SECTION 6C1 - DRIVEABILITY AND EMISSIONS (C22NE MODELS)

SPECIFICATION

TIGHTENING SPECIFICATIONS

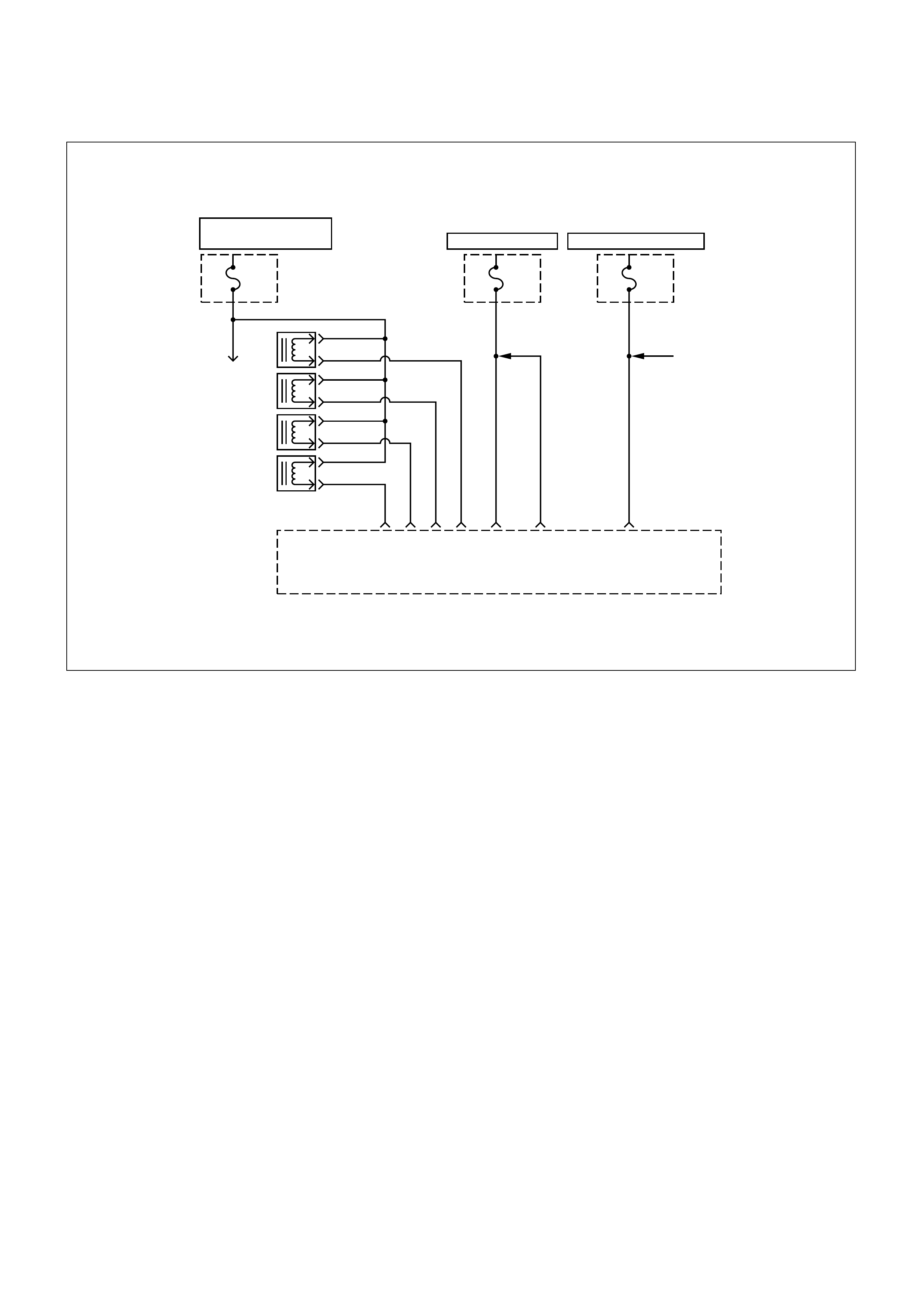

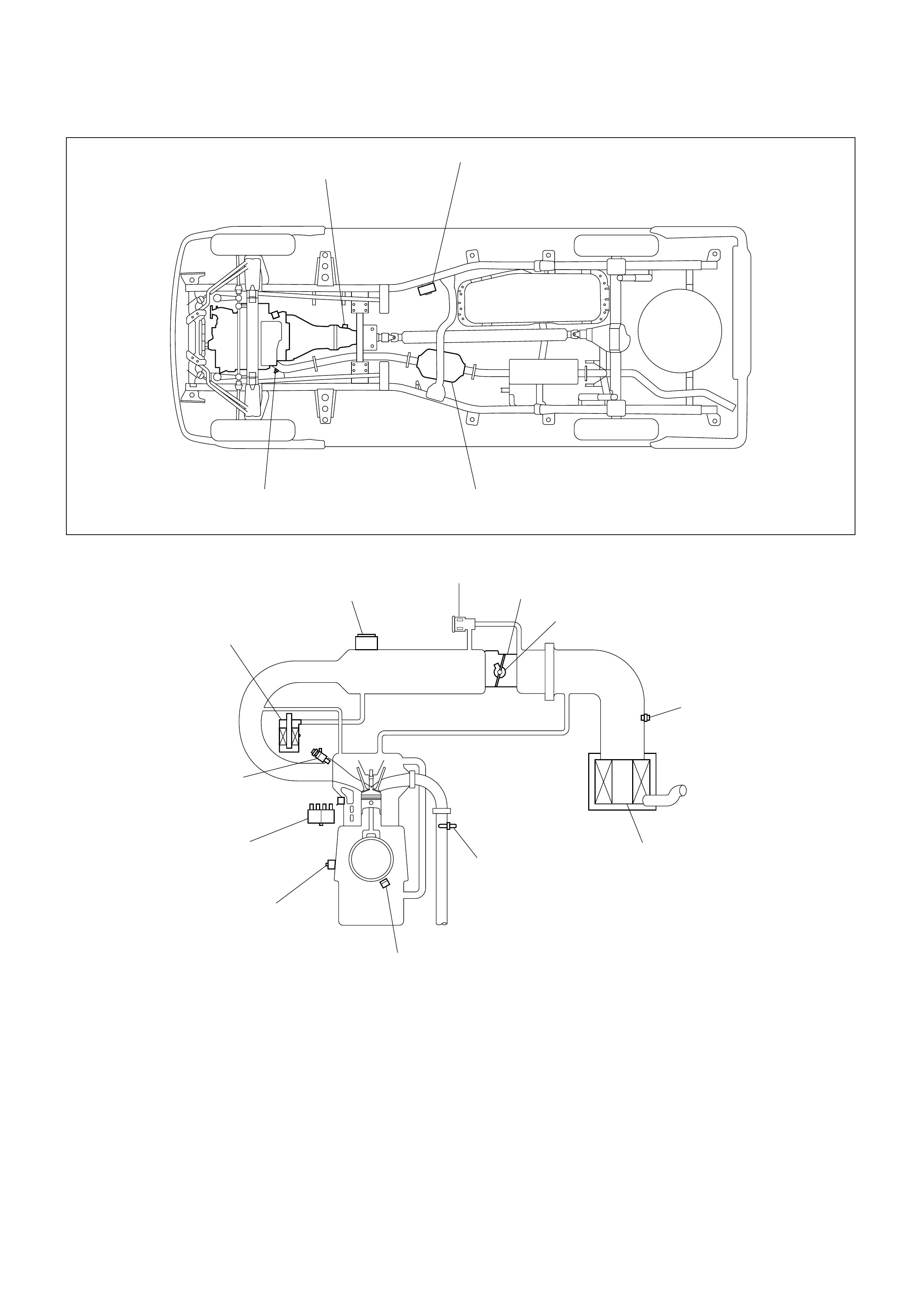

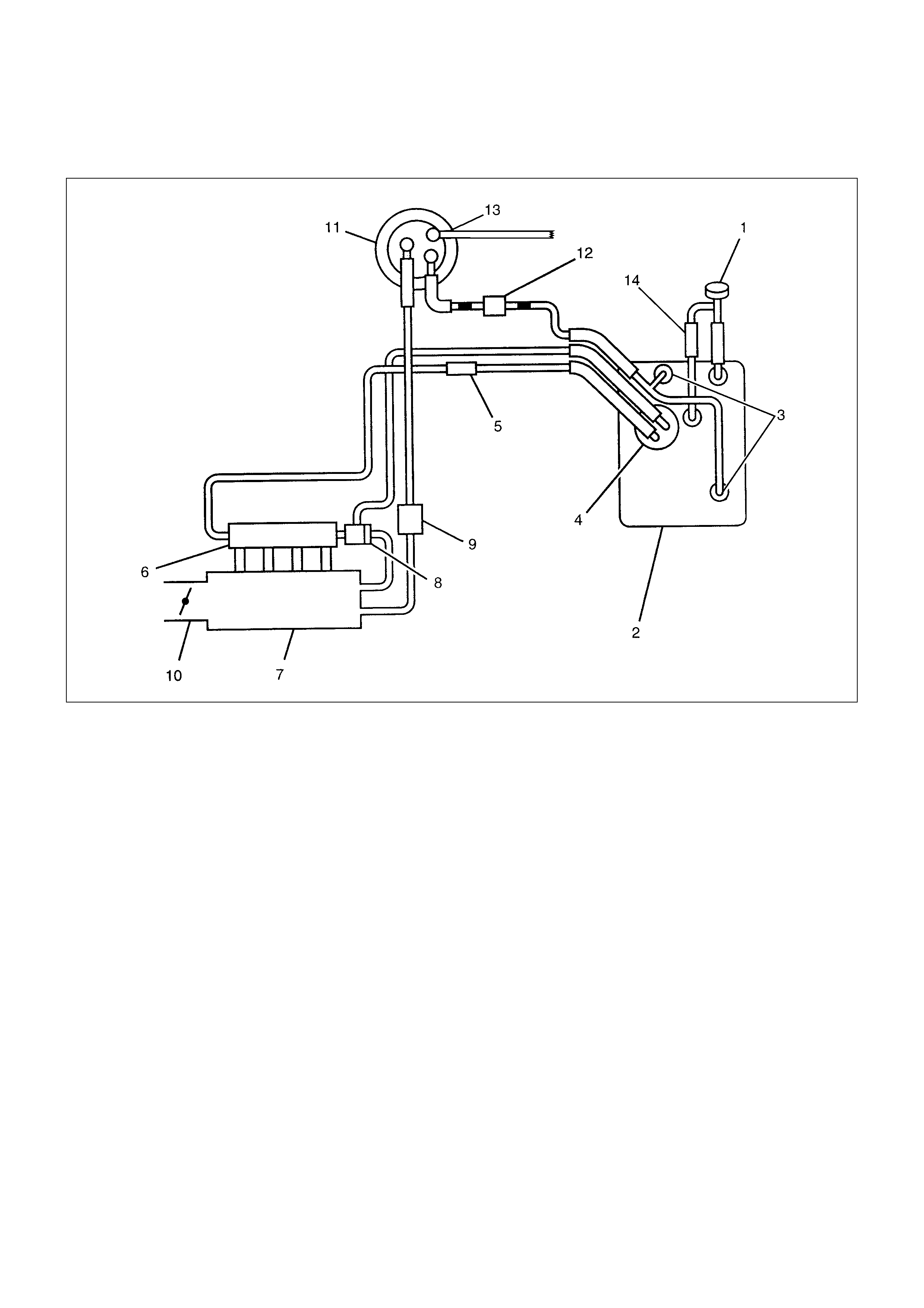

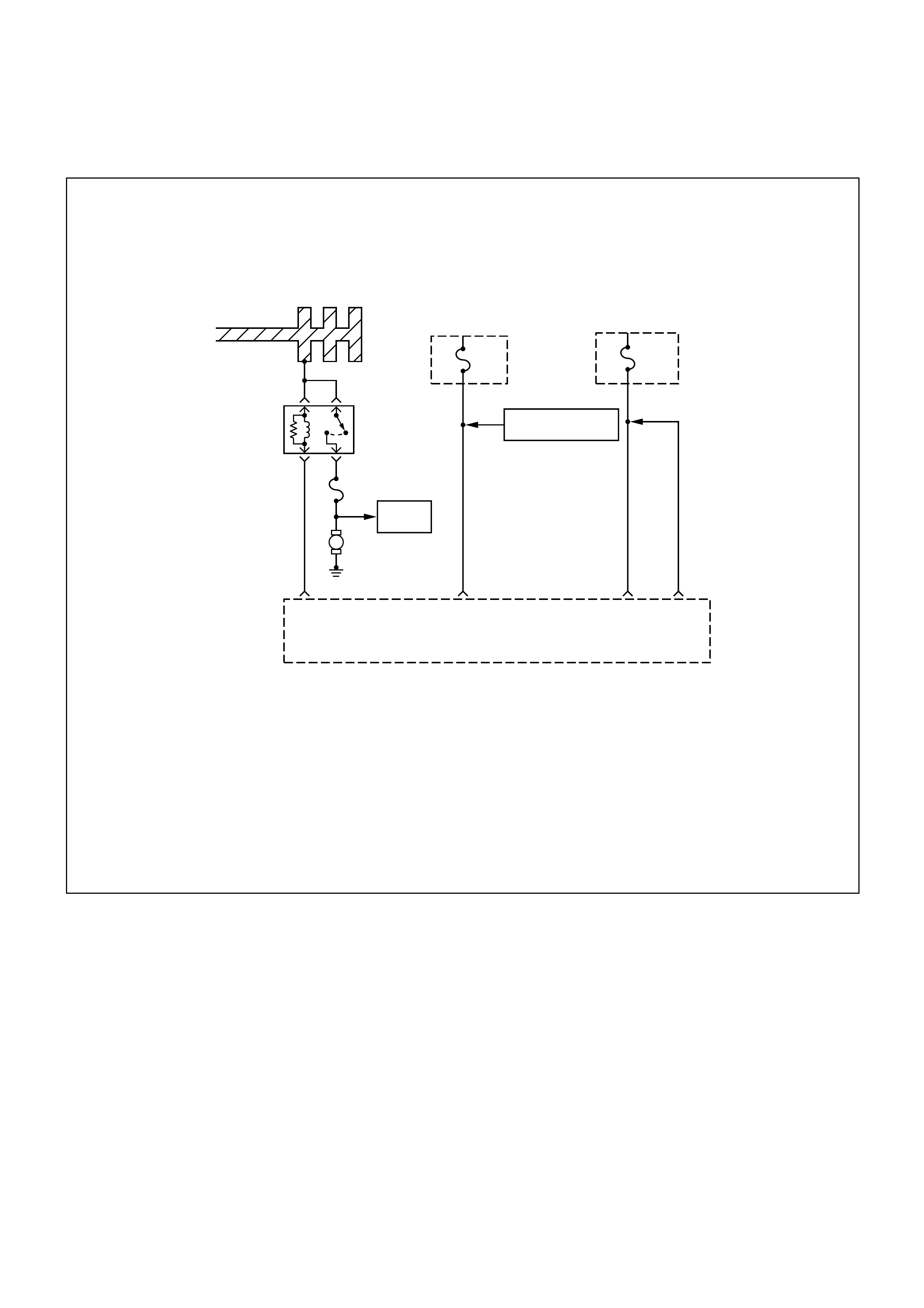

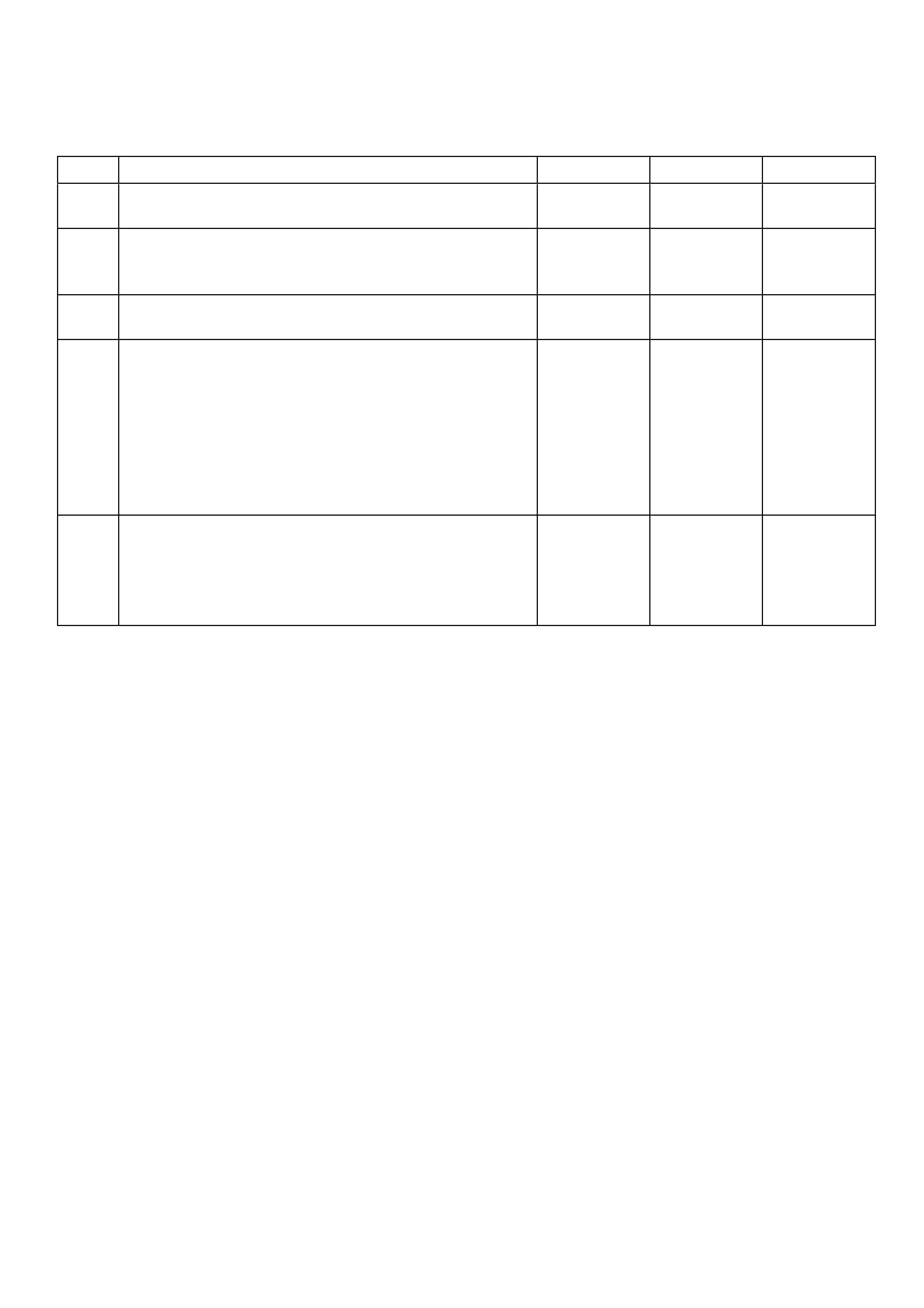

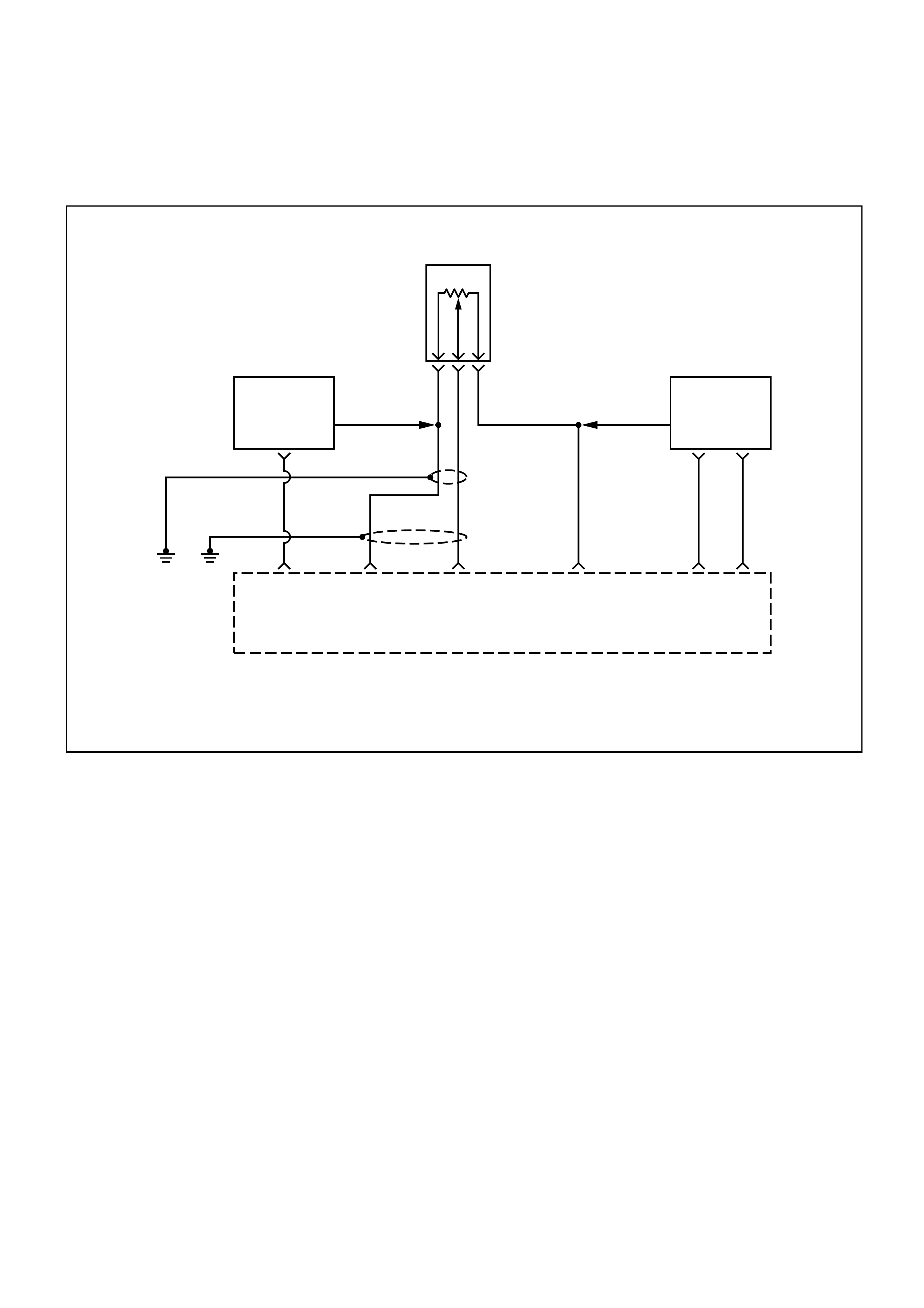

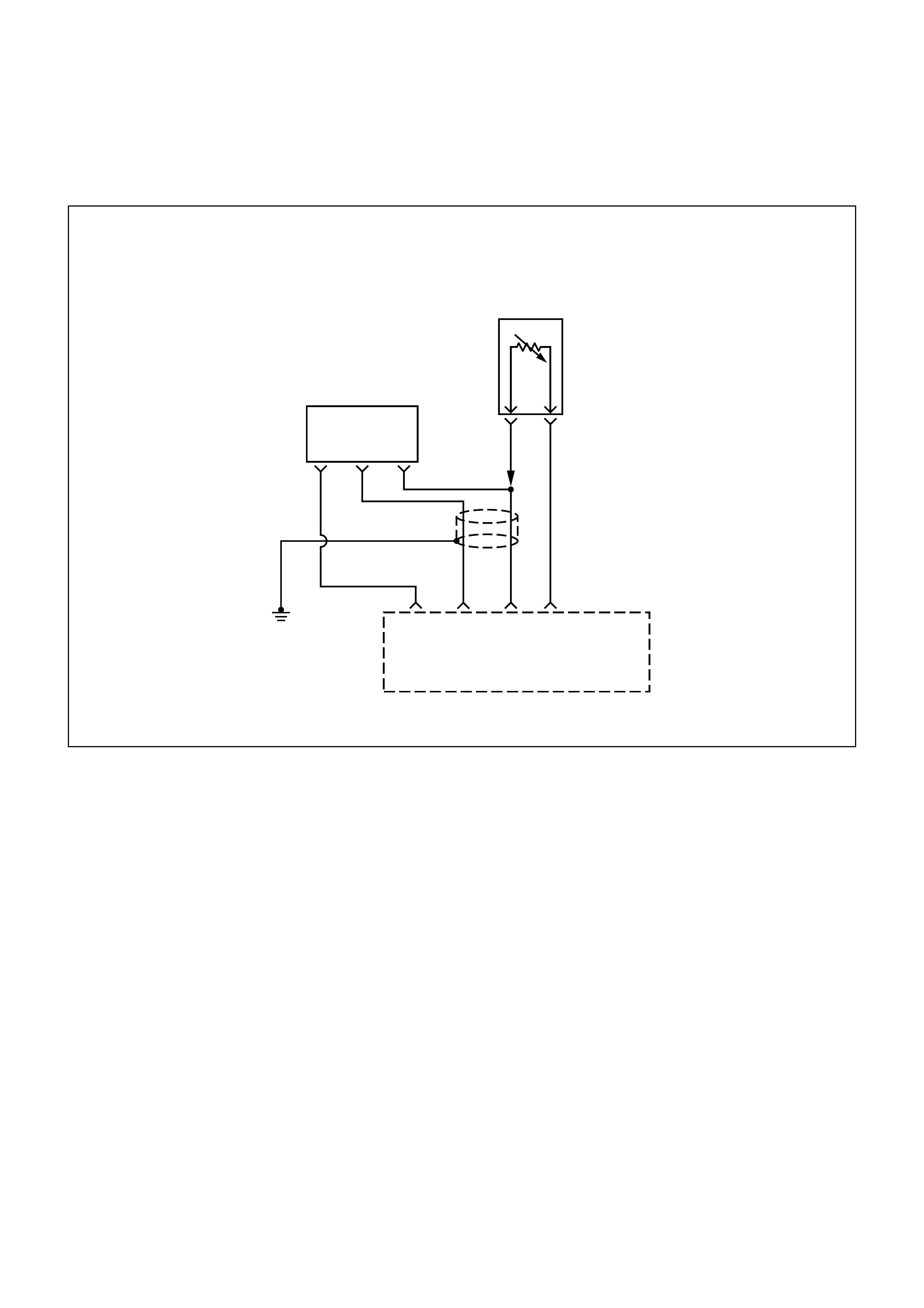

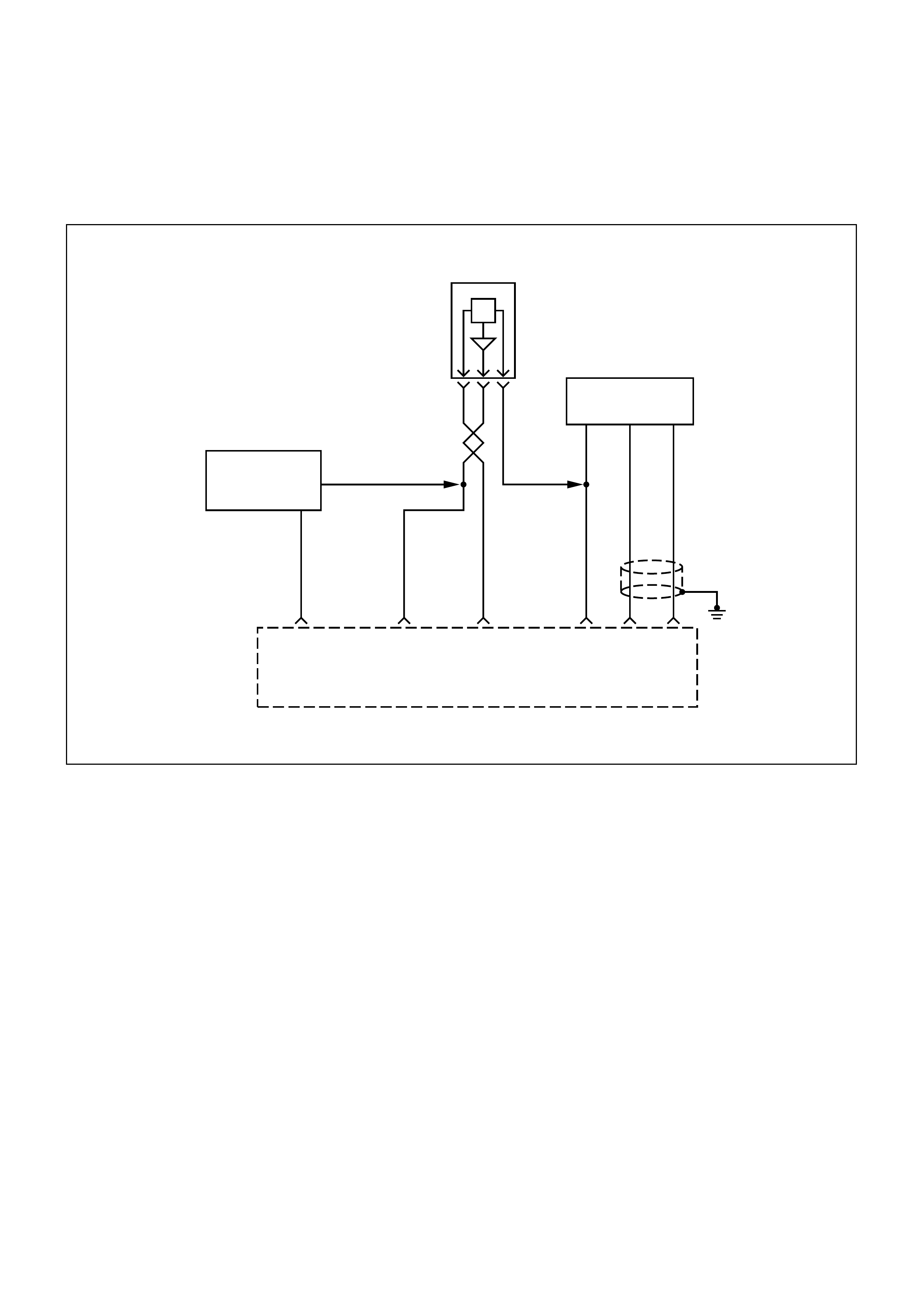

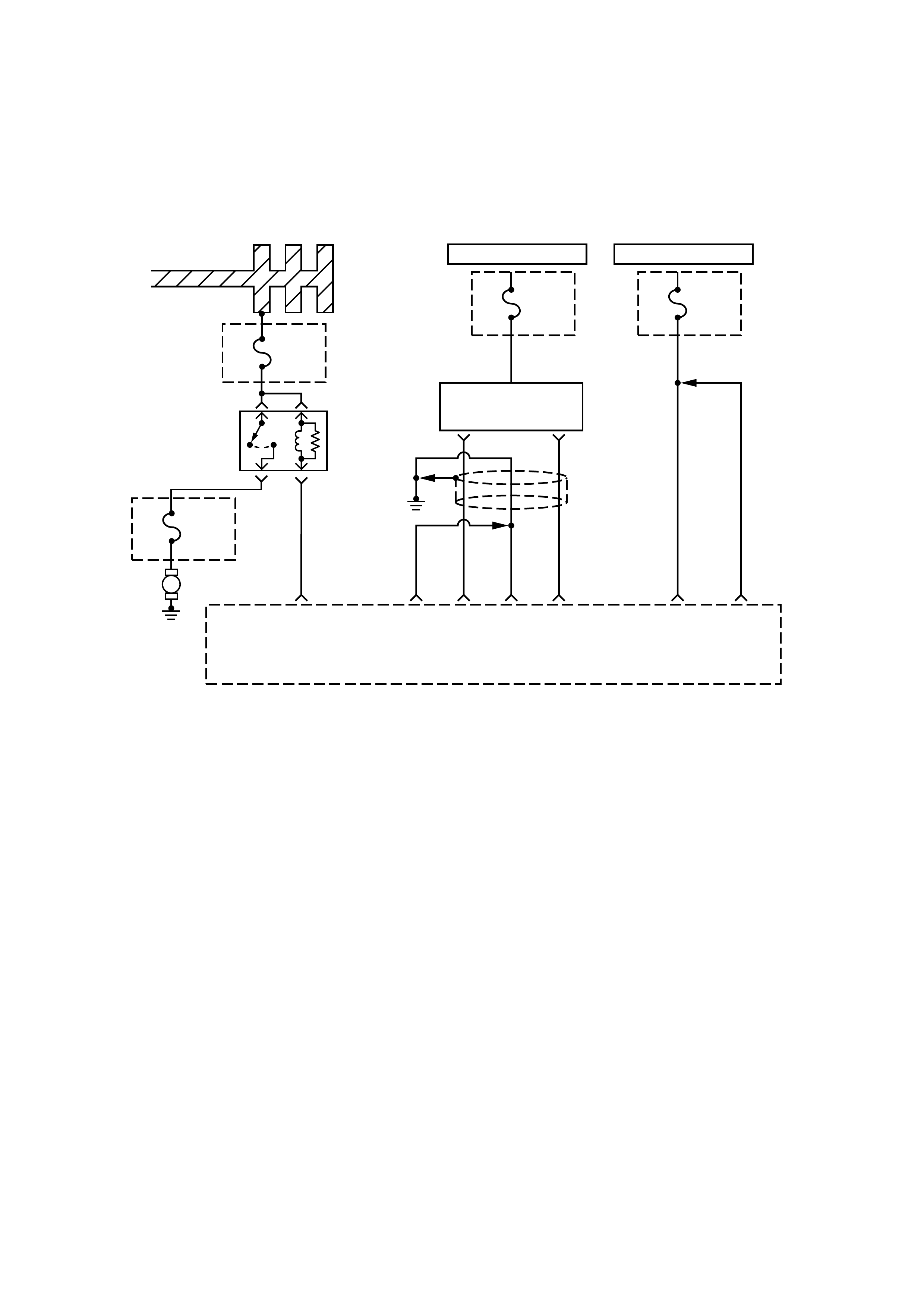

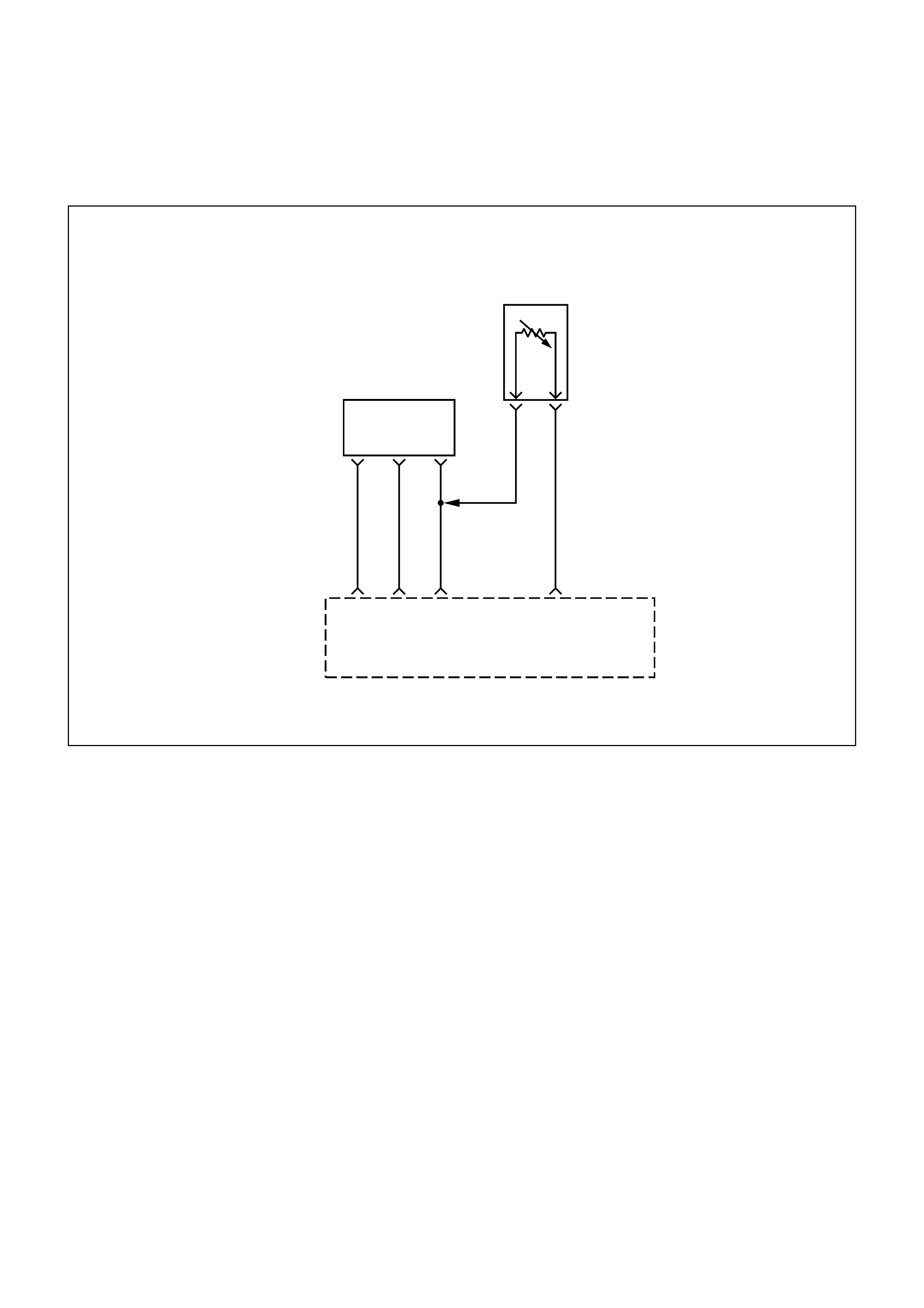

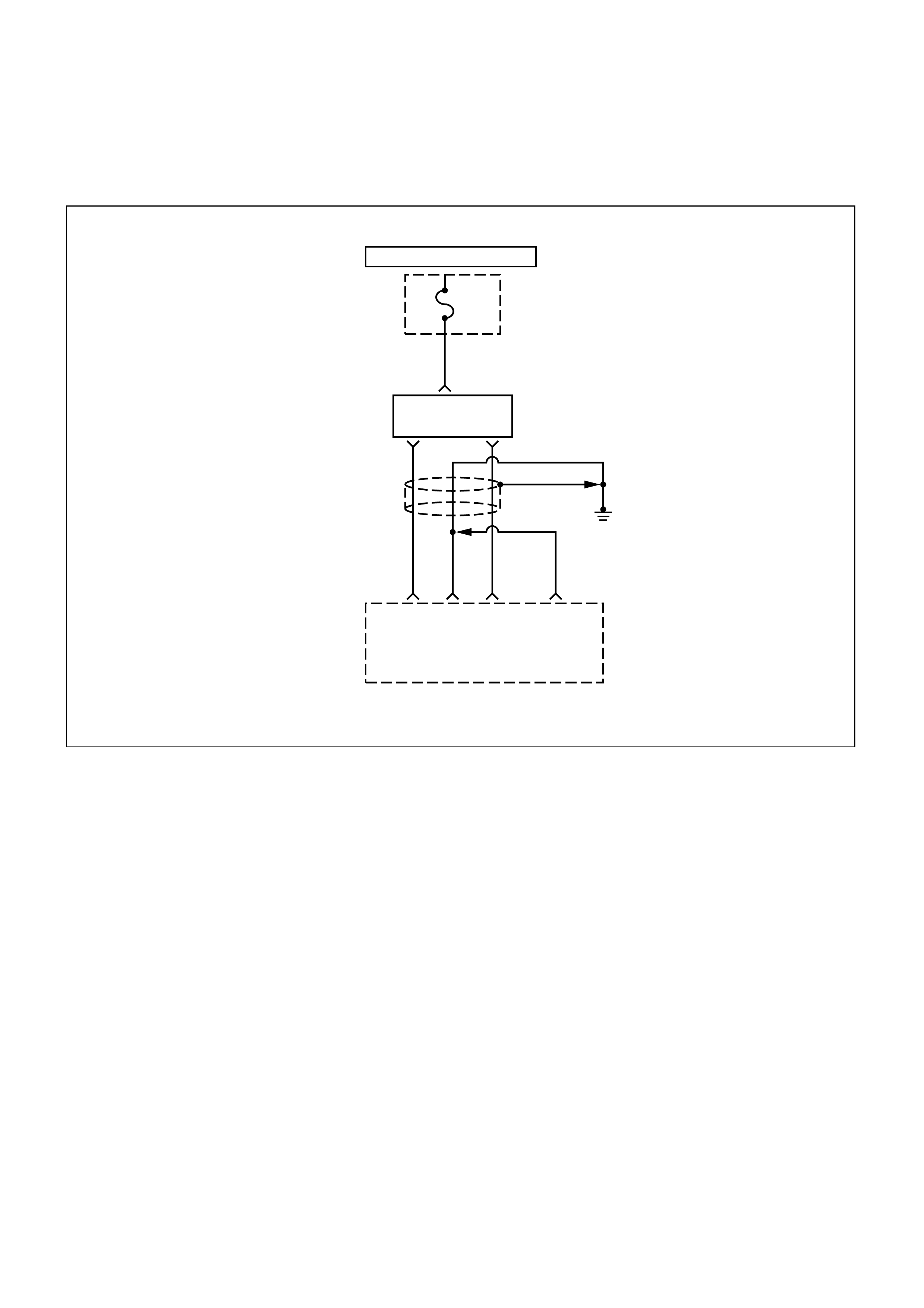

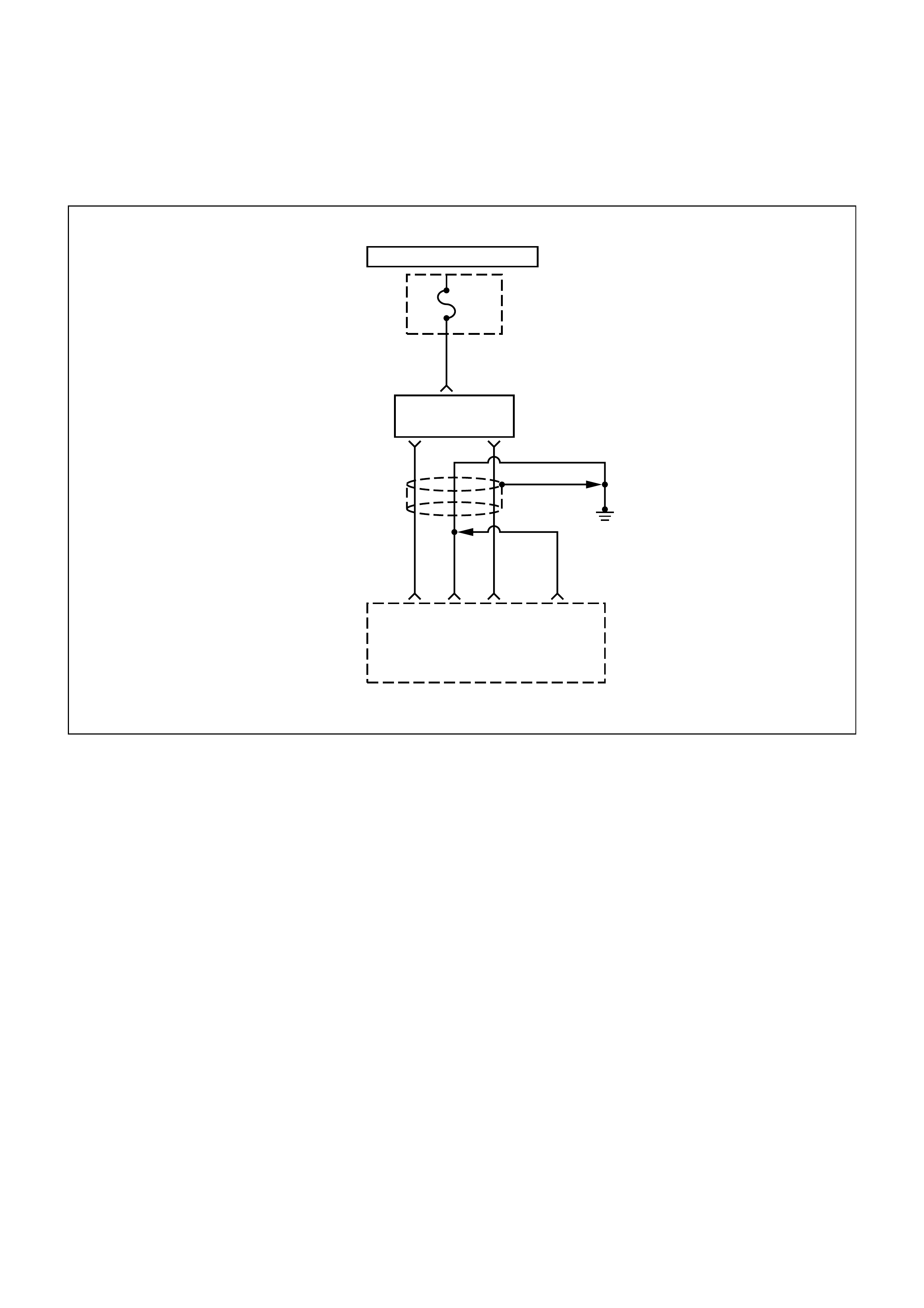

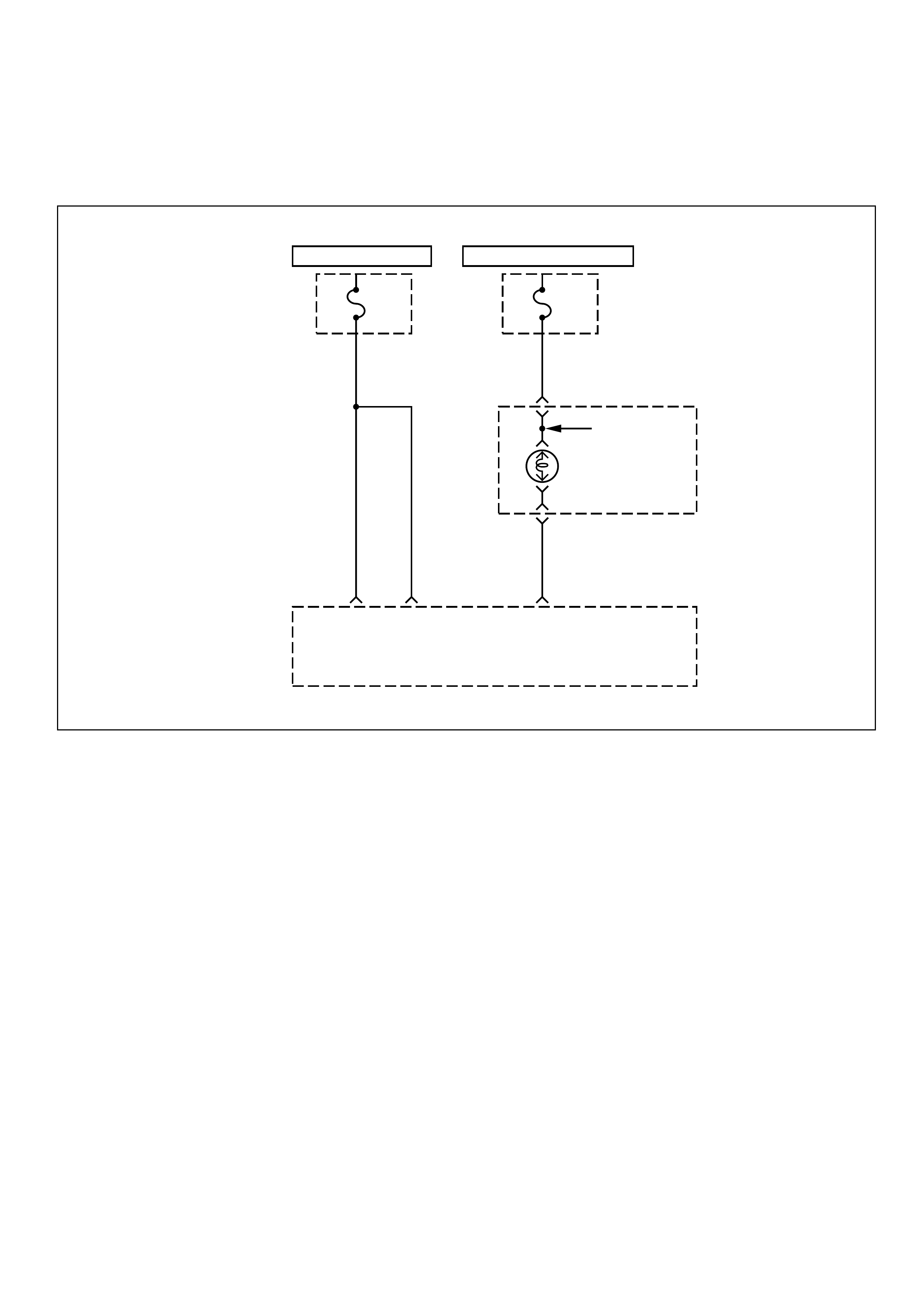

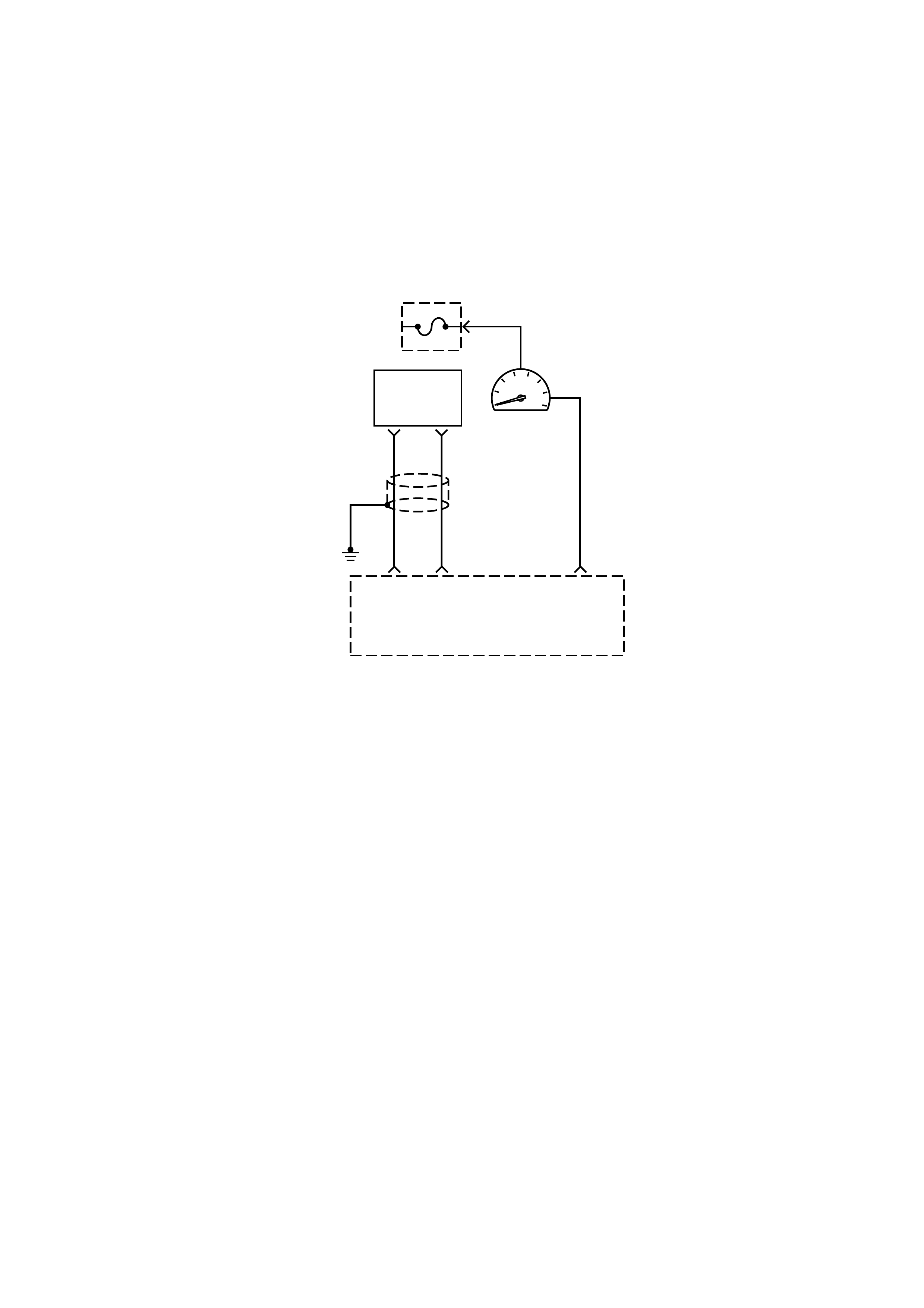

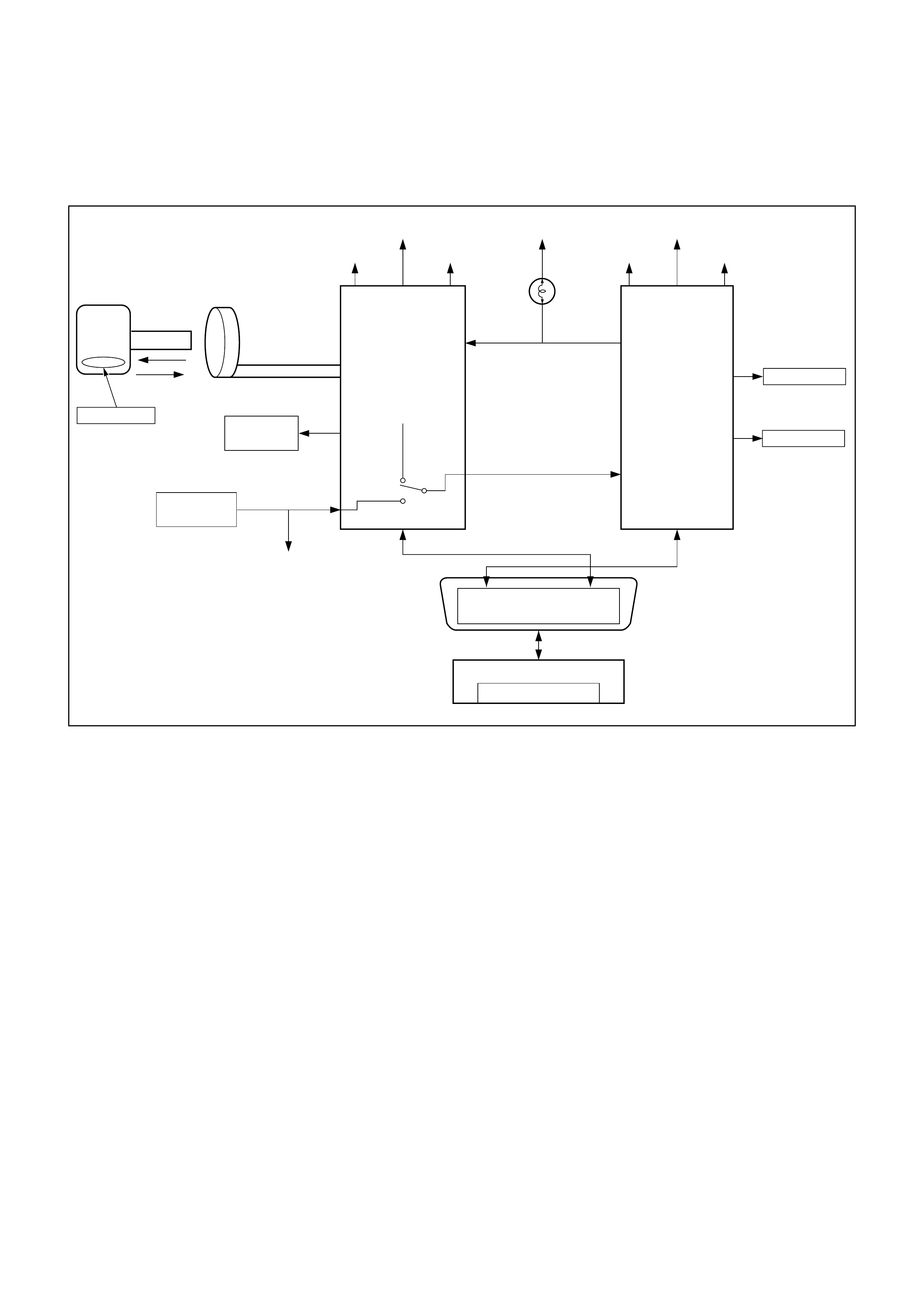

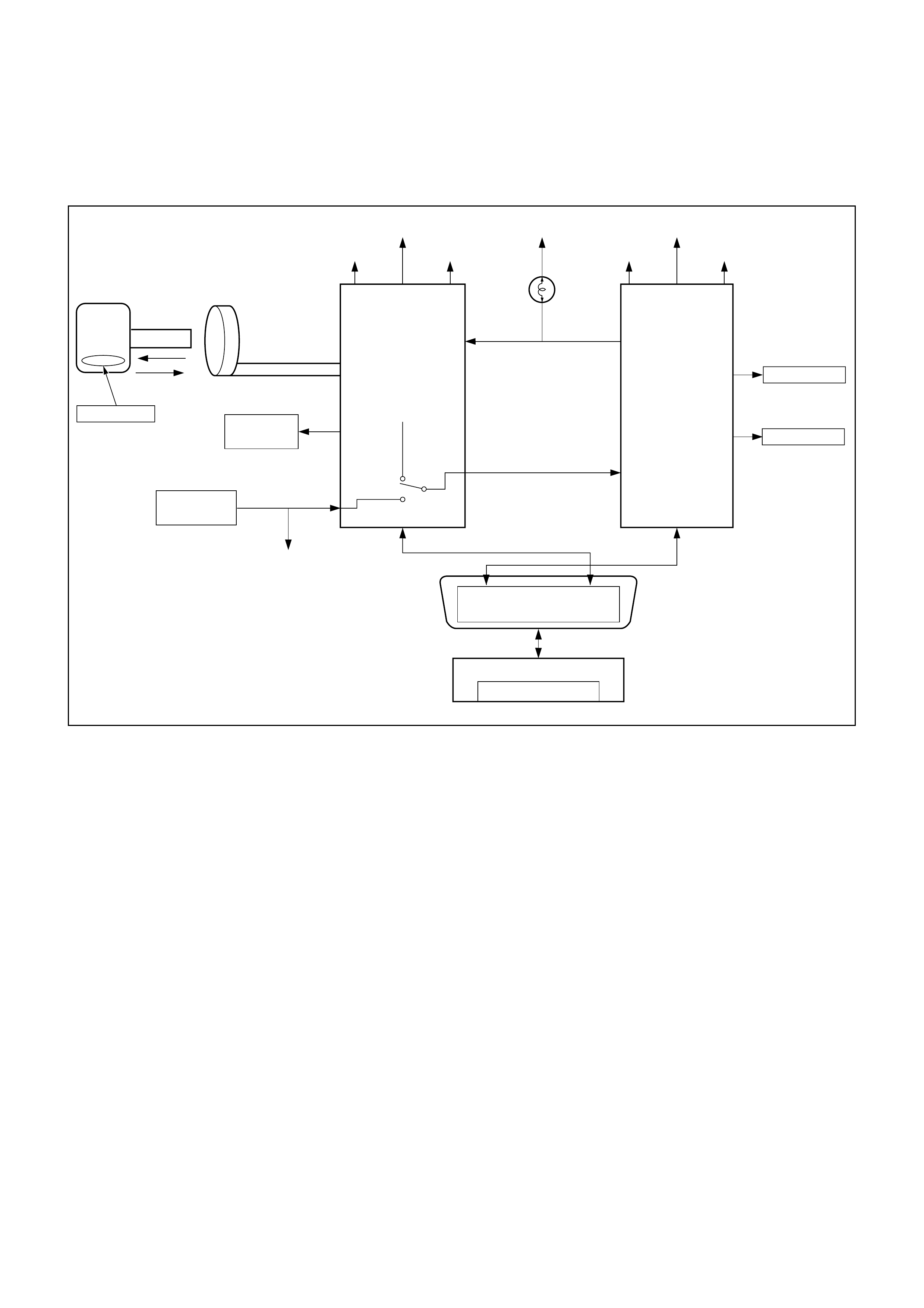

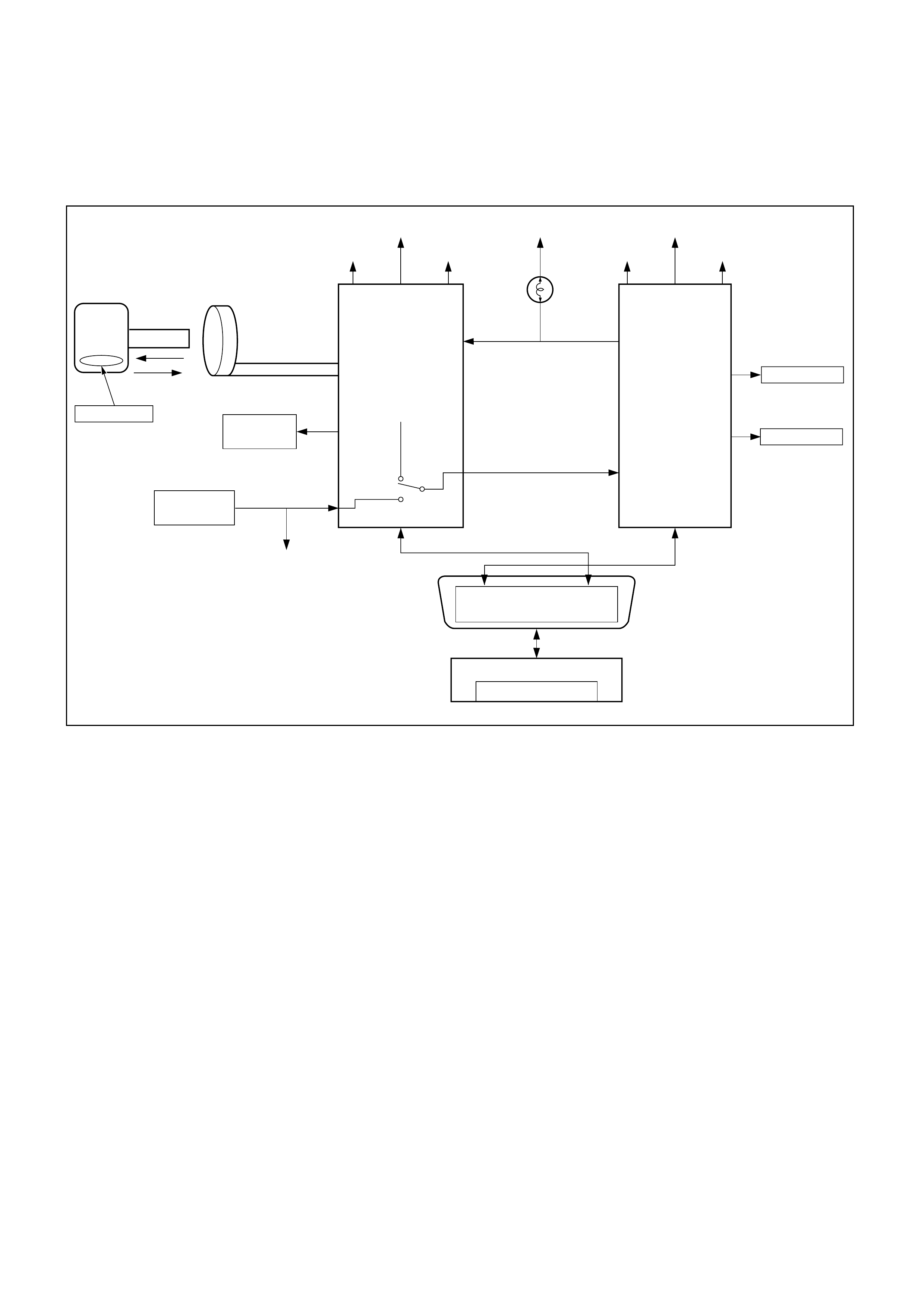

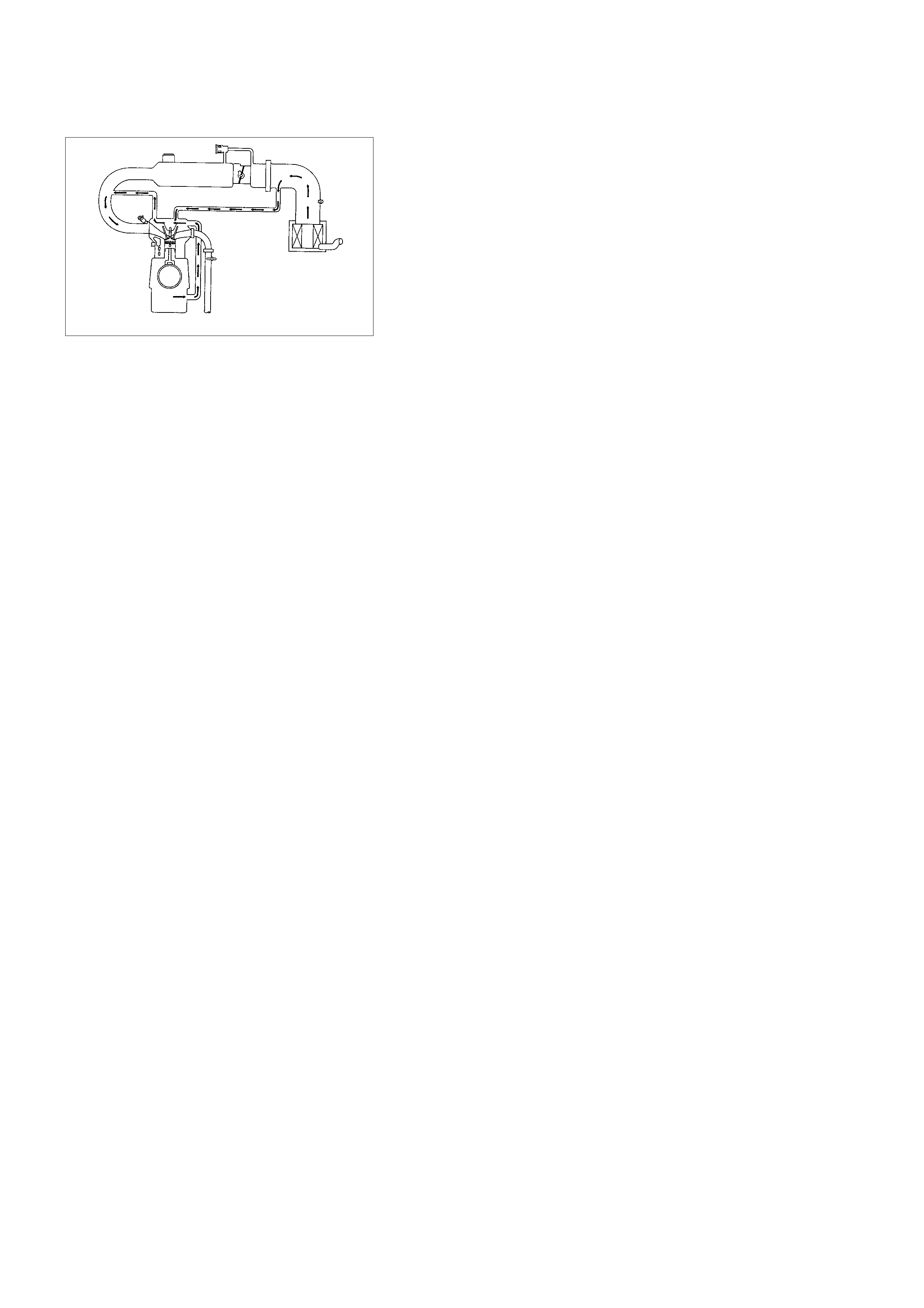

EMISSION CONTROL SYSTEM SCHEMATICS

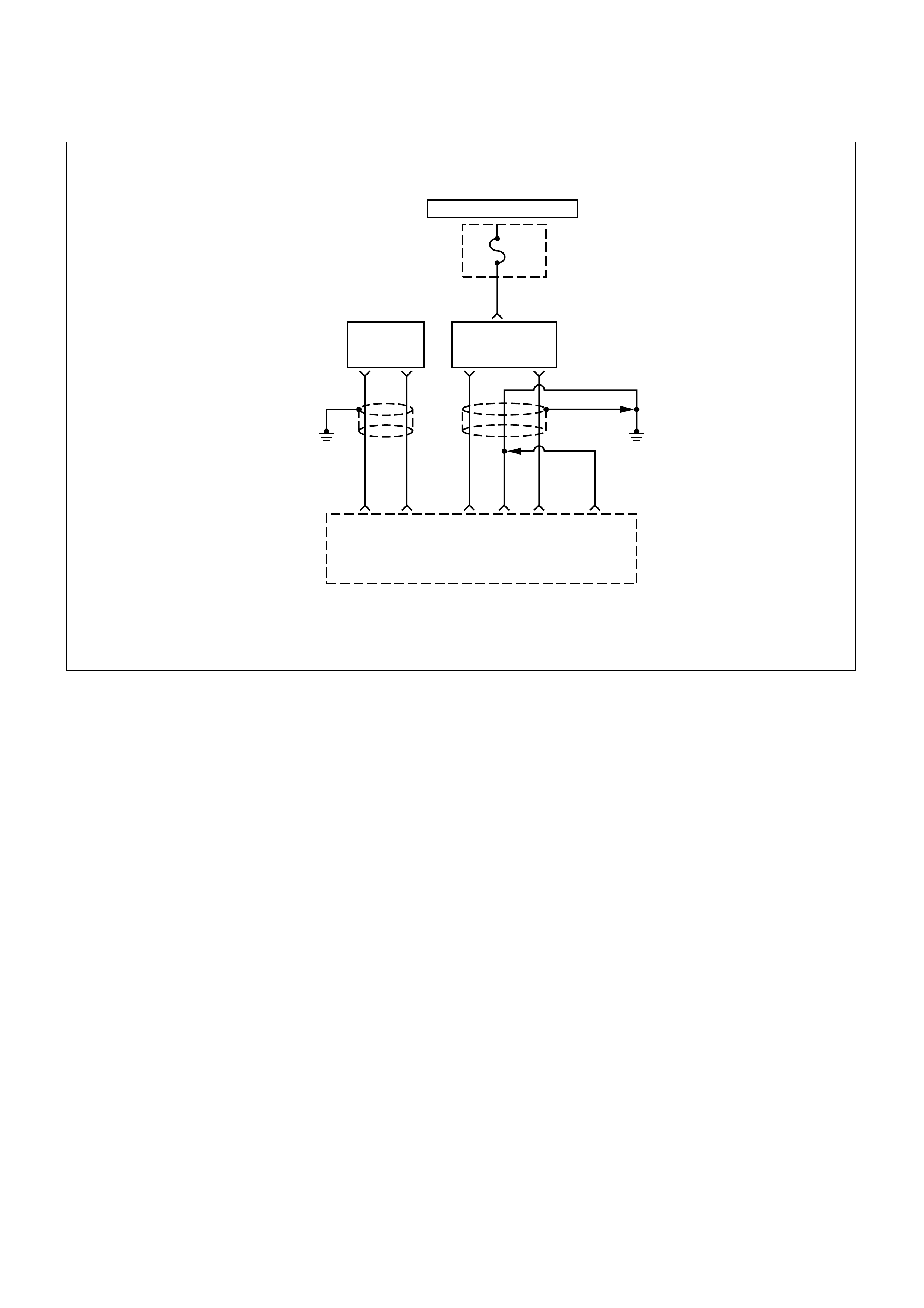

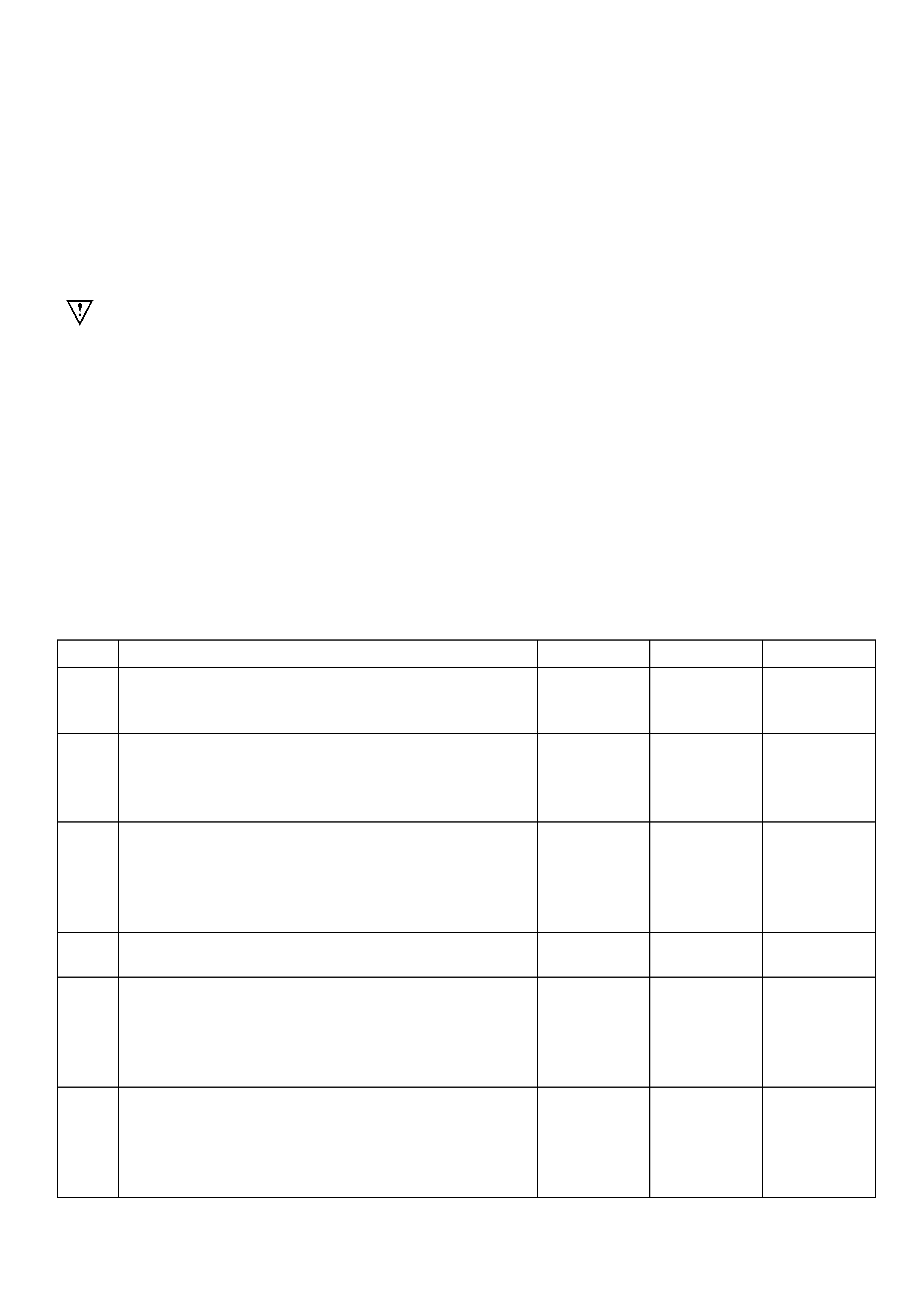

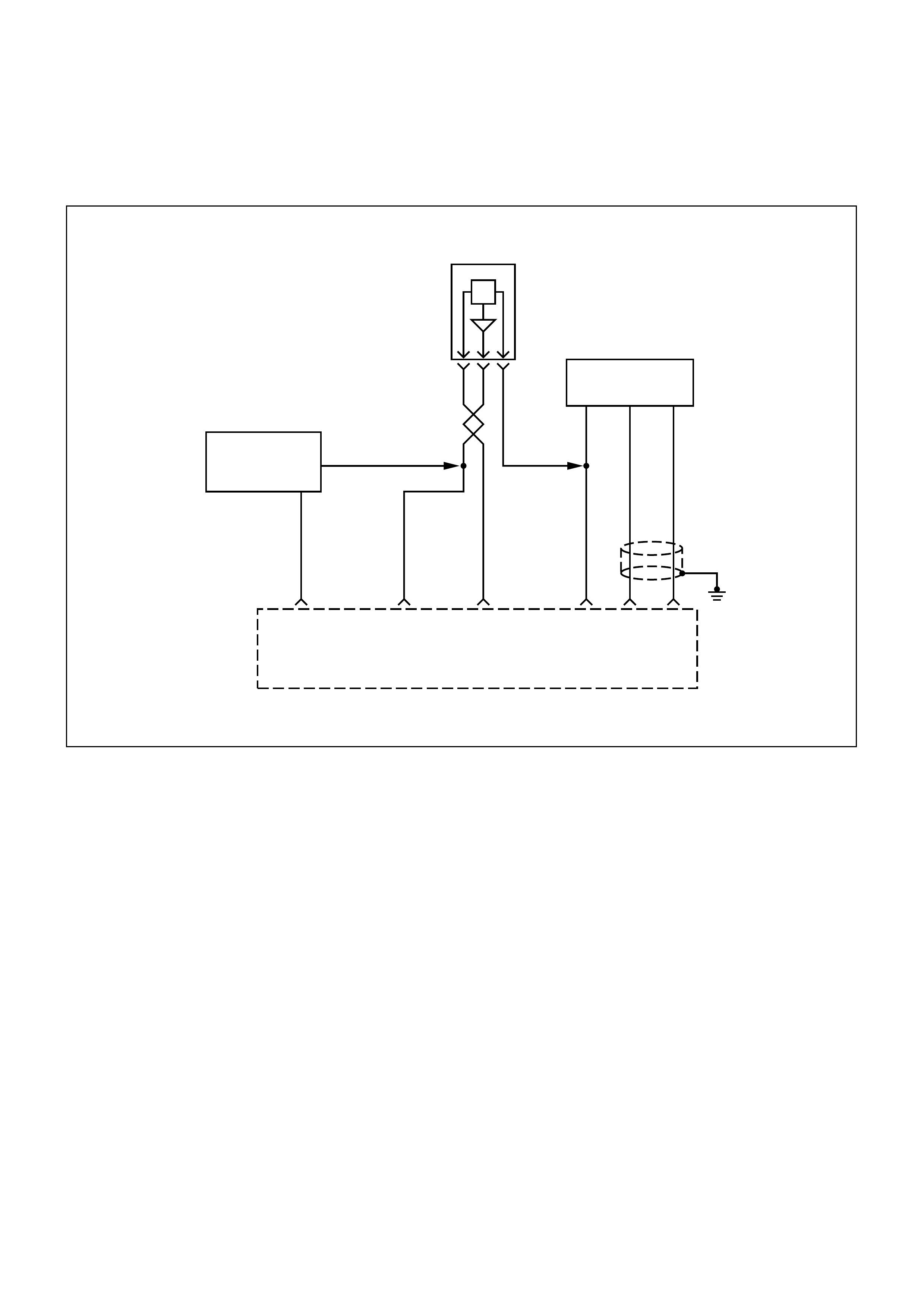

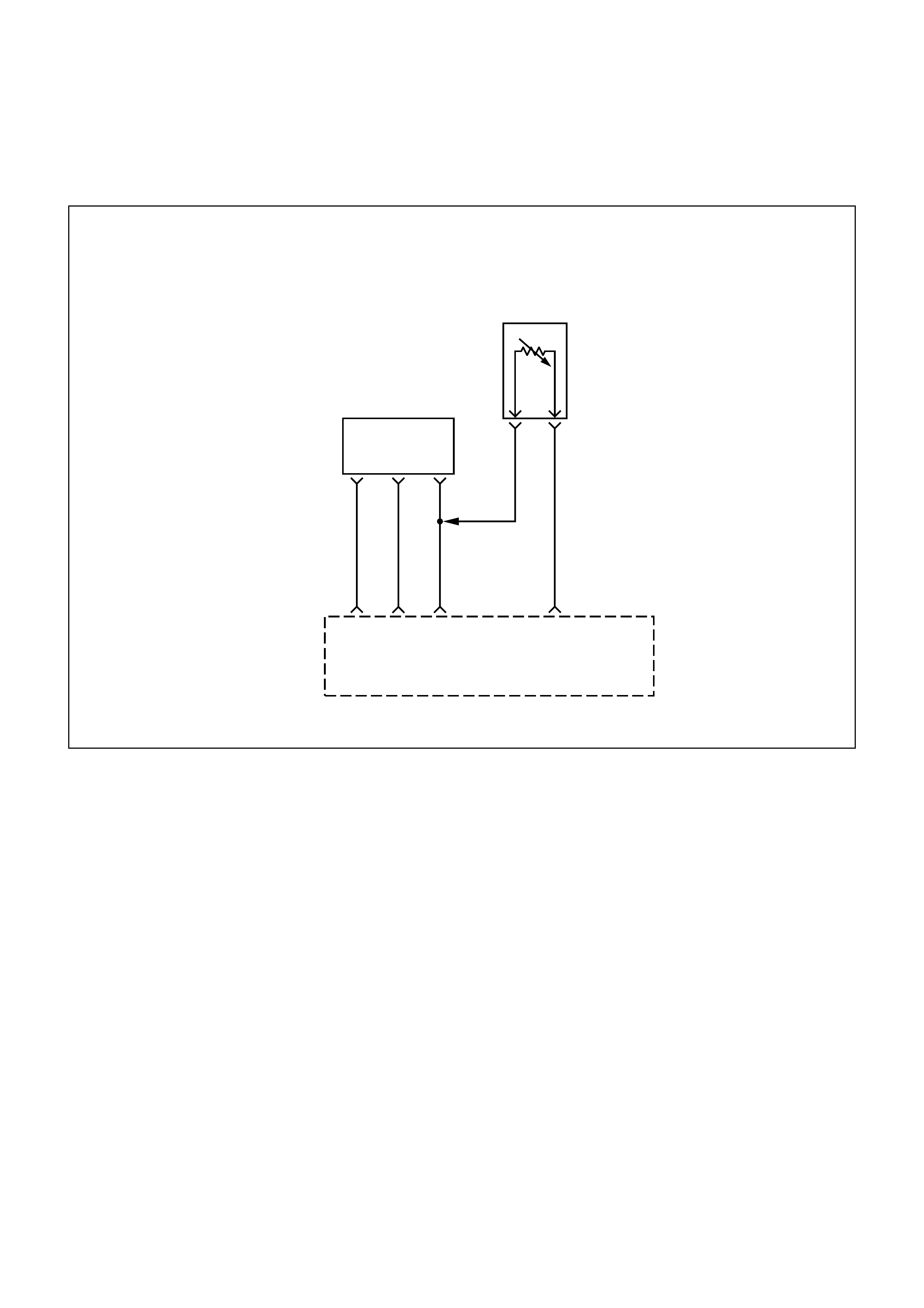

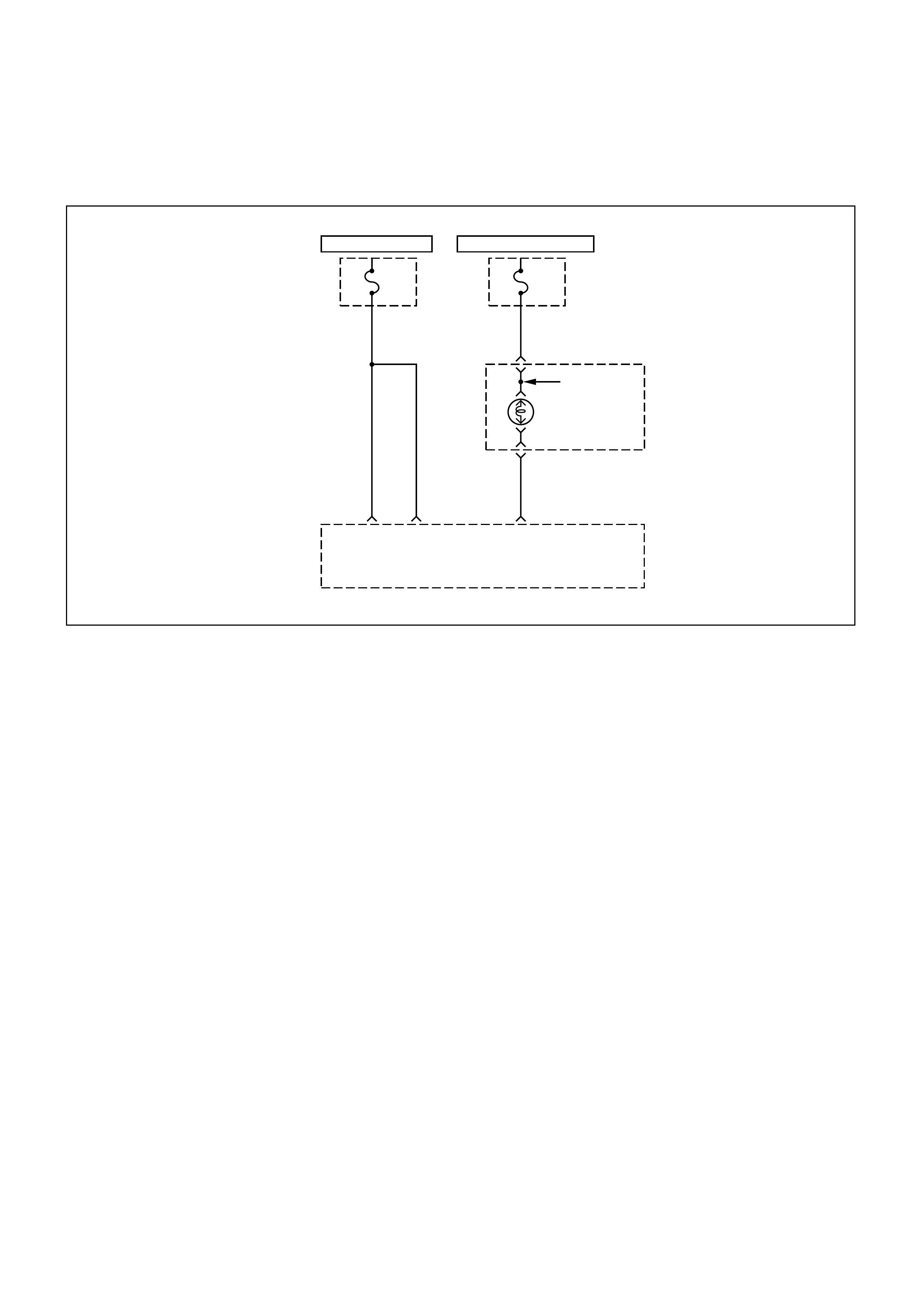

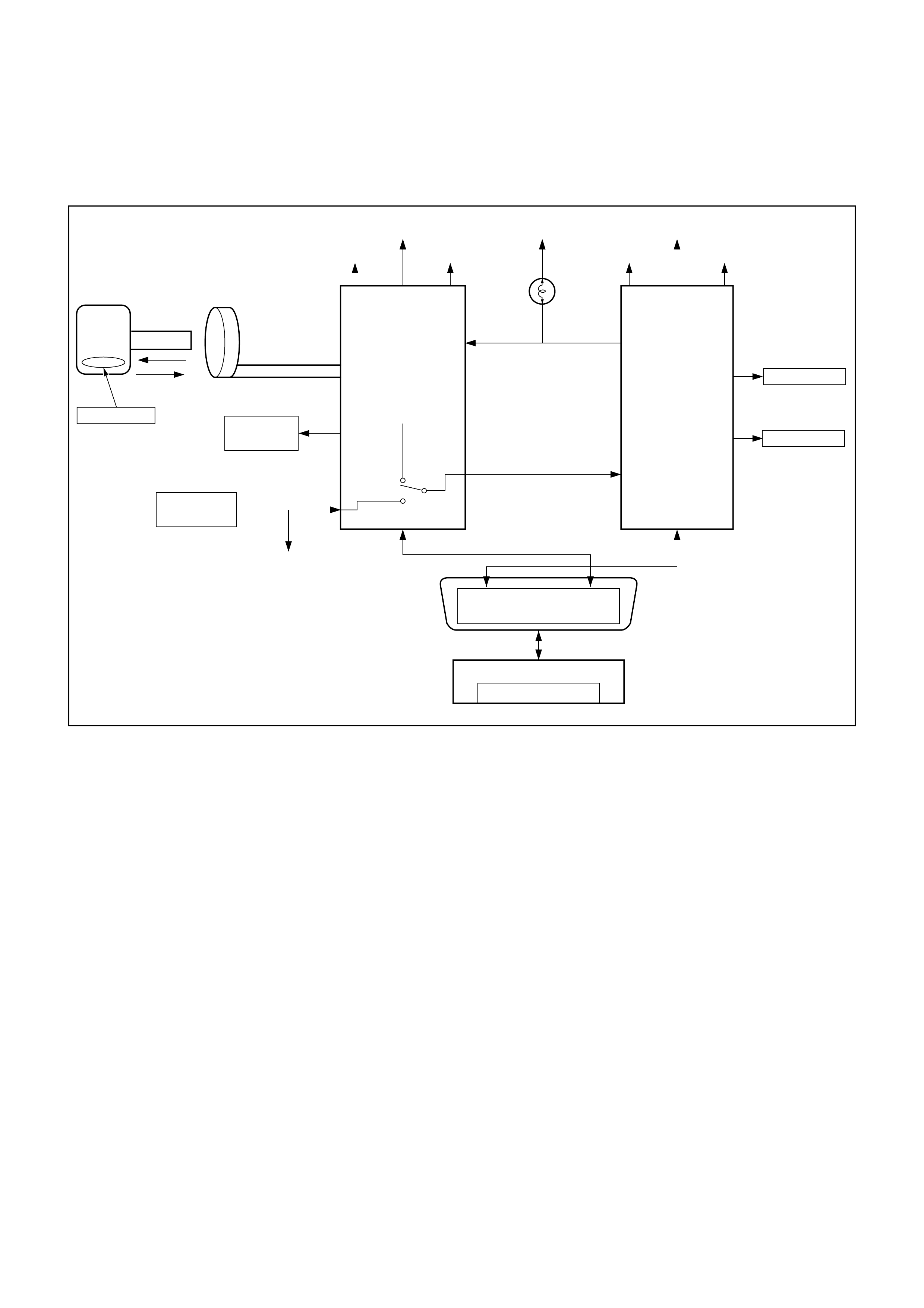

DIAGRAMS AND SCHEMATICS

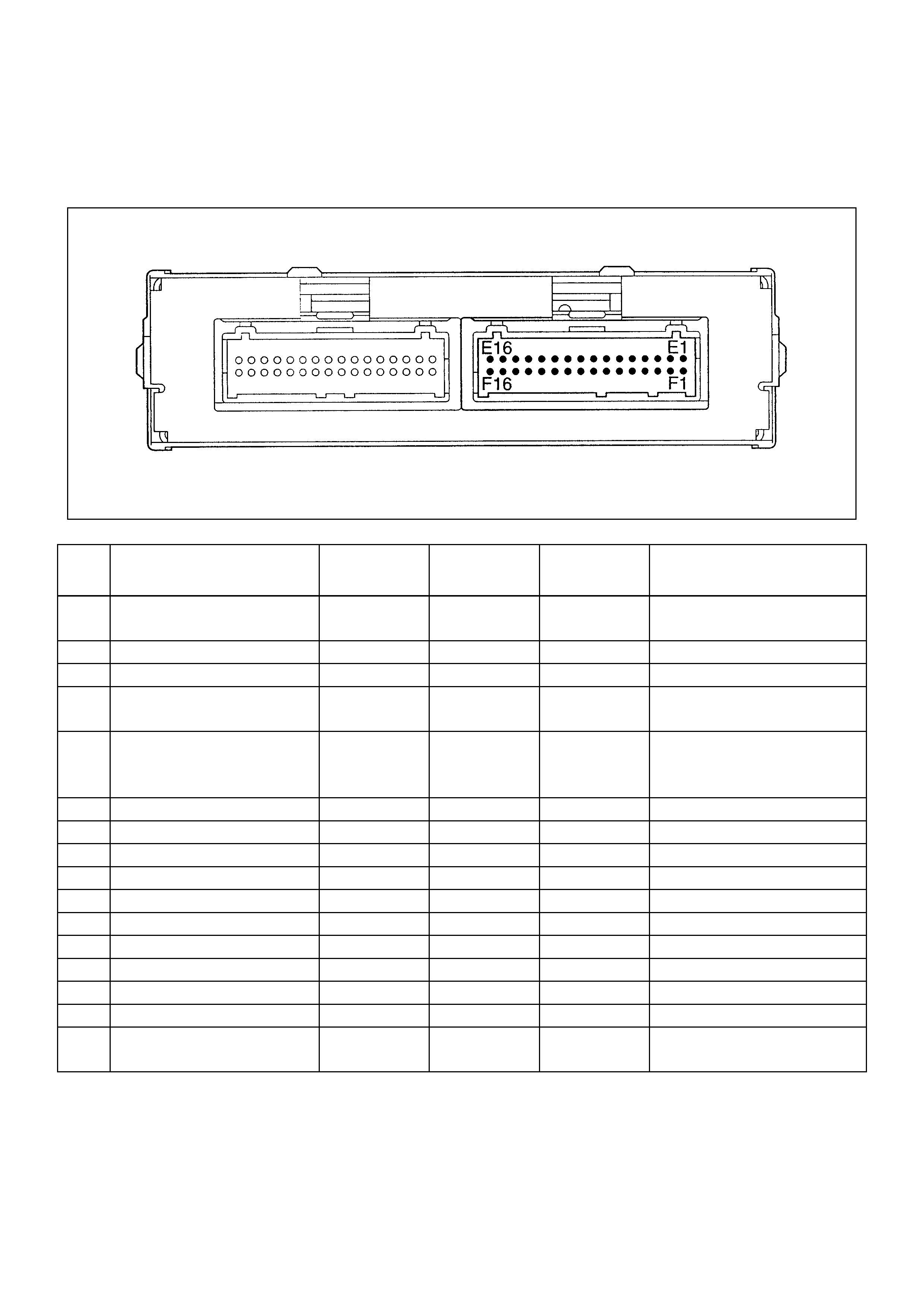

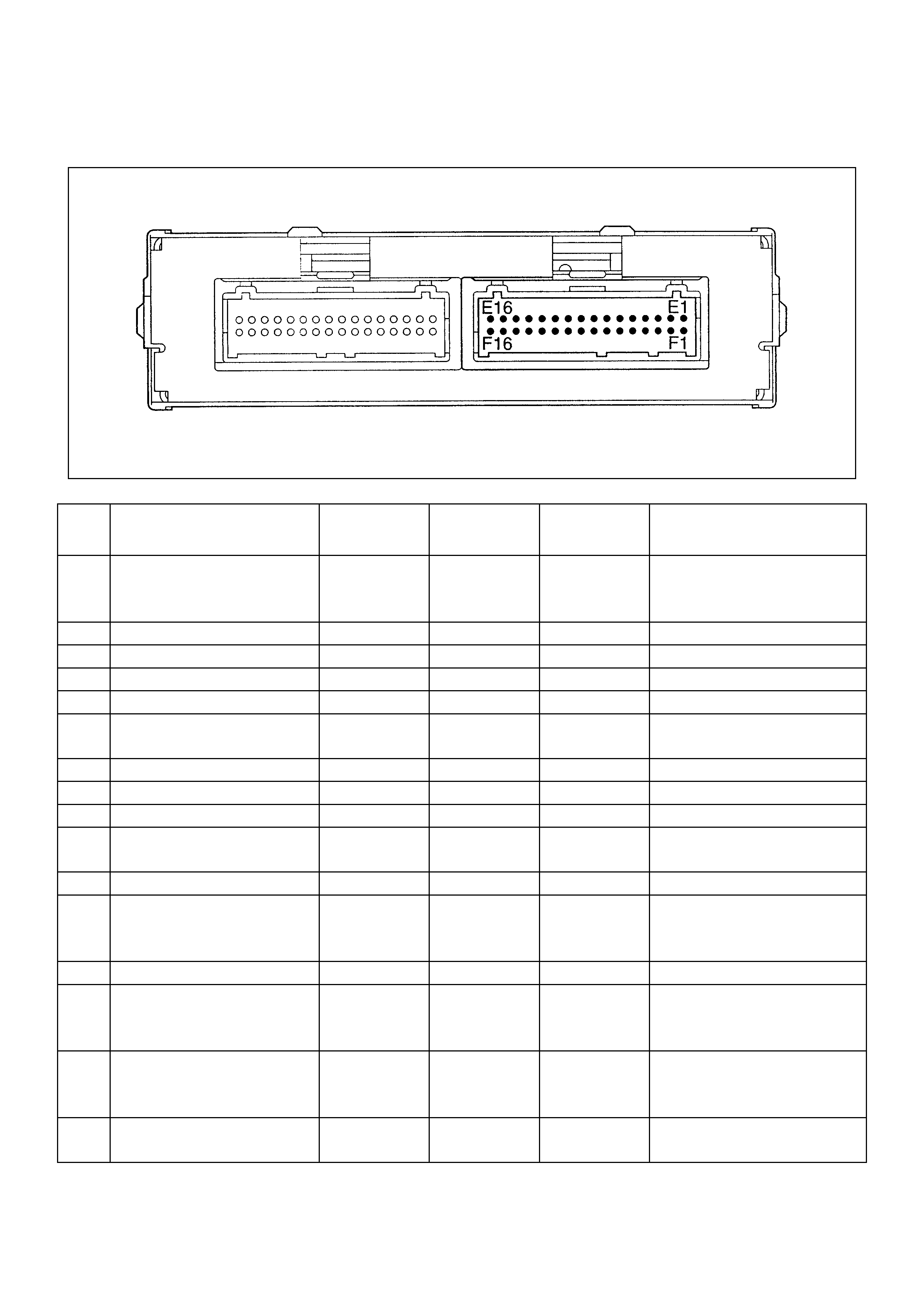

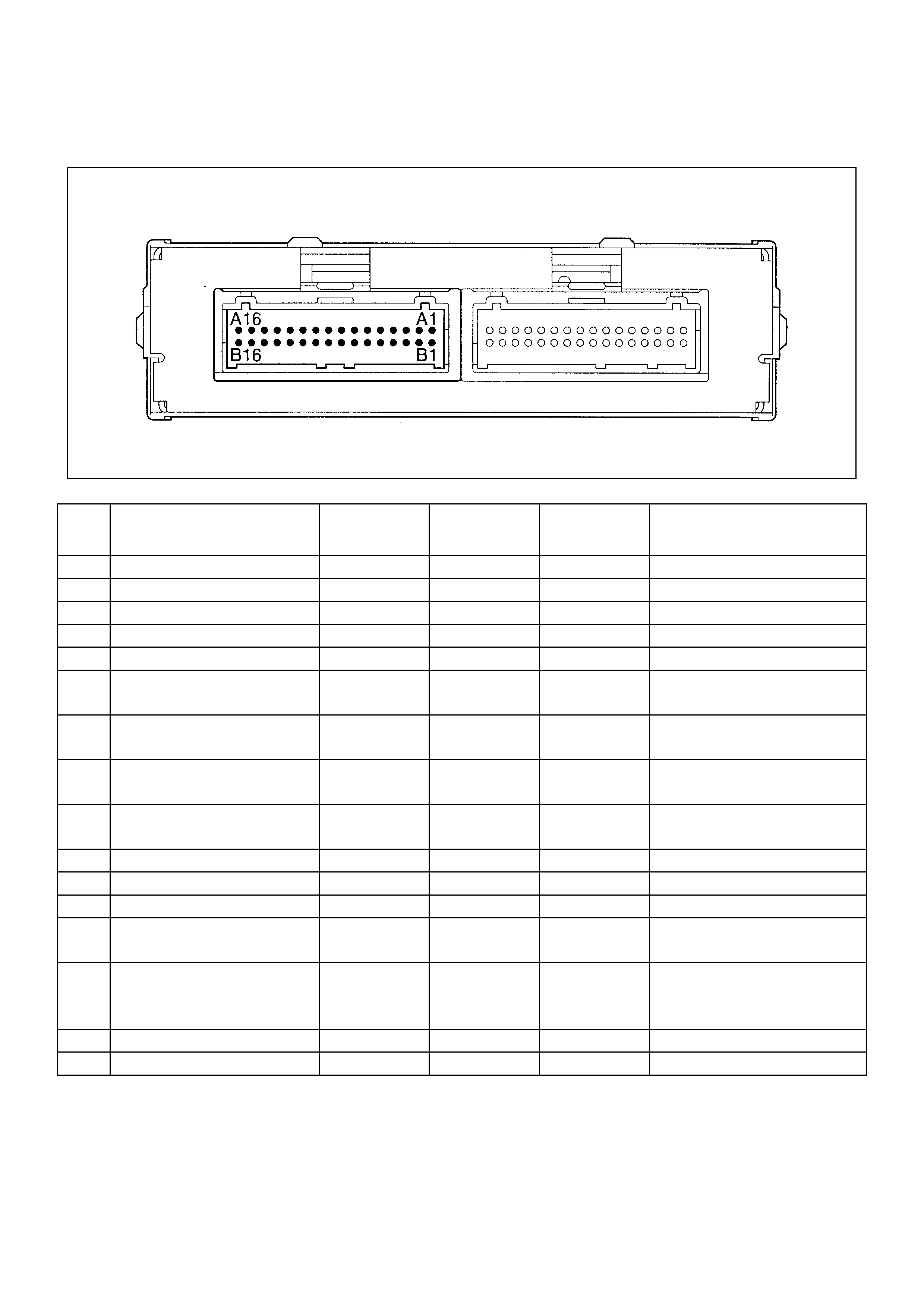

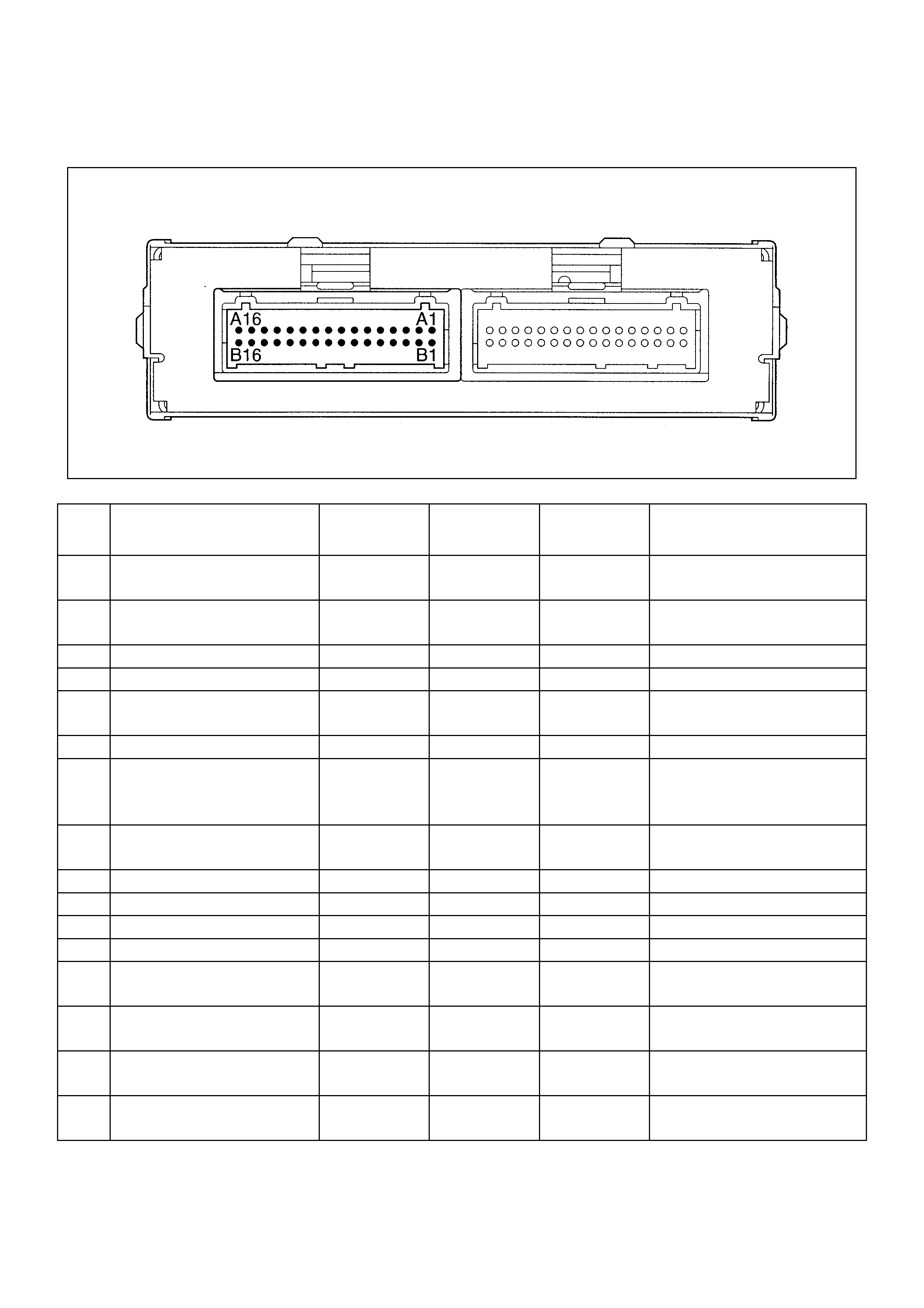

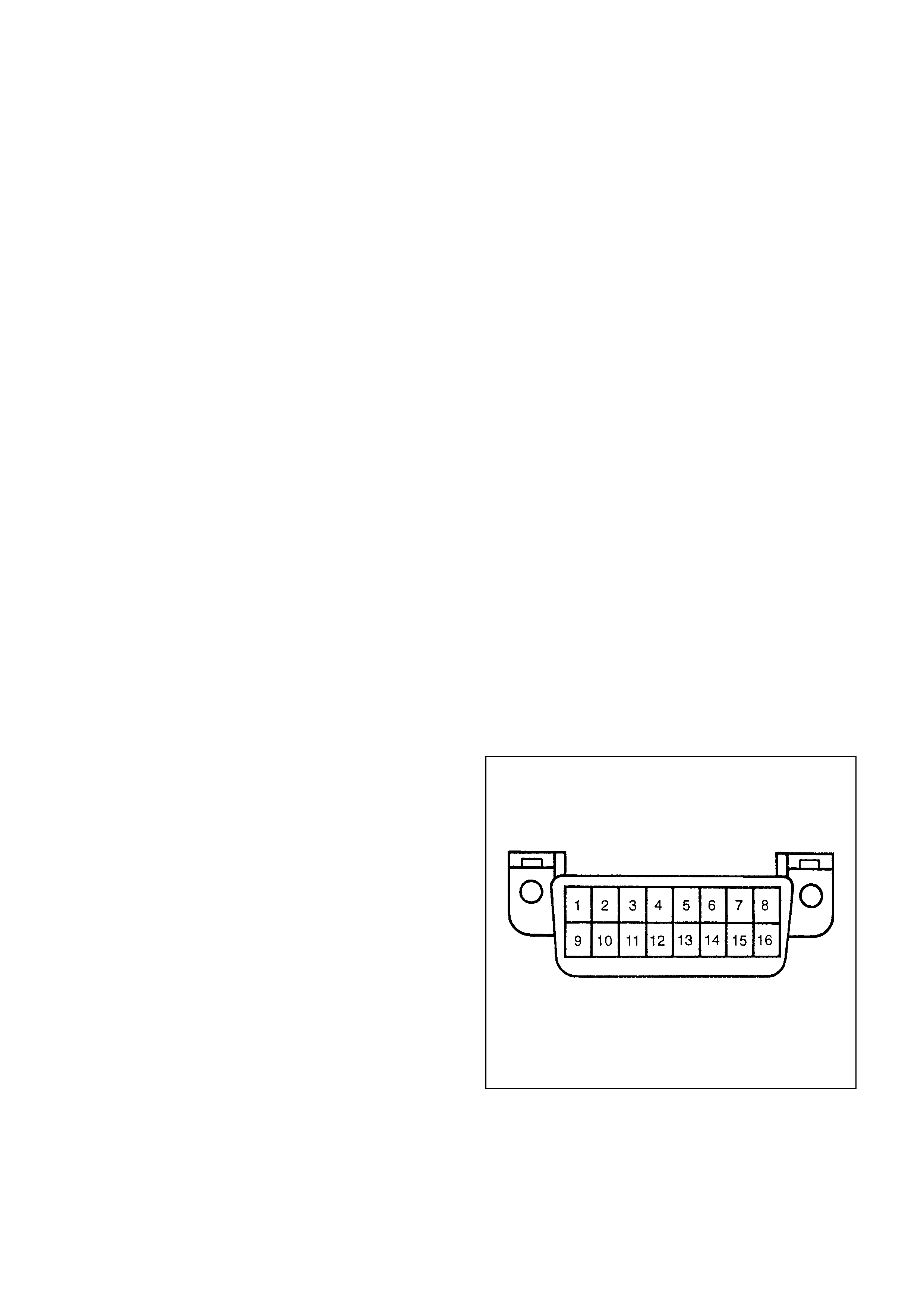

ECM PINOUTS

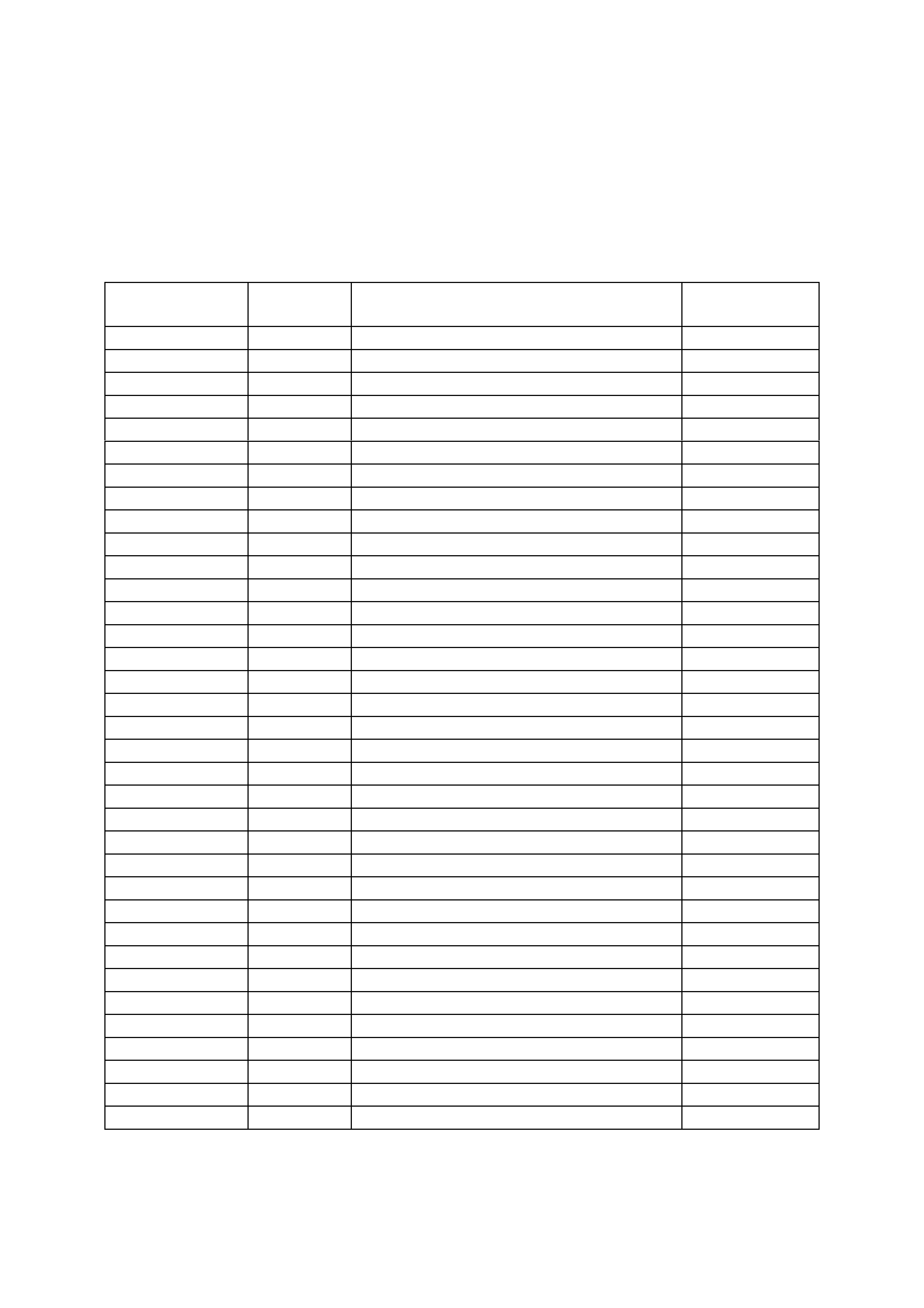

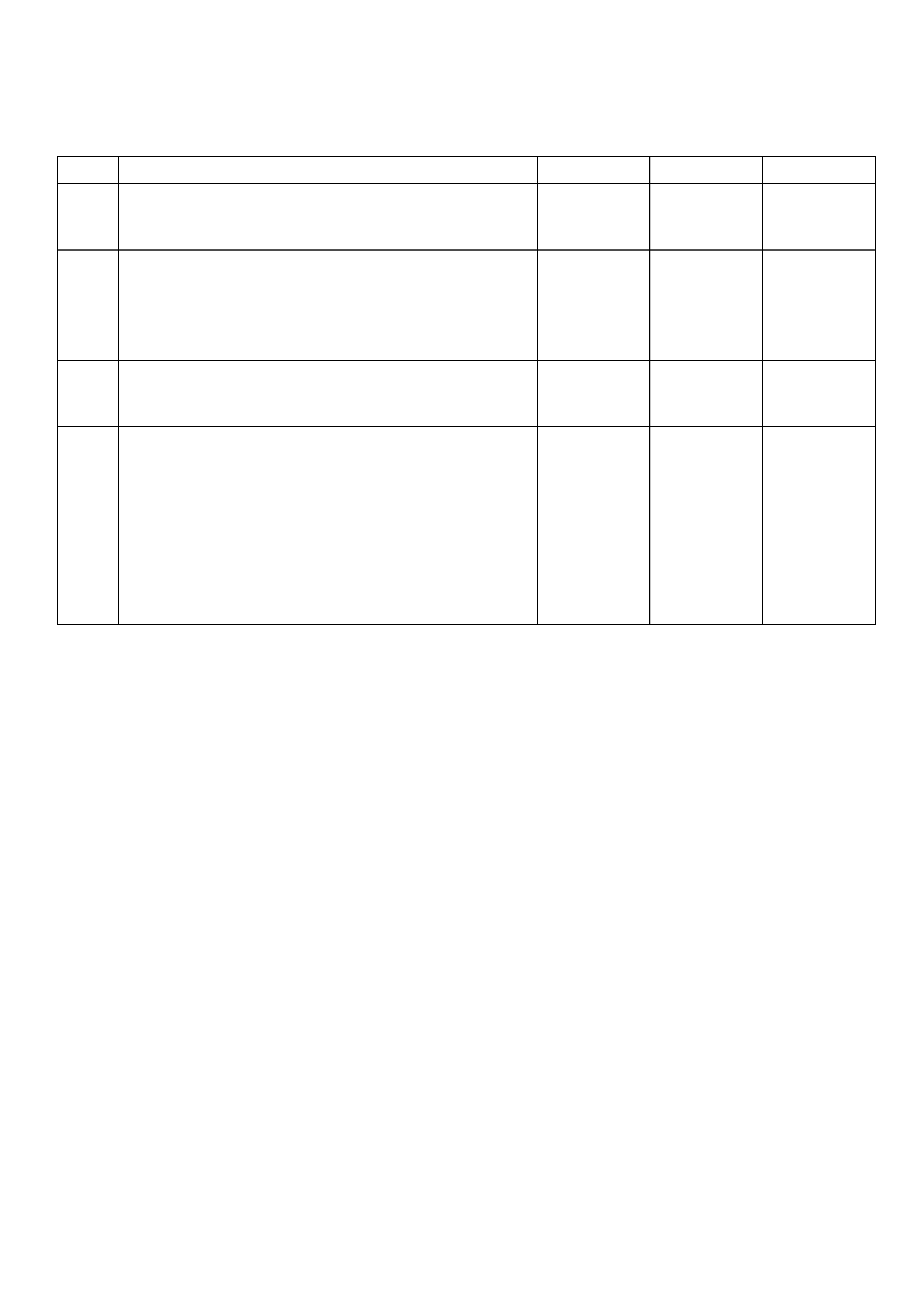

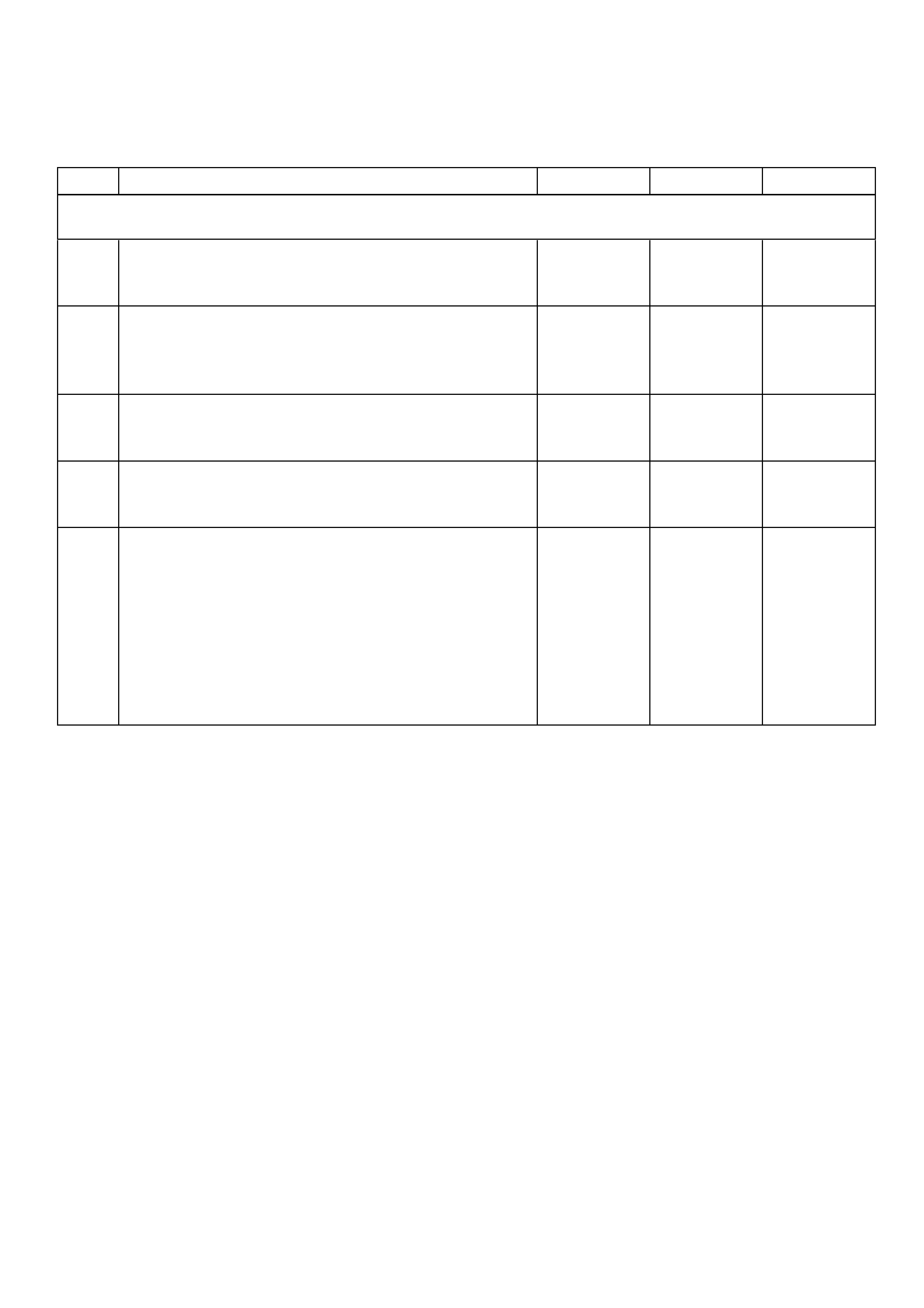

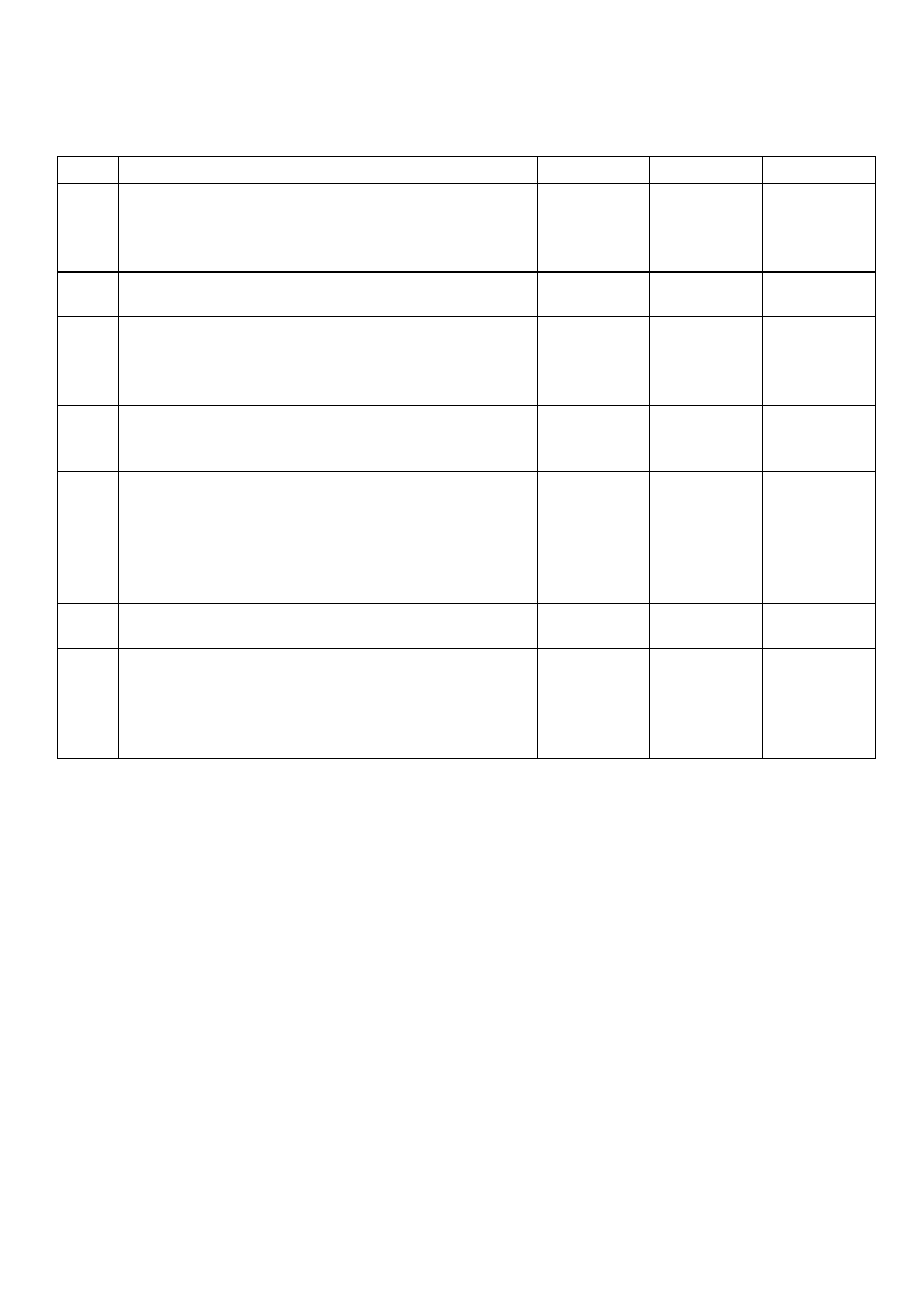

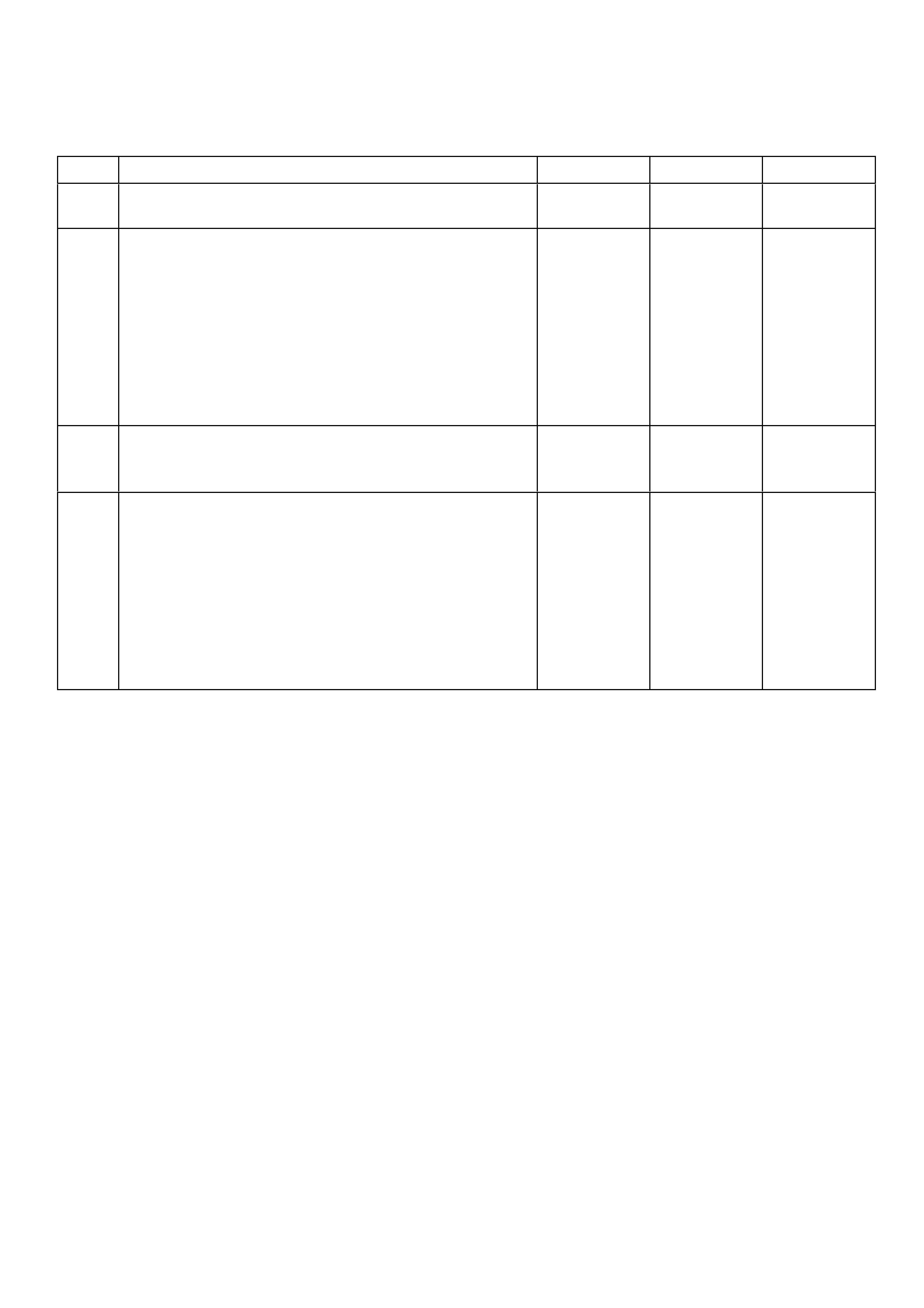

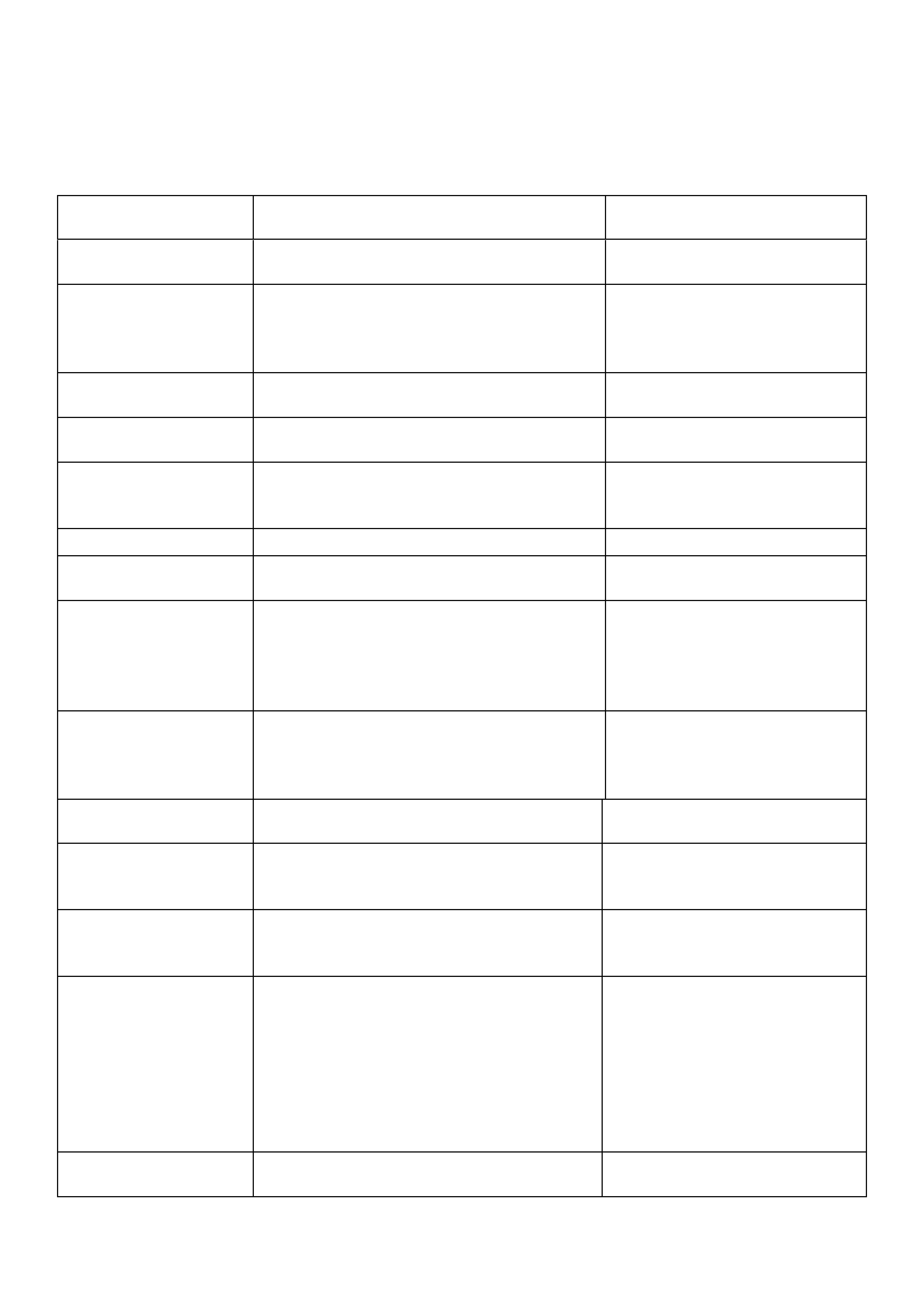

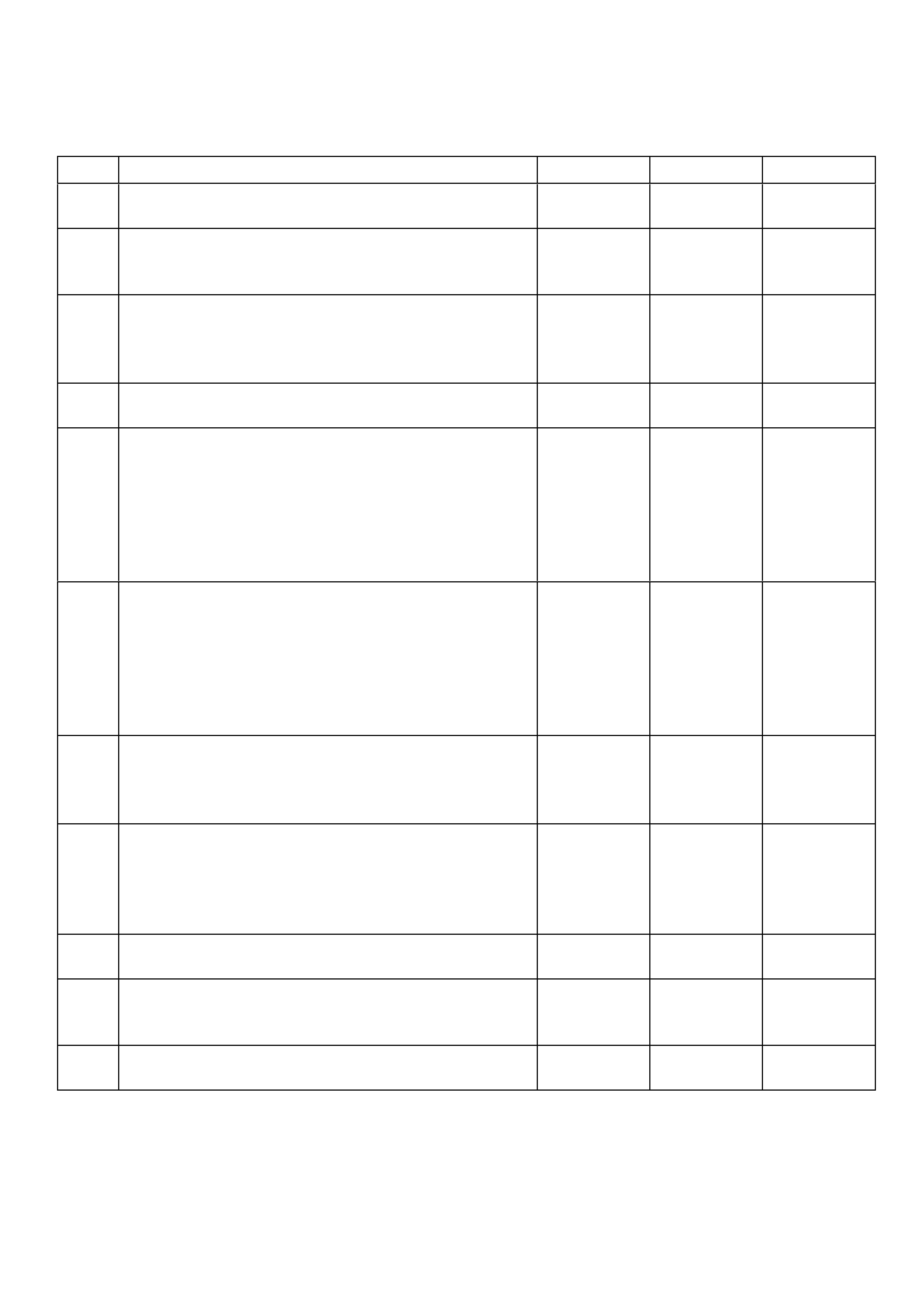

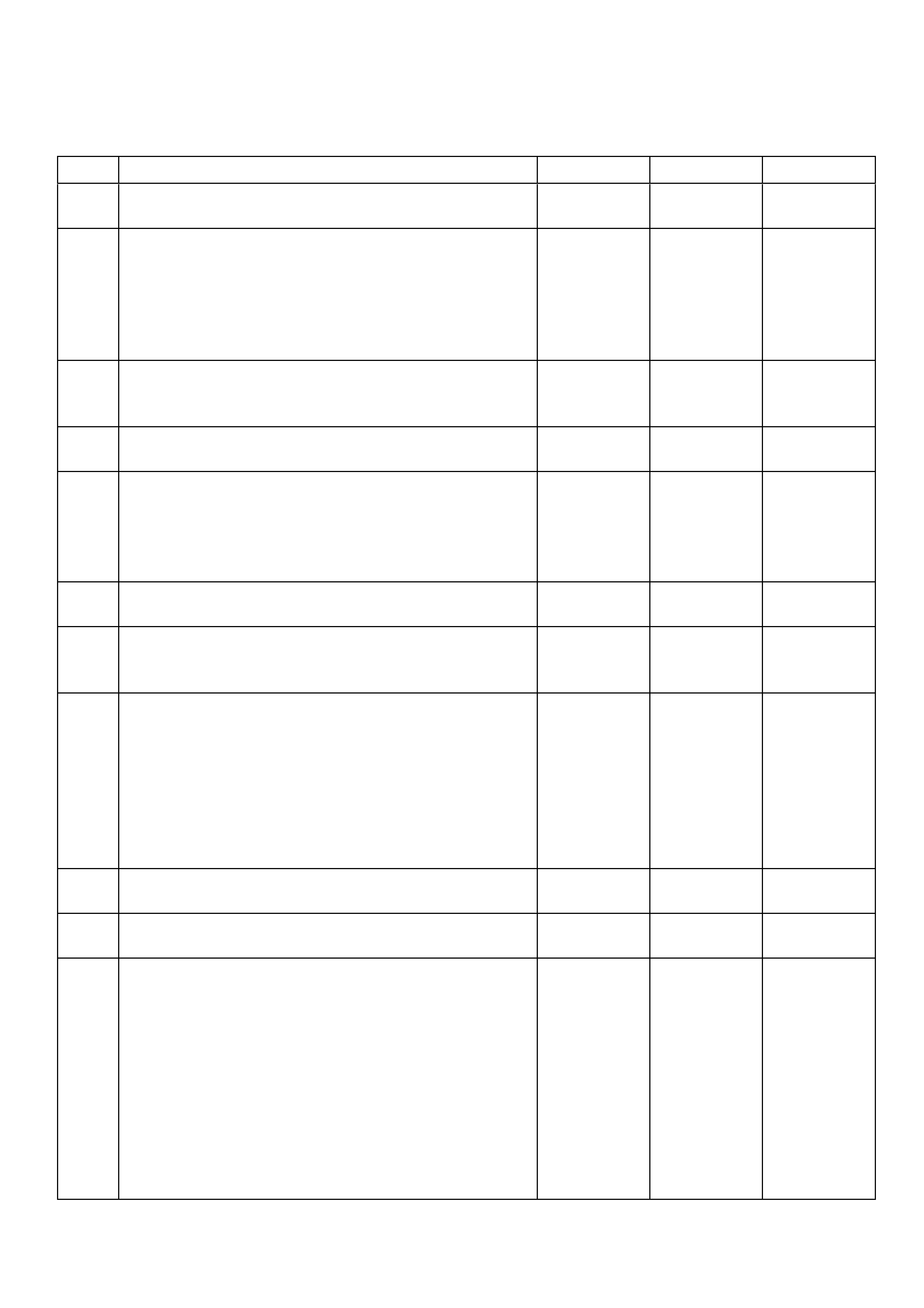

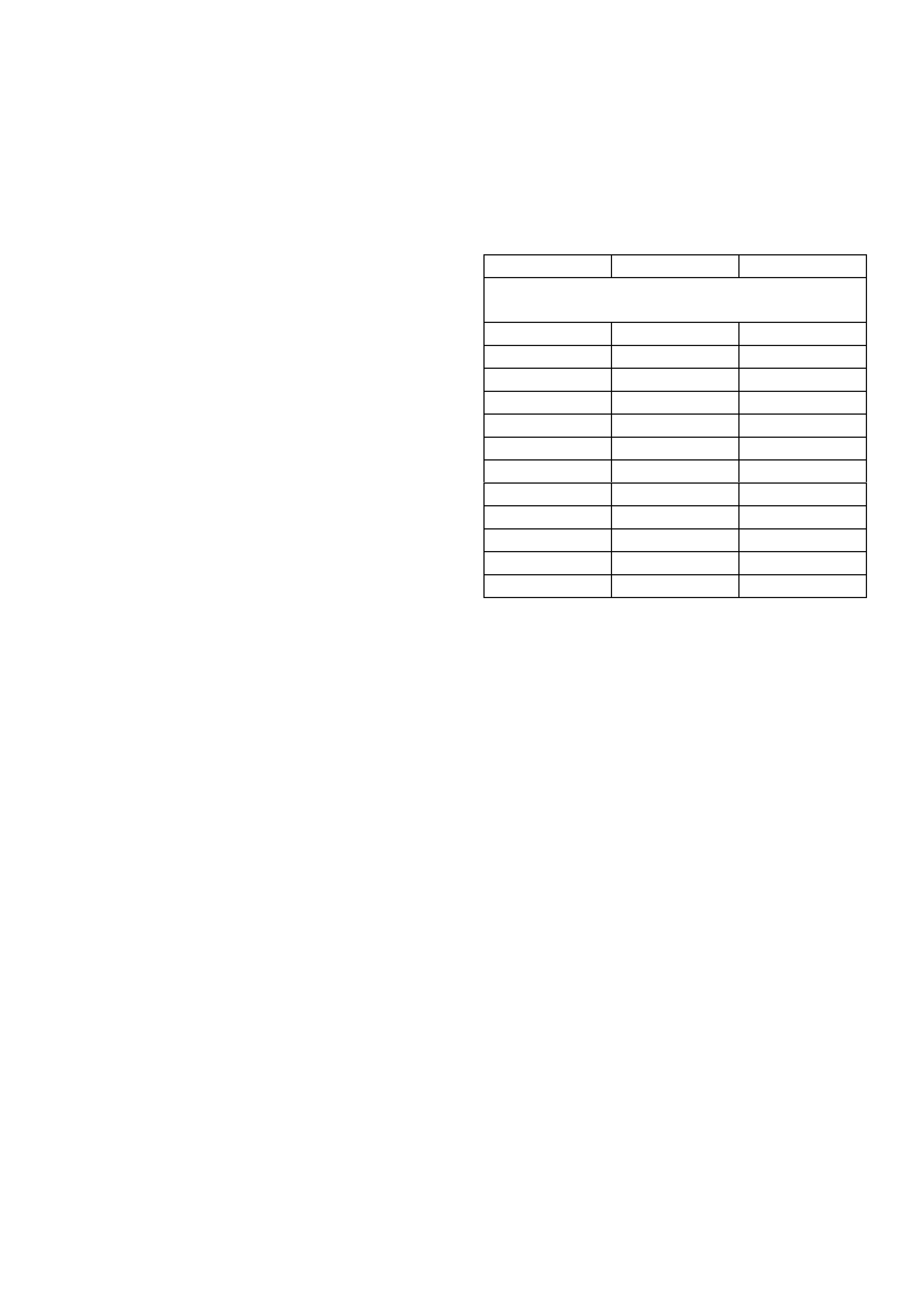

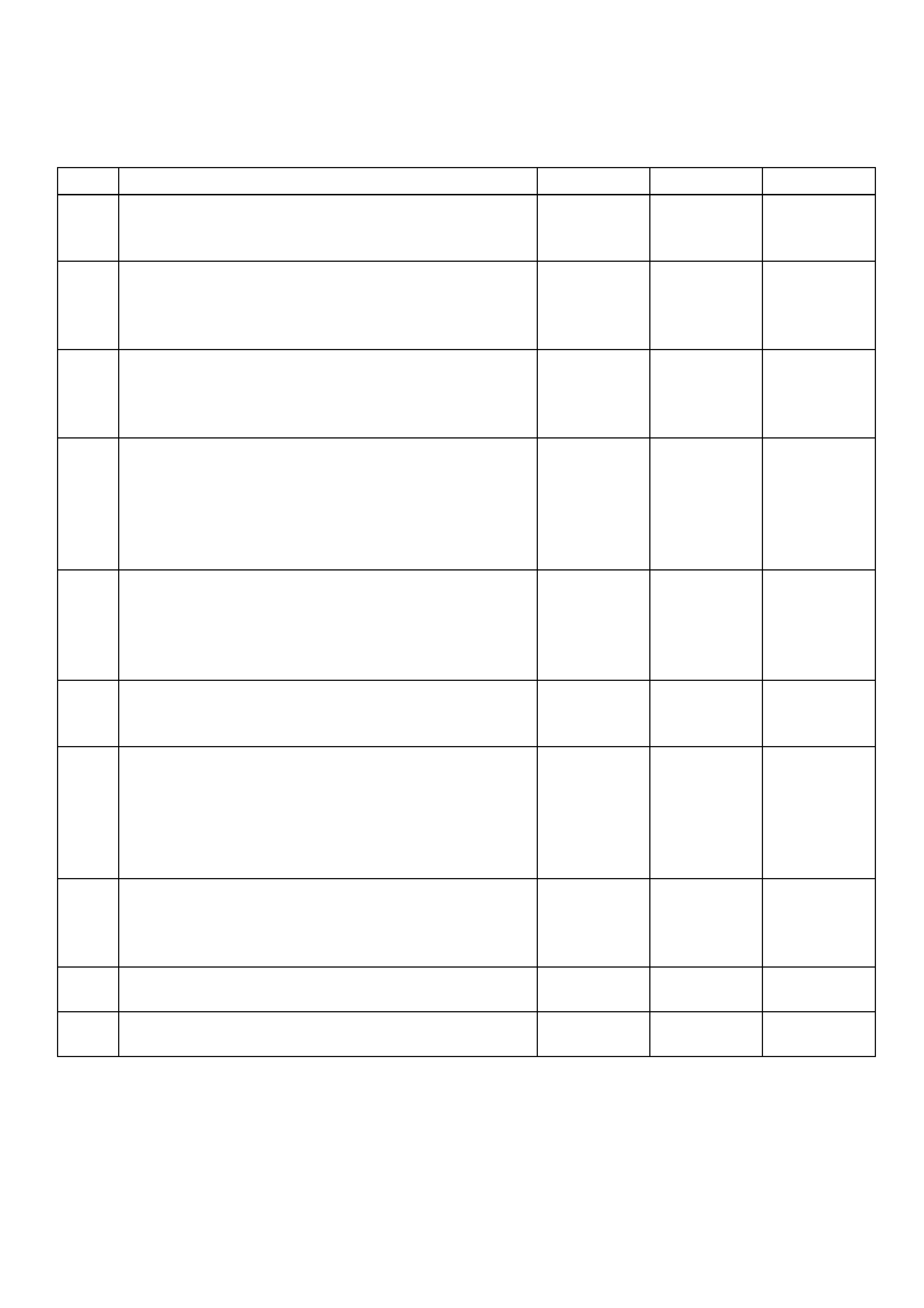

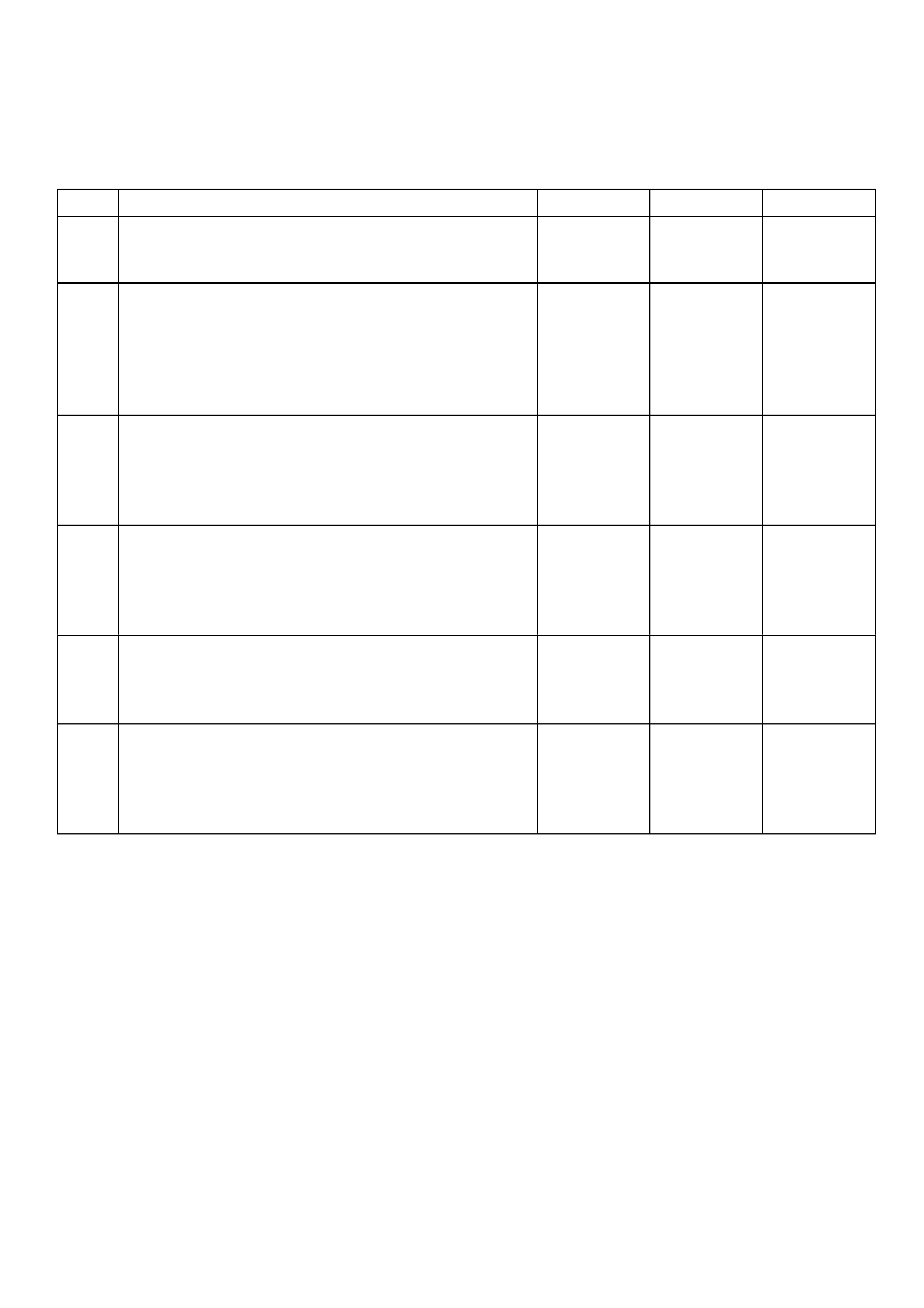

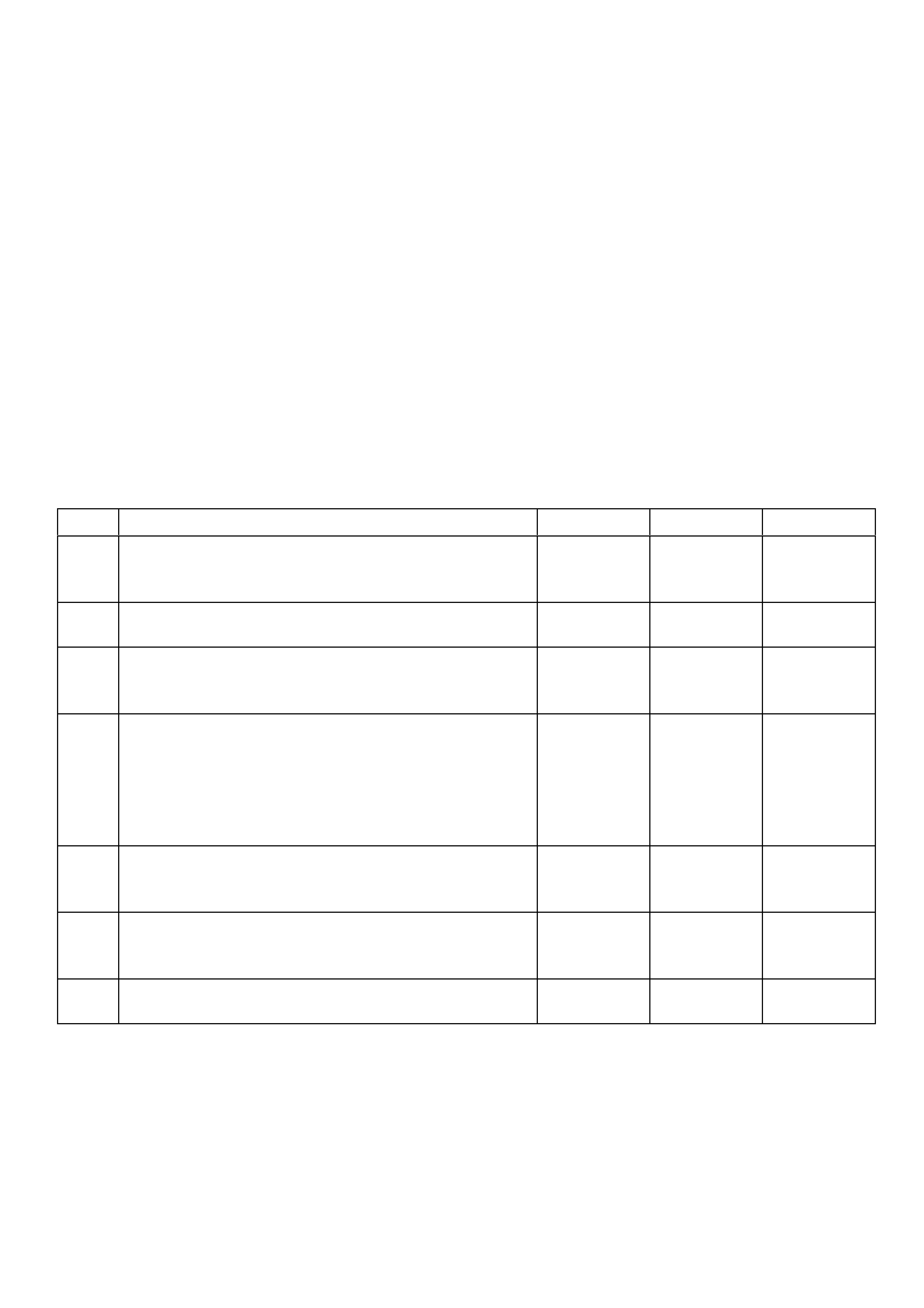

ECM PINOUT TABLE, 32-PI N BLUE CONNECTOR-ROW "J1"

ECM PINOUT TABLE, 32-PI N BLUE CONNECTOR-ROW "J1"

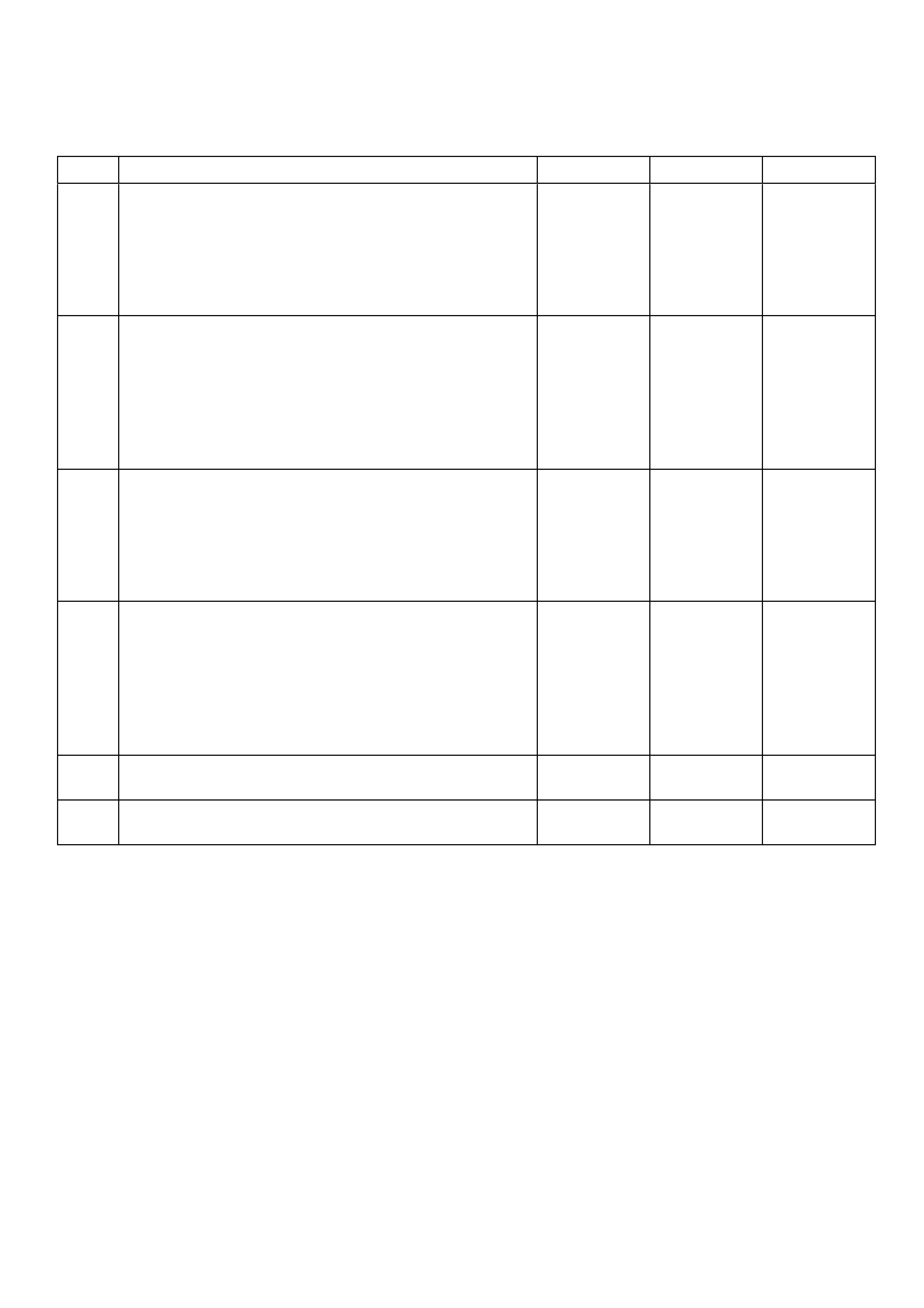

ECM PINOUT TABLE, 32-PIN RED CONNECTOR-ROW "J 2"

ECM PINOUT TABLE, 32-PIN RED CONNECTOR-ROW "J 2"

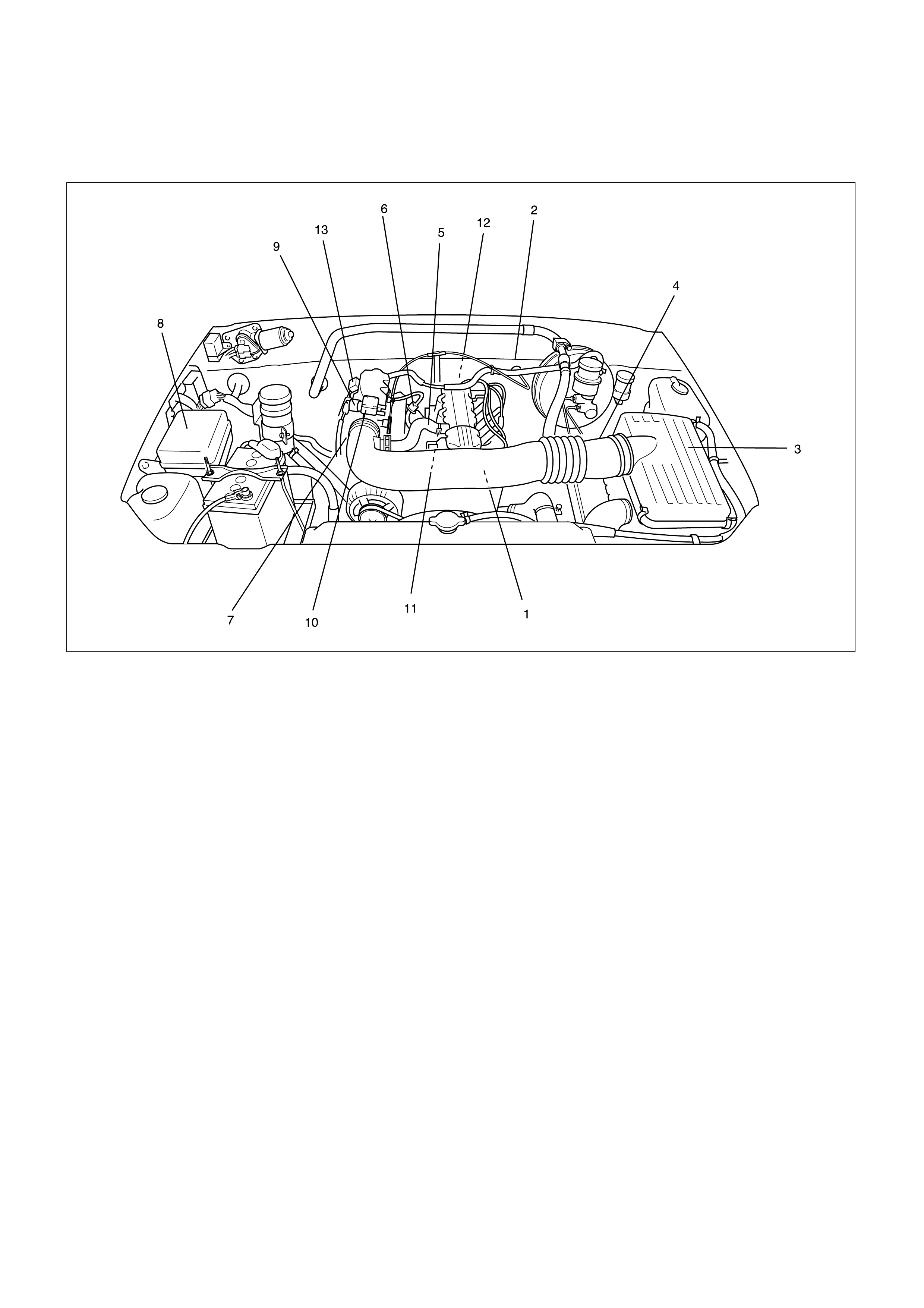

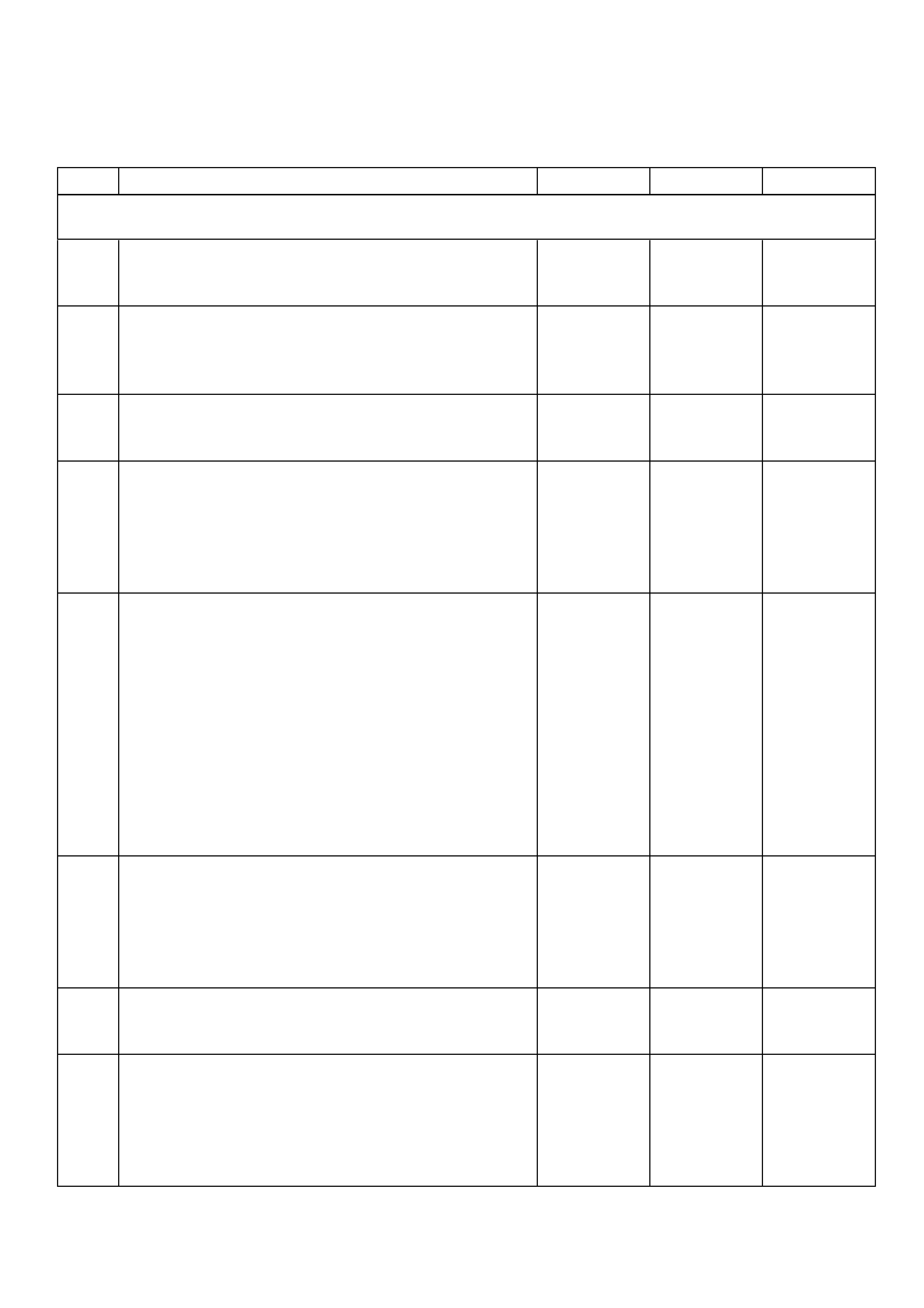

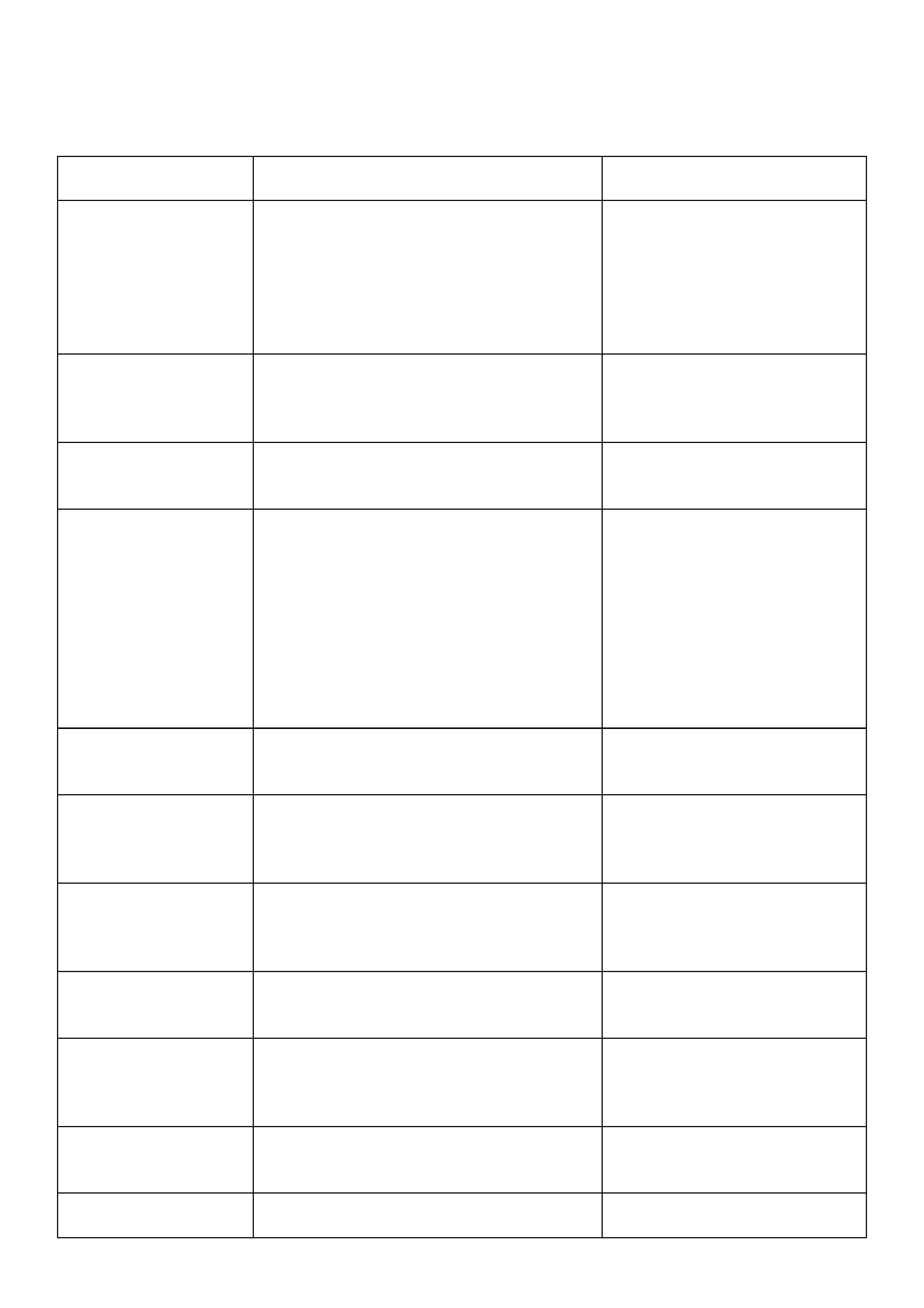

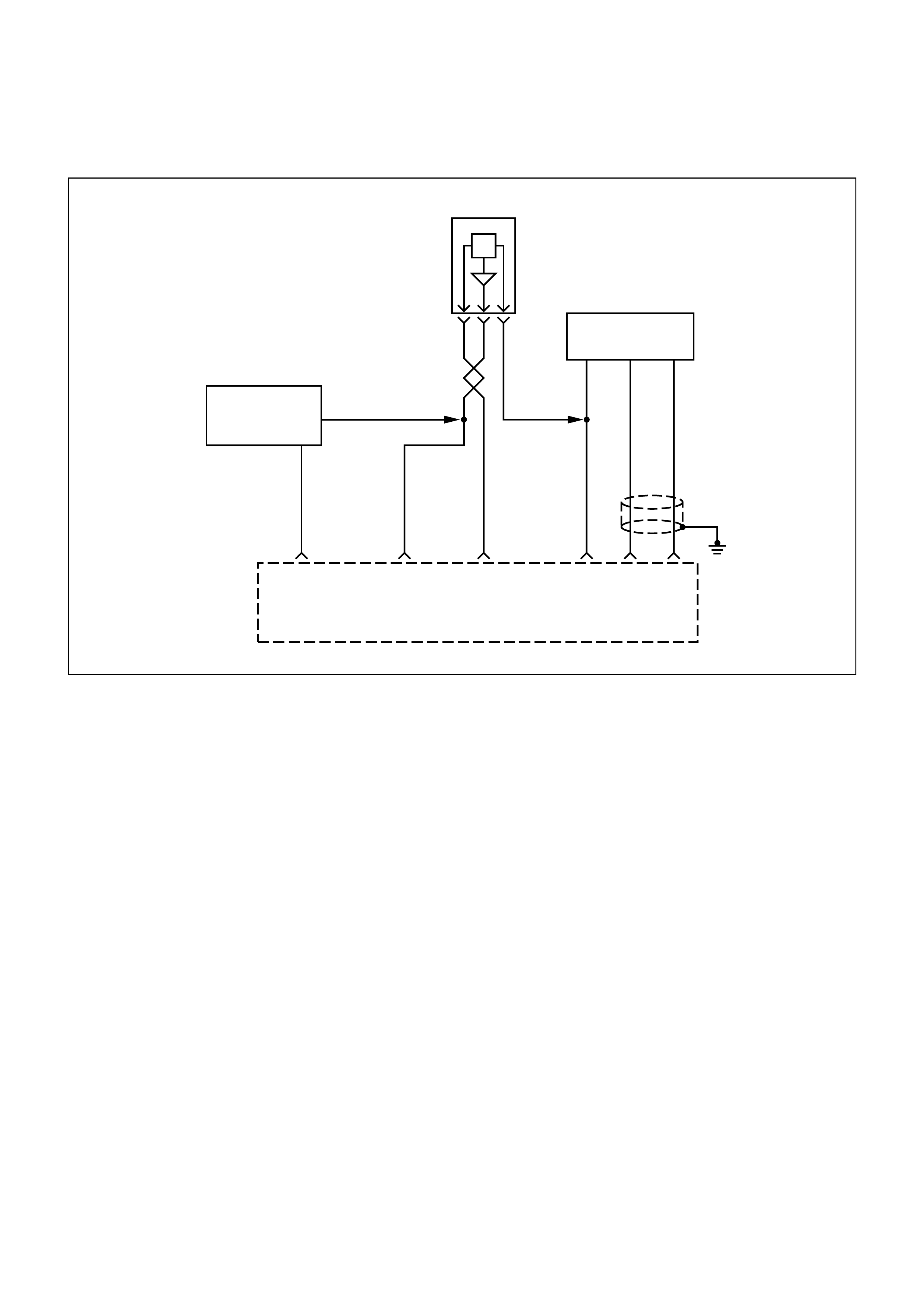

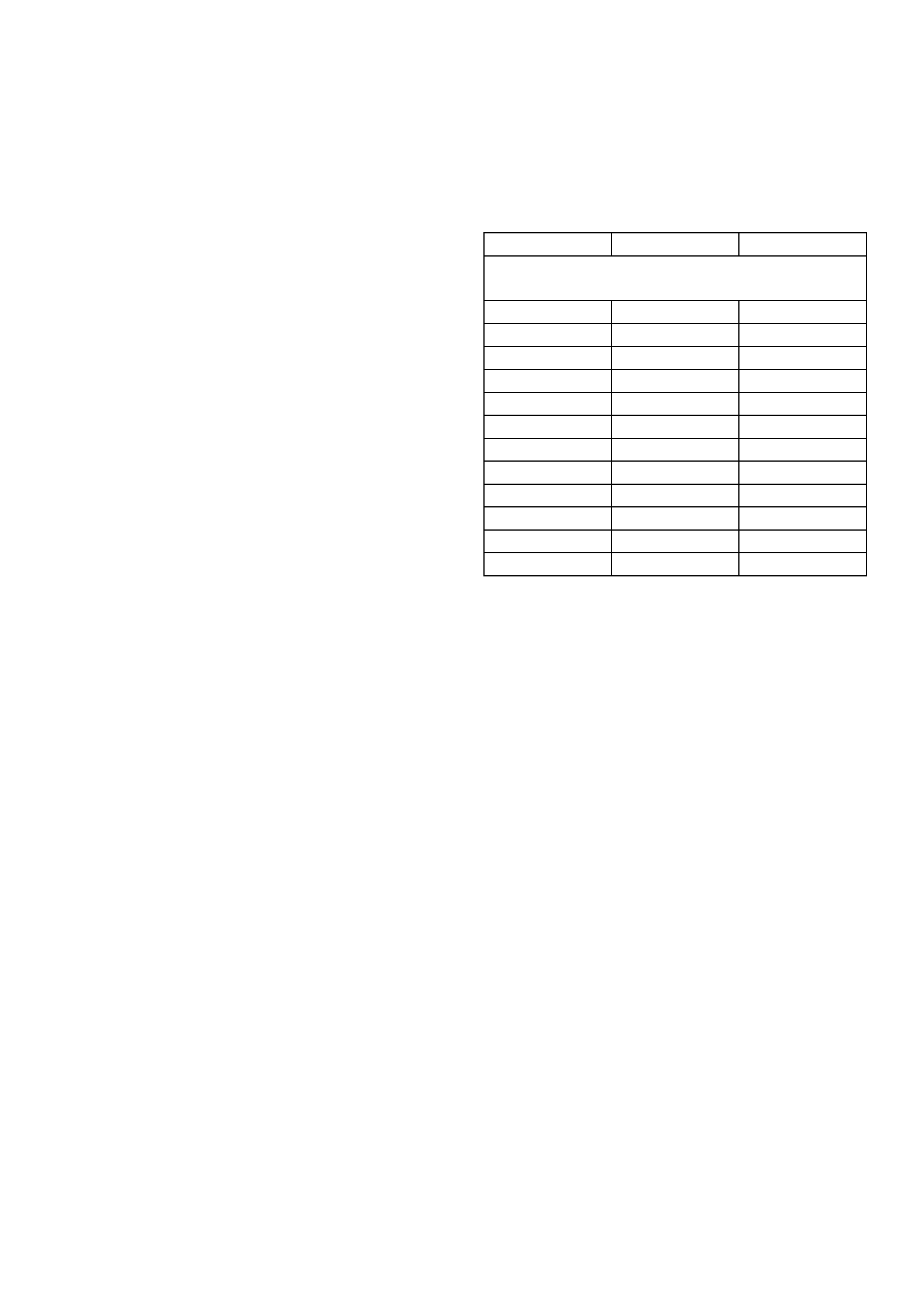

COMPONENT LOCATOR

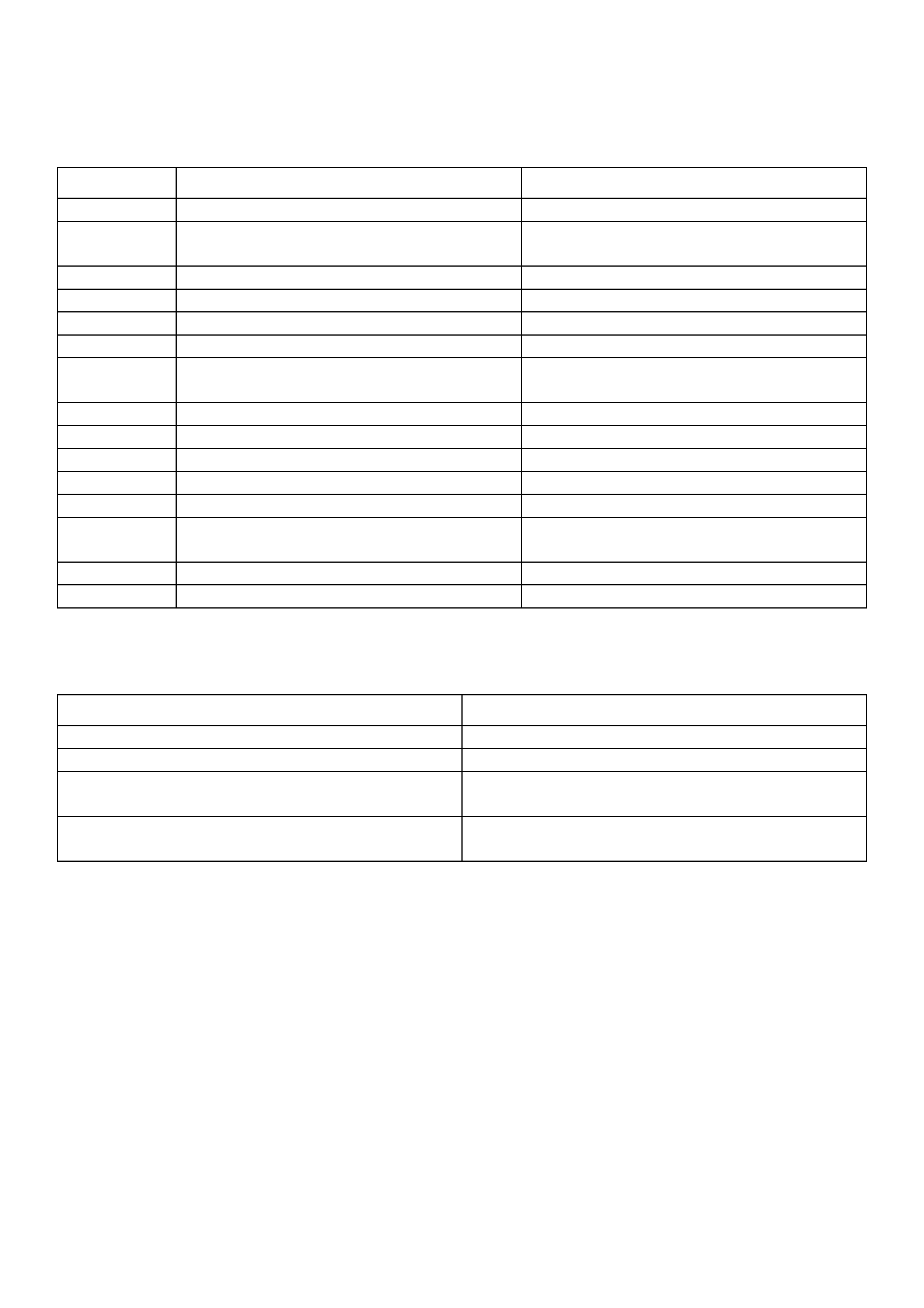

ENGINE COMPONENT LOCATOR TABLE

UNDERCARRIAGE COMPONENT LOCATOR TABLE

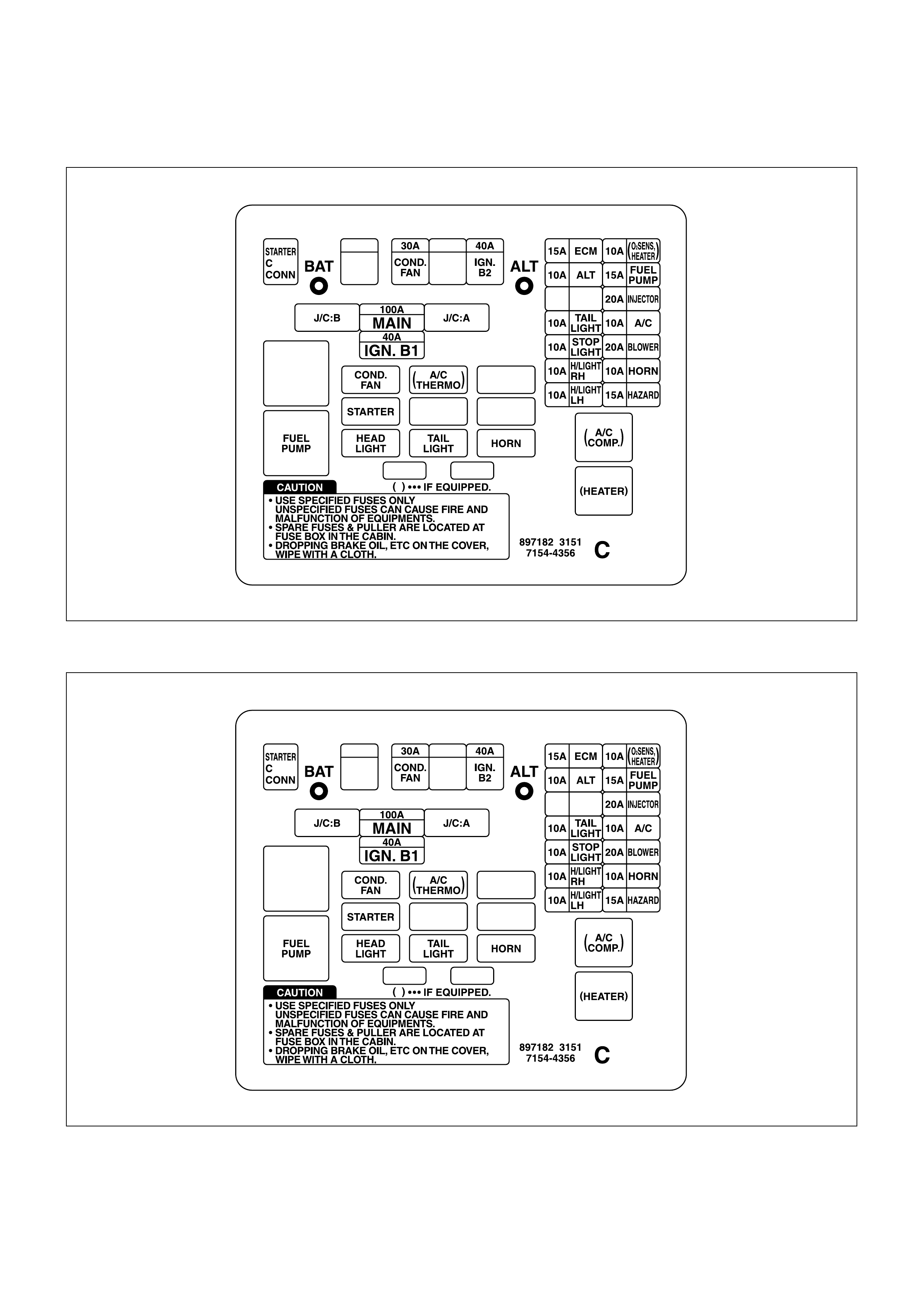

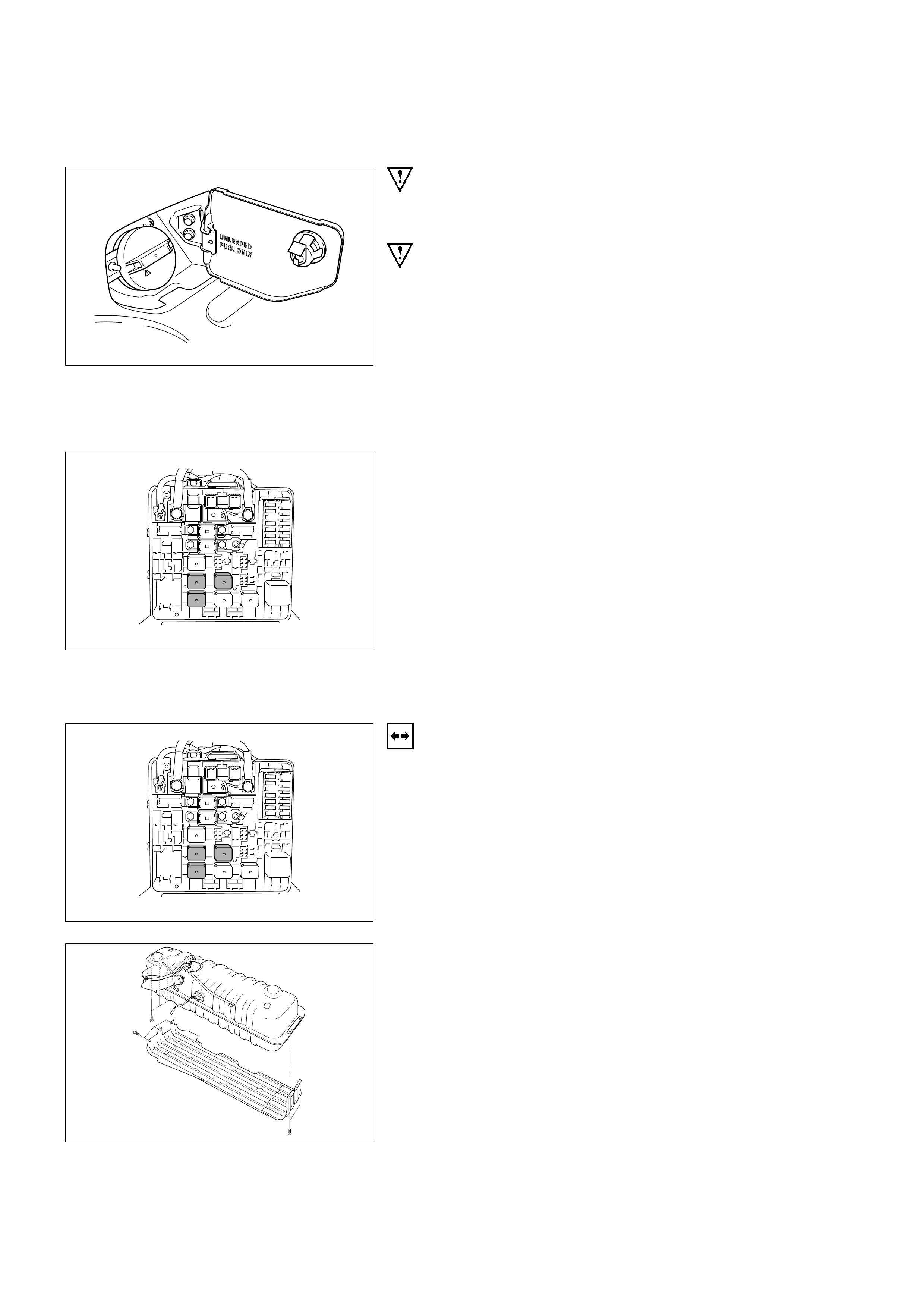

UNDERHOOD (U/H) FUSE AND RELAY PANEL

INSTRUMENT PANEL (I/P) FUSE BLOCK

DIAGNOSIS

STRATEGY-BASED DIAGNOSTICS

DTC STORED

NO DTC

NO MATCHING SYMPTOM

INTERMITTENTS

NO TROUBLE FOUND

VERIFYING VEHICLE REPAIR

Techline

Techline

Techline

GENERALSERVICE INFORMATION

OBD SERVICEABILITY ISSUES

FUEL QUALITY

NON-OEM PARTS

POOR VEHICLE MAINTENANCE

RELATED SYSTEM FAULTS

MAINTENANCE SCHEDULE

VISUAL/PHYSICAL ENGINE COMP ARTMENT INSPECTION

BASIC KNOWLEDGE OF TOOLS REQUIRED

SERIAL DATA COMMUNICATIONS

ON-BOARD DIAGNOSTIC (OBD)

ON-BOARD DIAGNOSTIC TESTS

COMPREHENSIVE COMP ONENT MONITOR DIAGNOSTIC OPE RATION

INPUT COMPONENTS

OUTPUT COMPONENTS

PASSIVE AND ACTIVE DIAGNOSIS TESTS

INTRUSIVE DIAGNOSIS TESTS

WARM-UP CYCLE

COMMON OBD TERMS

DIAGNOSTIC FOR CLOSED LOOP SYSTEM

FOR CLOSED LOOP SYSTEM

ENABLE CRITERIA

TRIP

THE DIAGNOS I TIC E XECUTIVE

DIAGNOSTIC INFORMATION

MALFUNCTION INDICATOR LAMP (MIL)

EXTINGUISH THE MIL

DATA LINK CONNECTOR (DLC)

READING FLASH DIAGNOSTIC TROUBLE CODES

READING DIAGNOSTIC TROUBLE CODES USING A TECH 2

CLEARING DIAGNOSTIC TROUBLE CODES

ON-BOARD DIAGNOSIS (SELF-DIAGNOSI S)

TECH 2 SCAN TOOL

GETTING STARTED

OPERATING PROCEDURE

MENU

VERIFYING VEHICLE REPAIR

READING DIAGNOSTIC TROUBLE CODES USING A SCAN TOOL

CLEARING DIAGNOSTIC TROUBLE CODES

DTC MODES

DTC INFORMATION MODE

CLEAR DTC INFORMATION

PRIMARY SYSTEM-BASED DIAGNOSTICS

FUEL CONTROL HEATED OXYGEN SENSORS (IF APPLICABLE)

HO2S HEATER

ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

A/C CLUTCH CONTROL CIRCUIT DIAGNOSIS

ELECTRIC IGNITION SYSTEM DIAGNOSIS

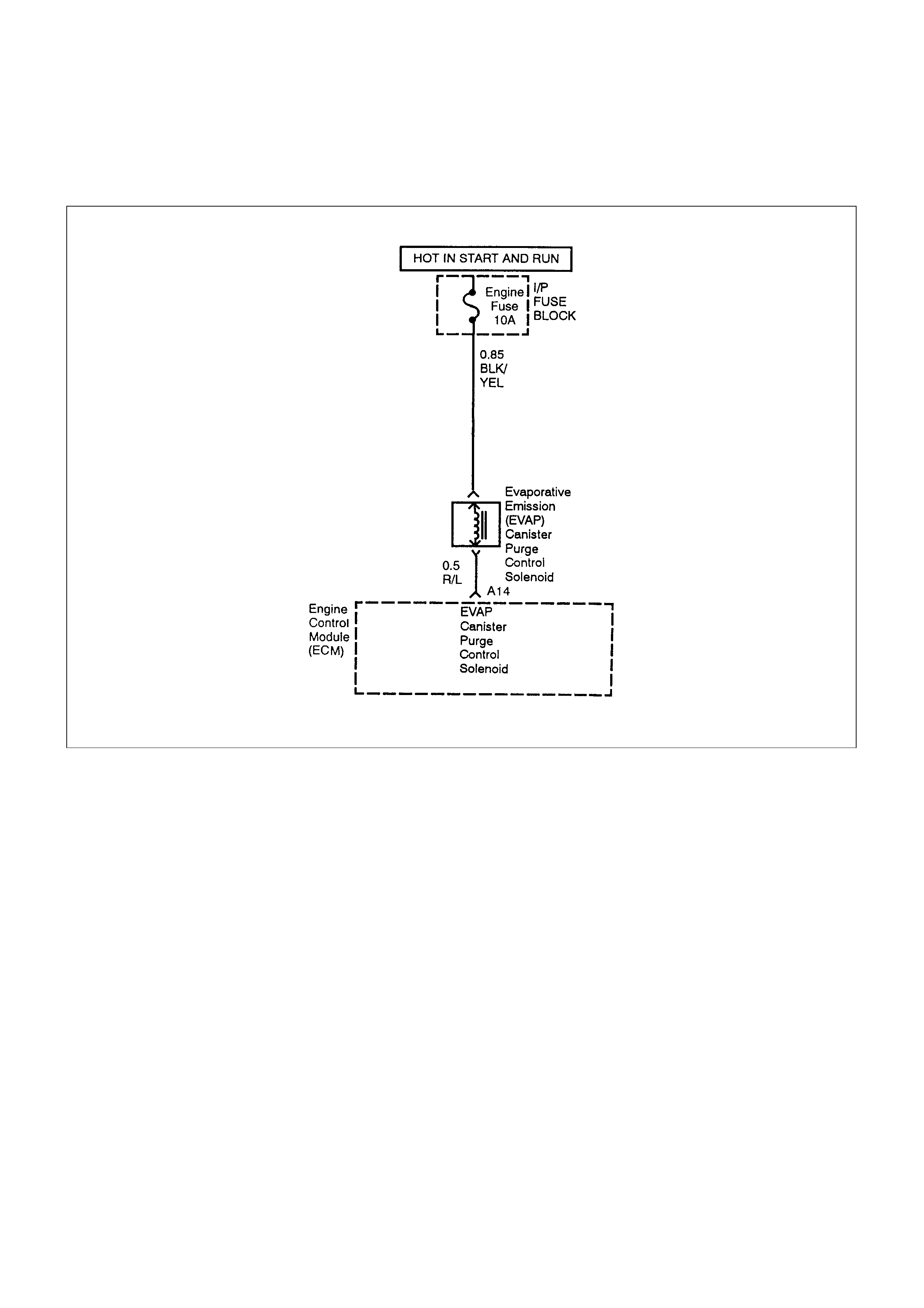

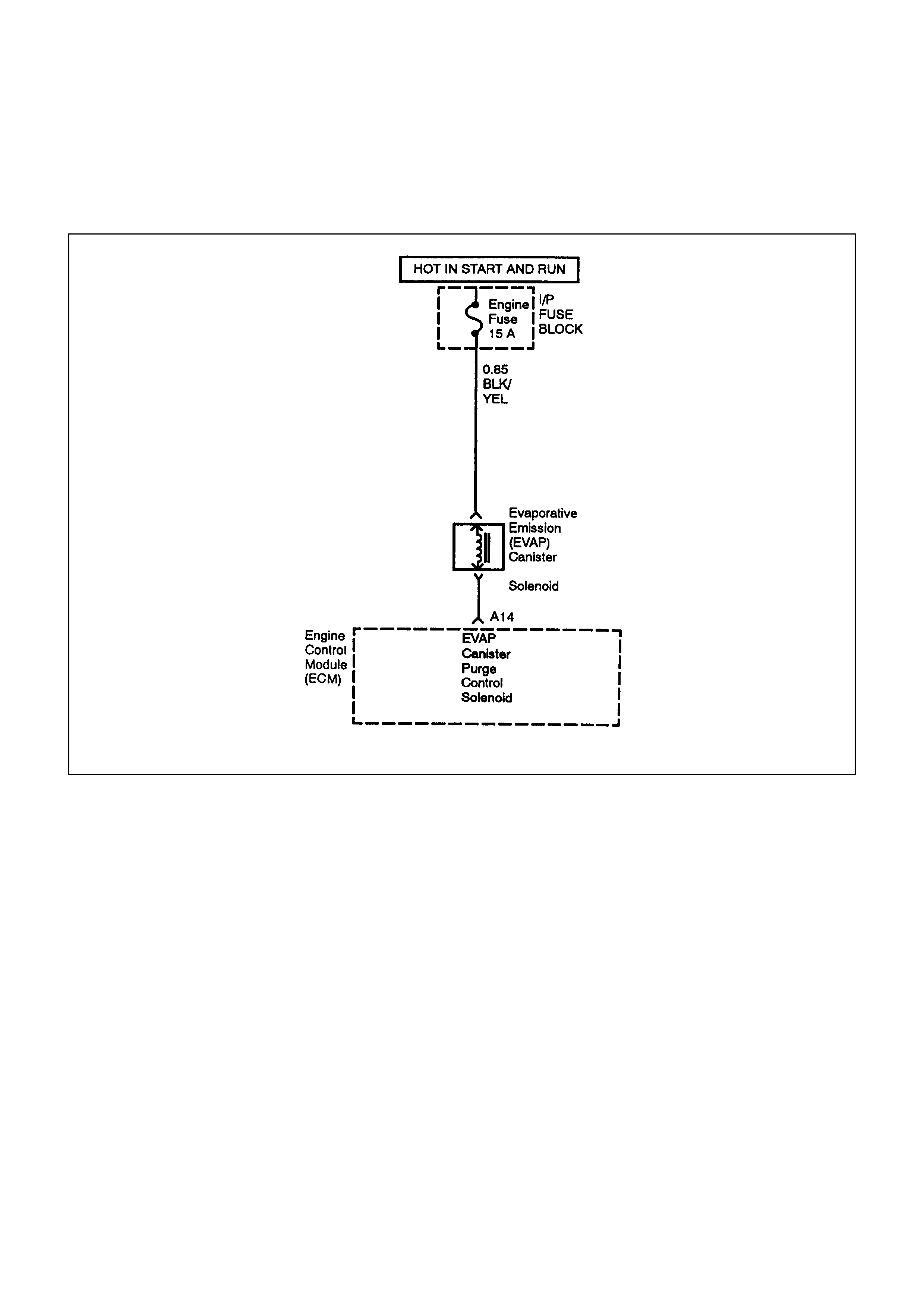

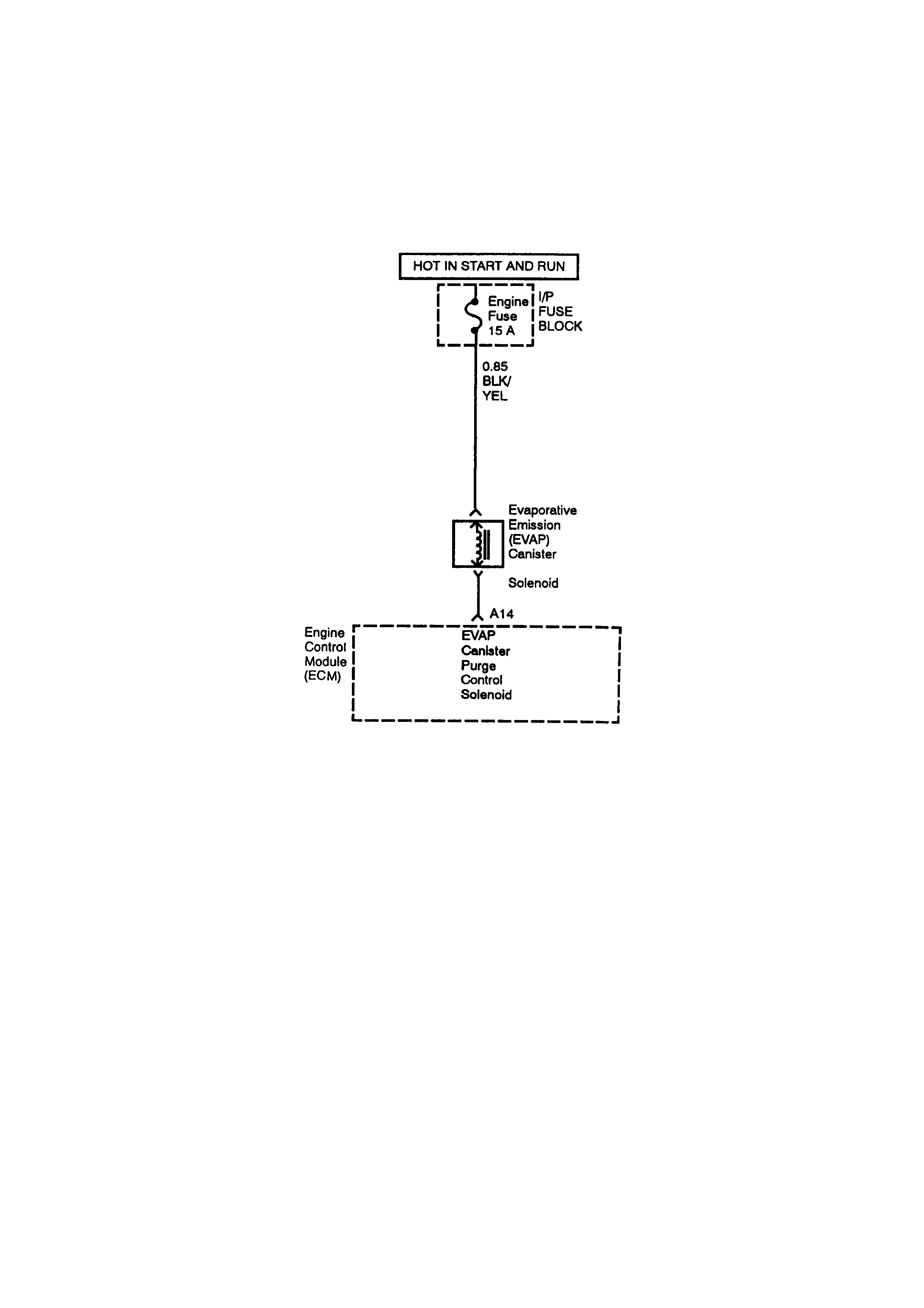

EVAP CANISTER PURGE SOLENOID (IF APPLICABLE)

VISUAL CHECK OF THE EVAPORATIVE EMISSION CANISTER (IF APPLICABLE)

IDLE AIR CONTROL (IAC) VALVE

FUEL SYSTEM PRESSURE TEST

FUEL METERING SYSTEM CHECK

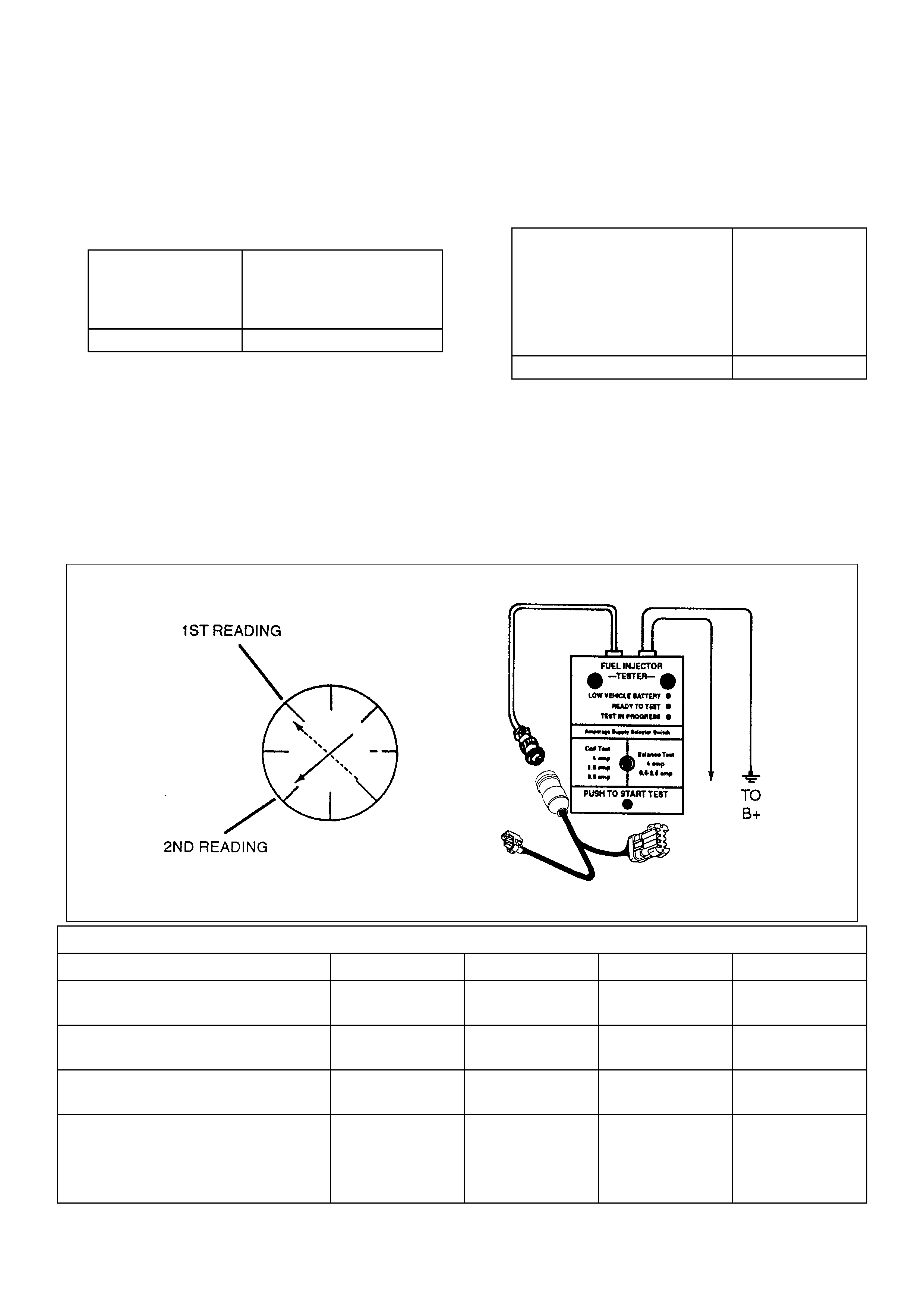

FUEL INJECTOR COIL TEST PROCEDURE AND

FUEL INJECTOR BALANCE TEST PROCEDURE

TEST DESCRIPTION

INJECTOR COIL TEST PROCE DURE (STEP1-6) AND

INJECTOR BALANCE TEST PROCEDURE (STEP7-11)

ENGINE CONTROL MODULE(ECM) DIAGNOSIS

MULTIPLE ECM INFORMATION SENSOR DTCS SET

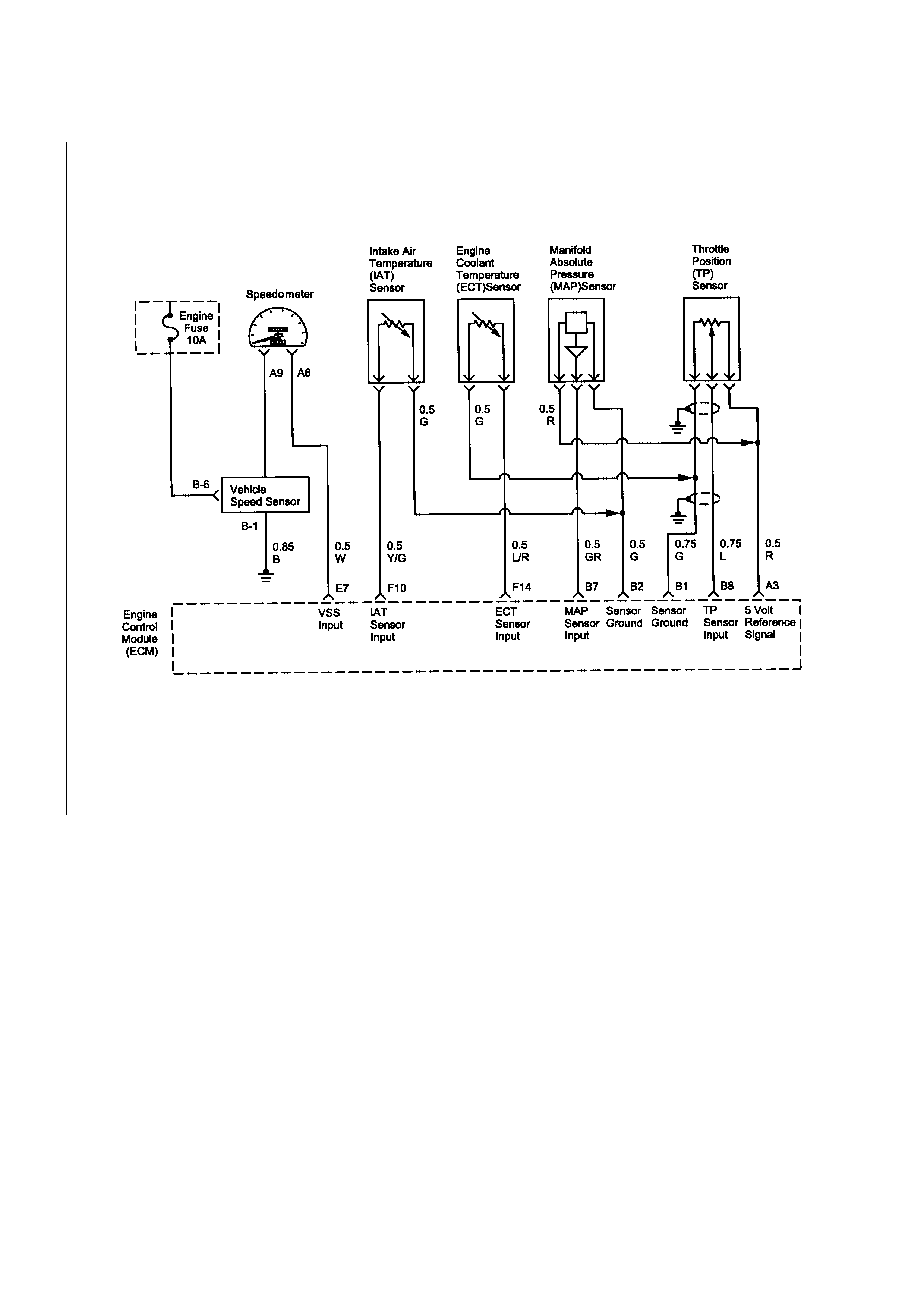

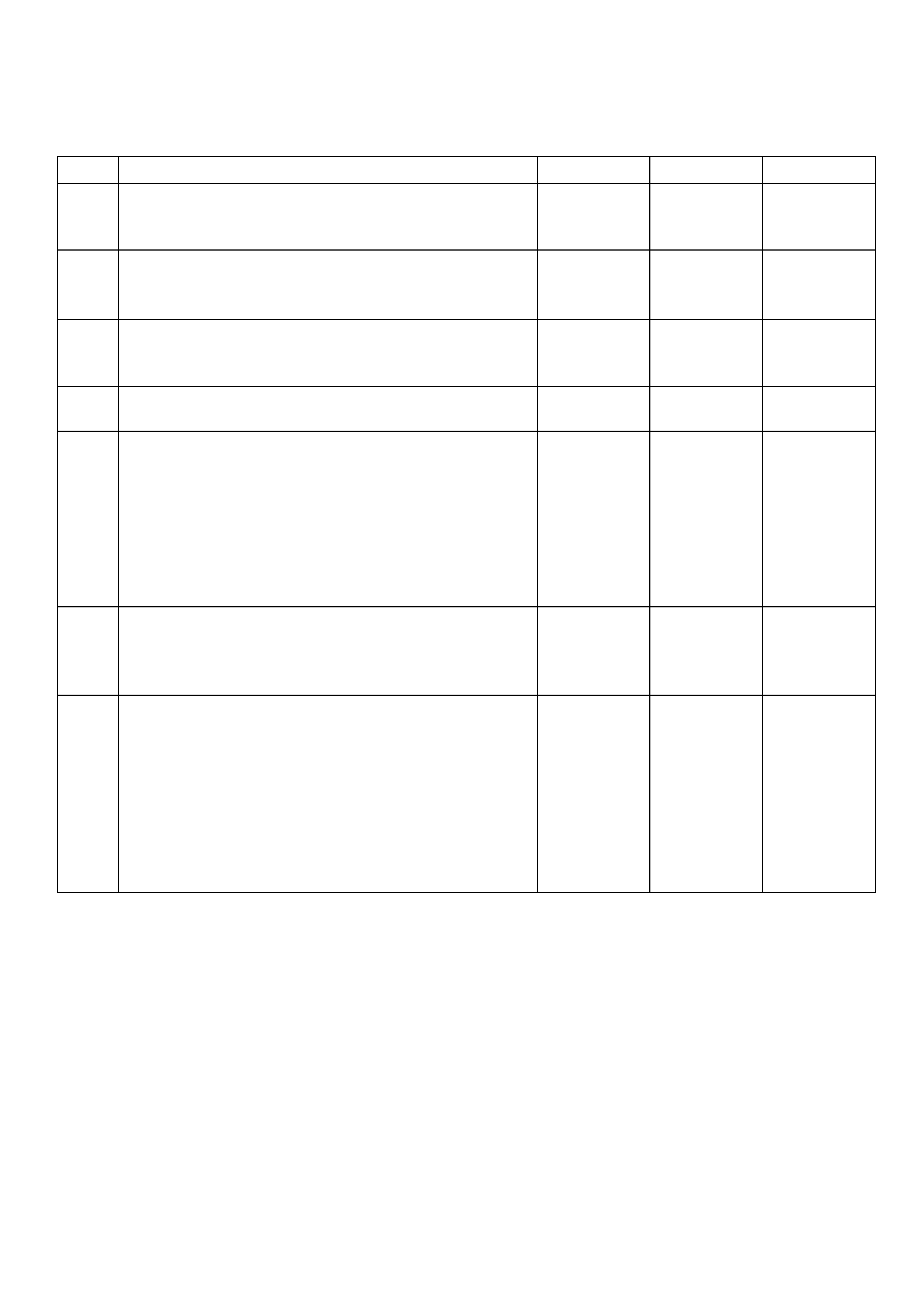

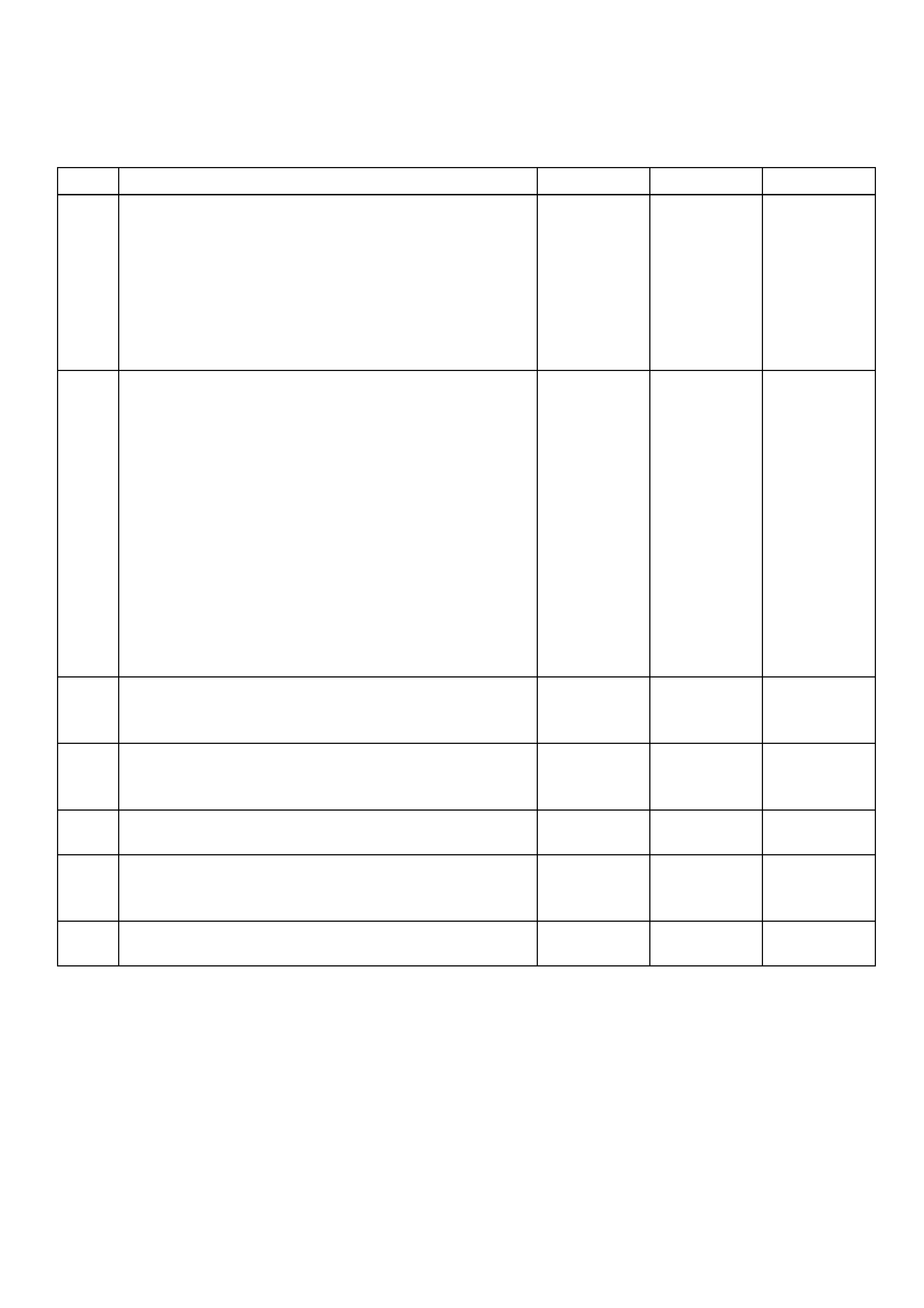

ENGINE SCAN TOOL DATA DEFINITIONS AND RANGES

TYPICAL SCAN DATA VALUES

TEST CONDITIONS

2.2L/2.0L L-4 ENGINE

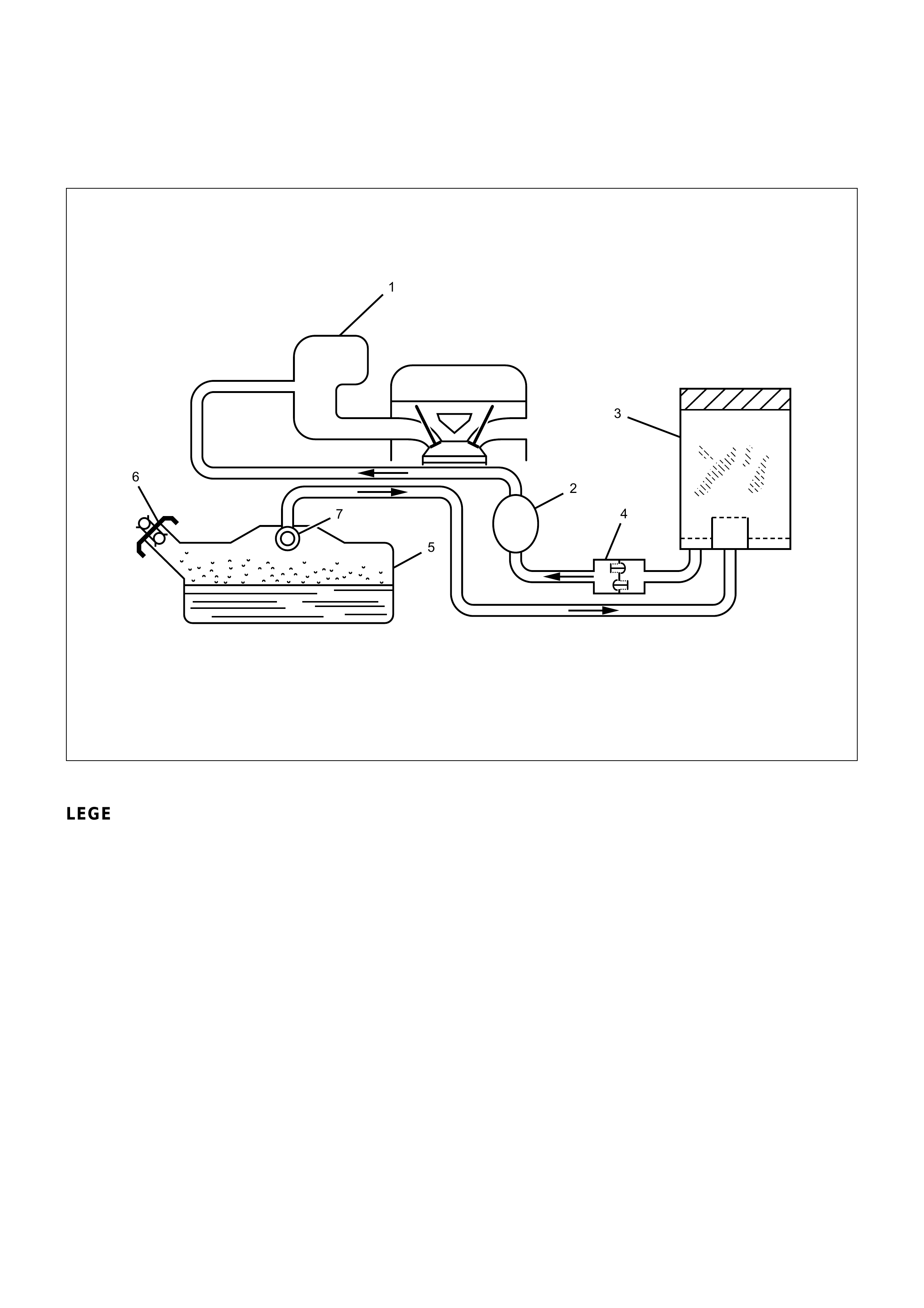

GENERAL DESCRIPTION (EVAPORATIVE (EVAP) EMISSION SYSTEM) (IF APPLICABLE)

EVAP EMISSION CONTROL SYSTEM PURPOSE

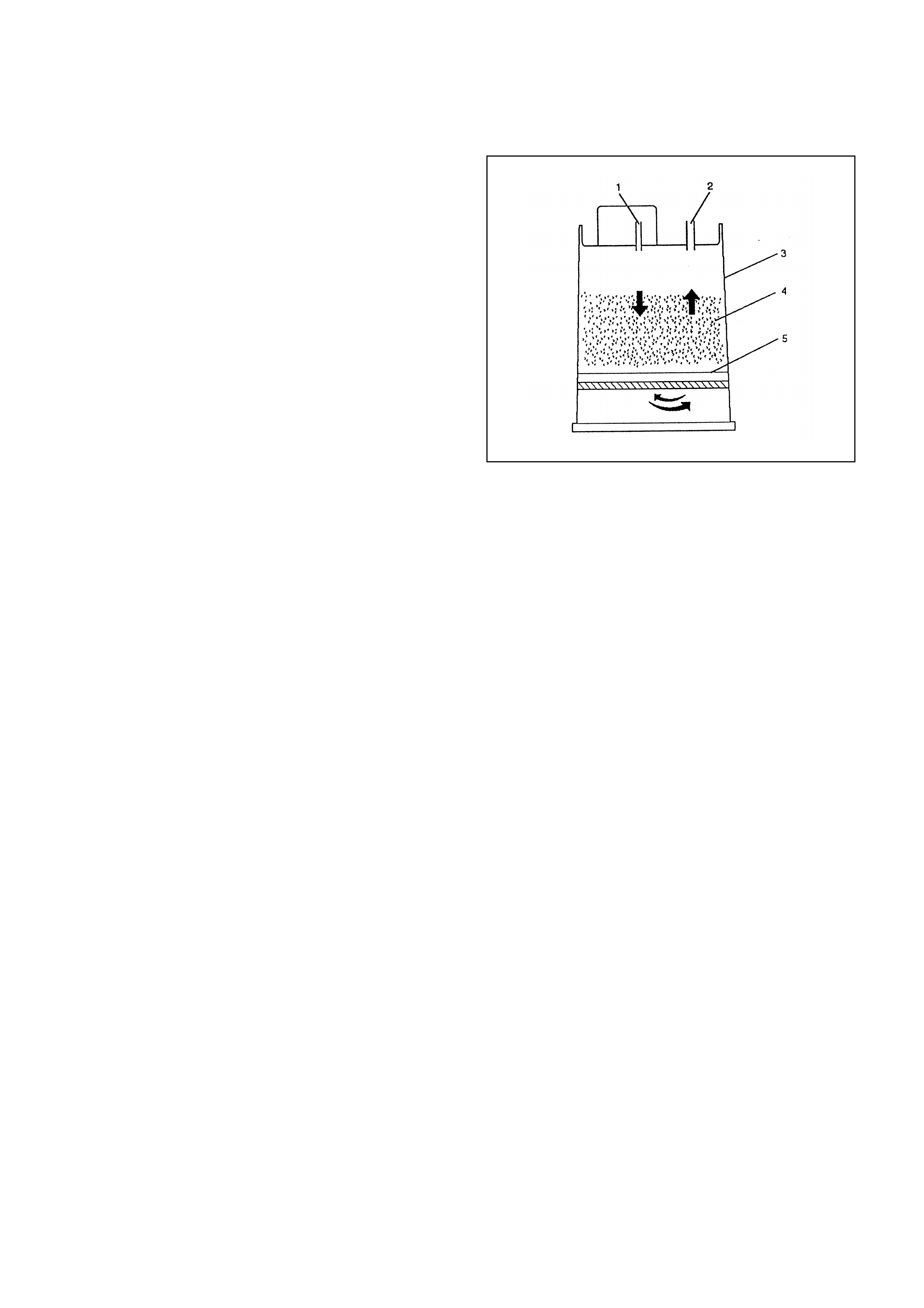

VAPOR CANISTER

EVAP CONTROL SYSTEM

RESULTS OF INCORRECT OPERATION

DIAGNOSIS

VISUAL CHECK OF CANISTE R

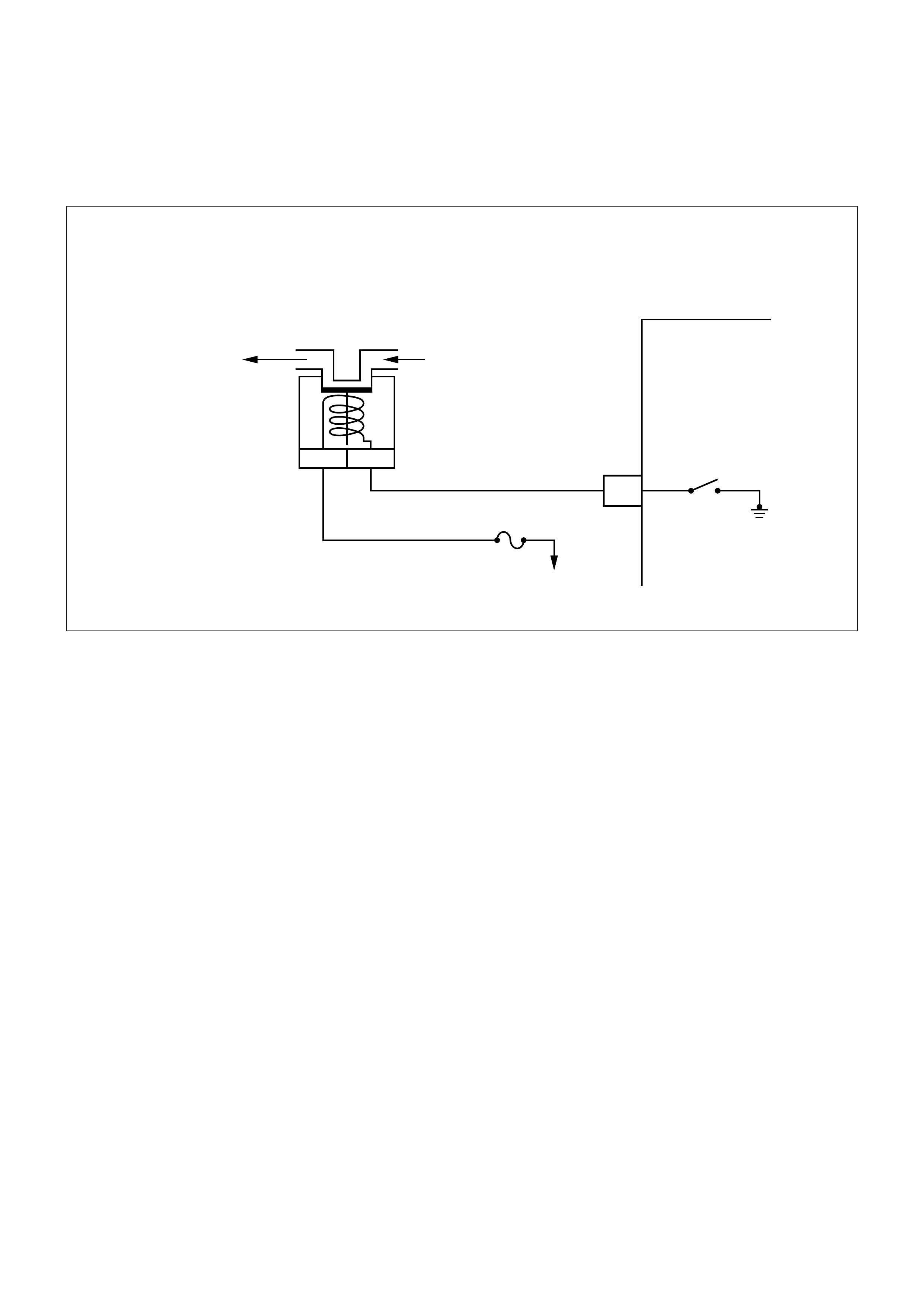

EVAPORATIVE EMISSION CANISTER PURGE CONTROL

SOLENOID VALVE CHECK (IF APPLICABLE)

GENERAL DE S CRIPTION

ECM DIAGNOSTIC TROUBLE CODES

SYMPTOM DIAGNOSIS

PRELIMINARY CHECKS

VISUAL/PHYSICAL CHECK

INTERMITTENT

HARD START SYMPTOM

SURGES AND/OR CHUGGLES SYMPTOM

LACK OF POWER, SLUGGISH OR SPONGY SYMPTOM

DETONATION/SPARK KNOCK SYMPTOM

ROUGH, UNSTABLE, OR INCORRECT IDLE,

STALLING SYMPTOM (FOR OPEN LOOP SYSTEM)

ROUGH, UNSTABLE, OR INCORRECT IDLE,

STALLING SYMPTON (FOR CLOSED LOOP SYSTEM)

IDLE CO CONCENTRATION CHECK AND ADJUSTMENT

POOR FUEL ECONOMY SYMPTOM

DIESELING, RUN-ON SYMPTOM

BACKFIRE S YMPTOM

CUTS, OUT, MISSES SYMPTOM

HESITATION, SAG, STUMBLE SYMPTOM

DEFAULT MATRIX TABLE

SERVICE P ROCE DURE DEFAULT STRATEGY

DEFAULT MATRIX TABLE

ENGINE CRANKS BUT WILL NOT RUN

FUEL SYSTEM ELECTRICAL TEST

FUEL SYSTEM DIAGNOSIS

MANIFOLD ABSOLUTE PRESSURE (MAP) OUTPUT CHECK

EVAPORATIVE EMISSIONS (EVAP) CANISTER PURGE

CONTROL SOLENOID VALVE CHECK

THROTTLE POSITION (TP) SENSOR CIRCUIT RANGE/PERFORMANCE PROBLEM

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=2 2)

THROTTLE POSITION (TP) SENSOR CIRCUIT LOW INPUT

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=2 1)

THROTTLE POSITION (TP) SENSOR CIRCUIT HIGH INPUT

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=1 3)

02 SENS O R CIRCUIT NOT READY DETECTED (IF APPLICABLE)

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=4 4)

02 SENSOR TOO LEAN (IF APPLICABLE)

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=4 5)

02 SENSOR TOO RICH (IF APPLICABLE)

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=1 4)

EINGINE COOLANT TEMPERATURE(ECT) SENSO R CIRCUIT HIGH INPUT

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=1 5)

ENGINE COOLANT TE MP ERATURE (ECT) S ENSOR CIRCUIT LOW INPUT

DIAGNOSI TC TROUBLE CODE (DTC) (FLASH DTC=16)

KNOCK SENSOR (KS) DISCONNE CTED MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=18) DIGITALLY

CONTROLED SIGNAL TO NOIS E ENHANCEME NT FILTER FAILURE

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=1 9)

CRANKSHAFT POSITION(CKP) SENSO R SIGNAL INCORRECT

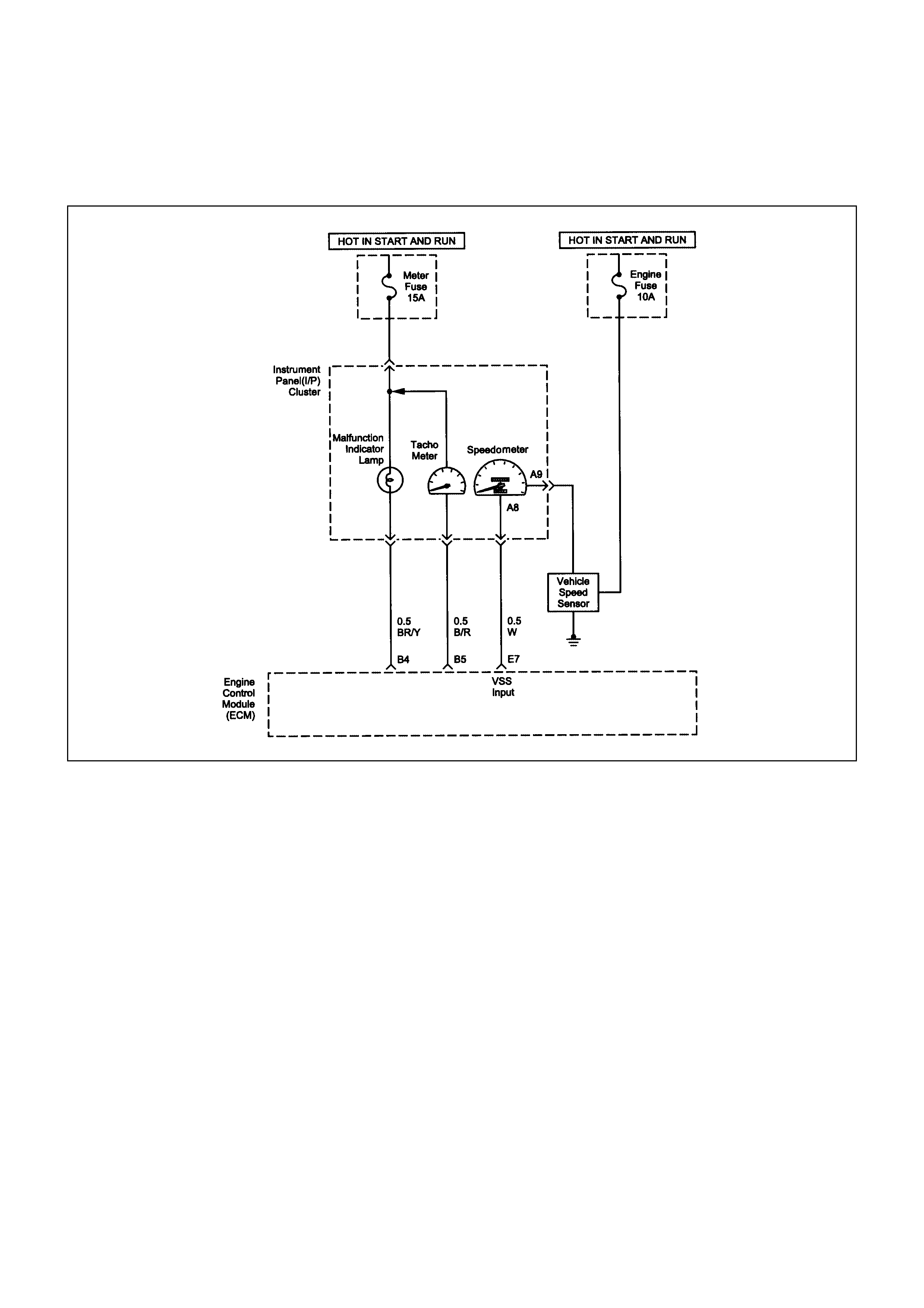

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=2 4)

VEHICLE SPEED SENSOR (VSS) FAULT

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=3 3)

MANIFOLD ABSOLUTE PRESSURE (MAP) TOO HIGH

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=3 4)

MANIFOLD ABSOLUTE PRESSURE (MAP) TOO LOW

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=4 9)

SYSTEM VOLTAGE HIGH

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=6 9)

INTAKE AIR TEMPERATURE (IAT) SENSOR TOO HIGH

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=7 1)

INTAKE AIR TEMPERATURE (IAT) SENSOR TOO LOW

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=1 7)

INJECTOR CIRCUIT MALFUNCTION

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=4 1)

IGNITION COIL DRIVER "B" SHORT TO BATTERY

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=4 2)

IGNITION COIL DRIVER "A" SHORT TO BATTERY

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=6 3)

IGNITION COIL DRIVER "B" SHORT TO GROUND

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=6 4)

IGNITION COIL DRIVER "A" SHORT TO GROUND

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=3 5)

IDLE AIR CONTROL (IAC) ERROR

DIAGNOSTIC TROUBLE CODE (DTC) 56 (FLASH DTC=56)

CHECK ENGINE LAMP LOW ERROR

DIAGNOSTIC TROUBLE CODE (DTC) 57 (FLASH DTC=57)

CHECK ENGINE LAMP HIGH ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=6 1)

EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM CANISTER

PURGE CONTROL VALVE CIRCUIT LOW ERROR (IF APPLICABLE)

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=6 2)

EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM CANISTER

PURGE CONTROL VALVE CIRCUIT HIGH ERROR (IF APPLICABLE )

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=8 7)

A/C COMPRESSOR CLUTCH RELAY LOW ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=8 8)

A/C COMPRESSOR CLUTCH RELAY HIGH ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=9 3)

QUAD DRIVER SUB MODULE

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=5 1)

ELECTRICALLY PROGRAMMABLE READ-ONLY MEMORY(EPROM) ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=5 5)

ELECTRICALLY ERASABLE PROGRAMMABLE READ-ONLY

MEMORY (EEPROM) ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=9 1)

TACHO OUT LOW ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=9 2)

TACHO OUT HIGH ERROR

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=2 9)

FUEL PUMP RELAY SHORTED TO GROUND

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=3 2)

FUEL PUMP RELAY SHORTED TO BATTERY

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=8 3)

RECEIVED RESPONSE WAS NOT CORRECT

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=8 4)

NO RESPONSE FROM IMMOBILIZER

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=8 5)

SECURITY CODE & SE CURITY KEY NOT PROGRAMME D

DIAGNOSTIC TROUBLE CODE (DTC) (FLASH DTC=86) RECEIVED INCORRECT

SECURITY CODE

ON-VEHICLE SERV I CE PROCEDURE ECM AND SENSOR

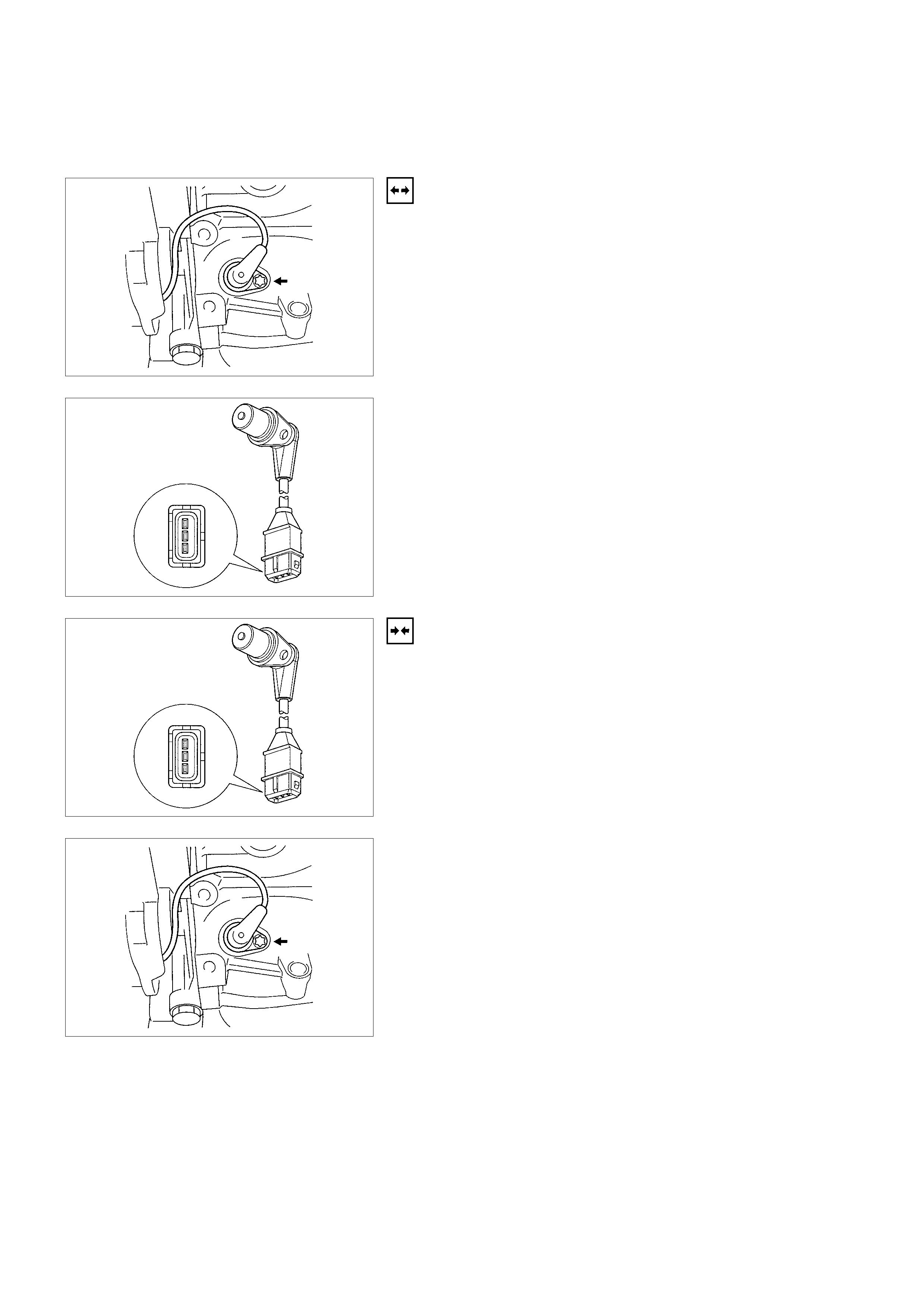

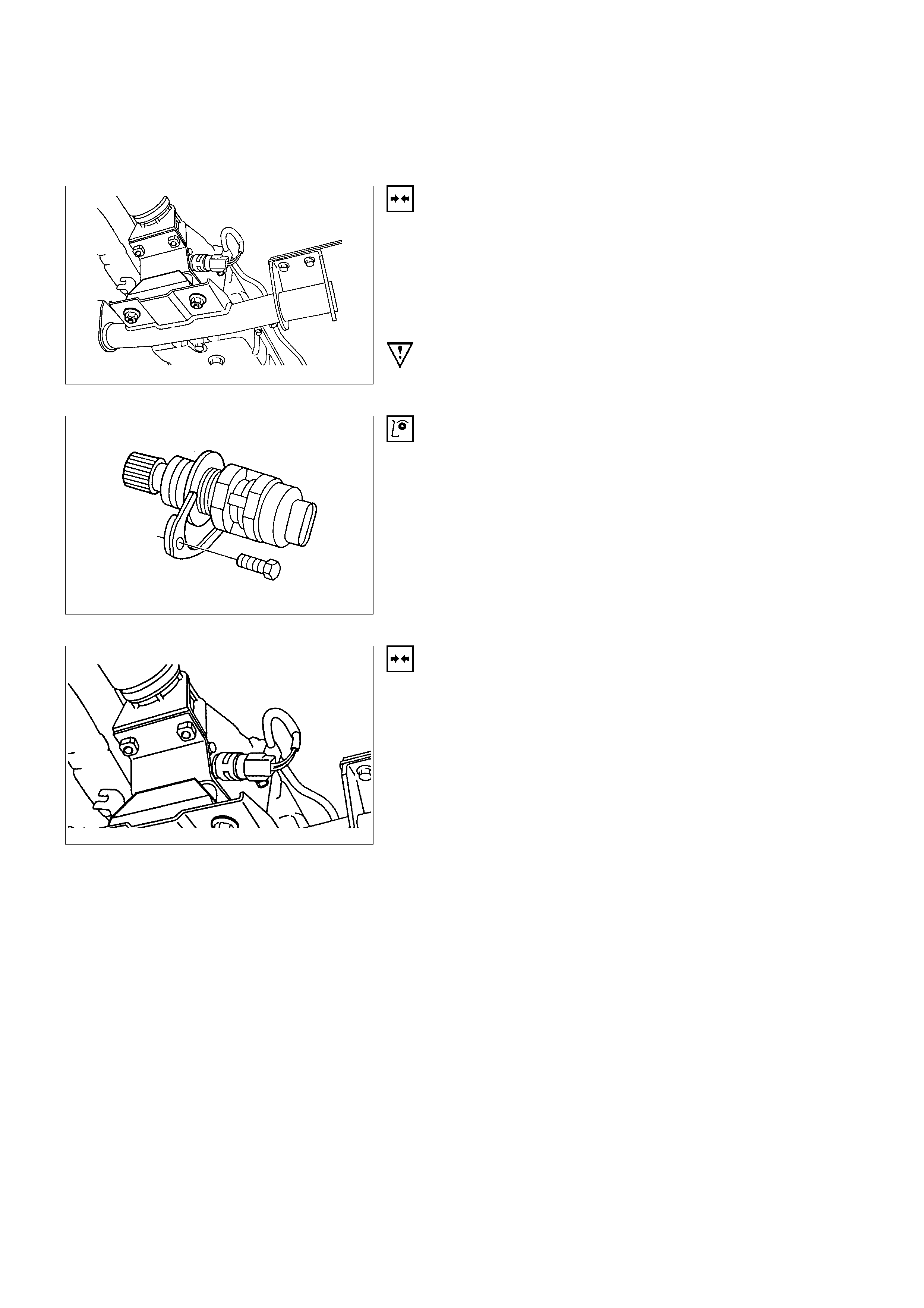

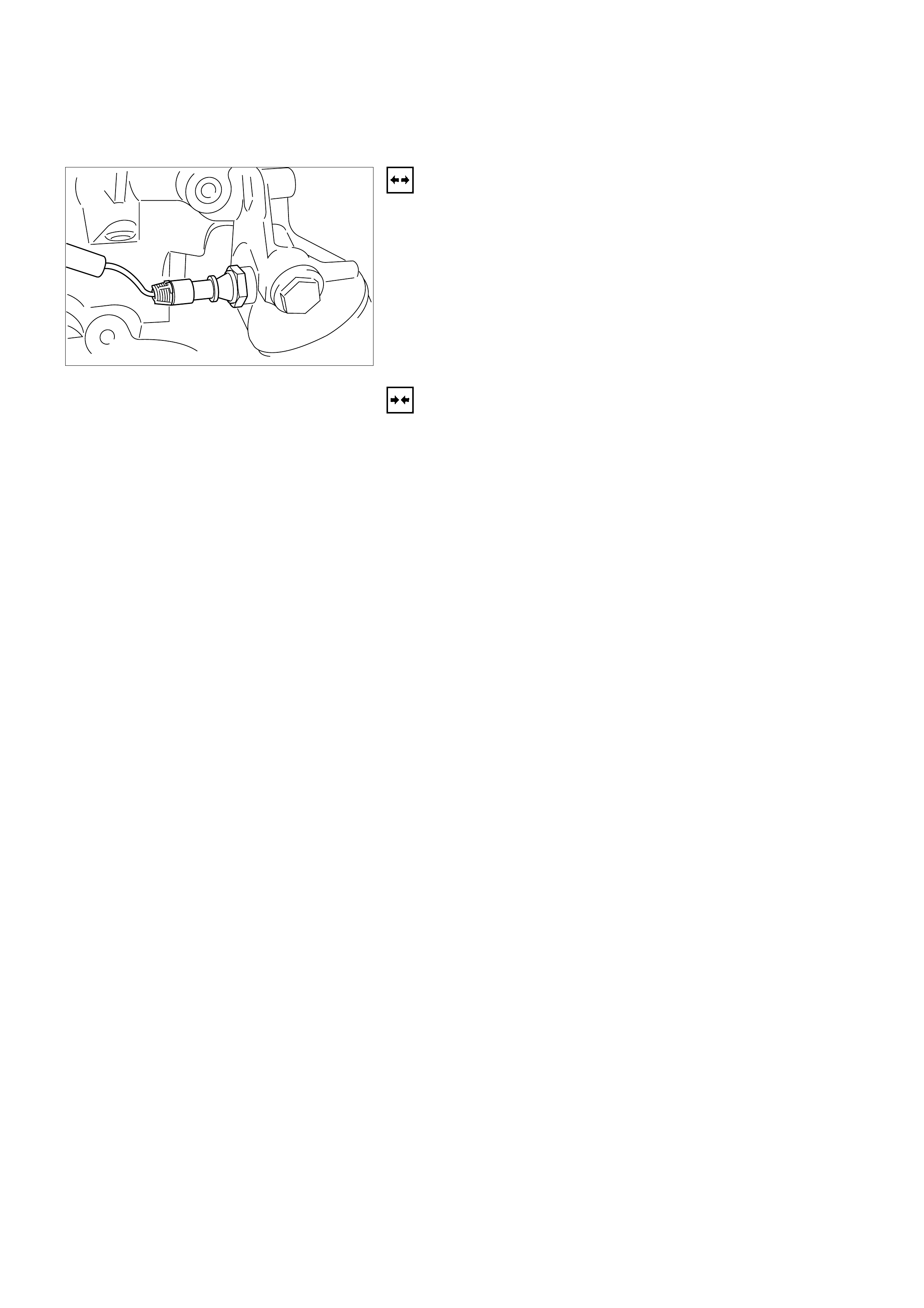

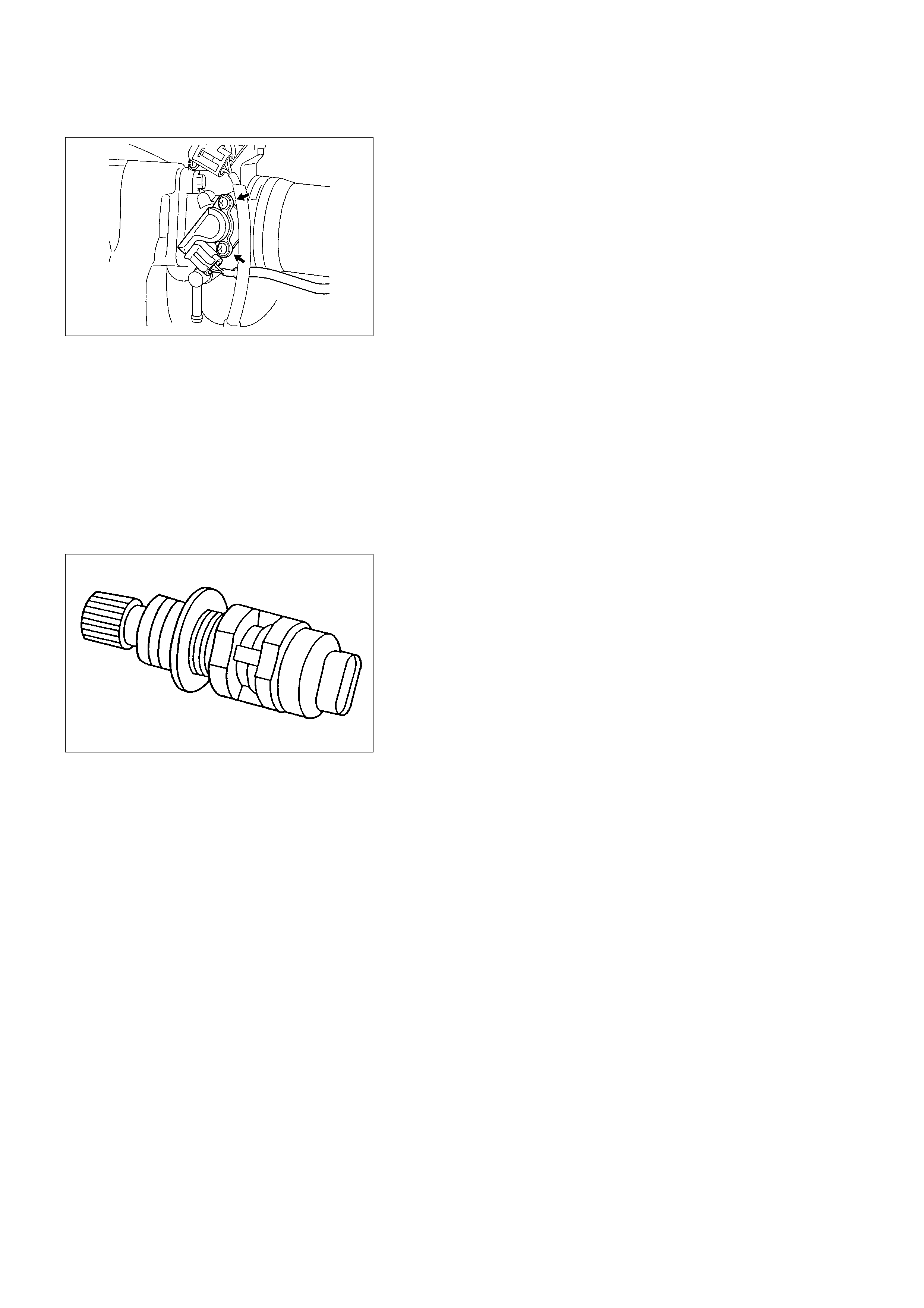

CRANKSHAFT POSITION (CKP) SENSOR

REMOVAL

INSTALLATION

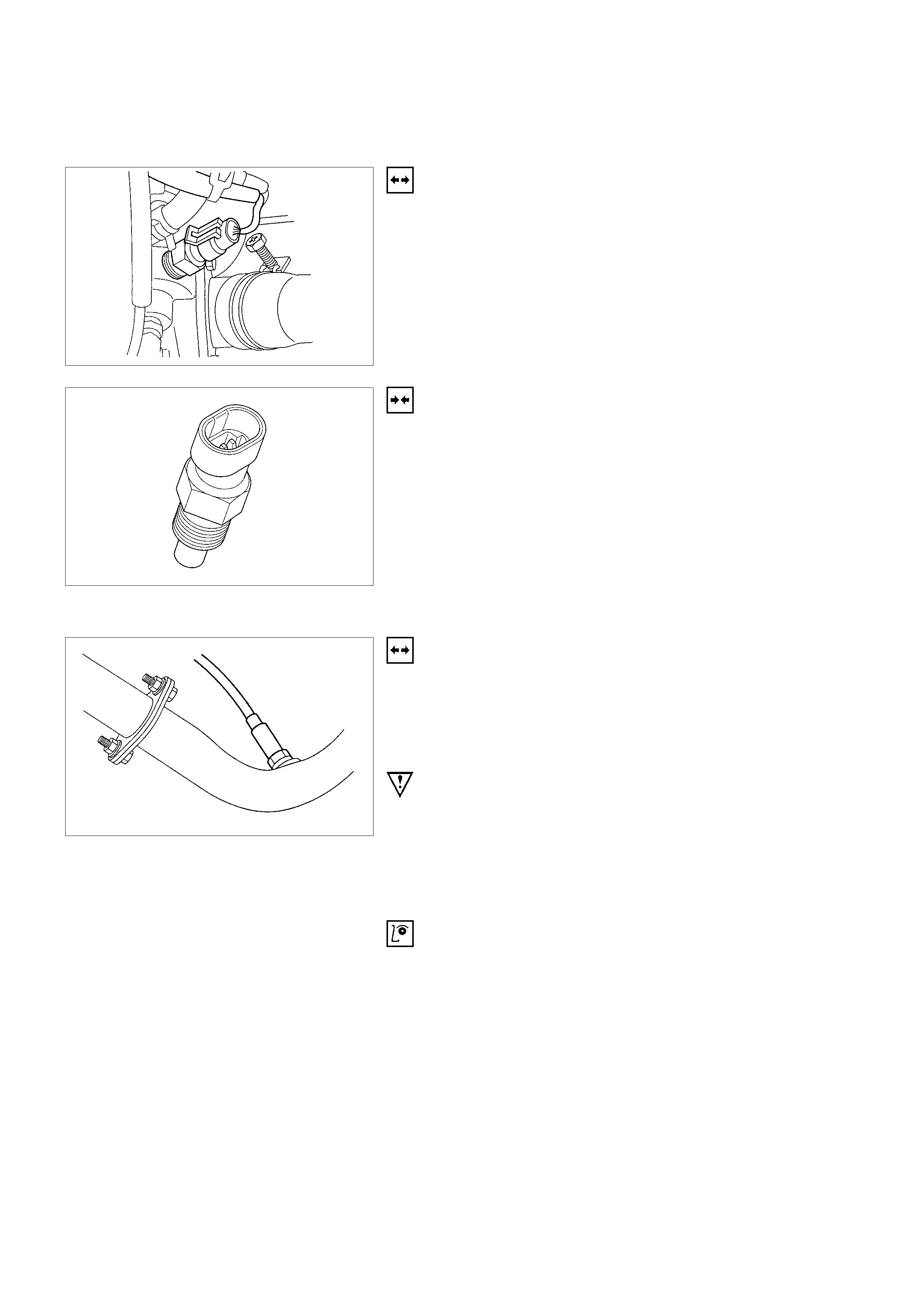

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

REMOVAL

INSTALLATION

HEATED OXYGEN SENSOR (HO2S) (IF APPLICABLE)

REMOVAL

INSPECTION

INSTALLATION

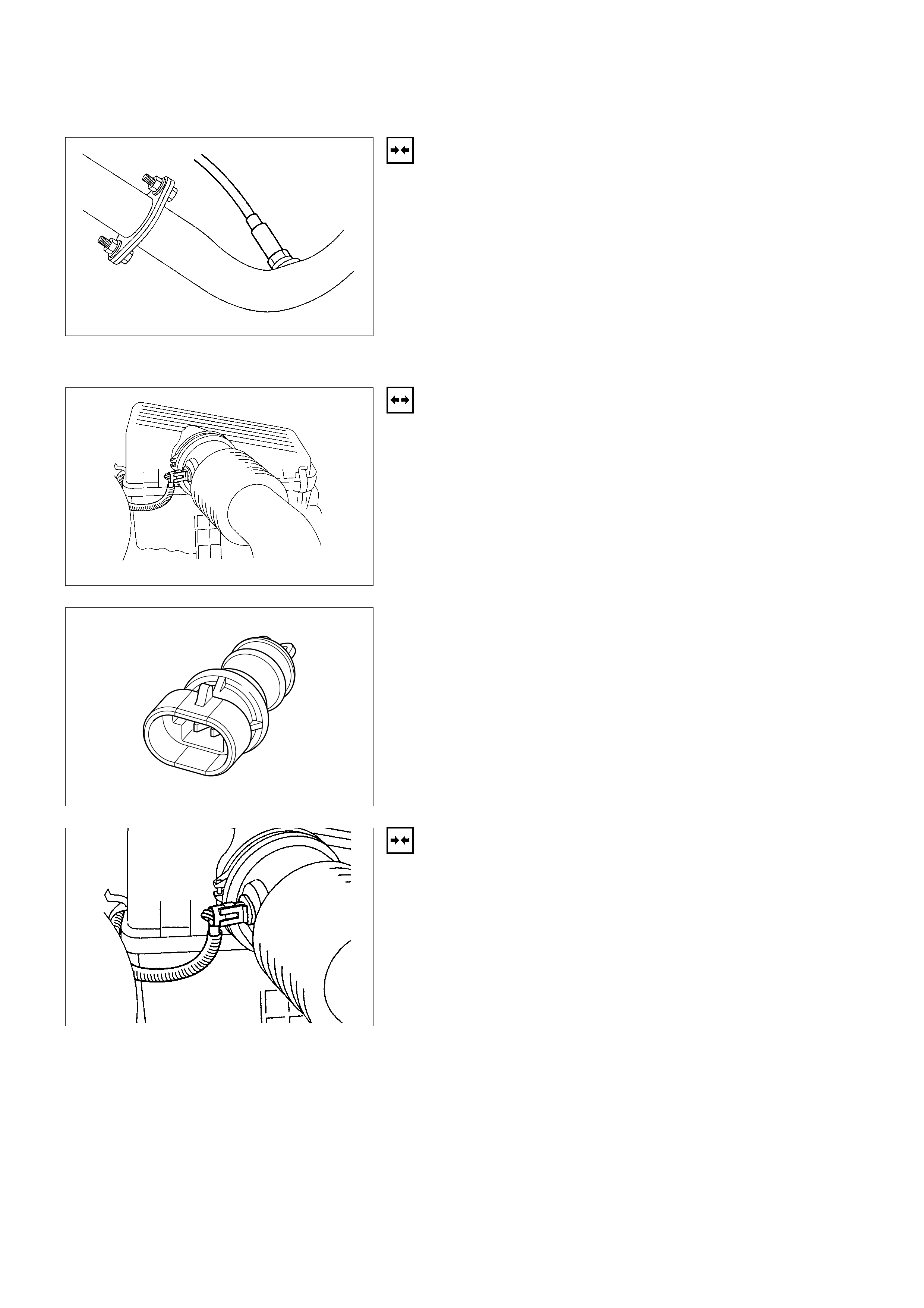

INTAKE AIR TEMPERATURE (IAT) SENSOR

REMOVAL

INSTALLATION

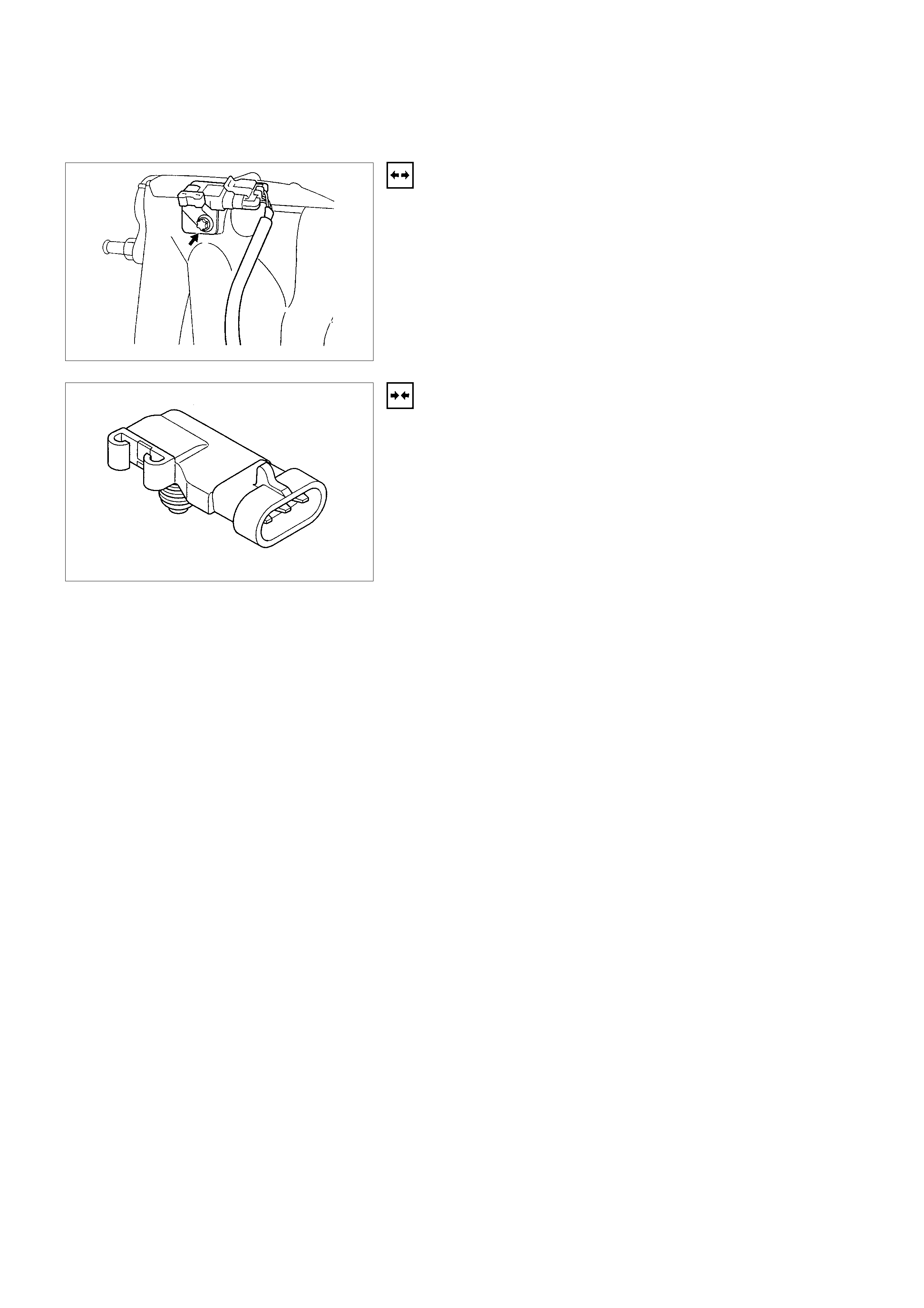

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

REMOVAL

INSTALLATION

MALFUNCTION INDICATOR LAMP(MIL)

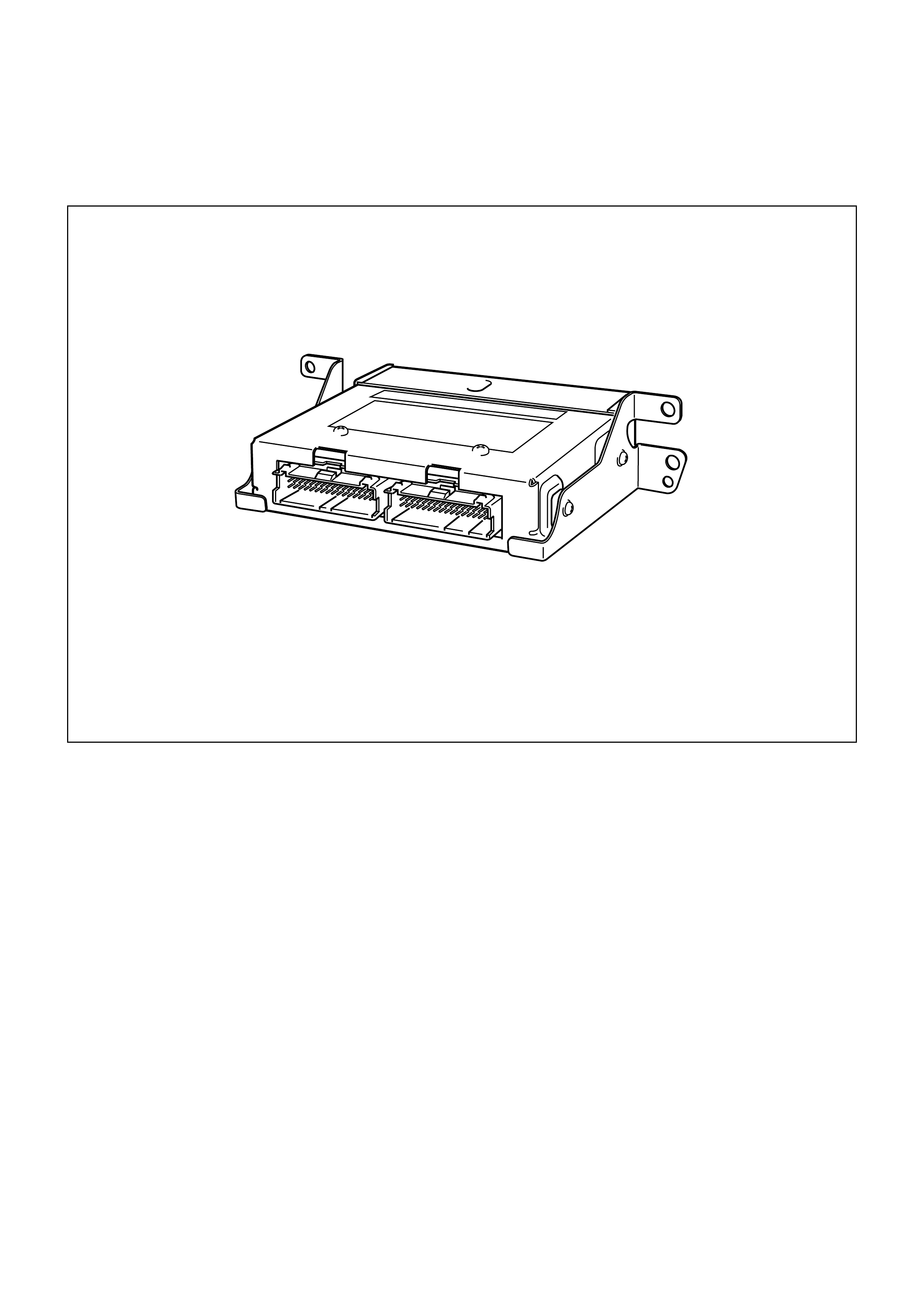

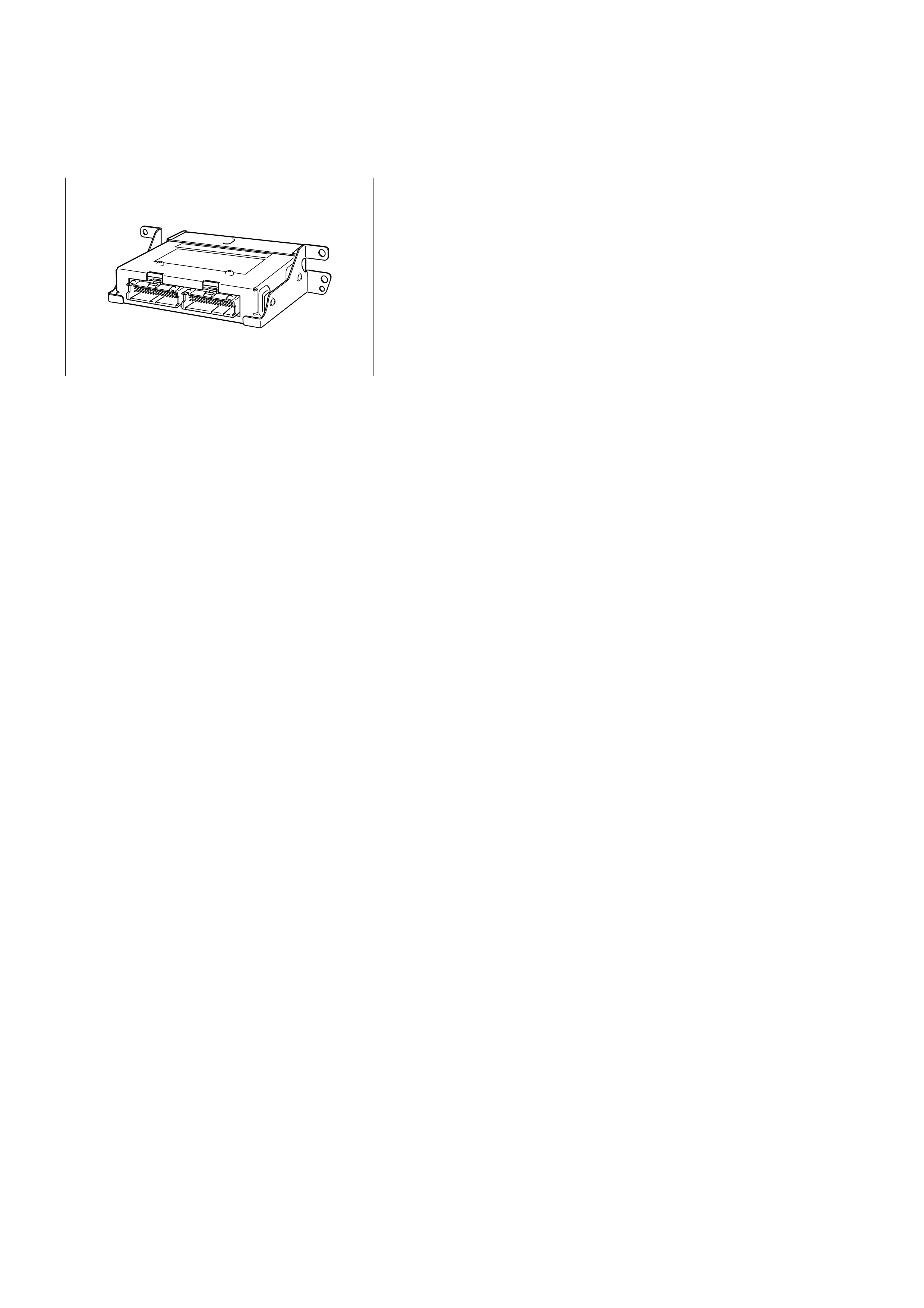

ENGINE CONTROL MODULE (ECM)

ELECTROSTATIC DISCHARGE (ESD) DAMAGE

ENGINE CONTROL MODULE (ECM)

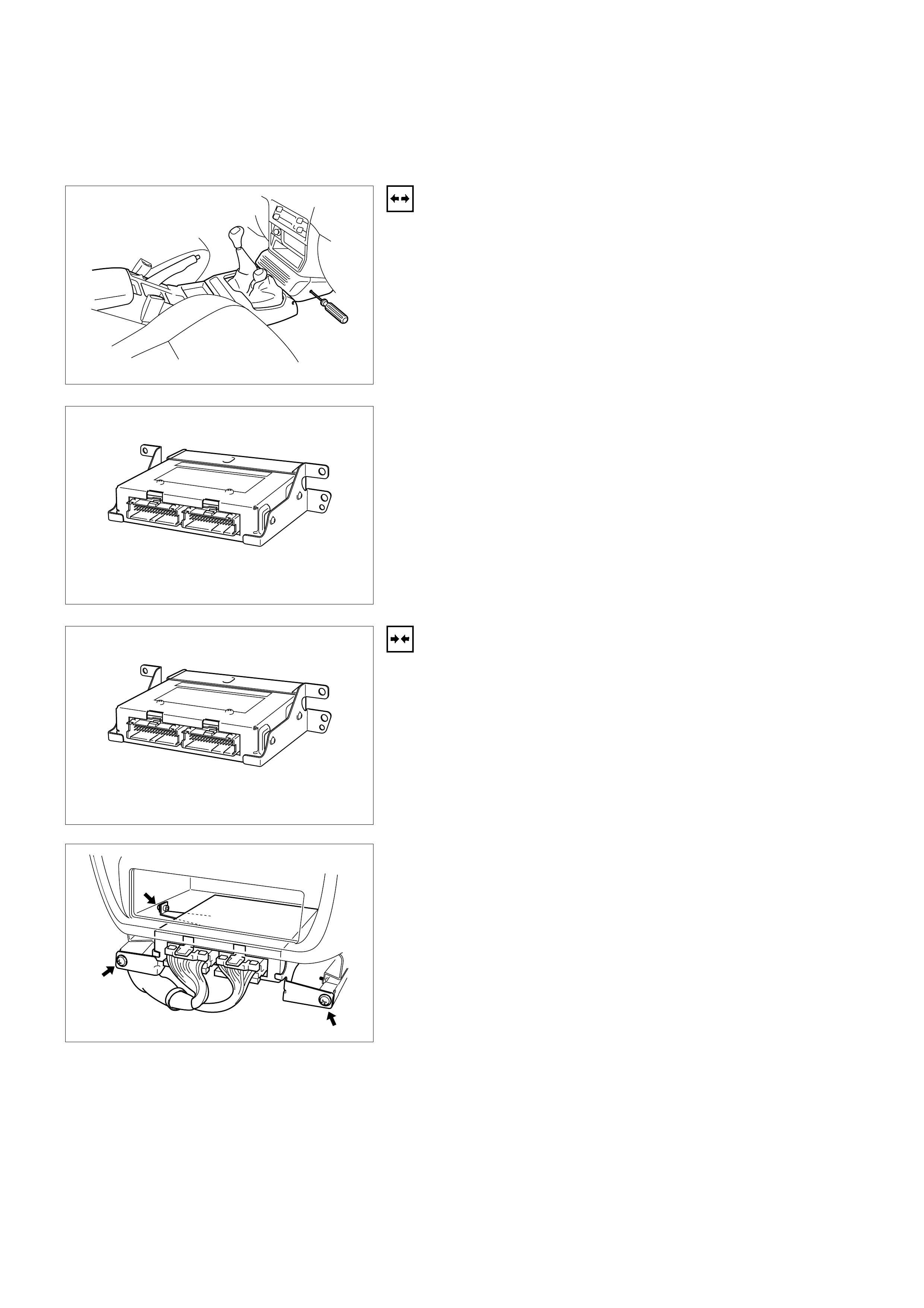

REMOVAL

INSTALLATION

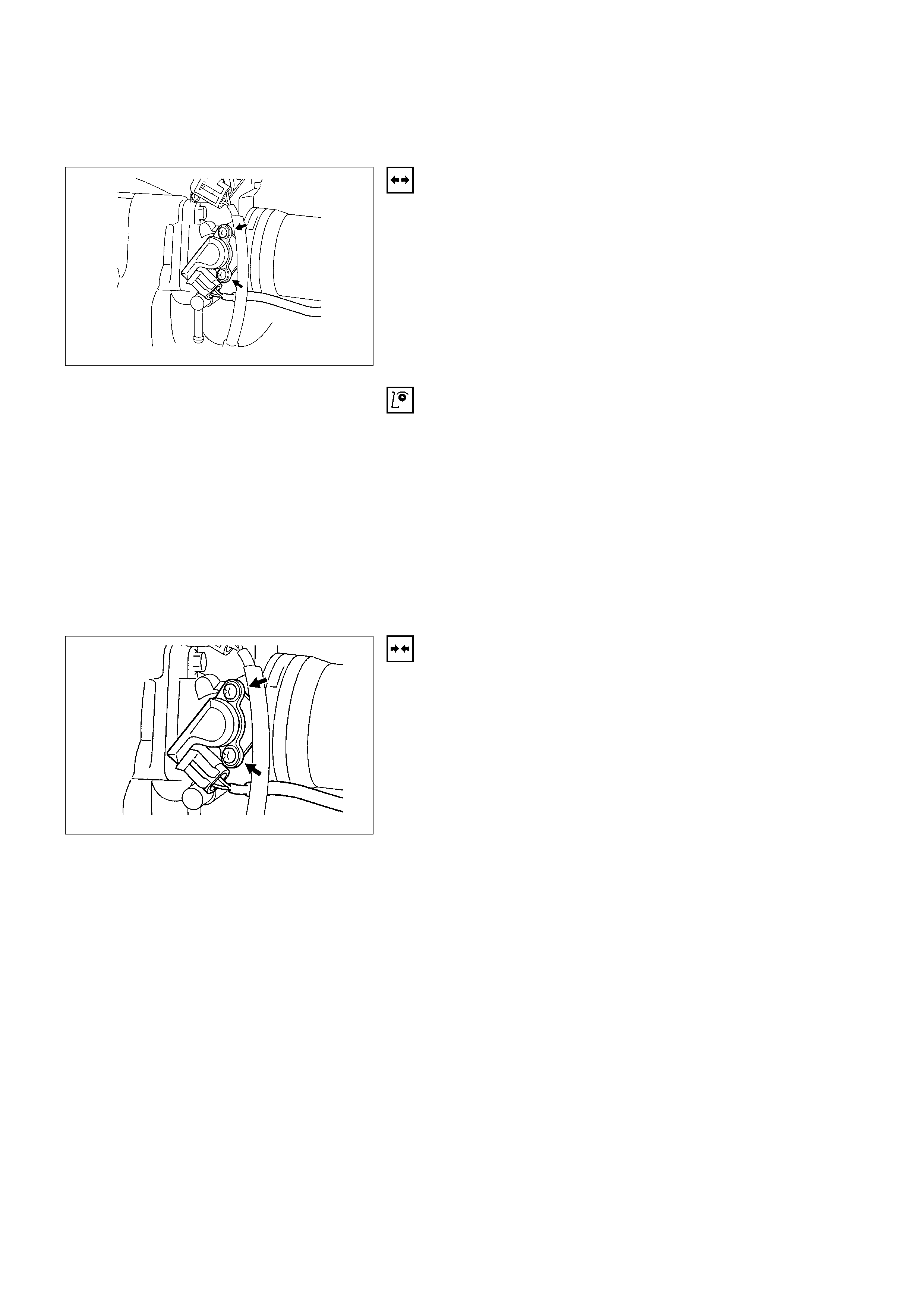

POWER STEERING PRESSURE (PSP) SWITCH

REMOVAL

INSTALLATION

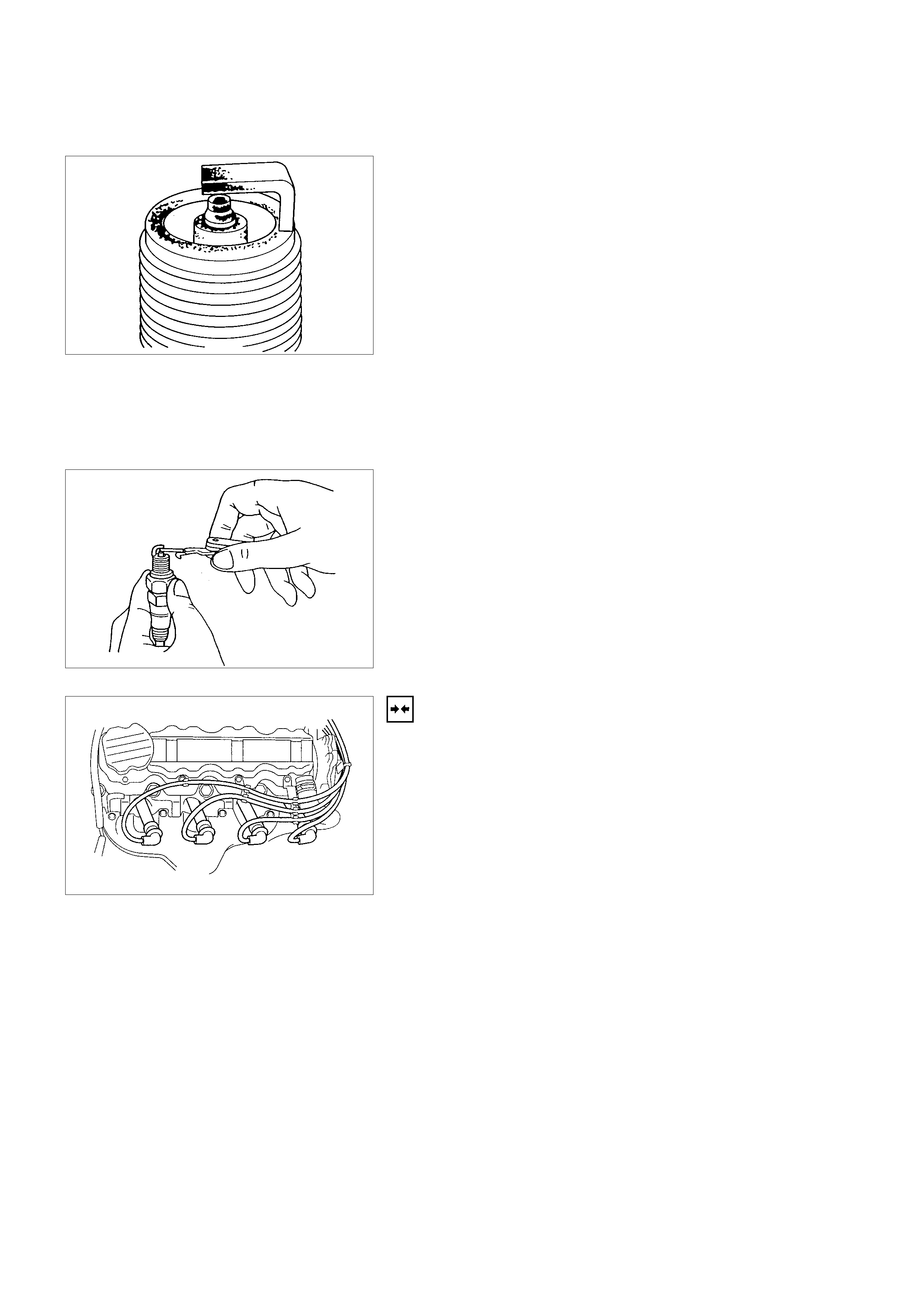

THROTTLE POSTION SENSOR (TPS)

REMOVAL

FUNCTION CHECK

INSTALLATION

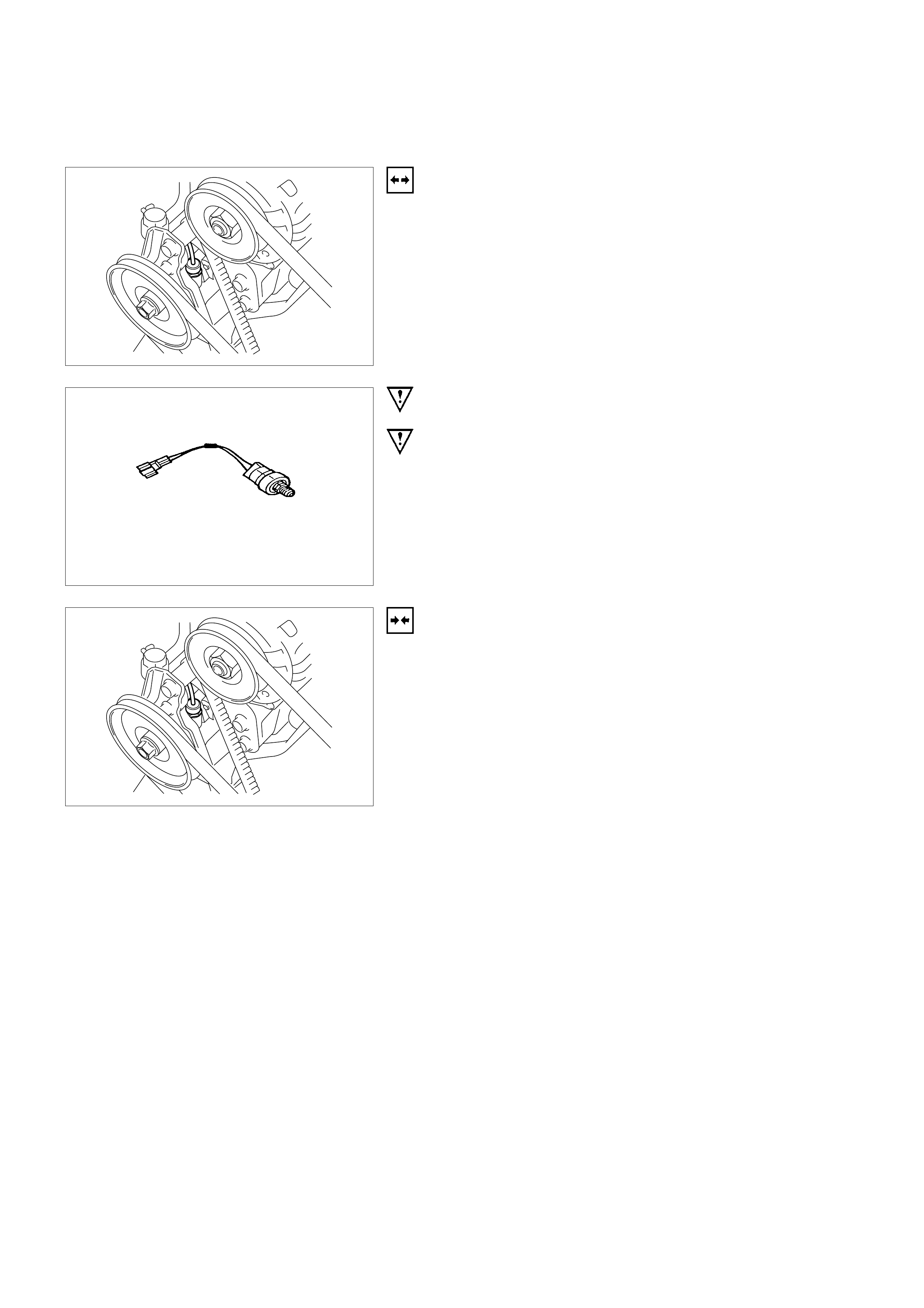

VEHICLE SPEED SENSOR (VSS)

REMOVAL

INSPECTION

INSTALLATION

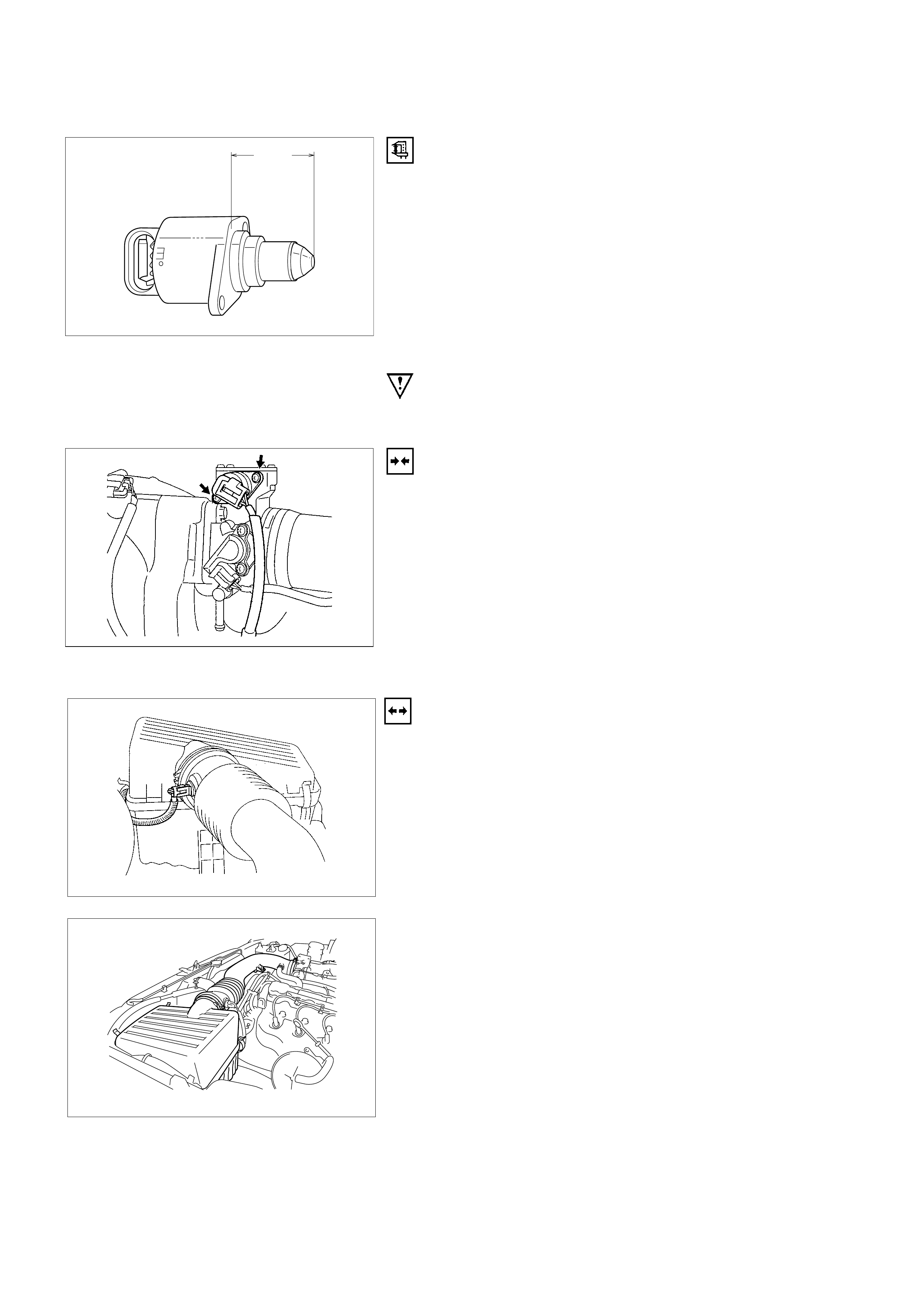

AIR INDUCTION SYSTEM

AIR FILTER

REMOVAL

INSTALLATION

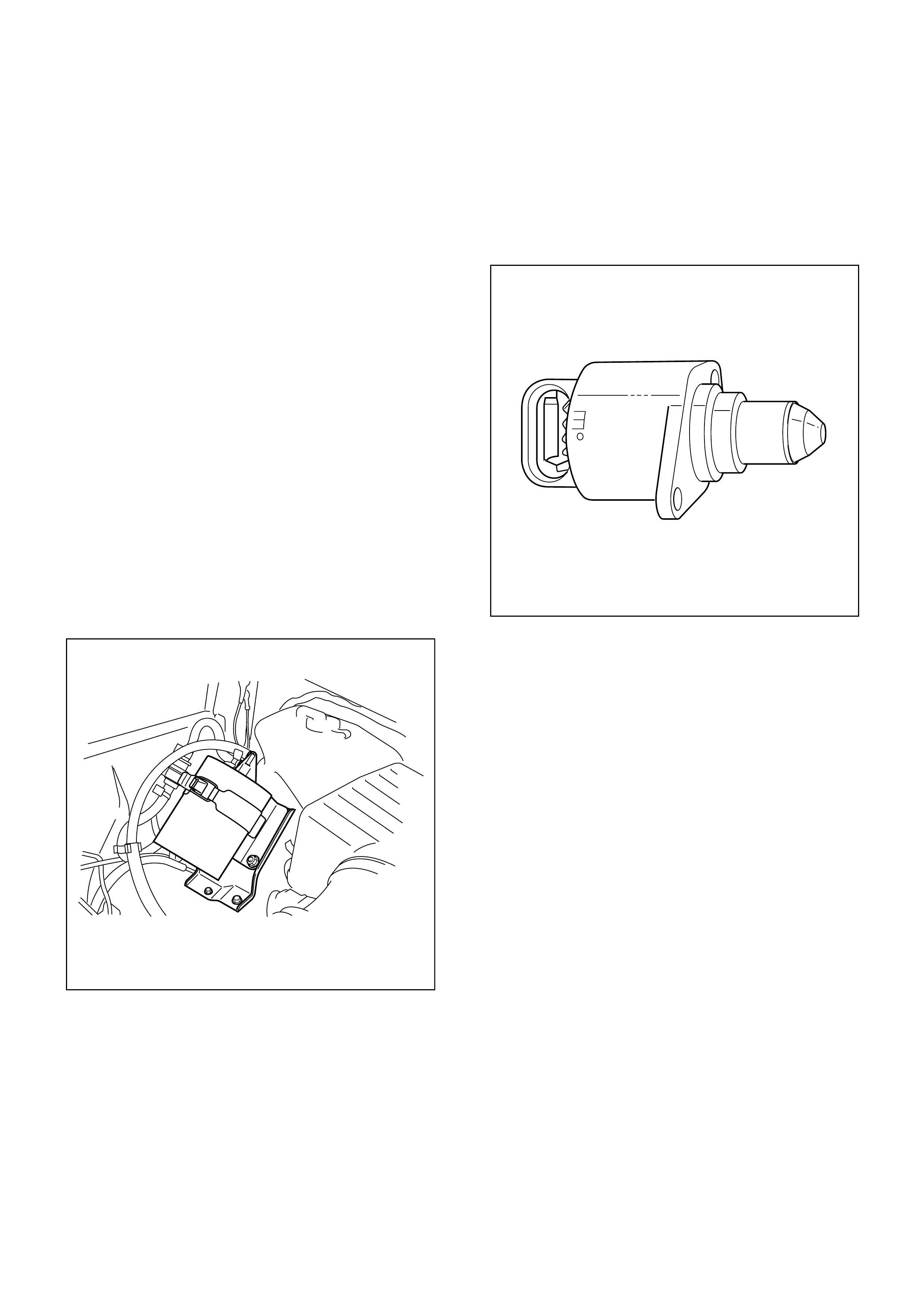

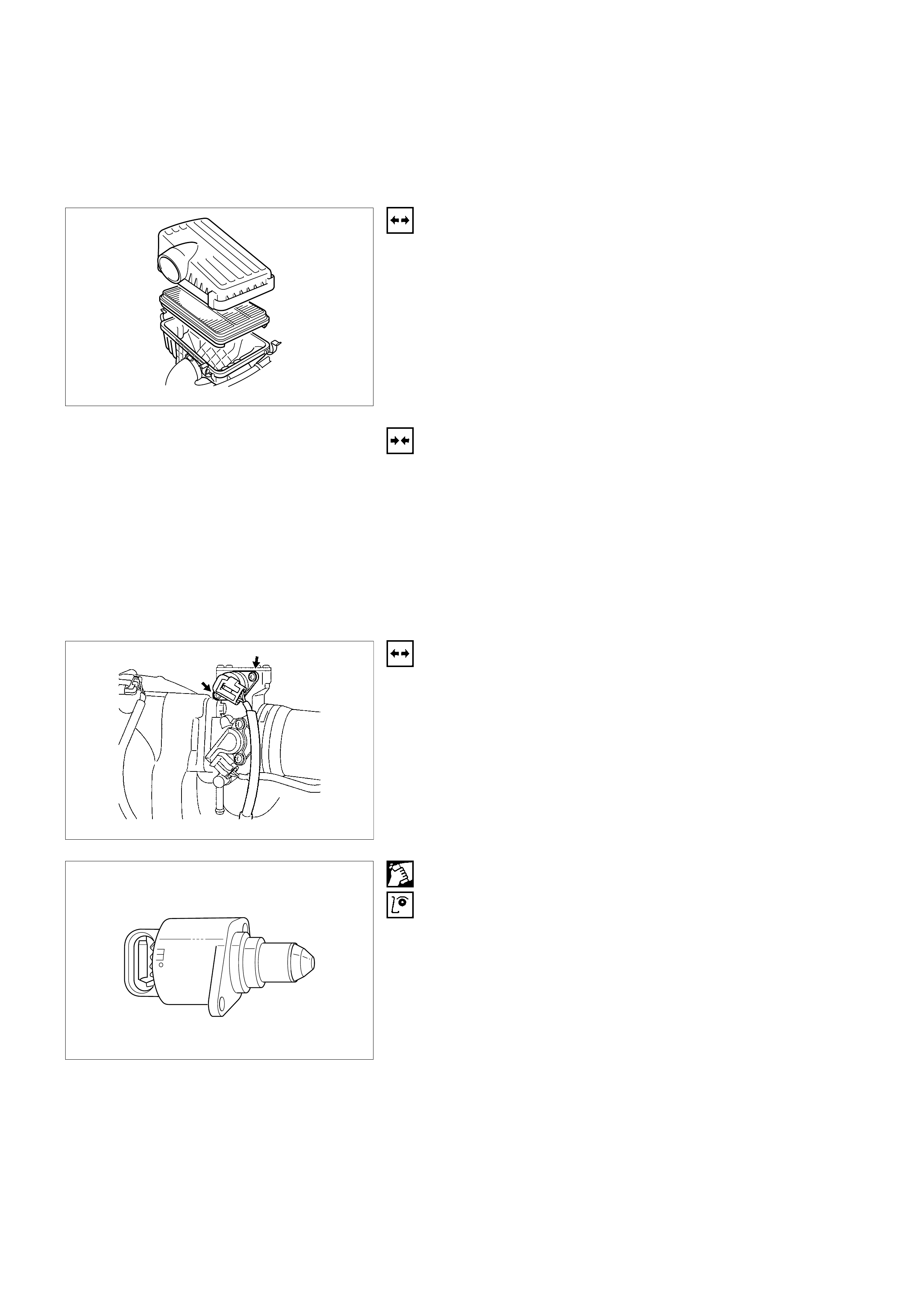

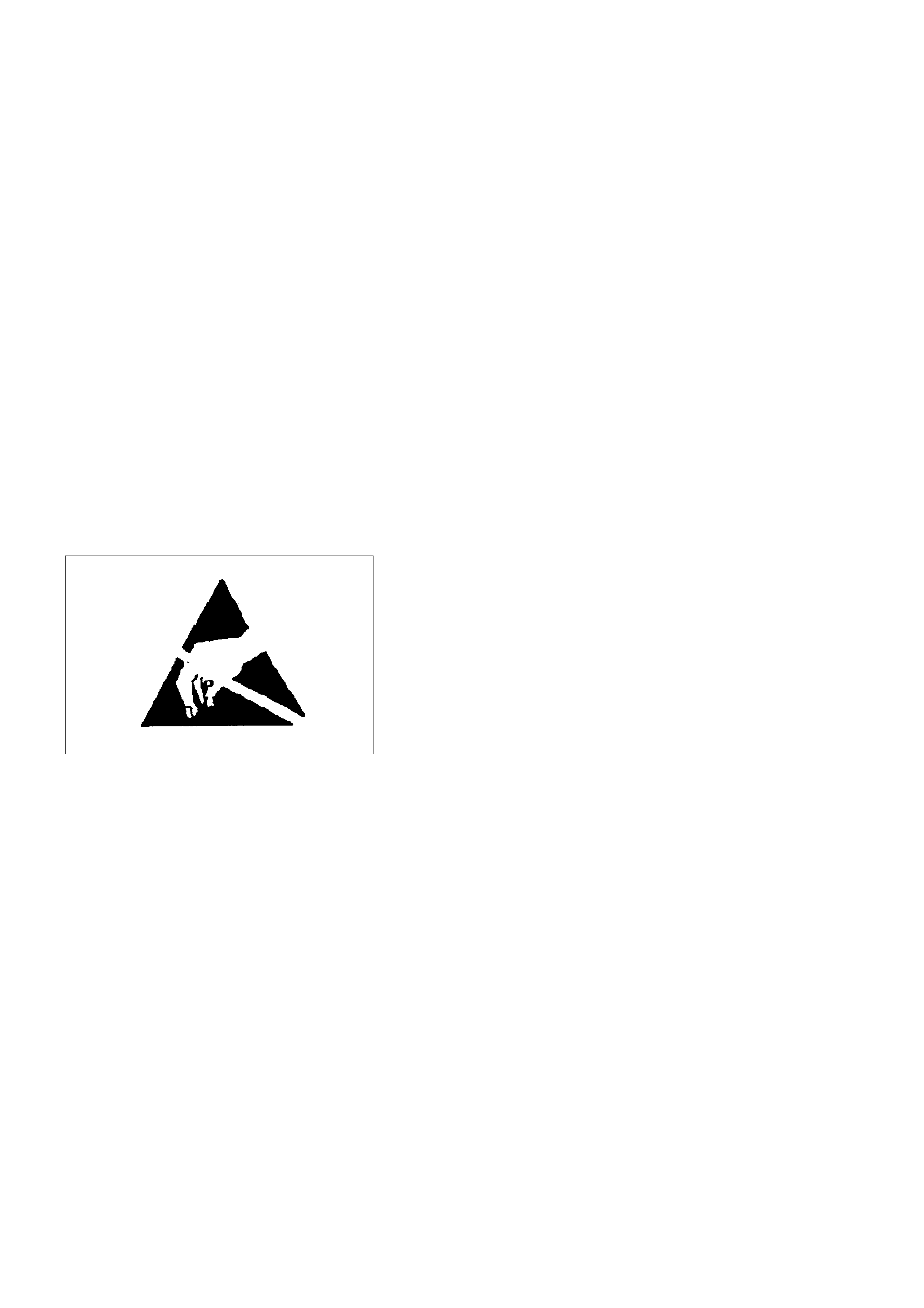

IDLE AIR CONTROL (IAC) VALVE

REMOVAL

CLEANING AND INSPECTION

MEASUREMENT

INSTALLATION

INTAKE AIR DUCT

REMOVAL

INSTALLATION

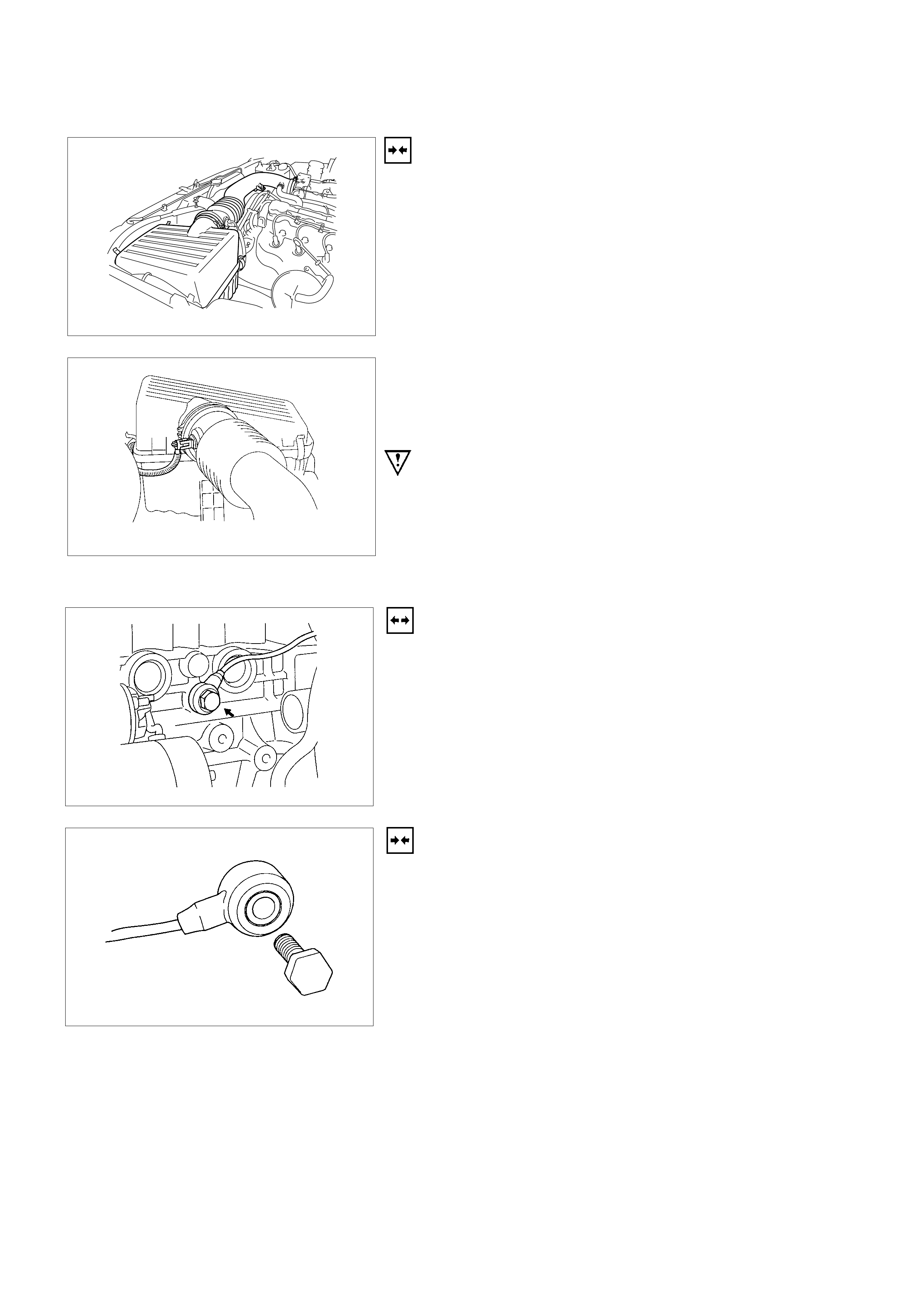

KNOCK SENSOR

REMOVAL

INSTALLATION

OIL PRESSURE SWITCH

REMOVAL

INSTALLATION

FUEL METERING SYSTEM

ACCELERATOR CABLE ASSEMBLY

REMOVAL

INSPECTION

INSTALLATION

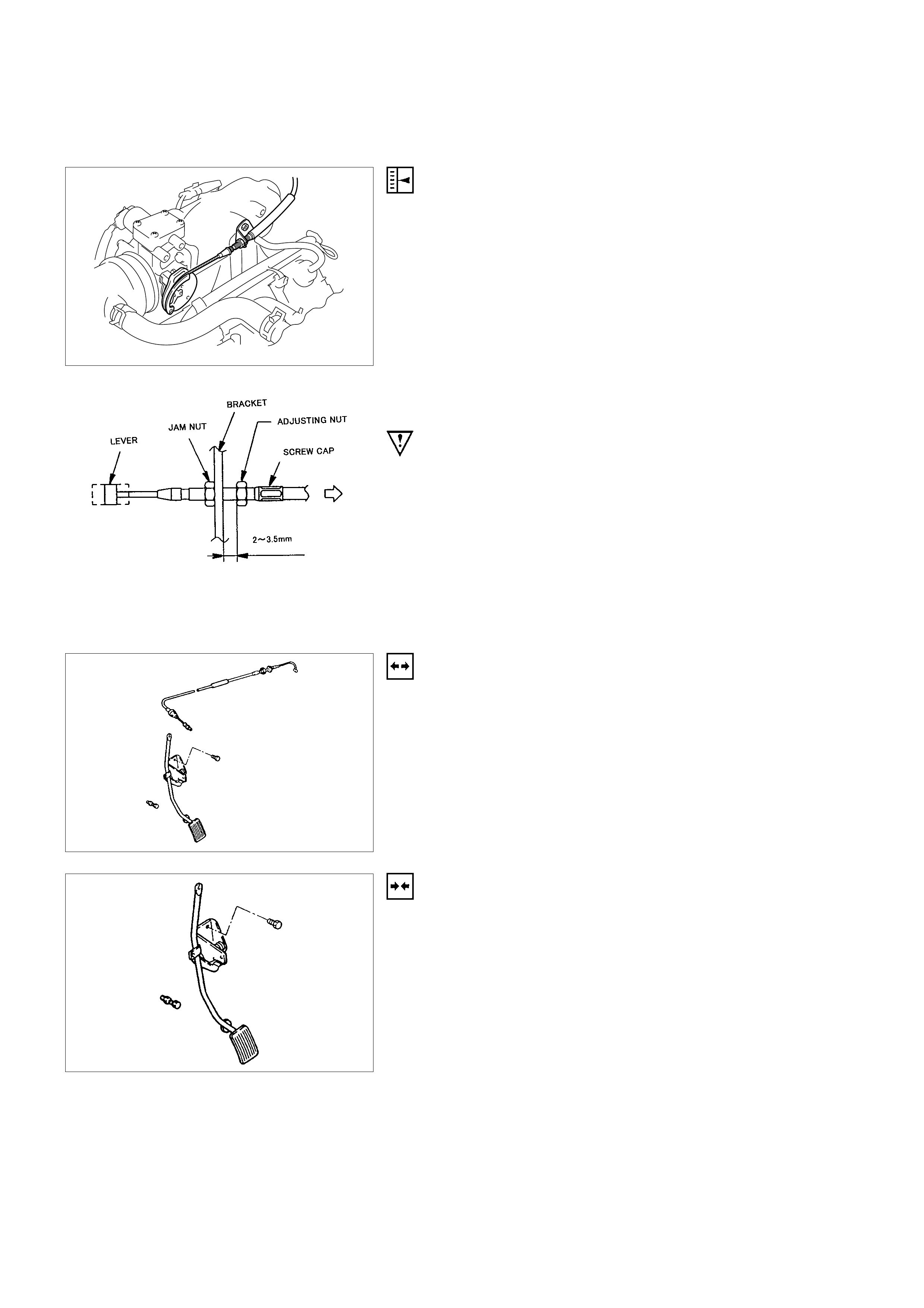

ACCELE RATOR CABLE ADJUSTMENT

ADJUSTMENT

ACCELELATOR PEDAL REPLACEMENT

REMOVAL

INSTALLATION

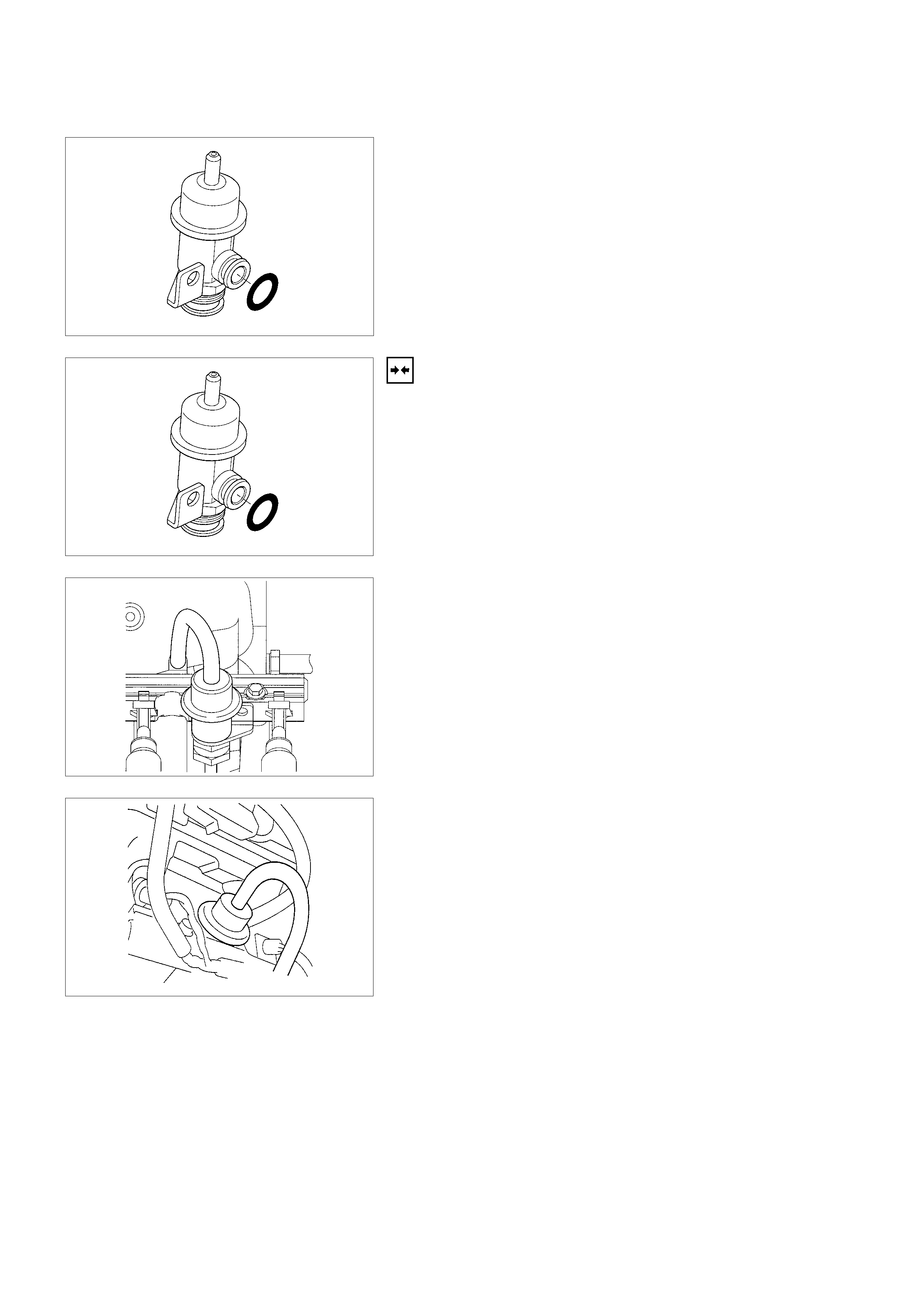

FUEL FILLER CAP

INSPECTION

FUEL FILTER

REMOVAL

INSPECTION

INSTALLATION

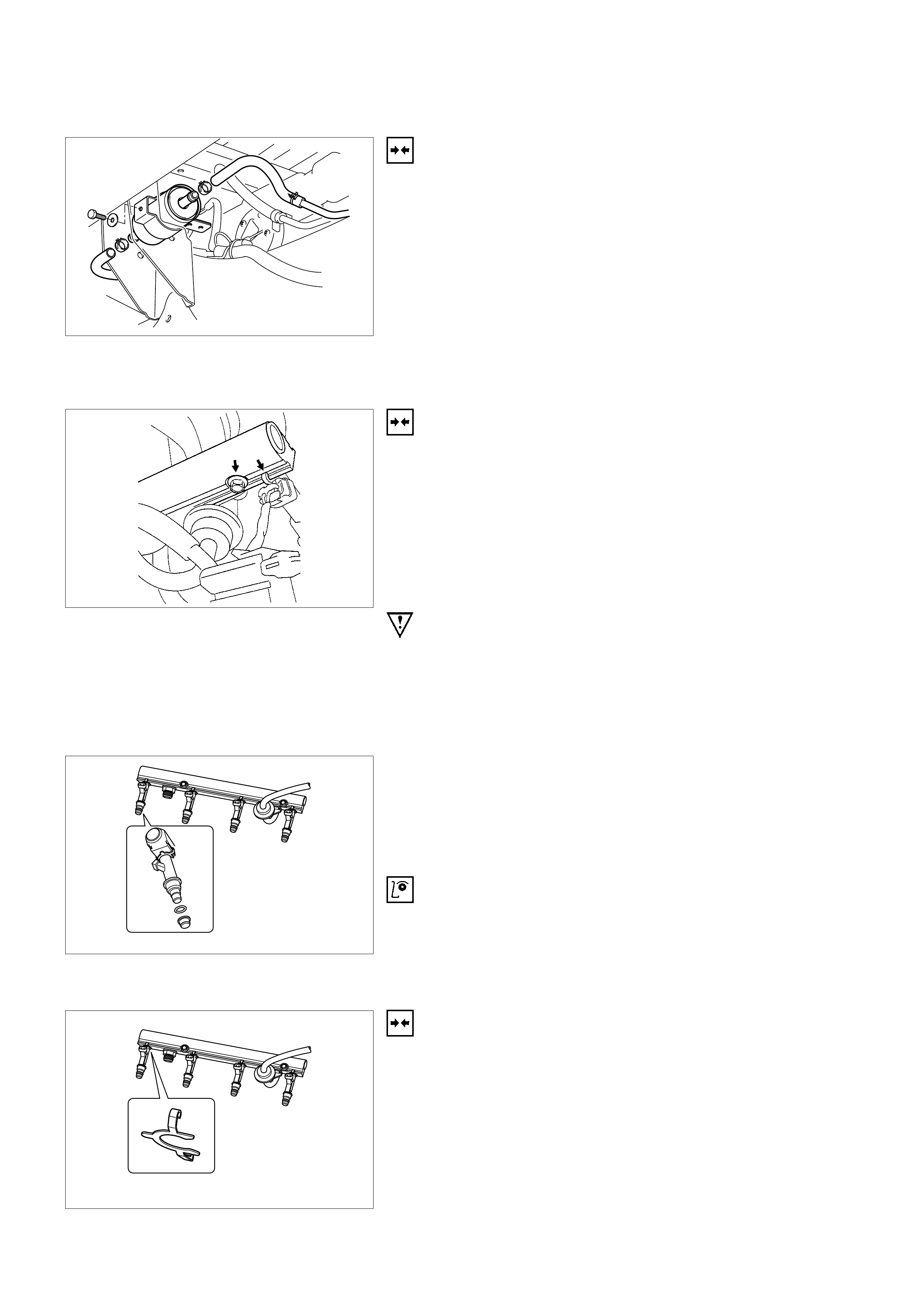

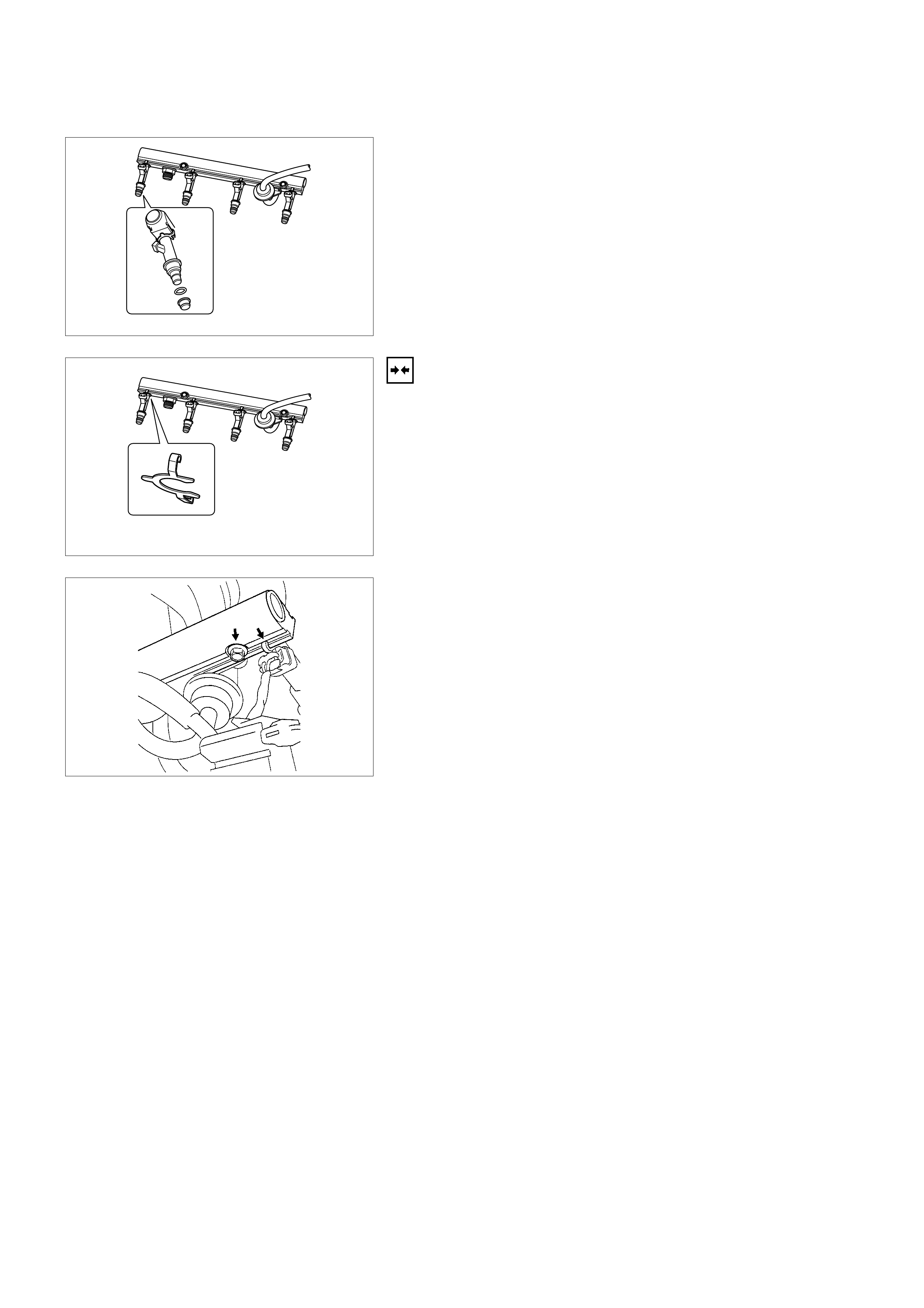

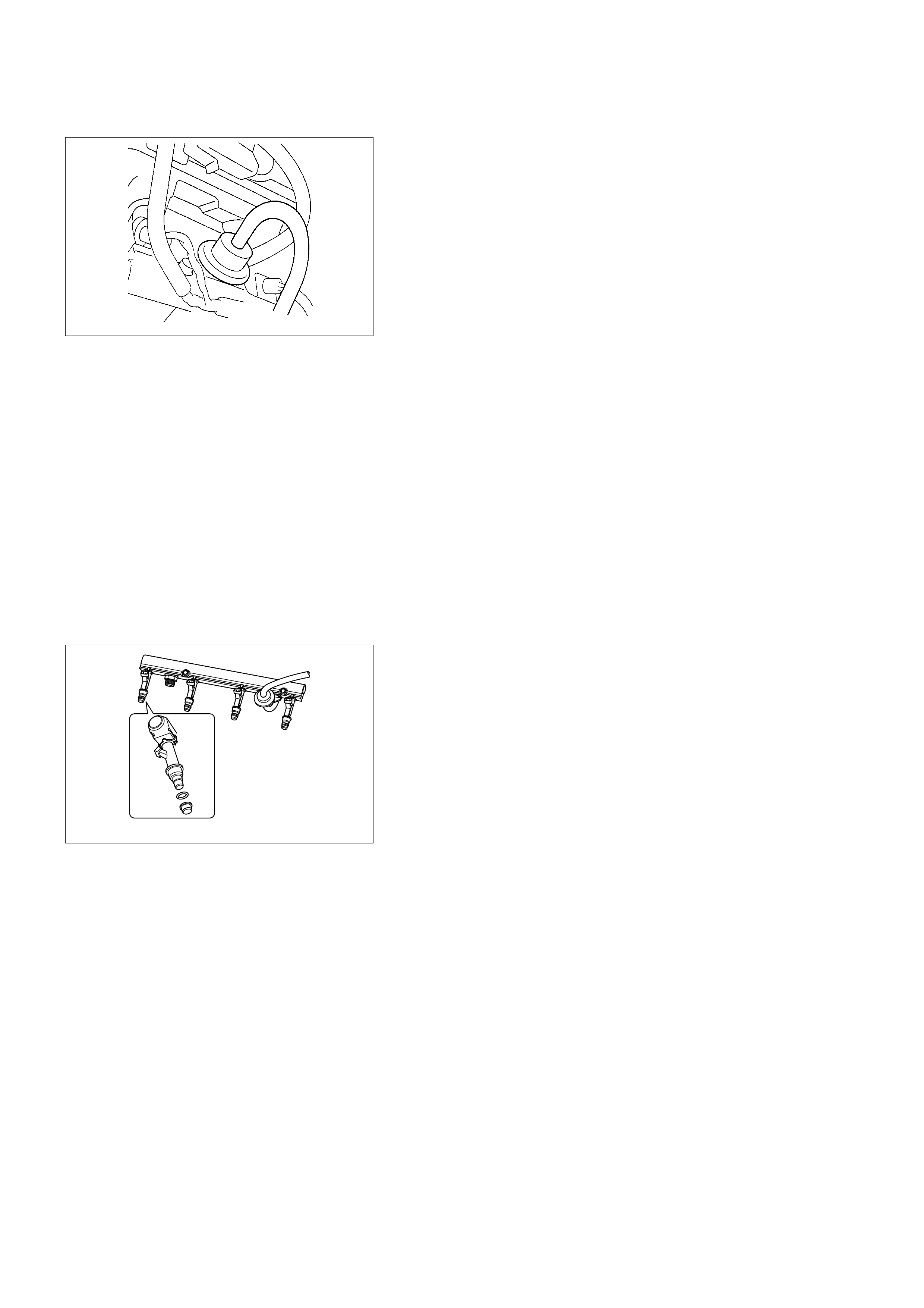

FUEL INJECTORS

REMOVAL

INSPECTION

INSTALLATION

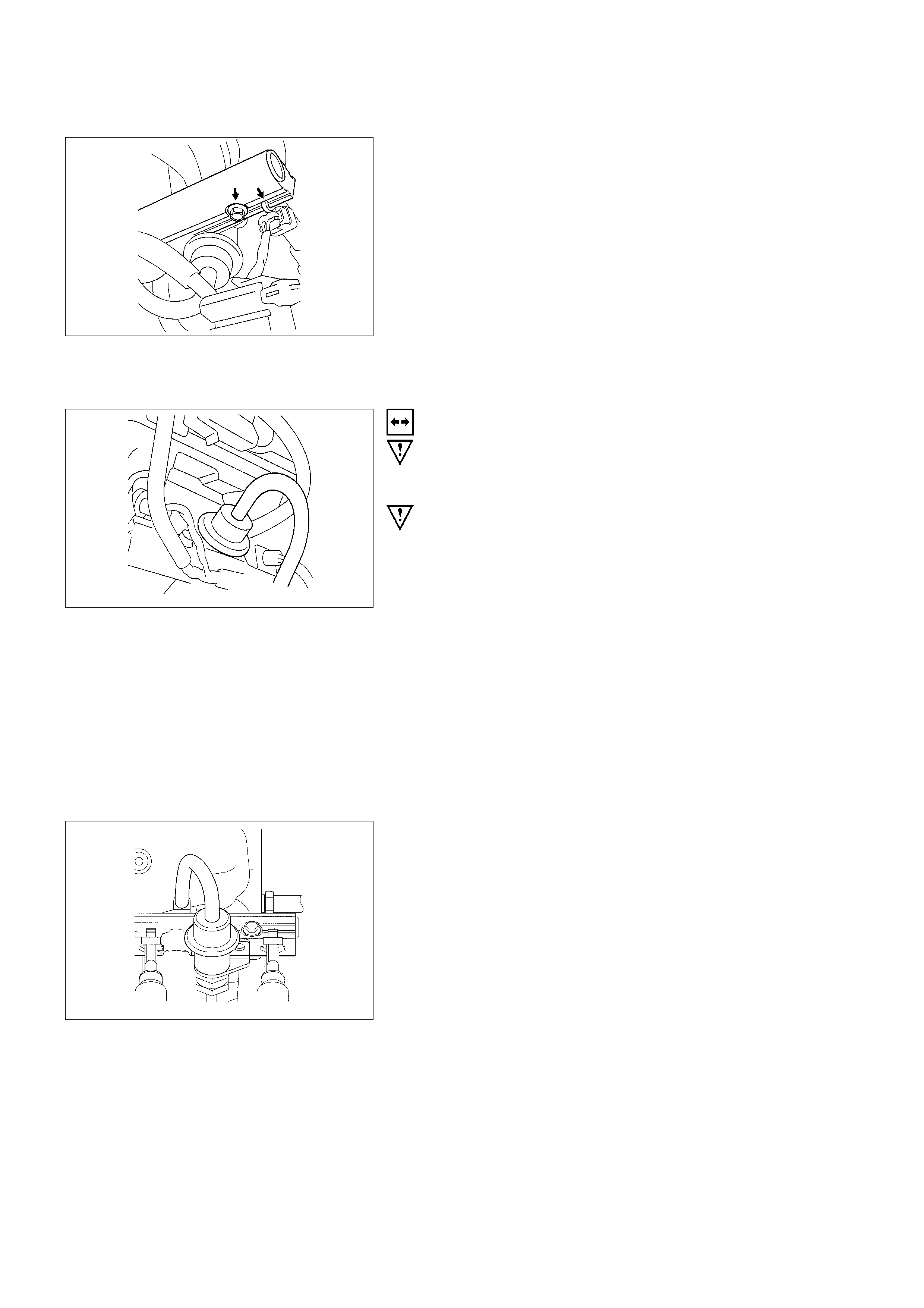

FUEL PRESSURE REGULATOR

REMOVAL

INSTALLATION

FUEL PRESSURE RELIEF

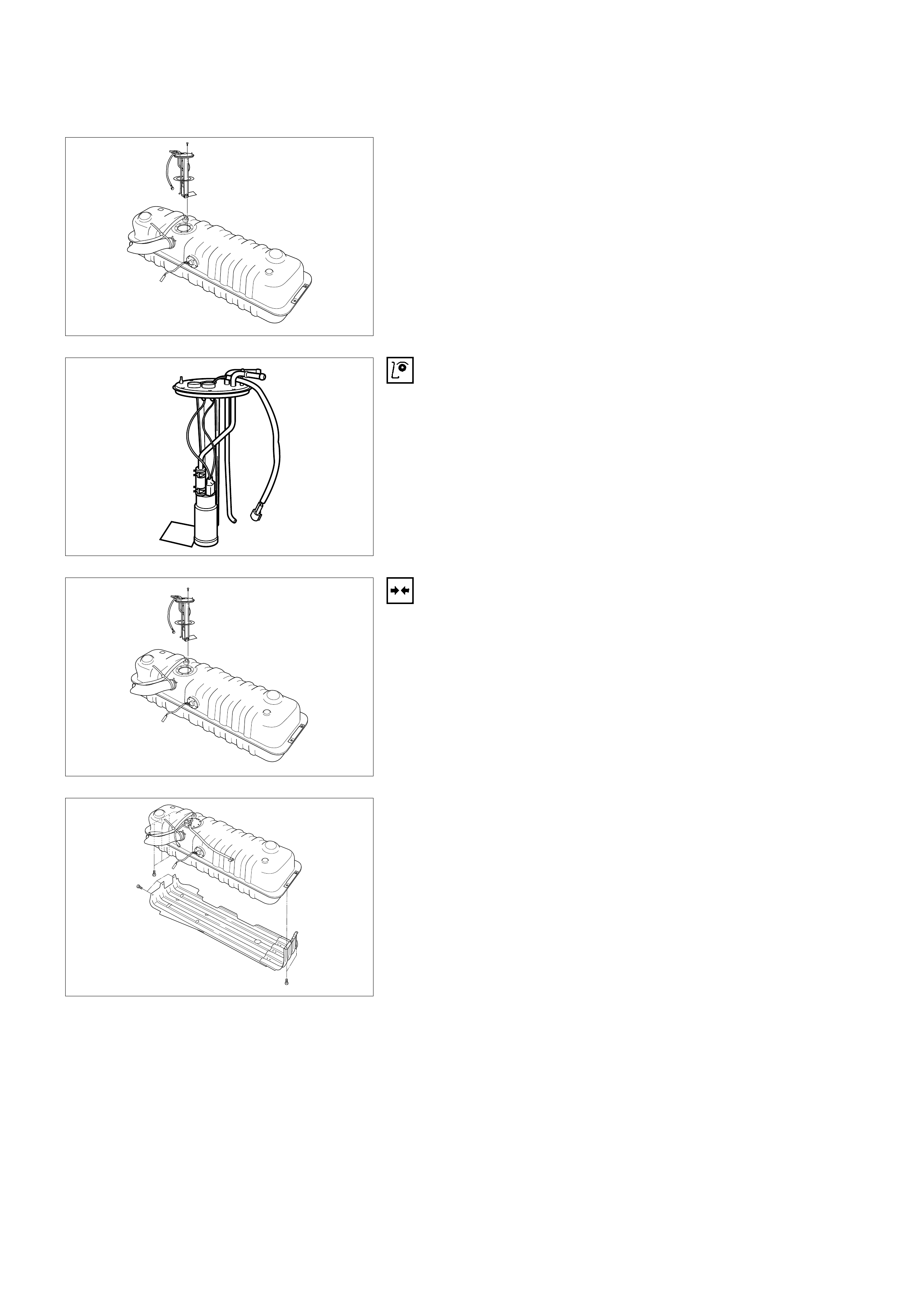

FUEL PUMP ASSEMBLY

REMOVAL

INSPECTION

INSTALLATION

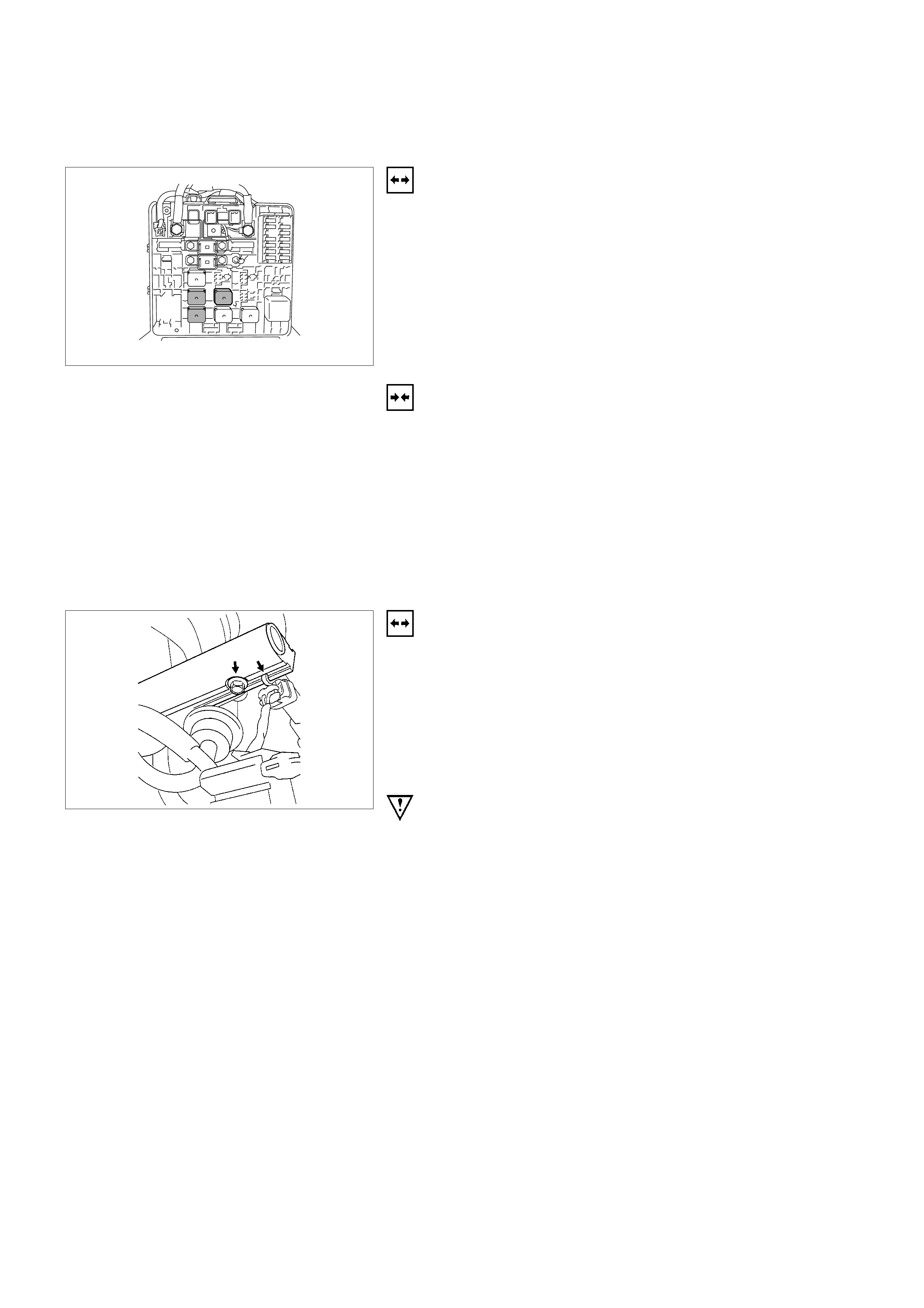

FUEL PUMP RELAY

REMOVAL

INSTALLATION

FUEL RAIL ASSEMBLY

REMOVAL

INSTALLATION

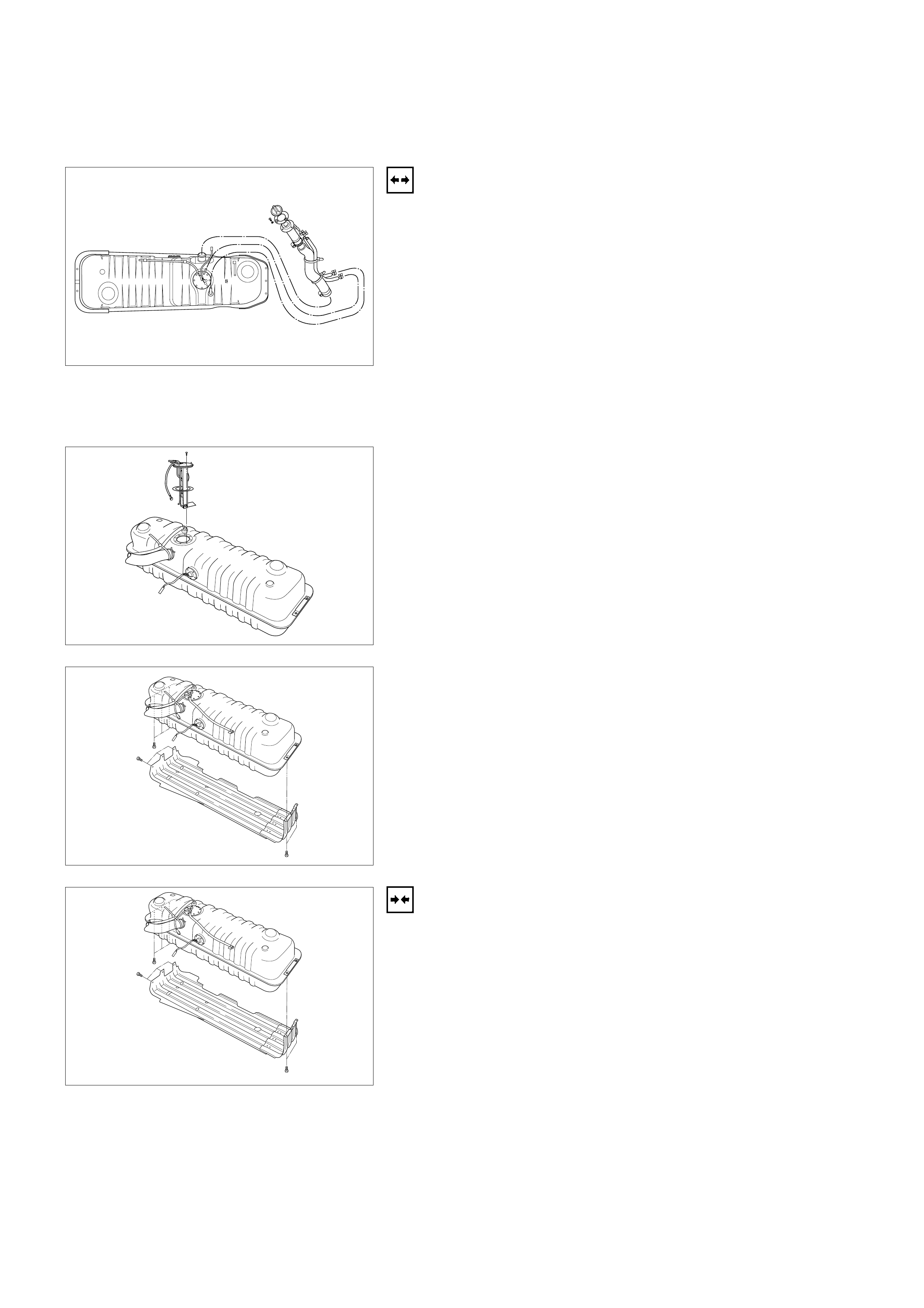

FUEL TANK

REMOVAL

INSTALLATION

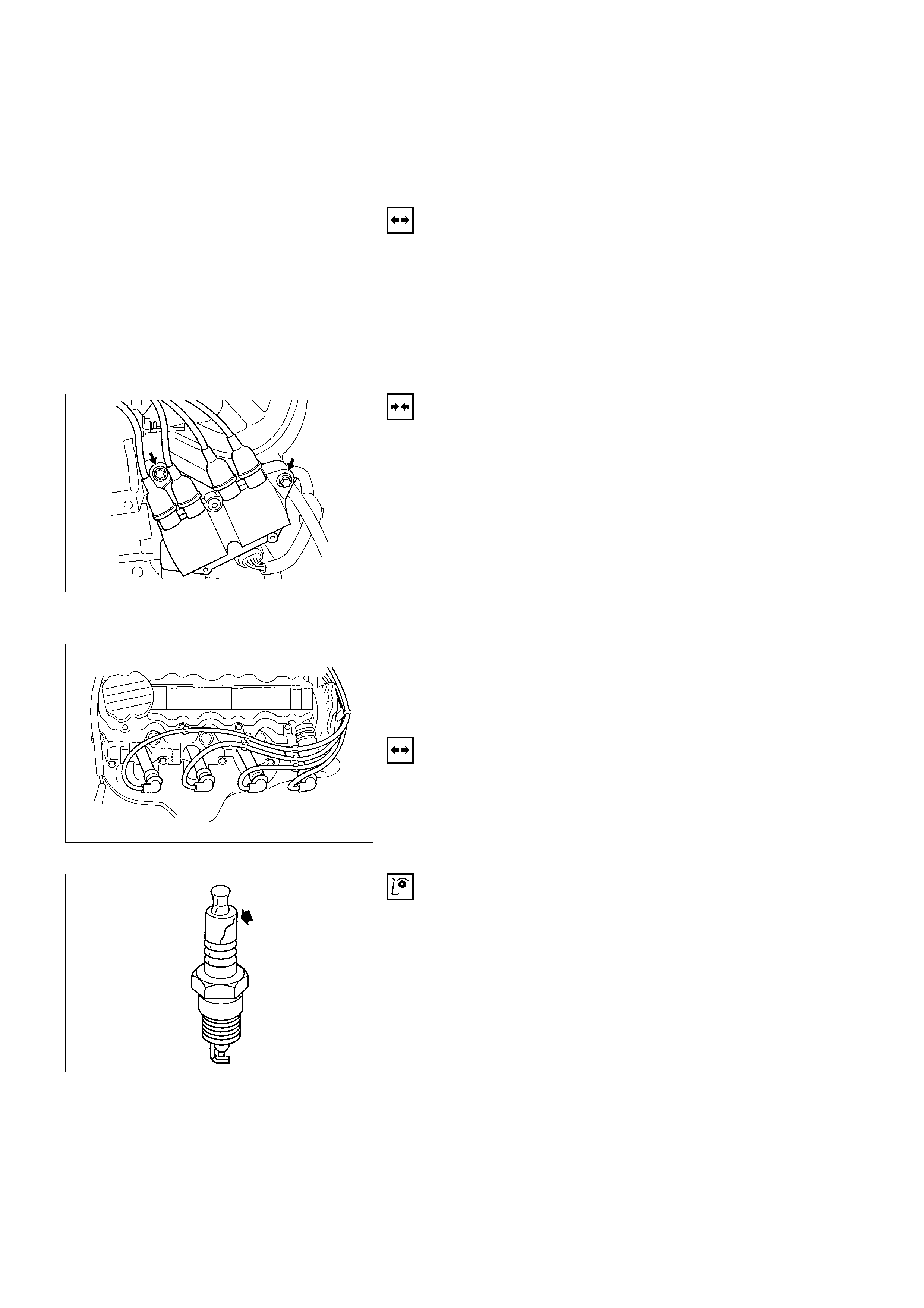

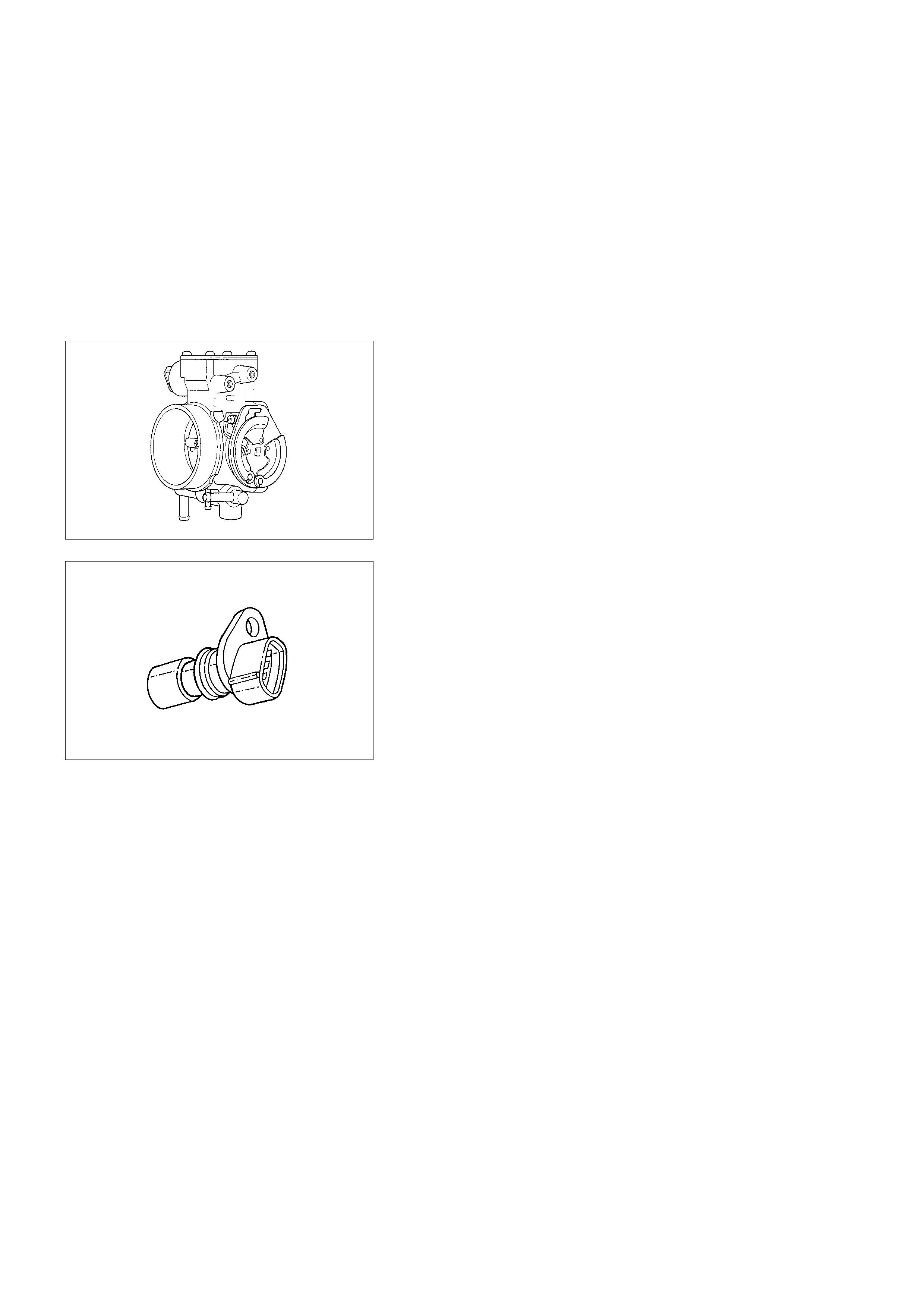

THROTTLE BODY (TB)

REMOVAL

INSPECTION

INSTALLATION

ELECTRONIC IGNITION SYSYTEM

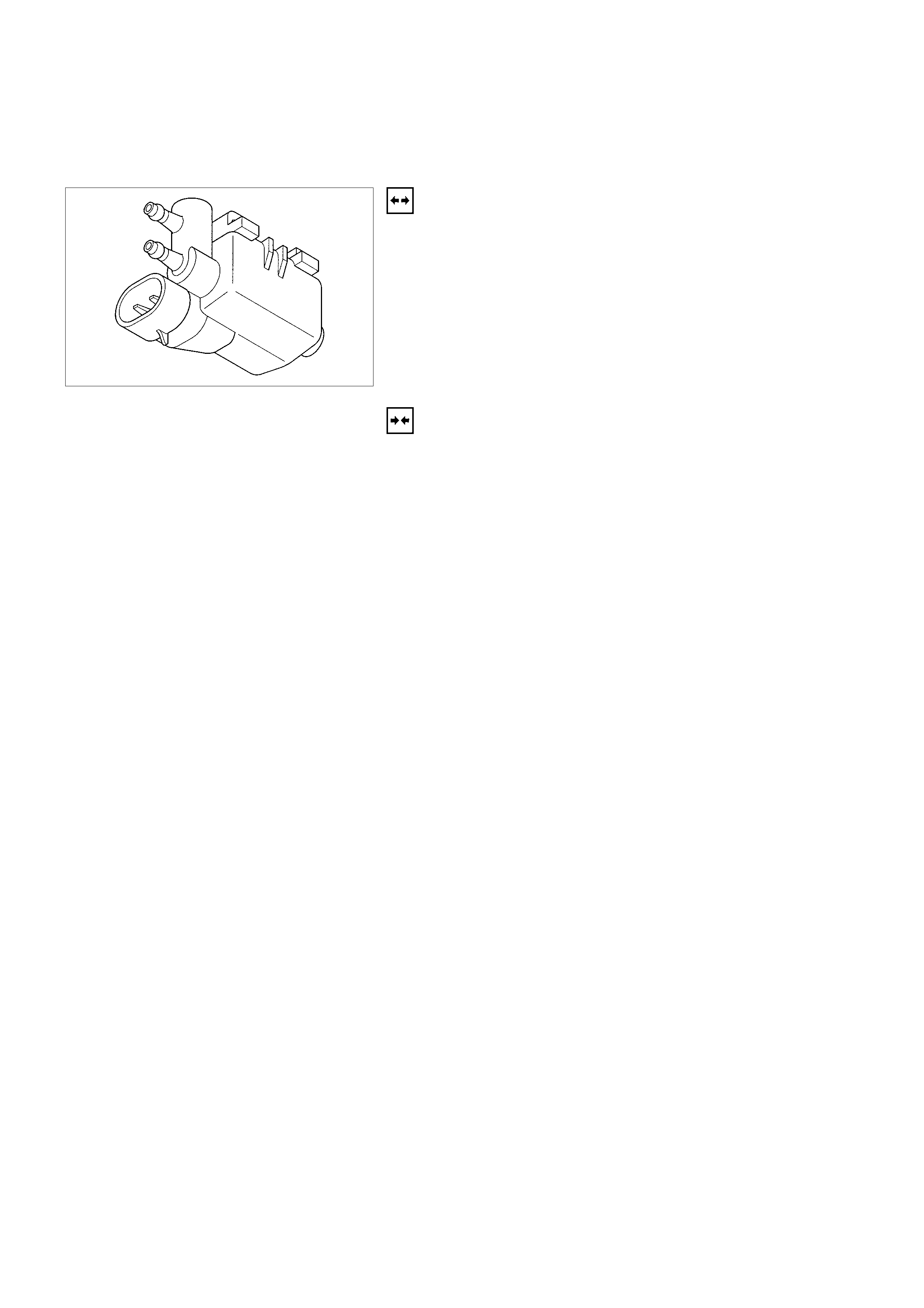

IGNITION COIL

REMOVAL

INSTALLATION

SPARK PLUGS

REMOVAL

INSPECTION

INSTALLATION

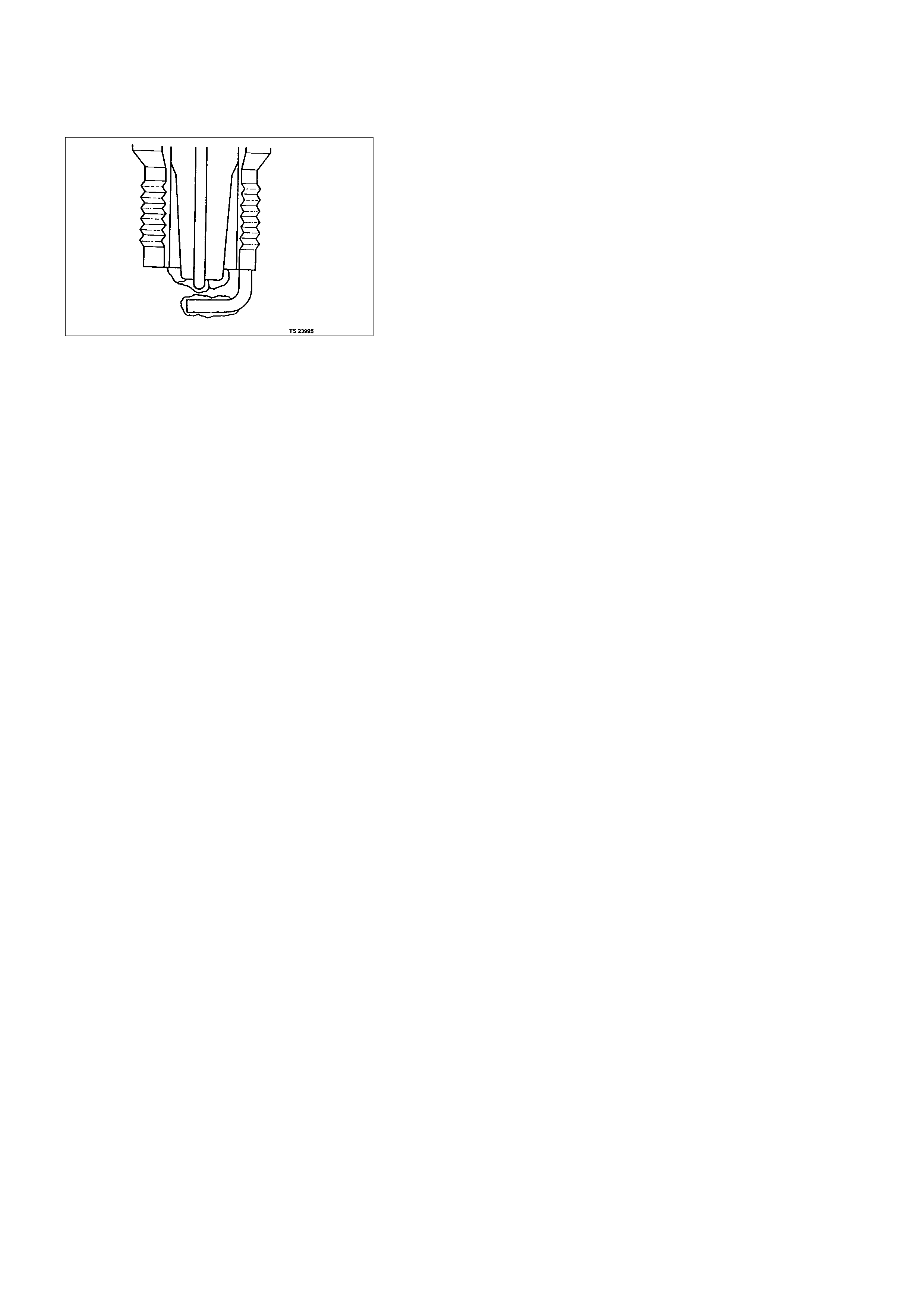

SPARK PLUG CABLES

INSPECTION

EMISSIONS

CATALYTIC CONVERTER (IF APPLICABLE)

AIR CONDITIONING RELAY

REMOVAL

INSTALLATION

IGNITION TIMING ADJUSTMENT

EVAP CANISTER HOSES (IF APPLICABLE)

EVAP CANISTER (IF APPLICABLE)

REMOVAL

INSPECTION

INSTALLATION

EVAP CANISTER PURGE VALVE SOLENOID (IF APPLICABLE)

REMOVAL

INSTALLATION

WIRING AND CONNECTORS

WIRING HARNESS SERVICE

ECM CONNECTORS AND TERMINALS

REMOVAL

INSTALLATION

CONNECTORS AND TERMINALS

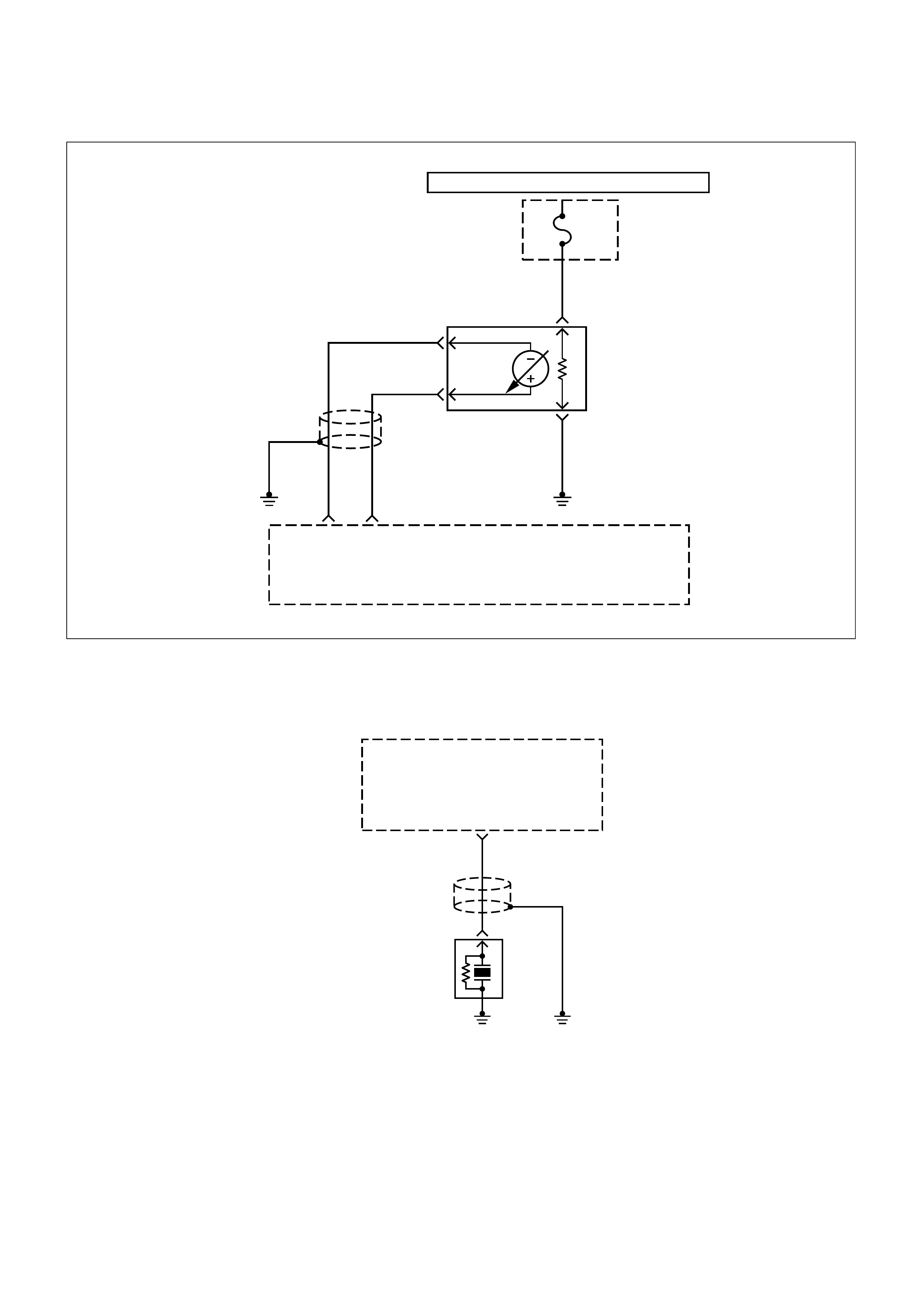

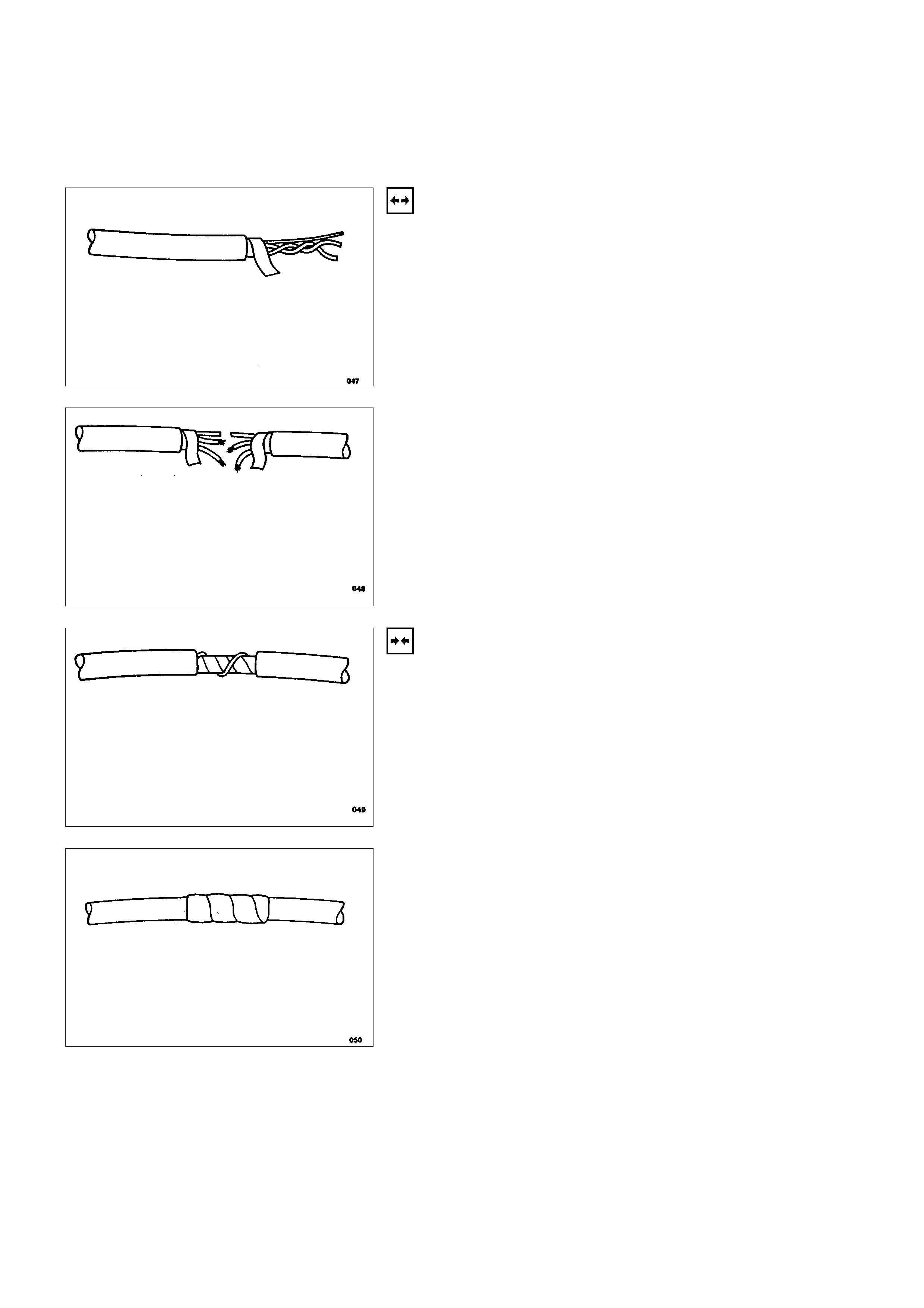

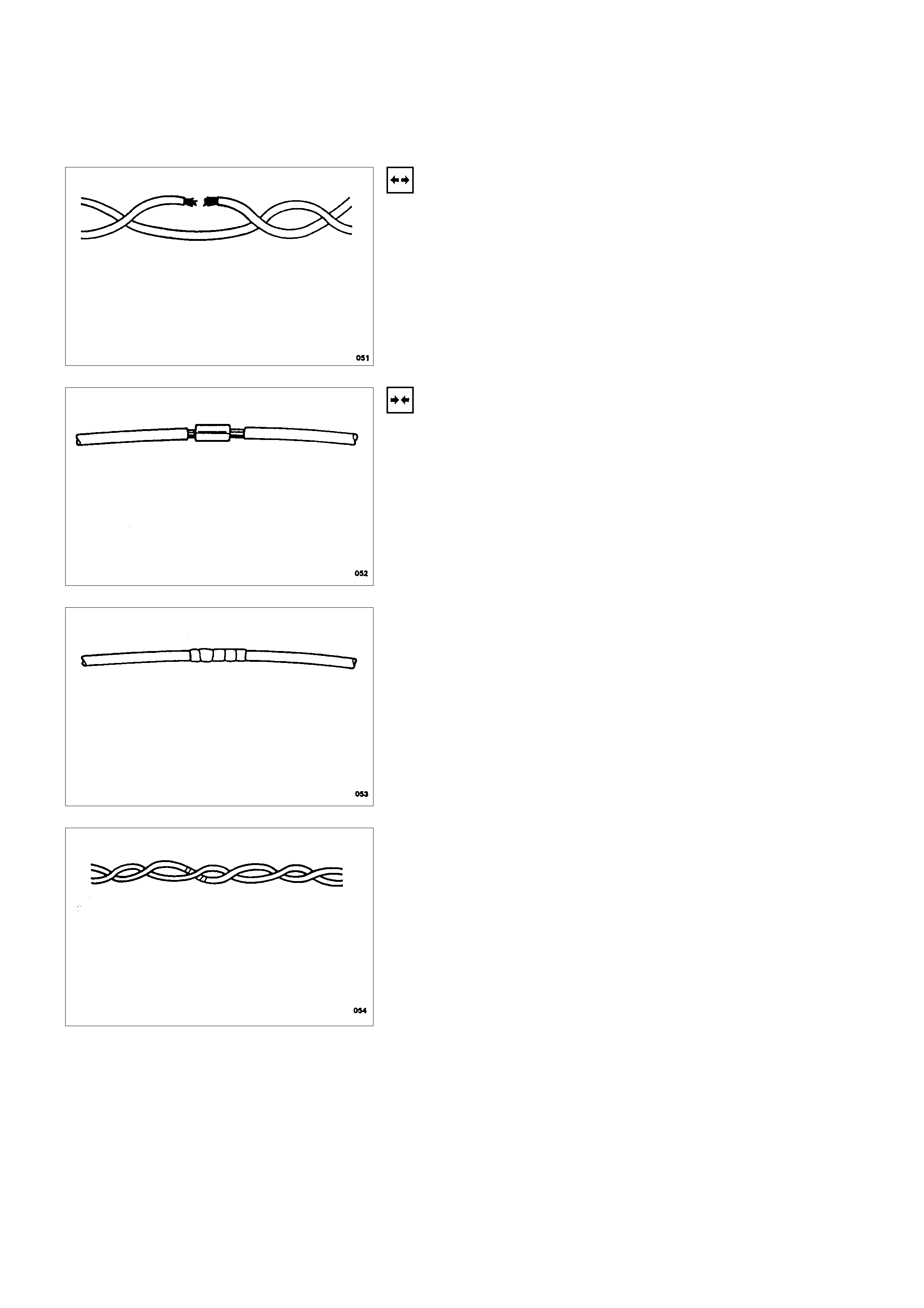

WIRE HARNESS REPAIR:TWISTED SHIELDED CABLE

REMOVAL

INSTALLATION

TWISTED LEADS

REMOVAL

INSTALLATION

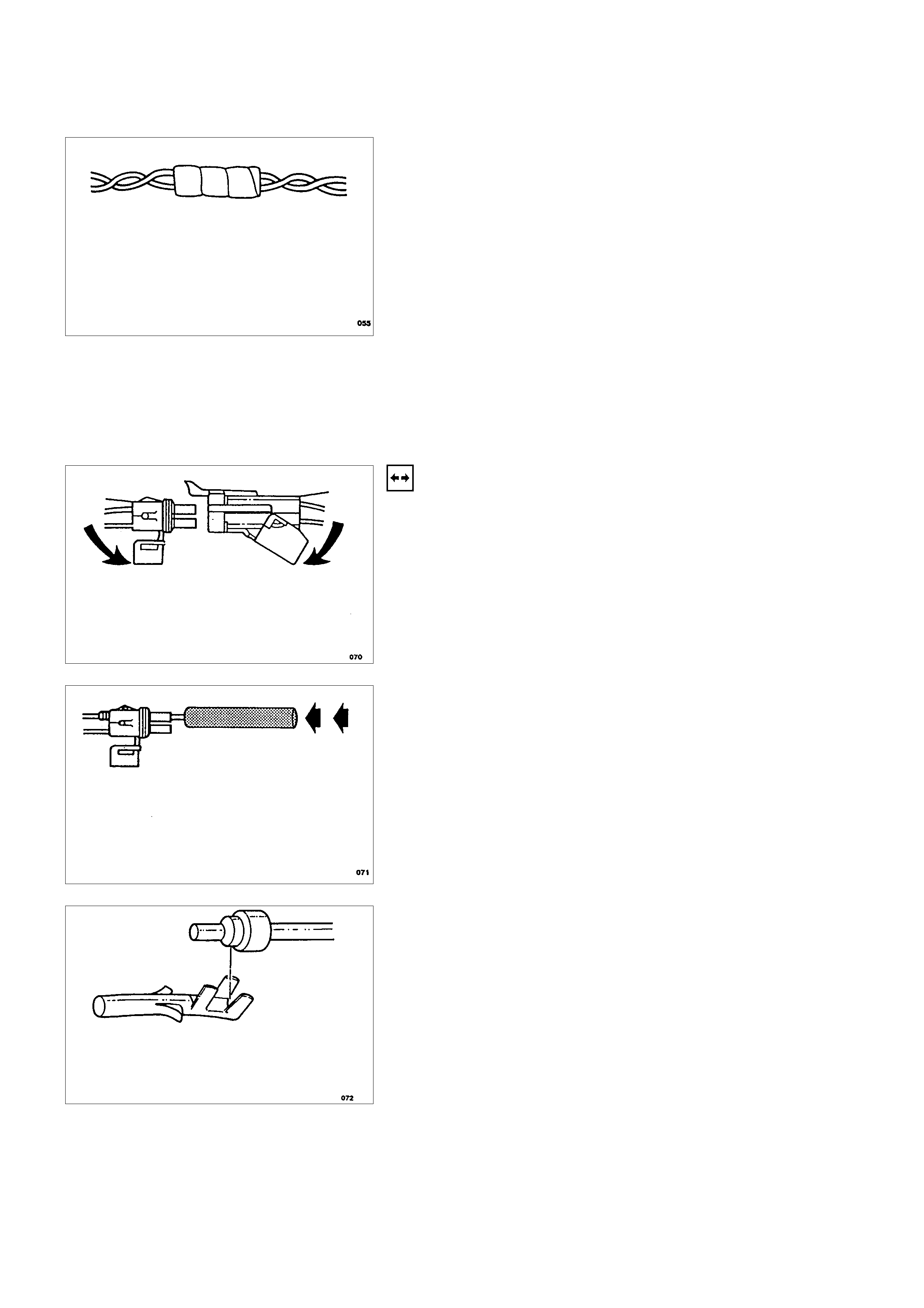

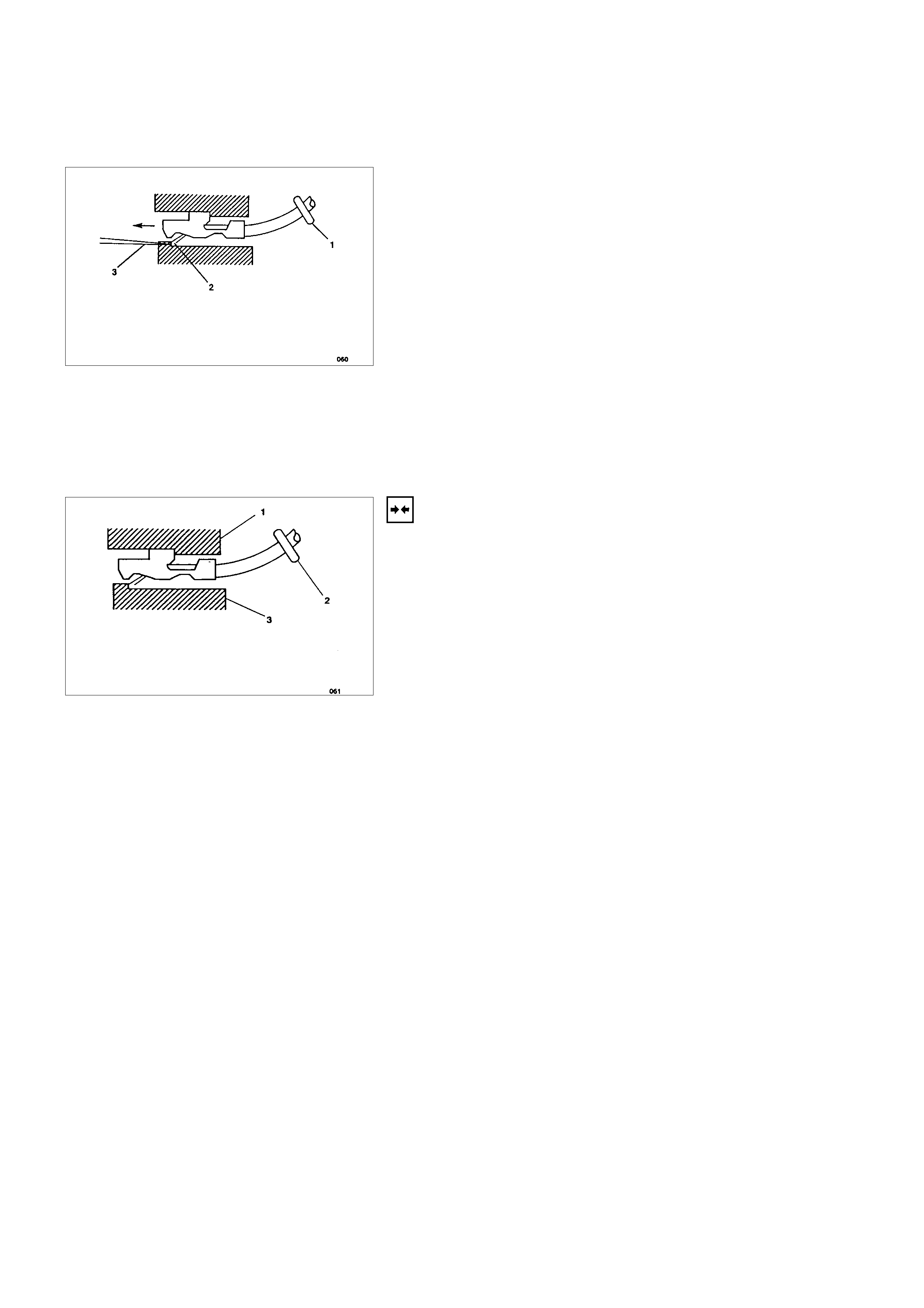

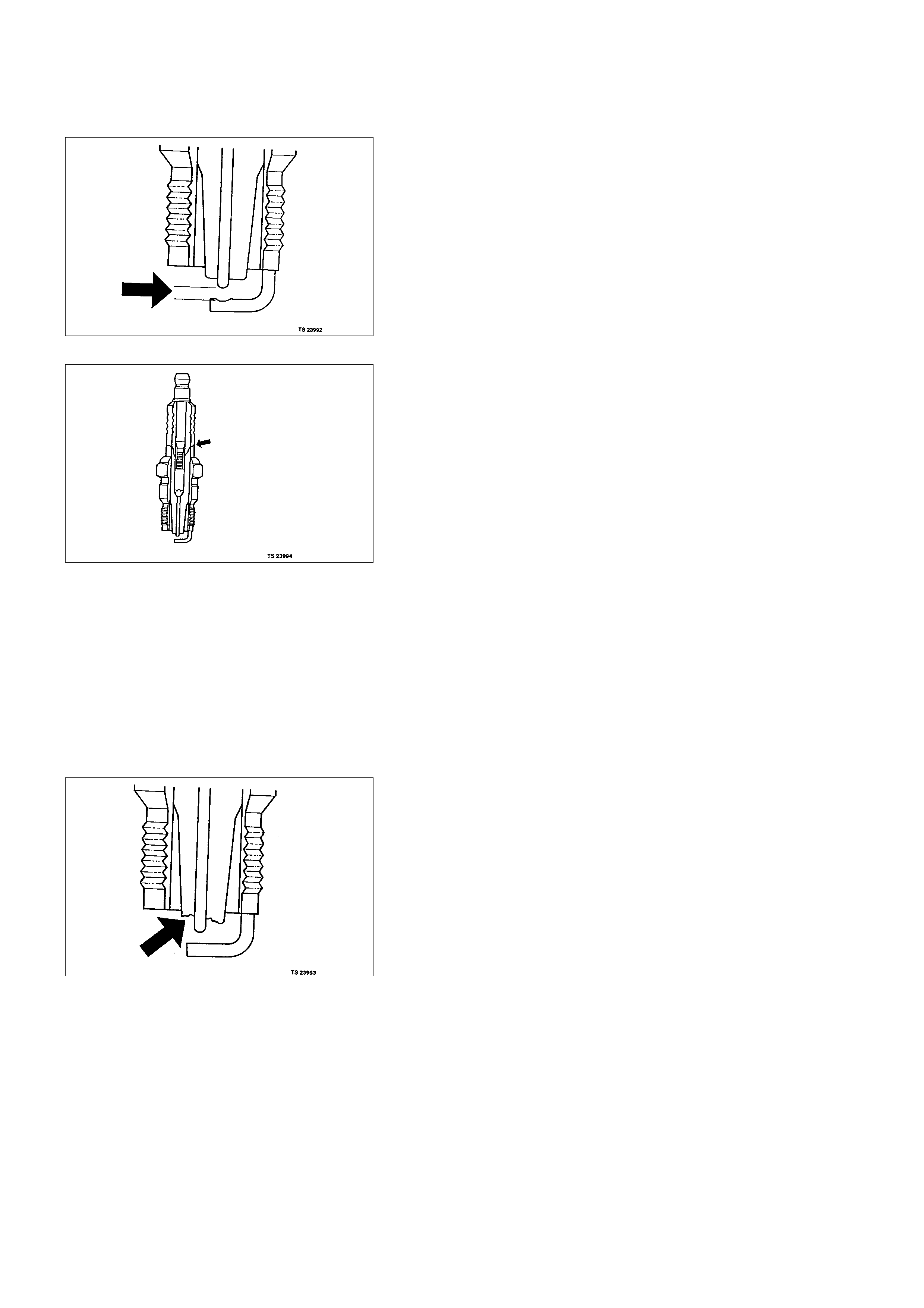

WEATHER-PACK CONNECTOR

TOOLS REQUIRED

REMOVAL

INSTALLATION

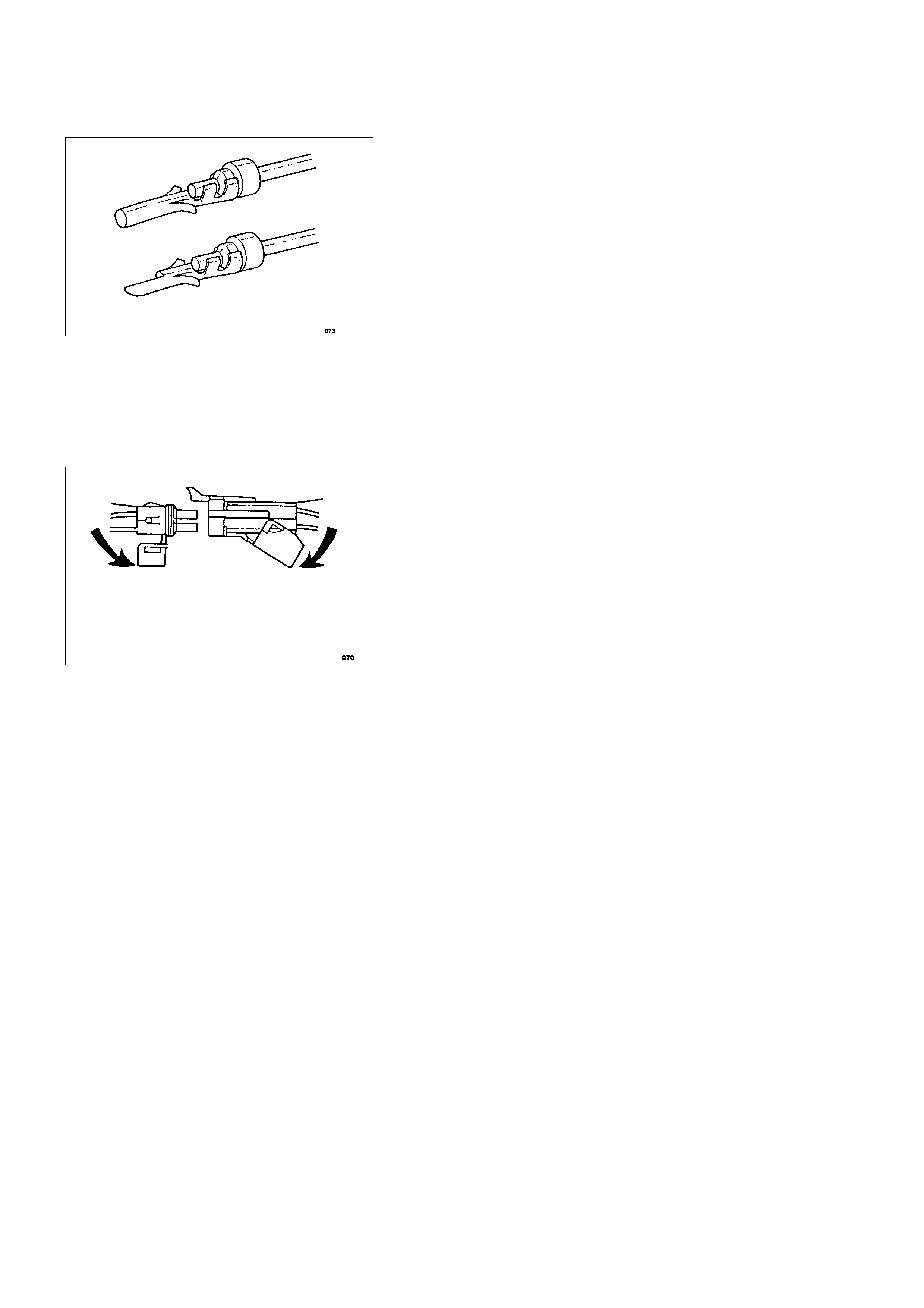

COM-PACK III

METRI-PACK

TOOLS REQUIRED

REMOVAL

INSTALLATION

GENERAL DE S CRIPTION

ECM AND SENSORS

58X REFE RENCE ECM INPUT

A/C REQUEST SIGNAL

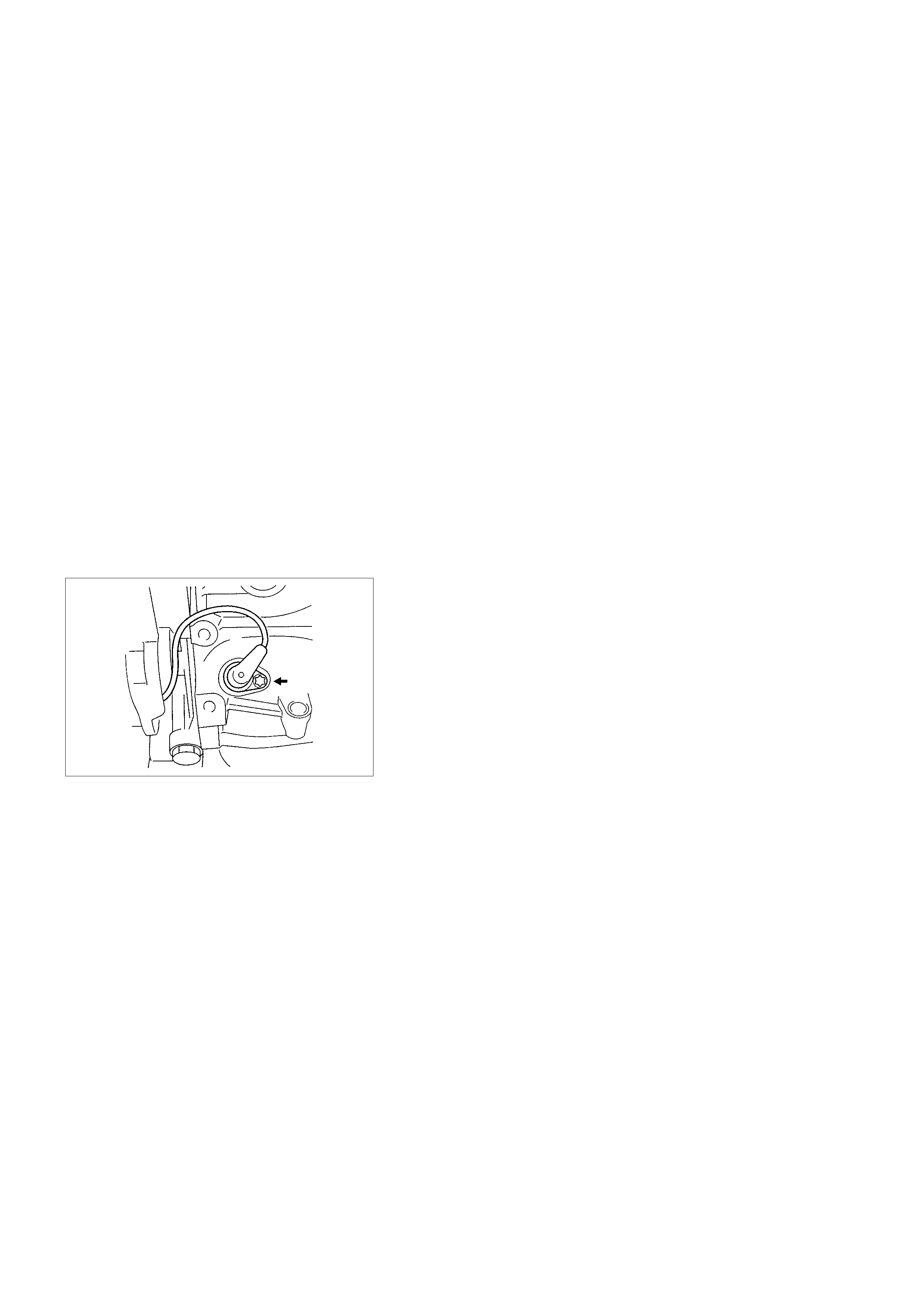

CRANKSHAFT POSITION (CKP) SENSOR

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

FUEL CONTROL HEATED OXYGEN SENSOR (IF APPLICABLE)

INTAKE AIR TEMPERATURE (IAT) SENSOR

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

ENGINE CONTROL MODULE (ECM)

ECM FUNCTION

ECM COMPONENTS

ECM VOLTAGE DESCRIPTION

ECM INPUT/OUTPUTS

INPUT-OPERATING CONDITIONS READ

OUTPUTS-SYSTEMS CONTROLLED

ECM SERVICE PRECAUTIONS

THROTTLE POSITION SENSOR (TPS)

VEHICLE SPEED SENSOR (VSS)

USE OF CIRCUIT TESTING TOOLS

AFTERMARKET ELECTRICAL AND VACUUM E Q UIPMENT

ELECTROSTATIC DISCHARGE DAMAGE

AIR INDUCTION

AIR INDUCTION SYSTEM

FUEL METERING

ACCELERATION MODE

ACCELERATOR CONTROLS

BATTERY VO LTAGE CORRECTION MODE

CLEAR FLOOD MODE

DECELERATION FUEL CUTOFF (DFCO) MODE

ENGINE SPEED/VEHICLE SPEED/FUEL DISABLE MODE

FUEL CUTOFF MODE

FUEL INJECTOR

FUEL METERING SYSTEM COMPONENTS

BASIC SYSTEM OPERATION

FUEL METERING SYSTEM PURPOSE

FUEL PRESSURE REGULATOR

FUEL PUMP ELECTRICAL CIRCUIT

FUEL RAIL

IDLE AIR CONTROL (IAC) VALVE

RUN MODE (APPLICABLE TO CLOSED LOOP SYSTEMS)

STARTING MODE

THROTTLE BODY UNIT

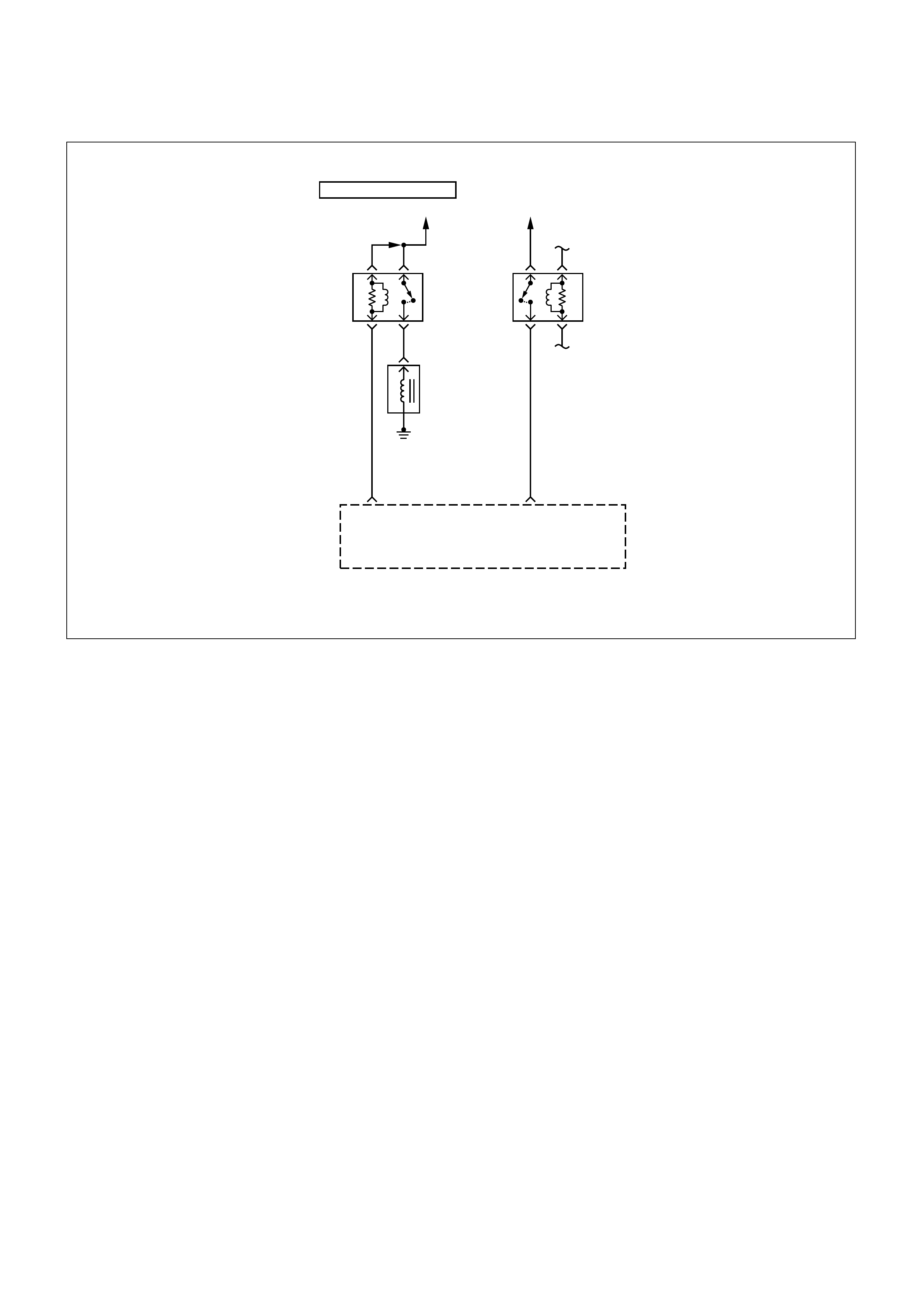

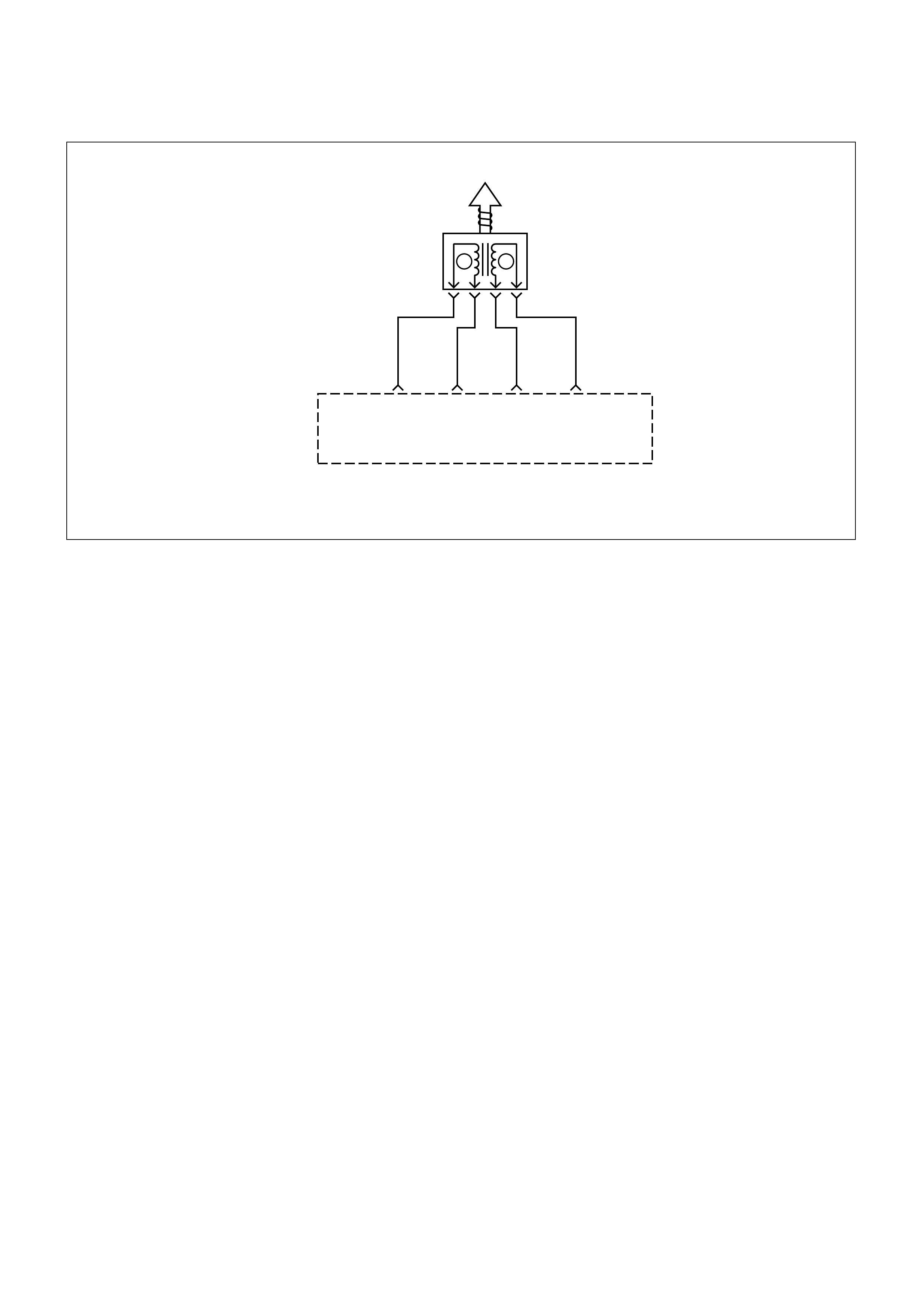

ELECTRONIC IGNITION SYSTEM

CRANKSHAFT POSITION (CKP) SENSOR

ELECTRONIC IGNITON

IGNITION COILS

IGNITION CONTROL

IGNITION CONTROL ECM OUTPUT

ENGINE CONTROL MODULE (ECM)

SPARK PLUG

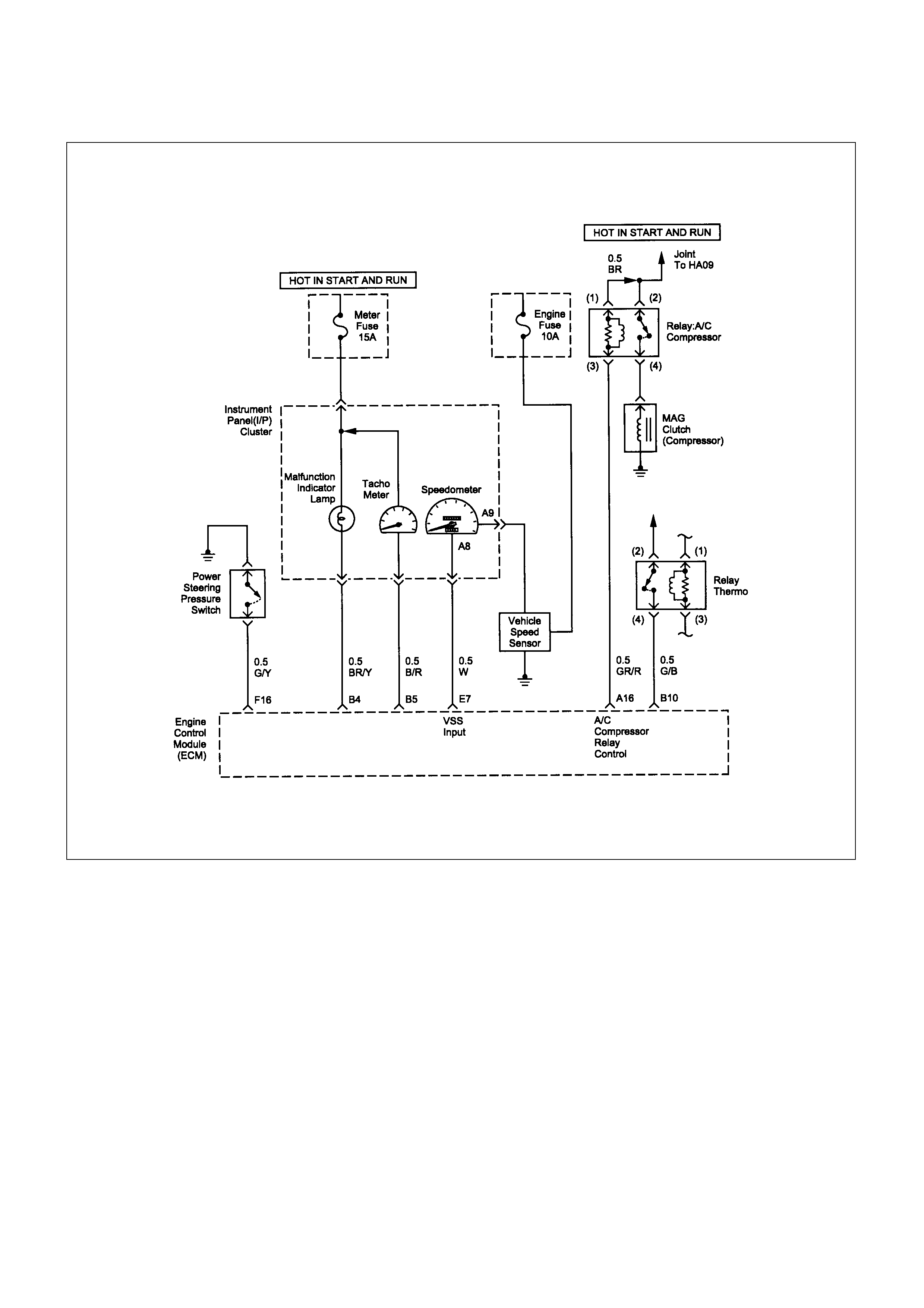

A/C CLUTCH DIAGNOSIS

A/C CLUTCH CIRCUIT OPE RATION

A/C CLUTCH CIRCUIT PURPOSE

A/C REQUEST SIGNAL

EVAPORATIVE EMISSION (EVAP) SYSTEM (IF APPLICABLE)

EVAP EMISSION CONTROL SYSTEM PURPOSE

EVAP EMISSION CONTROL SYSTEM OPERATION

SYSTEM FALUT DETECTION

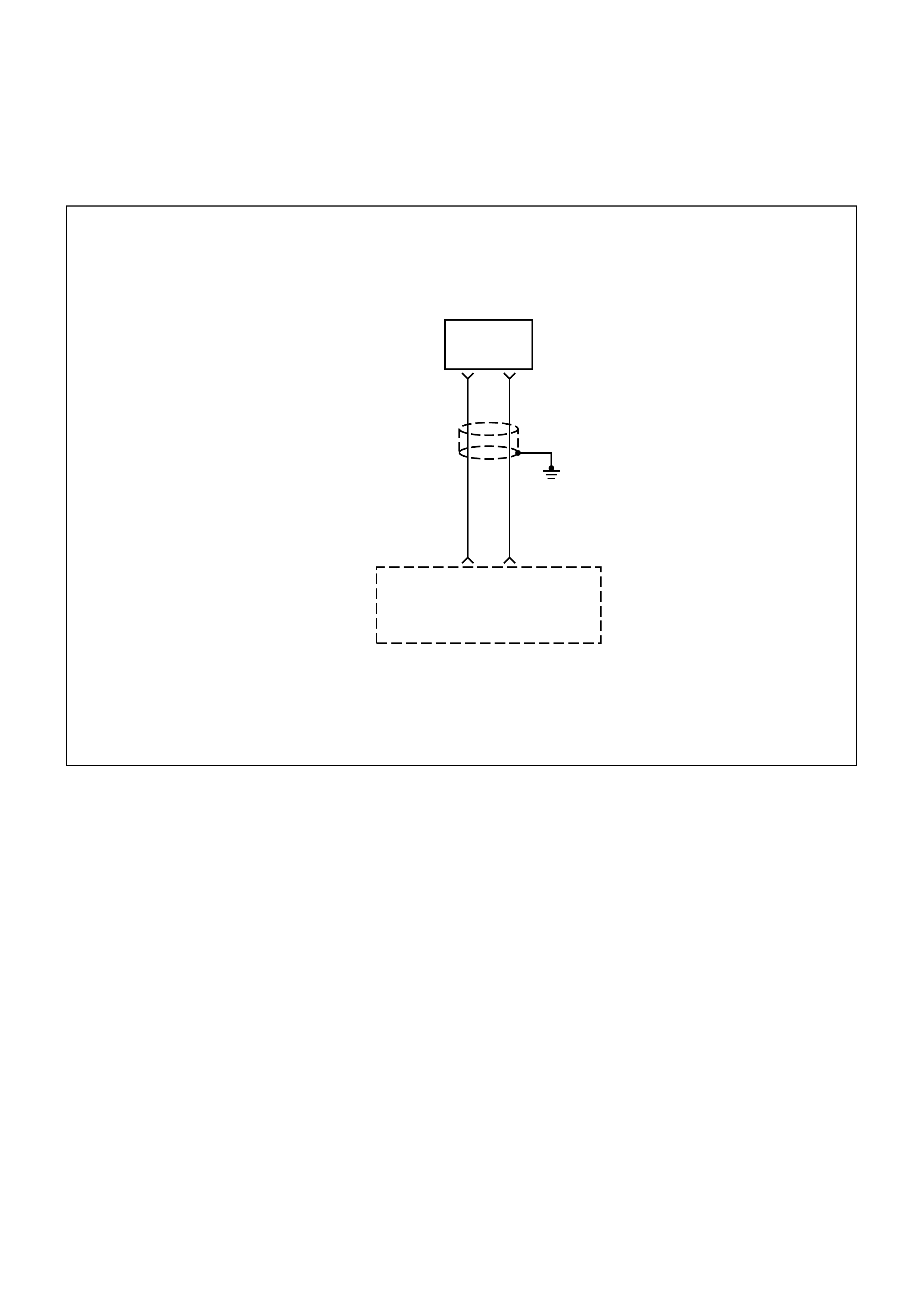

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

CRANKCASE VENTILATION SYSTEM PURPOSE

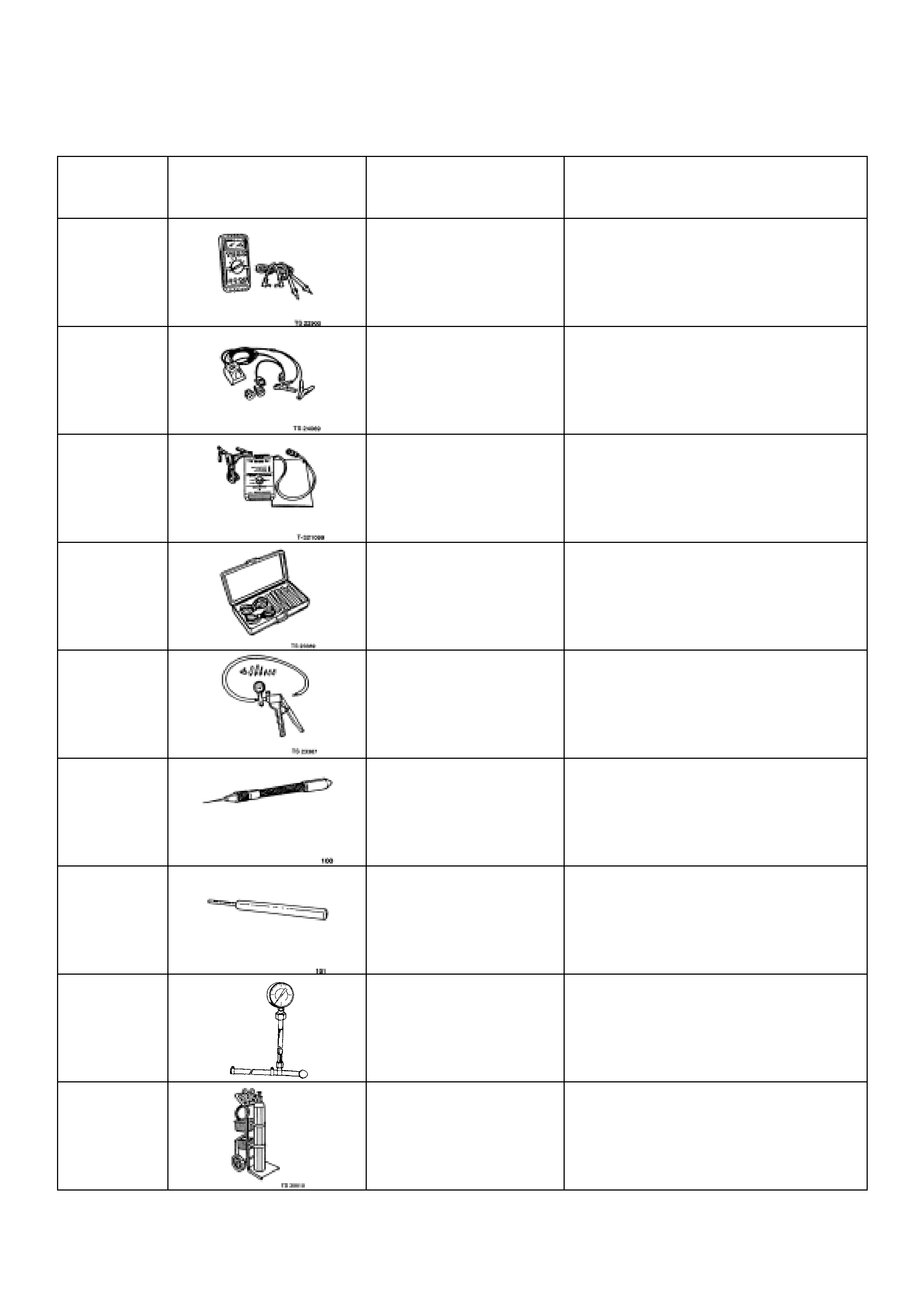

SPECIAL SERVICE TOOLS

SPECIFICATIONS

TIGHTENING SPECIFICATIONS

APPLICATION N⋅

⋅⋅⋅m Lb Ft. Lb In.

Crankshaft Position Sensor Mounting Bolt 9 - 78

Engine Coolant Temperature Sensor 30 22 -

Fuel Pressure Regulator Attaching Screw 6.5 - 60

Fuel Rail Bolts 7 - 75

Heated Oxygen Sensor (If applicable) 5 40 -

Spark Plugs 25 18 -

Throttle Body Mounting Bolts 13 - 120

VSS Retaining Bolt 13 - 120

Intake Manifold to Cylinder Head 22 16 -

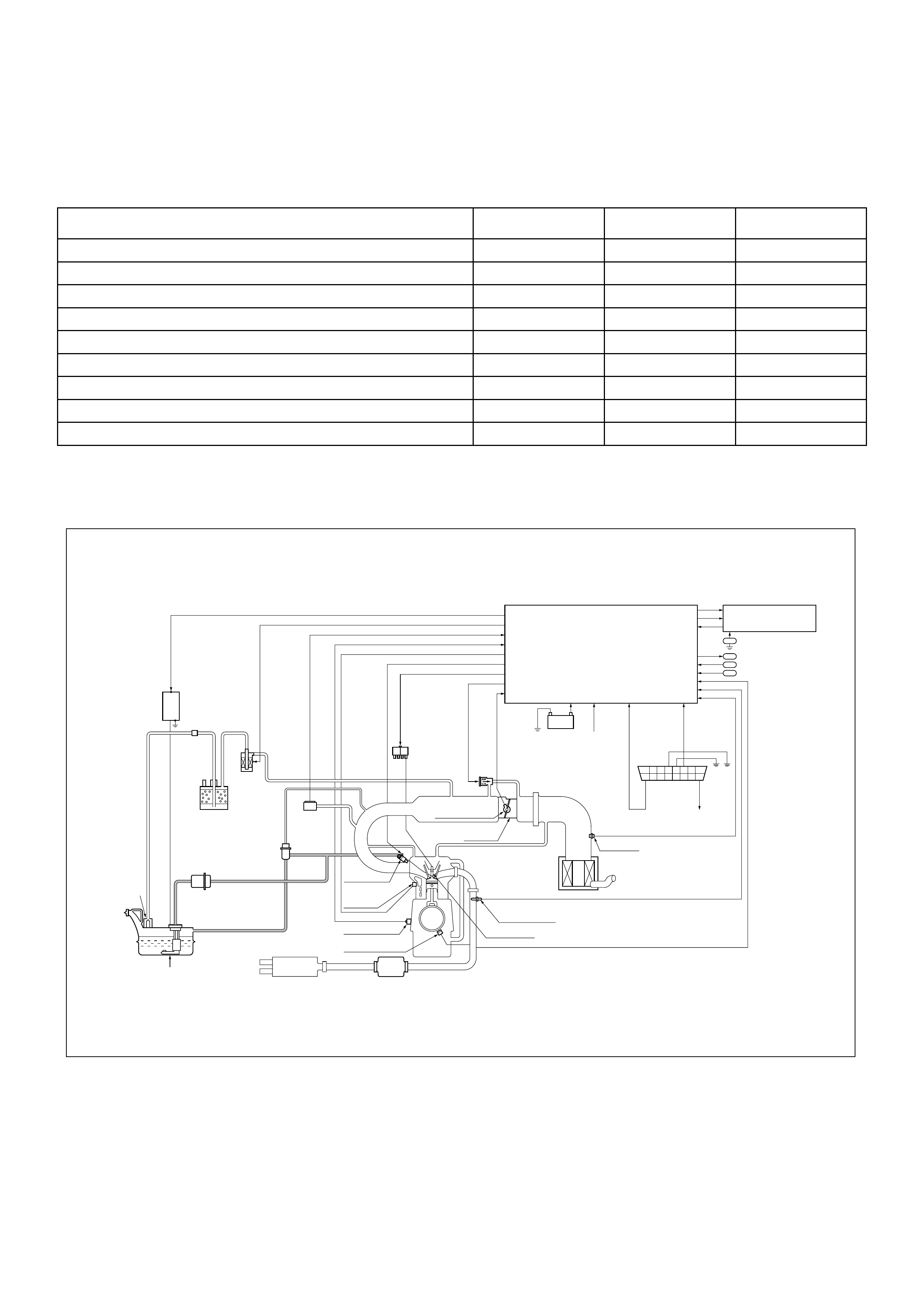

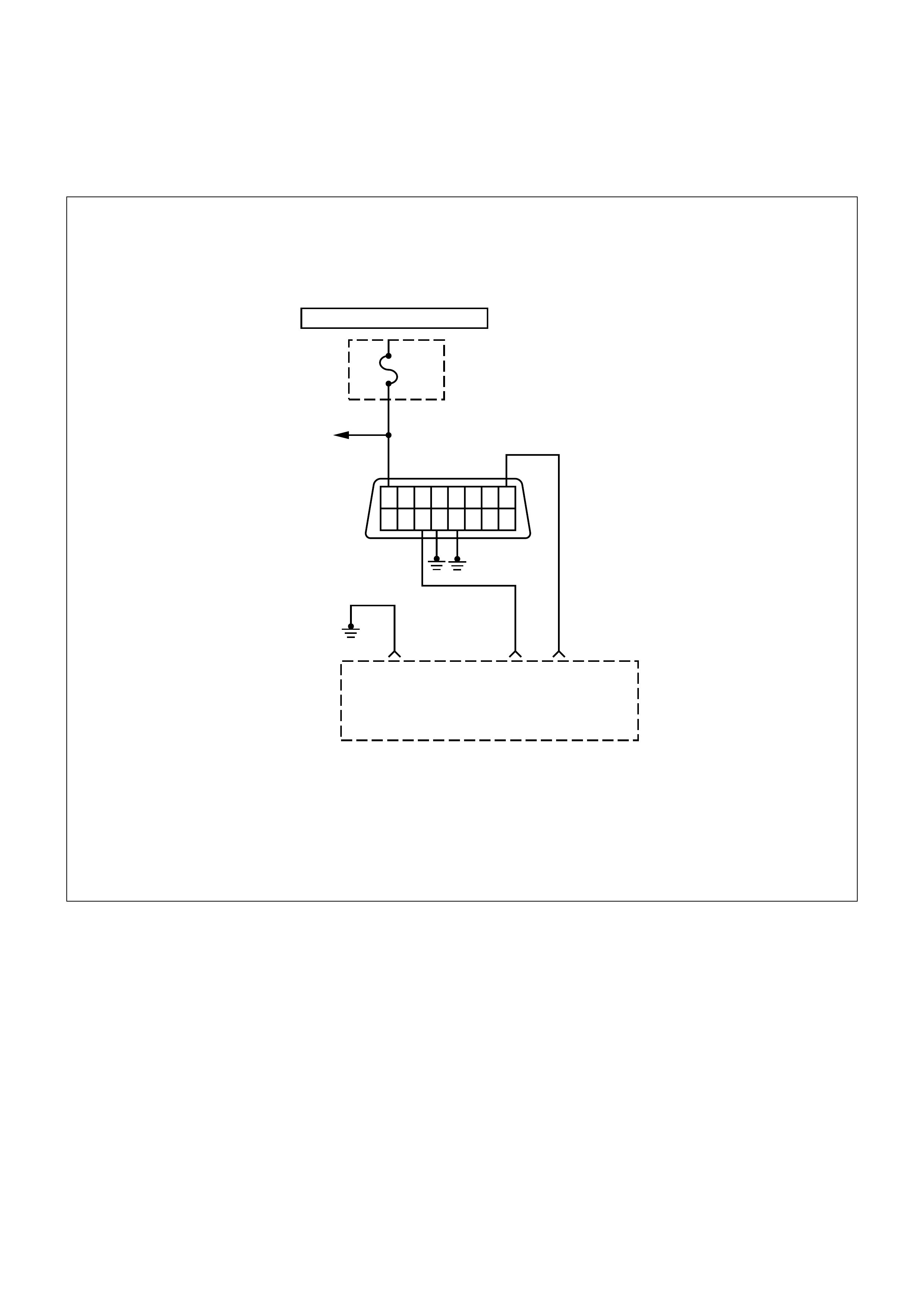

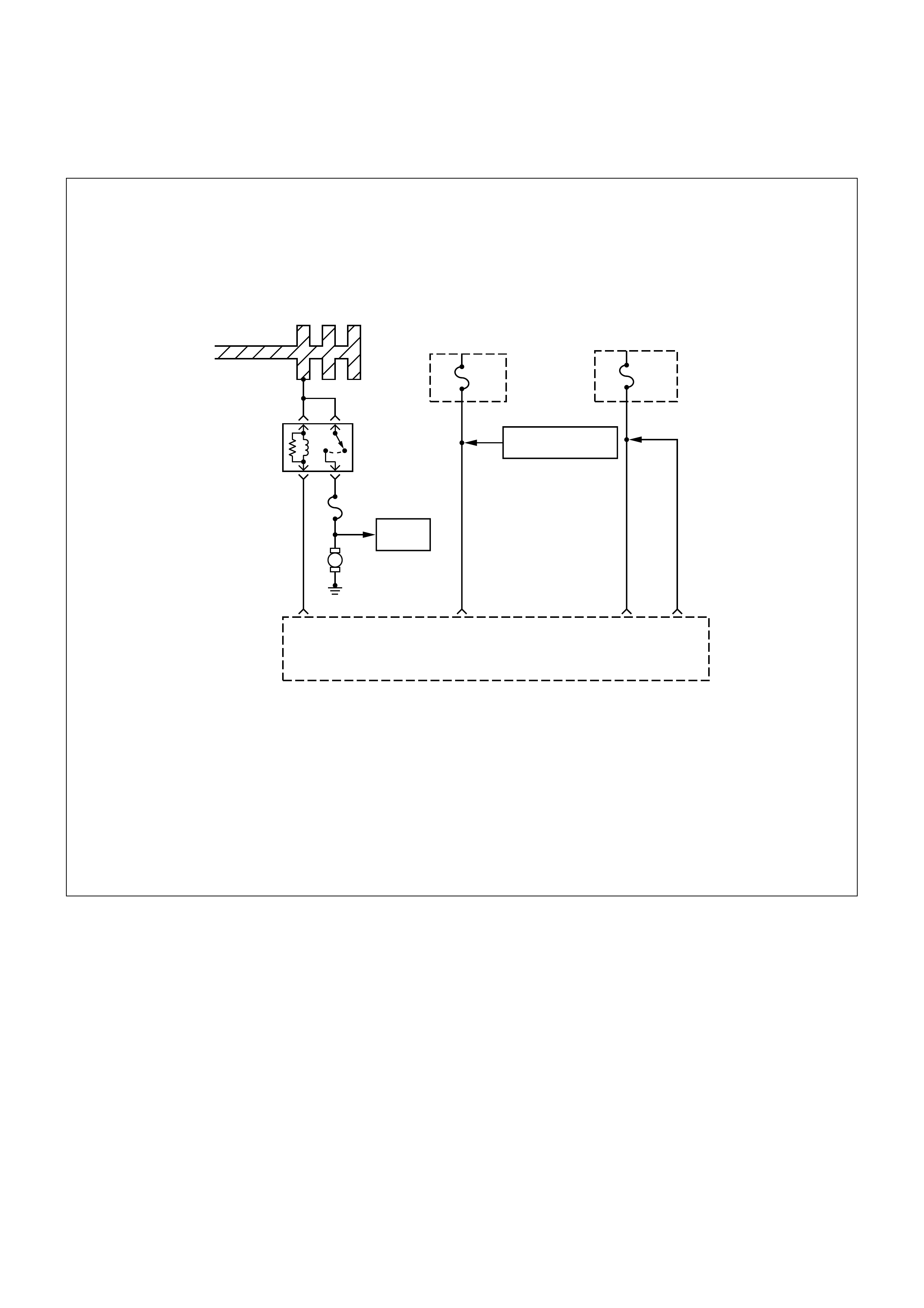

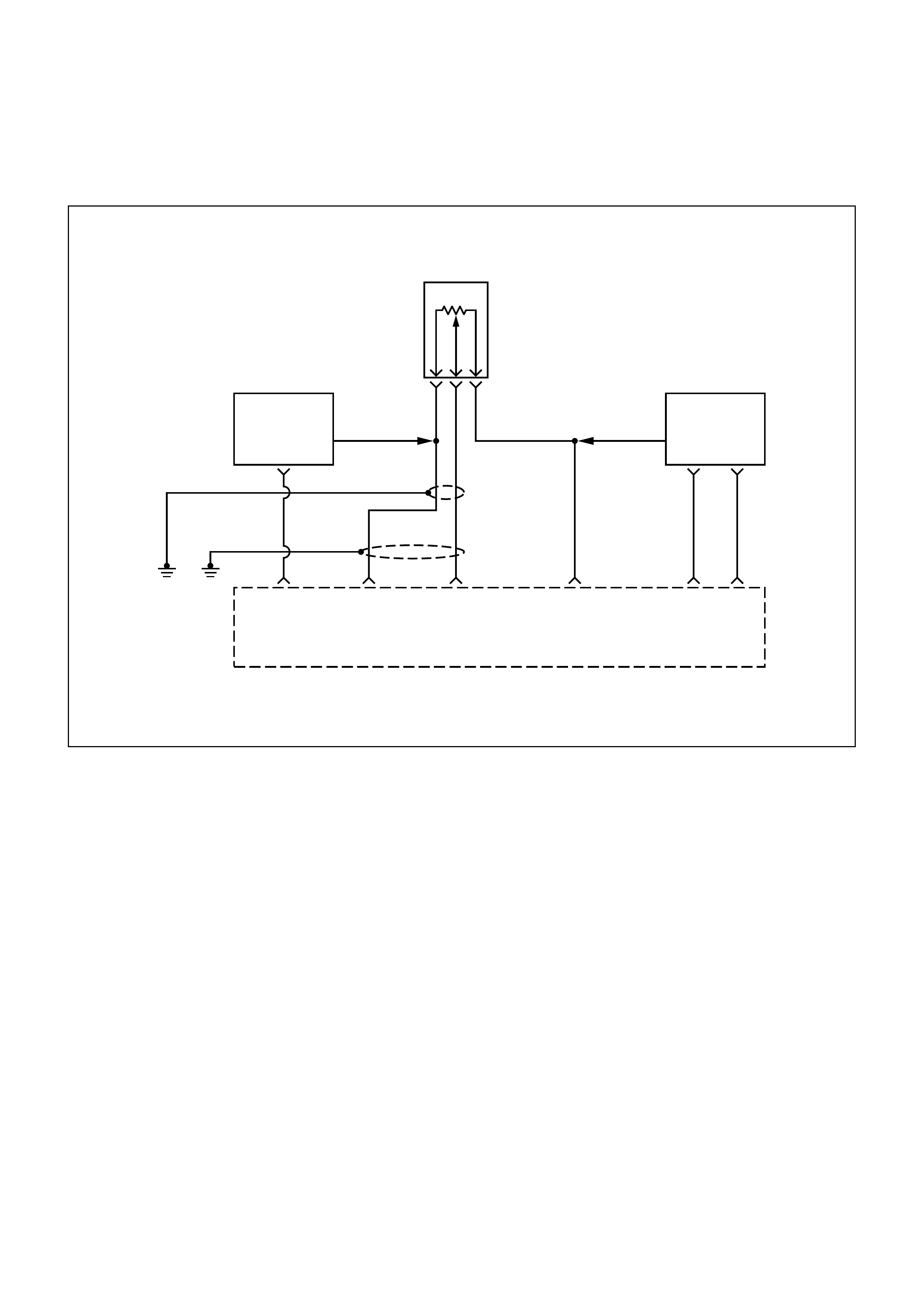

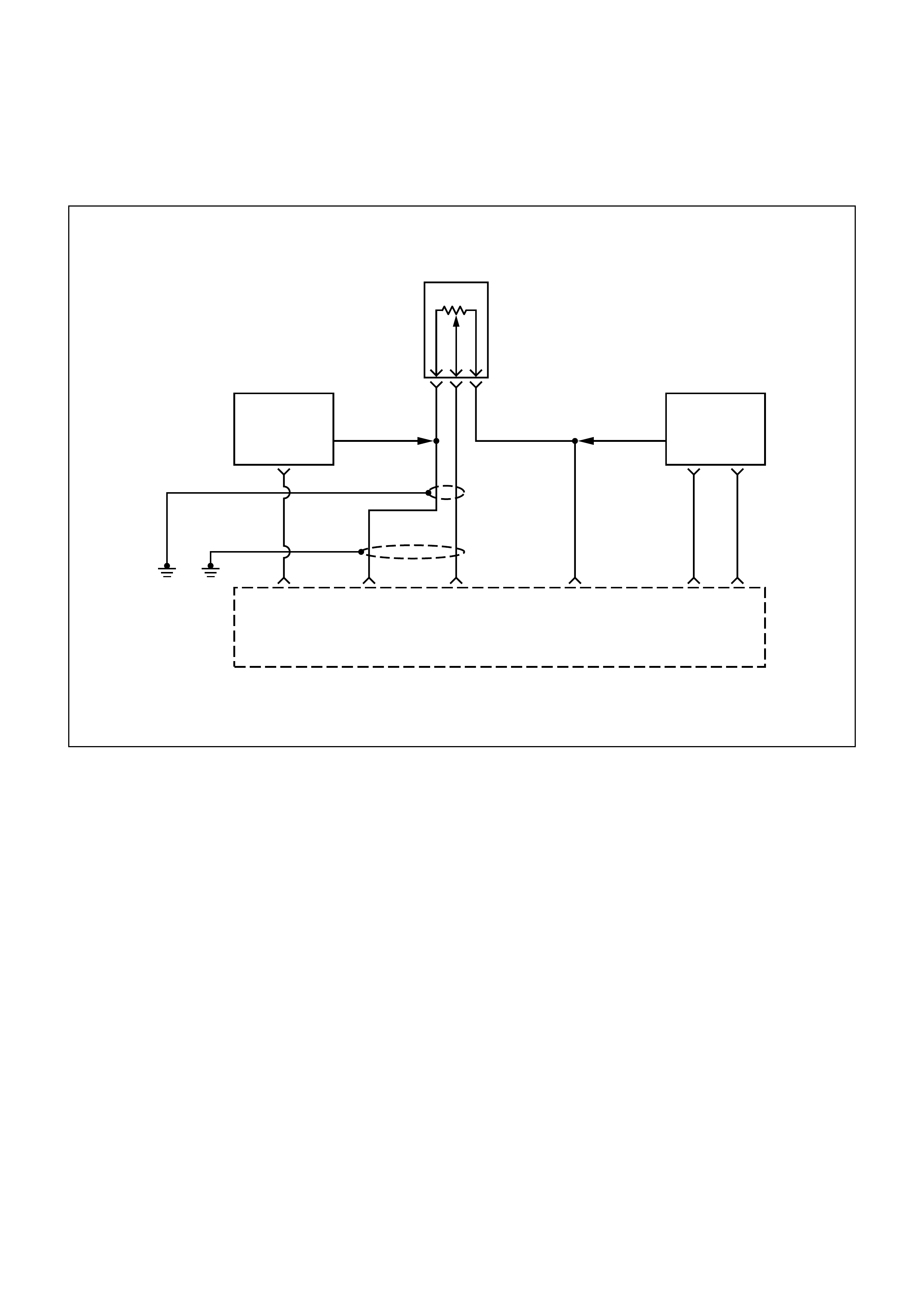

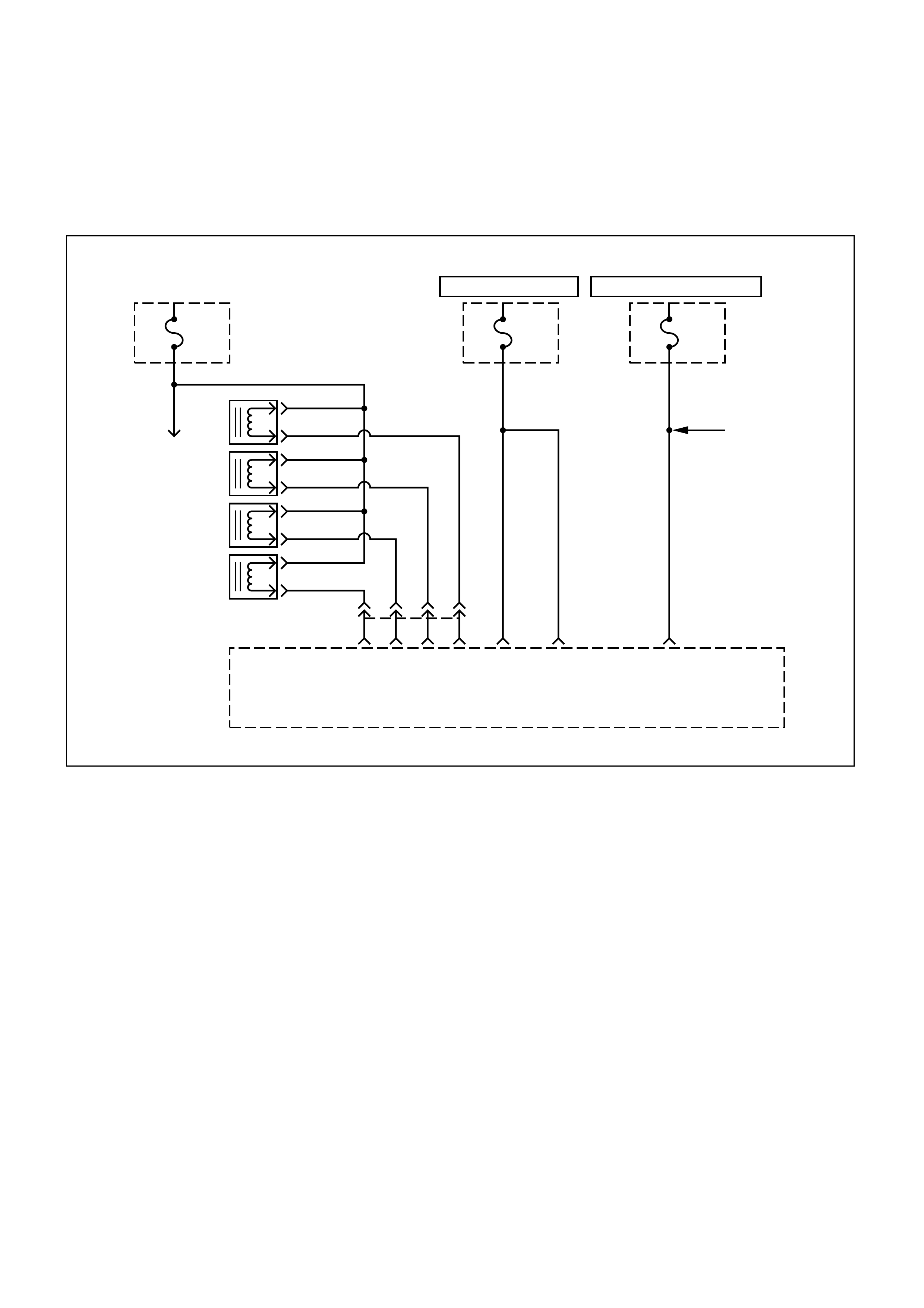

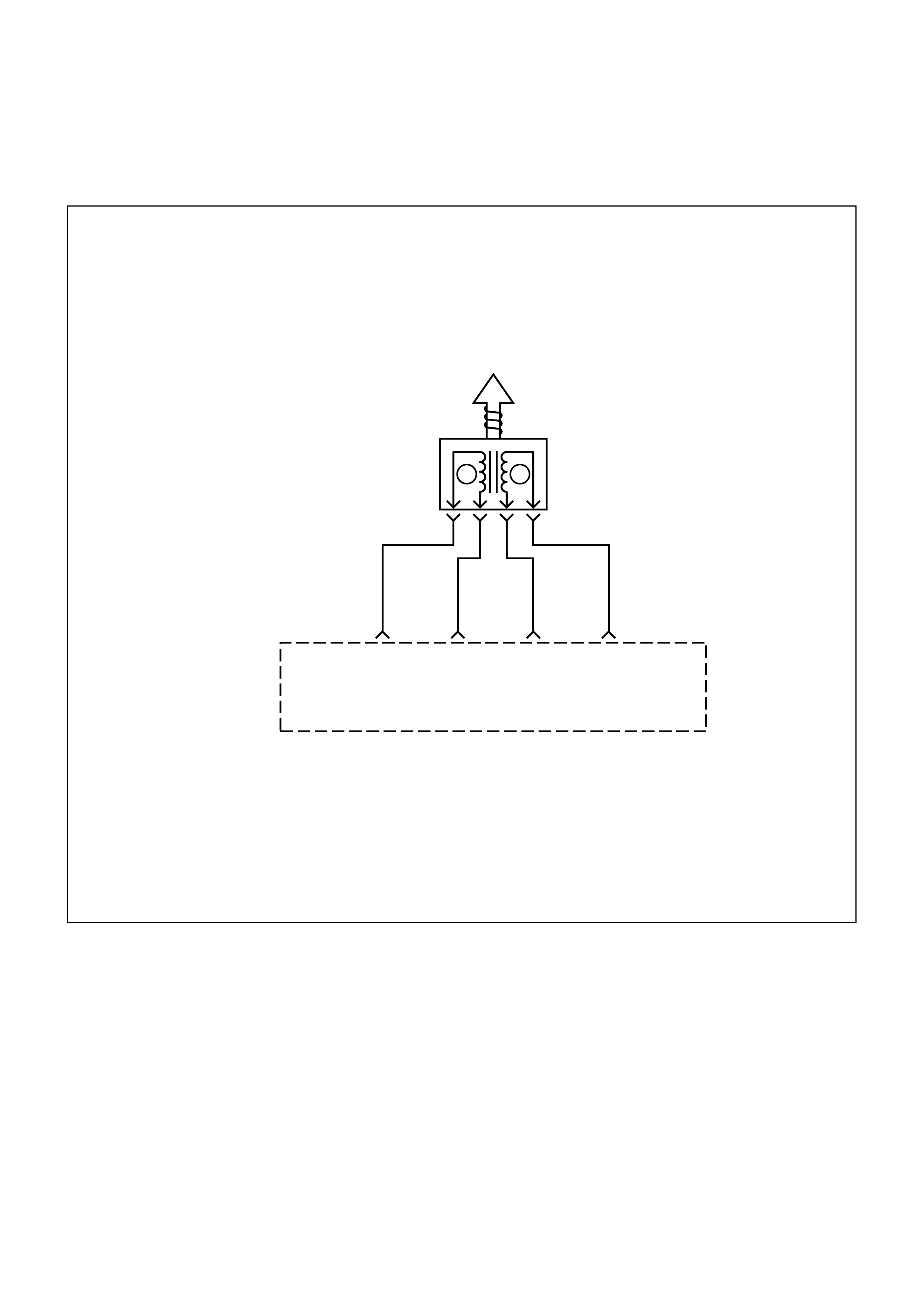

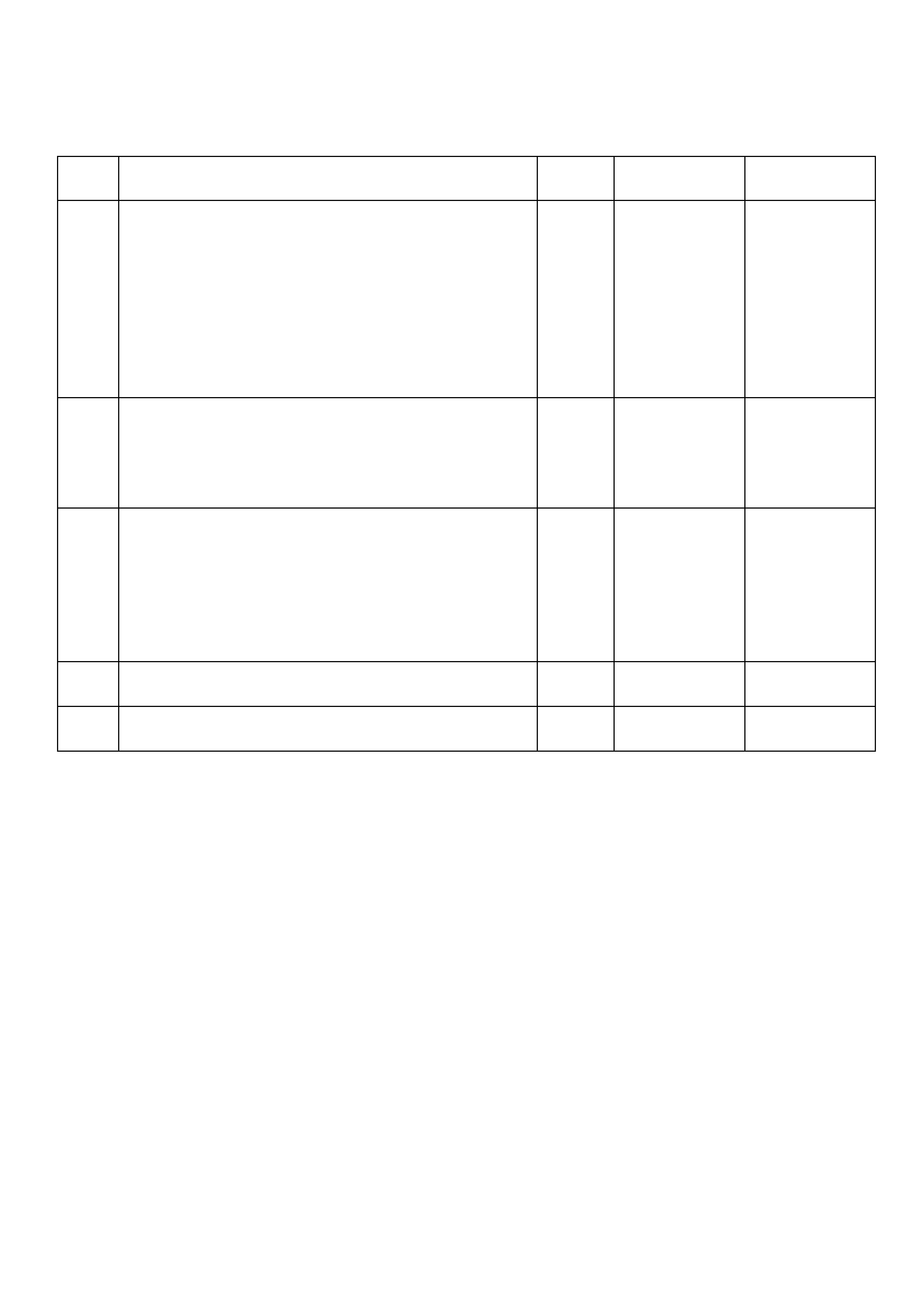

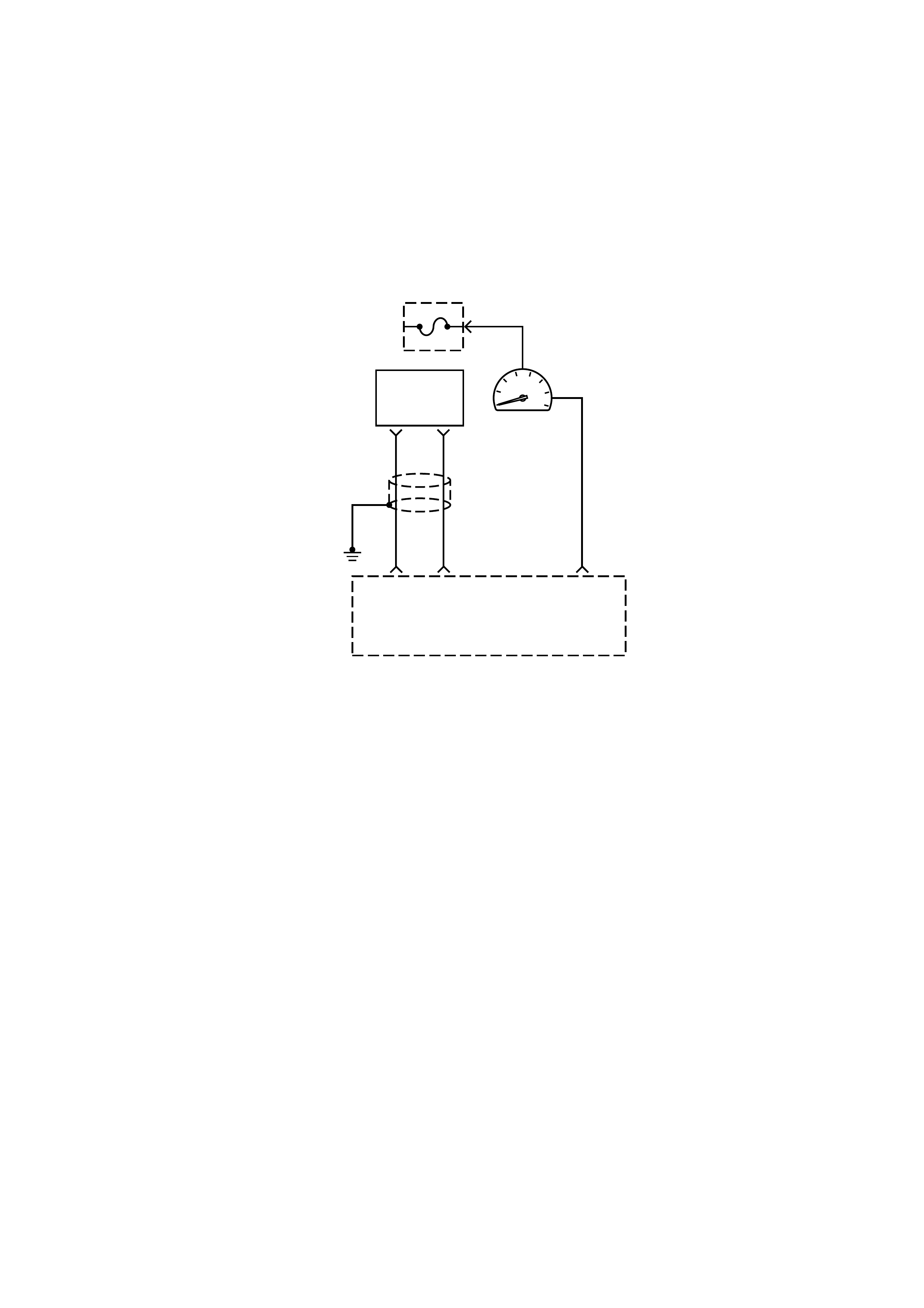

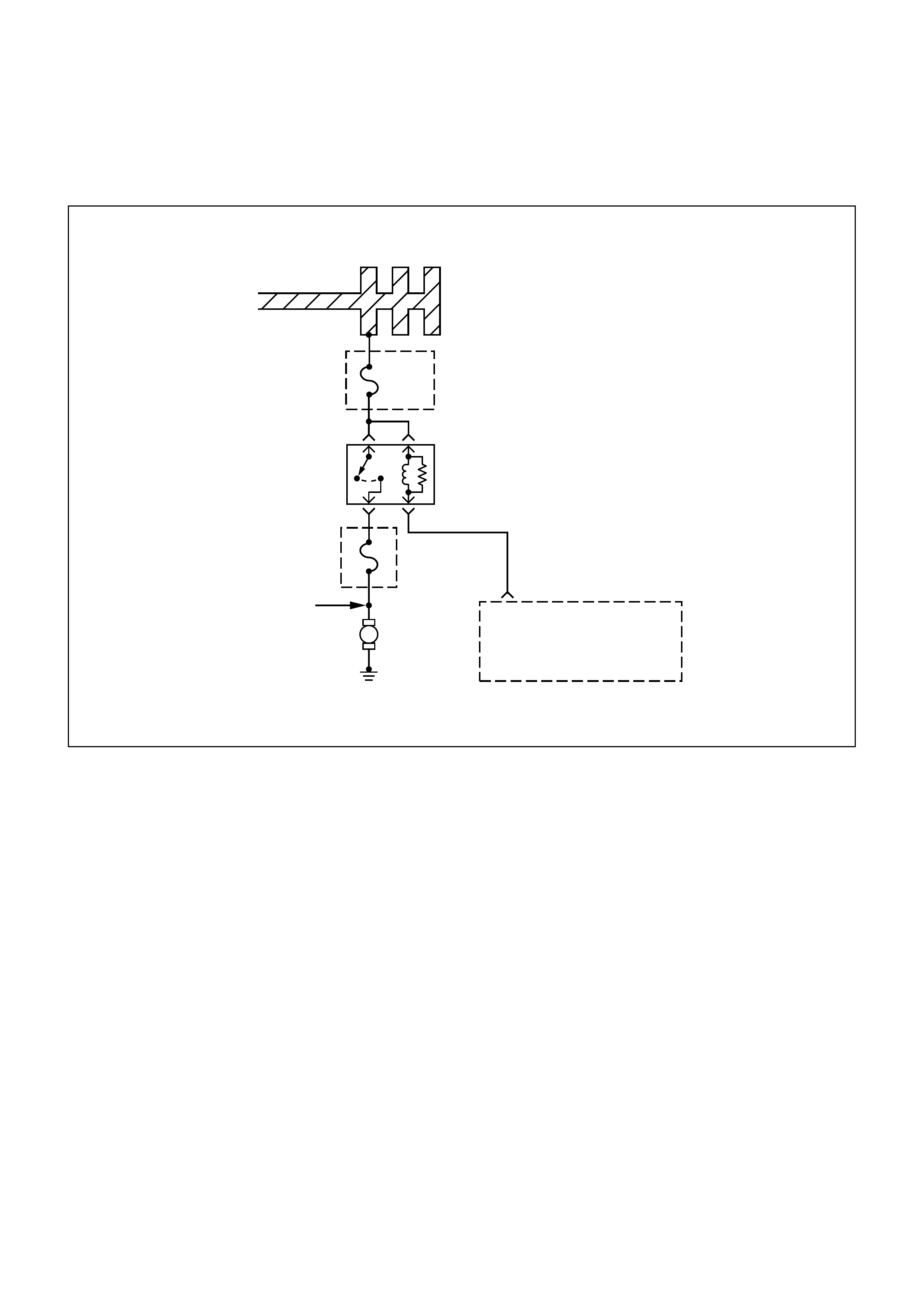

EMISSION CONTROL SYSTEM SCHEM ATICS

1

10 11 12 13 14 15 16

2345678

9

ROLL OVER&

FLOAT VALVE

FUEL PUMP

TWC CONVERTER

CRANKSHAFT

POSITION SENSOR

KNOCK SENSOR

COOLANT

TEMPERATURE

SENSOR

FUEL INJECTOR

MAP SENSOR

AIR CLEANER

HEATED

OXYGEN SENSOR

IGNITION PLUG

IAT SENSOR

THROTTLE

BODY

THROTTLE

POSITION SENSOR

IAC

VALVE

IGNITION

COIL

DUTY

SOLENOID

VALVE

CHARCOAL

CANISTER

FUEL PRESSURE

CONTROL VALVE

FUEL FILTER

FUEL PUMP

RELAY

CHECK VLV

BATTERY

+12V

IGUNITION

10A FUSE

(STOP)

DIAG

SDATA

DATA LINK

CONNECTOR

ENGINE CONTROL MODULE

METER CLUSTER

TACHO SIGNAL OUT

SPEED METER

VEHICLE SPEED SENSOR

A/C CLUTCH

A/C REQUEST

POWER STEERING SWITCH

MIL LAMP(CHECK ENGINE)

*

*

*

*

*

Refer to the matrix for engine specification, page 6A-11 thru 6A-17.

* If equipped.

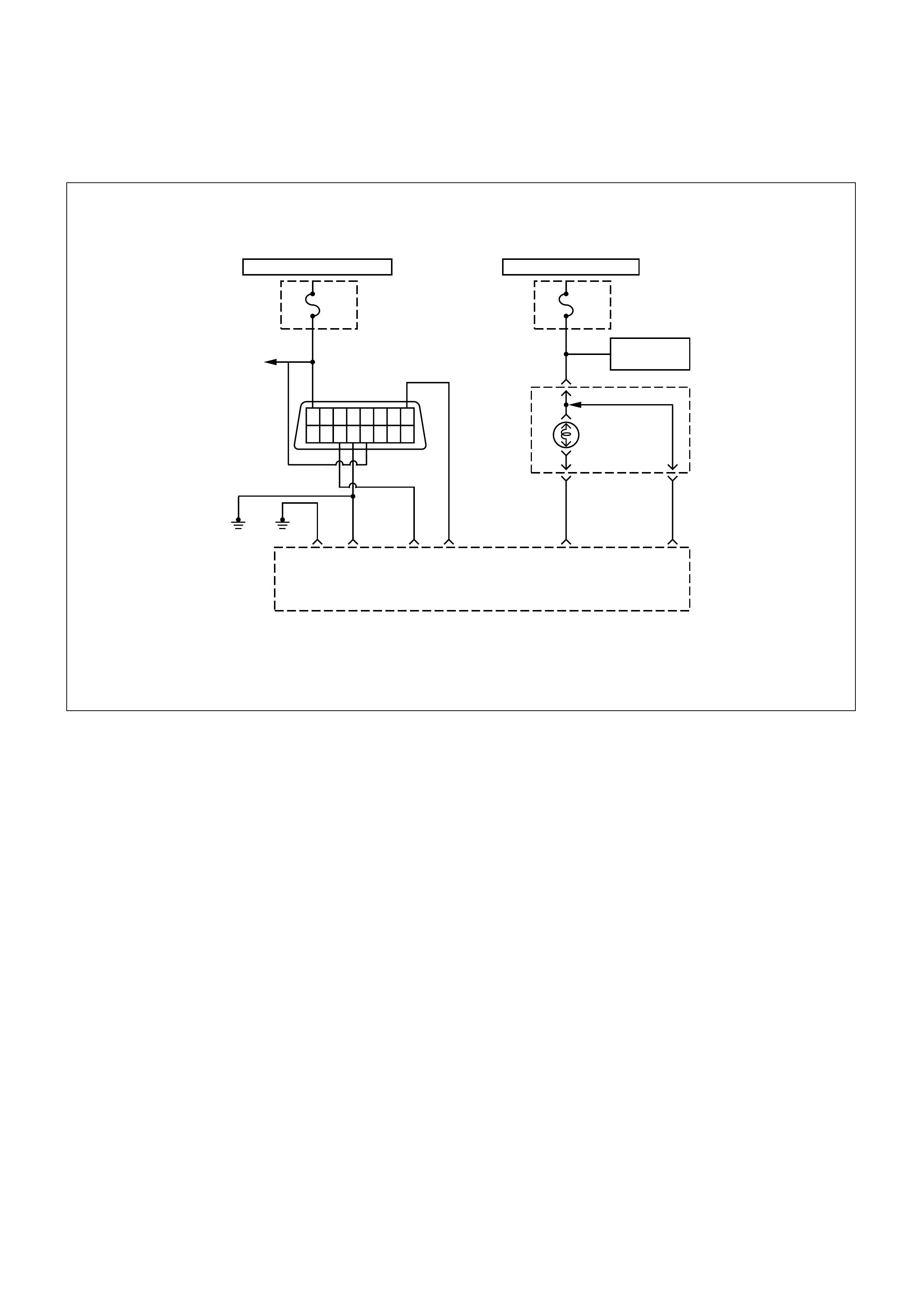

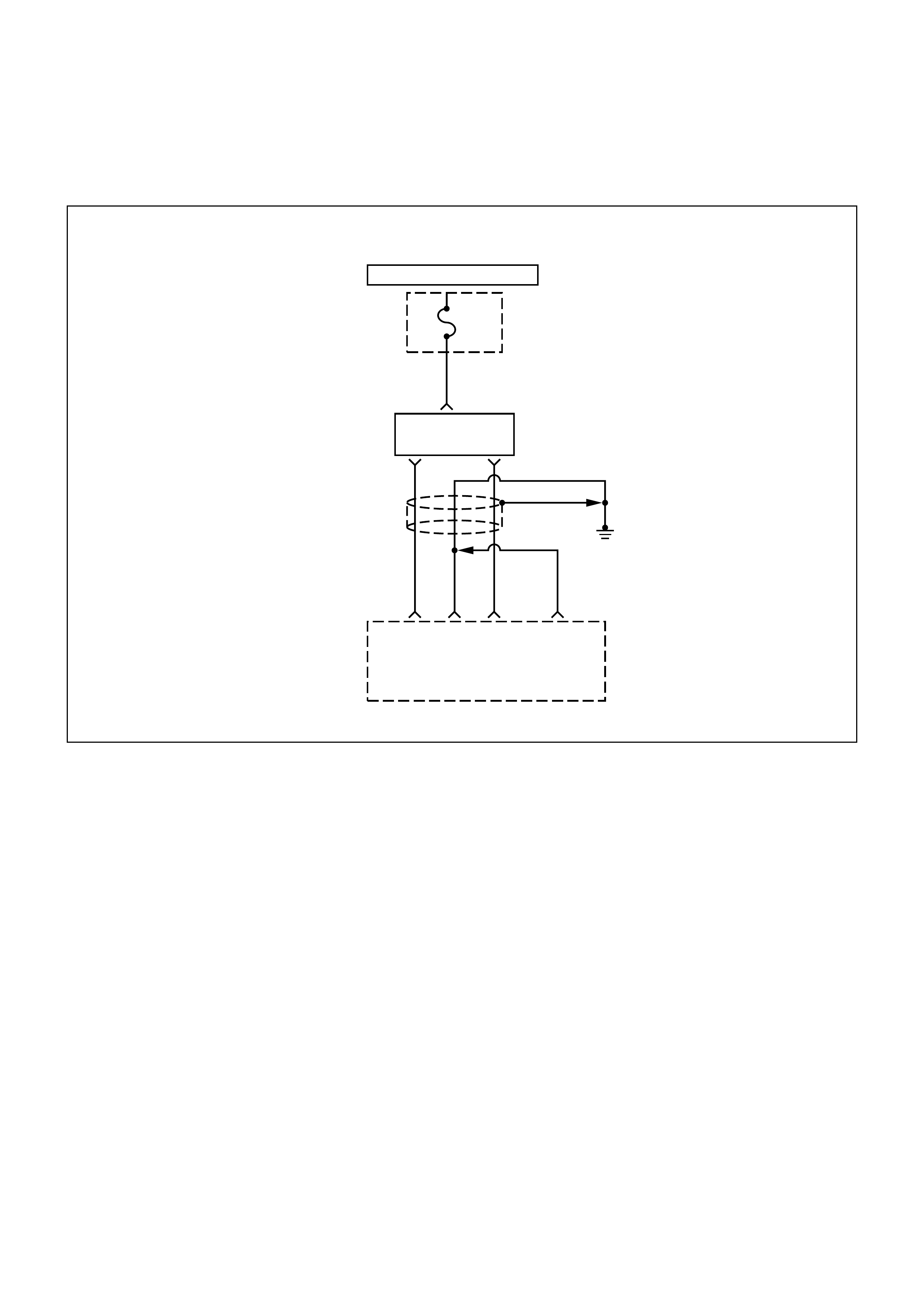

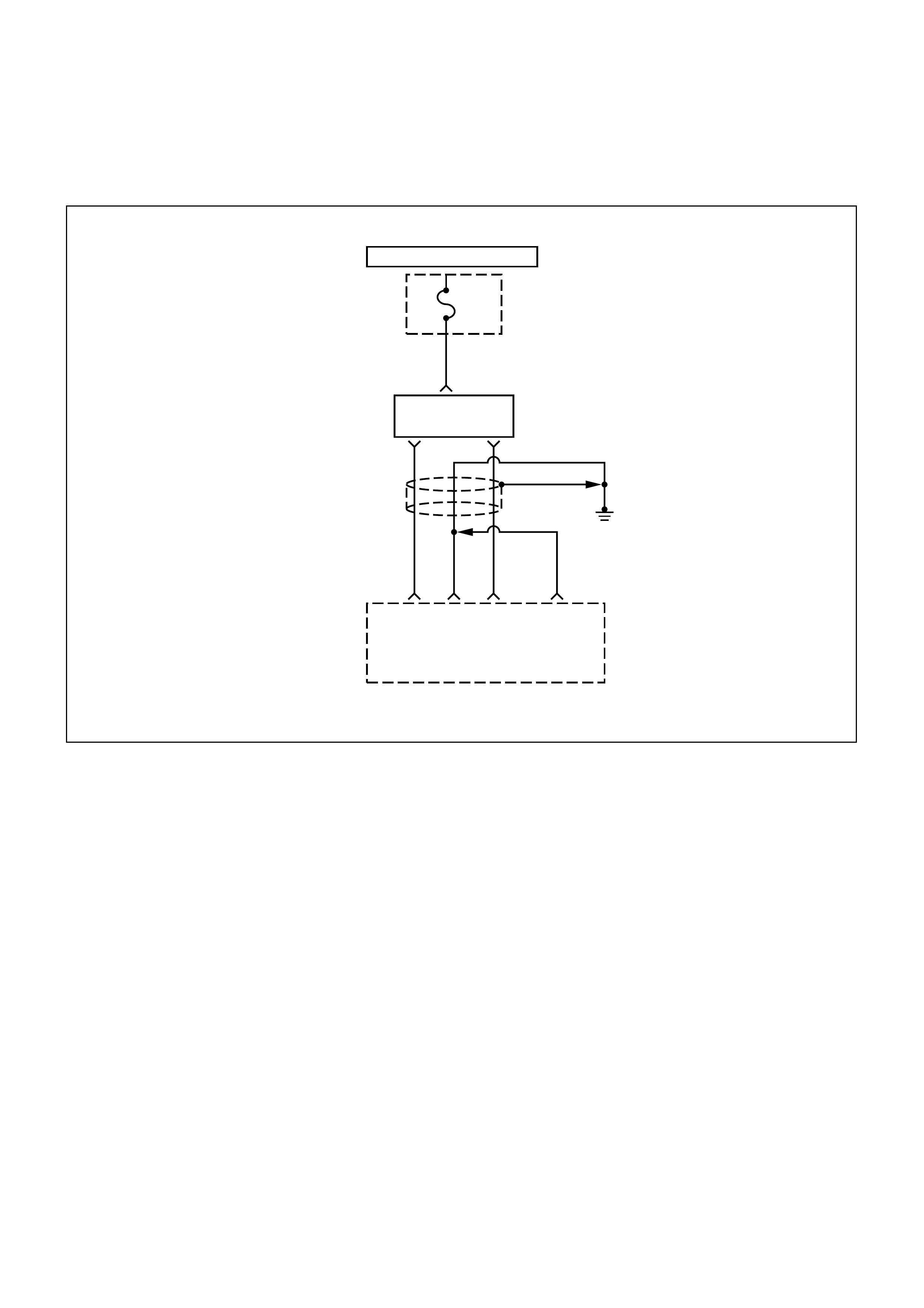

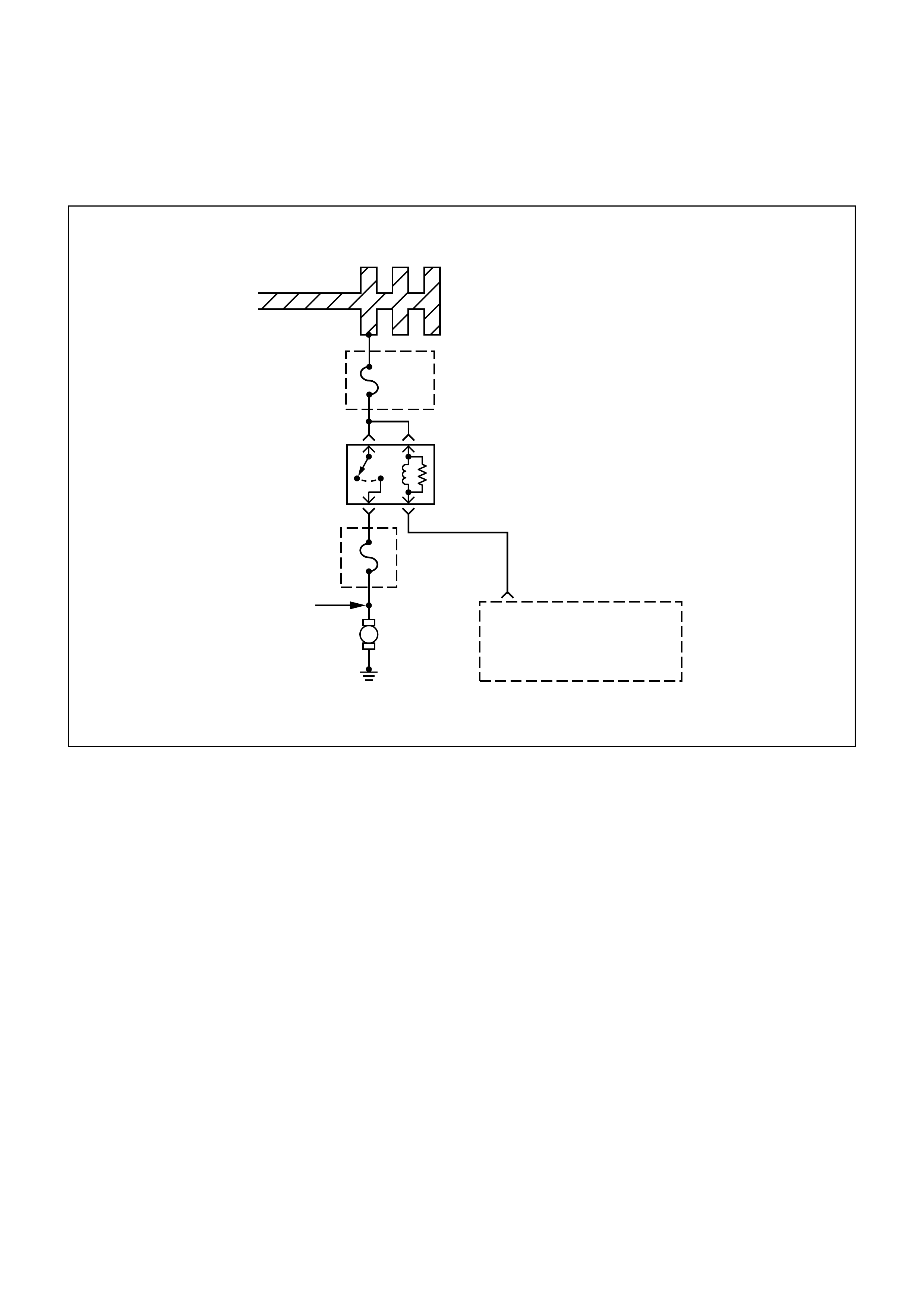

DIAGRAMS AND SCHEMATICS

16 15 14 13 12 11 10 9

87654321

HOT AT ALL TIMES

Fuse

Stop

U/H

FUSE

BLOCK

To

Stop

Lamp

Engine

Control

Module

(ECM)

R

A1 A2 B11 E8

B/R B/L B/W O

ECM

Grounds

(Engine Block)

Diag Serial Data

HOT IN START AND RUN

Meter

Fuse

15A

I/P

FUSE

BLOCK

Malfunction

Indicator

Lamp

0.85

YEL

Vehicle

Speed Sensor

0.5

BR/Y

Instrument

Panel(I/P)

Cluster

B4

Malfunction

Indicator

Lamp

Control

0.5

BR

B5

ECM

Fuse

15A

Engine

Fuse

10A

Canister

Purge

Solenoid

1.25

R/W

0.85G/W

2B/R

0.85G/R

0.85G/B

0.85G

1.25

R/W

0.85

L/Y

Fuel

Injector

Fuse

20A

Fuel

Pump

A4A6 A8 A9 A7 A5 E16

Fuel

Injector

Control

#4

A

B

#3

A

B

#2

A

B

#1

A

B

Engine

Control

Module

(ECM)

HOT WITH FUEL PUMP

RELAY ENERGIZED HOT AT ALL TIMES HOT IN RUN AND START

HOT IN START AND RUN

IG.

Coil

Fuse

15A

I/P

FUSE

BLOCK

0.85

B/O

Ignition

Coil

1.25

G

1.25

L

Engine

Control

Module

(ECM)

E1 E4 E3

Electronic Spark

Timing Control

1.25

B

1.25

B

E2

0.5

R

0.5

G

Crankshaft

Position

Sensor

F1

E5

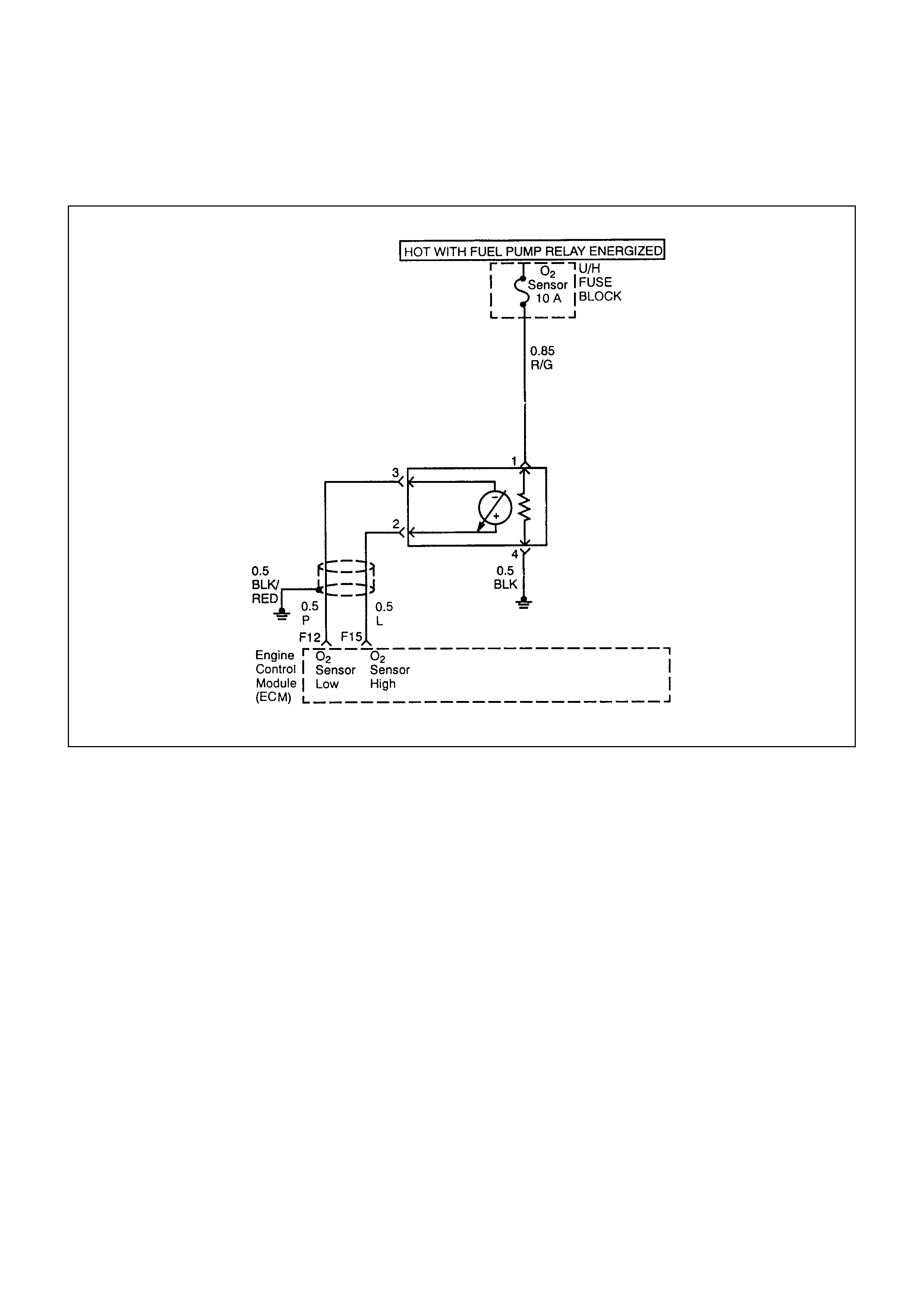

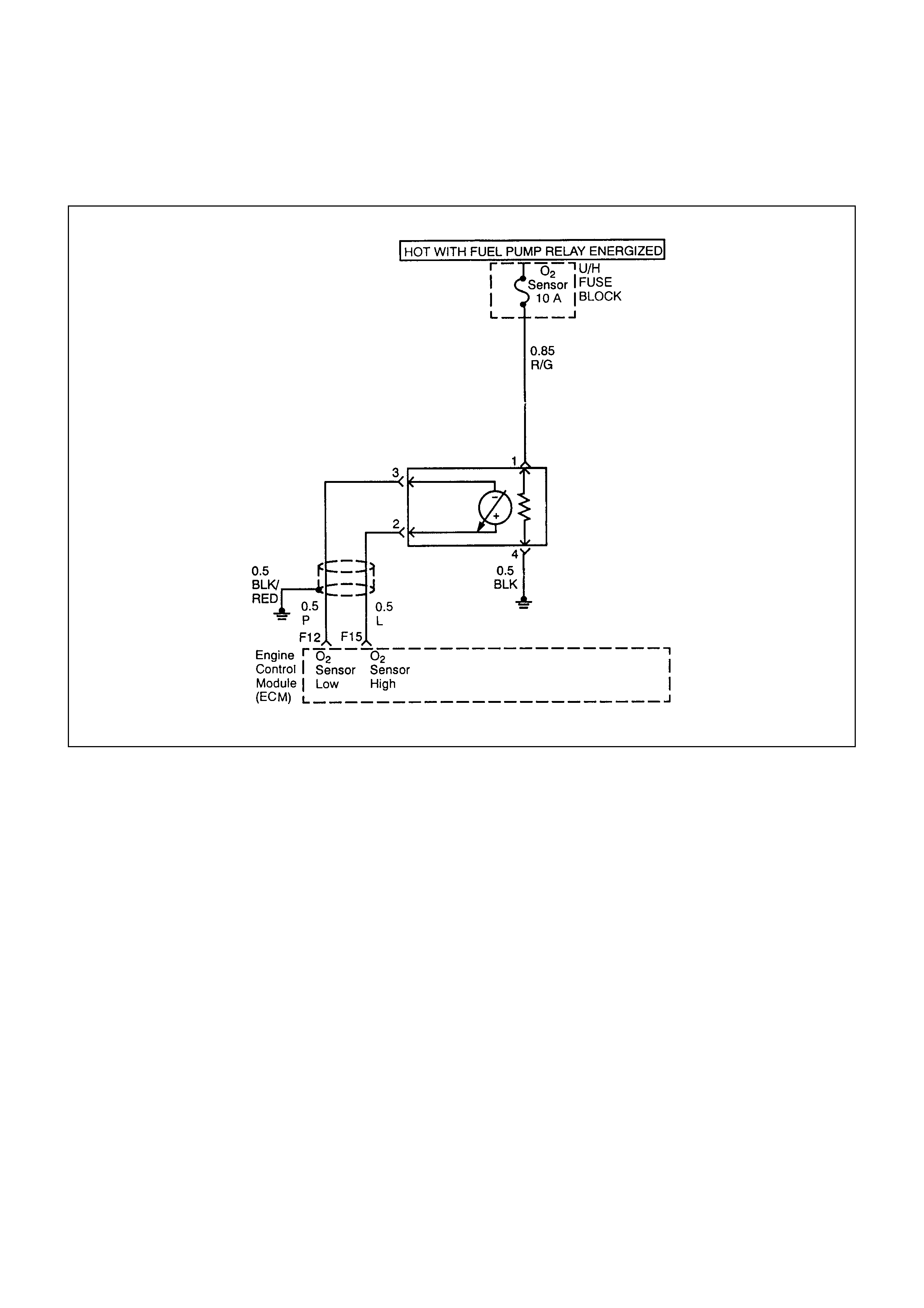

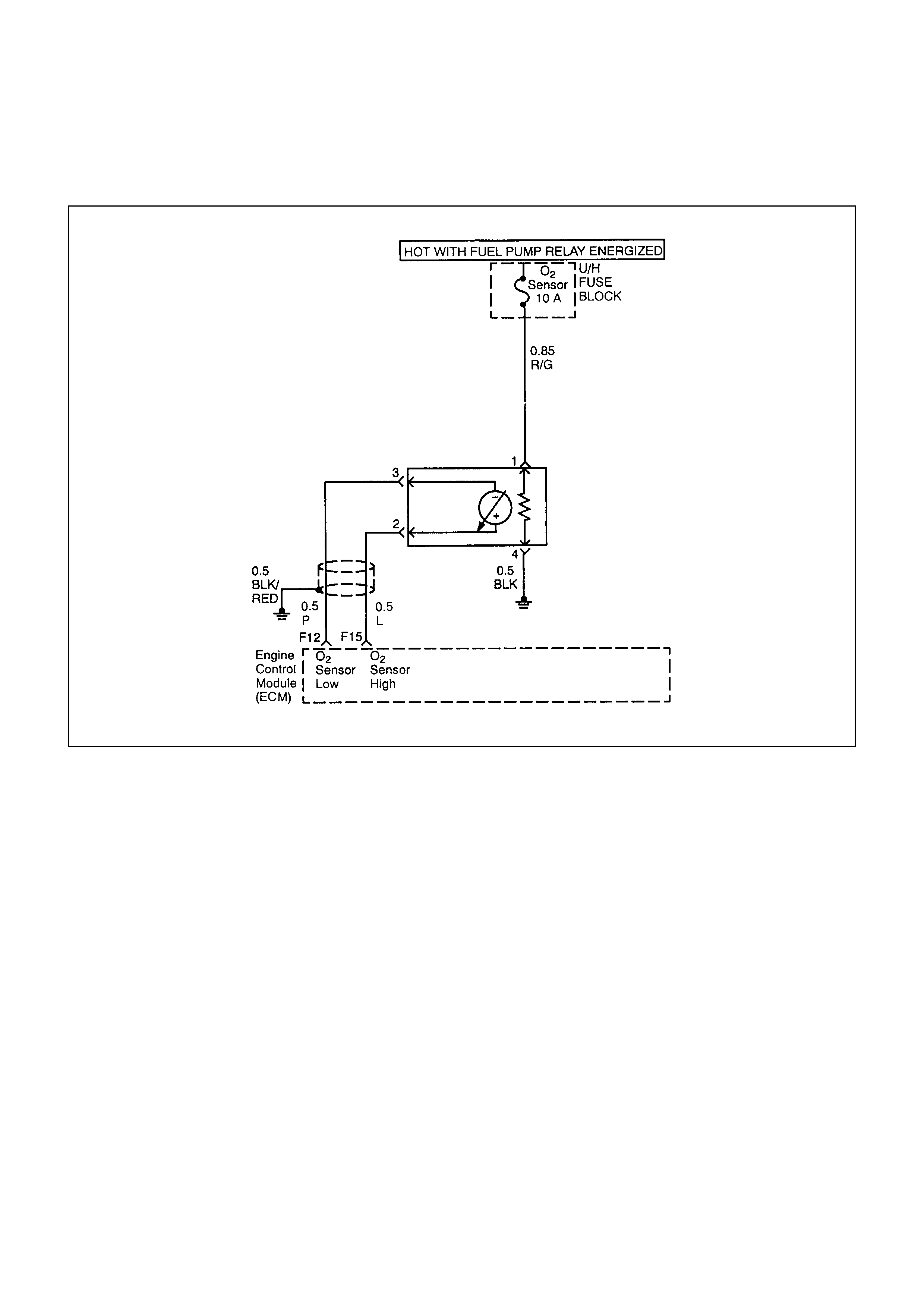

HOT WITH FUEL PUMP RELAY ENERGIZED

O

2

Sensor

10A

U/H

FUSE

BLOCK

0.85

R/G

0.5

BLK

0.5

L

0.5WHT

0.5RED

0.5

P

0.5

BLK/

RED

Engine

Control

Module

(ECM)

O

2

Sensor

Low

O

2

Sensor

High

Heated

O

2

Sensor

(D)

(C)

F12 F15

(B)

(A)

(If Applicable)

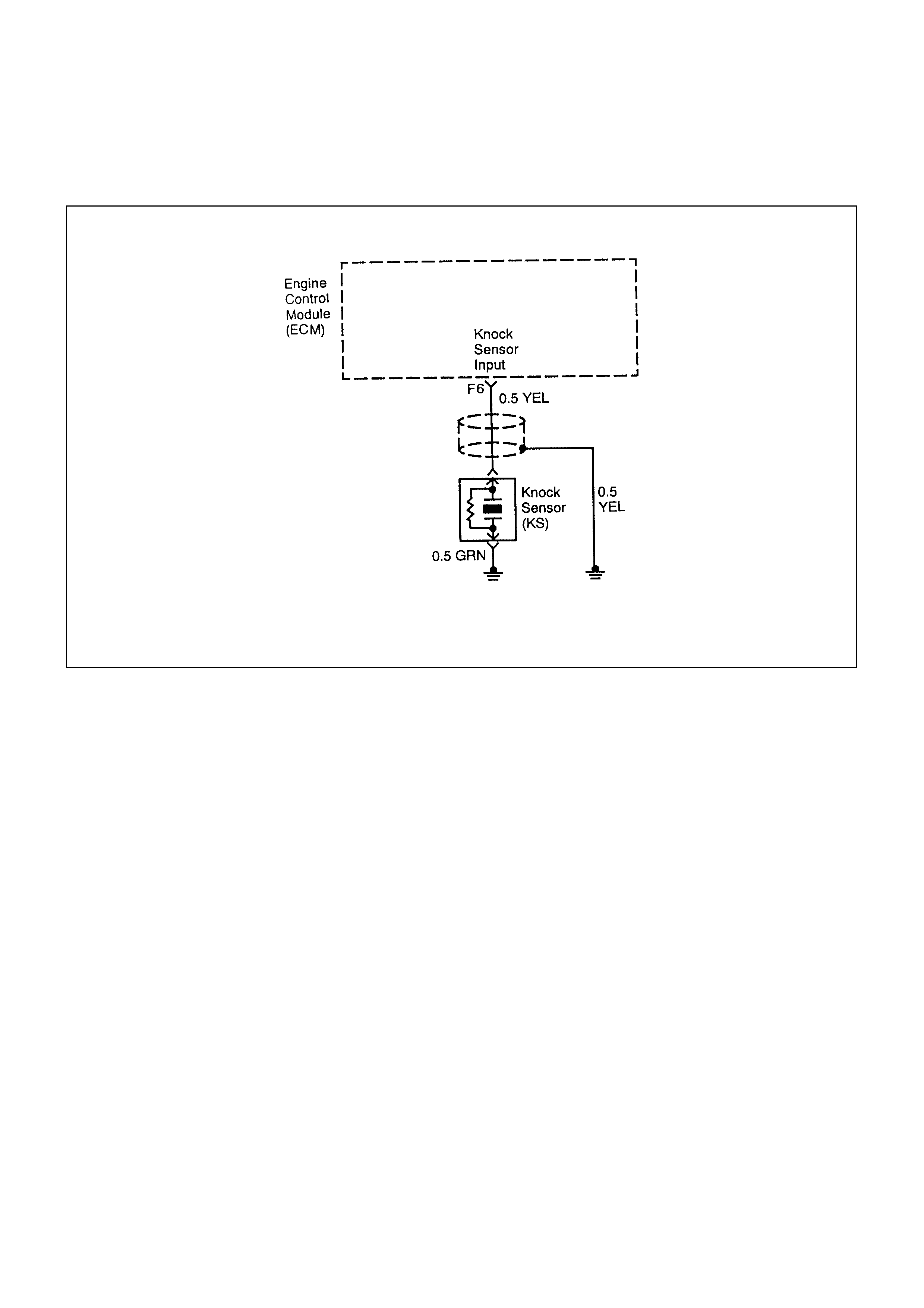

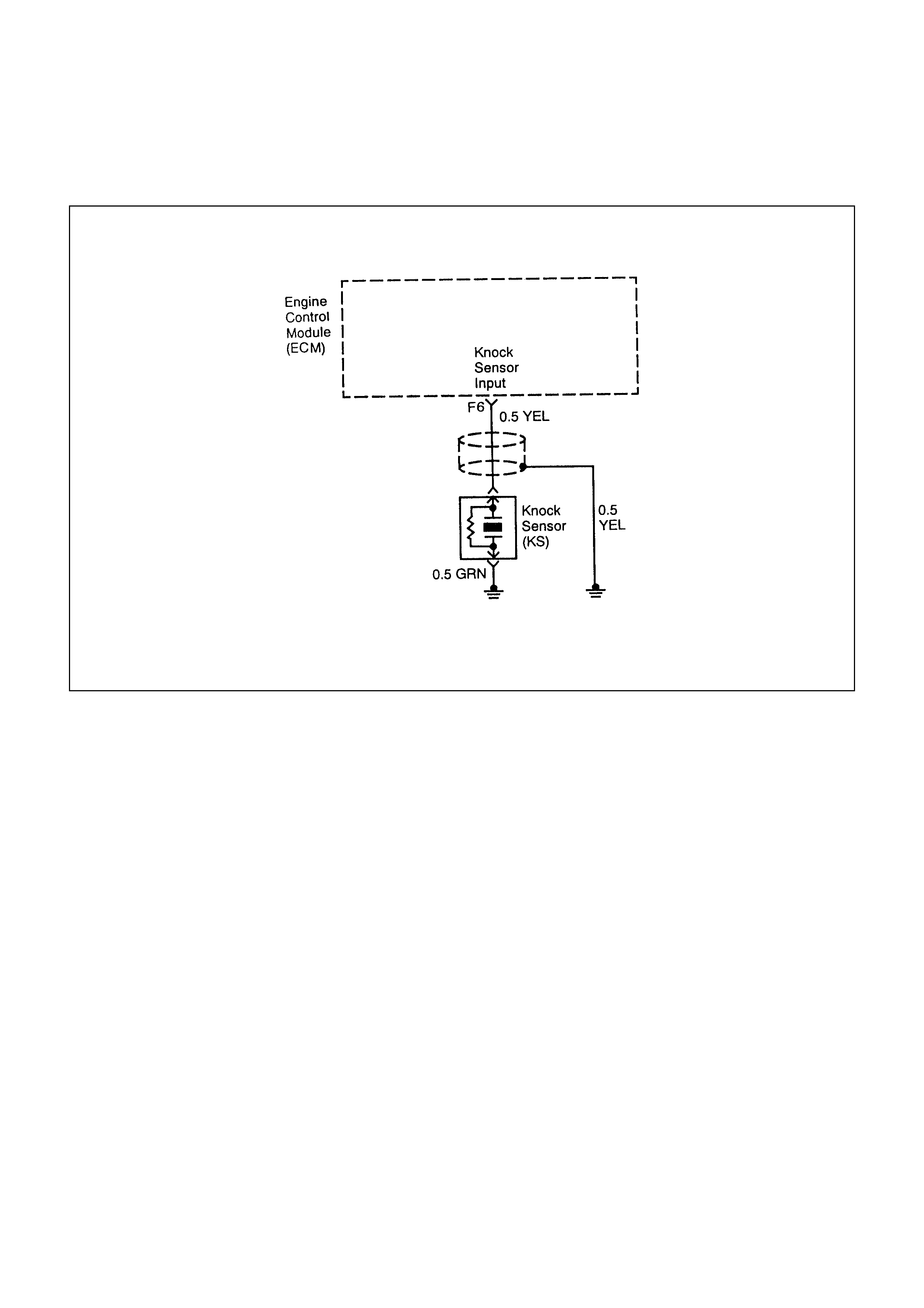

0.5 YEL

0.5 YEL

Knock

Sensor

Input

Knock

Sensor

(KS)

F6

Engine

Control

Module

(ECM)

A/C

Compressor

Relay

Control

A16

MAG

Clutch

(Compressor)

Relay

Thermo

(1) (2)

(3) (4)

Relay:A/C

Compressor

Joint

To HA09

0.5

BR

0.5

GR/R

B10

0.5

G/B

HOT IN START AND RUN

(2) (1)

(4) (3)

Engine

Control

Module

(ECM)

Engine

Control

Module

(ECM)

B16

0.5

L

0.5

L/W

0.5

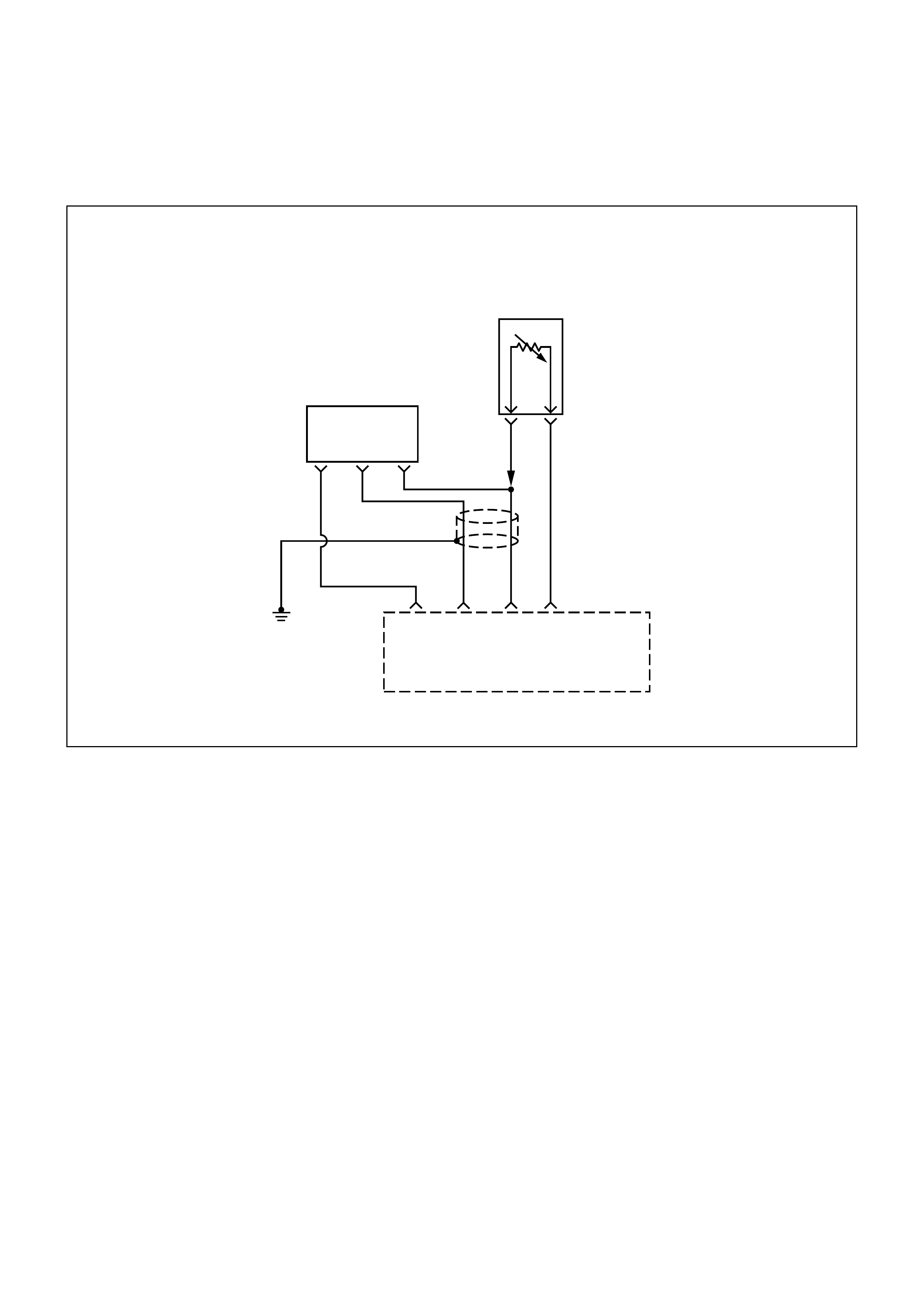

L/R

Idle Air

Control

(IAC)

Valve

0.5

L/B

B15

DCBA

B13 B14

IAC

A

High

IAC

A

Low

IAC

B

High

IAC

B

Low

A B

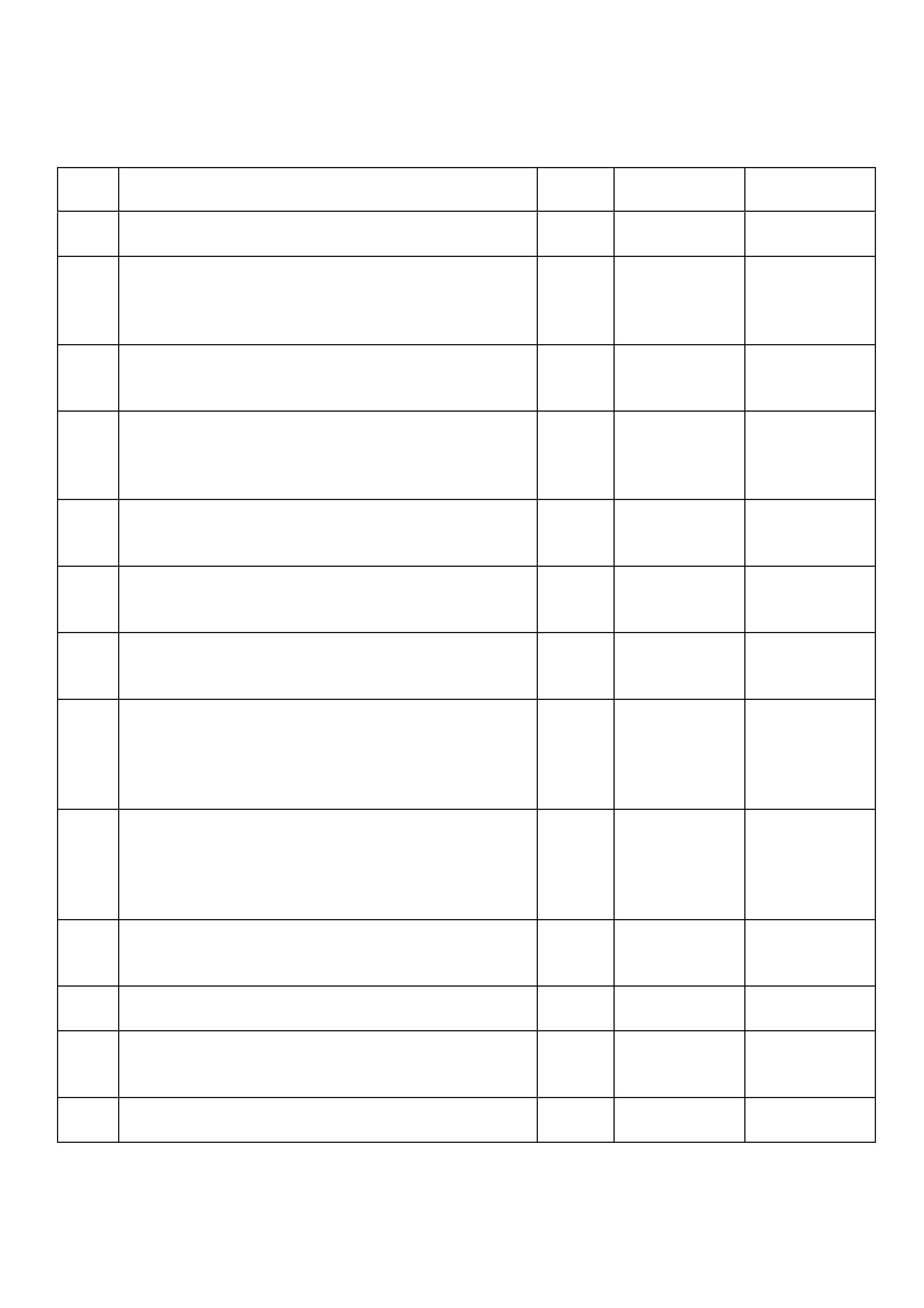

ECM PINOUTS

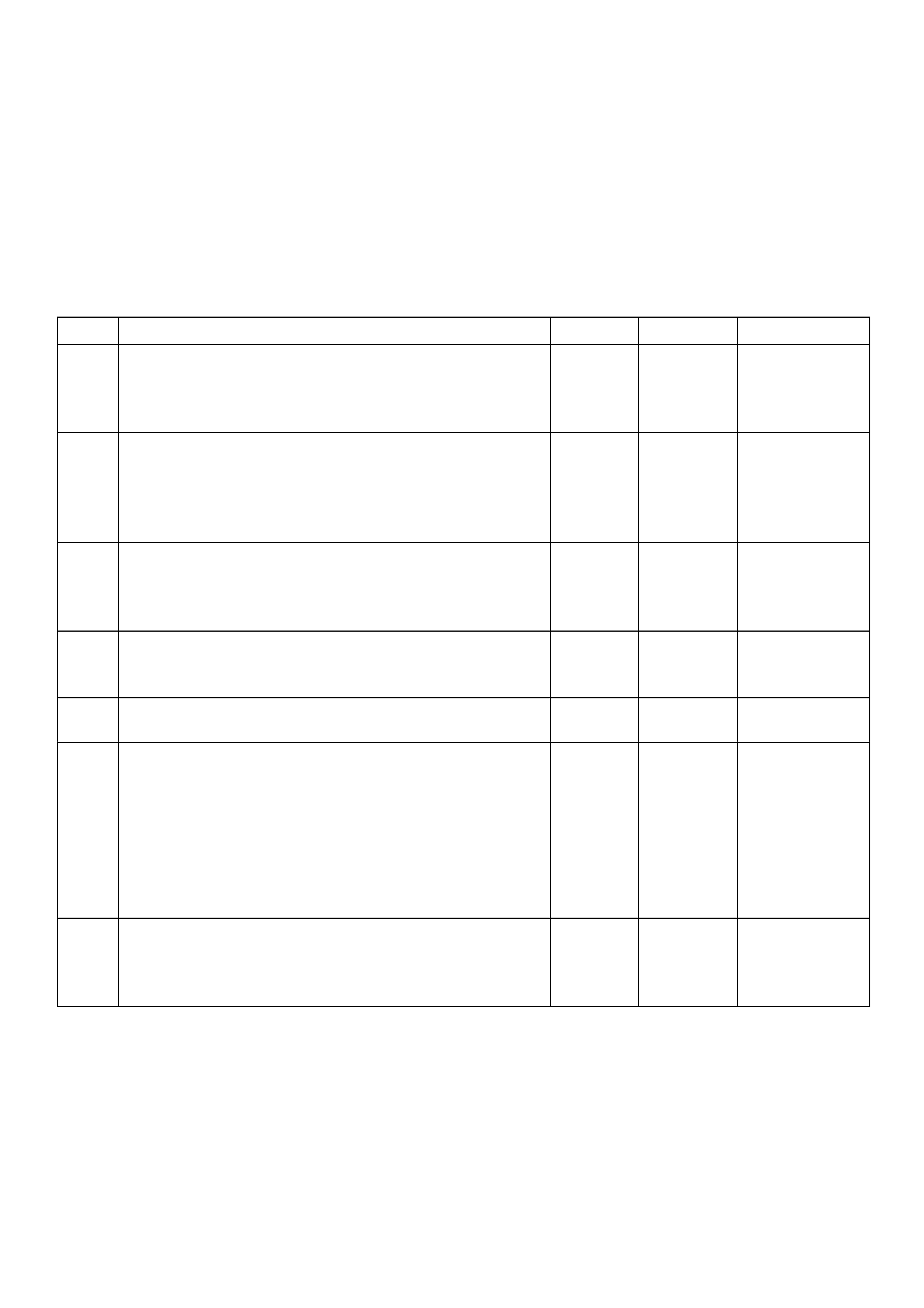

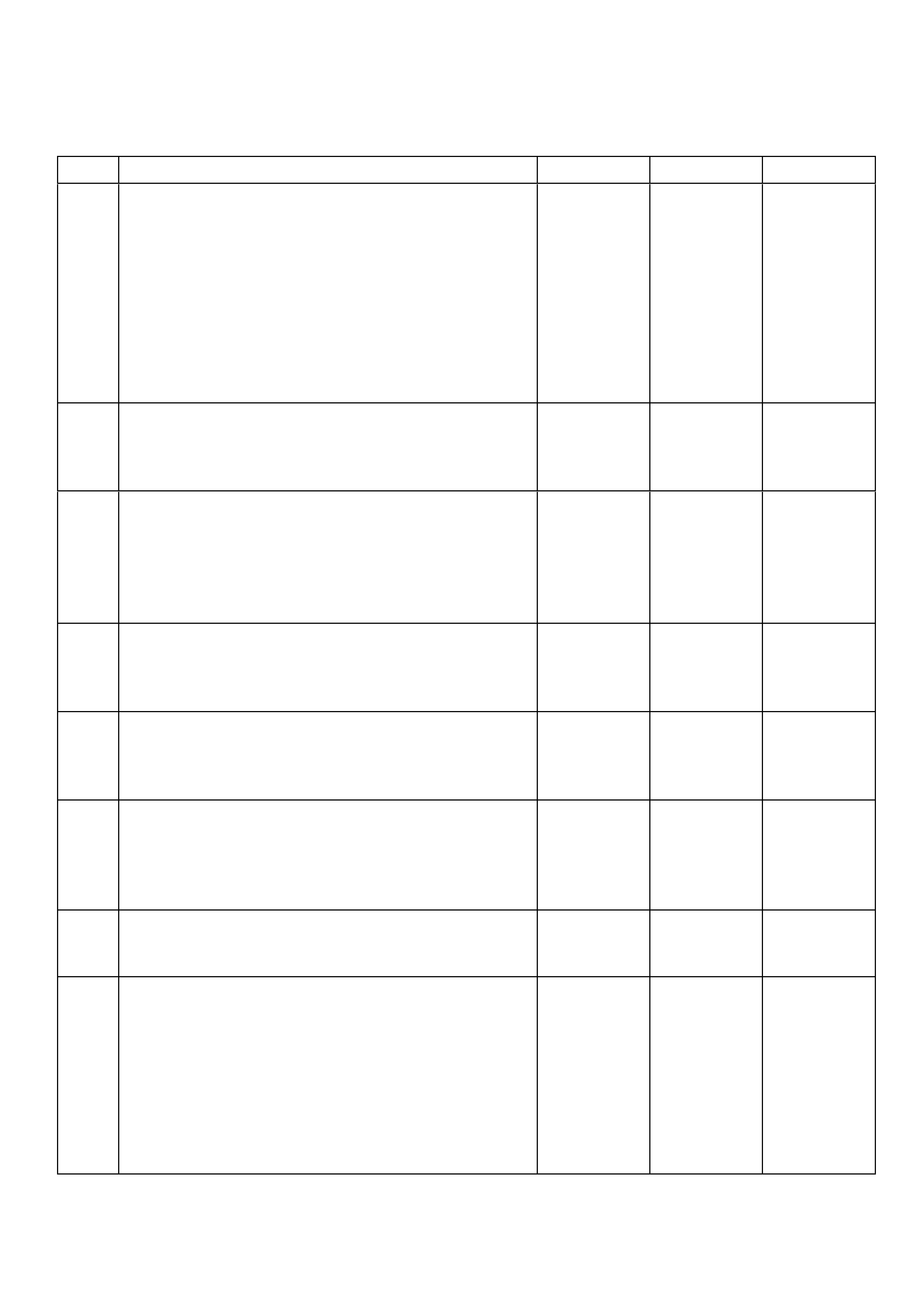

ECM PINO UT TABLE, 32- PIN BLUE CONNECTOR-RO W “J1”

PIN PIN FUNCTION WIRE

COLOR IGN ON ENG RUN REFER TO

E1 Electronic Spark Timing

Coil Driver A G 12V 14V -

E2 Coil Ground A B 0V 0V -

E3 Coil Ground B B 0V 0V -

E4 Electronic Spark Timing

Coil Driver B L 12V 14V -

E5 Crank Position Sensor High G 1V 1V General Description and

Operation, Crank Position

Sensor

E6 Not Used - - - -

E7 Vss Input W 9V 11V Chassis Electrical

E8 Serial Data R 5V 5V Serial Data

E9 Not Used - - - -

E10 Not Used - - - -

E11 Not Used - - - -

E12 Not Used - - - -

E13 Not Used - - - -

E14 Not Used - - - -

E15 Not Used - - - -

E16 Ignition Feed B/Y 12V 14V General Description and

Operation

ECM PINO UT TABLE, 32- PIN BLUE CONNECTOR-RO W “J1”

PIN PIN FUNCTION WIRE

COLOR IGN ON ENG RUN REFER TO

F1 Crankshaft Position Sensor

Low R 1V 1V General Description and

Operation, Crankshaft

Position Sensor

F2 Not Used - - - -

F3 Not Used - - - -

F4 Not Used - - - -

F5 Not Used - - - -

F6 Knock Sensor Input Y 0V 0V General Description and

Operation, Knock Sensor

F7 Not Used - - - -

F8 Not Used - - - -

F9 Not Used - - - -

F10 Intake Air Temperature

Sensor Y/G 2V 2V General Description and

Operation, IAT

F11 Not Used - - - -

F12 Heated O2 Sensor Low

(If applicable) - - - General Description and

Operation, Heated O2

Sensor

F13 Not Used - - - -

F14 Engine Coolant

Temperature L/R 2V

(0V=151°C) 3V

(5V=-40°C) General Description and

Operation, Engine Coolant

Temperature Sensor

F15 Heated O2 Sensor

(If applicable) L 1.0V 0V General Description and

Operation, Heated O2

Sensor

F16 Power Steering Pressure

Switch Input G/Y 12V 14V General Description and

Operation, PSP

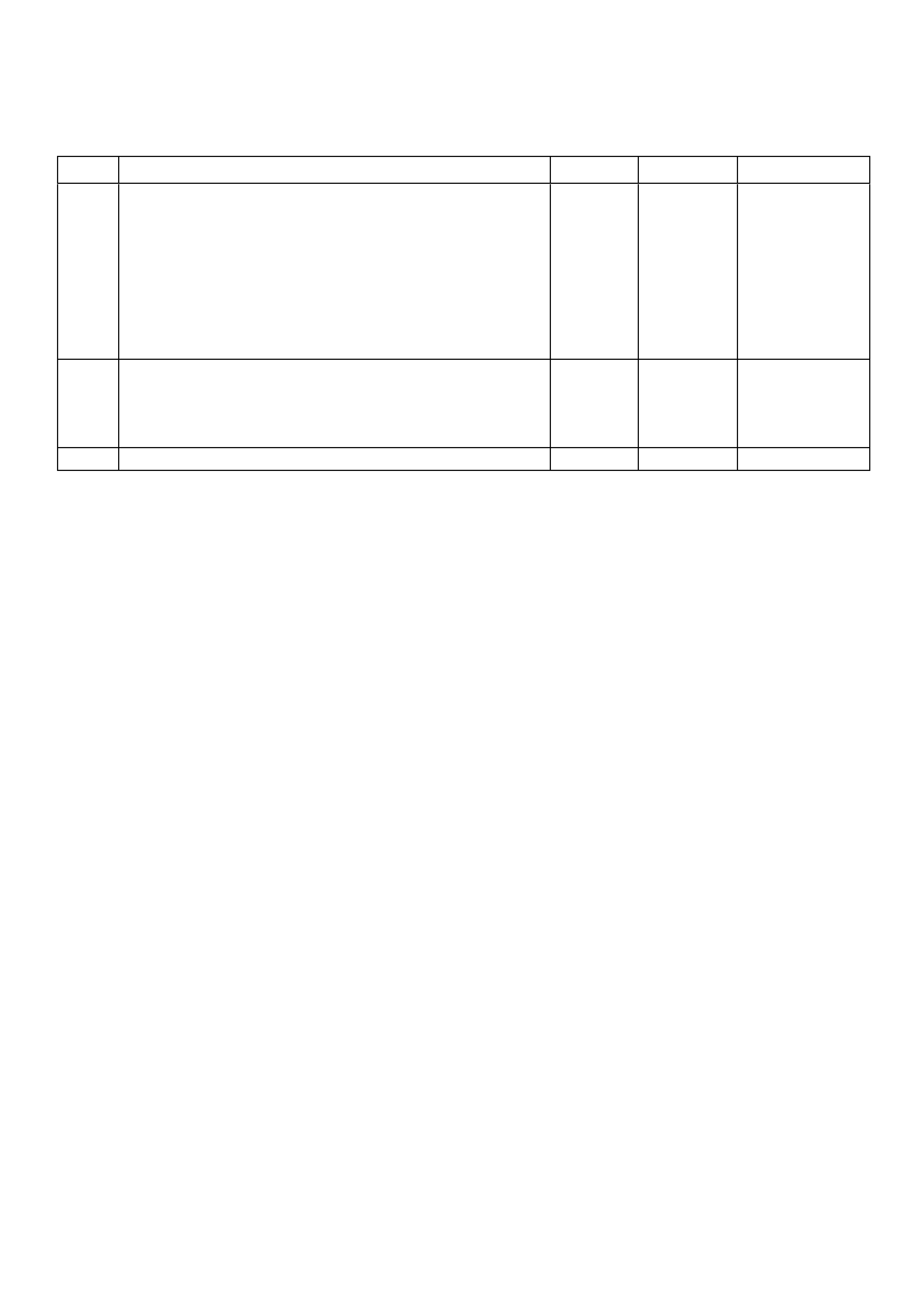

ECM PINO UT TABLE, 32- PIN RED CONNECTOR-RO W “J2”

PIN PIN FUNCTION WIRE

COLOR IGN ON ENG RUN REFER TO

A1 Power Ground A B/R 0.0V 0V Appropriate Sensor

A2 Sensor Ground B B/L 0.0V 0V Appropriate Sensor

A3 5 Volt Reference Signal R 5.0V 5V Appropriate Sensor

A4 Battery Feed R/W 12V 14V Chassis Electrical

A5 Battery R/W 12V 14V Chassis Electrical

A6 Injector #4 Cyl G 0V 14V General Description and

Operation, Fuel Injector

A7 Injector #1 Cyl G/W 0V 14V General Description and

Operation, Fuel Injector

A8 Injector #3 Cyl G/B 0V 14V General Description and

Operation, Fuel Injector

A9 Inject #2 Cyl G/R 0V 14V General Description and

Operation, Fuel Injector

A10 Not Used - - - -

A11 Not Used - - - -

A12 Not Used - - - -

A13 Fuel Pump Relay G/W 12V 0V On-Vehicle Service Fuel

Pump Relay

A14 Charcoal Canister Purge

Solenoid Valve

(If applicable)

R/L 12V 14V -

A15 Not Used - - - -

A16 A/C Clutch W/R 0V 0V -

ECM PINO UT TABLE, 32- PIN RED CONNECTOR-RO W “J2”

PIN PIN FUNCTION WIRE

CLOLR IGN ON ENG RUN RDFER TO

B1 TPS

5 Volt Reference Signal A G 0V 0V Appropriate Sensor

B2 TPS

5 Volt Reference Signal B G 0V 0V Appropriate Sensor

B3 Not Used - - - -

B4 Check Engine Lamp R/Y 0V 14V Chassis Electrical

B5 Tacho-meter Signal B/R 12V 8-10V General Description and

Operation

B6 Not Used - - - -

B7 Map Input W 5.0V

(0V=10kpa) 1.0V

(5V=104kpa) General Description and

Operation, Manifold Absolute

Sensor

B8 Throttle Position Sensor B 1.0V 1.0V General Description and

Operation, TPS

B9 Not Used - - - -

B10 A/C Request Signal G/B 0V 0V -

B11 DLC (Digital Input) B/W 12V 14V Diagnosis, Serial Data

B12 Not Used - - - -

B13 IAC ”B” High L/R 1V 1V General Description and

Operation, IAC

B14 IAC ”B” Low L/B 11V 13V General Description and

Operation, IAC

B15 IAC ”A” Low L/W 1V 1V General Description and

Operation, IAC

B16 IAC ”A” High L 11V 13V General Description and

Operation, IAC

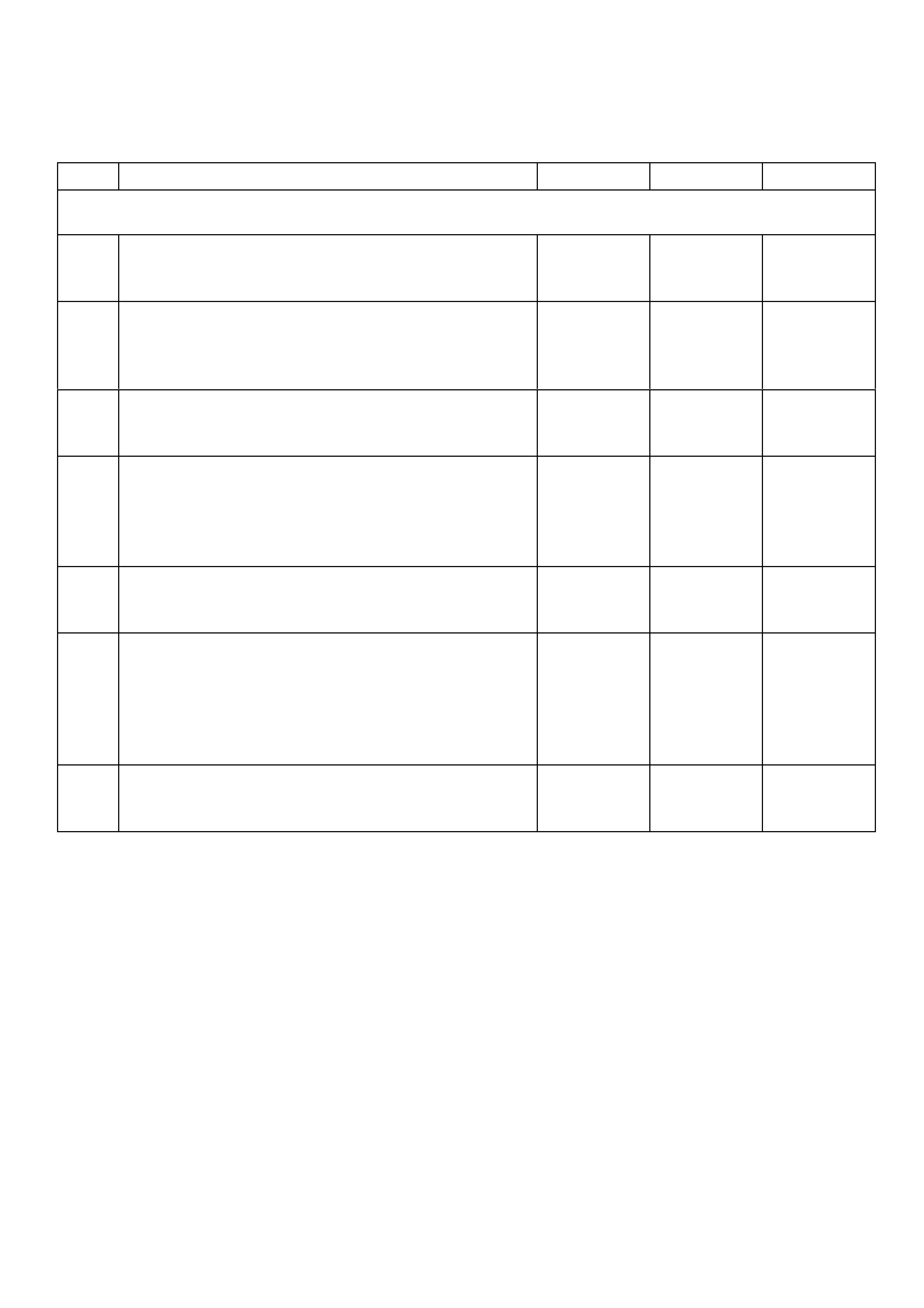

COMP ONENT LOCATOR

HO2S(if applicable) THREE-WAY CATALYTIC CONVERTER

(if applicable)

VEHICLE

SPEED SENSOR

(VSS)

FUEL FILTER

THROTTLE POSITION SENSOR

MAP SENSOR

EVAP PURGE CONTROL

SOLENOID VALVE

FUEL INJECTOR

IGNITION COIL

KNOCK SENSOR

CRANKSHAFT POSITION SENSOR

HEATED

OXGEN

SENSOR

(if applicable)

THROTTLE BODY

IAC VALVE

AIR CLEANER

INTAKE AIR

TEMPERATURE

SENSOR

ENGINE CO MPONENT LOCATO R TABLE

NUMBER NAME LOCATION

1 Engine Coolant Temperature (ECT) Sensor Front of engine, next to the thermostat housing

2Heated Oxygen Sensor (HO2S) On the exhaust pipe, left side of engine,

immediately behind the exhaust manifold

3 Air Cleaner Left front the engine bay

4 Intake Air Temperature (IAT) Sensor On the intake air duct near the air cleaner

5 Positive Crankcase Ventilation (PCV) Port On the right front corner of the valve cover

6 Fuel Pressure Regulator On the rear end of the fuel rail

7 Throttle Body Between the intake air duct and the intake

manifold

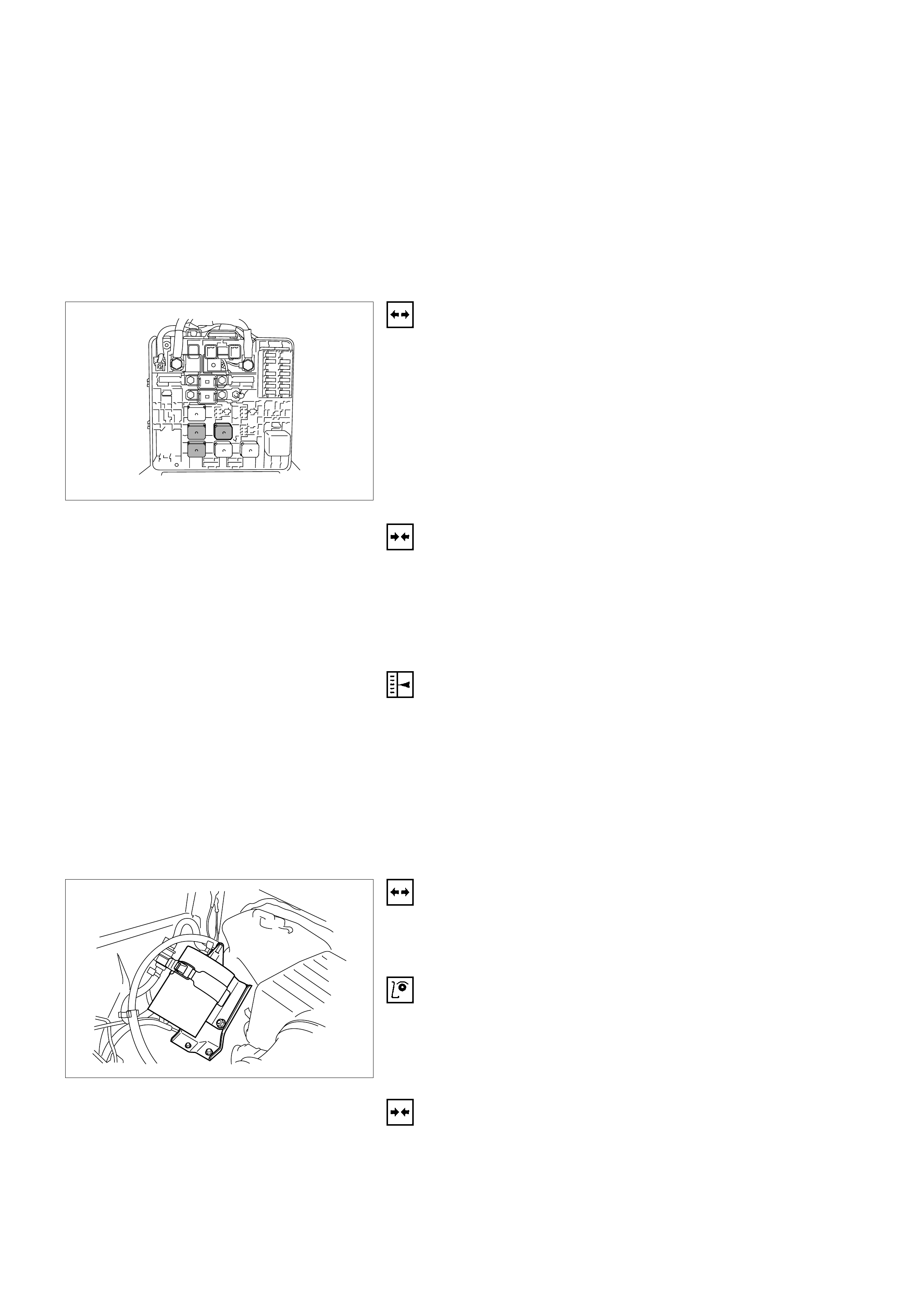

8 Fuse/Relay Box Along the inside of the right fender

9 Throttle Position (TP) Sensor On the front of the throttle body

10 Idle Air Control (IAC) Valve Under the TP sensor

11 EVAP Canister Purge Control Solenoid On the intake manifold

12 Ignition Coil Above the starter motor

13 Manifold Absolute Pressure (MAP) Sensor Bolted to the front edge of the intake

manifold, under the fuel rail

*14 EVAP Canister On the left side Tire house

*15 Check and Relief valve On the canister hold brace

* If applicable

UNDERCARRI AGE COMPONENT LOCATOR TABLE

NAME LOCATION

Fuel Pump Assembly Installed in the top of the fuel tank

EVAP Purge Control Solenoid Valve At the right rear of the engine

Vehicle Speed Sensor (VSS) Protrudes from the right side of the transmission

housing, rear the output shaft

Crankshaft Position (CKP) Sensor Lower left hand front of engine, behind power steering

pump bracket

UNDERHOOD ( U/H) FUSE AND RELAY PANEL

INSTRUMENT PANEL (I/P) FUSE BLO CK

DIAGNOSIS

STRATEGY-BASED DIAGNO STICS

The strategy-based diagnostic is a uniform approach

to repair all Electrical/Electronic (E/E) systems. The

diagnostic flow can always be used to resolve an E/E

system problem and is a starting point when repairs

are necessary. The following steps will instruct the

technician how to proceed with a diagnosis:

1. Verify the customer complaint.

•To verify the customer complaint, the technician

should know the normal operation of the system.

2. Perform preliminary checks.

•Conduct a thorough visual inspection.

•Review the service history.

•Detect unusual sounds or odors.

•Gather diagnostic trouble code information to

achieve an effective repair.

3. Check bulletins and other service information.

•This includes videos, newsletters, etc.

4. Refer to service info (manual) system check(s).

•“System checks” contain information on a

system that may not be supported by one or

more DTCs. System checks verify proper

operation of the system. This will lead the

technician in an organized approach to

diagnostics.

5. Refer to service diagnostics.

DTC STORED

Follow the designated DTC chart exactly to make an

effective repair.

NO DTC

Select the symptom from the symptom tables. Follow

the diagnostic paths or suggestions to complete the

repair. You may refer to the applicable

component/system check in the system checks.

NO MATCHING SYM PTOM

1. Analyze the complaint.

2. Develop a plat for diagnostics.

3. Utilize the wiring diagrams and the theory of

operation.

Call technical assistance for similar cases where

repair history may be available. Combine technician

knowledge with efficient use of the available service

information.

INTERMITTENTS

Conditions that are not always present are called

intermittents. To resolve intermittents, perform the

following steps:

1. Observe DTCs and DTC modes

2. Evaluate the symptoms and the conditions

described by the customer.

3. Use a check sheet or other method to identify the

circuit or electrical system component.

4. Follow the suggestions for intermittent diagnosis

found in the service documentation.

Most Scan T ools, suc h as the Tech 2 and the 5-8840-

2392-0, have data-capturing capabilities that can

assist in detecting intermittents.

NO TROUBLE FOUND

This condition exists when the vehicle is found to

operate normally. The condition described by the

customer may be normal. Verify the customer

complaint against another vehicle that is operating

norm ally. T he condition may be intermittent. Verif y the

complaint under the conditions described by the

customer before releasing the vehicle.

1. Re-examine the complaint.

When the complaint cannot be successfully found

or isolated, a re-evaluation is necessary. The

complaint should be re-verified and could be

intermittent as defined in Intermittents, or could be

normal.

2. Repair and verify.

After isolating the cause, the repairs should be

made. Validate for proper operation and verify that

the symptom has been c orrec ted. T his m ay involve

road testing or other methods to verify that the

complaint has been resolved under the following

conditions:

•Conditions noted by the customer.

•If a DTC was diagnosed, verify a repair by

duplicating conditions present when the DTC

was set as noted in the customer complaint.

VERIFYING VEHICLE REPAIR

Verification of the vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

IMPORTANT: Follow the steps below when you verif y

repairs on O BD system s. Failure to f ollow these steps

could result in unnecessary repairs.

1. Review and record the customer complaint for the

DTC which has been diagnosed.

2. Clear the DTC(s).

3. Operate the vehicle within conditions noted in the

customer complaint.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnos tic

test associated with that DTC runs.

GENERAL SERVICE INFORMATION

OBD SERVICEABILITY ISSUES

FUEL QUALITY

Fuel quality is not a new issue for the automotive

industry. The Reed Vapor Pressure of the fuel can

also create problems in the fuel system, especially

during the spring and fall months when severe

ambient temperature swings occur. A high Reed

Vapor Pressure could show up as a rich DTC due to

excessive canister loading. High vapor pressures

generated in the fuel tank can also affect the

Evaporative Emission diagnostic as well.

Using fuel with the wrong octane rating for your

vehicle may cause driveability problems. Many of the

major fuel companies advertise that using “premium”

gasoline will improve the performance of your vehicle.

Most premium fuels use alcohol to increase the

octane rating of the fuel. Although alcohol-enhanced

fuels may raise the octane rating, the fuel's ability to

turn into vapor in cold tem peratures deteriorates. This

may affect the starting ability and cold driveability of

the engine.

Low fuel levels can lead to fuel star vation, lean engine

operation, and eventually engine misfire.

NON-O E M PARTS

All of the OBD diagnos tics have been c alibrated to run

with OEM parts. Small leaks in the exhaust system

near the heated oxygen sensor can also cause the

MIL (“Check Engine“ lamp) to turn on.

Aftermarket electronics, such as cellular phones,

stereos, and anti-theft devices, may radiate EMI into

the control s ystem if they are improper ly installed. T his

may cause a f alse sens or reading and turn on the MIL

(“Check Engine” lamp).

POOR VEHICLE MAINTENANCE

The sensitivity of OBD diagnostics will cause the MIL

(“Check Engine” lam p) to turn ON if the vehicle is not

maintained properly. Restricted air filters, fuel filters,

and crankcase deposits due to lack of oil changes or

improper oil viscosity can trigger actual vehicle faults.

Poor vehicle maintenance can not be classified as a

“non-vehicle fault” , but with the sensitivity of OBD

diagnostics, vehicle maintenance schedules must be

more closely followed.

RELATED SYSTEM FAULTS

Many of the OBD system diagnostic s will not run if the

ECM detects a fault on a related system or

component. One example would be that if the ECM

detected a Evap. Purge Solenoid fault, The diagnosis

on the Oxygen Sensor (If applicable) would be

suspended until the Evap. Purge Solenoid repaired. If

this happened, the customer may have to make two

trips to the dealership in order to repair the vehicle.

MAINTENANCE SCHEDULE

Refer to the Maintenance Schedule.

VISUAL /PHYSICAL ENGINE

CO MPARTMENT INSPECTION

Perform a careful visual and physical engine

compartment inspection when performing any

diagnostic procedure or diagnosing the cause of an

emis sion test failure. T his can of ten lead to repairing a

problem without further steps. Use the following

guidelines when performing a visual/thysical

inspection:

•Inspect all vacuum hoses for punches, cuts,

disconnects, and correct routing.

•Inspect hoses that are difficult to see behind other

components.

•Inspect all wires in the engine compartment for

proper connections, burned or chafed spots,

pinched wires, contact with sharp edges or contact

with hot exhaust manifolds or pipes.

BASIC KNOWLEDGE OF TOOLS

REQUIRED

Notice: Lack of basic knowledge of this powertrain

when perform ing diagnostic pr ocedures c ould result in

an incorrect diagnosis or damage to powertrain

components. Do not attempt to diagnose a powertrain

problem without this basic knowledge.

A basic understanding of hand tools is necessary to

effectively use this section of the Service Manual.

SERIAL DATA CO MMUNICATIONS

This vehicle utilizes the serial data communication

system. Each bit of information can have one of two

lengths: long or short. This allows vehicle wiring to be

reduced by transmitting and receiving multiple signals

over a single wire. The messages carried on serial

data streams are also prioritized. If two messages

attempt to establish communications on the data line

at the same time, only the message with higher prior ity

will continue. The device with the lower priority

message must wait. For more information on this

system of coding. On this vehicle the Scan

Tool displays the actual values for vehicle parameters.

It will not be necessary to perform any conversions

from coded values to actual values.

ON-BOARD DIAGNOSTIC (OBD)

ON-BO ARD DIAGNOSTIC TESTS

Miscellaneous Test:

A miscellaneous test is a kind of the On-Board

Diagnostics.

Using a tech 2, the miscellaneous test can be

conducted, followings are brief description about the

miscellaneous tests.

To perform the miscellaneous test, allows the

displayed menu on the tech 2. Sub-menu of

miscellaneous test are as follows.

•Check powertrain lamp:

This test allows to turn on and off the powertrain

warning lamp in the instrument cluster.

•Fuel Pump:

Fuel pump test allows to turn on and off the fuel

pump.

If turned off while the engine is running, the engine

will stall.

•A/C Clutch:

The A/C Clutch test allows to turn on and off the

airconditioning.

•Canister Purge Control Solenoid Valve:

This function takes control of the canister purge

control solenoid valve.

The on command represents a 100% pwm, the off

command a 0% pwm.

•IAC (Idle Air Control) System:

•RPM control

This function allows the user to slew the desired

RPM via increments of 25 RPM with a minimum

of 600 RPM and a maximum of 2000 RPM.

The start value will be at 1150 RPM.

•IAC Control

This function allows the user to slew the IAC via

increments of 25 steps with a minim um of 0 s teps

and a maximum of 250 steps.

The start value will be at idle steps.

•IAC Reset

The user will have the ability to perform an IAC

reset.

Each keypress will actuate the command to reset.

•Fuel Trim Reset:

This function allows the user to command the ECM

to perform an Long Term Fuel Trim reset, also

known as a Block Learn Memory reset.

Each keypress will actuate the command to reset.

•Fueling Mode:

This function provides the user with the ability to

enable or disable closed loop fuel control.

•Air Fuel Ratio:

This function allows the user to slew the control

state of the A/F ratio within a minimum of 11.7:1

and a maximum of 17.7:1.

The test starts at an A/F ratio of 14.7 : 1.

The incremental control is 0.5 steps per keypress.

COMPREHENSIVE COMP ONENT

MO NITOR DIAGNOSTIC

OPERATION

Comprehensive component monitoring diagnostics

are involved to monitor emissions-related input and

output engine components.

INPUT COMPONENTS

Input components are monitored for circuit continuity

and out-of-range values. This includes rationality

checking. Rationality checking refers to indicating a

fault when the signal from a sensor does not seem

reasonable, i.e. Throttle Position (TP) sensor that

indicates high throttle position at low engine loads or

MAP voltage). Input com ponents may include, but are

not limited to the following sensors:

•Vehicle Speed Sensor (VSS)

•Crankshaft Position (CKP) sensor

•Throttle Position (TP) sensor

•Engine Coolant Temperature (ECT) sensor

•Intake Air Temperature Sensor (IAT)

•Manifold Absolute Pressure (MAP) sensor

In addition to the circuit c ontinuity and rationality c hec k

the ECT sensor is m onitored for its ability to ac hieve a

steady s tate tem perature to enable “Clos ed Loop” fuel

control (If applicable).

OUTPUT CO MPONENTS

Output components are diagnosed for proper

response to control module commands. Components

where functional monitoring is not feasible will be

monitor ed f or c irc uit continuity and out-of-r ange values

if applicable.

Output components to be monitored include, but are

not limited to the following circuit:

•Idle Air Control (IAC) Motor

•EVAP Canister Purge Valve Solenoid

•A/C relays

•VSS output

•MIL control

Refer to ECM and Sensors in General Descriptions.

PASSI VE AND ACTIVE DIAGNOSTIC TESTS

A passive test is a diagnostic test which simply

monitors a vehicle system or component. Conversely,

an active test, actually tak es s ome sor t of action when

perfor m ing diagnostic functions , often in res ponse to a

failed passive test.

INTRUSIVE DIAGNOSTIC TESTS

This is any on-board test run by the Diagnostic

Management System which may have an effect on

vehicle performance or emission levels.

WARM -UP CYCLE

A warm-up cycle means that engine at temperature

must reach a minimum of 70°C(160°F) and rise at

least 22°C(40°F) over the course of a trip.

COMMON OBD TERMS

DIAGNOSTIC FOR CLOSED LOOP SYSTEM

When used as a noun, the word diagnostic refers to

any on-board test run by the vehicle's Diagnostic

Management System . A diagnostic is sim ply a test run

on a system or component to determine if the system

or component is operating according to specification.

FOR CLOSED LO OP SYSTEM

There are many diagnostics, shown in the following

list:

•Oxygen sensors

•Oxygen sensor heaters

ENABLE CRITERI A

The term “enable criteria” is engineering language for

the conditions necessary for a given diagnostic test to

run. Each diagnostic has a specific list of conditions

which must be met before the diagnostic will run.

“Enable criteria” is another way of saying “conditions

required” .

The enable criteria for each diagnostic is listed on the

first page of the DTC description under the heading

“Conditions for Setting the DTC” . Enable criteria

varies with each diagnostic, and typically includes, but

is not limited to the following items:

•engine speed

•vehicle speed

•ECT

•MAP

•IAT

•TP

•high canister purge (If applicable)

•A/C ON

TRIP

Technically, a trip is a key on-run-key off cycle in

which all the enable criteria for a given diagnostic are

met, allowing the diagnostic to run. Unfortunately, this

concept is not quite that simple. A trip is official when

all the enable criteria for a given diagnostic are met.

But because the enable criteria vary from one

diagnostic to another, the definition of trip varies as

well. Some diagnostics are run when the vehicle is at

operating temperature, some when the vehicle first

start up; som e requir e that the vehicle be c ruising at a

steady highway speed, some run only when the

vehicle is at idle. Som e run only im mediately following

a cold engine start-up.

A trip then, is defined as a key on-run-key off cycle in

which the vehicle was operated in such a way as to

satisfy the enabled criteria for a given diagnostic, and

this diagnostic will consider this cycle to be one trip.

However, another diagnostic with a different set of

enable criteria (which were not m et) during this driving

event, would not consider it a trip. No tr ip will occ ur f or

that particular diagnostic until the vehicle is driven in

such a way as to meet al the enable criteria

THE DIAGNOSTIC EXECUTIVE

The Diagnostic Executive is a unique segment of

software which is des igned to coordinate and prioritize

the diagnostic procedures as well as define the

protocol f or recording and displaying their r esults. T he

main responsibilities of the Diagnostic Executive are

listed as follows:

•Commanding the MIL(“Check Engine” lamp) ON

and OFF

•DTC logging and clearing

•Current status information ON each diagnostic

The Diagnos tic Exec utive records DT Cs and tur ns ON

the MIL when em is sion- related f aults oc c ur. It c an als o

turn OFF the MIL if the conditions c ease which c aus ed

the DTC to set.

DIAGNOSTIC INFORMATION

The diagnostic charts and functional checks are

designed to locate a faulty circuit or component

through a process of logical decisions. The charts are

prepared with the requirement that the vehicle

functioned correctly at the time of assembly and that

there are not multiple faults present.

Ther e is a continuous self -diagnosis on certain control

functions. This diagnostic capability is complimented

by the diagnos tic proc edur es contained in this manual.

The language of communicating the source of the

malfunction is a system of diagnostic trouble codes.

When a malf unc tion is detec ted by the control m odule,

a diagnostic trouble code is set and the Malfunction

Indicator Lamp (MIL)(“Check Engine” lamp) is

illuminated.

MALFUNCTION INDICATOR LAMP (MI L)

The Malfunction Indicator Lamp (MIL) looks the same

as the MIL you are already familiar with (“Check

Engine” lamp).

Basically, the MIL is turned ON when the ECM detects

a DTC.

EXTINGUISHING THE MIL

The MIL (“Check Engine” lamp) is on the instrument

panel and has the following functions:

•It informs the driver that a fault that affects vehicle

emission levels has occurred and that the vehicle

should be taken for service as soon as possible.

•As a bulb and system check, the MIL will come on

with the key on and the engine not running. When

the engine is started, the MIL will turn OFF.

•When the MIL remains on while the engine is

running, or when a malfunction is suspected due to

a driveability or emissions problem, a Powertrain

On-Board Diagnostic (OBD) System Check must be

performed. The procedures for these checks are

given in On-Board Diagnostic (OBD) System

Check. These checks will expose faults which may

not be detected if other diagnostics are performed

first.

Once the ECM determines that a fault(s) has been

rectified then the MIL will switch OFF, although the

fault code will remain in the ECM memory.

Any fault codes will remain in ECM memory until -

1. They are cleared by disconnecting the Battery for

more than 30 seconds.

2. A service tool such as Tech 2 is used to clear them.

3. Ten consecutive starts without logging a fault.

Refer to clearing Diagnostic Trouble Code

DATA LINK CONNECTOR (DLC)

The Provision for communicating with the control

module is the Data Link Connector ( DLC). It is located

at the lower left of the instrum ent panel behind a s m all

square cover. The DLC is used to connect to a Scan

Tool. Some comm on uses of the Scan Tool are listed

below:

•Identifying stored Diagnostic Trouble Codes (DTCs)

•Clearing DTCs

•Performing output control tests

•Reading serial data

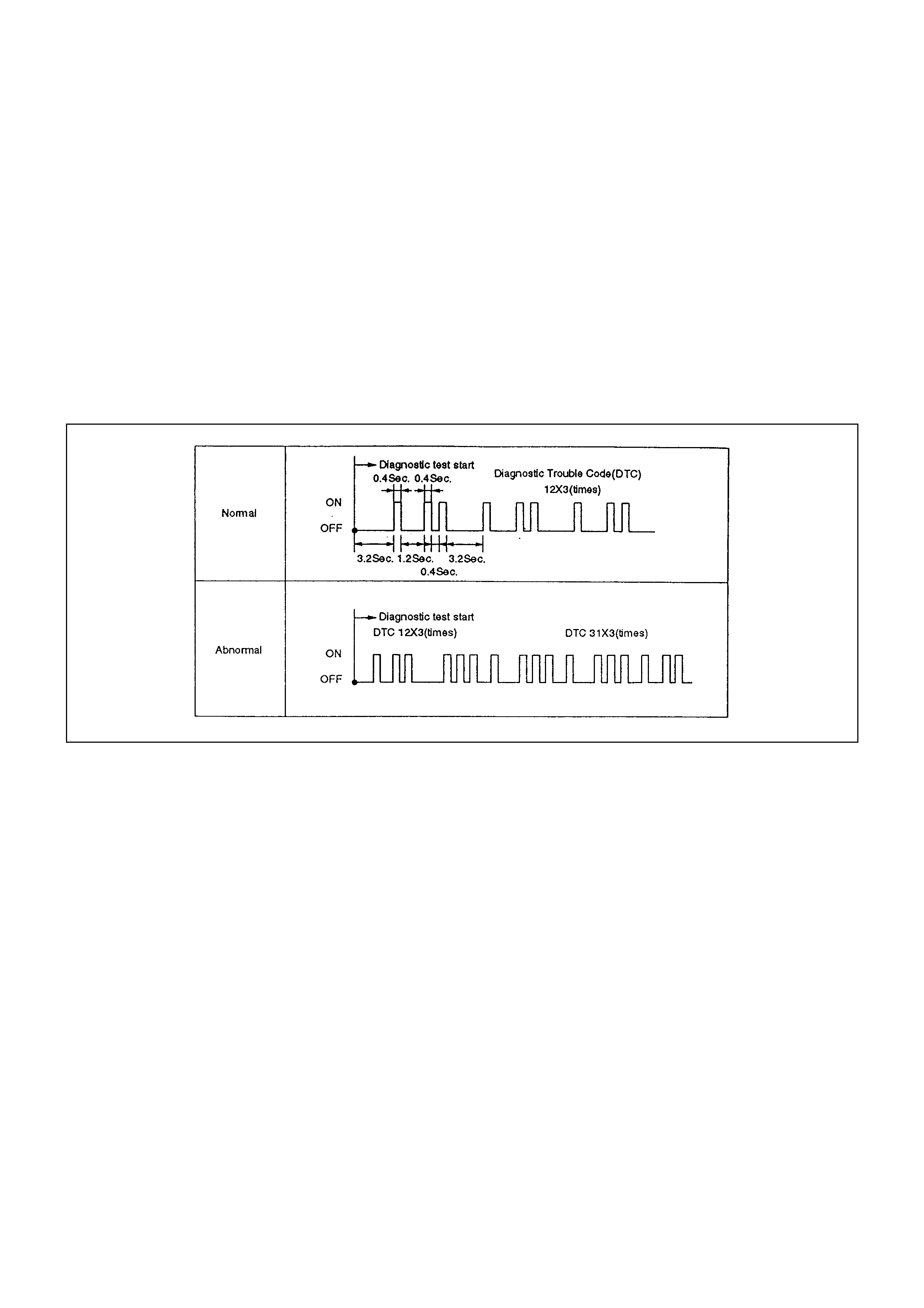

READING FLASH DIAGNOSTIC TROUBLE

CODES

The provision for communicating with the Engine

Control Module (ECM) is the Data Link Connector

(DLC). The DLC is located behind the lower front

instrument panel. It is used in the assembly plant to

receive information in checking that the engine is

operating properly before it leaves the plant.

The diagnostic trouble code(s) (DTCs) stored in the

ECM’s memory can be read either through a hand-

held diagnostic scanner plugged into the DLC or by

counting the number of f lashes of the ”Check Engine”

Malfunction lndicator Lamp (MIL) when the diagnostic

test terminal of the DLC is grounded. The DLC

terminal ”6” (diagnostic request) is pulled ”Low”

(grounded) by jumpering to DLC ter m inal ”5”, Whic h is

a ground wire.

This will signal the ECM that you want to ”flash”

DTC(s ), if any are pr esent. Once term inals ”5” and ”6”

have been connected, the ignition switch must be

moved to the ”ON” position, with the engine not

running. At this point, the ”Check Engine” MIL should

flash DTC12 three times consecutively.

This would be the following flash, sequence: ”flash,

pause, flash-flash, long pause, flash, pause, flash-

flash, long pause, flash, pause, flash-flash”. DTC12

indicates that the ECM’s diagnostic system is

operating. If DTC12 is not indicated, a problem is

present within the diagnostic system itself, and should

be addressed by consulting the appropriate diagnos tic

chart in DRIVEABILITY AND EMISSIONS.

Following the output of DTC12, the ”Check Engine”

MIL will indicate a DTC three times if a DTC is

present, or it will simply continue to output DTC12. If

more than one DTC three has been stored in the

ECM’s memory, the DTC(s) will be output from the

lowest to the highest, with each DTC being displayed

three times.

READING DIAGNOSTIC TROUBLE CODES

USING A TECH 2

The procedure for reading diagnostic trouble code(s)

is to used a diagnostic Tech 2. When r eading DTC(s ),

follow instructions supplied by Tech 2 manufacturer.

CLEARI NG DIAGNOSTIC TROUBLE CODES

IMPORTANT: Do not clear DTCs unless directed to

do so by the service information provided for each

diagnostic procedure.

If the fault that caused the DTC to be stored into

mem ory has been correc ted, the Diagnostic Executive

will begin to count the ”warm -up” c ycles with no further

faults detected, the DTC will automatically be cleared

from the ECM memory.

To clear Diagnostic Trouble Codes (DTCs), use the

Tech 2 ”clear DTCs” or ”clear information” function.

When clearing DTCs follow instructions supplied by

the Tech 2 manufacturer.

When a Tech 2 is not available, DTCs can also be

cleared by disconnecting one of the following sources

for at least thirty (30) seconds.

NOTE: To prevent system damage, the ignition key

must be ”OFF” when disconnecting or reconnecting

battery power.

•The power sour ce to the contr ol m odule. Exam ples :

fuse, pigtail at battery ECM connectors etc.

•The negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board memory data, such as preset radio

tuning).

ON-BO ARD DIAGNO SIS (SELF-DIAG NOSIS)

1. The Engine Control Module (ECM) conducts a self-

test of most of the wiring and components in the

system each tim e the key is turned to ON, and can

detect faults in the system while the key is ON. If a

fault is detected, the ECM will store a trouble code

in mem ory and flash the CHECK ENGINE indicator

to alert the driver.

2. The Diagnostic Trouble Codes (DTC) can be

displayed by shorting together terminals and of the

Data Link Connector (DLC) located behind front

console.

The CHECK ENGINE indicator will flash DTC 12

three times, followed by any DTC. If several DTC

are stored, each DTC will be displayed three times.

The DTC will be displayed in numerical order. The

DTC display will continue as long as the DLC is

shorted.

Some DT C can cause other DTC to be stored, It is

important to diagnose and repair the lowest

numbered DTC first before going on to the higher

numbered DTC.

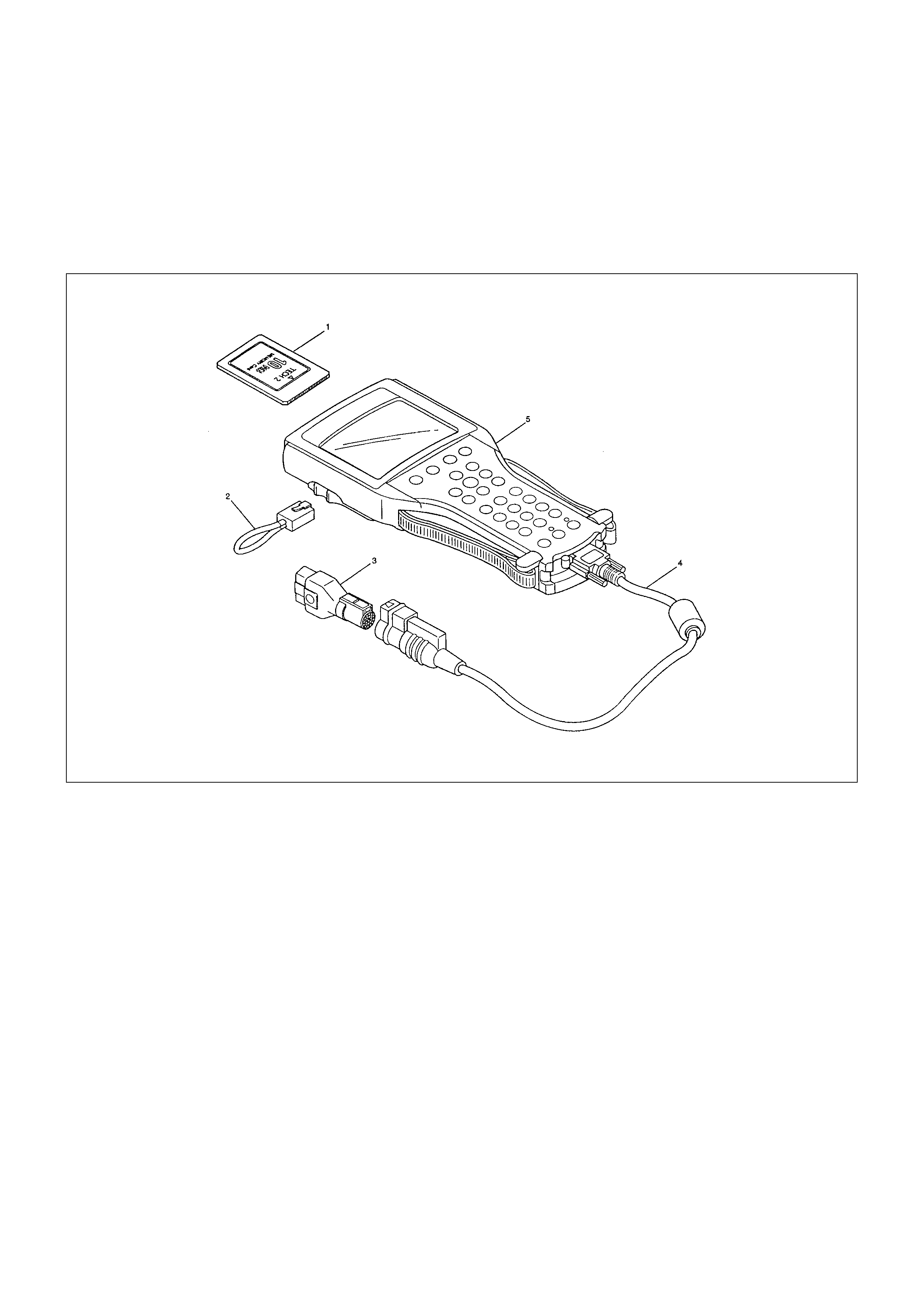

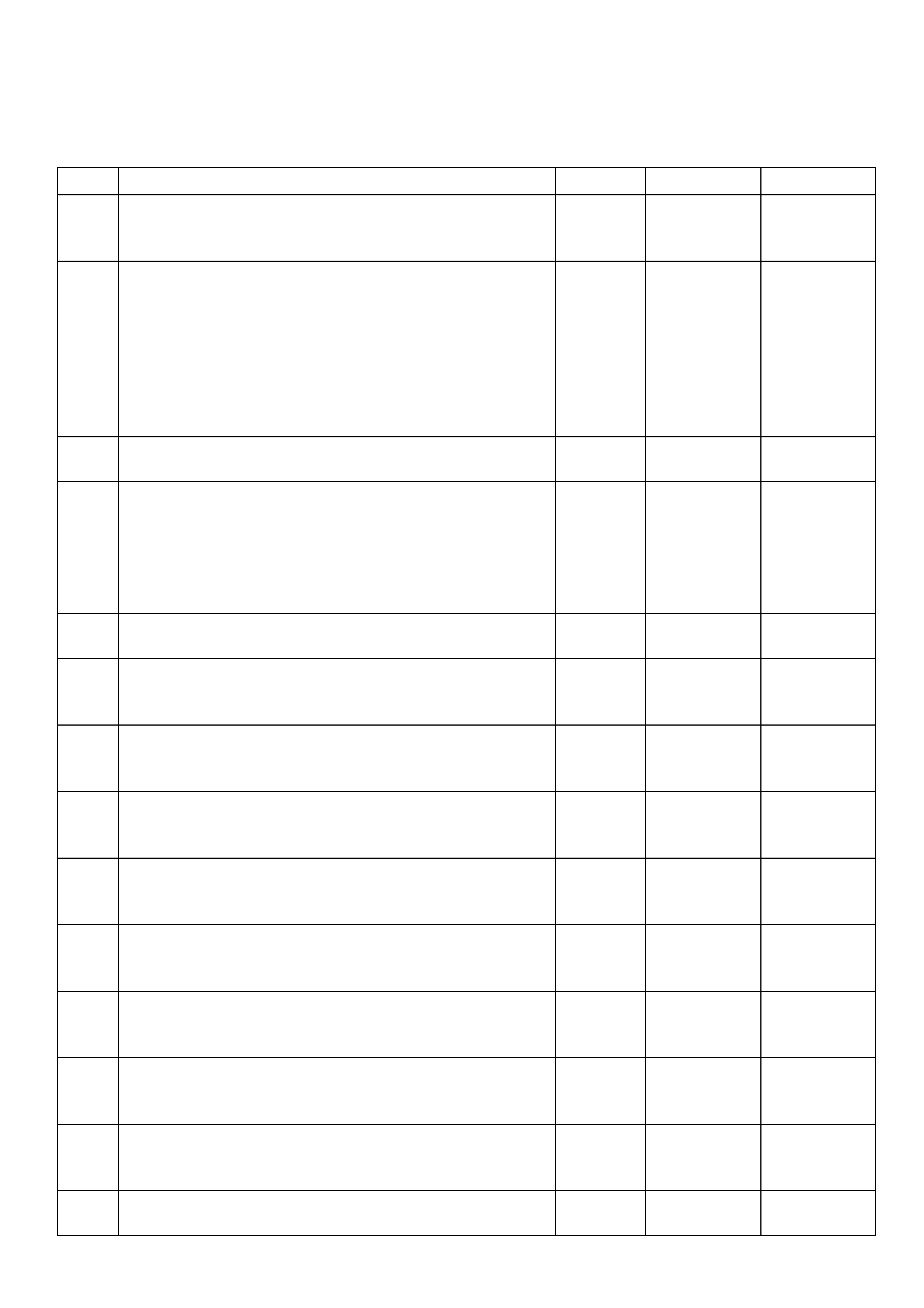

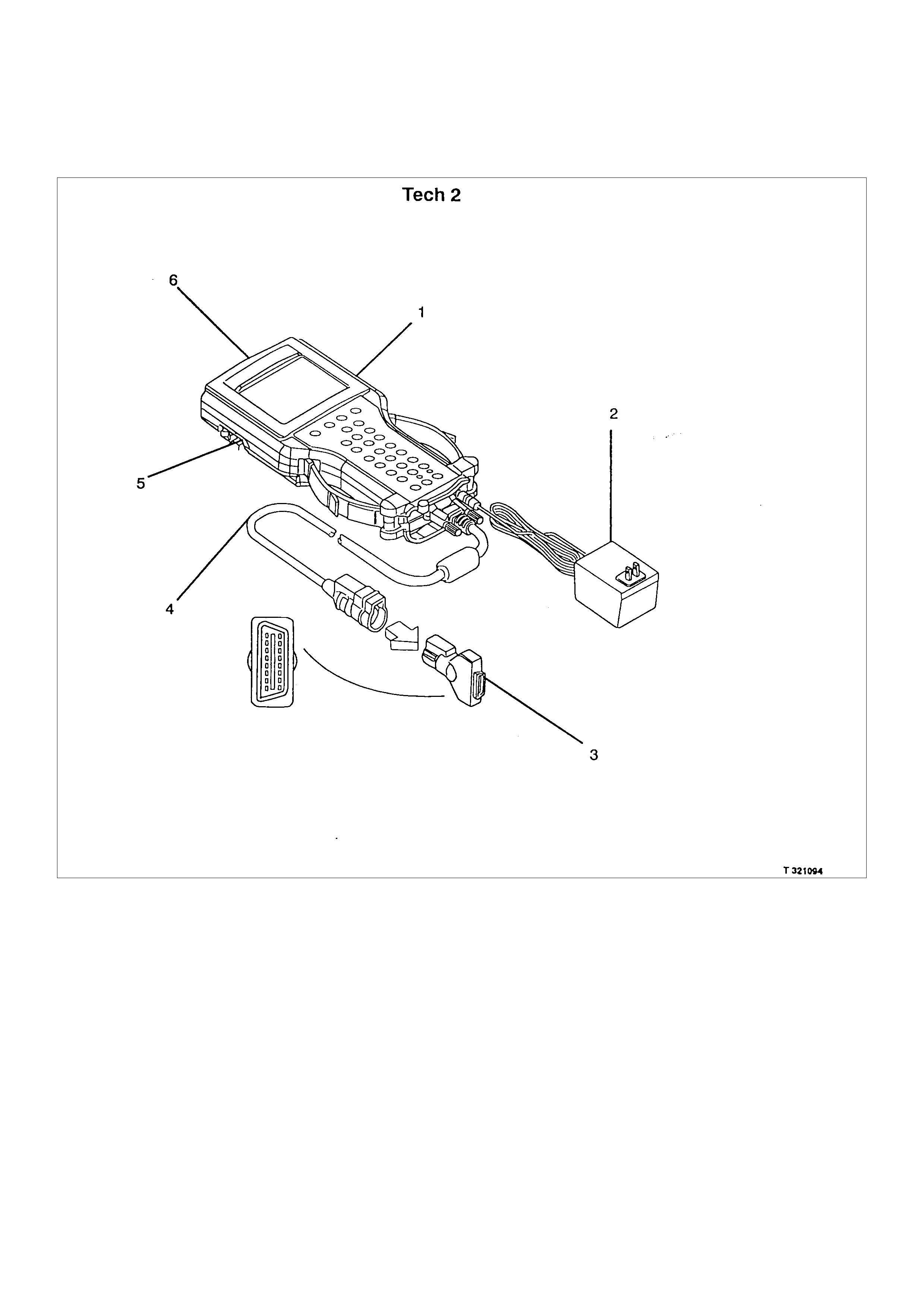

TECH 2 SCAN TOOL

From 98 MY, Isuzu dealer service departments are

recommended to use Tech 2. Please refer to Tech 2

user guide.

LEGEND

(1) PCMCIA Card

(2) RS 232 Loop Back Connector (3) SAE 16/19 Adaptor

(4) DLC Cable

(5) Tech-2

GE TTING STARTED

•Before operating the Isuzu PCMCIA card with the

Tech 2, the following steps must be performed:

1. The Is uzu 98 System PCMCIA c ard (1) inserts into

the Tech 2 (5)

2. Connect the SAE 16/19 adapter (3) to the DLC

cable (4).

3. Connect the DLC cable to the Tech 2 (5)

4. Make sure the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the

vehicle DLC.

6. The vehicle ignition turns on.

7. Verify the Tech 2 power up display.

NOTE: The RS232 Loop back connector is only to use

for diagnosis of Tech 2 and refer to user guide of the

Tech 2.

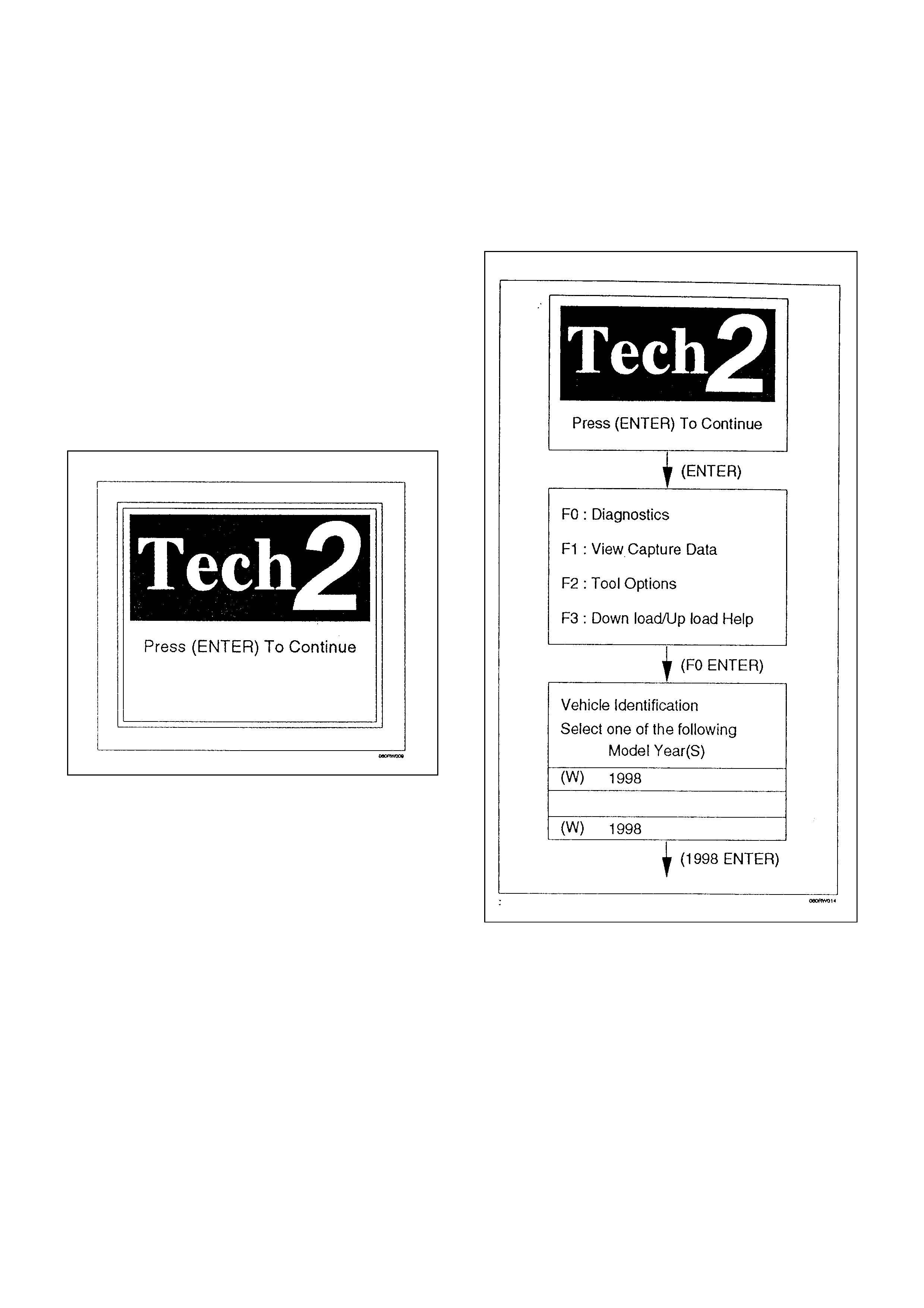

OPERATING PROCEDURE

The power up sc reen is displayed when you power up

the tester with the Isuzu systems PCMCIA card.

Follow the operating procedure below.

MENU

•The following table shows, the Tech 2 menu

structure.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Clear DTC Information

F1: Data Display

F0: Engine Data

F2: O2 Sensor Data

F2: Snapshot

F3: Miscellaneous Tests

F0: Engine Check Light

F1: Relays

F1: A/C Relay

F2: Fuel Pump Relay

*F3: Low Fan Replay

*F4: High Fan Replay

F2: Canister Purge Solenoid

F3: IAC System

F1: RPM Control

F2: IAC Control

F3: IAC Reset

F4: Fuel System

F1: Fuel Trim Reset

F2: Fueling Mode

F7: Air Fuel Ratio

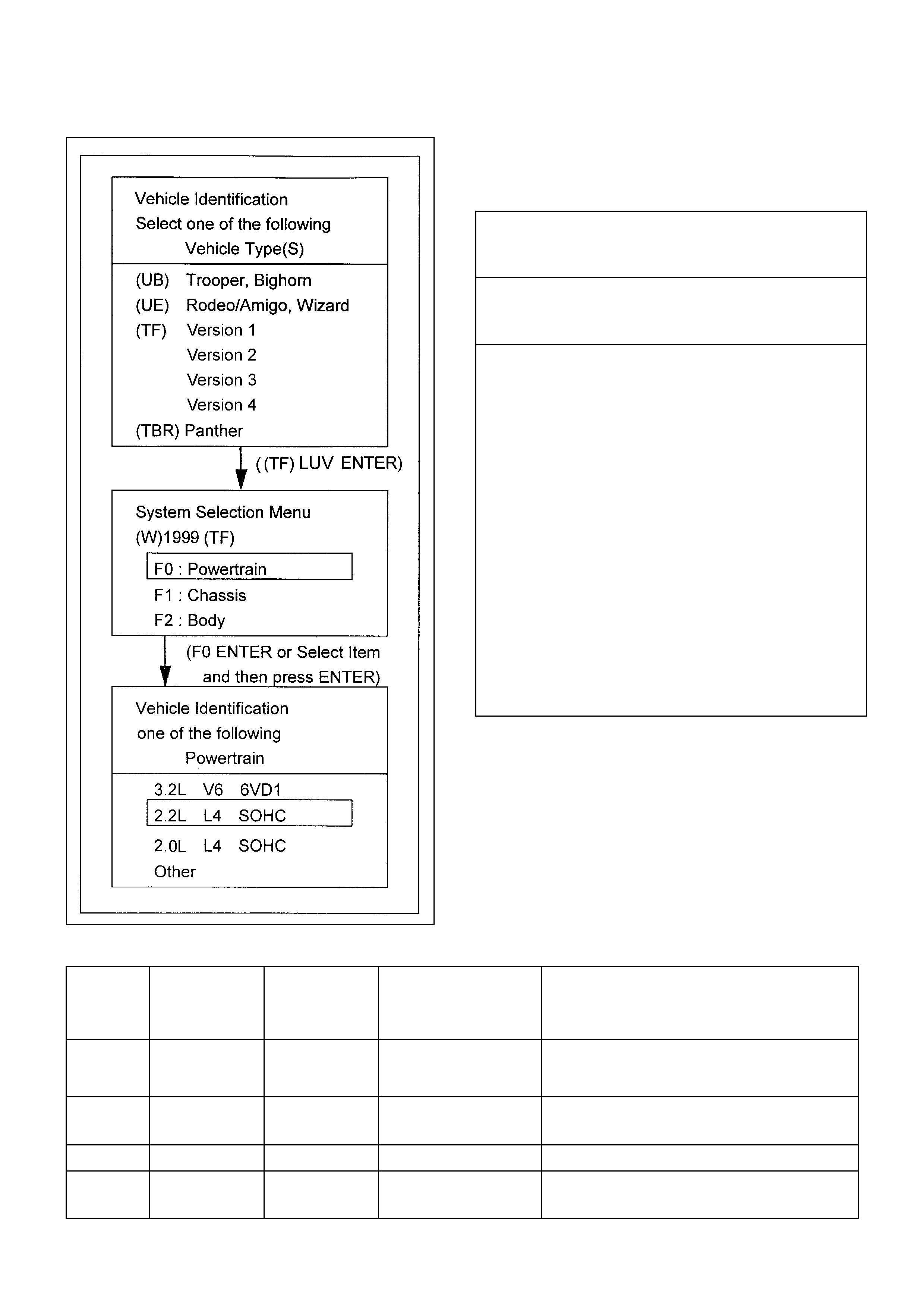

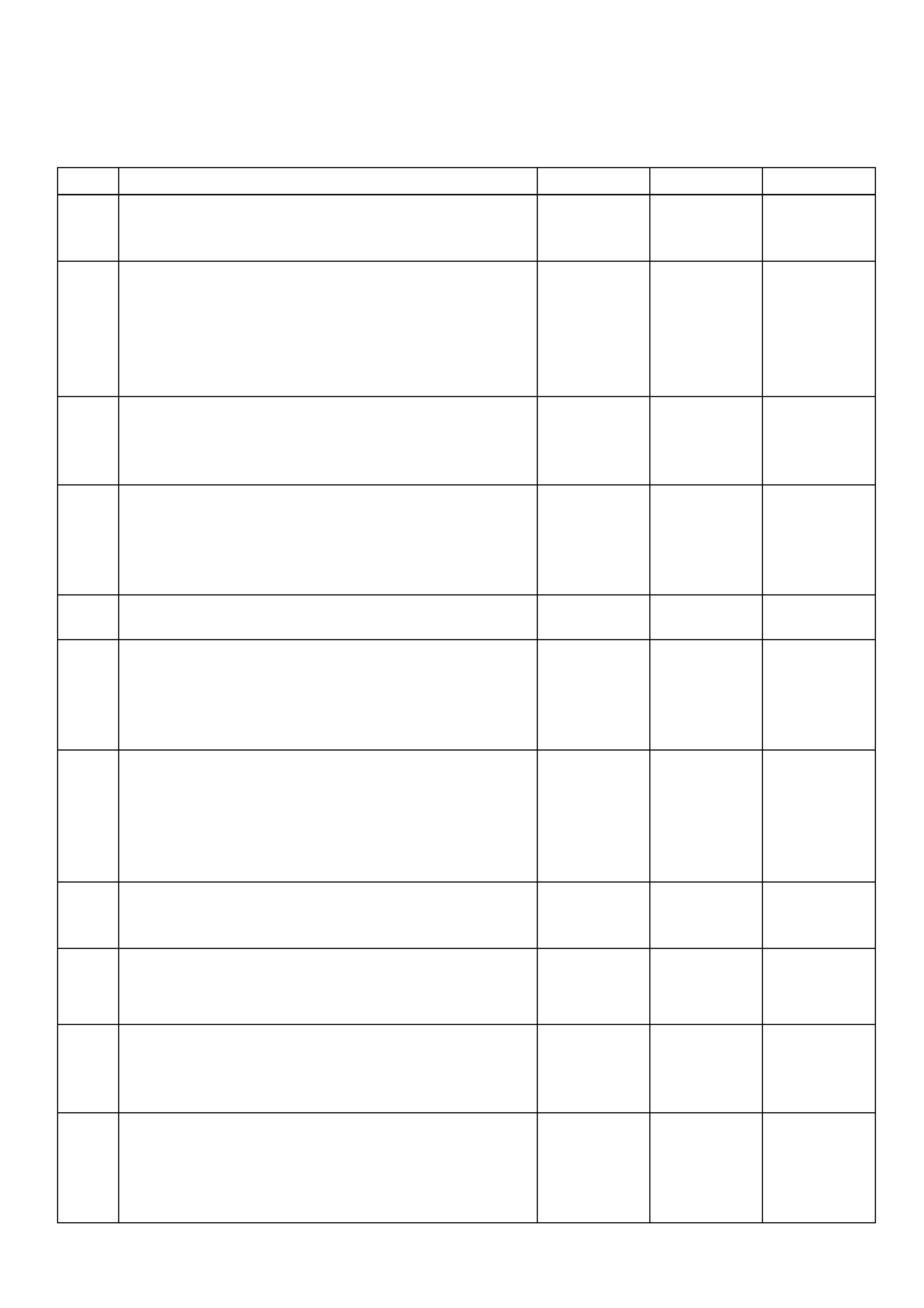

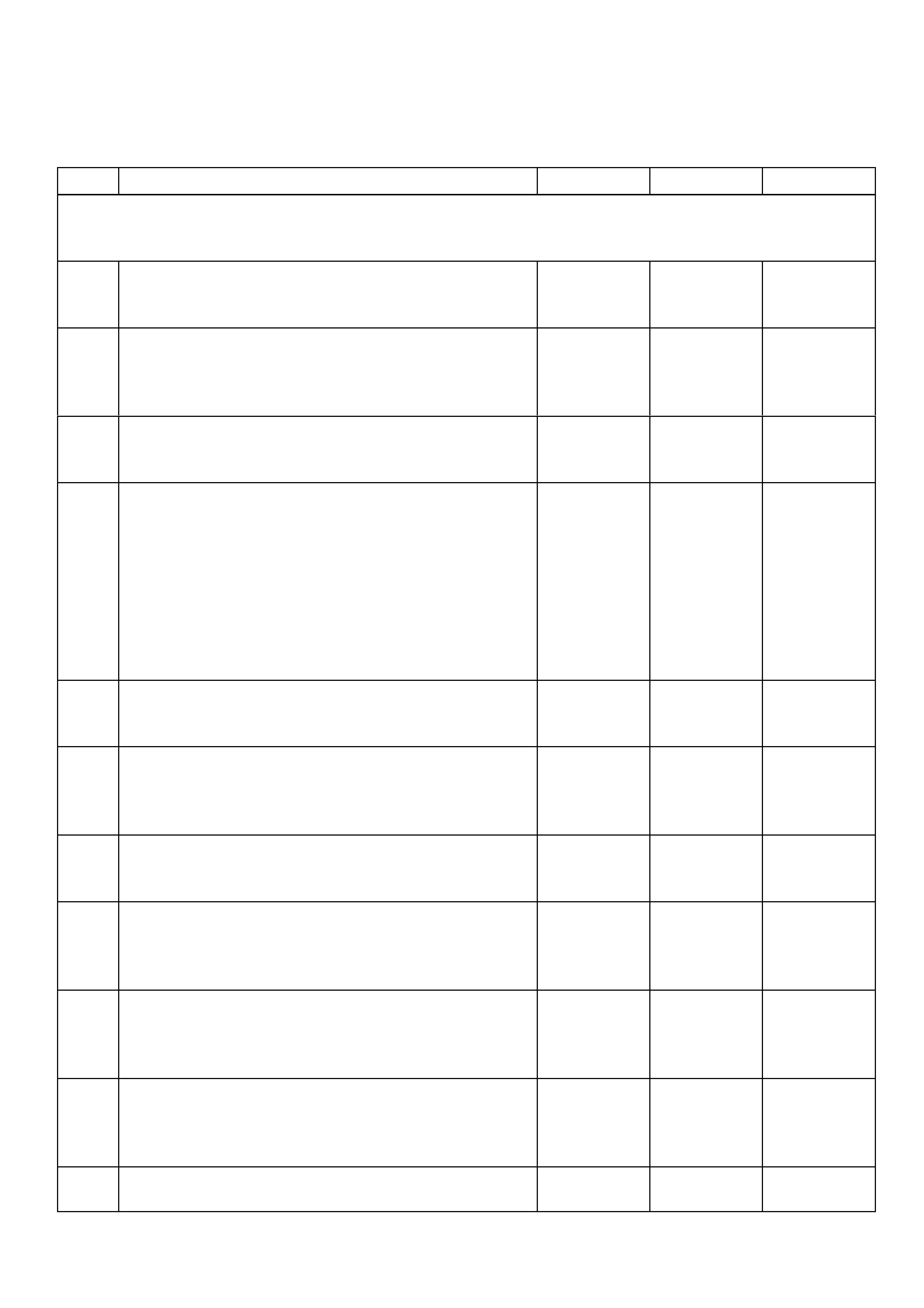

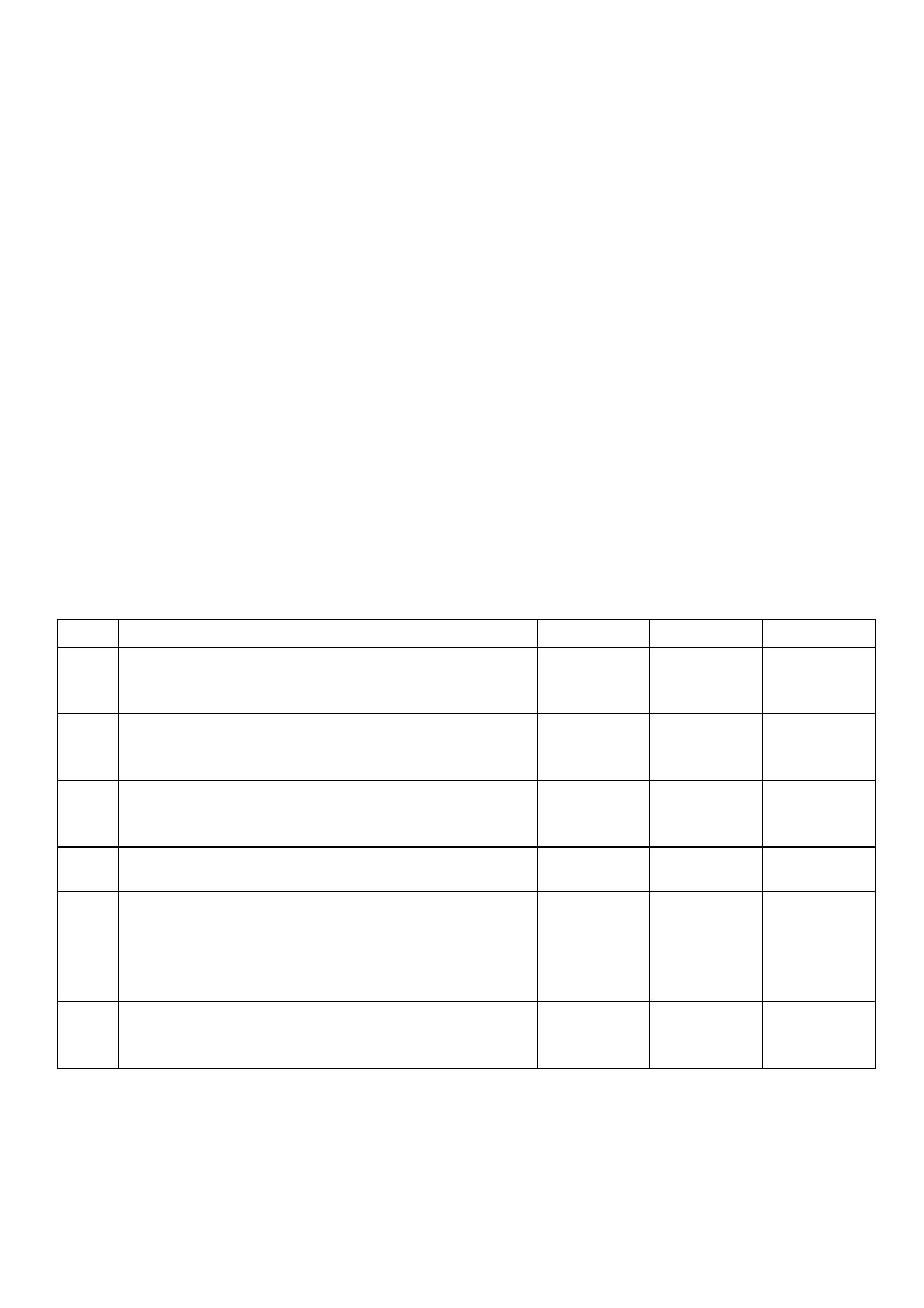

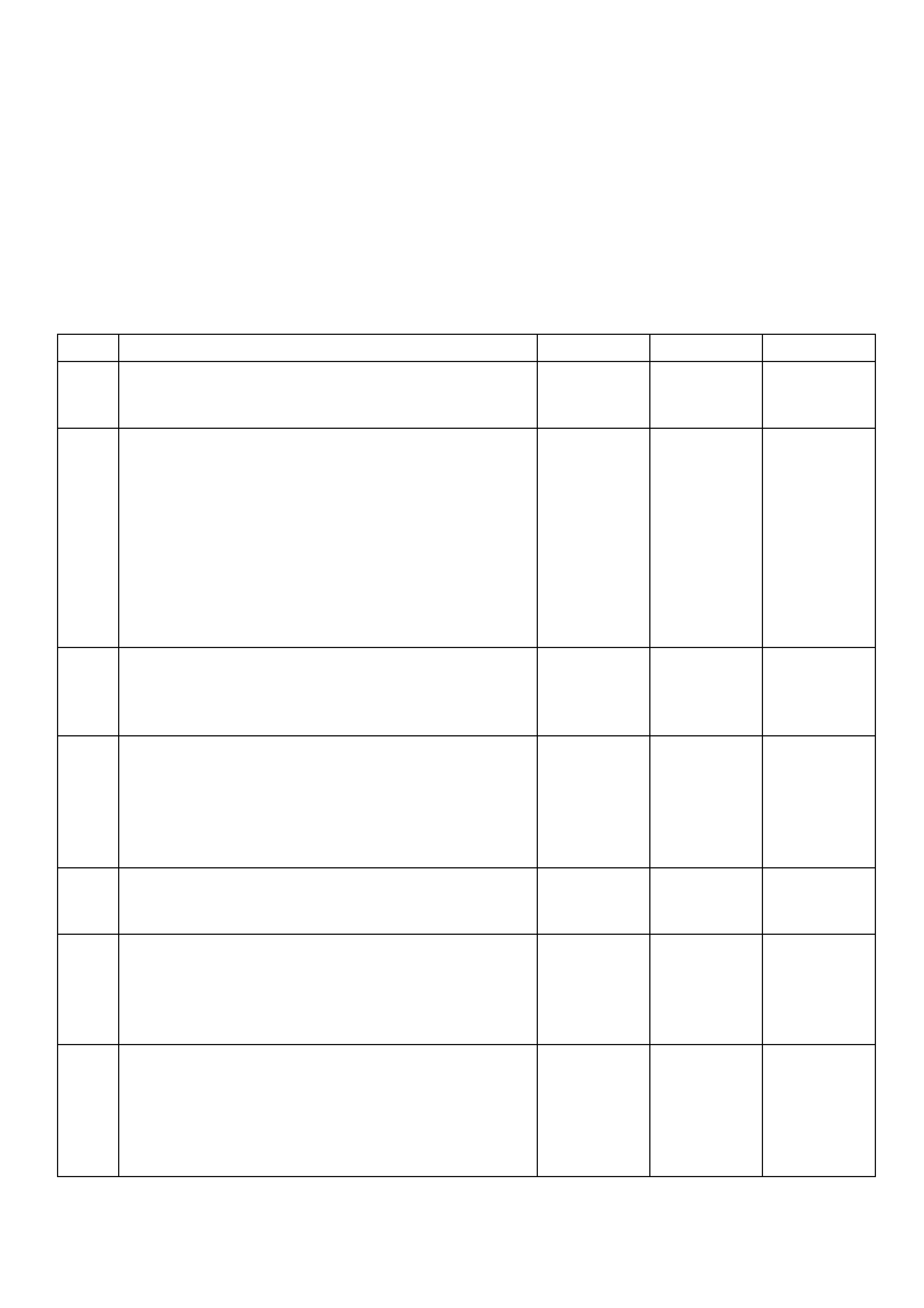

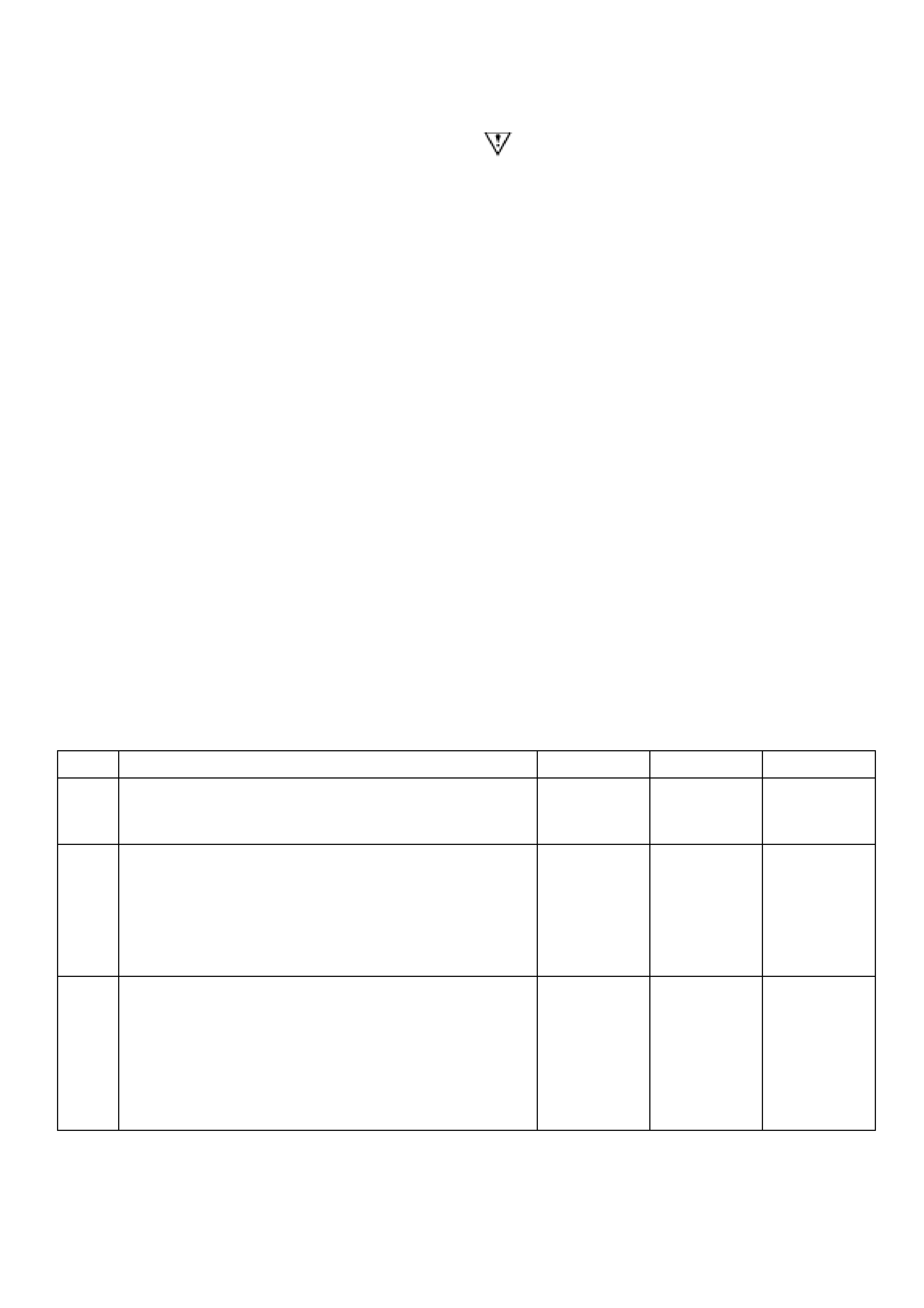

Note : *F3 & F4 not applicable to TF models

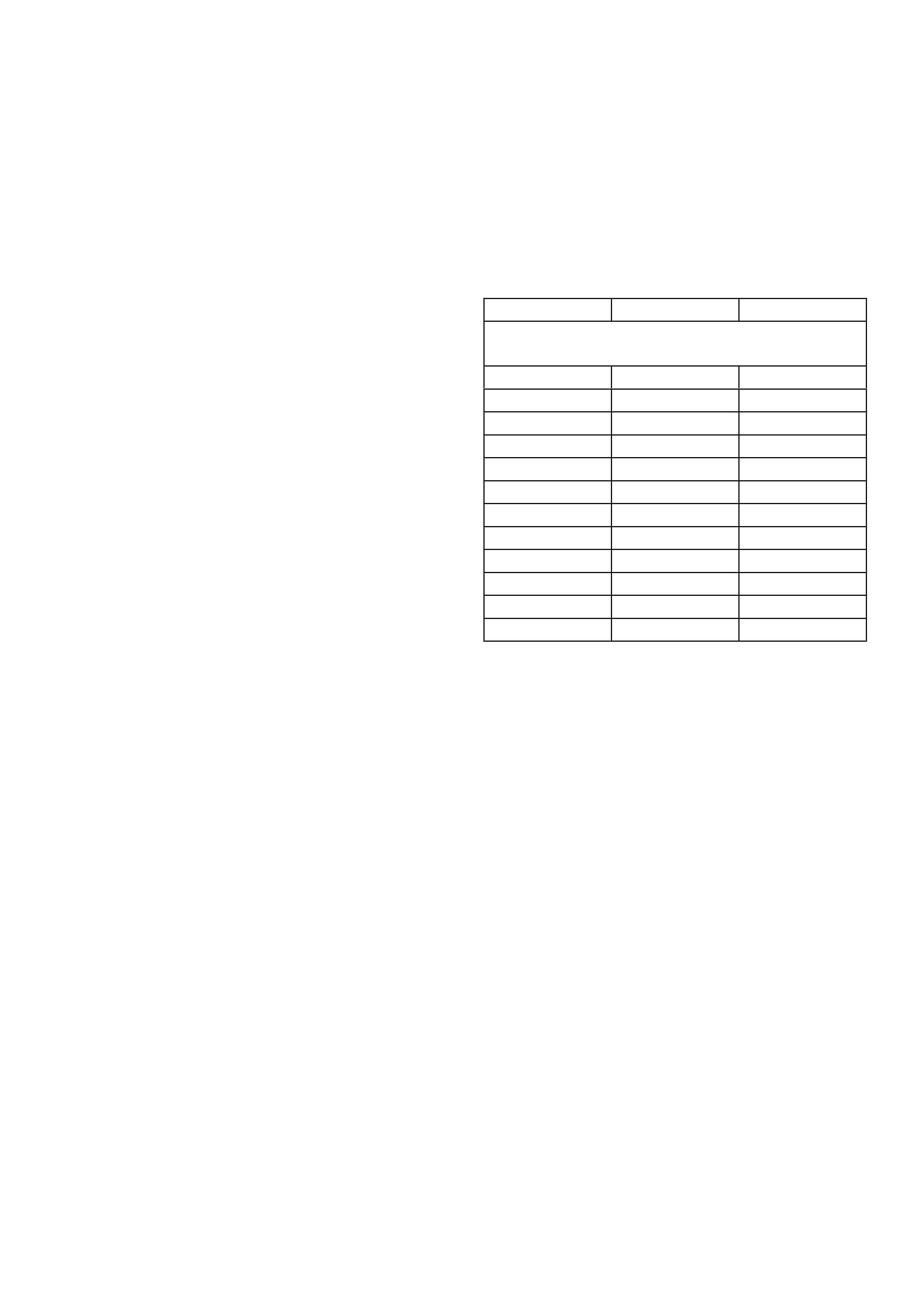

Note: Selection Table

Appricable

Version Engine

Displacement Compression

Ratio Fuel Octane No.

(RON)

Destination

*Shows w/canister for EVAP. Emission

control

Version 1 2.2L 8.6 80 Leaded/Un-

Leaded

*Ecuador, *Gulf, China, Egypt, Kenya,

Nigeria and Philippine

Version 2 2.2L 9.2 85 Leaded/Un-

Leaded Chile, Colombia, Guatemala and Costarica

Version 3 2.2L 9.2 91 Un-Leaded *Australia, *New Zealand and South Africa

Version 4 2.0L 8.8 91 Leaded/Un-

Leaded South Africa

VERIFYING VEHICLE REPAIR

Verification of vehicle repair will be more

comprehensive for vehicles with OBD system

diagnostics. Following a repair, the technician should

perform the following steps:

1. Review and record the customer complaint for the

DTC which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the

customer complaint.

4. Monitor the DTC status information for the specific

DTC which has been diagnosed until the diagnos tic

test associated with that DTC runs.

Following these steps are very important in verifying

repairs on OBD systems. Failure to follow these steps

could result in unnecessary repairs.

READING DI AGNOSTIC TROUBLE

CODES USING A SCAN TOOL

The procedure for reading diagnostic trouble code(s)

is to use a diagnostic Scan Tool. When reading

DTC(s), follow instructions supplied by tool

manufacturer.

CLEARI NG DIAGNOSTIC TROUBLE CODES

IMPORTANT: Do not clear DTCs unless directed to

do so by the service information provided for each

diagnostic procedure.

If the fault that caused the DTC to be stored into

mem ory has been correc ted, the Diagnostic Executive

will begin to count the “warm -up” c ycles with no further

faults detected, the DTC will automatically be cleared

form the ECM memory.

To clear Diagnostic Trouble Codes (DTCs), use the

diagnostic Scan Tool “clear DTCs” or “clear

information” function. When clearing DTCs follow

instructions supplied by the tool manufacturer.

W hen a Scan T ool is not available, DT Cs can als o be

cleared by disconnecting one of the following sources

for at least thirty (30) seconds.

Notice: To prevent system damage, the ignition key

must be OFF when disconnecting or reconnecting

battery power.

•The power sour ce to the contr ol m odule. Exam ples :

fuse, pigtail at battery ECM connectors etc.

•The negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board memory data, such as preset radio

tuning).

DTC MODES

There are 2 options available in the Scan Tool DTC

mode to display the enhanced information available.

After selecting DTC, the following menu appears:

•DTC Info

•Clear DTC Info

The following is a brief description of each of the sub

menus in DTC Info and Specific DTC. The order in

which they appear here is alphabetical and not

necessarily the way they will appear on the Scan Tool.

DTC INFORMATION MODE

Use the DTC info mode to search for a stored DTC

Refer to “Diagnostic Trouble Codes” list.

CLEAR DTC INFORMATIO N

The command for clearing DTC’s performs a

complete reset of the ECM.

PRIMARY SYSTEM-BASED

DIAGNOSTICS

There are primary system-based diagnostics which

evaluate system operation and its effect on vehicle

emissions. T he primary system-based diagnostics are

listed below with a brief description of the diagnostic

function:

FUEL CONTROL HEATED OXYGEN

SENSORS (IF APPLICABLE)

The main function of the fuel control heated oxygen

sensors is to provide the control module with exhaust

stream oxygen content information to allow proper

fueling and maintain emissions within mandated

levels. After it reaches operating temperature, the

sensor will generate a voltage, inversely proportional

to the amount of oxygen present in the exhaus t gas es.

The control module uses the signal voltage from the

fuel control heated oxygen sensors while in “Closed

Loop” to adjust fuel injector pulse width. While in

“Closed Loop” , the ECM can adjust fuel delivery to

maintain an air/fuel ratio which allows the best

combination of emission control and driveability. The

fuel control heated oxygen sensors are also used to

determine catalyst efficiency.

HO2S HEATER

Heated oxygen sensors are used to minimize the

amount of time requir ed for “Closed Loop” fuel contr ol

to begin operation and to allow accurate catalyst

monitoring. The oxygen sensor heater greatly

decreases the amount of tim e required for fuel control

sensor (HO2S) to become active.

ON-BO ARD DIAGNOSTIC (OBD) SYSTEM CHECK

16 15 14 13 12 11 10 9

87654321

HOT AT ALL TIMES

Fuse

Stop

10A

U/H

FUSE

BLOCK

To

Stop

Lamp

Engine

Control

Module

(ECM)

0.5G

A1 B11 E8

B/R 0.5

BW

0.5

R

ECM

Grounds

(Engine Block)

Diag Serial Data

1.25

CIRCUIT DESCRIPTION

The on-board diagnostic system check is the starting

point for any driveability complaint diagnosis. Before

using this procedure, perform a careful visual/physical

check of the ECM and engine grounds for cleanliness

and tightness.

The on-board diagnostic system check is an organized

approach to identifying a problem created by an

electronic engine control system malfunction.

DIAGNOSTIC AIDS

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside

the insulation. Check for poor connections or a

damaged harness. Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, poor

terminal-to-wire connection, and damaged harness.

TEST DESCRIPTION

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

1. The MIL (“Check Engine” lamp) should be ON

steady with the ignition ON/engine OFF. If not,

isolate the malfunction in the MIL circuit.

2. Checks the serial data circuit and ensures that the

ECM is able to transmit serial data.

3. This test ensures that the ECM is capable of

controlling the MIL and the MIL driver circuit is not

shorted to ground.

4. If the engine will not start, the Cranks But Will Not

Run chart should be used to diagnose the

condition.

7. A Scan Tool parameter which is not within the

typical range may help to isolate the area which is

causing the problem.

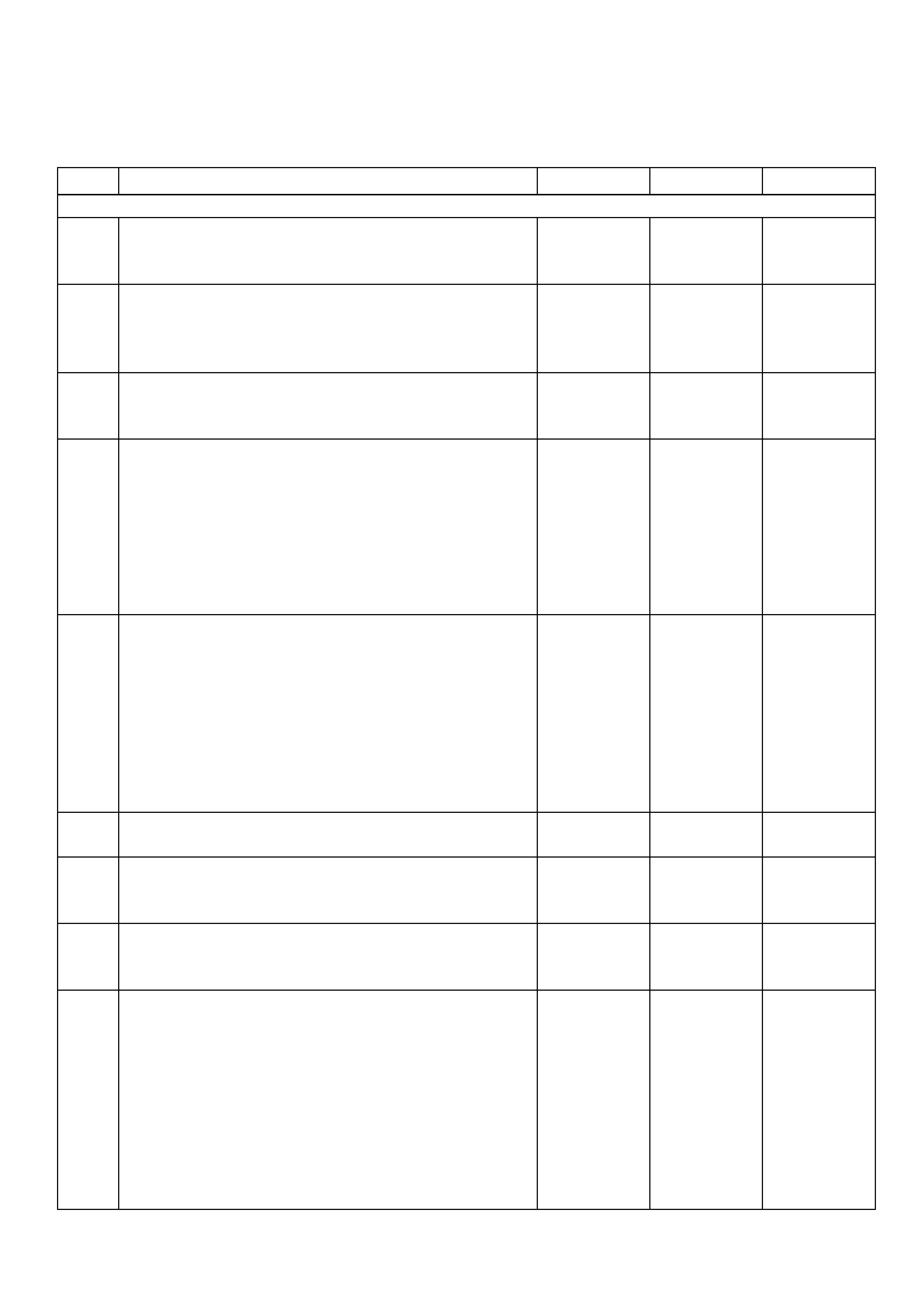

ON-BO ARD DIAGNOSTIC (OBD) SYSTEM CHECK

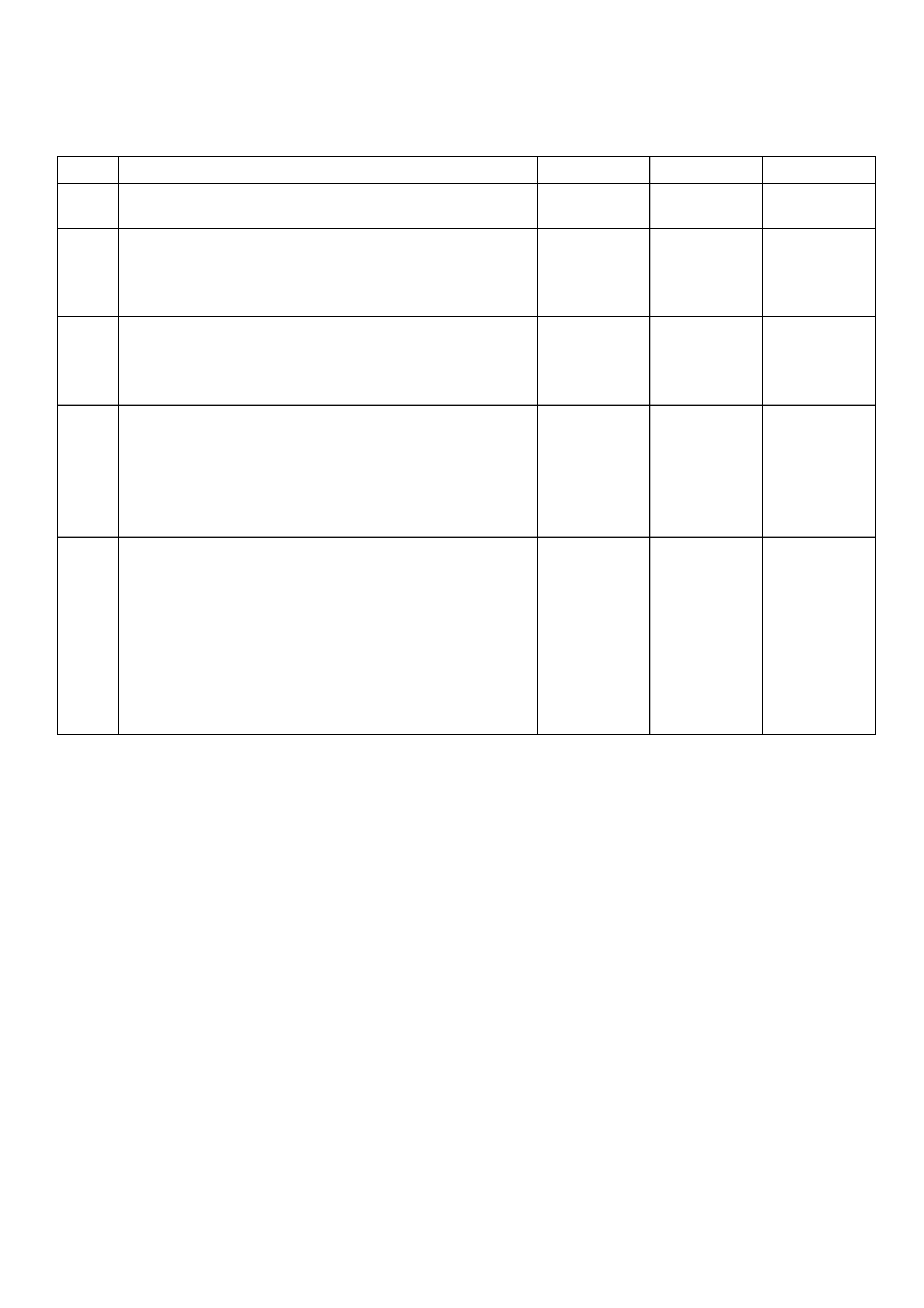

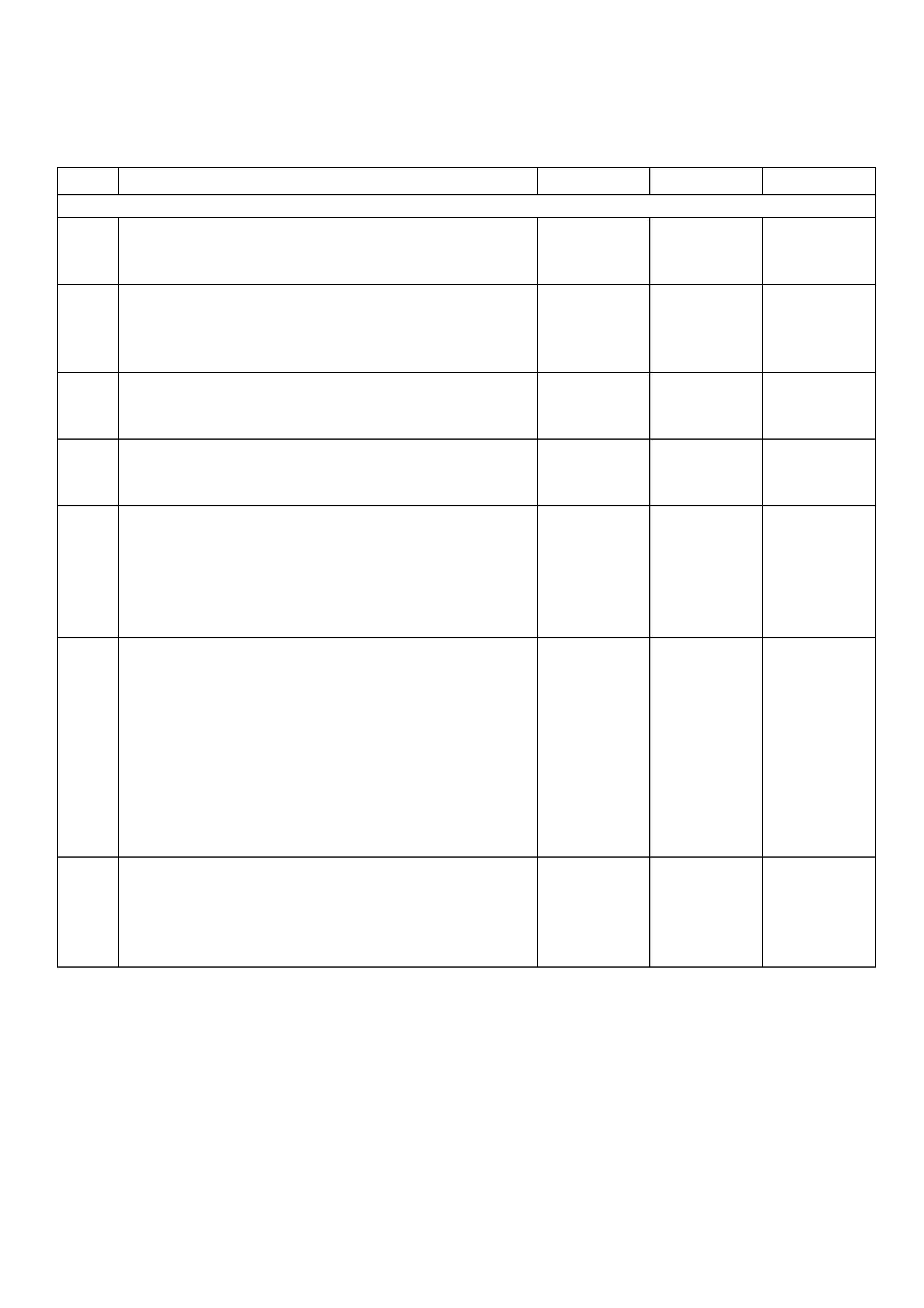

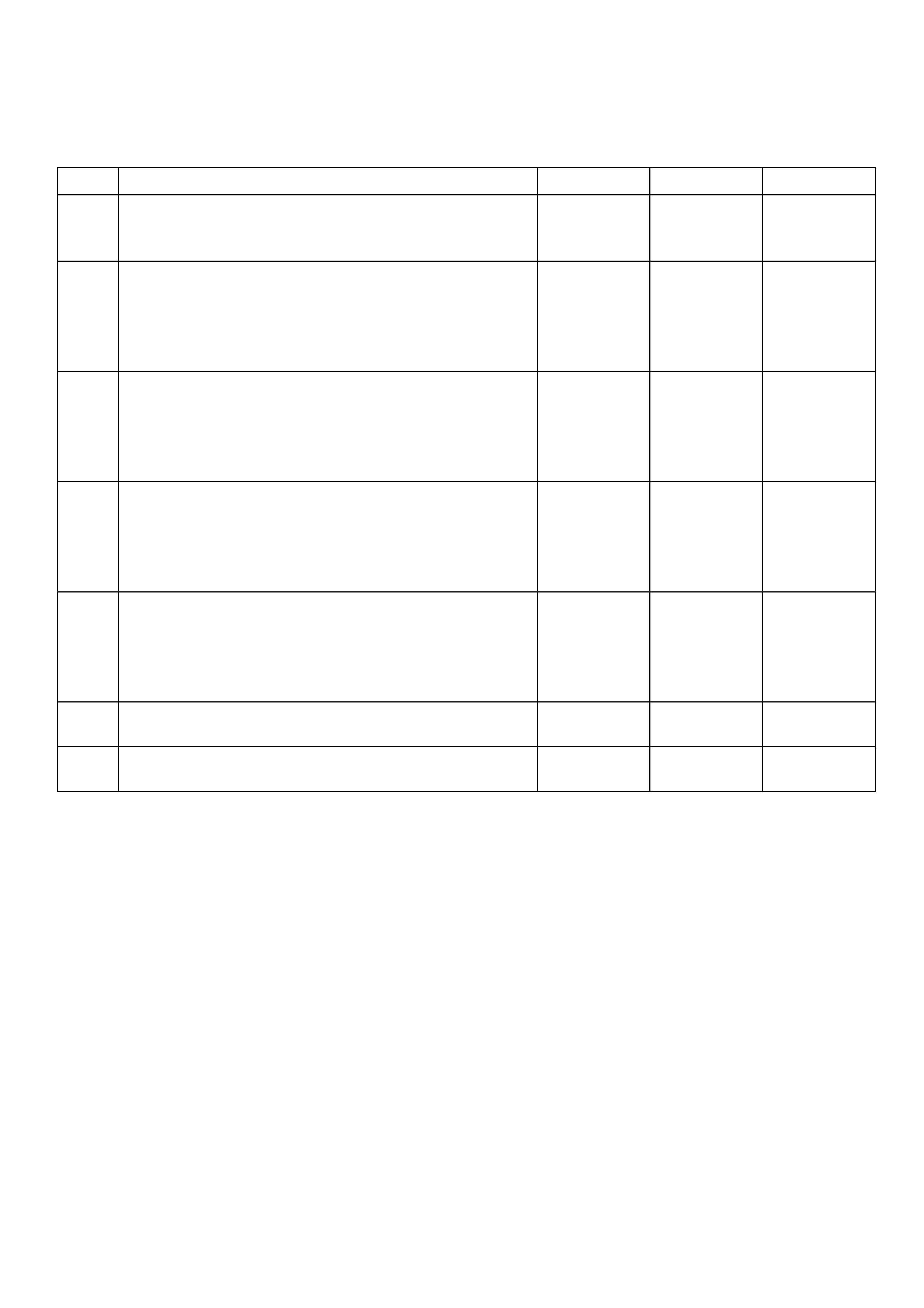

STEP ACTION VALUE(S) YES NO

1

1. Ignition ON engine OFF.

2. Observe the malfunction indicator lamp (MIL or

“Check Engine” lamp).

Is the MIL (“Check Engine” lamp) ON?

-

Go to Step 2

Go to

No MIL

2

1. Ignition OFF.

2. Install a Scan Tool.

3. Ignition ON.

4. Attempt to display ECM engine data w ith the Scan Tool.

Does the Scan Tool display ECM data?

-

Go to Step 3

Go to Step 8

3

1. Using the Scan Tool output tests function, select MIL dash

lamp control and command the MIL OFF.

2. Observe the MIL.

Did the MIL turn OFF?

-

Go to Step 4

Go to

MIL(“Check

Engine” Lamp)

On Steady

4Attempt to start the engine.

Did the engine start and continue to run? - Go to Step 5

Go to

Cranks But

Will Not Run

5Select “Display DTCs” with the Scan Tool.

Are any DTCs stored? -Go to Step 6 Go to Step 7

6

Are two or more of the following DTCs stored?

•14

•21

•22

•33

•34

•69

-

Go to

“Multiple

ECM

Information

Sensor

DTCs

Set”

Go to

applicable

DTC table

7

Compare ECM data values displayed on the Scan Tool to the

typical engine scan data values.

Are the displayed values normal or close to the typical values? -

Go to Step 8

Refer to

indicated

Component

System Checks

STEP ACTION VALUE(S) YES NO

8

1. Ignition OFF, disconnect the ECM.

2. Ignition ON, engine OFF.

3. Check the serial data circuit for an open, short to ground, or

short to voltage. Also, check the DLC ignition feed circuit for an

open or short to ground and the DLC ground circuits for an

open.

4. If a problem is found, repair as necessary. Was a problem

found?

Go to Step 2 Go to Step 9

9

1. Refer to Engine Control Module (ECM) in On-Vehicle Service.

2. Attempt to display ECM data with the Scan Tool.

Does the Scan Tool display ECM engine data? -

Go to Step 2 Go to Step 10

10 Replace the EPROM or ECM. Note) Refer to 6E1-243 - Verify Repair -

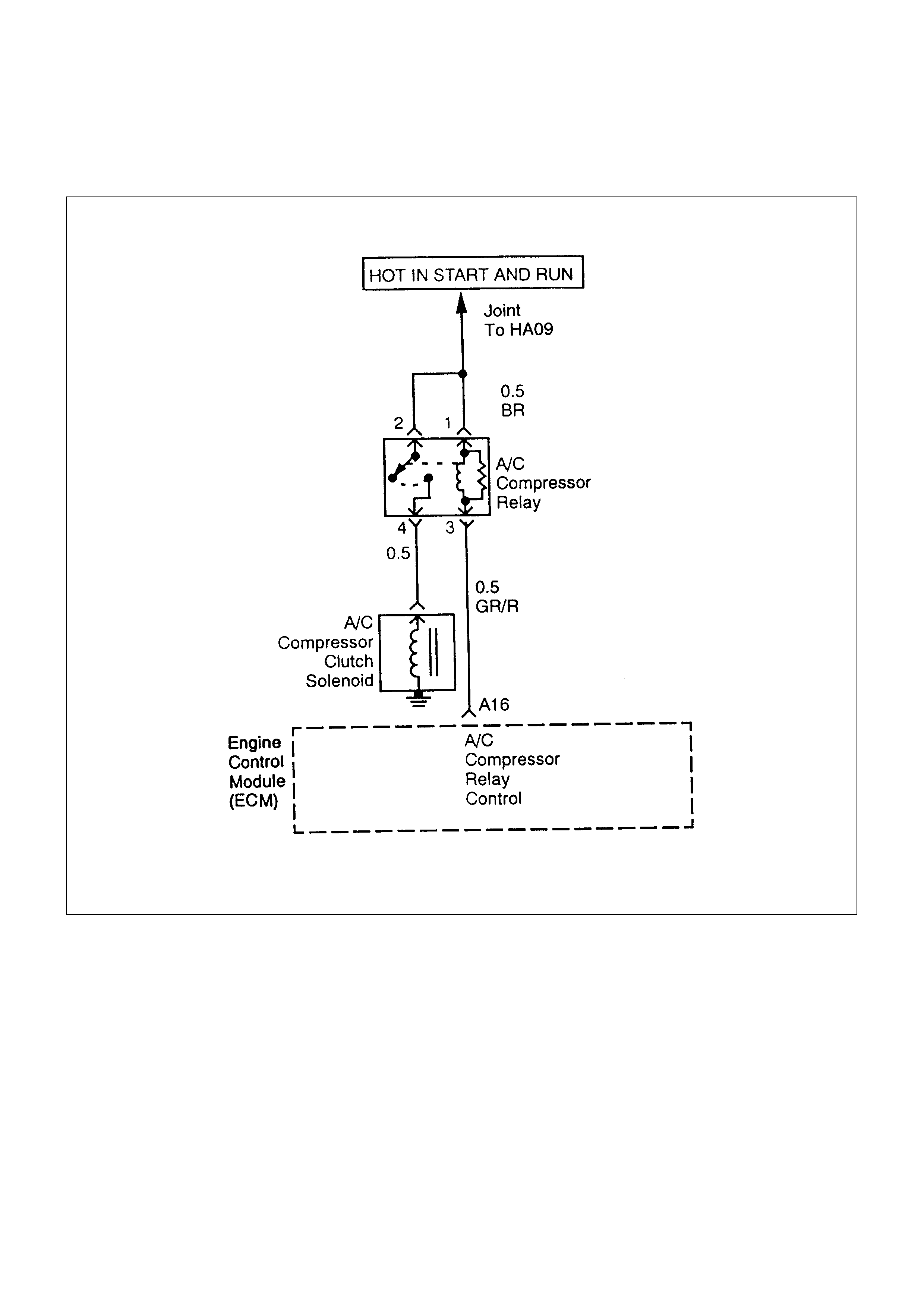

A/ C CLUTCH CONTROL CI RCUIT DIAGNOSIS

CIRCUIT DESCRIPTION

When air conditioning and blower fan are selected,

and if the system has a suf ficient refrigerant charge, a

12-volt signal is supplied to the A/C request input of

the engine control module (ECM). The A/C request

signal may be temporarily canceled during system

operation by the electronic thermostat in the

evaporator case. The electronic thermostat may

intermittently remove the control circuit ground for the

A/C thermostat relay to prevent the evaporator from

forming ice. W hen the A/C request signal is received

by the ECM, the ECM supplies a ground from the

compressor clutch relay if the engine operating

conditions are within acceptable ranges. W ith the A/C

compressor relay energized, battery voltage is

supplied to the compressor clutch coil.

The ECM will enable the c om press or clutch to engage

whenever A/C has been selected with the engine

running, unless any of the following conditions are

present:

•The throttle is greater than 95%.

•The engine speed is greater than 6000 RPM.

•The engine coolant temperature (ECT) is greater

than 122°C(252°F).

•Fan switch is OFF.

•A/C reguest switch is OFF.

• Thermo switch (FRT) is OFF.

• Pressure switch is OFF.

• Ignition switch is OFF.

DIAGNOSTIC AIDS

To diagnose an intermittent fault, check for the

following conditions:

• Poor connection at the ECM-Inspect harness

connections for backed-out terminals, improper

mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

• Damaged harness-Inspect the wiring harness for

damage; shorts to Ground, shorts to Battery

Voltage, and Open circuits. If the harness appears

to be OK, observe the A/C clutch while moving

connectors and wiring harnesses related to the A/C.

A sudden clutch malfunction will indicate the source

of the intermittent fault.

A/C CLUTCH DIAGNOSIS

This chart should be used for diagnosing the electrical

portion of the A/C compressor clutch circuit. A Scan

Tool will be used in diagnosing the system. The Scan

Tool has the ability to read the A/C request input to the

ECM. The Scan Tool can display when the ECM has

commanded the A/C clutch ON. The Scan Tool should

have the ability to override the A/C request signal and

energize the A/C compressor relay.

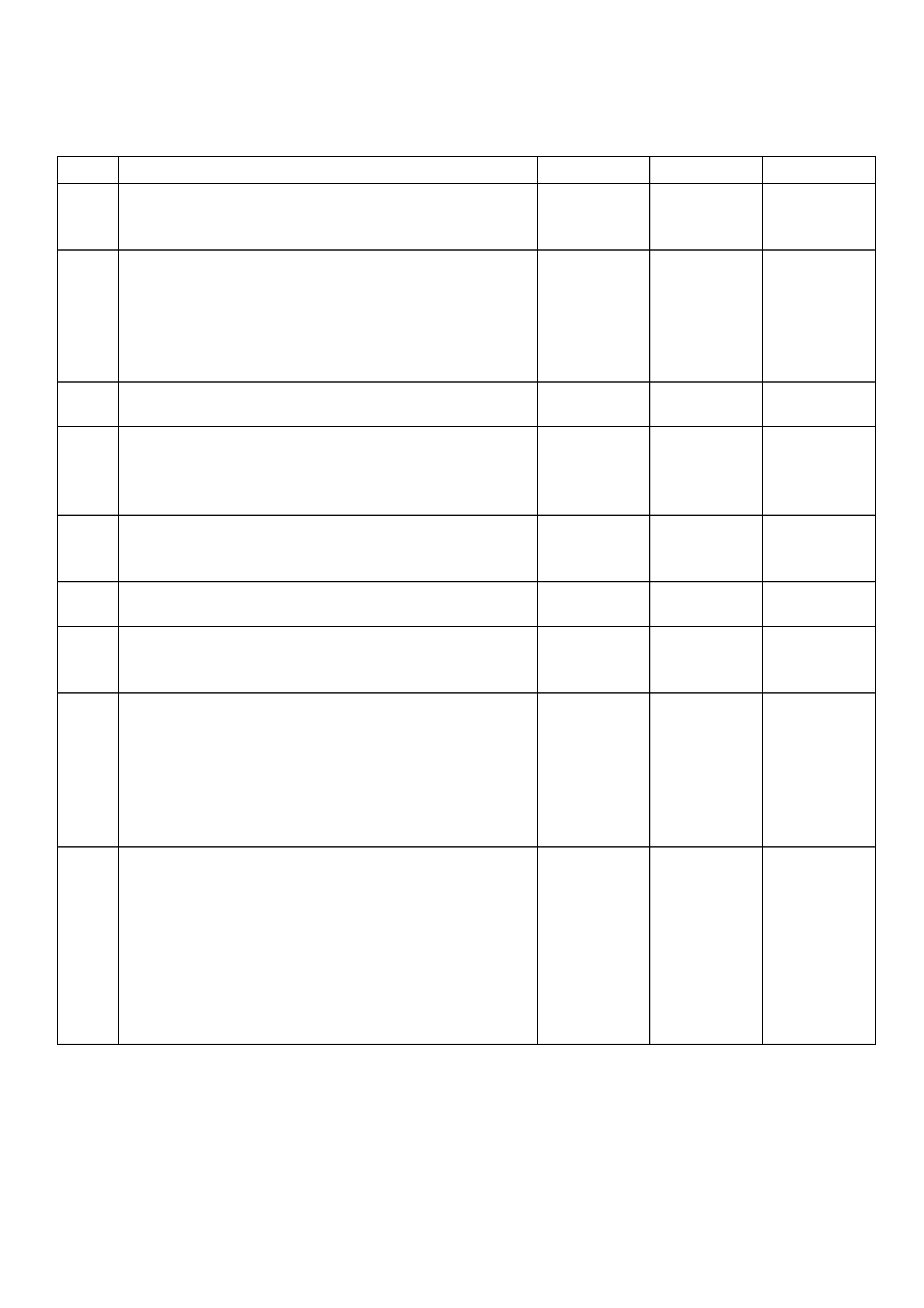

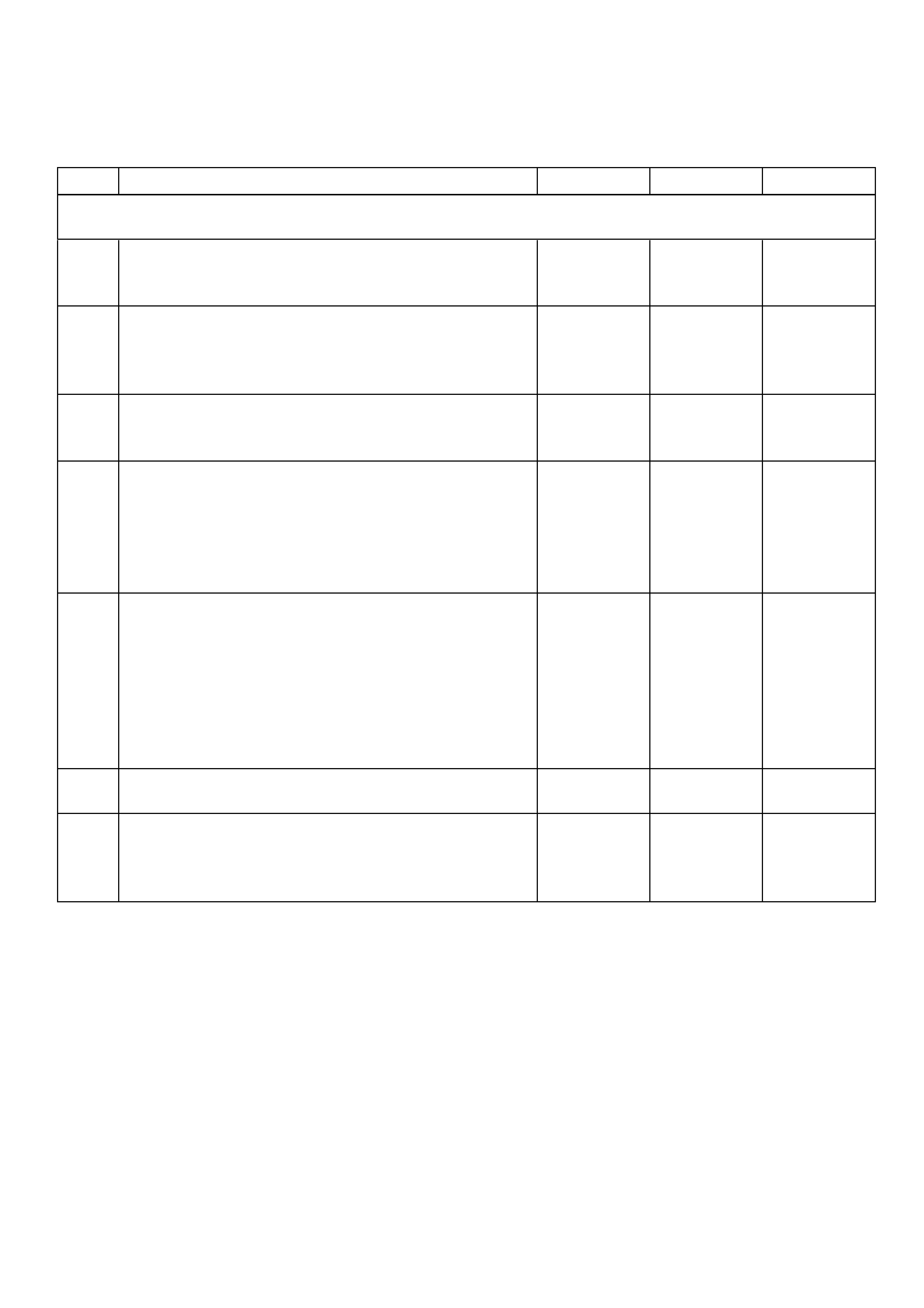

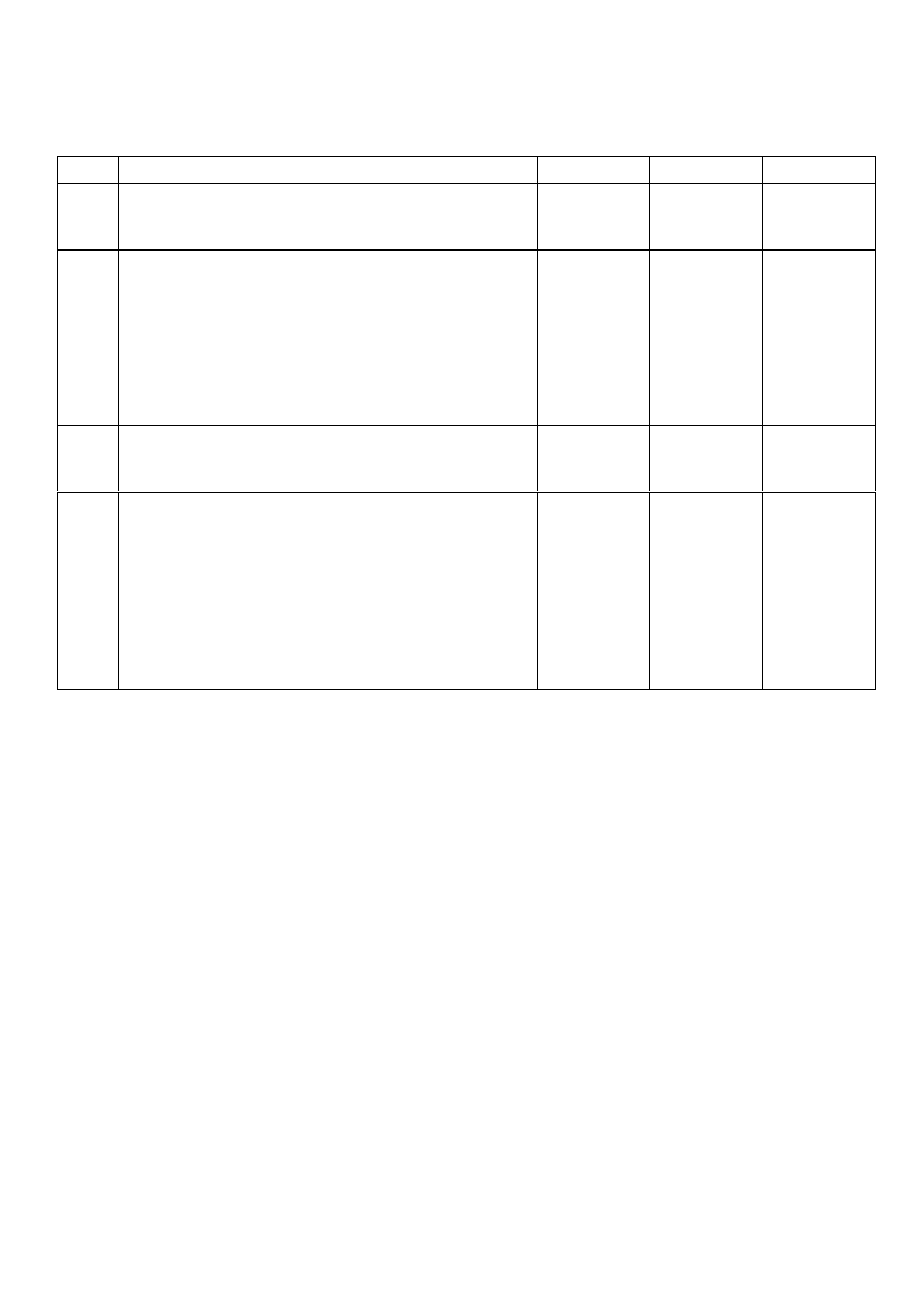

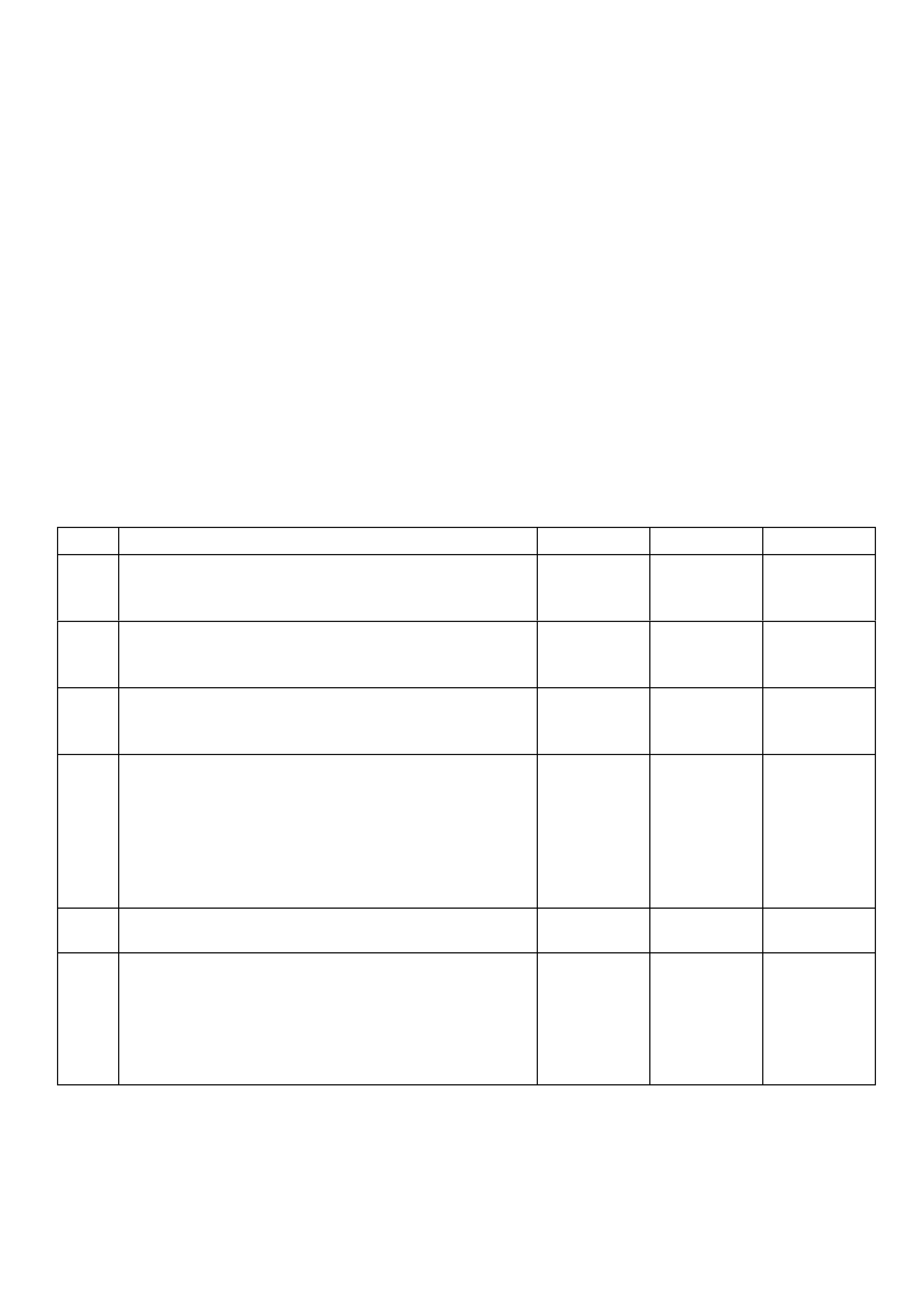

A/C CLUTCH CONTROL CIRCUIT DIAGNOSIS

STEP ACTION VALUE(S) YES NO

1Was the “On-Board Diagnostic (OBD) System Check”

performed? - Go to Step 2 Go to OBD

System Check

2

1. Ignition ON, Engine OFF.

2. Review and record the customer complaint.

3. Operate the vehicle within the costomer complaint conditions

as noted.

4. Using the Scan Tool, monitor “DTC” info for DTC 87 or 88.

-Refer to

Diagnostic Aids

Go to step 3

3

1. Ignition OFF.

2. Remove the A/C Compressor Clutch Rela y from the

Underhood Electrical Center.

3. Ignition ON, Engine OFF.

4. Using a Digital Voltmeter (DVM), check for voltage on the

Fused pins of the A/C Compressor Clutch Relay connector.

Does the DVM read the following value?

12 Volts Go to Step 5 Go to Step 4

4

Check the suspect circuit(s) between the A/C Compressor

Clutch Relay connector and the Fuse for the following

conditions:

•A short to ground

•An open circuit

•A short to voltage

Was the problem found?

-Verify Repair -

STEP ACTION VALUE(S) YES NO

5

1. Ignition OFF.

2. Disconnect the Engine Control Module (ECM) connectors

from the ECM.

3. Check the A/C Compressor Clutch Relay control circuit

between the ECM and Underhood Electrical Center for the

following conditions:

•A Short to ground

•An open circuit

•A short to voltage

Was the problem found?

-Verify Repair Go to Step 6

6

1. Reinstall the A/C Compressor Clutch Relay.

2. Using a fused jumper, ground the A/C Compressor Clutch

Relay control circuit at the ECM connector.

3. Ignition ON, Engine OFF.

Does the A/C Compressor turn ON?

-Go to Step 9 Go to Step 7

7

1. Ignition OFF.

2. Check the A/C Compressor Clutch circuit between the A/C

Compressor Clutch Relay and A/C Compressor Clutch for

the following conditions:

•A Short to ground

•An open circuit

•A short to voltage

Was the problem found?

-Verify Repair Go to Step 8

8Replace the A/C Compressor Clutch Relay.

Is the action complete? -Verify Repair -

9 Replace the EPROM or ECM. Note) Refer to 6E1-243 - --

ELECTRONIC IGNITION SYSTEM

DIAGNOSIS

If the engine cranks but will not run or immediately

stalls, the Engine Cranks But Will Not Start chart

must be used to determine if the failure is in the

ignition system or the fuel system. If DTC19, or

DTC18 is set, the appropriate diagnos tic trouble c ode

chart must be used for diagnosis.

If a misfire is being experienced refer to the

Symptoms section for diagnosis.

EVAP CANISTER PURGE

CONTROL SOLENOID (IF

APPLICABLE)

A continuous purge condition with no purge

commanded by the ECM will set a DTC62. Refer to

the DTC charts for further information.

VISUAL CHECK OF THE

EVAPORATIVE EMISSION

CANISTER (IF APPLICABLE)

•If the canister is cracked or damaged, replace the

canister.

•If fuel is leaking from the canister, replace the

canister and check hoses and hose routing.

IDLE AI R CONTROL (I AC) VALVE

The Scan Tool displays the IAC pintle position in

counts. A count of “O” indicates the ECM is

commanding the IAC pintle to be driven all the way

into a fully-seated position. This is usually caused by

a vacuum leak.

The higher the number of counts, the more air is

being comm anded to bypass the throttle blade. Ref er

to IAC System Check in order to diagnose the IAC

system. Refer to Rough, Unstable, or Incorrect

Idle, Stalling in Symptoms for other possible causes

of idle problems.

FUEL SYSTEM PRESSURE TEST

A fuel system pressure test is part of several of the

diagnostic charts and symptom checks. To perform

this test, refer to Fuel System Diagnosis.

FUEL METERING SYSTEM CHECK

Some failures of the fuel metering system will result

in an “Engine Cranks But Will Not Run” symptom. If

this condition ex ists , r ef er to the Cranks But Will Not

Run chart. This chart will determine if the problem is

caused by the ignition system, the ECM, or the fuel

pump electrical circuit.

Refer to Fuel System Electrical Test for the fuel

system wiring schematic.

If there is a fuel delivery problem, refer to Fu el System

Diagnosis, which diagnoses the fuel inj ectors, the fuel

pressure regulator, and the fuel pump.

Followings are applicable to the vehicles with

closed Loop S y ste m:

If a malfunction occurs in the fuel metering system, it

usually results in either a rich HO2S signal or a lean

HO2S signal. This condition is indicated by the HO2S

voltage, which causes the ECM to change the fuel

calculation (fuel injector pulse width) based on the

HO2S reading. Changes made to the fuel calculation

will be indicated by a change in the long term fuel trim

values which can be m onitor ed with a Scan T ool. Ideal

long term fuel trim values are around 0%; for a lean

HO2S signal, the ECM will add fuel, resulting in a fuel

trim value above 0%. Some variations in fuel trim

values are normal because all engines are not exactly

the same. If the evapor ative em ission c anister pur ge is

02 status may be rich condition. 02 status indic ates the

lean condition, refer to DTC44 for items which can

cause a lean HO2S signal.

FUEL INJECTOR COIL TEST

PROCEDURE AND FUEL

INJECTOR BALANCE TEST

PROCEDURE

TEST DESCRIPTION

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Relieve the fuel pressure by connecting 5-8840-

0378-0 T-Joint to the fuel pressure connection on

the fuel rail.

CAUTION: In order to reduce the risk of fire

and personal injury, wrap a shop towel

around the fuel pressure connection. The

tow el will absorb any fuel leakage that occurs

during the connection of the fuel pressure

gauge. Place the towel in an approved

container when the connection of the fuel

pressure gauge is complete.

Place the fuel pressure gauge bleed hose in an

approved gasoline container.

With the ignition switch OFF open the valve on the

fuel pressure gauge.

3. Record the lowest voltage displayed by the DVM

after the first second of the test. (During the first

second, voltage displayed by the DVM may be

inaccurate due to the initial current surge.)

Injector Specifications:

RESISTANCE

OHMS VOLTAGE

SPECIFICATION AT

10°C-35°C (50°F-95°F)

11.8-12.6 5.7-6.6

•The voltage displayed by the DVM should be

within the specified range.

•The voltage displayed by the DVM may

increase throughout the test as the fuel injector

windings warm and the resistance of the fuel

injector windings changes.

•An erratic voltage reading (large fluctuations in

voltage that do not stabilize) indicates an

intermittent connection within the fuel injector.

5. Injector Specifications:

HIGHEST ACCEPTABLE

VOLTAGE

READING

ABOVE/BELOW

35°C/10°C (95°F/50°F)

ACCEPTABLE

SUBTRACTED

VALUE

9.5Volts 0.6Volt

7. The Fuel Injector Balance Test portion of this

chart (Step 7 through Step 11) checks the

mechanical (fuel delivery) portion of the fuel

injector . An engine cooldown period of 10 minutes

is necessary in order to avoid irregular fuel

pressure readings due to “Hot Soak” fuel boiling.

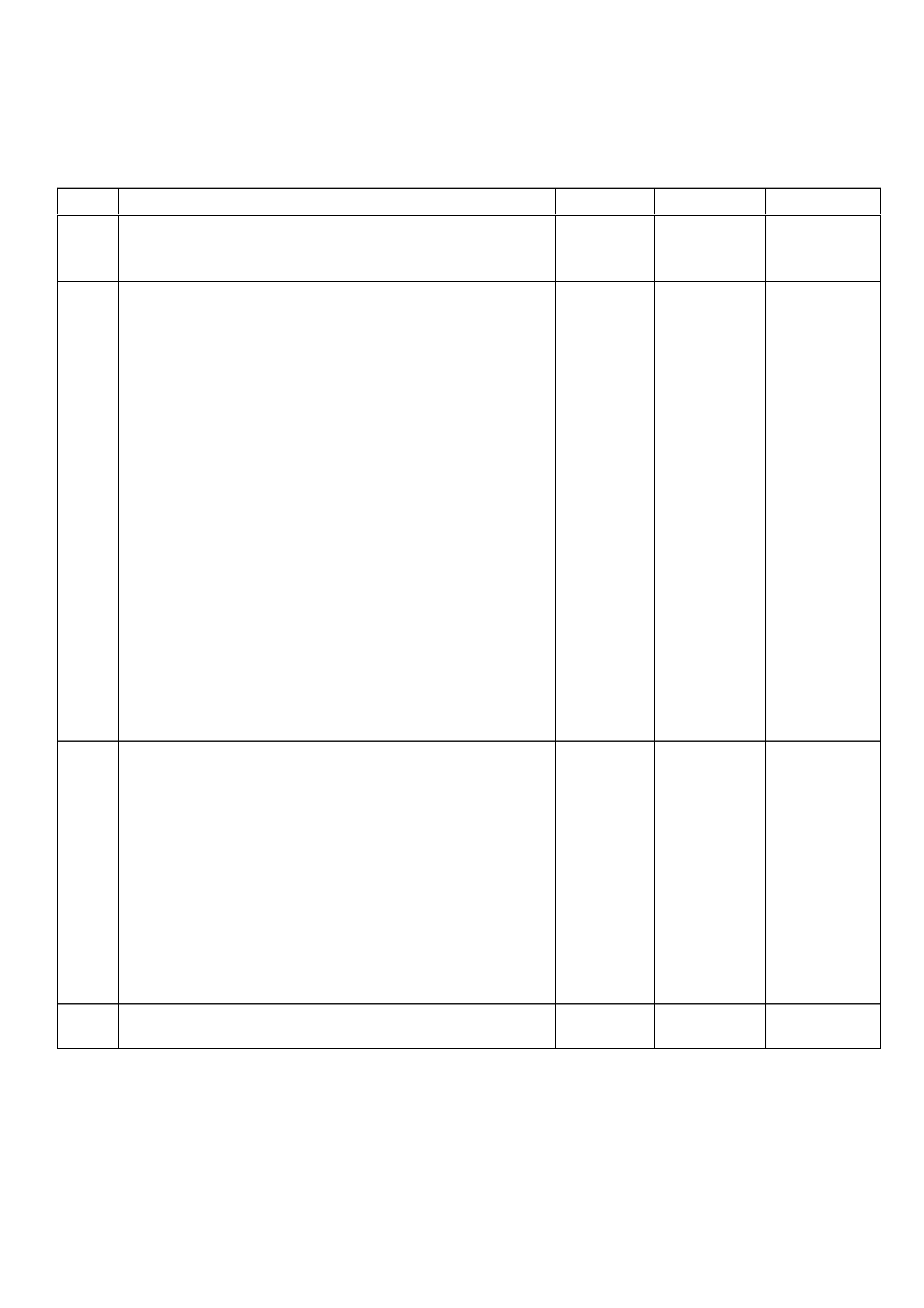

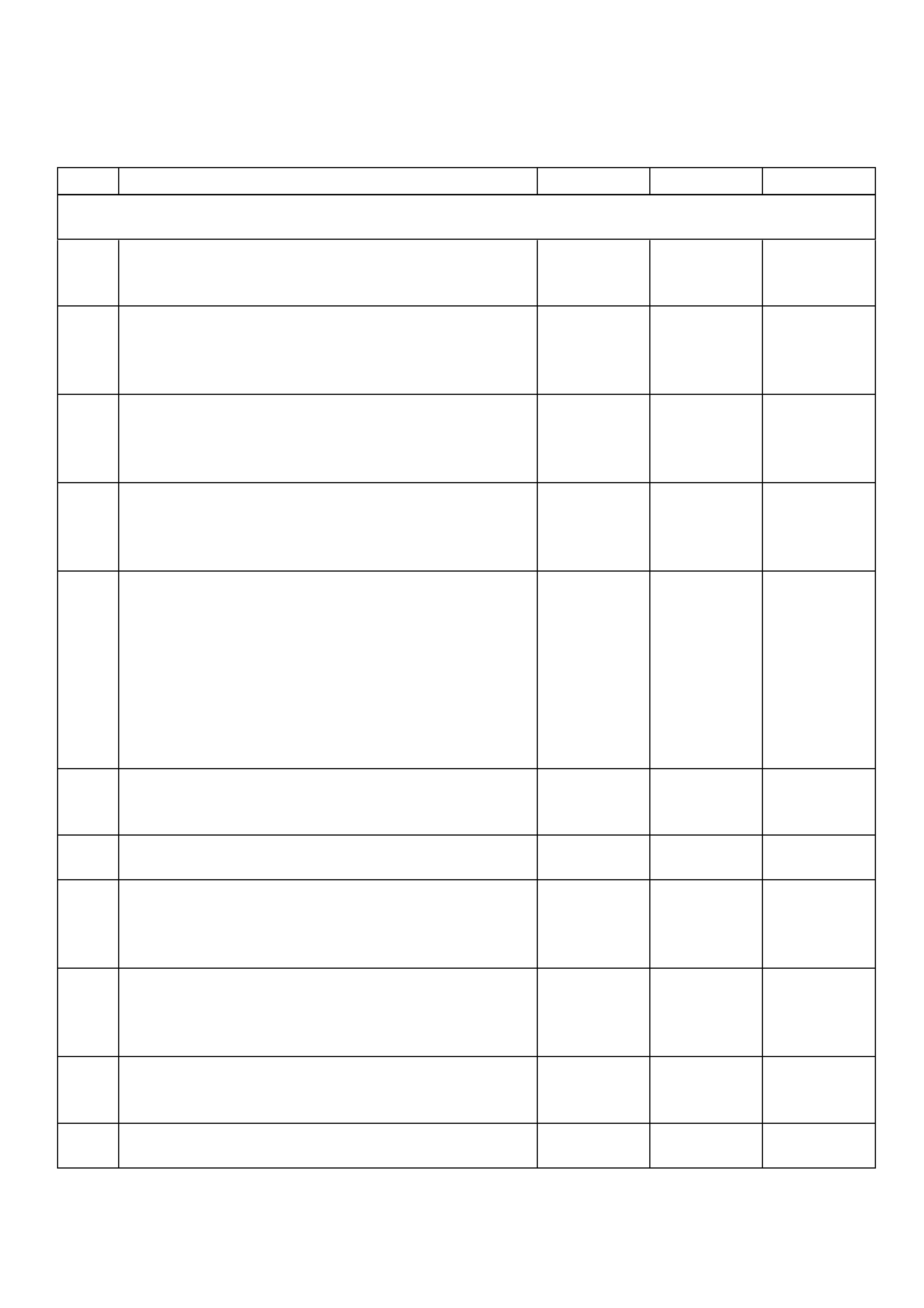

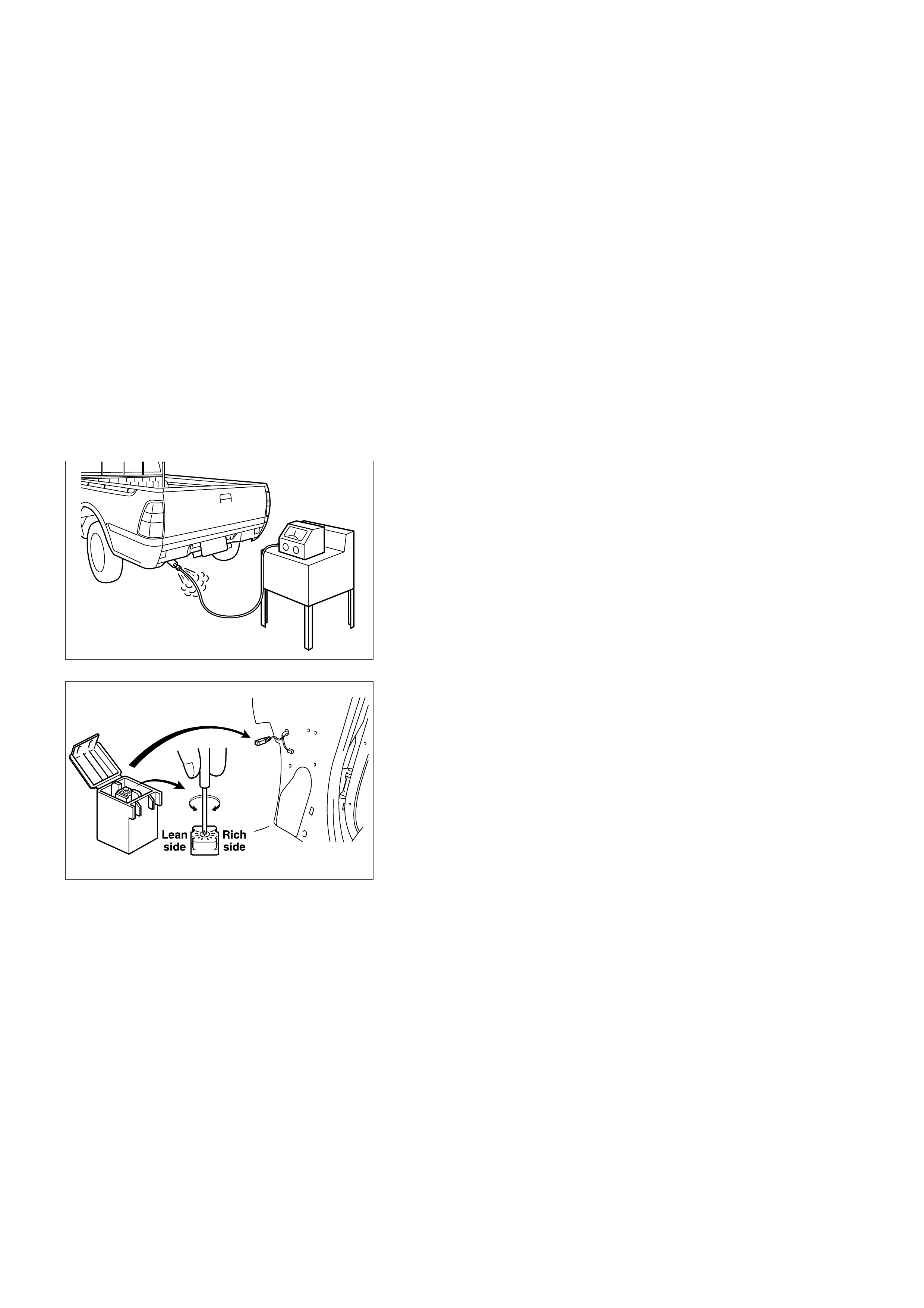

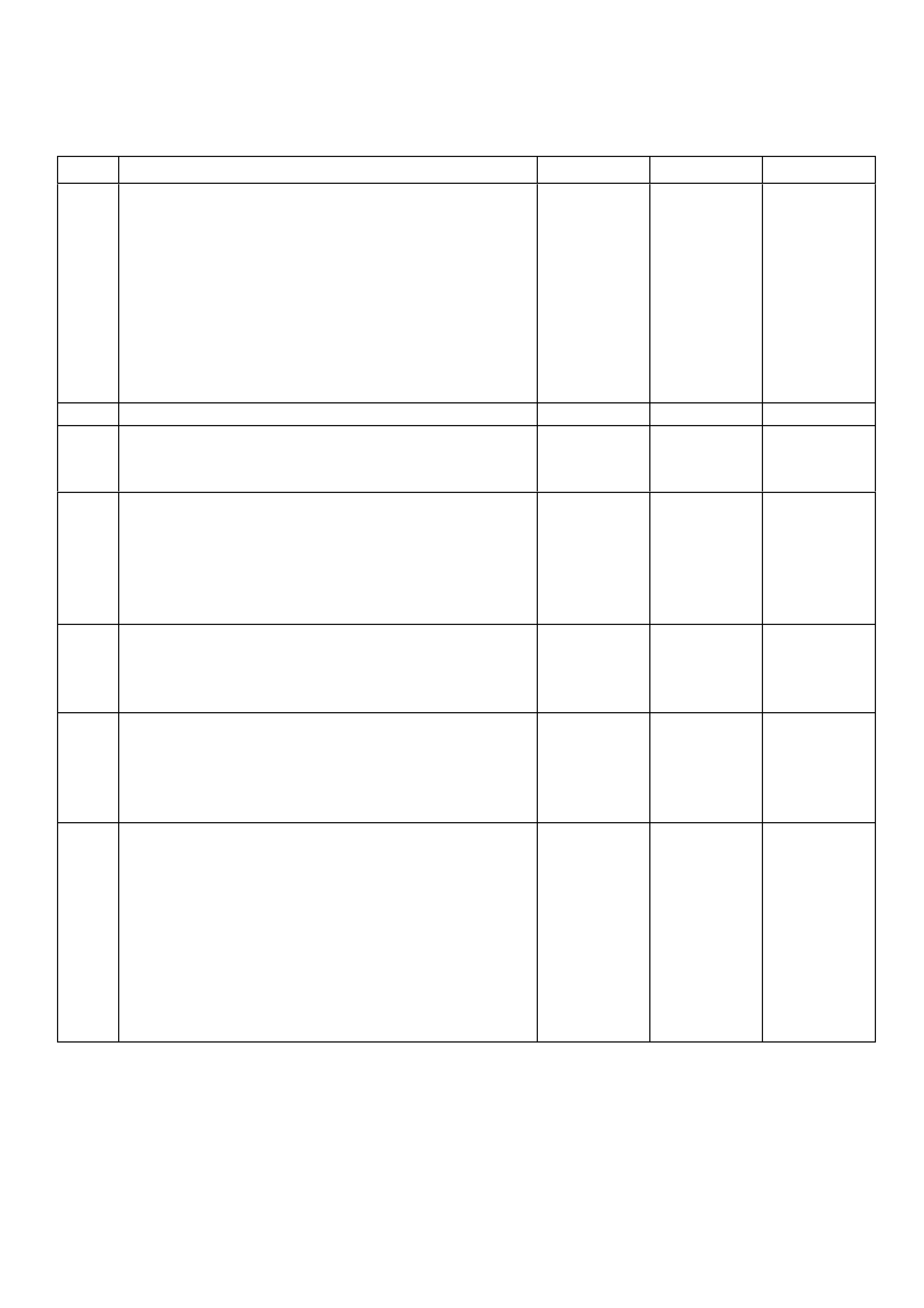

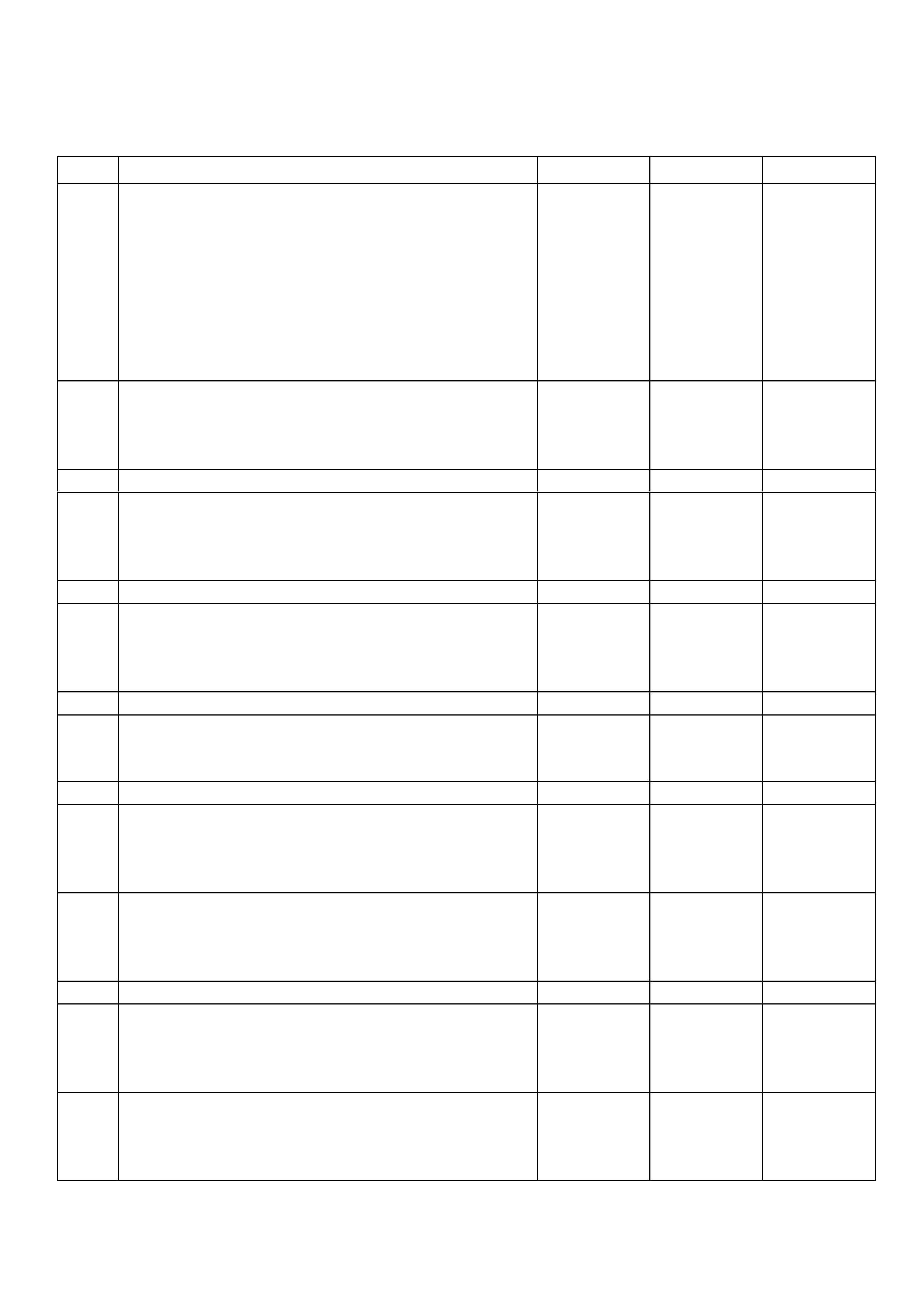

INJECTOR COIL TEST PROCEDURE (STEPS 1-6)

AND INJECTOR BALANCE TEST PROCEDURE (STEPS 7-11)

CYLINDER

1234

1st Reading (1) 296kPa

(43psi) 296kPa

(43psi) 296kPa

(43psi) 296kPa

(43psi)

2nd Reading (2) 205kPa

(29psi) 205kPa

(29psi) 196kPa

(28psi) 274kPa

(39psi)

Amount of Drop

(1st Reading-2nd Reading) 91kPa

(14psi) 91kPa

(14psi) 100kPa

(15psi) 22kPa

(4psi)

Av. Drop = 166kPa/24psi

±10kPa/1.5psi

= 156 − 176kPa or

22.5 − 25.5psi

Faulty, Lean

(Too Little

Fuel Drop)

Faulty, Lean

(Too Little

Fuel Drop)

Faulty, Lean

(Too Little

Fuel Drop)

Faulty, Lean

(Too Little

Fuel Drop)

NOTE: These figures are examples only.

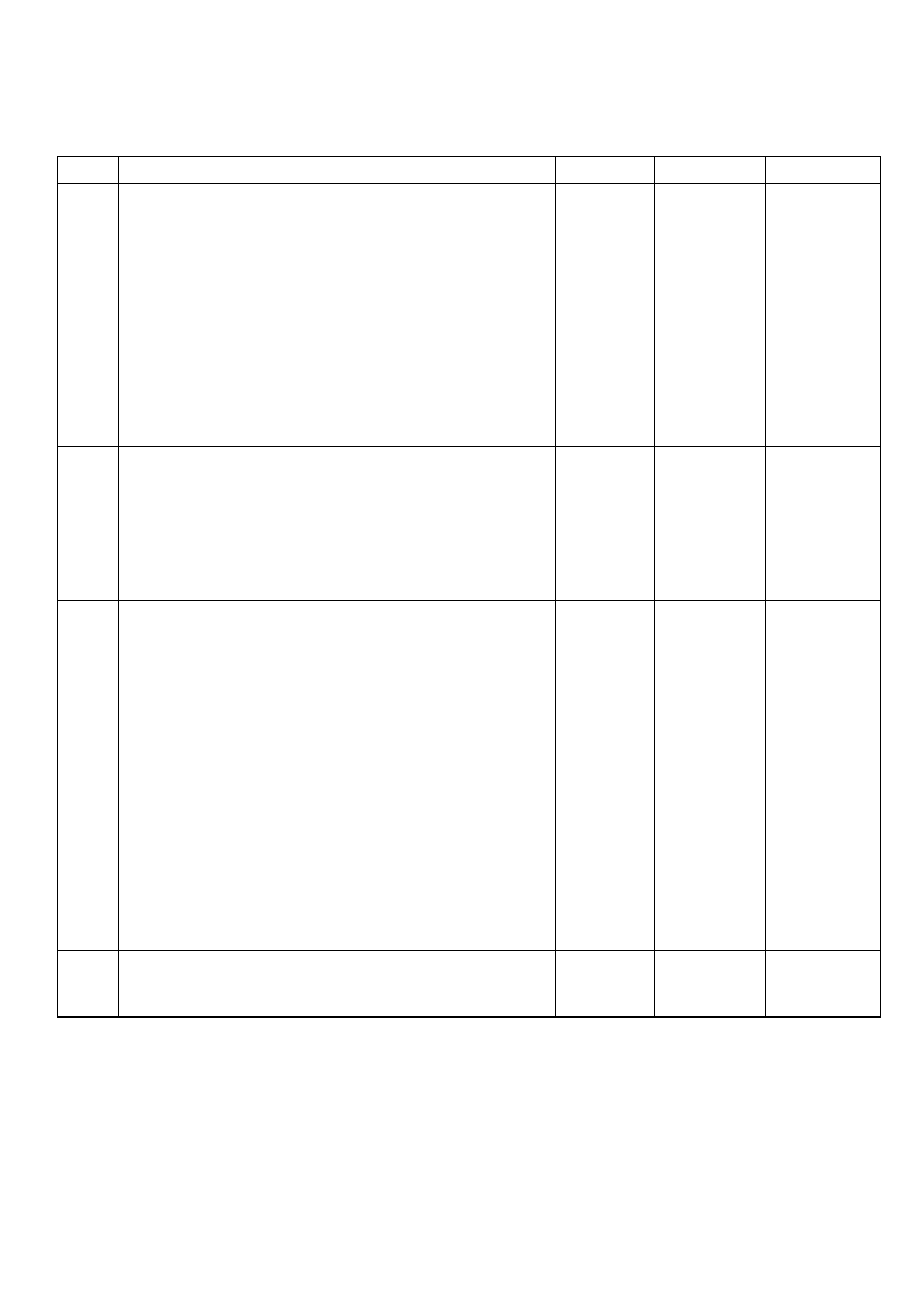

INJECTOR COIL TEST PROCEDURE (STEPS 1-6) AND

INJECTOR BALANCE TEST PROCEDURE (STEPS 7-11)

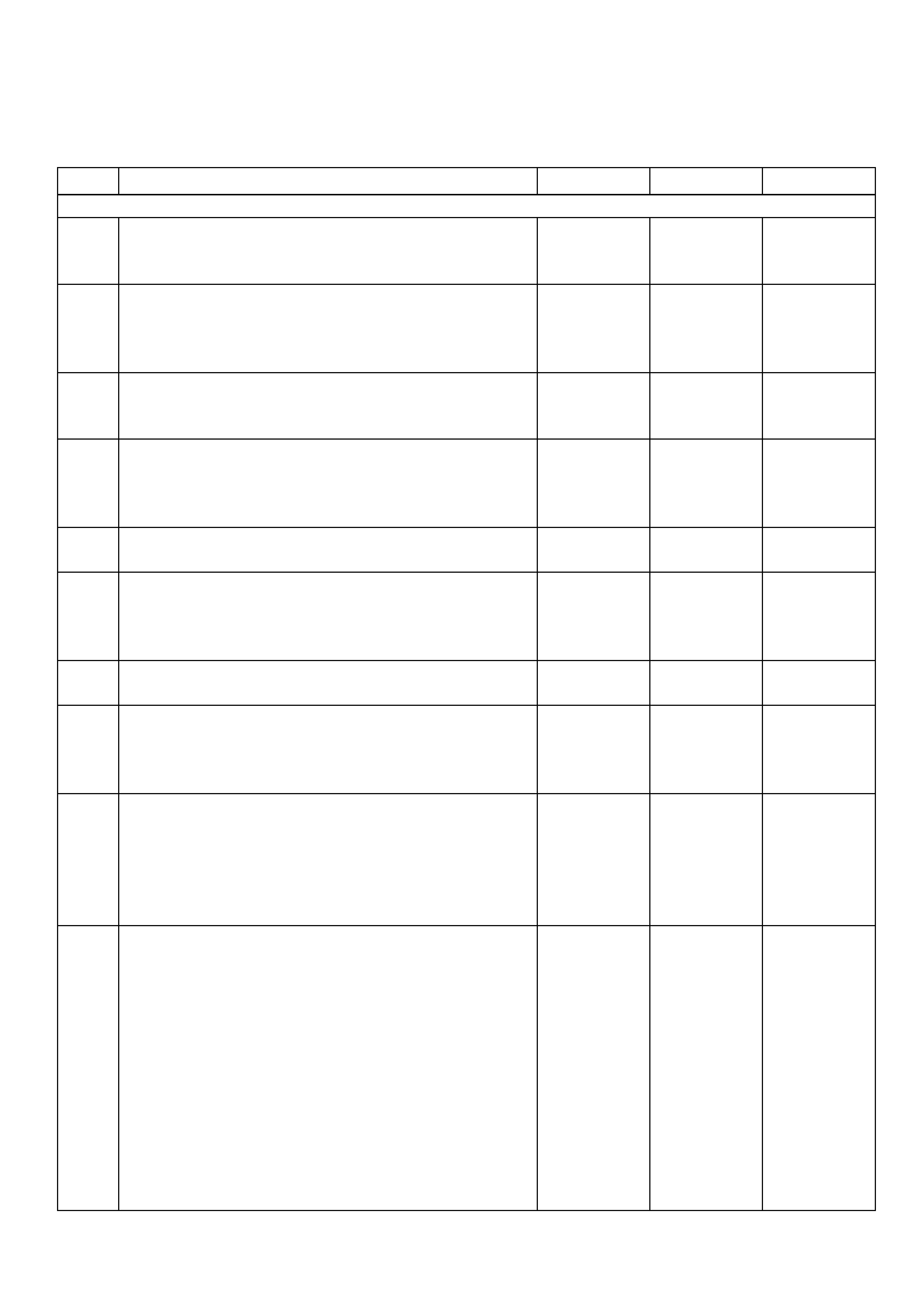

STEP ACTION VALUE(S) YES NO

1Was the “On-Board Diagnostic (OBD) System

Check” performed? -Go to Step 2

Go to OBD

System Check

2

1. Turn the engine OFF.

Notice: In order to prevent flooding of a single cylinder and

possible engine damage, relieve the fuel pressure before

performing the fuel injector coil test procedure.

2. Relieve the fuel pressure. Refer to Test Description Number 2.

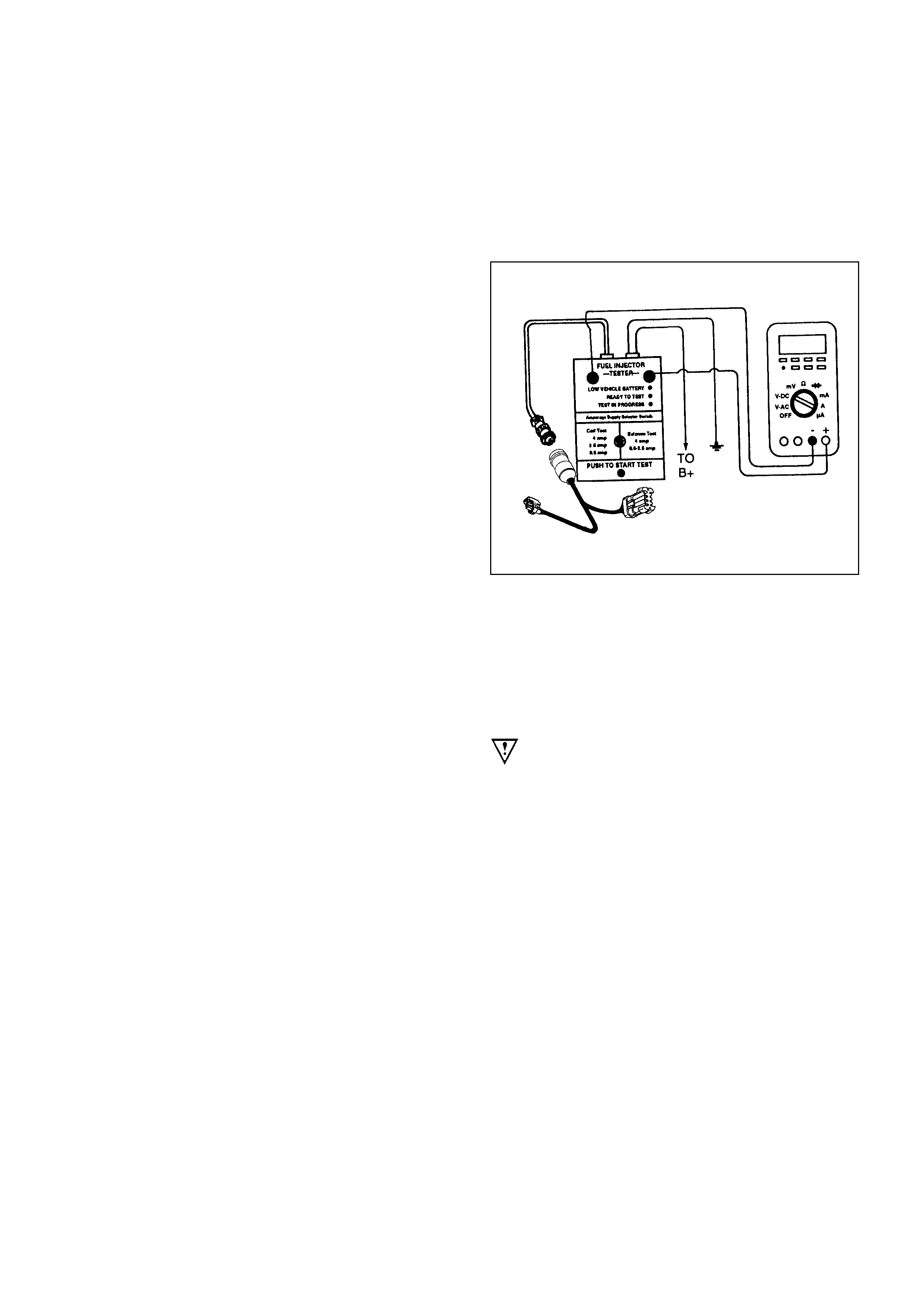

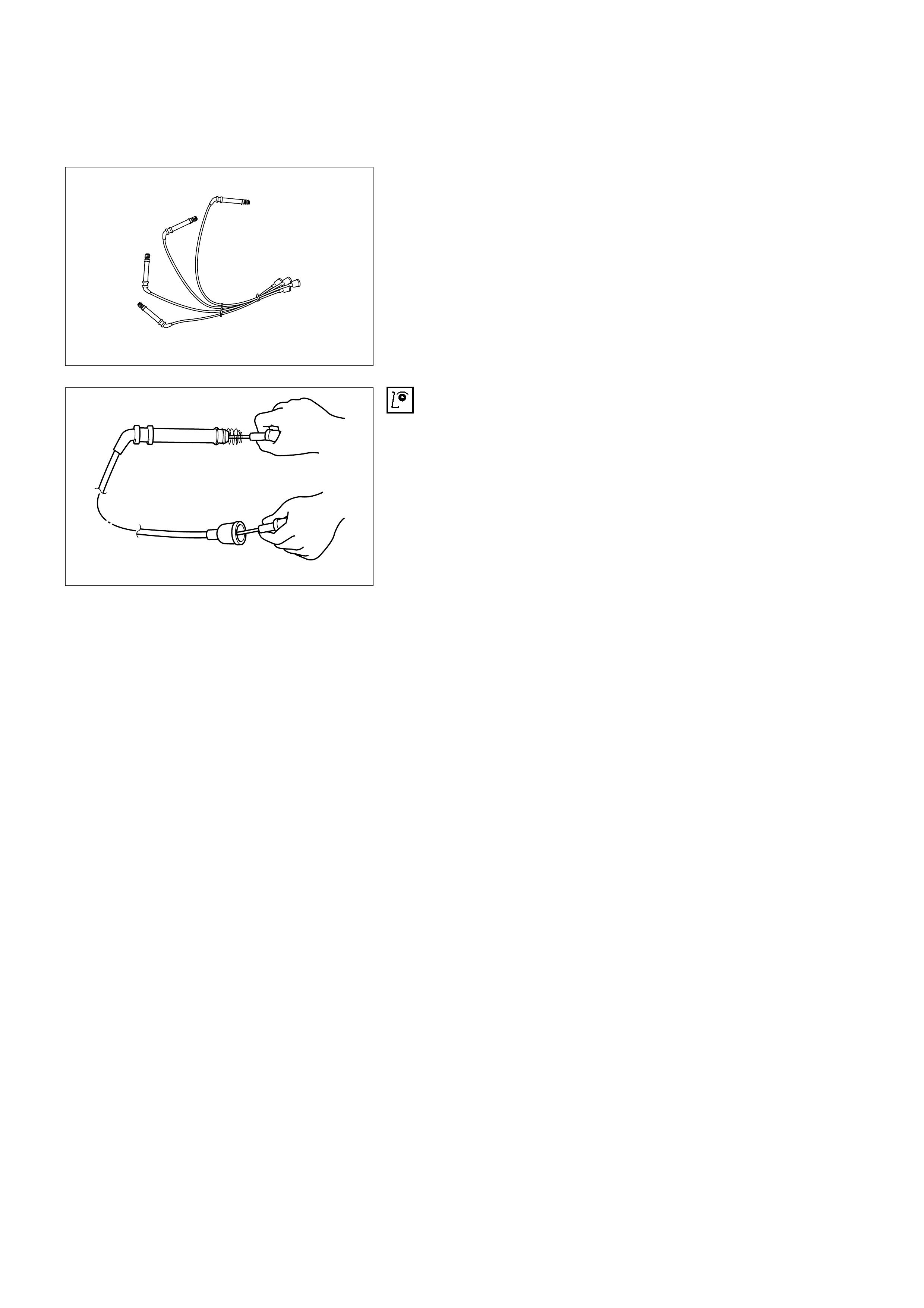

3. Connect the 5-8840-2618-0 Fuel Injector Tester to B+ and

ground, and to the 5-8840-2589-0 Injector Adapter Cable.

4. Remove the harness connector of the Fuel Injector and connect

the 5-8840-2589-0 Injector Adapter Cable for F/I check.

5. Set the amperage supply selector switch on the fuel injector

tester to the “Coil Test” 0.5 amp position.

6. Connect the leads from the 5-8840-2392-0 Digital Voltmeter

(DVM) to the fuel injector tester. Refer to the illustrations

associated with the test description.

7. Set the DVM to the tenths scale (0.0).

8. Observe the engine coolant temperature.

Is the engine coolant temperature within the specified values?

10°C (50°F)

to

35°C (95°F) Go to Step 3 Go to Step 5

3

1. Set the injector adapter cable to injector #1.

2. Press the “Push to Start Test” button on the fuel injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT: The voltage reading may rise during the test.

4. Record the lowest voltage observed after the first second of the

test.

5. Set the injector adapter cable to the next injector and repeat

steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading (large

fluctuations in voltage that did not stabilize) or a voltage reading

outside of the specified values? 5.7-6.6V Go to Step 4 Go to Step 7

4Replace the faulty fuel injector(S). Refer to Fuel Injector.

Is the action complete? -Go to Step 7 -

STEP ACTION VALUE(S) YES NO

5

1. Set the Injector Adapter Cable to injector #1.

2. Press the “Push to Start Test” button on the fuel injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT: The voltage reading may rise during the test.

4. Record the lowest voltage observed after the first second of the

test.

5. Set the Injector Adapter Cable to the next injector and repeat

steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading (large

fluctuations in voltage that did not stabilize) or a voltage reading

above the specified value? 9.5V Go to Step 4 Go to Step 6

6

1. Identify the highest voltage reading recorded (other than those

above 9.5V).

2. Subtract the voltage reading of each injector from the highest

voltage selected in step 1. Repeat until you have a subtracted

value for each injector.

For any injector, is the subtracted value in step 2 greater than the

specified value? 0.6V Go to Step 4 Go to Step 7

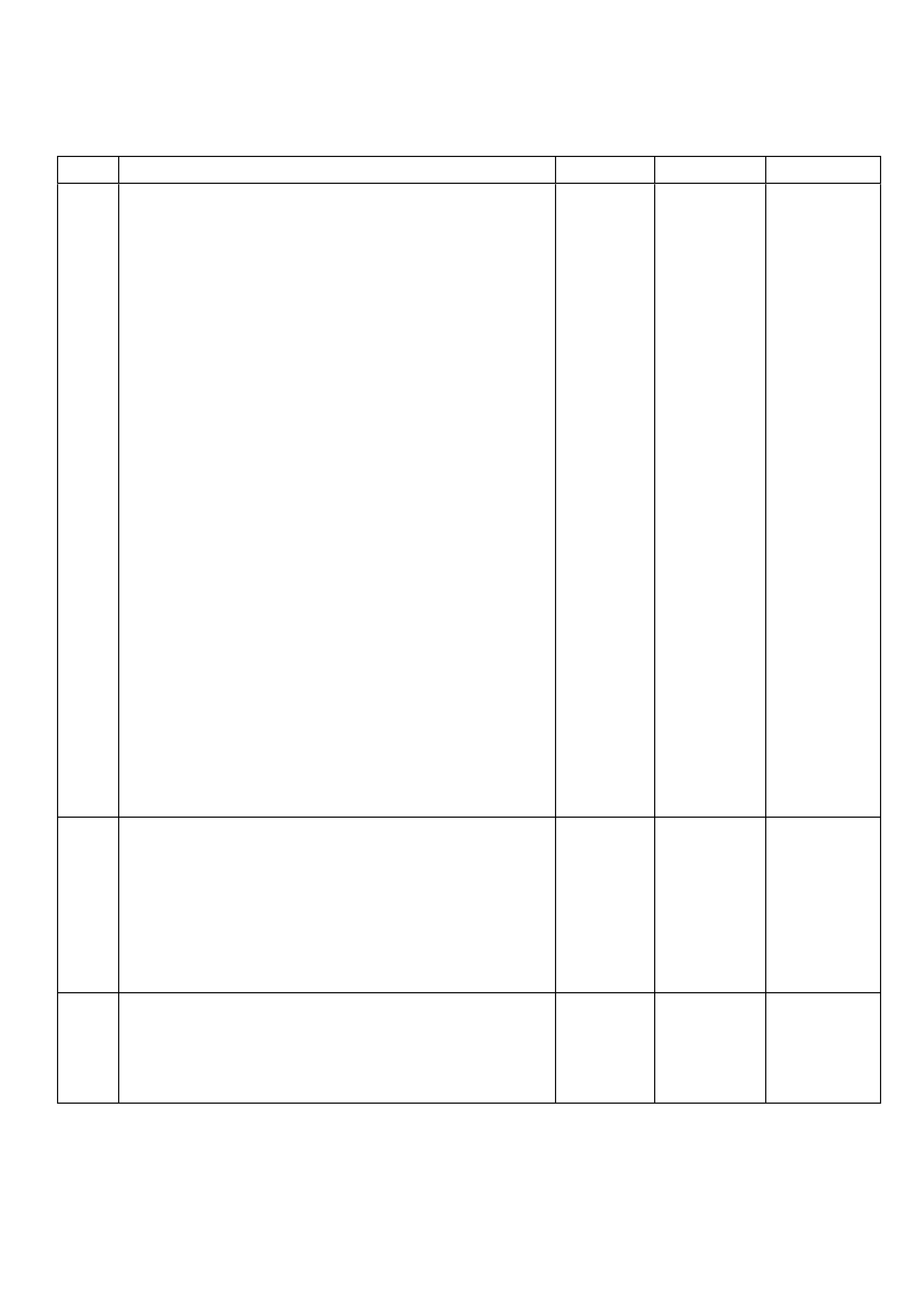

7

CAUTION: In order to reduce the risk of fire and personal

injury, wrap a shop towel around the fuel pressure connection.

The towel will absorb any fuel leakage that occurs during the

connection of the fuel pressure gauge. Place the Towel in an

approved container when the connection of the fuel pressure

gauge is complete.

1. Connect the 5-8840-0378-0 Fuel Pressure Gauge to the fuel

pressure test port.

2. Energize the fuel pump using the Scan Tool.

3. Place the bleed hose of the fuel pressure gauge into an

approved gasoline container.

4. Bleed the air out of the fuel pressure gauge.

5. With the fuel pump running, observe the reading on the fuel

pressure gauge.

Is the fuel pressure within the specified values?

296kPa-

376kPa

(43-55psi) Go to Step 8

Go to

Fuel System

Diagnosis

8Turn the fuel pump OFF.

Does the fuel pressure remain constant? -

Go to Step 9

Go to

Fuel System

Diagnosis

STEP ACTION VALUE(S) YES NO

9

1. Connect the 5-8840-0378-0 Fuel Injector Tester and 5-8840-

2589-0 Injector Adapter Cable to the fuel injector harness

connector.

2. Set the amperage supply selector switch on the fuel injector

tester to the “Balance Test” 0.5-2.5 amp position.

3. Using the Scan Tool turn the fuel pump ON then OFF in order

to pressurize the fuel system.

4. Record the fuel pressure indicated by the fuel pressure

gauge after the fuel pressure stabilizes.

This is the first pressure reading.

5. Energize the fuel injector by depressing the “Push to Start

Test” button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel pressure

gauge after the fuel pressure gauge needle has stopped

moving. This is the second pressure reading.

7. Repeat steps 1 through 6 for each fuel injector.

8. Subtract the second pressure reading from the first pressure

reading for one fuel injector. The result is the pressure drop

value.

9. Obtain a pressure drop value for each fuel injector.

10. Add all of the individual pressure drop values.

This is the total pressure drop.

11. Divide the total pressure drop by the number of fuel injectors.

This is the average pressure drop.

Does any fuel injector have a pressure drop value that is either

higher than the average pressure drop or lower than the average

pressure drop by the specified value? 10kPa

(1.5psi) Go to Step 10

Go to OBD

System Check

10

Re-test any fuel injector that does not meet the specification. Refer

to the procedure in step 11.

Notice: Do not repeat any portion of this test before running the

engine in order to prevent the engine from flooding.

Does any fuel injector still have a pressure drop value that is either

higher than the average pressure drop or lower than the average

pressure drop by the specified value? 10kPa

(1.5psi) Go to Step 11

Go to

Symptoms

11