SECTION 6B - ENGINE COOLING (6VD1 MODELS)

Service Precaution

General Description

Diagnosis

Draining and Refilling Cooling System

Water Pump

Water Pump and Associated Parts

Removal

Inspection

Installation

Thermostat

Thermostat and Associated Parts

Removal

Inspection

Installation

Radiator

Radiator and Associated Parts

Removal

Inspection

Installation

Drive Belt and Cooling Fan

Drive Belt and Associated Parts

Inspection

Installation

Main Data and Specifications

Special Tool

Service Precaution

WARNING:THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SER VICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHER WISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION:Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener . When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Techline

General Description

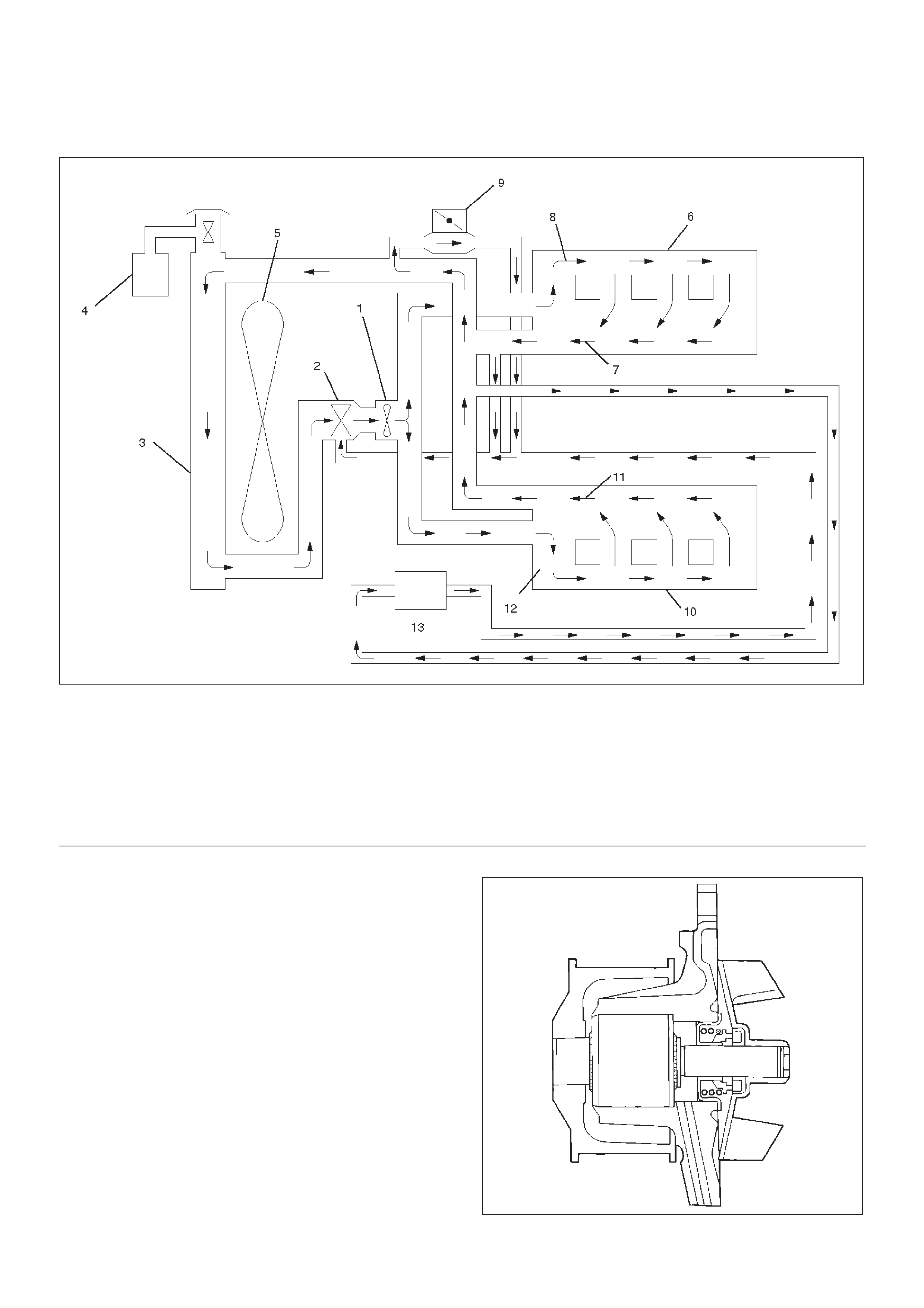

030RW001

Legend

(1) Water Pump

(2) Thermostat

(3) Radiator

(4) Reserve Tank

(5) Cooling Fan

(6) Cylinder Block

(7) Cylinder Head

(8) Right Bank

(9) Throttle Body

(10) Cylinder Block

(11) Cylinder Head

(12) Left Bank

(13) Heater

The cooling system is a pressurized Engine Coolant (EC)

forced circulation type which consists of a water pump,

thermostat cooling fan, radiator and other components.

The automatic transmission fluid is cooled by the EC in

radiator.

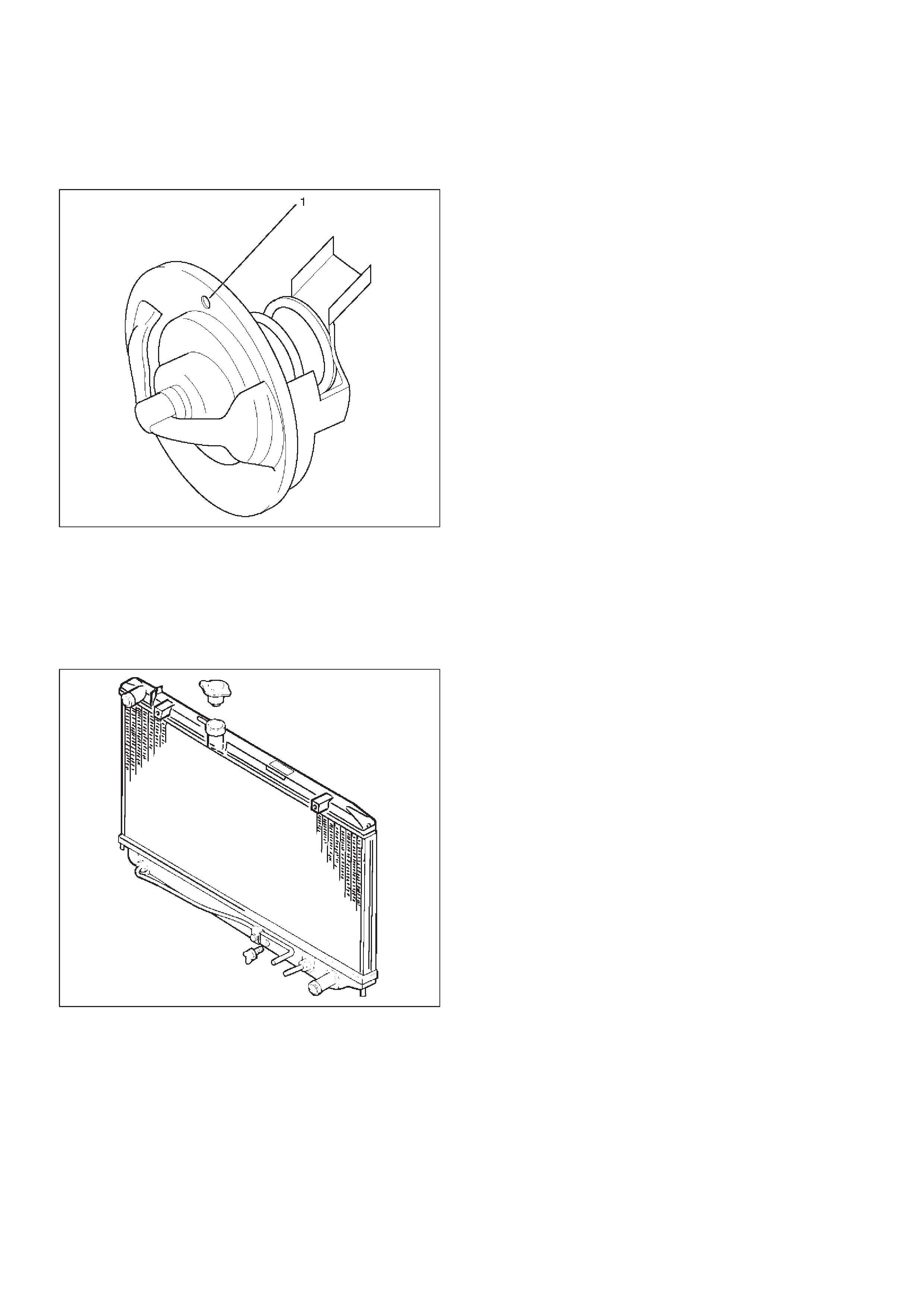

Water Pump

The EC pump is a centrifugal impeller type and is driven

by a timing belt.

030RS001

Thermostat

The thermostat is a wax pellet type with a air hole(1) and is

installed in the thermostat housing.

031RW002

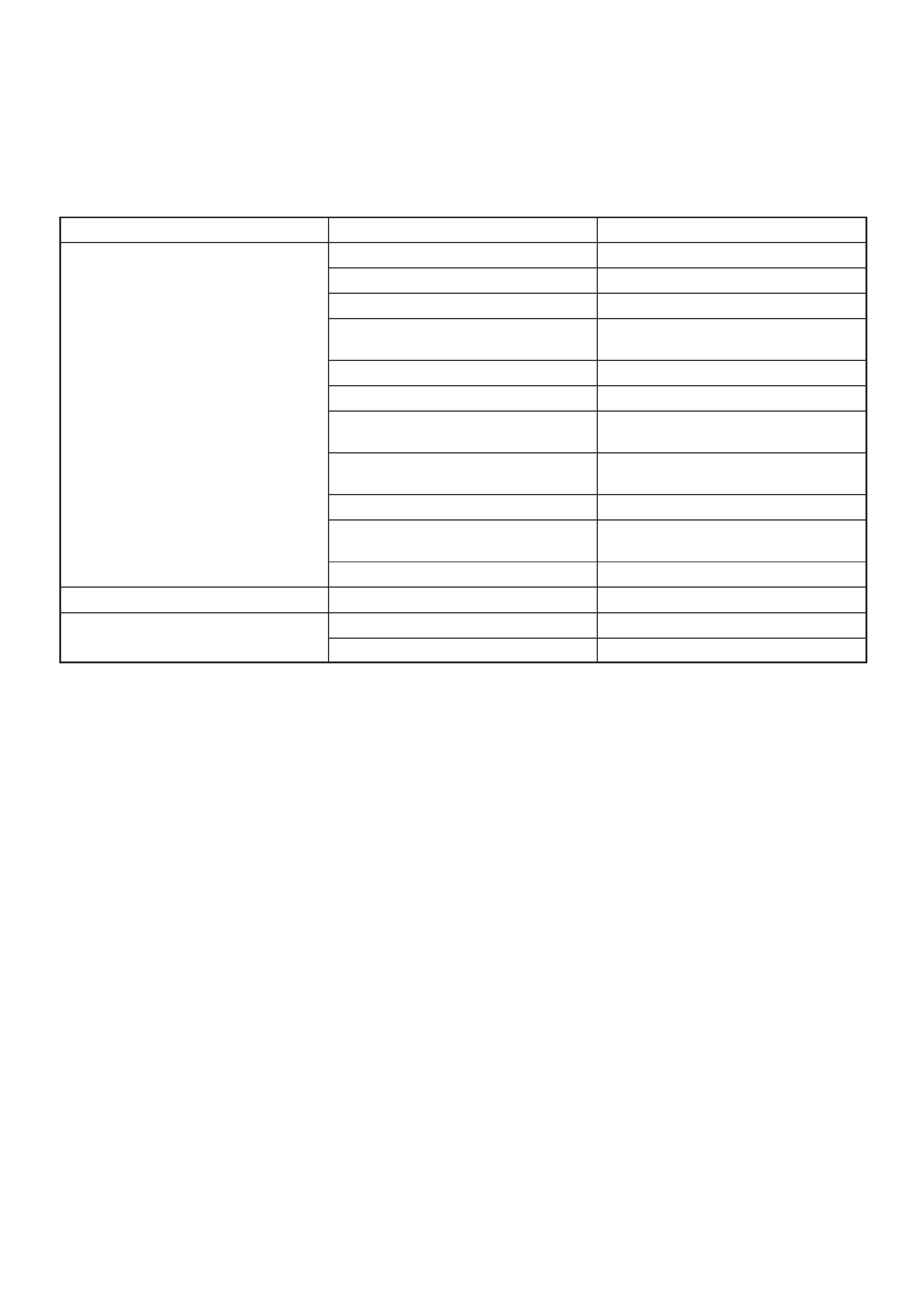

Radiator

The radiator is a tube type with corrugated fins. In order to

raise the boiling point of the coolant, the radiator is fitted

with a cap in which the valve is operated at 88.2 ∼ 117.6

kPa (12.8 ∼ 17.0 psi) pressure. (No oil cooler provided for

M/T)

110RS001

Coolant Specification

50% water and 50% Long Life Coolant to Holden

Specification HN2043

Total Cooling System Capacity

Manual Transmission - 11.2 litres

Automatic Transmission - 11.0 litres

Diagnosis

Engine Cooling Trouble

Condition Possible cause Correction

Engine overheating Low Engine Coolant level Replenish

Thermo meter unit faulty Replace

Faulty thermostat Replace

Faulty Engine Coolant temperature

sensor Repair or replace

Clogged radiator Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of

improper engine oil Replenish or change oil

Clogged exhaust system Clean exhaust system or replace

faulty parts

Faulty Throttle Position sensor Replace throttle valve assembly

Open or shorted Throttle Position

sensor circuit Repair or replace

Damaged cylinder head gasket Replace

Engine overcooling Faulty thermostat Replace

Engine slow to warm–up Faulty thermostat Replace

Thermo unit faulty Replace

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

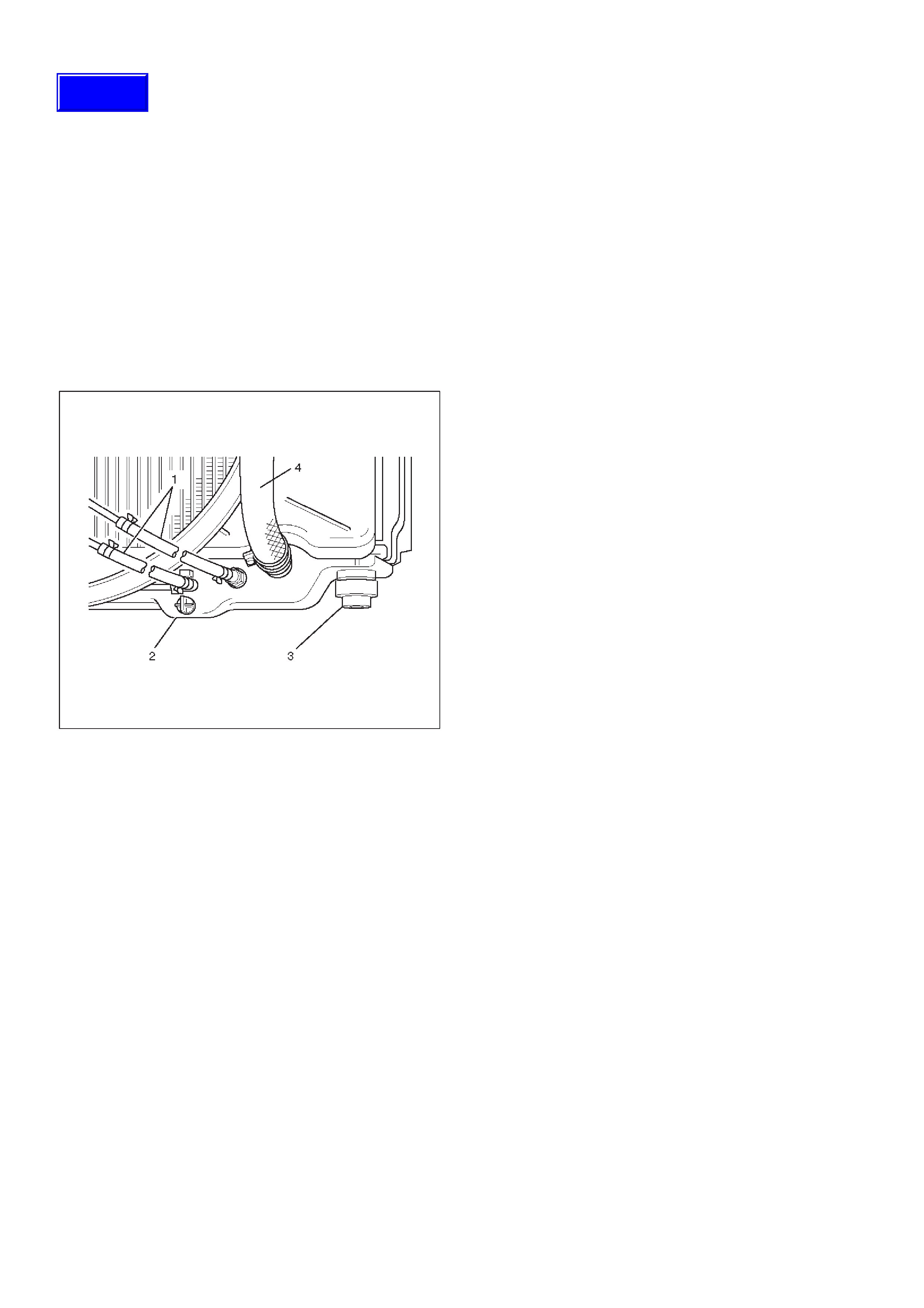

1.Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2.Remove the radiator cap.

WARNING:TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3.Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4.Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

Procedure for filling with coolant (in case of full change)

DMake sure that the engine is cool.

DOpen radiator cap pour coolant up to filler neck.

DPour coolant into reservoir tank up to “MAX” line.

DTighten radiator cap and start the engine. After idling

for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

WARNING:WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIA TOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY NOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

DAfter tightening radiator cap, warm up the engine at

about 2000 rpm. Set heater adjustment to the highest

temperature position, and let the coolant circulate

also into heater water system.

DCheck to see the thermostat has opened through the

needle position of water thermometer, conduct a

5–minute idling again and stop the engine.

DWhen the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant is found, check the

cooling system and reservoir tank hose for leakage.

DPour coolant into the reservoir tank up to “MAX” line.

Techline

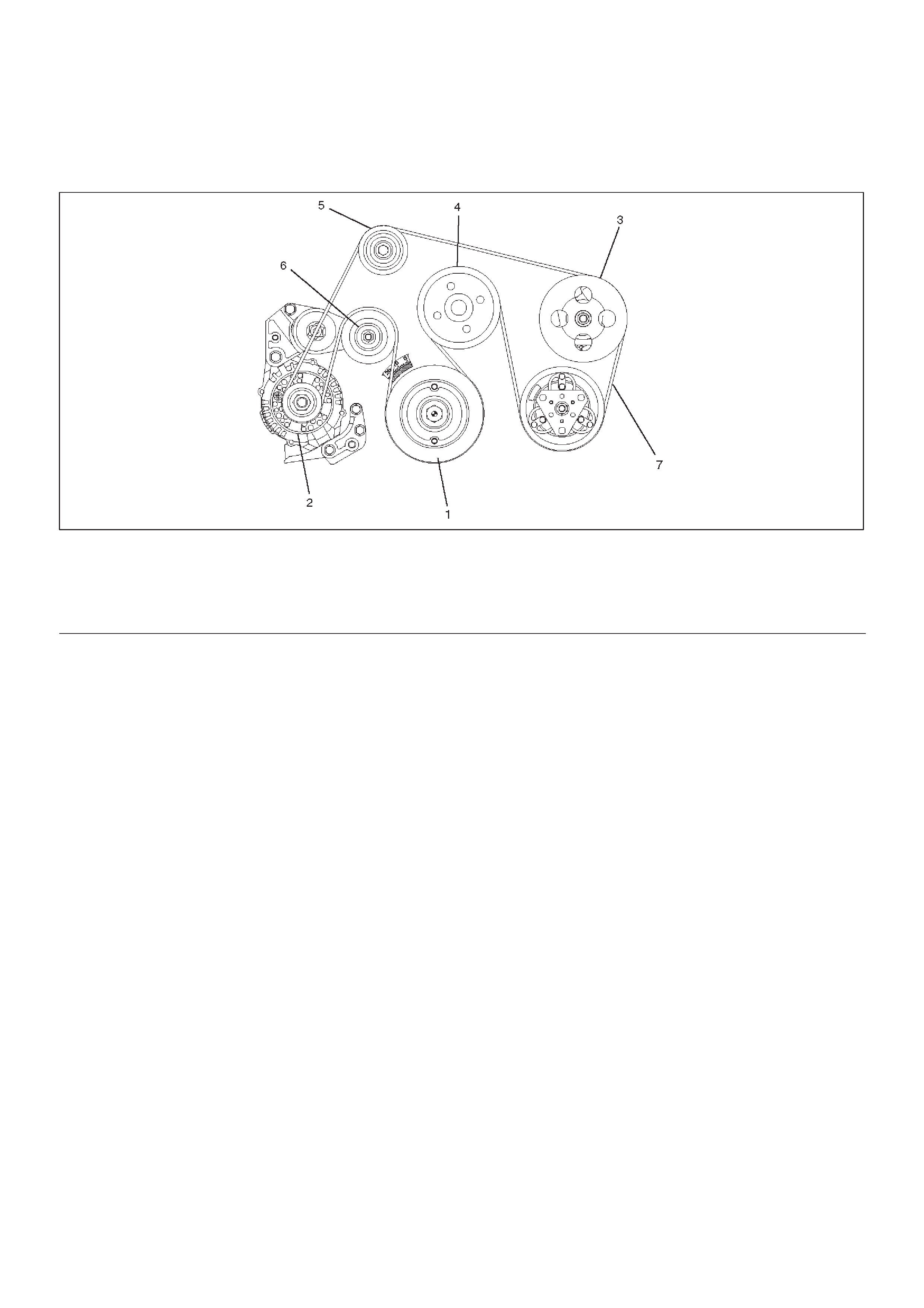

Water Pump

Water Pump and Associated Parts

030RS002

Legend

(1)Timing Belt

(2)Idle Pulley

(3)Water Pump Assembly

(4)Gasket

Removal

1.Disconnect battery ground cable.

2.Drain coolant.

3.Radiator hose (on inlet pipe side).

4.Remove timing belt. Refer to “Timing Belt” in this

service information.

5.Remove Idle pulley.

6.Remove water pump assembly.

7.Remove gasket.

Inspection

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection. Should any of

the following problems occur, the entire water pump

assembly must be replaced:

DCrack in the water pump body

DEC leakage from the seal unit

DPlay or abnormal noise in the bearing

DCracks or corrosion in the impeller.

Installation

1.Install gasket, clean the mating surface of gasket

before installation.

2.Install water pump assembly and tighten bolts to the

specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb ft)

DTightening order

The tightening order are in the illustrate.

NOTE: To prevent the oil leakage, apply the LOCTITE

262 or an equivalent, to the arrow marked fixing bolt

thread.

030RW008

3.Idle pulley

DInstall idle pulley and tighten bolt to the specified

torque.

Torque: 52 N·m (5.3kg·m/38 lb ft)

4.Timing belt

DInstall timing belt. Refer to timing belt installation

step in “Timing Belt” in this service information.

5.Connect radiator inlet hose and replenish EC.

6.Connect battery ground cable.

Thermostat

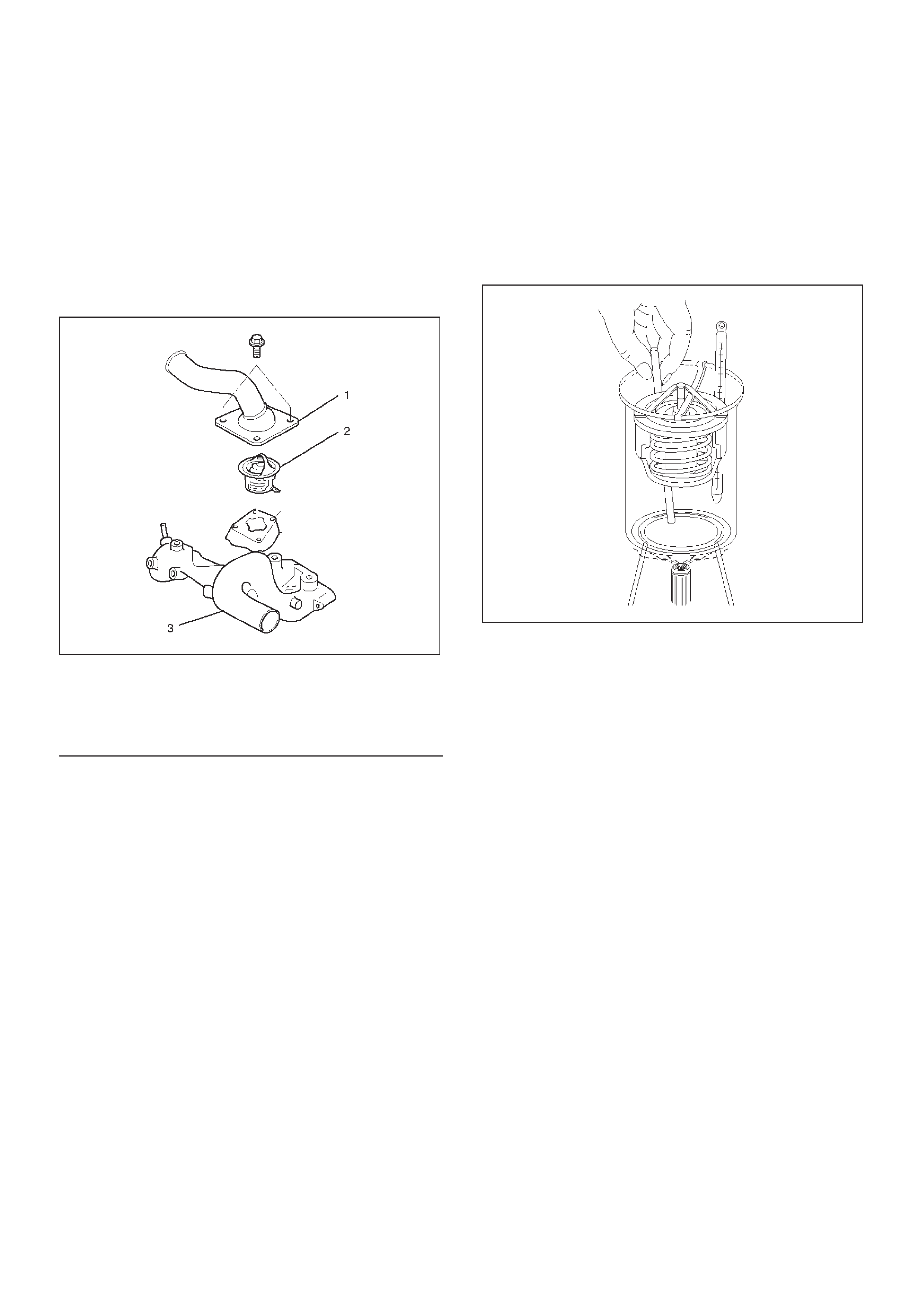

Thermostat and Associated Parts

031RW001

Legend

(1) Thermostat Housing

(2) Thermostat

(3) Outlet Pipe

Removal

1.Disconnect battery ground cable.

2.Drain engine coolant from the radiator and engine.

3.Disconnect radiator hose from the inlet pipe.

4.Remove thermostat housing.

5.Remove thermostat(2).

Inspection

Suspend the thermostat in a water–filled container using

thin wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water

so that the entire water is same temperature.

031RS003

Confirm the temperature when the valve first begins to

open.

Valve opening temperature 74.5C ∼ 78.5°C

(166.1°F ∼ 173.3°F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature and lift More than

8.5mm (0.33 in) at 90°C (194°F)

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection.

Installation

1.Install thermostat into the outlet pipe(4) making sure

that the air hole is in the up position.

2.Install thermostat housing and tighten bolts to the

specified torque.

Torque: 25 N·m (2.5 kg·m/18 lb ft)

3.Installation rubber hose.

4.Replenish engine coolant (EC).

5.Start engine and check for EC leakage.

Radiator

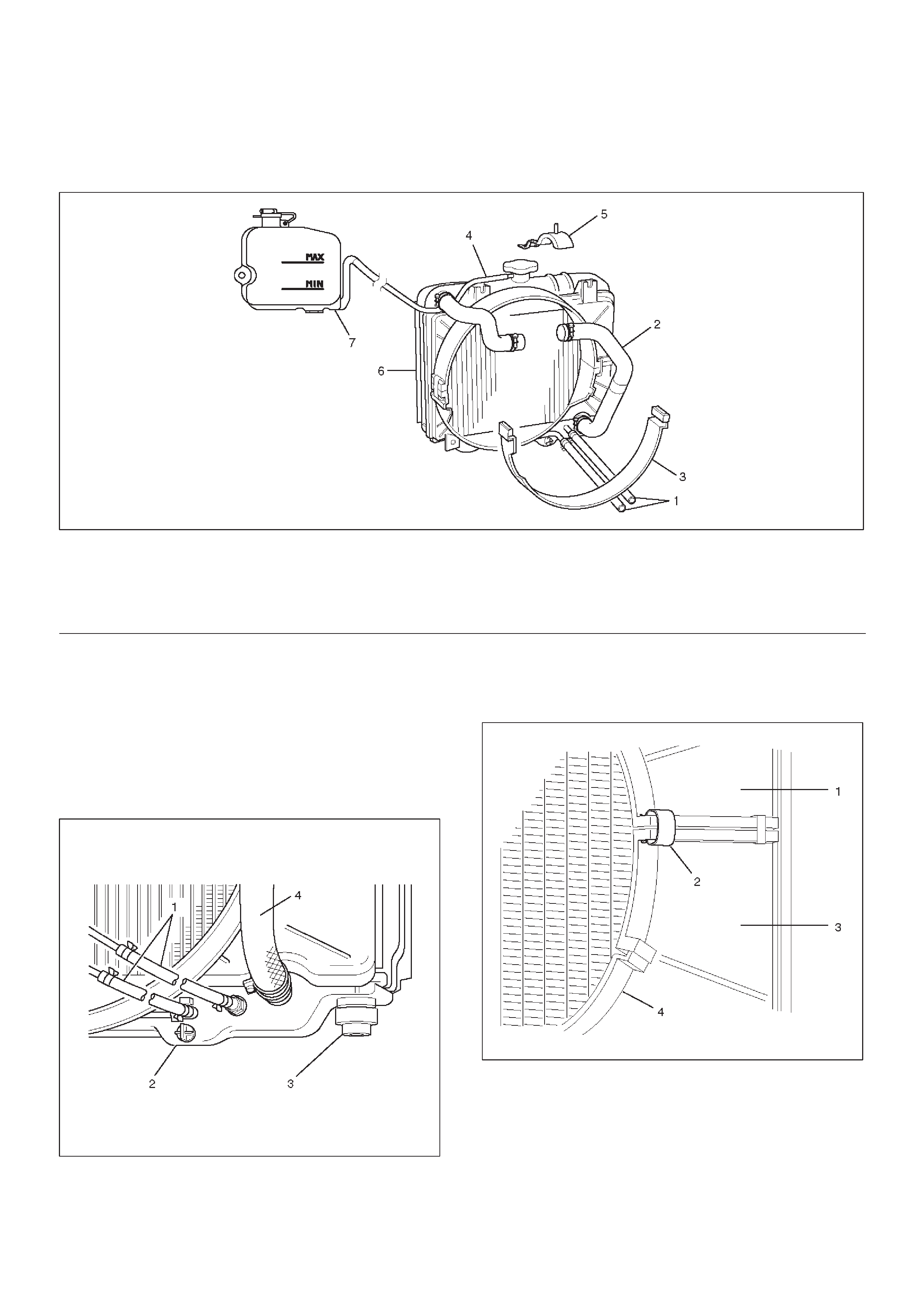

Radiator and Associated Parts

110RW003

Legend

(1) Oil Cooler Hose For Automatic Transmission

(2) Radiator Hose

(3) Fan Guide, Lower

(4) Reserve Tank Hose

(5) Bracket

(6) Radiator Assembly

(7) Reserve Tank

Removal

1.Disconnect battery ground cable.

2.Loosen a drain plug(2) to drain EC.

3.Disconnect oil cooler hose(1) on automatic

transmission (A/T).

4.Disconnect radiator inlet hose and outlet hose from

the engine.

110RW002

5.Remove fan guide(1), clips(3) on both sides and the

bottom lock, then remove lower fan guide(3) with fan

shroud(4).

110RW001

6.Disconnect the reserve tank hose(4) from radiator.

7.Remove bracket(5).

110RW004

8.Lift up and remove the radiator assembly with hose,

taking care not to damage the radiator core with a fan

blade.

9.Remove rubber cushions on both sides at the bottom.

Inspection

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure kPa (psi) 88.3 ∼ 117.7

(12.8 ∼17.1)

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the center of

the valve seat side of the cap. If considerable rust or dirt is

found, or if the valve seat cannot be moved by hand, clean

or replace the cap.

Valve opening vacuum kPa (psi) 1.96 ∼ 4.91

(0.28 ∼ 0.71)

110RS006

Radiator Core

1.A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the fin

when it is being straightened.

2.Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent.

Remove all signs of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196 kPa

(28.5 psi) with a cap tester:

DLeakage from the radiator

DLeakage from the coolant pump

DLeakage from the water hoses

DCheck the rubber hoses for swelling.

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

110RS005

Installation

1.Install rubber cushions on both sides of radiator

bottom.

2.Install radiator assembly with hose, taking care not to

damage the radiator core with a fan blade.

3.Install bracket (6) and support the radiator upper tank

with the bracket (5) and secure the radiator.

4.Connect reserve tank hose (4).

5.Install lower fan guide (3).

6.Connect radiator inlet hose and outlet hose to the

engine.

7.Connect oil cooler hose (1) to automatic

transmission.

110RW004

8.Connect battery ground cable.

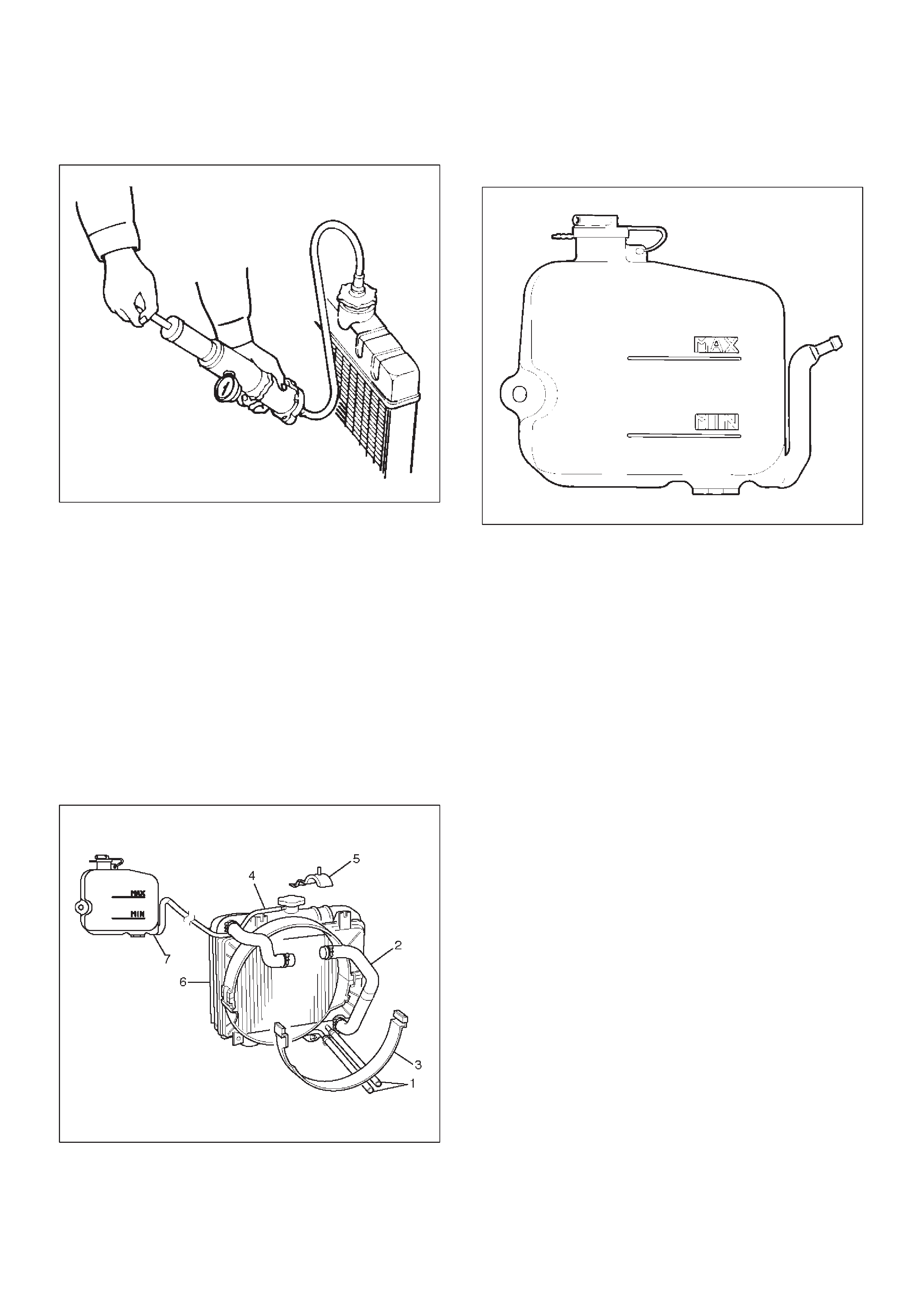

9.Pour engine coolant up to filler neck of radiator, and

up to MAX mark of reserve tank.

111RS001

Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

Engine coolant change

1.To change engine coolant, make sure that the engine

is cool.

WARNING:WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIATOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

2.Open radiator cap and drain the cooling system by

loosening the drain valve on the radiator and on the

cylinder body.

NOTE:For best result it is suggested that the engine

cooling system be flushed at least once a year. It is

advisable to flash the interior of the cooling system

including the radiator before using anti-freeze

(ethylene-glycol based).

Replace damaged rubber hoses as the engine anti-freeze

coolant is liable to leak out even minor cracks.

Isuzu recommends to use Isuzu genuine anti-freeze

(ethylen-glycol based) or equivalent, for the cooling sys-

tem and not add any inhibitors or additives.

CAUTION:A failure to correctly fill the engine

cooling system in changing or topping up coolant

may sometimes cause the coolant to overflow from

the filler neck even before the engine and radiator are

completely full.

If the engine runs under this condition, shortage of

coolant may possibly result in engine overheating.

To avoid such trouble, the following precautions

should be taken in filling the system.

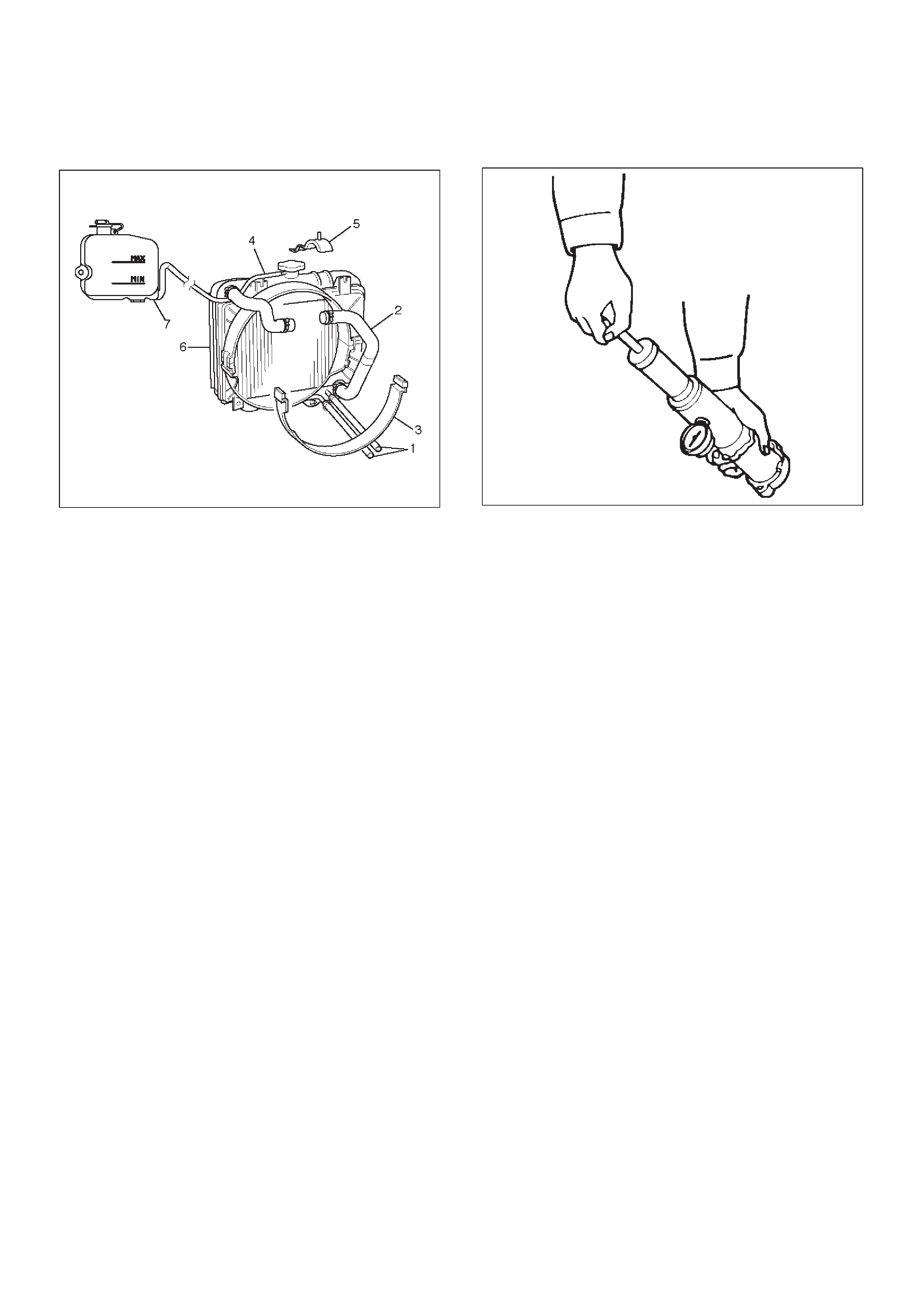

3.To refill engine coolant, pour coolant up to filler neck

using a filling hose which is smaller in outside

diameter of the filler neck. Otherwise air between the

filler neck and the filling hose will block entry,

preventing the system from completely filling up.

4.Keep a filling rate of 9 liter/min. or less. Filling over this

maximum rate may force air inside the engine and

radiator.

And also, the coolant overflow will increase, making

it difficult to determine whether or not the system is

completely full.

5.After filling the system to the full, pull out the filling

hose and check to see if air trapped in the system is

disclodged and the coolant level goes down. Should

the coolant level go down, repeat topping-up until

there is no more drop in the coolant level.

6.After directly filling the radiator, fill the reservoir to the

maximum level.

7.Install and tighten radiator cap and start the engine.

After idling for 2 to 3 minutes, stop the engine and

reopen radiator cap. If the water level is lower,

replenish.

WARNING:WHEN THE COOLANT IS HEATED TO A

HIGH TEMPERATURE, BE SURE NOT TO LOOSEN

OR REMOVE THE RADIA TOR CAP. OTHERWISE YOU

MIGHT GET SCALDED BY HOT VAPOR OR BOILING

WATER. TO OPEN THE RADIATOR CAP, PUT A

PIECE OF THICK CLOTH ON THE CAP AND LOOSEN

THE CAP SLOWLY TO REDUCE THE PRESSURE

WHEN THE COOLANT HAS BECOME COOLER.

8.After tightening radiator cap, warm up the engine at

about 2,000 rpm.

Set heater adjustment to the highest temperature

position, and let the coolant circulate also into heater

water system.

9.Check to see the thermostat has opened through the

needle position of water thermometer, conduct a

5-minute idling again and stop the engine.

10.When the engine has been cooled, check filler neck

for water level and replenish if required. Should

extreme shortage of coolant is found, check the

coolant system and reservoir tank hose for leakage.

11.Fill the coolant into the reservoir tank up to “MAX” line.

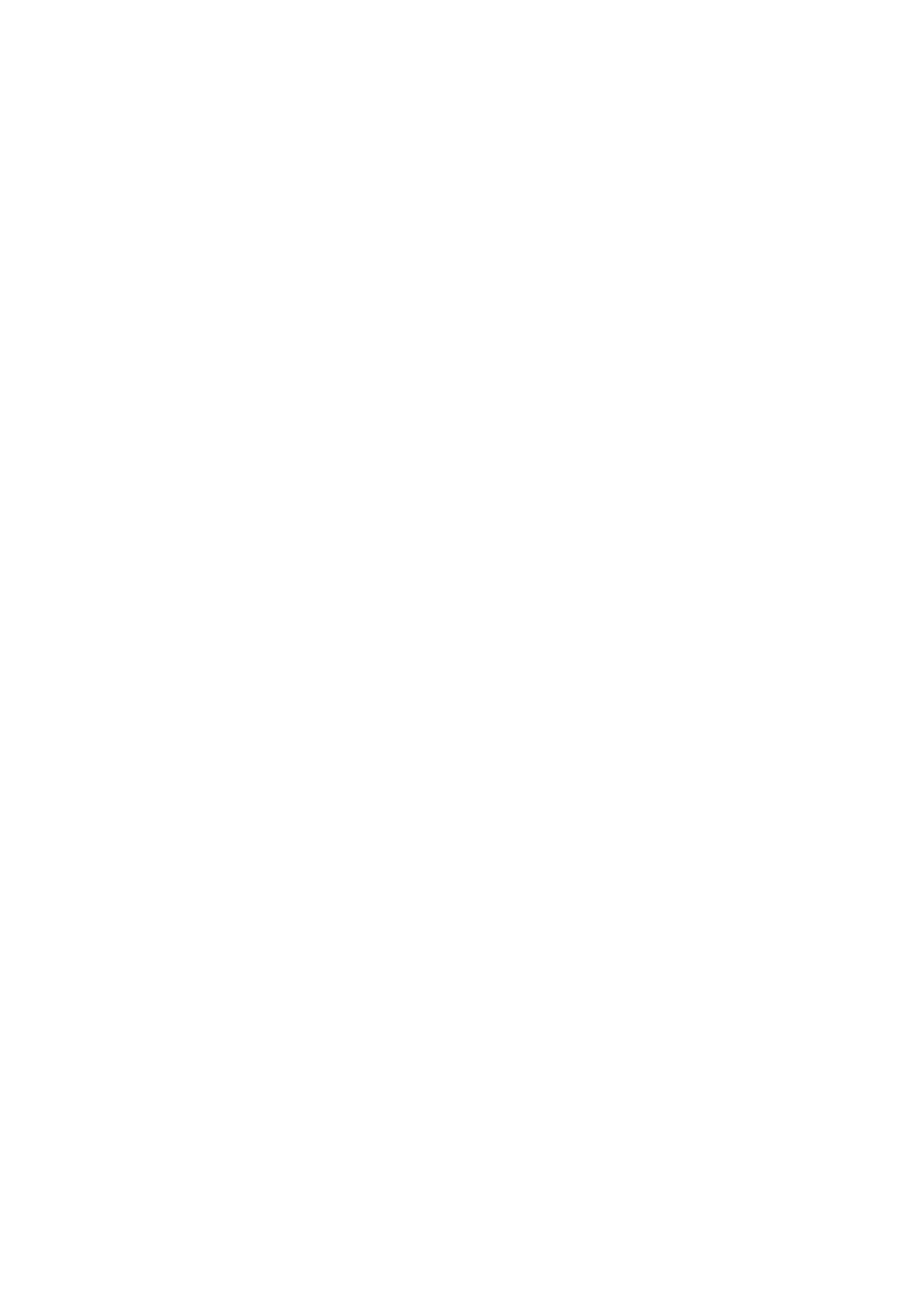

Drive Belt and Cooling Fan

Drive Belt and Associated Parts

015RW005

Legend

(1) Crankshaft Pulley

(2) Generator

(3) Power Steering Pump

(4) Water Pump and Cooling Fan Pulley

(5) Idle Pulley

(6) Tension Pulley

(7) Drive Belt

The drive belt adjustment is not required as automatic

drive belt tensioner is equipped.

Inspection

Check drive belt for wear or damage, and replace with a

new one as necessary.

Installation

Install cooling fan assembly and tighten bolts/nuts to the

specified torque.

Torque : 22 N·m (2.2 kg·m/16 lb ft) for fan pulley

and fan bracket.

Torque : 10 N·m (1.0 kg·m/88.5 lb in) for fan and

clutch assembly.

NOTE: A single serpentine accessory drive belt is fitted

to the 6VD1-W engine.

This results in the cooling fan rotating in the opposite direction

to that fitted to the previous 1992-97 6VD1-S engine.

Installation of the incorrect cooling fan will cause the cooling

air to flow in the opposite direction, and result in poor

air-conditioner performance and high engine temperatures.

Main Data and Specifications

General Specifications

M/T A/T

Cooling system Engine coolant forced circulation

Radiator (1 tube in row) Tube type corrugated (2 tube in row)

Heat radiation capacity 68,000 kcal/h 77,000 kcal/h

Heat radiation area 9.445m@ (0.878ft@) 11.21m@ (1.04ft@)

Radiator front area 0.302m@ (0.028ft@)

Radiator dry weight 39N (8.8lb) 44N (9.9lb)

Radiator cap valve opening pressure 93.3 ∼ 122.7kpa (13.5 ∼ 17.8psi)

Engine coolant capacity 2.5lit (2.6U.S q.t.) 2.4lit (16.3U.S q.t.)

Engine coolant pump Centrifugal impeller type

Delivery 300 (317) or more

Pump speed 5000 ± 50 rpm

Thermostat Wax pellet type with air hole

Valve opening temperature 74.5 ∼ 78.5°C (166.1 ∼ 173.3°F)

Engine coolant total capacity 10.4lit (11.0U.S qt) 10.5lit (11.1U.S qt)

Torque Specifications

N·m (kg·m/ lb·ft)

E06RW041

Special Tool

ILLUSTRATION TOOL NO.

TOOL NAME

5–8840–0277–0

(J–24460–01)

Tester; radiator cap

5–8840–2603–0

(J–33984–A)

Adapter; radiator cap