SECTION 6D - ENGINE ELECTRICAL -

CHARGING SYSTEM

Main Data & Speci fications

General Description

Generator

Charging Circuit Diagram

Wire Coding

Description

Wire Size

Wire Size Specifications

Wire Color

Wire Color-Coding

Symbols & Abbreviations

Description

Symbols

Symbol & Meaning

Abbreviations

Abbreviation & Meaning

Torque Specifications

Generator

Generator

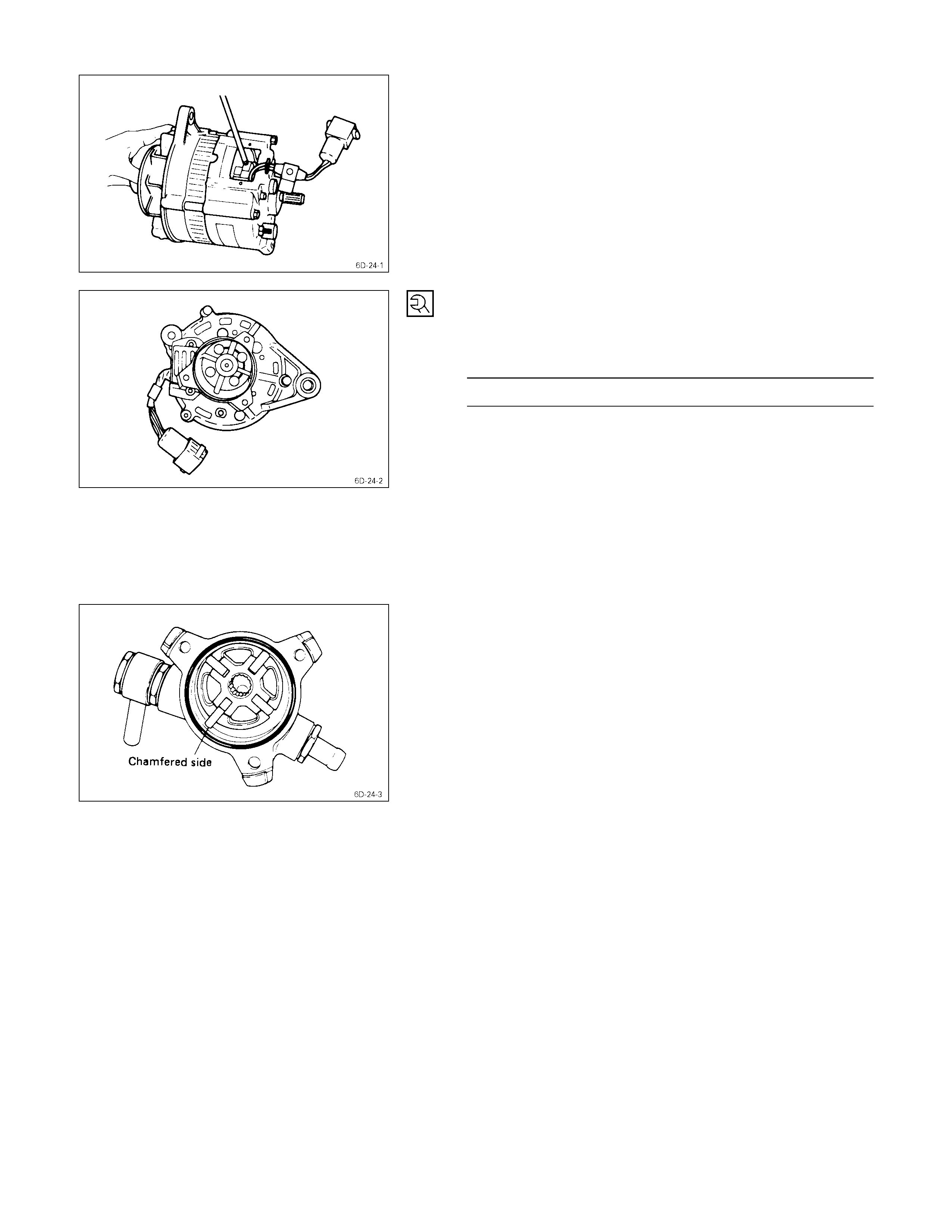

Removal & Installation

Disassembly

Inspection & Repair

Reassembly

Troubleshooting

Battery Charging and Noise Problems

1. No Charging

2. Overcharging

3. Undercharging

4. Unstable Charging Current

5. Noise

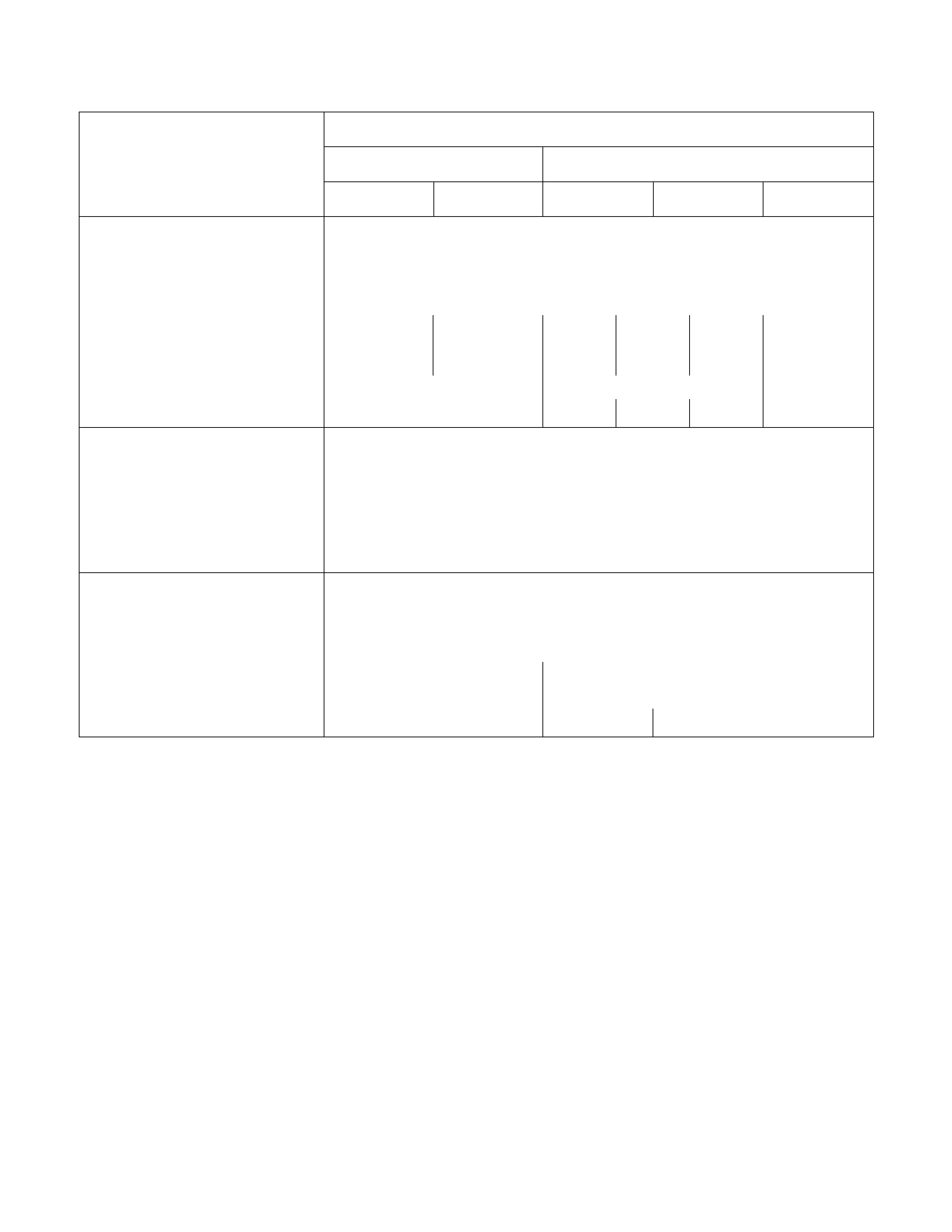

Main Data & Specifications

Description

4JH1TC 4JB1TItem

General Option General Option

Generator

Type

Voltage V

Drive and rotation

Ground polarity

AC brush with IC regulator and vacuum pump

12

V-belt, clockwise viewed from the drive pulley

Negative

Maximum output A 60

at 5,000 rpm 80

at 5,000 rpm 40

at 5,000

rpm

50

at 5,000

rpm

80

at 5,000

rpm

Engine speed ratio to 1 1.77 1.85

Maximum speed rpm 11,000 11,000 11,000 9,500

Starter Motor

Type

Rated voltage V Solenoid controlled

12

Rated output kW 2.3

Load characteristics

Terminal voltage V

Load current A 8.76

300

Vacuum Pump

Delivery volume cm3/rev

500 mmHg build up time 30

35 seconds or less at 1,000 rpm

7~10 seconds or less at 5,000 rpm

Maximum vacuum 680 mmHg or more at 5,000

rpm 650 mmHg or more at 5,000 rpm

Weight kg(lb) 0.65 (1.43) 0.9 (1.99) 1.2 (2.6)

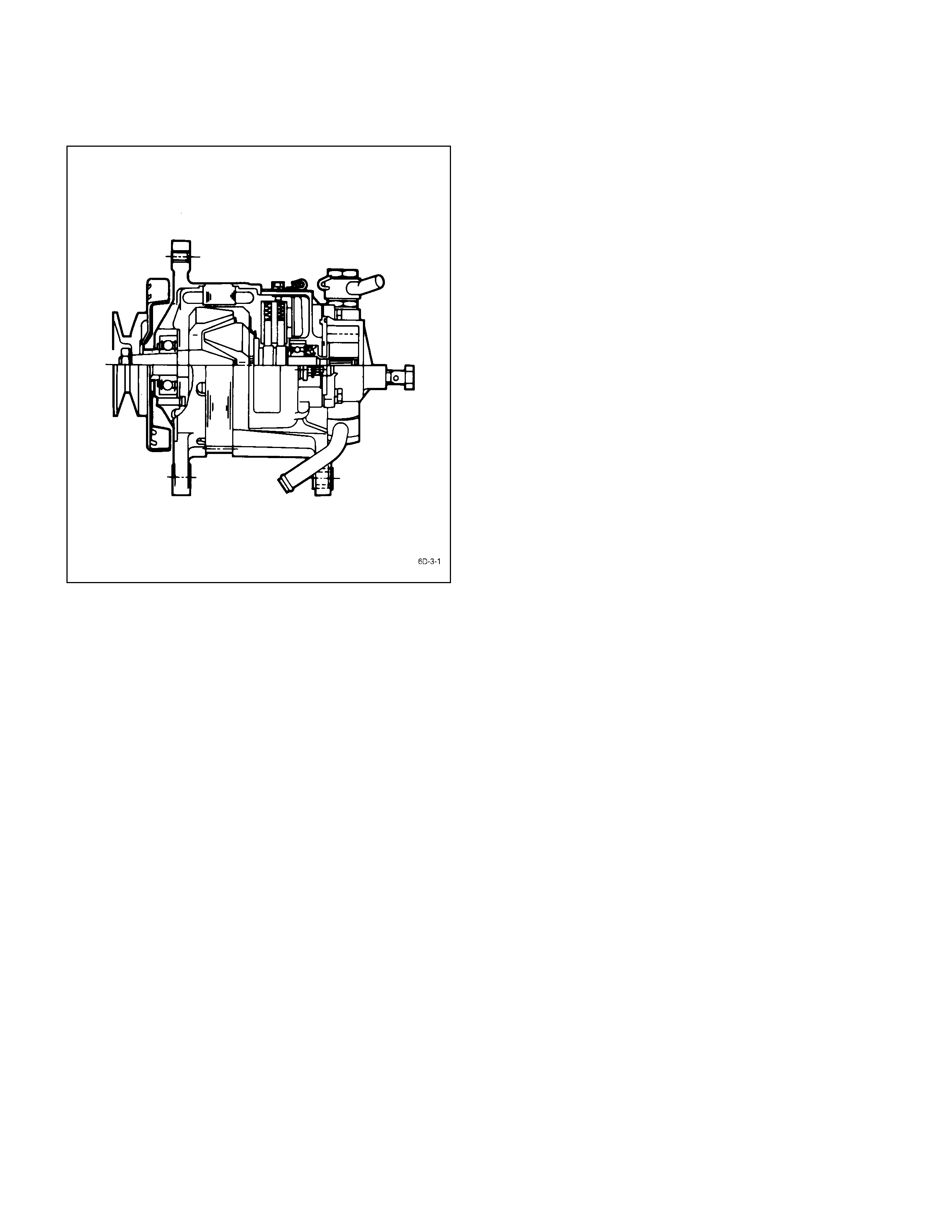

General Description

Generator

The basic charging system is the IC integral regulator charging system. The internal components are connected

electrically as shown in charging circuit diagram.

The generator features a solid state regulator that is mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brush holder assembly is attached to the slip ring end frame. The

generator voltage setting cannot be adjusted.

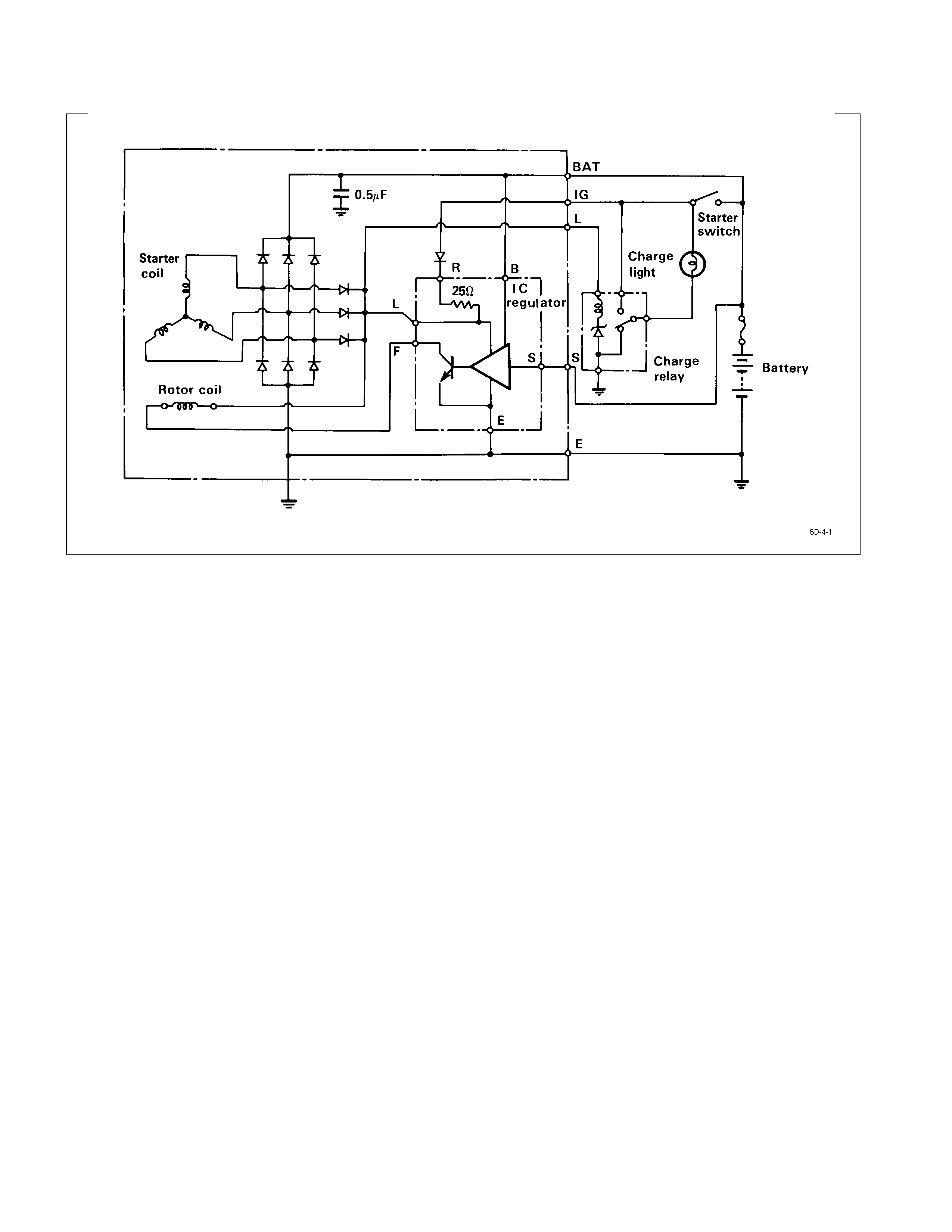

Charging Circuit Diagram

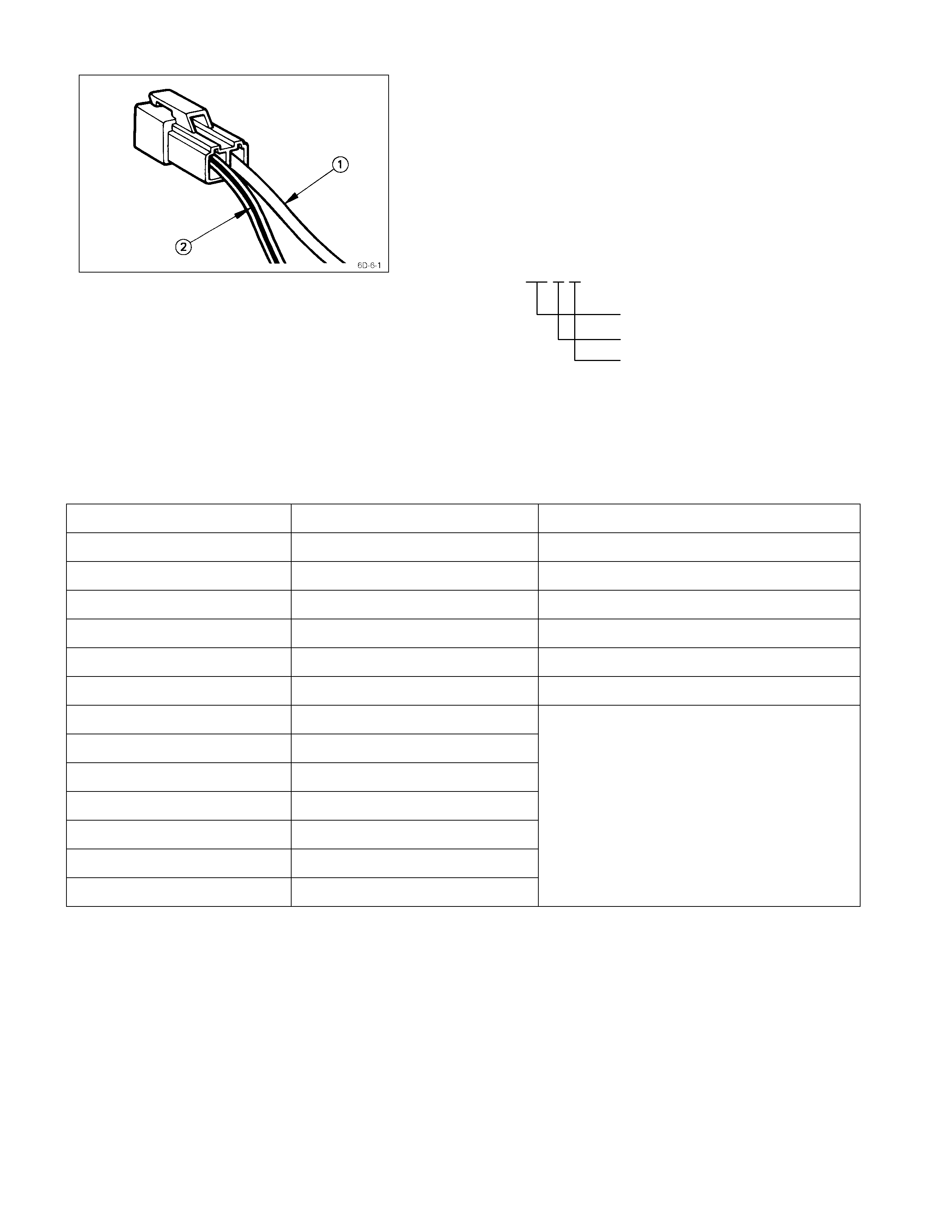

Wire Coding

Description

Codes used in the circuit diagram represent wire size and

color Q.

Example: 0.5 R

Wire color (Red)

Wire size (0.5 mm2)

Wire Size

Wire size is specified with the metric gauge system.

The metric gauge system gives the wire size in cross-

sectional area measured in square millimeters.

Wire Size Specifications

Wire size

mm2AWG

Number of wires/

Wire diameter

mm (in.)

Resistance at normal room

temperature of 20°C (68°F)

Ω/m (Ω/ft.)

Maximum allowable

current

A

0.5

0.85

1.25

2

3

5

8

15

20

30

20

18

16

14

12

10

8

6

4

2

7/0.32 (0.013)

11/0.32 (0.013)

16/0.32 (0.013)

26/0.32 (0.013)

41/0.32 (0.013)

65/0.32 (0.013)

50/0.45 (0.018)

84/0.45 (0.018)

41/0.80 (0.031)

70/0.80 (0.031)

0.03250 (0.00991)

0.02050 (0.00625)

0.01410 (0.00430)

0.00867 (0.00264)

0.00550 (0.00168)

0.00347 (0.00106)

0.00228 (0.00070)

0.00136 (0.00042)

0.00087 (0.00027)

0.00051 (0.00016)

11.3

14.8

18.8

25.4

34.2

45.9

59.8

82.8

110.9

147.0

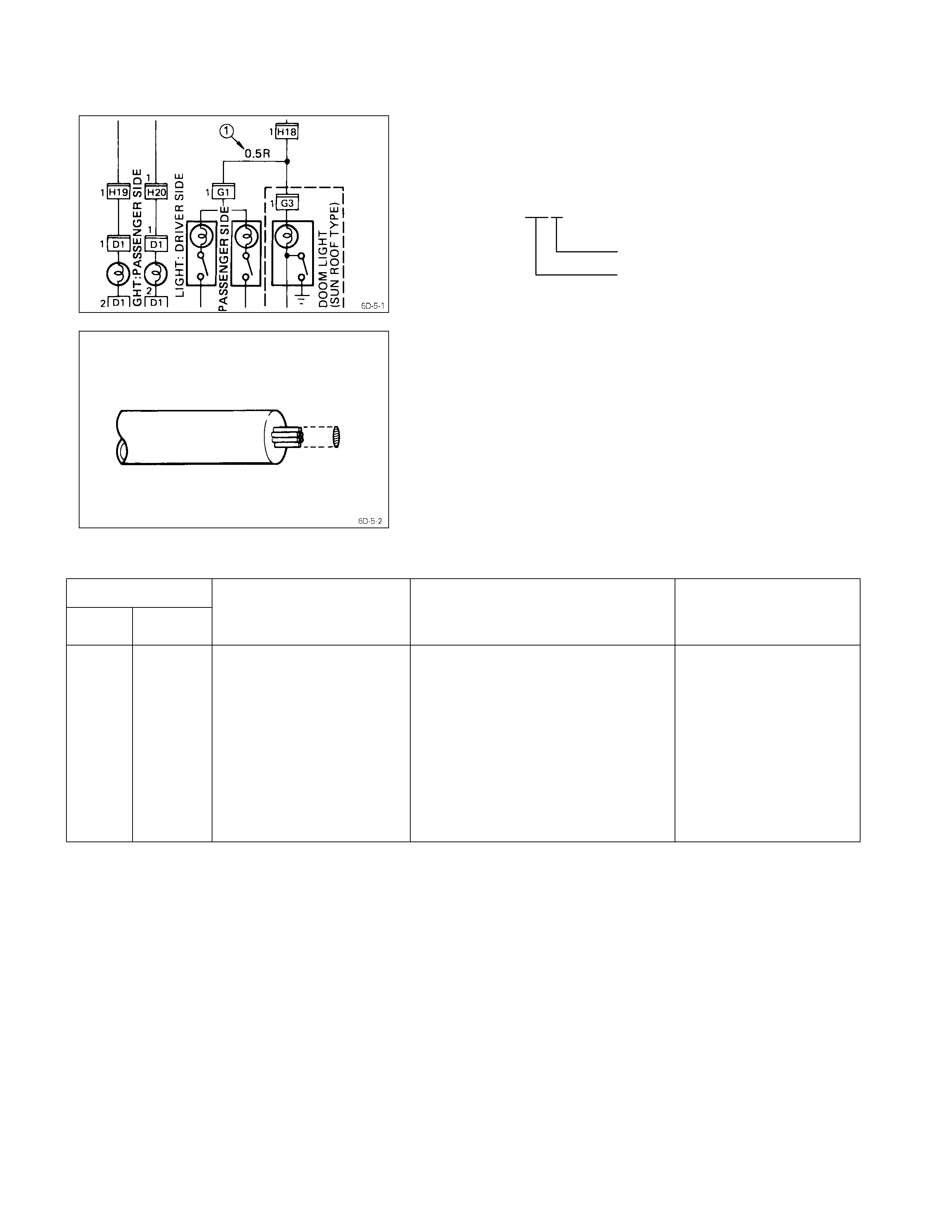

Wire Color

All wires have color-coded insulation.

Wires belonging to a system’s main harness will have a

single color Q.

Wires belonging to a system’s sub-circuits will have a

colored stripe R.

Striped wires use the following code to show wire size and

colors.

Example: 0.5 G R

Wire size (0.5 mm2)

Green (Base color)

Red (Stripe color)

Abbreviations are used to indicate wire color within a

circuit diagram.

Refer to the following table.

Wire Color-Coding

Color-coding Meaning Circuits

B Black Starter circuit and grounding circuit

W White Charging circuit

R Red Lighting circuit

G Green Signal circuit

Y Yellow Instrument circuit

L Blue Wiper circuit

O Orange

Br Brown

Lg Light green

Gy Grey

PPink

Sb Sky blue

V Violet

Other circuits

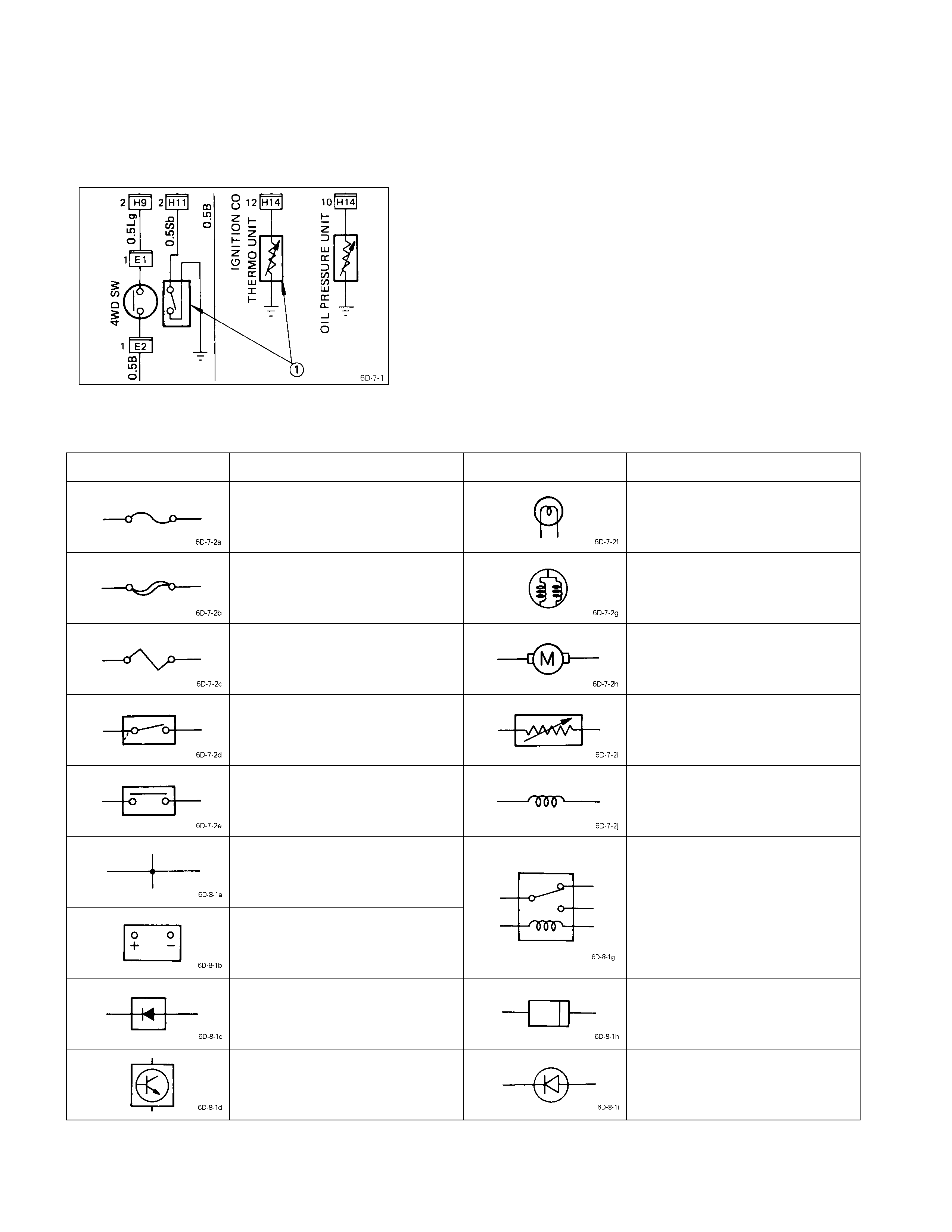

Symbol s & Abbreviations

Description

The symbols and abbreviations used in the circuit diagram

make the diagram easier to read and understand.

Symbols

The illustration at the left shows a ty pical symbol Q used

in circuit diagrams.

Refer to the following table.

Symbol & Meaning

Symbol Meaning Symbol Meaning

Fuse Single filament bulb

Main fuse Double filament bulb

Fusible link wire Motor

Switch Variable resistor

Switch Coil (Inductor)

Contact wiring

Battery

Relay

Note:

Relay contact shown in the

wiring diagram indicates

condition before a ctuation.

Diode Connector

Electronic part Light emitting diode

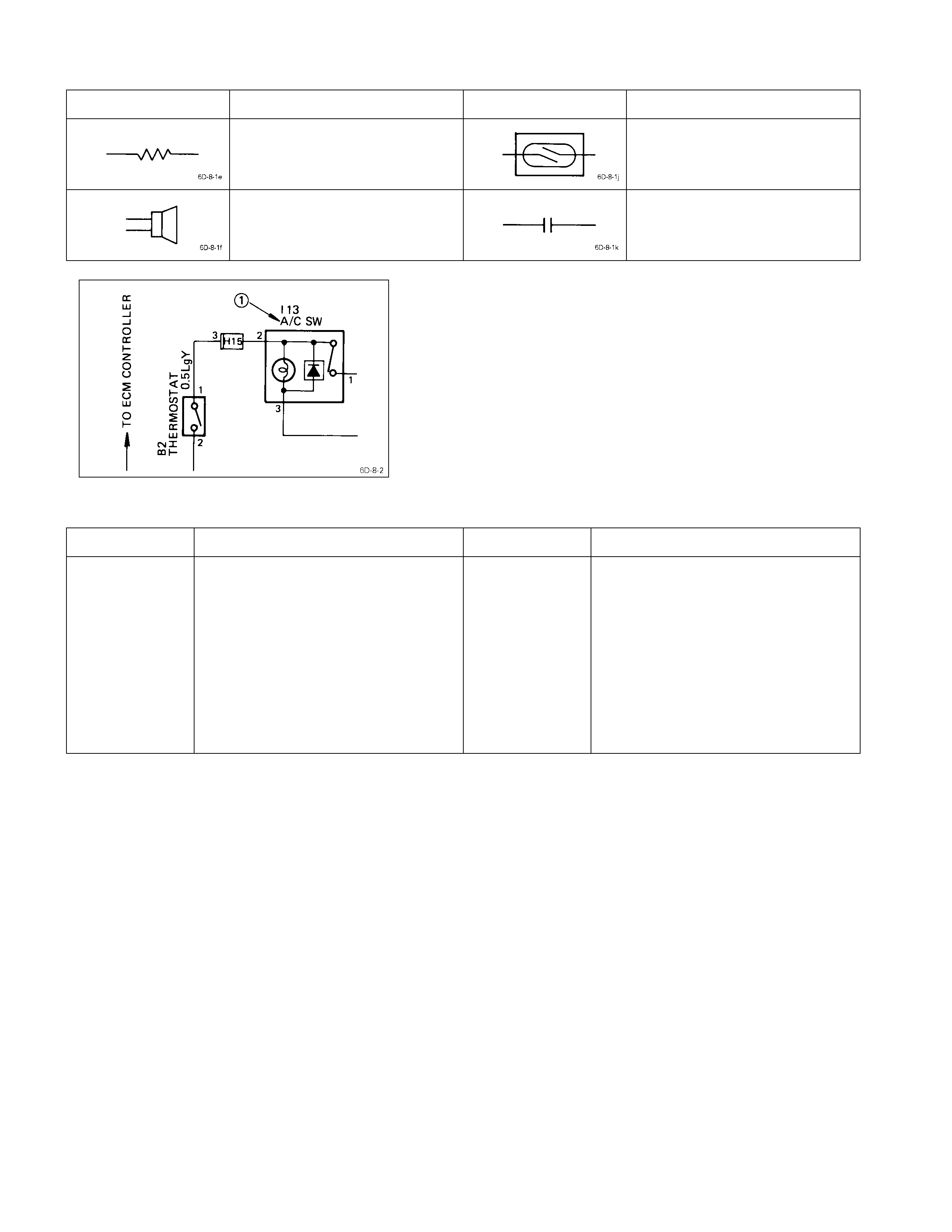

Symbol Meaning Symbol Meaning

Resistor Reed switch

Speaker Condenser

Abbreviations

The illustration at the left shows a ty pical abbreviation

used in circuit diagrams.

These same abbreviations may also appear in the next.

Refer to the following table.

Abbreviation & Meaning

Abbreviation Meaning Abbreviation Meaning

RH

LH

SW

M/T

A/T

FT

RR

FLW

TEMP

ECM

Right-hand side

Left-hand side

Switch

Manual transmission

Automatic transmission

Front

Rear

Fusible link wire

Temperature

Electronic control module

STD

OPT

W/

WO/

OD

ACC

A/C

ATF

VSV

Standard equipment

Optional equipment

With

Without

Overdrive

Accessories

Air conditioner

Automatic transmission fluid

Vacuum switching valve

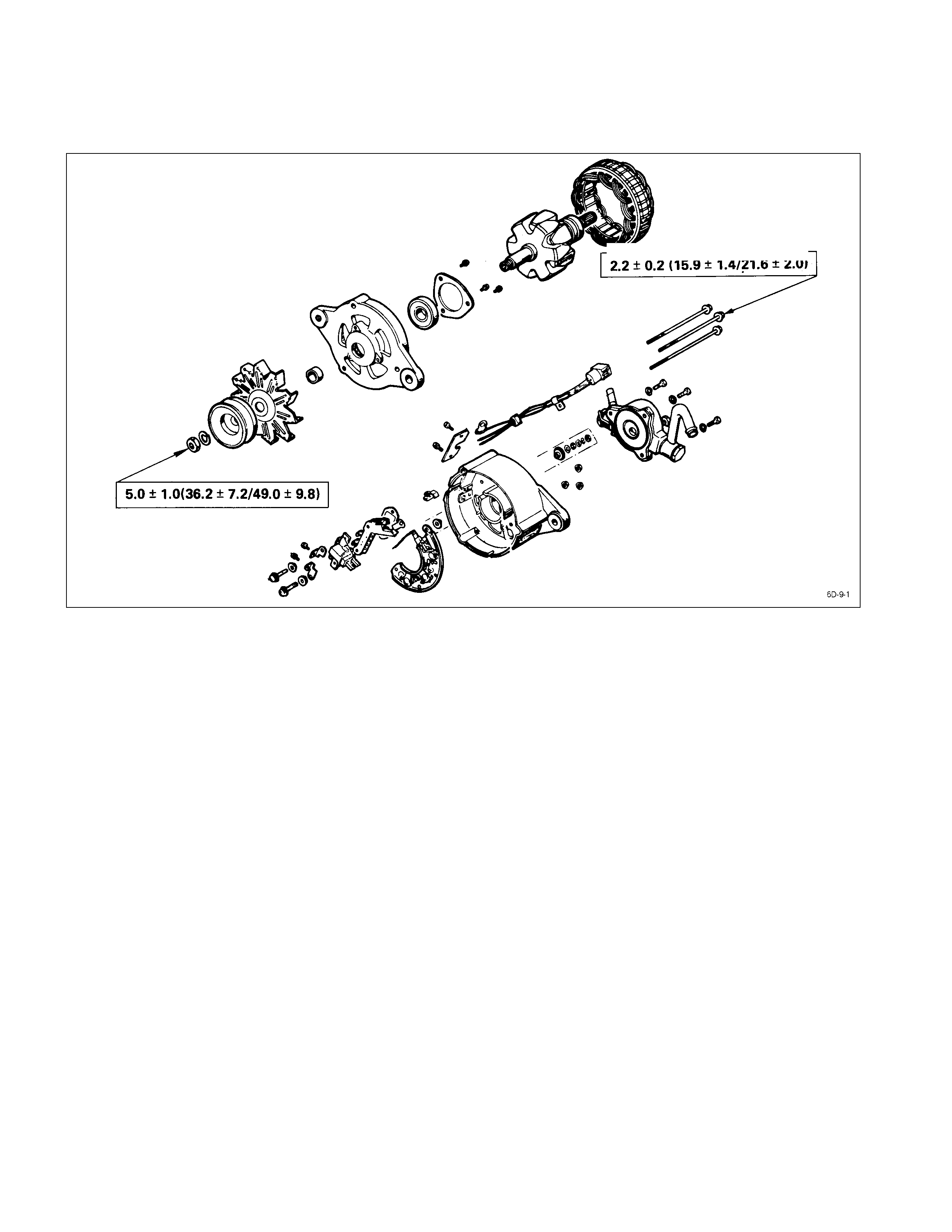

Torque Specifi cati ons

Generator kgm(ft. lbs/Nm)

0.65 ±

±±

± 0.5(4.7 ±

±±

± 3.6/6.3 ±

±±

± 4.9)

Generator

Removal & Installation

Read this Section carefully before performing any removal and installation procedure. This Section gives you important

points as well as the order of operation. Be sure that you understand everything in this Section before you begin.

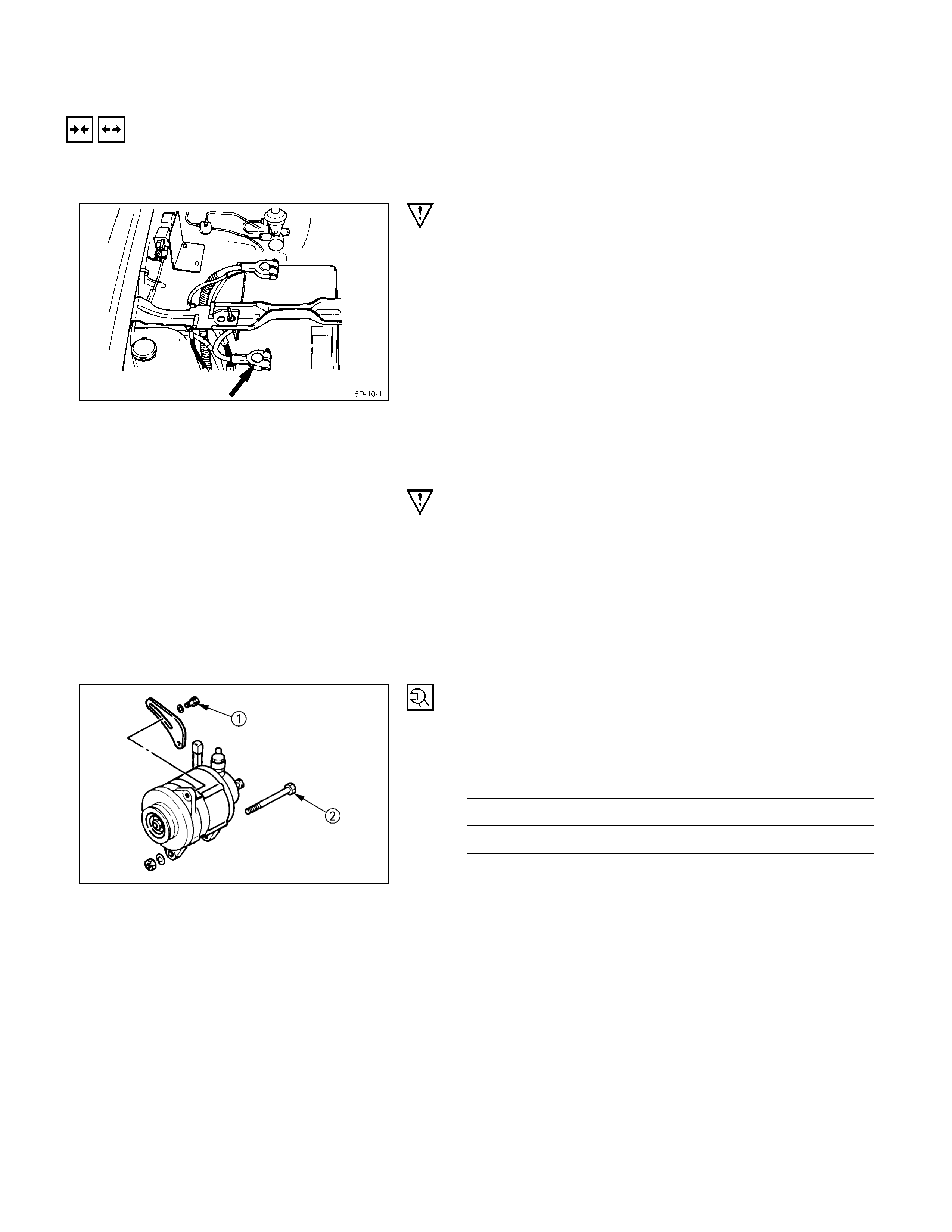

IMPO RTANT OPERATIONS-REMOVAL

COOLING FAN BELT

1) Disconnect the battery cables at the battery terminals.

2) Loosen and remove the fan belt adjusting plate bolts.

3) Remove the fan belt from the generator drive pulley.

GENERATOR

Remove the generator bolt and the generator from the

bracket.

IMPORTANT OPERATIONS-INSTALLATION

Follow the removal procedure in the reverse order to

perform the installation procedure. Pay careful attention to

the important points during the installation procedure.

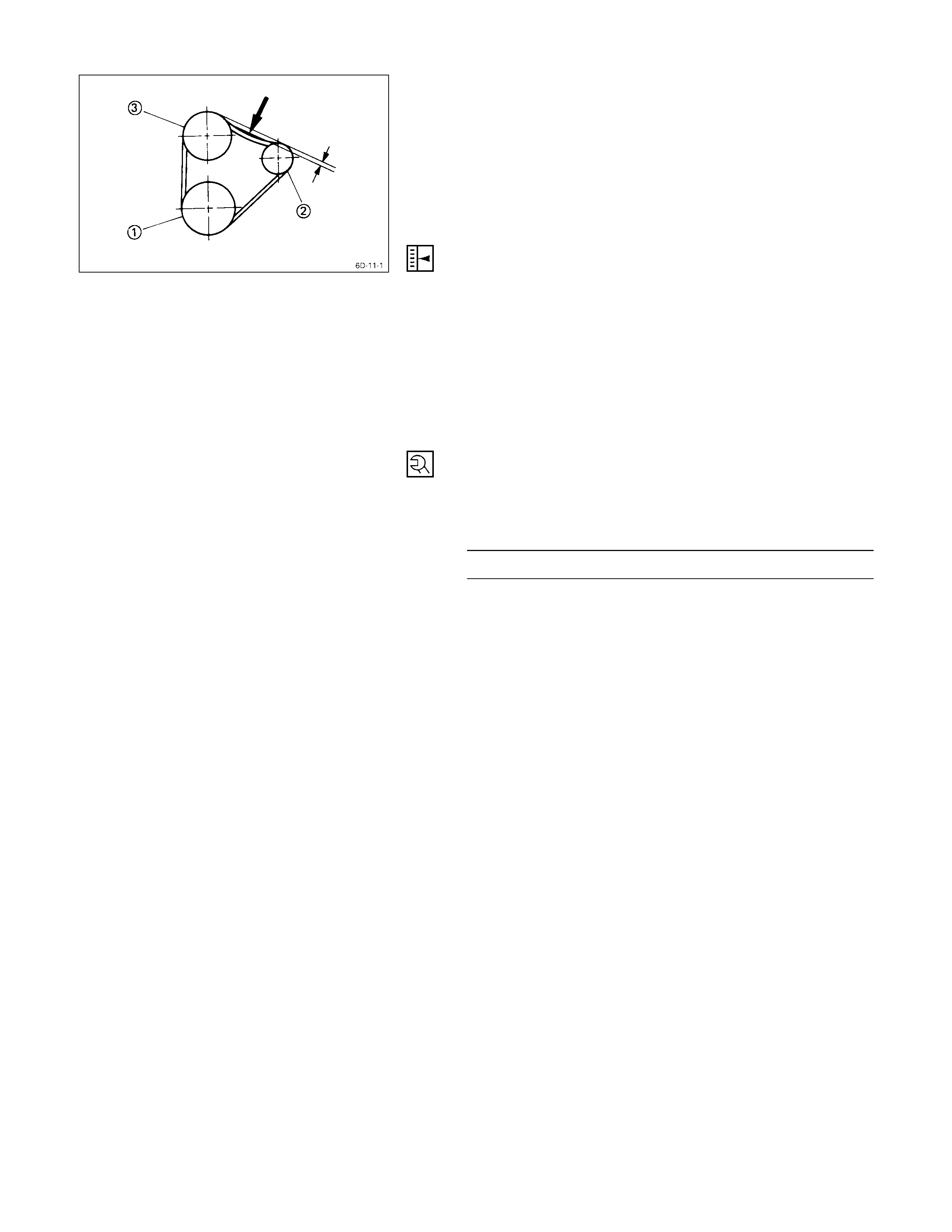

GENERATOR

1) Install the generator to the bracket.

2) Tighten the generator bolt to the specified torque.

Generator Bolt Torque kg·m (lb·ft/N·m)

Q1.9 ± 0.5 (13.7 ± 3.6/18.6 ± 4.9)

R4.1 ± 0.6 (29.6 ± 4.3/40.2 ± 5.9)

066L200001

COOLING FAN BELT

1) Hold the generator toward the engine.

2) Install the fan belt to the three pulleys.

(1) Crankshaft pulley

(2) Water pump pulley

(3) Generator pulley

3) Adjust the fan belt tension

(1) Use a bar to pull the generator away from the

engine as far as possible.

(2) Use your hand to apply a pressure of 10 kg (22

lb/98N) to the area of the fan belt indicated by the

arrow in the illustration.

There should be from 8 – 12 mm (0.3 – 0.5 in) of

belt deflection.

4) Tighten the adjusting plate bolts to the specified

torque.

Pulley Nut Torque kg·m (lb·ft/N·m)

1.9 ± 0.5 (13.7 ± 3.6/18.3 ± 4.9)

5) Reconnect the battery cable to the battery.

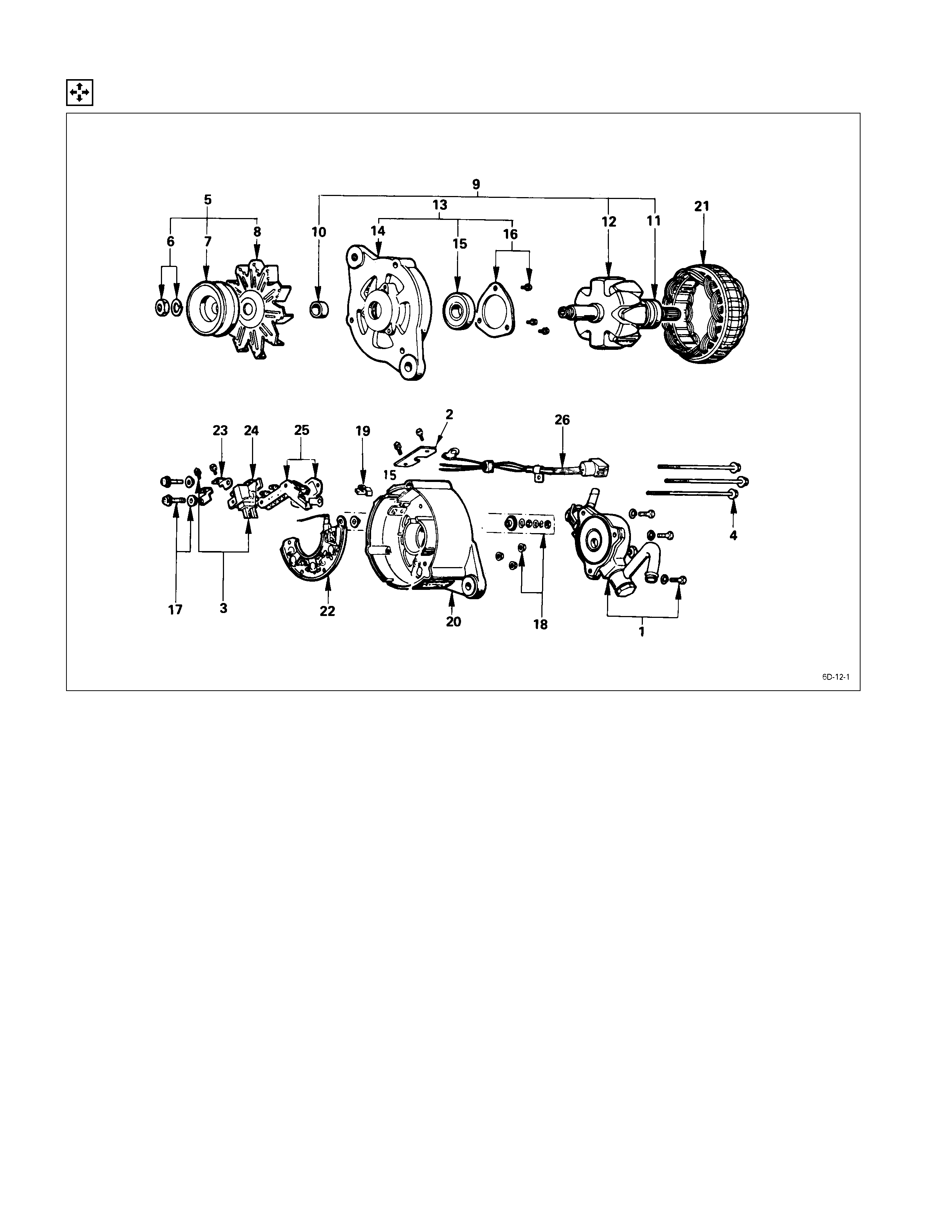

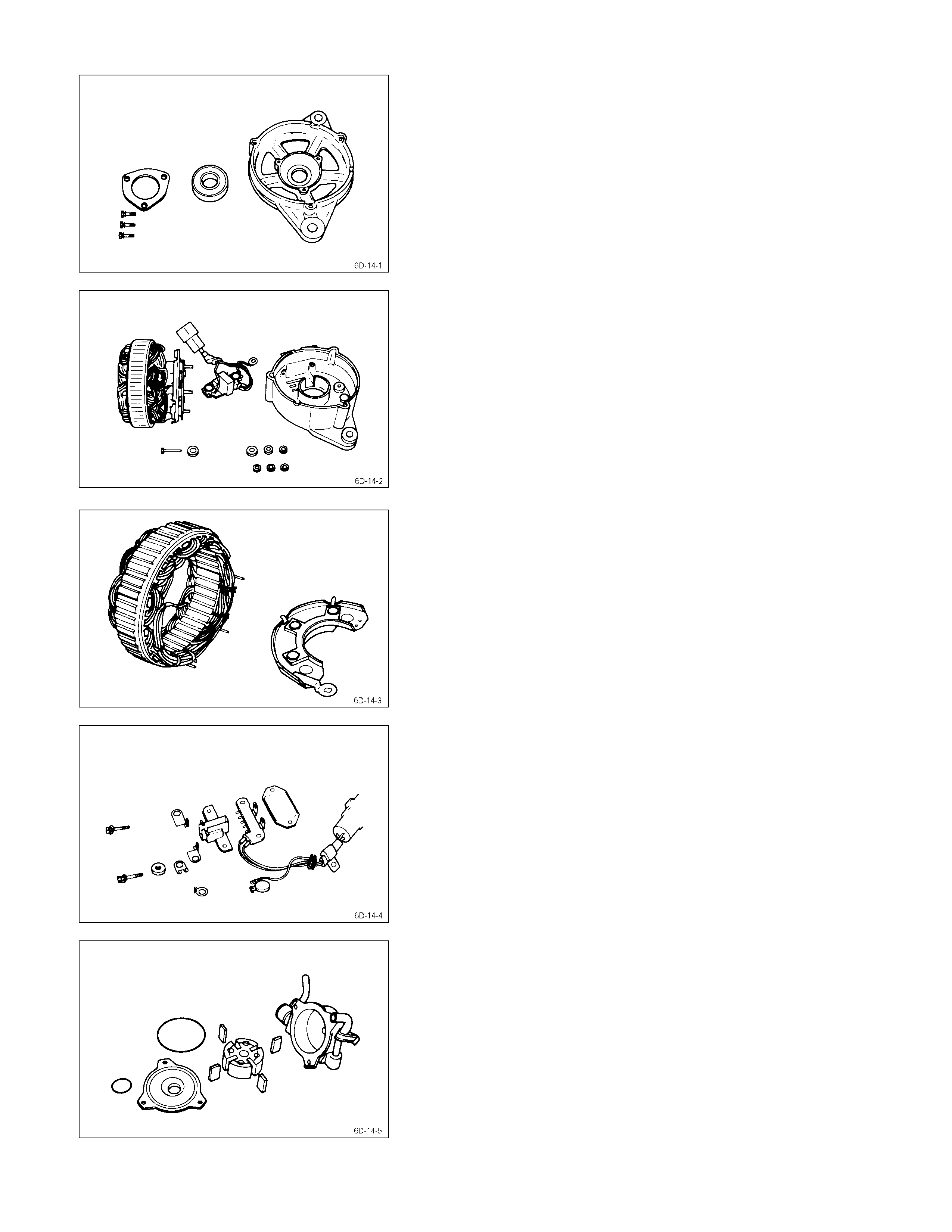

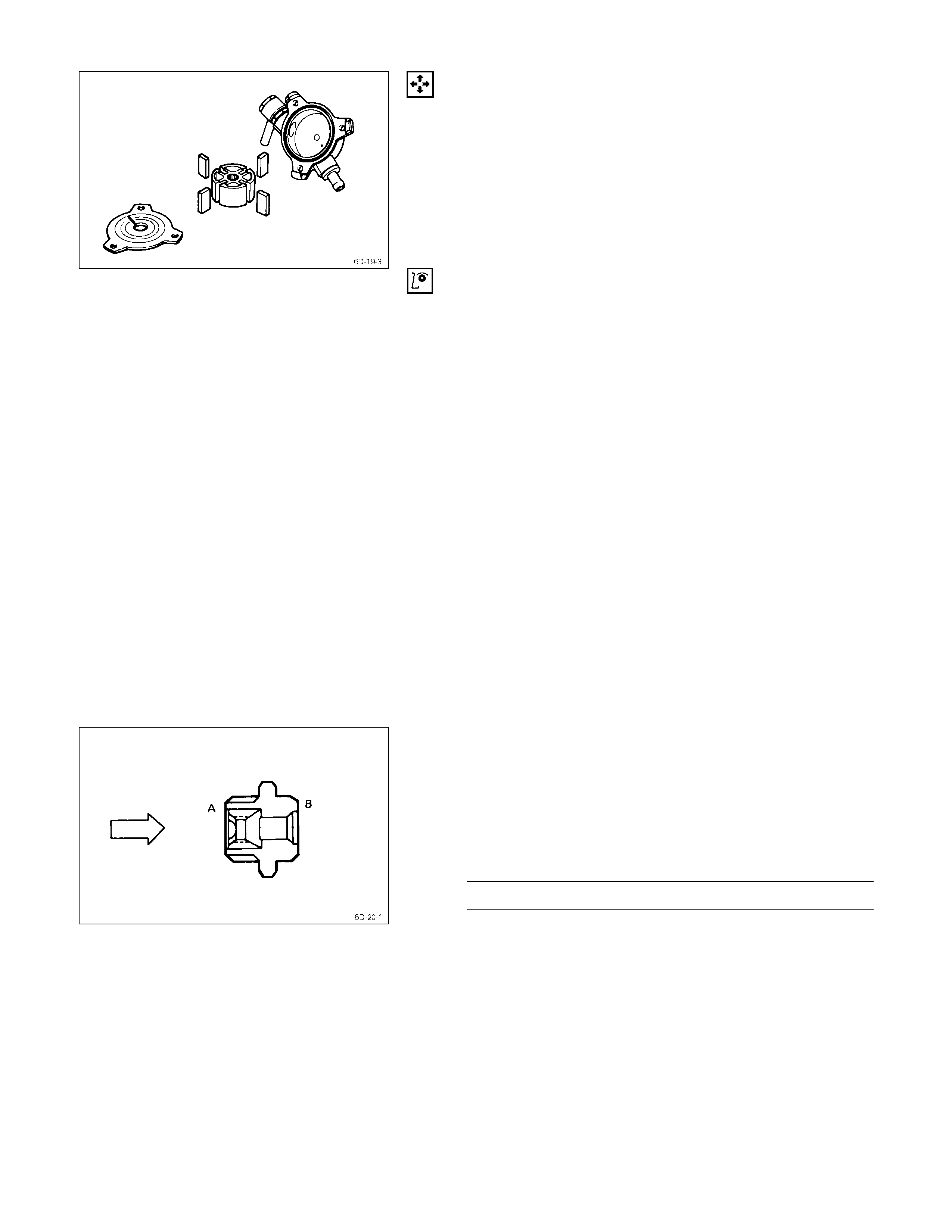

Disassembly

DISASSEMBLY STEPS

J

1. Vacuum pump 14. Front cover

J

2. Cover 15. Ball bearing

J

3. Brush 16. Bearing retainer

J

4. Through bolt 17. Screw

J

5. Pulley assembly

J

18. Terminal bolt and nut

6. Pulley nut 19. Condenser

7. Pulley

J

20. Rear cover

8. Fan

J

21. Stator

J

9. Rotor assembly

J

22. Diode

10. Spacer 23. Holder plate

11. Ball bearing 24. Brush holder

12. Rotor

J

25. IC regulator assembly

J

13. Front cover assembly 26. Lead wire

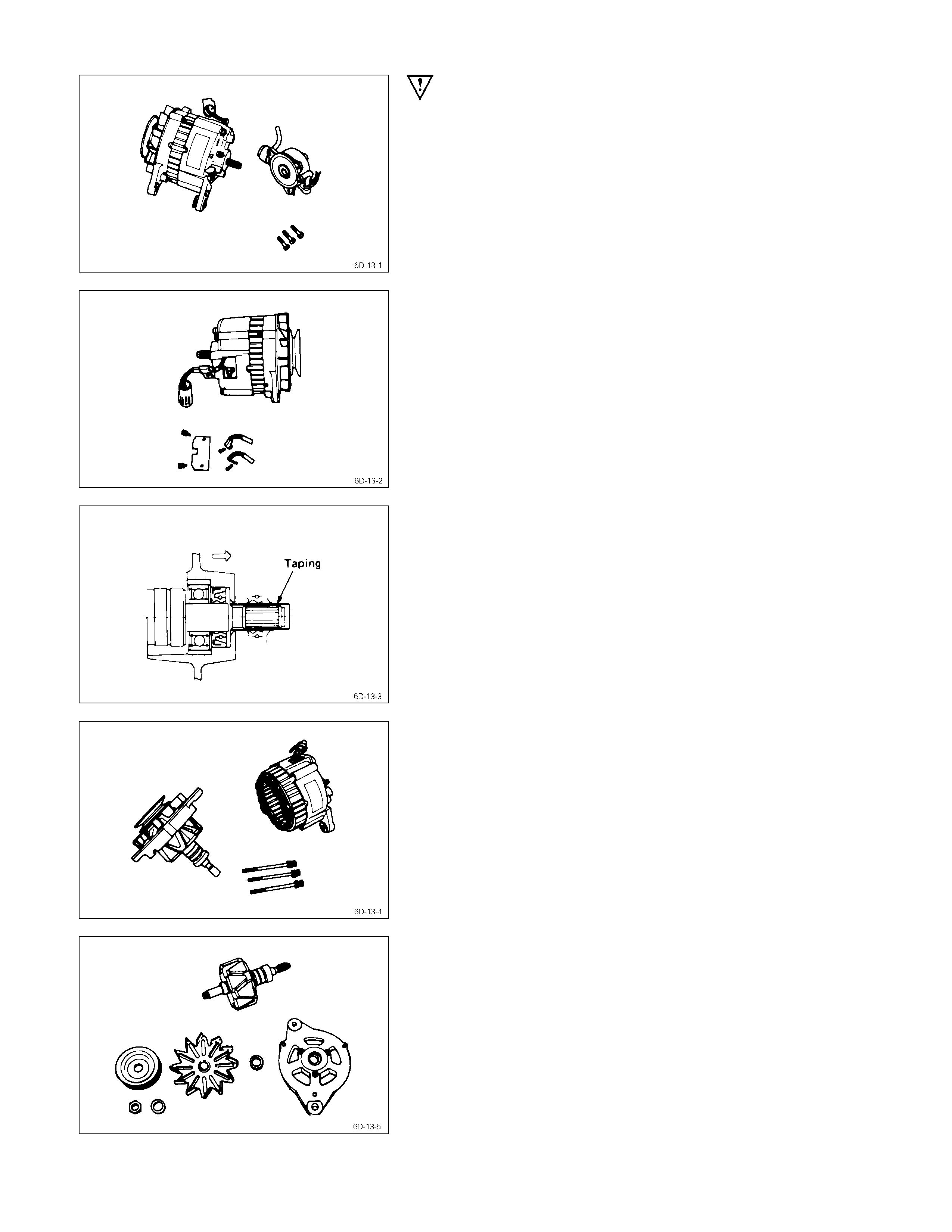

IMPORTANT OPERATIONS

1. Vacuum Pump

1) Loosen the vacuum pump fixing bolts.

2) Support the vacuum pump center plate.

3) Carefully remove the vacuum pump.

2. Cover

3. Brush

1) Remove the cover.

2) Remove the brush fixing bolts.

3) Remove the brushes from the brush holder.

4. Through Bolt

9. Rotor Assembly

1) Loosen the through bolts.

2) Remove the rotor and front cover assembly from the

stator and rear cover assembly.

Do not allow the stator to separate from the rear

cover.

Take care not to damage the oil seal.

3) Tape the rotor splines to protect them from damage.

5. Pulley Assembly

1) Carefully clamp the rotor assembly in a vise.

2) Loosen the pulley nut.

3) Remove the pulley and the front cover from the rotor.

13. Front Cover Assembly

1. Remove the front cover bearing retainer screws.

2. Remove the bearing.

18. Terminal Nut and Bolt

20. Rear Cover

21. Stator

22. Diode

1) Loosen the terminal nuts and bolts.

2) Remove the insulators and the washers.

3) Remove the stator together with the diodes.

4) Disconnect the stator coil leads between each diode

and the N-terminal by melting the solder connection.

Hold the lead wire between the solder and the diode

with a pair of long nose pliers.

This will prevent heat transfer and resultant damage to

the diode.

25. IC Regulator Assembly

1) Melt away the solder from the IC regulator holder plate

terminal.

2) Remove the IC regulator assembly.

Remove the center plate, rotor and vane in the vacuum

pump.

Inspection & Repair

Make the necessary adjustments, repairs, and part replacement if excessive wear or damage is discovered during

inspection.

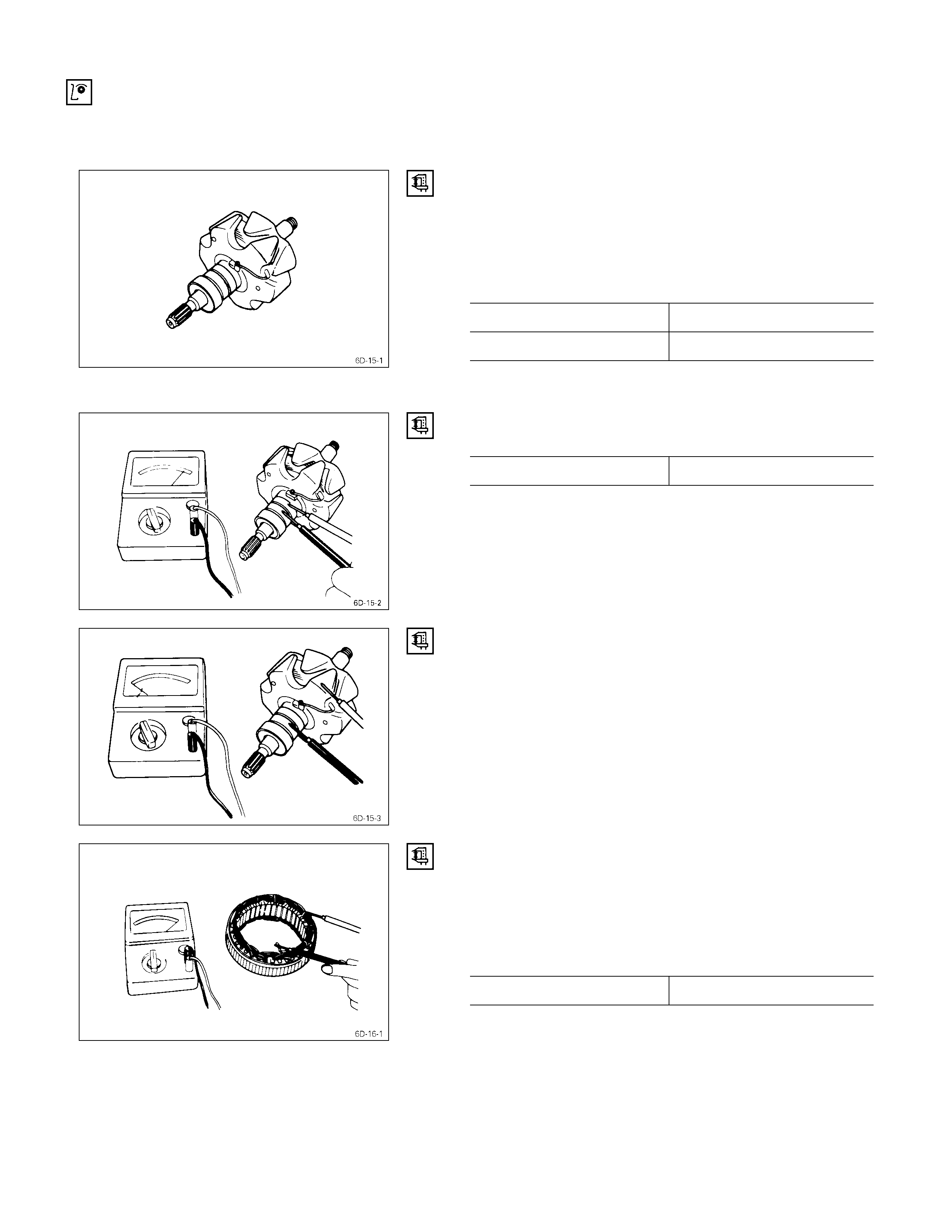

ROTOR ASSEMBLY

1. Inspect the slip ring faces for dirt and pitting.

Wipe away any dirt with a clean cloth soaked in

alcohol.

2. Measure the slip ring diameter.

Slip Ring Diameter mm (in)

Standard Limit

31.6 (1.245) 30.6 (1.183)

If the slip ring diameter is less than the specified limit, the

slip rings must be replaced.

3. Measure the rotor coil resistance.

Rotor Coil Resistance at 20°C (68°F) ohms

Standard 4.2

4. Check for continuity between the slip rings and the

rotor core or sh aft.

If there is continuity, the entire rotor assmbly must be

replaced.

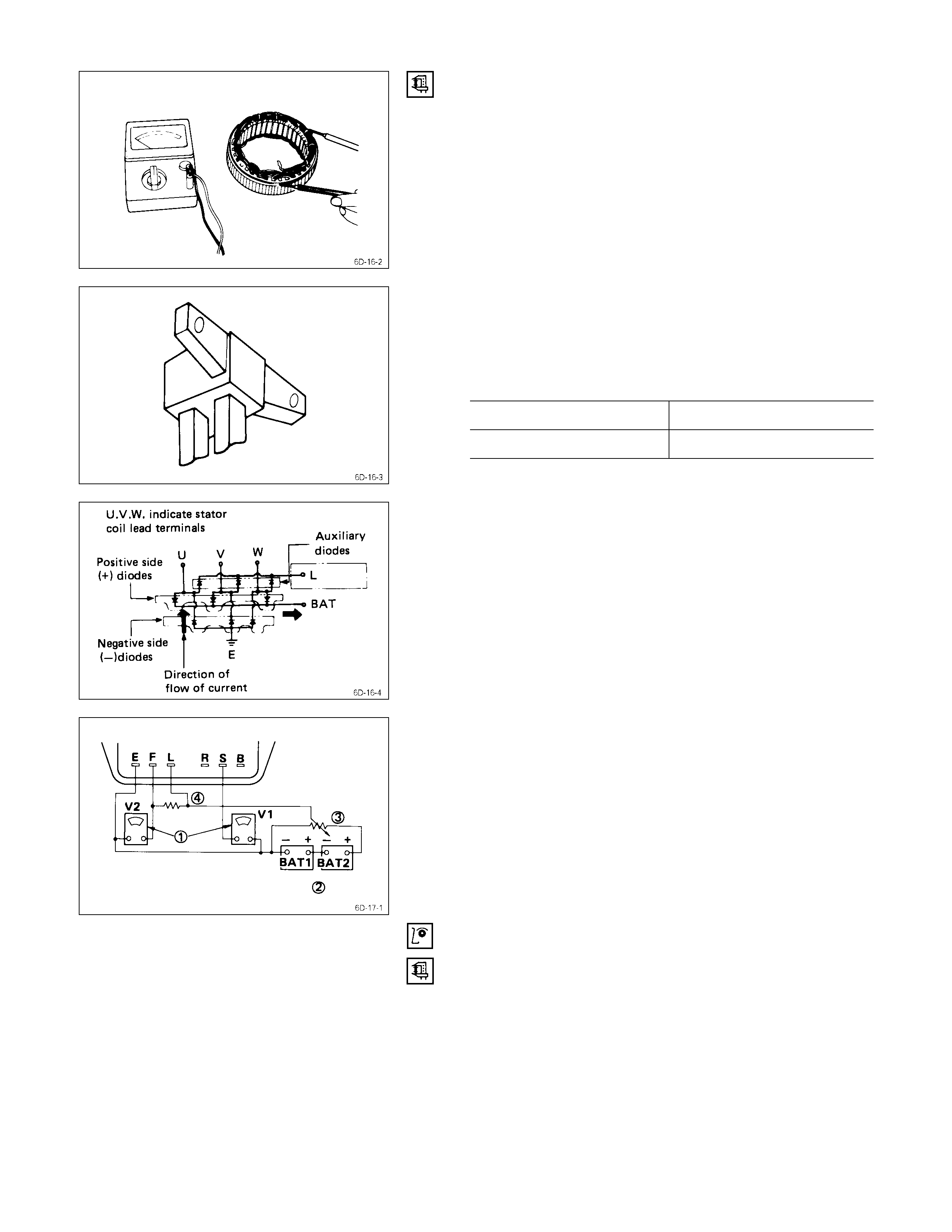

STATOR COIL ASSEMBLY

1. Check for continuity across the stator coils.

If there is no continuity, the stator coils must be

replaced.

Resistance Between The Terminal “N” and the Coil Ends

(Reference) ohms

Standard 0.1

2. Check for continuity between each stator coils and the

stator core.

If there is continuity, the stator coils must be replaced.

BRUSH

Each brush has a line to indicate whether or not the brush

is serviceable.

If the line is not visible, the brush must be replaced.

Brush Length (Reference) mm (in)

Standard Limit

20 (0.8) 6 (0.2)

DIODE

1. Check for continuity between the battery and each of

the three stator coil lead terminals.

If there is continuity, the diode is normal.

If there is no continuity, the diode must be replaced.

2. Reverse the polarity of the test probes.

If there is no continuity, the diode is normal.

If there is continuity, the diode must be replaced.

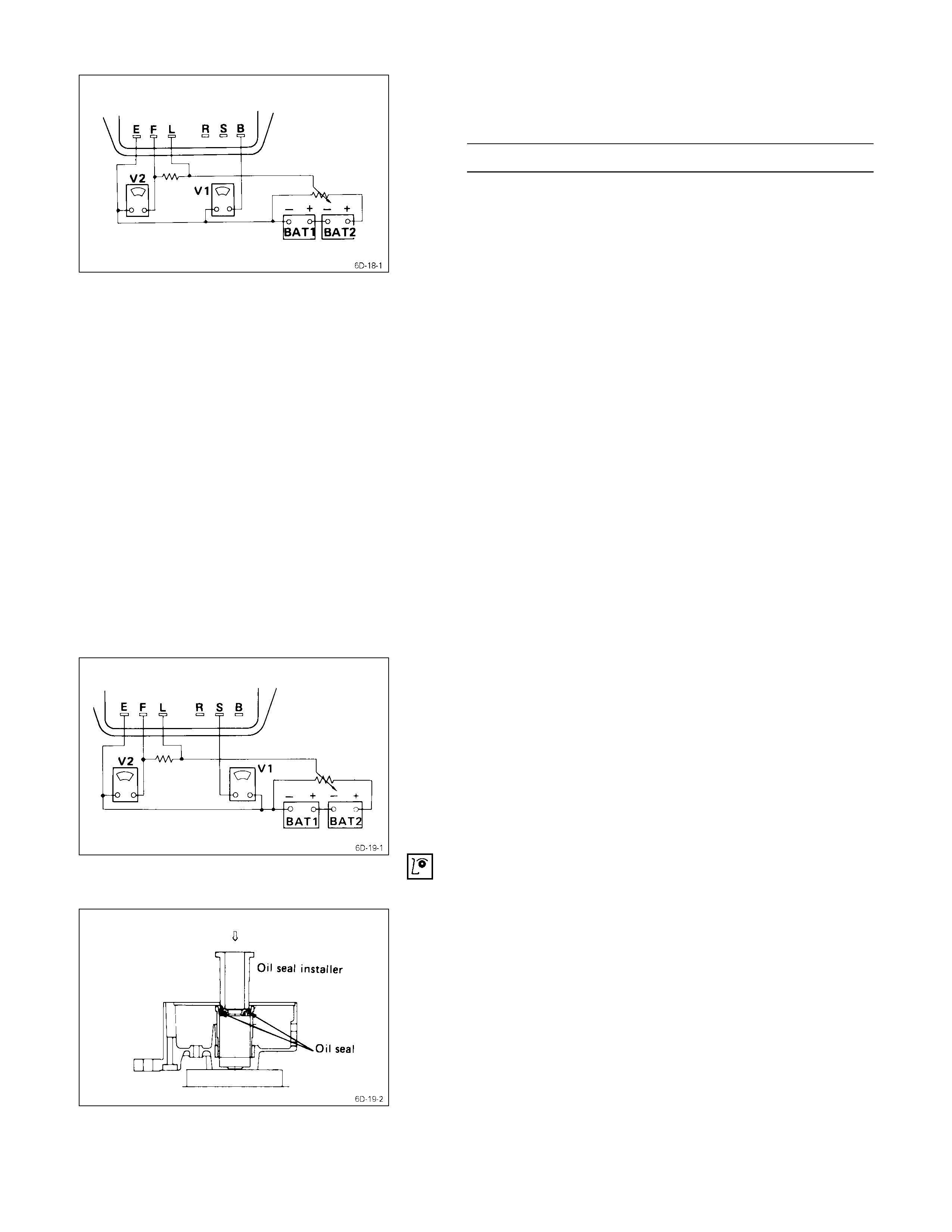

IC REGULATOR

The IC regulator may be tested with either a circuit tester

or a pair of standard voltmeters.

Refer to the illustration.

(1) Circuit tester (or voltmeter) range is from 0 to 50 volts

in 0.5 volt increments.

(2) Two 12-volt batteries are required.

(3) Note the variable resistor.

(4) This resistor is rated at 100 watts or 3 ohms.

Testing the IC Regulator

Refer to the wiring diagram in the illustration when testing

the IC regulator.

1. Connect the batteries in series.

2. Measure the battery power (Voltage).

Battery Power V

20 – 26

3. Connect the circuit tester (or voltmeter V2) as shown

in the illustration.

4. Set the variable resistor (3) to zero.

5. Slowly increase the resistance of the variable resistor

toward the build-up point.

Measure the voltage between E and F.

As long as the resistance is below the build-up point,

the voltage reading should be stable and less than two

volts.

When the resistance exceeds the build-up point, the

voltage reading should be two volts or greater.

If the voltage does not exceed two volts after reaching

the build-up point, the IC regulator must be replaced.

6. Return the variable resistor to zero.

7. Connect the circuit tester (or voltmeter V1) as shown

in the illustration.

8. Measure the voltage at terminals S, L, and E.

9. Slowly increase the resistance of the variable resistor.

Note the point at which the voltage quickly builds up to

between 2 and 6 volts.

This will indicate the point at which the voltage

regulator begins to function.

If the measured voltage is outside the specified range,

the voltage regulator must be replaced.

10. Repeat Steps 3 through 5 to measure the voltage

between terminals B, L, and E.

Refer to the illustration.

The regulator voltage should be between 0.5 and 3

volts higher than the measured voltage.

If the regulator voltage is outside this range, the

voltage regulator must be replaced.

OIL SEAL

Check the rear cover oil seal bore for oil leakage.

OIL SEAL REPLACEMENT

1. Use a screwdriver to remove the oil seal from the rear

cover side.

Take care not to damage the oil seal bore.

2. Discard the used oil seal.

3. Use the oil seal installer to install the new oil seal.

VACUUM PUMP

VACUUM PUMP DISASSEMBLY

1. Remove the center plate from the vacuum pump

housing.

2. Remove the vacuum pump rotor and the vanes from

the housing.

INSPECTION

VACUUM PUMP HO USI NG AND CENTER PLATE

Inspect the vacuum pump housing and the center plate for

excessive wear, abrasion, and scoring.

If any of these conditions are present, the vacuum pump

housing and center plate must be replaced.

VANE

Inspect the vanes for excessive wear and damage.

Replace all four vanes if either of these conditions are

present.

Never replace only one vane.

ROTOR

1. Inspect the rotor for excessive wear, abrasion, and

scoring.

Pay particular attention to the internal spline.

Replace the rotor if any of these conditions are

present.

2. Inspect the generator rotor shaft splines for backlash.

Replace the rotor if backlash is present.

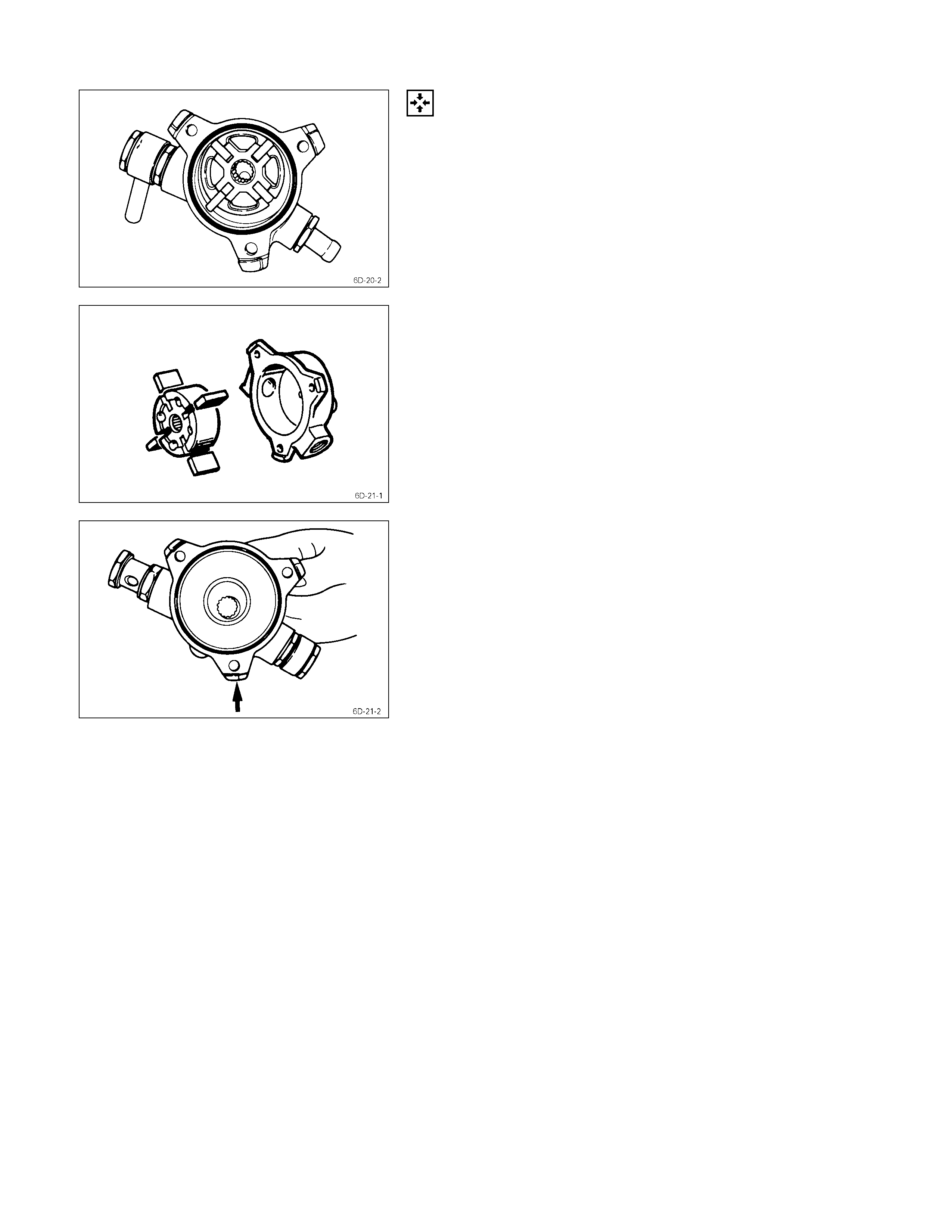

CHECK VALUE

1. Carefully force the valve from the “B” side as shown in

the illustration.

The valve must move smoothly.

If it does not, the check valve must be replaced.

2. Apply compressed air to the “A” side.

Air Pressure kg/cm2(psi/kPa)

1-5 (14 – 71/98 - 490)

Check for air leakage from the check valve.

If there is air leakage, the valve must be replaced.

VACUUM PUMP REASSEMBLY

1. Install the vanes to the rotor slits.

The rounded side of the vanes must be facing the

rotor housing.

2. Install the rotor with the concave side facing the center

plate.

3. Install the center plate to the rotor housing.

Be sure to use a new O-ring.

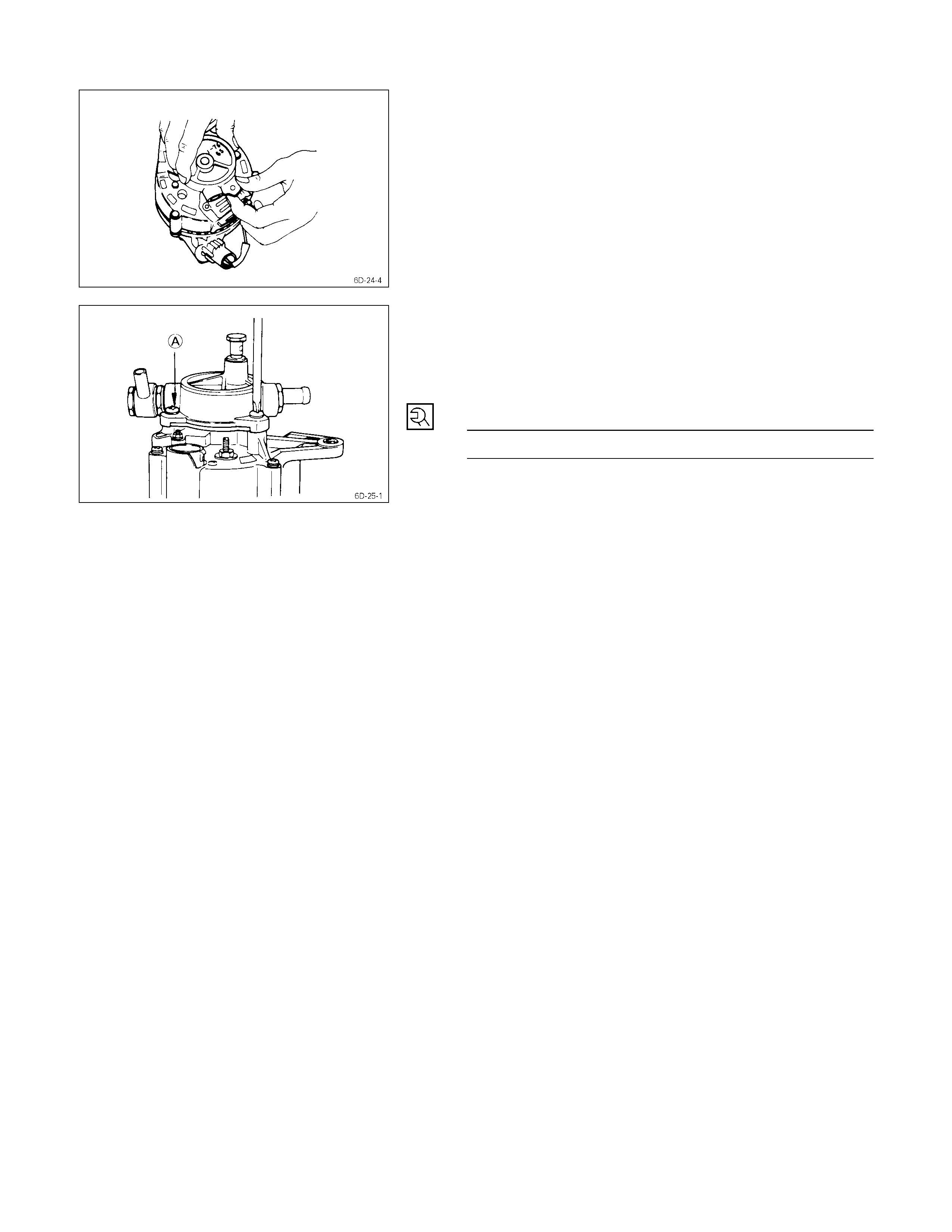

Reassembly

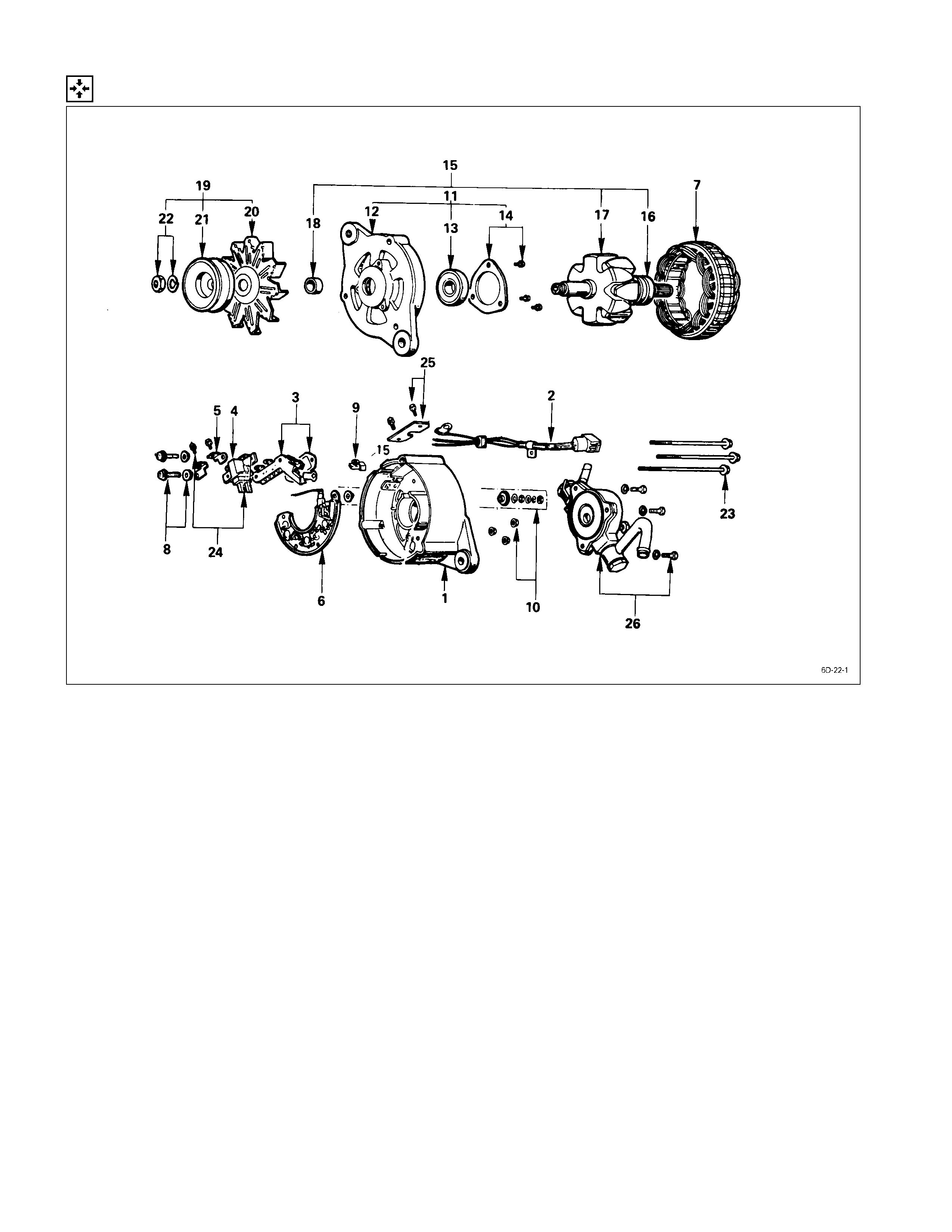

REASSEMBLY STEPS

1. Rear cover 14. Bearing retainer

J

2. Lead wire

J

15. Rotor assembly

J

3. IC regulator assembly 16. Ball bearing

4. Brush holder 17. Rotor

5. Holder plate 18. Spacer

J

6. Diode

J

19. Pulley assembly

J

7. Stator 20. Fan

8. Screw 21. Pulley

9. Condenser 22. Nut and washer

10. Terminal bolt and nut

J

23. Through bolt

11. Front cover assembly

J

24. Brush

12. Front cover

J

25. Cover

13. Ball bearing

J

26. Vacuum pump

IMPORTANT OPERATIONS

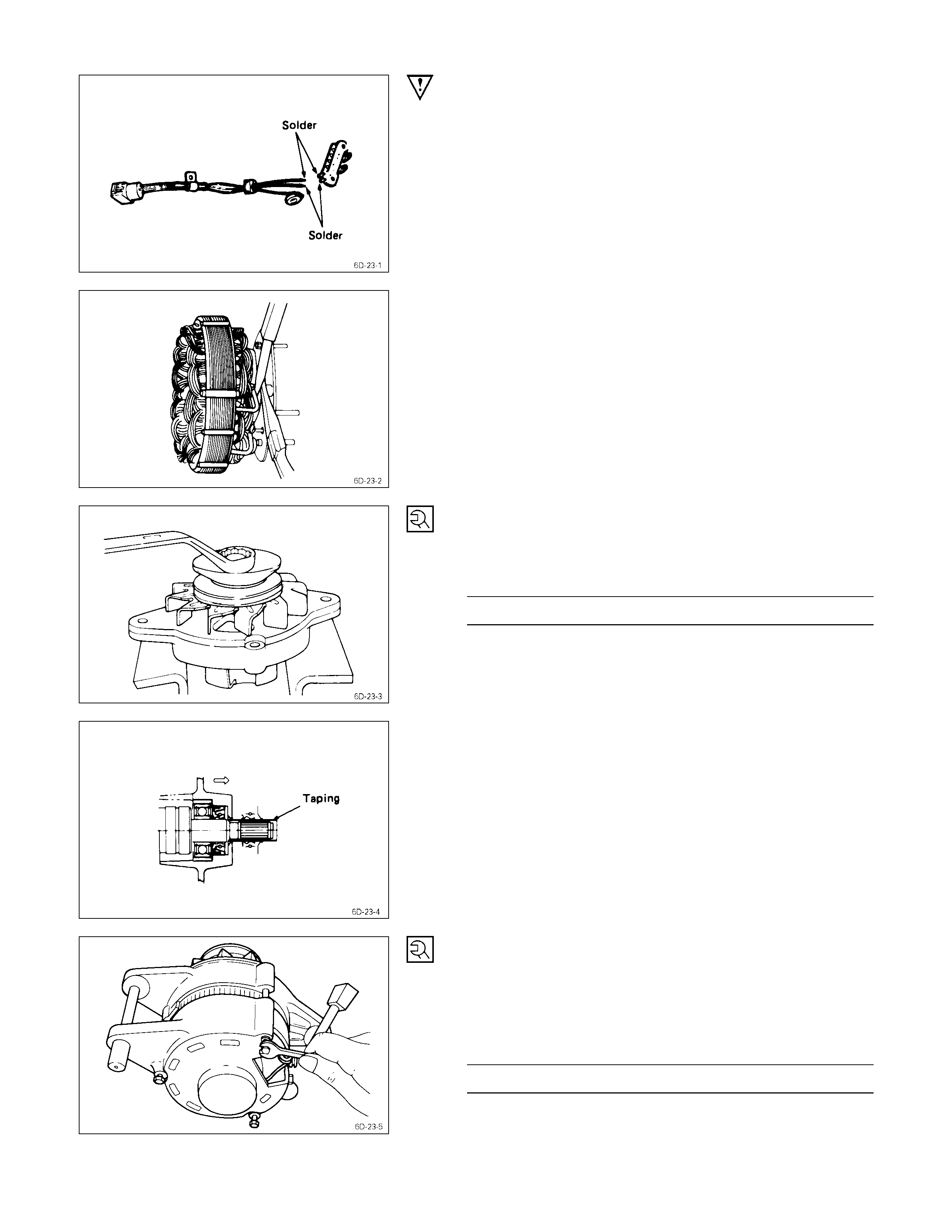

2. Lead Wire

3. IC Regulator

Solder the IC regulator lead wires.

6. Diode

7. Stator

Use a pair of long-nose plier to connect the stator coil

leads and the diode leads.

Finish the work as quickly as possible to prevent the diode

from heat transferred by the soldering.

15. Rotor Assembly

19. Pulley Assembly

Clamp the rotor in a vise and install the pulley nut.

Pulley Nut Torque kg⋅m(lb⋅ft)

5.0 ± 1.0 (36.2 ± 7.2/49.0 ± 9.8)

Remove the tape from the splines.

23. Through Bolt

1. Place a pilot bar into the through bolt hole to align the

front cover and the rear cover.

2. Install the through bolts and tighten them to the

specified torque.

Through Bolt Torque kg⋅m(lb⋅ft)

0.65 ± 0.5 (4.7 ± 3.6/6.3 ± 4.9)

24. Brush

Install the brush into the brush holders.

25. Cover

Install the brush cover and tighten the cover bolts to the

specified torque.

Brush Cover Bolt Torque kg⋅m(lb⋅ft)

0.35 ± 0.5 (2.5 ± 3.6/3.4 ± 5.0)

26. Vaccum Pump

Position the rotor, with the serrated boss turned up, on the

center plate and housing.

Align the holes in the center plate and the rotor.

Install vanes into slits in rotor.

The vanes should be installed with the chamfered side

facing outward.

Install the vacuum pump housing.

Make sure that the O-ring is not projecting beyond the

slots of the center plate.

Take care so that no scratching takes place on the vane

resulted by contact with the housing.

Install the housing in the generator and fix it with the three

bolts.

Supply engine oil (5cc or so) from the oil port and check

that the generator pulley can be turned smoothly with your

hand.

Generator Housing Bolt Torque kg⋅m(lb⋅ft)

0.65 ± 0.5 (4.7 ± 3.6/6.3 ± 4.9)

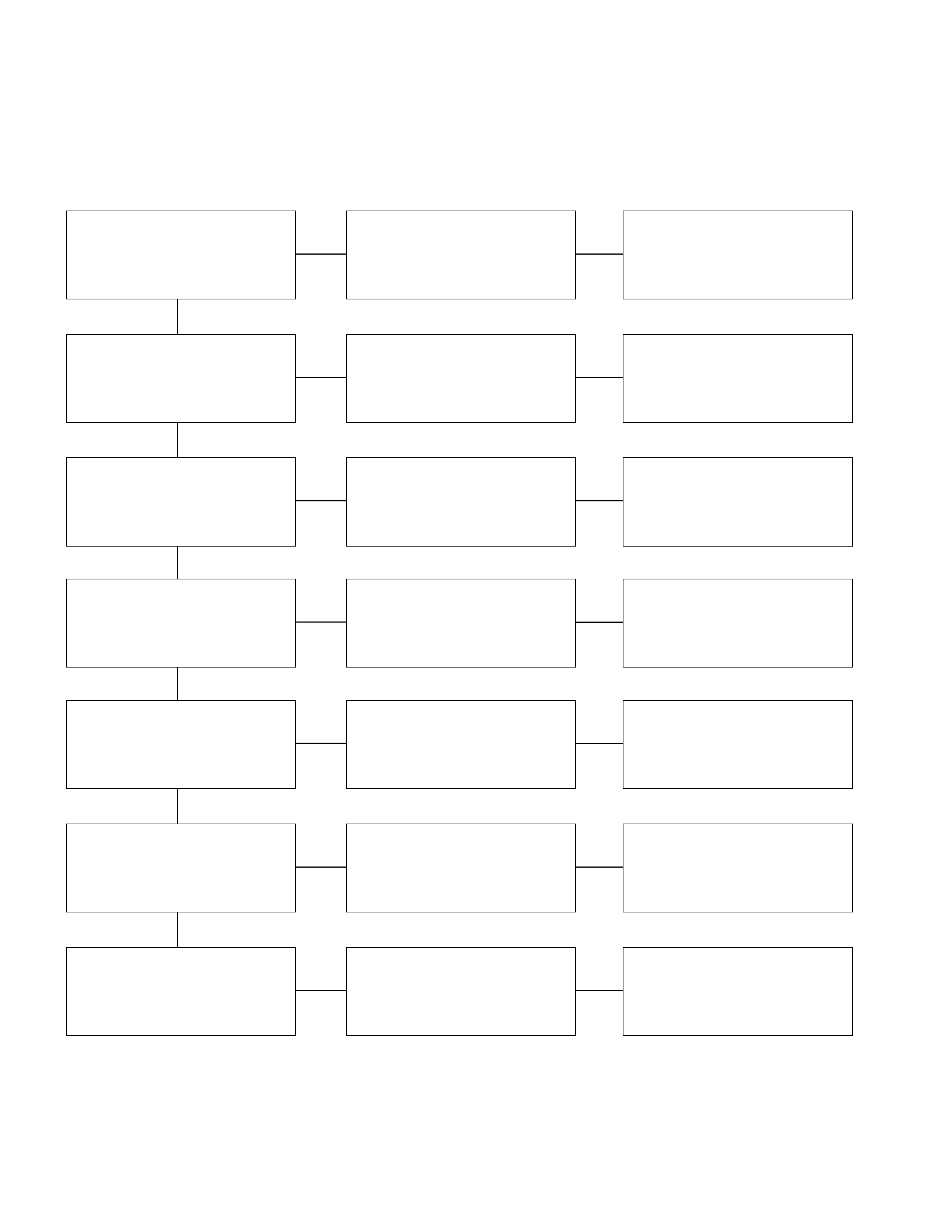

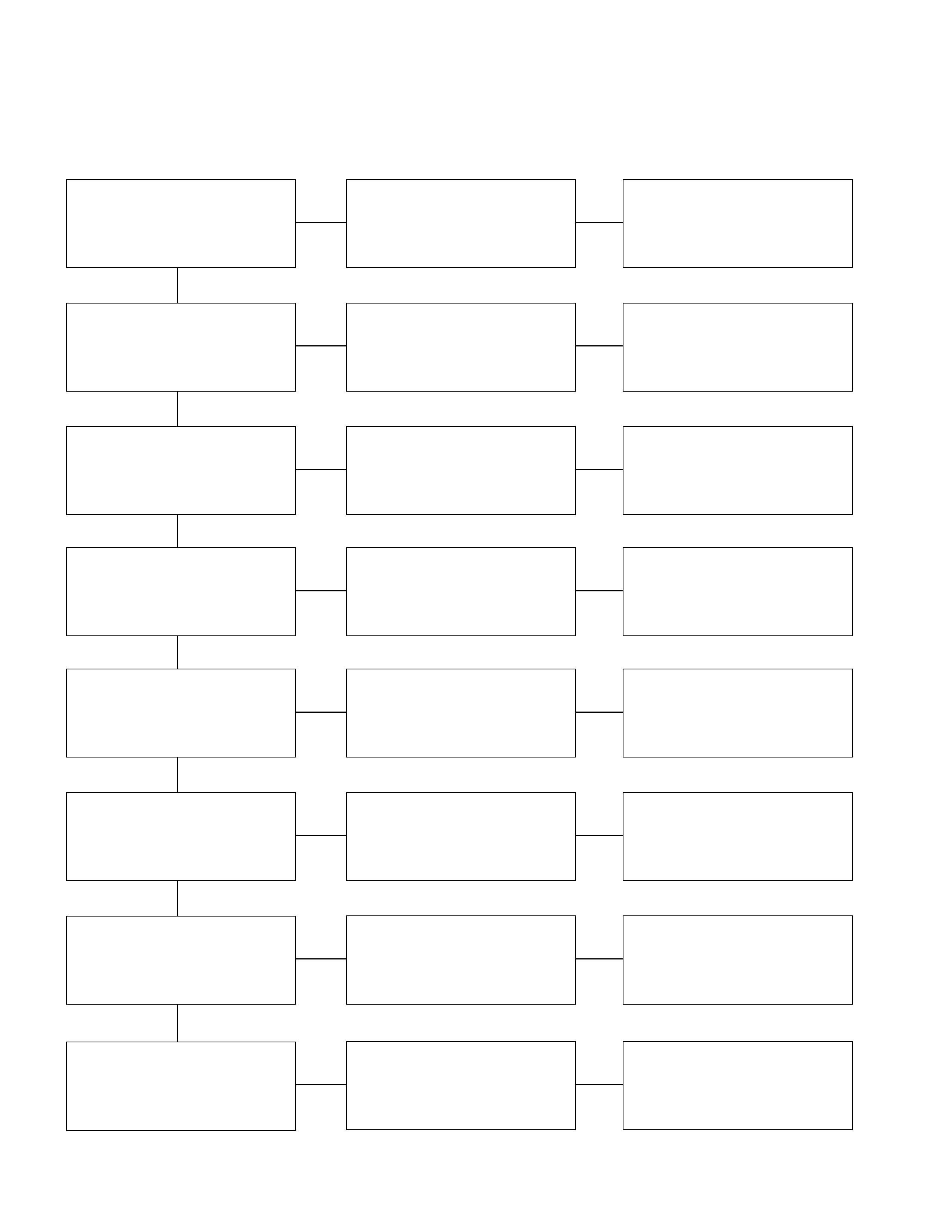

Troubleshooting

Refer to this Section to quickly diagnose and repair electrical problems.

Each troubleshooting chart has three headings arranged from left to right.

(1) Checkpoint (2) Trouble Cause (3) Countermeasure

Battery Charging and Noise Problems

1. No Charging

2. Overcharging

3. Undercharging

4. Unstable Charging Current

5. Noise

Battery Charging & Noise Problems

1. No Charging

Checkpoint Trouble Cause Countermeasure

Terminals and connectors Broken or defective Repair the push rod play

Ground connections Poorly grounded Correct

Brush with slip ring Poor contact Repair or replace

Generator stator coil Open or scorched Replace

Generator rotor coil Open or scorched Replace

Generator diode Defective Replace

IC regulator Defective Replace

OKOK

OK

OK

OK

OK

OK

NG

NG

NG

NG

NG

NG

NG

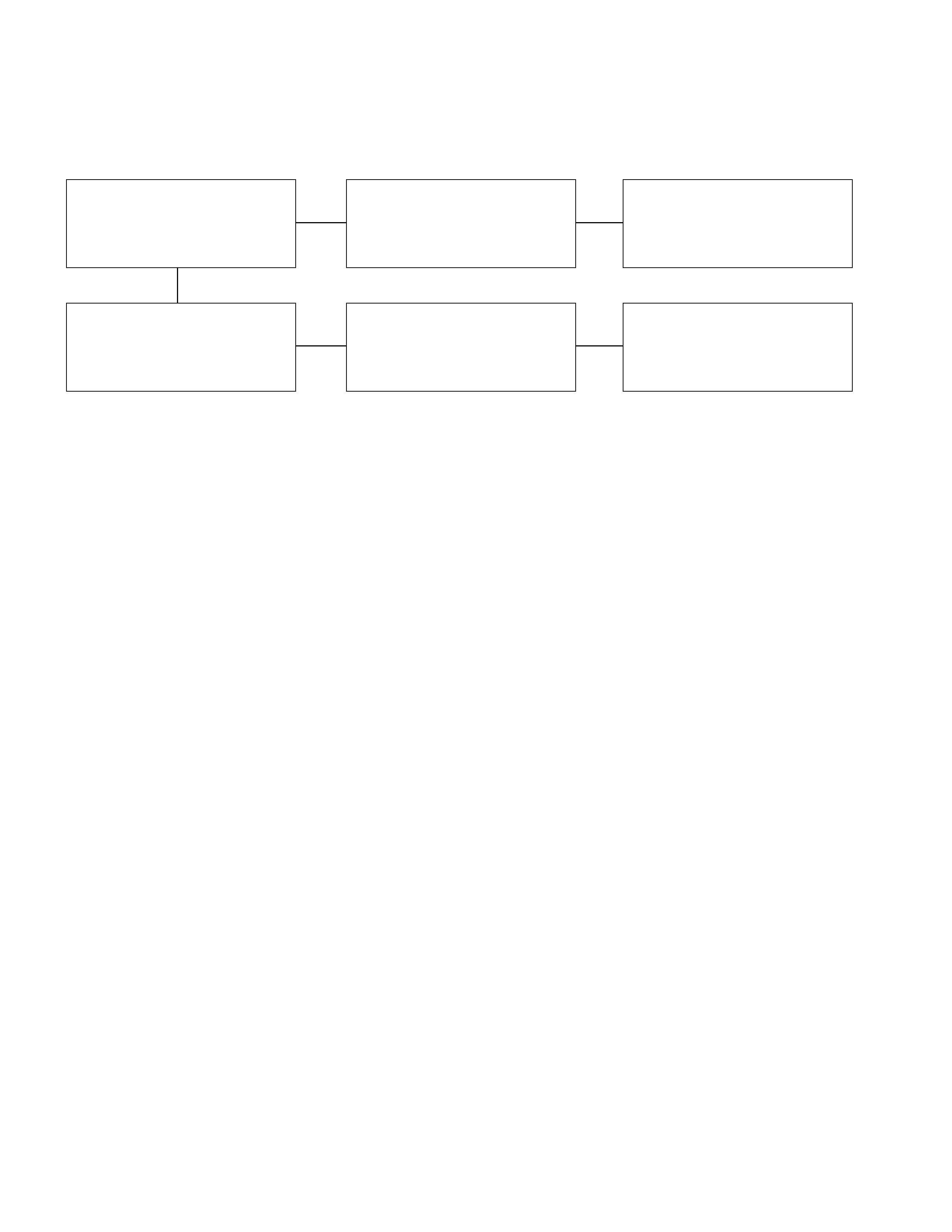

2. Overcharging

Checkpoint Trouble Cause Countermeasure

B and F terminal circuit Shorted Repair

IC regulator Excessive voltage Replace

OKOK

NG

NG

3. Undercharging

Checkpoint Trouble Cause Countermeasure

Battery terminals Loosely connected Retighten

Drive belt Slippage Adjust or replace

Brush and slip ring contact Intermittent Replace or repair the brush

holder assembly

Short circuit Repair or replace

Short or open circuit Repair or replace

Defective Replace

Insufficient voltage Replace

OKOK

OK

OK

NG

NG

NG

NG

NG

NG

NG

Generator rotor coil

Generator diode

Excessive Use a higher capacity alternator

or reduce the accessory load

NG

IC regulator

Electrical load

Generator stator coil

OK

OK

OK

OK

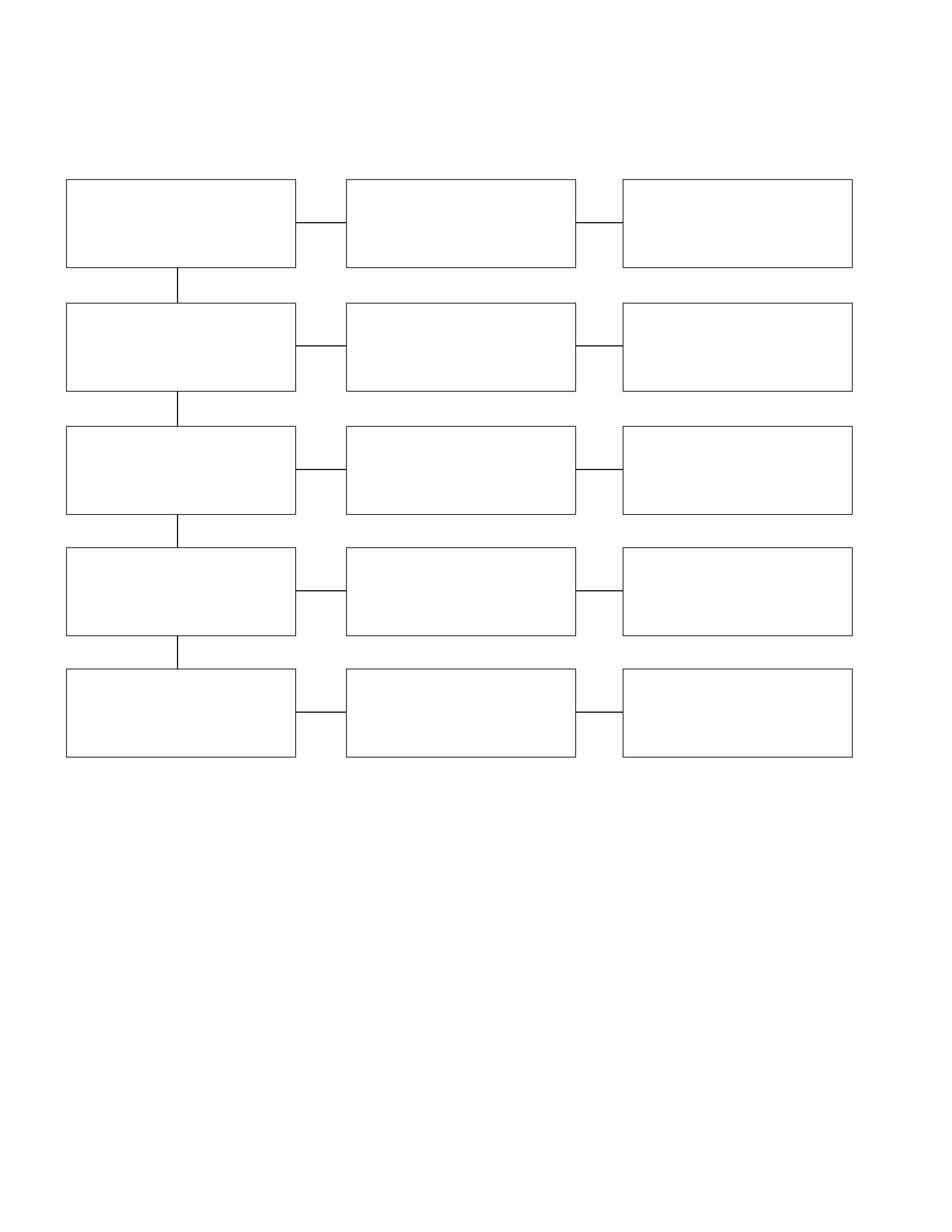

4. Unstable Charging Current

Checkpoint Trouble Cause Countermeasure

Terminals and connectors Broken or defective Repair the push rod play

Drive belt Loose Tighten (Readjust)

Brush with slip ring Poor contact Repair or replace

Generator rotor coil Open or short circuit Repair or replace

Generator stator coil Open or short circuit Repair or replace

Stator coil and diode

connections Loose Repair

IC regulator Defective Replace

OKOK

OK

OK

OK

OK

OK

NG

NG

NG

NG

NG

NG

NG

5. Noise

Checkpoint Trouble Cause Countermeasure

Part mounting fasteners Loose Tighten

Drive belt Defective Replace

Bearing Defective Replace

Diode Defective Replace

Stator coil Short circuited Repair or replace

OKOK

OK

OK

OK

NG

NG

NG

NG

NG