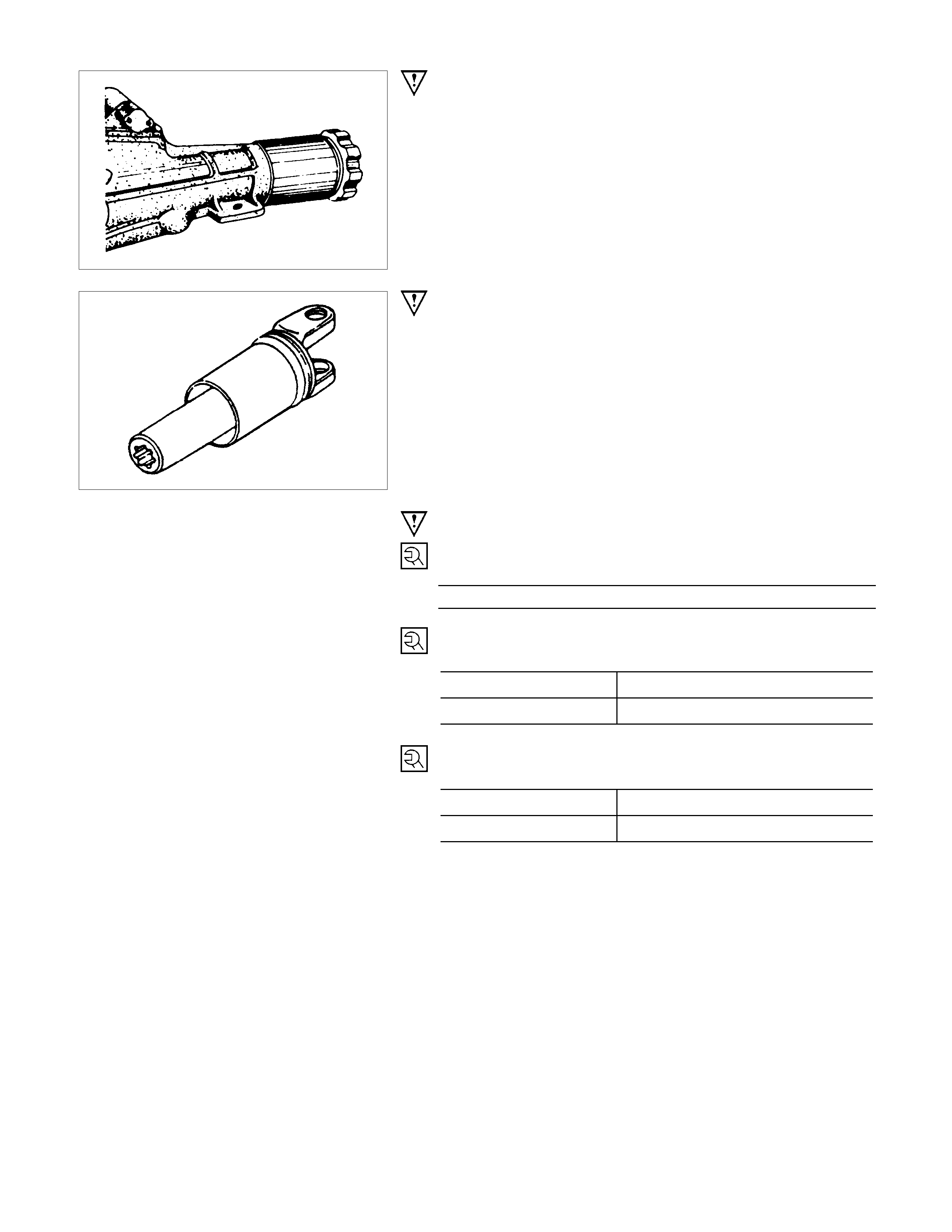

2a.Propeller Shaft Assembly

5. Propellers Shaft Assembly ; 1st

Install a plug at the transmission rear cover to prevent loss of

the transmission oil.

CAUTION:

Cover the slip yoke with cloth to avoid damage to the oil

seal contact surface, when

removing propeller shaft from transmission. Do not

damage the oil seal contact surface of

slip yoke with other parts at removal and installation.

IMPORTANT OPERATIONS - INSTALLATION

4. Bolt ; Center Bearing Bracket

Bolt Torque N⋅m (kgf⋅m/lb⋅ft)

68.6 ± 13.7 (7.0 ± 1.4 / 50.4 ± 10)

2. Bolt ; Flange

Bolt Torque N⋅m (kgf⋅m/lb⋅ft)

Bolt size M10 62.8 ± 3.9 (6.4 ± 0.4/46.3 ± 2.9)

Bolt size M8 35.3 ± 2.9 (3.6 ± 0.3/26 ± 2.2)

1. 1a. Bolt ; differential side

Bolt Torque N⋅m (kgf⋅m/lb⋅ft)

Bolt size M10 62.8 ± 3.9 (6.4 ± 0.4/46.3 ± 2.9)

Bolt size M8 35.3 ± 2.9 (3.6 ± 0.3/26 ± 2.2)

DISASSEM BLY

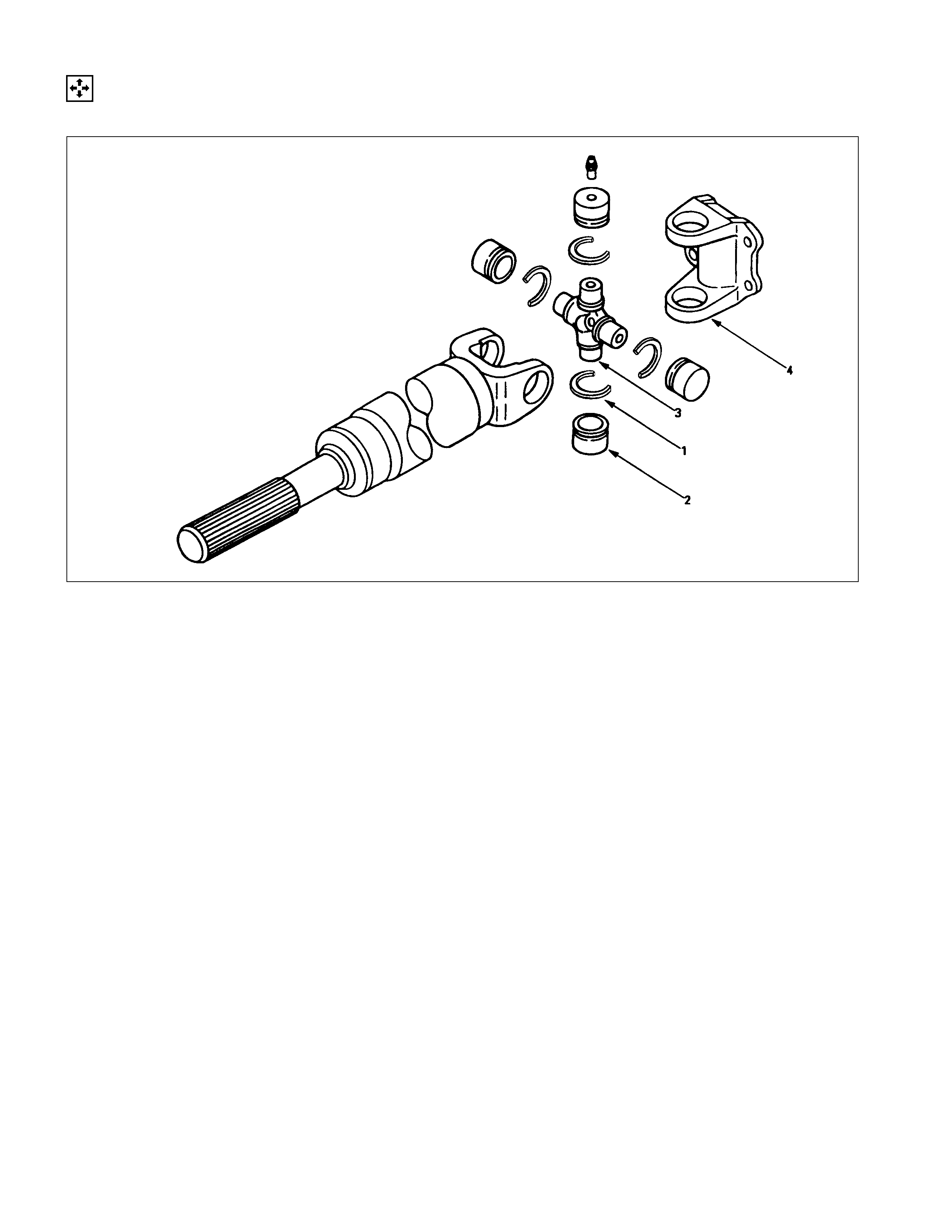

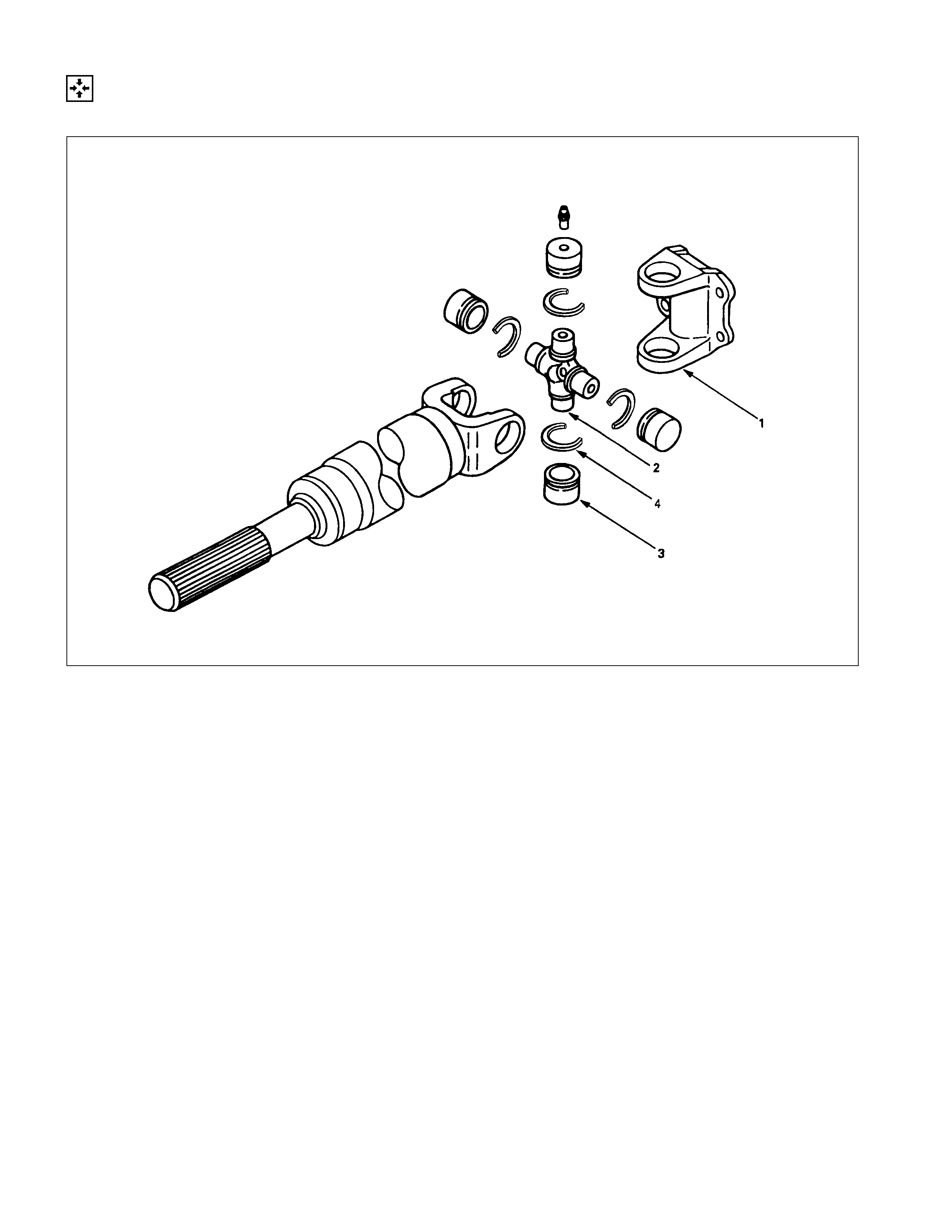

UNIVERSAL JO INT

DISASSEM BLY STEPS

1. Snap ring

2. Needle roller bearing

3. Spider

4. Flange yoke

REASSEMBLY STEPS

To reassemble, follow the disassembly steps

in the reverse order.

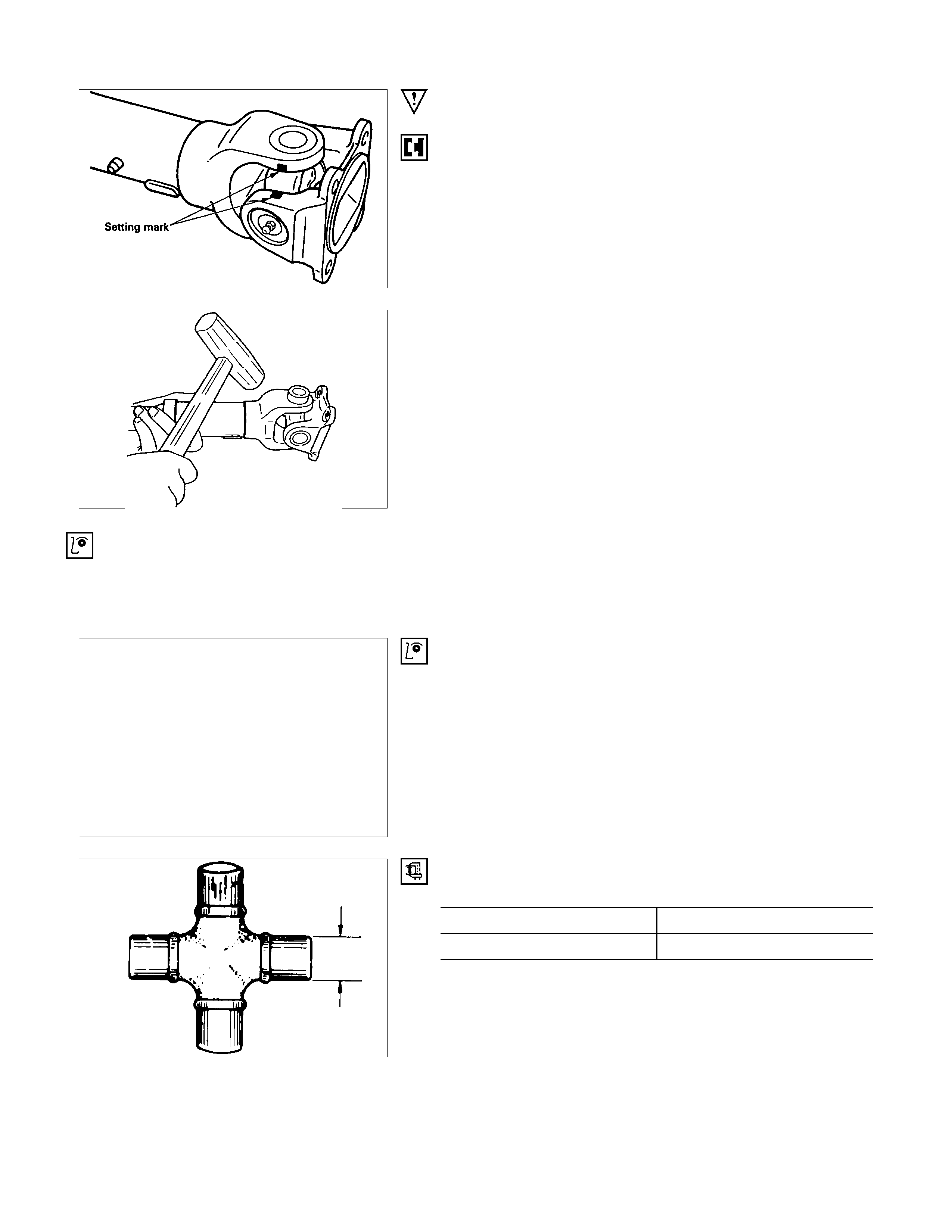

IMPORTANT OPERATION

1. Snap ring

•Apply alignment marks on the yokes of the universal

joint.

2. Needle roller bearing

•Tap out the bearing by gently strik ing the shoulder of the

yoke, using a mallet or a copper hammer.

3. Spider

•Make sure of proper position for reinstallation by

applying setting marks.

4. Flange Yoke

INSPECTION AND REPAIR

Make all necessary adjustment, repairs, and part replacements if wear, damage, or other problems are discovered

during inspection.

Spider

Needle roller bearing

Yoke

Flange

Center bearing

Cushioning rubber

Bracket

VISUAL CHECK

Inspect following parts for wear, damage, or other abnormal

conditions.

OUTSIDE DIAMETER OF SPIDER PINS mm(in)

Standard Limit

17 (0.67) 16.90 (0.665)

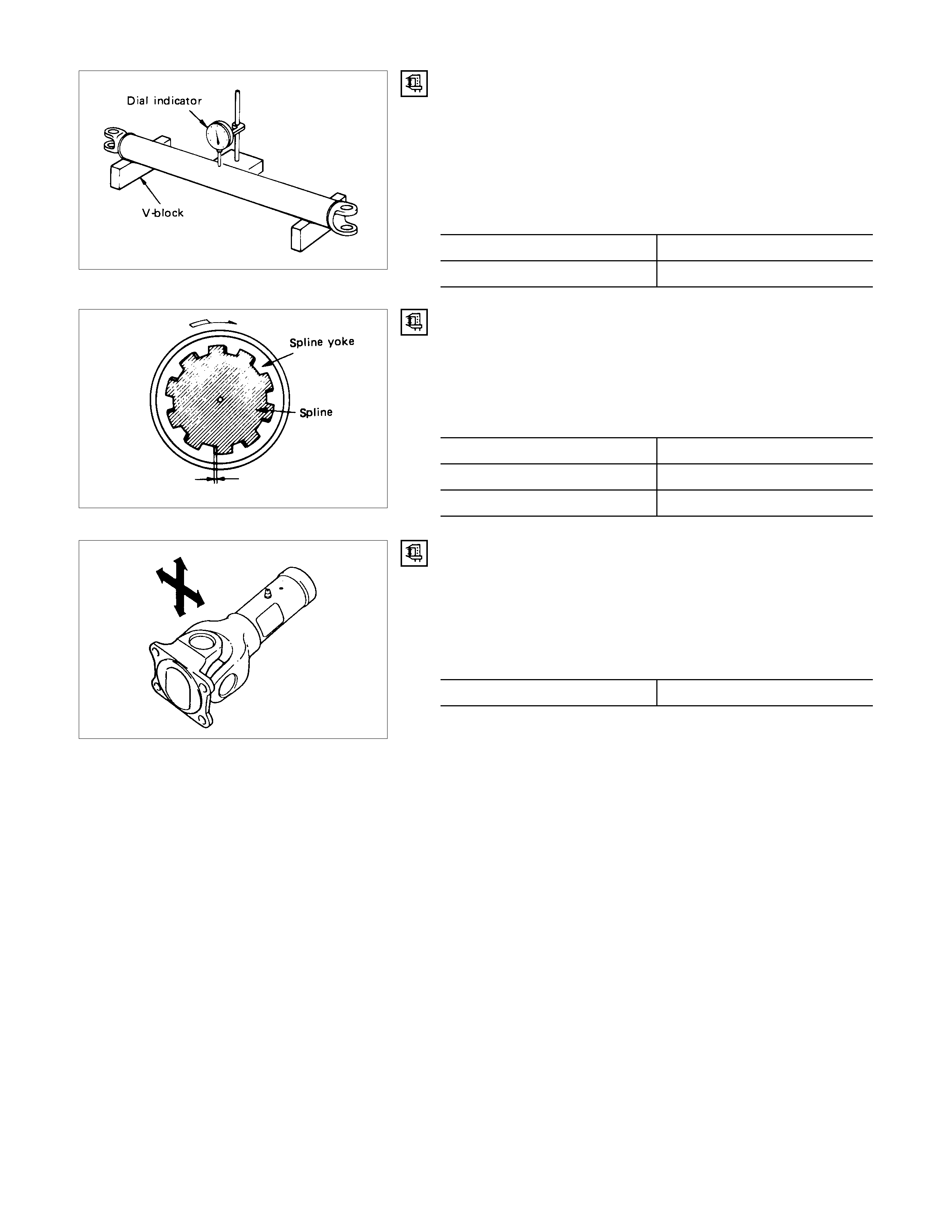

PROPELLER SHAFT RUN-OUT

Support the ends of the propeller shaft on V-blocks and check

for run-out by holding the probe of a dial indicator in contact

with the center part of the shaft.

If the amount of run-out is beyond the standard value for

assembly, correct with a bench press or replace the shaft with

a new one. mm(in)

Standard Limit

0.5 (0.02) 1.0 (0.04)

PLAY IN THE SPLINES IN THE NORMAL DIRECTION

OF ROTATION

Check the amount of play in the sleeve yoke and the propeller

shaft splines in the direction of rotation using a pointed feeler

gauge. mm(in)

Standard Limit

0.06 - 0.14 0.3 (0.012)

(0.002 - 0.006)

PLAY IN SPIDER BEARING

(1)Check the spider bearings for wear or damage.

(2)Check the amount of axial and radial play in spider bearing

by moving the yoke back and forth on the spider axes and

shaft axis. mm(in)

Limit 0.5 (0.02)

If the limit is exceeded, replace the shaft assembly.

REASSEMBLY

UNIVERSAL JO INT

DISASSEM BLY STEPS

1. Flange yoke

2. Spider

3. Needle roller bearing

4. Snap ring

REASSEMBLY STEPS

To reassemble, follow the disassembly steps

in the reverse order.

REASSEMBLY

1. Flange yoke

2. Spider

•Be sure to install the spider by aligning the setting marks

made during disassembly.

3. Needle Roller Bearing

1) Apply a molybdenum-disulfide grease or a multi-purpose.

type grease NLGI No.2 to inside of the bearing cap.

Grease Amount g(oz)

Approx. 1.2 (0.042)

2) Using either a mallet (or copper ham mer ) or a press, ins tall

the needle roller bearing into the yoke s o that snap ring c an

be installed in its groove.

CAUTION:

•

••

•The needle roller bearing cannot be installed smoothly

if it is set at an incorrect angle with the flange.

•

••

•Excessive hammering will damage the needle rolle

r

bearing.

3) Align setting marks and join the yokes.

NOTE:

Assemble the spider and spline yoke so that their grease

fittings are arranged on the same side.

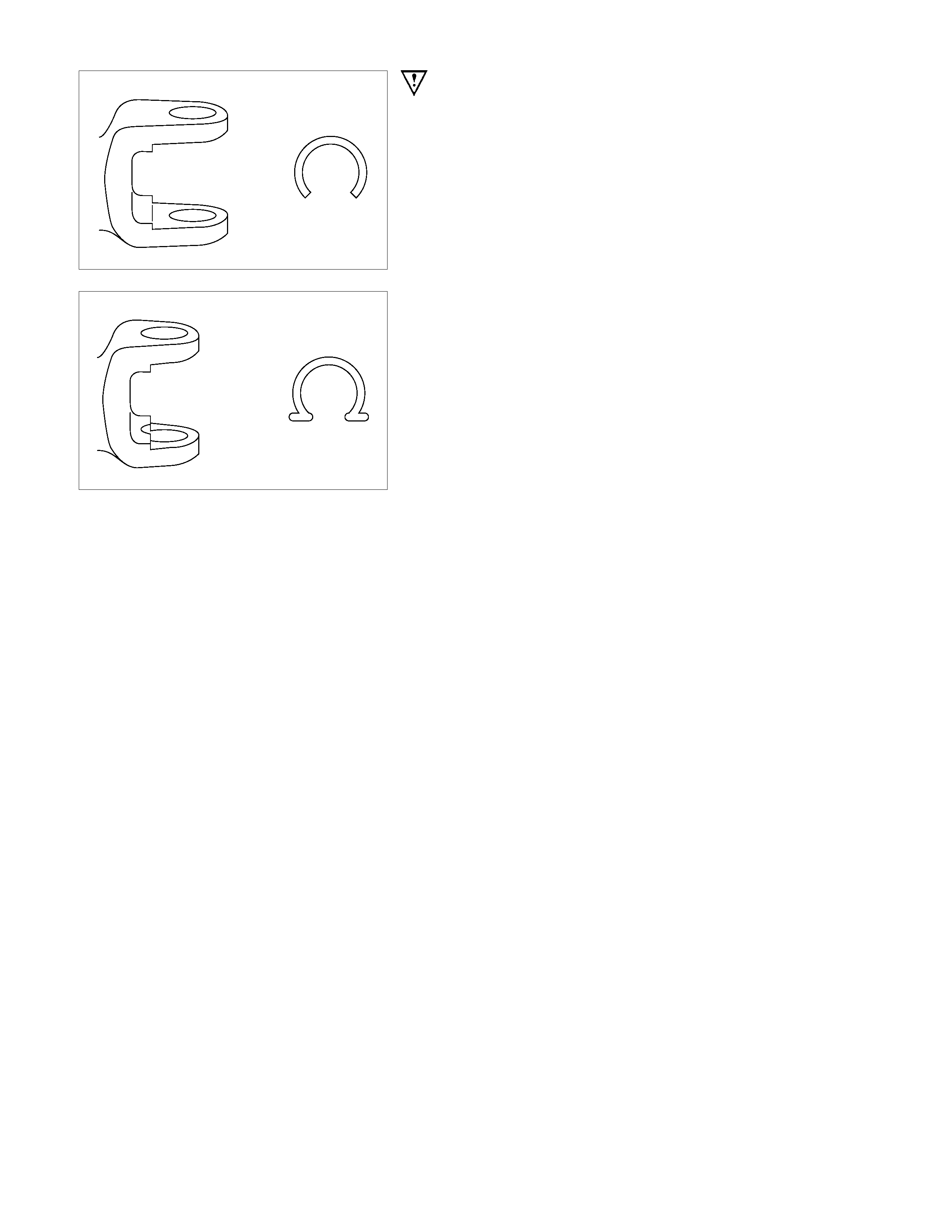

4. Snap ring

NOTE:

Discard used snap rings and install new ones.

When the bearing cap is in position, select and attach a snap

ring of suitable thickness so that the end play of the spider pin

is held within 0.1mm (0.004in). mm(in)

Snap ring thickness Identification color

1.5 (0.059) Blue

1.53 (0.060) White

1.59 (0.063) Yellow

1.62 (0.064) Green

1.68 (0.066) Not colored

NOTE:

Be sure to use snap rings of the same thickness on both sides.

CAUTION:

There are two types of flange yoke and snap rings. There

is no interchangeability between

them, so be sure not to misassemble them.

CENTER BEARING

DISASSEM BLY AND REASSEMBLY

DISASSEM BLY STEPS

1. Lock nut

▲2. Flange

3. Washer

4. Bearing assembly

REASSEMBLY STEPS

▲4. Bearing assembly

3. Washer

▲2. Flange

▲1. Lock nut

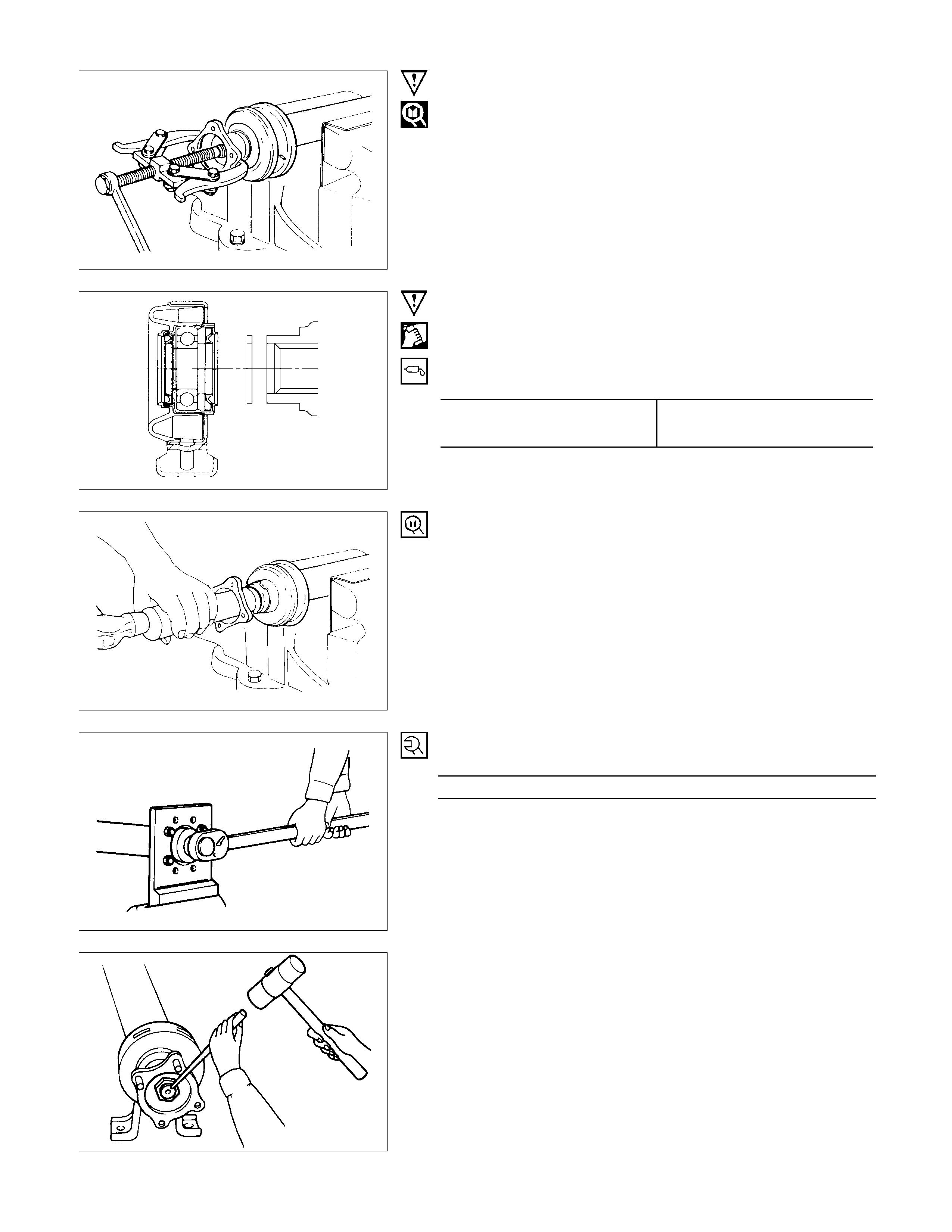

IMPO RTANT OPERATIONS - DISASSEMBLY

2. Flange

Use a suitable remover.

IMPO RTANT OPERATIONS - REASSEMBLY

3. Bearing assembly

Clean the bearing fitting face.

Repack the grease and apply a grease to the both sides of

washer.

Amount of grease

required g(oz) Approx. 12 (0.42)

2. Flange

Installer : 58522-0034-0

(J-6403-C)

1. Lock nut

Lock nut Torque N⋅m (kgf⋅m/lb⋅ft)

117.7 (12/86.8)

(1)Discard the flange nut and install a new one.

(2)Stake the outer f ace of the f lange nut against the slot in the

shaft.

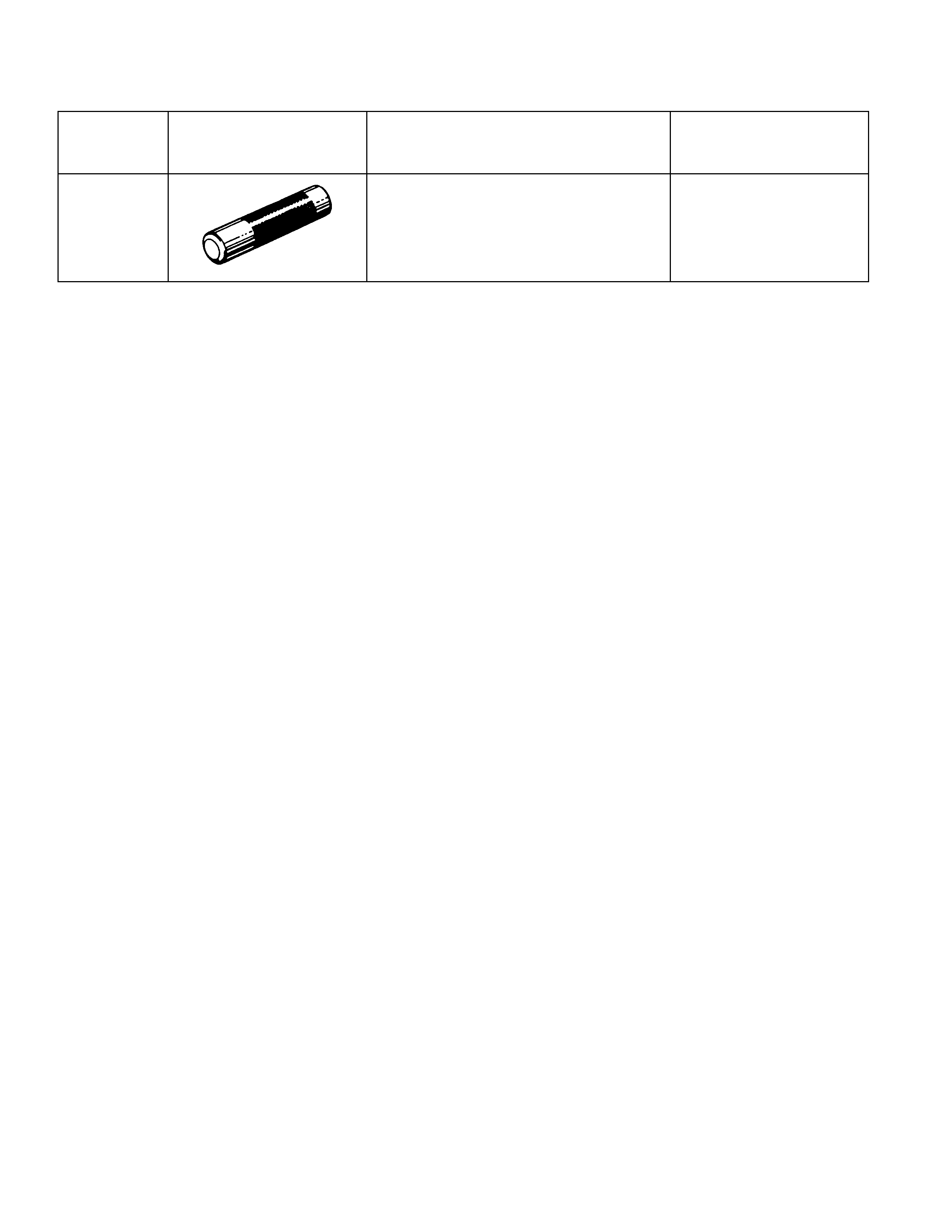

SPECIAL SERVICE TOOL

ITEM NO. ILLUSTRATION PART NO. PART NAME

PSL-1 5-8522-0034-0

(J-6403-C) Pinion flange installer