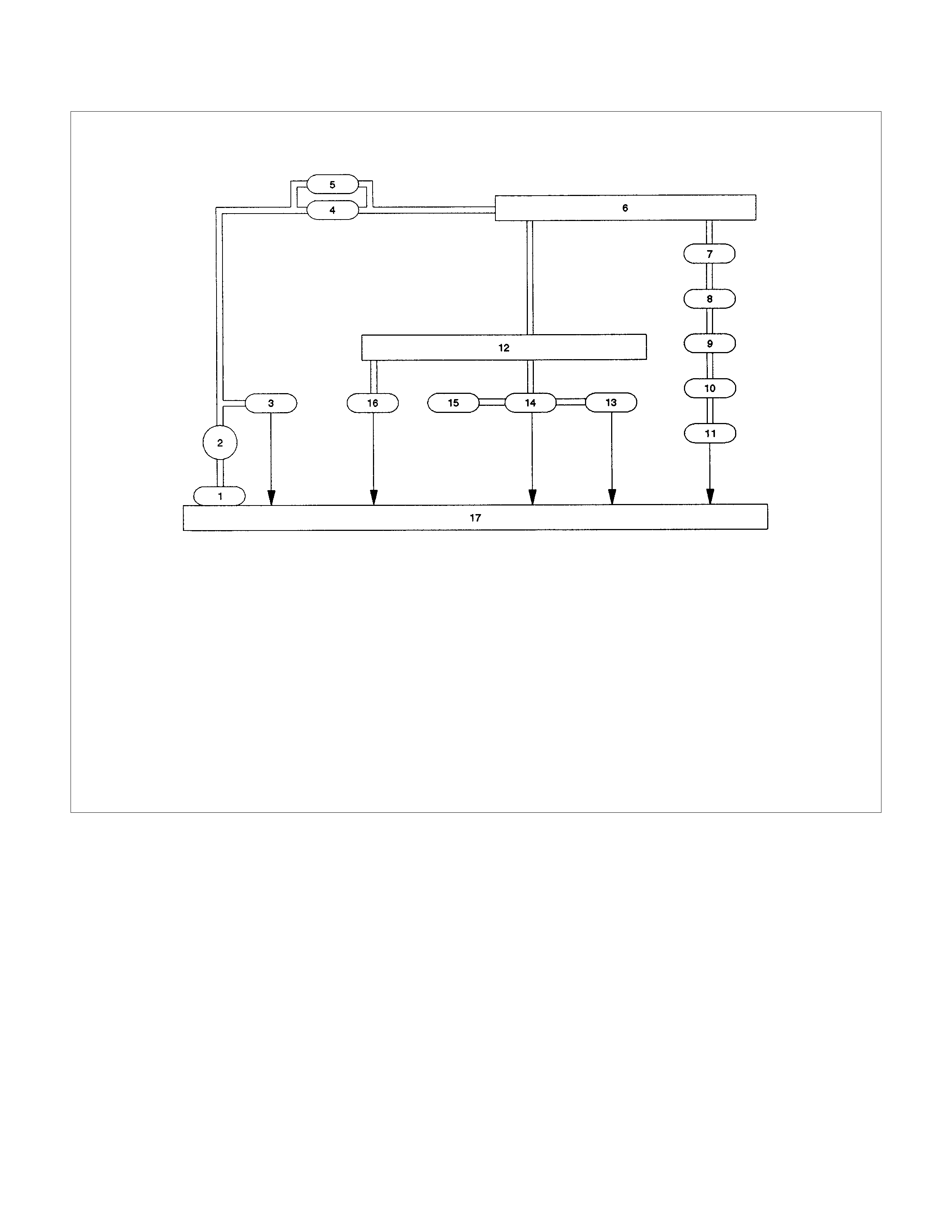

GENERAL DESCRIPTION

Legend

1 Oil Strainer

2 Oil Pump

3 Relief Valve

4 Oil Filter

5 Safety Valve

6 Oil Gallery

7 Crankshaft Bearing

8 Crankshaft

9 Connecting Rod Bearing

10 Connecting Rod

11 Piston

12 Oil Gallery; Cylinder Head

13 Camshaft

14 Camshaft Journal

15 HLV

16 Check relief valve

17 Oil Pan

A gear-type oil pump is directly driven by the crankshaft and

draws oil from the oil pan, via the suction pipe. If then passes

the pressured oil through a full-flow disposable oil filter, to the

main oil gallery in the cylinder Block. Oil pump pressure relief

valve and oil filter bypass valves are incorporated in the

system.

From the main oil gallery in the cylinder block, the cylinder

head and crankshaft main bearings are supplied with oil.

The camshaft bearings and hydraulic tappets are supplied

through the main feed galleries in the cylinder head. Vent

valves allow air to be expelled from the oil galleries in the

cylinder head. The balance shaft journals are directly fed from

the crankshaft main bearings. The connecting rod bearings are

fed via passages in the crankshaft. The oil returns to the oil

pan via passages in the cylinder block.

SERVICE PRECAUTION

CAUTION:

Always use the correct fastener in the proper location.

When you replace a fastener, use ONLY the exact part

number for that application. ISUZU will call out those

fasteners that require a replacement after removal. ISUZU

will also call out the fasteners that require thread lockers

or thread sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or fastener

joint interfaces. Generally, such coatings adversely affect

the fastener torque and the joint clamping force, and may

damage the fastener. When you install fasteners, use the

correct tightening sequence and specifications. Following

these instructions can help you avoid damage to parts

and systems.

INSPECTION AND REPAIR

CAUTION:

Make necessary correction or parts replacement if wear,

damage or any other abnormal conditions are found

through inspection.

BODY AND GEARS

The pump assembly must be replaced if one or more of the

conditions below is discovered during inspection:

Indentation of gear pair - Use feeler strip and straight edge.

Dimension: 0.03 mm to 0.10 mm

(0.0012 to 0.0039 in)

OIL STRAINER

Check the oil strainer for cracking and scoring. If cracking and

scoring are found, the oil strainer must be replaced.

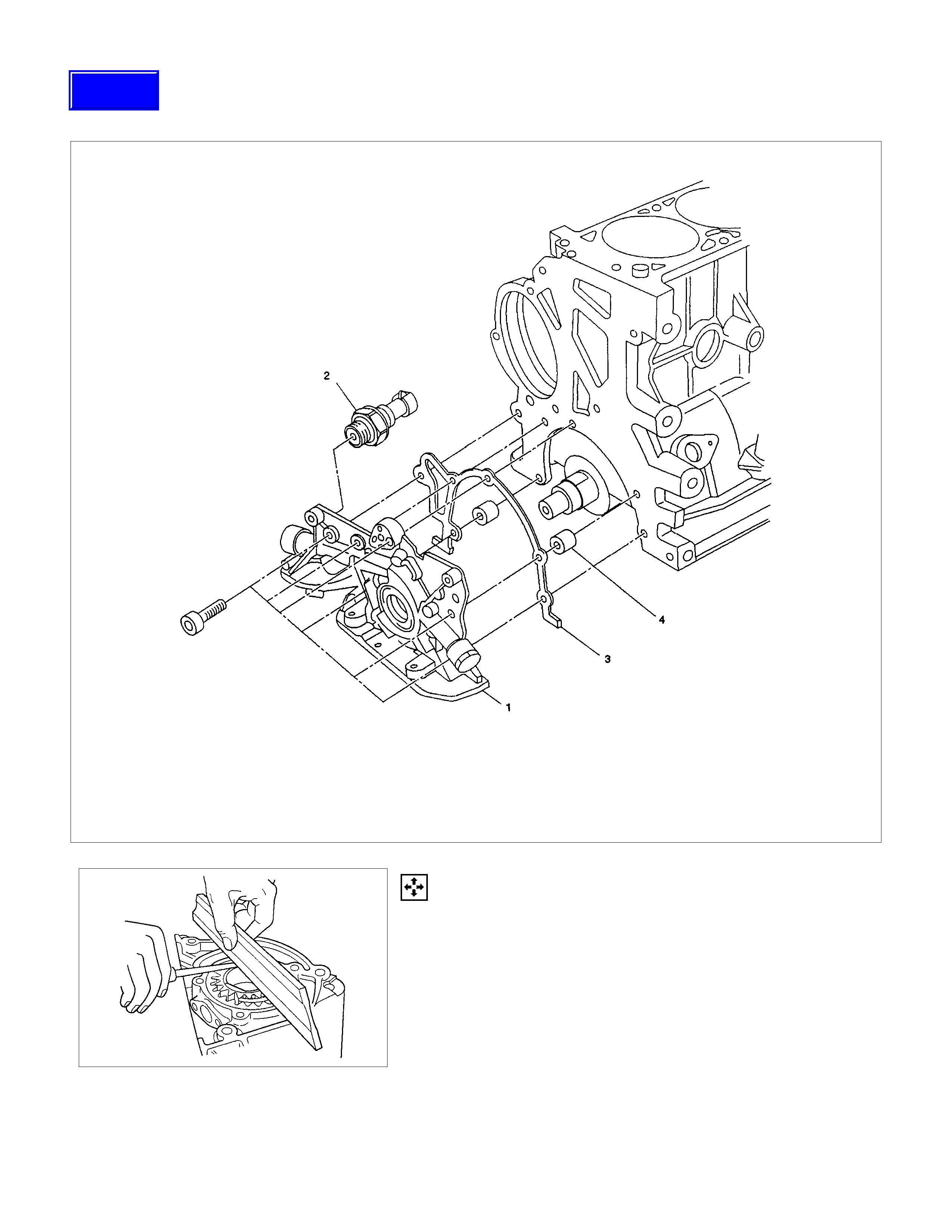

REASSEMBLY

1. Install oil pressure switch to the oil pump.

Torque: 40 N⋅

⋅⋅⋅m (4.1 kgf.m)

2. Install the oil pump with the sleeve and the gasket.

Torque: 6 N⋅

⋅⋅⋅m (0.6 kgf.m)

3. Install oil strainer.

Torque: 8 N⋅

⋅⋅⋅m (0.8 kgf.m)

4. Install the oil pan

Tighten the bolts:

15 N⋅

⋅⋅⋅m (1.5 kgf.m)

5. Install crankshaft timing pulley.

Tighten the bolts:

20 N⋅

⋅⋅⋅m (2.0 kgf.m)

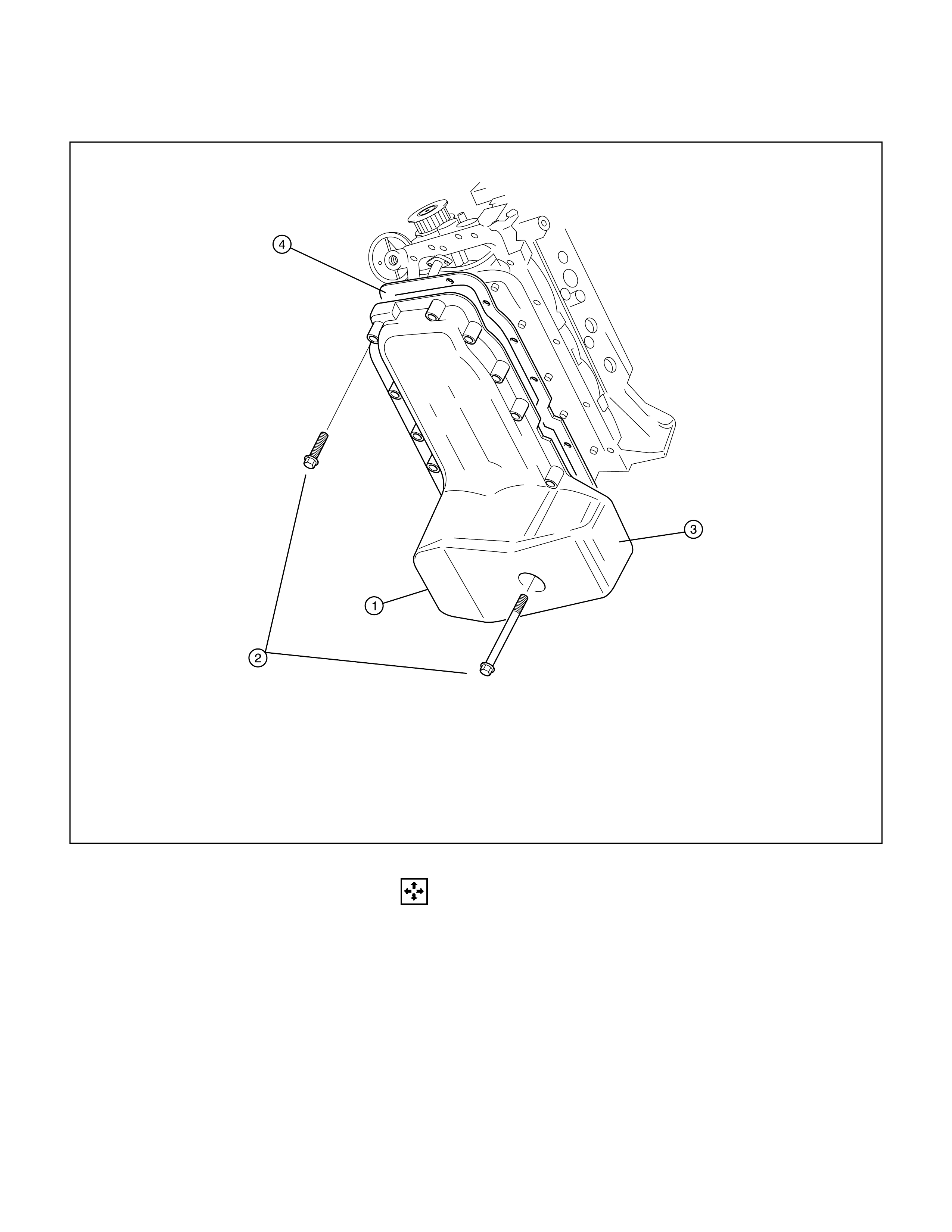

OIL PAN

OIL PAN AND ASSOCIATED PARTS

Legend

1 Drain Plug

2 Bolts

3.Oil Pan

4 Oil Pan Gasket

DISASSEMBLY

1. Loosen a drain plug to drain oil.

2. Remove engine hood.

3. Remove engine rear mounting.

4. Remove transmission assembly.

5. Remove engine front mounting.

6. Raise the vehicle and support with switch stands, and then

remove engine.

7. Remove oil pan.

INSPECTION AND REPAIR

CAUTION:

Make necessary correction or parts replacement if wear,

damage or any other abnormal conditions are found

through inspection.

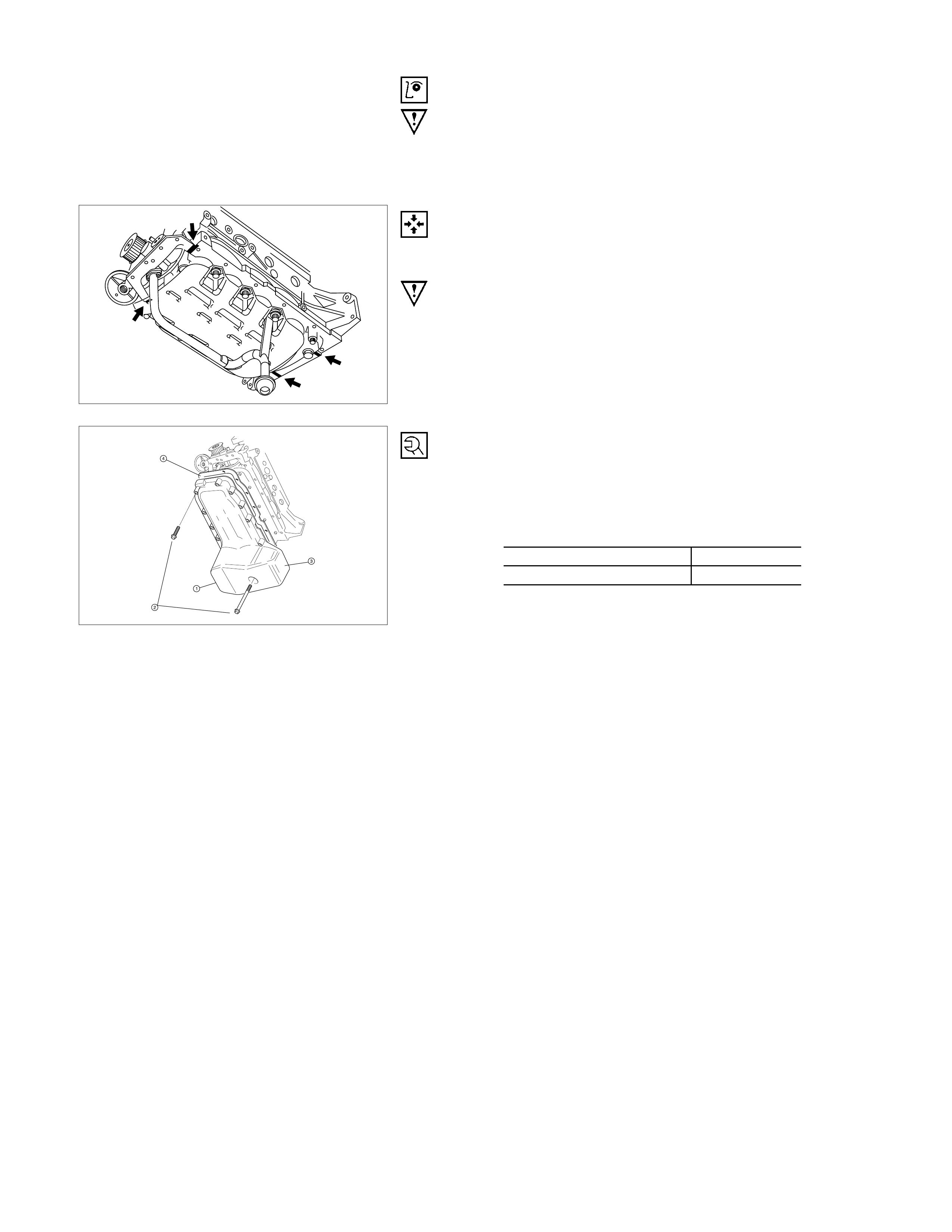

REASSEMBLY

To install follows the disassembly steps in the reverse order.

IMPORTANT:

Sealer - Apply silicon into groove in oil pan lugs prior to fitment

of oil pan to block, remove excess sealer after oil pan

is bolted to block.

TORQUE

Bolts - Tighten bolts to the specified torque.

Torque : 15 Nm (1.5 kgfm)

Engine oil - Refill engine oil to the oil pan. (Lit)

Without filter change 4.40

With filter change 4.70