SECTION 7A - CLUTCH

MAIN DATA AND SPECIFICATIONS

GENERAL DESCRIPTION

TORQUE SPECIFICATION

SERVICING

CLUTCH

REMOVAL AND INSTALLATION

INSPECTION AND REPAIR

CLUTCH CONTROL

REMOVAL AND INSTALLATION

MASTER CYLINDER

SLAVE CYLINDER (EXCEPT 6VD1 ENGINE)

DISASSEMBLY

INSPECTION AND REPAIR

REASSEMBLY

SLAVE CYLINDER (6VD1 ENGINE)

DISASSEMBLY

INSPECTION AND REPAIR

REASSEMBLY

HYDRAULIC DAMPER CYLINDER (EXCEP T 6VD1 ENGINE)

INSPECTION AND REPAIR

TROUBLESHOOTING

SPECIAL SERVICE TOOL

MAIN DATA AND SPECIFICATIONS

ENGINE C22NE 4JB1T 6VD1

Type Dry single plate with diaphragm

Size mm(in) 240 (9.449) 260 (10.24)

Clamping force kg(lb) 560 (1235) 735 (1621)

(N) (5492) (7208)

Pressure plate

Outside diameter mm(in) 240 (9.449) 260 (10.24)

Inside diameter mm(in) 160 (6.299) 170 (6.70)

Driven plate

Thickness mm(in)

at free 8.6 (0.339) 8.3 (0.327) 8.2 (0.323)

at compressed 8.0 (0.315) 8.0 (0.315) 8.0 (0.315)

CLUTCH CONTROL

Type Hydraulic

Pedal free play mm(in) 5.0-15.0 (0.2-0.6)

Pedal height mm(in) 216-226 (8.50-8.90)

Master cylinder

Bore×Stroke mm(in) 15.87×35 (0.625×1.38)

Slave cylinder

Bore×Stroke mm(in)

C22NE / 4JB1T 22.22x15 (0.875x0.59)

6VD1 22.22×17 (0.875×0.67)

GENERAL DESCRIPTI O N

HYDRAULIC CO NTROL TYPE

HEC Engine Series 4J Engine S eries

6VD1

The clutch assembly consists of the pressure plate, the clutch cover, the diaphragm spring pivot pin and the driven

plate assembly.

The clutch pedal is connected to the shift block through the clutch shaft and the shift fork.

The driven plate assembly is installed between the flywheel and the pressure plate.

Diaphragm spring pressure holds the driven plate against flywheel and the pressure plate to provide the friction

necessary to engage the clutch.

Depressing the clutch pedal moves the shift fork against the shift block.

The shift block forces the release bearing against the diaphragm to overcome the force of the diaphragm spring and

separate the driven plate from the flywheel and pressure plate to disengage the clutch.

Except 6VD1 (3.2L) engine model, the conventional push-type clutch is used.

For 6VD1 (3.2L) engine model, the pull-type clutch is employed. The pull-type clutch is disengaged by pulling the

release lever (release bearing) to disengage the pressure plate.

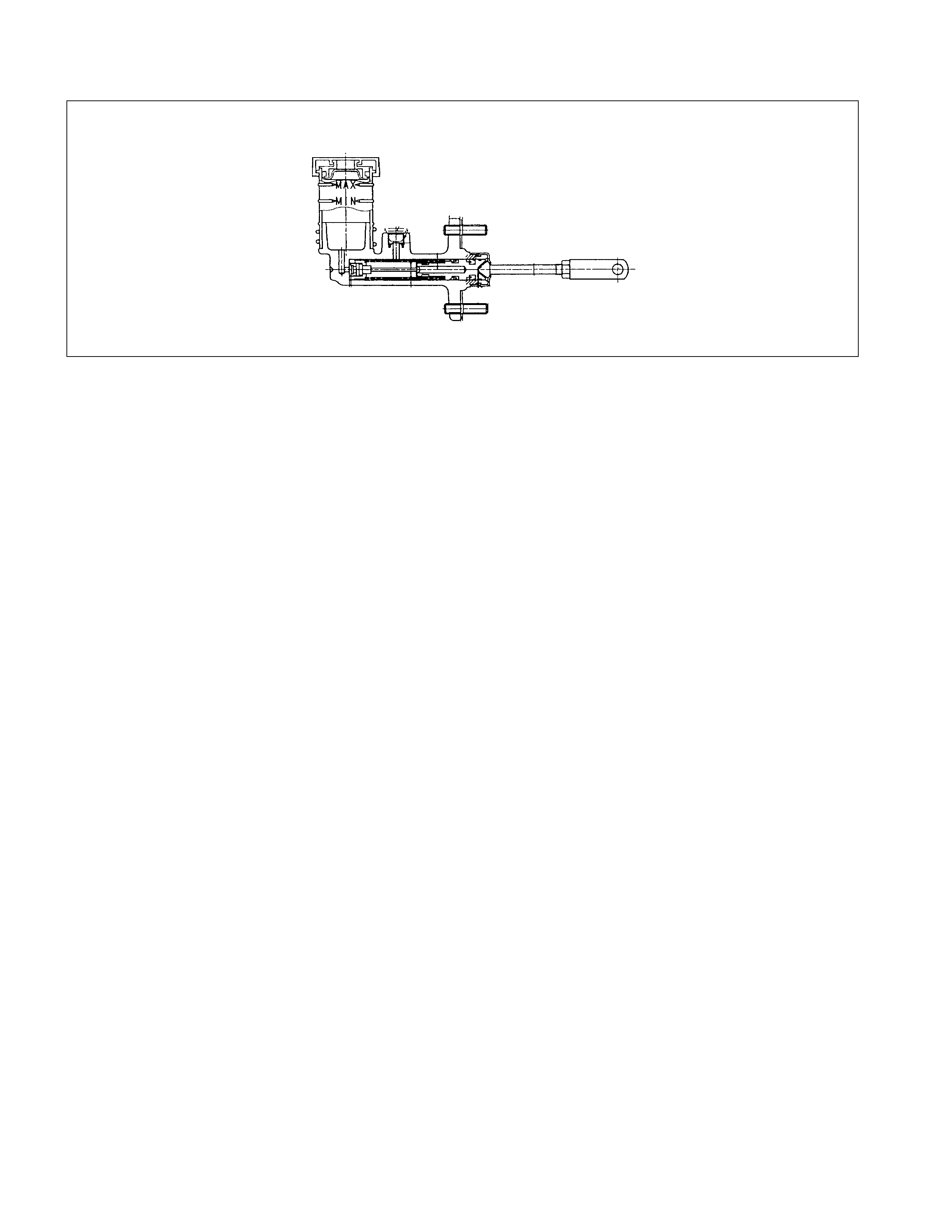

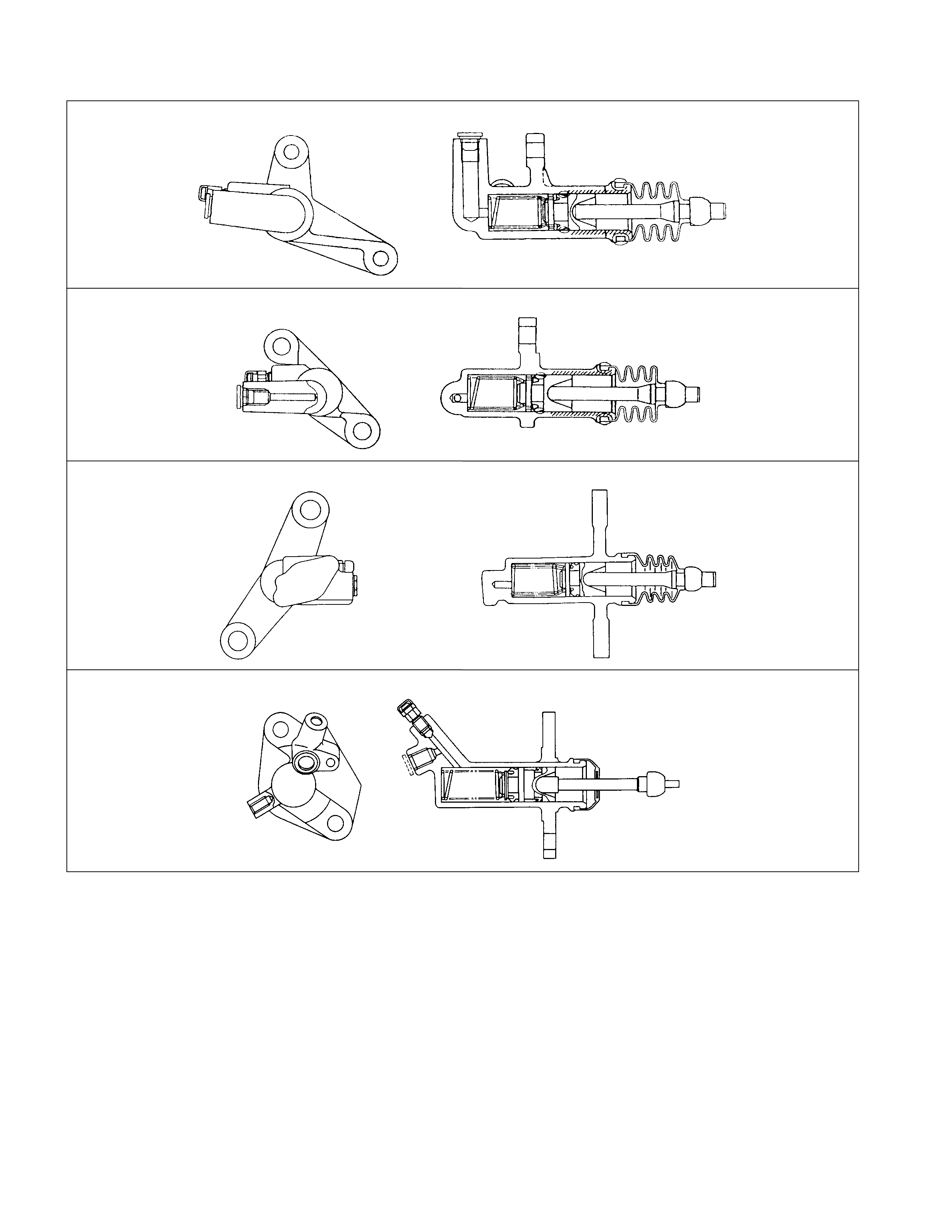

MASTER CYLINDER

6VD1

The master cylinder converts mechanical energy into hydraulic energy.

Depressing the clutch pedal causes the push rod to move against the piston to close the return port.

Clutch fluid is forced out of the master cylinder.

Releasing the clutch pedal causes the return spring to force the piston back to its original position.

The return port is opened and the clutch fluid flows back into the fluid reservoir.

Quickly releasing the clutch pedal will cause the fluid pressure at the return spring side to be lower than the fluid

pressure at the push rod side.

This allows the fluid at the push rod side to quickly flow to the return spring side through a port in the piston head.

This equalises the pressure at both sides of the piston.

SLAVE CYLINDER

MUA Series

MSG Series

4J Engine S eries

6VD1 Engine Series

The slave cylinder converts hydraulic energy into mechanical energy.

Hydraulic fluid supplied by the master cylinder moves the slave cylinder piston to actuate the shift fork.

The mechanical energy produced by the slave cylinder is directly proportional to the diameters of the master cylinder

and the slave cylinder.

A bleeder screw is provided to bleed the slave cylinder.

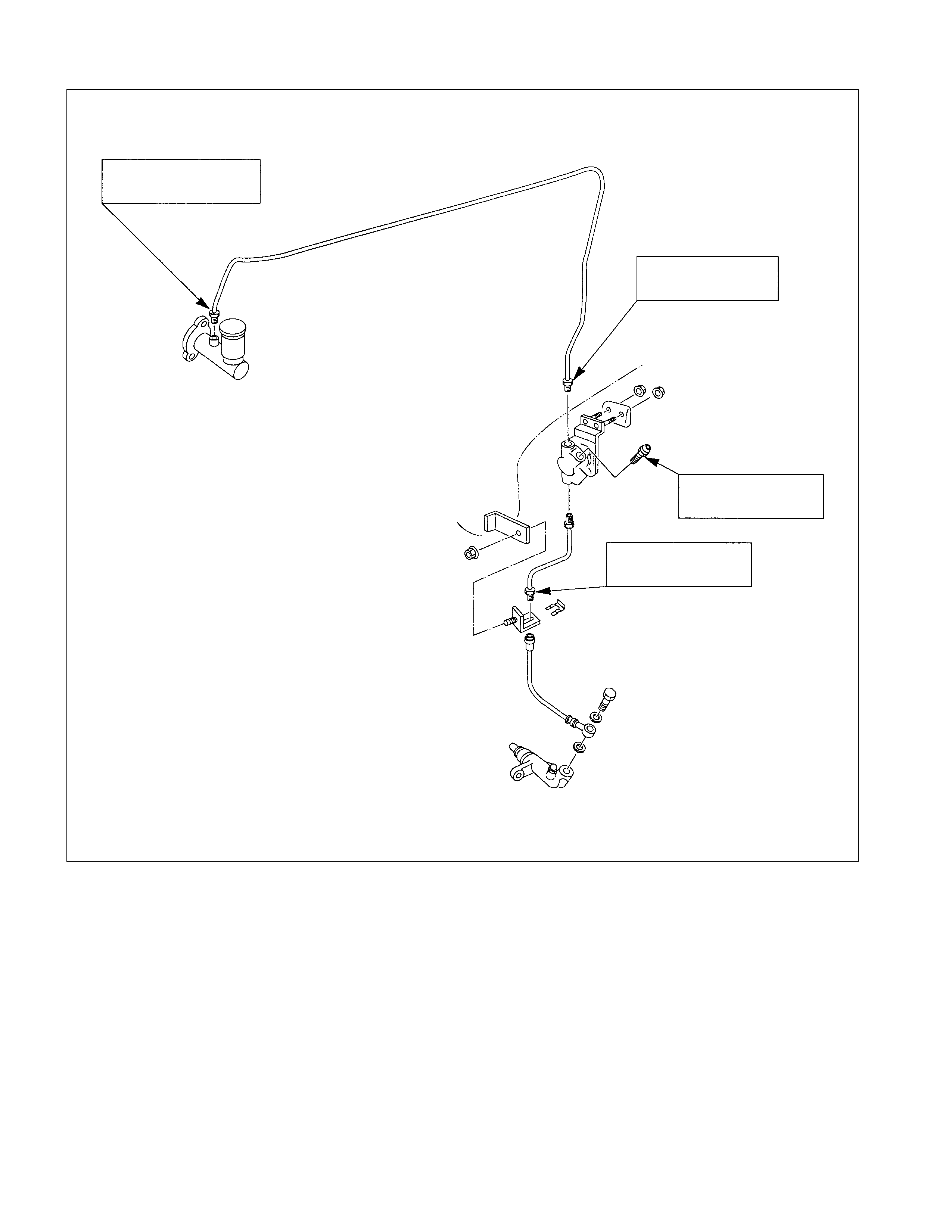

HYDRAULIC DAMPER CYLINDER

The hydraulic damper cylinder is installed between the master cylinder and the slave cylinder to smooth out variations in

clutch pedal feel.

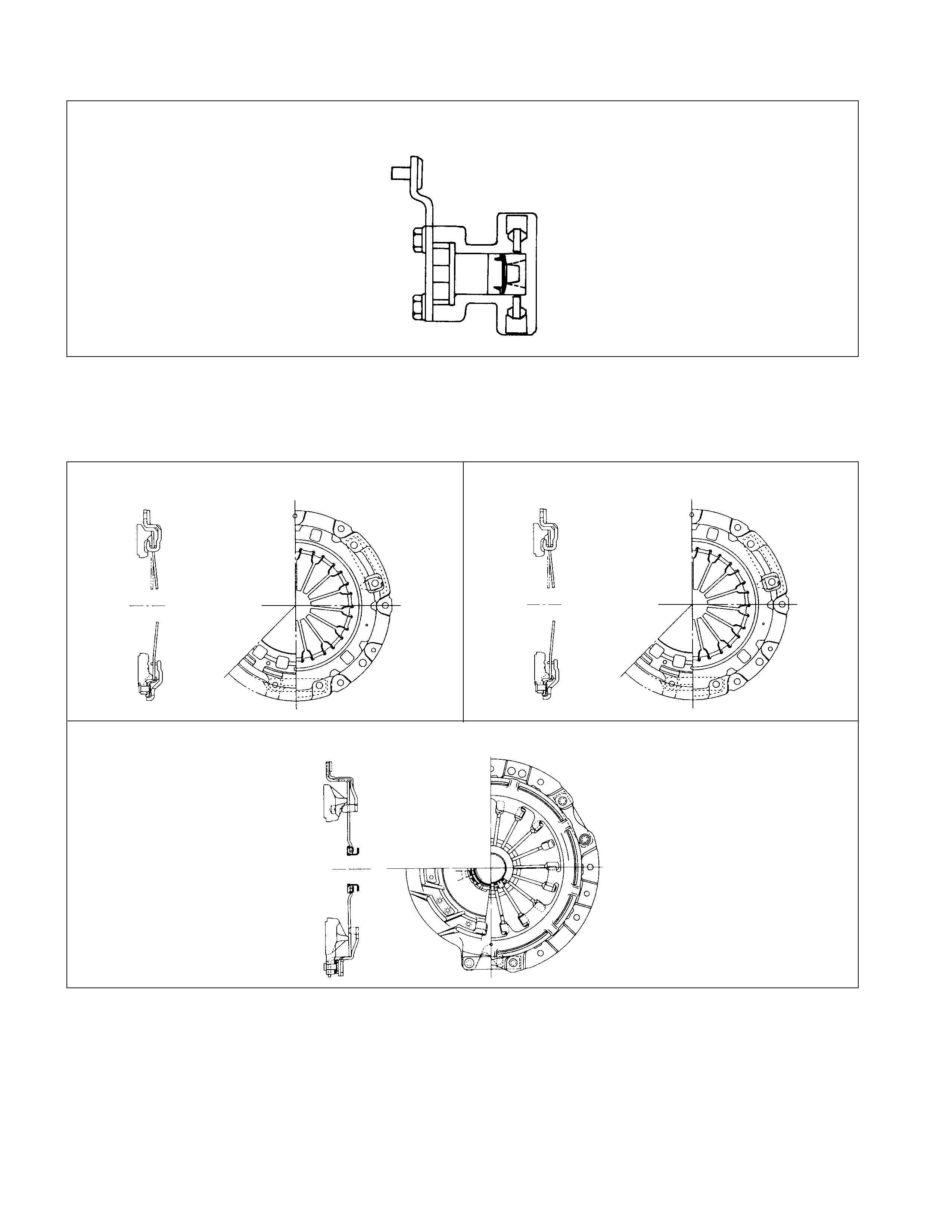

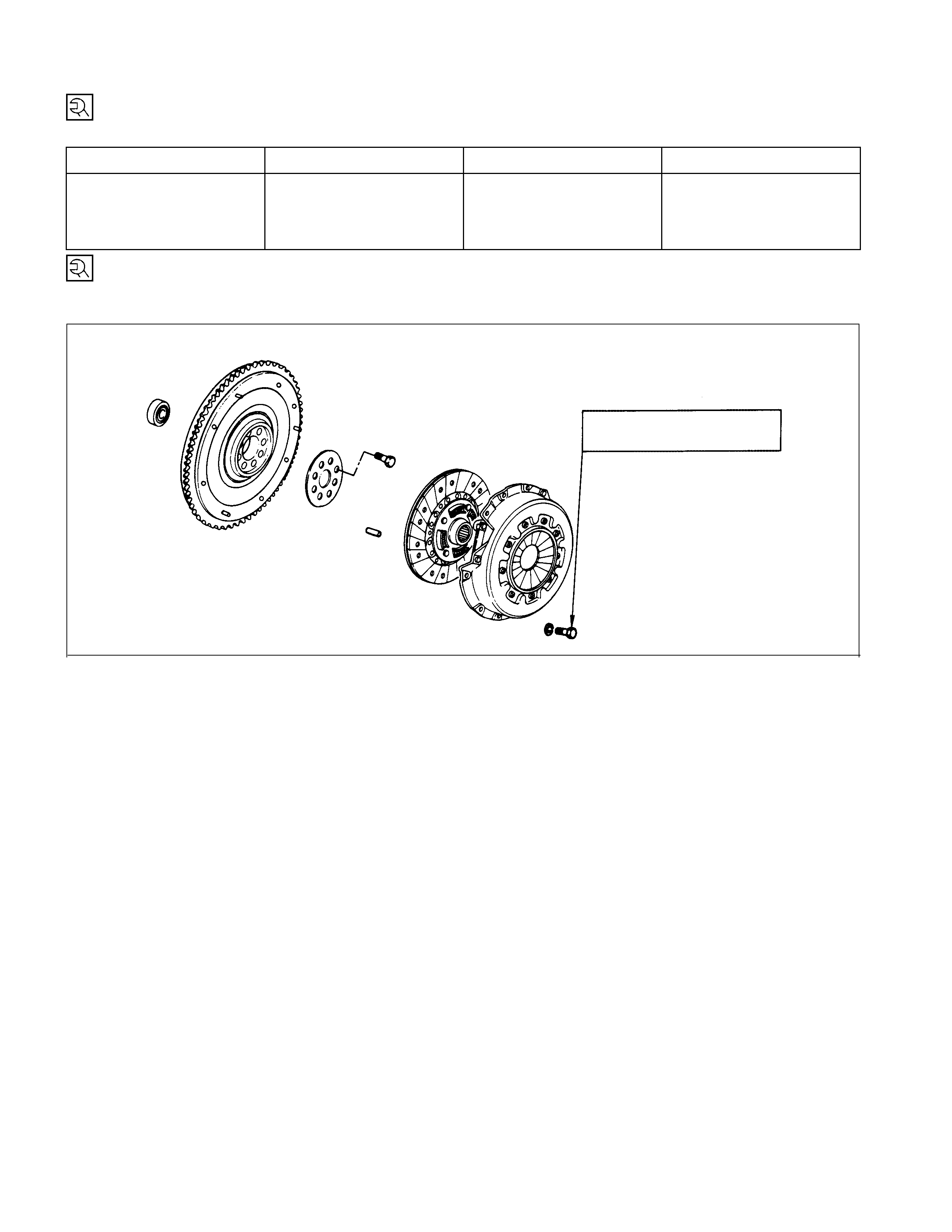

PRESSURE PLATE ASSEMBLY

HEC Engine Series 4J Engine S eries

6VD1 Engine Series

The pressure plate assembly consists of the clutch cover, the pressure plate with diaphragm spring.

Operating the clutch pedal causes the pressure plate to move in an axial direction to engage and disengage the clutch.

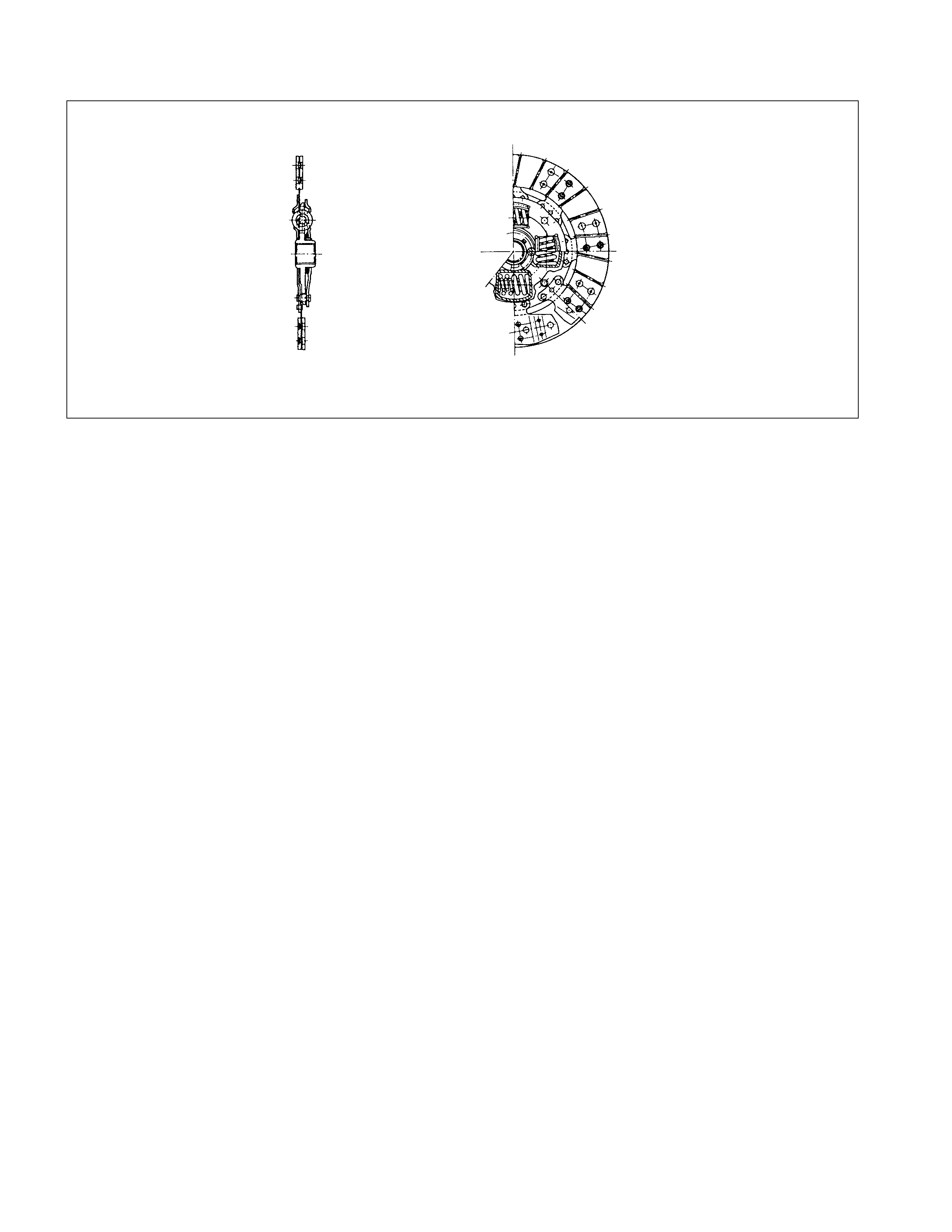

DRIVEN PLATE ASSEM BLY

The driven plate assembly consists of the plate and the facing.

The plate consists of the clutch centre, the cushioning plate and the torsion springs.

The facing is riveted to both sides of the cushioning plate.

The cushioning plate provides a longer service life by minimising wear and vibration at the clutch contact surfaces.

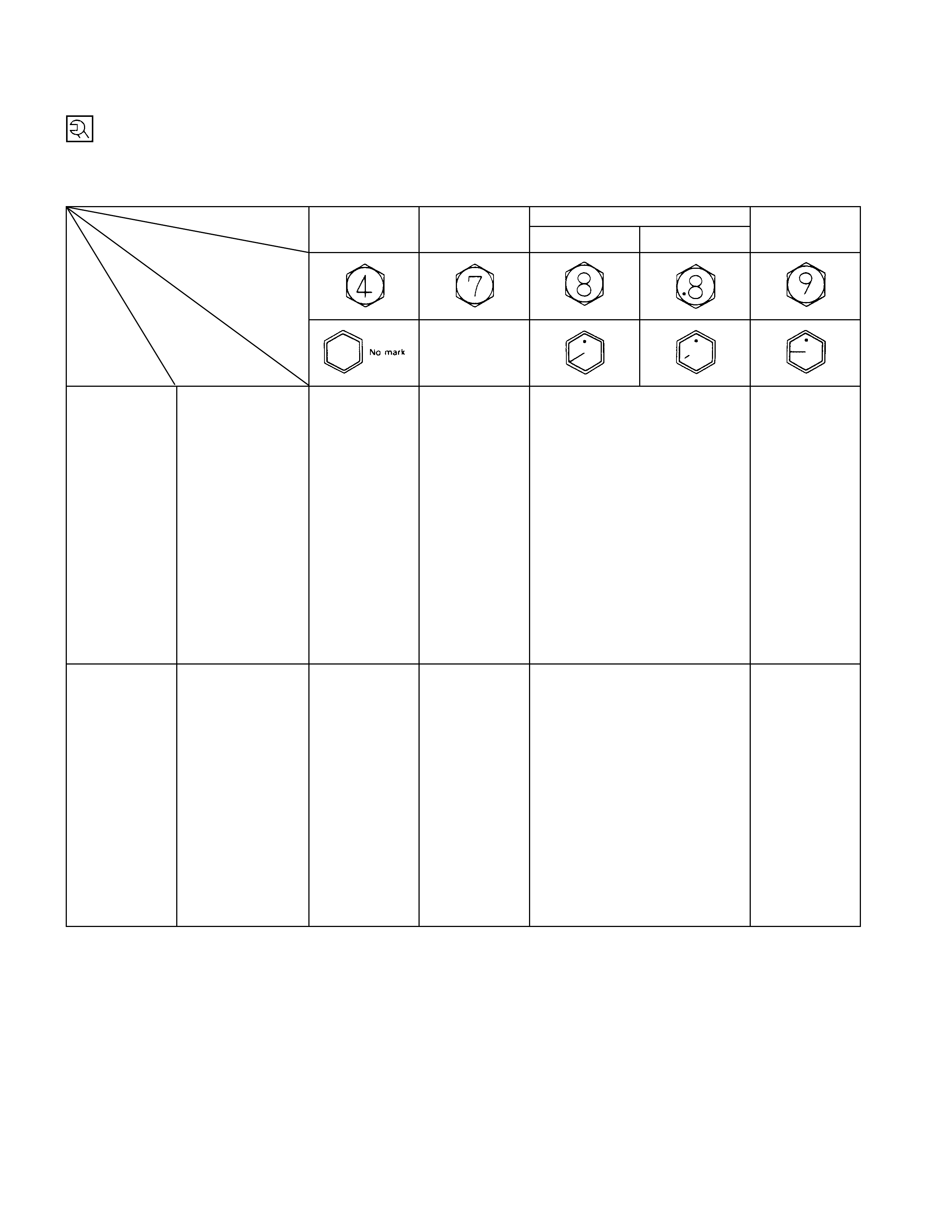

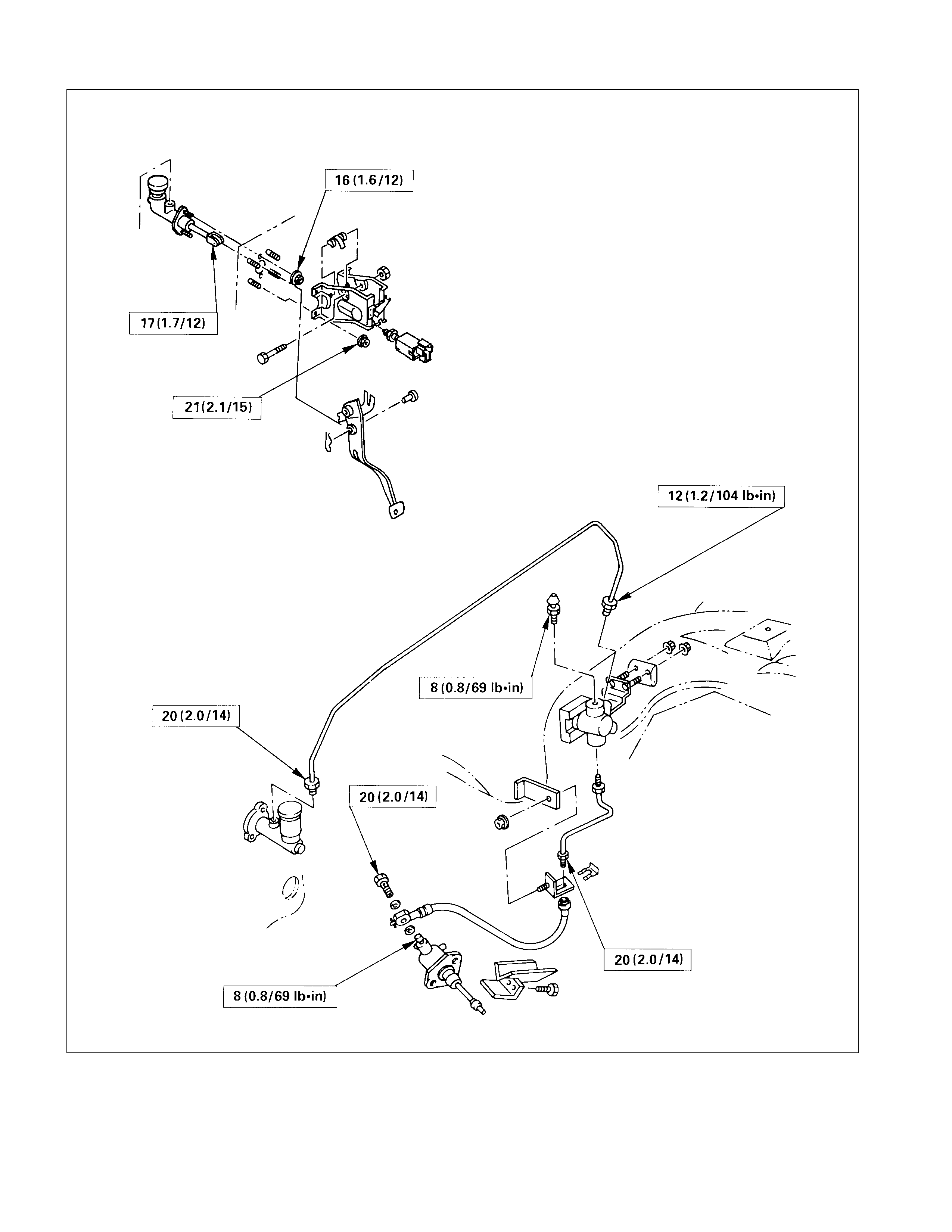

TORQUE SPECIFICATION

STANDARD BOLTS

The torque values given in the following table should be applied where a particular torque is not specified.

N⋅m (kgf⋅m/lb⋅ft)

Strength 4.8/4T 7T 8.8 9.8/9T

Class Refined Non-Refined

Bolt Identifi-

cation

Bolt

Diameter×

××

×

Pitch (mm) -

M6 × 1. 0 6 (0.6 / 52 lb. i n) 7 (0.7 / 61 lb. i n) 8 (0.8 / 69 lb. i n) -

M8 × 1. 25 13 (1.3 / 113

lb.in) 17 (1.7 / 12) 20 (2.0 / 14) 24 (2.4 / 17)

M10 × 1.25 27 (2.8 / 20) 37 (3.8 / 27) 42 (4.3 / 31) 50 (5.1 / 37)

M12 × 1.25 61 (6.3 / 45) 76 (7.8 / 56) 87 (8.9 / 64) 95 (9.7 / 70)

M14 ×1.5 96 (9.8 / 71) 116 (11.8 / 85) 133 (13.6 / 98) 142 (14.5 / 105)

M16 × 1.5 130 (13.3 / 96) 170 (17.3 / 125) 193 (19.7 / 143) 200 (20.4 / 148)

M18 × 1.5 188 (19.2 / 139) 244 (24.9 / 180) 278 (28.3 / 205) 287 (29.3 / 212)

M20 × 1.5 258 (26.3 / 190) 337 (34.4 / 249) 385 (39.3 / 284) 396 (40.4 / 292)

M22 × 1.5 332 (33.9 / 245) 453 (46.3 / 335) 517 (52.7 / 381) 530 (54.1 / 391)

M24 × 2.0 449 (45.8 / 331) 570 (58.2 / 421) 651 (66.3 / 480) 692 (70.6 / 511)

*M10 × 1.5 26 (2.7 / 20) 36 (3.7 / 27) 41 (4.2 / 30) 48 (4.9 / 35)

*M12 × 1.75 57 (5.8 / 42) 71 (7.2 / 52) 80 (8.2 / 59) 89 (9.1 / 66)

*M14 × 2.0 89 (9.1 / 66) 110 (11.2 / 81) 125 (12.7 / 92) 133 (13.6 / 98)

*M16 × 2.0 124 (12.7 / 92) 162 (16.5 / 119) 185 (18.9 / 137) 191 (19.5 / 141)

Flange Bolt M6 × 1. 0 7 (0.7 / 61 lb. i n) 8 (0.8 / 69 lb. i n) 9 (0.9 / 78 lb. i n) -

M8 × 1. 25 15 (1. 5 / 11) 19 (1.9 / 14) 22 (2.2 / 16) 26 (2. 7 / 20)

M10 × 1.25 31 (3.2 / 23) 41 (4.2 / 30) 47 (4.8 / 35) 56 (5.7 / 41)

M12 × 1.25 69 (7.0 / 51) 85 (8.7 / 63) 97 (9.9 / 72) 106 (10.8 / 78)

M14 × 1.5 104 (10.6 / 77) 126 (12.8 / 93) 144 (14.6 / 106) 154 (15.7 / 114)

M16 × 1.5 145 (14.8 / 127) 188 (19.2 / 139) 214 (21.8 / 158) 221 (22.5 / 163)

M18 × 1.5 - - - -

M20 × 1.5 - - - -

M22 × 1.5 - - - -

M24 × 2.0 - - - -

*M10 × 1.5 30 (3.1 / 22) 40 (4.1 / 30) 46 (4.7 / 34) 54 (5.5 / 40)

*M12 × 1.75 64 (6.5 / 47) 78 (8.0 / 58) 89 (9.1 / 66) 99 (10.1 / 73)

*M14 × 2.0 97 (9.9 / 72) 119 (12.1 / 88) 135 (13.8 / 99.7) 144 (14.7 / 107)

*M16 × 2.0 137 (14.0 / 101) 178 (18.2 / 132) 203 (20.7 / 132) 210 (21.5 / 155)

The asterisk * indicates that the bolts are used for female-threaded parts that are made of soft materials such as

casting, etc.

Standard Hex.

Head Bolt

FLARE NUTS

Pipe diameter mm (in) Torque N⋅

⋅⋅⋅m (kgf⋅

⋅⋅⋅m / lb⋅

⋅⋅⋅ft) Pipe diameter mm (in) Torque N⋅

⋅⋅⋅m (kgf⋅

⋅⋅⋅m / lb⋅

⋅⋅⋅ft)

4.76 (0.187) 16 (1.6 / 12) 10.00 (0.394) 54 (5.5 / 40)

6.35 (0.250) 26 (2.7 / 20) 12.00 (0.472) 88 (9.0 / 65)

8.00 (0.315) 44 (4.5 / 33) 15.00 (0.591) 106 (10.8 / 78)

SPECIAL PARTS FI XING NUTS AND BOLTS

N⋅m (kgf⋅m/lb⋅ft)

17.6±4.9 (1.8±0.5/13.0±3.6)

N⋅m (kgf⋅m/lb⋅ft)

HEC Engine Series RHD Model, 4J Engine Series

19.6±3.9

(2.0±0.4/14.5±2.9)

7.85±0.95

(0.8±0.1/5.8±0.7)

11.8±2.9

(1.2±0.3/8.8±2.2)

15.7±2.9

(1.6±0.3/11.6±2.2)

N⋅m (kgf⋅m/lb⋅ft)

6VD1 RHD Model

SERVICING

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

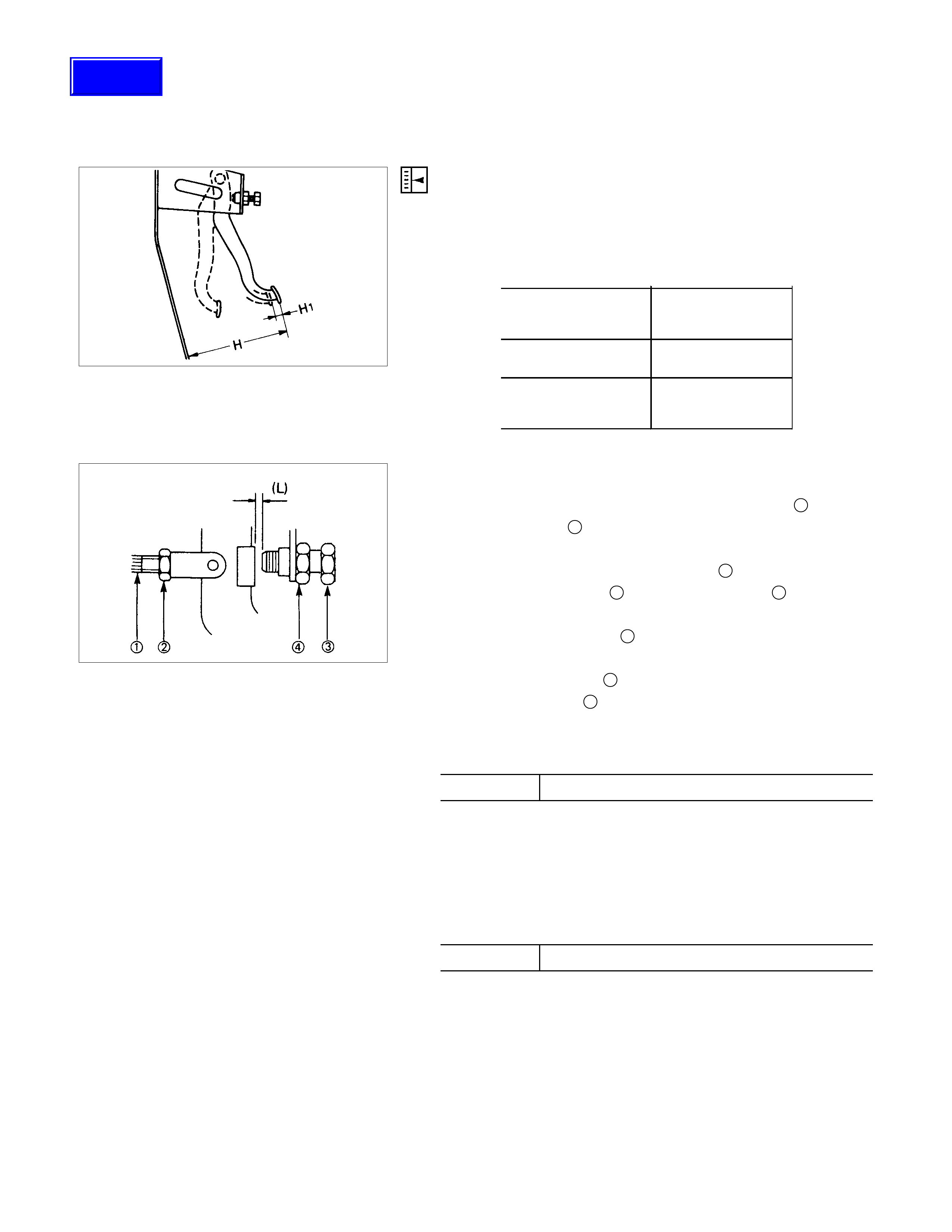

CLUTCH PEDAL HEIGHT

INSPECTION

Measure to verify that the distance from the upper surface of

the pedal pad to the firewall is within the standard value.

Clutch Pedal Height(H) mm(in)

HEC ENGINE 216-226

(8.50-8.89)

4JG2T ENGINE −

OTHER ENGINE 203-213

(7.99-8.39)

ADJUSTMENT

1. Loosen clutch master cylinder push rod lock nut 2.

Turn push rod 1 by hand to set clutch pedal height (H) to

within specification.

2. After the adjustment, tighten lock nut 2.

3. Turn the stopper bolt 3 until the stopper bolt 3 just touc hes

the clutch pedal arm.

Adjust or stopper bolt 3 by backing it out half a turn, and

measure the clearance (L) between the clutch pedal arm

and the stopper bolt 3.

Lock the lock nut 4.

Stopper Bolt and clutch pedal

Clearance mm(in)

(L) 0.5-1.5 (0.020-0.059)

CLUTCH PEDAL PLAY

INSPECTION

Depress the clutch pedal lightly by hand, and measure to

determine if the free play is wi thin the standard value.

Pedal Free Play mm(in)

H1 5.0-15.0 (0.2-0.6)

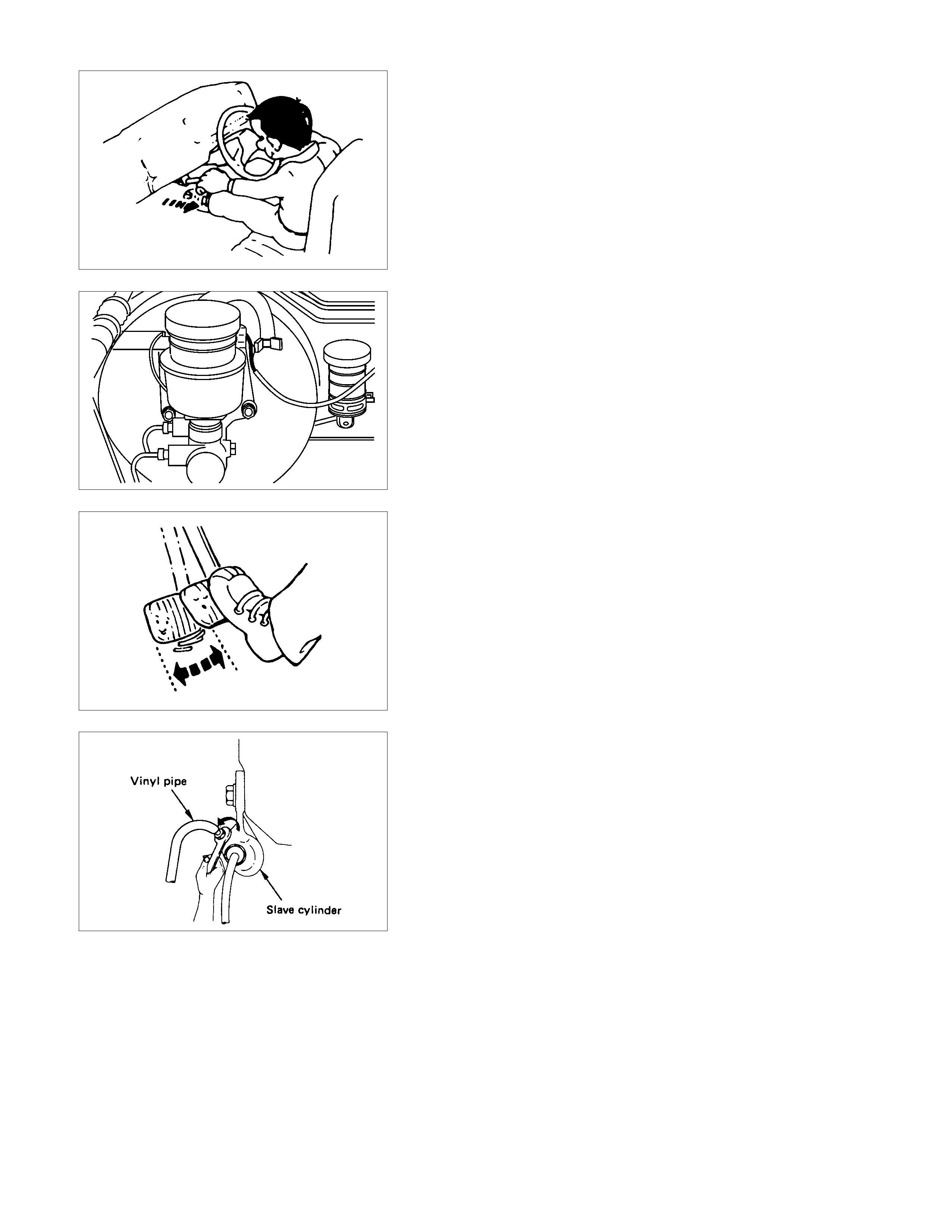

BLEEDING PROCEDURE

1. Bleed air from clutch operating cylinder according to the

following procedure.

Carefully monitor fluid level at master cylinder during

bleeding operation.

Techline

1. Set the paking brake.

2. Top up reservoir with recommended brake fluid.

3. Connect a transparent vinyl tube to air bleeder valve.

4. Fully depress clutch pedal several times.

5. W ith c lutch pedal depressed, open bleeder valve to r elease

air.

6. Close bleeder valve.

7. Repeat steps 5 through 6 above until brak e fluid flows fr om

air bleeder valve without air bubbles.

8. Bleed air from clutch damper according to the above

procedure.

9. Repeat the above bleeding procedure 1 and 2 several

times.

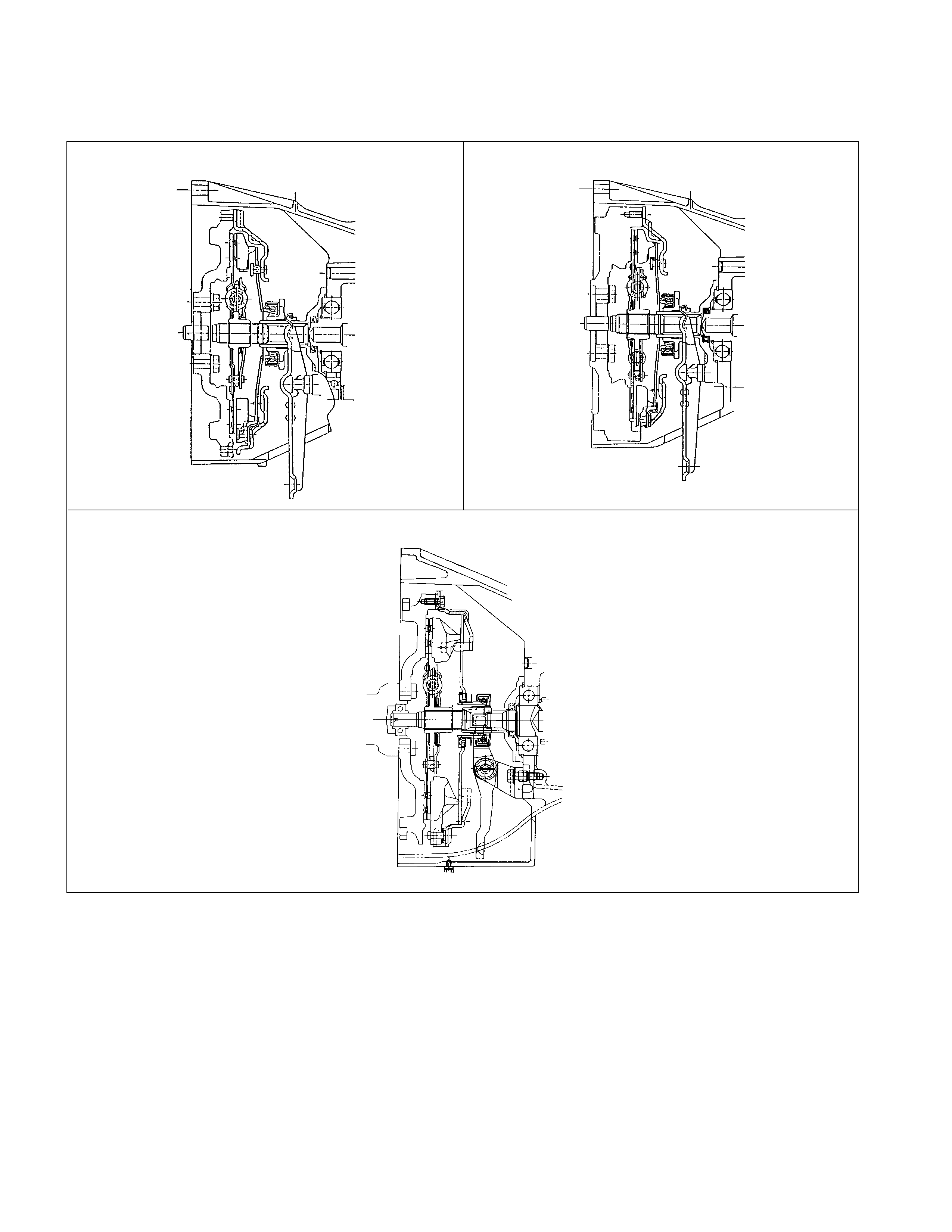

CLUTCH

REMOVAL AND INSTALLATION

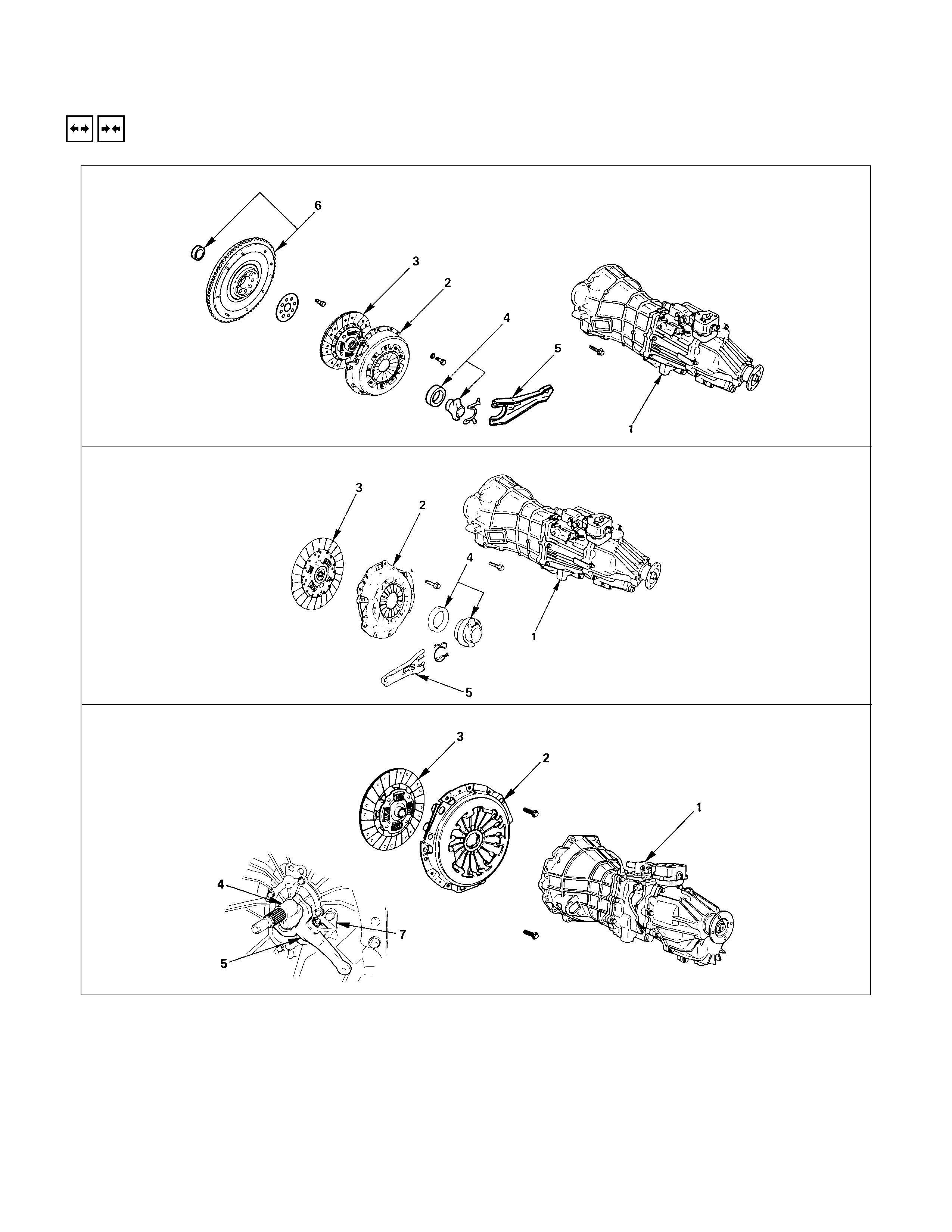

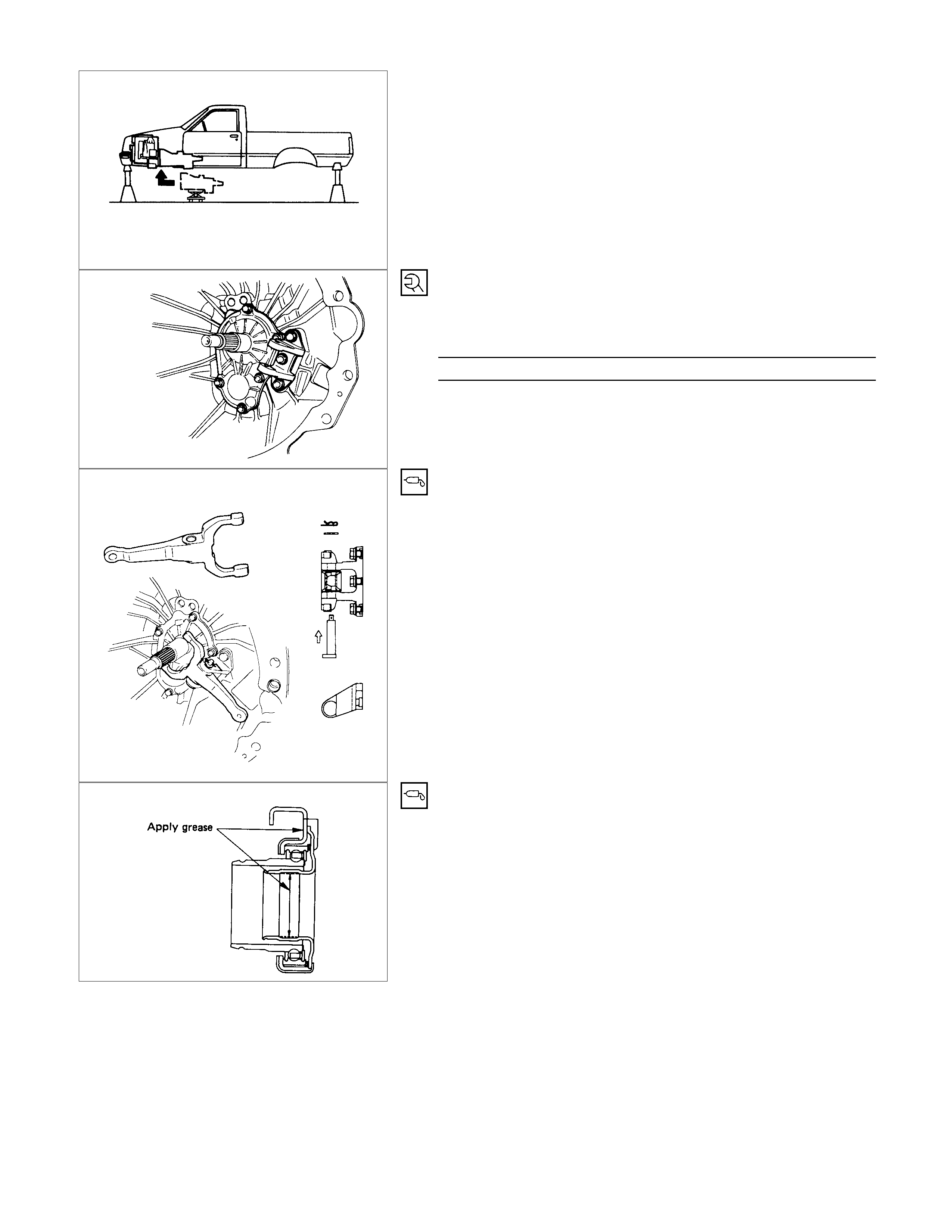

HEC Engine S e r ies

4J E ngine Ser ies

6VD1

REMOVAL STEPS

1. Transmission assembly

▲2. Pressure Plate assembly

▲3. Driven plate assembly

4. Release bearing

5. Shift fork

6. Fly wheel assembly and crank bearing

(HEC Engine Series)

7. Fulcrum bridge (6VD1)

INSTALLATION STEPS

To install, follow the removal steps in the

reverse order.

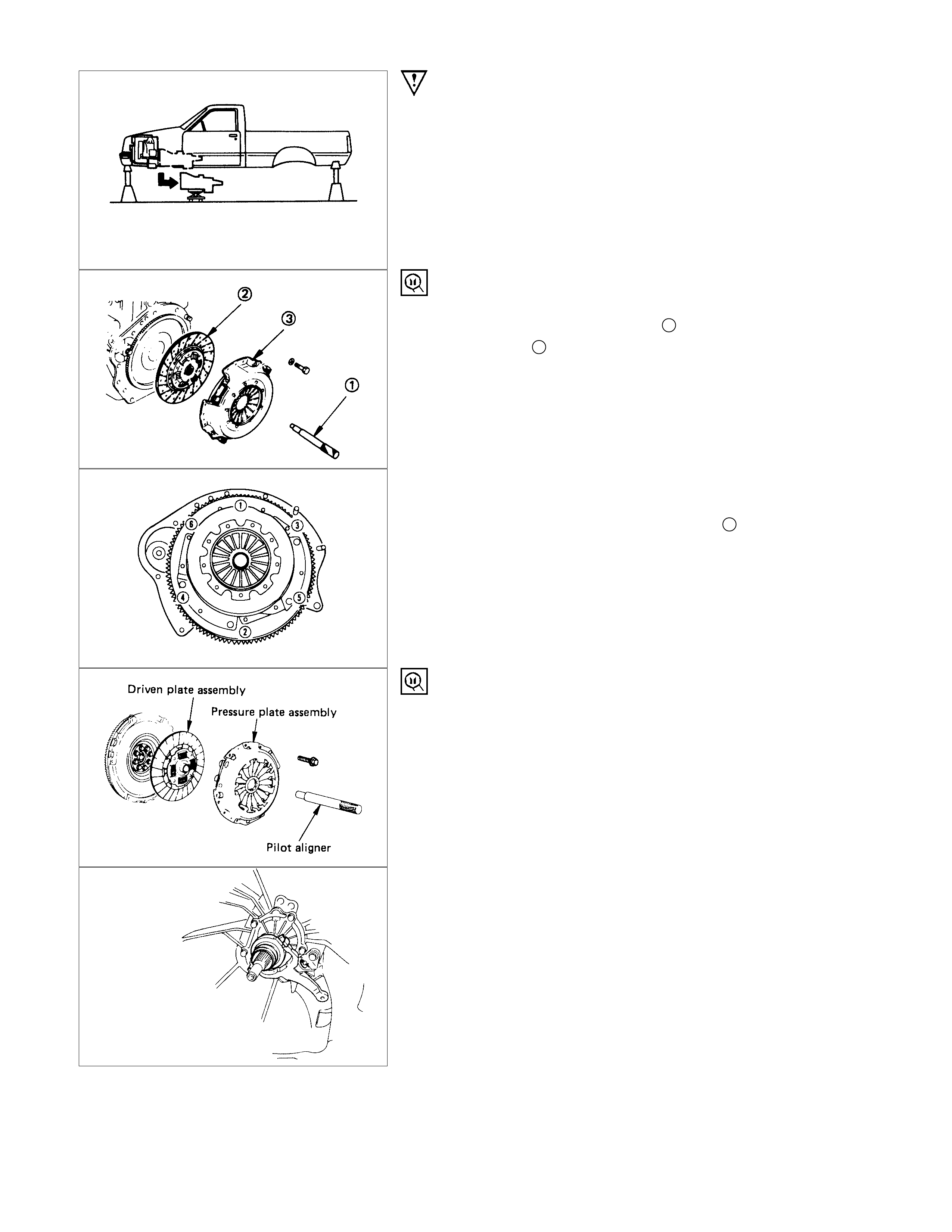

IMPO RTANT OPERATIONS - REMOVAL

1. Transmission Assembly

Refer to “MANUAL TRANSMISSION” of Section 7B and

Section 7B1 for “REMOVAL AND INSTALLATION” procedure.

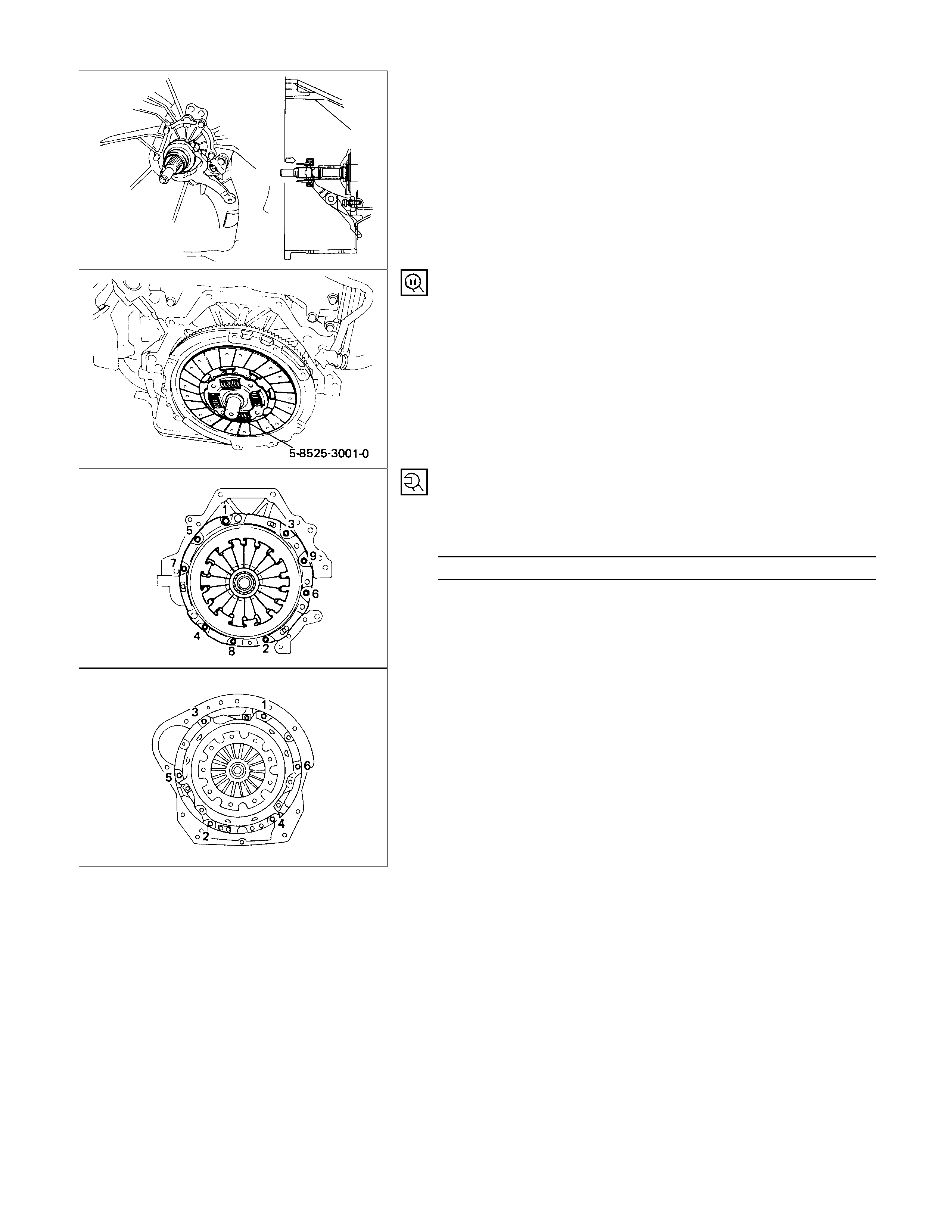

2. Clutch Pressure Plate Assembly (HEC Engine Series)

3. Driven Plate Assembly (HEC Engine Series)

(1)Use the clutch pilot aligner 1 to prevent the driven plate

assembly 2 from falling free.

Clutch Pilot Aligner : 5-8840-2634-0

(2)Loosen the clutch cover bolts in the numerical order shown

in the illustration.

(3)Remove the pressure plate assembly 3 from the flywheel.

(4)Remove the driven plate from the flywheel.

3. Driven Plate Assembly (Except HEC Engine Series)

(1)Use the pilot aligner to prevent the driven plate assembly

from falling free.

Pilot aligner: 5-8525-3001-0 (J-24547)

(2)Mark the flywheel, clutch cover and pressure plate lug fo

r

alignment when installing.

6VD1 4. Release Bearing (6VD1)

Remove the release bearing from the transmission case.

6VD1 5. Shift Fork (6VD1)

(1)Remove the snap pin.

(2)Remove the shift fork pin and shift fork from the fulcrum

bridge.

6VD1 7. Fulcrum Bridge (6VD1)

(1)Remove the fulcrum bridge bolts.

(2)Remove the fulcrum bridge from the transmission case.

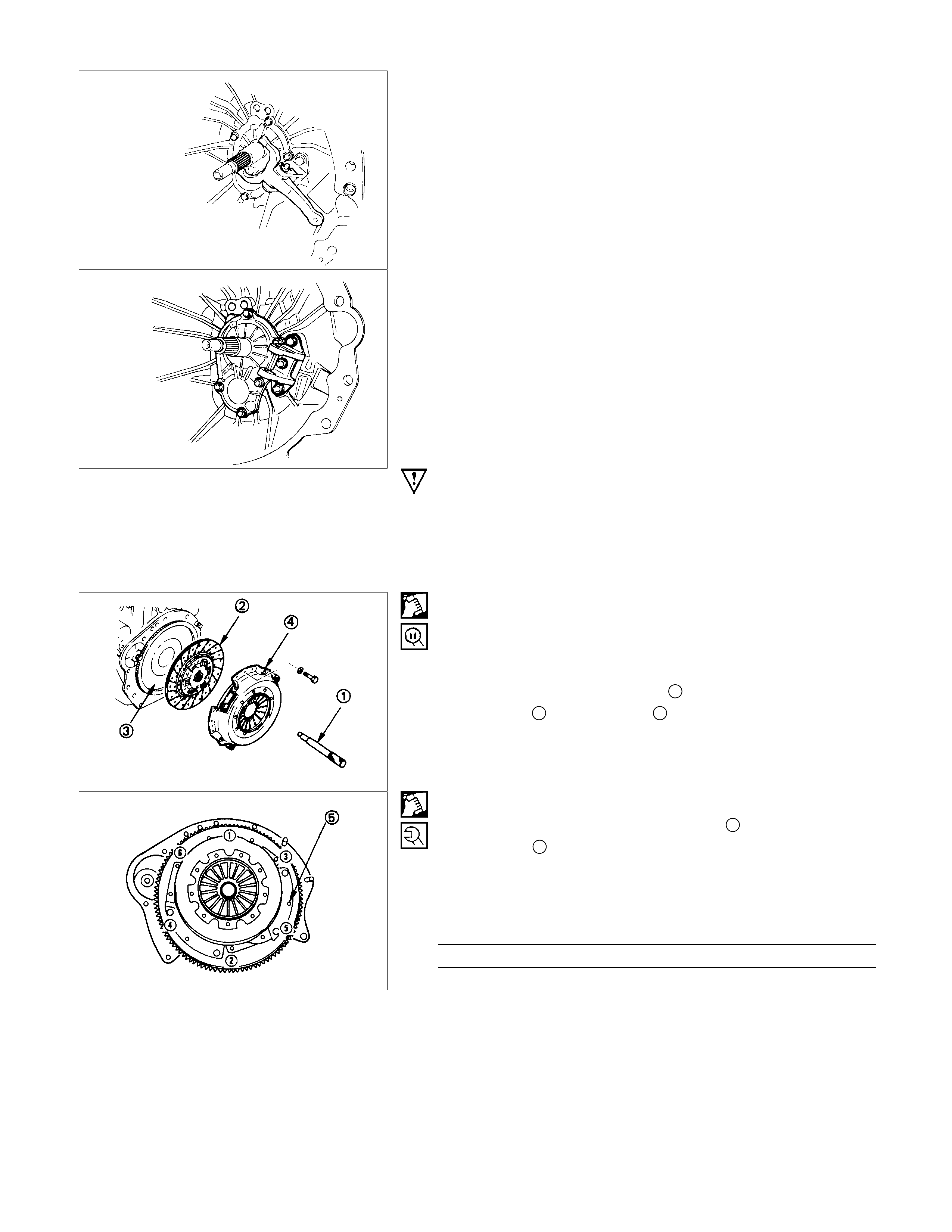

IMPORTANT OPERATIONS - INSTALLATION

Follow the removal procedure in reverse order to perform the

installation procedure.

Pay careful attention to the important points during the

installation procedure.

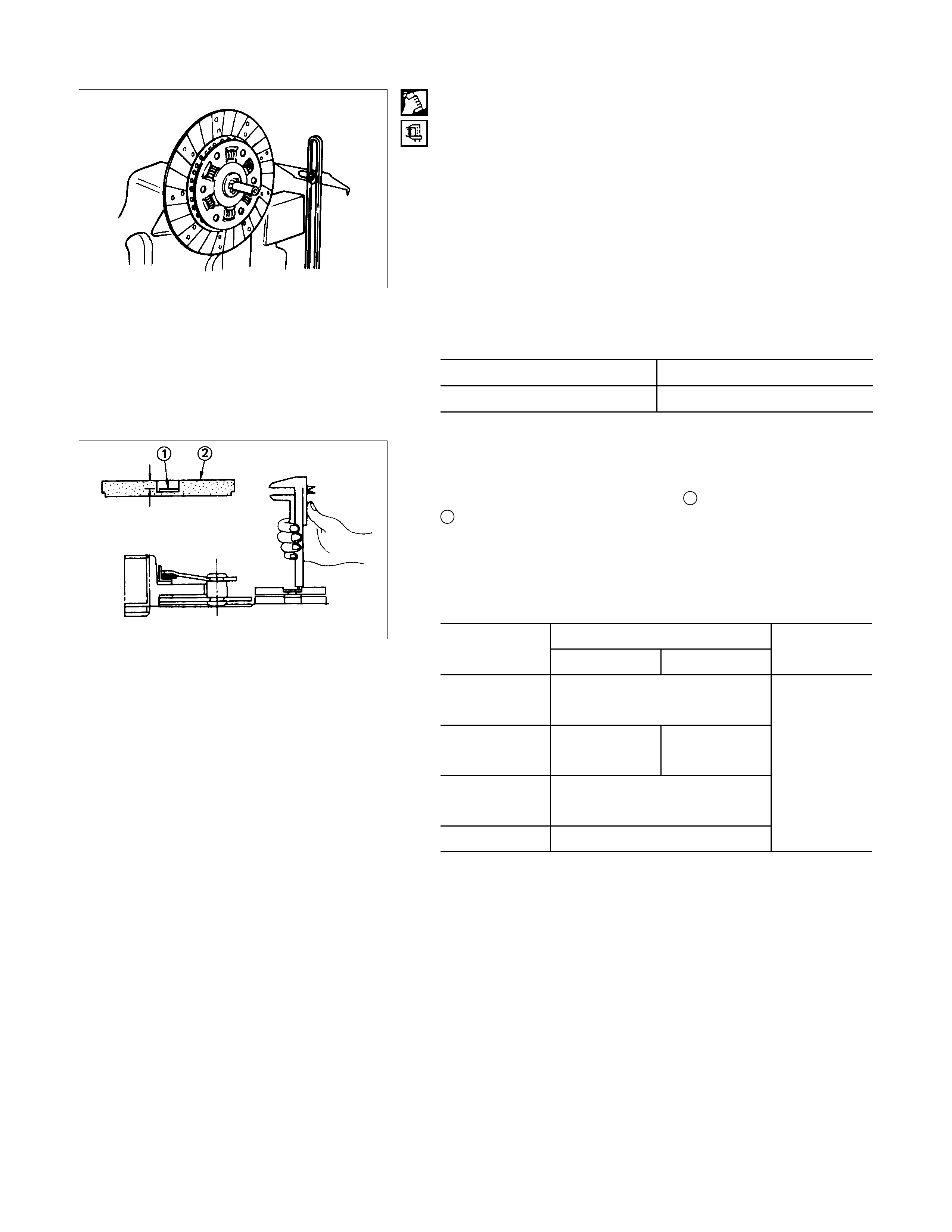

3. Driven plate Assembly (HEC Engine Series)

2. Clutch Pressure Plate Assembly (HEC Engine Series)

(1)Clean the flywheel surface.

(2)Clean the facing surface.

(3)Use the clutch pilot aligner 1 to install the driven plate

assembly 2 to the flywheel 3.

Clutch Pilot Aligner : 5-8840-2634-0

(4)Clean the pressure plate surfaces.

(5)Align the pressure plate assembly 4 with the flywheel

knock pin 5.

(6)Install the pressure plate assembly to the flywheel.

(7)Tighten the clutch cover bolts a little at a time in the

numerical order shown in the illustration.

Clutch Cover Bolt Torque N⋅m (kgf⋅m/lb⋅ft)

17.6 ± 4.9 (1.8 ± 0.5/13.0 ± 3.6)

8. Remove the clutch pilot aligner.

Note:

Do not strike the clutch pilot aligner with a hammer to

remove it.

6VD1 7. Fulcrum Bridge (6VD1)

(1)Install the fulcrum bridge to the transmission case.

(2)Tighten three fulcrum bridge bolts to the specified torque.

Fulcrum Bridge Bolt Torque N⋅m (kg⋅m/lb⋅ft)

39 (3.9/28)

6VD1 5. Shift Fork (6VD1)

(1)Apply molybdenum disulfide contained type grease to the

pin hole inner circumferences and thrust surfaces.

(2)Attach the shift fork to the fulcrum bridge and insert the pin

from below of the fulcrum bridge.

(3)Install the washer and snap pin.

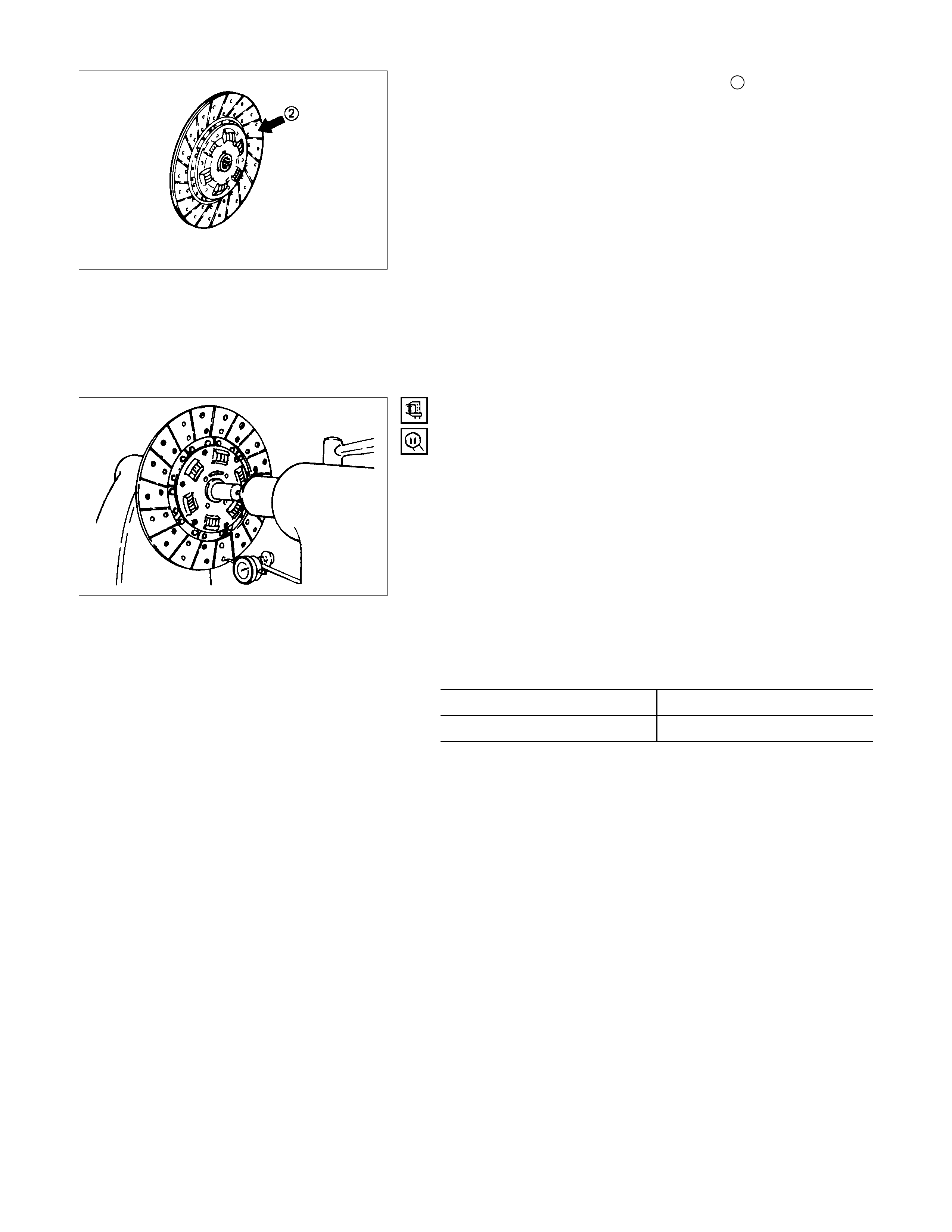

6VD1 4. Release Bearing (6VD1)

(1)Apply molybdenum disulfide contained type grease to the

areas shown in illustration.

6VD1 (2)Install the release bearing in the proper direction.

3. Driven Plate Assembly (Except HEC Engine Series)

Use the pilot aligner to install the driven plate assembly.

Pilot aligner: 5-8525-3001-0 (J-24547)

6VD1 2. Pressure Plate Assembly (6VD1)

(1)Tighten the bolts holding the press ure plate ass em bly in the

order shown in illustration.

Pressure Plate Bolt Torque N⋅m (kgf⋅m/lb⋅ft)

20.6±2.9 (2.1±0.3/15.2±2.2)

(2)Remove the aligner.

NOTE:

Do not strike the aligner with a hammer to remove it.

1. Transmission Assembly

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

PRESSURE PLATE ASSEMBLY

Visually inspect the pressure plate friction surface for

excessive wear and heat cracks.

If excessive wear or deep heat cracks are present, the

pressure plate must be replaced.

PRESSURE PLATE WARPAGE

Use a straight edge and a feeler gauge to measure the

pressure plate friction surface flatness in four directions.

If any of the measured values exceed the specified limit, the

pressure plate must be replaced.

Pressure Plate Warpage mm(in)

Limit

0.3 (0.012)

CLUTCH COVER

Visually inspect the entire clutch cover for excessive wear,

cracking, and other damage.

The clutch cover must be replaced if any of these conditions

are present.

1. Abrasion, sc ratc hes , c rac ks and def lec tion of f r ic tion f ac e to

the disc, loose rivet and wear of ring

•Grind small scratches, or replace the assembly if extreme

scratches are found.

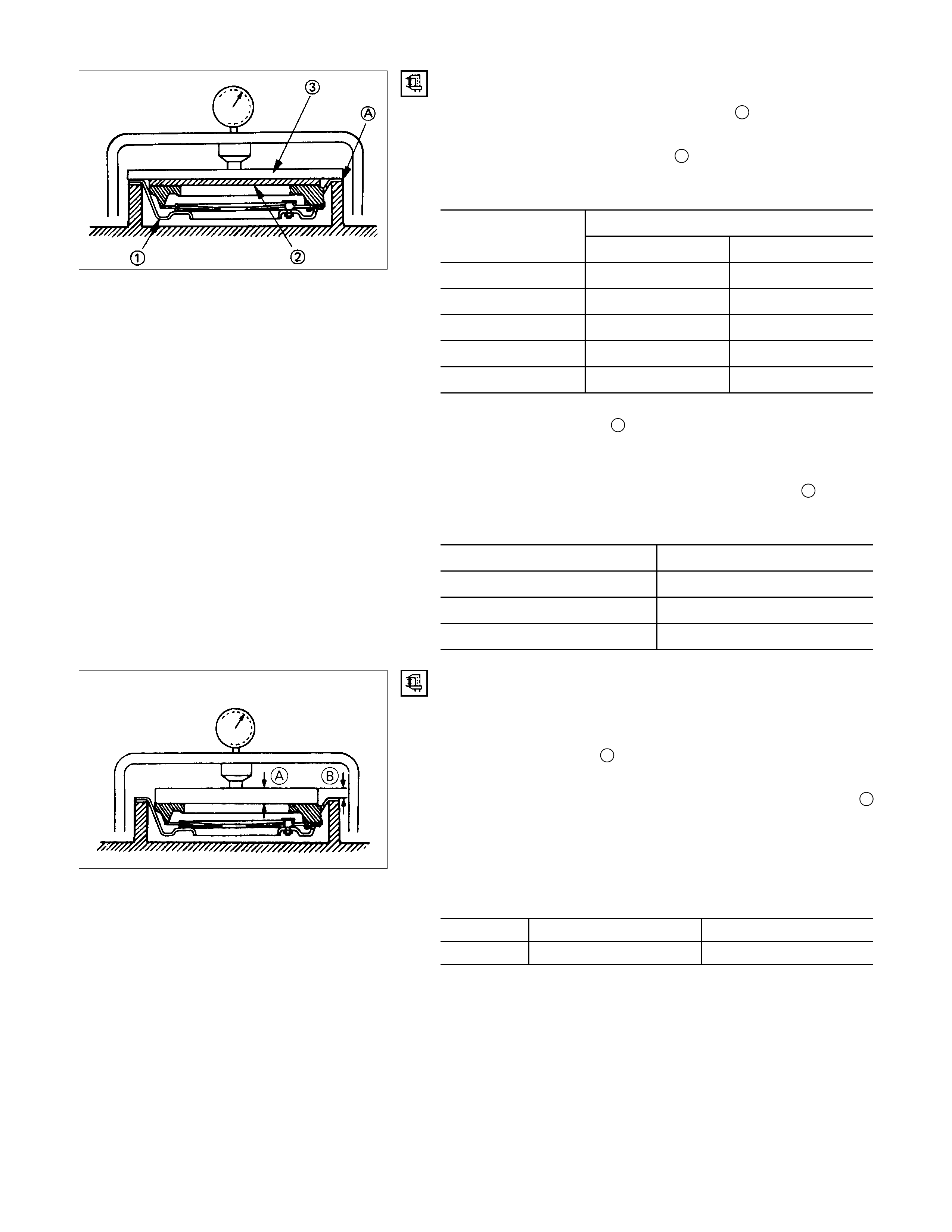

CLUTCH SET FORCE (EXCEPT 6VD1)

1. Position the pressure plate assembly 1 as shown in the

illustration.

2. Place the new driven plate 2 over the pressure plate

assembly.

Driven Plate Thickness (Reference) mm(in

)

Standard

Free Compressed

HEC (MSG) 8.4 (0.330) 8.0 (0.315)

HEC (MUA) 8.6 (0.338) 8.0 (0.315)

4JG2T 8.2 (0.323) 8.0 (0.315)

4JA1 8.0 (0.315) 7.8 (0.307)

4JB1T 8.0 (0.315) 7.8 (0.307)

3. Place a metal sheet 3 between the press and the driving

plate.

4. Compress the metal sheet and the driven plate until the

driven plate is flush with the drive plate assembly A.

5. Note the pressure gauge reading.

Driven Plate Clamping Force N (kg/Ib)

Standard

HEC (MSG), 4JA1 4,903 (500/1,103)

HEC (MUA), 4JB1T 5,492 (560/1,235)

4JG2T 6,276 (640/1,411)

CLUTCH SET FORCE (6VD1)

1. Invert the pressure plate assembly.

2. Place a new driven plate over the pressure plate.

A metal sheet with A thickness of 8.0 mm (0.315 in) may

be used in place of the driven plate.

3. Comp ress the press ure plate ass em bly until the distance B

becomes 12 mm (0.472 in).

4. Note the pressure gauge reading.

If the measured value is less than the specified limit, the

pressure plate assembly must be replaced.

Clutch Set Force N (kg/Ib)

Standard Limit

6VD1 7,208 (735/1,621) 6,669 (680/1,499)

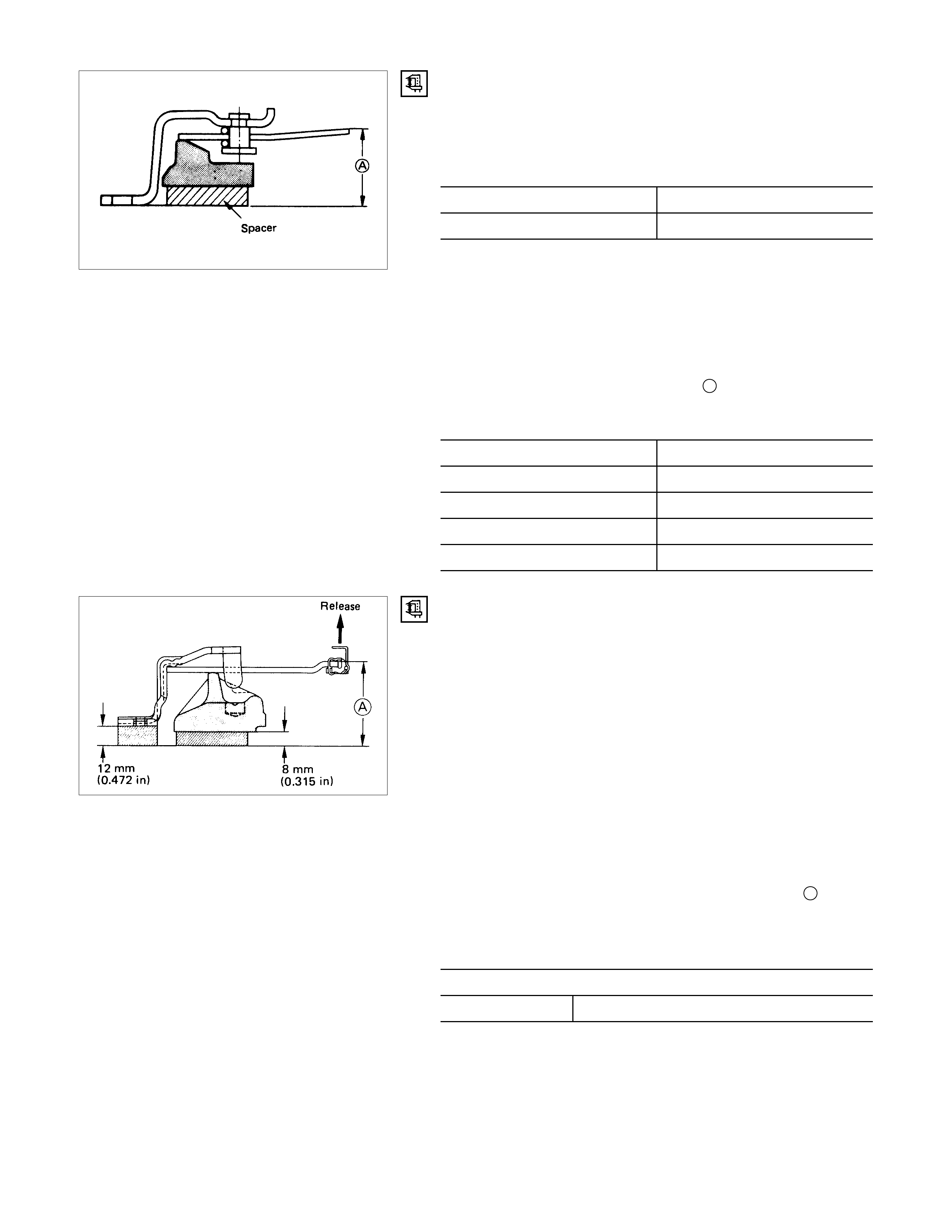

DIAPHRAGM SPRING FINGER HEI G HT

(EXCEPT 6VD1)

1. Place the appropriate spacer beneath the pressure plate.

Refer to the table below.

Spacer Thickness mm(in)

HEC, 4JG2T 8.0 (0.315)

4JA1, 4JB1T 7.8 (0.307)

2. Fully compress the pressure plate and the diaphragm

spring.

There are two ways to do this.

1) Use a bench pres s to pres s down the ass embly from the

top.

2) Tighten the fixing bolts.

3. Measure the spring finger height A from the base to the

spring tip.

Spring Finger Height mm(in

)

HEC MSG 37-39

HEC MUA 39.9-41.9

4JA1 30.5-32.5 (1.20-1.28)

4JB1T 35.0-37.0 (1.38-1.46)

4JG2T 39.0-41.0 (1.53-1.61)

6VD1 DIAPHRAGM SPRING FINGER HEIGHT (6VD1)

1. Place a new driven plate or an 8.0 mm (0.315 in) space

r

beneath the pressure plate.

2. Fully compress the pressure plate and diaphragm spring.

There are two ways to do this.

1) Use a bench pres s to press down on the ass embly from

the top.

2) Tighten the fixing bolts.

NOTE: (6VD1)

Pre-load on diaphragm spring finger must be 49 - 98N (5.0

- 10.0 kg / 11 - 22 lb) in direction of release, when clutch

cover assembly is bolted to the flywheel.

3. Measure the spring height from base to spring tip A.

If the measured value exceeds the specified limit, the

pressure plate assembly must be replaced.

Spring Finger Height mm(in

)

Standard

6VD1 49.9-51.9 (1.965-2.043)

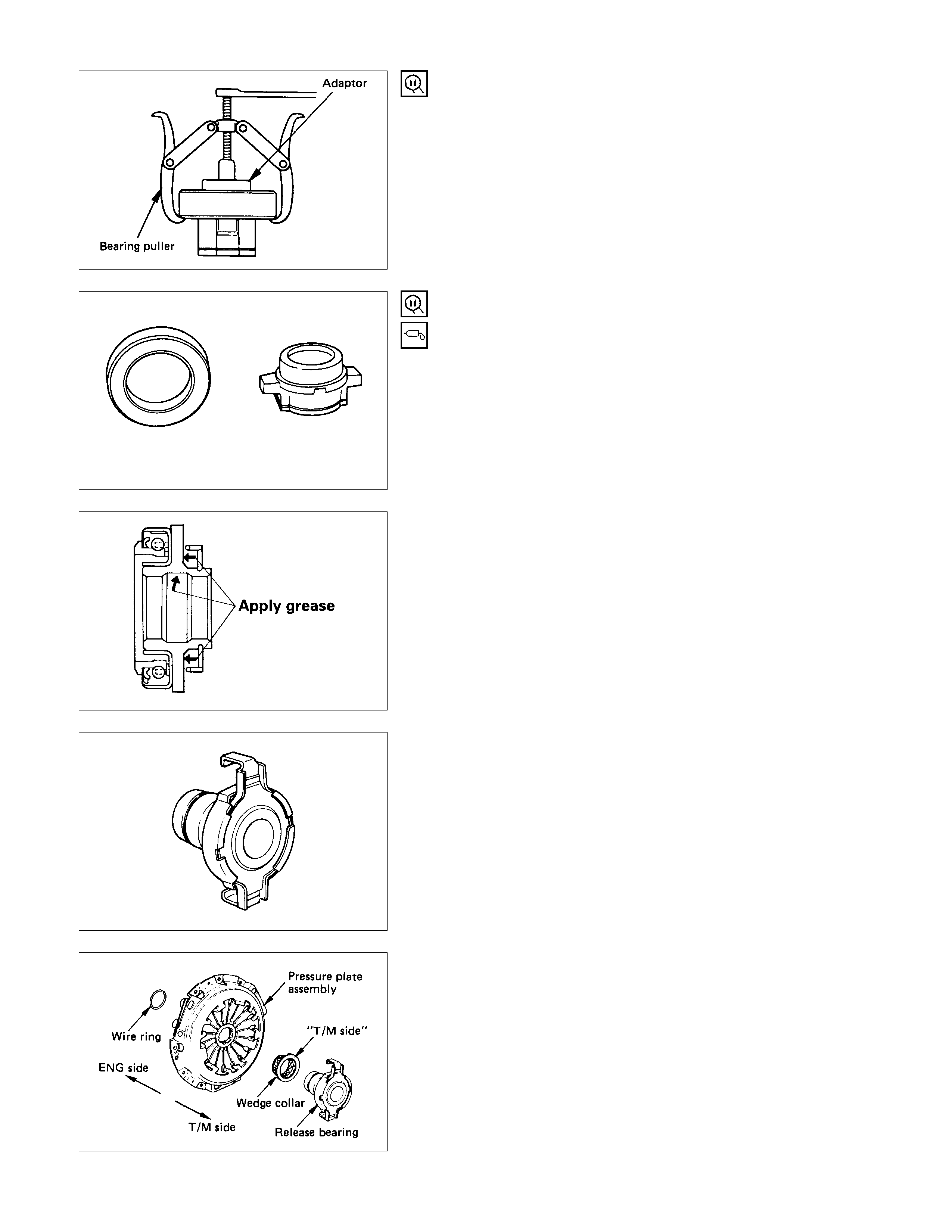

RELEASE BEARI NG REPLACEMENT

REMOVAL (EXCEPT 6VD1)

Use the bearing puller and the adapter to remove the release

bearing.

Bearing Puller : 5-8840-0013-0 (J-22888)

Adapter : 5-8840-0124-0 (J-2241-11)

RELEASE BEARING INSTALLATION (EXCEPT 6VD1)

1. Set the release bearing to the shift block bearing fitting

surfaces.

The release bearing must be perfectly horizontal.

2. Use a bench press to fit the release bearing to the shift

block.

Install the parts as illustrated after applying wheel bearing

grease or multi-purpose type grease (NLGI No.2 or No.3).

6VD1 RELE\ASE BEARING (6VD1)

1. Visually chec k the release bear ing for exc essive play, noise

and breakage.

If any of these conditions are discovered, the release

bearing must be replaced.

6VD1 NOTE:

When replacing the release bearing, replace both the

wedge collar and wire ring at the same time.

WEDGE COLLAR (6VD1)

1. Visually check the surfaces of the wedge collar making

contact with the release bearing for excessive wear and

damage.

2. Replace any exhibiting excessive wear damage.

SHIFT FORK (EXCEPT 6VD1)

1. Visually inspect the surfaces of the shift fork making contact

with the shift block for excessive wear and damage.

2. Remove any minor s tepping or abr asion f r om the shift block

with an oil stone.

Replace any exhibiting excessive wear or damage.

3. Apply multi-purpose type grease (NLGI No.2 or No.3) to

area.

6VD1 SHIFT FORK (6VD1)

1. Visually check the surfaces of the shift fork m aking contact

with the release bearing for excessive wear and damage.

2. Remove any m inor stepping or abrasion fr om shif t fork with

an oil stone.

Replace any exhibiting excessive wear of damage.

DRIVEN PLATE ASSEM BLY

1. Visually inspect the torsion spring 1 for looseness,

breakage, and weakening.

If any of these conditions are discovered, the driven plate

assembly must be replaced.

2. Visually inspect the facing surfaces 2 for cracking and

excessive scorchi ng.

Visually inspect the facing surfaces for the presence of oil

or grease.

If any of these conditions are discovered, the facing must

be cleaned or replaced.

3. Check that the driven plate moves smoothly on the

transmission top gear shaft spline.

Minor ridges on the top gear shaft spline may be removed

with an oil stone.

DRIVEN PLATE WARPAGE

1. Insert the clutch pilot aligner into the driven plate splined

hub.

The clutch pilot aligner must be held perfectly horizontal.

Clutch Pilot Aligner : 5-8840-2634-0 (HEC Engine Series)

5-8525-3001-0 (J-24547) (Except HEC Engine Series)

2. Set a dial indicator to the driven plate outside

circumference.

3. Slowly turn the driven plate.

Read the dial indicator as you turn the driven plate.

If the measured value exceeds the specified limit, the driven

plate assembly and/or the facing must be replaced.

Driven Plate Warpage mm(in)

Standard Limit

0.7 (0.028) 1.0 (0.039)

DRIVEN PLATE SPLINED HUB SPLI NE W EAR

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear shaft

spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

Measure the spline rotation play as you turn the driven

plate.

If the measured value exceeds the specified limit, the driven

plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear mm(in)

Standard Limit

0.5 (0.020) 1.0 (0.039)

RIVET HEAD DEPRESSIO N

Use a depth gauge or a straight edge with steel rule to

measure the rivet head depression 1 from the facing surface

2.

Be sure to measure the rivet head depression on both sides of

the driven plate.

If the measured value is less than the specified limit, the facing

must be replaced.

Rivet Head Depression mm(in)

Standard

Fly wheel side P/P l ate side

HEC 1.65∼2.25

(0.065-0.089)

4JA1 1.35∼1.95

(0.053-0.077) 1.65∼2.25

(0.065-0.089) 0.2

(0.008)

4JB1T, 4J G2T 1. 3∼1.9

(0.051-0.075)

6VD1 1.6 (0.063)

Limit

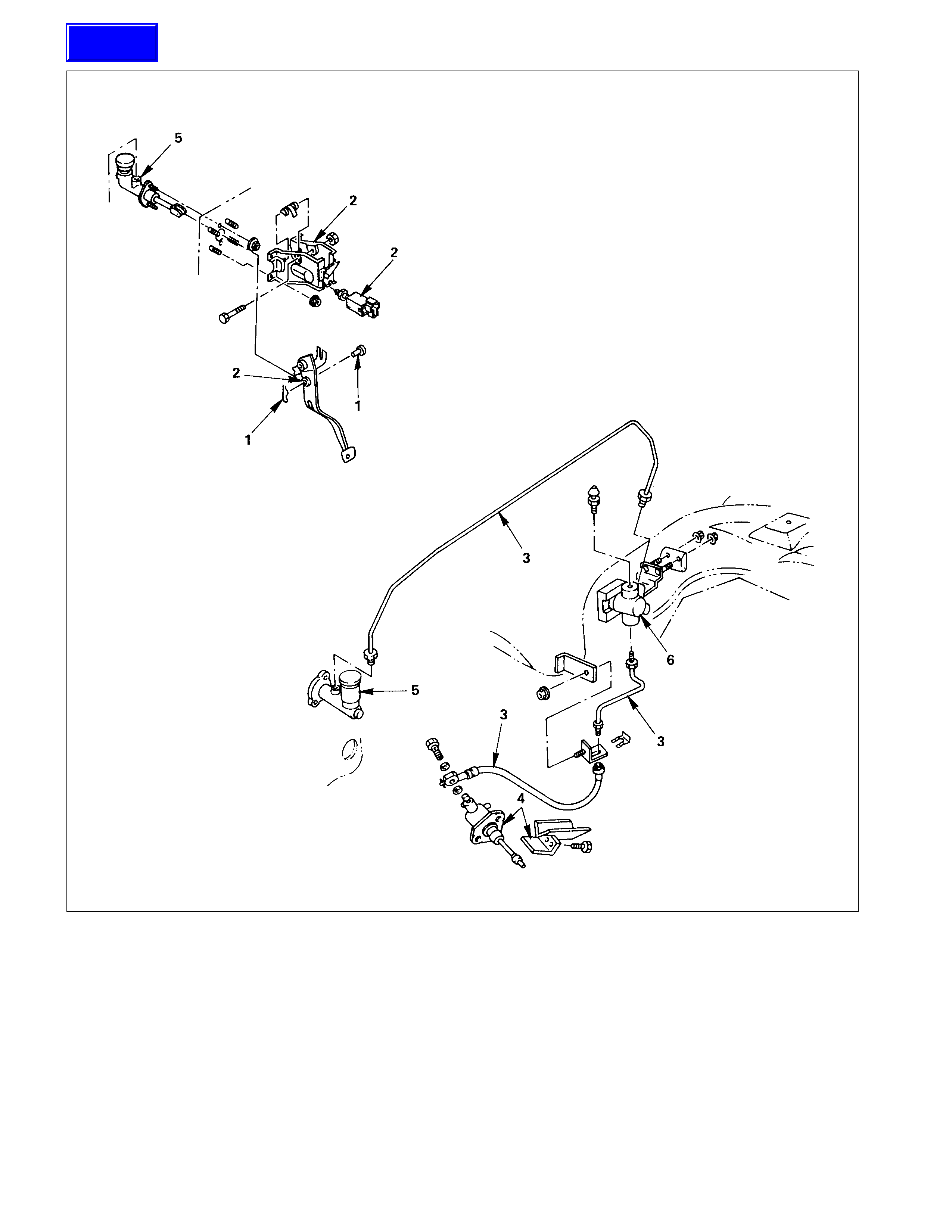

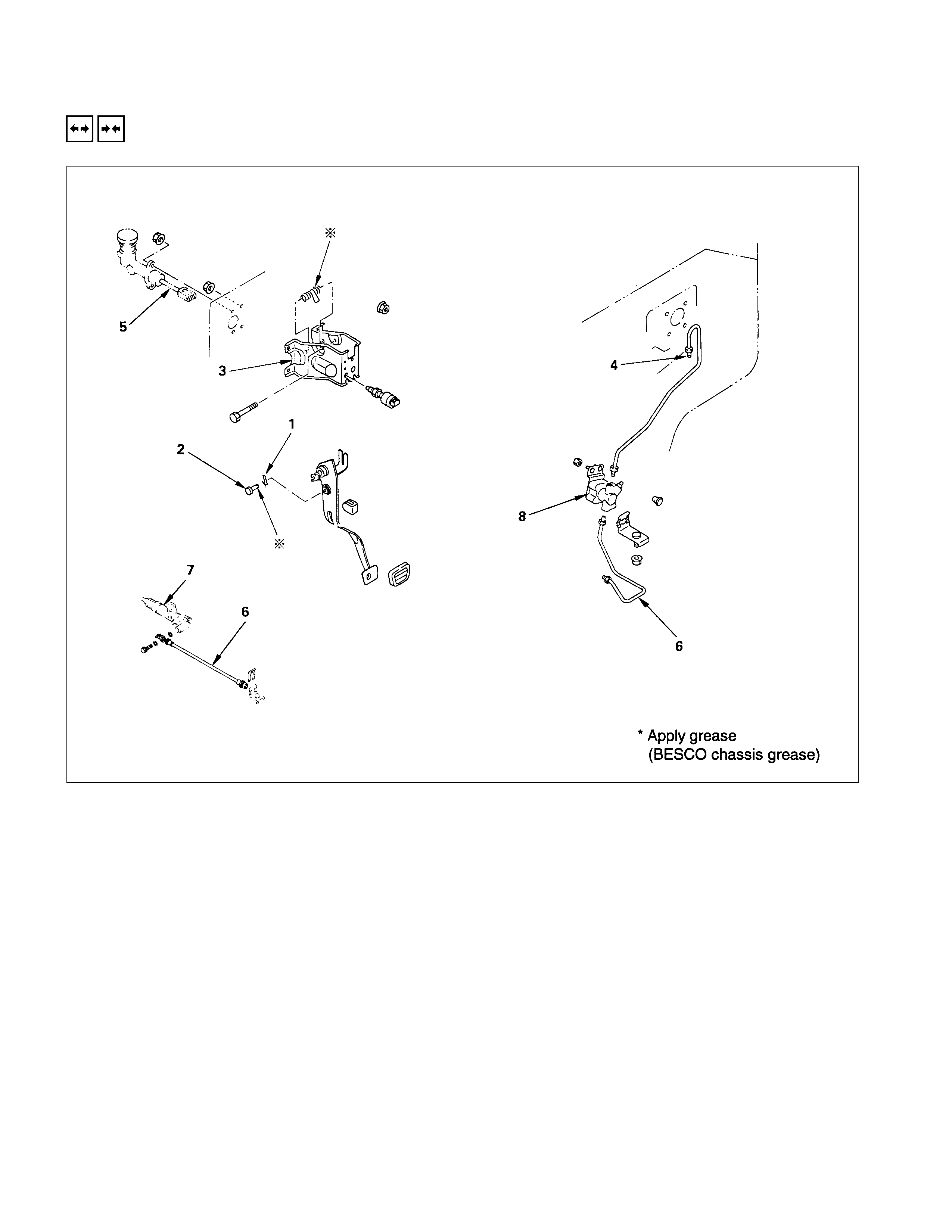

CLUTCH CONTROL

REMOVAL AND INSTALLATION

Except 6VD1 Engine

REMOVAL STEPS

1. Pin

2. Jaw joint pin

3. Pedal assembly

4. Oil line

5. Master cylinder assembly

6. Oil line

7. Slave cylinder assembly

8. Damper cylinder assembly

INSTALLATION STEPS

To install, follow the removal steps in the

reverse order.

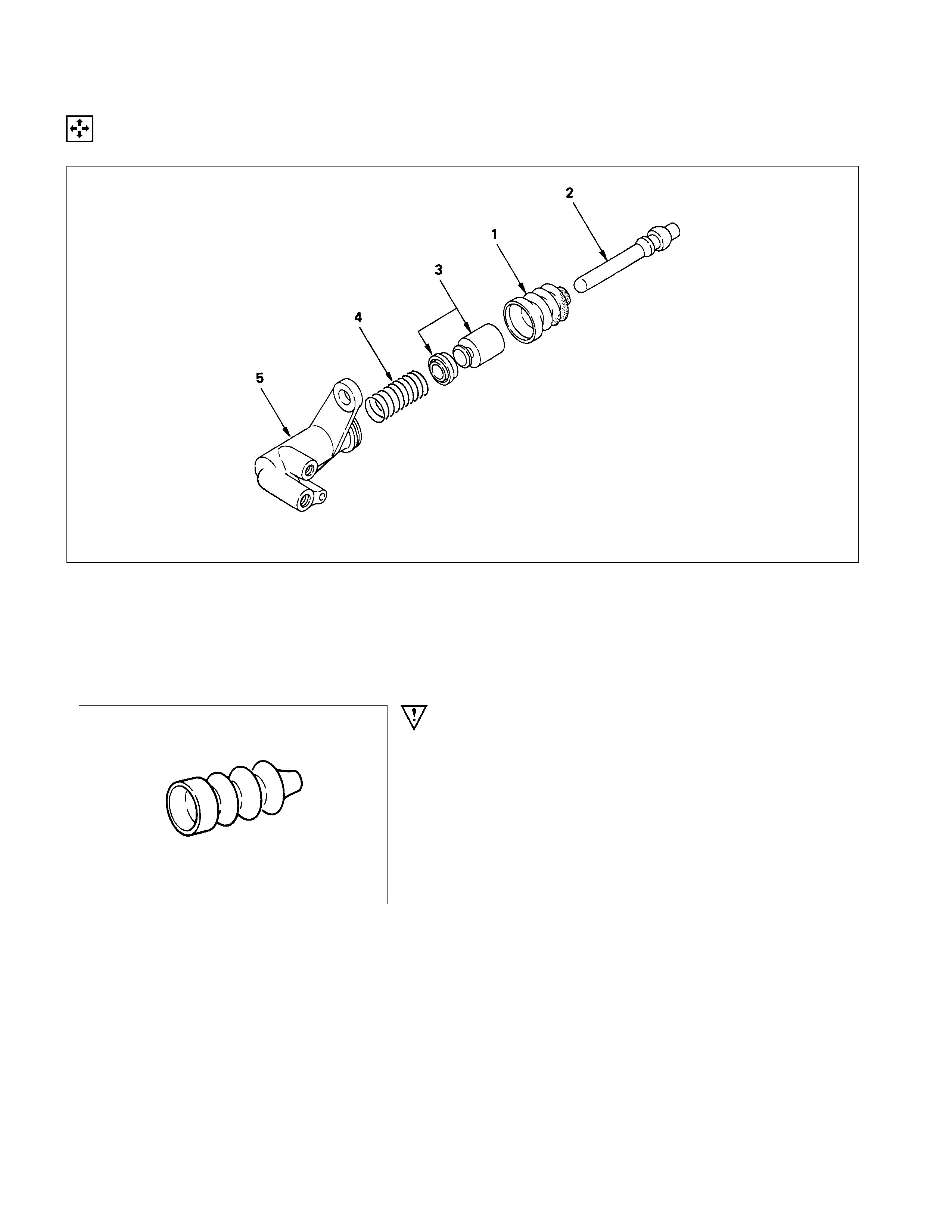

SLAVE CYLINDER (EXCEPT 6VD1 ENGINE)

DISASSEM BLY

DISASSEM BLY STEPS

▲1. Boot

2. Push rod

3. Piston and piston cup

4. Spring

5. Cylinder body

6. Solenoid switch

IMPORTANT OPERATIONS

1. Boot

Brake fluid spilled on painted or plastic surfaces will cause

serious damage.

Take care not to spill brake fluid.

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

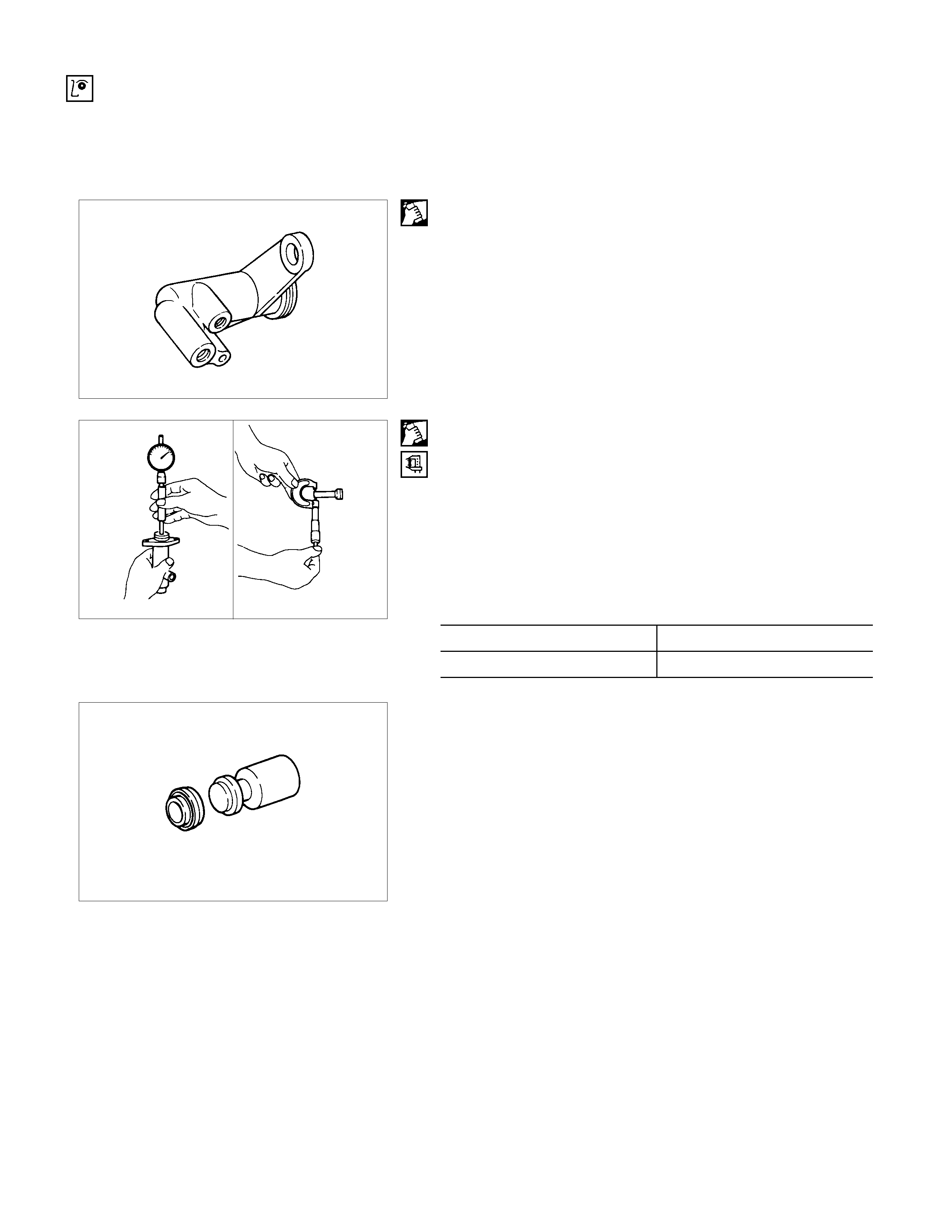

CYLINDER BODY

1. Clean the cylinder body.

2. Check the fluid return port for restrictions and clean it i

f

necessary.

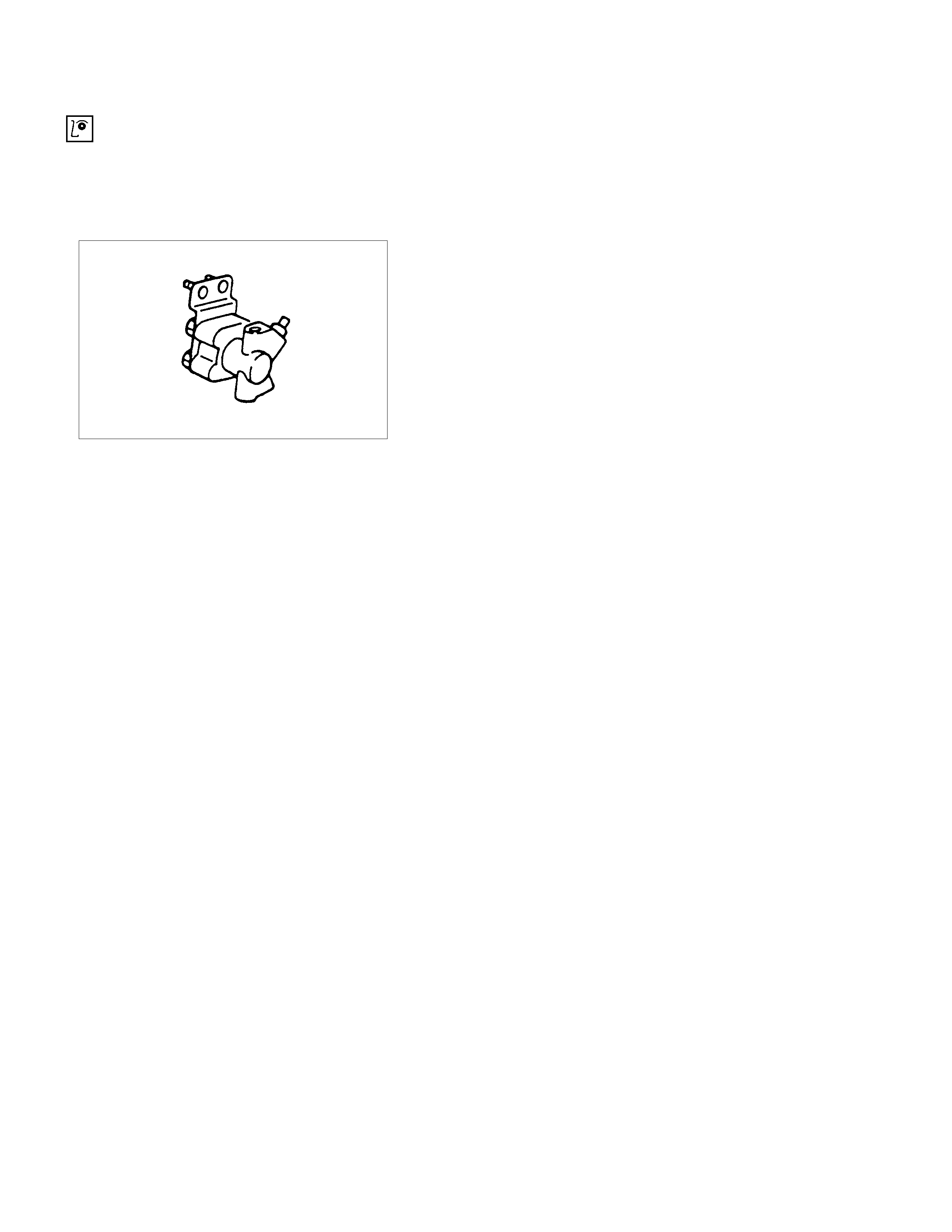

CYLINDER BORE AND PISTON CLEARANCE

1. Clean the cylinder body and the piston.

2. Use an inside dial indicator to measure the cylinder bore.

3. Use a micrometer to measure the piston diameter.

4. Calculate the clearance between the cylinder bore and the

piston diameter.

If the clearance exceeds the limit, the entire slave cylinde

r

assembly must be replaced.

Cylinder Bore and Piston Clearance mm(in)

Standard Limit

0.07 (0.0028) 0.15 (0.006)

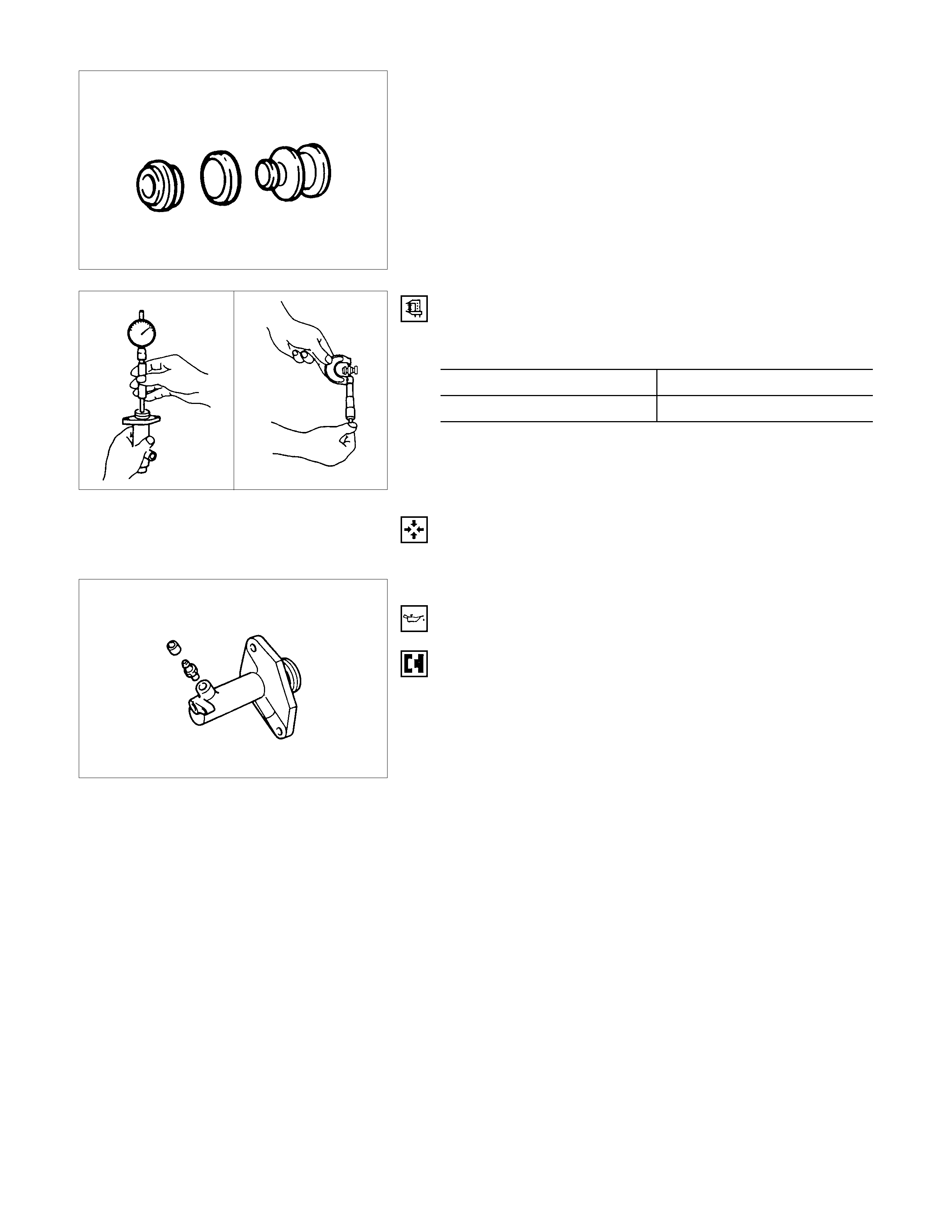

PISTON AND PI STO N CUP

Visually inspect the disassembled piston and piston cup for

excessive wear and damage.

Replace the inner parts with new parts (Repair kit A) shown in

the illustration.

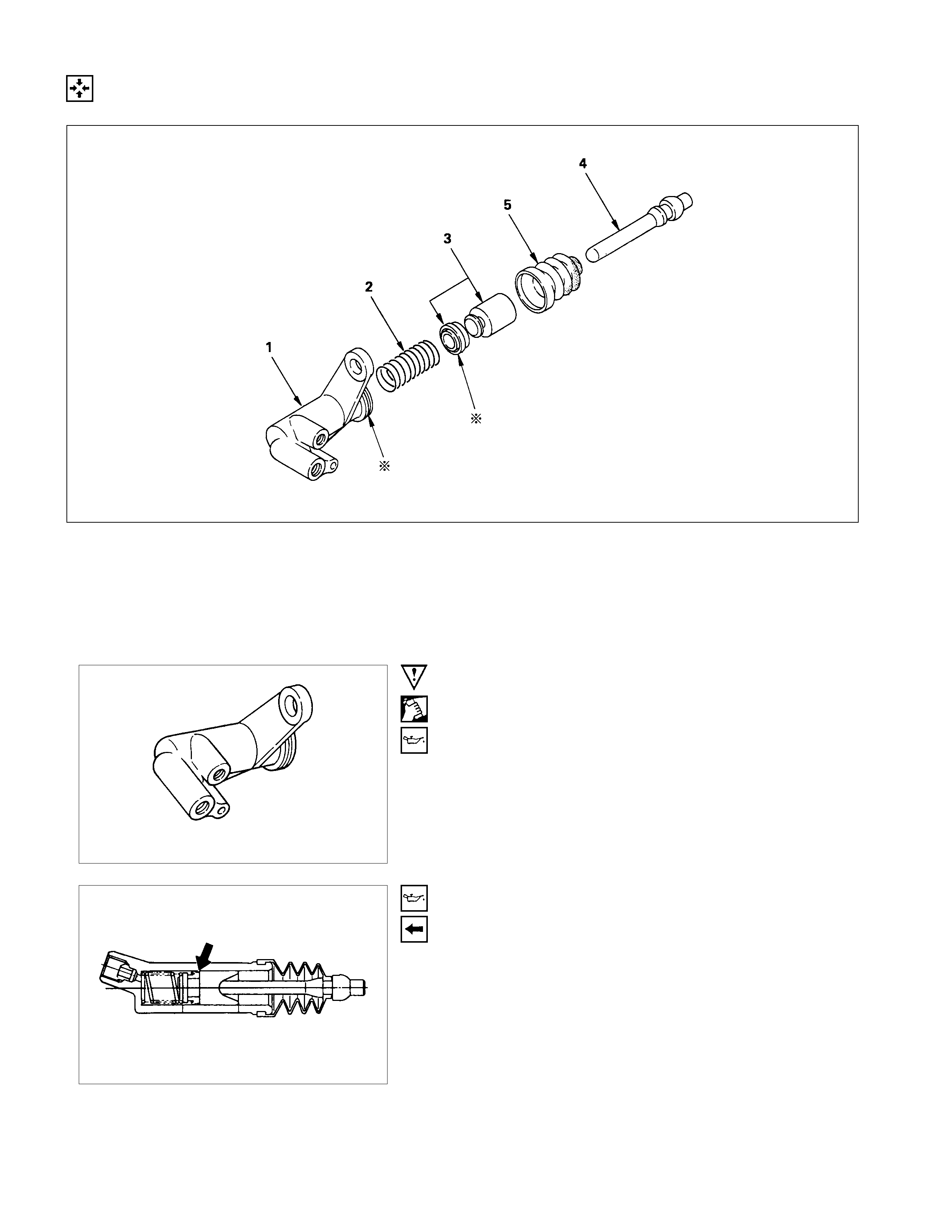

REASSEMBLY

* Apply grease

(COSMO rubber grease)

REASSEMBLY STEPS

▲1. Cylinder body

2. Spring

▲3. Piston and piston cup

4. Push rod

5. Boot

6. Solenoid switch

IMPORTANT OPERATIONS

1. Cylinder Body

1) Clean the cylinder body.

2) Apply brake fluid to the cylinder bore.

3. Piston and piston Cup

1) Apply brake fluid to the piston and piston cup.

2) Install the cups to the piston.

Note the installation direction of the piston cups in the

illustration.

3) Install the piston and piston cup to the cylinder body .

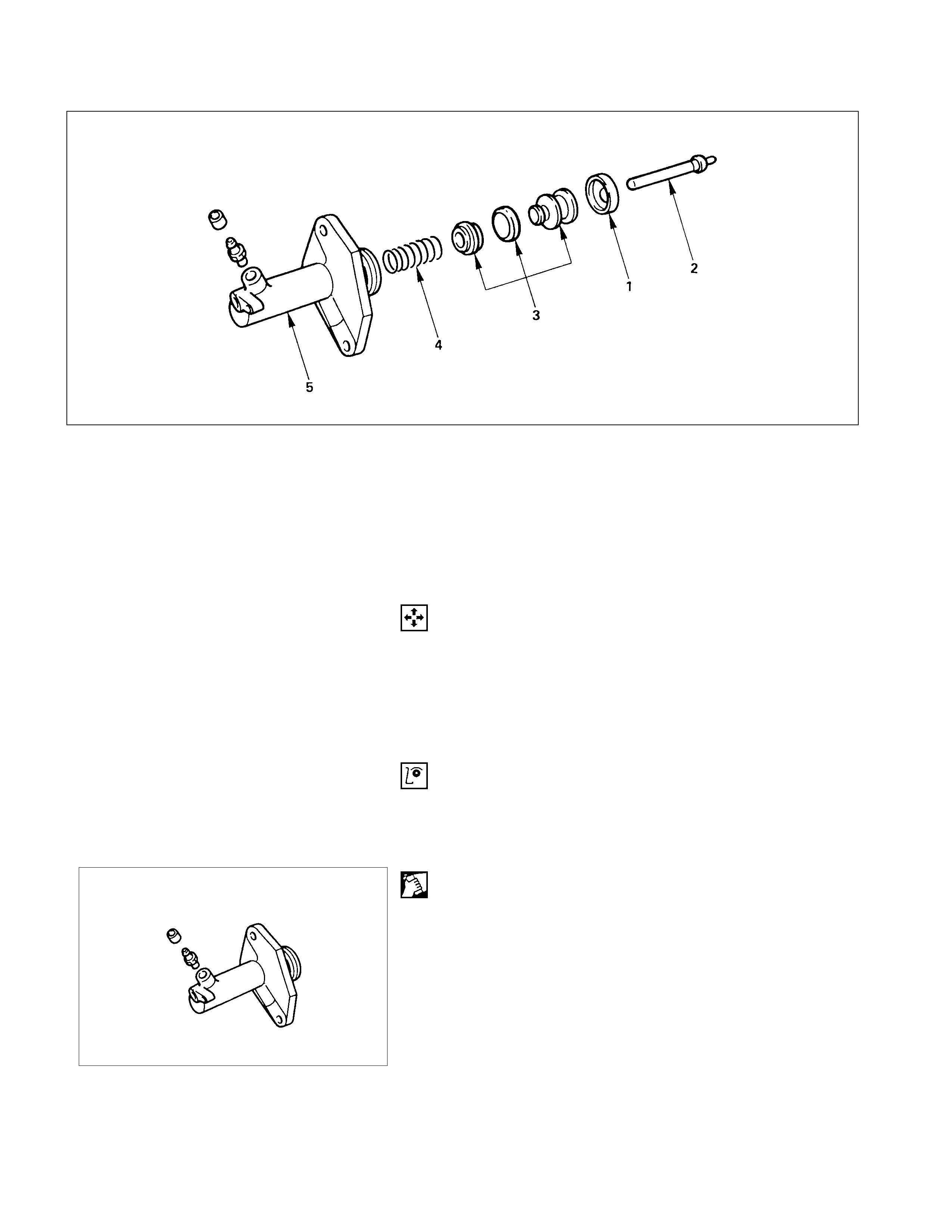

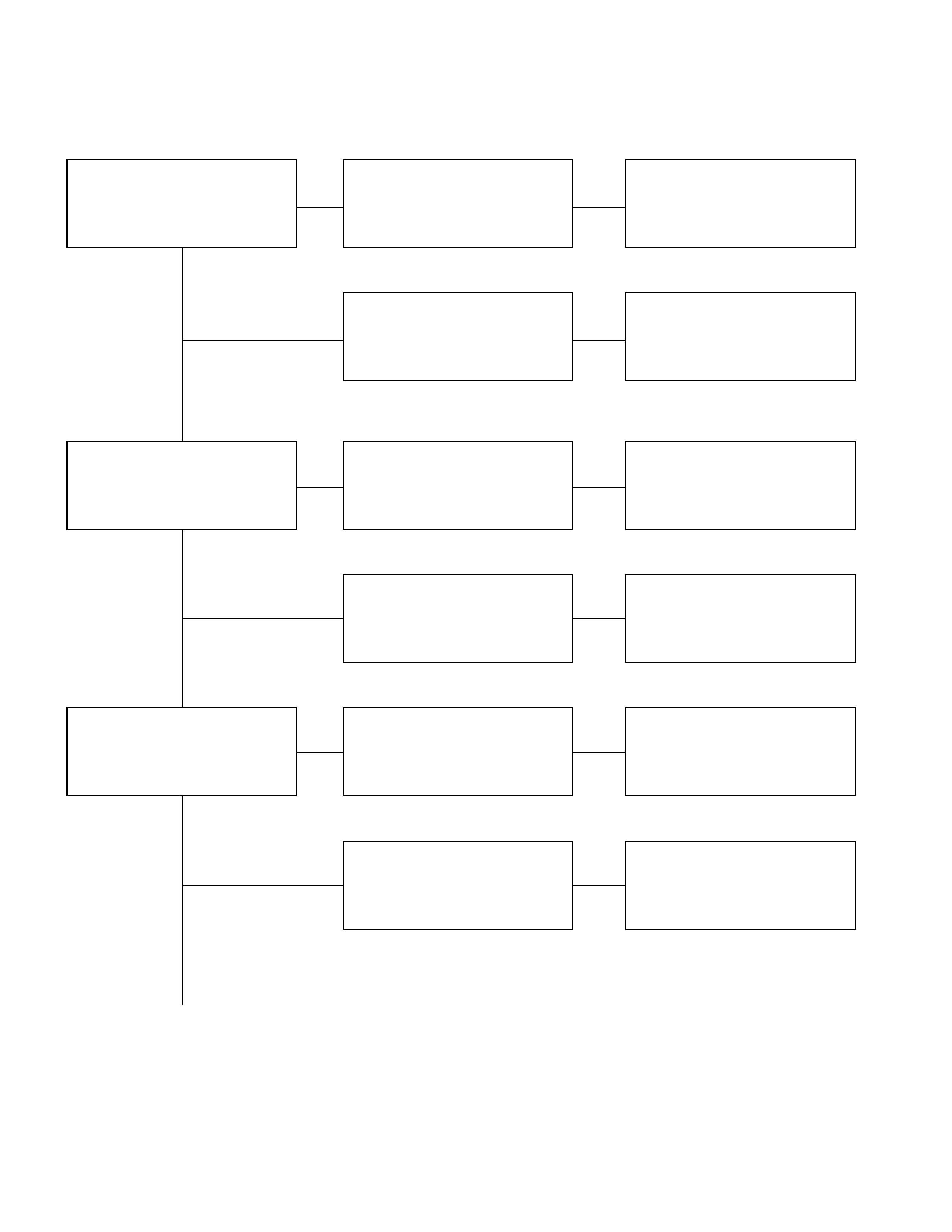

SLAVE CYLINDER (6VD1 ENGINE)

6VD1

DISASSEM BLY STEPS

1. Boot

2. Push rod

3. Piston and piston cup

4. Spring

5. Cylinder body

REASSEMBLY STEPS

To reassemble, follow disassembly steps in

the reverse order.

DISASSEMBLY

1. Boot

2. Push Rod

3. Piston and Piston Cup

4. Spring

5. Cylinder Body

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

6VD1 CYLINDER BODY

1) Clean the cylinder body.

2) Check the fluid return port for restrictions and clean it i

f

necessary.

6VD1 PISTON AND PI STO N CUP

Visually inspect the disassembled piston and piston cup for

excessive wear and damage.

Replace the inner parts with new parts shown in the illustration.

Measure the clearance between slave cylinder wall and piston

If the measured value exceeds the specified limit, the slave

cylinder assembly must be replaced.

Slave Cylinder Wall and Piston Clearance mm(in)

Standard Limit

0.07 (0.0028) 0.15 (0.0059)

REASSEMBLY

To reassemble, follow the disassembly steps in the reverse

order, noting the following points:

6VD1 1. Piston Assembly

1) Before installing the parts, apply a thin coat of rubbe

r

grease.

2) Ins tall c up in groove in pis ton with the lip turned to the f ront

of cylinder. Use care so as not to scratch the cylinder.

HYDRAULIC DAMPER CYLINDER (EXCEPT 6VD1 ENGINE)

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Visually check for oil leakage and other damage.

If oil leakage or other damage is discovered during the

inspection; the damper cylinder assembly must be replaced as

a unit.

TROUBLESHOOTING

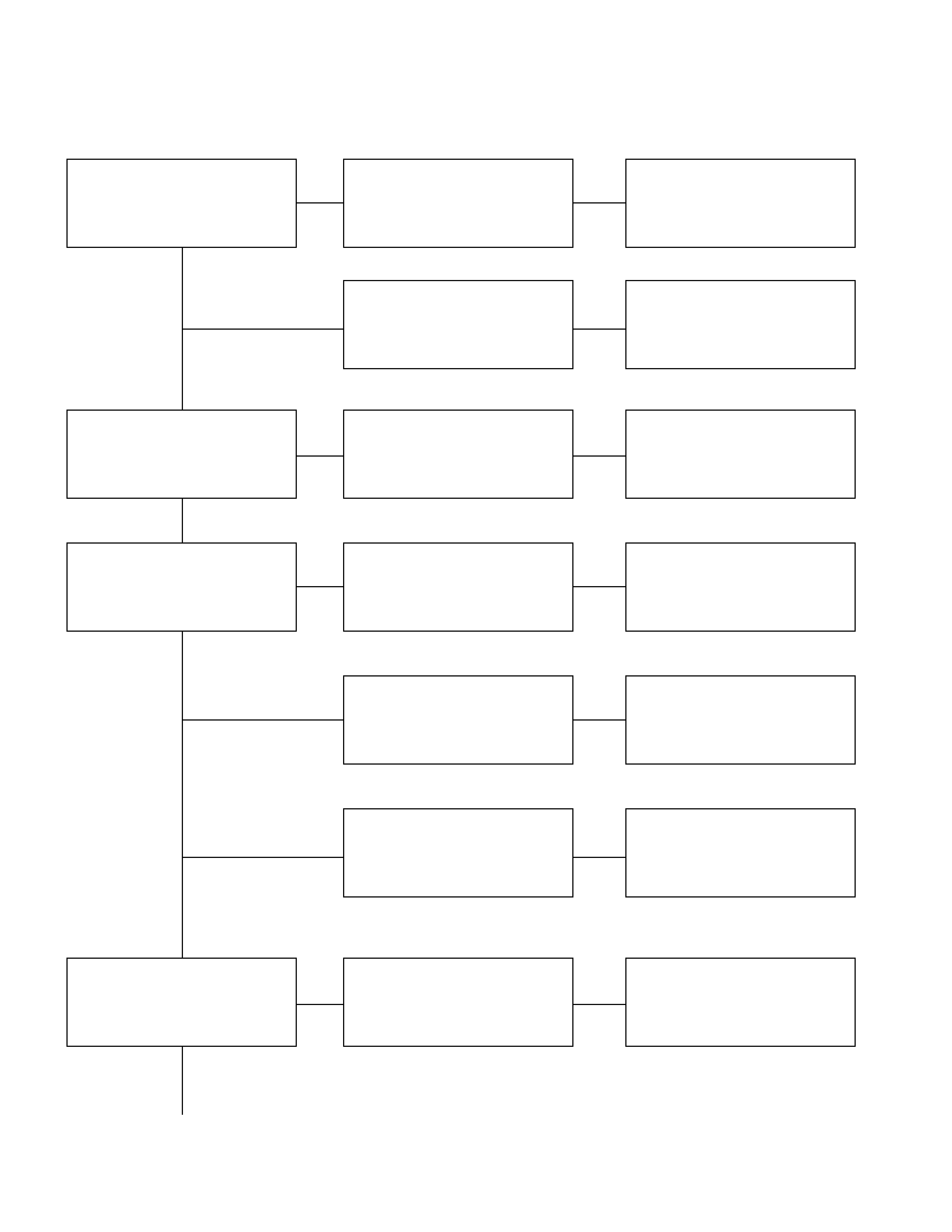

Refer to this Section to quickly diagnose and repair clutch problems.

Each troubleshooting chart has three headings arranged from left to right.

(1) Checkpoint (2) Trouble Cause (3) Countermeasure

This Section is divided into five sub-sections:

1. Clutch Slippage

2. Clutch Does Not Release Properly

3. Clutch Shudder

4. Clutch Noise

1) Clutch pedal Depressed (Clutch Disengaged)

2) Clutch pedal Not Depressed (Clutch Engaged)

5. Oil Leakage

1. CLUTCH SLIPPAG E

Checkpoint Trouble Cause Countermeasure

Adjust the push rod play

No push rod play in the master

cylinder

NG

Clean the related parts and/or

replace the facing

Replace the transmission front

cover oil seal

Clean the related parts and/or

replace the facing

Repair or replace the

transmission front cover

Adjust the push rod play

Defective transmission front

cover oil seal

Continued on the next page

Grease or oil adhering to the

facing Too much grease

Transmission front cover

unevenly worn

No push rod play in the slave

cylinder

Clean and grease the shift

block

Shift block Insufficient grease on the front

cover contact surfaces

NG

NG

NG

NG

NG

OK

OK

Clutch pedal free play

OK

Checkpoint Trouble Cause Countermeasure

Replace the release bearingRelease bearing broken

Clean the related parts and/or

replace the facing

Replace the crankshaft rear oil

seal

Defective crankshaft rear oil

seal

NG

NG

OK

OK

Grease or oil adhering to the

facing

Clutch diaphragm spring Replace the clutch pressure

plate assembly

Weak or broken clutch

diaphragm spring

Replace the driven plate

assembly

Worn facing

NG

NG

OK

Facing

Continued from the previous page

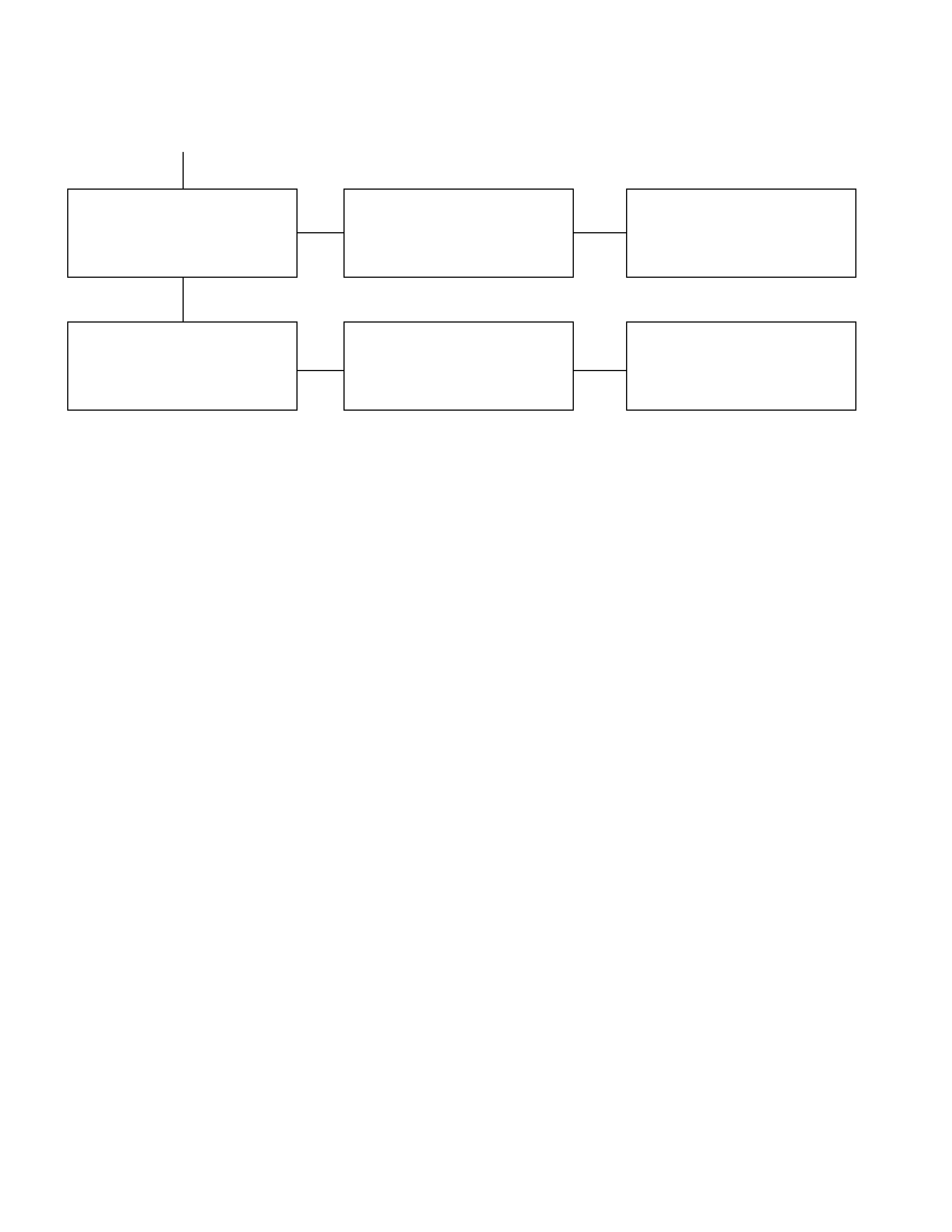

2. CLUTCH DOES NOT RELEASE PRO PERLY

Checkpoint Trouble Cause Countermeasure

Driven plate Replace the driven plate

Adjust the push rod play

Driven plate warped or

unevenly worn

Too much push rod play in the

slave cylinder

Hydraulic circuit Bleed the hydraulic circuit

Adjust the push rod play

Air in the hydraulic circuit

Too much push rod play in the

master cylinder

OK

NG

NG

NG

NG

OK

Clutch pedal free play

Clean or repair the top gear

shaft spline

Replace the top gear shaft

Corrosion or step wear on the

top gear shaft spline

Pressure plate Replace the pressure plate

assembly

Clean and grease the splined

contact surface

Pressure plate unevenly worn

Insufficient grease on the

spline contact surface of the

splined hub

OK

NG

NG

NG

OK

Continued on the next page

Checkpoint Trouble Cause Countermeasure

Crankshaft pilot bearing Replace the pilot bearing

Top gear shaft wobble is

causing pilot bearing wear

Repair or replace the flywheelFlywheel unevenly worn

NG

NG

OK

OK

Flywheel

Continued from the previous page

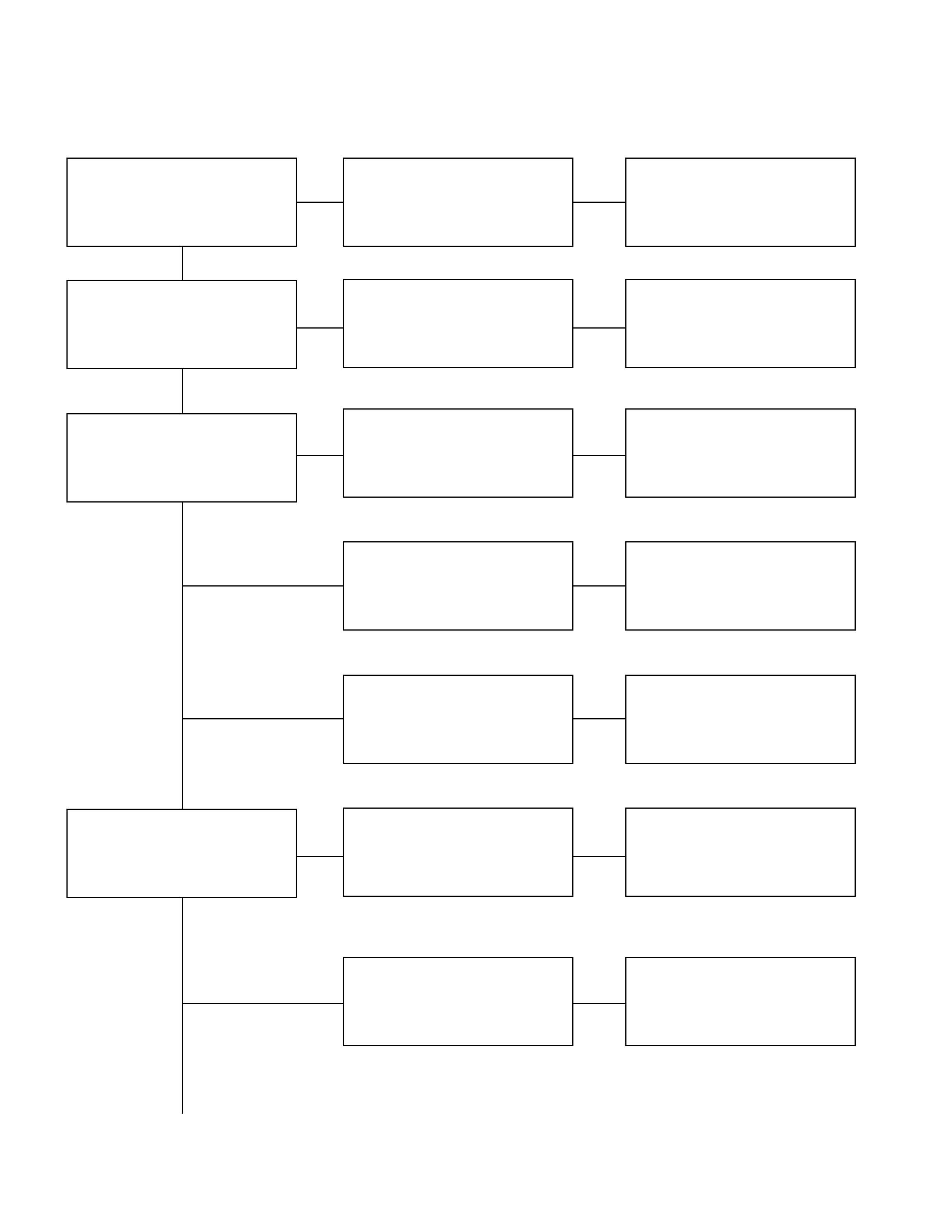

3. CLUTCH SHUDDER

Checkpoint Trouble Cause Countermeasure

Grease or oil adhering to the

facing

Clean the related parts and/or

replace the facing

Replace the transmission front

cover oil seal

Replace the pressure plate

assembly

Defective transmission front

cover oil seal

Pressure plate unevenly worn

Pressure plate

Clean the related parts and/or

replace the facing

Tighten the connections

Repair or replace the

applicable parts

Too much grease

Poorly connected components

causing looseness and

abrasion

OK

NG

NG

NG

NG

OK

Power train

Clean and grease the spline

contact surface

Insufficient grease on the

spline contact surface of the

splined hub

Driven plate

Clean or repair the top gear

shaft spline

Replace the top gear shaft

Clean the related parts and/or

replace the facing

Replace the crankshaft rear oil

seal

Corrosion or step wear on the

top gear shaft spline

Defective crankshaft rear oil

seal

OK

NG

NG

NG

OK

Continued on the next page

Checkpoint Trouble Cause Countermeasure

Replace the driven plate

assembly

Warpage and/or uneven wear

Replace the driven plate

assembly

Loose facing rivets

NG

NG

OK

Driven plate

Continued from the previous page

Flywheel Repair or replace the flywheelFlywheel uneven wear

NG

OK

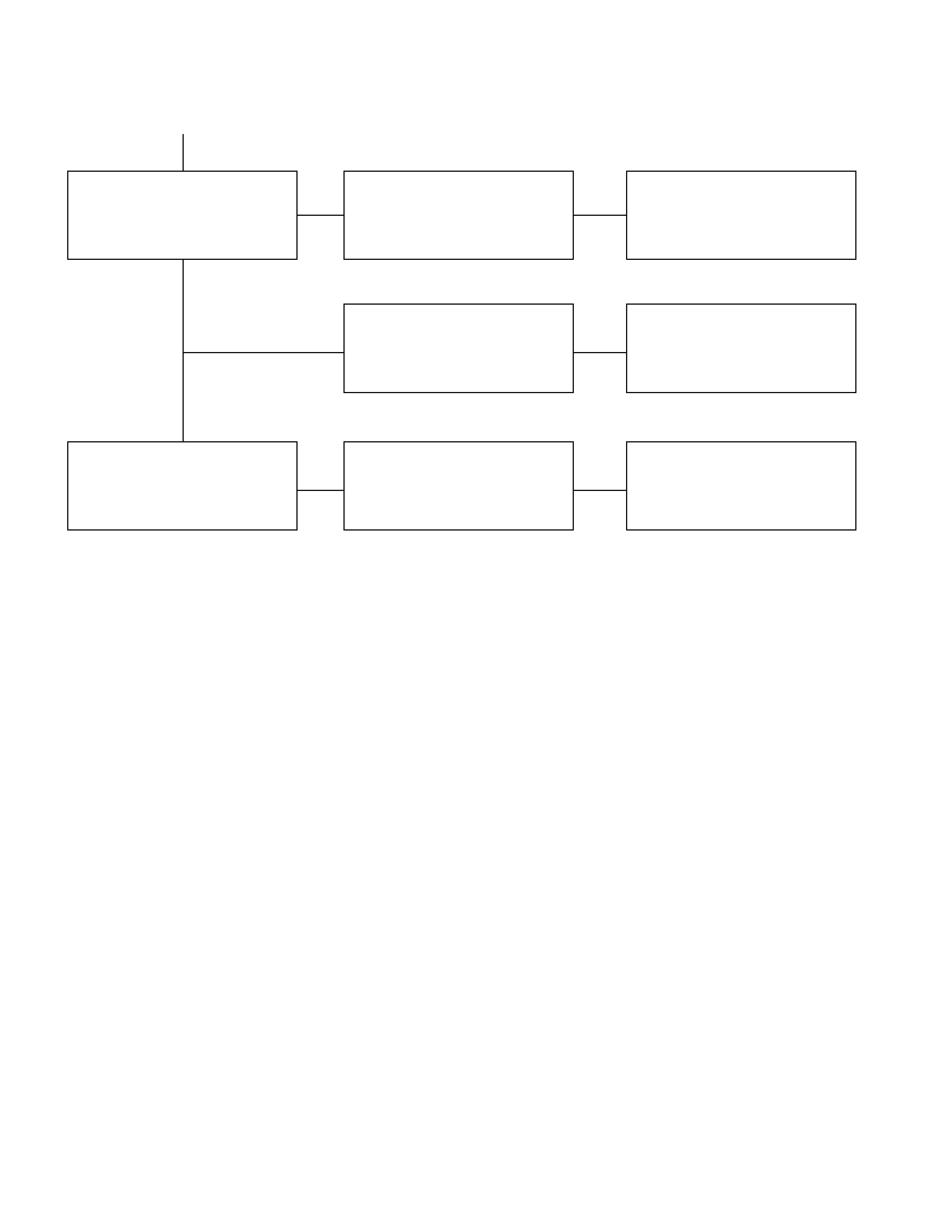

4. CLUTCH NOISE

1) Clutch Pedal Depressed (Clutch Disengaged)

Checkpoint Trouble Cause Countermeasure

Replace the pedal shaft with

the sleeve

Worn pedal shaft and/or

sleeve

Clean and grease the pedal

shaft and sleeve

Insufficient grease at the

pedal shaft and sleeve

NG

NG

Pedal shaft and sleeve

Master cylinder piston and

push rod contact faces

Clean and grease the master

cylinder piston and push rod

contact faces

Insufficient grease at the

maser cylinder piston and

push rod contact faces

NG

OK

Driven plate Replace the driven plate

assembly

Loose or broken damper

spring

NG

OK

Crankshaft pilot bearing Replace the crankshaft pilot

bearing

Insufficient grease at the

crankshaft pilot bearing (pilot

bearing worn)

NG

OK

2) Clutch Pedal Not Depressed (Clutch Engaged)

Replace the driven plate

Weak or broken damper

spring

NG

Driven plate damper spring

Replace the crankshaft pilot

bearing

Insufficient grease at the

crankshaft pilot bearing (pilot

bearing worn)

OK

NG

Crankshaft pilot bearing

5. OIL LEAKAGE

Checkpoint Trouble Cause Countermeasure

Replace the piston capWeak or damaged piston cap

NG

Tighten the oil pipe

Tighten the oil pipe connection

Tighten the fluid pipe and/or

hose connections

Fluid reservoir Loosely connected oil pipe

Loosely connected oil pipe

Master cylinder fluid pipe and

hose Loosely connected fluid pipe

and/or hose

Slave cylinder oil pipe

Replace the piston cupSlave cylinder Weak or damaged piston cup

NG

NG

NG

NG

OK

OK

OK

OK

Master cylinder

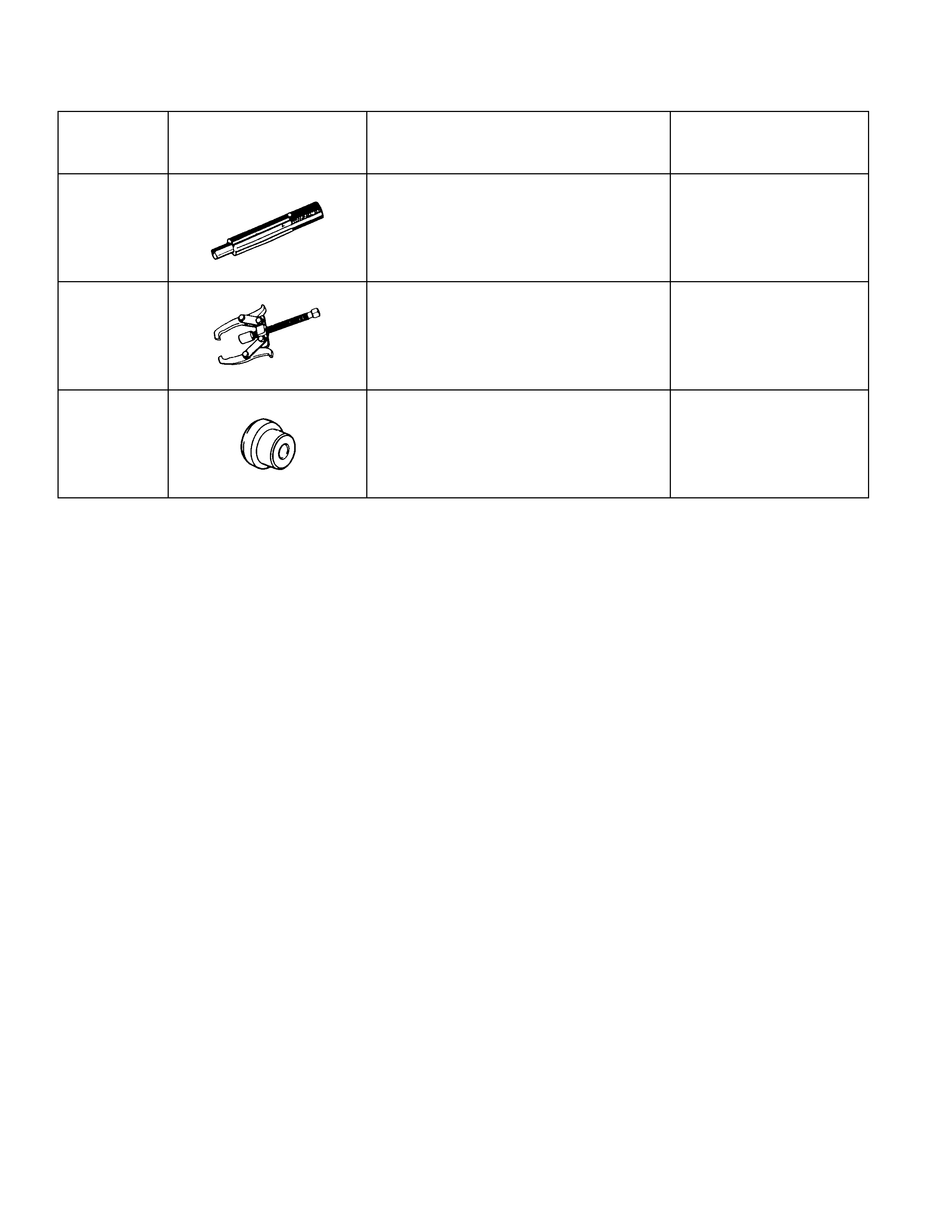

SPECIAL SERVICE TOOL

ITEM NO. ILLUSTRATION PART NO. PART NAME

5-8840-2634-0 Clutch pilot aligner

(HEC Engine Series)

CLL-3 5-8840-0013-0

(J-22888) Bearing puller

(Except 6VD1 Engine)

CLL-4 5-8840-0124-0

(J-2241-11) Bearing puller adapter

(Except 6VD1 Engine)