SECTION 6E - STARTING SYSTEM (6VD1 MODELS)

Service Precaution

Starting System

General Description

Diagnosis

Starter

Removal

Installation

Disassembled View

Disassembly

Inspection and Repair

Reassembly

Main Data and Specifications

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require

replacement after removal. Holden will call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

coatings and corrosion inihibitors cleaned from

fastener joint interfaces). Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you instal l fasteners , use the correc tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

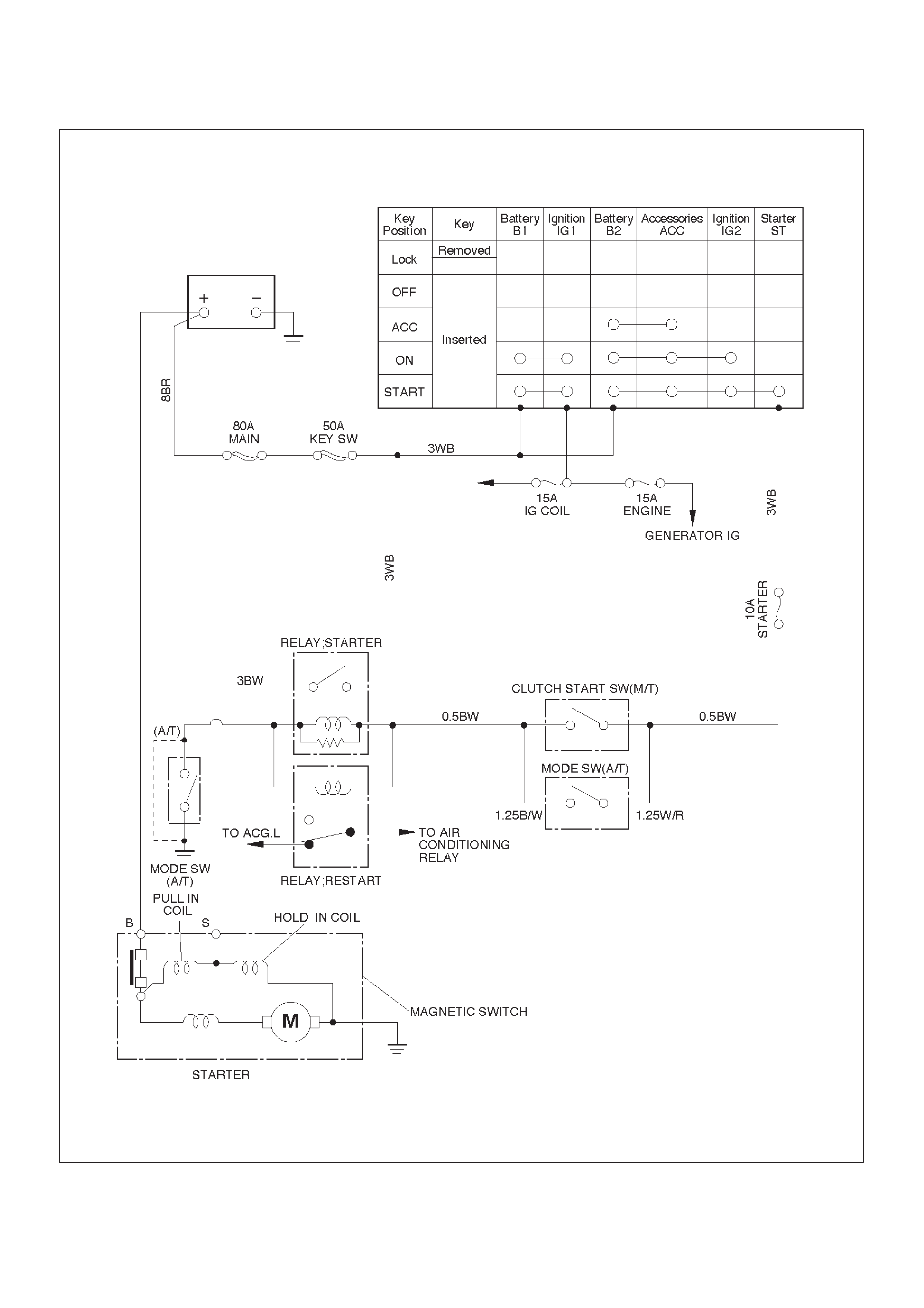

Starting System

General Description

Cranking Circuit

The cranking system consists of a battery, starter , starter

switch, starter relay, etc. These main components are

connected.

Starter

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion

shaft. When the starter switch is turned on, the contacts of

magnetic switch are closed, and the armature rotates. At

the same time, the plunger is attracted, and the pinion is

pushed forward by the shift lever to mesh with the ring

gear.

Then, the ring gear runs to start the engine. When the

engine starts and the starter switch is turned off, the

plunger returns, the pinion is disengaged from the ring

gear, and the armature stops rotation. When the engine

speed is higher than the pinion, the pinion idles, so that

the armature is not driven.

C06RW005

Diagnosis

Condition Possible cause Correction

Starter does not run Charging failure Repair charging system

Battery Failure Replace Battery

Terminal connection failure Repair or replace terminal connector

and/or wiring harness

Starter switch failure Repair or replace starter switch

Starter failure Repair or replace starter

Starter

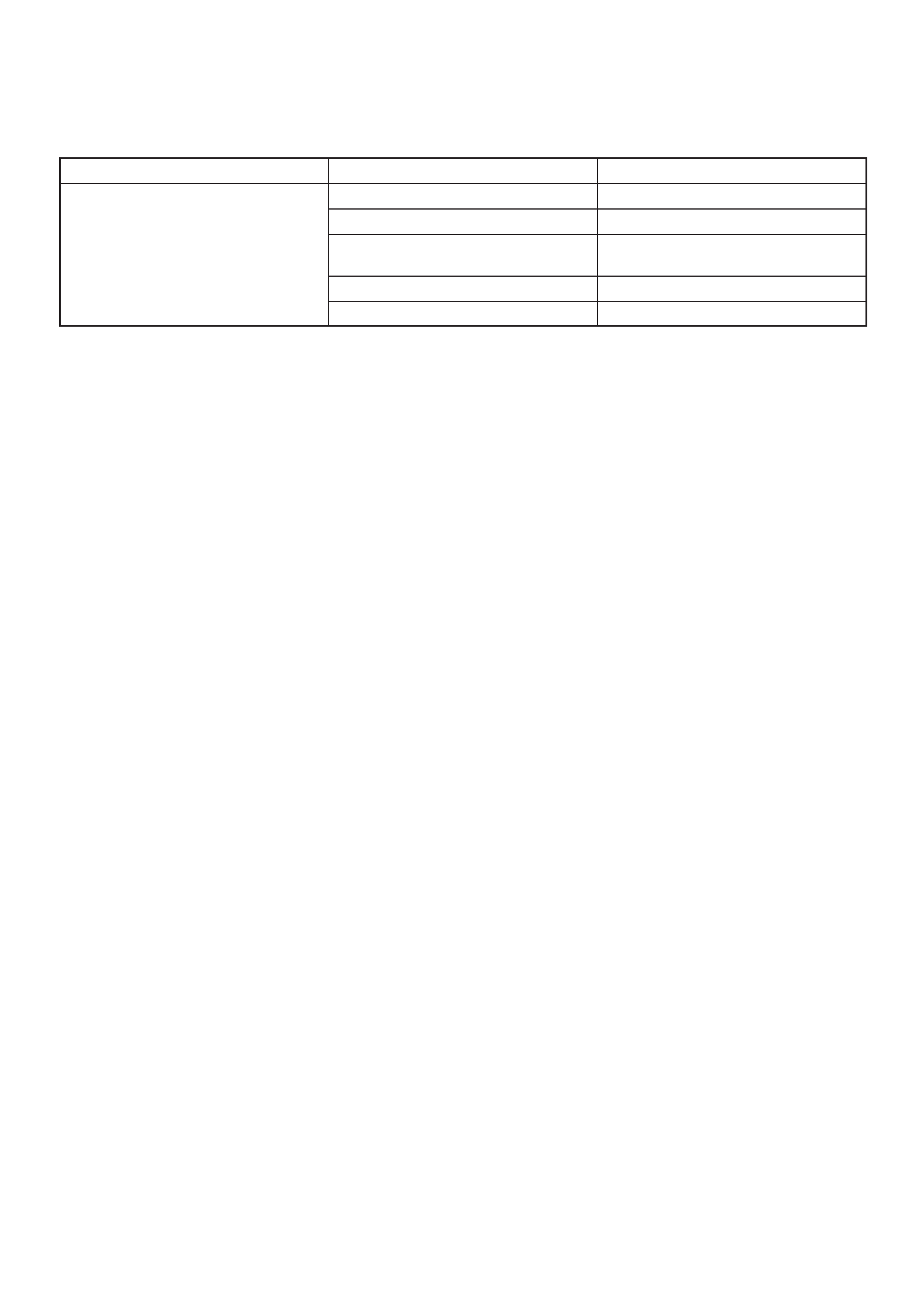

Removal

1.Battery ground cable.

2.Remove exhaust front left pipe.

3.Remove heat protector(3).

4. Disconnect starter wiring connector from terminals

“B” and “S”(4).

5.Remove starter assembly mounting bolts on inside

and outside(5).

6.Remove starter assembly toward the bottom of

engine(6).

065RW001

Installation

1.Install starter assembly(6).

2.Install mounting bolts and tighten bolts to specified

torque(5).

Torque: 40 N·m (4.1 kg·m/30 lb ft)

3.Reconnect the connectors to terminals “B” and “S”

and tighten Terminals “B” to specified torque.

Torque: 9 N·m (0.9 kg·m/80 lb in)

4.Install heat protector(3).

065RW001

5. Install exhaust front left pipe and tighten bolts and

nuts to specified torque(2).

Stud Nuts

Torque: 67 N·m (6.8 kg·m/49 lb ft)

Nuts

Torque: 43 N·m (4.4 kg·m/32 lb ft)

6.Reconnect the battery ground cable.

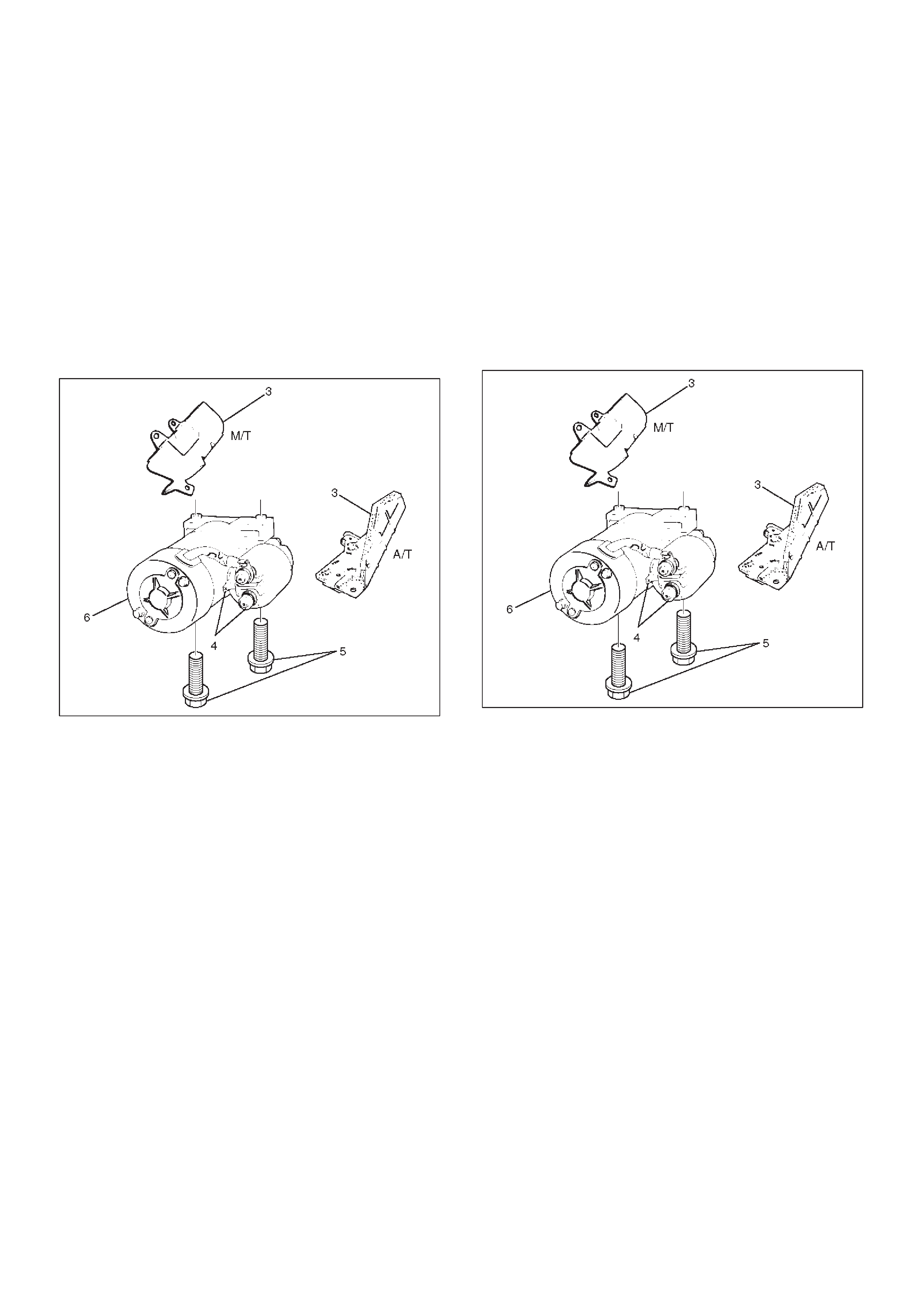

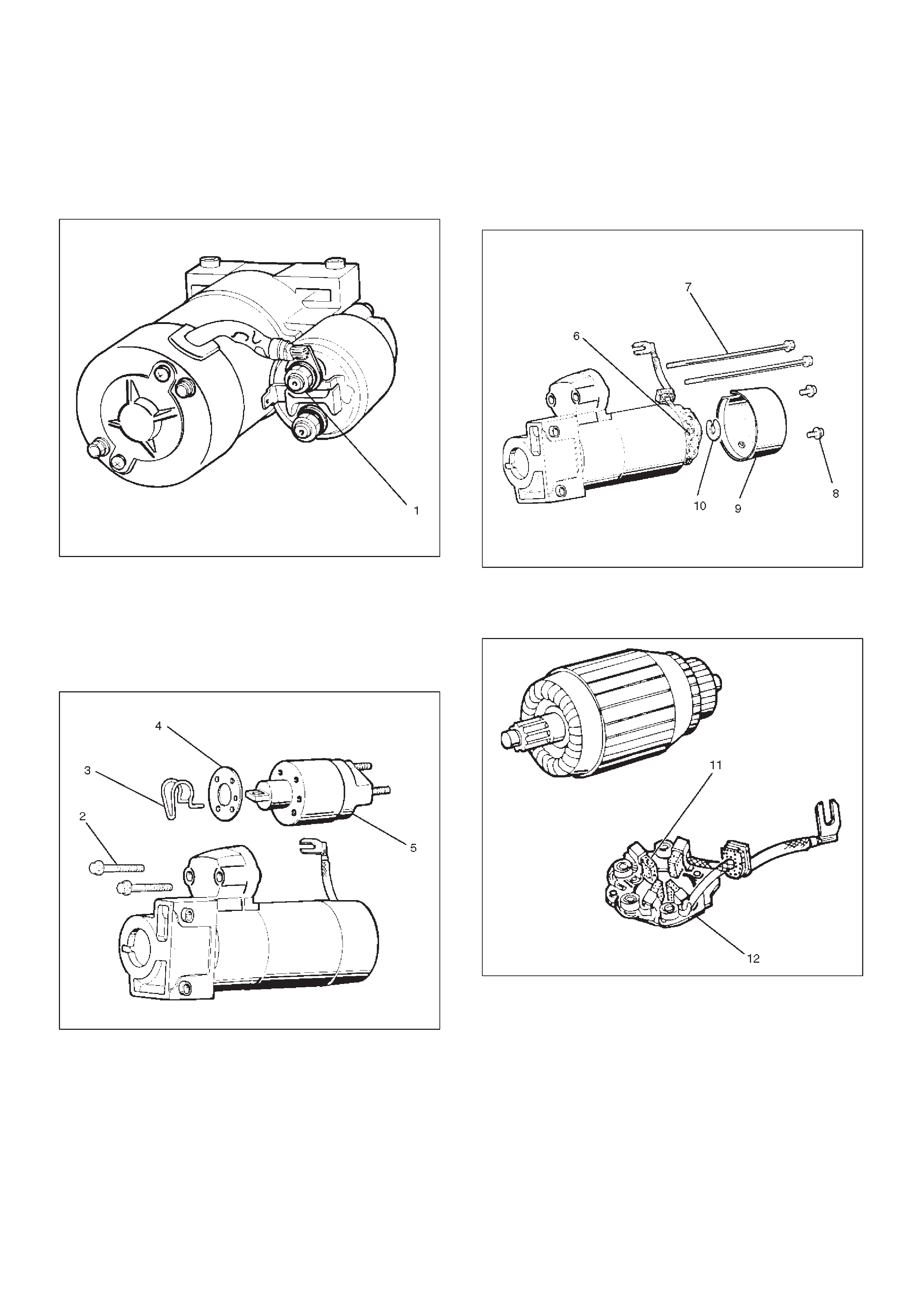

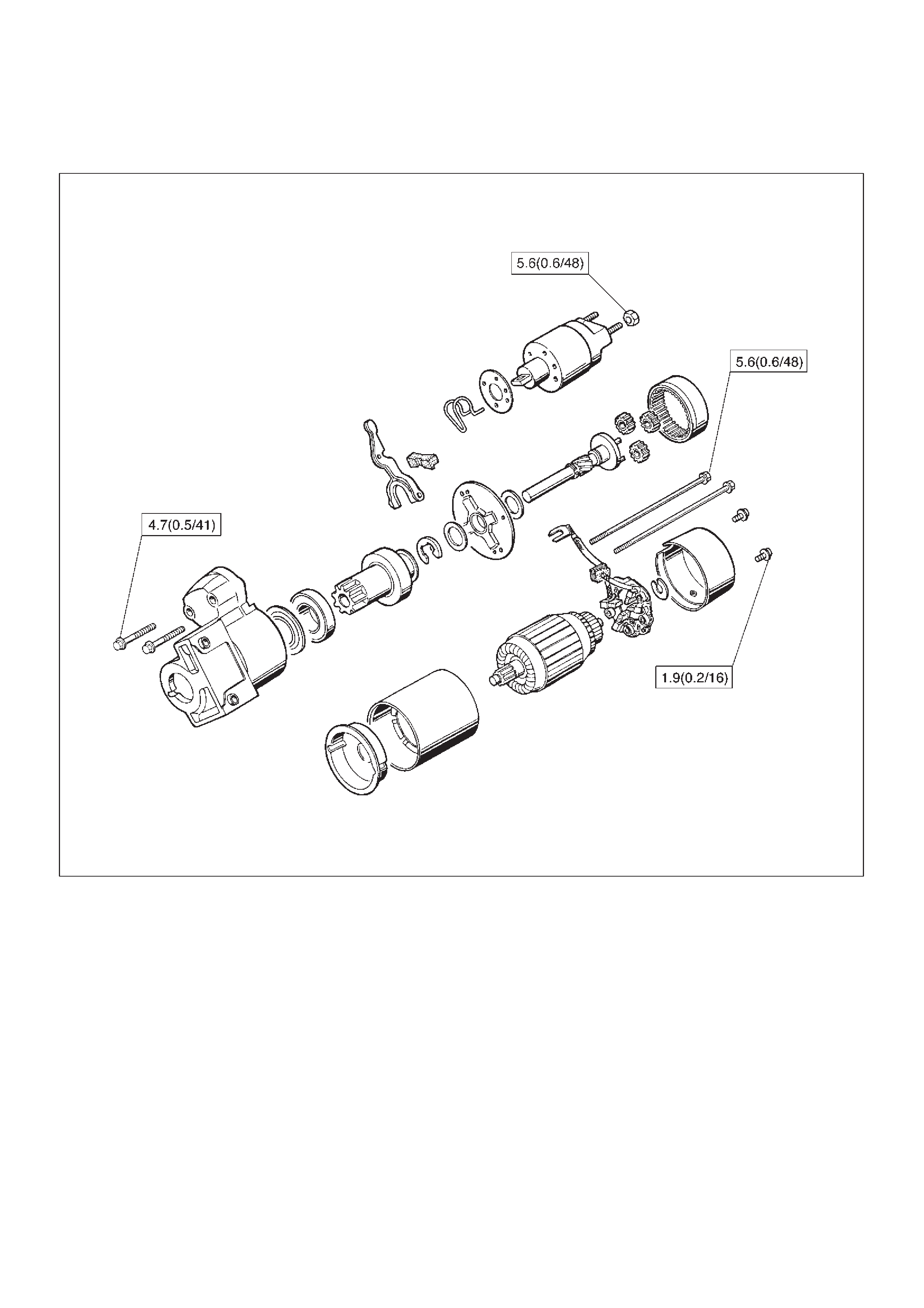

Disassembled View

065RW002

Legend

(1) Bolt (2 pcs)

(2) Ball Bearing

(3) Pinion

(4) Shift Lever

(5) Dust Cover

(6) Torsion Spring

(7) Dust Cover

(8) Magnetic Switch

(9) Nut

(10) Gear Case

(11) Bearing Cover

(12) E–ring

(13) Thrust Washer (2)

(14) Center Bracket

(15) Pinion Shaft

(16) Planet Gear (3)

(17) Internal Gear

(18) Center Bracket (A)

(19) Yoke Assembly

(20) Armature

(21) Brush

(22) Brush Holder

(23) Thrust Washer

(24) Rear Cover

(25) Screw (2 pcs)

(26) Through Bolt (2 pcs)

Disassembly

1.Loosen the nut(1) on terminal “M” of magnetic switch

and disconnect the connector cable.

2.Remove bolt (2 pcs) (2).

065RW003

3.Remove magnetic switch(5).

4.Remove dust cover(4).

5.Remove torsion spring bolts, then the magnetic

switch assembly.

6.Remove torsion spring(3) from magnetic switch

assembly(5).

065RW004

7.Remove screw (2 pcs) (8).

8.Remove through bolt (2 pcs) (7).

9.Remove screws and through bolts, then the rear

cover(9) then remove thrust washer(10).

10.Remove brush holder(6).

065RW005

11.Raise a brush spring to detach brushes (4 pcs) from

the commutator face and pull off the brush holder(12)

and brush(11).

065RW006

12.Remove yoke assembly(14).

13.Remove armature(15).

14.Pull off the yoke assembly, then remove armature,

washer and center bracket.(A) (13).

NOTE: In disassembling the yoke assembly, hold the

armature and pull off slowly the yoke assembly. Because

of strong magnetic force, avoid placing a metallic part

near armature.

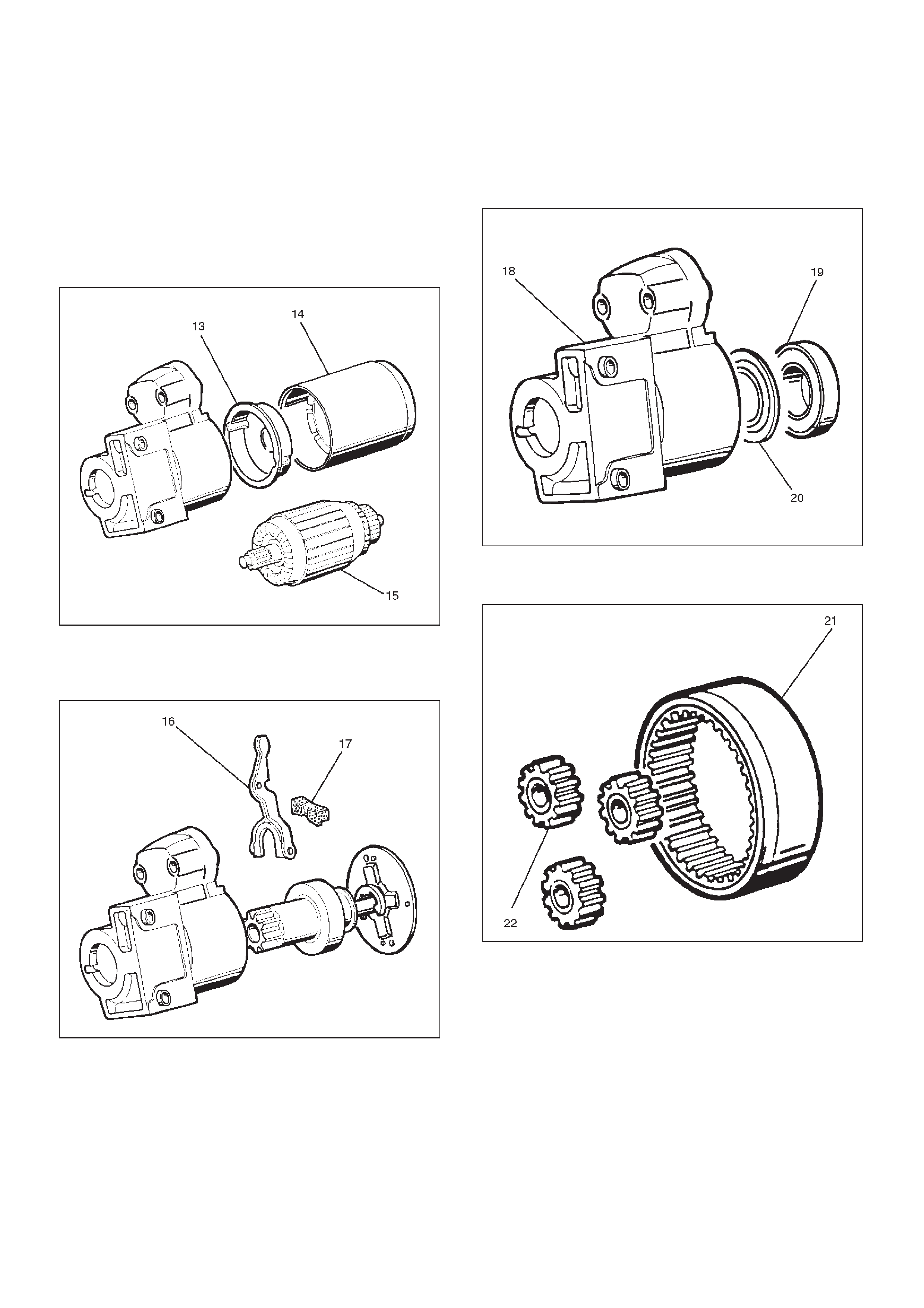

065RW007

15.Remove dust cover(17).

16.Remove a dust cover and shift lever(16) from the gear

case.

065RW008

17.Remove ball bearing(19).

18.Remove bearing cover(20).

19.Remove a ball bearing and bearing cover from the

gear case(18).

065RW021

20.Internal gear(21).

21.Remove internal gear and planet gear(3) (22).

065RW009

22.Remove an E–ring(23) from the pinion shaft using a

flat blade screwdriver.

065RW010

23.Holding the pinion shaft, push pinion toward the

center bracket and turn the pinion clockwise or

counterclockwise by one tooth of spline, then pull of f

the pinion.

24.Remove thrust washer(24).

25.Remove center bracket

26.Remove pinion shaft.

065RW011

Inspection and Repair

Repair or replace necessary parts if extreme wear or

damage is found during inspection.

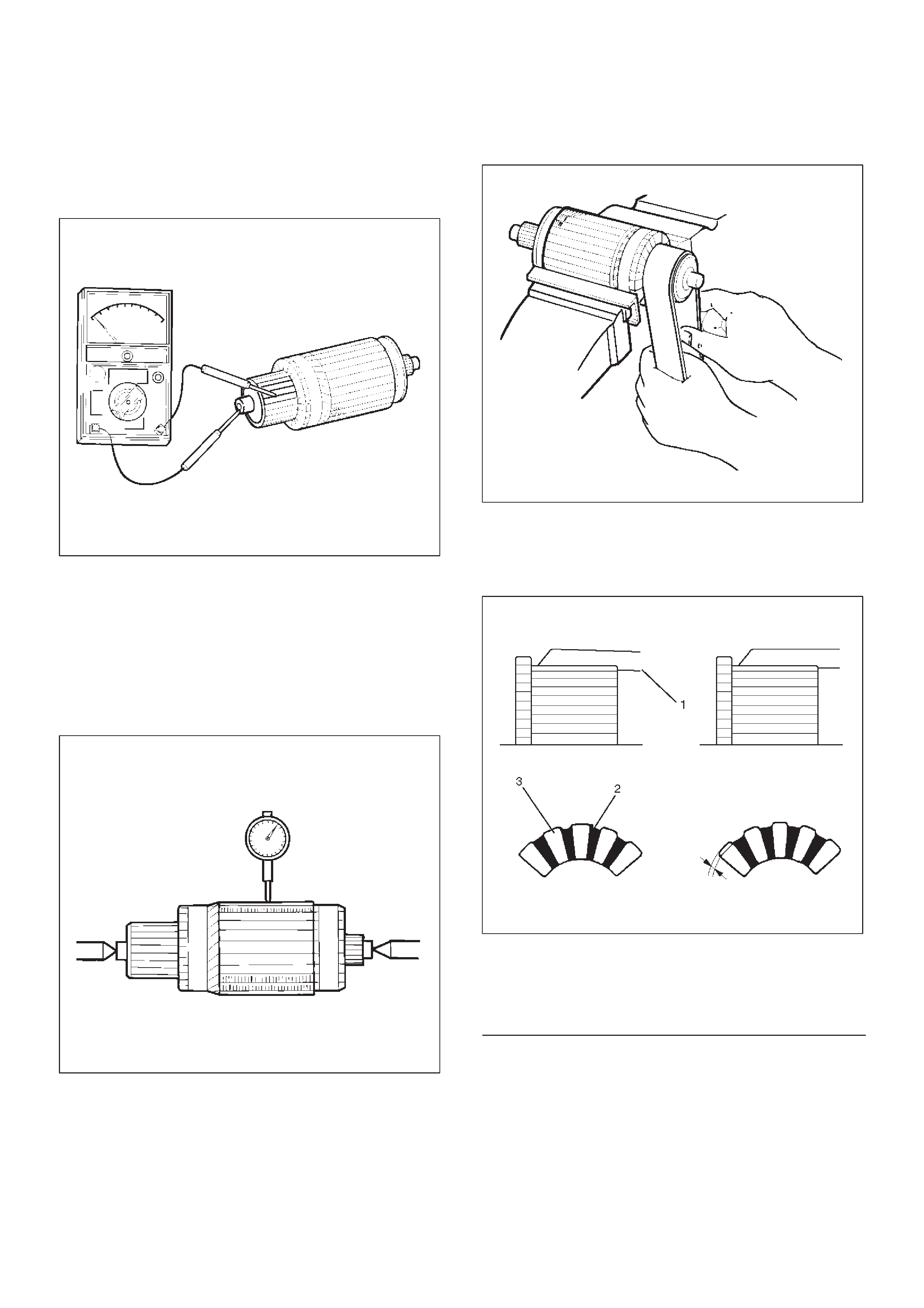

Armature

Measure the outer diameter of commutator, and replace

with a new one if it is out of the limit.

Standard: 33.0 mm (1.30 in)

Limit: 32.0 mm (1.26 in)

065RS014

Check for continuity between commutator and segment.

Replace commutator if there is no continuity (i.e.,

disconnected).

065RS015

Check for continuity between commutator and shaft.

Also, check for continuity between commutator and

armature core,armature core and shaft. Replace

commutator if there is continuity (i.e., internally

grounded).

065RS016

Measure runout of armature core and commutator with a

dial gauge. Repair or replace, if it exceeds the limit.

Armature

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

Commutator

Standard: 0.05 mm (0.002 in) Max.

Limit: 0.10 mm (0.004 in)

065RS017

Polish the commutator surface with sandpaper #500 to

#600 if it is rough.

065RW012

Measure the depth of insulator in commutator. Repair, if it

is below the limit.

Standard: 0.05 mm to 0.8 mm (0.02 in to 0.03 in)

Limit: 0.2 mm (0.008 in)

065RW013

Legend

(1) Steel Saw

(2) Insulator

(3) Commutator Segments

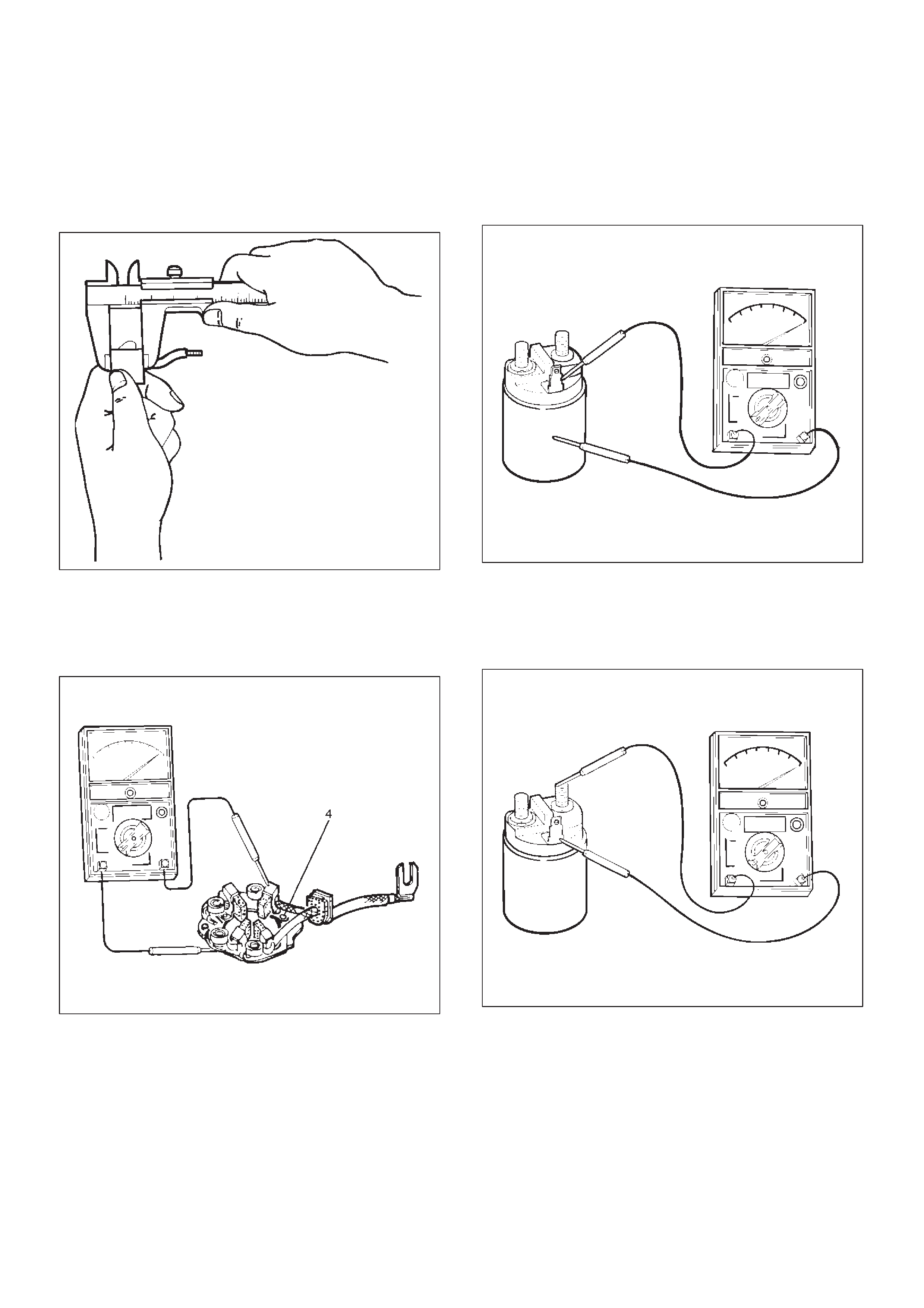

Brush

Measure the length of brush.

Replace with a new one, if it is below the limit.

Standard: 16 mm (0.63 in)

Limit: 11 mm (0.43 in)

065RW014

Brush Holder

Check for continuity between brush holder (+) (4) and

base (–). Replace, if there is continuity (i.e., insulation is

broken).

065RW015

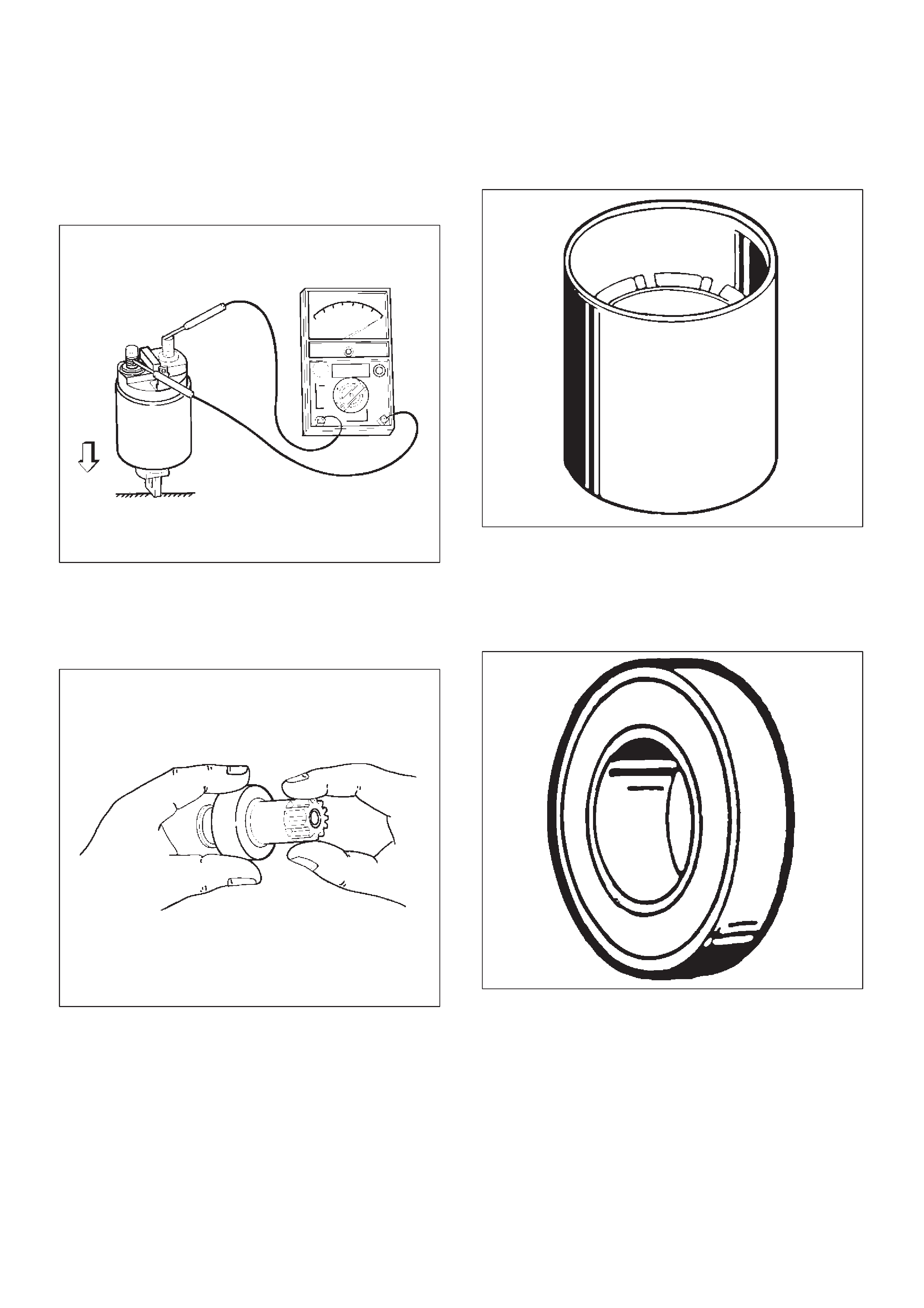

Magnetic Switch

Check for continuity of shunt coil between terminals S and

M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW016

Continuity of Series Coil

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is

disconnected).

065RW017

Continuity of Contacts

With the plunger faced downward, push down the

magnetic switch. In this state, check for continuity

between terminals B and M. Replace, if there is no

continuity (i.e., contacts are faulty).

065RW018

Pinion

Check if the pinion rotates smoothly in drive direction by

hand, or if it is locked when it is rotated in reverse. If not,

replace the pinion.

065RS025

Yoke Assembly

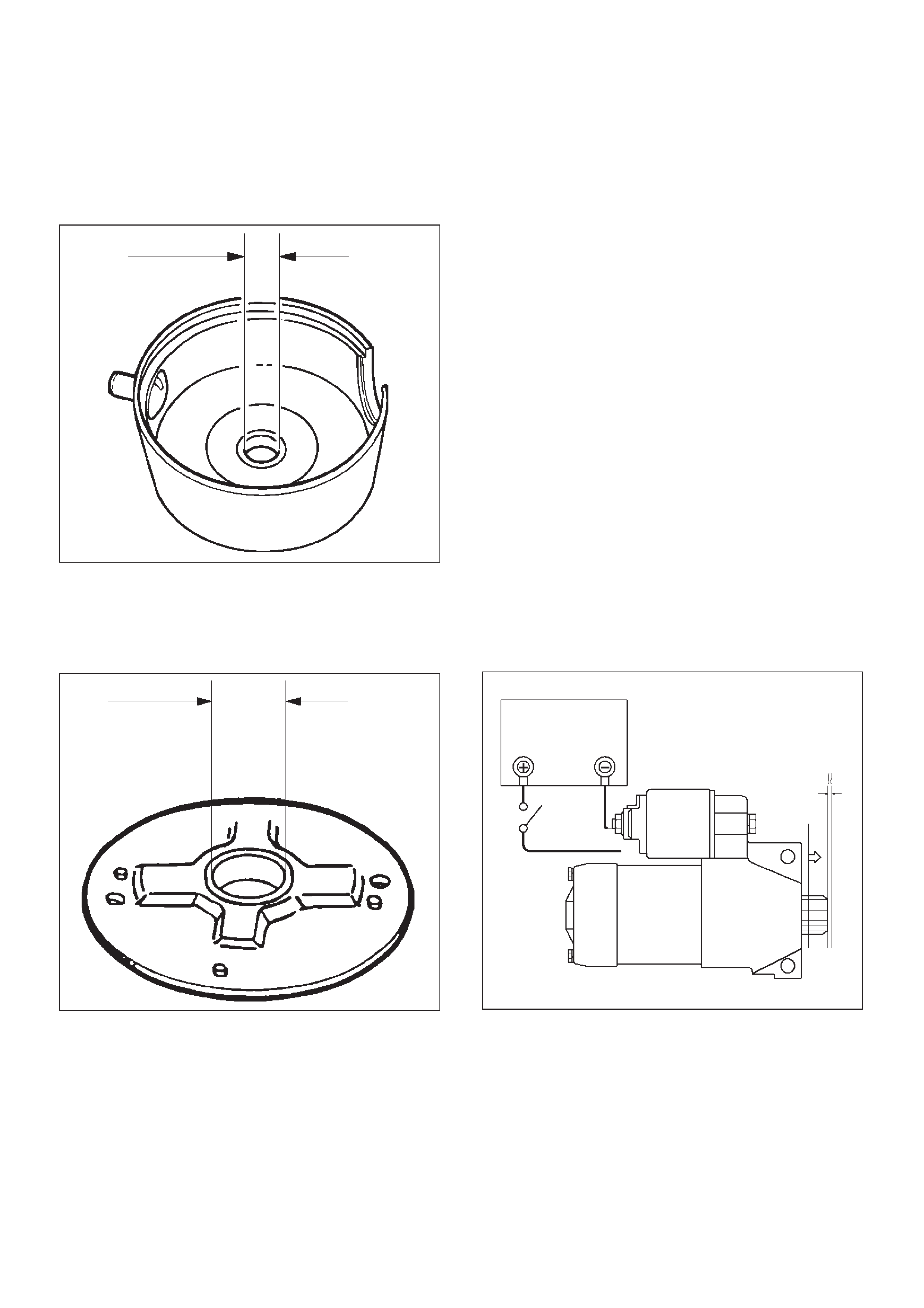

Check a magnet inside the yoke.

Replace the yoke assembly if it is broken.

065RS026

Ball Bearing

Clamp the inner race of the ball bearing with your finger,

and check for sticking or play when rotating the outer

race.

Replace, if abnormality is found.

065RS027

Measure inner diameter of bushing in the rear cover , and

replace if it exceeds the limit.

Standard: 12.50 mm to 12.527 mm (0.492 in to

0.4932 in)

Limit: 12.60 mm (0.4961 in)

065RS028

Measure inner diameter of bushing in the center bracket

(P), and replace if it exceeds the limit.

Standard: 18.01 mm to 18.127 mm (0.7091 in to

0.7137 in)

Limit: 18.15 mm (0.7146 in)

065RS029

Reassembly

To install, follow the removal steps in the reverse order,

noting the following points:

Grease application places

DBushing in rear cover and center bracket

DGears in reduction gear

DShift lever operating portion

DSliding portion of pinion

DPlunger sliding portion of magnetic switch

Reassembling Yoke Assembly

Before reassembly, make sure that no metallic parts

attach to the yoke assembly . Because of strong magnetic

force, hold the yoke assembly and insert it slowly into the

armature.

Torque

Torque for each part (See Torque Specifications in

this section)

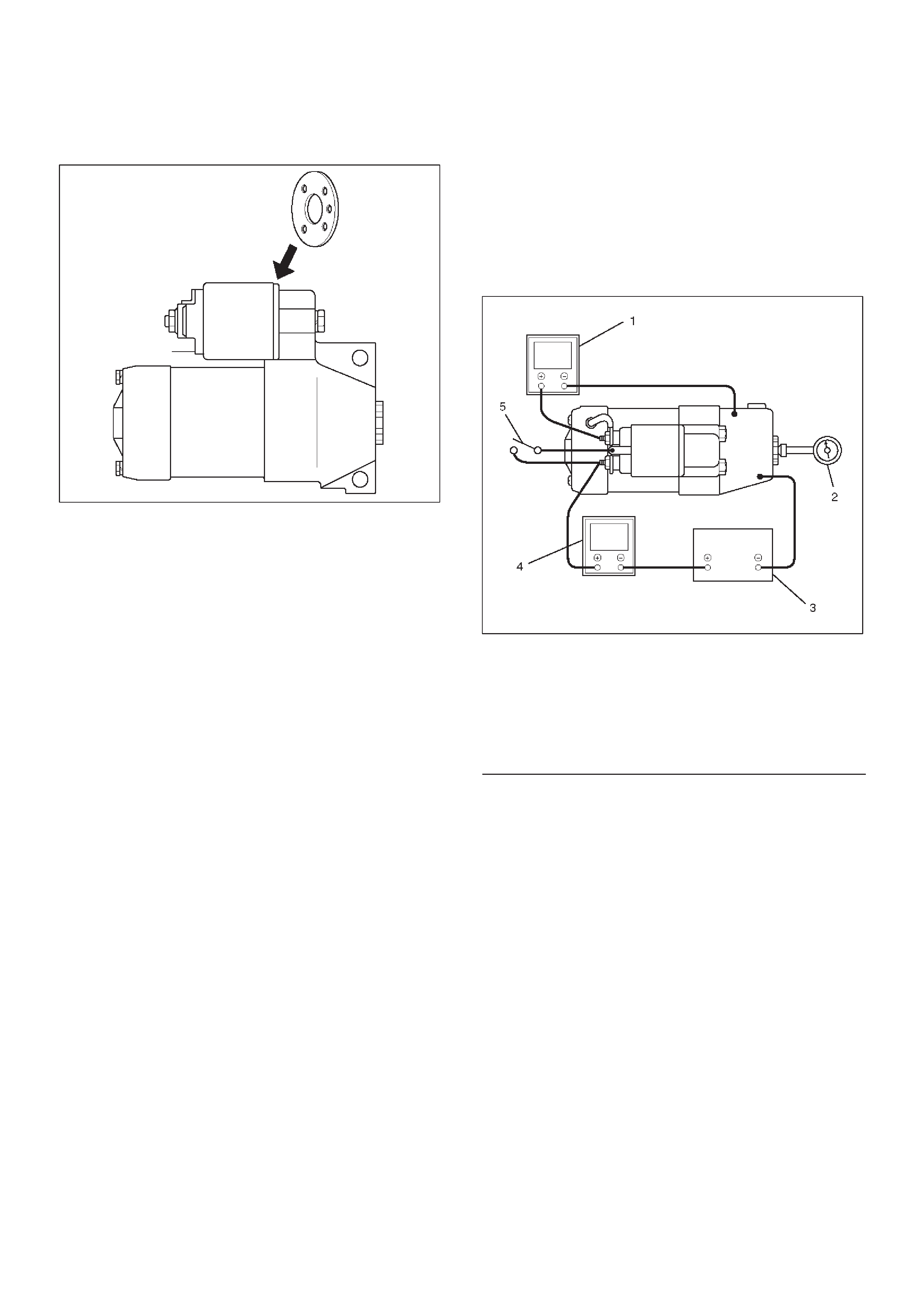

Pinion Jump–out Dimension

Connect the “+” cable of battery to terminal S and the “–”

cable to terminal M. Turn the switch on, and measure

pinion travel dimension in thrust direction from the

jump–out position.

In measuring the dimension, pull the pinion out a little in

the arrow direction.

Dimension(L): 0.05 mm to 1.5 mm (0.002 in to

0.06 in)

065RS030

If the measured value is out of standard, insert dust cover,

or disassemble and adjust.

065RW019

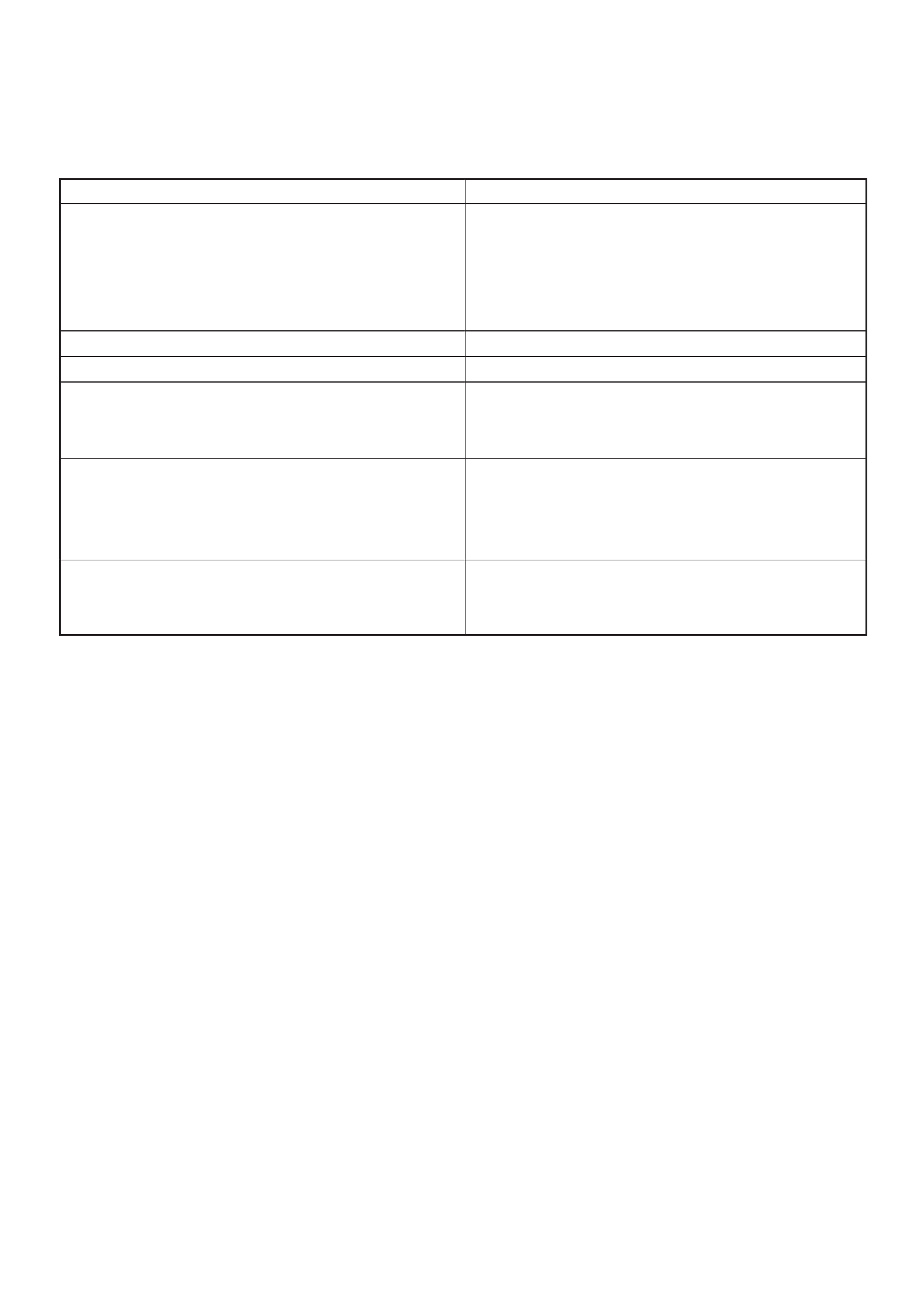

Characteristic Test

For easily confirming the characteristics, conduct the no

load test as follows:

Rating as short as 30 seconds requires rapid testing.

Fix the starter on the test bench, and wire as shown in

illustration. When the switch is closed, the current flows

and the starter runs under no load. At this time, measure

current, voltage and speed to check if they satisfy the

standard.

065RW020

Legend

(1) Volt Meter

(2) Tachometer

(3) Battery

(4) Ammeter

(5) Switch

Main Data and Specifications

General Specifications

Model HITACHI GD002350

Rating

Voltage 12 V

Output 1.4 Kw

Time 30 sec

Number of teeth of pinion 9

Rotating direction(as viewed from pinion) Clockwise

Weight(approx.) 34 N

No–load characteristics

Voltage /Current 11V/90A or less

Speed 2700rpm or more

Load characteristics

Voltage/current 8.4V/250A

Torque 7.3N·m(64lb·in.) or more

Speed 1200rpm or more

Locking characteristics

Voltage/current 3V/750A or less

Torque 19N·m(14lb·in) or more

Torque Specifications

N·m (kg·m/ lb·in)

E06RW044