SECTION 6F - ENGINE LUBRICATION (6VD1 MODELS)

Service Precaution

General Description

Oil Pump

Oil Pump and Associated Parts

Disassembly

Inspection and Repair

Reassembly

Oil Pan and Crankcase

Removal

Installation

Oil Pump

Removal

Installation

Oil Pump Oil Seal

Removal

Installation

Main Data and Specification

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

HOLDEN will call out those fasteners that require

replacement after removal. holden will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Techline

General Description

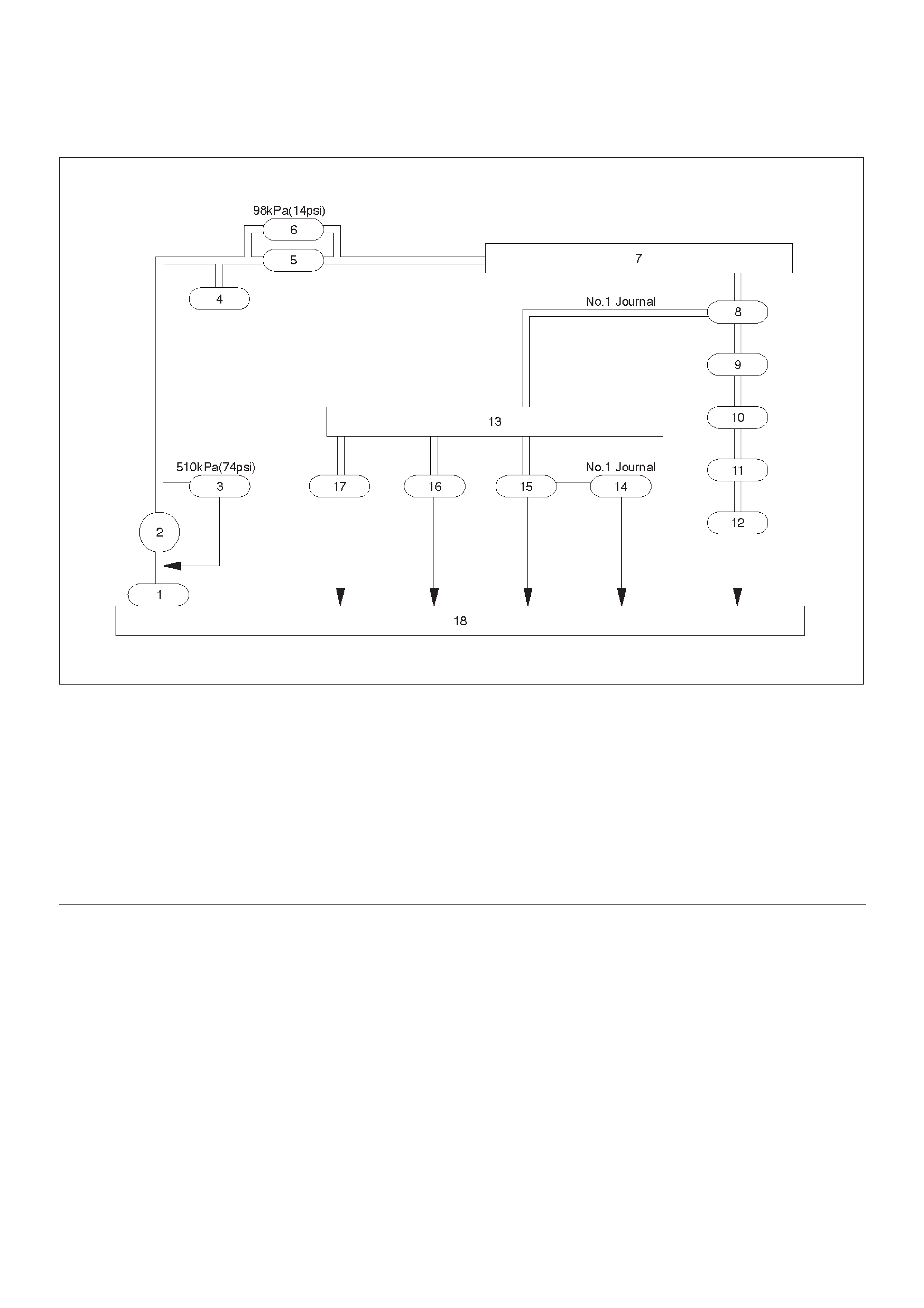

C06RW003

Legend

(1) Oil Strainer

(2) Oil Pump

(3) Relief Valve

(4) Oil Pressure Switch

(5) Oil Filter

(6) Safety Valve

(7) Oil Gallery

(8) Crankshaft Bearing

(9) Crankshaft

(10) Connecting Rod Bearing

(11) Connecting Rod

(12) Piston

(13) Oil Gallery; Cylinder Head

(14) Camshaft

(15) Camshaft Journal

(16) Front Journal; Camshaft Drive Gear

(17) Rear Journal; Camshaft Drive Gear

(18) Oil Pan

Oil Pump

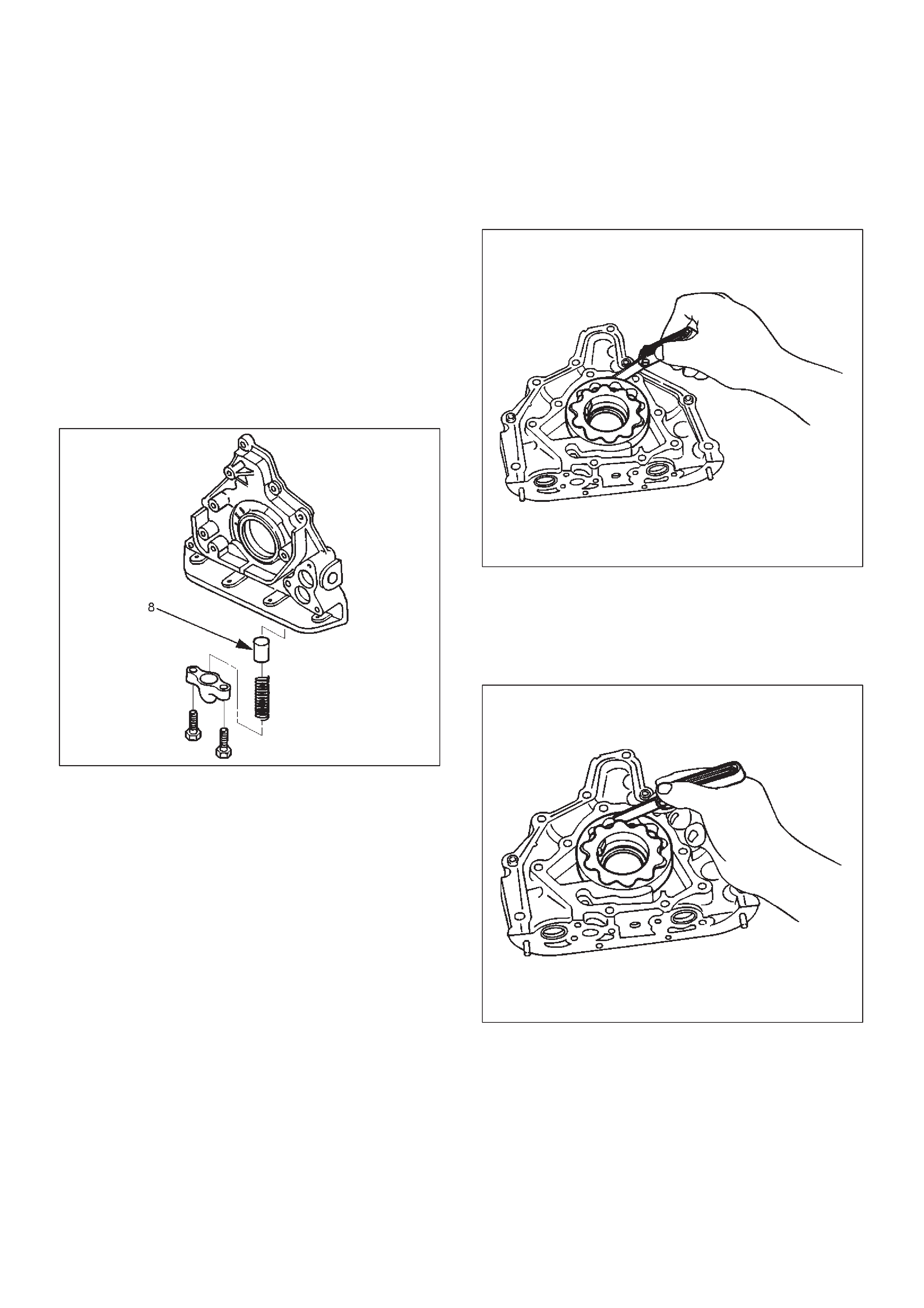

Oil Pump and Associated Parts

051RW005

Legend

(1) Crankshaft Timing Pulley

(2) Crankcase with Oil Pan

(3) Oil Pipe

(4) Oil Strainer

(5) Oil Pump Assembly

(6) Plug

(7) Spring

(8) Relief Valve

(9) Oil Pump Cover

(10) Driven Gear

(11) Drive Gear

(12) Oil Seal

(13) O-ring

(14) Oil Pump Body

Disassembly

1.Remove crankshaft timing pulley.

2.Remove crankcase with oil pan.

3.Remove oil pipe.

4.Remove oil strainer.

5.Remove oil pump assembly.

6.Remove plug.

7.Remove spring.

8.Remove relief valve.

9.Remove oil pump cover.

10.Remove driven gear.

11.Remove drive gear.

12.Remove oil seal.

13.Remove O-ring.

Inspection and Repair

CAUTION:Make necessary correction or parts

replacement if wear, damage or any other abnormal

conditions are found during inspection.

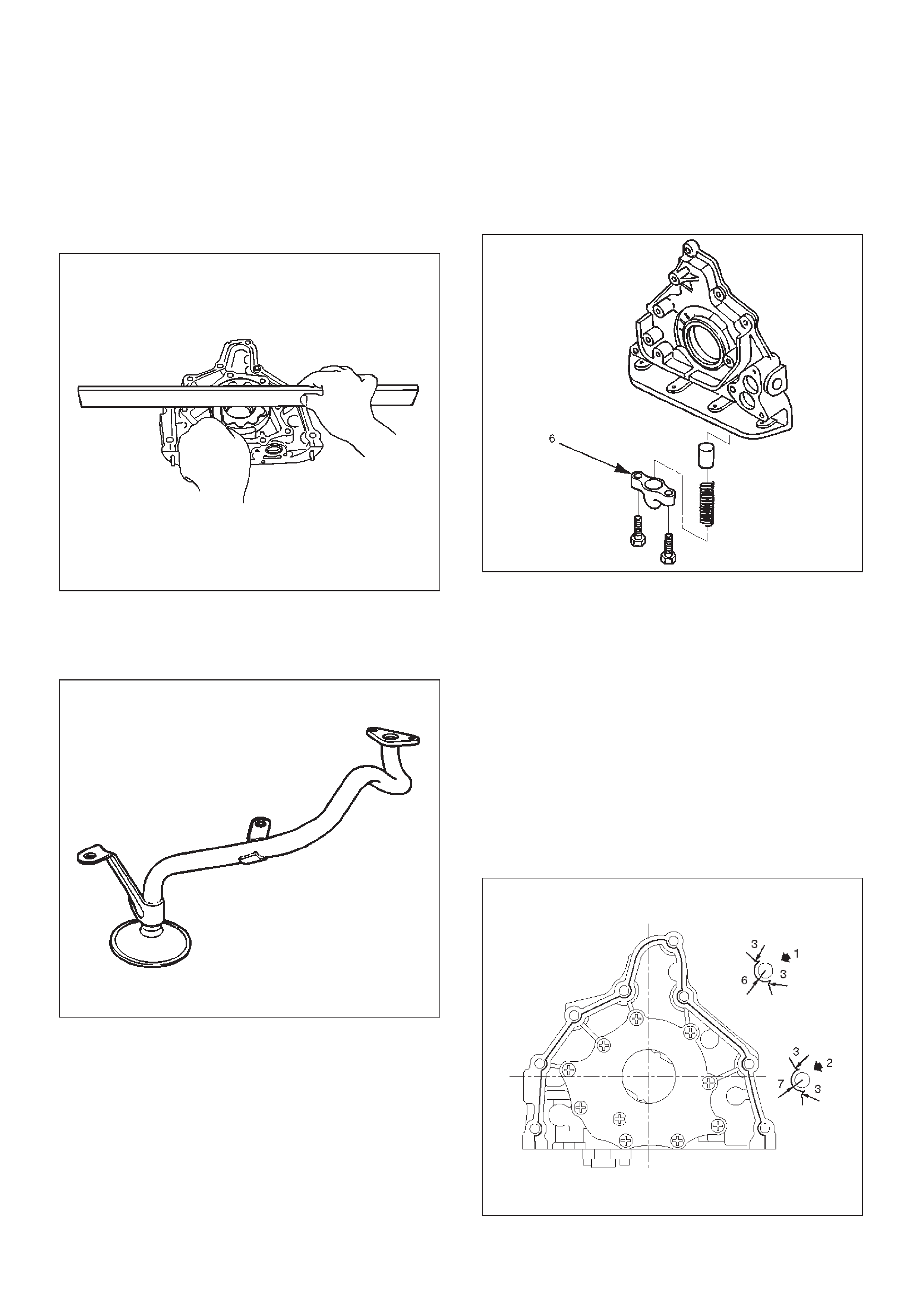

Relief Valve (8)

DCheck to see that the relief valve slides freely.

DThe oil pump must be replaced if the relief valve does

not slide freely.

DReplace the spring and/or the oil pump assembly (5) if

the spring is damaged or badly worn.

051RS002

Body (14) and Gears (10, 11)

The pump assembly must be replaced if one or more of

the conditions below is discovered during inspection.

DBadly worn or damaged driven gear (10).

DBadly worn drive gear (11) driving face.

DBadly scratched or scored body sliding face (14) or

driven gear (10).

DBadly worn or damaged gear teeth.

Measure the clearance between the body and the driven

gear with a feeler gauge.

Standard : 0.10 mm–0.18 mm

(0.0039 in.–0.0070 in)

Limit : 0.20mm (0.0079 in)

051RS004

DMeasure the clearance between the drive gear and

driven gear with a feeler gauge.

Standard : 0.11 mm–0.24 mm

(0.0043 in–0.0094 in)

Limit : 0.35mm (0.0138 in)

051RS003

DMeasure the side clearance with a precision straight

edge and a feeler gauge.

Clearance

Standard : 0.03 mm–0.09 mm

(0.0011 in–0.0035 in)

Limit : 0.15mm (0.0059 in)

051RS005

Oil Strainer

Check the oil strainer for cracking and scoring. If cracking

and scoring are found, the oil strainer must be replaced.

051RS006

Reassembly

1.Install drive gear (11).

2.Install driven gear (10).

3.Install oil pump cover (9) and first, loosely tighten all of

the attaching screws. Next, tighten the attaching

screws to the specified torque.

Torque : 10 N·m (1.0 kg·m/89 lb in)

After installation, check that the gear rotates

smoothly.

4.Install relief valve (8) and apply engine oil to the relief

valve and spring (7).

5.Install spring (7).

6.Install the plug (6).

Torque : 8 N·m (0.8 kg·m/69 lb in)

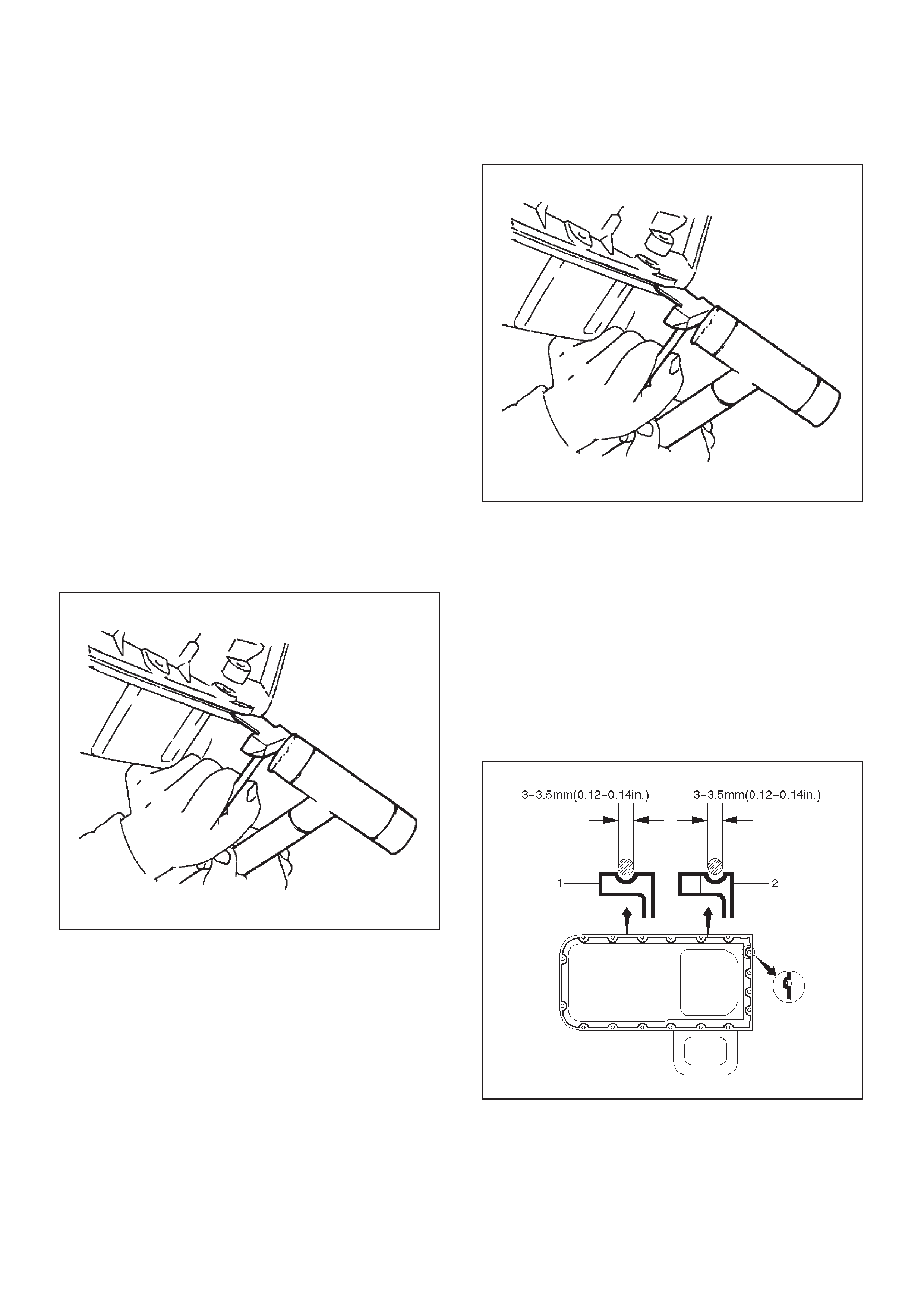

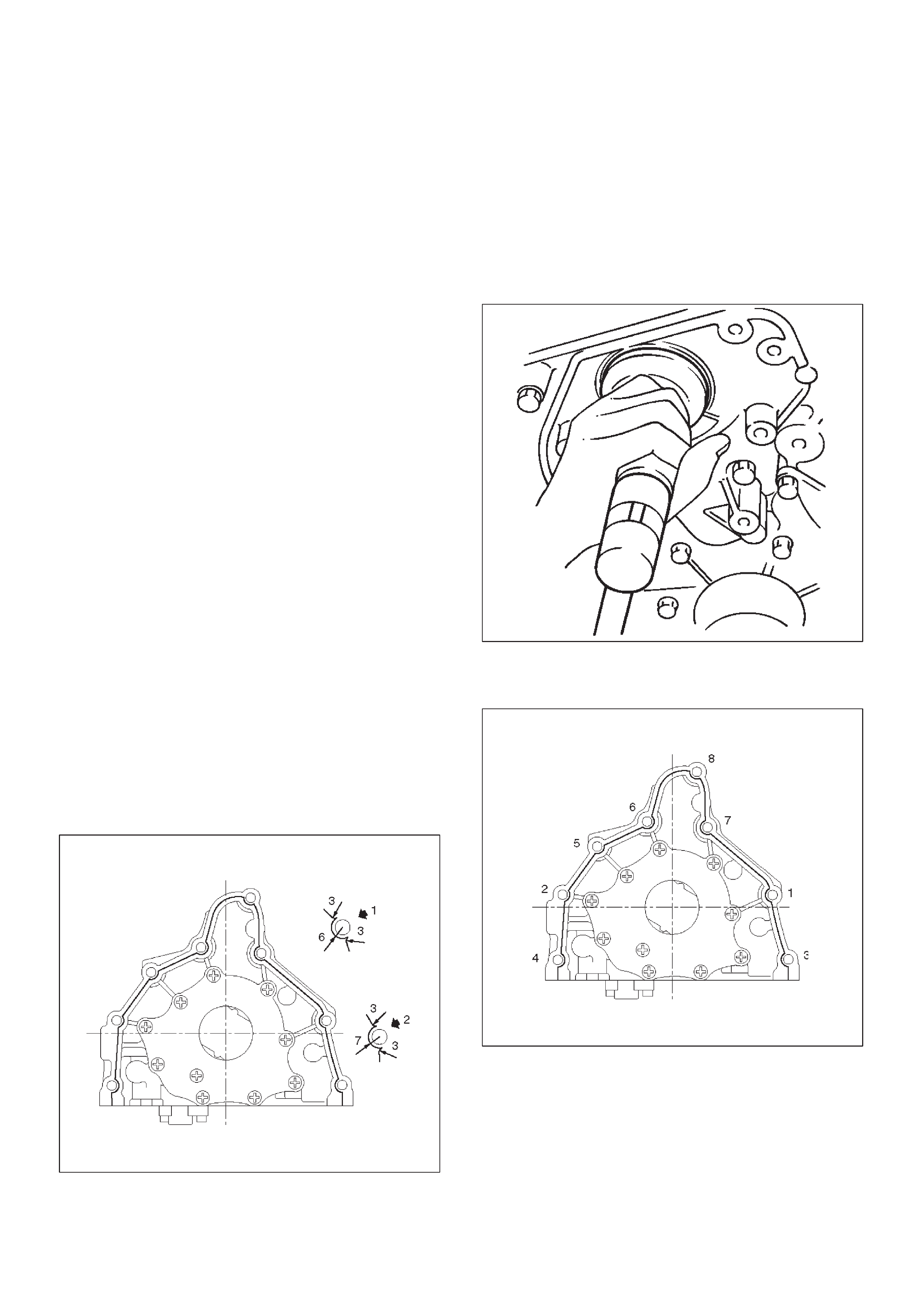

051RS007

7.Install oil pump assembly (5).

DCarefully remove any oil from the cylinder body and

the pump. Apply sealant (TB–1207B or equivalent)

to the pump fitting face as shown in illustration. T ake

care that sealant is not applied to oil port surfaces.

The oil pump assembly must be installed within 5

minutes after sealant application to prevent

premature hardening of sealant.

CAUTION:Do not apply an excessive amount of

sealant to the contact surface. Applying too much

sealant will overflow the contact surfaces. This

could cause serious damage to the engine.

DAttach oil pump assembly to cylinder body.

DTighten the oil pump fixing bolts.

Torque : 25 N·m (2.6 kg·m/18 lb·ft)

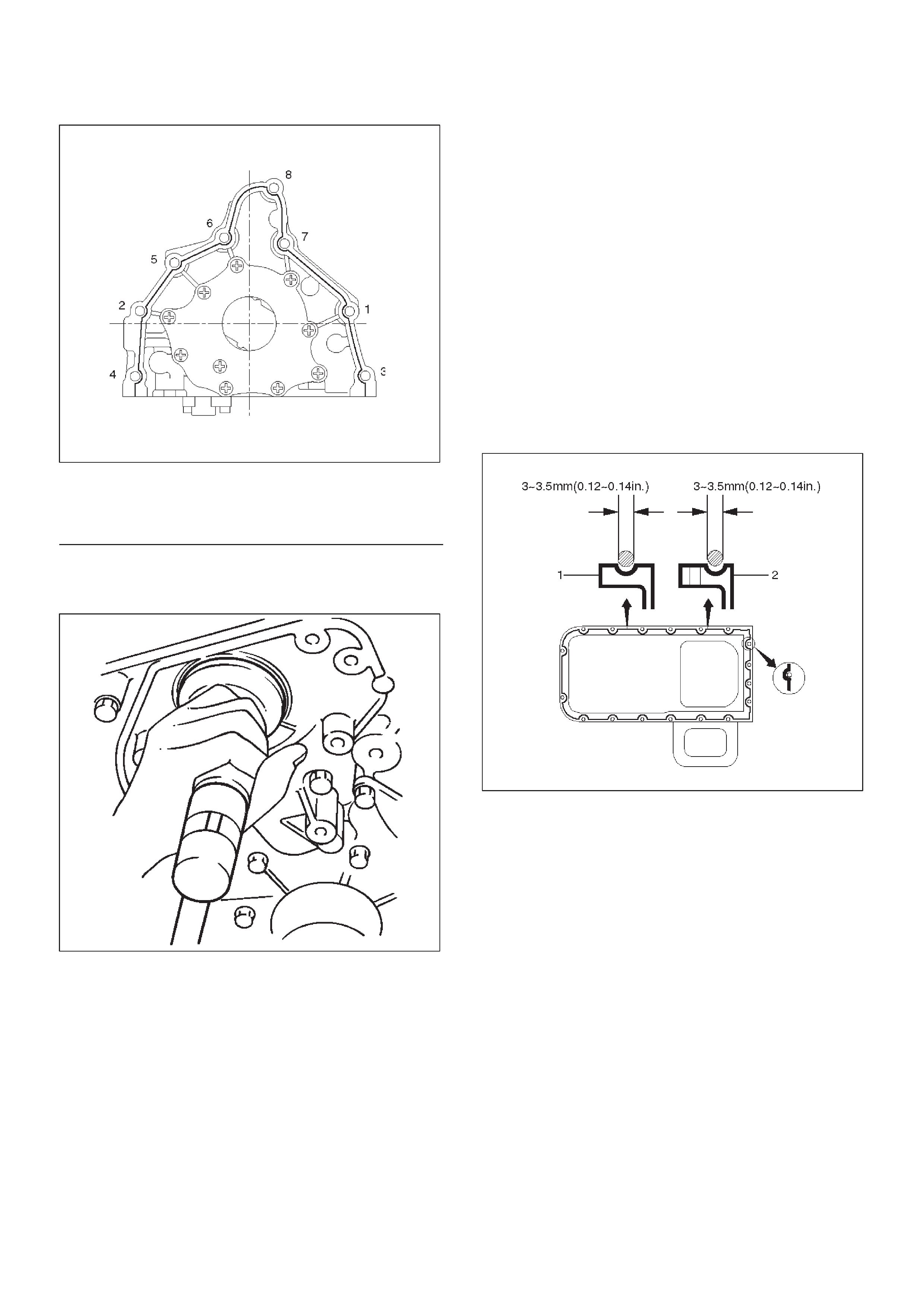

051RW002

051RW001

Legend

(1) Around Bolt Holes

(2) Around Dowel Pin

8.Install the new oil seal (12). Apply engine oil to the oil

seal lip before installation then use 5–8840–2287–0

oil seal Installer, install oil seal.

015RS001

9.Install oil strainer (4) with O-ring (13).

Torque: 25 N·m (2.6 kg·m/18 lb ft)

10.Install oil pipe (3) with O-ring (13).

Torque: 25 N·m (2.6 kg·m/18 lb ft)

11.Install crankcase with oil pan (2).

DRemove oil on crankcase mounting surface and dry

the surface.

DApply a proper 4.5 mm (0.7 in) wide bead of sealant

(TB1207C or equivalent) to the crankcase

mounting surface. The bead must be continuous.

DThe crankcase must be installed within 5 minutes

after sealant application to prevent premature

hardening of sealant.

DTighten fixing bolts to the specified torque.

Torque : 10 N·m (1.0 kg·m/89 lb in)

013RW010

12.Install crankshaft timing pulley.

Oil Pan and Crankcase

Removal

1.Disconnect battery ground cable.

2.Drain engine oil.

3.Lift vehicle by supporting the frame.

4.Remove front wheels.

5.Remove oil level dipstick from level gauge tube.

6.Remove stone guard.

7. Remove radiator under fan shroud.

8.Remove suspension cross member fixing bolts, 2 pcs

each per side and remove suspension cross member.

9.Remove pitman arm and relay lever assembly, using

the 5–8840–2005–0 remover, remove pitman arm

from the steering unit and remove four fixing bolts for

relay lever assembly.

10.Remove axle housing assembly four fixing bolts from

housing isolator side and mounting bolts from wheel

side. At this time support the axle with a garage jack

and remove axle housing assembly.

11.Remove oil pan fixing bolts.

12.Remove oil pan, using 5–8840–2153–0 sealer cutter ,

remove oil pan.

013RS003

13.Remove crankcase fixing bolts.

14. Remove crankcase, using 5–8840–2153–0 sealer

cutter, remove crankcase.

NOTE: Do not deform or damage the flange of oil pan and

crankcase.

Replace the oil pan and/or crankcase if deformed or dam-

aged.

013RS003

Installation

1.Install crankcase.

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of crankcase.

Sealant beat must be continuous.

DThe crankcase must be installed within 5

minutes after sealant application before the

sealant hardens.

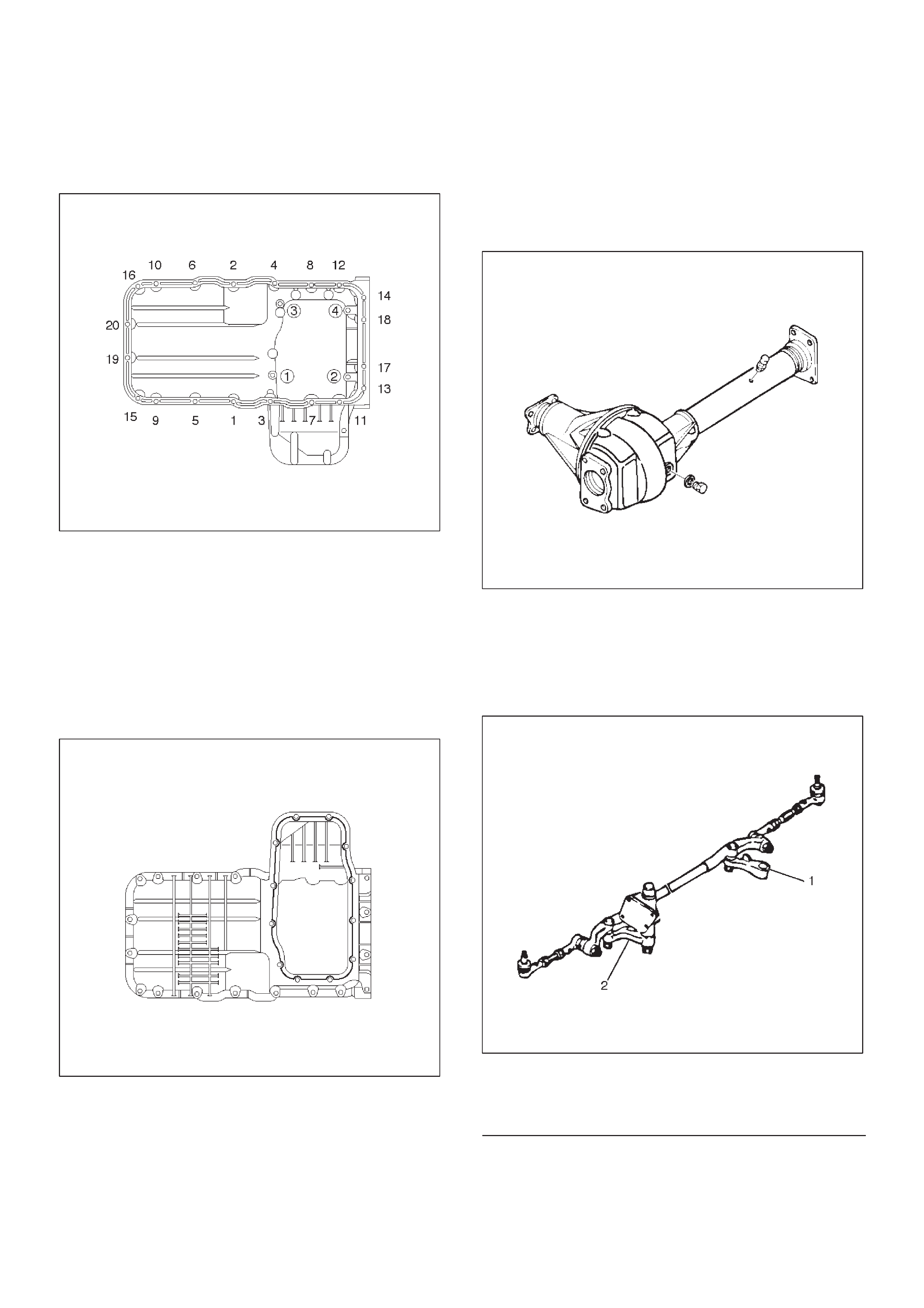

013RW010

3. Install crankcase, tighten crankcase fixing bolts

to the specified torque.

Torque : 10 N·m (1.0 kg·m/89 lb in)

013RW004

2.Install oil pan

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (07 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of oil pan.

Sealant beat must be continuous.

DThe crankcase must be installed within 5

minutes after sealant application befor the

sealant hardens.

013RW003

3. Install oil pan, tighten oil pan fixing bolts to the

specified torque.

Torque : 25 N·m (2.5 kg·m/18 lb ft)

3.Install axle housing assembly and tighten fixing bolts

to the specified torque.

Axle case bolts

Torque : 82 N·m (8.4 kg·m/60 lb ft)

Mounting bolts

Torque : 152 N·m (15.5 kg·m/112 lb ft)

013RW005

4.Install relay lever assembly and tighten fixing bolts.

Torque: 44 N·m (4.5 kg·m/32 lb ft)

5.Engage teeth of pitman arm and steering unit, and

tighten nut to the specified torque.

Torque : 216 N·m (22.0 kg·m/159 lb ft)

013RW006

Legend

(1) Pitman Arm

(2) Relay Lever

6.Install suspension cross member and tighten fixing

bolts to the specified torque.

Torque : 78 N·m (8.0 kg·m/58 lb ft)

013RW007

7.Install radiator under fan shroud.

8.Install stone guard.

9.Install engine oil level dipstick.

10.Fill engine oil until full level on engine oil gauge

dipstick.

Oil Pump

Removal

1.Disconnect battery ground cable.2.Drain engine oil.

3.Remove crankcase assembly.

D Refer to removal procedure for Oil Pan and

Crankcase in this section.

4.Remove crankshaft pulley.

DRefer to removal procedure for Crankshaft Pulley in

this service information.

5.Remove timing belt.

DRefer to removal procedure for Timing Belt in this

service infromation.

6.Remove timing pulley from crankshaft.

7.Remove four fixing bolts from oil filter assembly.

8. Remove oil strainer fixing bolts, remove oil strainer

assembly with O-ring.

9.Remove three bolts from oil pipe and O-ring.

10. Remove eight oil pump fixing bolts, then oil pump

assembly.

11.Remove sealant from mounting surface of oil pump

assembly , cylinder block and take care not to damage

mounting surfaces of oil pump and cylinder block.

Installation

1.Install oil pump assembly

DApply sealant (TB-1207B or equivalent) to the oil

pump mounting surfaces as shown in the

illustration.

DThe oil pump assembly must be installed within 5

minutes after sealant application before the sealant

hardens.

NOTE: Do not apply sealant to the oil ports.

051RW002

DUse 5–8840–2287–0 installer when installing new

oil seal.

DApply engine oil to oil seal lip.

DInstall oil pump assembly to the cylinder block.

NOTE: Do not damage oil seal during installation of oil

pump assembly.

015RS001

DTighten fixing bolts to the specified torque.

Torque : 25 N·m (2.5 kg·m/18 lb ft)

051RW001

2.Install oil pipe with O-ring, tighten fixing bolt to the

specified torque.

Torque : 10 N·m (1.0 kg·m/89 lb in)

3.Install oil strainer with O-ring, tighten fixing bolt to the

specified torque.

Torque : 25 N·m (2.5 kg·m/18 lb ft)

4.Install oil filter assembly and tighten bolts to the

specified torque.

Torque : 25 N·m (2.5 kg·m/18 lb ft)

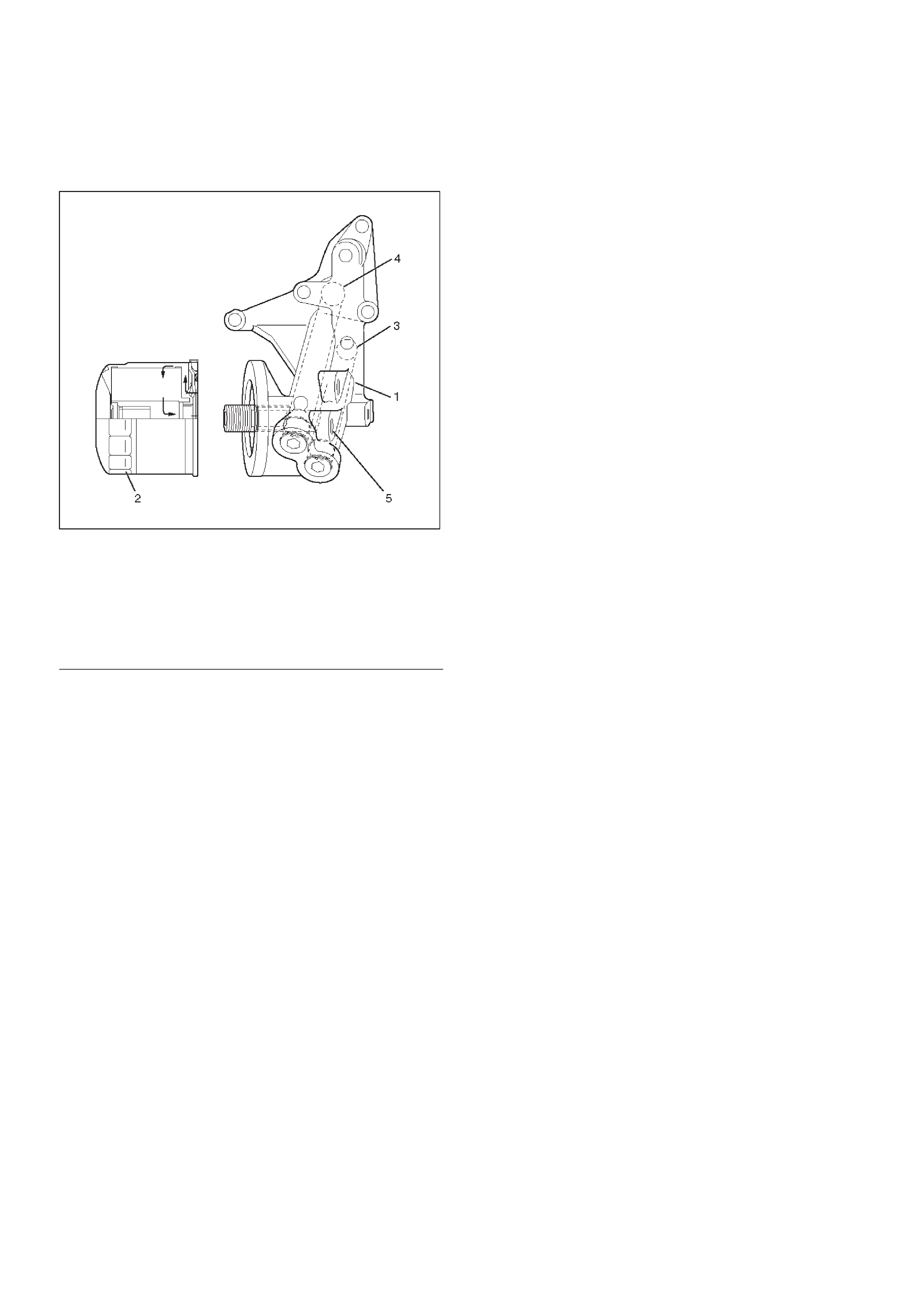

050RW001

Legend

(1)Oil Pump

(2)Oil Filter

(3)Oil Gallery

(4)From Oil Filter

(5)To Oil Filter

5.Install timing pulley on crankshaft.

Install timing belt.

DRefer to installation procedure for Timing Belt in this

service information.

6.Install crankshaft pulley.

DRefer to install procedure for Crankshaft Pulley in

this service information.

7.Install crankcase assembly.

DRefer to installation procedure for Oil Pan and

Crankcase in this section.

8.Refill engine oil until full level on engine oil dipstick.

Oil Pump Oil Seal

Removal

1.Disconnect battery ground cable.

2.Drain engine oil.

3.Remove crankshaft pulley.

DRefer to removal procedure for Crankshaft Pulley in

this service information.

4.Remove timing belt.

DRefer to removal procedure for Timing Belt in this

information.

5.Remove timing pulley from crankshaft.

6.Remove oil pump oil seal using a sealer puller.

NOTE:Take care not to damage sealing surfaces of oil

pump and crankshaft when removing oil seal.

Installation

1.Install oil pump oil seal, apply engine oil to oil seal lip,

then install oil seal using 5–8840–2287–0 installer.

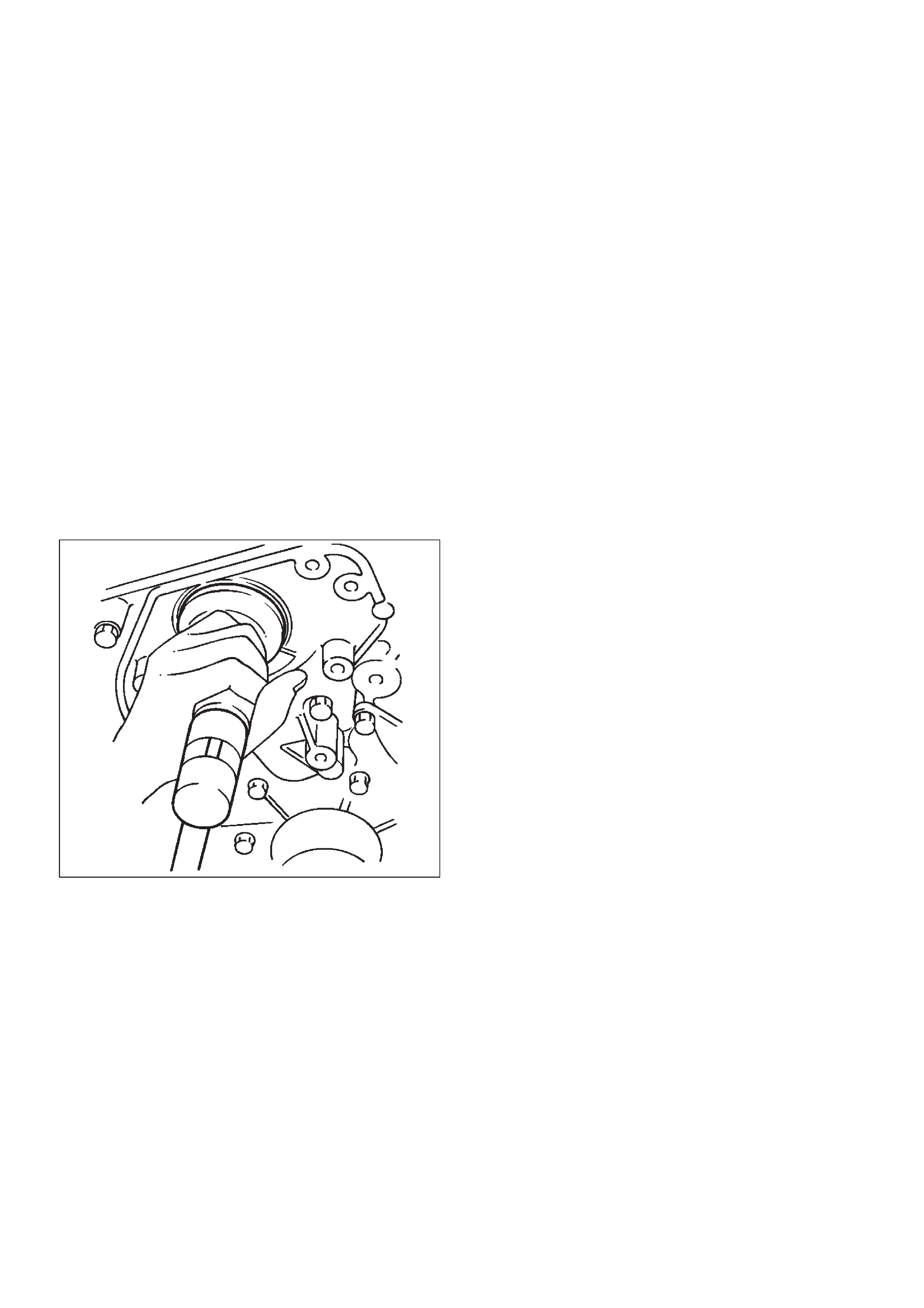

015RS001

2.Install timing pulley to crankshaft.

3.Install timing belt.

DRefer to installation procedure for Timing Belt in this

service information.

4.Install crankshaft pulley.

DRefer to installation procedure for Crankshaft

Pulley in this service information.

5.Refill engine oil until full level.

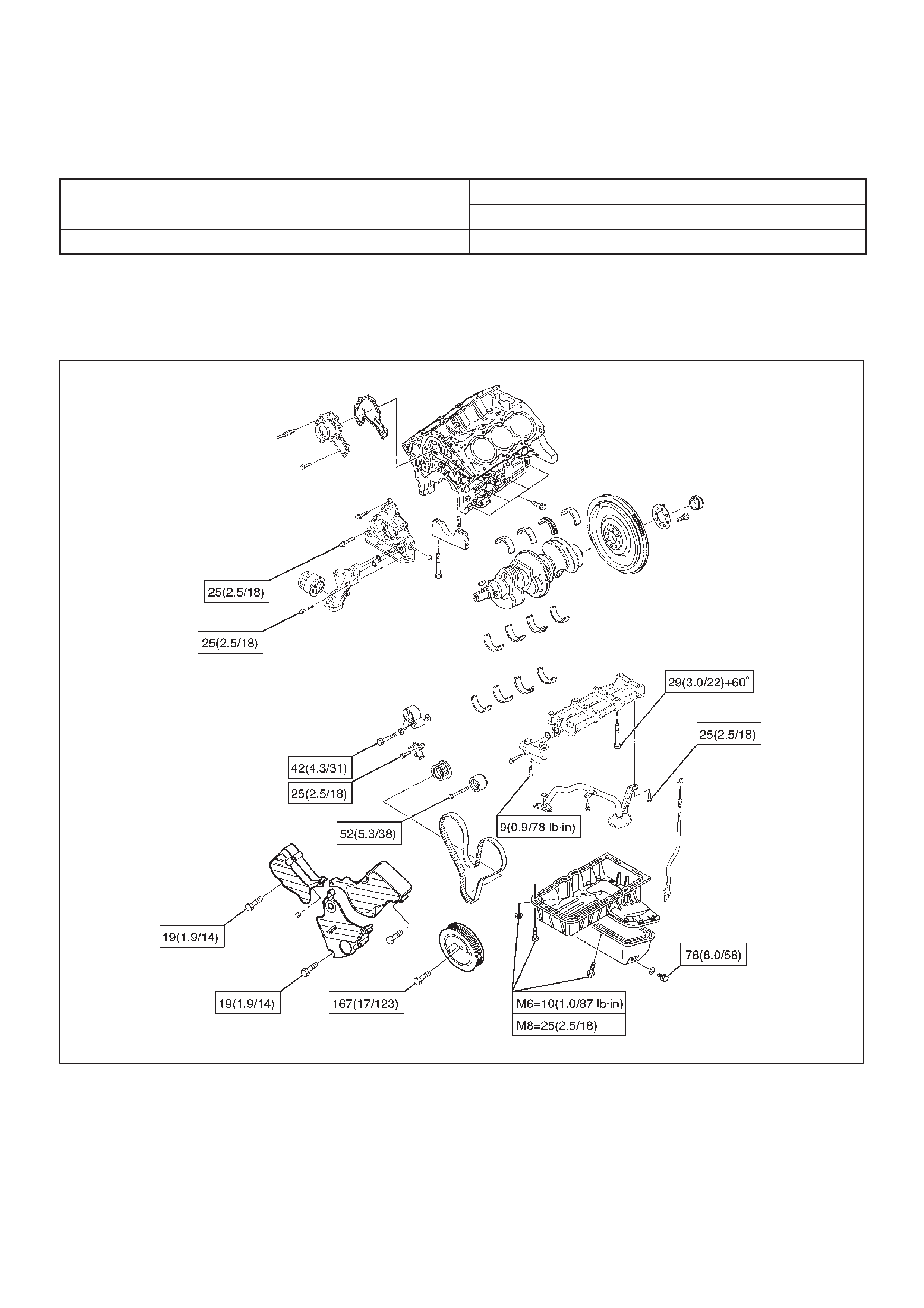

Main Data and Specification

General Specification

Item

Specifications

Item

6VD1

Oil capacity 5.3 liters

Torque Specifications

Crankcase, Oil pan, Timing belt tensioner, Timing pulley, timing belt cover, Oil pump, Oil gallery, Oil strainer

N·m (kg·m/ lb·ft)

E06RW045