SECTION 6E - STARTING SYSTEM (C22NE MODELS)

STARTING SYSTEM

GENERAL DESCRIPTION

CRANKING CIRCUIT

STARTER

SERVICE PRECAUTION

DIAGNOSIS

STARTER

REMOVAL

INSTALLATION

DISASSEMBLED VIEW

INSPECTION AND REPAIR

ARMATURE

BRUSH

BRUSH HOLDER

MAGNETIC SWITCH

CONTINUITY OF SERIES COIL

CONTINUITY OF CONTACTS

PINION

CHARACTERISTIC TEST

STARTING SYSTEM

GENERAL DESCRIPTION

CRANKING CIRCUIT

The cranking system consists of a battery, starter, starter

switch, starter relay, etc. These main components are

connected.

STARTER

The cranking system employs a magnetic type reduction

starter in which the motor shaft is also used as a pinion shaft.

When the starter switch is turned on, the contacts of magnetic

switch are closed, and the armature rotates. At the same time,

the plunger is attracted, and the pinion is pushed forward by

the shift lever to mesh with the ring gear.

Then, the ring gear runs to start the engine. When the engine

starts and the starter switch is turned off, the plunger returns,

the pinion is disengaged from the ring gear, and the armature

stops rotation. When the engine speed is higher than the

pinion, the pinion idles, so that the armature is not driven.

SERVICE PRECAUTION

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. HOLDEN will call out those

fasteners that require a replacement after removal.

HOLDEN will also call out the fasteners that require thread

lockers or thread sealant. UNLESS OTHERWISE

SPECIFIED, do not use supplemental coatings (Paints,

greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When you

install fasteners, use the correct tightening sequence and

specifications. Following these instructions can help you

avoid damage to parts and systems.

DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

Starter does not run Charging failure Repair charging system

Battery Failure Replace Battery

Terminal connection failure Repair or replace terminal connector

and/or wiring harness

Starter switch failure Repair or replace starter switch

Starter failure Repair or replace starter

STARTER

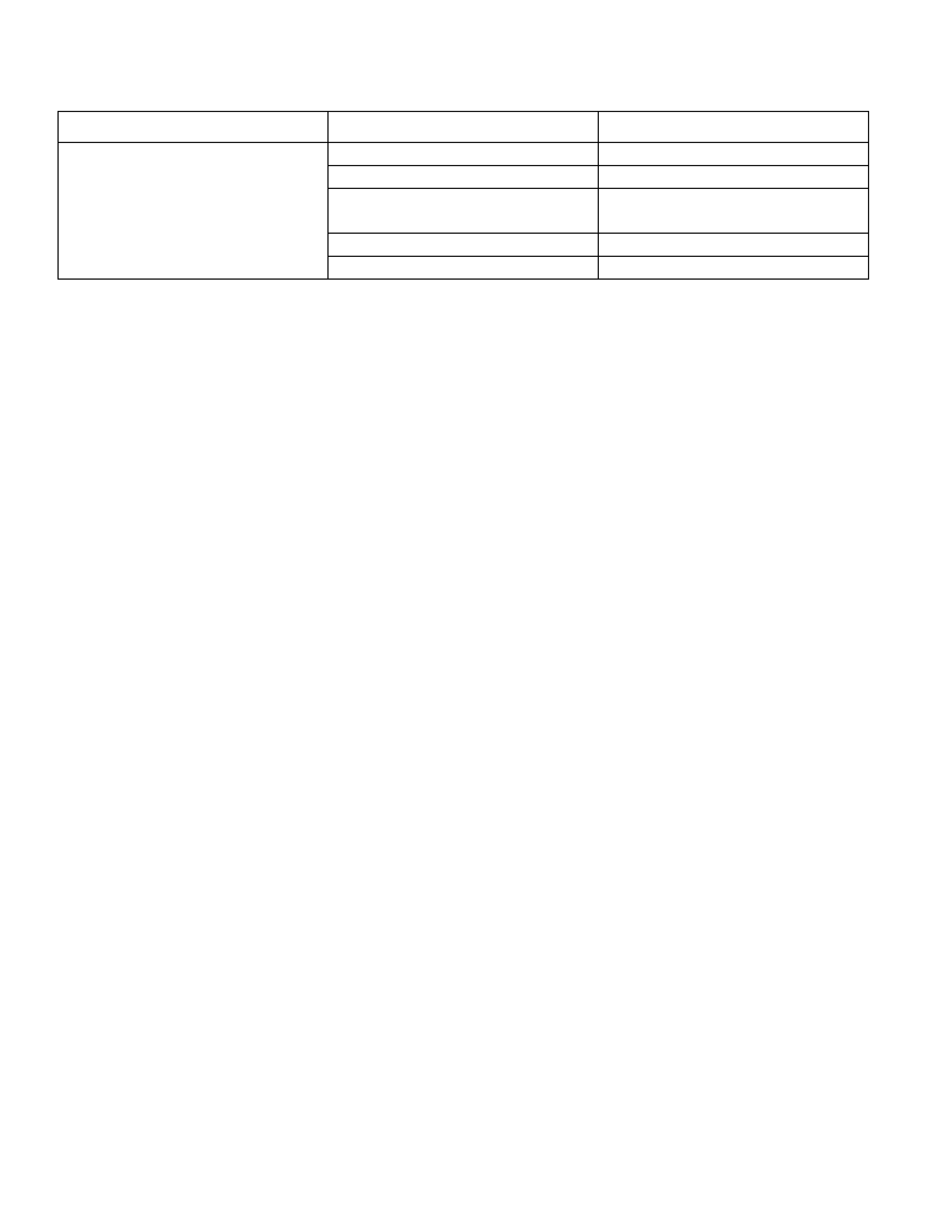

REMOVAL

1. Battery ground cable.

2. Remove harness connectors (1) and (2).

3. Remove bolts from starter.

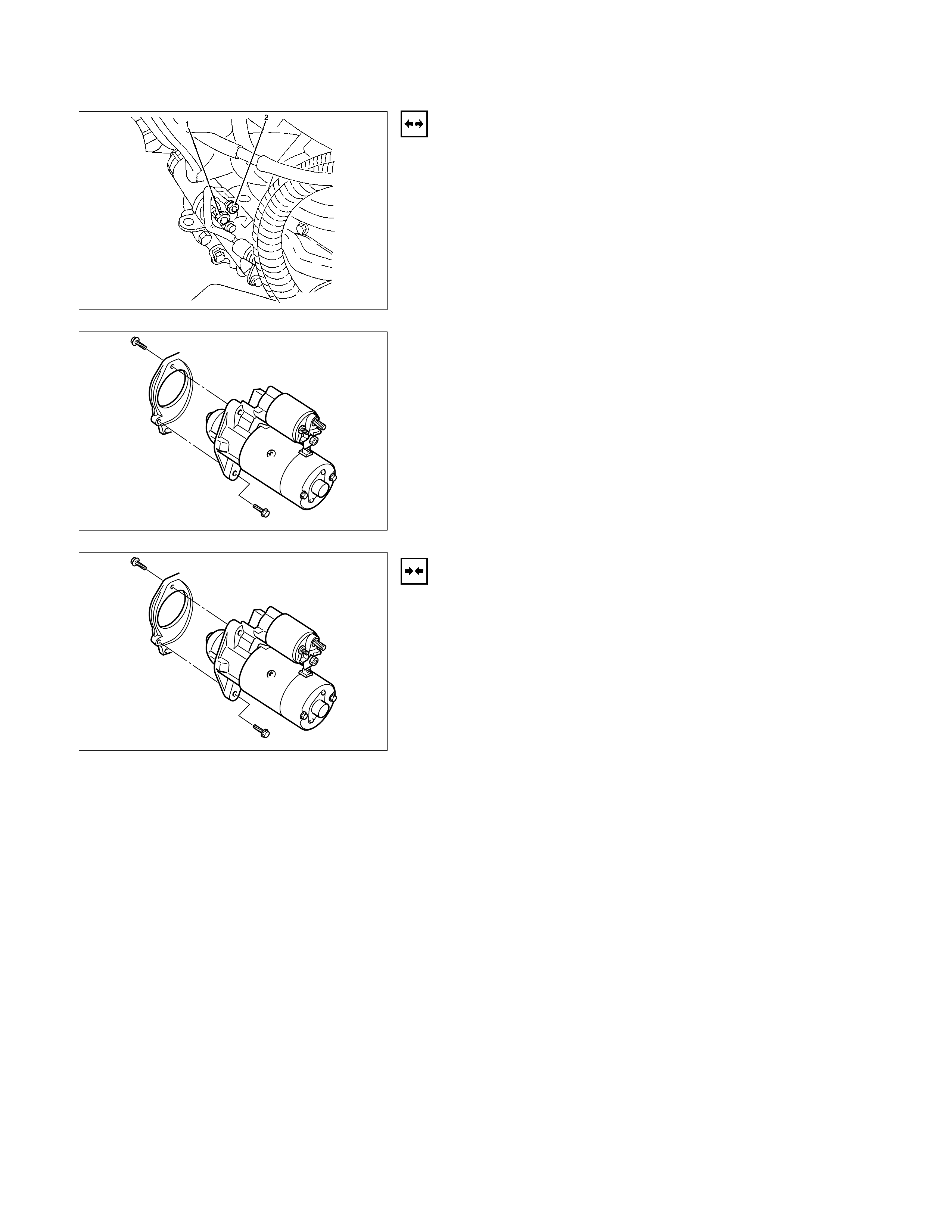

INSTALLATION

1. Install starter assembly.

2. Install mounting bolts and tighten bolts to specified torque.

Torque: 25 N⋅

⋅⋅⋅m (2.5 kgf.m)

3. Connect harness.

4. Reconnect the battery ground cable.

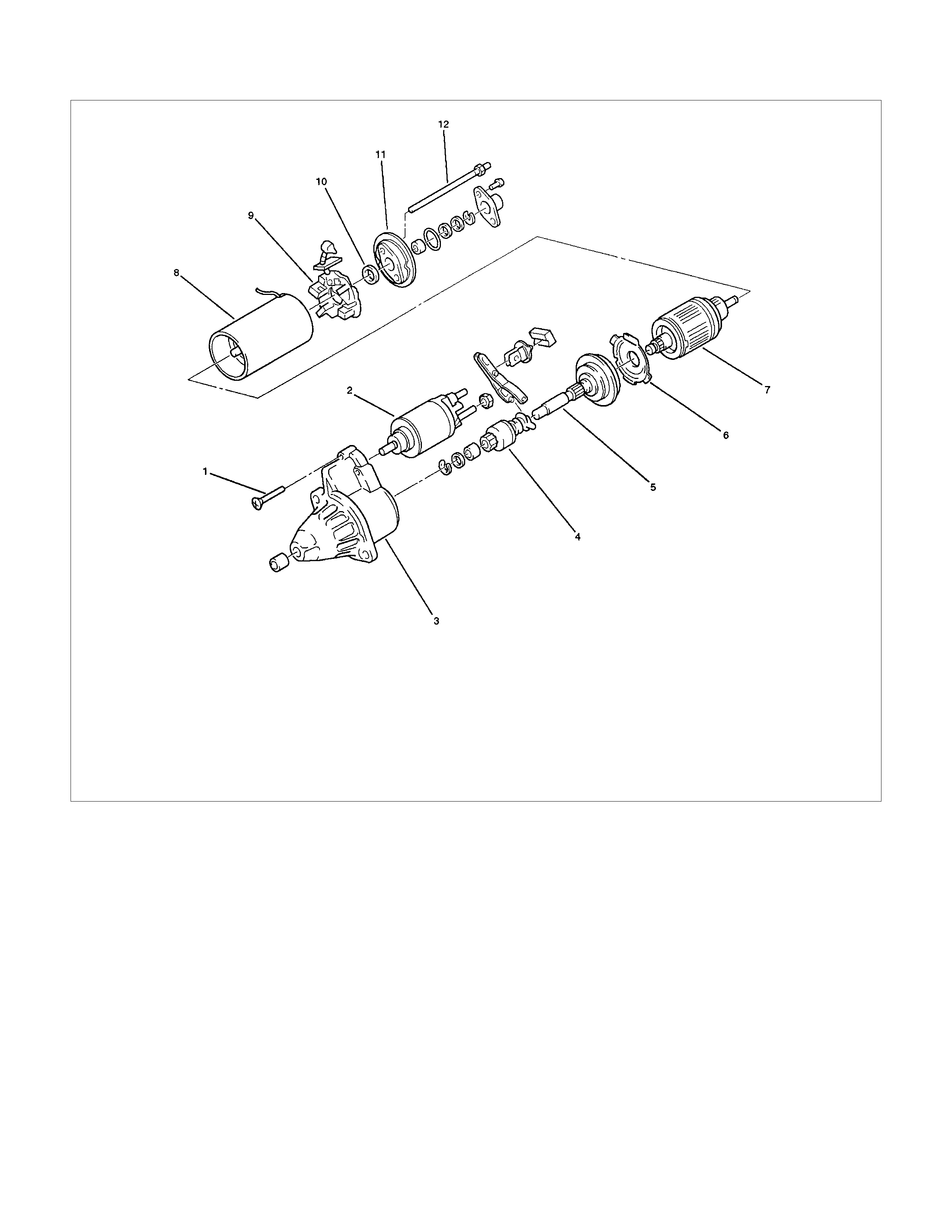

DISASSEMBLED VIEW

Legend

1 Bolt

2 Magnetic Switch

3 Gear Case

4 Piston

5 Piston Shaft

6 Center Bracket

7 Armature

8 Yoke Assembly

9 Brush and Brush Holder

10 Washer

11 Rear Cover

12 Through Bolt

INSPECTION AND REPAIR

Repair or replace necessary parts if extreme wear or damage

is found during inspection.

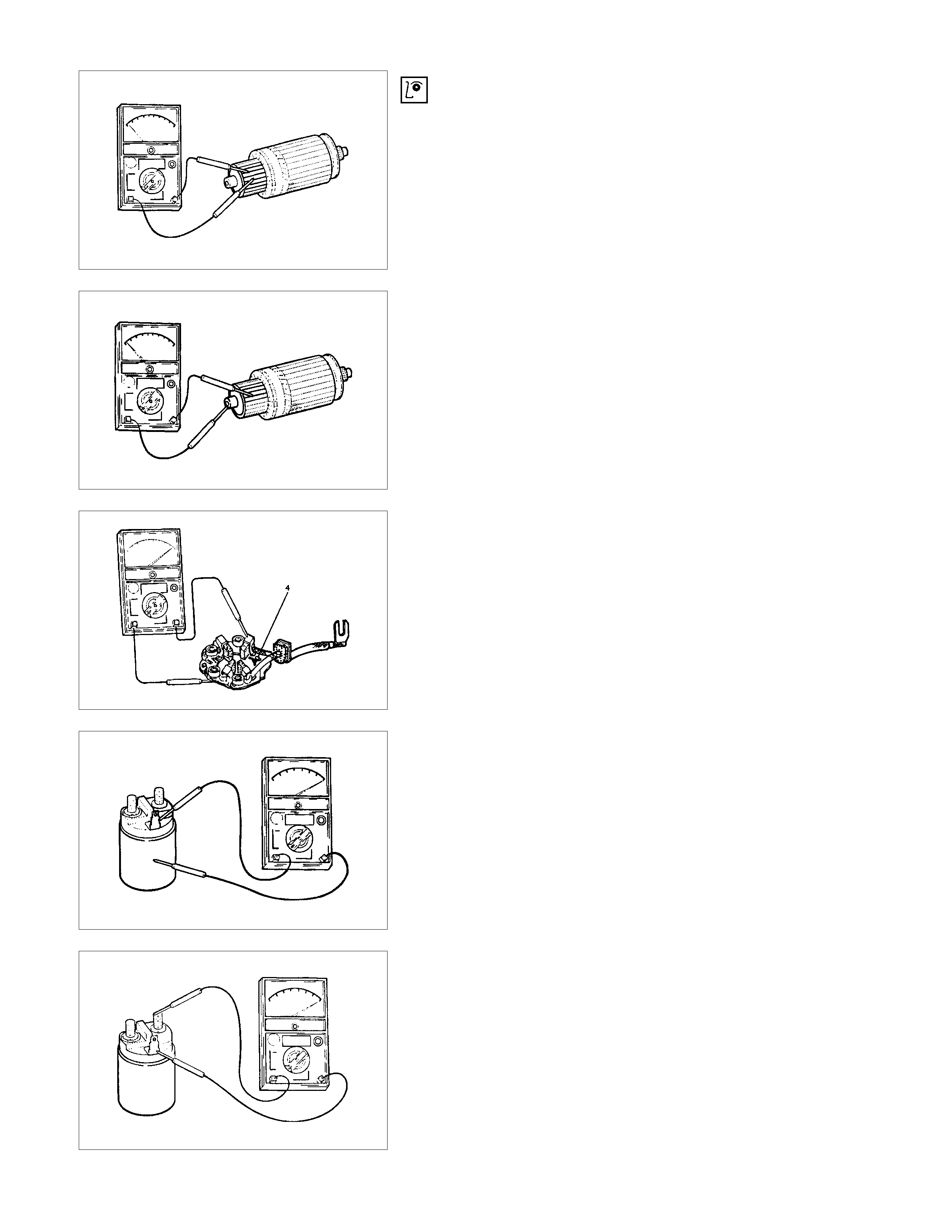

ARMATURE

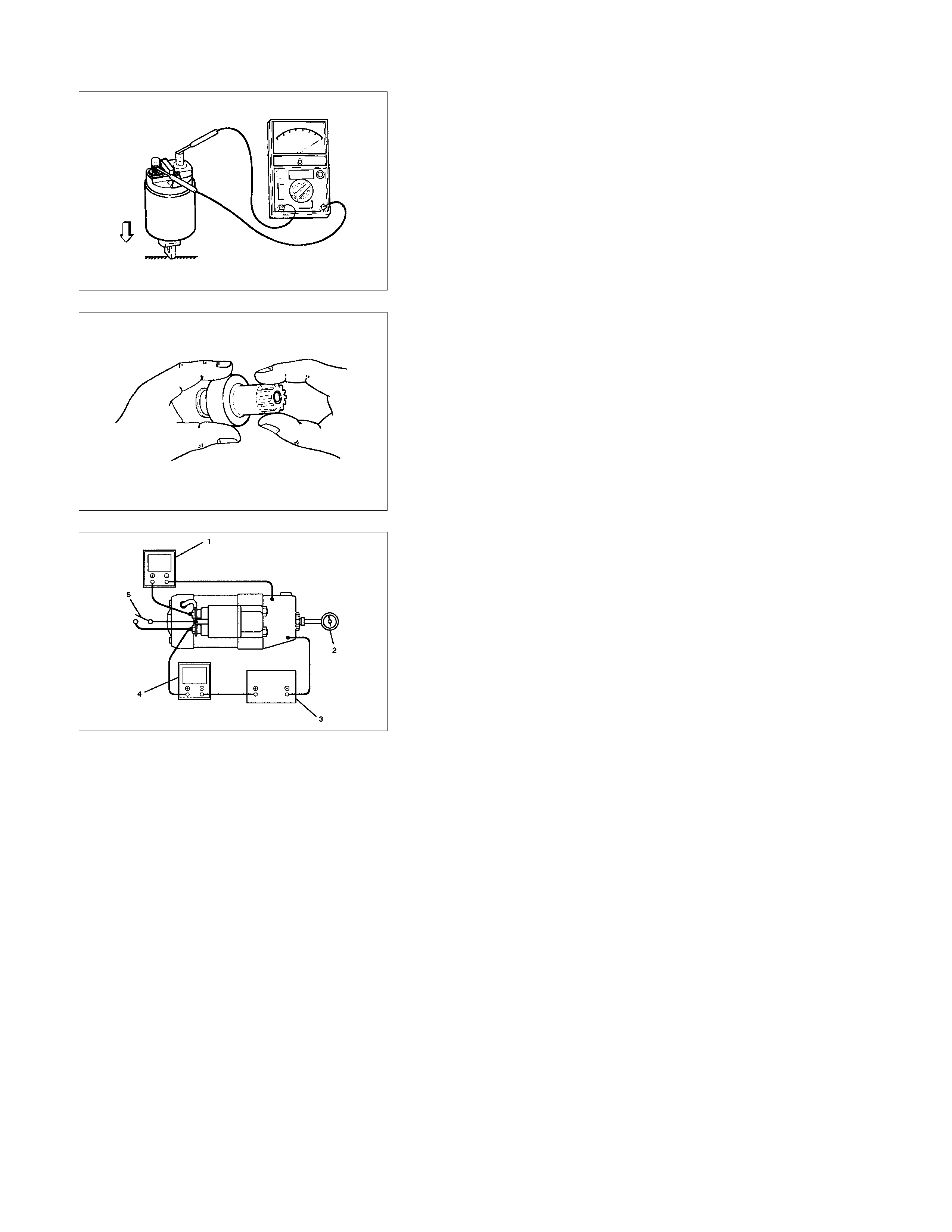

Check for continuity between commutator and segment.

Replace commutator if there is no continuity (i.e.,

disconnected).

Check for continuity between commutator and shaft.

Also, check for continuity between commutator and armature

core, armature core and shaft. Replace commutator if there is

continuity (i.e., internally grounded).

BRUSH

Measure the length of brush.

Replace with a new one, if it is below the limit.

BRUSH HOLDER

Check for continuity between brush holder (+) (4) and base (-).

Replace, if there is continuity (i.e., insulation is broken).

MAGNETIC SWITCH

Check for continuity of shunt coil between terminals S and M.

Replace, if there is no continuity (i.e., coil is disconnected).

CONTINUITY OF SERIES COIL

Check for continuity between terminals S and M.

Replace, if there is no continuity (i.e., coil is disconnected).

CONTINUITY O F CONTACTS

With the plunger faced downward, push down the magnetic

switch. In this state, check for continuity between terminals B

and M. Replace, if there is no continuity (i.e., contacts are

faulty).

PINION

Check if the pinion rotates smoothly in drive direction by hand,

or if it is locked when it is rotated in reverse. If not, replace the

pinion.

CHARACTERISTIC TEST

For easily confirming the characteristics, conduct the noload

test as follows:

Rating as short as 30 seconds requires rapid testing.

Fix the starter on the test bench, and wire as shown in

illustration. When the switch is closed, the current flows and

the starter runs under no load. At this time, measure current,

voltage and speed to check if they satisfy the standard.

LEGEND

1 Volt Meter

2 Revolution Indicator

3 Battery

4 Ammeter

5 Switch