SECTION 6B - ENGINE COOLING (C22NE MODELS)

GENERAL DESCRIPTION

SERVICE PRECAUTION

WATER PUMP

THERMOSTAT

RADIATOR

DIAGNOSIS

ENGINE COOLING TROUBLE

DRAINING AND REFILLING COOLING SYSTEM

WATER PUMP

WATER PUMP AND ASSOCIATED PARTS

REMOVAL

INSPECTION

INSTALLATION

THERMOSTAT

REMOVAL

INSPECTION

INSTALLATION

FAN CLUTCH WITH COOLING FAN

INSPECTION AND REPAIR

RADIATOR

RADIATOR AND ASSOCIATED PARTS

REMOVAL

INSPECTION

RADIATOR CAP

RADIATOR CORE

FLUSHING THE RADIATOR

COOLING SYSTEM LEAKAGE CHECK

INSTALLATION

MAIN DATA AND SPECIFICATIONS

GENERAL SPECIFICATIONS

SPECIAL SERVICE TOOL

Techline

Techline

Techline

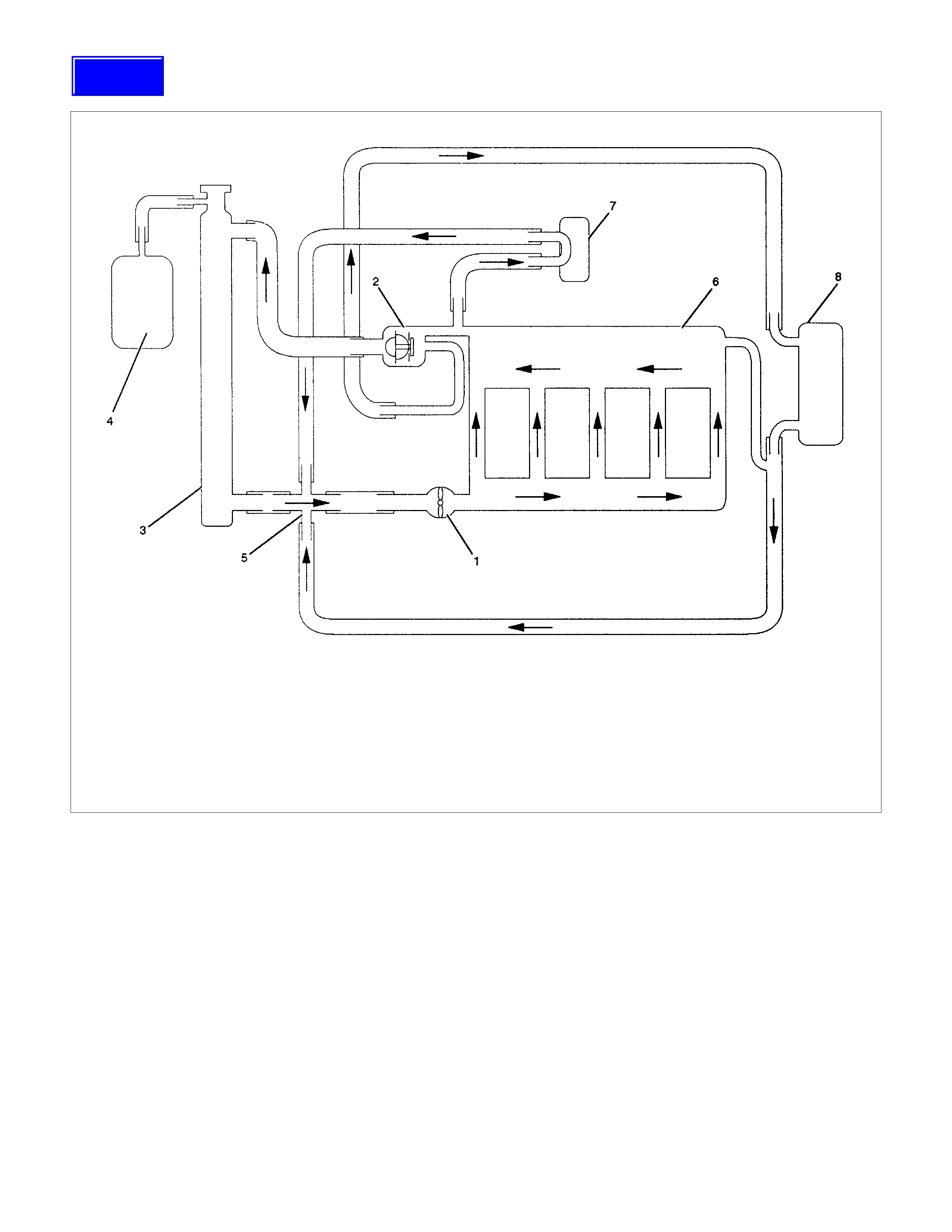

GENERAL DESCRIPTION

Legend

1 Water Pump

2 Thermostat

3 Radiator

4 Reserve Tank

5 Coolant Distributor

6 Cylinder Block and Head

7 Throttle Body

8 Heater

The Cooling System is a pressurized type, where the water pump, which is cam-belt driven, forces the circulation of the

coolant through the cylinder block and head. The thermostat regulates the flow of coolant between the radiator and the

bypass circuit. The heater is part of the bypass circuit. The throttle body pre-heat is a separate circuit, which is not

regulated by the thermostat. An oil cooler may be fitted as part of this circuit.

Techline

SERVICE PRECAUTION

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. HOLDEN will call out those

fasteners that require a replacement after removal.

HOLDEN will also call out the fasteners that require thread

lockers or thread sealant. UNLESS OTHERWISE

SPECIFIED, do not use supplemental coatings (Paints,

greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When you

install fasteners, use the correct tightening sequence and

specifications. Following these instructions can help you

avoid damage to parts and sys tems.

WATER PUMP

The water pump is centrifugal type and is driven by the

camshaft timing belt.

THERMOSTAT

The thermostat is a bypass type and is a wax pellet type with

an air hole (1).

RADIATOR

The radiator is a flow type with corrugated fins.

COOLANT

50% HN 2043 with w a ter

DIAGNOSIS

ENGINE COOLING TROUBLE

CONDITION POSSIBLE CAUSE CORRECTION

Engine overheating Low Engine Coolant level Replenish

Faulty Temp. Gauge unit faulty Replace

Faulty thermostat Replace

Faulty Engine Coolant temperature

sensor Repair or replace

Clogged radiator Clean or replace

Faulty radiator cap Replace

Low engine oil level or use of

improper engine oil Replenish or change oil

Clogged exhaust system Clean exhaust system or replace

faulty parts

Faulty Throttle Position sensor Replace throttle valve assembly

Open or shorted Throttle Position

sensor circuit Repair or replace

Damaged cylinder head gasket Replace

Loosen V-belt tension Adjust belt tension or replace.

Collapsed hoses Replace

Faulty Fan clutch Replace

Engine overcooling Faulty thermostat Replace

Engine slow to warm-up Faulty thermostat Replace

Temp gauge faulty Replace

DRAINING AND REFILLING COOLING SYSTEM

Before draining the cooling system, inspect the system and

perform any necessary service to ensure that it is clean, does

not leak and is in proper working order. The engine coolant

(EC) level should be between the "MIN" and "MAX" lines of

reserve tank when the engine is cold. If low, check for leakage

and add EC up to the "MAX" line. There should not be any

excessive deposit of rust or scales around the radiator cap or

radiator filler hole, and the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Completely drain the cooling system by opening the drain

plug at the bottom of the radiator.

2. Remove the radiator cap.

WARNING:

TO AVOID THE DANGER OF BEING BURNED, DO NOT

REMOVE THE CAP WHILE THE ENGINE AND RADIATOR

ARE STILL HOT. SCALDING FLUID AND STEA M CAN BE

BLOWN OUT UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the ins ide of the reserve tank with soap and

water. Flush it well with clean water, and then drain it.

Install the reserve tank and hoses.

4. Refill the cooling system with 50% HN 2043 coolant with

water.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to "MAX" line when the engine is

cold.

6. Block the drive wheels and firmly apply the park ing brake.

Shift an autom atic transm ission to "P" (Park ) or a manual

transmission to neutral.

7. Remove the r adiator cap. Start the engine and warm it up

at 2,500 - 3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck and

the EC level has gone down, replenish with the EC.

Repeat this procedure until the EC level does not go

down. Then stop the engine and install the radiator cap.

Let the engine cool down.

9. After the engine has cooled, replenish with EC up to the

"MAX" line of the reserve tank.

10. Start the engine. With the engine running at 3,000 rpm,

make sure there is no running water sound from the

heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to 10.

WATER PUMP

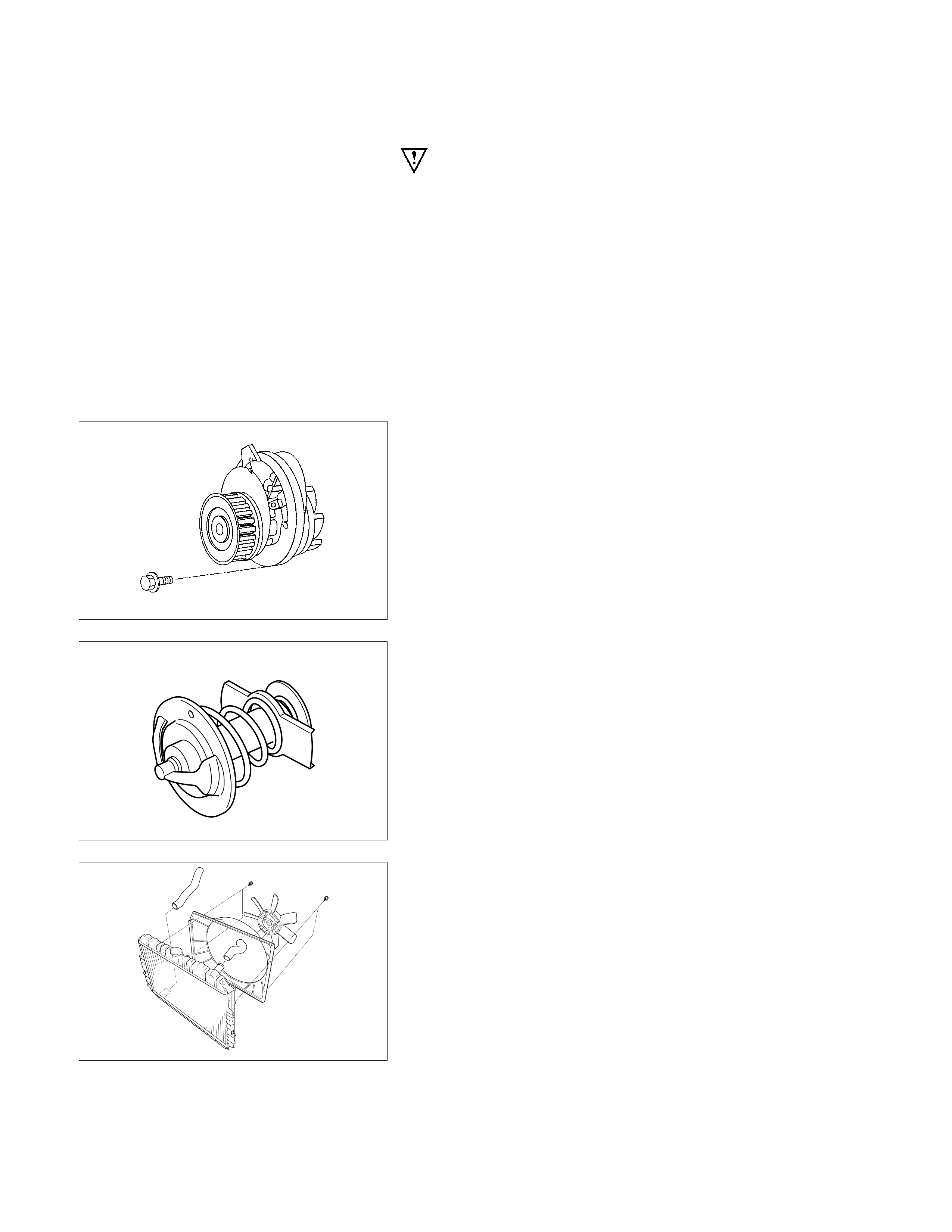

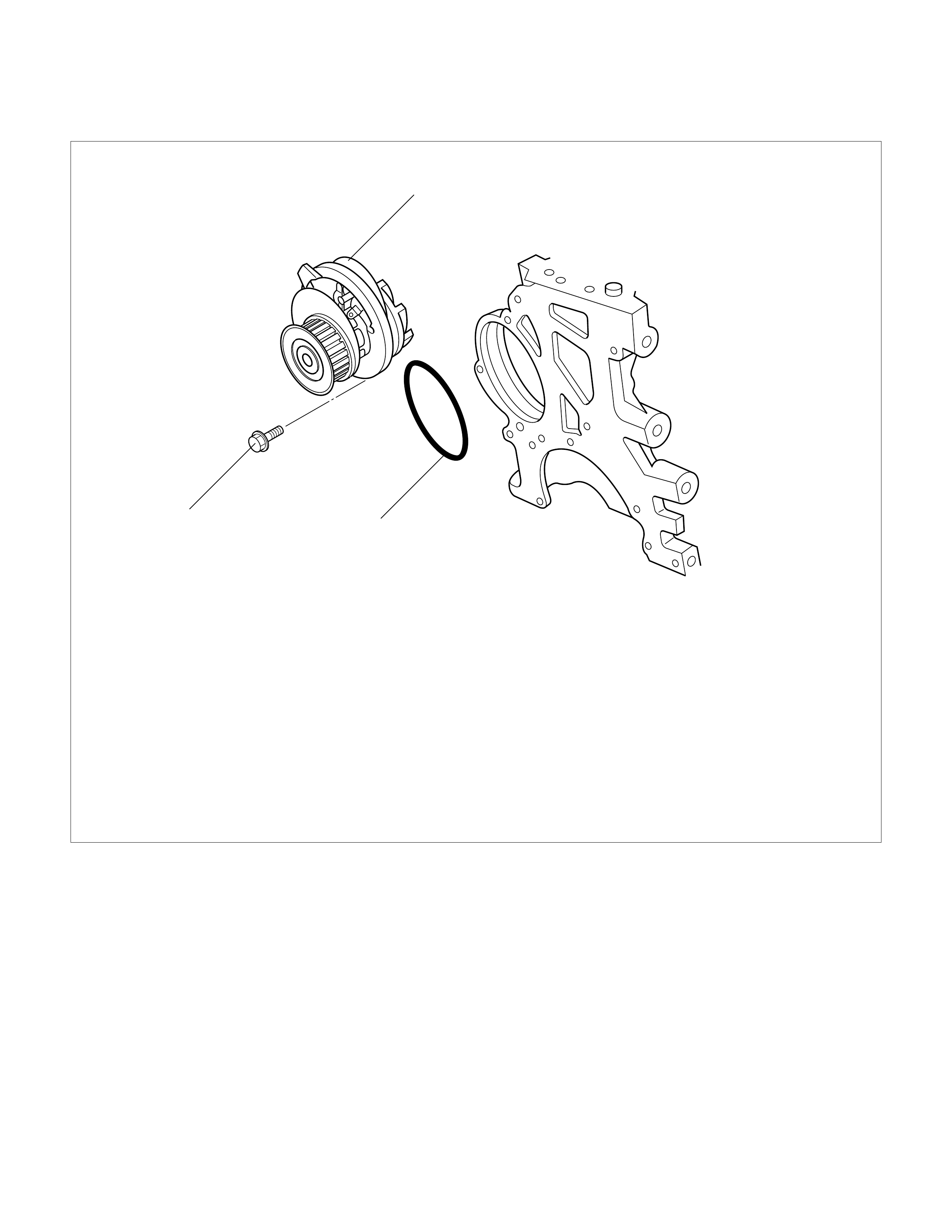

WATER PUMP AND ASSOCIATED PARTS

Legend

1 Water Pump Assembly 2 O-Ring

3 Bolt

2

3

1

REMOVAL

1. Disconnect battery ground cable.

2. Drain coolant.

3. Radiator hose (on inlet pipe side).

4. Remove timing belt, refer to "Timing Belt" in this manual.

5. Remove water pump assembly.

INSPECTION

Make necessary repair and parts replacement if extreme wear

or damage is found during inspection. Should any of the

following problems occur, the entire water pump assembly

must be replaced:

•Crack in the water pump body

•EC leakage from the seal unit

•Play or abnormal noise in the bearing

•Cracks or corrosion in the impeller

INSTALLATION

1. Before installing water pump, coat sealing surface with

silicon grease.

2. Install water pump assembly and tighten bolts to the

specified torque.

Torque: 25 N⋅

⋅⋅⋅m (2.5 kgf.m)

3. Timing belt

•Install timing belt, refer to timing belt installation step in

"Timing Belt" in this manual.

4. Connect radiator hose and replenish EC.

5. Connect battery ground cable.

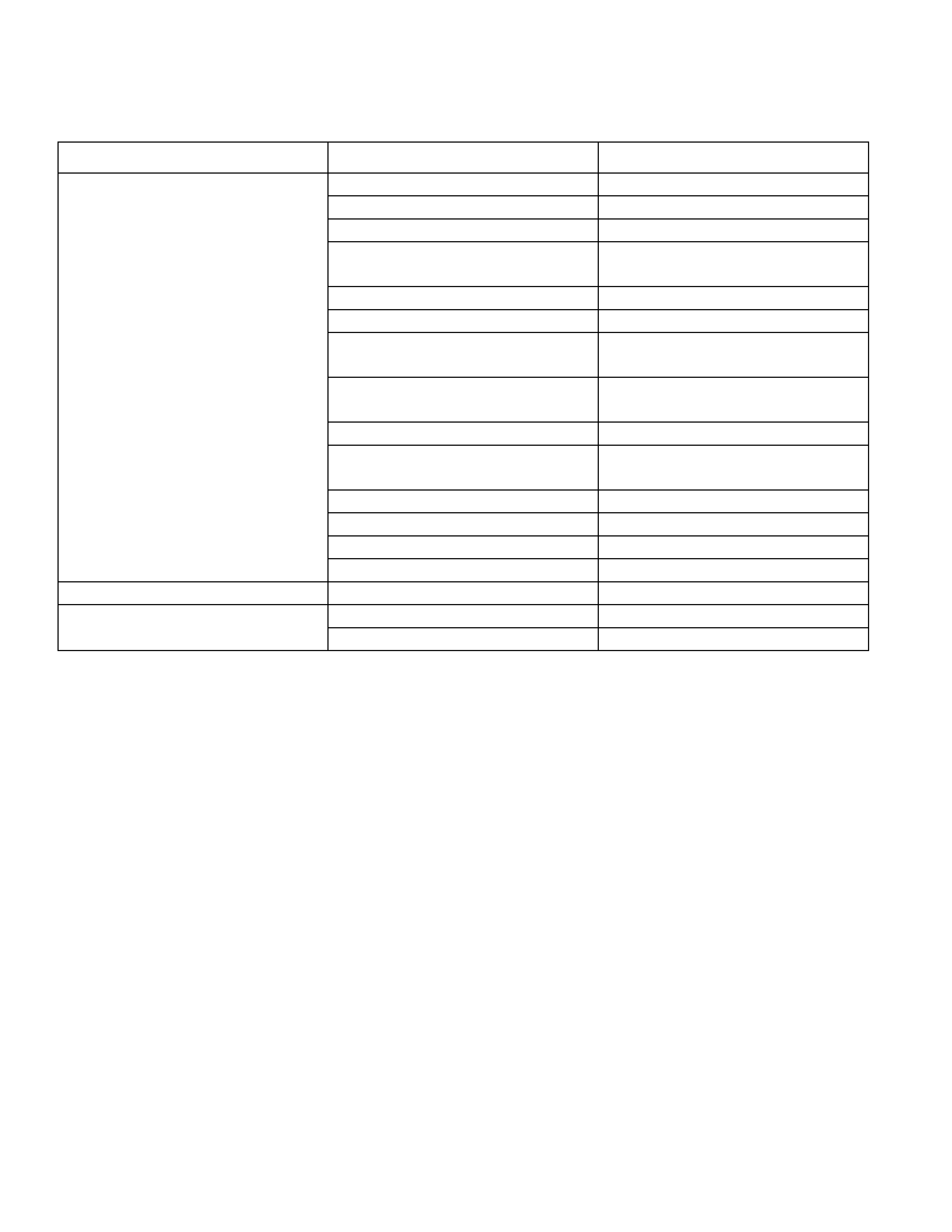

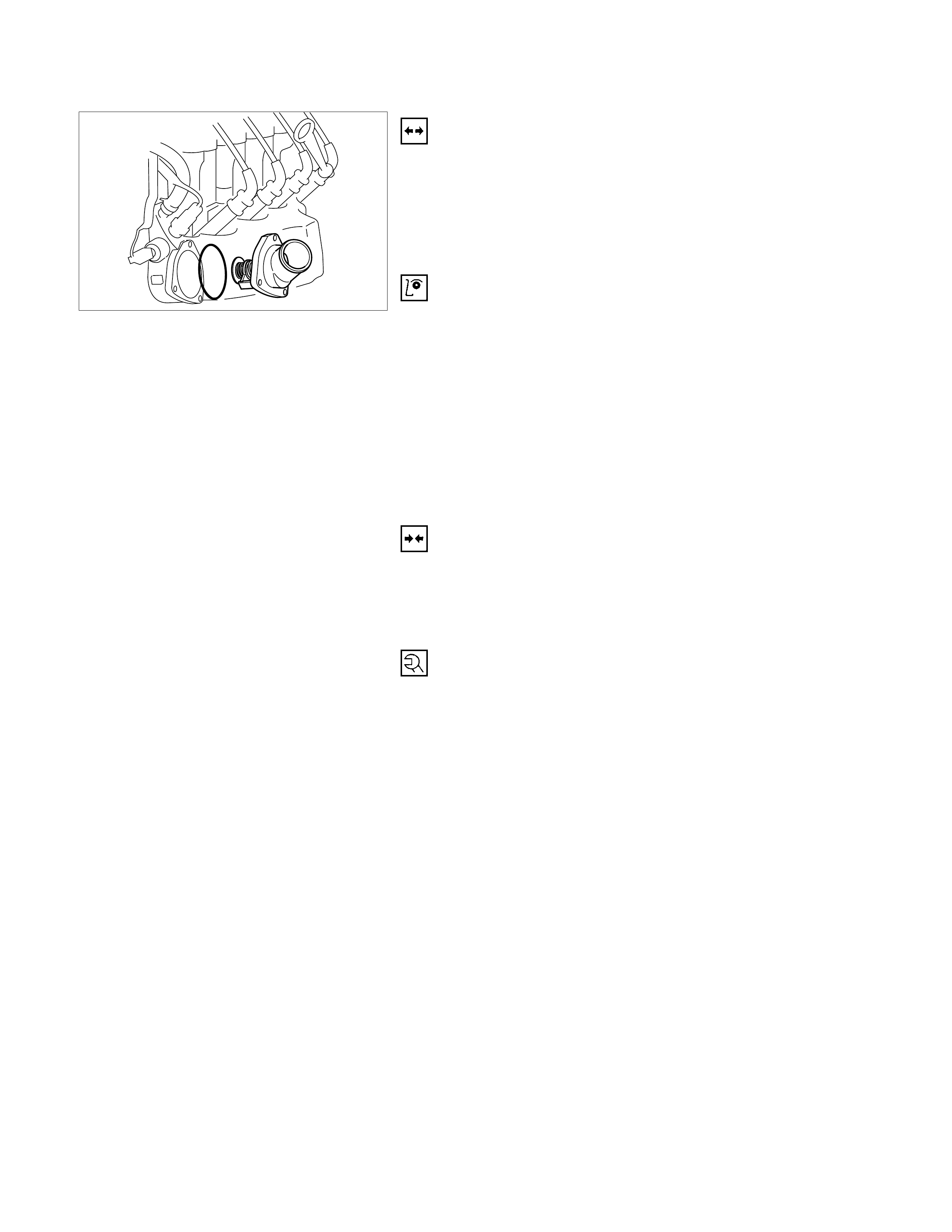

THERMOSTAT

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant from the radiator and engine.

3. Disconnect radiator hose from the inlet pipe.

4. Remove thermostat housing.

5. Remove thermostat from thermostat housing.

INSPECTION

Suspend the thermostat in a water-filled container using thin

wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water so

that the entire water is same temperature.

Confirm the temperature when the valve first begins to open.

Valve opening temperature 92°

°°

°C (197.6°

°°

°F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature 107°

°°

°C(224.6°

°°

°F)

Make necessary repairs and parts replacement if extreme

wear or damage is found during inspection.

INSTALLATION

1. Before installing thermostat, coat sealing surface with

silicon grease.

2. Install O-ring.

3. Install thermos tat housing and tighten bolts to the specified

torque.

Torque: 15 N⋅

⋅⋅⋅m (1.5 kgf.m)

4. Installation rubber hose.

5. Replenish engine coolant (EC).

6. Start engine and check for EC leakage.

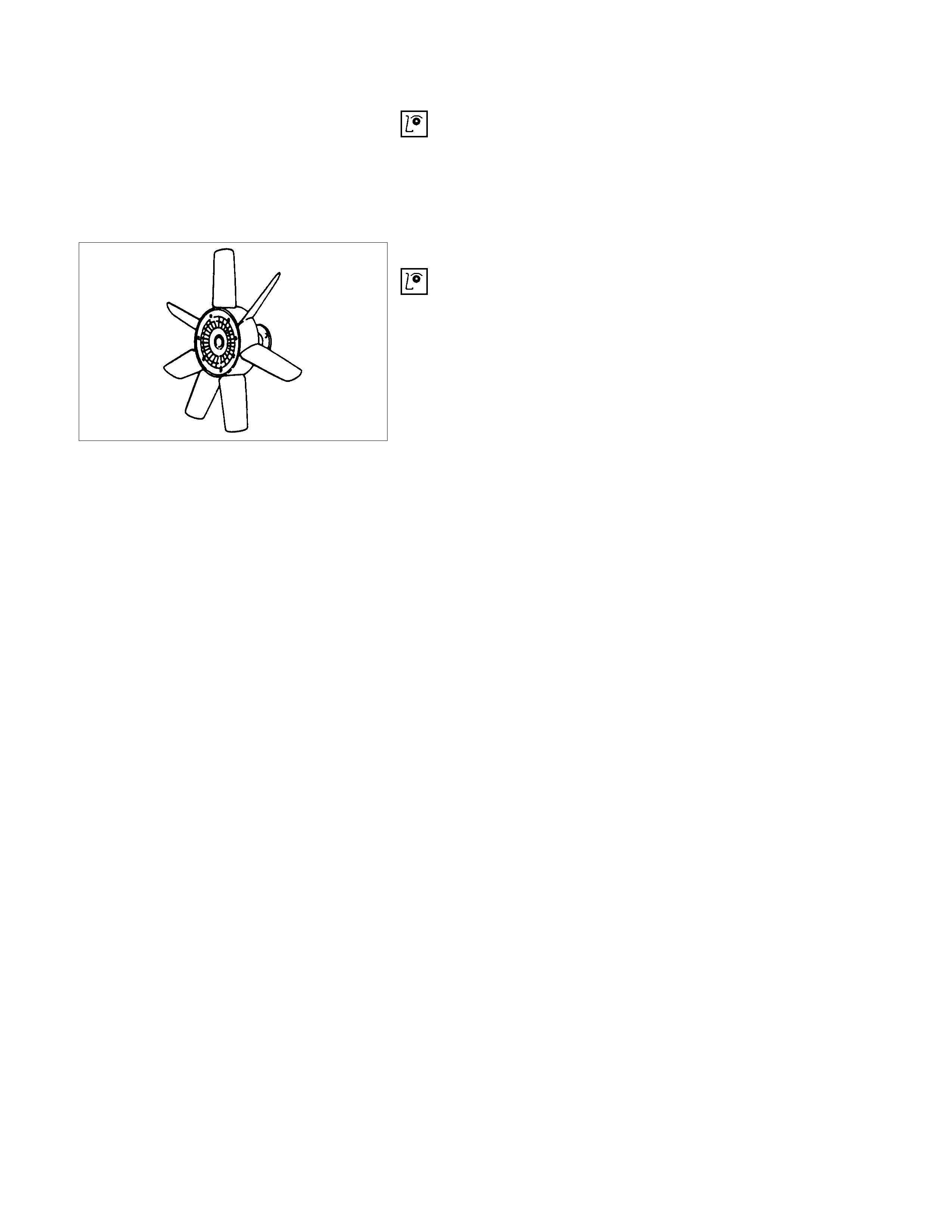

FAN CLUTCH WITH COOLING FAN

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear,

damage or any other abnormal condition is found through

inspection.

Visually inspect for damage, leak (silicon grease) or other

abnormal conditions.

1. Inspection (on-vehicle)

1) Turn the fan clutch by hand when in a low temperature

condition before starting the engine, and confirm that it

can be turned readily.

2) Start the engine to warm it up until the temperature at the

fan clutch portion gets to around 80°C. Then stop the

engine and confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned by hand.

If the fan clutch rotates more readily, however, this

indicates that the silicon grease is leaking internally.

Replace the fan clutch with a new one.

2. Inspection (in unit)

Warm up the bimetal of the f an c lutch by using the heat gun

until the temperature gets to about 80°C when measured

with the thermistor . Then confir m that the fan clutc h can be

turned with considerable effort (clutch torque).

If the fan clutch rotates m ore readily at this tim e, this indicates

that the silicon grease is leaking internally.

Replace the fan clutch with a new one.

RADIATOR

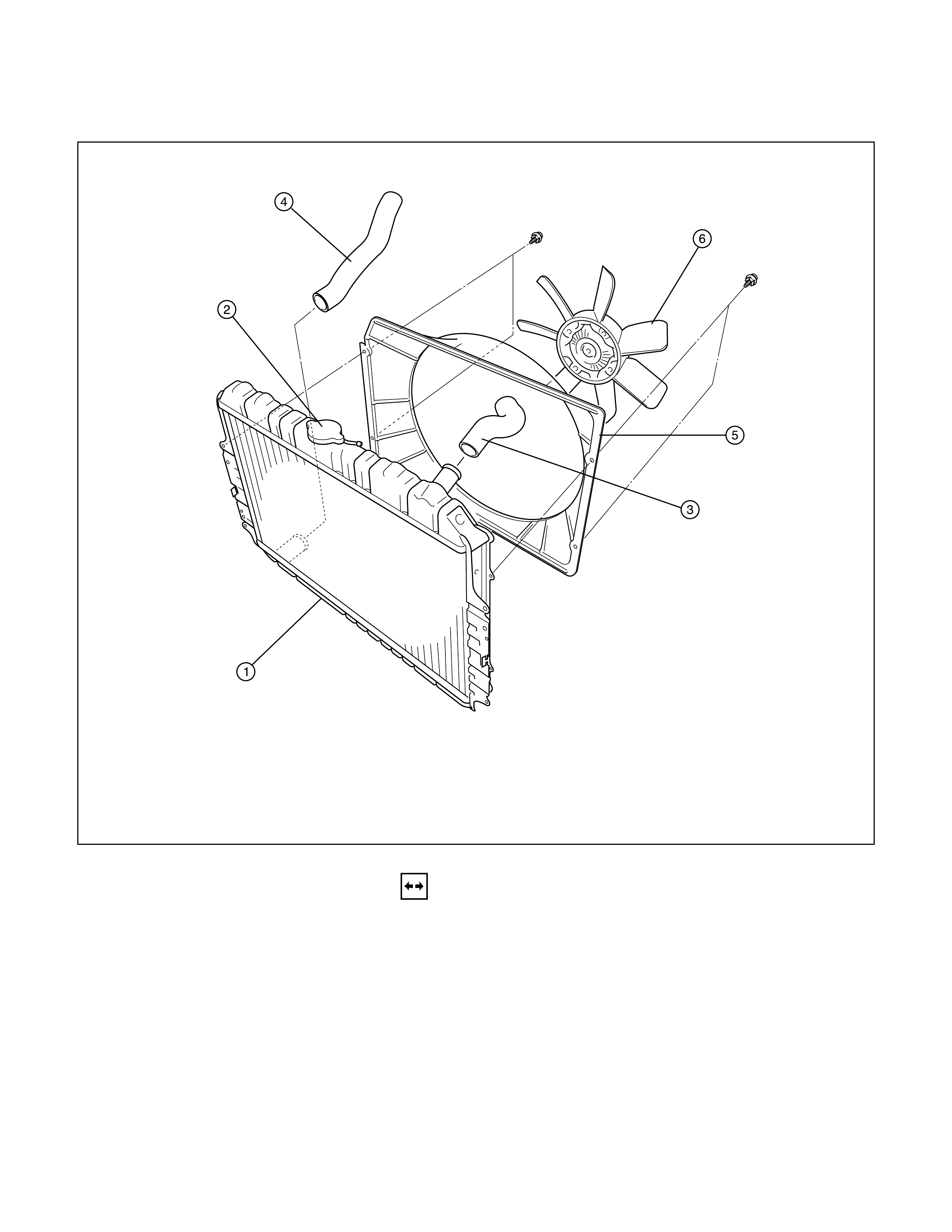

RADIATOR AND ASSOCIATED PARTS

Legend

1 Radiator

2 Radiator Cap

3 Radiator Upper Hose

4 Radiator Lower Hose

5 Cooling Fan Shroud

6 Cooling Fan

REMOVAL

1. Disconnect battery ground cable.

2. Loosen a drain plug to drain engine coolant (EC).

3. Disconnect radiator inlet hose and outlet hose.

4. Disconnect the reserve tank hose from radiator.

5. Lift out the radiator assembly, taking care not to damage

the radiator core.

INSPECTION

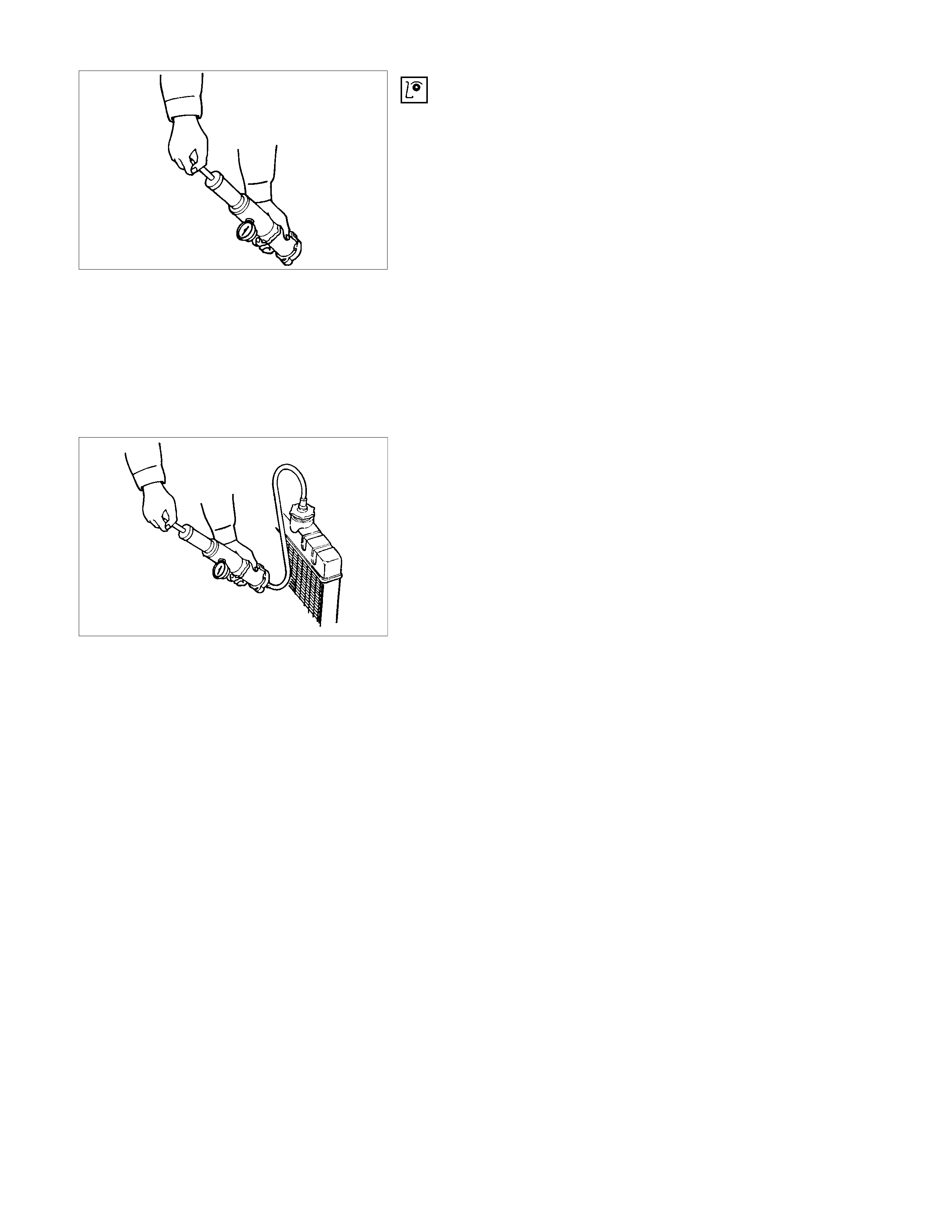

RADIATOR CAP

Measure the valve opening pressure of the pressurizing valve

with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside the

standard range.

Valve opening pressure kPa (psi) 88.3 - 1117.7

(13.5 - 17.8)

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

Check the condition of the vacuum valve in the center of the

valve seat side of the cap. If considerable rust or dirt is found,

or if the valve seat cannot be moved by hand, clean or replace

the cap.

Valve opening vacuum kPa (psi) 1.9 - 4.9

(0.28 - 0.71)

RADIATOR CORE

1. A bent fin m ay result in r educed ventilation and overheating

may occur. All bent fins must be straightened. Pay close

attention to the base of the fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

FLUSHING THE RADIATOR

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent. Remove

all sign of scale and rust.

COOLING SYSTEM LEAKAGE CHECK

Use a radiator cap tester to force air into the radiator through

the filler neck at the specified pressure of 196 kPa (28.5 psi)

with a cap tester:

•Leakage from the radiator

•Leakage from the coolant pump

•Leakage from the water hoses

•Check the rubber hoses for swelling.

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

INSTALLATION

1. Install radiator assembly, taking care not to damage the

radiator core.

2. Install the radiator assembly.

3. Connect reserve tank hose.

4. Connect radiator inlet hose and outlet hose.

5. Pour engine coolant up to filler neck of radiator, and up to

MAX mark of reserve tank.

Important operation (in case of 100% engine coolant

change) procedure for filling with engine coolant.

•Remove radiator cap.

•Fill with engine coolant (EC) to the radiator filler neck.

•Fill with EC to the "MAX" line on the reservoir tank.

•Start the engine with the radiator cap removed and bring to

operating temperature by running engine at 2,500 - 3,000

rpm for 30 minutes.

•By EC temperature gauge reading make sure that the

thermostat is open.

•If air bubbles come up to the radiator filler neck, replenish

with EC. Repeat until the EC level does not dr op any further .

Install the radiator cap and stop the engine.

•Replenish EC to the "MAX" line on the reservoir tank and

leave as it is until the engine gets cool.

•After the engine gets cool, start the engine and make sure

there is no water running noise heard from the heater core

while the engine runs at 3000 rpm.

•Should water running noise be heard, repeat the same

procedure from the beginning.

MAIN DATA AND SPECIFICATIONS

GENERAL SPECIFICATIONS

Cooling system Engine Coolant forced circulation

Radiator Tube type corrugated (2 tube in row)

Heat radiation capacity 59.100 kcal/h

Heat radiation area 10.915

Radiator front area 0.228

Radiator dry (weight) 66.6N, 6.9kg

Radiator cap valve opening pressure 88.3 - 117.7kpa

Engine coolant capacity 2.3L

Engine coolant pump Centrifugal type

Thermostat Bypass type

Engine coolant total capacity 6.9 litres

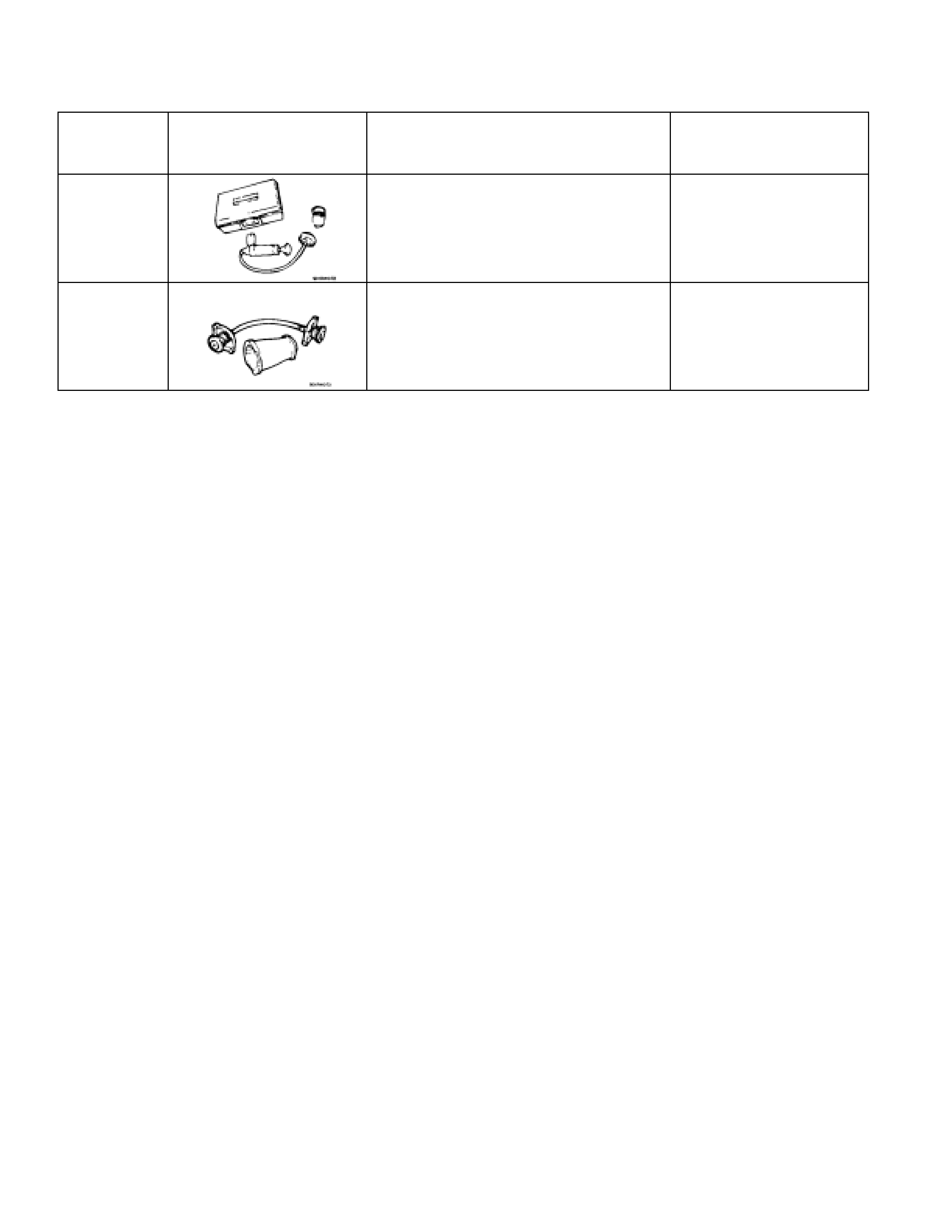

SPECIAL SERVICE TOOL

ITEM NO. ILLUSTRATION PART NO. PART NAME

15-8840-0277-0 Tester; radiator cap

25-8840-2603-0 Adapter; radiator cap