SECTION 6A - ENGINE MECHANICAL (4JB1T MODELS)

MAIN DATA AND SPECIFICATIONS

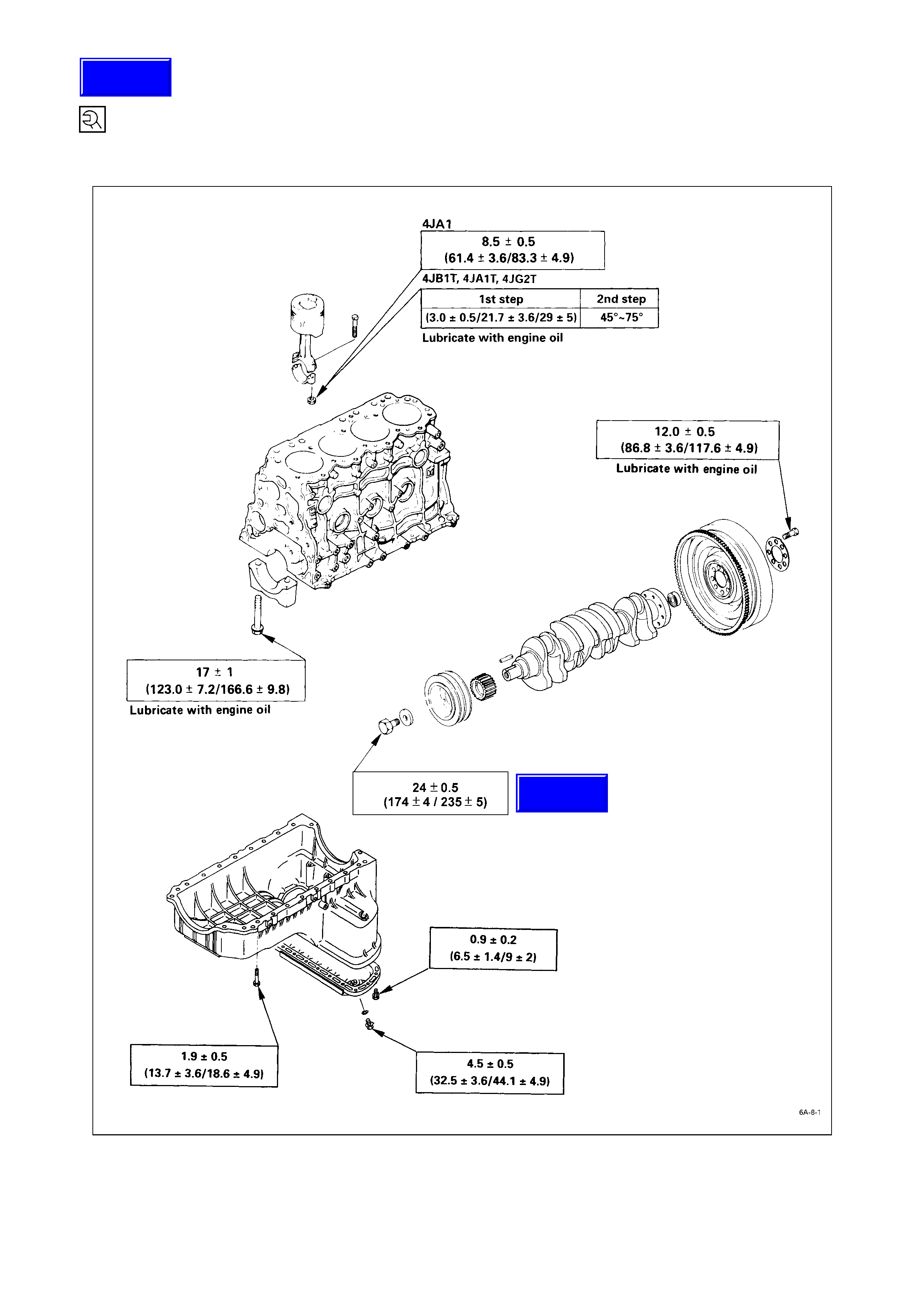

TORQUE SPECIFICATIONS

STANDARD BOLTS

SPECIAL PARTS FIXING NUTS AND BOLTS

CYLINDER HEAD COVER, CYLINDER HEAD, AND ROCKER ARM SHAFT BRACKET

CRANKSHAFT BEARING CAP, CONNECTING ROD BEARING CAP,CRANKSHAFT DAMPER PULLEY,

FLYWHEEL, AND OIL PAN

TIMING GEAR CASE, PULLEY HOUSING, TIMING GEAR, AND CAMSHAFT

COOLING AND LUBRICATING SYSTEM

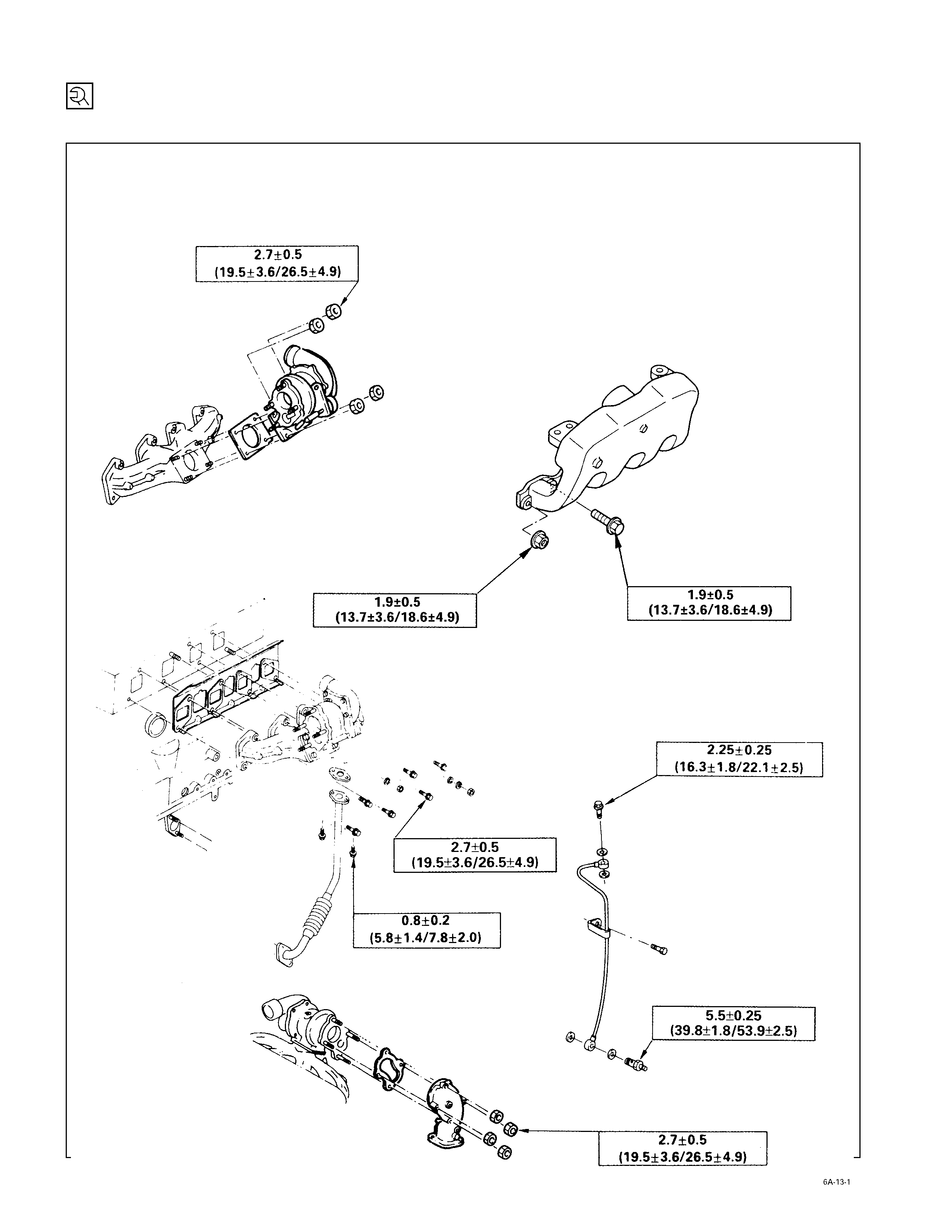

INTAKE MANIFOLD, EXHAUST MANIFOLD, AND TURBOCHARGER

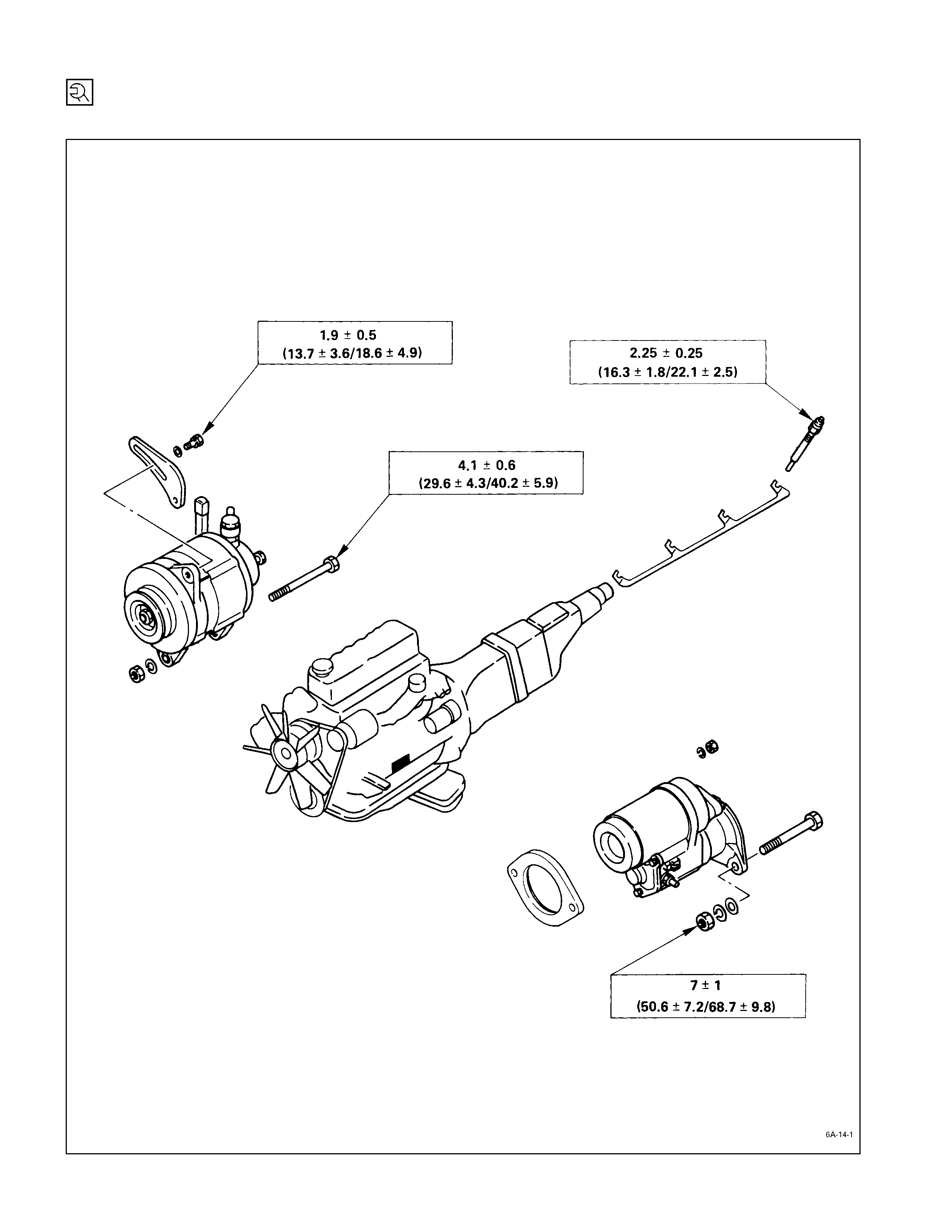

ENGINE ELECTRICA LS

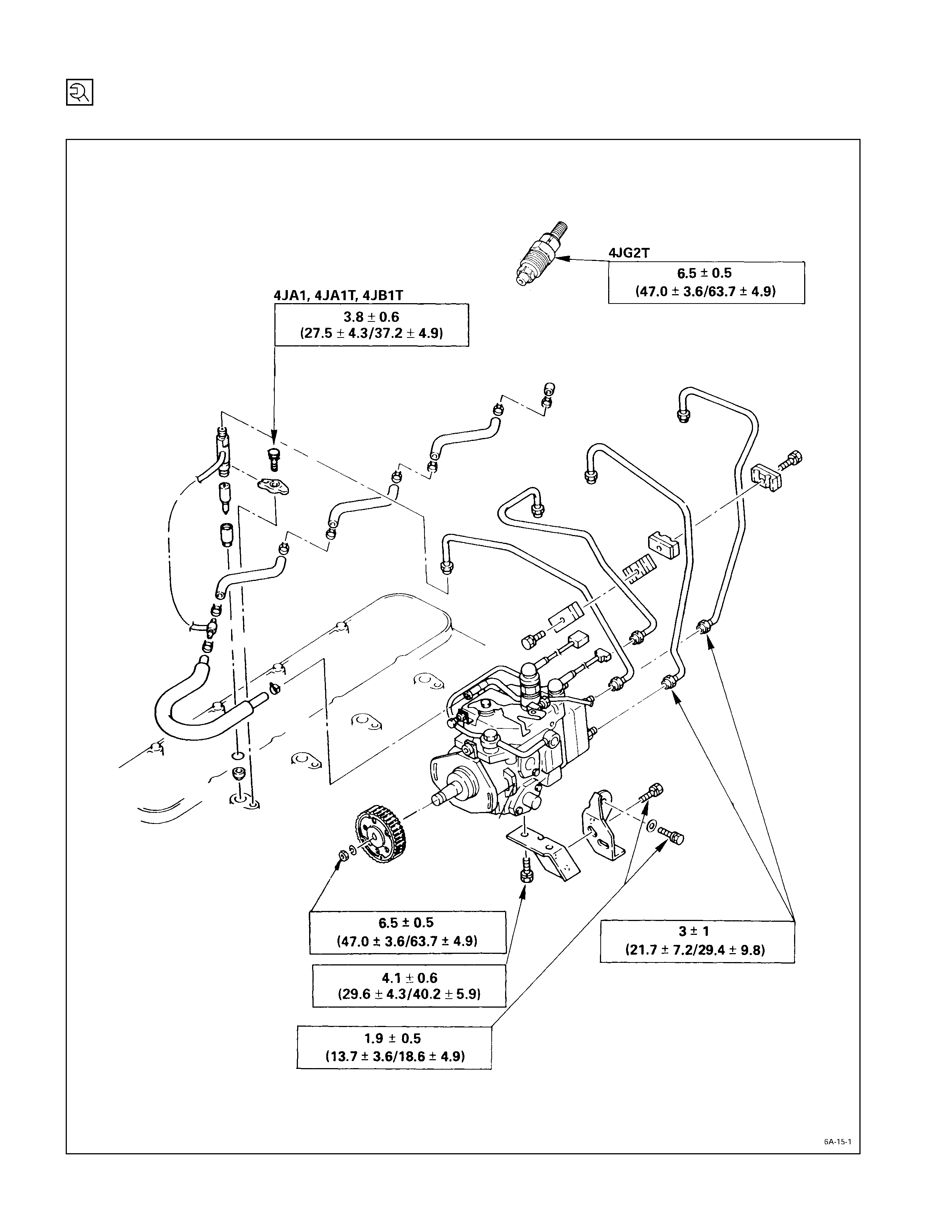

FUEL INJECTION SYSTEM

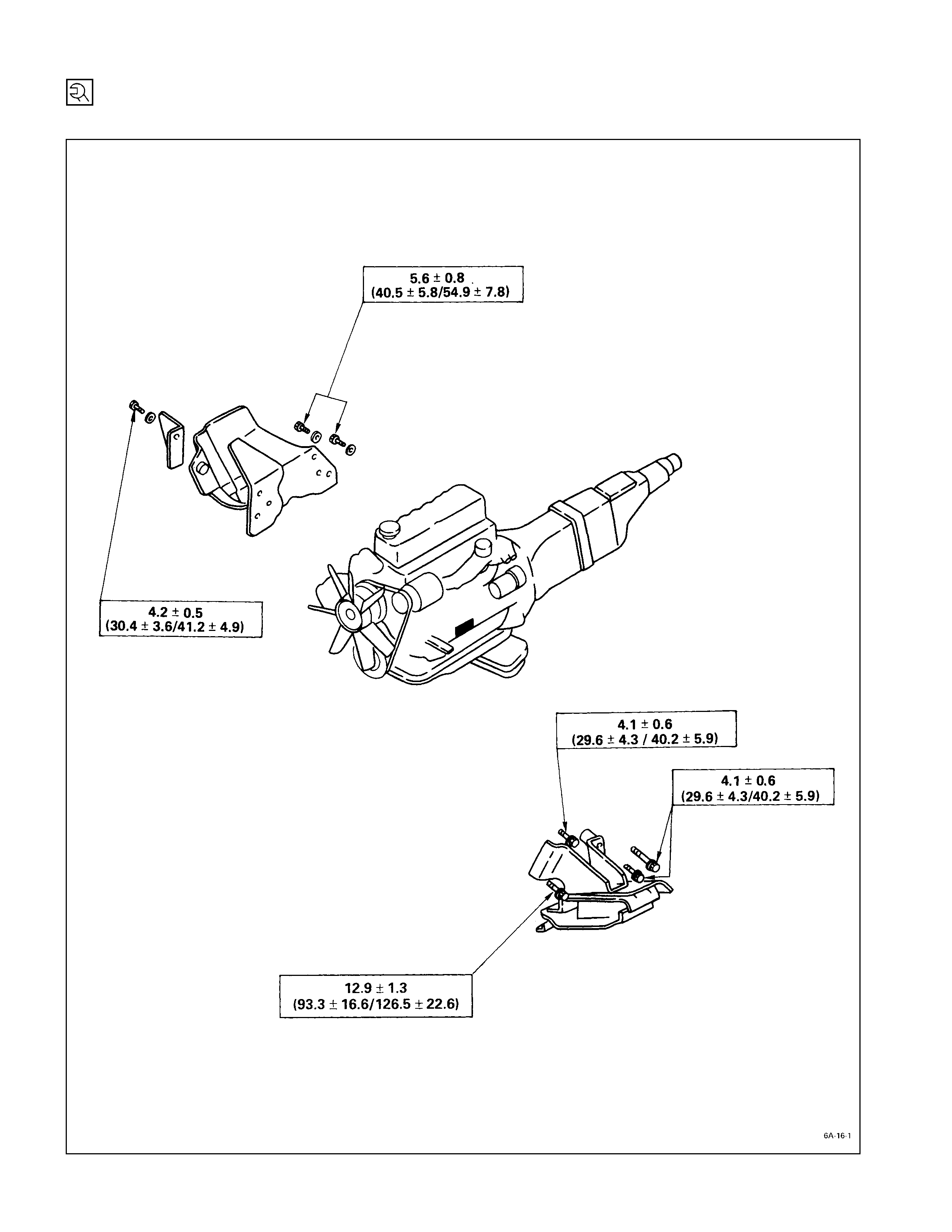

ENGINE MOUNTING BRACKET

RECOMMENDED LIQUID GASKET

LOCTITE APPLICATION PROCEDURE

SERVICING

LUBRICATING SYSTEM

FUEL SYSTEM

COOLING SYSTEM

ENGINE CONTROL

ACCELERA TOR CONTROL

PRE-HEATING SYSTEM

GENERAL DESCRIPTION

REMOVAL AND INSTALLATION

BATTERY

ENGINE HOOD

FUEL FILTER AND WATER SEPARATOR

AIR CLEANER

COOLANT

GEAR SHIFT LEVER

TRANSFER CHANGE LEVER (FOR 4 × 4)

RADIATOR

SUPPORTING THE VEHICLE

ENGINE OIL DRAINING

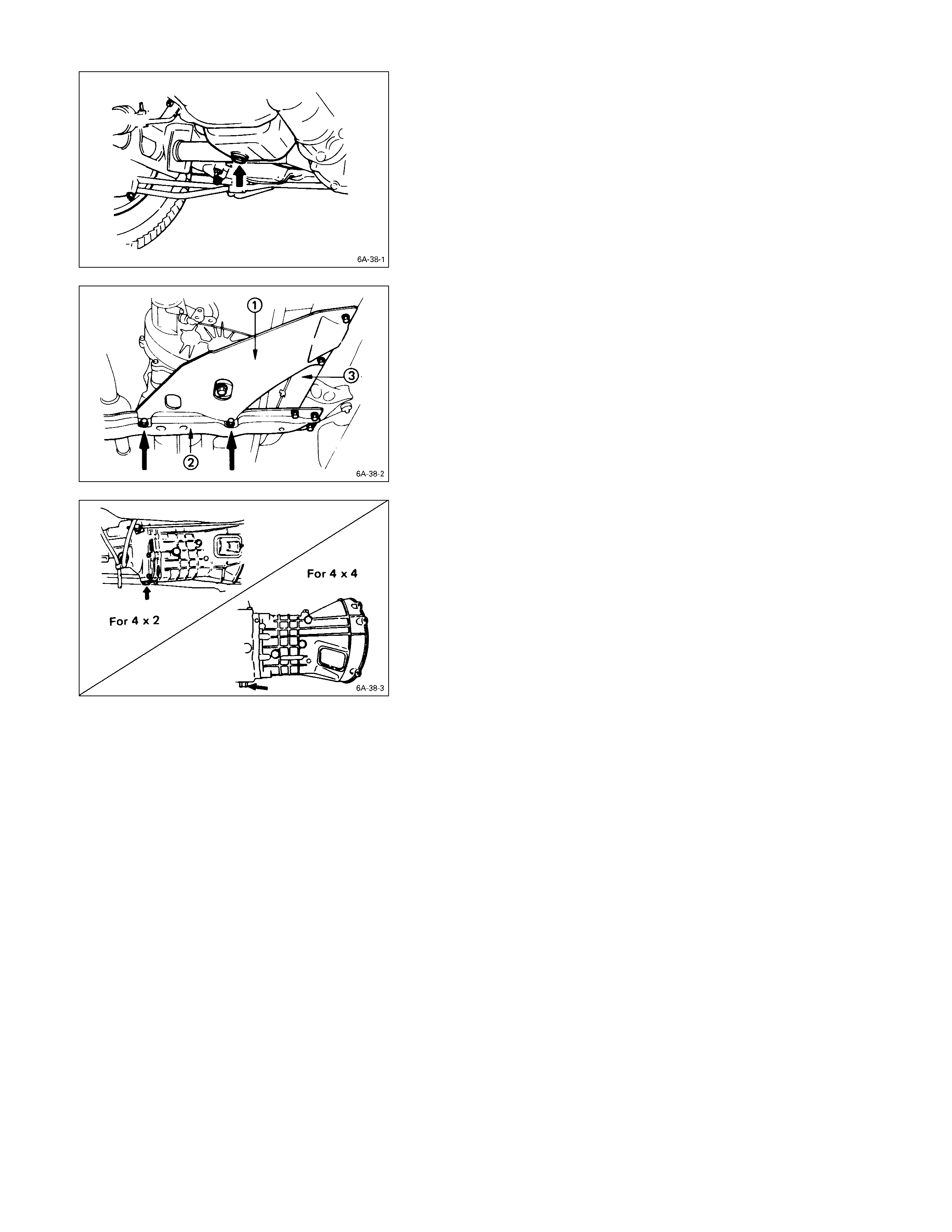

TRANSFER CASE PROTECTOR (4 × 4 MODEL)

TRANSMISSION OIL DRAINING

CONTROL CABLES OR RODS

EXHAUST PIPE

REAR PROPELLER SHAFT

FRONT PROPELLER SHAFT (FOR 4 × 4)

TRANSMISSION

ENGINE

TRANSMISSION

Techline

Techline

Techline

Techline

Techline

EXHAUST PIPE

FRONT PROPELLER SHAFT (FOR 4 × 4)

REAR PROPELLER SHAFT

TRANSFER CASE PROTECTOR (FOR 4 × 4)

GEAR SHIFT LEVER

TRANSFER CHANGE LEVER (FOR 4 × 4)

RADIATOR

LOWERING THE VEHICLE

COOLANT REPLENISHMENT

ENGINE OIL REPLENISHMENT

ENGINE HOOD

BATTERY

ENGINE WARM-UP

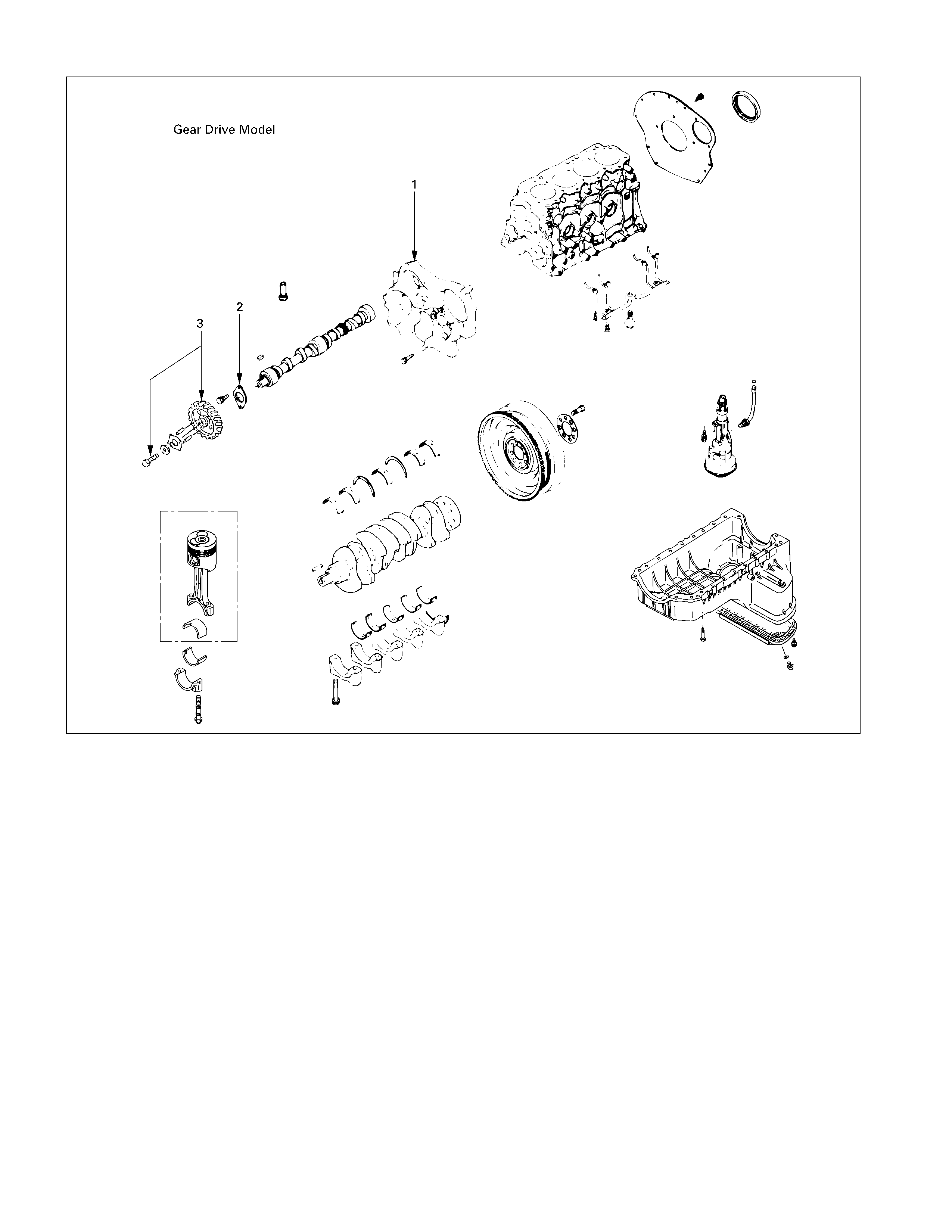

ENGINE REPAIR KIT

ENGINE OVERHAUL

REMOVAL

EXTERNAL PARTS

INTERNAL PARTS

MAJOR COMPONENTS

MINOR COMPONENTS

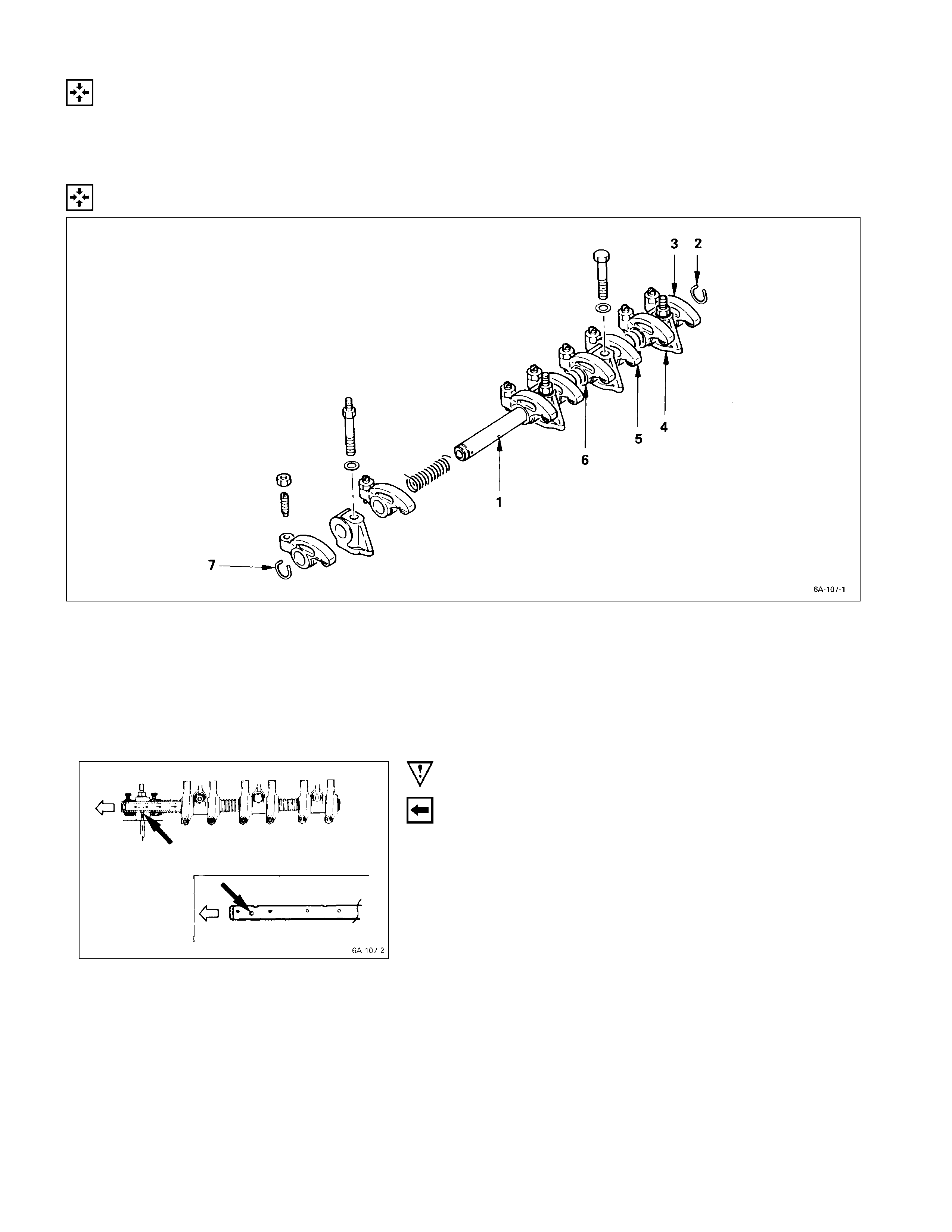

ROCKER ARM SHAFT AND ROCKER ARM

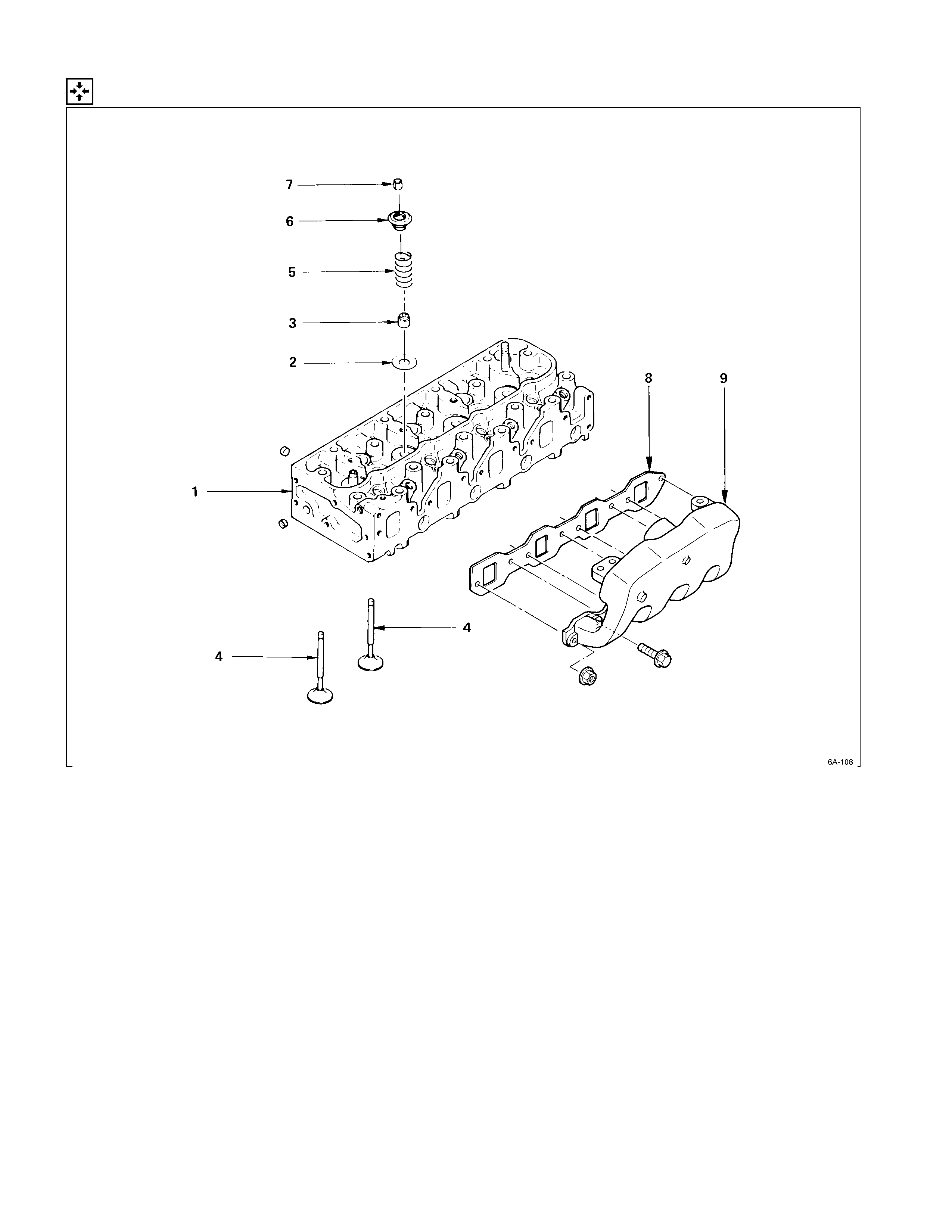

CYLINDER HEAD

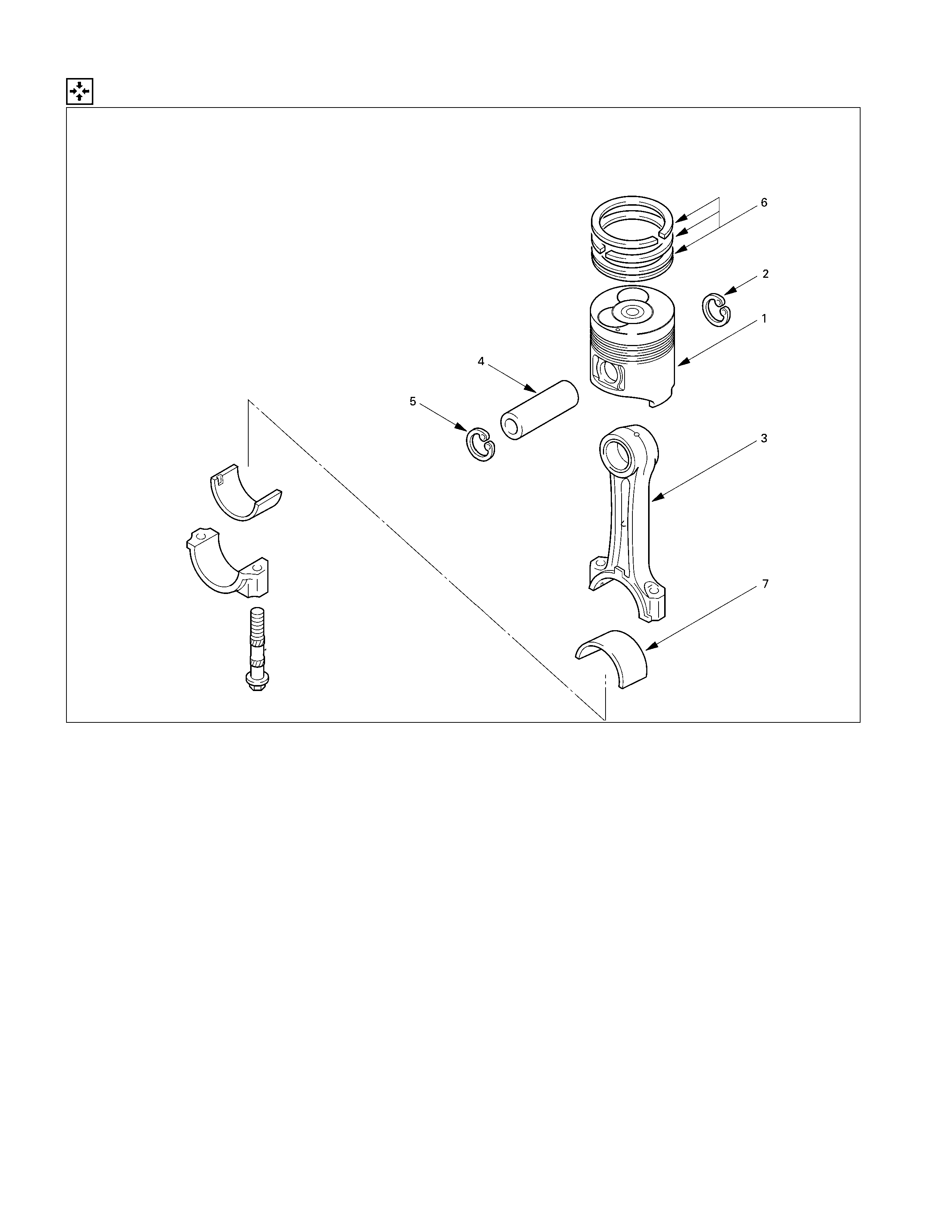

PISTON AND CONNECTING ROD

INSPECTION AND REPAIR

CYLINDER HEAD

VALVE GUIDE

VALVE AND VALVE SEAT INSERT

CYLINDER BODY

ROCKER ARM SHAFT AND ROCKER ARM

VALVE SPRING

TAPPET AND PUSH ROD

CAMSHAFT

CRANKSHAFT AND BEARING

CRANKSHA FT BEARING SELECTION

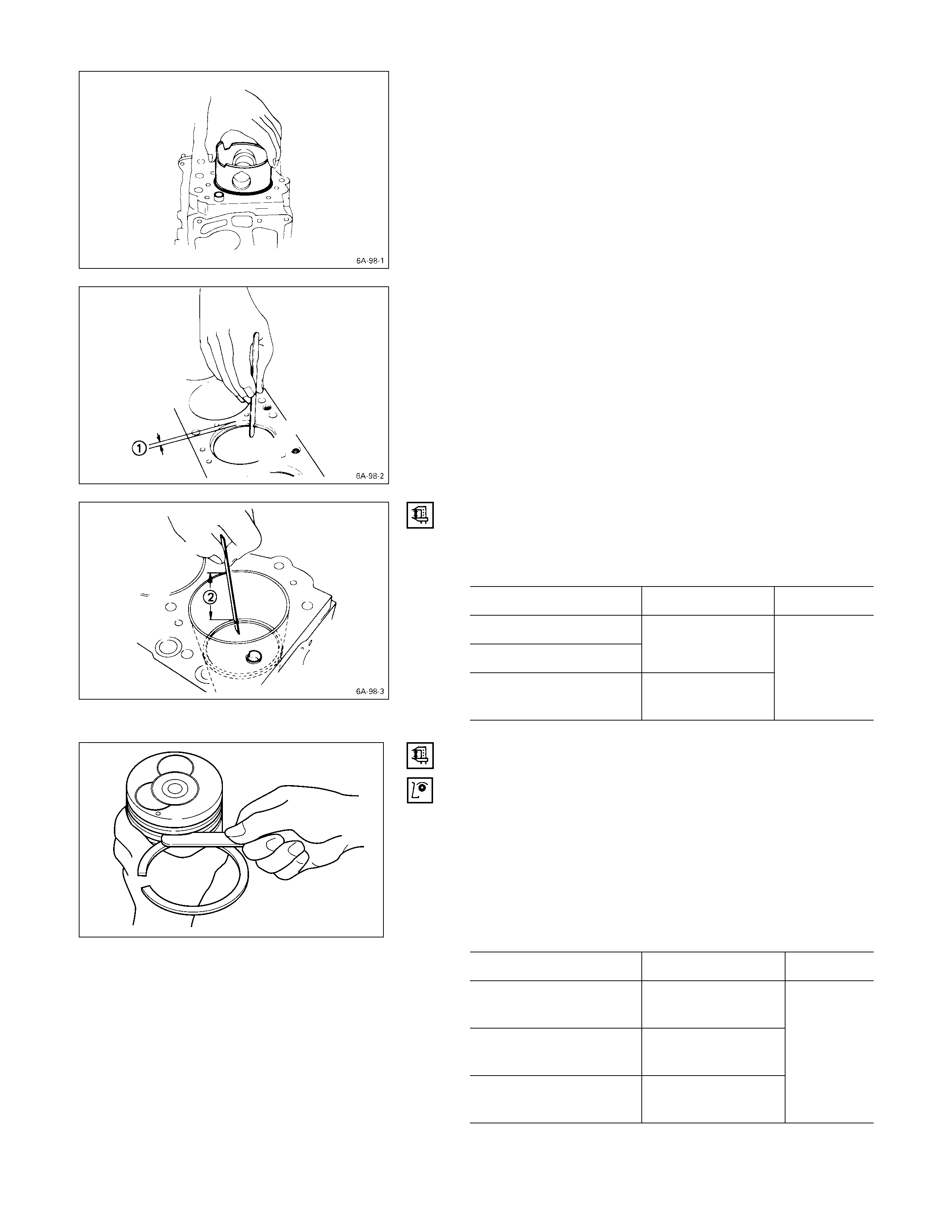

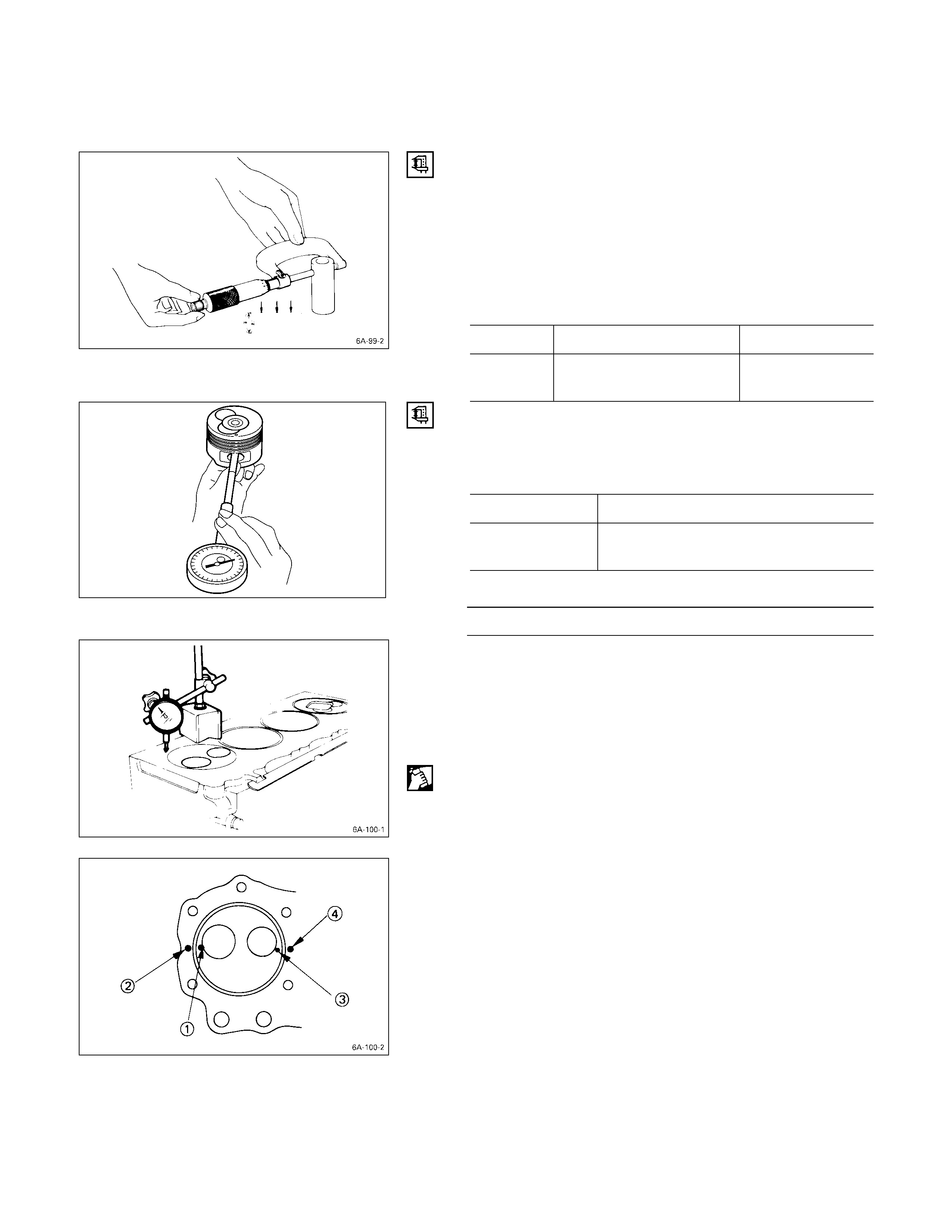

FLYWHEEL AND RING GEAR

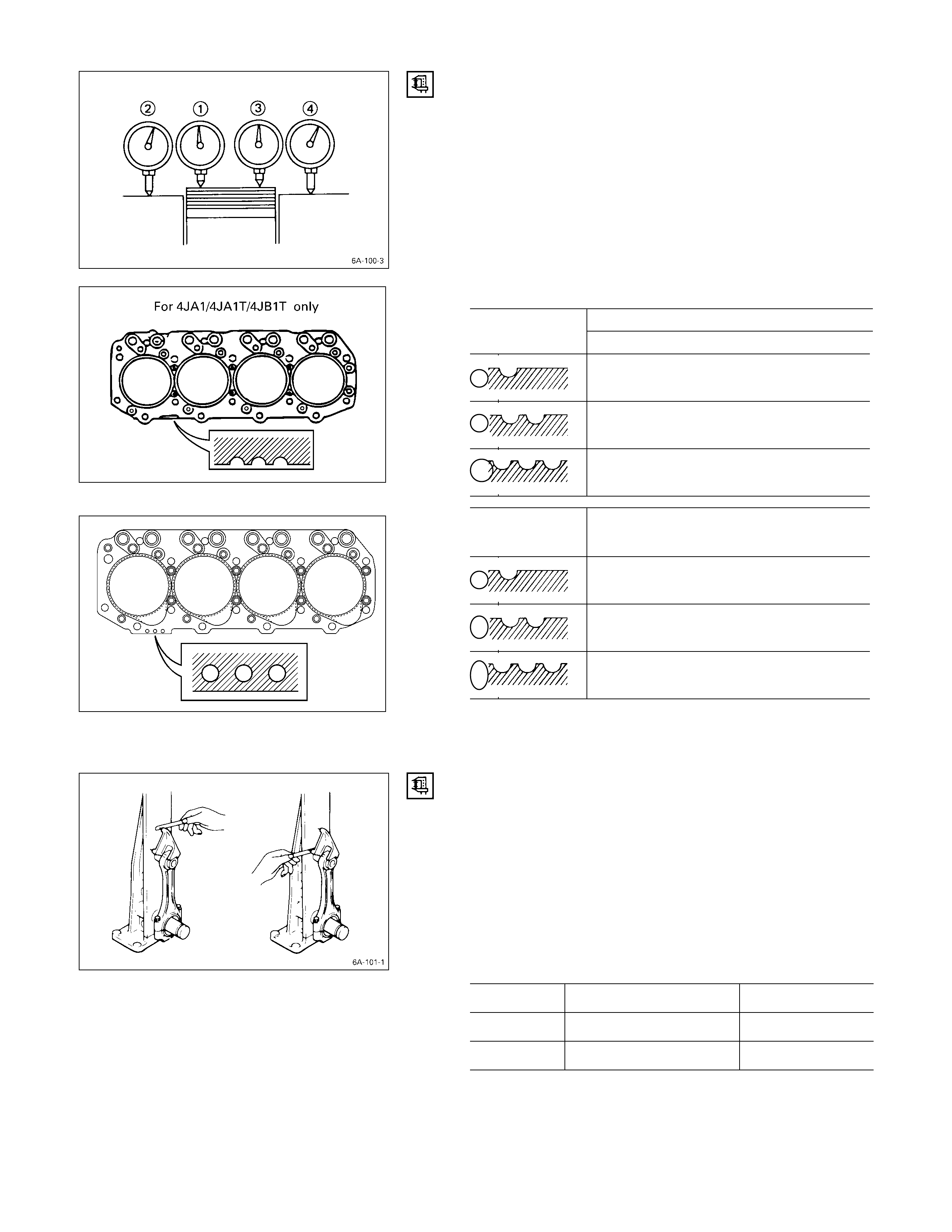

PISTON

PISTON RING

PISTON PIN

CYLINDER HEAD GASKET SELECTION

CONNECTING ROD

TIMING PULLEY HOUSING

IDLER GEAR SHAFT AND IDLER GEAR (GEAR DRIVE MODEL)

TIMING GEAR CASE COVER

REASSEMBLY

INTERNAL PARTS

MINOR COMPONENTS

ROCKER ARM SHAFT AND ROCKER ARM

CYLINDER HEAD

PISTON AND CONNECTING ROD

MAJOR COMPONENTS

INSTALLATION

EXTERNAL PARTS

LUBRICATING SYSTEM

MAIN DATA AND SPECIFICATIONS

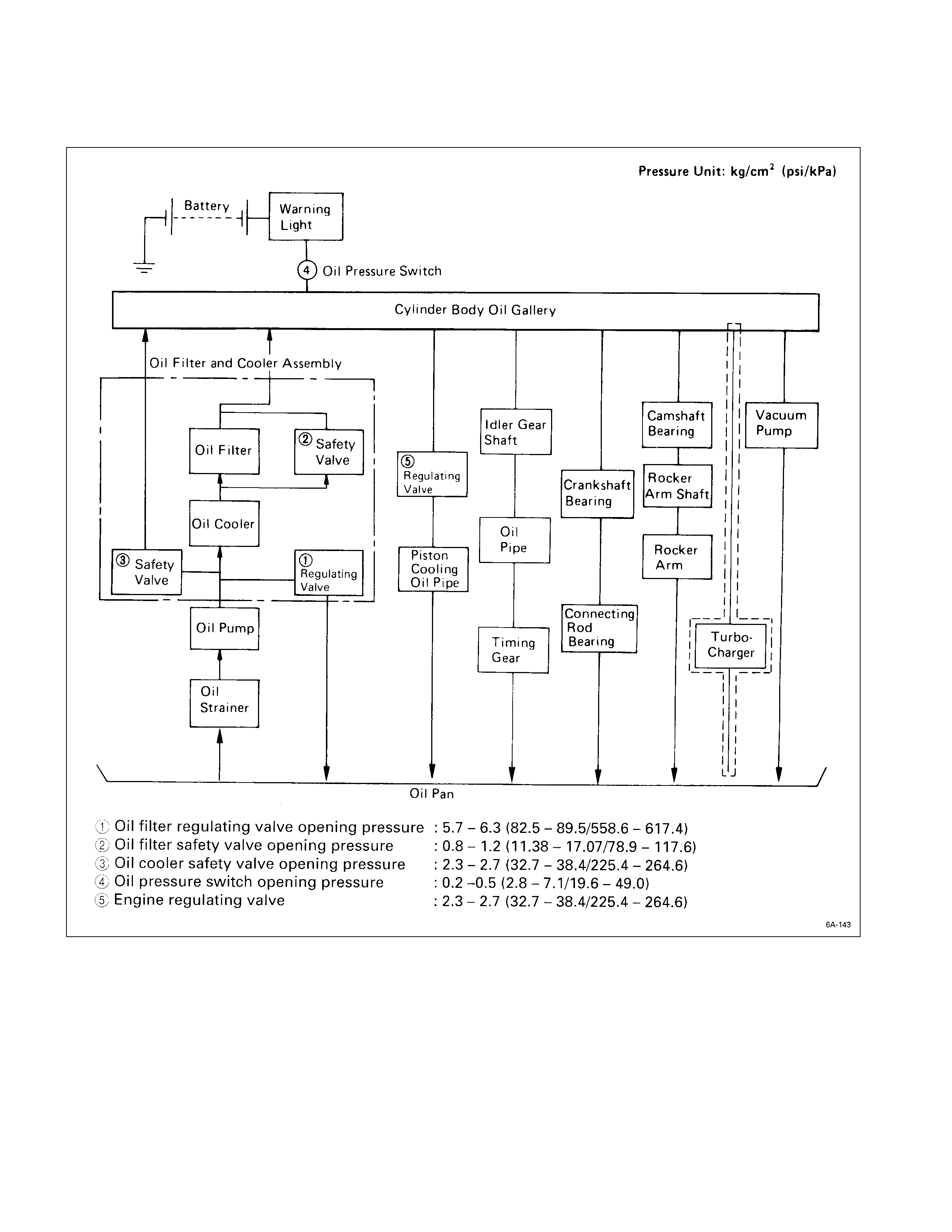

GENERAL DESCRIPTION

LUBRICATING OIL FLOW

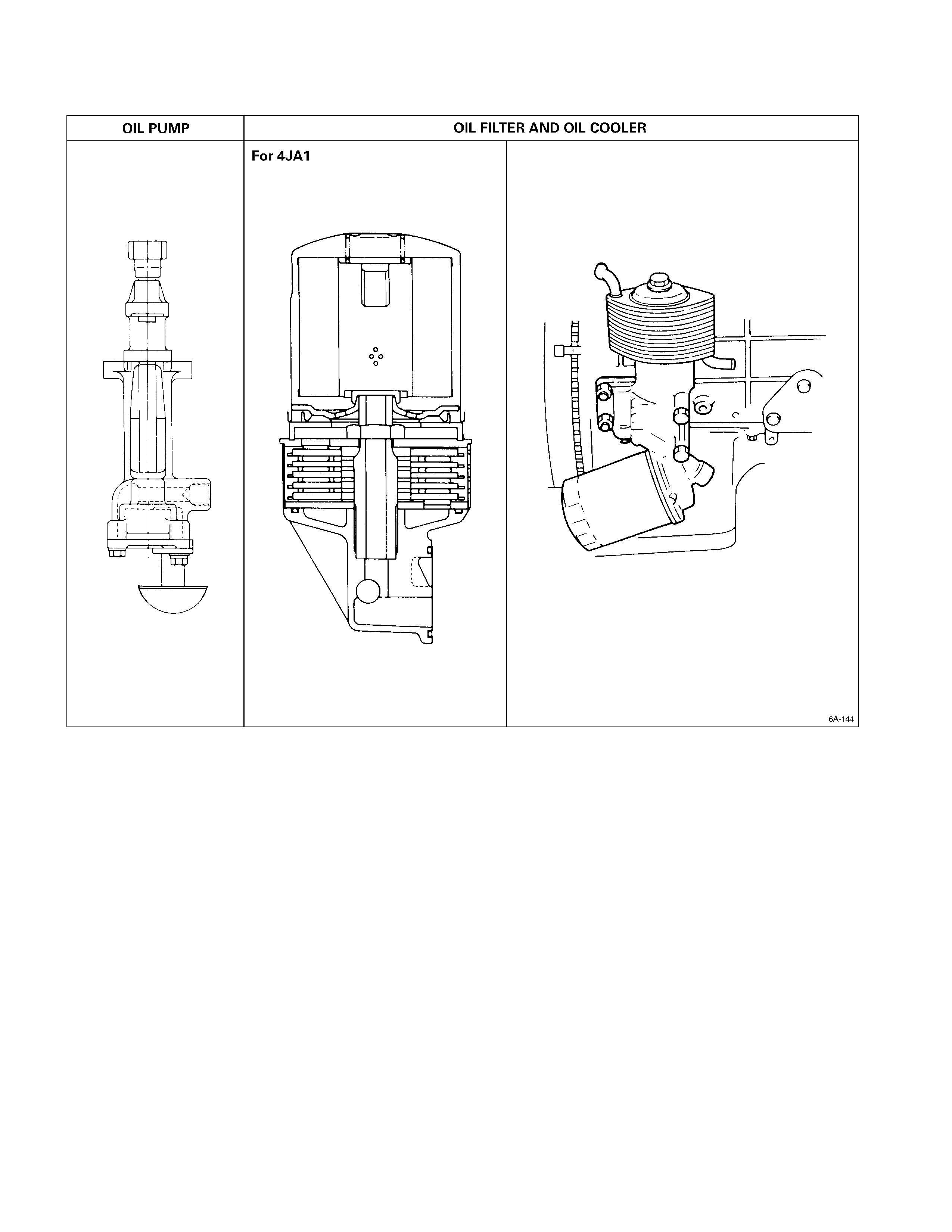

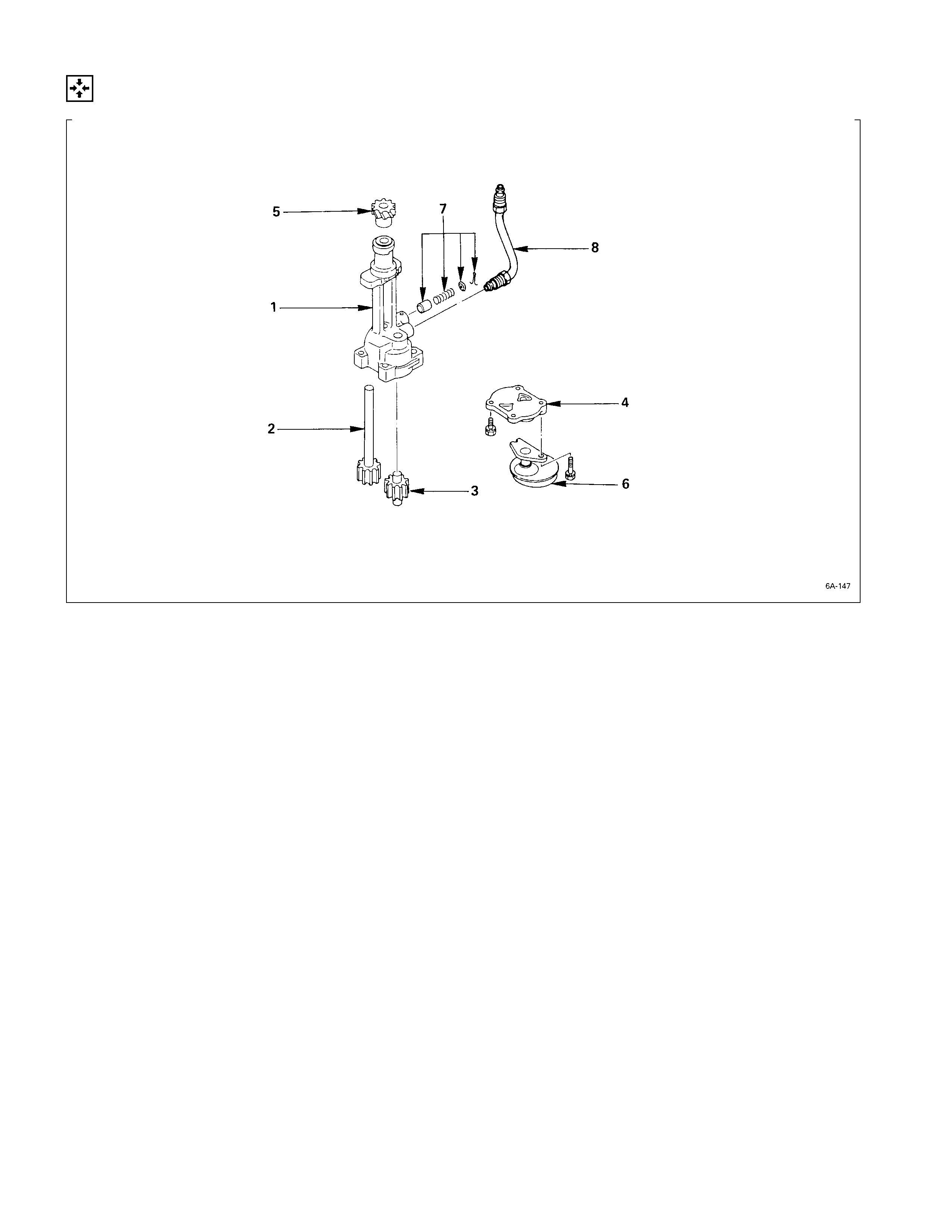

OIL PUMP AND OIL FILTER

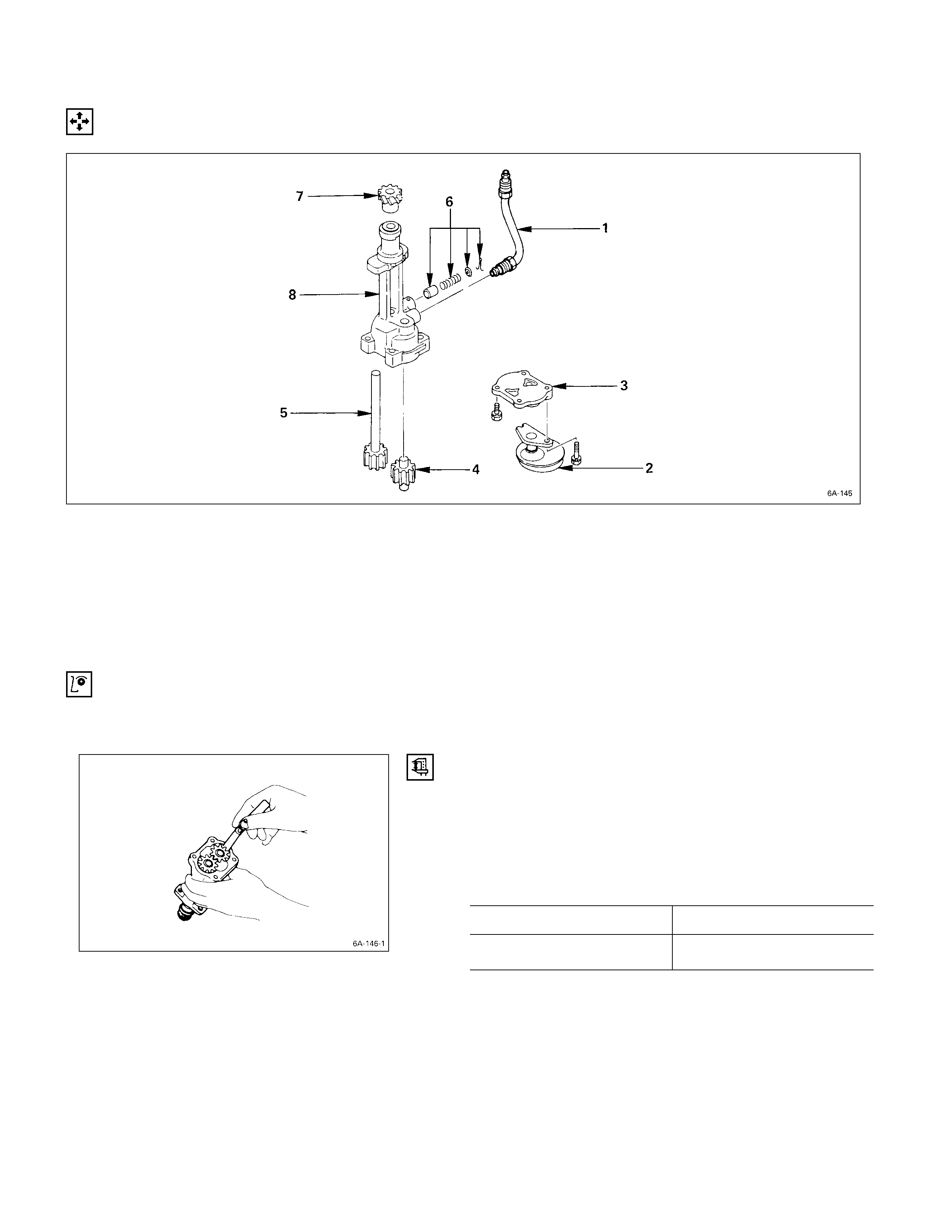

OIL PUMP

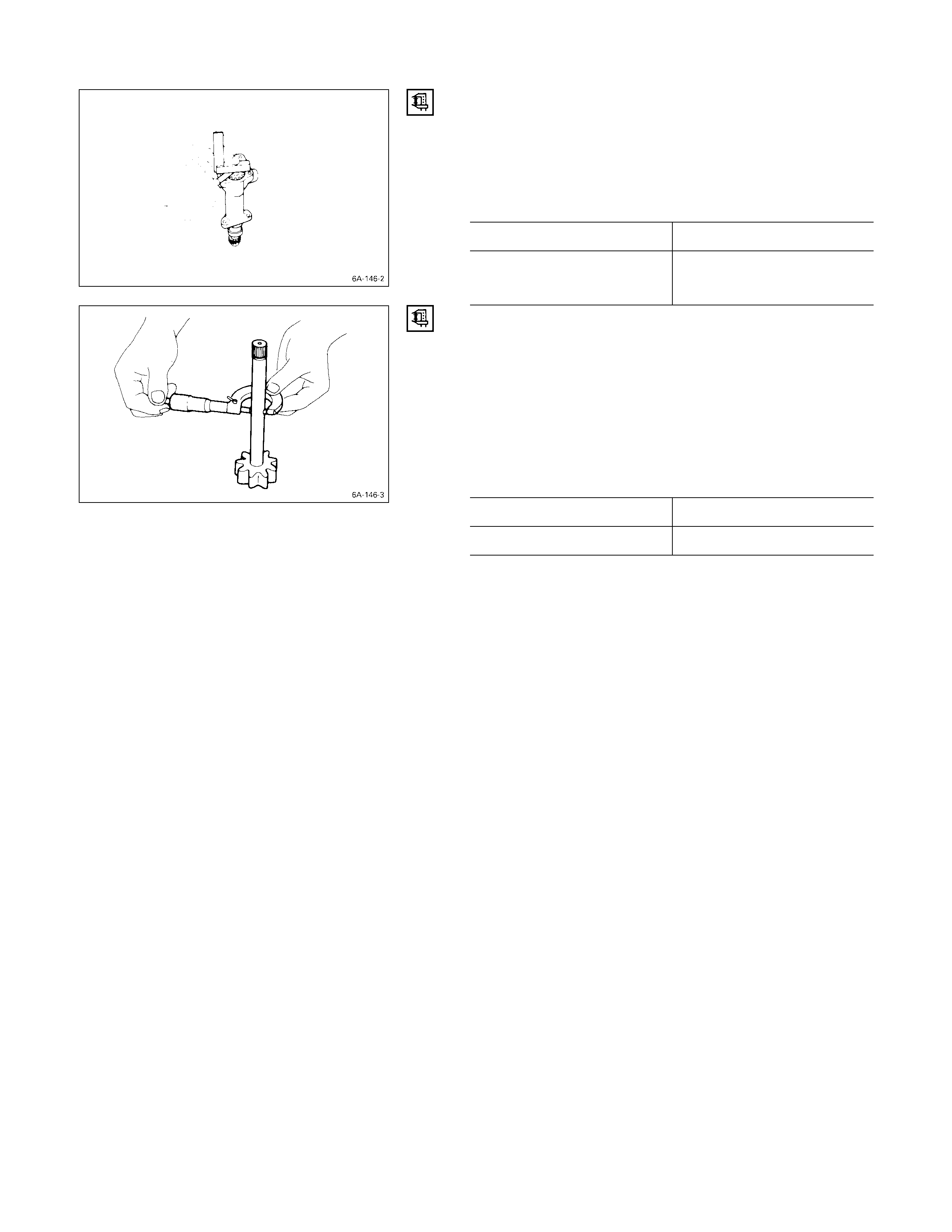

DISASSEMBLY

INSPECTION AND REPAIR

REASSEMBLY

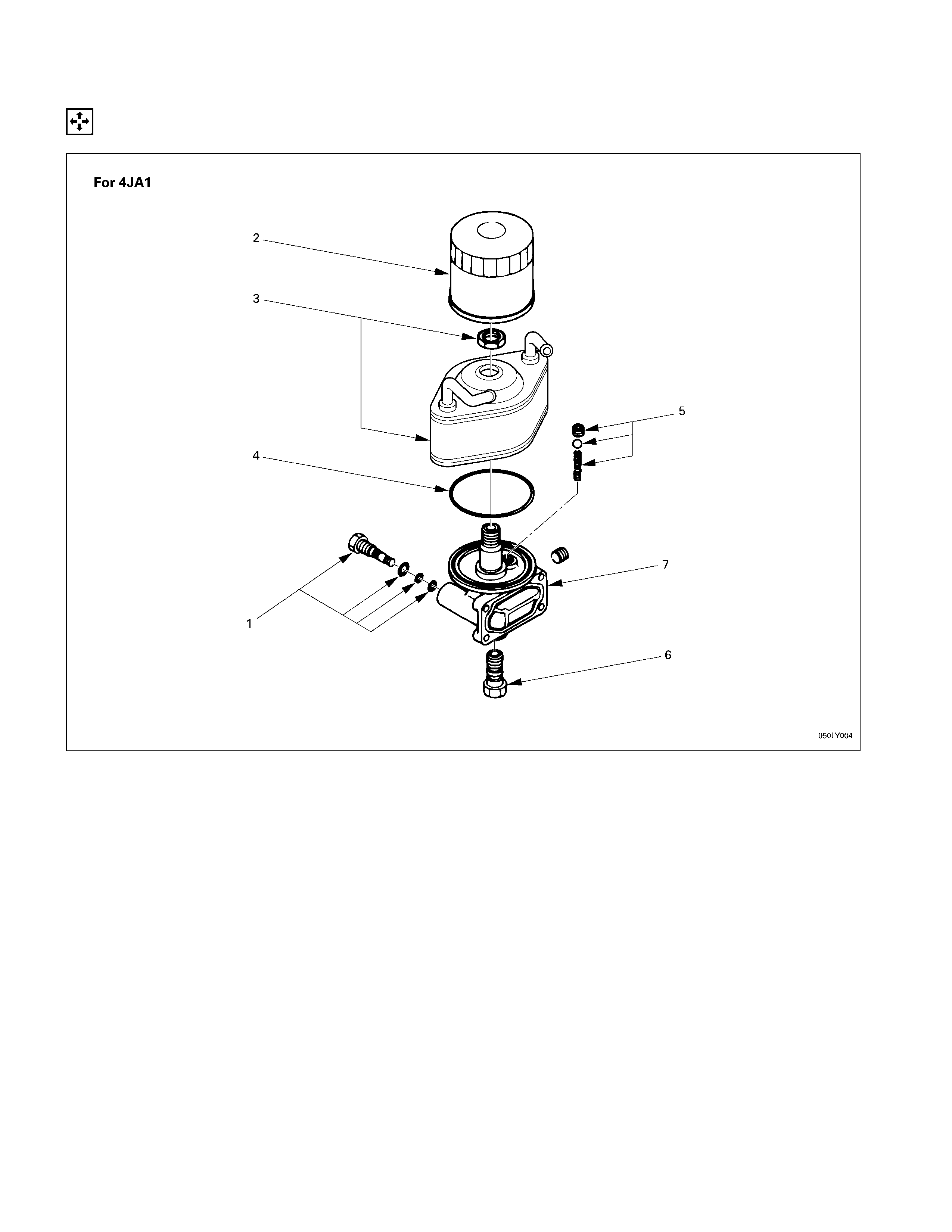

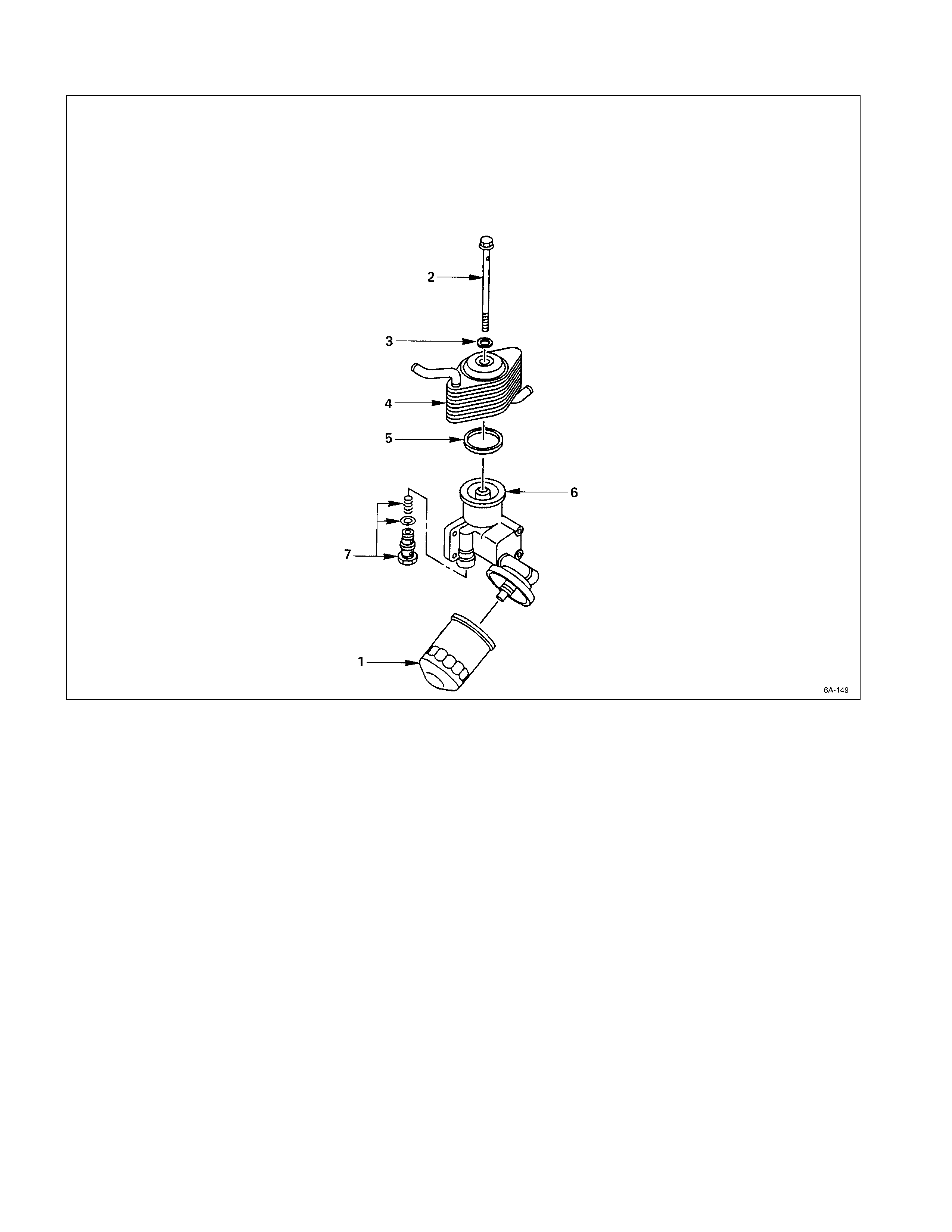

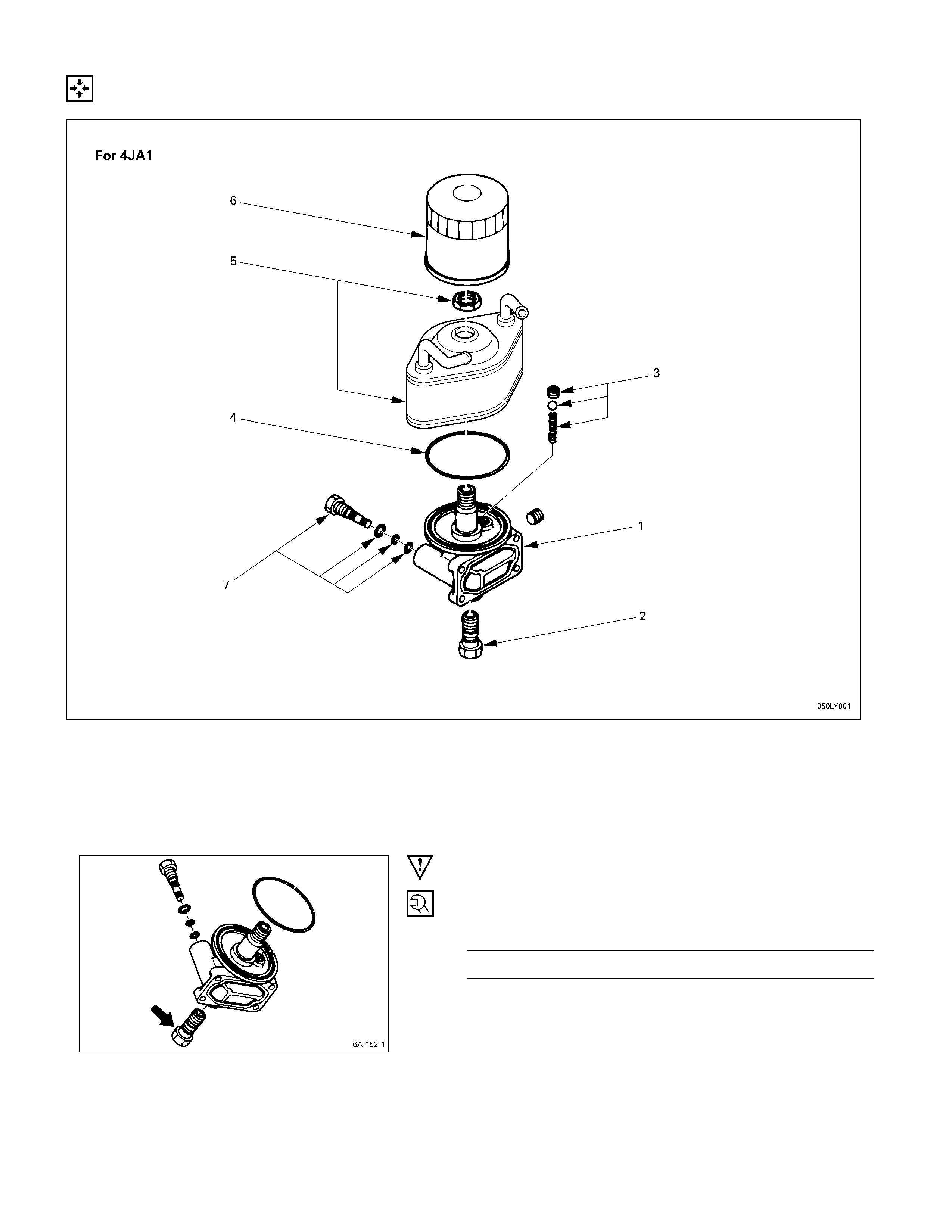

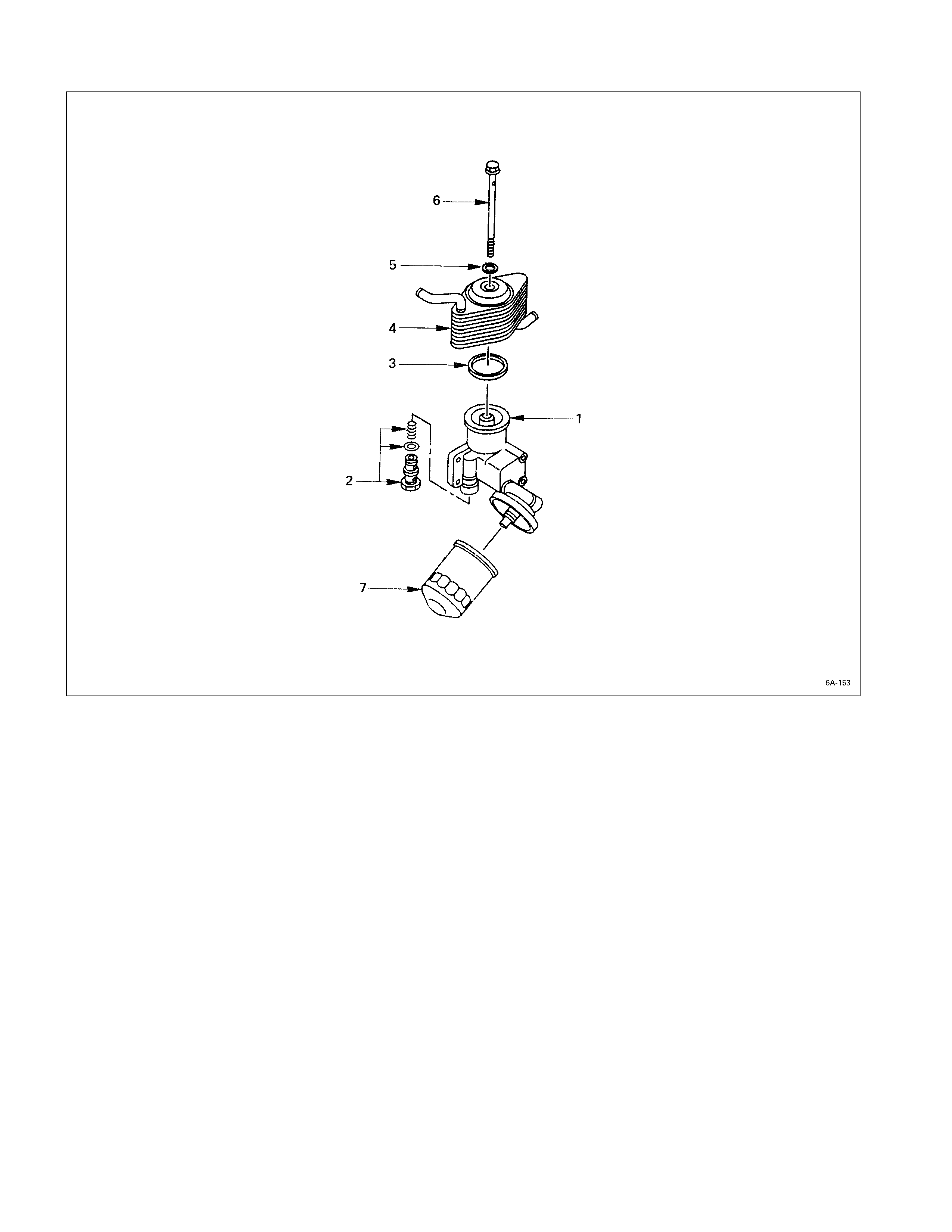

OIL FILTER AND OIL COOLER

DISASSEMBLY

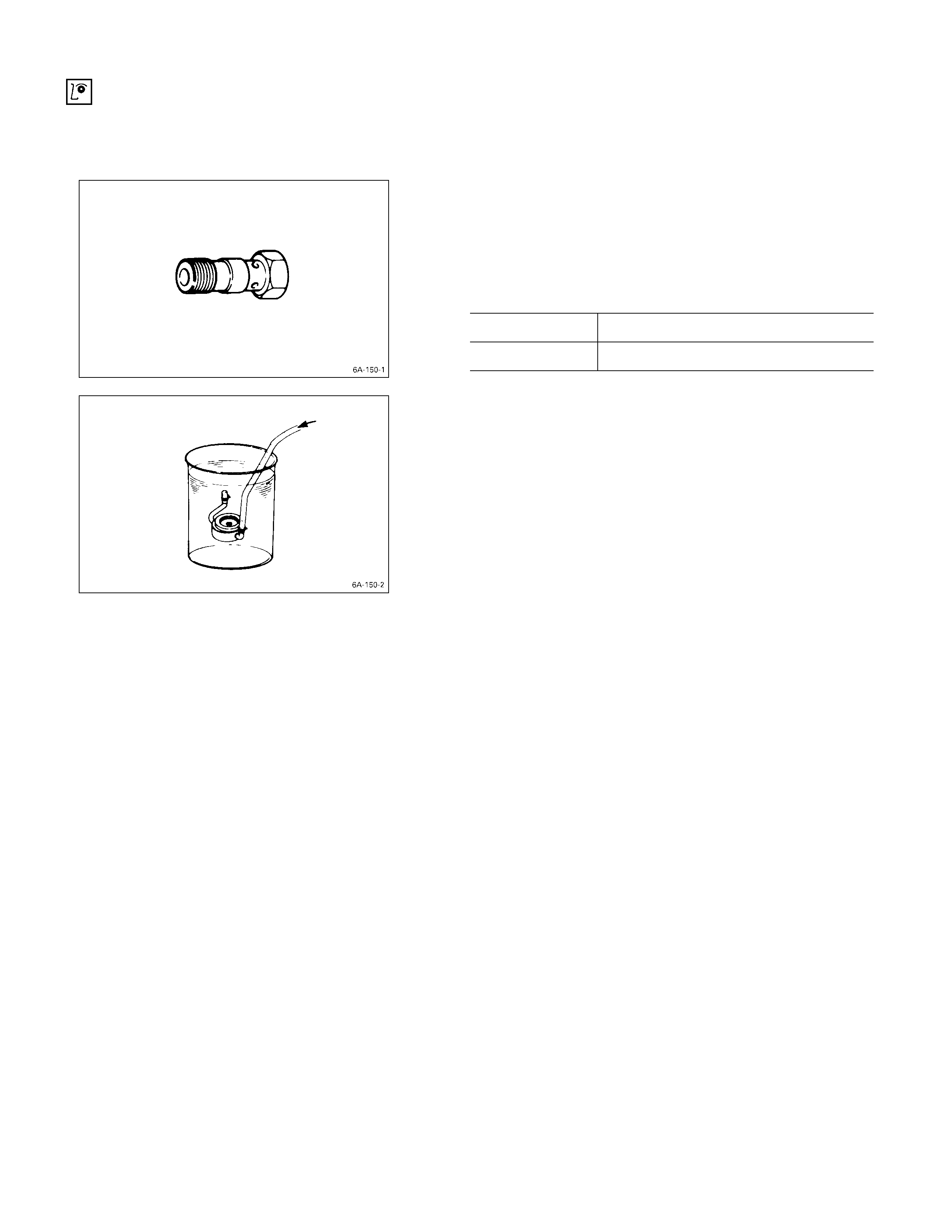

INSPECTION AND REPAIR

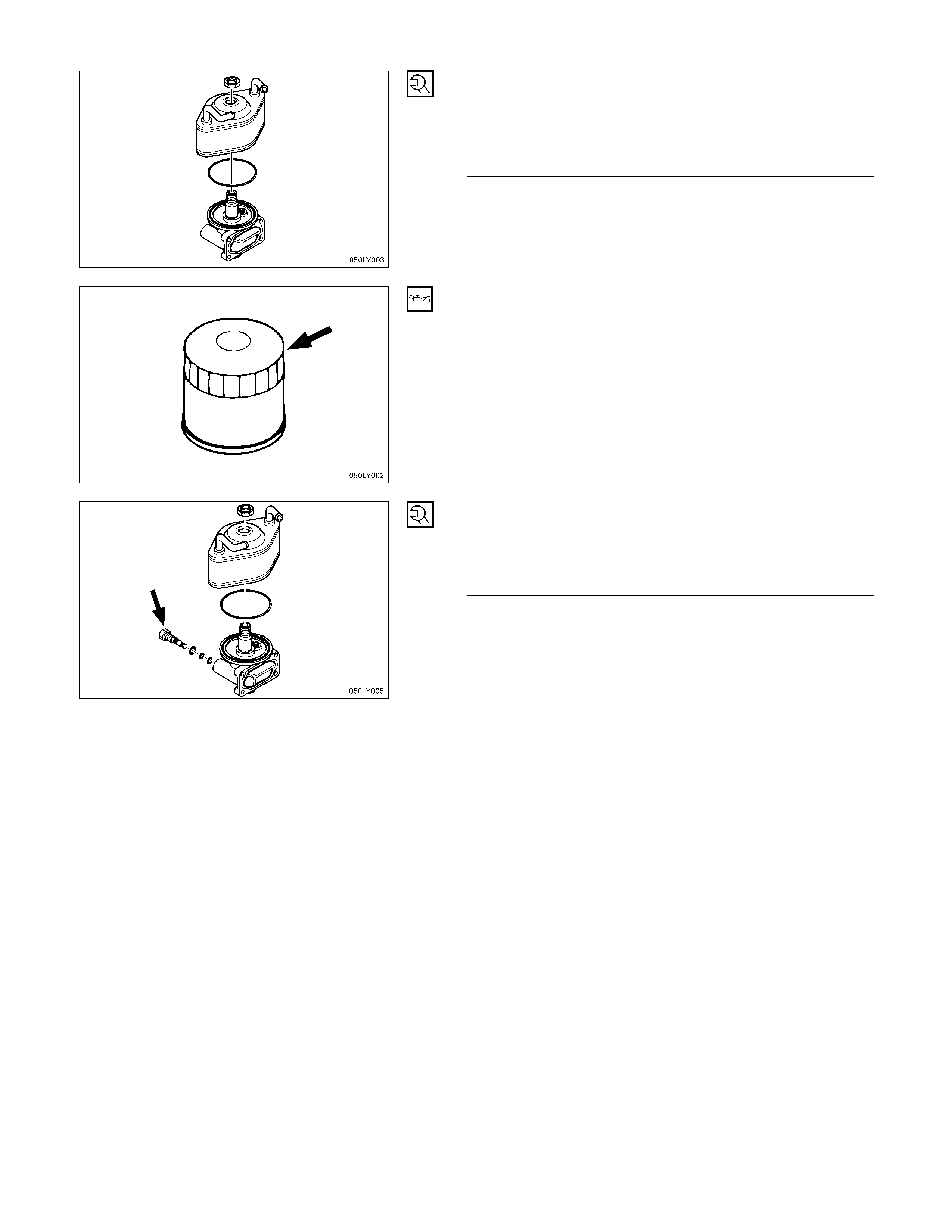

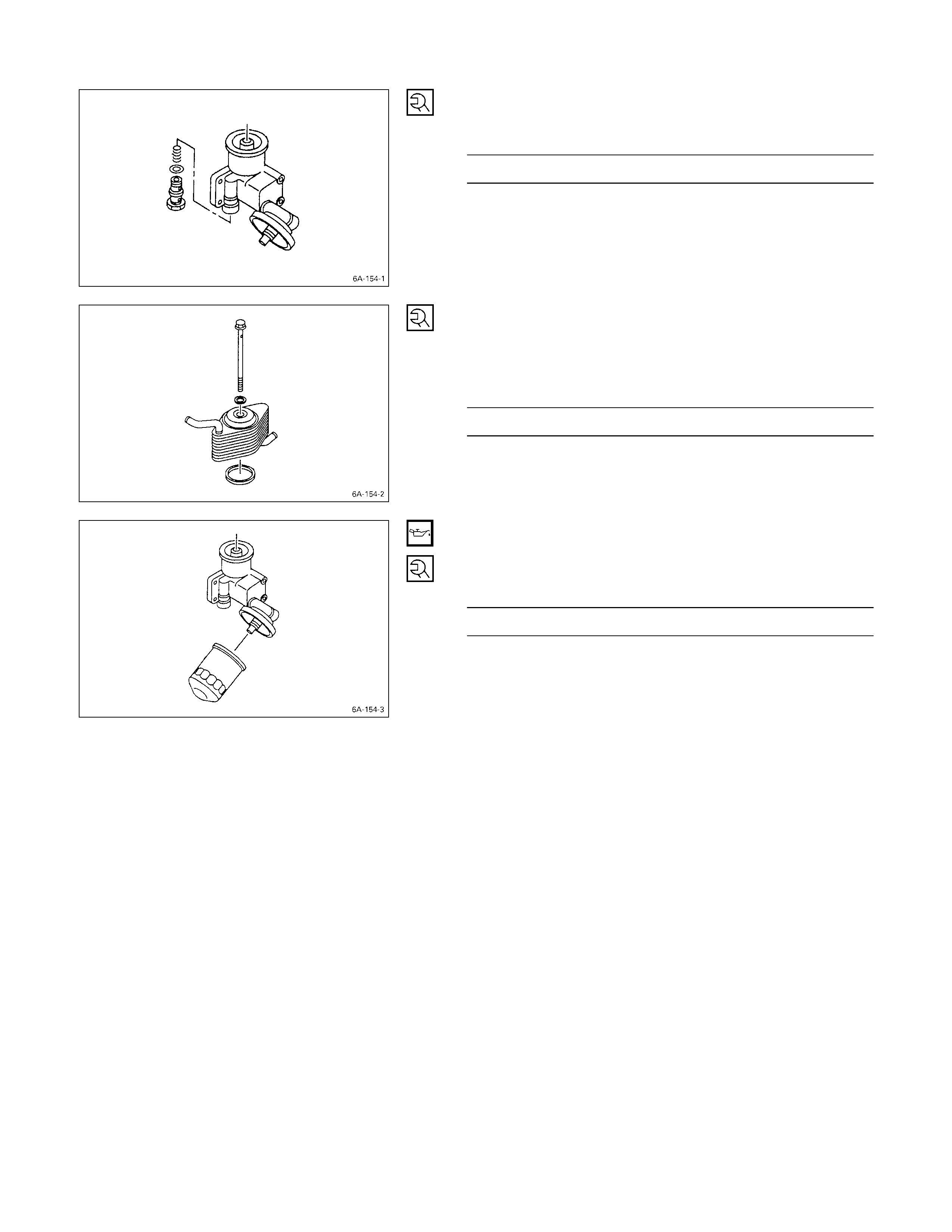

REASSEMBLY

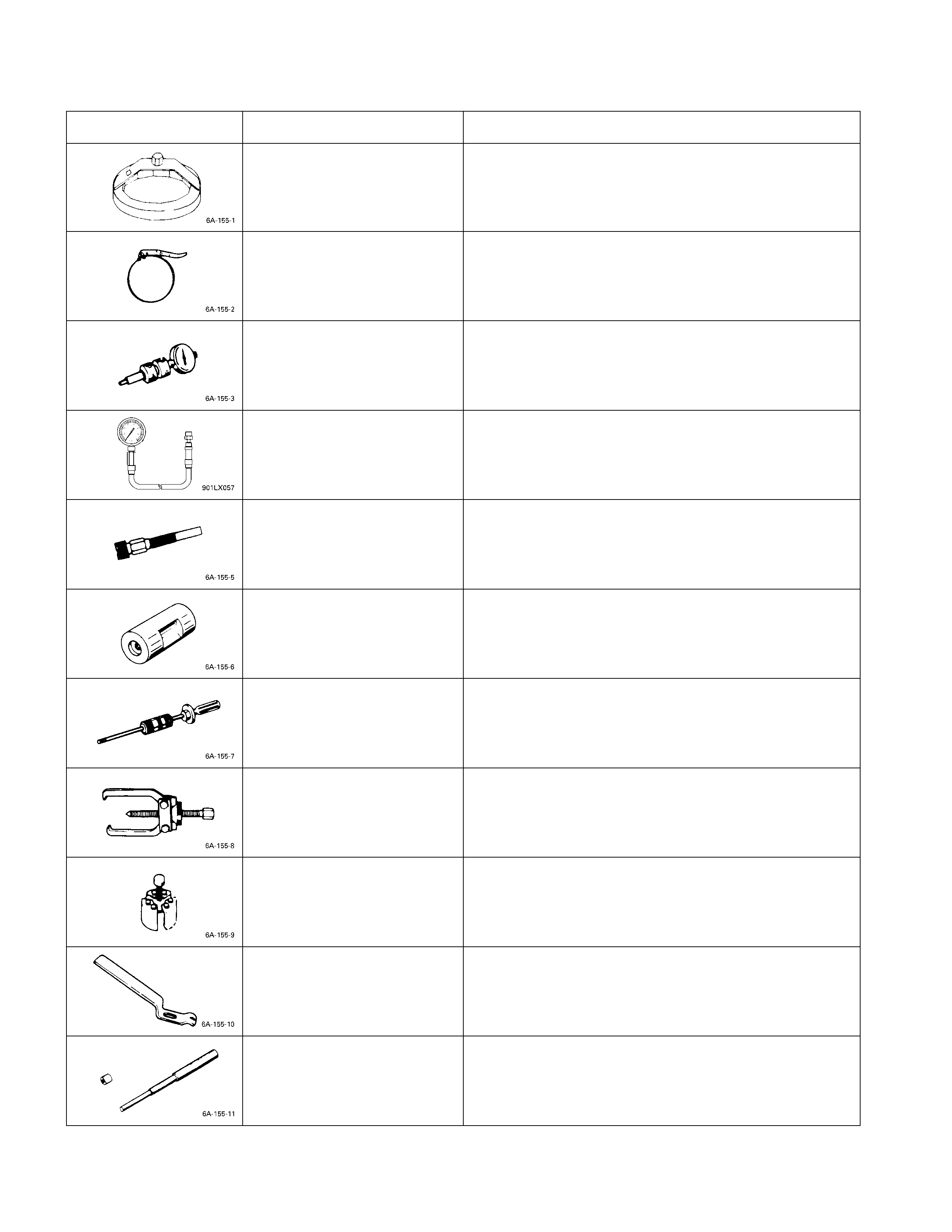

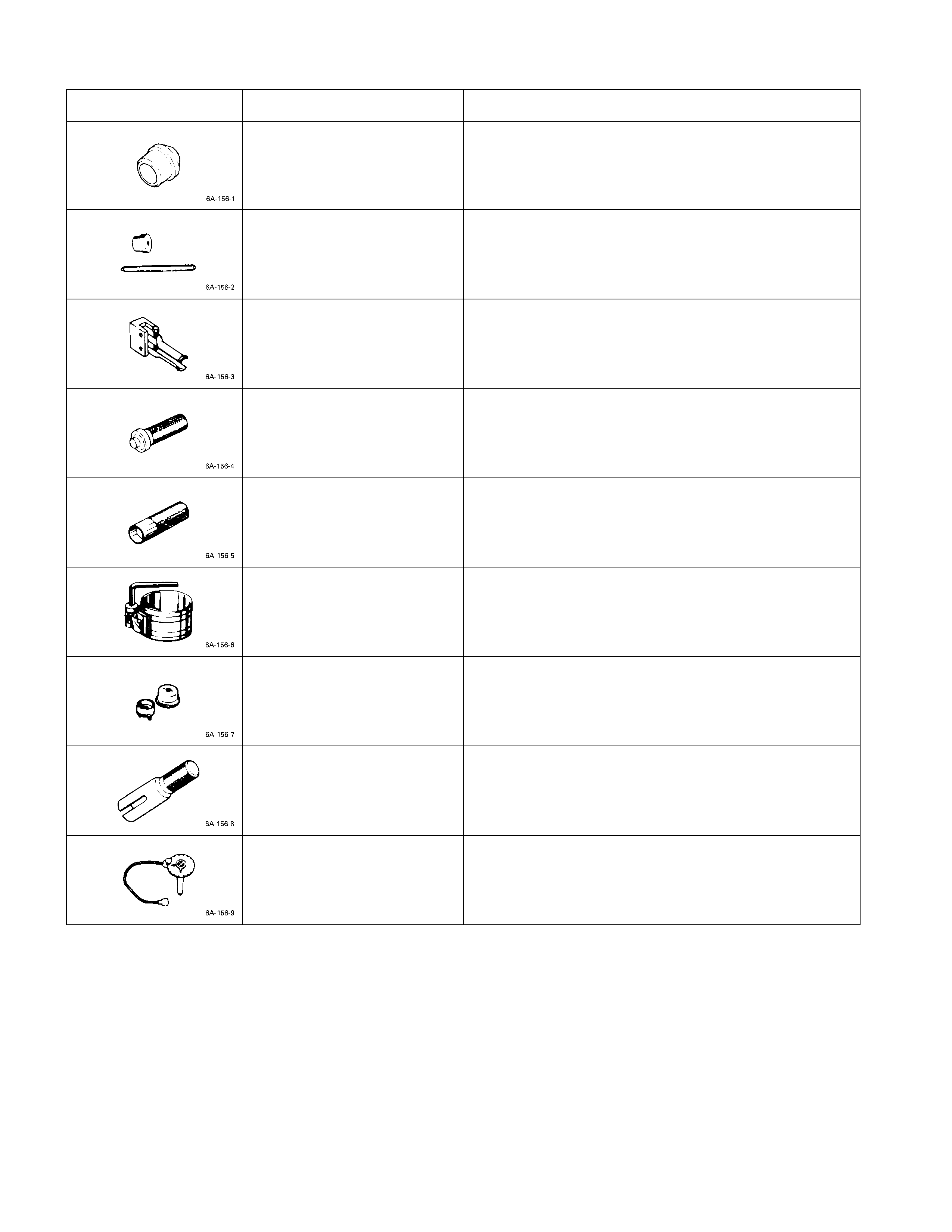

SPECIAL TOOLS

MAIN DATA AND SPECIFICATIONS

Engine model

Item 4JB1T

Engine type

Combustion chamber type

Cylinder liner type

Timing gear train system

Four-cycle, overhead valve, water cooled

Direct injection

Dry type, chrome plated, stainless steel tube

Gear drive

No. of cylinders-bore × stroke mm (in) 4 – 93 × 102 (3.66 × 4.02)

No. of piston rings Compression ring: 2 / Oil ring: 1

Total piston displacement cm3 (in3)

Compression ratio

2,771 (169.0)

18.1:1

Compression pressure kg/cm2 (psi/kPa) 31 (441/3) – 200 rpm

Engine weight kg (lb) Approximately 250 (550)

Fuel injection order 1 – 3 – 4 - 2

Fuel injection timing BTDC deg 11

Specified fuel type

Idling speed rpm

Valve clearances (At cold): Intake mm (in)

Exhaust mm (in)

Intake valves Open at (BTDC) deg

Close at (ABDC) deg

Exhaust valves Open at (BBDC) deg

Close at (ATDC) deg

Fuel system

Injection pump type

SAE No. 2 diesel fuel

750

0.4 (0.016)

0.4 (0.016)

24.5

55.5

54.0

26.0

BOSCH distributor VE type

Governor type Mechanical (Limit speed)

Injection nozzle type

Injection nozzle opening pressure

(Design value) kg/cm2 (psi/kPa)

Single spring type

Main fuel filter type

Lubricating system

Lubricating method

Hole with 5 orifices

185 (2,631/18,143)

Cartridge paper element and water separator

Pressu re circulation

Specified engine oil (API grade) CD / CG4

Oil pump type

Oil filter type

Oil capacity (engine dry) litres (US/UK gal))

Oil cooler type

Gear

Cartridge paper element

6.5 (1.7/1.43)

Water cooled

4JB1T : 4JB1 Engine with turbocharger.

Engine model

Item 4JB1T

Cooling system

Water pump type

Thermostat ty pe

Air cleaner type

Battery type/voltage × No. of units

Centrifugal

Wax pellet with jiggle valve

Dry paper element

95D31R-12 × 1

Generator capacity V-A (Kw) 12 – 50 (600)

Starter motor output V-Kw 12 – 2.0 or 12 – 2.8

Turbocharger model

Turbine type

Compressor type

Maximum permissible speed rpm

*IHI RHF4H

Radial-inflow

Radial-outflow

172,000

*IHI : Ishikawajima-Harima Heavy Industries., Ltd.

TORQUE SPECIFICATION

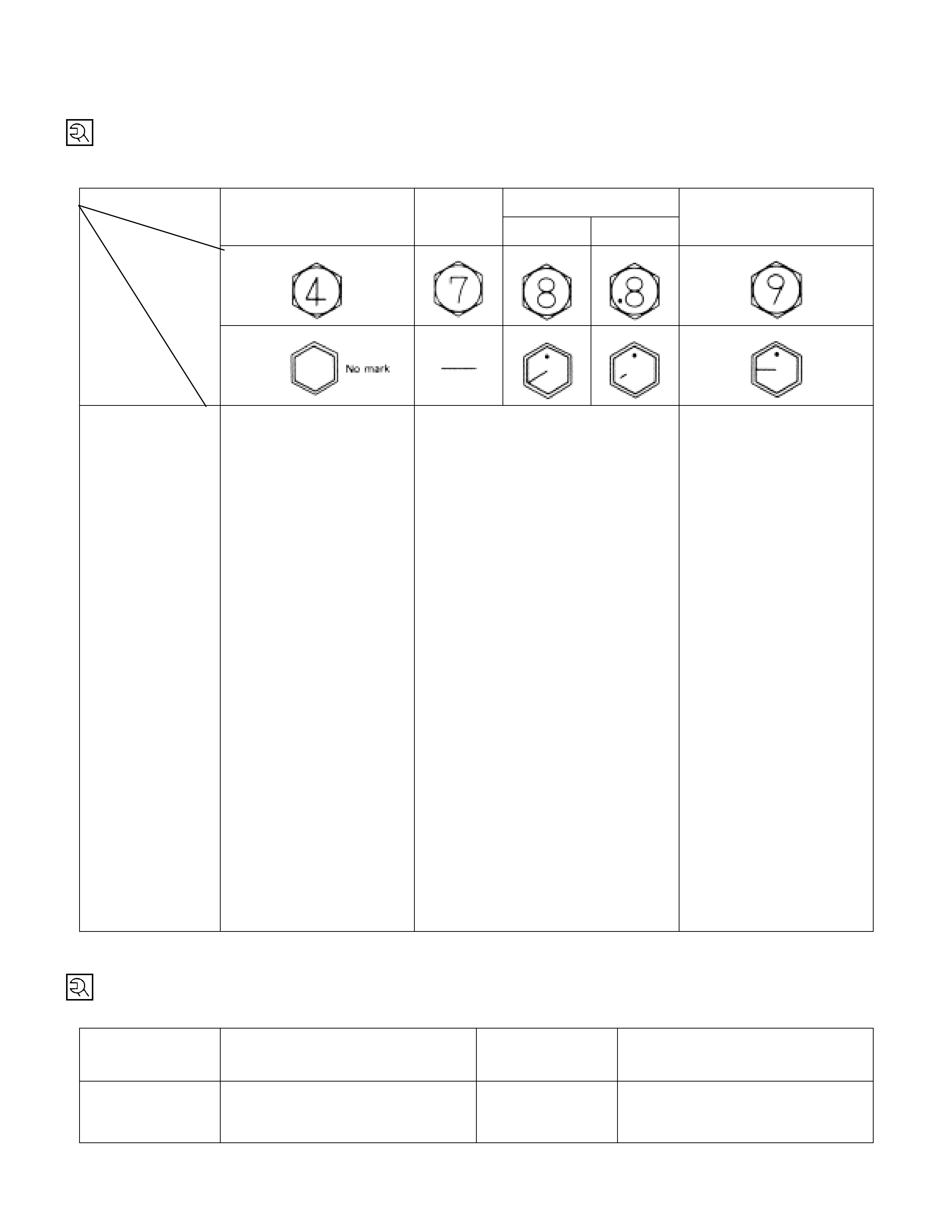

STANDARD BOLTS

The torque values given in the following table should be applied whenever a particular torque is not specified.

kg·m (lb·ft/N·m)

8.8

4.8 (4T) (7T) Refined Non-Refined 9.8 (9T)

Strength

Class

Bolt

Identification

Bolt

Diameter ×

Pitch (mm)

M6×

××

×1.0

M8×

××

×1.25

M10 ×

××

×1.25

M12 ×

××

×1.25

M14 ×

××

×1.5

M16 ×

××

×1.5

M18 ×

××

×1.5

M20 ×

××

×1.5

M22 ×

××

×1.5

M24 ×

××

×2.0

*M10×

××

×1.5

*M12×

××

×1.5

*M14×

××

×2.0

*M16×

××

×2.0

0.60 ± 0.20

(4.33 ± 1.44/5.88 ± 1.96)

1.30 ± 0.50

(9.40 ± 3.62/12.74 ± 4.90)

2.80 ± 0.70

(20.25 ± 5.06/27.44 ± 6.86)

6.25 ± 1.25

(45.21 ± 9.04/61.25 ± 12.25)

9.75 ± 1.95

(70.52 ± 14.10/95.55 ± 19.11)

13.30 ± 2.70

(96.20 ± 19.53/130.34 ± 26.46)

19.20 ± 3.80

(138.87 ± 27.49/188.16 ± 37.24)

26.30 ± 5.30

(190.23 ± 38.33/257.74 ± 51.94)

33.90 ± 8.30

(245.20 ± 60.03/332.22 ± 81.34)

45.80 ± 9.20

(331.27 ± 66.54/448.84 ± 90.16)

2.70 ± 0.70

(19.53 ± 5.06/26.46 ± 6.86)

5.80 ± 1.20

(41.95 ± 8.68/56.84 ± 11.76)

9.10 ± 1.80

(65.82 ± 13.02/89.18 ± 17.64)

12.70 ± 2.50

(91.86 ± 18.08/124.46 ± 24.50)

0.75 ± 0.25

(5.43 ± 1.80/7.35 ± 2.45)

1.75 ± 0.55

(12.66 ± 4.00/17.15 ± 5.39)

3.75 ± 0.95

(27.12 ± 6.87/36.75 ± 9.31)

7.75 ± 1.55

(56.06 ± 11.21/75.95 ± 15.19)

11.85 ± 2.35

(85.71 ± 17.00/116.13 ± 23.03)

17.30 ± 3.50

(125.13 ± 25.32/169.54 ± 34.30)

24.90 ± 5.00

(180.10 ± 36.17/244.02 ± 49.00)

34.40 ± 6.90

(248.82 ± 49.41/337.12 ± 67.62)

46.25 ± 9.25

(334.53 ± 66.91/453.25 ± 90.65)

58.20 ± 14.30

(420.96 ± 103.43/570.36 ± 140.14)

3.70 ± 0.90

(26.76 ± 6.50/36.26 ± 8.82)

7.20 ± 1.40

(52.08 ± 10.13/70.56 ± 13.72)

11.20 ± 2.20

(81.01 ± 15.91/109.76 ± 21.56)

16.50 ± 3.30

(119.34 ± 23.87/161.70 ± 32.34)

-

2.40 ± 0.70

(17.36 ± 5.06/23.52 ± 6.86)

5.10 ± 1.30

(36.89 ± 9.40/49.98 ± 12.74)

9.65 ± 1.95

(69.80 ± 14.10/94.57 ± 19.11)

14.50 ± 2.90

(104.88 ± 21.00/142.10 ± 28.42)

20.40 ± 4.10

(147.55 ± 29.66/199.92 ± 40.18)

29.30 ± 5.90

(211.93 ± 42.67/287.14 ± 57.82)

40.40 ± 8.10

(292.21 ± 58.59/395.92 ± 79.38)

54.10 ± 10.80

(391.30 ± 78.12/530.18 ± 105.84)

70.60 ± 14.10

(510.65

±

101.99/691.88

±

138.18)

4.90 ± 1.20

(35.44 ± 8.68/48.02 ± 11.76)

9.10 ± 1.80

(65.82 ± 13.02/89.18 ± 17.64)

13.60 ± 2.70

(98.37 ± 19.53/133.28 ± 26.46)

19.50 ± 3.90

(141.04 ± 28.21/191.10 ± 38.22)

An asterisk (*) indicates that the bolts are used for female threaded parts that are made of soft materials such

as casting. Those shown in parentheses in the strength class indicate the classification by the old standard.

FLARE NUTS kg·m (lb·ft/N·m)

Pipe diam eter m m

(in) Torque Pipe diam eter m m

(in) Torque

4.76 (0.187)

6.35 (0.250)

8.00 (0.315)

1.55 ± 0.25 (11.2 ± 1.8/15. 2 ± 2.45)

2.70 ± 0.30 (19.5 ± 2.1/26. 48 ± 2.94)

4.50 ± 0.50 (32.5 ± 3.6/44. 14 ± 4.90)

10.00 (0.394)

12.00 (0.472)

15.00 (0.591)

5.50 ± 0.5 (39.7 ± 3.6/53. 95 ± 4.90)

9.00 ± 1.0 (65.0 ± 7.2/88. 29 ± 9.80)

10.75 ± 1.25 (77.7 ± 9.0/105. 45 ± 12.26)

SPECIAL PARTS FI XING NUTS AND BO LTS

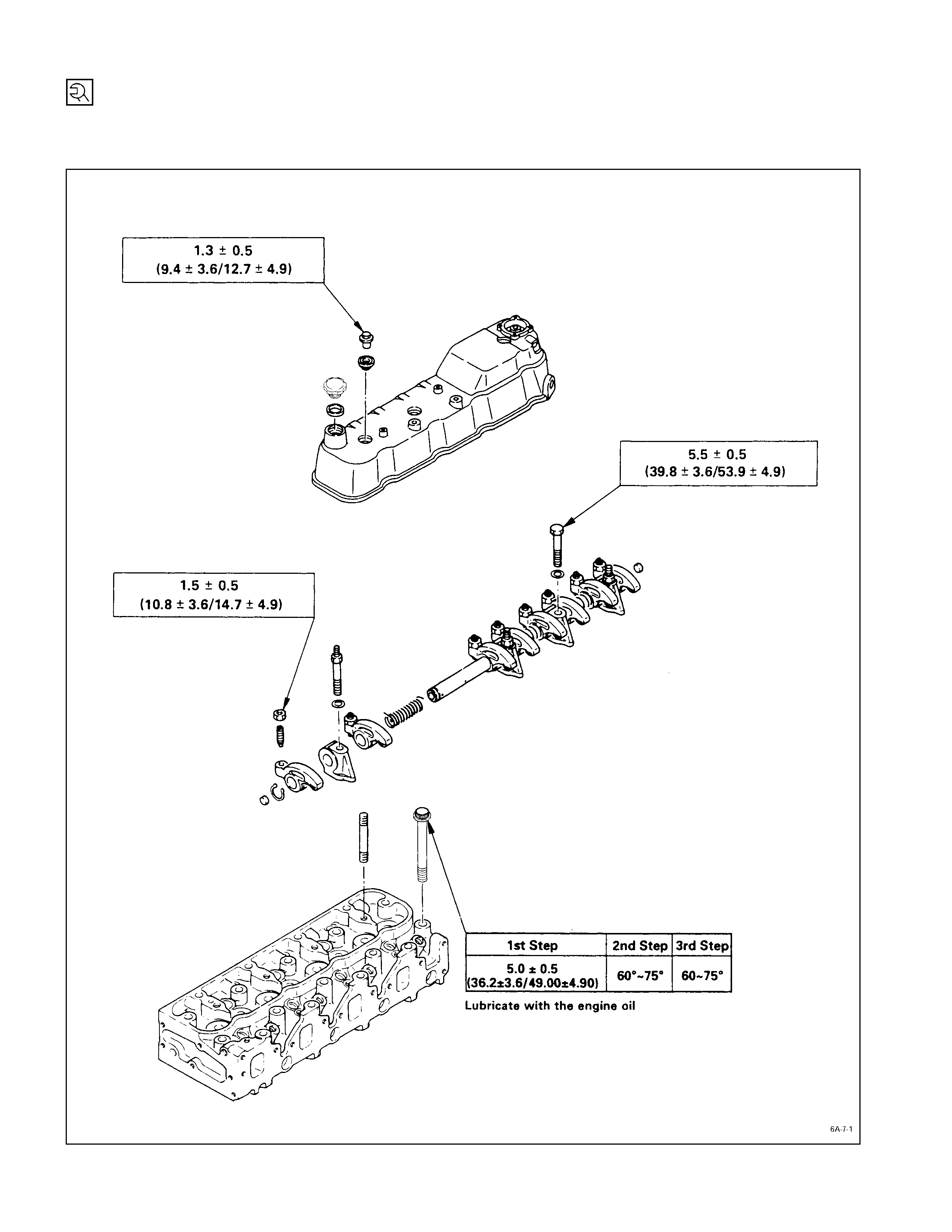

CYLINDER HEAD CO VER, CYLINDER HEAD, AND ROCKER ARM SHAFT BRACKET

kg·m (lb·ft/N·m)

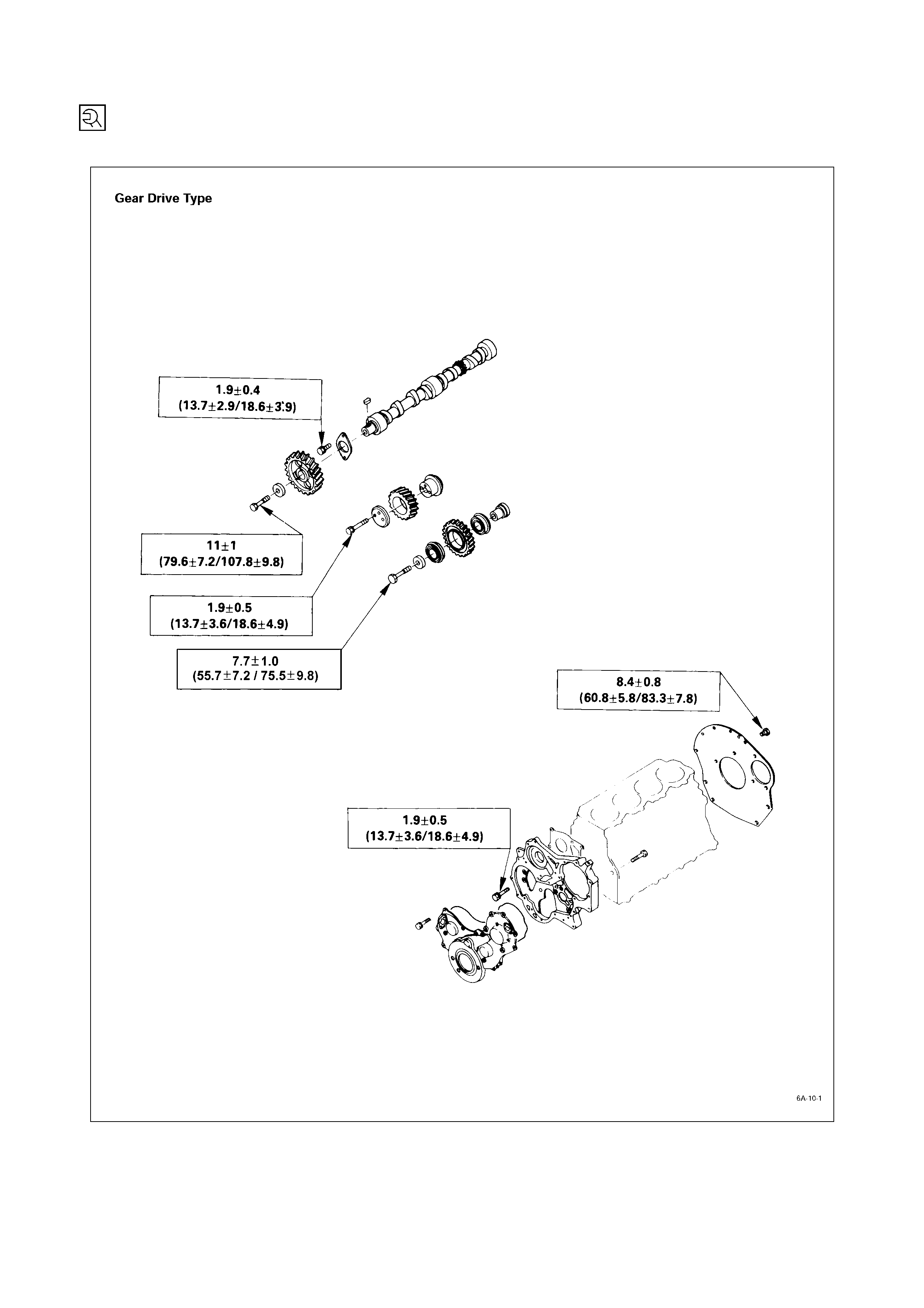

TIMING GEAR CASE, PULLEY HOUSING, TIMING GEAR, AND CAMSHAFT

kg m (lb ft / N.m)

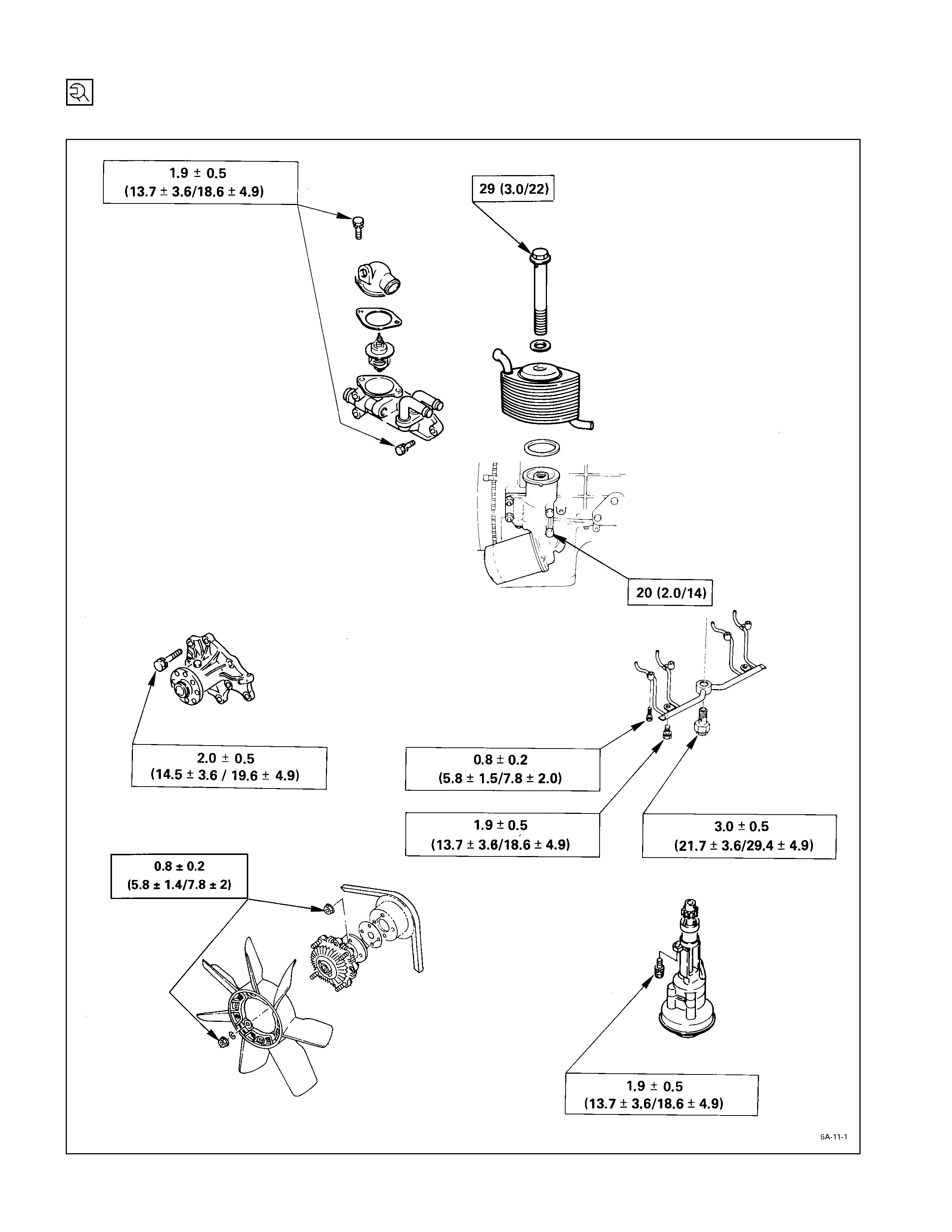

COOLING AND LUBRICATING SYSTEM

kg·m (lb·ft/N·m)

INTAKE MANIFOLD, EXHAUST MANIFOLD, AND TURBOCHARGER

kg·m (lb·ft/N·m)

ENGINE ELECTRICALS

kg·m (lb·ft/N·m)

FUEL INJECTION SYSTEM

kg·m (lb·ft/N·m)

ENGINE M OUNTING BRACKET

kg·m (lb·ft/N·m)

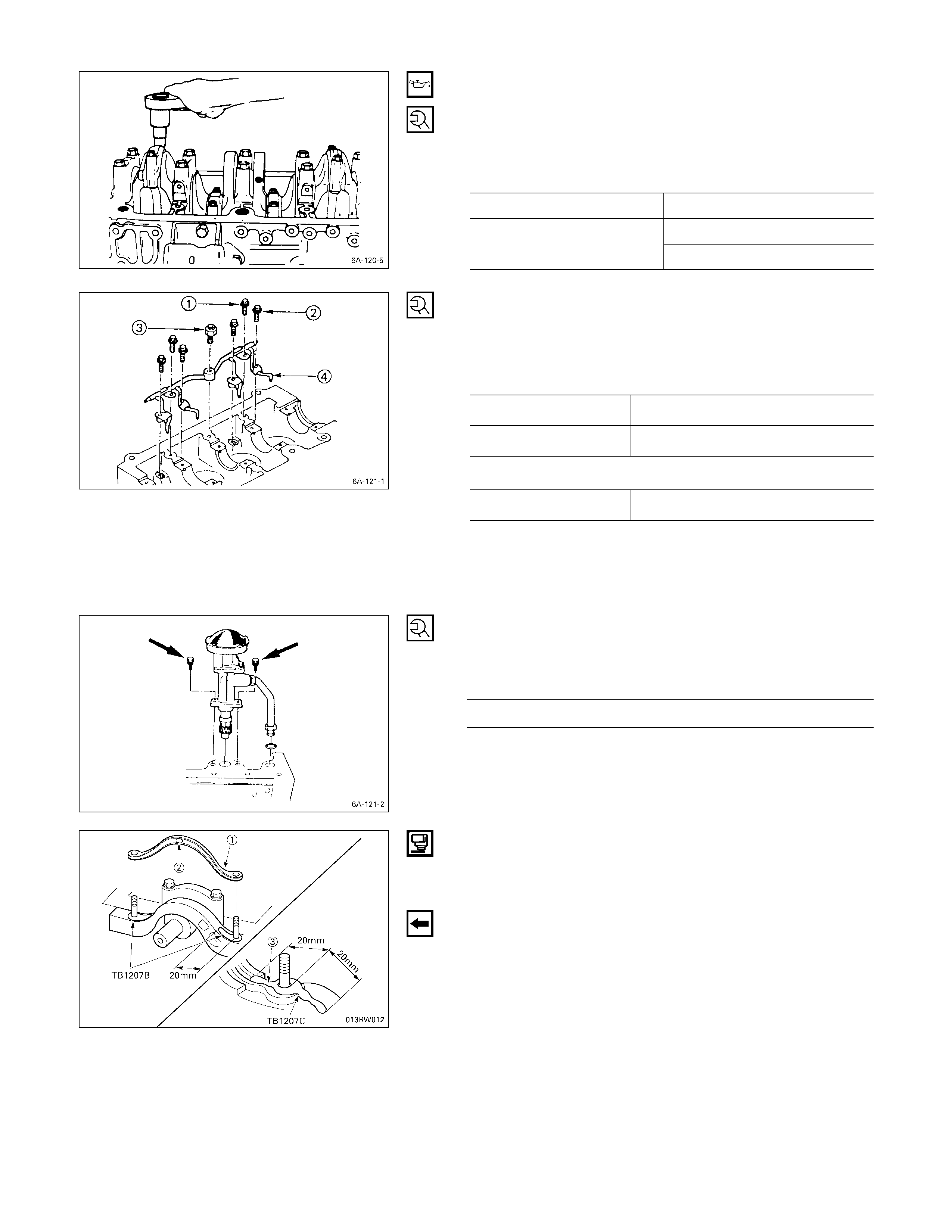

RECOMMENDED LI QUID GASKET

Type Brand Name Manufacturer Remarks

RTV*

Silicon Base ThreeBond 1207B

ThreeBond 1207C Three Bond

Three Bond

Water Base ThreeBond 1141E Three Bond

Solvent ThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402

Three Bond

Isuzu

Isuzu

Isuzu

Anaerobic LOCTITE 515

LOCTITE 518 Loctite

Loctite Recommended for

transaxle repairs

* RTV : Room Temperature Vulcanizer

Note:

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacturer’s instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before applying

the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance of greater

than 0.25 mm (0.01 in). Poor adhesion will result.

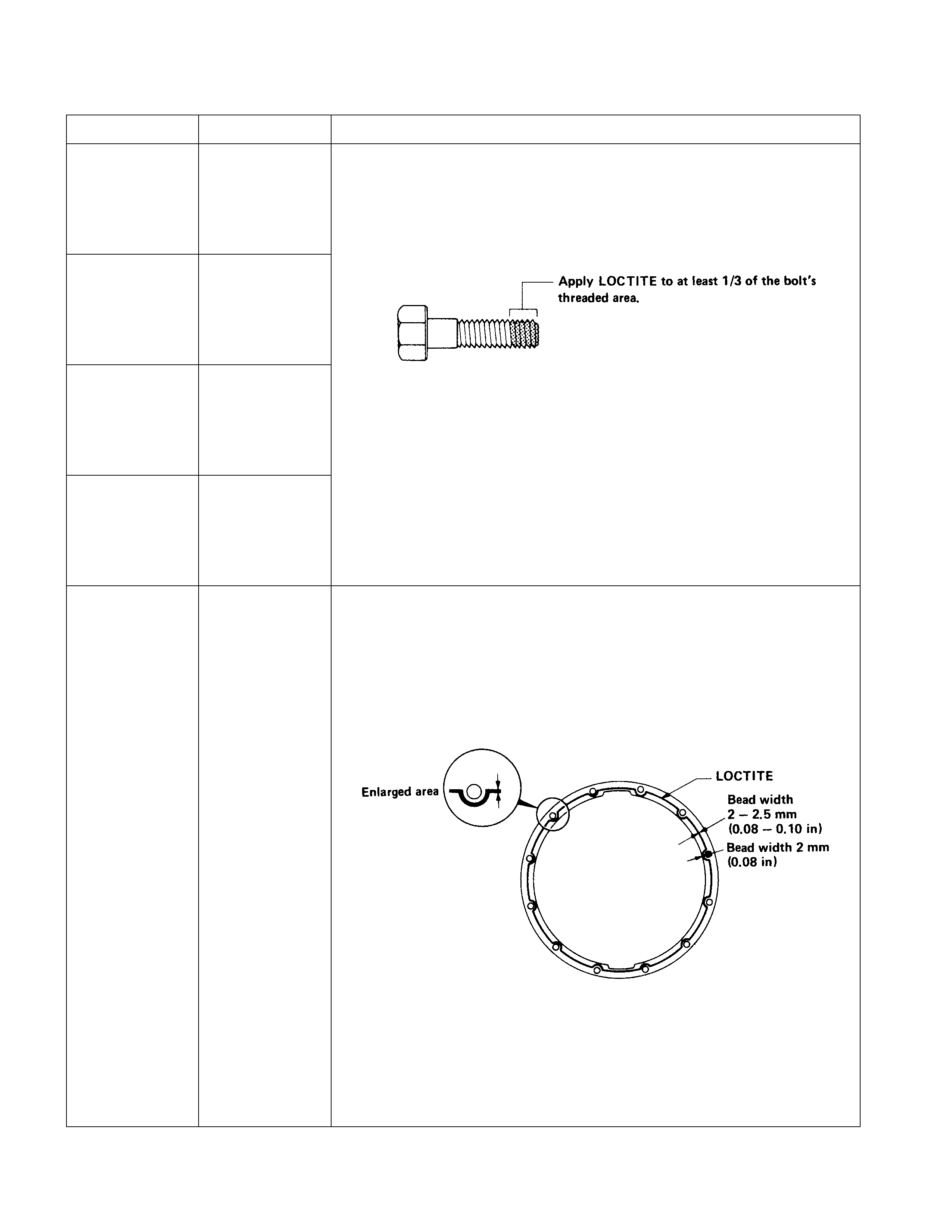

LOCTITE APPLI CATION PROCEDURE

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 270 Green

LOCTITE 271 Red

1. Completely remove all lubricant and moisture from the bolts and the

female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

3. Tighten the bolts to the specified torque.

4. Wait at least one hour before continuing the installation procedure.

LOCTITE 515 Violet

1. Completely remove lubricant and moisture from the connecting

surfaces.

The surfaces must be perfectly dry.

2. Apply a 2.0 – 2.5 mm bead of LOCTITE to one of the connecting

surfaces.

There must be no gaps in the bead.

3. Tighten the bolts to the specified torque.

4. Let the joined parts set for at least thirty minutes.

SERVICING

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

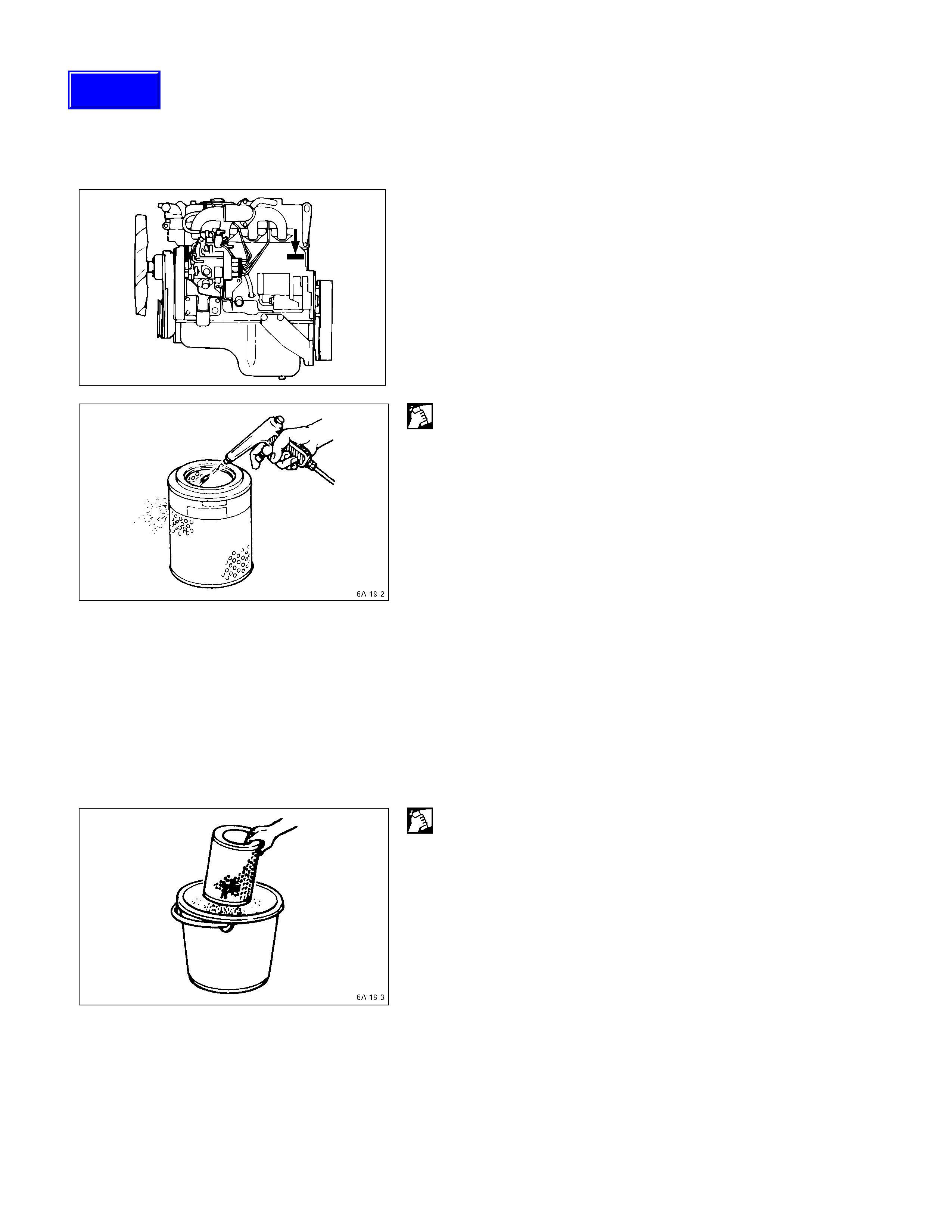

MODEL IDENTIFICATION

ENGINE SERI AL NUMBER

The engine number is stamped on the front left hand side

of the cylinder body.

AIR CLEANER

Element cleaning procedures will vary according to the

condition of the element.

OIL W ETTED (VISCOUS) TYPE PAPER ELEM ENT

The air cleaner has an oil wetted paper element. No

servicing is required until the replacement interval is

reached. Never attempt to clean the element, no matter

how dirty may appear. The element is designed to provide

normal filtering efficiency until it becomes due for

replacement. Refer to the Item “Service and Maintenance”

in the Owner’s and Driver’s Manual for general service

information.

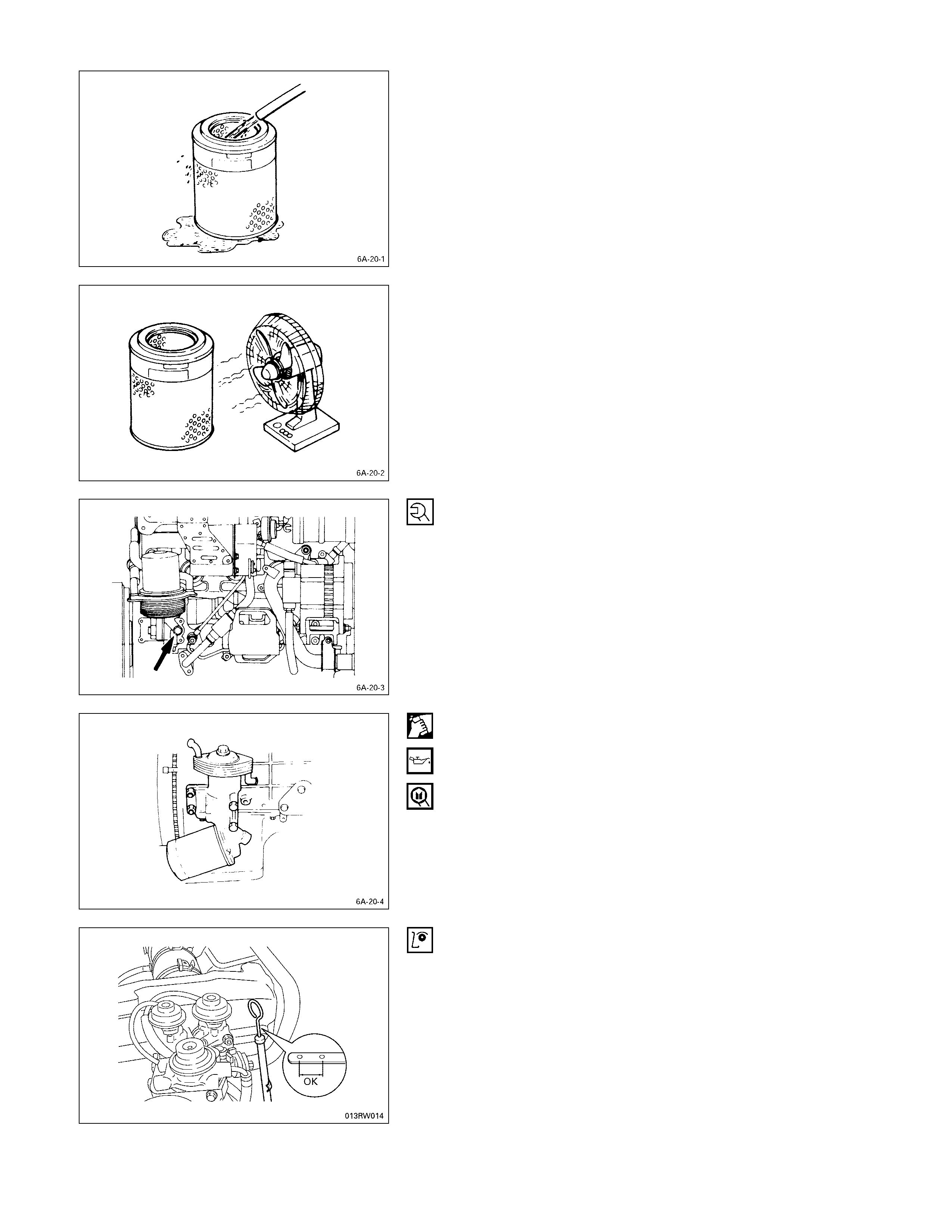

DUST FOULED ELEMENT

Rotate the element with your hand while applying

compressed air to the inside of the element. This will blow

the dust free.

Compressed air pressure must not exceed 7 kg/cm2 (99.6

psi/686 kPa).

CARBON AND DUST FO ULED ELEMENT

1. Prepare a cleaning solution of Isuzu Genuine Element

Cleaner (Donaldson D1400) diluted with water.

2. Submerge the element in the solution for twenty

minutes.

Techline

3. Remove the element from the solution and rinse it well

with running water.

Water pressure must not exceed 2.8 kg/cm2 (39.8

psi/274 kPa).

4. Dry the element in a well ventilated area.

An electric fan will hasten drying.

Note:

Do not use compressed air or an open flame to dry the

element quickly. Damage to the element will result.

It will usually take two or three days for the element to

dry completely. Therefore, it is a good idea to have a

spare on hand to use in the interim.

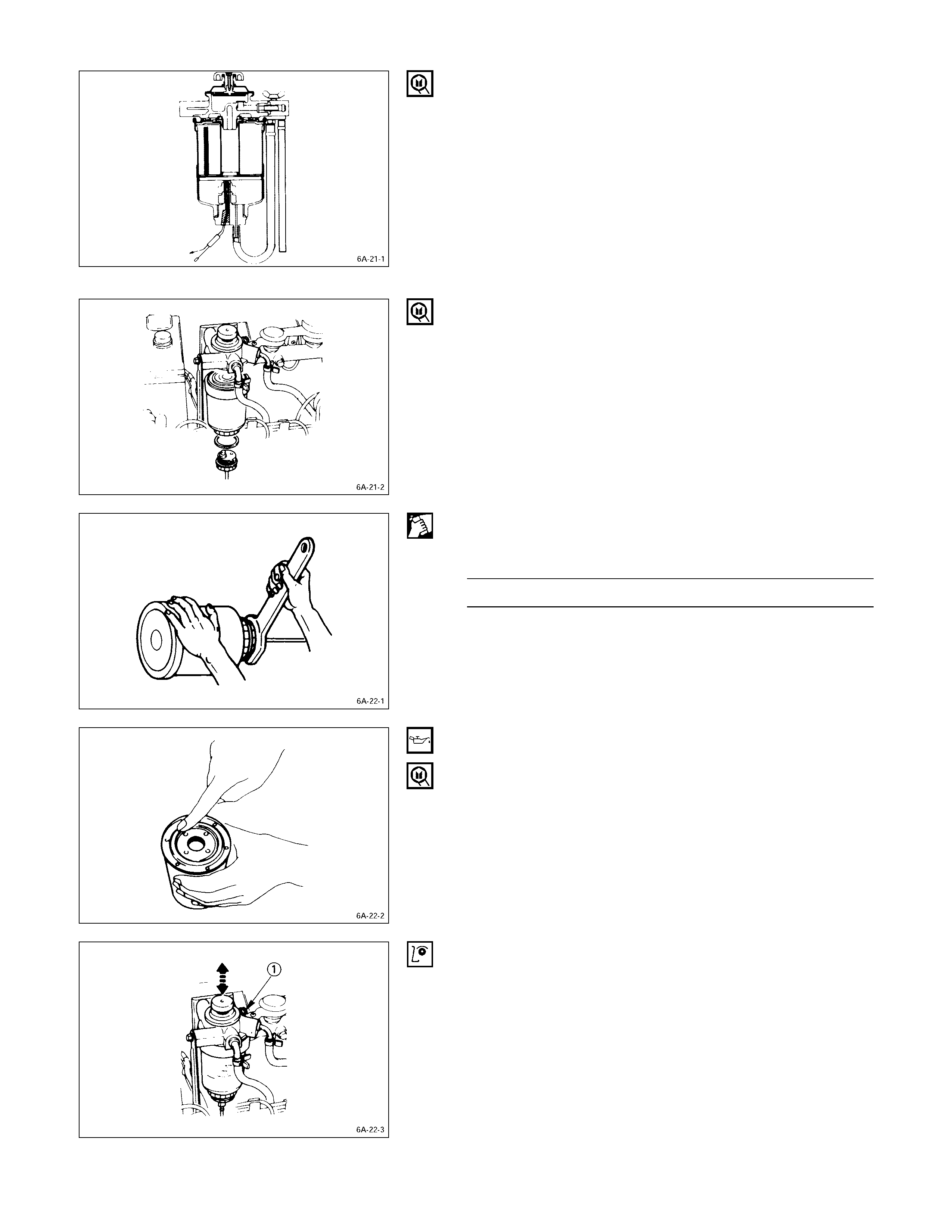

LUBRICATING SYSTEM

MAIN OIL FILTER (CARTRIDGE TYPE PAPER

ELEMENT) REPLACEM ENT PROCEDURE

1. Loosen the drain plug to drain the engine oil.

2. Wait a few minutes and then retighten the drain plug.

3. Loosen the used oil filter by turning it counterclockwise

with a filter wrench.

4. Clean the oil cooler fitting face. This will allow the new

oil filter to seat properly.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the new oil filter until the filter O-ring is fitted

against the sealing face.

7. Use the filter wrench to turn in the filter an additional 1

and 1/8 turns.

Filter Wrench: 5-8840-0200-0

8. Check the engine oil level and replenish to the

specified level if required.

Replenished Engine Oil 6.5 lit

9. Start the engine and check for oil leakage from the

main oil filter.

FUEL SYSTEM

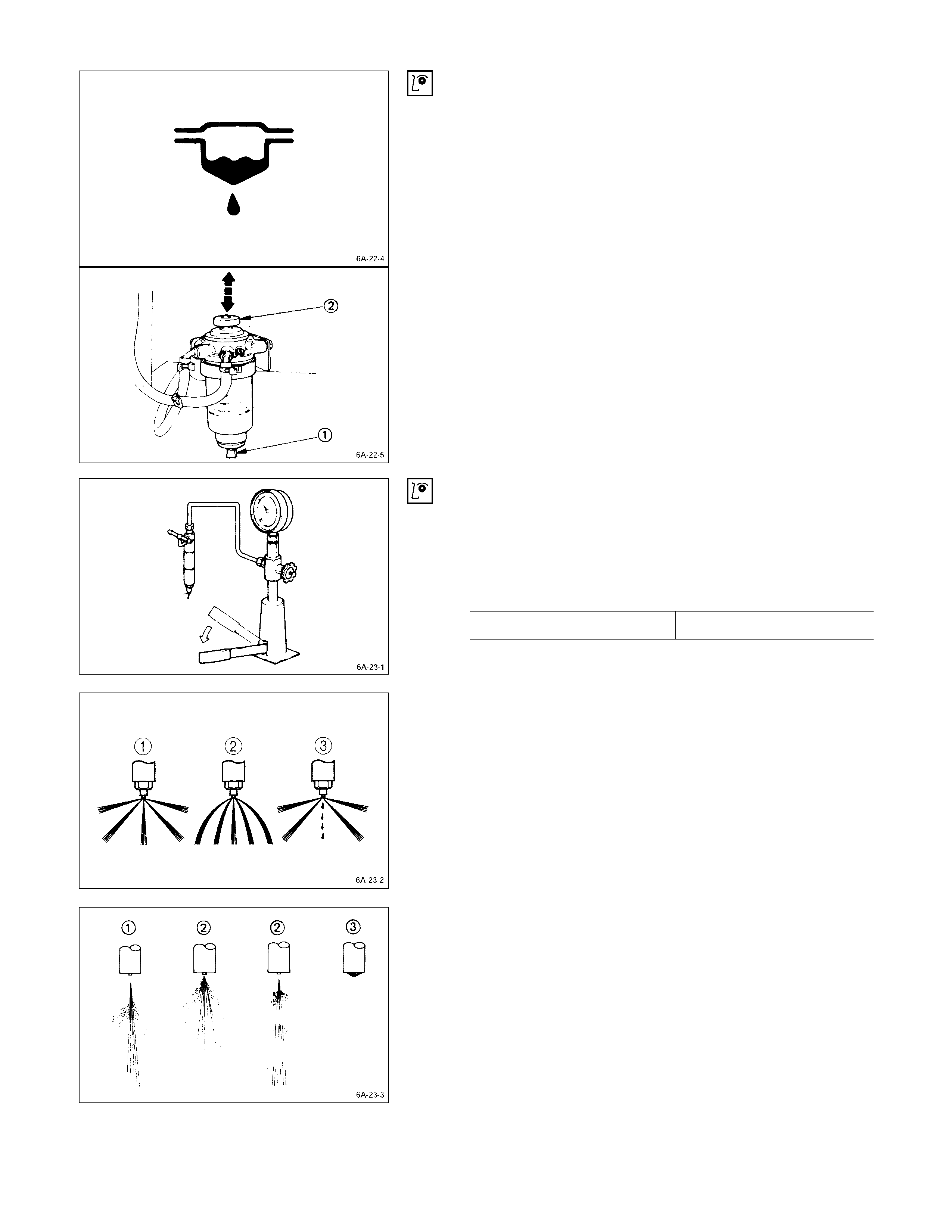

FUEL FILTER REPLACEMENT PROCEDURE

1. Place the end of the vinyl hose (beneath the drain

plug) in a container.

2. Open the drain plug.

3. Operate the priming pump several times to drain water

from the fuel filter.

4. Close the drain plug.

5. Operate the priming pump and check for fuel leakage.

6. Check that the water level warning light is off.

FUEL FILTER REPLACEMENT PROCEDURE

1. Remove the fuel filter by turning it counterclockwise

with a filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

2. Remove the level sensor from the filter by turning it

counterclockwise with a wrench.

3. Install the level sensor to the water separator body

with wrench.

Level Sensor Torque kg·m (lb.ft/N·m)

1.3 (9.4/12.7)

4. Clean the water separator cover fitting faces.

This will allow the new fuel filter to seat properly.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the fuel filter until the sealing face comes in

contact with the O-ring.

7. Turn in the fuel filter an additional 2/3 of a turn with a

filter wrench.

Filter Wrench : 5-8840-0253-0 (J-22700)

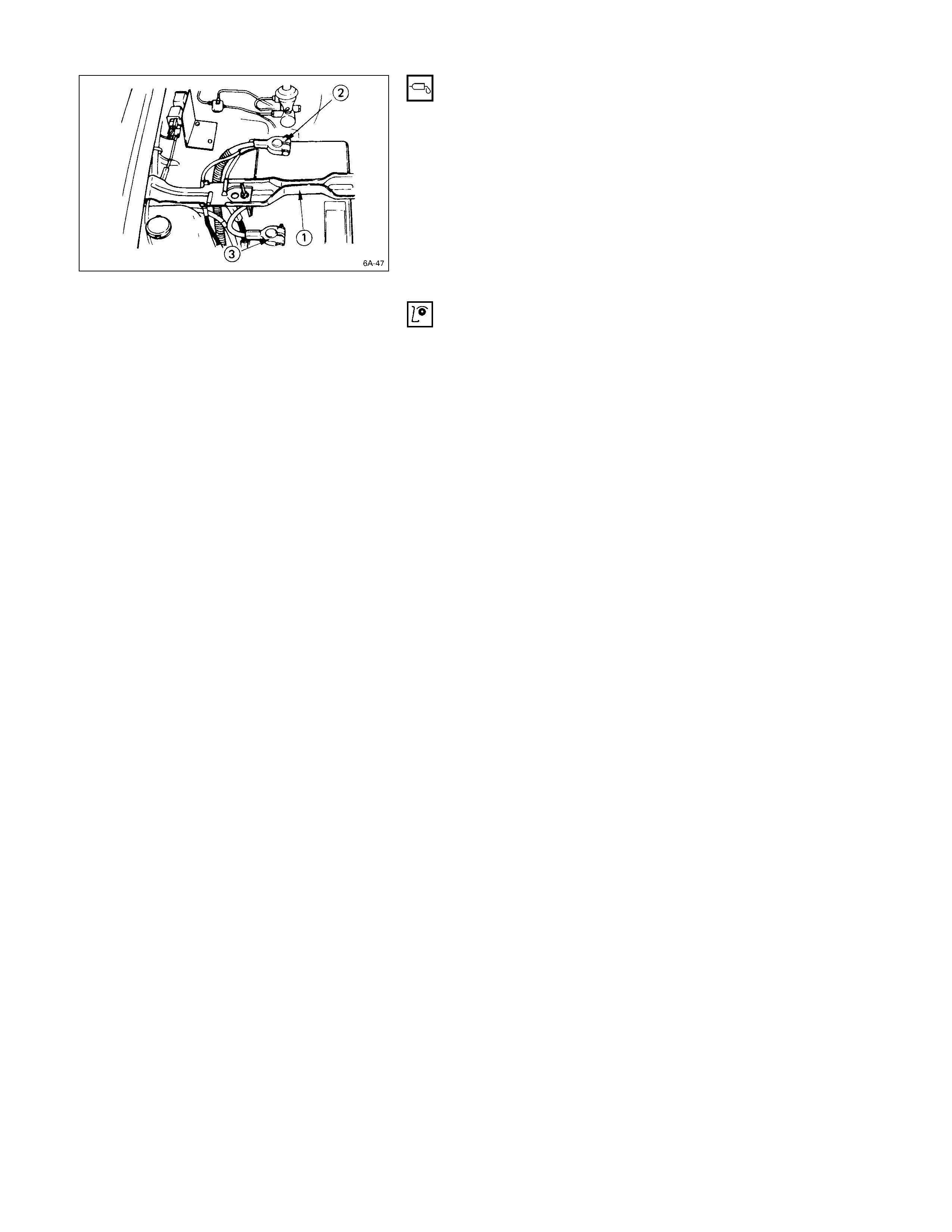

8. Loosen the bleeder plug Q on the priming pump body.

9. Operate the priming pump until fuel begins to flow

from the fuel filter.

10. Retighten the bleeder plug Q.

11. Operate the priming pump several times and check for

fuel leakage.

Note:

The use of an HOLDEN genuine fuel filter is strongly

recommended.

DRAINING PRO CEDURE

The indicator light will come on when the water level in the

water separator exceeds the specified level.

Drain the water and foreign material from the water

separator with the following procedure.

1. Place the end of the vinyl hose (beneath the drain

plug) in a container.

2. Loosen the drain plug Q.

3. Operate the priming pump R several times to drain

the water.

4. After draining the water, tighten the drain plug Q .

5. Operate the priming pump several times and check for

fuel leakage.

6. Check the water separator indicator light. It should be

off.

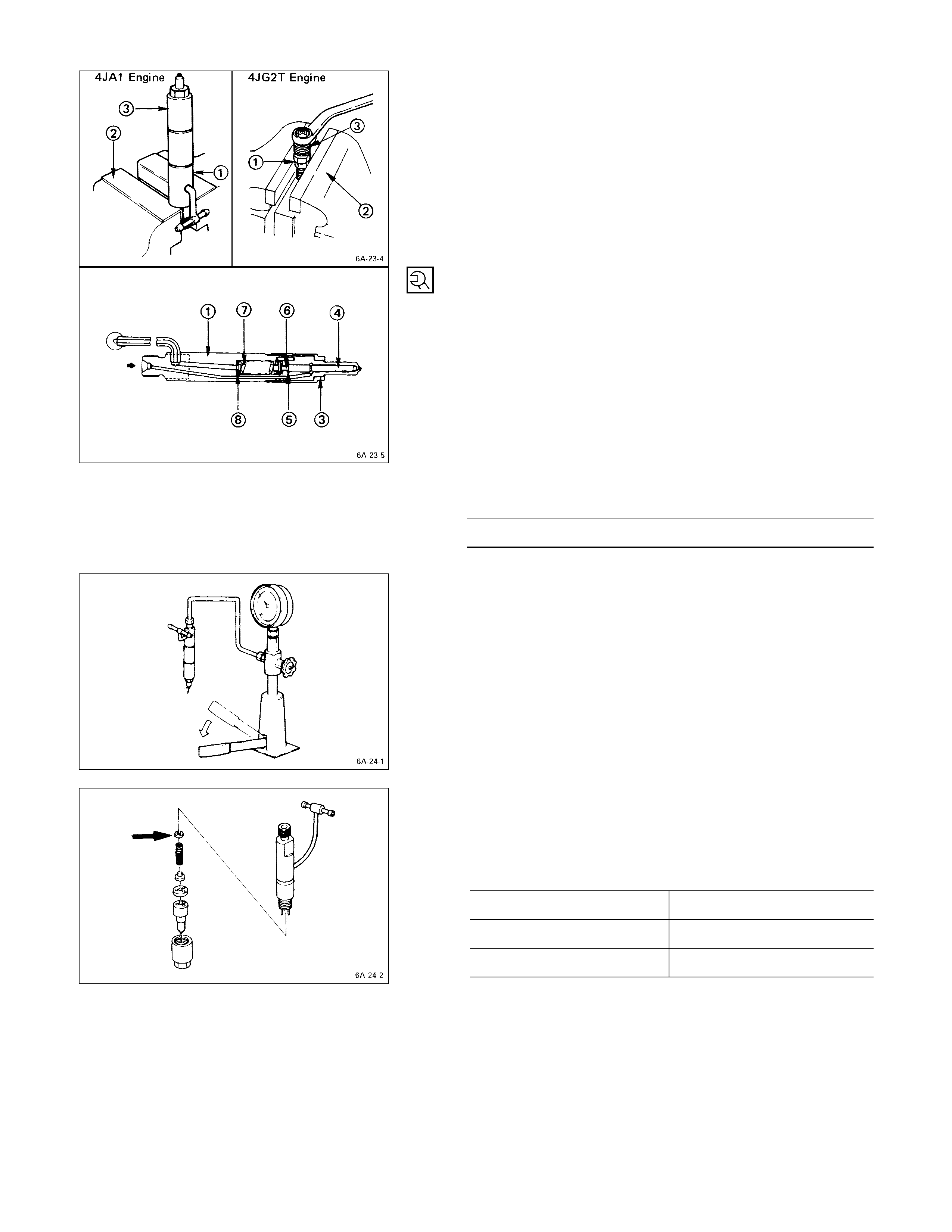

INJECTION NOZZLE INSPECTION

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or adjusted.

Injection Nozzle Opening Pressure kg/cm2 (psi/kPa)

4JB1T 185 (2,631/18,143)

If the spray condition is bad, the injection nozzle must be

replaced or repaired.

Spray Condition

QCorrect

R Incorrect (Restrictions in orifice)

SIncorrect (Dripping)

INJECTION NOZZLE ADJUSTMENT

1. Clamp the injection nozzle holder Q in a vise R.

2. Use a wrench to remove the injection nozzle retaining

nut S.

3. Remove the injection nozzle holder from the vise.

4. Remove the injection nozzle T, the spacer U, the

spring seat V, the spring W and the adjusting shim

X.

5. Install the new adjusting shim, the spring, the spring

seat, the spacer, the injection nozzle, and the retaining

nut.

6. Clamp the injection nozzle holder in the vise.

7. Tighten the injection nozz le holder retaining nut to the

specified torque.

Injection Nozzle Holder Retaining Nut

Torque kg·m (ft.lbs/N·m)

3.5 ± 0.5 (25.3 ± 3.6/34.3 ± 4.9)

8. Remove the injection nozzle holder from the vise.

9. Attach the injection nozzle holder to the injection

nozzle tester.

10. Apply pressure to the nozzle tester to check that the

injection nozzle opens at the specified pressure.

If the injection nozzle does not open at the specified

pressure, install or remove the appropriate number of

adjusting shims to adjust it.

(Reference)

Removing or installing one shim will increase or decrease

the nozzle opening pressure approximately 3.77 kg/cm2

(53.6 psi/370 kPa)

Adjusting Shim Availability mm (in)

Range 0.5 – 1.5 (0.02 – 0.06)

Increment 0.025 (0.001)

Total No. of Shims 41

Warning:

Test fluid from the injection nozzle tester will spray

out under great pressure. It can easily puncture a

person’s skin. Keep your hands away from the

injection nozzle holder tip at a ll times.

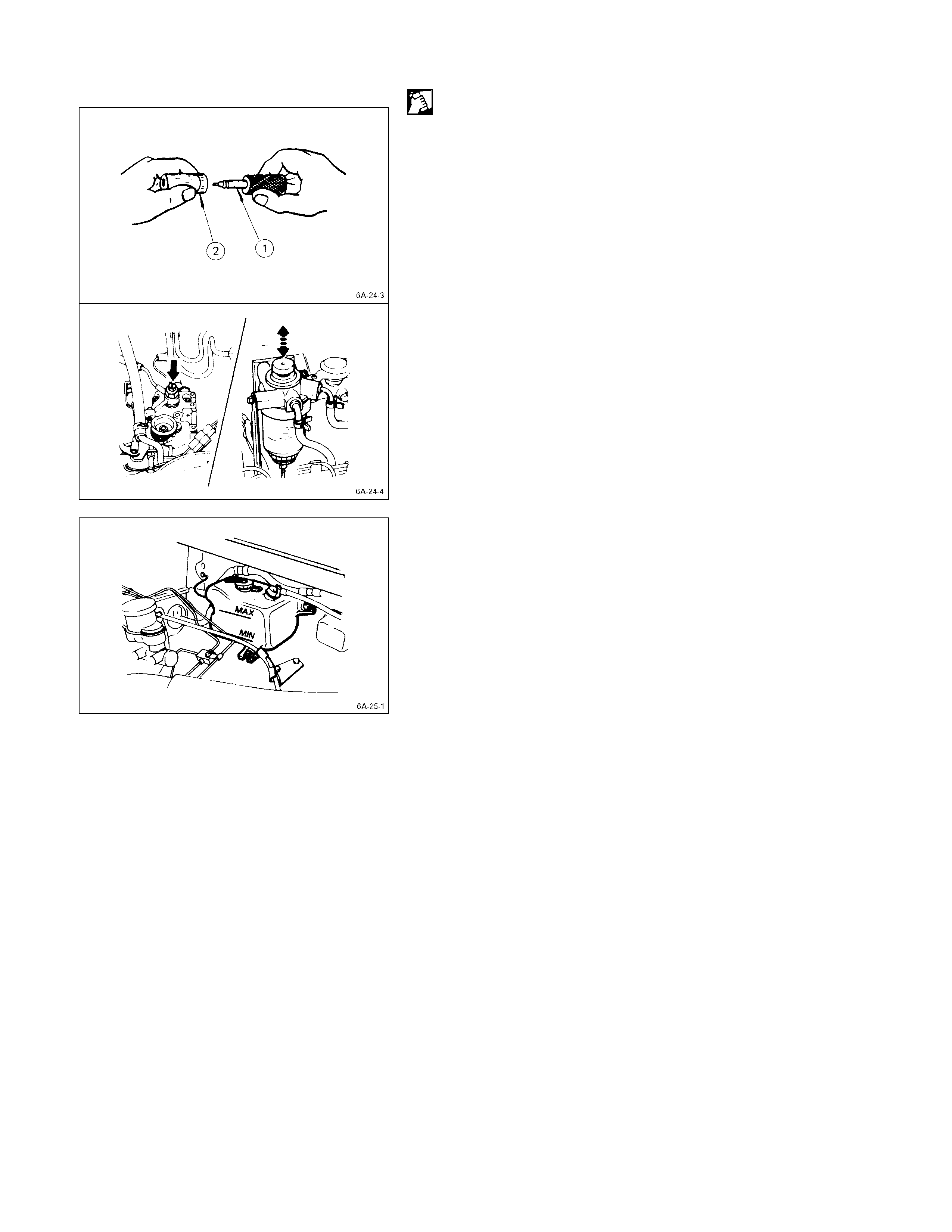

NOZZLE LAPPI NG PROCEDURE

1. Lap the nozzle needle Q and the nozzl e body R by

applying a compound of oxidized chrome and animal

oil.

Note:

Do not apply an excessive amount of the oxidized

chrome and animal oil compound to the injection

needle valve seat area.

2. Carefully wash the needle valve and the nozzle body in

clean diesel fuel after lapping.

AIR BLEEDING

1. Loosen the bleeder screw on the injection pump

overflow valve.

2. Operate the priming pump until fuel mixed with foam

flows from the bleeder screw.

3. Tighten the bleeder screw.

4. Operate the priming pump several times and check for

fuel leakage.

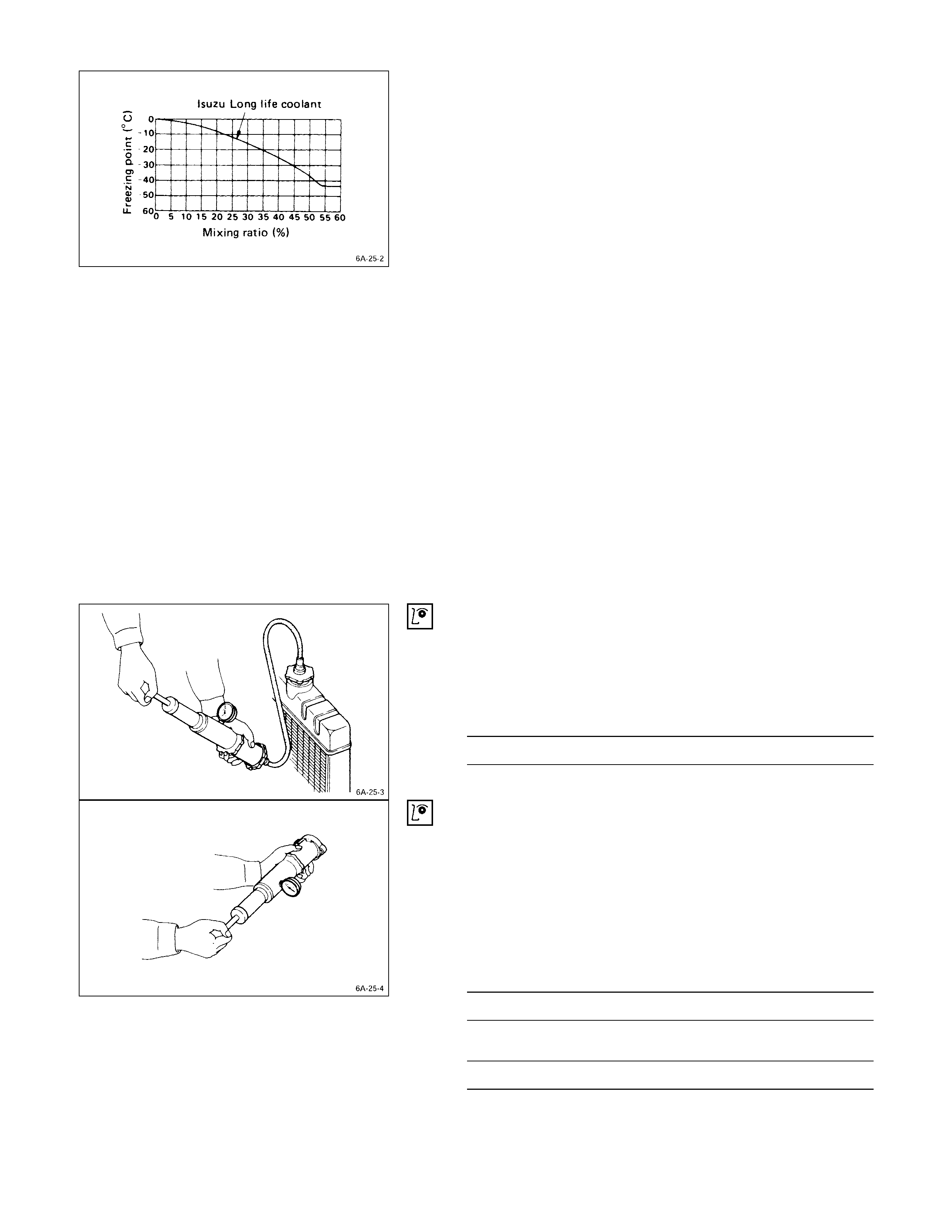

COOLING SYSTEM

COOLANT LEVEL

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the “MIN” line, carefully

check the cooling system for leakage. Then add enough

coolant to bring the level up to the “MAX” line.

ENGINE CO OLANT FILLI NG UP PROCEDURE

1. Make sure that the engine is cool

Warning:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the rediator cap.

Otherwise you might get scalded by hot vapor or

boiling water.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

2. Open rediator cap pour coolant up to filler neck

3. Pour coolant into reservoir tank up to “MAX” line

4. Tighten radiator cap and start the engine. After idling

for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

5. After replenish the coolant tighten radiator cap, warm

up the engine at about 2000 rpm. Set heater

adjustment to the highest temperature position, and let

the coolant circulate also intoheater water system.

6. Chech to see the thermometer, continuously idling 5

minutes and stop the engine.

7. When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant is found, check the

coolant system and reservoir tank hosefor leakage.

8. Pour coolant into the reservoir tank up to “MAX” line.

COOLING SYSTEM INSPECTION

Install a radiator filler cap tester to the radiator. Apply

testing pressure to the cooling system to check for

leakage. The testing pressure must not exceed the

specified pressure.

Testing Pressure kg/cm2 (psi/kPa)

2 (28.45/196)

RADIATOR CAP INSPECTION

The radiator filler cap is designed to maintain coolant

pressure in the cooling system at 1.05 kg/cm2 (15 psi/103

kPa).

Check the radiator filler cap with a radiator filler cap tester.

The radiator filler cap must be replaced if it fails to hold the

specified pressure during the test procedure.

Radiator Filler Cap Pressure

Pressu re Valve kg/cm2 (psi/kPa)

0.9 – 1.2 (12.8 – 17.1/88.2 – 117.6)

Negative Valve (Reference) kg/cm2 (psi/kPa)

0.01 – 0.04 (0.14 – 0.57/0.98 – 3.92)

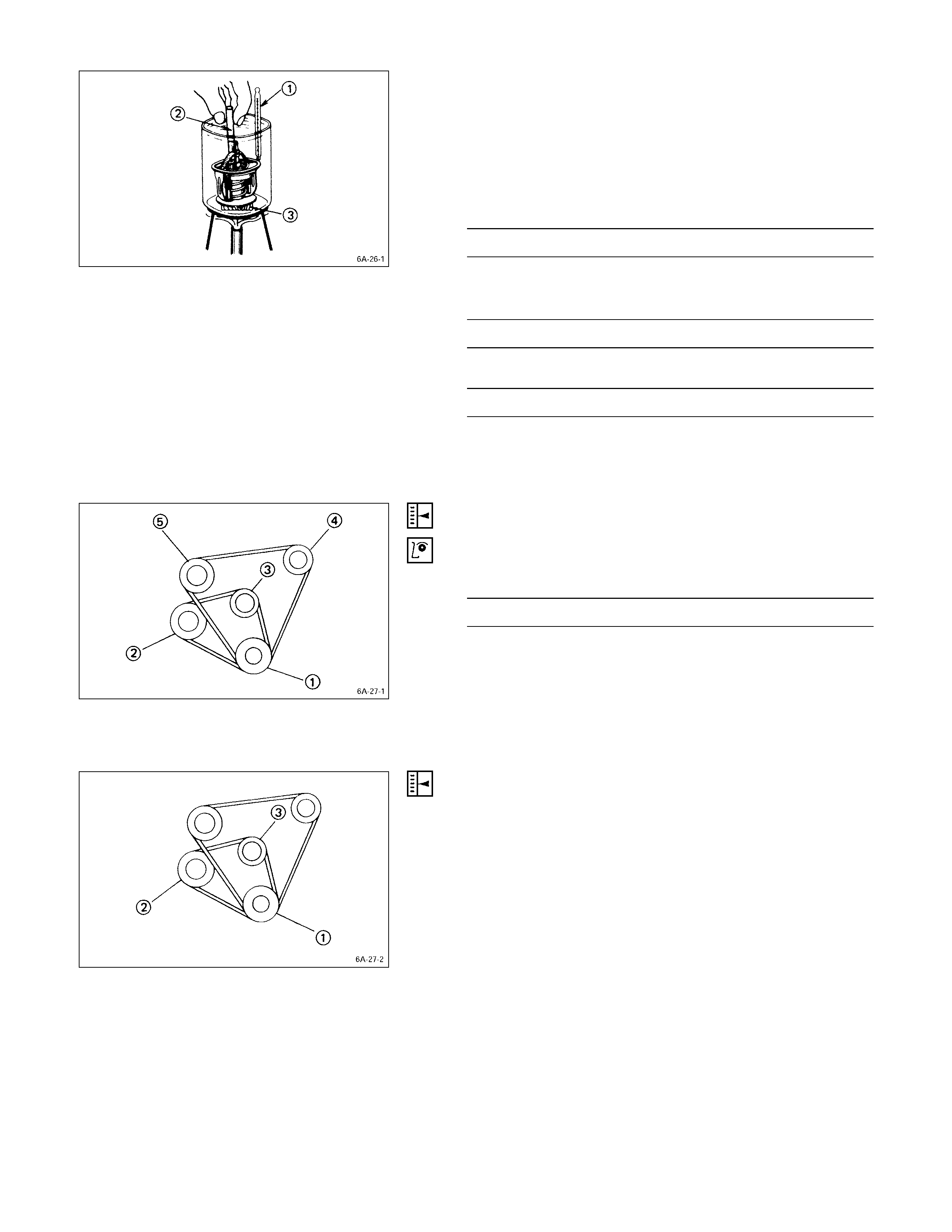

THERMOSTAT OPERATING TEST

1. Completely submerge the thermostat in water.

2. Heat the water.

Stir the water constantly to avoid direct heat being

applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature °C (°F)

82 (180)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature °C (°F)

95 (203)

Valve Lift at Fully Open position mm (in)

9.5 (0.37)

QThermometer

RAgitating rod

SWooden piece

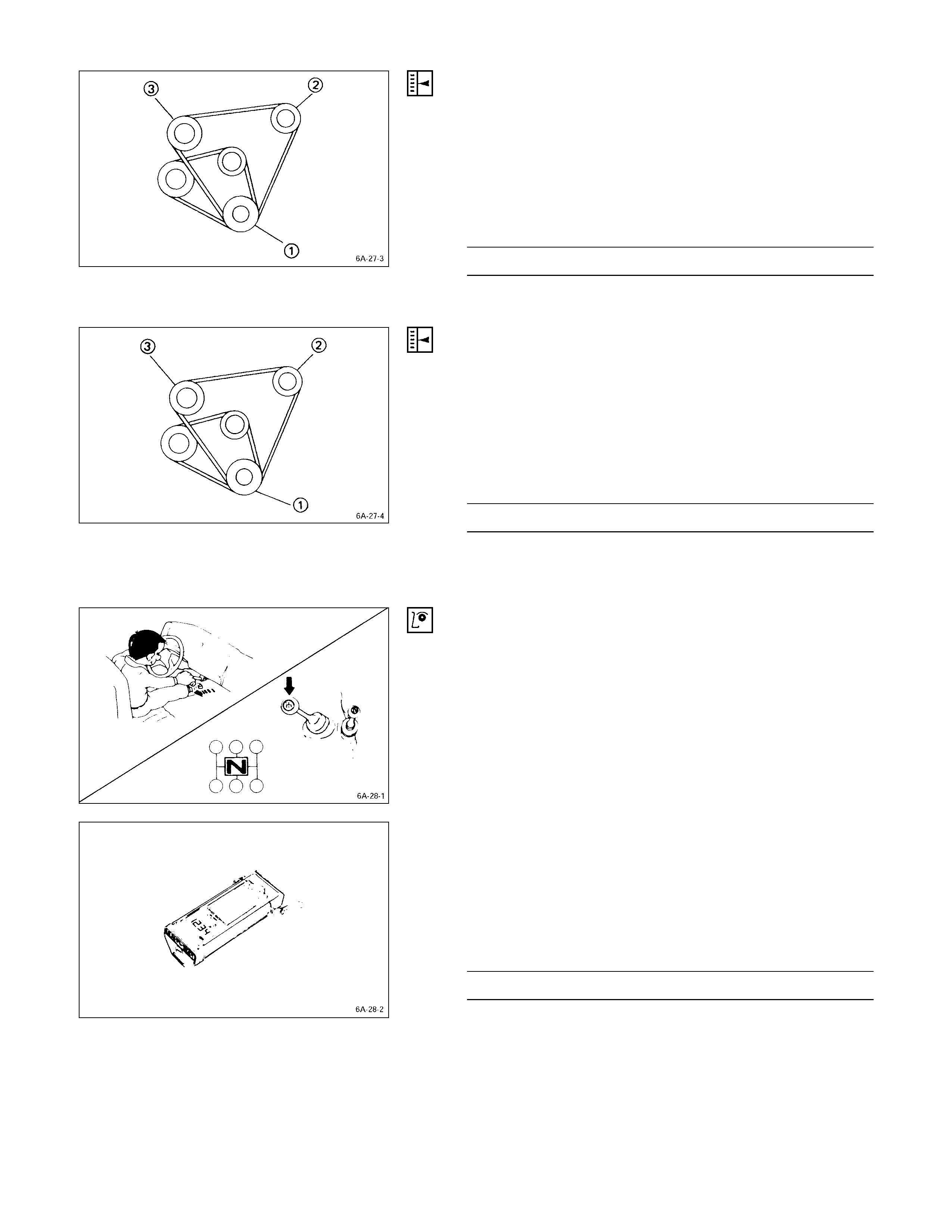

DRIVE BELT ADJUSTMENT

Depress the drive belt mid-portion with a 10 kg (22 lb/98N)

force.

Drive Belt Deflection mm (in)

10 (0.39)

Check the drive belt for cracking and other damage.

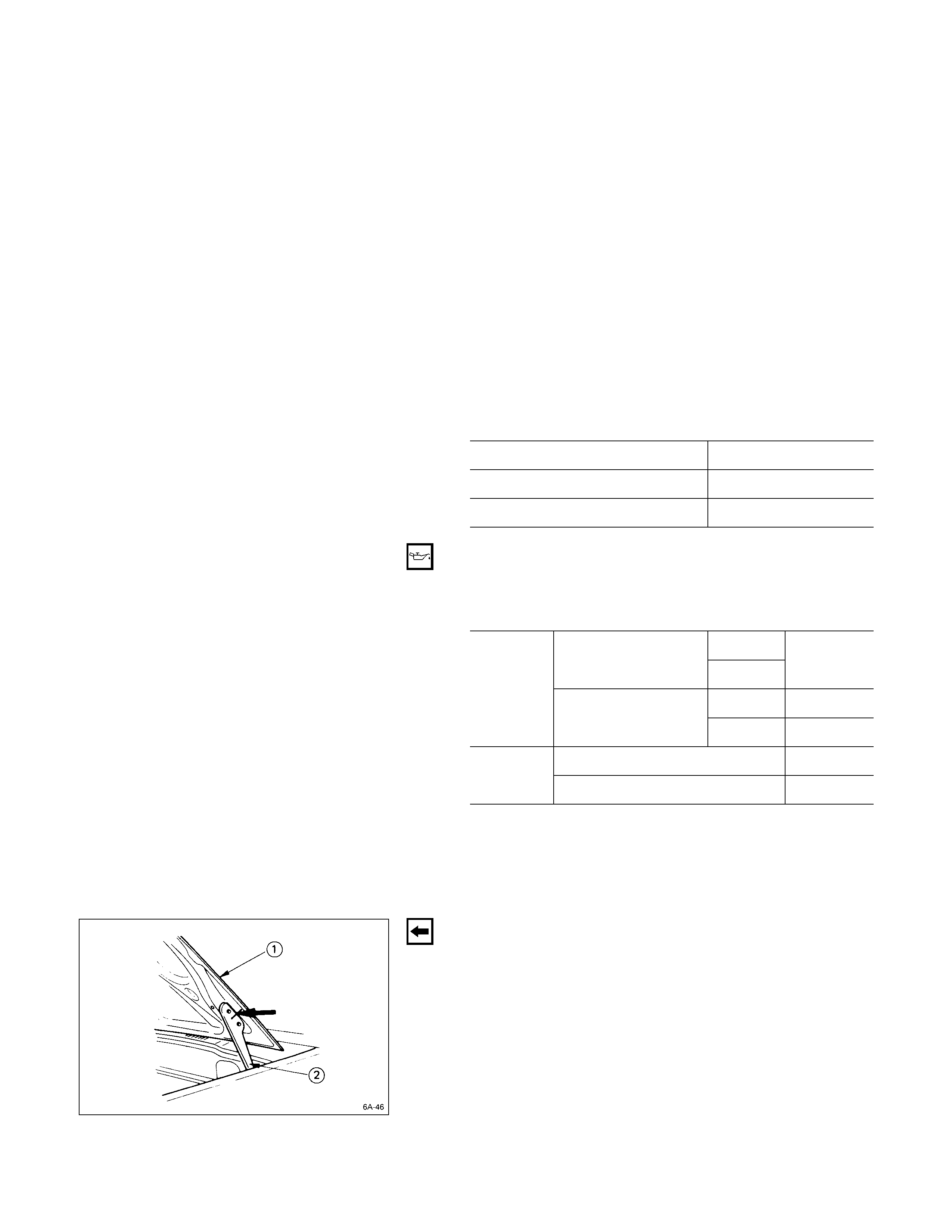

QCrankshaft damper pulley

RGenerator pulley

SCooling fan pulley

TOil pump pulley or idler pulley

UCompressor pulley or idler pulley

COOLING FAN PULLEY DRIVE BELT

Fan belt tension is adjusted by moving the generator.

Depress the drive belt mid-portion with a 10 kg (22 lb/98N)

force.

QCrankshaft damper pulley

RGenerator pulley

SCooling fan pulley

COMPRESSO R PULLEY DRIVE BELT

Move the idler pulley as required to adjust the compressor

drive belt tension.

If the vehicle is equipped with power steering, move the oil

pump as required

Depress the drive belt mid-portion with a 10 kg (22 lb/98

N) force.

Belt Deflection mm (in)

12 – 15 (0.47 – 0.59)

QCrankshaft damper pulley

ROil pump pulley or idler pulley

POWER STEERING OIL PUM P PULLEY DRIVE BELT

Move the oil pump as required to adjust the oil pump drive

belt tension.

On air conditioner equipped models, both drive belts pulley

must always be replaced as a set.

Depress the drive belt mid-portion with a 10 kg (22 lb/98

N) force.

Belt Deflection mm (in)

14 - 17 (0.55 – 0.67)

QCrankshaft damper pulley

ROil pump pulley

SCompressor pulley or idler pulley

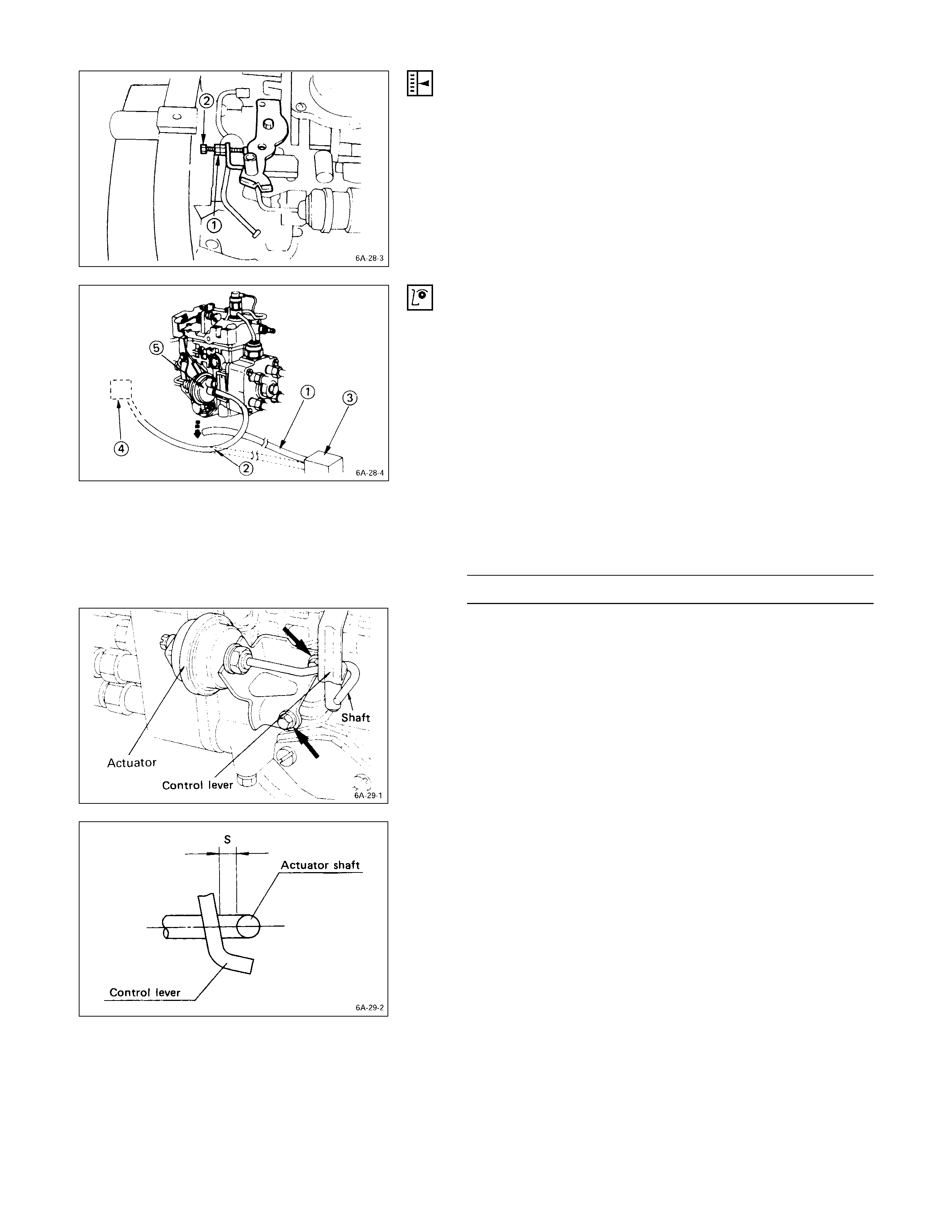

ENGINE CONTROL

IDLING SPEED ADJUSTM ENT

1. Set the vehicle parking brake and chock the drive

wheels.

2. Place the transmission in neutral.

3. Start the engine and allow it to idle until the coolant

temperature reaches 70 - 80°C (158 - 176°F).

4. Disconnect the engine control cable from the control

lever.

5. Set a tachometer to the engine.

6. Check the engine idling speed.

If the engine idling speed is outside the specified

range, it must be adjusted.

Engine Idling Speed rpm

750 ± 50

IDLING SPEED ADJUSTM ENT

1. Loosen the idling set screw lock nut Q on the injection

pump idling set bolt.

2. Adjust the idling speed to the specified range by

turning the idling set bolt R.

3. Lock the engine set bolt with the idling set screw lock

nut.

4. Check that the idling control cable is tight (free of

slack). If required, remove the slack from the cable.

FAST IDLING SPEED I NSPECTION

1. Set tachometer to the engine.

2. Disconnect the vacuum hose Q from the fast idle

actuator U on the injection pump.

3. Disconnect the other vacuum hose R from the

vacuum switching valve S and connect it to the fast

idle actuator U.

The vacuum line will now be connected directly from

the vacuum pump T to the fast idle actuator.

4. Check the engine fast idling speed.

If the engine idling speed is outside the specified

range, it must be adjusted.

Fast Idling Speed rpm

850 - 950

FAST IDLING SPEED ADJUSTM ENT

1. Loosen the fast idle actuator bracket bolts.

2. Adjust the fast idling speed by moving the actuator

bracket, so that the clearance “S” can be 1 ~ 2 mm

(0.04 ~ 0.08 in.).

3. Tighten the bracket bolts.

ACCELERATOR CONTROL

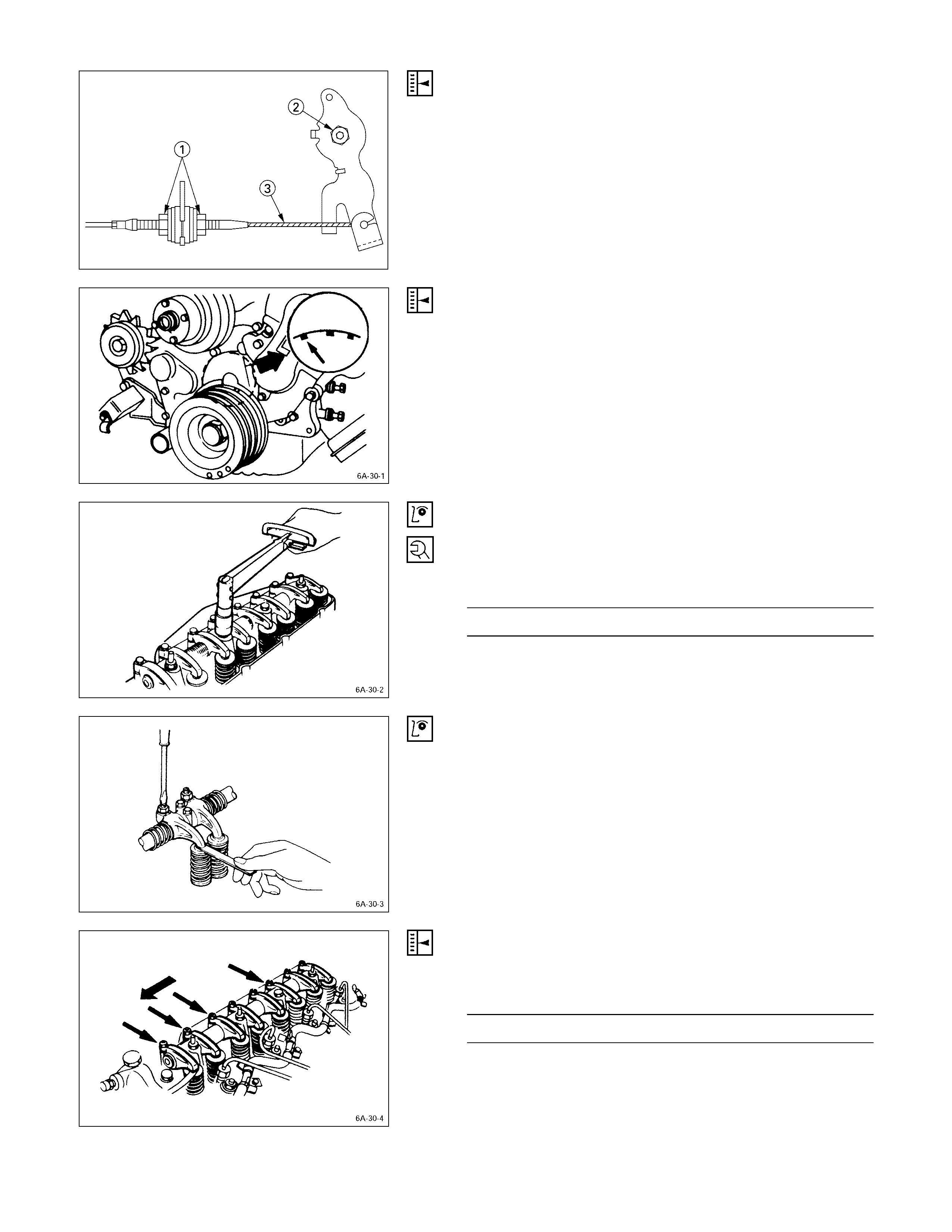

ACCELERATOR CO NTROL CABLE ADJUSTMENT

1. Loosen the accelerator cable clamp bolt Q.

2. Check that the idling control knob is in the engine

idling position.

3. Hold the accelerator lever R in the fully closed

position and stretch the control cable S in the

direction indicated by the arrow to remove any slack.

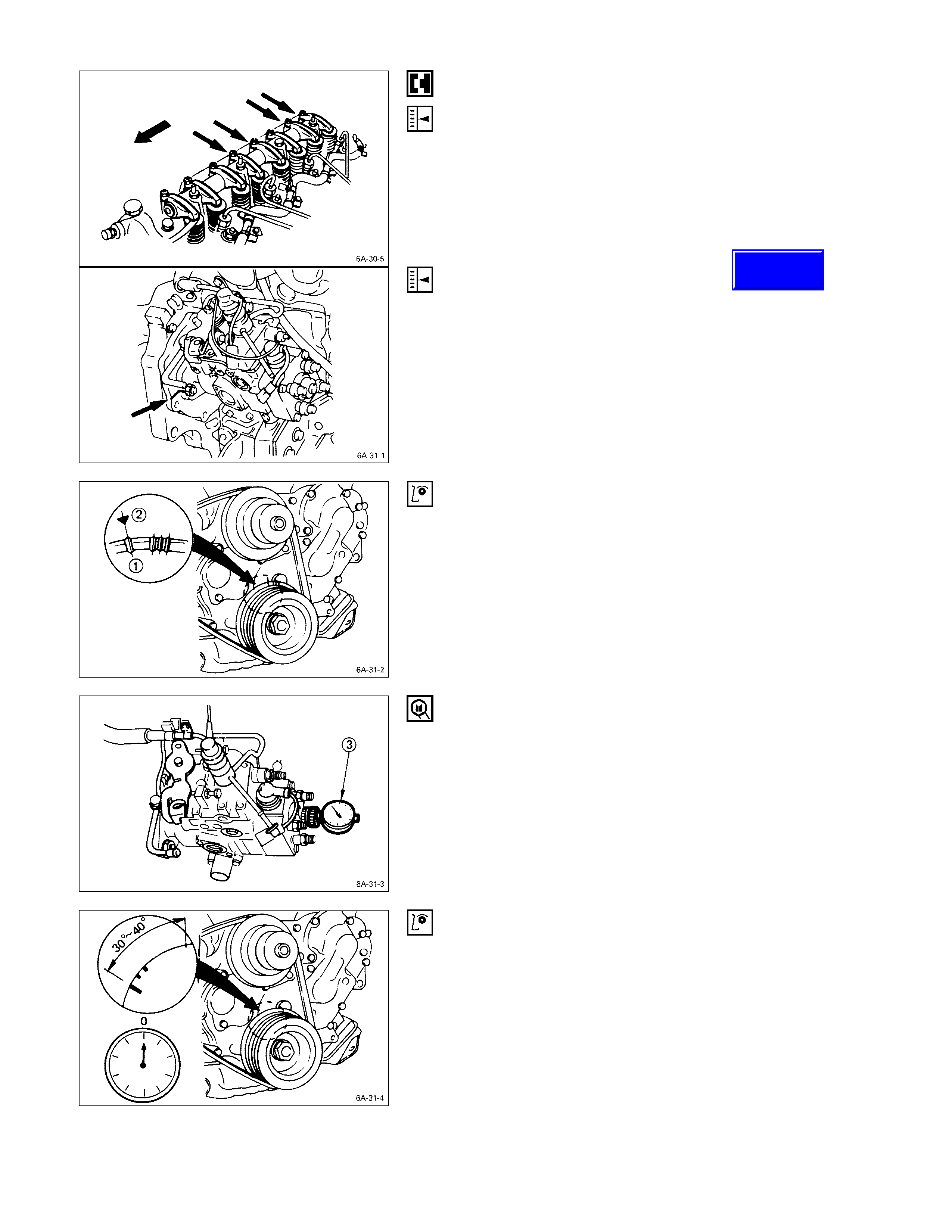

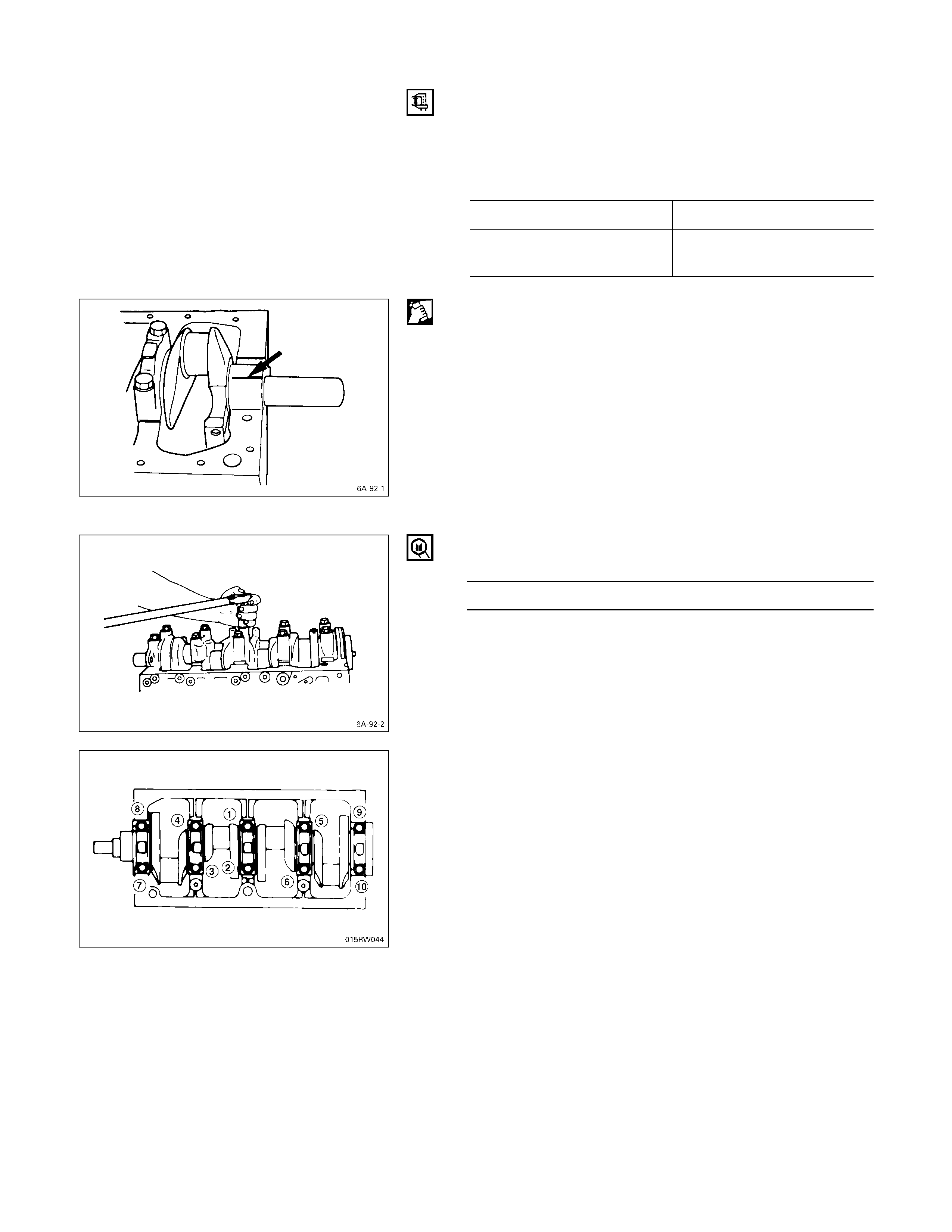

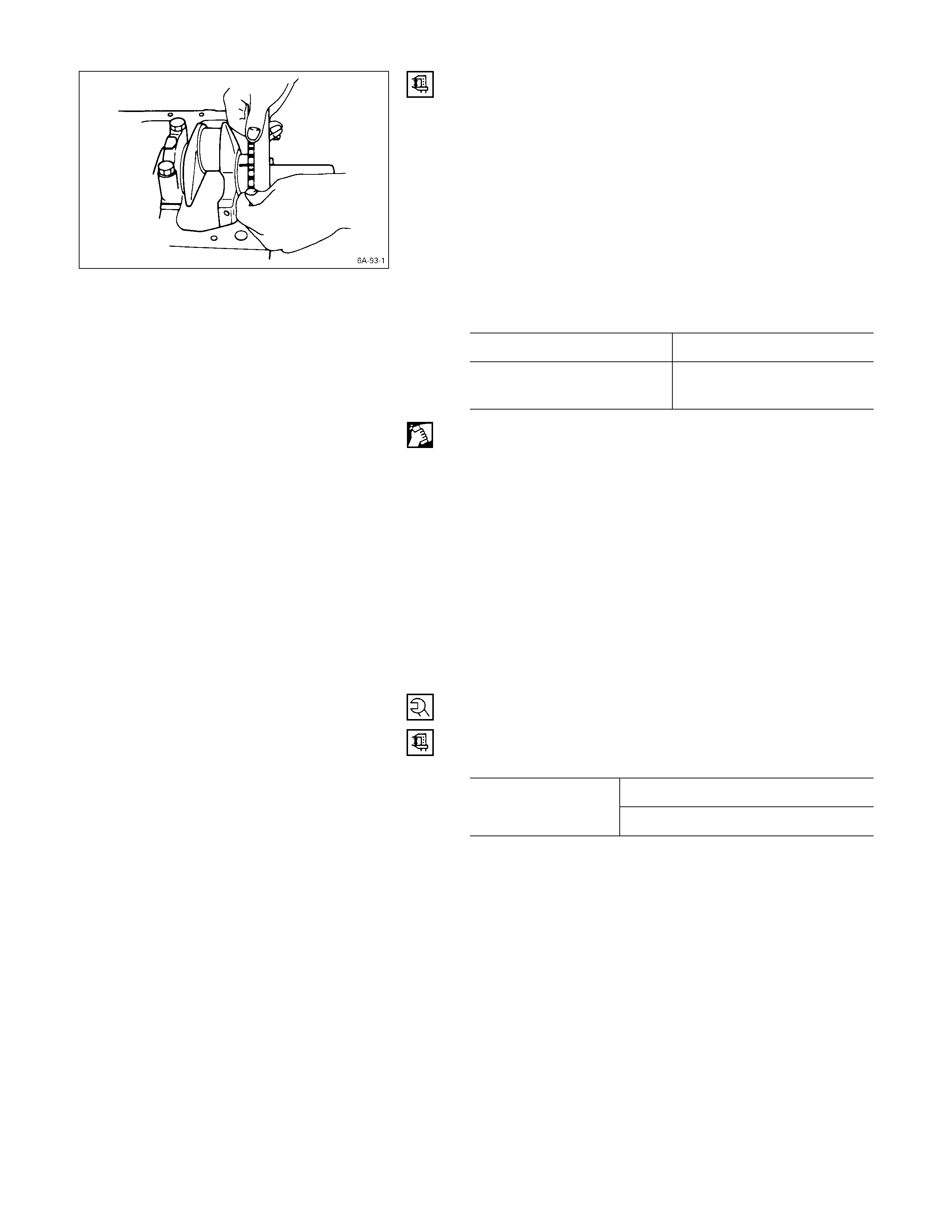

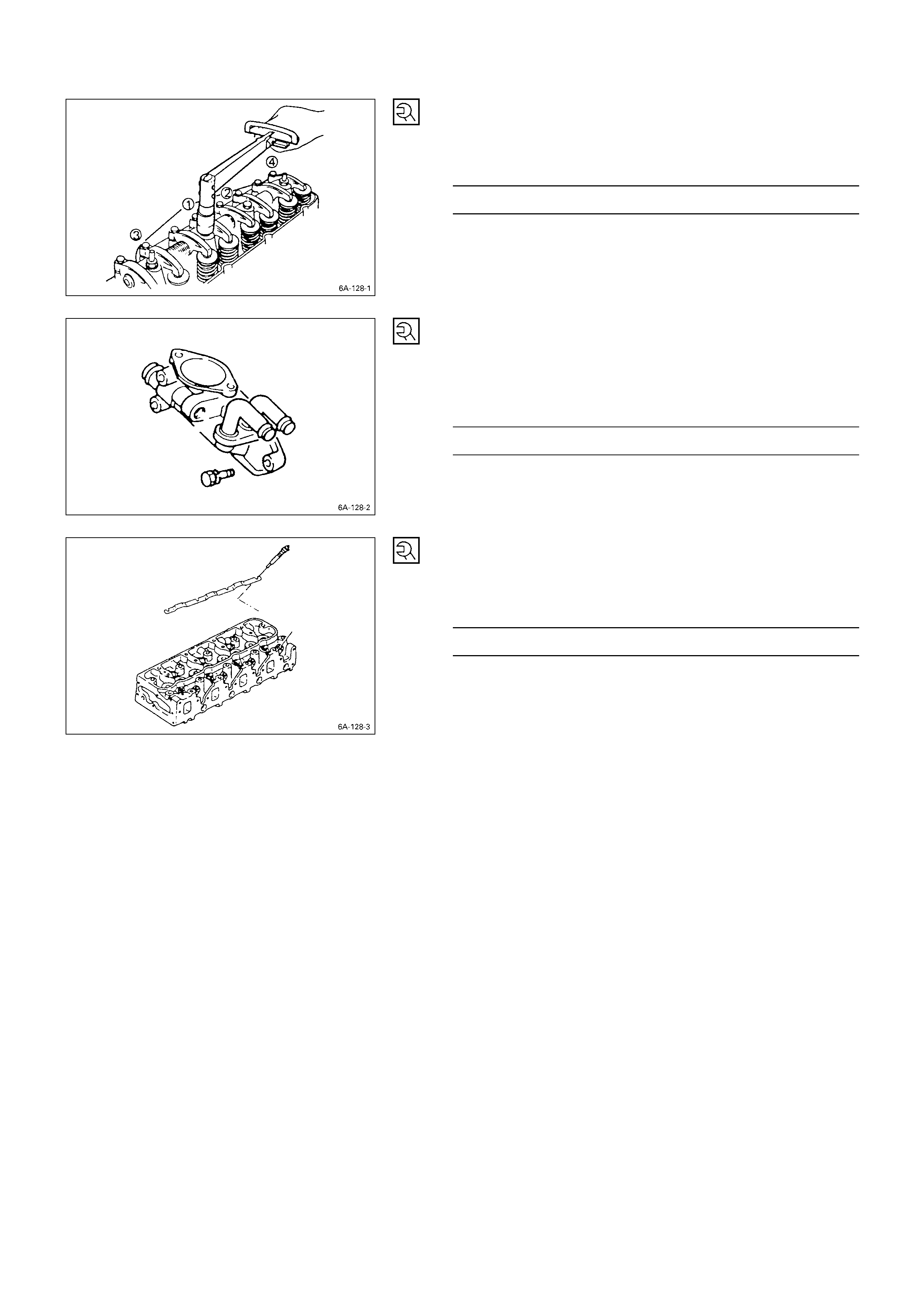

VALVE CLEARANCE ADJUSTMENT

1. Bring the piston in either the No. 1 cylinder or the No. 4

cylinder to TDC on the compression stroke by turning

the crankshaft until the crankshaft damper pulley TDC

line is aligned with the timing pointer.

2. Check the rocker arm shaft bracket nuts for

looseness.

Tighten any loose rocker arm shaft bracket nuts

before adjusting the valve clearance.

Rocker Arm Shaft Bracket Nut Torque kg·m (lb·ft/N·m)

5.5 ± 0.5 (39.8 ± 3.6/53.9 ± 4.9)

3. Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve push

rods are depressed, the No. 4 piston is at TDC on the

compression stroke.

Adjust the No.1 or the No. 4 cylinder valve clearances

while their respective cy linders are at TDC on the

compression stroke.

Valve Clearance (At Cold) mm (in)

0.4 (0.016)

4. Loosen each valve clearance adjusting screw as

shown in the illustration.

5. Insert a feeler gauge of the appropriate thickness

between the rocker arm and the valve stem end.

6. Turn the valve clearance adjusting screw until a slight

drag can be felt on the feeler gauge.

7. Tighten the lock nut securely.

8. Rotate the crankshaft 360°.

9. Realign the crankshaft damper pulley TDC notched

line with the timing pointer.

10 Adjust the clearances for the remaining valves as

shown in the illustration.

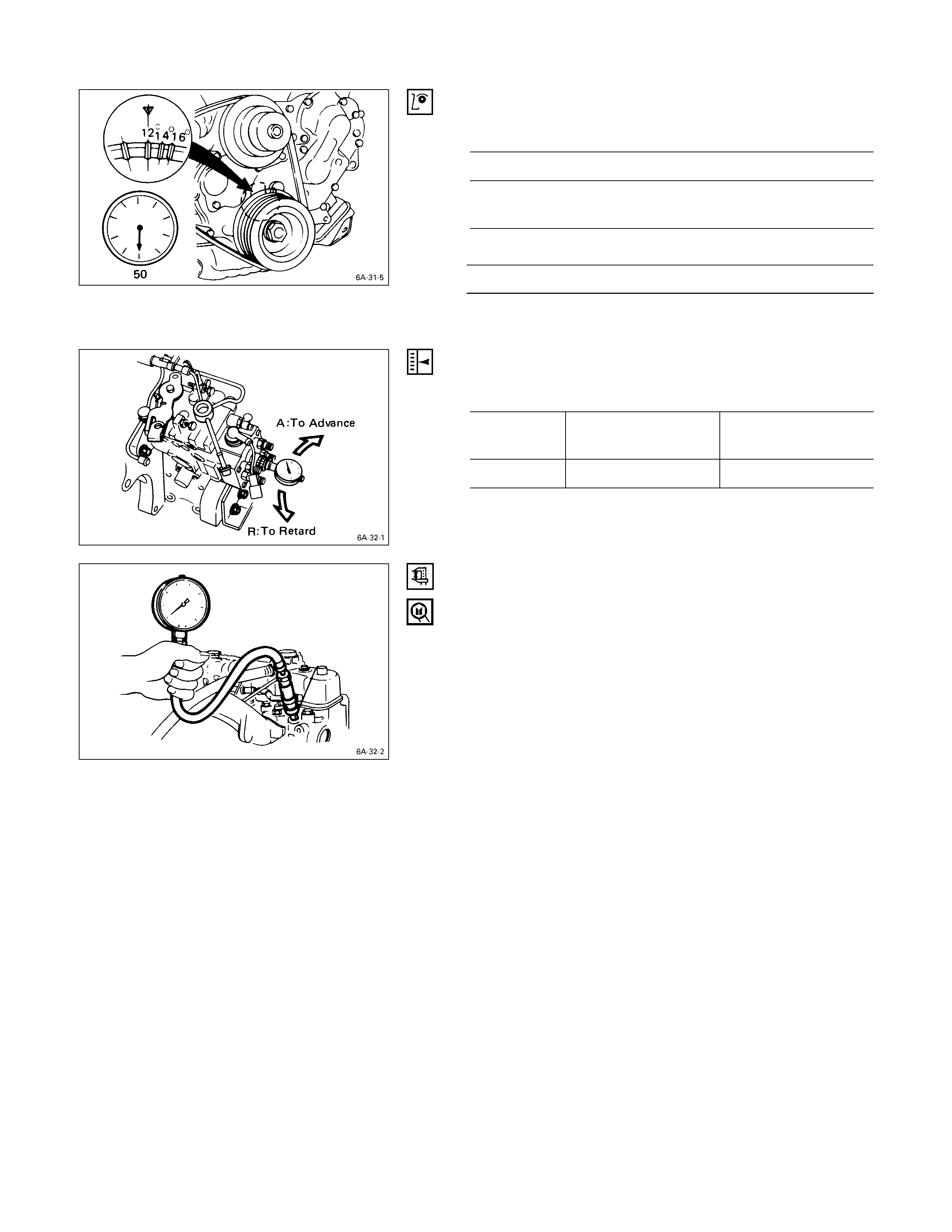

INJECTION TIMING ADJUSTMENT

1. Check that the notched line on the injection pump

flange is aligned with the front plate or the timing gear

case notched line.

2. Bring the piston in the No. 1 cylinder to TDC Q on the

compression stroke by turning the crankshaft until the

crankshaft pulley TDC line is aligned with the timing

mark R.

Note:

Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

3. Disconnect the injection pipe from the injection pump

4. Remove one bolt from the distributor head.

5. Insert a screwdriver into a hole in the fast idle lever

and turn the lever to release the W-C.S.D. function. (if

so equipped)

6. Install the static timing gauge S.

The probe of the gauge should be depressed inward

approximately 2 mm (0.079 in).

Static Timing Gauge: 5-8840-0145-0 (J-28827)

7. Rotate the crankshaft to bring the piston in the No. 1

cylinder to a point 30 - 40° BTDC.

8. Set the timing gauge needle to zero.

9. Move the crankshaft pulley slightly in both directions to

check that the gauge indication is stable.

Techline

10. Turn the crankshaft clockwise and read the gauge

indication when the crankshaft pulley timing mark

11° (4JB1T) on pulley is aligned with the pointer.

4JB1T

BTDC

11 ± 2°

Standard Reading mm (in)

0.5 (0.02)

If the injection timing is outside the specified range,

continue with the following steps.

11. Loosen the injection pump fixing nuts and bracket

bolts.

12. Adjust the injection pump setting angle.

When large than

standard value When smaller than

standard value

Gear drive R A

A: Move the injection pump toward the engine.

R: Move the injection pump away from the engine.

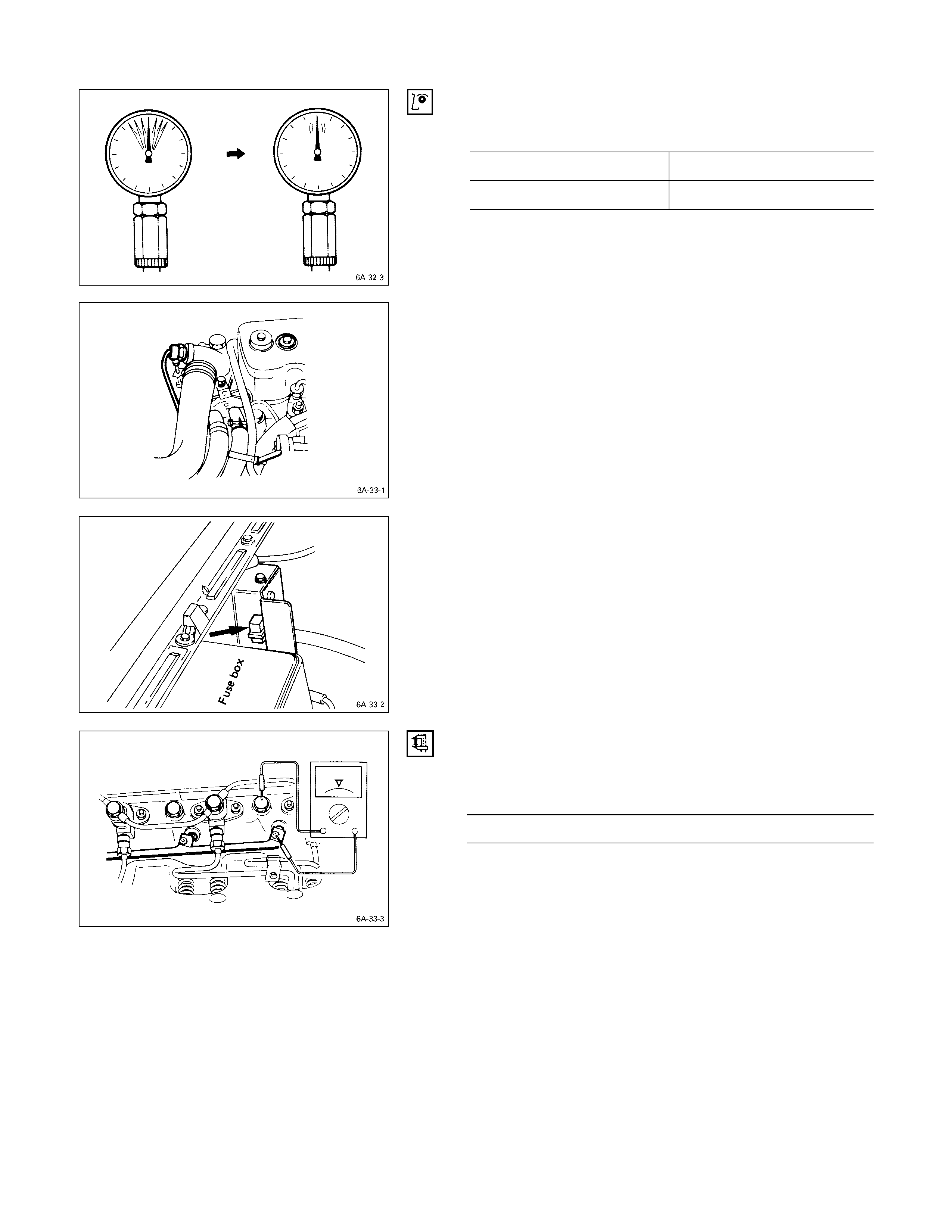

COMPRESSI ON PRESSURE MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80 °C (158 – 176 °F).

2. Remove the following parts.

•Glow plugs

•Fuel cut solenoid connector

3. Set the adapter and compression gauge to the No. 1

cylinder glow plug hole.

Compression Gauge: 5-8840-2675-0

Adapter; Compression Gauge: 5-8531-7001-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure kg/cm2 (psi/kPa) at 200 rpm

Standard Limit

31 (441/3,038) 22 (313/2,156)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

If the measured value is less than the specified limit,

refer to “Troubleshooting” in this Manual.

PRE-HEATING SYSTEM

SYSTEM INSPECTION PRO CEDURE

1. Disconnect the thermo-switch on the thermostat outlet

pipe.

2. Turn the starter switch to the “ON” position.

If the Pre-heating System is operating properly, the

glow relay will make a clicking sound about seven

seconds after the starter switch is turned on.

3. Measure the glow plug terminal voltage with a circuit

tester immediately after turning the starter switch to

the “ON” position.

Glow Plug Terminal Voltage V

Approx. 11

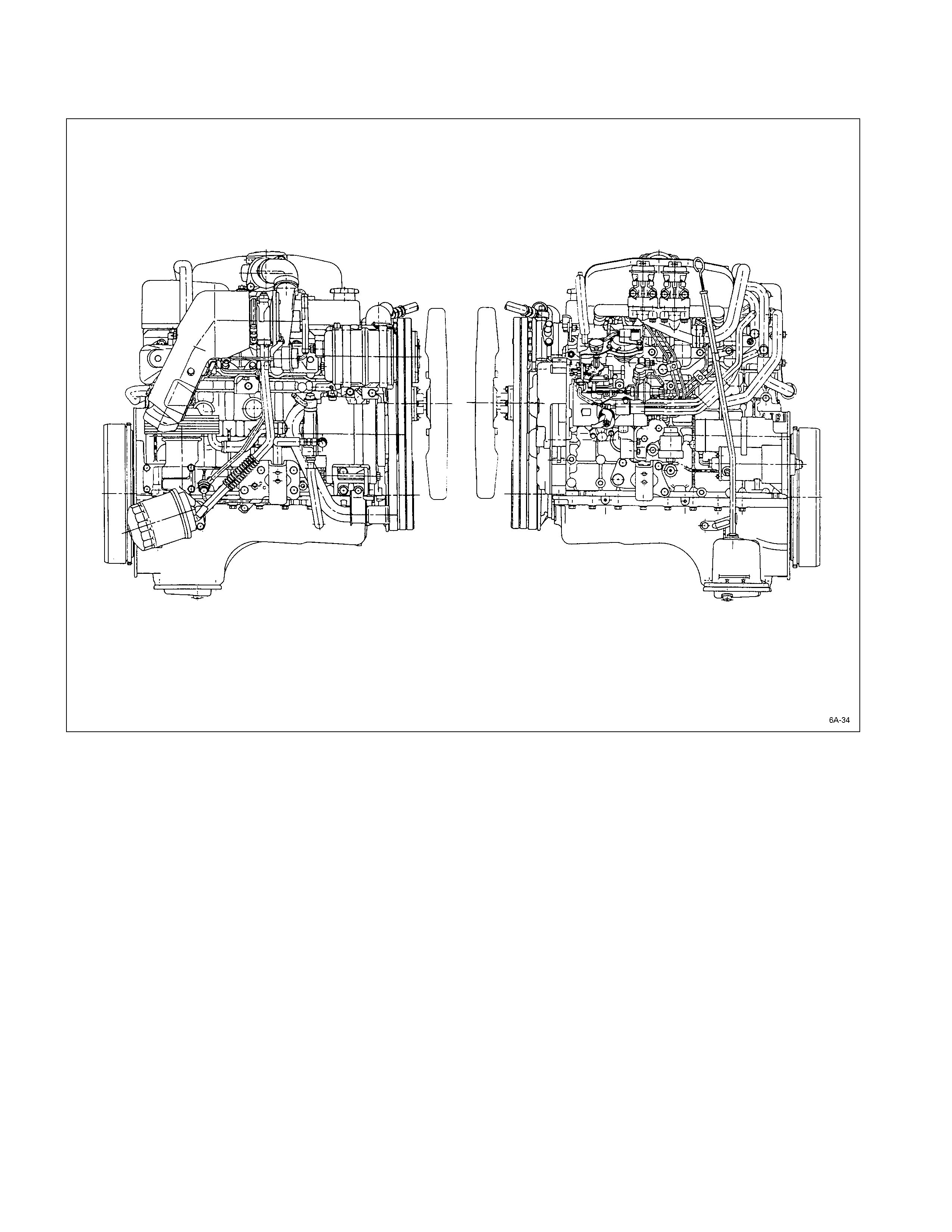

GENERAL DESCRIPTI O N

The 4J series automotive diesel engine has SPECIAL DESIGNED combustion chambers in the piston. This design

provides superior fuel economy over a wi de range of driving conditions.

The model 4JG2 diesel engine has swirl type combustion chambers.

Auto-thermatic pistons with cast steel struts are used to reduce thermal expansion and resulting engine noise when the

engine is cold.

Chrome plated dry type cylinder liners provide the highest durability .

The laminated steel sheet cylinder head gasket is very durable and, to increase the head gasket reliability.

The crankshaft has been tufftrided to provide a longer service life. Because the crankshaft is tufftrided, it cannot be

reground.

The engines are equipped with the VE-Type distributor injection pump.

The 4JG2T, 4JB1T and 4JA1T engines are turbocharger equipped.

REMO VAL AND INSTALLATI ON

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

IMPO RTANT OPERATI ONS – REMO VAL

J

Carefully remove the piping, hoses, wiring harness

connectors, engine control cables, and control rods

from the engine.

J

Remove the clutch sleeve cylinder, the back up light

switch connector, and the speedometer cable from the

transmission.

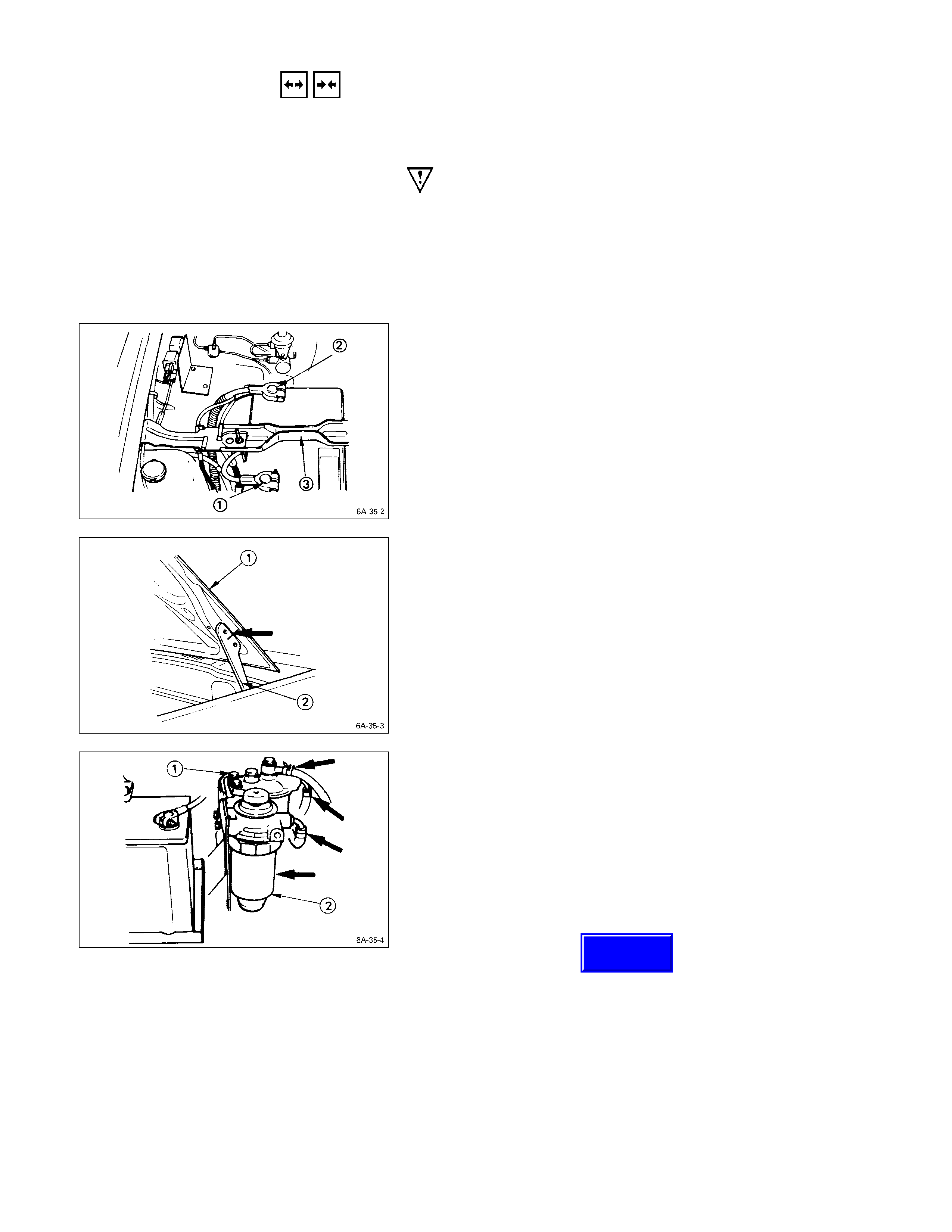

BATTERY

1. Disconnect the battery cable Q and the grounding

cable R from the battery terminals.

2. Remove the battery clamp S.

Take care not to accidentally short the battery with the

spanner or some other tool.

3. Remove the battery.

4. Disconnect the battery cable at the starter motor and

the ground cable at the cylinder body.

ENGINE HOOD

Apply setting marks to the engine hood Q and the engine

hood hinges R before removing the engine hood.

This will facilitate reinstallation of the engine hood to its

original position.

FUEL FILTER AND WATER SEPARATOR

1. Pull the fuel hose from the fuel filter Q and the water

separator R.

2. Plug the fuel hose to prevent fuel leakage.

3. Remove the fuel filter and the water separator.

AIR CLEANER

Remove the air cleaner duct from the engine.

Techline

COOLANT

Remove the coolant drain plug (at the lower left of the

engine) and the radiator drain plug.

Allow the engine coolant to drain completely.

GEAR SHI FT LEVER

1. Place the gear shift lever in the neutral position.

2. Remove the front console from the floor panel.

3. Pull the gear shift lever grommet Q and the dust

cover R to the top of the gear shift lever.

4. Remove the gear shift lever cover bolt S.

5. Remove the gear shift lever T.

6. Remove the gear shift lever hole cover U or the

center console from the floor.

7. Remove the quadrant box V from the transmission

rear cover.

Note:

Cover the quadrant box hole to prevent the entry of

foreign material into the transmission.

TRANSFER CHANGE LEVER (F OR 4 ×

××

× 4)

Perform this procedure after removing the gear shift lever.

1. Place the transfer change lever in the “H” position.

2. Pull the transfer change lever grommet Q and the

dust cover R to the top of the transfer change lever.

3. Remove the retainer bolts S.

4. Remove the transfer change lever T along with the

retainer and the ball seat cover.

5. Remove the change lever hole cover U or the center

console from the floor.

6. Remove the quadrant box V from the transfer case

adapter.

Note:

Cover the quadrant box hole and the change lever

hole to prevent the entry of foreign mater ial into the

transmission.

RADIATOR

1. Remove the cooling fan Q, the pulley R, and the belt

S.

2. Disconnect the radiator upper hose T and the

radiator lower hose U from the engine.

3. Remove the radiator shroud V.

4. Remove the radiator grille from the deflector panel.

5. Remove the radiator W.

Take care not to damage the radiator core.

6. Remove the radiator undercover from the chassis

frome.

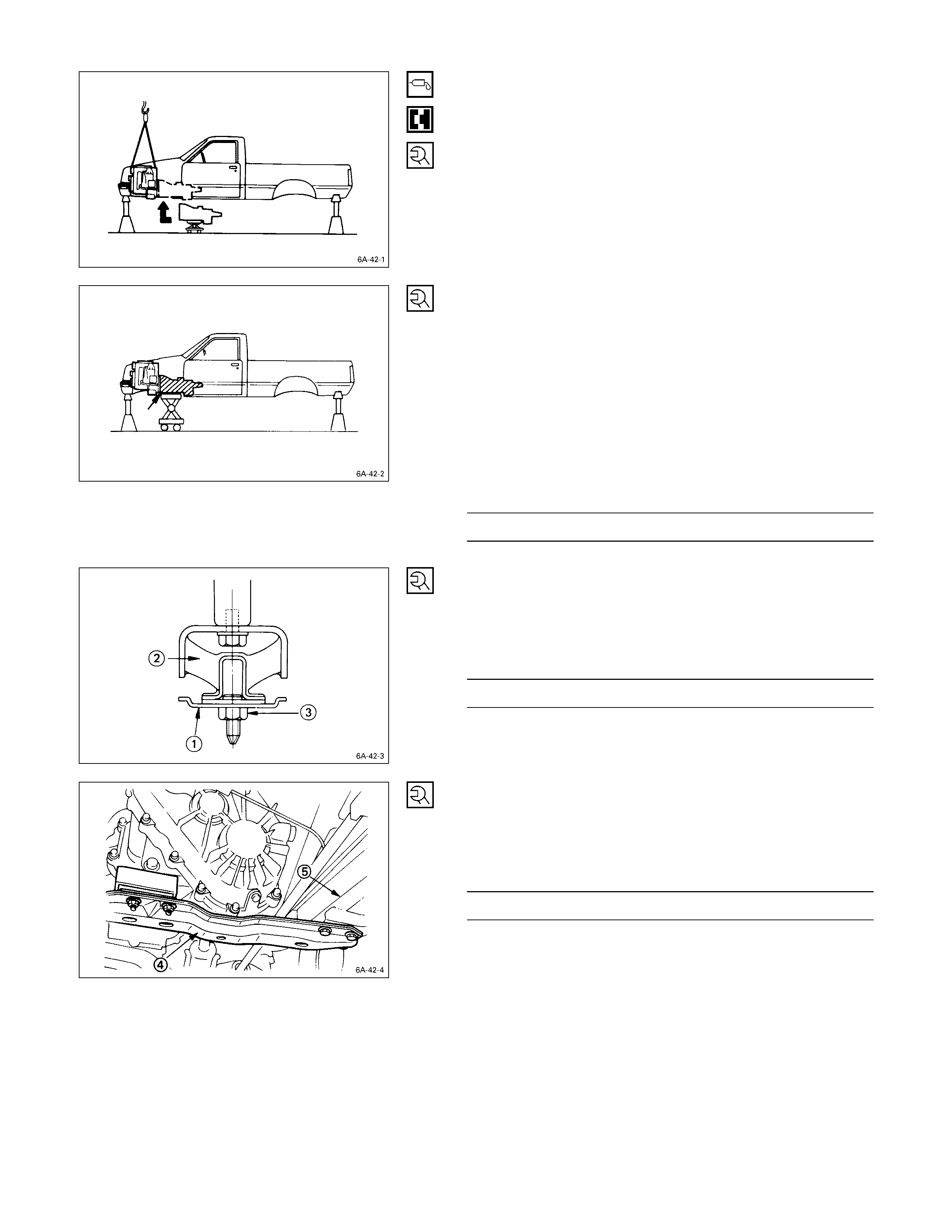

SUPPORTING THE VEHICLE

1. Jack up the vehicle.

2. Place chassis stands at the front and the rear of the

vehicle.

3. Remove the wheels from the vehicle.

ENGINE OIL DRAINING

Remove the oil pan drain plug to drain the engine oil.

Do this while the engine is hot.

Do not forget to reinstall the drain plug after draining the

engine oil.

TRANSFER CASE PROTECTOR (4 ×

××

× 4 MODEL)

Remove the transfer case protector Q from the

transmission mounting member R and the side menber

S.

TRANSMISSION OIL DRAINING

1. Remove the transmission oil drain plug.

2. Replace the drain plug after draining the oil.

CONTROL CABLES O R RODS

1. Disconnect the clutch control cable or the hydraulic

cylinder from the transmission.

2. Disconnect the parking brake control cable from the

rear wheel brake back plate.

3. Disconnect the speedometer drive cable from the

transmission.

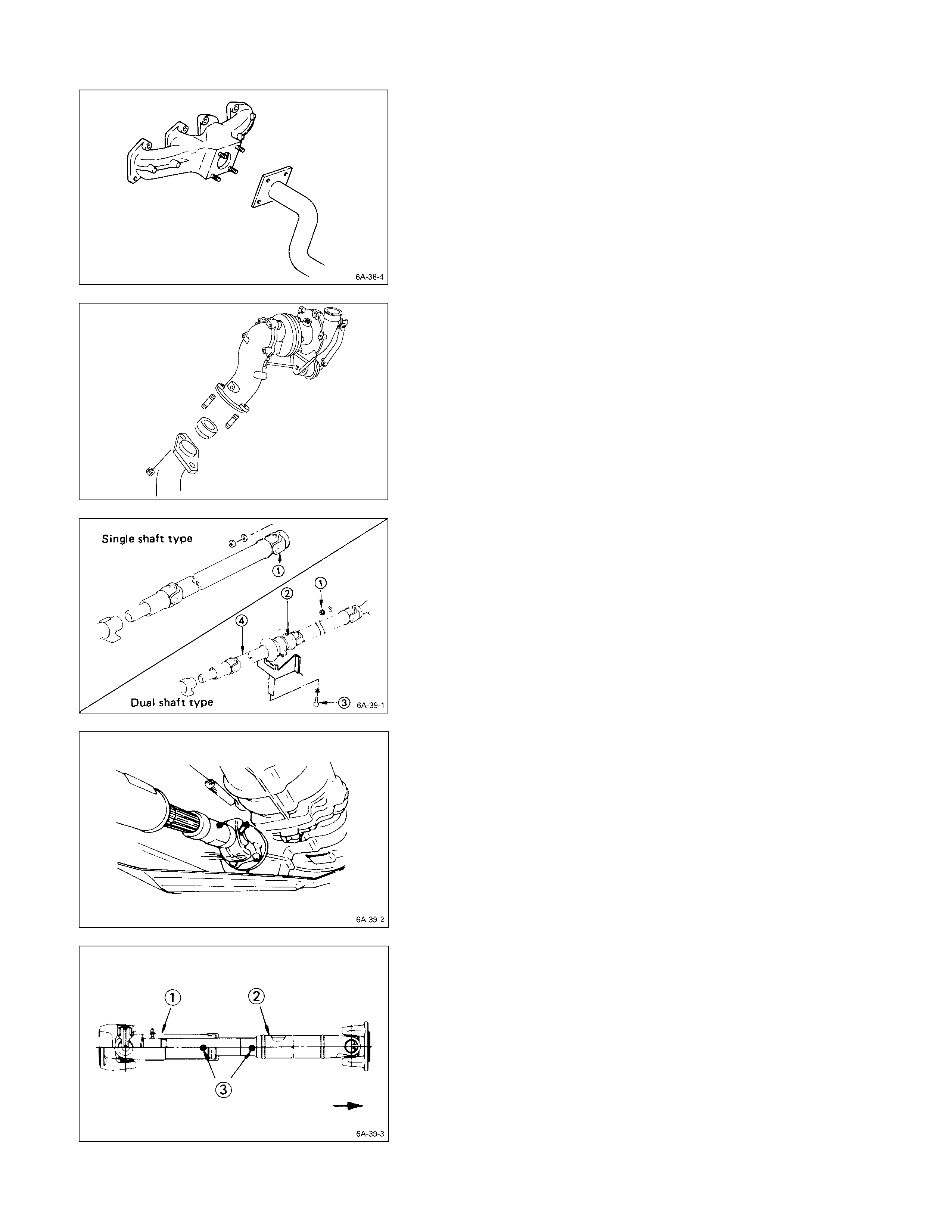

EXHAUST PIPE

1. Disconnect the exhaust pipe from the exhaust

manifold.

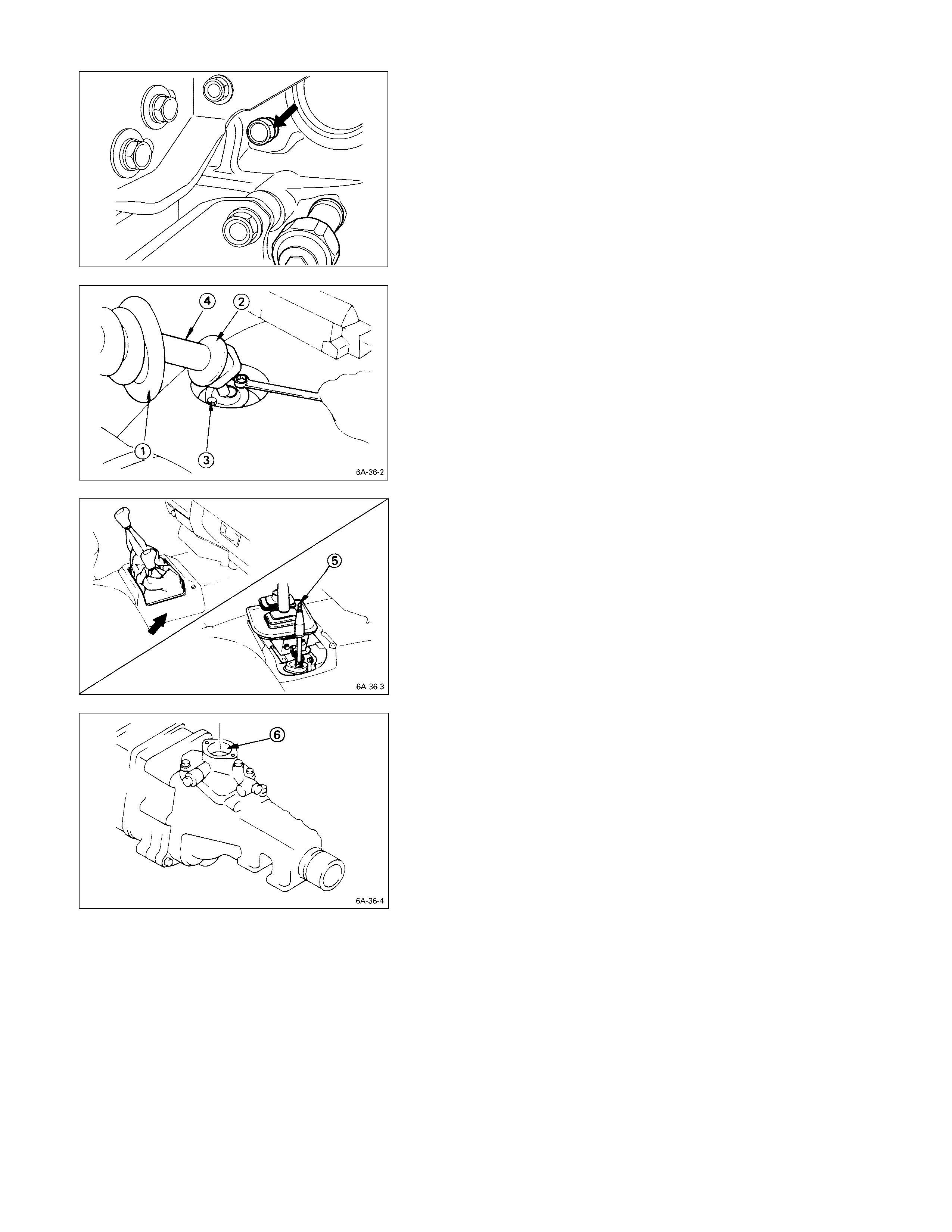

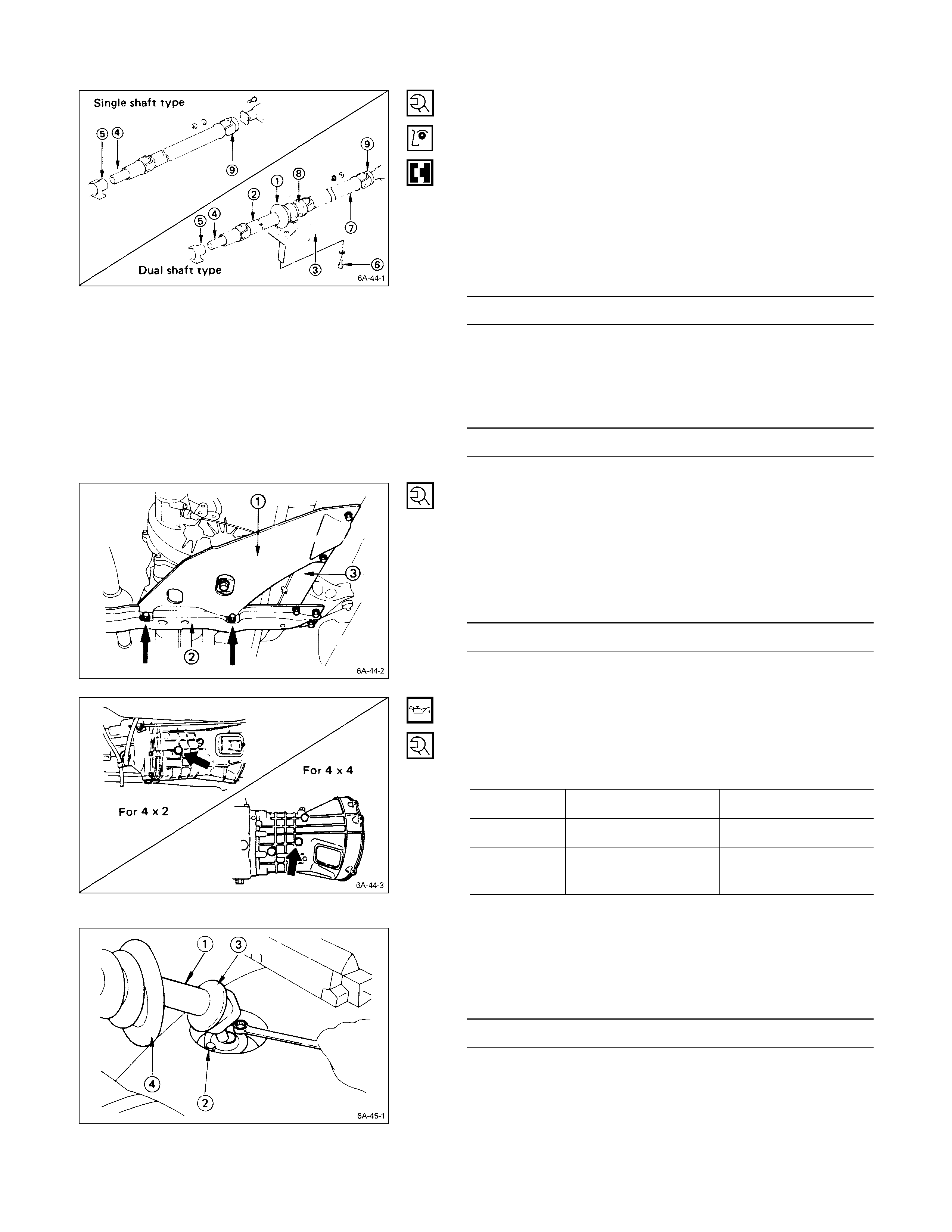

REAR PROPELLER SHAFT

1. Remove the propeller shaft flange yoke at the drive

pinion Q.

2. Remove the 2nd propeller shaft flange yoke bolts R

at the center bearing.

3. Remove the center bearing retainer bolts S.

4. Remove the 1st propeller shaft T together with the

center bearing from the transmission mainshaft spline.

FRONT PROPELLER SHAFT (FOR 4 ×

××

× 4)

Remove the splined yoke flange bolt at the transfer output

shaft.

Do not allow the splined yoke to fall away from the front

propeller shaft.

If the splined yoke should fall away from the front propeller

shaft, align the setting marks S on the splined yoke Q

and the propeller shaft R to reassemble the two parts.

The setting marks are puncked circles approximately S

mm (0.12 in) in diameter.

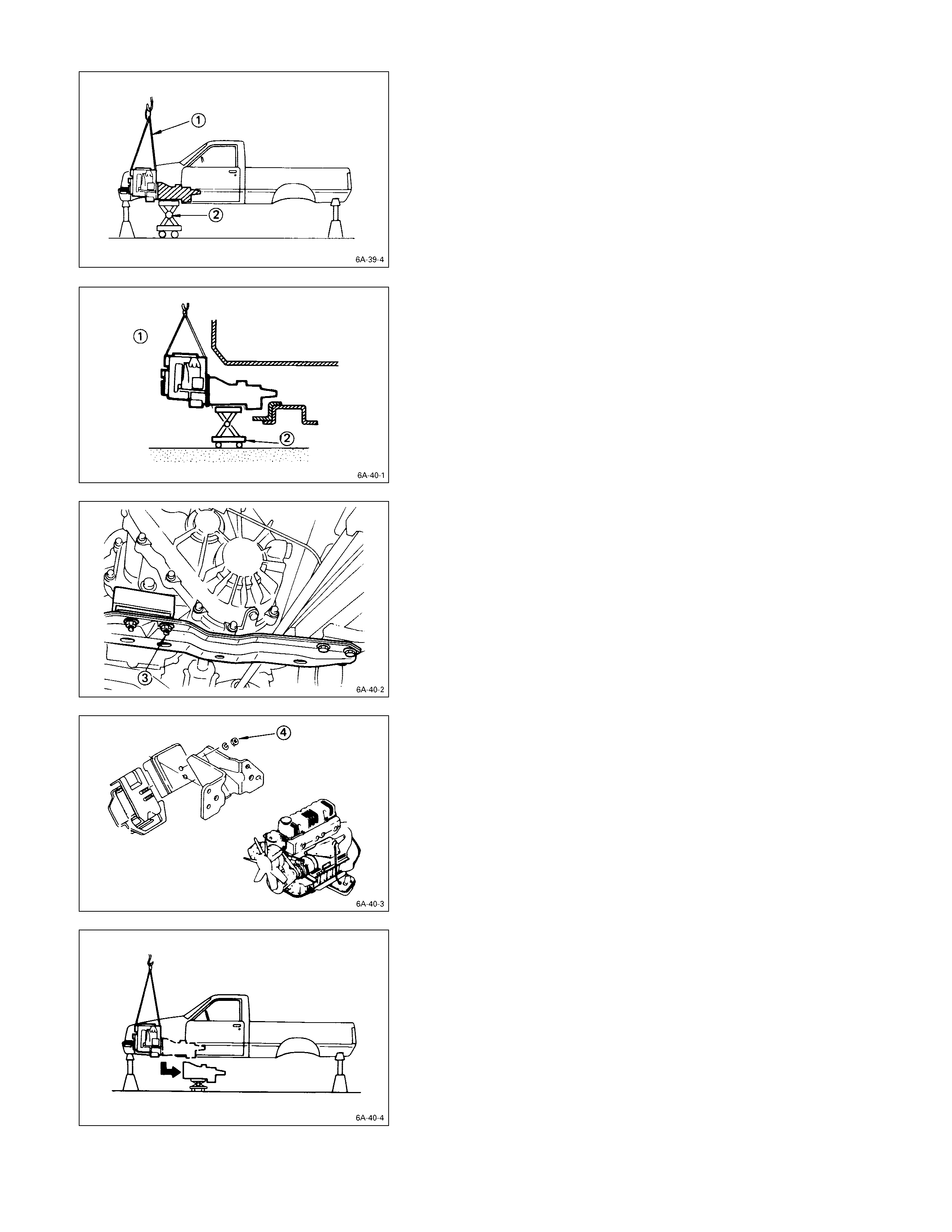

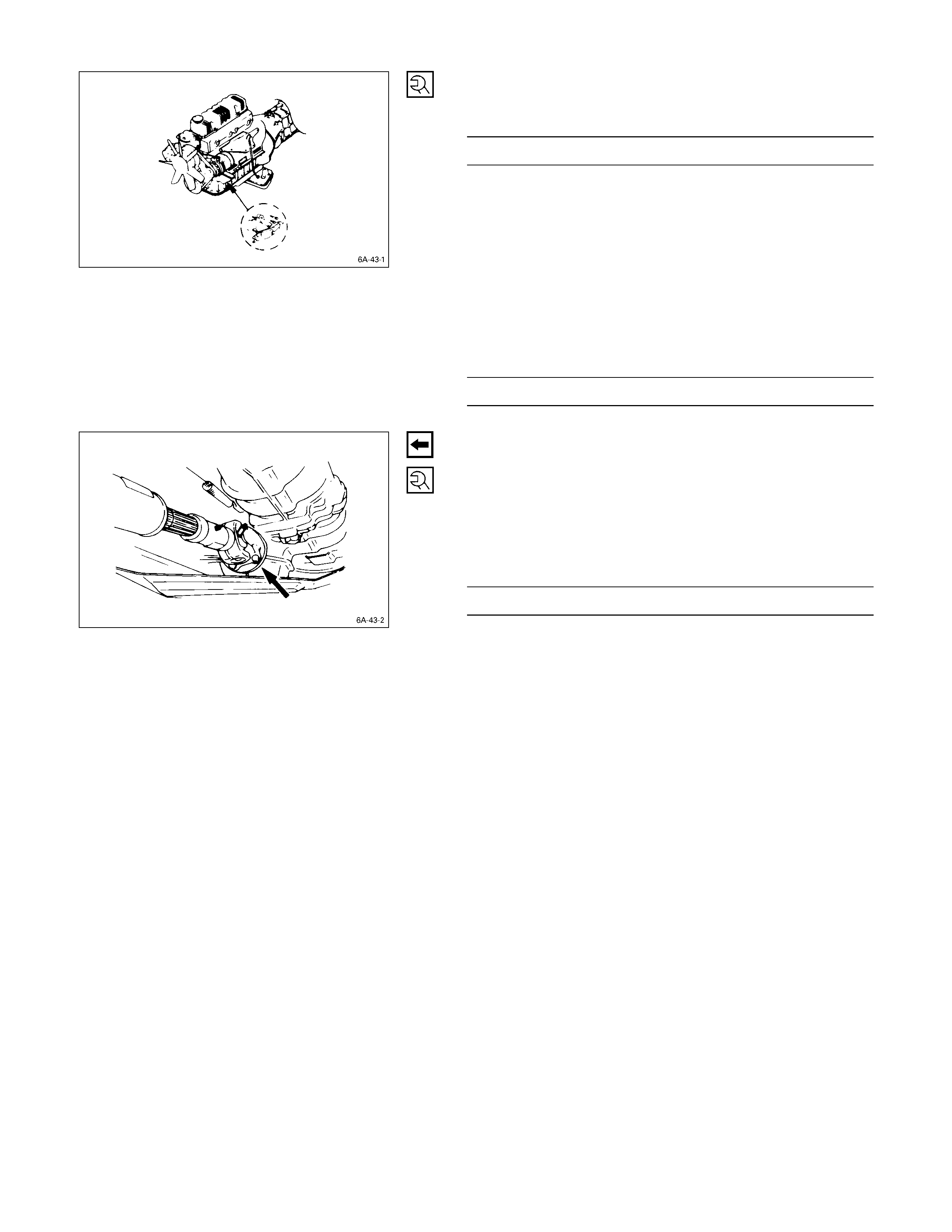

TRANSMISSION

1. Check that the lifting wires Q are securely attached.

2. Operate the hoist to slightly raise the engine.

Warning:

Take care not to lift the chassis from the chassis

stands.

If you do accidentally raise the chassis from the

chassis stands, make absolutely certain that the

chassis stands are correctly positioned before

lowering the chassis.

3. Place the jack R beneath the transmission case.

4. Operate the jack to slightly raise the transmission.

5. Remove the transmission member lower mounting

bolts S fixing the transmission member to the chassis

frame rail.

6. Loosen the engine mounting nuts T at the rubber

mountings.

7. Use the jack to slightly lower the transmission.

8. Remove the remaining transmission coupling bolts.

9. Separate the transmission from the engine.

Take care not to damage the transmission, the

engine, and their related parts.

10. Use the jack to lower the transmission together with

the mounting member to the floor.

11. Remove the engine mounting bolts U from the

chassis frame.

12. Use the hoist to lift the engine from the engine

compartment.

IMPORTANT OPERATIONS – INSTALLATION

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

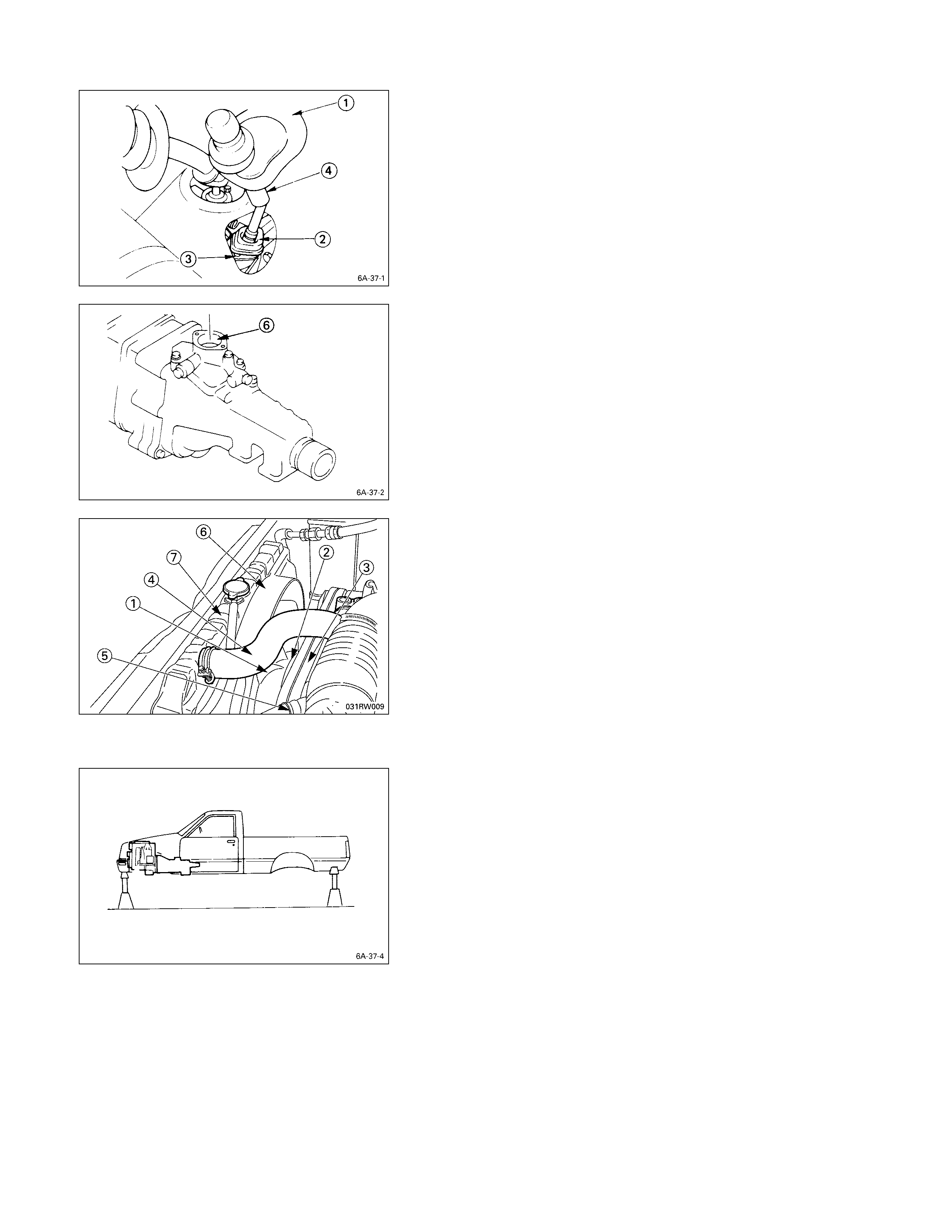

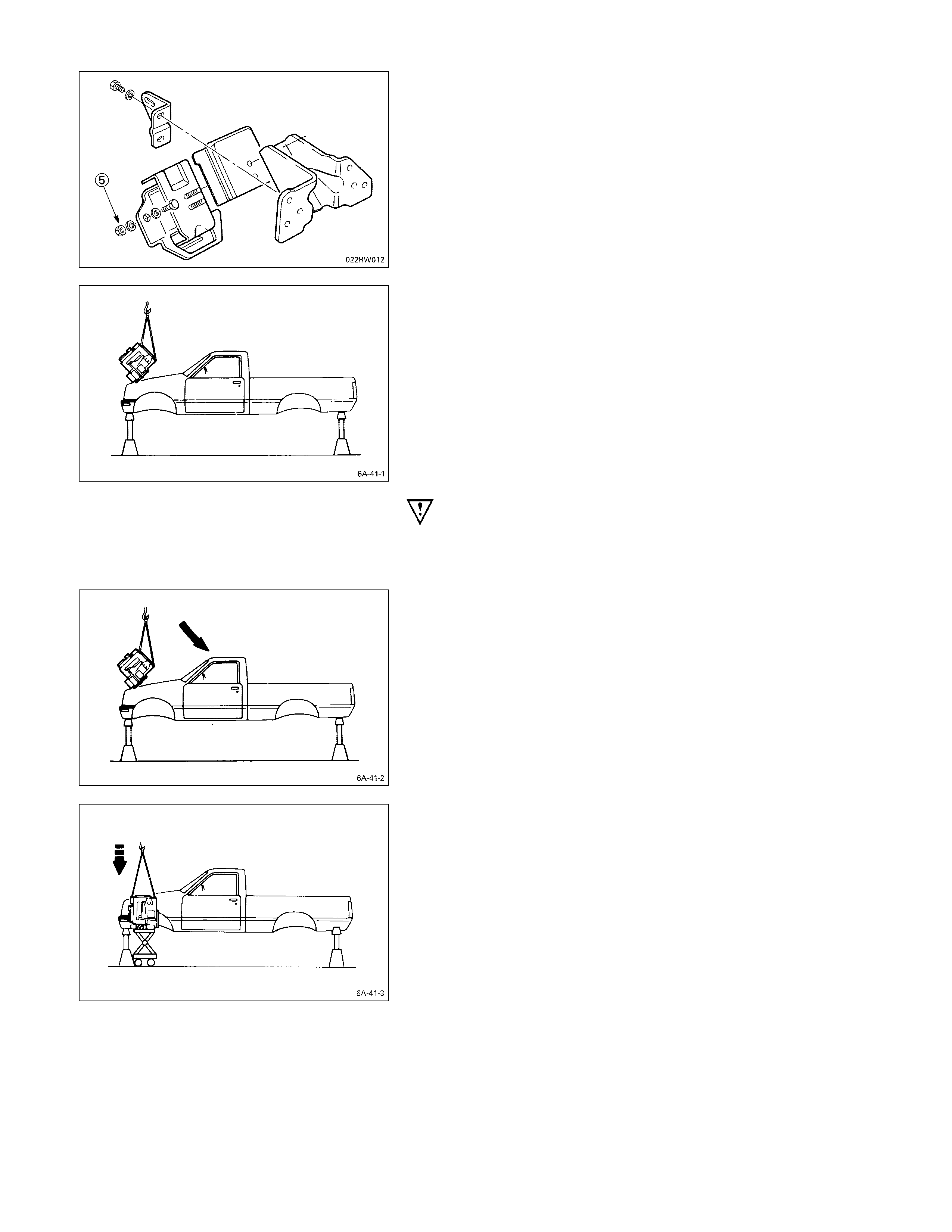

ENGINE

1. Attach a lifting wire to the engine lifting hanger.

2. Operate the hoist to position the engine above the

engine compertment.

Hold the front of the engine slightly higher than the

rear.

3. Slowly lower the engine into the engine compartment.

Be careful not to damage the brake pipes, the fuel

pipes, and other exposed parts.

4. Support the oil pan with a jack.

5. Temporarily tighten the engine front mounting rubber

nuts.

TRANSMISSION

1. Apply a thin coat of molybdenum disulfide grease to

the top gear shaft spline.

2. Place the transmission with the mounting rubbers on a

transmission jack.

3. Carefully move the transmission jack and

transmission into position behind the cab.

4. Slowly raise the transmission jack until the front of the

transmission is aligned with the engine flywheel.

The slope of the engine and the transmission must be

the same.

5. Align the top gear shaft spline with the clutch driven

plate internal spline.

6. Install the transmission to the engine.

Tighten the transmission coupling nuts and bolts to

the specified torque.

Transmission Coupling Nut and Bolt

Torque kg·m (lb.ft/N·m)

3.8 ± 0.8 (27.5 ± 5.8/37.2 ± 7.8)

7. Install the mounting member Q to the mounting

rubber R.

8. Tighten the mounting member nuts S to the specified

torque.

Mounting Rubber Nut Torque kg·m (lb.ft/N·m)

4.2 ± 0.5 (30.4 ± 3.6/41.2 ± 4.9)

9. Install the mounting member T to the sidemembers

U.

10. Tighten the mounting member bolts to the specified

torque.

Mounting Member Bolt Torque kg·m (lb.ft/N·m)

7.8 ± 1.6 (56.1 ± 11.2/76.0 ± 15.2)

11. Tighten the engine mounting rubber nuts to the

specified torque.

Engine Mounting Rubber Nut Torque kg·m (lb.ft/N·m)

4.2 ± 0.5 (30.4 ± 3.6/41.2 ± 4.9)

EXHAUST PIPE

Connect the exhaust pipe to the exhaust manifold.

Torque kg·m (lb.ft/N·m)

7.8 ± 0.5 (49 ± 3.6/67 ± 5)

FRONT PROPELLER SHAFT (FOR 4 ×

××

× 4)

1. Connect the propeller shaft flange yoke to the

matching flange.

2. Tighten the propeller shaft flange yoke bolt to the

specified torque.

Propeller Shaft Flange Yoke Bolt

Torque kg·m (lb.ft/N·m)

3.6 ± 0.3 (26.1 ± 2.2/35.3 ± 3.0)

Note:

If the splined yoke and the front propeller shaft have

accidentally separated, align their setting marks and

recouple them.

Refer to “FRONT PROPELLER SHAFT REMOVAL.”

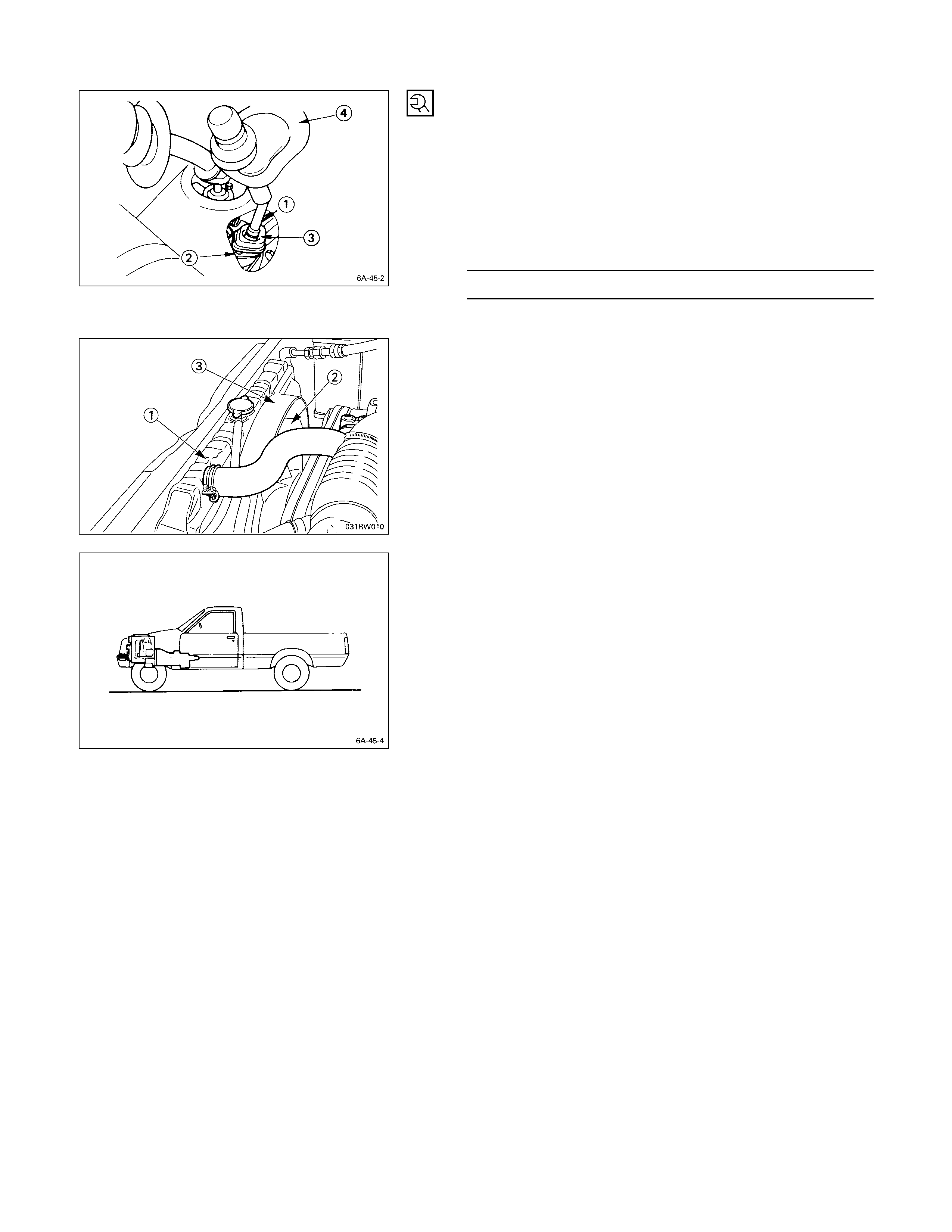

REAR PROPELLER SHAFT

1. Place the center bearing and retainer Q together with

the 1st propeller shaft R on the No. 4 crossmember

S.

2. Insert the splined yoke T into the transmission main

shaft spline U.

3. Tighten the center bearing retainer bolts V to the

specified torque.

Center Bearing Retainer Bolt Torque kg·m (lb.ft/N·m)

6.2 ± 0.2 (44.8 ± 1.5/60.8 ± 2.0)

4. Connect the 2nd propeller shaft W center coupling

side X and drive pinion side Y.

Propeller Shaft Flange Yoke Bolt

Torque kg·m (lb.ft/N·m)

3.6 ± 0.3 (26.0 ± 2.2/35.3 ± 2.9)

TRANSFER CASE PROTECTOR (FO R 4 ×

××

× 4)

1. Install the transfer case protector Q to the mounting

member R and the sidemembers S.

2. Tighten the transfer case protector bolts to the

specified torque.

Transfer Case Protector Bolt Torque kg·m (lb.ft/N·m)

3.7 ± 1.0 (26.8 ± 7.2/36.3 ± 9.8)

GEAR SHI FT LEVER

1. Replenish the transmission case and the transfer case

with the specified engine oil.

Transmission and Transfer Case Oil lit (US/UK gal)

4 × 24 × 4

MSG 1.55 (0.41/0.34) 4.40 (1.16/0.97)

MUA 2.95 (0.65/0.54) 2.95 (T/M)

1.45 (Transter)

2. Install the quadrant box to the transmission rear cover.

3. Install the gear shift lever Q to the transmission case.

4. Tighten the gear shift lever cover R bolts to the

specified torque.

Shift Lever Cover Bolt Torque kg·m (lb.ft/N·m)

2.0 ± 0.2 (14.5 ± 1.5/19.6 ± 2.0)

5. Install the dust cover S and the grommet T.

TRANSFER CHANGE LEVER (F OR 4 ×

××

× 4)

1. Insert the transfer change lever Q into the transfer

side case.

2. Install the ball seat cover along with the change lever

retainer R.

3. Tighten the change lever retainer bolts to the specified

torque.

Change Lever Retainer Bolt Torque kg·m (lb.ft/N·m)

2.0 ± 0.2 (14.5 ± 1.5/19.6 ± 2.0)

4. Install the dust cover S and the grommet T.

RADIATOR

1. Install the radiator Q.

Be careful not to damage the radiator core.

2. Install the cooling fan R and the fan shroud S.

3. Connect the radiator upper and lower hoses.

4. Install the radiator undercover to the chassis frame.

5. Install the radiator grill to the deflector panel.

LOWERI NG THE VEHICLE

1. Install the wheels to the vehicle.

2. Place a jack beneath the vehicle.

3. Raise the jack to remove the chassis stands.

4. Lower the vehicle to the ground.

COOLANT REPLENISHMENT

Replenish the cooling system with coolant.

When radiator is emptied (for coolant change, etc.):

After filling with coolant up to the inlet port level, put the

radiator cap on and idle the engine for 5 to 6 consecutive

minute. Then remove the radiator cap and check and see

the coolant level. If the coolant is short, add to the radiator

as well as to the reserve tank.

If the reserve tank coolant level is lower than MIN,

replenish coolant to the reserve tank only.

In case there is no coolant in the reserve tank, make sure

of a drop in coolant temperature and add coolant through

the radiator inlet port. Then remove the cap and check the

coolant level after idling the engine for 5 to 6 consecutive

minutes.

Then add coolant into reserve tank fill up to full level.

Coolant Capacity lit (US/UK gal)

4JA1, 4JA1T 7.0 (1.8/1.5)

4JB1 with turbo engine 9.5 (2.5/2.1)

4JG2T 8.6 (2.3/1.9)

ENGINE O IL REPLENISHM ENT

1. Fill the engine through the filler port with new engine

oil of the specified grade.

Engine Oil Capacity and Grade lit (US/UK gal)

4 × 2

4JA1, 4JA1T, 4JB1T 4 × 4 6.5

4 × 2 6.5

Capacity

4JG2T 4 × 4 7.3

For 4JA1 CC or CD

Grade For 4JB1T, 4JG2T, 4JA1T CD

2. Start the engine and allow it to idle for several

minutes.

3. Stop the engine and wait five minutes for the oil to

settle.

4. Recheck the oil level and replenish if necessary.

ENGINE HOOD

Align the setting marks (applied at removal) on the engine

hood Q and the engine hood hinges R to install the

engine hood.

BATTERY

1. Check the battery fluid level and the specific gravity.

2. Secure the battery with the battery clamp.

Do not overtighten the battery clamp.

3. Connect the battery cable R and the ground cable S

to the battery.

4. Connect the battery cable to the starter motor and the

ground cable to the cylinder body.

5. Apply grease to the battery terminals.

ENGINE WARM-UP

After completing the required maintenance procedures,

start the engine and allow it to idle until it is warm.

Check the following:

1. Engine idling speed

Refer to “SERVICING” for the idle speed adjustment

procedure.

2. Engine noise level.

3. Engine lubricating system and cooling system

Carefully check for oil and coolant leakage.

4. Engine control cable operation

5. Clutch engagement

6. Indicator warning light operation

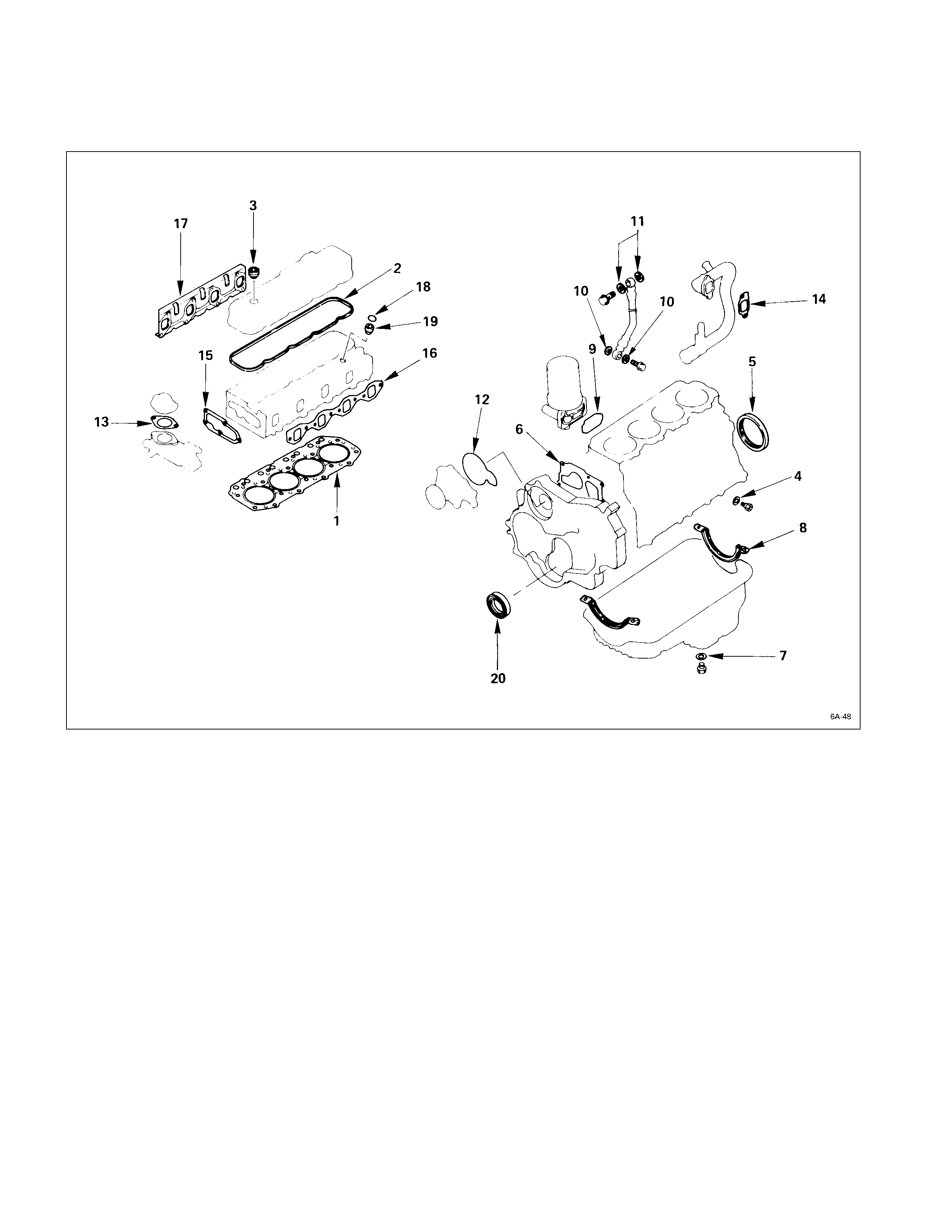

ENGINE REPAIR KIT

All of the numbered parts listed below are included in the Engine Repair Kit.

The gaskets marked with an asterisk (*) are also included in the Top Overhaul Kit.

* 1. Cy linder head gasket 11. Vacuum pump gasket

* 2. Head cover gasket 12. Water pump O-ring

* 3. Head cover cap nut gasket * 13. Water outlet pipe gasket

4. Drain cock gasket * 14. Intake pipe gasket

5. Crankshaft rear oil seal 15. Thermostat housing gasket

6. Gear case gasket * 16. Intake manifold gasket

7. Oil pan drain plug gasket * 17. Exhaust manifold gasket

8. Oil pan gasket * 18. Nozzle holder O-ring

9. Oil filter gasket * 19. Nozzle holder gasket

10. Joint bolt gasket 20. Crankshaft front oil seal

ENGINE OVERHAUL

REMOVAL

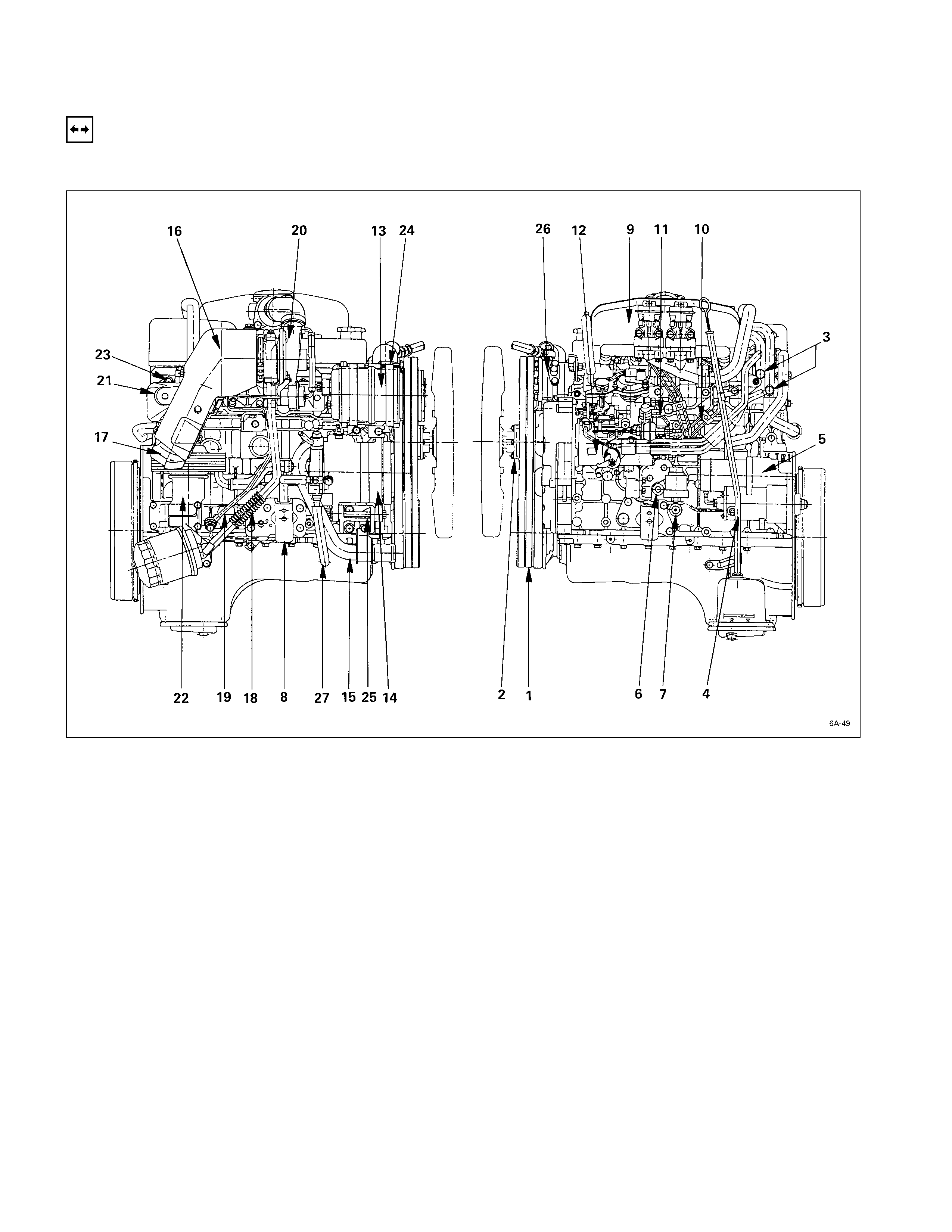

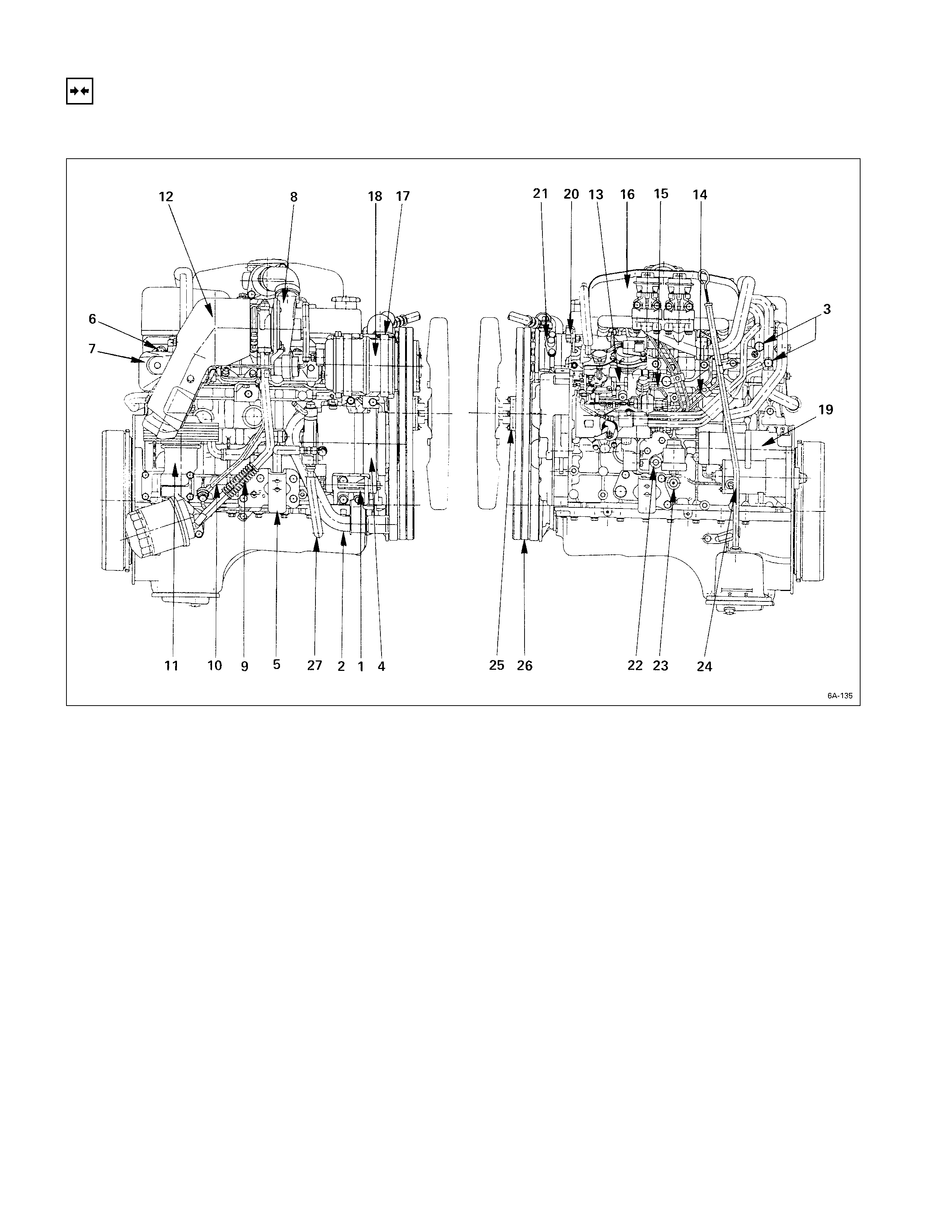

EXTERNAL PARTS

REMOVAL STEPS

1. Cooling fan drive belt 16. Turbocharger heat protector

2. Cooling fan pulley 17. Exhaust adaptor

3. Heater pipe (rear side) 18. Turbocharger oil return pipe

4. Oil level gauge and guide tube 19. Turbocharger oil feed pipe

5. Starter motor

J

20. Turbocharger

6. Water drain cock 21. Exhaust manifold heat protector

7. Oil pressure warning switch and 22. Oil cooler with Oil filter

nipple 23. Exhaust manifold

8. Engine mounting bracket 24. Compressor bracket

J

9. Intake manifold 25. Generator bracket

J

10. Fuel injection pipe with clip 26. Power steering oil pump

11. Fuel leak off pipe 27. Vacuum pipe

12. Injection pump

13. Compressor

14. Generator and adjusting plate

15. Water inlet pipe

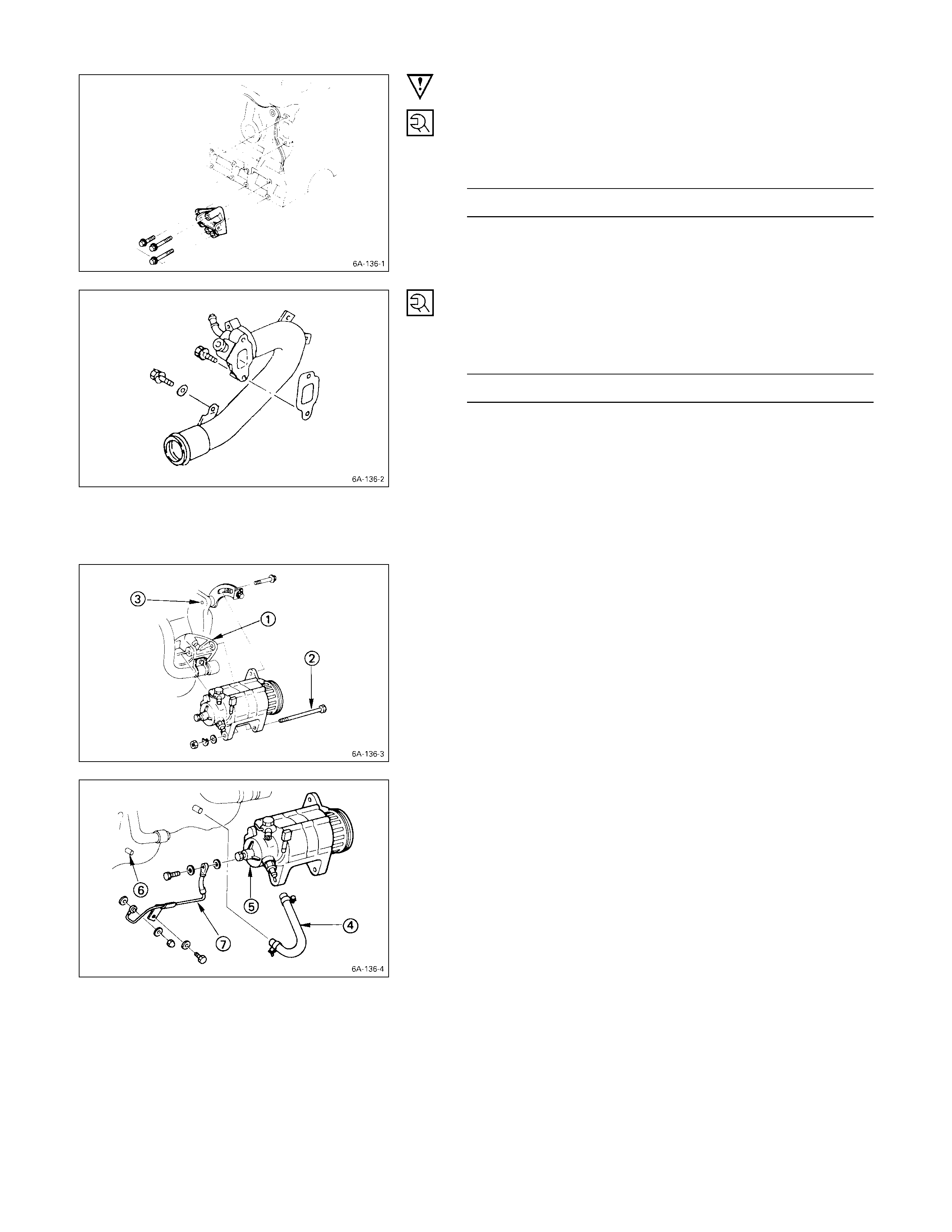

IMPORTANT OPERATIONS

9. Intake Manifold

1) Disconnect the PCV hose from the cylinder head

cover.

2) Disconnect the intake duct and intake rubber hose

from the turbocharger.

3) Remove the upper intake manifold the lower intake

manifold with intake duct, and the PCV hose.

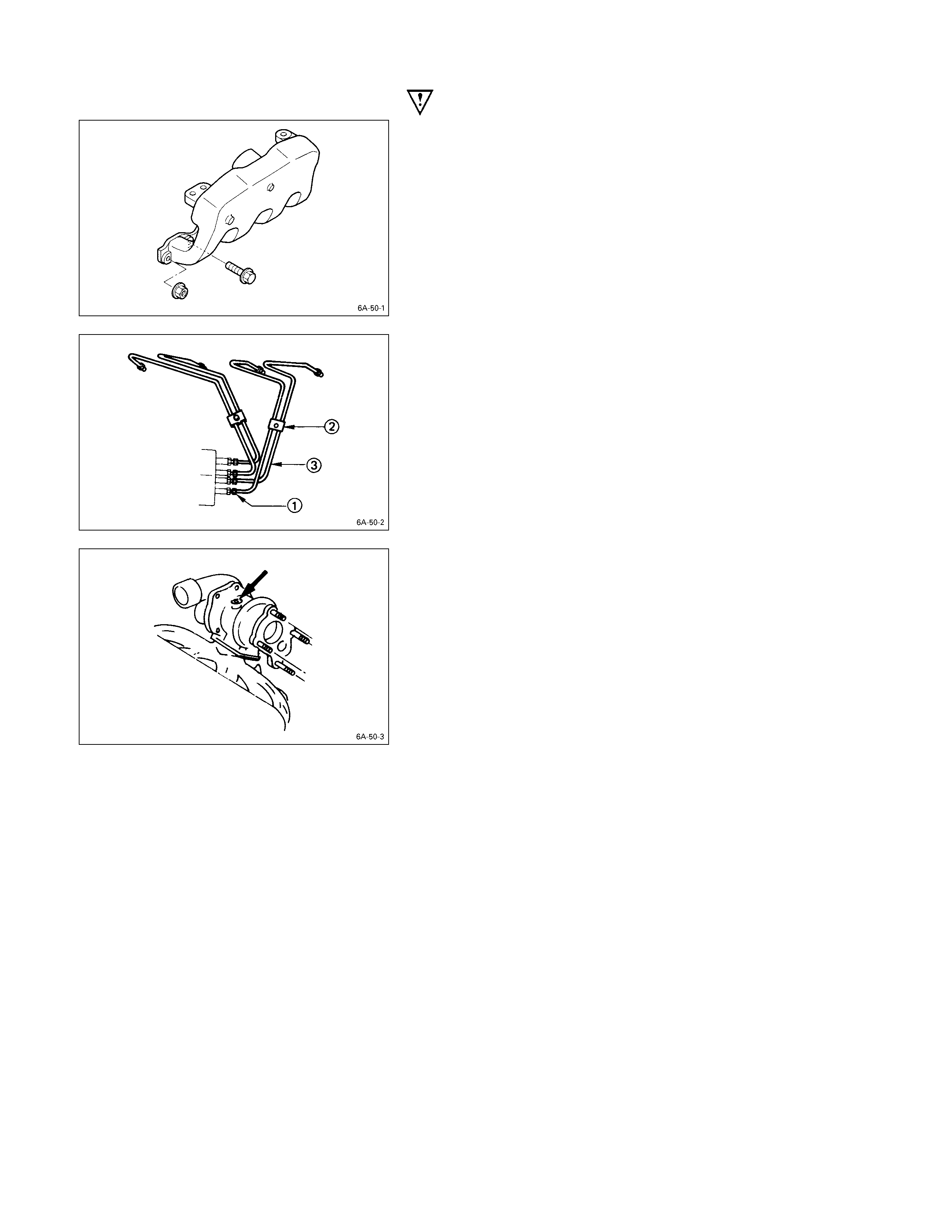

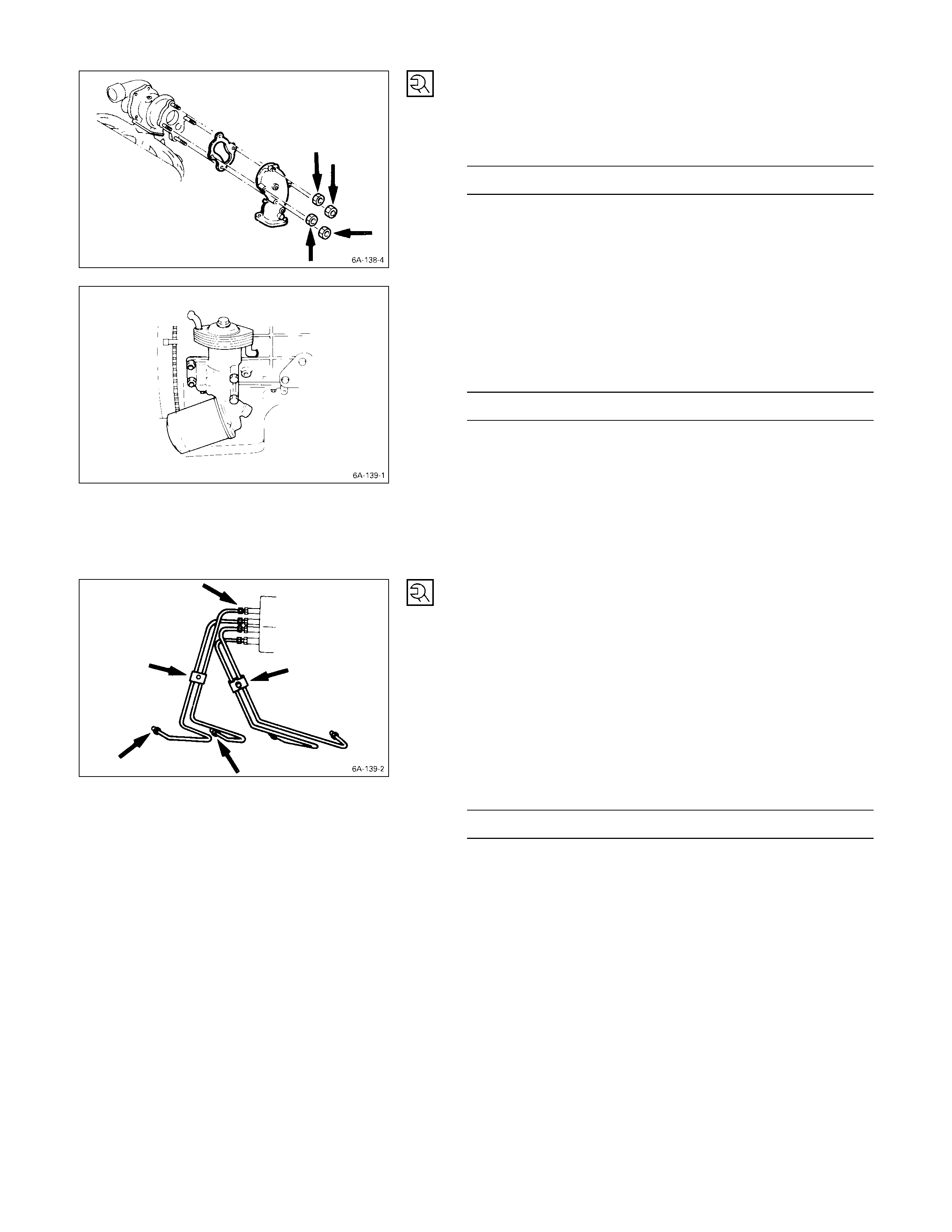

10. Fuel Injection Pipe with Clip

1) Loosen the injection pipe sleeve nuts at the delivery

valve side Q and injection nozzle side.

Do not apply excessive force to the injection pipes.

2) Loosen the injection pipe clips R.

3) Remove the injection pipes S.

Note:

Plug the delivery holder ports with the shipping caps

to prevent the entry of foreign material.

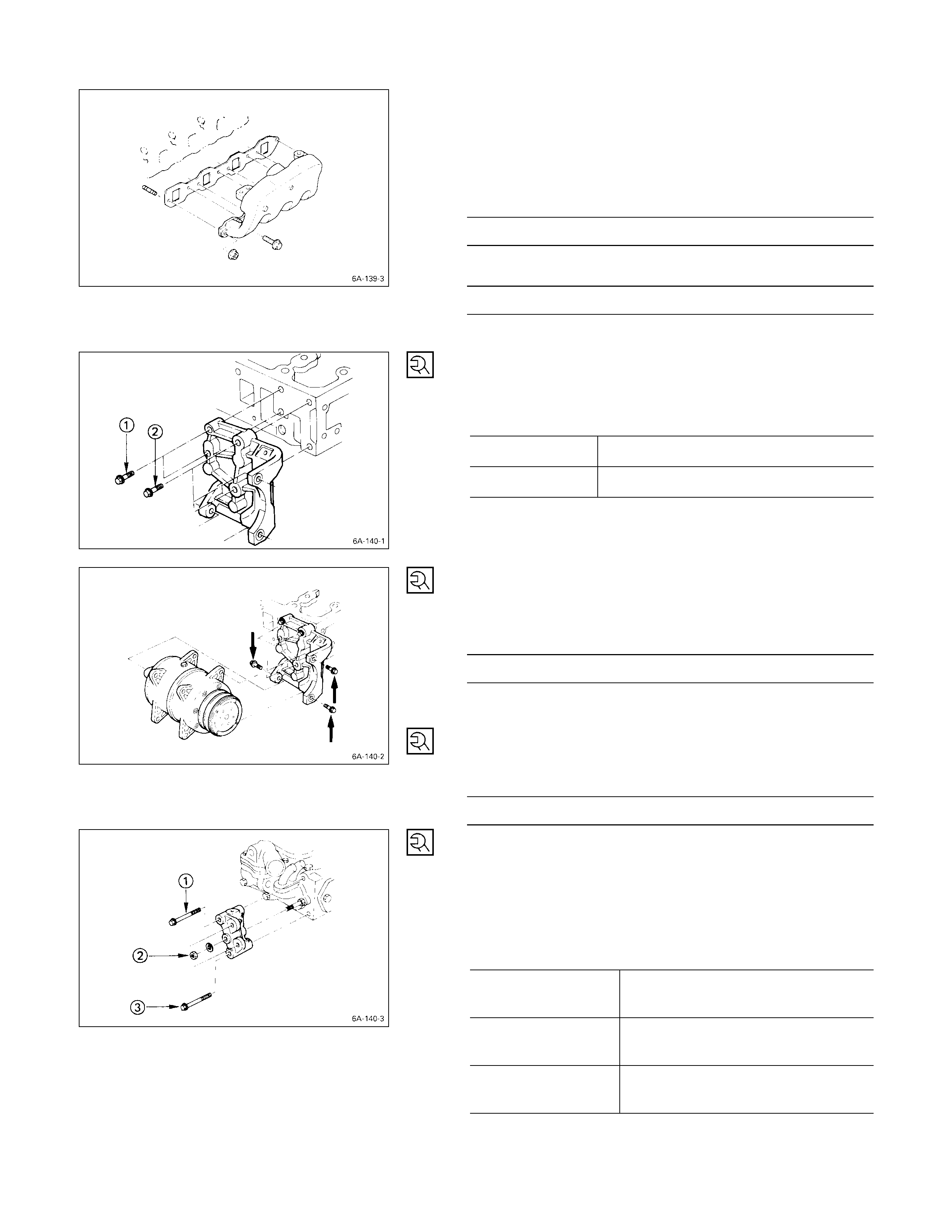

20. Turbocharger

Plug the turbocharger body oil ports after removing the

turbocharger assembly to prevent the entry of foreign

material.

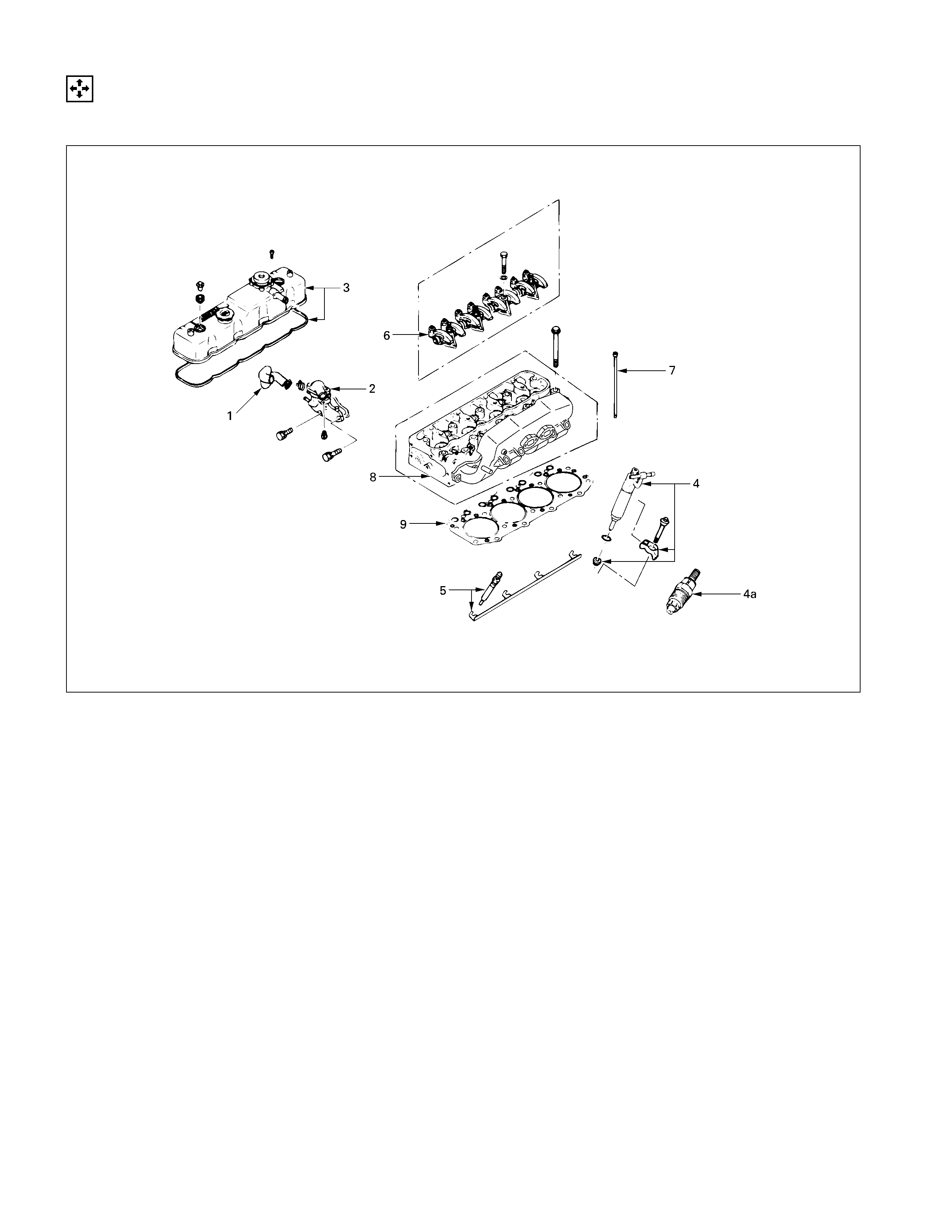

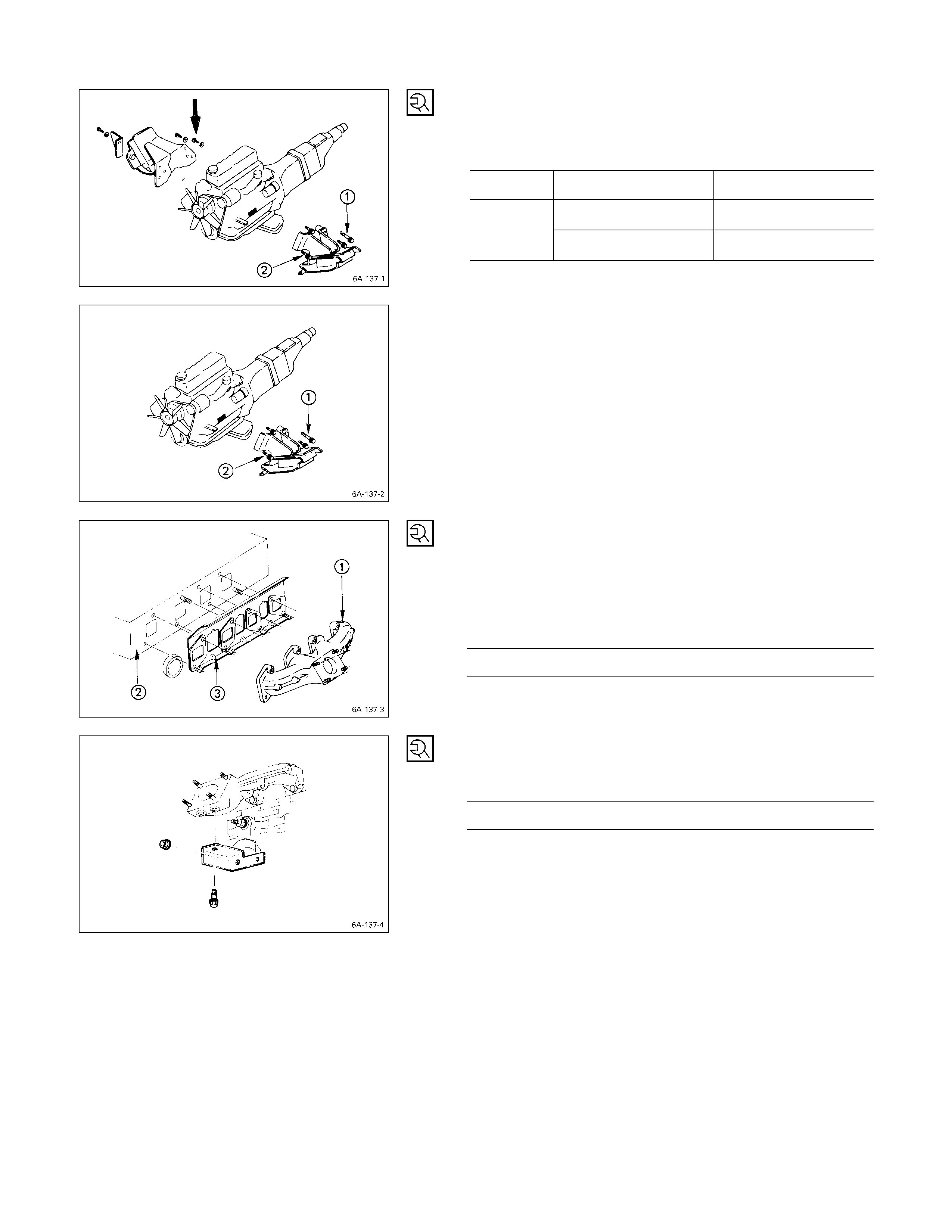

INTERNAL PARTS

MAJO R COMPONENTS

DISASSEM BLY STEPS-1

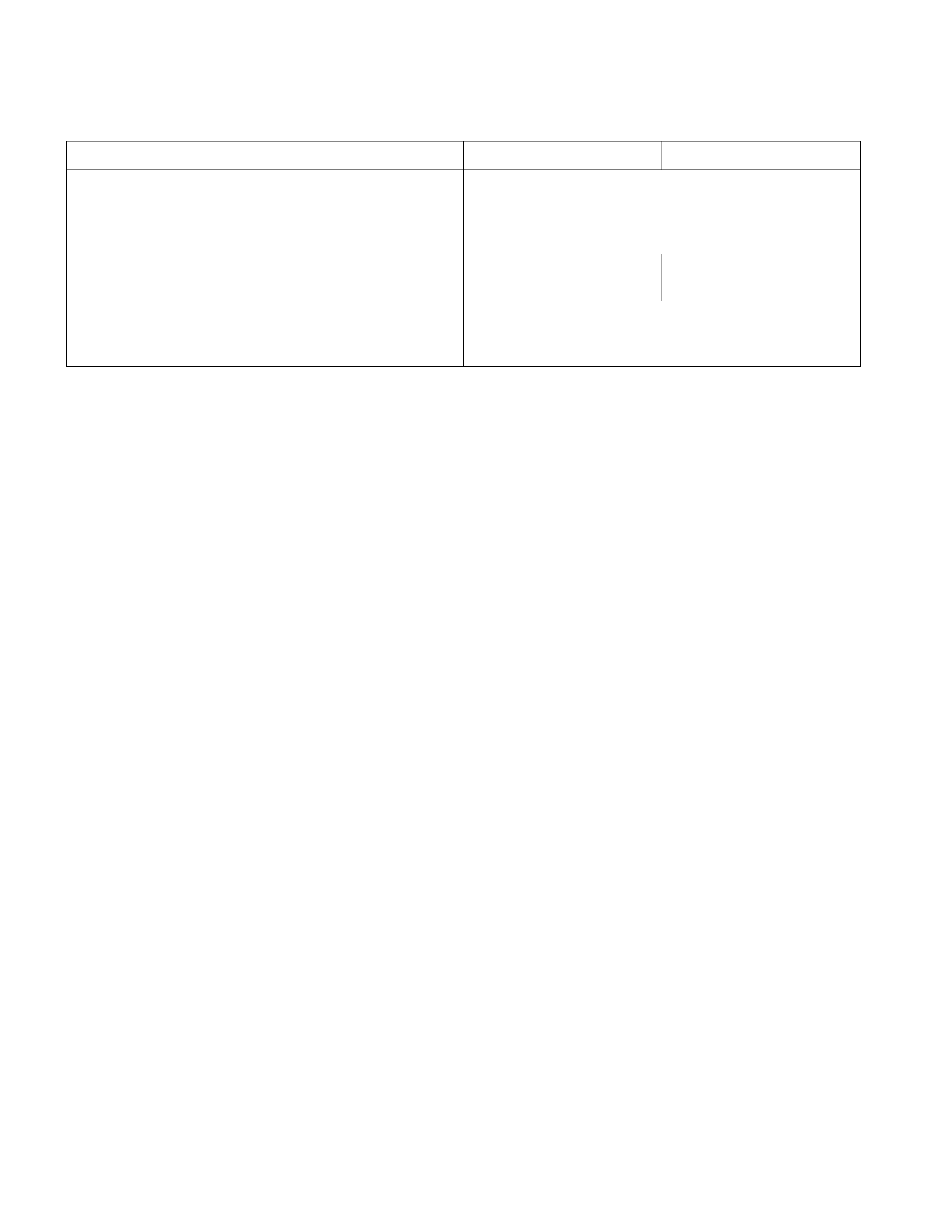

1. Water bypass pipe

J

6. Rocker arm shaft and rocker

2. Thermostat housing with thermo arm

switch 7. Push rod

3. Cylinder head cover

J

8. Cylinder head

J

4. Injection nozzle and Injection 9. Cylinder head gasket

nozzle holder

4a. Injection nozzle (4JG2T)

5. Glow plug and glow plug

connector

025RY00009

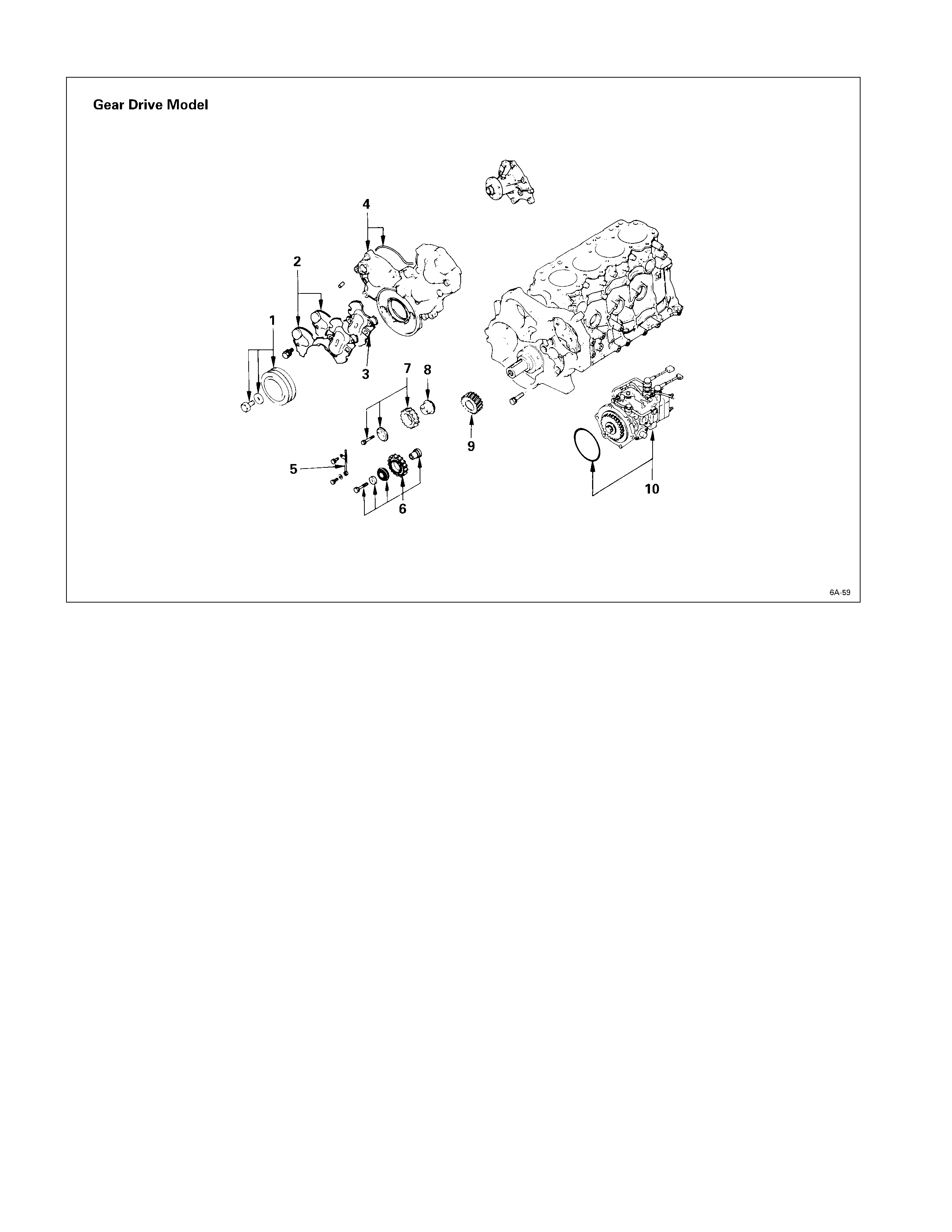

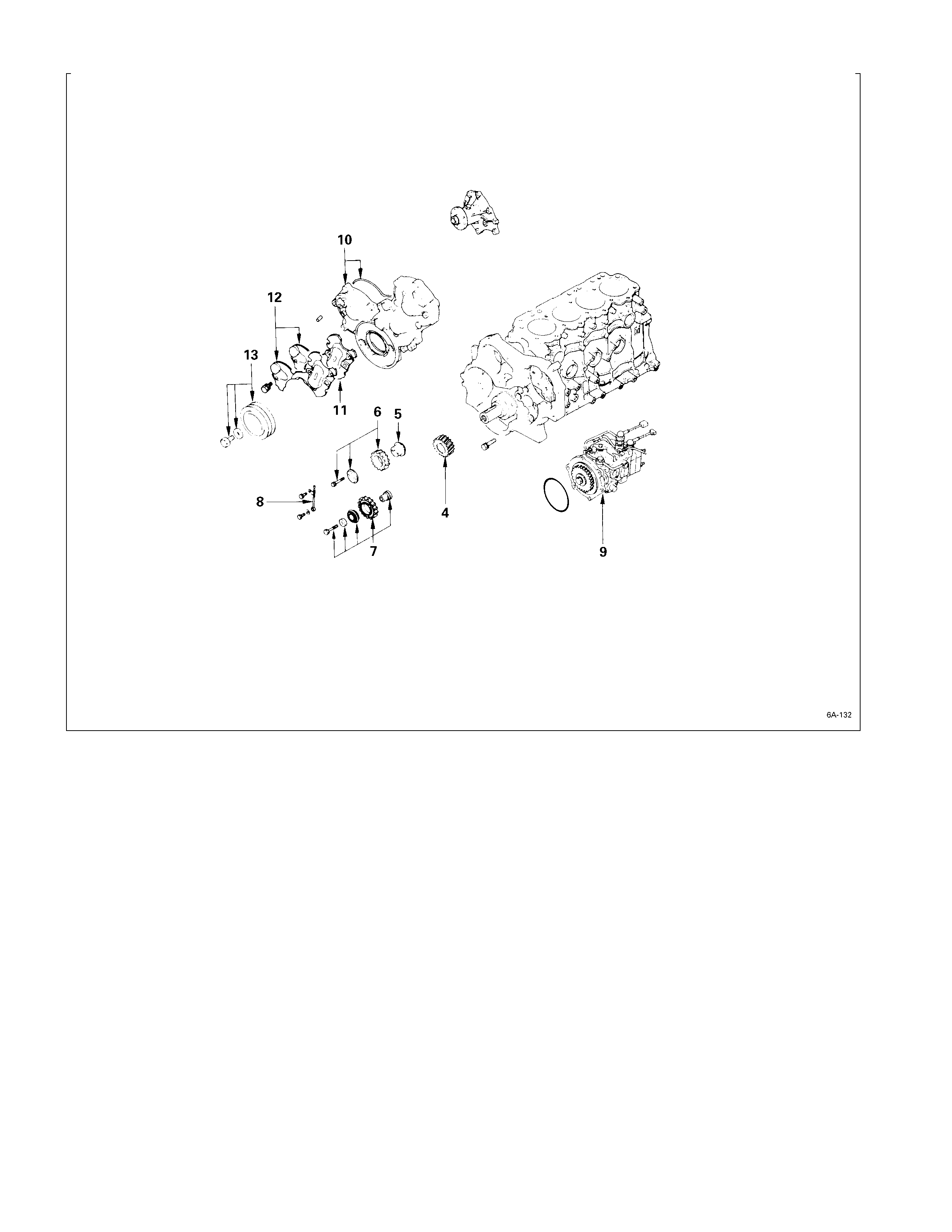

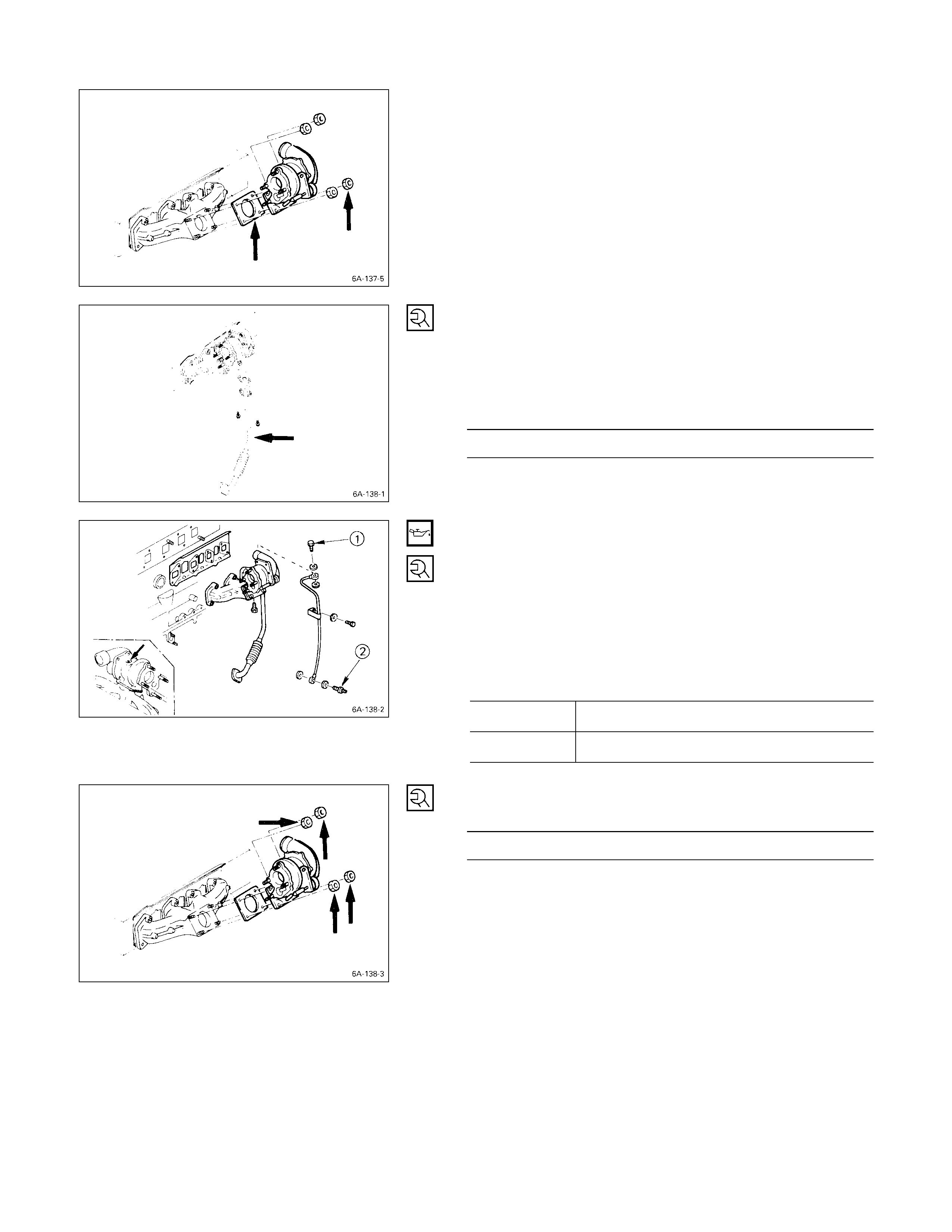

DISASSEM BLY STEPS-2

J

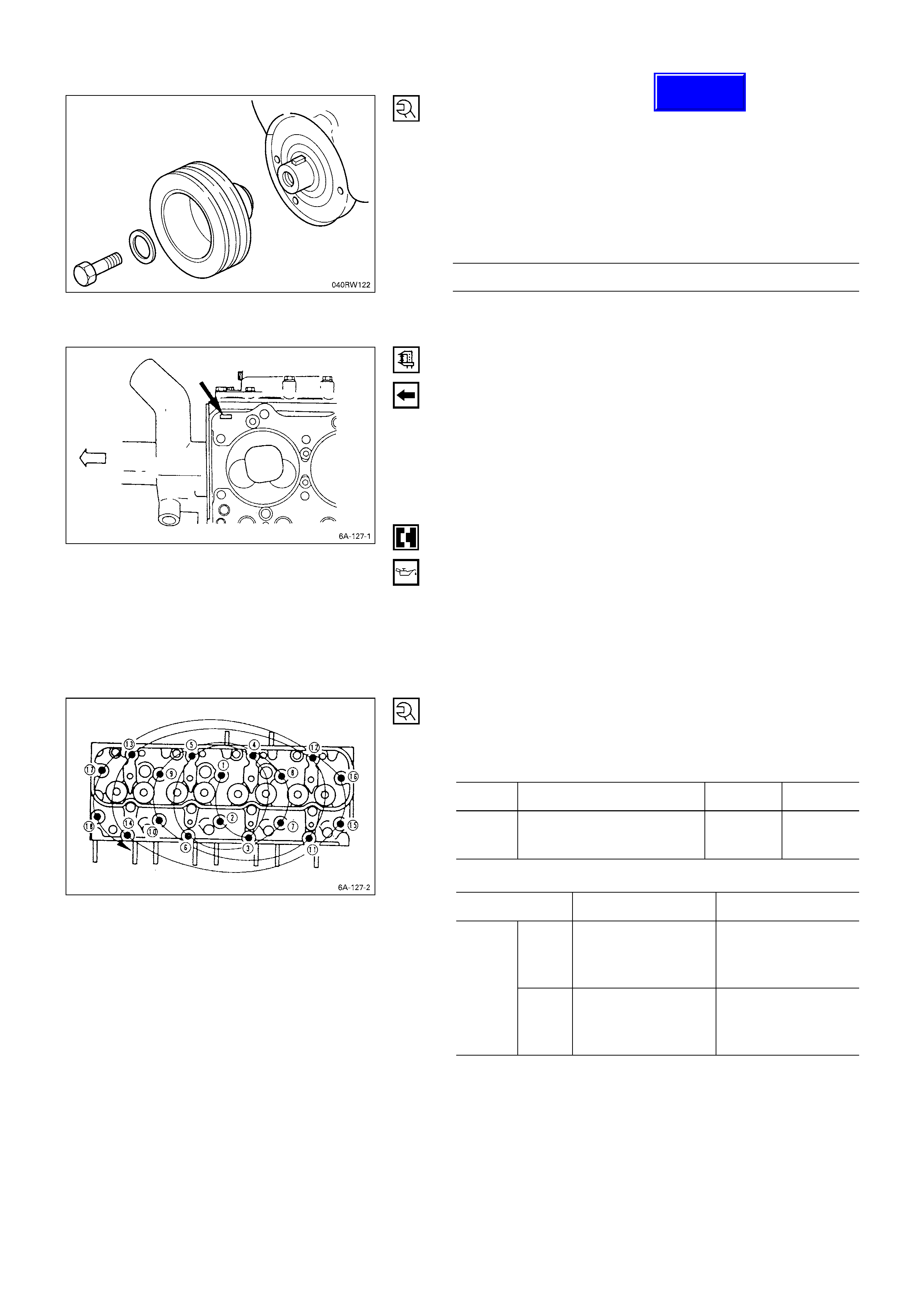

1. Crankshaft damper pulley

2. Gear case upper cover and

lower cover

3. Space rubber

4. Timing gear case cover

5. Timing gear oil pipe

6. Idler gear “B” and shaft

J

7. Idler gear “A”

8. Idler gear shaft

9. Crankshaft timing gear

J

10. Injection pump

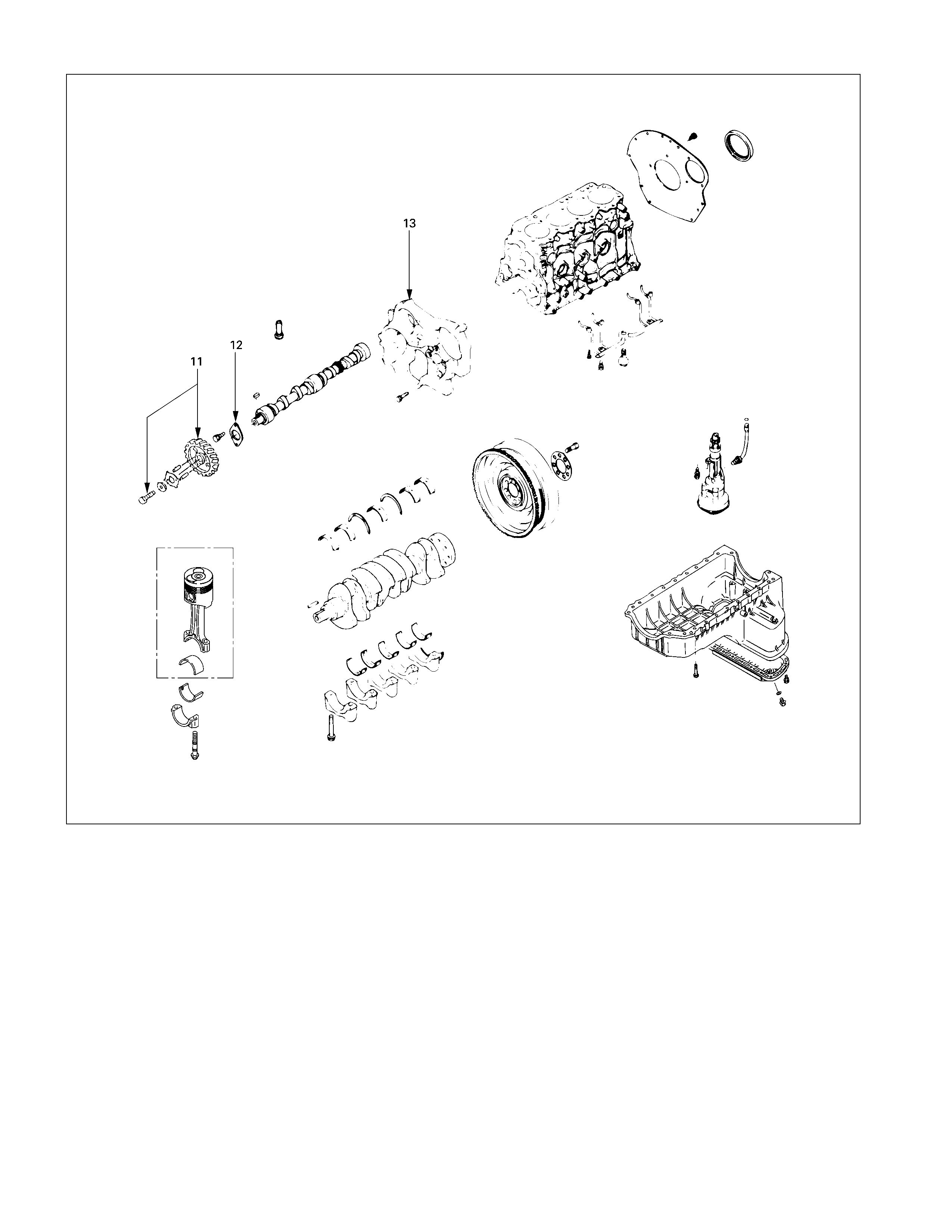

DISASSEM BLY STEPS-3

J

11. Camshaft timing gear

12. Camshaft thrust plate

13. Timing gear case

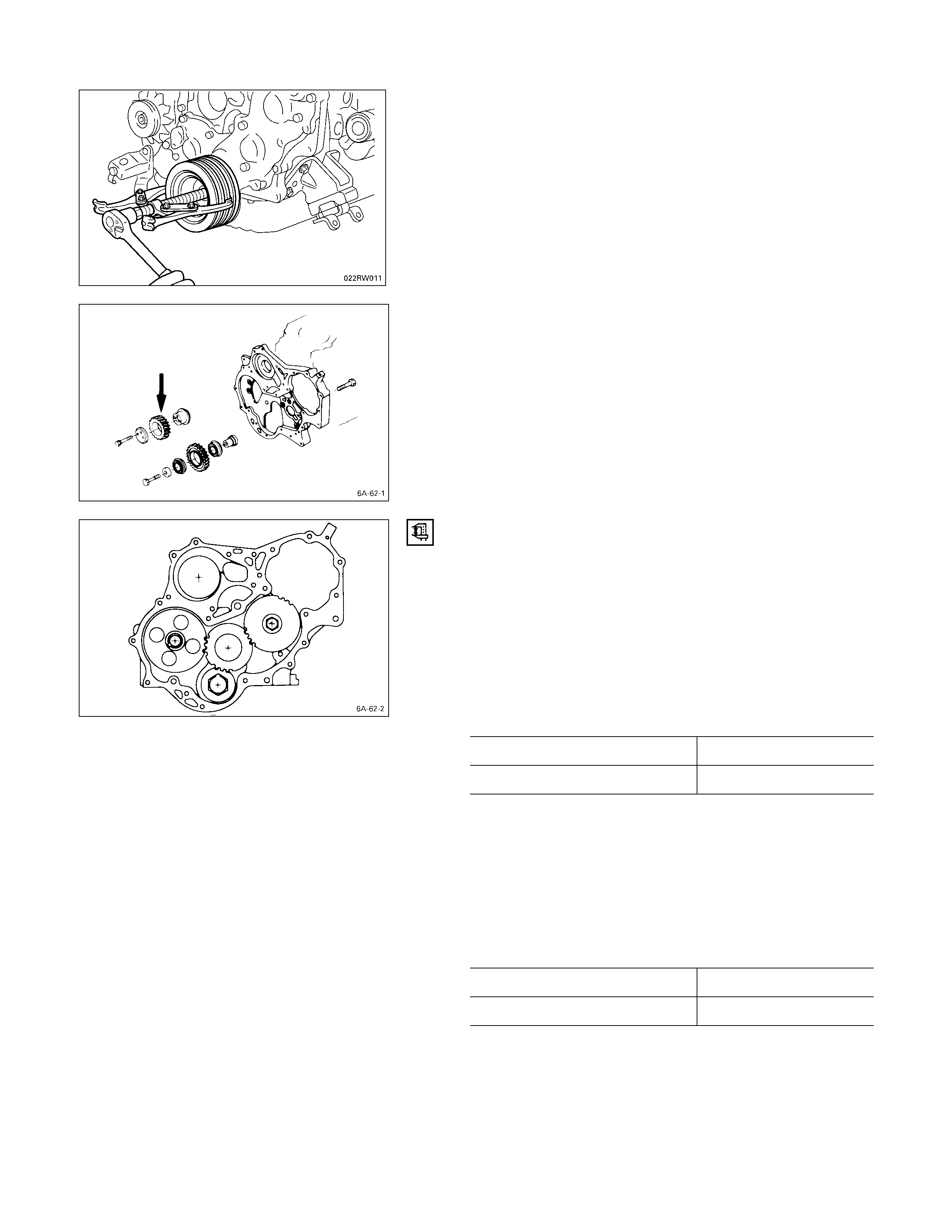

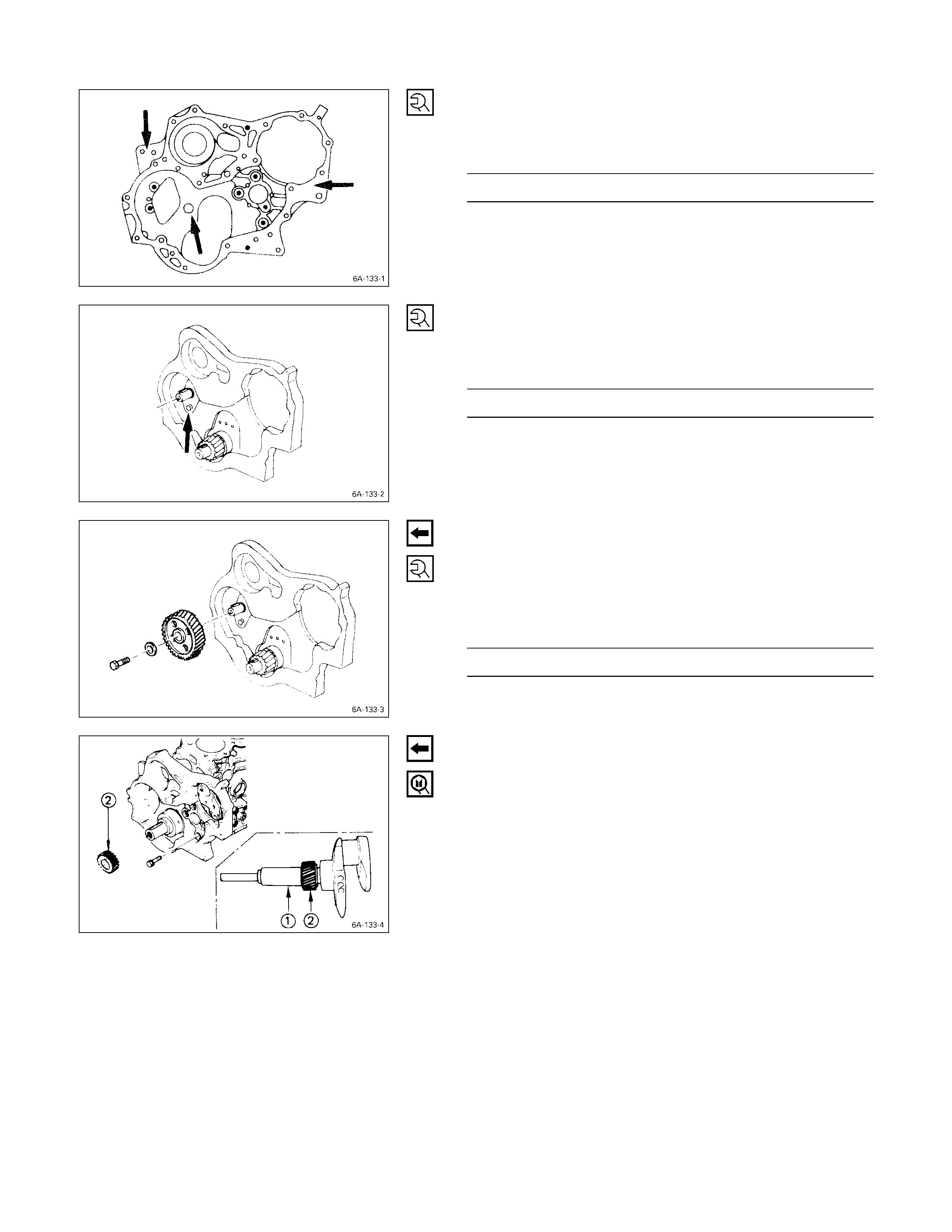

1. Crankshaft Damper Pulley

Use the remover to remove the damper pulley

NOTE:

Hold the flywheel ring gear stationary to prevent the

crankshaft from turning when removing the

crankshaft pulley.

7. Idler Gear “A”

1. Measure the camshaft timing gear backlash and the

crankshaft timing gear backlash before removing the

idler gear.

2. Measure the idler gear end play before removing the

idler gear.

Note:

Refer to the following items for details on the

backlash and end play measurement procedures.

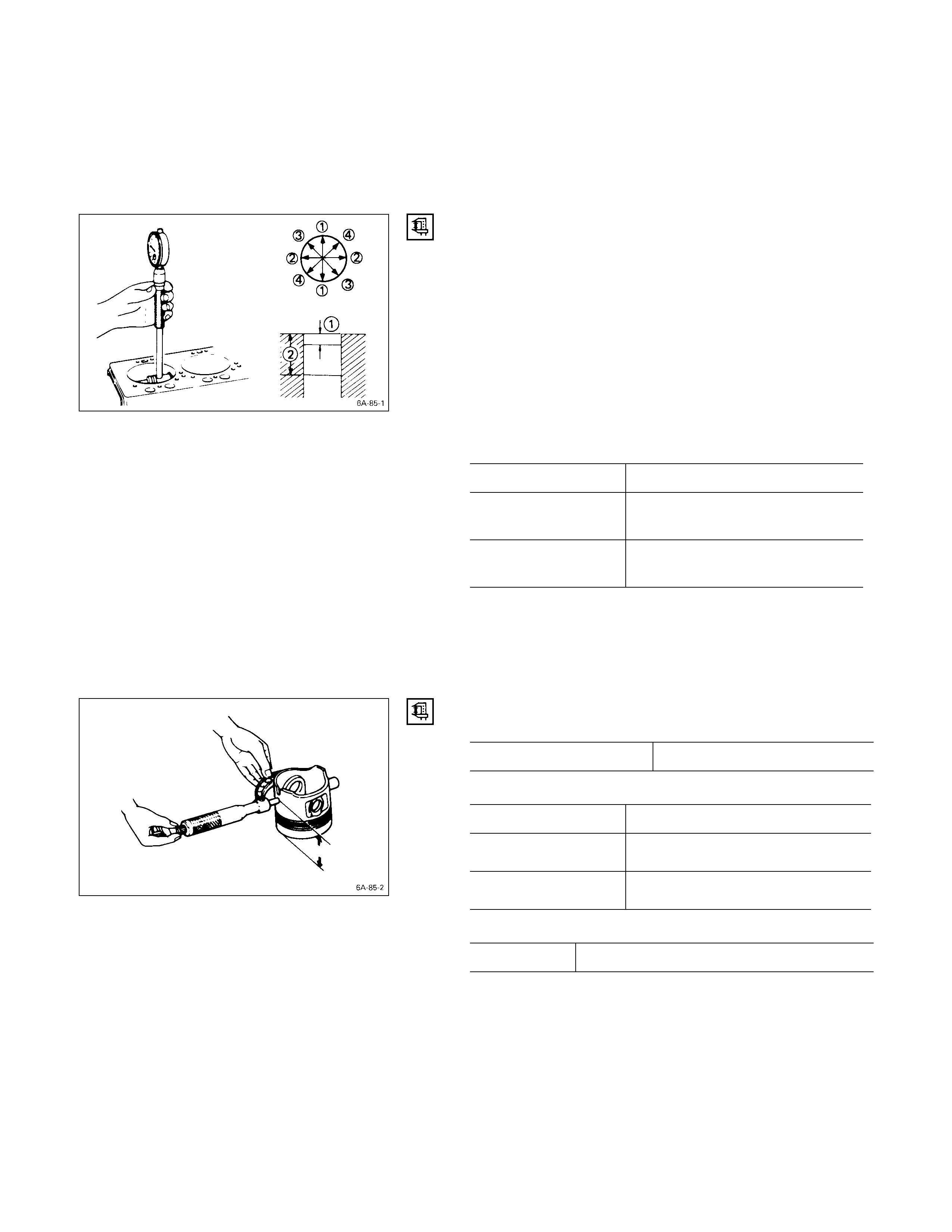

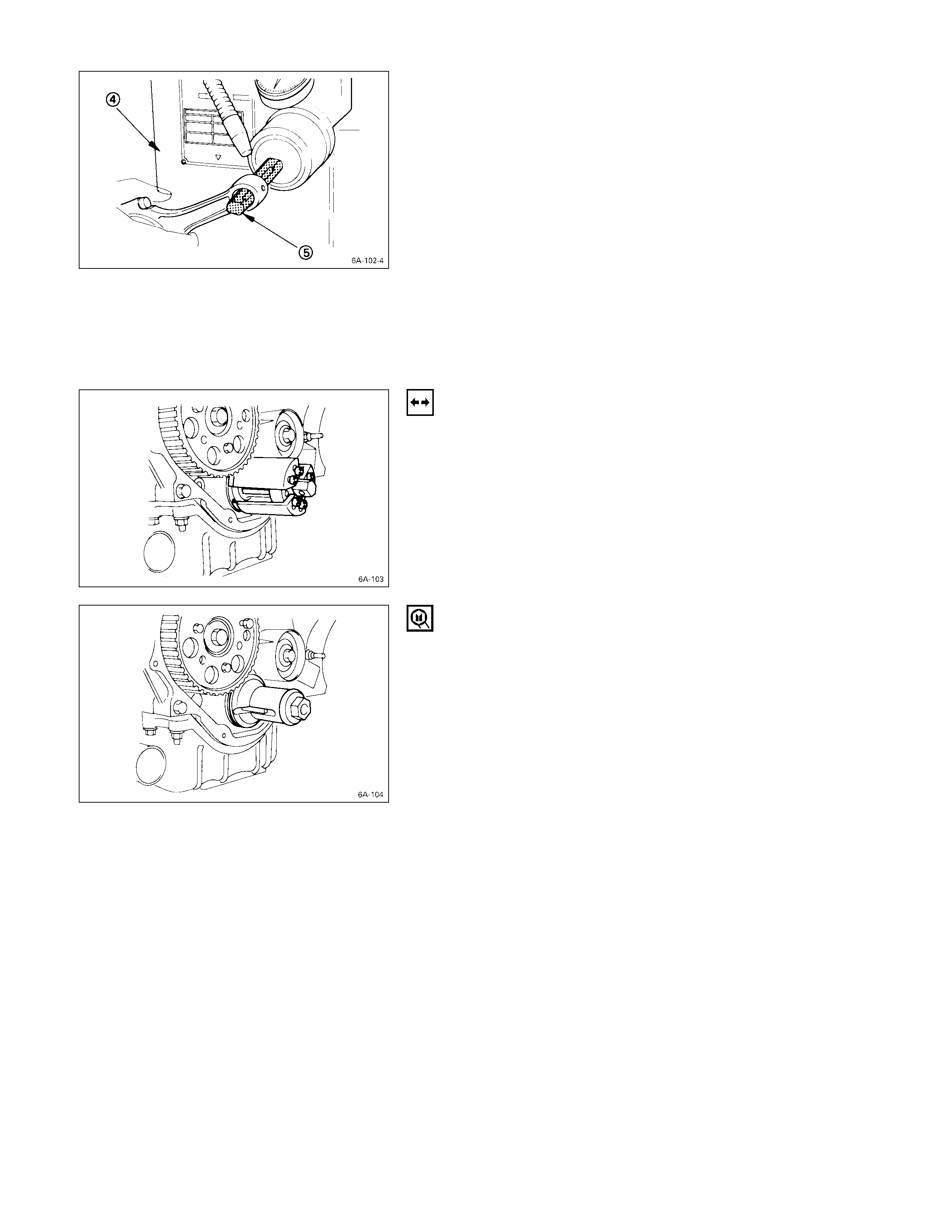

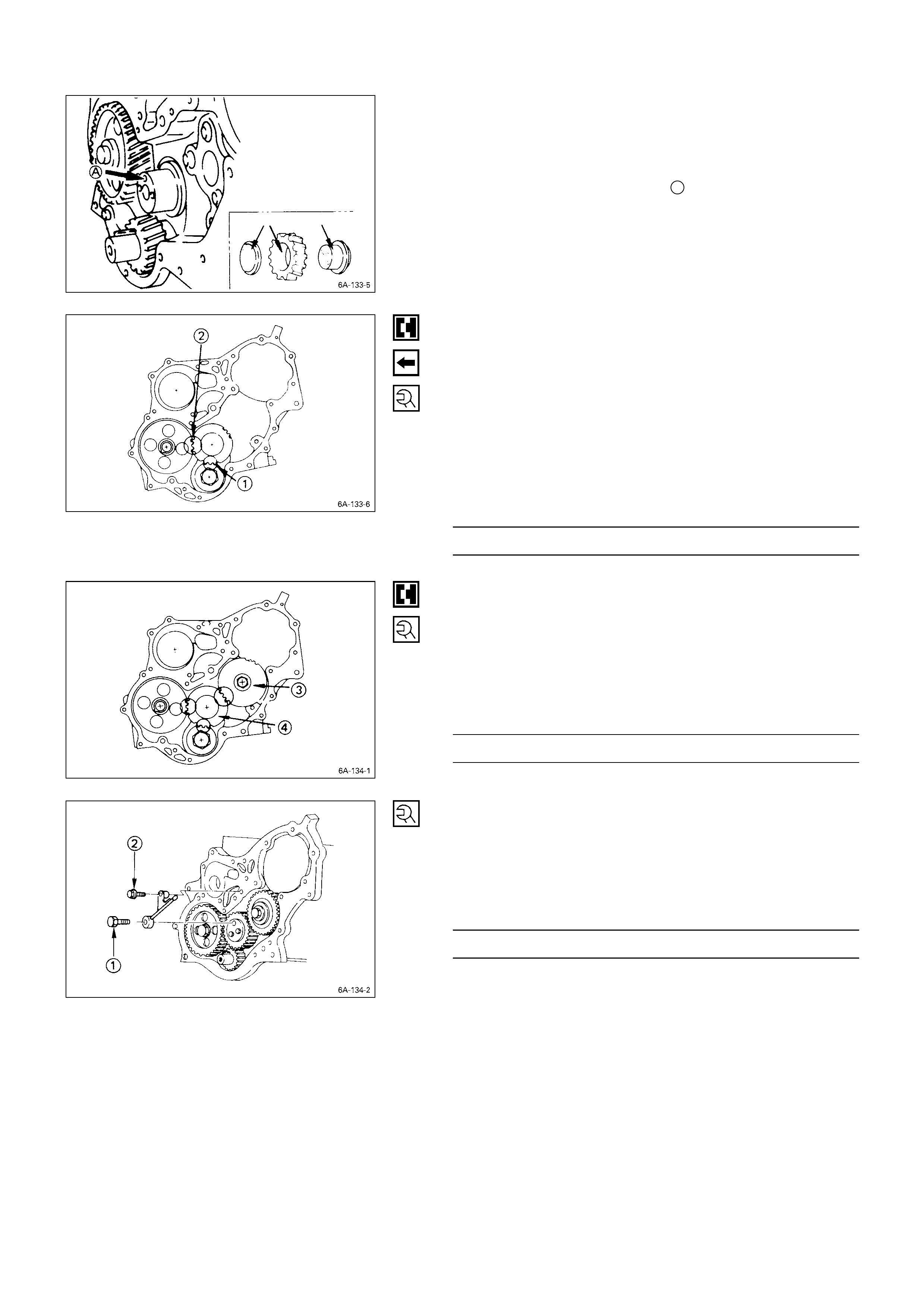

TIMING GEAR BACKLASH MEASUREMENT

1) Set a dial indicator to the timing gear to measured.

Hold both the gear to be checked and the adjusting

gear stationary.

2) Move the gear to be checked as far as possible to

both the right and the left.

Take the dial indicator reading.

If the measured value exceeds the specified limit, the

timing gear must be replaced.

Timing Gear Backlash mm (in)

Standard Limit

0.10 – 0.17 (0.0039 – 0.0067) 0.30 (0.012)

IDLER GEAR “A” END PLAY MEASUREMENT

Insert a feeler gauge between the idler gear and the thrust

collar to measure the gap and determine the idler gear

end play.

If the measured value exceeds the specified limit, the

thrust collar must be replaced.

Idler Gear End Play mm (in)

Standard Limit

0.07 (0.0028) 0.2 (0.0079)

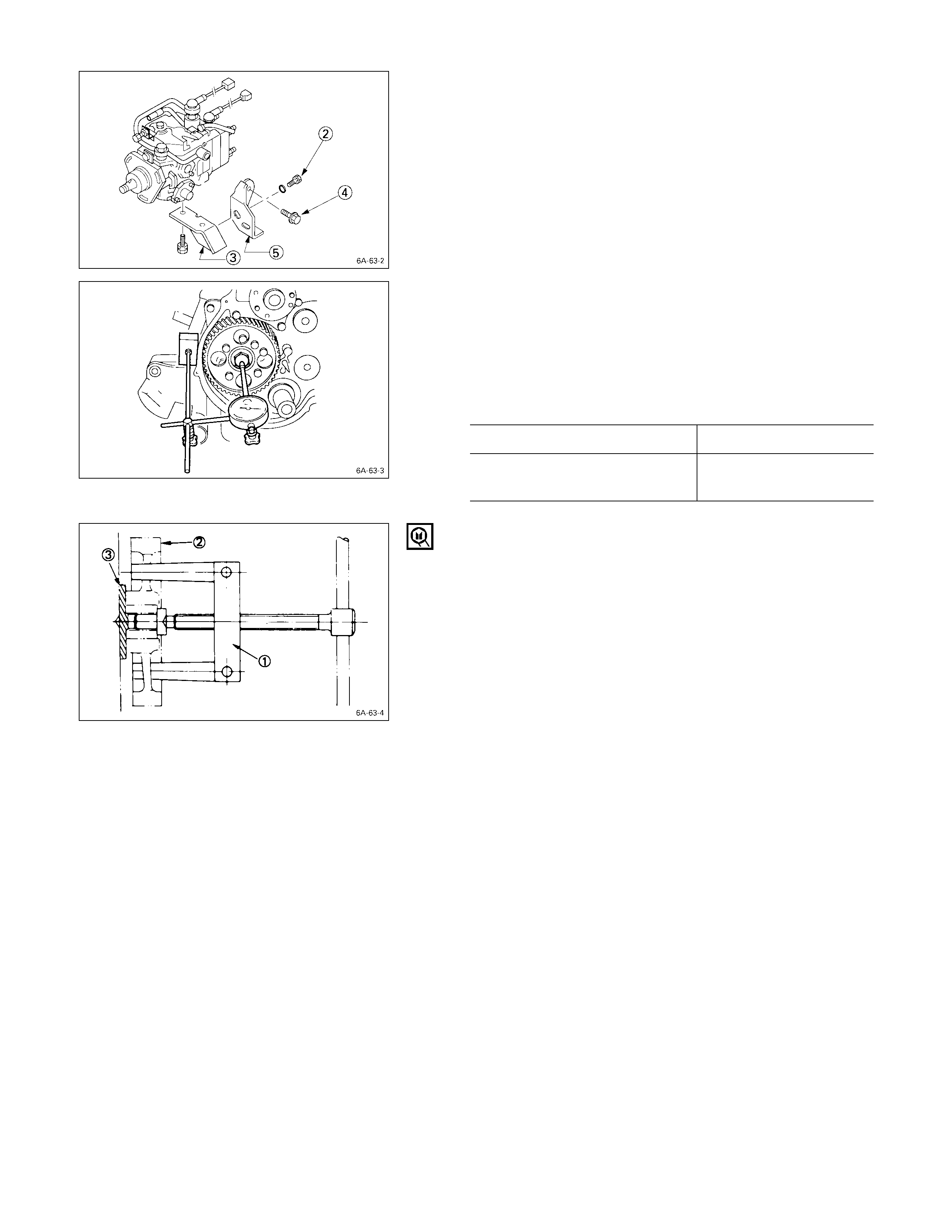

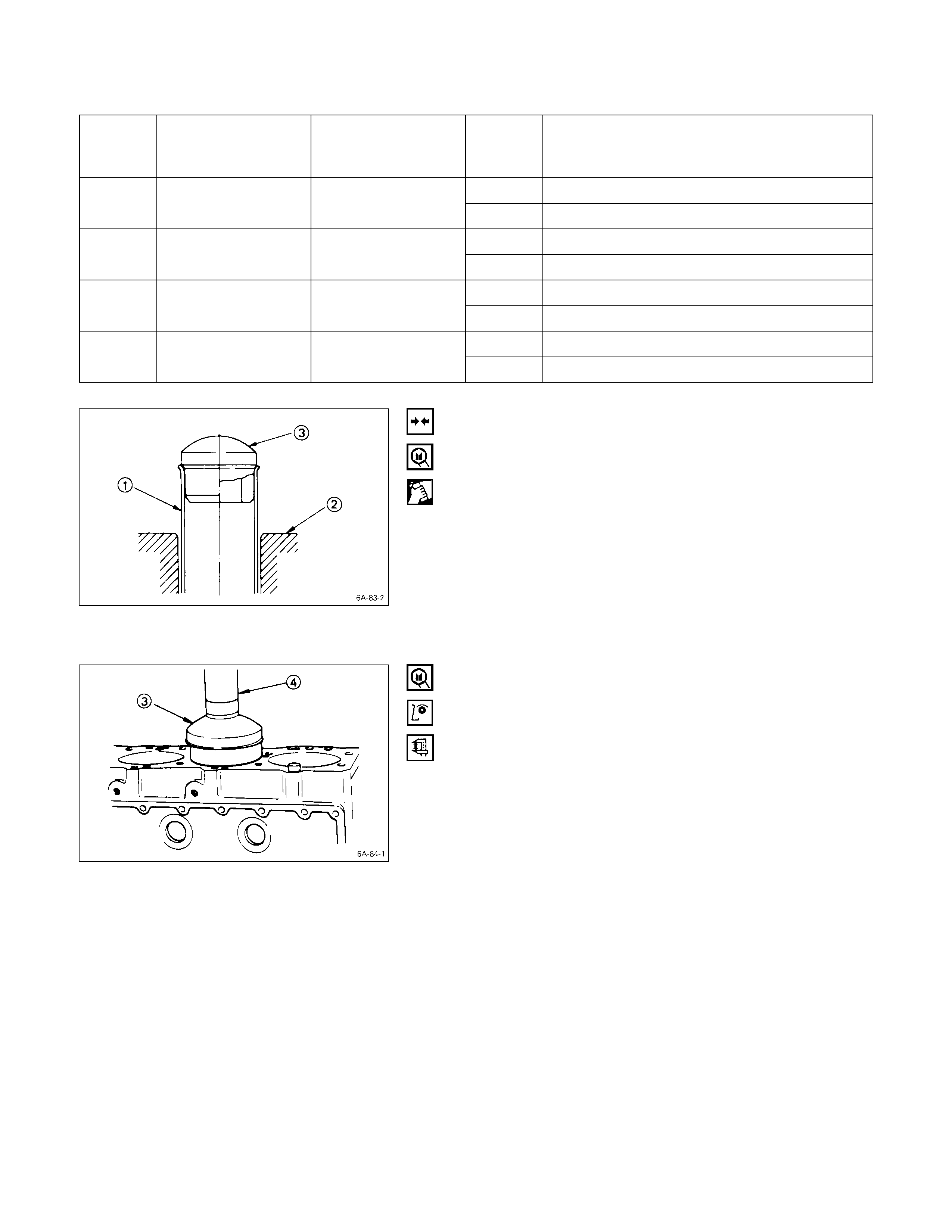

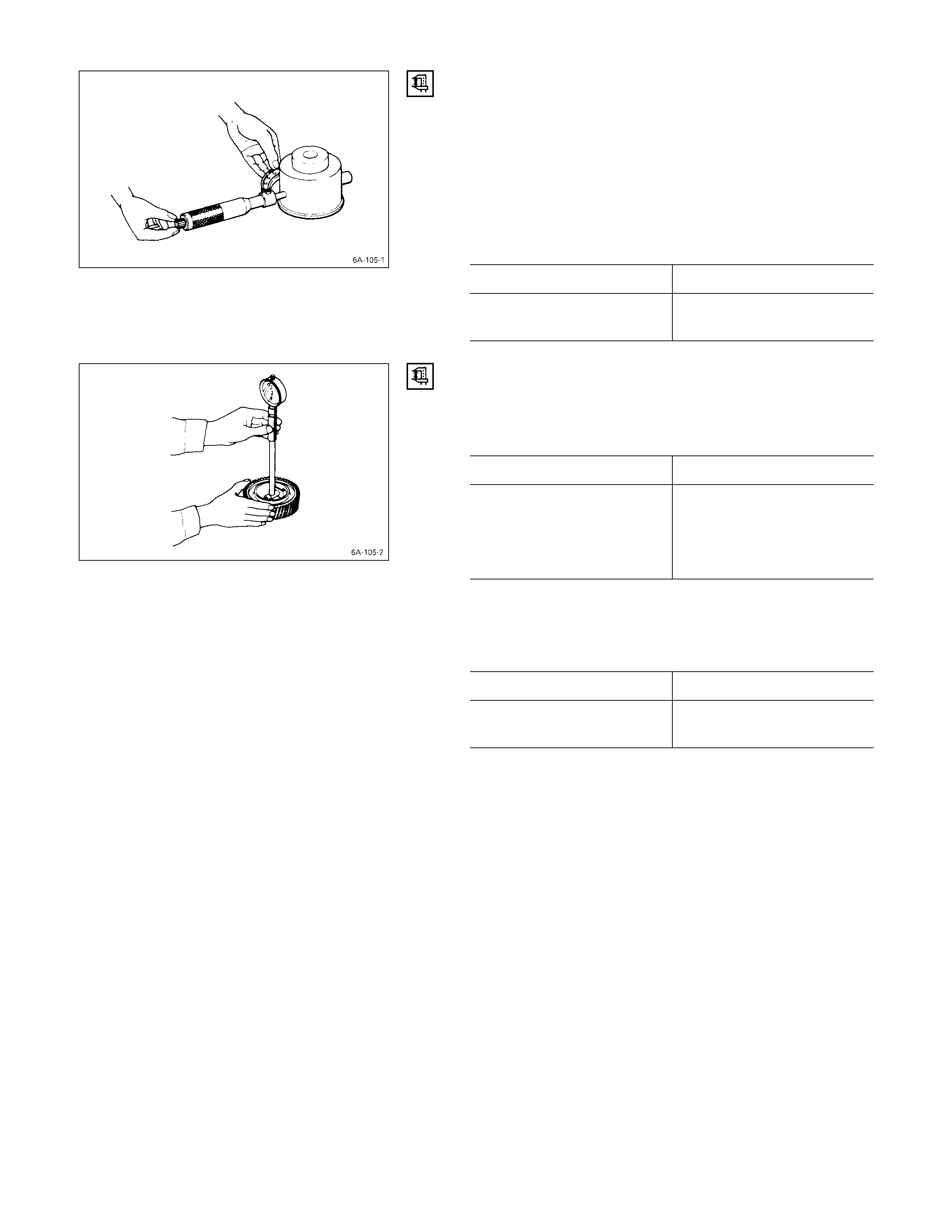

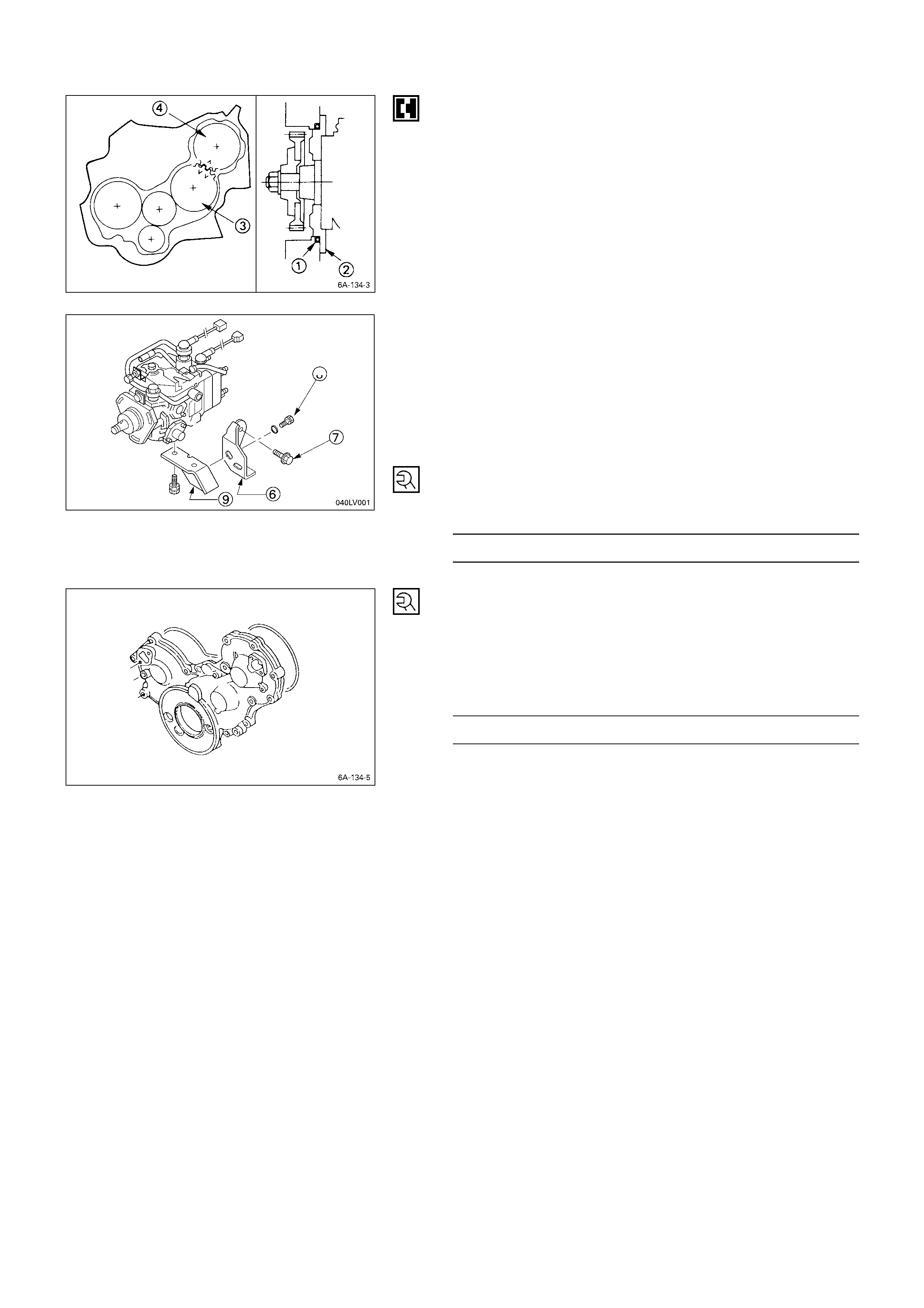

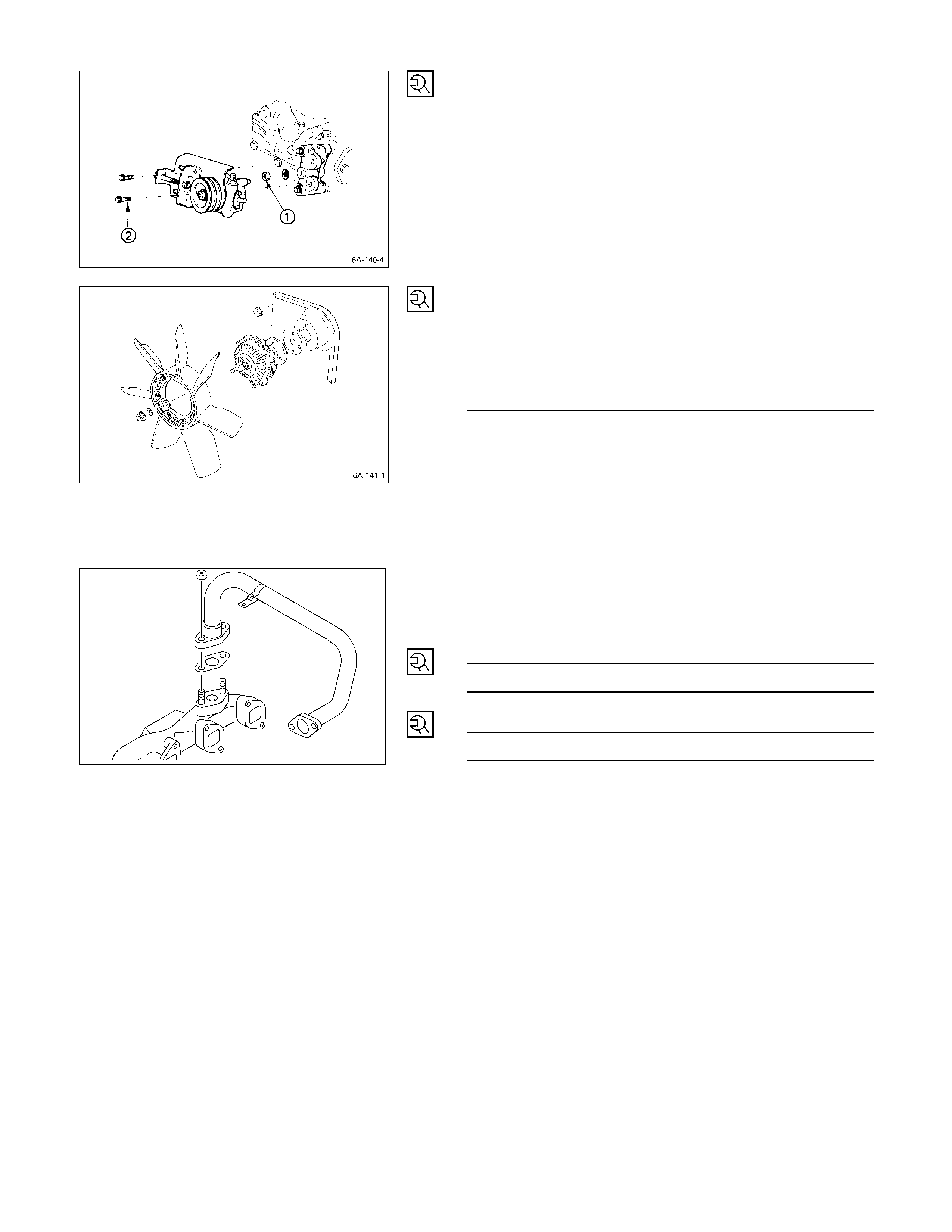

10. Injection Pump

1. Remove the six injection pump backet bolts Q from

the timing gear case.

2 Remove the injection pump rear bracket bolts R from

the injection pump bracket S.

3. Remove the injection pump rear bracket bolts T and

the bracket U from the cylinder body.

4. Pull the injection pump along with the injection pump

timing gear free toward the rear of the engine.

Note:

Plug the injection pump delivery holder ports with the

shipping caps (or the equivalent) to prevent the entry

of foreign material.

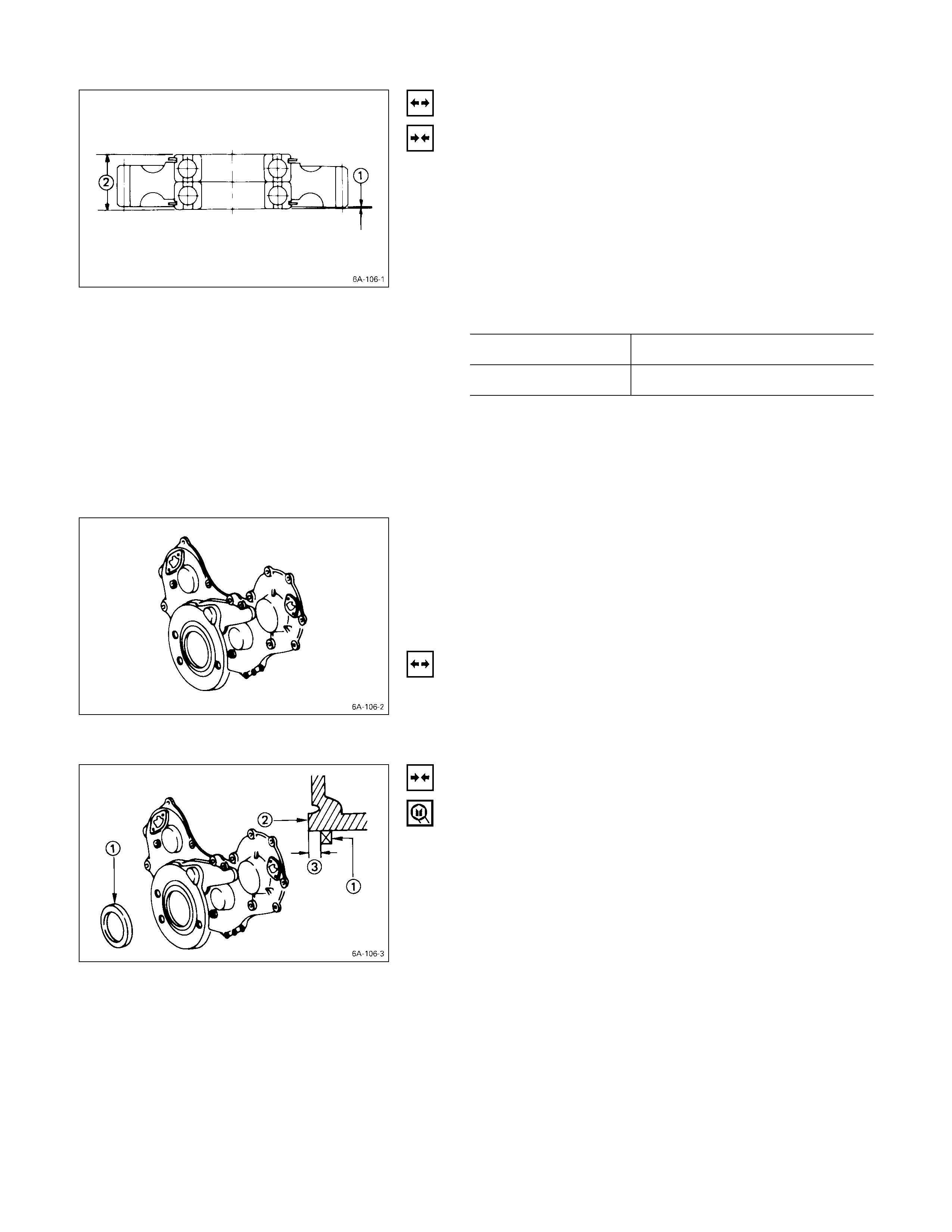

11. Camshaft Timing Gear

1. Use a dial indicator to measure the camshaft end play.

This must be done before removing the camshaft

gear.

If the camshaft end play exceeds the specified limit,

the thrust plate must be replaced.

Camshaft End Play mm (in)

Standard Limit

0.050 – 0.114

(0.002 – 0.0044) 0.20

(0.008)

2. Remove the camshaft timing gear bolt from the

camshaft.

Note:

Hold the camshaft stationary to prevent the camshaft

from turning.

3. Use the universal puller Q to pull out the camshaft

timing gear R.

Universal Puller: 5-8521-0002-0

4. Remove the thrust plate S.

MINOR COMP ONENTS

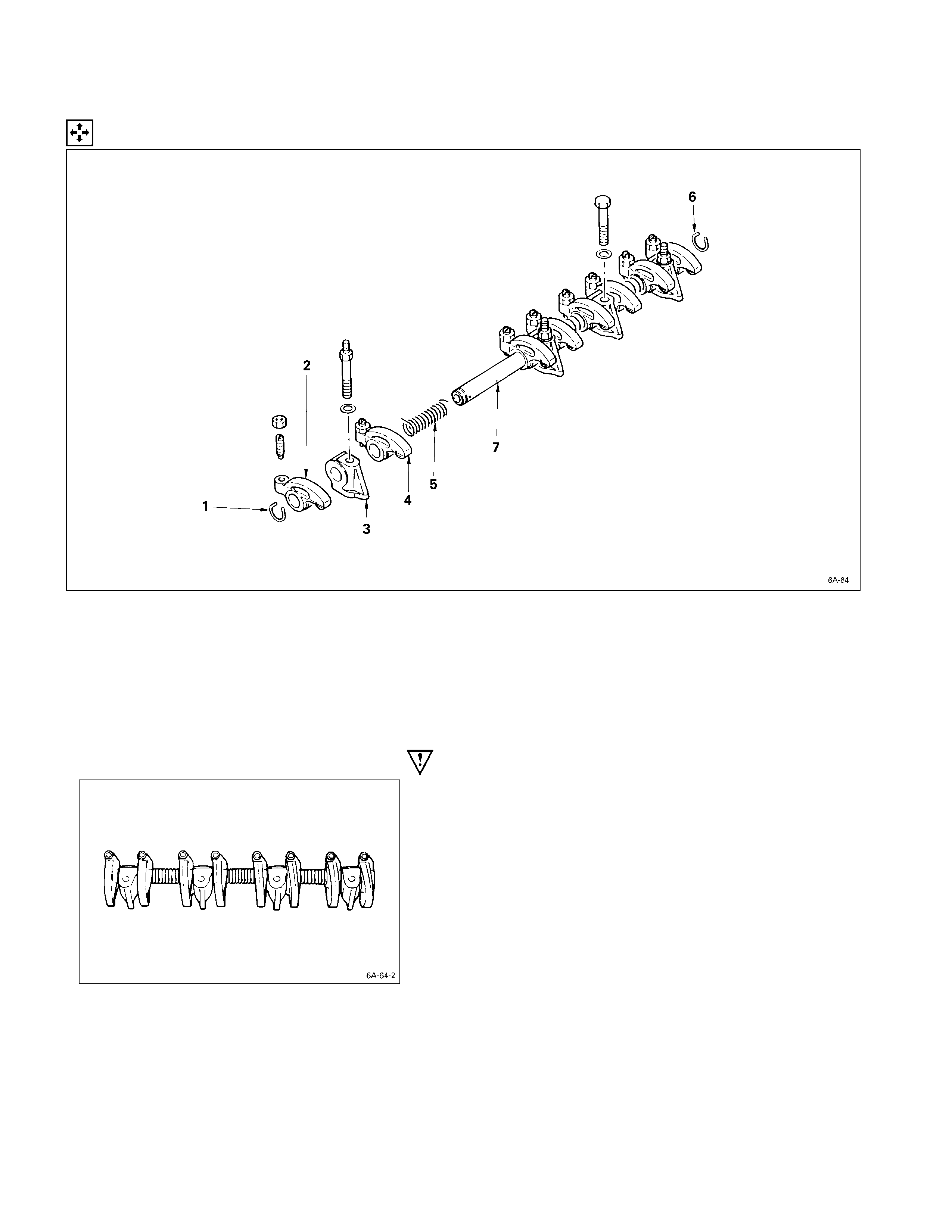

ROCKER ARM SHAFT AND ROCKER ARM

DISASSEM BLY STEPS

J

1. Rocker arm shaft snap ring 5. Rocker arm shaft spring

J

2. Rocker arm 6. Rocker arm shaft snap ring

J

3. Rocker arm shaft bracket 7. Rocker arm shaft

4. Rocker arm

IMPORTANT OPERATIONS

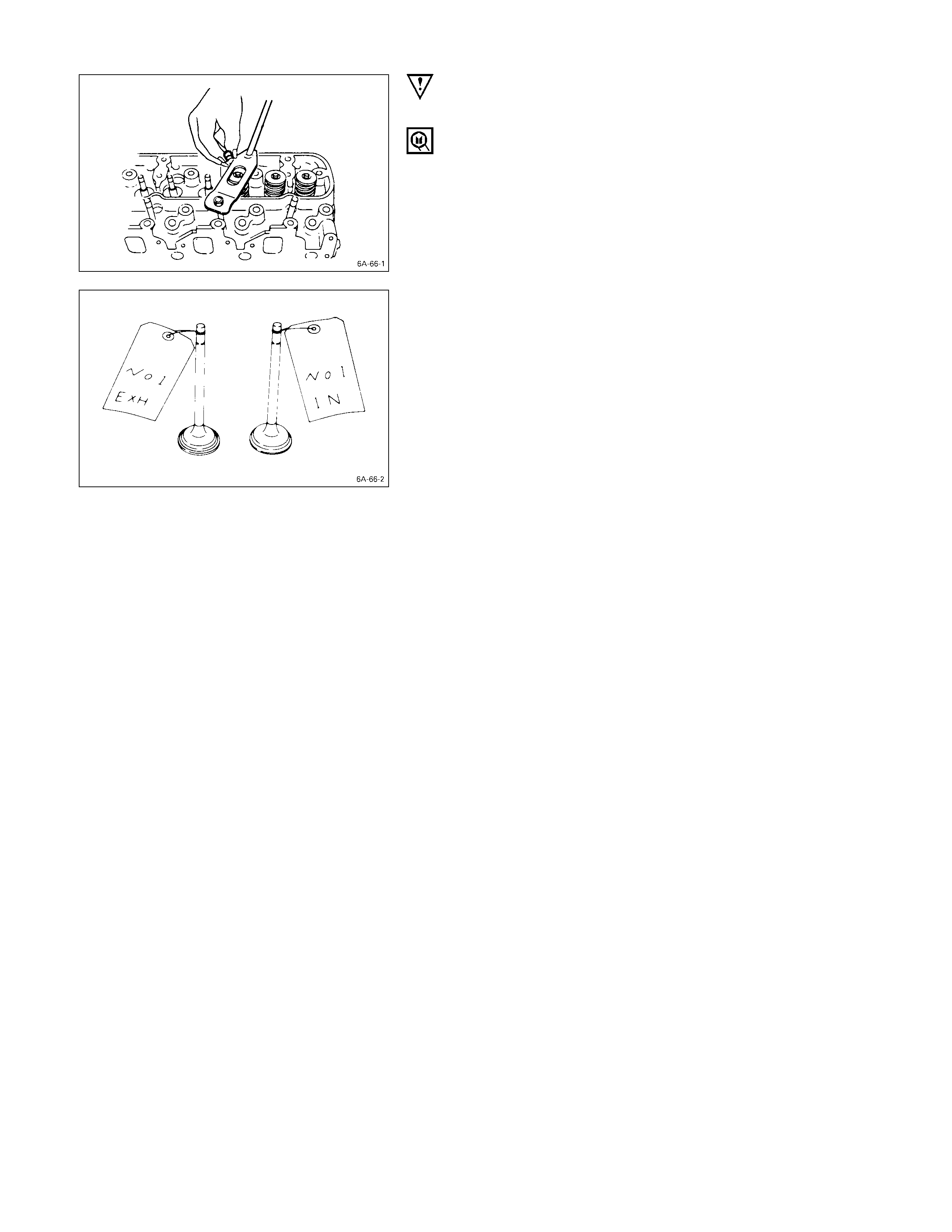

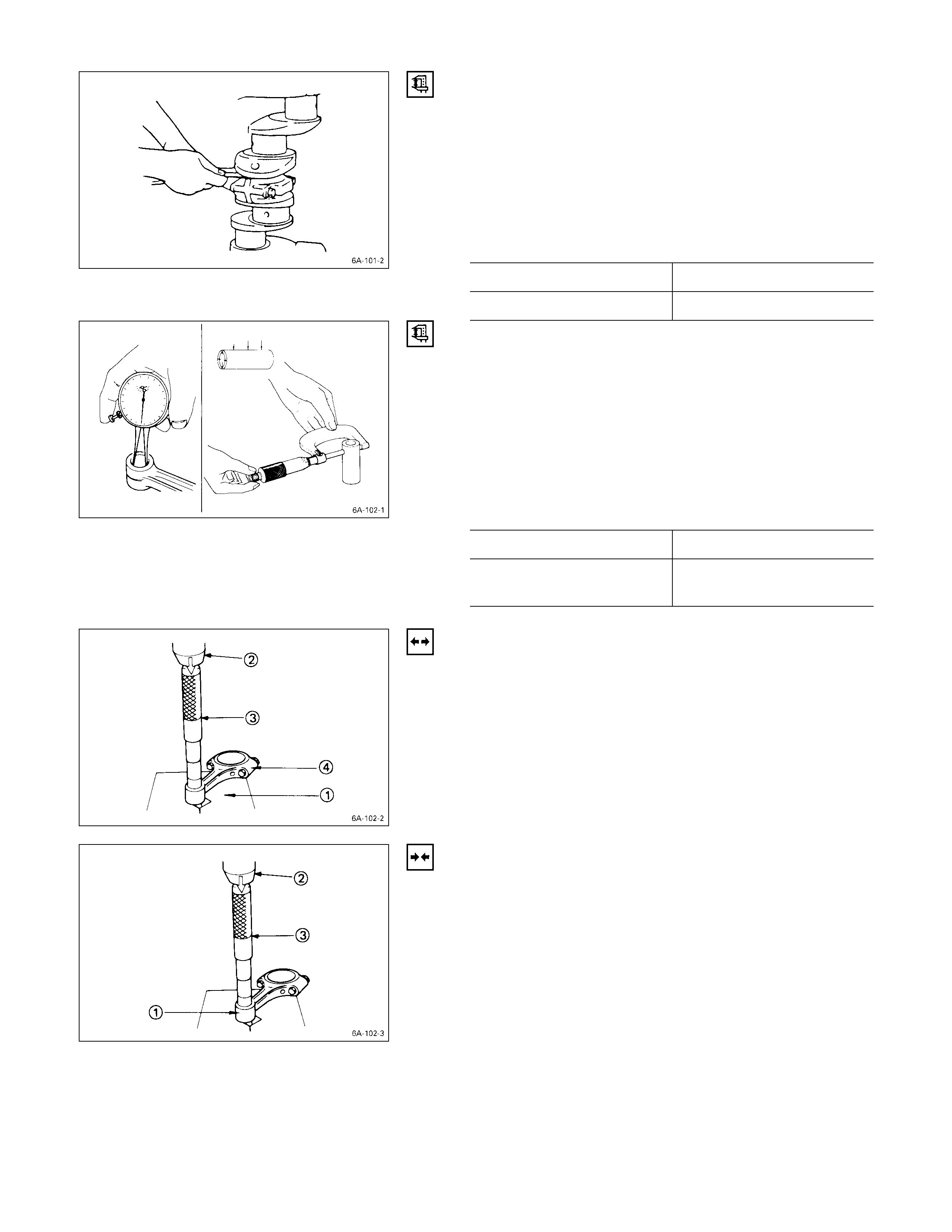

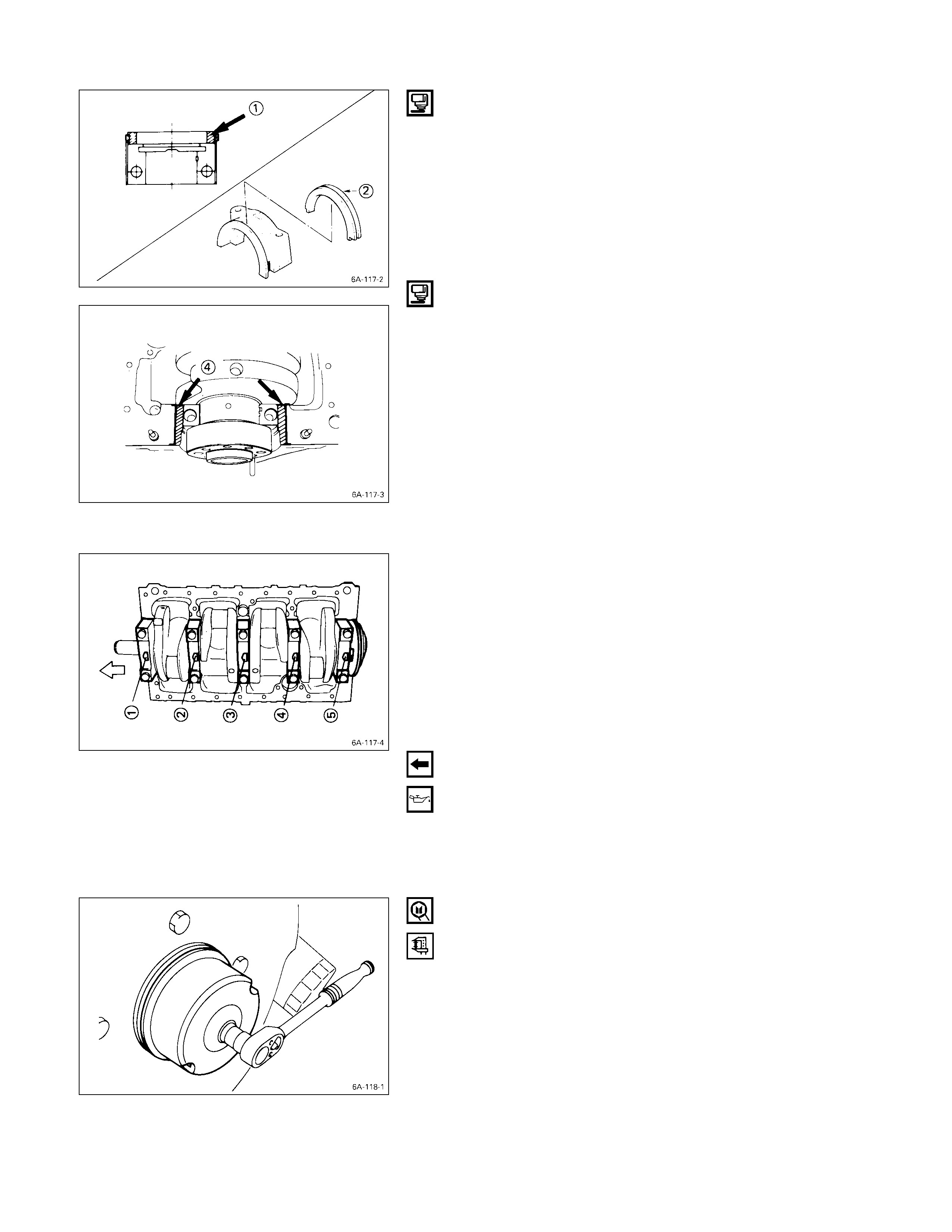

1. Rocker Arm Shaft Snap Ring

2. Rocker Arm

3. Rocker Arm Shaft Bracket

1) Use a pair of pliers to remove the snap rings.

2) Remove the rocker arms.

3) Remove the rocker arm shaft brackets.

If the rocker arms and rocker arm shaft brackets are

to be reinstalled, mark their installation positions by

tagging each rocker arm and rocker arm shaft bracket

with the cylinder number from which it was removed.

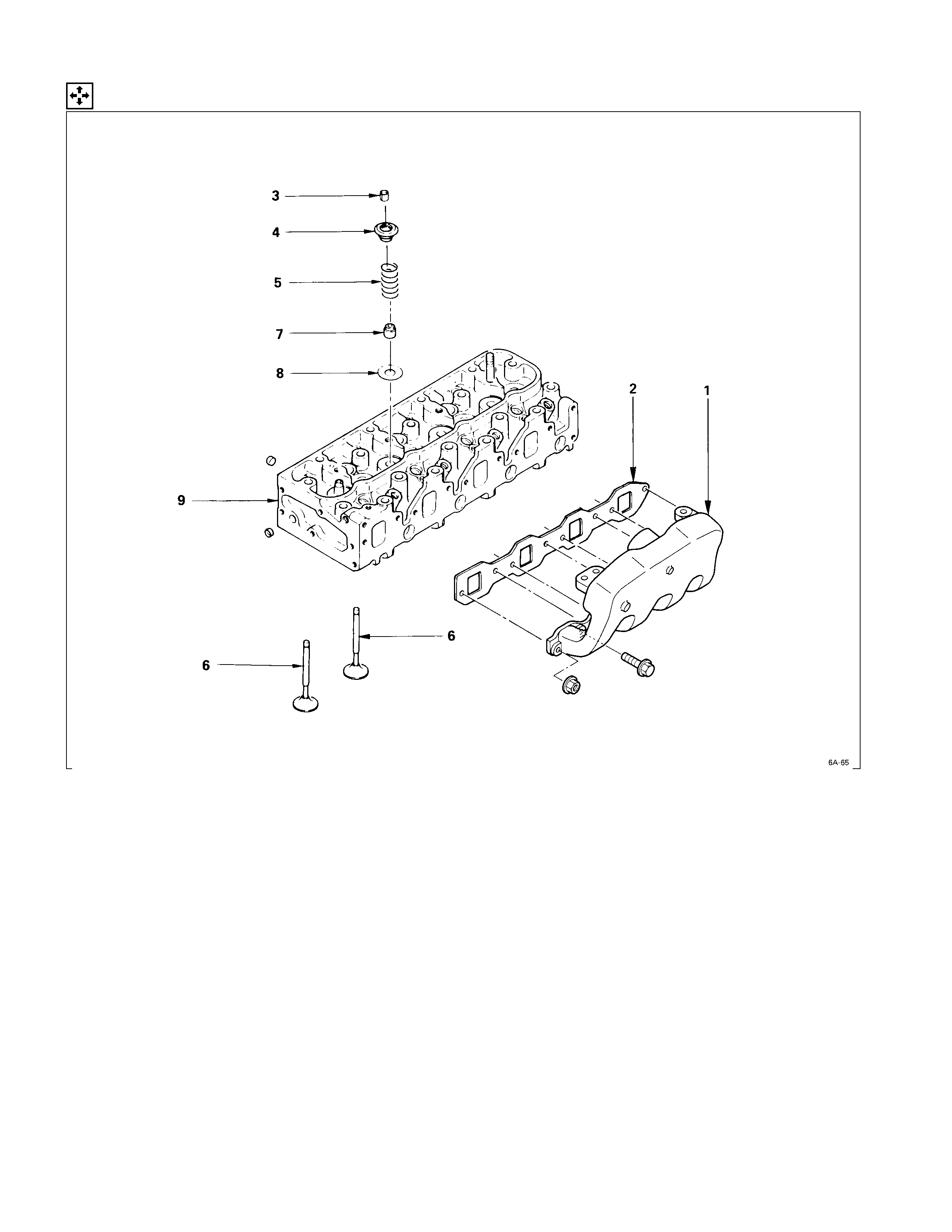

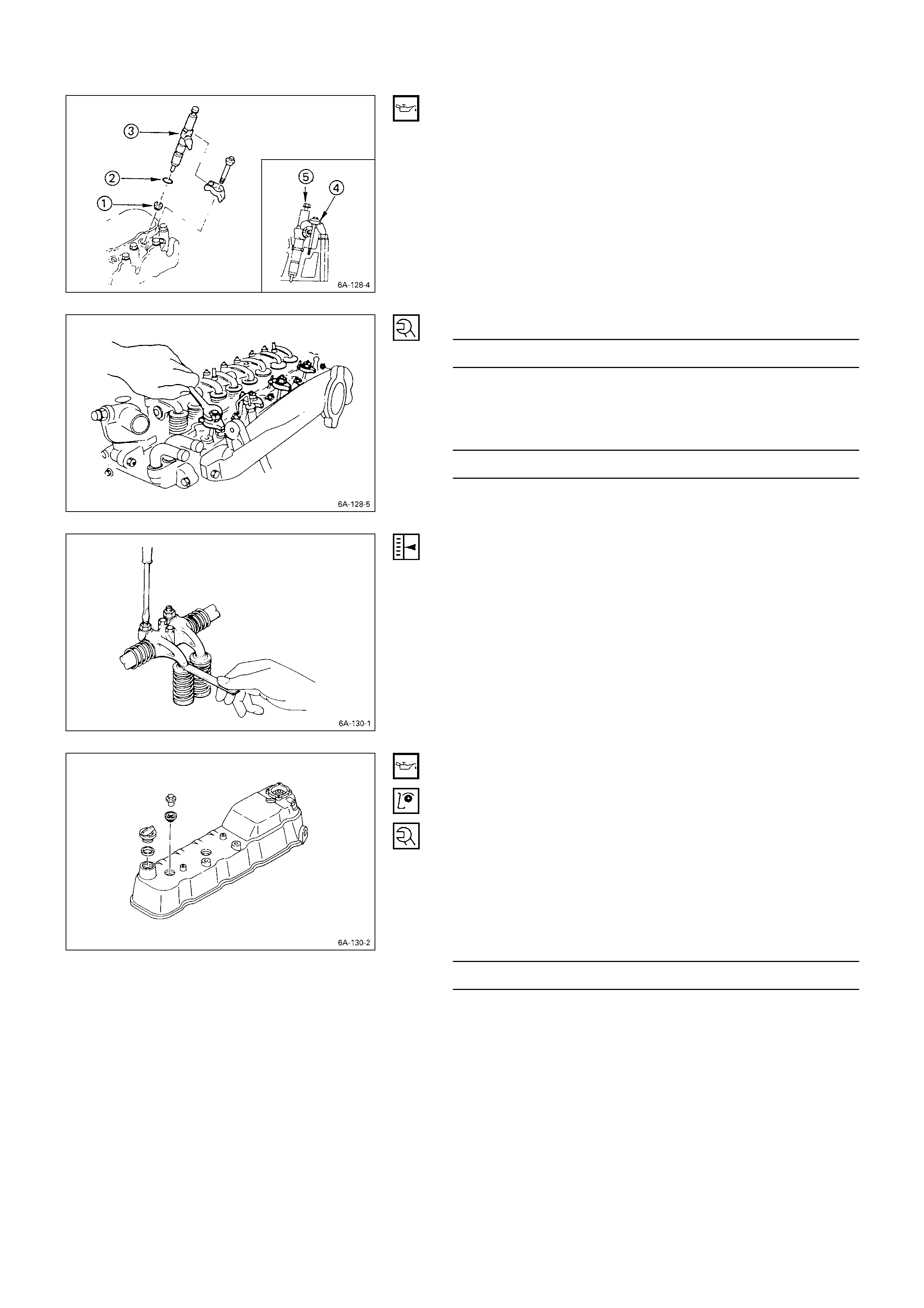

CYLINDER HEAD

DISASSEM BLY STEPS

1. Intake manifold

J

6. Intake and exhaust valve

2. Intake manifold gasket 7. Valve stem oil seal

J

3. Split collar 8. Valve spring lower seat

4. Valve spring upper seat 9. Cylinder head

5. Valve spring

IMPORTANT OPERATIONS

3. Split Collar

1) Place the cylinder head on a flat wooden surface.

2) Use the spring compressor to remove the split collars.

Do not allow the valve to fall from the cylinder head.

Spring Compressor: 9-8523-1423-0 (J-29760)

4. Intake and Exhaust Valve

If the intake and exhaust valves are to be reinstalled, mark

their installation positions by tagging each valve with the

cylinder number from which it was removed.

If the intake and exhaust valves are to be replaced, the

valve guides must also be replaced.

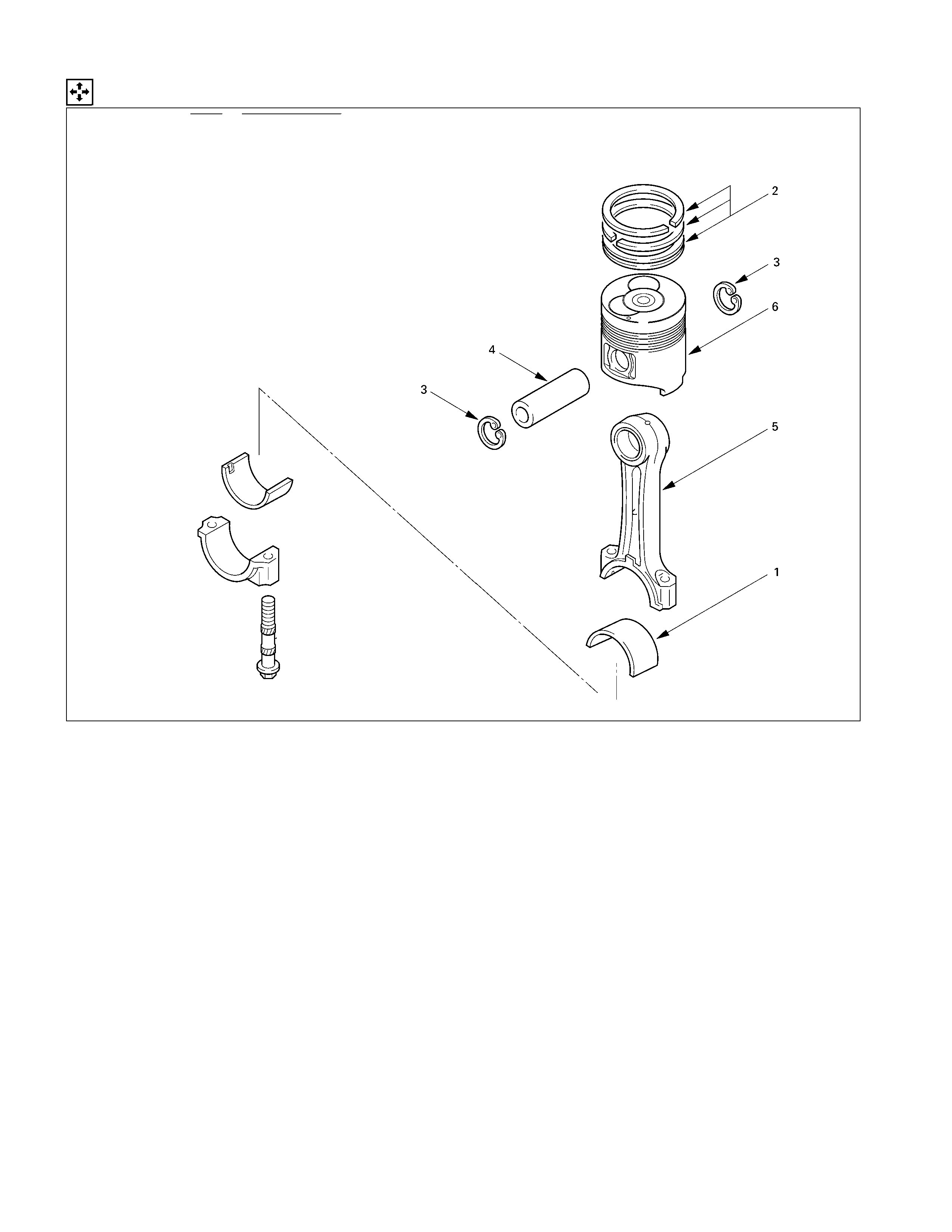

PISTON AND CONNECTING RO D

DISASSEM BLY STEPS

J

1. Connecting rod bearing

J

4. Piston pin

J

2. Piston ring 5. Connecting rod

J

3. Piston pin snap ring

J

6. Piston

IMPORTANT OPERATIONS

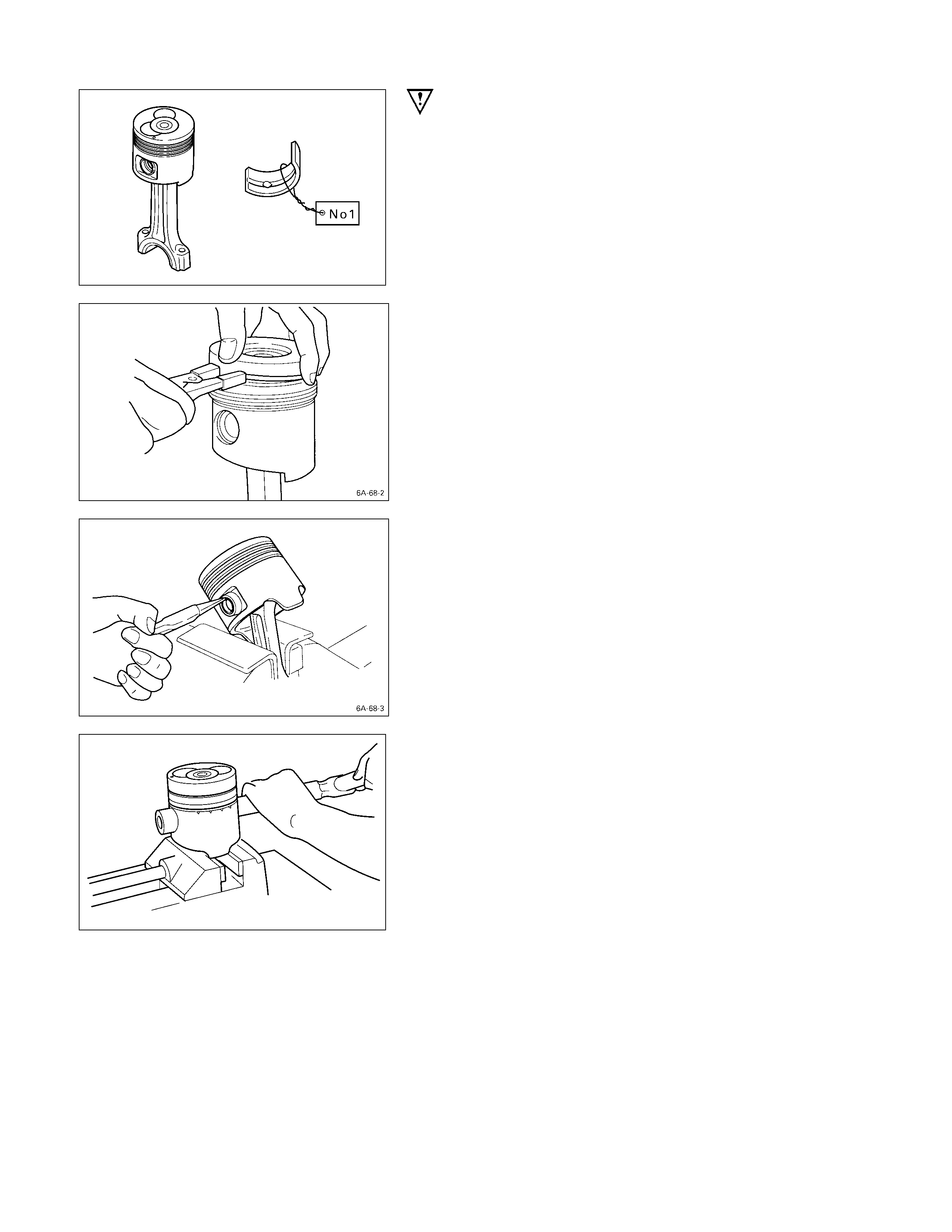

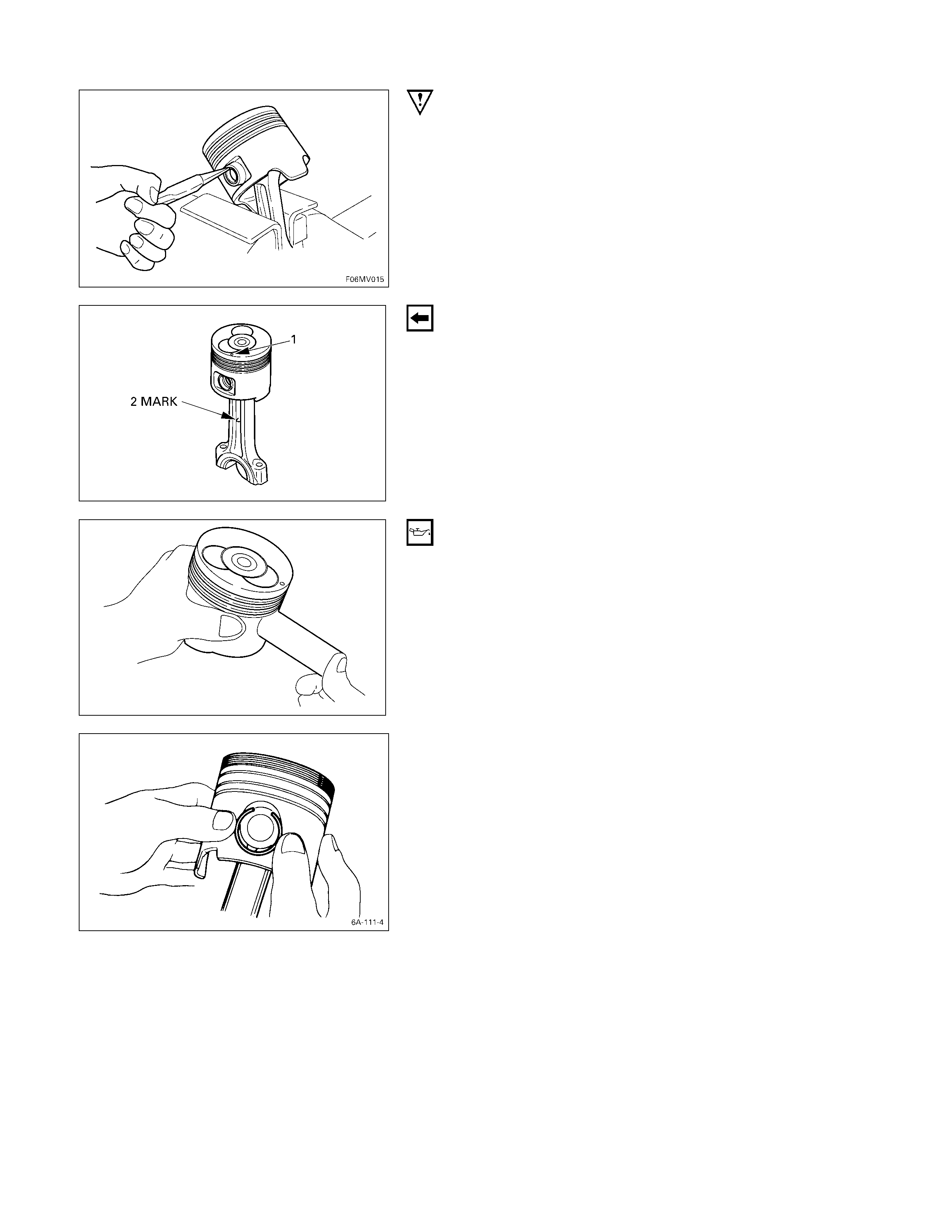

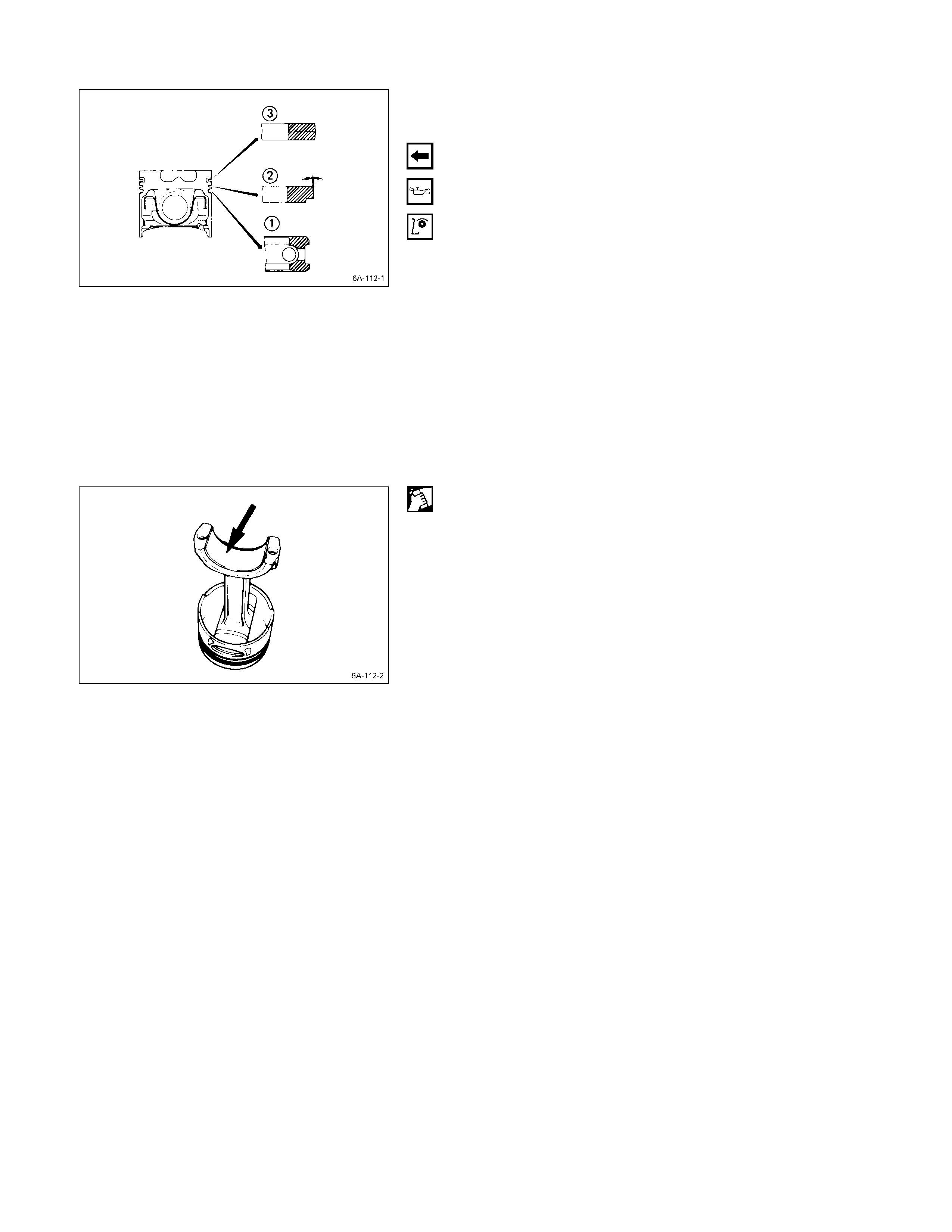

1. Connecting Rod Bearing

If the connecting rod bearings are to be reinstalled, mark

their fitting positions by tagging each bearing with the

cylinder number from which it was removed.

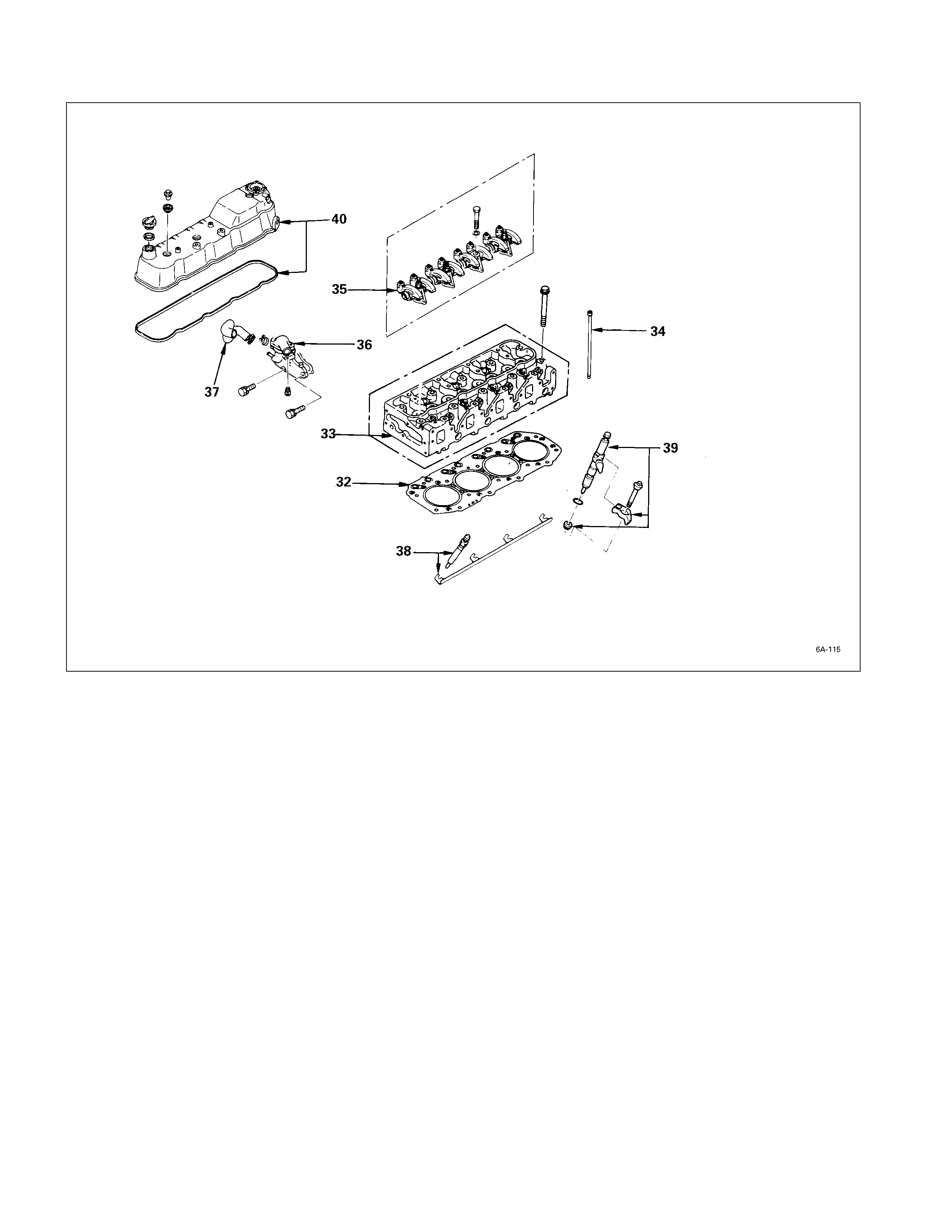

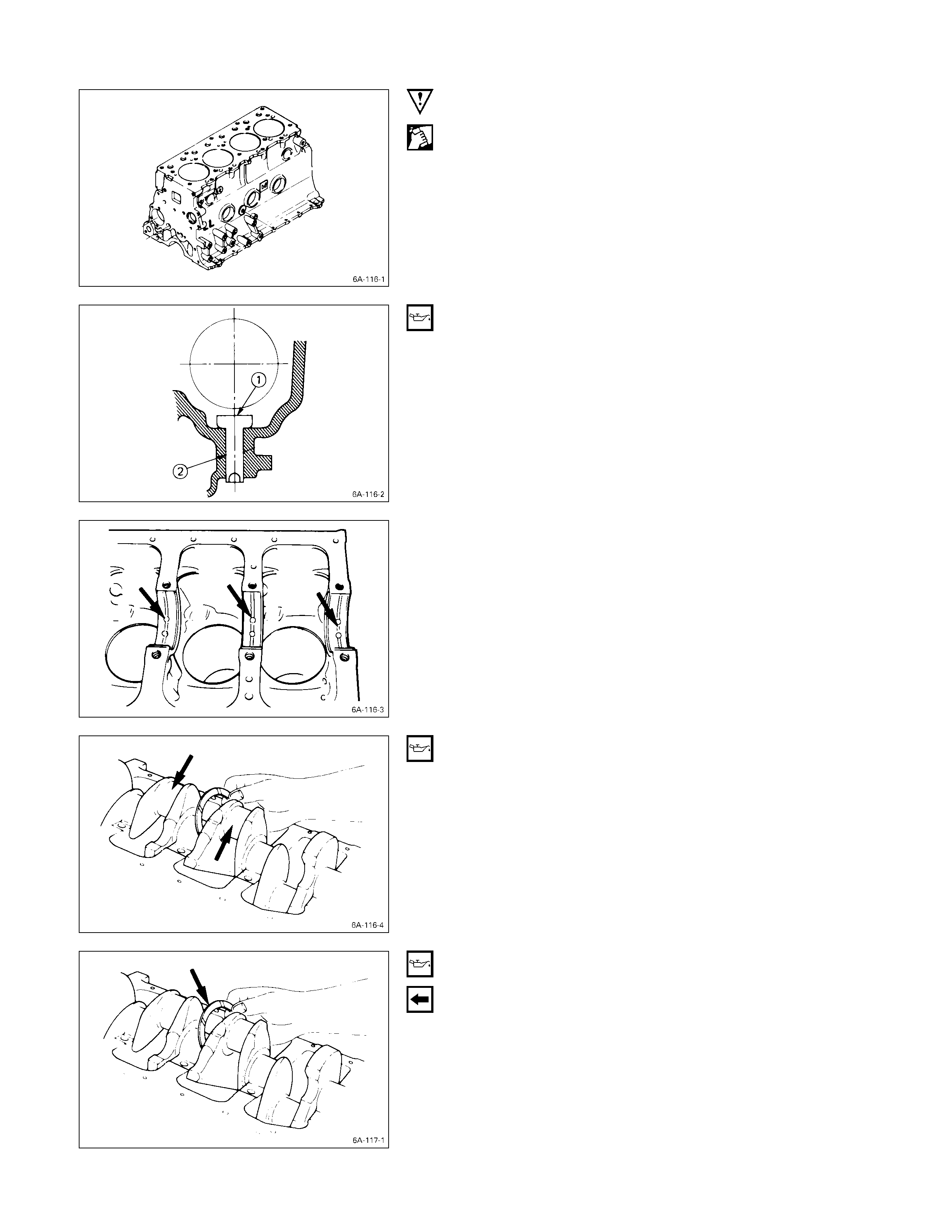

2. Piston Ring

1) Clamp the connecting rod in a vise.

Take care not to damage the connecting rod.

2) Use a piston ring replacer to remove the piston rings.

Piston Ring Replacer

Do not attempt to use some other tool to remove the

piston rings. Piston ring stretching will result in

reduced piston ring tension.

3. Piston Pin Snap Ring

Use a pair of pliers to remove the piston pin snap rings.

4. Piston Pin

6. Piston

Tap the piston pin out with a hammer and a brass bar.

If the pistons and piston pins are to be reinstalled, mark

their installation positions by tagging each piston and

piston pin with the cylinder number from which it was

removed.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

CYLINDER HEAD

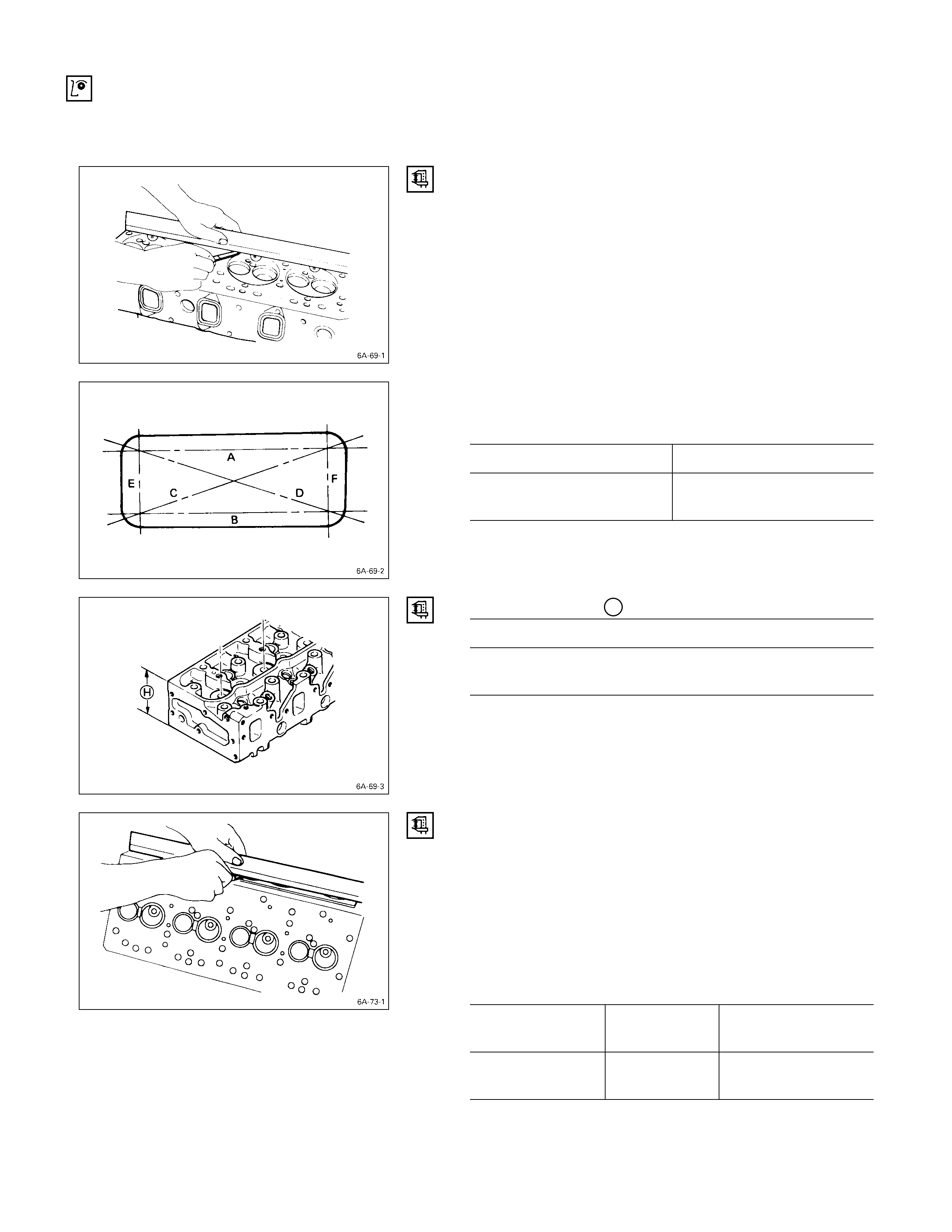

CYLINDER HEAD LO W ER FACE WARPAGE

1. Use a straight edge and a feeler gauge to measure

the four sides and the two diagonals of the cylinder

head lower face.

If the measured values exceed the limit, the cylinder head

must be replaced.

Cylinder Head Lower Face Warpage mm (in)

Standard Limit

0.05

(0.002) or less 0.20

(0.008)

Note:

The cylinder head lower face cannot be reground.

Cylinder Head Height H (Reference) mm (in)

Standard

91.95 – 92.05

(3.620 – 3.624)

MANIFOLD FITTING FACE WARPAGE

Use a straight edge and a feeler gauge to measure the

manifold cylinder head fitting face warpage.

Regrind the manifold cylinder head fitting surfaces if the

measured values are greater than the specified limit but

less than the maximum grinding allowance.

If the measured values exceed the maximum grinding

allowance, the cylinder head must be replaced.

Manifold Fitting Face Warpage mm (in)

Standard Limit Maximum Grinding

Allowance

0.05

(0.002) or less 0.20

(0.008) 0.40

(0.016)

EXHAUST MANI FO LD WARPAGE

Use a straight edge and a feeler gauge to measure the

manifold cylinder head fitting face warpage.

If the measured values exceed the specified limit, the

manifold must be replaced.

Exhaust Manifold Warpage mm (in)

Standard Limit

0.05 (0.002) or less 0.20 (0.008)

VALVE GUIDE

VALVE STEM AND VALVE GUIDE CLEARANCE

Measuring Method-I

1. With the valve stem inserted in the valve guide, set

the dial indicator needle to “0”.

2. Move the valve head from side to side.

Read the dial indicator.

Note the highest dial indication.

If the measured values exceed the specified limit, the

valve and the valve guide must be replaced as a set.

Valve Stem Clearance mm (in)

Standard Limit

Intake Valve 0.039 – 0.069

(0.0015 – 0.0027) 0.200

(0.008)

Exhaust Valve 0.064 – 0.093

(0.0025 – 0.0037) 0.250

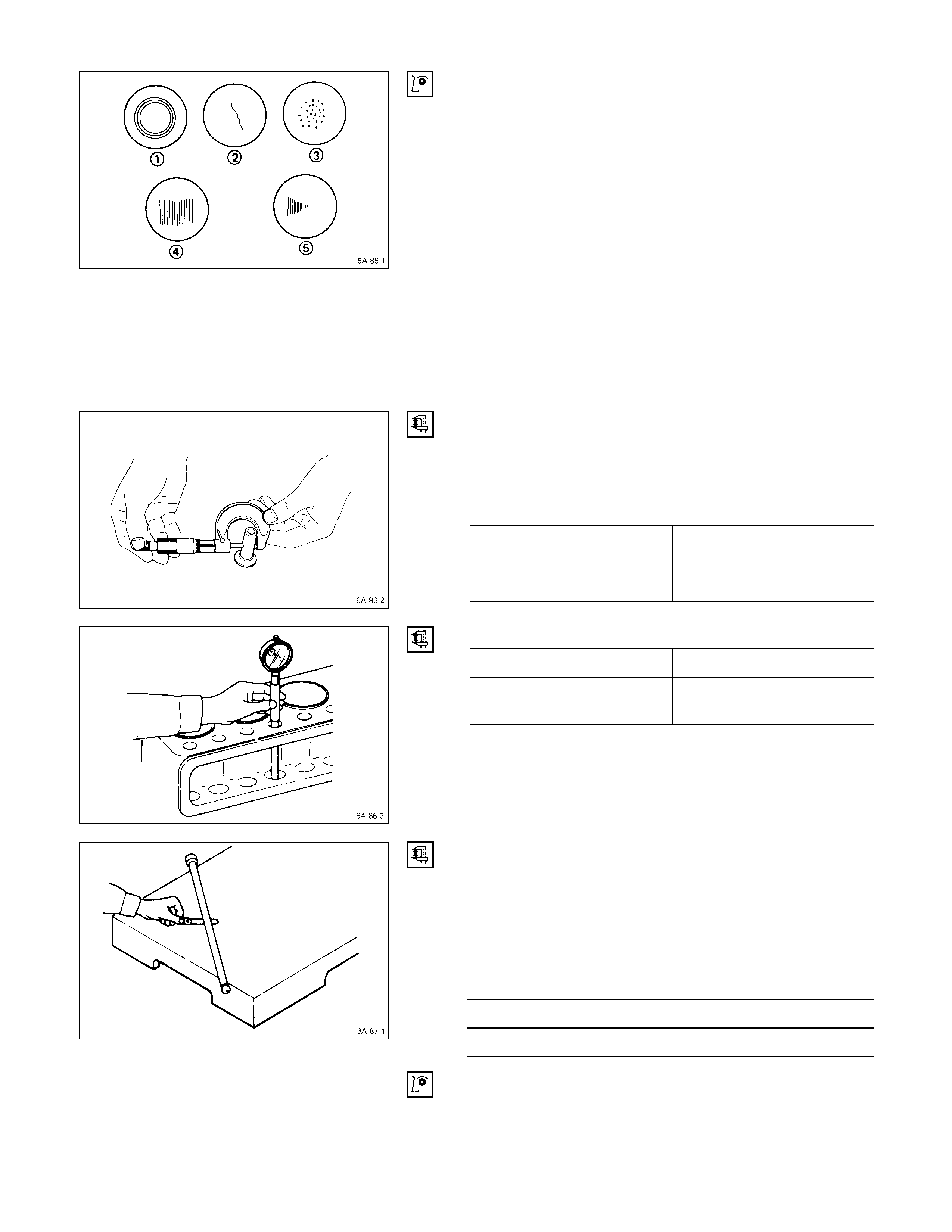

(0.0098)

Measuring Method-II

1. Measure the valve stem outside diameter.

Refer to the Item “Valve Stem Outside Diameter”.

2. Use a caliper calibrator or a telescoping gauge to

measure the valve guide inside diameter.

VALVE GUI DE REPLACEMENT

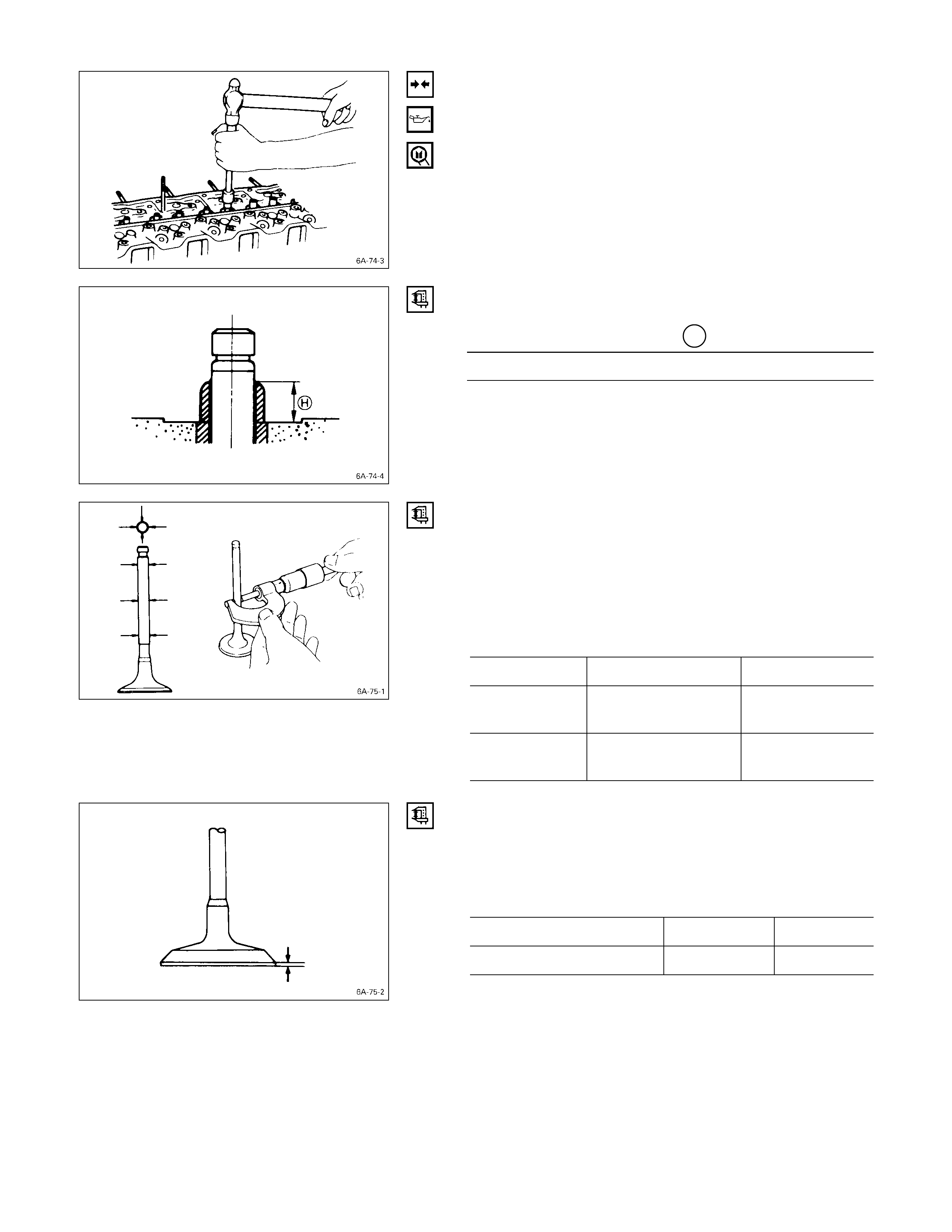

Valve Guide Removal

Use a hammer and the valve guide replacer to drive out

the valve guide from the cylinder head lower face.

Valve Guide Replacer: 9-8523-1212-0

Valve Guide Installation

1. Apply engine oil to the valve guide outer

circumference.

2. Attach the valve guide installer to the valve guide.

3. Use a hammer to drive the valve guide into position

from the cylinder head upper face.

Valve Guide Replacer: 9-8523-1212-0

4. Measure the height of the valve guide upper end from

the upper face of the cylinder head.

Valve Guide Upper End Height H (Reference) mm (in)

13 (0.51)

Note:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

VALVE AND VALVE SEAT INSERT

VALVE STEM OUTSIDE DI AMETER

Measure the valve stem diameter at three points.

If the measured value is less than the specified limit, the

valve and the valve guide must be replaced as a set.

Valve Stem Outside Diameter mm (in)

Standard Limit

Intake Valve 7.946 – 7.961

(0.3128 – 0.3134) 7.880

(0.3102)

Exhaust Valve 7.921 – 7.936

(0.3119 – 0.3124) 7.850

(0.3090)

VALVE THICKNESS

Measure the valve thickness.

If the measured value is less than the specified limit, the

valve and the valve guide must be replaced as a set.

Intake and Exhaust Valve Thickness mm (in)

Standard Limit

4JB1T 1.8 (0.07) 1.5 (0.06)

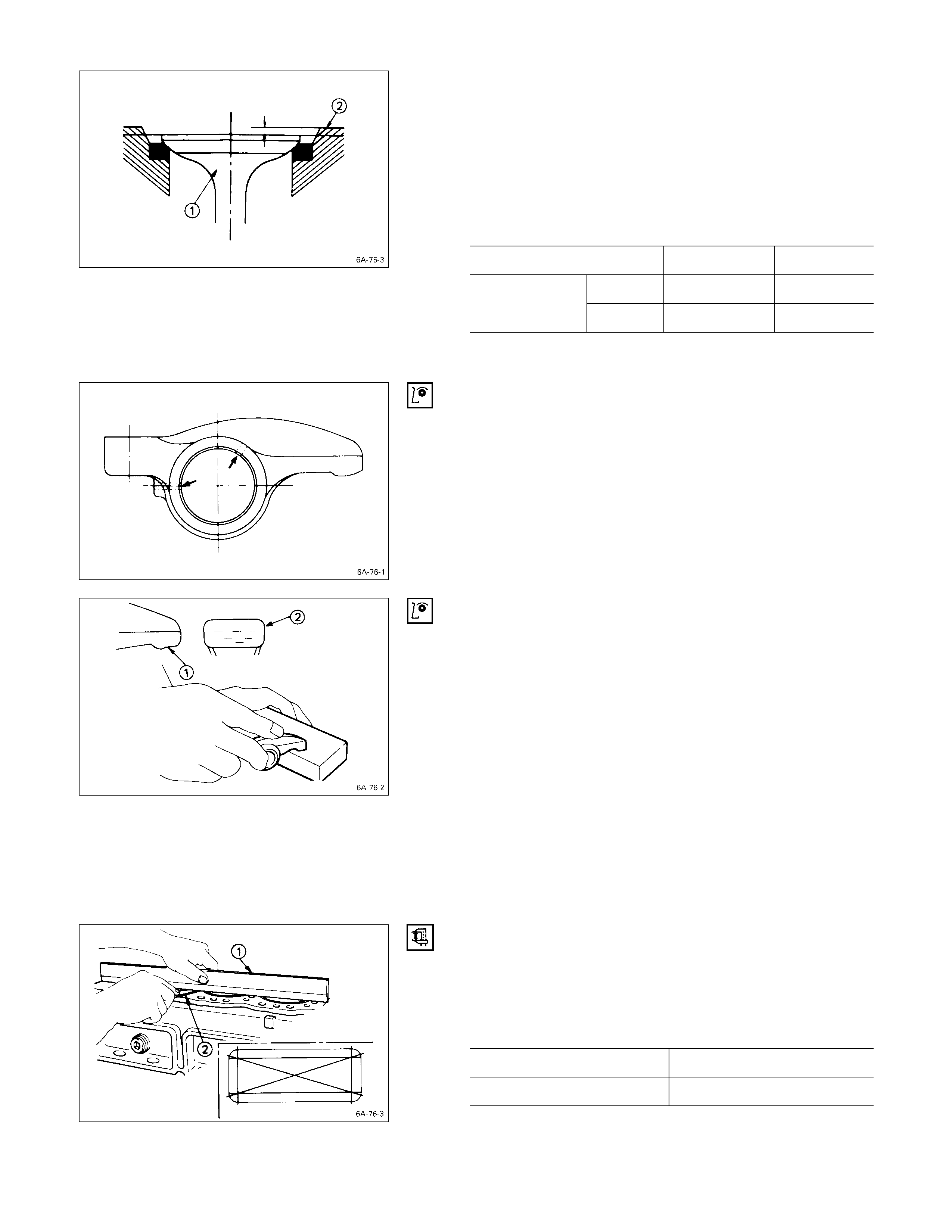

VALVE DEPRESSIO N

1. Install the valve Q to the cylinder head R.

2. Use a depth gauge or a straight edge with steel rule to

measure the valve depression from the cylinder head

lower surface.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Valve Depression mm (in)

Standard Limit

Intake 0.73 (0.029) 1.28 (0.050)

4JB1T Exhaust 0.70 (0.028) 1.20 (0.047)

3. Check that the rocker arm oil port is free of

obstructions.

If necessary, use compressed air to clean the rocker

arm oil port.

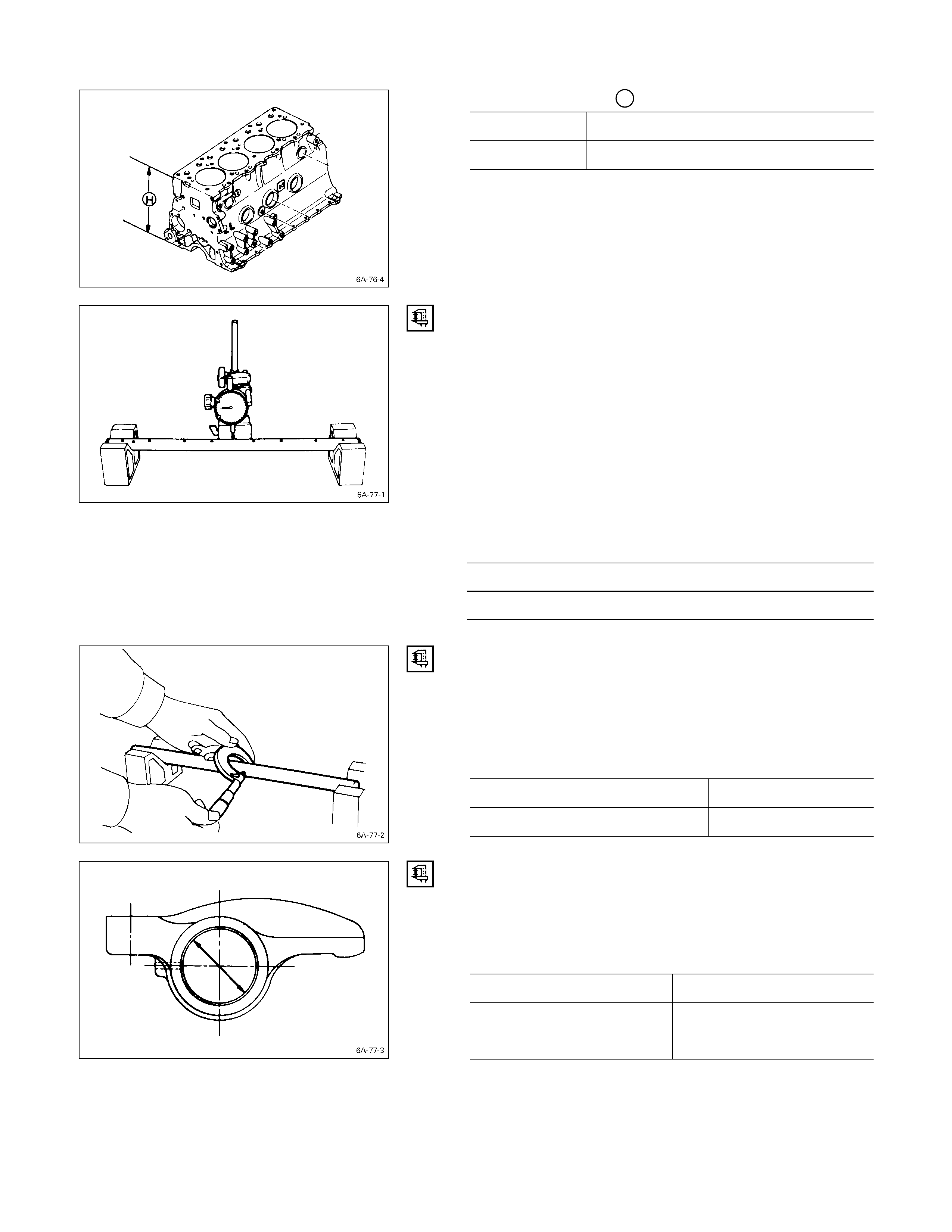

ROCKER ARM CORRECTIO N

Inspect the rocker arm valve stem contact surfaces for

step wear Q and scoring R.

If the contact surfaces have light step wear or scoring,

they may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must

be replaced.

CYLINDER BODY

CYLINDER BODY UPPER FACE WARPAGE

1. Remove the cylinder body dowel.

2. Remove the cylinder liner.

Refer to “Cylinder Liner Replacement”.

3. Use a straight edge Q and a feeler gauge R to

measure the four sides and the two diagonals of the

cylinder body upper face.

If the measured values exceeds the limit, the cylinder

body must be replaced.

Cylinder Body Upper Face Warpage mm (in)

Standard Limit

0.05 (0.002) or less 0.20 (0.008)

Cylinder Body Height H (Reference) mm (in)

Standard

4JB1T 269.945 – 270.055 (10.6277 – 10.6320)

5. Reinstall the cylinder liner.

Refer to “Cylinder Liner Replacement”.

6. Reinstall the cylinder body dowel.

ROCKER ARM SHAFT AND ROCKER ARM

ROCKER ARM SHAFT RUN-O UT

1. Place the rocker arm shaft on a V-block.

2. Use a dial indicator to measure the rocker arm shaft

central portion run-out.

If the run-out is very slight, correct the rocker arm

shaft run-out with a bench press. The rocker arm must

be at cold condition.

If the measured rocker arm shaft run-out exceeds the

specified limit, the rocker arm shaft must be replaced.

Rocker Arm Shaft Run-Out mm (in)

Limit

0.3 (0.012)

ROCKER ARM SHAFT OUTSIDE DIAMETER

Use a micrometer to measure the rocker arm fitting

portion outside diameter.

If the measured value is less than the specified limit, the

rocker arm shaft must be replaced.

Rocker Arm Shaft Outside Diameter mm (in)

Standard Limit

18.98 – 19.00 (0.747 – 0.748) 18.90 (0.744)

ROCKER ARM SHAFT AND ROCKER ARM

CLEARANCE

1. Use either a vernier caliper or a dial indicator to

measure the rocker arm inside diameter.

Rocker Arm Inside Diameter mm (in)

Standard Limit

19.010 – 19.030

(0.748 – 0.749) 19.100 (0.752)

2. Measure the rocker arm shaft outside diameter.

If the measured value exceeds the specified limit,

replace either the rocker arm or the rocker arm shaft.

Rocker Arm Shaft and Rocker Arm

Clearance mm (in)

Standard Limit

0.01 – 0.05

(0.0004 – 0.0020) 0.20 (0.008)

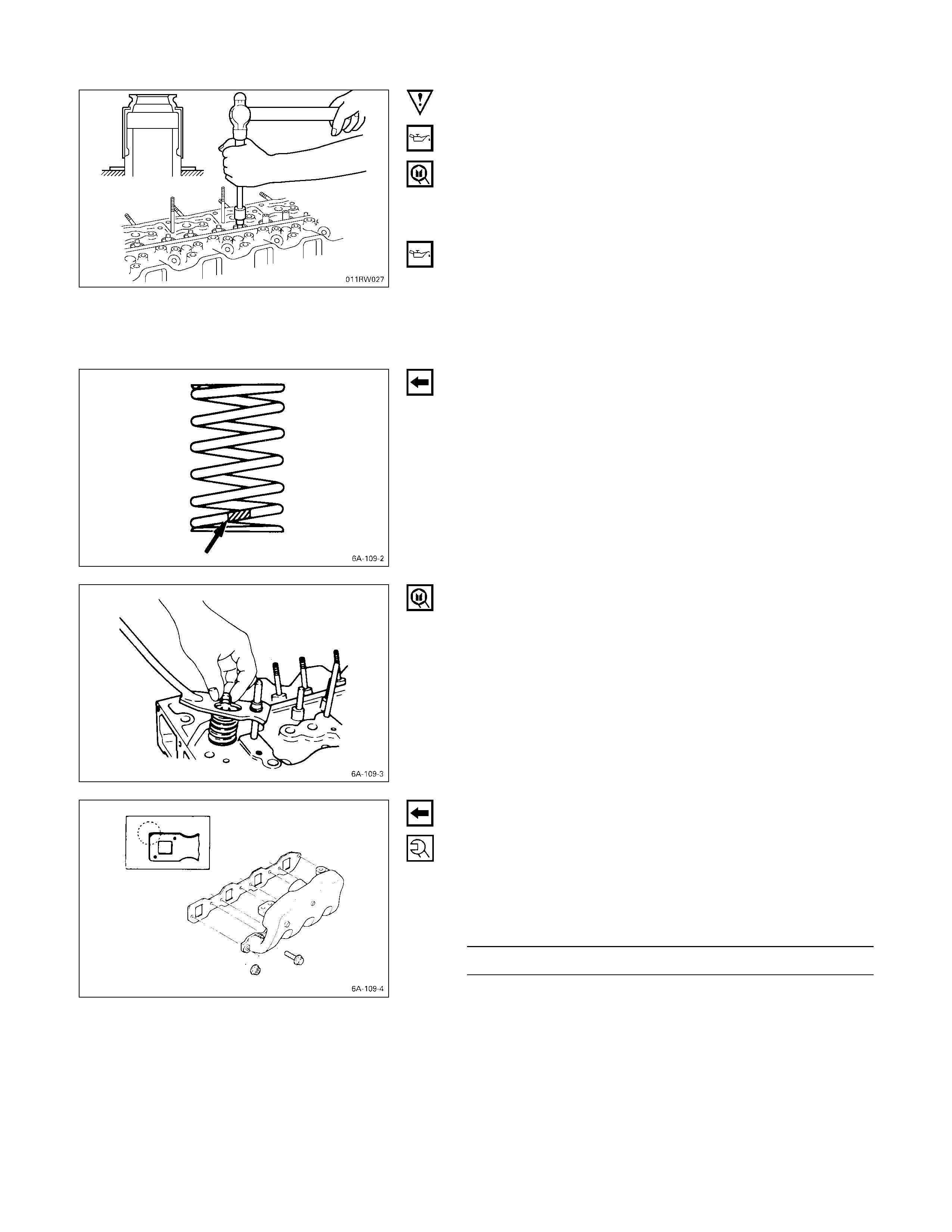

VALVE SPRING

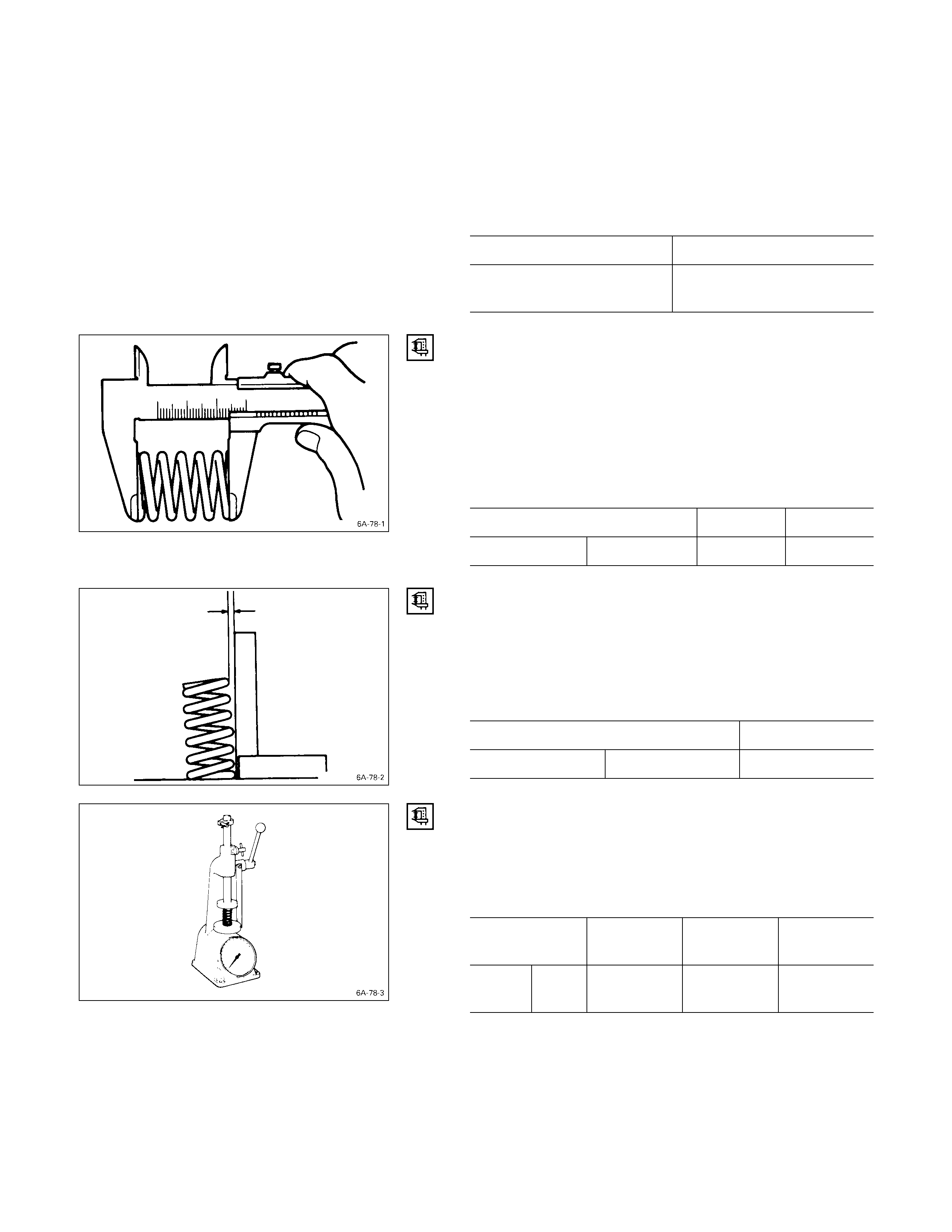

VALVE SPRING FREE HEIGHT

Use a vernier caliper to measure the valve spring free

height.

If the measured value is less than the specified limit, the

valve spring must be replaced.

Inner and Outer Spring Free Height mm (in)

Standard Limit

4JB1T Single spring 48.0 (1.89) 47.1 (1.85)

VALVE SPRING SQUARENESS

Use a surface plate and a square to measure the valve

spring squareness.

If the measured value exceeds the specified limit, the

valve spring must be replaced.

Inner and Outer Spring Squareness mm (in)

Limit

4JB1T Single Spring 1.7 (0.07)

VALVE SPRING TENSION

Use a spring tester to measure the valve spring tension.

If the measured value is less than the specified limit, the

valve spring must be replaced.

Valve Spring Tension kg (lb/N)

Compressed

Height Standard Limit

4JB1T Single

Spring 38.9 mm

(1.53 in) 30.2

(66.4/296.0) 26.3

(57.9/257.7)

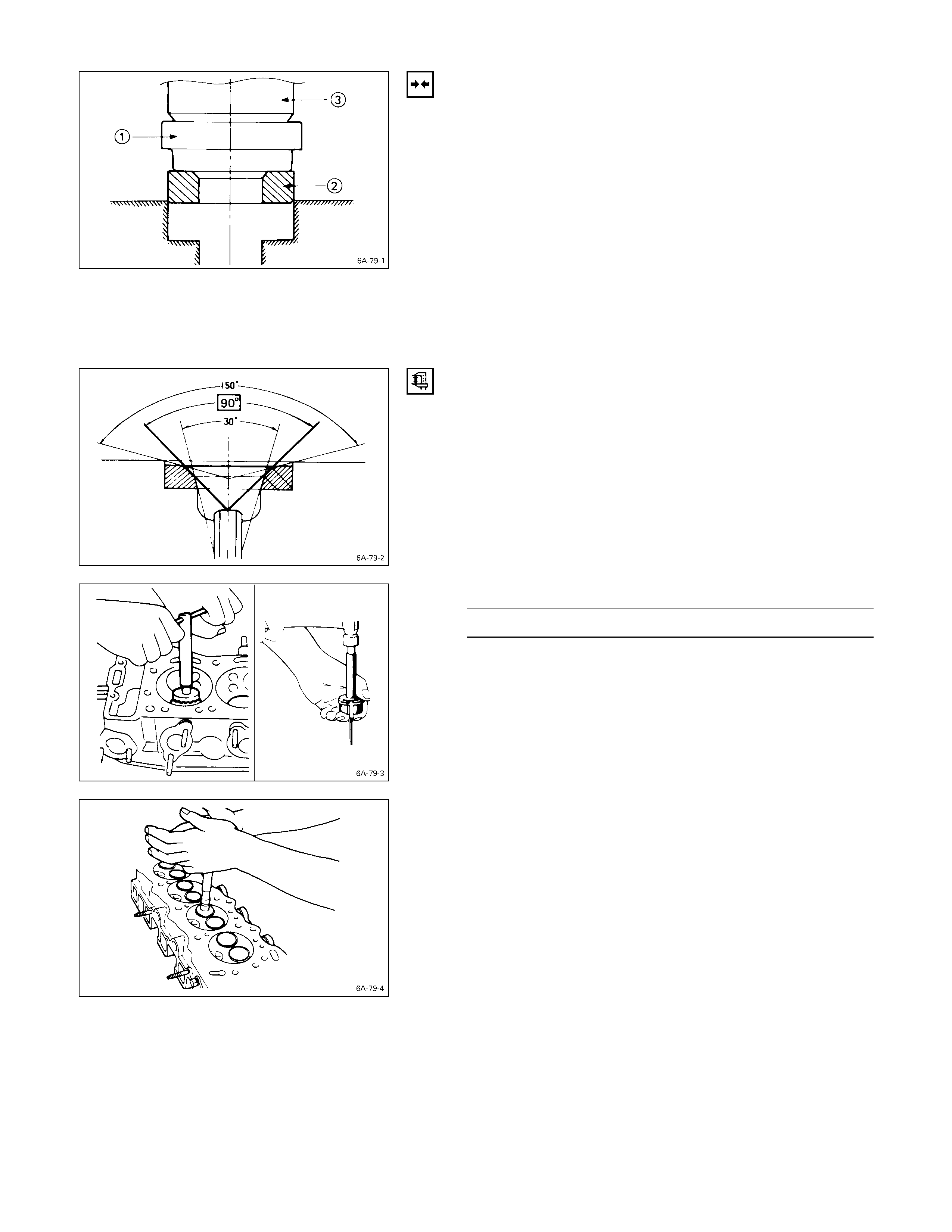

VALVE SEAT INSERT INSTALLATION

1. Carefully place the attachment Q (having a smaller

outside diameter than the valve seat insert) on the

valve seat insert R.

Note:

The smooth side of the attachment must contact the

valve seat insert.

2. Use a bench press S to gradually apply pressure to

the attachment and press the valve seat insert into

place.

Note:

Do not apply an excessive amount of pressure with

the bench press. Damage to the valve seat insert will

result.

VALVE SEAT INSERT CORRECTIO N

1. Remove the carbon from the valve seat insert surface.

2. Use a valve cutter (15°, 45°, and 75° blades) to

minimize scratches and other rough areas. This will

bring the contact width back to the standard value.

Remove only the scratches and rough areas. Do not

cut away too much. Take care not to cut away

unblemished areas of the valve seat surface.

Valve Seat Angle degree

45

Note:

Use an adjustable valve cutter pilot.

Do not allow the valve cutter pilot to wobble inside the

valve guide.

3. Apply abrasive compound to the valve seat insert

surface.

4. Insert the valve into the valve guide.

5. Turn the valve while tapping it to fit the valve seat

insert.

6. Check that the valve contact width is correct.

7. Check that the valve seat insert surface is in contact

with the entire circumference of the valve.

VALVE CONTACT WI DTH

1. Check the valve contact faces for roughness and

unevenness. Make smooth the valve contact surfaces.

2. Measure the valve contact width.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Valve Contact Width mm (in)

Standard Limit

Intake 1.7 (0.067) 2.2 (0.087)

Exhaust 2.0 (0.079) 2.5 (0.078)

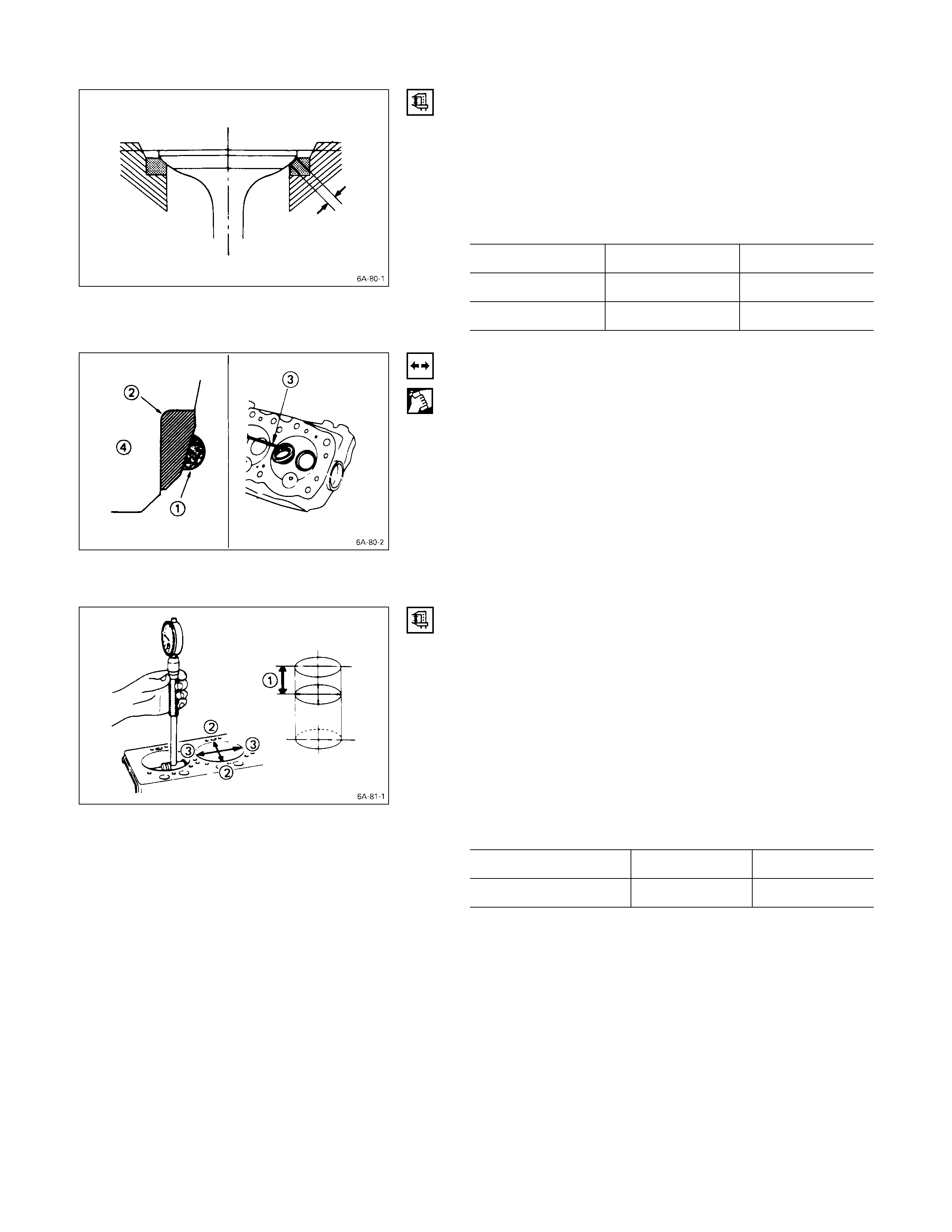

VALVE SEAT INSERT REPLACEM ENT

VALVE SEAT INSERT REMO VAL

1. Arc weld the entire inside circumference Q of the

valve seat insert R.

2. Allow the valve seat insert to cool for a few minutes.

This will invite contraction and make removal of the

valve seat insert easier.

3. Use a screwdriver S to pry the valve seat insert free.

Take care not to damage the cylinder head T.

4. Carefully remove carbon and other foreign material

from the cylinder head insert bore.

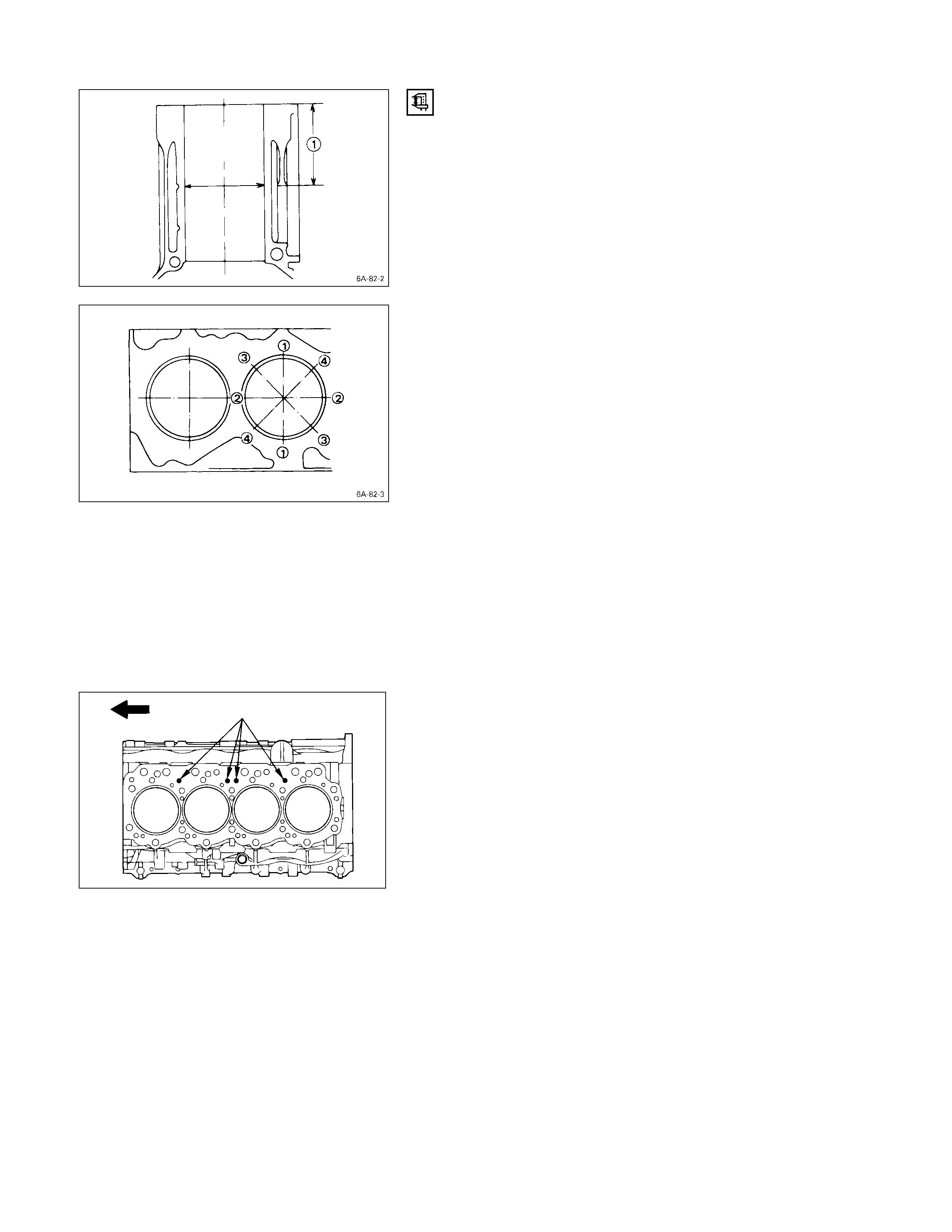

CYLINDER LINER BO RE MEASUREM ENT

Use a cylinder indicator to measure the cylinder bore at

measuring point Q in the thrust R-R and axial S-S

directions of the crankshaft.

Measuring Point Q 20 mm (0.79 in)

If the measured value exceeds the specified limit, the

cylinder liner must be replaced.

Cylinder Liner Bore mm (in)

Standard Limit

4JB1T 93.021 (3.662) 93.100 (3.665)

Note:

The inside of the dry type cylinder liner is chrome

plated. It cannot be rebored or honed.

If the inside of the cylinder liner is scored or

scorched, the cylinder liner must be replaced.

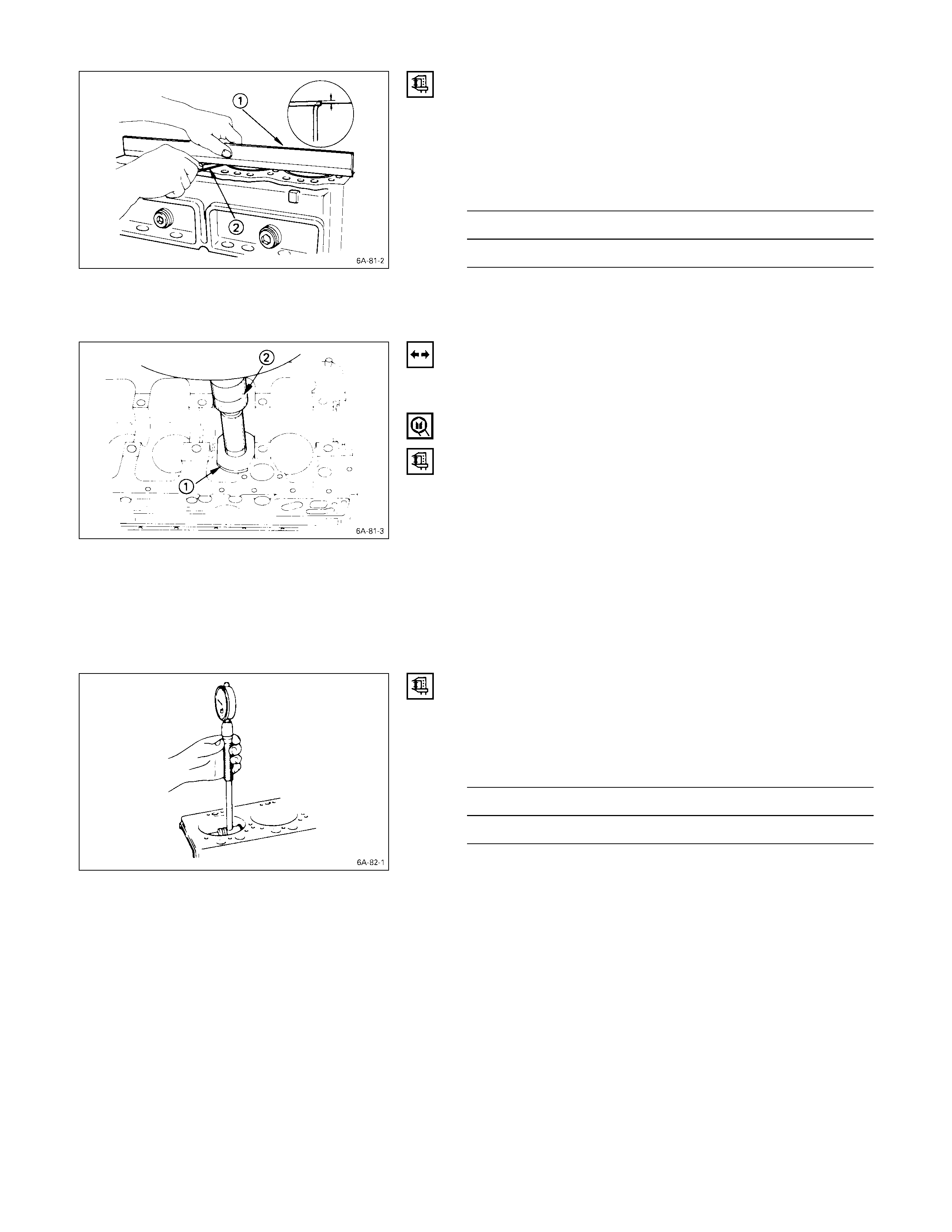

CYLINDER LINER PRO J ECTION INSPECTION

1. Hold a straight edge Q along the top edge of the

cylinder liner to be measured.

2. Use a feeler gauge R to measure each cylinder liner

projection.

Cylinder Liner Projection mm (in)

Standard

0 – 0.1 (0 – 0.004)

The difference in the cylinder liner projection height

between any two adjacent cylinders must not exceed

0.03 mm (0.0012 in).

CYLINDER LINER REPLACEMENT

CYLINDER LINER REM OVAL

1. Insert the cylinder liner remover Q into the cylinder

body (from the lower side of the cylinder body) until it

makes firm contact with the cy linder liner.

Cylinder Liner Remover:

5-8840-2039-0

5-8840-2304-0: 4JG2T Engine

2. Use a bench press R to slowly force the cylinder liner

from the cylinder body.

Note:

Take care not to damage the cylinder body upper face

during the cylinder liner removal procedure.

3. Measure the cylinder body upper face warpage.

Refer to “Cylinder Body Upper Face Warpage”.

CYLINDER LINER G RADE SELECTION

Subtract the average cylinder body bore from the average

cylinder liner outside diameter to obtain the fitting

interference.

Fitting Interference mm (in)

Standard

– 0.0010* – 0.019 (– 0.00004* – 0.0007)

* A minus (–) value indicates that the cylinder body bore

is smaller than the liner outside diameter.

CYLINDER BODY BORE MEASUREMENT

1. Take measurements at measuring point Q across

positions Q-Q, R-R, S-S, and T-T.

Measuring Point Q 98 mm (3.86 in)

2. Calculate the average value of the four measurements

to determine the correct cylinder grade.

3. Consult the following table with the resultant diameter

for the correct liner application.

CYLINDER LINER G RADE SELECTION AND

STANDARD FITTING INTERFERENCE

Accurately measured fitting interference and proper

cylinder liner grade selection are extremely important.

If the cylinder liner fitting interference is too small, engine

cooling efficiency will be adversely affected.

If the cylinder liner fitting interference is too large, it will be

difficult to insert the cylinder liner into the cylinder body.

A mark was stamped on the upper of the cylinder block

during production to indicate the correct liner.

The liner grade (i.e.1.2.3.4) is indicated in metal stamp.

Cylinder Liner Grade mm (in)

Liner

Outside

Grade Cylinder Body

Bore Diameter Liner Outside

Diameter Liner

Bore

Grade Service Liner Bore Measurement

AX 93.035 – 93.050 (3.6628 – 3.6634)

195.001 – 95.010

(3.7402 – 3.7405) 95.011 – 95.020

(3.7406 – 3.7409) CX 93.051 – 93.066 (3.6634 – 3.6640)

AX 93.035 – 93.050 (3.6628 – 3.6634)

295.011 – 95.020

(3.7406 – 3.7409) 95.021 – 95.030

(3.7410 – 3.7413) CX 93.051 – 93.066 (3.6634 – 3.6640)

AX 93.035 – 93.050 (3.6628 – 3.6634)

395.021 – 95.030

(3.7410 – 3.7413) 95.031 – 95.040

(3.7414 – 3.7417) CX 93.051 – 93.066 (3.6634 – 3.6640)

AX 93.035 – 93.050 (3.6628 – 3.6634)

495.031 – 95.040

(3.7414 – 3.7417) 95.041 – 95.050

(3.7418 – 3.7421) CX 93.051 – 93.066 (3.6634 – 3.6640)

CYLINDER LINER I NSTALLATI ON

1. Cylinder Liner Installation Using The Special Tool

1) Use new kerosene or diesel oil to thoroughly clean

the cylinder liners and bores.

2) Use compressed air to blow-dry the cylinder liner

and bore surfaces.

Note:

All foreign material must be carefully removed from

the cy linder liner and the cylinder bore before

installation.

3) Insert the cylinder liner Q into the cylinder body R

from the top of the cylinder body.

4) Set the cylinder liner installer S to the top of the

cylinder liner.

Cylinder Liner Installer: 5-8840-2040-0

5-8840-2313-0 (4JG2T)

5) S is directly beneath the bench press shaft center

T.

Note:

Check that the cylinder liner is set perpendicular to

the bench press and that there is no wobble.

6) Use the bench press to apply a seating force of

500 kg (1,100 lb/4,900 N) to the cylinder liner.

7) Apply a force of 2,500 kg (5,500 lb/24,500 N) to

fully seat the cylinder liner.

8) After installing the cylinder liner, measure the

cylinder liner projection.

Refer to “Cylinder Liner Projection Inspection”.

2. Cylinder Liner Installation Using Dry Ice

Cylinder liner is a chrome plated dry type, it is

advisable to use dry ice during the installation

procedure.

Cooling the cylinder liner with dry ice will cause the

cylinder liner to contract, thus making installation

easier.

Note:

It is important that the cylinder liner be inserted to the

cylinder body immediately after it has been cooled.

Warning:

Dry ice must be used with great care. Careless

handling of dry ice can result in severe frostbite.

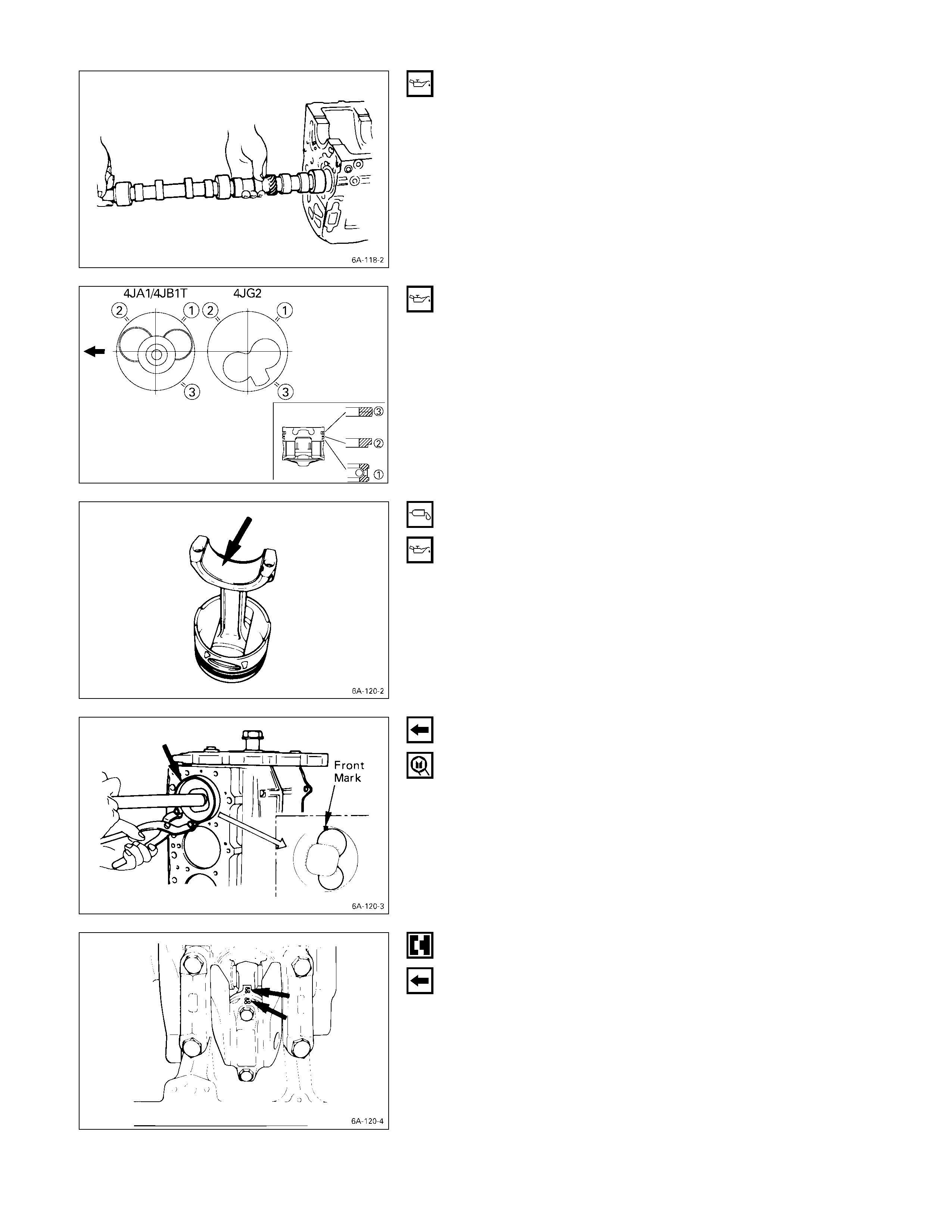

PISTON GRADE SELECTION

Measure the cylinder liner bore after installing the cylinder

liner. Then select the appropriate piston grade for the

installed cylinder liner.

1. Measure the cylinder liner bore.

Refer to “Cylinder Liner Bore Measurement”

Measuring Points Q20 mm (0.8 in) for 4JA1 and 4JB1T

R140 mm (5.5 in) for 4JA1

R160 mm (6.3 in) for 4JB1T

R165 mm (6.49 in) for 4JG2T

Cylinder Liner Bore (Service Part) mm (in)

Grade

AX 93.035 – 93.050

(3.6628 – 3.6634)

CX 93.051 – 93.066

(3.6634 – 3.6640)

Note:

It is most important that the correct piston grade be

used. Failure to select the correct piston grade will

result in engine failure. Always measure the cylinder

bore and select the correct piston grade.

2. Measure the piston diameter.

Piston Measuring Point mm (in)

4JB1T 74 (2.91)

Piston Grade (Service Part) mm (in)

Grade 4JB1T

AX 92.974 – 92.989

(3.6604 – 3.6610)

CX 92.990 – 93.005

(3.6610 – 3.6616)

Cylinder Liner and Piston Clearance mm (in)

4JB1T 0.046 – 0.076 (0.0018 – 0.0030)

Note:

Cylinder liner kit clearances are preset. However, the

cylinder liner installation procedure may result in

slight decreases in cylinder liner clearances. Always

measure the cylinder liner clearance after installation

to be sure that it is correct.

TAPPET AND PUSH ROD

Visually inspect the tappet contact surfaces for pitting,

cracking, and other abnormal conditions. The tappet must

be replaced if any of these conditions are present.

Refer to the illustration at the left.

QNormal contact

RCracking

SPitting

TIrregular contact Uneven contact

UIrregular contact One-sided contact

Note:

The tappet surfaces are spherical. Do not attempt to

grind them with an oil stone or similar tool in an effort

to repair the tappet. If the tappet is damaged, it must

be replaced.

TAPPET OUTSIDE DIAM ETER

Measure the tappet outside diameter with a micrometer.

If the measured value is less than the specified limit, the

tappet must be replaced.

Tappet Outside Diameter mm (in)

Standard Limit

12.97 – 12.99

(0.510 – 0.511) 12.95 (0.510)

Tappet and Cylinder Body Clearance mm (in)

Standard Limit

0.01 – 0.046

(0.0004 – 0.0018) 0.10 (0.004)

PUSH ROD CURVATURE

1. Lay the push rod on a surface plate.

2. Roll the push rod along the surface plate and measure

the push rod curvature with a thickness gauge.

If the measured value exceeds the specified limit, the

push rod must be replaced.

Pushrod Curvature mm (in)

Limit

0.3 (0.012)

3. Visually inspect both ends of the push rod for

excessive wear and damage. The push rod must be

replaced if these conditions are discovered during

inspection.

CAMSHAFT

Visually inspect the journals, the cams, the oil pump drive

gear, and the camshaft bearings for excessive wear and

damage. The camshaft and the camshaft bearings must

be replaced if these conditions are discovered during

inspection.

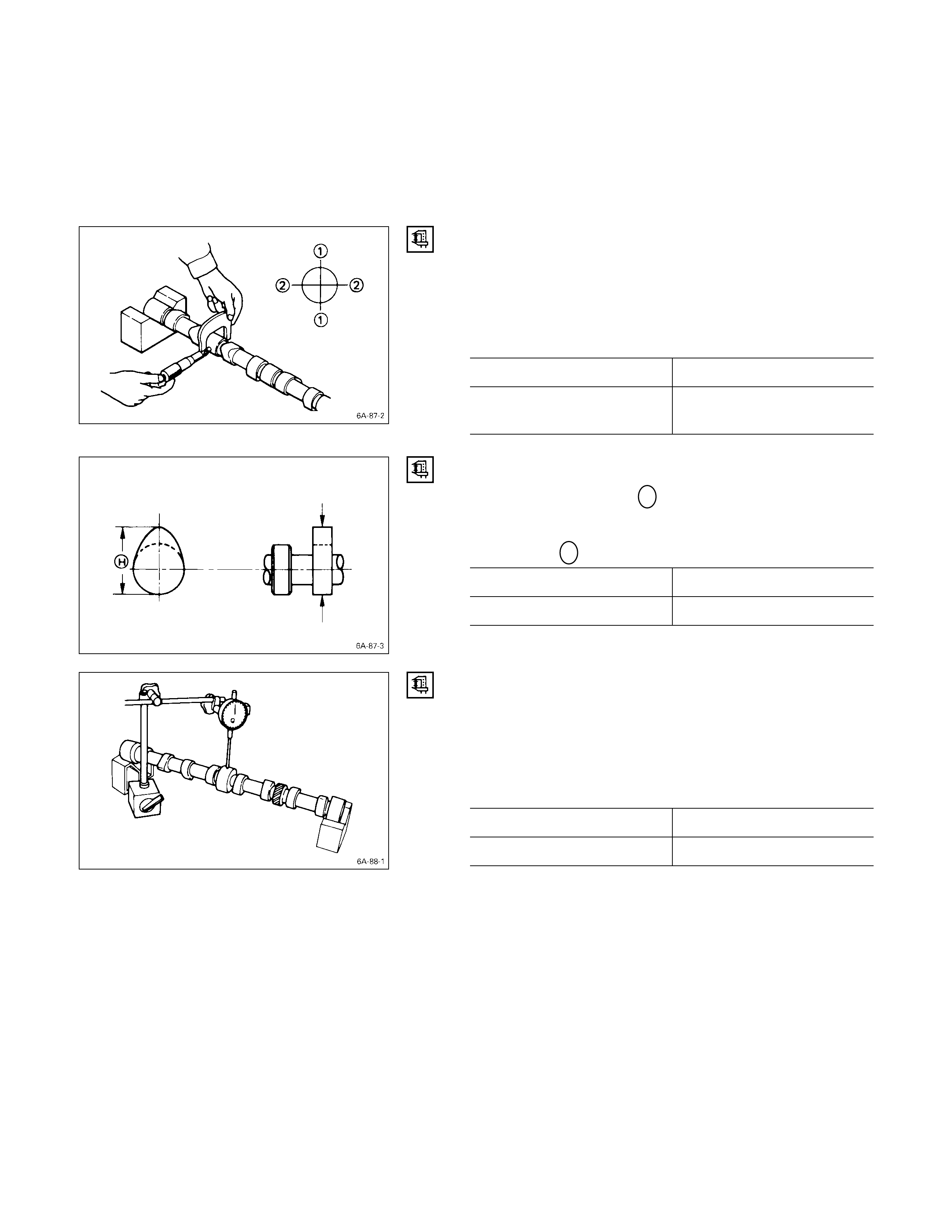

CAMSHAFT JO URNAL DIAMETER

Use a micrometer to measure each camshaft journal

diameter in two directions (Q and R). If the measured

value is less than the specified limit, the camshaft must be

replaced.

Camshaft Journal Diameter mm (in)

Standard Limit

49.945 – 49.975

(1.9663 – 1.9675) 49.60 (1.953)

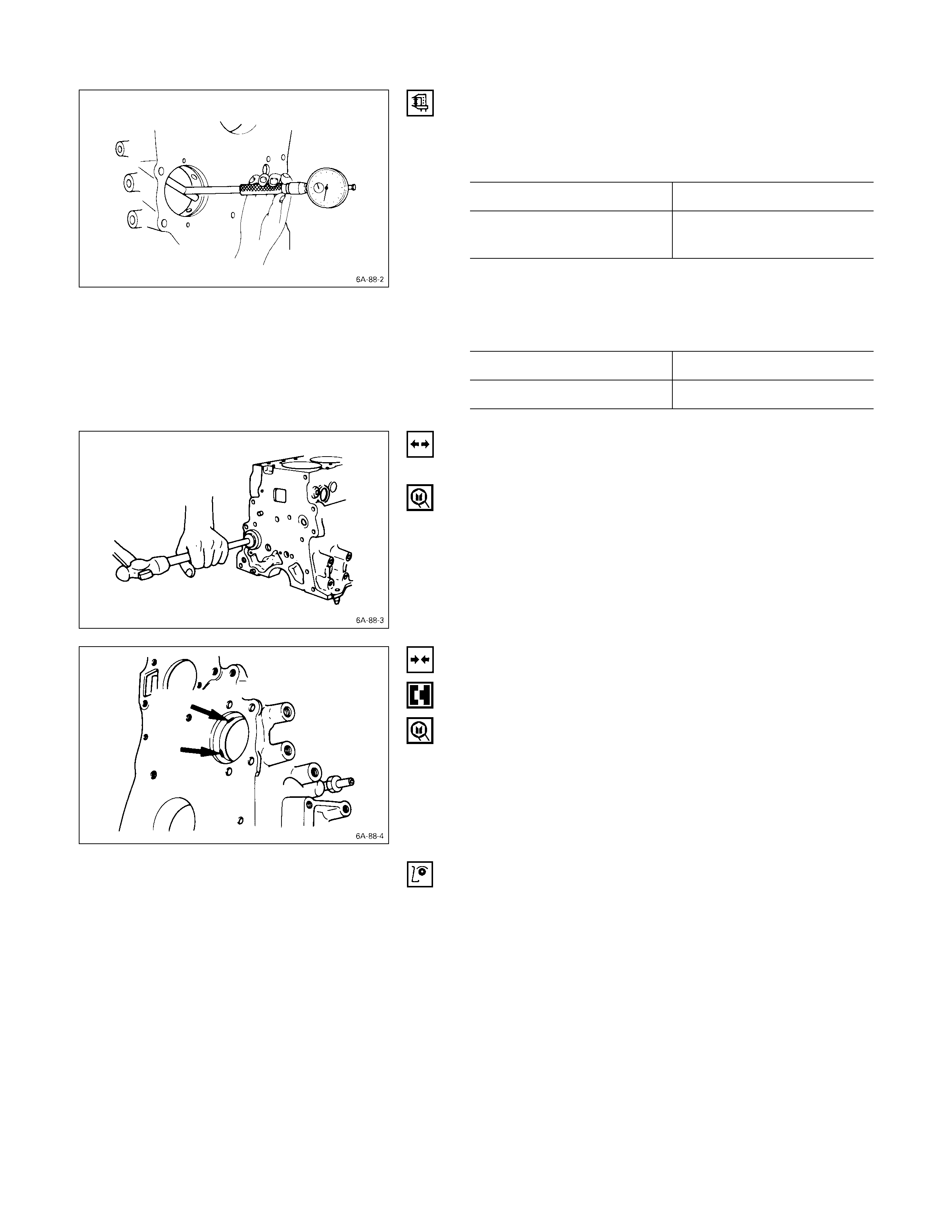

CAM HEI GHT

Measure the cam height H with a micrometer. If the

measured value is less than the specified limit, the

camshaft must be replaced.

Cam Height Hmm (in)

Standard Limit

42.08 (1.657) 41.65 (1.640)

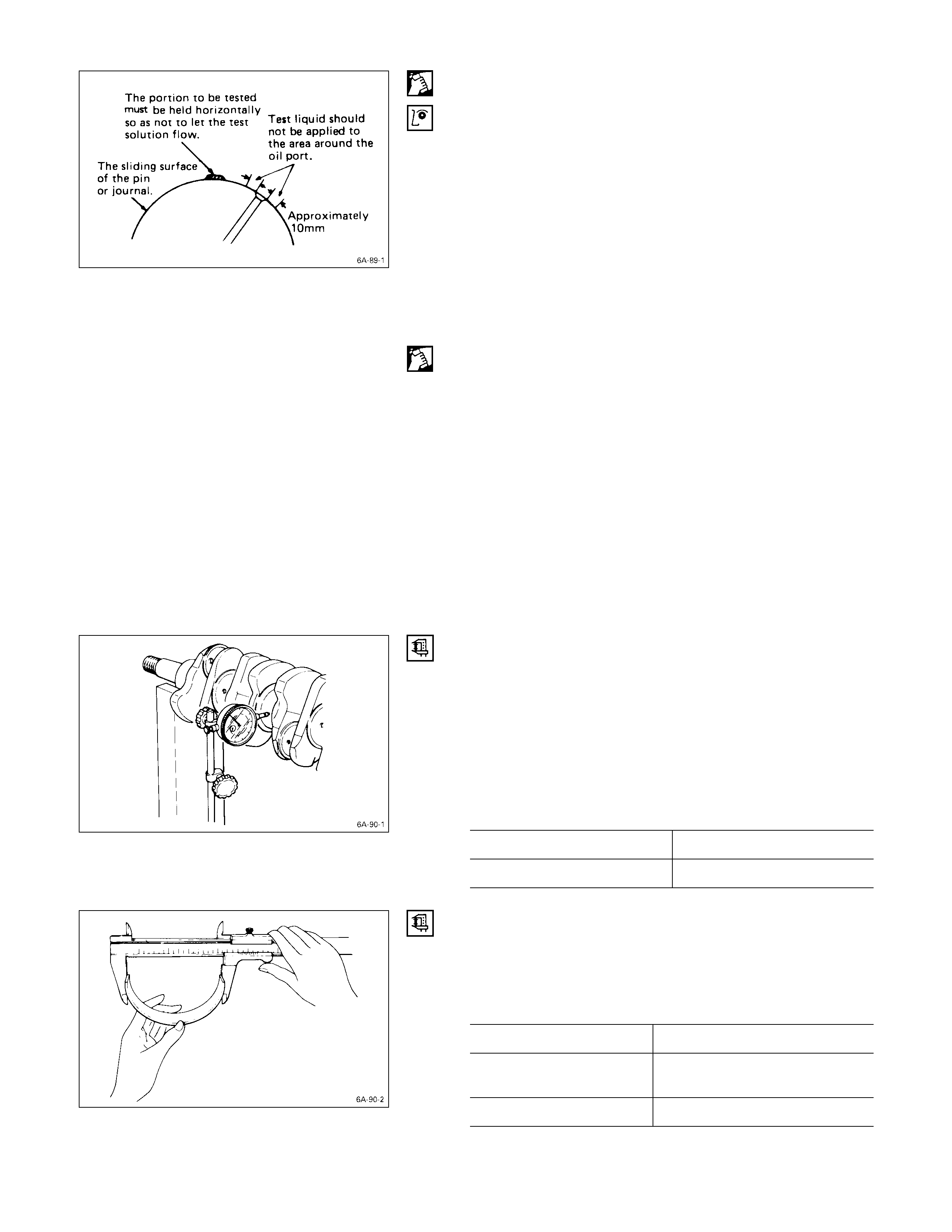

CAMSHAFT RUN- OUT

1. Mount the camshaft on V-blocks.

2. Measure the run-out with a dial indicator.

If the measured value exceeds the specified limit, the

camshaft must be replaced.

Camshaft Run-Out mm (in)

Standard Limit

0.02 (0.0008) 0.10 (0.004)

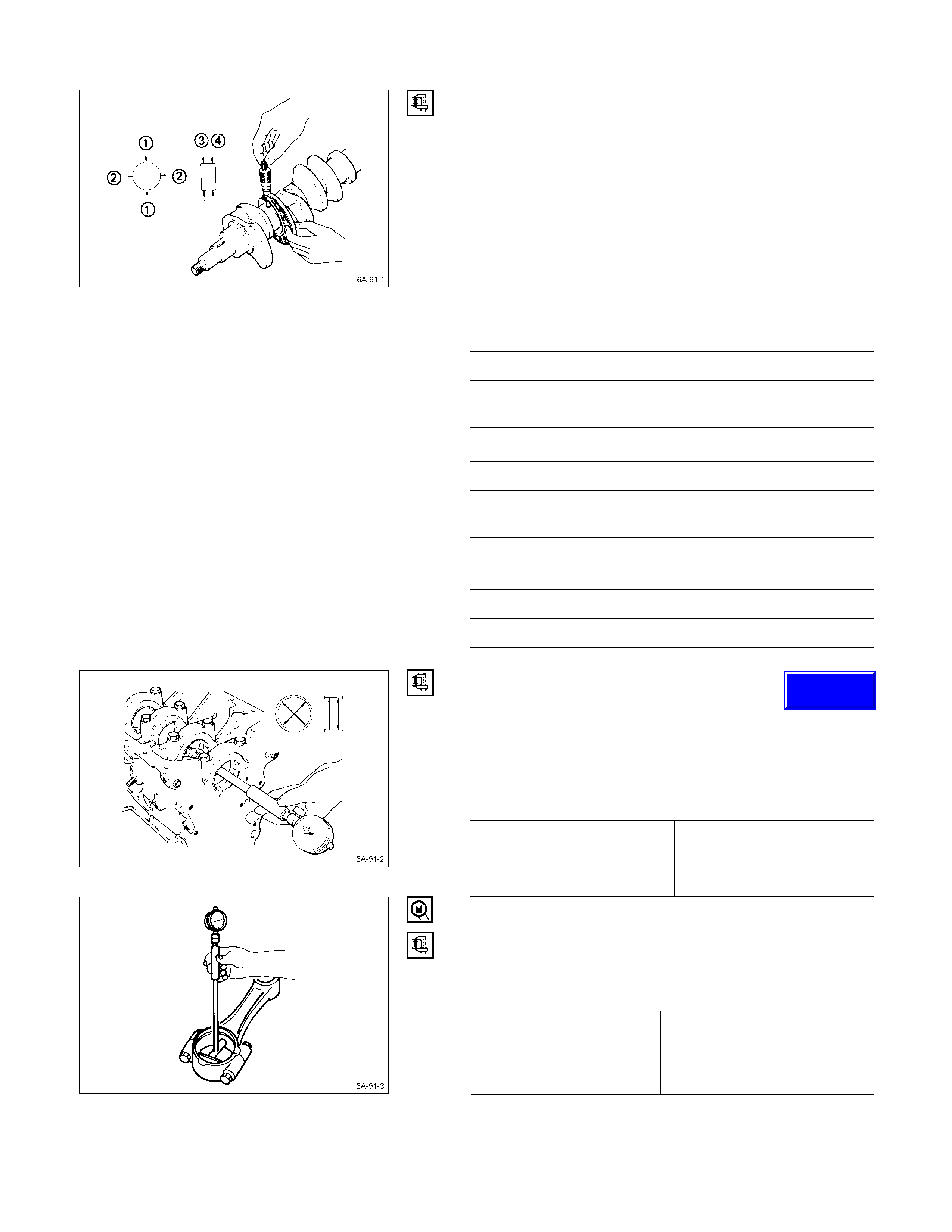

CAMSHAFT AND CAMSHAFT BEARING CLEARANCE

Use an inside dial indicator to measure the camshaft

bearing inside diameter.

Crankshaft Bearing Inside Diameter mm (in)

Standard Limit

50.00 – 50.03

(1.968 – 1.970) 50.08 (1.972)

If the clearance between the camshaft bearing inside

diameter and the journal exceeds the specified limit, the

camshaft bearing must be replaced.

Camshaft Bearing Clearance mm (in)

Standard Limit

0.05 (0.002) 0.12 (0.005)

CAMSHAFT BEARING REPLACEMENT

CAMSHAFT BEARING REMOVAL

1. Remove the cylinder body plug plate.

2. Use the bearing replacer to remove the camshaft

bearing.

Bearing Replacer: 5-8840-2038-0

CAMSHAFT BEARING INSTALLATION

1. Align the bearing oil holes with the cylinder body oil

holes.

2. Use the replacer to install the camshaft bearing.

Bearing Replacer: 5-8840-2038-0

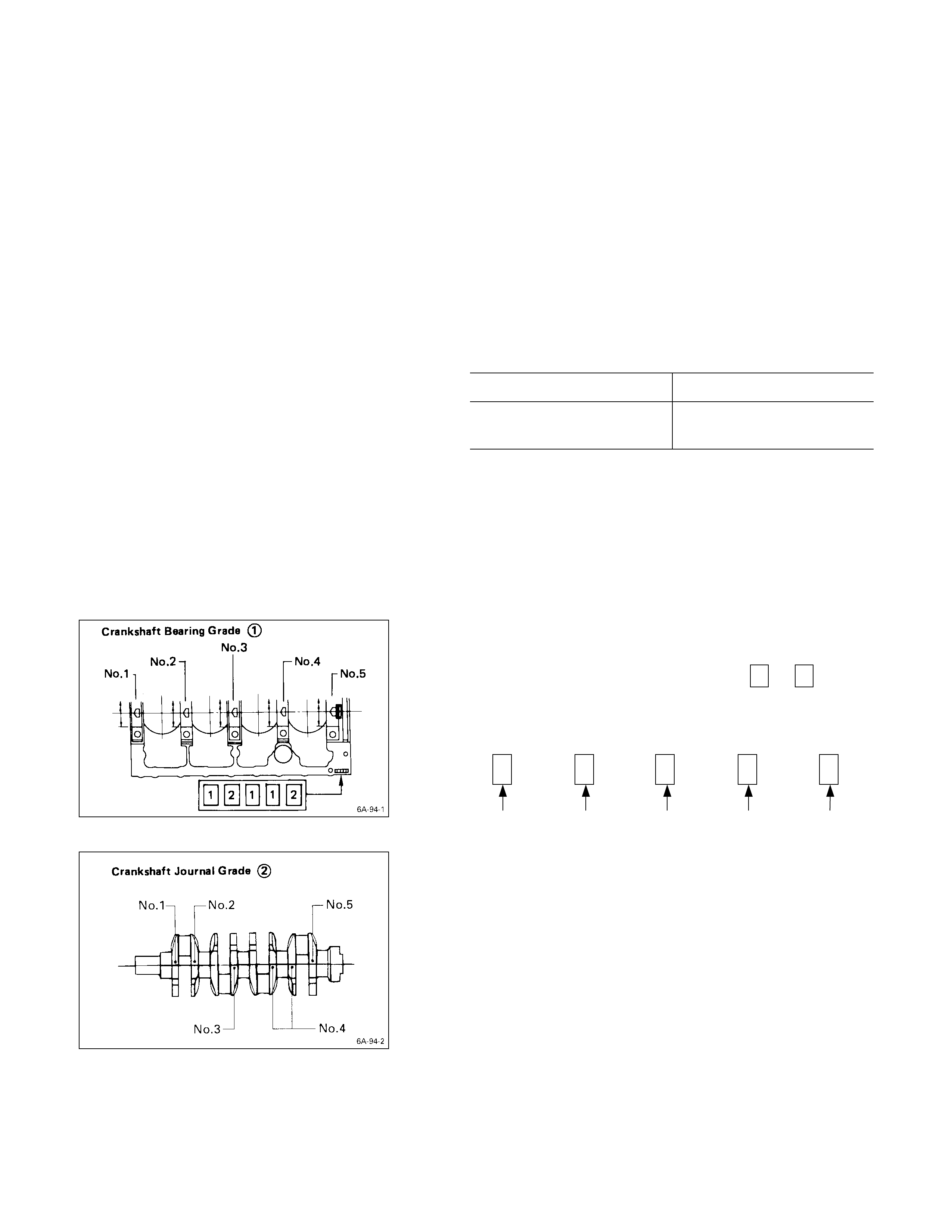

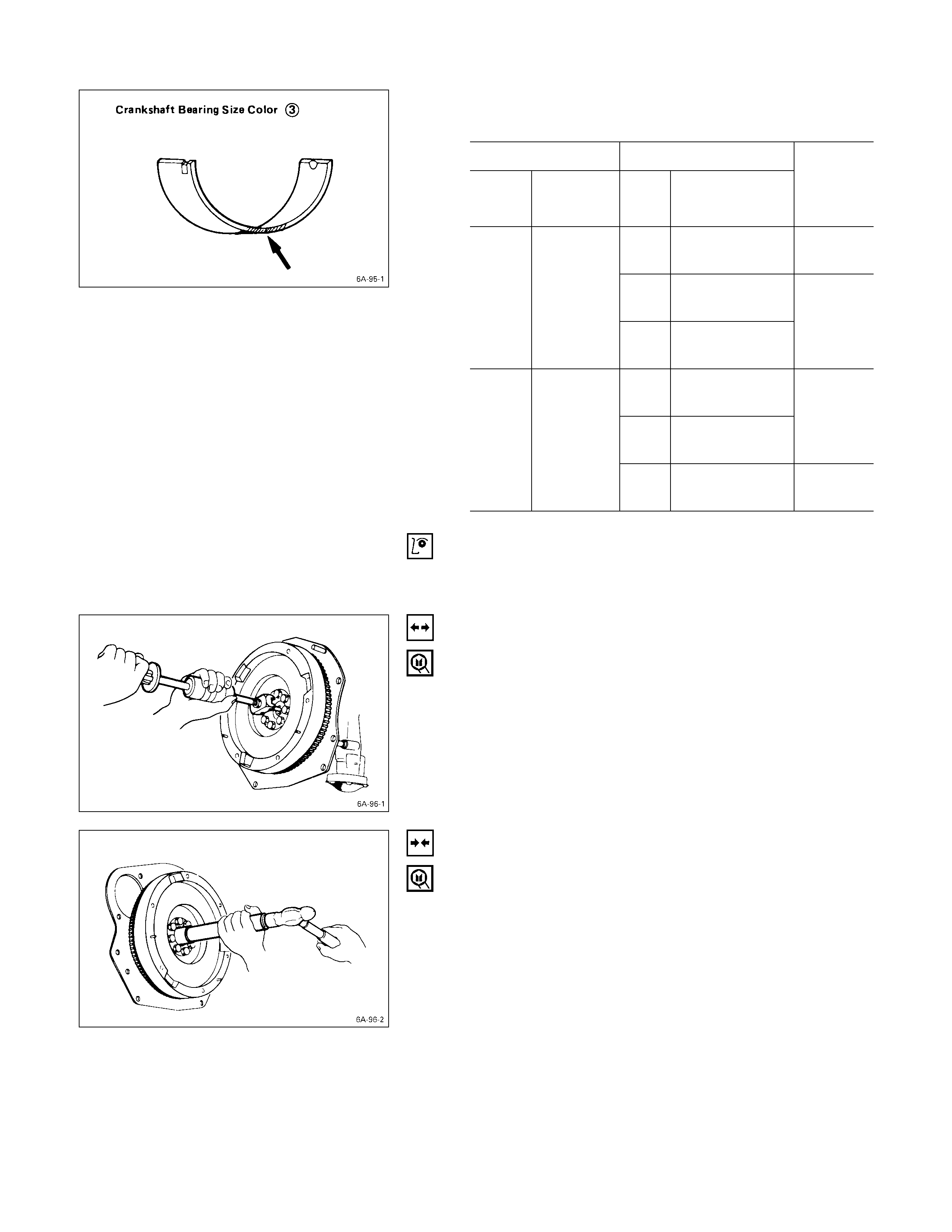

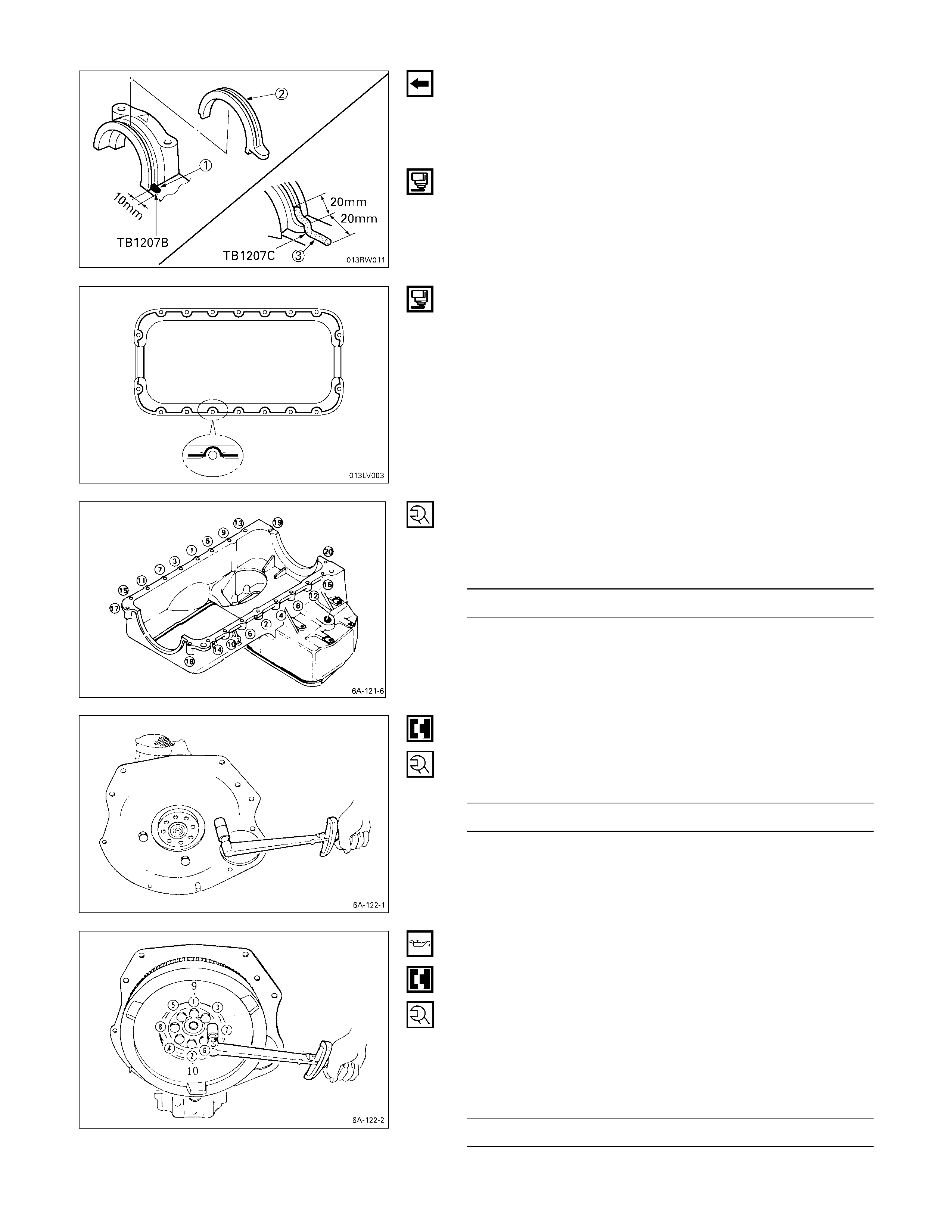

CRANKSHAFT AND BEARING