SECTION 5 - BRAKES

General Description

Main Data and Specifications

Special Parts Fixing Nut and Bolt

Load Sensing Proportioning Valve (LSPV)

Front Brake Assembly

Removal and Installation

Removal and installation of Disc Pad

Disassembly

Inspection and Repair

Reassembly

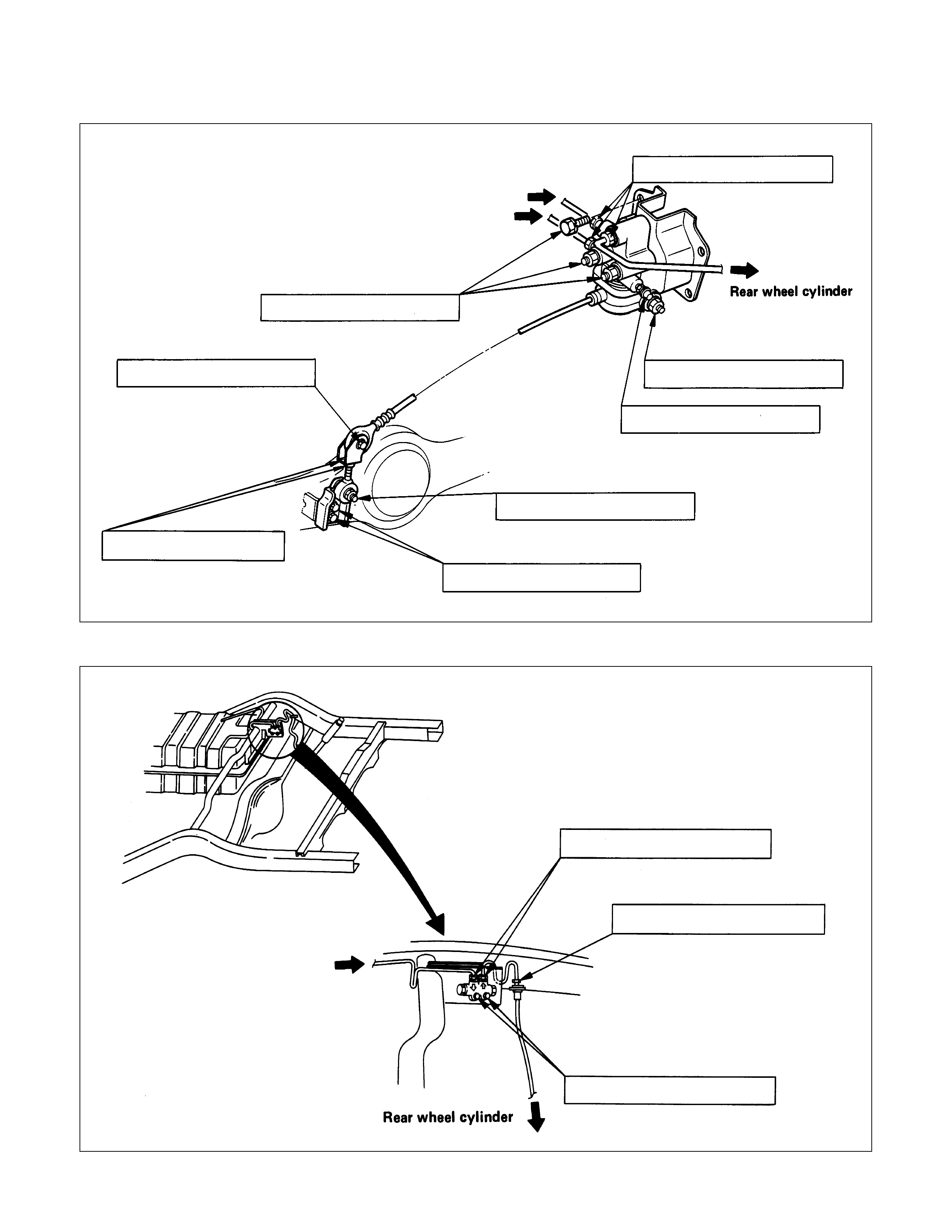

Rear Drum Brake Assembly

Disassembly

Inspection and Repair

Reassembly

Brake Control

Removal and Installation

Master Cylinder

Removal and Installation

Disassembly

Inspection and Repair

Reassembly

Vacuum Servo

Removal and Installation

Parking Brake (Stem Type)

Removal and installation

Disassembly and Reassembly

Inspection and Repair

Parking Brake (Floor Mount Type)

Techline

Techline

Techline

GENERAL DESCRIPTION

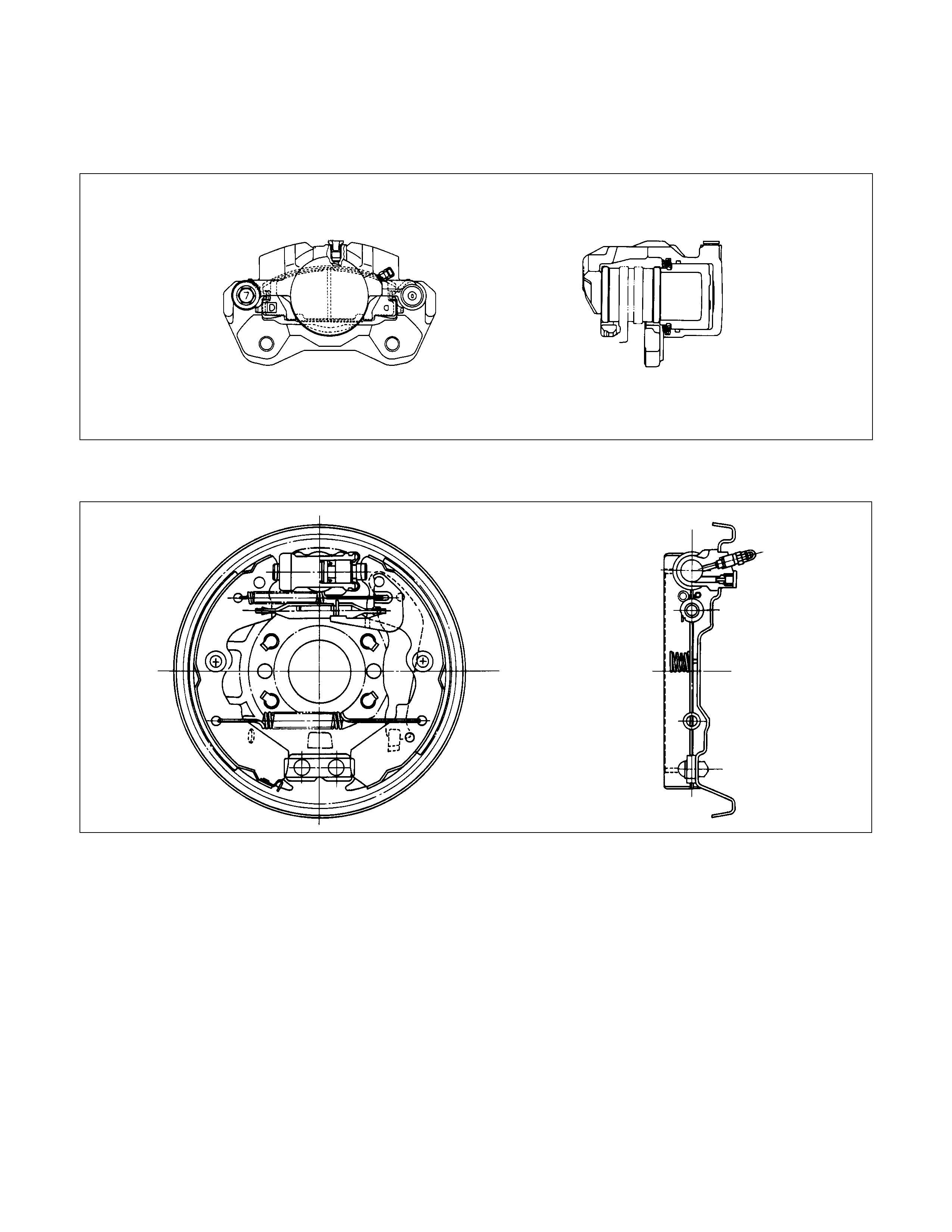

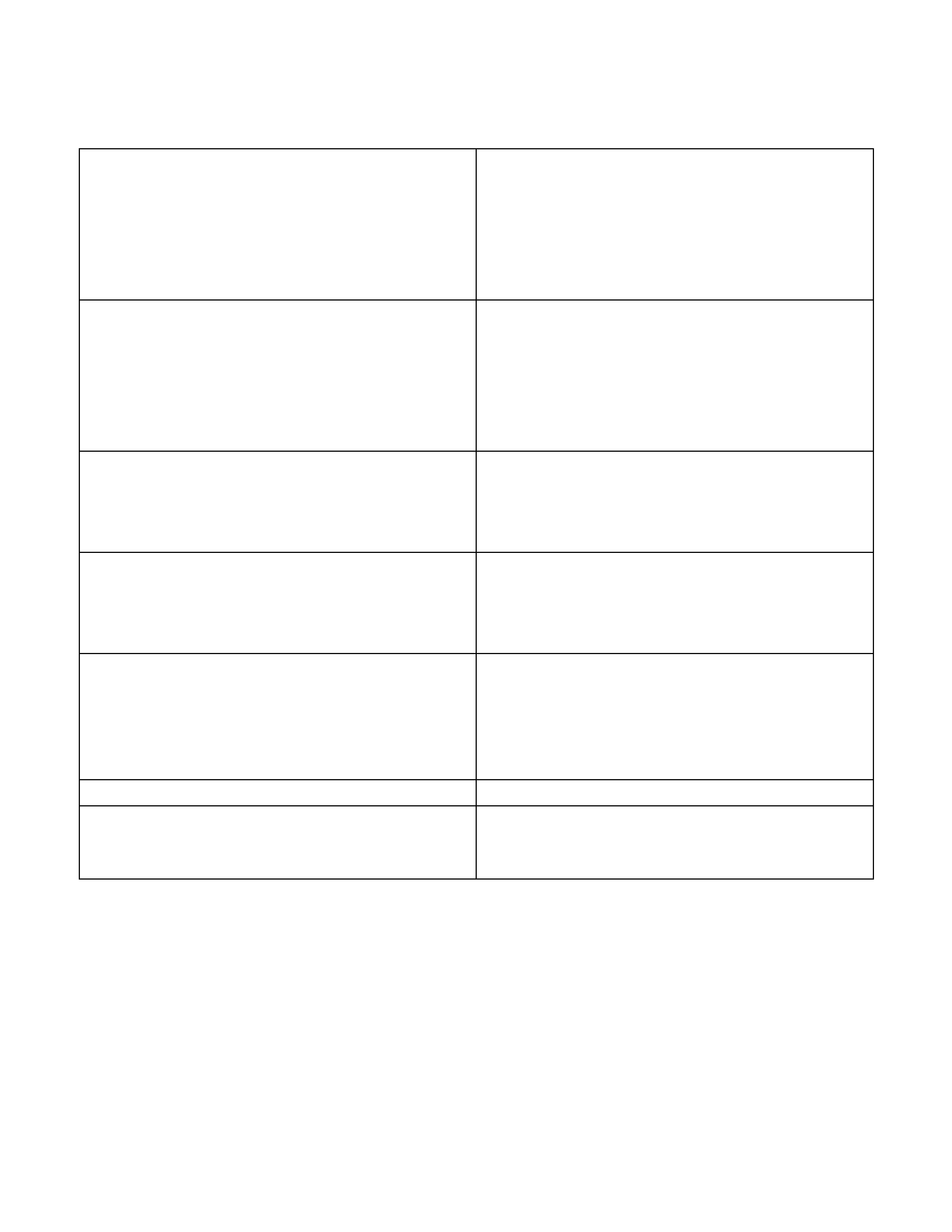

FRONT DISC BRAKE

REAR DRUM BRAKE

REAR WHEEL CYLINDER

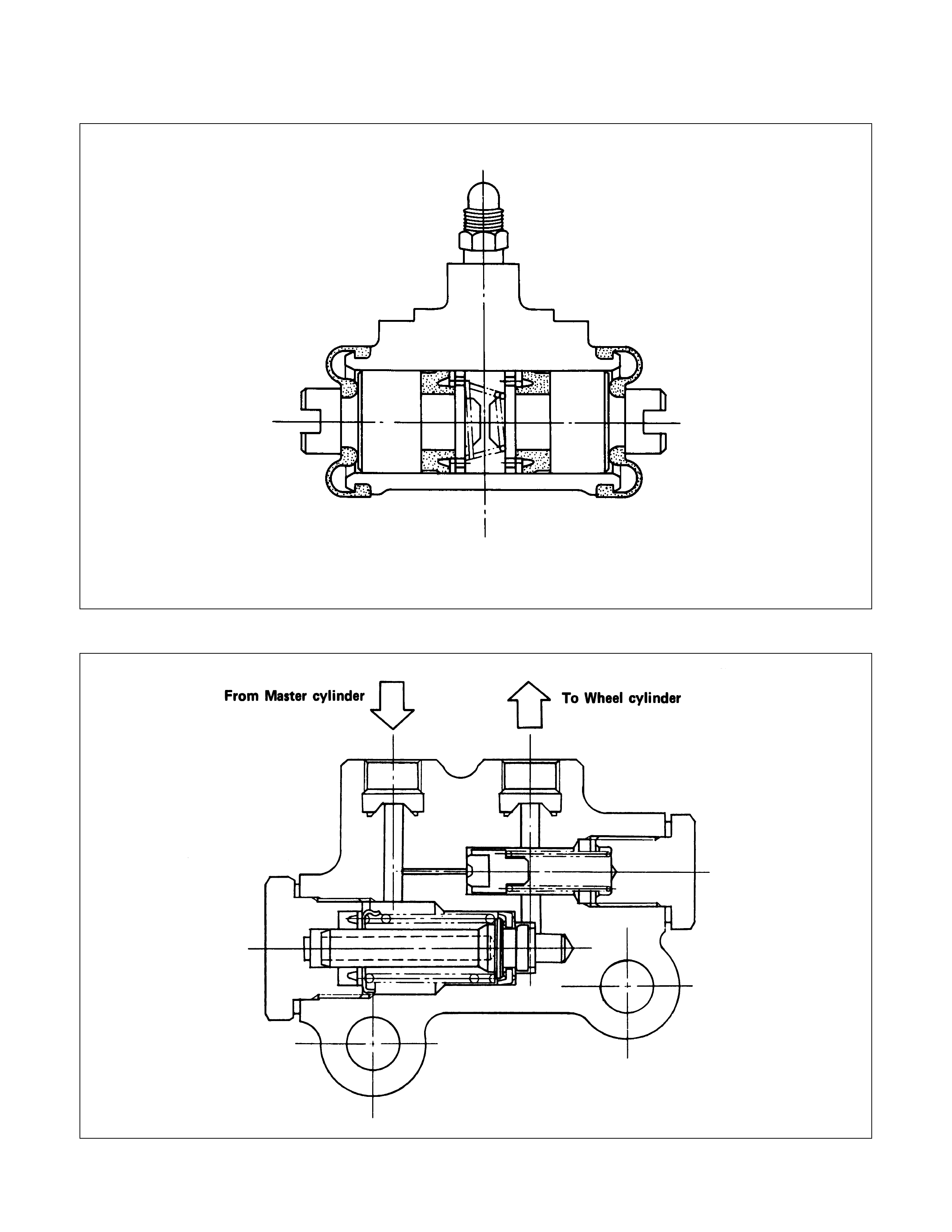

BLEND PROPORTIONING VALVE

LOAD SENSING PROPORTIONING VALVE (LSPV)

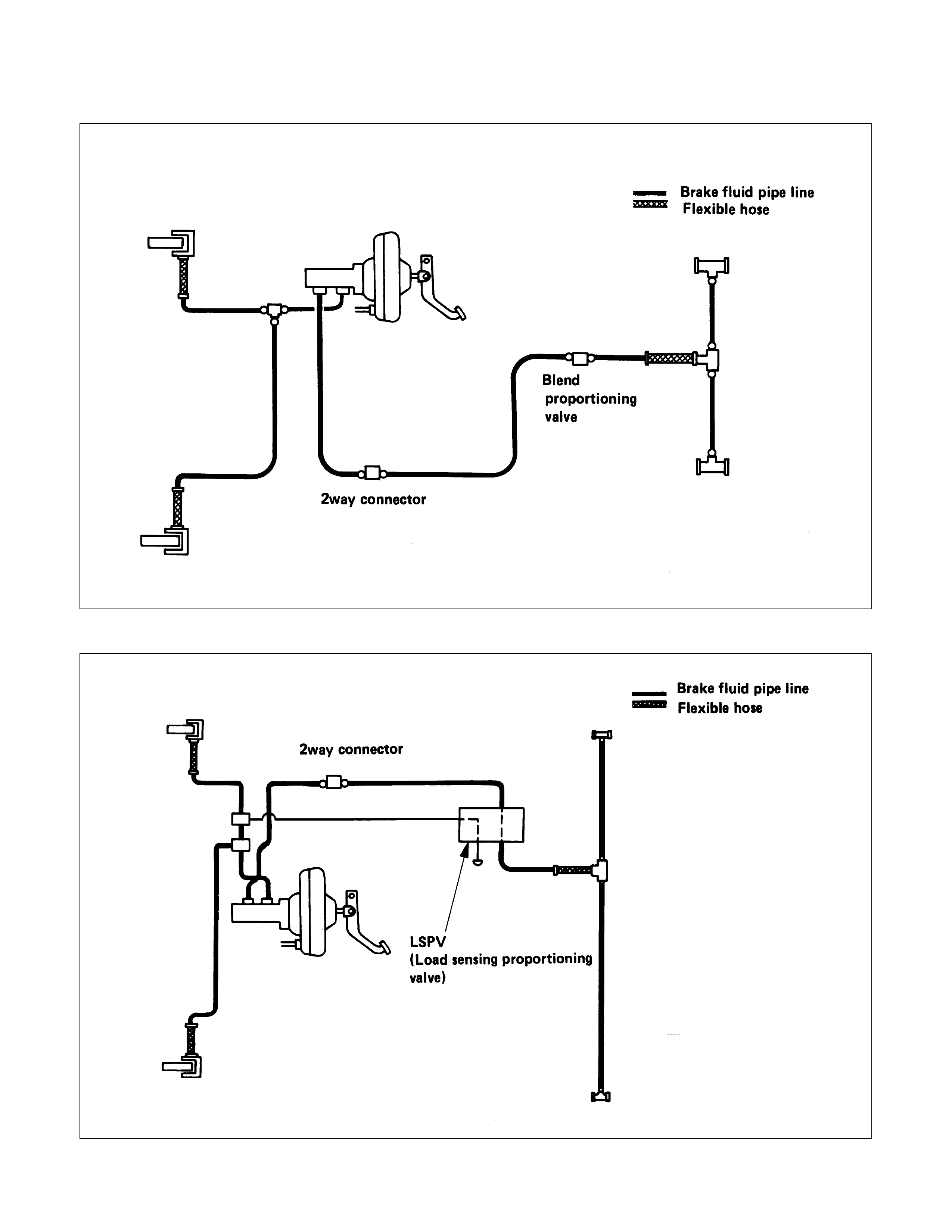

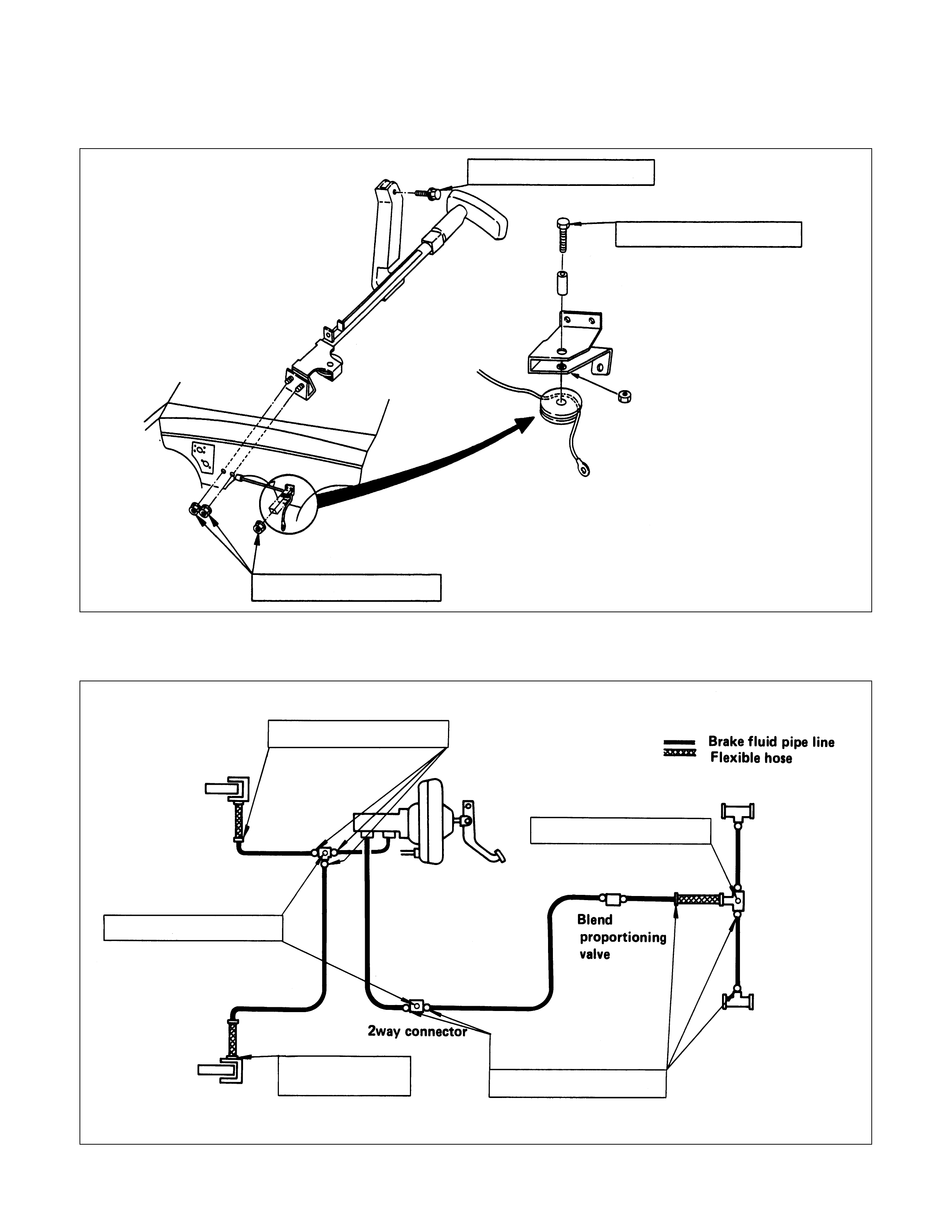

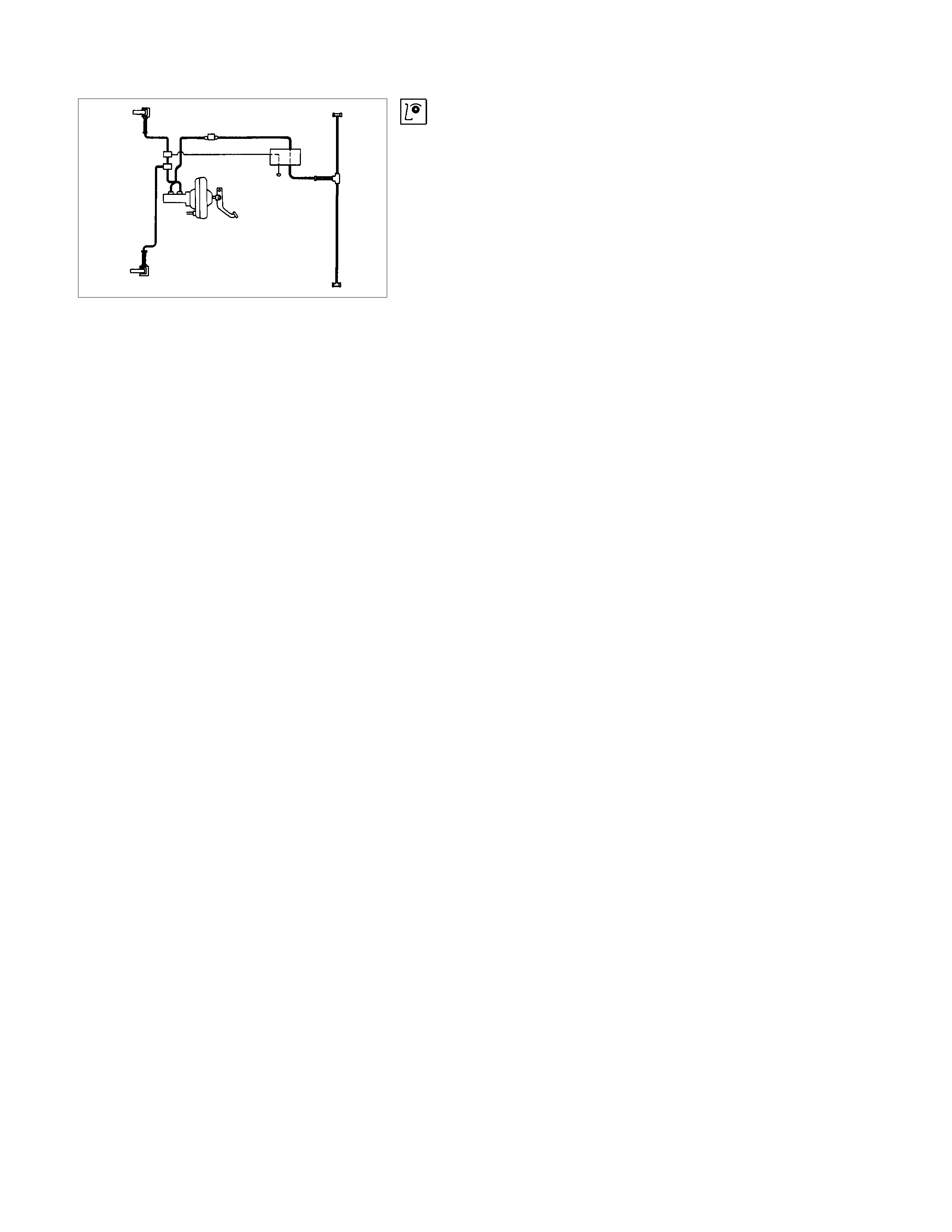

PIPING DIAGRAM (MODEL WITH BLEND PROPORTIONING VALVE)

PIPING DIAGRAM (MODEL WITH LSPV)

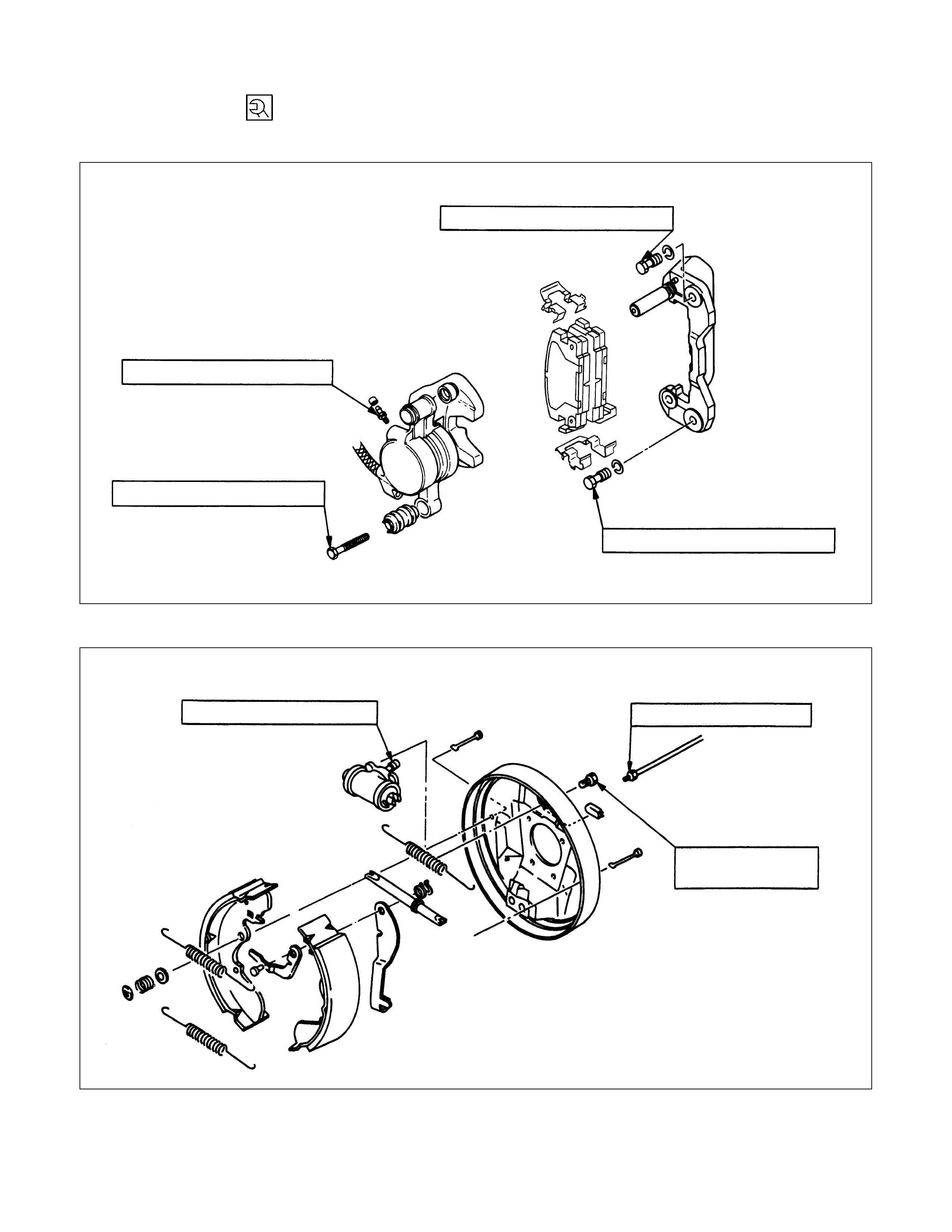

VACUUM SERVO WITH MASTER CYLINDER (Except Australia)

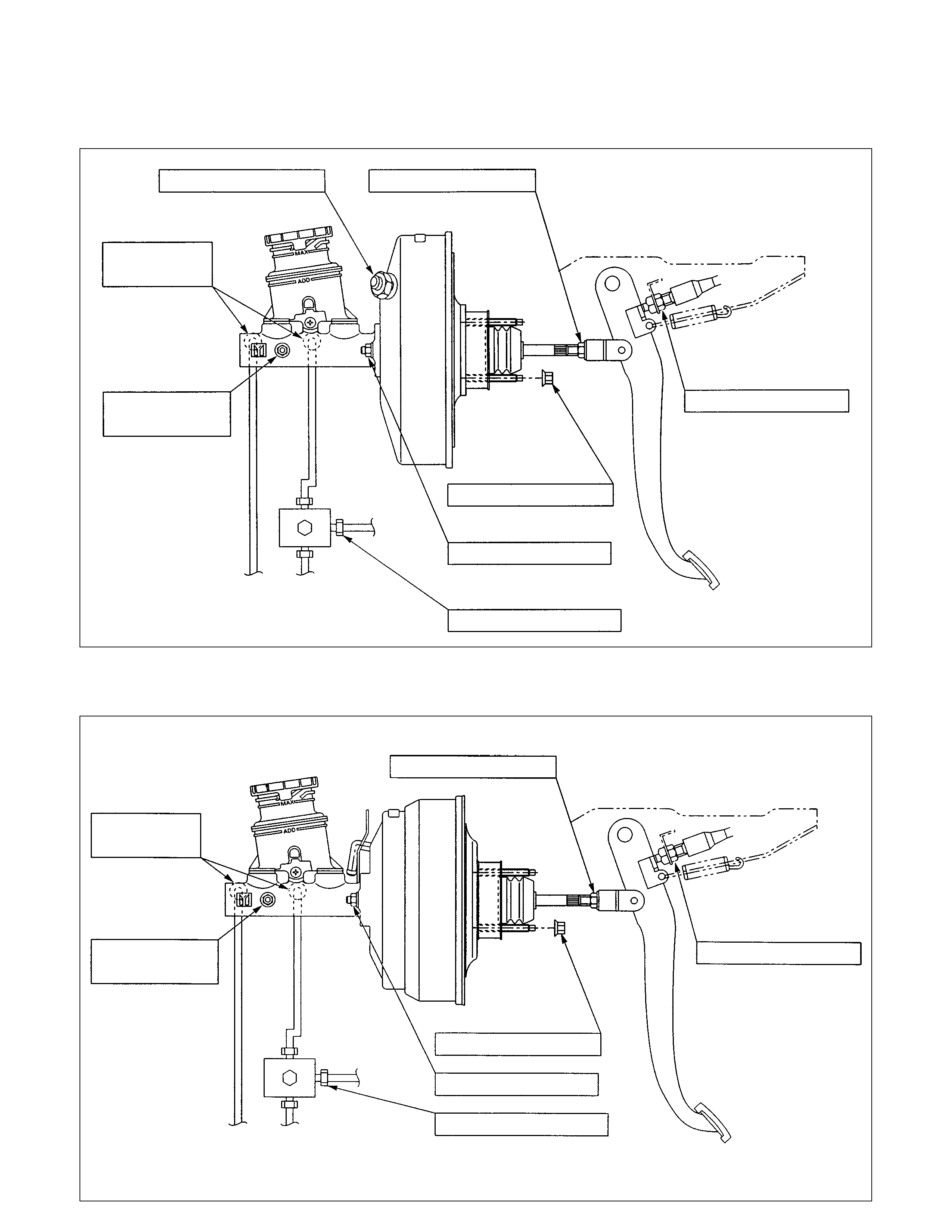

VACUUM SERVO WITH MASTER CYLINDER (For Australia)

MAIN DATA AND SPECIFICATIONS

FRONT DISC BRAKE mm(in.)

Caliper type Pin slide

Disc outside diameter 257 (10.118)

Disc thickness 22 (0.866)

Piston diameter 60.33 (2.375)

Adjustment method Self-adjusting

REAR DRUM BRAKE mm(in.) 4 × 24 × 4

Type Leading and Trailing

Drum inside diameter 254(10.008) 295 (11.614)

Brake lining dimension 221 × 50 × 5 283 × 45 × 4

(Length × Width × Thickness) (8.71 × 1.97 × 0.20) (11.14 × 1.77 × 0.16)

Adjustment method Self-adjusting

WHEEL CYLINDER mm(in.)

Inside diameter : rear

Europe and South Africa 25.40 (1.000)

Others 22.22 (0.875)

MASTER CYLINDER mm(in.)

Type Split

Bore diameter 23.81 (0.938)

Piston stroke (Primary + Secondary) 19 + 12 (0.75 + 0.47)

VACUUM SERVO mm(in.)

Diaphragm diameter

Except Australia 230 (9.055)

For Australia 180 (7.087) + 205 (8.077)

Power cylinder stroke 32.5 (1.281)

PEDAL RATIO 4.04

BALANCE

Type Blend proportioning valve/Load sensing proportioning

valve

SPECIAL PARTS FIXING NUT AND BOLT

FRONT WHEEL BRAKE N⋅m(kgf⋅m/lb⋅ft)

27-37 (2.8-3.8/20-27)

139-171 (14.2-17.4/103-126)

139-171 (14.2-17.4/103-126)

5.9-8.8 (0.6-0.9/4.3-6.5)

REAR WHEEL DRUM BRAKE N⋅m(kgf⋅m/lb⋅ft)

11-15

(1.1-1.5/8-11)

13-19 (1.3-1.9/9-14)

6.9-11.8 (0.7-1.2/5.1-8.7)

VACUUM SERVO WITH MASTER CYLINDER AND BRAKE PEDAL

(Except Australia) N⋅m(kgf⋅m/lb⋅ft)

6.9-8.8

(0.7-0.9 / 5.1-6.5) 15-25 (1.5-2.5 / 11-18)

13-19 (1.3-1.9 / 9.4-14)

9.8-16 (1.0-1.6 / 7-12)

18-24 (1.8-2.4 / 13-17)

15-25 (1.5-2.5 / 11-18)

20-25 (2.0-2.5 / 14-18)

9-15

(0.9-1.5 / 6.5-11)

VACUUM SERVO WITH MASTER CYLINDER AND BRAKE PEDAL

(For Australia only) N⋅m(kgf⋅m/lb⋅ft)

6.9-8.8

(0.7-0.9 / 5.1-6.5)

9-15

(0.9-1.5 / 6.5-11)

13-19 (1.3-1.9 / 9.4-14)

9.8-16 (1.0-1.6 / 7-12)

18-24 (1.8-2.4 / 13-17)

15-25 (1.5-2.5 / 11-18)

15-25 (1.5-2.5 / 11-18)

LOAD SENSING PROPORTIONING VALVE N⋅m(kgf⋅m/lb⋅ft)

Primary Master Cylinder

Secondary Master Cylinder

19-30 (1.9-3.1/14-22)

14-24 (1.4-2.4/10-17)

10-16 (1.0-1.6/7-12)

7-10 (0.7-1.0/5-7)

15-22 (1.5-2.2/11-16)

13-19 (1.3-1.9/9.4-14)

15-22 (1.5-2.2/11-16)

14-24 (1.4-2.4/10-17)

BLEND PROPORTIONING VALVE N⋅m(kgf⋅m/lb⋅ft)

14-24 (1.4-2.4/10-17)

13-19 (1.3-1.9/9.4-14)

13-19 (1.3-1.9/9.4-14)

Secondary master cylinder

BRAKE PEDAL ASSEMBLY N⋅m(kgf⋅m/lb⋅ft)

This illustration is besed on the LHD model

11-20 (1.1-2.0/8-14

29-39 (3.0-4.0/22-29)

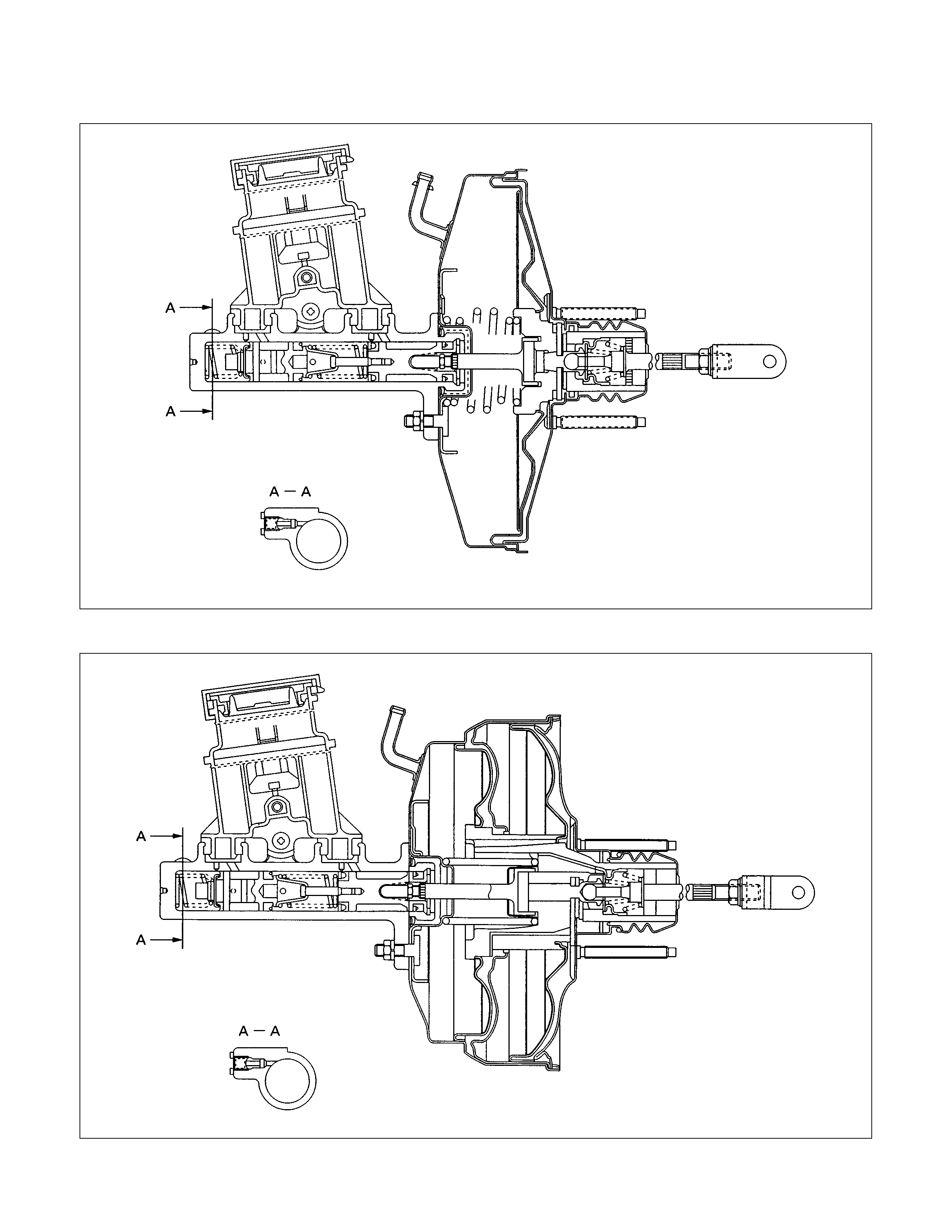

PARKING BRAKE STEM ASSEMBLY

(STEM TYPE, LEFT HAND DRIVE MODEL) N⋅m(kgf⋅m/lb⋅ft)

21-34 (2.1-3.5/15-25)

11-20 (1.1-2.0/8-14) 14-25 (1.4-2.5/10-18)

PARKING BRAKE STEM ASSEMBLY

(STEM TYPE, RIGHT HAND DRIVE MODEL) N⋅m(kgf⋅m/lb⋅ft)

18-24 (1.8-2.4/13-17)

11-20 (1.1-2.0/8-14)

14-25 (1.4-2.5/10-18)

BRAKE LINES (HOSES AND PIPES)

(MODEL WITH BLEND PROPORTIONING VALVE) N⋅m(kgf⋅m/lb⋅ft)

29-39

(3.0-4.0/22-29) 13-19 (1.3-1.9/9.4-14)

11-20 (1.1-2.2/8-14)

7.8-18 (0.8-1.8/5.8-13)

13-19 (1.3-1.9/9.4-14)

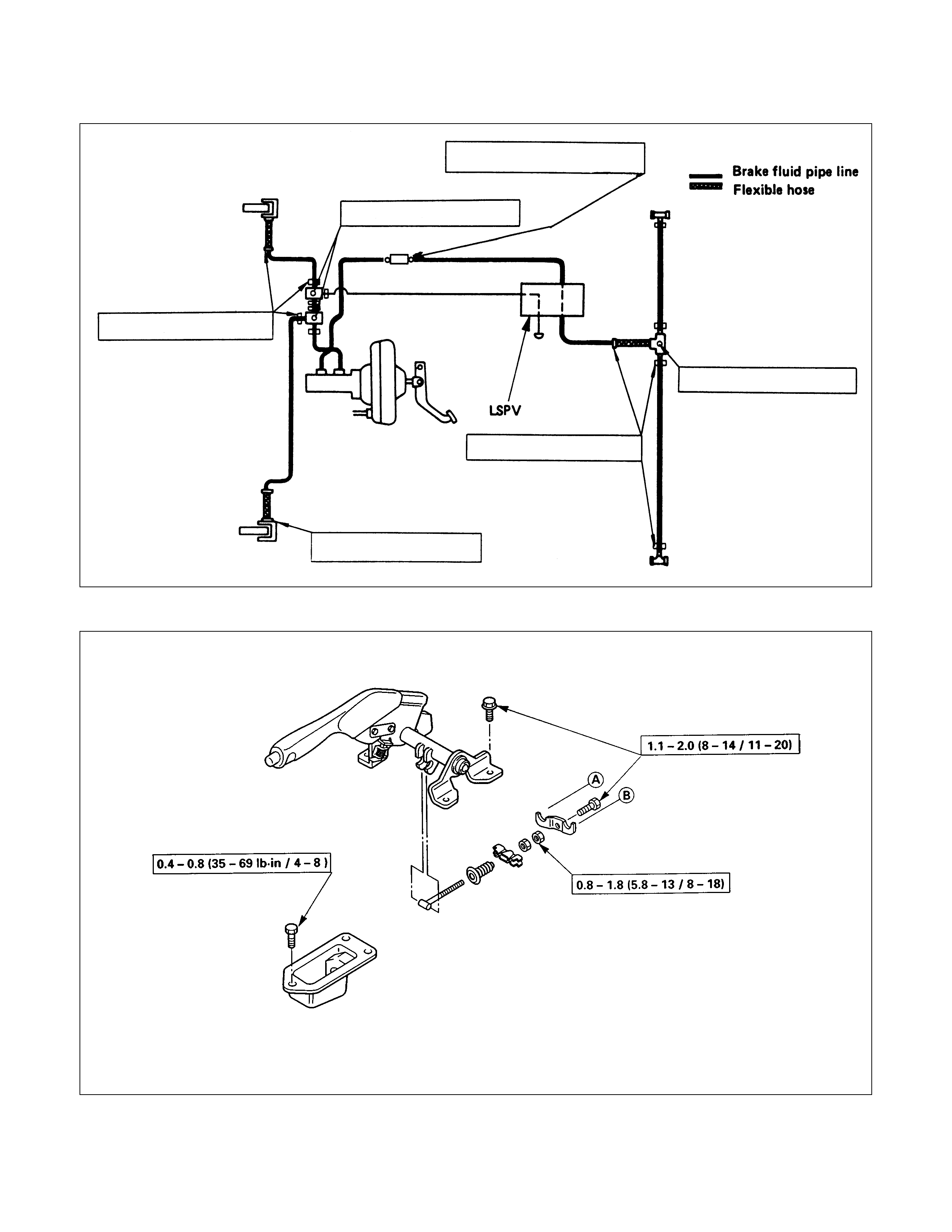

BRAKE LINES (HOSES AND PIPES) (MODEL WITH LSPV) N⋅m(kgf⋅m/lb⋅ft)

29-39 (3.0-4.0/22-29)

13-19 (1.3-1.9/9.4-14)

11-20 (1.1-2.0/8-14)

13-19 (1.3-1.9/9.4-14)

7.8-18 (0.8-1.8/5.8-13)

13-19 (1.3-1.9/9.4-14)

PARKING BRAKE LEVER ASSEMBLY (FLOOR MOUNT TYPE) N⋅m(kgf⋅m/lb⋅ft)

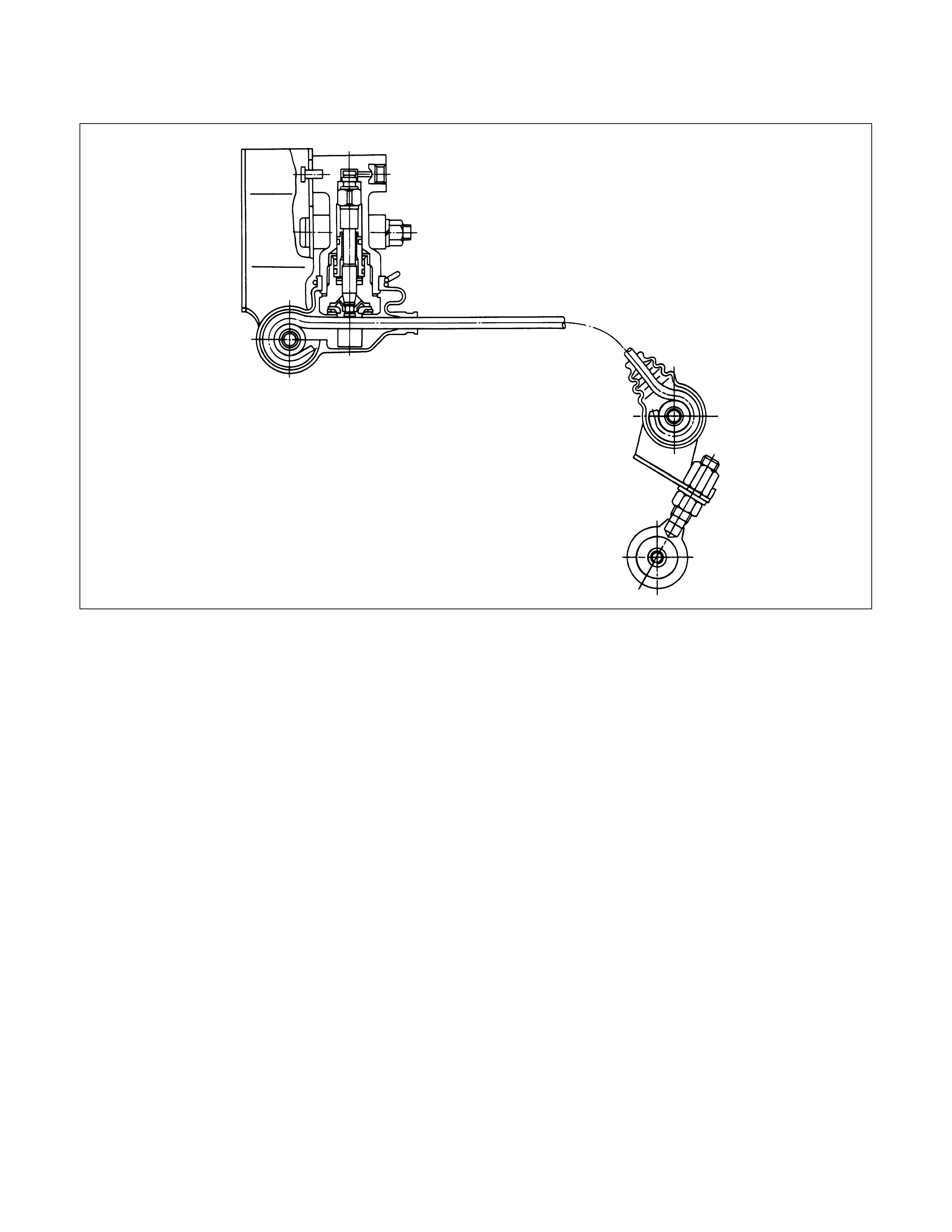

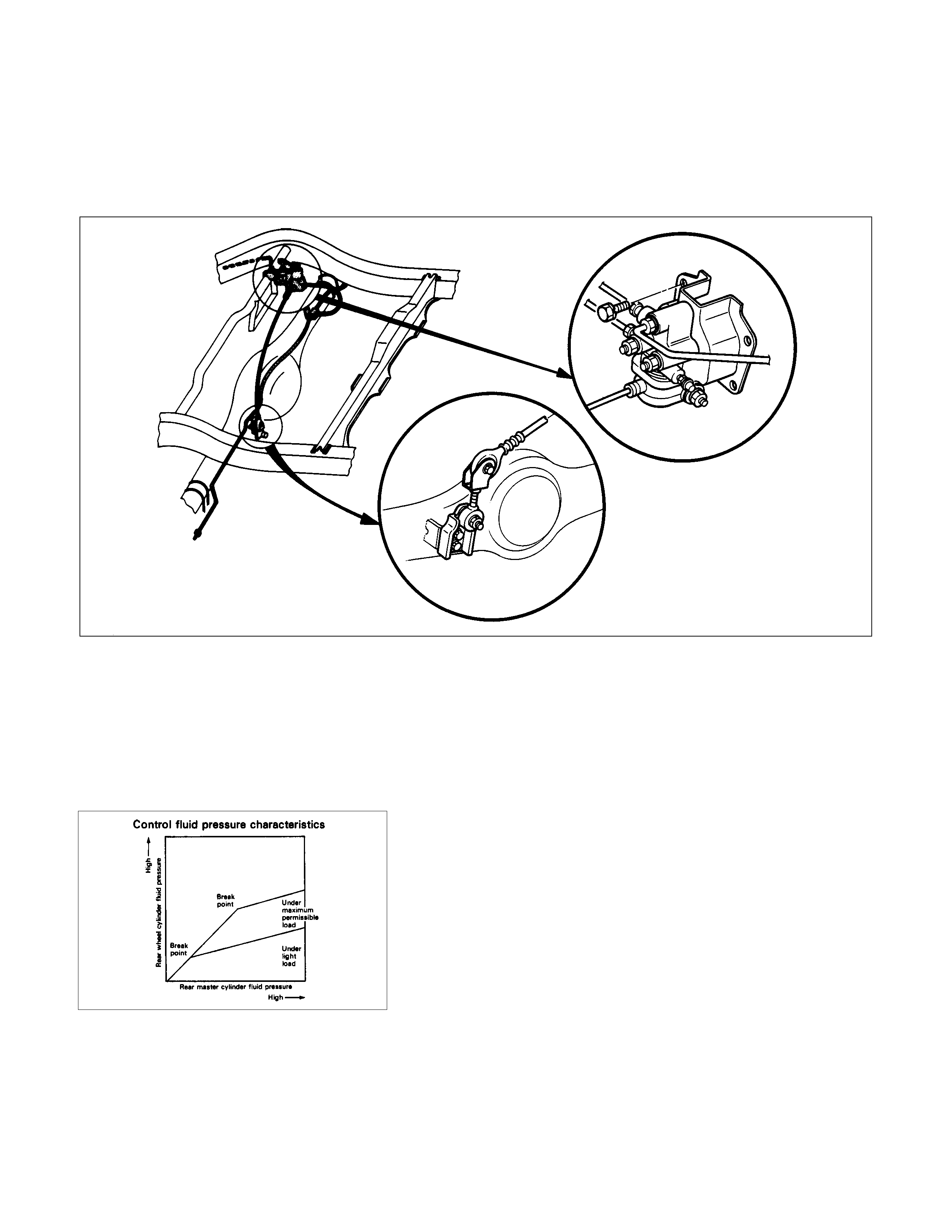

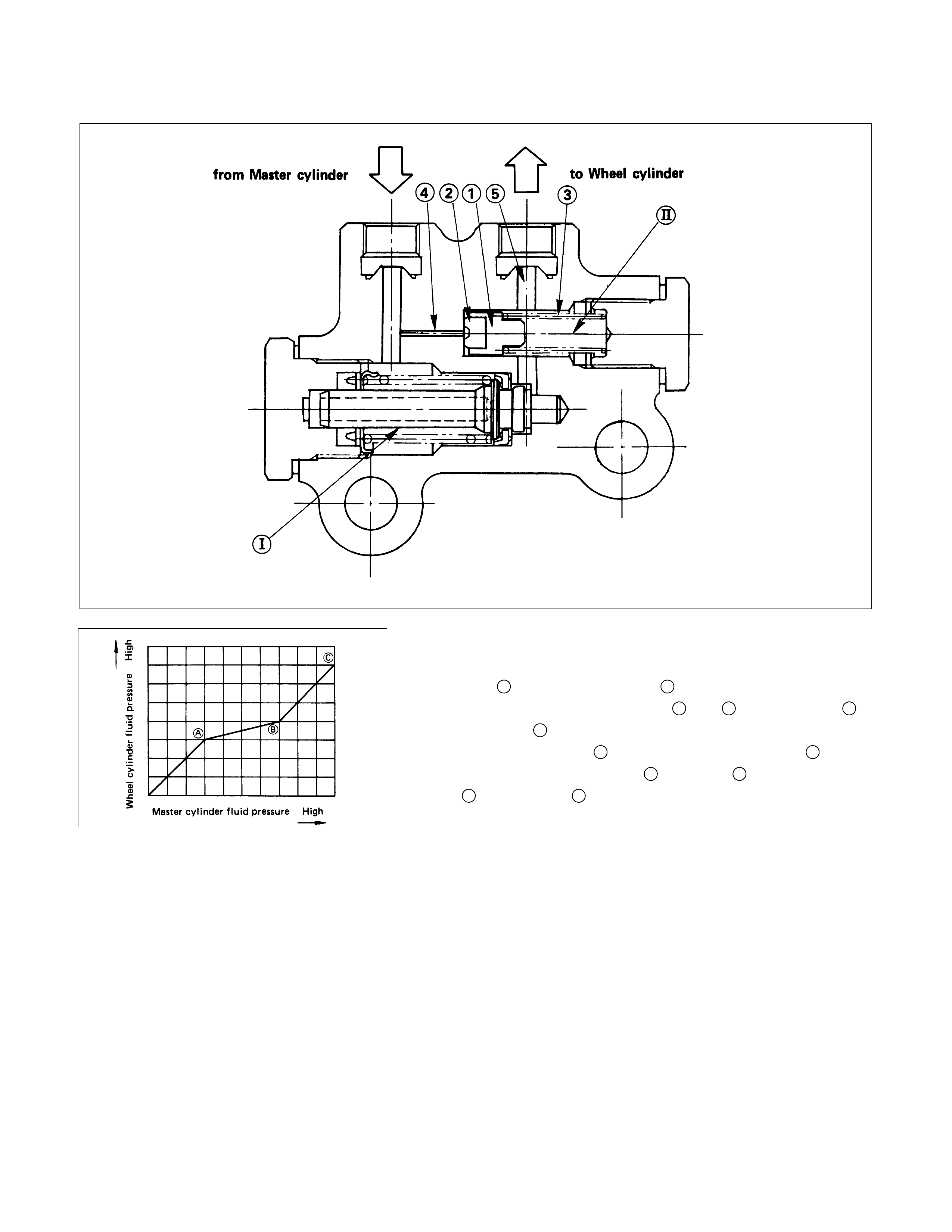

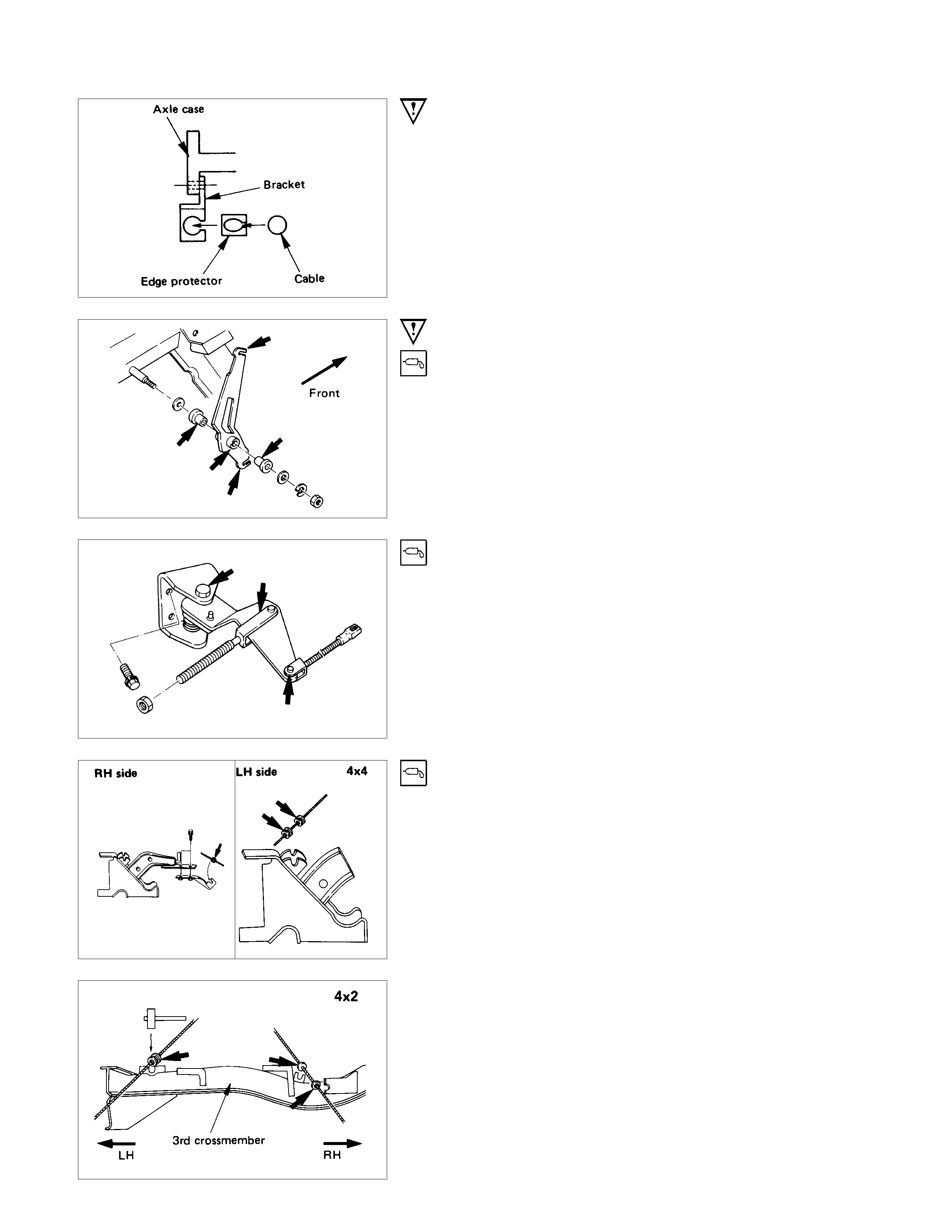

LOAD SENSING PROPORTIONING VALVE (LSPV)

Location of LSPV

Structure and Operation

The following is an explanation of the structure and operation

of the linkage type load sensing device.

This device controls the fluid pressure to the rear brakes in

accordance with changes in rear axle load (vertical

displacements of the rear axle springs).

•Structure

This device consists of a load sensing spring (bending bar)

and a valve.

The valve is mounted through a bracket to the frame.

One end of the load sensing spring is fixed to the valve at

the frame and the other end to the rear axle housing

through a shackle.

From

primary

master cy linder

From

Secondary

master cy linder

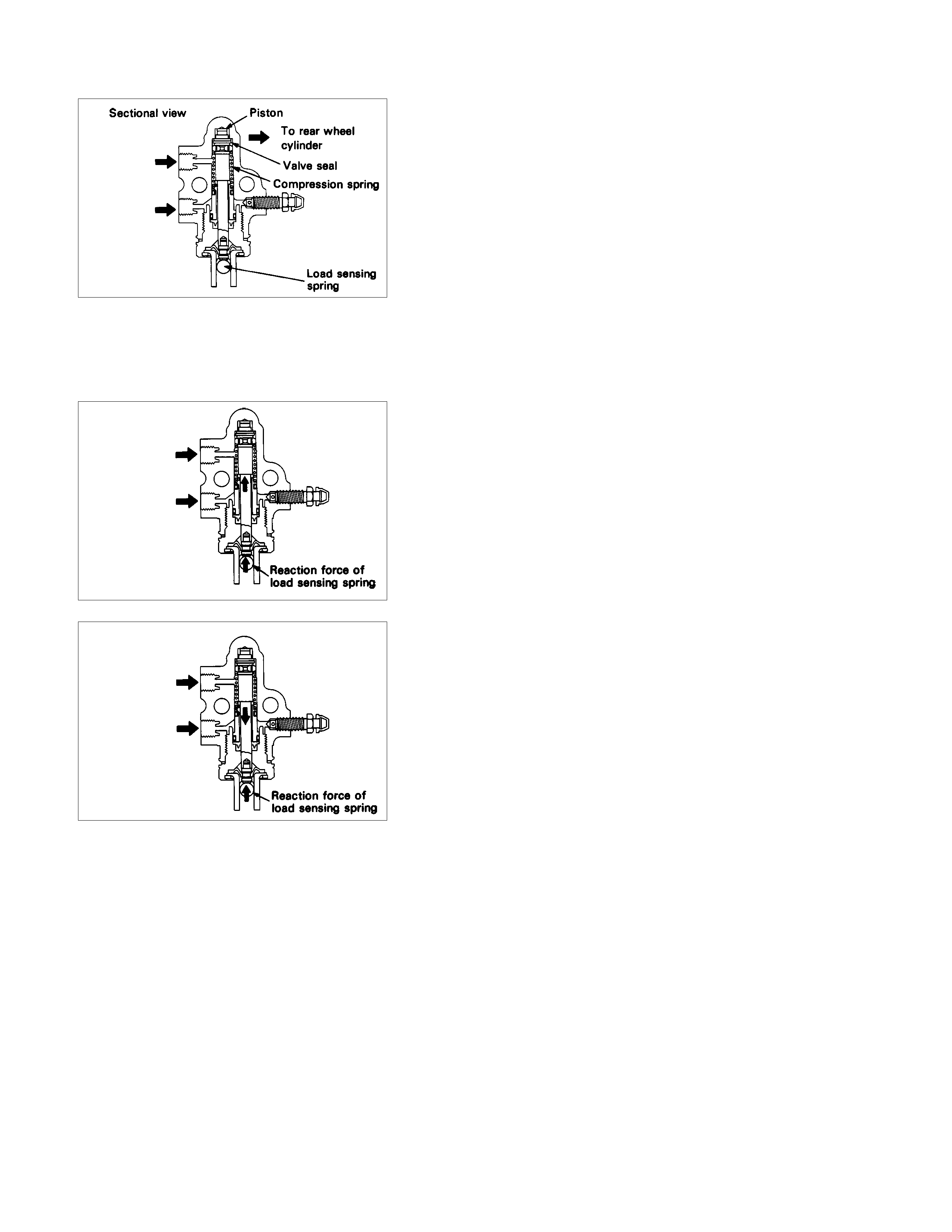

•Operation

1) Outline

When the L.S.P.V.(Load Sensing Proportioning Valve)

detects a change in load weight, the load sensing spring

deflects.

Its reaction force is transmitted to the bottom of the load

sensing valve to secure an optimum rear wheel cylinder

fluid pressure break point in proportion to the actual load

weight.

Besides, if the front brake system should fail, the device is

designed to prevent the master cylinder fluid pressure from

decreasing and to apply it directly to the rear wheel cylinder

to obtain a sufficient braking performance.

Primary master

cy linder fluid

pressure

Secondary master

cy linder fluid

pressure

2) Operation

(1)When the fluid pressure is under the break point.

The fluid pressure of the rear master cylinder passes

through a clearance between the valve seal and the piston

and acts on the rear wheel cylinder.

At this moment, a downward force is applied to the piston.

However, the compression spring force and reaction force

of the load sensing spring keep the piston in the upper

position by pushing upwards. (See the left figure.)

Primary master

cy linder fluid

pressure

Secondary master

cy linder fluid

pressure

(2)When the fluid pressure is equal to the break point.

As the rear wheel cylinder pressure increases, it surpasses

the compression spring force and reaction force of the load

sensing spring, causing the piston to move downwards, so

that the piston butts against the valve seal to shut off the

fluid line between the master cylinder and rear wheel

cylinder. (See the left figure.)

(3)When the fluid pressure is over the break point.

When the fluid press ur e incr eas es further, the piston moves

upwards.

The moment the piston comes apart from the valve seal,

fluid pressure is applied to the rear wheel cylinder and the

piston moves downwards so that the fluid line is shut off

again.

This process goes on repeatedly to control the fluid

pressure to the rear wheel cylinder.

Secondary master

cy linder fluid

pressure

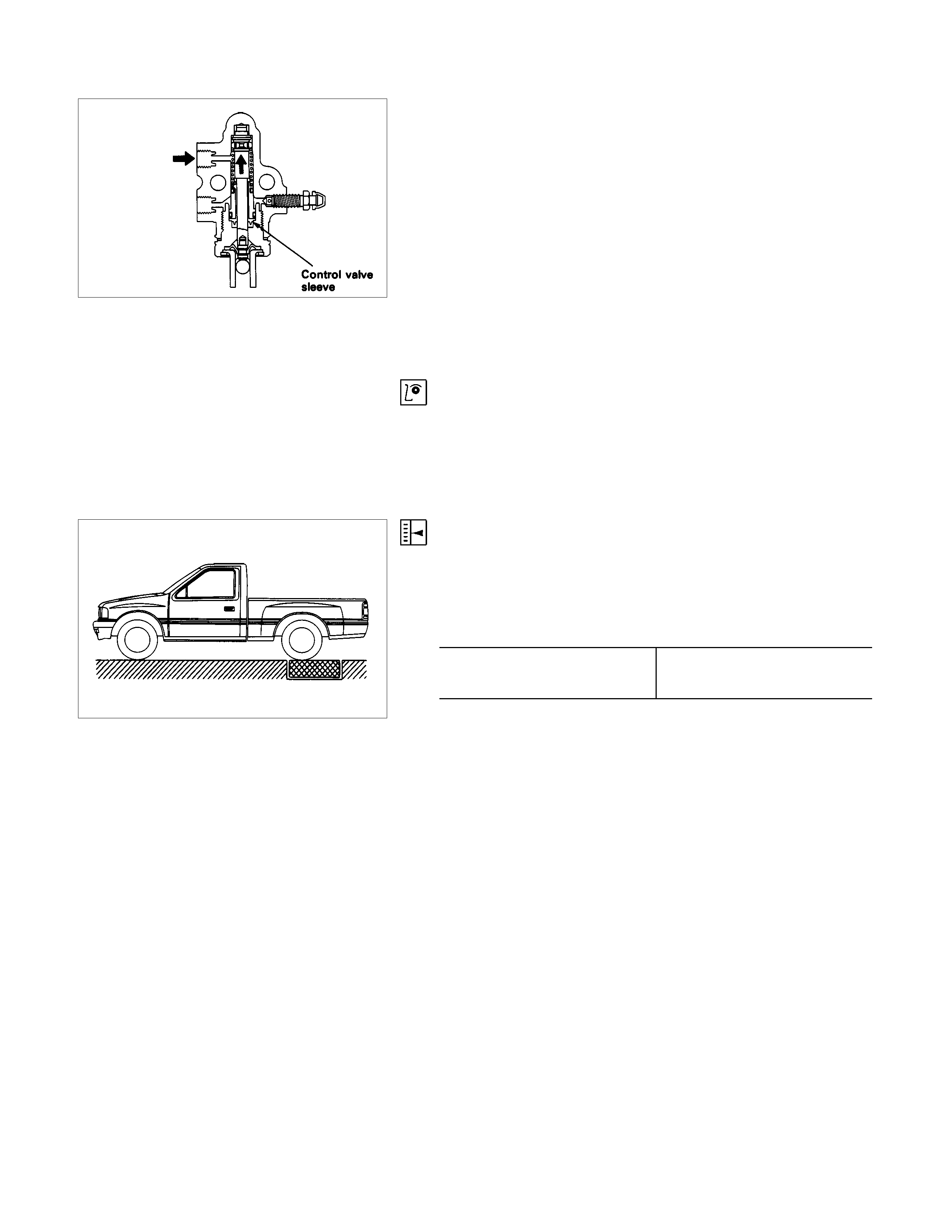

(4)When the front brake system fails.

When there is a failure in the front brake system, the fluid

pressure from the front master cylinder decreases.

As a result, the balance between the front and rear brake

side fluid pressures are lost at the control valve sleeve so

that the control valve sleeve moves upwards.

The control valve sleeve strikes against the piston, thereby

pushing the piston upwards.

Accordingly, the fluid pressure of the rear mater cylinder is

not decreased and is applied directly to the rear wheel

cylinder to secure a sufficient braking performance of the

rear brakes. (See the left figure.)

Valve Maintenance

In the case of fluid lead or other a abnormalities, faulty valve

should be replaced.

Note:

The load sensing proportioning valve is not repairable and

must be replaced as a completed assembly.

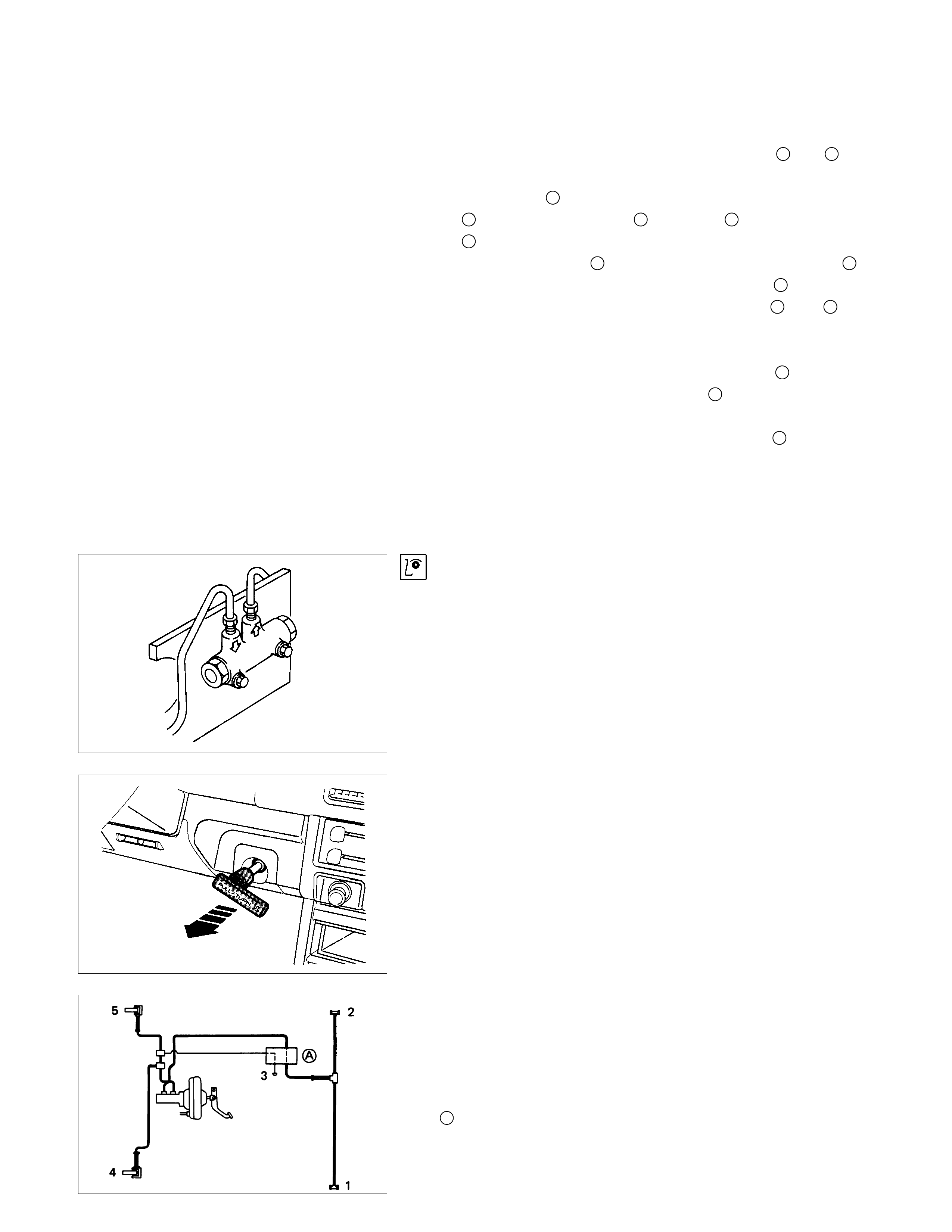

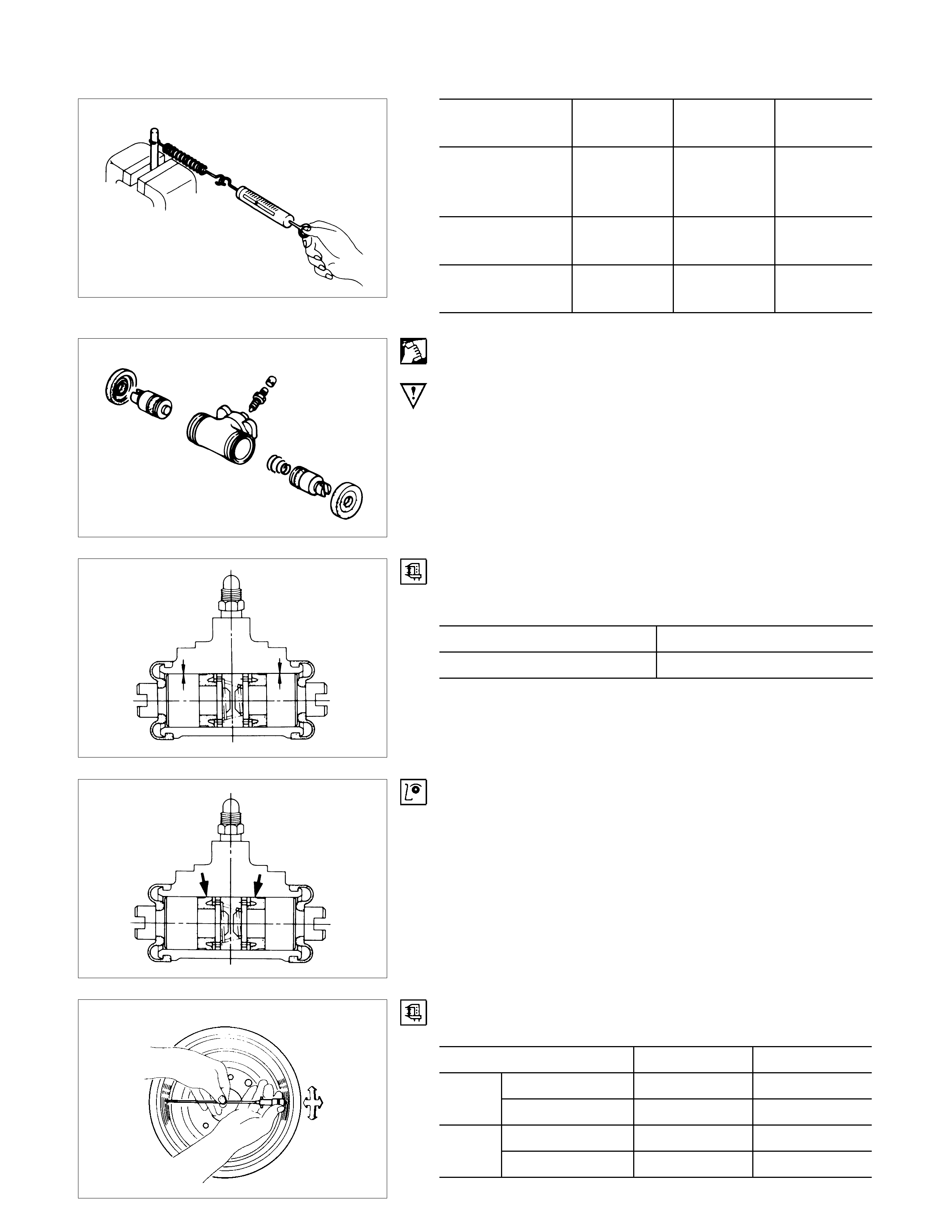

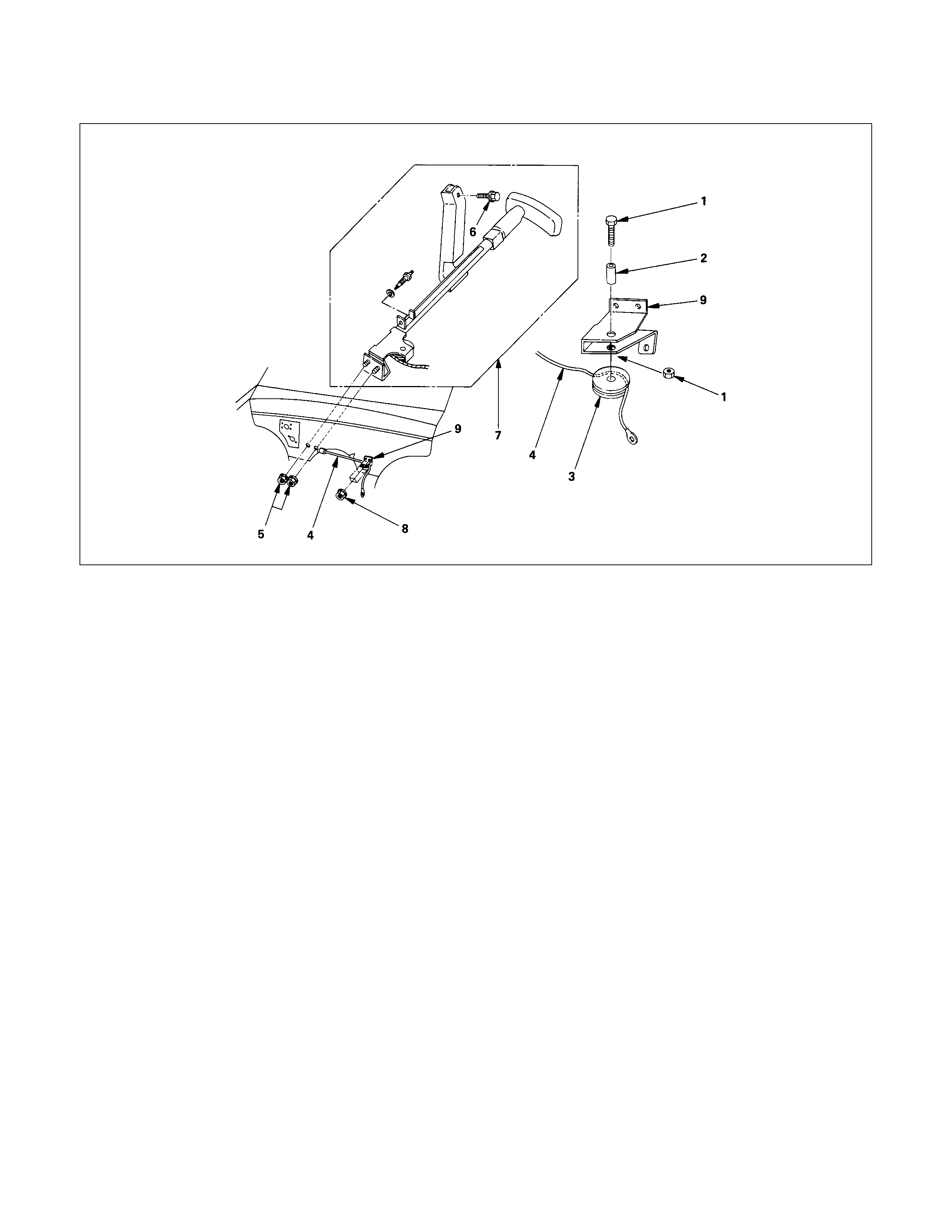

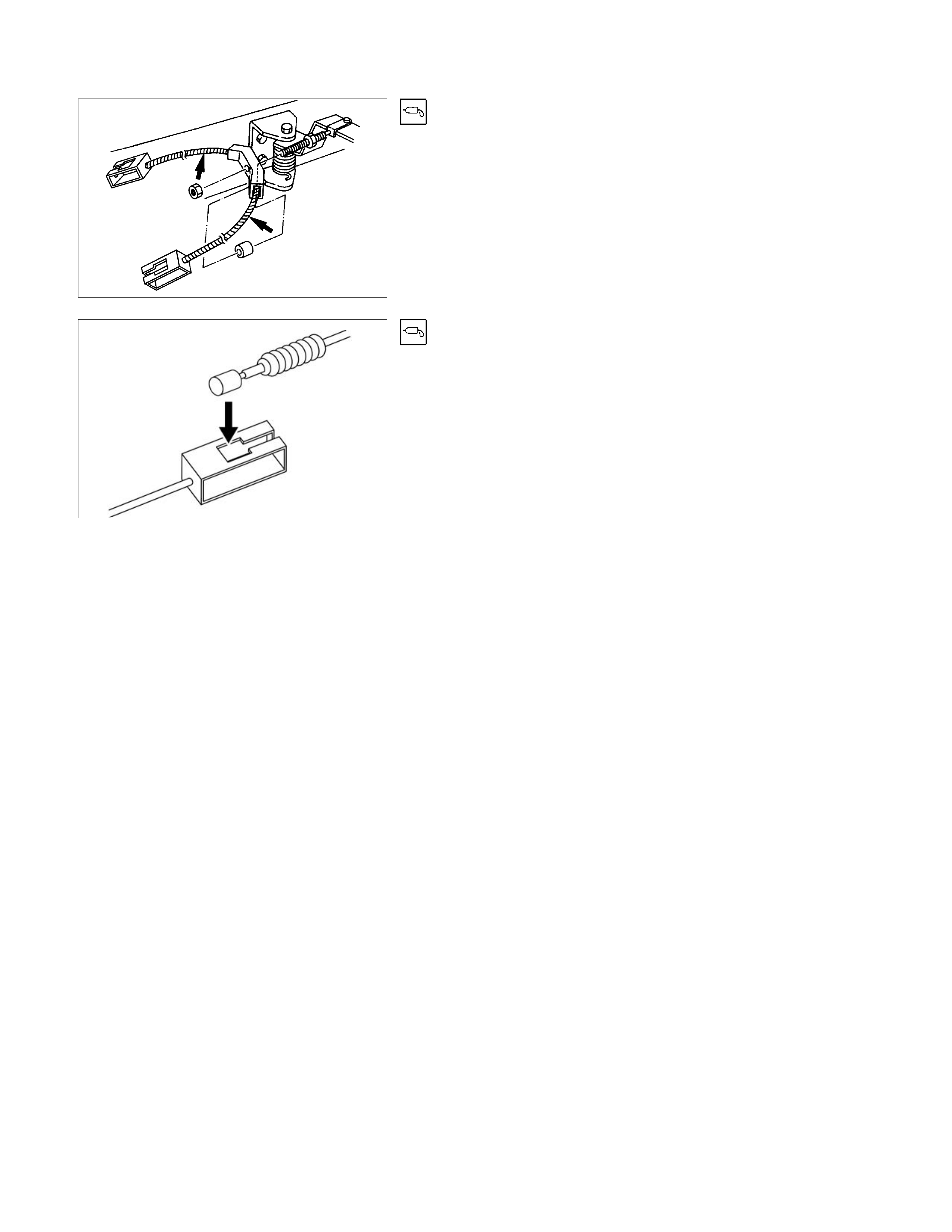

ADJUSTMENT PROCEDURE OF LSPV

This adjustment should be performed with the battery voltage

applied to the valve.

1. Adjust the rear axle weight by loading the rear body as

necessary.

Rear axle weight kg (lbs)

TFR 750(1.654)

TFS 900(1.985)

Note:

The rear axle weight should be adjusted to the specified

value with a man seated in the driver seat.

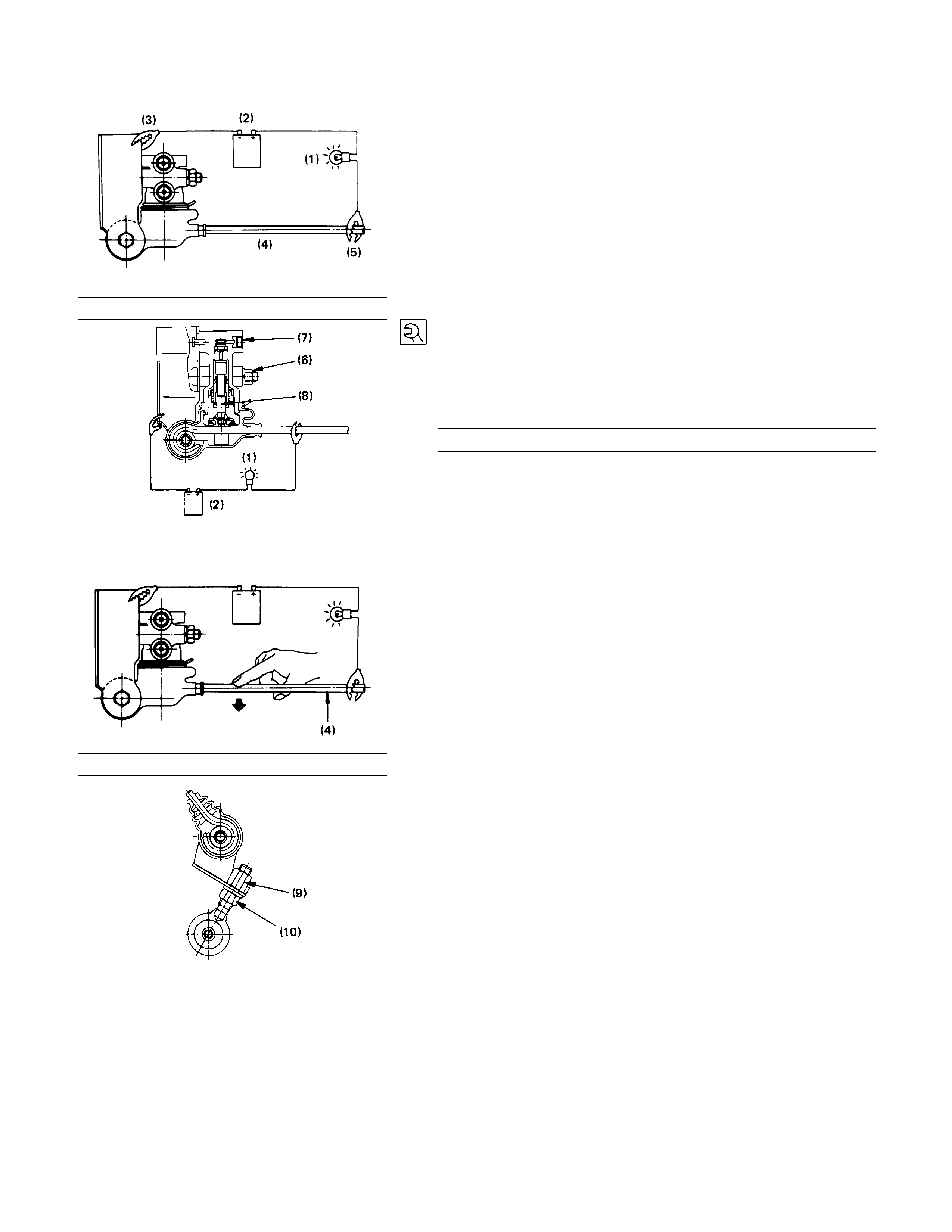

2. Connect the wiring with miniature lam p (1) and a battery (2)

between valve bracket (3) and linkage (4) with each end of

wiring clipped.

This wiring is necessary to find the mom ent at which piston

within the valve assembly is brought into connect with the

linkage.

Note:

As the linkage is coated with insulation material, turn the

clip (5) with 2 or 3 turns to break insulation.

3. Loosen the nut (6) and raise the valve assembly (7) all the

way.

Then lower the valve as se mbly gradually and tighten the nut

(6) when miniature lamp (1) turns on.

Torque N⋅m(kgf⋅m/lb⋅ft)

17(1.7/12)

Note:

If the miniature lamp (1) goes out as the nut (6) is

tightened, lower the valve assembly (7) slightly with the

nut loosened, then retighten the nut(6).

4. Depress the linkage (4) near the valve assembly slightly

downward with finger (test pressue:0.5-0.8kg) and check to

see if the miniature lamp (1) goes out.

Lamp goes out : OK Adjustment is completed.

Lamp remains on : NG Repeat adjustment operation

outline under paragraph 3.

Excessive force is exerted on

linkage by piston (8) within the

valve assembly.

Note:

Adjustment can also be made by means of nuts (9) and

(10) on shackle at rear axle case side.

However, shackle nut is not normally used for adjustment

as it is for making fine adjustment.

5. Inspection of brake fluid pressure (Reference value)

1) Adjust the rear axle weight as specified under the

paragraph 1.

2) Install the pressure gauge on bleeder screws on the

front and rear brakes.

3) Depress the brake pedal and take reading of the

pressure gauges.

The brake f luid pr es sur e is nor mal if the pr ess ur e of fluid

within the rear wheel cylinders is within the range of 34.4

±5.5 kg/c m2 when press ure of fluid within the front wheel

cylinders reaches 50 kg/cm2.

Note:

The brake pedal should be depressed gradually until

specified pressure is reached without pumping or

adjusting foot pressure.

BLEND PROPORTIONING VALVE (IF SO EQUIPPED)

Structure and Operation

•Structure

Side I shows P-valve ; side II shows bypass valve.

Bypass valve s eals the routes 4 and 5 using the seal 2 at

the piston 1 end.

In addition, spring 3 presses against the piston 1, and in

order to seal out the route 4 and route 5 sufficiently, spring

3 presses seal 2 against cylinder end surface.

The left figure is a characteristic curve diagram.

•Operation

The operation of the P-valve by the master cylinder

pressure is unchanged up to the brake points A and B.

If master cylinder fluid pressure penetrates into the second

break point B, the fluid pressure pressing against the seal

2, (which isolated route 4 and route 5), passing the route

4 of the master cylinder side, overcomes the operating

force of the spring 3 + fluid pressur e af fecting the s eal 2 of

the wheel cylinder, and presses the piston 1 to the right

side, resulting in the opening of the routes 4 and 5, and

canceling of the P-valve operation.

Then, because the master cylinder fluid pressure and the

wheel cylinder fluid pressure, up to the point C, operate on

the identical surface of the seal 2, both have identical

ascending ratio.

However, because of the operation of s pring 3 in the wheel

cylinder side, wheel cylinder fluid pressure operate to

preserve the balance against the master cylinder fluid

pressure on the lower level with the difference in pressure

resulting from this spring.

Valve Maintenance

In the case of fluid leak or other abnormalities, faulty valve

should be replaced.

The valve is set up at the right hand side of the 5th

crossmember near the rear axle.

Note:

The blend proportioning valve is not repairable and must

be replaced as a complete assembly.

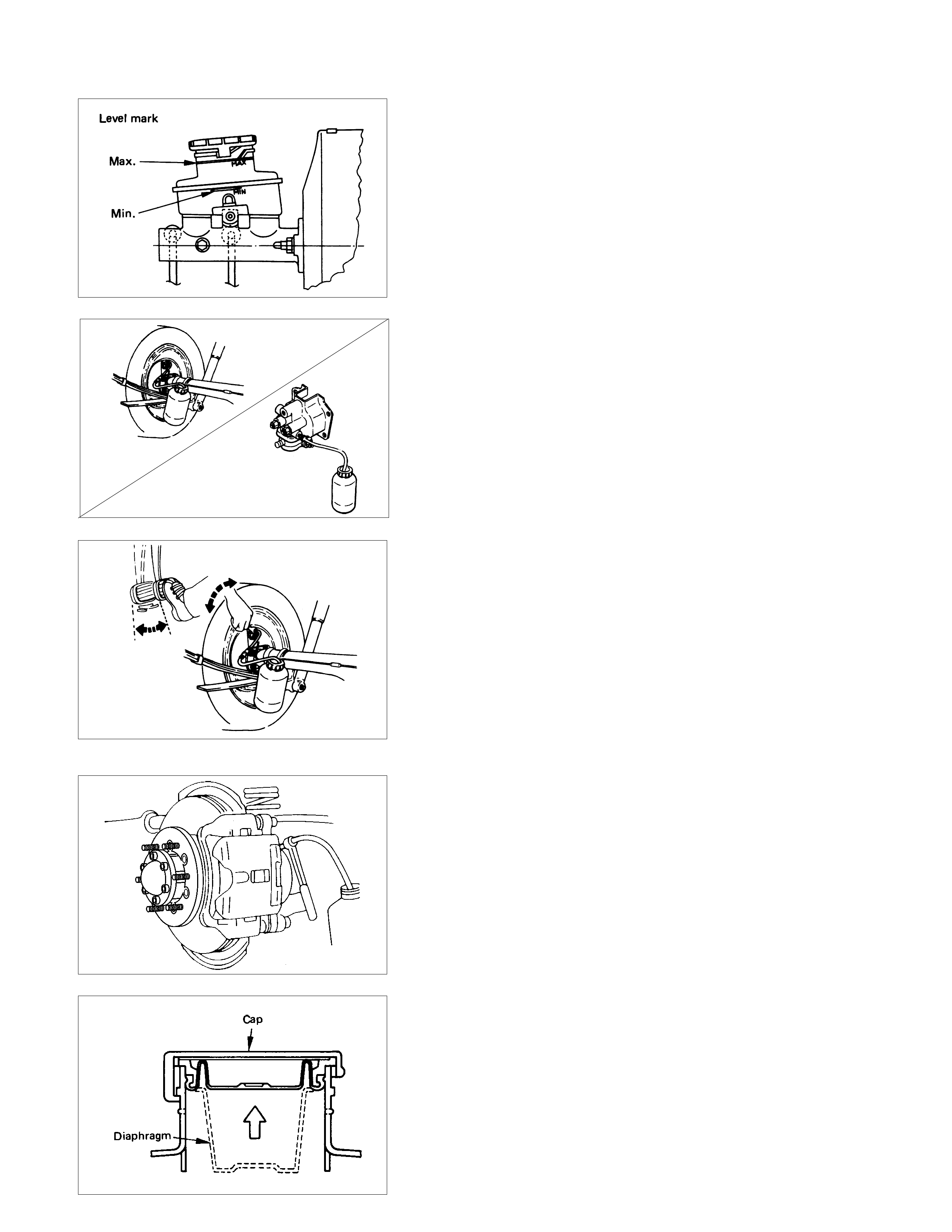

BLEEDING OF THE BRAKE HYDRAULIC

CIRCUIT

If air enters the bake lines, it will cause poor brake action.

Therefore, bleeding should be performed if the brakes have

been used with the level of brake fluid in the reservoir

excessively low or if brake pipes have been disconnected in

the course of brake servicing.

Bleeding operation calls for co-operative action of 2 persons.

•Set the parking brake firmly while bleeding.

•Perform bleeding operation with ENGINE RUNNING, to

prevent damage to push rod seal.

Make sure exhaust is suitably ventilated.

•Bleed the hydraulic system with the fluid reservoir filled to

the specified level.

•Bleed the system starting with the rear wheel cylinder

farthest from the master cylinder.

A : Load sensing proportioning valve (If so equipped).

1. Fill the brake fluid reservoir with brake fluid.

Handle the brake with reasonable care to avoid spillage as it

is damaging to paint.

Note:

Take care to prevent foreign matter from entry, when

replenishing or replacing brake fluid.

When pouring brake fluid, if diaphragm in the oil tank cap

is stretched, be sure to place it into original position,

(fasten it), and then cap it.

2. Connect a vinyl pipe to the bleeder screw on the wheel

cylinder, caliper bode or LSPV and the other end of the pipe

in a transparent container.

3. Pump the brake pedal several times and hold it depressed.

Loosen the bleed screw to release brake f luid together with

air bubbles.

Tighten the bleeder screw before pressure is released

completely.

4. Repeat the step in paragraph 3 above until the air bubbles

disappear completely.

Securely tighten the bleeder screw when the air bubbles

disappear completely.

5. Repeat the step in paragraph 4 above on the remaining

wheel cylinders.

Bleed the system starting with rear side farthest from the

brake fluid reservoir.

6. Fill the brake fluid reservoir to the specified level.

Pour brake fluid carefully so as not to produce air bubbles.

7. If the cap diaphragm is s tretched, f asten the diaphr agm and

the sure to cap it after it is placed to the original position.

Note:

Never reuse the old brake fluid.

BRAKE LINE (HOSES AND PIPES)

•Inspect all hoses and pipes for wear, bending, chafing,

cracks, dents, or any other damage.

Make necessary correction or parts replacement if these

abnormal conditions are found through inspection.

•All hoses, pipes and joints can be damaged easily.

Do not allow the hose to become excessively twisted and

bent when working with then, and pay special attention to all

the brake lines not to damage them when repairing or

replacing other parts (axle, suspension, etc).

•Inspection for leakage should be performed by depressing

the brake pedal fully.

If leakage is apparent at the circumference of joints,

retighten or replace these parts.

This procedure must be performed whenever brake lines

are installed.

•After disconnecting the hoses and pipes, cap or tape the

openings to prevent entry of foreign material.

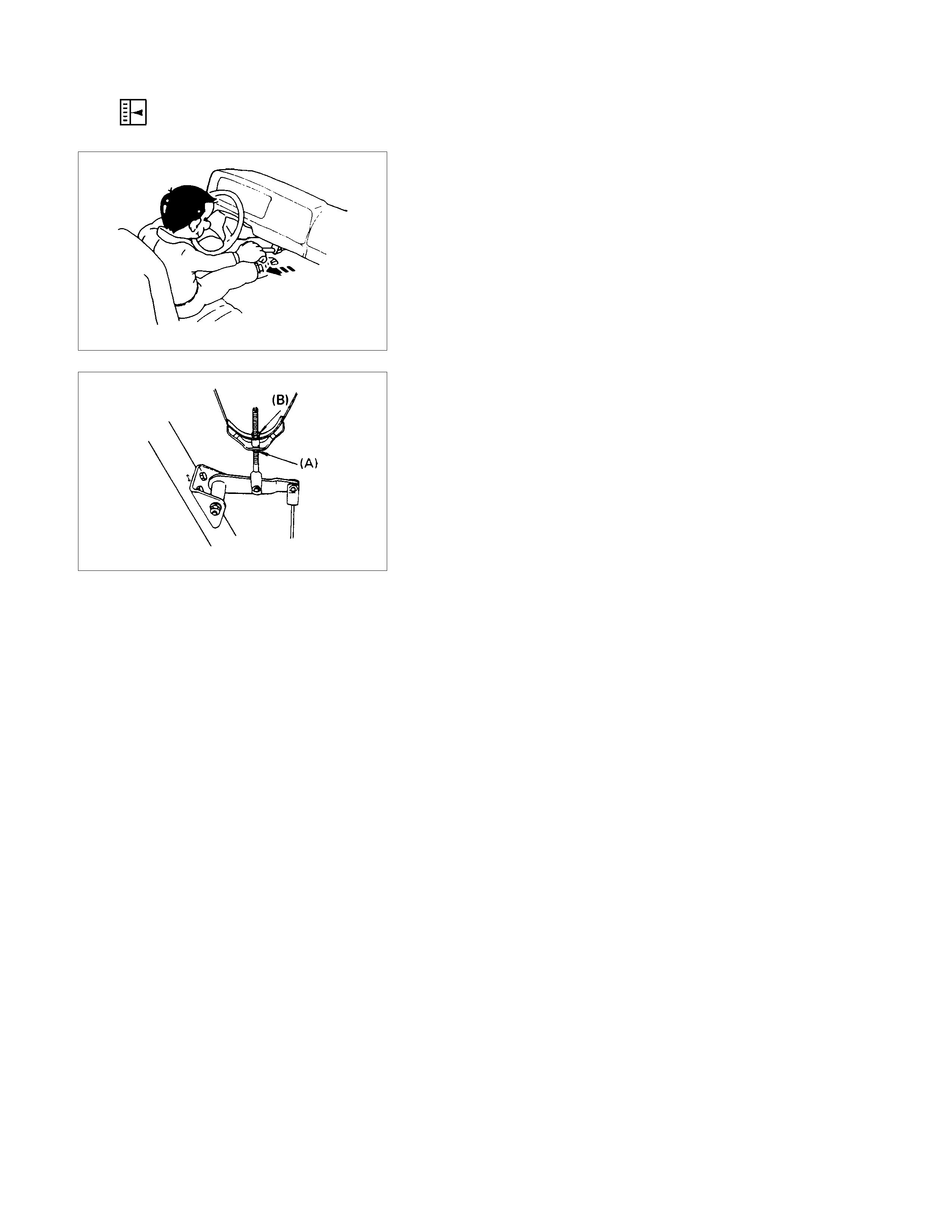

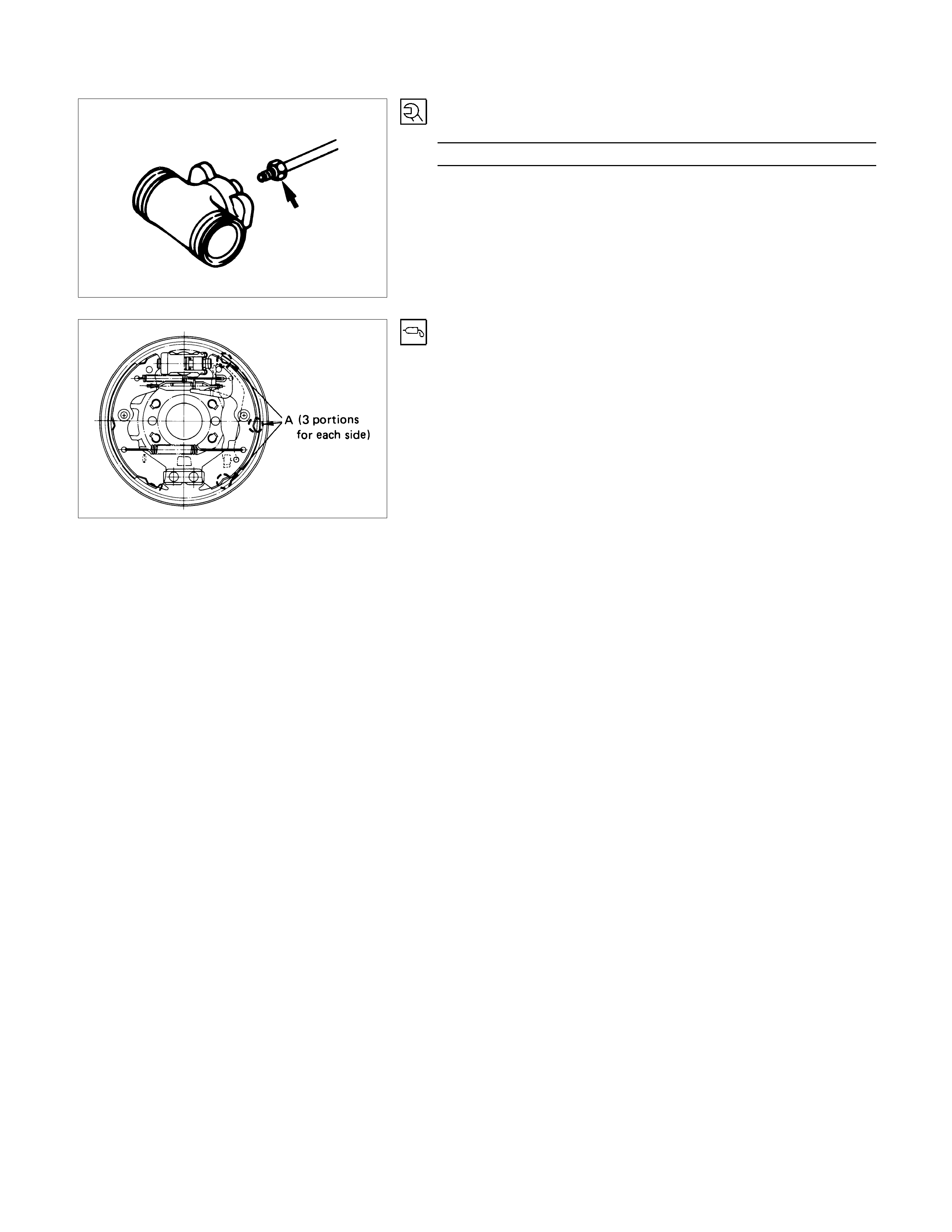

ADJUSTMENT PROCEDURE OF SERVICE AND PARKING BRAKE

Stem type

All brakes are self-adjusting.

Brake are adjusted by repeated stepping on the brake pedal.

The parking brake adjustment should be performed as follows:

1. Release the parking brake lever fully.

2. Loosen the lock nut (A).

3. Repeat stepping the brak e pedal firm ly and releasing it until

the rear brake auto-adjuster completes the function.

4. Rotate the adjust nut (B) until all slack disappears from the

cable.

5. Set the lock nut.

The parking brake lever travel is normal when the lever comes

out 9 to 11 notches when pulled with a force of 30 kg (66 lbs.).

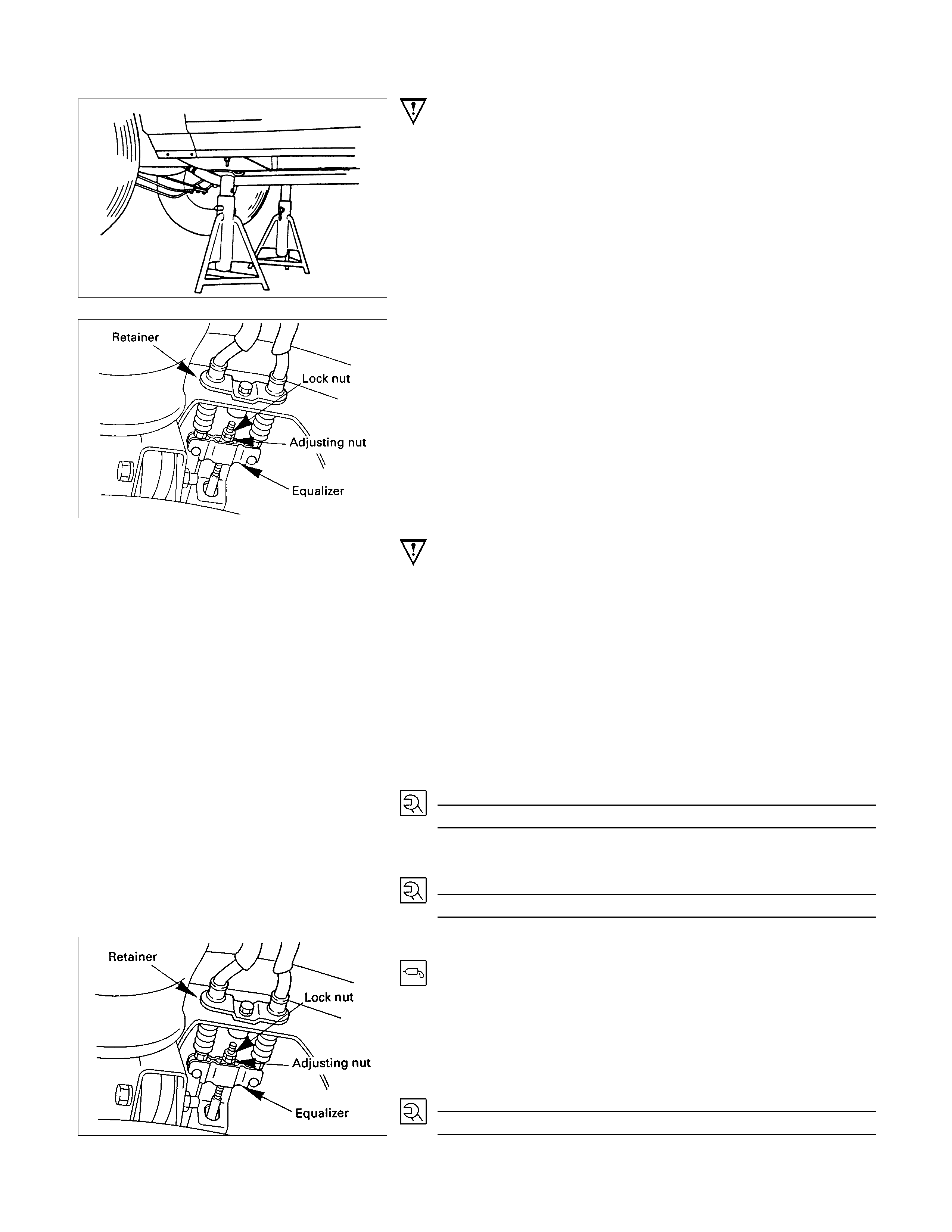

Floor mount type

All brakes are self-adjusting.

Brakes are adjusted by repeated stepping on the brake pedal.

(After stepping on the pedal and releasing it, the rear auto-

adjuster, in the rear brake, produces a clicking sound.

the same operation should be repeated until the sound

disappears.)

Take the following steps after overhauling the rear brake

assembly.

1. Move the parking brake lever to its fully released position.

2. Parking cable must be loosened sufficiently.

(Loosen the adjust nut and the lock nut.)

3. Repeat stepping on the brake pedal firmly, and releasing it

until the clicking sound can no longer be heard.

If the dif ference between the brake dr um inside diam eter of

the brake shoes is adjusted to be 0.5 mm, the number of

times for depressing the brake pedal can be reduced.

4. Remove the drum.

Measure the brake drum inside diameter and diameter and

diameter of the brake shoes.

Shoe Clearance mm(in)

0.25 - 0.40 (0.0098 - 0.0157)

If incorrect, check the brake auto-adjusting system.

5. Turn the equalizer nut so that the parking brake lever

travels 6 or 7 notches when pulled up with a force 30 k g (66

lbs.).

6. Make sure ther e is not brak e dragging and tighten the c able

lock nut.

Torque N⋅m(kgf⋅m/lb⋅ft)

8 - 18 (0.8 - 1.8 / 5.8 - 13)

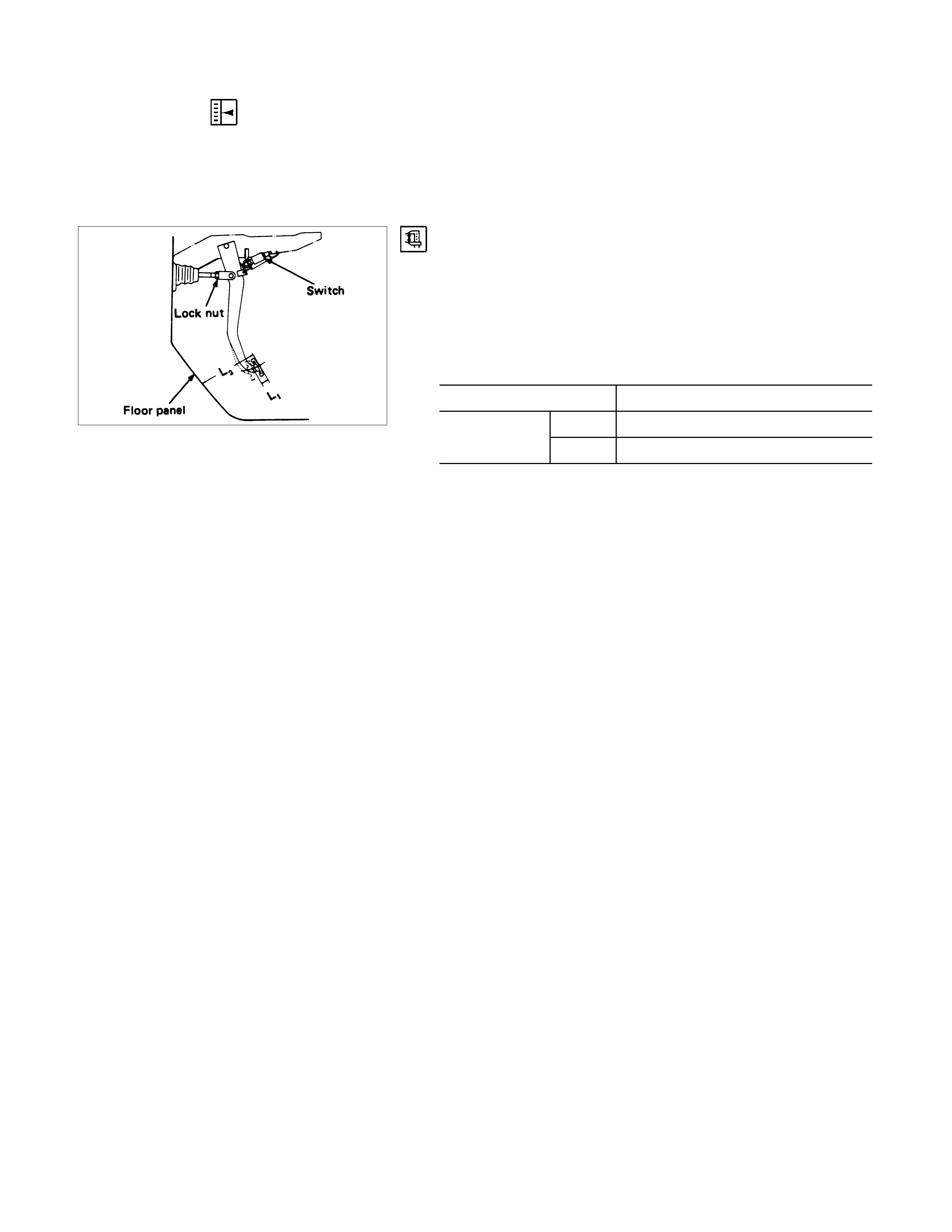

ADJUSTMENT PROCEDURE OF BRAKE PEDAL

The push rod serves as the brake pedal stopper when the

pedal is fully released.

Brake pedal height adjustment should be performed as follows.

Brake Pedal - Height

Measure the brake pedal height after making sure the pedal is

fully returned by the pedal return spring.

Note:

Pedal height (L2) must be measured after starting the

engine and increasing the revolution several times by

stepping on the accelerator pedal. mm(in)

Pedal free play (L1) 6-10 (0.23 - 0.39)

LHD 174-184 (6.85-7.24)

RHD 193-203 (7.60 7.99)

Height (L2)

Note:

Pedal free play must be measured after turning off the

engine and stepping on the brake pedal firmly five times or

more.

If the measured value deviates from the above range, adjust

the brake pedal as follows:

a) Disconnect the stop lamp switch.

b) Loosen the lock nut on the push rod.

c) Adjust the brak e pedal to the s pec if ied height by rotating the

push rod in the appropriate direction.

Lock Nut Torque N⋅m(kgf⋅m/lb⋅ft)

15- 25 (1.5 - 2.5 / 11 - 18)

d) Install the stop lamp switch.

Note:

Pedal height (L2) must be 95 mm (3.7 in.) or more when

applying about 50 kg (110.25 lbs.) of stepping force.

Clearance

Between the Switch Housing and the Brake Pedal (A). mm(in)

0.5 - 1.0 (0.02 - 0.04)

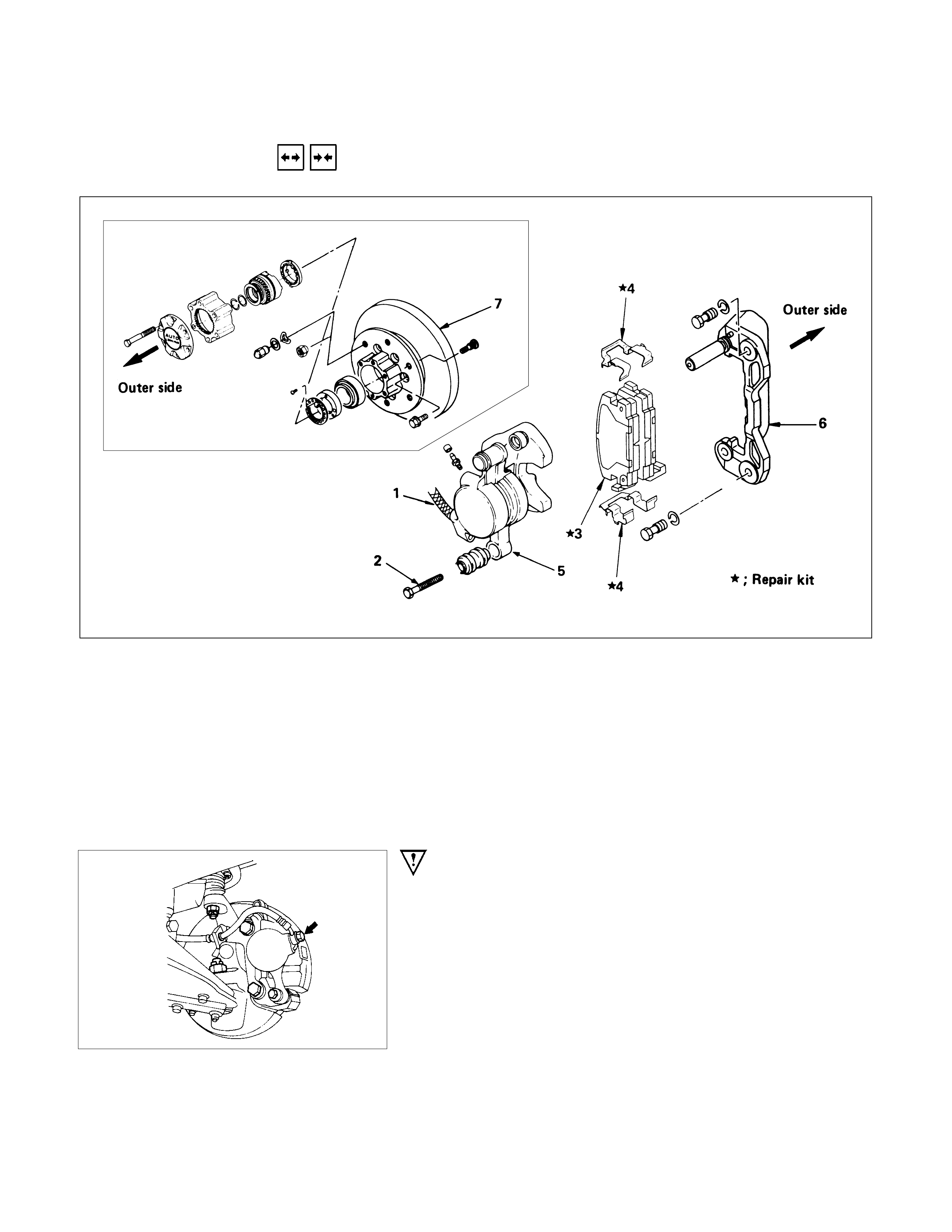

FRONT BRAKE ASSEMBLY

REMOVAL AND INSTALLATION

Removal Steps

▲1. Brake flexible hose

▲2. Lock bolt

▲3. Pad assembly with shim

4. Clip ; pad

5. Caliper assembly

▲6. Support bracket

▲7. Front hub and disc assembly

Installation Steps

▲7. Front hub and disc assembly

▲6. Support bracket

5. Caliper assembly

▲4. Clip ; pad

3. Pad assembly with shim

▲2. Lock bolt

▲1. Brake flexible hose

Important Operations - Removal

1. Brake Flexible hose

Remove the bolt and gasket and disconnect the brake flexible

hose from the caliper.

After disconnecting the flexible hose, cap or tape the openings

to prevent entry of foreign material.

2.Lock Bolt

Remove the lock bolt from the caliper.

3.Pad Assembly with Shim

Rotate the caliper upward.

Mark the lining locations if they are to be reinstalled.

6.Support Bracket

Take care not to damage the flexible brake hose when

removing the support bracket.

7.Front Hub and Disc Assembly

For the removal procedure, refer to Section 4B "FRONT

AXLE & PROPELLER SHAFT".

Important Operations - Installation

7.Front Hub and Disc Assembly

For the installation procedure, refer to the front hub and disc

reassembly procedure in Section 4B "FRONT AXLE".

6. Support Bracket

Torque N⋅m(kgf⋅m/lb⋅ft)

139 - 171 (14.2 - 17.4 / 103 - 126)

Set up the clip and pad before installation of the support racket.

4. Clip ; Pad

Install new parts if necessary.

2. Lock Bolt

Torque N⋅m(kgf⋅m/lb⋅ft)

27 - 37 (2.8 - 3.8 / 20 - 27)

1. Brake Flexible Hose

Attach the bolt and new gasket

Torque N⋅m(kgf⋅m/lb⋅ft)

29 -39 (3.0 - 4.0 / 22 - 29)

After installation, bleeding and replenishing procedure must be

performed.

Wipe the circumference of the hose clean.

Note:

•Always use new gaskets.

•Be sure to put the hooked edge of the f lexible hose end

into the anti-rotation cavity.

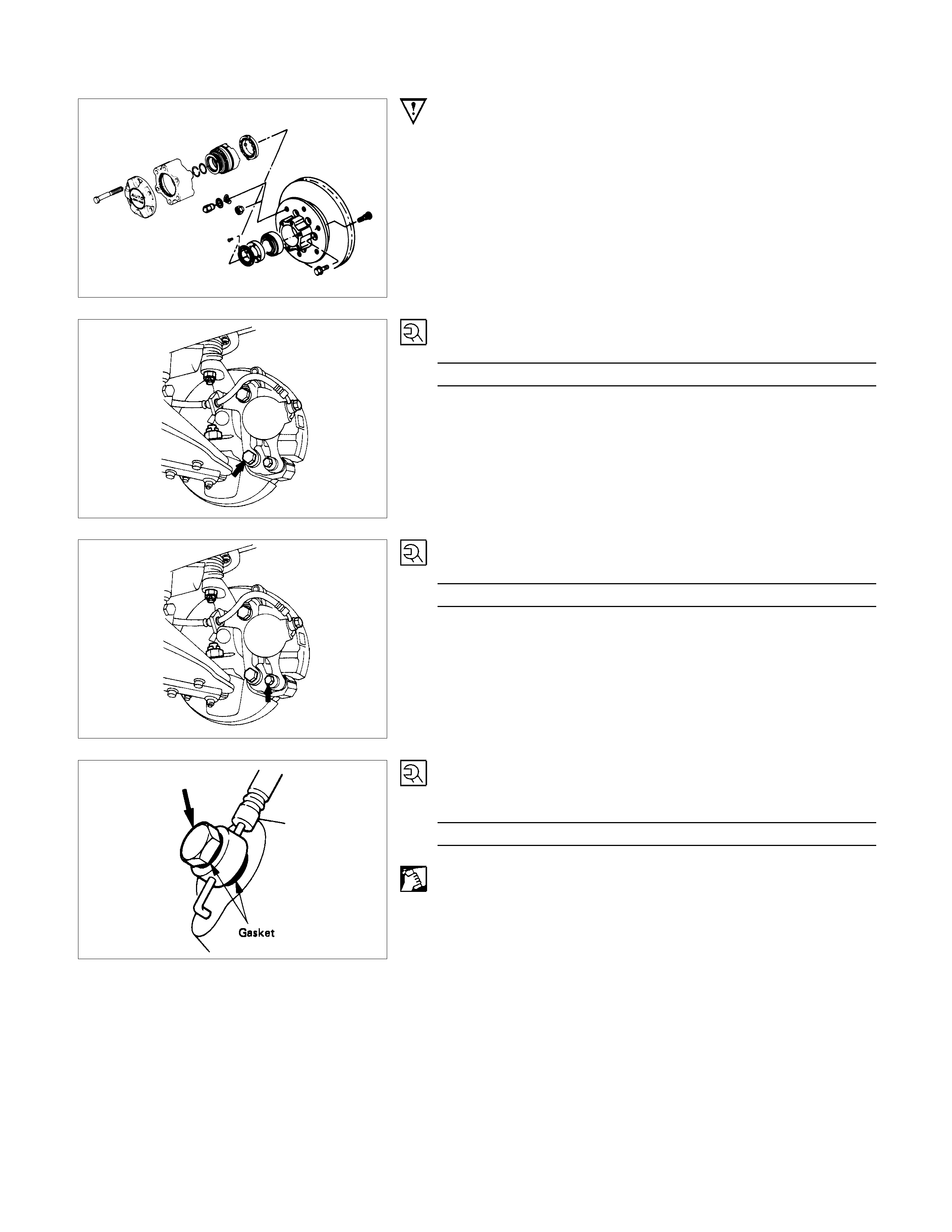

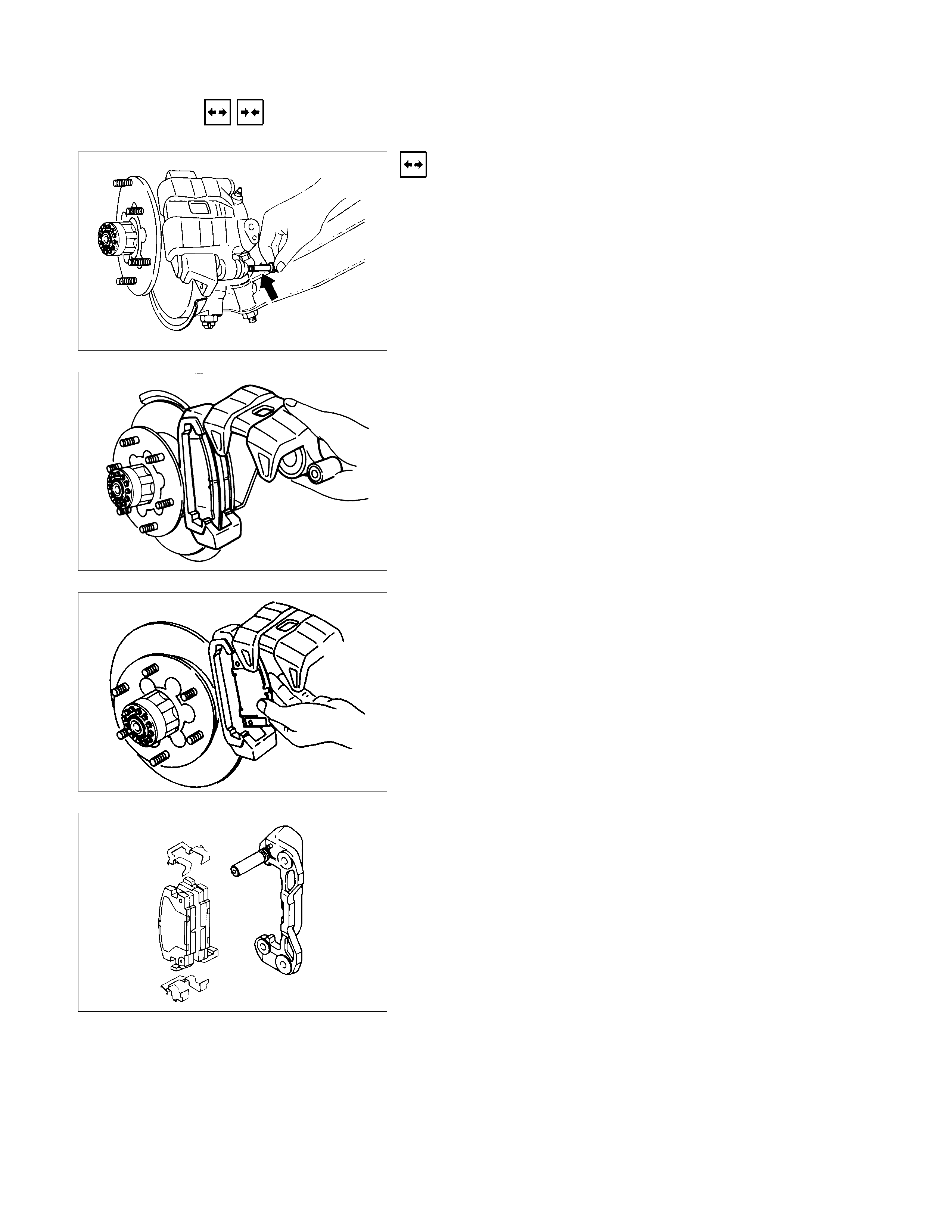

REMOVAL AND INSTALLATION OF DISC PAD

Removal Steps

1. Lock Bolt

Remove the lock bolt from the caliper.

Note:

Don't remove the brake hose from caliper when replacing

pads.

2. Rotate the Caliper Upward

Remove the caliper from the support bracket and ire the caliper

to the upper link or the frame.

Note:

While caliper is removed from support bracket, never step

on the brake pedal or the piston will protrude rapidly.

3. Pad Assembly with Shim

Remove the pad assembly with the shim.

Mark the pad locations if they are to be reinstalled.

4. Clip ; Pad

Discard the used clip and install a new one.

Installation Steps

1. Clip ; Pad

2. Pad Assembly with Shim

After attaching the pad assembly with the shim to the support

bracket, position the wear indicator to the lower side of the pad.

3. Caliper Assembly

Lower the caliper into its original position.

Do not damage the flexible hose by twisting or pulling it.

4. Lock Bolt

Attach the lock bolt to the caliper.

Torque N⋅m(kgf⋅m/lb⋅ft)

27 - 37 (2.8 - 3.8 / 20 - 27)

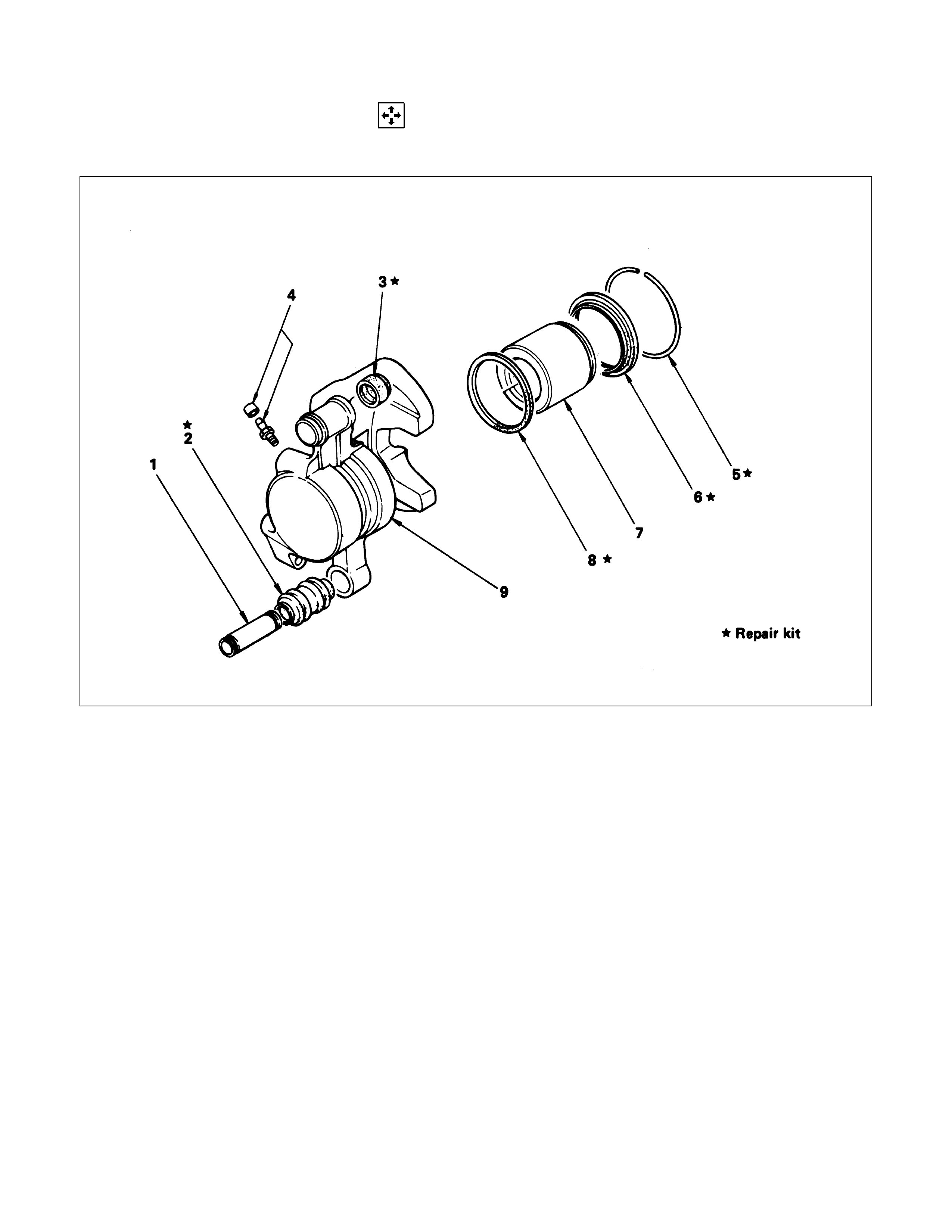

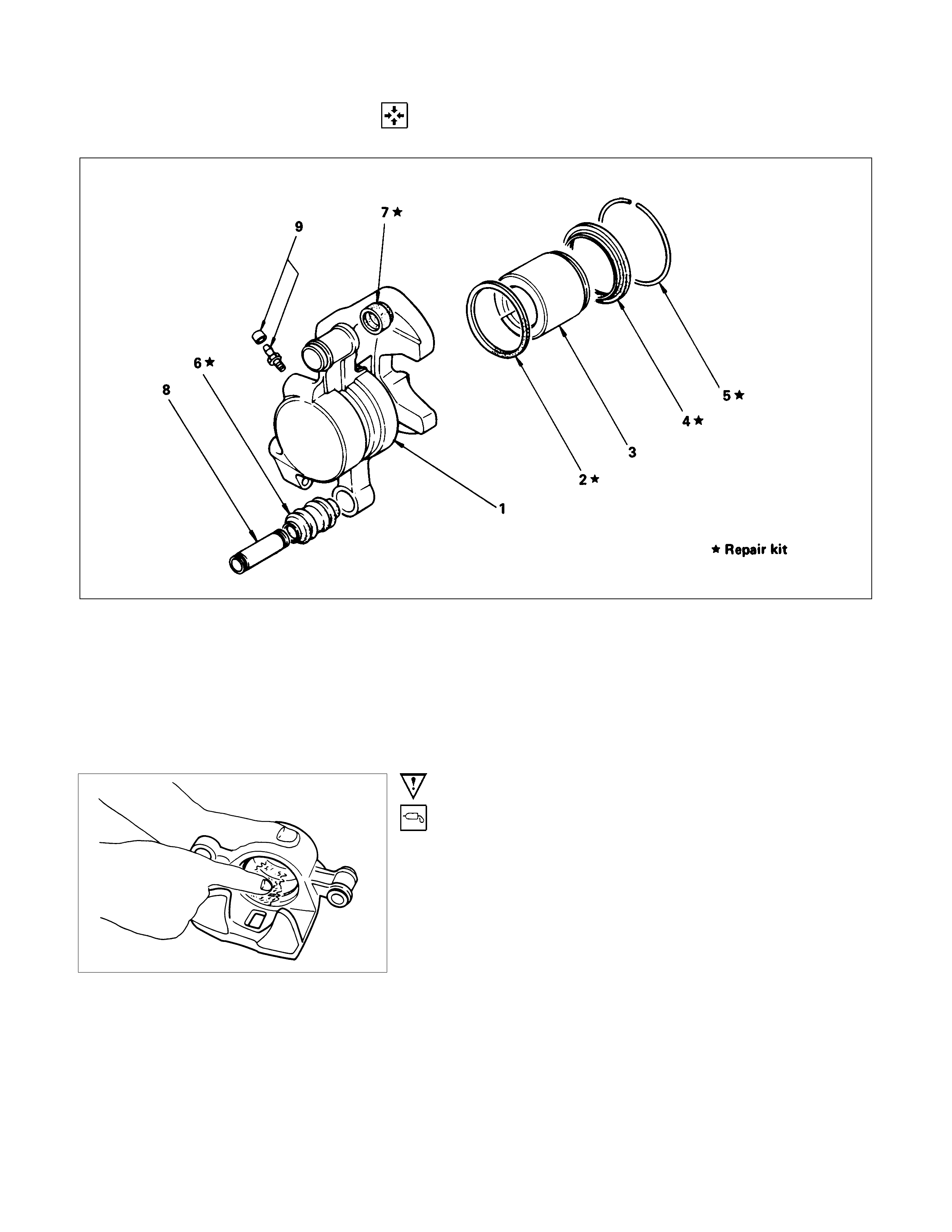

DISASSEMBLY

CALIPER ASSEMBLY

Disassembly Steps

1. Sleeve

2. Dust boot ; sleeve

3. Dust boot ; guide pin

4. Bleeder with cap

▲5. Dust seal ring

6. Dust seal ; piston

▲7. Piston (with seal ring)

8. Ring seal

9. Body ; caliper

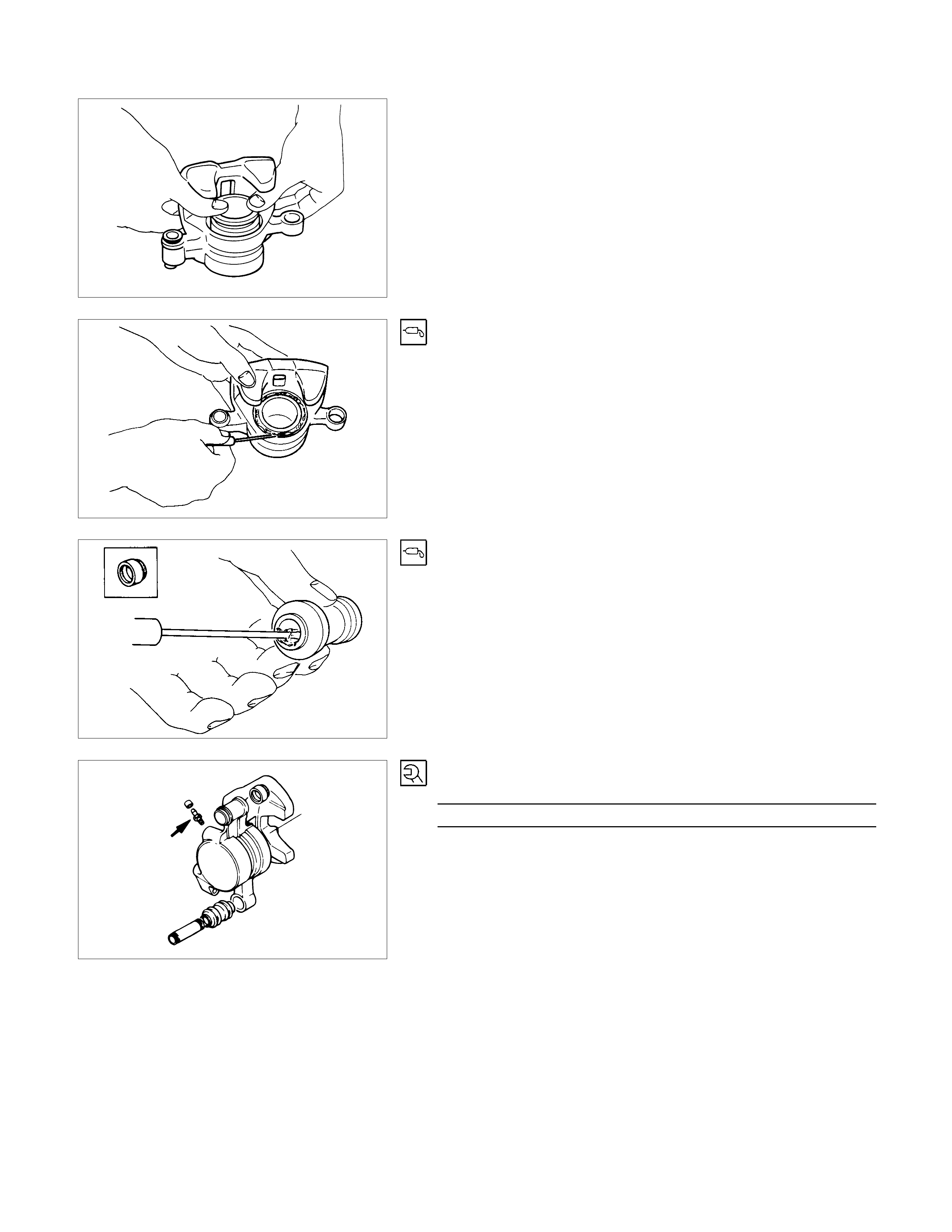

Important Operations

5.Dust Seal Ring

Using a small screwdriver, remove the dust boot.

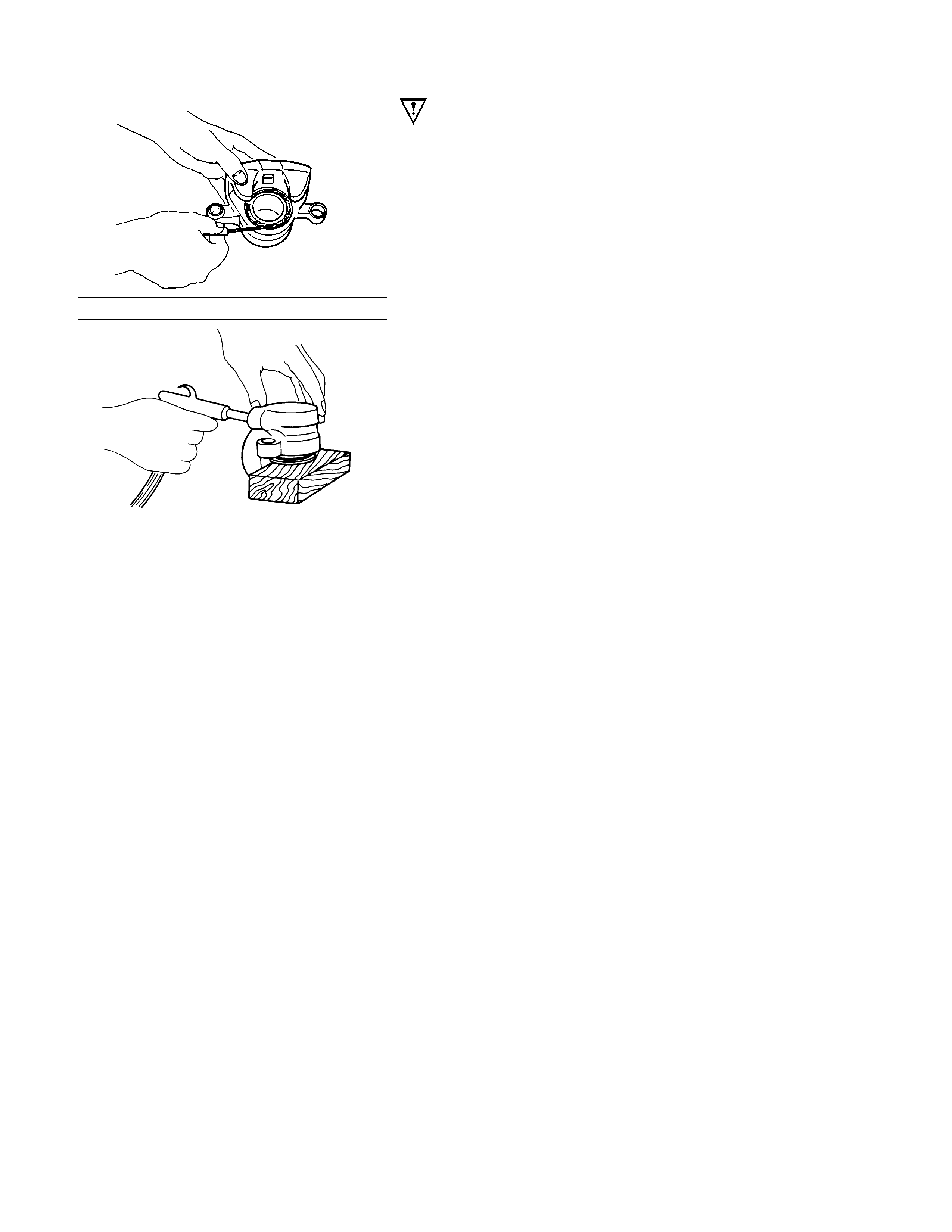

7.Piston (with Ring Seal)

Insert a block of wood into the caliper and force out the piston

by blowing compressed air into the caliper at the flexible hose

attachment.

This procedure must be done prior tor removal of dust seal.

CAUTION:

Do not place your fingers in front of the piston in an

attempt to catch or protect it when applying compressed

air.

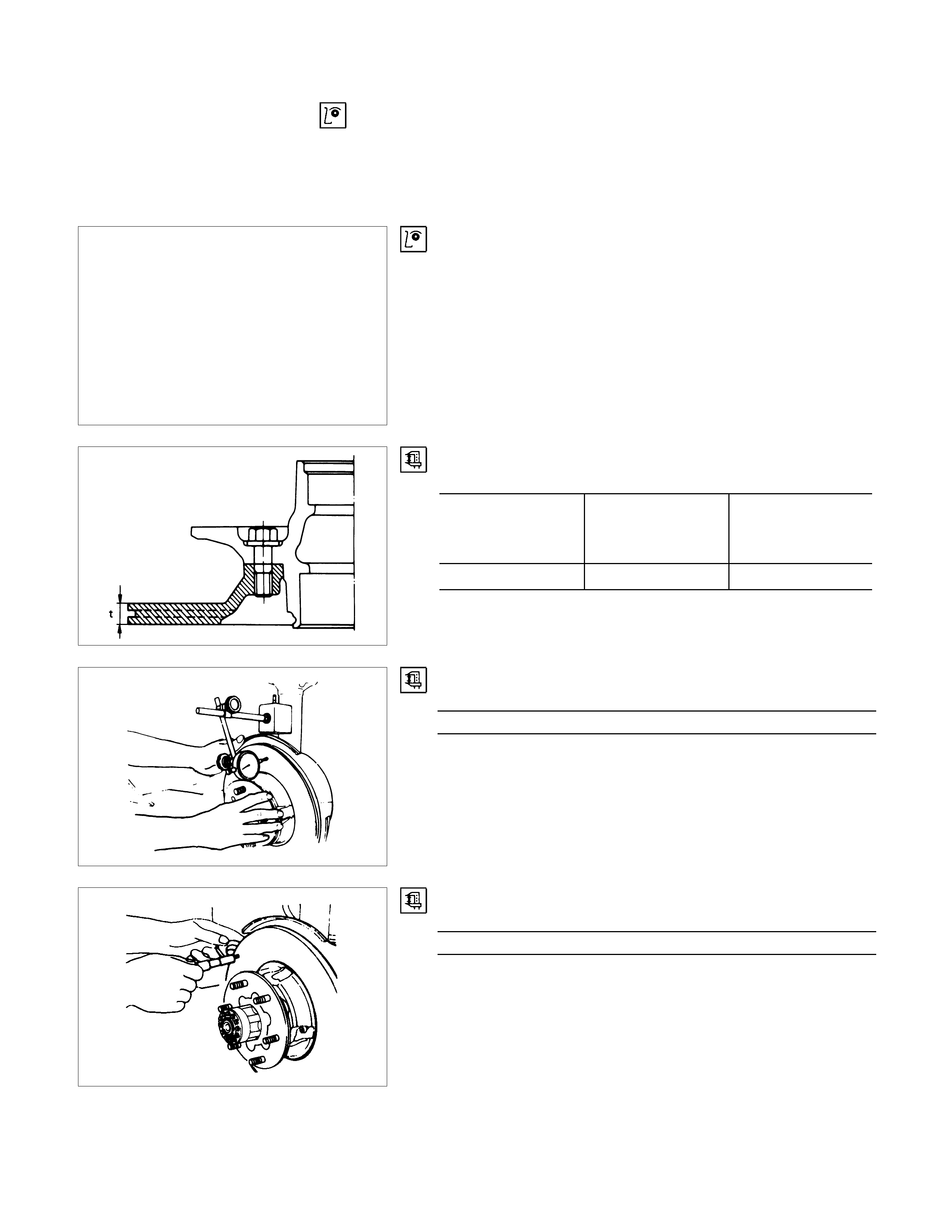

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

• Rotor

• Caliper body

• Cylinder bore

• Piston

• Support bracket

• Lock bolt

• Guide pin

Visual Check

Inspect the following parts for wear, bending, distortion,

cracking, corrosion, or other abnormal conditions.

Rotor

•Thickness (t) mm(in)

Standard Minimum

thickness after

refinishing

Replacement

thickness

(Discard)

22.0(0.866) 20.97(0.826) 20.6(0.811)

•Run out

Limit mm(in)

0.13 (0.005)

Before inspection, adjust the wheel bearing correctly.

Using a dial gauge, measure the run out at the center of disc

pad contact surface.

•Parallelism (Total circumferential thickness variation)

Limit mm(in)

0.15 (0.0006)

Contact surface must be within 0.015 mm at the circumference

of 203 mm dia. Circle.

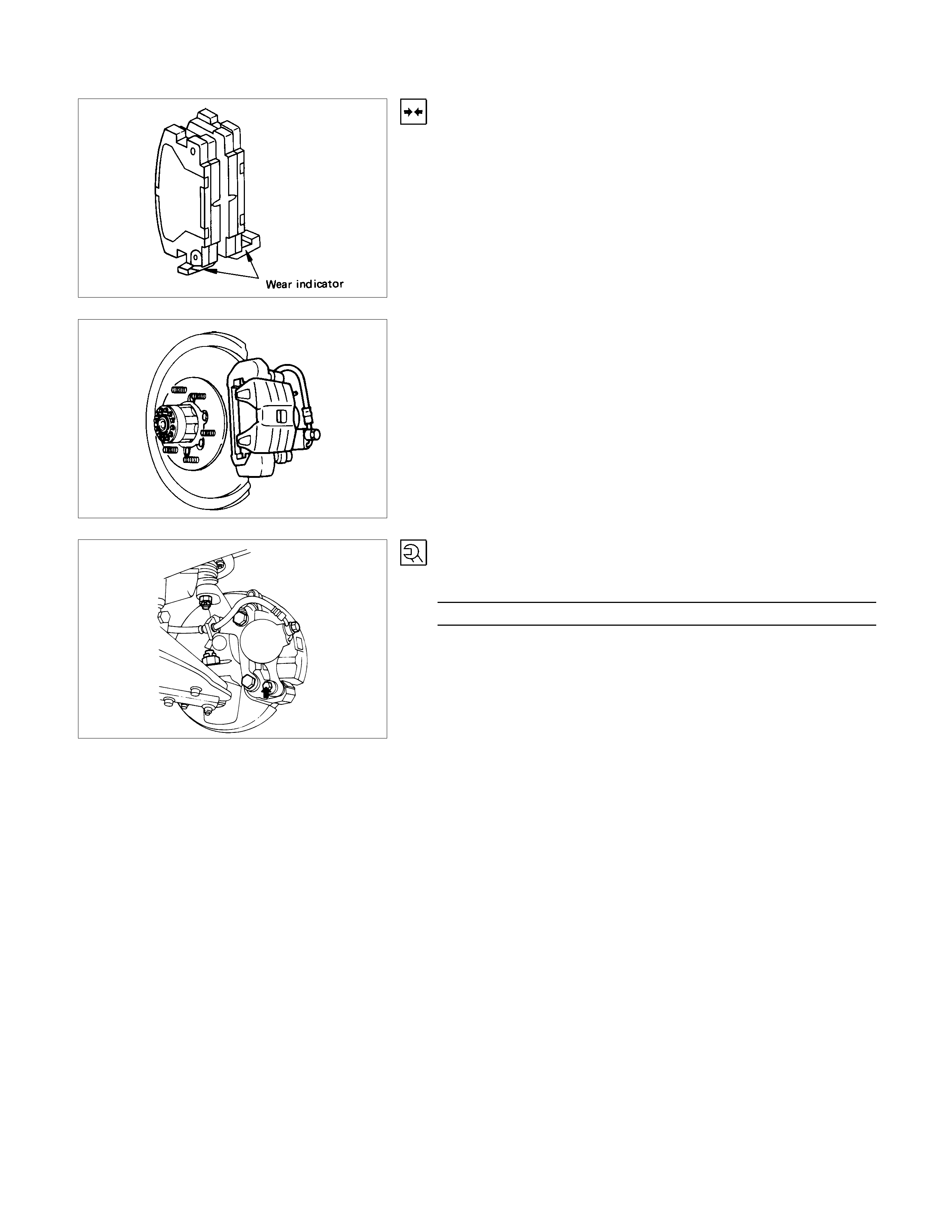

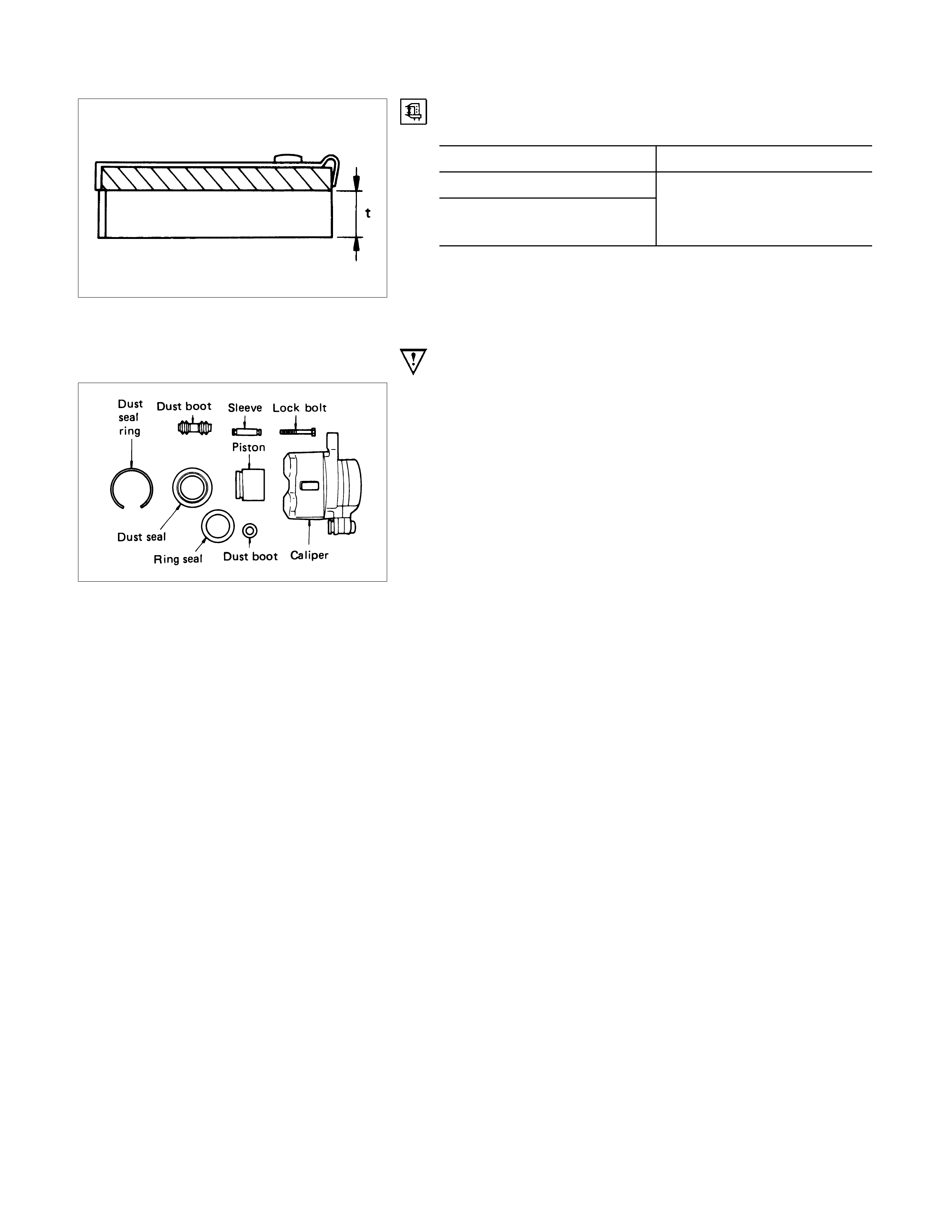

Thickness of Disc Pad

Thickness (t) mm(in)

Standard Limit

10.5 (0.413)

9.5 (0.374)

(For Australia only) 1.0 (0.039)

Replace the front disc pad whenever the pad wear indicator

makes a squeaking noise or when the pad is worn to within 1

mm of the shoe table.

All four brake pads should be replaced together.

Seal and Boot

The dust seal, dust boot and ring seal are to be replaced each

time the caliper is overhauled.

Discard thee used rubber parts.

REASSEMBLY

CALIPER ASSEMBLY

Disassembly Steps

▲1. Body ; caliper

▲2. Ring seal

▲3. Piston

▲4. Dust seal ; piston

▲5. Dust seal ring

▲6. Dust boot ; sleeve

▲7. Dust boot ; guide pin

8. Sleeve

▲9. Bleeder with cap

Important Operations

1. Body ; Caliper

2. Ring Seal

Apply special grease to the ring seal and cylinder wall, then

insert the ring seal into the cylinder.

The special grease is included in the repair kit.

3. Piston

When inserting the piston into the cylinder, use finger pressure

only.

Do not use a mallet or other impact tools, since damage to the

cylinder wall or ring seal can result.

4. Dust Seal ; Piston

5. Dust Seal Ring

Apply special grease (Approx. 1g) to the piston and attach the

dust seal to the piston and caliper.

Insert the dust seal ring into the dust seal.

6. Dust Boot ; Sleeve

7. Dust Boot ; Guide Pin

Install the sleeve dust boot on the caliper after applying special

grease (Approx. 1g) into the sleeve and guide pin boot, then

insert the sleeve into the dust boot.

9. Bleeder with Cap

Torque N⋅m(kgf⋅m/Ib⋅ft)

5.9-8.8 (0.6 - 0.9 / 4.3 - 6.5)

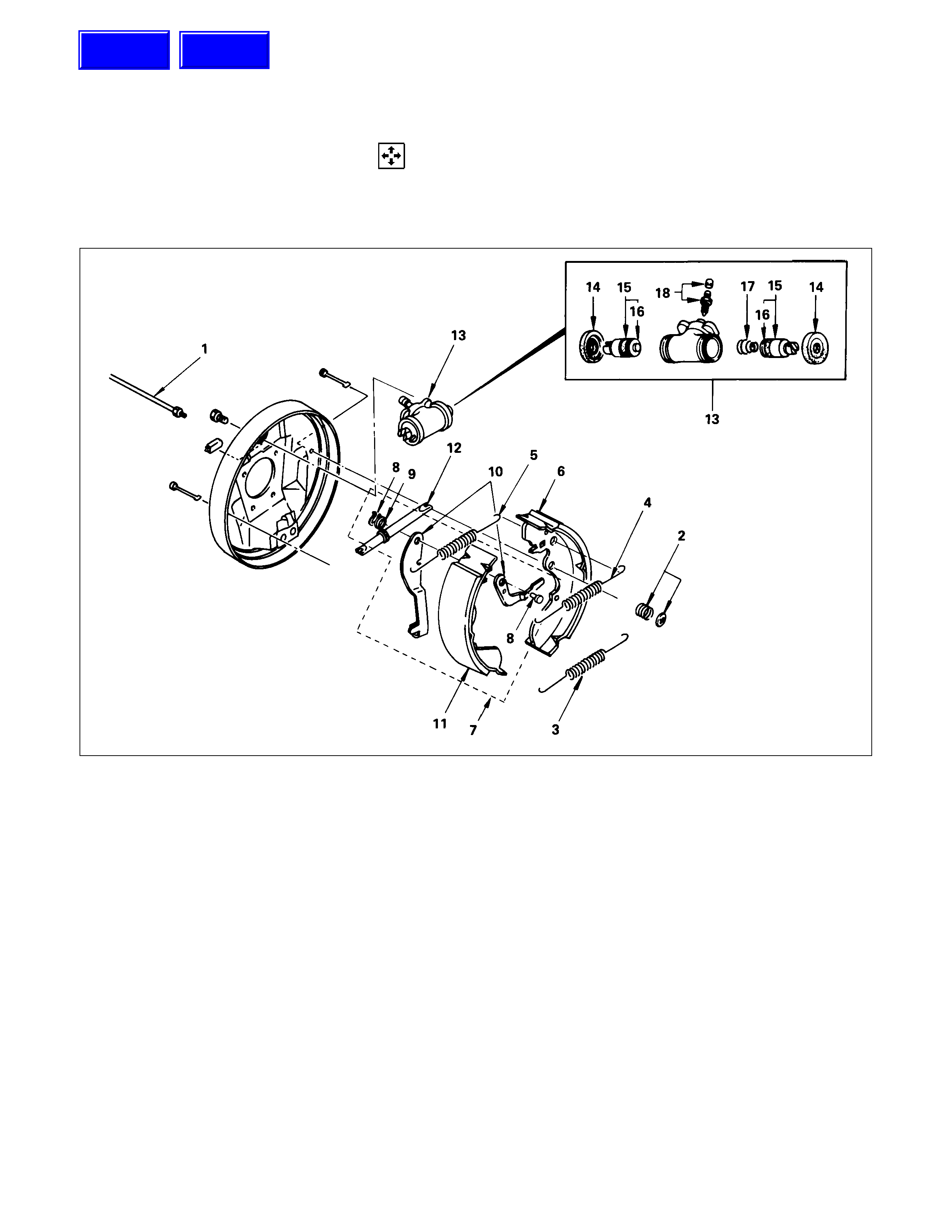

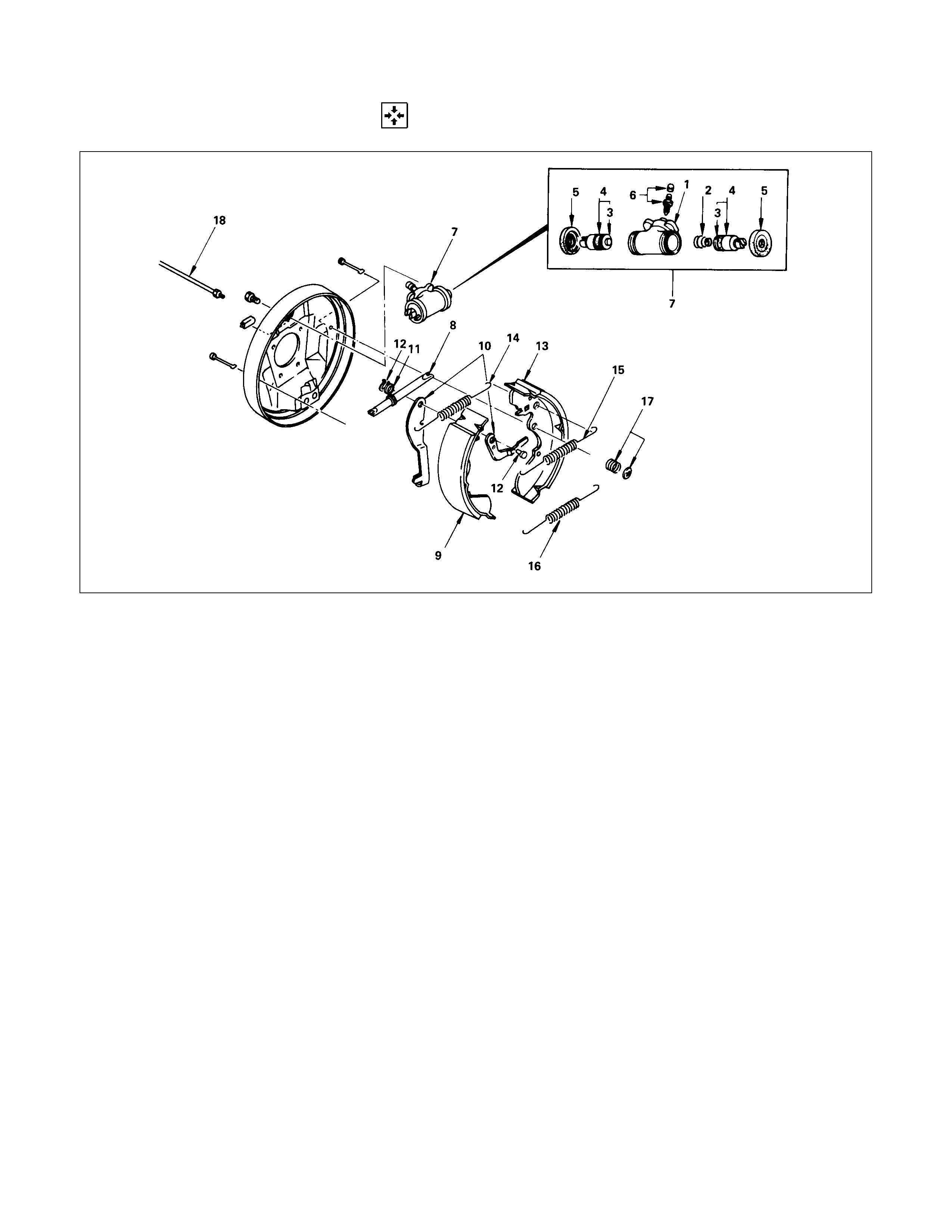

REAR DRUM BRAKE ASSEMBLY

DISASSEMBLY

First, disassemble the brake drum. Then disassemble the rear brake assembly.

Refer to the “REAR AXLE” section for the brake drum disassembly procedure.

MAJOR COMPONENTS

Disassembly Steps

1. Brake line

2. Holding spring and cups

▲3. Return spring ; lower

4. Return Spring ; upper

(shoe to adjust lever)

5. Return spring ; upper

(shoe to shoe)

6. Shoe assembly (primary)

7. Shoe assembly with lever

8. Retainer with pin

9. Washer ; wave

10. Lever ; auto adjust

11. Shoe assembly (secondary)

12. Adjuster assembly

13. Wheel cylinder assembly

MINOR COMPONENTS

Disassembly Steps

Wheel Cylinder Assembly (13)

14. Boot ; wheel cylinder

15. Piston assembly

16. Cup ; piston

17. Return spring ; piston

18. Bleeder ; wheel cylinder

Techline

Techline

Important Operations

3. Return Spring ; Lower

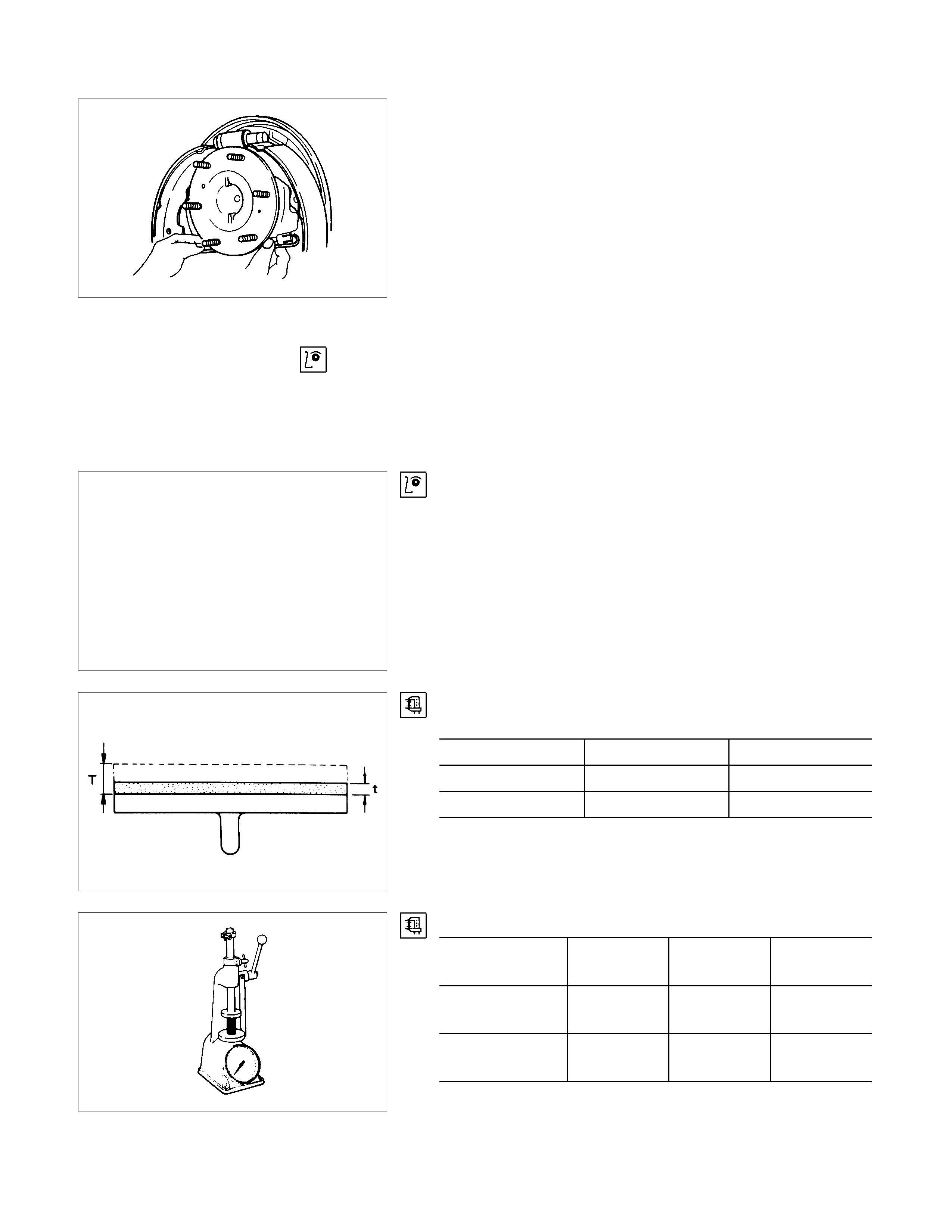

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

• Brake drum

• Back plate

• Brake lining

• Wheel cylinder body

• Piston

• Piston cup

• Return spring

Visual check

Inspect the following parts for wear scuffs, scratches,

corrosion, stains, deterioration, or other abnormal conditions.

Thickness of the Brake Lining

Thickness mm(in)

standard (T) Limit (t)

TFR 5.0 (0.197) 1.0 (0.039)

TFS 4.0 (0.157) 1.9 (0.039)

Inspection of the Return Spring

Free length

mm(in.) Set length

mm(in.) Set load

kg (Ibs.)

Holding spring 15.0 (0.591) 11.2 (0.441) 10.0±1.0

(22.3±2.2)

Wheel cylinder

spring 37.4 (1.472) 8.0 (0.315) 1.0±0.1

(2.2±0.2)

Free length

mm(in.) Set length

mm(in.) Set load

kg(lbs.)

Return spring :

upper

(adjust lever)

124.9

(4.917) 134.9

(5.311) 7±0.7

(15.4±1.6)

Shoe return

spring : upper 112.4

(4.425) 121.5

(4.783) 2±0.2

(4.4±0.4)

Shoe return

spring : lower 167.2

(6.583) 190.2

(7.488) 28.0±2.8

(61.7±6.4)

Clean wheel Cylinder Parts

Always use clean brake fluid to clean wheel cylinder parts.

Note:

Do not use mineral-vase cleaning solvents such as

gasoline, kerosene, acetone, paint thinner, or carbon

tetrachloride.

Clearance Between the Wheel Cylinder

and the Piston mm(in)

Standard Limit

0.02 - 0.1(0.001 - 0.004) 0.15(0.006)

Piston Cups

Inspect the piston cups for wear, distortion, fatigue, fatigue or

other abnormal conditions.

Measuring the Brake Drum mm(in)

Standard Limit

Inside diameter 254(10.000) 255.5(10.059)

Run out 0.05(0.002) 0.15(0.006)

Inside diameter 295(11.614) 296.5(11.673)

Run out 0.05(0.02) 0.15(0.006)

TFS

TFR

REASSEMBLY

MINOR COMPONENTS

Reassembly Steps

Wheel cylinder Assembly (7)

▲1. Bode ; wheel cylinder

2. Return spring ; piston

3. Cup ; piston

▲4. Piston assembly

5. Boot ; wheel cylinder

▲6. Bleeder ; wheel cylinder

MAJOR COMPONENTS

Reassembly Steps

▲7. Wheel cylinder assembly

8. Adjuster assembly

9. Shoe assembly (secondary)

10. Lever ; auto adjuster

11. Washer ; wave

12. Retainer with pin

13. Shoe assembly (primary)

14. Return spring ; upper

(shoe to shoe)

15. Return spring ; upper

(shoe to adjust lever)

16. Return spring ; lower

17. Holding spring and cups

▲18. Brake line

Important Operations

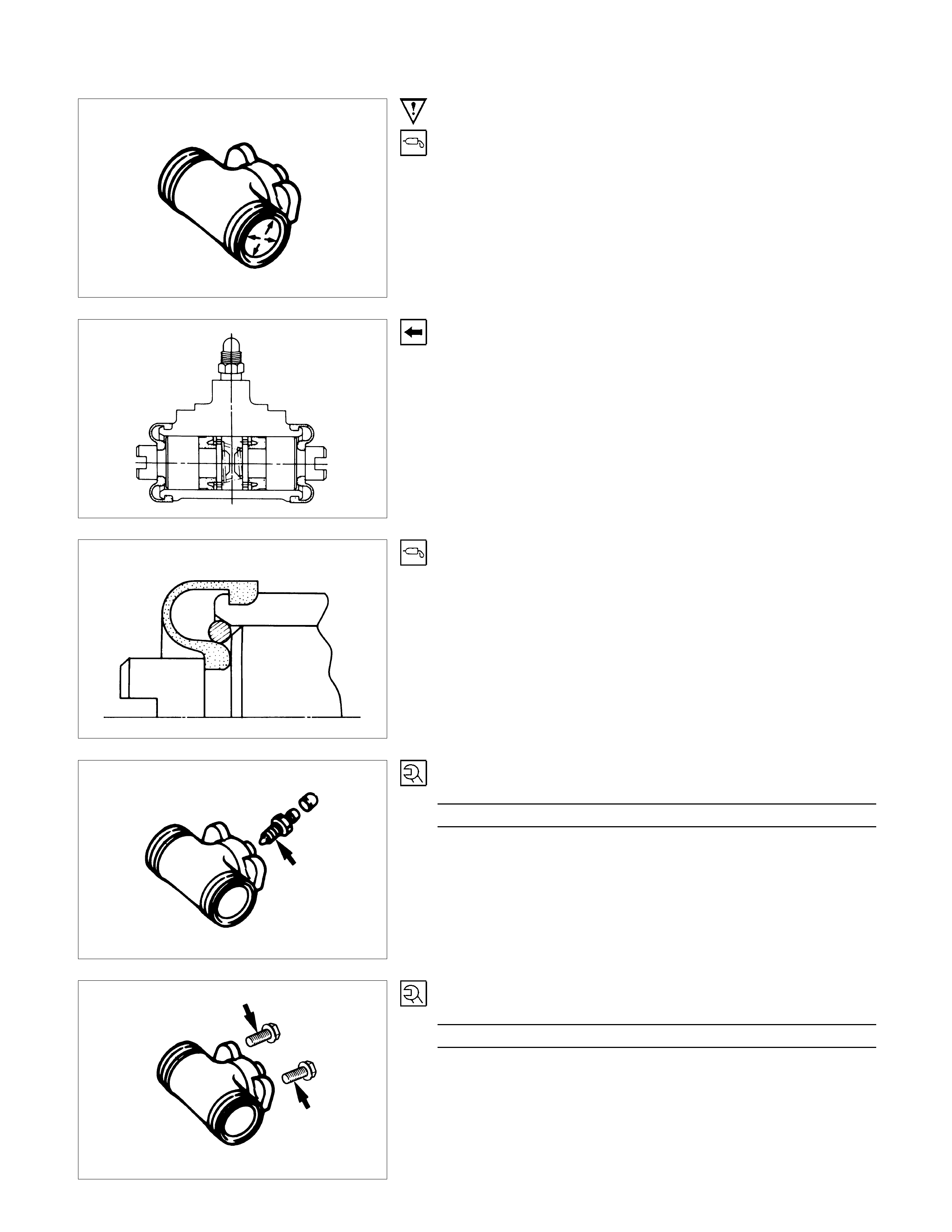

1. Bode ; Wheel Cylinder

Lubricate the cylinder bore with clean rubber grease.

4. Piston Assembly

Install new piston cups on each piston so that the flared end of

the cups are turned to the inboard side of the pistons.

Attach the return spring and the boot to the piston.

Apply DELCO silicone lube No.5459912 (or equivalent) to the

piston and the inner face of the boots.

6. Bleeder ; Wheel Cylinder

Torque N⋅m(kgf⋅m/Ib⋅ft)

6.9 - 11.8 (0.7 - 1.2 / 5.1 - 8.7)

7. Wheel Cylinder Assembly

Torque N⋅m(kgf⋅m/Ib⋅ft)

11 - 15 (1.1 - 1.5 / 8 - 11)

18.Brake Line

Torque N⋅m(kgf⋅m/Ib⋅ft)

13 - 19 (1.3 - 1.9 / 9 - 14)

Apply grease lightly to back plate A.

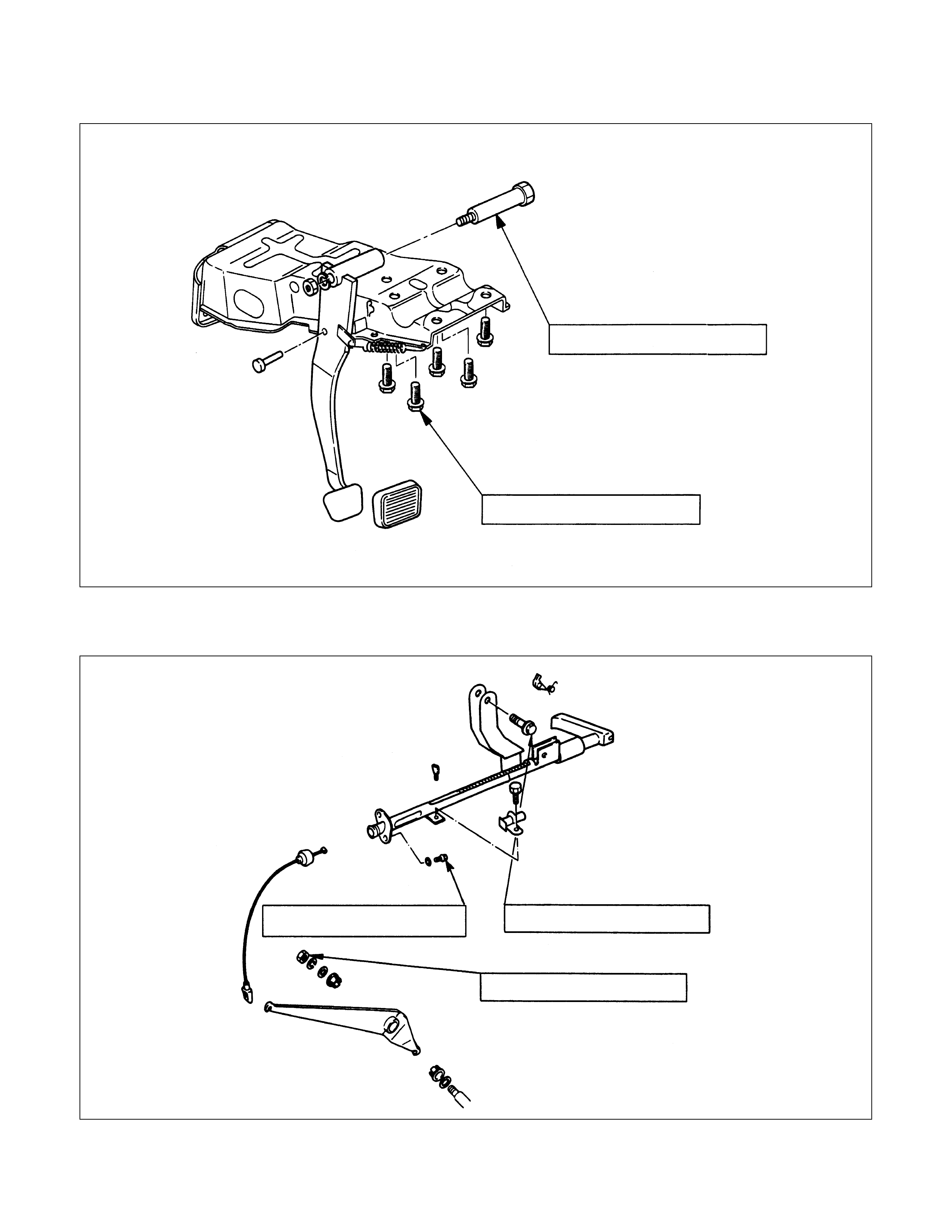

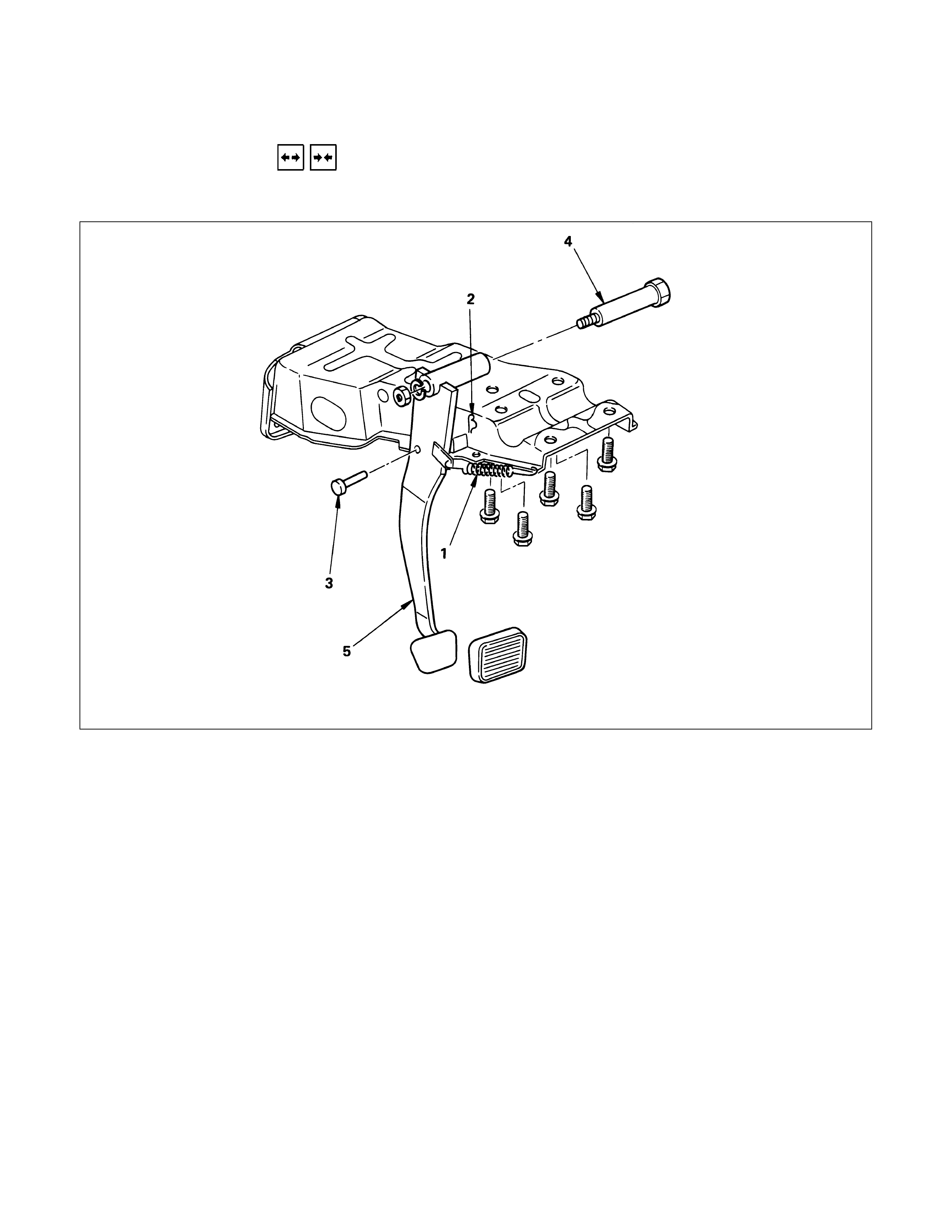

BRAKE CONTROL

REMOVAL AND INSTALLATION

BRAKE PEDAL ASSEMBLY

This illustration based on the LHD model

Removal Steps

1. Return spring

2. Snap pin

3. Pin ; push rod to pedal

4. Pin ; fulcrum, pedal to bracket

5. Pedal assembly with bush

Installation steps

To install, follow the removal procedure in

reverse order.

Before installation, appyl grease to the entire

circumference of the fulcrum pin (4) and push

rod pin (3).

Refer to "SERVICING" in this section for

adjustment procedure of brake pedal.

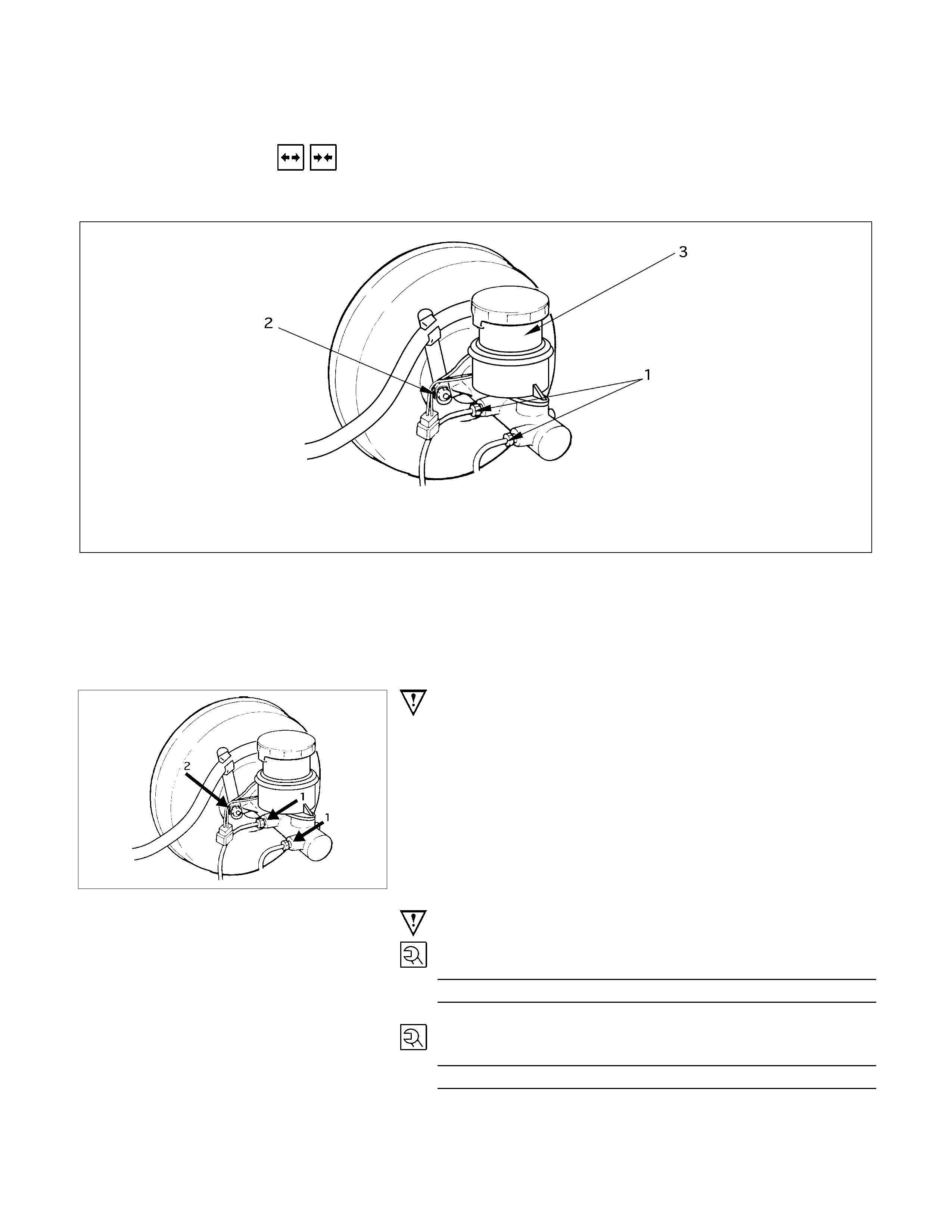

MASTER CYLINDER

REMOVAL AND INSTALLATION

BRAKE PEDAL ASSEMBLY

This illustration based on the LHD model.

Removal Steps

▲1. Brake line

2. Nut ; master cylinder to vacuum servo

3. Master cylinder assembly

Installation Steps

3. Master cylinder assembly

▲2. Nut ; master cylinder to vacuum servo

▲1. Brake line

Important Operation - Removal

1. Brake Line

Be very careful not to spill brake fluid on the painted surface.

Damage to the painted surface will result.

Important Operation - Installation

2. Nut ; Master Cylinder to Vacuum Servo

Torque N⋅m (kgf⋅m/lb⋅ft)

1.0 - 1.6 (7 - 12 / 9.8 - 16)

1. Brake Line

Torque N⋅m (kgf⋅m/lb⋅ft)

0.9 - 1.5 (6.5 - 11 / 8.8 - 15)

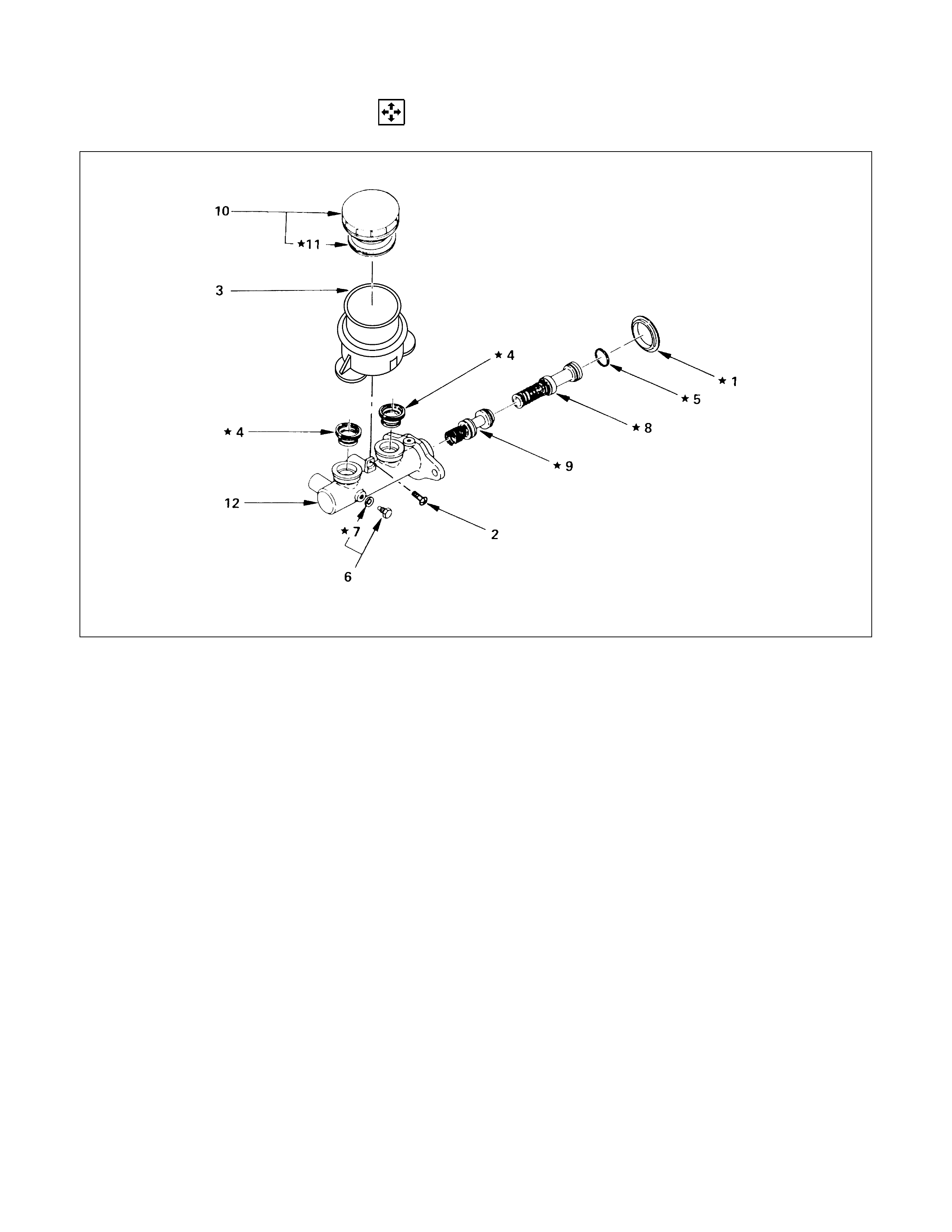

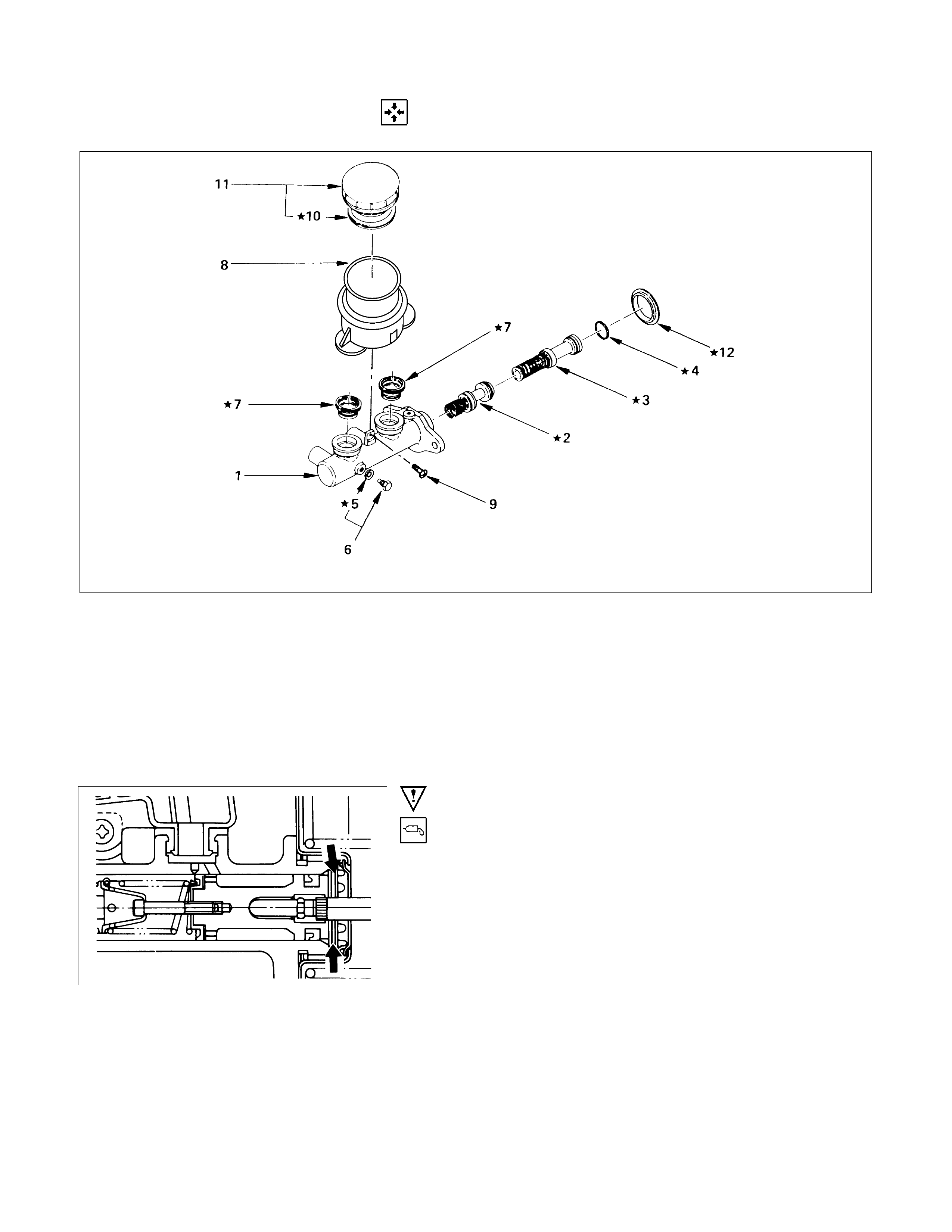

DISASSEMBLY

Disassembly Steps

1. Dust seal

2. Screw

3. Reservoir ; fluid, brake

4. Grommet

▲5. Ring ; snap

▲6. Bolt ; stopper

7. Gasket

▲8. Piston assembly ; primary and spring

▲9. Piston assembly ; secondary and spring

10. Cover ; fluid reservoir

11. Seal

12. Cylinder assembly ; brake, master

Important Operations

When disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. Wash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

5. Ring ; Snap

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

6. Bolt ; Stopper

Push in the primary and secondary pistons and remove the

stopper bolt completery from the cylinder body, then remove

the primary and secondary piston assemblies.

8. Piston Assembly ; Primary and Spring

9. Piston Assembly ; Secondary and Spring

Don’t remove the spring from the piston.

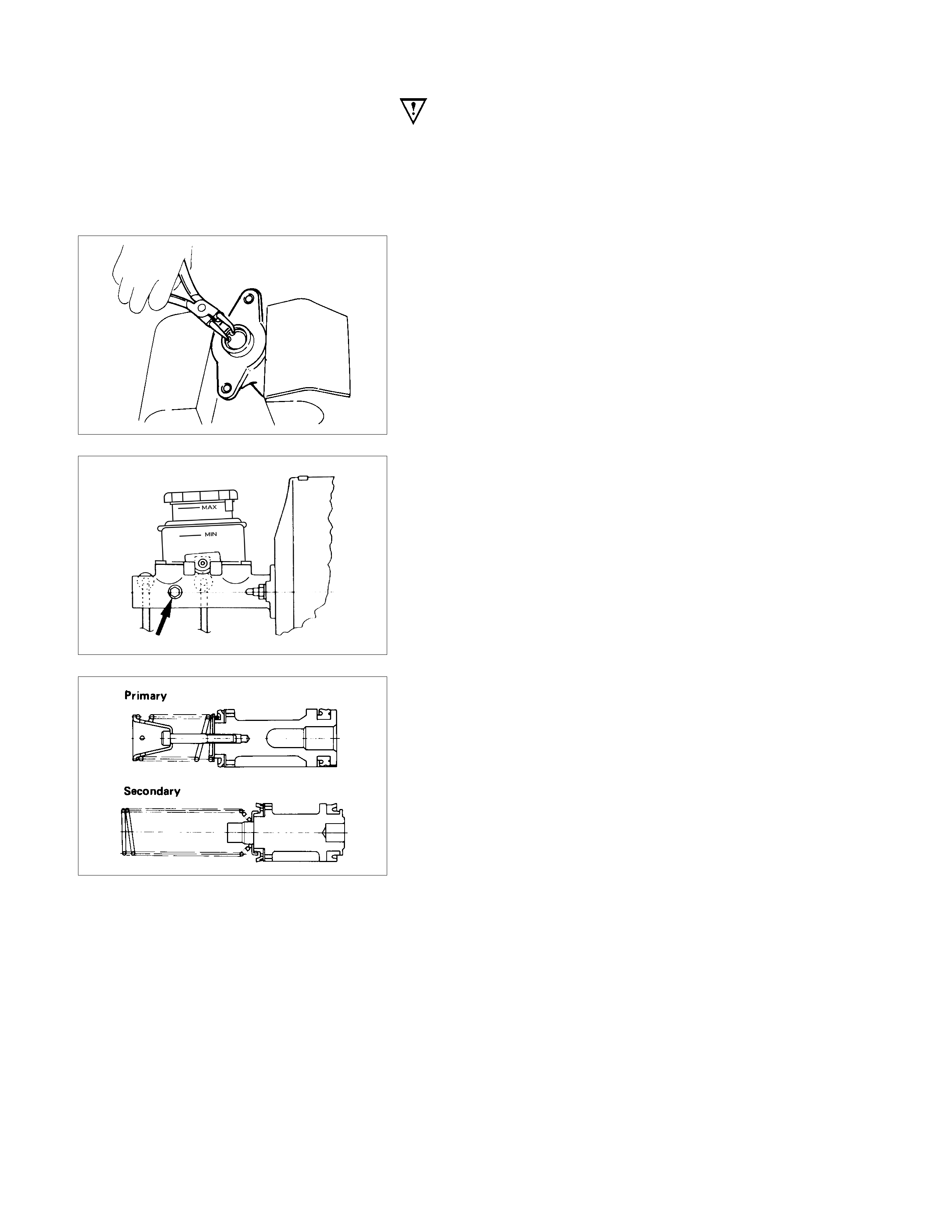

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

• Cylinder inside face

• Piston

• Piston cap

• Piston cap spacer

• Return port

• Return spring

Visual Check

Inspect the following parts for wear, distortion, cuts, nicks,

corrosion, or other abnormal conditions.

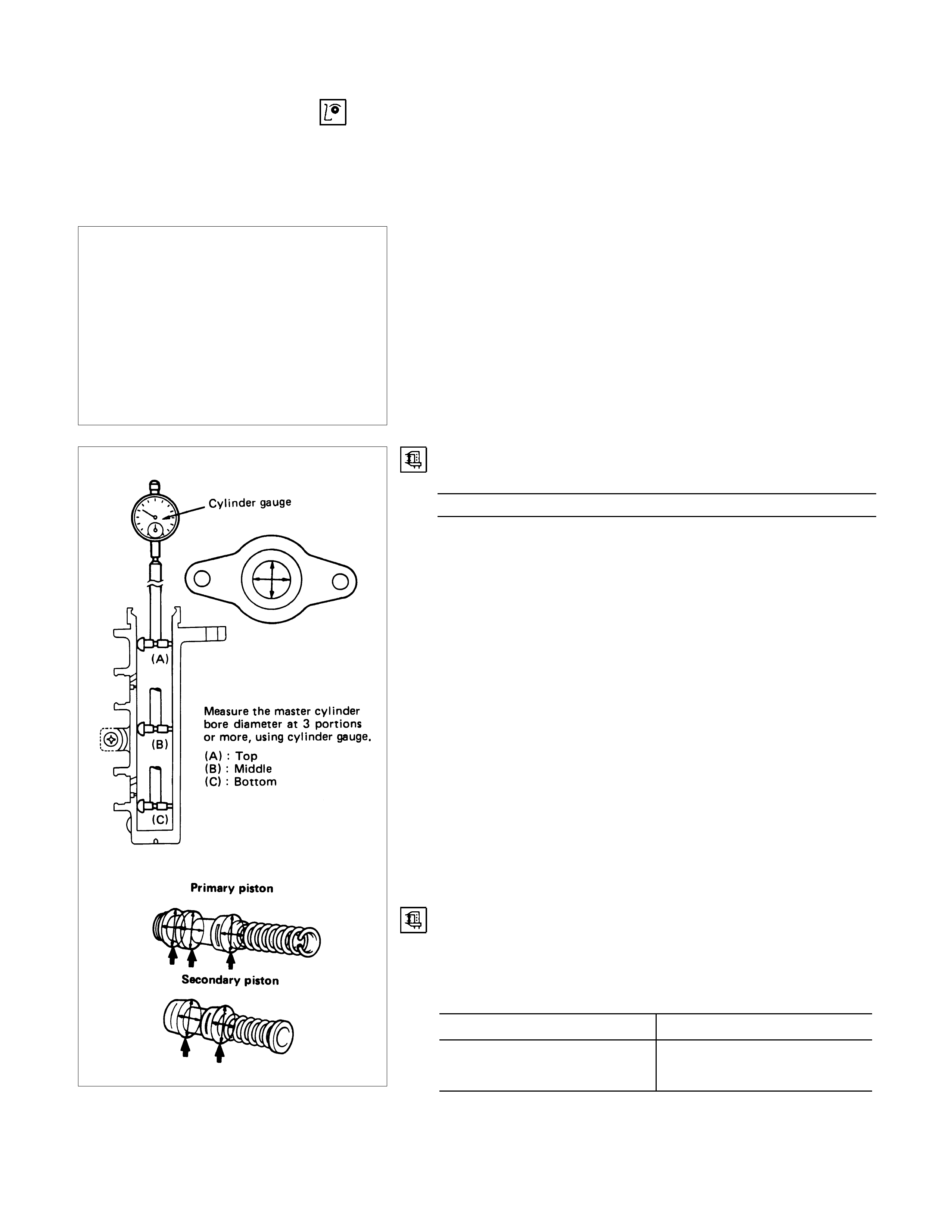

Master Cylinder Bore Diameter

Standard mm(in)

23.81 (0.938)

Clearance between the Master Cylinder

and the Piston

Measure the outer diameter of the piston assembly at the

portions shown in the left figure. mm(in)

Standard Limit

0.04 - 0.125

(0.00158 - 0.00493) 0.15 (0.00591)

Note:

If the clearance deviates from the range shown above,

replace the master cylinder and the piston assembly

together.

Return Port

Check the return port for obstructions and if necessary, clean

with a tag wire.

Blow away foreign matter with compressed air.

Primary Piston

After reassembly, push in the primary piston to see that returns

smoothly.

Repeat the test two or three times to see that brake fluid is

forced out from the front and rear outlets.

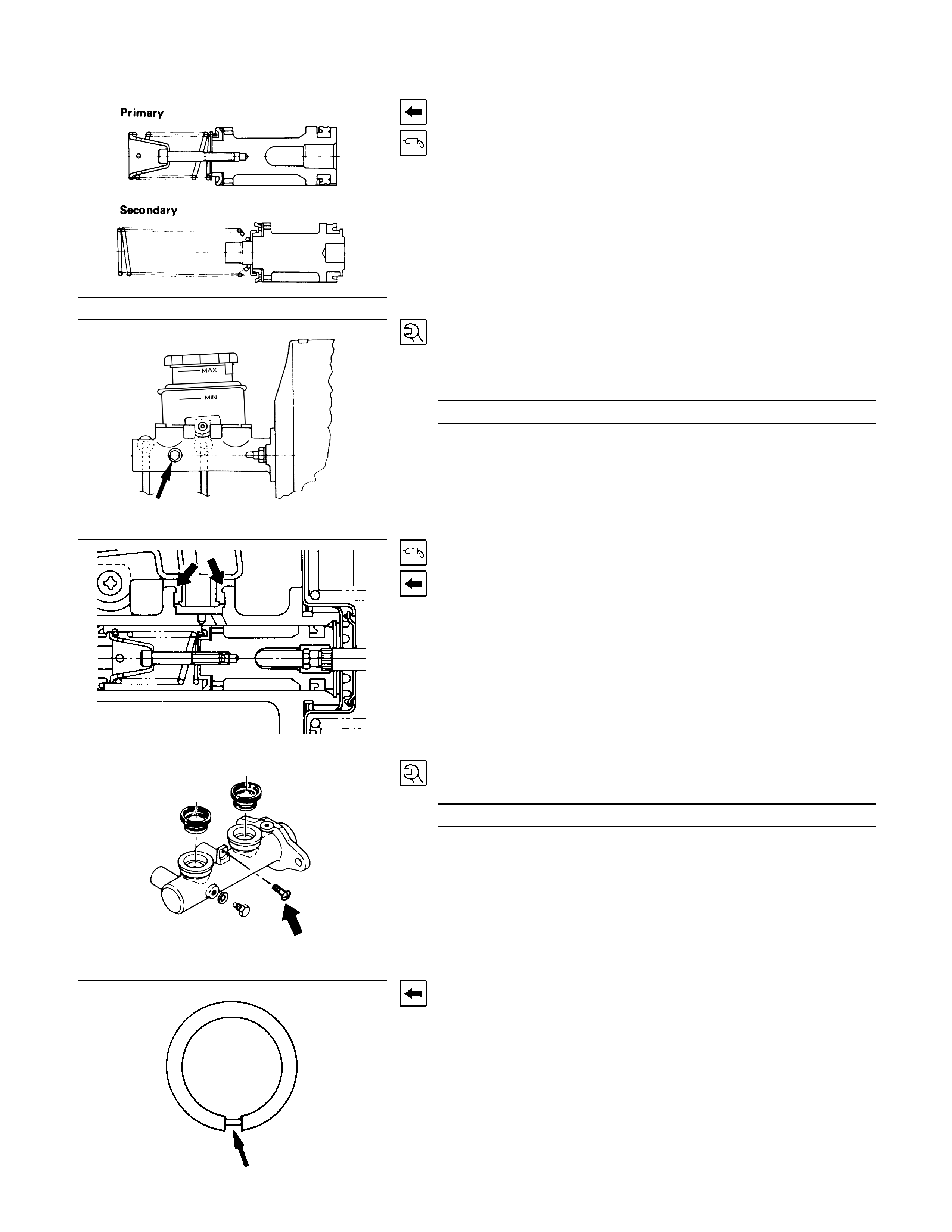

REASSEMBLY

★; Repair Kit

Reassembly Steps

▲1. Cylinder assembly ; brake, master

▲2. Piston assembly ; secondary and spring

▲3. Piston assembly ; primary and spring

4. Ring ; snap

5. Gasket

▲6. Bolt ; stopper

▲7. Grommet

8. Reservoir ; fluid, brake

▲9. Screw

10. Seal

11. Cover ; fluid reservoir

▲12. Dust seal

Important Operations

1. Cylinder Assembly ; Brake, Master

Lubricate the master cylinder bore with clean rubber

grease.(arrowed portion)

2. Piston Assembly ; Secondary and Spring

3. Piston Assembly ; Primary and Spring

Lubricate the piston cups on the primary piston assemblies with

rubber grease.

Take care not to scratch the piston cup when installing the

piston assemblies.

Note:

Don't remove the spring from the piston.

6. Bolt ; Stopper

Depress the primary piston and install the piston stopper bolt

with a new gasket.

Torque N⋅m(kgf⋅m/lb⋅ft)

6.9 - 8.8 (0.7 - 0.9 / 5.1 - 6.5)

7. Grommet

Lubricate the new grommets with clean rubber grease.

Insert the grommets, with the flared side up, into the cylinder

body.

Apply rubber grease to the dust seal portion.

(The portion indicated by the arrows in the left diagram.)

9. Screw

Torque N⋅m(kgf⋅m/lb⋅ft)

1.0 - 2.0 (0.01 - 0.20 / 0.7 - 1.5)

12.Dust Seal

Install the dust seal so that its groove faces downward.

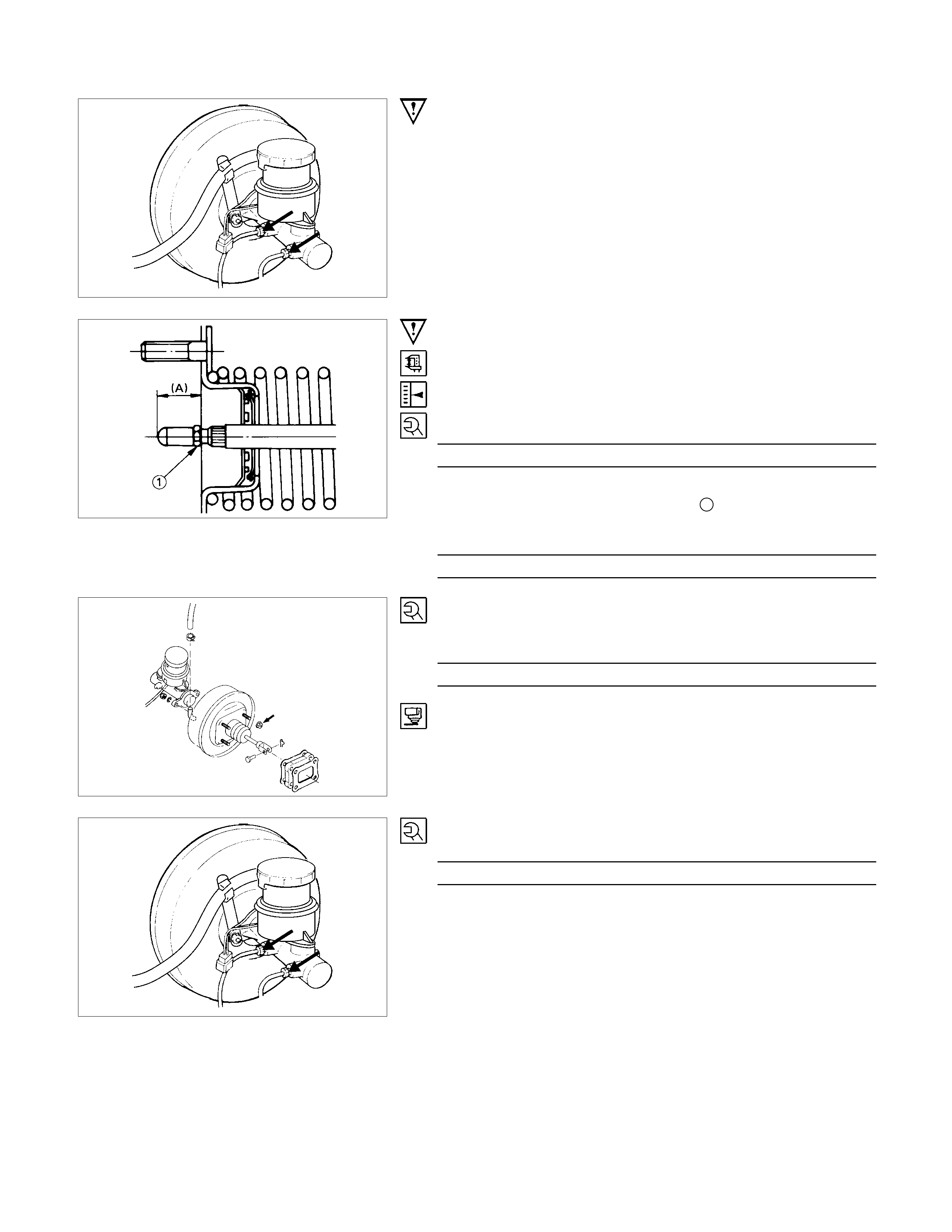

VACUUM SERVO

REMOVAL AND INSTALLATION

Removal Steps

1. Clamp ; vacuum hose

2. Vacuum hose

▲3. Brake line

4. Return spring ; brake pedal

5. Snap pin

6. Pin ; push rod to brake pedal

7. Vacuum servo to dash panel and pedal

mounting bracket

8. Maser cylinder assembly

9. Vacuum servo assembly

Installation Steps

9. Vacuum servo assembly

▲8. Maser cylinder assembly

▲7. Vacuum servo to dash panel and pedal

mounting bracket

6. Pin ; push rod to brake pedal

5. Snap pin

4. Return spring ; brake pedal

▲3. Brake line

▲2. Vacuum hose

1. Clamp ; vacuum hose

Important Operation - Removal

3. Brake Line

When handling, be careful not to spill brake fluid over the

painted surfaces, as damage to the paint finish will result.

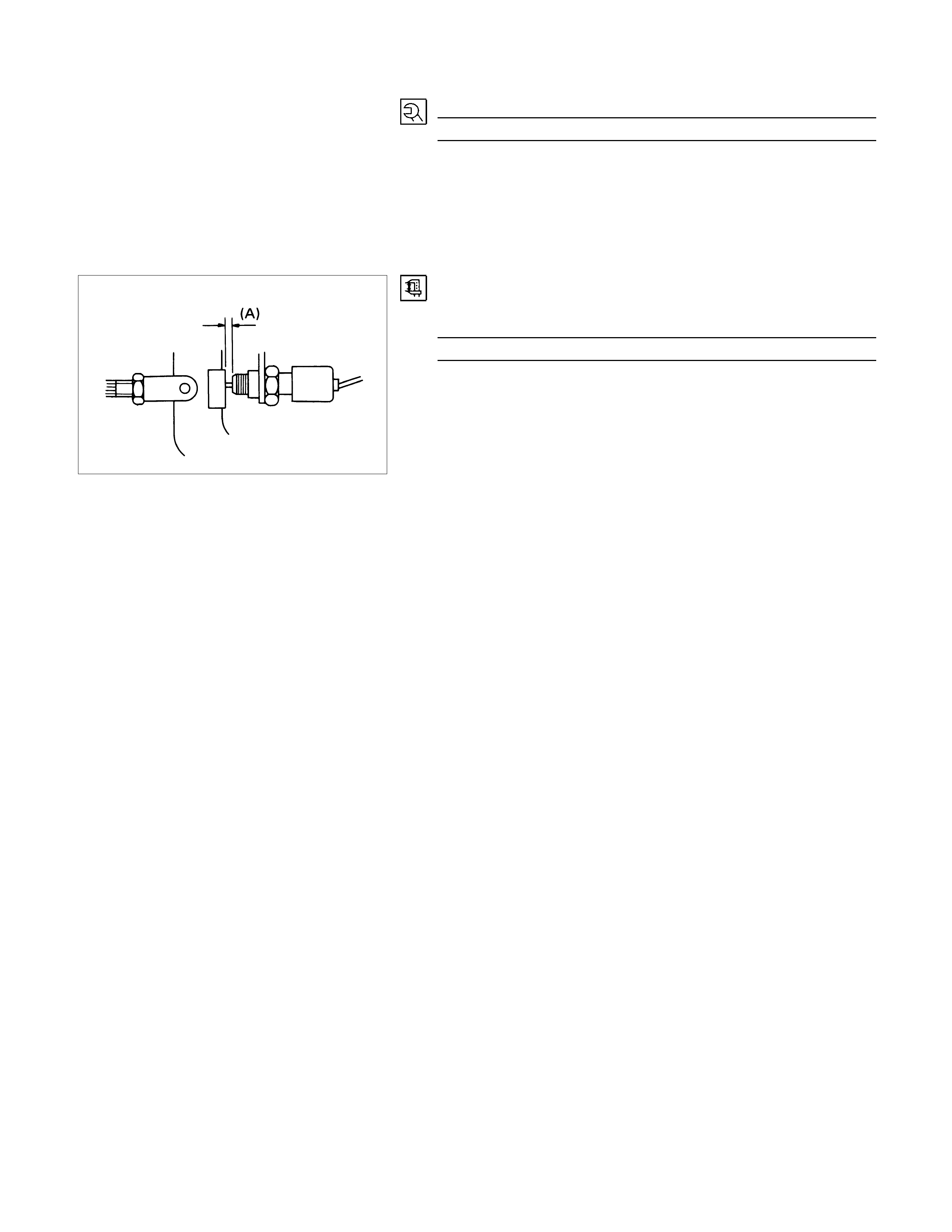

Important Operation - Installation

8. Master Cylinder Assembly

Check the distance from the flange face of the vacuum servo

to the end of the push rod before installation of the master

cylinder.

Projection (A) mm(in)

18.0 - 18.2 (0.709 - 0.717)

If the measured distance deviates from the specified range,

make an adjustment with the lock nut 1 at the end of the push

rod.

Torque N⋅m(kgf⋅m/lb⋅ft)

15 - 25 (1.5 - 2.5 / 11 - 18)

7. Vacuum Servo to Dash Panel and Pedal Mounting

Bracket

Torque N⋅m(kgf⋅m/lb⋅ft)

22 - 31 (2.2 - 3.2 / 16 - 23)

Apply sealer to the dashboard fitting face.

3. Brake Line

Torque N⋅m(kgf⋅m/lb⋅ft)

9 - 15 (0.9 - 1.5 / 6.5 - 11)

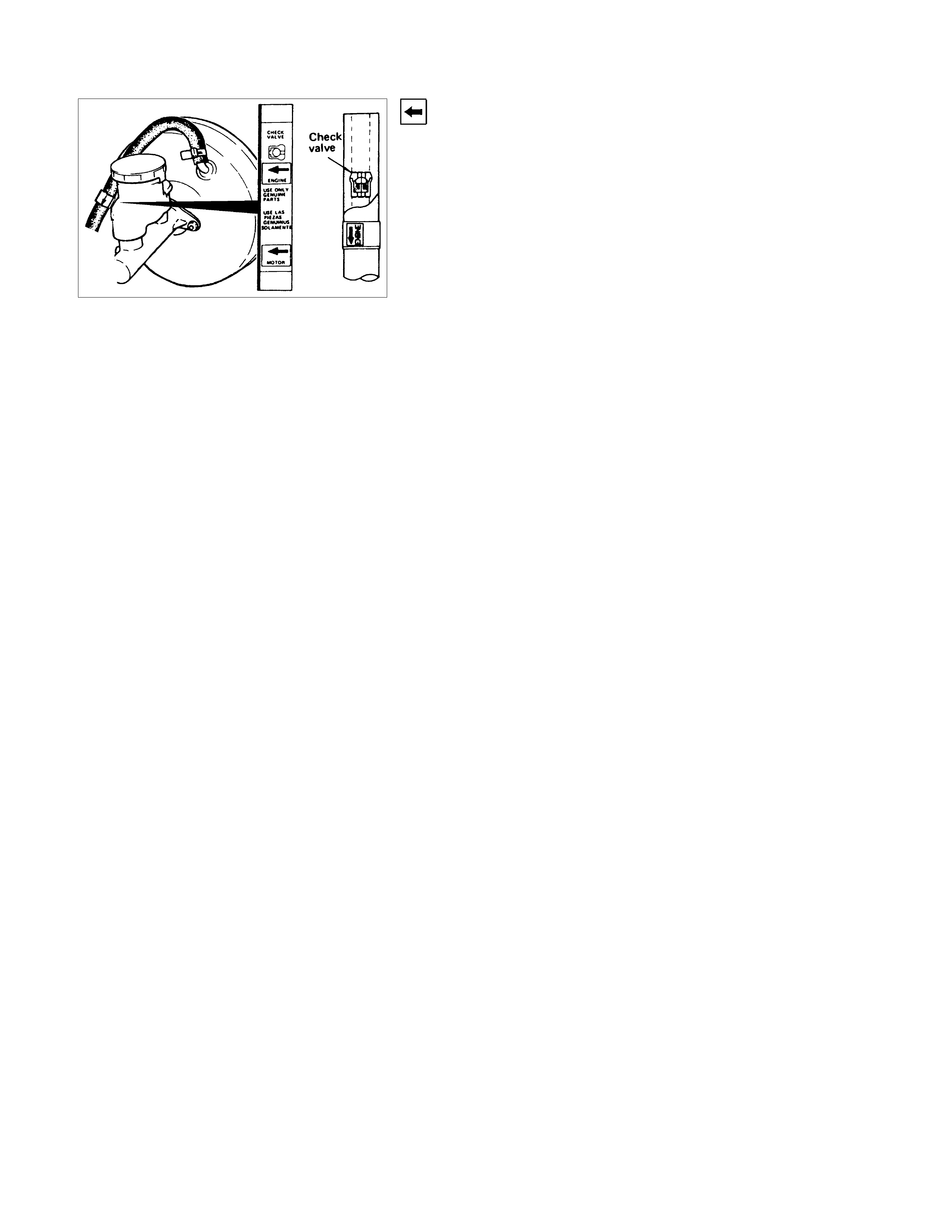

2. Vacuum Hose

1) When removing or replacing the vacuum hose make sure

that the arrow on the label of the hose is facing the engine.

2) Also confirm that the check valve is facing the engine.

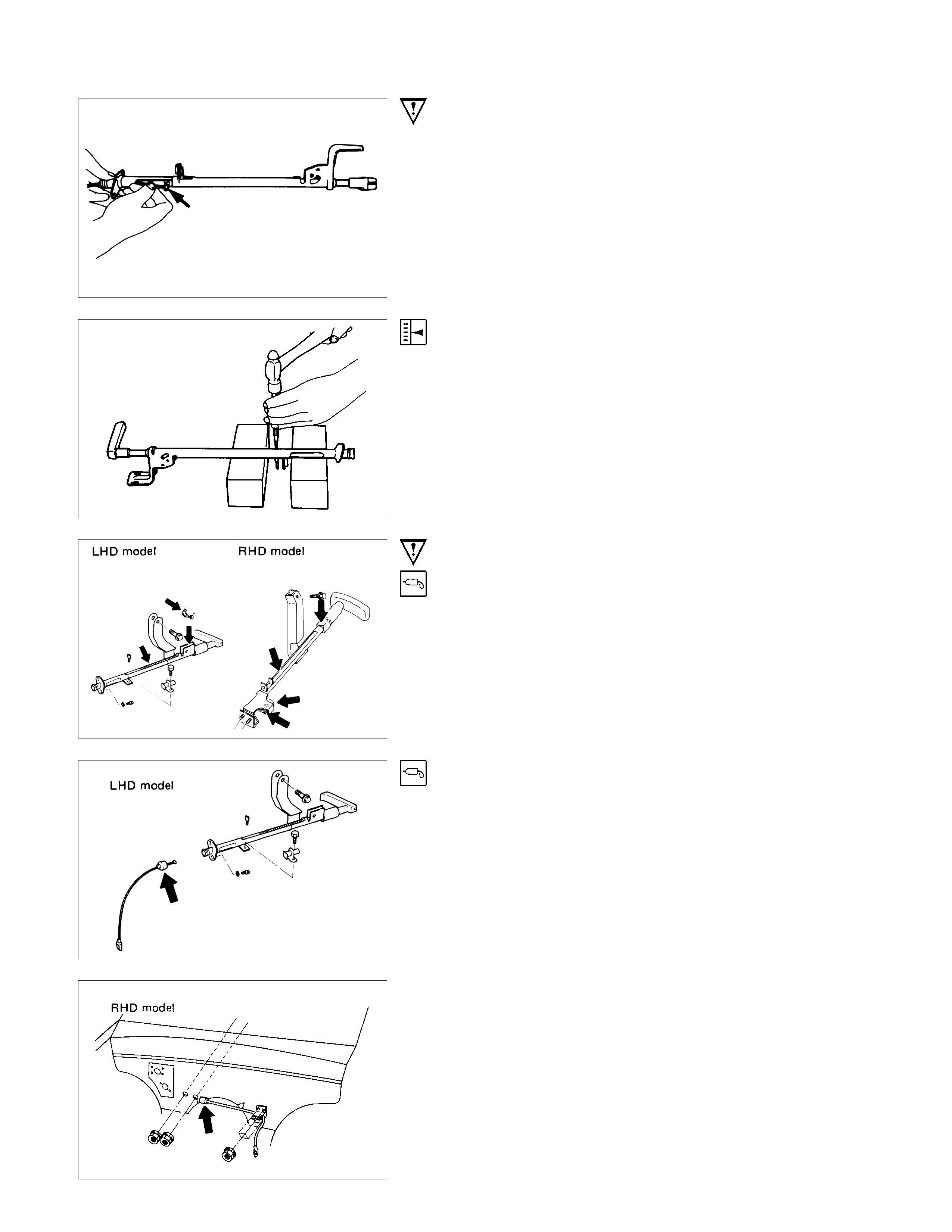

PARKING BRAKE (STEM TYPE)

REMOVAL AND INSTALLATION

PARKING BRAKE STEM ASSEMBLY (LEFT HAND DRIVE MODEL)

Removal Steps

1. Cable front, relay lever side

2. Bolt ; bracket to dash

3. Bolt ; bracket to cross beam

4. Parking brake stem assembly

Installation Steps

To install, follow the removal procedure in

reverse order.

PARKING BRAKE STEM ASSEMBLY (RIGHT HAND DRIVE MODEL)

Removal Steps

1. Bolt and nut

2. Collar

3. Roller

4. Cable front, relay lever side

5. Nuts ; bracket to dash

6. Bolt ; bracket to cross beam

7. Parking brake stem assembly

8. Nuts

9. Bracket ; roller

Installation Steps

To install, follow the removal procedure in

reverse order.

Before installation, apply chassis grease to the

roller (3)'s contact surface to the collar (2) and

cable (4).

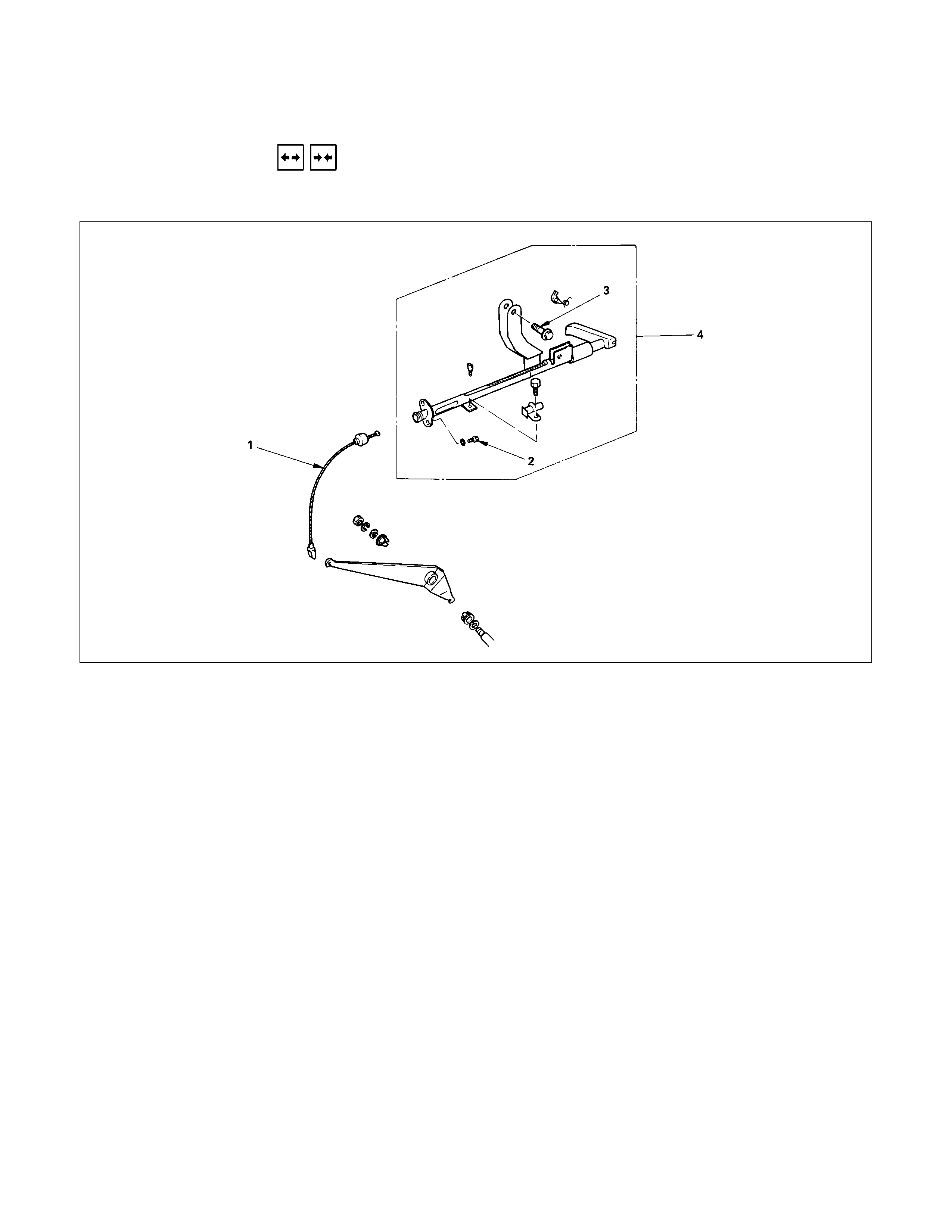

FRONT AND REAR CABLE ASSEMBLY

Removal Steps

1. Nut

2. Equalizer bracket

3. Snap pin, with plan washer

4. Pin with curved washer

5. Cable ; front lower

6. Pin with curved washer

7. Parking brake stem assembly

8. Nuts

9. Clip

10. Clip ; fixing bracket

▲11. Cable assembly ; rear

12. 2nd relay lever assembly with return

spring

13. 1st relay lever assembly

Installation Steps

▲13. 1st relay lever assembly

▲12. 2nd relay lever assembly with return

spring

11. Cable assembly ; rear

10. Clip ; fixing bracket

9. Clip

▲8. Nuts

▲7. Parking brake stem assembly

▲6. Pin with curved washer

5. Cable ; front lower

4. Pin with curved washer

▲3. Snap pin, with plan washer

2. Equalizer bracket

1. Nut

Important Operations - Removal

11.Cable Assembly ; Rear

When abrasion or wear is evident on edge protector, in must

be replaced with new one.

Important Operations - Installation

13.1st Relay Lever Assembly

Apply grease (BESCO L-2 or equivalent) to the inner and outer

surface of the bushes and cable connecting portions.

12.2nd Relay Lever Assembly with Return Spring

Apply grease (BESCO L-2 or equivalent) to the arrowed portion

in the left figure.

8. Intermediate Cable

After applying grease (BESCO L-2 or equivalent) to the cable

guide, set it to the bracket by striking lightly with a mallet.

Apply grease (BESCO L-2 or equivalent) to the arrowed portion

in the left figure.

7. Pin with Curved Washer

Apply grease (BESCO L-2 or equivalent) to the circumference

of the pin and joint.

6. Snap pin, with Plain Washer

3. Snap pin, with Plain Washer

Discard the used snap pins and use new parts.

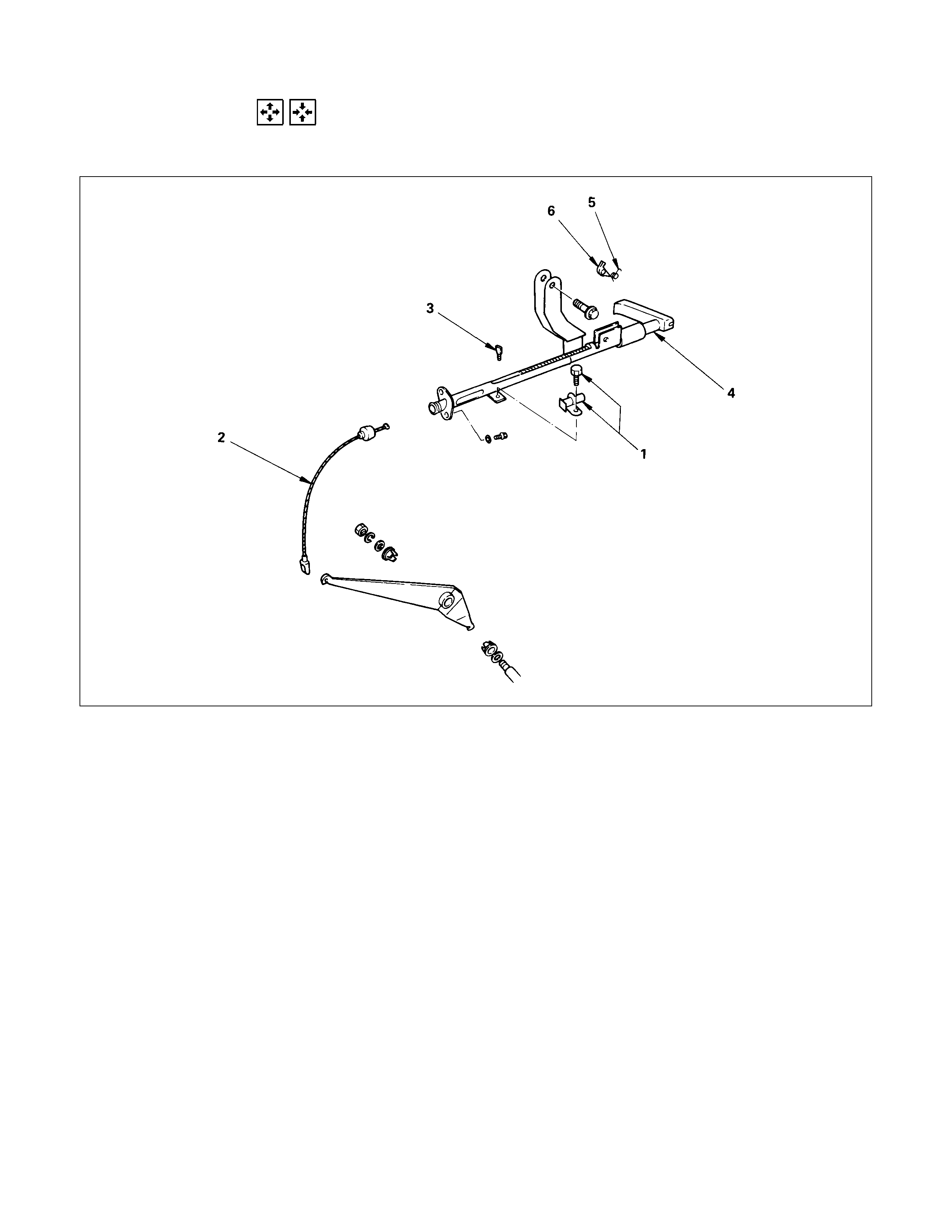

DISASSEMBLY AND REASSEMBLY

PARKING BRAKE STEM ASSEMBLY

This illustration is based on the LHD model

Disassembly Steps

1. Switch ; parking brake and bolt

▲2. Cable ; front

▲3. Switch actuating pin

4. Stem

5. Spring

6. Pole

Reassembly Steps

▲6. Pole

5. Spring

▲4. Stem

3. Switch actuating pin

▲2. Cable ; front

1. Switch ; parking brake and bolt

Important Operations - Disassembly

2. Cable ; Front

Manually release the lever ratchet and depress the stem until

the cable attachment at the lower end of the stem is visible.

Remove the cable from the stem lower end.

3. Switch Actuating Pin

Align the parking brake switch actuating pin with the hole in the

housing.

Using a flat head punch, drive out the pin.

Important Operations - Reassembly

6. Pole

4. Stem

Before reassembly, apply chassis grease to the arrowed

portion in the left figures.

2. Cable ; Front

Before reassembly, apply chassis grease to the entire inside

surface of the cable boot (arrowed in the left figure)fully.

INSPECTION AND REPAIR

Make necessary adjustments, repairs, and parts replacements if wear, damage or other problems are discovered

during inspection.

Refer to "SERVICING" in this section for

adjustment procedure of parking brake.

Adjustment Procedure of Parking Brake

•Parking brake

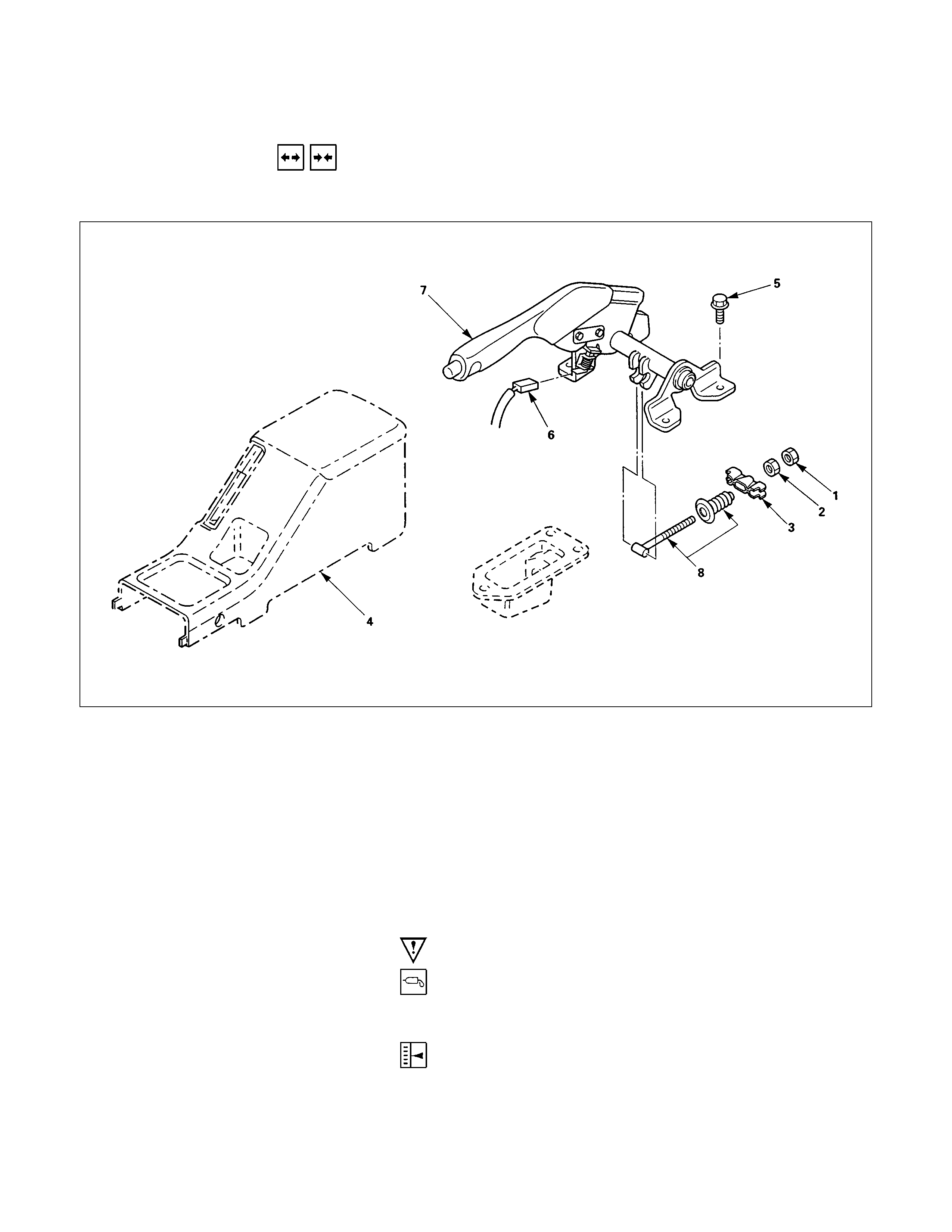

PARKING BRAKE (FLOOR MOUNT TYPE)

REMOVAL AND INSTALLATION

PARKING BRAKE LEVER AND FRONT CABLE ASSEMBLY

Removal Steps

1. Lock nut

2. Adjust nut

3. Equalizer

4. Center console

5. Bolt

6. Switch connector

7. Parking brake lever

8. Parking brake front cable

Installation Steps

▲8. Parking brake front cable

7. Parking brake lever

6. Switch connector

▲5. Bolt

4. Center console

3. Equalizer

2. Adjust nut

1. Lock nut

Important Operation - Installation

8.Parking Brake Front Cable

Apply grease (BESCO L-2 or equivalent) to the front cable

before installation.

•After installation, be sure to adjust the parking brake.

Refer to "SERVICING" of this section.

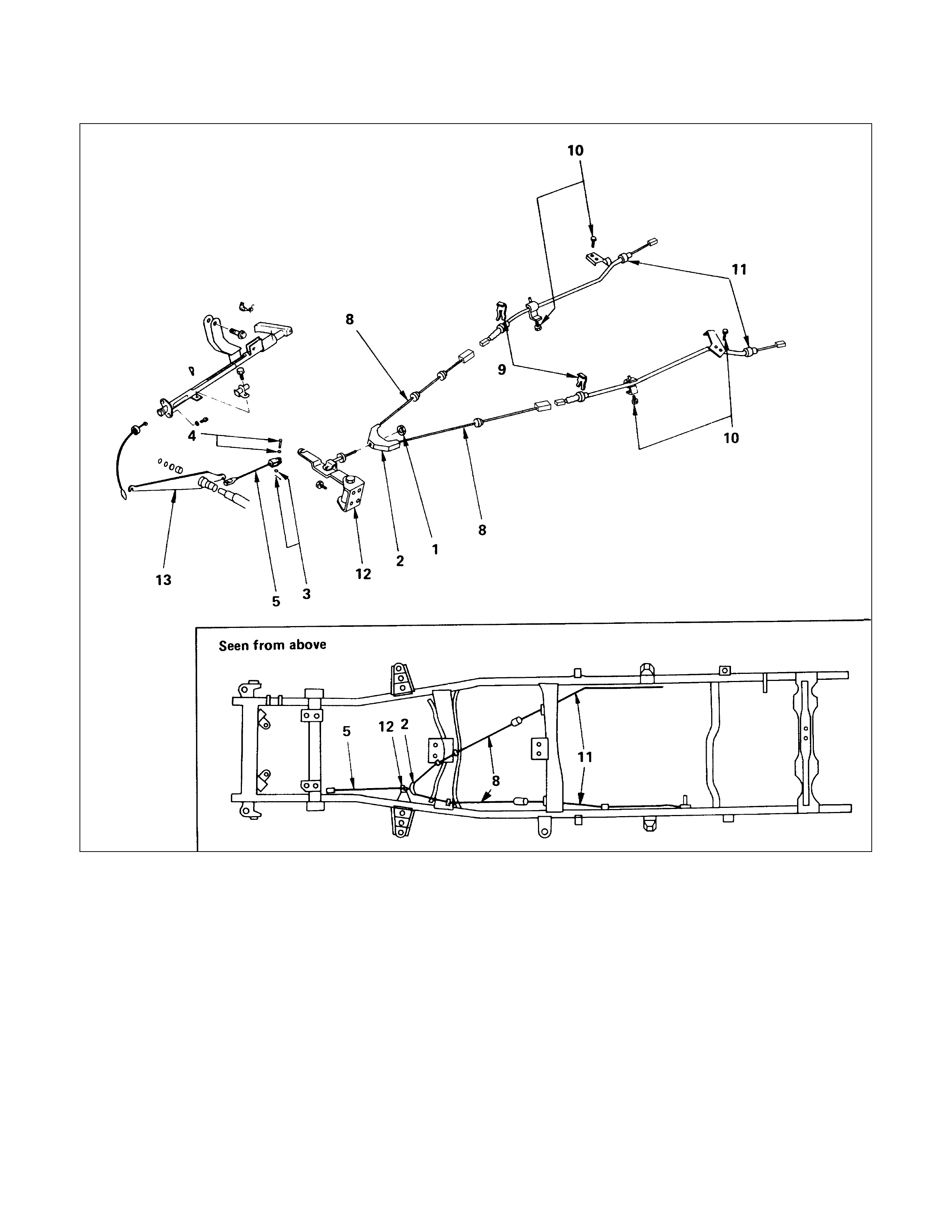

REAR CABLE ASSEMBLY

Removal Steps

▲1. Lock nut

▲2. Adjusting nut

▲3. Bolt

▲4. Retainer

5. Clip and bolt ; crossmember

6. Clip and bolt ; side member

7. Clip and bolt ; side member

8. Clip and bolt ; spring eye

9. Clip and bolt ; leaf spring

10. Hand brake rear cable

Installation Steps

▲10. Hand brake rear cable

▲9. Clip and bolt ; leaf spring

▲8. Clip and bolt ; spring eye

▲7. Clip and bolt ; side member

▲6. Clip and bolt ; side member

▲5. Clip and bolt ; crossmember

▲4. Retainer

▲3. Bolt

▲2. Adjusting nut

▲1. Lock nut

Important Operations - Removal

Preparation

•Raise vehicle to the working level.

Support the axle assembly with the proper jack and chassis

stands.

•Remove the tire and wheel.

•Remove the brake drum.

1.Lock Nut

2.Adjusting Nut

3.Bolt

4.Retainer

•Loosen lock nut and adjusting nut, then disconnect rear

cable from the equalizer.

•Remove bolt and retainer.

Important Operations - Installation

10.Hand Brake Rear Cable

•Apply grease (BESCO L-2 or equivalent) to the

circumference of the pin and joint.

•Apply grease (BESCO L-2 or equivalent) to the equalizer

joint portion.

9.Clip and Bolt; Leaf Spring

8.Clip and Bolt; Spring Eye

7.Clip and Bolt; Side Member

6.Clip and Bolt; Side Member

5.Clip and Bolt; Crossmember

TorqueN⋅m (kgf⋅m/lb⋅ft)

6 (0.6 / 4.3)

4.Retainer

3.Bolt

TorqueN⋅m(kgf⋅m/lb⋅ft)

16 (0.6 / 4.3)

2.Adjusting Nut

1.Lock Nut

•Apply grease (BESCO L-2 or equivalent) to the front cable

contact portion.

•Connect rear cable to the equalizer, then adjust the parking

brake. Refer to "SERVICING".

•Tighten lock nut to the specified torque.

Torque N⋅m(kgf⋅m/lb⋅ft)

16 (0.6 / 4.3)

TROUBLESHOOTING

Condition and Cause Correction

Poor Brake Action

Master cylinder faulty Correct or replace

Power cylinder faulty Correct or replace

Level of brake fluid in reservoir too low Replenish and bleed

Air in hydraulic circuit Bleed

Front disc brake caliper faulty Clean or replace

Rear brake wheel cylinder faulty Clean or replace

Water or oil on brake pads or linings Clean or replace

Brake pads or linings hardened Replace

Brake pads or linings in poor contact with rotor or brake drum Correct

Brake pads or linings worn Replace

Brake disc or drum rusted Grind or replace

Check valve in vacuum hose faulty Correct or replace

Brake Squeak

Brake pads or linings worn Replace

Brake pads or linings hardened Replace

Brake pads or linings in poor contact with rotor or brake drum Correct

Brake disc(s) warped, worn or damaged Grind or replace

Disc brake anti-squeak shims fatigued Replace

Front hub bearings loose or preload is incorrect Adjust or replace

Brake disc or drum rusted Grind or replace

Brake Pull

Tire inflation pressures unequal Adjust

Front wheel alignment incorrect Adjust

Water or oil on brake pads or linings Clean or replace

Brake pads or linings hardened Replace

Brake pads or linings worn excessively Replace

Brake drum or rotor worn or scored Grind or replace

Front or rear wheel cylinder or disc brake caliper malfunctioning Clean or replace

Front hub bearing preload incorrect Adjust or replace

Brake pad or lining clearances unequal Adjust or replace

Brake Drag

Parking brake maladjusted Adjust

Brake pad or lining clearance insufficient Adjust

Brake pedal free play insufficient Adjust brake pedal height or power cylinder operating rod

Piston in master cylinder sticking Clean or replace

Pistons in disc brake caliper sticking Replace piston seals

Pistons in rear brake wheel cylinders sticking Clean or replace

Brake pads sticking in caliper Clean

Return springs weakened Replace

Parking brake binding Overhaul rear brakes

Front hub bearing preload incorrect Adjust or replace

Rear brake shoes not returning Correct or replace brake back plate, check automatic adjuster and

replace as necessary

Obstructions in hydraulic circuit Clean

Rotor warped excessively Grind or replace

Rear brake drum distorted Grind or replace

Piston cups swollen Replace brake fluid and piston cups

Check valve ; vacuum hose faulty Replace

Parking cable sticking Clean or replace

Rear disc brake over adjust Adjust or overhaul rear brakes

Excessive Brake Pedal Travel

Air in hydraulic circuit Bleed hydraulic circuit

Level of brake fluid in reservoir too low Replenish brake fluid reservoir to specified level and bleed hydraulic

circuit as necessary.

Master cylinder push rod clearance excessive Adjust

Leakage in hydraulic system Correct or replace defective parts

Rear disc brake autoadjuster malfunction Overhaul rear brakes