SECTION 6C - FUEL SYSTEM

Main Data & Speci fications

General Description

Fuel Flow

Injection Pump

Aneroid Compensator

Boost Compensator

Fast Idle Actuator

Wax Type Cold Start Device (W–CSD) (If So Equipped)

Fuel Filter With Built-In Water Separator

Injection Nozzle

Injection Pump

Removal & Installation

4JB1T

4JH1TC

Injection Pump Calibration Data

Injection Volume Adjustment

Identification Plate & Number

Injection Volume & Governor Performance Diagram

Injection Nozzle

Disassembly

Inspection & Repair

Reassembly

Inspection & Adjustment

Adjustment Procedure For Potentiometer

Techline

Main Data & Specifications

Description

Item 4JB1T

Injection pump type

Plunger outside diameter mm (in)

Plunger prestroke mm (in)

Bosch Distributor

11 (0.43)

0.45 (0.0177)

Governor type Mechanical limit speed

Timer type

Fuel feed pump type

Injection nozzle type

Number of injection nozzl e orifices

Oil pressure

Vane with input shaft

Hole type

5

Injection nozzle orifices mm (in) 0.27 (0.0106)

Inside diameter

Injection nozzle opening kg/cm2 (psi/MPa)

Main fuel filter type

185 (2,631/18.1)

Disposable cartridge paper element and water separator

Item 4JH1TC

Injection pump type BOSCH VP44

(electronic controlled fuel injection pump)

Injection nozzle type Hole type (Double spring type)

Number of injection nozzl e orifices 5

Injection nozzle orifices mm (in)

Inside diameter 0.21 (0.0083)

Injection nozzle opening kg/cm2 (psi/MPa) 1st: 198 (2,816/19.4)

2nd: 344 (4,906/33,800)

Main fuel filter type Disposable cartridge paper element and water separator

NOTE:

The VP44 Injection Pump and the Inject ors f itted to t he 4JH1TC engine are non-serviceabl e i tems.

Refer to the lat est service inf ormat i on bul letin for t he correct change- over procedure BEFORE

removing the injector pump or injectors f r om t he vehicle.

General Description

When working on the fuel system, there are several things to keep in mind:

・ Any time the fuel system is being worked on, disconnect the negative battery cable except for those tests where

battery voltage is required.

・ Always keep a dry chemical (Class B) fire extinguisher near the work area.

・ Replace all pipes with the same pipe and fittings that were removed.

Clean and inspect “O” rings. Replace where required.

・ Always relieve the line pressure before servicing any fuel system components.

・ Do not attempt repairs on the fuel system until you have read the instructions and checked the pictures relating to

that repairs.

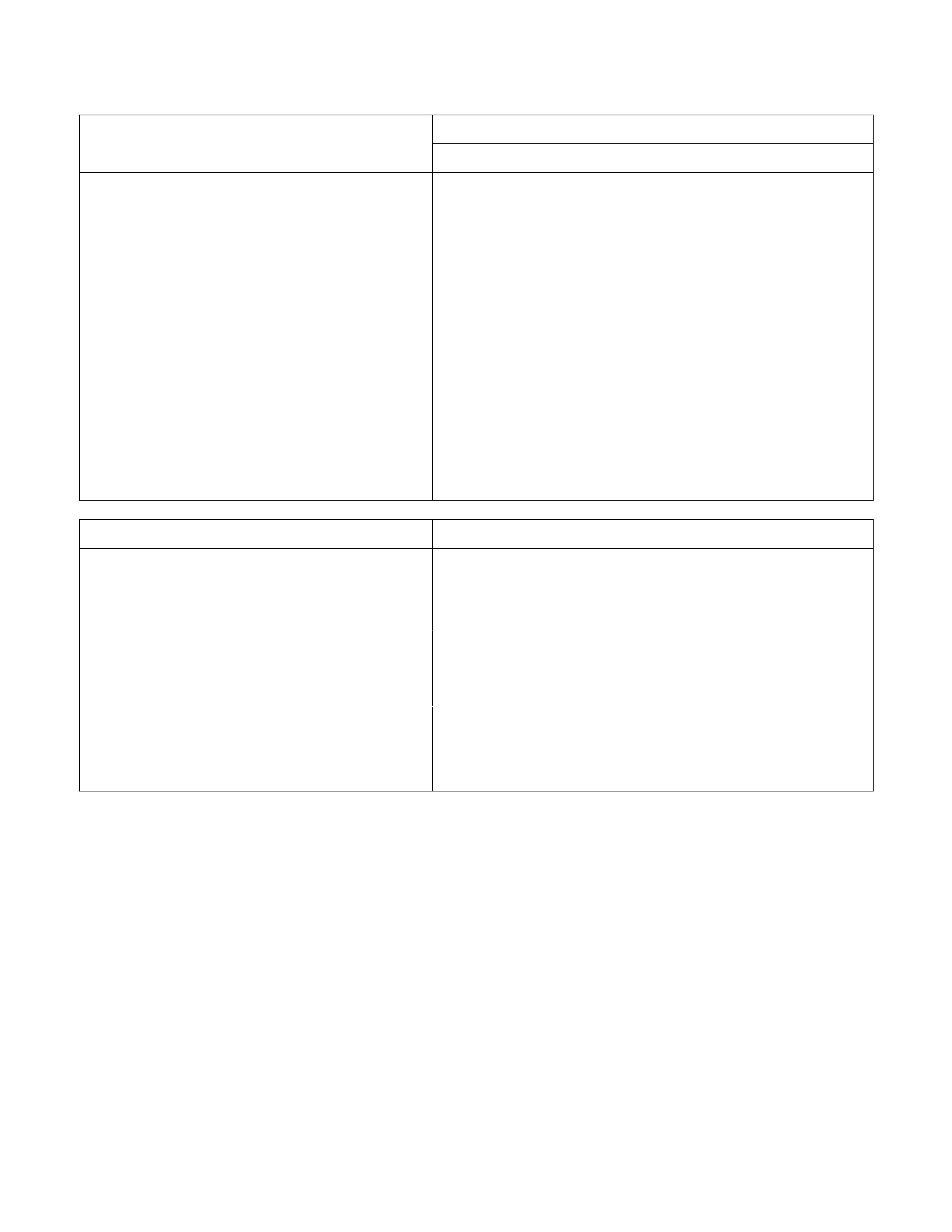

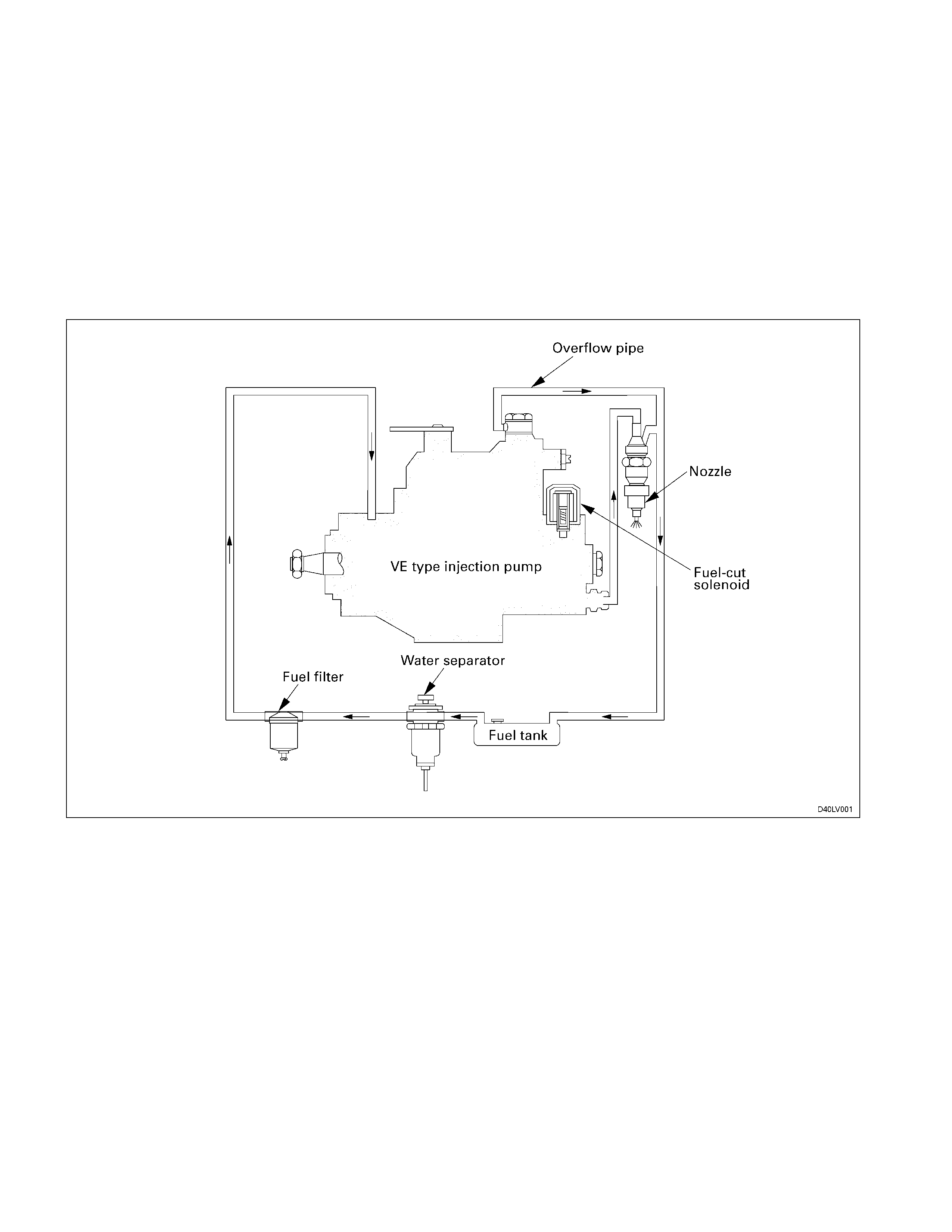

Fuel Flow

The fuel system consists of the fuel tank, the water separator, the fuel filter, the injection pump, and the injection nozzle.

The fuel from the fuel tank passes through the water separator and the fuel filter where water particles and other foreign

material are removed from the fuel.

Fuel, fed by the injection pump plunger, is delivered to the injection nozzle in the measured volume at the optimum

timing for efficient engine operation.

4JB1T En

g

ine

・ The 4JH1TC engine are equipped with the electronically controlled fuel injection system. For information on fuel

injection pump maintenance and/or part replacement, contact the Bosch Automotive Systems Corporation.

・ Contact the Bosch Automotive Systems Corporation for information on 4JH1TC engine fuel injection nozzle

maintenance.

4JH1TC En

g

ine

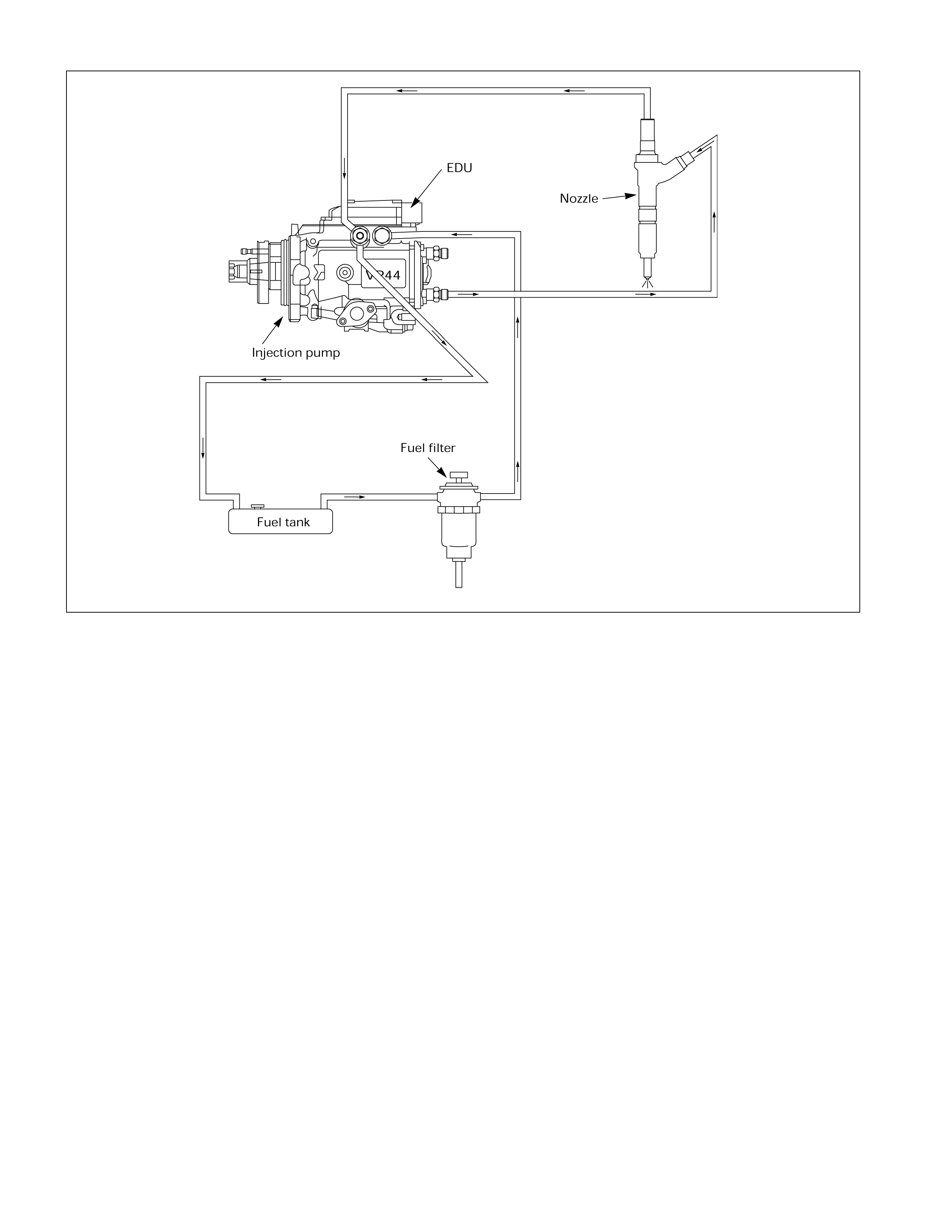

Injection Pump

A Bosch Distributor Type Injection Pump is used. A single reciprocating/revolving plunger delivers the fuel uniformly to

the injection nozzles, regardless of the number of cylinders.

The governor, the injection timer, and the feed pump are all contained in the injection pump housing. The injection

pump is compact, light weight, and provides reliable high-speed operation.

An aneroid compensator is available as an option for vehicles to be operated at high altitudes. It adjusts the fuel and air

mixing ratio.

A boost compensator is installed on turbocharger equipped vehicles.

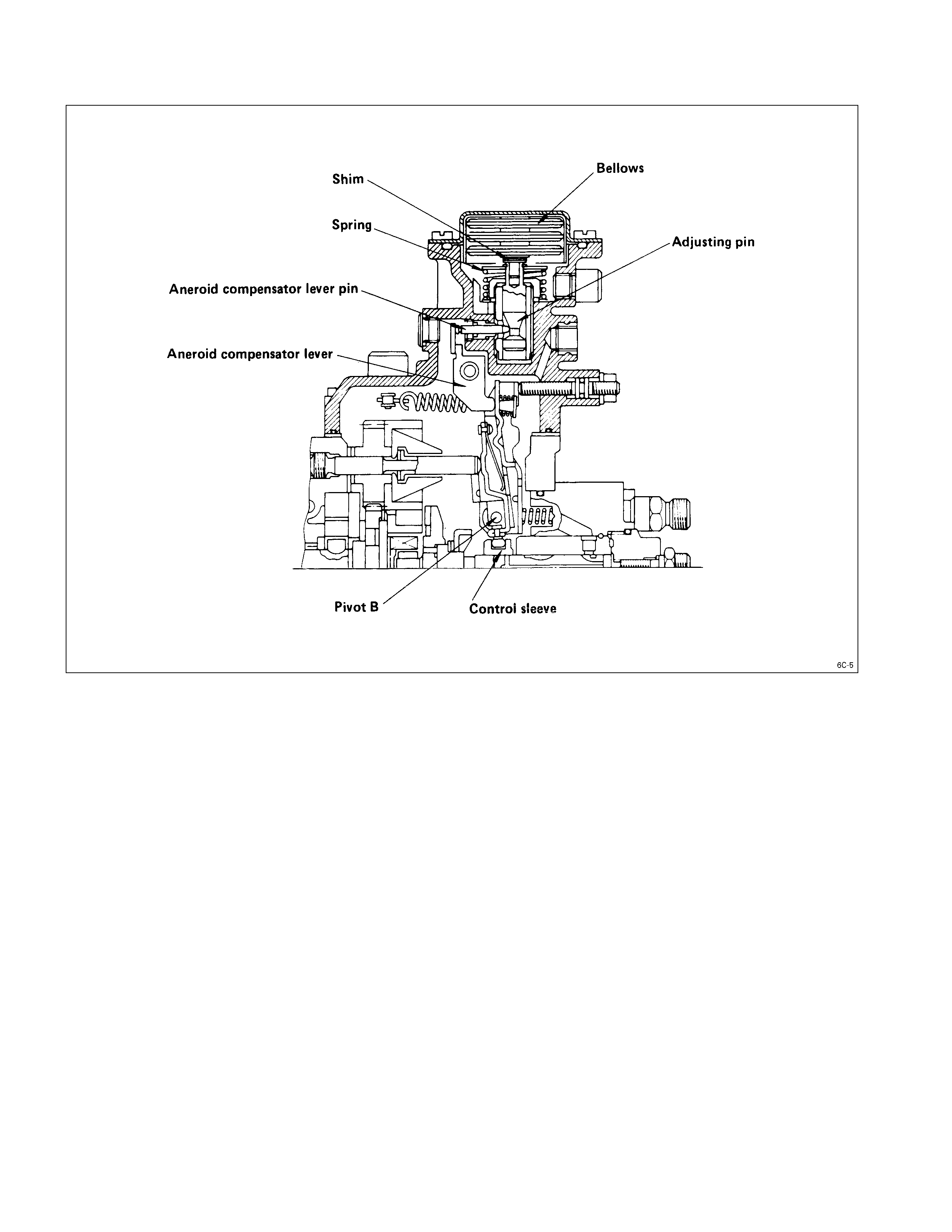

Aneroid Compensator

The aneroid compensator consists of the compensator housing, the bellows, the adjusting pin, the aneroid

compensator lever pin, and the aneroid compensator lever.

Atmospheric pressure decreases as altitude increases. The decreased atmospheric pressure causes the bellows to

expand and push the adjusting pin down.

The adjusting pin pushes the aneroid compensator lever pin and the aneroid compensator lever to the left.

The aneroid compensator lever pushes the tension lever to the right.

The tension lever actuates the control sleeve to decrease the fuel flow.

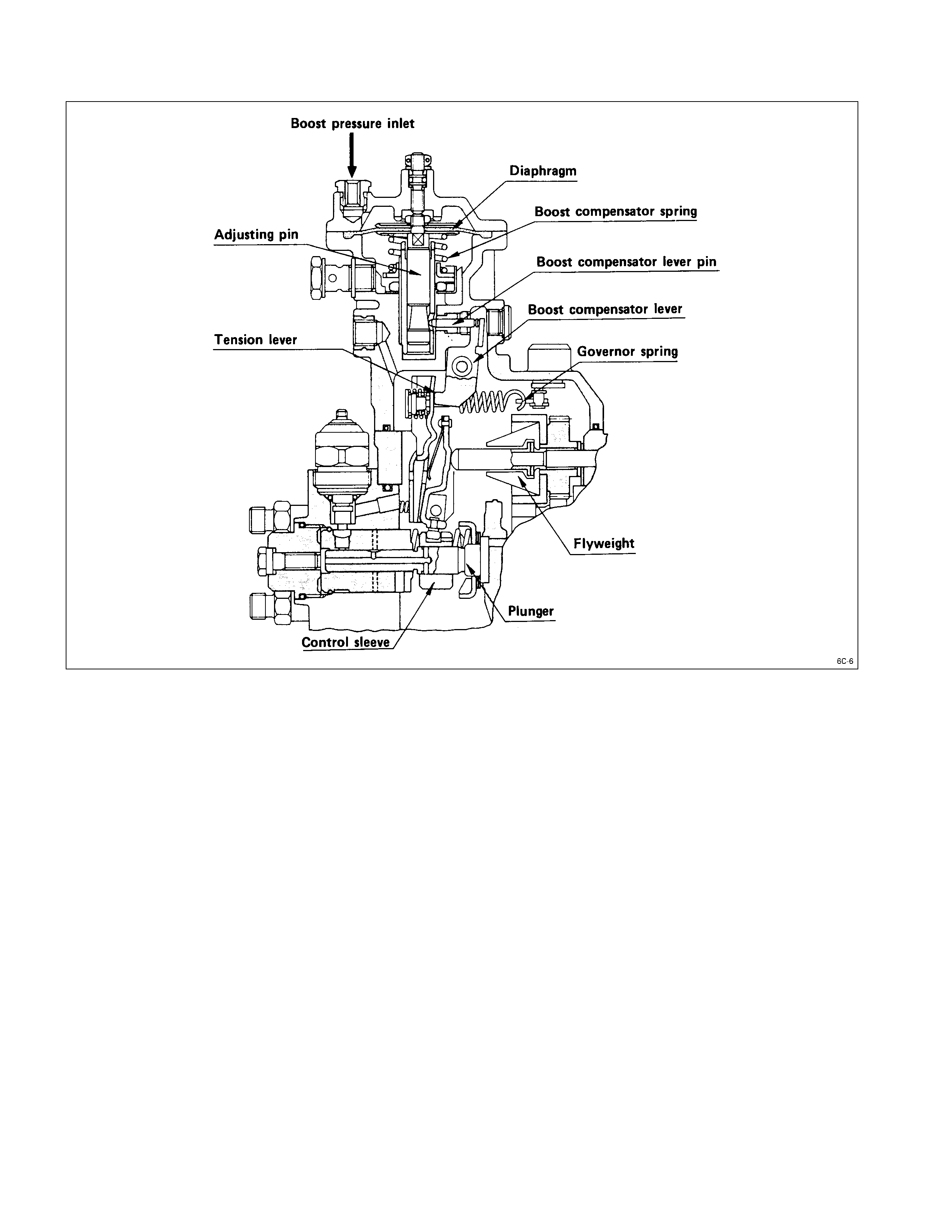

Boost Compensator

The boost compensator consists of the compensator housing, the diaphragm, the adjusting pin, the boost compensator

lever pin, and the boost compensator lever.

The increase boost pressure cause the diaphragm to lower and push the adjusting pin down.

The adjusting pin pushes the boost compensator lever pin and the boost compensator lever to the left.

The boost compensator lever pushes the tension lever to the right.

The tension lever actuates the control sleeve to increase the fuel flow.

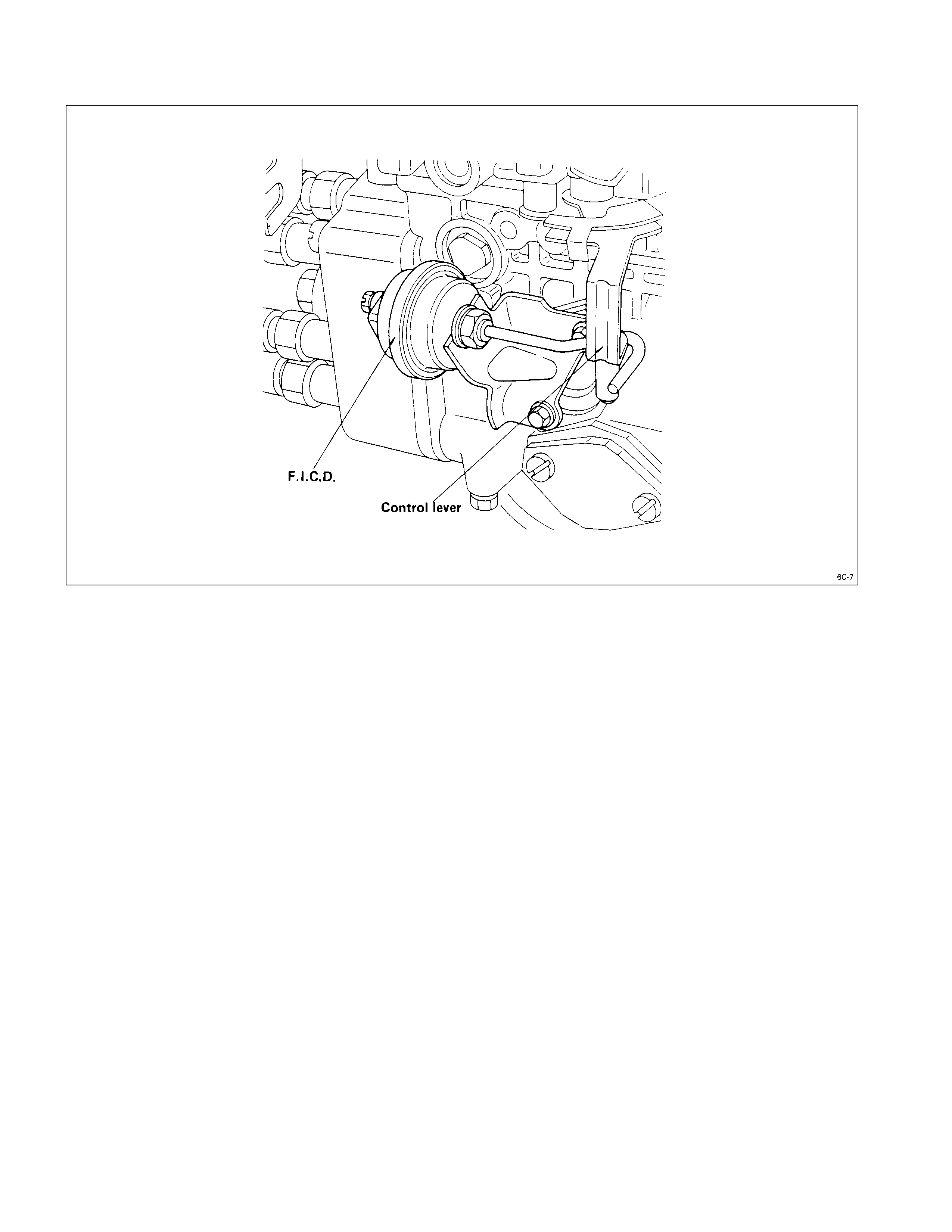

Fast Idle Actuator

The vacuum-type fast idle actuator increases the engine idling speed to provide the additional power required to

operate the air conditioner.

Fast idler diaphragm movement is caused by changes in the negative pressure created by the engine’s vacuum pump.

The diaphragm motion is transferred to the injection pump control lever to increase or decrease the idling speed.

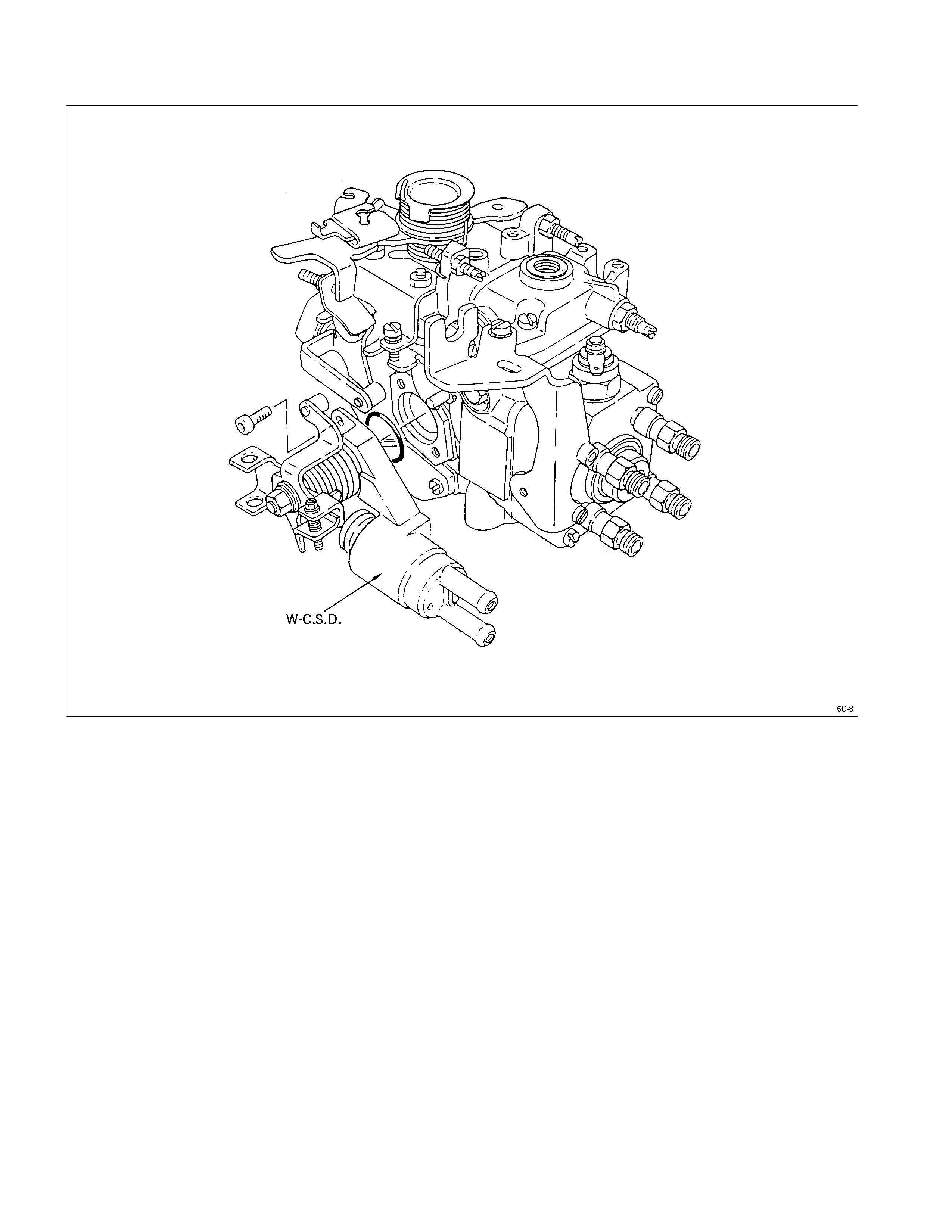

Wax Type Cold Start Device (W–CSD) (If So Equipped)

Because engine starting in cold conditions is very difficult, the W-C.S.D. (wax ty pe cold start device) has been

developed to provide the optimum fuel injection timing for engine starting by responding to temperature changes.

The thermo-wax piston contains a wax that changes its volume according to the temperature changes of the engine

coolant which flows through the unit at all times.

The engine coolant temperature above A °C the wax expands in proportion to the coolant temperature, below A °C it

contracts.

The coolant temperature A is classified as –20, -10 and 0°C.

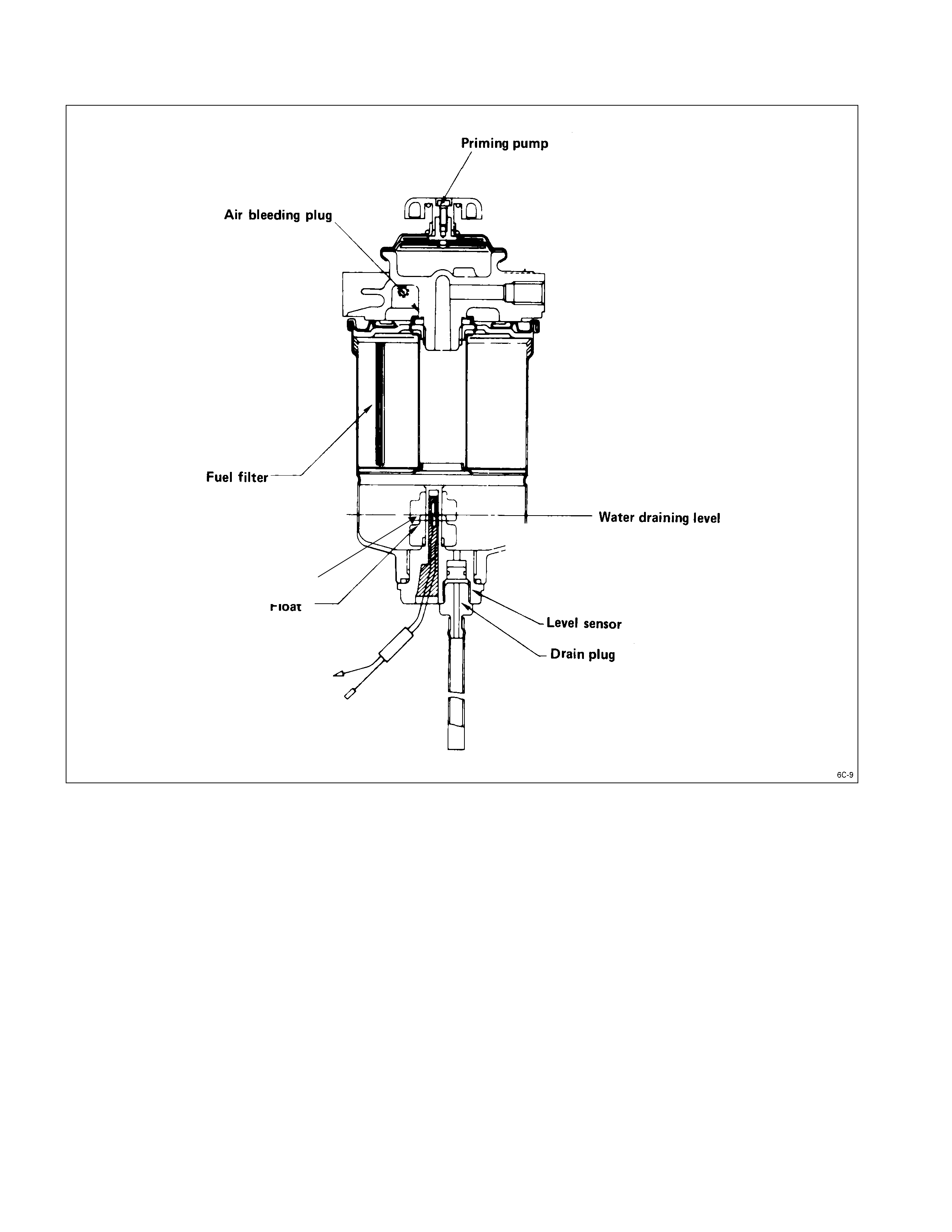

Fuel Filter With Built-In Water Separator

A fuel filter with a built-in water separator is used along with the VE type injection pump.

As the inside of the injection pump is lubricated by the fuel which it is pumping, the fuel must be perfectly clean. The

fuel filter and the water separator remove water particles and other foreign material from the fuel before it reaches the

injection pump.

The water separator has an internal float. When the float reaches the specified level, a warning light comes on to

remind you to drain the water from the water separator.

A diaphragm ty pe priming pump is installed at the top of the water separator. It is used during the water draining and

the air bleeding procedures.

Level Sensor

Injection Nozzle

A hole (with 5 orifices) type injection nozzle is used for 4JB1T Engine. It consists of the nozzle body and the needle

valve assembly.

The injection nozzle assembly sprays pressurized fuel from the injection pump into the combustion chamber through

the nozzle body injection orifice.

Injection Pump

Removal & Installation

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

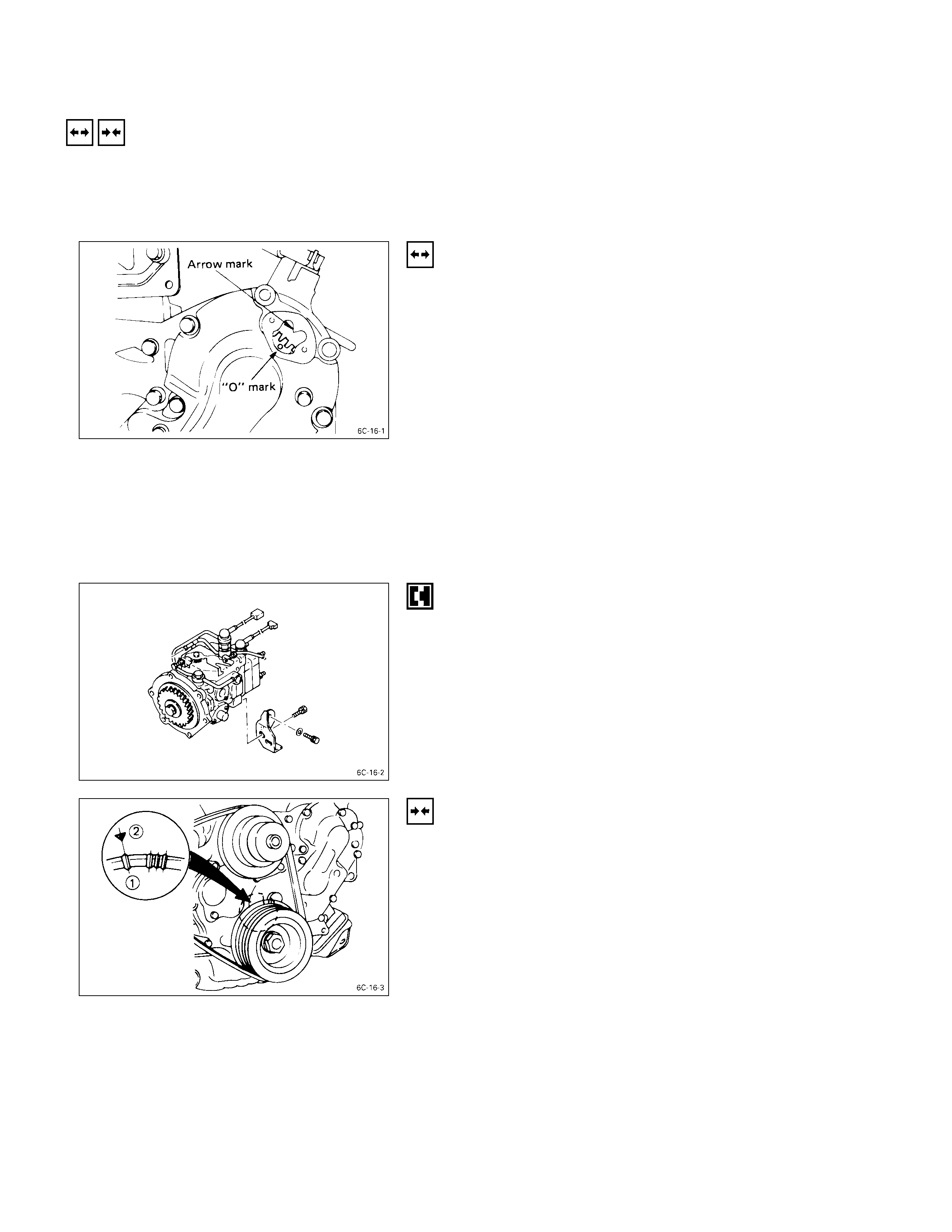

4JB1T

REMOVAL STEPS

1. Disconnect the battery ground cable.

2. Disconnect the air cleaner duct.

3. Disconnect the PCV hose.

4. Remove the head cover.

5. Remove the power steering V belt. (if so equipped)

6. Disconnect the accelerator cable and harness from

injection pump.

7. Remove the fuel pipes and injection pipes.

8. Remove the cover of timing gear case cover. (injection

pump side only)

9. Remove the timing hole cover.

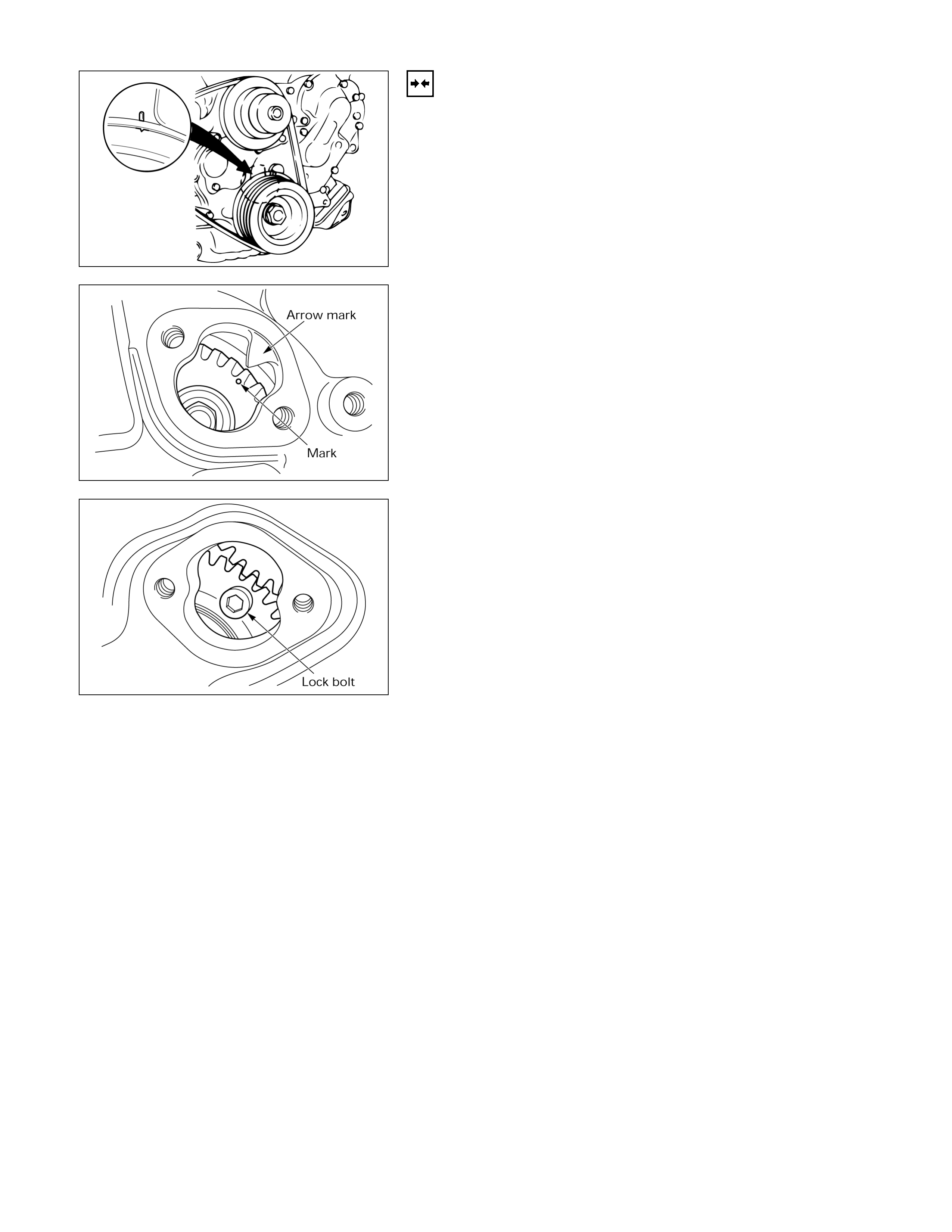

10. For ease in reinstalling the injection pump, align the

timing “O” mark on the pump gear with the allow mark

on the timing gear case cover using the crank shaft

turning wrench.

11. Remove the six injection pump mounting bolts from

the timing gear case cover.

12. Remove the rear bracket bolts from the injection pump

bracket.

13. Pull the injection pump together with pump gear free

toward the rear of the engine.

INSTALLATION STEPS

To install, follow the removal procedure in reverse order

and note the following point.

•Recheck the crankshaft to align the timing mark on the

crank pulley with the TDC mark.

•Install injection pump so that the timing “O” mark on

the pump gear the arrow mark on the timing gear case

cover.

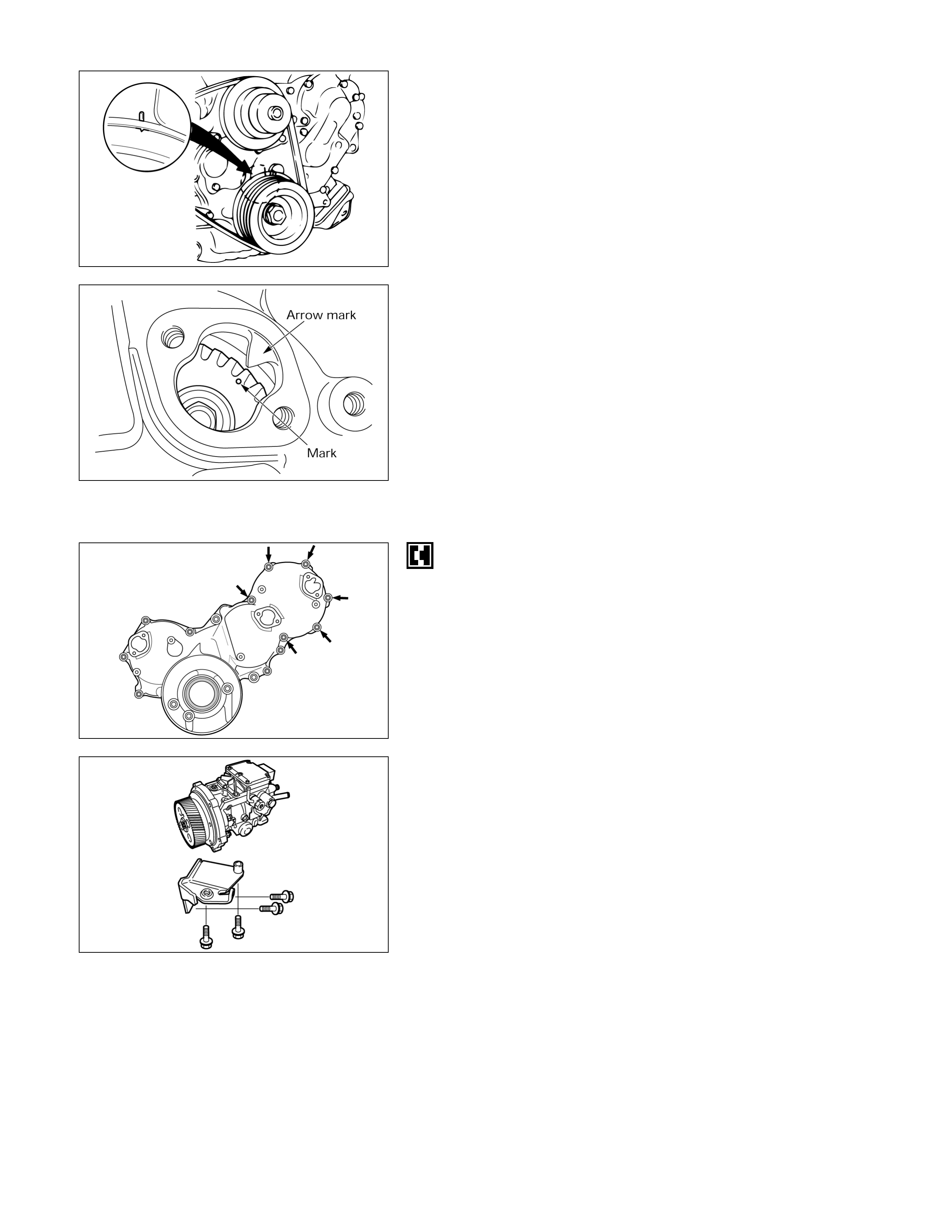

4JH1TC

REMOVAL STEPS

1. Disconnect the battery ground cable.

2. Remove the intercooler.

3. Separate the air cleaner duct from the air cleaner.

4. Disconnect the radiator upper hose.

5. Remove the air conditioner V-belt.

6. Remove the power steering V-belt.

7. Remove the power steering oil tank. Place the tank in

a safe place.

8. Remove the fuel filter and its bracket.

9. Disconnect the accelerator cable and connector at the

intake duct.

10. Remove the intake duct.

11. Remove the accelerator control lever.

12. Remove the check hole cover from the timing gear

case.

13. Rotate the crank pulley until the scissor gear fixing

hole becomes visible through the check hole (2).

14. Insert a lock bolt (M6×1 L=30) into the scissor gear

fixing hole to prevent the scissor gear from turning.

Note:

If the check hole cover is reinstalled with the lock bolt

still in place, the crank pulley will not turn.

020L200016

020L200018

15. Rotate the crank pulley to align the crank pulley TDC

mark and the timing gear case TDC mark.

16. Look through check hole (1) to confirm that the

injection pump alignment mark is visible. If it is not

visible, turn the crank pulley an additional full turn.

17. Remove the fuel piping and the injection pipes.

18. Remove the connector from the injection pump.

19. Remove the injection pump mounting bolts (6 bolts)

from the timing gear case.

20. Remove the injection pump bracket.

21. Remove the injection pump and pump gear by pulling

it toward the rear of the engine.

015L200004

020L200017

080L200006

INSTALLATION STEPS

Follow the removal procedure in reverse order.

Pay close attention to the following.

•Be sure to align the crank pulley TDC mark and the

timing gear case TDC mark.

•Install the injection pump and pump gear so that the

timing mark (dot) on the pump gear is aligned with the

arrow on the timing gear case cover.

Note:

• Do not forget to remove the lock bolt from the

scissor gear. (if you have forgotten to remove the

bolt, the bolt will strike the check hole guides and

the crank pulley will not turn)

• Injection pump Air bleeding is required to start

the engine when the injection pump has been

replaced.

Refer to Injection Pump Air Bleeding.

015L200004

020L200017

020L200018

Injection Pump Calibration Data

Injection Volume Adjustment

TEST CONDITIONS

Item Condition

Injection nozzle

Injection nozzle holder

Injection nozzle opening pressure

kg/cm2 (psi/kPa)

Injection line dimensions mm (in)

Inside diameter

Outside diameter

Length

Fuel delivery pressure kg/cm2 (psi/kPa)

Test fuel

Test fuel temperature °C (°F)

Identification numbers

ZEXEL Part No.: 105780-0060

Bosch Type No.: DNOSD1510

ZEXEL Part No.: 105780-2150

133 (1,891/13,000)

2 (0.079)

6 (0.236)

450 (17.7)

0.2 (2.84/19.6)

Bosch Diesel Fuel OL61V11

SAE Standard Test Diesel Fuel (SAE967D)

45 – 50 (113 – 122)

104746-6192

104746-6162

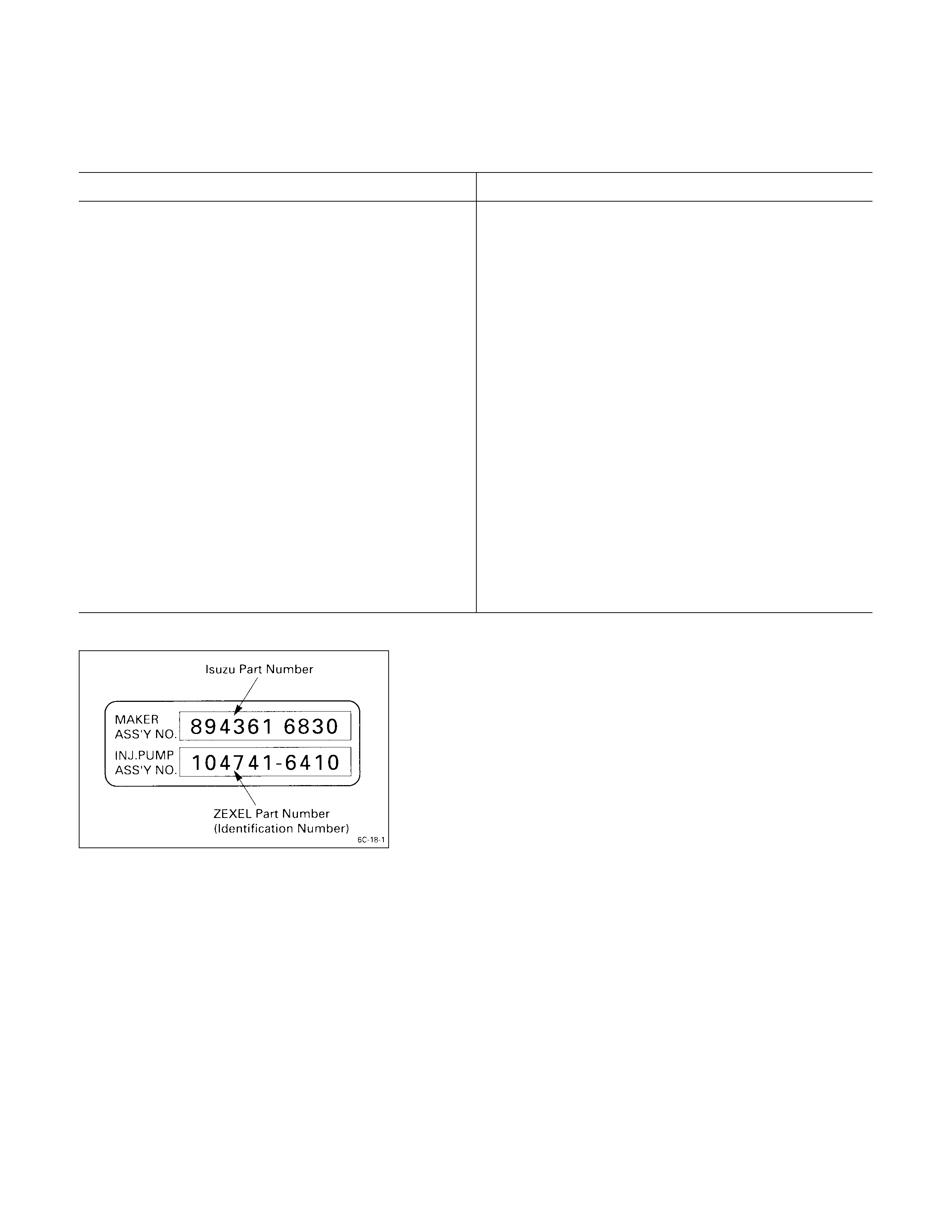

Identification Plate & Number

Use the data following the injection pump identification

number to adjust the injection volume.

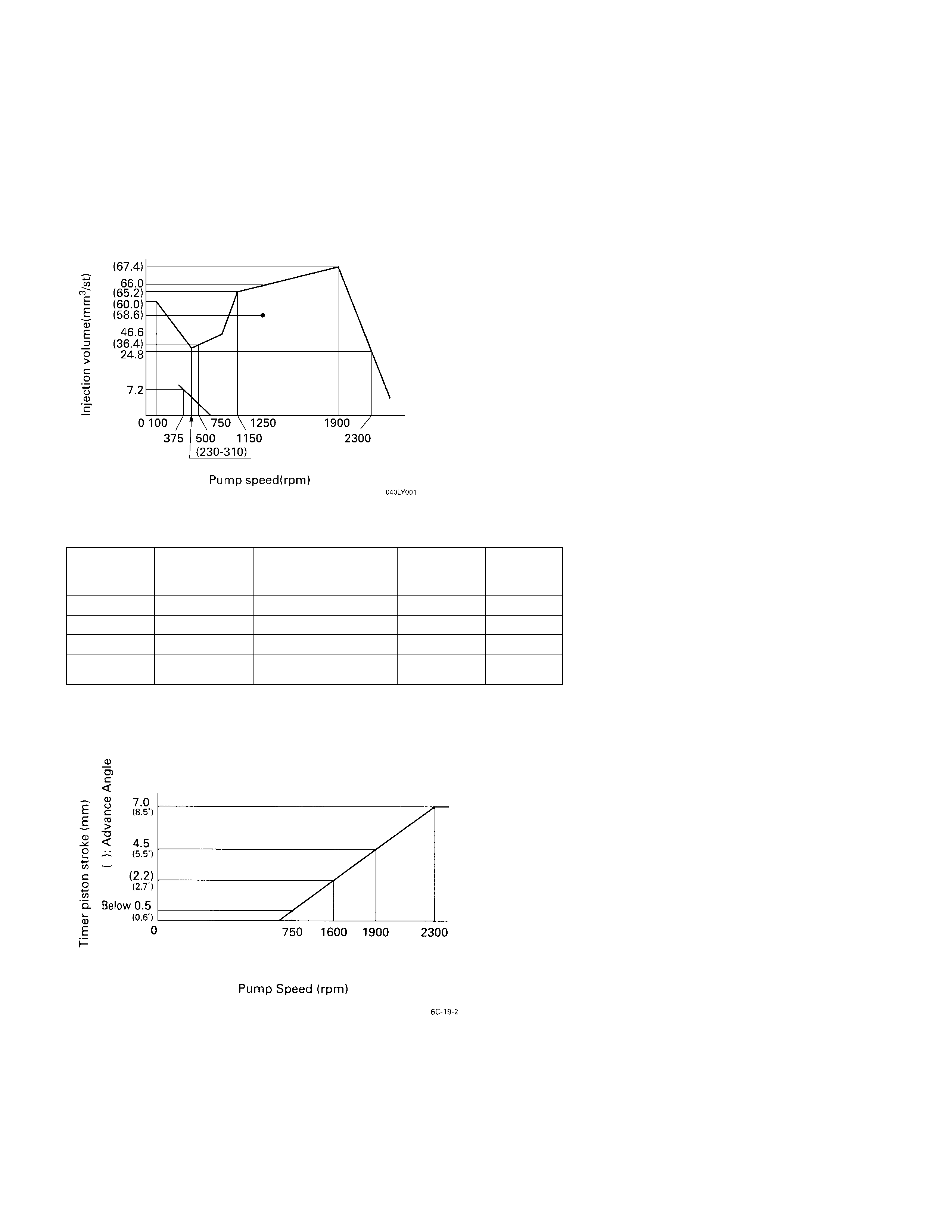

Injection Volume & Governor Performance Diagram

ENGINE: 4JB1T

IDENTIFICATION NUM BERS: 104746-6152 (I SUZU PART NUMBER 8- 97132- 678-2)

TEST FUEL: STANDARD DIESEL FUEL SAE J967D (OR ISO 4113)

GOVERNO R ADJUSTMENT

TIMER AND PUMP CASE PRESSURE

Pump

speed rpm Timer piston

stroke mm Pump case

pressure kpa

(kg/cm2)

Boost

pressure kpa

(kg/cm2)Reference

750 Below 0.5 73.3 (0.75)

1600 (2.2 ± 0.4) 73.3 (0.75)

1900 4.5 ± 0.2 618 ± 20 (6.3 ± 0.2) 73.3 (0.75) Base

2300 7.0 +0.4 73.3 (0.75)

TIMER PERFORM ANCE DIAGRAM

-0.3

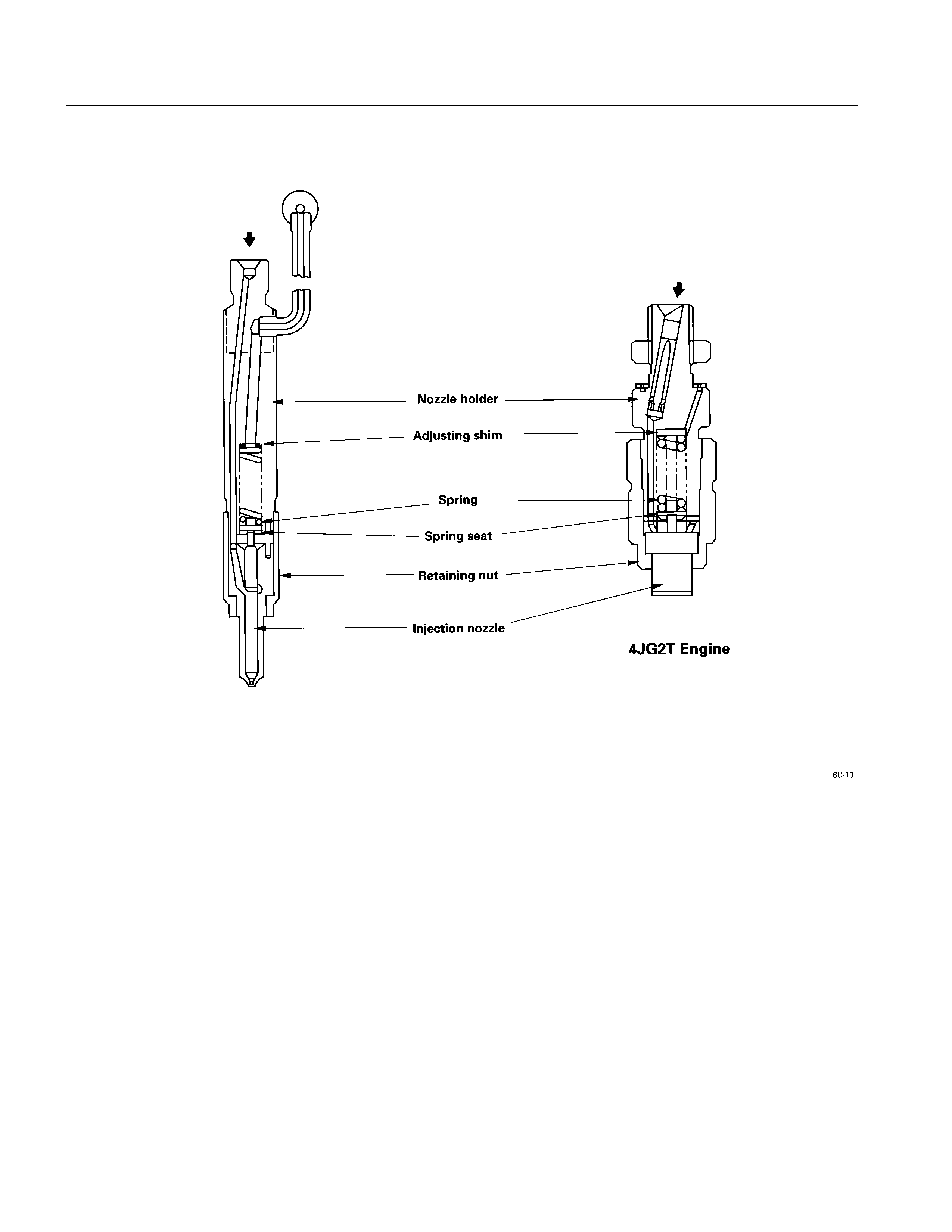

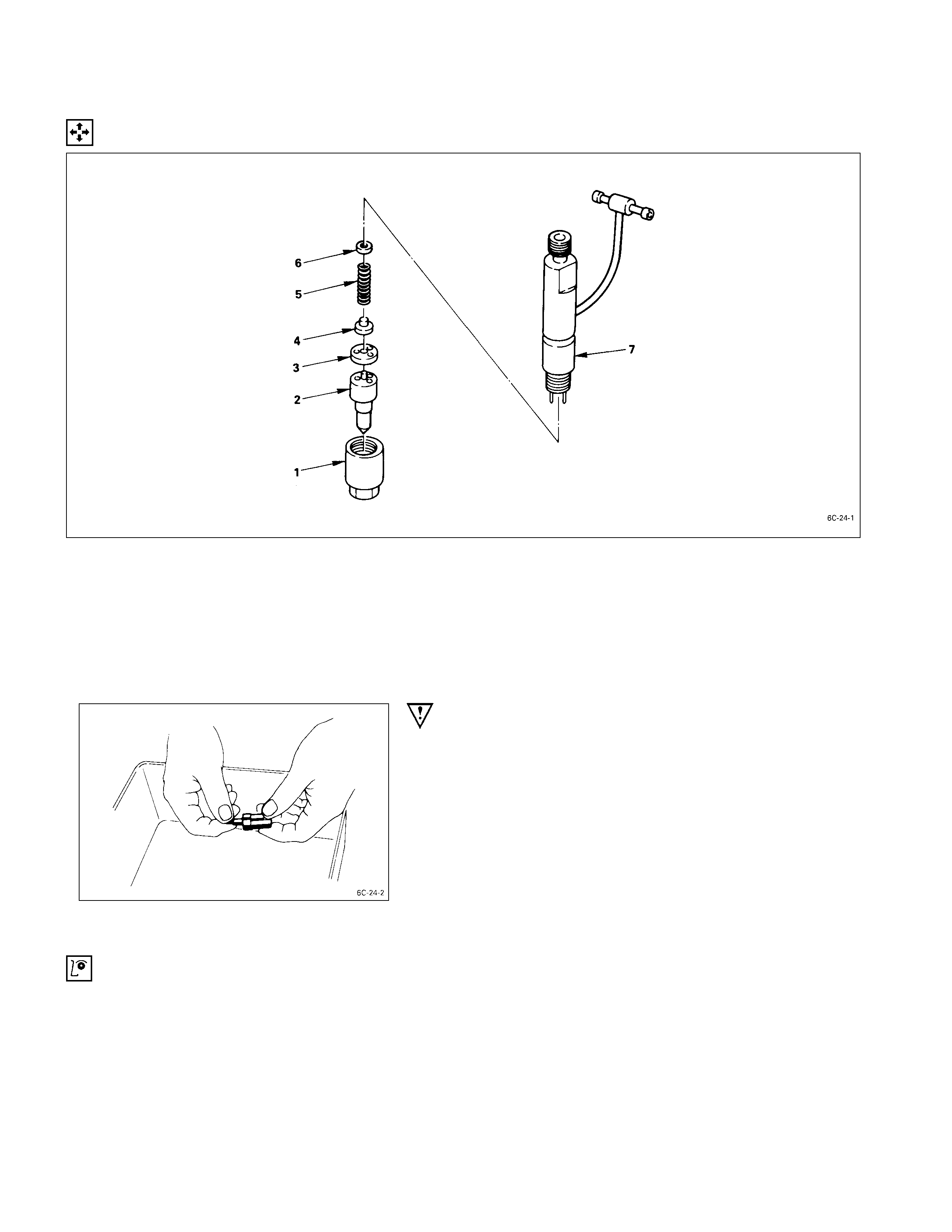

Injection Nozzle

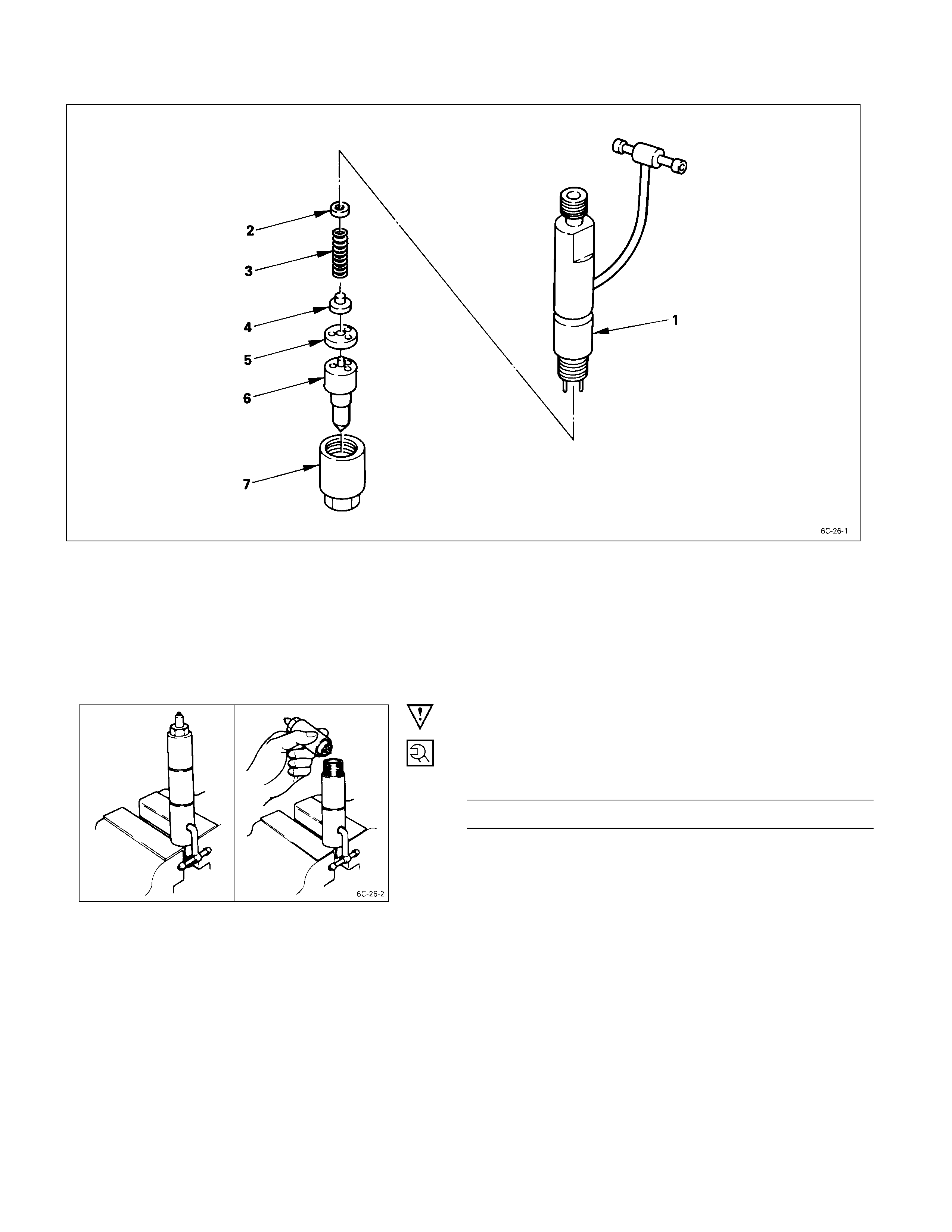

Disassembly

Disassembly Steps

1. Retaining nut 5. Spring

J

2. Injection nozzle 6. Adjusting shim

3. Spacer 7. Nozzle holder

4. Spring seat

IMPORTANT OPERATIONS

2. Injection nozzle

1) Remove the nozzle assemblies from the nozzle

holders.

Tag the nozzle assemblies and the nozzle holders to

ensure that they are reinstalled in their original

positions.

The nozzle assembly and nozzl e holder combinations

must not be interchanged.

2) Immerse the injection nozzles in a tool tray filled with

clean diesel oil to protect them from dust.

Inspection & Repair

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

INJECTION NO ZZLE NEEDLE I NSPECTION

1. Remove the nozzle needle from the nozzle body.

2. Carefully wash the noz zle needle and the nozzle body

in clean diesel fuel.

3. Check that the nozzle needle moves smoothly inside

the injection nozzle body.

If the nozzle needle does not move smoothly, it must

be replaced.

NOZZLE BODY AND NEEDLE VALVE INSPECTIO N

Check the nozzle body and the needle valve for damage

and deformation.

The nozzle and body assembly must be replaced if either

of these two conditions are discovered during inspection.

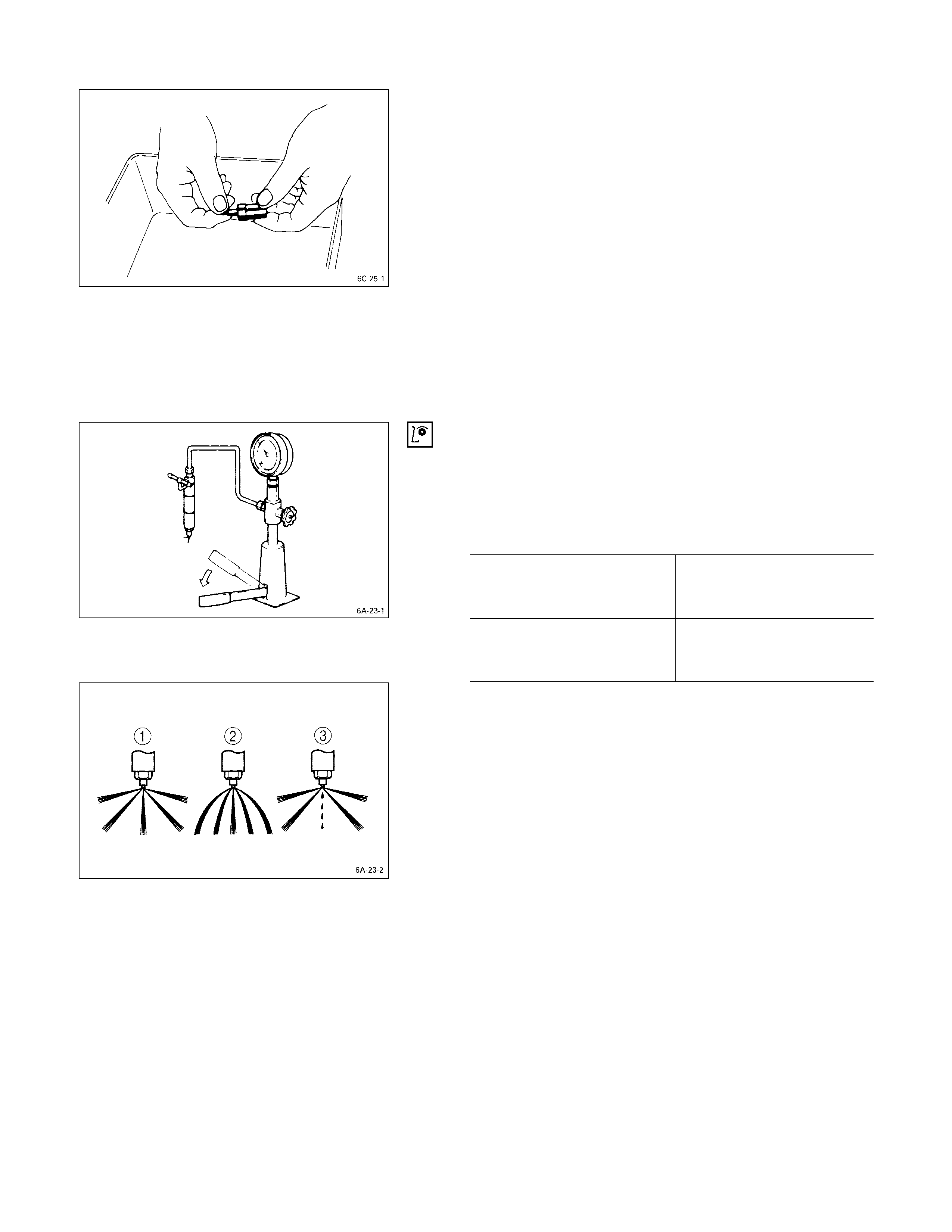

INJECTION NOZZLE INSPECTION

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or adjusted.

Injection Nozzle Opening Pressure kg/cm2 (psi/kPa)

4JA1T, 4JA1, 4JB1T 185 (2,631/18,1)

4JB1T

For ARGENTINA and

MALAYSIA only. 220 (3,128/21,575)

If the spray condition is bad, the injection nozzle must be

replaced or repaired.

Spray Condition

QCorrect

R Incorrect (Restrictions in orifice)

SIncorrect (Dripping)

Reassembly

REASSEMBLY STEPS

1. Nozzle holder 5. Spacer

2. Adjusting shim 6. Injection nozzle

3. Spring

J

7. Retaining nut

4. Spring seat

IMPORTANT OPERATIONS

7. Retaining Nut

Tighten the retaining nut to the specified torque.

Retaining Nut Torque kg·m (lb.ft/N·m)

3.5 ± 0.5 (25.3 ± 3.6/34.3 ± 4.9)

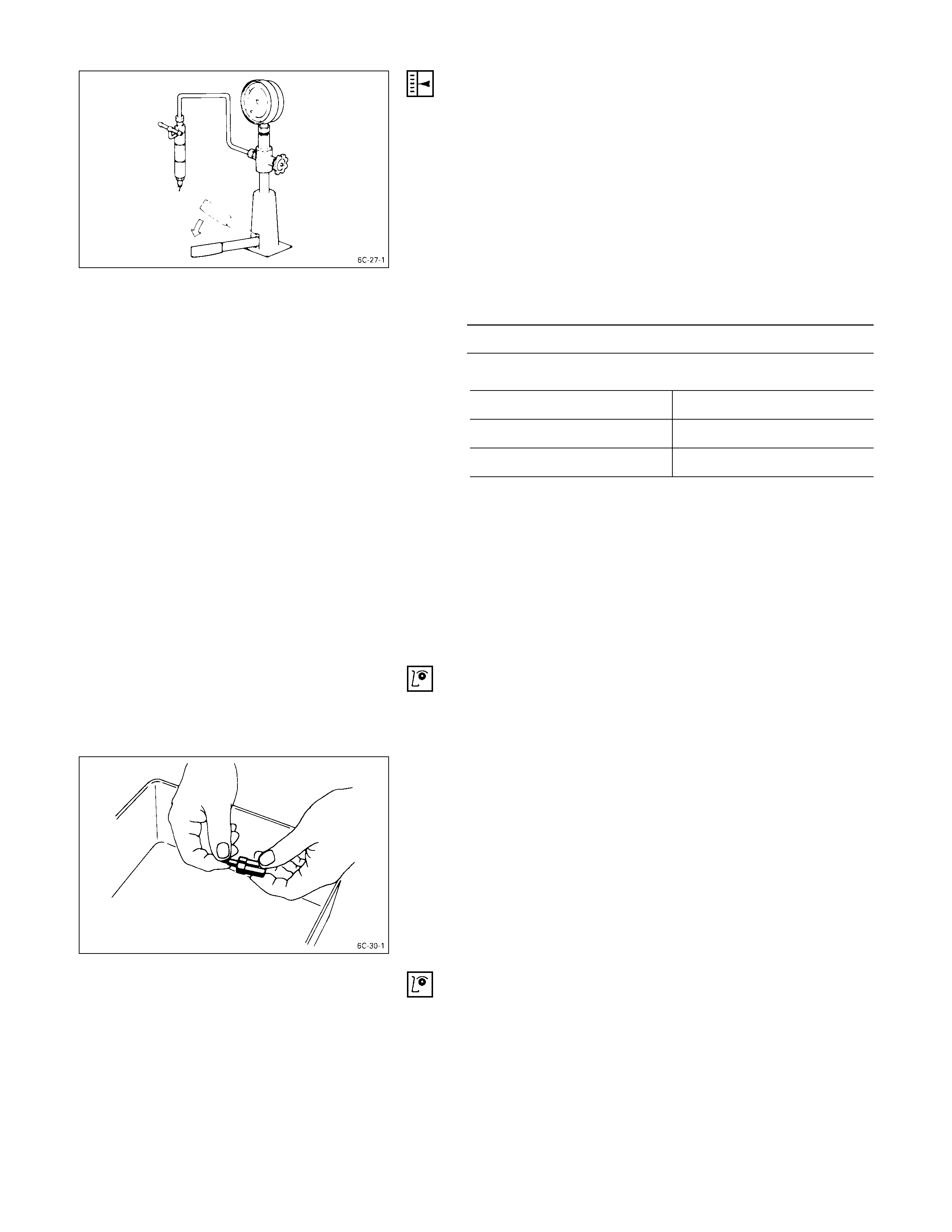

INJECTION NOZZLE ADJUSTMENT

The fuel injection starting pressure adjustment of this

injection nozzle is done by rereplacing or decreasing or

increasing the number of shims installed.

1) Attach the injection nozzle holder to the injection

nozzle tester.

2) Apply pressure to the nozzle tester to check that the

injection nozzle opens at the specified pressure.

If the injection nozzle does not open at the specified

pressure, install or remove the appropriate number of

ajusting shims to adjust it.

Nozzle Opening Pressure kg/cm2 (psi/MPa)

185 (2,631/18.1)

Adjusting Shim Availability rnm(in)

Range 0.50 – 1.50 (0.02 – 0.06)

Increment 0.025 (0.001)

Total No. of Shims 41

Removing or installing one shim will increase or decrease

the nozzle opening pressure approximately 3.77 kg/cm3

(53.6 psi/369.46 kPa).

WARNING:

TEST FLUID FROM THE INJECTION NOZZLE TESTER

WILL SPRAY OUT UNDER GREAT PRESSURE. IT CAN

EASILY PUNCTURE A PERSON’S SKIN. KEEP YOUR

HANDS AWAY FROM THE INJECTION NOZZLE

TESTER AT ALL TIMES.

Inspection & Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

INJECTION NO ZZLE NEEDLE SEI ZURE INSPECTION

1) Remove the injection nozzle needle from the injection

nozzle body.

2) Carefully wash the injection nozzle needle and the

injection nozzle body in clean diesel fuel.

3) Check that the injection needle valve moves smoothly

inside the injection nozzle body.

If the injection needle valve does not move smoothly, it

must be replaced.

INJECTION NO ZZLE BODY AND INJECTION NEEDLE

INSPECTION

Check the injection nozzle body and the injection needle

valve for damage and deformation.

The injection nozzl e assembly must be replaced if either of

these two conditions are discovered during inspection.

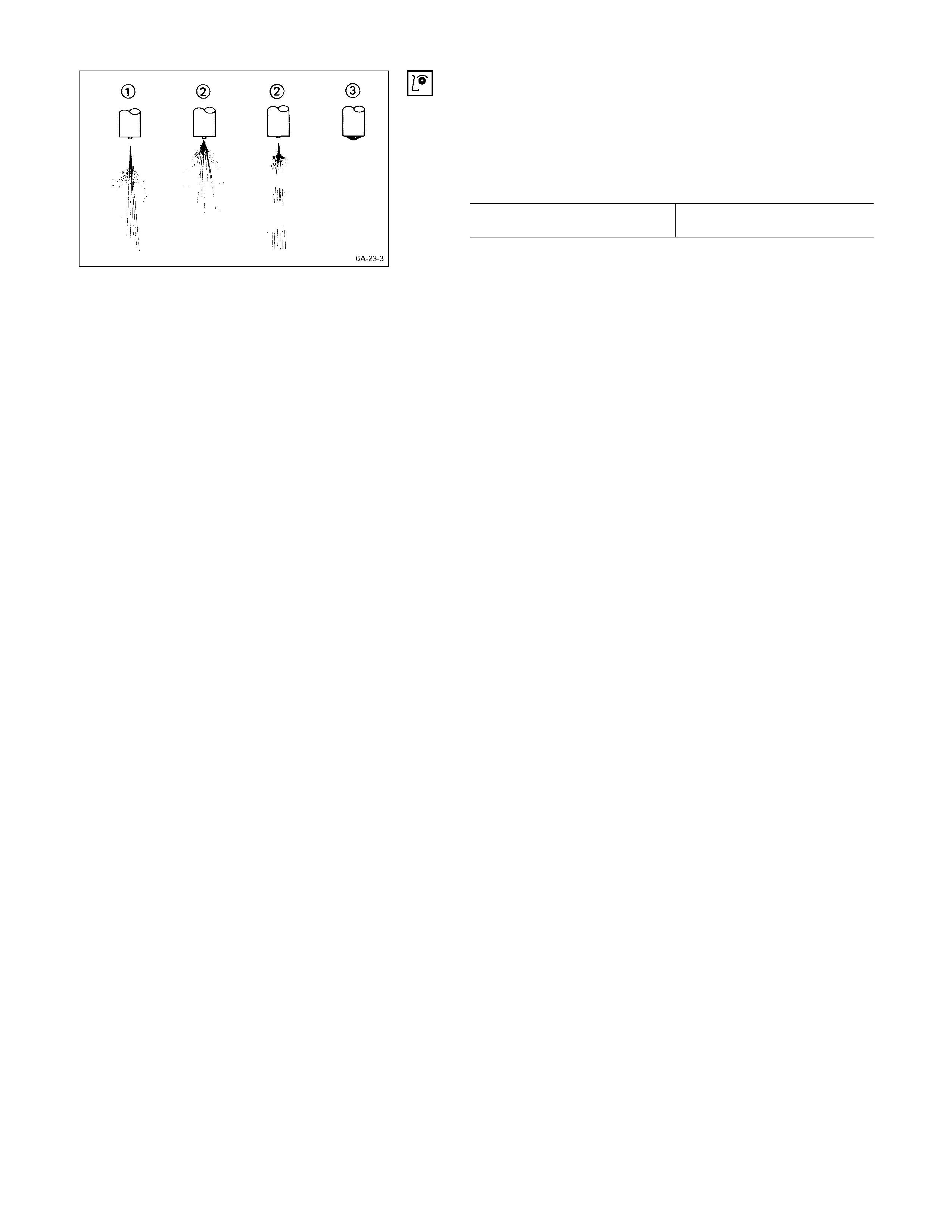

INJECTION NOZZLE INSPECTION

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or adjusted.

Injection Nozzle Opening Pressure kg/cm2 (psi/MPa)

4JG2T 150 (2,133/14.7)

If the spray condition is bad, the injection nozzle must be

replaced or repaired.

Spray Condition

QCorrect

R Incorrect (Restrictions in orifice)

SIncorrect (Dripping)

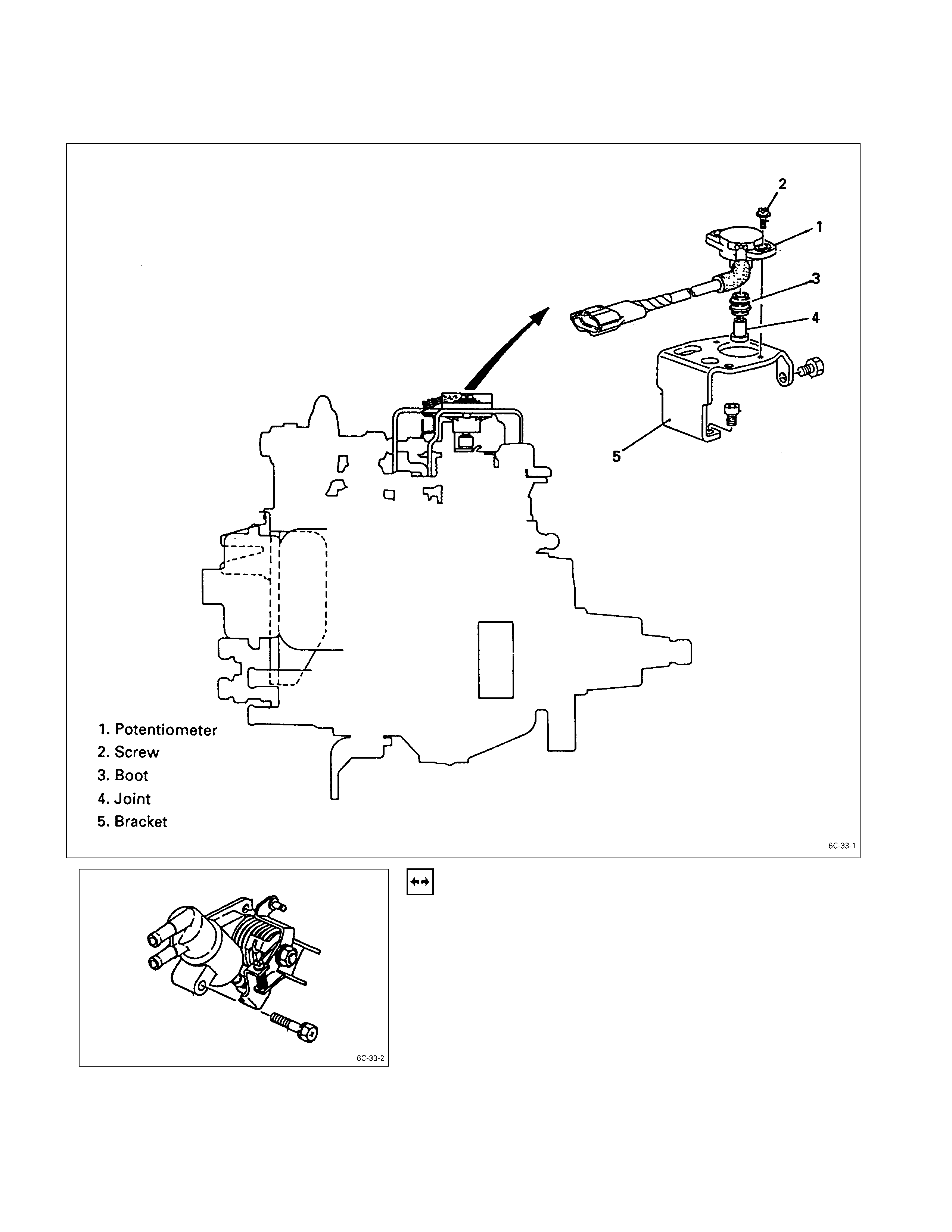

Adjustment Procedure For Potenti ometer

DEVELOPMENT VIEW OF POTENTIOM ETER

1. Advance Assembly (CSD)

Remove the advance assembly from the injection pump

assembly.

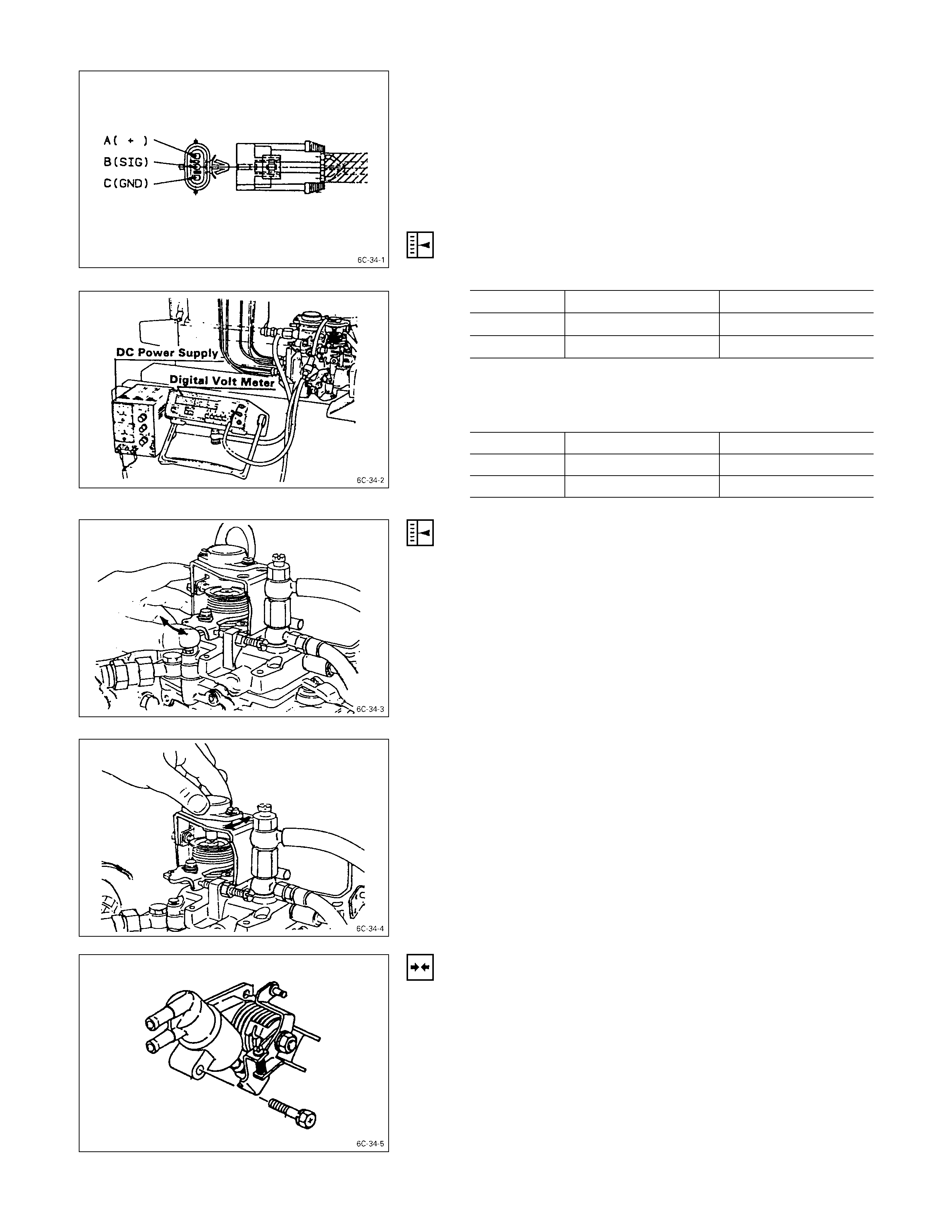

2. Digital Volt Meter and DC Constant Voltage Power

Supply.

1) Connect digital volt meter to B and C connector on

wire harness from potentiometer.

2) Connect DC constant voltage power supply to A (for

positive electricity) and C (for negative electricity)

connector on wire harness from potentiometer.

3) Supply DC 10V to between A and C connector.

4) Measure the output voltage from potentiometer at

idling position on the fuel control lever.

Idling Position Output Voltage Volt

Until 99 Model From 00 Model

4JA1T 1.62 ± 0.45 2.12 ± 0.45

4JG2T 1.41 ± 0.45 1.41 ± 0.45

5) Measure the output voltage from potentiometer at full

load position on the fuel control lever.

Full Load Position Output Voltage Volt

Until 99 Model From 00 Model

4JA1T 7.7 ± 0.45 4.1 ± 0.03

4JG2T - 3.65 ± 0.03

3. Adjustment of Output Voltage from Potentiome ter

If the Measuring value is without standard above, readjust

setting position of the potentiometer as below.

1) Loose the potentiometer fixing bolts.

2) Keep fuel control lever on idling position then move

the potentiometer until reading the output voltage

within standard.

3) Same time read the output voltage with full load

position on the control lever.

4) Make sure that fuel control lever return to idling

position by return spring.

5) Fix the advance assembly to the injection pump

assembly.

Note:

If can not be readjusted potentiometer output voltage,

recommend to contact Zexel or Bosch argent near

your garage.