Main Data & Specifications

Engine Model 4JB1T, 4JH1TC

Oil pump type

Oil pressure switch operating pressure kg/cm2 (psi/kPa)

Oil filter type

Gear

0.2 – 0.5 (2.8 – 7.1/19.6 – 49.0)

Full flow with cartridge paper element

Relief valve opening pressure kg/cm2 (psi/kPa) 5.7 – 6.3

(82.5 – 89.5/558.6 – 617.4)

Safety valve opening pressure kg/cm2 (psi/kPa)

Oil cooler type

Safety valve opening pressure kg/cm2 (psi/kPa)

0.8 – 1.2 (11.38 – 17.07/78.9 – 117.6)

Water-cooled

2.3 – 2.7 (32.7 – 38.4/225.4 – 264.6)

General Description

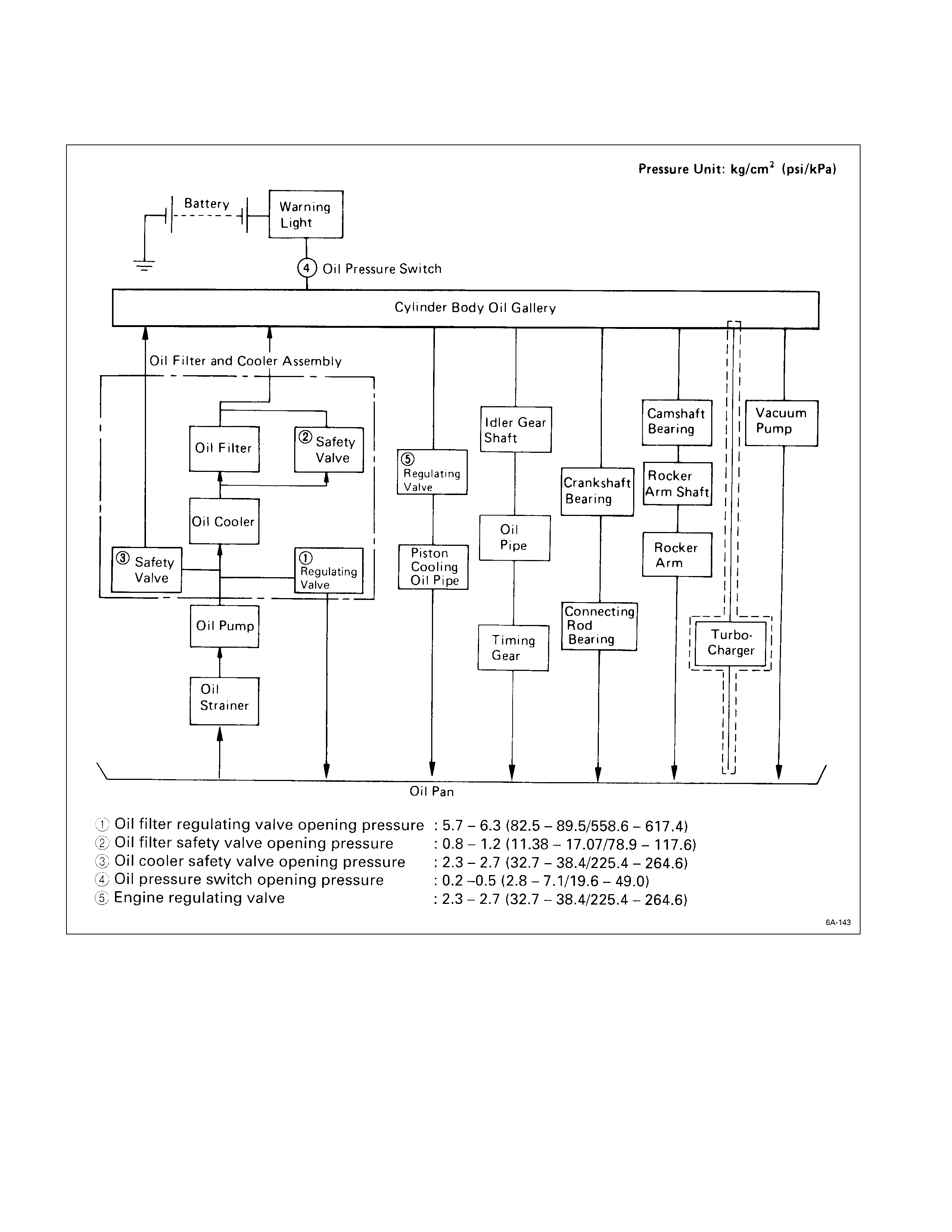

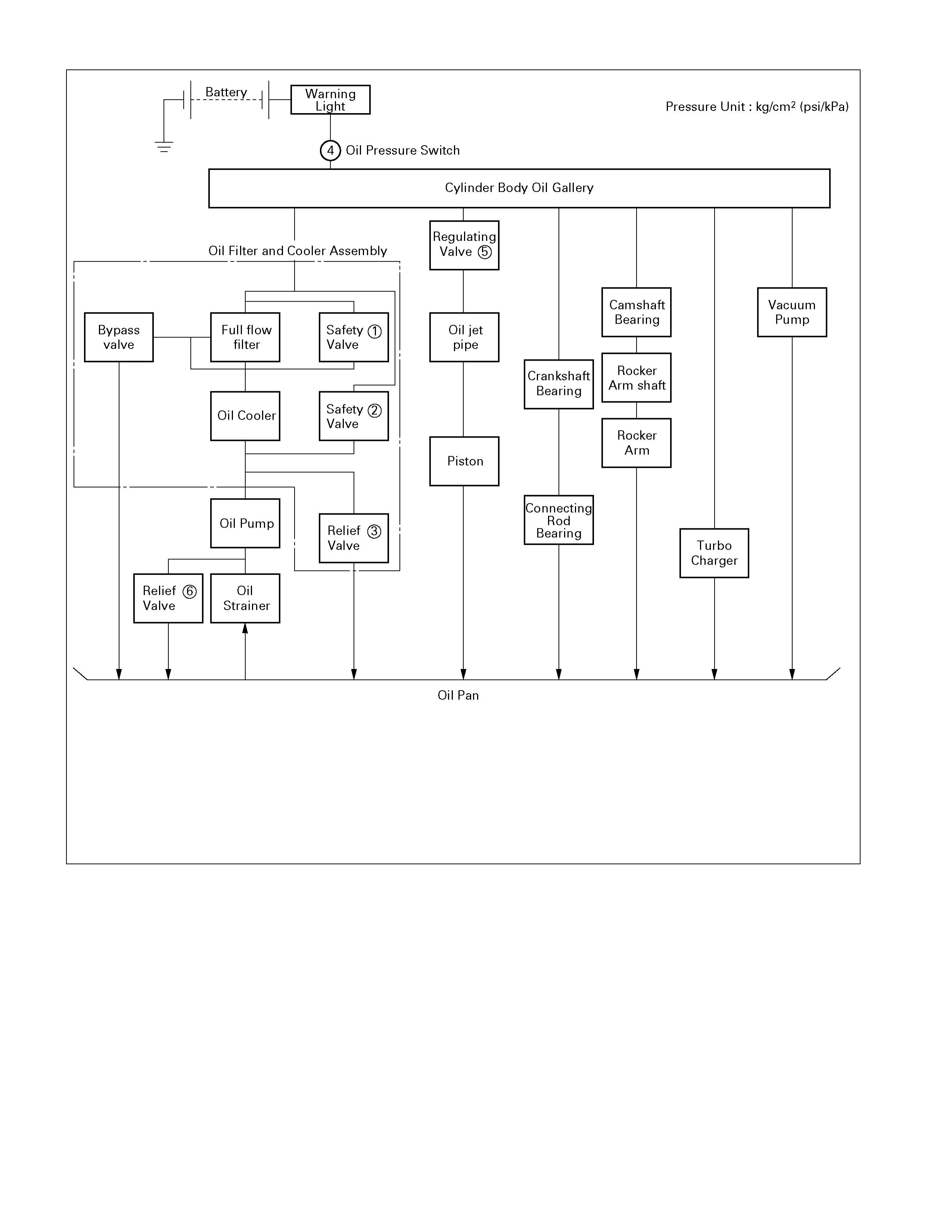

Lubricating Oil Flow

Q Oil filter safety valve opening pressure : 0.8 – 1.2 (11.4 – 17.1/78.9 – 117.6)

R Oil cooler safety valve opening pressure : 2.3 – 2.7 (32.7 – 38.4/225.4 – 264.6)

S Oil filter relief valve opening pressure : 5.7 – 6.3 (82.5 – 89.5/558.6 – 617.4)

T Oil pressure switch opening pressure : 0.2 – 0.5 (2.8 – 7.1/19.6 – 49.0)

U Engine regulating valve : 2.3 – 2.7 (32.7 – 38.4/225.4 – 264.6)

V Oil pump relief valve opening pressure : 6.7 – 7.8 (95.3 – 110.9/657.0 – 764.9)

C06L200010

The 4J series engine has a full flow type lubricating system.

Lubricating oil is pumped from the oil pump to the cylinder body oil gallery through the oil cooler and the oil filter. It is

then delivered to the vital parts of the engine from the cylinder body oil gallery.

Oiling jets installed on the cylinder body spray engine oil to the piston backside faces to achieve maximum piston

cooling effect.

4JH1TC

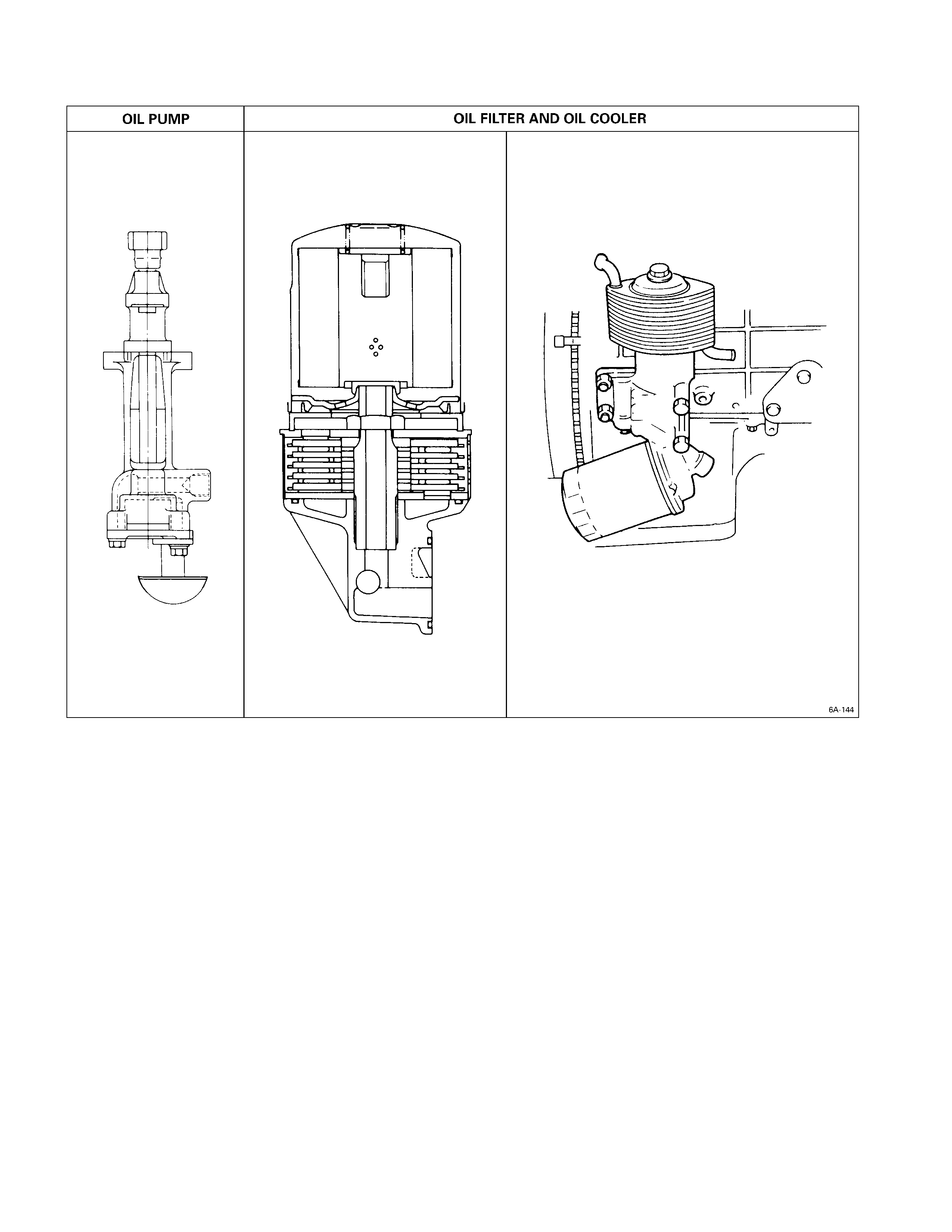

Oil Pump & Oil Filter

The 4J series engine is equipped with a gear type oil pump.

The oil filter and the water cooled oil cooler integrated a single unit to increase the cooling effect.

Except 4JA1

For 4JA1

Oil Pump

Disassembly

051L200001

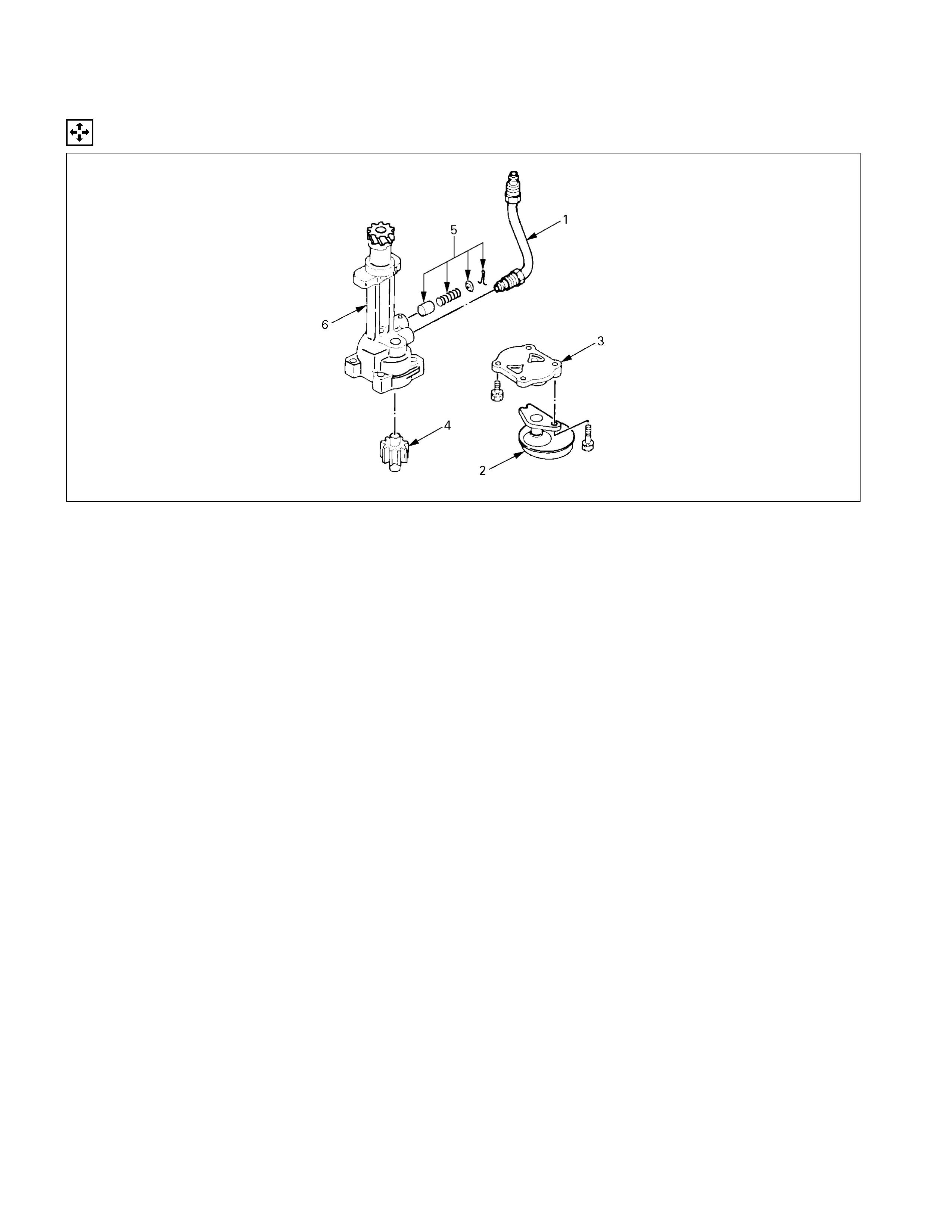

DISASSEMBLY STEPS

1. Oil pipe 4. Driven gear with bush

2. Strainer 5. Relief valve asm.

3. Pump cover 6. Oil pump body

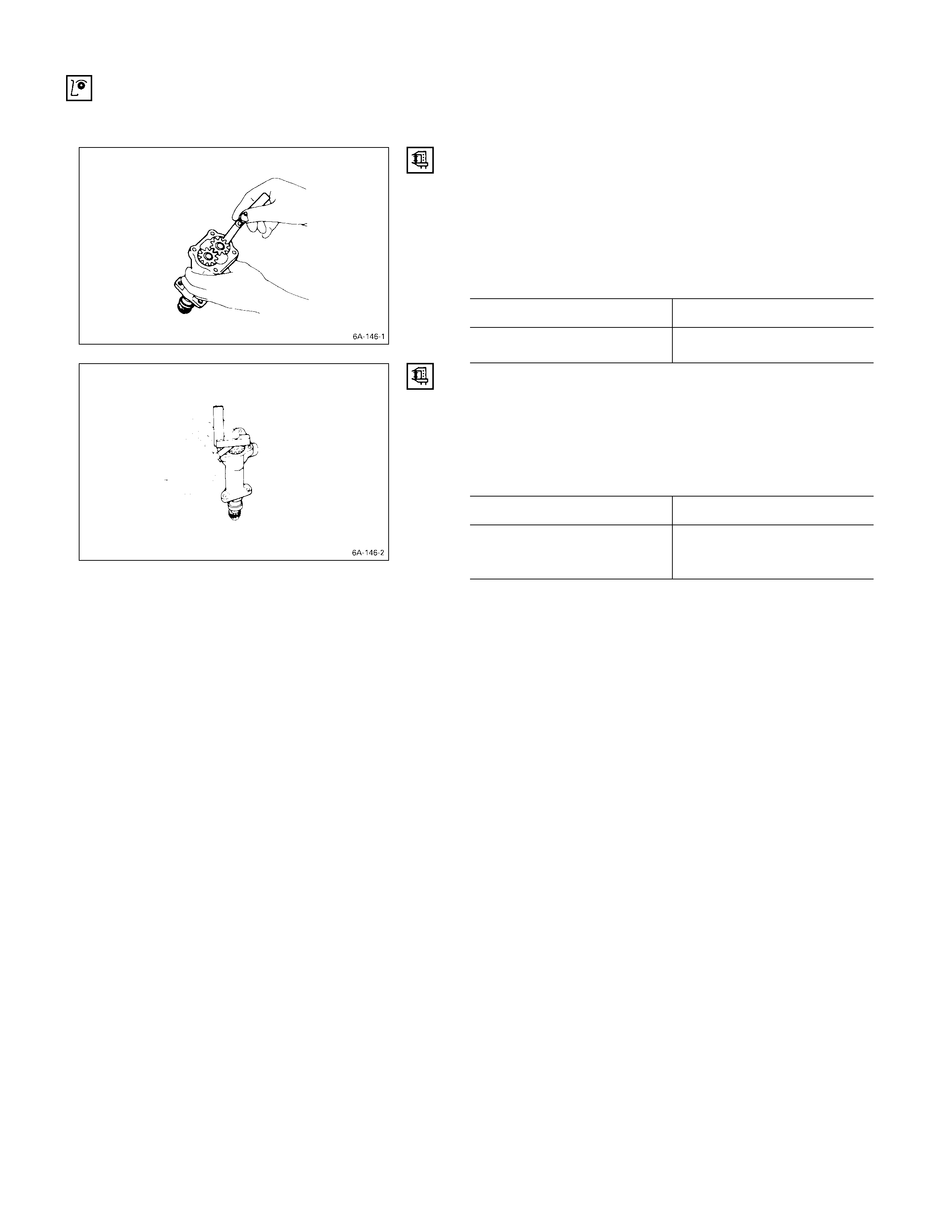

Inspection & Repair

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection. G EAR TEETH AND BODY I NNER W ALL CLEARANCE

Use a feeler gauge to measure the clearance between the

gear teeth and the body inner wall.

If the clearance between the gear teeth and the body inner

wall exceeds the specified limit, either the gear or the body

must be replaced.

Gear Teeth and Body Inner Wall Clearance mm (in)

Standard Limit

0.14 (0.0055) 0.20 (0.0079)

GEAR AND BODY CLEARANCE

Use a feeler gauge to measure the clearance between the

body and the gear.

If the clearance between the gear and the body exceeds

the specified limit, the body must be replaced.

Gear and Body Clearance mm (in)

Standard Limit

0.06 (0.024) 0.15 (0.0059)

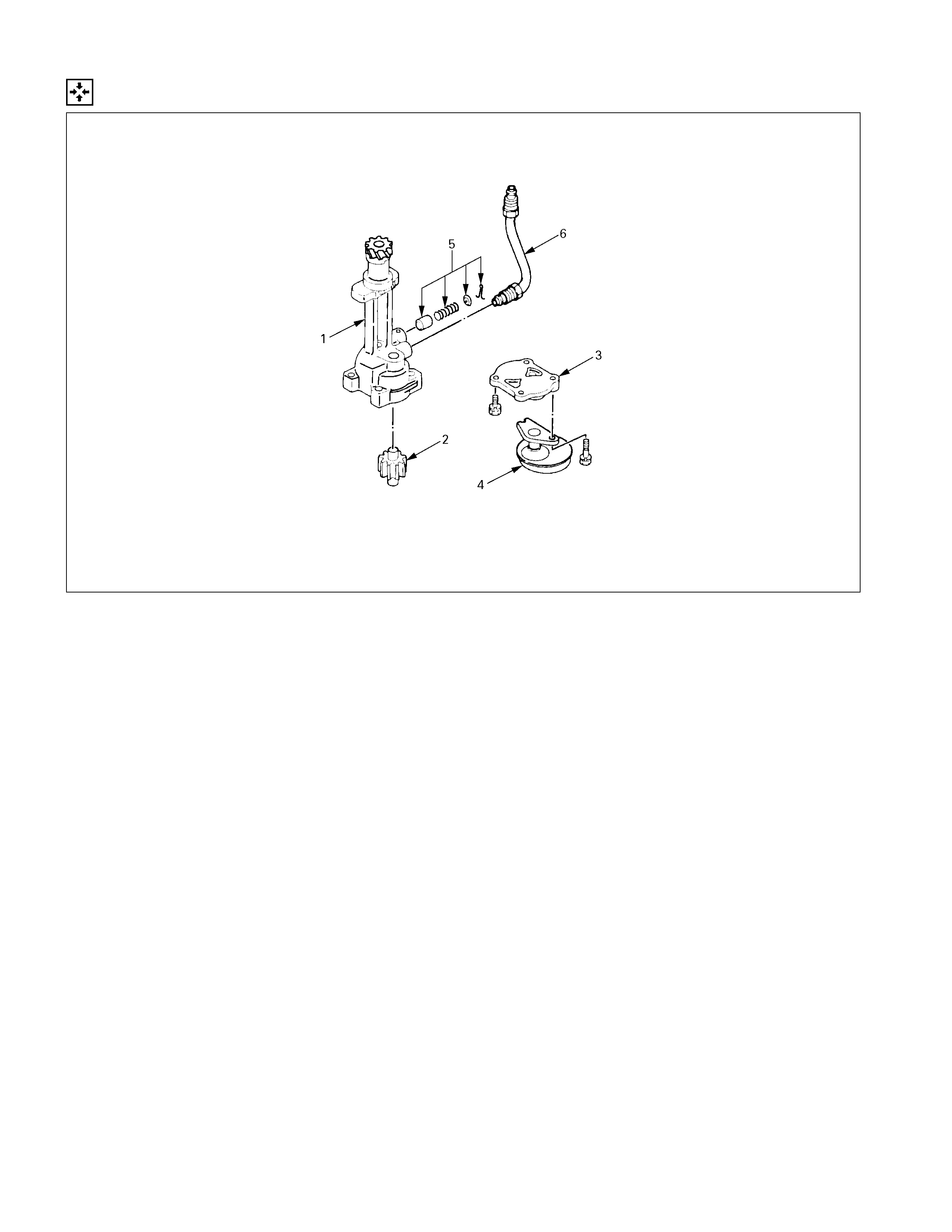

Reassembly

051L200002

REASSEMBLY STEPS

1. Oil pump body 4. Strainer

2. Driven gear with bush 5. Relief valve asm.

3. Pump cover 6. Oil pipe

Oil Filter & Oil Cooler

Disassembly

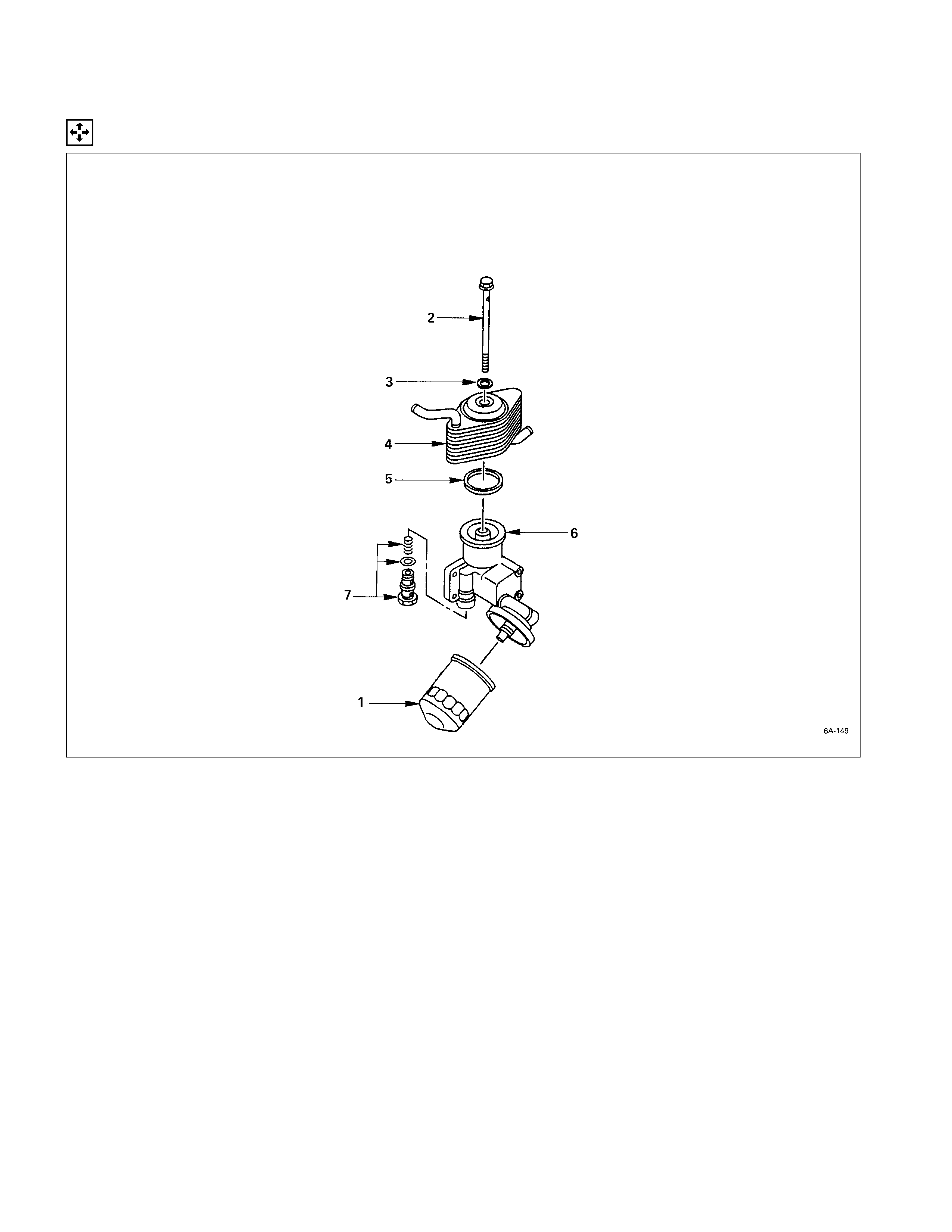

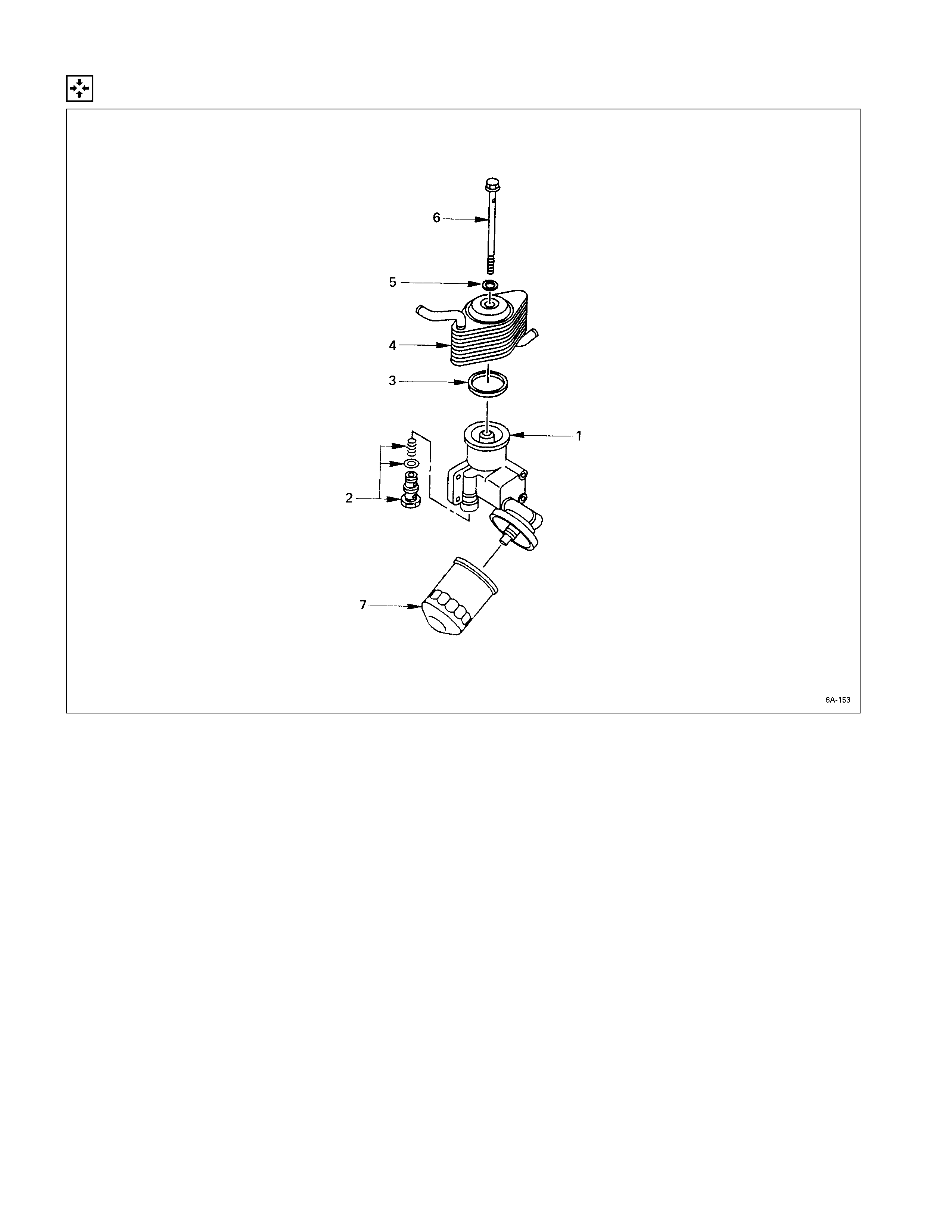

DISASSEMBLY STEPS

1. Oil filter cartridge 5. Gasket

2. Bolt 6. Body

3. Gasket 7. Relief valve

4. Oil cooler

Inspection & Repair

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

RELIEF VALVE

1. Attach an oil pressure gauge to the oil gallery near the

oil filter.

2. Start the engine to check the relief valve opening

pressure.

Relief Valve Opening Pressure kg/cm2 (psi/kPa)

4JB1T, 4JH1TC 5.7 – 6.3 (82.5 – 89.5/558.6 – 617.4)

OIL COOLER

Water Leakage at Water Passage

1. Plug one side of the oil cooler water passage.

2. Submerge the oil cooler in water.

3. Apply compressed air (2 kg/cm2 (28 psi/200 kPa)) to

the other side of the oil cooler water passage.

If air bubbles rise to the surface, there is water leakage.

Reassembly

REASSEMBLY STEPS

1. Body 5. Gasket

J

2. Relief valve

J

6. Bolt

3. Gasket

J

7. Oil filter cartridge

J

4. Oil cooler

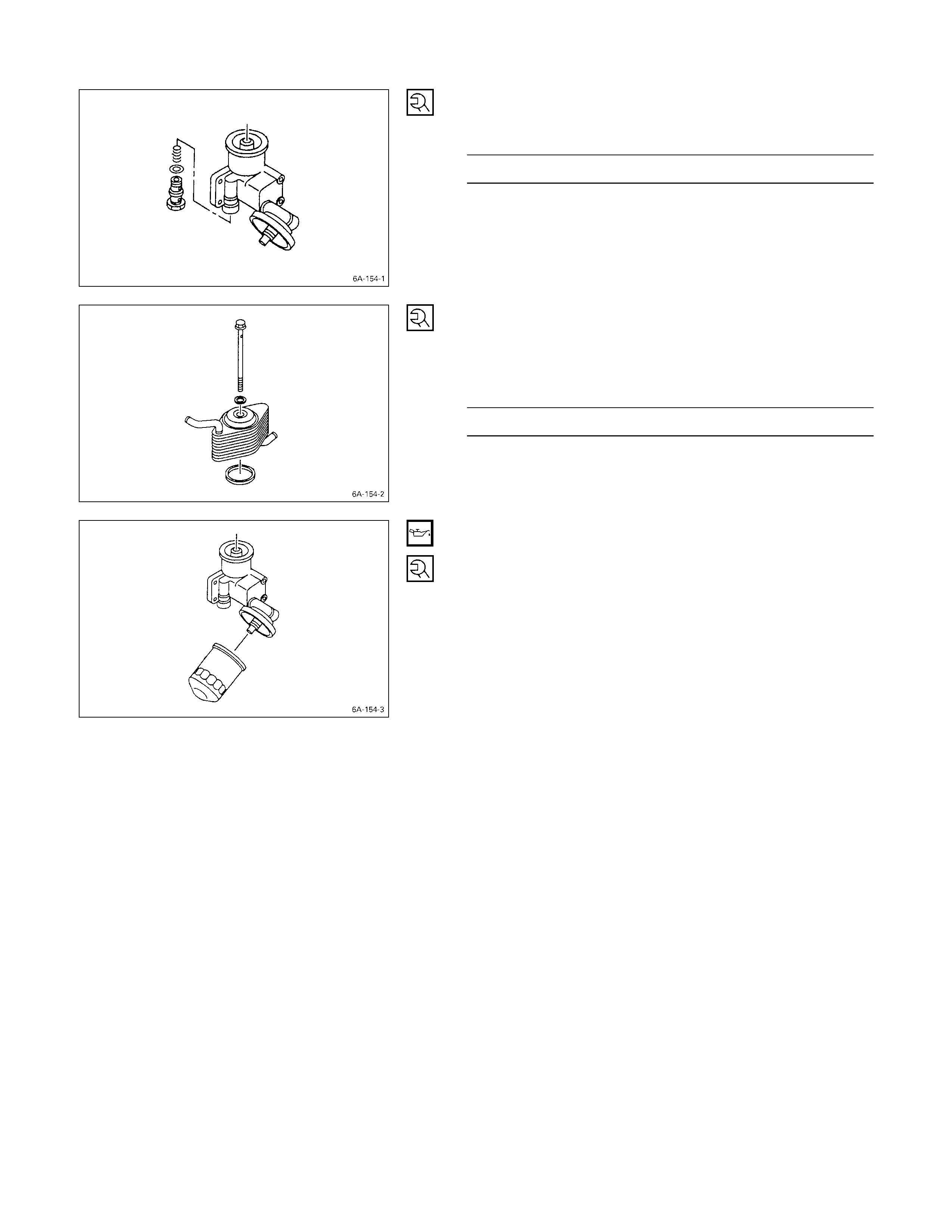

2. Relief Valve

Tighten the safety valve to the specified torque.

Safety Valve Torque kg·m (lb.ft/N·m)

0.3 ± 00.5 (4.3 ± 0.7/29.4 ± 4.9)

4. Oil Cooler

6. Bolt

Tighten Bolt with gaskets and oil cooler to the specified

torque.

Bolt Torque kg·m (lb.ft/N·m)

3.0 ± 0.5 (21.7 ± 3.6/29.4 ± 4.9)

7. Oil Filter Cartridge

1) Lightly oil the O-ring of oil filter cartridge.

2) Turn in the new oil filter cartridge by hand until the

sealing face is fitted again the O-ring.

3) Use the filter wrench to turn in the oil filter and

additional one and 1·1/8 turns.

4) Start the engine and check for oil leakage from oil

filter.